Solid electrolyte capacitor with ultra-low equivalent series resistance and manufacturing method thereof

A technology of equivalent series resistance and solid electrolysis, which is applied in the direction of solid electrolytic capacitors, electrolytic capacitors, capacitors, etc., can solve the problems of low equivalent series resistance, failure, and instability of polymerization liquid, and achieve high frequency and impedance frequency Good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

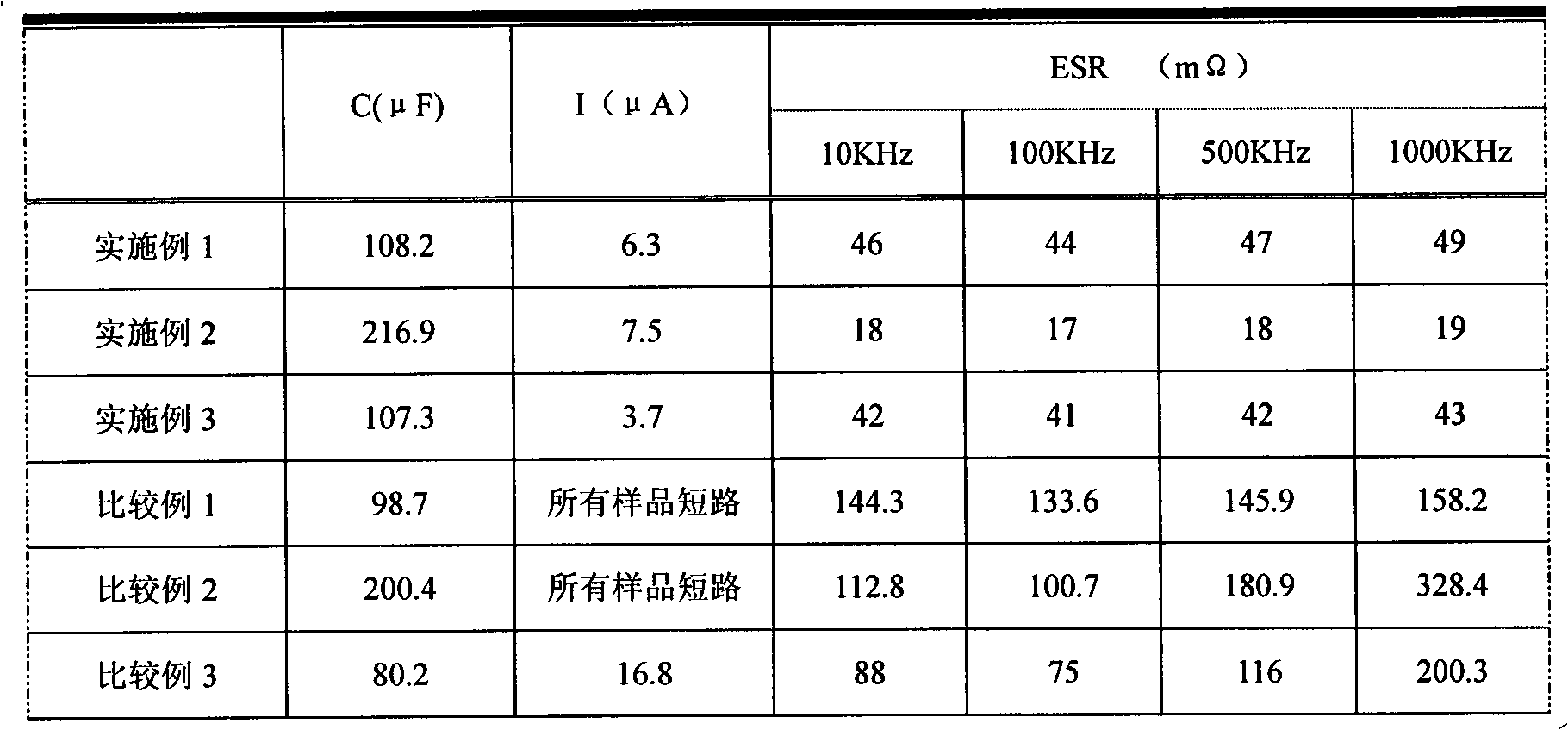

Embodiment 1

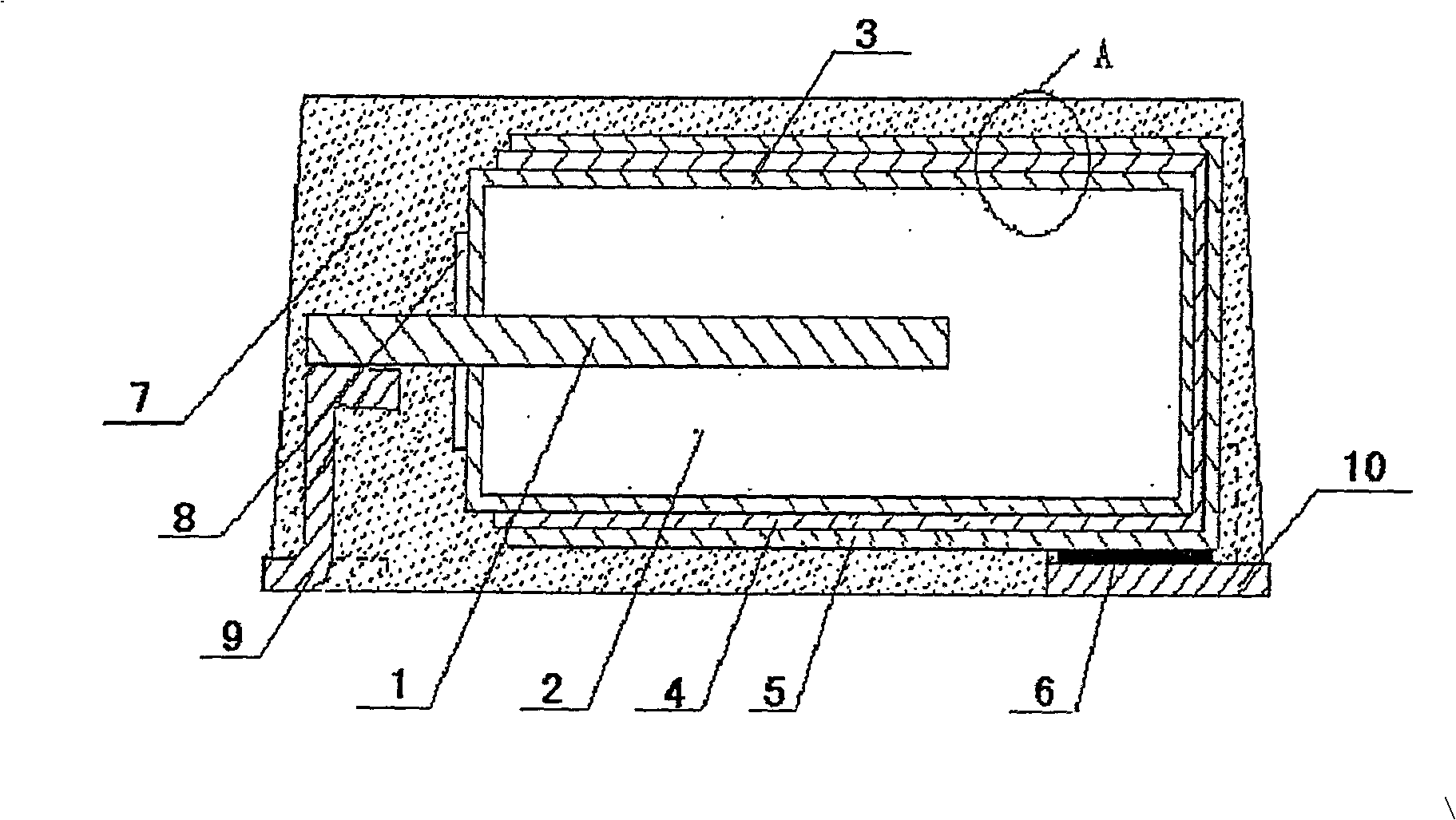

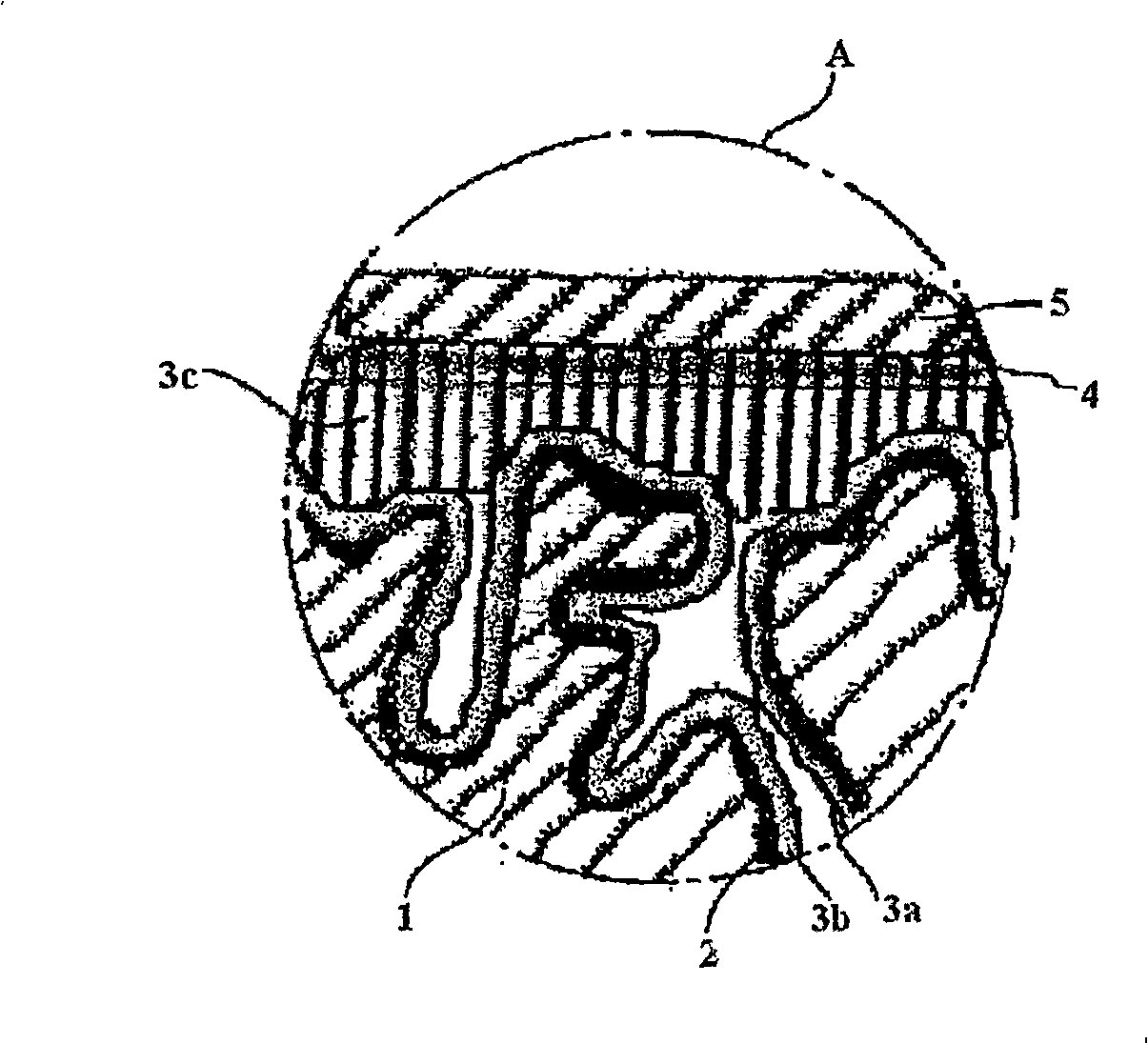

[0035] Example 1: Select tantalum powder with a CV value of 50,000 μFv / g, press it into a tablet, and sinter it at 1390°C under high temperature and high vacuum to form an anode porous sintered block with a size of 4.3mm×3.1mm×1.2mm containing a tantalum lead (referred to as sintered block), the sintered block is anodized to 33V in dilute phosphoric acid aqueous solution to form a dielectric oxide film layer, and then a polytetrafluoroethylene gasket with insulating properties is placed on the anode lead, and then the oxide film layer is sintered. The block is immersed in the first polymerization solution at a low temperature of 0-10°C. The first polymerization solution contains 2wt% monomer 3,4-ethylenedioxythiophene, 40wt% oxidant iron p-toluenesulfonate, and 0.3% Silane coupling agent, the rest are solvents n-butanol and isopropanol, the weight ratio of n-butanol and isopropanol is 1:1, soak for 6 minutes, take out the sintered block, place it at room temperature for 10 minu...

Embodiment 2

[0037] The tantalum powder with 50,000μFV / g is pressed into a sheet, and then formed into a porous anode body with a size of 4.3mm×3.0mm×0.6mm, and the sintered anode body is anodized to 30V in dilute phosphoric acid aqueous solution, Form a dielectric oxide film layer. Then in situ chemically coat the first electrolyte layer, the second electrolyte layer and the polymer outer layer according to the steps of Example 1, only when making the second electrolyte layer, the polyvinylpyrrolidone of 0.3wt% in the polymer solution is replaced with 0.4% by weight polymethylmethacrylate. When making the outer polymer, 1 wt% of dimethyl sulfoxide NMP in the outer polymer solution was replaced with 1 wt% of DMSO. And through the above impregnation, polymerization, cleaning and re-formation process twice, a polymer outer layer with a thickness of about 20 μm to 50 μm is prepared. Then, a low-temperature conductive graphite layer and a conductive silver paste layer are coated on the outer...

Embodiment 3

[0039] According to Example 1, the anode porous sintered body was made, and a dielectric oxide film was formed on the surface of the sintered body, and then the first electrolyte layer, the second electrolyte layer and the polymer outer layer were chemically coated in situ according to the steps of Example 1, except that the first electrolyte layer Change the impregnation, polymerization, cleaning and re-formation process of the first electrolyte layer to 4 times, change the impregnation, polymerization, cleaning and re-formation process of the second electrolyte layer to 2 times, and add 0.2wt% butyl carbitol and 0.1wt% sodium dodecylbenzenesulfonate were used as surfactants. And add 0.2wt% butyl carbitol and 0.1wt% sodium dodecylbenzenesulfonate in the graphite slurry at the same time as surfactants, complete the graphite, silver paste, complete the welding of the lead frame, and complete the bonding of the resin layer packaged to form an electrolytic capacitor.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com