Patents

Literature

977 results about "Volumetric efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

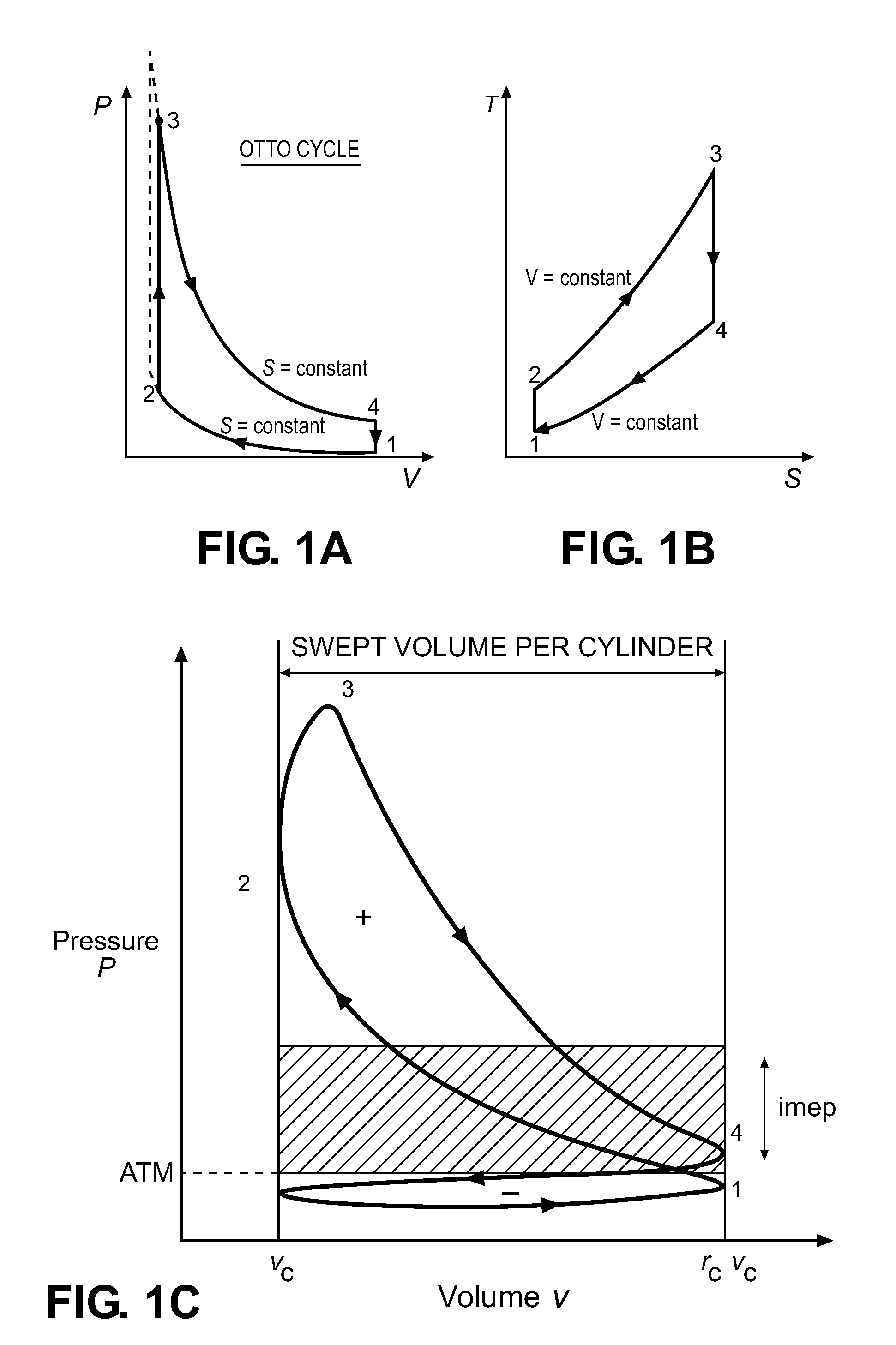

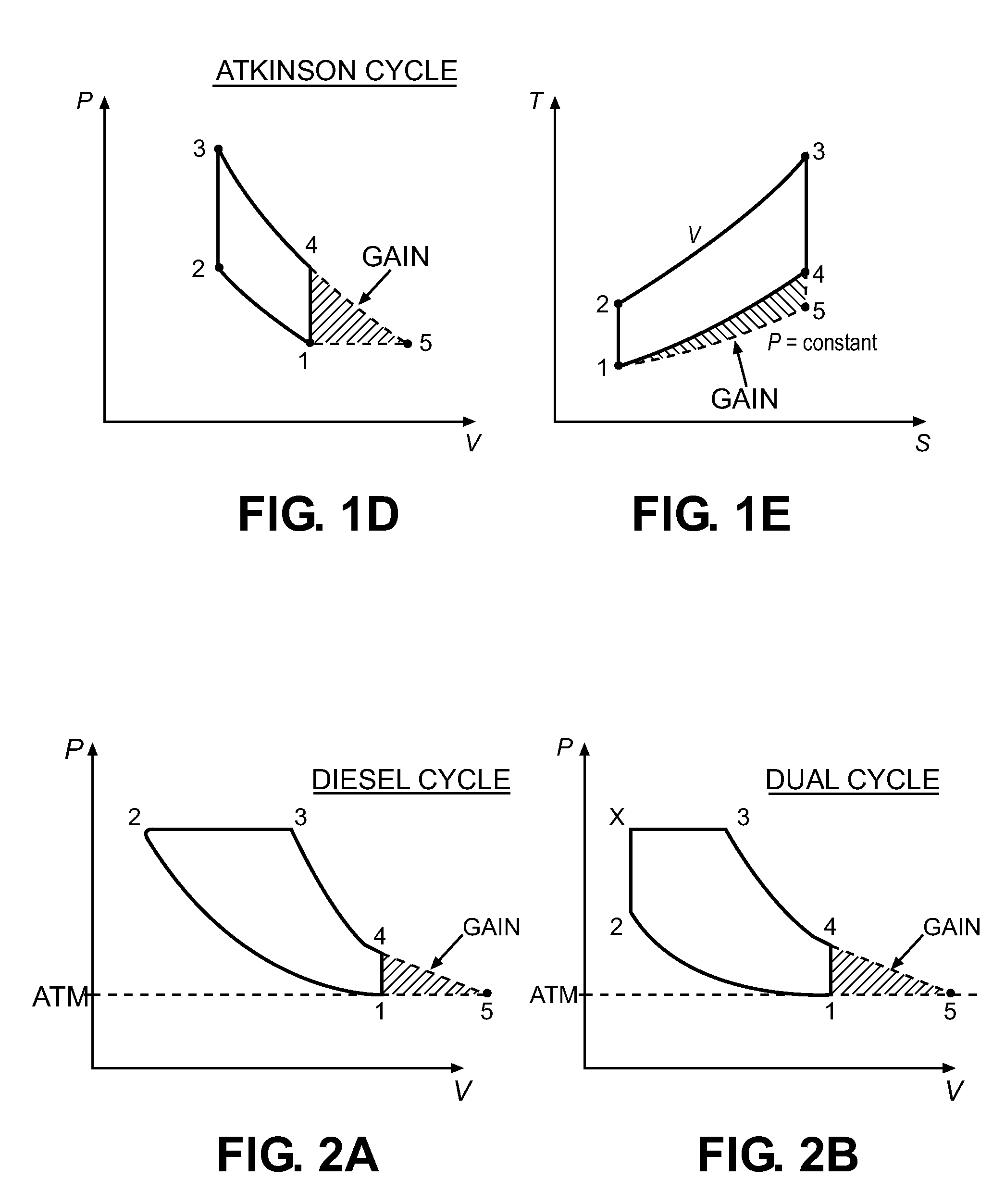

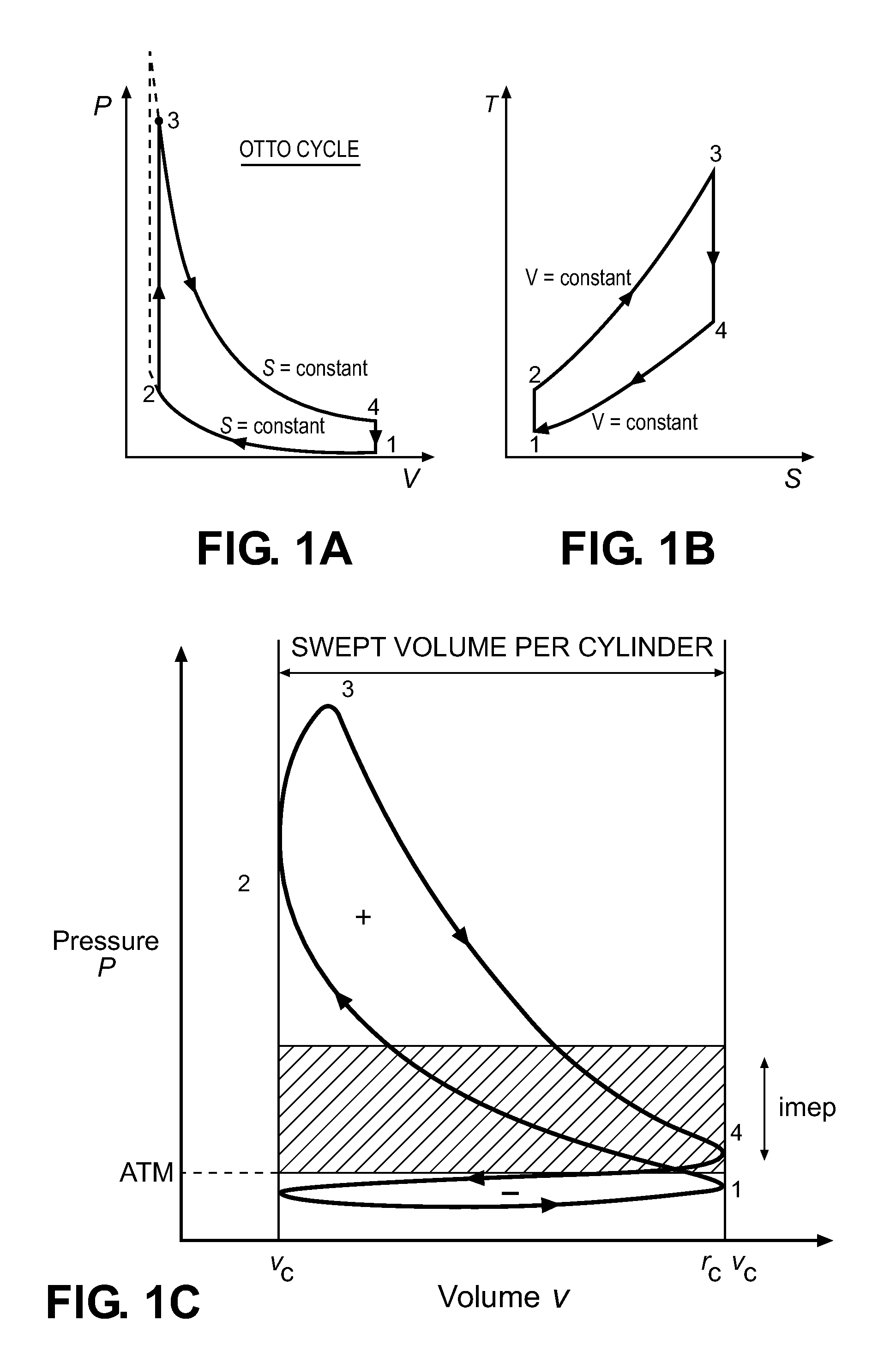

Volumetric efficiency (VE) in internal combustion engine engineering is defined as the ratio of the mass density of the air-fuel mixture drawn into the cylinder at atmospheric pressure (during the intake stroke) to the mass density of the same volume of air in the intake manifold. The term is also used in other engineering contexts, such as hydraulic pumps and electronic components.

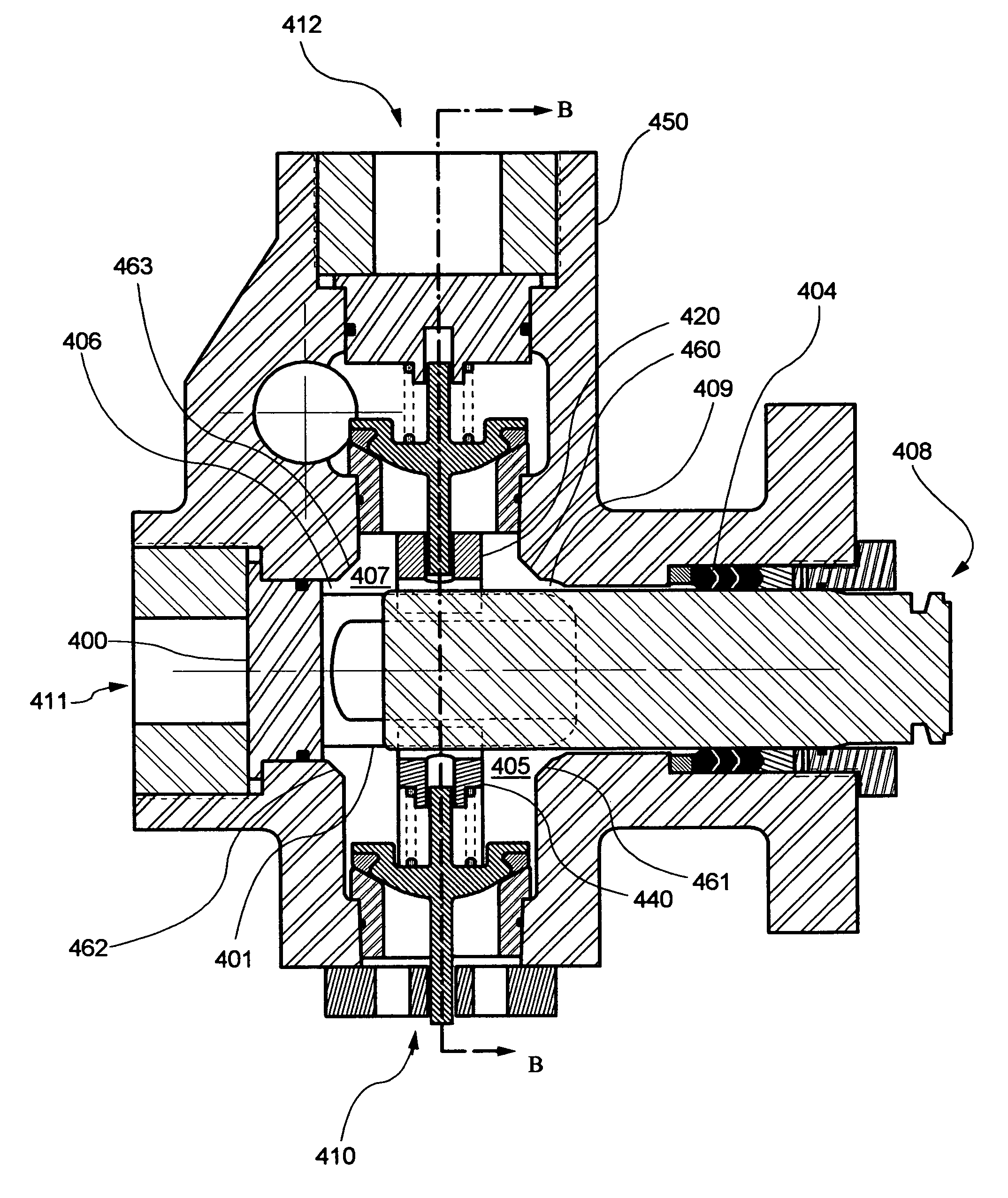

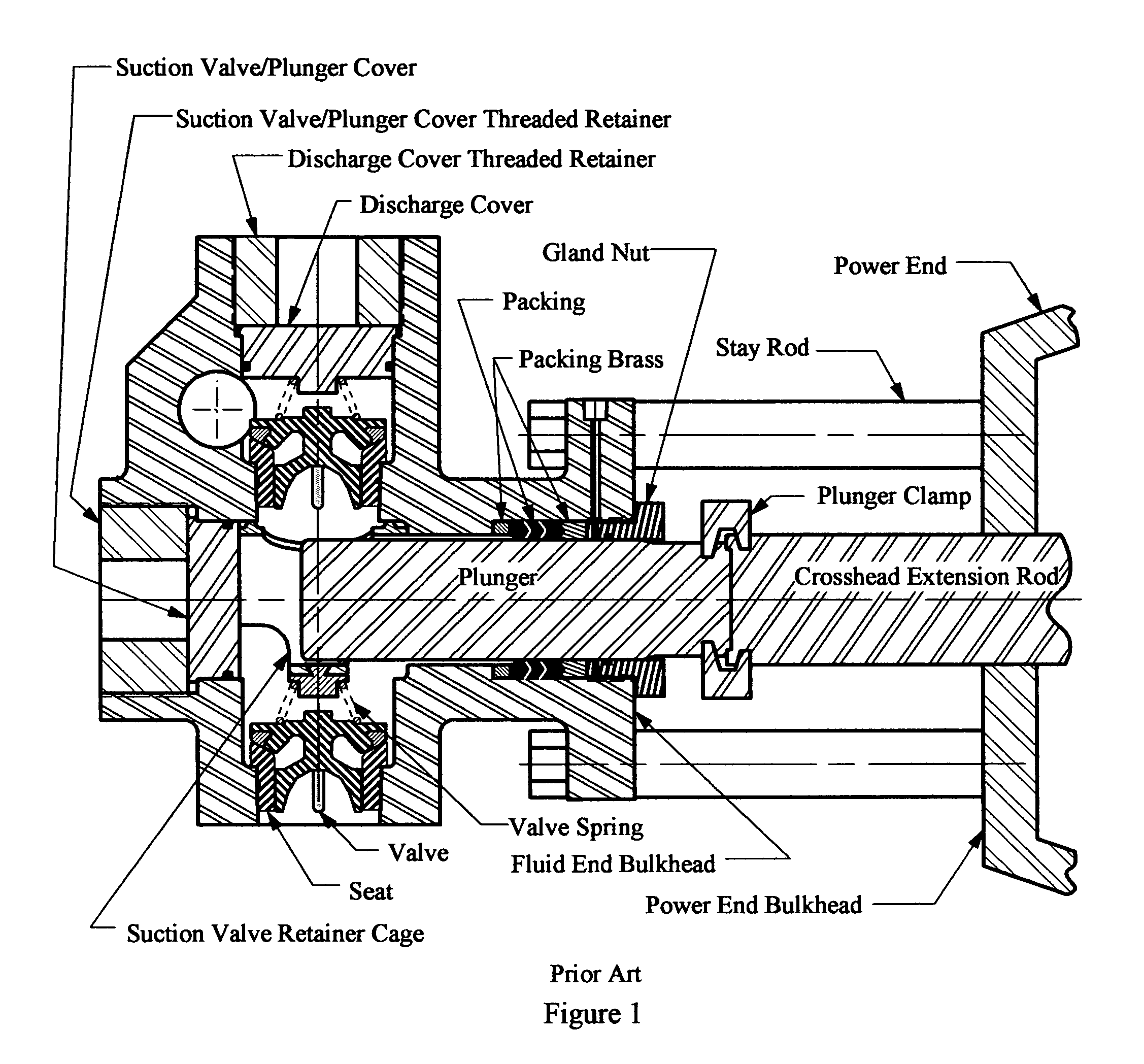

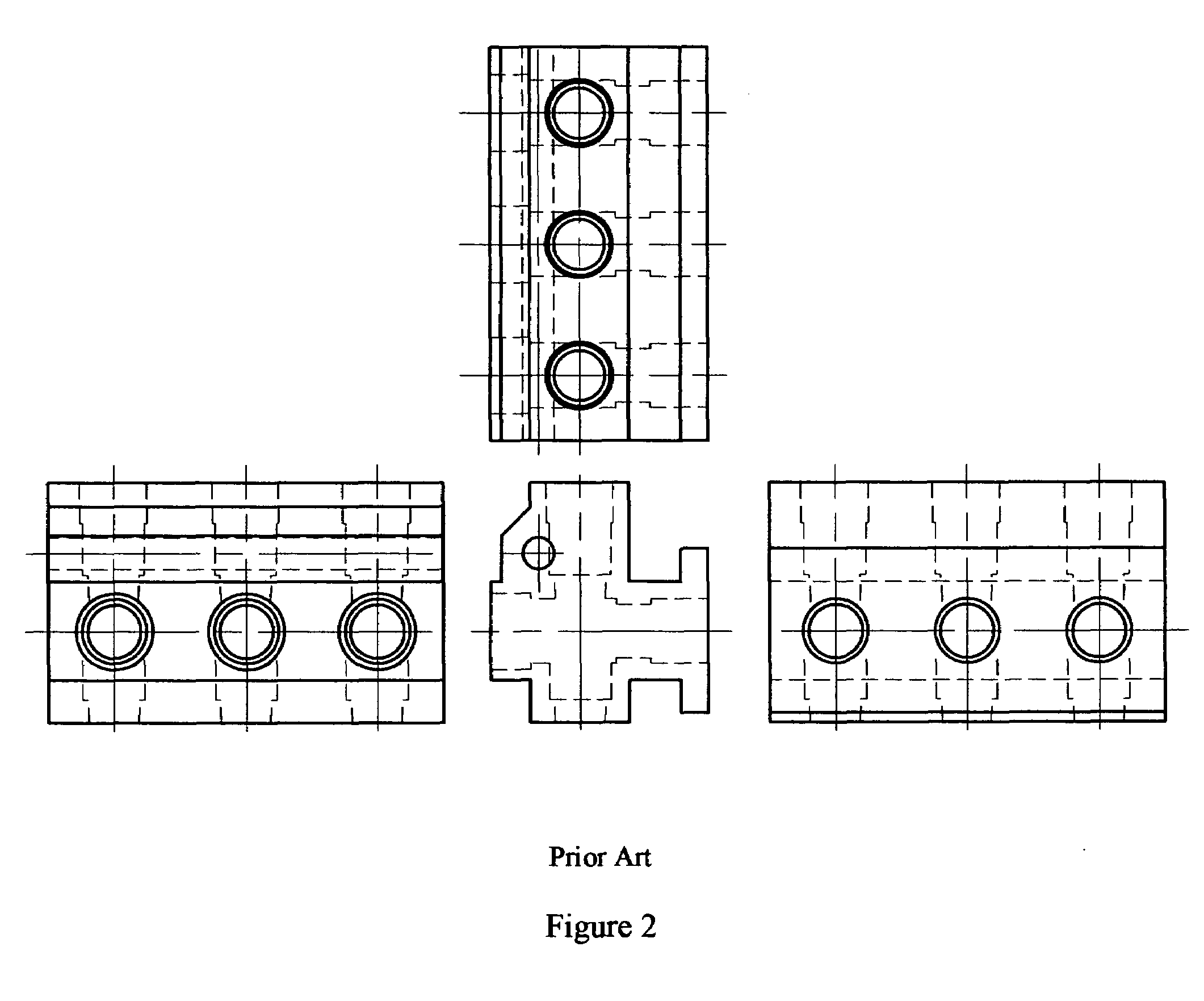

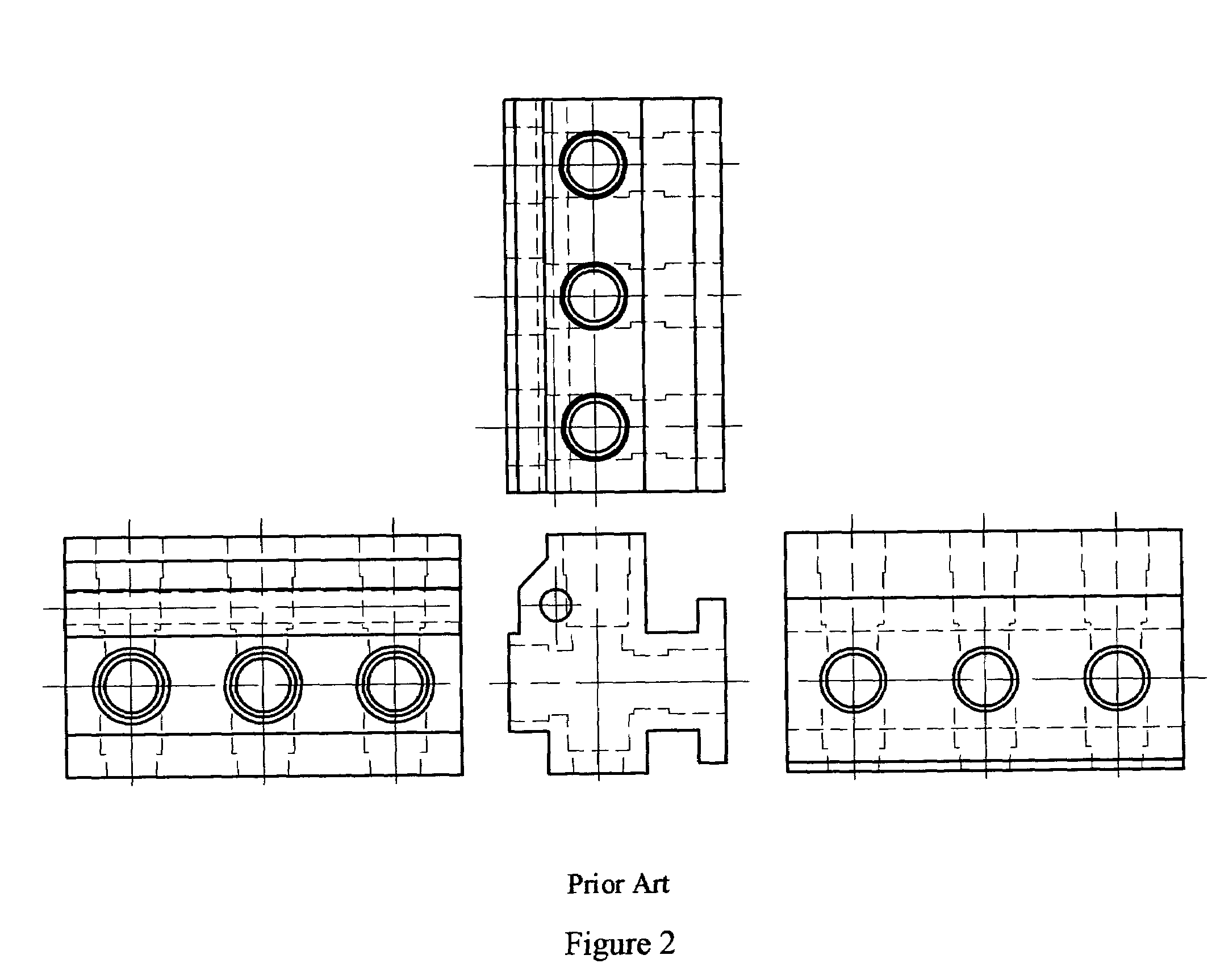

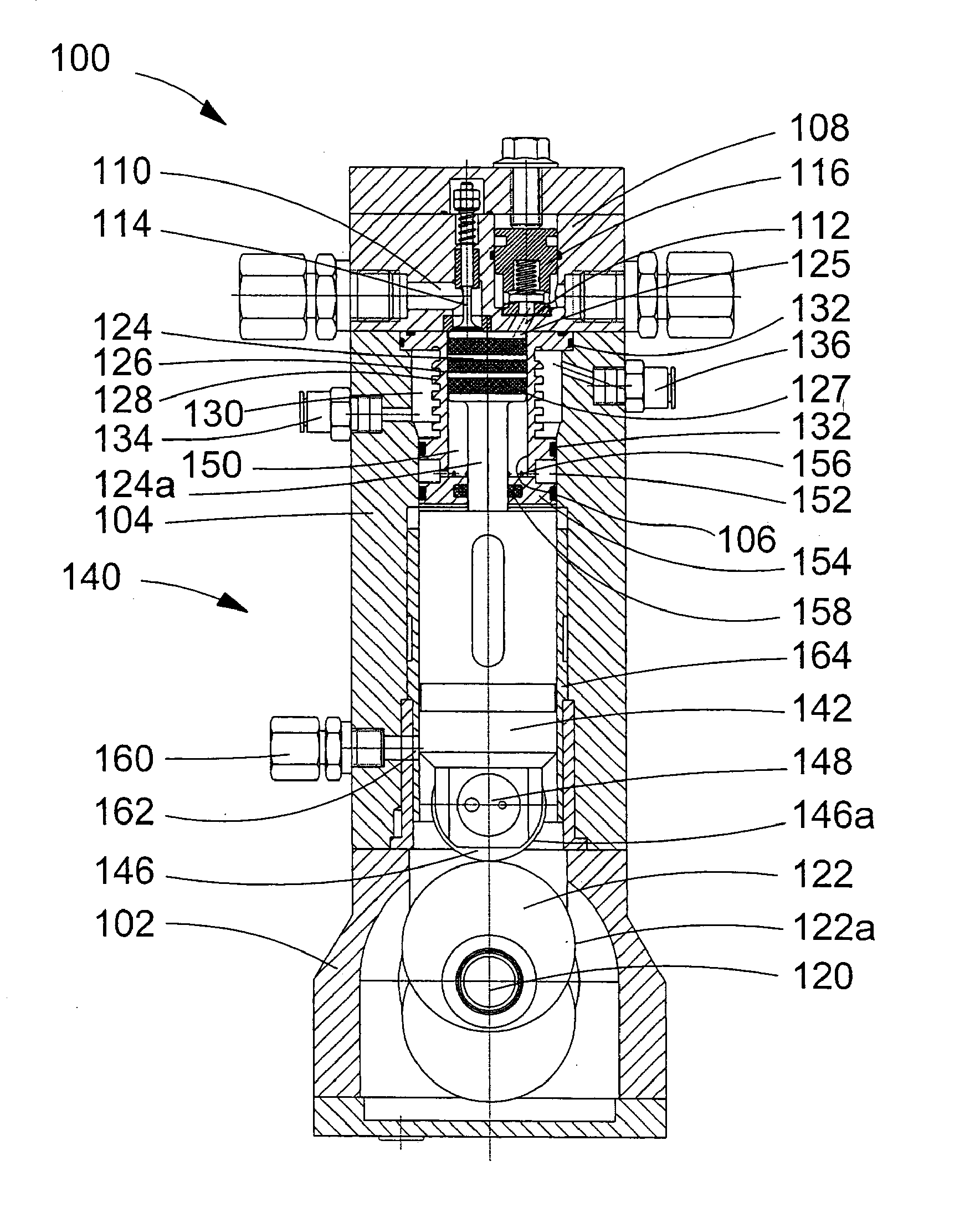

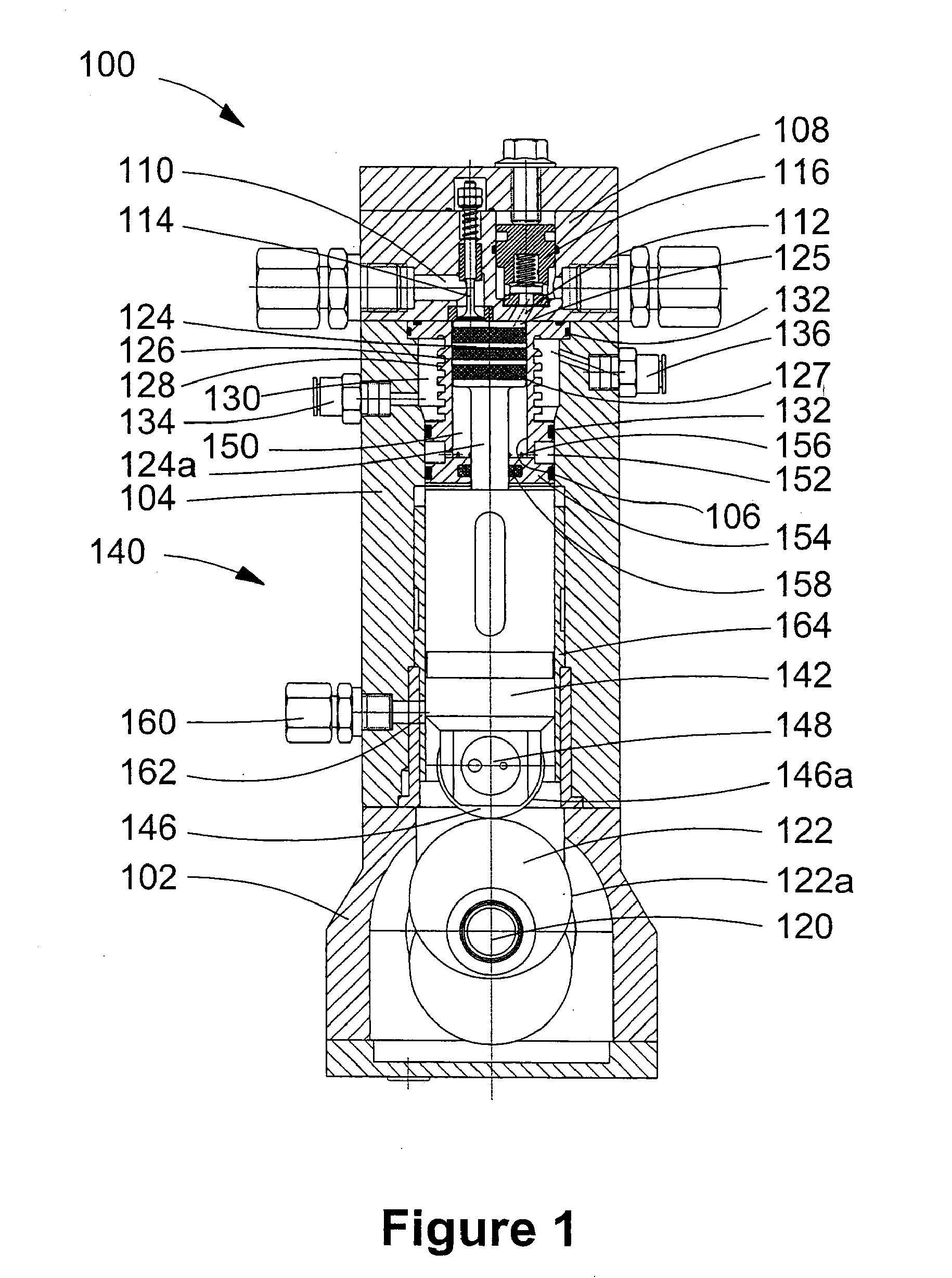

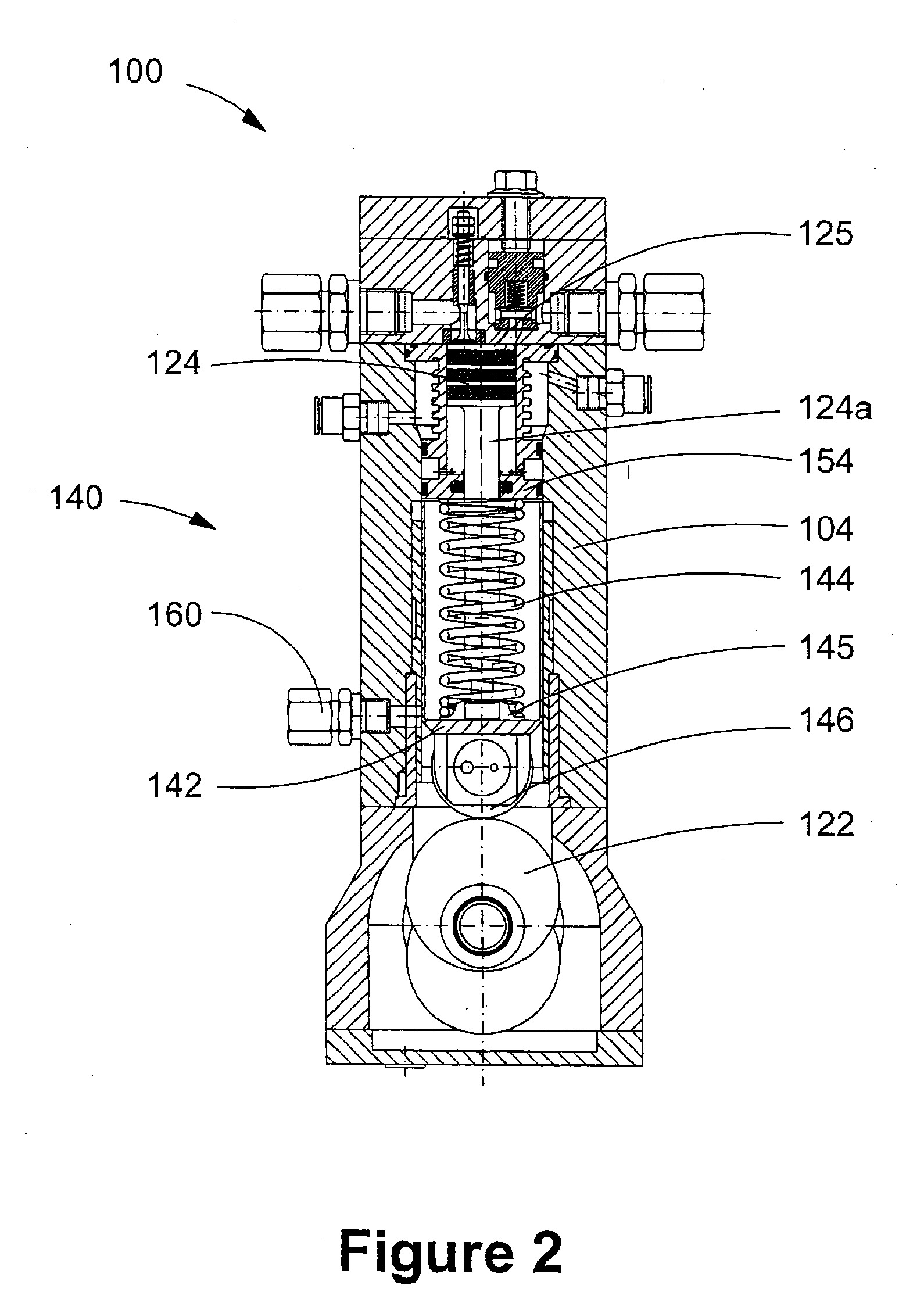

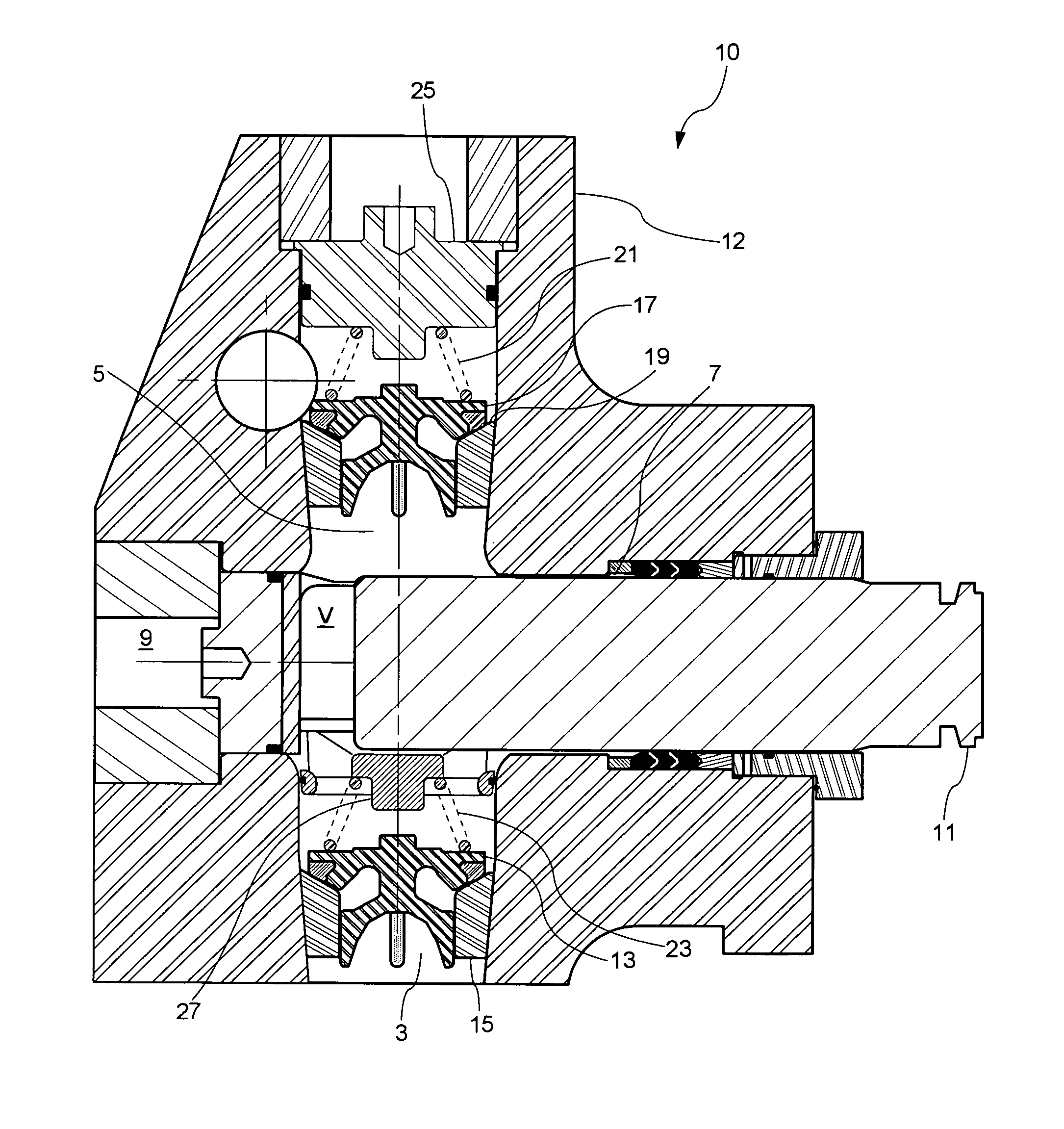

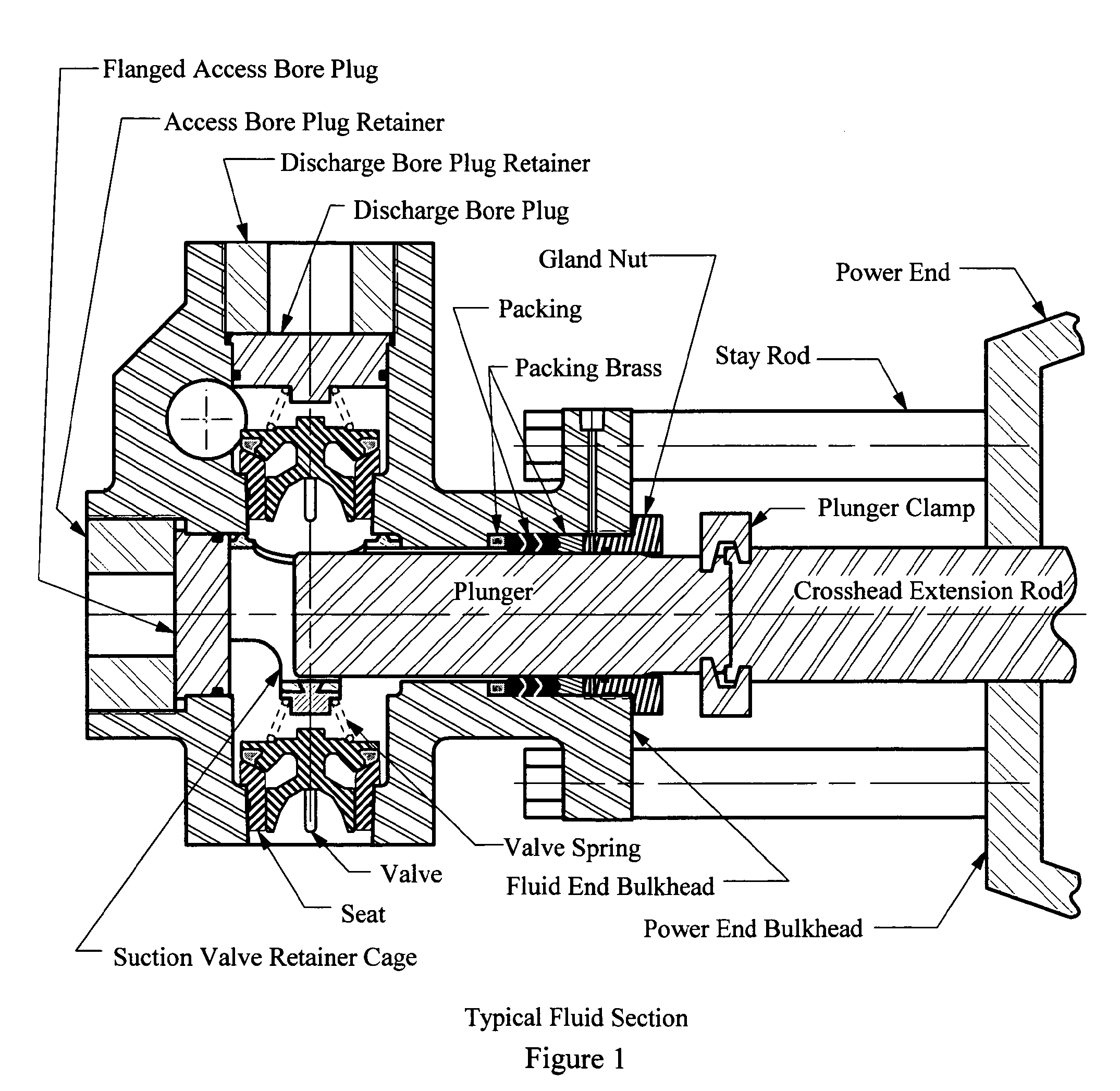

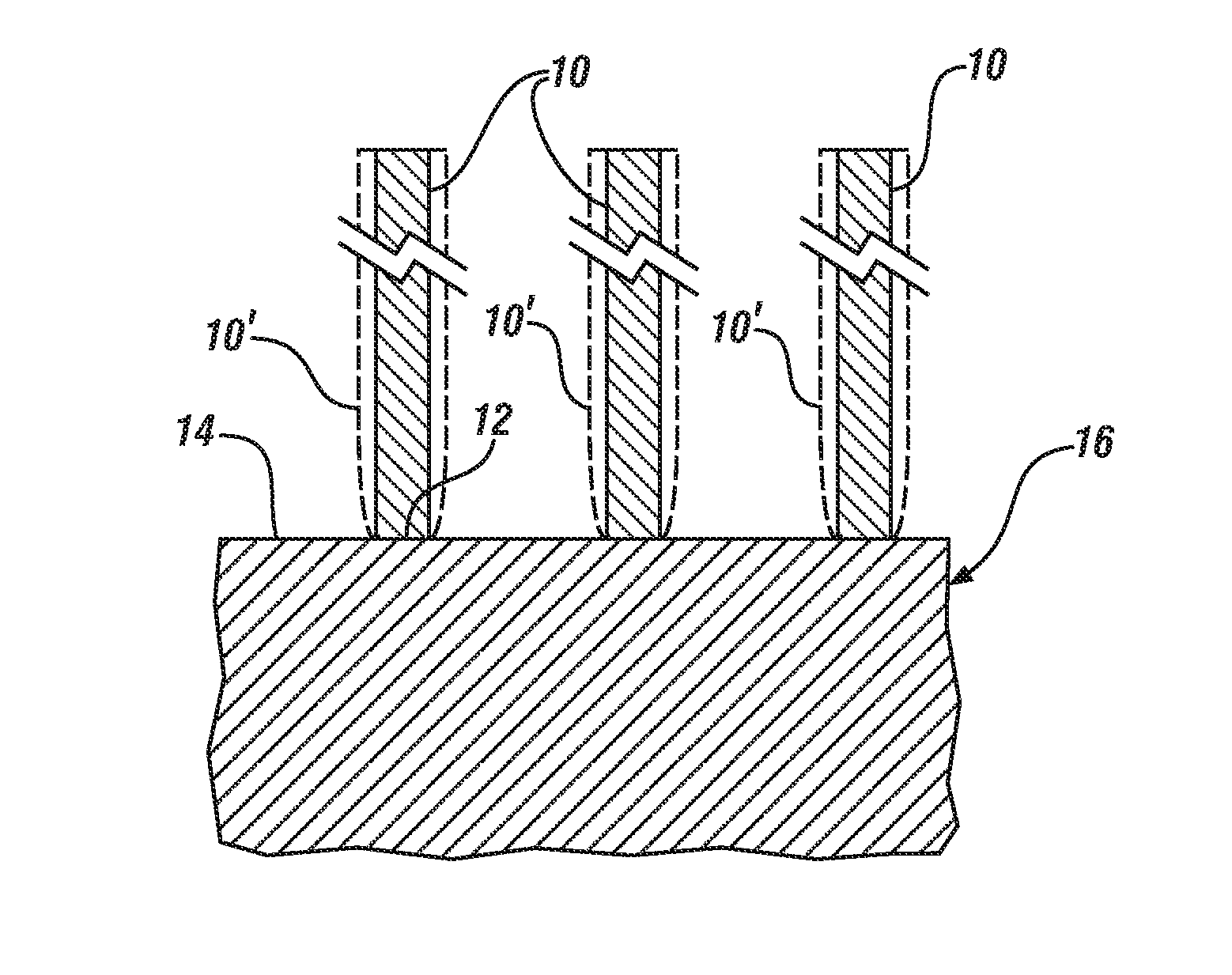

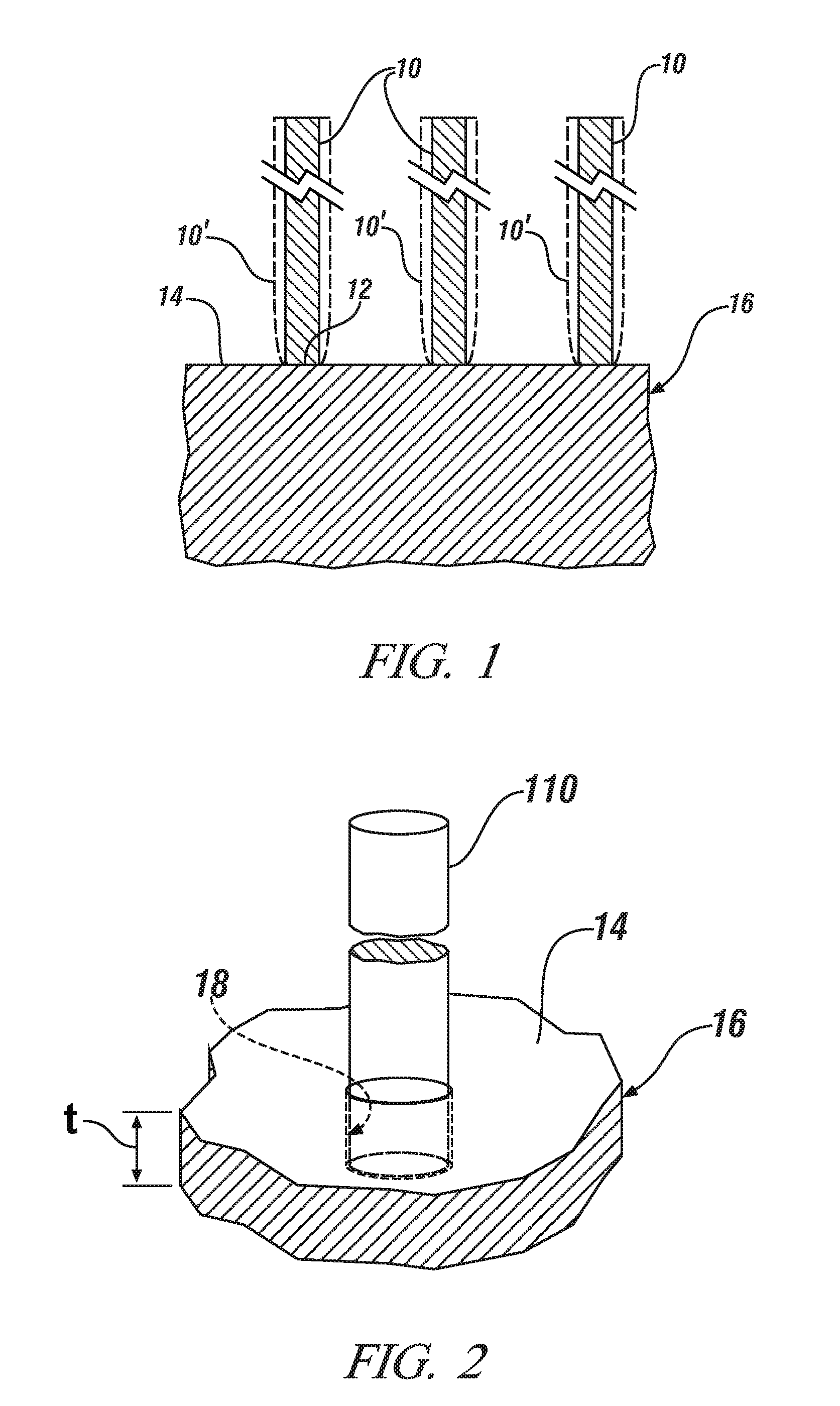

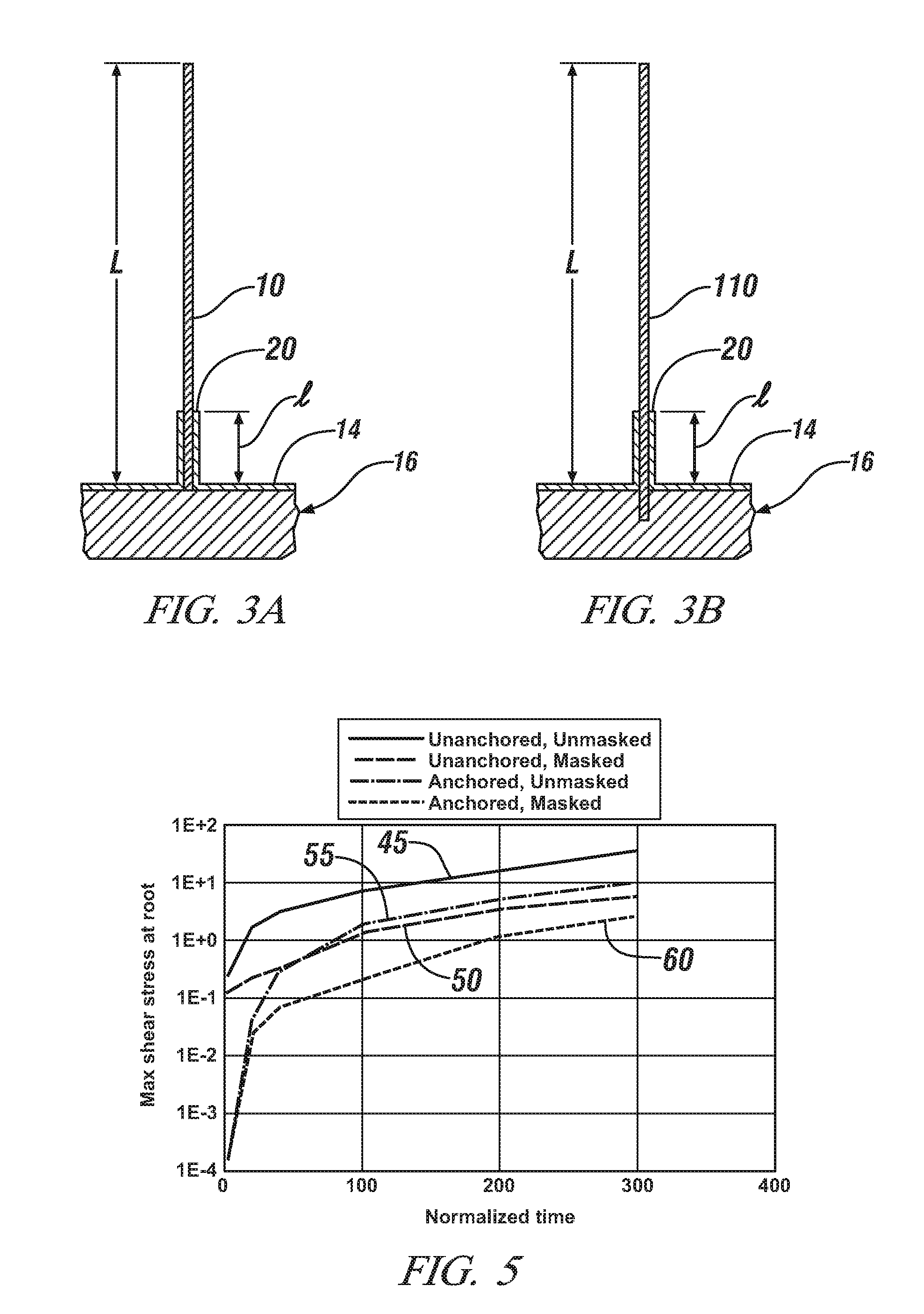

Valve guide and spring retainer assemblies

InactiveUS6910871B1Improve volumetric efficiencyEasy to insertPositive displacement pump componentsCheck valvesStress reliefEngineering

Valve guide and spring retainer assemblies are described for use in plunger pump housings that incorporate structural features for stress-relief. These pump housing structural features accommodate correspondingly-shaped valve guides and / or spring retainers that are internally fixed in place using one or more non-threaded spacers. Plunger pumps so constructed are relatively resistant to fatigue failure because of stress reductions, and they may incorporate a variety of valve styles, including top and lower stem-guided valves and crow-foot-guided valves, in easily-maintained configurations. Besides securing valve guides and / or spring retainers, non-threaded spacers may be shaped and dimensioned to aid in further reducing stress and to improve volumetric efficiency of the pumps in which they are used.

Owner:ALTIS INVESTMENTS LLC

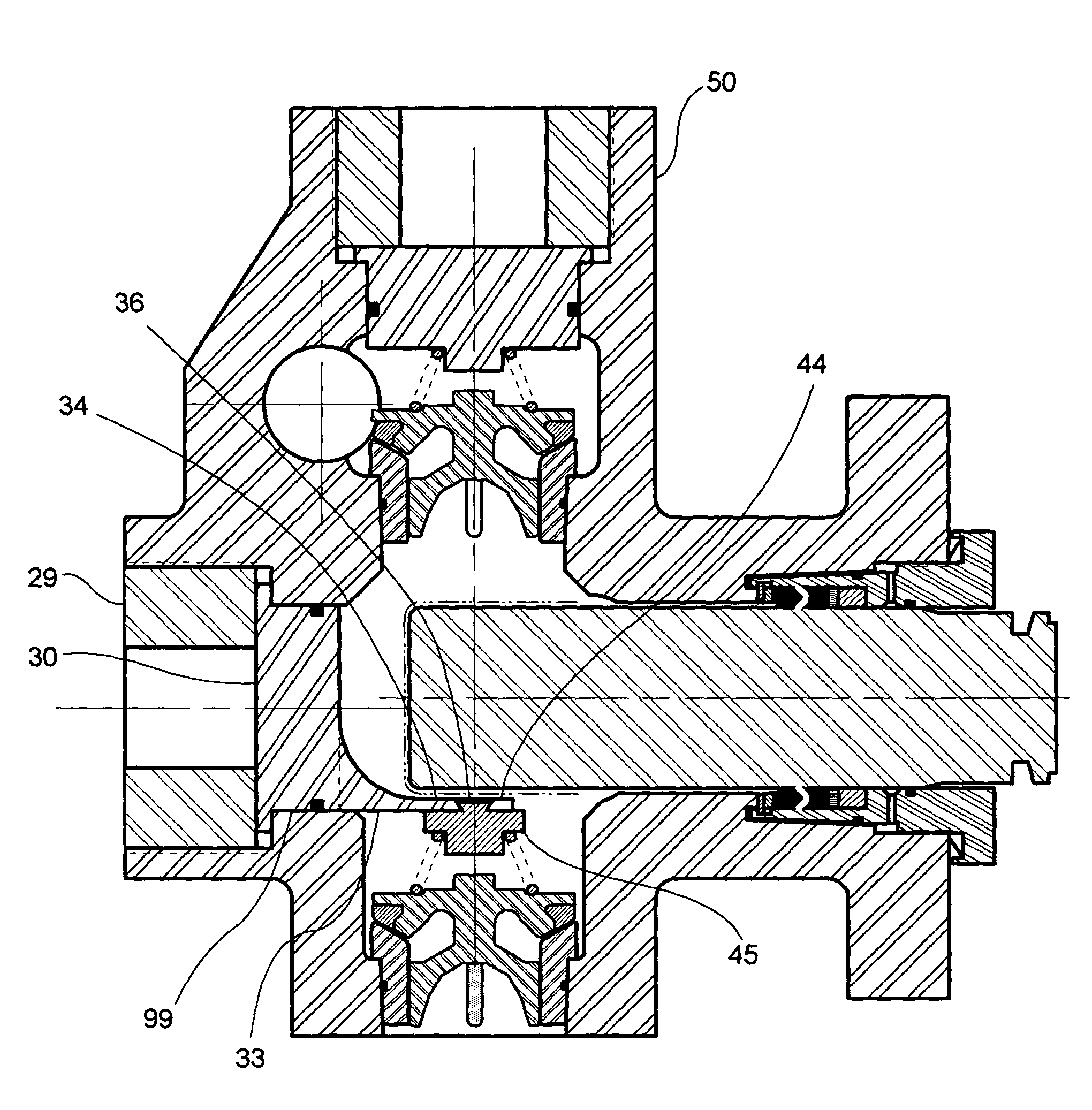

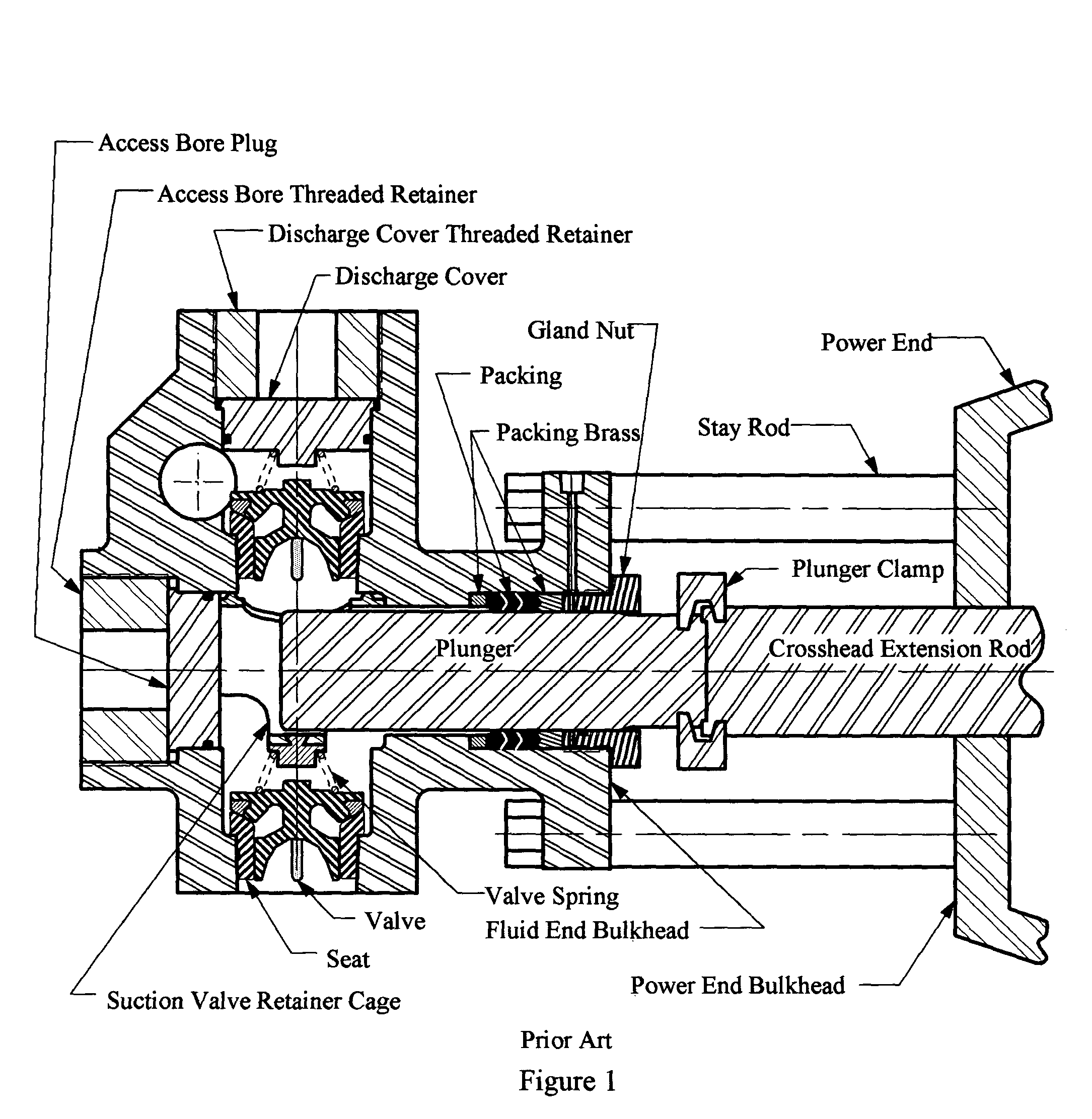

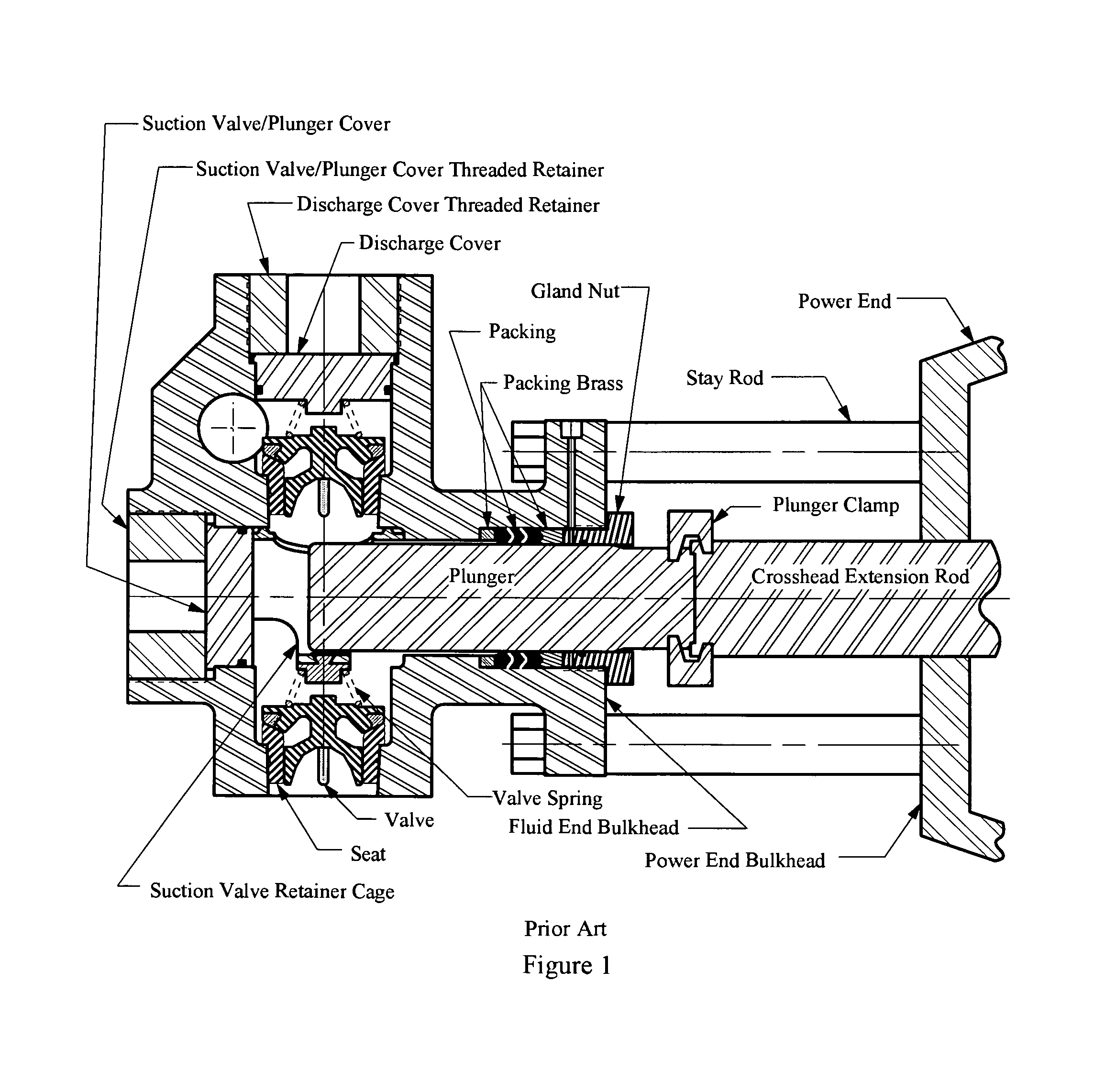

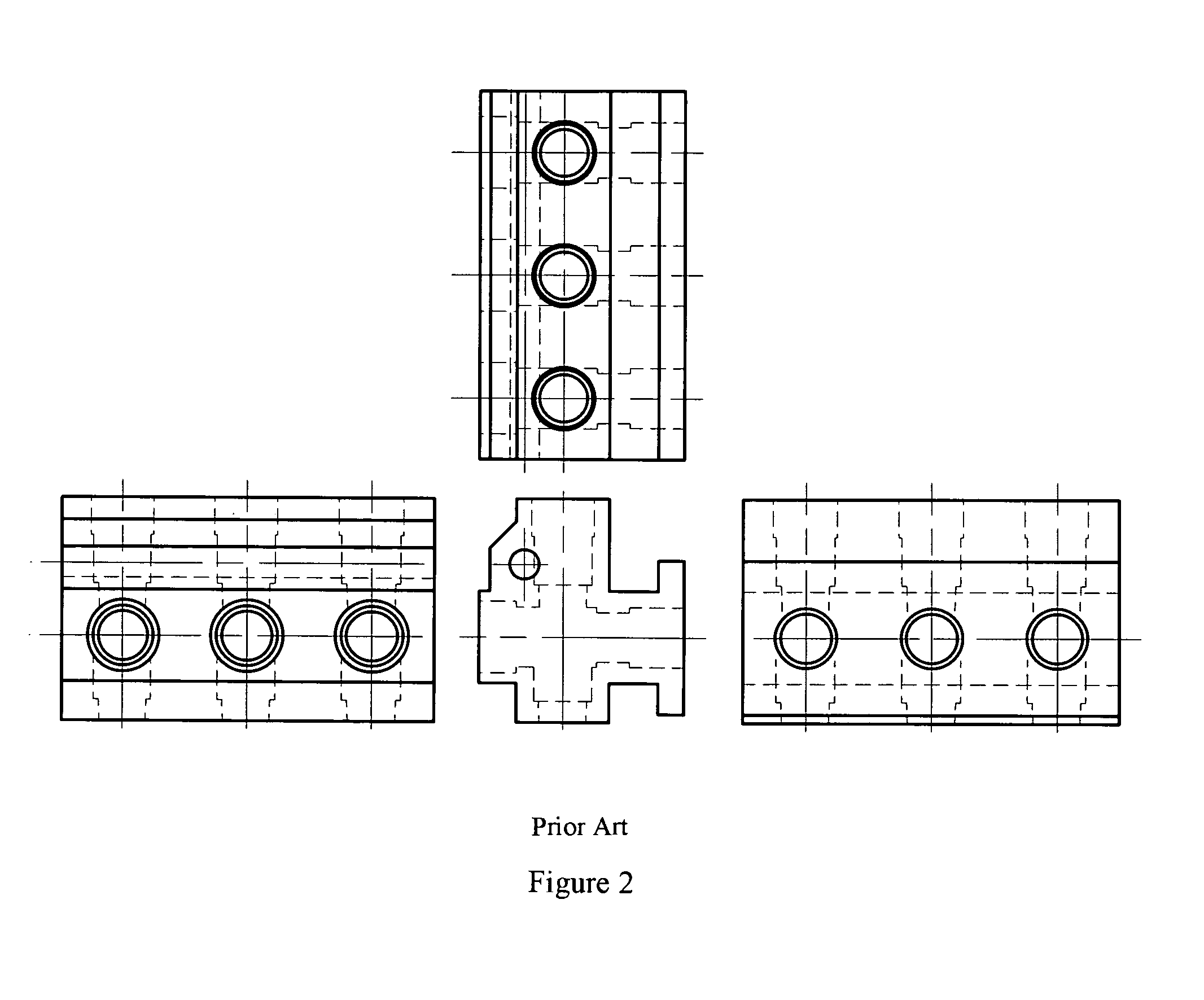

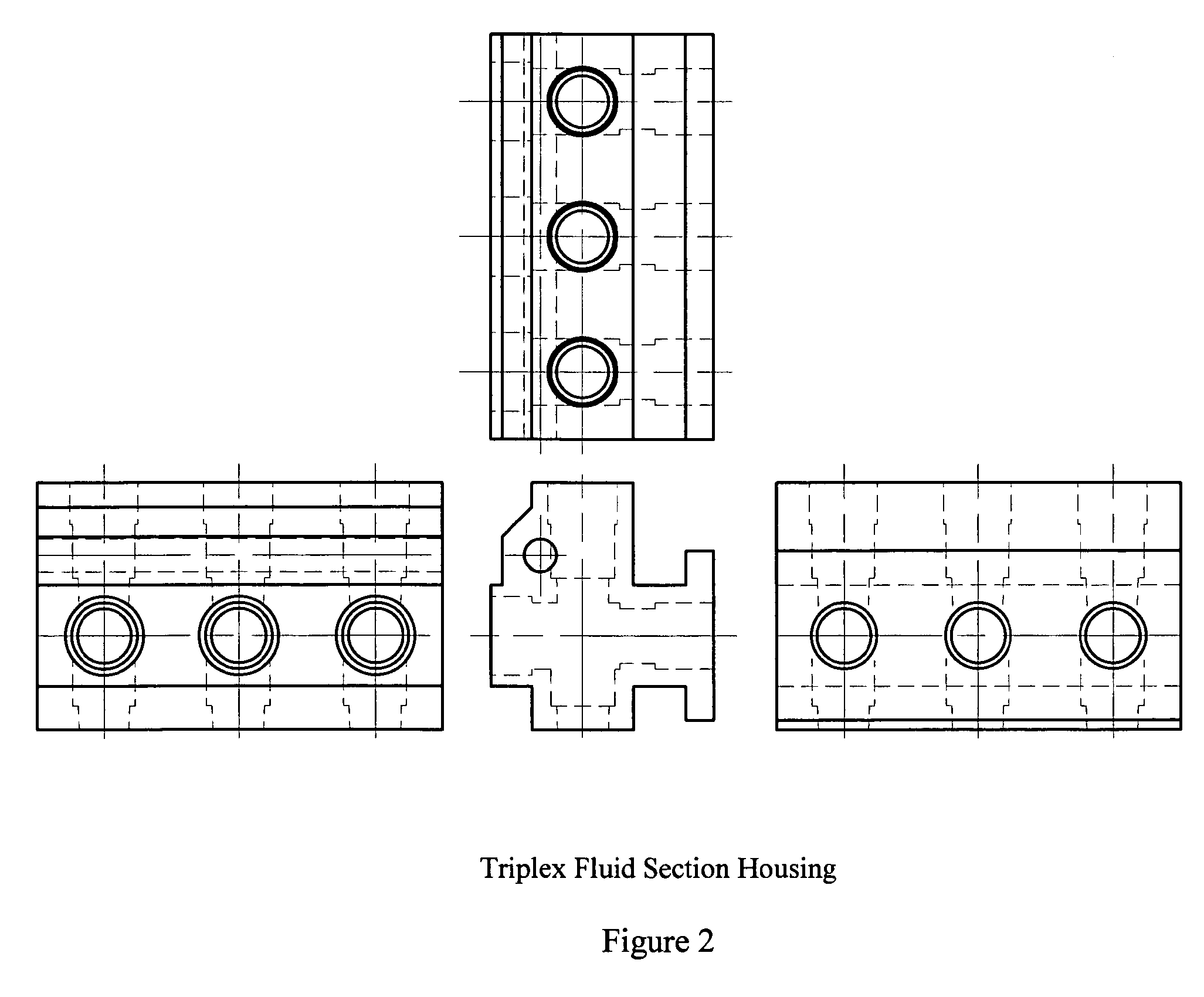

Plunger pump housing and access bore plug

ActiveUS7186097B1Positive displacement pump componentsPositive-displacement liquid enginesStress reliefEngineering

Suction valve spring retainers mounted using an access bore plug are described for use in plunger pump housings having an offset access bore and incorporating structural features for stress-relief. These pump housing structural features accommodate access bore plugs that secure suction valve spring retainers that are internally located substantially centrally over the suction bore transition area of the plunger pump housing. Access bore plugs are secured in place on the pump housing using one or more threaded retainers. Plunger pumps so constructed are relatively resistant to fatigue failure because of stress-reducing structural features, and they may incorporate a variety of valve styles, including top and lower stem-guided valves and crow-foot-guided valves, in easily-maintained configurations. Suction valve spring retainers mounted in plunger pump housings may also incorporate a suction valve top stem guide. Further, certain structural features of access bore plugs may be dimensioned to aid in improving volumetric efficiency of the pumps in which they are used.

Owner:HARRIS CORP

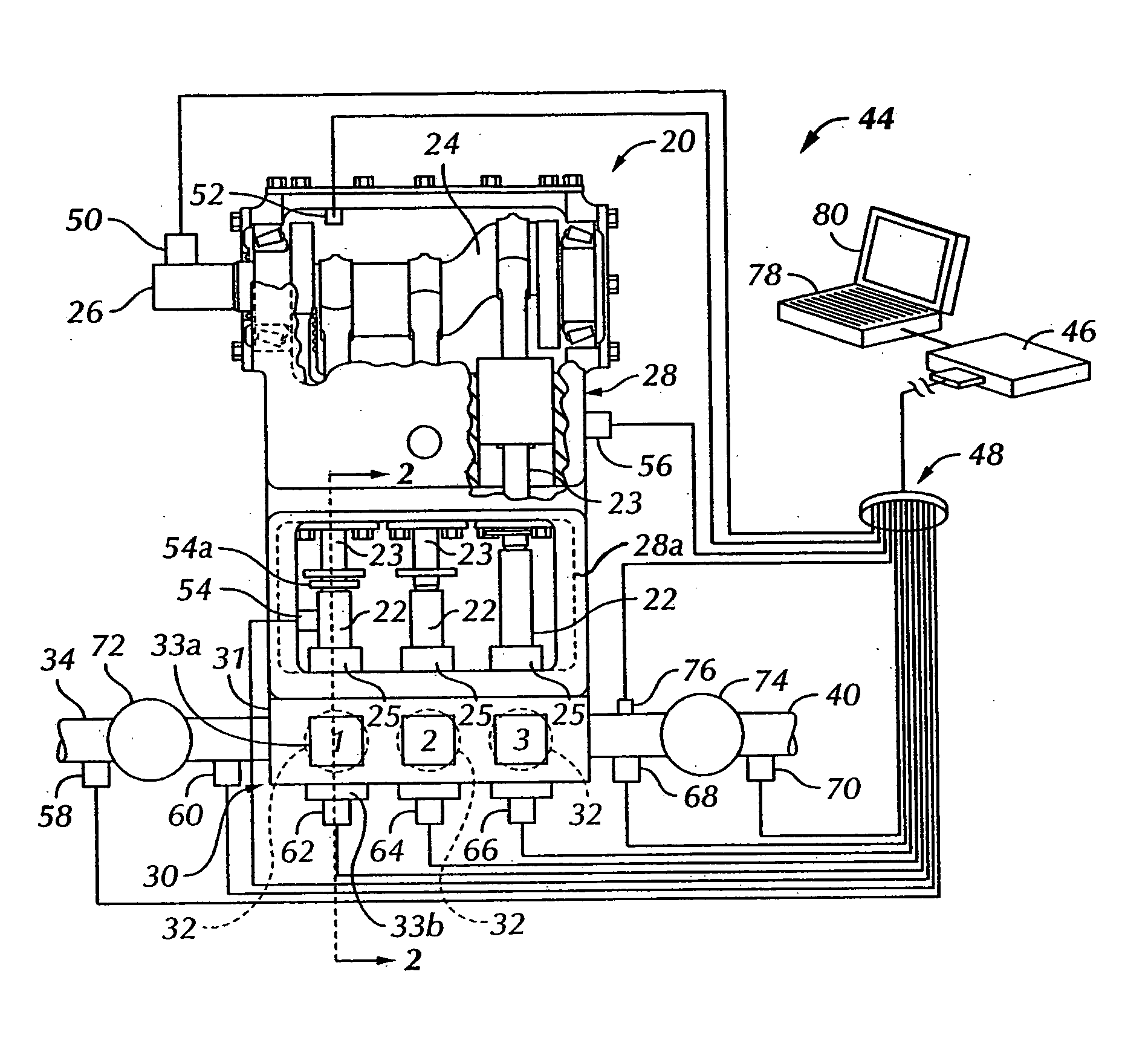

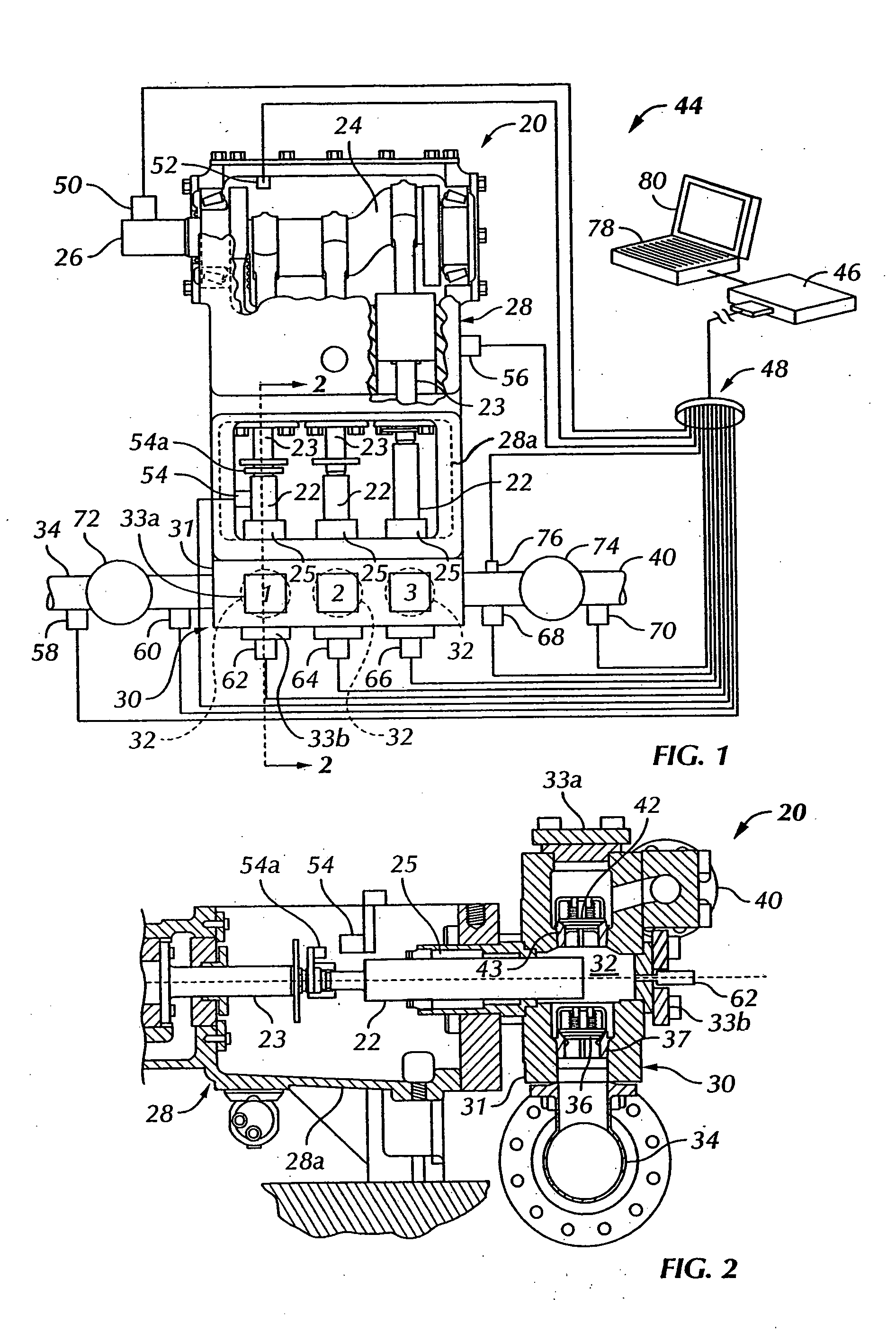

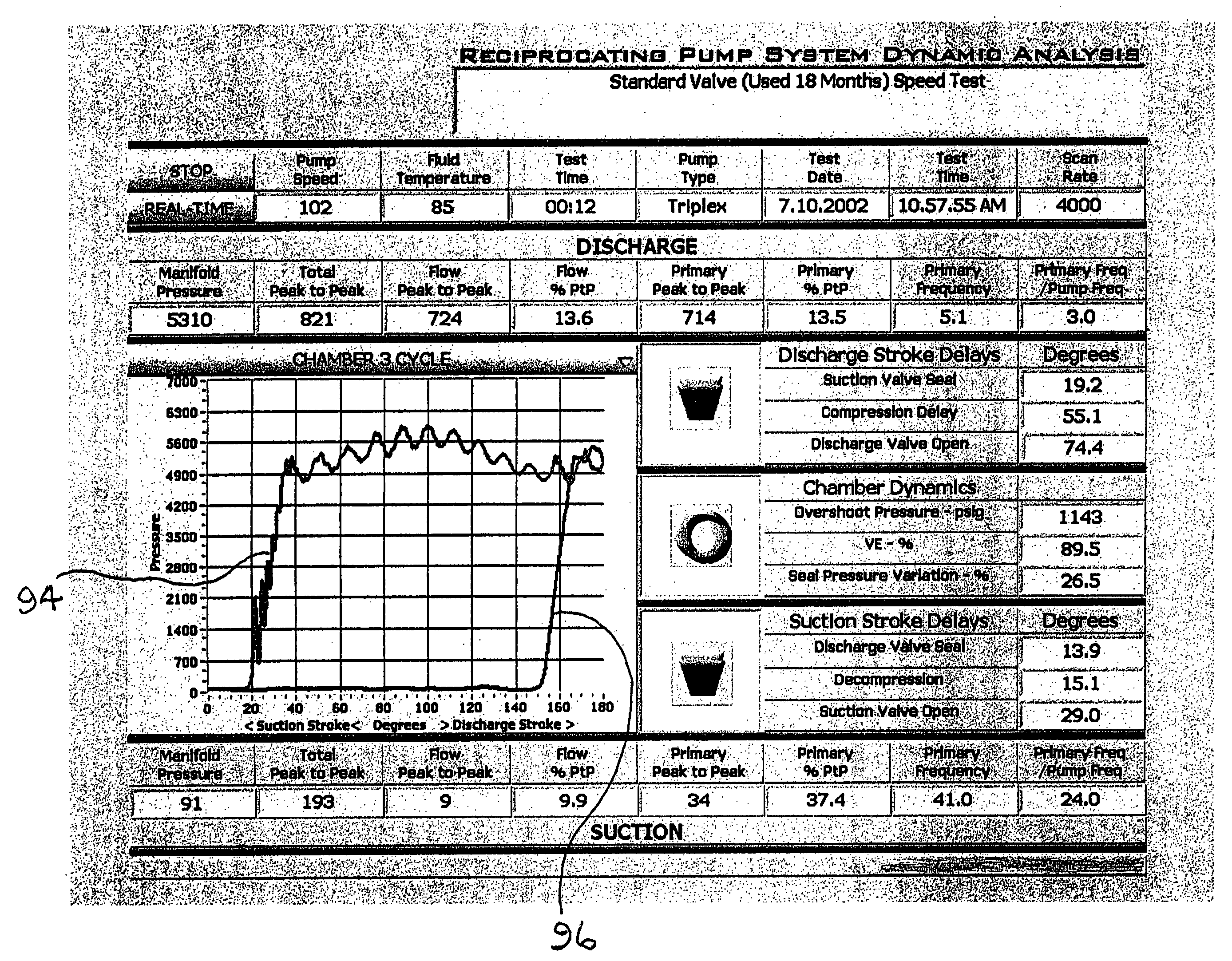

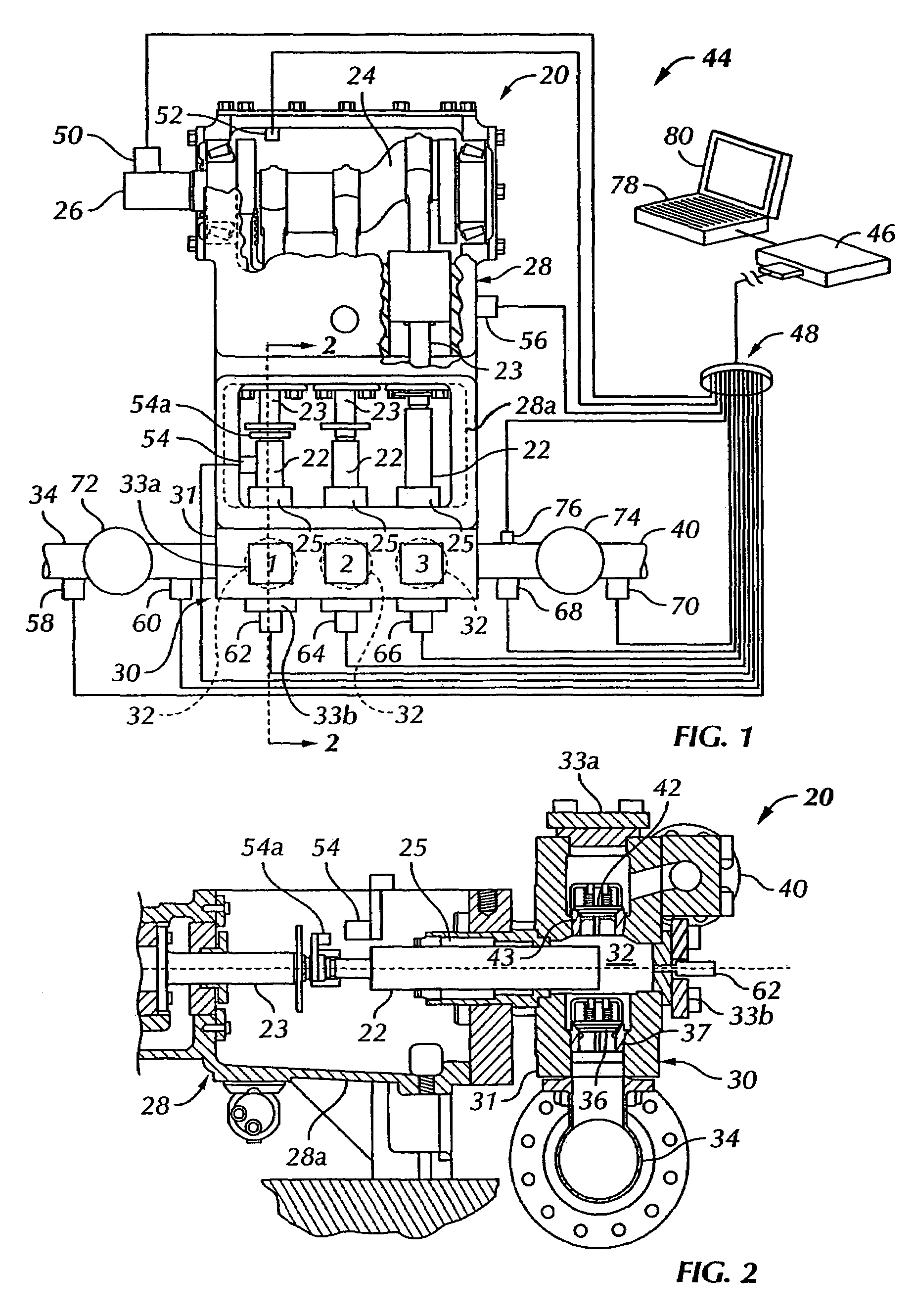

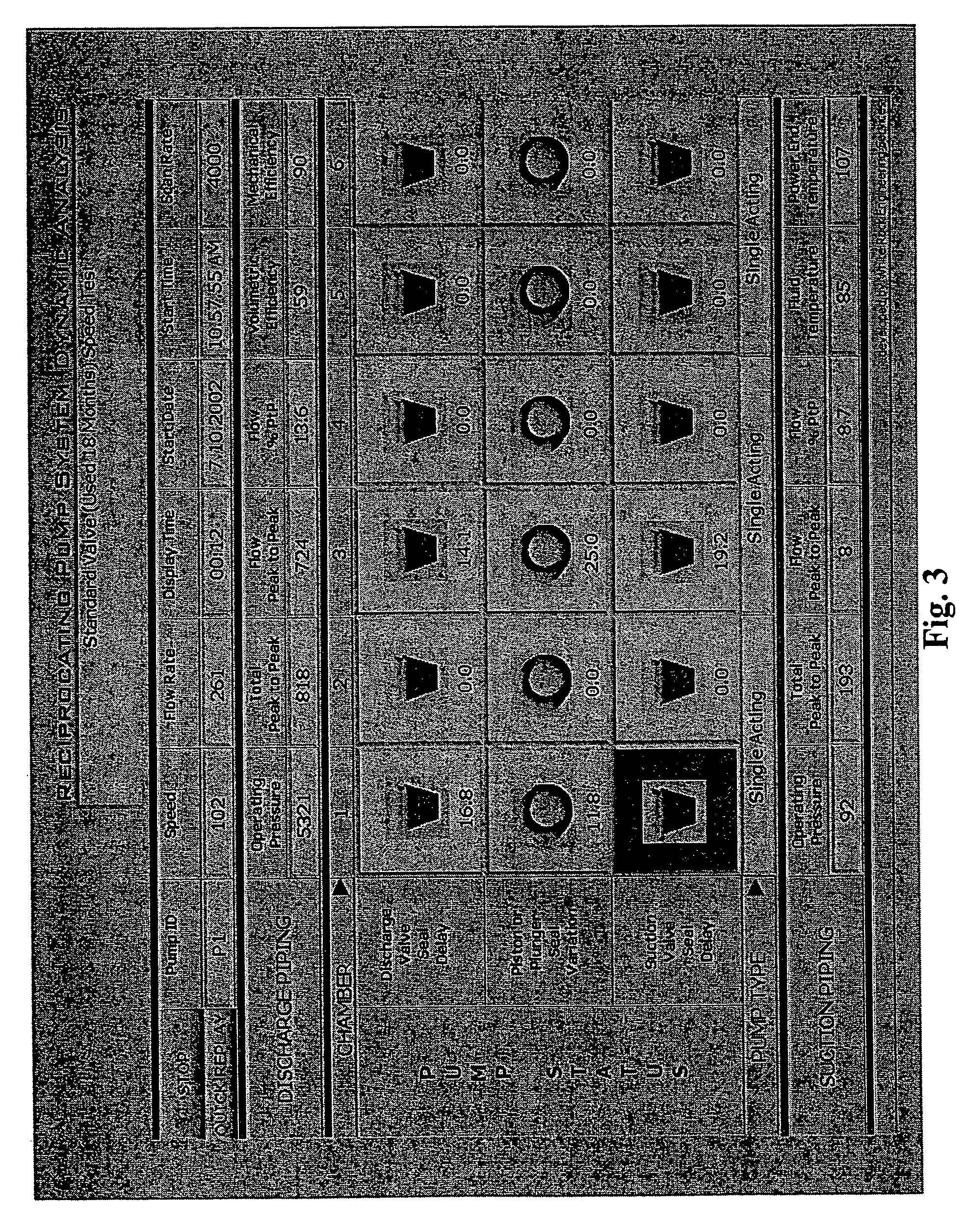

System and method for power pump performance monitoring and analysis

InactiveUS20050180868A1Easy to useEasy to provideTime indicationProgram control using stored programsDisplay deviceEngineering

A power pump performance analysis system includes a signal processor connected to pressure sensors for sensing pressures in the cylinder chambers and inlet and discharge piping of a single or multi-cylinder pump. Pump speed and piston position are determined by a crankshaft position sensor. Pump vibration, fluid temperatures, and power input may also be measured by sensors connected to the processor. Performance analyses, including determination of pump volumetric efficiency, mechanical efficiency, suction and discharge valve sealing delay, valve and piston seal leakage, flow induced pressure variations, acceleration induced pressure detection, hydraulic resonance detection and pulsation dampener performance may be measured and selected parameters displayed on a visual display connected to the processor directly or via a network.

Owner:MHWIRTH

System and method for power pump performance monitoring and analysis

InactiveUS7623986B2Easy to useEasy to provideTime indicationProgram control using stored programsEngineeringStreamflow

A power pump performance analysis system includes a signal processor connected to pressure sensors for sensing pressures in the cylinder chambers and inlet and discharge piping of a single or multi-cylinder pump. Pump speed and piston position are determined by a crankshaft position sensor. Pump vibration, fluid temperatures, and power input may also be measured by sensors connected to the processor. Performance analyses, including determination of pump volumetric efficiency, mechanical efficiency, suction and discharge valve sealing delay, valve and piston seal leakage, flow induced pressure variations, acceleration induced pressure detection, hydraulic resonance detection and pulsation dampener performance may be measured and selected parameters displayed on a visual display connected to the processor directly or via a network.

Owner:MHWIRTH

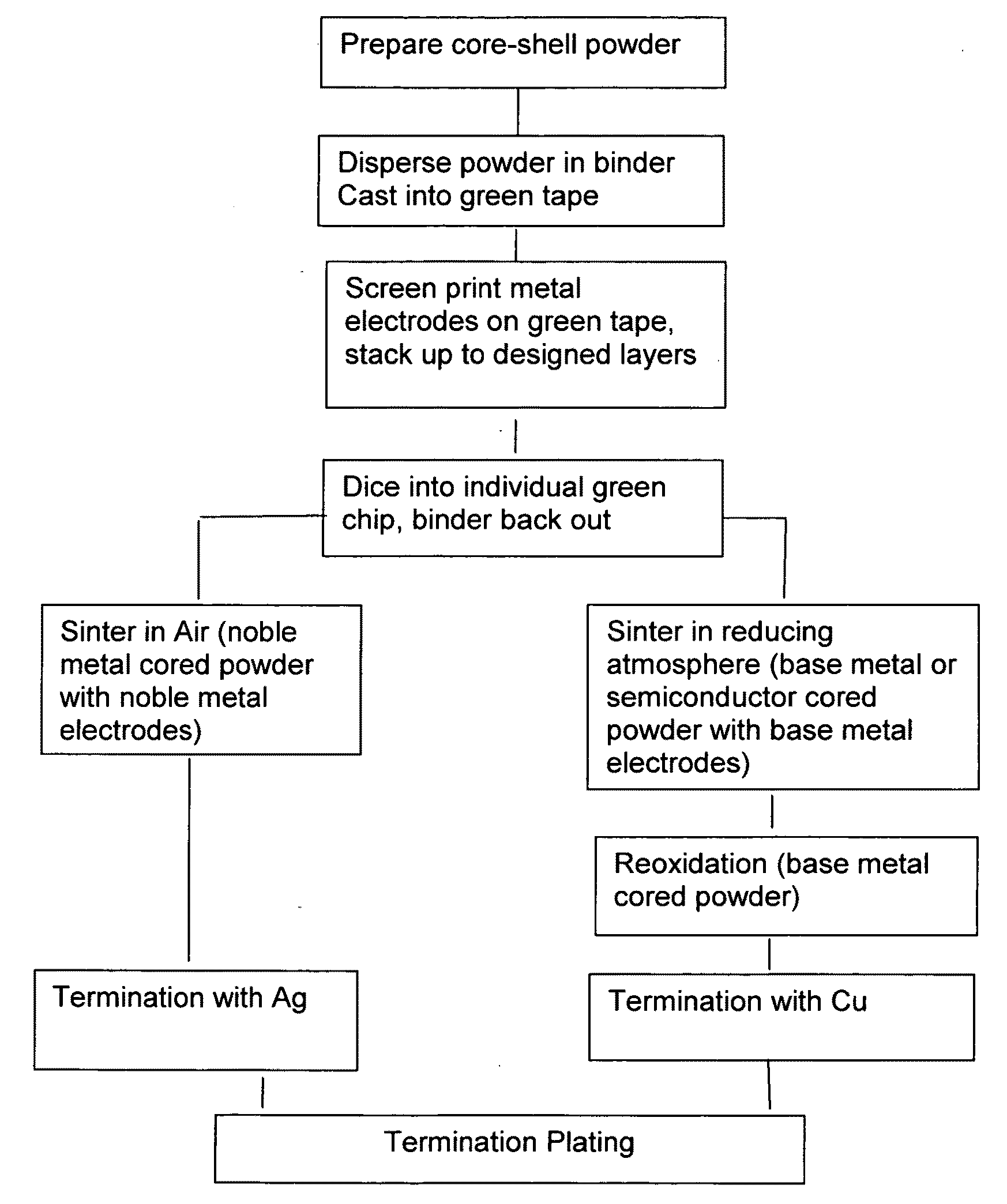

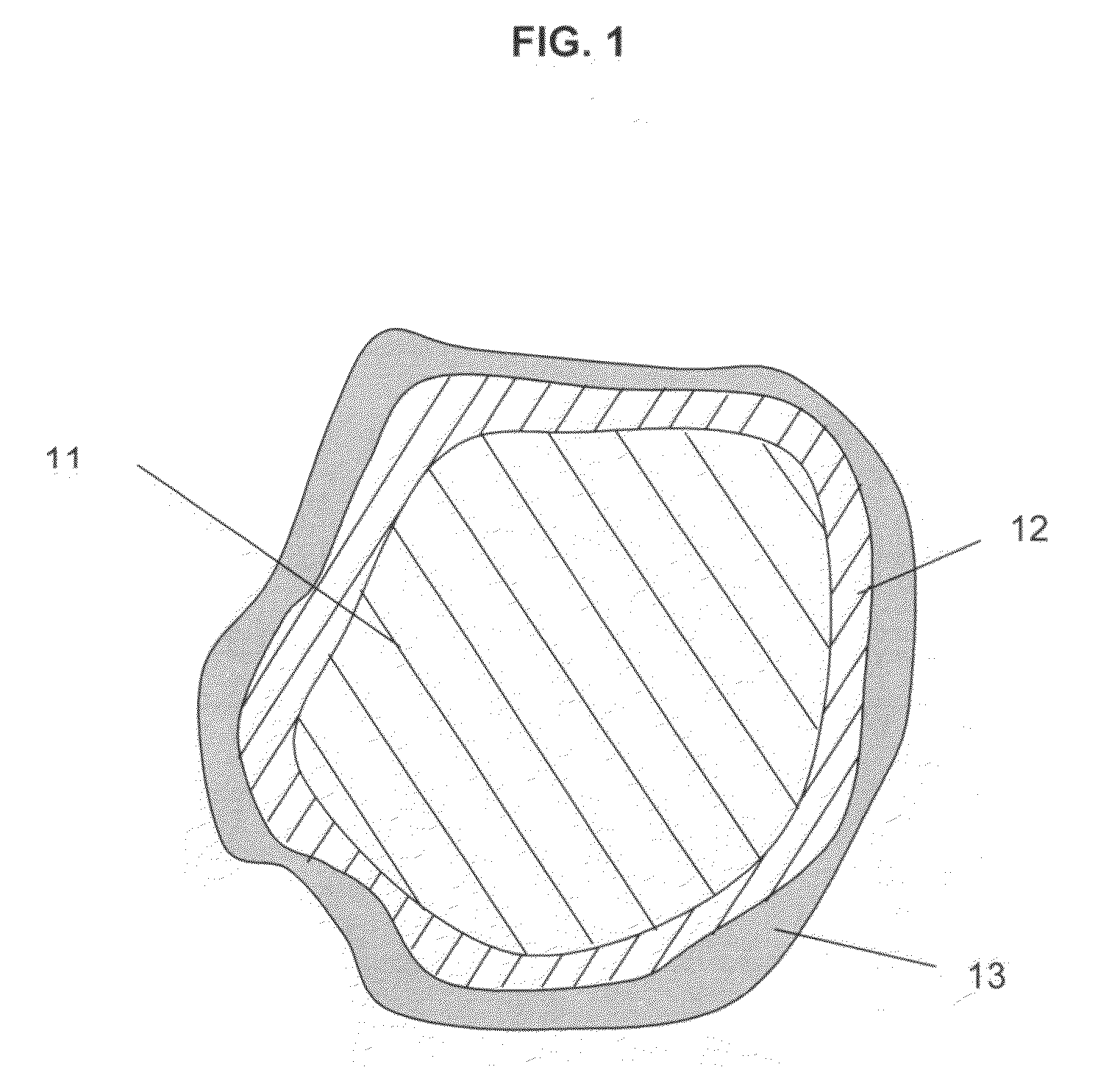

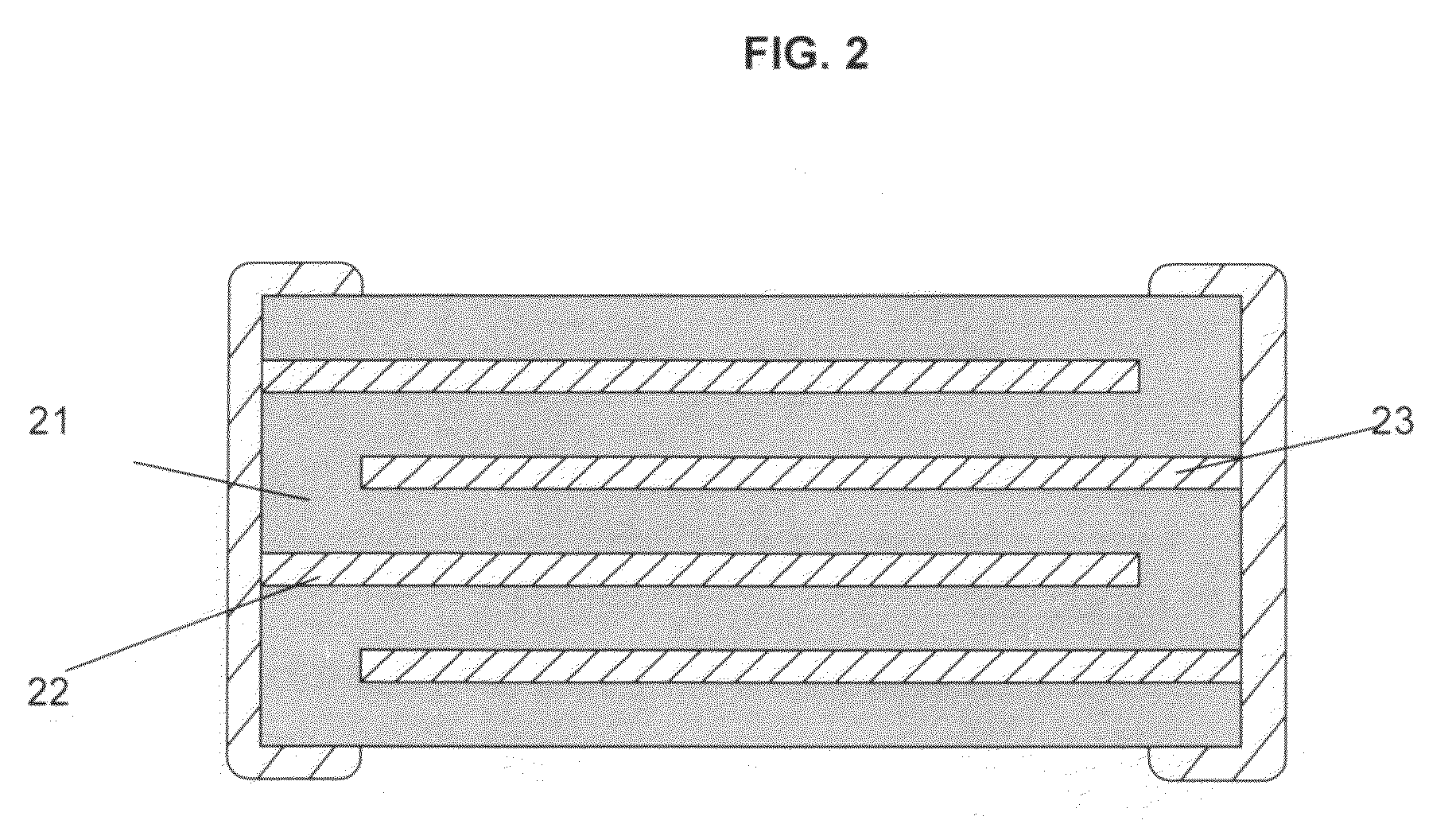

Core-shell structured dielectric particles for use in multilayer ceramic capacitors

InactiveUS20100110608A1Simplifies MLCC manufacturing processImprove propertiesFixed capacitor dielectricStacked capacitorsCapacitanceThin shells

This invention provides a method to make core-shell structured dielectric particles which consist of a conductive core and at least one layer of insulating dielectric shell for the application of multilayer ceramic capacitors (MLCC). The use of said core-shell instead of conventionally solid dielectric particles as the capacitor's active layers simplifies the MLCC manufacturing processes and effectively improves the MLCC properties. In particular, the use of core-shell particles with a thin shell of high permittivity dielectric material improves the capacitance volumetric efficiency, and the use of core-shell particles with a thick shell of dielectric will improve capacitor device's energy storage capacity as the results of improved electrical and mechanical strength.

Owner:WEI FRANK +1

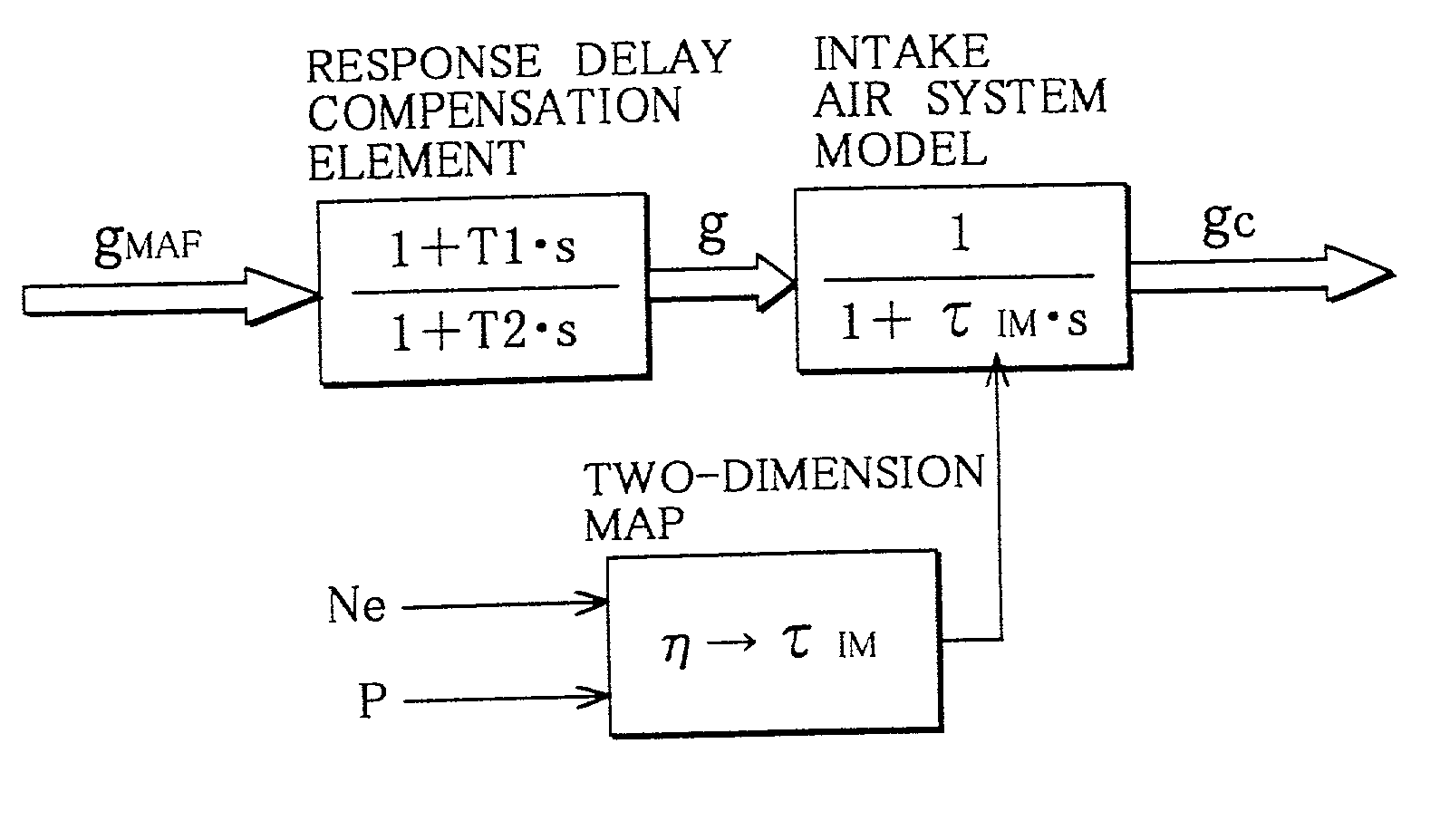

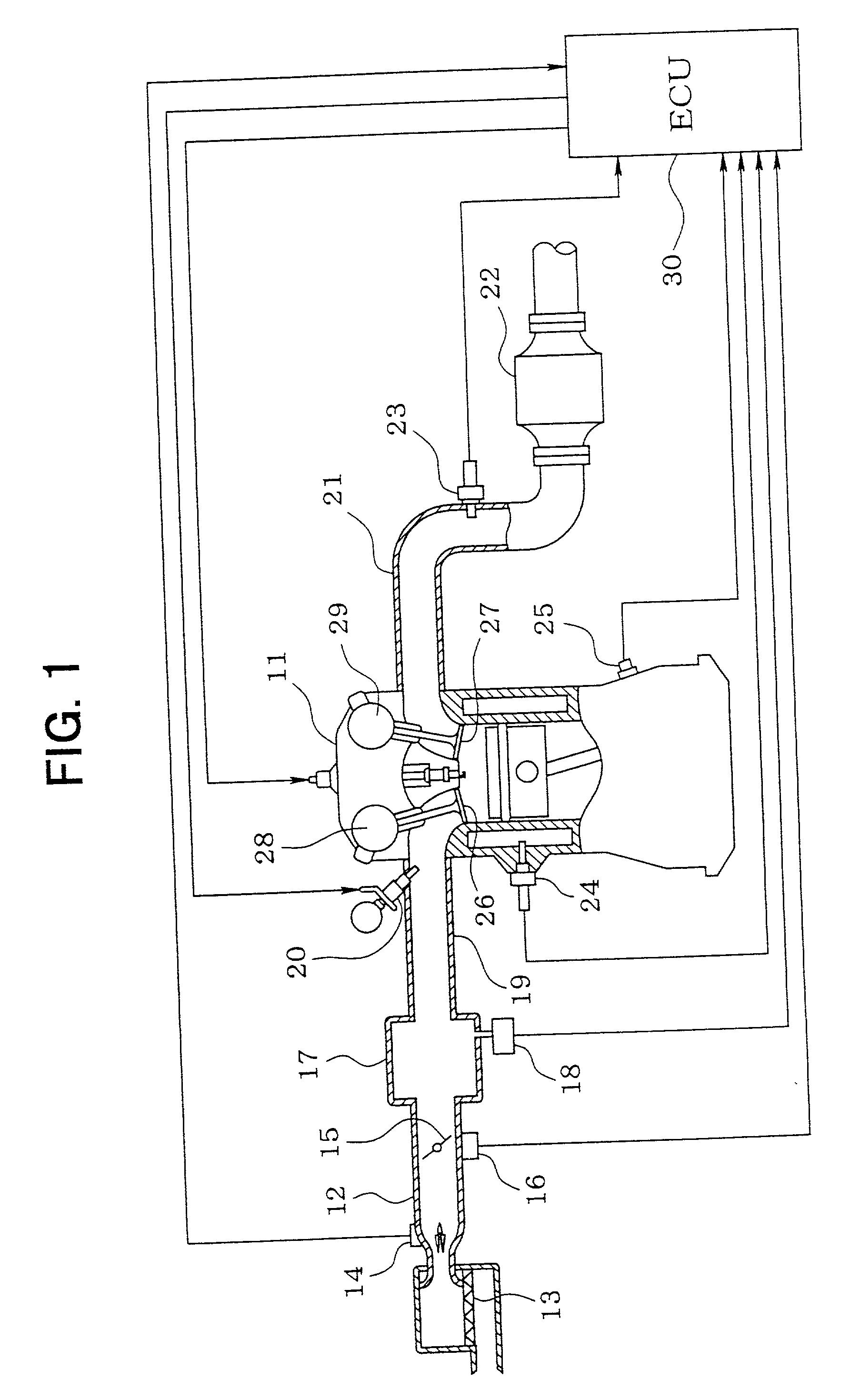

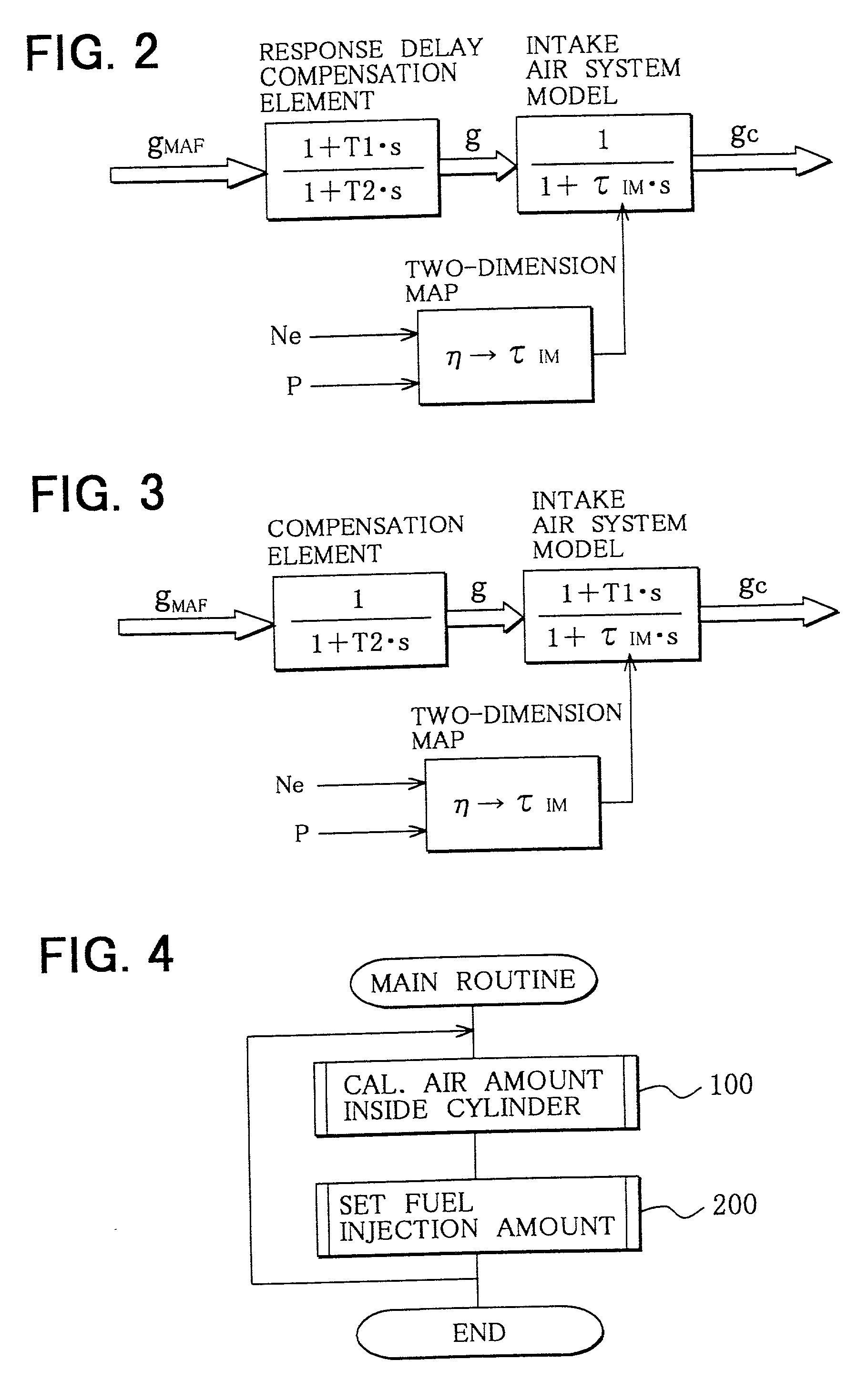

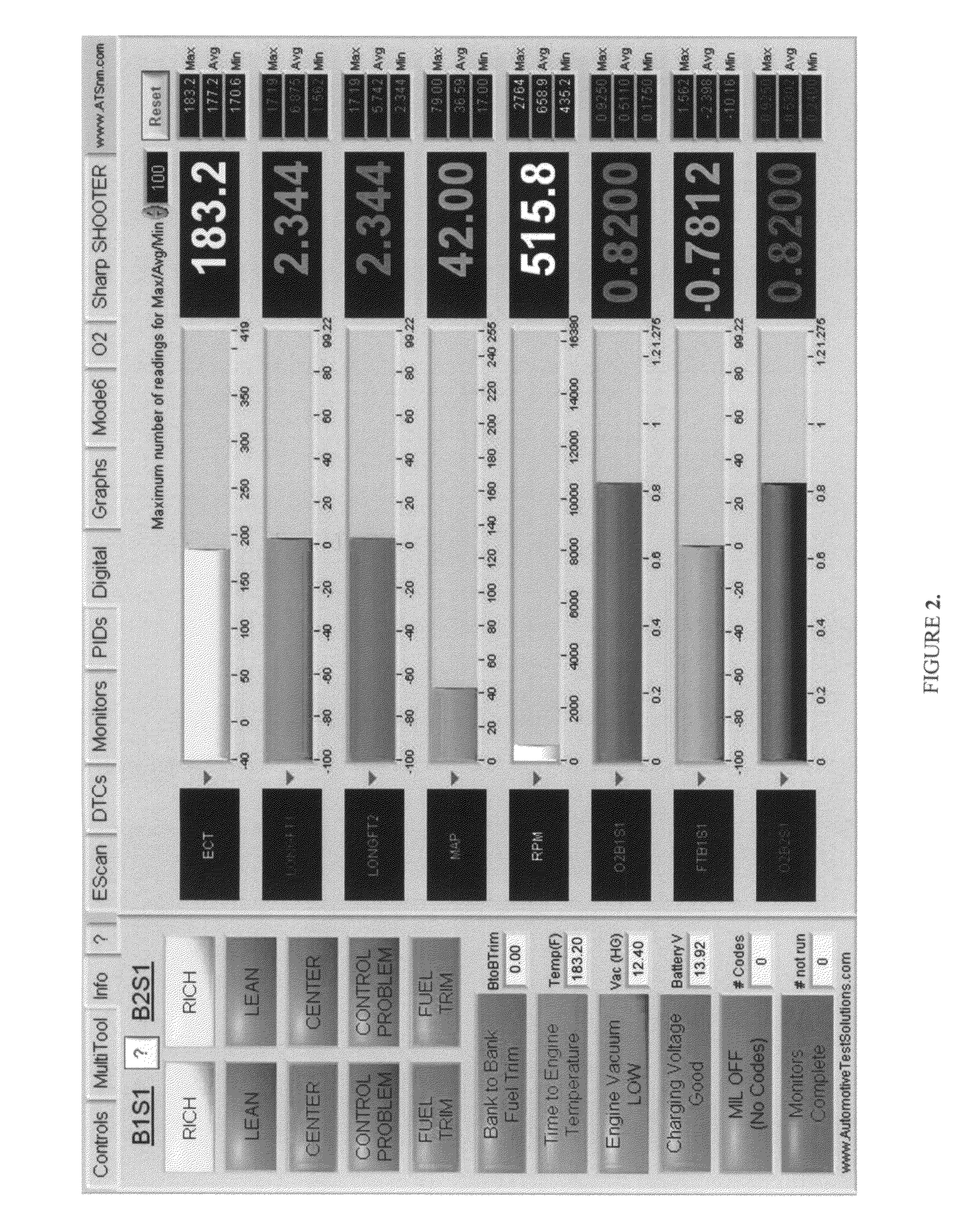

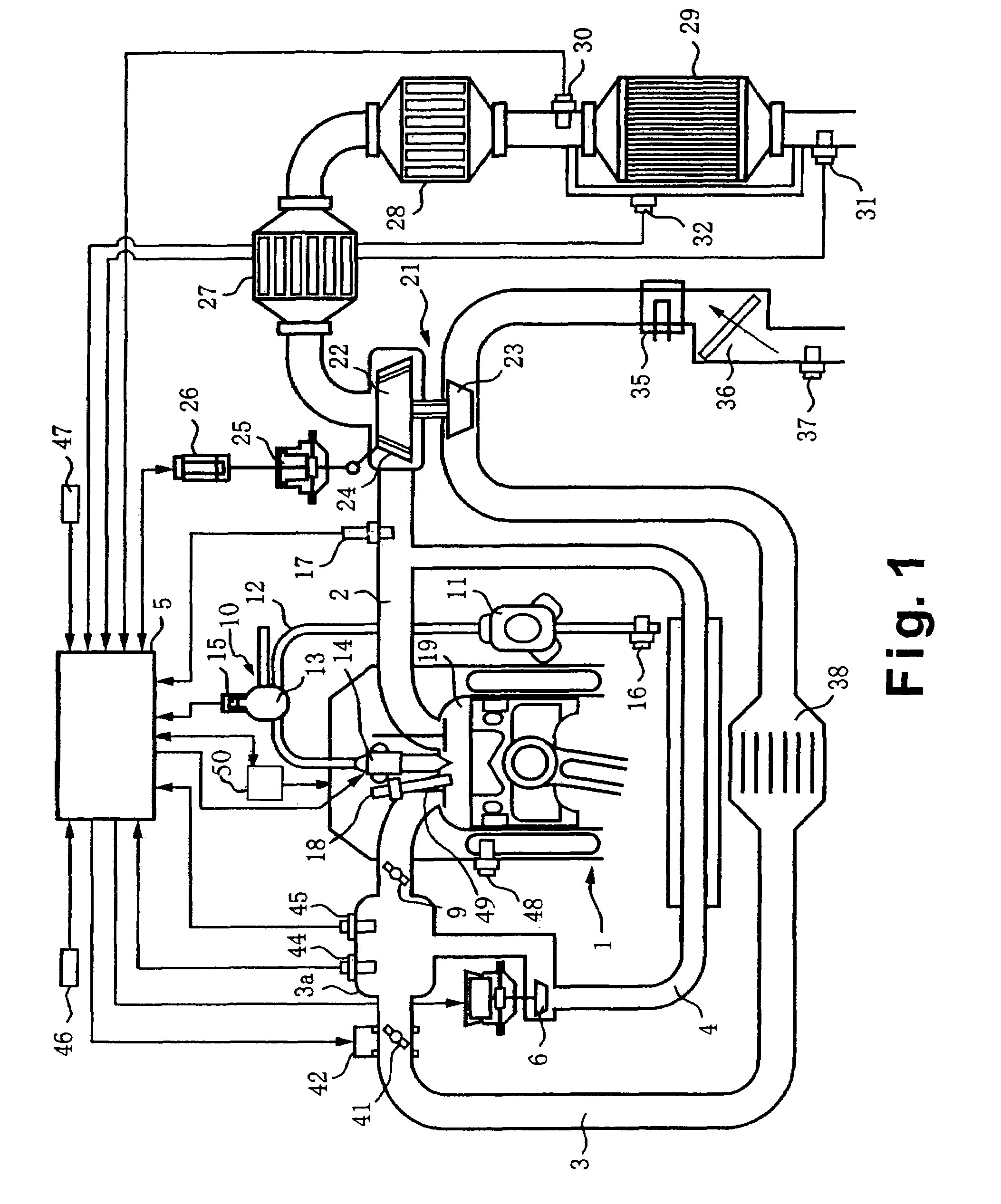

Air amount detector for internal combustion engine

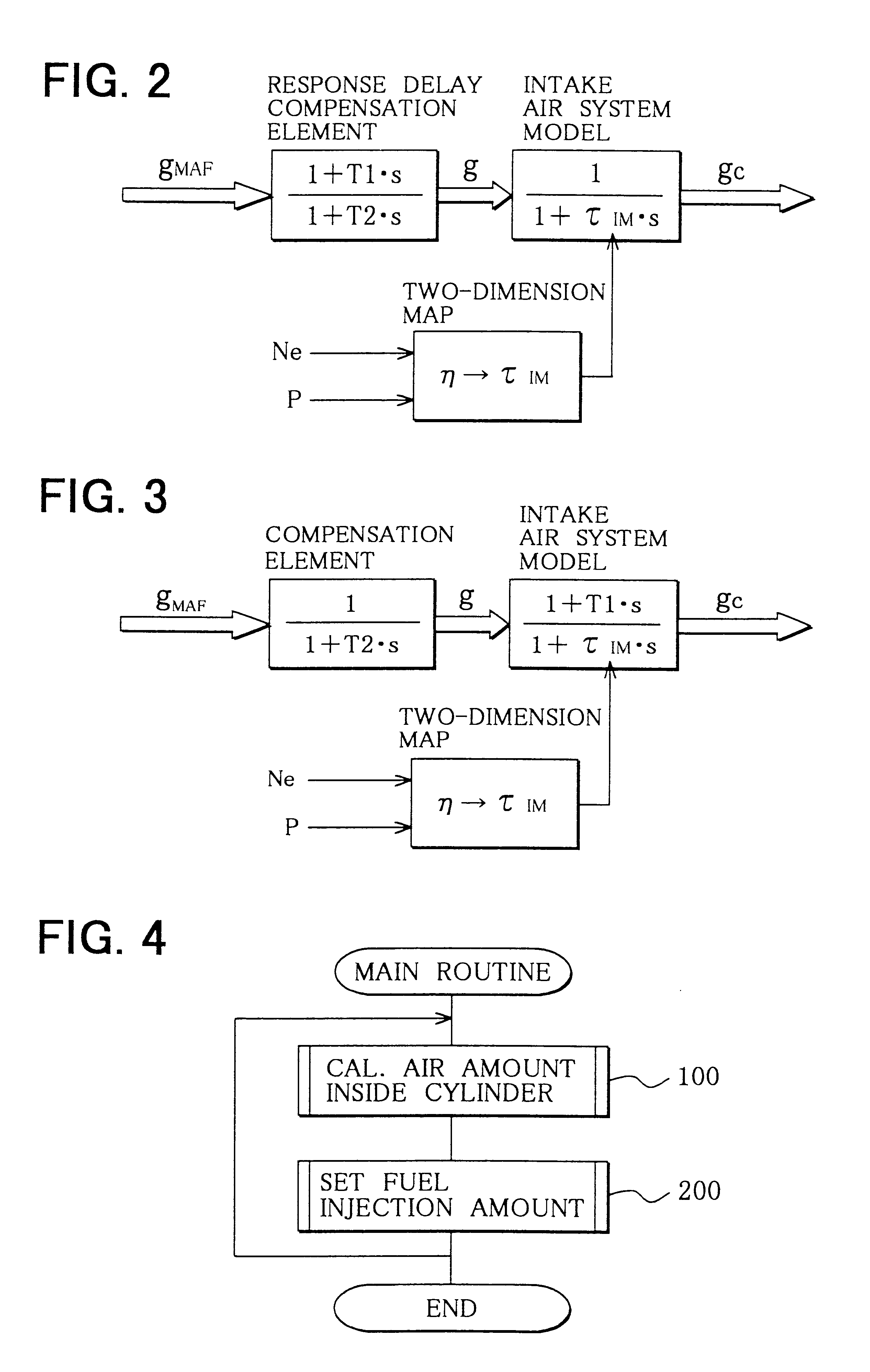

InactiveUS20020107630A1Improve calculation accuracyAnalogue computers for vehiclesElectrical controlResponse delayPhase advance

A response delay compensation element for compensating a response delay of an output gMAF of an airflow meter by a phase advance compensation is provided so that an output g of the response delay compensation element is input to the intake air system model. A transfer function of the phase advance compensation is <paragraph lvl="0"><in-line-formula>g=(1+T1.s) / (1+T2s).gMAF< / in-line-formula>where T1 and T2 are time constant of the phase advance compensation, which is set based on at least one of the output gMAF of the airflow meter, engine speed, an intake air pressure, and a throttle angle. The model time constant τIM of the intake air system model is calculated by variables including volumetric efficiency and the engine speed. The volumetric efficiency is calculated by two-dimensional map having the engine speed and the intake air pressure as parameters thereof.

Owner:DENSO CORP

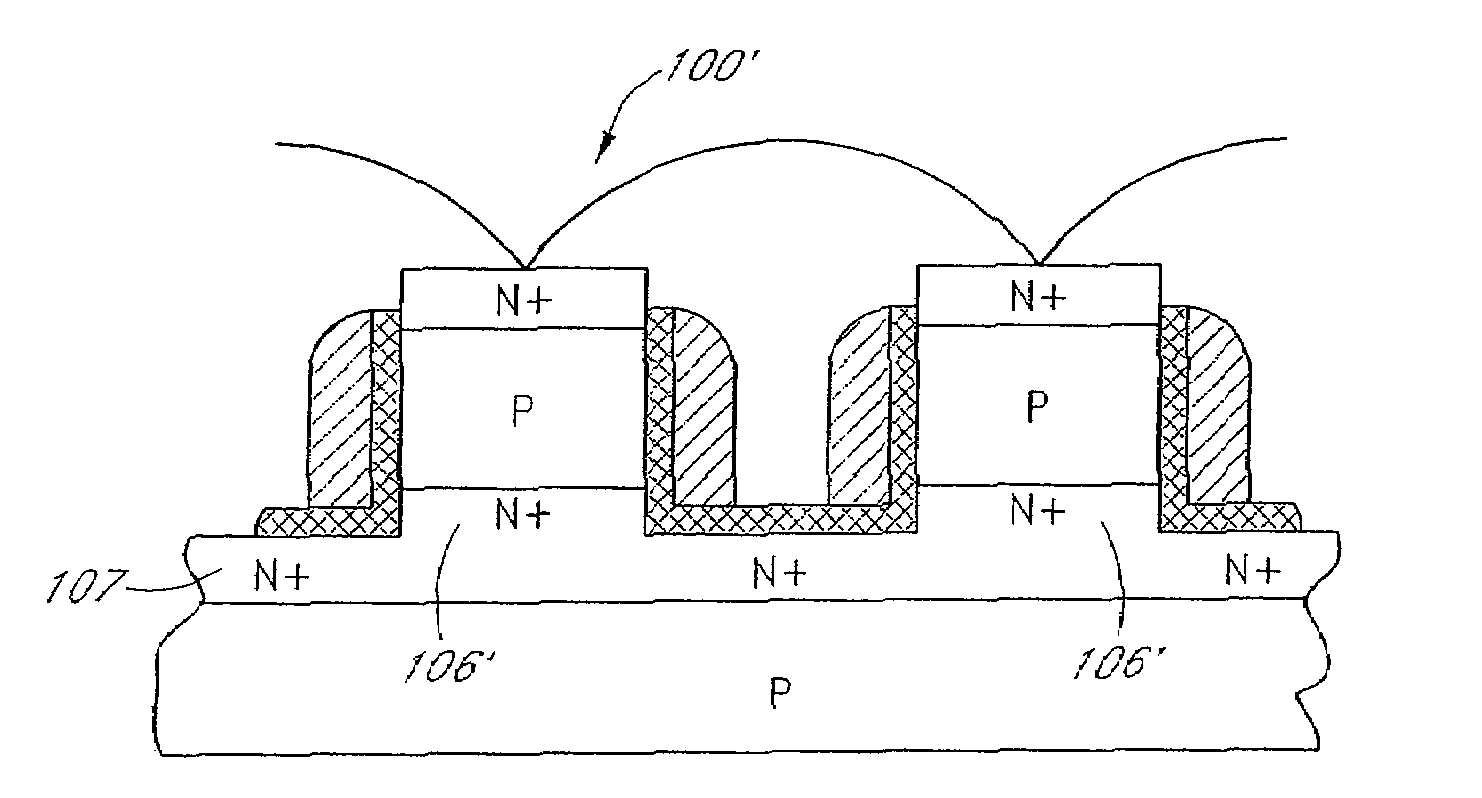

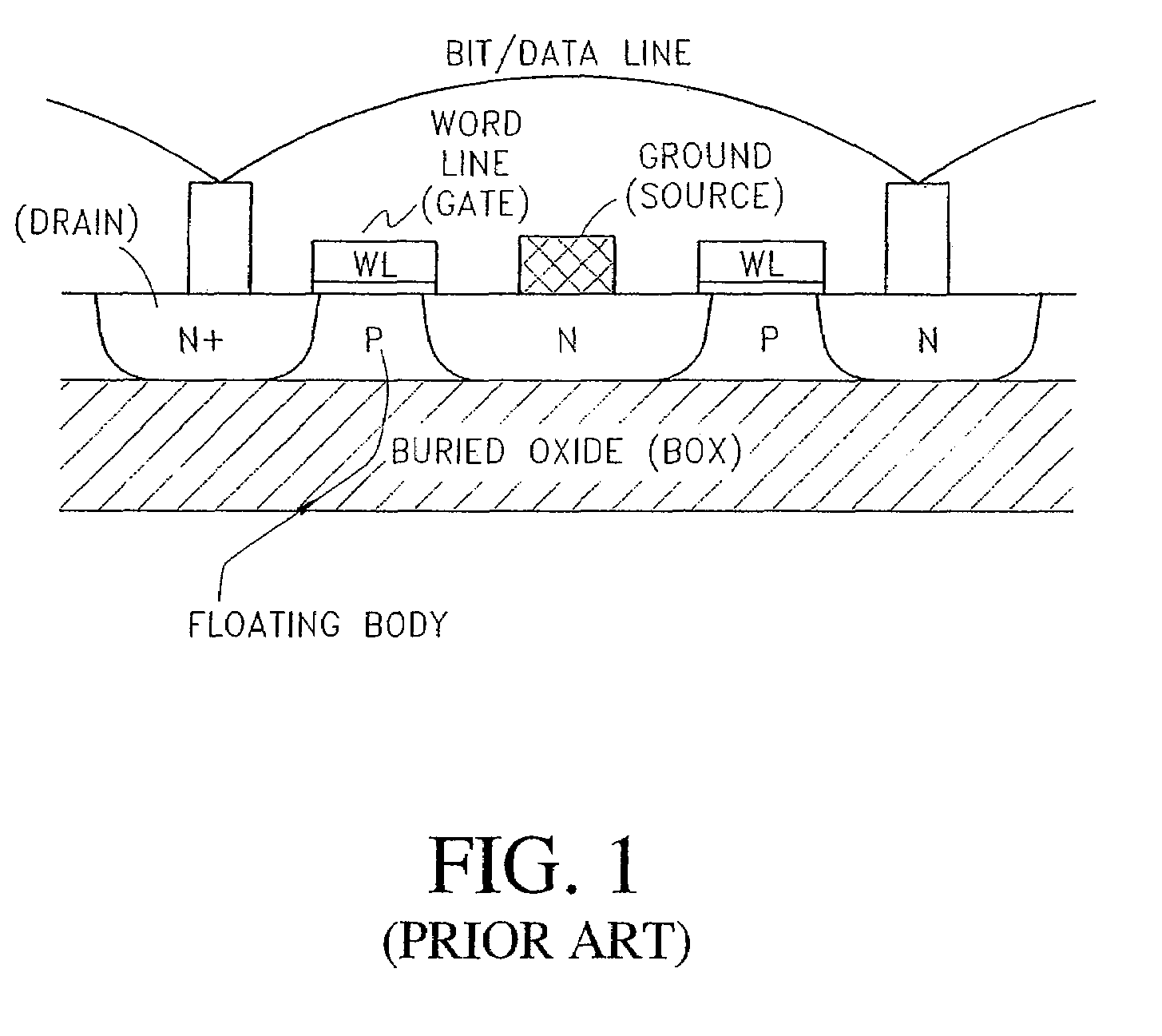

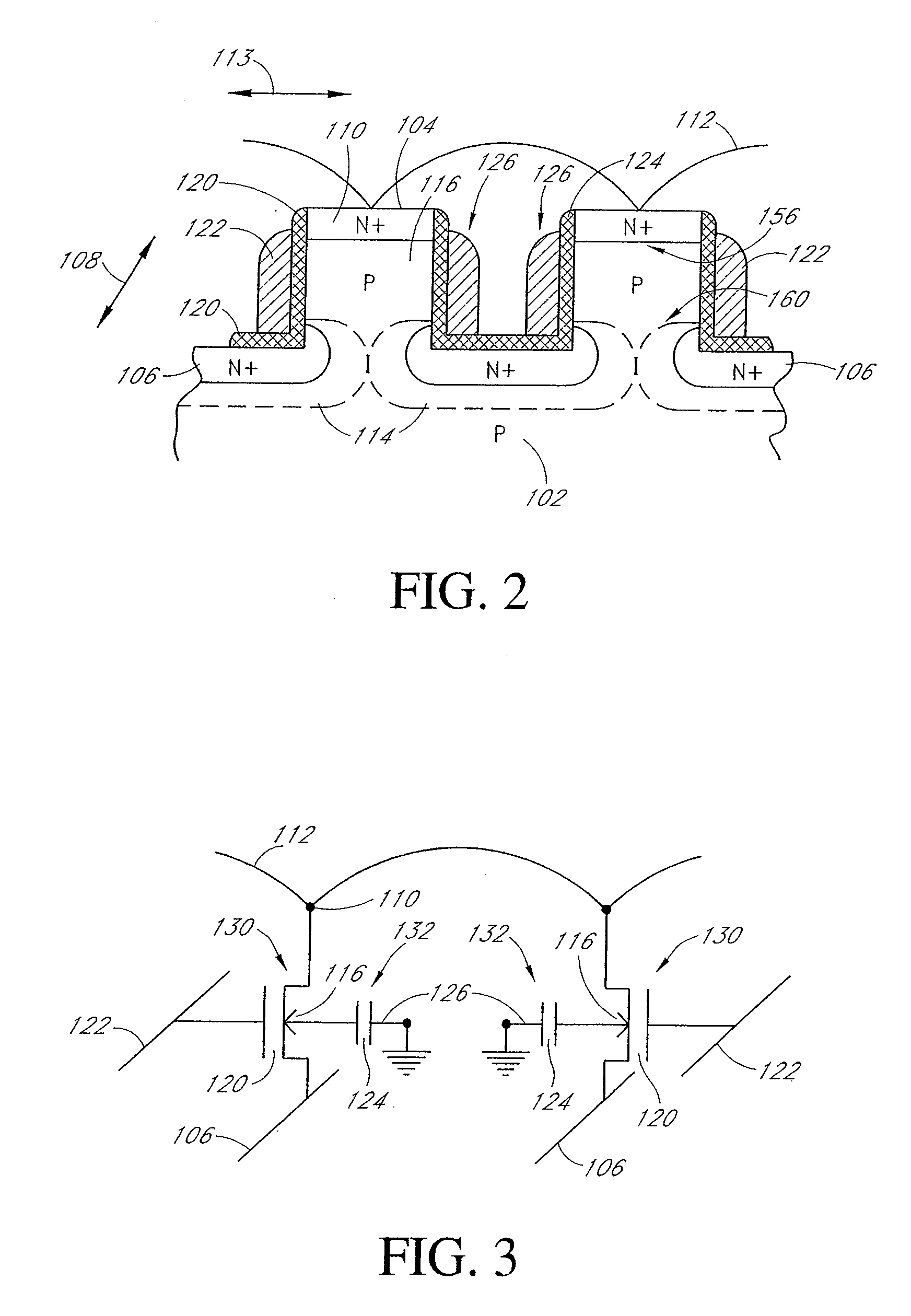

Long retention time single transistor vertical memory gain cell

ActiveUS7271052B1High band gap energyAvoid excessive leakage currentTransistorSolid-state devicesHigh cellRetention time

A single transistor vertical memory gain cell with long data retention times. The memory cell is formed from a silicon carbide substrate to take advantage of the higher band gap energy of silicon carbide as compared to silicon. The silicon carbide provides much lower thermally dependent leakage currents which enables significantly longer refresh intervals. In certain applications, the cell is effectively non-volatile provided appropriate gate bias is maintained. N-type source and drain regions are provided along with a pillar vertically extending from a substrate, which are both p-type doped. A floating body region is defined in the pillar which serves as the body of an access transistor as well as a body storage capacitor. The cell provides high volumetric efficiency with corresponding high cell density as well as relatively fast read times.

Owner:MICRON TECH INC

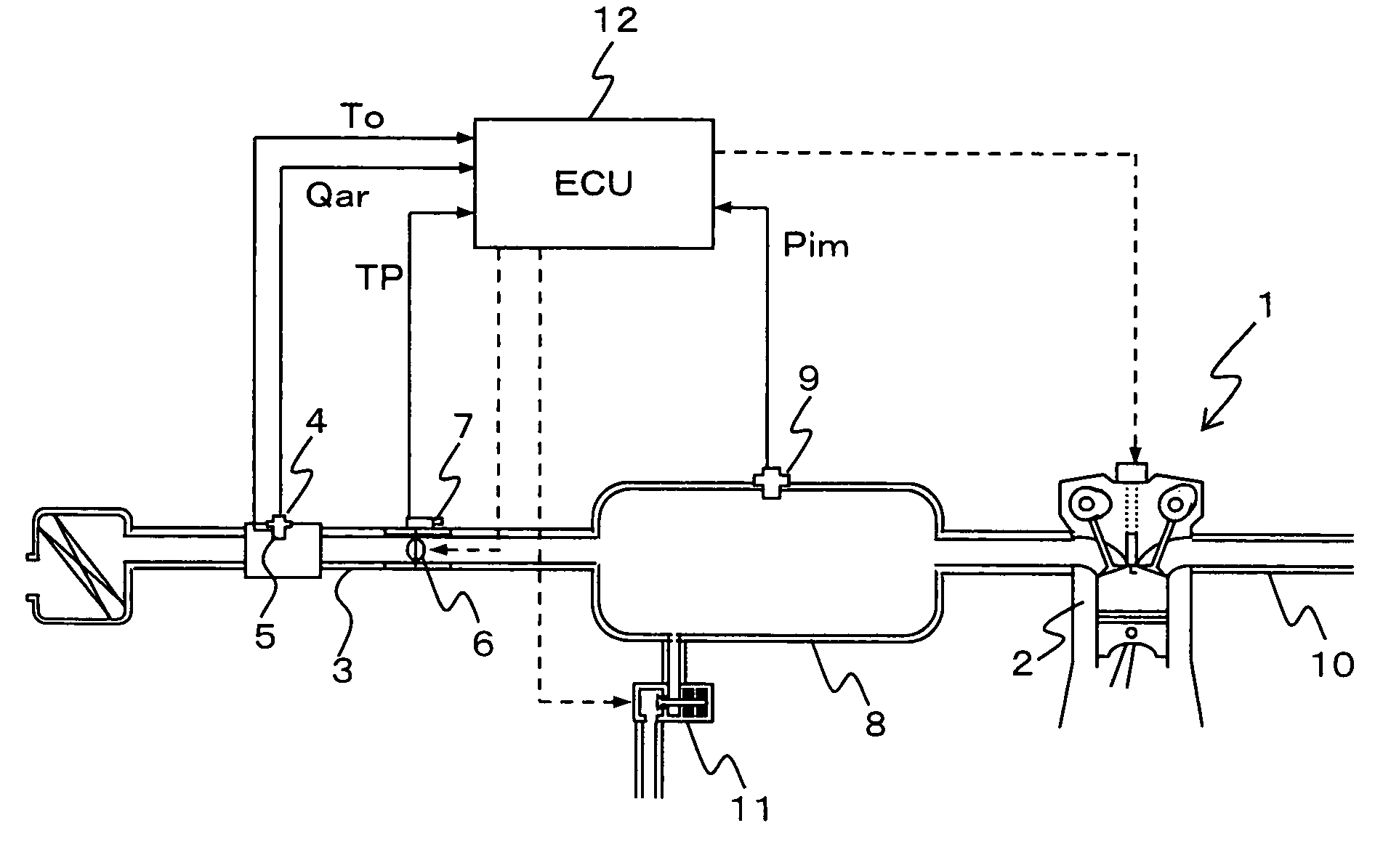

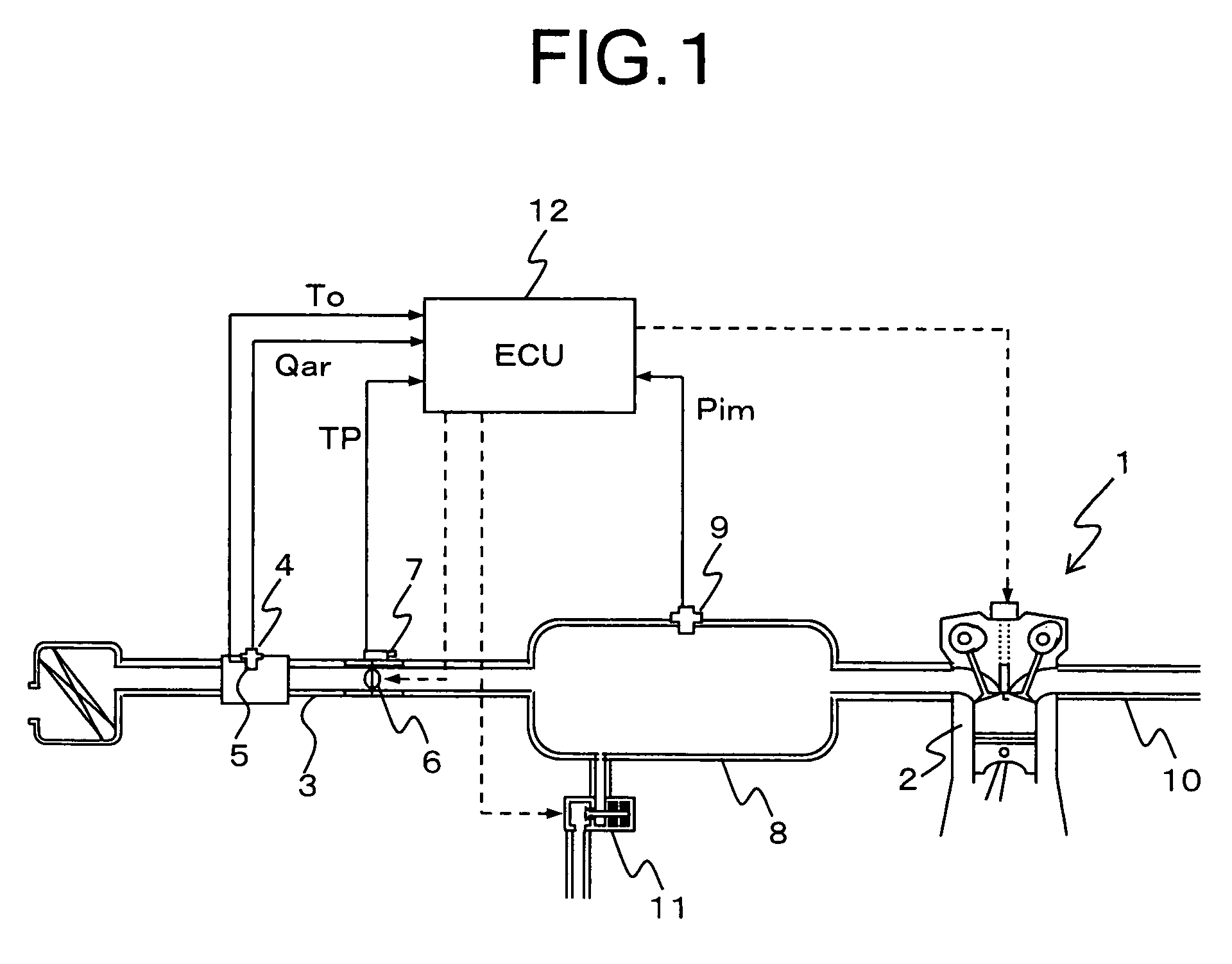

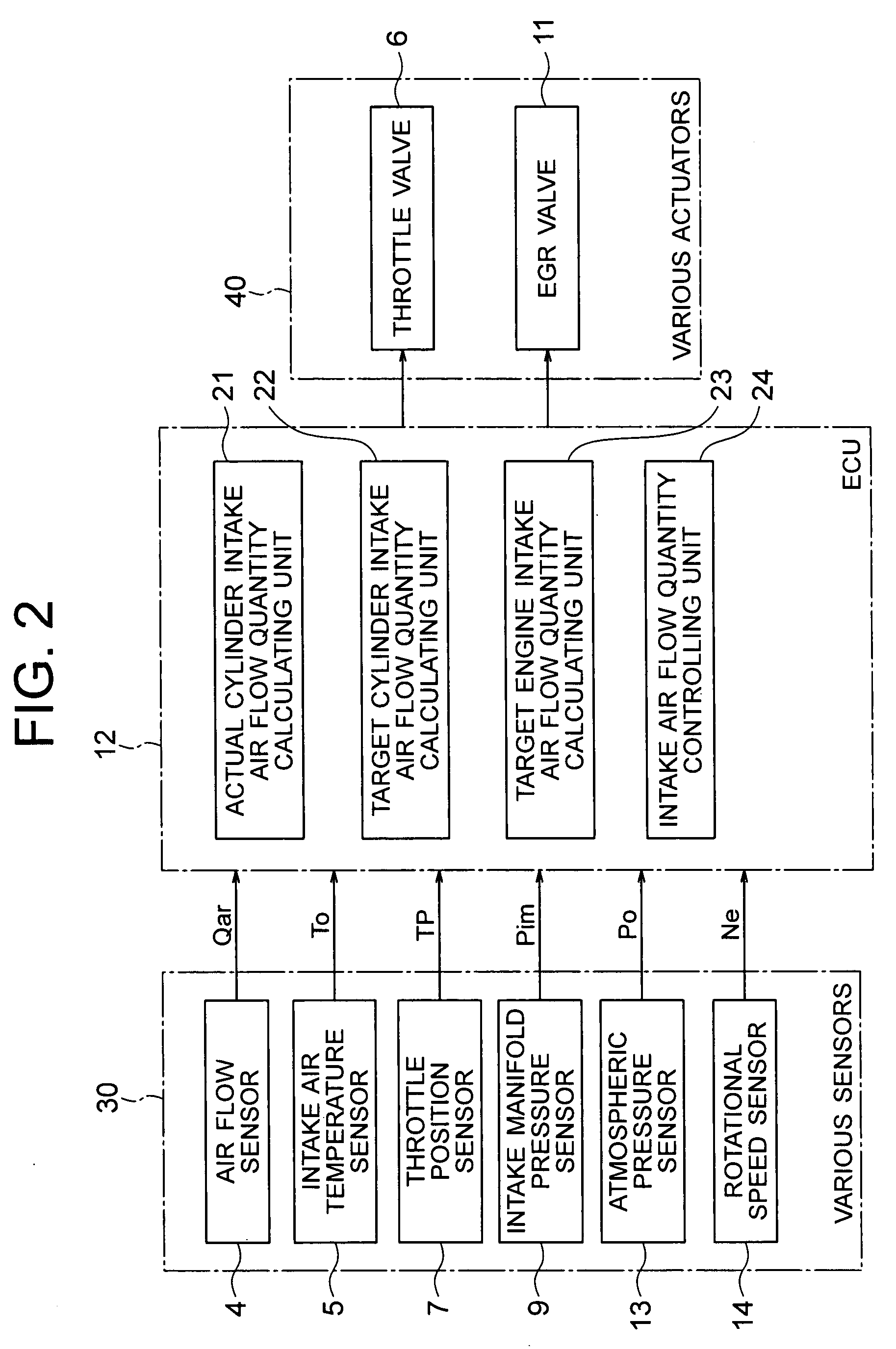

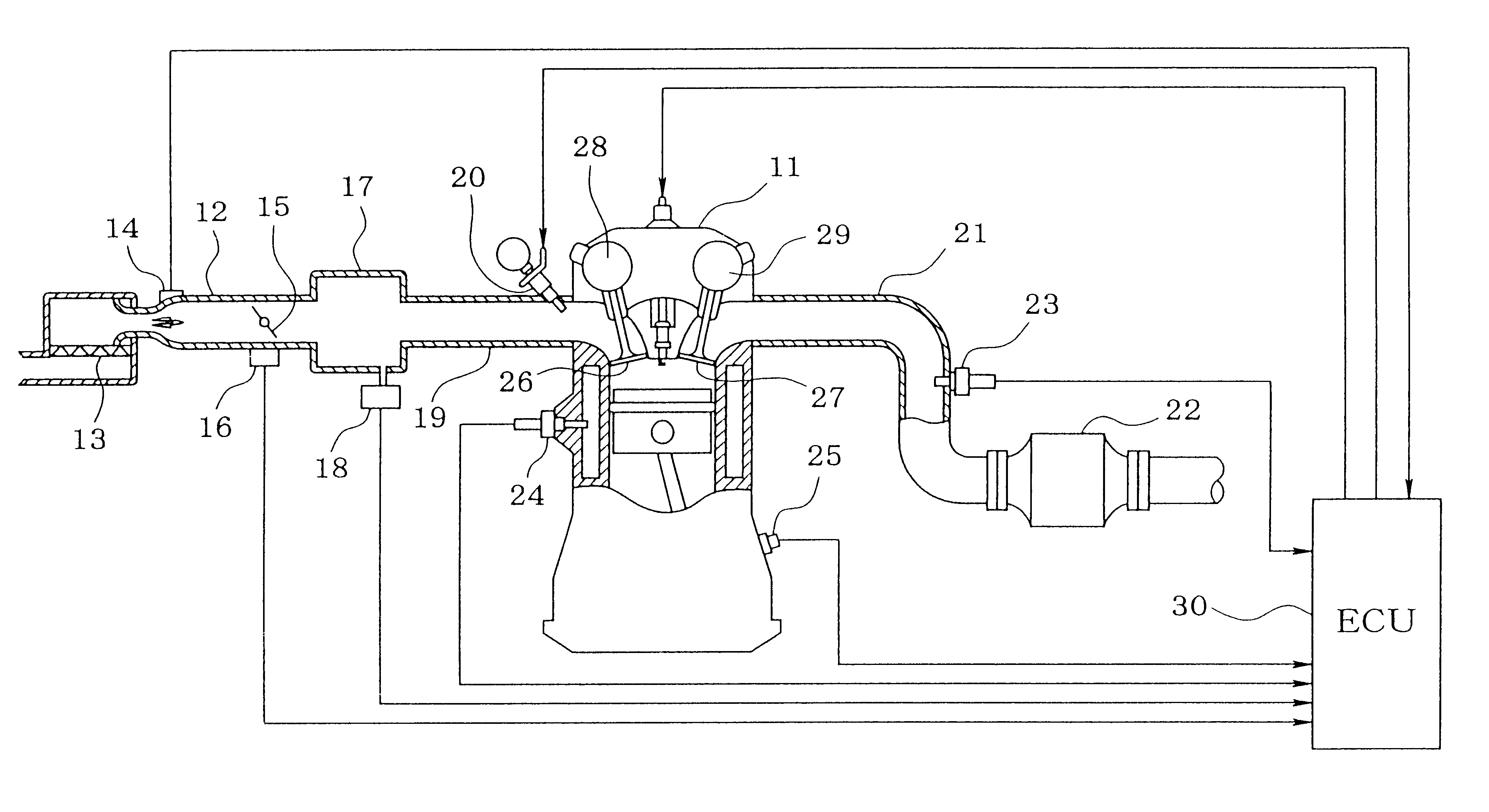

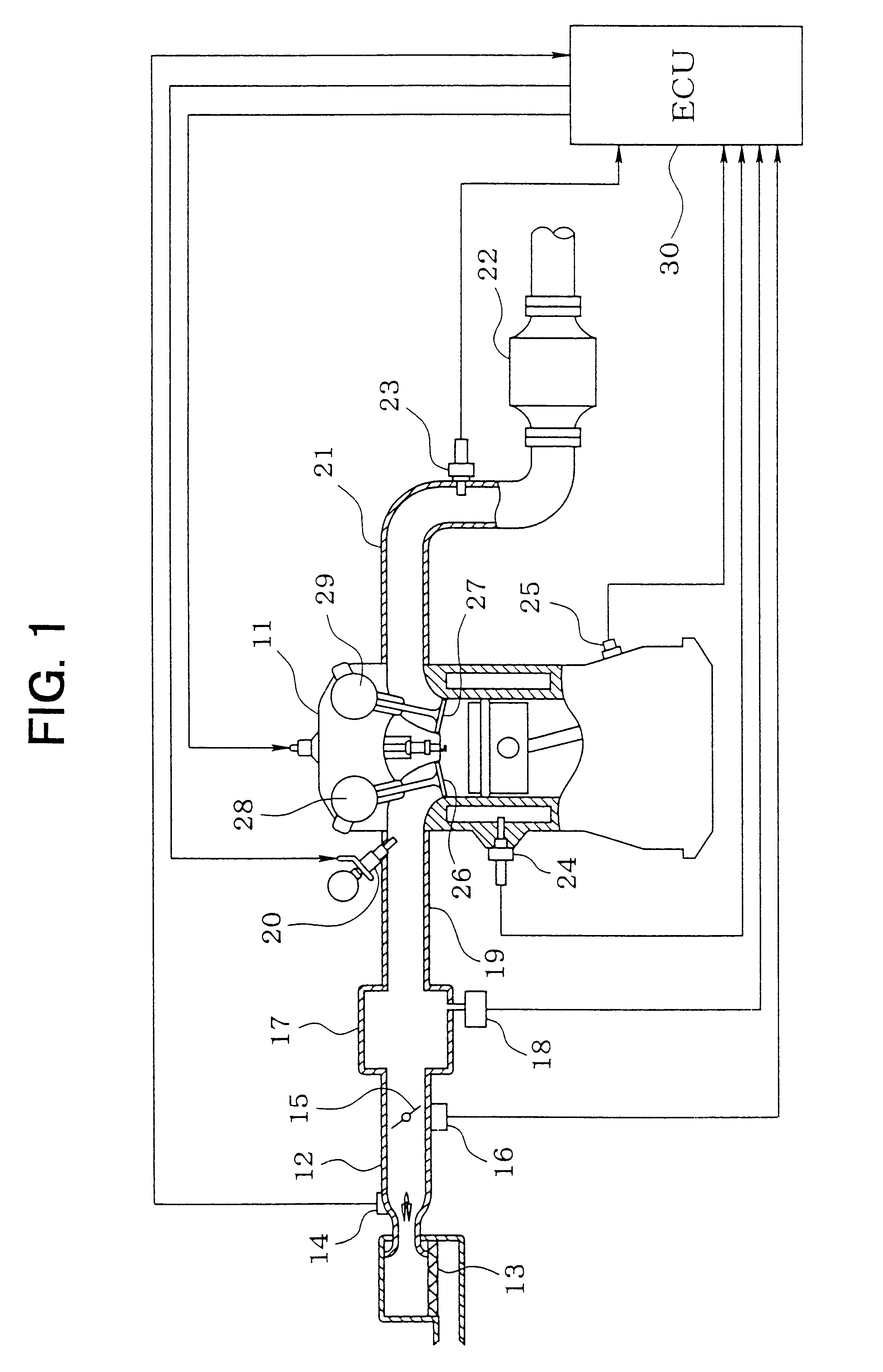

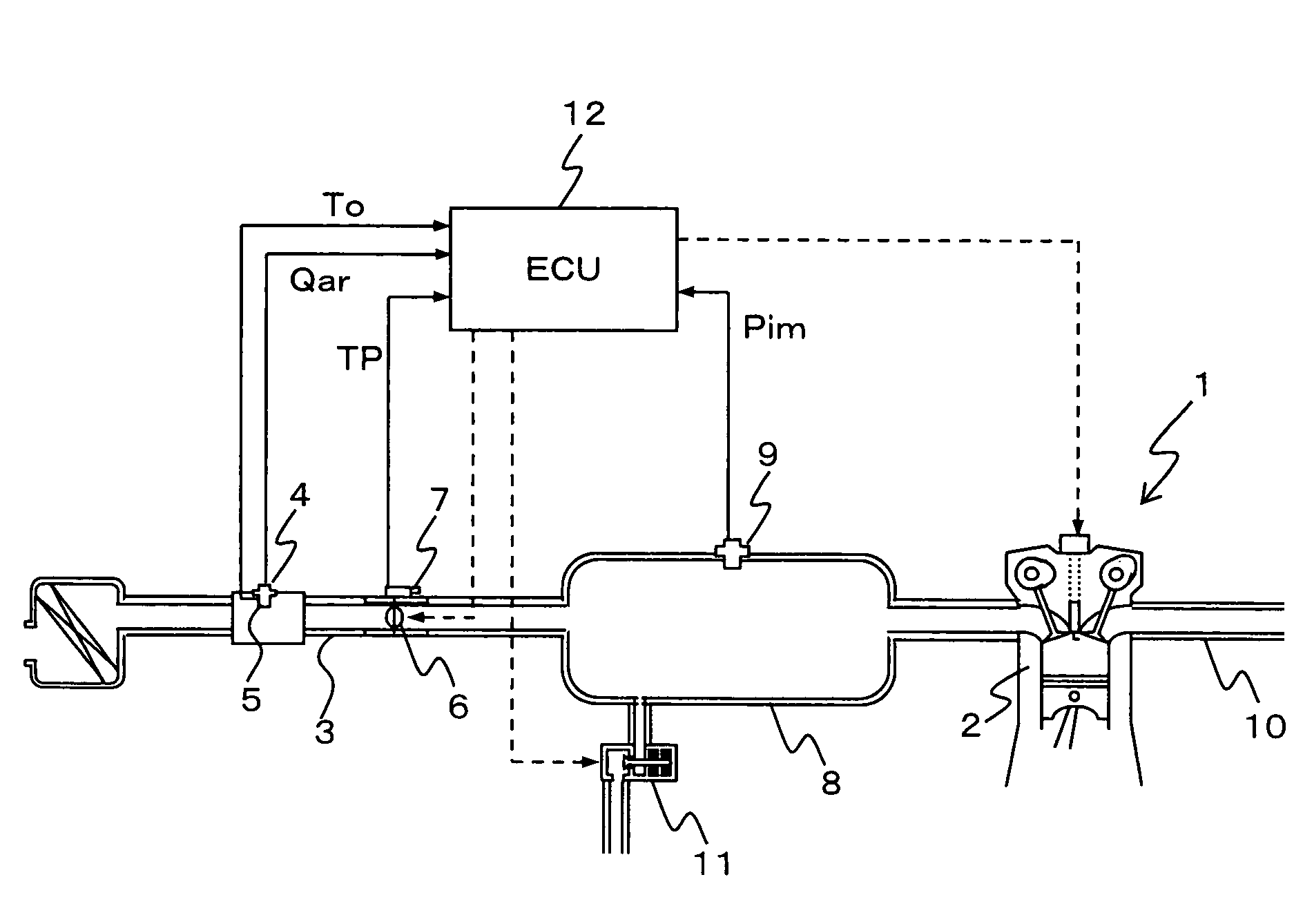

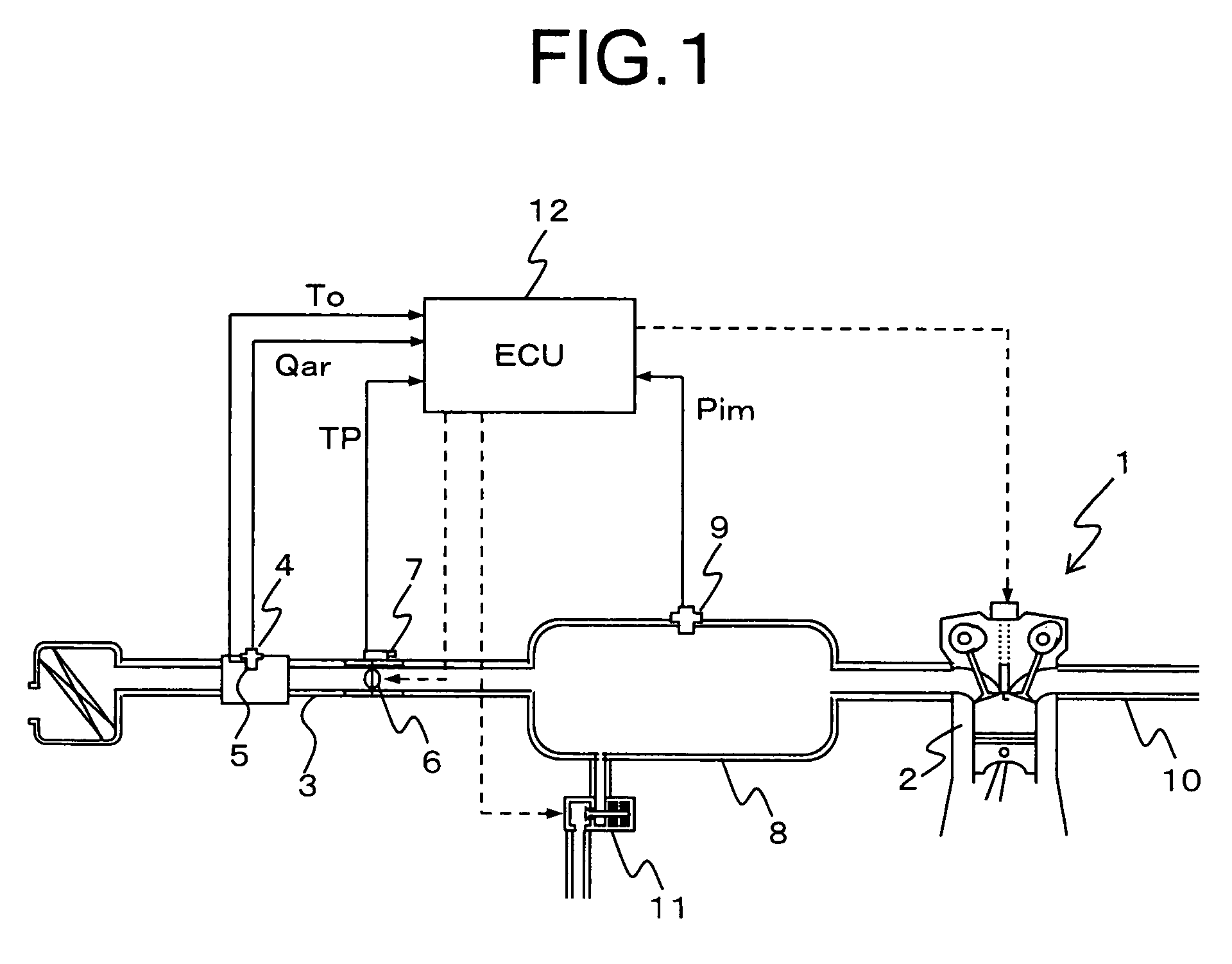

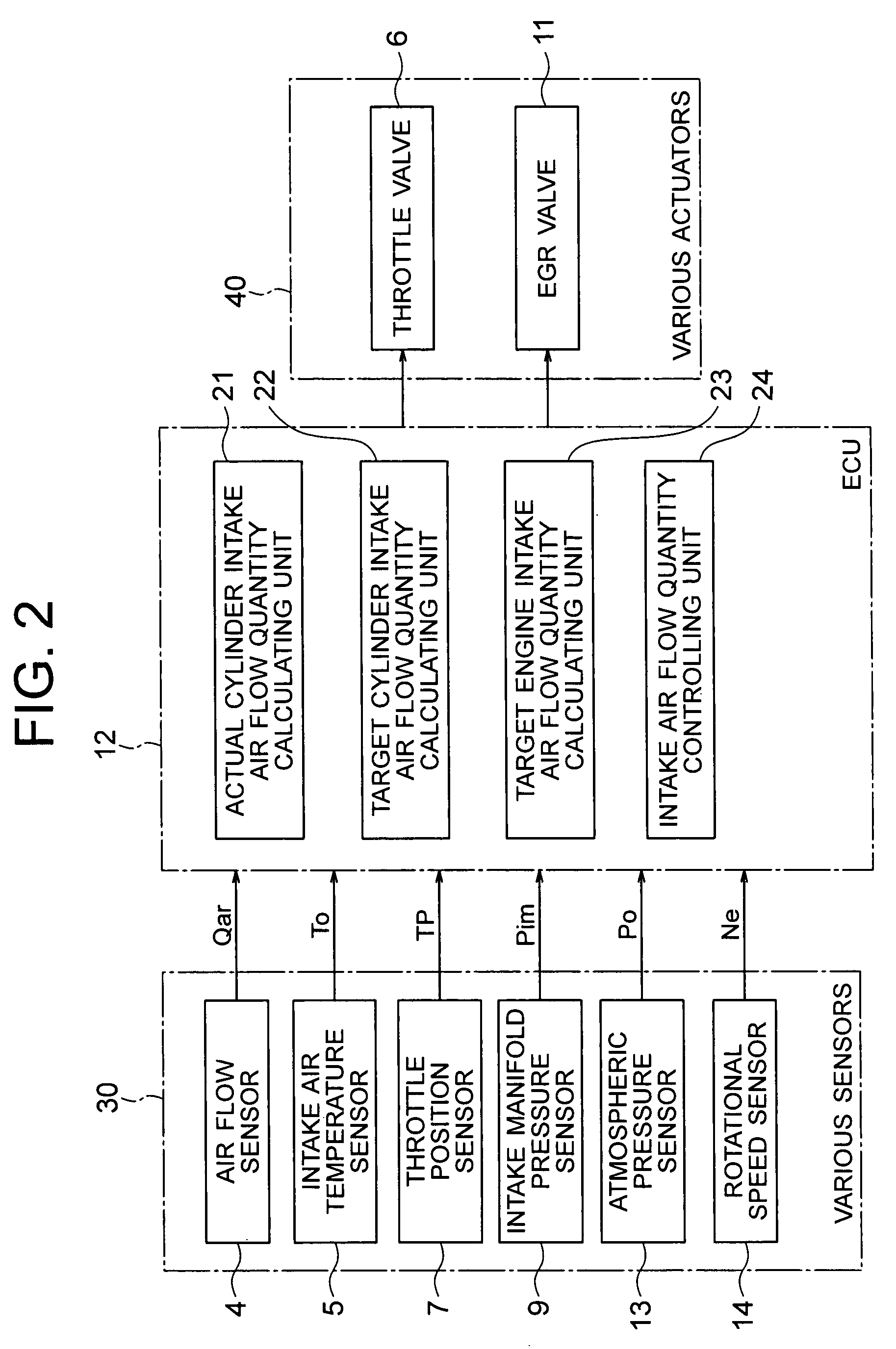

Control device for internal combustion engine

ActiveUS20080127938A1Reduce in quantityShort calculation timeElectrical controlInternal combustion piston enginesResponse delayThrottle opening

Provided is a control device for an internal combustion engine, which is provided to allow a throttle opening degree to be controlled in accordance with a target engine intake air flow quantity even during transitional operation. The actual cylinder intake air flow quantity calculating unit (21) calculates a response delay model for an intake system from a volumetric efficiency equivalent value (Kv) calculated from a rotational speed (Ne) of an engine (1) and an intake manifold pressure (Pim), an intake pipe volume (Vs), and a displacement (Vc) of each of cylinders (2), and calculates an actual cylinder intake air amount (Qcr) from an actual engine intake air amount (Qar) obtained from an air flow sensor (4) and the response delay model. The intake air flow quantity controlling unit (24) controls the throttle opening degree (TP) in accordance with the target engine intake air amount (Qat).

Owner:MITSUBISHI ELECTRIC CORP

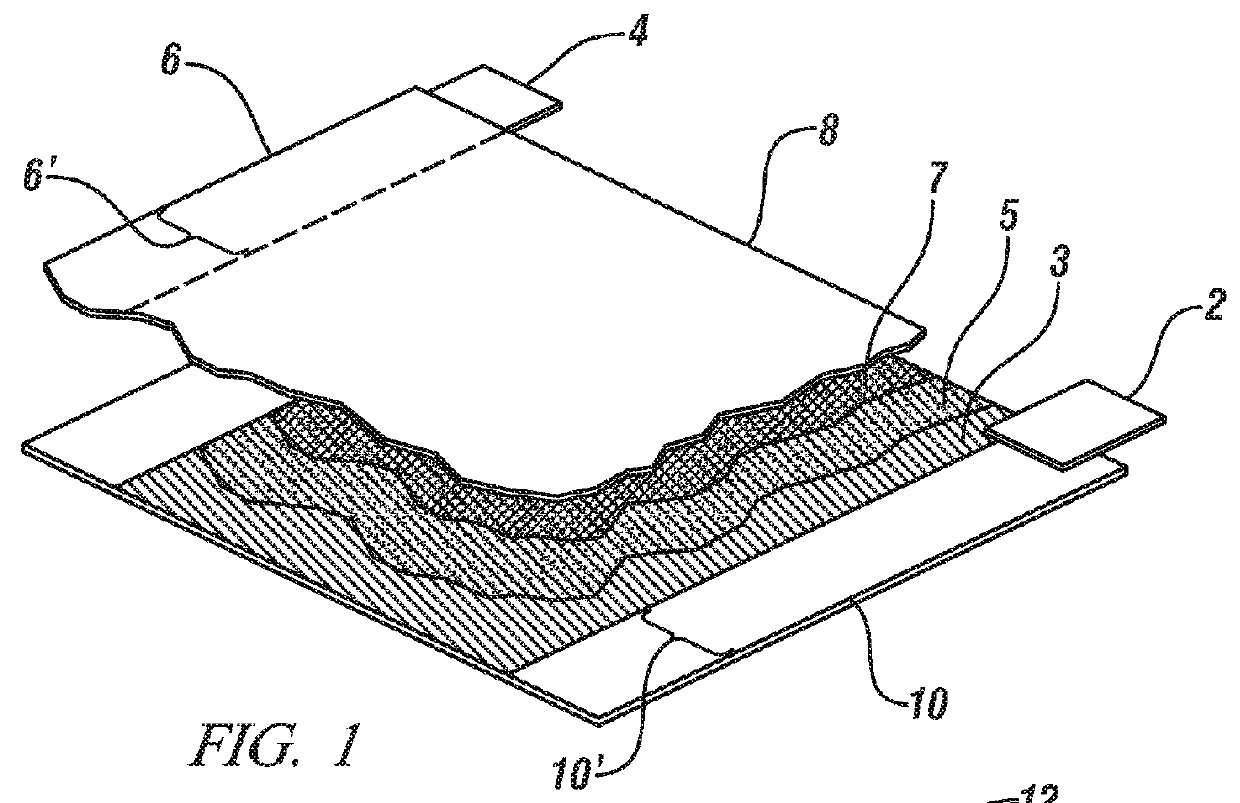

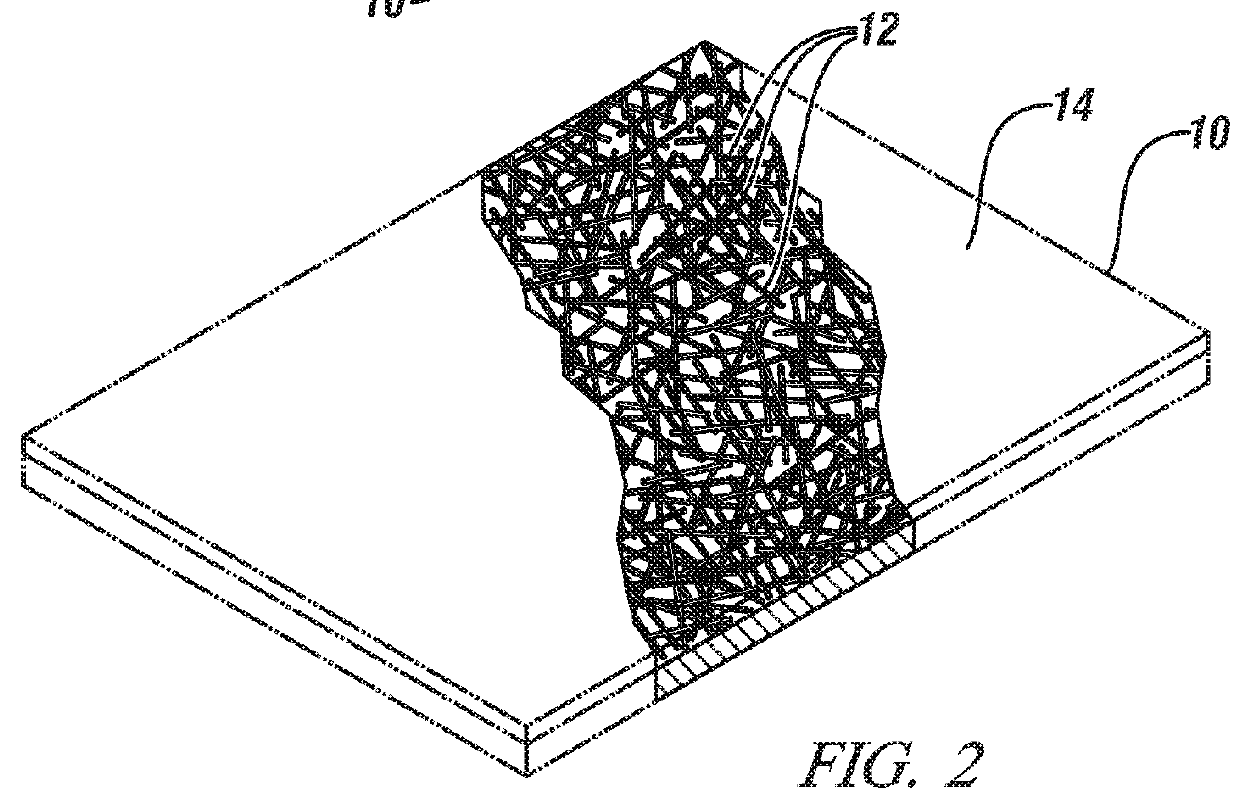

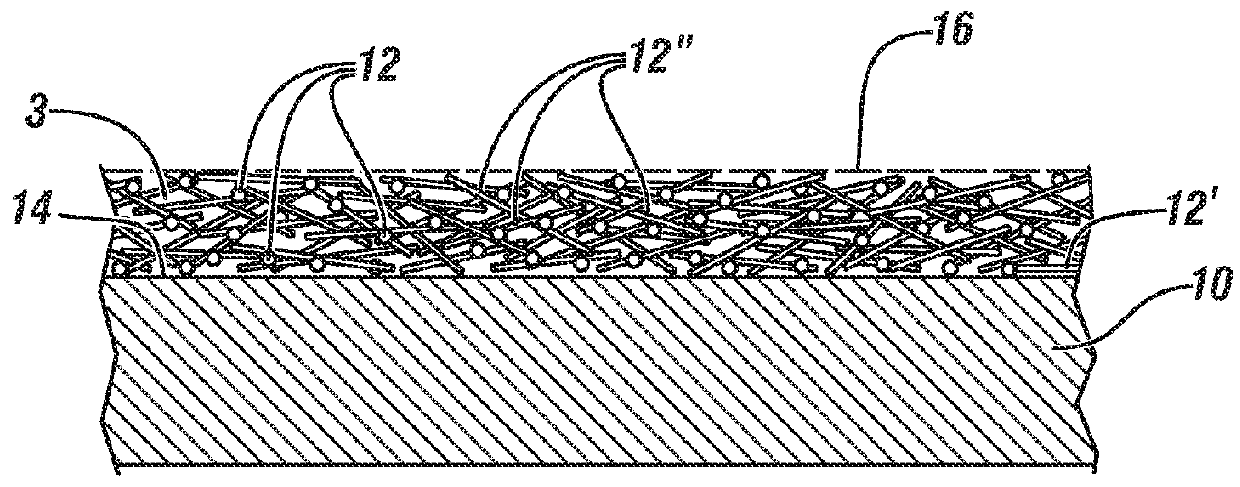

Reinforced battery electrodes

ActiveUS9362551B2Avoid strainMaintain electrical continuityElectrode carriers/collectorsActive material electrodesElectrical batteryShape-memory alloy

The gravimetric and volumetric efficiency of lithium ion batteries may be increased if high capacity materials like tin and silicon may be employed as the lithium-accepting host in the negative electrode of the battery. But both tin and silicon, when fully charged with lithium, undergo expansions of up to 300% and generate appreciable internal stresses which have potential to spall off material from the electrode on each discharge-charge cycle, resulting in a progressive reduction in battery capacity, also known as battery fade. A method of reinforcing such electrode materials by incorporating within them fiber reinforcements or shaped, elongated reinforcements fabricated of shape memory alloy is described. Electrode materials incorporating such reinforcements are less prone to damage under applied stress and so less prone to battery fade.

Owner:GM GLOBAL TECH OPERATIONS LLC

High-Pressure Gas Compressor And Method Of Operating A High-Pressure Gas Compressor

ActiveUS20080213115A1Reduce in quantitySimple manufacturing processPositive displacement pump componentsFlexible member pumpsFriction reductionInlet valve

A high-pressure gas compressor comprises a single-acting cam driven piston with a pressure compensation chamber disposed between the piston and the cam. A roller tappet assembly transmits reciprocating motion from the cam to the piston. A pressurized gas directed to the pressure compensation chamber offsets forces acting on the piston from the compression chamber gas pressure, thereby reducing Hertzian pressure between the tappet roller and the cam. Overall efficiency and durability can be improved by reducing friction between compressor components, for example by employing thin film coatings to reduce friction, pressurized oil lubrication systems and higher cylinder bore diameter to piston stroke ratios. The service life of gas seals and compression efficiency can be improved by thermal management strategies, including liquid-cooled compressor cylinder liners and intercoolers between compression stages. Employing a poppet-style intake valve and reducing parasitic volume in the compression chamber can improve compressor volumetric efficiency.

Owner:WESTPORT FUEL SYST CANADA INC

Volumetrically efficient wet electrolytic capacitor

A wet electrolytic capacitor that contains a sintered anode positioned with an interior space of a metal casing is provided. The anode and metal casing are of a size such that the anode occupies a substantial portion of the volume of the interior space. More particularly, the anode typically occupies about 70 vol. % or more, in some embodiments about 75 vol. % or more, in some embodiments from about 80 vol. % to about 98 vol. %, and in some embodiments, from about 85 vol. % to 95 vol. % of the interior space. Among other things, the use of an anode that occupies such a large portion of the interior space enhances volumetric efficiency and other electrical properties of the resulting capacitor.

Owner:KYOCERA AVX COMPONENTS CORP

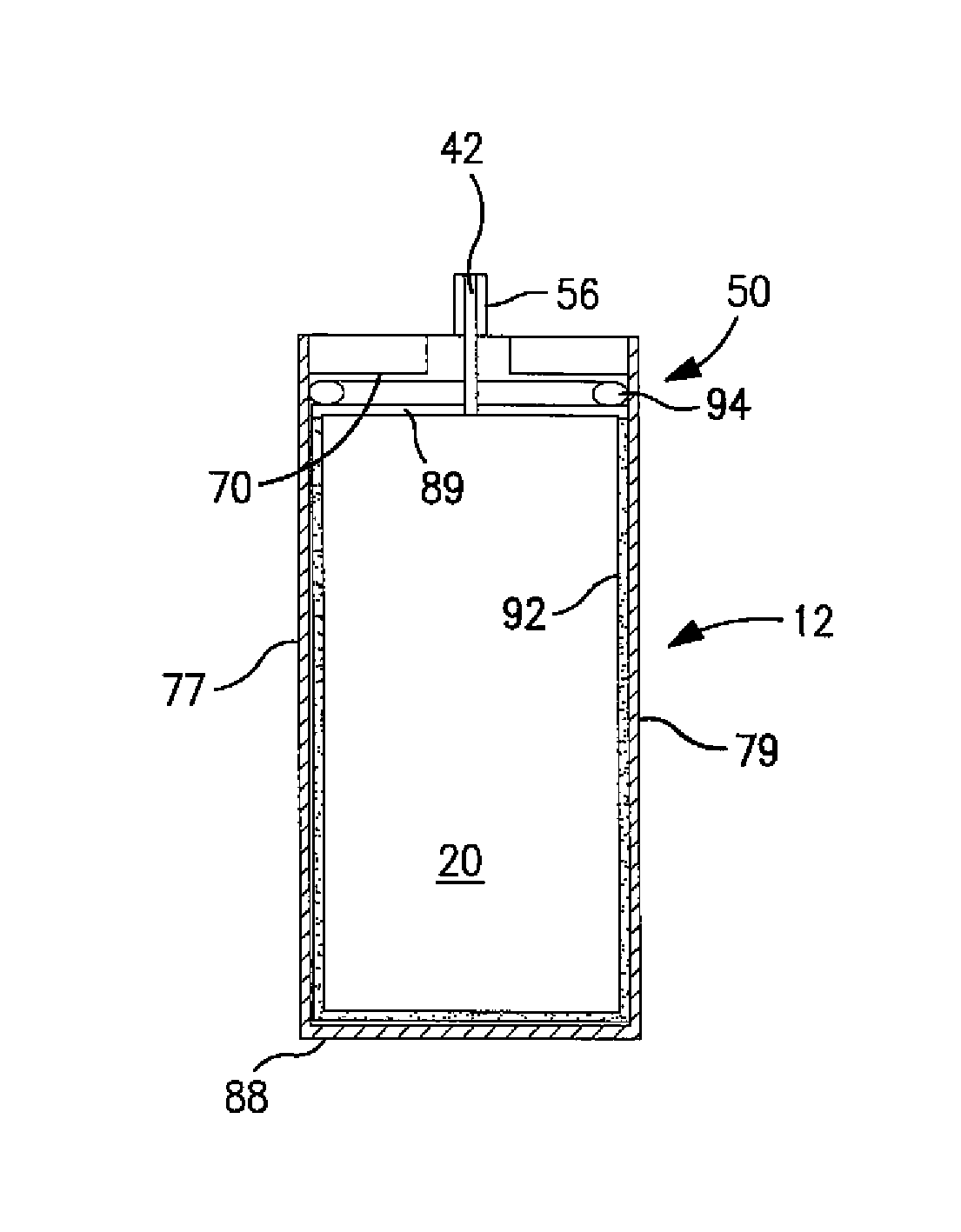

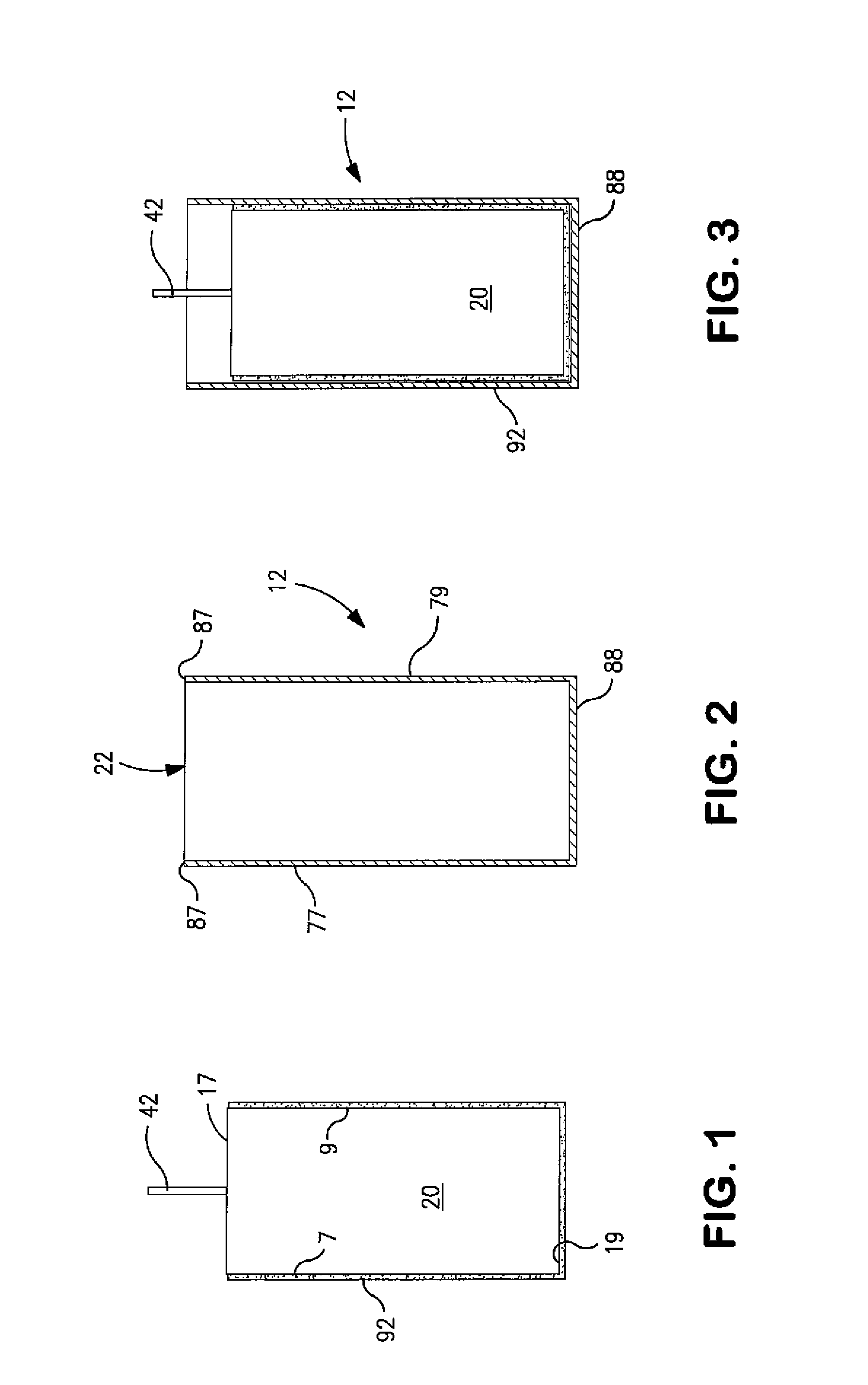

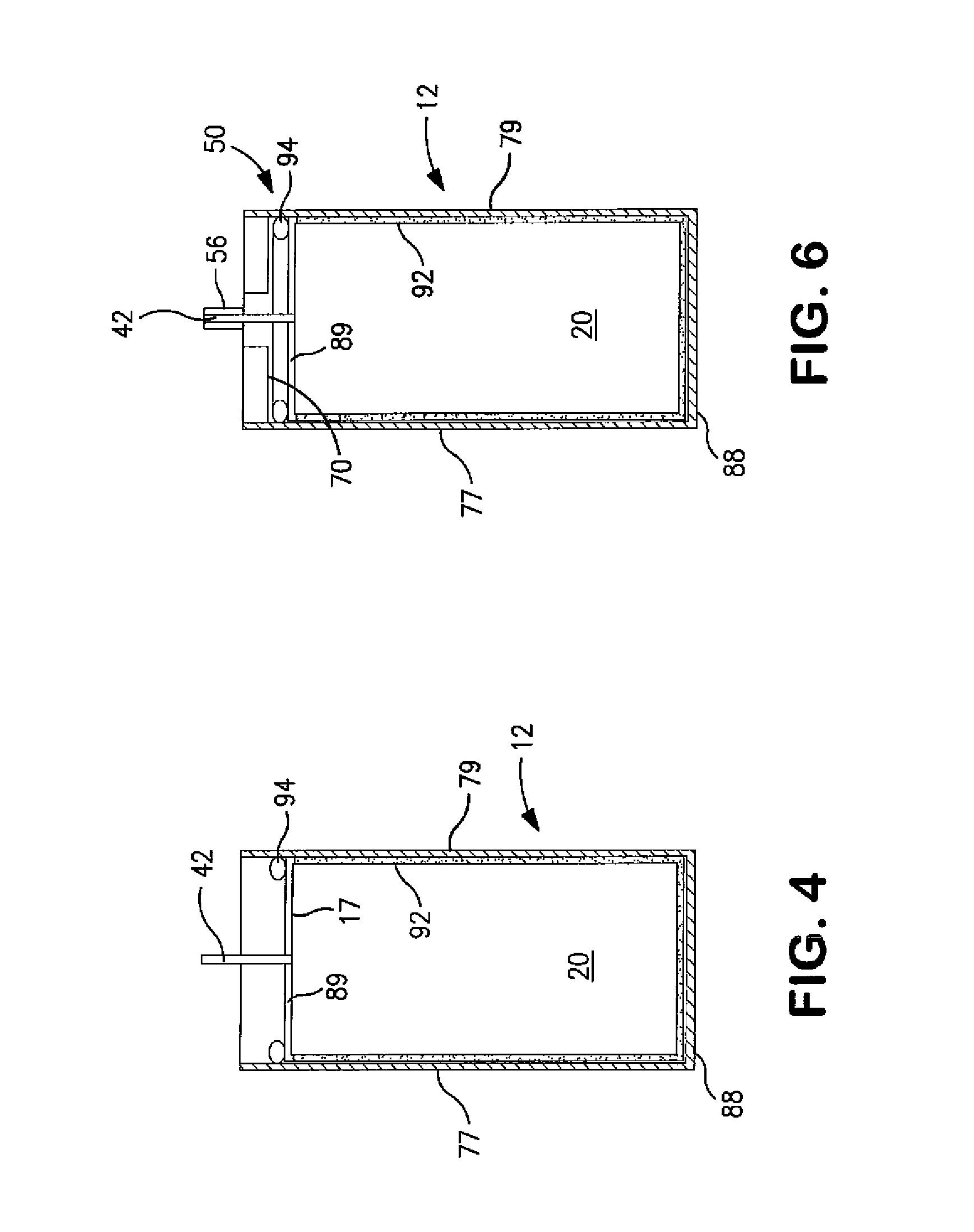

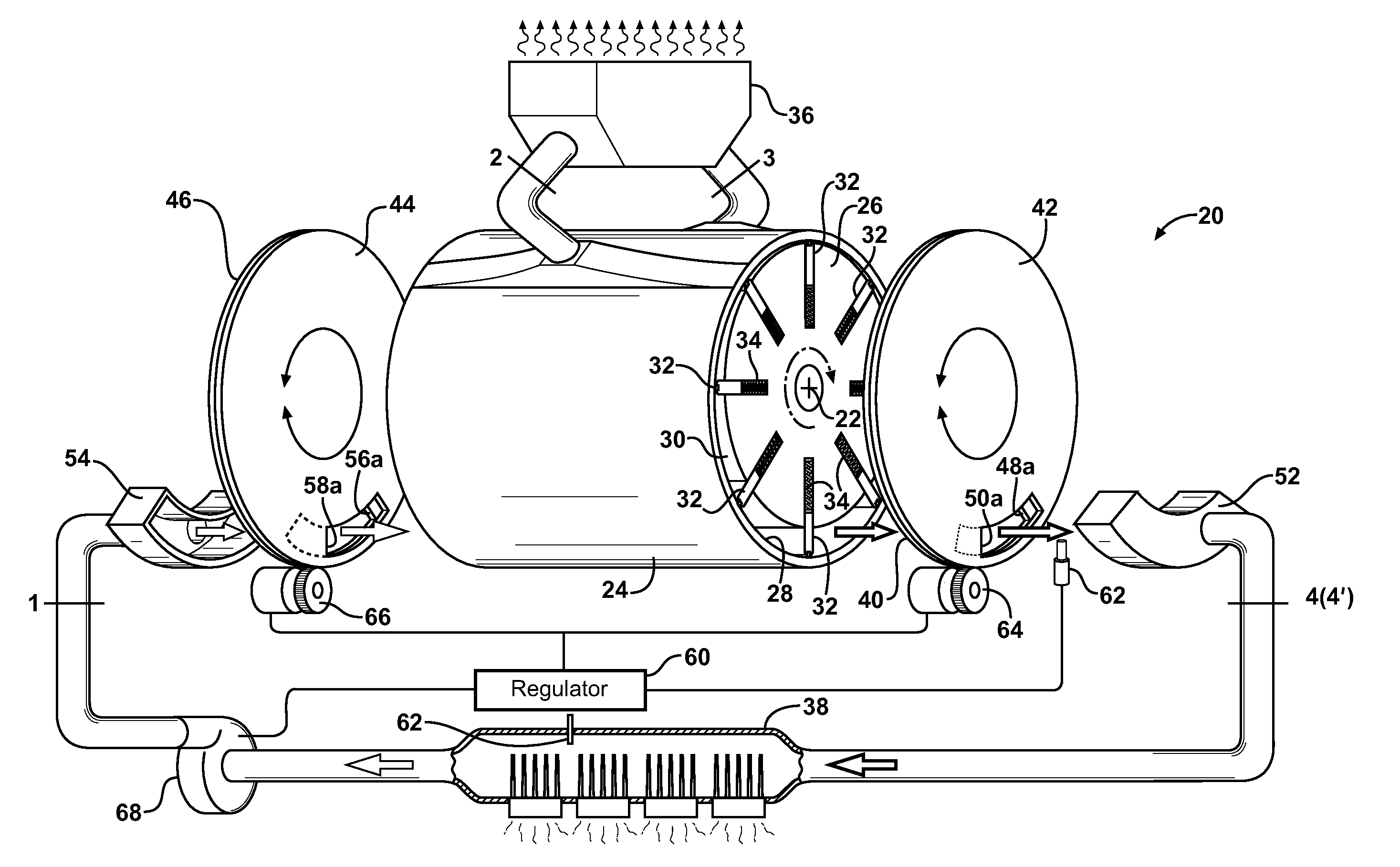

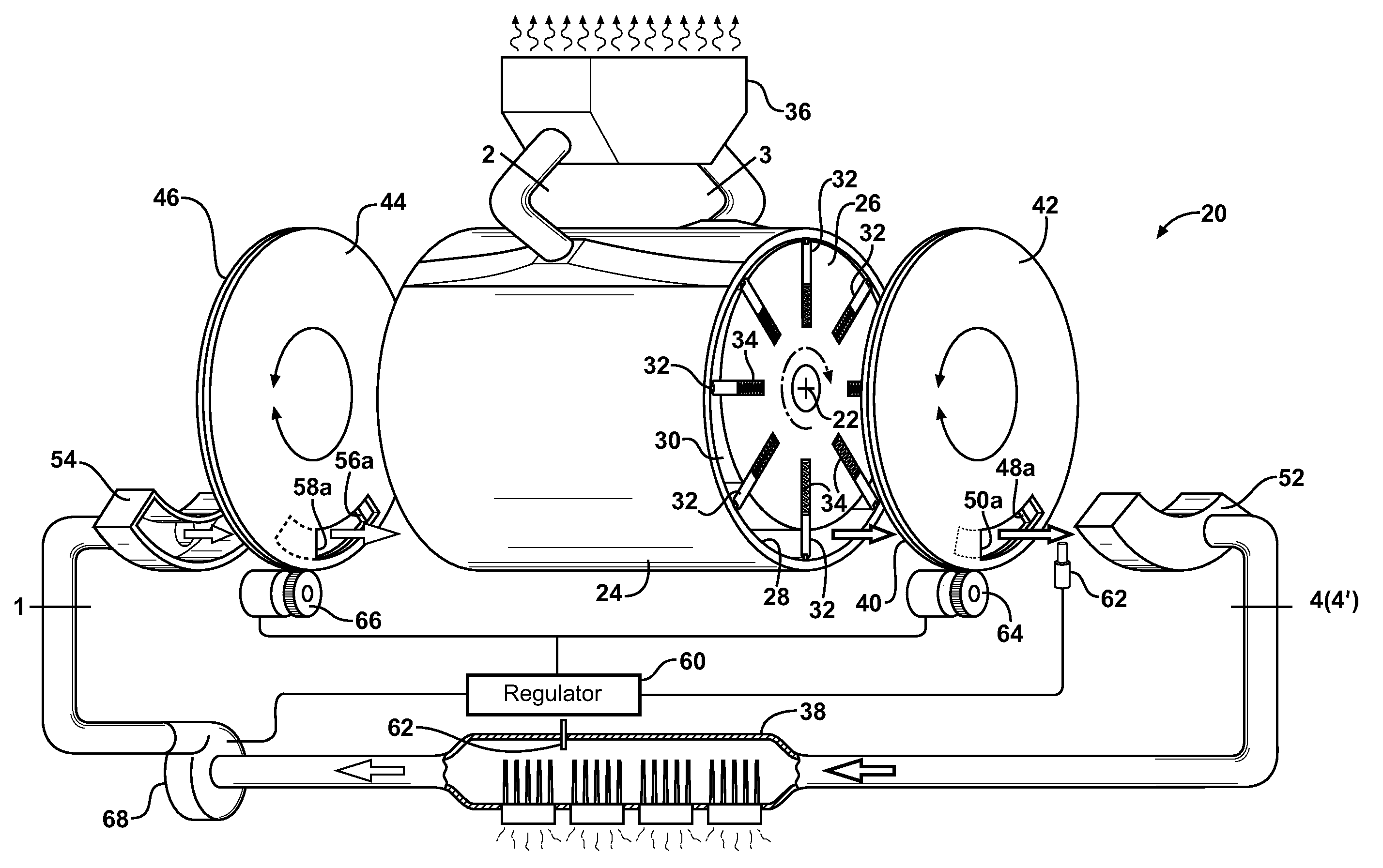

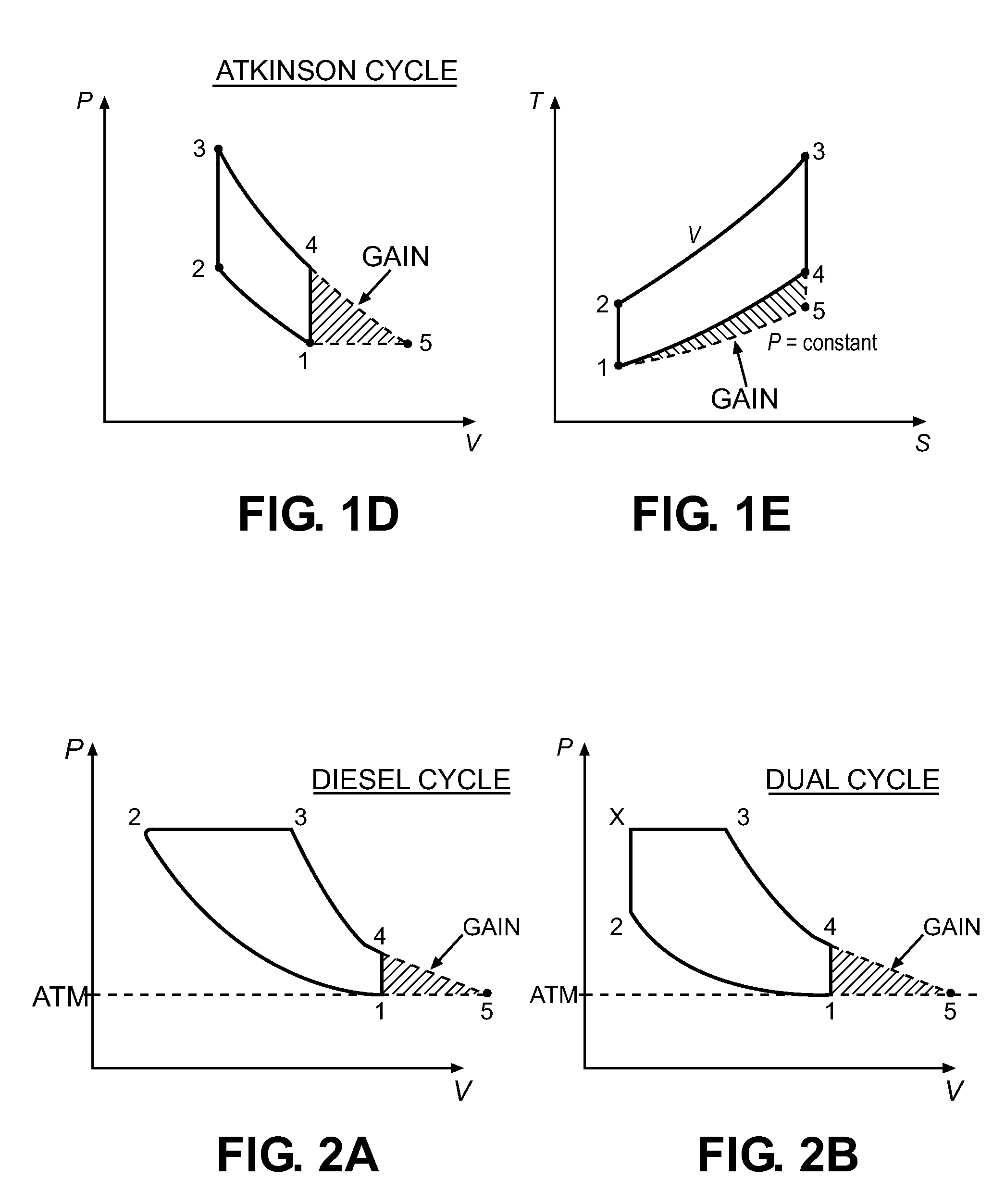

High efficiency positive displacement thermodynamic system

ActiveUS8424284B2Without decreasing volumetric efficiencySave heatInternal combustion piston enginesCombination enginesPower modeWorking fluid

Devices and methods for moving a working fluid through a controlled thermodynamic cycle in a positive displacement fluid-handling device (20, 20′, 20″) with minimal energy input include continuously varying the relative compression and expansion ratios of the working fluid in respective compressor and expander sections without diminishing volumetric efficiency. In one embodiment, a rotating valve plate arrangement (40, 42, 44, 46) is provided with moveable apertures or windows (48, 50, 56, 58) for conducting the passage of the working fluid in a manner which enables on-the-fly management of the thermodynamic efficiency of the device (20) under varying conditions in order to maximize the amount of mechanical work needed to move the target quantity of heat absorbed and released by the working fluid. When operated in refrigeration modes, the work required to move the heat is minimized. In power modes, the work extracted for the given input heat is maximized.

Owner:STAFFEND GILBERT

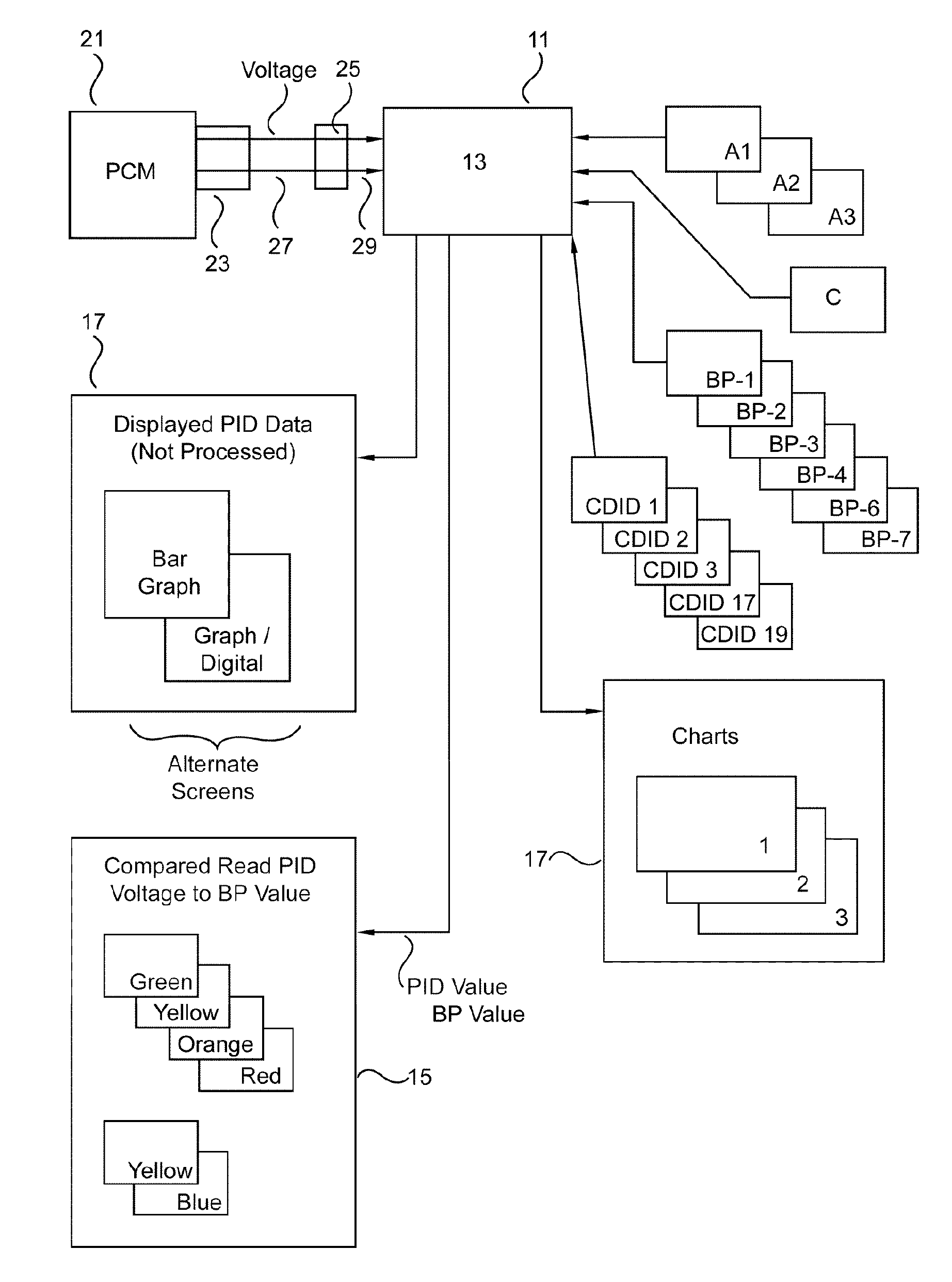

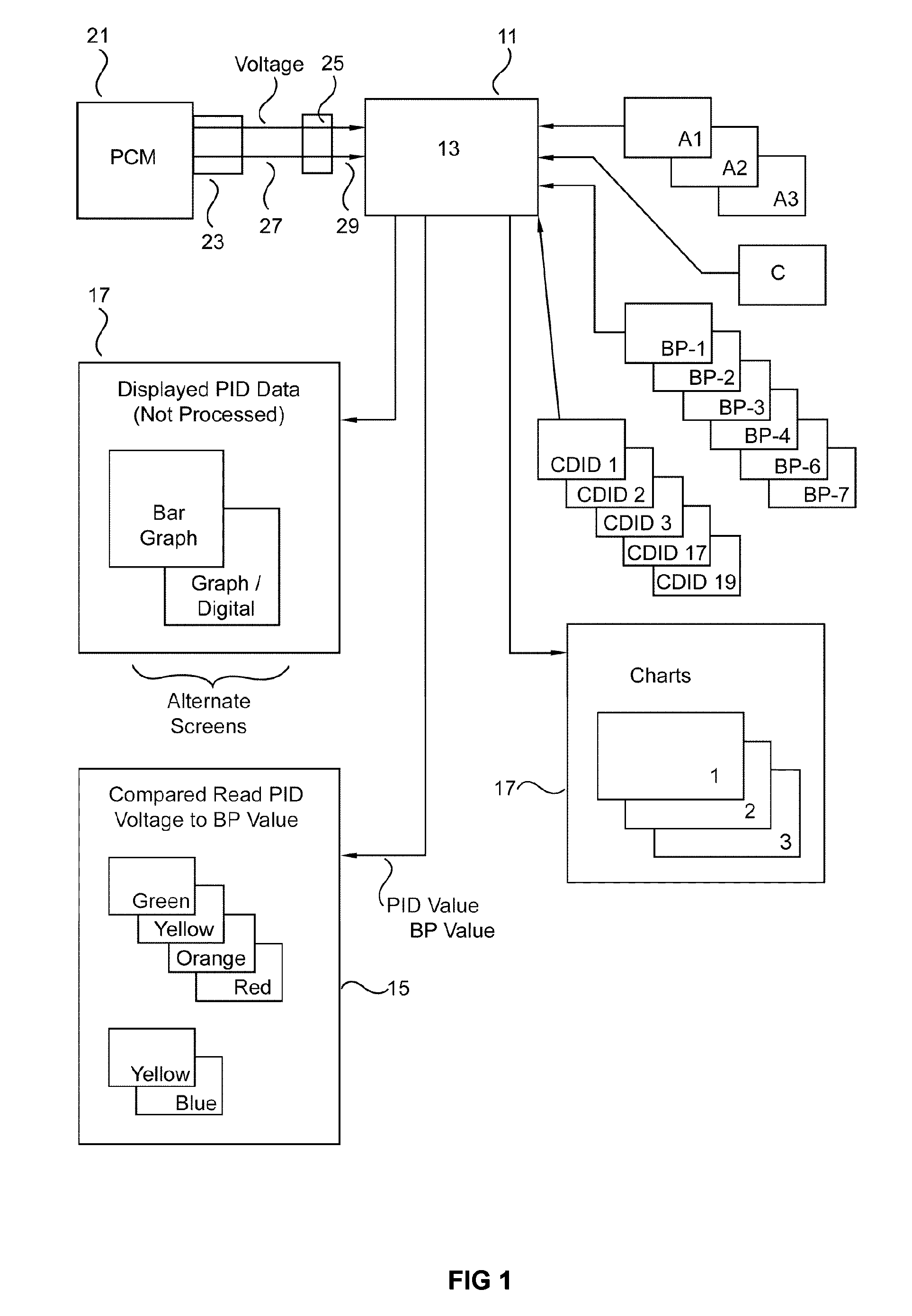

Vehicle diagnostic tool

ActiveUS7953530B1Firmly connectedDiagnose the power plant systems quickly and accuratelyVehicle testingAnalogue computers for vehiclesReal-time dataComputer module

An analysis tool which extracts all the available parameter identifications (i.e. PIDS) from a vehicle's power train control module for diagnostic decisions. This is done by checking these PIDS and other information (e.g., calculated PIDS, Break Points, charts and algorithms) in three states; key on engine off, key on engine cranking, key on engine running. In all three modes the tool is comparing the live data from PIDS and voltage to the other information (e.g, Break Points). If any of this data are outside the programmed values a flag is assigned to the failure or control problem. The relationship between a particular PID and its associated preprogrammed value(s) may be indicated by a light. The depth of the problem (if any) is conveyed by the color of the light. Also included are tests / charts for fuel trim, engine volumetric efficiency, simulated injector, power, catalyst efficiency, and engine coolant range.

Owner:AUTOMOTIVE TEST SOLUTIONS

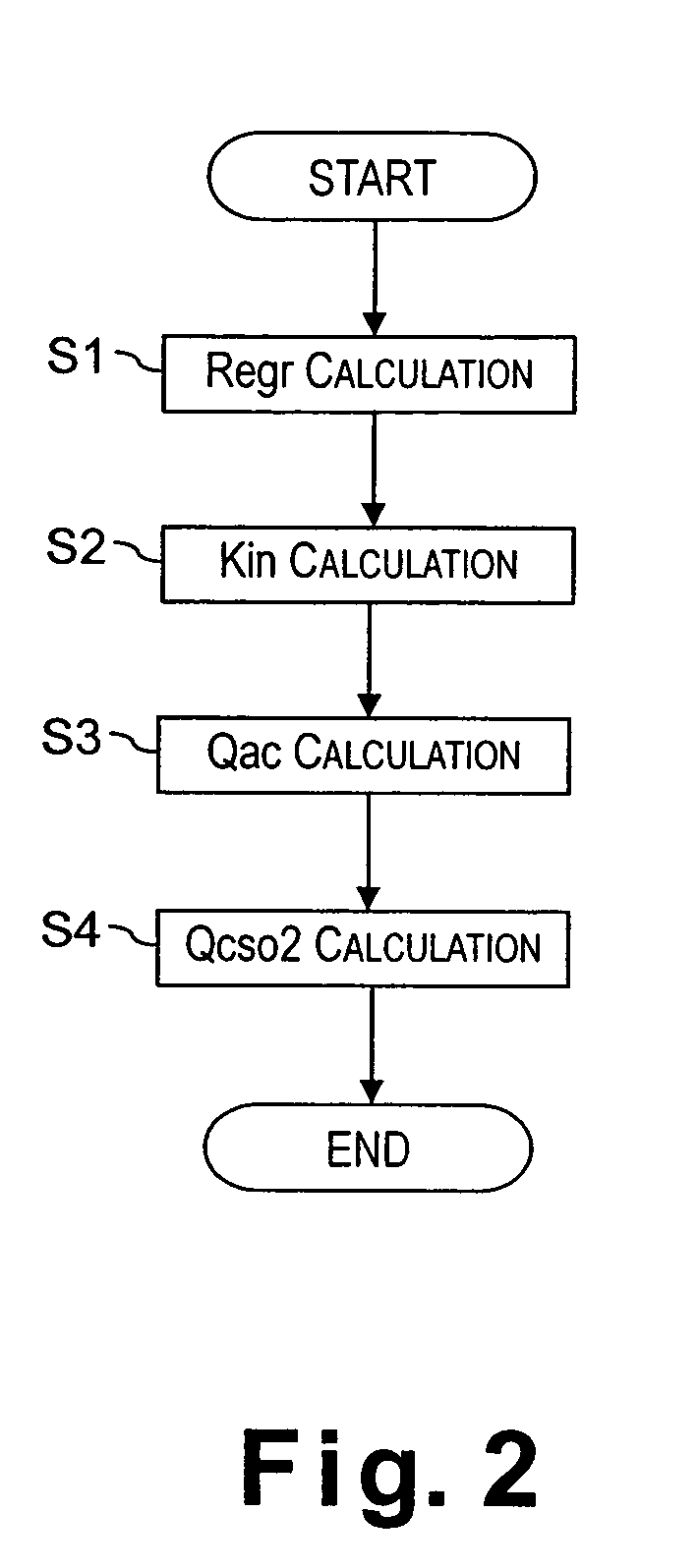

Engine control system

ActiveUS7107978B2Improve estimation accuracyElectrical controlInternal combustion piston enginesCombustion chamberControl system

An engine control system is configured to improve the estimation accuracy of a fresh intake air quantity and a total intake air quantity that flows into the combustion chambers. The engine control system is configured to estimate an estimated EGR rate value Regr using a primary lag process for a target EGR rate, calculate a volumetric efficiency equivalency value based on the estimated EGR rate value Regr, estimate an estimated fresh intake air value Qac that flows into the combustion chamber based on a rate of change in a volumetric efficiency equivalency value Kin / Kinn-1 of the estimated EGR rate value Regr and the volumetric efficiency equivalency value Kin, and estimate an estimated total intake air quantity value Qsco2 that includes the EGR gas based on the estimated fresh intake air value Qac and the estimated EGR rate value Regr.

Owner:NISSAN MOTOR CO LTD

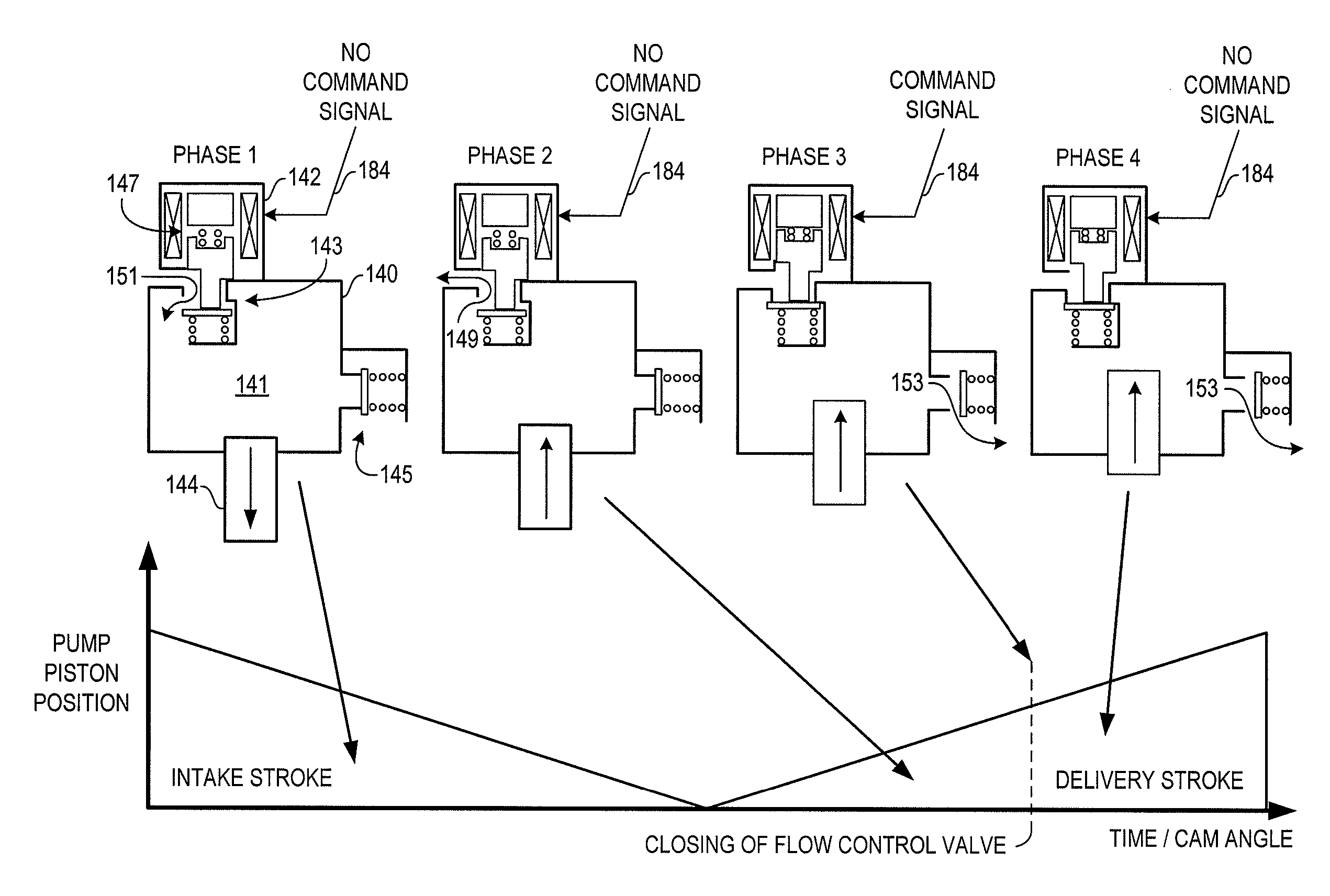

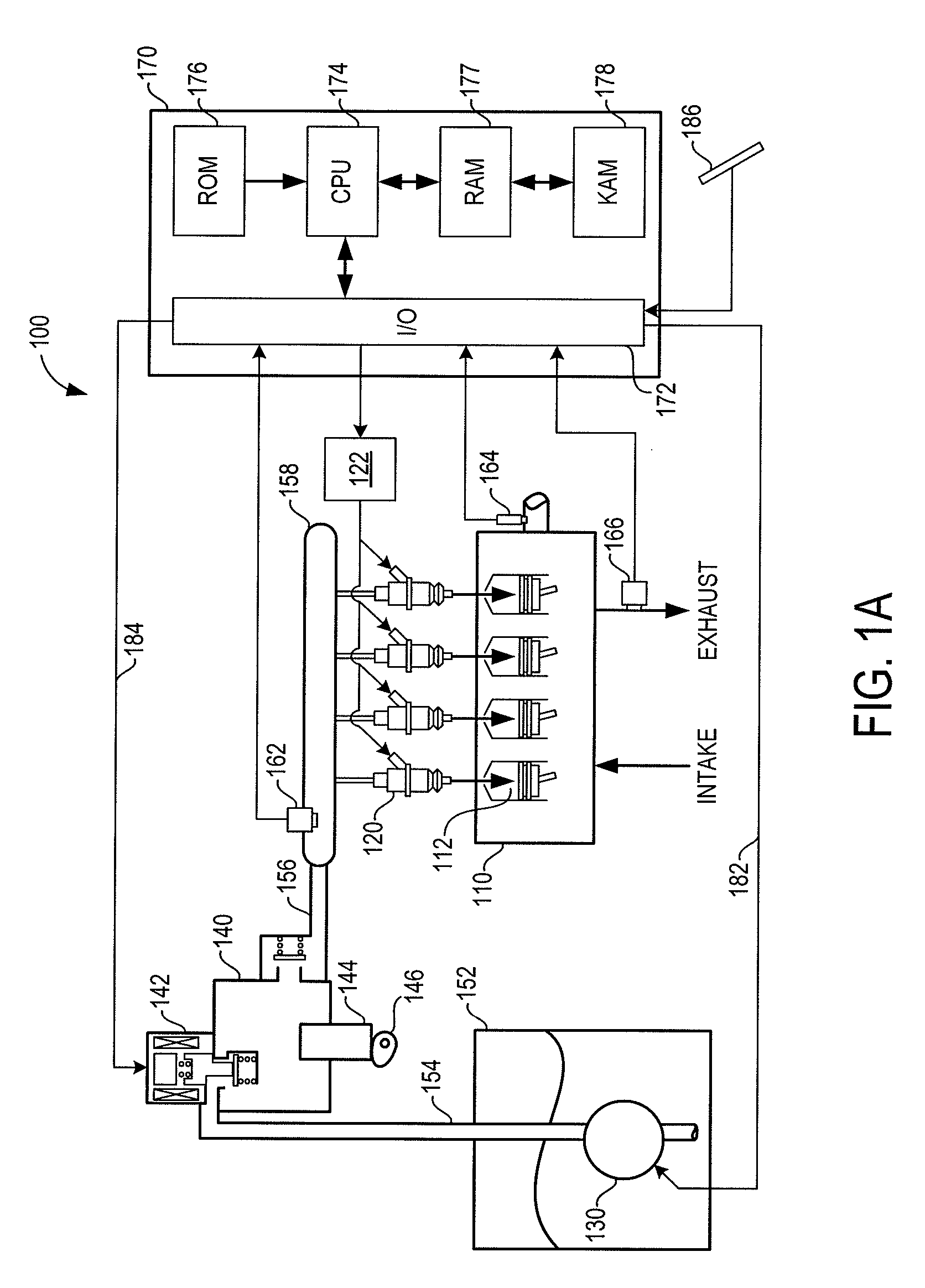

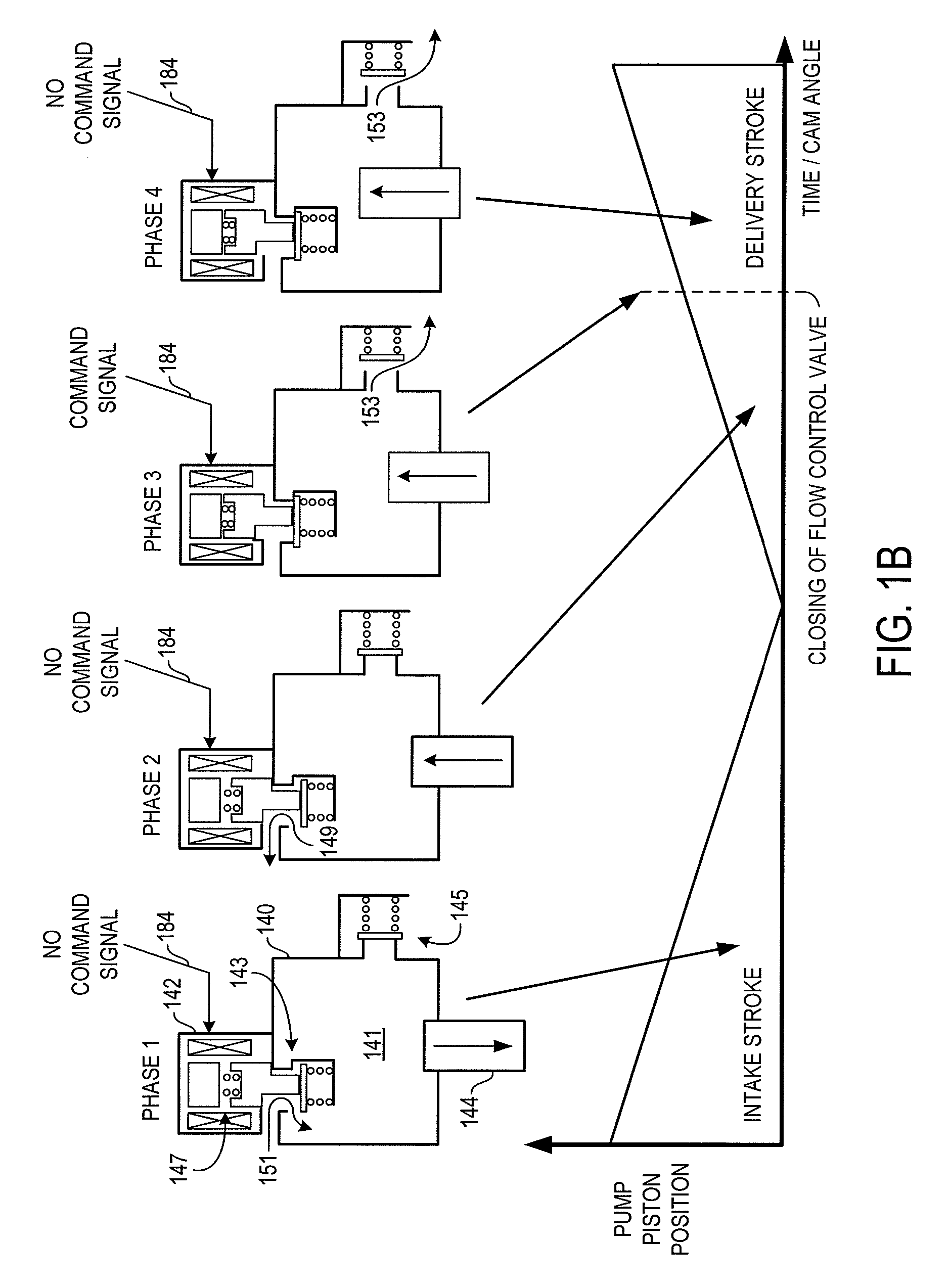

Volumetric Efficiency Based Lift Pump Control

InactiveUS20090090331A1Maintain efficiencyImprove fuel economyFuel injection apparatusPump controlEngineeringInternal combustion engine

As one example, a method of operating a fuel delivery system of a directly injected internal combustion engine including a plurality of in-cylinder direct fuel injectors, a higher pressure fuel pump and a lower pressure fuel pump is provided. The method comprises operating the lower pressure fuel pump and the higher pressure fuel pump to maintain a prescribed fuel pressure at the fuel injectors; and varying an amount of pump work that is provided by the lower pressure fuel pump relative to the higher pressure fuel pump responsive to an indication of the efficiency of the higher pressure pump.

Owner:FORD GLOBAL TECH LLC

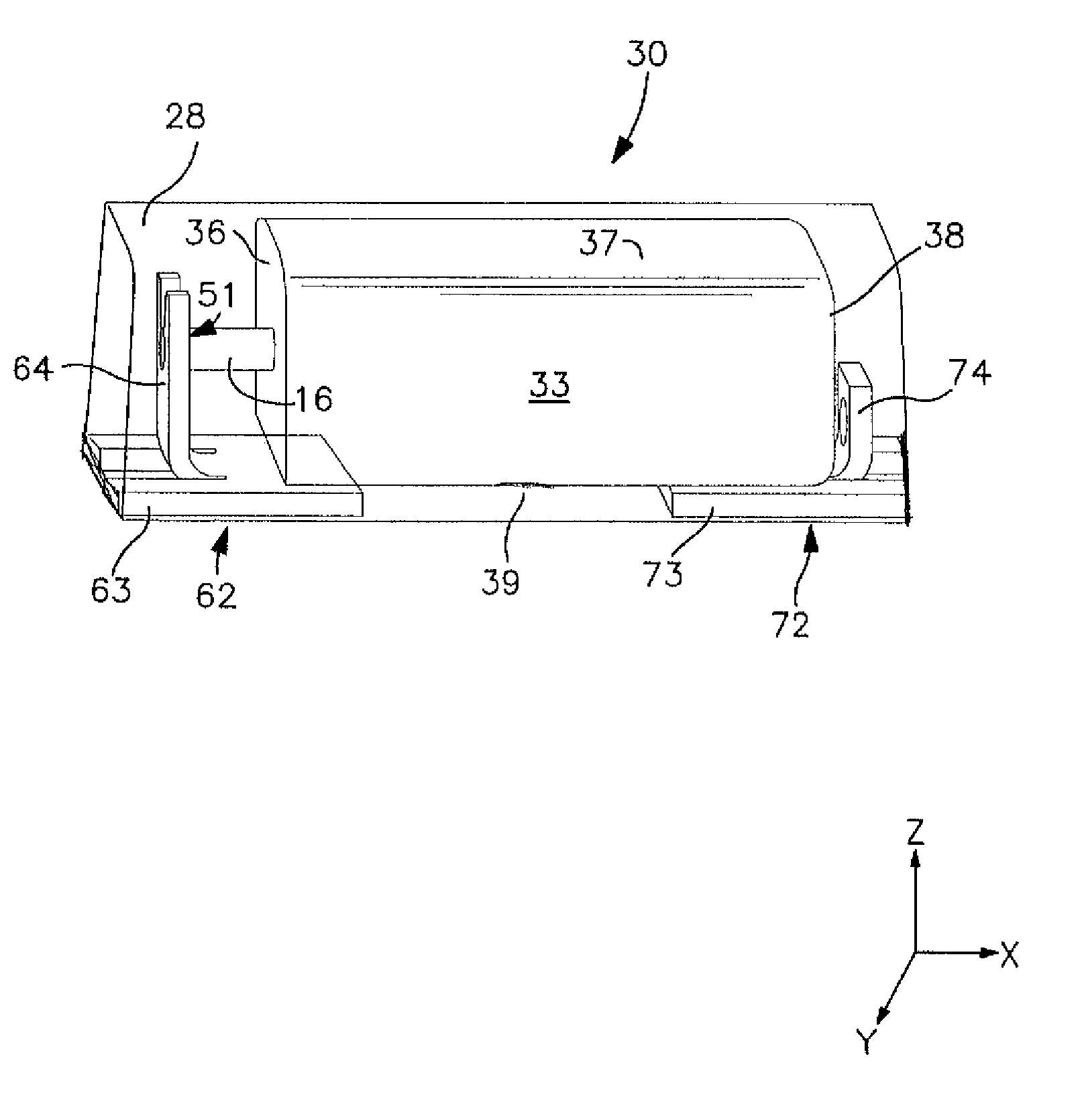

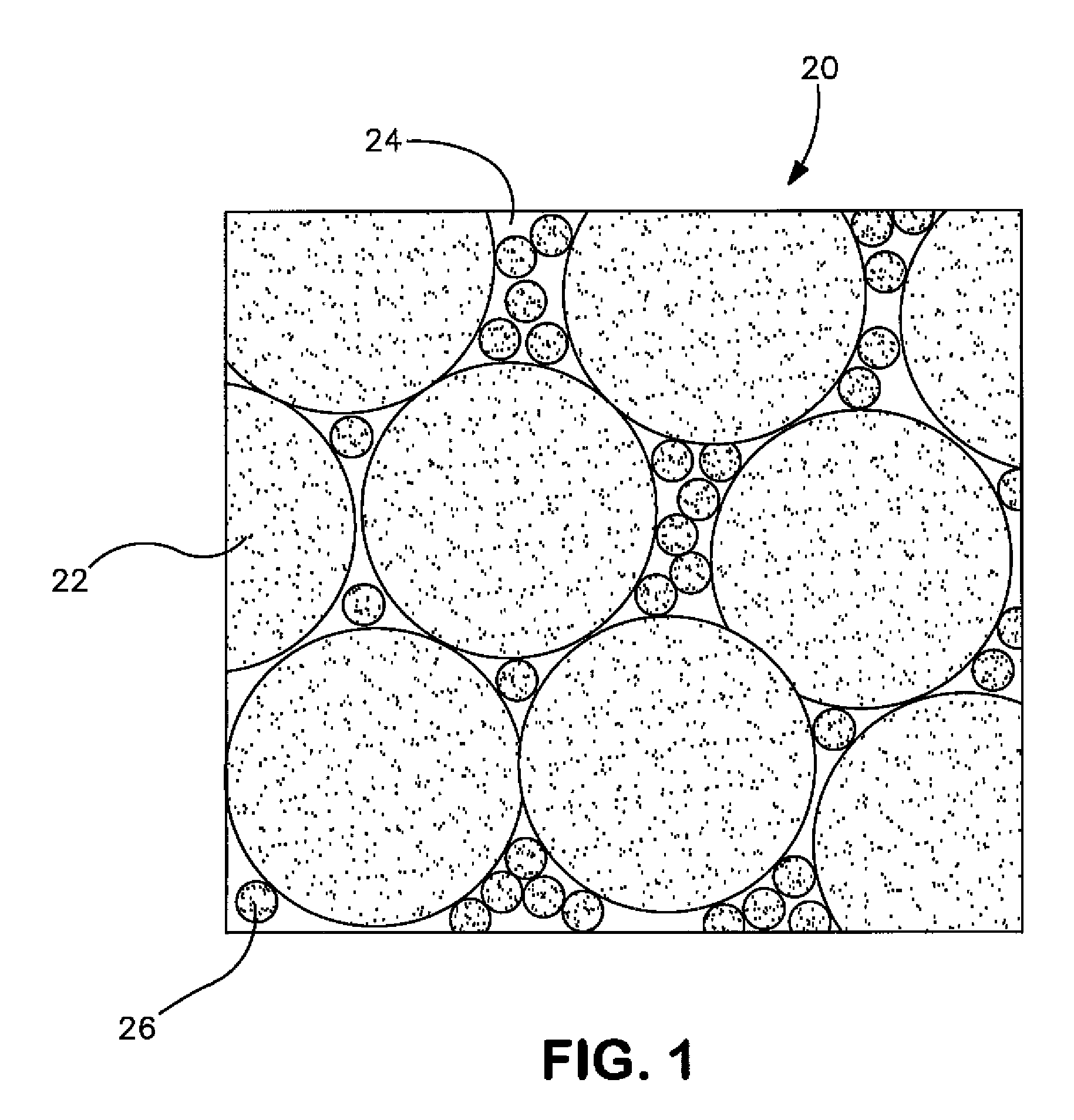

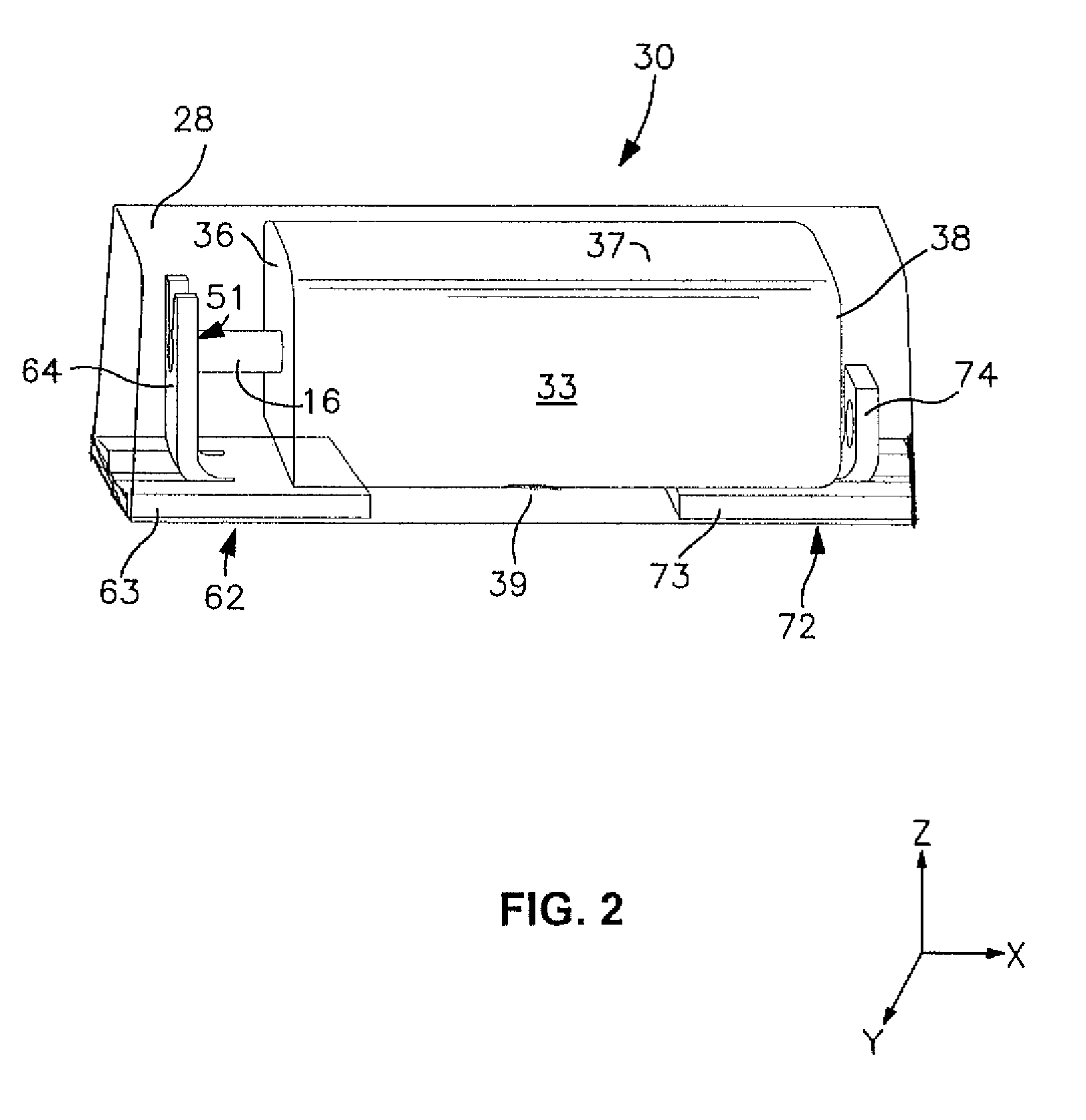

Capacitor Anode Formed From a Powder Containing Coarse Agglomerates and Fine Agglomerates

A pressed anode formed from an electrically conductive powder that contains a plurality of coarse agglomerates and fine agglomerates is provided. The fine agglomerates have an average size smaller than that of the coarse agglomerates so that the resulting powder contains two or more distinct particle sizes, i.e., a “bimodal” distribution. In this manner, the fine agglomerates can effectively occupy the pores defined between adjacent coarse agglomerates (“inter-agglomerate pores”). Through the occupation of the empty pores, the fine agglomerates can increase the apparent density of the resulting powder, which improves volumetric efficiency.

Owner:AVX CORP

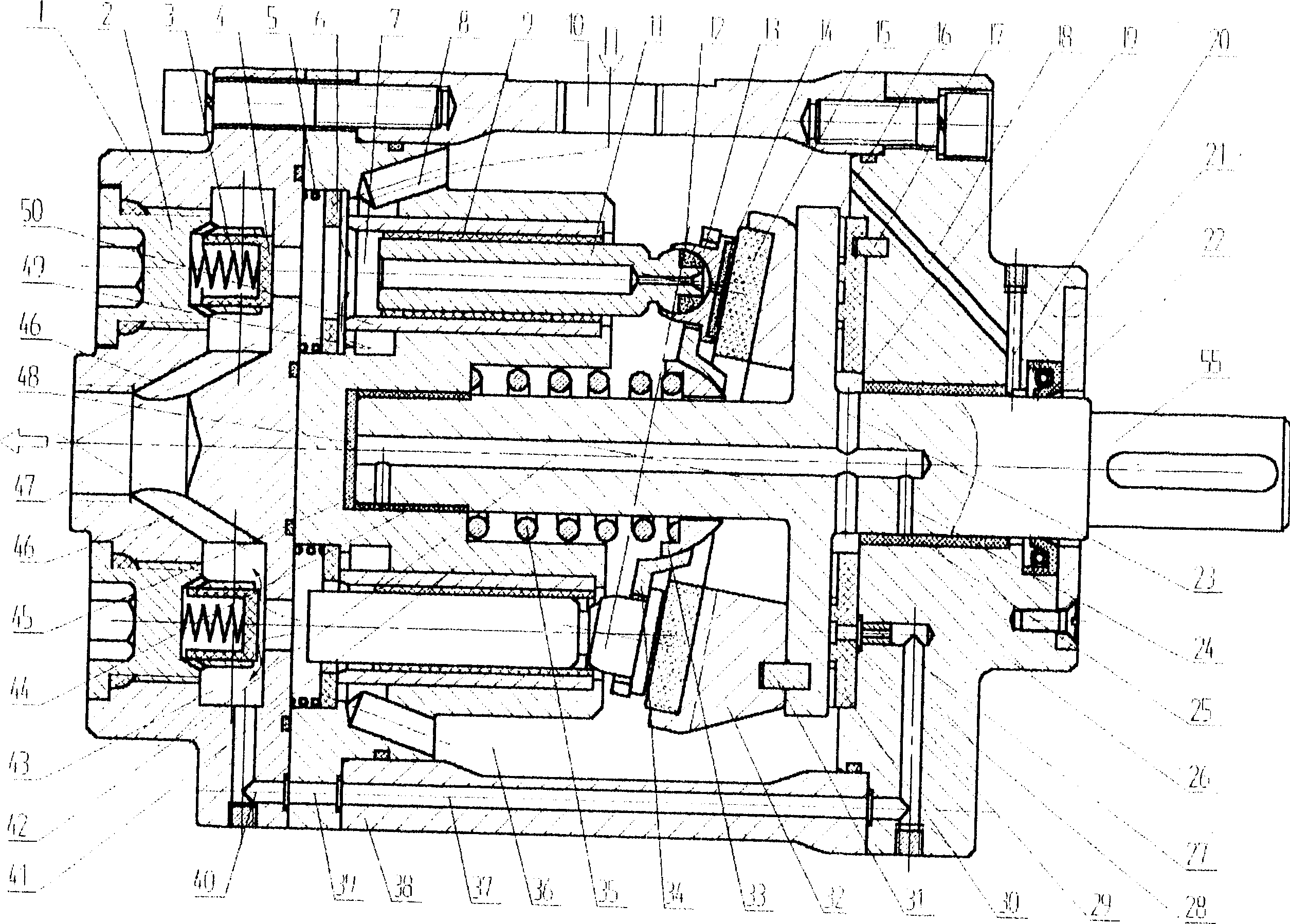

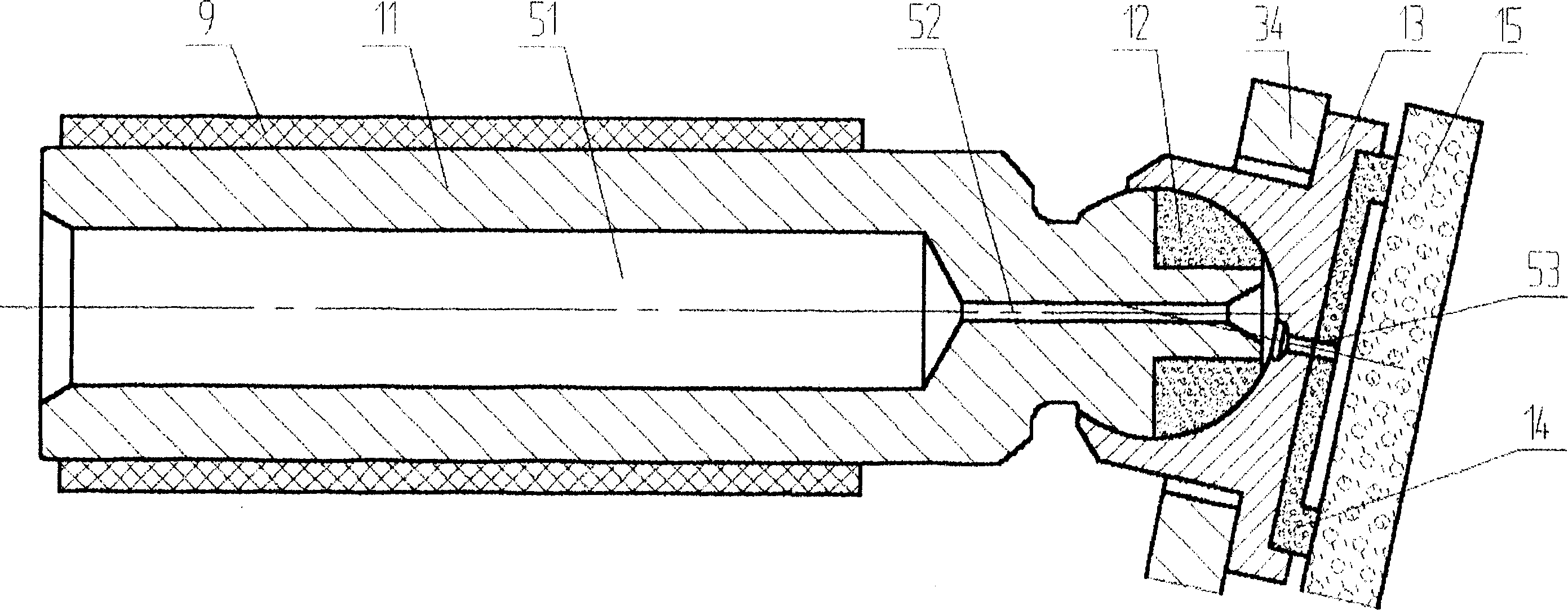

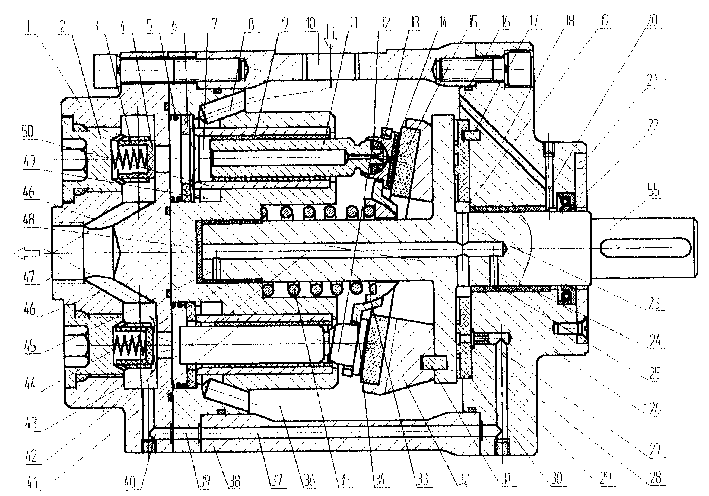

Axial plunger type water hydraulic pump

InactiveCN1434209AImprove responsivenessStable flowPositive-displacement liquid enginesMulti-cylinder pumpsReciprocating motionHydraulic pump

The axial plunger water hydraulic pump is characterized by that it adopts plate value to make flow distribution, the plunger and plunger hole are axial uniformly distributed on the periphery relativeto main shaft, it utilizes an oblique plate and central spring to implement reciprocation of plunger, the plunger, plunger bulb and slipper are equipped with central holes respectively, and on the rear end cover, cylinder body, pump shell and front end cover the flow passages are cut, and the central position of thrust bearing has a ring chavity chamber, interior of the main shaft is equipped with an axial flow passage, and its surface is equipped with a radial flow passage, all the flow passage are communicated to directly water lubricate and cool all the friction pairs.

Owner:HUAZHONG UNIV OF SCI & TECH

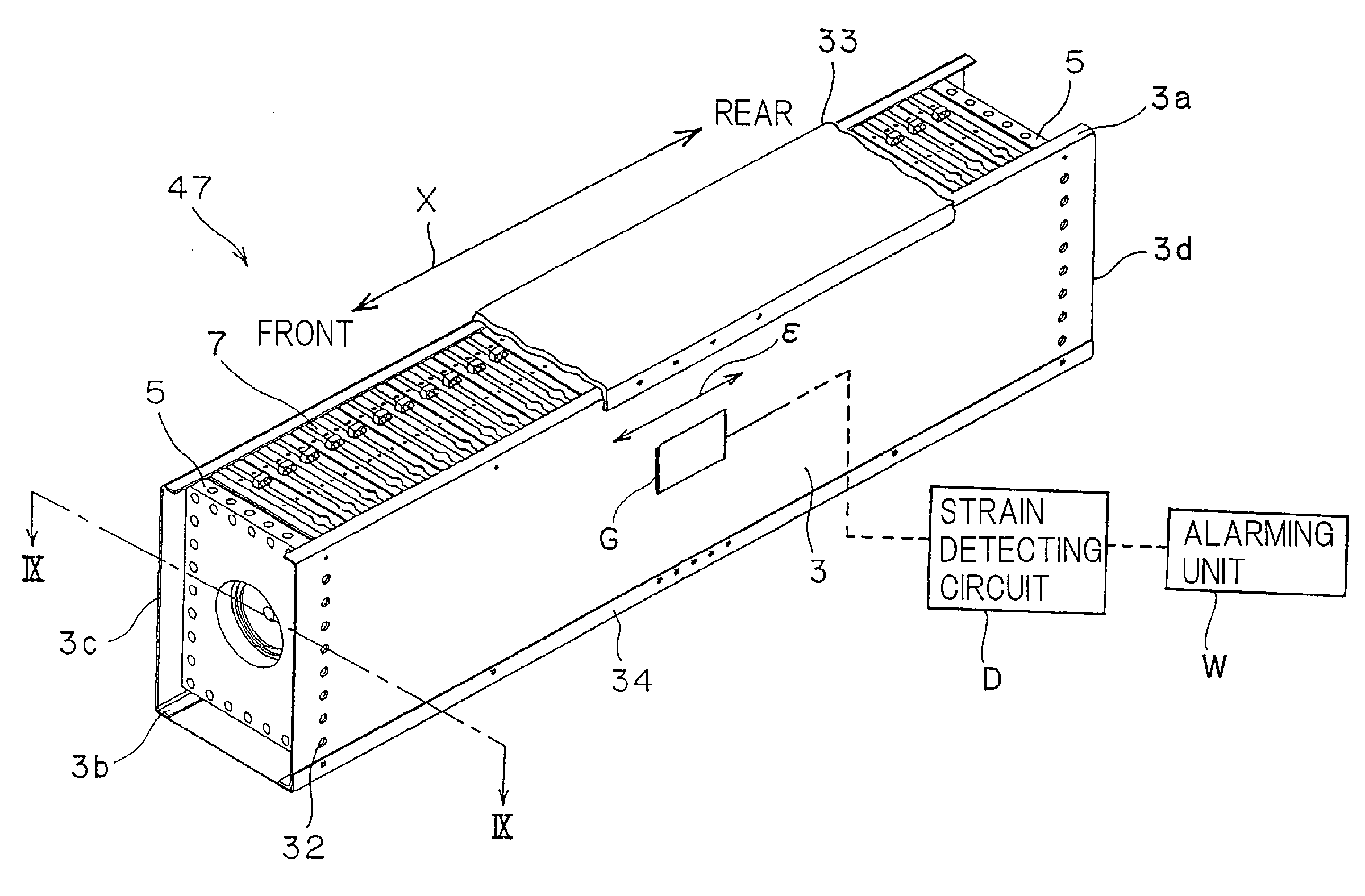

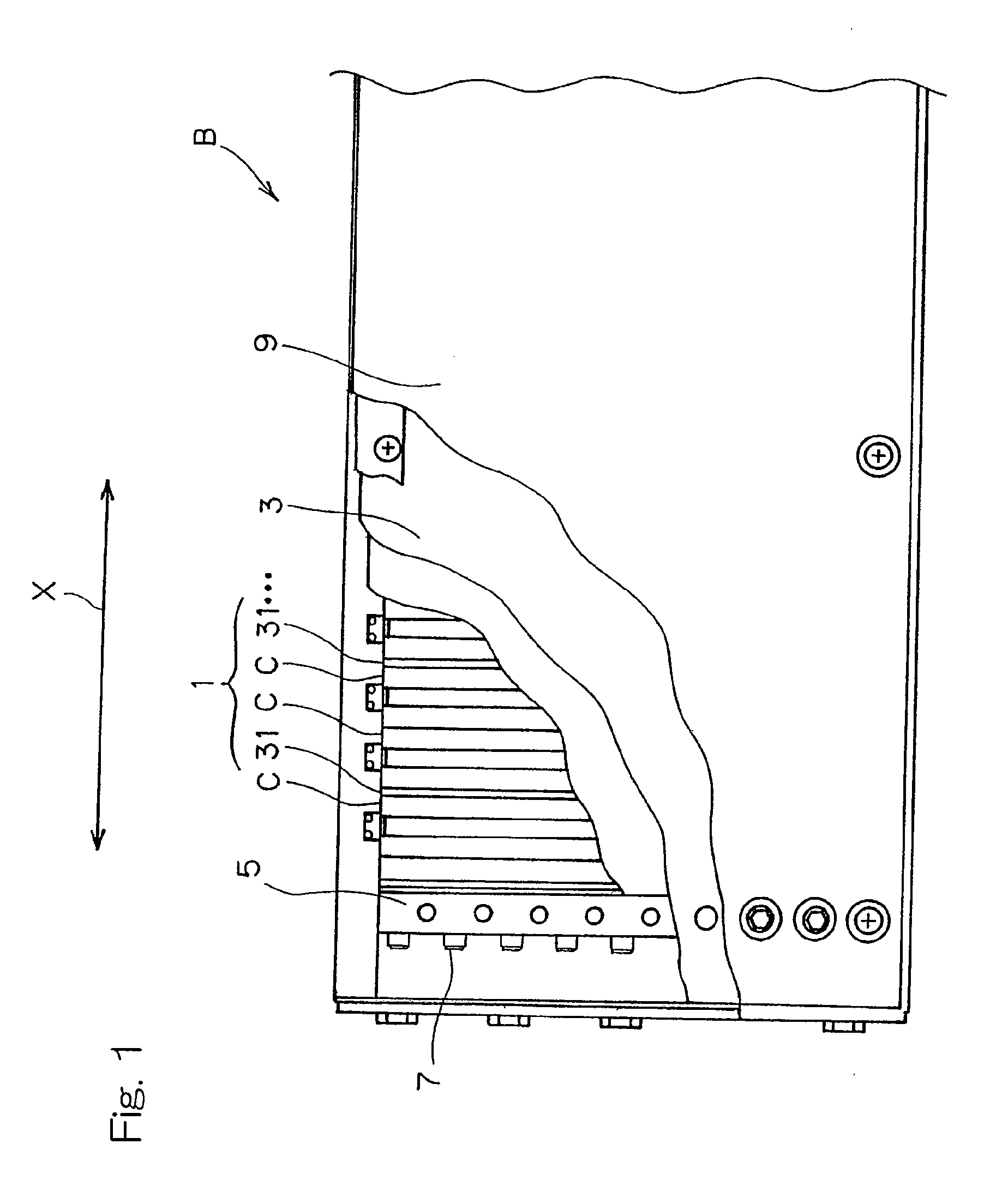

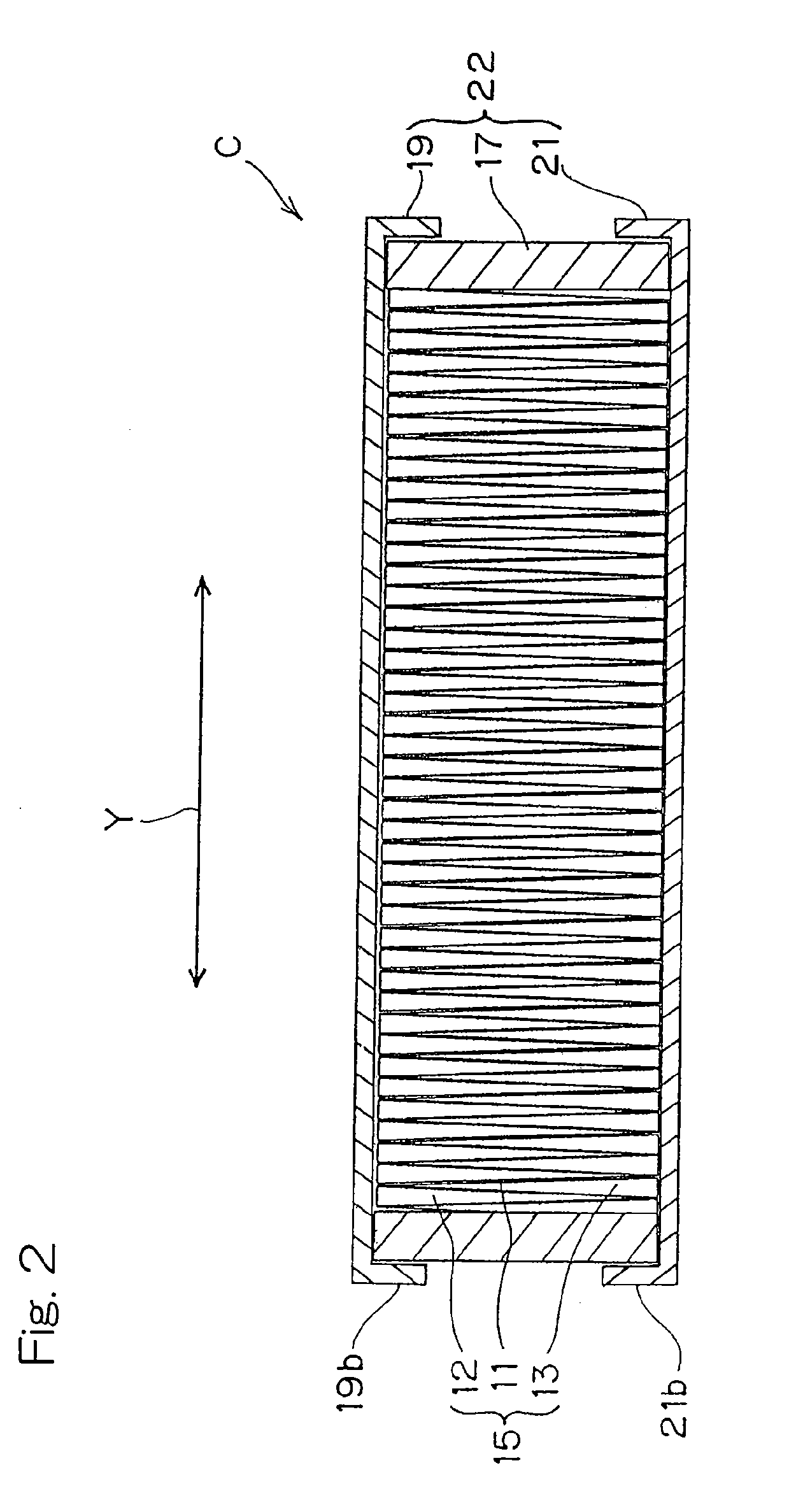

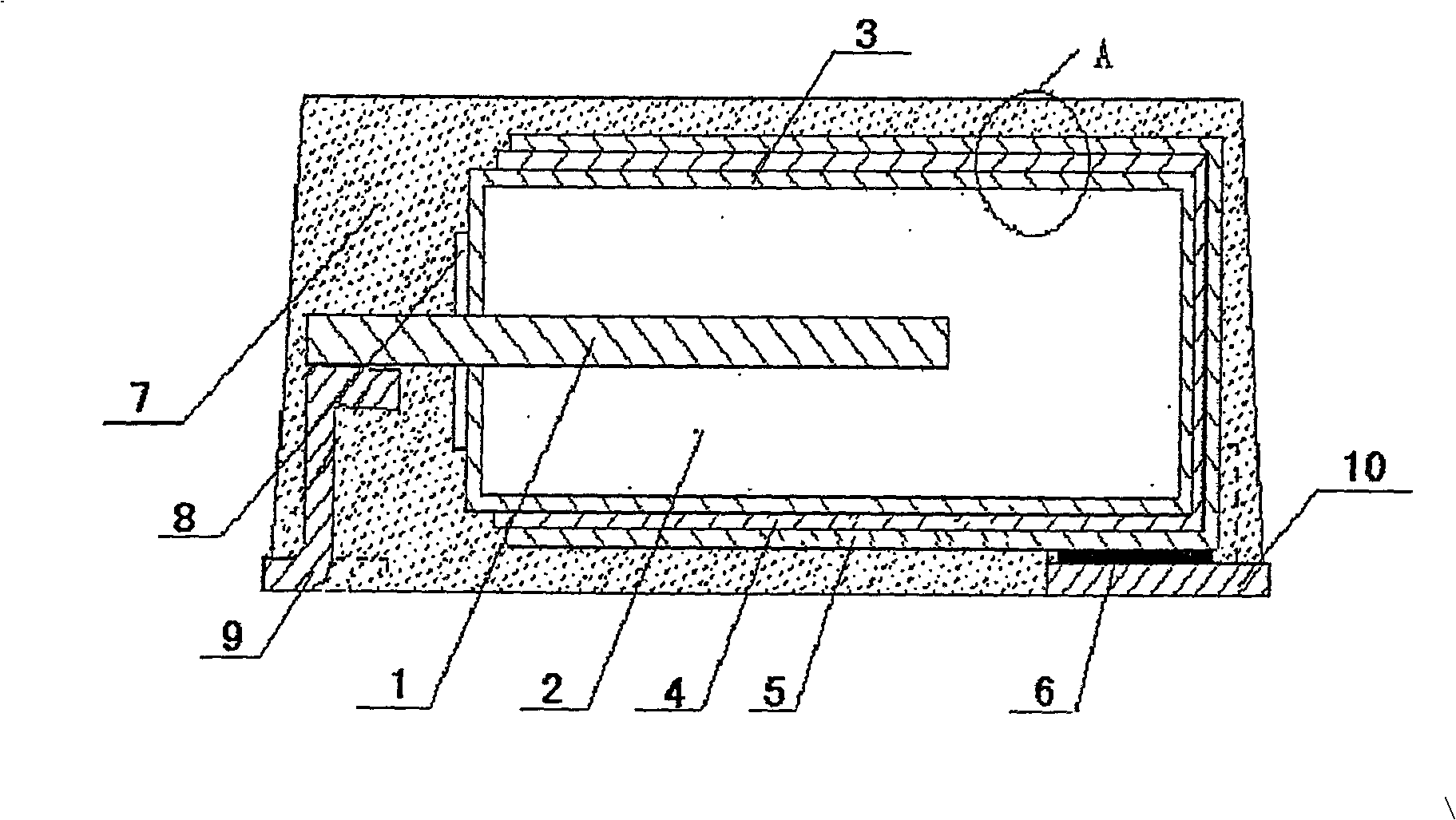

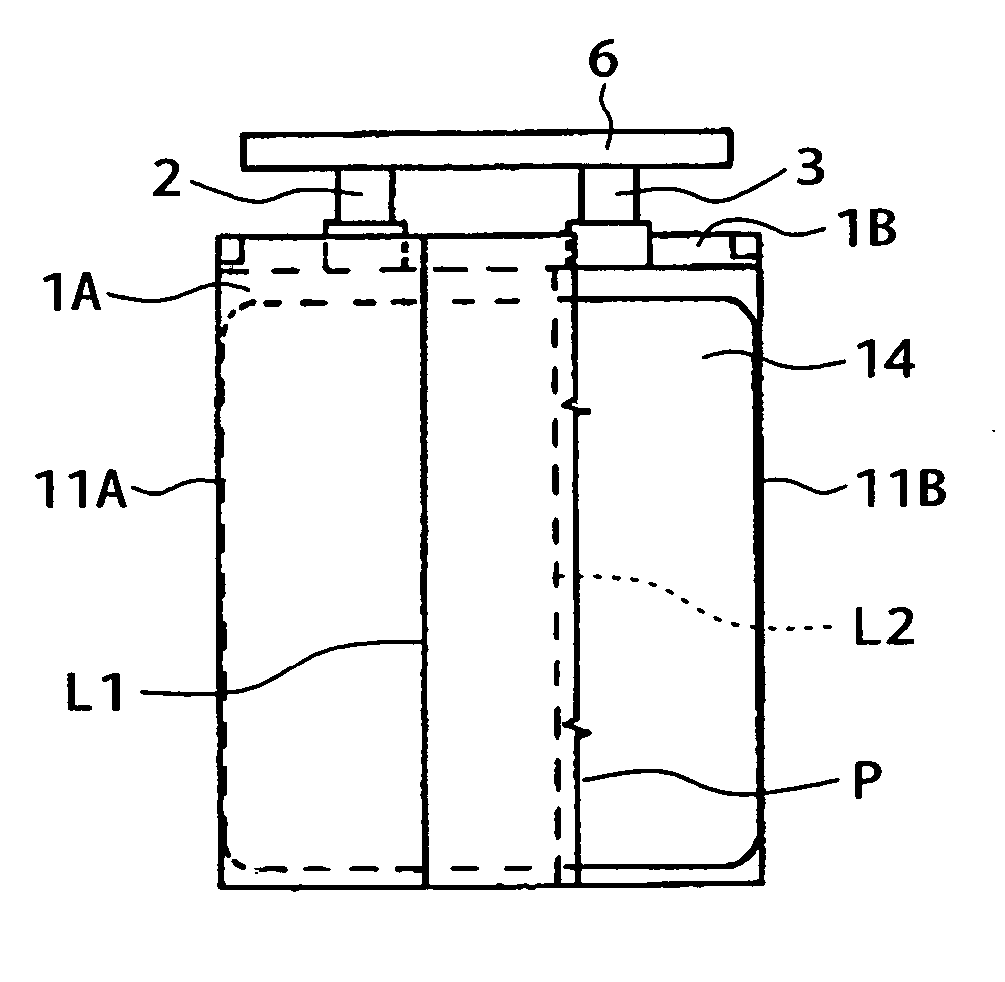

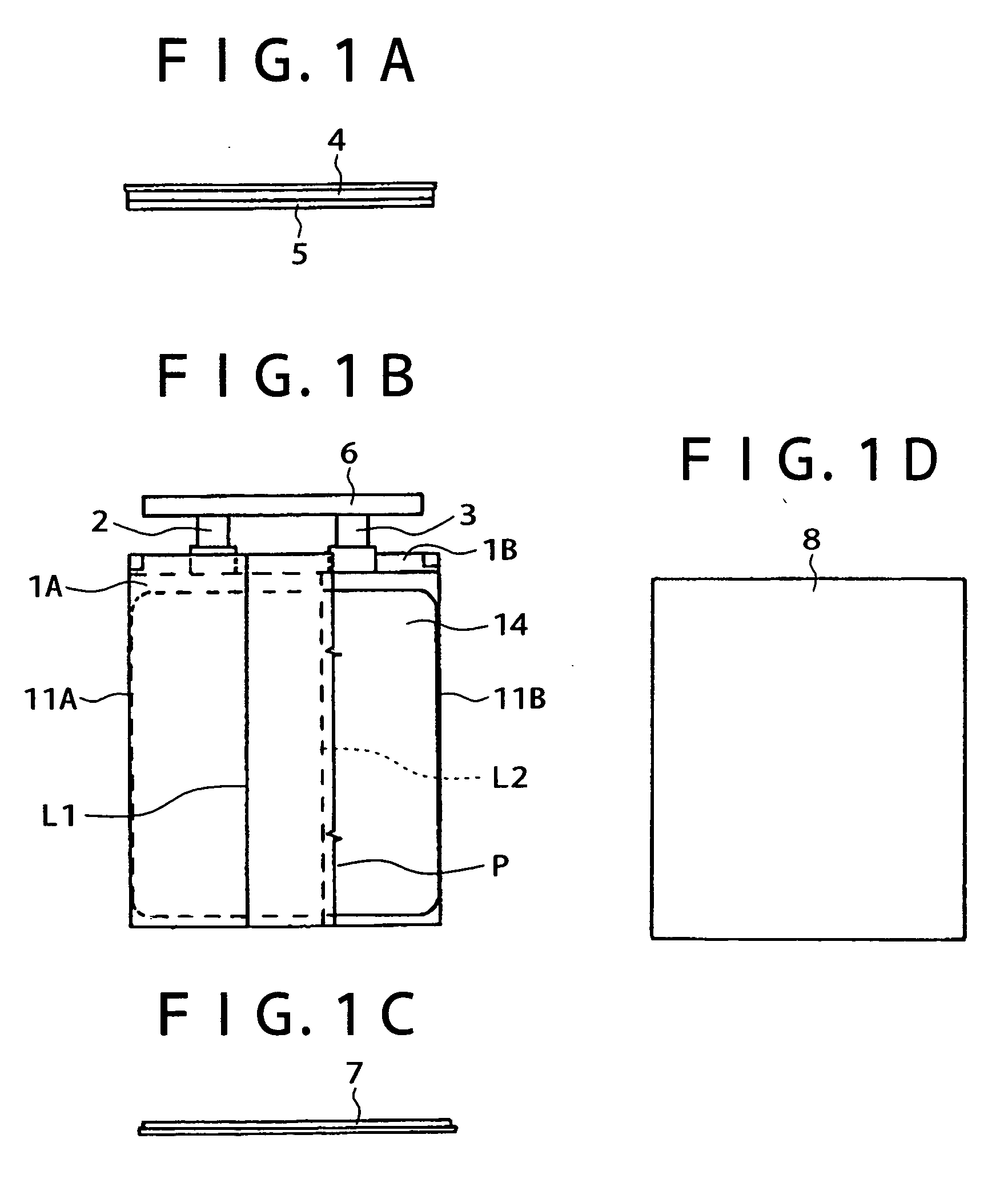

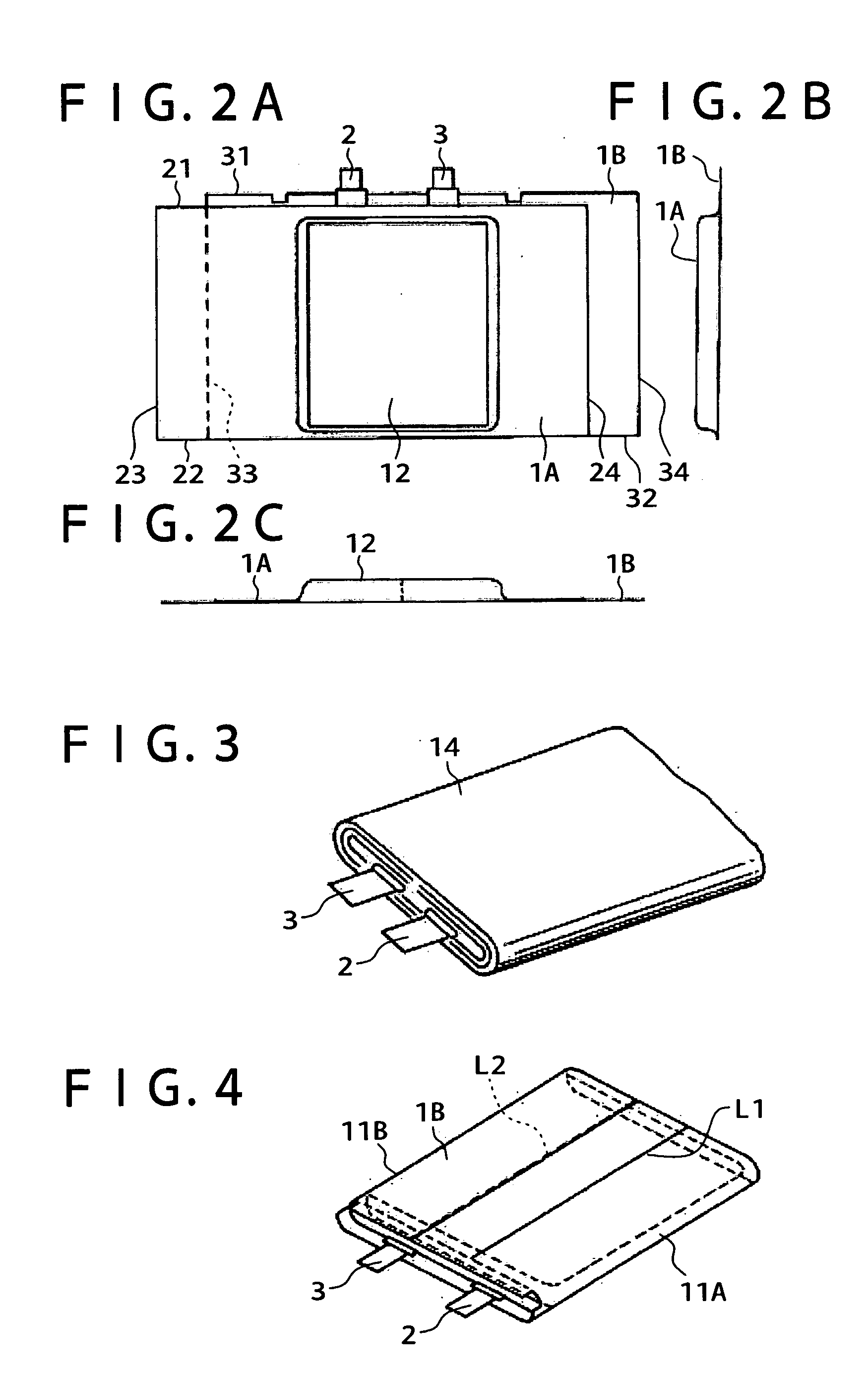

Sealed rectangular battery and battery module using same

ActiveUS20110027630A1Improve side strengthEasy to installCell seperators/membranes/diaphragms/spacersLarge-sized flat cells/batteriesEngineeringElectrolyte

A sealed rectangular battery excellent in volumetric efficiency and pressure resistance is provided. The sealed rectangular battery includes an electrode group having a positive electrode and a negative electrode and a cell casing for accommodating therein the electrode group and an electrolyte solution, which casing includes a rectangular frame member, a first lid member and a second lid member. Each of the first and second lid members includes a body portion for covering one of the openings of the frame member, and a side portion formed so as to protrude from the body portion substantially along at least one set of sides opposite to each other.

Owner:KAWASAKI MOTORS LTD

Air amount detector for internal combustion engine

InactiveUS6662640B2Improve calculation accuracyAnalogue computers for vehiclesElectrical controlResponse delayPhase advance

A response delay compensation element for compensating a response delay of an output gMAF of an airflow meter by a phase advance compensation is provided so that an output g of the response delay compensation element is input to the intake air system model. A transfer function of the phase advance compensation iswhere T1 and T2 are time constant of the phase advance compensation, which is set based on at least one of the output gMAF of the airflow meter, engine speed, an intake air pressure, and a throttle angle. The model time constant tauIM of the intake air system model is calculated by variables including volumetric efficiency and the engine speed. The volumetric efficiency is calculated by two-dimensional map having the engine speed and the intake air pressure as parameters thereof.

Owner:DENSO CORP

Control device for internal combustion engine

ActiveUS7441544B2Short calculation timeImprove accuracyElectrical controlInternal combustion piston enginesResponse delayThrottle opening

Provided is a control device for an internal combustion engine, which is provided to allow a throttle opening degree to be controlled in accordance with a target engine intake air flow quantity even during transitional operation. The actual cylinder intake air flow quantity calculating unit (21) calculates a response delay model for an intake system from a volumetric efficiency equivalent value (Kv) calculated from a rotational speed (Ne) of an engine (1) and an intake manifold pressure (Pim), an intake pipe volume (Vs), and a displacement (Vc) of each of cylinders (2), and calculates an actual cylinder intake air amount (Qcr) from an actual engine intake air amount (Qar) obtained from an air flow sensor (4) and the response delay model. The intake air flow quantity controlling unit (24) controls the throttle opening degree (TP) in accordance with the target engine intake air amount (Qat).

Owner:MITSUBISHI ELECTRIC CORP

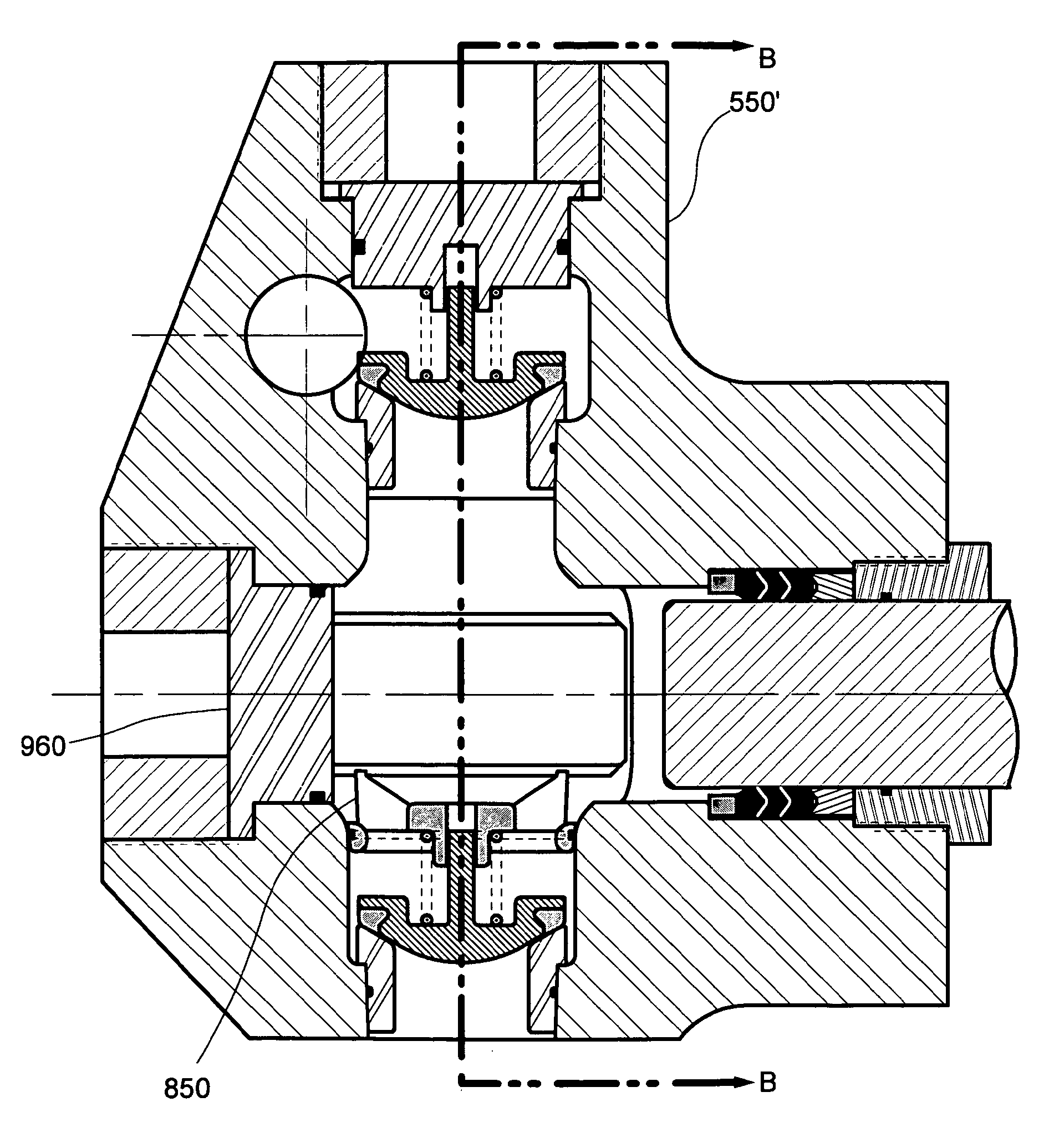

Integrated fluid end

Tapered valve guide and spring retainer assemblies are described for use in plunger pump housings that incorporate corresponding outwardly flared discharge and suction bores, as well as structural features for stress-relief. Plunger pumps so constructed are relatively resistant to fatigue failure because of stress reductions, and they may incorporate essentially any style of valves, including top and lower stem-guided valves and crow-foot-guided valves, in easily-maintained configurations. Besides forming a part of valve guide and spring retainer assemblies, side spacers may be shaped and dimensioned to improve volumetric efficiency of the pumps in which they are used. The present disclosure provides, for the first time, the use of tungsten carbide valve seats, which significantly increase durability and service life of a pump, especially when abrasive fluids are being pumped, as in various oilfield operations.

Owner:ALTIS INVESTMENTS LLC

Valve guide and spring retainer assemblies

InactiveUS8147227B1Easy to insertEasy to removePositive displacement pump componentsCheck valvesStress reliefStress reduction

Tapered valve guide and spring retainer assemblies are described for use in plunger pump housings that incorporate corresponding outwardly flared discharge and suction bores, as well as structural features for stress-relief. Plunger pumps so constructed are relatively resistant to fatigue failure because of stress reductions, and they may incorporate a variety of valve styles, including top and lower stem-guided valves and crow-foot-guided valves, in easily-maintained configurations. Besides forming a part of valve guide and spring retainer assemblies, side spacers may be shaped and dimensioned to improve volumetric efficiency of the pumps in which they are used.

Owner:ALTIS INVESTMENTS LLC

High efficiency positive displacement thermodynamic system

ActiveUS20100050628A1Without decreasing volumetric efficiencySave heatInternal combustion piston enginesCombination enginesPower modeWorking fluid

Devices and methods for moving a working fluid through a controlled thermodynamic cycle in a positive displacement fluid-handling device (20, 20′, 20″) with minimal energy input include continuously varying the relative compression and expansion ratios of the working fluid in respective compressor and expander sections without diminishing volumetric efficiency. In one embodiment, a rotating valve plate arrangement (40, 42, 44, 46) is provided with moveable apertures or windows (48, 50, 56, 58) for conducting the passage of the working fluid in a manner which enables on-the-fly management of the thermodynamic efficiency of the device (20) under varying conditions in order to maximize the amount of mechanical work needed to move the target quantity of heat absorbed and released by the working fluid. When operated in refrigeration modes, the work required to move the heat is minimized. In power modes, the work extracted for the given input heat is maximized.

Owner:STAFFEND GILBERT

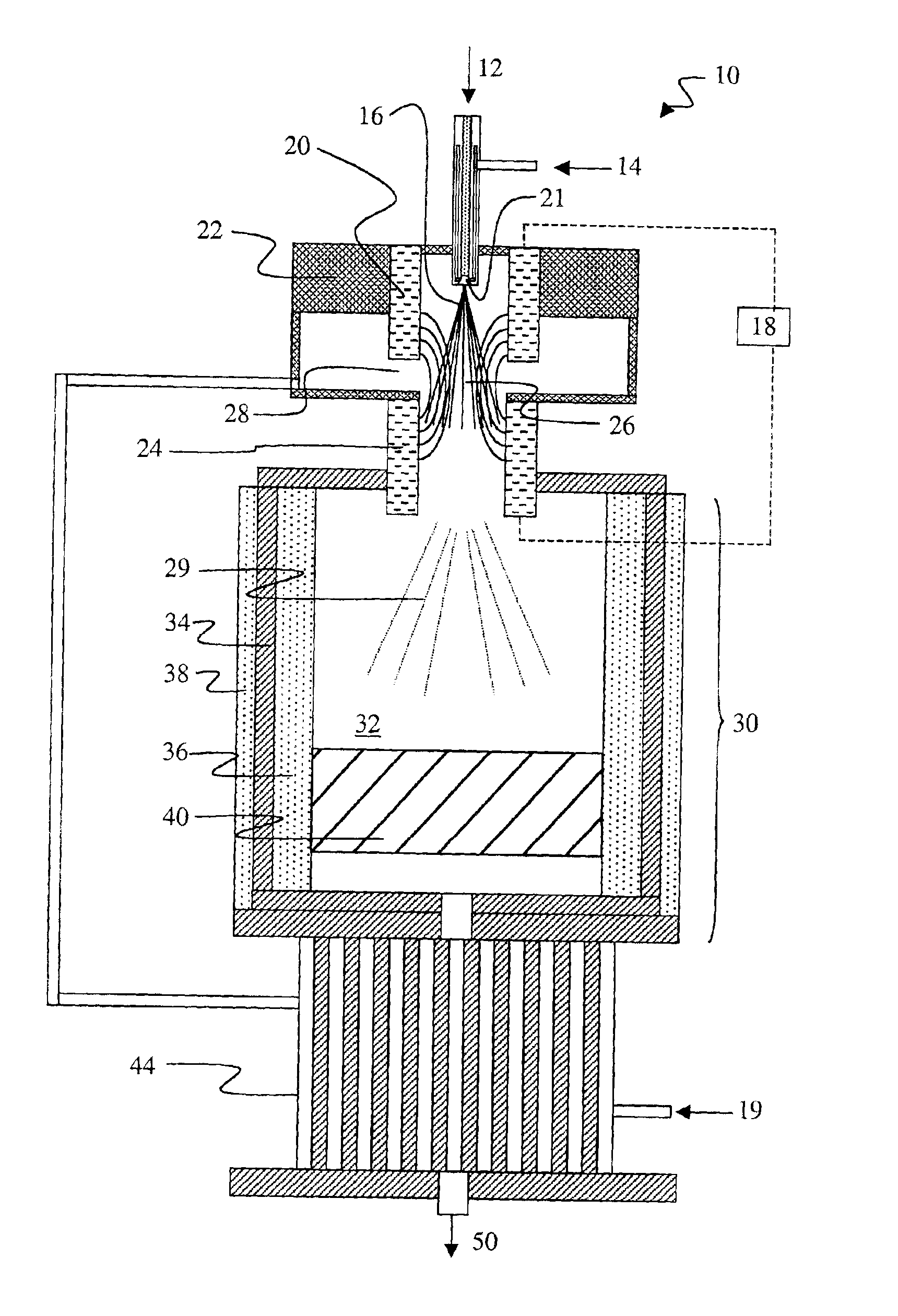

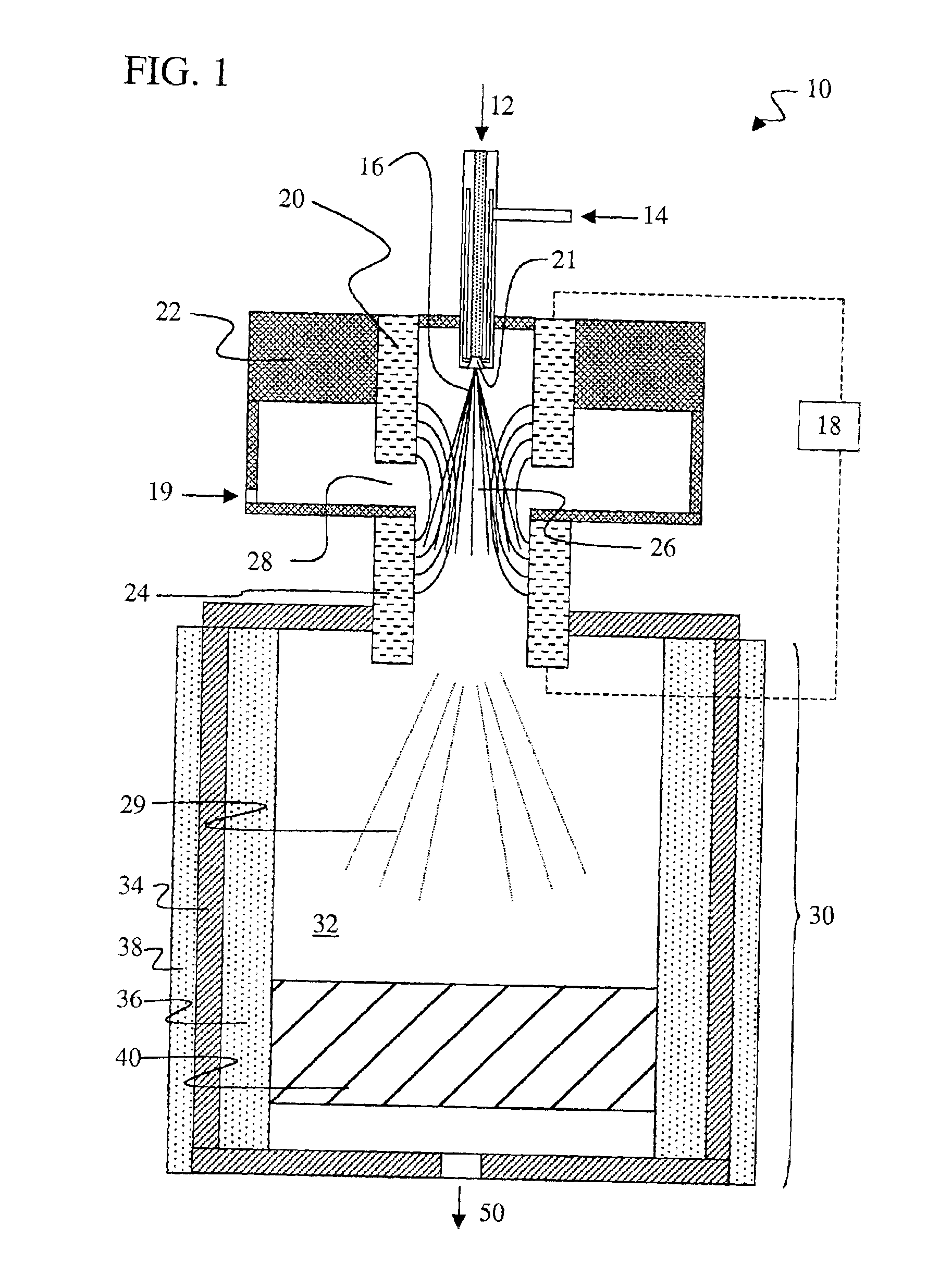

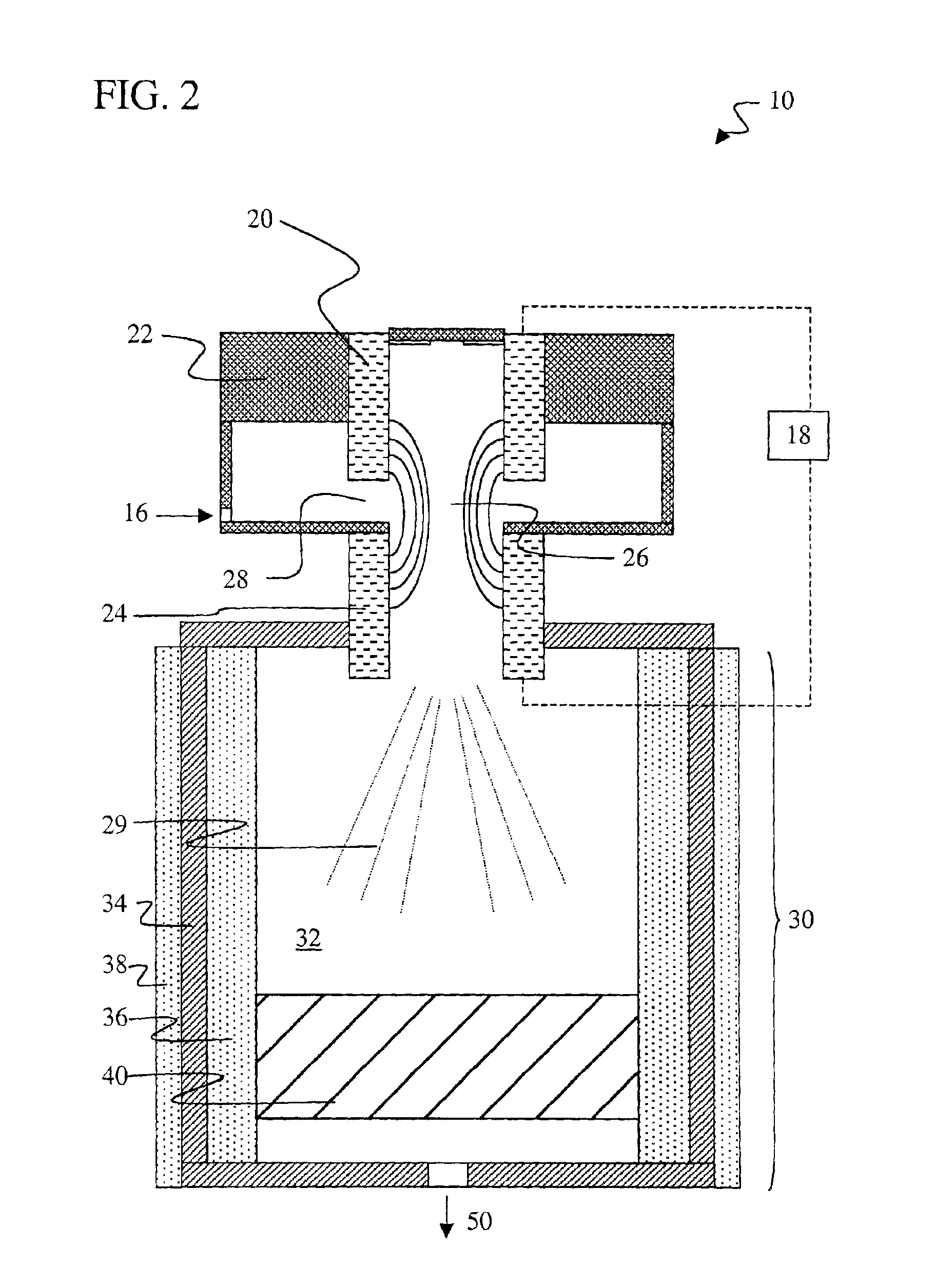

Low current plasmatron fuel converter having enlarged volume discharges

InactiveUS6881386B2Efficiently usLarge effective plasma discharge volumeHydrogenNon-fuel substance addition to fuelHydrogenChemical reaction

A novel apparatus and method is disclosed for a plasmatron fuel converter (“plasmatron”) that efficiently uses electrical energy to produce hydrogen rich gas. The volume and shape of the plasma discharge is controlled by a fluid flow established in a plasma discharge volume. A plasmatron according to this invention produces a substantially large effective plasma discharge volume allowing for substantially greater volumetric efficiency in the initiation of chemical reactions within a volume of bulk fluid reactant flowing through the plasmatron.

Owner:MASSACHUSETTS INST OF TECH

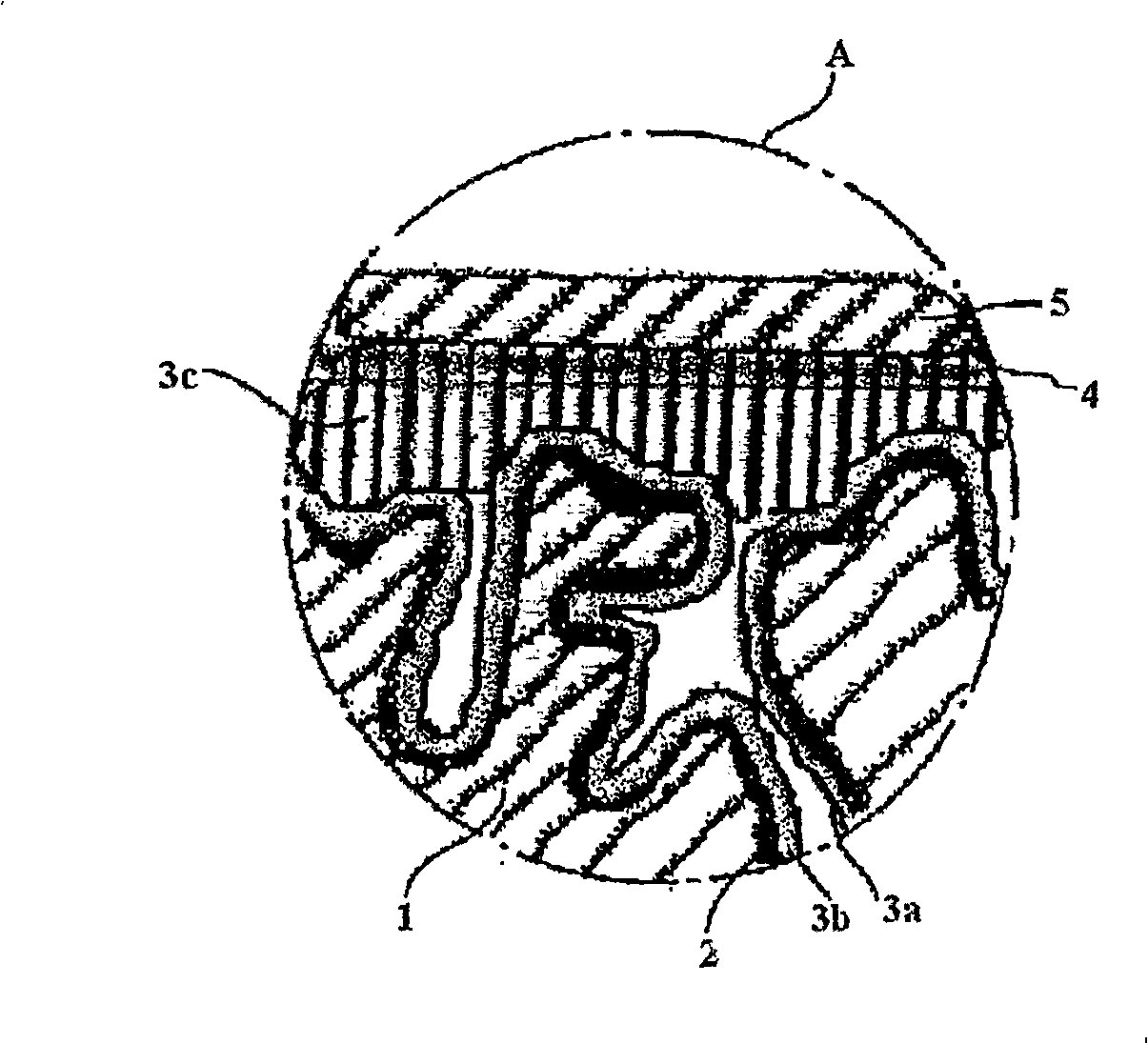

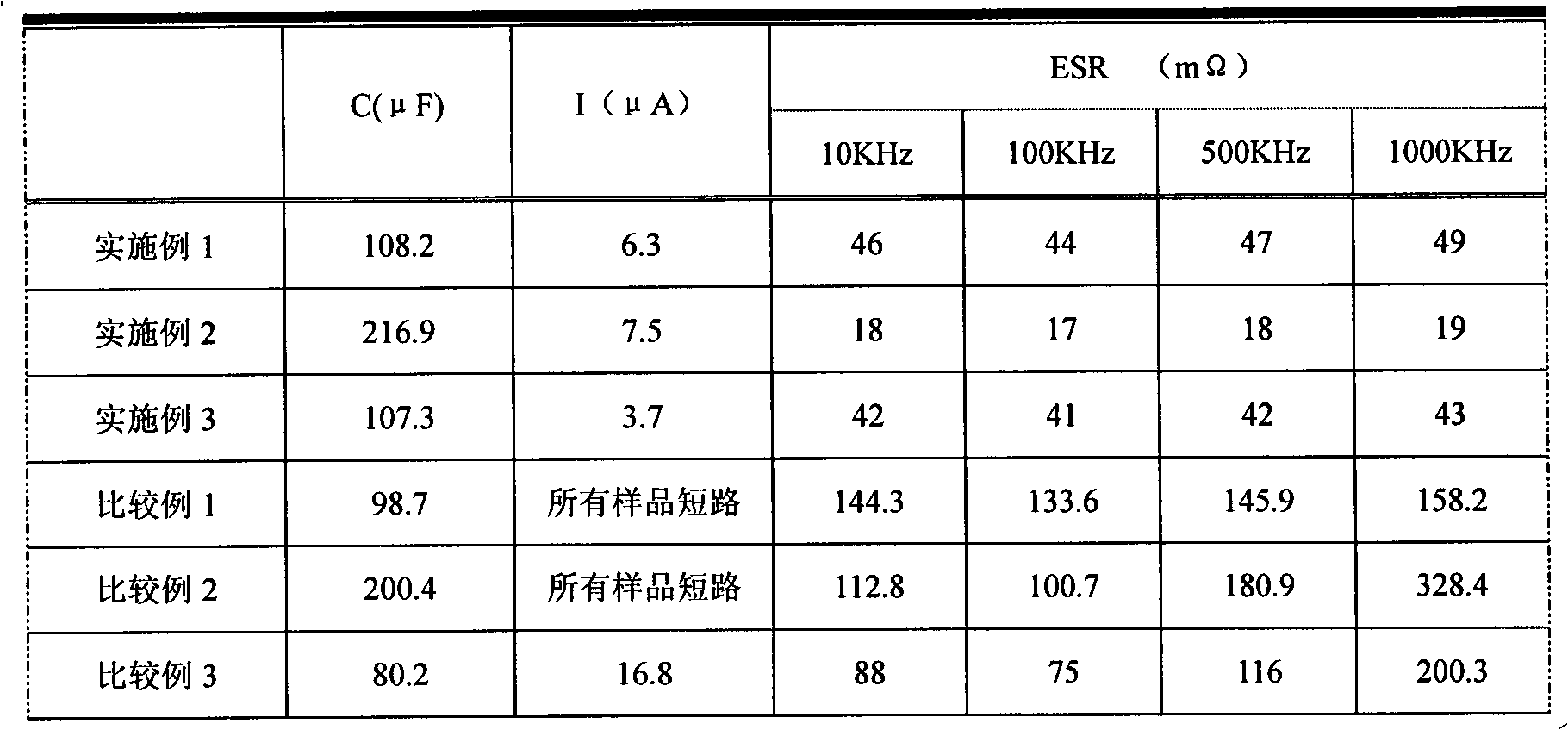

Solid electrolyte capacitor with ultra-low equivalent series resistance and manufacturing method thereof

ActiveCN101350253AImprove volumetric efficiencyTightly boundSolid electrolytic capacitorsCapacitor terminalsElectrolysisNiobium

The invention relates to a solid electrolytic capacitor and the method for preparing the solid electrolytic capacitor, wherein the solid electrolytic capacitor takes solid conducting high molecular polymer as electrolyte and takes valve metals, such as tantalum, niobium, titanium, aluminum and the like as an anode. The solid electrolytic capacitor is characterized by sufficiently explaining the techniques for the design of the anode, the function assignment, the chemical oxidative in-situ polymerization, the dip-coating graphite silver paste, the making of bottom extraction electrode and the like, with the technical proposal of the invention, a high polymer film, a graphite layer and a silver layer can be compactly combined, the manufactured electrolytic capacitor can be provided with very low equivalent series resistance (ESR), very high volumetric efficiency and good impedance frequency characteristic, the ESR value can be stable in the range of 10KHz-1000KHz, and the requirements of the frequency of a modern electronic equipment can be satisfied.

Owner:CHINA ZHENHUA GRP XINYUN ELECTRONICS COMP ANDDEV CO LTD

Solid Electrolytic Capacitor for Use in High Voltage and High Temperature Applications

A capacitor assembly for use in high voltage and high temperature environments is provided. More particularly, the capacitor assembly includes a solid electrolytic capacitor element containing an anode body, a dielectric overlying the anode, and a solid electrolyte overlying the dielectric. To help facilitate the use of the capacitor assembly in high voltage applications, it is generally desired that the solid electrolyte is formed from a dispersion of preformed conductive polymer particles. In this manner, the electrolyte may remain generally free of high energy radicals (e.g., Fe2+ or Fe3+ ions) that can lead to dielectric degradation, particularly at relatively high voltages (e.g., above about 60 volts). Furthermore, to help protect the stability of the solid electrolyte at high temperatures, the capacitor element is enclosed and hermetically sealed within a housing in the presence of a gaseous atmosphere that contains an inert gas. It is believed that the housing and inert gas atmosphere are capable of limiting the amount of oxygen and moisture supplied to the conductive polymer of the capacitor. In this manner, the solid electrolyte is less likely to undergo a reaction in high temperature environments, thus increasing the thermal stability of the capacitor assembly. In addition to functioning well in both high voltage and high temperature environments, the capacitor assembly of the present invention may also exhibit a high volumetric efficiency.

Owner:KYOCERA AVX COMPONENTS CORP

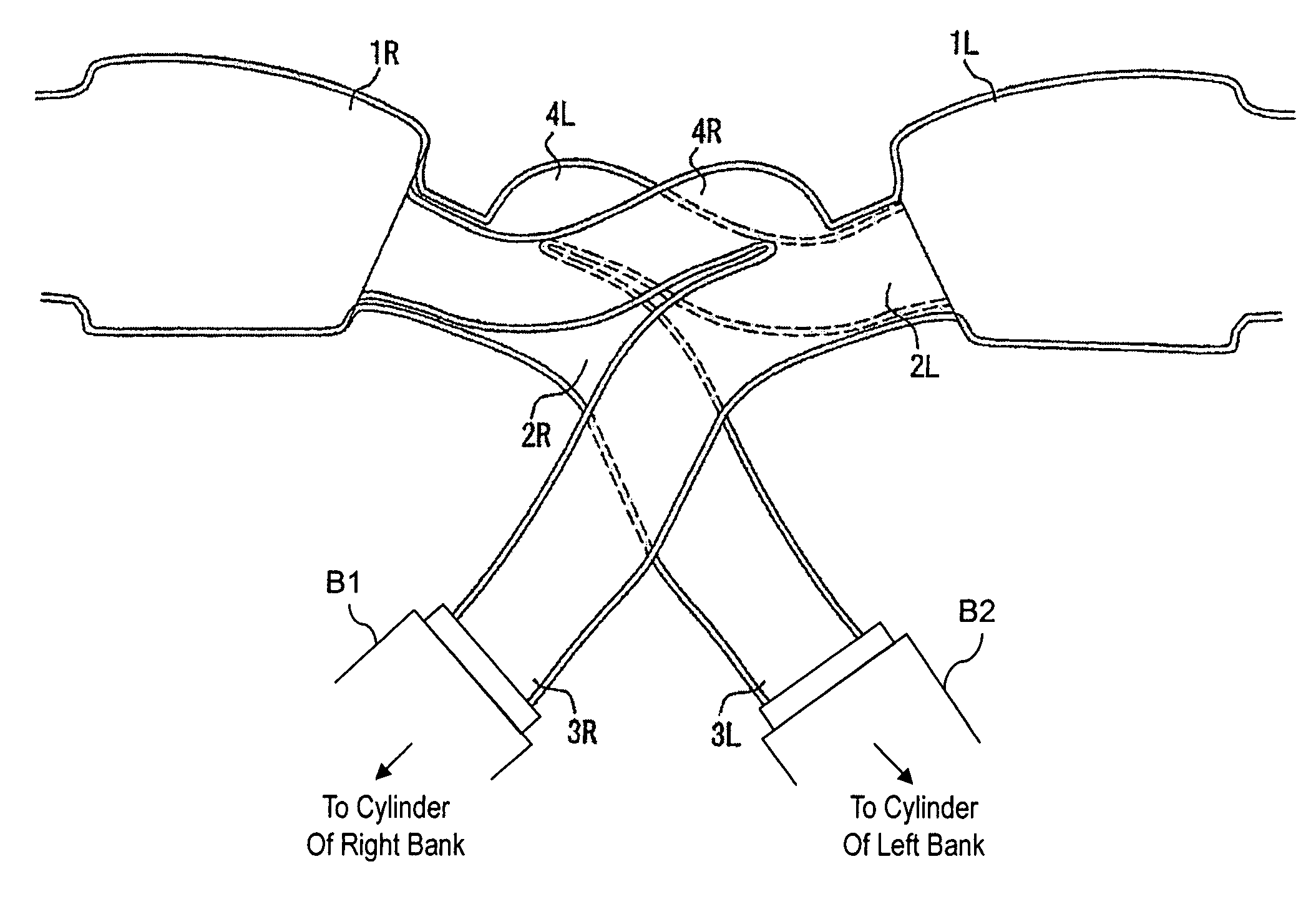

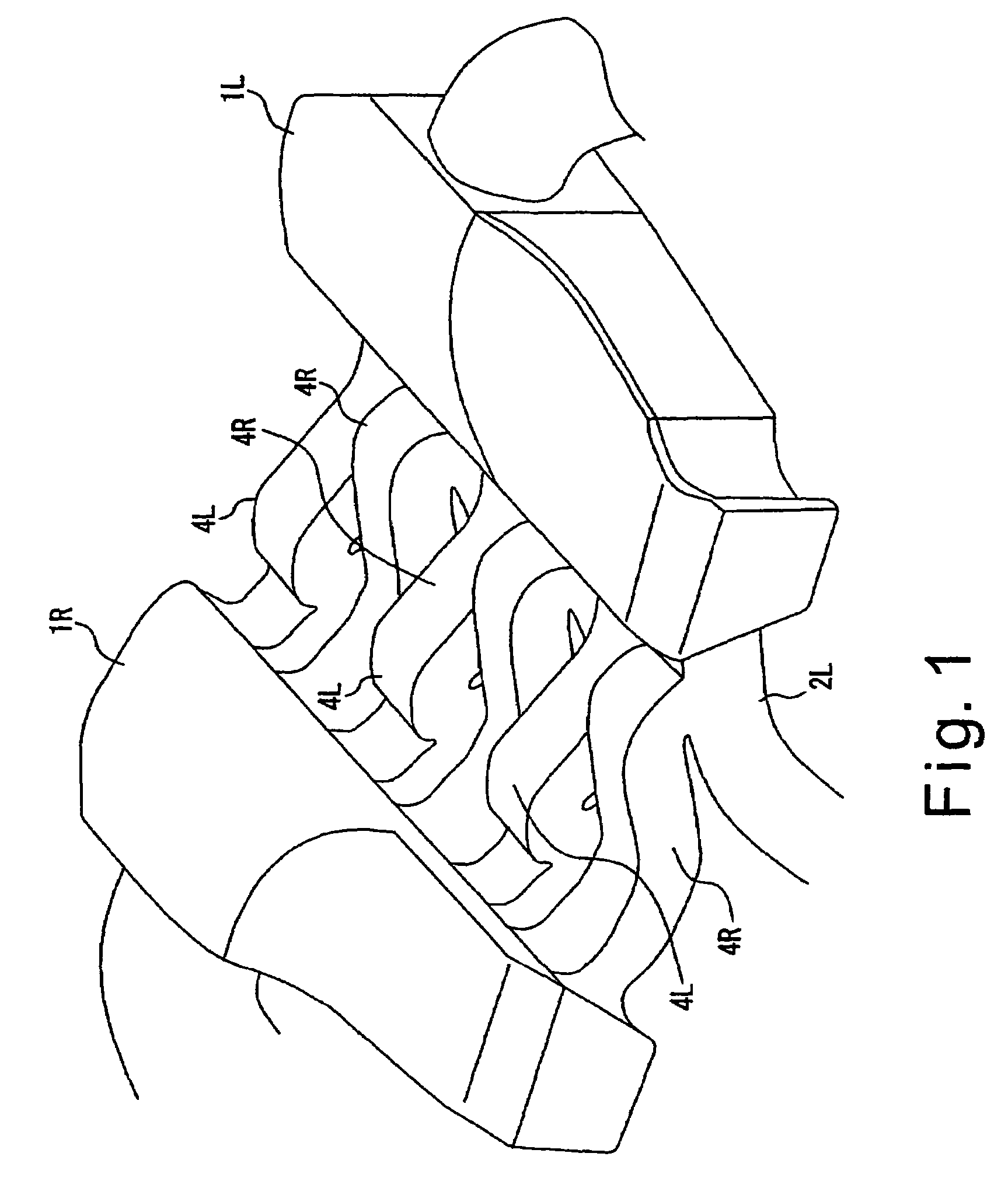

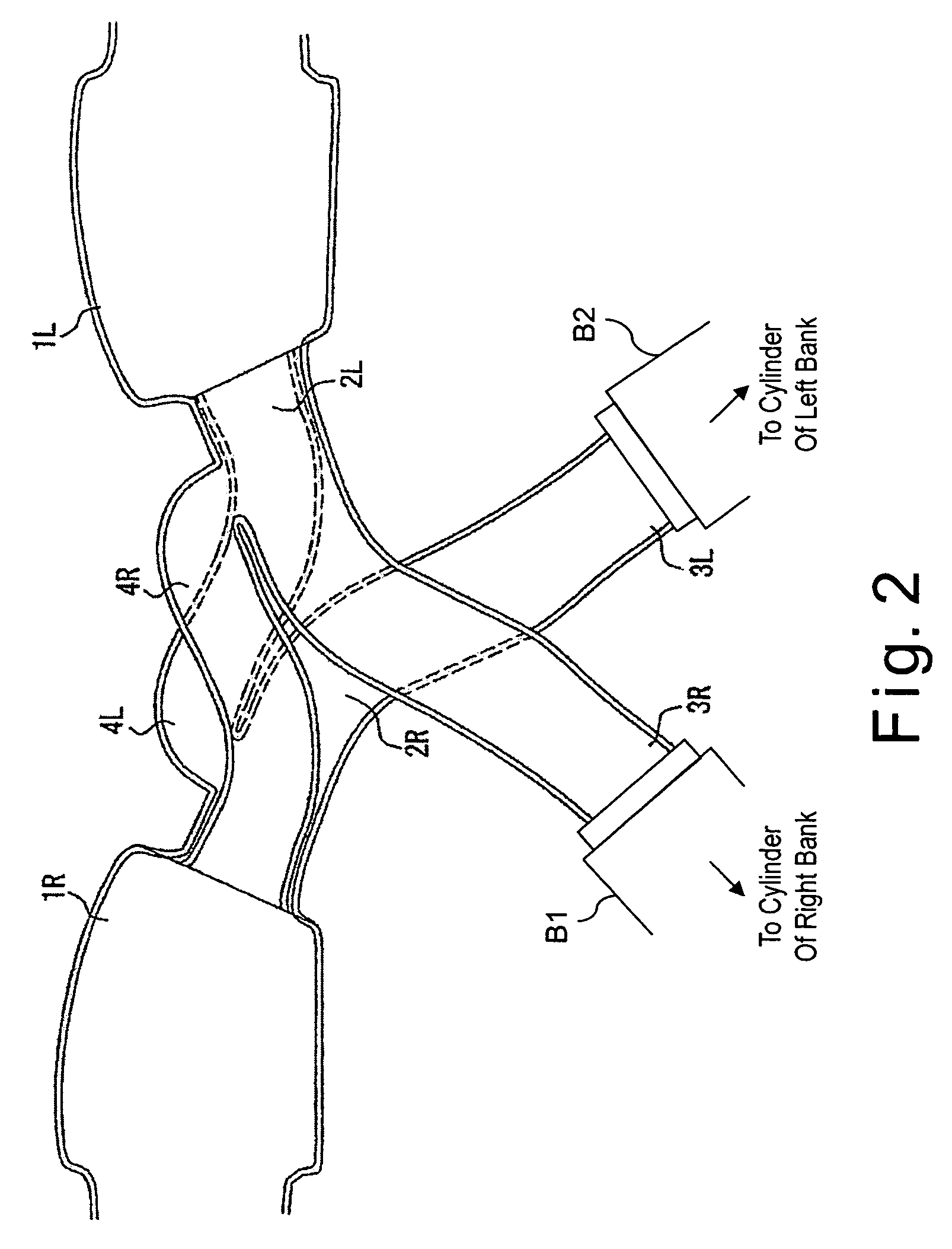

V-type multiple-cylinder air intake device

InactiveUS7004137B2Simple designInternal combustion piston enginesAir intakes for fuelVolumetric efficiencyResonance effect

A V-type multiple cylinder air intake is being configured to improve the volumetric efficiency by utilizing the resonance effect while also eliminating the adverse influence of the resonance effect (residual resonance) when the engine is operating in regions of medium to high rotational speeds. The V-type multiple-cylinder air intake device has two collectors with one arranged on each bank of the V-type multiple-cylinder engine; a plurality of branch pipes extending from the collectors to a respective intake port of an opposite bank; and a plurality of crossover passages extending from the collectors to a respective branch pipes extending from the collector of the opposite bank.

Owner:NISSAN MOTOR CO LTD

Battery pack

ActiveUS20050136324A1Increase energy densityVolume energy density is lowPrimary cell maintainance/servicingFinal product manufactureEngineeringPolypropylene

A battery pack which can increase of the volumetric efficiency of the battery pack without being contained in a resin mold case is provided. A first laminate material has a concave portion formed by drawing where a battery element is contained. A second laminate material is stacked so as to cover the opening of the concave portion to seal up the periphery of the opening. The first and second laminate materials are bend inwards so as to cover the battery element, and bonded and fixed together by heating. The first laminate material has three-layer structure including a polypropylene layer, a soft aluminum layer, and a nylon layer or PET layer. The second laminate material has a similar structure but includes a hard aluminum layer. Therefore, the second laminate material has enough strength to resist deformation without being contained a cell in a resin mold case.

Owner:MURATA MFG CO LTD

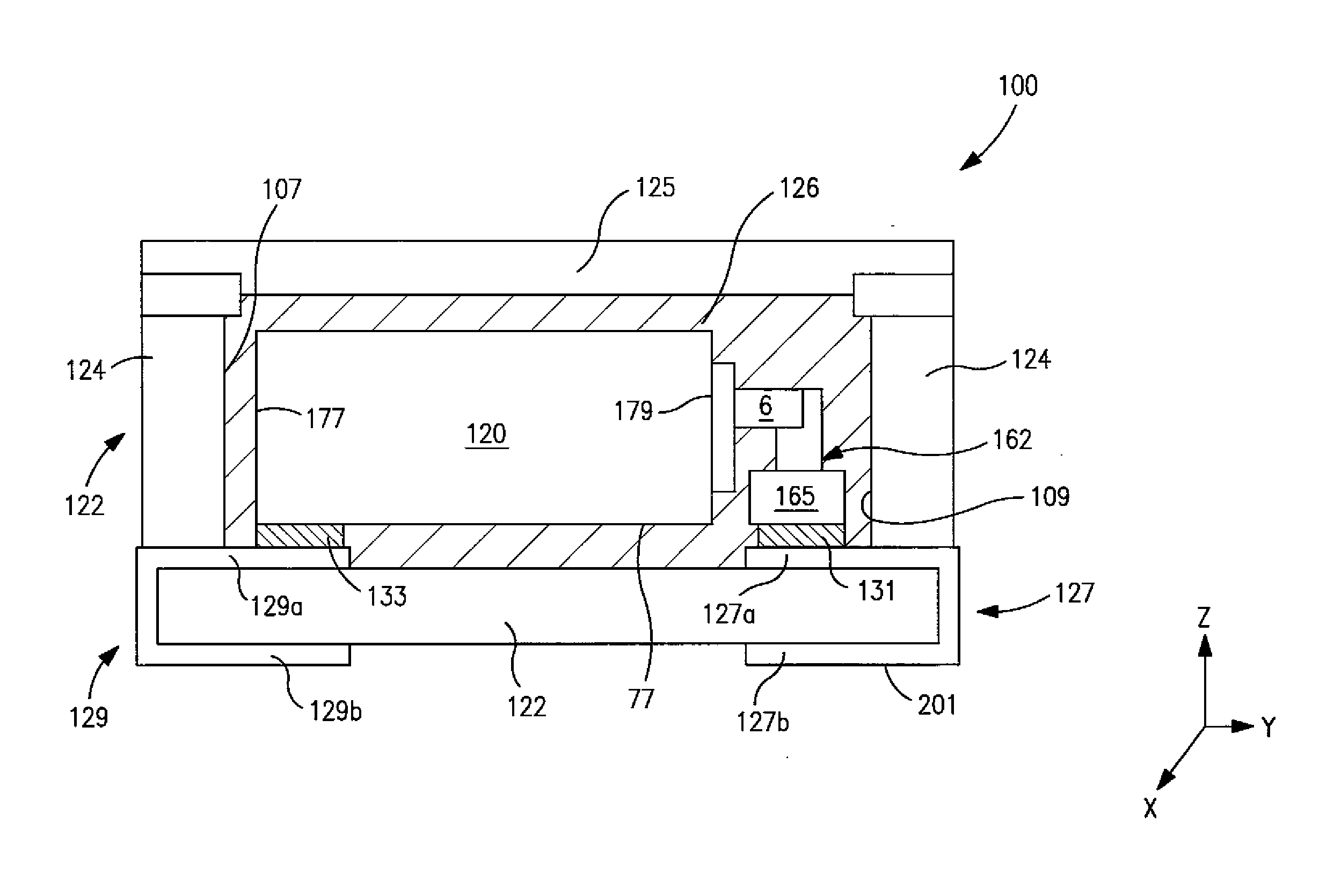

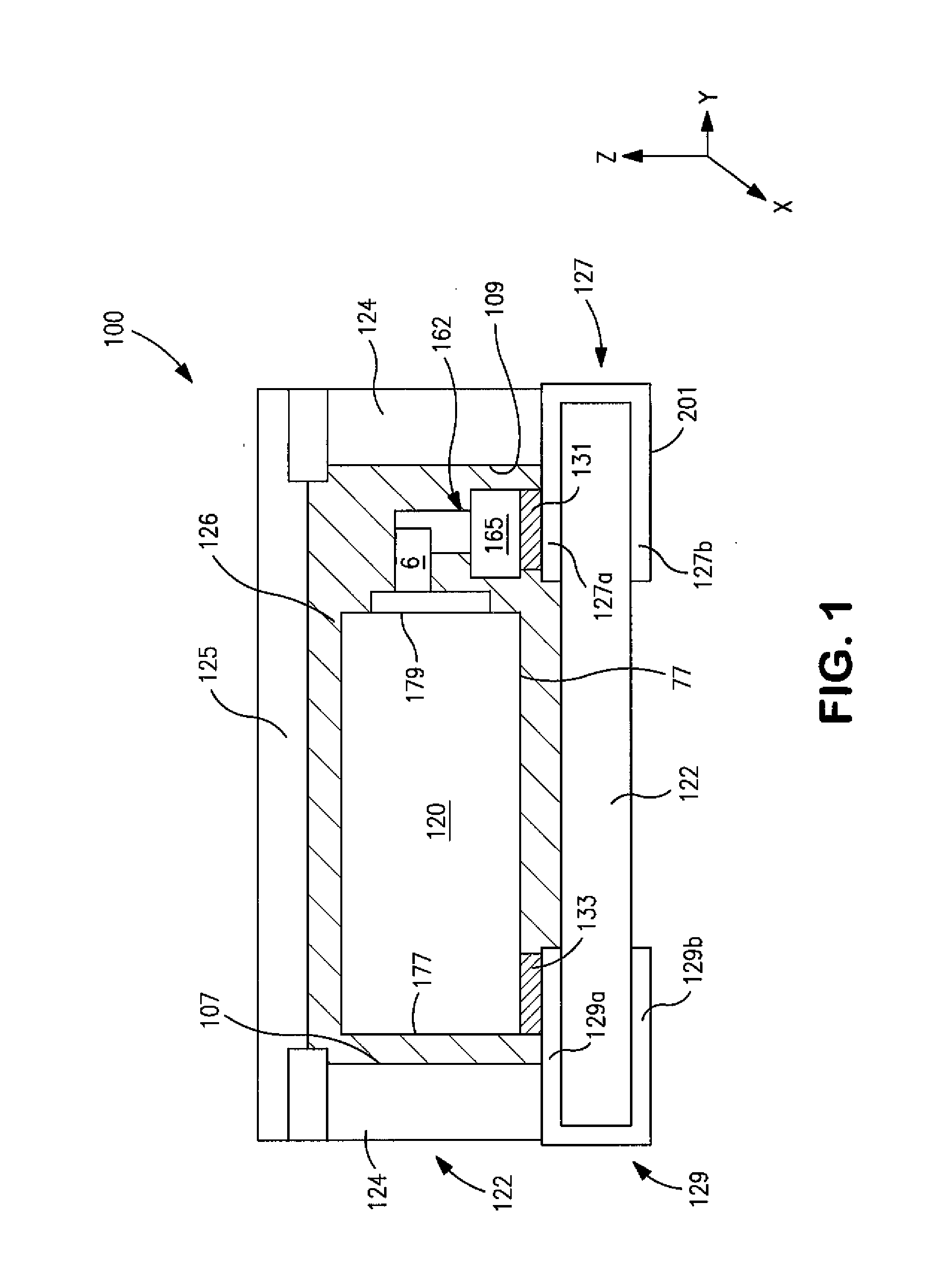

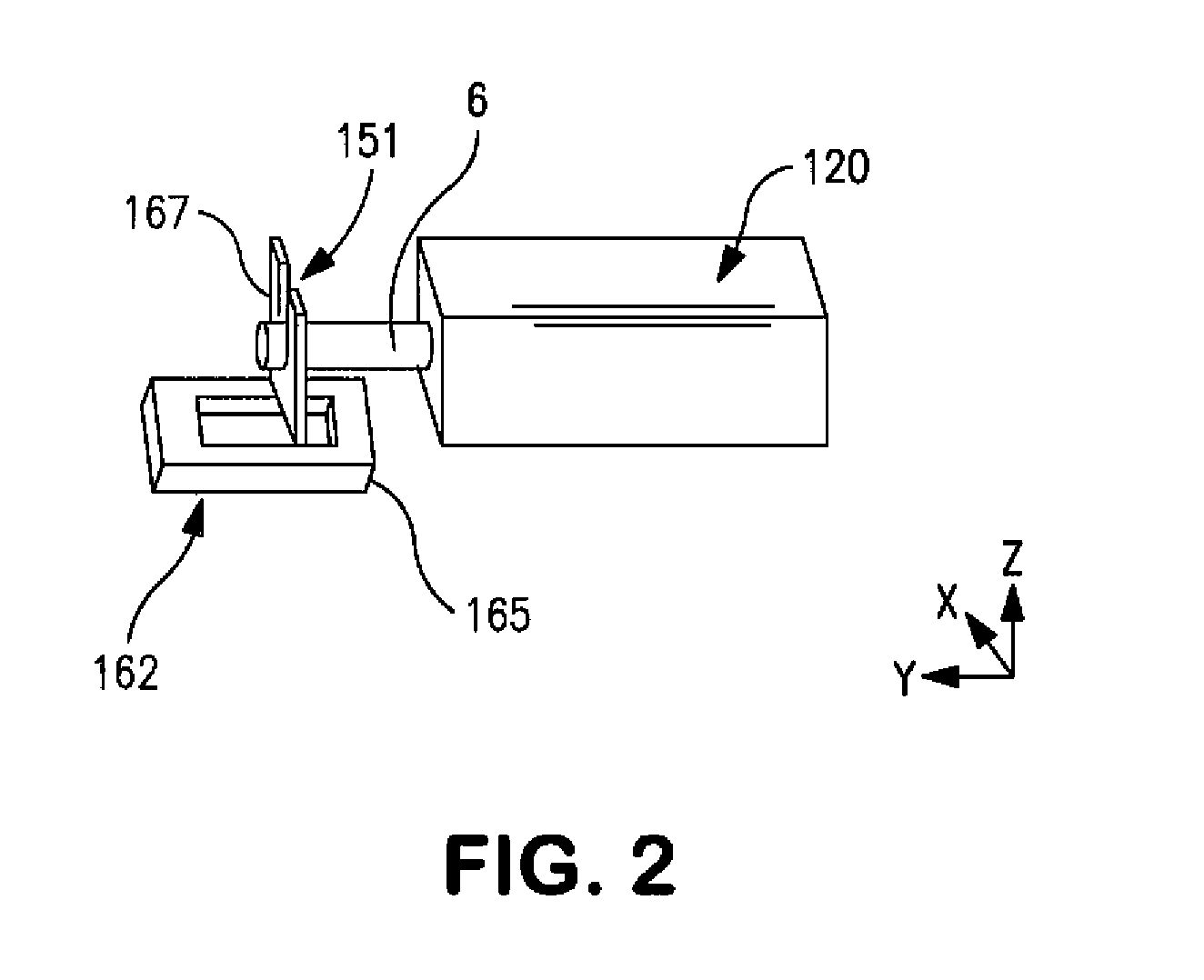

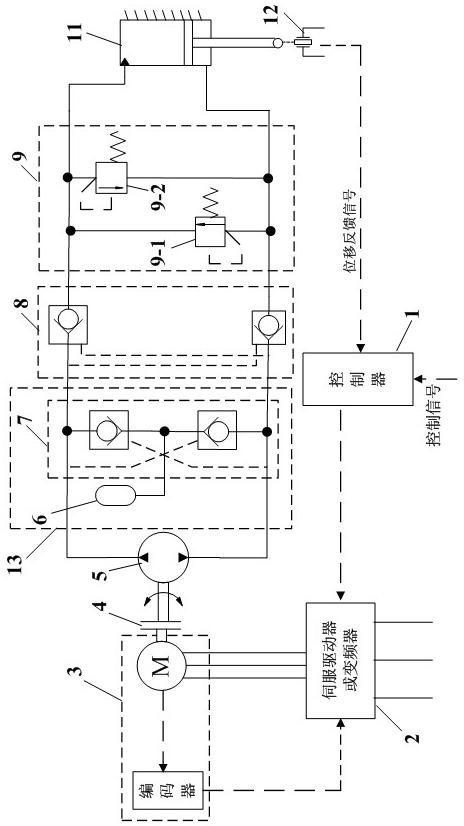

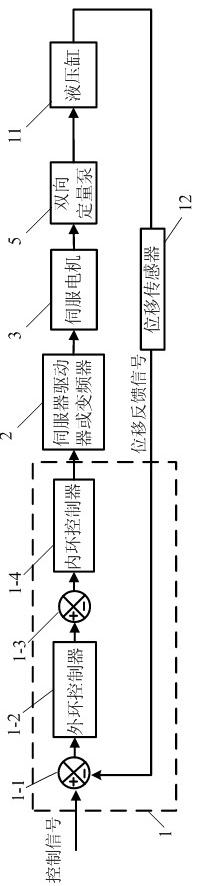

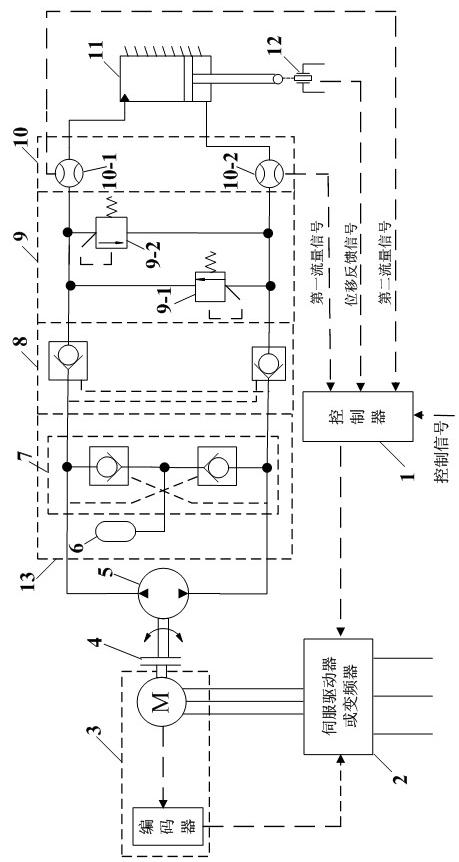

Position and flow double-close-loop direct-drive volume control electro-hydraulic servo system

InactiveCN101865190ALower requirementAvoid distortionFluid-pressure actuator componentsFrequency changerStart time

The invention relates to a position and flow double-close-loop direct-drive volume control electro-hydraulic servo system, belonging to the electro-hydraulic servo field. The invention solves the defect of low volumetric efficiency at lower speed of the hydraulic pump of the existing direct-drive volume control electro-hydraulic servo system and the system performance problem caused by the delay of the starting time of an oil supplementation mechanism and a hydraulic lock. The controller of the system is provided with four input ends and a control signal output end. The control signal output end of the controller is connected with the control signal input end of a servo driver or a frequency converter. The control end of the servo driver or the frequency converter is connected with the controlled end of a servo motor. The power output shaft of the servo motor is connected with the power input shaft of a bidirectional constant flow pump. Two oil passages between the bidirectional constant flow pump and a hydraulic cylinder form a closed loop through the oil supplementation mechanism, the hydraulic lock, an overflow safety mechanism and flow sensors. The output end of the displacement sensor, the output end of a first flow sensor and the output end of a second flow sensor are connected with the three output ends of the controller. Since the flow sensors are added on the original system, the control structure is changed.

Owner:HARBIN INST OF TECH +1

Fade-resistant high capacity electrodes for a lithium-ion battery

ActiveUS9012075B2Improve gravimetric and volumetric efficiencyIncreasing battery fadeSecondary cellsActive material electrodesSilicon nanowiresEngineering

Owner:GM GLOBAL TECH OPERATIONS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com