Single-plunger three-function high-pressure electric pump based on regular triangle cam

A technology of triangular and electric pumps, which is applied to components of pumping devices for elastic fluids, piston pumps, pumps, etc., can solve problems such as large shock and vibration, large recoil flow, and low volumetric efficiency, and achieve The effect of short lifting time, extended service life and high volumetric efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

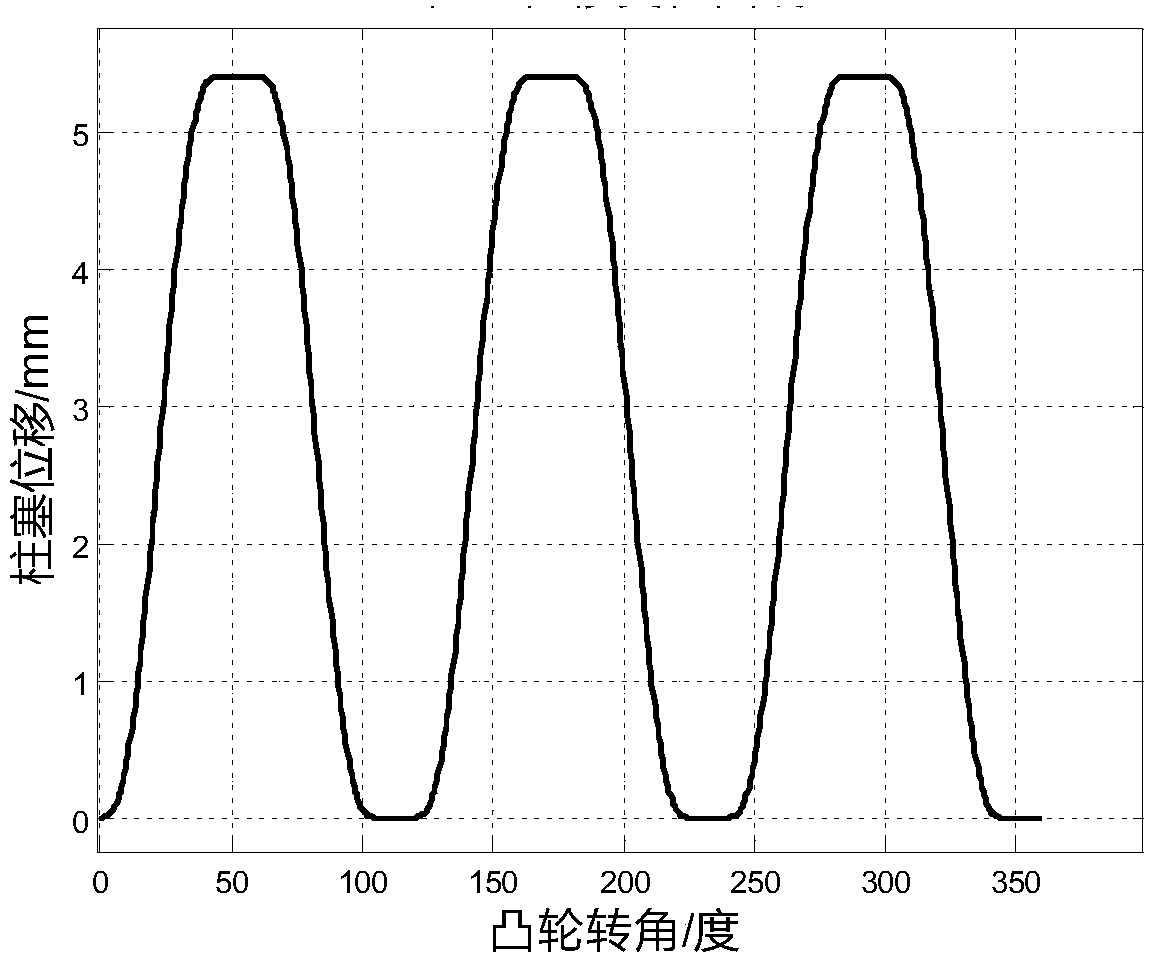

[0026] The present invention aims at the shortcomings of the existing single plunger single-acting high-pressure electric pump with a flat-bottomed push rod eccentric wheel structure, and innovatively proposes a technical scheme of "a single-plunger three-acting high-pressure electric pump based on a regular triangular cam", The purpose is to reduce the speed of the pump, reduce the impact and vibration, reduce friction and wear, improve the volumetric efficiency of the pump, and prolong the service life of the pump and its driving motor.

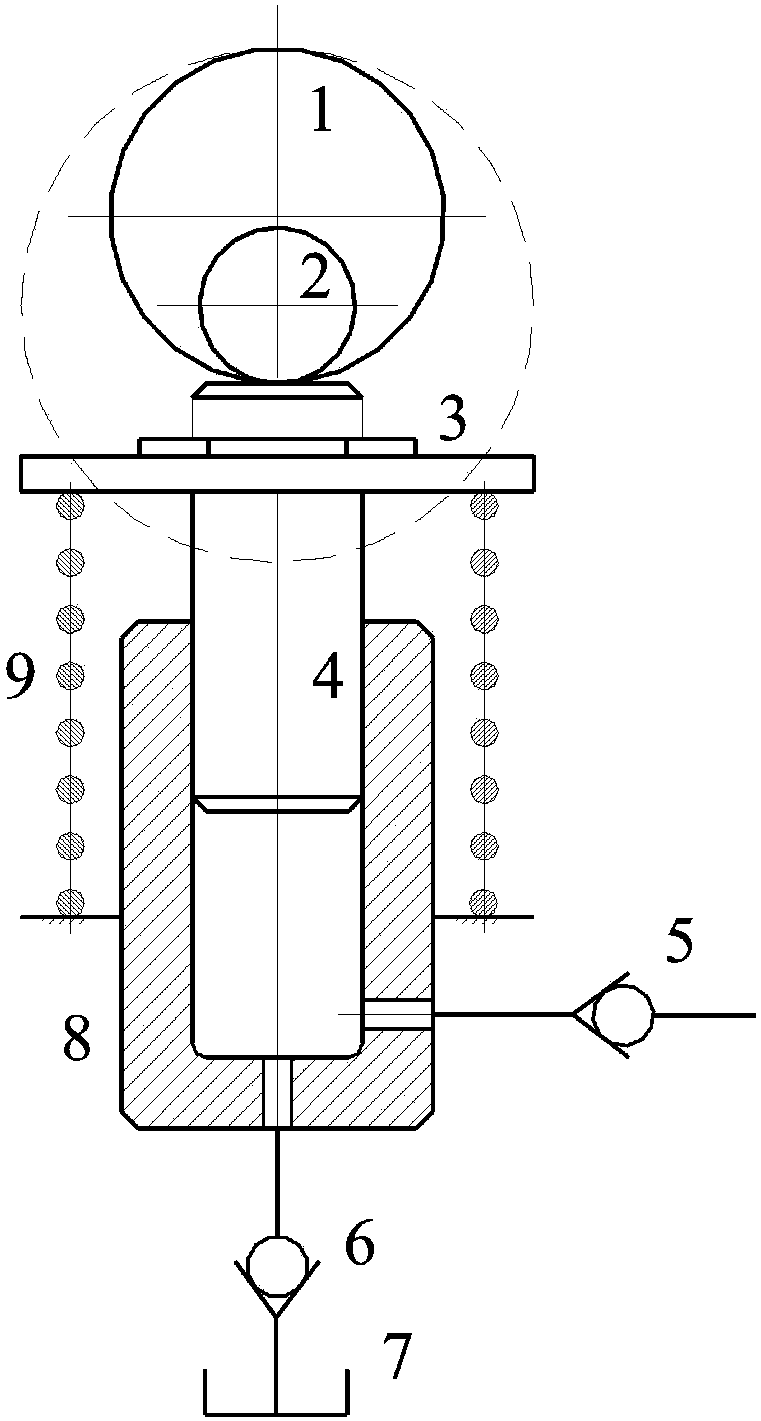

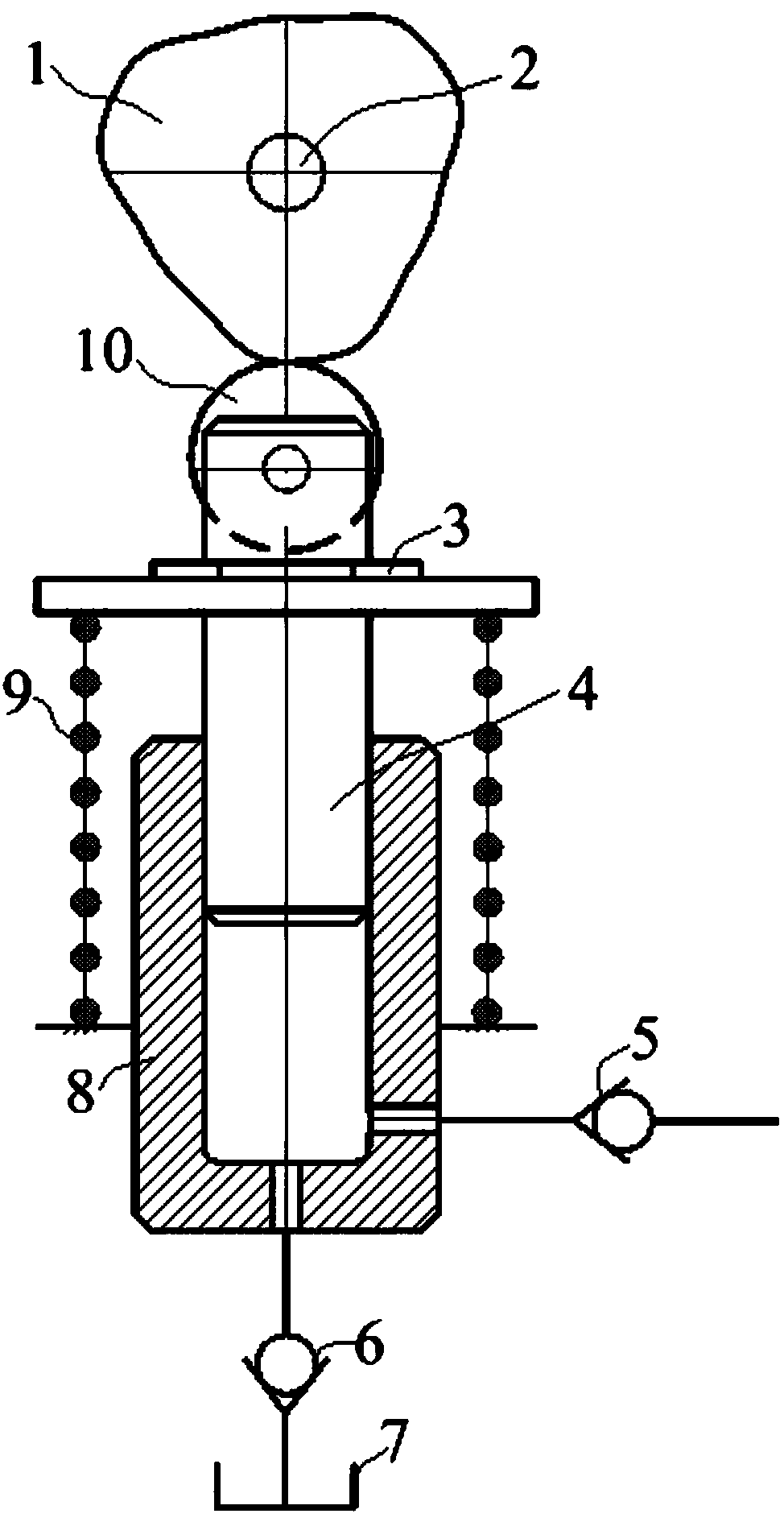

[0027] A single-plunger three-acting high-pressure electric pump based on a regular triangular cam, such as figure 2 As shown, it mainly includes: cam 1, transmission shaft 2, support ring 3, plunger 4, oil discharge valve 5, oil suction valve 6, oil tank 7, pump body 8, locking spring 9 and roller bearing 10;

[0028] The drive s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com