Patents

Literature

56 results about "Tantalum compound" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tantalum: compounds information. This section lists some binary compounds with halogens (known as halides), oxygen (known as oxides), hydrogen (known as hydrides), and some other compounds of tantalum. For each compound, a formal oxidation number for tantalum is given, but the usefulness of this number is limited for p-block elements in particular.

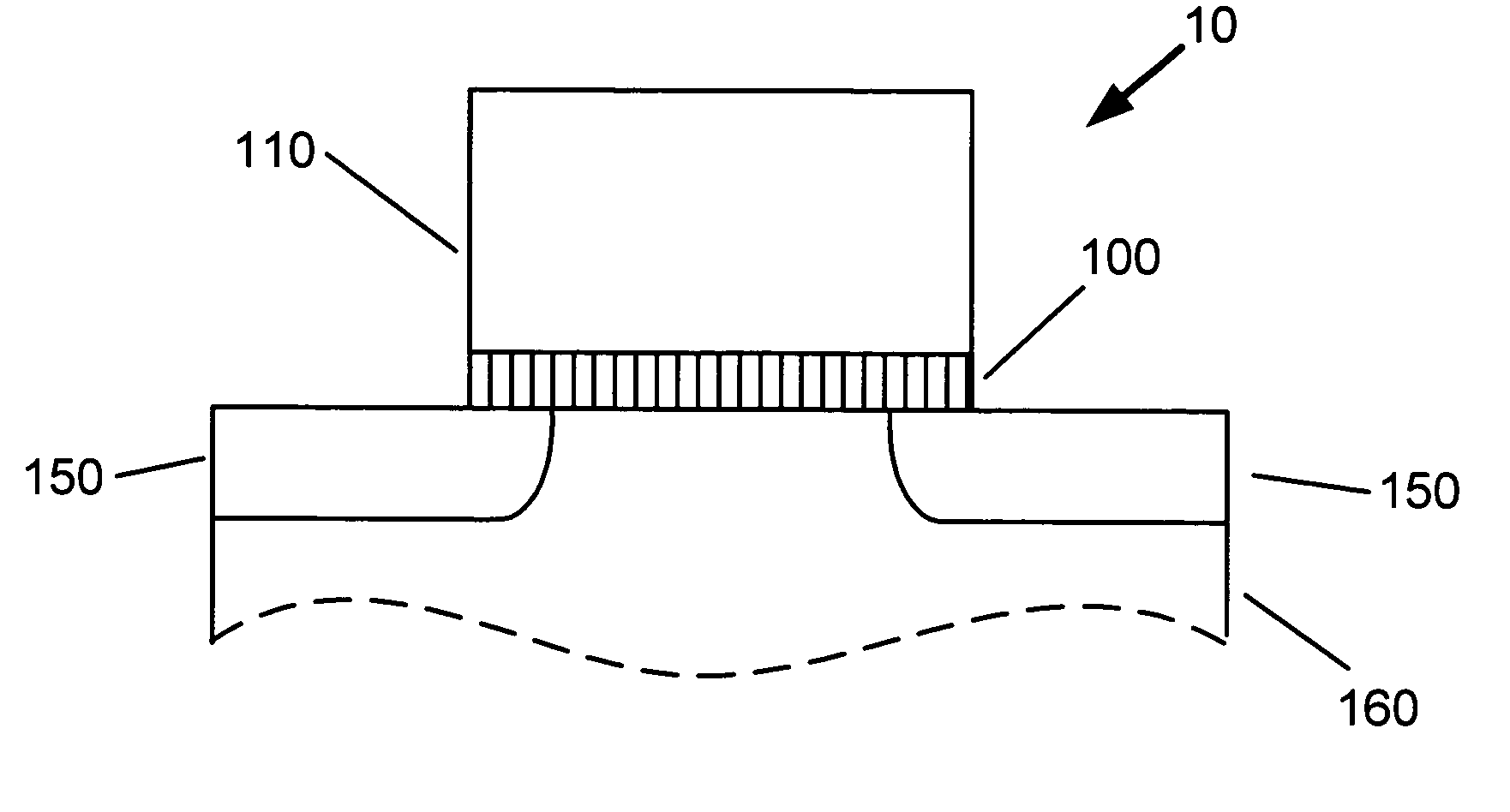

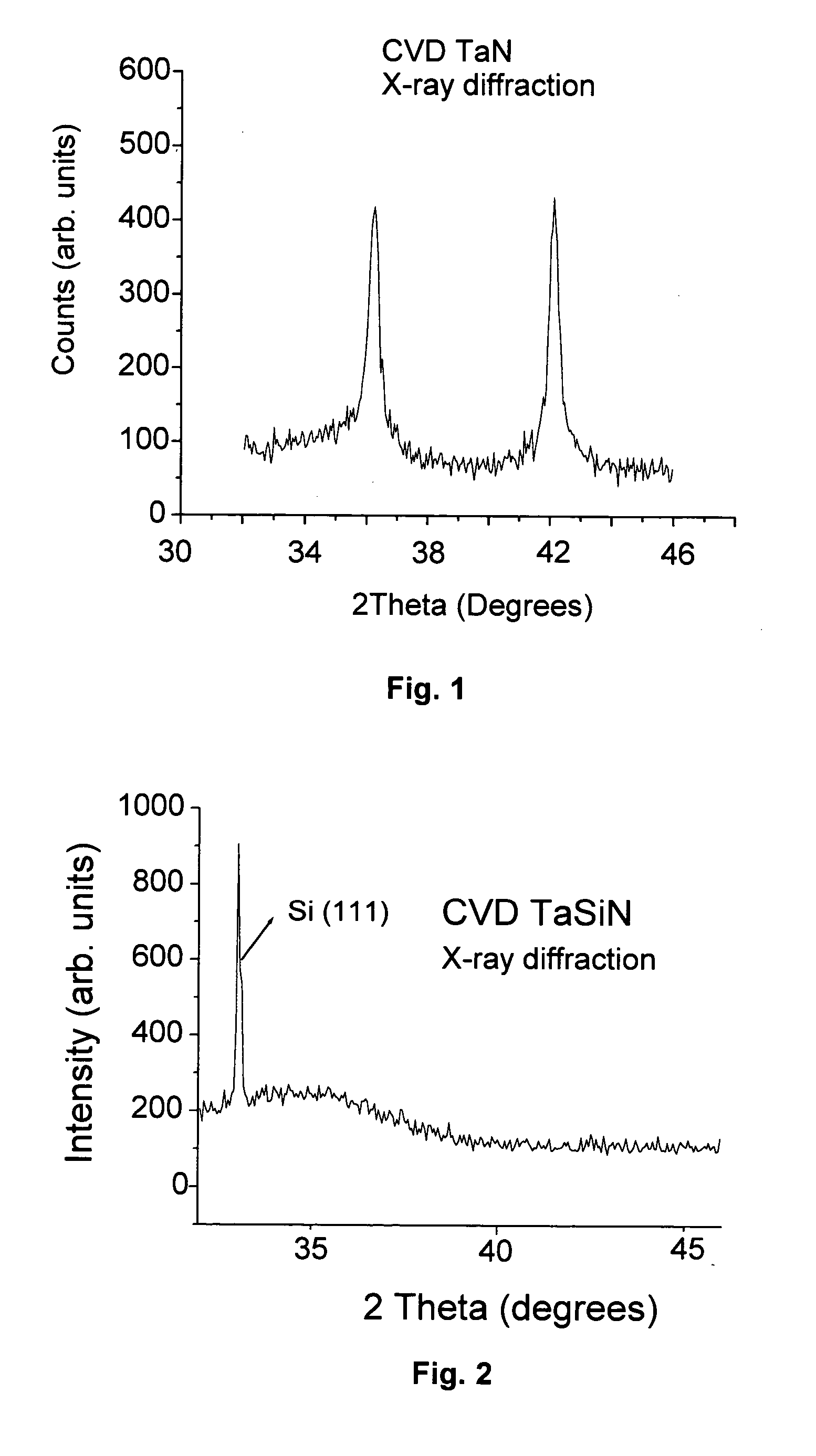

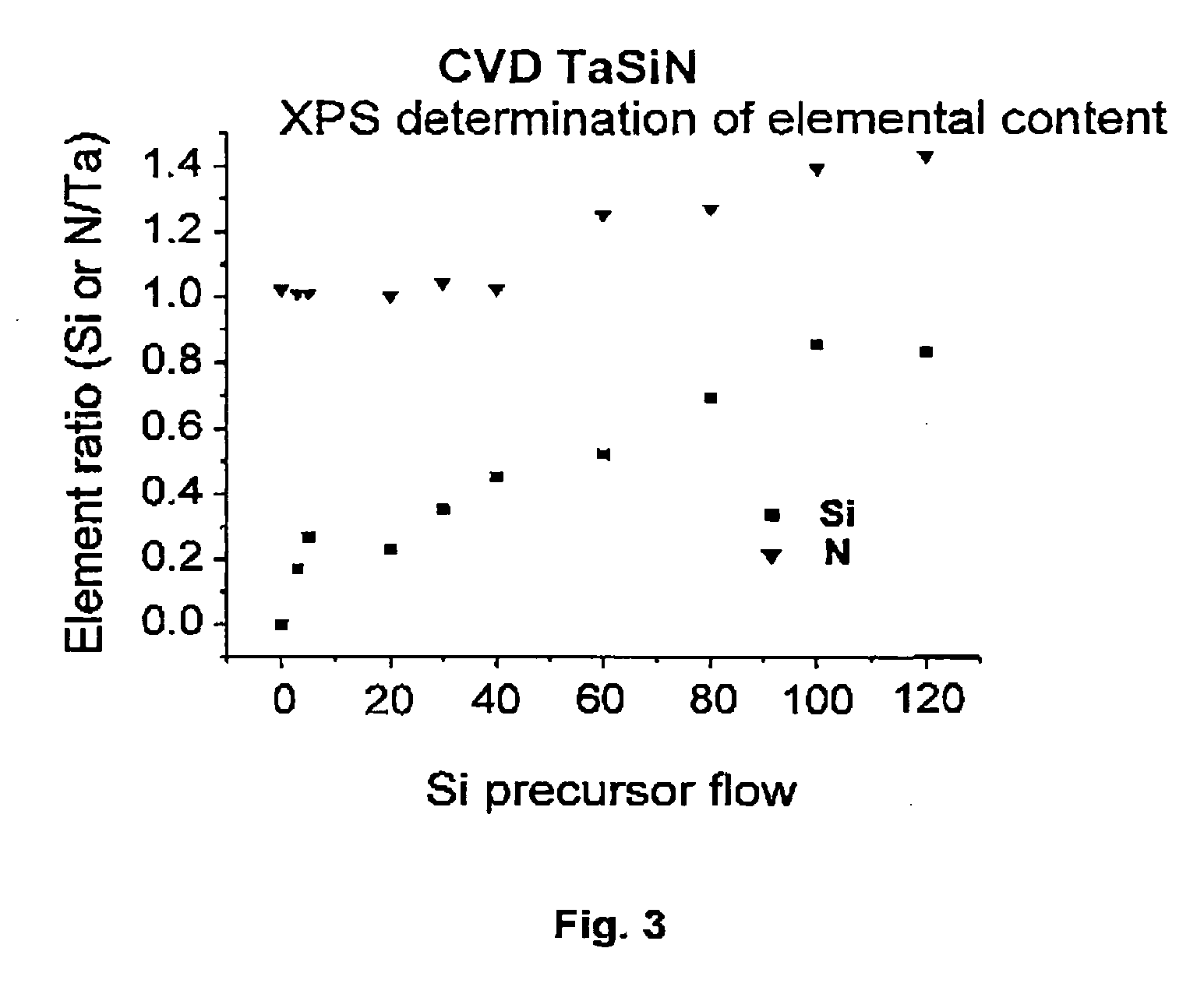

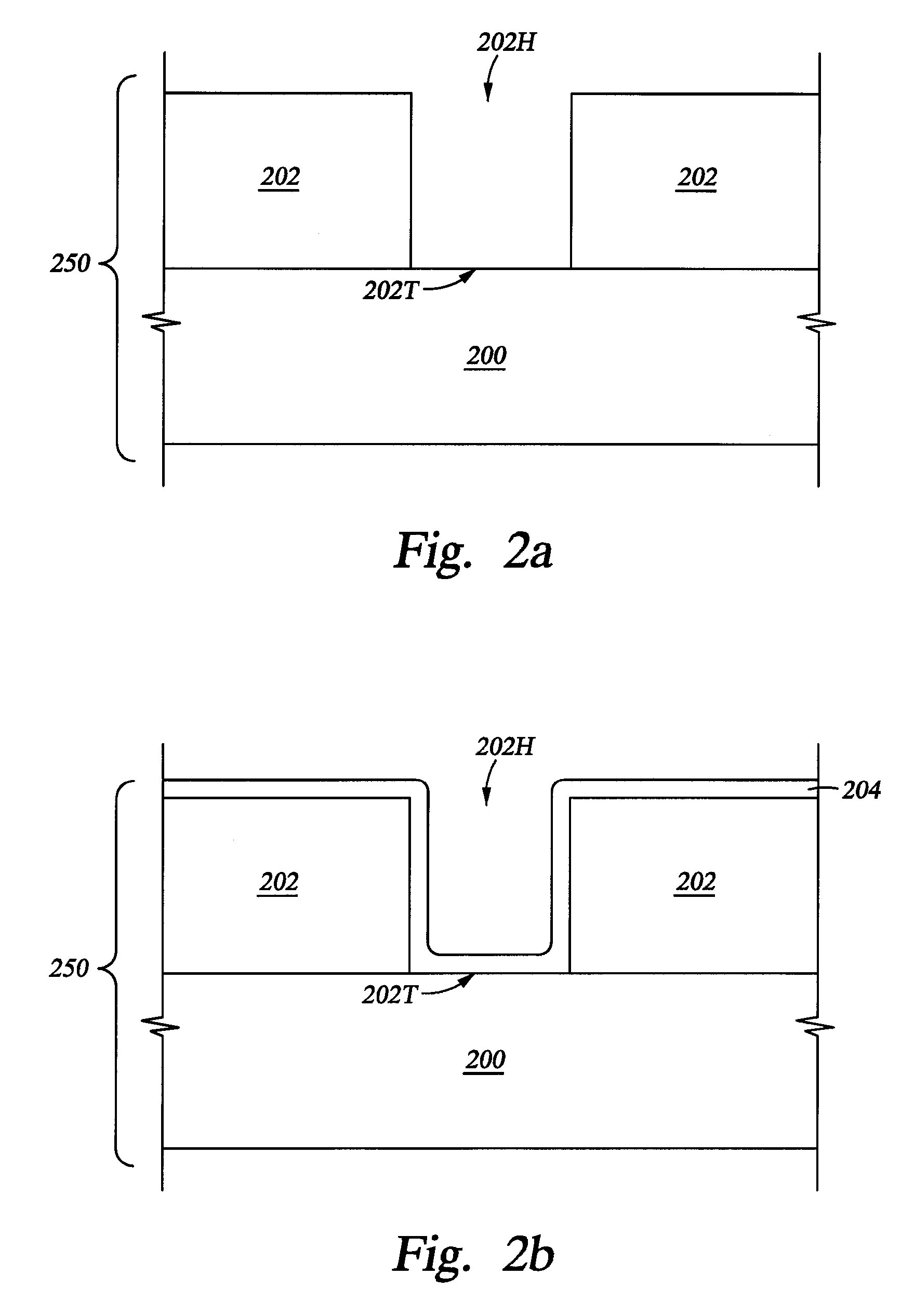

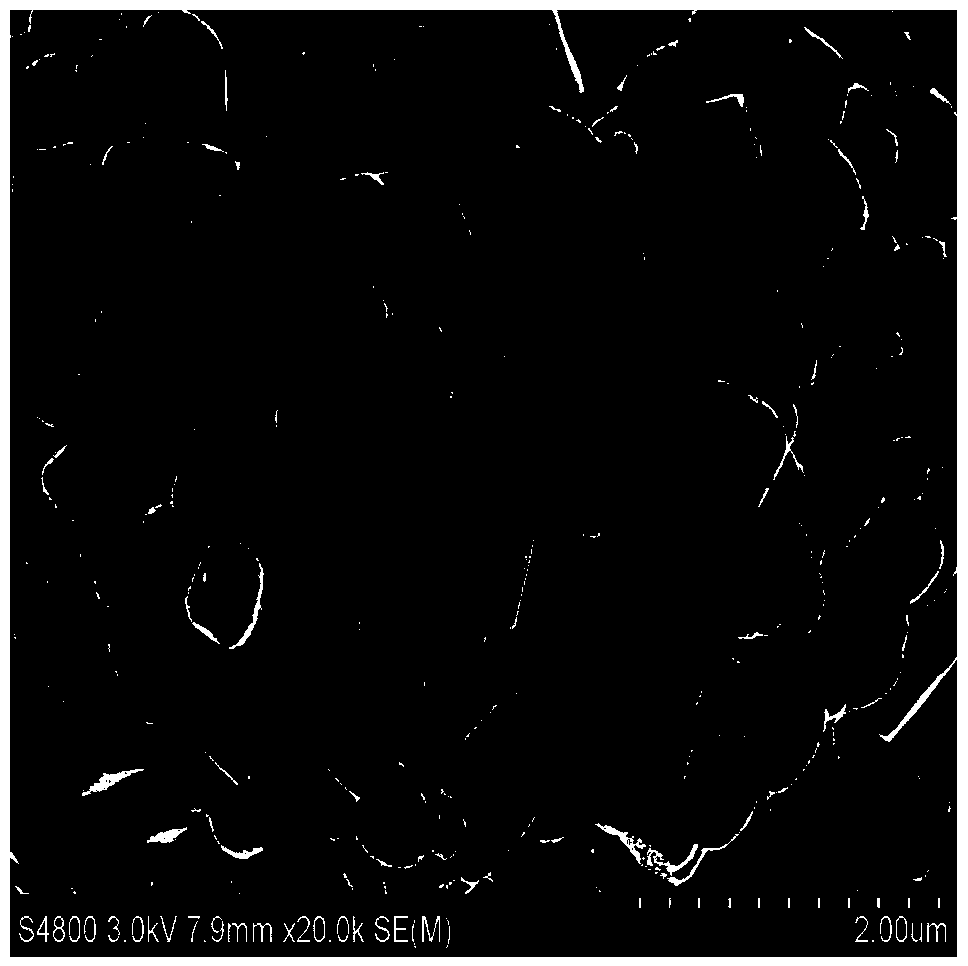

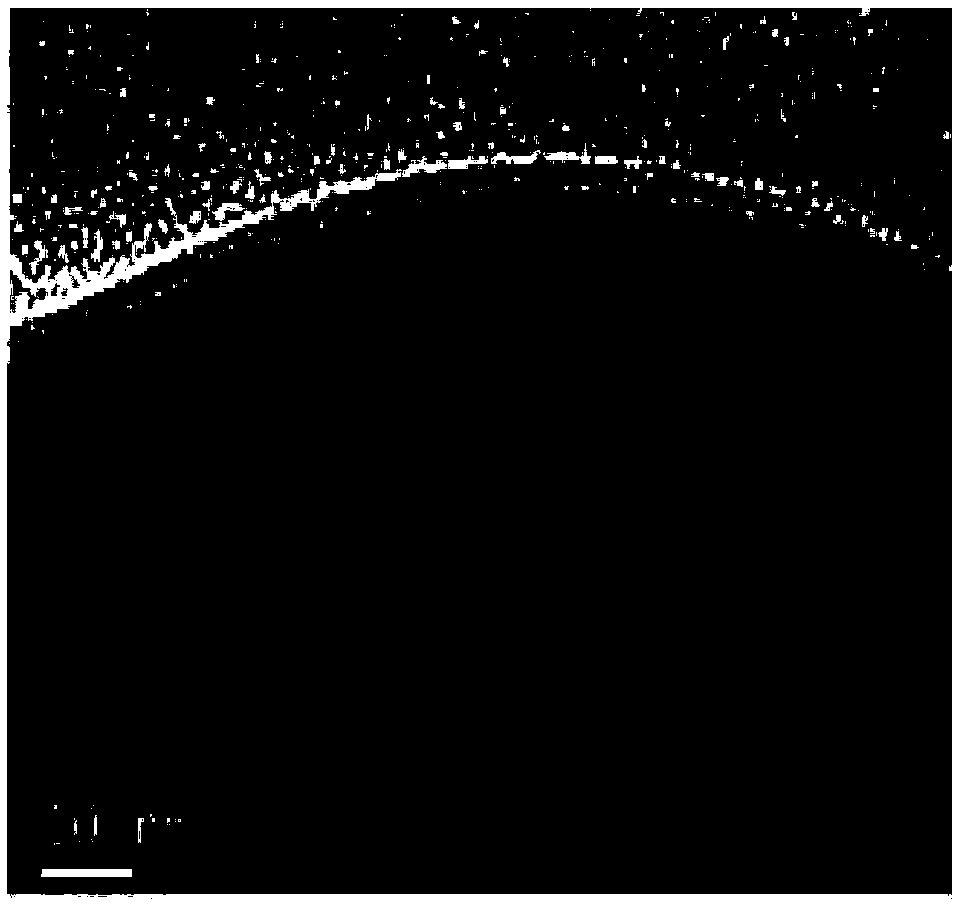

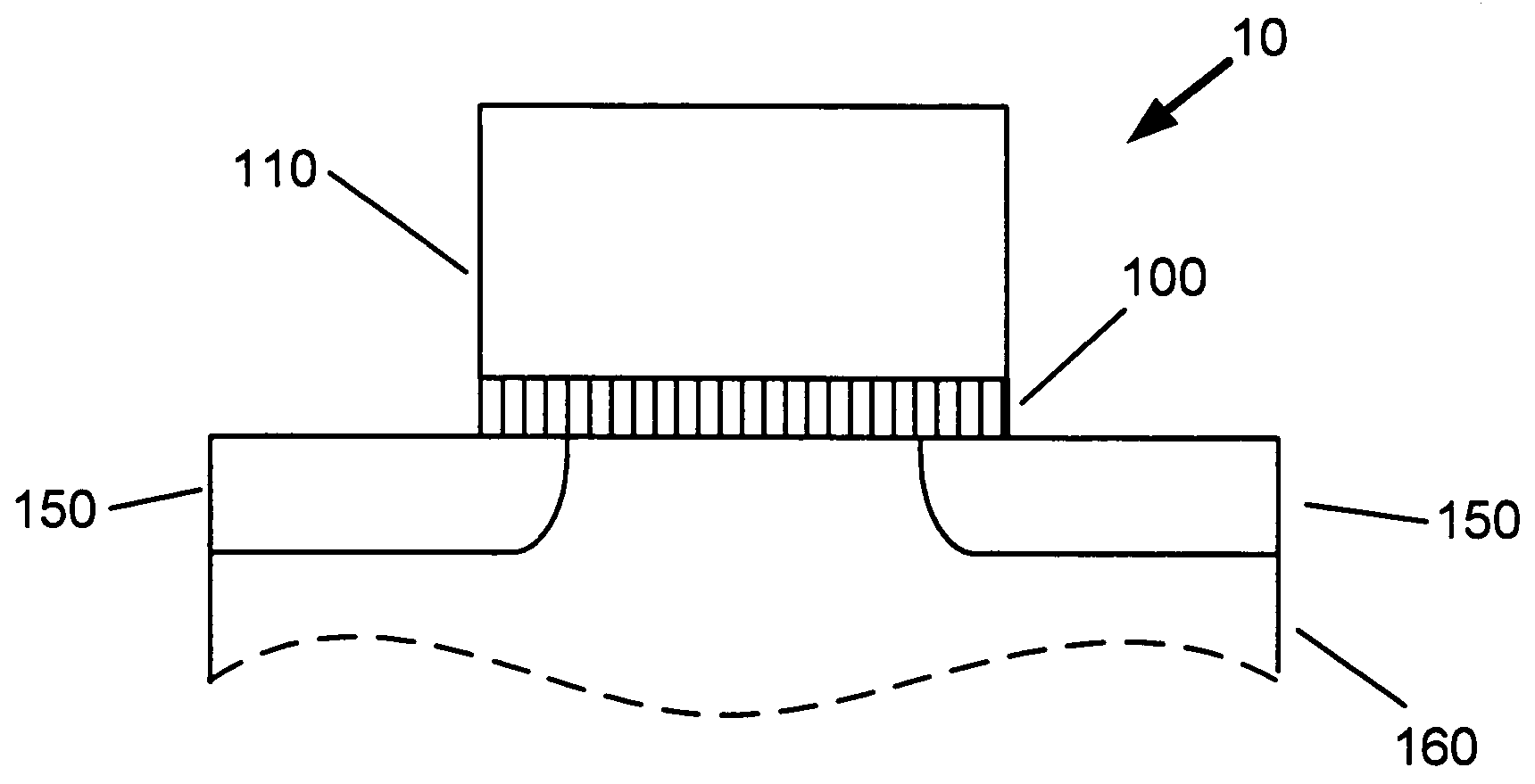

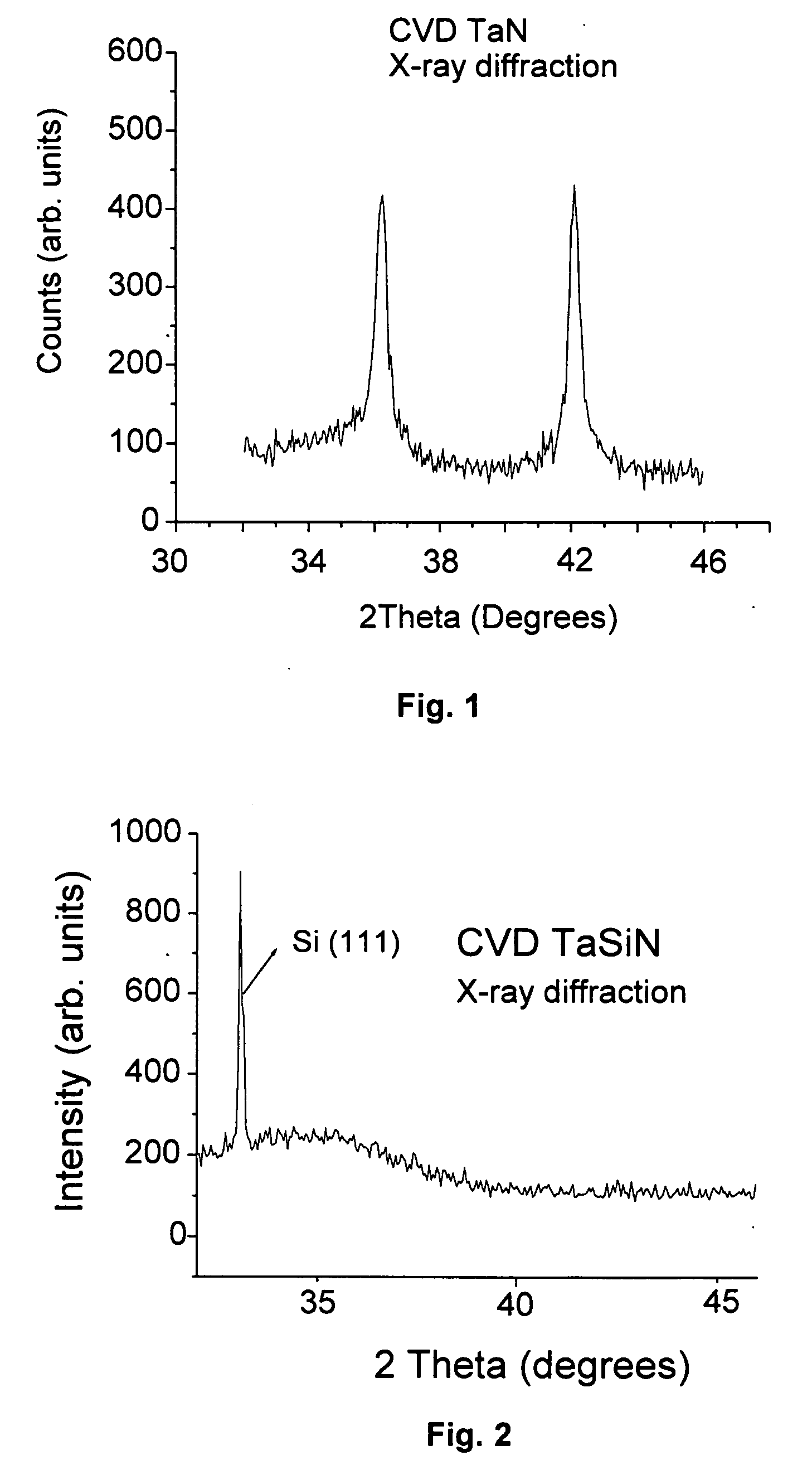

CVD tantalum compounds for FET get electrodes

InactiveUS20050104142A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingCMOSTantalum compound

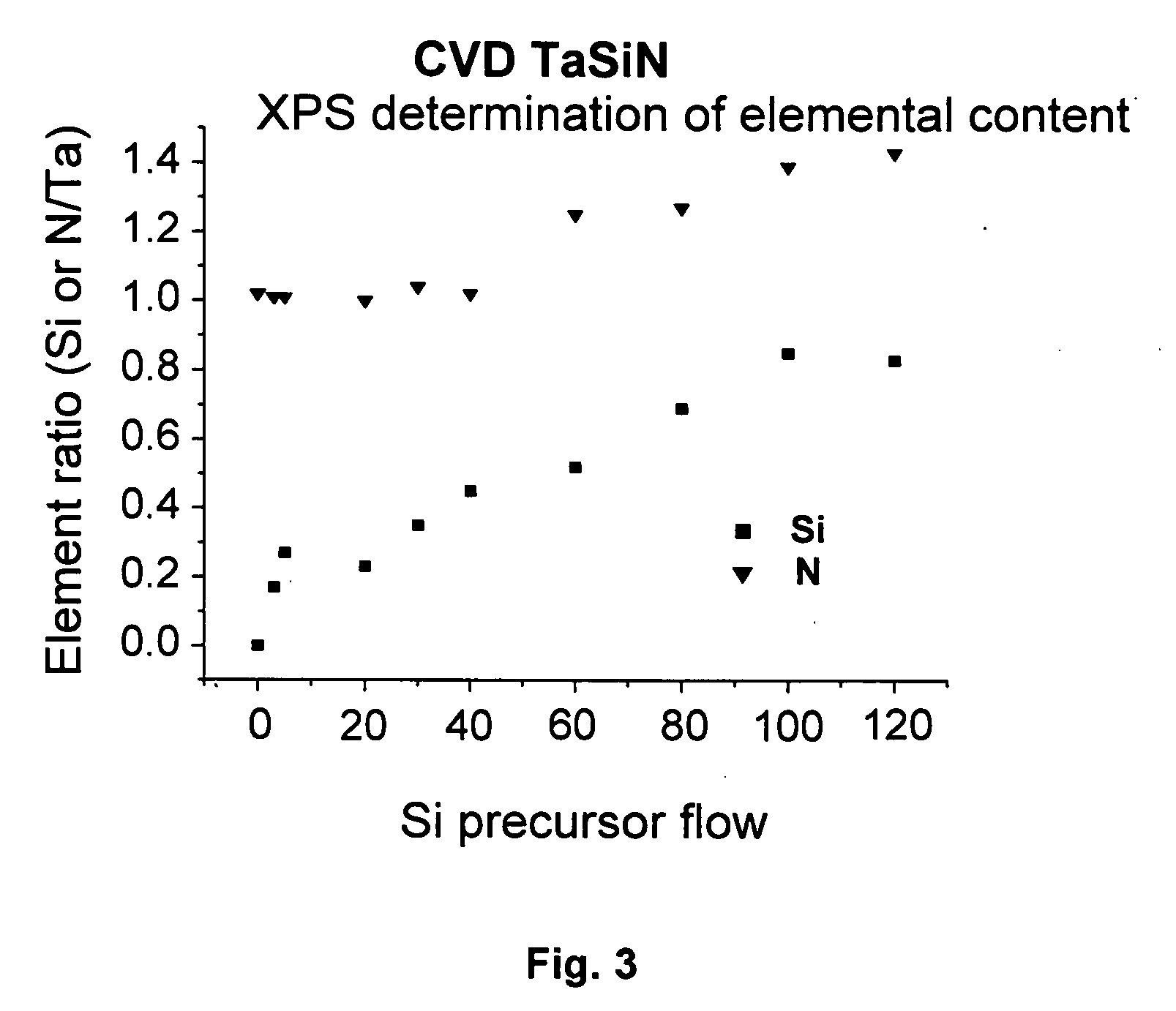

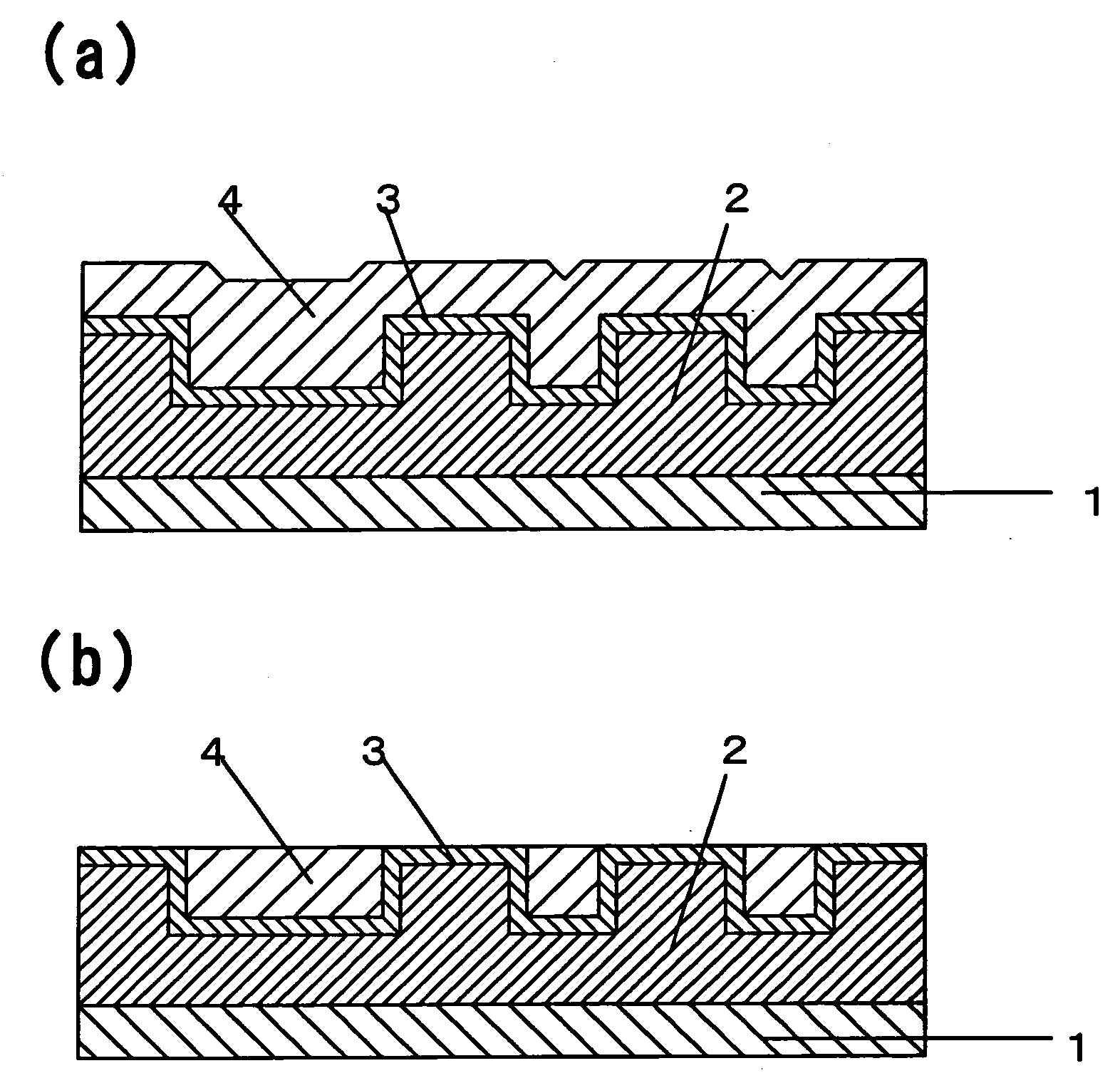

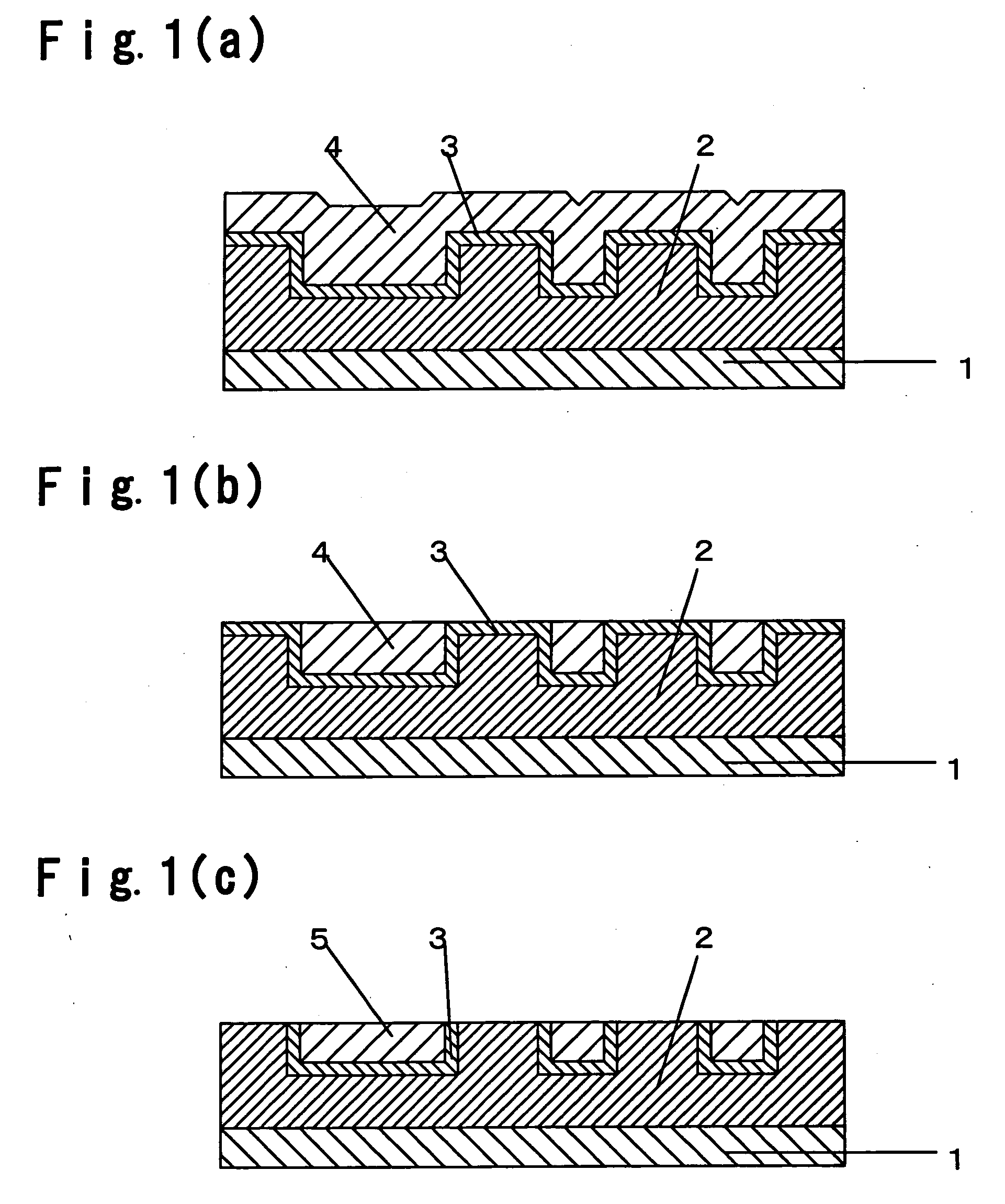

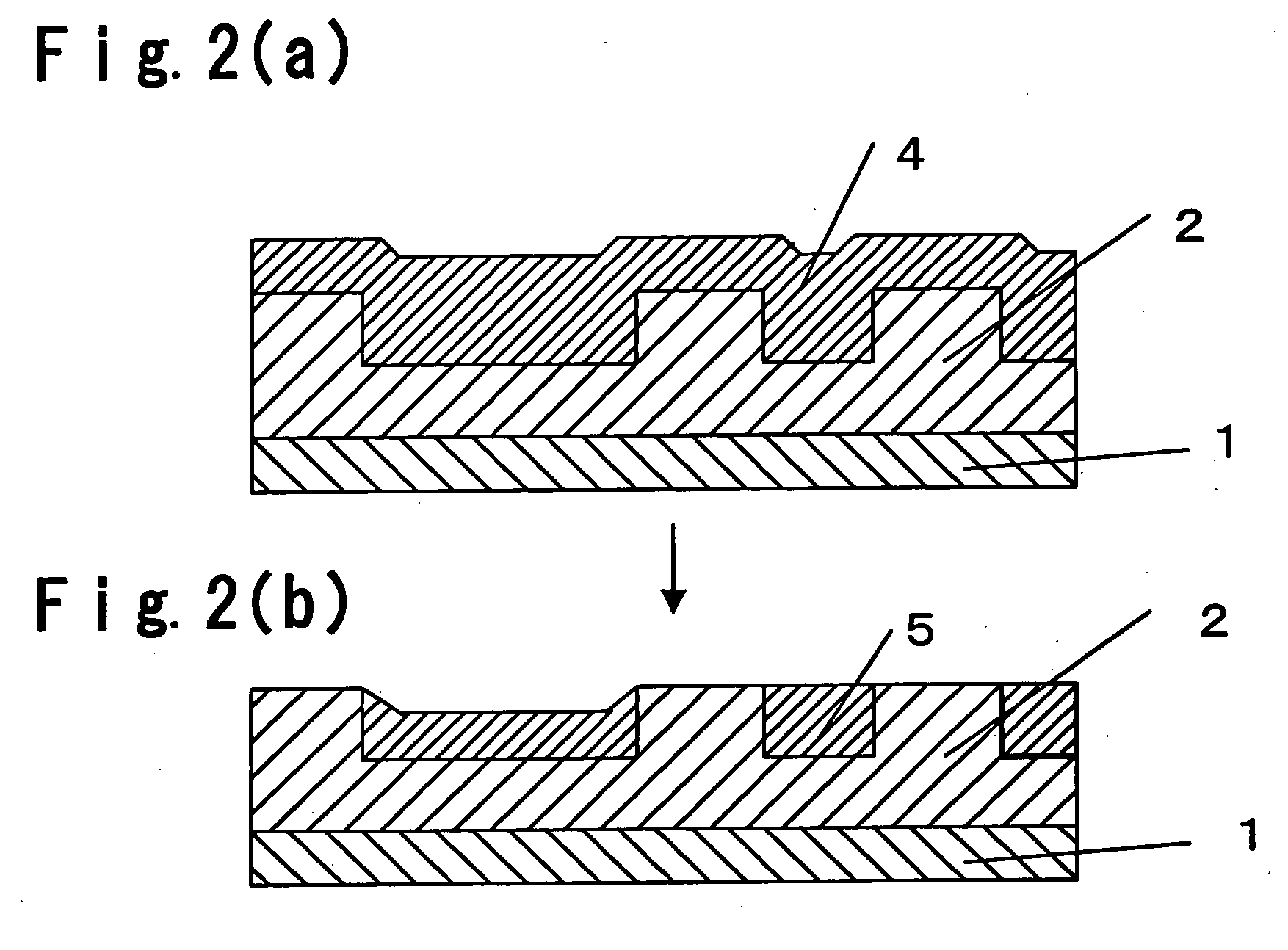

Compounds of Ta and N, potentially including further elements, and with a resistivity below about 20 mΩcm and with the elemental ratio of N to Ta greater than about 0.9 are disclosed for use as gate materials in field effect devices. A representative embodiment of such compounds, TaSiN, is stable at typical CMOS processing temperatures on SiO2 containing dielectric layers and high-k dielectric layers, with a workfunction close to that of n-type Si. Metallic Ta—N compounds are deposited by a chemical vapor deposition method using an alkylimidotris(dialkylamido)Ta species, such as tertiaryamylimidotris(dimethylamido)Ta (TAIMATA), as Ta precursor. The deposition is conformal allowing for flexible introduction of the Ta—N metallic compounds into a CMOS processing flow. Devices processed with TaN or TaSiN show near ideal characteristics.

Owner:IBM CORP

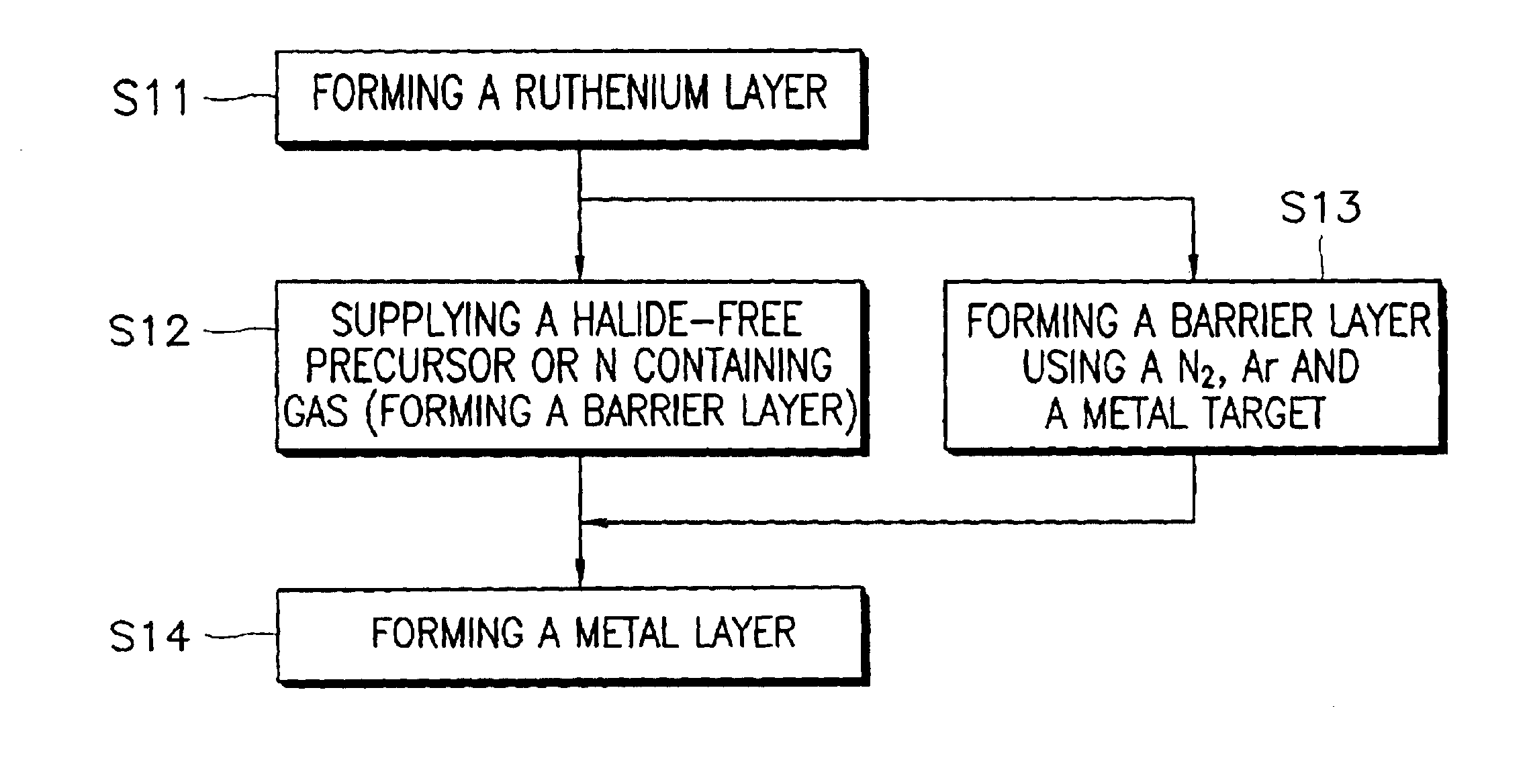

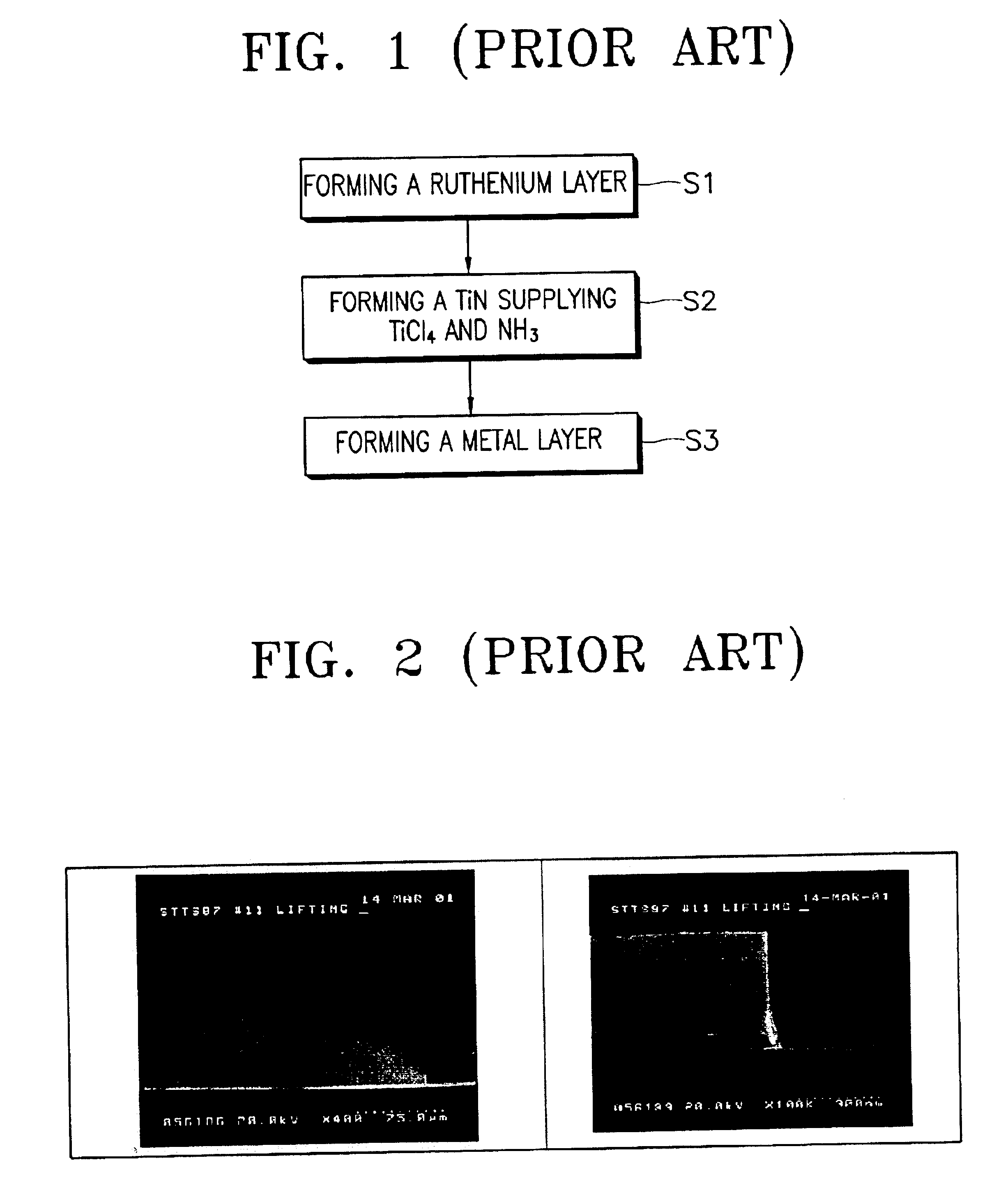

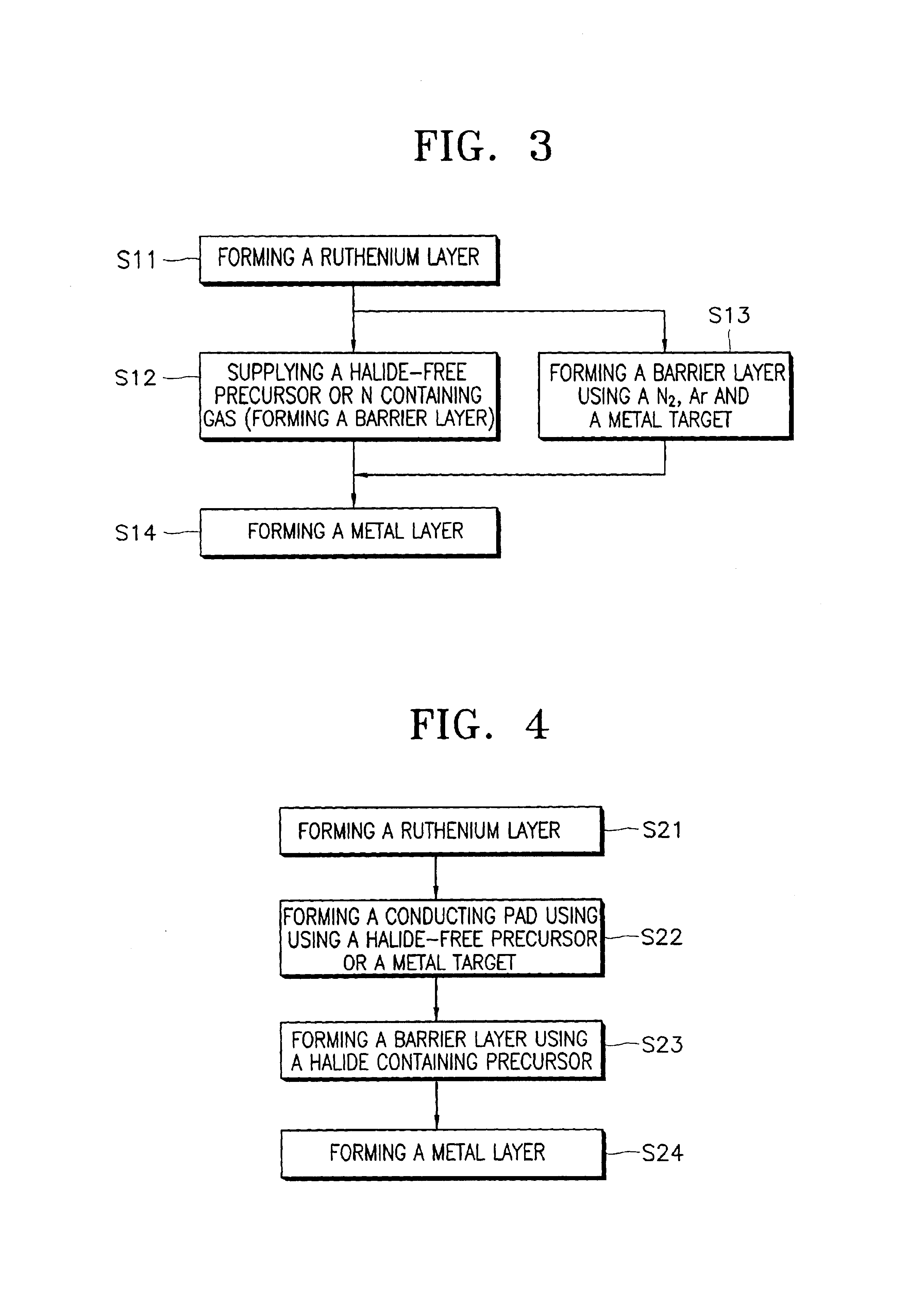

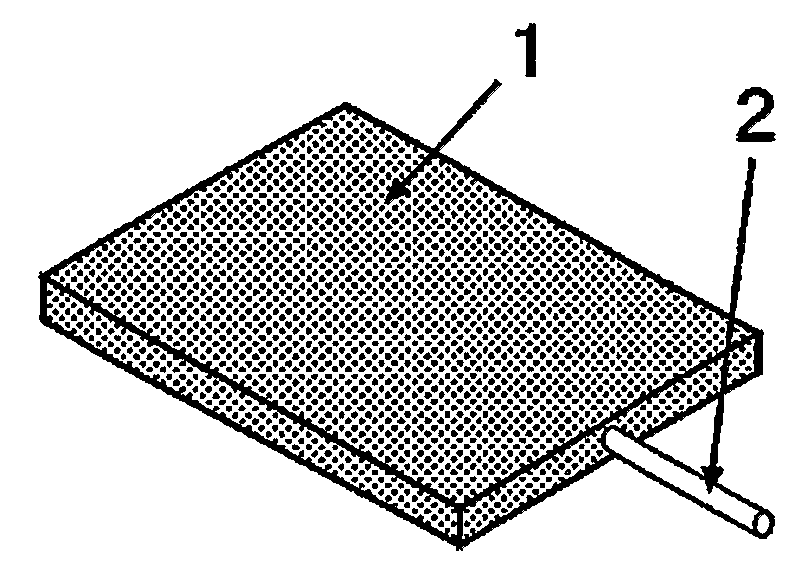

Semiconductor device having barrier layer between ruthenium layer and metal layer and method for manufacturing the same

A method for fabricating a semiconductor device is provided. A ruthenium layer is formed on a semiconductor substrate in a processing chamber. A barrier layer is formed on the ruthenium layer supplying a halide-free precursor in the processing chamber. A metal layer such as an aluminum layer, an aluminum alloy layer, a tungsten layer, or a copper layer is formed on the barrier layer. The barrier layer is one of a TiN layer, a TaN layer, a WN layer, and an MoN layer. The TiN layer is one of formed by using an MOCVD process and an ALD process, and the halide-free precursor is a titanium compound selected from the group consisting of pentakis(diethylamino) titanium, tetrakis(diethylamino) titanium, tetrakis(dimethylamino)titanium, and pentakis(dimethylamino)titanium. The TaN layer is formed by using one of an MOCVD process and an ALD process, and the halide-free precursor is a tantalum compound selected from the group consisting of t-butyltrikis(diethylamino)tantalum, pentakis(diethylamino)tantalum, tetrakis(dimethylamino)tantalum, and pentakis(dimethylamino)tantalum.

Owner:SAMSUNG ELECTRONICS CO LTD

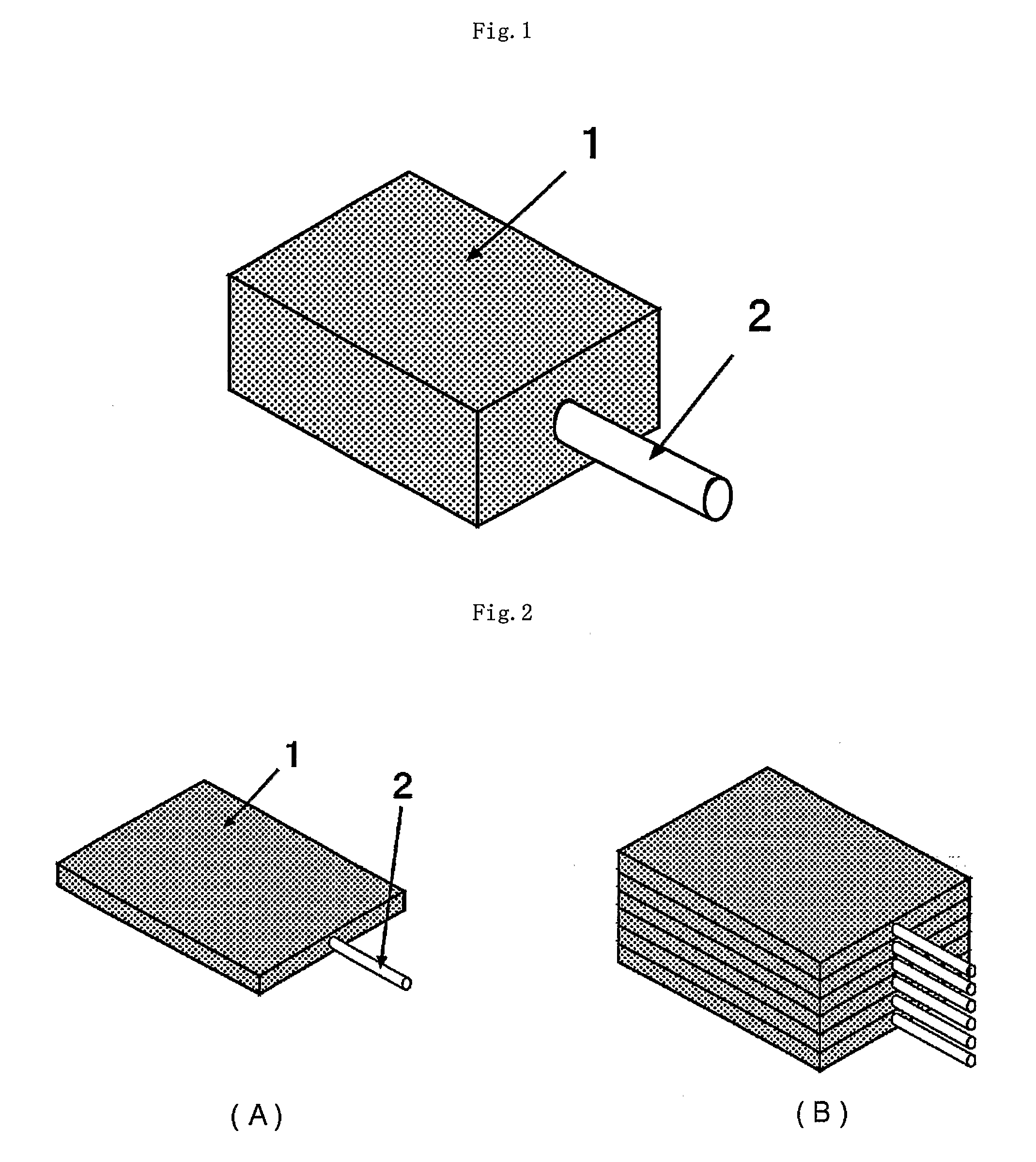

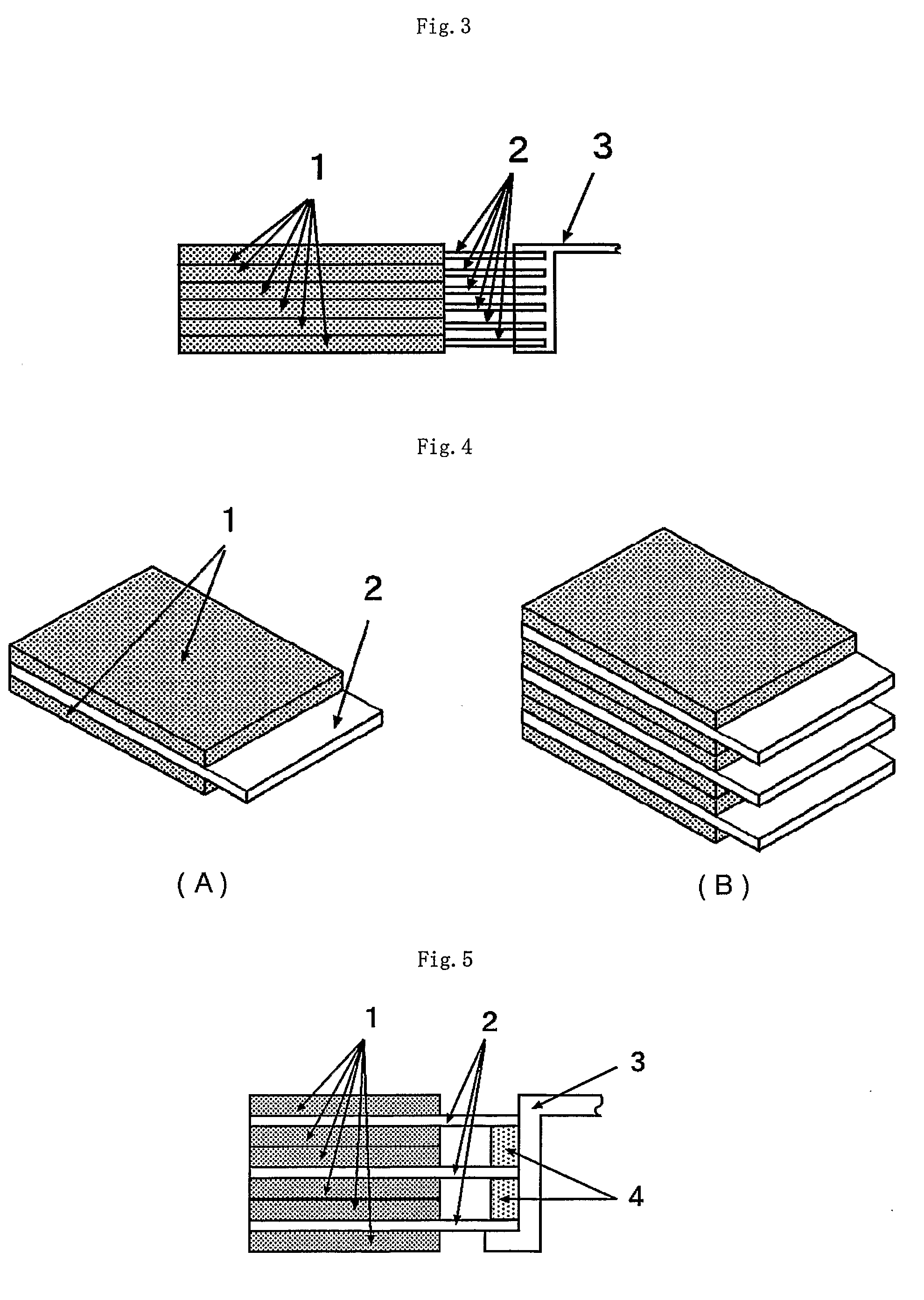

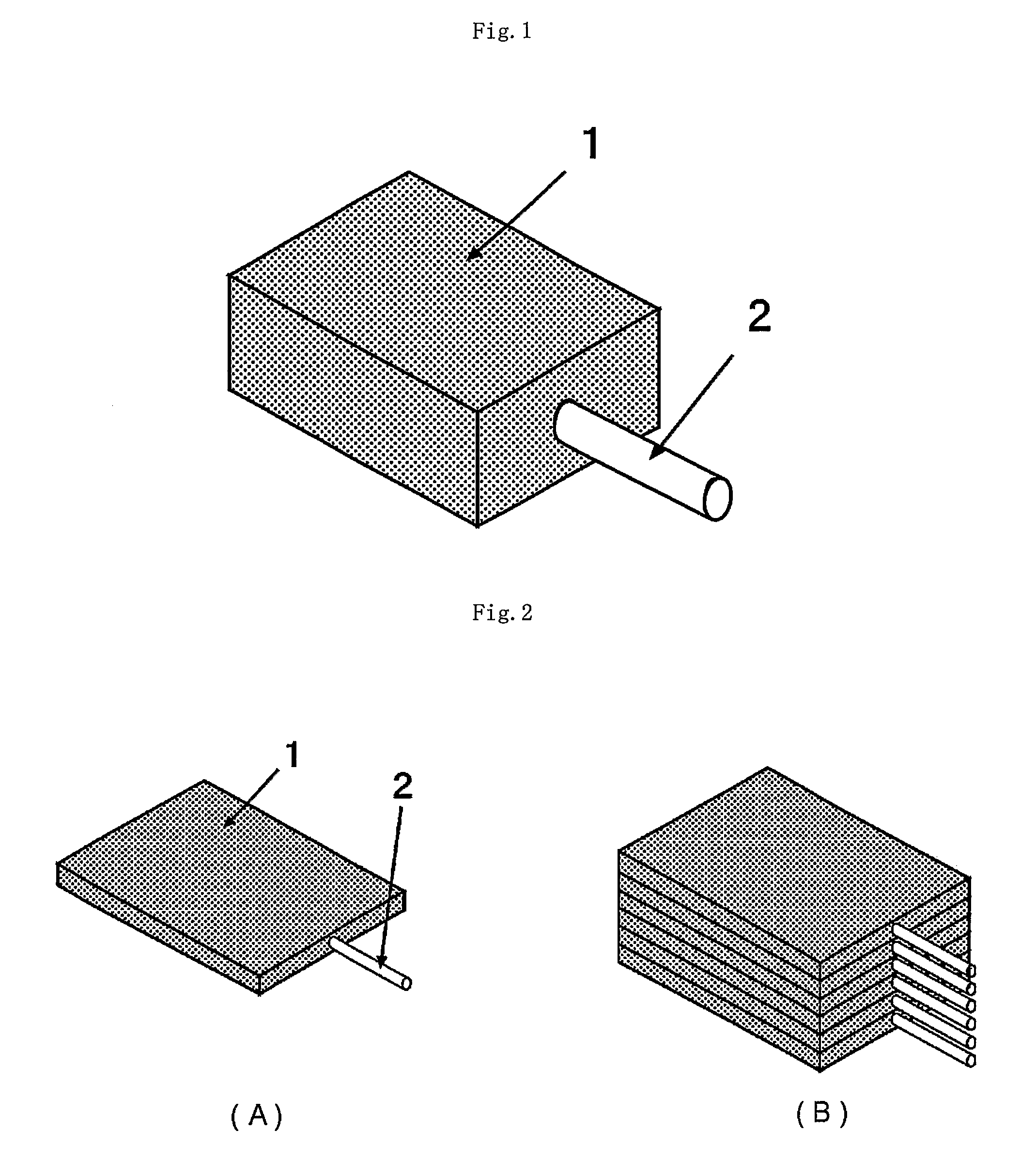

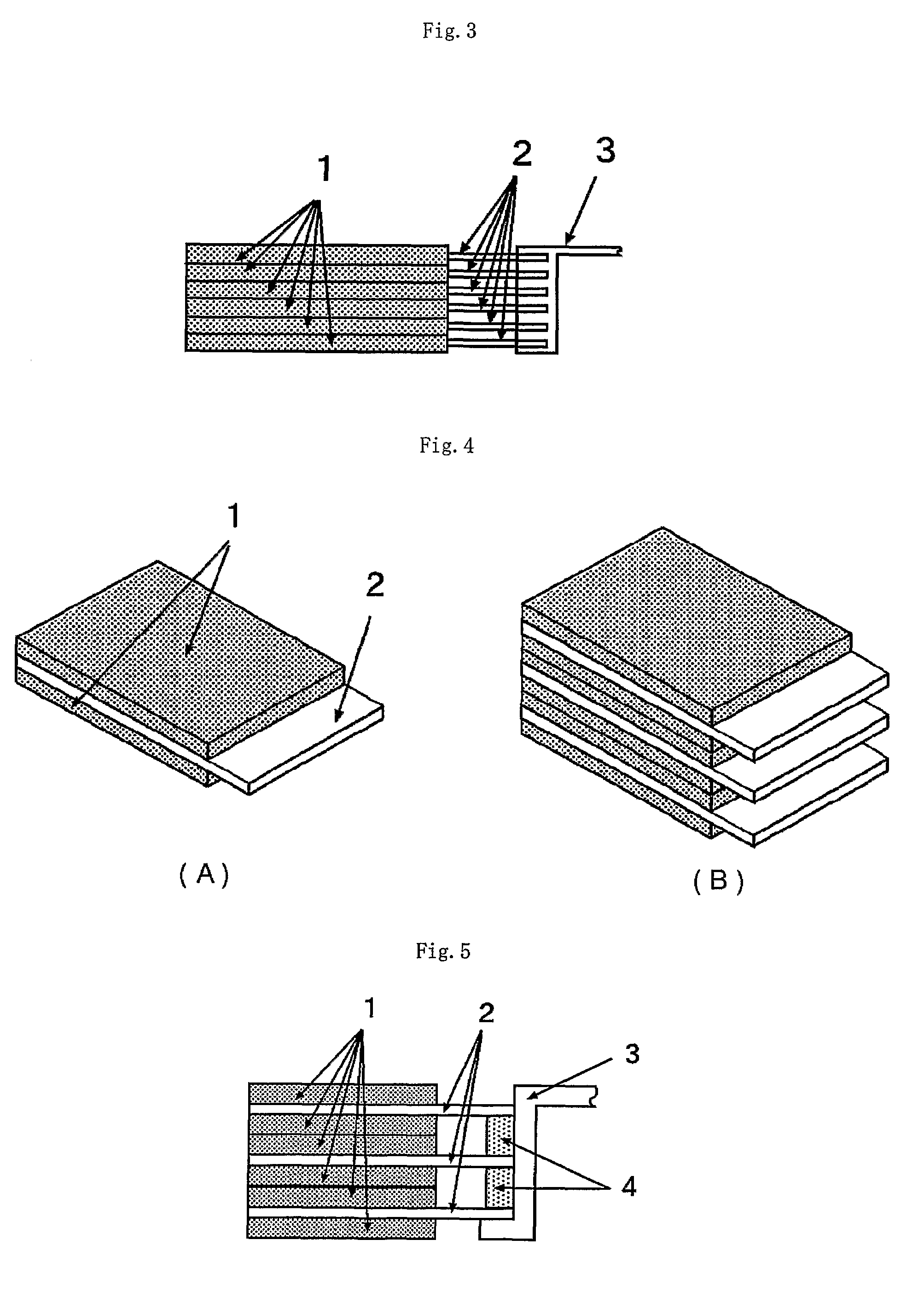

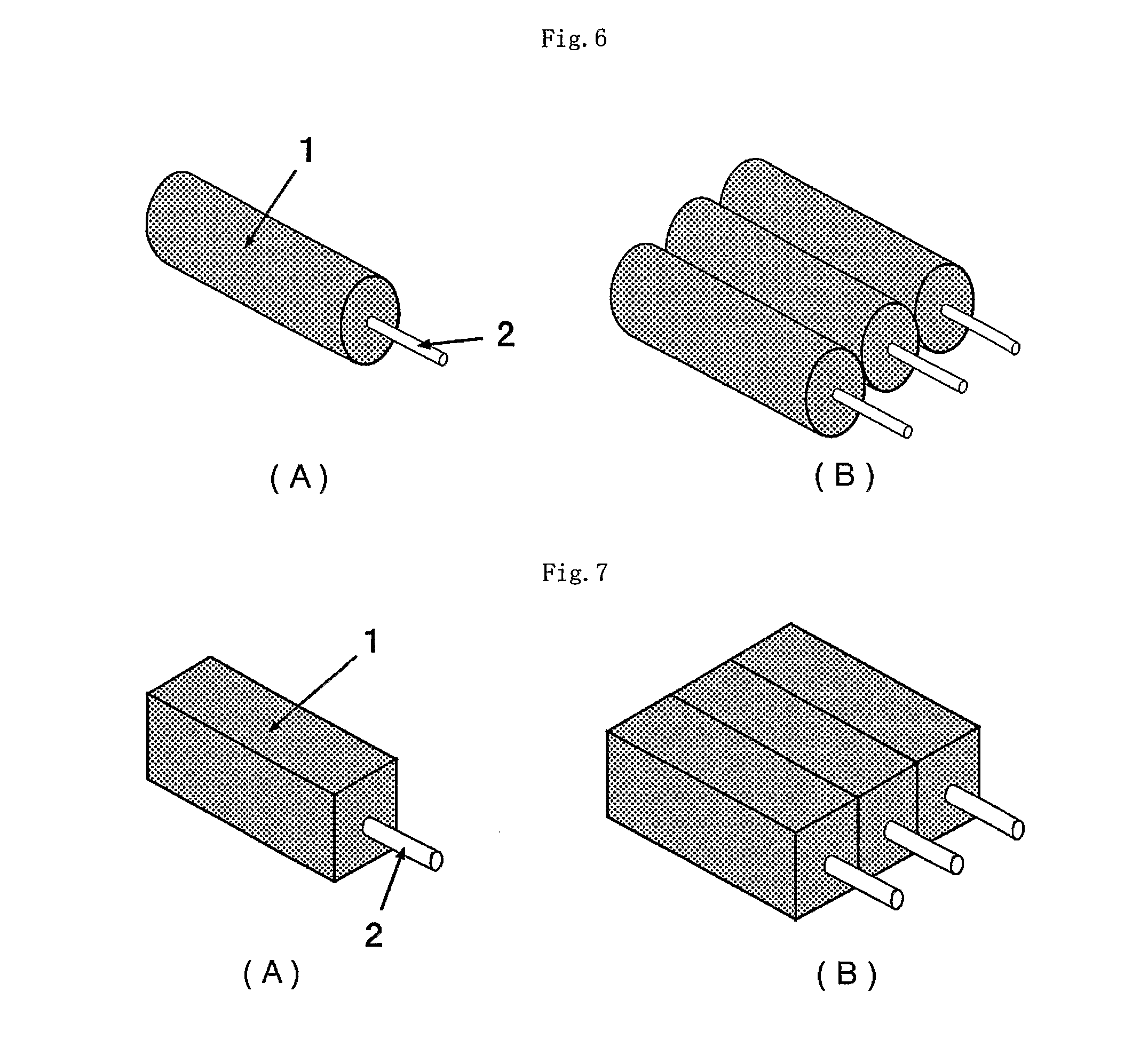

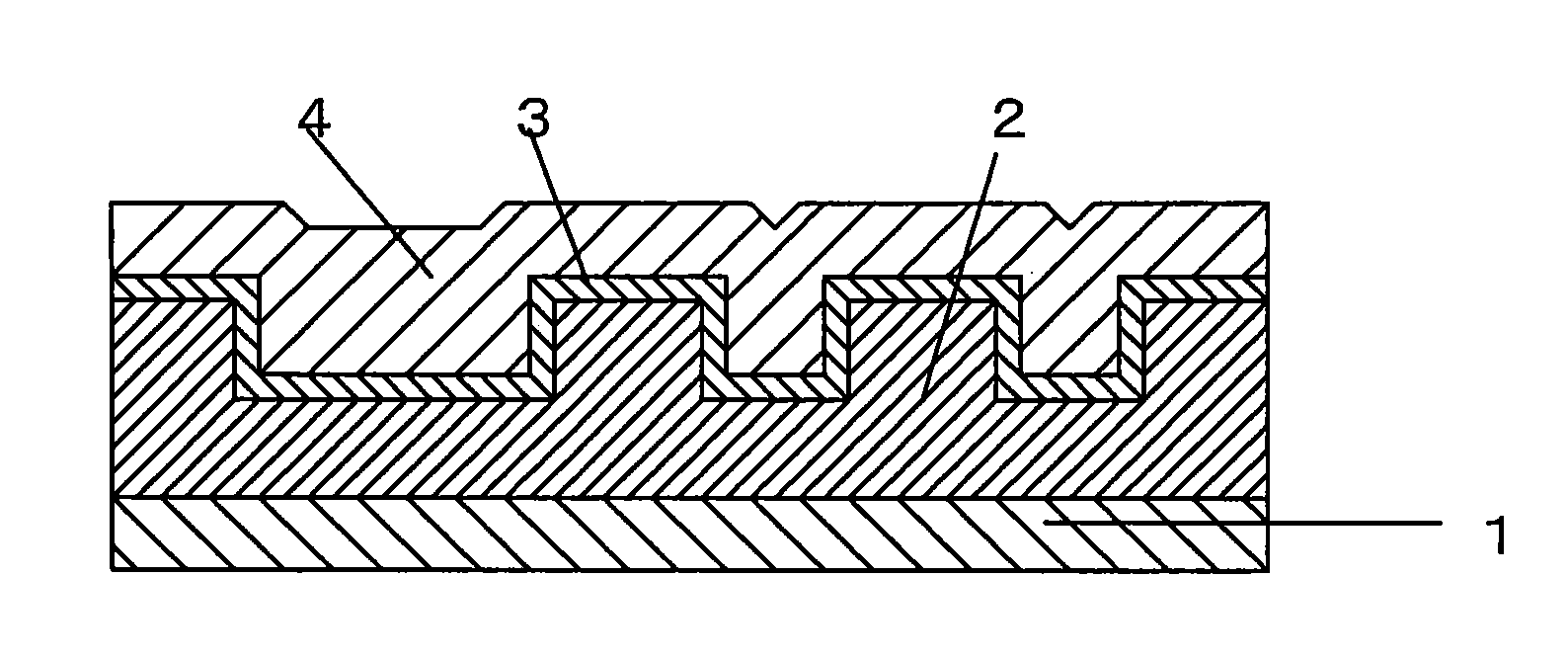

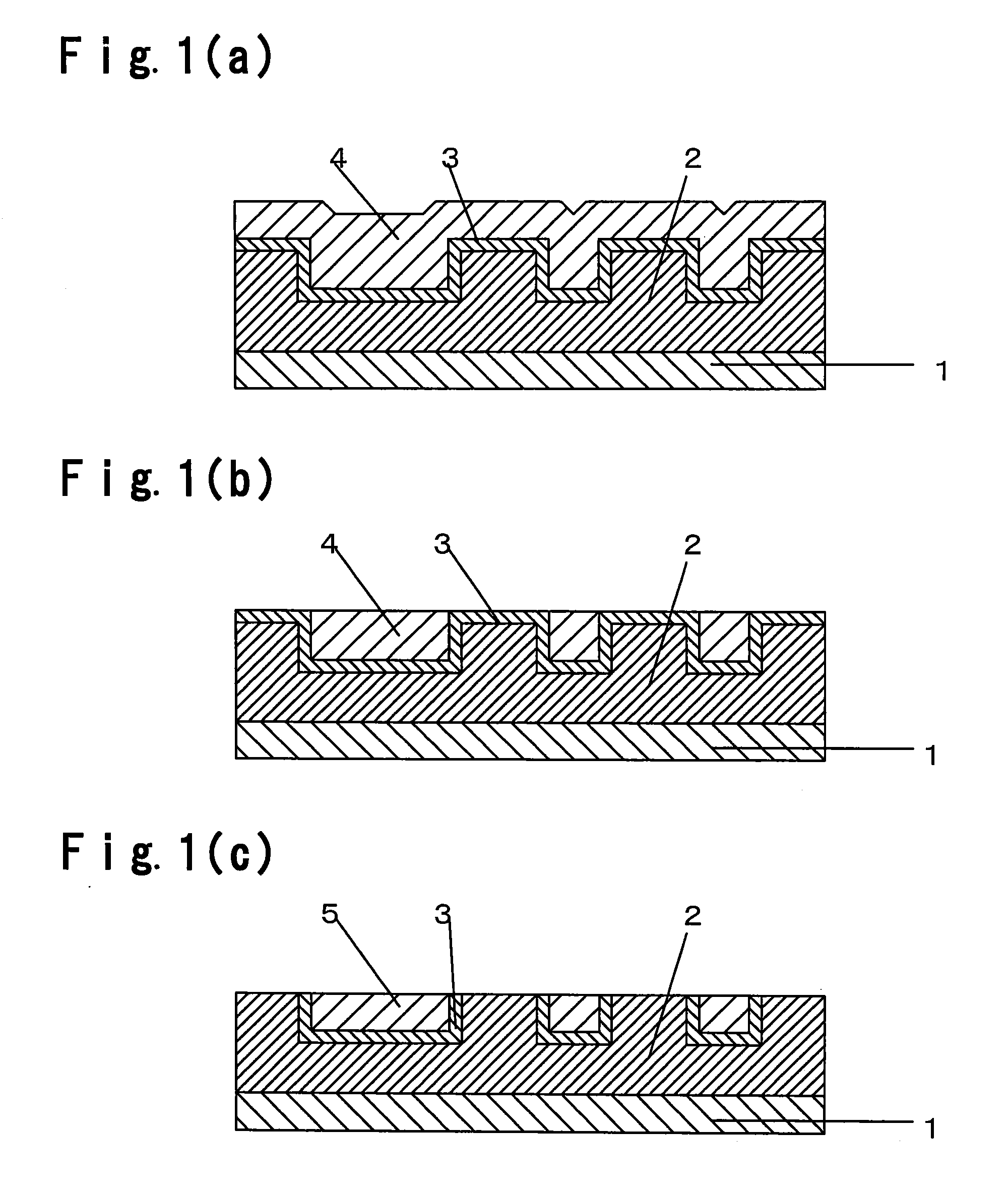

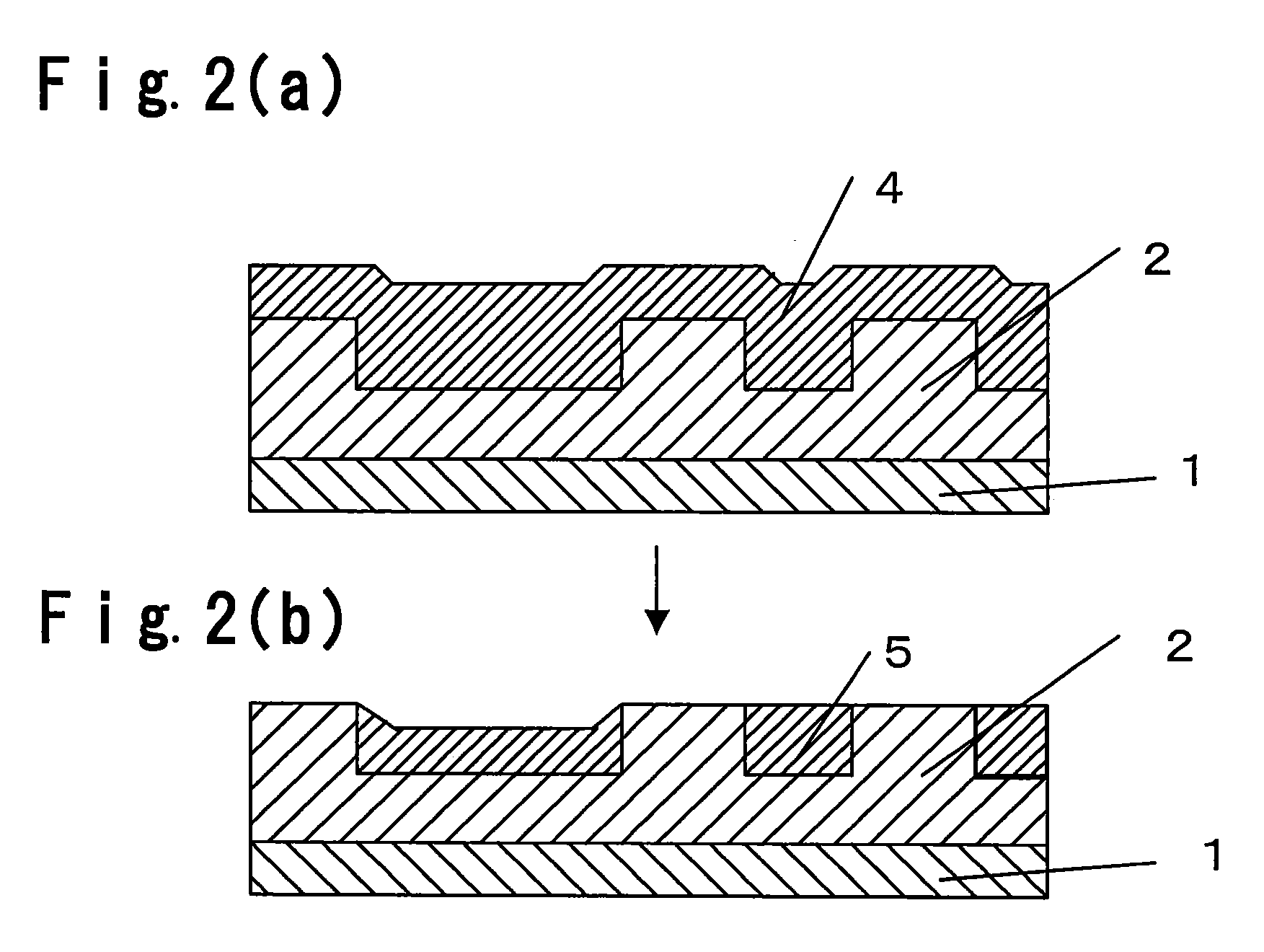

Porous Anode Body For Solid Electrolytic Capacitor, Production Method Thereof and Solid Electrolytic Capacitor

InactiveUS20080106852A1Increase capacitanceLow ESRLiquid electrolytic capacitorsSemiconductor/solid-state device manufacturingCapacitanceTantalum compound

The invention provides a method of manufacturing a porous anode for a solid electrolytic capacitor, comprising a step of subjecting a molded body containing powder of at least one material selected from oxygen-containing niobium material and oxygen-containing tantalum material and a pore-forming agent which is solid at reduction temperature to reduction reaction using reducing agent and another step of removing the pore-forming agent from the reduction reaction product and a solid electrolytic capacitor using an anode obtained thereby. As niobium material and tantalum material, at least one material selected from niobium, niobium alloy, niobium compound, tantalum, tantalum alloy and tantalum compound is used respectively. In the invention, the peak position, the number and quantity of pores can be optimized according to the cathode agent used, whereby a solid electrolytic capacitor having an improved property for impregnation with cathode agent, high capacitance, low ESR, good tan δ characteristics and long-term reliability, is obtained.

Owner:SHOWA DENKO KK

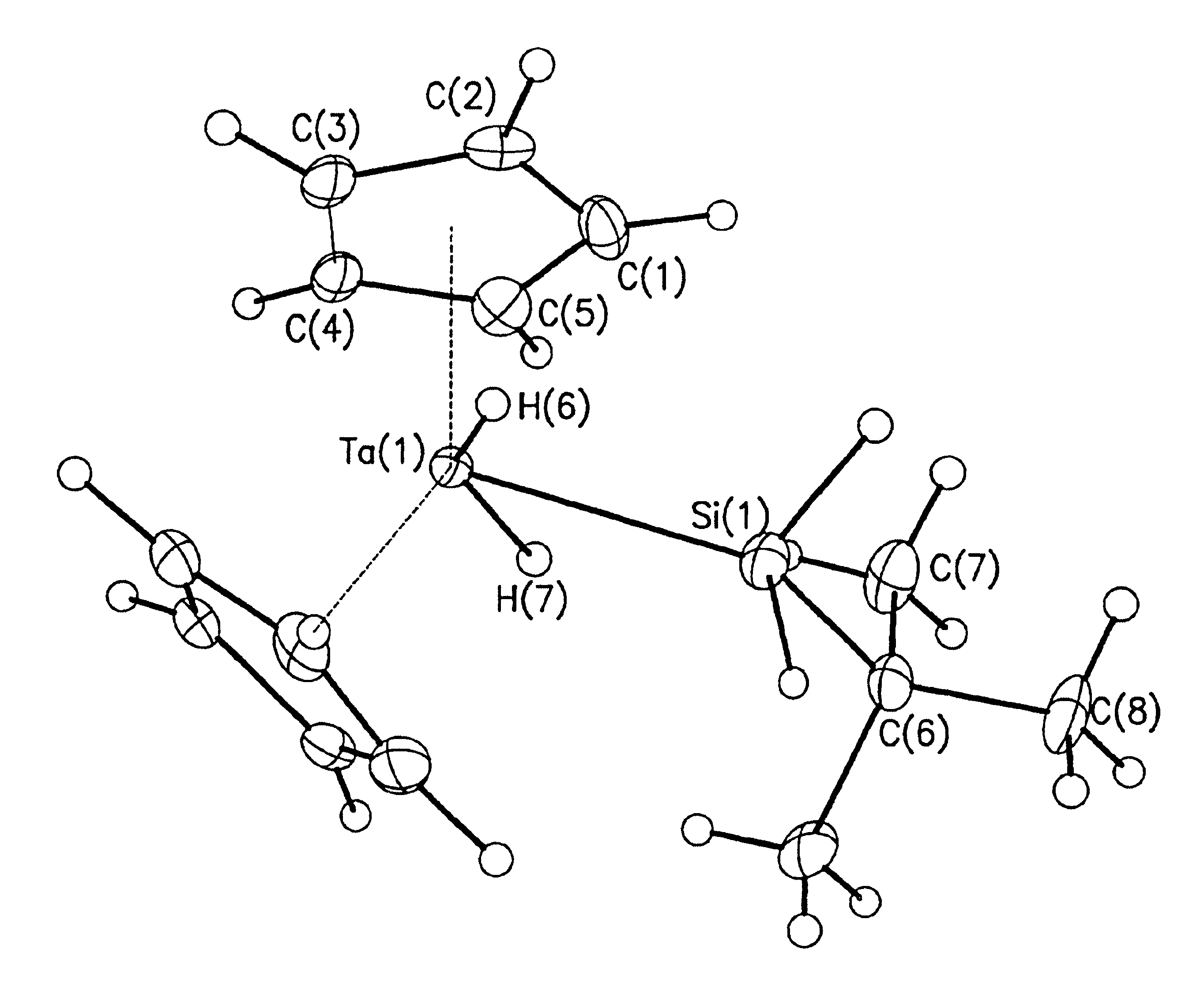

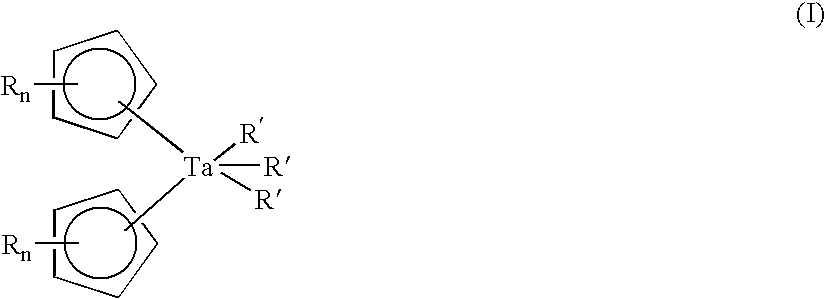

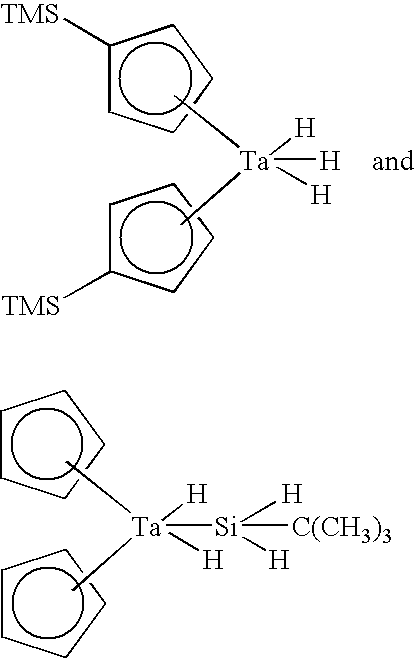

Chemical vapor deposition precursors for deposition of tantalum-based materials

InactiveUS20040142555A1Furnaces without endless coreSilicon organic compoundsTantalum compoundGas phase

Tantalum precursors suitable for chemical vapor deposition of tantalum-containing material, e.g., tantalum, TaN, TaSiN, etc., on substrates. The tantalum precursors are substituted cyclopentadienyl tantalum compounds. In one aspect of the invention, such compounds are silylated to constitute tantalum / silicon source reagents. The precursors of the invention are advantageously employed in semiconductor manufacturing applications to form diffusion barriers in connection with copper metallization of the semiconductor device structure.

Owner:ENTEGRIS INC

Porous anode body for solid electrolytic capacitor, production method thereof and solid electrolytic capacitor

InactiveUS7594937B2Increase capacitanceLow ESRLiquid electrolytic capacitorsSemiconductor/solid-state device manufacturingCapacitanceTantalum compound

The invention provides a method of manufacturing a porous anode for a solid electrolytic capacitor, comprising a step of subjecting a molded body containing powder of at least one material selected from oxygen-containing niobium material and oxygen-containing tantalum material and a pore-forming agent which is solid at reduction temperature to reduction reaction using reducing agent and another step of removing the pore-forming agent from the reduction reaction product and a solid electrolytic capacitor using an anode obtained thereby. As niobium material and tantalum material, at least one material selected from niobium, niobium alloy, niobium compound, tantalum, tantalum alloy and tantalum compound is used respectively. In the invention, the peak position, the number and quantity of pores can be optimized according to the cathode agent used, whereby a solid electrolytic capacitor having an improved property for impregnation with cathode agent, high capacitance, low ESR, good tan δ characteristics and long-term reliability, is obtained.

Owner:SHOWA DENKO KK

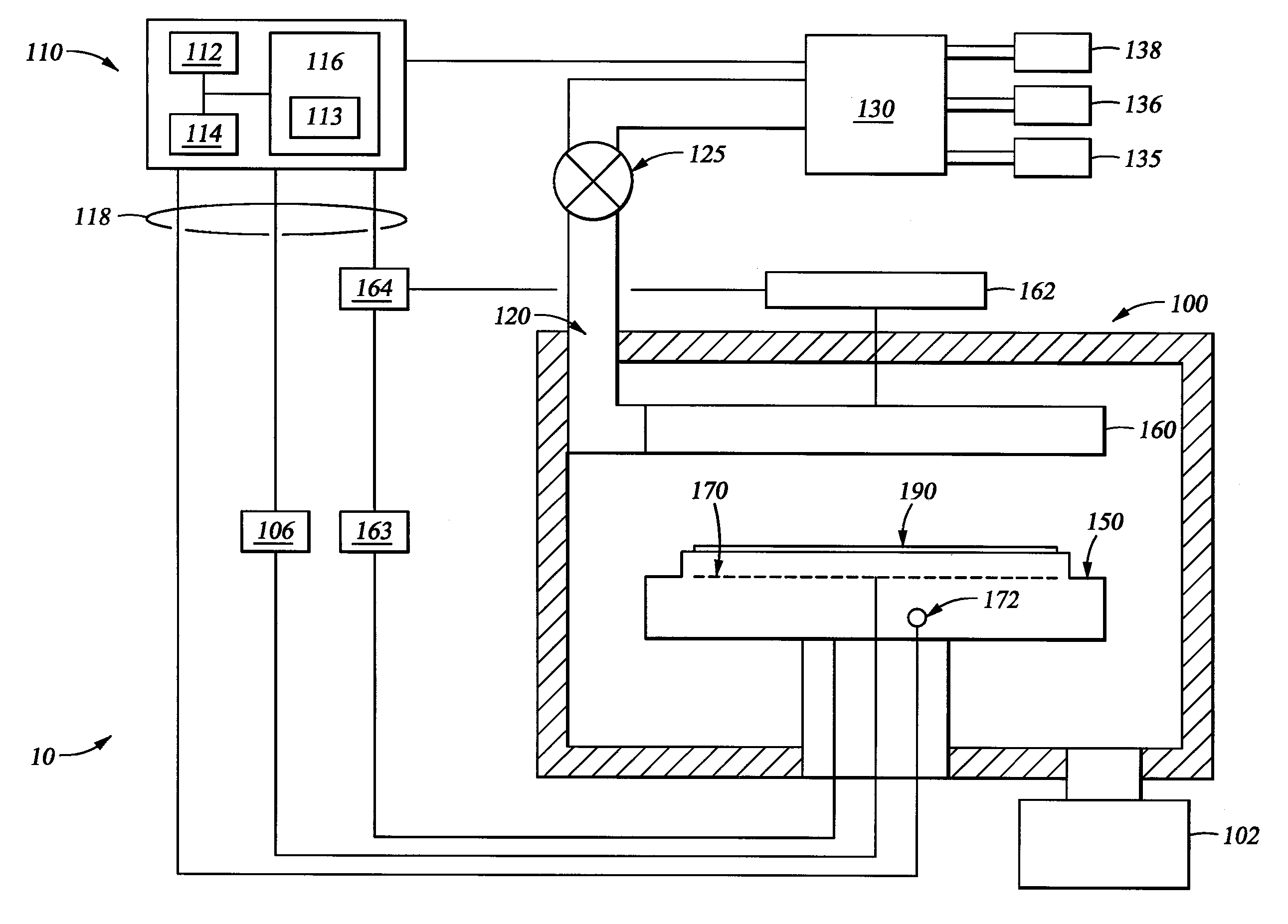

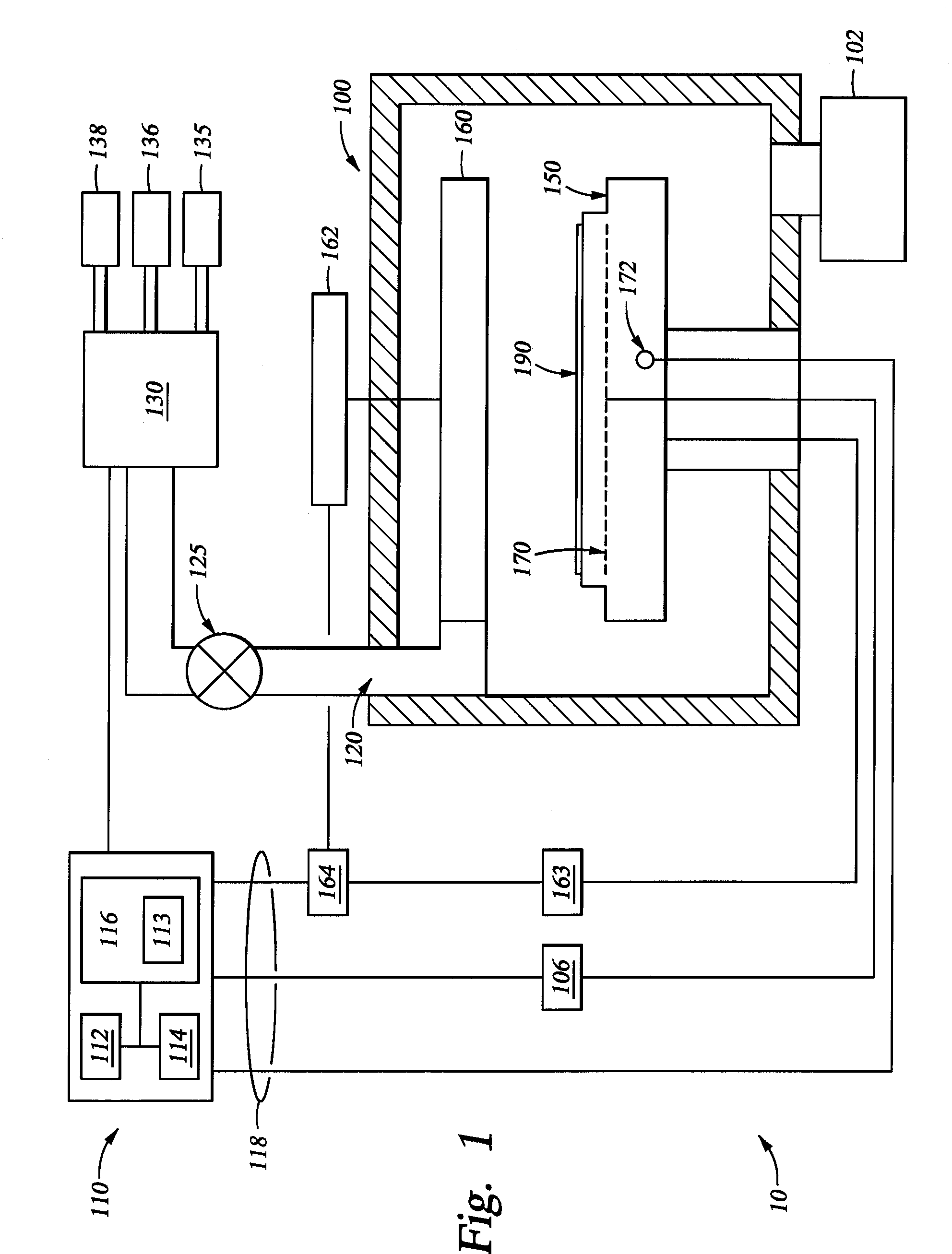

Apparatus for integration of barrier layer and seed layer

A system for processing a substrate is provided which includes at least one atomic layer deposition (ALD) chamber for depositing a barrier layer containing tantalum and at least one physical vapor deposition (PVD) metal seed chamber for depositing a metal seed layer on the barrier layer. The at least one ALD chamber may be in fluid communication with a first precursor source providing a tantalum-containing compound and a second precursor source. In one example, the tantalum-containing compound is an organometallic tantalum precursor, such as PDMAT. In another example, the second precursor source contains a nitrogen precursor, such as ammonia. The PDMAT may have a chlorine concentration of about 100 ppm or less, preferably, about 30 ppm or less, and more preferably, about 5 ppm or less. In some examples, the PVD metal seed chamber is used to deposit a copper-containing metal seed layer.

Owner:APPLIED MATERIALS INC

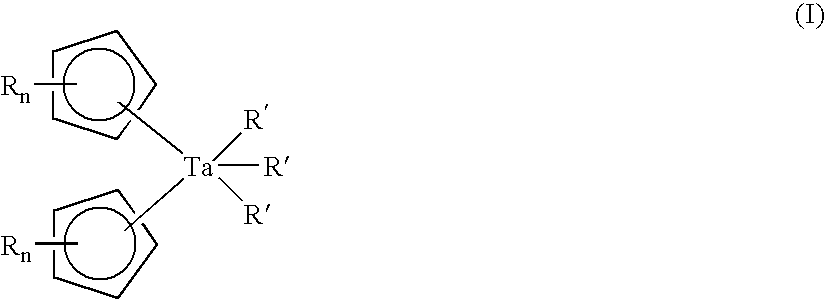

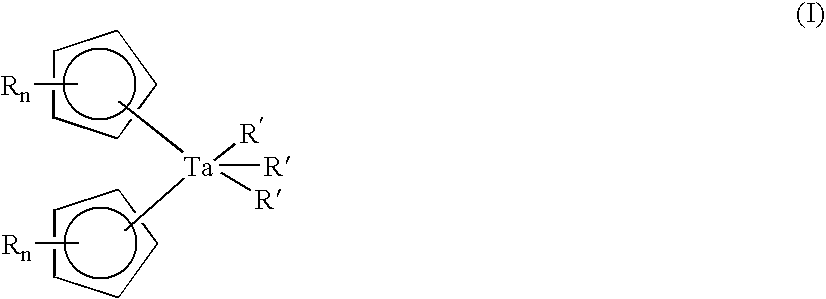

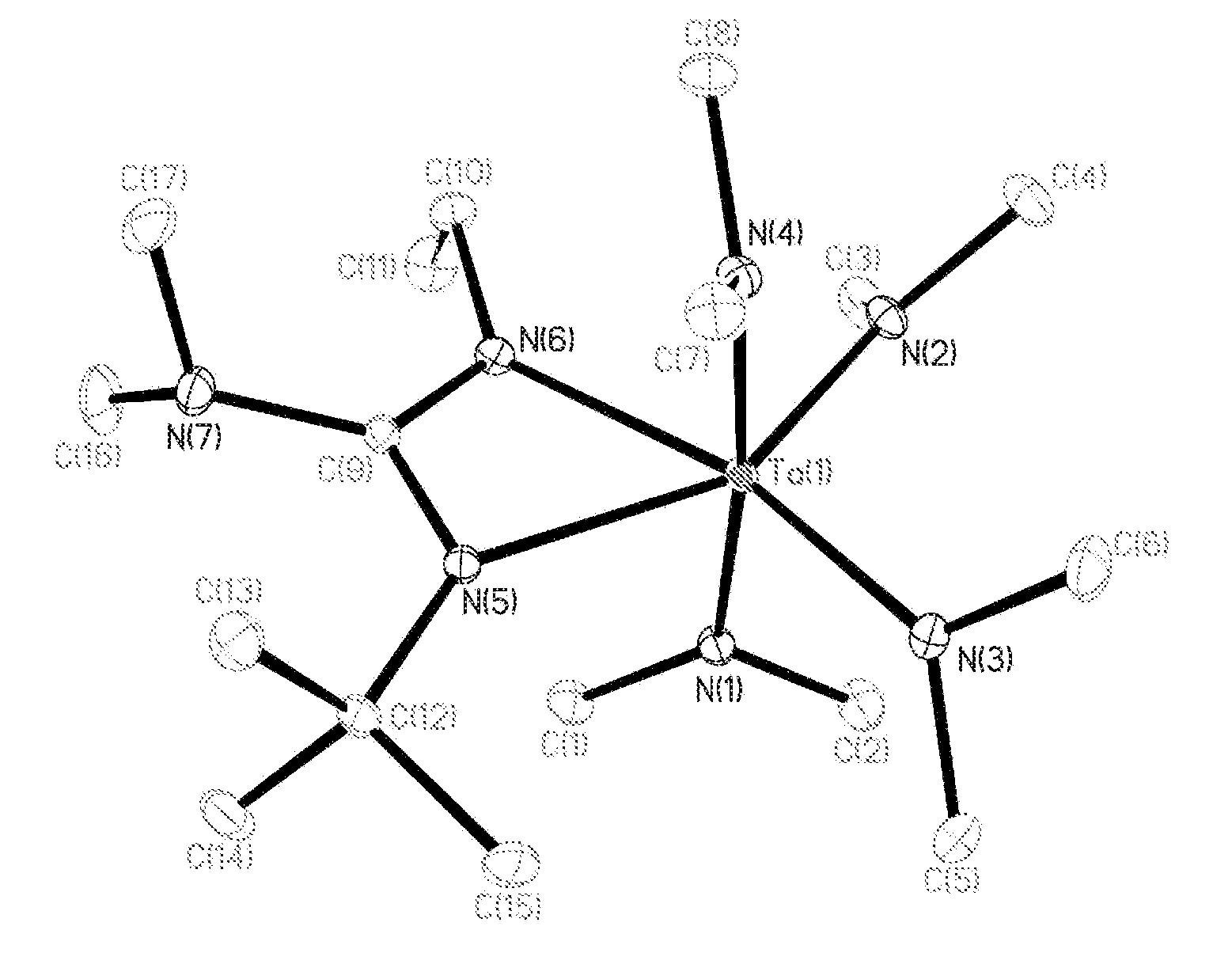

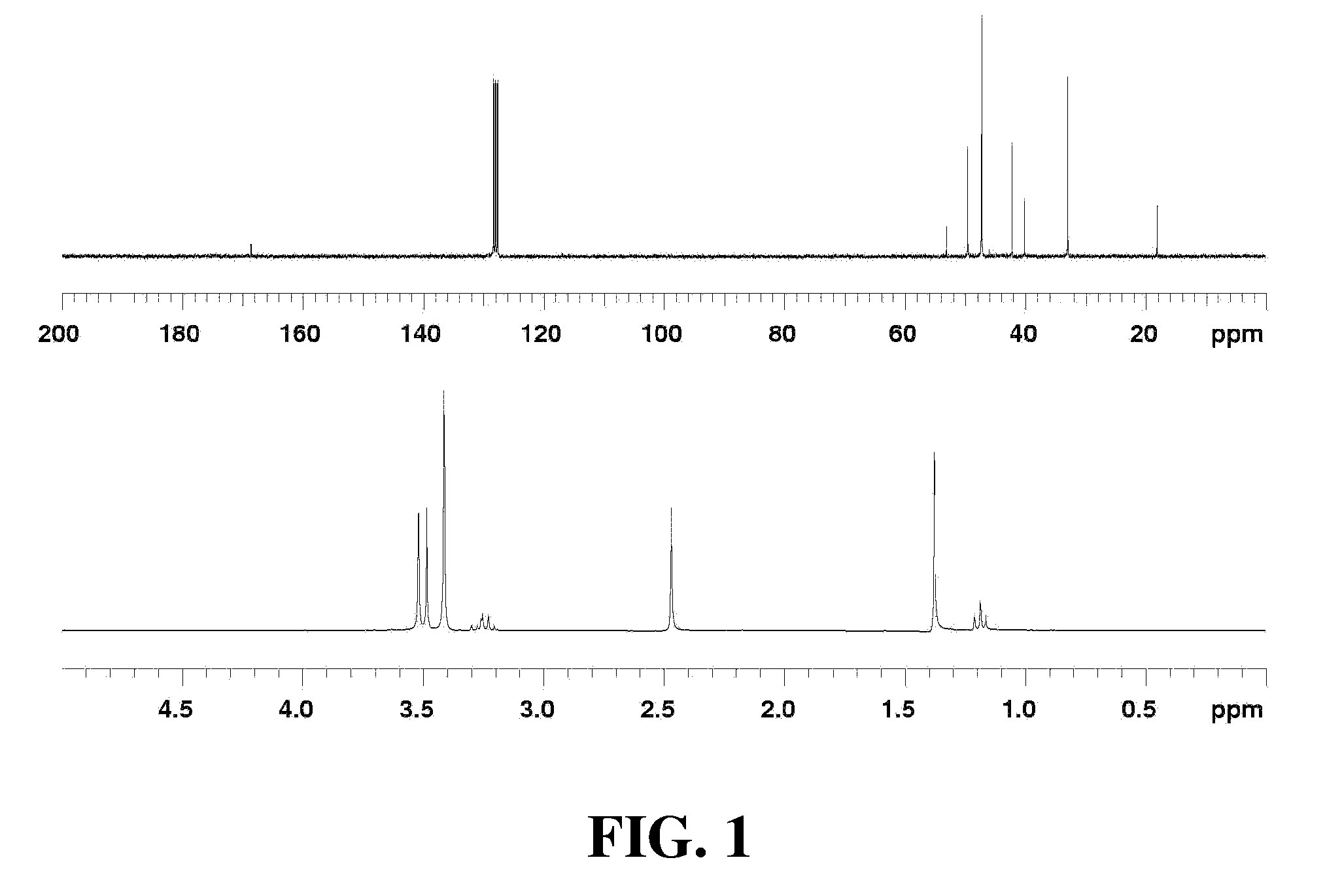

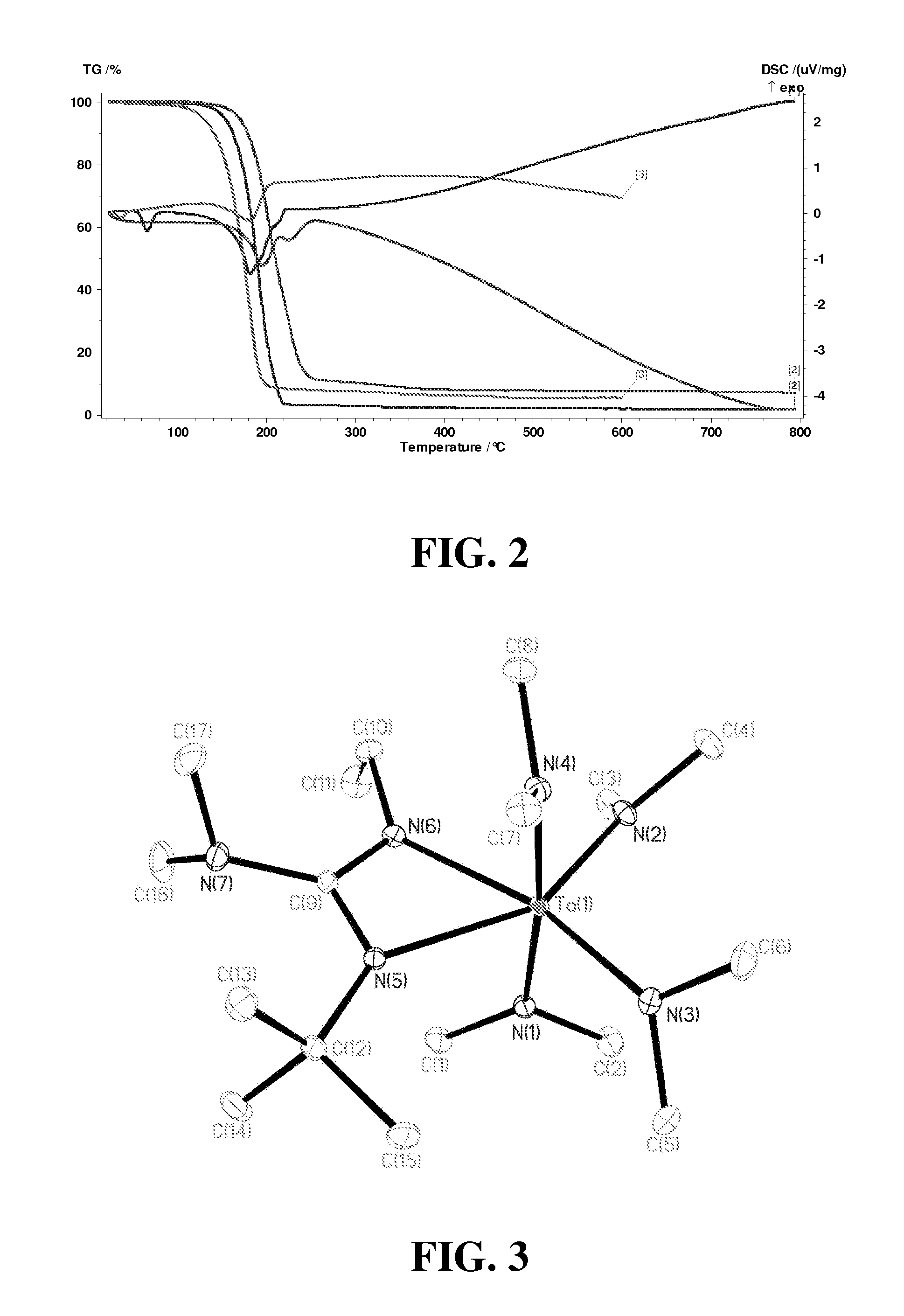

TANTALUM AMIDO-COMPLEXES WITH CHELATE LIGANDS USEFUL FOR CVD AND ALD OF TaN AND Ta205 THIN FILMS

ActiveUS20090032952A1High conformalityRapid depositionGroup 5/15 element organic compoundsTantalum compoundsTantalum compoundCopper

Tantalum compounds of Formula I hereof are disclosed, having utility as precursors for forming tantalum-containing films such as barrier layers. The tantalum compounds of Formula I may be deposited by CVD or ALD for forming semiconductor device structures including a dielectric layer, a barrier layer on the dielectric layer, and a copper metallization on the barrier layer, wherein the barrier layer includes a Ta-containing layer and sufficient carbon so that the Ta-containing layer is amorphous. According to one embodiment, the semiconductor device structure is fabricated by depositing the Ta-containing barrier layer, via CVD or ALD, from a precursor including the tantalum compound of Formula I hereof at a temperature below about 400° C. in a reducing or inert atmosphere, e.g., a gas or plasma optionally containing a reducing agent.

Owner:ENTEGRIS INC

Tantalum powder, method for preparing the same, and electrolytic capacitor anode made of the tantalum powder

InactiveUS20100226070A1High specific capacitanceImprove performanceElectrolytic capacitorsTransportation and packagingTantalum compoundElectrolysis

The present invention relates to the tantalum powder and the process for preparing the same, and also relates to the electrolytic capacitor anode made of the tantalum powder. More particularly, the present invention relates to the tantalum powder having a BET surface area not more than 0.530 m2 / g, Fisher mean particle size not less than 3.00 μm. The present invention relates to the process for preparing the tantalum powder, wherein the tantalum powder is prepared through reducing tantalum compound with a reducing agent, wherein the tantalum powder as seed is added during reduction, and said tantalum powder as seed is the tantalum powder that has been milled.

Owner:NINGXIA ORIENT TANTALUM IND

Coated ternary positive electrode material and preparation method and application thereof

PendingCN110970604AImprove cycle stabilityImproved magnification performanceSecondary cellsPositive electrodesTantalum compoundLithium

The invention discloses a coated ternary positive electrode material and a preparation method and application thereof. The coated ternary positive electrode material comprises a ternary positive electrode material and a lithium-and-tantalum-containing coating layer coated on the surface of the ternary positive electrode material. According to the preparation method, a tantalum compound is used asa coating raw material to coat a ternary material containing residual alkali on the surface, the residual alkali reacts with the tantalum compound to form the lithium-and-tantalum-containing coating layer on the surface of the ternary positive electrode material, so that the coated ternary positive electrode material is obtained, and the residual alkali comprises Li2CO3 and / or LiOH. By adopting the preparation method disclosed by the invention, the electrochemical properties such as rate capability and cycle performance of the material can be improved while the solubility of residual alkali and the material is reduced.

Owner:SHENZHEN CITY BATTERY NANOMETER TECH

CVD tantalum compounds for FET gate electrodes

InactiveUS20050250318A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingCMOSTantalum compound

Compounds of Ta and N, potentially including further elements, and with a resistivity below about 20 mΩcm and with the elemental ratio of N to Ta greater than about 0.9 are disclosed for use as gate materials in field effect devices. A representative embodiment of such compounds, TaSiN, is stable at typical CMOS processing temperatures on SiO2 containing dielectric layers and high-k dielectric layers, with a workfunction close to that of n-type Si. Metallic Ta—N compounds are deposited by a chemical vapor deposition method using an alkylimidotris(dialkylamido)Ta species, such as tertiaryamylimidotris(dimethylamido)Ta (TAIMATA), as Ta precursor. The deposition is conformal allowing for flexible introduction of the Ta—N metallic compounds into a CMOS processing flow. Devices processed with TaN or TaSiN show near ideal characteristics.

Owner:NARAYANAN VIJAY +12

Polishing compound, its production process and polishing method

InactiveUS20050194565A1High removal rateSuppresses wiring defectOther chemical processesSemiconductor/solid-state device manufacturingTectorial membraneCopper-wiring

A polishing compound for chemical mechanical polishing of a substrate, which comprises (A) abrasive grains, (B) an aqueous medium, (C) tartaric acid, (D) trishydroxymethylaminomethane and (E) at least one member selected from the group consisting of malonic acid and maleic acid, and more preferably, which further contains a compound having a function to form a protective film on the wiring metal surface to prevent dishing at the wiring metal portion, such as benzotriazole. By use of this polishing compound, the copper wirings on the surface of a semiconductor integrated circuit board can be polished at a high removal rate while suppressing formation of scars as defects in a polishing step. Particularly in a first polishing step of polishing copper wirings having a film made of tantalum or a tantalum compound as a barrier film, excellent selectivity will be obtained, dishing and erosion due to polishing are less likely to occur, and an extremely high precision flat surface of a semiconductor integrated circuit board can be obtained.

Owner:ASAHI GLASS CO LTD +1

Tantalum doped nickel-cobalt-manganese lithium iron battery positive material

InactiveCN107819114ABreak up fullyHigh mechanical strengthCell electrodesSecondary cellsLithiumTantalum compound

The invention discloses a tantalum doped nickel-cobalt-manganese lithium iron battery positive material and a preparation method thereof. The chemical expression of the tantalum doped nickel-cobalt-manganese-lithium iron battery positive material is LiaNixCoyMnzTabO2, wherein a is more than or equal to 1 and less than or equal to 1.2, x is more than or equal to 0.3 and less than or equal to 0.98,y is more than or equal to 0.01 and less than or equal to 0.6, z is more than or equal to 0.001 and less than or equal to 0.6, b equals to 4 / 5-a / 5-3x / 5-3y / 5-3z / 5, and b is more than or equal to 0.00001 and less than or equal to 0.2. According to the invention, a single crystal nickel-cobalt-manganese compound precursor and a tantalum compound are premixed at a superhigh speed, and the mixture of the single crystal nickel-cobalt-manganese compound precursor and the tantalum compound are mixed with a common poly-crystal nickel-cobalt-manganese precursor, so as to improve the mixing effect; sincea single crystal compound precursor is high in mechanical strength, superhigh-speed mixing can be adopted instead of breaking, and the single crystal compound precursor can play a role of a collisionmedium, so as to sufficiently scatter the tantalum compound and sufficiently mix doped elements and main elements.

Owner:JINGMEN GEM NEW MATERIAL

Tantalum oxide film, use thereof, and method and composition for forming the same

A composition for forming a high-quality tantalum film which is advantageously used as an capacitor insulating film and a process for forming the high-quality tantalum film. The composition for forming a tantalum oxide film, which comprises at least one tantalum compound selected from the group consisting of a reaction product of a compound capable of reacting with a tantalum alkoxide and a tantalum alkoxide and a hydrolyzate of the reaction product, and a solvent, and the process for forming the tantalum oxide film by applying this composition to a substrate and heating it.

Owner:JSR CORPORATIOON

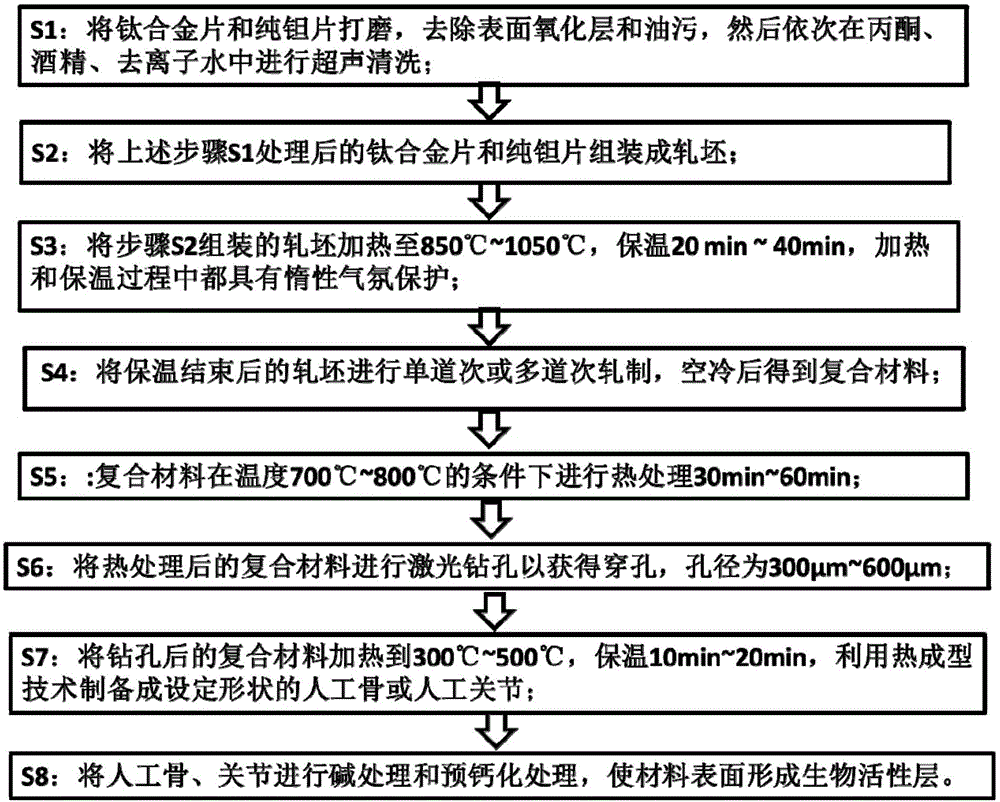

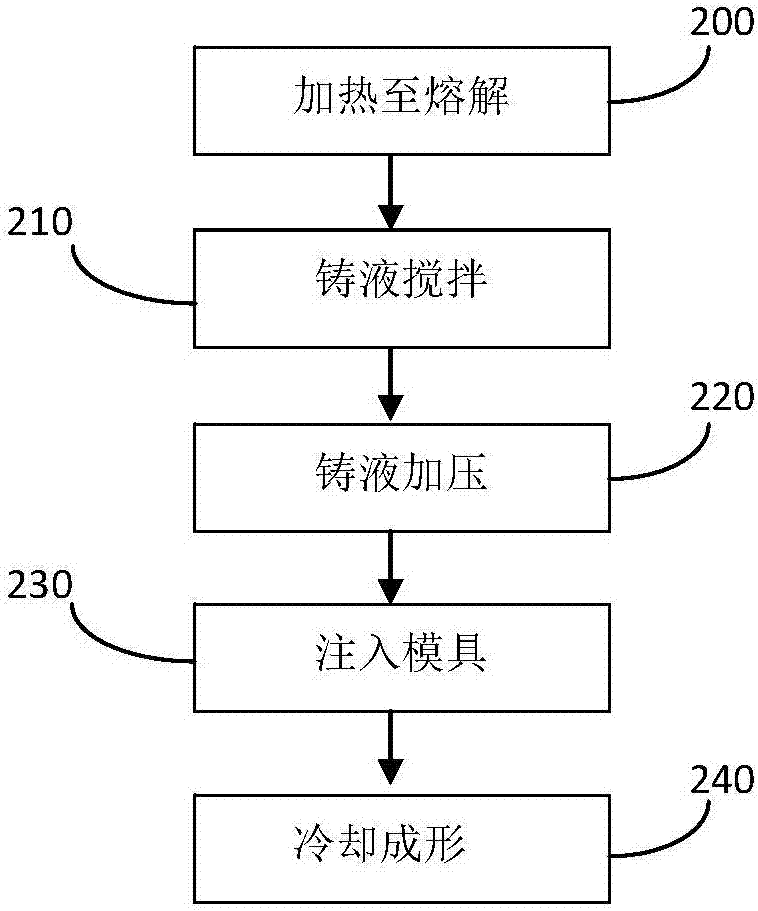

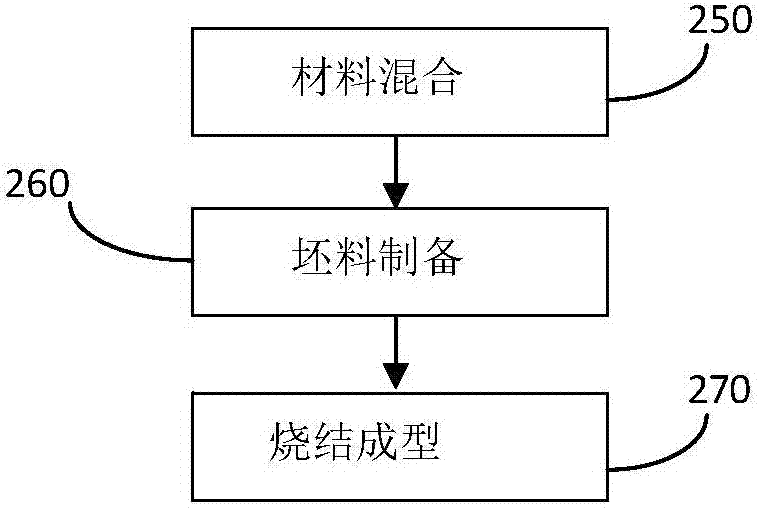

Method for preparing medical porous titanium-tantalum artificial bone and artificial joint, and products thereof

ActiveCN106693069AGuaranteed bonding qualityReliable workmanshipPharmaceutical delivery mechanismTissue regenerationBiocompatibility TestingArtificial bone

The invention discloses a method for preparing porous titanium-tantalum artificial bone and joint and products thereof, and belongs to the field of biological materials. The method comprises the following steps: S1, grinding to-be-bonded surfaces of a titanium alloy sheet and a tantalum sheet, and performing ultrasonic washing sequentially with acetone, alcohol and deionized water; S2, fitting the titanium alloy sheet and the tantalum sheet, heating to 850-1050 DEG C, insulating for 20-40 minutes, pressurizing to perform plastic deformation, and air-cooling to room temperature to form metallurgic bonding between the two materials; S3, quickly preparing pores having a pore size of 300-600mu m in a compound plate by utilizing a solid laser; S4, preparing various artificial bones and joints from the titanium-tantalum compound plate by utilizing a thermal forming technology; and S5, performing alkali and pre-calcifying treatment to improve the biocompatibility of the compound material. Compared with a traditional explosive compound method, the hot-rolling compound method is safer, controllable, convenient and firm in bonding. The product has relatively high biocompatibility.

Owner:HUAZHONG UNIV OF SCI & TECH

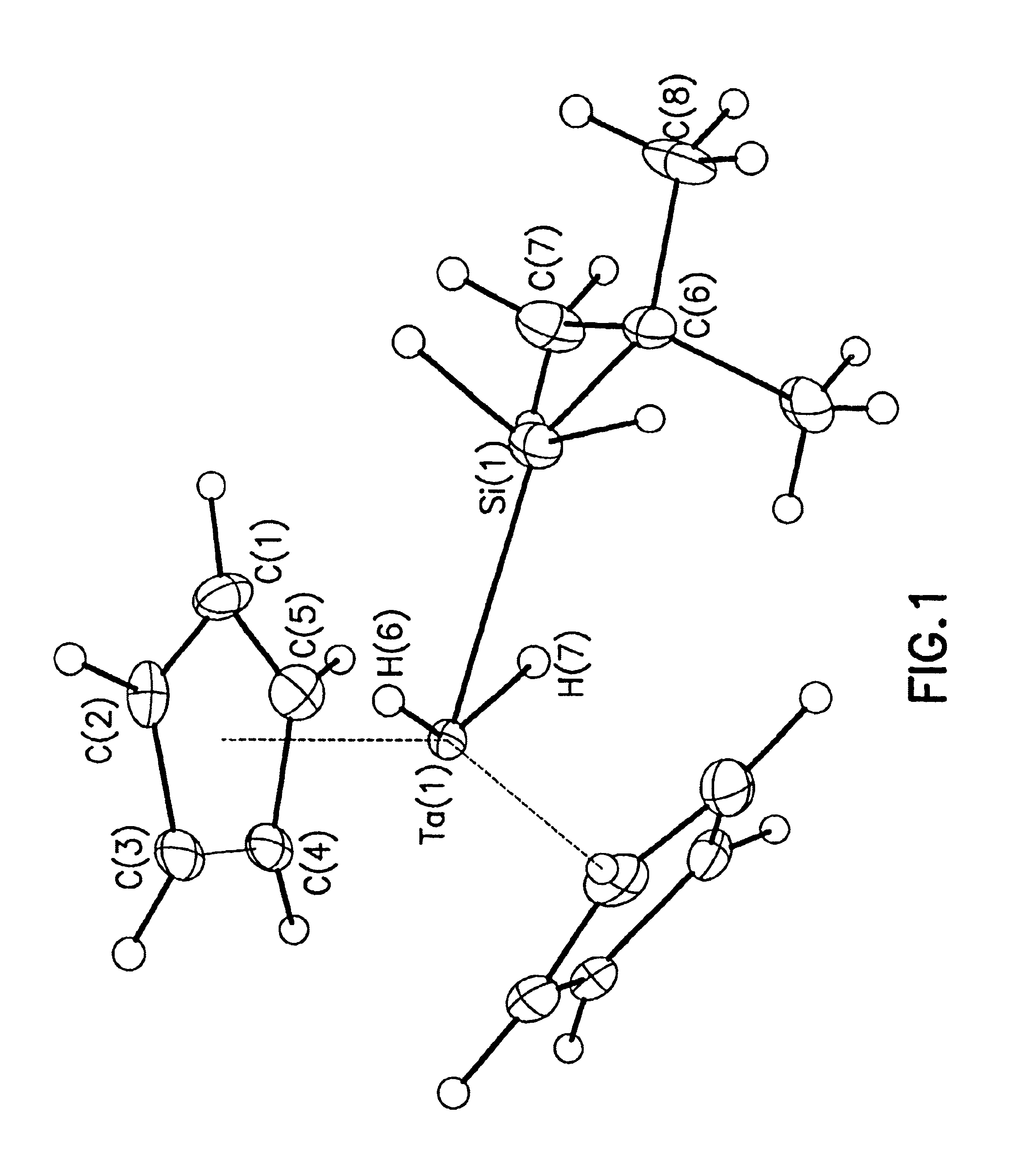

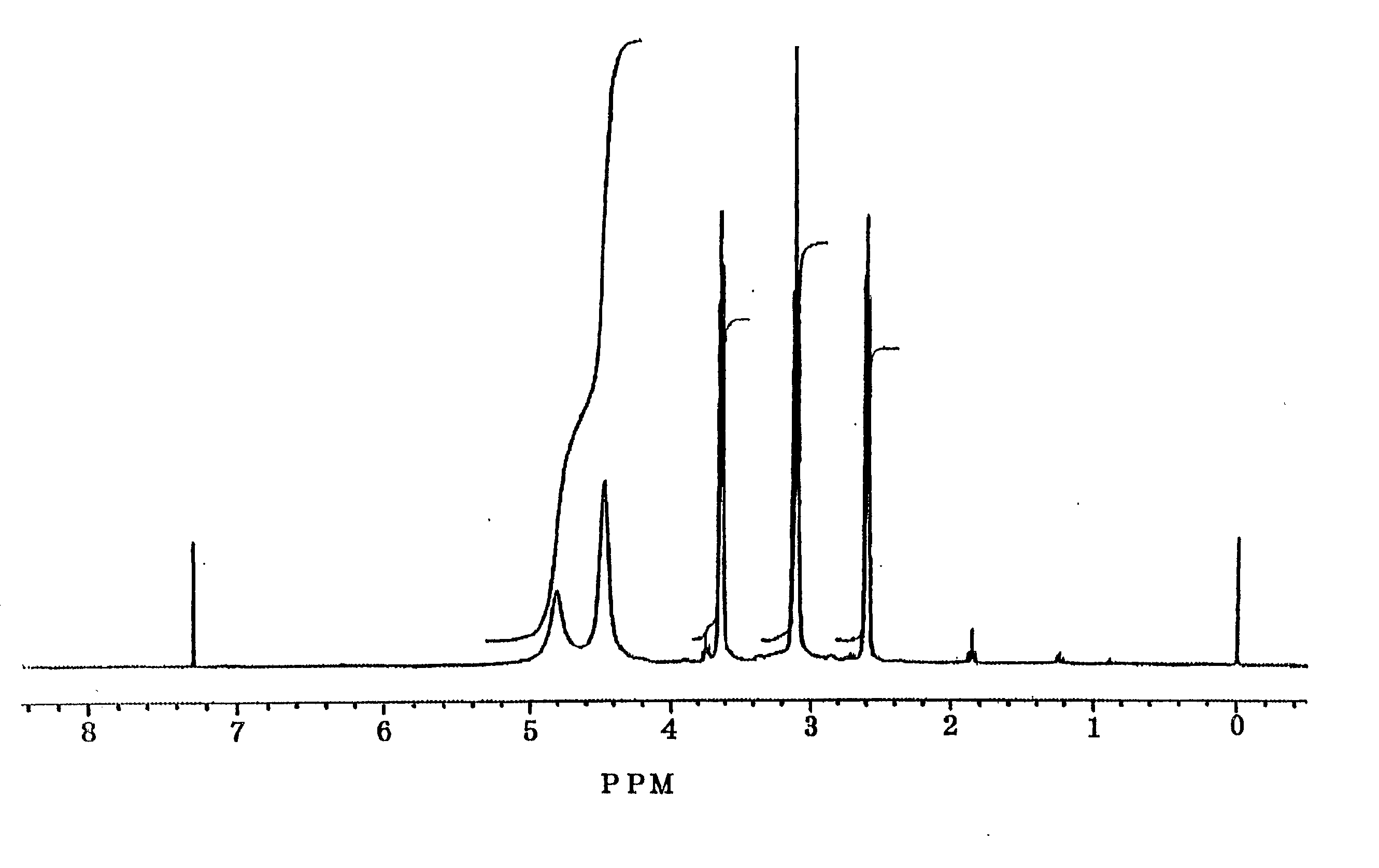

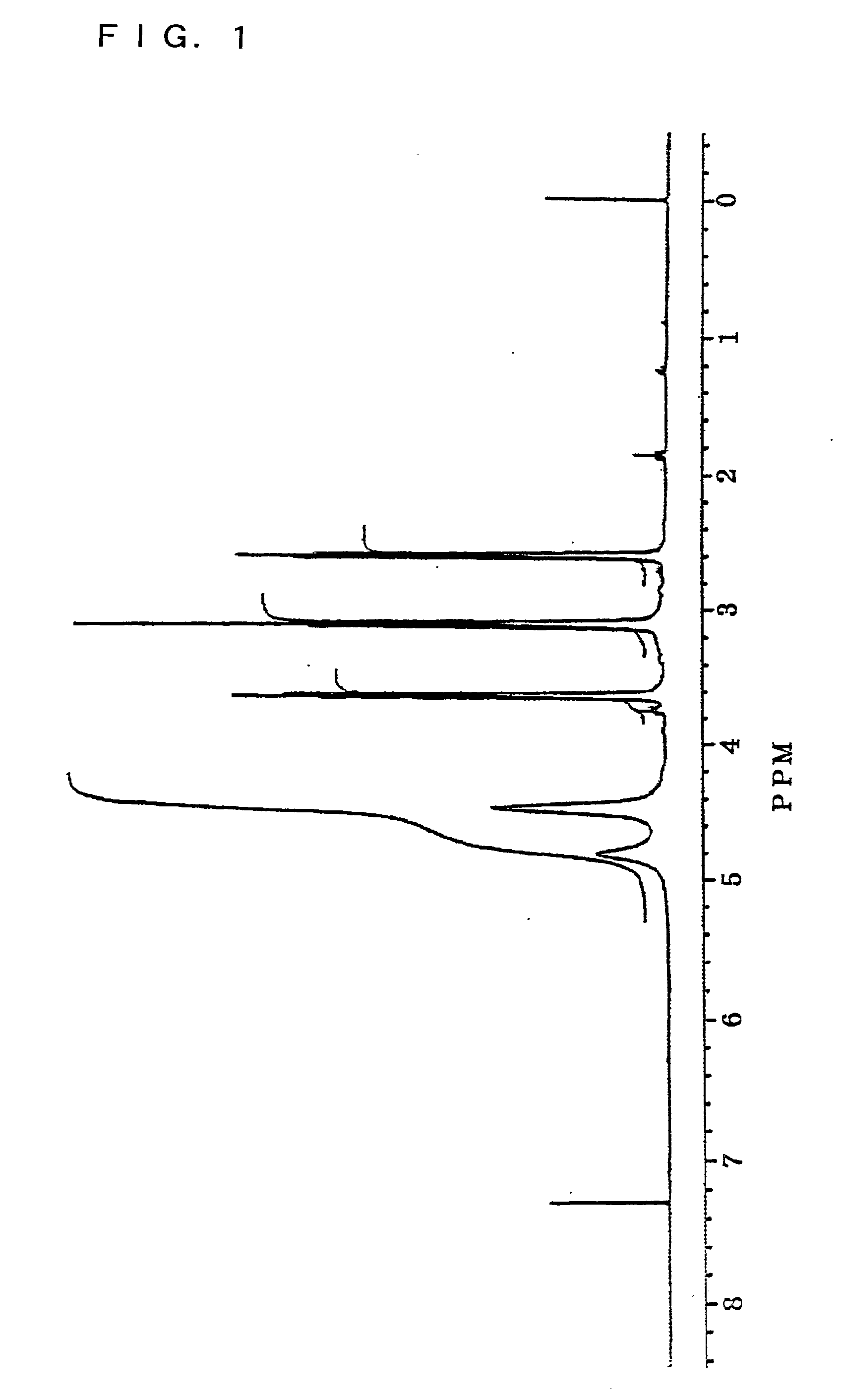

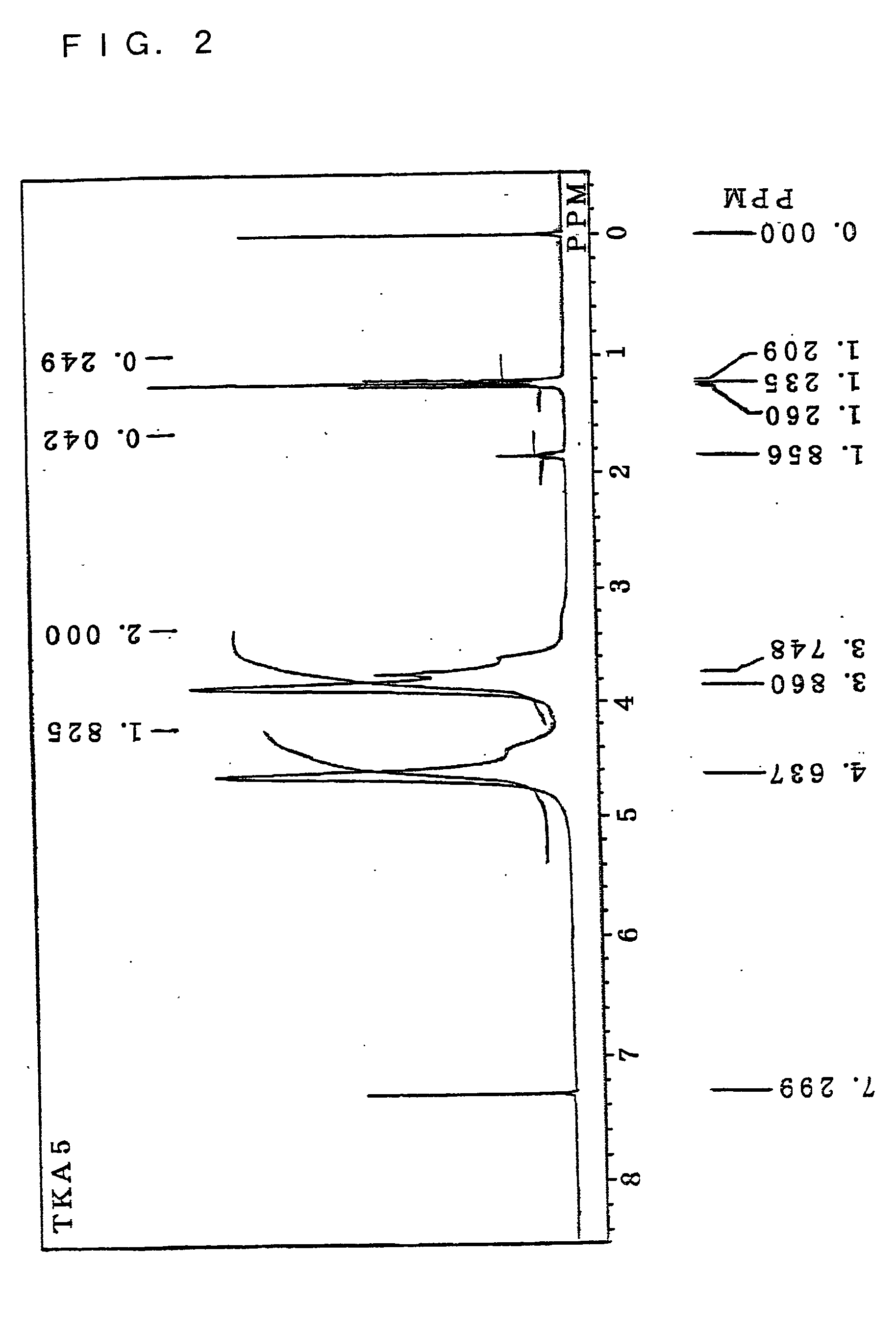

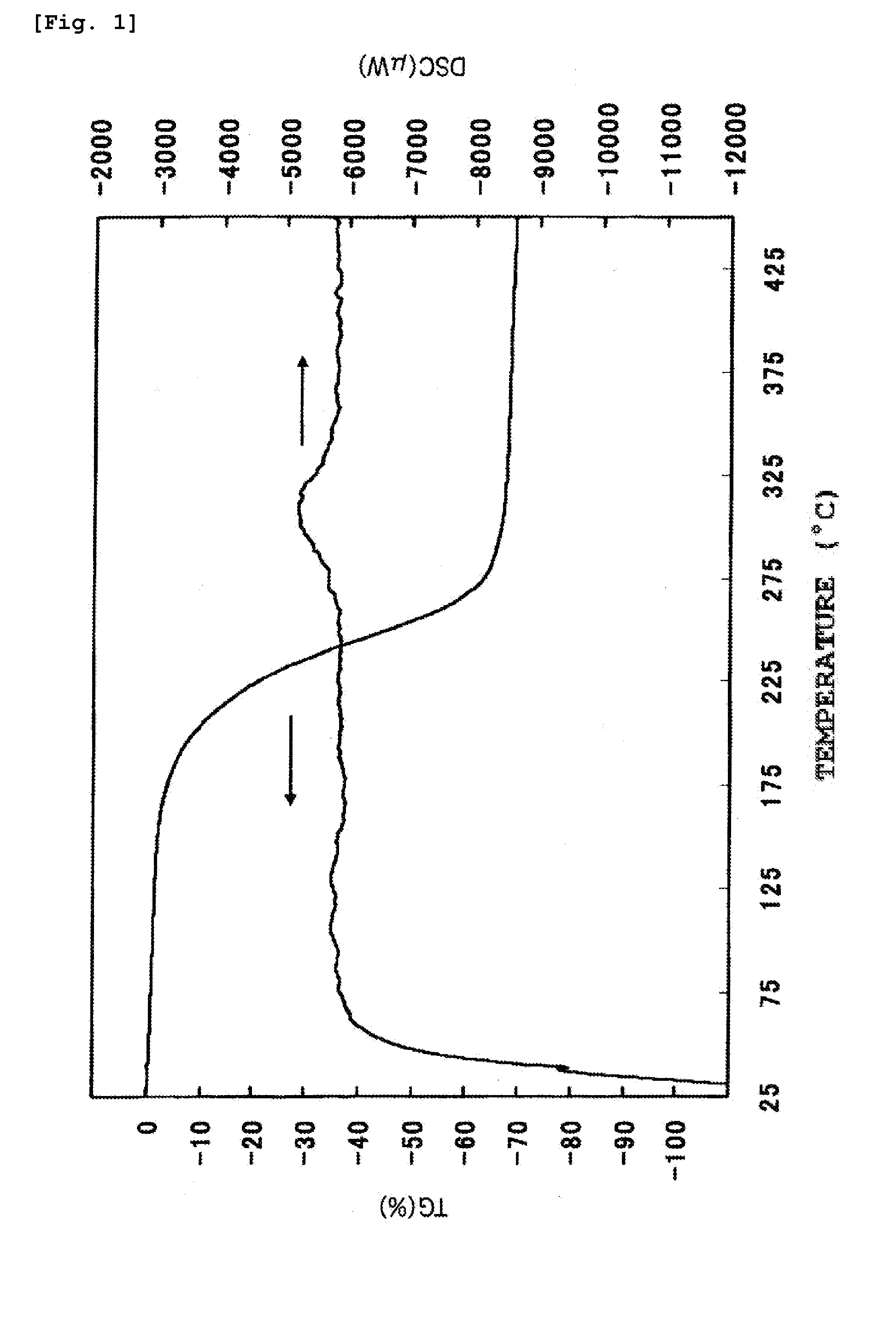

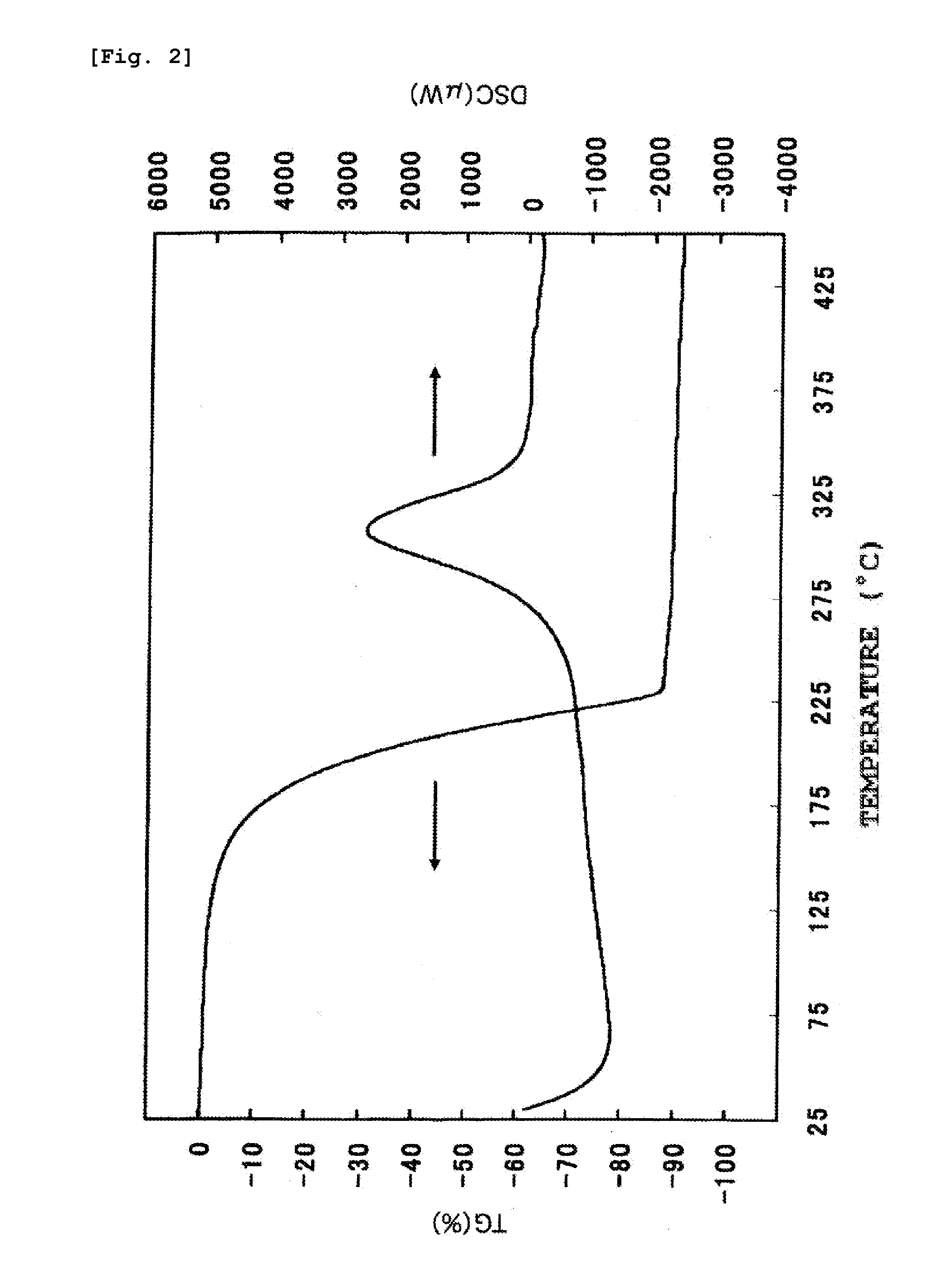

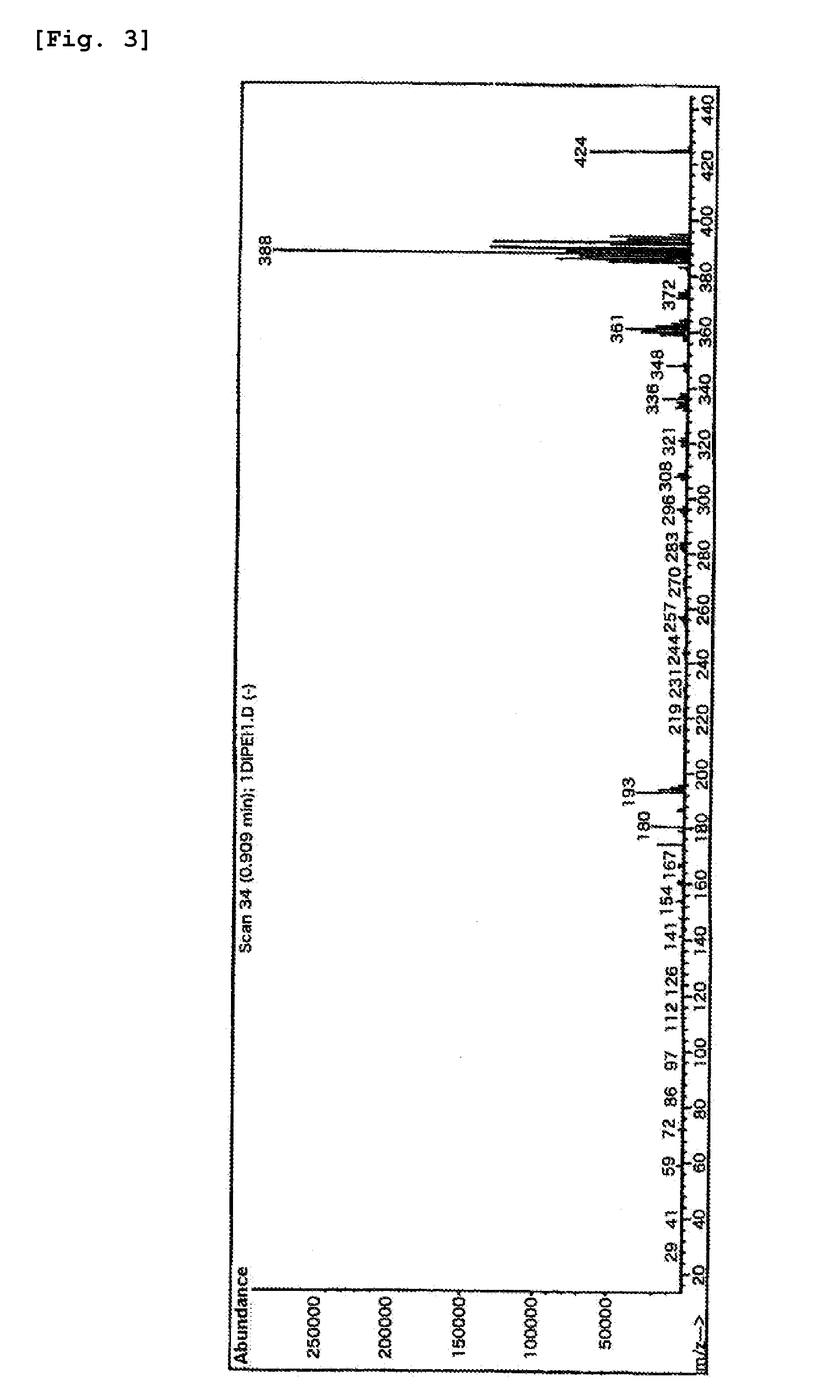

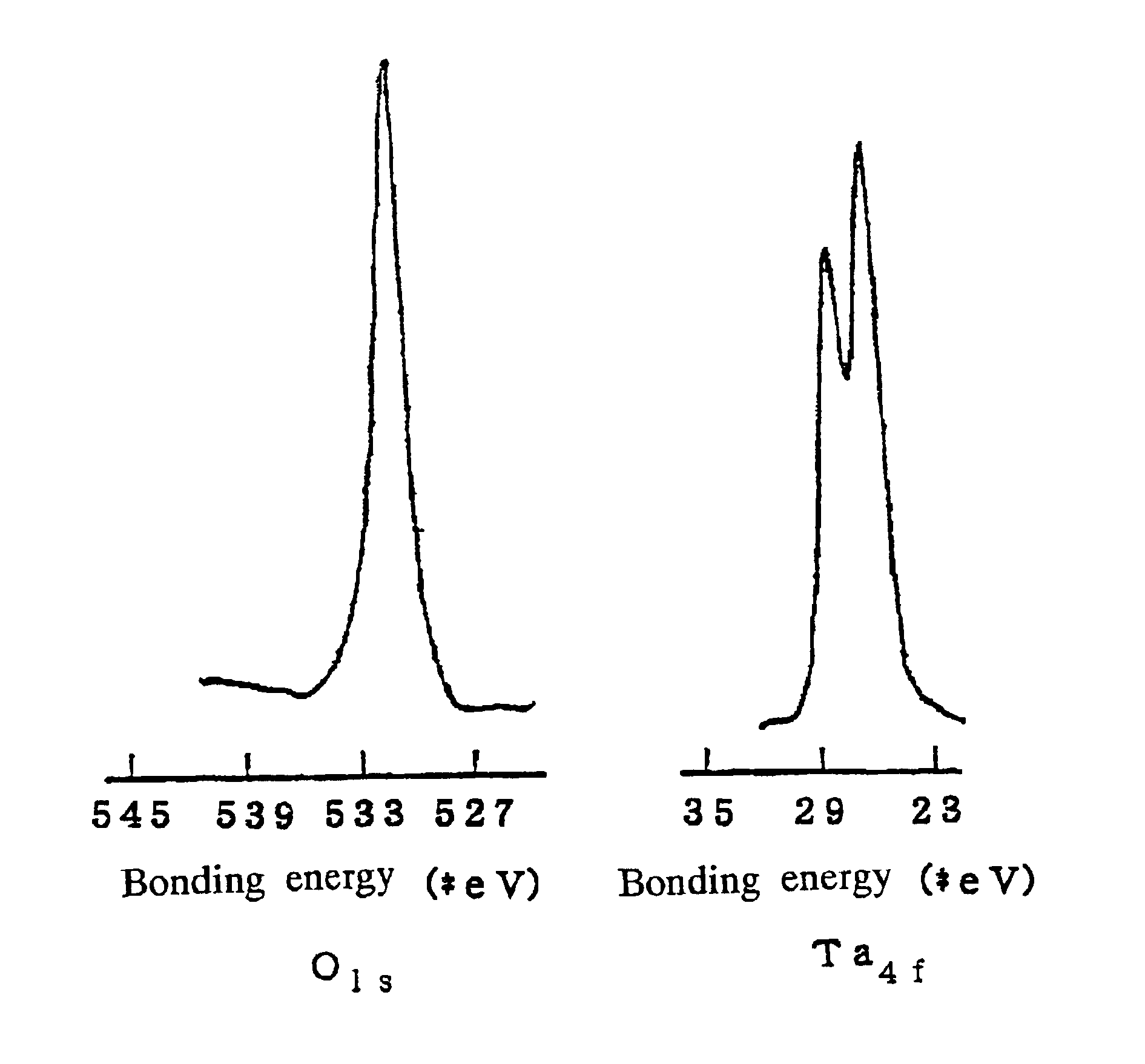

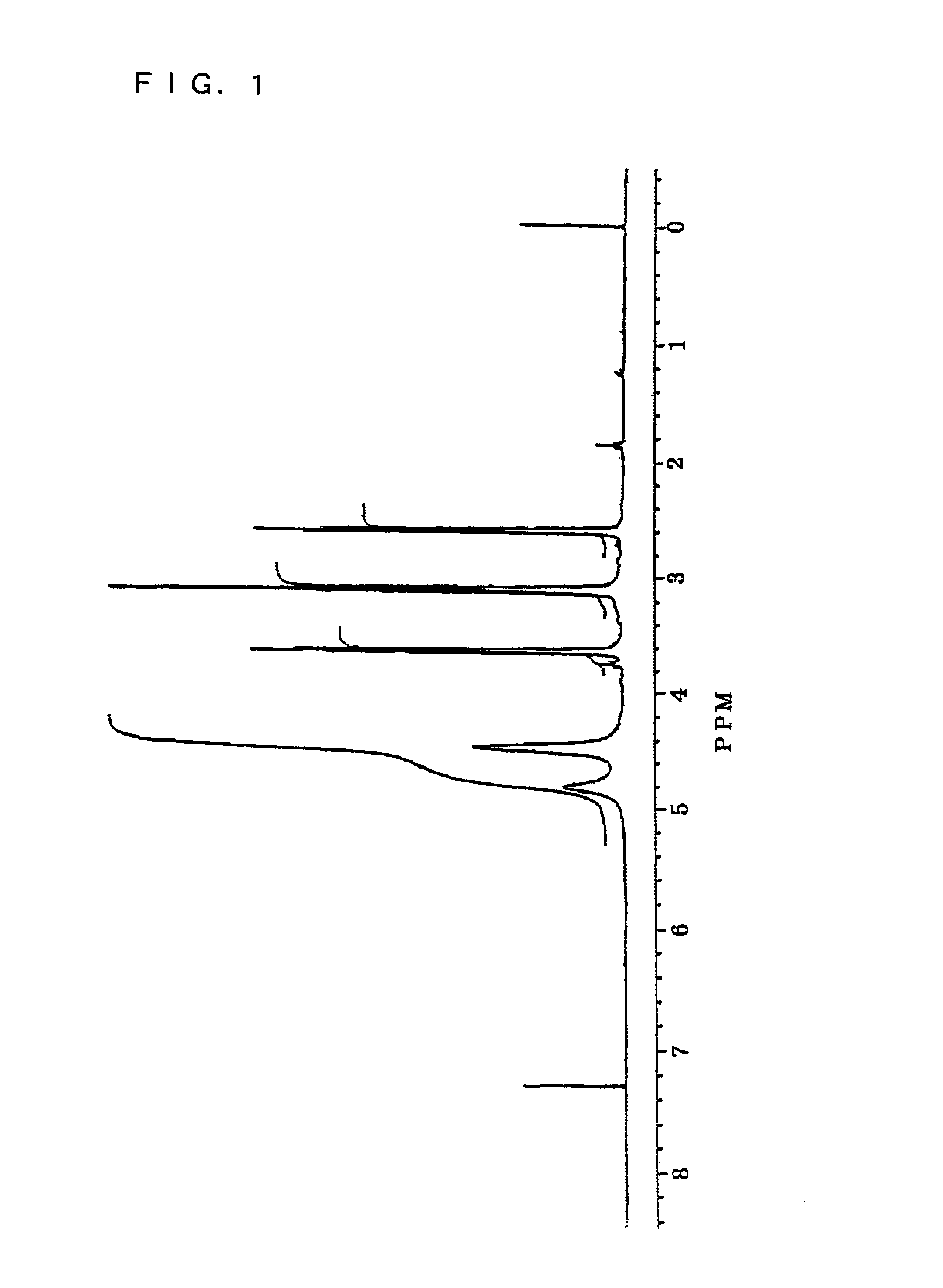

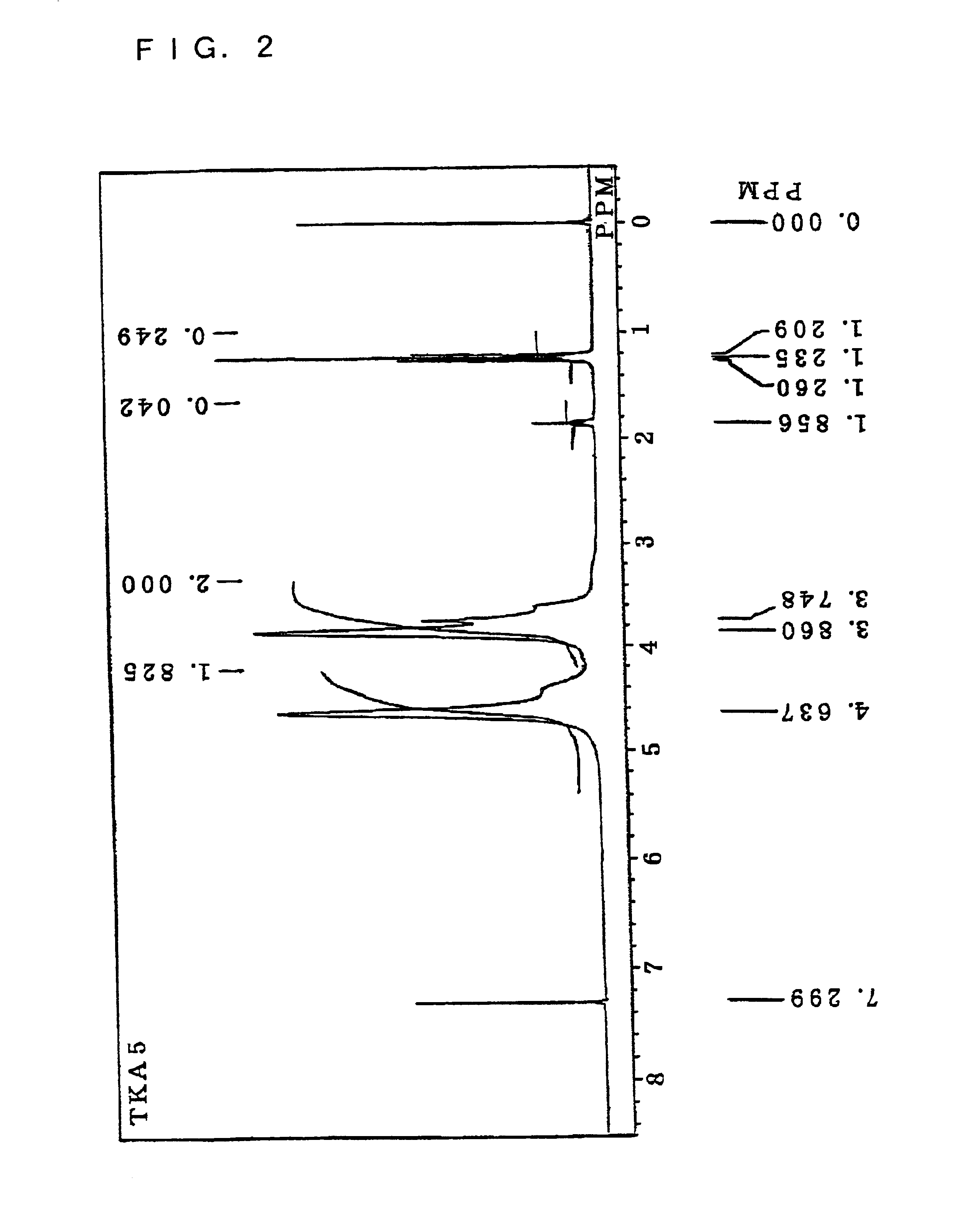

Tantalum compound, method for producing same, tantalum-containing thin film and method for forming same

ActiveUS20090043119A1Stably formGroup 5/15 element organic compoundsSemiconductor/solid-state device manufacturingTantalum compoundHalogen

Objects of the present invention are to provide a novel tantalum compound which enables to selectively form a tantalum-containing thin film free of halogen and the like, and various tantalum-containing thin films which contain the desired element, and a method for producing the same, and further provide a method for stably forming a tantalum-containing thin film which contains the desired element.The present invention relates to a tantalum compound represented by the following formula (1)(In the formula, R1 represents a straight-chain alkyl group having from 2 to 6 carbon atoms),or a tantalum compound represented by the general formula (2)(In the formula, R2 represents a straight-chain alkyl group having from 2 to 6 carbon atoms), and a method for producing the same.The present invention further relates to form a tantalum-containing thin film by using a tantalum compound represented by the following general formula (6)(In the formula, j, k, m and n is an integer of from 1 to satisfying j+k=5 and m+n=5, and R3 to R6 represent a hydrogen atom, an alkyl group having from 1 to 6 carbon atoms, and the like) as a raw material.

Owner:SAGAMI CHEM RES CENT +1

Polishing compound, its production process and polishing method

InactiveUS20100009540A1High removal rateSuppresses wiring defectOther chemical processesSemiconductor/solid-state device manufacturingTectorial membraneCopper-wiring

A polishing compound for chemical mechanical polishing of a substrate, which comprises (A) abrasive grains, (B) an aqueous medium, (C) tartaric acid, (D) trishydroxymethylaminomethane and (E) at least one member selected from the group consisting of malonic acid and maleic acid, and more preferably, which further contains a compound having a function to form a protective film on the wiring metal surface to prevent dishing at the wiring metal portion, such as benzotriazole. By use of this polishing compound, the copper wirings on the surface of a semiconductor integrated circuit board can be polished at a high removal rate while suppressing formation of scars as defects in a polishing step. Particularly in a first polishing step of polishing copper wirings having a film made of tantalum or a tantalum compound as a barrier film, excellent selectivity will be obtained, dishing and erosion due to polishing are less likely to occur, and an extremely high precision flat surface of a semiconductor integrated circuit board can be obtained.

Owner:ASAHI GLASS CO LTD +1

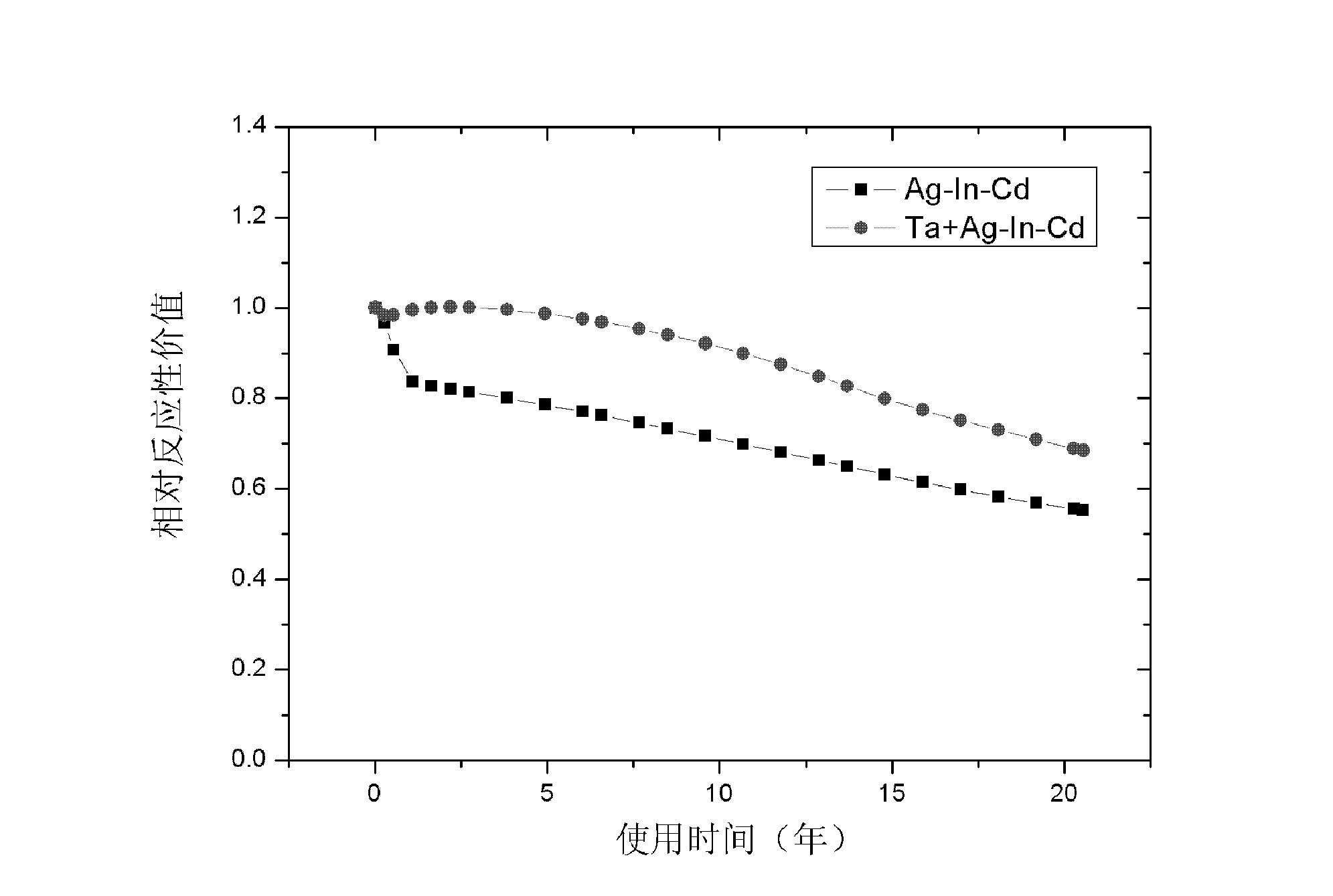

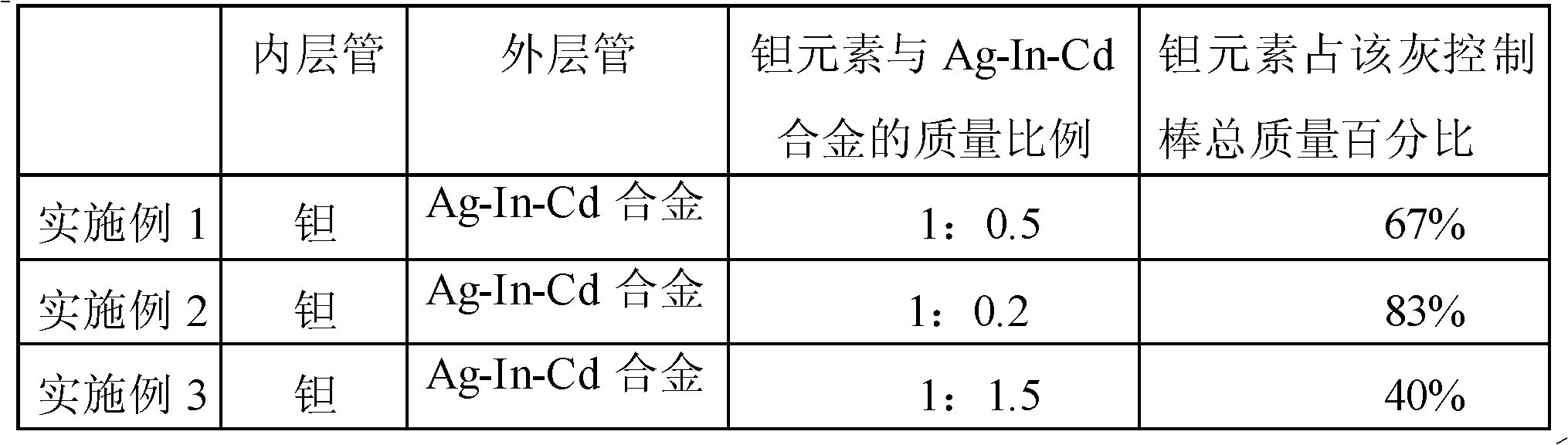

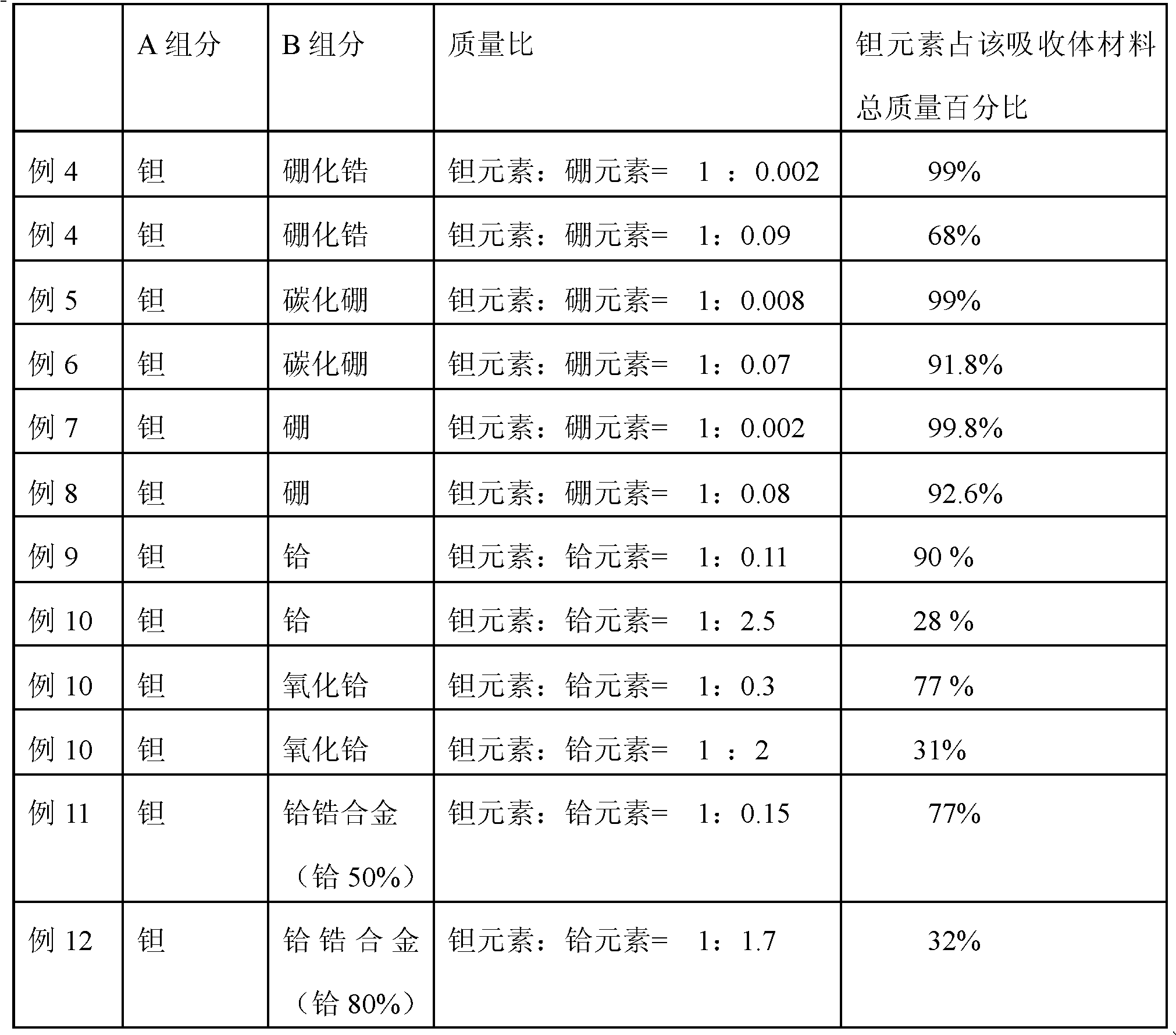

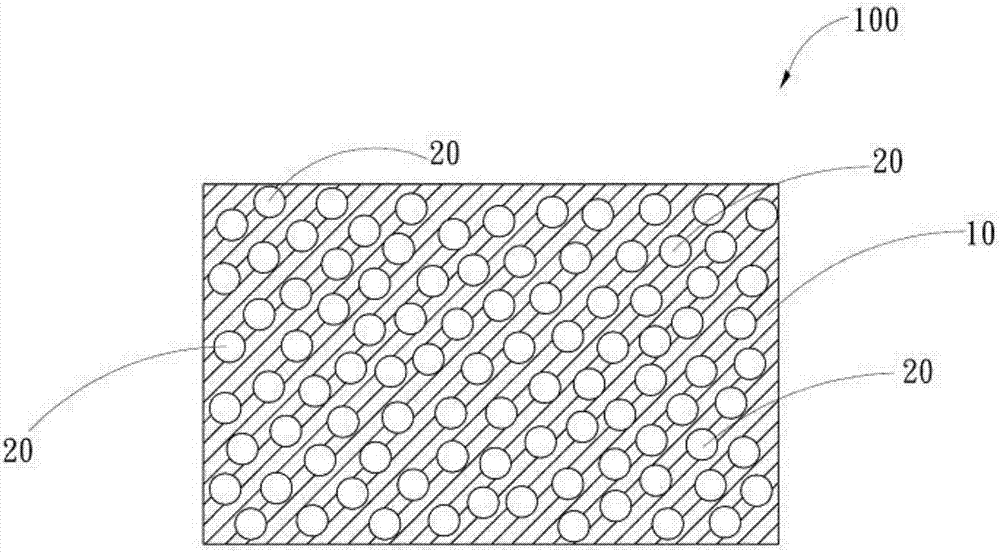

Gray control rod and absorber

ActiveCN102915773AReactive value deferredReactive value is smallNuclear energy generationNuclear reaction controlTantalum compoundIrradiation

The invention provides a gray control rod and an absorber. An absorber material comprises tantalum, a tantalum alloy or a tantalum compound, wherein the tantalum element occupies 30 to 99.8 percent of the mass percentage of the absorber material. The gray control rod is a slender solid tubular structure; and the gray control rod is made of the material comprising the tantalum, the tantalum alloy or the tantalum compound, wherein the tantalum element occupies 30 to 99.8 percent of the mass percentage of the absorber material. According to the invention, the tantalum, the tantalum alloy or the tantalum compound is adopted, so that the obtained tendency that the reactivity worth of the gray control rod is reduced along with the fuel consumption is obviously delayed; and the irradiation swelling and irradiation creep effects are also very low, so that the service life of a gray control rod assembly is greatly prolonged.

Owner:SHANGHAI NUCLEAR ENG RES & DESIGN INST CO LTD

Titanium-based composite material and manufacturing method thereof

The invention provides a titanium-based composite material and a manufacturing method thereof. The titanium-based composite material is selected from alpha-phase pure titanium or titanium alloy parent metal, alpha-phase and beta-phase pure titanium or titanium alloy parent metal, beta-phase pure titanium or titanium alloy parent metal and Omega-phase mesoporous metal titanium parent metal; at least one ceramic powder enhanced composite material, which contains 10% of the components, of carbide, nitride, oxide or boride is added; or at least one ceramic powder enhanced composite material or one powder enhanced composite material composed of ferroelectric powder, which contains 10% of the components, of titanate, niobide, a barium compound, a strontium compound, a tantalum compound and a yttrium compound is added; or at least one magnetic powder enhanced composite material, which contains 10% of the components, of a neodymium-iron-boron compound or a samarium-cobalt compound is added; and the powder enhanced composite material and the titanium parent metal are mixed according to the total volume ratio of 10% to 70% and a mixture is processed in a casting, sintering or pressurizing manner to prepare the titanium-based composite material which has physical or chemical and electrical properties of the parent metal and the composite material.

Owner:BRILO TECH CO LTD

Preparation method of ferrous lithium phosphate cathode composite material

ActiveCN101527354ACoated evenlyGuaranteed tap densityElectrode manufacturing processesPhosphorus compoundsCarbon coatingPhosphate

The invention relates to a preparation method of a ferrous lithium phosphate cathode composite material. The method comprises the following steps: stocking a ferric iron-source compound, a lithium-source compound, phosphate, doped tantalum compounds and carbon black according to a certain proportion; firstly adding the ferric iron-source compound into an ultrafine ball mill so as to have the grain diameter of 100 nm to 500 nm by ball milling; then, adding other raw materials and using acetone as a dispersant for ball milling and mixing, drying in vacuum and sintering at a low temperature in an inert protective atmosphere oven to deacidize ferric iron; afterwards, adding a certain amount of conductive agent material to obtain ferrous lithium phosphate, ball milling, mixing and drying and sintering at a high temperature in the inert protective atmosphere oven; and finally, shattering, crushing and elutriating to obtain the ferrous lithium phosphate cathode composite material. The invention has the advantages that the materials ensure the tap density and can achieve favorable capacity and magnification performance, and secondary sintering enables the carbon coating to be more even and the granular magnification to be better.

Owner:JIANGXI SHENGHUA NEW MATERIAL CO LTD

Tantalum oxide film, use thereof, process for forming the same and composition

Owner:JSR CORPORATIOON

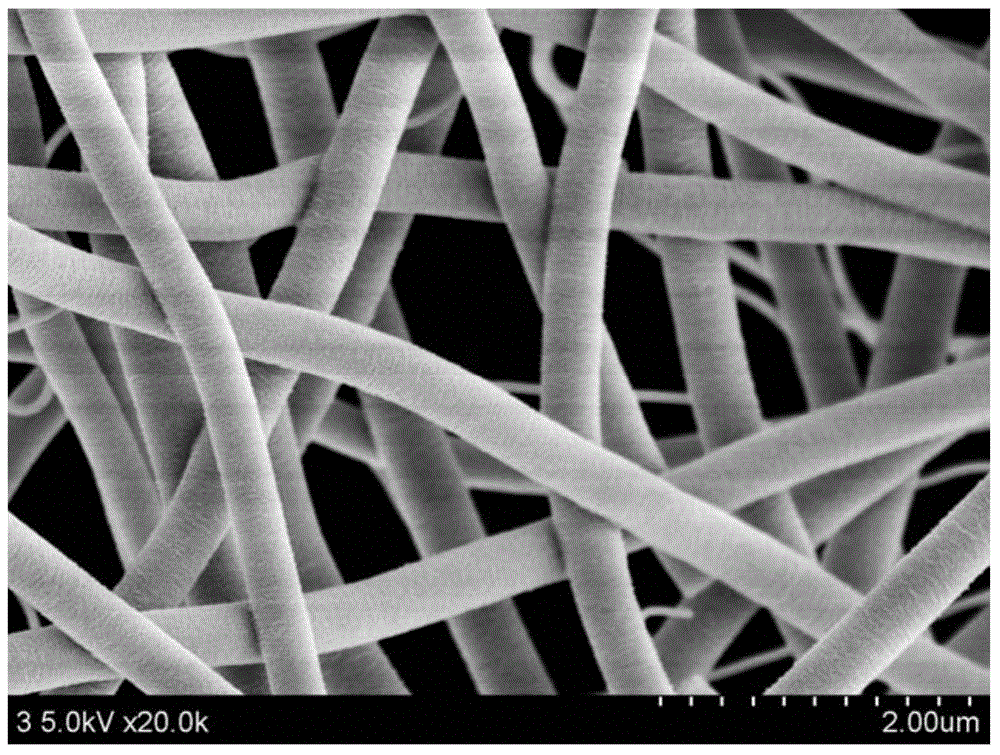

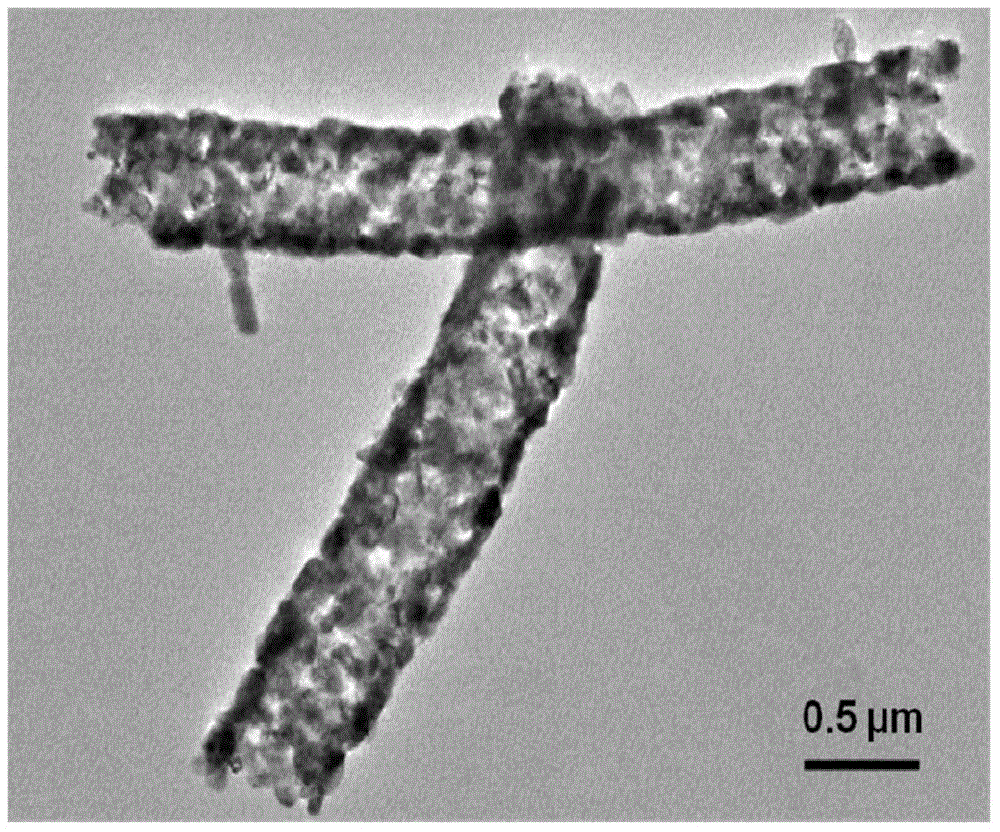

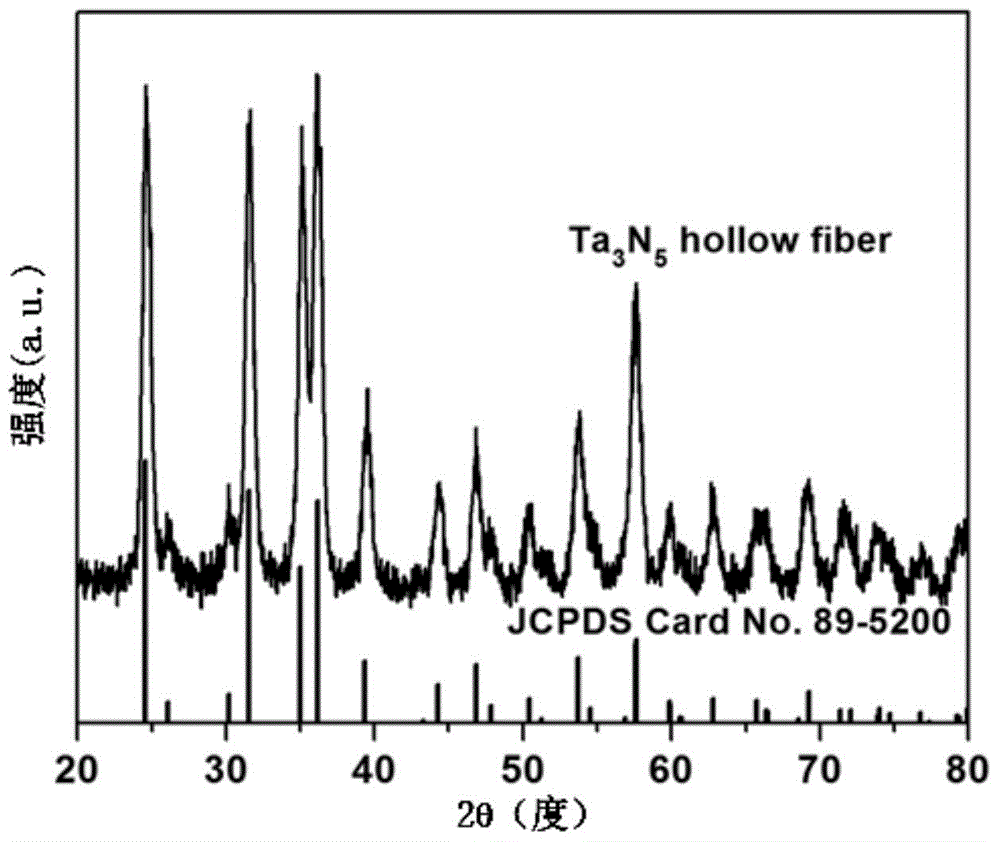

Hollow nano fiber photocatalyst for tantalum compound and preparation method of hollow nano fiber photocatalyst

ActiveCN104874415ALarge specific surface areaFully contactedPhysical/chemical process catalystsWater/sewage treatment by irradiationTantalum compoundFiber

The invention discloses a hollow nano fiber photocatalyst for a tantalum compound and a preparation method of the hollow nano fiber photocatalyst. The preparation method comprises the following steps: preparing a shell-core solution; carrying out electrostatic spinning by virtue of coaxial electrostatic spinning equipment, and drying a composite fiber, so as to obtain dried composite fiber; burning the dried composite fiber to obtain a Ta2O5 hollow fiber; and carrying out high-temperature nitridation on the Ta2O5 hollow fiber, and thus obtaining a Ta3N5 or TaON hollow nano fiber. The preparation method is simple to operate; and the hollow nano fiber photocatalyst with high photocatalytic activity, large specific surface area and easy-to-recover characteristic can be rapidly prepared.

Owner:浙江百汇建设工程管理有限公司

Transparent conductive layer, target for transparent conductive layer and a process for producing the target for transparent conductive layer

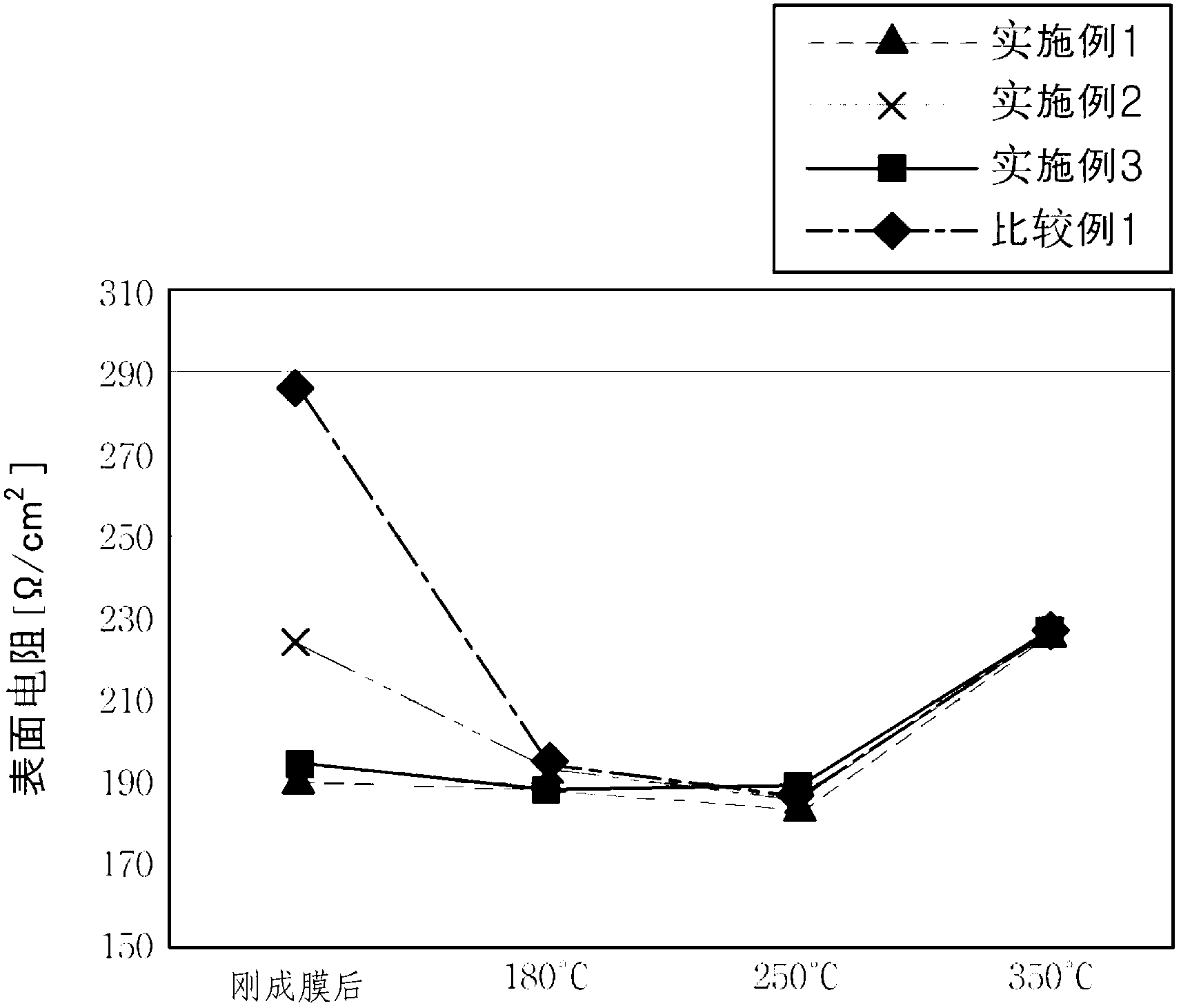

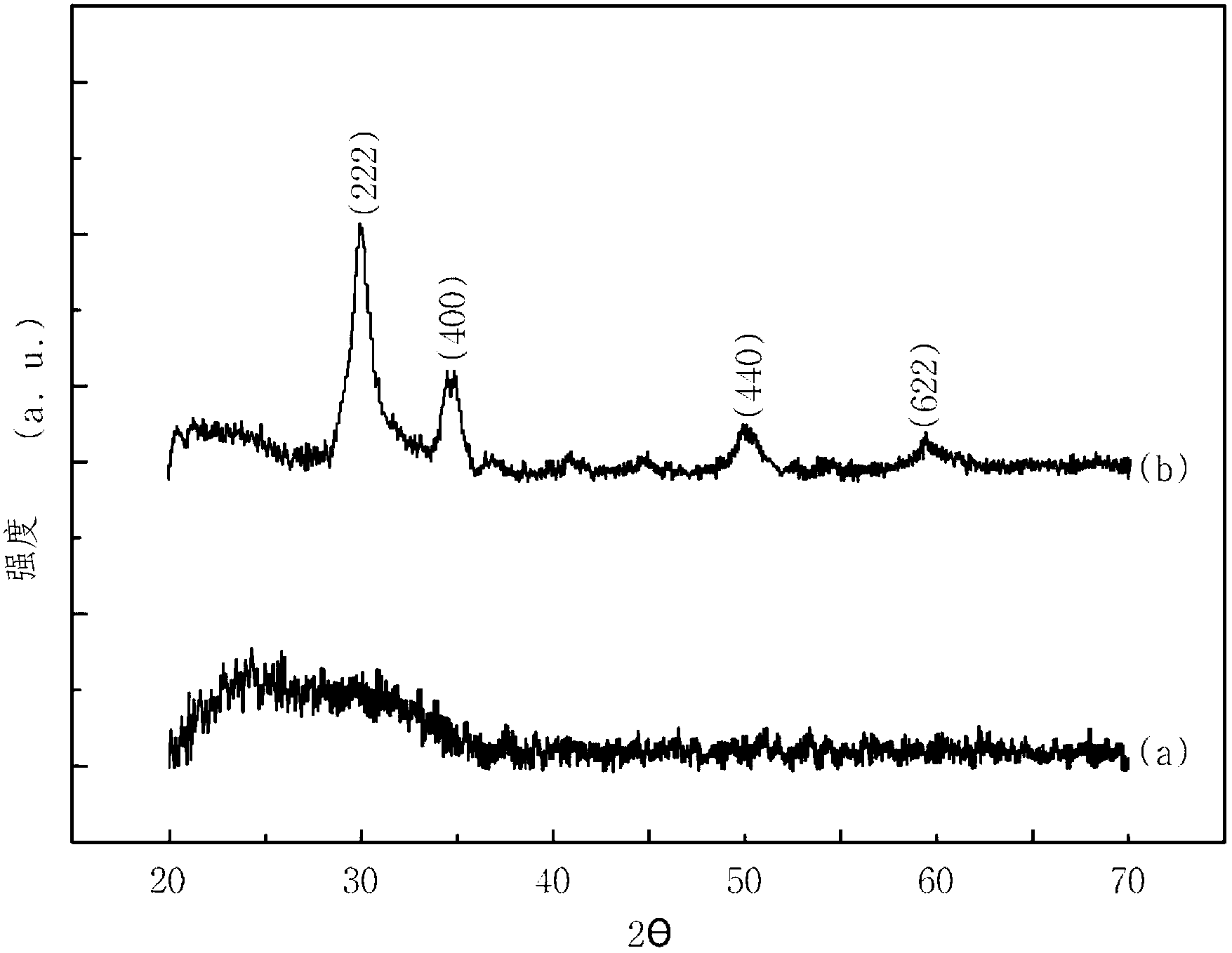

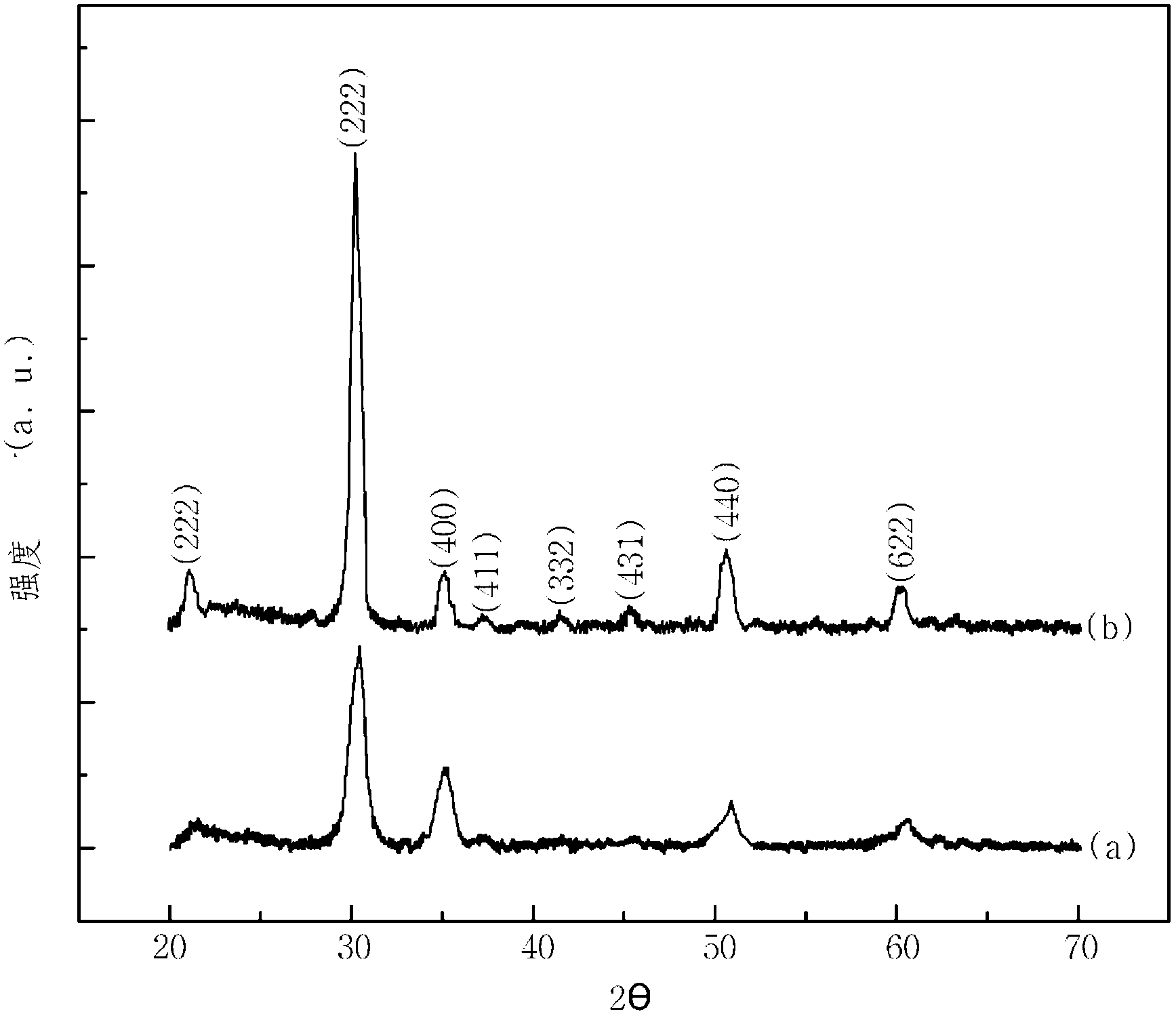

InactiveCN103038834AStable resistivityImprove thermal stabilityConductive layers on insulating-supportsVacuum evaporation coatingVanadium CompoundsTantalum compound

The present invention relates to a transparent conductive layer, which comprises, based on a total weight of the transparent conductive layer, 0.01 - 10 wt% of an additive comprising a compound having at least one or two selected from the group that consists of tantalum, niobium and vanadium; and 90 - 99.99 wt% of an indium tin oxide (ITO).

Owner:ADVANCED NANO PROD CO LTD

Method of purifying niobium compound and/or tantalum compound

InactiveCN1639071AHigh purityProcess efficiency improvementNiobium compoundsTantalum compoundSolvent

The invention provides a more convenient and low-cost method for refining niobium compounds and / or tantalum compounds. The method for purifying such a niobium compound and / or tantalum compound is characterized in that it purifies from a solution of the niobium compound and / or tantalum compound by crystallization.

Owner:STELLA CHEMIFA CORP

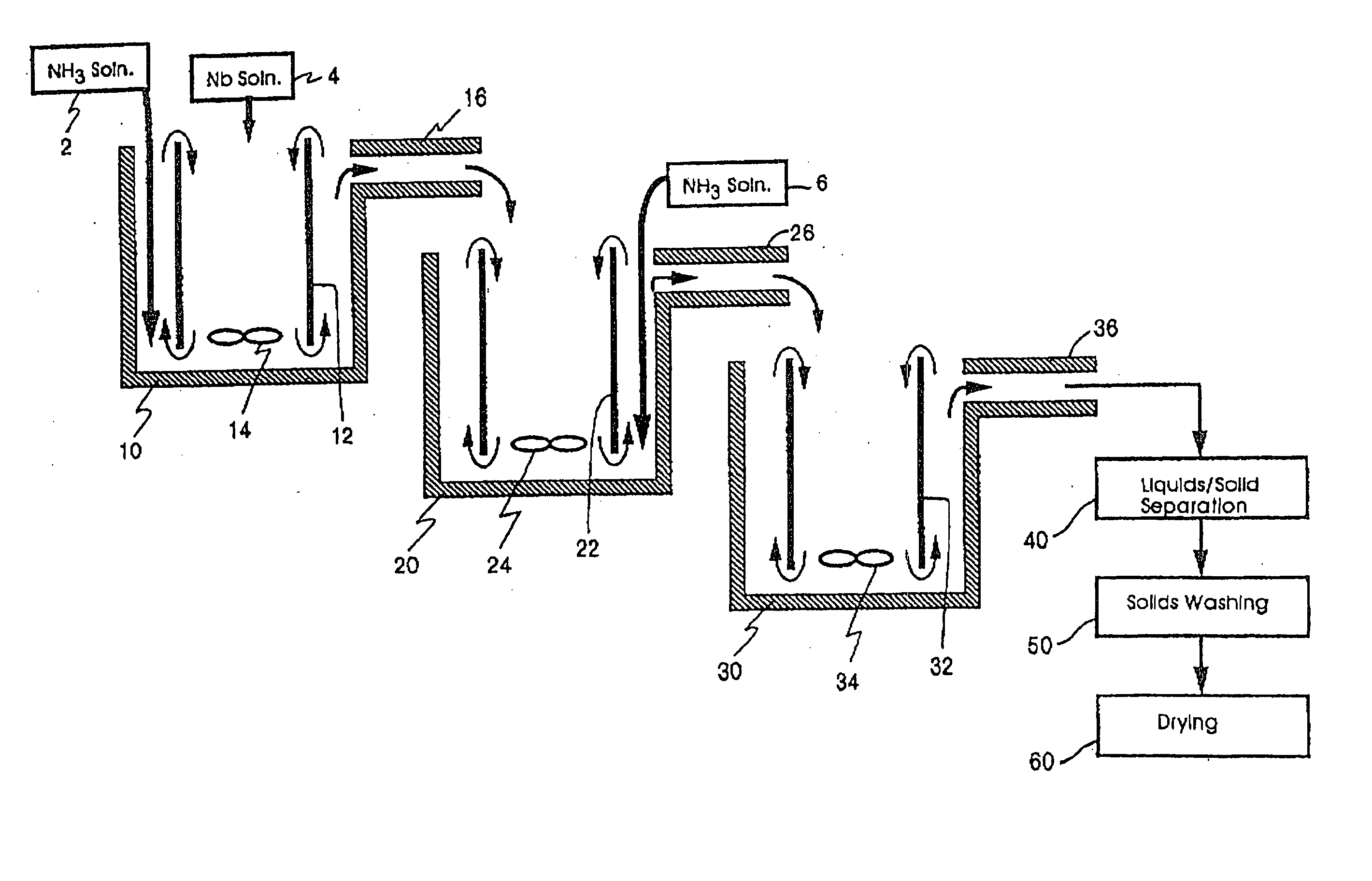

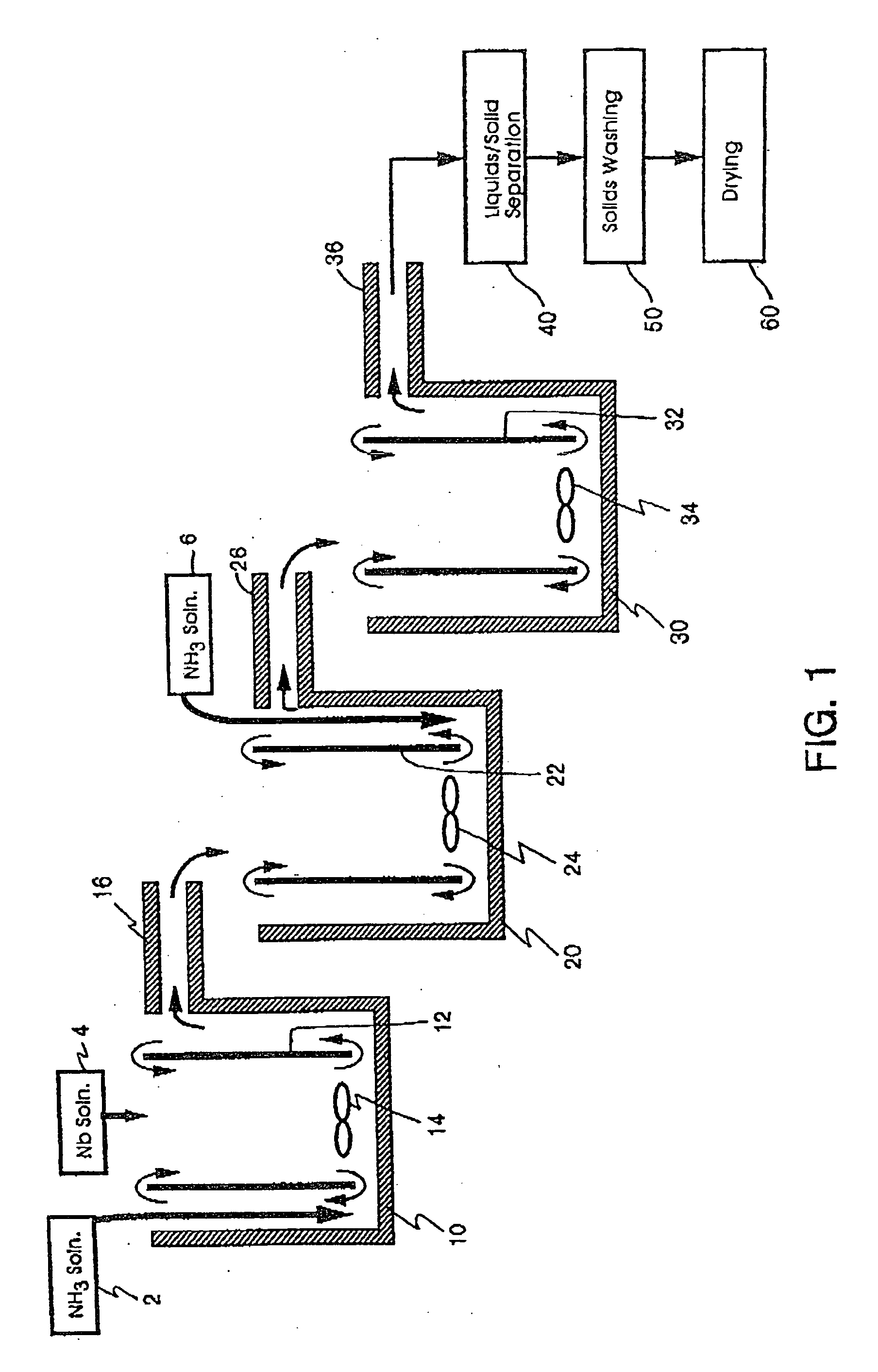

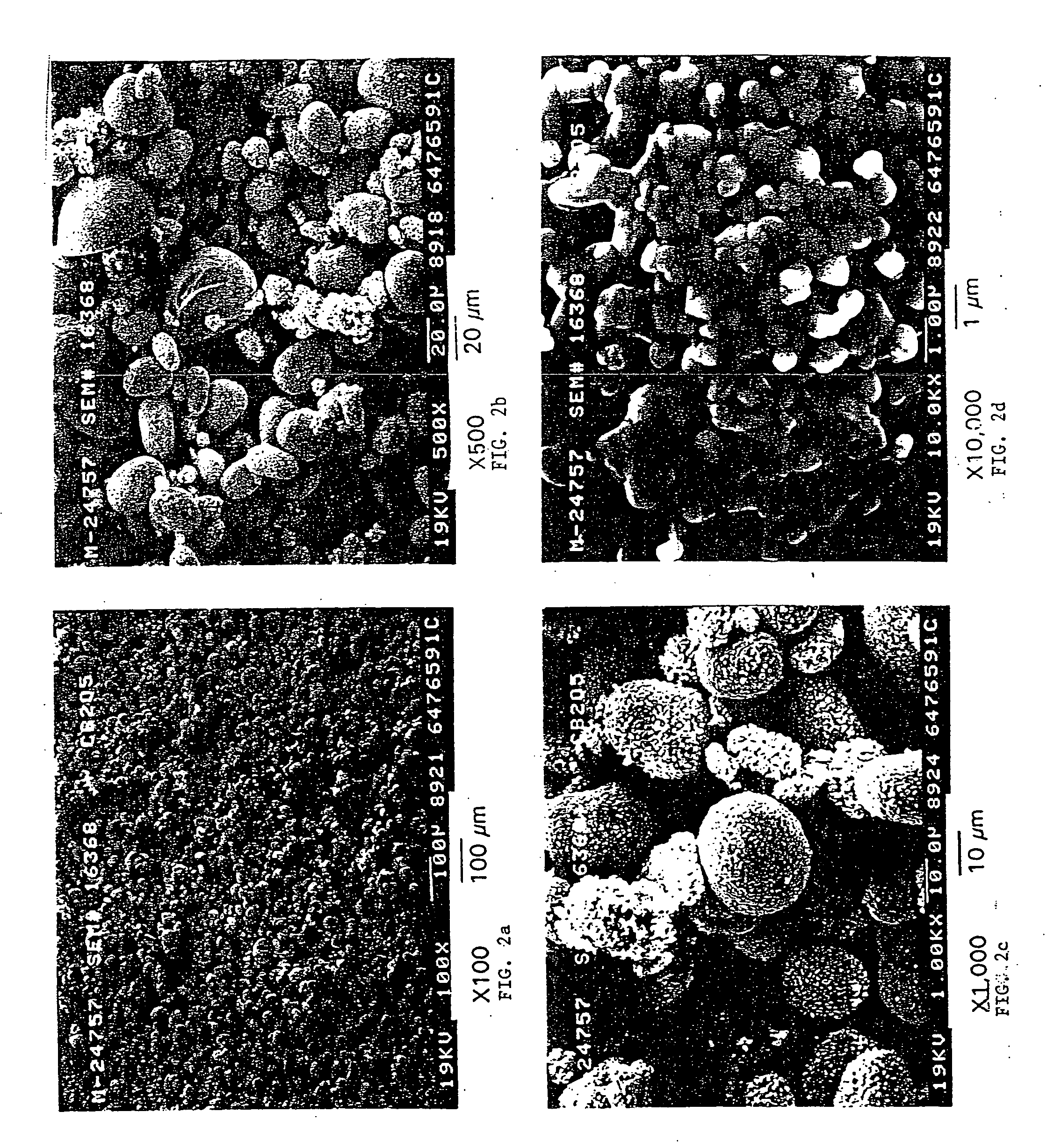

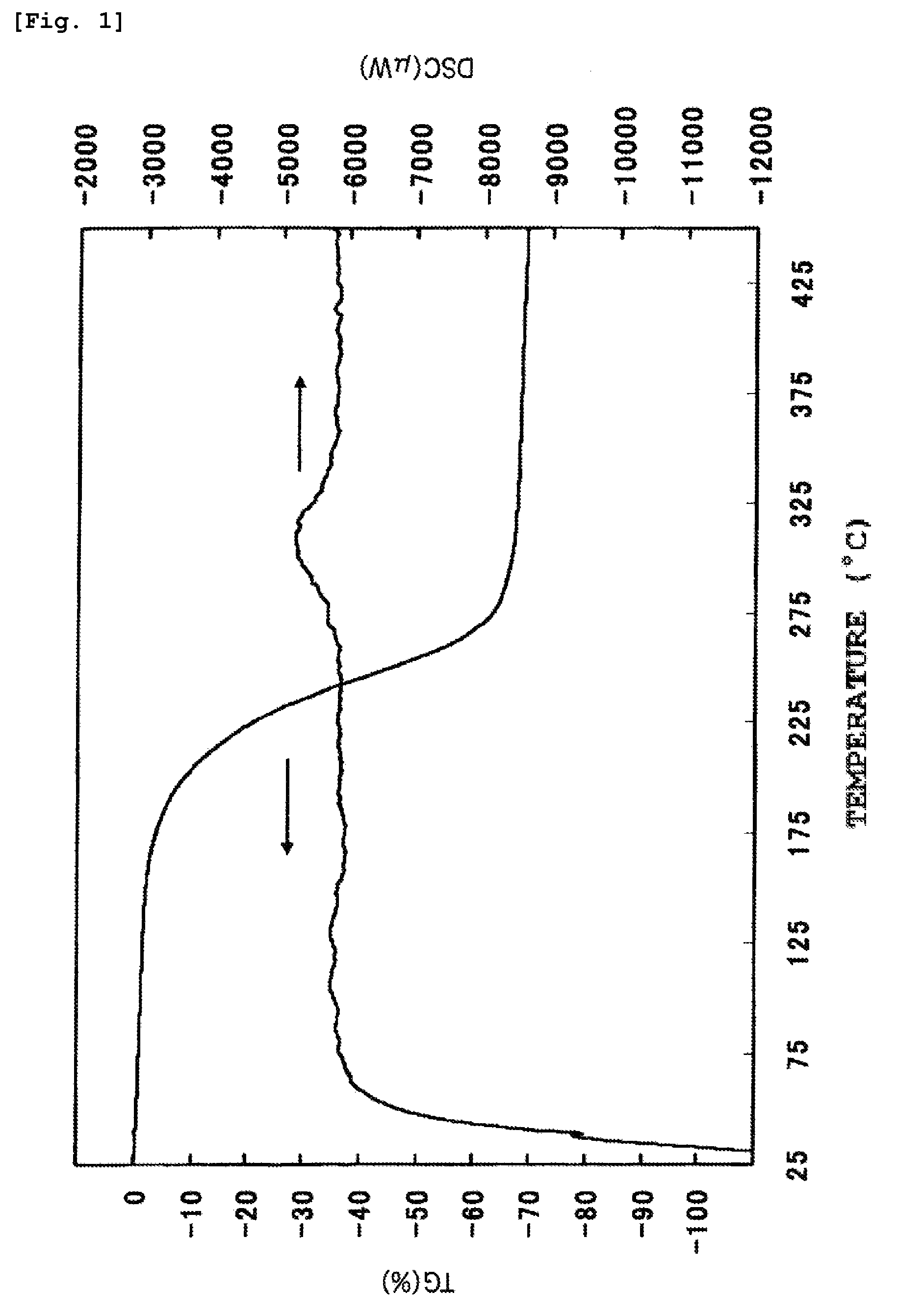

Process for producing niobium and tantalum compounds

A process for producing valve metal oxides, such as tantalum pentoxide or niobium pentoxide with a narrow particle size distribution within a desired particle size range, is provided. According to the process of the present invention, the valve metal fraction from digestion of valve metal material containing ore is processed under controlled temperature, pH, and residence time conditions to produce the valve metal pentoxide and pentoxide hydrates. Also, disclosed are new tantalum pentoxide and niobium pentoxide products and new tantalum pentoxide precursors and niobium pentoxide precursors.

Owner:GLOBAL ADVANCED METALS USA

Method of metal recovery

A method by which tantalum compounds and niobium compounds dissolved in water such as a liquid detergent are insolubilized and recovered. An aqueous solution containing tantalum compounds and / or niobium compounds dissolved therein is regulated so as to have a pH and an oxidation-reduction potential E which satisfy E<60x(10-pH) to thereby insolubilize the tantalum compounds and / or niobium compounds. The tantalum compounds and / or niobium compounds thus insolubilized are recovered through a membrane treatment. Thus, the metal compounds can be more effectively recovered. This method is especially suitable for use in the treatment of a wastewater generated in the production of a tantalum powder or niobium powder through the reduction of a raw tantalum compound and / or raw niobium compound in a diluting salt.

Owner:CABOT SUPERMETALS

Trimerization catalyst for olefin

InactiveUS20070093622A1High catalytic activityEffectively trimerizedOrganic-compounds/hydrides/coordination-complexes catalystsOrganic chemistry methodsArylTantalum compound

The present invention provides a catalyst comprising (A) a tantalum compound, and (B) an organic metal compound, wherein the organic metal compound (B) comprises at least one group selected from the group consisting of the following (1) to (5): (1) a branched or cycloalkyl-substituted primary alkyl group having 4 to 15 carbon atoms, (2) an aryl-substituted primary alkyl group having 7 to 15 carbon atoms, (3) a 3-alkenyl group having 4 to 15 carbon atoms, (4) a secondary alkyl group having 3 to 15 carbon atoms which may be substituted with an aryl group or a cyclic alkyl group having 3 to 15 carbon atoms, and (5) a secondary alkenyl group having 4 to 15 carbon atoms, the catalyst showing good olefin trimerizing activity.

Owner:SUMITOMO CHEM CO LTD

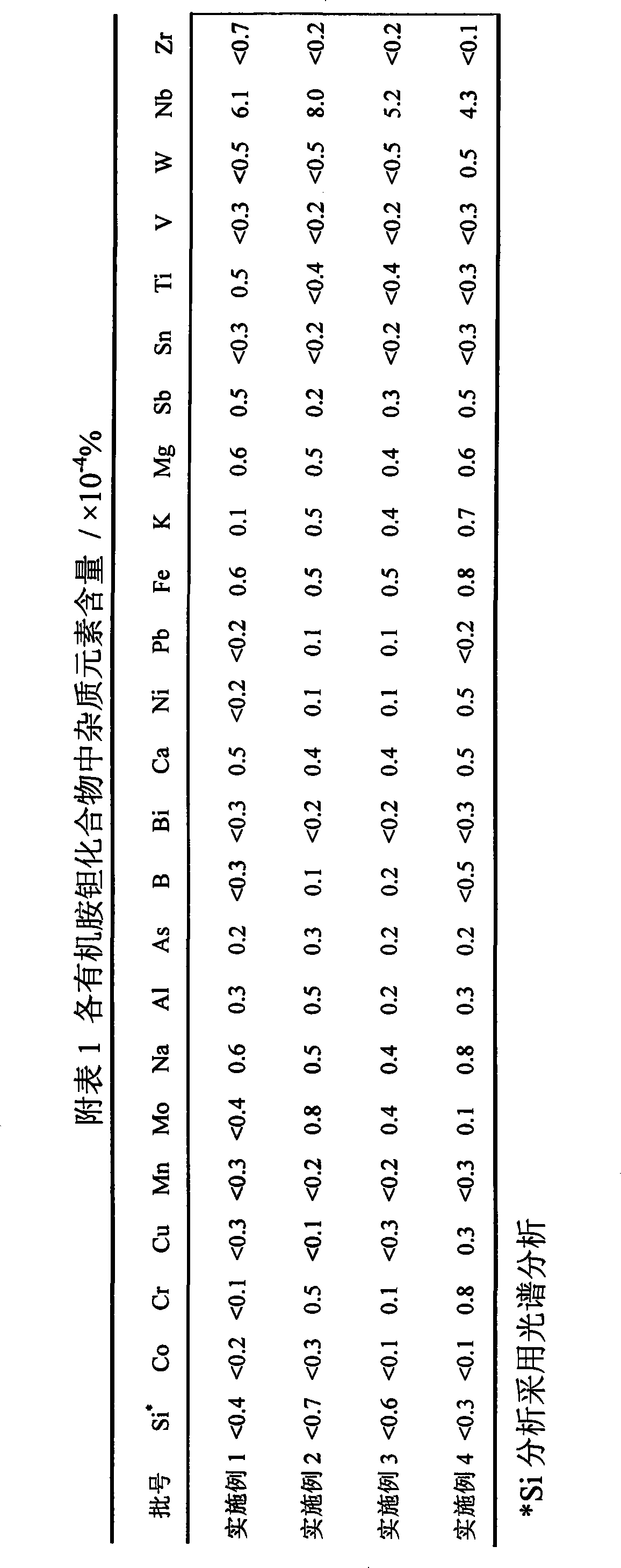

Method for producing high purity organic amine tantalum compound

InactiveCN101250712AHigh purityMeet purity requirementsElectrolysis componentsElectrolytic organic productionTantalum compoundTantalite

The invention relates to a method for producing organic amine tantalum compound with high purity, which comprises following steps: taking metallic tantalum and organic amine as raw materials, adding conductive agent in the organic amine as electrolyte, taking the metallic tantalum as an anode, adopting an electrochemical method of a 'sacrificial' anode to synthesize mixed solution of the organic amine tantalum compound and the organic amine, distilling the mixed solution, and lastly decompressing and distilling to obtain the organic amine tantalum compound with high purity. In the products of the organic amine tantalum compound which is obtained through adopting the method of the invention, impurity elements such as Al, As, B, Ba, Ca and the like are less than or equal to 0.0001%, Nb is less than or equal to 0.0010%, the purity of the products is more than 99.99%, the production process flow is short, the equipment is simple, and the production environment is friendly.

Owner:CENT SOUTH UNIV

Method of purifying niobium compound and/or tantalum compound

InactiveUS20050123459A1Reduce concentrationConcentration adjustableVanadium compoundsProcess efficiency improvementTantalum compoundSolvent

The present invention provides a method for purifying a niobium compound and / or tantalum compound in a simplified manner at a low cost. This is accomplished by providing a method for purifying a niobium compound and / or tantalum compound whereby a niobium compound and / or tantalum compound dissolved in a solvent is allowed to precipitate to be isolated.

Owner:STELLA CHEMIFA CORP

Tantalum compound, method for producing same, tantalum-containing thin film and method for forming same

ActiveUS7592471B2Group 5/15 element organic compoundsSemiconductor/solid-state device manufacturingTantalum compoundHalogen

A novel tantalum compound, a method for producing the novel tantalum compound, and a method for stably forming a tantalum-containing thin film which contains the desired element. The tantalum compound enables one to selectively form a tantalum-containing thin film free of halogen and the like, and various tantalum-containing thin films which contain the desired element.

Owner:SAGAMI CHEM RES CENT +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com