Patents

Literature

862results about How to "Good high temperature oxidation resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Austenitic stainless steel, steel tube thereof and manufacturing method thereof

ActiveCN101633999AImprove high temperature creep resistanceExcellent resistance to high temperature steam corrosionTemperature control deviceManufacturing convertersSS - Stainless steelIngot

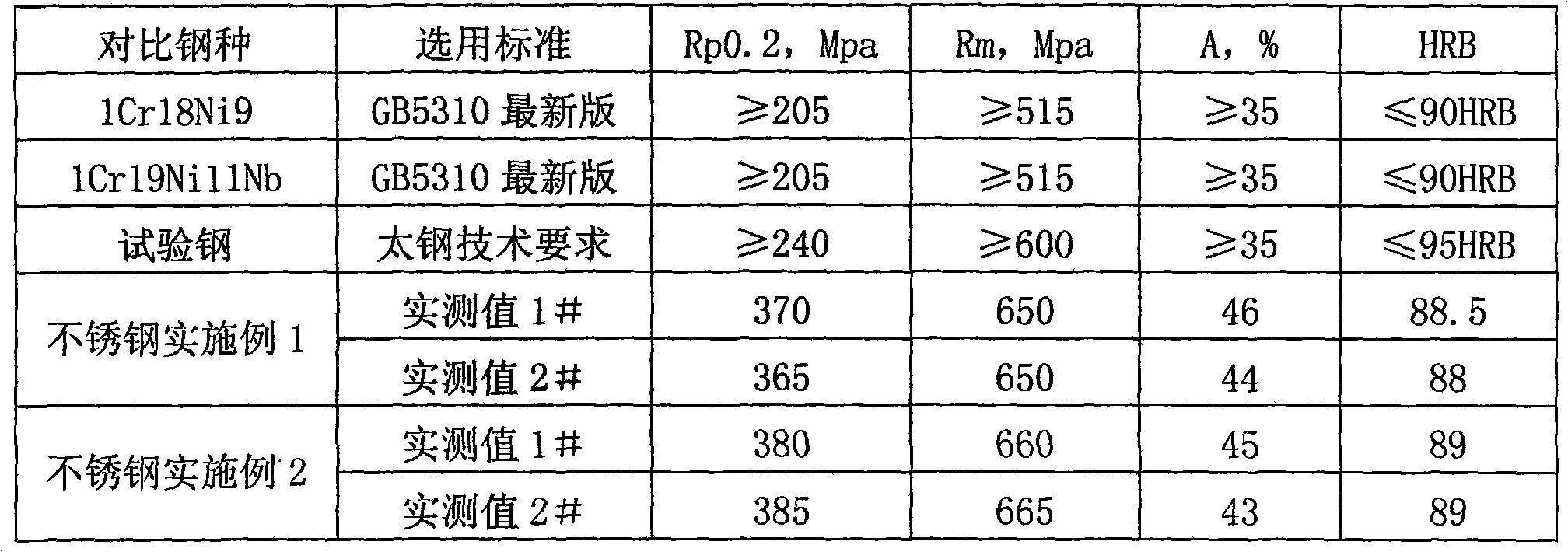

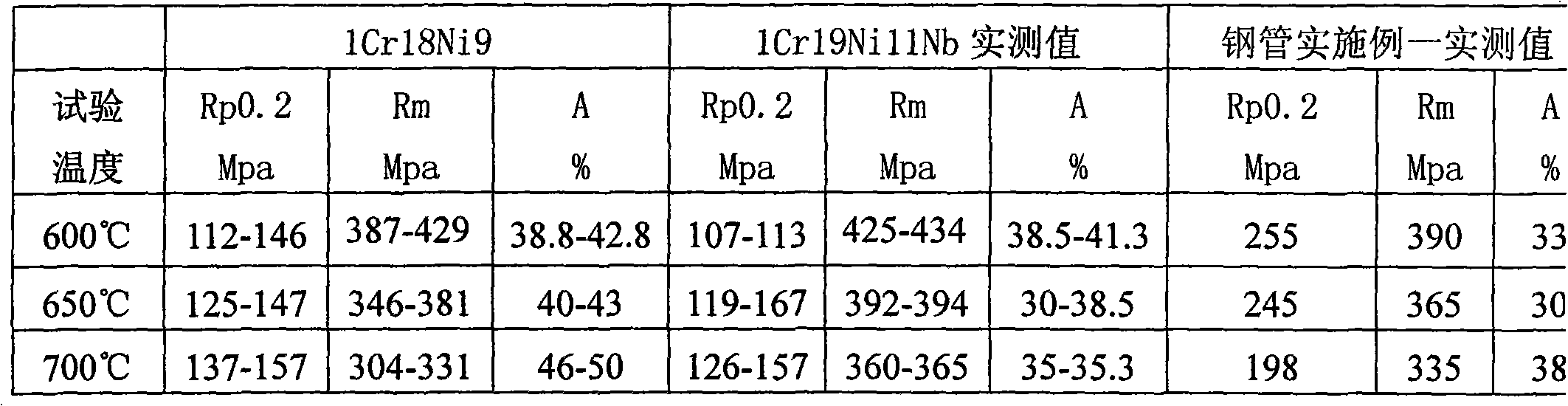

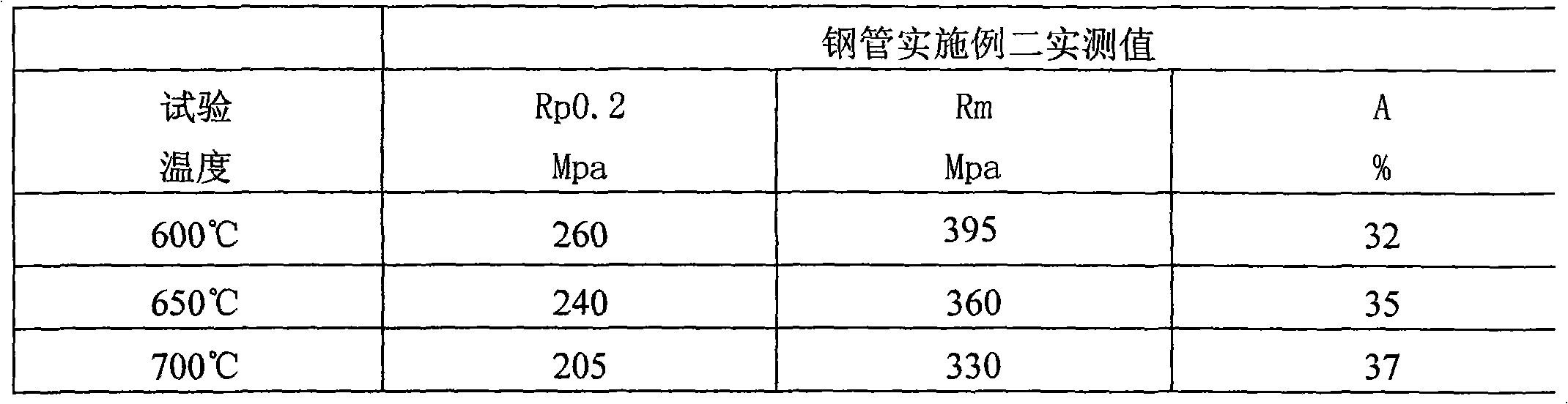

The invention relates to an austenitic stainless steel, a steel tube thereof and a manufacturing method thereof, wherein the austenitic stainless steel and the stainless steel tube comprise the components by mass percent: 0.060-0.14% of C, more than 0 and less than or equal to 0.50% of Si, more than 0 and less than or equal to 1.00% of Mn, less than 0.040% of P, less than 0.015% of S, 17.00-20.00% of Cr, 8.00-11.00% of Ni, 2.50-4.00% of Cu, 0.30-0.60% of Nb, 0.15-0.50% of Mo, 0.15-0.50% of Co, 0.05-0.14% of N, 0.001-0.01% of B, the rest of Fe and unavoidable impurity. The manufacturing method of the steel tube comprises: smelting and pouring to form steel ingots or continuously cast bloom, processing bar material, preparing tubular billet and further processing the steel tube; the method comprises the steps: the heating temperature of processing the bar material is 1250-1270 DEG C, heating temperature of preparing the tubular billet is 1100-1220 DEG C, and the finished product solid solution temperature is 1120-1190 DEG C. The austenitic stainless steel tube has high temperature creep strength and corrosion resisting performance at the high temperature.

Owner:SHANXI TAIGANG ENG TECH +1

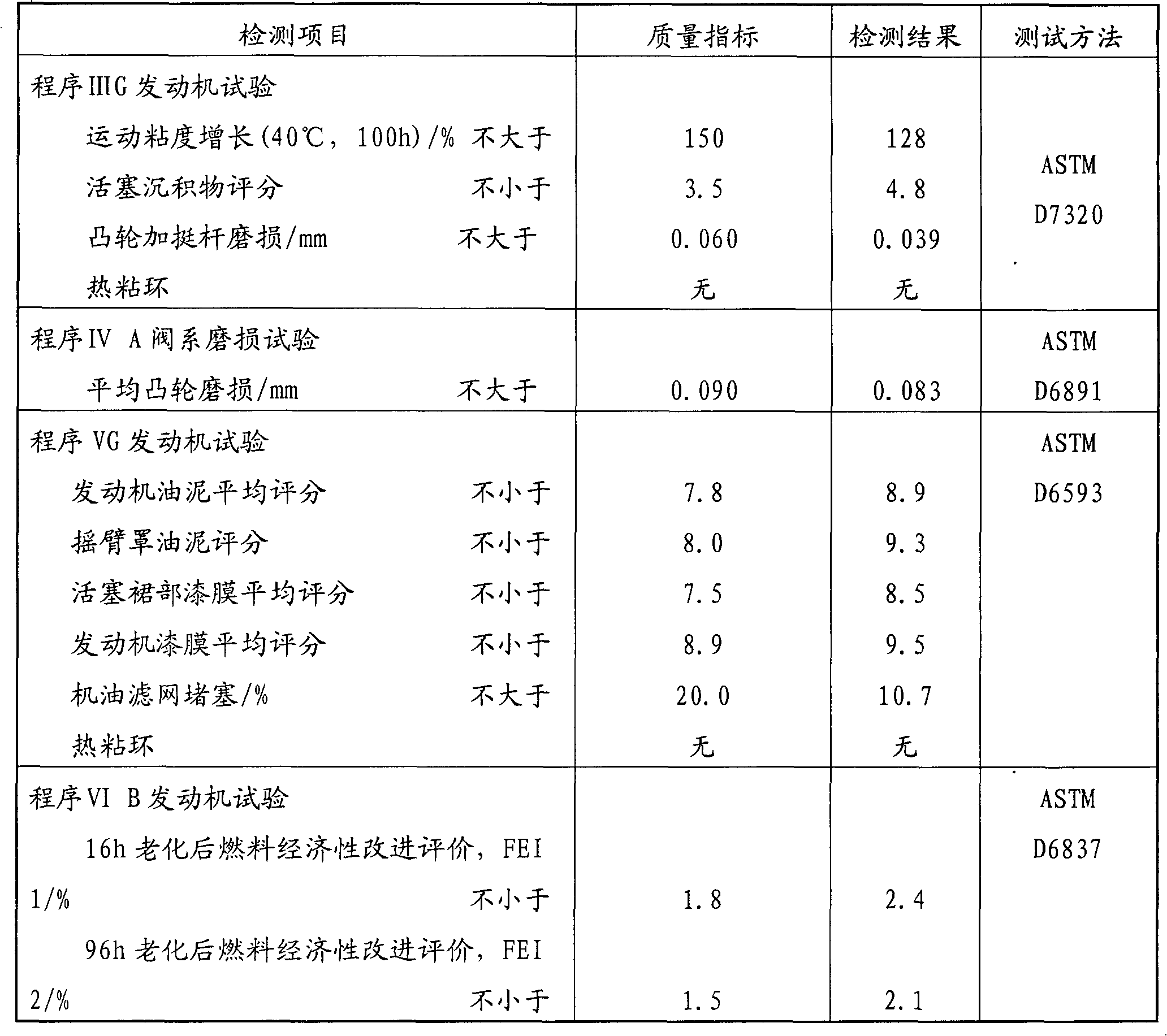

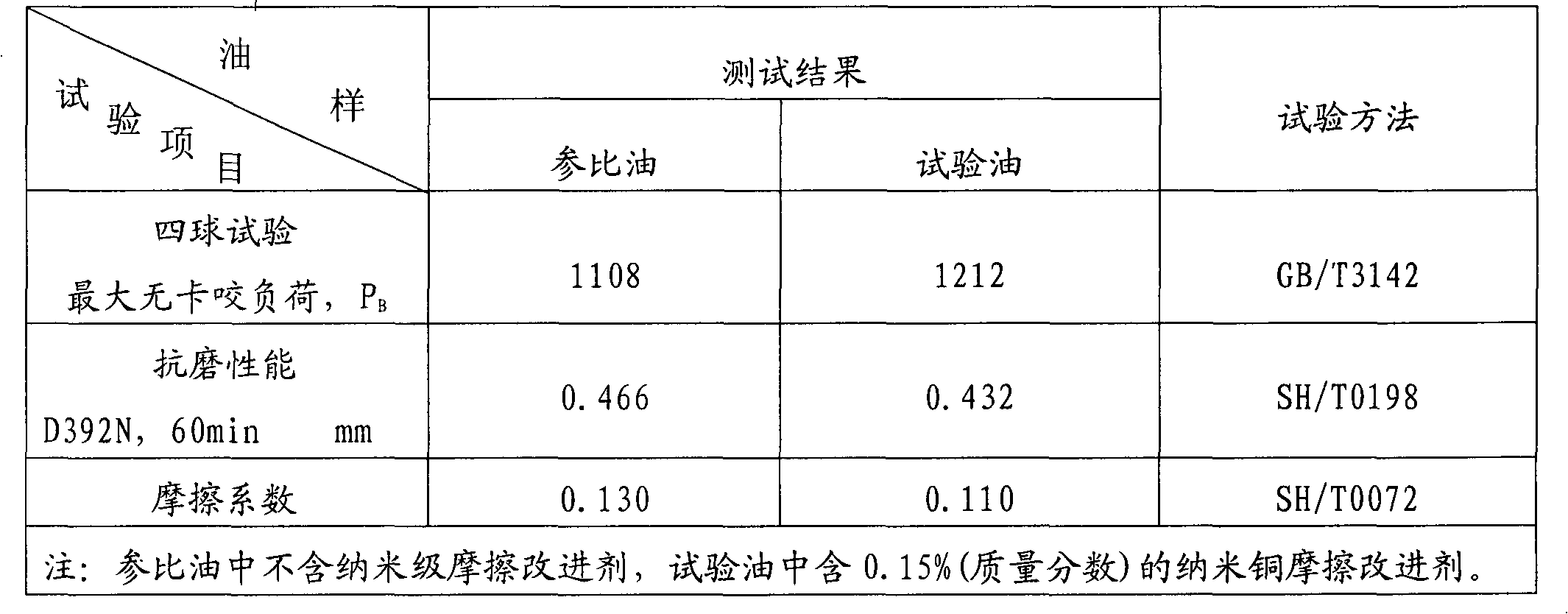

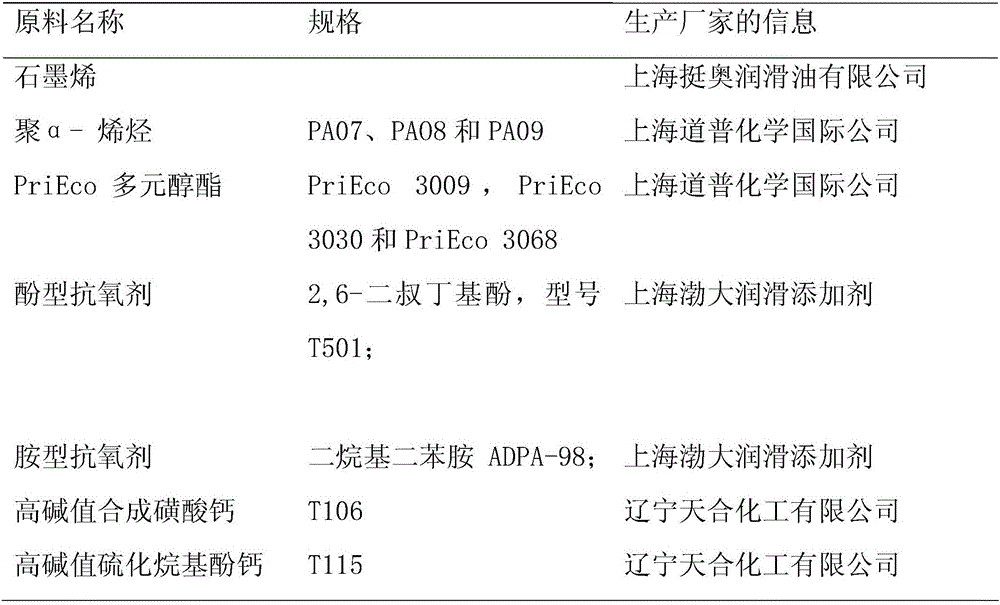

Energy-efficient long-life gasoline engine oil

InactiveCN101982534AReduce sulfur and phosphorus contentImprove carrying capacityLubricant compositionEcological environmentOil sludge

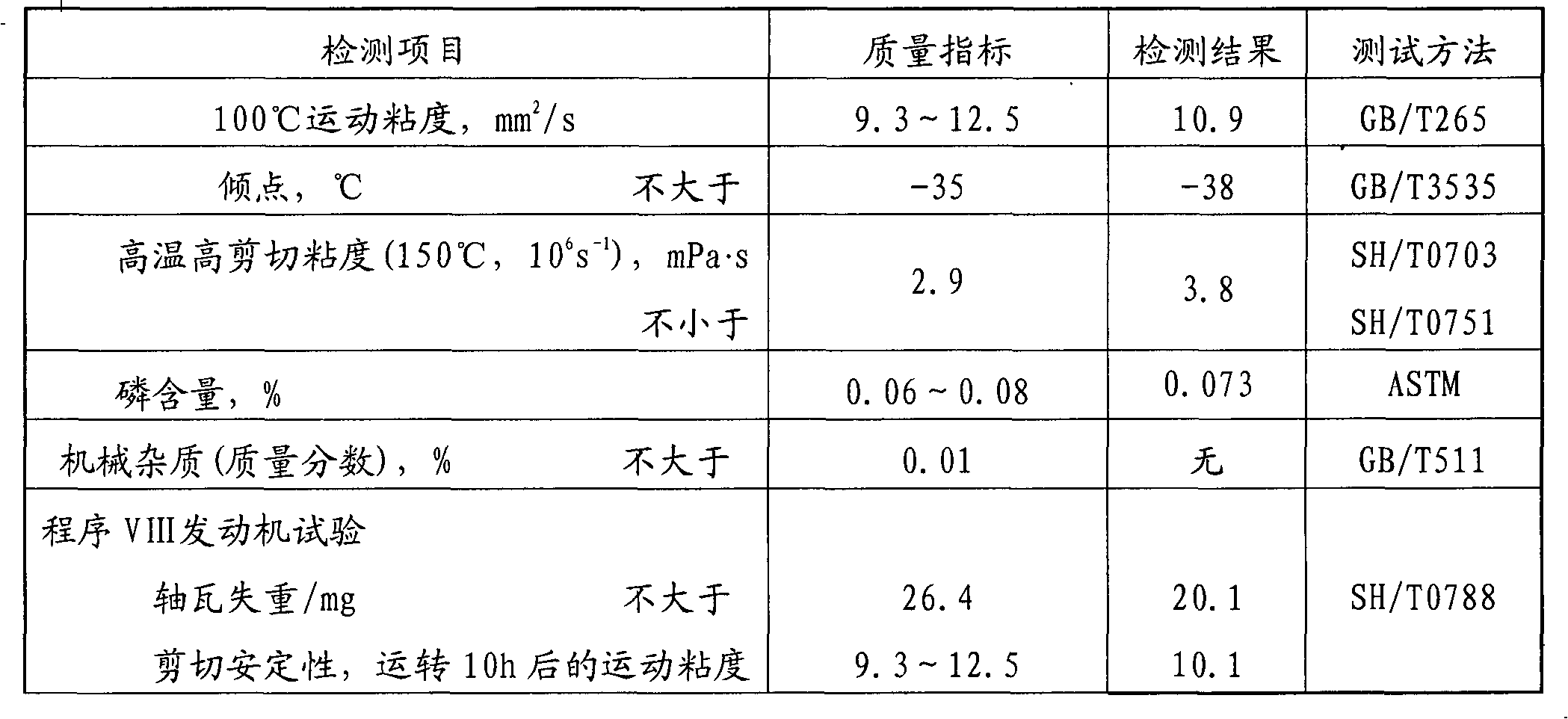

The invention discloses energy-efficient long-life gasoline engine oil prepared from the following components: synthetic base oil, a composite antioxygen, a metal cleaning agent, an ashless dispersant, a nano-level friction improver, a viscosity improver and a pour point reducer. The gasoline engine oil provided by the invention has the following advantages: requirements of API SM, ILSAC GF-4 and SAEJ300 are met and the service life is long; the complete synthetic base oil features low pour point, high viscosity index, good economy of fuel, degradability and reduced harm to the ecological environment; the phenol type antioxygen is combined with ZDDP, the anti-oxygen and antifriction properties are good and the catalyst poisoning in a tail gas processing unit is prevented; the acid neutralization capacity is good, the cleaning dispersibility is good and the oil sludge and carbon deposit are prevented from being generated; and the nano-level friction improver is added, the frictional factor is low, and the oil film features high carrying capacity and can automatically repair abraded surface and lengthen the service life of the engine.

Owner:GUANGDONG SANVO CHEM IND TECH

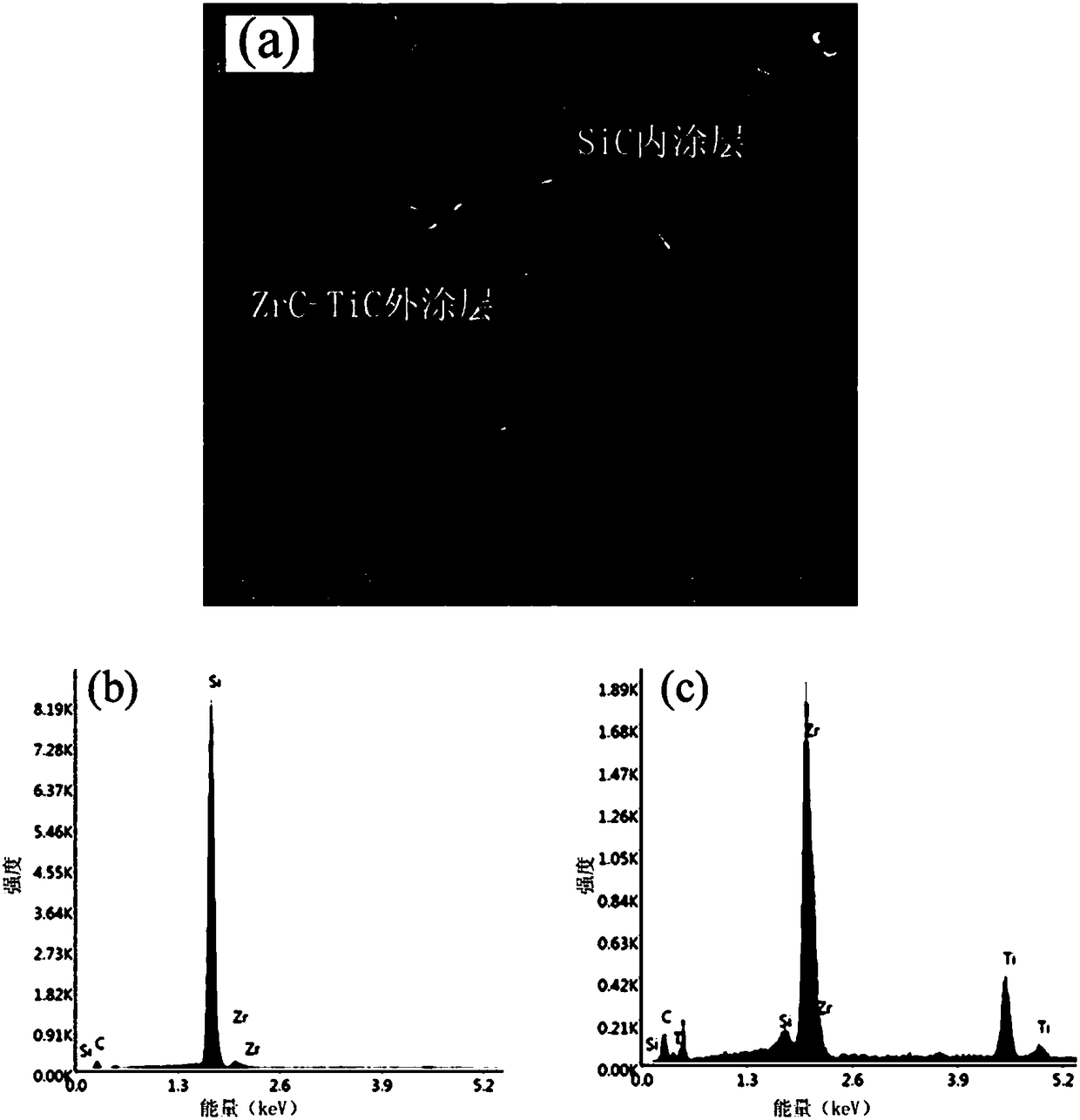

C/C composite material superhigh temperature ceramic coating, and preparation method thereof

InactiveCN108530110AExtended service lifeReduce Mismatch ProblemsUltra-high-temperature ceramicsCeramic coating

The invention discloses a C / C composite material superhigh temperature ceramic coating, and a preparation method thereof. The C / C composite material superhigh temperature ceramic coating is composed of an anti-oxidation SiC transition internal layer and a superhigh temperature ablation-resistant ceramic external layer; the superhigh temperature ablation-resistant ceramic external layer is composedof more than one ingredients selected from SiC, ZrC, HfC, TaC, TiC, ZrB2, HfB2, TaB2, and TiB2. The preparation method is suitable for industrialized production, is simple in equipment, is convenientin operation, is capable of controlling coating thickness, satisfying preparation requirements of large size C / C composite material superhigh temperature ceramic coating with complex shapes, and is asuperhigh temperature ceramic coating preparation method with excellent development potential.

Owner:CENT SOUTH UNIV

Overlaying manufacture repair technology for roll forging die

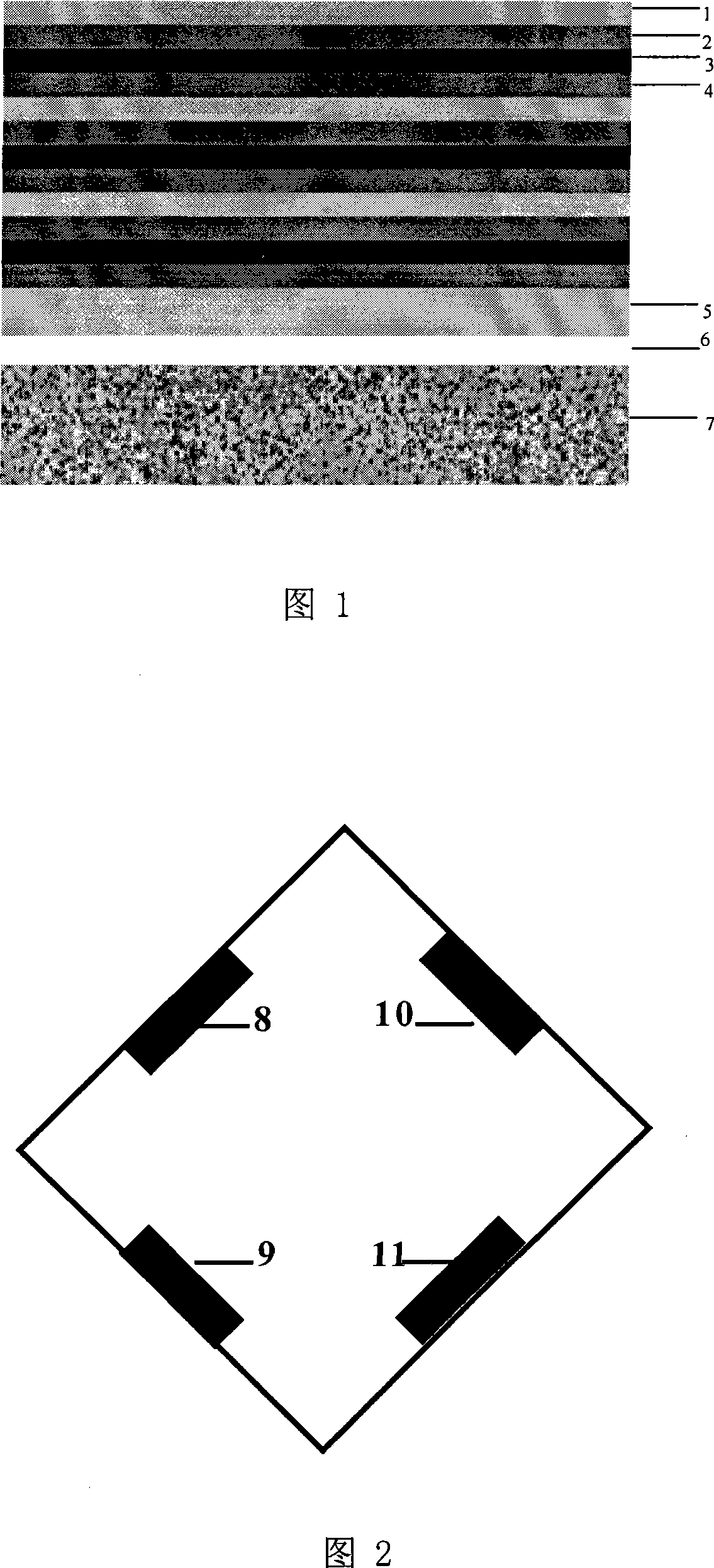

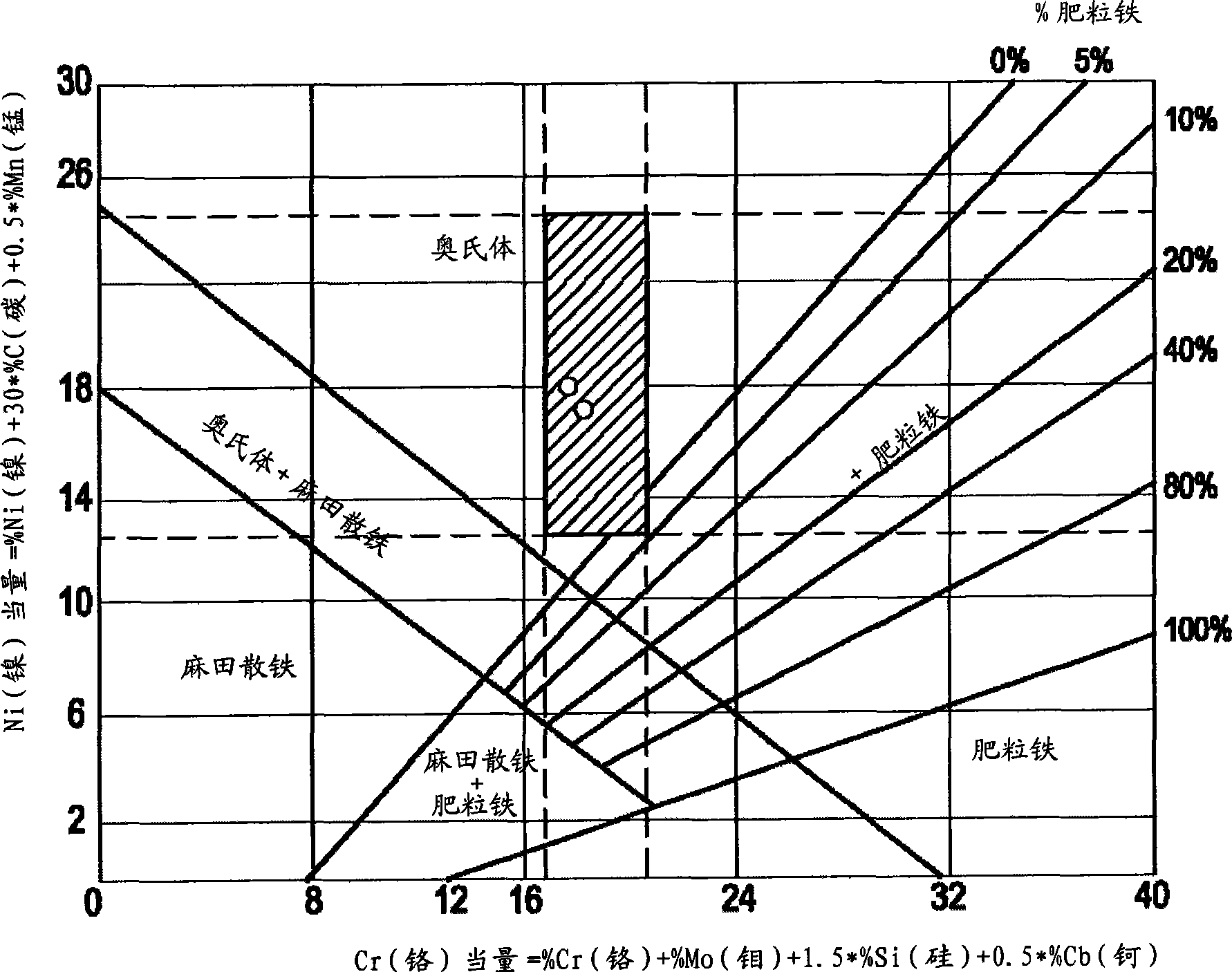

The invention discloses an overlaying manufacture repair technology for a roll forging die, belonging to the technical field of die overlaying technologies. According to the overlaying manufacture repair technology, the problems of poorer wear resistance at normal temperature and high temperature, cold-heat fatigue resistance, heat stability and high-temperature oxidation resistance due to direct use of low-heat-resistant steel 5CrMnMo and 5CrNiMo in the prior art are mainly solved. The overlaying manufacture repair technology is mainly characterized by comprising the following treatment steps of selecting the low-heat-resistant steel 5CrMnMo and 5CrNiMo die steel as substrates and enabling the heat treatment hardness HRC (Rockwell Hardness) to be 34-42, or integrally processing the surface of a die cavity to be repaired downwards or outwards for 10-15mm and preheating before welding the die; overlaying a priming coat with the thickness of 3-6mm by using an overlaying metal welding material with HRC of 34 to 42; overlaying a transition layer with the thickness of 3-6mm by using a die overlaying welding material with HRC of 42 to 48; overlaying a work layer with the thickness of 5-8mm by using an alloy overlaying material with HRC greater than 55; and carrying out tempering treatment after welding, furnace cooling to 90-190DEG C and discharging the material out of the furnace. The overlaying manufacture repair technology disclosed by the invention has the characteristics that the manufacturing period of the die is shortened, processing expenses are saved and the downtime is shortened and is mainly used for an overlaying manufacture and repair method of a hot forging rotary die.

Owner:HUBEI TRI RING AXLE

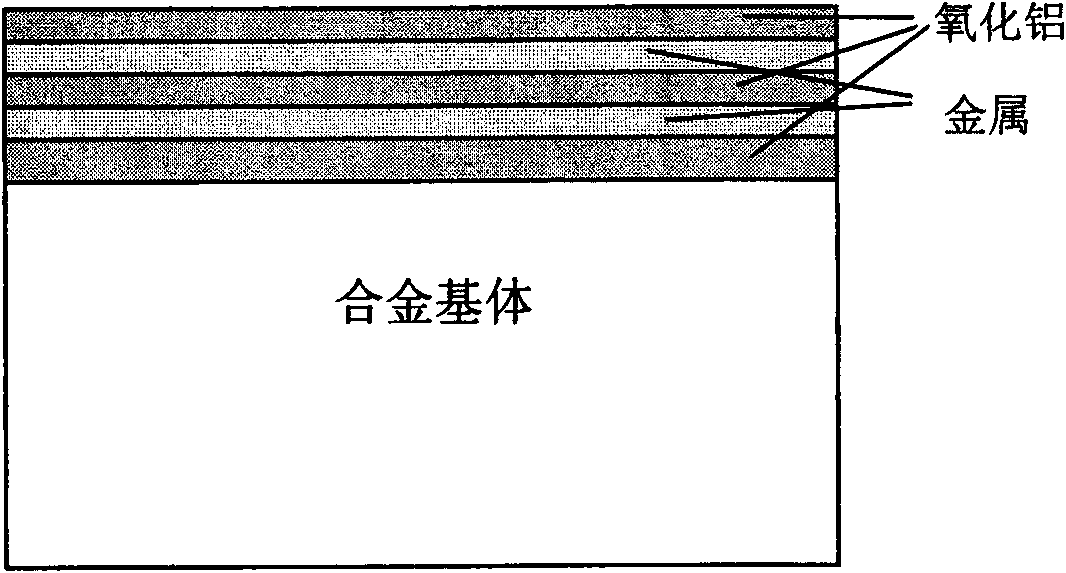

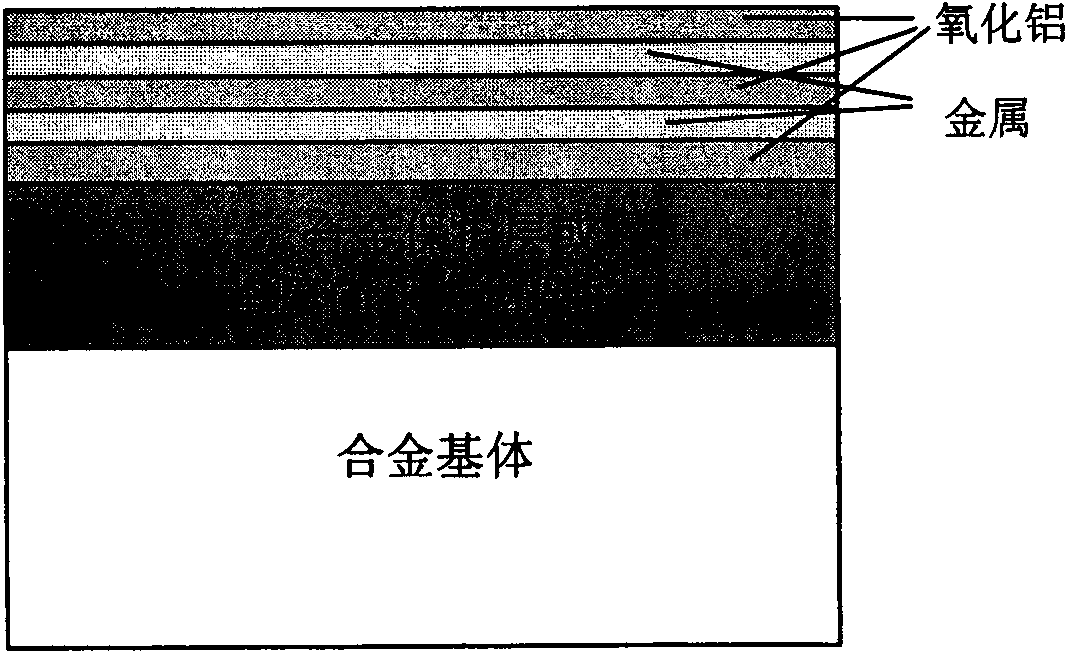

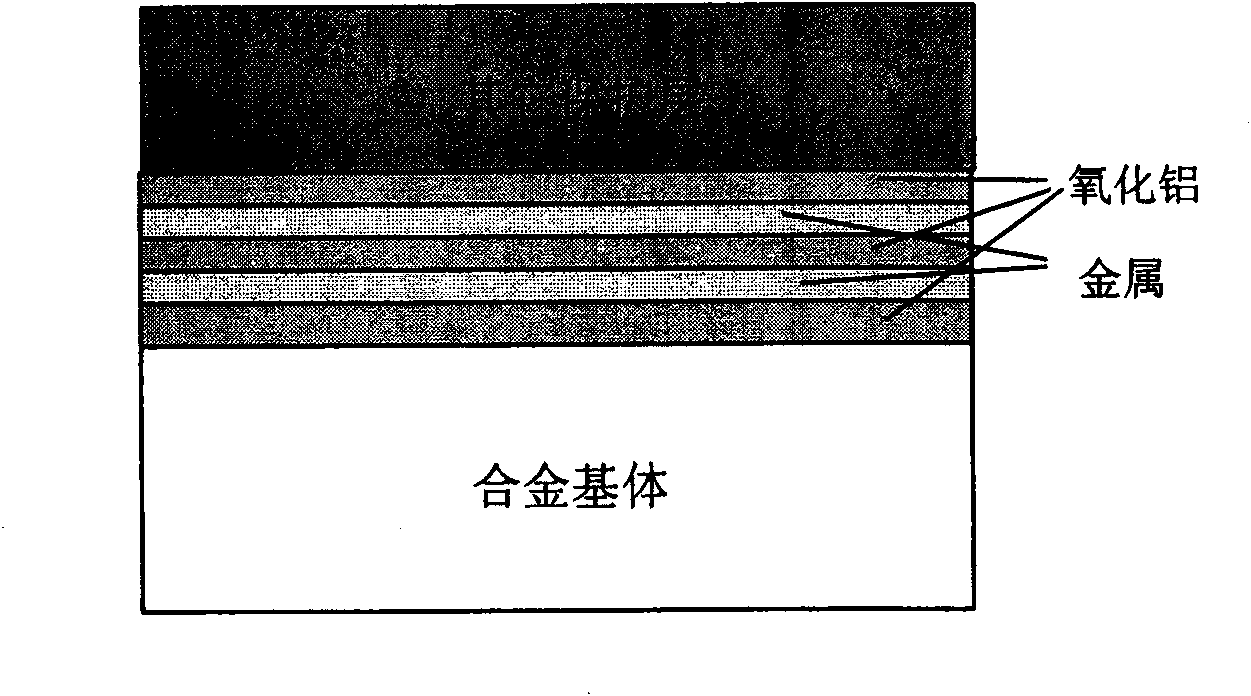

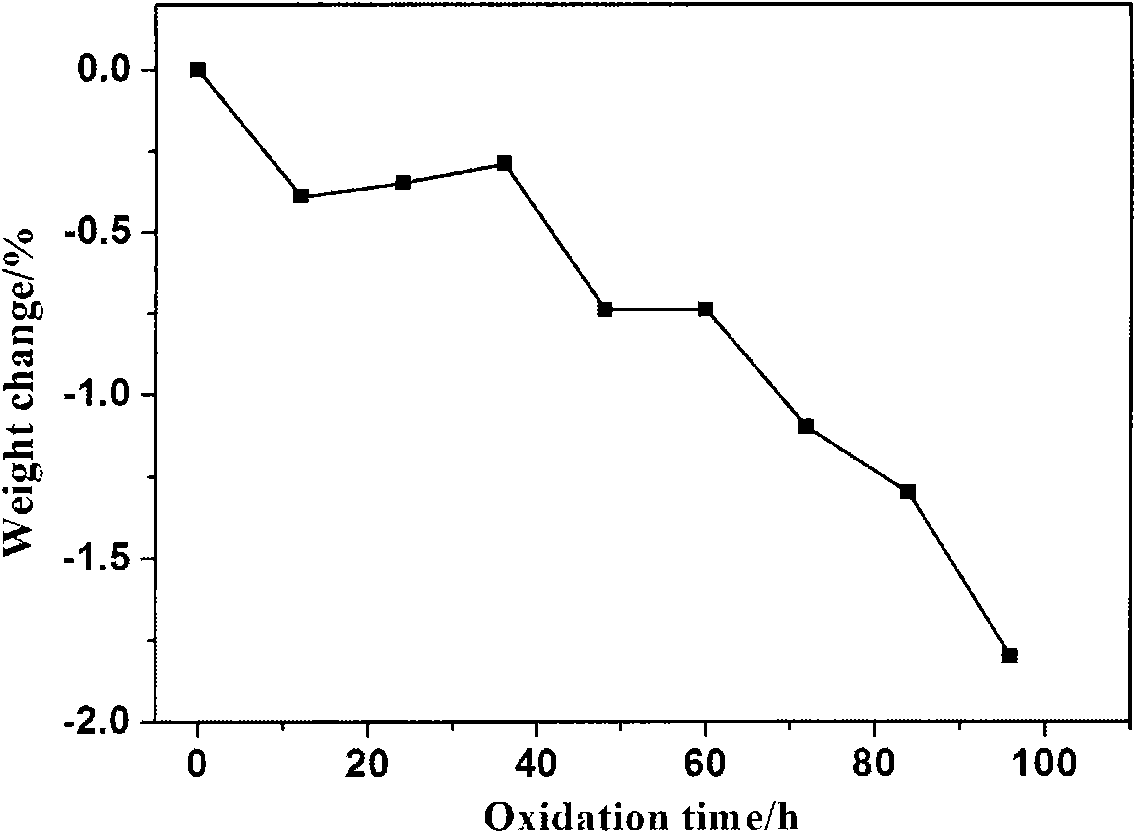

Multifunctional alumina/metal micro-laminated coating

The invention provides a multifunctional alumina / metal micro-laminated coating, which belongs to composite material made from metals and ceramic and coating technology thereof and is used for high-temperature protection, anti-tritium permeation, and anti-hydrogen damage of alloys with wide temperature scope. The micro-laminated coating adopts a high-pure alumina or alumina doped with a small amount of rear earth oxide, or alumina doped with a small amount of zirconia as an alumina coating, wherein the metals can be Pt, or Rh, or Ir, or Au, or alloys of all, or M-Cr-Al-rare earth alloy, or Fe, Co, Ni-based aluminum-containing alloy. The thickness of each laminated coating is 20-1000nm. The micro-laminated coating can be obtained by adopting a plurality of methods through the alternative sedimentation of the alumina coating and a metal coating. The micro-laminated coating has the following characteristics: (1) excellent binding force with the alloy substrate; (2) excellent high-temperature protection performance and anti-tritium penetration performance, and anti-hydrogen damage performance; (3) wide operating temperature range from room temperature to 2000 DEG C; (4) the evaporation inhibition of precious metal coatings at high temperature; and (5) and synergistic protective effect with other coatings.

Owner:UNIV OF SCI & TECH BEIJING

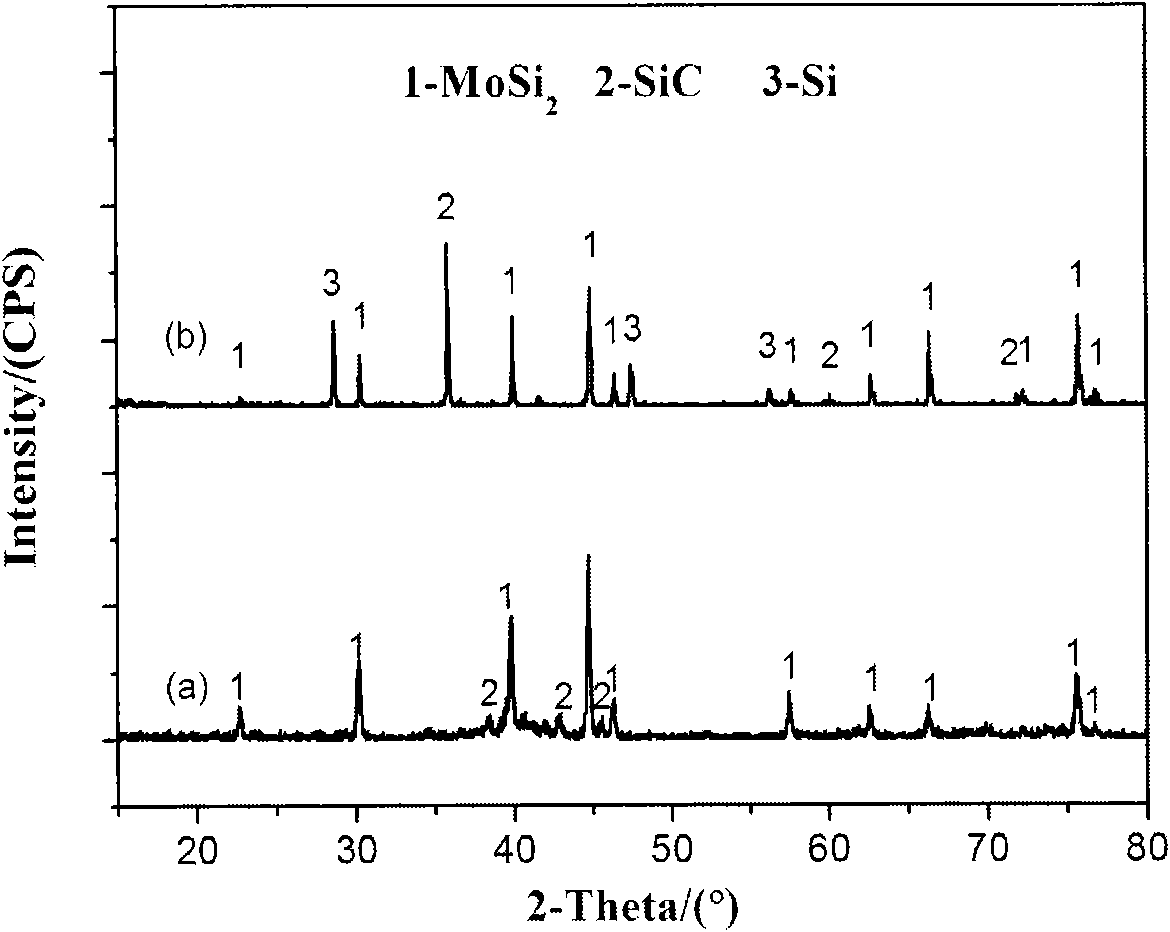

Anti-oxidation coating and preparation method thereof

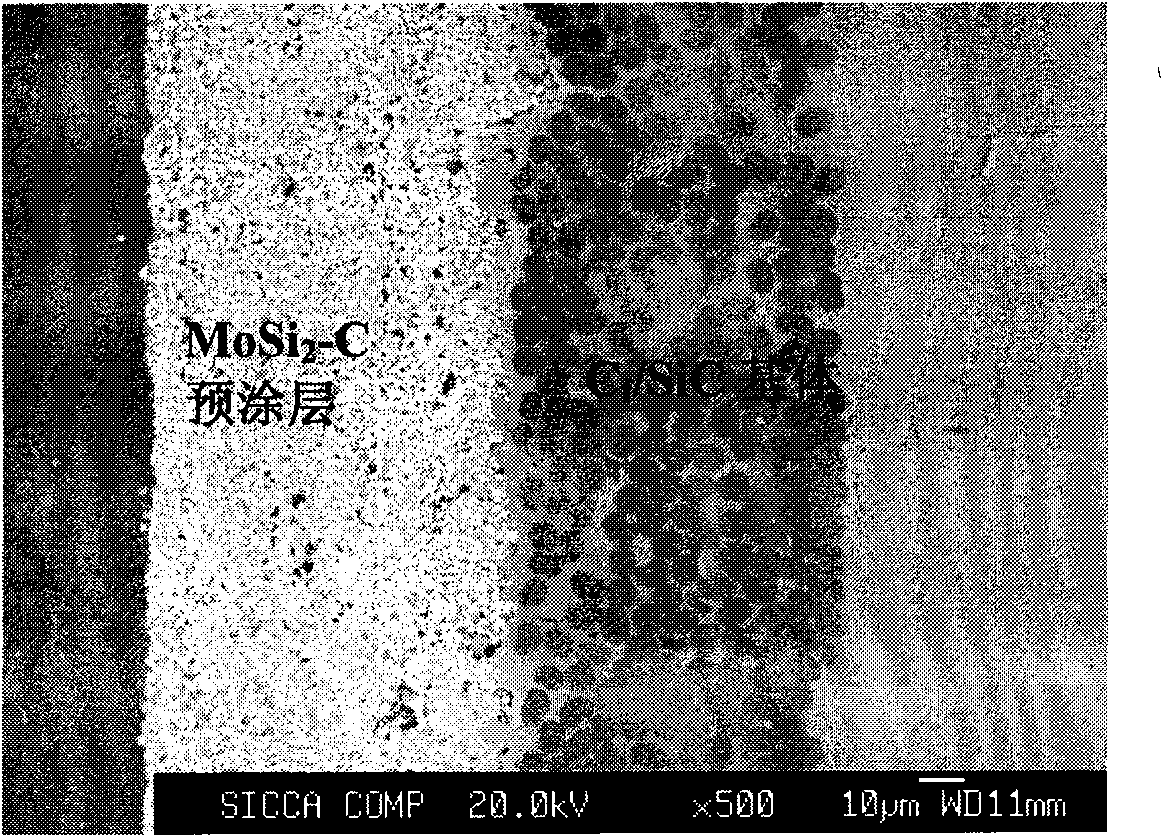

ActiveCN101863683AHigh bonding strengthImprove antioxidant capacityMaterials preparationCoating system

The invention relates to a preparation method of an anti-oxidation coating, which belongs to the field of coating material preparation. In the invention, a composite material is taken as a basal body, and the coating comprises the following main components: a SiC phase, a free Si phase and an M phase, wherein the M phase is an MoSi2, WSi2 and TaSi2 single ceramic phase or a multiple ceramic mixing phase; the thickness of the coating is about 20mu m to 600mu m; the coating adopts a process for preparing the coating by a slurry coating-liquid phase ihrigizing in-suit reaction method; the coating system has wide application range, and contains the whole Si ceramic coatings; and the invention effectively control the thickness and the components of the coating by means of the slurry solid content and slurry coating frequency, thereby meeting the in-service use requirements.

Owner:嘉兴睿创新材料有限公司

Oil and bushing low-temperature powder embedding aluminizing agent for petroleum

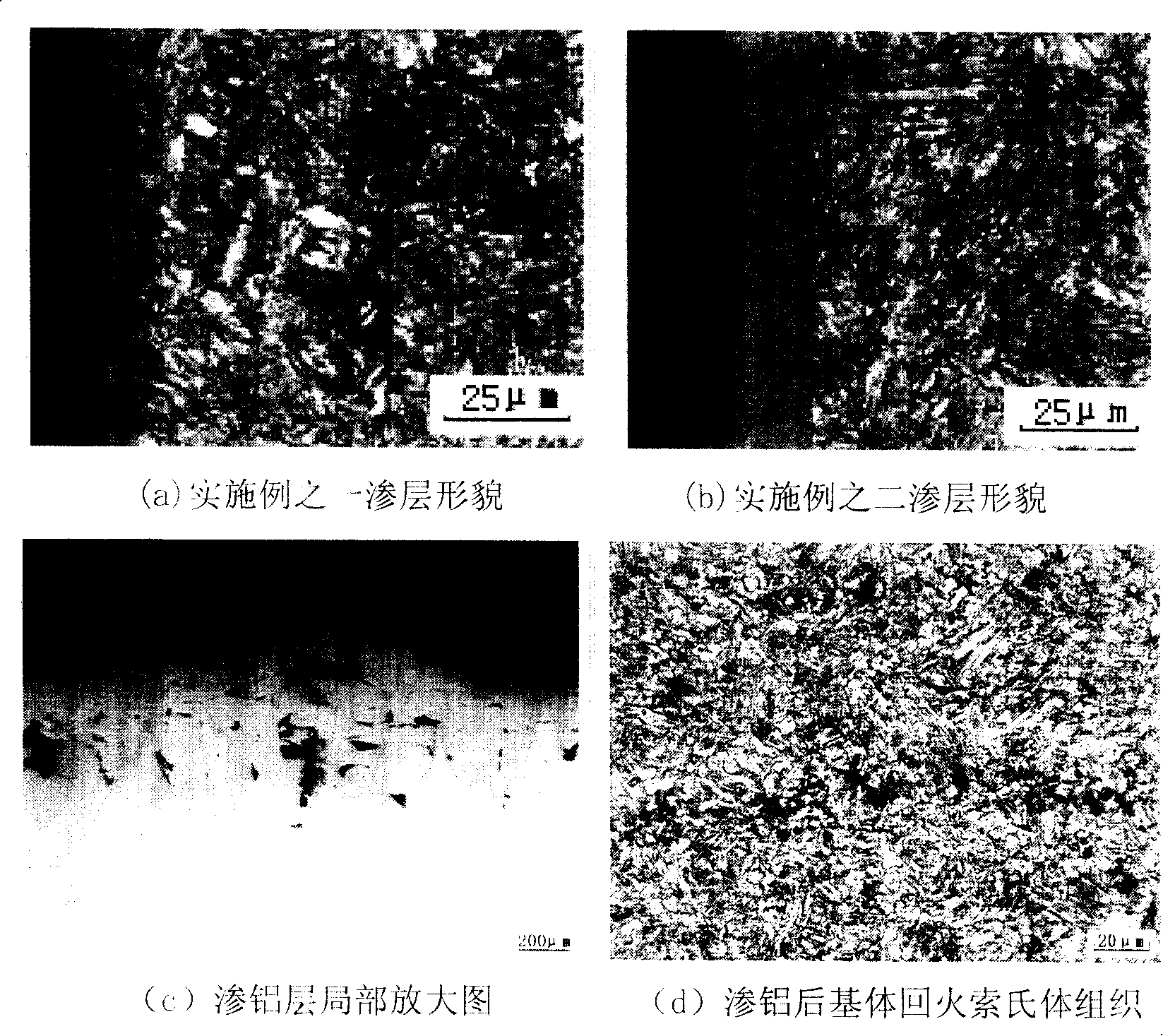

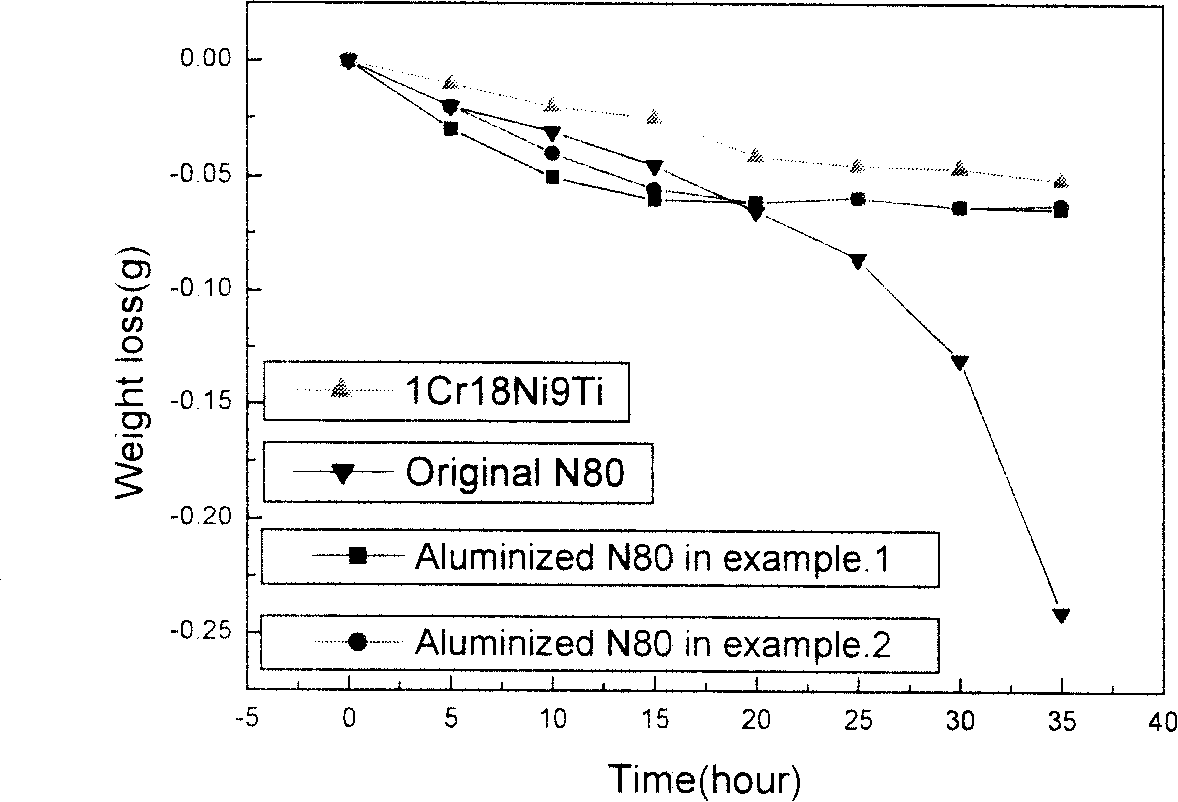

ActiveCN101165204AHigh bonding strengthDiffusion fastSolid state diffusion coatingAl powderSodium fluoride

The low temperature quick aluminizing agent specially for petroleum pipe and casing consists of metal source, activator, catalyst and stuffing. The metal source consists of 150-mesh Al powder in 10-20 wt% of the aluminizing agent, 120-mesh Zn powder in 10-25 wt%, 150-mesh Zn-Fe alloy powder in 10-20 wt% and / or 150-mesh Fe-Al alloy powder in 10-15 wt%. The activator consists of ammonium chloride, aluminum chloride, sodium fluoride and / or potassium bifluoride. The catalyst consists of 100-mesh Mo powder in 0-3 wt% and La and Os 0-3 wt%, with La and Os in the weight ratio of 1 to 1. The stuffing is 100-mesh alumina powder. The aluminizing agent is applied at 380-500 deg.c to obtain aluminized layer.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

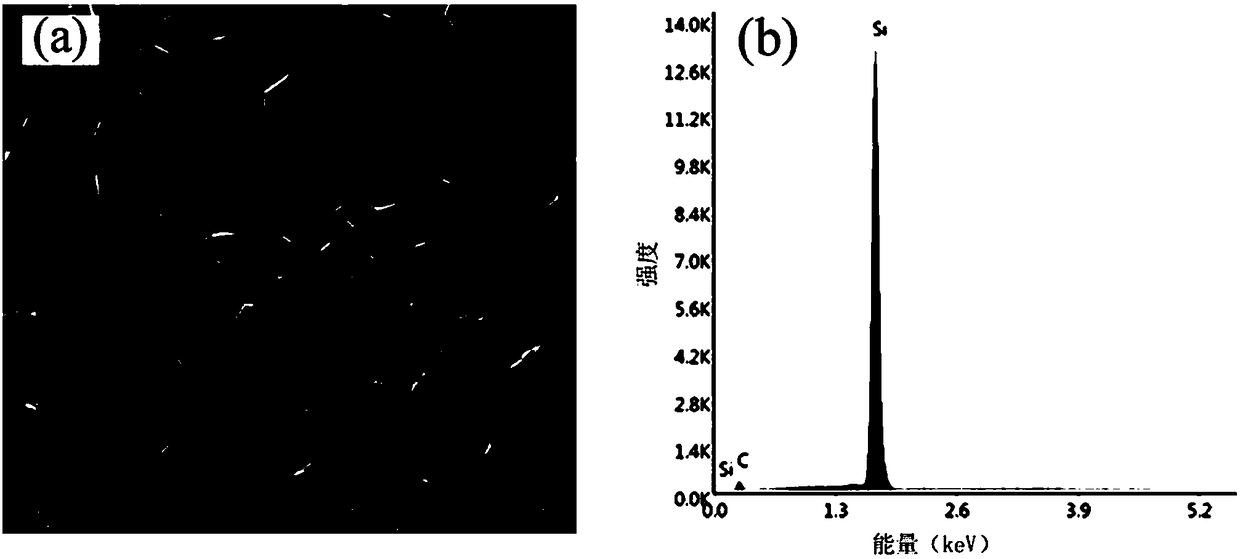

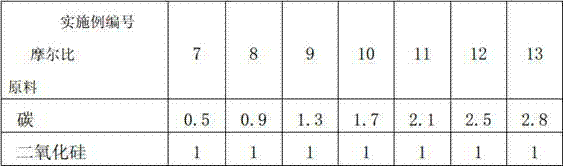

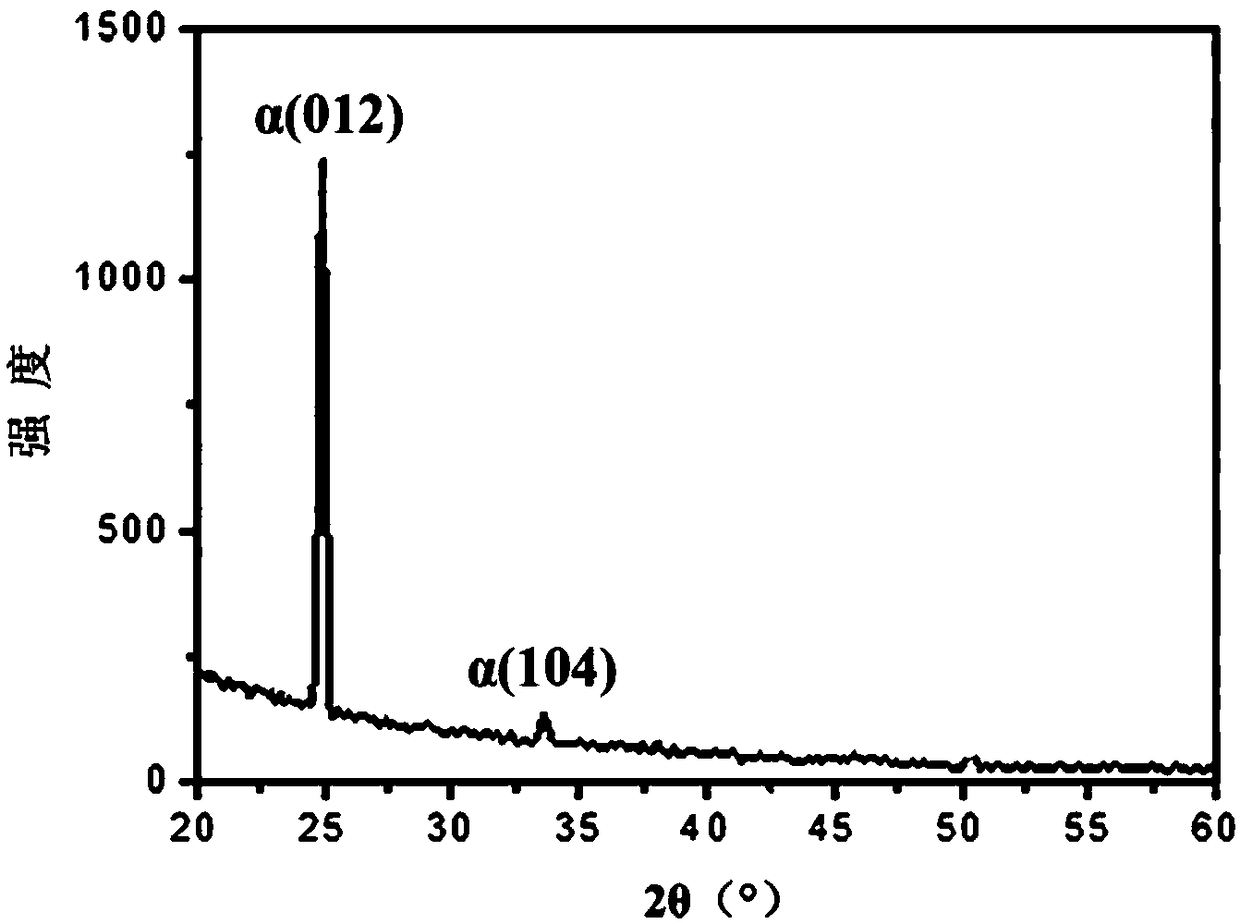

Preparation method of fibrous nano silicon carbide

InactiveCN103496703APlay the role of "template"High yieldMaterial nanotechnologySilicon carbideFiberRocket

The invention discloses a preparation method of fibrous nano silicon carbide. The preparation method is characterized by comprising the following steps: taking a carbon source and chrysotile asbestos of which the main chemical ingredient is silicon dioxide according to the molar ratio of carbon to silicon dioxide being (0.3-3):1; separately grinding the carbon source and chrysotile asbestos, evenly mixing to obtain a mixture; putting the mixture into a reaction device, vacuumizing, and continuously introducing argon in the reaction device; heating to 1350-2500 DEG C and carrying out thermal reaction for 0.2-6 hours; cooling to room temperature, stopping introduction of argon; collecting the reduction product, and grinding into fine powder which is the fibrous nano silicon carbide powder product. The preparation method has the advantages that raw materials are easily availably and equipment and technology are simple; moreover, the preparation method is friendly to environment and high in productivity. The prepared fibrous nano silicon carbide has good performances, can be widely applied to high-tech equipments such as nose cones of space shuttles, brakes of airplanes and racing bicycles, rocket nozzles, satellite antennas, guided missiles and the like, and also has broad use in nanometer microsystems.

Owner:SOUTHWEAT UNIV OF SCI & TECH

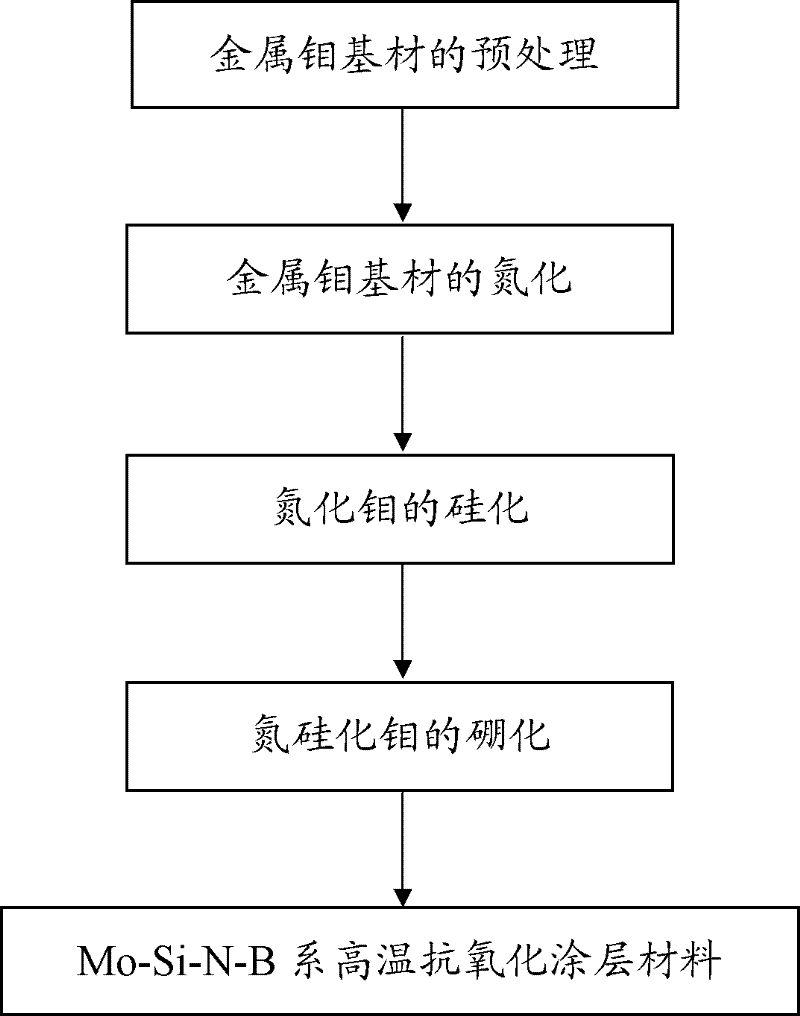

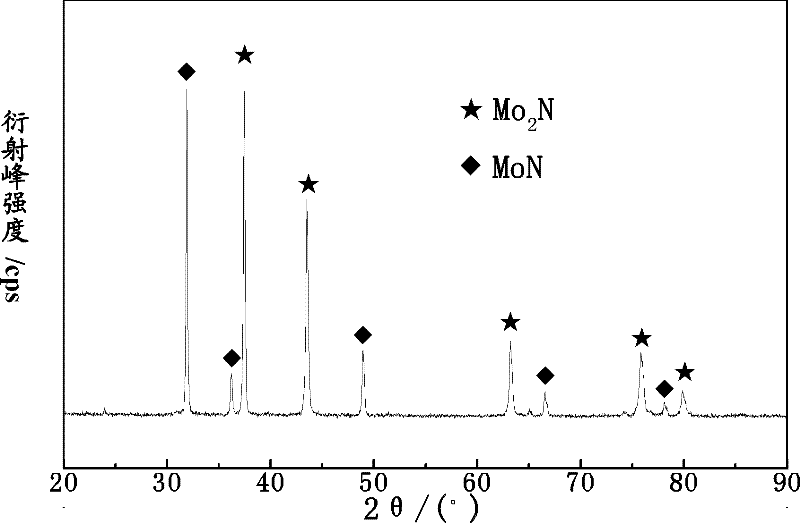

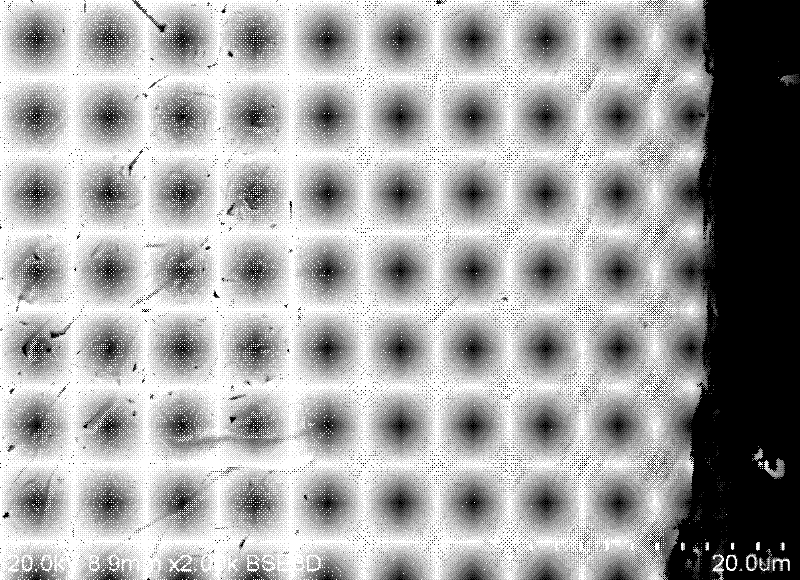

High temperature anti-oxidation coating molybdenum material and preparation method thereof

ActiveCN102534469AImprove compactnessGood heat matchingSolid state diffusion coatingSynthesis methodsSlurry

The invention discloses a high temperature anti-oxidation coating molybdenum material and a preparation method thereof. The surface of a product is provided with a Mo-N-Si-B anti-oxidation coating which is synthesized by adopting a three-step in situ synthesis method. Compared with the prior art, the product has good high temperature anti-oxidation performance and is good in material compactness, and hot matching performance between the coating and a base body is good. The preparation method does not need expensive devices such as plasma spraying, chemical vapor deposition or infiltration, avoids a complex process of a slurry method and is simple in preparation process, low in production cost and easy in controlling of coating structures and phase states.

Owner:XIAMEN HONGLU TUNGSTEN MOLYBDENUM IND CO LTD +1

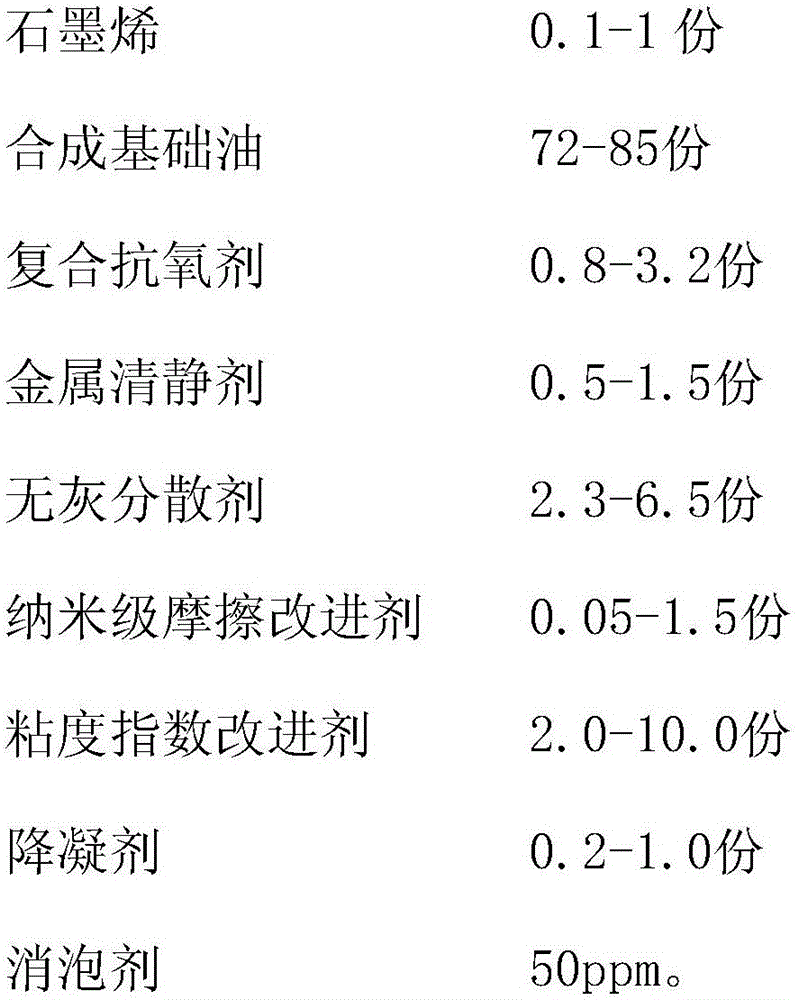

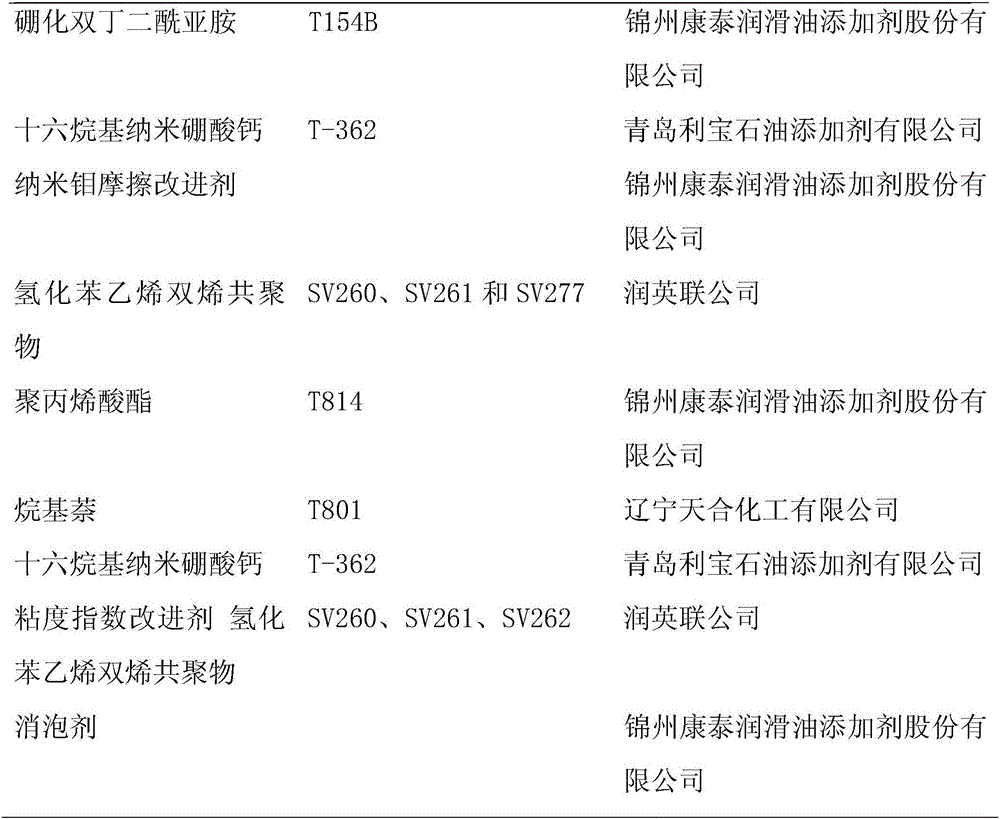

Graphene-containing lubricating oil and preparation method thereof

The invention relates to a graphene-containing lubricating oil and a preparation method thereof. The graphene-containing lubricating oil comprises the following components by weight: 0.1-1 part of graphene, 72-85 parts of synthetic base oil, 0.8-3.2 parts of a composite antioxidant, 0.5-1.5 parts of a metal detergent, 2.3-6.5 parts of an ashless dispersant, 0.05-1.5 parts of a nanoscale friction modifier, 2.0-10.0 parts of a viscosity index improver, 0.2-1.0 part of a pour point reducer, and 50ppm of a defoamer. The preparation method includes: putting the synthetic base oil into a blending kettle, performing stirring, then adding the pour point reducer, the viscosity index improver, the composite antioxidant, the metal detergent, the ashless dispersant, and the nanoscale friction modifier, stirring the substances evenly, adding graphene and the defoamer, maintaining the original temperature, stirring the materials evenly, and performing standing. The graphene-containing lubricating oil provided by the invention solves the problems of corrosion and selectivity in traditional lubricating oil additives, at the same time the process is improved, and the ultrasonic dispersion link of graphene is eliminated.

Owner:SHANGHAI INST OF TECH

Nonuniform cemented carbide for hot extruding hot die and method for preparing same

The invention discloses a material for a hot heading die and a preparation process thereof. The compositions by weight percentage of the material are: 12 to 20 percent of cobalt, 3 to 10 percent of nickel, 50 to 70 percent of tungsten carbide with 20 to 25mu m, 10 to 30 percent of tungsten carbide with 1.0 to 1.5mu m. The preparation method for the material comprises the following steps: a step of mixing, during which the raw materials are taken in proportion and mixed evenly to obtain a mixture; a step of wet-grinding of the mixture, which is carried out inside a ball mill by using alcohol or acetone as the medium with a rotating speed of 36r / min and a grinding time of between 20 and 30 hours under the condition that the mixture is in accordance with the ratio of balls and the materials of 3-5 to 1, and the liquid-to-solid ratio of the mixture is 450-520ml / kg; a step of drying and press forming, and sintering in a vacuum furnace, thus the product is obtained. The invention uses the uneven structure theory of the hard alloy material, under the condition of certain content of cobalt in alloy, the fracture intensity and toughness of the alloy can be improved by reasonably collocating the proportion of coarse tungsten carbide powder and fine tungsten carbide powder, and inevitably the hardness and wear resistance can be improved thereafter. The different proportion between cobalt and nickel can obtain alloys with different impacting toughness and wear resistance. Furthermore, nickel powder is favorable to improve high-temperature oxidation resistance of the alloy.

Owner:ZHUZHOU JINGGONG CEMENTED CARBIDE

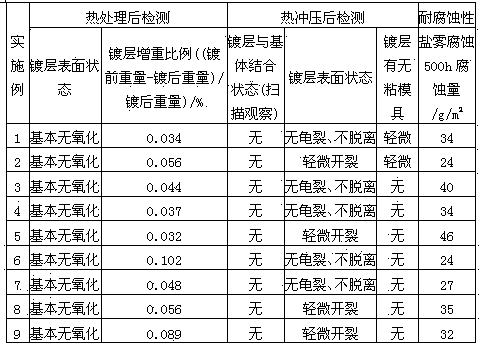

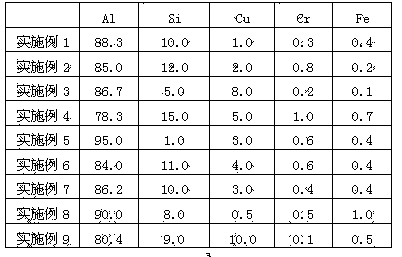

High-temperature oxidation resistant plating layer material and hot dipping method for hot stamping formed steel

ActiveCN104233149AImprove high temperature oxidation resistanceImprove corrosion resistanceHot-dipping/immersion processesHot stampingSheet steel

The invention discloses a high-temperature oxidation resistant plating layer material and a hot dipping method for hot stamping formed steel. A hot stamping formed steel plate enters a plating solution for hot dipping and then is subjected to cooling and heat treatment so that a hot dipping steel plate can be obtained, wherein the plating solution comprises the following components in percentage by mass: 1.0%-15.0% of Si, 0.5%-10.0% of Cu, 0.1%-1.0% of Cr, less than or equal to 1.0% of Fe and the balance of Al and inevitable impurities. According to the method, the Cu element and Al element which are contained in a plating layer form a high-melting point intermetallic compound in a cooling process after the hot dipping, and Cr is gathered on the surface of the plating layer to form a compact oxidation film, so that the high-temperature oxidation resistant property of the plating layer is greatly enhanced; the Cu element is enriched on the surface of the plating layer, so that the corrosion-resisting property of the plating layer is greatly enhanced. The high-temperature oxidation resistance and the high-temperature corrosion resistance of the plating layer are enhanced by utilizing the intermetallic compounds formed among Al, Si, Cr, Cu and Fe; and the obtained plating layer has the advantages of reasonability in structure, tight combination with a substrate and good high-temperature oxidation resistance and corrosion-resisting property.

Owner:HEBEI IRON AND STEEL

Special-purpose welding rod for built-up welding of hot work die restoration

ActiveCN105033507AImprove toughnessImprove crack resistanceWelding/cutting media/materialsSoldering mediaWear resistantOxidation resistant

The invention provides a special-purpose welding rod for built-up welding of hot work die restoration. The special-purpose welding rod comprises a coating and a welding core. Nanometer chromium-nitride powder is added into alloy powder and a fine nitride interstitial phase is formed in deposited metal, so that the deposited metal has excellent toughness and crack-resistant performances. Meanwhile, yttrium oxide is added into the alloy powder, so that the deposited metal can be purified, occluded foreign substances can be spheroidized, formation of the nitride strengthening phase can be promoted, and the anti-fatigue performance of the deposited metal is improved. When the welding rod is used for restoring the hot work die, the obtained deposited metal has the excellent high-temperature anti-oxidation performance, wear-resistant performance, cleanliness and anti-fatigue performance.

Owner:SHANDONG UNIV

High-strength and high-toughness molybdenum alloy and preparation method thereof

InactiveCN102534334AGood high temperature oxidation resistanceReasonable designRare-earth elementHigh energy

The invention discloses high-strength and high-toughness molybdenum alloy. Doped alloy elements of Ti, Zr, Si and B and rare earth elements of La are mixed by a solid-solid or solid-liquid mixing method, pre-alloy powder with uniform particles is prepared through mechanical ball milling or high-energy ball milling, the alloy powder after the ball milling is subjected to high-temperature sinteringafter being pressed and formed, and high-strength and high-toughness molybdenum alloy materials are obtained. The molybdenum alloy prepared by the method provided by the invention has high tensile strength, high elongation and high recrystallization temperature, and in addition, excellent high-temperature oxidation resistance performance is realized, so wide application prospects and popularization values are realized.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Special flux-cored wire for hot-working die repairing surfacing

ActiveCN105057926AGood workmanshipSuitable for automatic weldingArc welding apparatusWelding/cutting media/materialsSlagGas metal arc welding

The invention provides a special flux-cored wire for hot-working die repairing surfacing. The special flux-cored wire comprises the wire tube wall and powder covered by the wire tube wall, wherein the powder comprises a deoxidation alloying agent and a slag former; by adding nanometer chromium nitride powder into iron-base alloy powder, a thin nitride interstitial phase is formed in the deposited metal, so that the deposited metal has good tenacity and anti-cracking capacity; meanwhile, yttria is added into the alloy powder, so that the deposited metal is purified, the occluded foreign substances are nodulized, the nitride strengthening phase is formed, and the anti-fatigue performance of the deposited metal is improved; by adopting the gas metal arc welding technology combining flux-cored wire and argon-rich gas protection to repair the hot-working die, the obtained deposited metal has excellent high-temperature oxidation resistance, excellent abrasive resistance, excellent cleanliness and good anti-fatigue performance.

Owner:SHANDONG UNIV

PVD nano multiple-layer coating for cutting stainless steel and preparation method thereof

InactiveCN101200797AHas high temperature oxidation resistanceExcellent high temperature oxidation resistanceLayered productsVacuum evaporation coatingSurface cleaningOxidation resistant

The invention discloses a PVD nanometer multiple-layer coating used for cutting stainless steel and a preparation method thereof. The specific manufacturing process is as follows: firstly, implementing the surface cleaning treatment on carbide base; secondly, adopting a multiple targets magnetic sputtering method to alternatively deposit the nanometer multiple-layer coating which takes TiN (Tix, Al1-x)N / (Tiy, Al1-y)N / (Tix, Al1-x)N as a modulation period on the rotating carbide base; adopting Ar2 as the sputtering gas. The flow of Ar is 180-300cm3 / s, the partial pressure is 1.7-9.0'10<-1>Pa, the reaction gas is N2, and the total pressure is controlled through controlling the partial pressure of N2. The invention introduces TiAlN with high Al content and perfect high temperature oxidation resistance into a multiple-layer coating material system, improves the high temperature oxidation resistance and the hardness of the coating, enhances the toughness of the coating through the microstructure optimization design and enables the coating to obtain both the high temperature oxidation resistance and excellent mechanical properties. The nanometer multiple-layer coating prepared through the invention is provided with great application value in the stainless steel cutting process.

Owner:CENT SOUTH UNIV

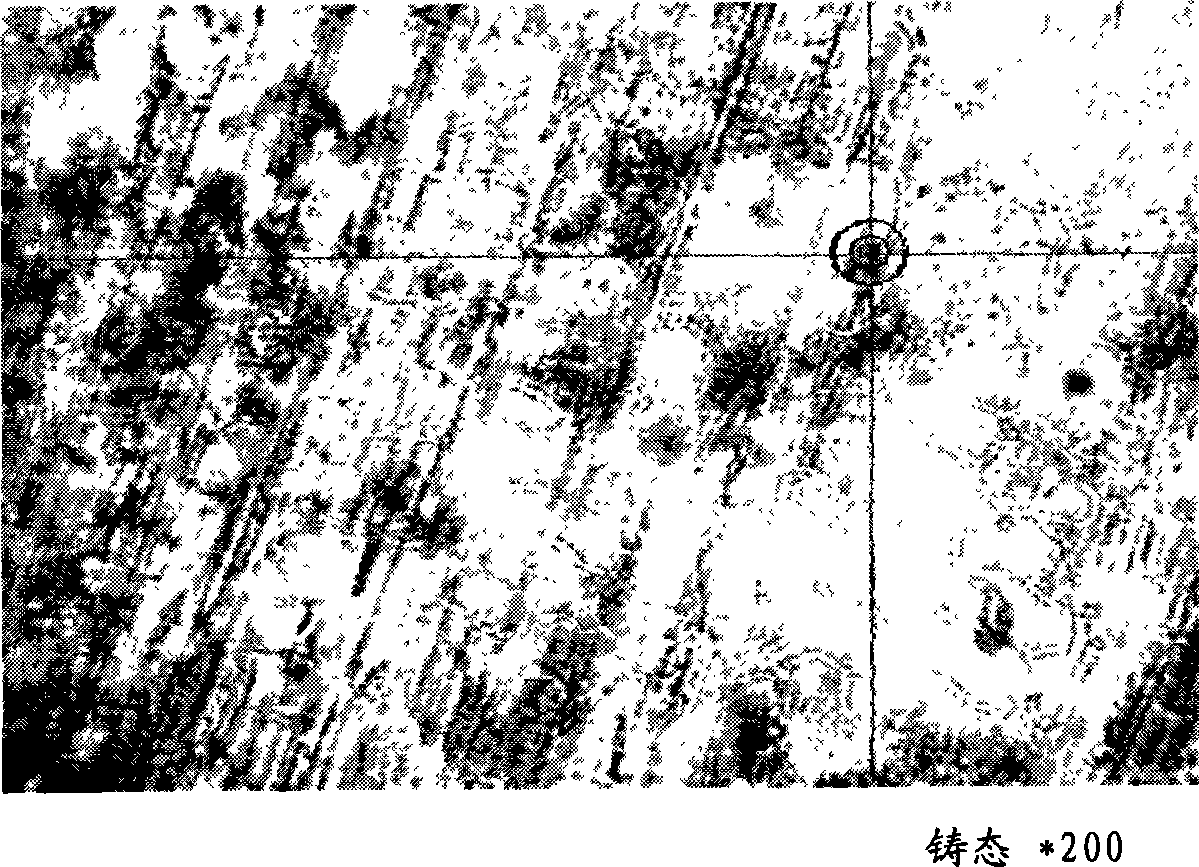

Chromium-manganese-nitrogen austenitic stainless steel

The invention relates to Cr-Mn-N austenite stainless steel. A proper amount of Mn and N are used to substitute expensive nickel to produce a novel Cr-Mn-N steel grade for reducing the cost for materials and maintaining the prior physical property and mechanical property. The Cr-Mn-N austenite stainless steel comprises the following composing elements in percentage by weight: 0.005 to 0.08 percent of carbon element, 0.3 to 0.9 percent of silicon element, 12.1 to 14.8 percent of manganese element, 0.001 to 0.04 percent of phosphorus element, 0.001 to 0.03 percent of sulfur element, 16 to 19 percent of chromium element, 0.5 to 1.8 percent of nickel element, 0.2 to 0.45 percent of nitrogen element, 0.001 to 0.3 percent of molybdenum element, 0.001 to 0.3 percent of copper element, and unavoidable trace elements during most manufacturing processes. The corrosion resistance, the strength and the elongation percentage of the Cr-Mn-N austenite stainless steel in marine atmosphere and acid atmosphere are the same as those of a 304 stainless steel material or are better than those of the 304 stainless steel material, and the Cr-Mn-N austenite stainless steel can reduce the cost for the materials. The Cr-Mn-N austenite stainless steel has the advantages of high elongation percentage, strong corrosion resistance, excellent casting formability and good high-temperature oxidation resistance.

Owner:ADVANCED INT MULTITECH CO LTD

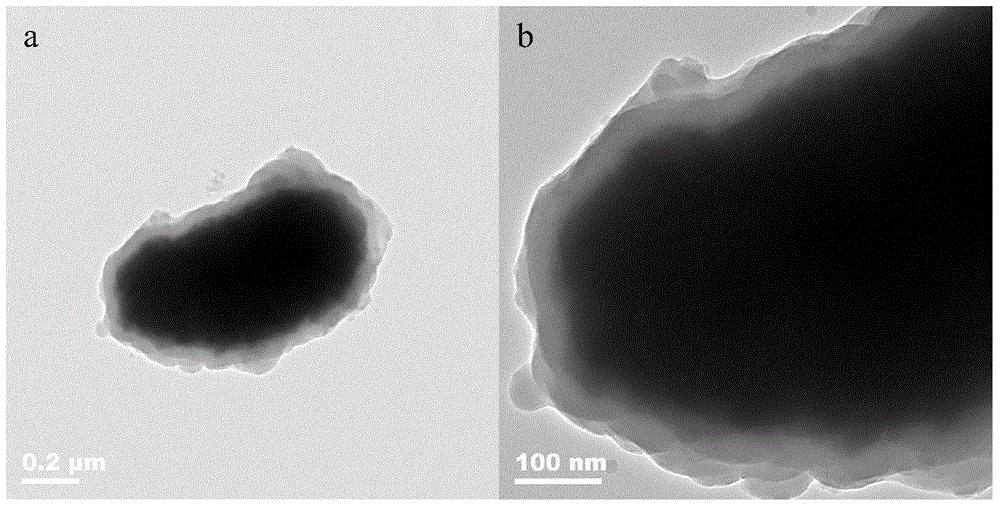

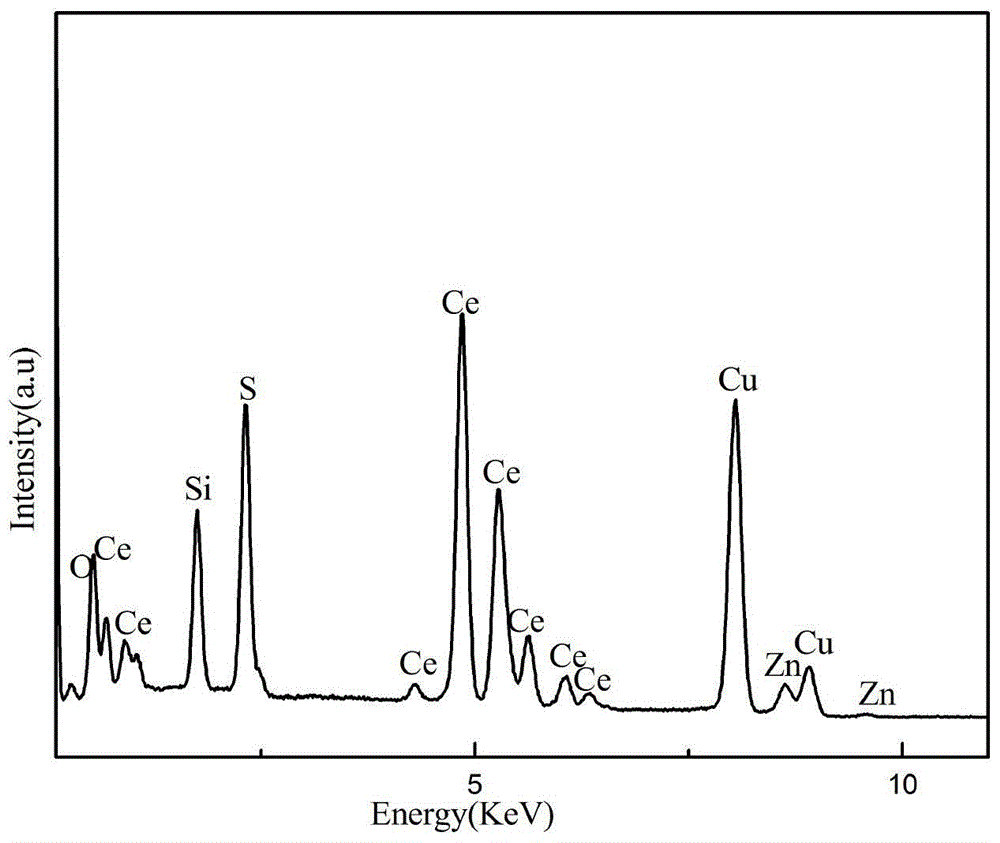

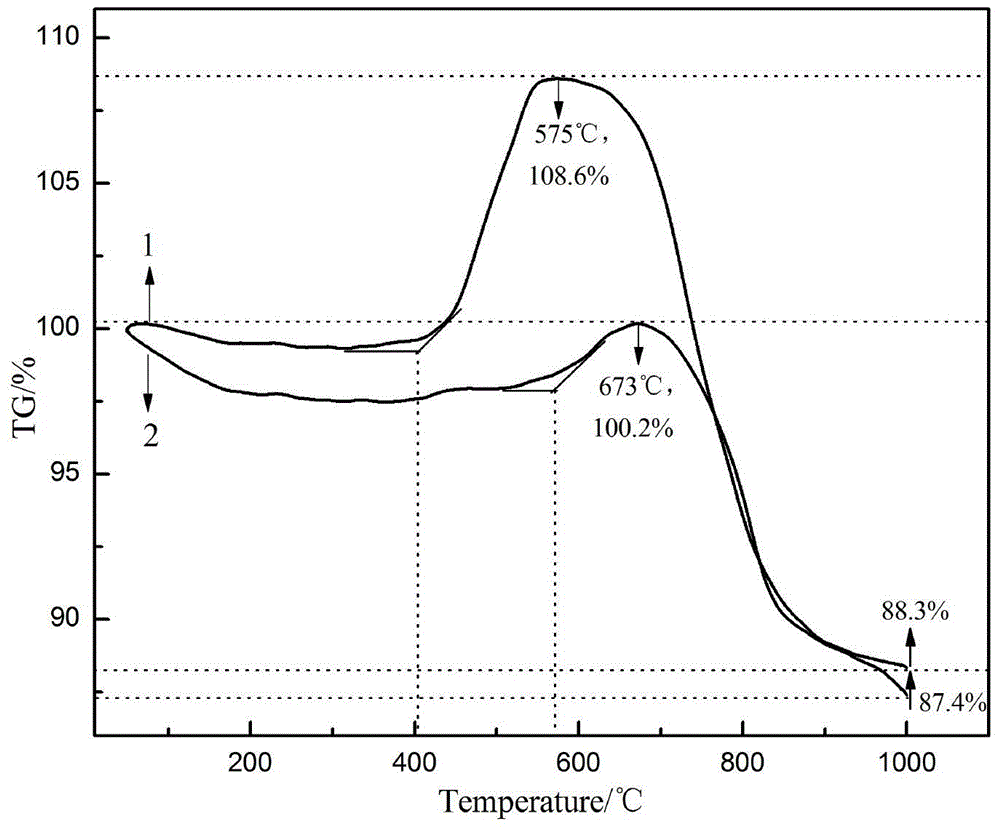

Preparation method of silica-coated cerium sulphide red pigment and prepared product thereof

ActiveCN104877392AHigh densityImprove high temperature oxidation resistancePigment treatment with non-polymer organic compoundsCeriumOxidation resistant

The invention discloses a preparation method of a silica-coated cerium sulphide red pigment. The preparation method comprises the following steps of firstly, preparing pigment suspension liquid and silicon source solution; secondly, adding the silicon source solution into the pigment suspension liquid at the speed of 0.02-0.15ml / min according to the mole ratio of Si4+:Ce2S3=1-3:1-2, stirring to react, and obtaining precursor powder after cleaning and drying a reaction product; thirdly, calcining the precursor powder under the non-oxidizing atmosphere, and obtaining the compact encapsulated silica-coated cerium sulphide red pigment. The invention also discloses a product prepared by the preparation method. The preparation method is high in encapsulating efficiency and complete in encapsulating, the obtained product is thick and compact in the encapsulated layer, the high-temperature oxidation resistance of the cerium sulphide pigment is greatly improved, the cerium sulphide pigment can be in red under the oxidizing atmosphere with the temperature above 450 DEG C, and the application field is greatly expanded; in addition, the preparation process is simple to operate and easy to popularize and use, and the product is wide in application range and beneficial to the development of high-temperature ceramic pigment technology and application.

Owner:JINGDEZHEN CERAMIC INSTITUTE

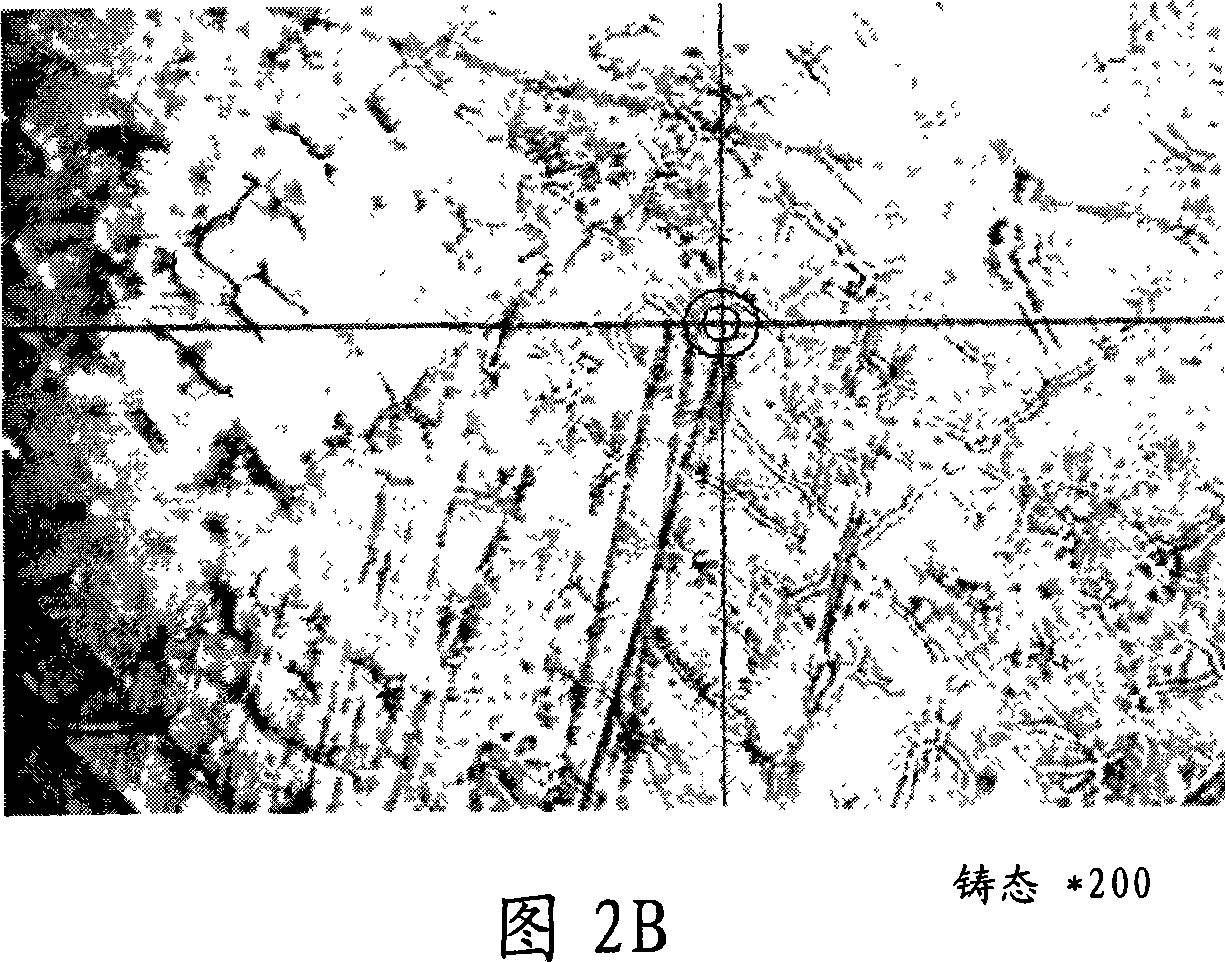

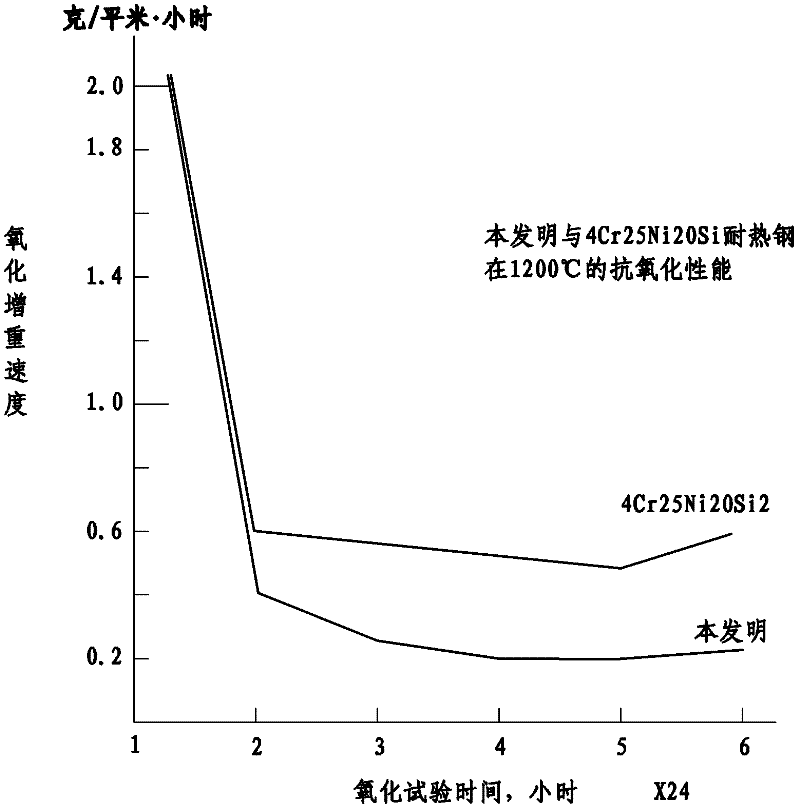

Austenitic heat-resistant stainless steel and processing method thereof

InactiveCN102230137AGood high temperature oxidation resistanceImprove carburization resistanceRare-earth elementManganese

The invention relates to austenitic stainless steel, and in particular relates to austenitic heat-resistant stainless steel and a processing method thereof. The austenitic heat-resistant stainless steel is characterized by comprising the following elements by mass percentage: 0.25-0.45% of carbon, 0.5-2% of silicon, 0.5-2% of manganese, 23-27% of chromium, 6-10% of nickel, 0.15-0.3% of nitrogen, 0.1-0.5% of rare-earth (RE) elements and the balance of iron. The austenitic heat-resistant stainless steel obtained by the processing method has the advantages of good high-temperature oxidation resistance, good carburizing resistance, good sulfurization corrosion resistance and lowered production cost.

Owner:XUANDA IND GRP

High-temperature-tolerance frequency selection wave-transmitting structure and preparation method thereof

ActiveCN106630979AImprove mechanical propertiesImprove electrical performanceLaser beam welding apparatusFiberElectrical conductor

The invention discloses a high-temperature-tolerance frequency selection wave-transmitting structure. The high-temperature-tolerance frequency selection wave-transmitting structure successively comprises a wave-transmitting layer, a modification bonding layer and a frequency selection layer from inside to outside, wherein the wave-transmitting layer is made of a continuous fiber reinforced ceramic-based wave-transmitting composite material; the modification bonding layer is made of a low-dielectric-constant material; the frequency selection layer is a noble metal physical plating layer or a noble metal glass conductor coating with periodic structure patterns. The high-temperature-tolerance frequency selection wave-transmitting structure can tolerate high temperature of 700 DEG C or more, and has excellent high temperature tolerance. The invention also provides a production method of the high-temperature-tolerance frequency selection wave-transmitting structure; the modification bonding layer is produced by using a plasma spraying process; the thermal damage to the substrate can be avoided, so that the substrate has high strength retention rate; the size accuracy of the frequency selection layer produced by a laser processing process can be higher than 20 microns; the frequency selection layer has high size accuracy.

Owner:NAT UNIV OF DEFENSE TECH +1

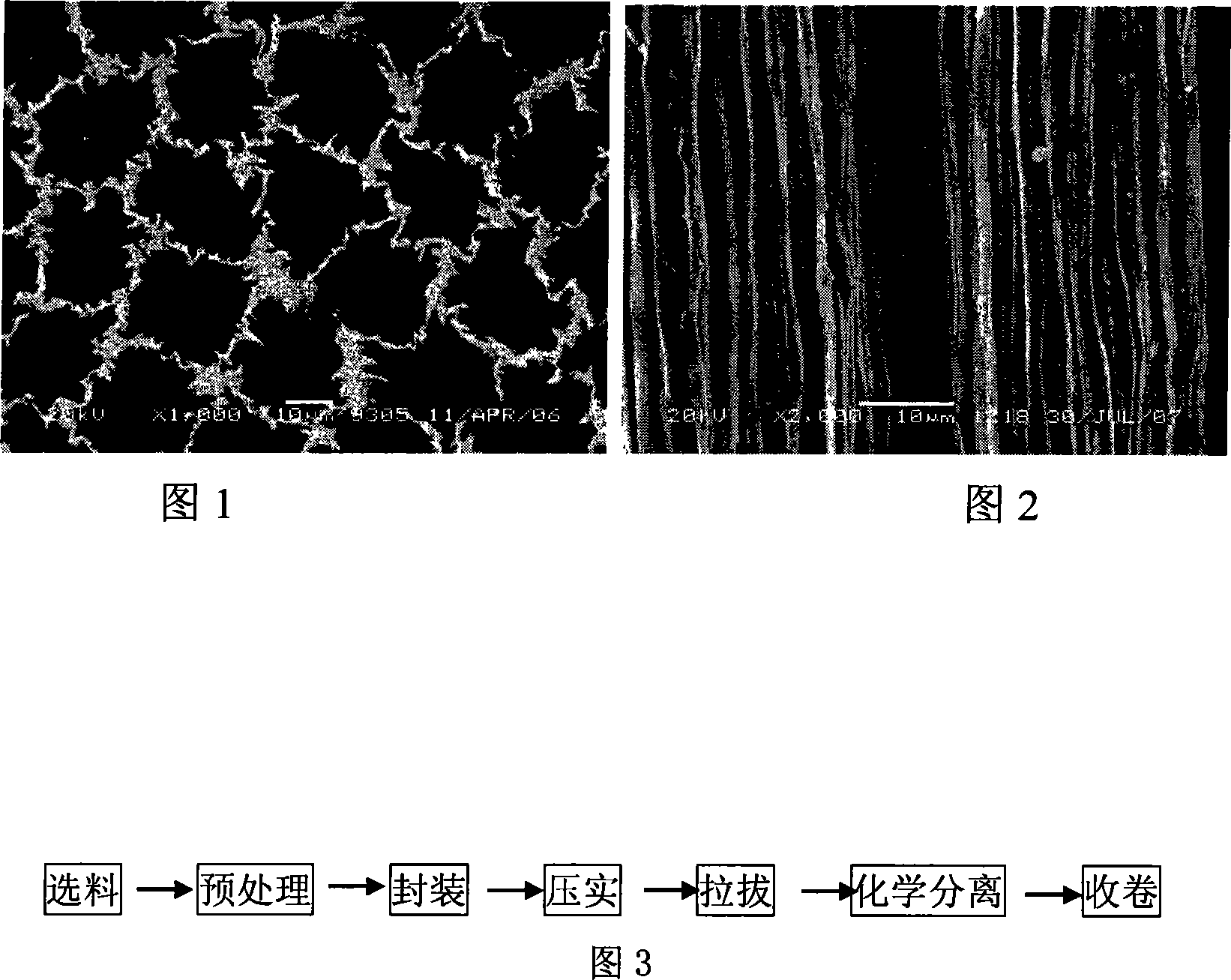

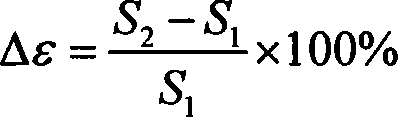

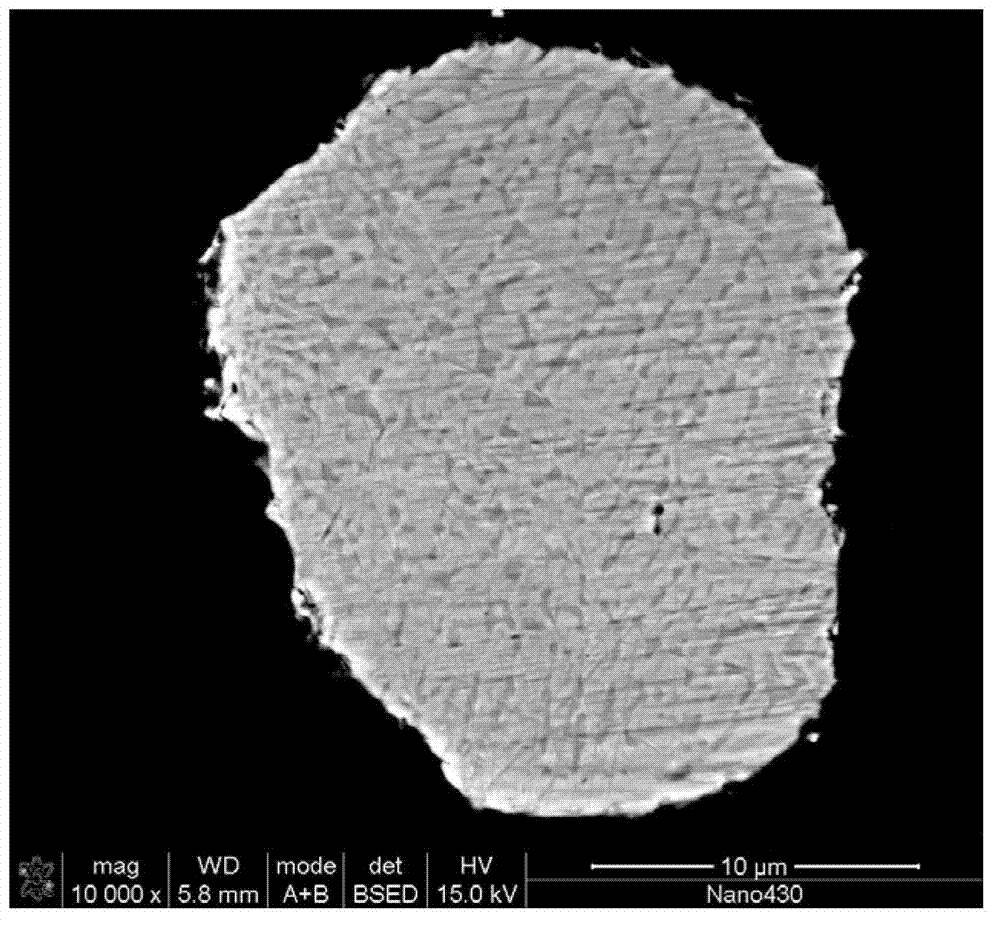

Fire resistant iron chromium aluminum filament and production technique

The invention relates to a high temperature resistant iron-chromium-aluminum fiber yarn and a preparing process, belongs to the field of stainless steel processing and obtains the iron-chromium-aluminum fibers by bundle drawing iron-chromium-aluminum wire rods embedded in base materials; the iron-chromium-aluminum fibers comprise iron and the following components (represented by wt. percent) of more than or equal to 0.005 percent and less than or equal to 0.03 percent of C, more than or equal to 15 percent and less than or equal to 27 percent of Cr, more than or equal to 5.95 percent and less than or equal to 7.0 percent of Al, more than or equal to 0.05 percent and less than or equal to 0.2 percent of Cu, more than or equal to 0.4 percent and less than or equal to 0.6 percent of Si, more than or equal to 0.2 percent and less than or equal to 0.4 percent of Mn, more than or equal to 0.03 percent and less than or equal to 0.04 percent of S, more than or equal to 0.010 percent and less than or equal to 0.045 percent of P and more than or equal to 0.01 percent and less than or equal to 0.04 percent of RE; the manufacturing process comprises the following procedures of material choosing, pretreatment, encapsulation, compaction, drawing, separation and rolling. The manufacturing process of the iron-chromium-aluminum fiber of the invention is suitable for drawing and processing high-aluminum iron-chromium-aluminum wire rods and can reach the yield of 98 percent with little influence on the environment.

Owner:HUNAN HUITONG ADVANCED MATERIALS

Nickel base casting high temperature alloy for high temperature mould

ActiveCN1718803AImprove performanceImprove high temperature durabilityChemical compositionOxidation resistant

A high-temp casting Ni-base alloy for high-temp die contains proportionally Co, Al, Cr, Ti, W, Mo, No, Ta, Hf, C, B, Y and Ni. Its advantages are high high-temp strength, plasticity, anti-oxidizing, performance and stability, and better thermal fatigure nature.

Owner:BEIJING AVIATION MATERIAL INST NO 1 GRP CORP CHINA AVIATION IND

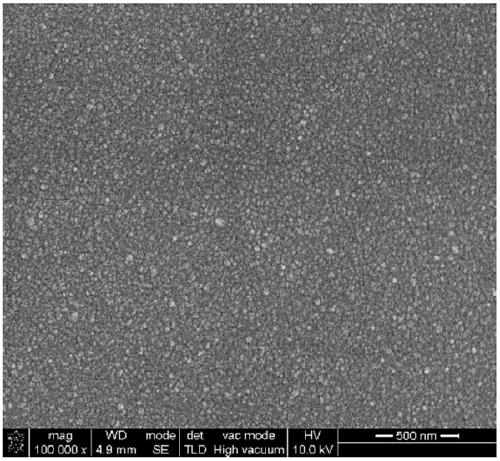

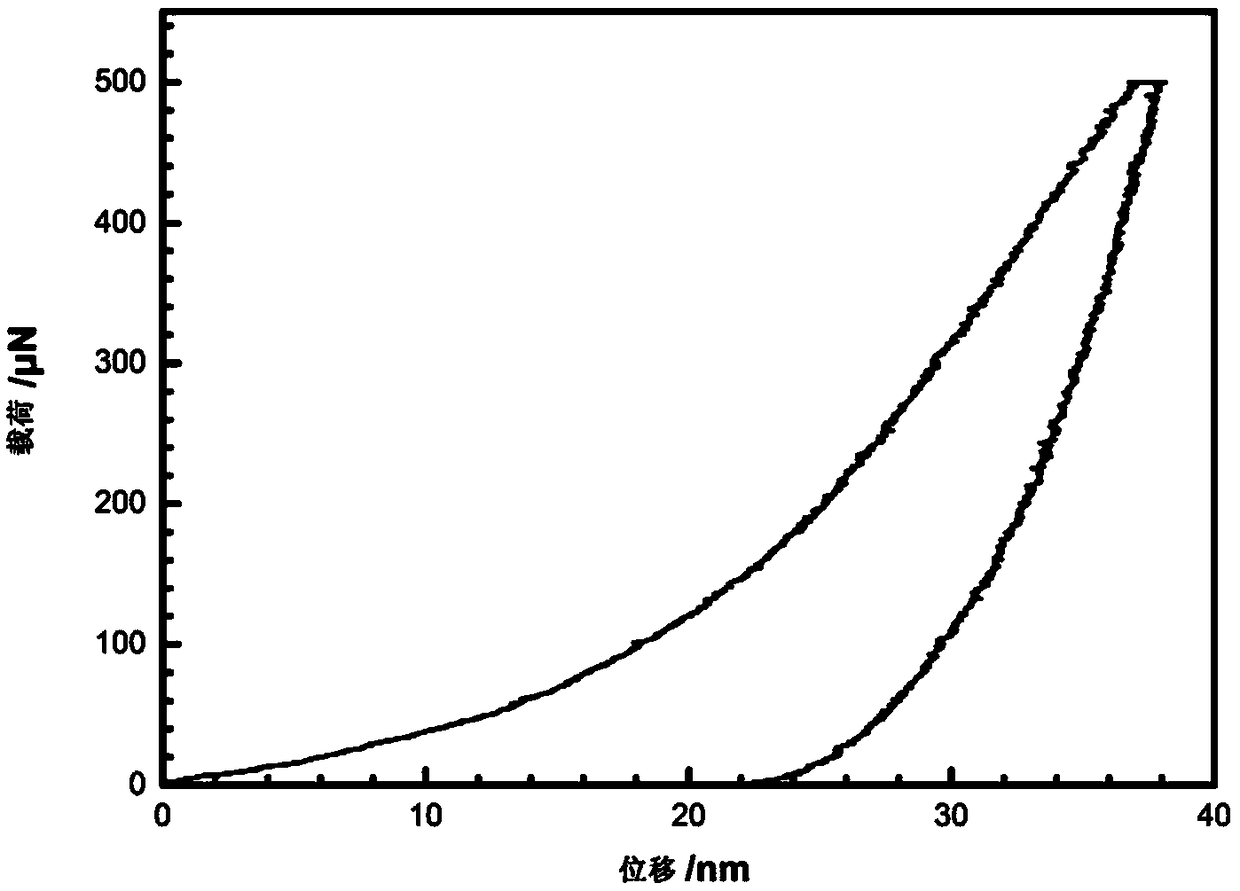

High-temperature alloy surface nanometer composite coating and preparation method thereof

The invention discloses a high-temperature alloy surface nanometer composite coating and a preparation method of the high-temperature alloy surface nanometer composite coating. The high-temperature alloy surface nanometer composite coating specifically comprises the following steps of: (1) ultrasonically washing an alloy substrate through acetone and deionized water in sequence; wiping the substrate through a filtering paper after the washing, and drying in the air for stand-by use; (2) carrying out sand blasting on the substrate processed in step (1) through emery; (3) preheating the substrate processed in step (2) through plasma bright eruption; (4) coating the substrate processed in step (3) through a plasma coating method, wherein the powder for coating is the nanometer MoSi2-CoNiCrAlY composite structure particle feedstock obtained by high-energy ball milling and sieving; and (5) naturally cooling the coated sample. With adoption of the method, the surface of a base body can be directly coated, and the prepared coating can effectively solve the problems that the pure MoSi2 coating has the defects of low toughness, poor combining performance to the base body, and easily-occured low-temperature 'pesting' phenomenon.

Owner:SOUTH CHINA UNIV OF TECH

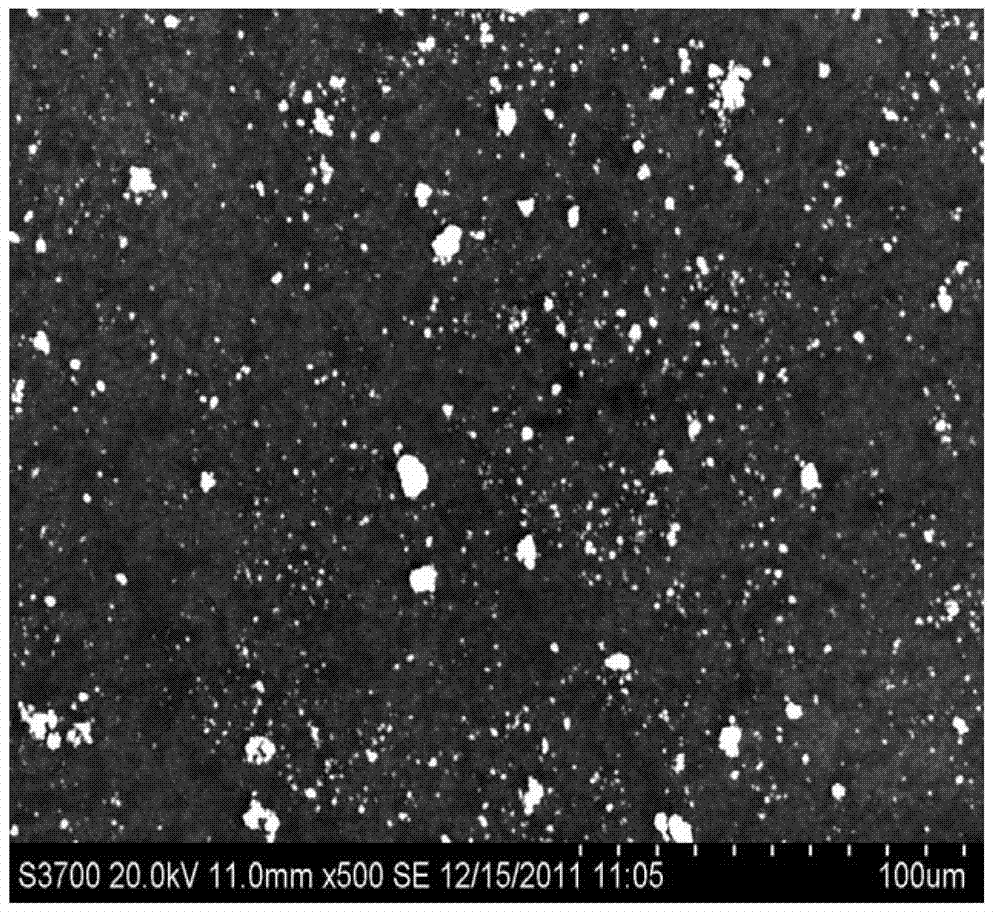

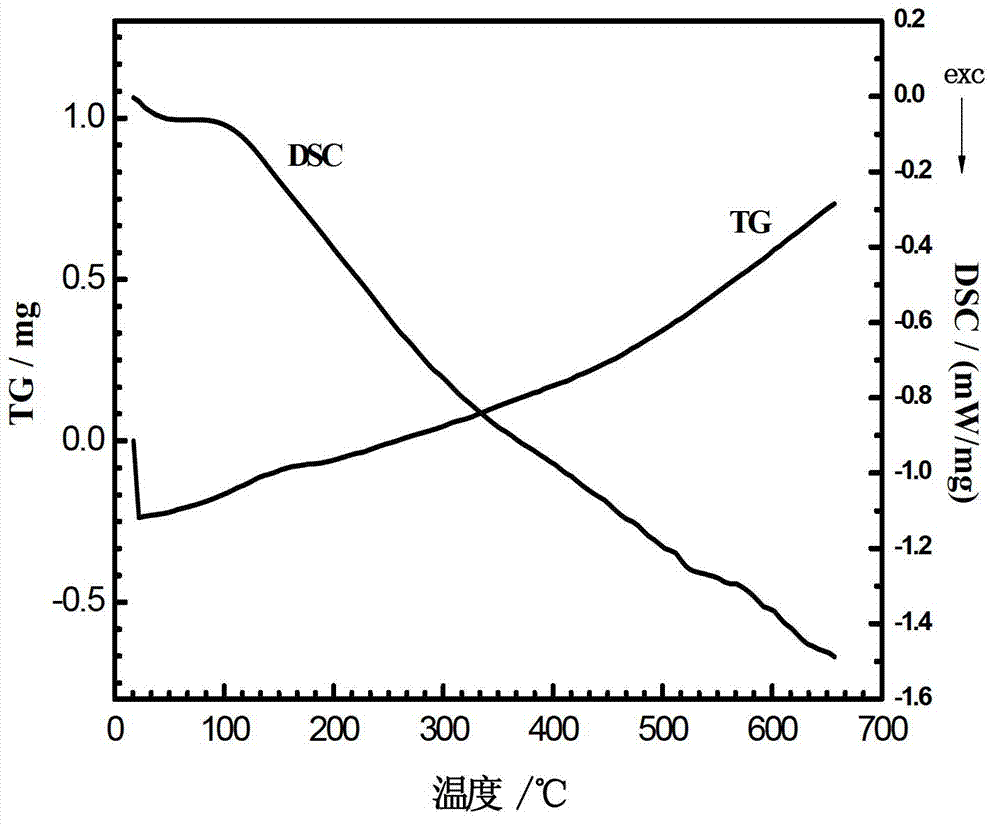

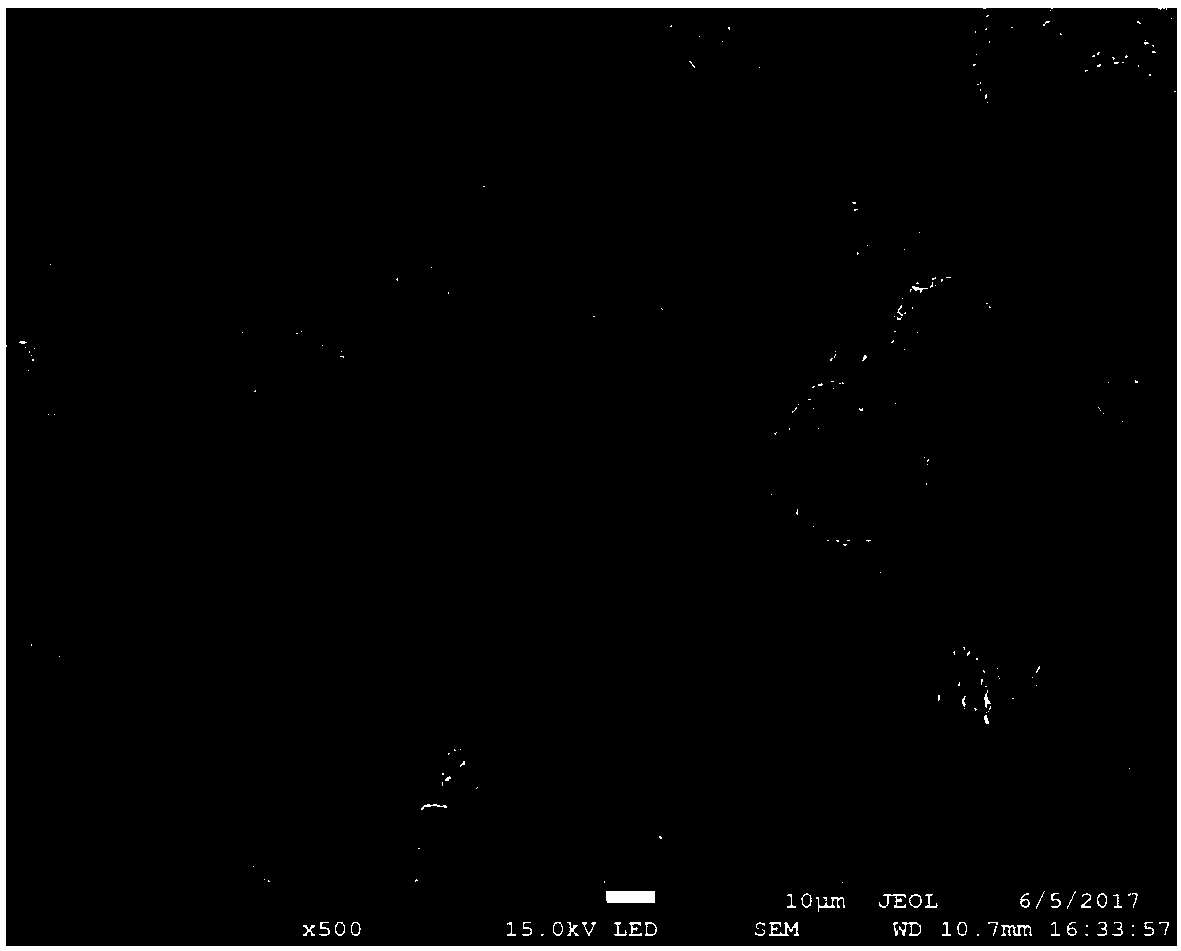

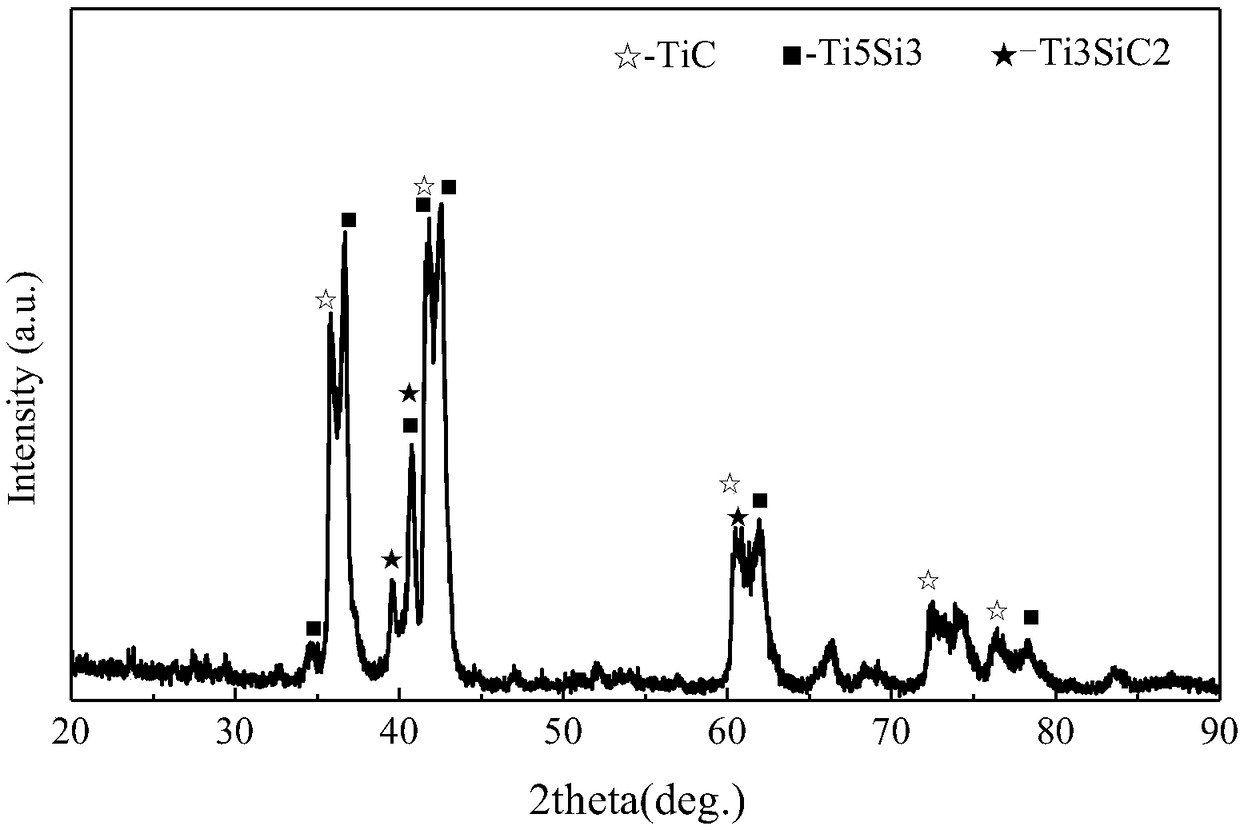

Plasma spraying method used for preparing titanium-silicon-carbon composite coating layer

The invention discloses a plasma spraying method used for preparing a titanium-silicon-carbon composite coating layer. The plasma spraying method comprises following steps: raw material powder, including 55 to 80% of Ti powder, 10 to 30% of Si powder, and 10 to 15% of graphite powder, is weighted at a mass ratio; the raw material powder is mixed with deionized water, a gel, and a dispersant so asto obtain a mixed slurry; the mixed slurry is subjected to spray drying so as to obtain an agglomerate composite powder; and a bonding layer is coated with the obtained spray material powder via spraying so as to obtain the titanium-silicon-carbon composite coating layer. The thickness of the titanium-silicon-carbon composite coating layer ranges from 200 to 300<mu>m. The obtained titanium-silicon-carbon composite coating layer is high in coating hardness, and excellent in wear resistance.

Owner:HEBEI UNIV OF TECH

Solid oxide fuel cell stainless steel bipolar connector and manufacturing method thereof

InactiveCN104393315AExcellent high temperature oxidation resistanceGood electronic conductivityFinal product manufactureFuel cell detailsOxideIron based

The invention discloses a solid oxide fuel cell stainless steel bipolar connector and a manufacturing method thereof. The iron-based connector comprises a base and a surface modification layer arranged on the surface of the base. The base is a ferrite stainless steel plate with thickness of 0.3-3.0mm and chromium content of 10-30wt%. The surface modification layer is a spinel-structure alloy oxide with thickness of 3-30 microns. The solid oxide fuel cell stainless steel bipolar connector has excellent high temperature oxidation resistance and good electronic conductivity. The manufacturing method has simple processes and realizes compact combination of the spinel oxide modification layer and the base. The solid oxide fuel cell stainless steel bipolar connector has excellent interfacial compatibility, produces modification layer and base synergism and can be massively produced easily.

Owner:DALIAN MARITIME UNIVERSITY

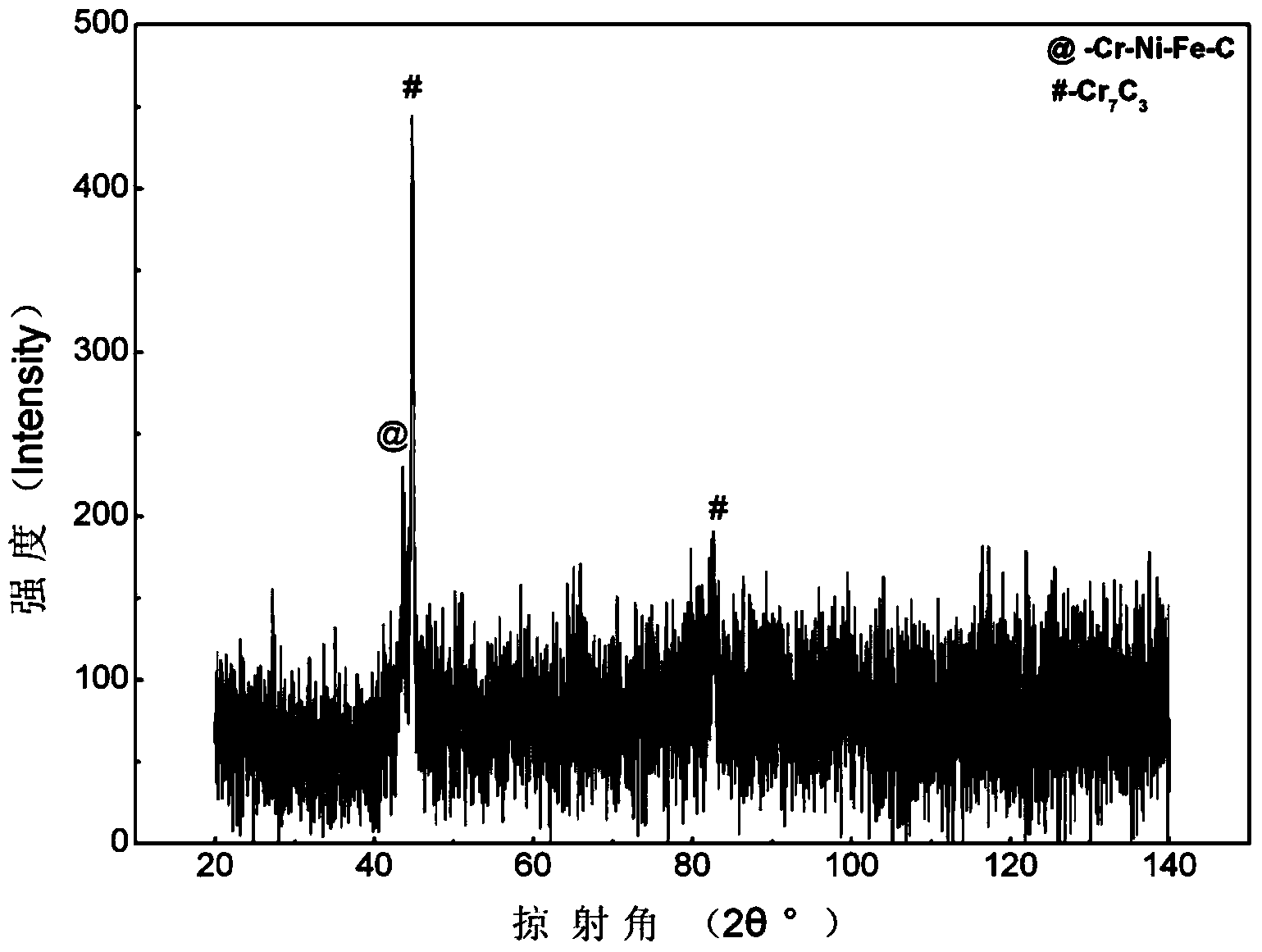

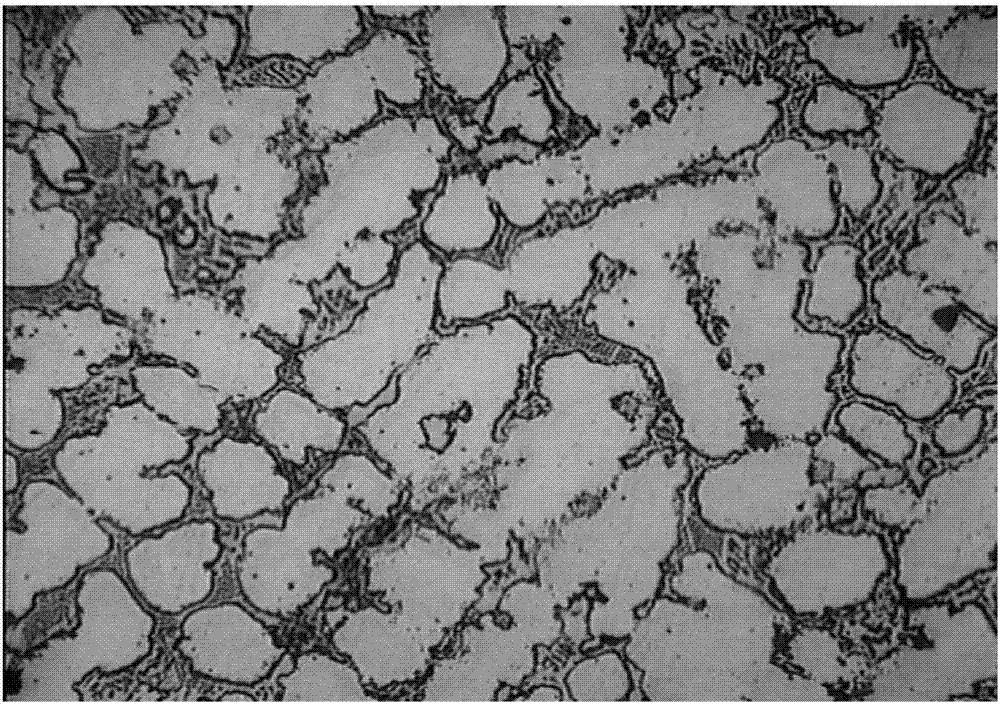

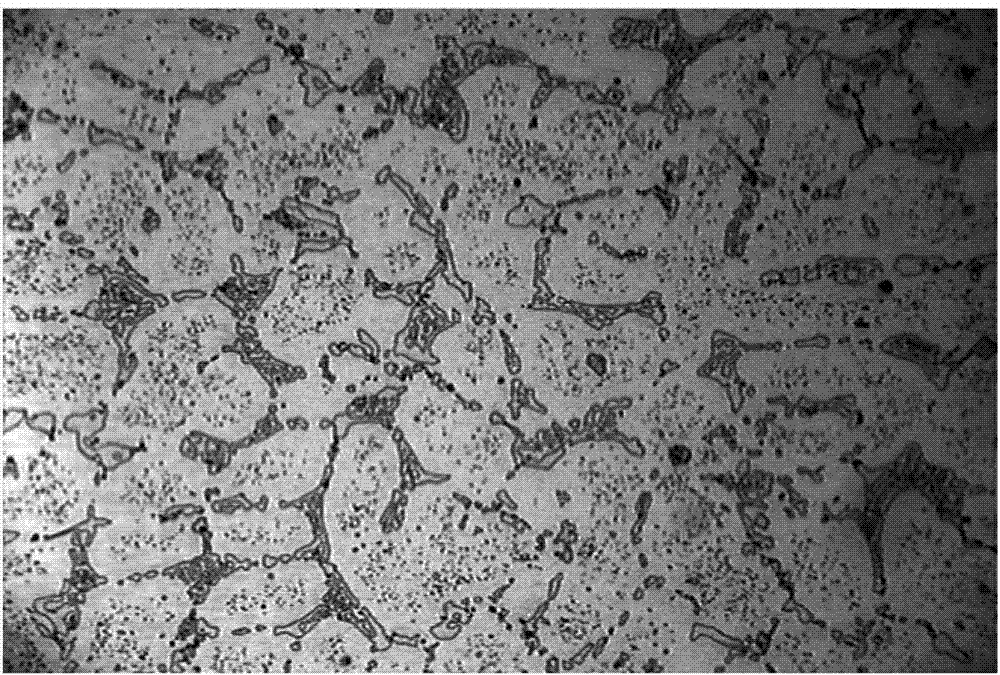

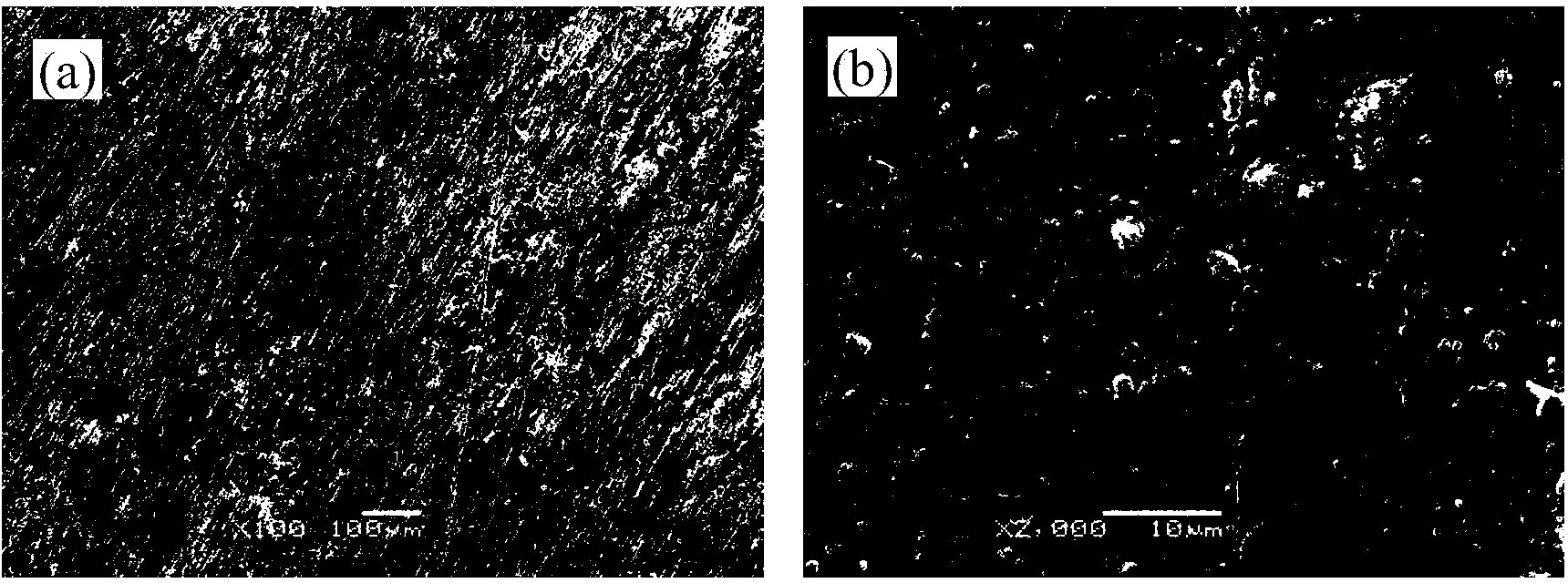

Plasma spray coating on aluminum alloy base surface and preparation method thereof

InactiveCN103643195AGood high temperature oxidation resistanceAvoid excessive oxidationMolten spray coatingChromiumNickel

The invention provides a plasma spray coating on an aluminum alloy base surface, which is composed of the following components in percentage by weight: 14-25% of chromium, 6-15% of nickel, 0.5-1.5% of carbon, 2.0-4.0% of silicon, 0.8-1.5% of manganese and the balance of iron. A Cr7C3 strengthening phase is dispersed in the austenite microstructure of the coating. The experiment proves that the coating has favorable wear resistance and antiseptic property, and is suitable for an aluminum alloy base surface working in a wearing and corrosive environment, such as an automobile engine cylinder made of an aluminum alloy material.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

High-temperature alloy, alloy hood manufactured from same and manufacturing technology of alloy hood

ActiveCN103173692AHigh hardnessImprove high temperature oxidation resistanceChemical/physical processesManufacturing technologyHardness

The invention provides a high-temperature alloy which comprises the components such as C, Cr, Ni, Mo, Mn, Si, Nb, RE, N, Ti, B, Zr and the like, wherein the optimal content of each component is selected after reasonable analysis and repeated tests so that the components of the alloy realize the best interaction effect; and the tests prove that the high-temperature alloy provided by the invention is obviously superior to 25-20 steel and 316 steel in terms of average hardness, high-temperature oxidation resistance, high-temperature corrosion resistance and high-temperature washout resistance, and has good high-temperature comprehensive performance.

Owner:浙江科得力新材料有限公司

High temperature durable, oxidation resistant and lead nickel free conductor pulp and preparing method thereof

InactiveCN101290817AImprove antioxidant capacityReduce manufacturing costNon-conductive material with dispersed conductive materialCable/conductor manufactureMean diameterElectrical conductor

The invention discloses high temperature-resisting antioxidative leadless nickel conductor slurry. The compositions in percentage by weight of the slurry are: 50 to 70 percent of nickel powder, 1 to 5 percent of antioxidative protective agent, 5 to 15 percent of inorganic agglomerant and 15 to 30 percent of organic carrier. The compositions are evenly mixed and ground to obtain leadless nickel conductor slurry product with granularity less than 15mu m and viscosity of between 65 and 75 Pa.s, wherein the nickel powder is selected from spherical nickel powder with the mean diameter of between 0.1 and 2.0 mu m; the antioxidative protective agent is selected from one sort or more than one sort of B, Cr and Y which are spherical micropowder with the mean diameter less than 1mu m; and the inorganic agglomerant is leadless glass powder. The slurry product has excellent high temperature-resisting antioxidative performance and is suitable for sintering under atmospheric condition with the antioxidative temperature adjusted between 800 and 900 DEG C. Moreover, the slurry has simple preparation process, low production cost and energy conservation and is propitious to environmental protection.

Owner:HUAZHONG UNIV OF SCI & TECH

Three-layer film structure coating layer and fabrication method thereof

ActiveCN109082641AReduce stressPrevents Diffusion Adhesive WearVacuum evaporation coatingSputtering coatingRadio frequency magnetron sputteringSuperalloy

The invention belongs to the technical field of fabrication of a metal coating layer, and discloses a three-layer film structure coating layer and a fabrication method thereof. The three-layer film structure coating layer comprises a dual-phase Cr+Alpha-(Al, Cr)2O3 matrix pasting layer, a single phase Alpha-(Al, Cr)2O3 support layer and a single-phase nanometer Alpha-Al2O3 surface layer. The fabrication method comprises the steps of sequentially depositing the Cr+Alpha-(Al, Cr)2O3 matrix pasting layer and the Alpha-(Al, Cr)2O3 support layer by DC magnetron sputtering and by a CrAl alloy target; and obtaining the single-phase nanometer Alpha-Al2O3 surface layer by radio-frequency magnetron sputtering by an Al+Alpha-Al2O3 compost target. The surface working layer of the obtained coating layer is of a single-phase nanometer Alpha-Al2O3 structure, the coating layer is high in hardness, good in toughness, high in high-temperature thermal stability, low in friction coefficient during friction with a metal matrix and is firmly combined with a matrix such as high-speed steel, a hot work die steel and high-temperature alloy.

Owner:SOUTH CHINA UNIV OF TECH

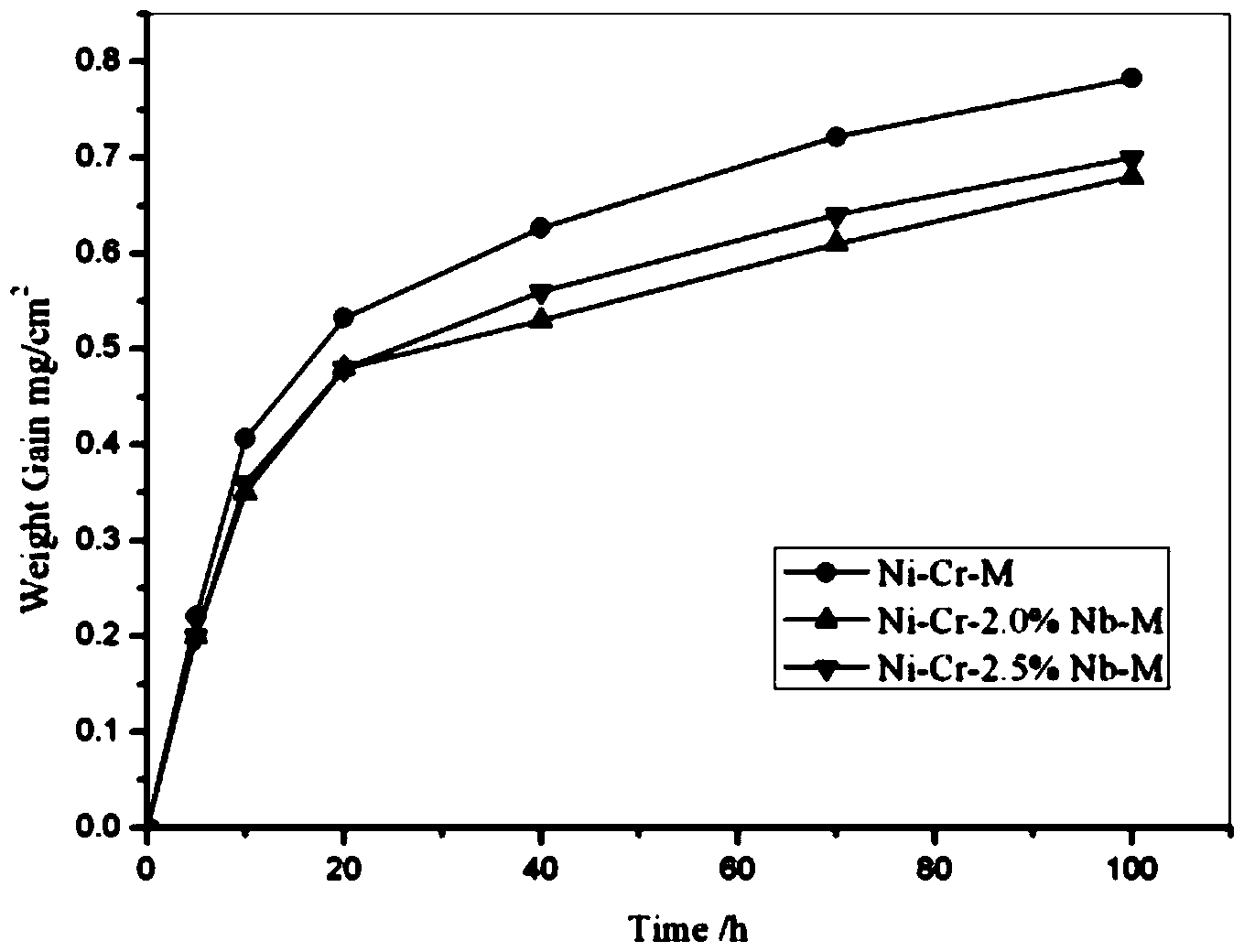

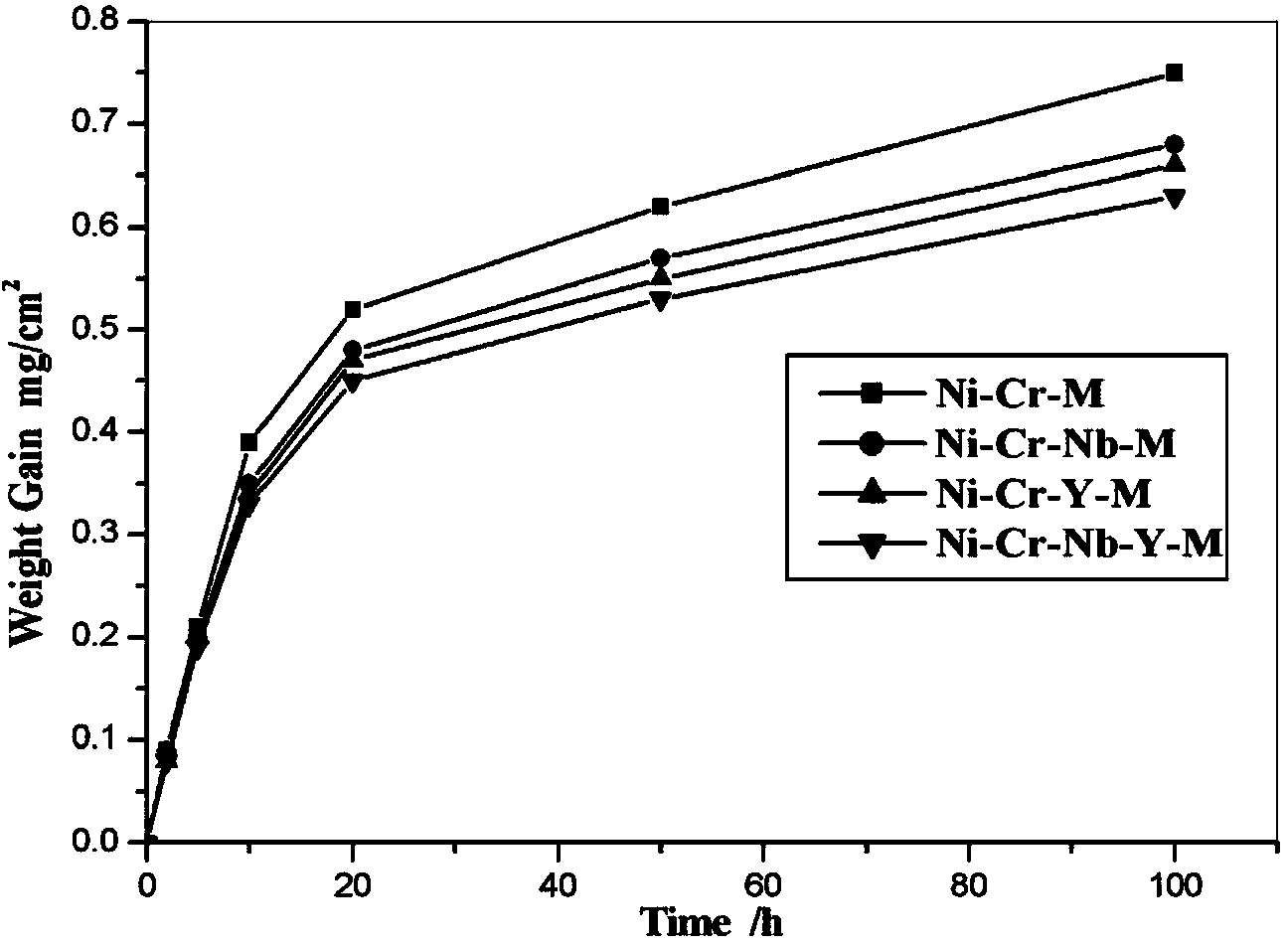

Nickel-based high temperature alloy, preparation method thereof as well as application thereof in spark plug electrode

The invention relates to a nickel-based high temperature alloy, a preparation method thereof as well as application thereof in a spark plug electrode. The nickel-based high temperature alloy contains the following components in percent by weight: 0.04%-0.06% of C, 19%-21% of Cr, 7%-9% of W, 5%-7% of Mo, 1%-2% of Ti, 0.5%-2% of Al, 0.004%-0.006% of B, 0.03%-0.05% of Zr, 0.7%-0.9% of Fe, 0-3% of Nb, 0-1% of Y, and the balance of Ni and inevitable impurities. The preparation method of the nickel-based high temperature alloy comprises the following steps of: mixing the components in a vacuum electric-arc melting furnace according to a proportion, smelting, getting out and forming; heating up to 1200 DEG C in a heating furnace, carrying out thermal-insulation solid-solution treatment for 4 hours, and carrying out air-cooling; and carrying out thermal-insulation aging treatment for 10 hours at 800 DEG C, and carrying out air-cooling to prepare the nickel-based high temperature alloy. The nickel-based high temperature alloy disclosed by the invention has good high-temperature oxidation resistance and corrosion resistance, and can be applied to the spark plug electrode material so as to prolong the service life of an electrode and the service life of a spark plug.

Owner:SHANDONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com