Patents

Literature

73results about How to "Short boost time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production of electrolytic capacitor anode aluminum foil

InactiveCN101030487AIncrease temperatureIncrease concentrationAnodisationElectrolytic capacitorsElectrolysisPhosphoric acid

The invention is concerned with the manufacture method for the anodic foil of the electrolytic capacitor, which is the manufacture method by using motor, it is: cleans the corrosive foil with pure water - oxalic acid forming - cleans with hot water - conducts forming in four stages - heat treatment - re-forming - treats with the phosphoric acid - re-forming - heat treatment - re-forming - drying. The advantages of the invention are low wastage, better flexibility, shorter voltage boosting, and better hydration proof.

Owner:DONGGUAN HEC CONDENSER CO LTD

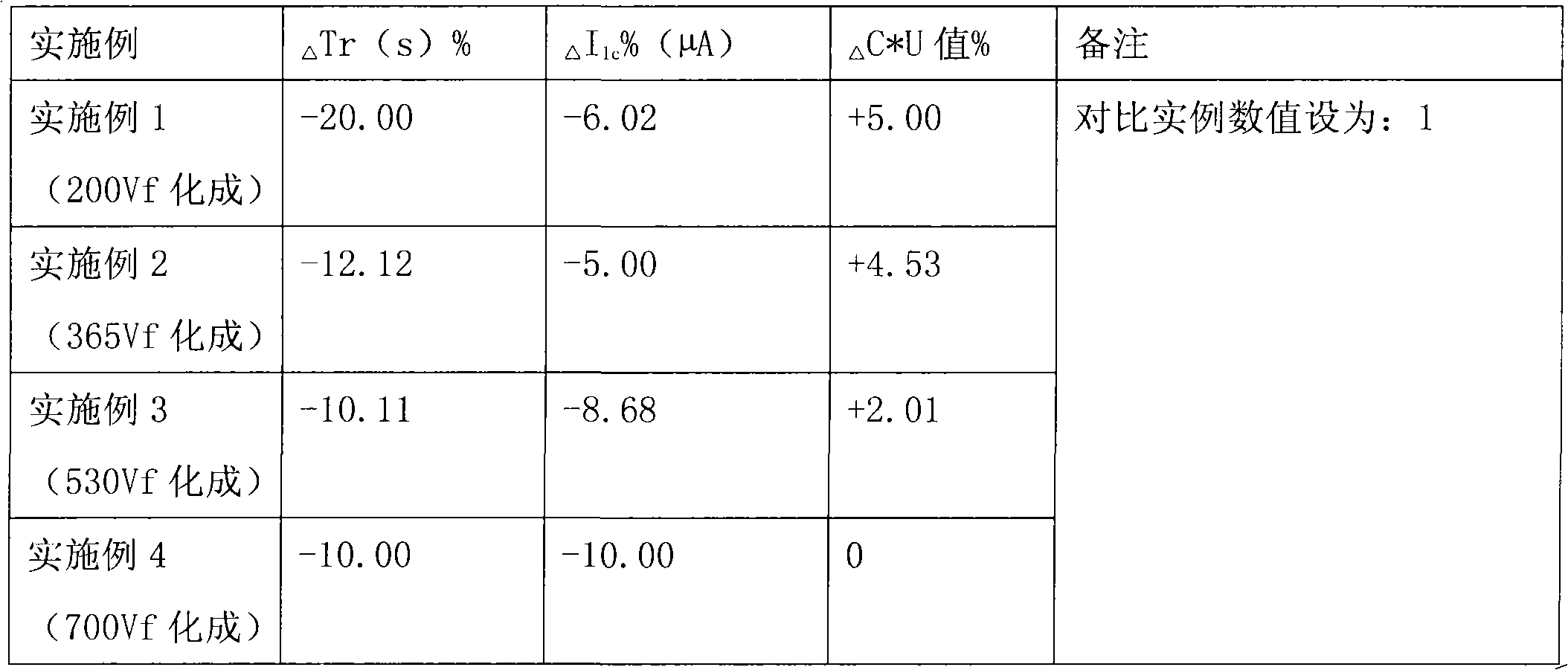

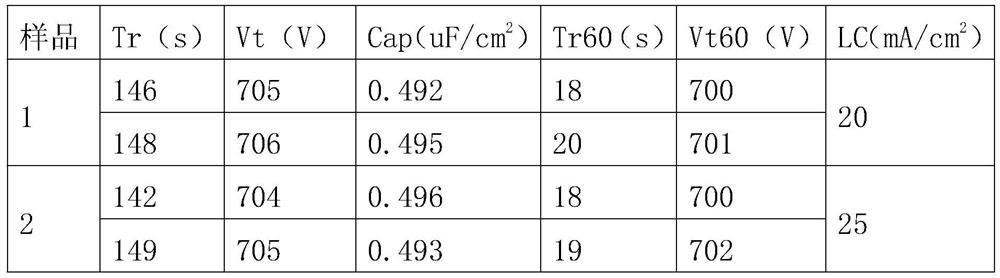

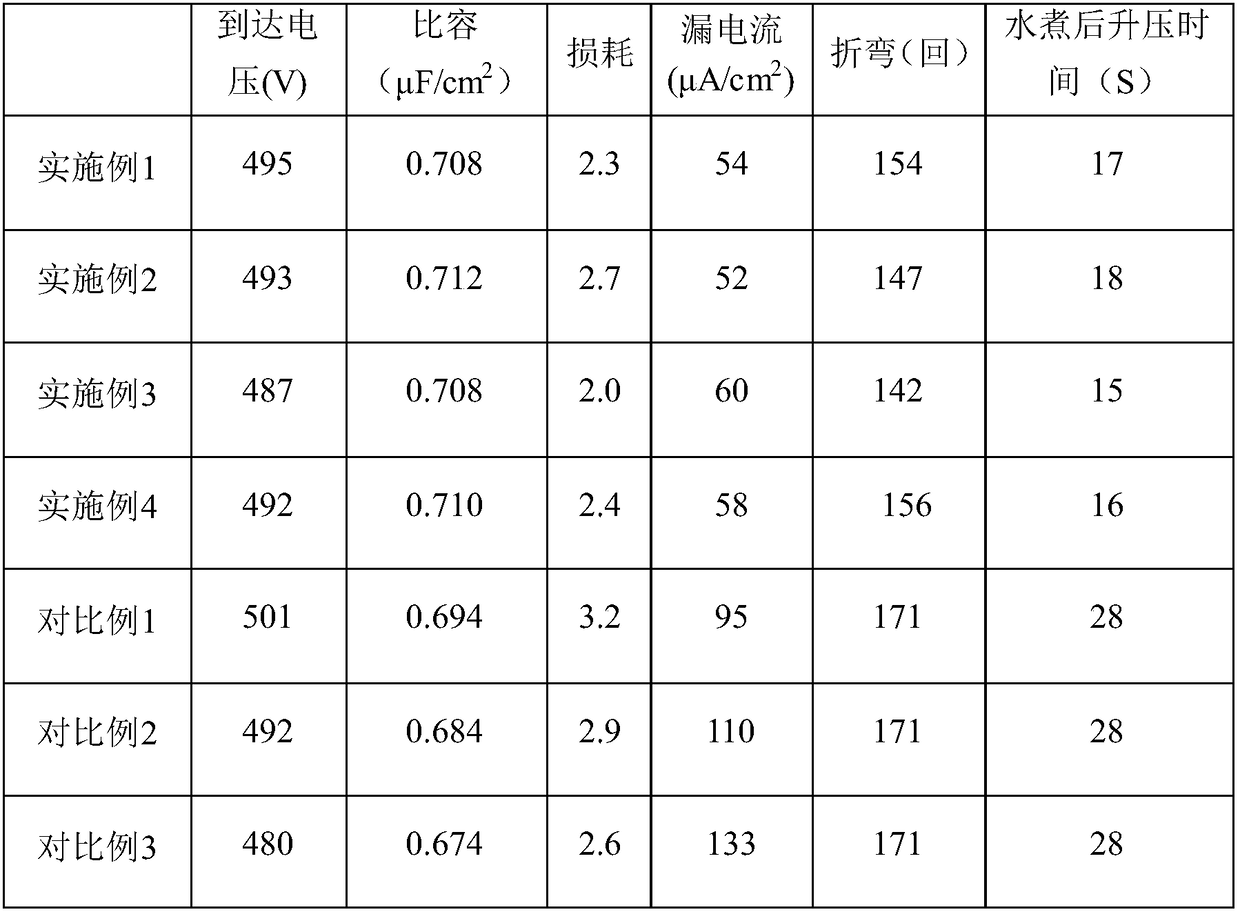

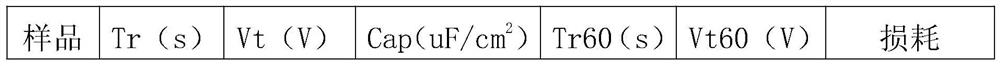

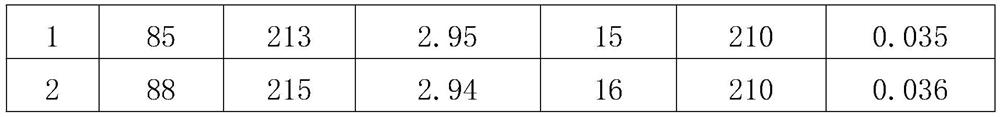

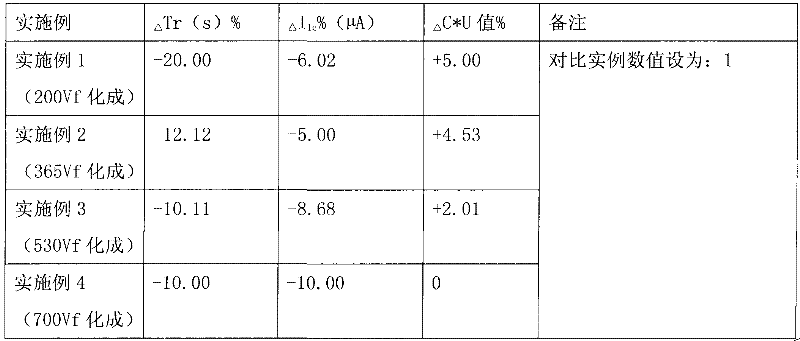

Formation technique of medium/high-voltage anode aluminum foil for enhancing aluminum electrolytic capacitance

ActiveCN103243369AIncrease capacityShort boost timeSurface reaction electrolytic coatingCapacitanceElectrolysis

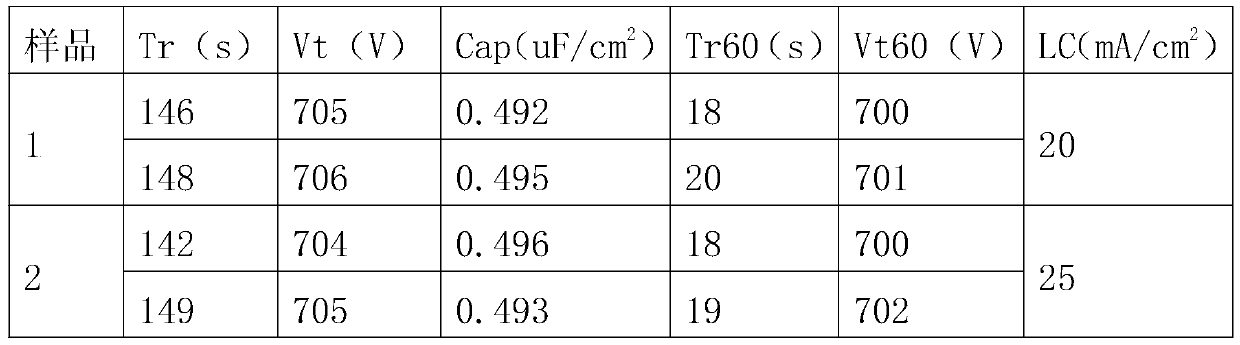

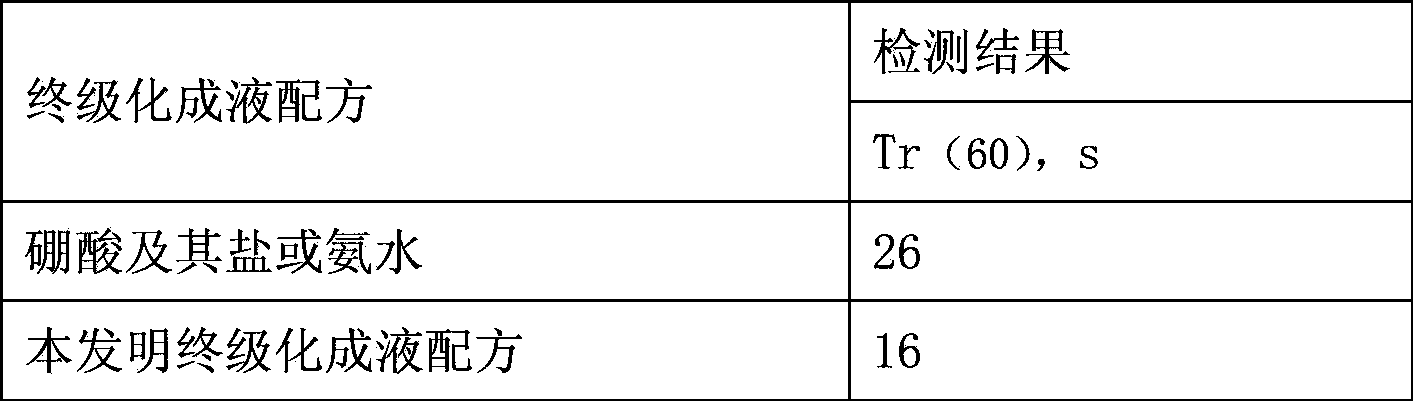

The invention relates to the technical field of medium / high-voltage formation of anode foils, particularly a six-stage formation technique for enhancing capacity of an anode foil for an aluminum electrolytic capacitor and lowering the boosting time Tr and Tr60 by medium / high voltage. The technique is characterized by comprising the following steps: treating an aluminum foil subjected to electrolytic corrosion treatment in 50-100 DEG C pure water, and forming with phytic acid and citrate solution in the primary, secondary and tertiary stages; forming in phytic acid, boric acid and citrate solution in the quaternary, quinary and senary stages; and depolarizing by heat treatment and phosphate treatment. The boosting time Tr is at least lowered by 23%, the boosting time Tr60 is at least lowered by 66%, and the specific capacity effect of the aluminum foil is enhanced by 10-20%.

Owner:YIDU DONGYANGGUANG FORMED FOIL

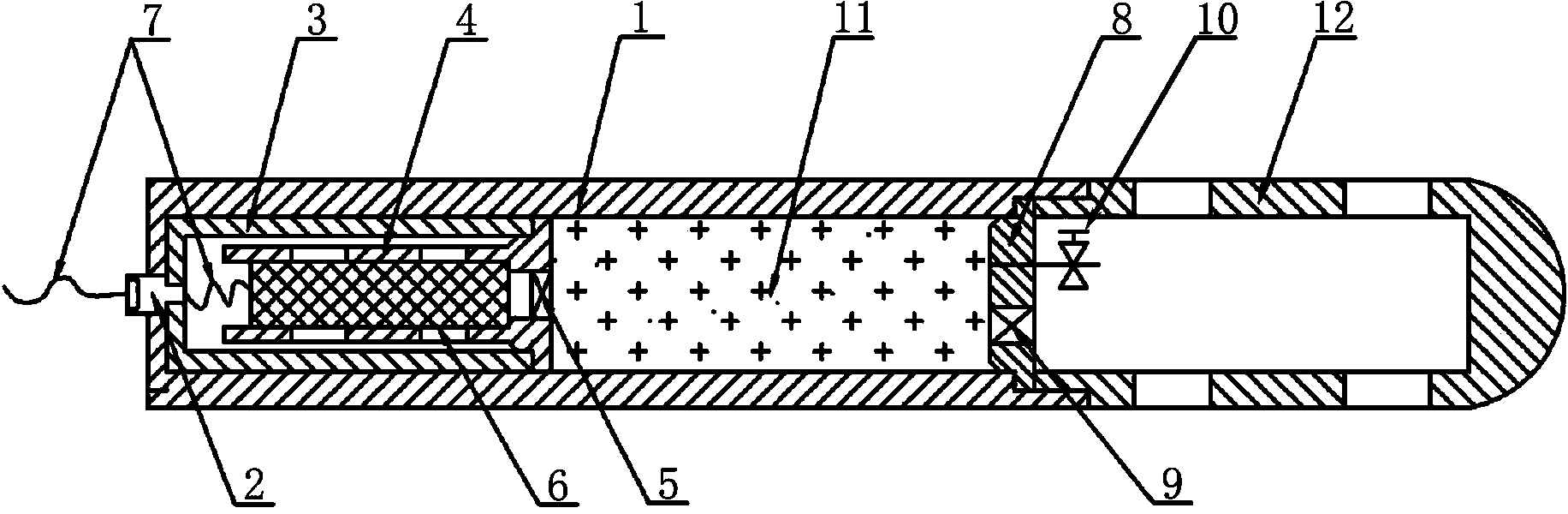

Chemical and physical combined explosion fracturing device and manufacturing method thereof

ActiveCN103352684ASolve the limited effect of fracturingSolution rangeFluid removalInterference fitHigh pressure

The invention relates to the fracturing technology, in particular to a chemical and physical combined explosion fracturing device and a manufacturing method of the chemical and physical combined explosion fracturing device. The chemical and physical combined explosion fracturing device and the manufacturing method of the chemical and physical combined explosion fracturing device resolve the problems at the existing fracturing technology is limited in fracturing effect, narrow in application range and poor in use safety. The chemical and physical combined explosion fracturing device comprises a fracturing device outer shell, wherein the front portion of an inner cavity of the fracturing device outer shell is in interference fit with a powder chamber outer barrel, an inner cavity of the powder chamber outer barrel is provided with a powder screening pipe in a sleeved mode, a first explosion film is arranged on an opening in the rear end of the powder screening pipe in a sealing mode, an inner cavity of the powder screening pipe is filled with a powder pillar which is connected with an ignition line, a pressing nut is arranged on an opening in the rear end of the fracturing device outer shell in a sealing mode, a through hole penetrating through the front portion and the rear portion is formed between the front end surface and the rear end surface of the pressing nut, a second fracturing film is arranged on the through hole in a sealing mode, and the rear portion of the inner cavity of the fracturing device outer shell is filled with high-pressure CO2 in a sealing mode. The chemical and physical combined explosion fracturing device and the manufacturing method of the chemical and physical combined explosion fracturing device are suitable for the development of petroleum, natural gas, coal bed gas, shale gas and the like, and suitable for a pre-fracturing and permeability-increasing process of extraction of coal bed gas under a coal mine shaft.

Owner:ZHONGBEI UNIV

Forming technique for reducing voltage rising time of aluminum electrolytic capacitor anode foil

InactiveCN1990914AShort boost timeMeet the characteristic requirementsElectrolytic capacitorsSurface reaction electrolytic coatingPre treatmentCapacitance

The invention relates to a process for reducing bossting time for formation of aluminum electorlytic capacitance anode foil, comprising boiling with pure water, forming, depolarizing and reforming. There is a pretreatment before boiling with pure water: putting corrosive foil into nitrate liquid for 1-60 seconds at room temperature, the proportion by weight of nitrate liquid is 1% -15%. The invention keeps the initial range of the product CV of specific capacitance and withstand voltage, and reduces the bossting time for aluminum electorlytic capacitance anode foil, which can meet the specific requirement for raw material of anode foil, and it is suitable for high and low pressure aluminum electrolytic capacitance.

Owner:XINJIANG JOINWORLD CO LTD

Formation method for anode foil of intermediate-voltage aluminum electrolytic capacitor

InactiveCN102709059AIncrease specific volumeGood hydration resistanceElectrolytic capacitorsPhosphateThree stage

The invention discloses a formation method for an anode foil of an intermediate-voltage aluminum electrolytic capacitor, and belongs to the technical field of manufacture of anode foils of aluminum electrolytic capacitors. According to the formation method for the anode foil of the intermediate-voltage aluminum electrolytic capacitor, ammonium adipate is adopted as four-stage formation electrolyte. The technical scheme is that: the method comprises the following steps of: performing three-stage formation by adopting a solution of ammonium adipate as electrolyte, performing the formation of a fourth stage by using a boric acid and ammonium dihydrogen phosphate, performing high-temperature treatment, performing treatment by using a phosphate solution, and performing drying to obtain the anode foil of the intermediate-voltage aluminum electrolytic capacitor. The ammonium adipate is adopted as the formation electrolyte, so that the obtained anode foil of the capacitor is high in specific capacity and high in hydration resistance, boosting time is shortened, and a Tr60 value is decreased.

Owner:YONGJI SUHAI ALUMINUM

Formation treatment method for improving water resistance of high-middle-pressure formed foil

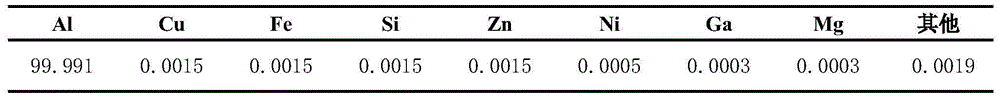

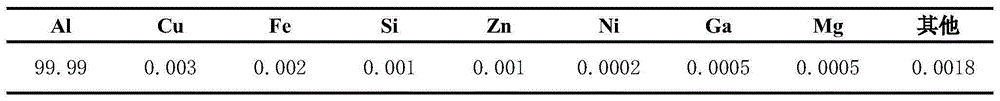

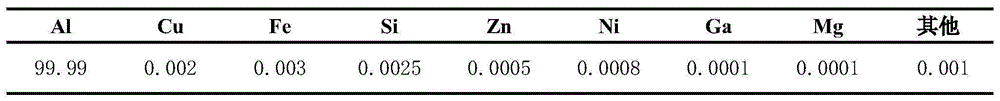

ActiveCN102677056AThe chemical conversion method is simpleEasy to implementSuperimposed coating processO-Phosphoric AcidPhosphate

The invention discloses a formation treatment method for improving water resistance of high-middle-pressure formed foil. The formation treatment method comprises immersing corroded aluminum foil with purity of 99.99% in water, taking the aluminum foil out, immersing the aluminum foil into fumaric acid water solution and then taking out; putting the aluminum foil into dihydric phosphate water solution to perform first-grade formation; taking out to perform washing; putting the washed aluminum foil into the dihydric phosphate water solution to perform second-grade formation; taking out to perform washing; putting the secondarily-washed aluminum foil into mixed water solution formed by boric acid and borate to perform third-grade formation; taking out the third-grade formed aluminum foil andputting into the water solution to perform fourth-grade formation; taking out the fourth-grade formed aluminum foil to perform high-temperature heat treatment and then putting into the water solutionto perform fifth-grade formation; taking out the fifth-grade formed aluminum foil and putting into phosphoric acid solution to perform processing; taking out the aluminum foil to perform washing and putting into the water solution to perform sixth-grade formation; and taking out the sixth-grade formed aluminum foil, immersing the aluminum foil in the dihydric phosphate water solution to perform washing, and performing drying. The formation treatment method has the advantages that the formation treatment method is simple, pressure rising time of manufactured products after boiling is shortened, and the water resistance is improved.

Owner:NANTONG HAIYI ELECTRONICS

Anode aluminium foil after treatment method for aluminium electrolytic capacitor

InactiveCN101740227AHigh capacitanceReduce the problem of broken foil caused by riveting instabilityCapacitor electrodesCleaning using liquidsPressure riseAfter treatment

The invention relates to an anode aluminium foil after treatment method for an aluminium electrolytic capacitor, comprising the steps: pretreatment, first-grade corrosion A, second-grade corrosion B1, second-grade corrosion B2, after treatment and drying of corrosion foil, wherein the after treatment comprises the steps of chemical cleaning and ultrasonic cleaning; the after treatment comprises the steps of: putting aluminium foil processed by the second-grade corrosion B2 into 0.3-5wt% nitric acid solution at the temperature of 30-85 DEG C, and performing ultrasonic treatment for 5-60s at the ultrasonic frequency of 1-50KHz and the power of 0.5-5KW. Compared with the electrode corrosion foil prepared by the original technique, the electrostatic capacity of the cleaned anode aluminium corrosion foil is increased by 1-3%, and the pressure rising time is shortened by 6-12%.

Owner:GUANGXI HEZHOU GUIDONG ELECTRONICS TECH

Formation method for anode foil of extra-high voltage aluminum electrolytic capacitor

ActiveCN110219032AImprove leakage currentIncrease lossAnodisationElectrolytic capacitor manufacturePhosphoric acidPre treatment

The invention relates to a formation method for an anode foil of an extra-high voltage aluminum electrolytic capacitor. The formation method for the anode foil of the extra-high voltage aluminum electrolytic capacitor comprises the following steps: (1) pre-treatment; (2) first level formation; (3) second level formation; (4) third level formation; (5) four level formation; (6) five level primary formation; (7) primary high temperature treatment; (8) phosphoric acid treatment; (9) fifth level secondary formation; (10) secondary high temperature treatment; (11) fifth level third formation; and (12) post-treatment. According to the formation method, the voltage in each level formation is greater than that applied in the previous level formation. The formation method also comprises a liquid feeding treatment which is carried out after second level formation or third level treatment. The formation method for the anode foil of the extra-high voltage aluminum electrolytic capacitor is simpleto control, and the bath solution components are relatively simple and better to control, so that the formation method is suitable for industrial batch production.

Owner:XINJIANG JOINWORLD CO LTD

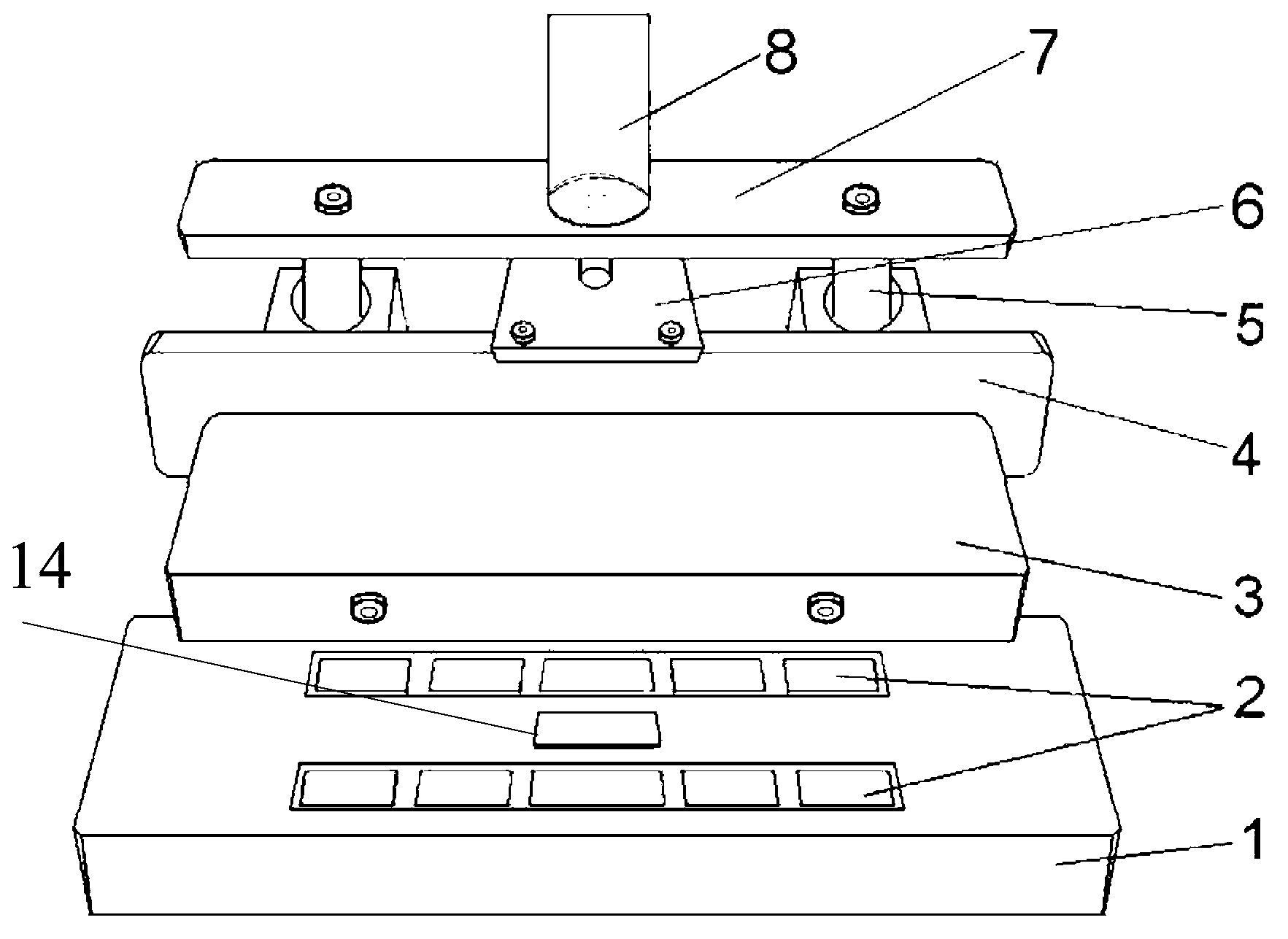

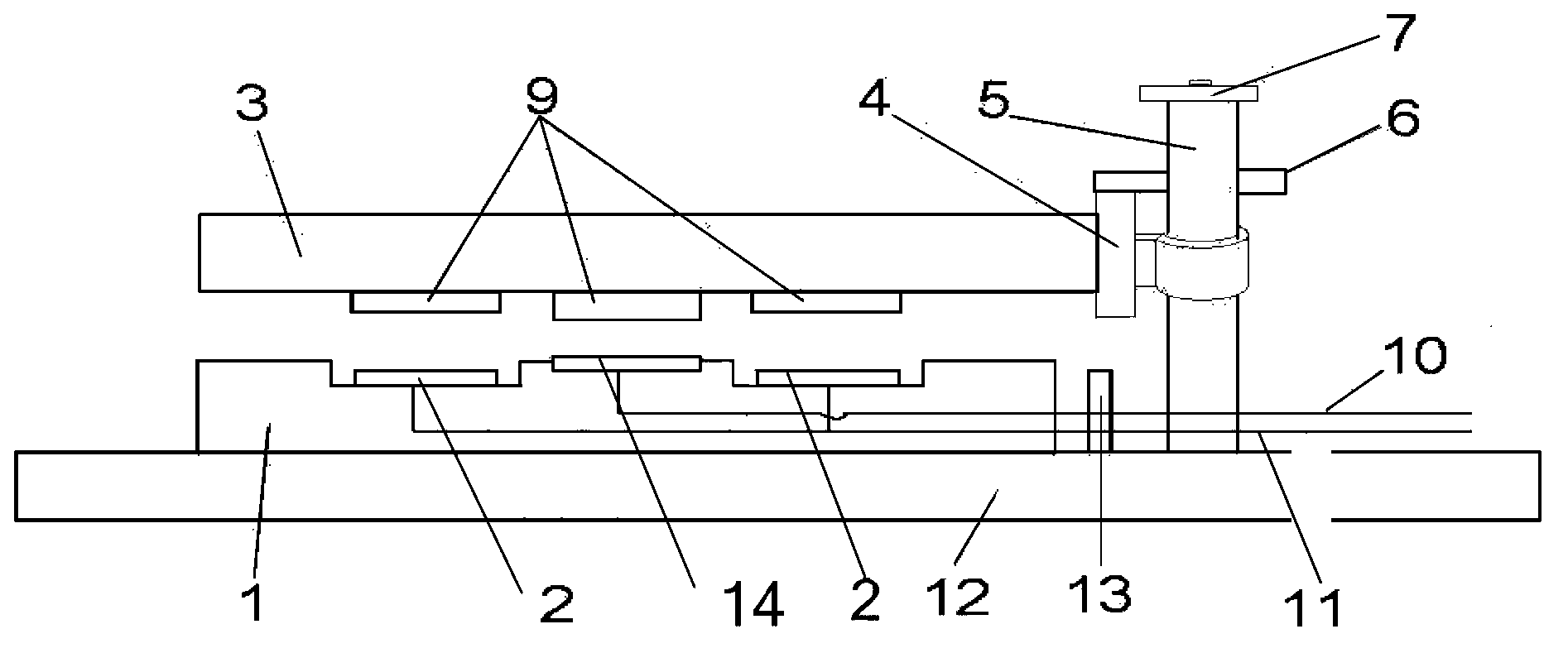

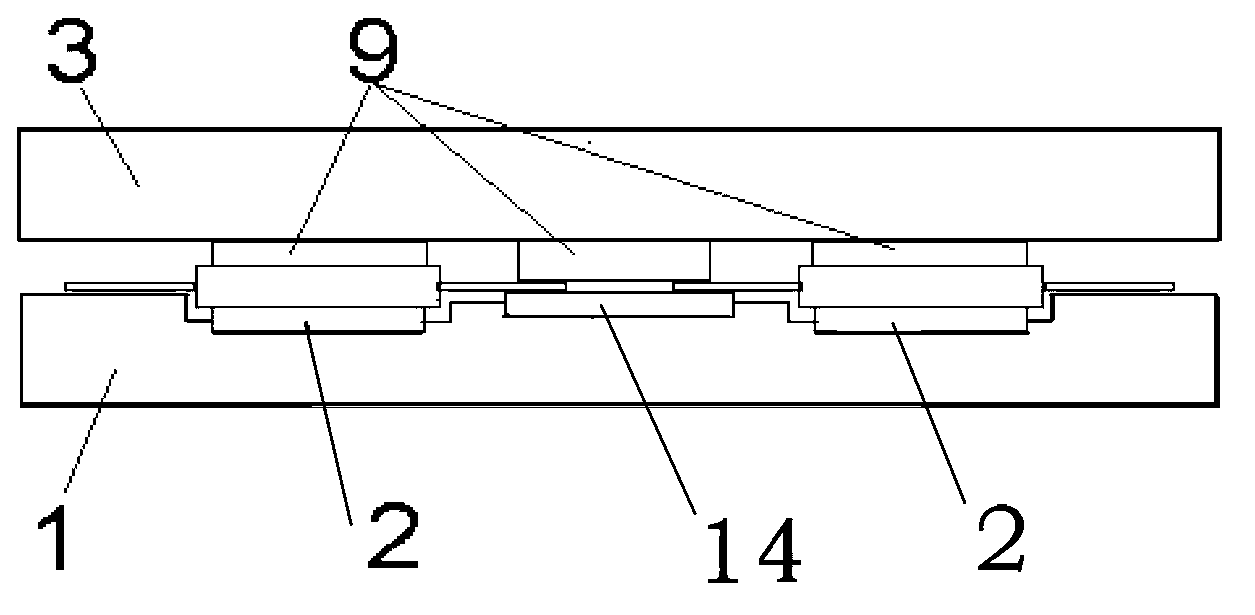

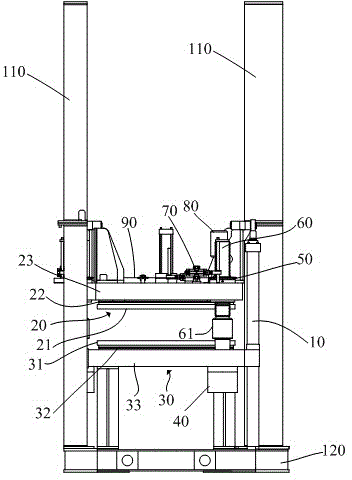

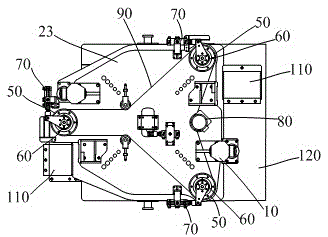

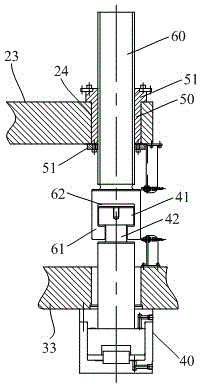

IC (Integrated Circuit) plastic-package body voltage withstand test clamp and test methods

InactiveCN102798739AReduce the number of timesShort boost timeTesting dielectric strengthMeasurement instrument housingElectricityTest efficiency

The invention discloses an IC (Integrated Circuit) plastic-package body voltage withstand test clamp which comprises a fixed base, a pressing plate and a guide pillar, wherein at least one bearing body which is used for placing a whole IC plastic-package body is arranged on the fixed base; the bearing body is internally provided with a plurality of first metal gaskets which are arranged at intervals and electrically connected with the cathode of a voltage withstand tester; a second metal gasket which is connected with the anode of the voltage withstand tester is also arranged on the fixed base; and the pressing plate is arranged on the guide pillar and is capable of moving up and down relative to the guide pillar. The invention discloses two plastic-package body voltage withstand test methods. According to the clamp and the methods, a voltage withstand test can be carried out on the whole IC plastic-package body before products are subjected to trimming and forming, so that the test efficiency is improved and the voltage withstand test can be carried out on a plurality of IC plastic-package bodies at the same time.

Owner:HANGZHOU SILAN INTEGRATED CIRCUIT

Cleaning method of electronic energy storage materials

ActiveCN105200509AImprove electrical performanceHigh capacitanceElectrolytic capacitorsCleaning methodsElectron

The invention discloses a cleaning method of electronic energy storage materials. The electronic energy storage materials are anode foils for aluminum electrolytic capacitors, the cleaning method is a technological process for conducting cleaning treatment on the aluminum foils which are subjected to pretreatment, electrochemical hole corrosion, intermediate treatment and electrochemical reaming corrosion, and the cleaning treatment comprises first-time cleaning treatment, second-time cleaning treatment and third-time cleaning treatment. According to the cleaning method of the electronic energy storage materials, electrical properties of the corrosion foils for the aluminum electrolytic capacitors are effectively improved by introducing the ultrasonic cleaning effect and improving the formula of cleaning fluid and the cleaning technology. Compared with the prior art, the electrostatic capacity of the anode corrosion foils produced through the cleaning method of the electronic energy storage materials is increased by 4.91%-5.95%, the voltage rising time of formed foils is shortened by 2-10 s, and meanwhile the problem that riveting of a front roll and a back roll is not stable during formation production is effectively solved.

Owner:新疆广投桂东电子科技有限公司

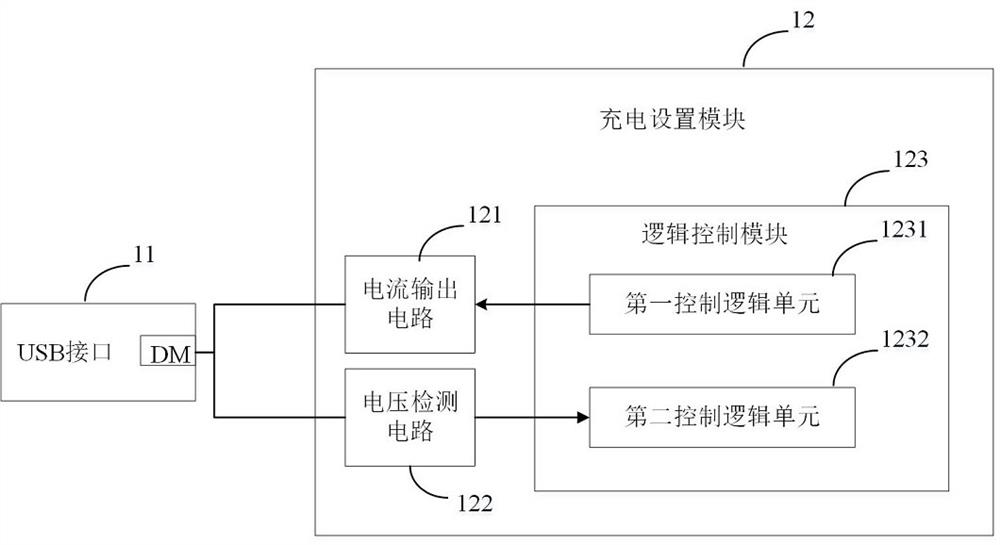

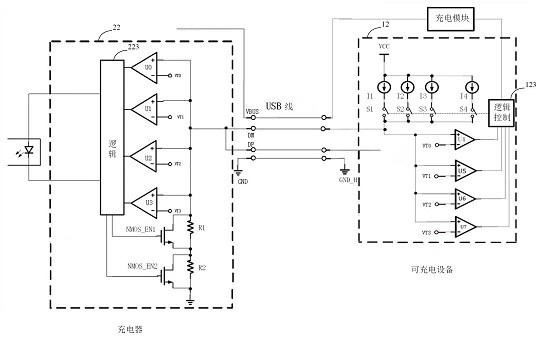

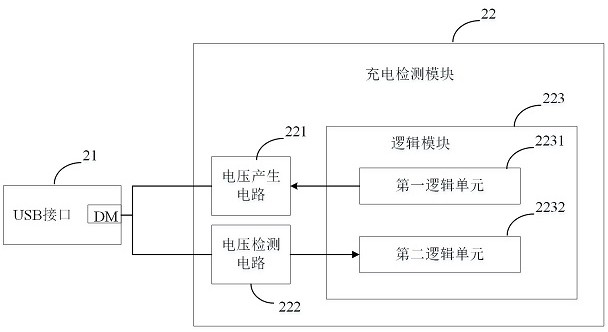

Rechargeable device, charger and charging system

ActiveCN112436577ADirect controlShort boost timeElectric powerCharging/discharging current/voltage regulationSignal onEngineering

The invention discloses a rechargeable device, a charger and a charging system. The rechargeable device includes: a USB interface, the USB interface including a DM pin; a current output circuit whichis used for outputting a first signal to the DM pin, wherein the first signal is a current signal and is used for controlling the charger; a first control logic unit which is used for controlling thecurrent value of the first signal; a voltage detection circuit which is used for detecting a second signal on the DM pin, wherein the second signal is a voltage signal and is used for feeding back whether the control of the first signal to the charger is responded or not; and a second control logic unit which is used for identifying the second signal by judging the voltage interval in which the voltage is located. The rechargeable device and the charger can perform analog signal interaction through the DM pin of the USB interface, particularly, the charger can make a corresponding feedback signal after receiving the signal indication of the rechargeable device, the rechargeable device can know the state of the charger through the feedback signal, and the charger does not need to be detected.

Owner:SPREADTRUM COMM (SHANGHAI) CO LTD

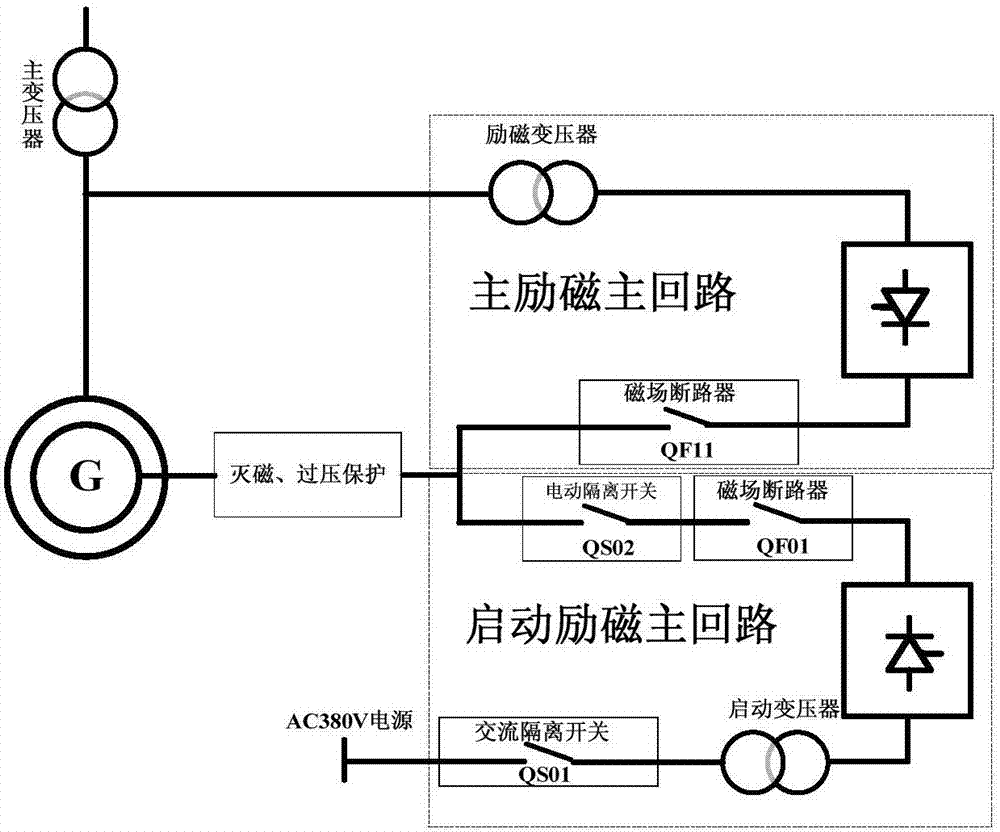

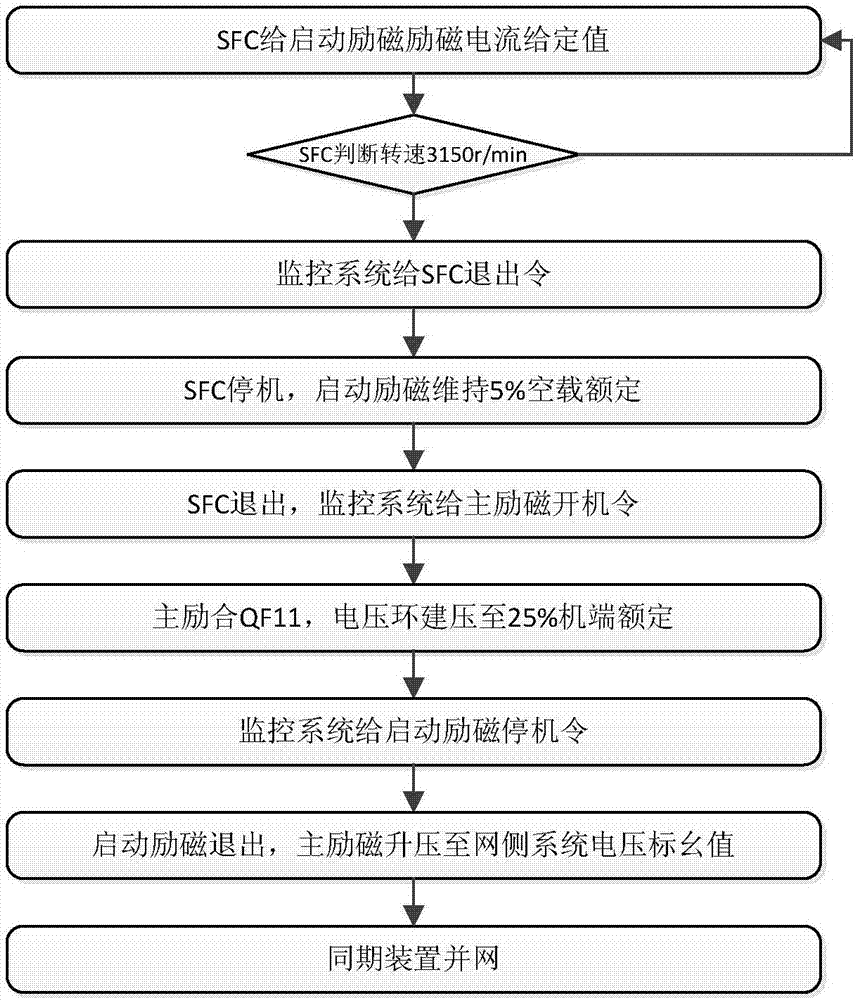

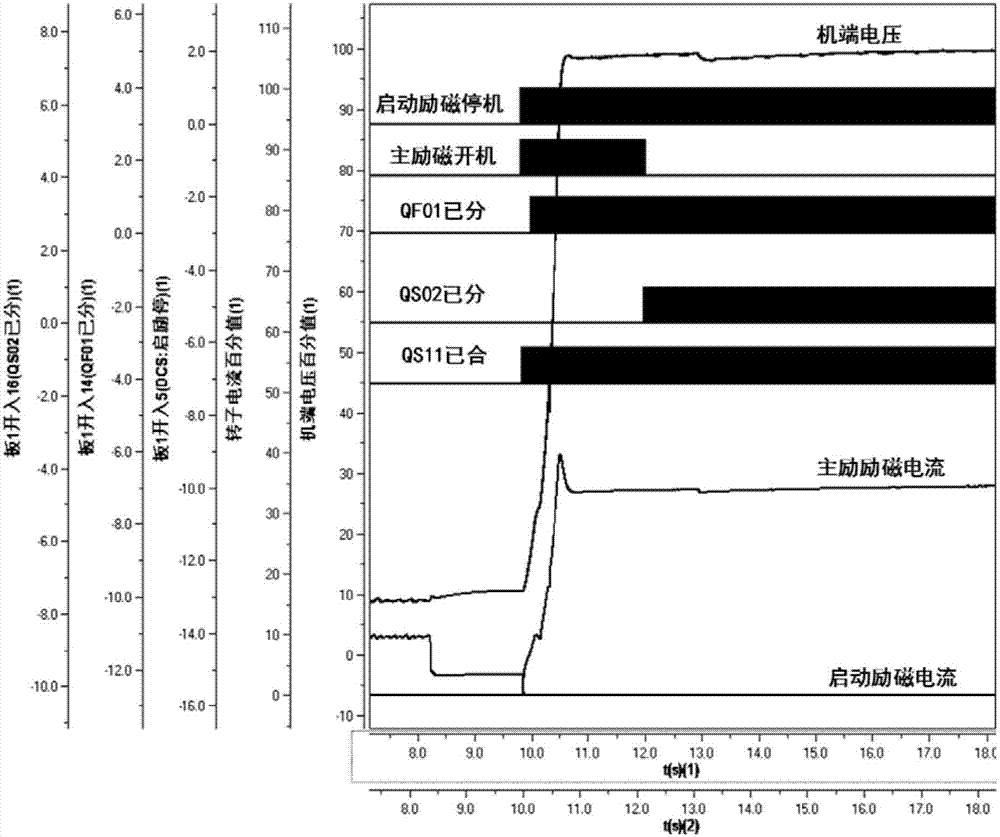

Excitation control method of large-size phase modifier during starting and grid-connected process

ActiveCN107979096AReduce shockGuaranteed uptimeElectric power transfer ac networkReactive power adjustment/elimination/compensationOvervoltageExcitation current

The invention discloses an excitation control method of a large-size phase modifier during the starting and grid-connected process. A self excitation system and a separate excitation system are independent at an AC side and a rectification unit, are connected in parallel at a DC side and share a group of de-excitation and overvoltage protection device, the switching time of the two excitation systems is short, no disturbance is generated during the switching process, a boost mode of a phase modifier end employs two-segment boosting, inversion and zero-starting boosting are not needed, and an excitation current is rapidly and smoothly transferred to the other excitation system from one of the excitation systems. By coordinated control of a corresponding excitation regulator, the problem ofrapid switching of the two excitation systems during the running down process of the large-size phase modifier is solved, the disturbance of the two excitation systems during the switching process issuppressed, the complete protection function is achieved, the impact caused by voltage difference during grid connection of the large-size phase modifier is reduced, and the excitation control methodhas the important significance to the safe, efficient and reliable running of the large-size phase modifier.

Owner:NARI TECH CO LTD +1

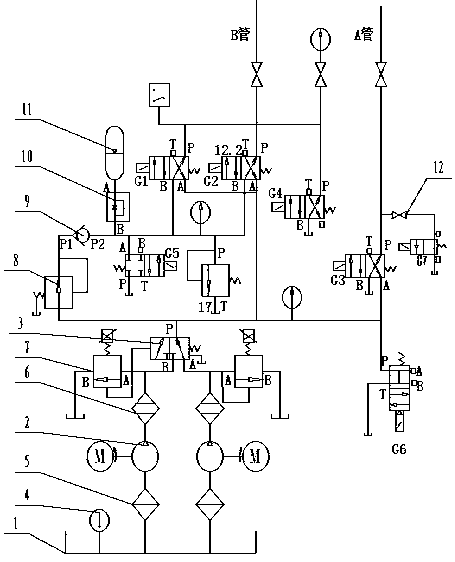

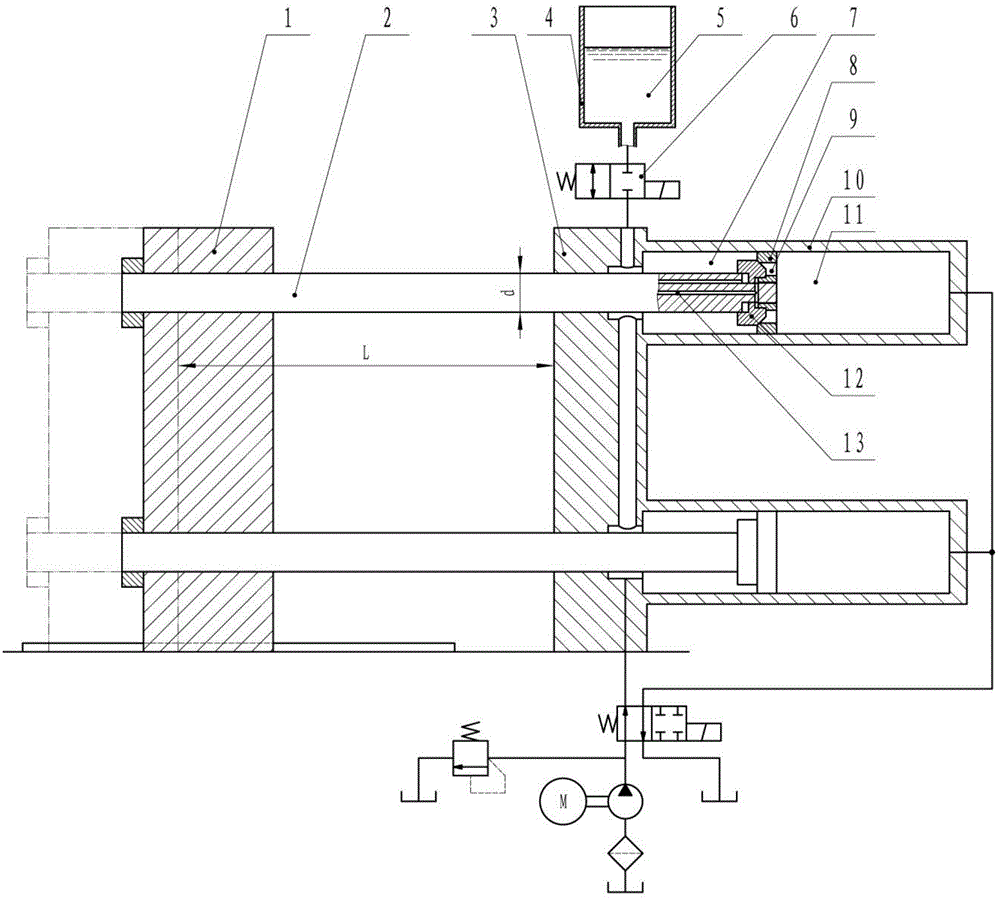

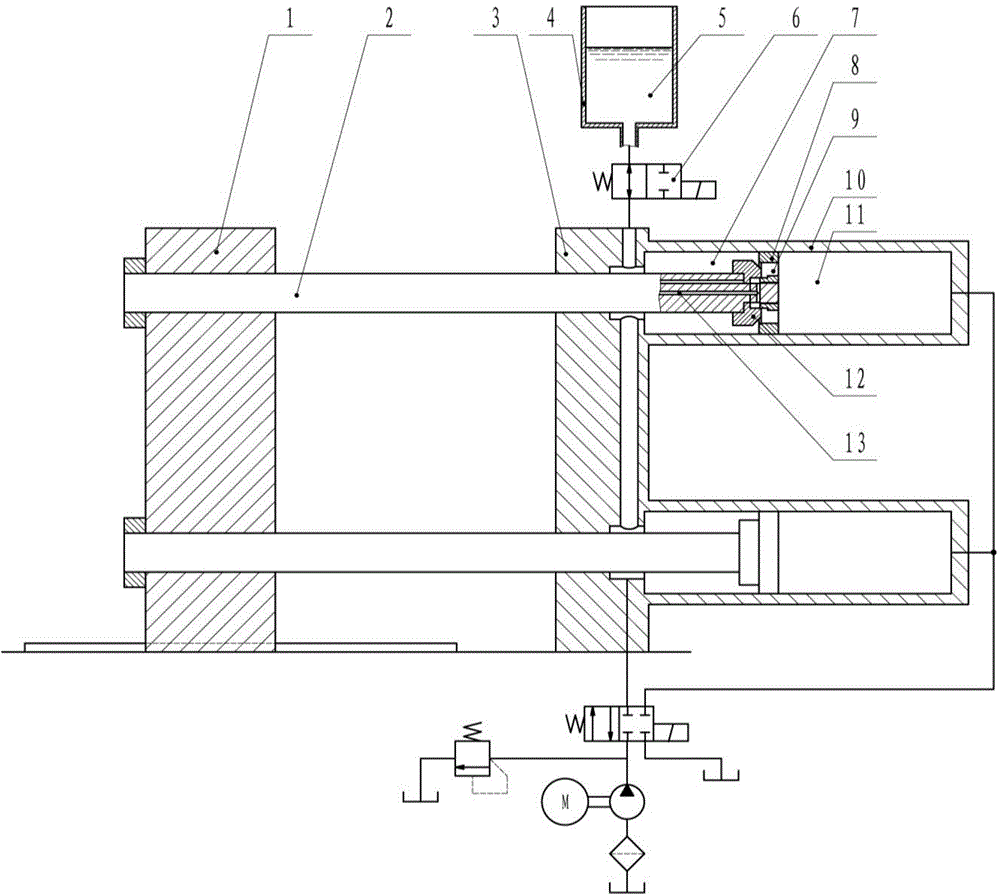

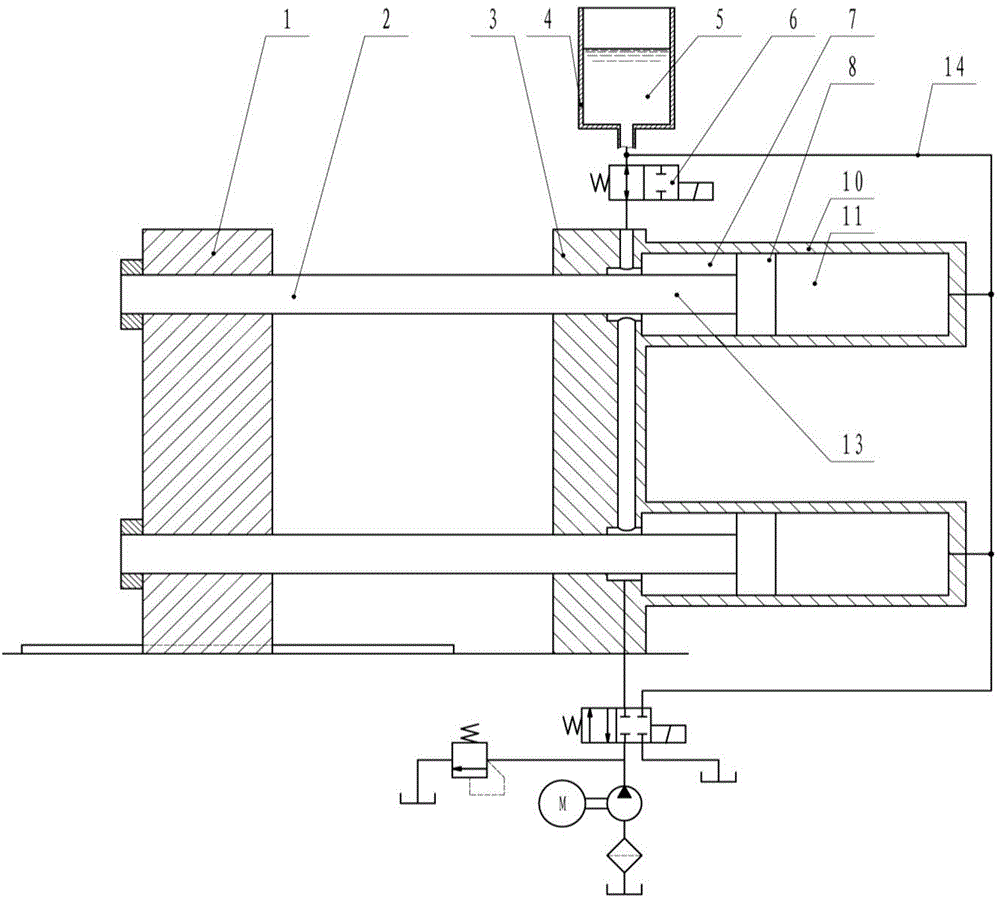

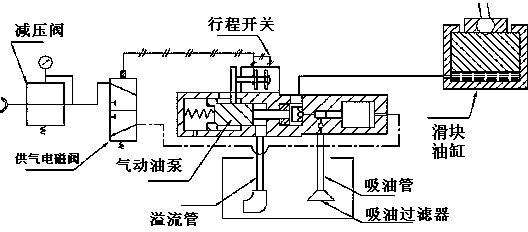

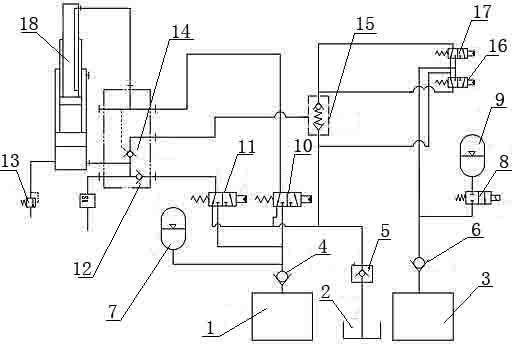

Hydraulic tire vulcanizing machine

InactiveCN106142404ASimple structureIncrease equipment installation and maintenance spaceEngineeringMaterials science

The invention provides a hydraulic tire vulcanizing machine. The hydraulic tire vulcanizing machine comprises vulcanizing chambers, a mould opening and closing oil cylinder, a base and a plurality of guild pillars fixedly arranged on the base. The upper vulcanizing chamber comprises an upper hot plate, an upper thermal baffle and an upper main board; the lower vulcanizing chamber comprises a lower hot plate, a lower thermal baffle and a lower main board; and a plurality of integrated mechanisms are arranged on the vulcanizing chambers, and the integrated mechanisms integrate functions of mould clamping, stress application and mould adjusting. According to the hydraulic tire vulcanizing machine, the three functions of mold clamping, stress application and mold adjusting can be achieved only by arranging the integrated mechanisms, and thus the vulcanizing machine structure is simplified greatly, and space for equipment installation and maintaining is enlarged; an stress application oil cylinder only works in the process of vulcanization stress application, so the travel of the oil cylinder is short, and the stress application time is short; mould adjusting is achieved through the mould opening and closing motions and the relative motions of screw nuts and screw rods; mould clamping is also achieved through the integrated mechanisms, clamping rings in the prior art are omitted, the center distance between two moulds of a dual-mould hydraulic vulcanizing machine can be reduced, the occupied area of the whole machine can be reduced, the maintenance space is enlarged, and the maintenance is convenient.

Owner:QINGDAO MESNAC ELECTROMECHANICAL ENG +1

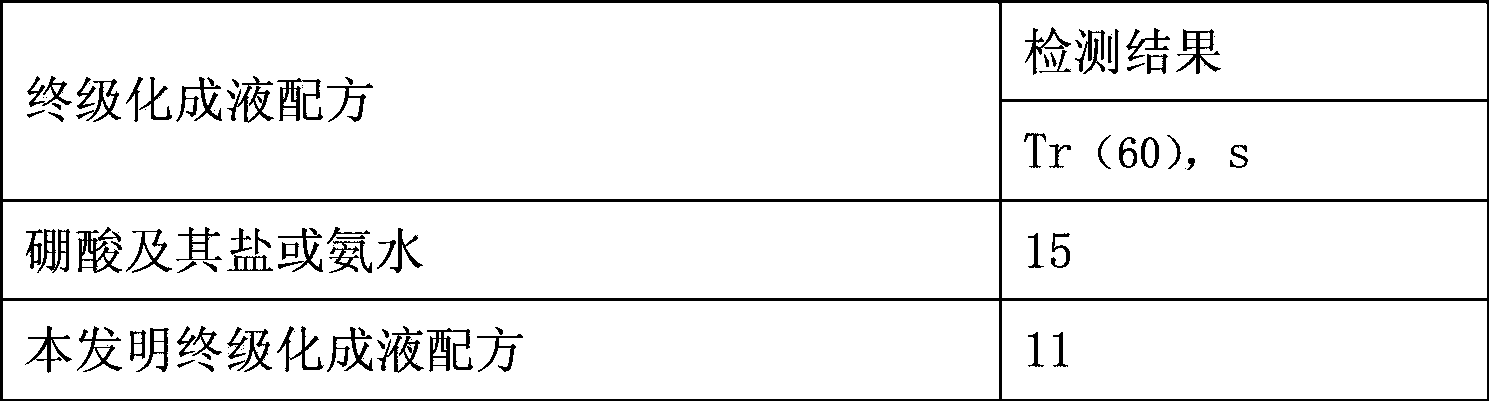

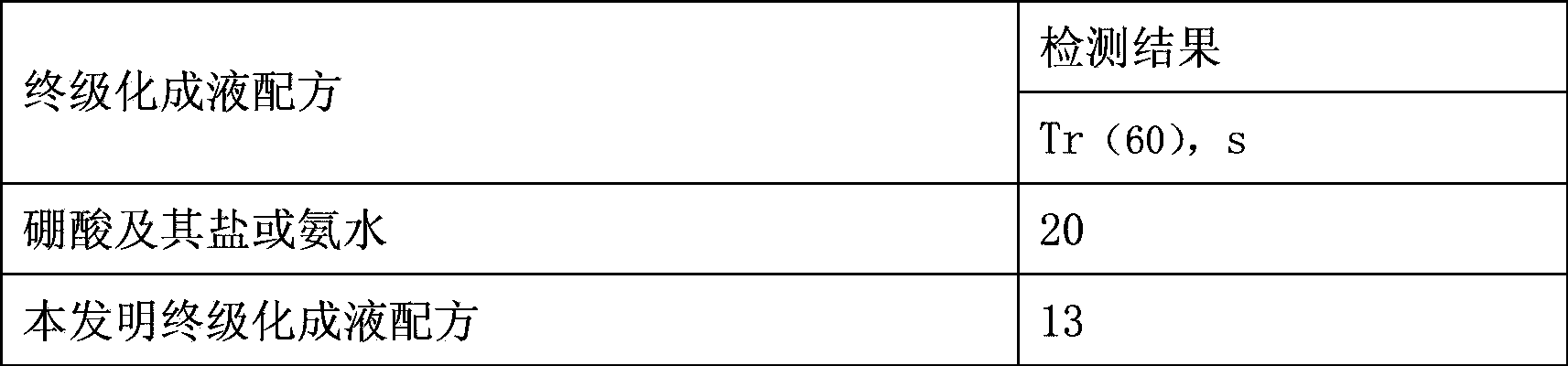

Additive for ultimate formation liquid of middle and high pressure formed foil and adding method thereof

The invention discloses an additive for an ultimate formation liquid of middle and high pressure formed foil and an adding method thereof, the additive is a long-carbon-chain dicarboxylic acid or a salt thereof, and comprises one or more than one from azelaic acid, ammonium hydrogen azelate, sebacic acid and ammonium sebacate, and the additive content is 0.001-0.500wt%. According to the method by adding the additive into the ultimate formation liquid, hydration resistance of the middle and high pressure formed foil can be effectively improved, and the formed foil is more stable in performance.

Owner:GUANGXI HEZHOU GUIDONG ELECTRONICS TECH

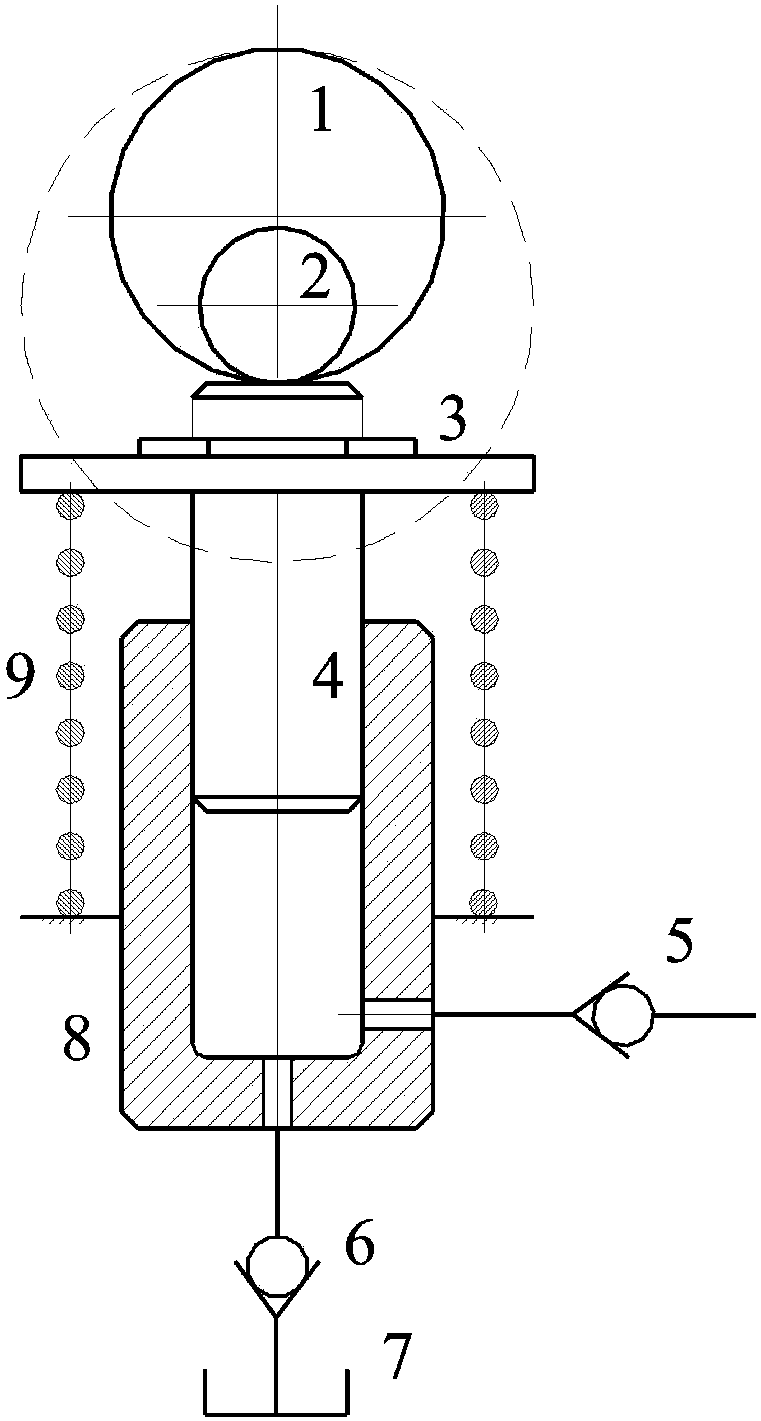

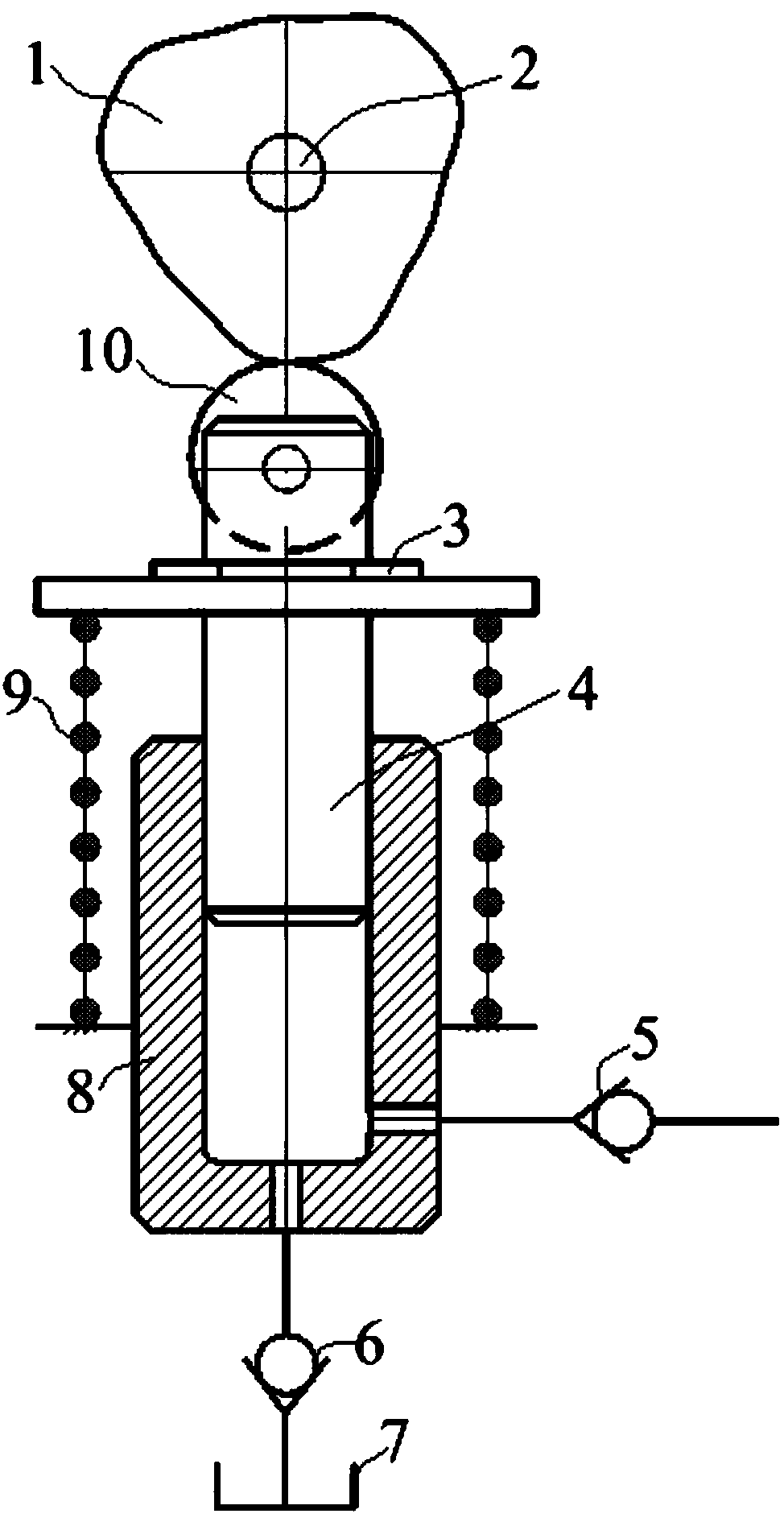

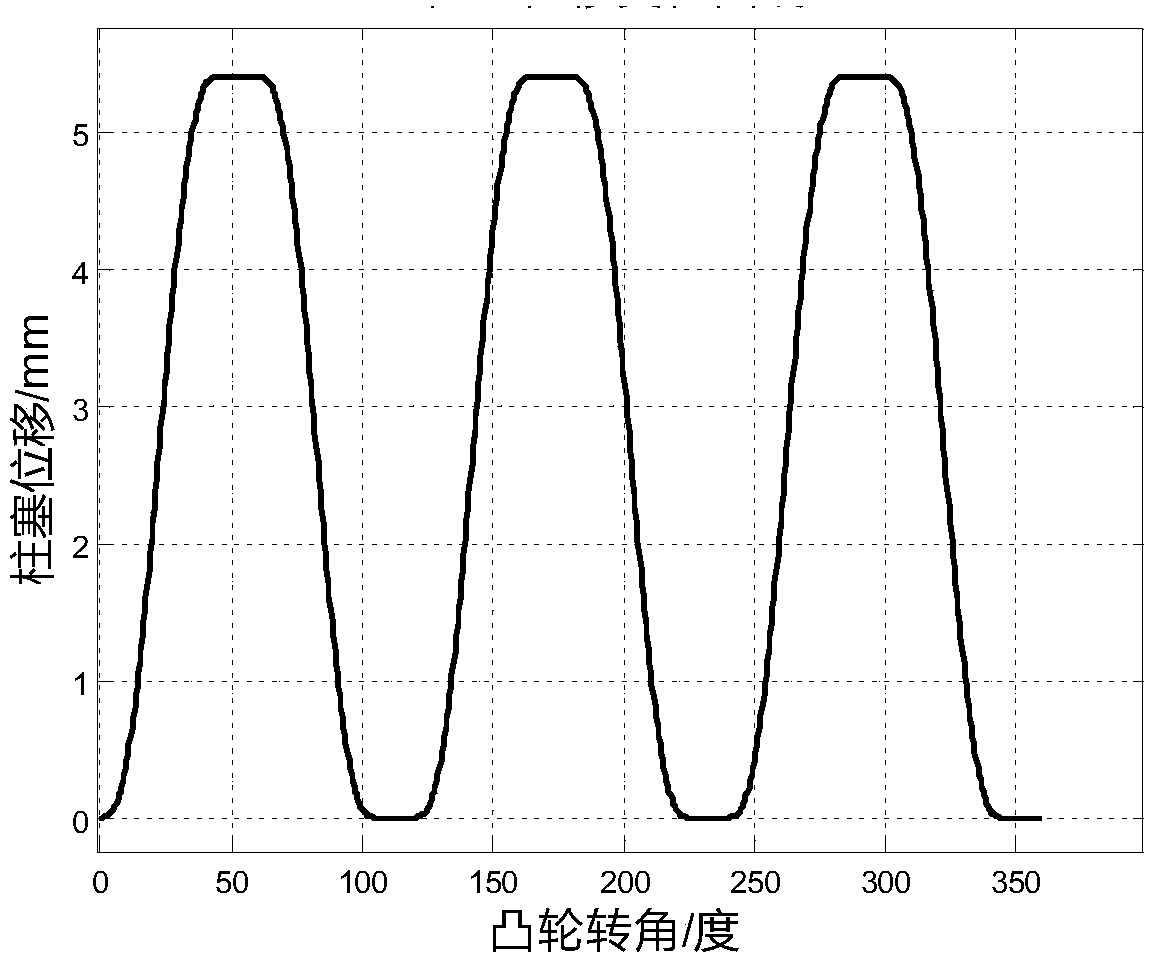

Single-plunger three-function high-pressure electric pump based on regular triangle cam

PendingCN108457830AReduce speedExtended service lifePositive displacement pump componentsPiston pumpsDrive shaftFuel tank

The invention discloses a single-plunger three-function high-pressure electric pump based on a regular triangle cam. The single-plunger three-function high-pressure electric pump comprises a cam, a plunger and a roller bearing. A transmission shaft is arranged at the center position of the cam, one end of the plunger is located in a pump body, and the roller bearing is hinged to the other end of the plunger and located between the plunger and the cam. A lock spring is connected between the plunger and the outer wall of the pump body. The side wall of the pump body is connected with an oil discharging valve, and the bottom wall of the pump body is connected to an oil tank through an oil suction valve. A regular triangle disc-shaped cam structure is adopted, and the three-function oil suction and discharging manner is achieved. The motion law in which the denary polynomial function curve and the multi-arc section function curve are effectively combined is adopted as the outline curve ofthe regular rectangle cam. The problem about centrifugal force of eccentric wheels or common cams and the problem of the low pump volume efficiency due to too slow oil suction and discharging valve opening and closing are solved, and the beneficial effects that the volume efficiency is high, flexible impacts are weak, and vibration and noise are low are achieved. The alignment roller push rod technology is adopted, and the beneficial effects that abrasion is little, and the service life is long are achieved.

Owner:安徽德鸿机件制造有限公司

Elevator braking system redundancy loop

PendingCN107673158ARealize Parallel Redundant LoopImprove securityElevatorsHoisting equipmentsControl engineeringControl theory

The invention relates to an elevator braking system redundancy loop which is provided with a solenoid directional valve G7. Oil is returned when the solenoid directional valve G7 is powered off, the solenoid directional valve G7 is connected with a solenoid directional valve G3 in parallel to achieve oil returning, a hydraulic pressure station does not need to be replaced, the construction amountis small, the lifting influencing time is short, the number of replaced accessories is small, cost is low, the parallel connection redundancy loop of a braking system is achieved, the regulation requirement is met, and the lifting machine safety factor is improved.

Owner:XINAN COAL IND ZAOZHUANG COAL MINING GROUP

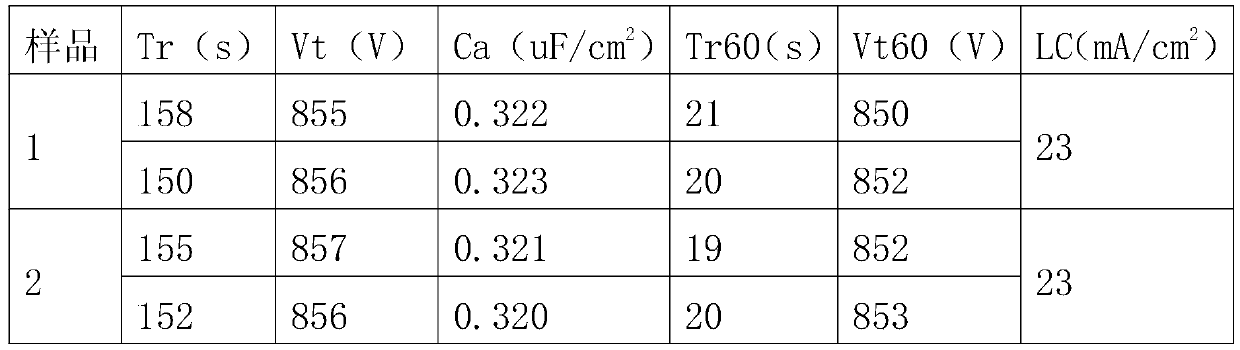

Depolarization method in foiling process of electronic aluminum foil

ActiveCN102021627AShort boost timeReduce leakage currentElectrolytic capacitorsSurface reaction electrolytic coatingSpecific volumeThermal treatment

The invention discloses a depolarization method in the foiling process of an electronic aluminum foil, wherein a depolarization process is added after each foiling process before the thermal treatment, and the depolarization process is a high-temperature water purification process in which the water purification temperature is 60-90DEG C and the treatment time is 3-5min. By adopting the depolarization method, the boosting time and the leakage current of a foil sample are effectively reduced, and the specific volume is improved.

Owner:新疆广投桂东电子科技有限公司

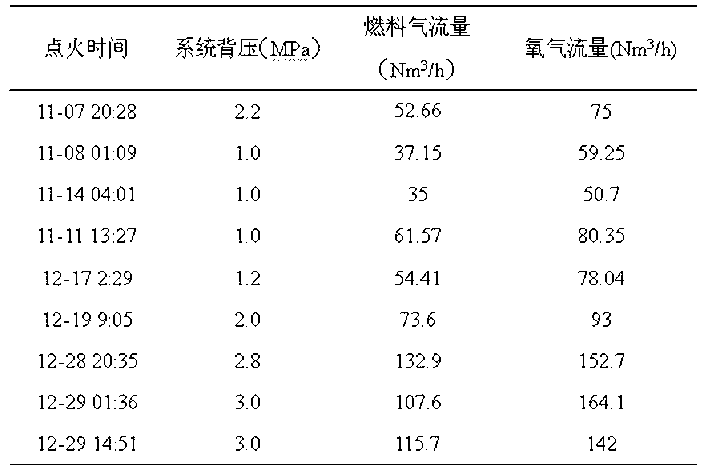

High back pressure igniting method of gasification furnace

ActiveCN103134076AExplain reliabilityIncrease success rateCombustion ignitionPressure riseHigh energy

The invention discloses a high back pressure igniting method and structure of a gasification furnace. The igniting back pressure is in a range from 1.0MPa to 3.0MPa, the fuel gas flow is in a range from 30Nm3 / h to 150Nm3 / h, the oxygen flow is in a range from 45Nm3 / h to 160Nm3 / h, the ratio between the fuel gas flow and the oxygen flow is 1: (1-1.5), and a high energy igniter with more than 15J power is used for igniting. According to the high back pressure igniting method and structure of the gasification furnace, high system back pressure is used as a precondition of igniting, an appropriate igniting environment is provided for the gasification furnace by controlling over the fuel gas flow and the oxygen flow, and final igniting is performed by means of the high energy igniter. The igniting method has the advantages that an extremely high success rate is achieved, the pressure rising time after igniting is greatly shortened, the production efficiency is effectively improved, and the equipment safety can be effectively guaranteed. The method is a first igniting technology which comes into use in relevant fields in China, other gasification technologies have not the advantages of the method, a groundbreaking significance is achieved, and the development of coal gasification technologies is positively influenced.

Owner:YANKUANG GRP CO LTD

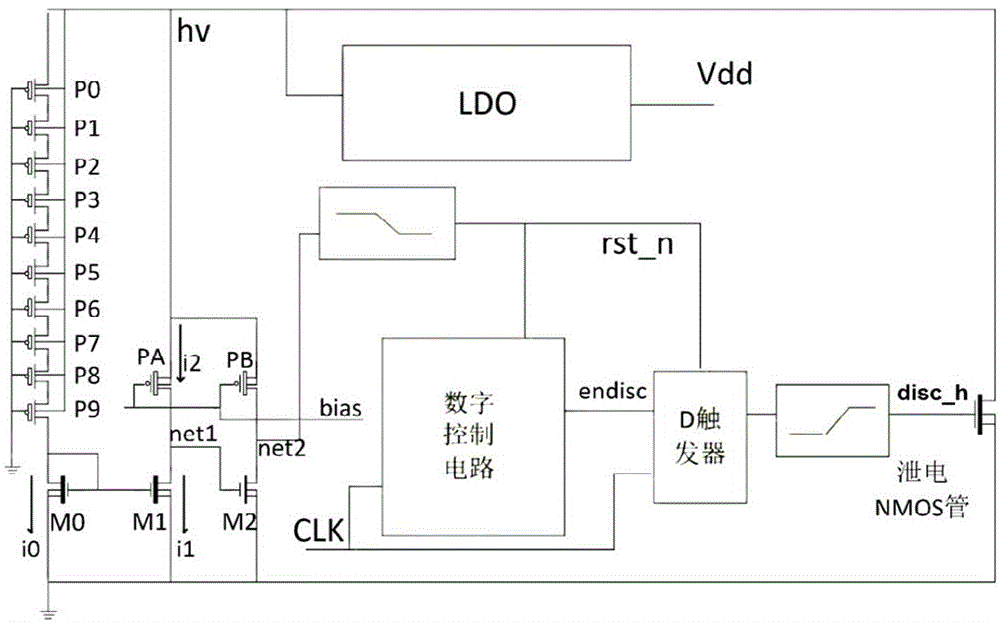

Electricity discharging self-feedback circuit of low-frequency half-duplex passive radio frequency card

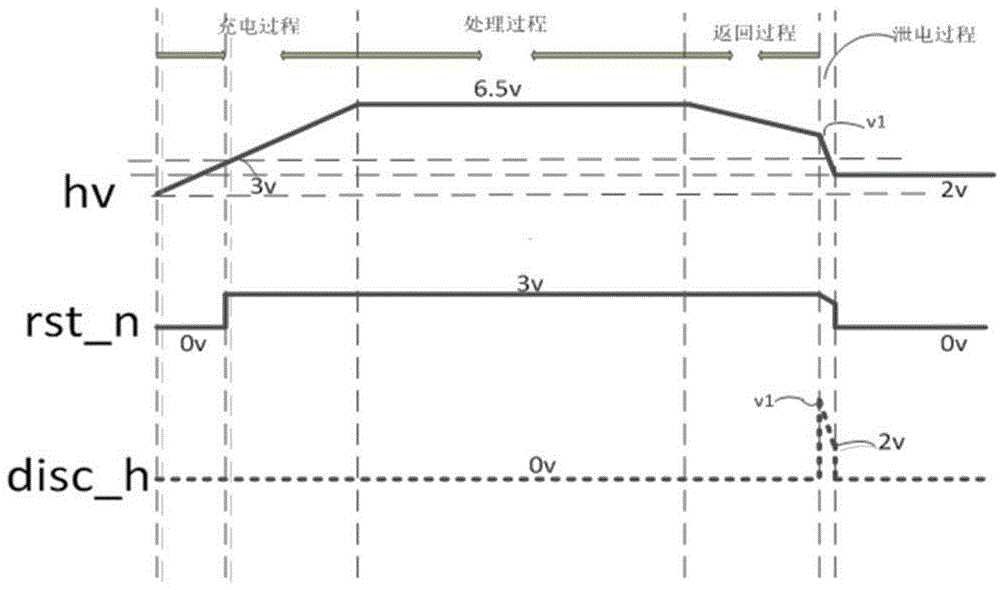

InactiveCN104573792AAvoid Signal Read ErrorsShort boost timeRecord carriers used with machinesStart signalCapacitance

The invention relates to an electricity discharging self-feedback circuit of a low-frequency half-duplex passive radio frequency card, and belongs to the technical field of radio frequency circuits. The electricity discharging self-feedback circuit of the low-frequency half-duplex passive radio frequency card is used for controlling the stored electric quantity of an electric storage capacitor in the low-frequency half-duplex passive radio frequency card. The electricity discharging self-feedback circuit comprises a voltage comparator and an electricity discharging MOS tube, wherein the voltage comparator is used for comparing the voltage of the two ends of the electric storage capacitor with a preset voltage and controlling a work starting signal and a reset signal to output; the electricity discharging MOS tube is used for carrying out the electricity discharging operation of the electric storage capacitor after carrying out data reading operation, while the preset voltage is maintained on the electric storage capacitor, and the preset voltage is not zero. Compared with the prior art, capacity charge begins from the preset voltage but not 0V when the electricity discharging self-feedback circuit disclosed by the invention carries out subsequent commands, so that the voltage-rise time is shortened, the power consumption is reduced, and the processing of the commands is accelerated.

Owner:BEIHAI YUNXIN ELECTRONICS TECH

A method for the formation of anode foil for ultra-high voltage aluminum electrolytic capacitors

ActiveCN110219032BImprove leakage currentIncrease lossAnodisationElectrolytic capacitor manufactureO-Phosphoric AcidPhysical chemistry

Owner:XINJIANG JOINWORLD CO LTD

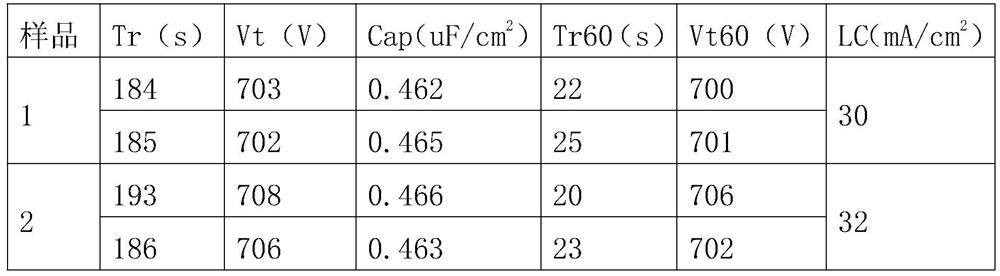

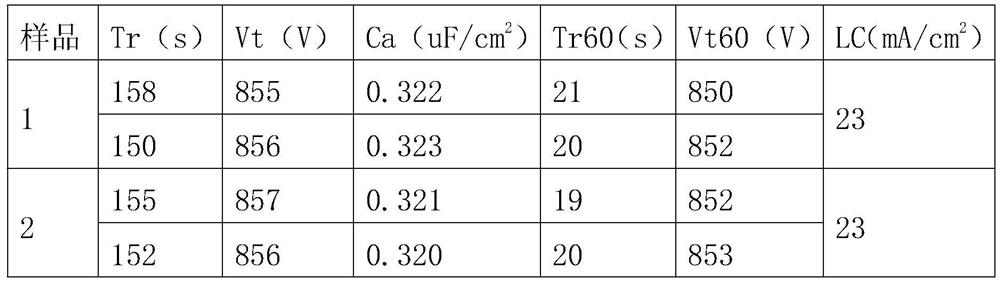

Method for forming extra high voltage anode foil

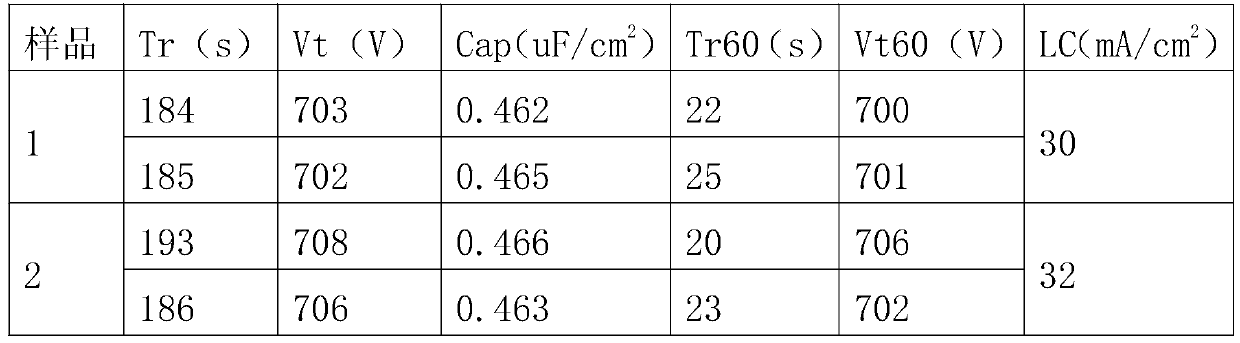

ActiveCN103177878AImprove performanceShort boost timeCapacitor electrodesUltra high voltagePhysical chemistry

Disclosed is a method for forming extra high voltage anode foil. Extra high voltage etched foil is placed in steam of 130-150 DEG C for 5-20 minutes, the extra high voltage etched foil is taken out and placed in a diammonium hydrogen citrate solution of 0.2-1.0wt% for 1-5 minutes, and the extra high voltage etched foil is taken out and subjected to sequent processing. By the aid of the method, the formed anode foil is stable in performance, the voltage rising time is less than 200 seconds, and the drain current of products is less than 25 mu A / cm2.

Owner:新疆广投桂东电子科技有限公司

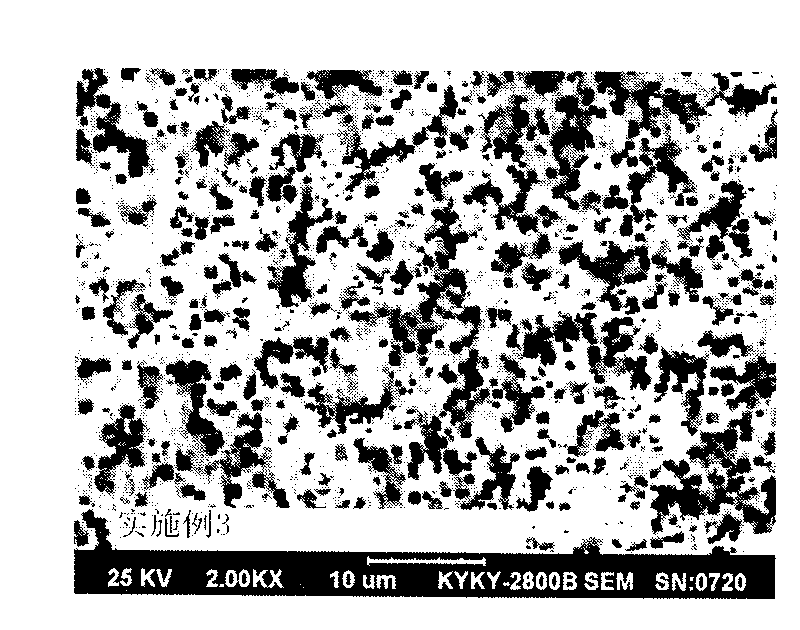

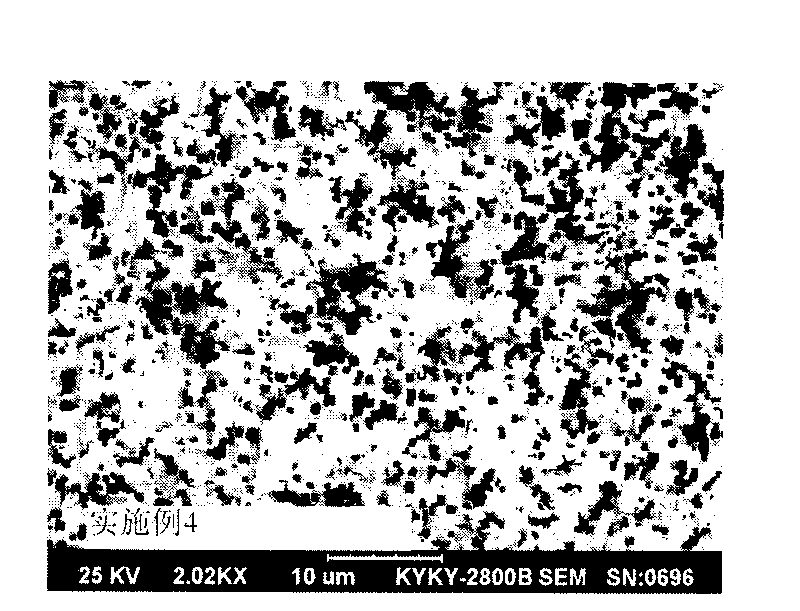

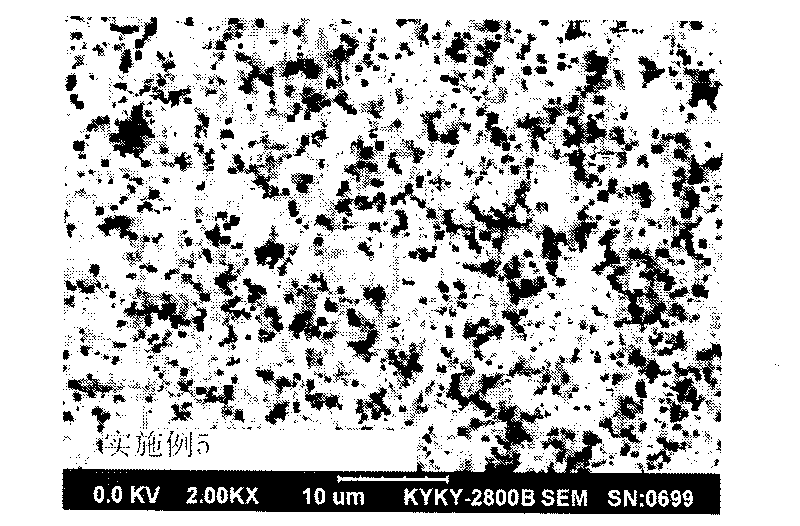

Processing method of electrode foil used for aluminum electrolytic capacitor

InactiveCN108155017AQuality improvementGood dispersionElectrolytic capacitorsEngineeringAluminum electrolytic capacitor

The invention discloses a processing method of an electrode foil used for an aluminum electrolytic capacitor. The method comprises pre-processing, corrosion, postprocessing and multistage formation. The method is characterized in that in each stage of formation, an asymmetrical intermittent positive and negative combination pulse power up mode is used to carry out formation. Compared with an existing continuous power up formation mode, by using the method of the invention, the quality of a formed foil can be greatly improved, boost time is shortened, a leakage current is reduced and formationefficiency is increased.

Owner:DONGGUAN DONGYANG SOLAR SCI RES & DEV CO LTD

High-capacity low-loss medium-voltage anode foil and formation process thereof

ActiveCN113470977AIncrease capacitySpeed up bendingElectrolytic capacitorsAluminium electrolysisO-Phosphoric Acid

The invention relates to a high-capacity low-loss medium-voltage anode foil and a formation process thereof. The formation process of the high-capacity low-loss medium-voltage anode foil disclosed by the invention comprises the following steps: (1) pretreatment; (2) first-stage formation; (3) second-stage formation; (4) third-stage formation; (5) fourth-stage formation; (6) fifth-stage primary formation; (7) cleaning with ammonia water or phosphoric acid; (8) primary high-temperature treatment; (9) phosphoric acid treatment; (10) fifth-stage secondary formation; (11) secondary high-temperature treatment; (12) fifth-stage tertiary formation; (13) tertiary high-temperature treatment; (14) fifth-stage quaternary formation; and (15) post-treatment. According to the high-capacity low-loss medium-voltage anode foil and the formation process thereof, and under a voltage specification of 200-400 vf, the medium-voltage anode foil for an aluminum electrolytic capacitor is produced by adopting the formation process and simultaneously introducing a part of inorganic and organic acids; and the high-capacity low-loss medium-voltage anode foil has the advantages of high capacity and low loss, a production process is simple to operate, product stability is good, and the process is suitable for industrial batch production.

Owner:XINJIANG JOINWORLD CO LTD

Volume supplementary type mold locking device adopting equivalent volume replacement

The invention relates to the technical field of a mold closing mechanism, and provides a volume supplementary type mold locking device adopting equivalent volume replacement and having wider using adaptability. The device comprises a movable template, a fixed template, mold locking oil cylinders, a supplementing oil cylinder and a communicating and stopping valve, wherein each mold locking oil cylinder comprises a cylinder body, a piston and a piston rod. Hydraulic oil in the supplementing oil cylinder is used for supplementing volumes of parts occupied by the piston rods in rod cavities, real equivalent volume replacement is realized, that is, the hydraulic oil is not required to return to an oil tank during mold closing, oil suction from the oil tank is not required during mold opening, so that the energy consumption is low, the pressure rising time is short, the reaction is fast, and the device has the advantages of energy saving and high efficiency; the device is simple in structure, small in size, high in mold opening, closing and locking performance and precision, uniform in stressing and stable and reliable to use, and is applicable to various specifications and models of direct-press type mold closing mechanisms.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

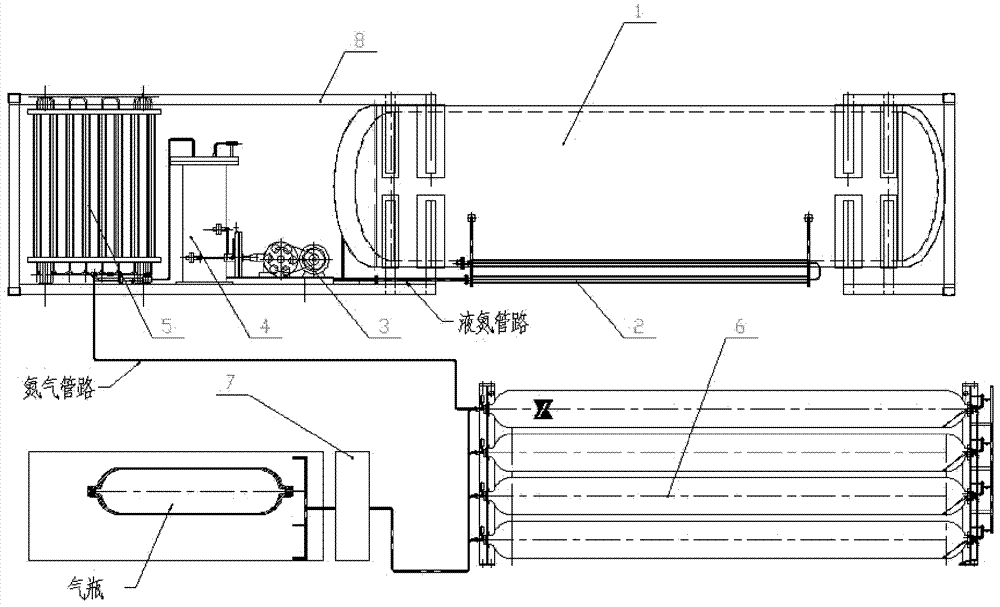

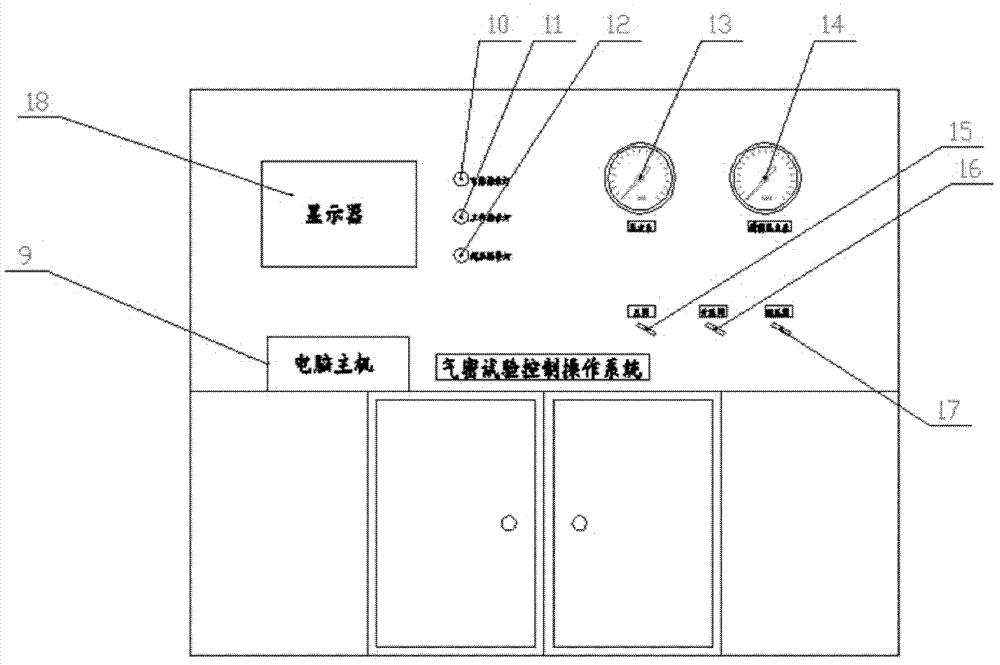

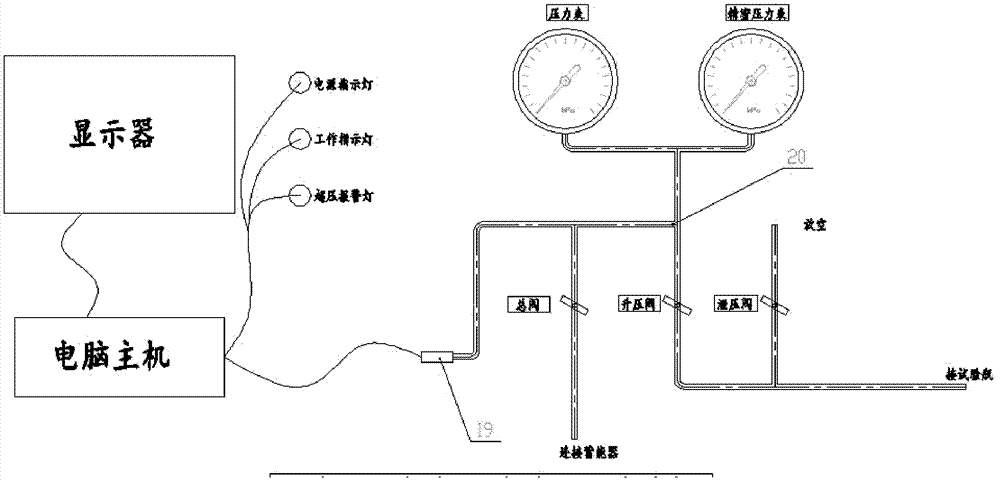

Airtightness test and nitrogen replacement device used for high-pressure air cylinder

ActiveCN102589823BShort boost timeAvoid pollutionMeasurement of fluid loss/gain rateWater bathsControl system

The invention discloses an airtightness test and nitrogen replacement device used for a high-pressure air cylinder, which belongs to the technical field of the airtightness test. The airtightness test and nitrogen replacement device used for a high-pressure air cylinder comprises a liquid nitrogen storage tank, a self-boosting gasifier, a liquid nitrogen pump, a water bath type gasifier, an air temperature type gasifier, an energy storage device, an airtightness test operation and control system and a frame, wherein the liquid nitrogen storage tank and the self-boosting gasifier are horizontally arranged in the frame side by side; the front end of the frame is provided with the liquid nitrogen pump, the air temperature type gasifier and the water bath type gasifier; in the frame, one end of the liquid nitrogen storage tank is connected with the self-boosting gasifier, the other end of the liquid nitrogen storage tank is connected with the liquid nitrogen pump, the liquid nitrogen pump is connected with the water bath type gasifier, and the water bath type gasifier is connected with the air temperature type gasifier; outside the frame, the air temperature type gasifier is connected with the energy storage device and the energy storage device is connected with the airtightness test operation and control system. The airtightness test and nitrogen replacement device has the advantage that the problems of high operation cost and maintenance cost, unstable working state, high incidence rate of various faults, complex production work, low production efficiency and the like can be solved.

Owner:XINXING ENERGY EQUIP

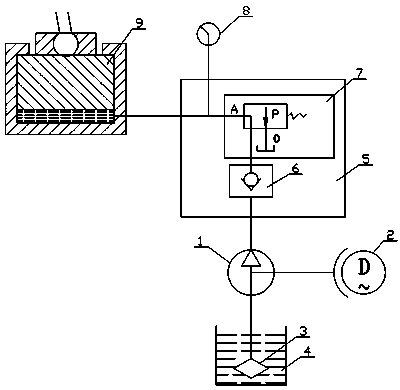

Oil inlet system of 160T punch press overload protection hydraulic oil cylinder

ActiveCN103362895AShort boost timeInspection is accurateFluid-pressure actuator safetyPunch pressSystem pressure

The invention relates to the technical field of punch press overload protection design, in particular to an oil inlet system of a 160T punch press overload protection hydraulic oil cylinder. The oil inlet system is applied to normal production of a product with punching shear in a range of 1,600 kN; and meanwhile, when the punching shear exceeds 1,600 kN, the 160T punch press overload protection hydraulic oil cylinder is unloaded to perform overload protection. According to the designed oil inlet system of the 160T punch press overload protection hydraulic oil cylinder, pressure oil is supplied by a mechanical oil pump, so that the pressure of the overload protection hydraulic oil cylinder can reach required pressure for punching and shearing normal force of 1,600 kN. By designing a high-pressure one-way valve in a hydraulic oil path, the pressure of the overload protection hydraulic oil cylinder can be maintained. By designing a high-pressure unloading overflow valve in the hydraulic oil path, the overload protection is ensured; and when the pressure of the hydraulic oil cylinder exceeds the punch press normal force, an overflow port of the unloading overflow valve is opened to perform overflowing for the overload protection. A pressure display is designed in the oil inlet system of the 160T punch press overload protection hydraulic oil cylinder and is used for checking whether the pressure is normal or not at any time.

Owner:CHANGZHOU SHENLI MOTOR

Pressurizing and speeding-up loop and pressurizing and speeding-up method for hydraulic stand column

PendingCN113669333ARapid drop columnImprove practicalityServomotor componentsAccumulator installationsPressure riseControl theory

The invention provides a pressurizing and speeding-up loop for a hydraulic stand column, which is connected with the hydraulic stand column. A rodless cavity of the hydraulic stand column is connected with a hydraulic control one-way valve and a third one-way valve, the hydraulic control one-way valve is connected with a bypass valve, one end of the bypass valve is connected with an oil tank, the other end of the bypass valve is connected with a high-pressure pump station through a third electro-hydraulic reversing valve and a fourth electro-hydraulic reversing valve, and a second energy accumulator is arranged on a connecting line; the third one-way valve is connected with a second electro-hydraulic reversing valve, one end of the second electro-hydraulic reversing valve is connected with the oil tank, the other end of the second electro-hydraulic reversing valve is connected with a booster pump station, and a first energy accumulator is arranged on a connecting line connecting the second electro-hydraulic reversing valve and the booster pump station; and a rod cavity of the hydraulic stand column is connected with the hydraulic control one-way valve and a first electro-hydraulic reversing valve, one end of the first electro-hydraulic reversing valve is connected with the oil tank, and the other end of the first electro-hydraulic reversing valve is connected with the booster pump station. The initial supporting force of the hydraulic stand column can be effectively improved, the descending speed of the hydraulic stand column can be accelerated, the time of a pressure rising stage can be shortened, meanwhile, the pressurizing and speeding-up loop for the hydraulic stand column is used for column lifting of a hydraulic support, so that energy is recycled, and energy is saved.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

Depolarization method in foiling process of electronic aluminum foil

ActiveCN102021627BShort boost timeReduce leakage currentElectrolytic capacitorsSurface reaction electrolytic coatingSpecific volumeThermal treatment

The invention discloses a depolarization method in the foiling process of an electronic aluminum foil, wherein a depolarization process is added after each foiling process before the thermal treatment, and the depolarization process is a high-temperature water purification process in which the water purification temperature is 60-90DEG C and the treatment time is 3-5min. By adopting the depolarization method, the boosting time and the leakage current of a foil sample are effectively reduced, and the specific volume is improved.

Owner:新疆广投桂东电子科技有限公司

Formation method of extra-high-voltage electrode foil

InactiveCN113026073AEasy production controlEasy to handleElectrolytic capacitorsSurface reaction electrolytic coatingElectrolytic agentMaterials science

The invention discloses a formation method of extra-high-voltage electrode foil, and relates to the technical field of electrode foil. The formation method comprises the following step of 1, digesting corrosion foil in a silicate solution at the temperature of 95 DEG C or above to obtain pretreated foil; 2, conducting formation on the pretreated foil in a boric acid and ammonium pentaborate solution to obtain first-stage formed foil; 3, conducting formation on the first-stage formed foil in a boric acid and ammonium pentaborate solution to obtain second-stage formed foil; and 4, conducting multi-stage formation on the second-stage formed foil in a boric acid, ammonium pentaborate and ammonium pentenedioate solution to obtain a final formed foil product. The formation method has the beneficial effects that electrolyte is simple in composition and easy to produce and control, and wastewater treatment is relatively simple; and sparking voltage is not increased by reducing the conductivity of formation liquid, so that the invalid electric loss in the formation process is greatly reduced, the surface of the formed foil has no sparking spots, the dielectric properties of an oxide film are good, the boosting time of the product is less than 150 seconds, the leakage current is less than 12 [mu]A / cm<2>, and the method meets the production requirement for 1000-1500V extra-high-voltage electrode foil.

Owner:NANTONG HAIXING ELECTRONICS +2

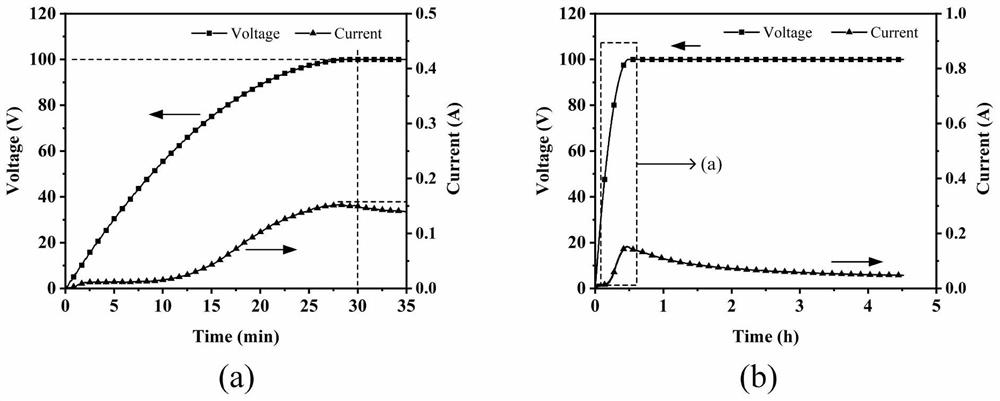

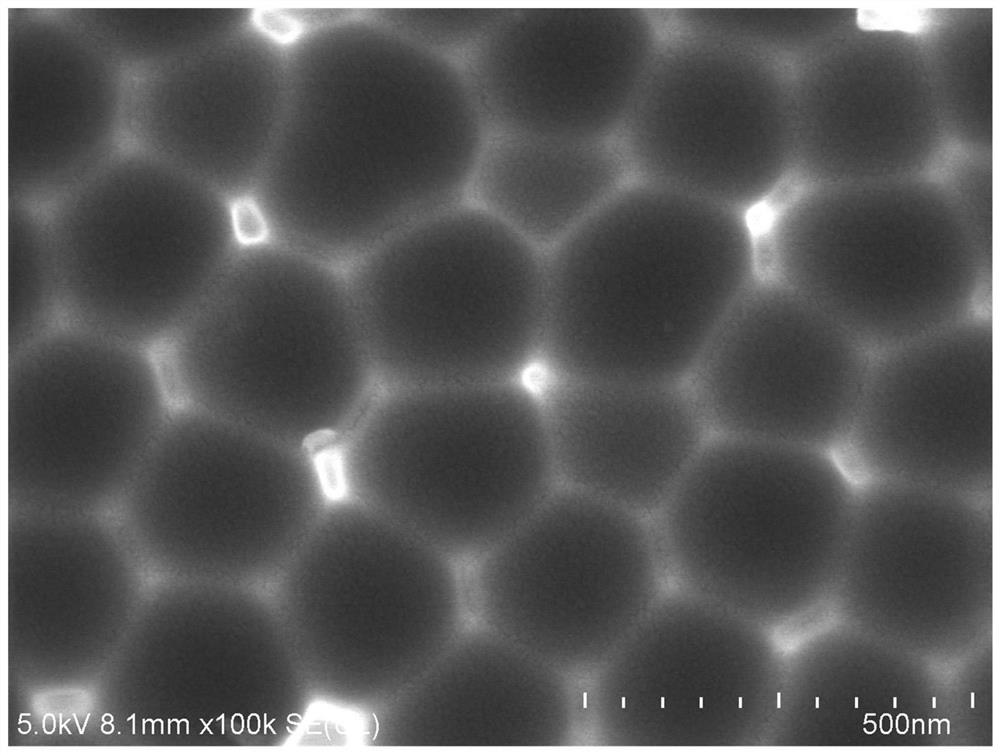

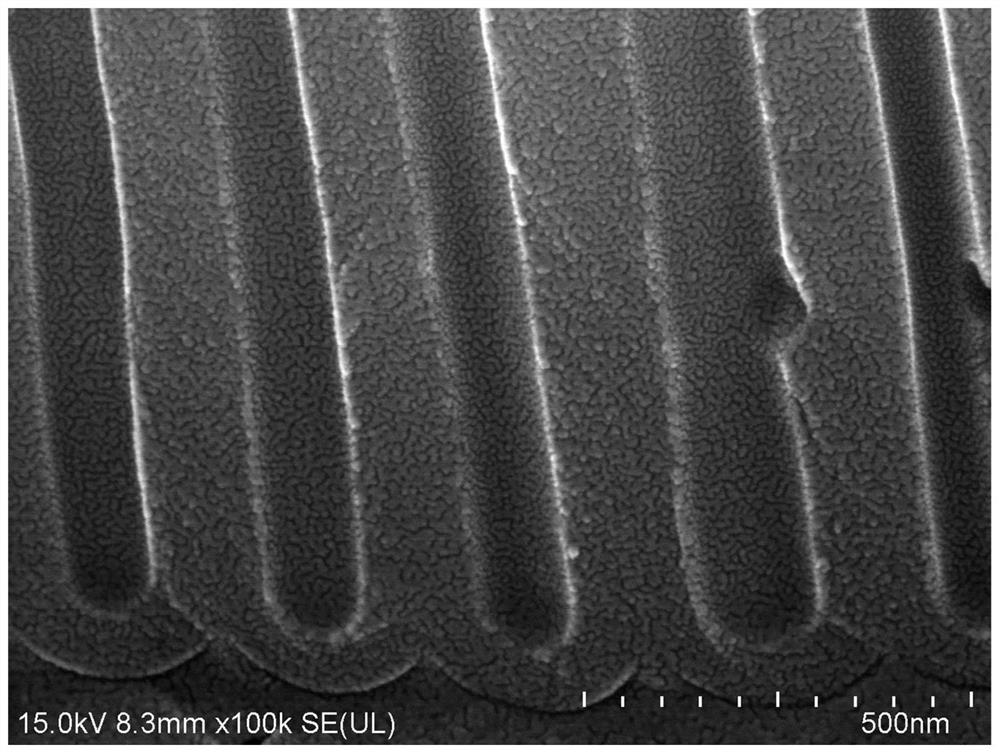

Large-hole-pitch anodized aluminum oxide film based on parabolic equation boosting and preparation method and application of large-hole-pitch anodized aluminum oxide film

The invention belongs to the technical field of material surface preparation, and discloses a large-hole-pitch anodized aluminum oxide film based on parabolic equation boosting and a preparation method and application of the large-hole-pitch anodized aluminum oxide film. The preparation method comprises the following steps: ultrasonically cleaning the surface of a high-purity aluminum foil, and chemically etching to remove a compact oxide layer on the aluminum surface; performing electrochemical polishing treatment on the clean aluminum foil to enable the surface to be smooth and flat; carrying out anodic oxidation in electrolyte by taking the obtained polished aluminum foil as an anode and a graphite flake as a cathode, and boosting based on a parabolic equation in the process, so as to obtain a large-hole-pitch anodic aluminum oxide film with an aluminum substrate; the obtained large-hole-pitch anodic aluminum oxide film with the aluminum substrate is placed in a supersaturated copper chloride solution to be etched, the aluminum substrate is removed, and the large-hole-pitch anodic aluminum oxide film is obtained; or etching in a chromic acid and phosphoric acid mixed solution, removing the anodic aluminum oxide film to obtain an aluminum substrate with large-hole-pitch pits, and then performing secondary anodic oxidation to obtain the regular and ordered large-hole-pitch anodic aluminum oxide film.

Owner:GUANGDONG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com