Patents

Literature

2271 results about "Aluminum electrolytic capacitor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

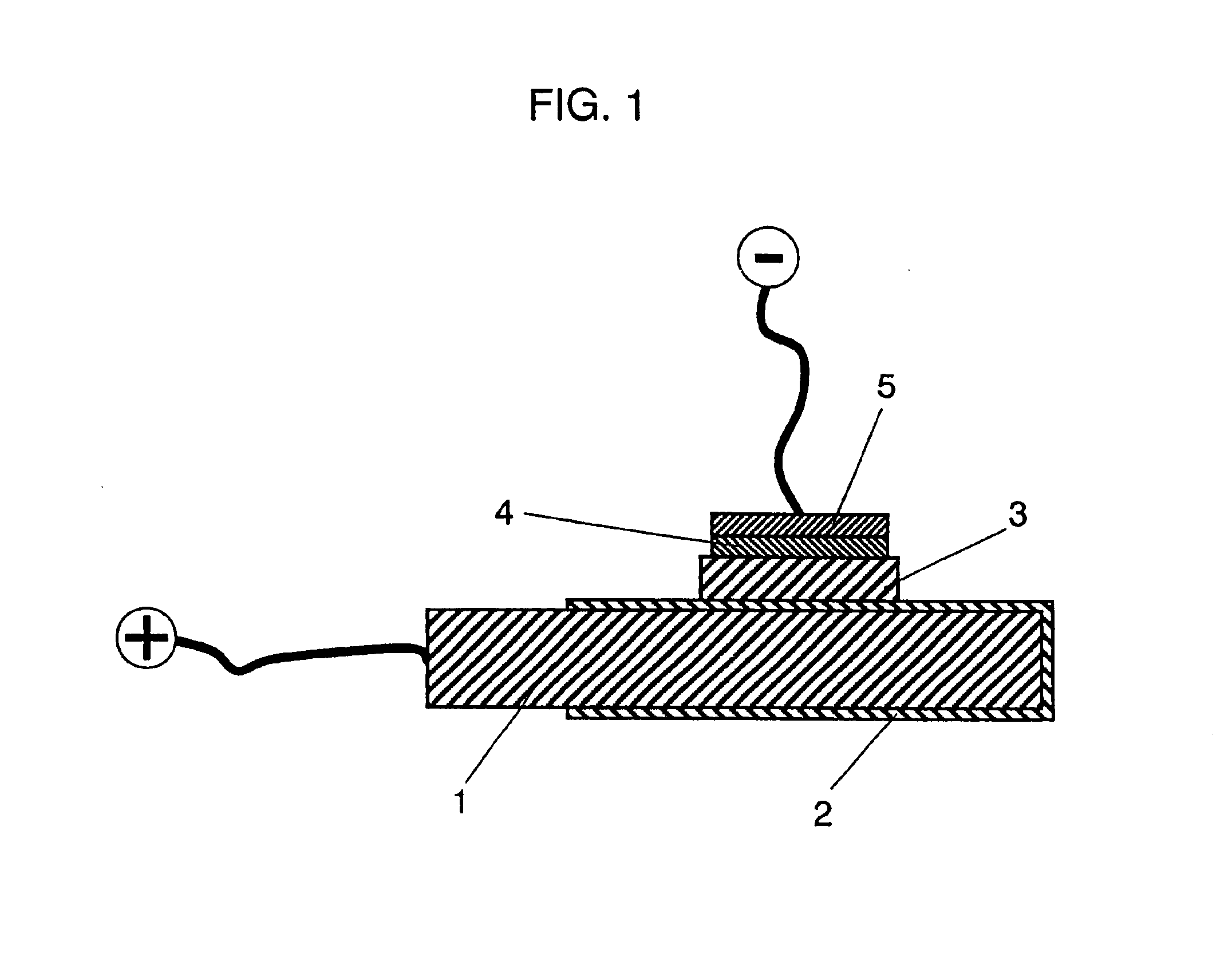

Aluminum electrolytic capacitors are polarized electrolytic capacitors whose anode electrode (+) is made of a pure aluminum foil with an etched surface. The aluminum forms a very thin insulating layer of aluminium oxide by anodization that acts as the dielectric of the capacitor. A non-solid electrolyte covers the rough surface of the oxide layer, serving in principle as the second electrode (cathode) (-) of the capacitor. A second aluminum foil called “cathode foil” contacts the electrolyte and serves as the electrical connection to the negative terminal of the capacitor.

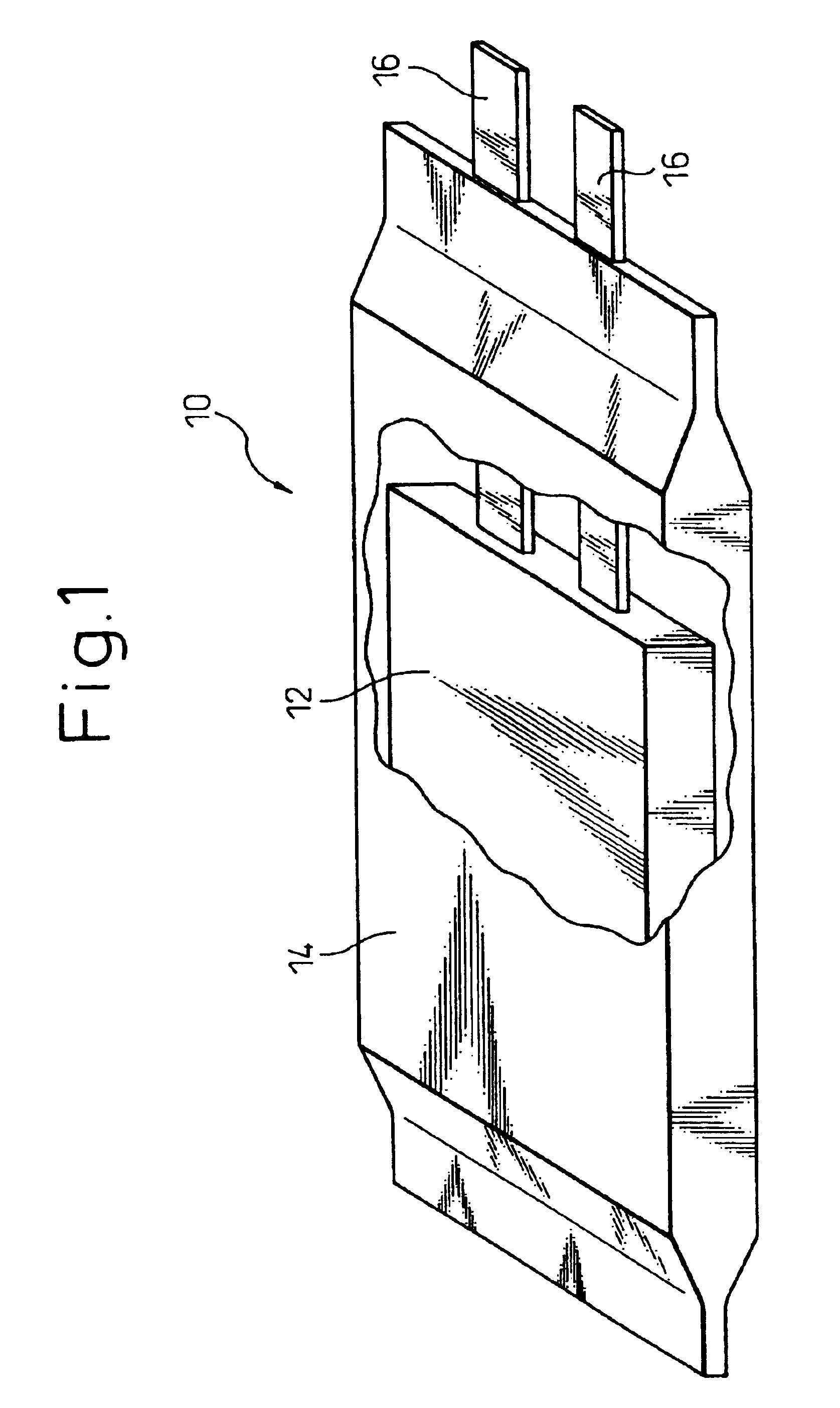

Implantable medical device having flat electrolytic capacitor fabricated with laser welded anode sheets

ActiveUS6922330B2Robust electrical and mechanical connectionMinimize damageLiquid electrolytic capacitorsCapacitor terminalsElectrolysisOptoelectronics

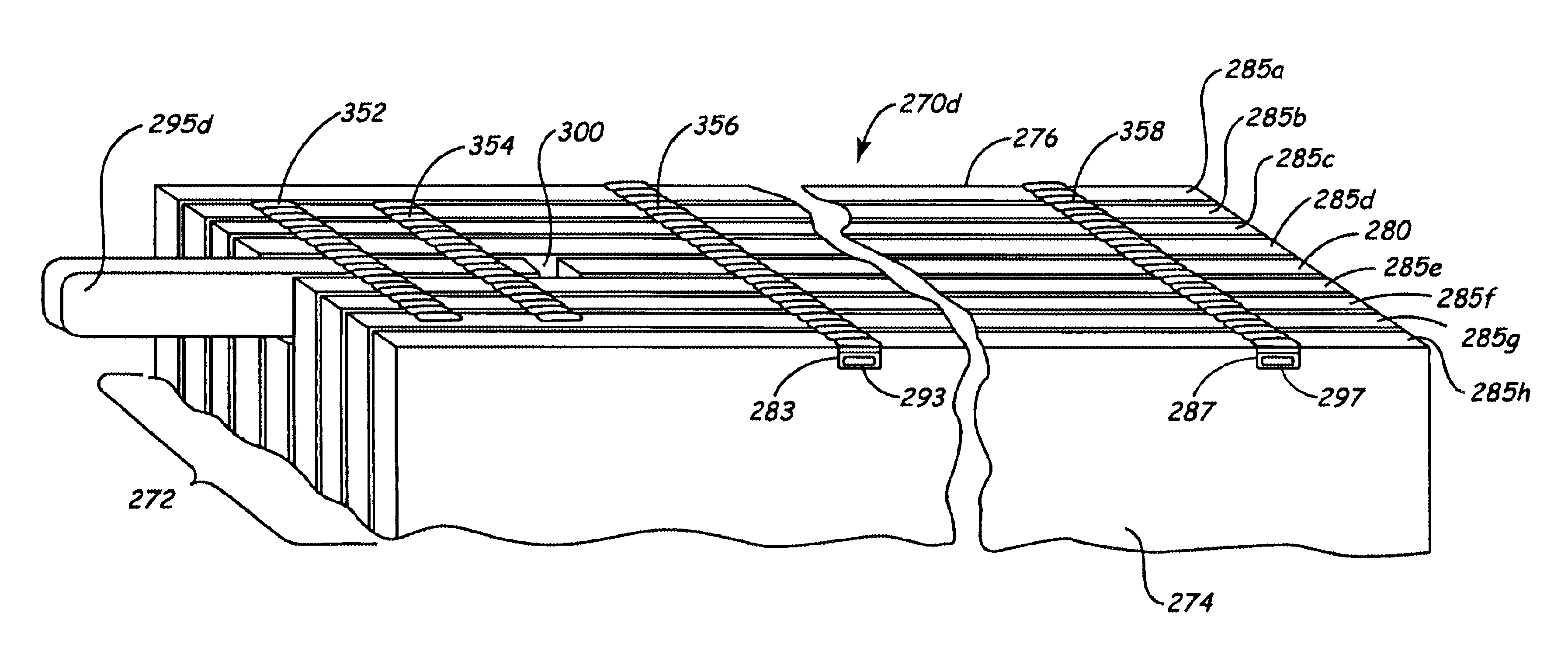

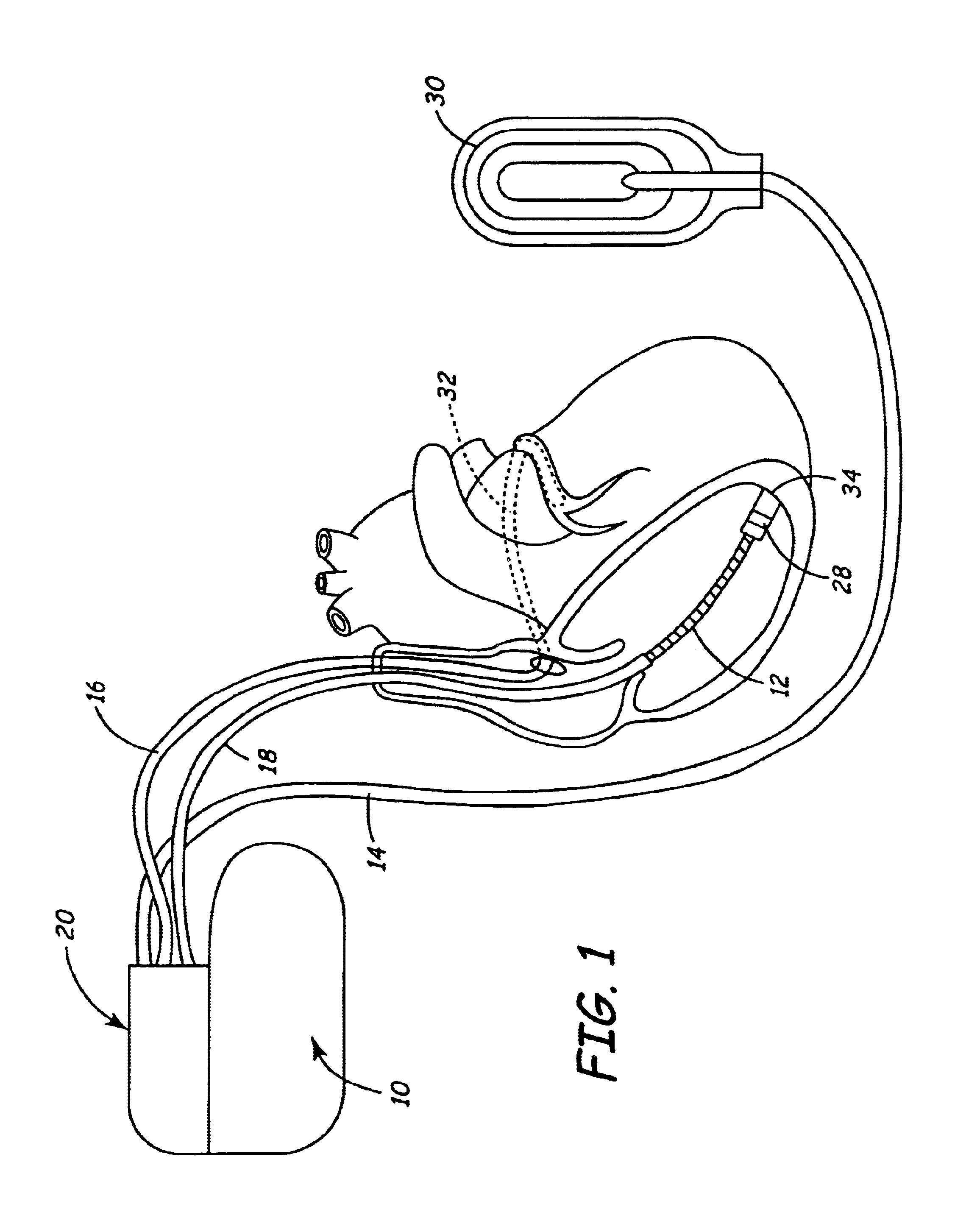

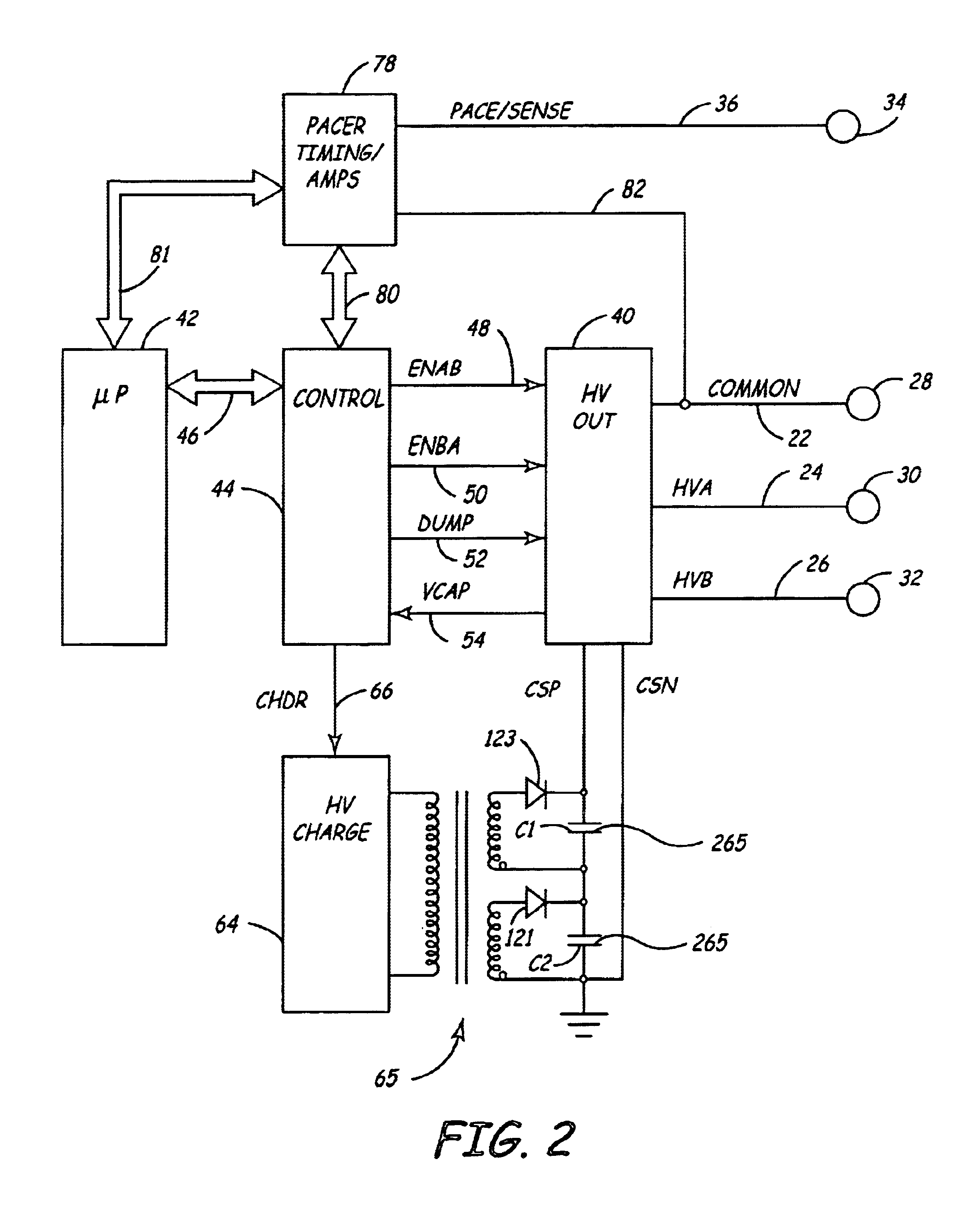

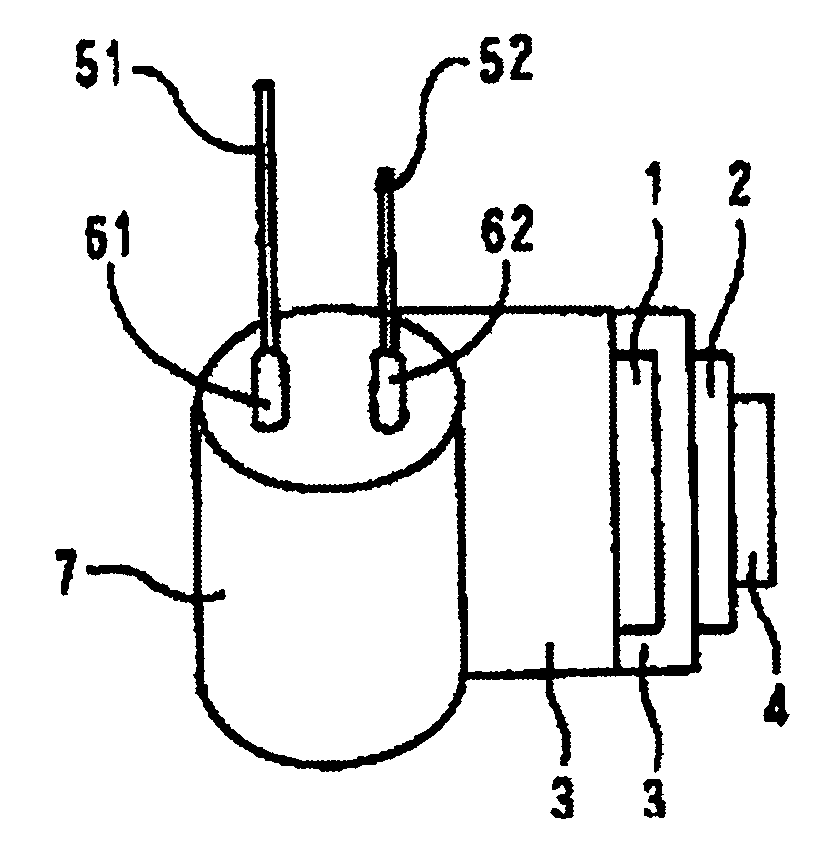

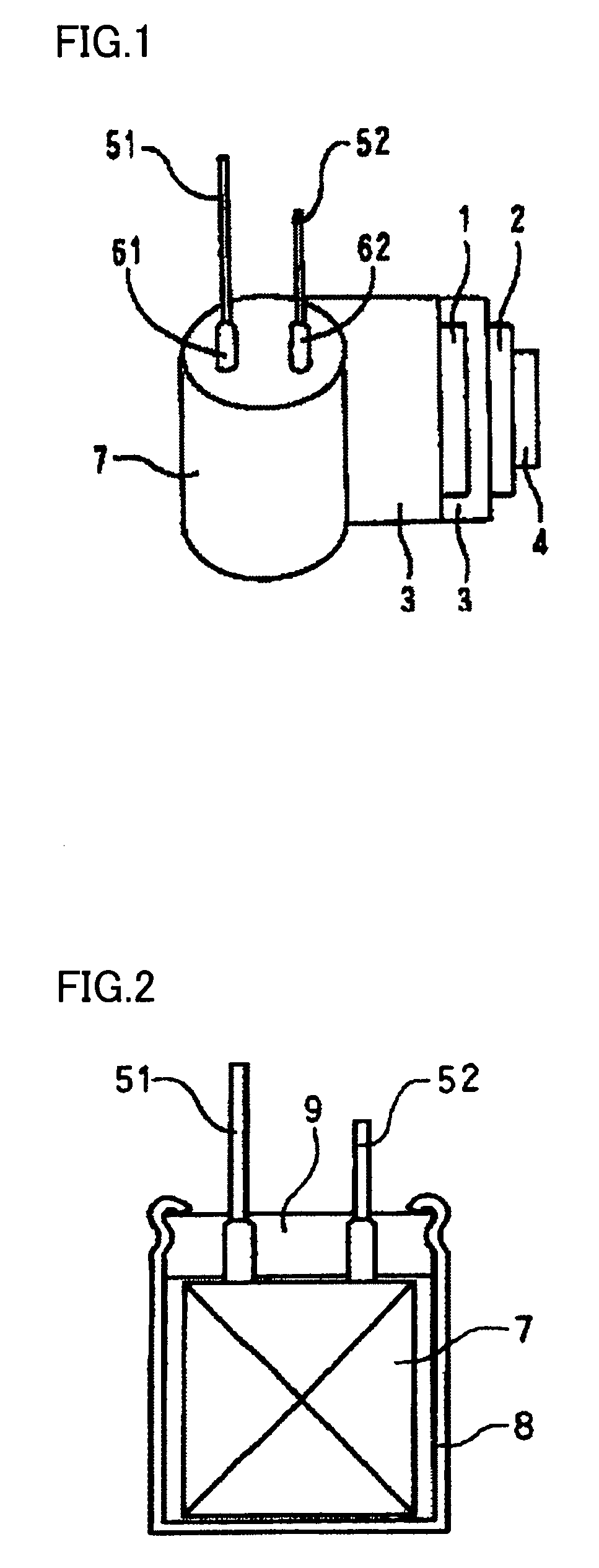

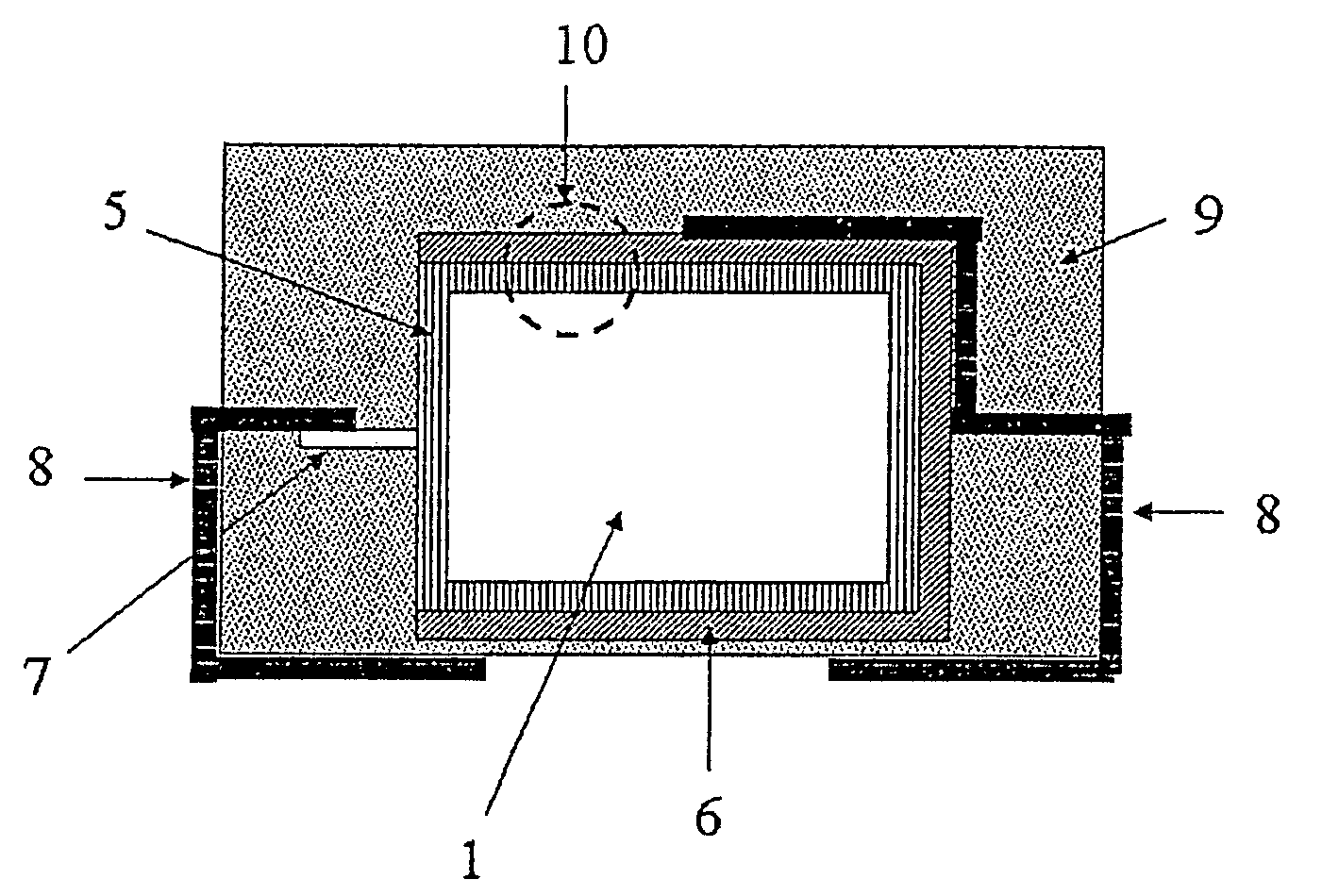

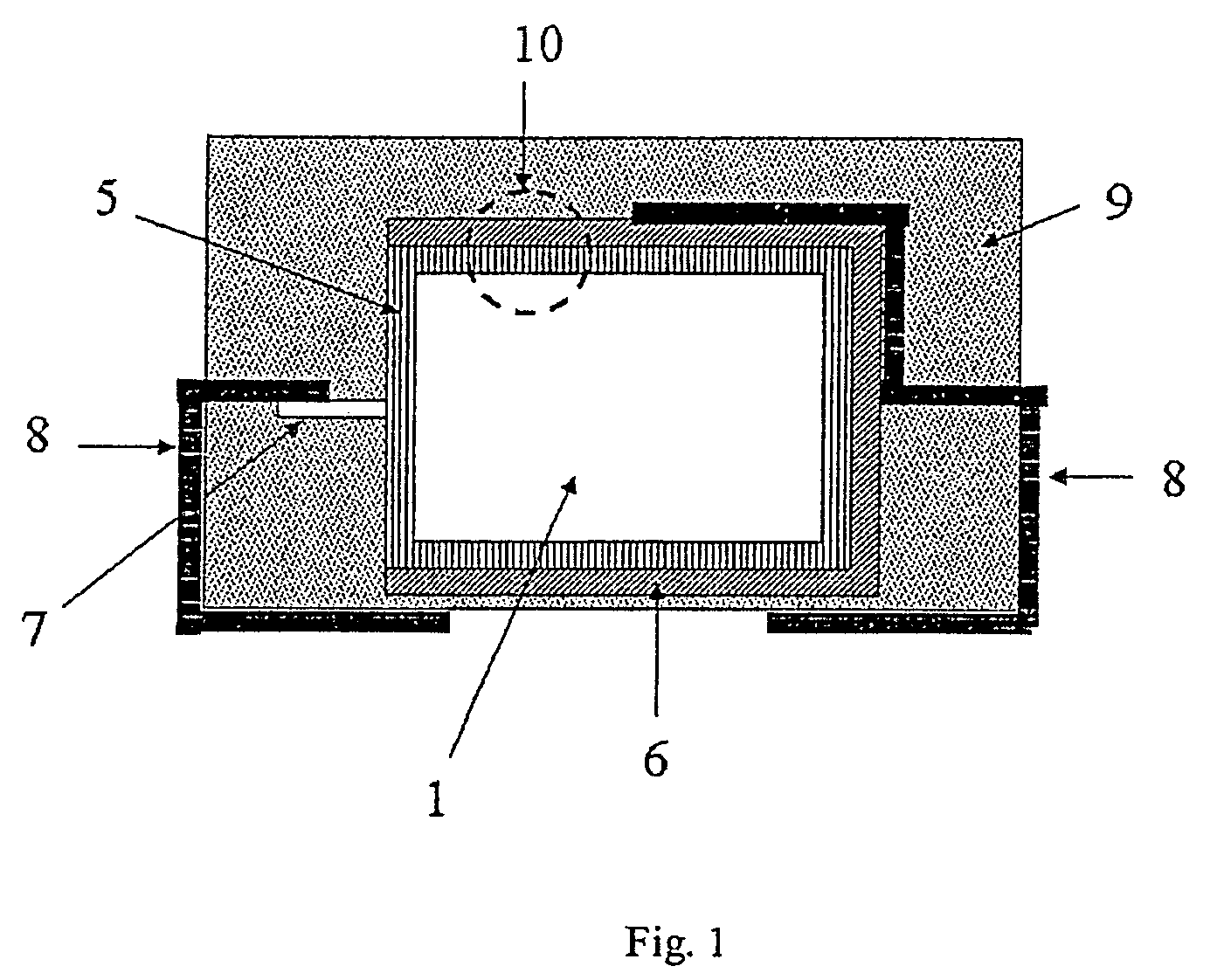

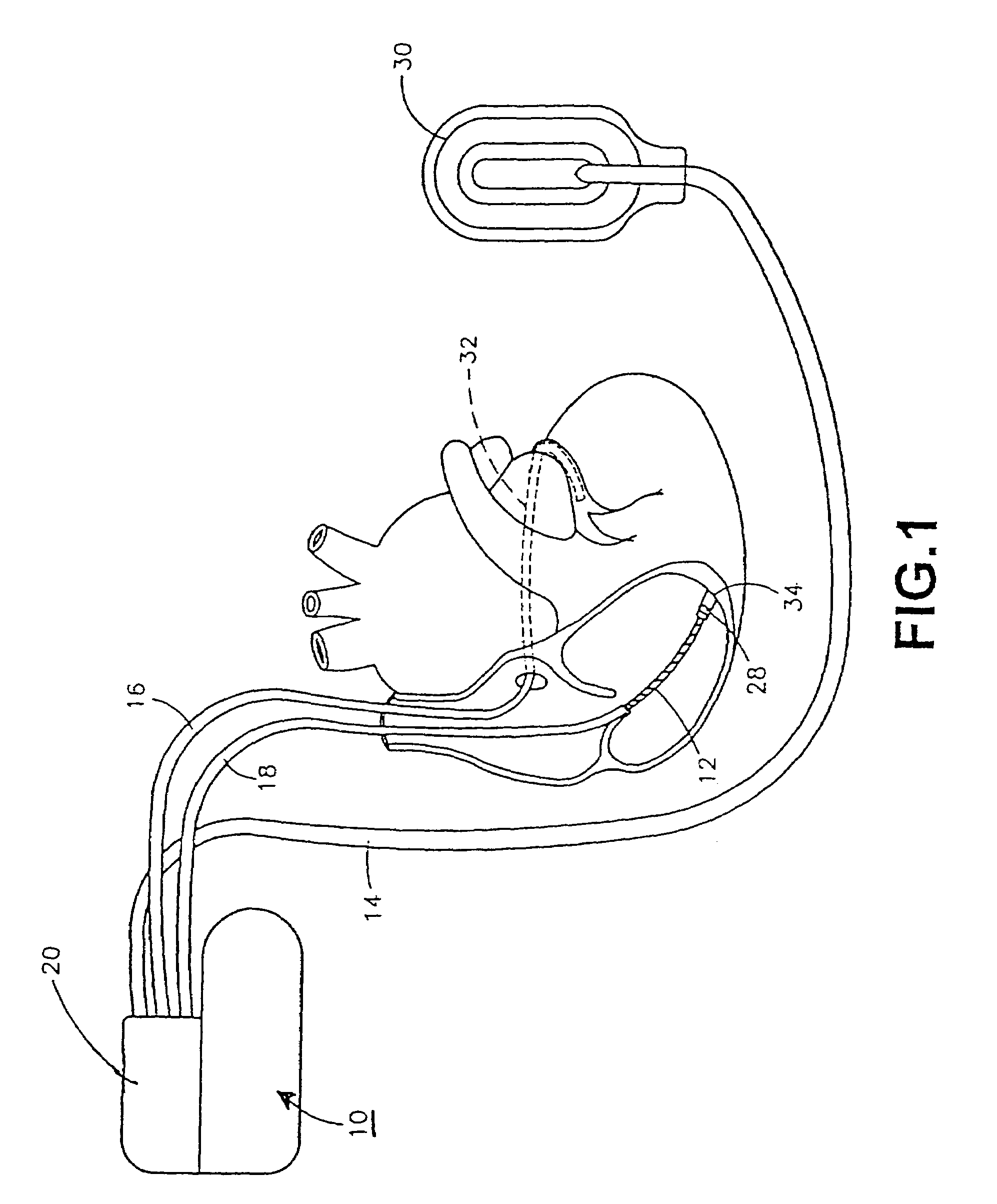

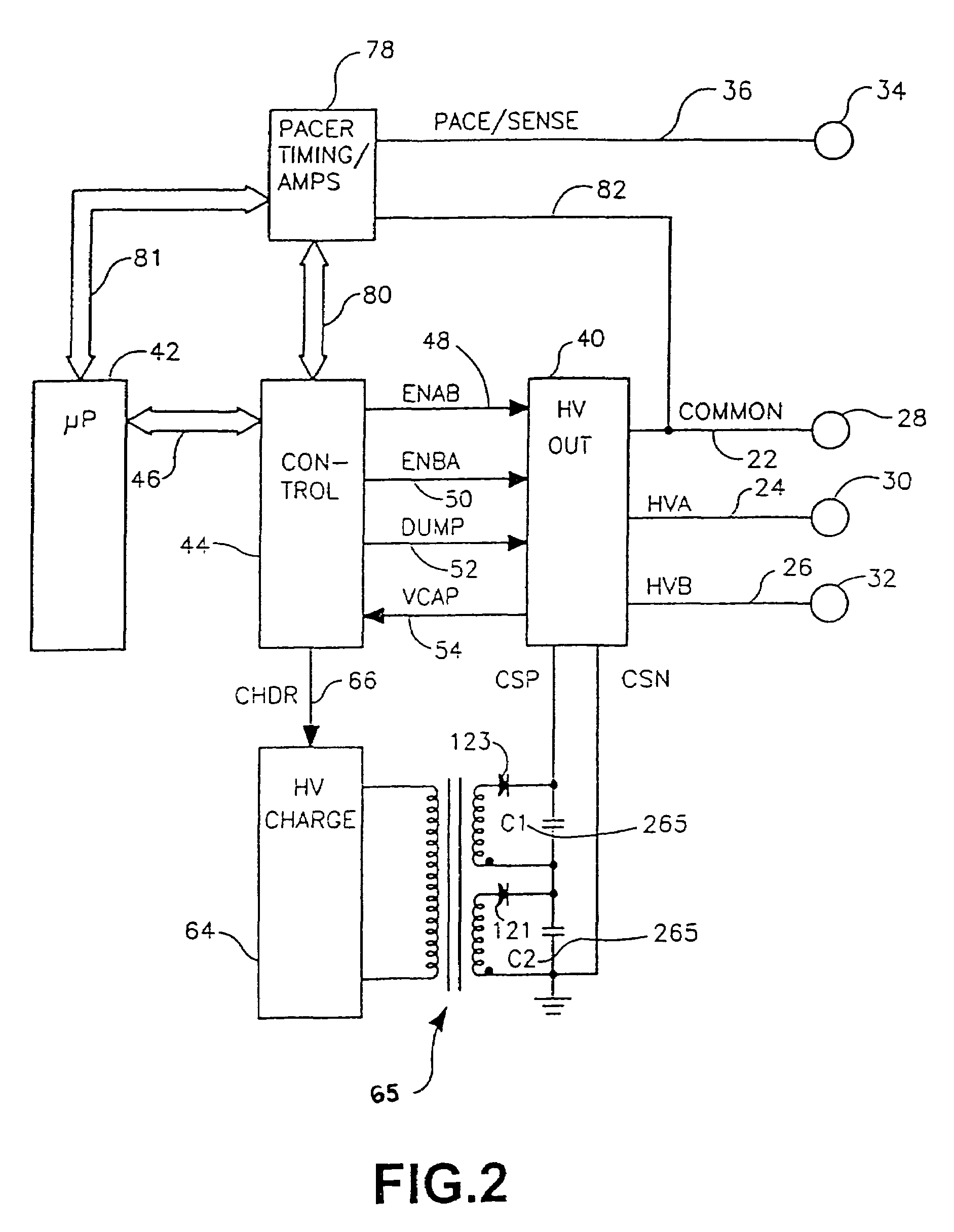

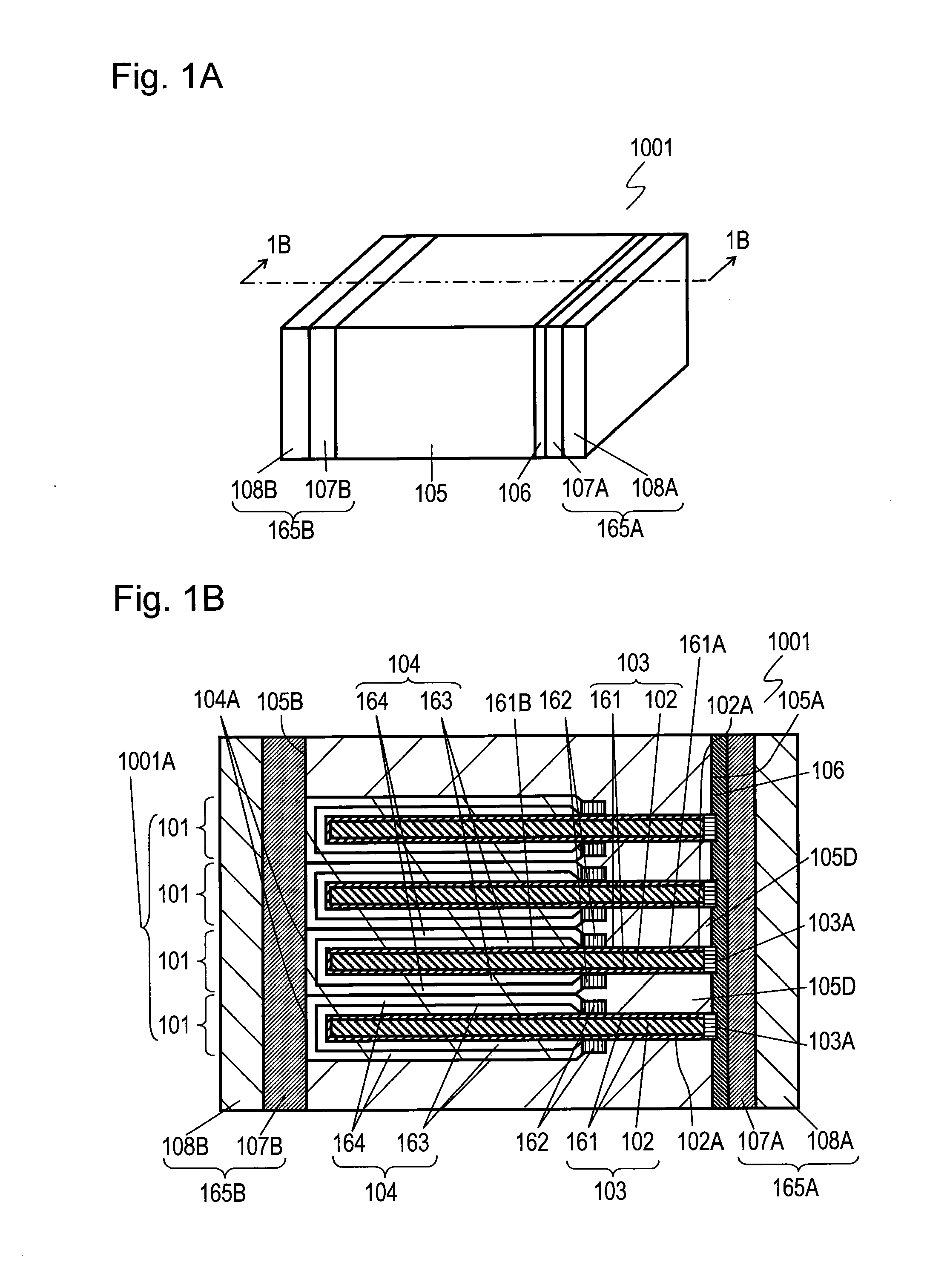

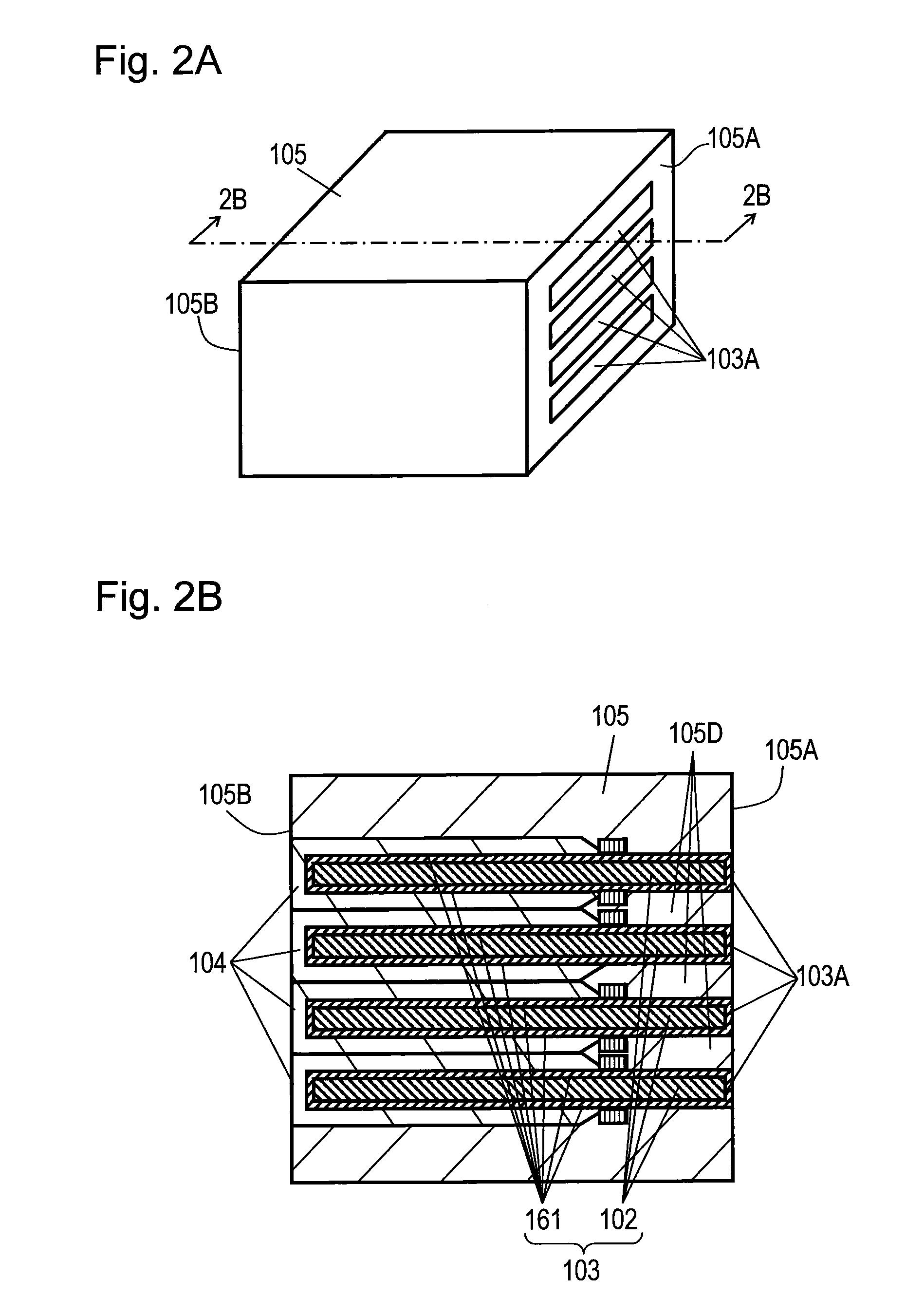

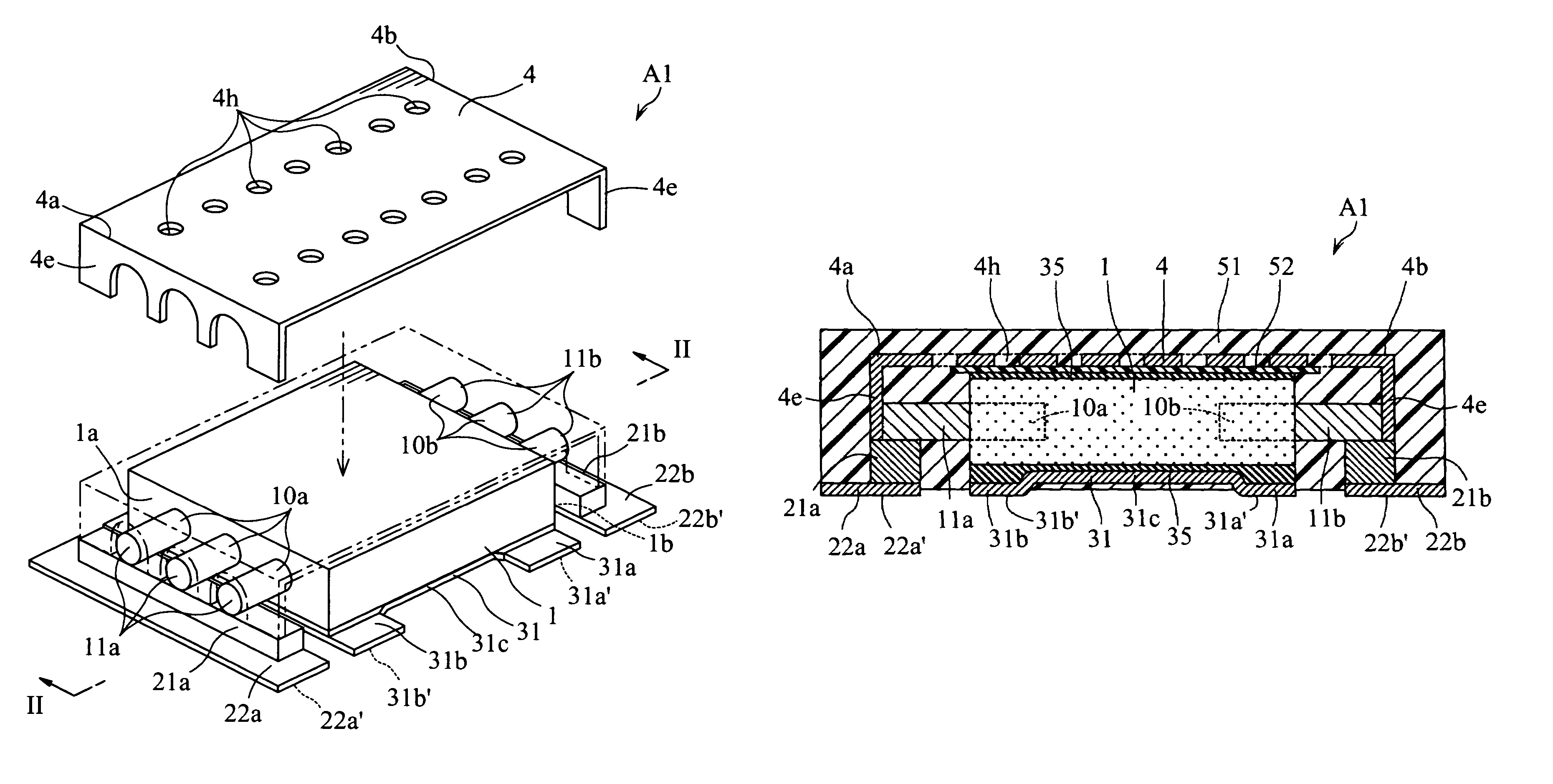

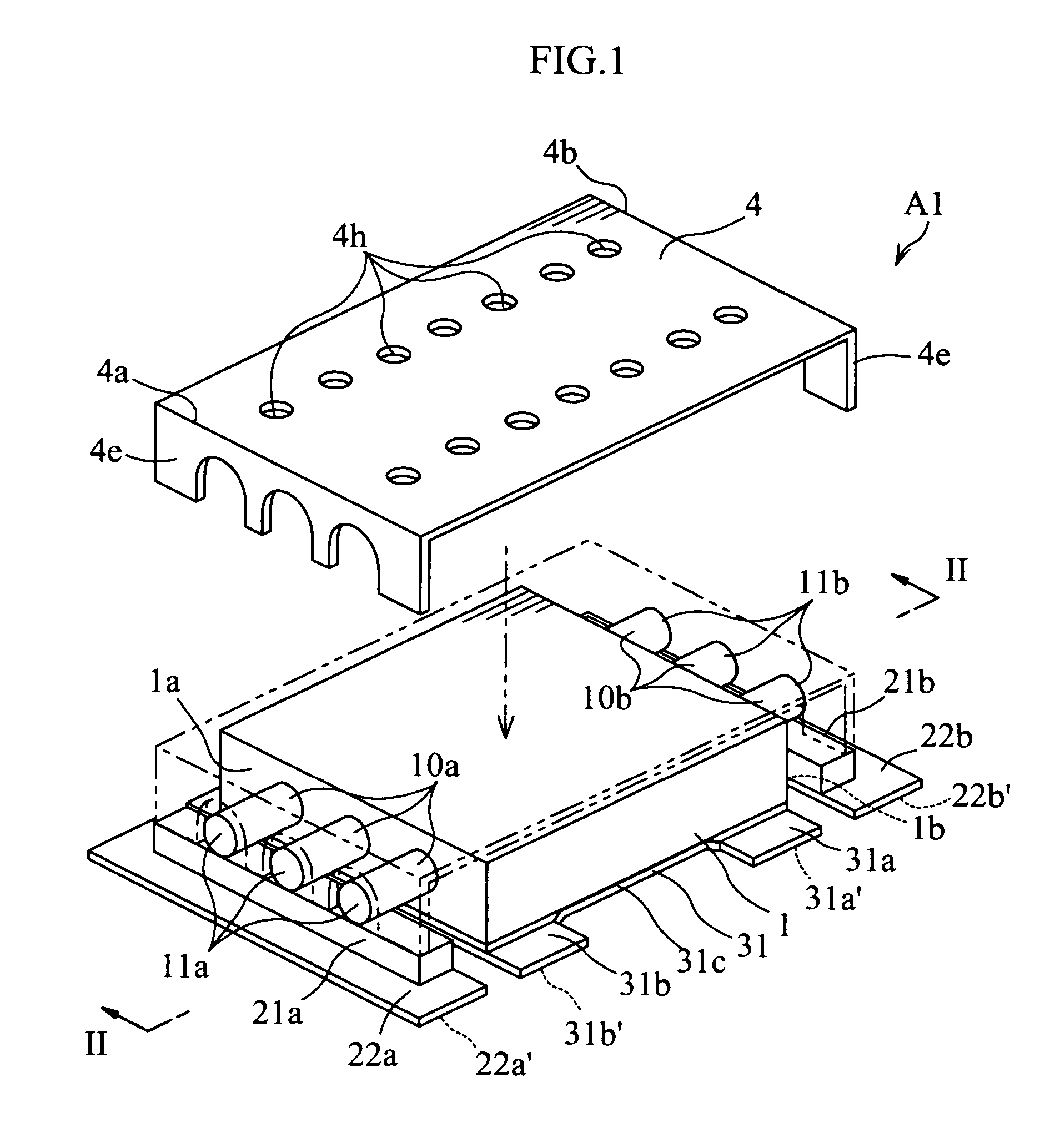

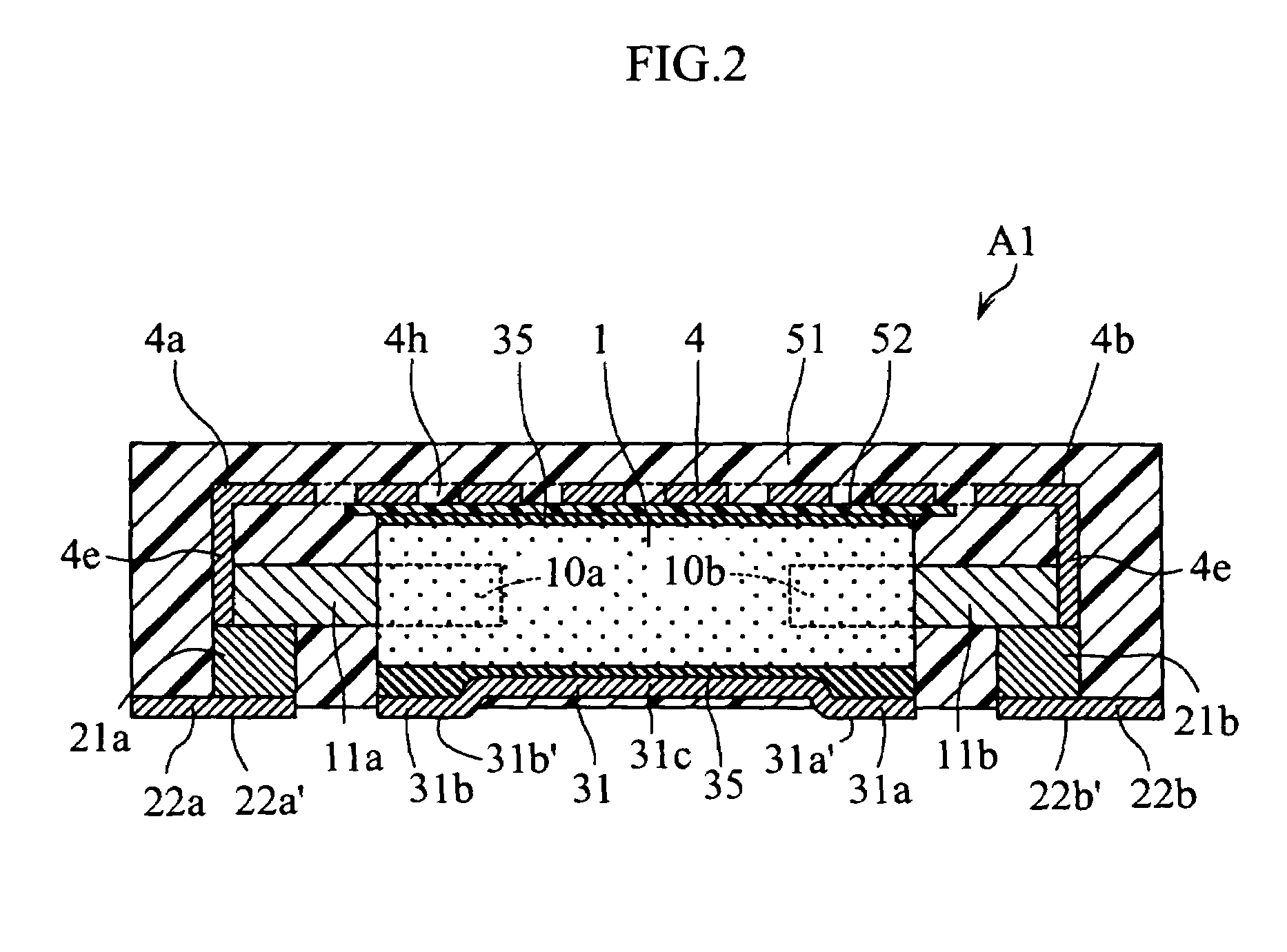

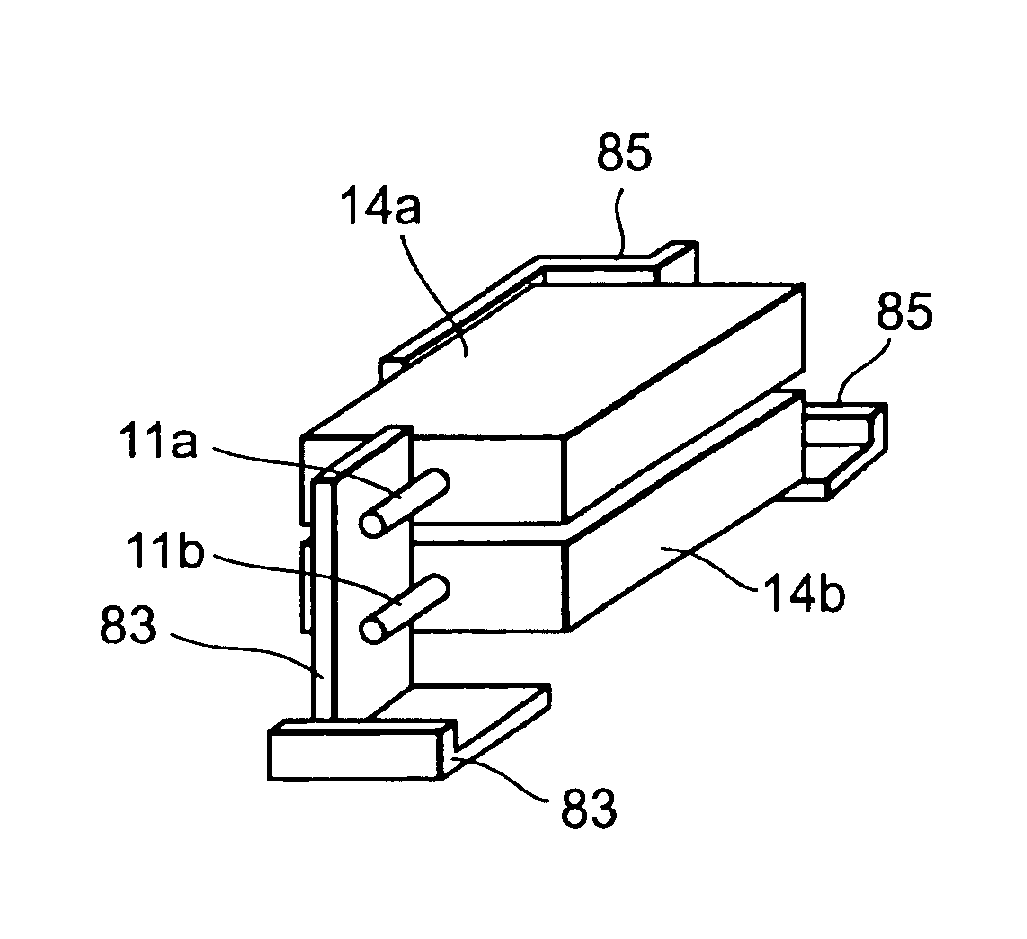

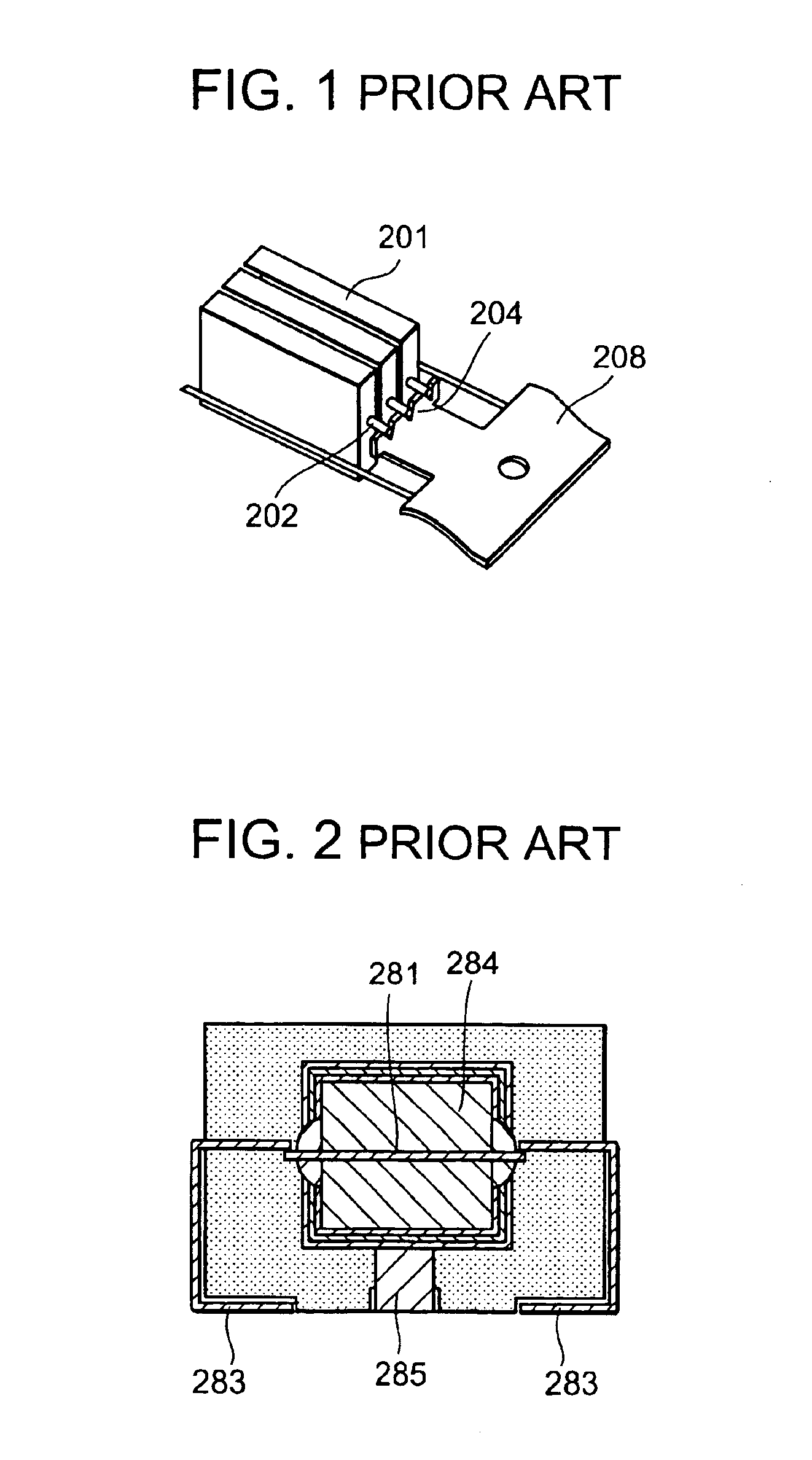

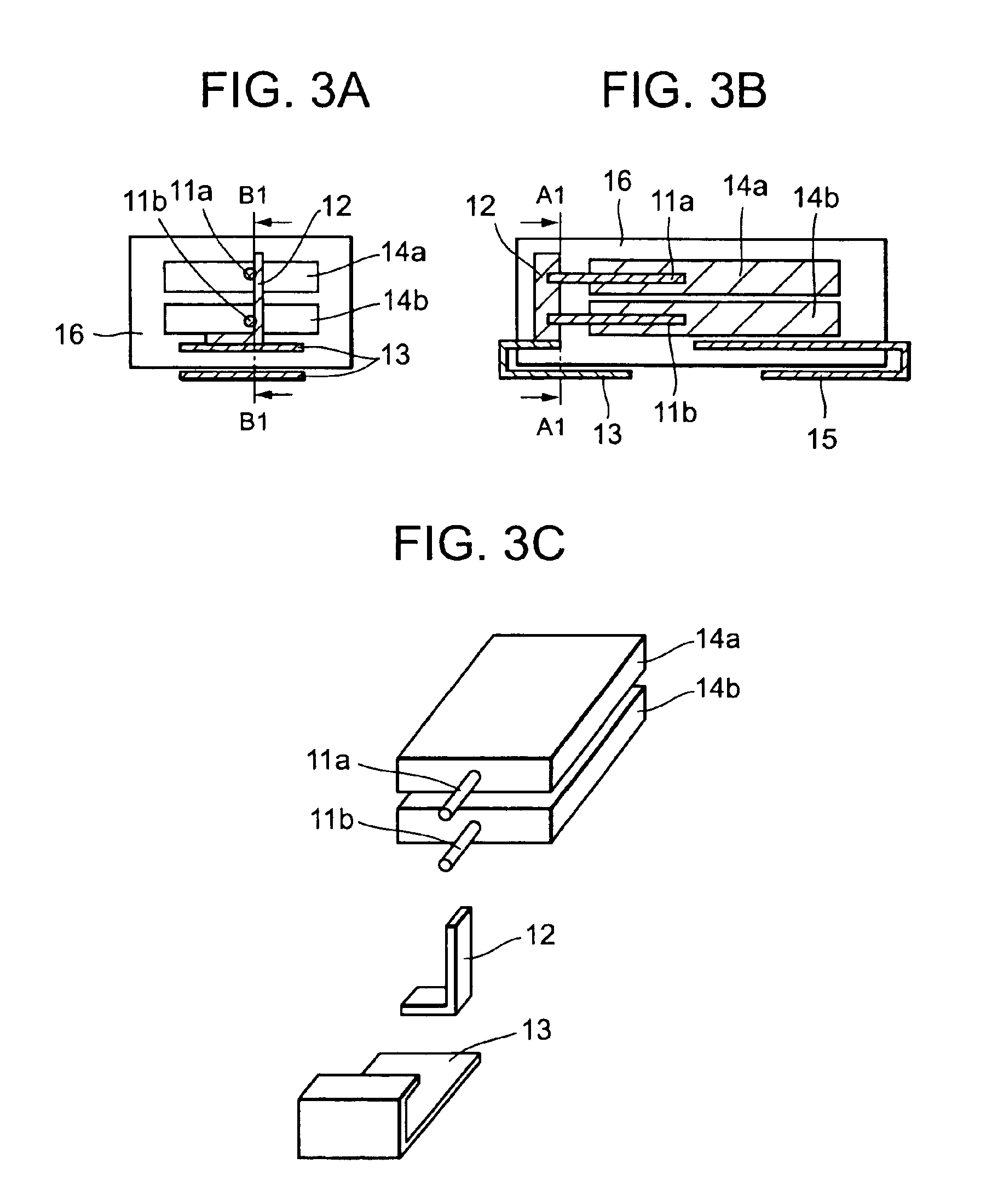

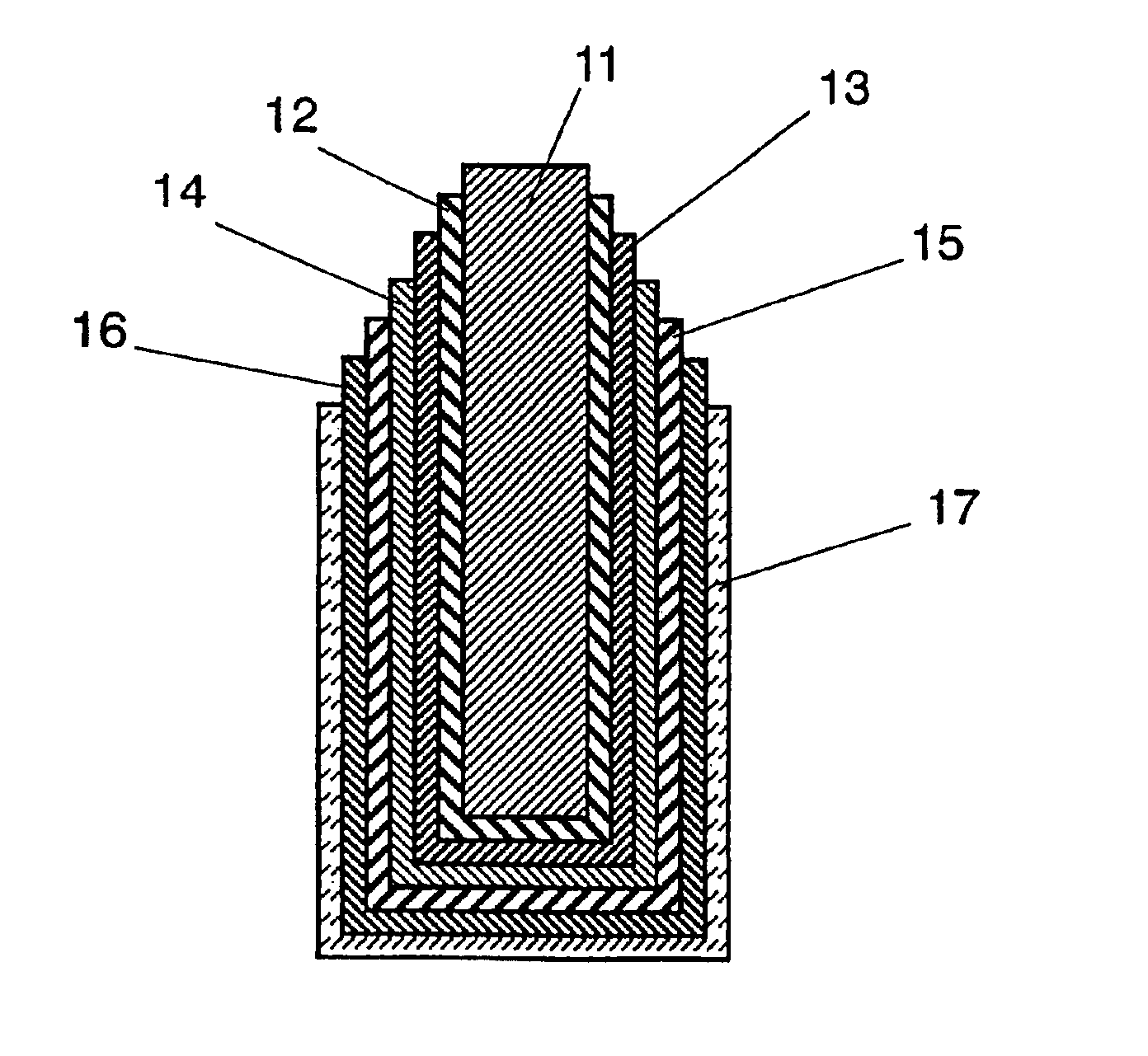

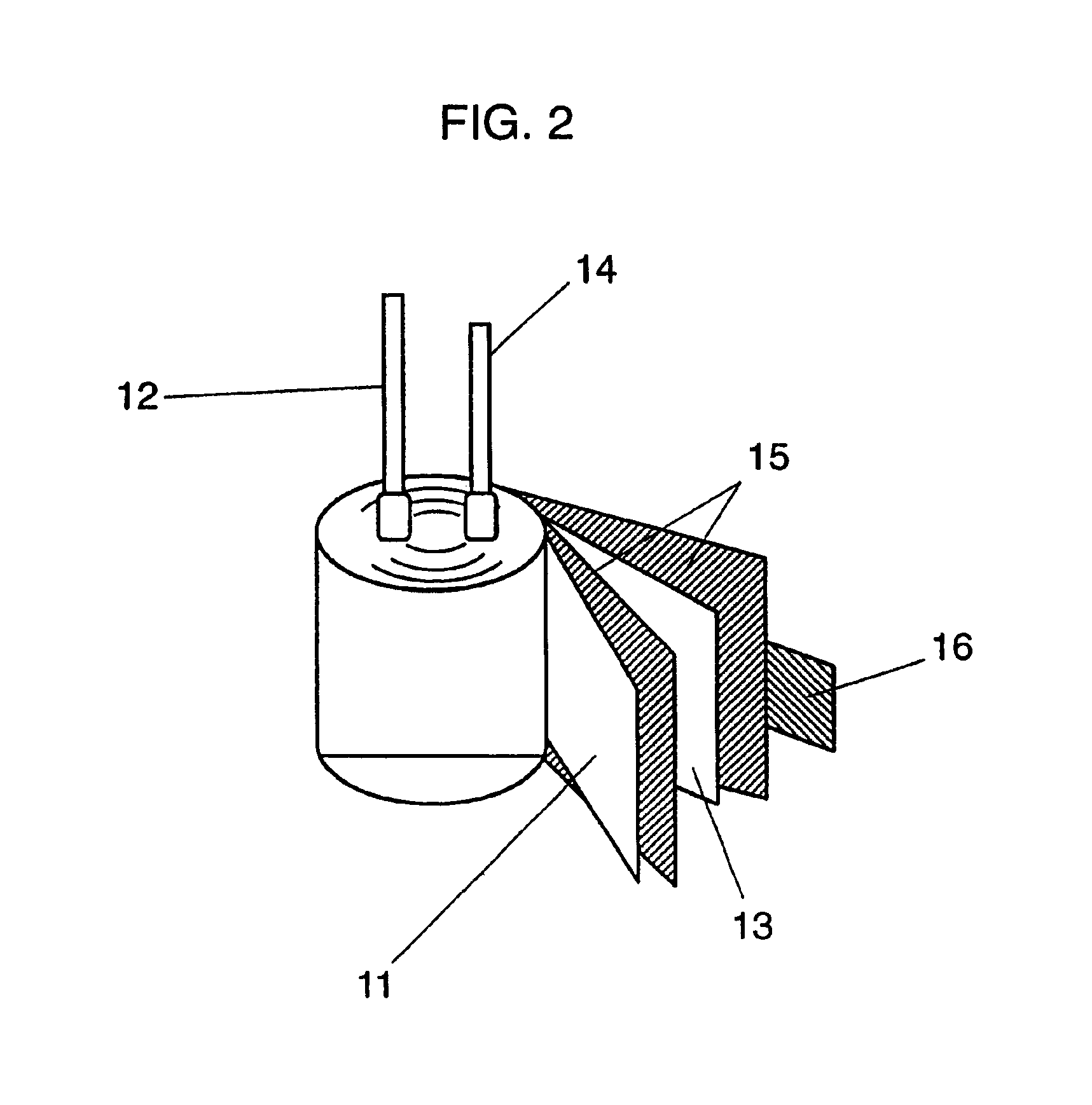

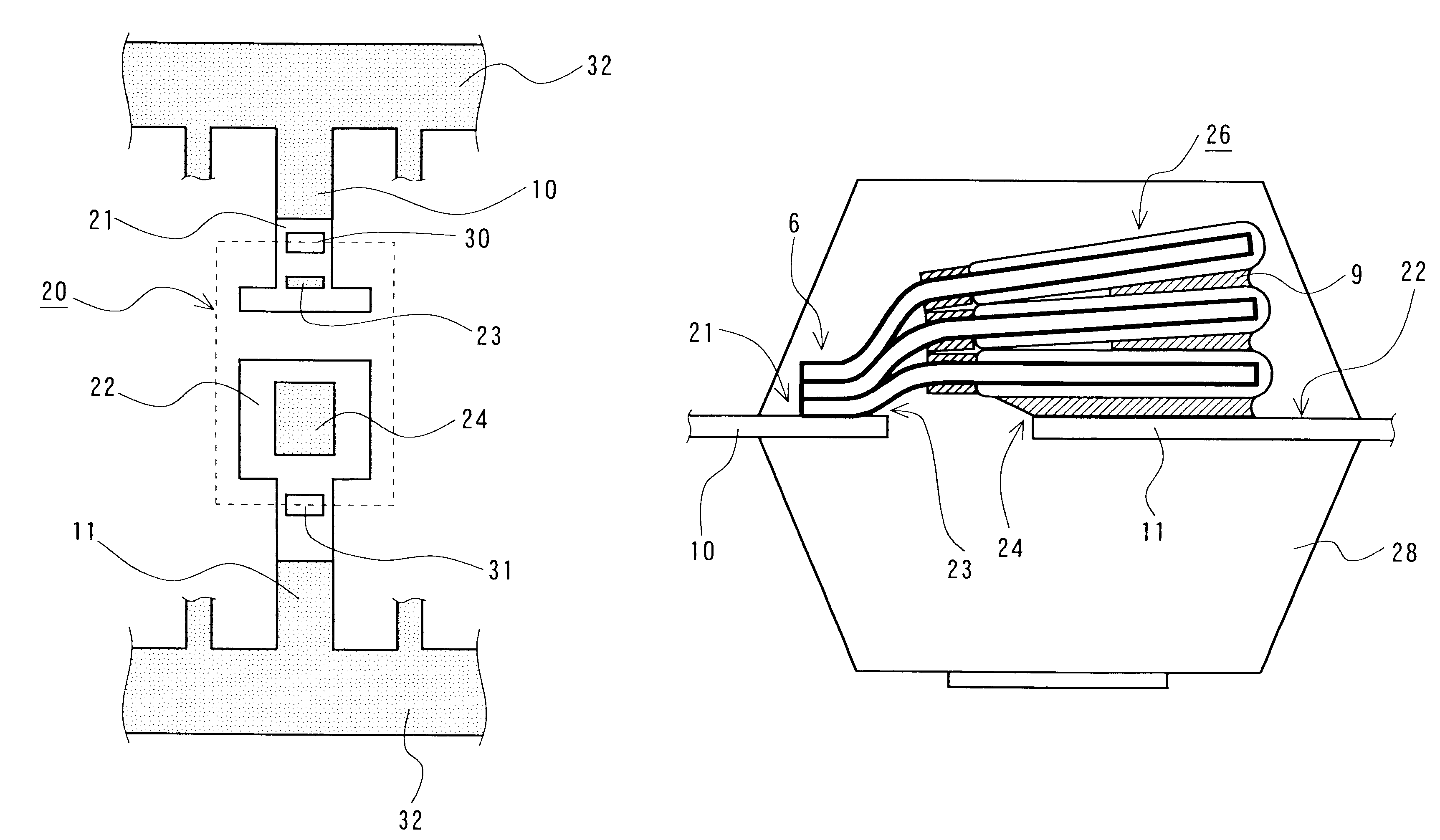

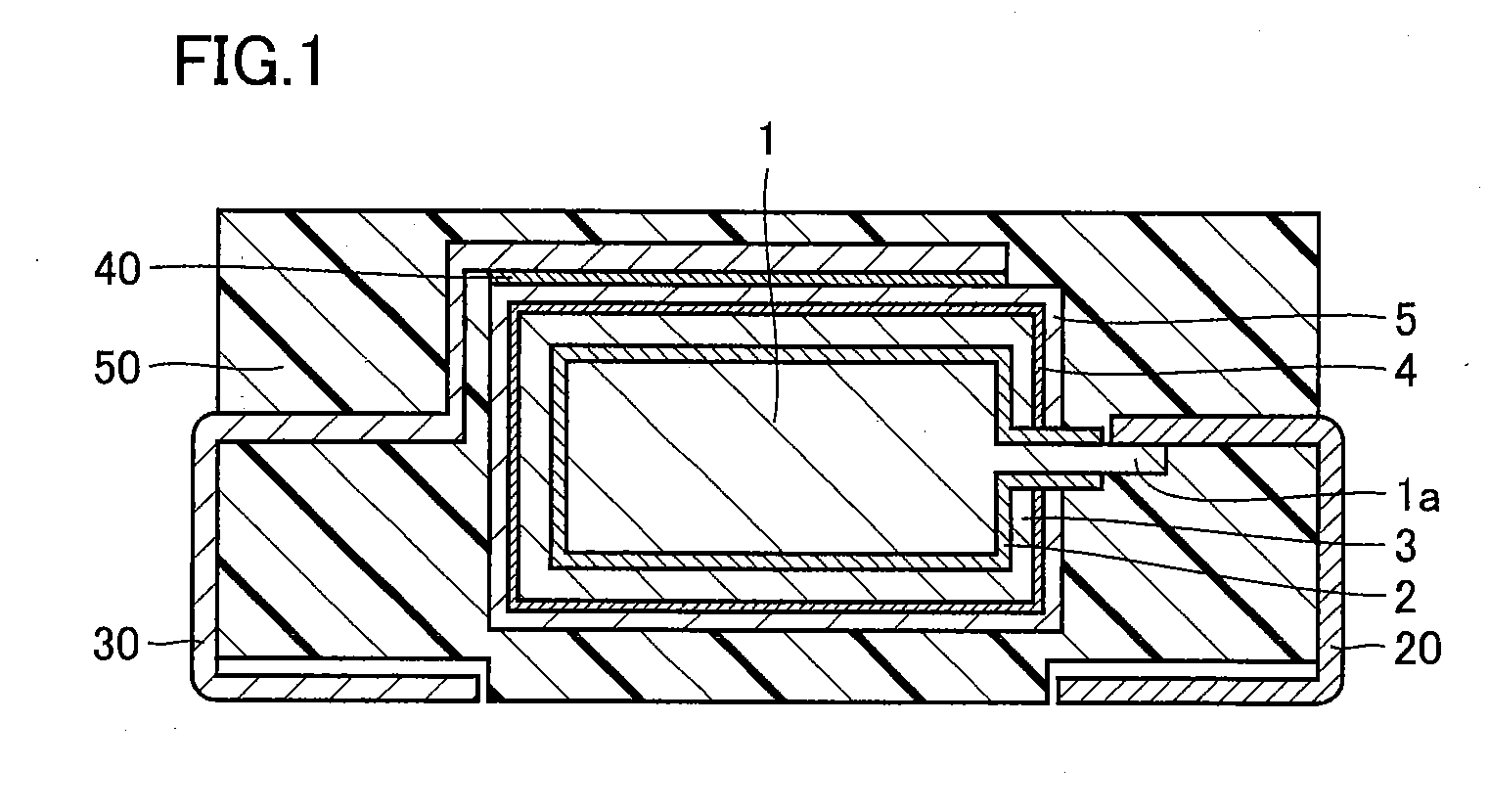

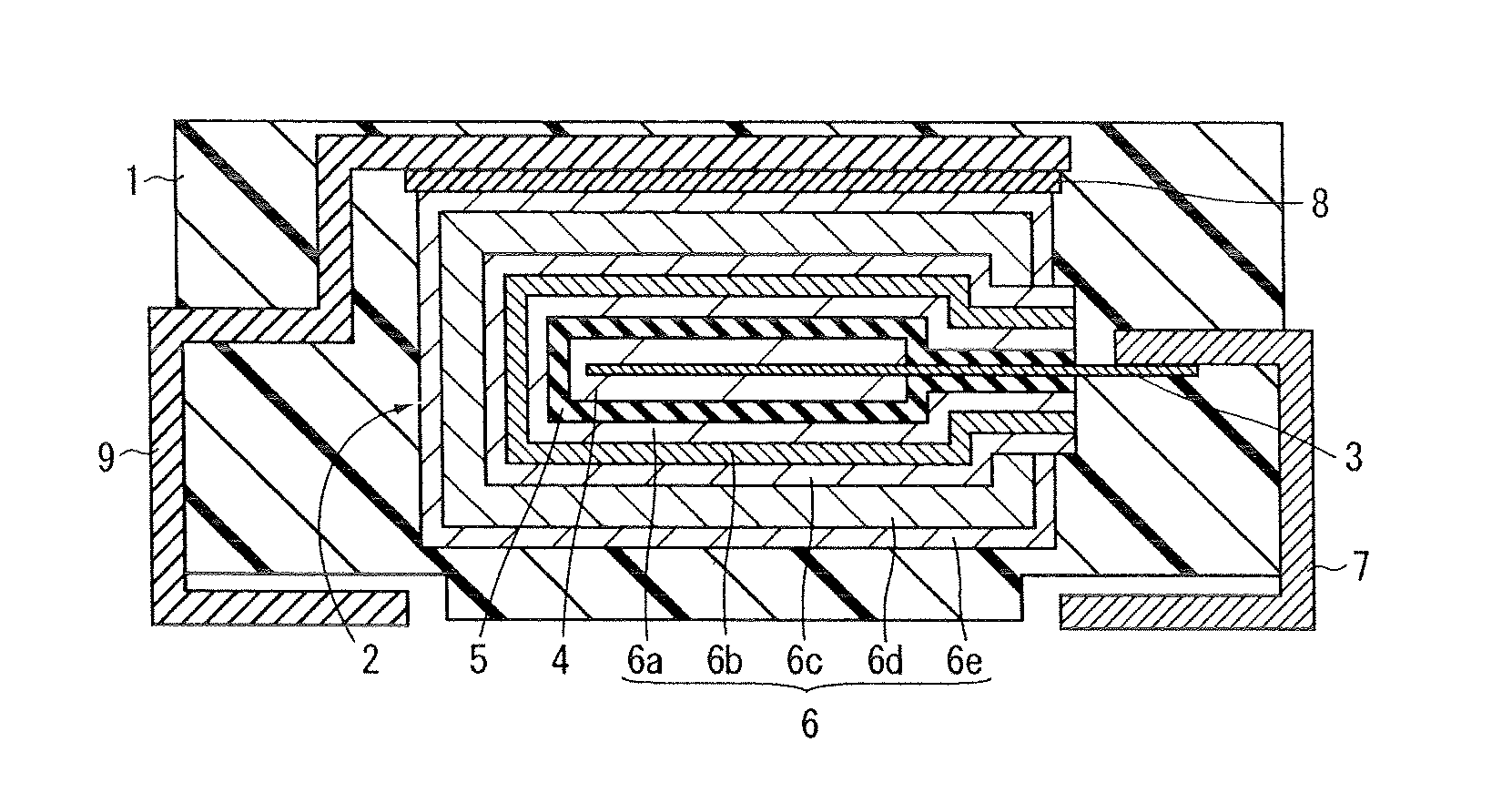

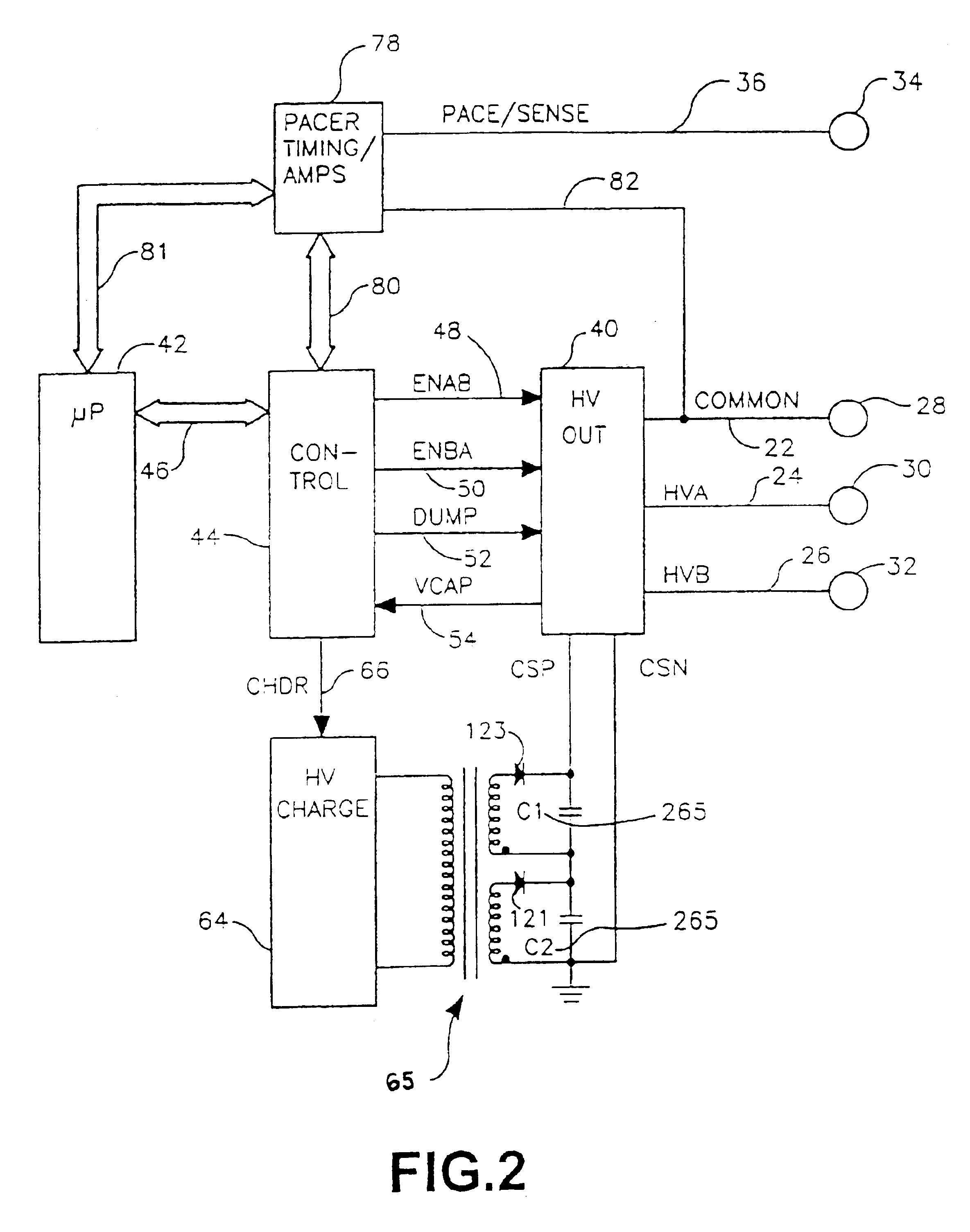

Implantable medical devices (IMDs) and components, including flat electrolytic capacitors and methods of making and using same, particularly an improved electrolytic capacitor fabricated of an electrode stack assembly comprising a plurality of capacitor layers stacked in registration upon one another. Each capacitor layer comprises a valve metal cathode layer having a cathode tab, a valve metal anode layer having an anode tab, and a separator layer located between the cathode layers. The anode layer is assembled from a plurality of valve metal anode sheets that are etched and anodized, stacked side-by-side, and electrically and mechanically joined together by laser weld beads. A valve metal anode tab having a thickness equal to one or more anode sheet is inserted into a tab notch in one or more stacked anode sheet and joined to the anode sheet stack by laser welding the tab and sheet edges together.

Owner:MEDTRONIC INC

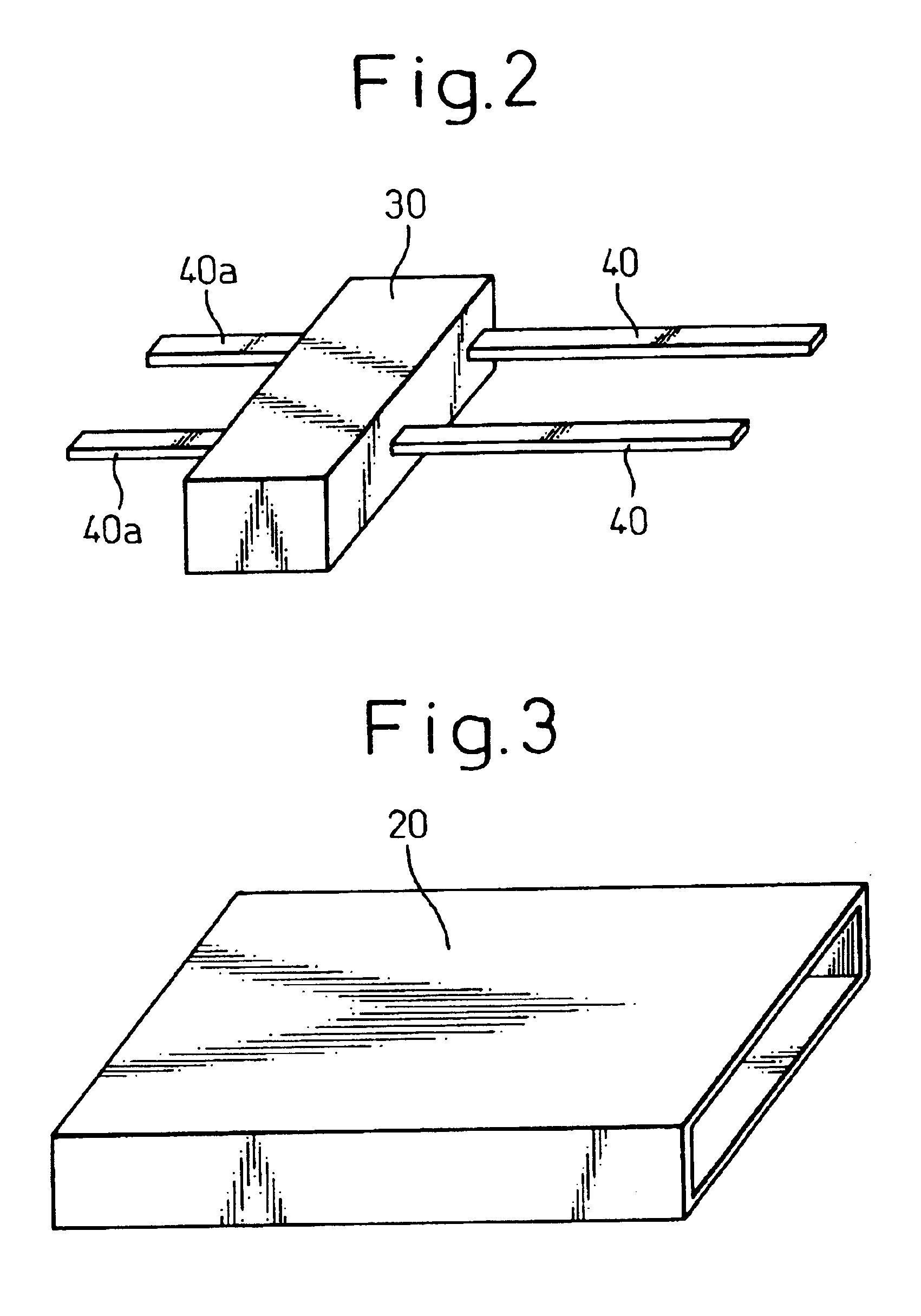

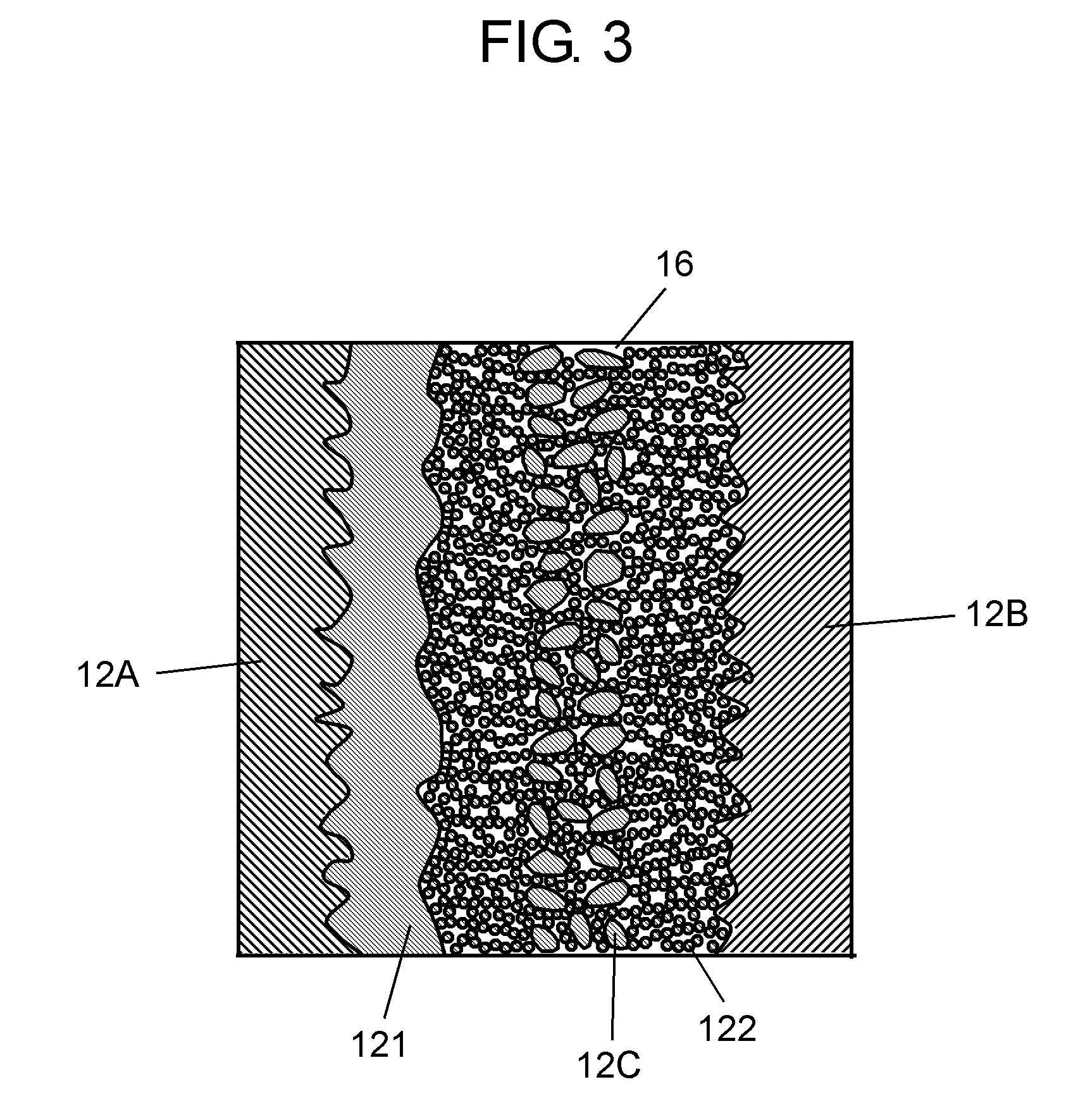

Electronic component separator and method for producing the same

InactiveUS20050208383A1Improve reliabilityImprove machinabilityHybrid capacitor separatorsCell seperators/membranes/diaphragms/spacersLithiumElectronic component

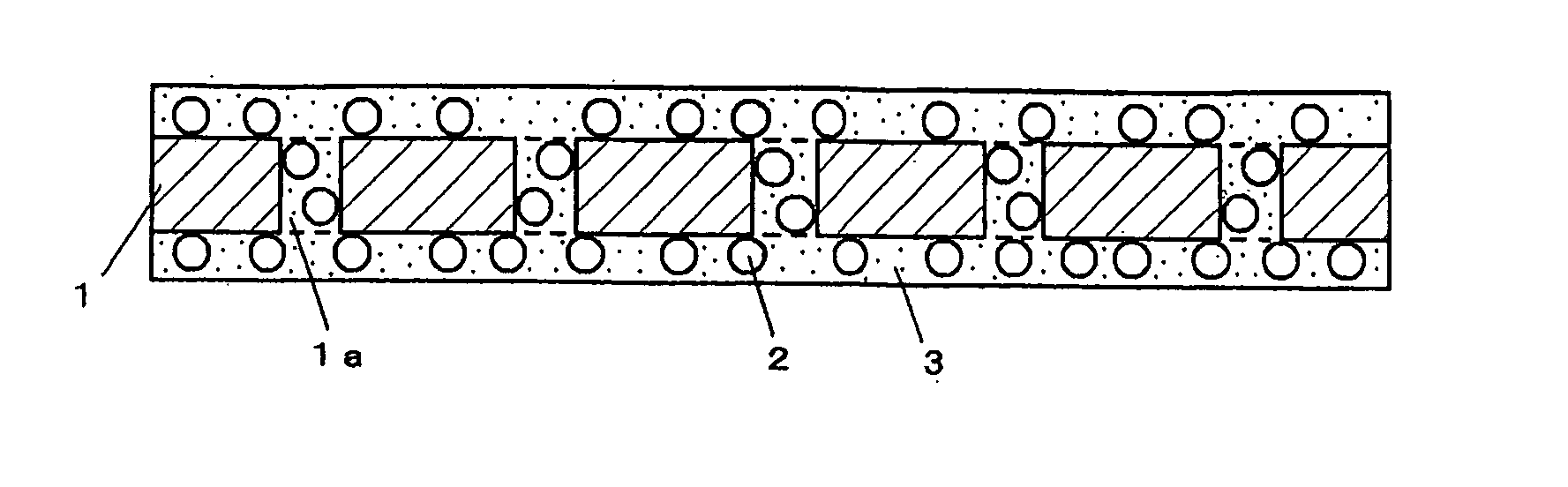

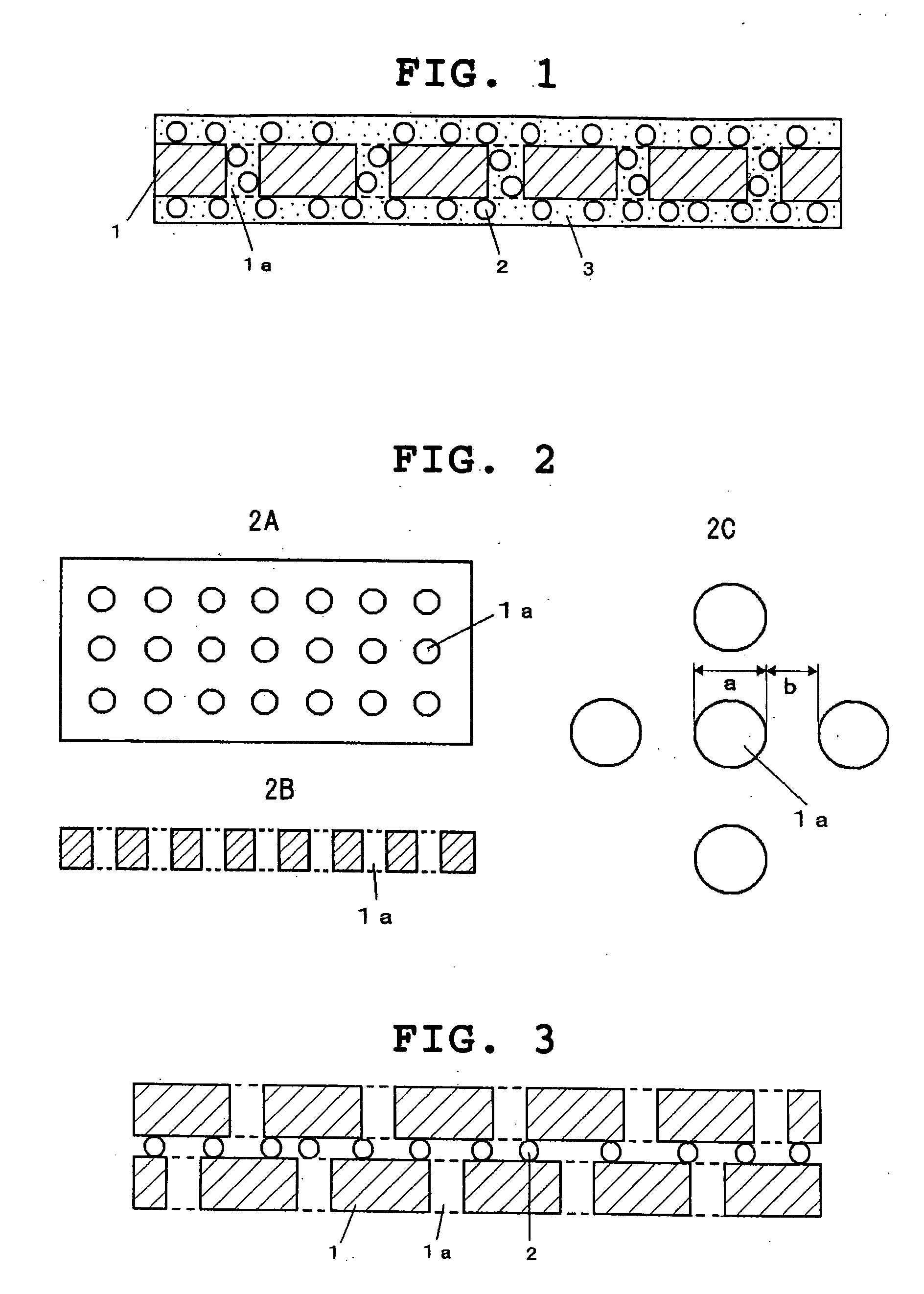

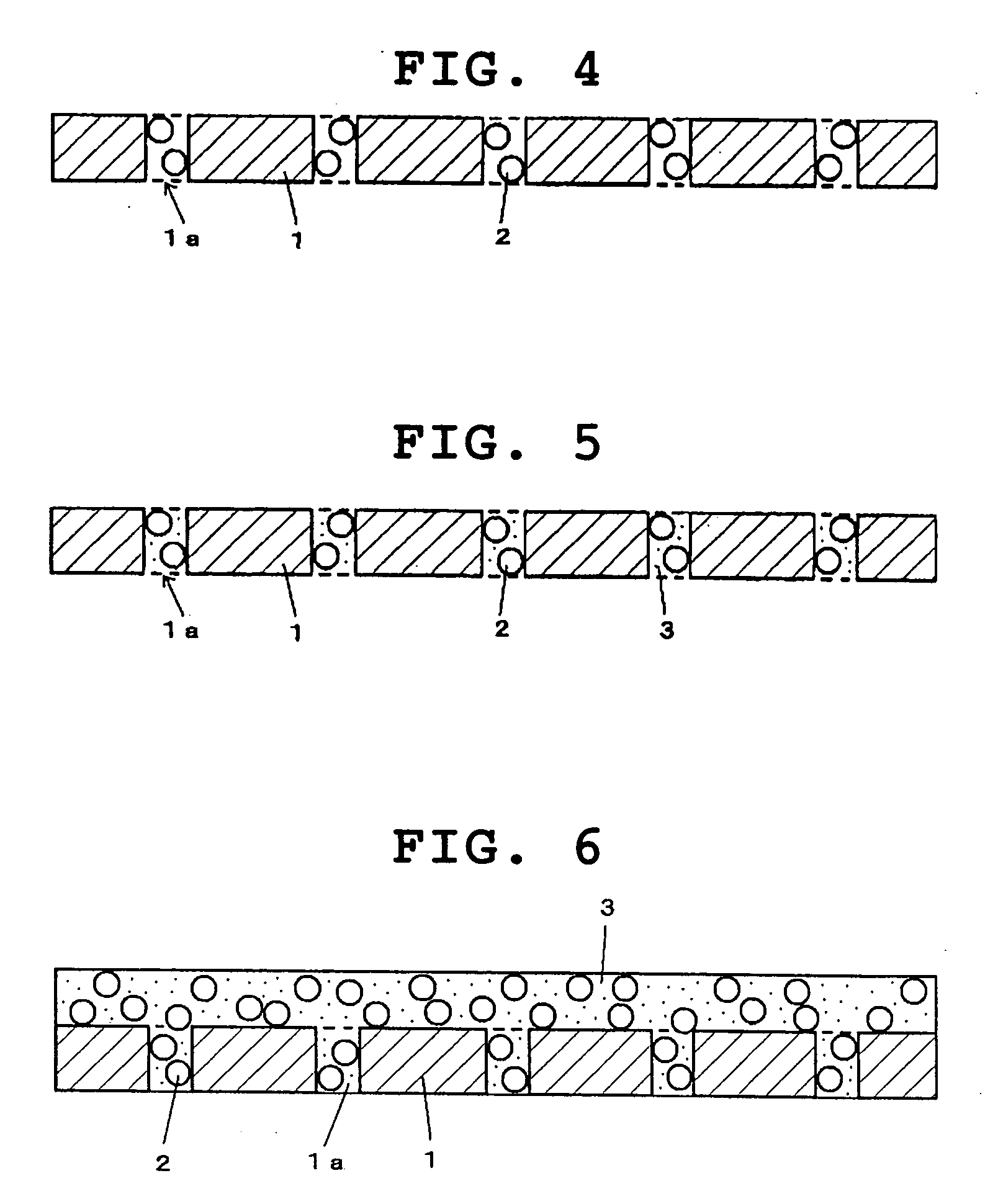

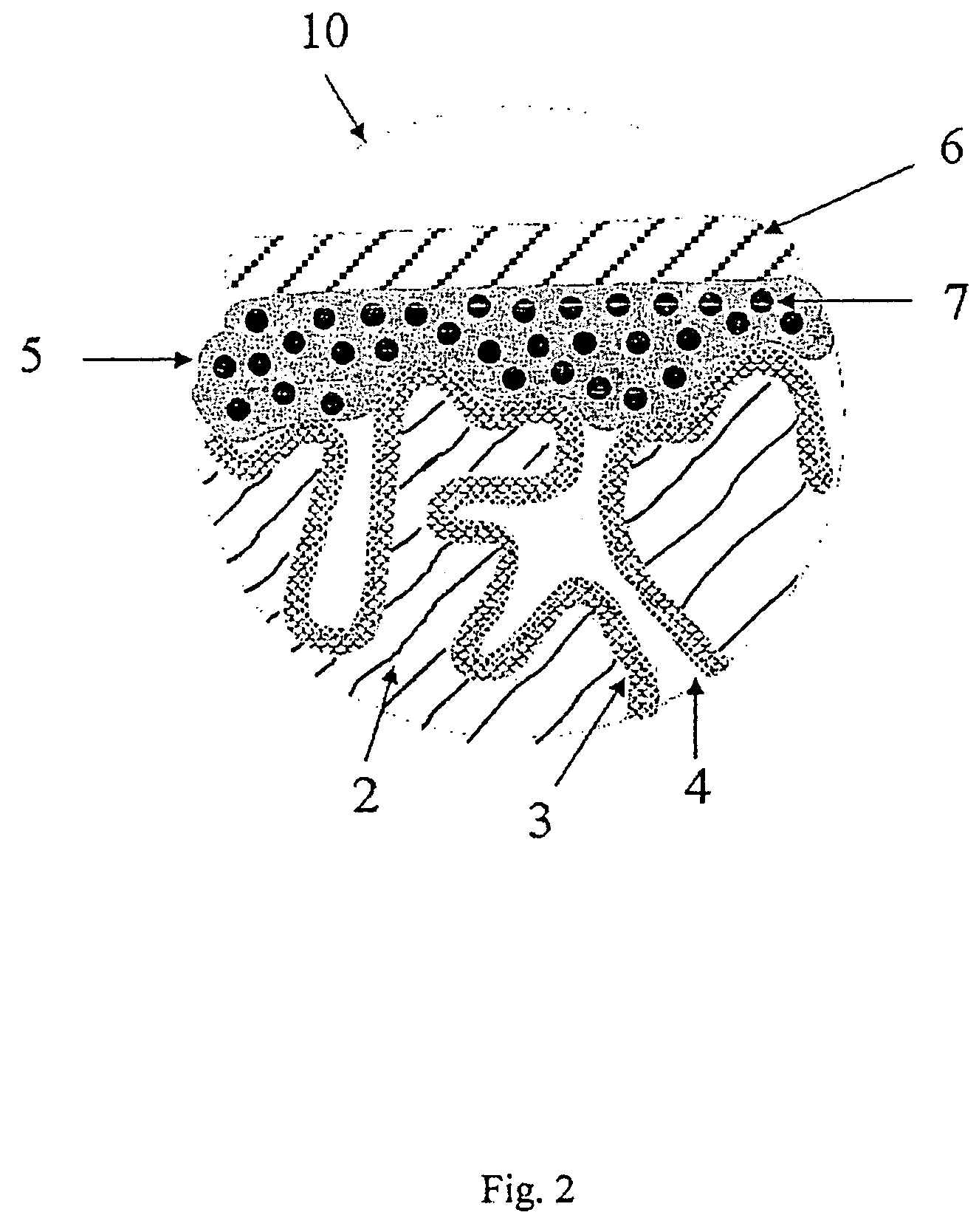

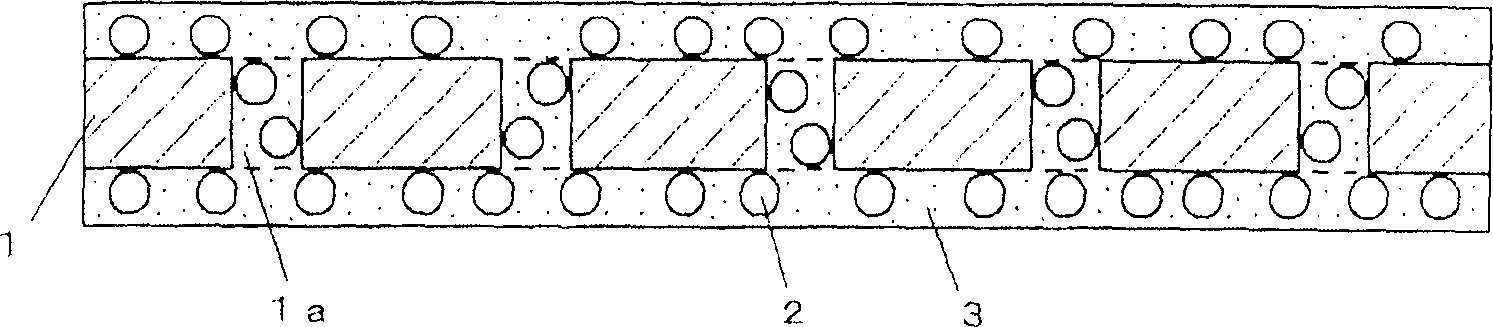

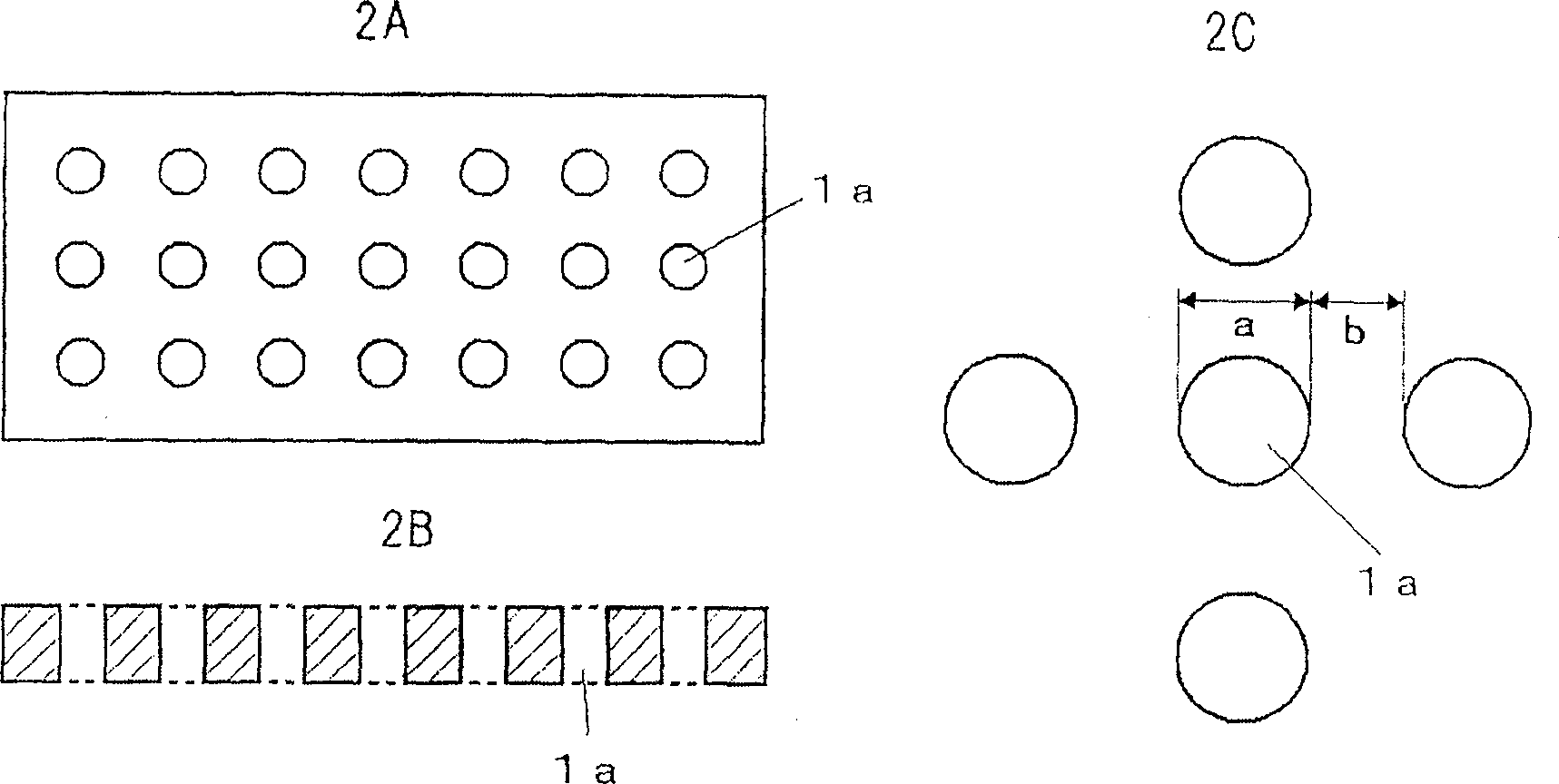

The present invention provides a separator that, when used in a lithium ion secondary battery, polymer lithium secondary battery, aluminum electrolytic capacitor or electric double-layer capacitor, offers desired levels of various practical characteristics, undergoes minimal heat shrinkage even when overheated, and exhibits high reliability and excellent workability. The electronic component separator proposed by the present invention comprises a porous base made of a substance having a melting point of 180° C. or above, and a resin structure provided on at least one side of and / or inside the porous base, and the porous base and / or resin structure contains filler grains.

Owner:TOMOEGAWA PAPER CO LTD

Method of manufacturing electrolytic capacitor and electrolytic capacitor

ActiveUS7497879B2Improve pressure resistanceSmall currentHybrid capacitor electrolytesSolid electrolytic capacitorsDielectricElectrolysis

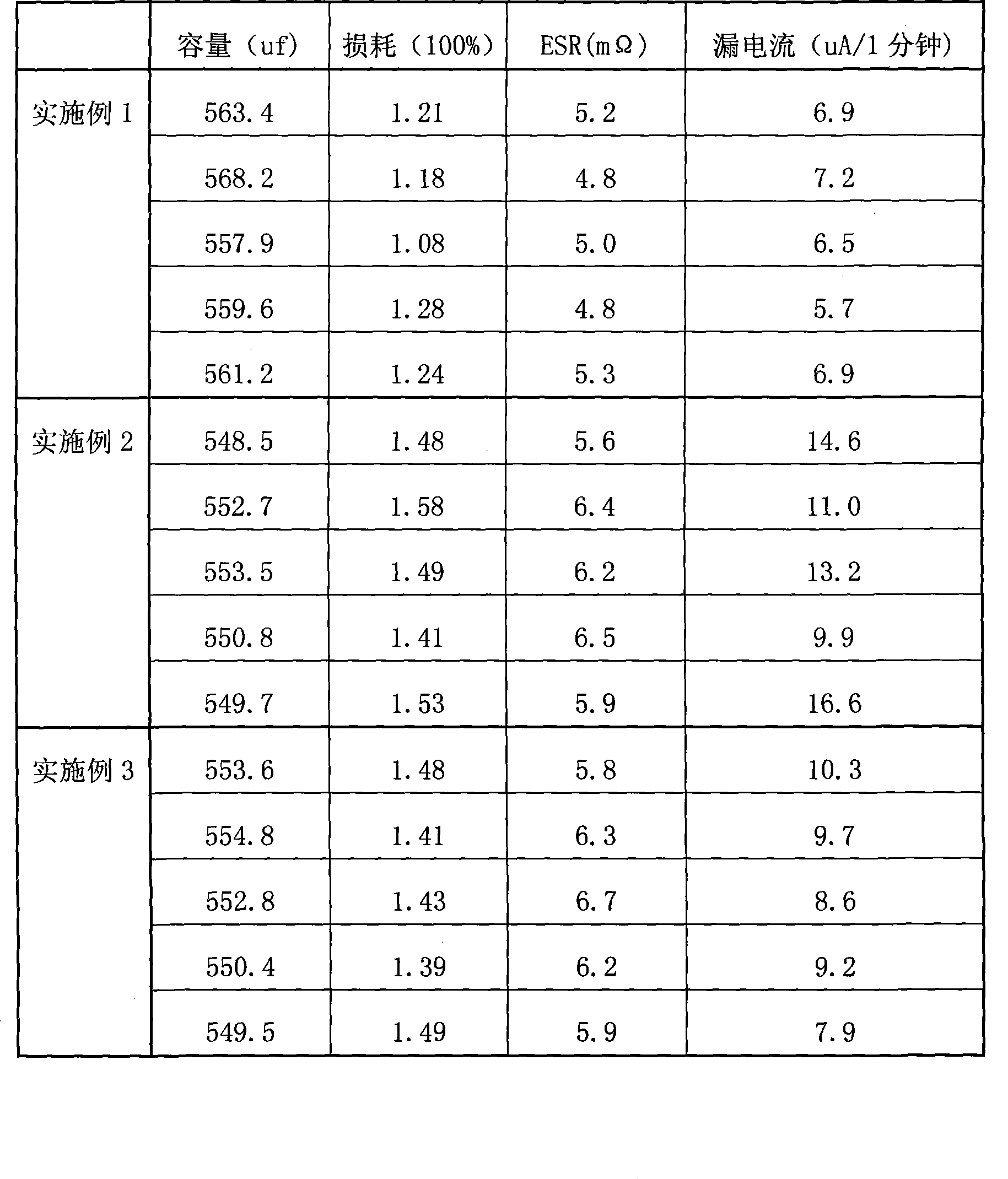

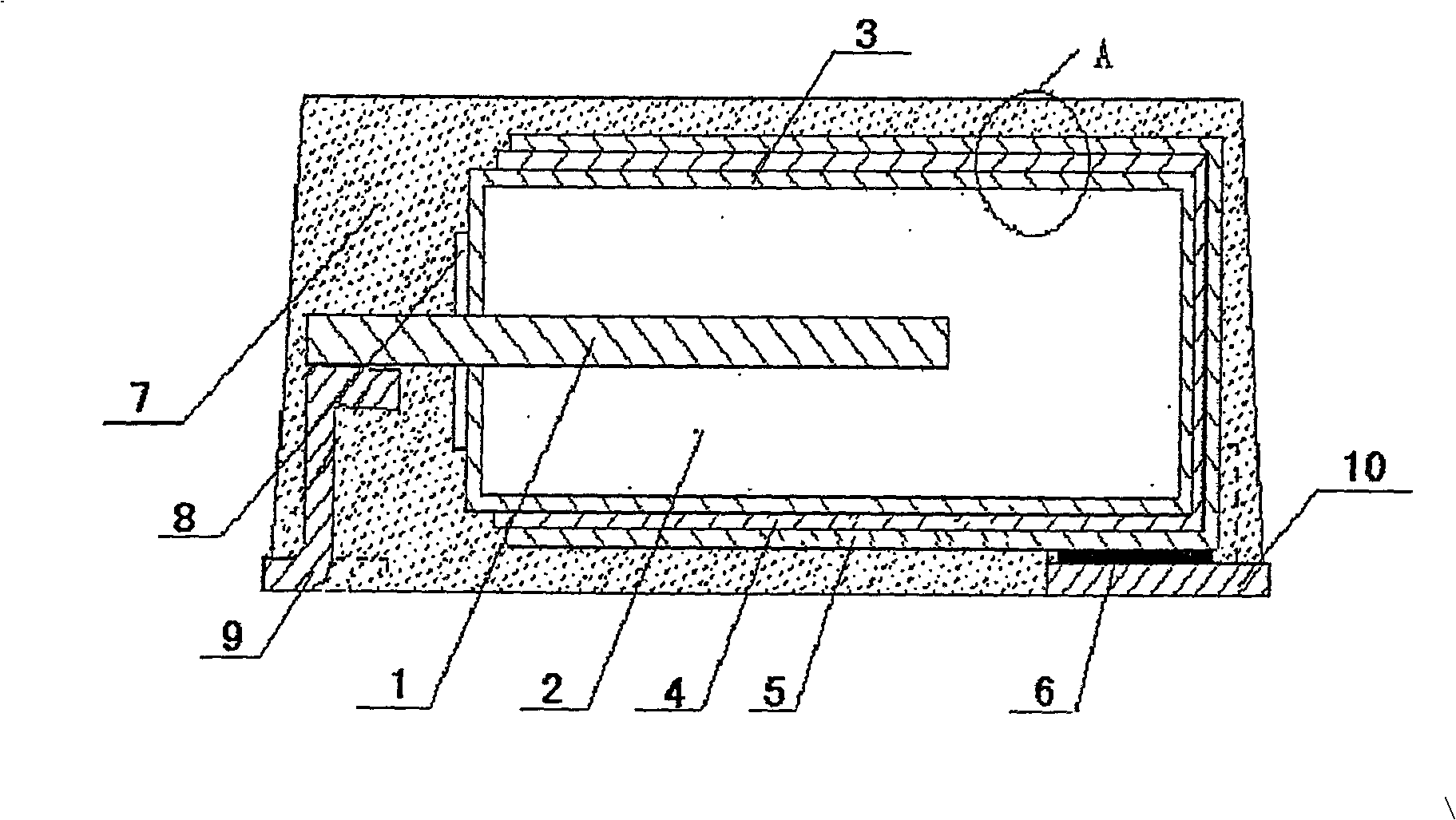

A method of manufacturing an electrolytic capacitor including the following steps as well as an electrolytic capacitor manufactured by the method are provided. The method includes: a dispersion impregnation step of impregnating, with a dispersion containing electrically conductive solid particles or powder and a solvent, a capacitor element having an anode foil with a dielectric coating film formed thereon and an opposite cathode foil that are wound with a separator interposed therebetween; a dry step of evaporating the solvent after the dispersion impregnation step to form an electrically conductive solid layer on a surface of the dielectric coating film; and an electrolytic solution impregnation step of impregnating a gap in the electrically conductive solid layer with an electrolytic solution. Accordingly, an electrolytic capacitor that can be manufactured more easily that is excellent in voltage proofing property and that has a lower ESR and a lower leakage current is provided.

Owner:SANYO ELECTRIC CO LTD +1

Electrolytic capacitors with a polymeric outer layer and process for the production thereof

ActiveUS7411779B2Lower equivalent series resistanceIncrease coverageHybrid capacitor electrolytesSolid electrolytic capacitorsElectrolysisConductive polymer

The invention relates to a process for the production of electrolytic capacitors with low equivalent series resistance and low residual current consisting of a solid electrolyte made of conductive polymers and an outer layer containing conductive polymers, to electrolytic capacitors produced by this process and to the use of such electrolytic capacitors.

Owner:HERAEUS PRECIOUS METALS GMBH & CO KG

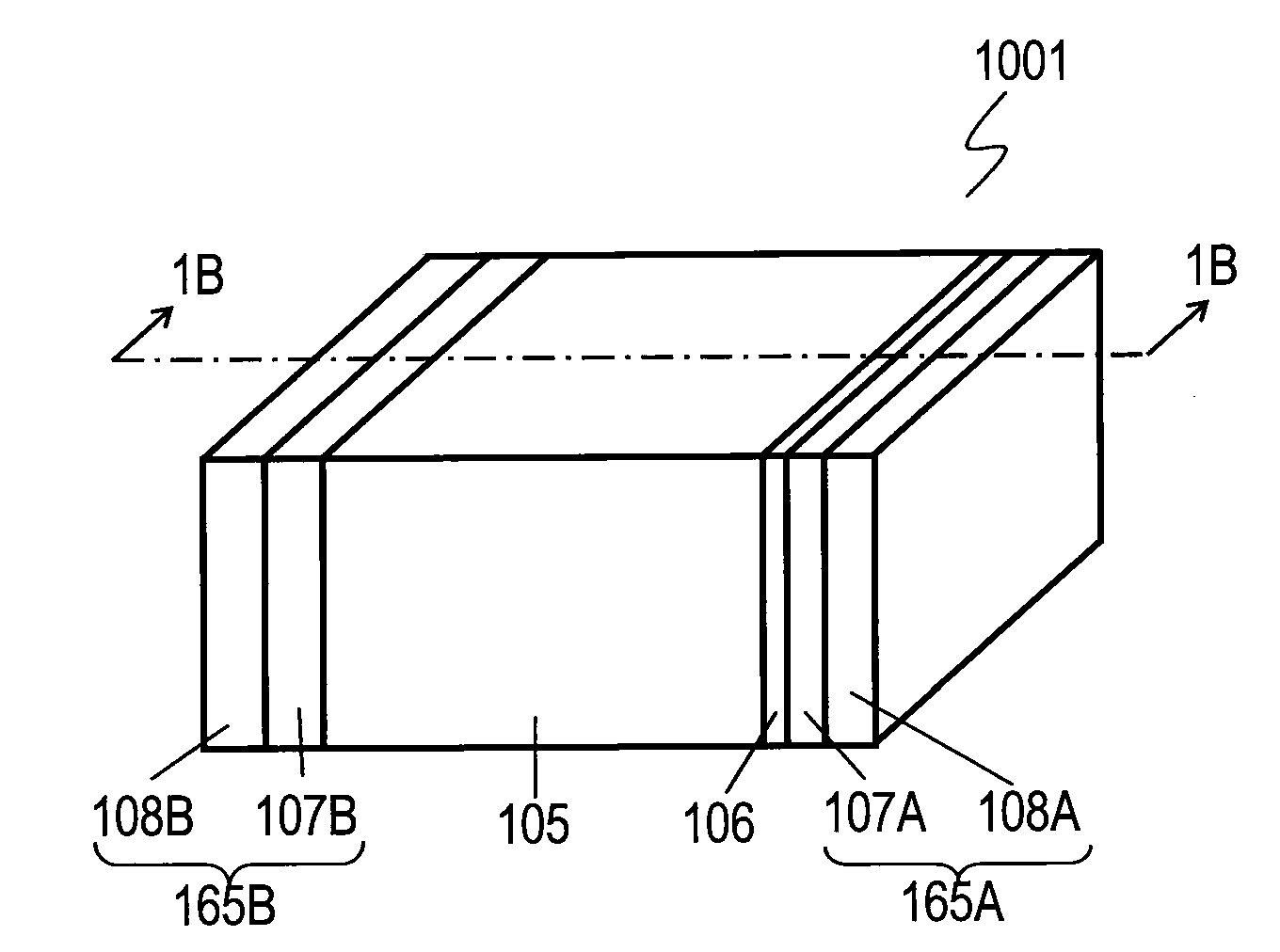

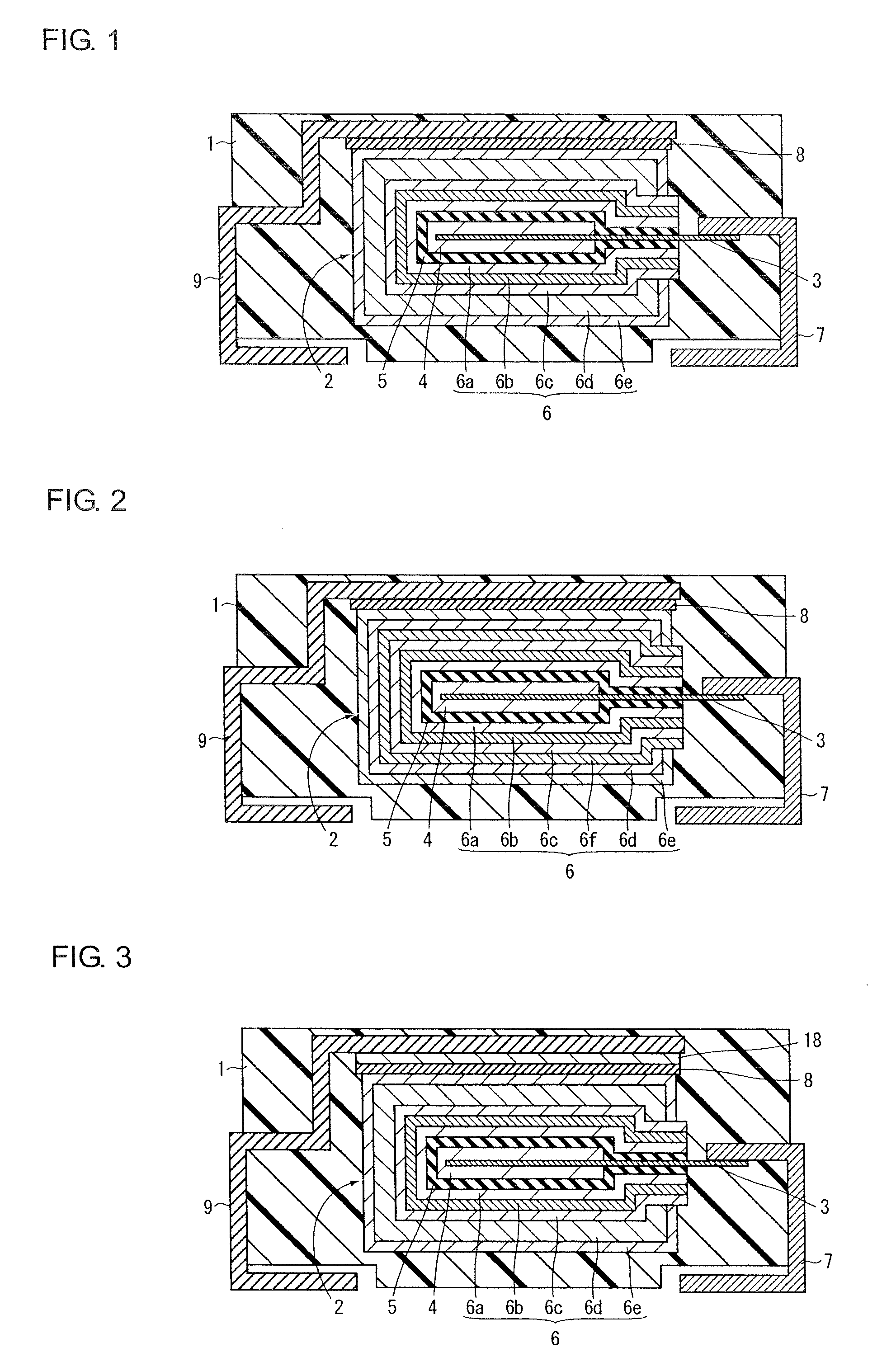

Implantable medical device having flat electrolytic capacitor with differing sized anode and cathode layers

InactiveUS7110240B2Area maximizationEasy to useAnti-noise capacitorsFeed-through capacitorsEngineeringMedical device

A capacitor is described. The capacitor includes a case chamber. An electrode stack assembly is disposed within the case chamber. The electrode stack assembly includes a layer. The layer includes an anode subassembly. The anode subassembly comprises at least one anode layer that has an anode edge disposed at a first distance from an interior wall of the case chamber. The layer also includes a capacitor layer. The capacitor layer includes a cathode edge disposed at a second distance from the wall interior. The second distance is greater than the first distance.

Owner:MEDTRONIC INC

Solid electrolytic capacitor and manufacturing method thereof

InactiveUS6215652B1Avoid volatilityIncrease capacitanceLiquid electrolytic capacitorsFixed capacitor dielectricElectrolysisMetal powder

A solid electrolytic capacitor is here disclosed in which a dielectric layer formed on the surface of an anode obtained by molding and then sintering a niobium metal powder which includes a niobium oxide layer and a niobium nitride region, and a method for manufacturing the solid electrolytic capacitor is also disclosed.

Owner:TOKIN CORP

Wet electrolytic capacitor containing a gelled working electrolyte

ActiveUS9105401B2Hybrid capacitor electrolytesCapacitor electrolytes/absorbentsElectrolysisConductive polymer

A wet electrolytic capacitor is provided. The capacitor contains an anode comprising an anodically oxidized pellet formed from a pressed and sintered powder, a cathode that contains a metal substrate coated with a conductive polymer, and a working electrolyte in communication with the anode and the cathode. The working electrolyte is in the form of a gel and comprises an ammonium salt of an organic acid, inorganic oxide particles, an acid, and a solvent system that comprises water. The working electrolyte has a pH value of from about 5.0 to about 8.0.

Owner:KYOCERA AVX COMPONENTS CORP

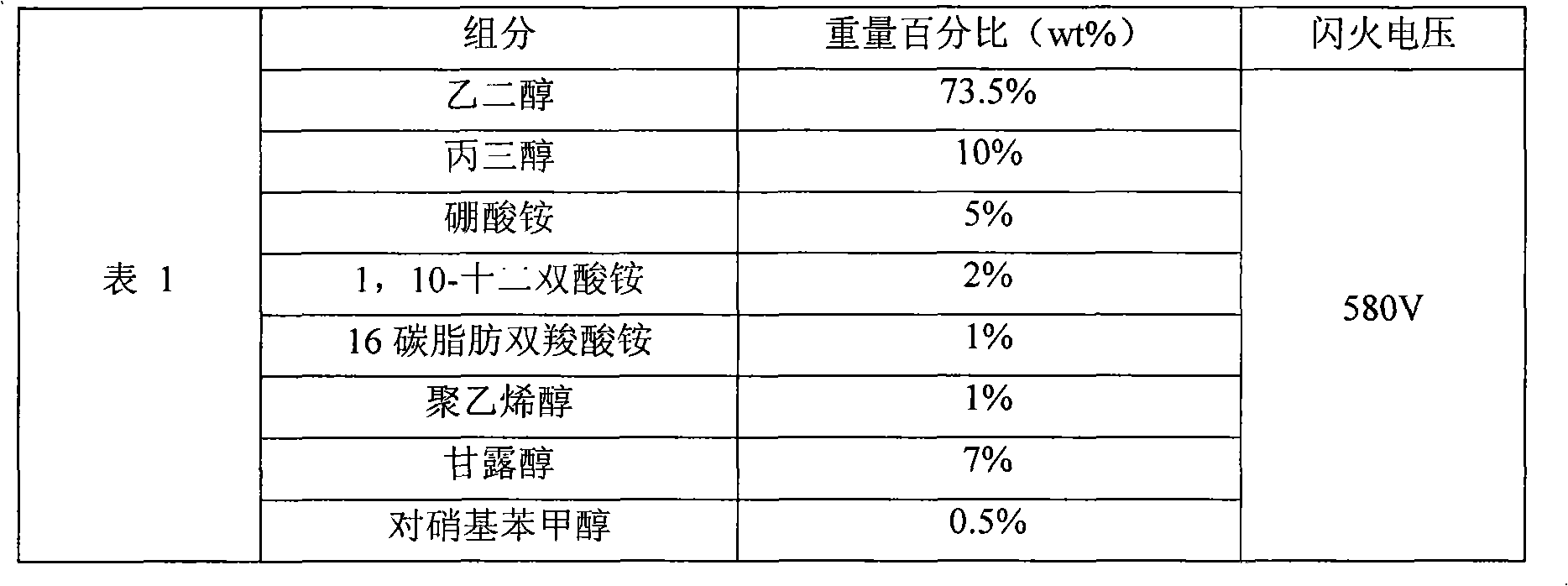

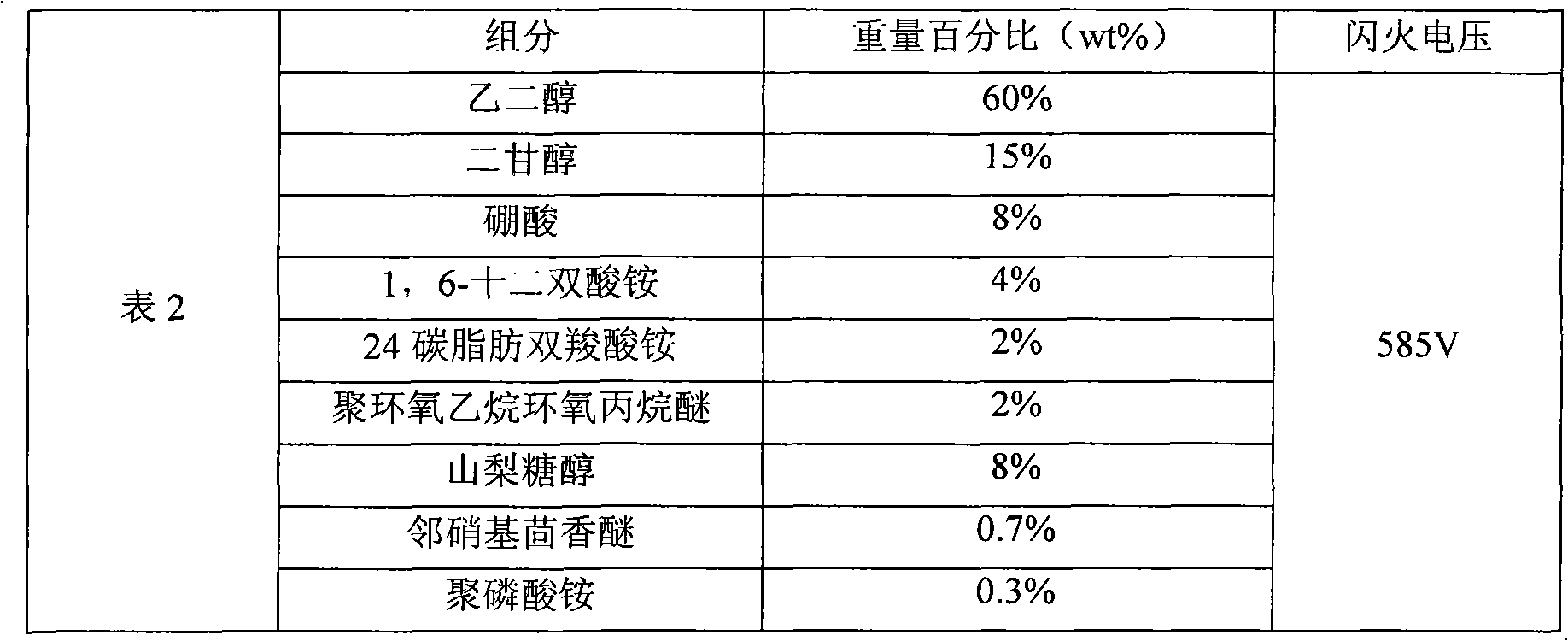

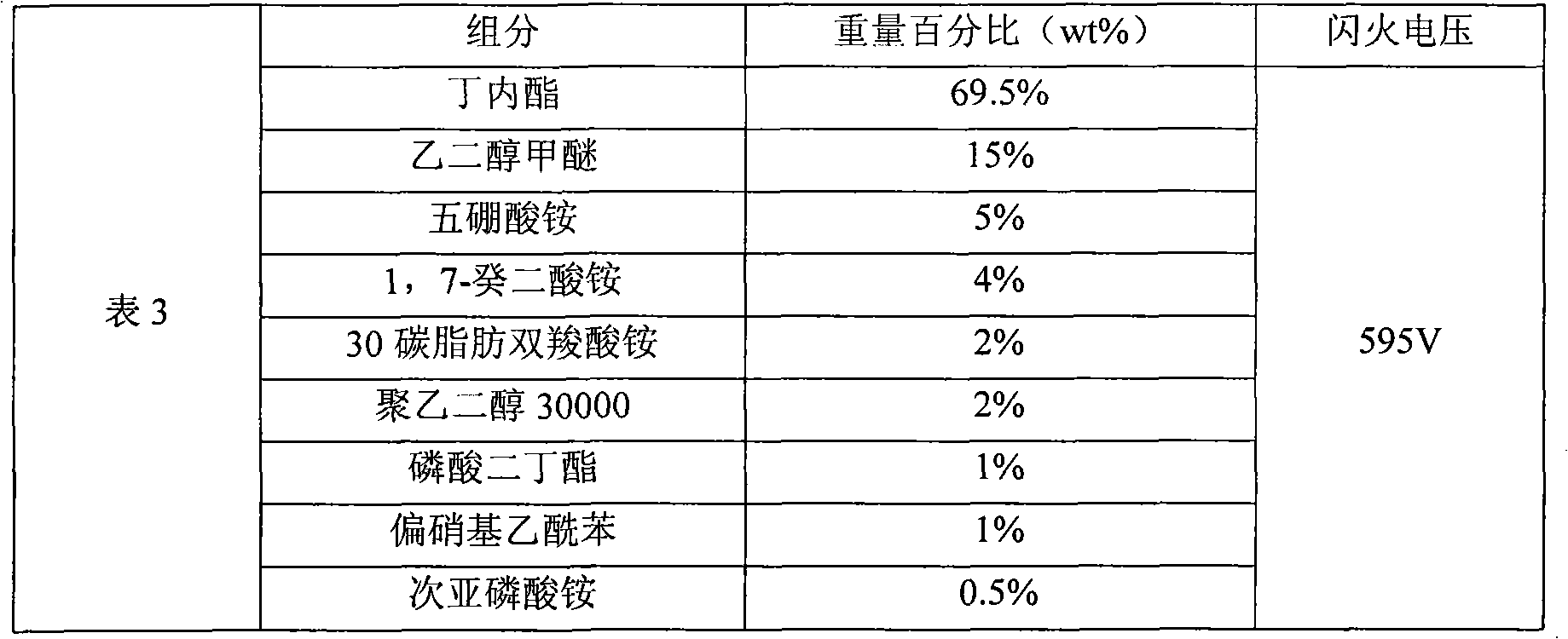

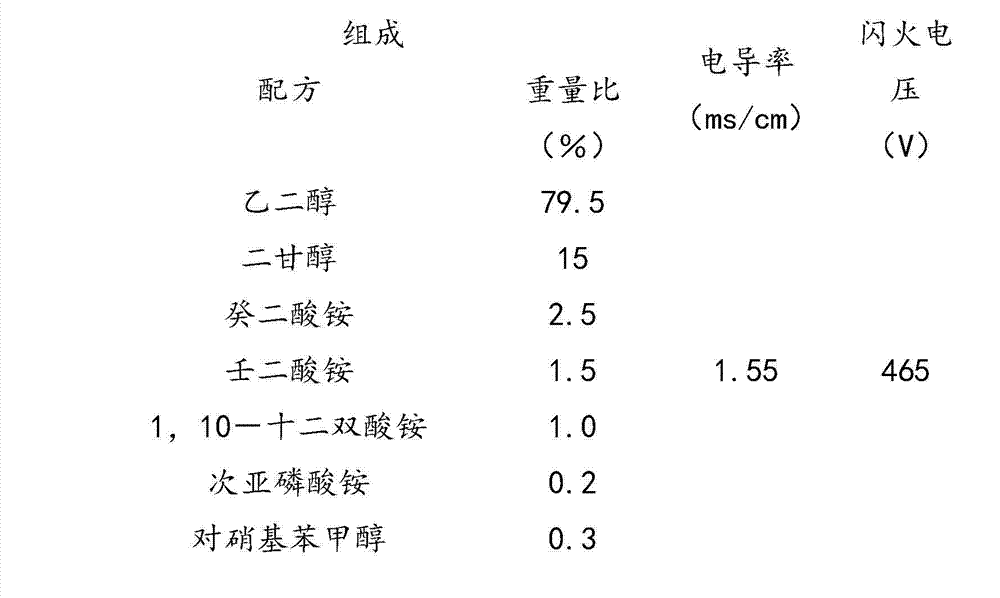

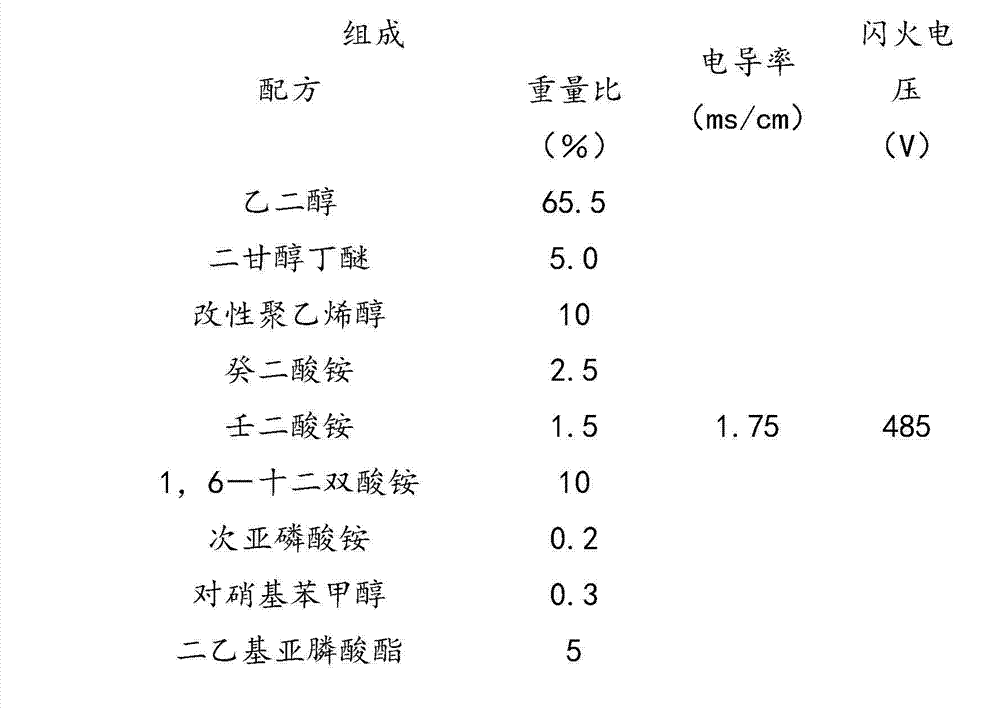

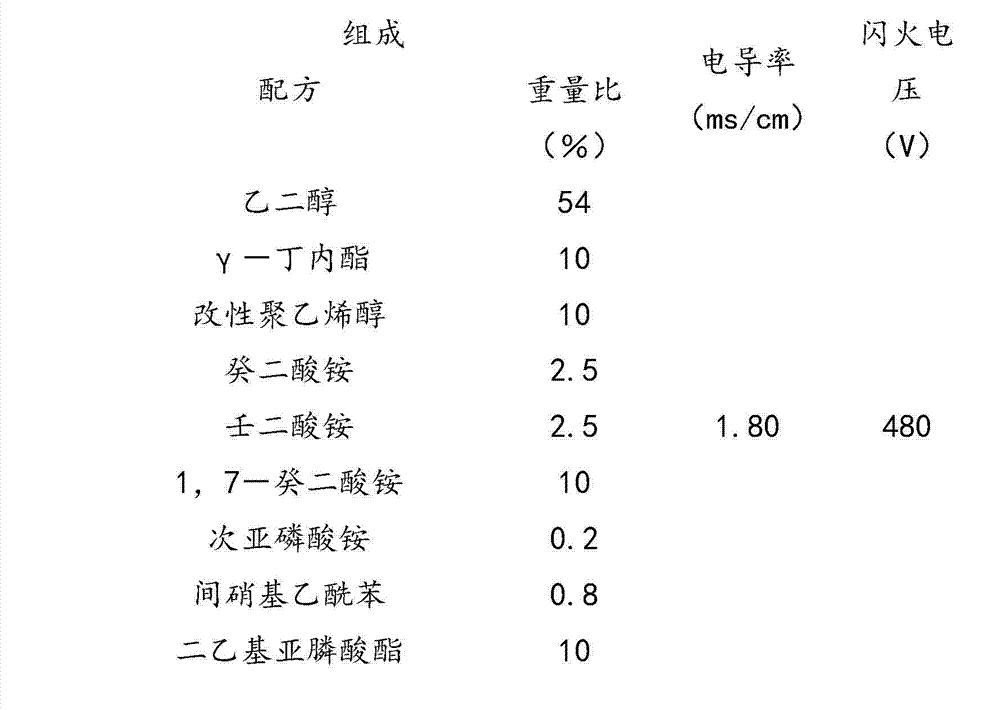

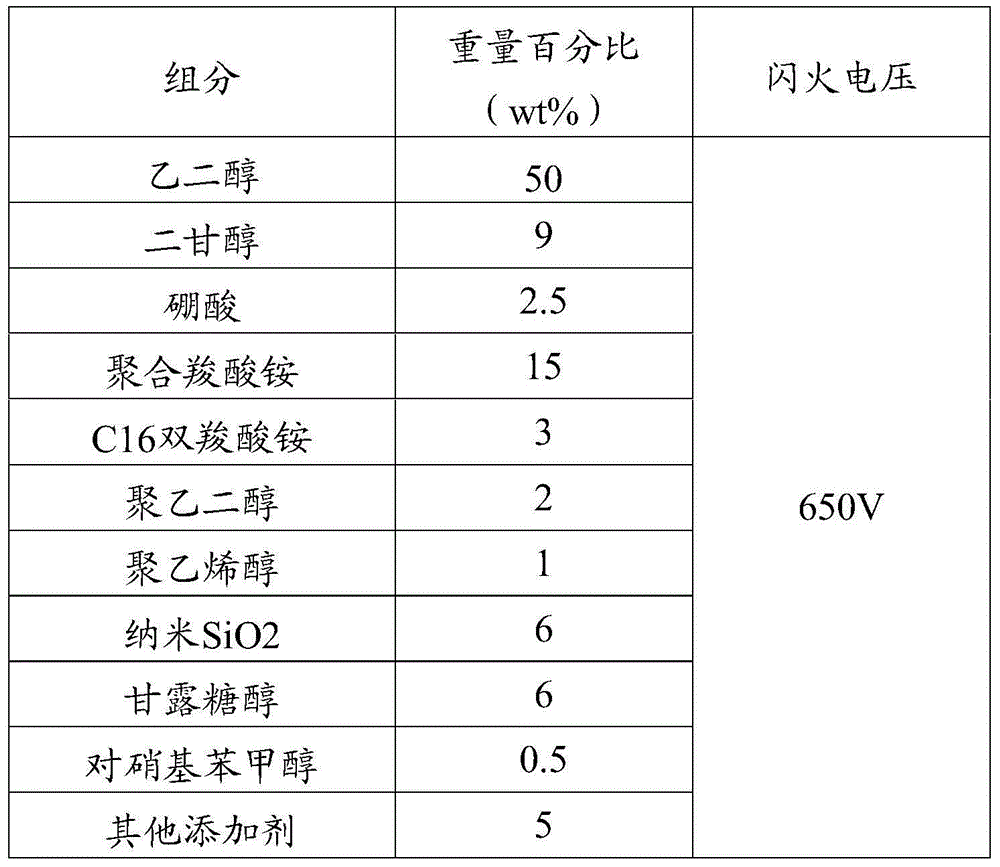

600V extra-high voltage aluminum electrolyte capacitor working electrolyte and preparation and application thereof

ActiveCN101599367AImprove high pressure resistanceImprove high temperature resistanceLiquid electrolytic capacitorsElectrolytic agentHydrogen

The invention relates to a 600V extra-high voltage aluminum electrolyte capacitor working electrolyte and a preparation and an application thereof; the working electrolyte comprises the following materials: 44.5-80.3% of main solvent, 5-15% of auxiliary solvent, 8-15% of solute, 0.5-2.5% of sparking voltage enhancer, 6-10% of stabilizer and 0.2-3% of hydrogen absorbent; the preparation method comprises the following steps: mixing the main solvent and the auxiliary solvent evenly, heating the mixture to 60-90 DEG C; adding sparking voltage enhancer, heating the mixture to 135-155 DEG C; cooling the heated mixture to 65-80 DEG C by circulating water, adding the solute and the stabilizer, heating the product to 105-135 DEG C; finally, adding the hydrogen absorbent and natural cooling to obtain the working electrolyte. Proper sparking voltage enhancer and stabilizer are added in the electrolyte to improve the high voltage resistant and high temperature resistant properties of electrolyte and to ensure the electrolyte to have low aerogenesis property; the aluminum electrolyte capacitor prepared by using the electrolyte has long service life and high voltage resistant property, and can not be broken down as the sparking voltage of the electrolyte is unstable.

Owner:NANTONG JIANGHAI CAPACITOR CO LTD

Solid electrolytic capacitor

ActiveUS20100165547A1Reduce in quantitySmall sizeSolid electrolytic capacitorsLiquid electrolytic capacitorsElectrolysisEdge surface

A capacitor element includes a positive electrode body made of valve metal, a dielectric oxide layer on the positive electrode body, a solid electrolytic layer made of conductive polymer on the dielectric oxide layer, and a negative electrode layer on the solid electrolytic layer. A solid electrolytic capacitor includes the capacitor element, a package made of insulating resin covering the capacitor element, a base electrode provided at an edge surface of the package and made of non-valve metal coupled with the positive electrode body, a diffusion layer for connecting the positive electrode body to the base electrode, an external electrode on the base electrode, and an external electrode connected to the negative electrode layer. The solid electrolytic capacitor reduces the number of components and processes to reduce its cost and to have a small size, and has a small equivalent series resistance and a small equivalent series inductance.

Owner:PANASONIC CORP

Electronic component separator and method for producing the same

ActiveCN1670989AImprove reliabilityImprove workabilityHybrid capacitor separatorsCell seperators/membranes/diaphragms/spacersLithiumElectronic component

The present invention provides a separator that, when used in a lithium ion secondary battery, polymer lithium secondary battery, aluminum electrolytic capacitor or electric double-layer capacitor, offers desired levels of various practical characteristics, undergoes minimal heat shrinkage even when overheated, and exhibits high reliability and excellent workability. The electronic component separator proposed by the present invention comprises a porous base made of a substance having a melting point of 180° C. or above, and a resin structure provided on at least one side of and / or inside the porous base, and the porous base and / or resin structure contains filler grains.

Owner:SUMITOMO CHEM CO LTD

Solid electrolytic capacitor and electric circuit

InactiveUS7031141B2Large capacitanceLow ESRSolid electrolytic capacitorsLiquid electrolytic capacitorsElectrolysisOptoelectronics

A solid electrolytic capacitor includes a cathode including a solid electrolytic layer, an anode, and a dielectric layer provided between the cathode and the anode. The anode includes an anode body, an input anode terminal and an output anode terminal. A bypass current path for causing circuit current to detour around the anode body is formed between the input anode terminal and the output anode terminal.

Owner:ROHM CO LTD

Solid electrolytic capacitor and method of manufacturing the same

ActiveUS6912117B2Low ESRLarge capacitySolid electrolytic capacitorsLiquid electrolytic capacitorsNiobiumMetal

A solid electrolytic capacitor having at least two capacitor elements using a valve action metal, such as tantalum or niobium, and laminated in a direction perpendicular to a mounting surface of a substrate. The capacitor elements have a width parallel to the mounting surface of the substrate greater than a thickness perpendicular to the mounting surface of the substrate, and an anode terminal is connected with anode leads led out to at least one side of an anode body made of the valve action metal generally in parallel to the mounting surface of the substrate. A cathode layer on a dielectric oxide film of the anode body is connected to a cathode terminal and is coated with exterior coating resin with a part of the anode terminal and a part of the cathode terminal exposed.

Owner:TOKIN CORP

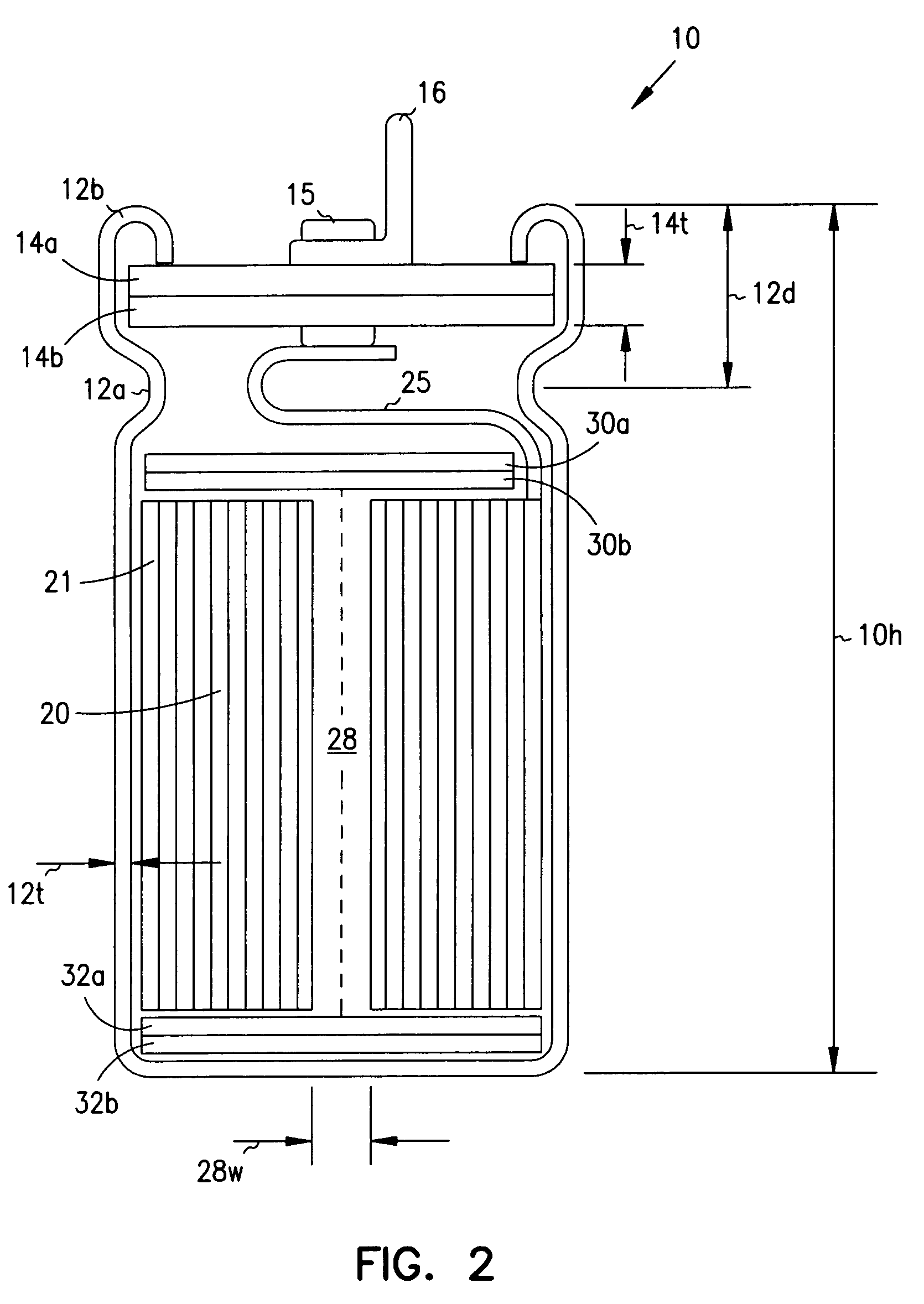

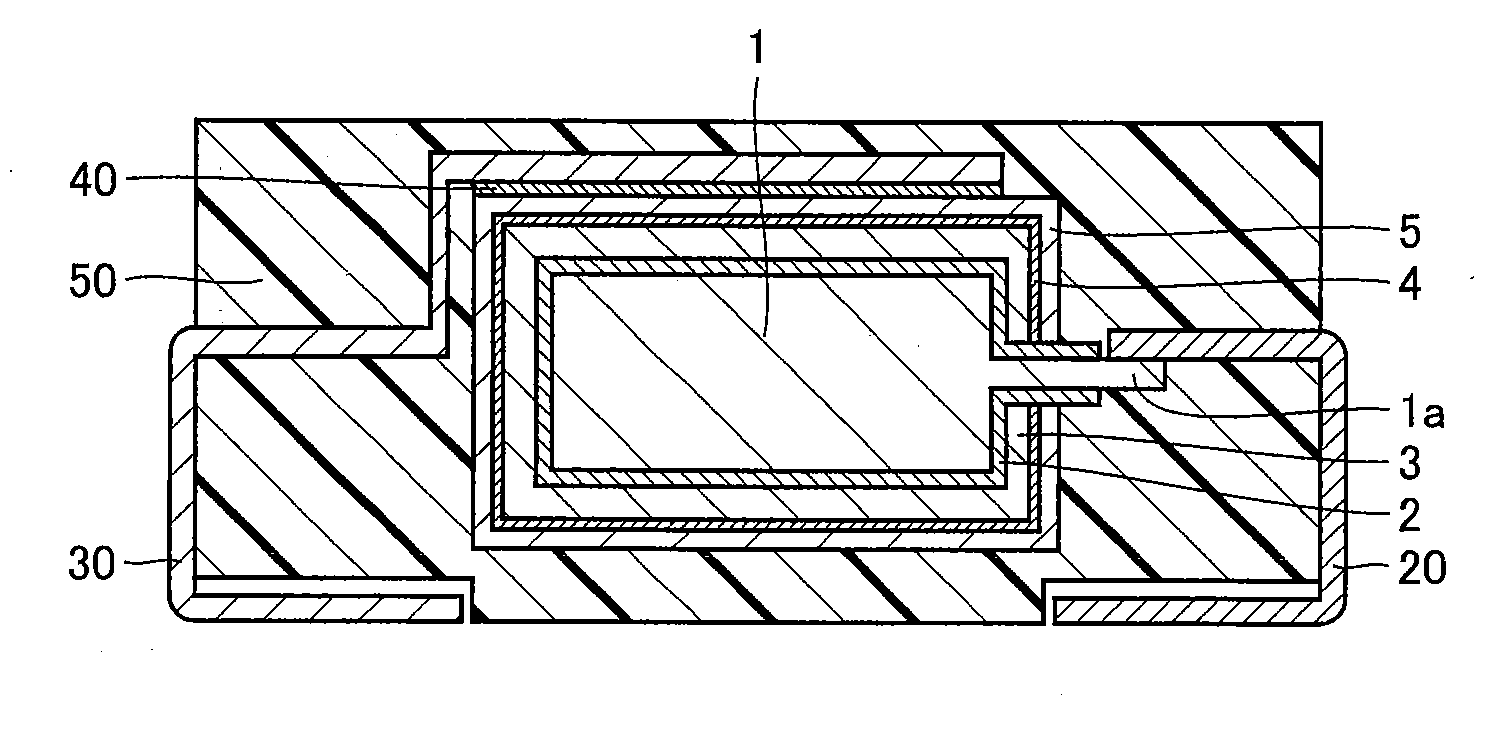

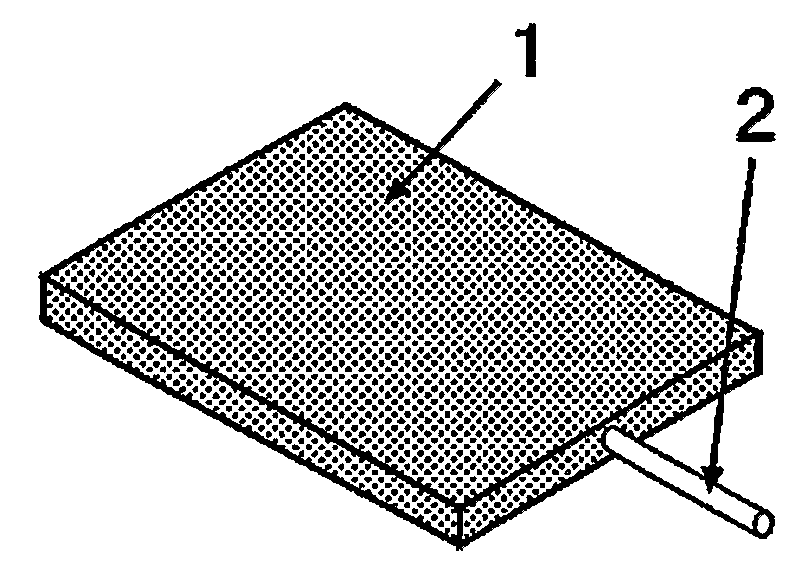

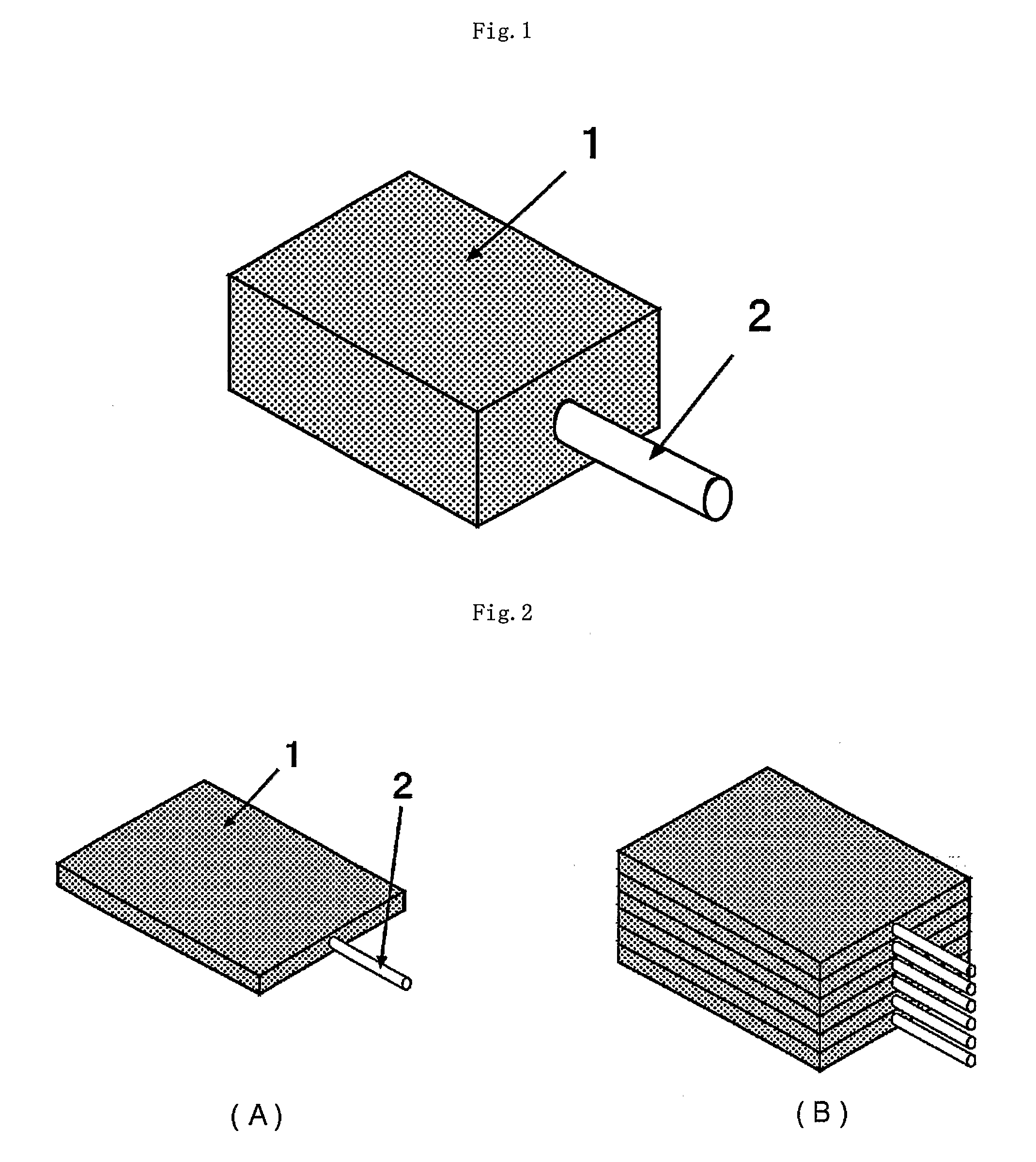

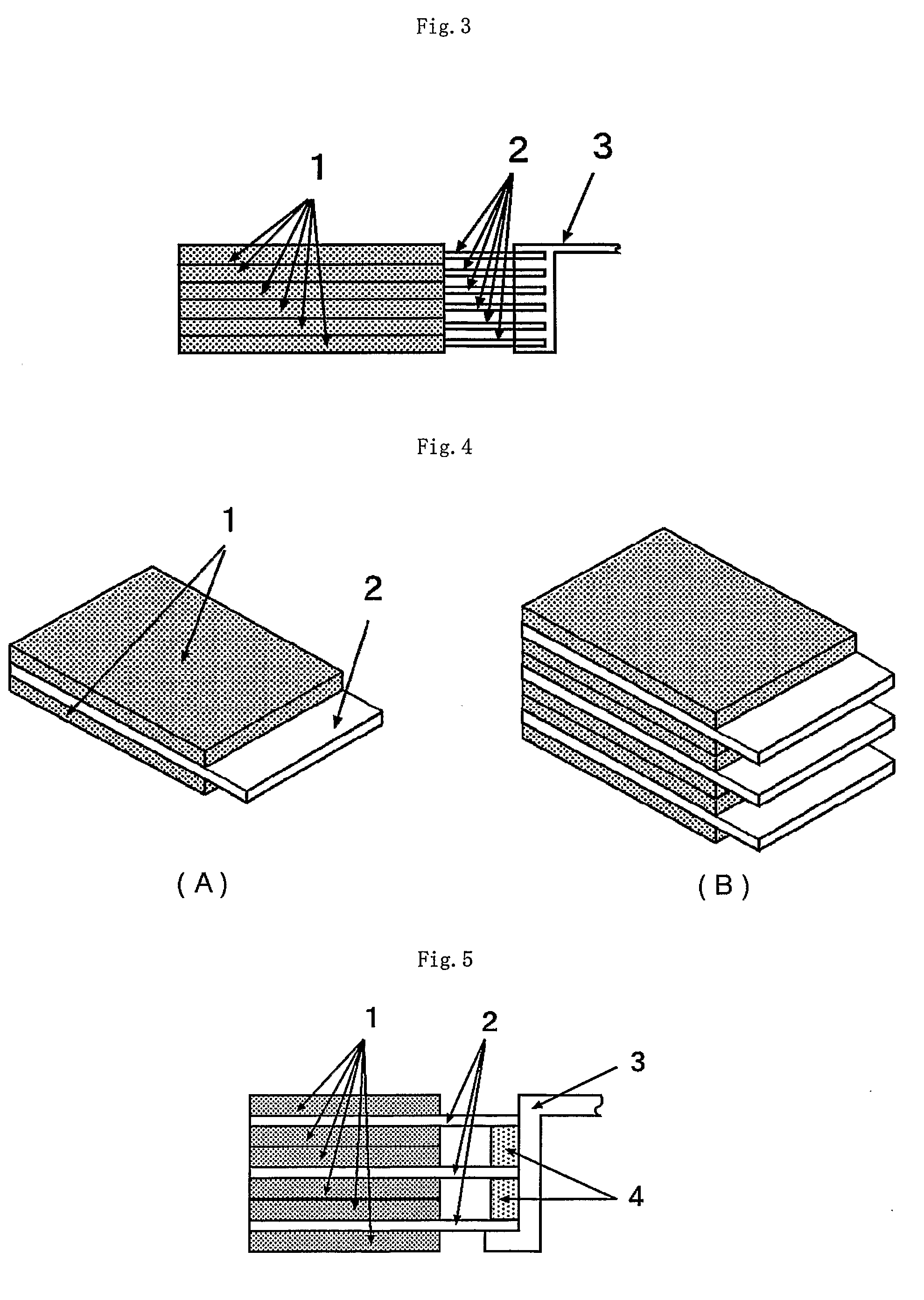

Flat aluminum electrolytic capacitor and method of manufacturing the same

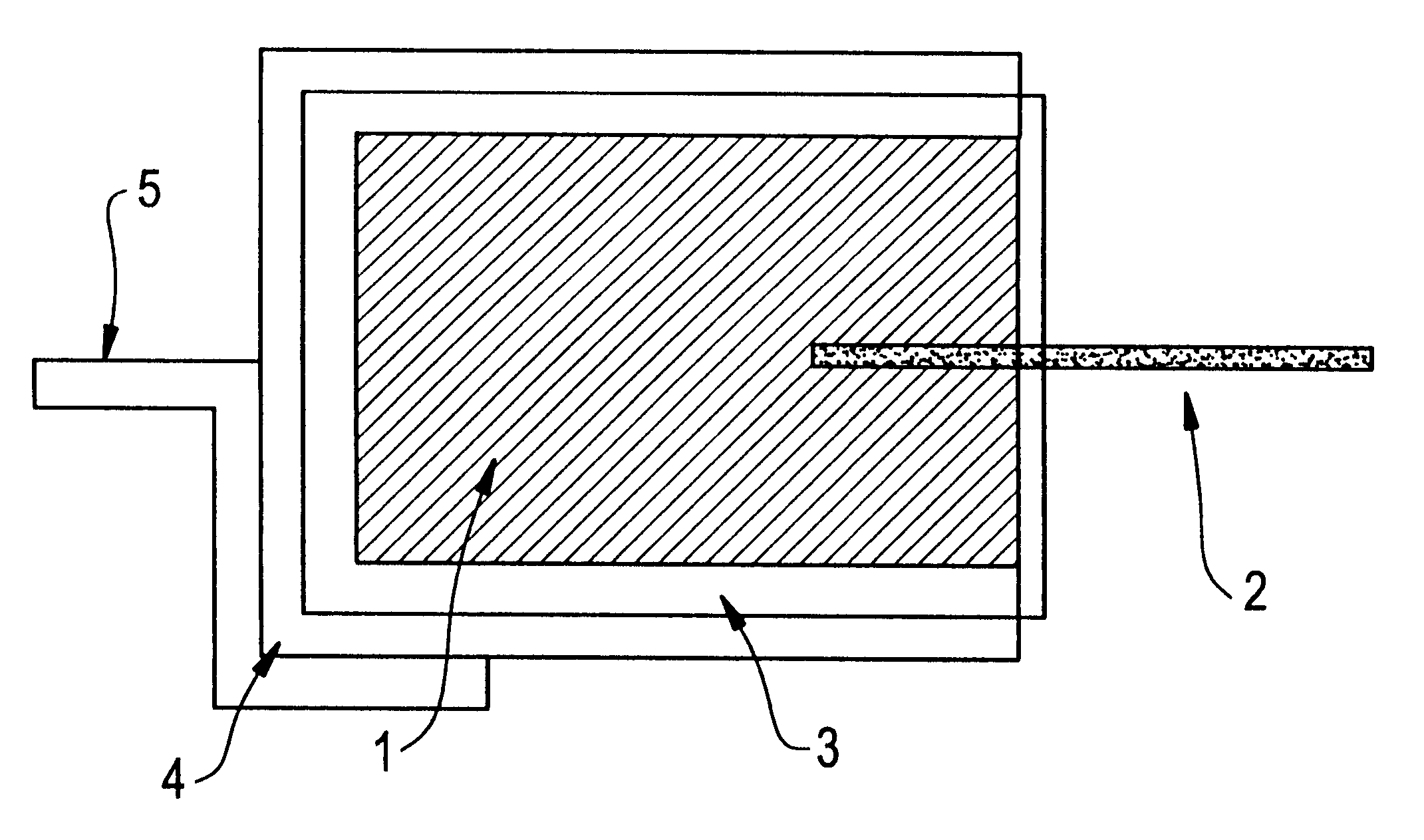

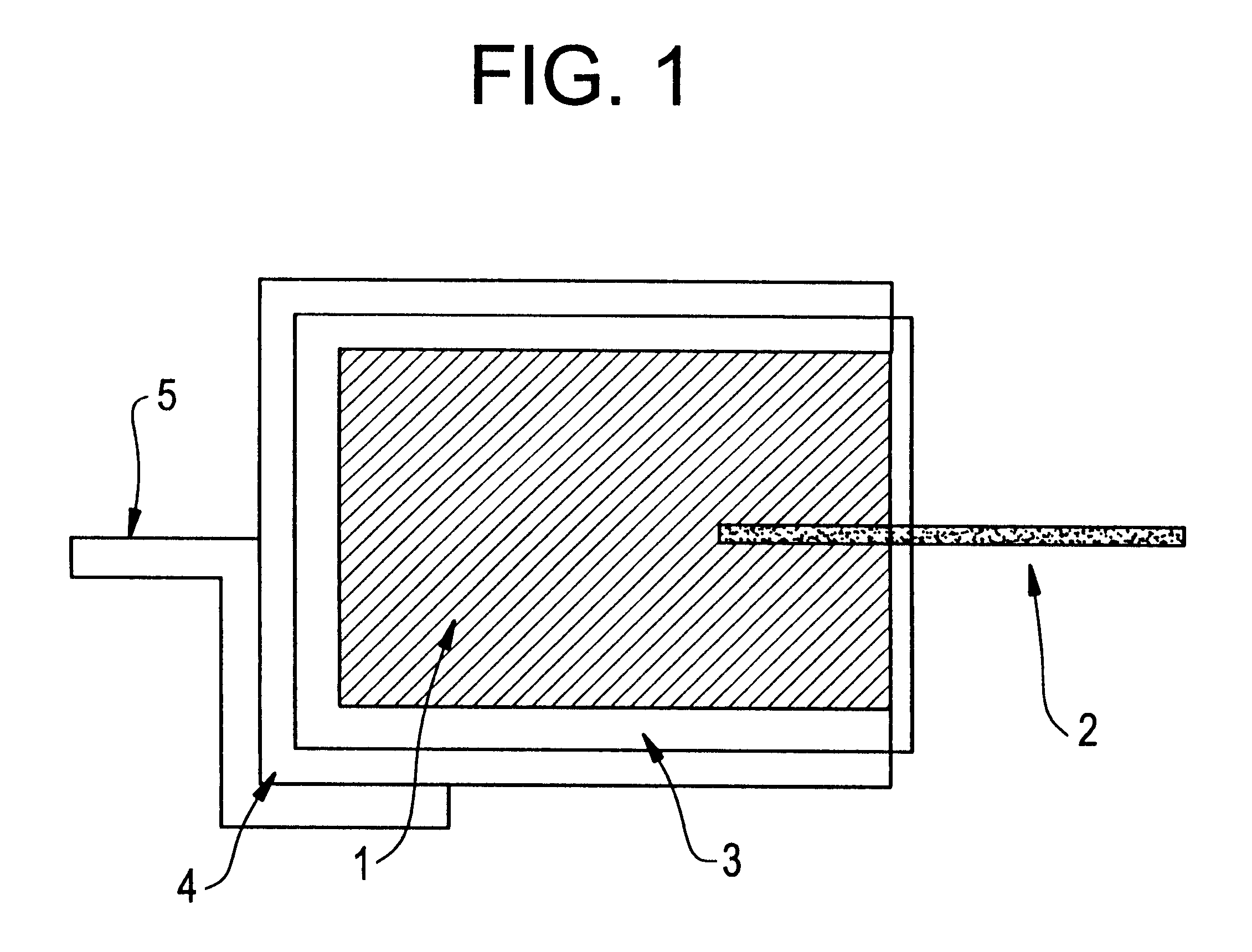

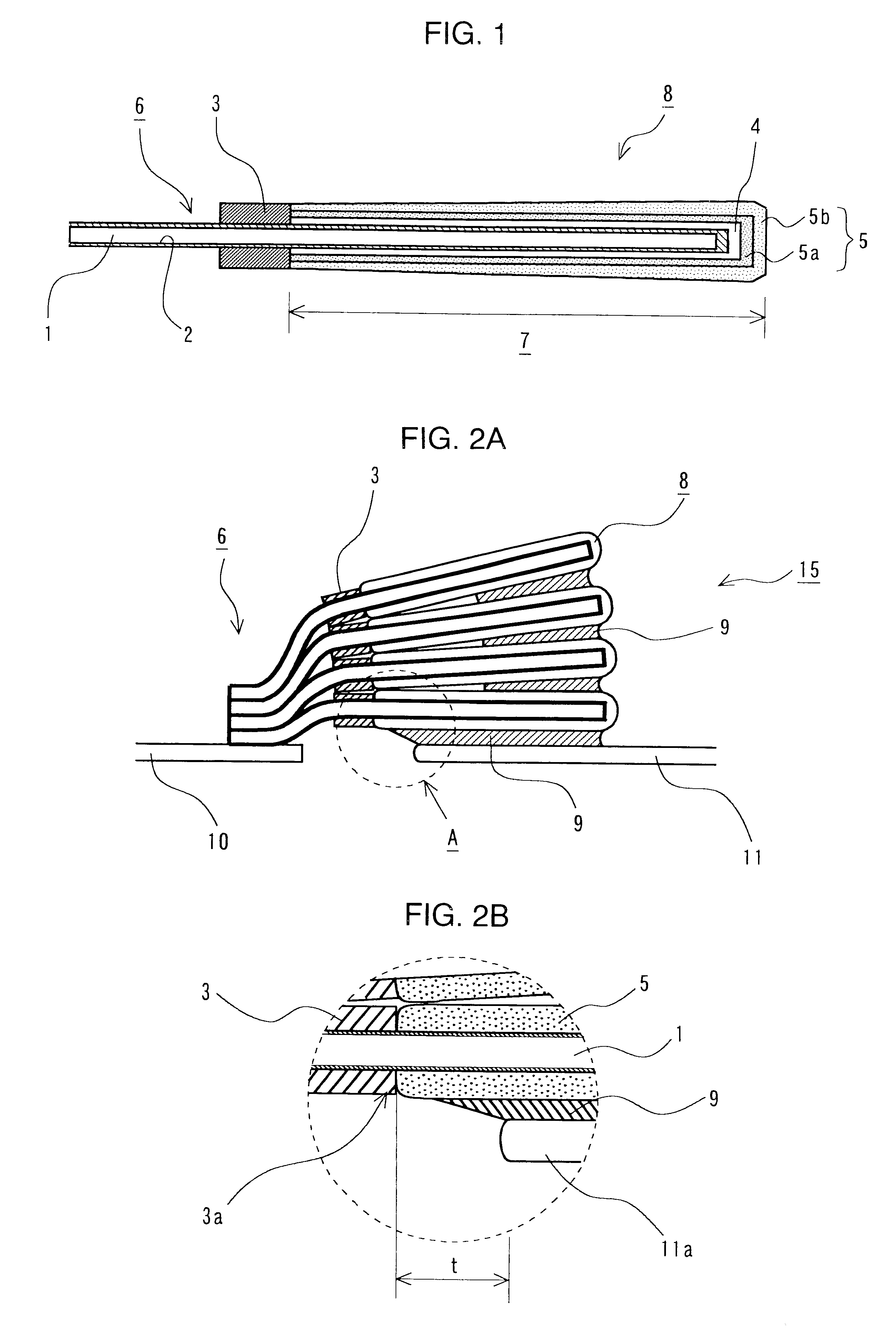

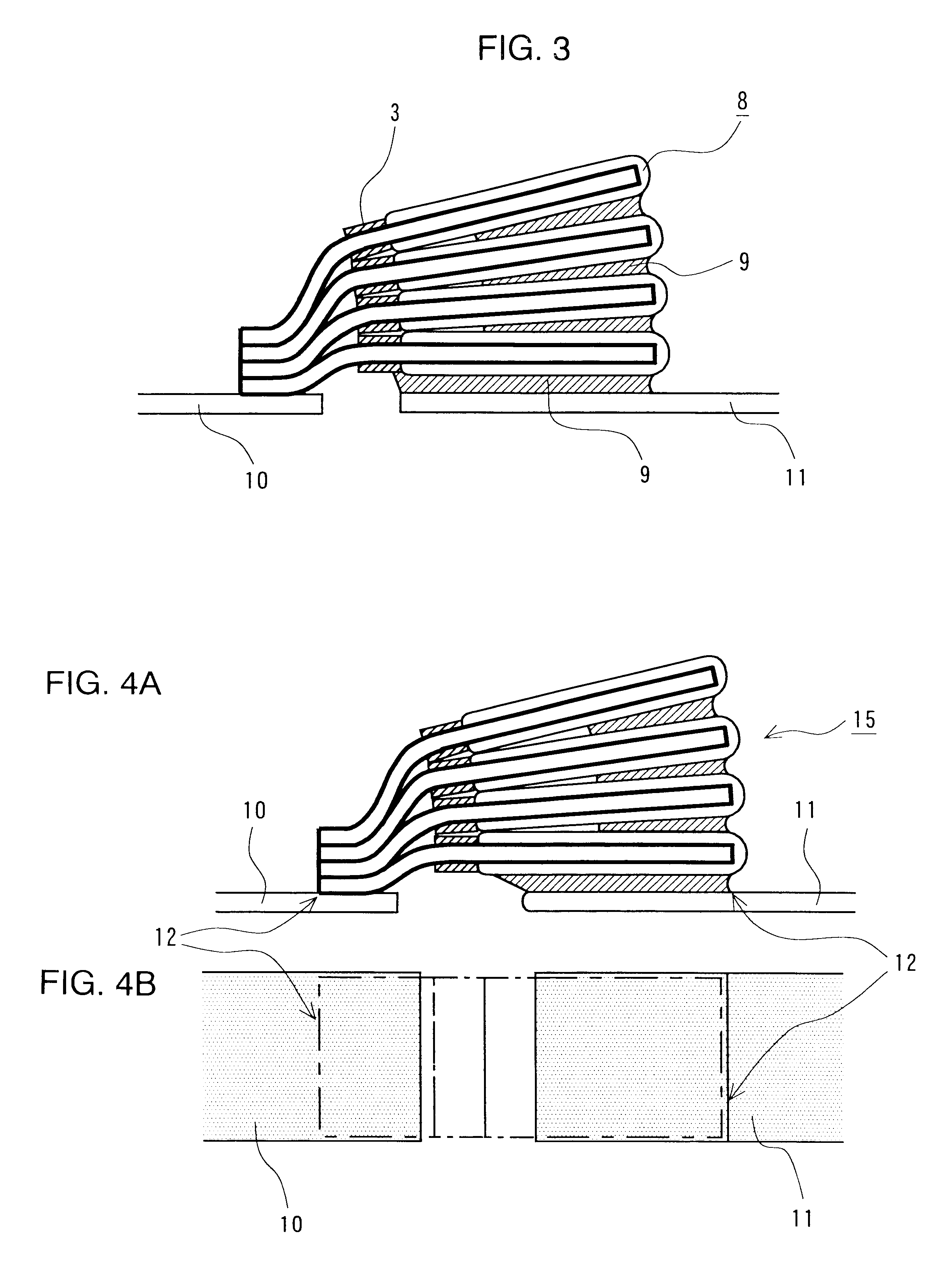

The present invention relates to a method of manufacturing a flat aluminum electrolytic capacitor comprising a separator impregnated with an electrolytic solution, an anode foil and a cathode foil, a flat capacitor element that has external lead-out terminals connected respectively to the anode foil and the cathode foil, and a flexible casing that houses the capacitor element and is hermetically sealed, said method comprising the steps of encasing the capacitor element in the flexible casing and applying aging treatment before hermetically sealing the casing, and hermetically sealing the flexible casing, and also relates to a flat aluminum electrolytic capacitor comprising a separator impregnated with the electrolytic solution, the anode foil and the cathode foil, the flat capacitor element that has the external lead-out terminals connected respectively to the anode foil and the cathode foil, and the flexible casing that houses the capacitor element and is hermetically sealed, wherein the electrolytic capacitor is subjected to an aging treatment before the capacitor element is encased in the flexible casing which is hermetically sealed.

Owner:RUBYCON CORPORATION

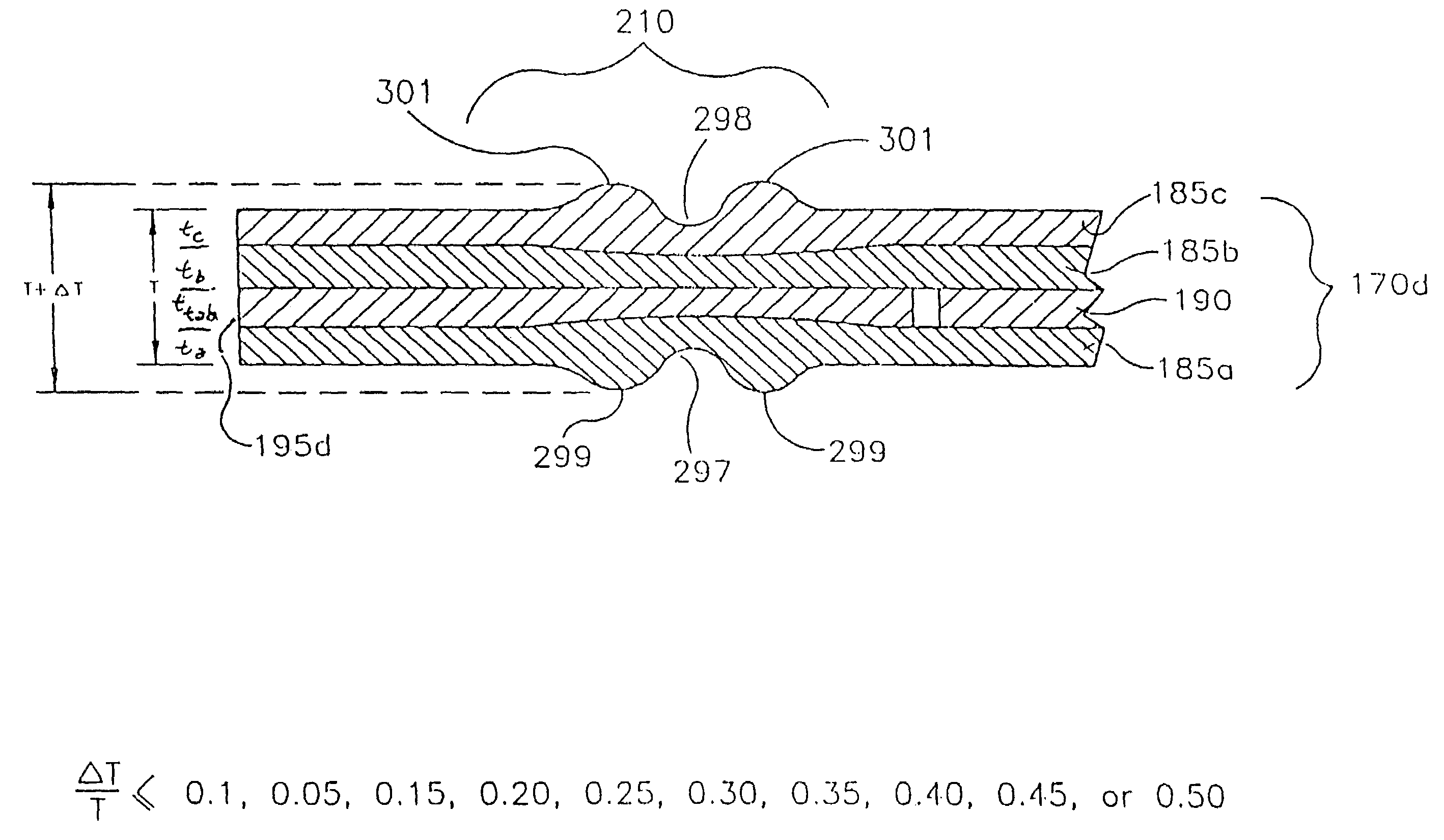

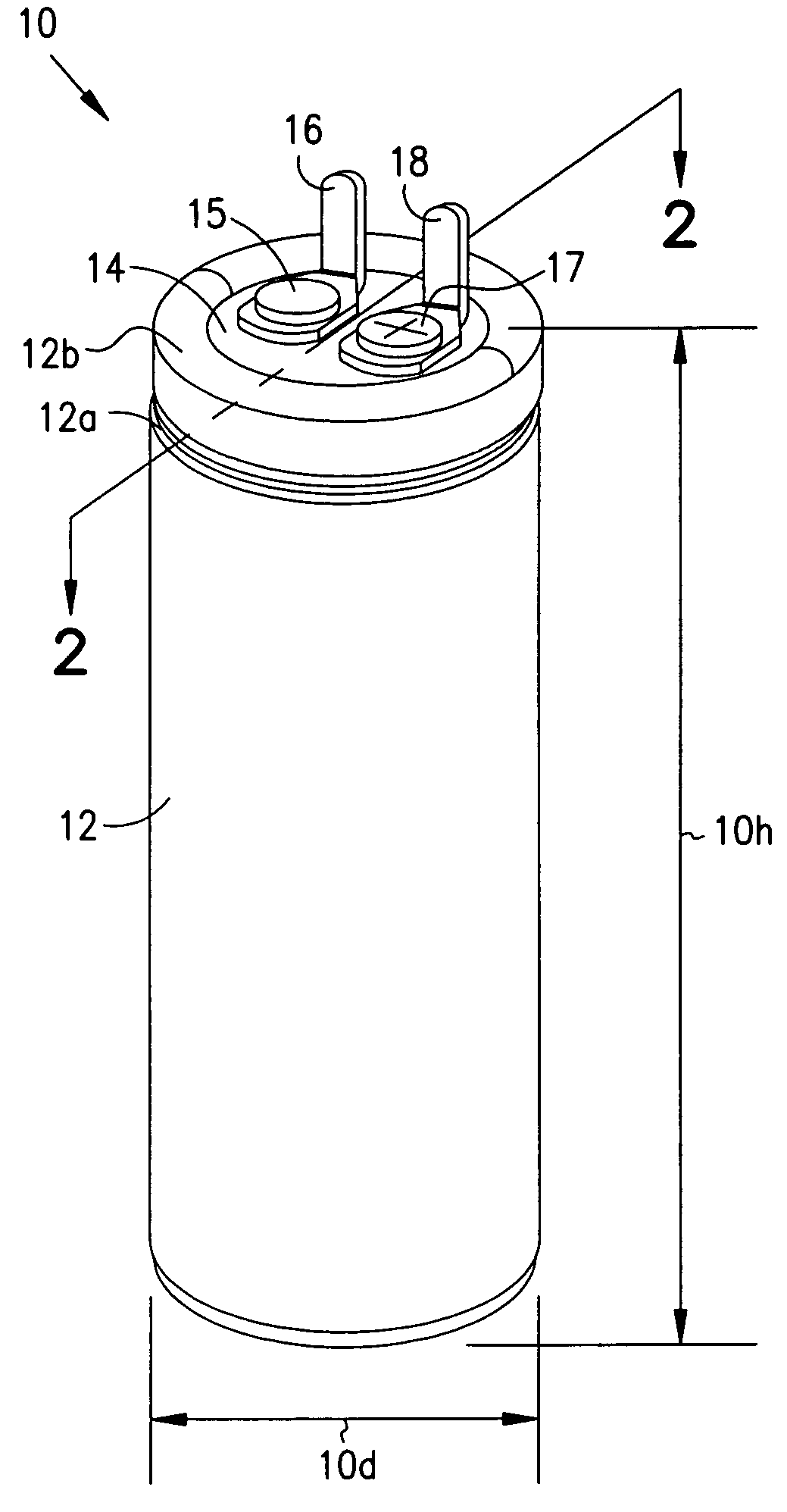

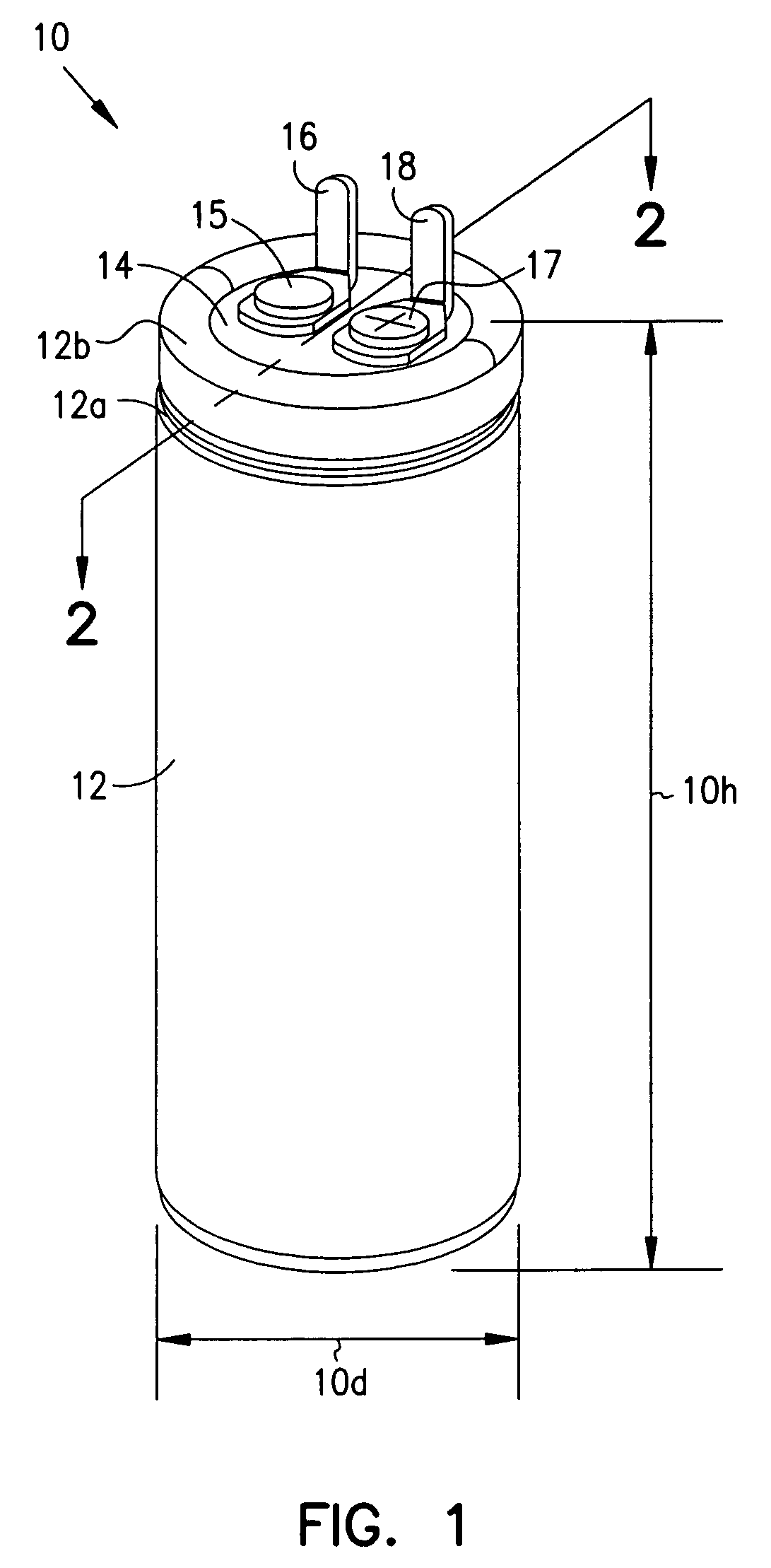

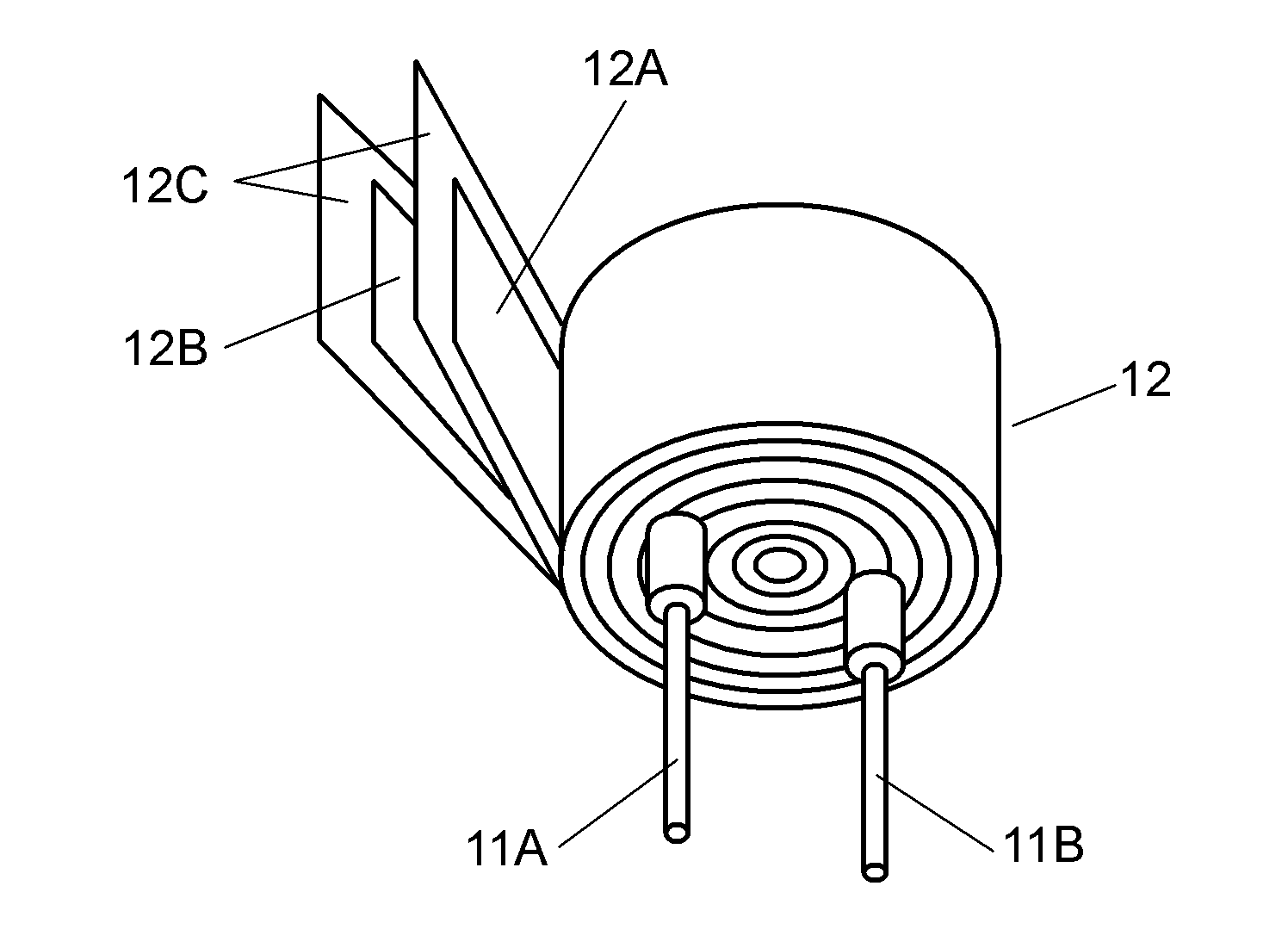

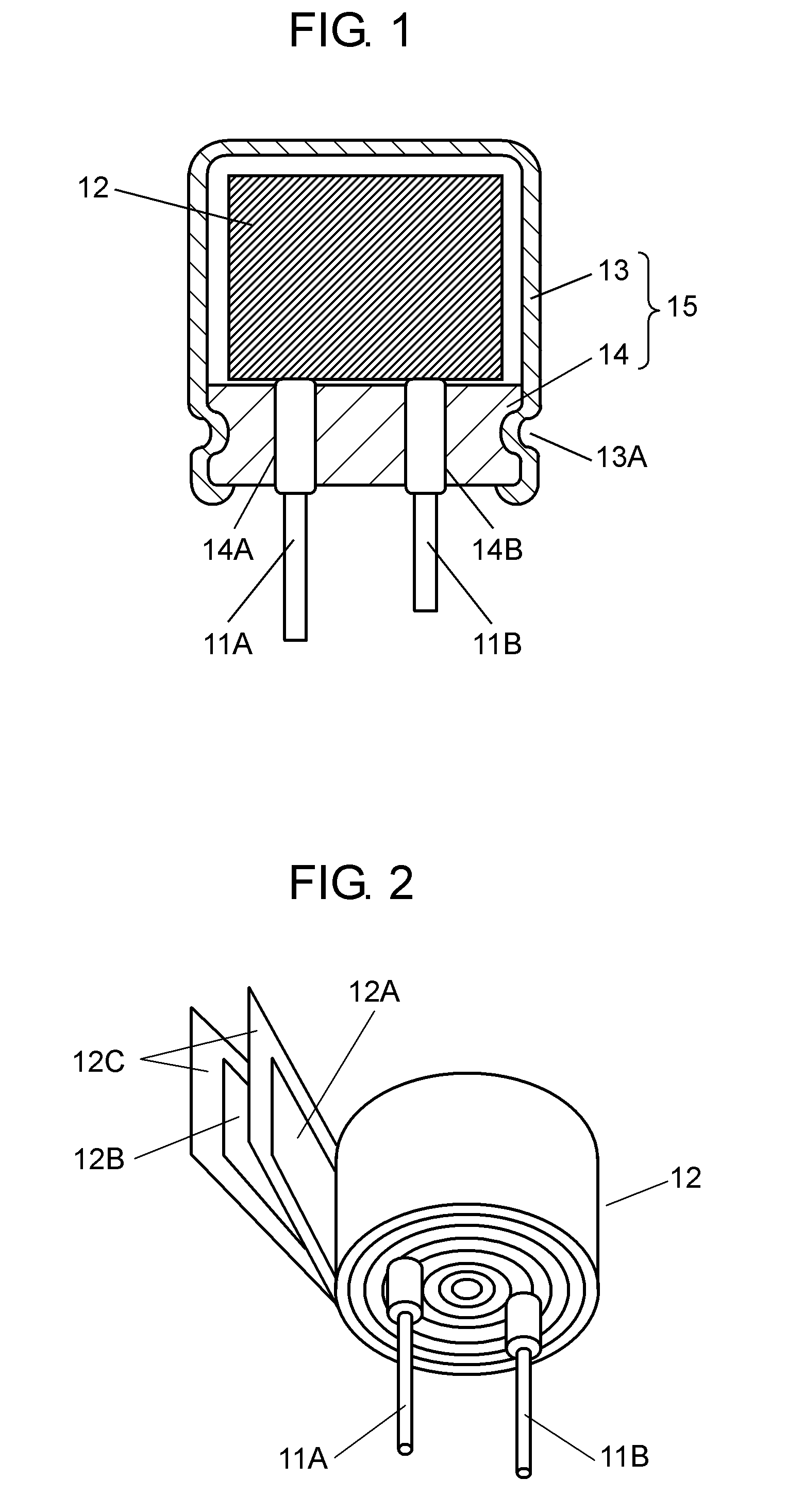

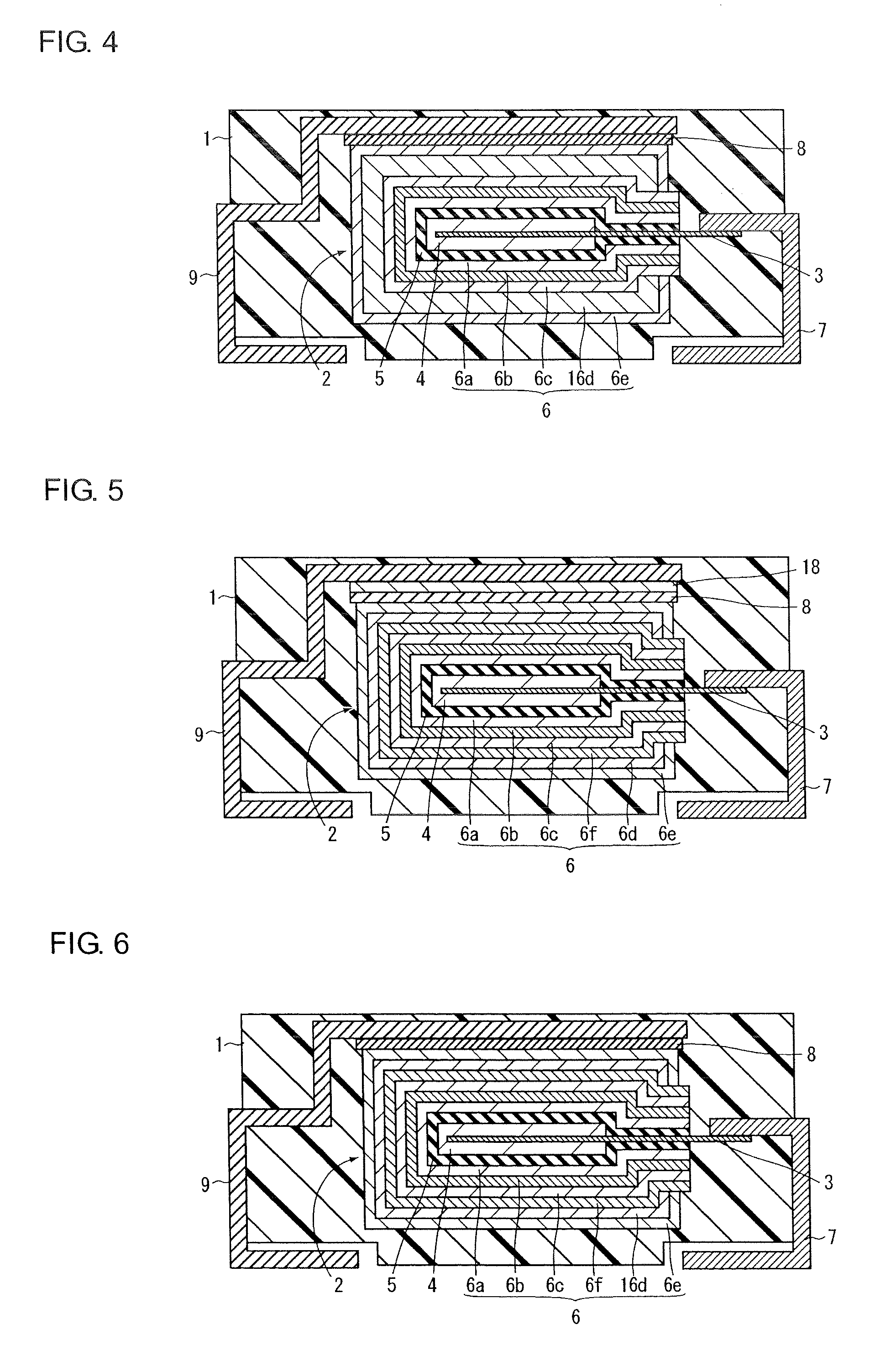

Smaller electrolytic capacitors for implantable defibrillators

InactiveUS7251123B2Reduce the overall diameterReduce volumeLiquid electrolytic capacitorsHeart defibrillatorsFiberElectrolysis

Implantable defibrillators are implanted into the chests of patients prone to suffering ventricular fibrillation, a potentially fatal heart condition. A critical component in these devices is an aluminum electrolytic capacitors, which stores and delivers one or more life-saving bursts of electric charge to a fibrillating heart. These capacitors make up about one third the total size of the defibrillators. Unfortunately, conventional manufacturers of these capacitors have paid little or no attention to reducing the size of these capacitors through improved capacitor packaging. Accordingly, the inventors contravened several conventional manufacturing principles and practices to devise unique space-saving packaging that allows dramatic size reduction. One embodiment of the invention uses thinner and narrower separators and top and bottom insulative inserts to achieve a 330-volt operating, 390-volt surge, 190-microfarad, 30-Joule aluminum electrolytic capacitor which is 33 percent smaller than conventional capacitors having similar electrical traits.

Owner:CARDIAC PACEMAKERS INC

Electrolytic capacitor

ActiveUS20120300368A1Small sizeLarge capacitanceHybrid capacitor separatorsHybrid capacitor electrolytesElectrolysisDielectric layer

An electrolytic capacitor includes a capacitor element, an electrolyte solution with which the capacitor element is impregnated, and an outer package enclosing the capacitor element and the electrolyte solution. The capacitor element includes an anode foil having a dielectric layer on a surface thereof, a cathode foil, a separator disposed between the anode foil and the cathode foil, and a solid electrolyte layer in contact with the dielectric layer of the anode foil and the cathode foil. The electrolyte solution contains a low-volatile solvent that is at least one of polyalkylene glycol and a derivative of polyalkylene glycol.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Conductive composition precursor, conductive composition, solid electrolytic capacitor, and their manufacturing method

InactiveUS6853540B2Improve pressure resistanceAvoid conductionHybrid capacitor electrolytesClosuresConductive polymerOptoelectronics

A solid electrolytic capacitor including a valve metal positive electrode, an anodized layer formed on a surface of the positive electrode, a conductive polymer-containing negative electrode conductive layer, and a coupling agent layer and a surface active agent layer placed between the anodized layer and the negative electrode conductive layer.

Owner:PANASONIC CORP

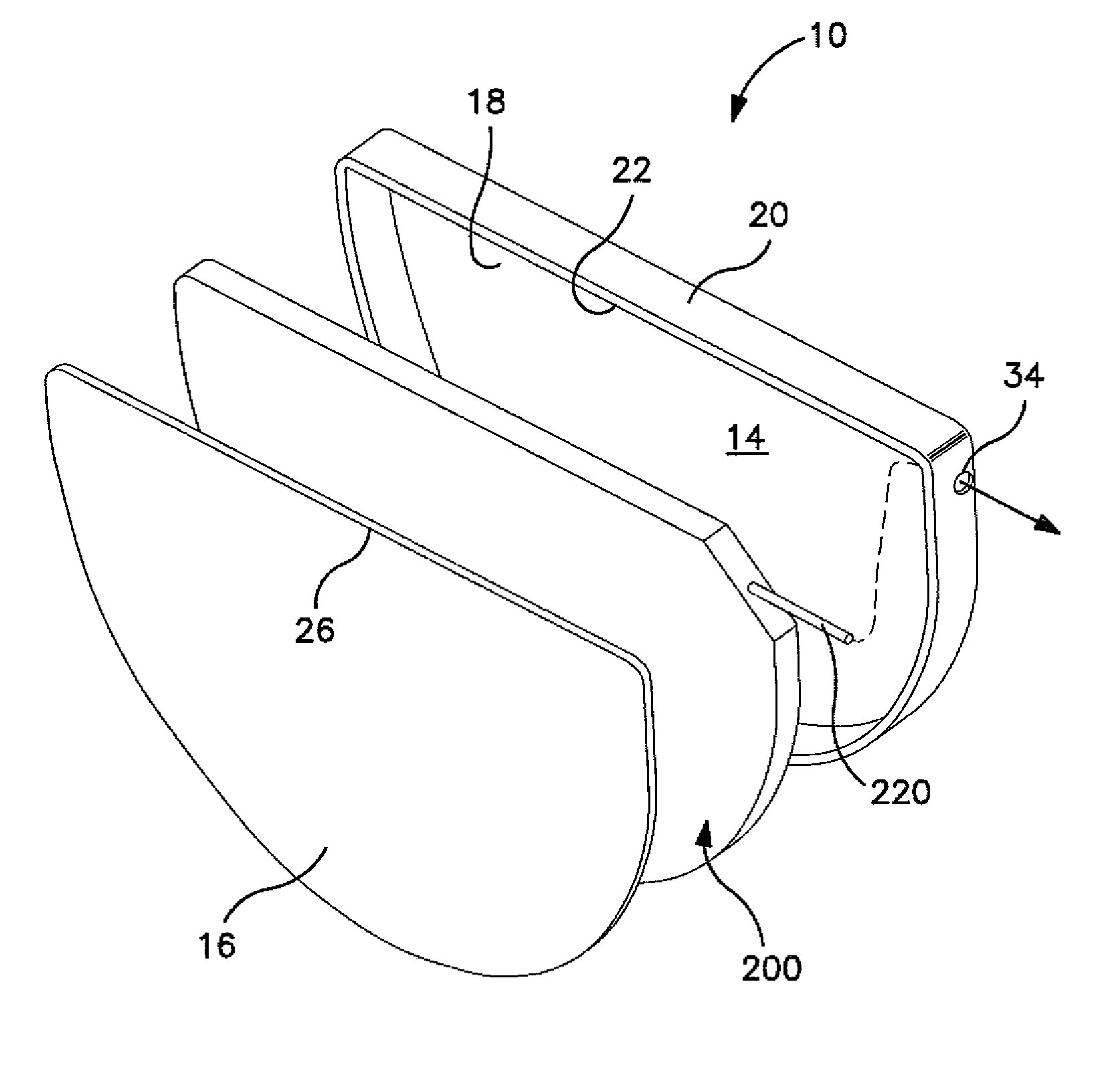

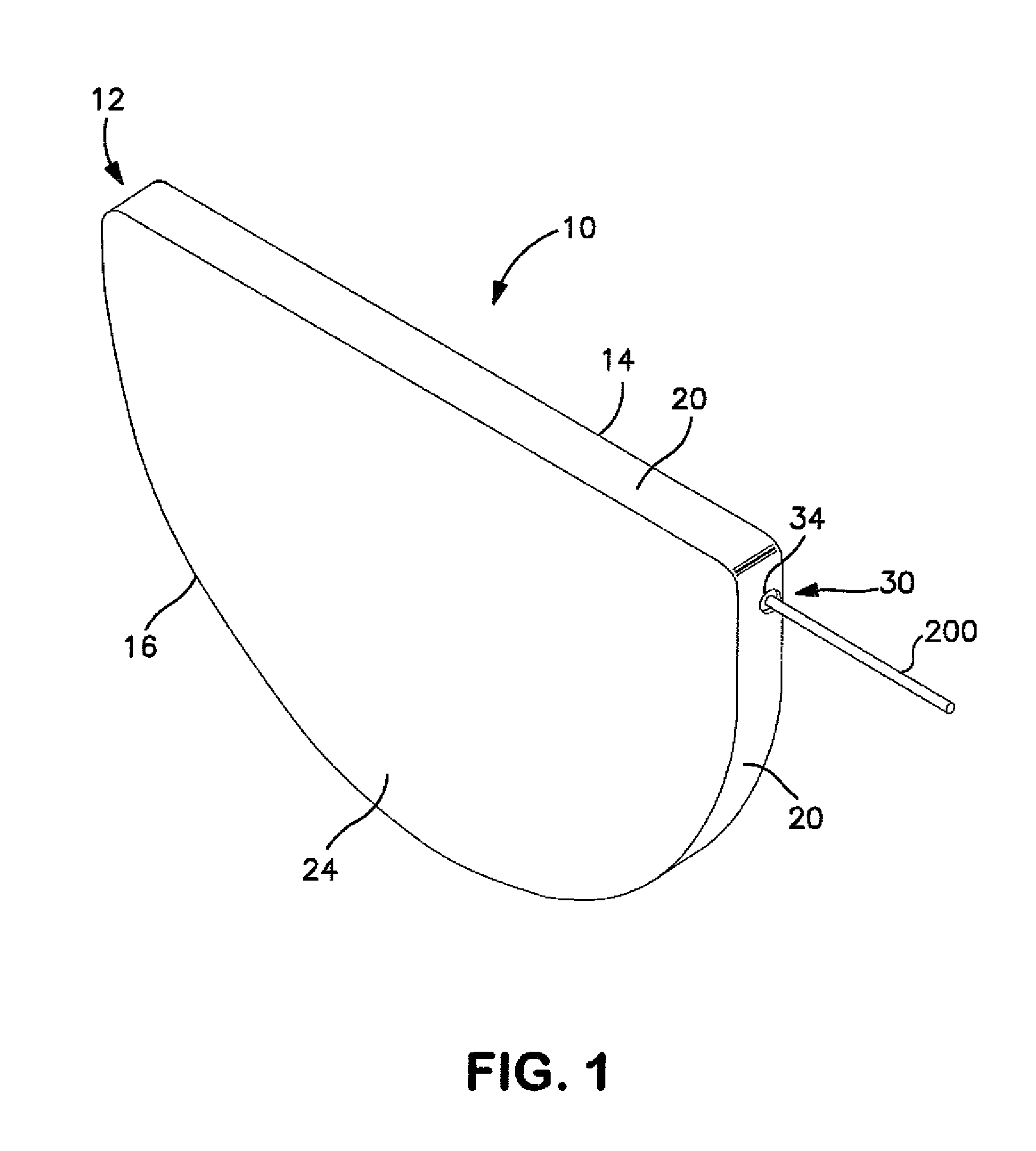

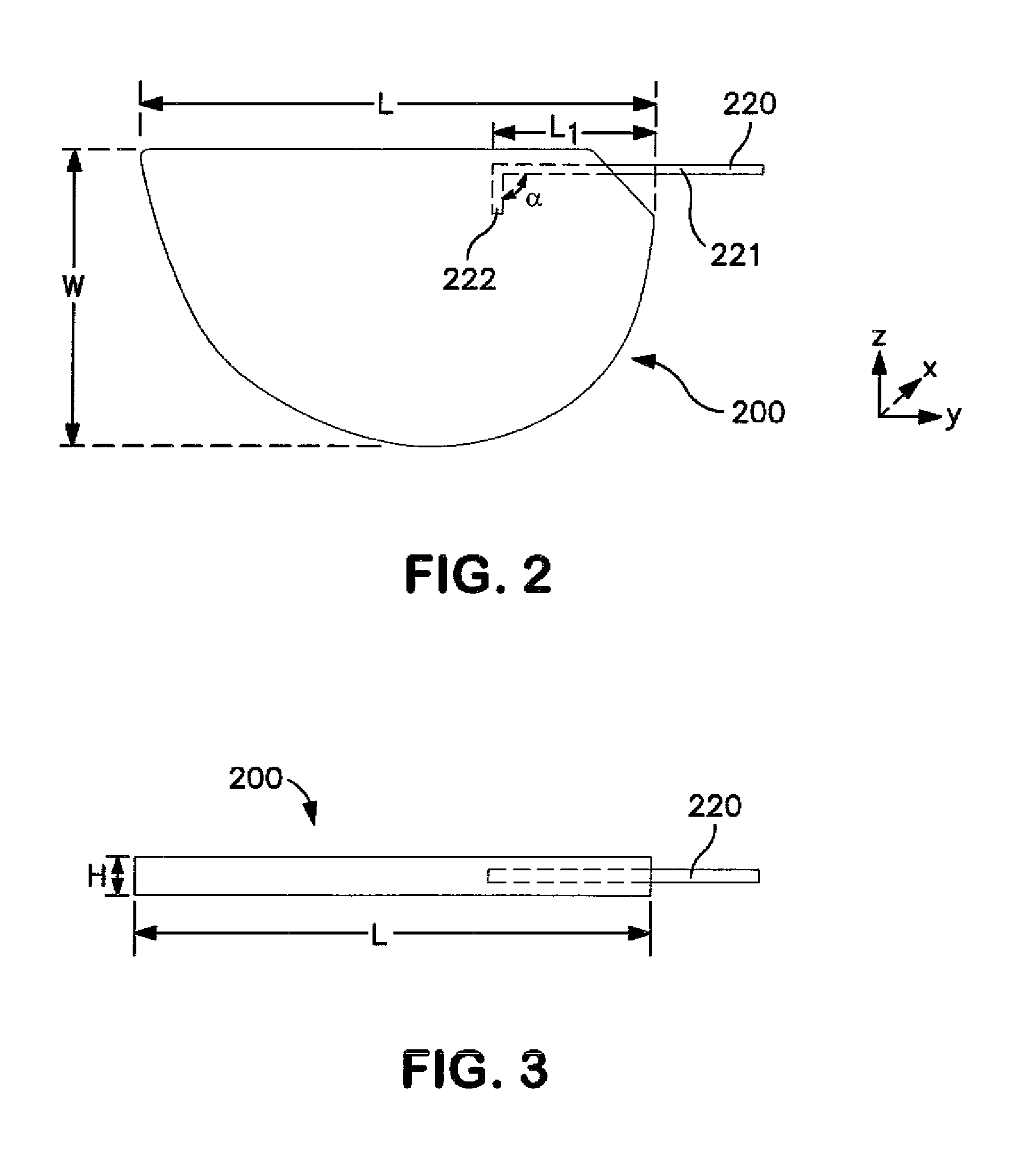

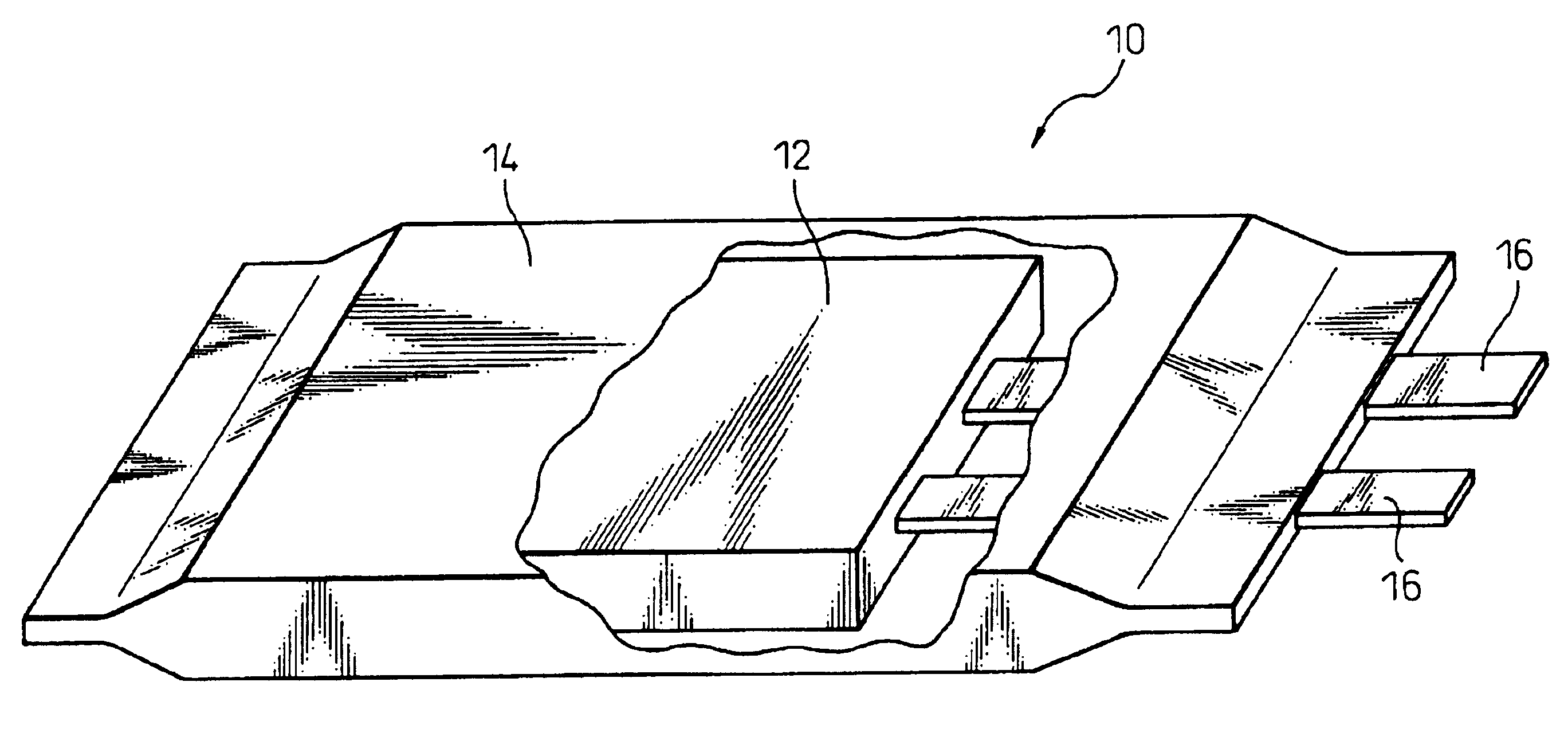

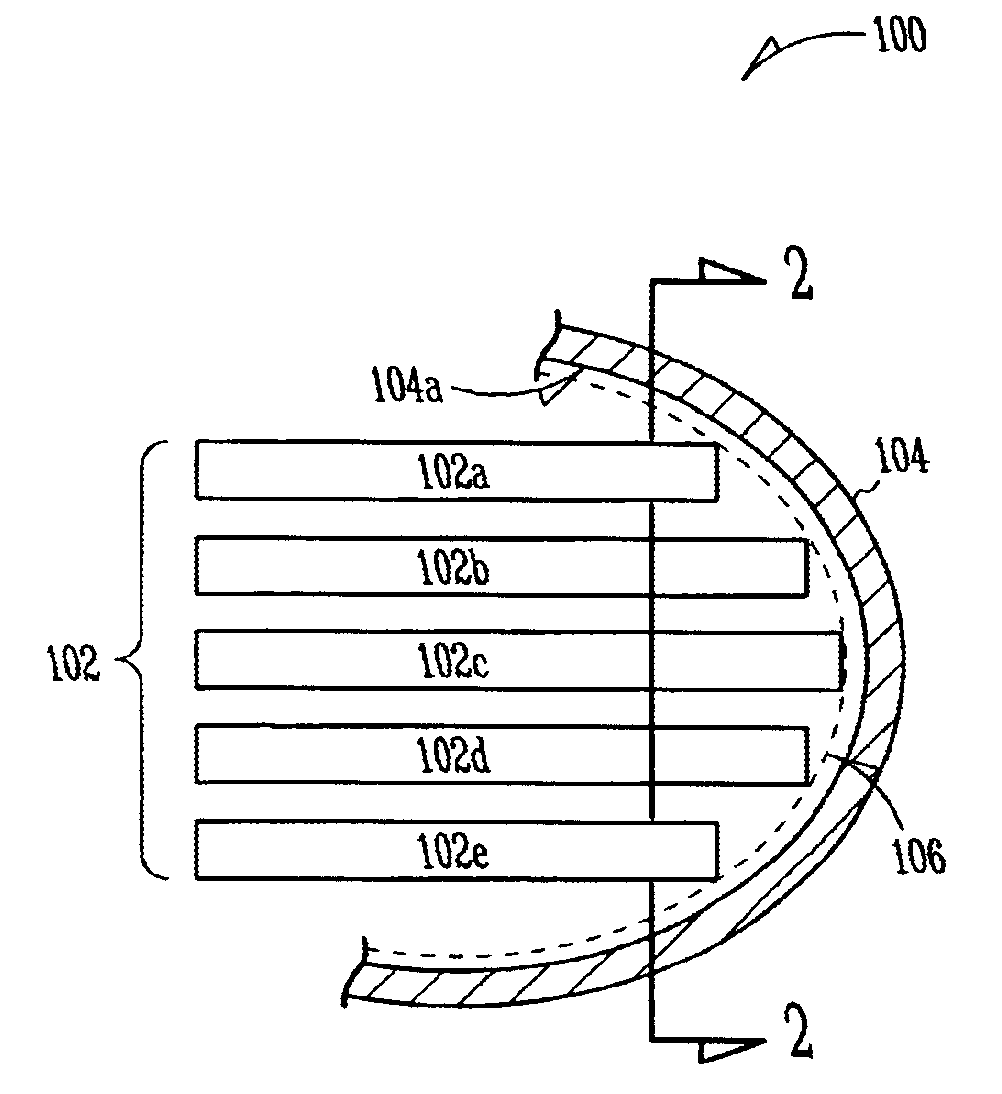

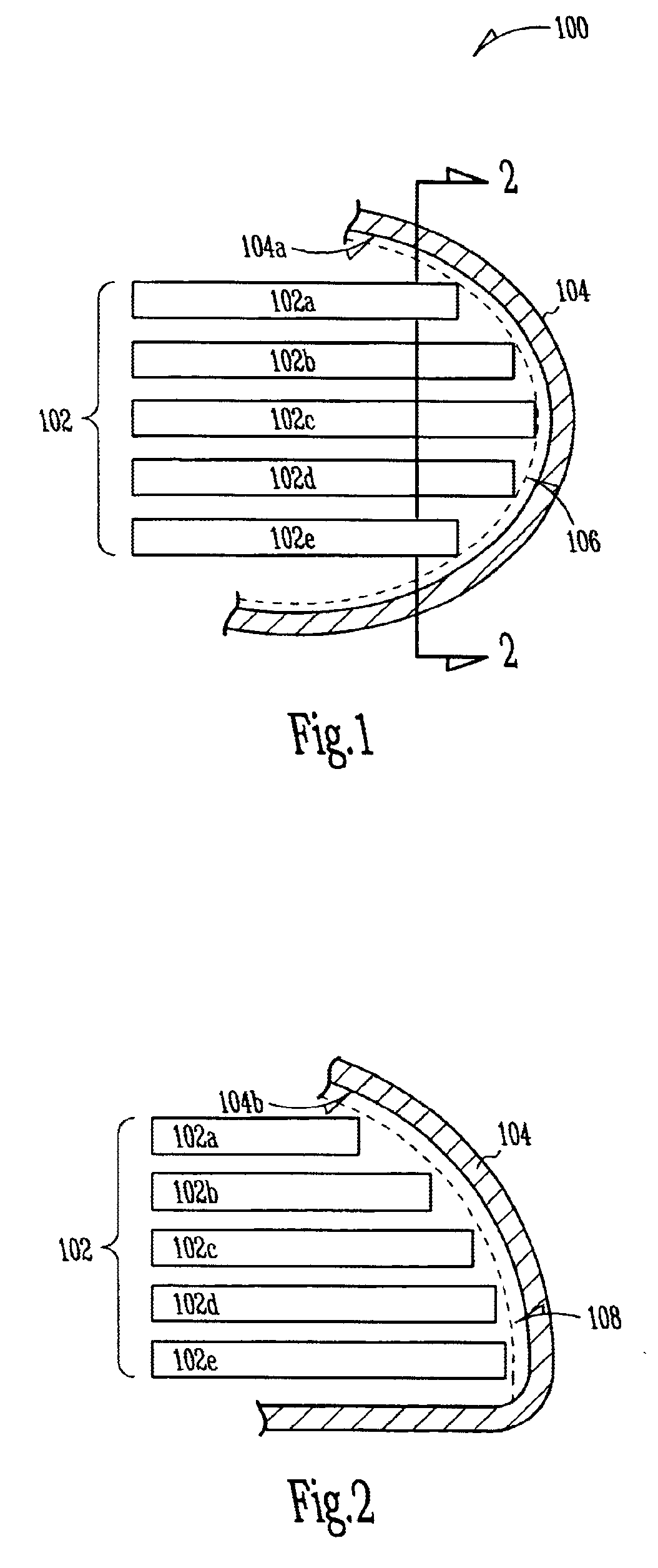

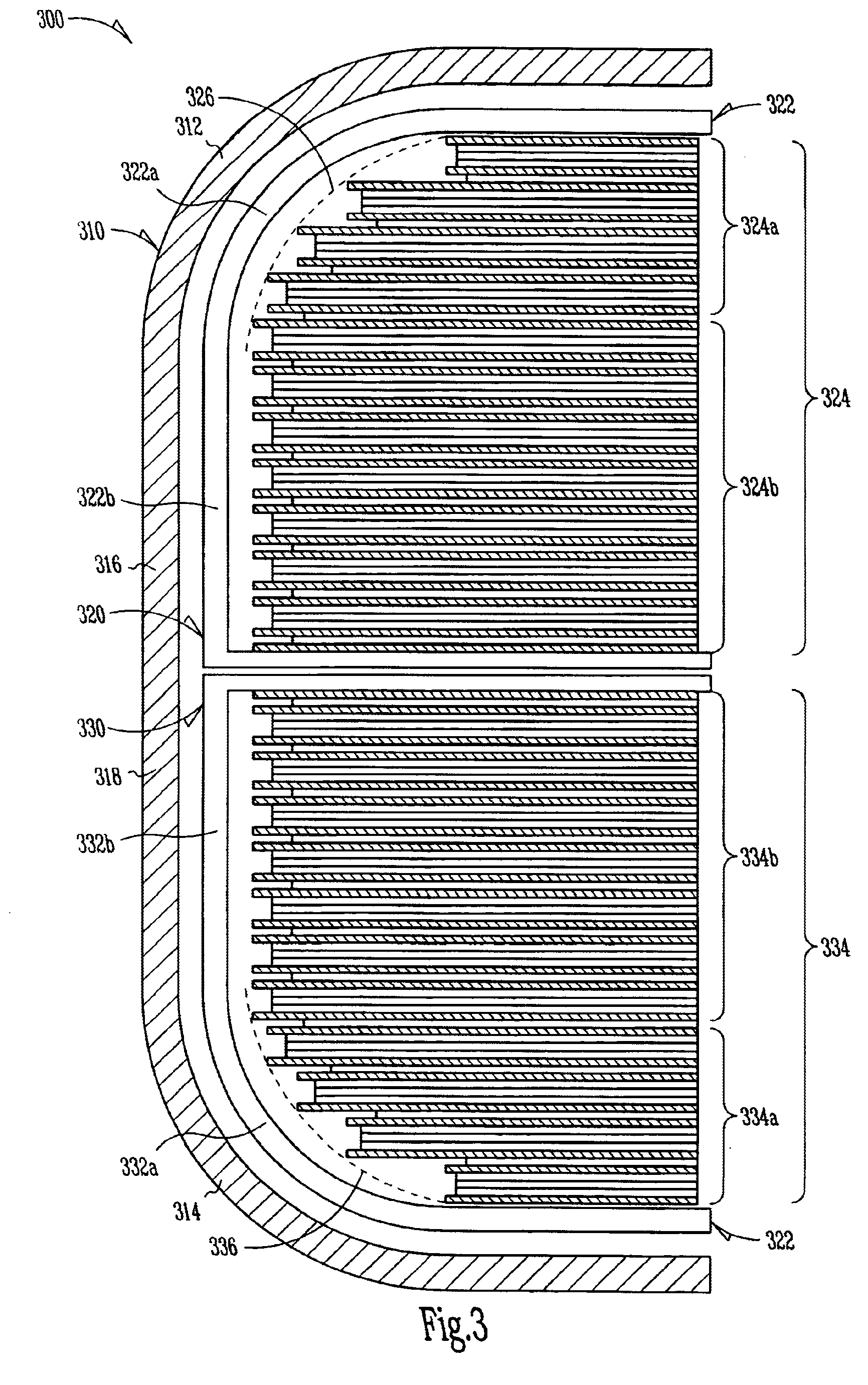

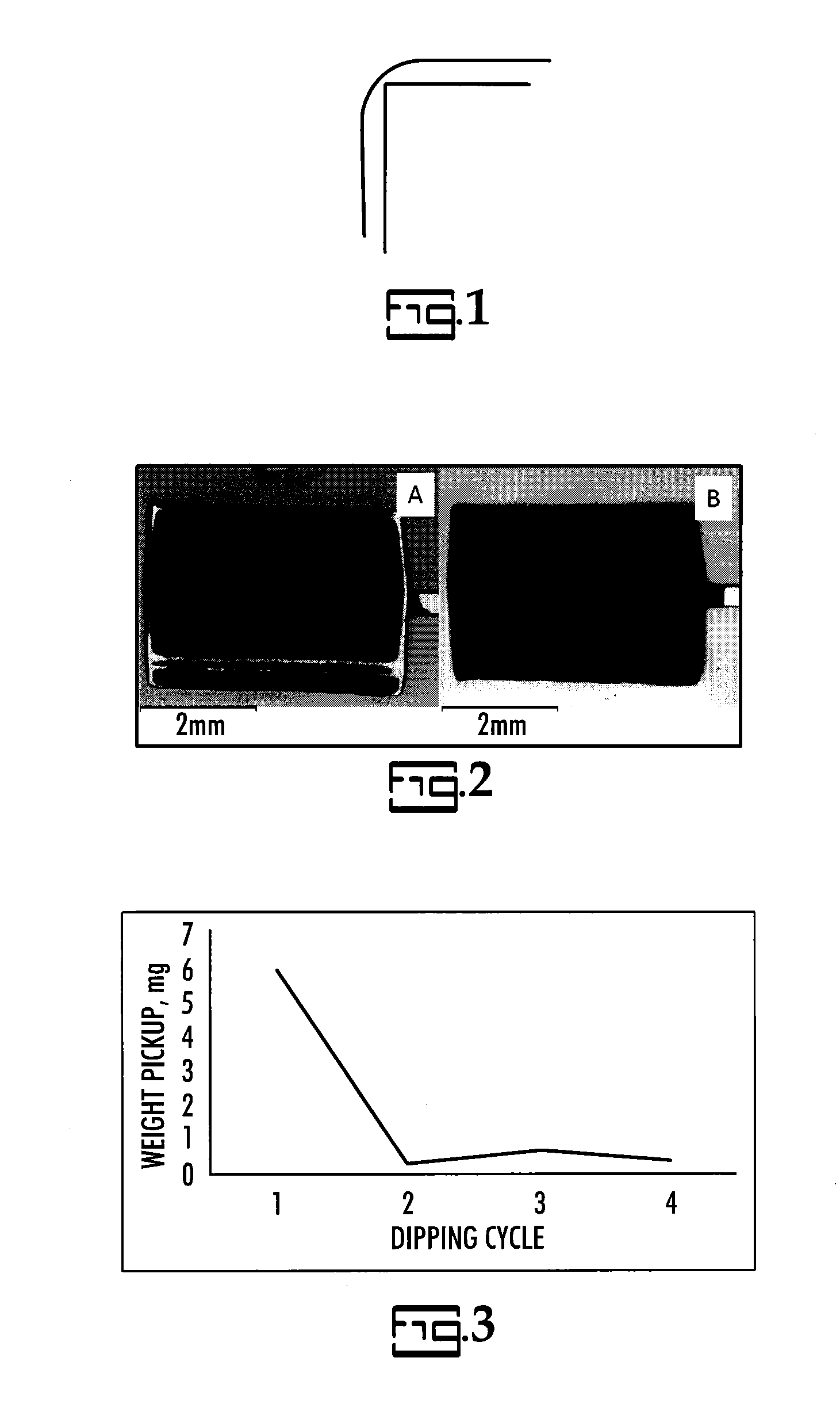

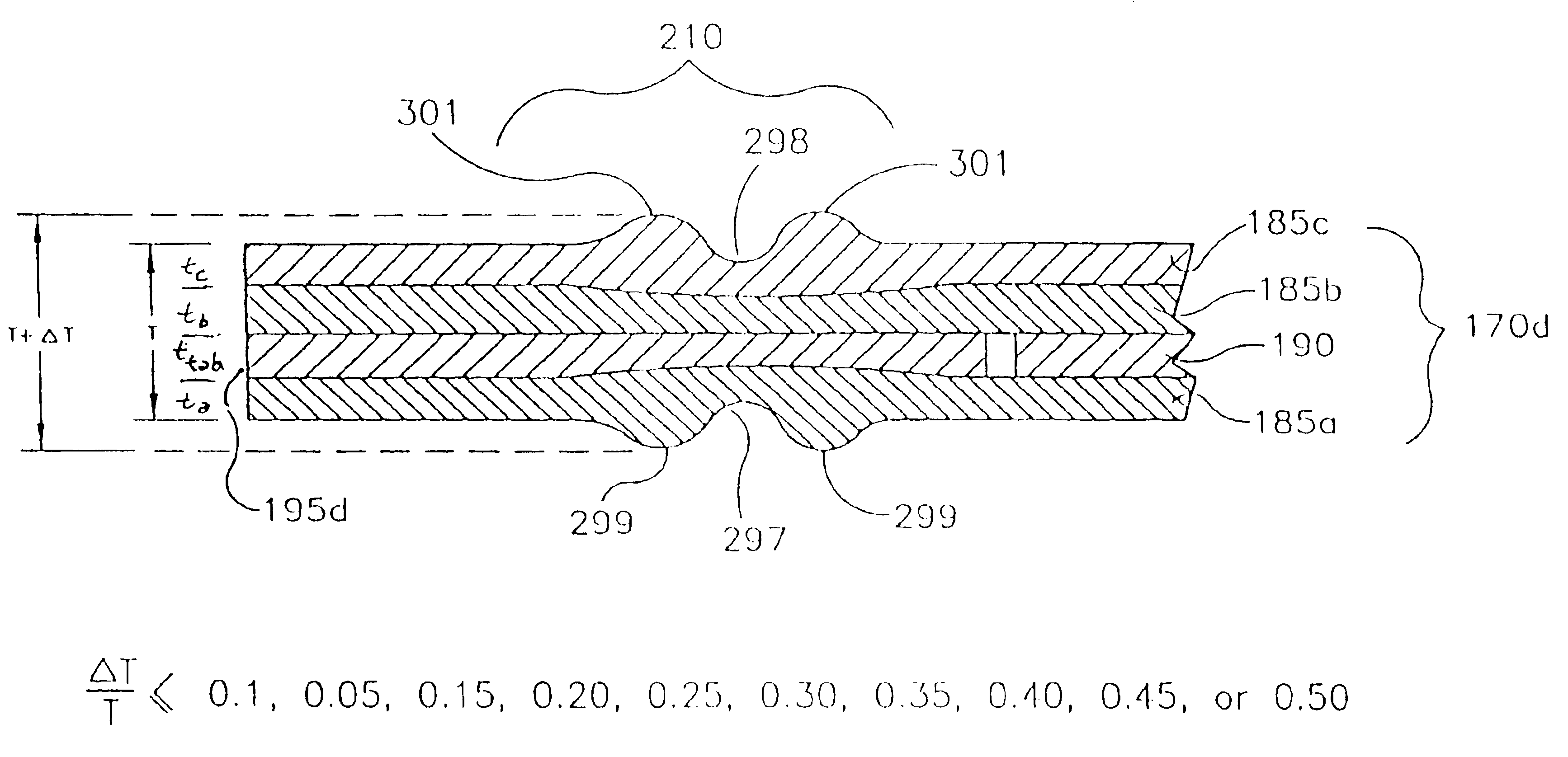

Implantable heart monitors having flat capacitors with curved profiles

Implantable heart-monitoring devices, such as defibrillators, pacemakers, and cardioverters, detect onset of abnormal heart rhythms and automatically apply corrective electrical therapy, specifically one or more bursts of electric charge, to abnormally beating hearts. Critical parts in these devices include the capacitors that store and deliver the bursts of electric charge. Some devices use flat aluminum electrolytic capacitors have cases with right-angle corners which leave gaps when placed against the rounded interior surfaces of typical device housings. These gaps and voids not only waste space, but ultimately force patients to endure implantable devices with larger housings than otherwise necessary. Accordingly, the inventors devised several capacitor structures that have curved profiles conforming to the rounded interior surfaces of device housings. Some exemplary capacitor embodiments include two or more staggered capacitor elements, and other embodiments stagger capacitors of different types and / or sizes.

Owner:CARDIAC PACEMAKERS INC

Method for forming ultrahigh-voltage anode foil for aluminum electrolytic capacitors

ActiveCN102610390AImprove compactnessIncrease costSurface reaction electrolytic coatingCapacitor electrodesConvertersPhosphorous acid

The invention relates to the production of electronic components, and discloses a method for forming anode foil for electrolytic capacitors. The ultrahigh-voltage anode foil is formed through six stages, wherein from the stage 1 to stage 5, each stage has a formation tank, and in the stage 6, three formation tanks are connected in parallel; and an acid fluid mixture containing a boric acid, a citric acid or an azelaic acid (the electric conductance and pH value thereof are adjusted by using carbon-containing inorganic salts) and ammonium hypophosphite or sodium monophosphate for improving the boiled performance of an oxidation film is filled in each formation tank. Correspondingly, the processing step is also adjusted, and the produced anode foil not only can be applied to the fields and industries of aerospace and automotive frequency converters and industrial frequency converters and the like meeting the ultrahigh voltage requirements on a withstand voltage of 700-1200V, but also is dense in oxidation film surface, high in specific volume and short in boosting time.

Owner:新疆金泰新材料技术股份有限公司

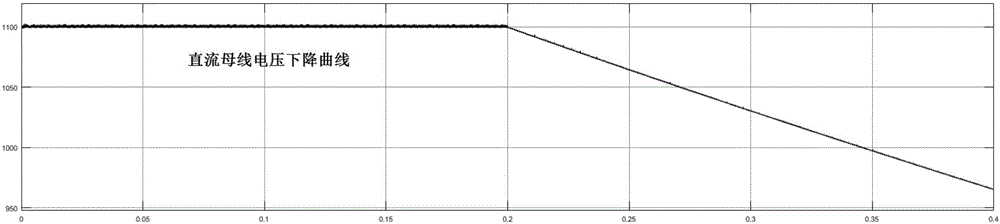

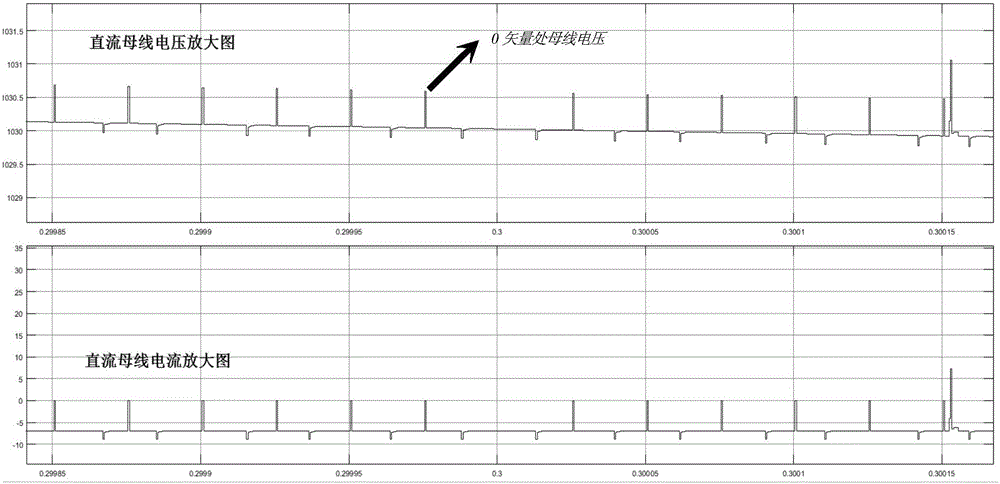

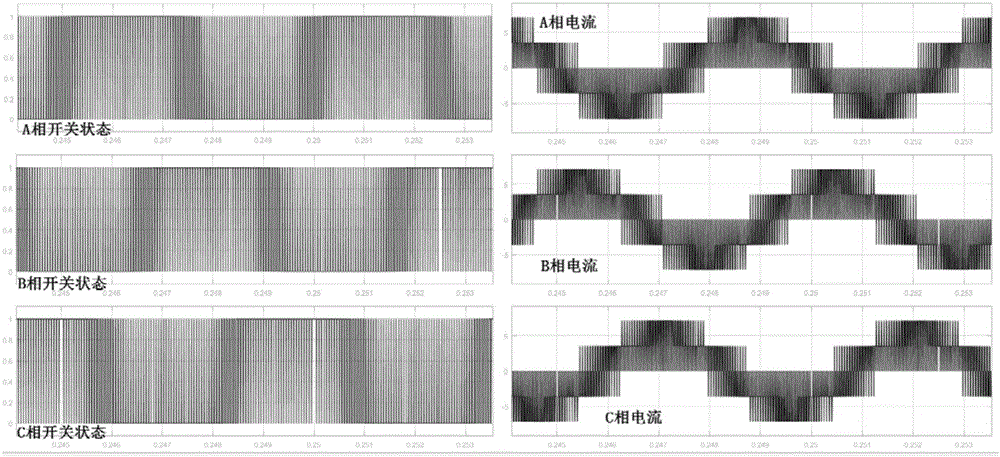

Online monitoring method for DC-link capacitor of three-phase system

ActiveCN105717368AEnables non-intrusive online monitoringAccurate calculationCapacitance measurementsAviationControl signal

The invention provides an online monitoring method for a DC-link capacitor of a three-phase system. The method comprises that voltage of the DC-link capacitor is collected, and a voltage drop curve of the DC-link capacitor is obtained; three-phase output current is collected, and capacitive current is reconstructed according to the three-phase output current; and the capacitance (C) and equivalent serial resistance (ESR) of the DC-link capacitor are obtained according to the voltage drop curve and the capacitive current of the DC-link capacitor. The voltage drop curve and the three-phase output current of the DC-link capacitor as well as control signals of a semiconductor switch are monitored in the process that power equipment as a three-phase frequency converter is switched off, so that the C and ESR of the DC-link capacitor are calculated accurately, and non-invasive online monitoring for the DC-link capacitor of the AC / DC / AC system is realized. The method can be applied to online monitoring for an aluminum electrolytic capacitor, other capacitors as a film capacitor as well as other three-phase systems including a wind power converter, a photovoltaic AC / DC / AC system and a three-phase aviation power system.

Owner:CHONGQING UNIV

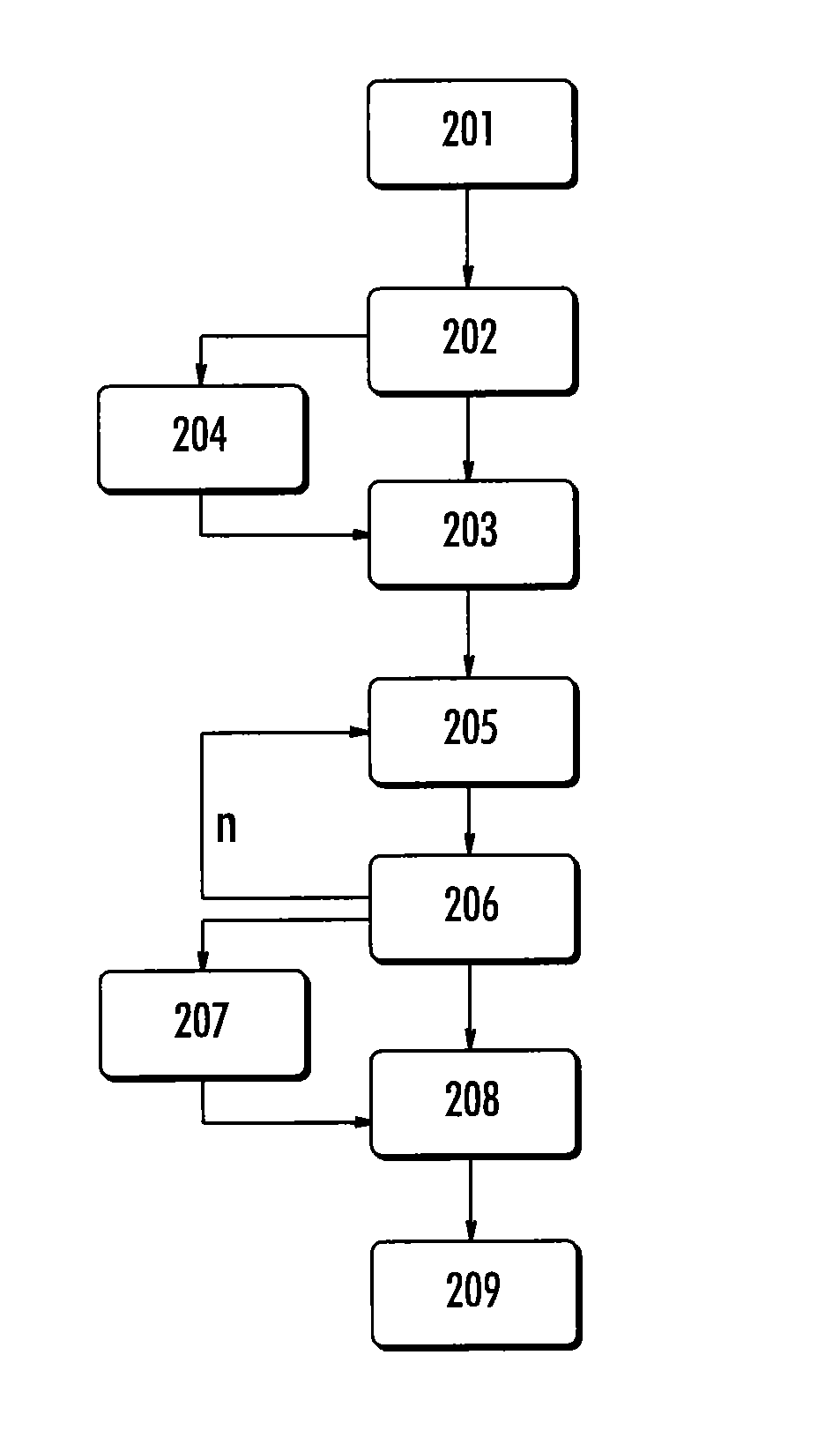

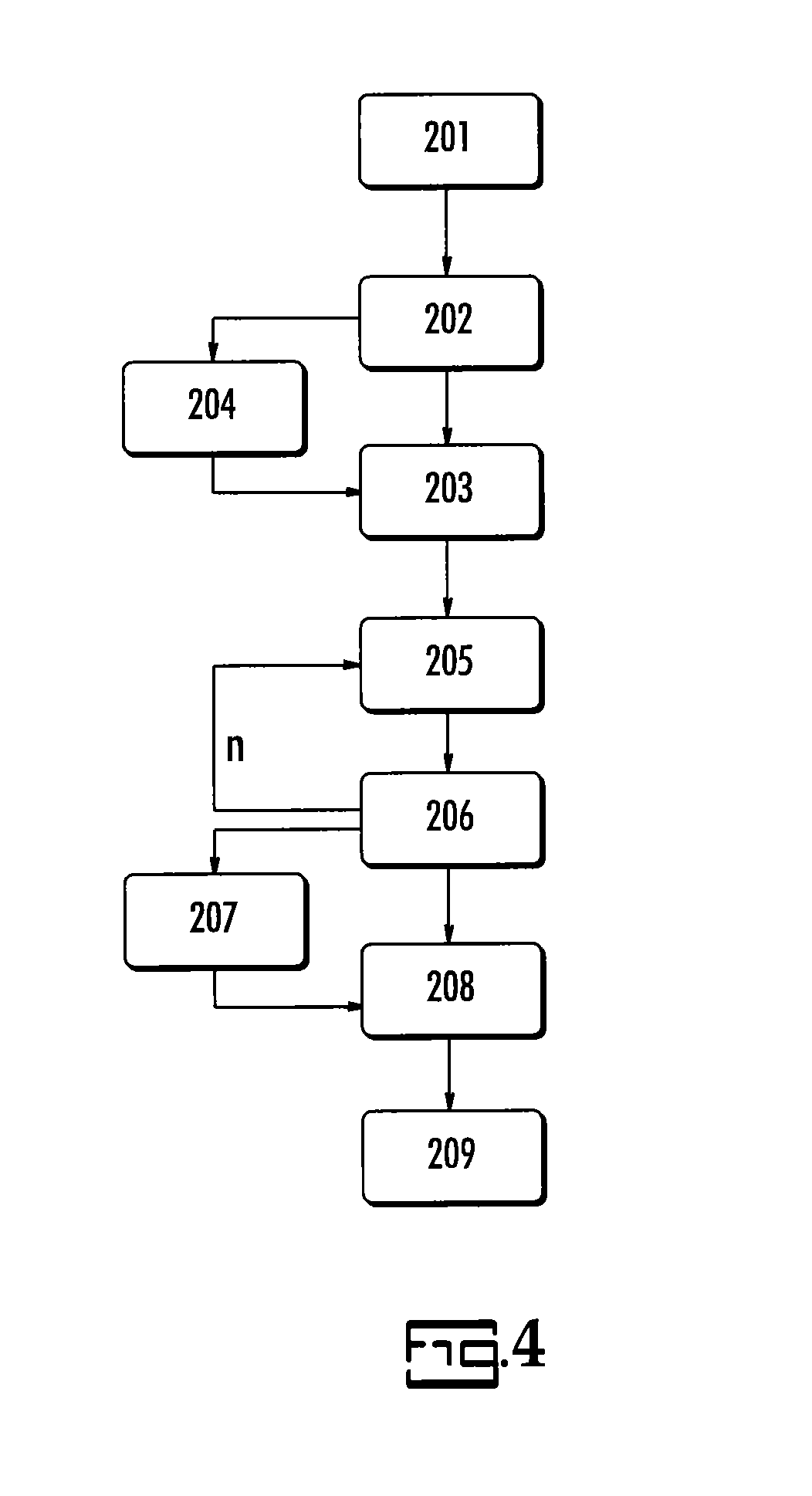

Process for solid electrolytic capacitors using polymer slurries

ActiveUS8808403B2Improve performanceImprove electrical performanceSolid electrolytic capacitorsLiquid electrolytic capacitorsDielectricElectrolysis

A process for forming a solid electrolytic capacitor and an electrolytic capacitor formed by the process. The process includes: providing an anode wherein the anode comprises a porous body and an anode wire extending from the porous body; apply a thin polymer layer onto the dielectric, andforming a dielectric on the porous body to form an anodized anode;applying a first slurry to the anodized anode to form a blocking layer wherein the first slurry comprises a first conducting polymer with an median particle size of at least 0.05 μm forming a layer of crosslinker on the blocking layer; andapplying a layer of a second conducting polymer on the layer of crosslinker.

Owner:KEMET ELECTRONICS CORP

Solid electrolytic capacitor and manufacturing method thereof

InactiveUS6661645B1Reduce resistanceLower impedanceHybrid capacitor electrolytesClosuresHeat resistanceHigh intensity

A solid electrolytic capacitor comprising a capacitor element comprising a valve-acting metal substrate having on the surface thereof a dielectric film and a solid electrolytic layer provided on the dielectric film, the capacitor element provided with lead wires (lead frames), in which the bonding structure between the capacitor element and the lead frames is improved. The solid electrolytic capacitor has high strength at the bonded portion between the capacitor element and the lead frames and has excellent heat resistance and is highly reliable. Also, a method for manufacturing such a solid electrolytic capacitor is disclosed.

Owner:MURATA MFG CO LTD

Manufacturing method for solid aluminum electrolytic capacitor

ActiveCN101504887AImprove electrical performanceEfficient dischargeSolid electrolytic capacitorsCapacitor housing/encapsulationOvervoltageConductive polymer

The invention discloses a method for manufacturing a solid aluminum electrolytic capacitor. The manufacturing method comprises the step of impregnating a core by a monomer and an oxidant respectively after restoration and carbonizing treatment of the coiled core. The method is characterized in that the impregnated core is subjected to two-stage polymerization, namely, firstly low-temperature polymerization and then high-temperature polymerization, so that the polymerization of the monomer and the oxidant fully generates a stable conductive polymer layer; a solvent can be discharged out of the capacitor more efficiently so as to improve the electrical property of the capacitor; and voltages of 0.5, 1 and 1.2 times of a rated voltage are applied to a product in an ageing treatment process respectively to carry out stepwise ageing treatment so as to avoid damage of the core caused by overvoltage shock during disposable ageing, reduce ESR and leakage current LC and achieve the aim of improving the electrical property.

Owner:ZHUHAI LEAGUER CAPACITOR

Electrolyte for flame-retardant wide-temperature high-voltage aluminum electrolytic capacitor and preparation method thereof

ActiveCN102779644AWide temperature rangeGuaranteed stabilityElectrolytic capacitorsCapacitanceCarboxylic salt

The invention provides a working electrolyte for a flame-retardant wide-temperature high-voltage aluminum electrolytic capacitor, which comprises the following components in percentage by weight: 45-80% of main solvent, 0.1-5% of oxidation film stabilizer, 5-15% of secondary solvent, 0.2-3% of hydrogen absorption agent, 5-10% of solute, 5-15% of flame retardant and 5-15% of spark voltage increasing agent. The invention also provides a preparation method of the electrolyte and application of the electrolyte in preparation of a high-voltage electrolytic capacitor. In the electrolyte, appropriate solvent combination is adopted, thus the wide temperature from -40 DEG C to 105 DEG C is realized; a composite solute of an organic carboxylate with a branched chain and a straight-chain carboxylate with a long carbon chain is adopted, thus the stability is ensured, and the cost is controlled; the appropriate spark voltage increasing agent, oxidation film stabilizer and hydrogen absorption agent are added, thus the spark voltage of the electrolyte is increased, and the characteristic parameters of the aluminum electrolytic capacitor are not deteriorated after the aluminum electrolytic capacitor is used for a long time; and the flame retardant is added, thus the aluminum electrolytic capacitor is difficult to burn after striking fire.

Owner:SHENZHEN ZHONGYUAN ELECTRONICS

Solid electrolytic capacitor

InactiveUS20100157510A1Low ESRLow LCSolid electrolytic capacitorsFixed capacitor dielectricDielectricElectrolysis

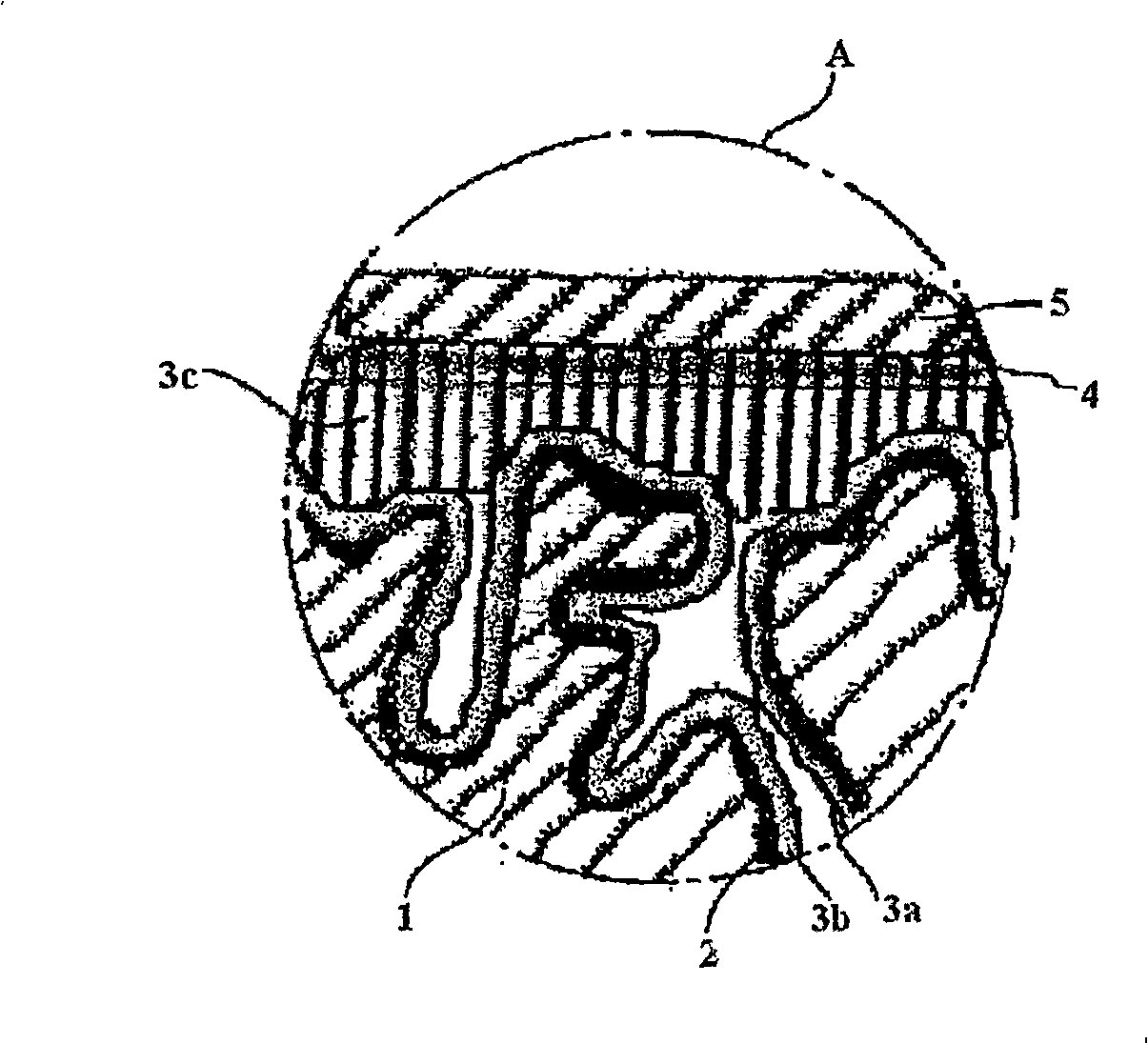

A solid electrolytic capacitor includes a capacitor element including: an anode body; a dielectric coating film deposited on a surface of the anode body; a conductive polymer layer deposited on the dielectric coating film; and a mixture layer deposited on the conductive polymer layer and containing a conductive matrix and carbon nanotubes, the anode body, the dielectric coating film, the conductive polymer layer and the mixture layer being deposited in sequence.

Owner:SANYO ELECTRIC CO LTD

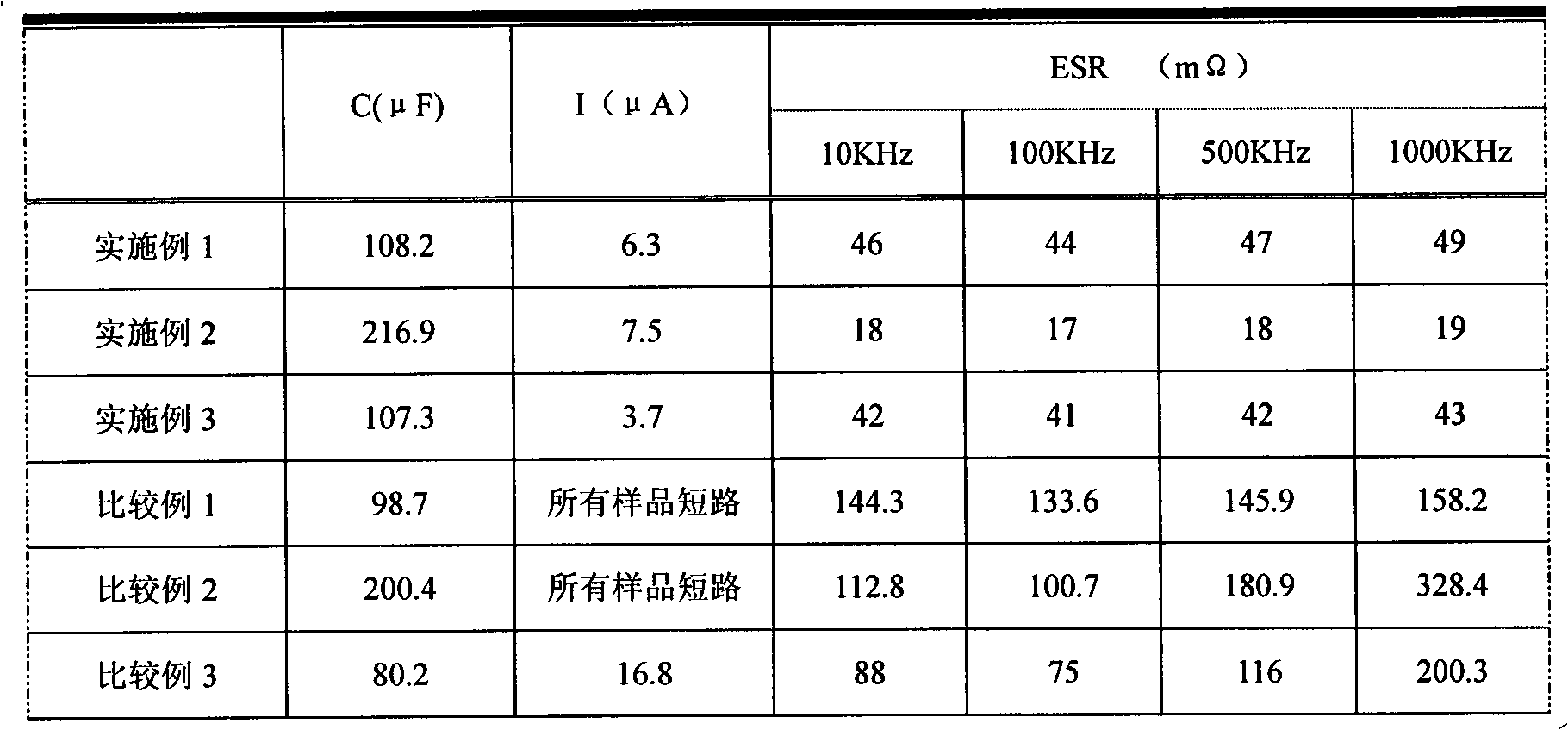

Solid electrolyte capacitor with ultra-low equivalent series resistance and manufacturing method thereof

ActiveCN101350253AImprove volumetric efficiencyTightly boundSolid electrolytic capacitorsCapacitor terminalsElectrolysisNiobium

The invention relates to a solid electrolytic capacitor and the method for preparing the solid electrolytic capacitor, wherein the solid electrolytic capacitor takes solid conducting high molecular polymer as electrolyte and takes valve metals, such as tantalum, niobium, titanium, aluminum and the like as an anode. The solid electrolytic capacitor is characterized by sufficiently explaining the techniques for the design of the anode, the function assignment, the chemical oxidative in-situ polymerization, the dip-coating graphite silver paste, the making of bottom extraction electrode and the like, with the technical proposal of the invention, a high polymer film, a graphite layer and a silver layer can be compactly combined, the manufactured electrolytic capacitor can be provided with very low equivalent series resistance (ESR), very high volumetric efficiency and good impedance frequency characteristic, the ESR value can be stable in the range of 10KHz-1000KHz, and the requirements of the frequency of a modern electronic equipment can be satisfied.

Owner:CHINA ZHENHUA GRP XINYUN ELECTRONICS COMP ANDDEV CO LTD

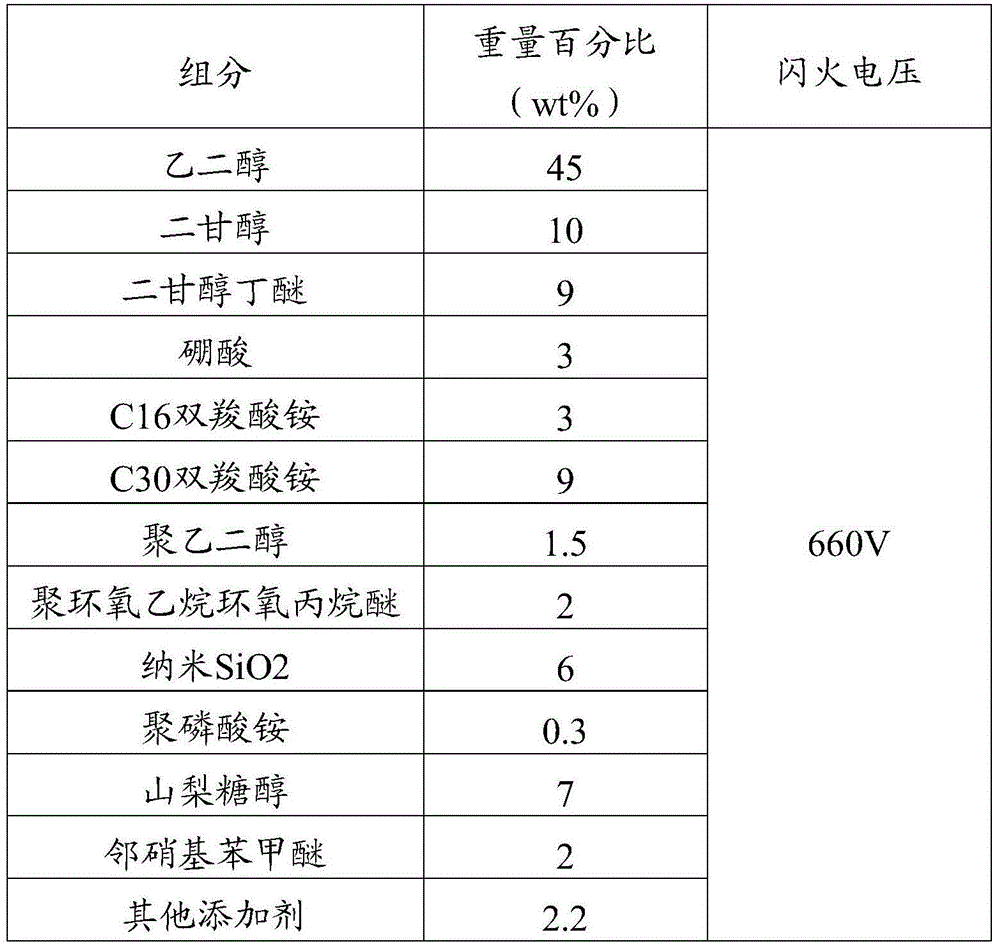

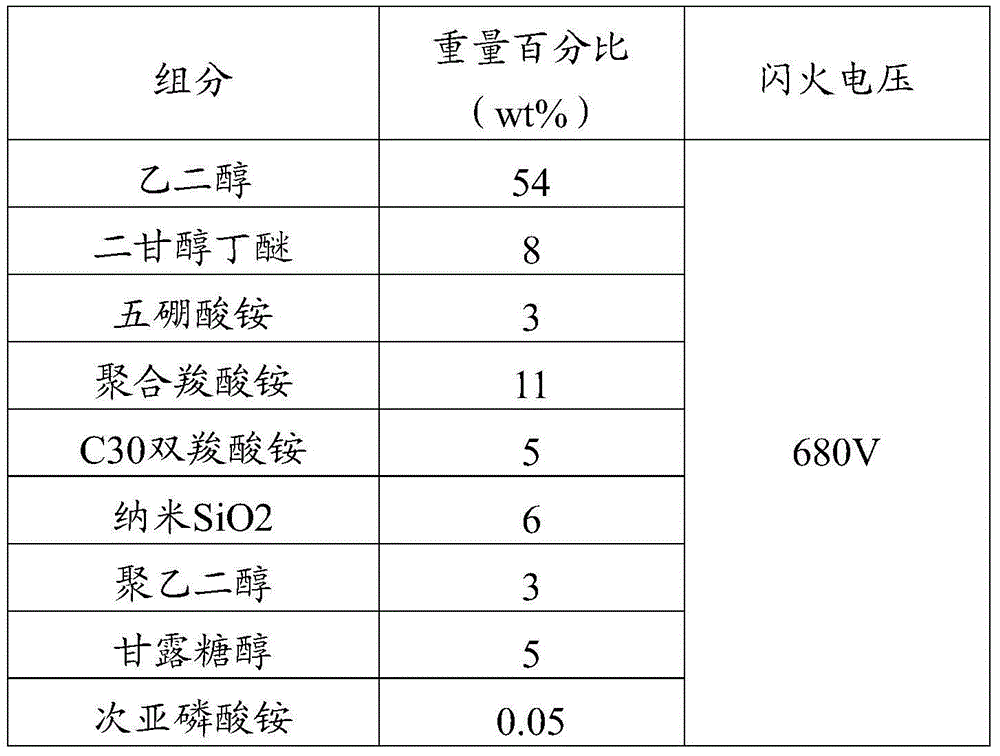

650V-700V extra-high-voltage aluminum electrolytic capacitor, working electrolyte and preparation method thereof

InactiveCN103915258AImprove high pressure resistanceImprove high temperature resistanceElectrolytic capacitorsHydrogenBreakdown phenomenon

The invention discloses working electrolyte of a 650V-700V extra-high-voltage aluminum electrolytic capacitor. The working electrolyte of the 650V-700V extra-high-voltage aluminum electrolytic capacitor comprises, by weight, 45-65% of primary solvents, 5-20.5% of secondary solvents, 10-20% of solutes, 8-25% of spark voltage improvers, 5-10% of stabilizers, 0.2-3% of hydrogen absorbents, and 2-5% of other additives. The invention further discloses a preparation method of the working electrolyte of the 650V-700V extra-high-voltage aluminum electrolytic capacitor and the 650V-700V extra-high-voltage aluminum electrolytic capacitor. According to the 650V-700V extra-high-voltage aluminum electrolytic capacitor, the working electrolyte and the preparation method of the working electrolyte, the spark voltage improvers and the stabilizers within the reasonable ranges are used, the high-voltage resistance and high-temperature resistance of the electrolyte are improved, and meanwhile the working electrolyte has low gas production performance. When the aluminum electrolytic capacitor with the electrolyte is subjected to a ripple current life test at 85 DEG C for 2000 hours, the aluminum electrolytic capacitor can resist the voltage of 650-700V and even higher voltage, and a breakdown phenomenon caused by unstable spark voltage of the electrolyte is avoided.

Owner:深圳市智胜新电子技术有限公司

Solid electrolytic capacitor and method for producing the same

ActiveUS7800887B2Improve adhesionReduce contact resistanceHybrid capacitor electrolytesHybrid capacitor electrodesEpoxyElectrolysis

A solid electrolytic capacitor, having a small equivalent series resistance, is formed by burying a capacitor element inside an epoxy resin outer package. The capacitor element includes an anode, having part of an anode lead buried therein, a dielectric layer formed on the anode and containing a niobium oxide, and a cathode formed on the dielectric layer. The cathode includes a first electrolyte layer containing a conductive polymer and formed on the dielectric layer, an intermediate layer containing an organic silane and formed on the first electrolyte layer, a second electrolyte layer containing a conductive polymer and formed on the intermediate layer, a first conductive layer containing carbon particles and formed on the second electrolyte layer, and a second conductive layer containing silver particles and formed on the first conductive layer.

Owner:SANYO ELECTRIC CO LTD

Implantable medical device having flat electrolytic capacitor with differing sized anode and cathode layers

InactiveUS6963482B2Area maximizationEasy to useAnti-noise capacitorsFeed-through capacitorsElectrolysisElectrical connection

Flat electrolytic capacitors, particularly, for use in implantable medical devices (IMDs), and the methods of fabrication of same are disclosed. The capacitors are formed with an electrode stack assembly comprising a plurality of stacked capacitor layers each comprising an anode sub-assembly of at least one anode layer, a cathode layer and separator layers wherein the anode and cathode layers have differing dimensions that avoid electrical short circuits between peripheral edges of adjacent anode and cathode layers but maximize anode electrode surface area. The electrolytic capacitor is formed of a capacitor case defining an interior case chamber and case chamber periphery, an electrode stack assembly of a plurality of stacked capacitor layers having anode and cathode tabs disposed in the interior case chamber, an electrical connector assembly for providing electrical connection with the anode and cathode tabs through the case, a cover, and electrolyte filling the remaining space within the interior case chamber. The plurality of capacitor layers and further separator layers are stacked into the electrode stack assembly and disposed within the interior case chamber such that the adjacent anode and cathode layers are electrically isolated from one another. The anode layer peripheral edges of the anode sub-assemblies of the stacked capacitor layers extend closer to the case side wall than the cathode peripheral edges of the cathode layers of the stack of capacitor layers throughout a major portion of the case chamber periphery. The separator layer peripheral edges extend to the case periphery and space the anode layer peripheral edges therefrom. Any burrs, debris or distortions along or of any of the anode layer peripheral edges causing the anode layer edges to effectively extend in the electrode stack height direction causes the anode layer peripheral edges having such tendency to contact an adjacent anode layer. In this way, anode layer surface area is maximized, and short circuiting of the anode layers with the cathode layers is avoided. A case liner can also be disposed around the electrode stack assembly periphery.

Owner:MEDTRONIC INC

Electrolytic capacitor, circuit board containing electrolytic capacitor, and method for producing the same

InactiveUS6504705B2Hybrid capacitor electrolytesSolid electrolytic capacitorsRough surfaceElectrolysis

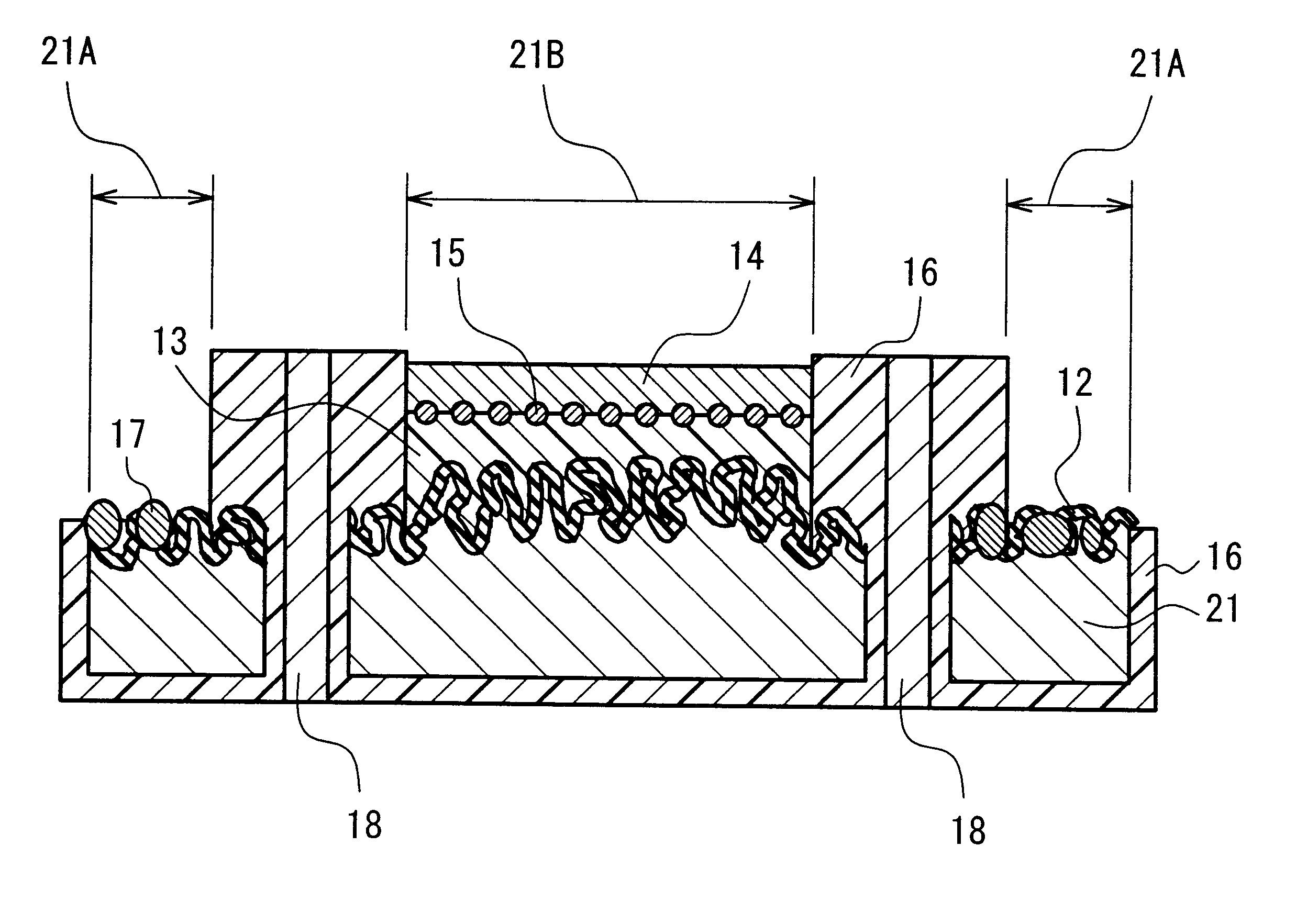

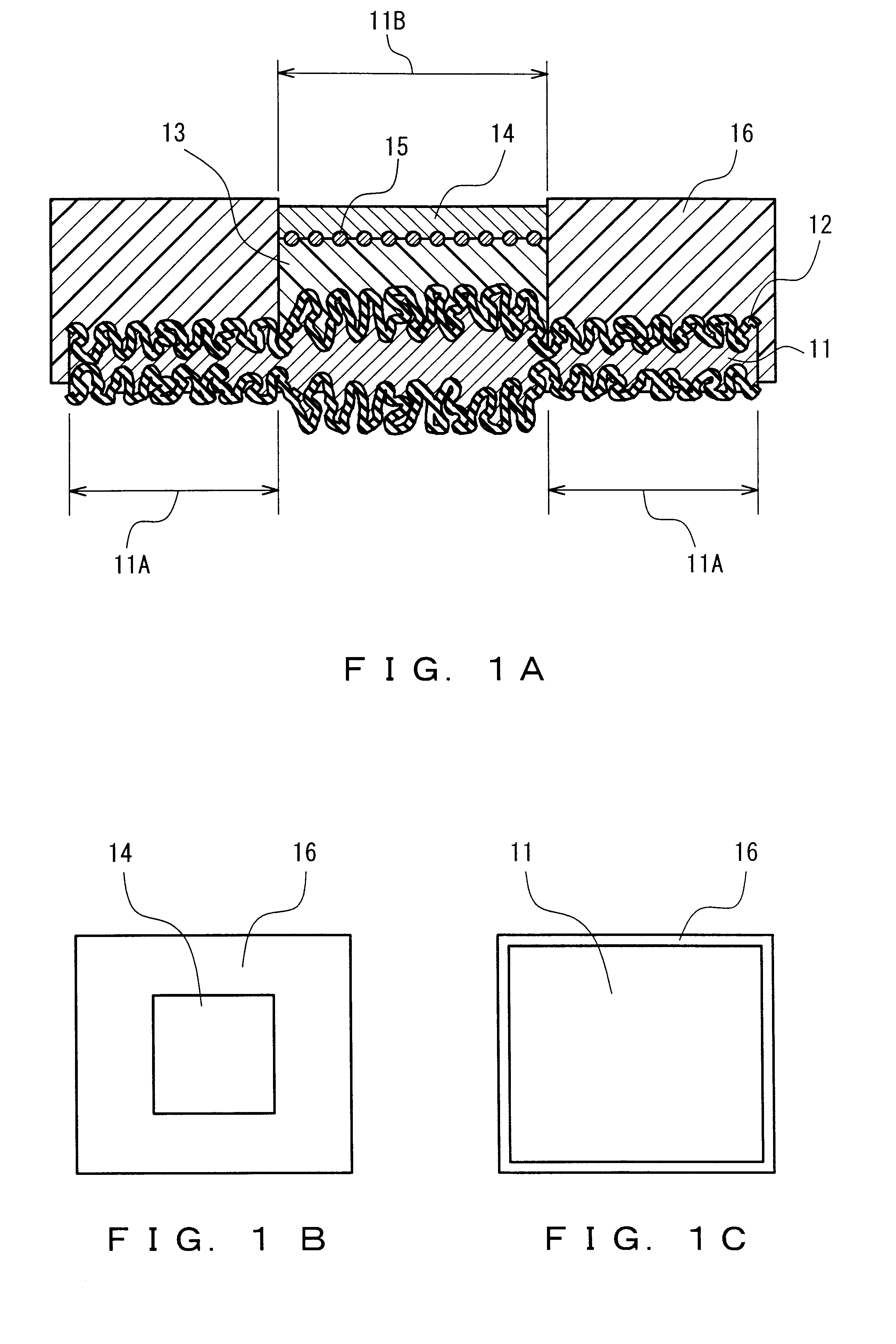

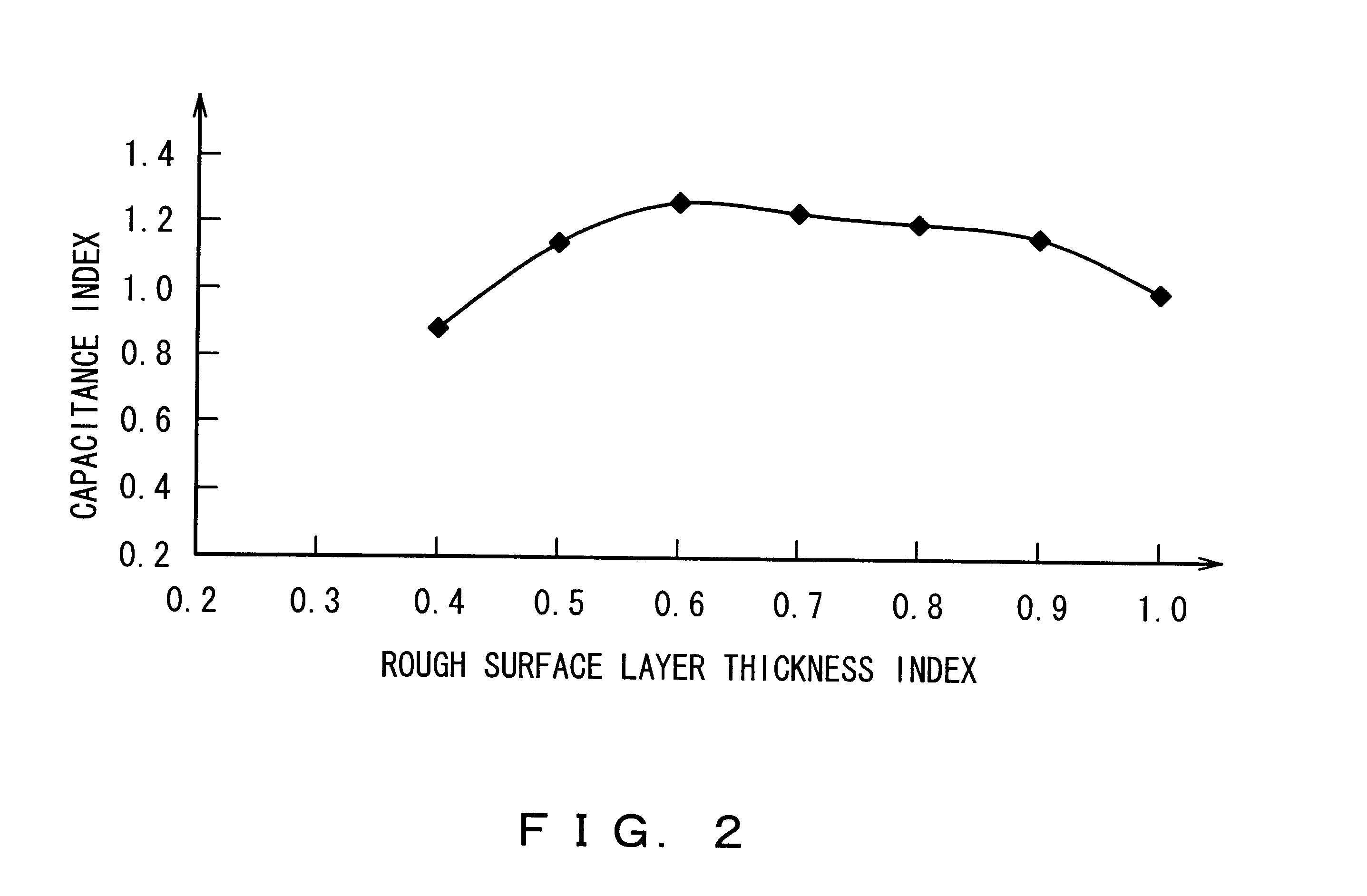

In an electrolytic capacitor of the present invention, a dielectric layer is provided on a surface of a valve metal element for an anode having a capacitor forming part and an electrode lead part, and further, a solid electrolyte layer and a charge collecting layer for a cathode are provided in this order thereon. The capacitor forming part and the electrode lead part of the valve metal element for an anode have rough surface layers on their surfaces, and are compressed in the thickness direction of the rough surface layers. Further, a region other than the electrode lead part and the charge collecting element for cathode is molded with a molding material. Exposed portions of the electrode lead part and the charge collecting element for cathode function as electrode terminals, respectively.

Owner:PANASONIC CORP

Porous Anode Body For Solid Electrolytic Capacitor, Production Method Thereof and Solid Electrolytic Capacitor

InactiveUS20080106852A1Increase capacitanceLow ESRLiquid electrolytic capacitorsSemiconductor/solid-state device manufacturingCapacitanceTantalum compound

The invention provides a method of manufacturing a porous anode for a solid electrolytic capacitor, comprising a step of subjecting a molded body containing powder of at least one material selected from oxygen-containing niobium material and oxygen-containing tantalum material and a pore-forming agent which is solid at reduction temperature to reduction reaction using reducing agent and another step of removing the pore-forming agent from the reduction reaction product and a solid electrolytic capacitor using an anode obtained thereby. As niobium material and tantalum material, at least one material selected from niobium, niobium alloy, niobium compound, tantalum, tantalum alloy and tantalum compound is used respectively. In the invention, the peak position, the number and quantity of pores can be optimized according to the cathode agent used, whereby a solid electrolytic capacitor having an improved property for impregnation with cathode agent, high capacitance, low ESR, good tan δ characteristics and long-term reliability, is obtained.

Owner:SHOWA DENKO KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com