High-temperature alloy, alloy hood manufactured from same and manufacturing technology of alloy hood

A high-temperature alloy and manufacturing process technology, applied in the field of high-temperature alloys, can solve problems such as low wear resistance, low oxidation and corrosion resistance, and short service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

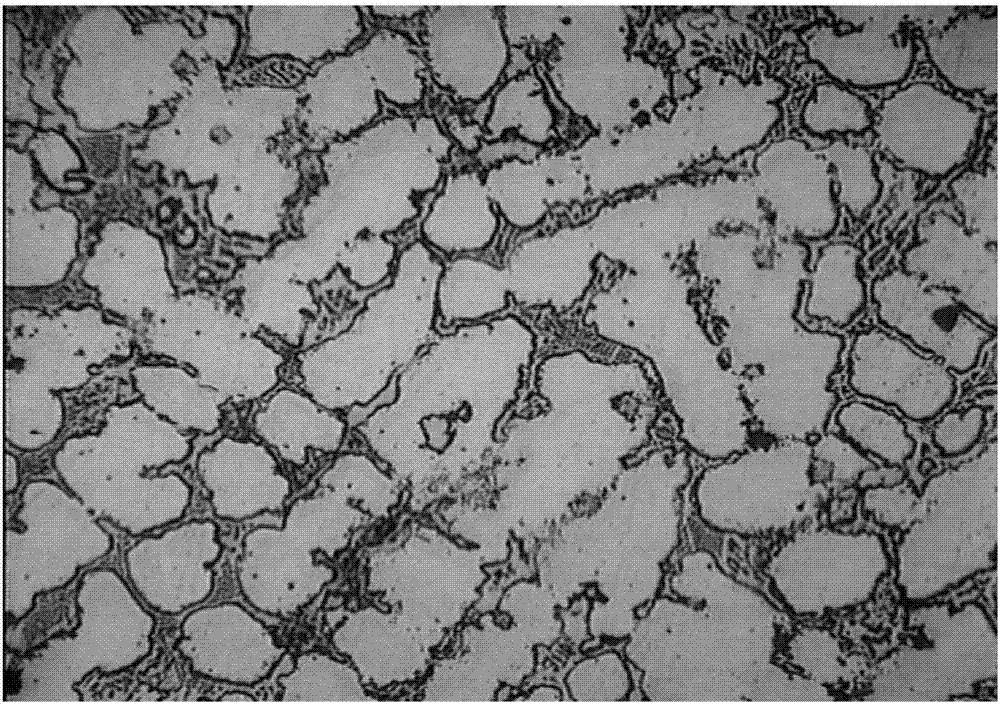

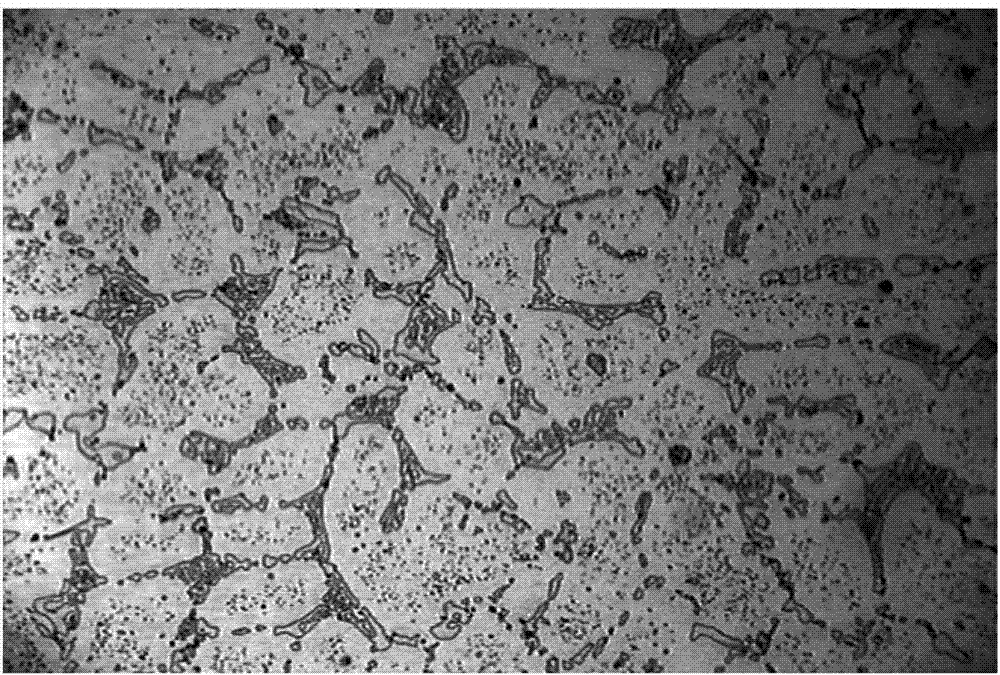

Image

Examples

Embodiment 1

[0097] This implementation provides a kind of alloy that is used to manufacture the wind distribution plate wind cap of circulating fluidized bed, and its component and the content of each component are as follows:

[0098] C 0.45

[0099] Cr 25

[0100] Ni 35

[0101] Mo 2.4

[0102] Mn 1.7

[0103] Si 1.5

[0104] Nb 1.5

[0105] RE 0.2 (0.1 each for La and Ce)

[0106] N 0.3

[0107] Ti 0.2

[0108]B 0.1

[0109] Zr 0.15

[0110] Fe balance

[0111] The process of using the above-mentioned alloy provided in this embodiment to manufacture the wind cap of the circulating fluidized bed air distribution plate includes the following steps in turn:

[0112] A. In the intermediate frequency induction furnace, the melting temperature is controlled at 1640°C for smelting, specifically: adding nickel, chromium, carbon, niobium, manganese, molybdenum, boron, silicon, titanium, zirconium, Nitrogen and rare earth, among them, nickel, chromium and carbon are added when the f...

Embodiment 2

[0123] This implementation provides a kind of alloy that is used to manufacture the wind distribution plate wind cap of circulating fluidized bed, and its component and the content of each component are as follows:

[0124] C 0.50

[0125] Cr 27

[0126] Ni 33

[0127] Mo 2.5

[0128] Mn 1.75

[0129] Si 1.7

[0130] Nb 1.4

[0131] RE 0.27 (0.135 each for La and Ce)

[0132] N 0.25

[0133] Ti 0.3

[0134] B 0.09

[0135] Zr 0.1

[0136] Fe balance

[0137] The process of using the above-mentioned alloy provided in this embodiment to manufacture the wind cap of the circulating fluidized bed air distribution plate includes the following steps in turn:

[0138] A. In the intermediate frequency induction furnace, the melting temperature is controlled at 1660°C for smelting, specifically: adding nickel, chromium, carbon, niobium, manganese, molybdenum, boron, silicon, titanium, zirconium, Nitrogen and rare earth, among them, nickel, chromium and carbon are added when...

Embodiment 3

[0149] This implementation provides a kind of alloy that is used to manufacture the wind distribution plate wind cap of circulating fluidized bed, and its component and the content of each component are as follows:

[0150] C 0.55

[0151] Cr 28

[0152] Ni 32

[0153] Mo 2.6

[0154] Mn 1.6

[0155] Si 1.6

[0156] Nb 1.6

[0157] RE 0.3 (0.15 each for La and Ce)

[0158]N 0.2

[0159] Ti 0.25

[0160] B 0.085

[0161] Zr 0.2

[0162] Fe balance

[0163] The process of using the above-mentioned alloy provided in this embodiment to manufacture the wind cap of the circulating fluidized bed air distribution plate includes the following steps in turn:

[0164] A. In the intermediate frequency induction furnace, the smelting temperature is controlled at 1680°C for smelting, specifically: add nickel, chromium, carbon, niobium, manganese, molybdenum, boron, silicon, titanium, zirconium, Nitrogen and rare earth, among them, nickel, chromium and carbon are added when the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com