Patents

Literature

504 results about "Niobium alloy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A niobium alloy is one in which the most common element is niobium.

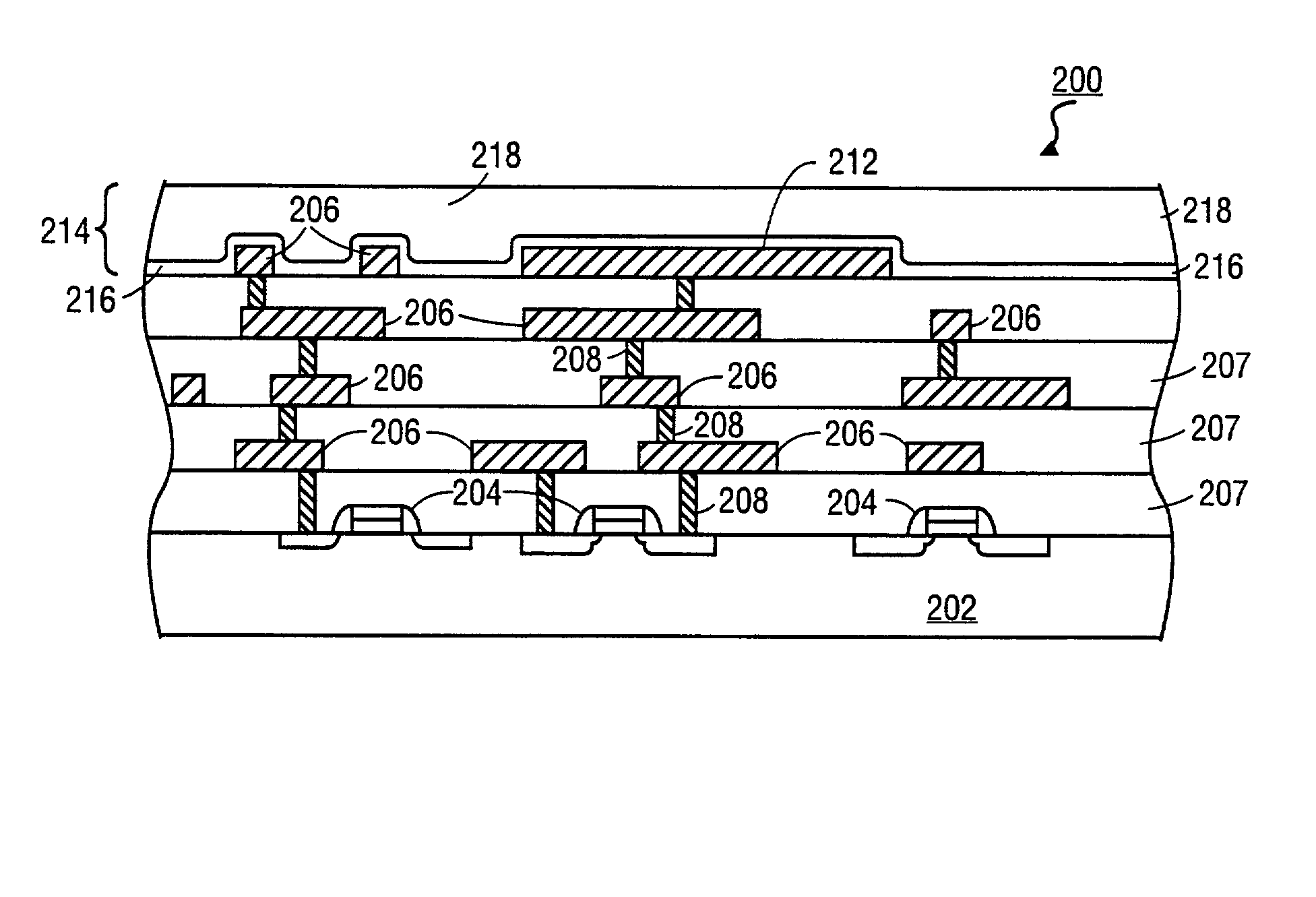

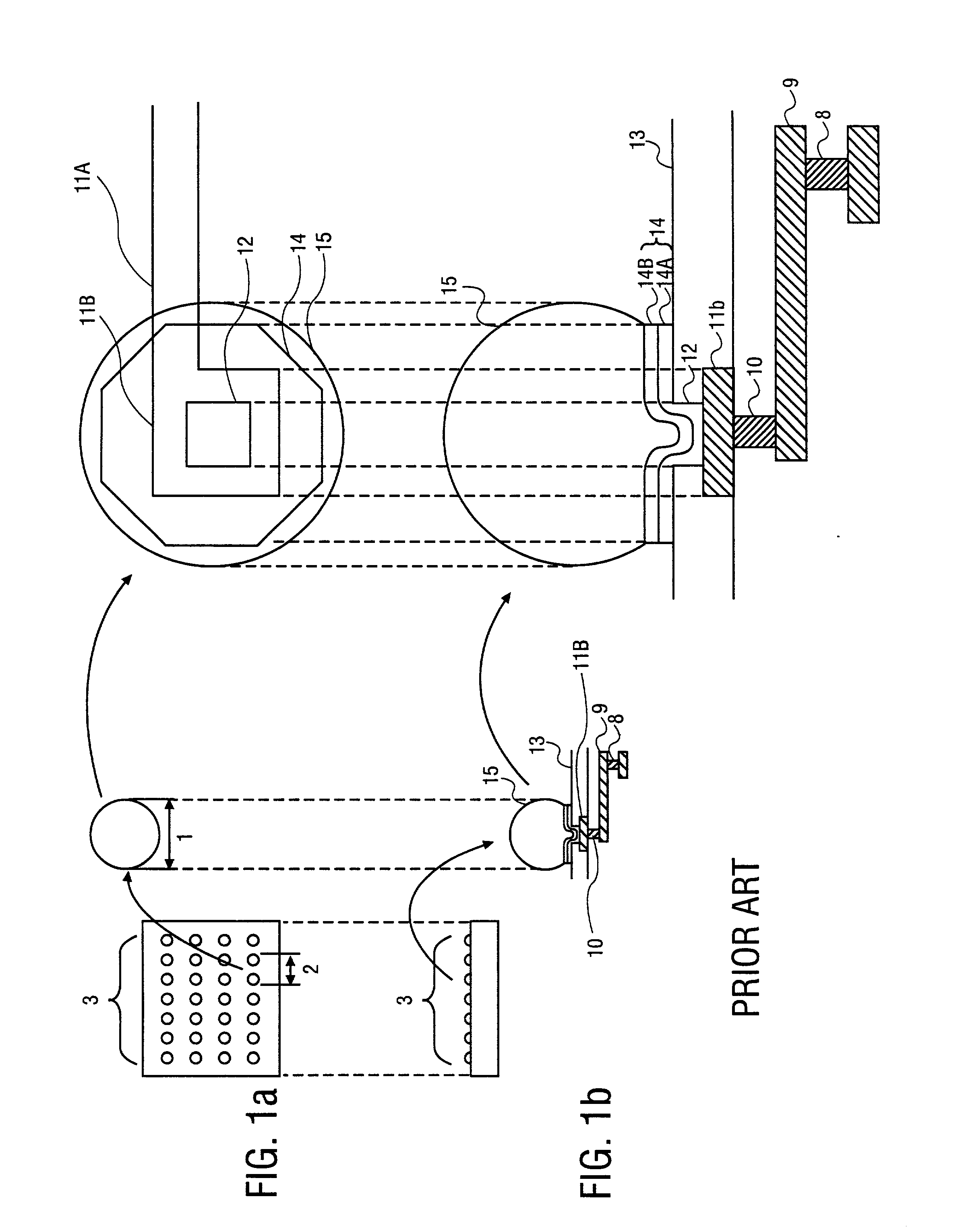

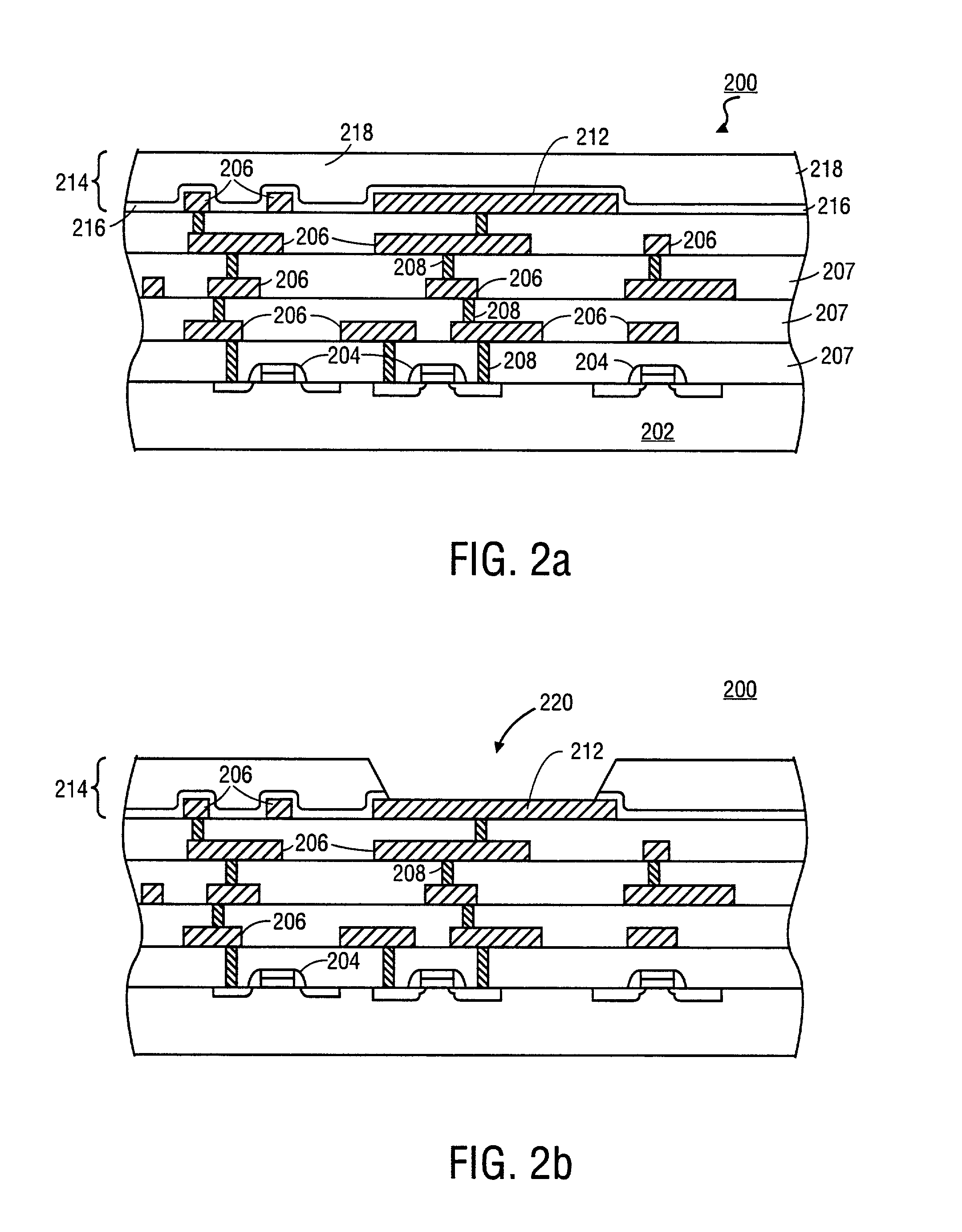

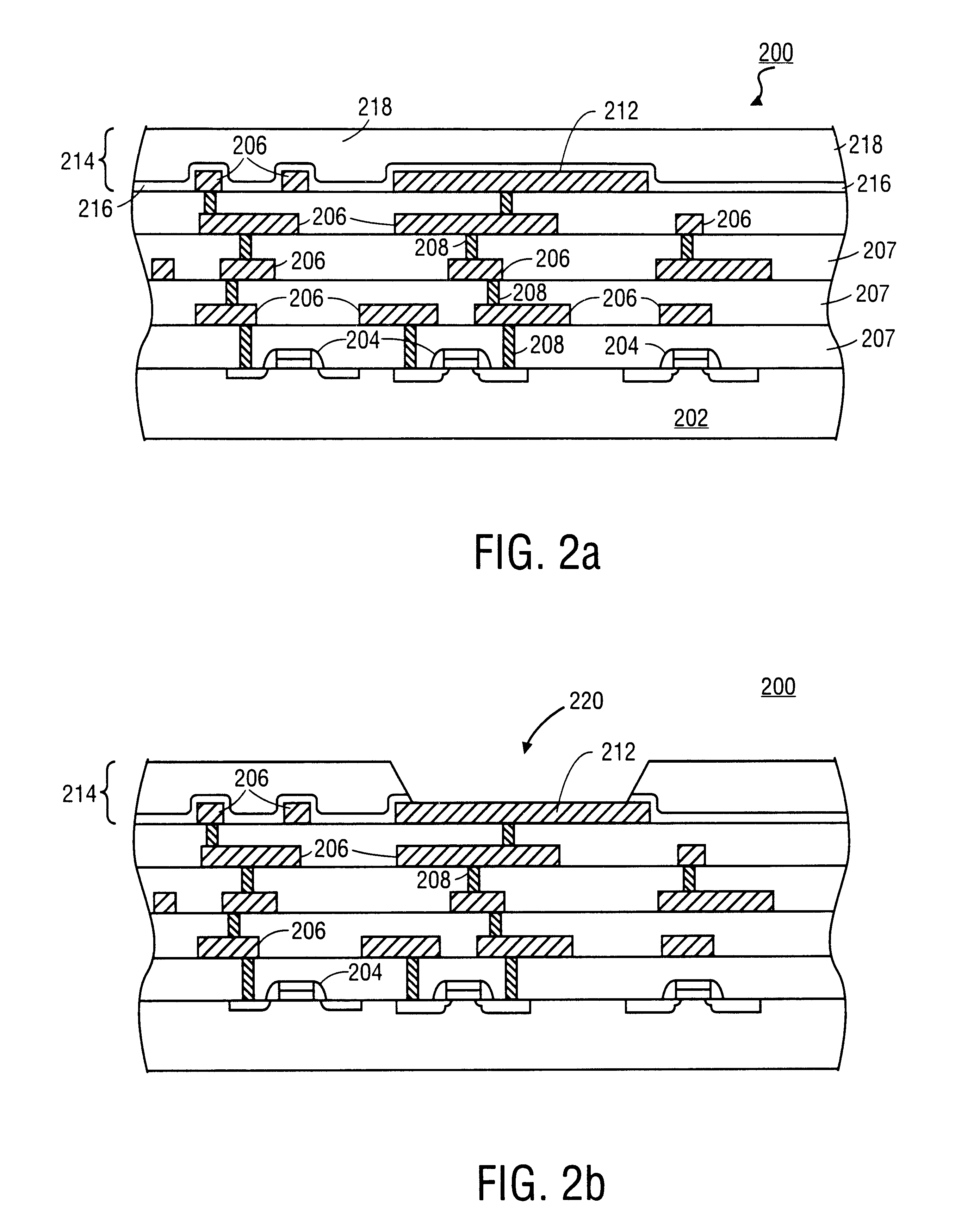

Ball limiting metallurgy for input/outputs and methods of fabrication

InactiveUS20020079576A1Semiconductor/solid-state device detailsSolid-state devicesNitrogenOptoelectronics

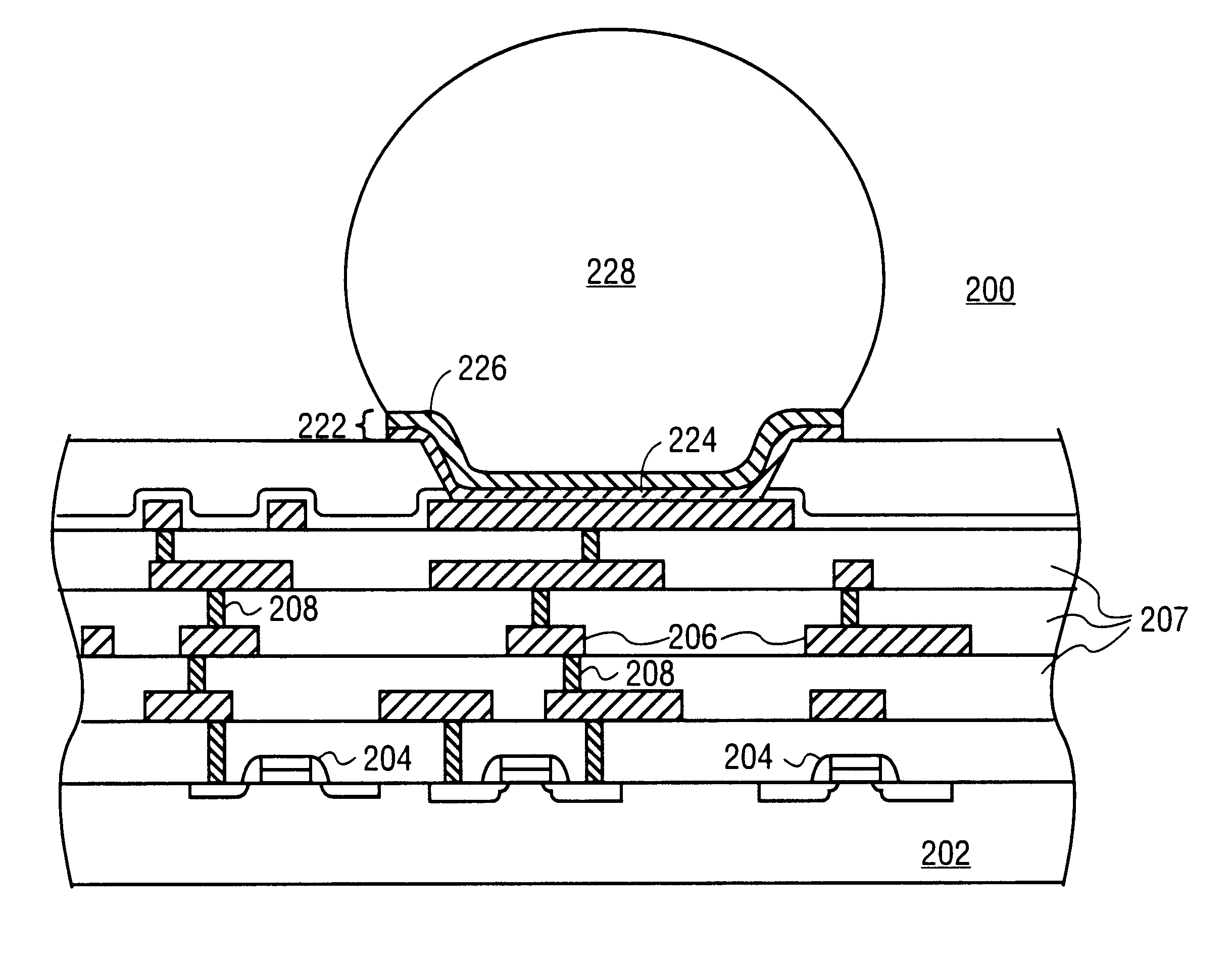

The present invention is an input / output for a device and it method of fabrication. The input / output of the present invention comprises a bond pad having a ball limiting metallurgy (BLM) formed thereon and a bump formed on the ball limiting metallurgy (BLM). In an embodiment of the present invention the ball limiting metallurgy comprises a first film comprising nickel, vanadium, and nitrogen. In the second embodiment of the present invention the bump limiting metallurgy includes a first alloy film comprising a nickel-niobium alloy.

Owner:INTEL CORP

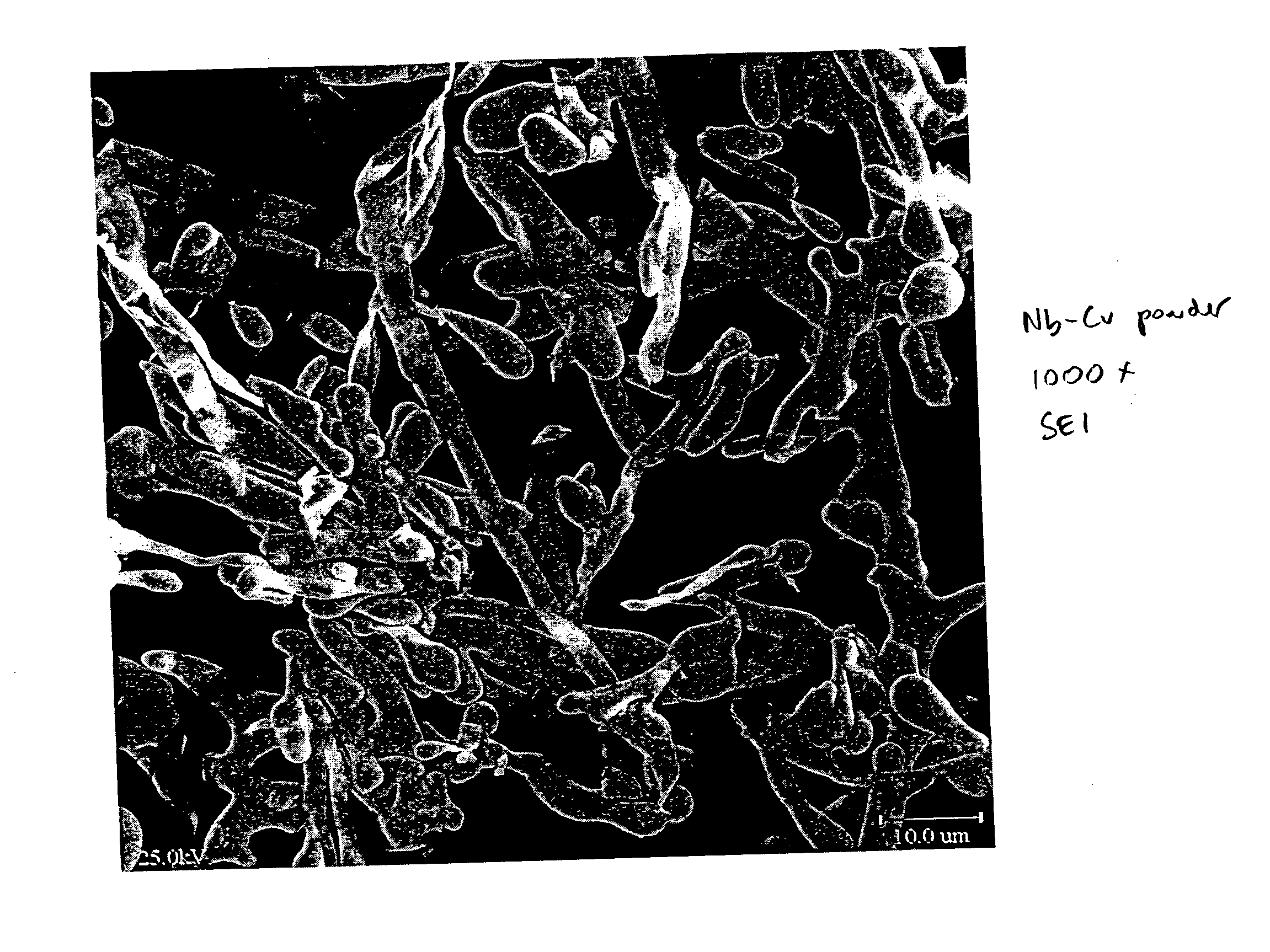

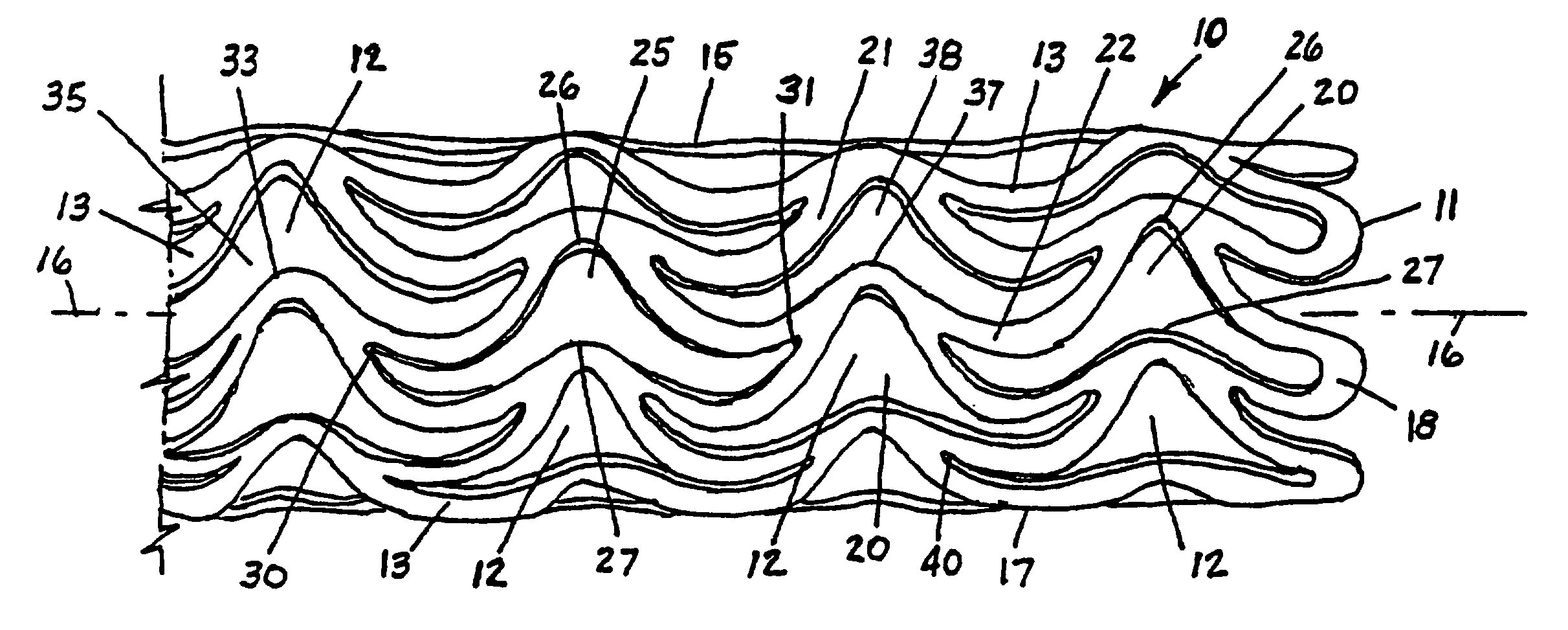

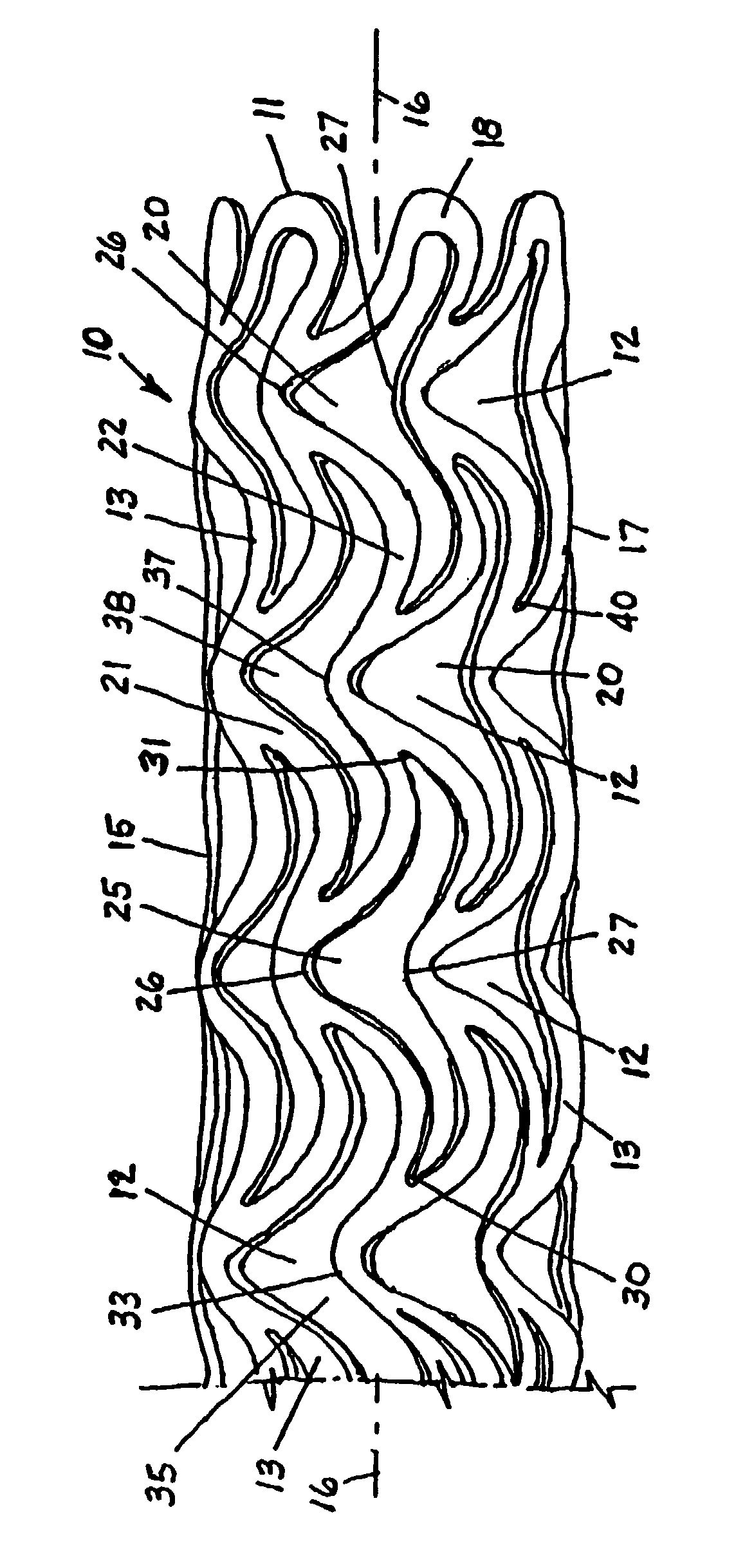

Method for producing metal fibers

InactiveUS20050000321A1Transportation and packagingMetal-working apparatusO-Phosphoric AcidMetal fibers

A method of producing metal fibers including melting a mixture of at least a fiber metal and a matrix metal, cooling the mixture to form a bulk matrix comprising at least a fiber phase and a matrix phase and removing at least a substantial portion of the matrix phase from the fiber phase. Additionally, the method may include deforming the bulk matrix. In certain embodiments, the fiber metal may be at least one of niobium, a niobium alloy, tantalum and a tantalum alloy and the matrix metal may be at least one of copper and a copper alloy. The substantial portion of the matrix phase may be removed, in certain embodiments, by dissolving of the matrix phase in a suitable mineral acid, such as, but not limited to, nitric acid, sulfuric acid, hydrochloric acid and phosphoric acid.

Owner:ATI PROPERTIES

Ball limiting metallurgy for input/outputs and methods of fabrication

InactiveUS6521996B1Semiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsNitrogenOptoelectronics

The present invention is an input / output for a device and it method of fabrication. The input / output of the present invention comprises a bond pad having a ball limiting metallurgy (BLM) formed thereon and a bump formed on the ball limiting metallurgy (BLM). In an embodiment of the present invention the ball limiting metallurgy comprises a first film comprising nickel, vanadium, and nitrogen. In the second embodiment of the present invention the bump limiting metallurgy includes a first alloy film comprising a nickel-niobium alloy.

Owner:INTEL CORP

Method for producing metal fibers

Owner:ATI PROPERTIES

Primarily niobium stent

InactiveUS7101391B2Improved performance structurallyAvoid brittlenessStentsSurgeryNiobium alloyTitanium alloy

In a process of fabricating a stent composed primarily of niobium alloyed with a trace amount of zirconium, tantalum, or titanium for hardening, the stent is annealed under vacuum in a substantially oxygen-free environment. The vacuum is preferably maintained at pressure less than 10−4 millibars, oxygen-content less than about 80 parts per million, and the annealing temperature exceeds 400° C. for at least one hour, and is preferably kept in a range from about 1100–1200° C. for several hours. This may be followed by applying a surface layer of oxide, such as iridium oxide, with a thickness of 299–300 nm to the stent.

Owner:BOSTON SCI SCIMED INC

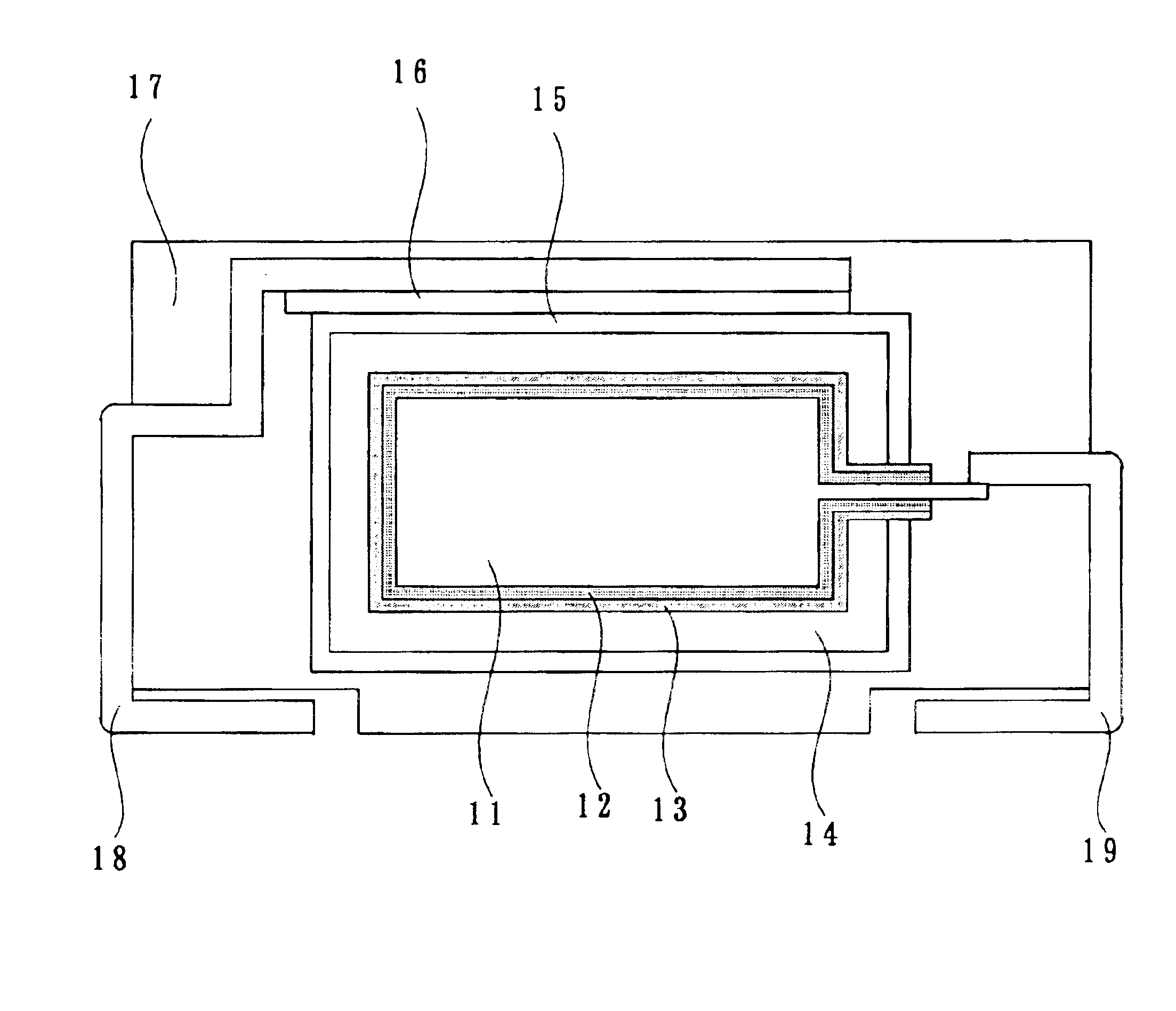

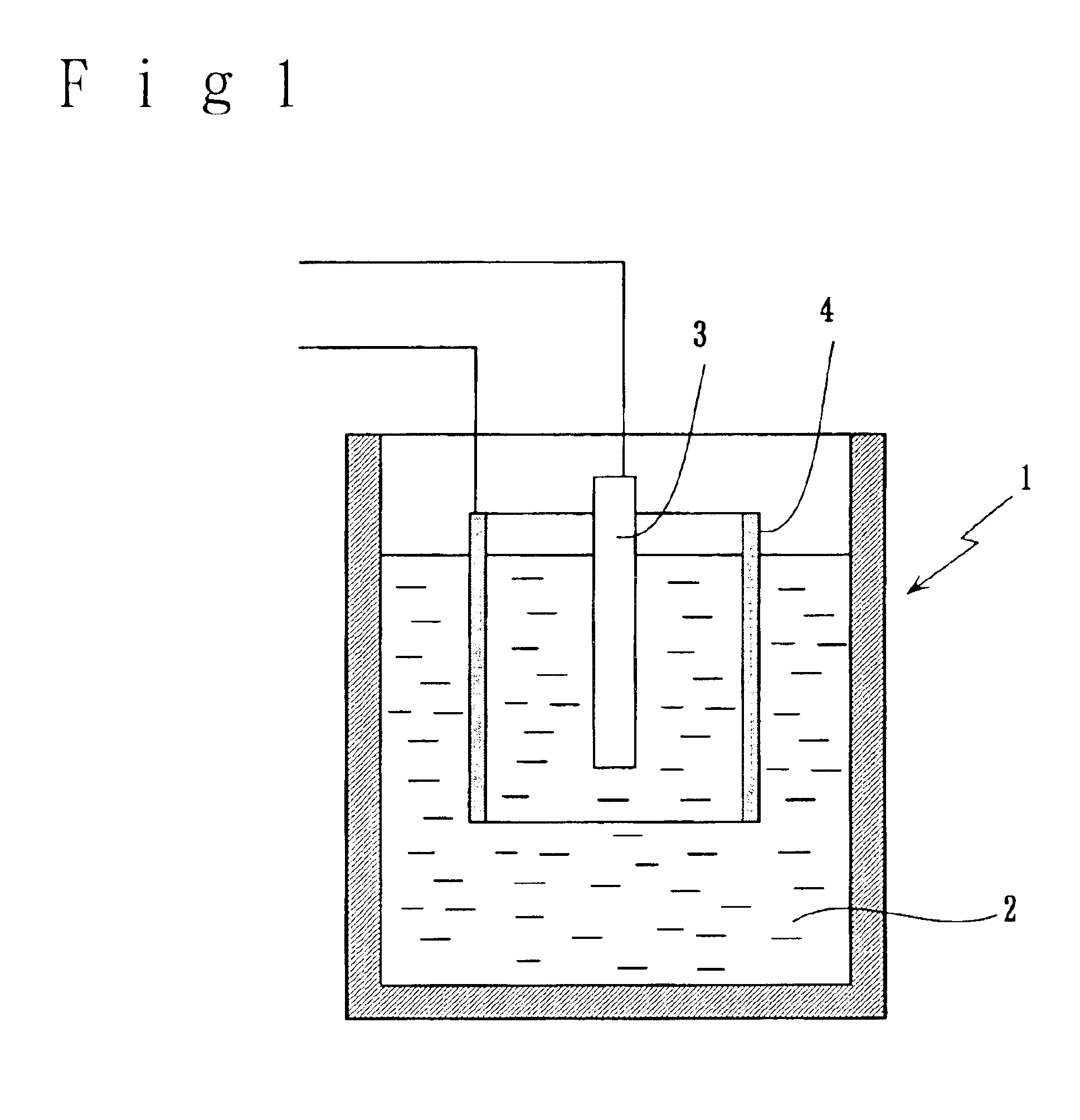

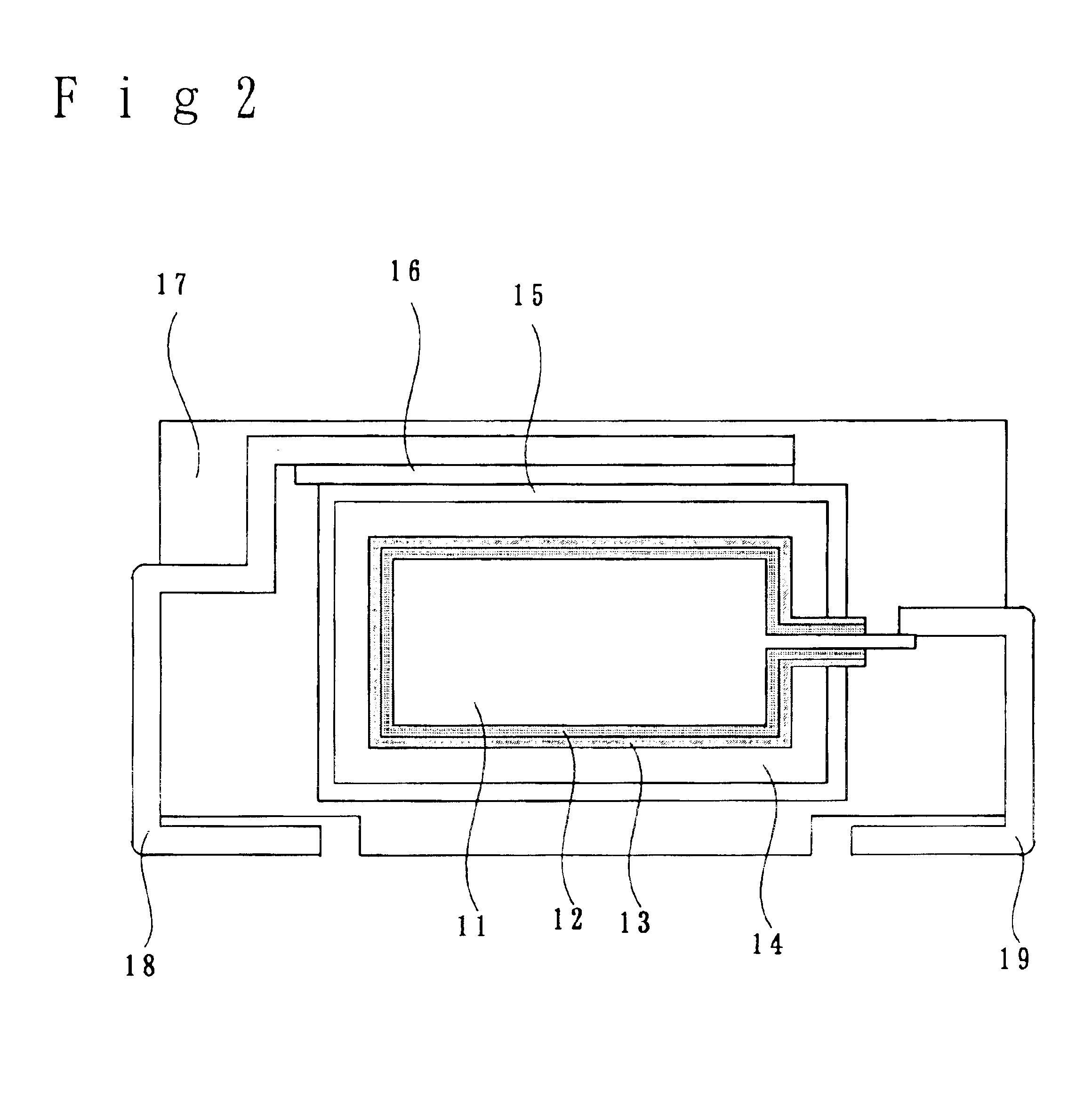

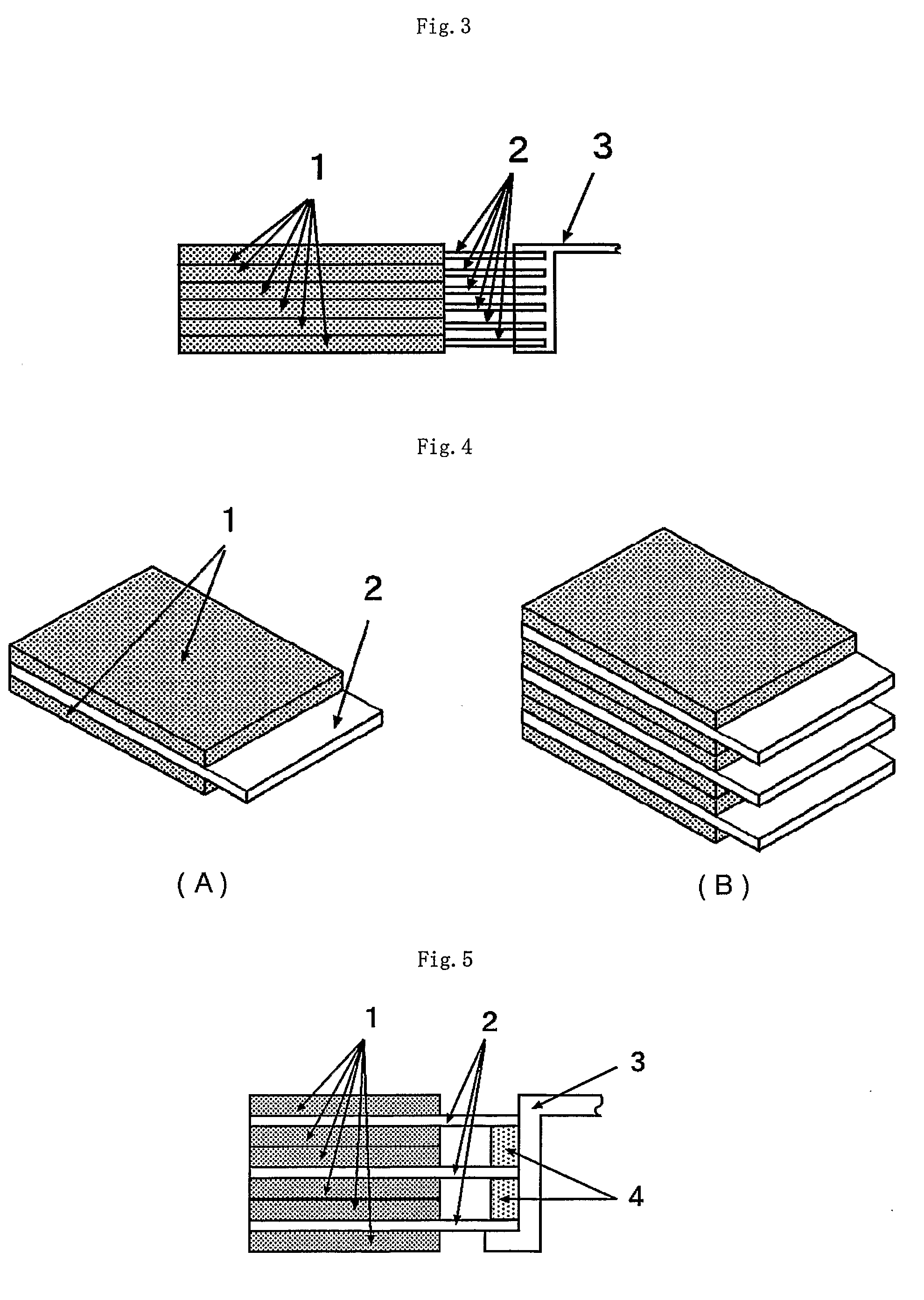

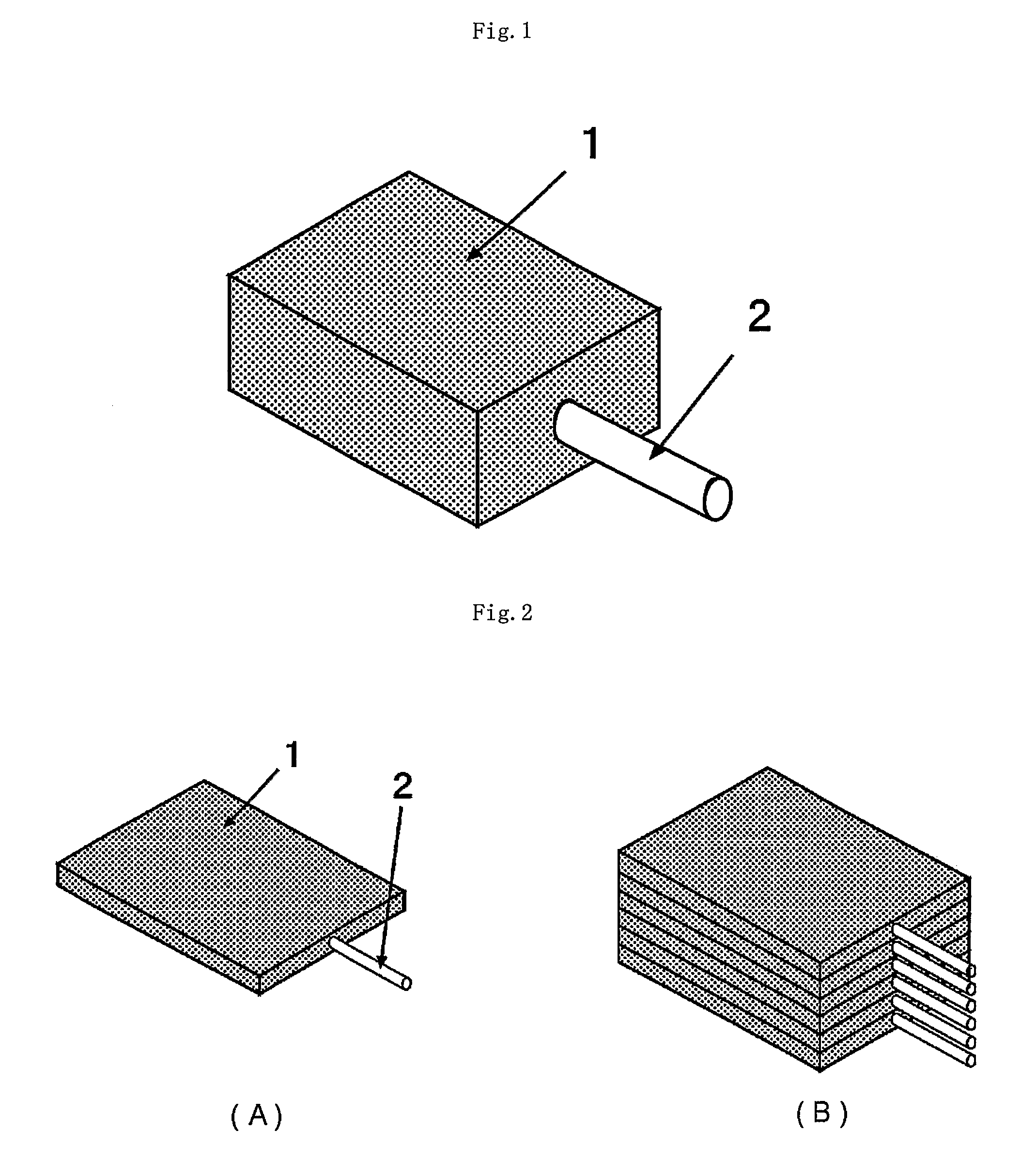

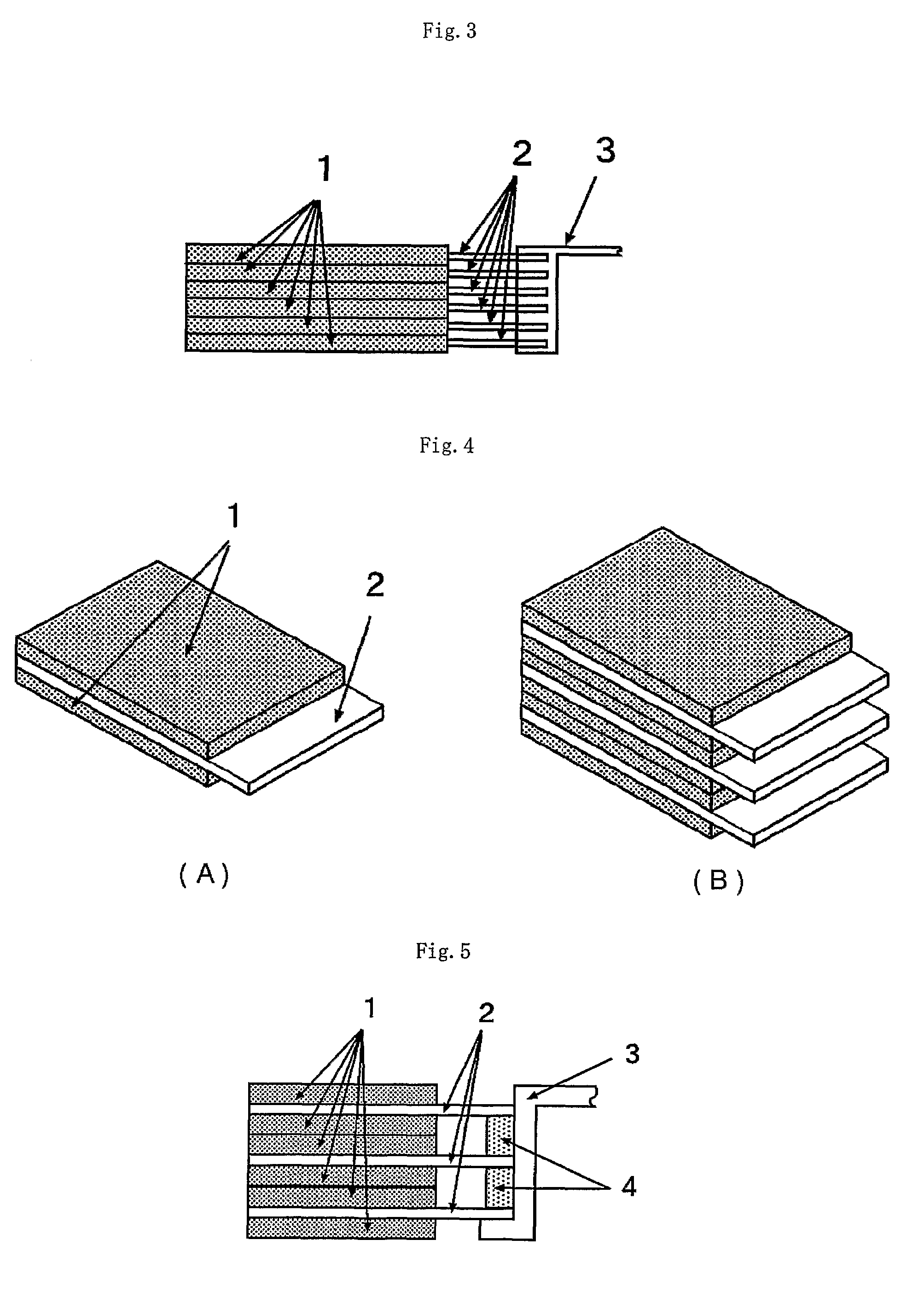

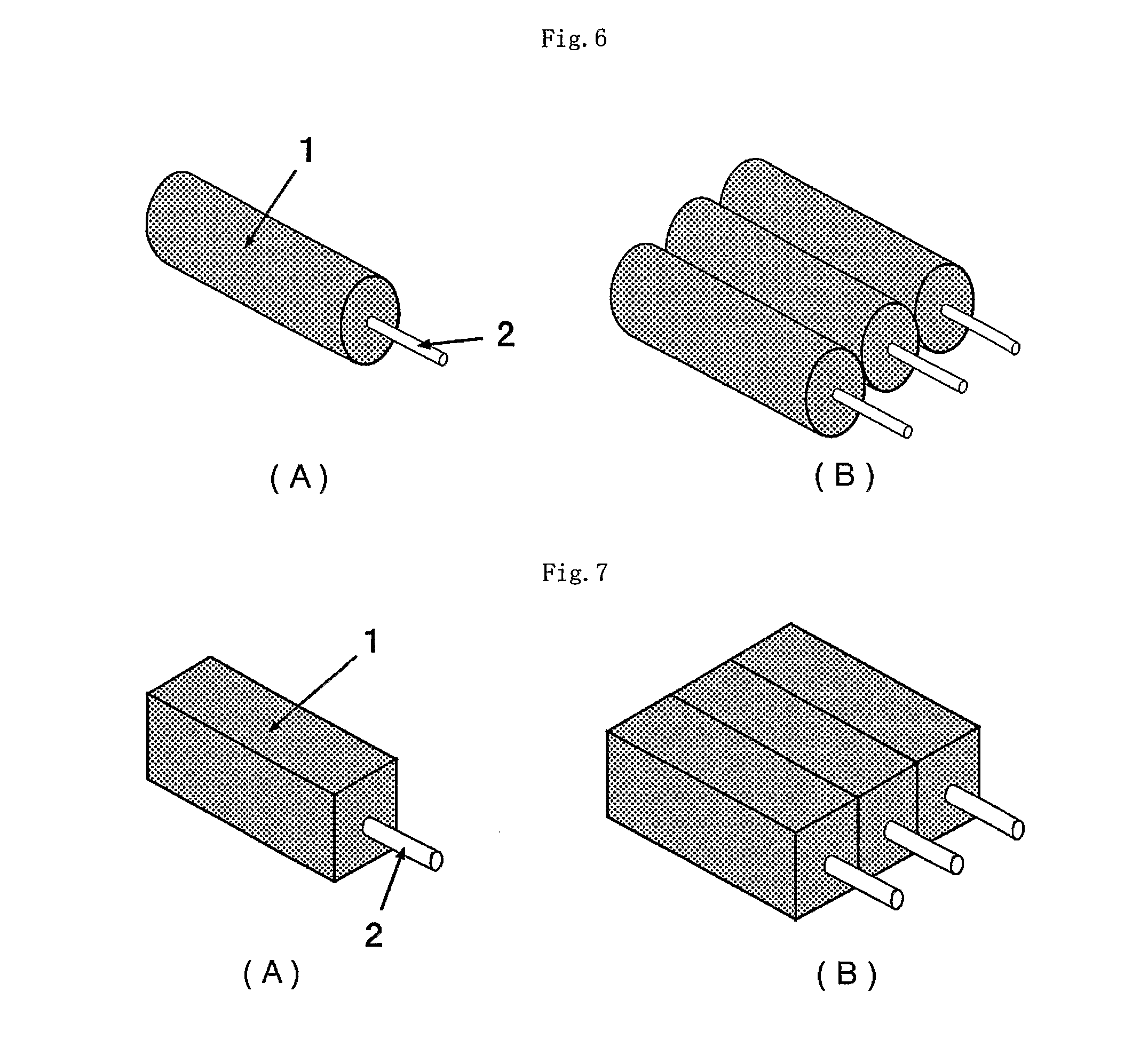

Electrolytic capacitor and a fabrication method therefor

InactiveUS6876083B2Avoid excessive leakage currentAvoid excessive currentTransistorSolid electrolytic capacitorsElectrolytic capacitorNiobium alloy

An electrolytic capacitor including one type of electrode selected from a group consisting of an electrode of at least one type of alloy selected from a group consisting of niobium alloy, titanium alloy, and tungsten alloy, an electrode of mixed sinter of niobium and aluminum, or a fluorine-doped electrode of niobium or niobium alloy and on a surface of each electrode a dielectric layer is formed by anodizing the electrode.

Owner:SANYO ELECTRIC CO LTD

Nickel-base high-temperature alloy with low density and high melting point and preparation process thereof

The invention relates to high-temperature alloy technology, and in particular provides an isometrical cast nickel-base high-temperature alloy with low density, high incipient melting temperature and good casting property and a preparation process thereof, which can be used for floating tile materials of a combustion chamber. The alloy comprises the following compositions by mass percentage: 0.03 to 0.06 percent of C, 5 to 12 percent of Cr, 5.5 to 6.5 percent of Al, 3 to 8 percent of Co, 3 to 7 percent of W, 2 to 4 percent of Mo, 1.6 to 3.2 percent of Nb, 0.01 to 0.03 percent of B, 0.008 to 0.025 percent of Y and the balance of Ni. A vacuum induction furnace is adopted to smelt a master alloy, and a smelting crucible is a CaO crucible or a MgO crucible; and the operation process comprises the following steps: putting alloying elements such as carbon, chromium, cobalt, tungsten, molybdenum and niobium in proportion and a nickel plate into the crucible; melting the alloy when the vacuum degree reaches between 50 and 0.1 Pa; and after completion of the melting, refining for 30 to 300 seconds at a temperature of between 1,550 and 1,600 DEG C, cutting off electricity, forming a film, breaking the film to add Al and Al-Y and Ni-B interalloy for uniform stirring, and casting a master alloy pig at a temperature of between 1,450 and 1,500 DEG C. The invention solves the problems of low incipient melting temperature, poor plasticity and inoxidability and the like of the nickel-base high-temperature alloy.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

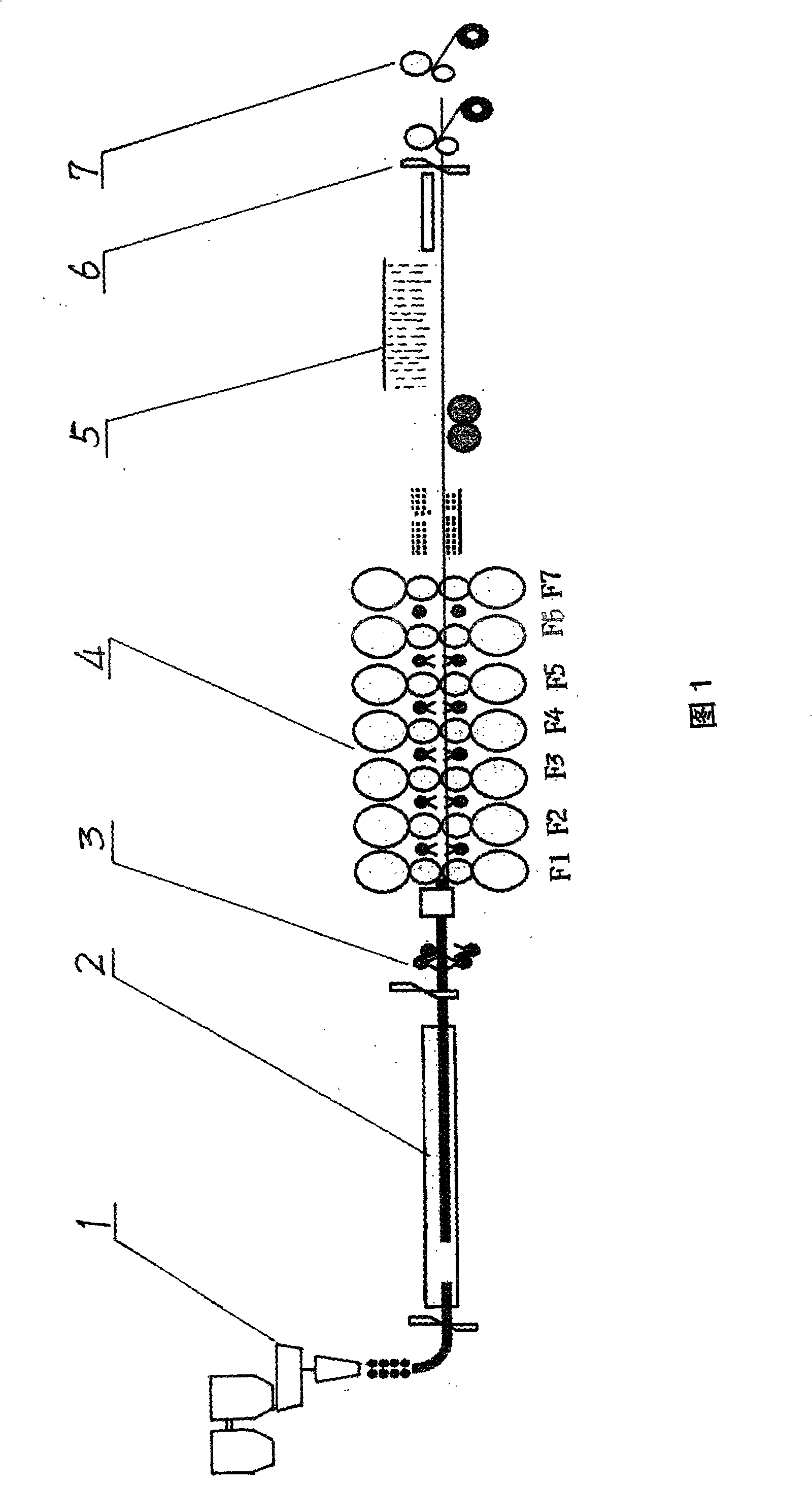

Method for producing hot rolled steel strip for automotive frame

The invention discloses a method for producing a hot rolled steel band used for an automotive frame, comprising the following steps: the pretreated liquid iron is smelt conventionally in a top and bottom combined-blowing revolving furnace, argon is blown at the bottom of the furnace in the whole process, the contents of carbon, phosphorus, silicon and manganese at the terminal of the liquid iron are controlled; the liquid iron discharged from the furnace is refined by an LF furnace, argon is blown to the liquid iron and is stirred and decarbolized at the same time of blowing the argon at the bottom of the LF furnace in the whole process, the liquid iron is subjected to microalloying by adding vanadium, titanium, niobium alloy or niobium and titanium alloy, the content of the microalloy in the liquid iron is controlled to between 0.15 and 0.20 percent, the refined liquid iron is continuously cast into a casting blank through a CSP sheet billet conticaster, the casting blank is soaked in a roller-hearth type soaking furnace and is rolled initially through a vertical miller as well as is sent to a finishing mill set to be rolled, the rolling force of each stander and the finishing temperature of the steel band are controlled, and the hot rolled steel band is cooled through a laminar flow and is cut by a pair of flying shears as well as is wound into a steel coil through a recoiling machine. The produced steel band in 510 L and 590 L or 610 L used for the automotive frame has excellent comprehensive mechanical property, and technique processing and welding performances, can be taken as the automotive frames of a light truck, a medium truck and a heavy truck as well as an agricultural automobile and has remarkable benefits.

Owner:湖南华菱涟源钢铁有限公司

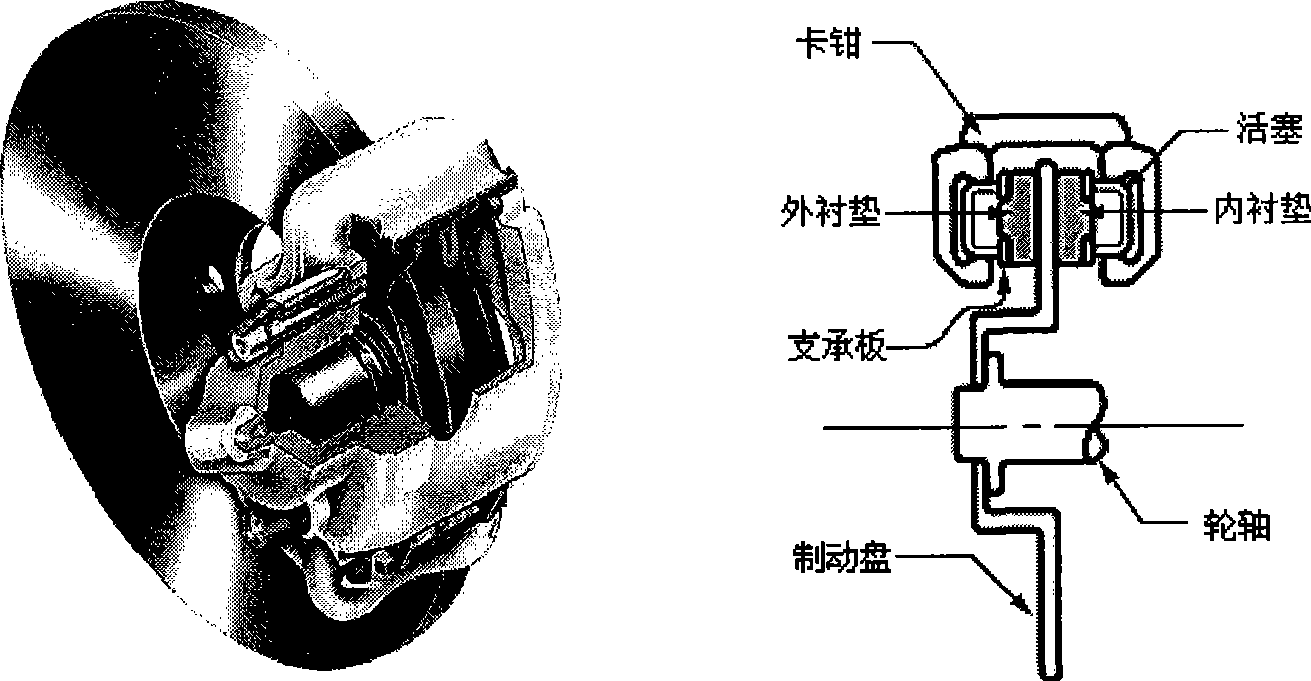

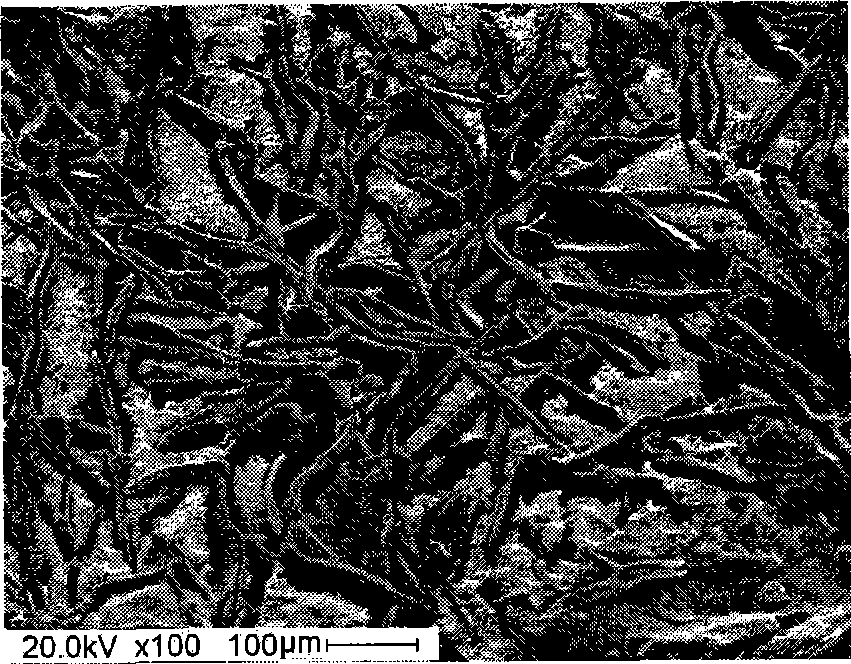

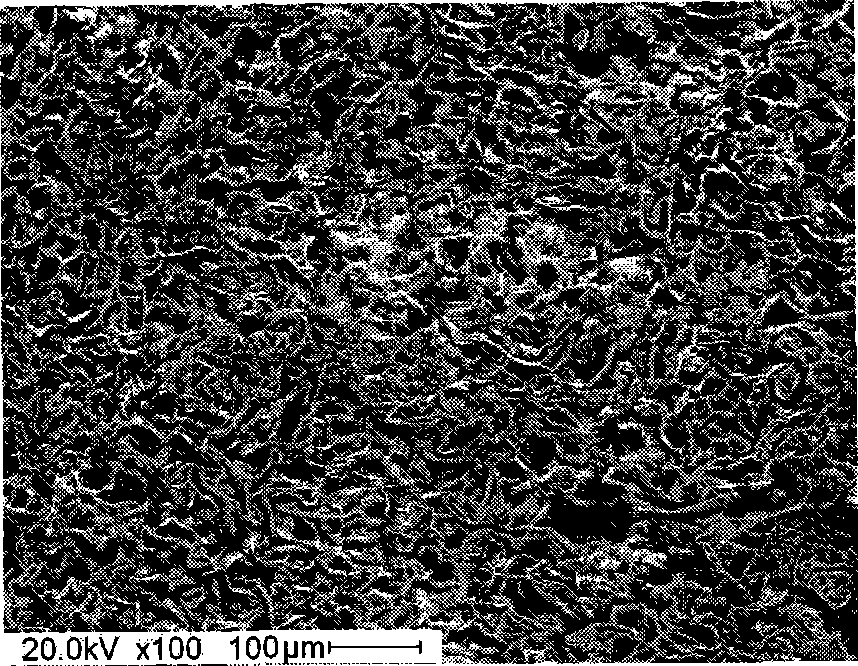

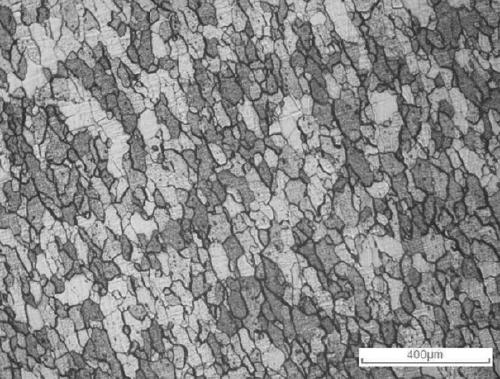

Niobium alloy cast iron brake disk material and technique for producing the same

The invention relates to a material for a niobium alloy cast iron braking disc and a production technology thereof, and belongs to the field of production technology of high-carbon equivalent hypereutectic gray cast iron. The material for the niobium alloy cast iron braking disc comprises the following chemical compositions in weight percentage: 3.7 to 3.9 percent of carbon, 1.8 to 2.2 percent of silicon, 0.5 to 0.8 percent of manganese, less than or equal to 0.08 percent of sulfur, less than or equal to 0.60 percent of copper, less than or equal to 0.20 percent of nickel, less than or equal to 0.05 percent of vanadium, less than or equal to 0.05 percent of stannum, less than or equal to 0.05 percent of titanium, less than or equal to 0.25 percent of chrome molybdenum, 0.08 to 0.3 percent of niobium, and the balance being iron, wherein the iron is melted by an intermediate frequency furnace. The structure of the material is characterized by comprising pearlite, graphite (A3-5), and a small amount of ferrite The performance characteristics of the material are as follows: the hardness HB is more than or equal to 150 and the tensile strength is more than or equal to 170 N / mm<2>. The material is suitable for braking discs for medium-to-high grade sedans made of gray cast iron, and has the advantages of stable performance, low cost, longer service life, and convenient processing.

Owner:SHANGHAI UNIV +1

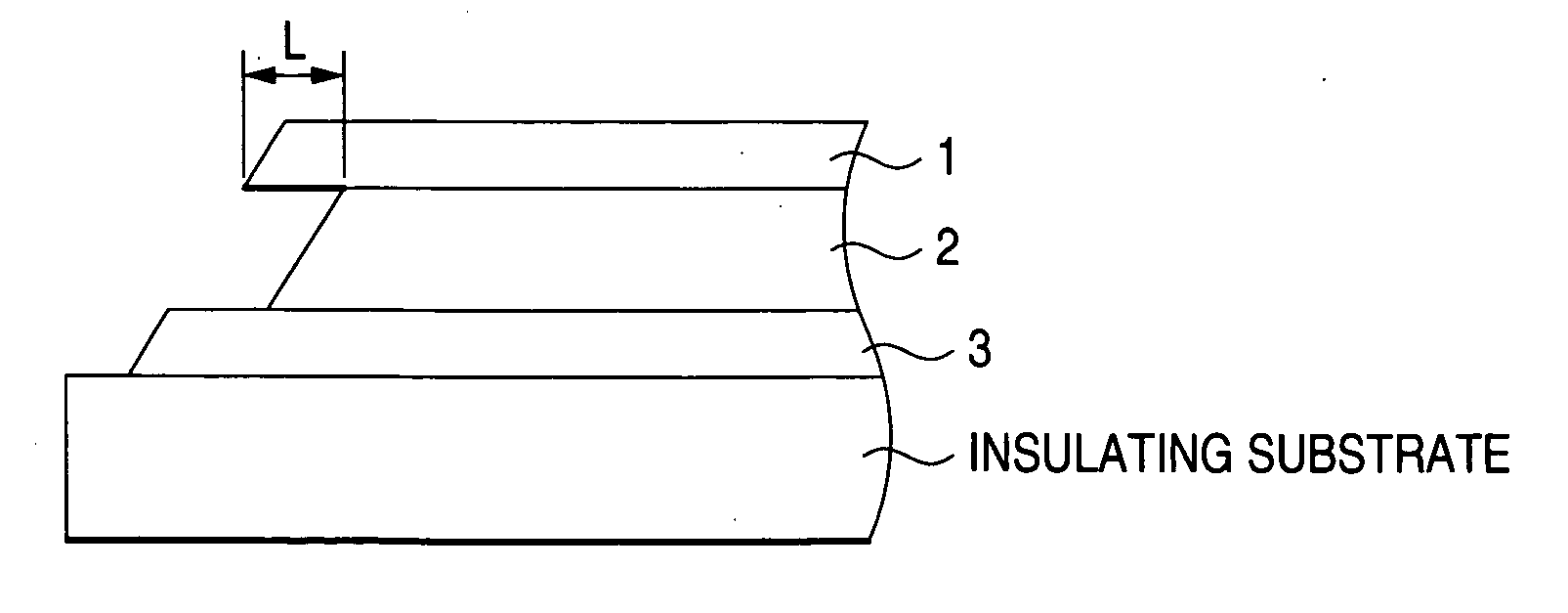

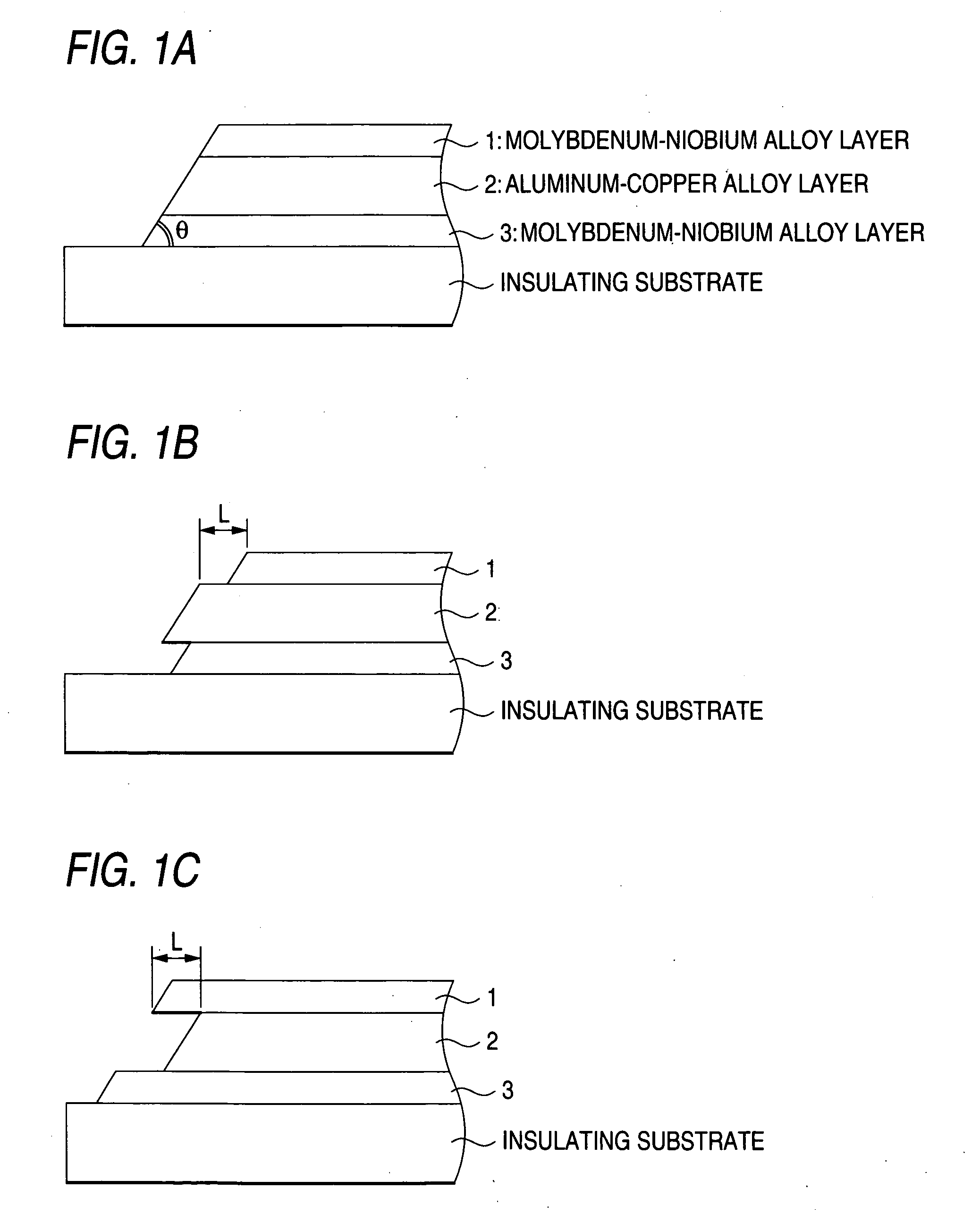

Etchant and method of etching

InactiveUS20060189123A1Reduce adhesionSatisfied with precisionSemiconductor/solid-state device detailsSolid-state devicesOrganic acidO-Phosphoric Acid

A fine wiring line profile with satisfactory precision is formed from a multilayer film containing a first layer made of an aluminum alloy and a second layer formed thereon made of a molybdenum-niobium alloy, by simultaneously etching the two layers constituting the multilayer film through only one etching operation while preventing the upper layer from forming overhangs. An etchant for etching a multilayer film containing an aluminum alloy layer formed over a substrate and a molybdenum-niobium alloy layer formed thereon having a niobium content of 2-19% by weight contains an aqueous solution of an acid mixture containing phosphoric acid, nitric acid, and an organic acid; and a method of etching is carried out with this etchant. The etchant preferably has a phosphoric acid concentration Np of 50-75% by weight, a nitric acid concentration Nn of 2-15% by weight, and an acid ingredient concentration defined by Np+(98 / 63)Nn of 55-85% by weight.

Owner:MITSUBISHI ELECTRIC CORP +1

Porous Anode Body For Solid Electrolytic Capacitor, Production Method Thereof and Solid Electrolytic Capacitor

InactiveUS20080106852A1Increase capacitanceLow ESRLiquid electrolytic capacitorsSemiconductor/solid-state device manufacturingCapacitanceTantalum compound

The invention provides a method of manufacturing a porous anode for a solid electrolytic capacitor, comprising a step of subjecting a molded body containing powder of at least one material selected from oxygen-containing niobium material and oxygen-containing tantalum material and a pore-forming agent which is solid at reduction temperature to reduction reaction using reducing agent and another step of removing the pore-forming agent from the reduction reaction product and a solid electrolytic capacitor using an anode obtained thereby. As niobium material and tantalum material, at least one material selected from niobium, niobium alloy, niobium compound, tantalum, tantalum alloy and tantalum compound is used respectively. In the invention, the peak position, the number and quantity of pores can be optimized according to the cathode agent used, whereby a solid electrolytic capacitor having an improved property for impregnation with cathode agent, high capacitance, low ESR, good tan δ characteristics and long-term reliability, is obtained.

Owner:SHOWA DENKO KK

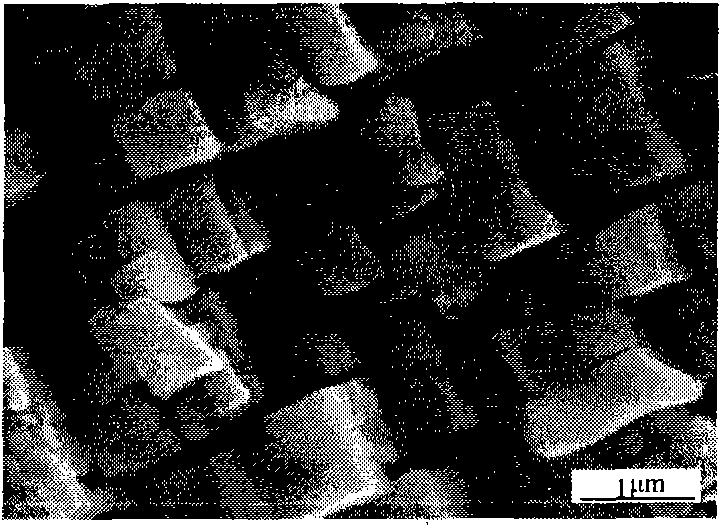

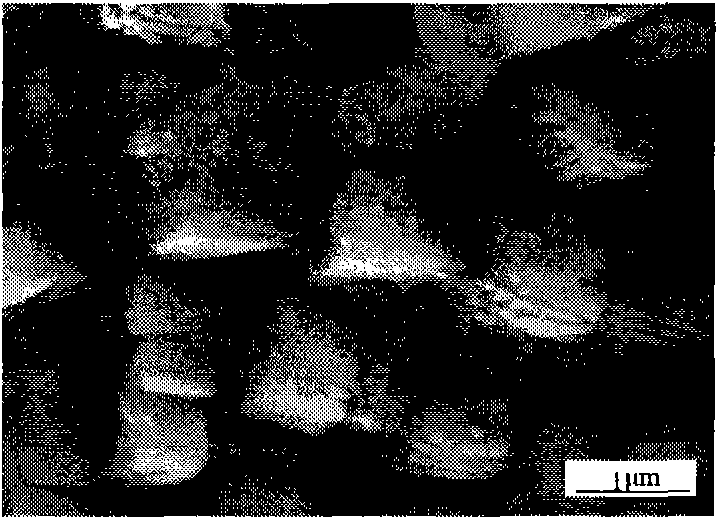

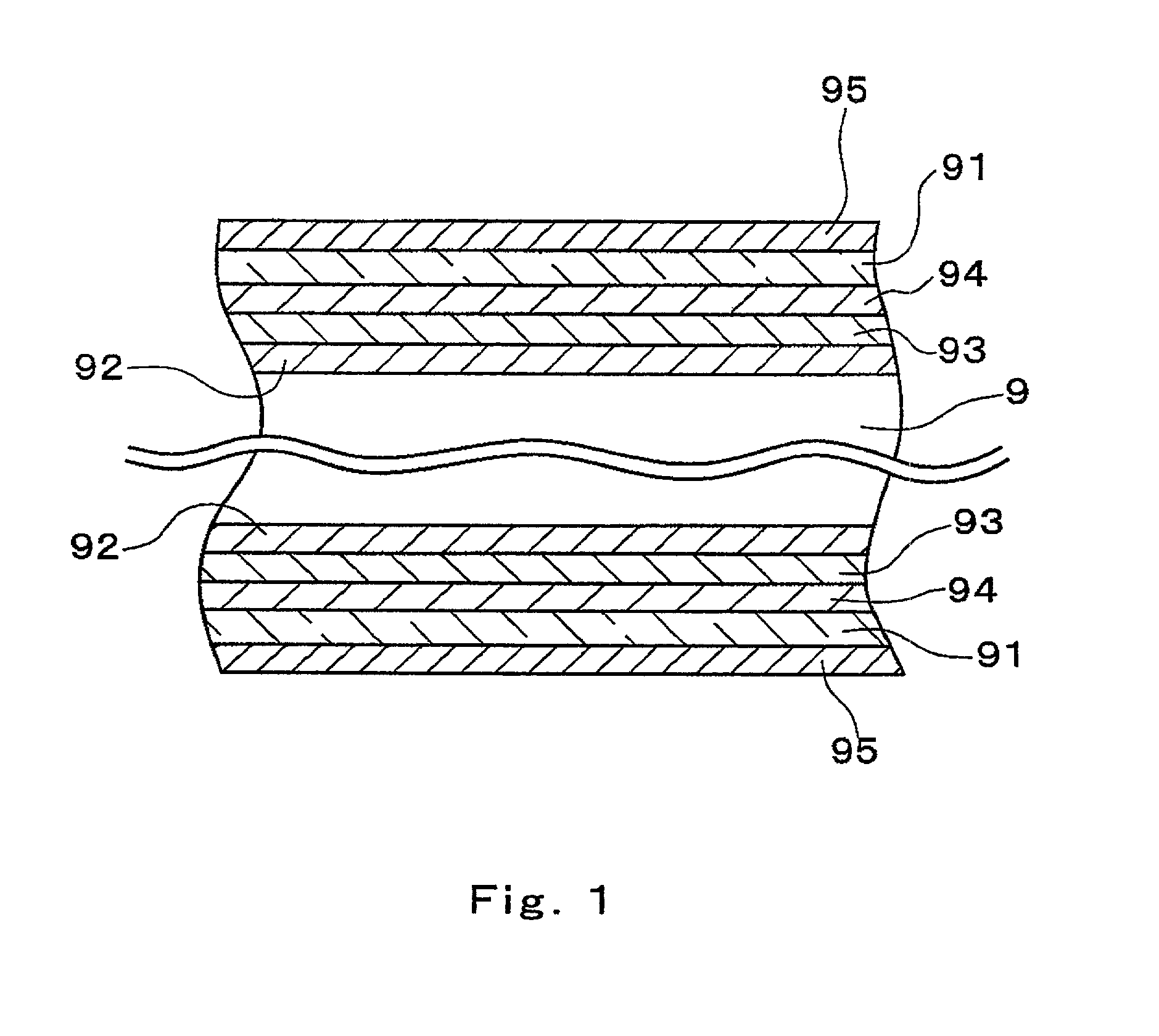

Niobic alloy high temperature antioxidation silicide coating and preparation method thereof

InactiveCN101200801AUniform compositionUniform thicknessSolid state diffusion coatingSuperimposed coating processCementation processVolumetric Mass Density

The invention discloses a niobium alloy high temperature antioxidation silicide coating and a preparation method thereof. Firstly, molybdenum layers, the particle size of most of which is 0.6-1.0 Mu m and the thickness of which is 50 Mu m-80 Mu m, are sintered through vacuum on a niobium alloy substrate surface layer. Under the protection of argon, a MoSi2 coating is made through the pack cementation silicification. The pack cementation silicification activator is NaF, the promoter is Al2O3, and the weight ratio of Si to Al2O3 to NaF is 35-45 to 50-65 to 3-5. The complex pack cementation process is suitable for preparing the silicide coating with high melting point and can coat the inside and the external surface of irregular structural components without the influences of the shape and the size of the components. The components and the thickness of the coating prepared through the method are uniform. The density is greatly improved compared with that of a material pulp reaction sintering method. With simple process and low requirement on equipment, the invention is a novel high temperature coating preparation technology.

Owner:CENT SOUTH UNIV

Preparation process of sputtered rotary molybdenum-sodium-alloy tubular target

ActiveCN103045925AHigh densitySmall grain sizeVacuum evaporation coatingSputtering coatingSodium molybdateNiobium alloy

The invention discloses a preparation process of a sputtered rotary molybdenum-sodium-alloy tubular target. The preparation process comprises the following steps of: (1) preparing materials, wherein used powder comprises molybdenum powder and sodium molybdate powder, the physical property of the powder is as follows: the Mo content of the molybdenum powder is at least 99.95% with the granularity of 3-5 microns, and the sodium molybdate content of the sodium molybdate powder is at least 99.0% with the granularity of 20-40 microns; (2) blending the powder: weighing the molybdenum powder and the sodium molybdate powder proportionately, controlling the mass percentage content of the molybdenum powder to be 90-99% and that of the sodium molybdate powder to be 1-10%; (3) carrying out mechanical alloying: synthesizing nanometer molybdenum-sodium alloy powder; (4) filling into a die; (5) carrying out cold isostatic pressing; (6) sintering; (7) forging; (8) performing vacuum annealing; and (9) mechanically processing to obtain the sputtered rotary molybdenum-sodium-alloy tubular target. A produced molybdenum-niobium-alloy tubular target has characteristics of uniform elements, no segregation, fine grain size and high purity, completely meets requirements of CIGS (Copper Indium Gallium Selenide) photovoltaic cells and increases the use efficiency of the cells.

Owner:LUOYANG SIFON ELECTRONICS

Porous anode body for solid electrolytic capacitor, production method thereof and solid electrolytic capacitor

InactiveUS7594937B2Increase capacitanceLow ESRLiquid electrolytic capacitorsSemiconductor/solid-state device manufacturingCapacitanceTantalum compound

The invention provides a method of manufacturing a porous anode for a solid electrolytic capacitor, comprising a step of subjecting a molded body containing powder of at least one material selected from oxygen-containing niobium material and oxygen-containing tantalum material and a pore-forming agent which is solid at reduction temperature to reduction reaction using reducing agent and another step of removing the pore-forming agent from the reduction reaction product and a solid electrolytic capacitor using an anode obtained thereby. As niobium material and tantalum material, at least one material selected from niobium, niobium alloy, niobium compound, tantalum, tantalum alloy and tantalum compound is used respectively. In the invention, the peak position, the number and quantity of pores can be optimized according to the cathode agent used, whereby a solid electrolytic capacitor having an improved property for impregnation with cathode agent, high capacitance, low ESR, good tan δ characteristics and long-term reliability, is obtained.

Owner:SHOWA DENKO KK

Niobium alloy and hydrogen permeation membrane produced from it

InactiveUS6800392B2High hydrogen permeation rateReduce riskMembranesSemi-permeable membranesRheniumPlatinum

Owner:W C HERAEUS GMBH

Isotope dilution mass spectrometry method for determining content of uranium in uranium niobium alloy

InactiveCN104597174AEasy to measureOvercoming Disadvantages of Susceptibility to InterferenceComponent separationElement analysisDecomposition

The invention discloses an isotope dilution mass spectrometry method for determining the content of uranium in a uranium niobium alloy. A formula for calculating the content of uranium in the uranium niobium alloy is derived according to an isotope dilution mass spectrometry principle. A decomposition process of the uranium niobium alloy is researched, the sampling quantity and the amount of a diluent are optimized, and the influences of mass spectrum line interference and alloy element interference on a measurement result are discussed. The method comprises the following steps: adding nitric acid and hydrofluoric acid to quantitatively dissolve the uranium niobium alloy, adding a quantitative amount of a uranium isotope diluent to directly prepare a mixed sample solution, determining the mixed solution and the uranium isotope proportion in the uranium niobium alloy sample through mass spectrometry, and calculating the content of uranium in the uranium niobium alloy. Quantitative separation of uranium is not needed by the determined method. An XRF technique, an ICP-AES technique and an element analysis technique are used to measure the content of niobium and the total content of impurity elements in the uranium niobium alloy, and back stepping is carried out to obtain the corresponding uranium content order in order to verify the accuracy of the analytical result, and the obtained result is consistent with a result obtained through the experiment method. When the method disclosed in the invention is used to analyze the uranium niobium alloy sample, the relative standard uncertainty of determination results is 0.2% (6 determinations), and the expanded uncertainty is 0.5% (95% confidence level).

Owner:青岛齐力铸钢有限公司

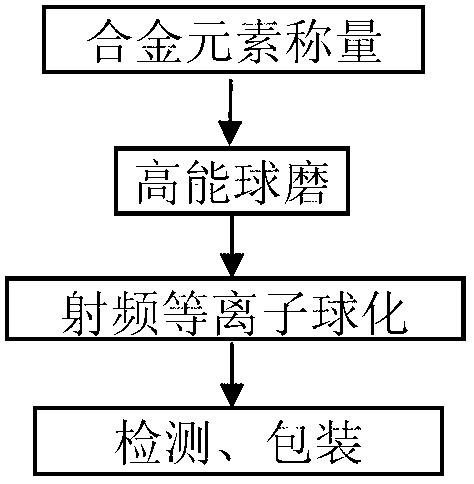

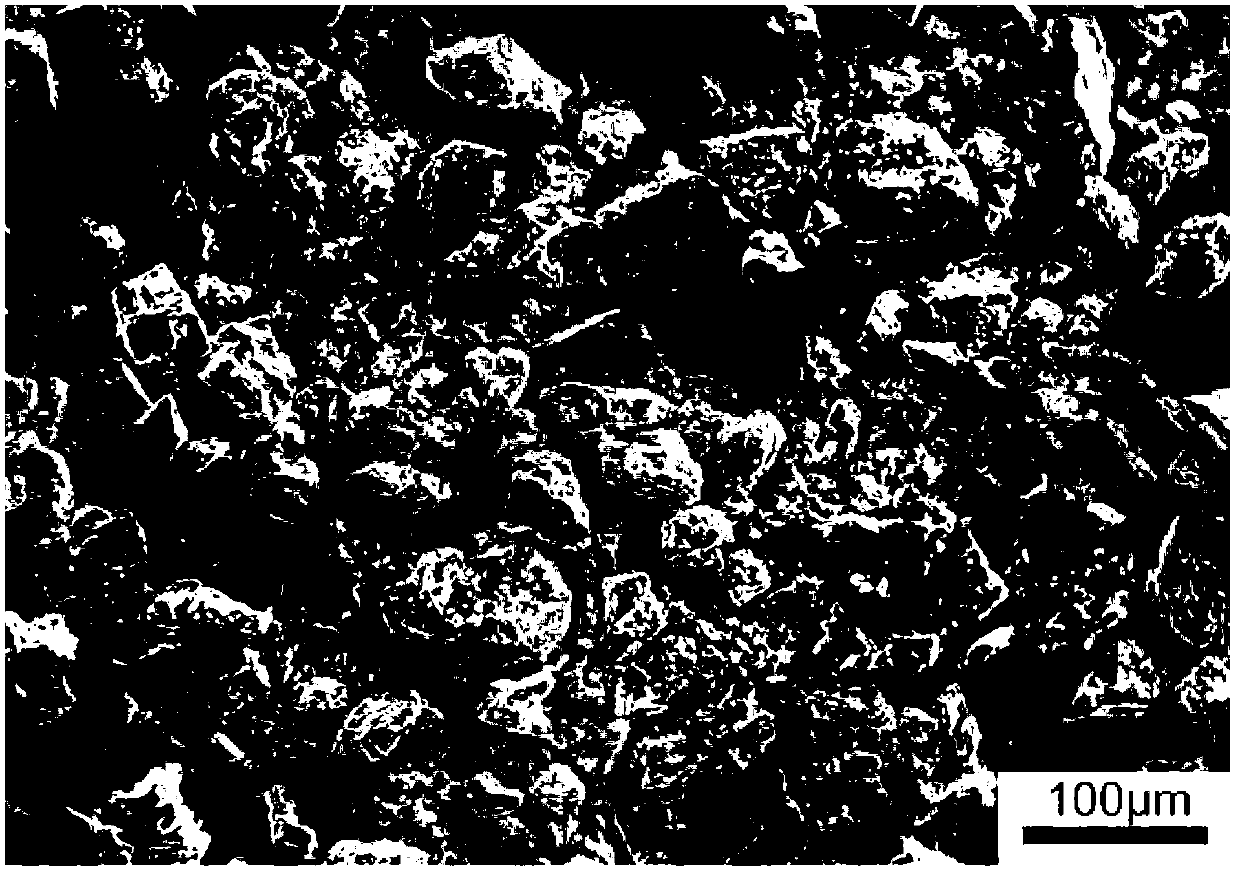

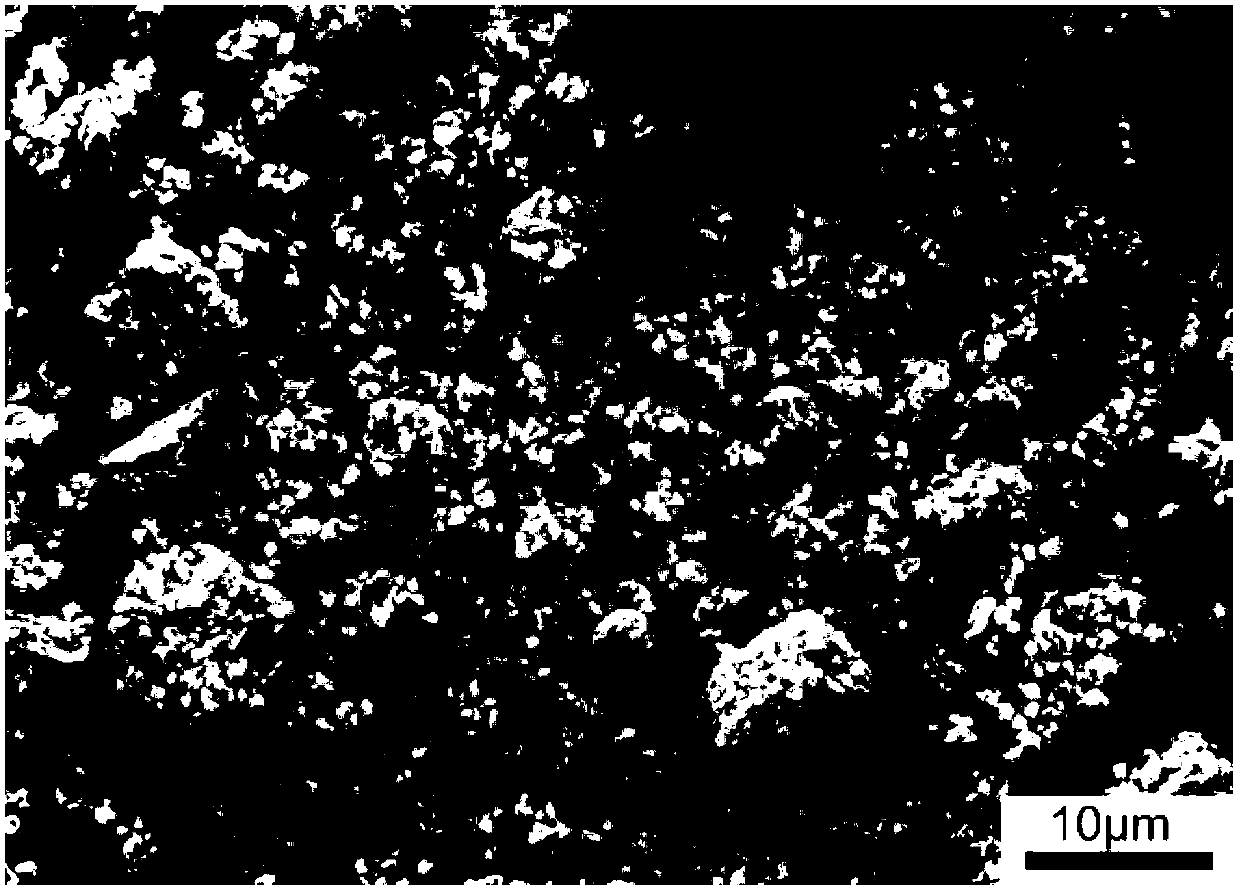

Method for preparing micro spherical niobium (Nb)-wolfram (W)-molybdenum (Mo)-zirconium (Zr) alloy powder

Owner:UNIV OF SCI & TECH BEIJING

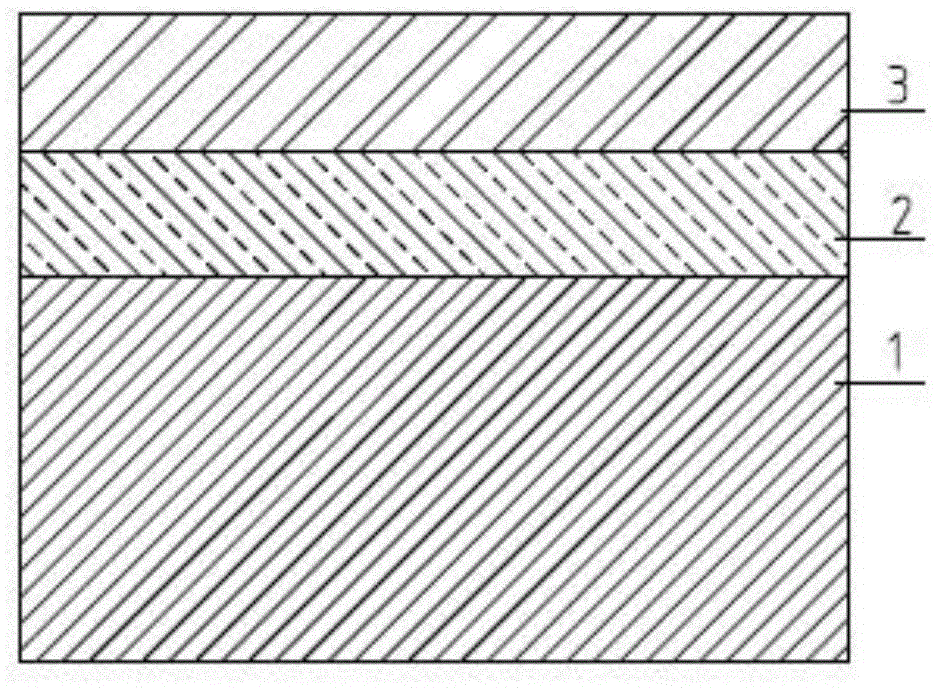

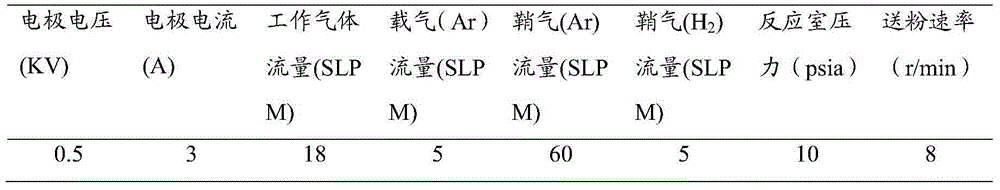

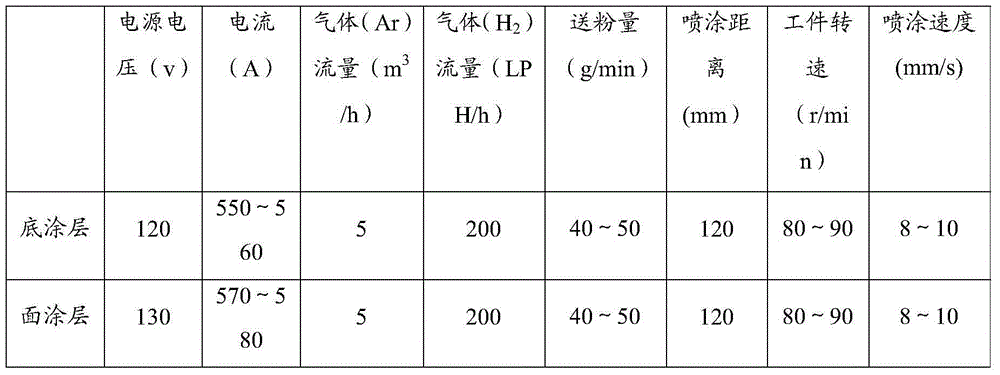

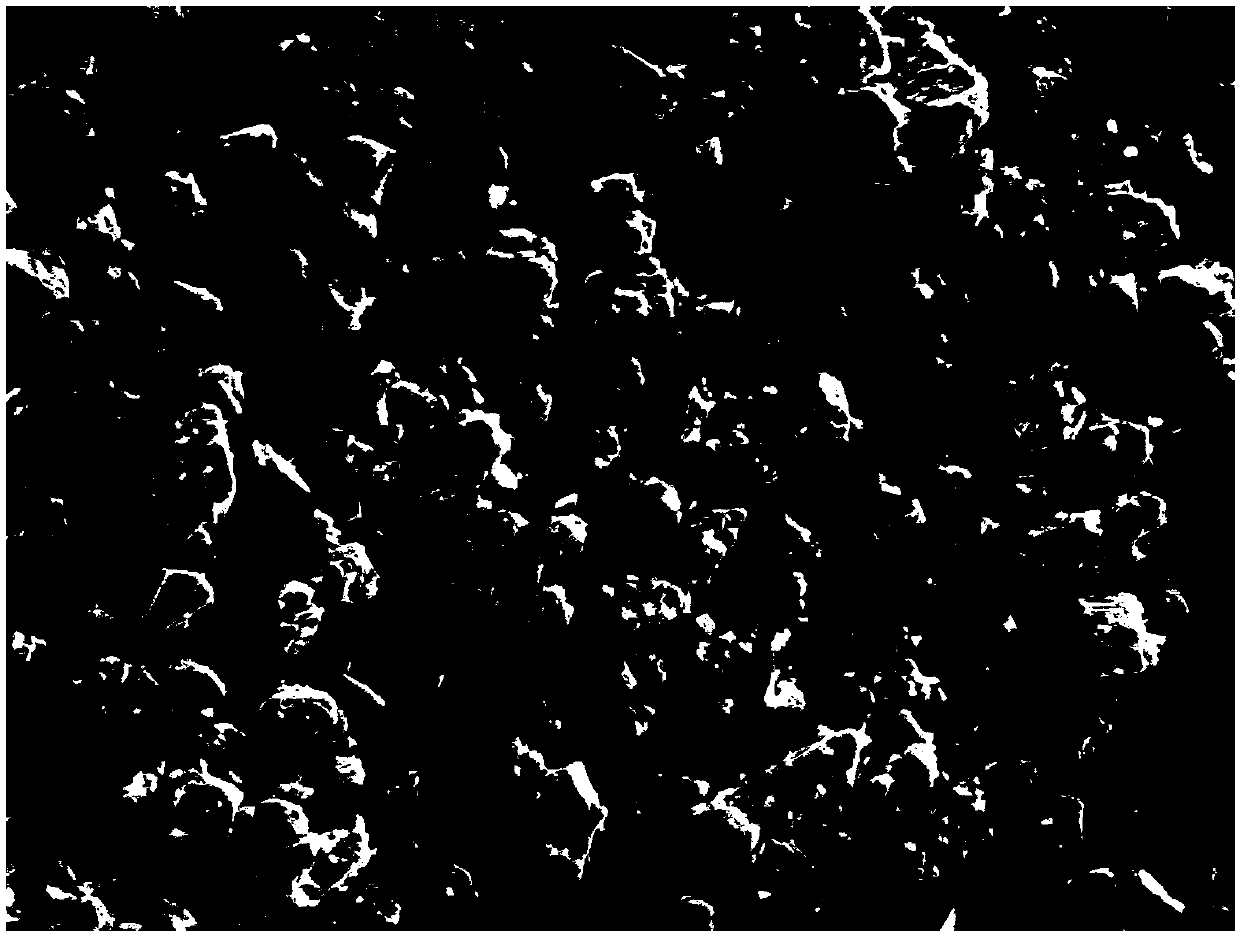

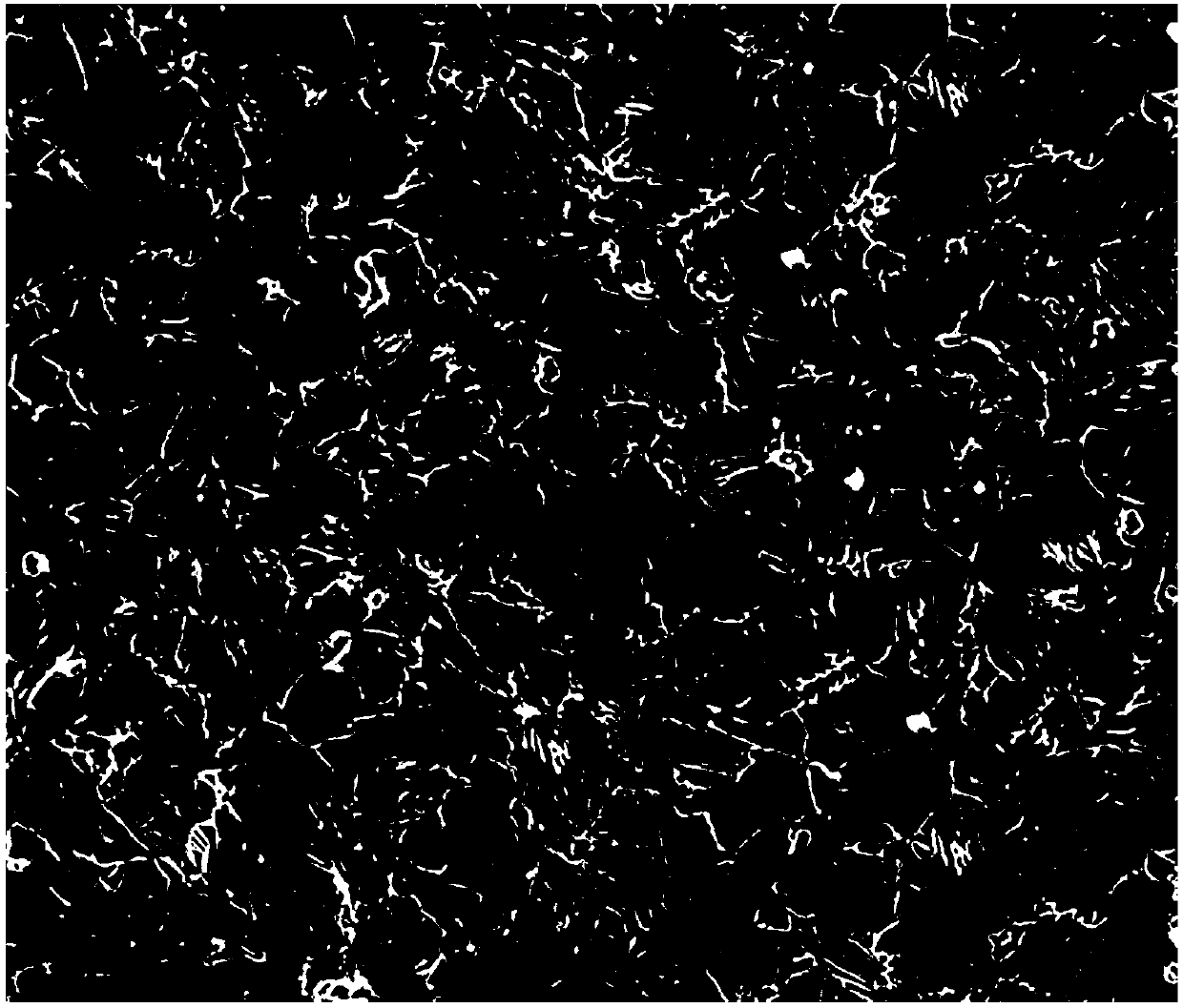

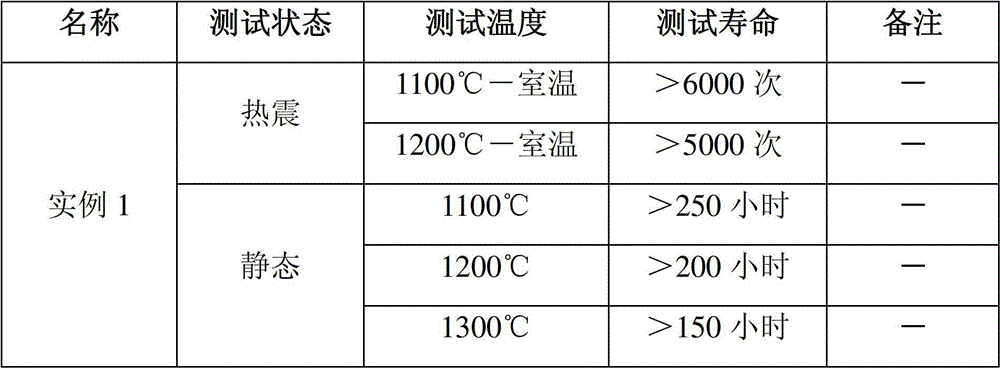

High-temperature oxidation resistant coating on niobium alloy surface and preparation method of high-temperature oxidation resistant coating

InactiveCN104561882AHigh strengthImprove toughnessMolten spray coatingHigh energyOxidation resistant

The invention belongs to the field of thermal spraying, and relates to a high-temperature oxidation resistant coating on a niobium alloy surface and a preparation method of the high-temperature oxidation resistant coating. The coating is in a dual-layer structure with a bottom coating Mo1-xWx(Si1-y-zAlyBz)2 and a surface coating Mo1-xWx(Si1-y-zAlyBz)2-(10-20)%wt HfSi2, and prepared on a niobium alloy matrix surface by a high-energy plasma spraying process, wherein a bottom coating powder material Mo1-xWx(Si1-y-zAlyBz)2 is prepared by a self-propagating process, and the spherical particles meeting the requirements of the spraying process are obtained by applying a plasma spheroidizing process; surface coating powder materials Mo1-xWx(Si1-y-zAlyBz)2 and HfSi2 are mixed evenly in a mechanical mixing manner. The coating has excellent high-temperature oxidation resistance at 1500-1800 DEG C, and can be applied to high-temperature protection of niobium alloy parts.

Owner:CHINA IRON & STEEL RES INST GRP +1

Method for preparing Ti2AlNb base alloy through powder metallurgy

The invention provides a method for preparing a Ti2AlNb base alloy through a powder metallurgy process, and belongs to the technical field of titanium alloy preparation. The method is characterized bypreparing a Ti2AlNb base intermetallic compound by using alloy powder, prepared by a hydrogenation / dehydrogenation method, through vacuum pressureless sintering, and comprises the following steps: sponge titanium and an aluminum-niobium alloy are added in a hydrogenation furnace for hydrogenation and crushing classification; and then, simple substance aluminum powder is added for self-propagatingdispersion at 700-900 DEG C to form primary prealloying powder. Finally, a high-compactness and large-size Ti2AlNb alloy ingot is prepared through cold isostatic pressing and vacuum pressureless sintering. A Ti2AlNb alloy material is prepared by using low-cost element powder through hydrogenation / dehydrogenation, cold isostatic pressing and vacuum sintering; the process is simple; and the cost islow. The method can prepare the nearly full-compactness Ti2AlNb alloy with the compactness of more than 98%; and the Ti2AlNb alloy is uniform and fine in material organization, excellent in hot working performance and suitable for industrial scale popularization.

Owner:天钛隆(天津)金属材料有限公司

Thermal treatment process capable of reducing microsegregation of directionally-solidified high-niobium TiAl alloy

The invention provides a thermal treatment process capable of reducing the microsegregation of directionally-solidified high-niobium TiAl alloy. The high-niobium TiAl alloy containing trace elements such as W, B, Y, Mn and the like is prepared from the following components by atomic percent: 44-46% of Ti, 6-9% of Al, 0-2% of Nb, 0-0.5% of W and Mn, and the balance of B and Y; and a fastener ingot is obtained by virtue of electric arc melting, the fastener ingot is sucked and cast into an alloy test bar, and a directionally-solidified high-niobium TiAl alloy sample is prepared by utilizing a Bridgeman method. A directional solidification technology is utilized, so that alloy grains grow along a forced direction, the transversal grain boundary is eliminated, and the high-temperature property is improved, but as the cast high-niobium TiAl alloy has structural defects caused by ubiquitous S segregation, beta segregation and alpha segregation, the mechanical property of the alloy is finally influenced. According to the invention, heat preservation is carried out on the directionally-solidified sample at the temperature of 1250-1290 DEG C for 6-24 hours, and when the sample is cooled to 890-910 DEG C along with a furnace, heat preservation is carried out for 30-35 minutes, thus the beta segregation and the alpha segregation are greatly reduced, simultaneously recrystallization and grain growth phenomena do not appear, and the mechanical property of the alloy is effectively improved. The process provided by the invention is simple and reliable in method, low in cost and strong in practicability; and the obtained high-strength, high-toughness and directionally-solidified high-niobium TiAl alloy has a wide application prospect in the aerospace field.

Owner:NANJING UNIV OF SCI & TECH

Turning method and turning tool

The invention provides a turning method. The method comprises the following step: turning the outer surface of a niobium alloy target material or a niobium alloy target material by adopting a turning tool, wherein the front angle of the turning tool is 20-40 degrees, the rear angle is 4-15 degrees, the main deflection angle is 45-60 degrees, the auxiliary deflection angle is 45-90 degrees, and the blade inclination angle is 10-25 degrees. By selecting the front angle, rear angle, main deflection angle, auxiliary deflection angle and blade inclination angle of the turning tool, cuttings can be discharged from processed surfaces, so that the cuttings are prevented from sticking to the tool, and the cutting difficulty is lowered. The invention further provides a turning tool. The front angle of the turning tool is 20-40 degrees, the rear angle is 4-15 degrees, the main deflection angle is 45-60 degrees, the auxiliary deflection angle is 45-90 degrees, and the blade inclination angle is 10-25 degrees.

Owner:NINGXIA ORIENT TANTALUM IND

Process for manufacturing high-density molybdenum-niobium alloy sputtering target material

InactiveCN110257784ALow oxygenHigh purityVacuum evaporation coatingSputtering coatingVolumetric Mass DensityMixed materials

The invention belongs to the field of manufacturing high-temperature refractory metal target materials, and particularly relates to a process for manufacturing a high-density molybdenum-niobium alloy sputtering target material. The process comprises the steps of mixing raw materials; loading mixed material powder in a rubber sleeve; performing cold isostatic pressing operation, after the pressure is increased to a certain pressure, maintaining the pressure for a period of time, then depressurizing, and finally taking out a pressed blank from the rubber sleeve; carrying out vacuum sintering or hydrogen protection sintering; carrying out hot isostatic pressing operation directly on the sintered blank; performing hot rolling operation, namely performing metal sleeve rolling on a molybdenum-niobium alloy, and annealing after hot rolling to remove stress; and carrying out machining operations such as grinding to obtain the final required product size. The process is simple in processing steps and convenient to operate, the purity and the relative density of the manufactured molybdenum-niobium alloy sputtering target material all meet the use requirements in the film coating field of high-end electronic products; and the process is low in production cost, wide in production size range, and convenient for industrial batch production.

Owner:LUOYANG SIFON ELECTRONICS

Preparation method of high-strength and high-conductivity beryllium copper alloy

ActiveCN102383078AConductivity has little effectLittle tensile strengthNiobium alloyComposite structure

The invention relates to a preparation method of a high-strength and high-conductivity beryllium copper alloy. In the method, the high-strength and high-conductivity beryllium copper alloy is obtained through hot working, high-working rate cold working, solution treatment, finish rolling or product drawing and aging treatment after smelting the low-beryllium alloy and copper-niobium composite materials together and casting into an ingot. The dispersively distributed copper-niobium composite materials are added into the high-conductivity low-beryllium alloy, the dispersively distributed niobium particles form an ordered composite structure in the low-beryllium alloy after one-time hot working and multiple high-working rate cold working, so that the strength and hardness of the low-beryllium alloy are greatly improved, the conductivity of the low-beryllium alloy is not influenced, and the beryllium copper alloy with the tensile strength sigma b equal to 1200-1400Mpa, hardness HB equal to 334-374 and conductivity g equal to 45-60% IAC is finally obtained. The beryllium niobium alloy prepared by the invention has high strength, high hardness, high elasticity and high wear resistance of the high-beryllium alloy and high conductivity and thermal conductivity of the low-beryllium alloy at the same time, and the comprehensive property of the beryllium copper alloy is greatly improved.

Owner:CNMC NINGXIA ORIENT GRP

Micro fine-grained titanium-nickel-niobium shape memory alloy block material preparing method

The invention is a manufacturing method for a kind of micron tiny crystal titanium nickel-niobium shape memorizing alloy block materials, 45%-50% titanium, 40%-45% nickel, 5%-10% niobium are melted and produced into titanium nickel-niobium alloy cast ingot, and cuts the titanium nickel-niobium alloy block material into blank, and carries on surface finish process, and paints with glass lubricate, uses isometric curved squeezing mould with 90-120 degrees channel angle, the mould cavity surface is painted with black lead lubricate, the blank and mould are heated and carries on temperature reservation, and takes them out to be squeezed at the same time, finally gets the product. The invention solves the problem that the bad plastic property of titanium nickel-niobium shape memorizing alloy in room temperature, enhances the alloy mechanical performance, and lowers the cost.

Owner:SHANGHAI JIAO TONG UNIV

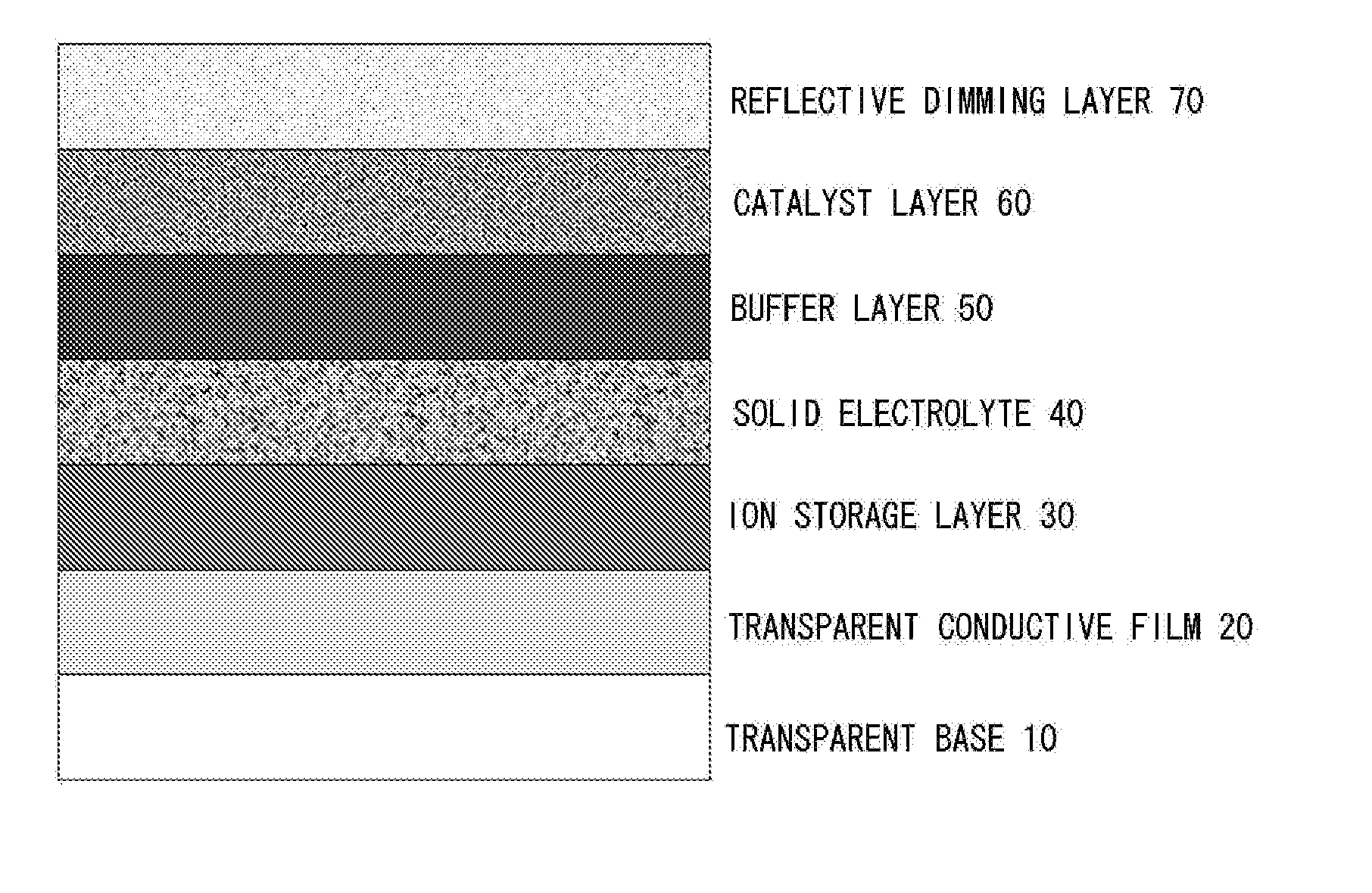

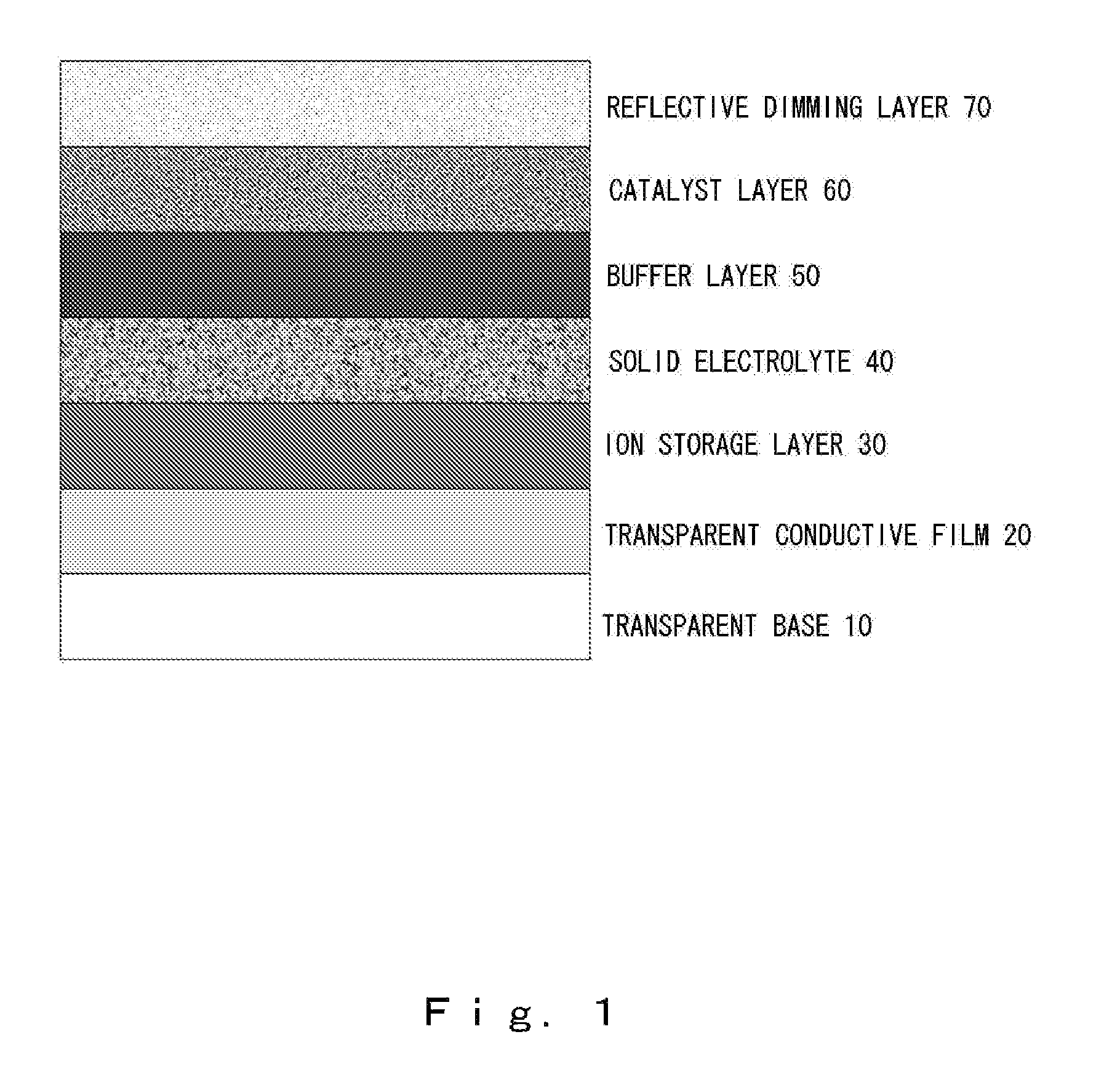

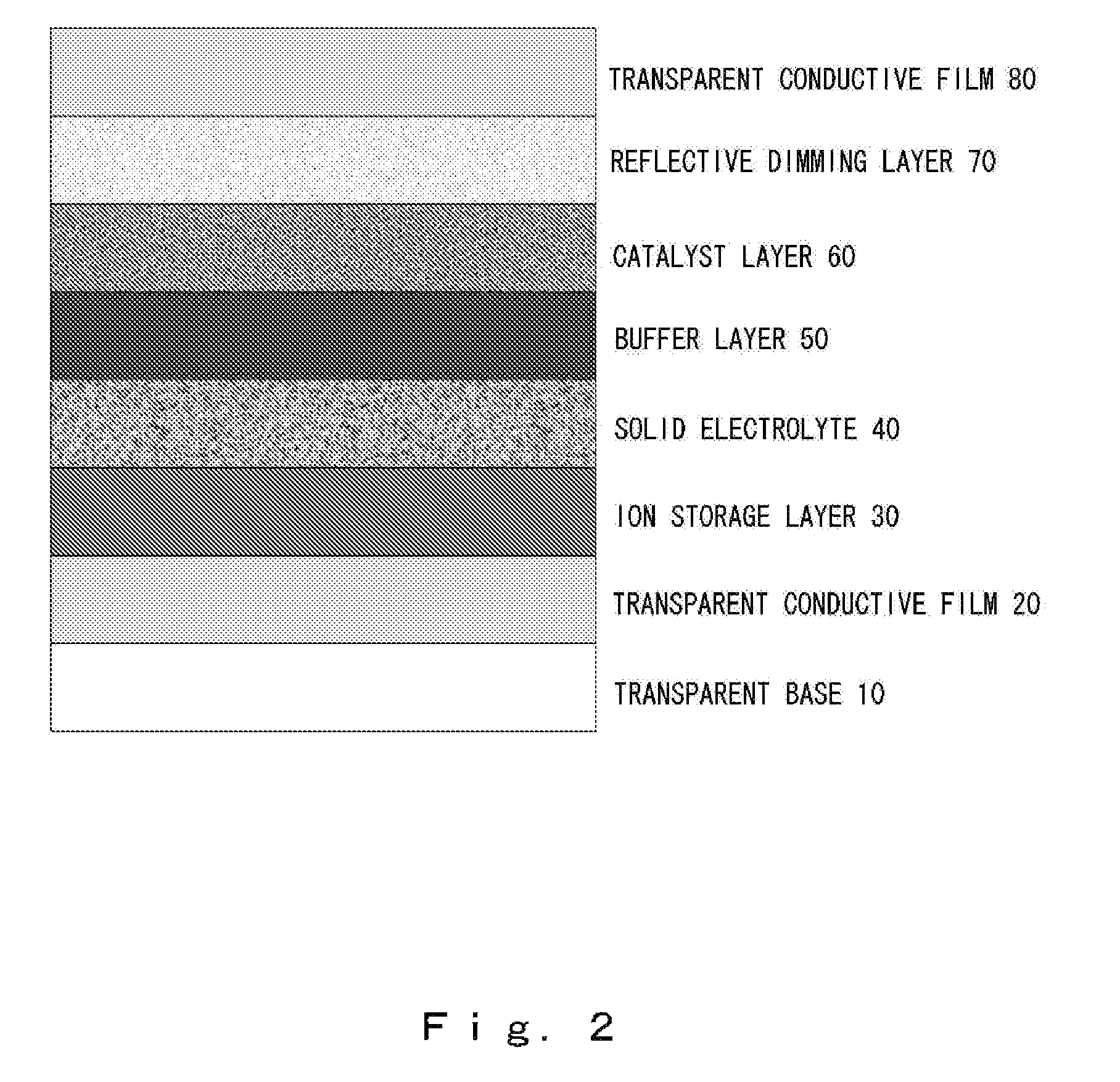

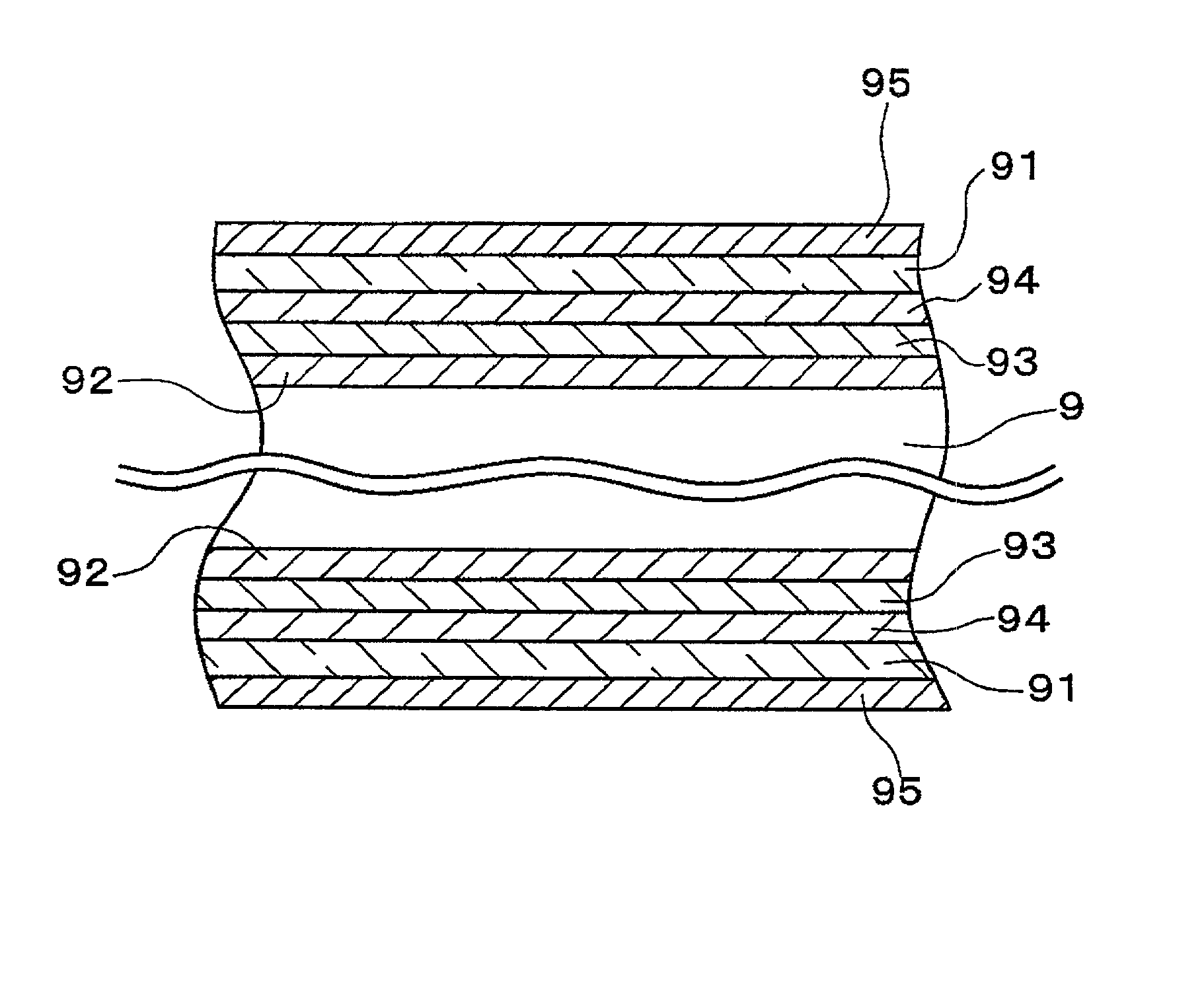

All-solid-state reflective dimming electrochromic device having buffer layer and dimmer member using the same

The present invention provides an all-solid-state type reflection light controllable electrochromic device having a buffer layer, and the constitution thereof comprises an all-solid-state reflective dimming electrochromic device in which a transparent conductive film layer, an ion storage layer, a solid electrolyte layer, a buffer layer, catalyst layer, and a reflective light controllable layer of a magnesium alloy thin film, in particular a multilayer thin film that uses a magnesium-nickel alloy, magnesium-titanium alloy or magnesium-niobium alloy, are formed on a transparent base that uses a glass or resin sheet, and a method for manufacturing the device, and an optical switchable component that incorporates the reflective light controllable electrochromic device, and according to the present invention, a reflective light controllable electrochromic device having a novel multilayer structure can be provided that enables high transmittance when it is transparent and enables switching in a short time over a wide area.

Owner:NAT INST OF ADVANCED IND SCI & TECH

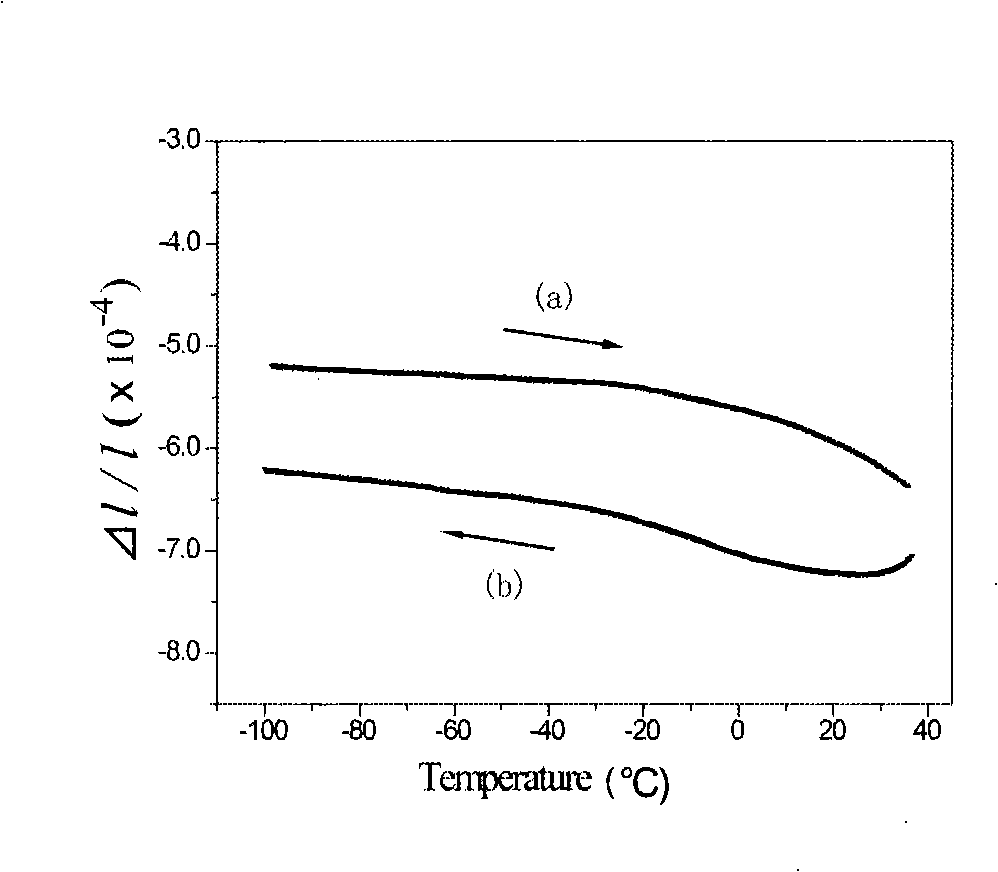

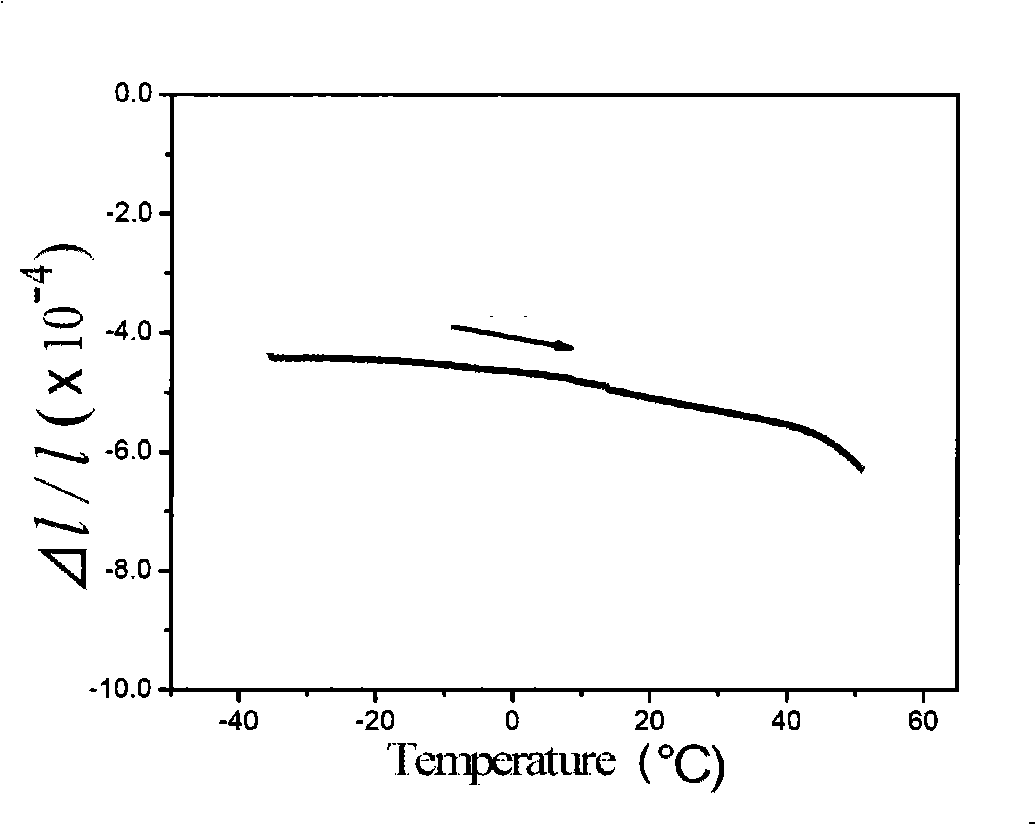

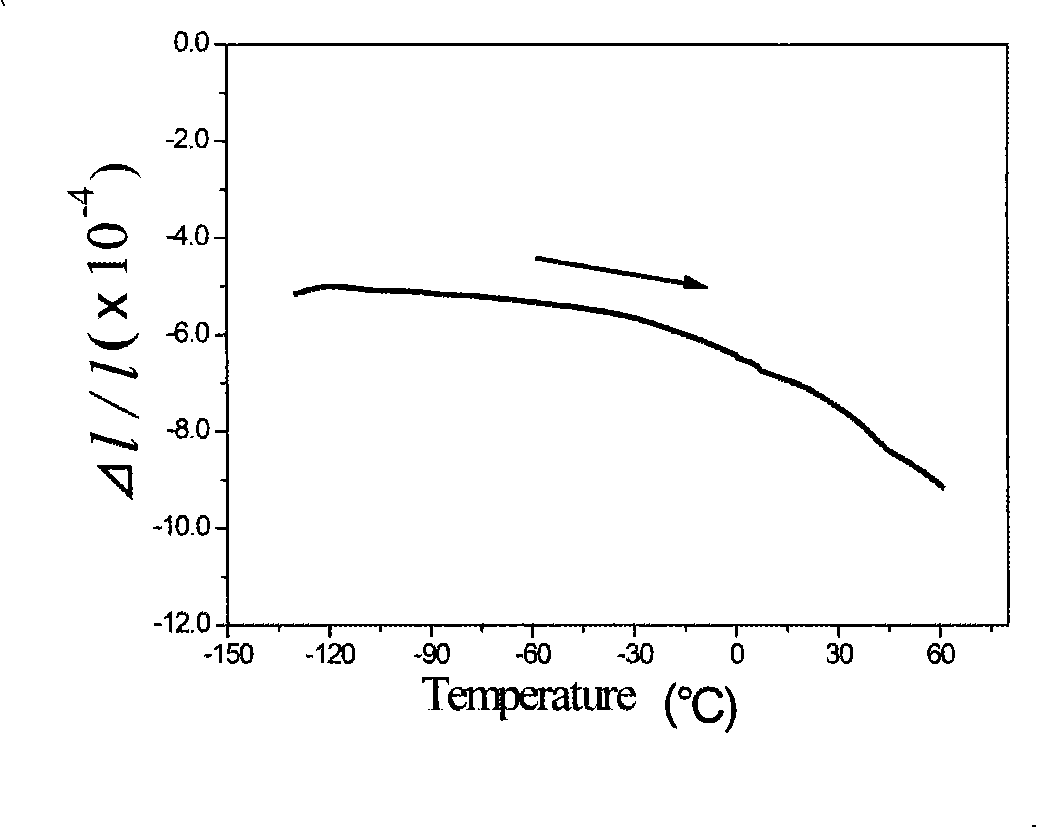

Nickel titanium niobium negative thermal expansion alloy and method of producing the same

InactiveCN101270424AHas negative thermal expansionSignificant negative thermal expansionRoll force/gap control deviceTemperature control deviceIngotTitanium

The invention discloses a negative thermal expansion alloy of Nickel-Titanium-Niobium and a preparation method thereof, relates to an alloy in particular to a negative thermal expansion alloy of Nickel-Titanium-Niobium and a preparation method thereof. The invention provides a negative thermal expansion alloy of Nickel-Titanium-Niobium which has negative thermal expansion characteristics in a wider temperature range and a preparation method. The component and the content in atom percentage is 40 to 49 percent of Nickel, 42 to 50 percent of Titanium and 1 to 18 percent of Niobium. The raw material of Nickel, Titanium and Niobium are added in furnace, the furnace is vacuumed and filled with Argon, and the Nickel-Titanium-Niobium alloy ingot is obtained after melting in 2500 to 2900 DEG C; the Nickel-Titanium-Niobium alloy ingot is hot-rolled to bulk alloy in 800 to 950 DEG C; the bulk alloy obtained is packaged in a quartz tube for heat treatment in the temperature of 800 to 950 DEG C and cooled in air. The bulk alloy after cooling is cool-rolled in 3 to 15 percent of the rolling reduction along the same direction and consequently the negative thermal expansion alloy of Nickel-Titanium-Niobium is obtained.

Owner:XIAMEN UNIV

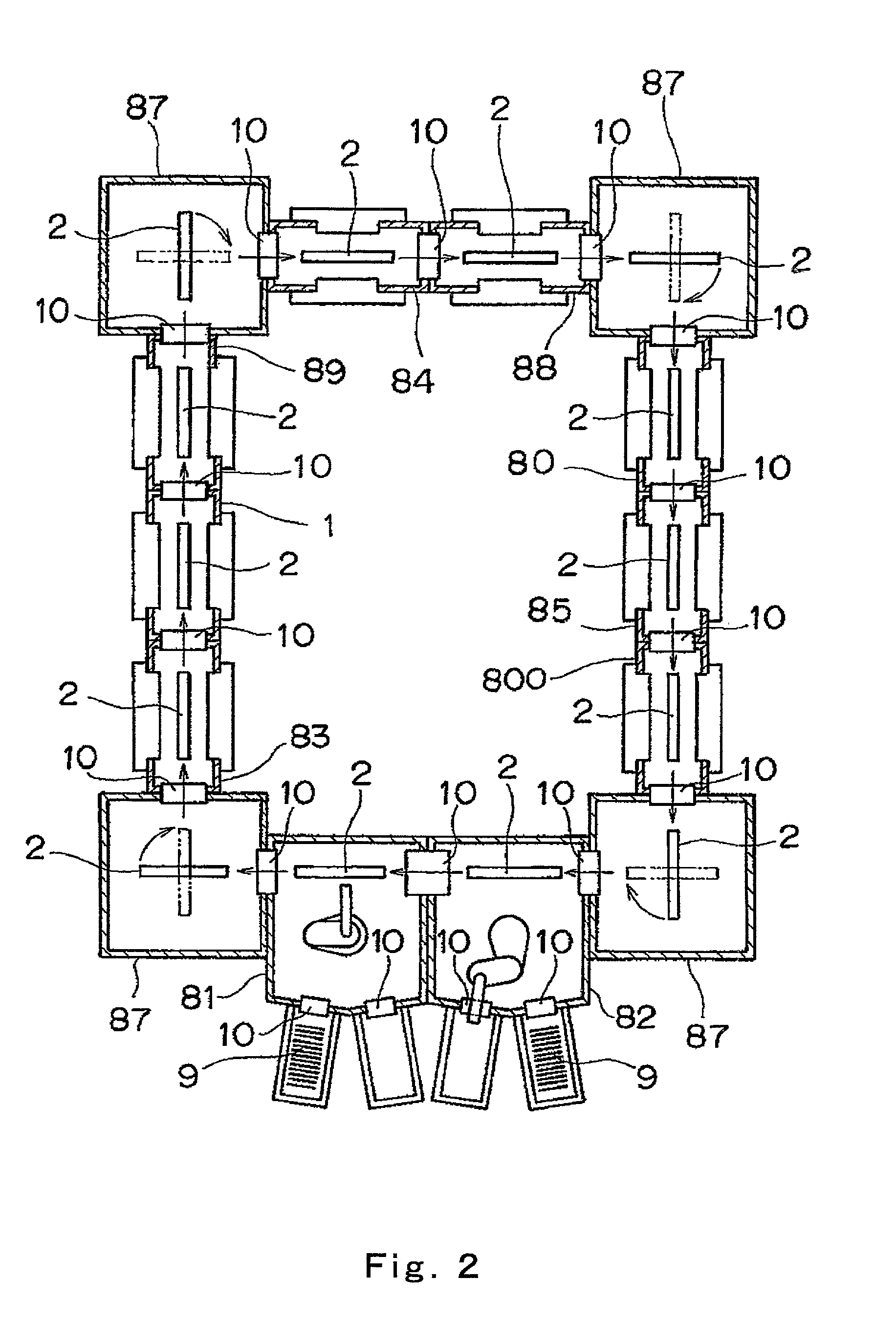

Magnetic recording disk, magnetic recording disk manufacturing method and magnetic recording disk manufacturing system

InactiveUS20020127436A1Base layers for recording layersVacuum evaporation coatingMagnetic anisotropyEngineering

This invention presents a magnetic recording disk where an anisotropy-allowing layer to allow magnetic anisotropy to a magnetic recording layer is provided between a substrate and the magnetic recording layer. This invention also presents a magnetic-recording-disk manufacturing method comprising a step to prepare an anisotropy-allowing layer to allow magnetic anisotropy to a magnetic recording layer, prior to a step to prepare the magnetic recording layer. This invention also presents a magnetic-recording-disk manufacturing system comprising an anisotropy-allowing-layer preparation chamber, in which an anisotropy-allowing layer to allow magnetic anisotropy to a magnetic recording layer is prepared on a substrate, prior to preparation of the magnetic recording layer. In this invention, the anisotropy-allowing layer is made of; nitride of niobium, tantalum, niobium alloy or tantalum alloy, or nitride-including niobium, tantalum, niobium alloy or tantalum alloy.

Owner:CANON ANELVA CORP

High temperature oxidation-resistant material for low-density niobium alloy and method for preparing high temperature oxidation-resistant coating from high temperature oxidation-resistant material

InactiveCN102719713AStop erosionGood high temperature oxidation resistanceHeat inorganic powder coatingCoated surfaceOxidation resistant

The invention relates to a high temperature oxidation-resistant material for low-density niobium alloy and a method for preparing a high temperature oxidation-resistant coating from the high temperature oxidation-resistant material. The high temperature oxidation-resistant material is characterized by comprising the following components in weight percentage: 10-15wt% of Si, 2-3wt% of Ti, 1-2wt% of Mo, 0.8-1.2wt% of HfO2, 0.7- 0.9wt% of W and the balance of Al. The high temperature oxidation-resistant coating prepared from the high temperature oxidation-resistant material effectively solves the problem of severe oxidation of low-density niobium alloy in an atmospheric environment above 800-degree C, especially about 1100-degree C, keeps high-temperature mechanical properties of the low-density niobium alloy to the maximum extent, expands the application range of low-density niobium alloy and prolongs the service life of low-density niobium alloy; moreover, the high temperature oxidation-resistant coating prepared from the high temperature oxidation-resistant material has good high temperature oxidation resistance, a uniform coating surface and a dense microstructure.

Owner:NINGXIA ORIENT TANTALUM IND

Manufacture method of nuclear grade zirconium-niobium alloy cast ingot

The invention relates to the field of a manufacture method of a nuclear grade zirconium-niobium alloy cast ingot, adopting the following technical scheme: firstly, forming a pure niobium bar and sponge zirconium into zirconium-niobium master alloy scraps by the steps of pressing an electrode block, firstly smelting, secondly smelting and thirdly smelting, and the like; using the zirconium-niobium master alloy scraps and the sponge zirconium to form the zirconium-niobium alloy cast ingot by the steps of materials mixing, materials distributing, electrodes manufacturing and vacuum self-consumable electric arc smelting; and detecting that the zirconium-niobium alloy cast ingot has no defects such as components segregation and niobium impurity, and the like, to complete the manufacture of the nuclear grade zirconium-niobium alloy cast ingot. The nuclear grade zirconium-niobium alloy cast ingot has even components, has no metallurgical defects such as niobium impurity, and the like, has high raw materials yield, saves the production cost to a certain degree, and voids the waste.

Owner:国核宝钛锆业股份公司 +1

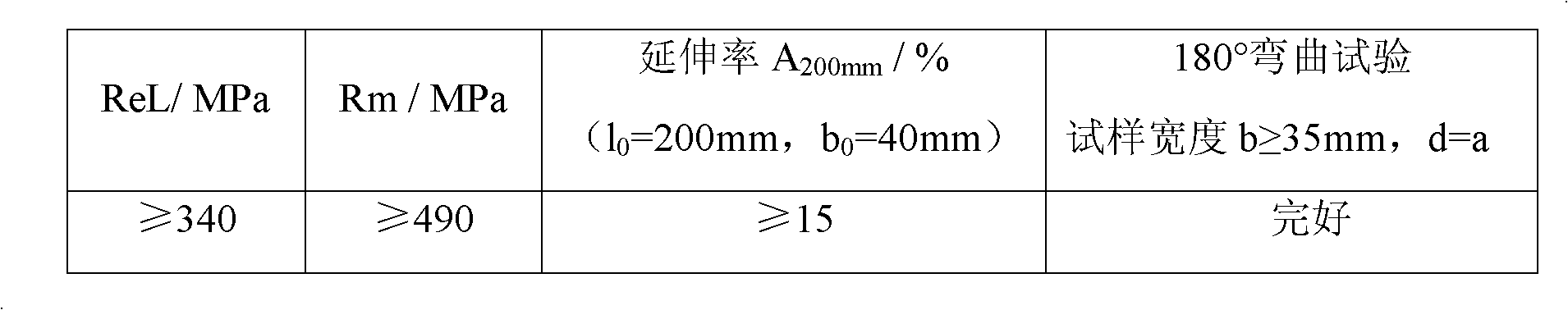

Hot rolled steel plate of 490 MPa level and production method thereof

InactiveCN101935801AGood cold bending performanceGood welding performanceSheet steelRoom temperature

The invention belongs to the technical field of metallurgy, and in particular relates to a micro-niobium alloy hot rolled steel plate of a 490 MPa level and a production method thereof, aiming to solving the first technical problem of providing the hot rolled steel plate of the 490 MPa level with excellent comprehensive performance. The hot rolled steel plate of the 490 MPa level is prepared from the following chemical components in percentage by weight: 0.04-0.11 percent of C, 0.13-0.27 percent of Si, 0.9-1.30 percent of Mn, 0.001-0.007 percent of N, 0-0.027 percent of P, 0-0.017 percent of S, 0.01-0.09 percent of Al, 0.013-0.027 percent of Nb, 0.004-0.012 percent of Ti and the balance of Fe. The hot rolled steel plate of the 490 MPa level, which is provided by the invention, reaches the yield strength not less than 380 MPa, tensile strength not less than 490 MPa, elongation not less than 17 percent and excellent cold bending performance, has favorable room-temperature mechanical performance and process performance and fully accords with the requirements on technical indexes.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com