Patents

Literature

2142 results about "High entropy alloys" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-entropy alloys (HEAs) are alloys that are formed by mixing equal or relatively large proportions of (usually) five or more elements. Prior to the synthesis of these substances, typical metal alloys comprised one or two major components with smaller amounts of other elements. For example, additional elements can be added to iron to improve its properties, thereby creating an iron based alloy, but typically in fairly low proportions, such as the proportions of carbon, manganese, and the like in various steels. Hence, high entropy alloys are a novel class of materials. The term “high-entropy alloys” was coined because the entropy increase of mixing is substantially higher when there is a larger number of elements in the mix, and their proportions are more nearly equal.

High-strength and ultra heat-resistant high entropy alloy (HEA) matrix composites and method of preparing the same

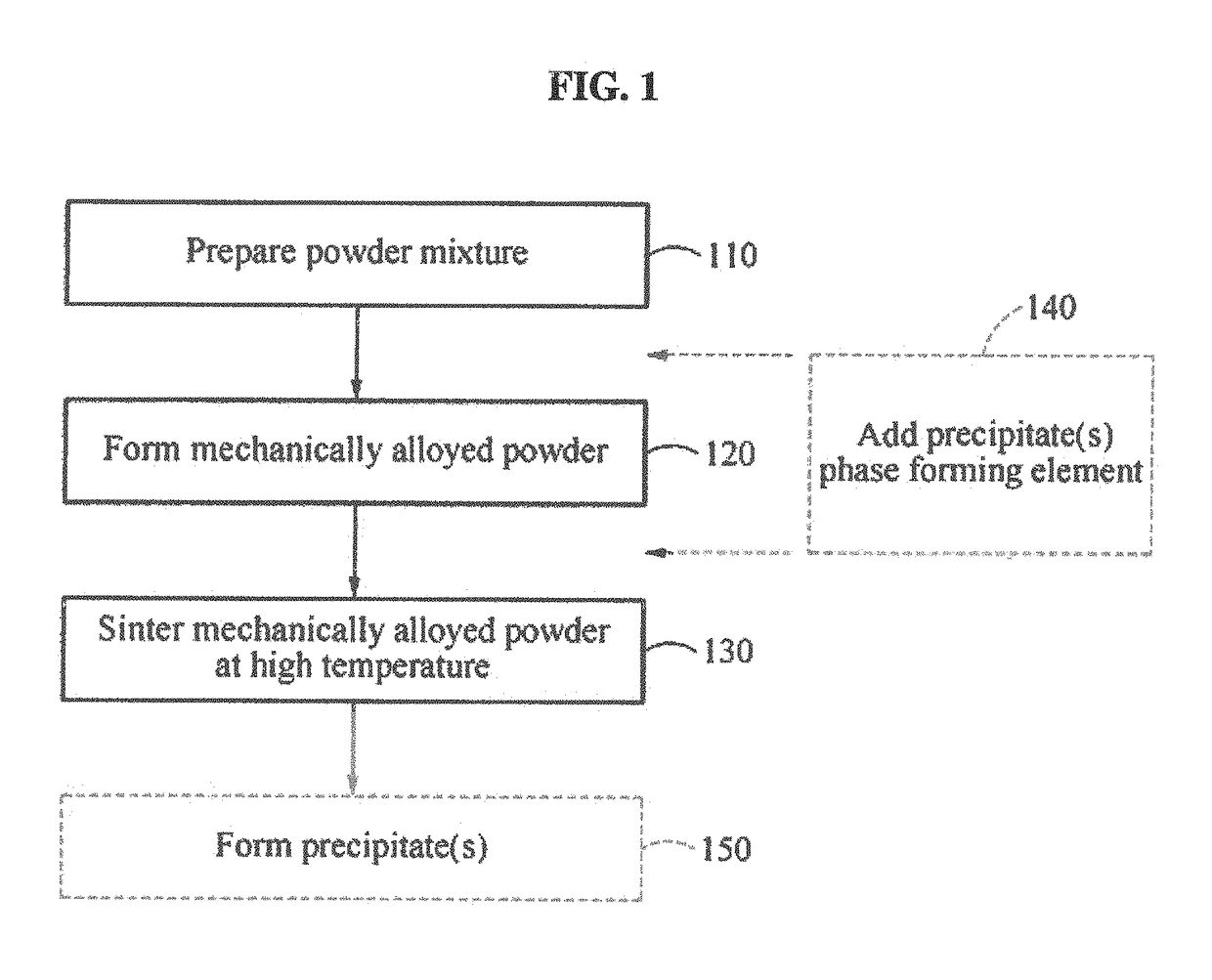

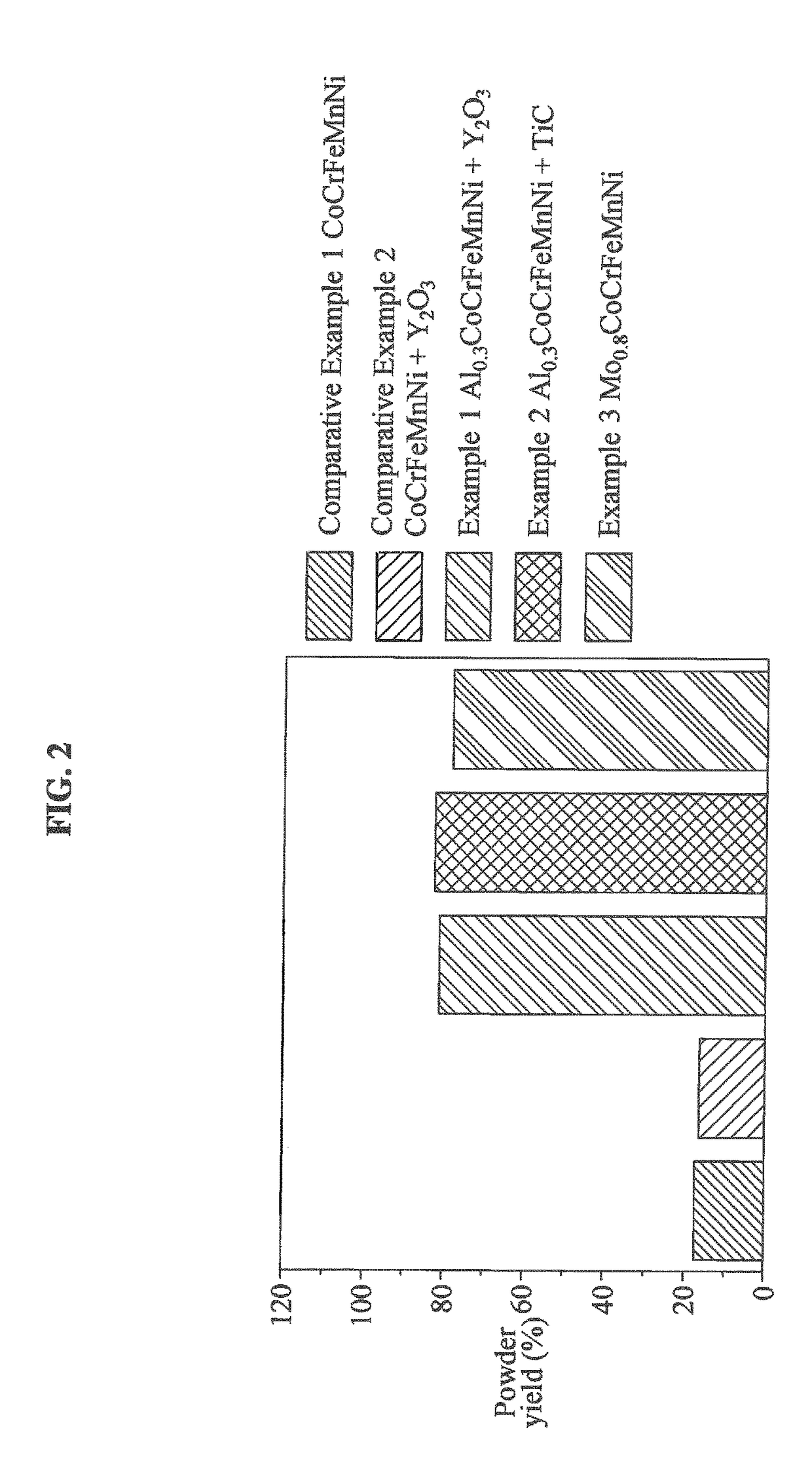

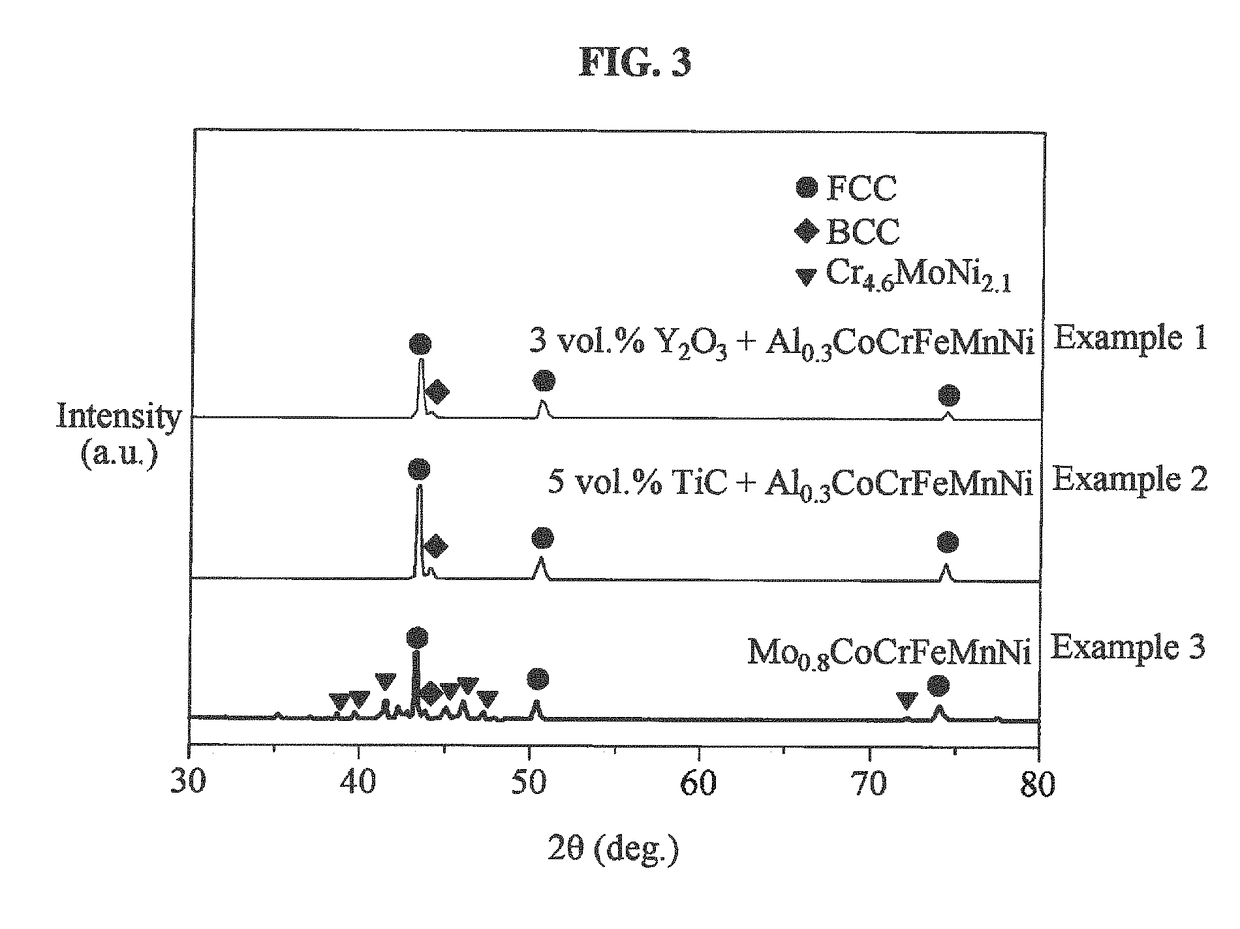

A high-strength and ultra heat-resistant high entropy alloy (HEA) matrix composite material and a method of preparing the HEA matrix composite material are provided. The HEA matrix composite material may include at least four matrix elements among Co, Cr, Fe, Ni, Mn, Cu, Mo, V, Nb, Ta, Ti, Zr, W, Si, Hf and Al, and a body-centered cubic (BCC) forming alloy element.

Owner:KOREA ADVANCED INST OF SCI & TECH

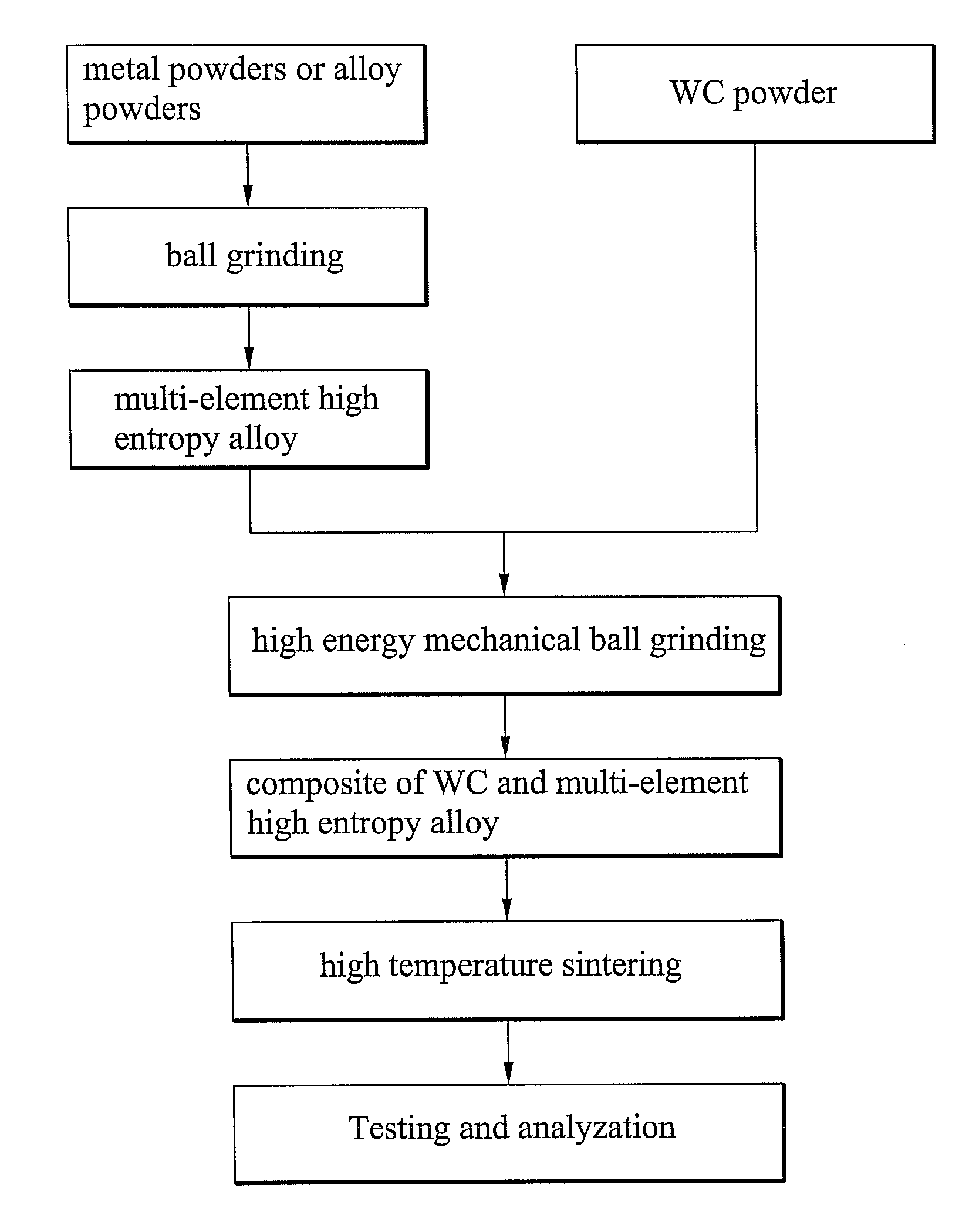

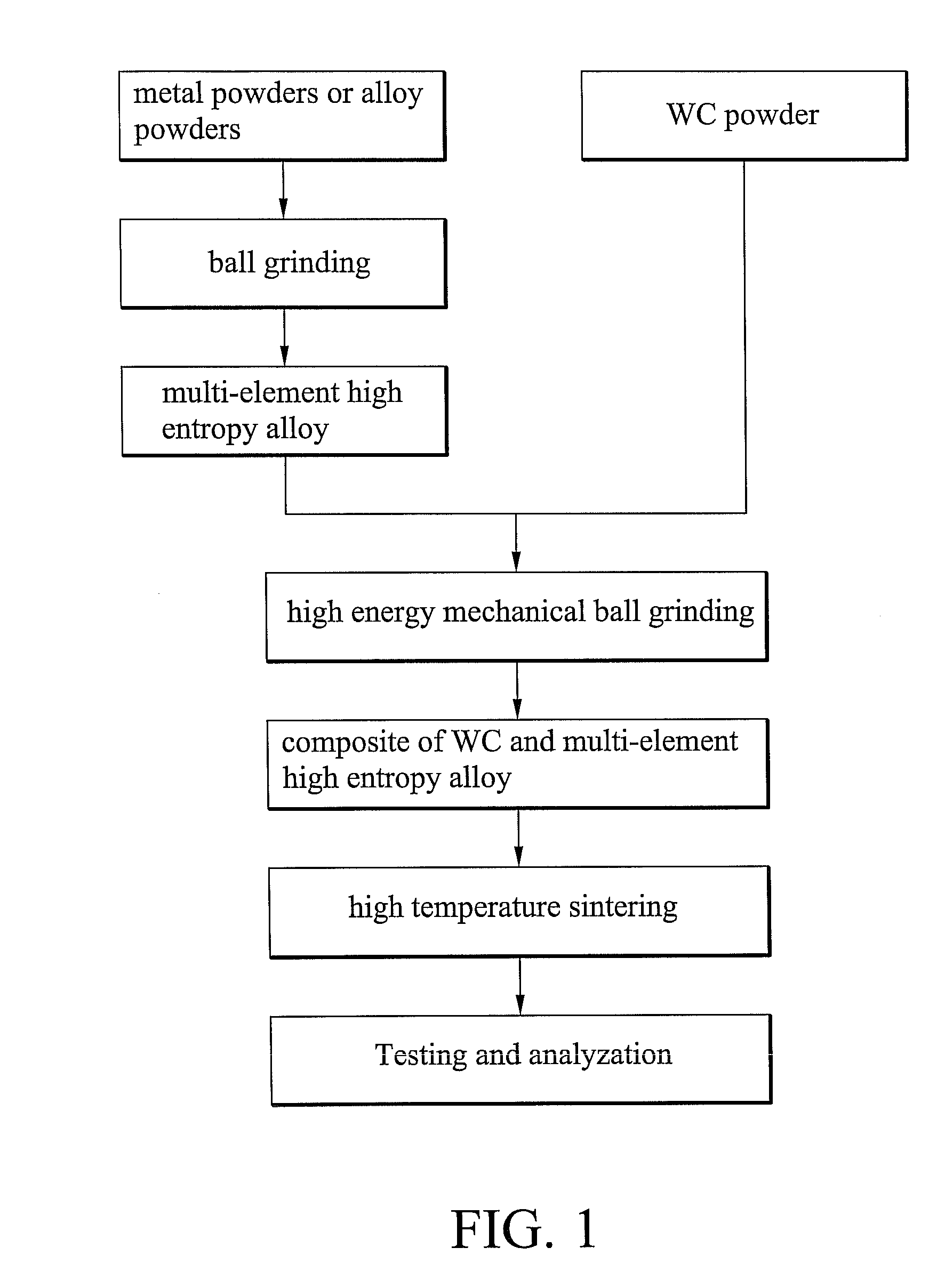

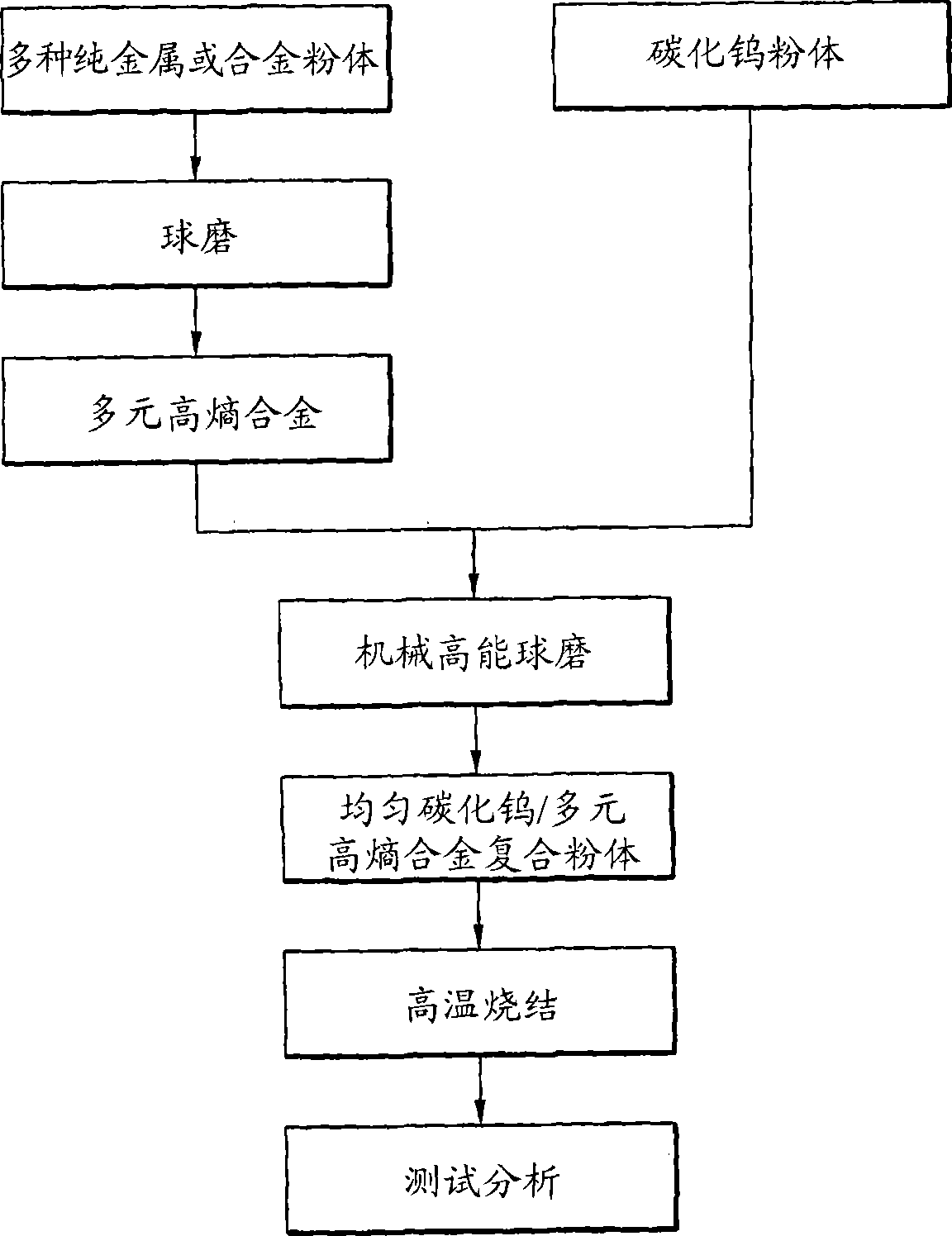

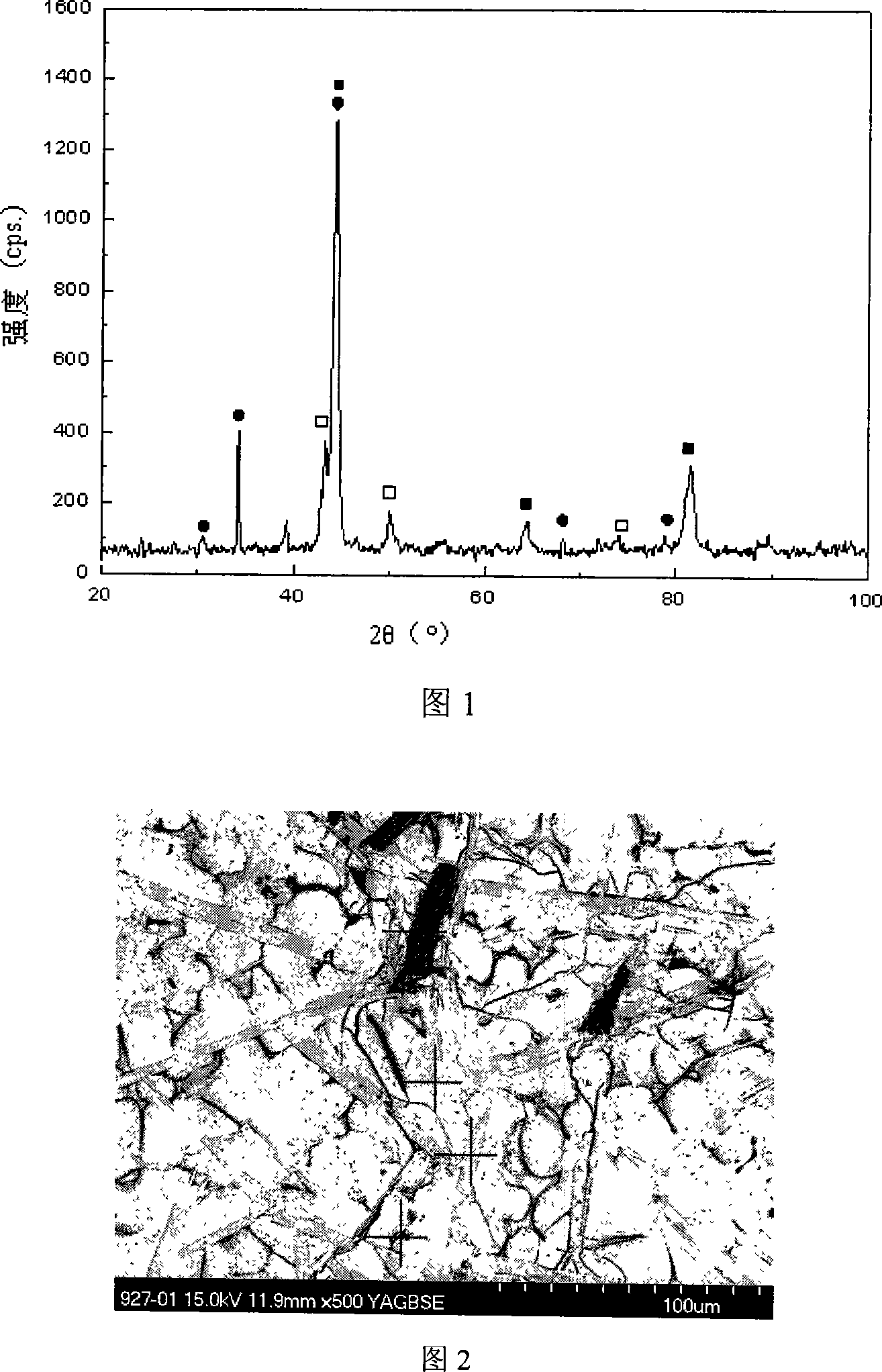

Ultra-hard composite material and method for manufacturing the same

The disclosed is an ultra-hard composite material. The method for manufacturing the ultra-hard composite material includes mixing a metal carbide powder and a multi-element high-entropy alloy powder to form a mixture, green compacting the mixture, and sintering the mixture to form the ultra-hard composite material. The described multi-element high-entropy alloy consists of five to eleven principal elements, with every principal element occupying a 5 to 35 molar percentage of the alloy.

Owner:IND TECH RES INST

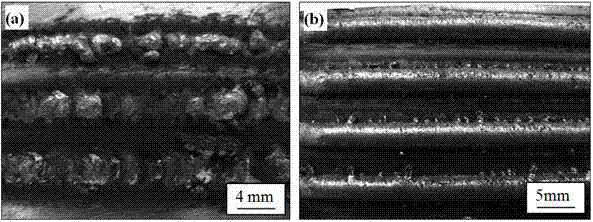

Laser-cladding high-entropy alloy powder and preparation method of high-entropy alloy coating

ActiveCN103290404AImprove coating qualityHigh hardnessMetallic material coating processesHigh entropy alloysOperability

The invention discloses laser-cladding high-entropy alloy powder. The laser-cladding high-entropy alloy powder comprises the following elements in percentage by weight: 10%-15% of Fe, 14%-17% of Cr, 22%-25% of Ni, 22%-24% of Co, 22%-24% of Mn, 0%-4% of Si and 0%-4% of B. The invention further discloses a scheme of adding another element Al based on the gradients of the scheme, and a method for preparing a high-entropy alloy coating by using the laser-cladding high-entropy alloy powder. According to the technical scheme, after laser cladding, good coating quality is realized; a phase structure of the coating retains peculiar solid solution structure of high-entropy alloy, and the atomic percent of each main metal element in the cladding coating satisfies nominal category of the high-entropy alloy; the coating has a plurality of excellent performances of high rigidity, high temperature resistance, wear resistance, corrosion resistance and the like; the technical repeatability and operability are both greatly improved, so that the high-entropy alloy is popularized and applied in surface modification of laser materials.

Owner:ZHEJIANG UNIV OF TECH +1

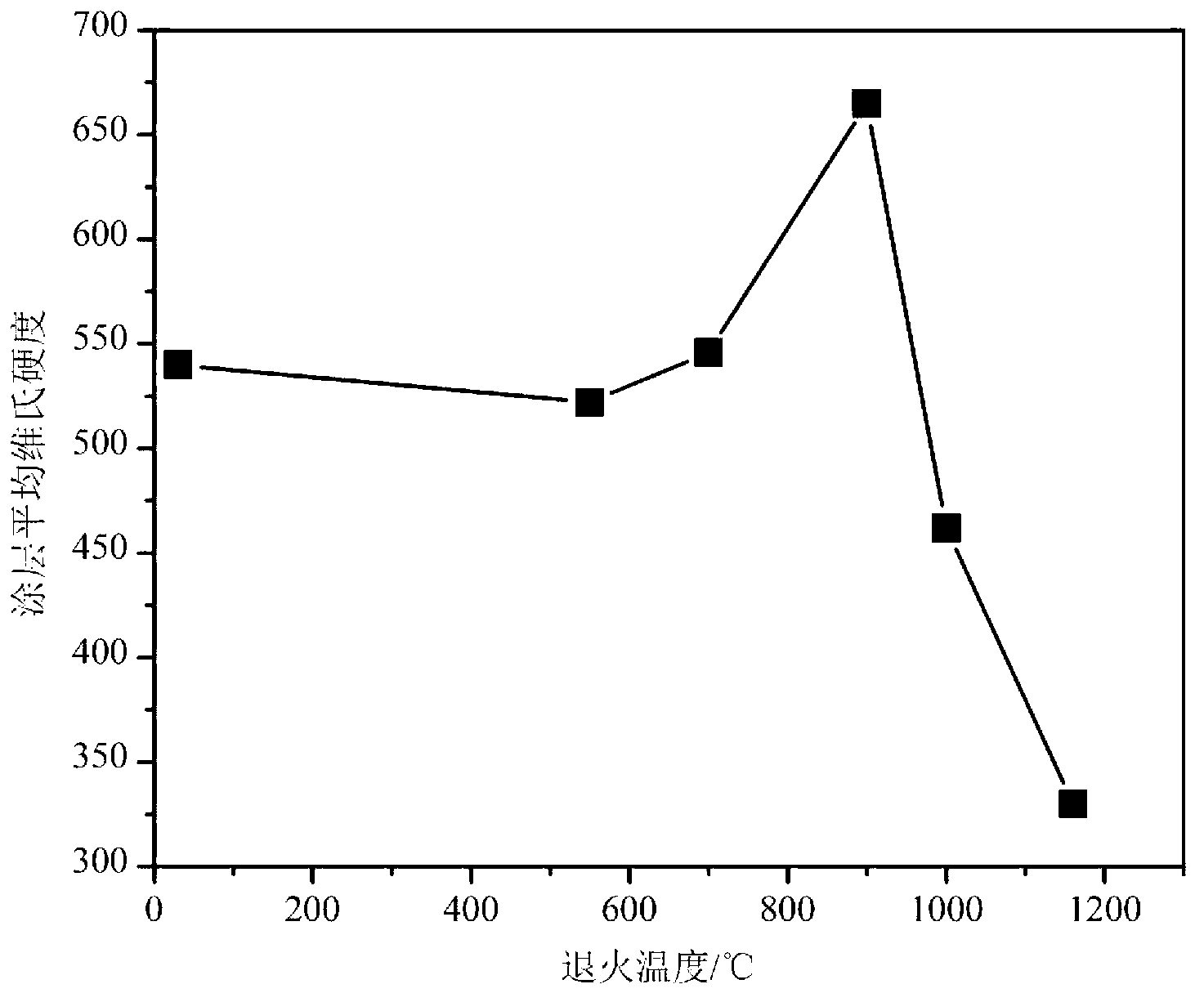

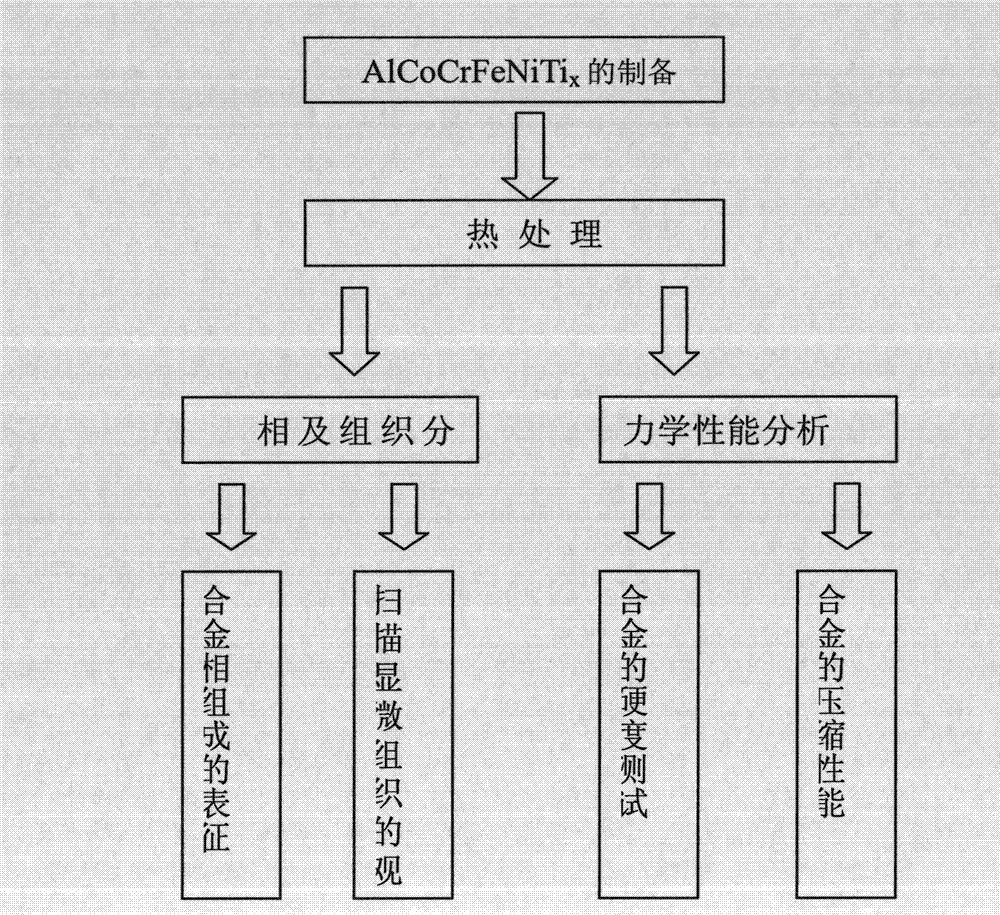

AlCoCrFeNiTix high-entropy alloy material and method for preparing same

The invention relates to a high-entropy alloy material and a method for preparing the same. The component of the high-entropy alloy material is AlCoCrFeNiTix, wherein x represents a molar ratio, and the value range is between 0.1-0.4. The method for preparing the material comprises: preparing raw materials, adopting the alloy smelting raw materials including Al, Co, Cr, Fe, Ni and Ti, and accurately weighing and proportioning according to the molar ratio; then, purifying oxide on a metal surface; putting the prepared raw materials into a tank in a water-cooling copper-formed mold smelting pool, vacuumizing, filling argon, controlling smelting current to be at about 250 ampere and smelting time for 30-60 seconds, turning an alloy block after alloys are fully mixed, putting an alloy ingot into a tank of a water-cooling copper-formed mold, regulating the smelting current, opening a suction casting air suction valve after the alloys are uniformly smelted, utilizing the negative pressure in a pump for suction casting, and taking out the alloy ingot after an alloy mould is cooled. Compared with the conventional crystalline state alloy, the high-entropy alloy material has relative high thermal stability, hardness, yield strength, breaking tenacity, plastic deformation and work hardening capacity.

Owner:TAIYUAN UNIV OF TECH

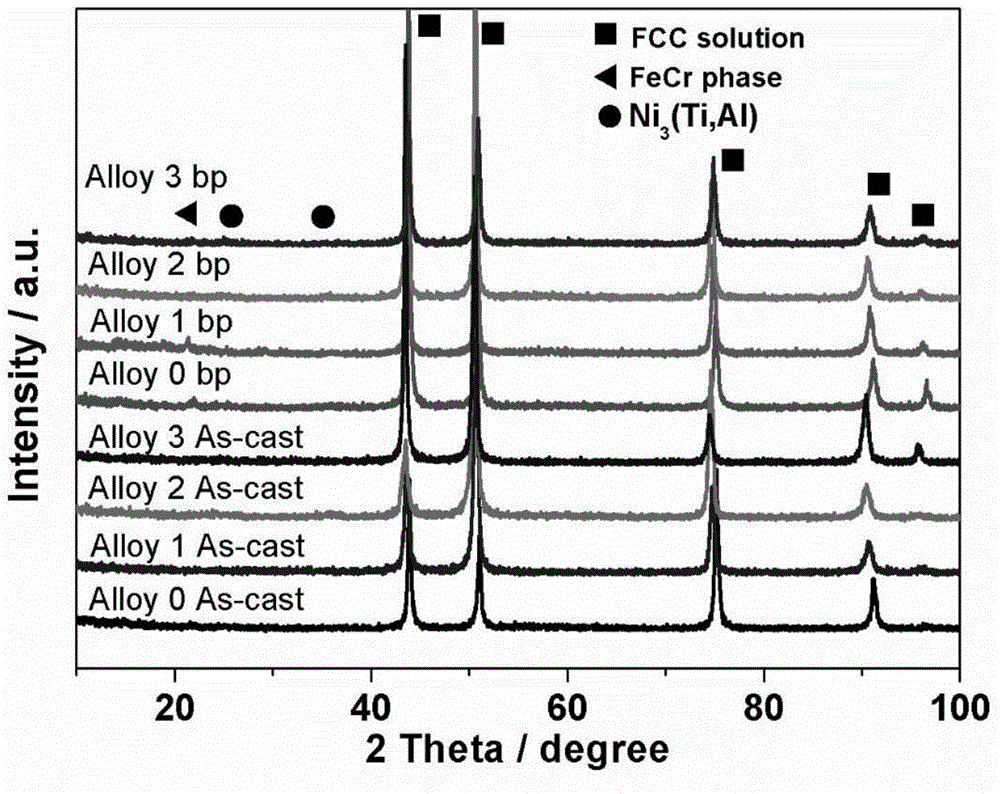

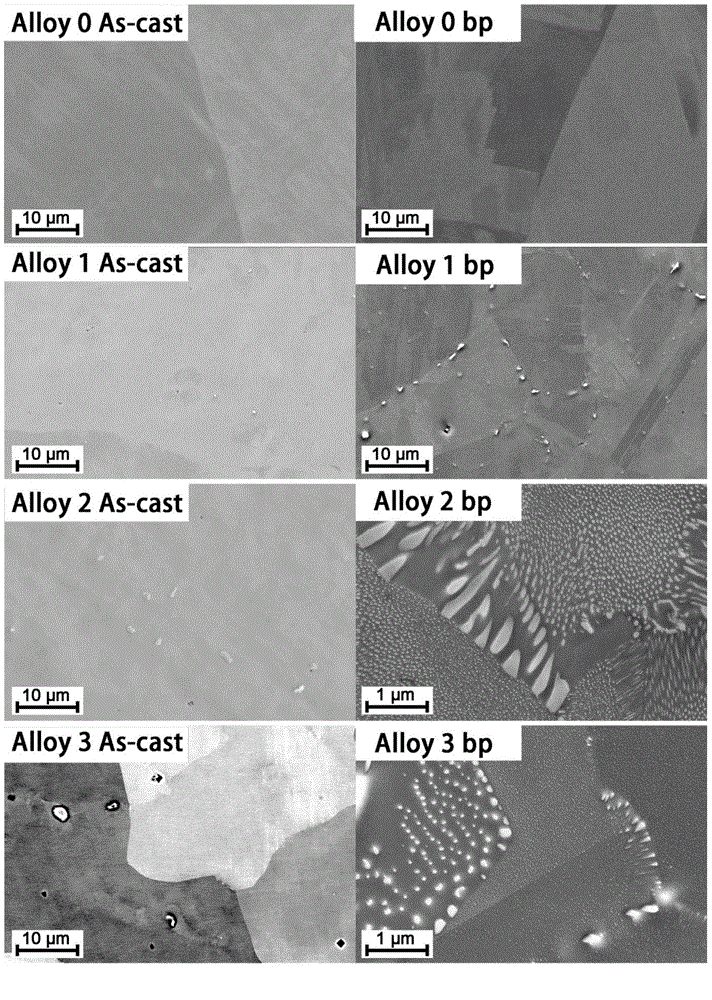

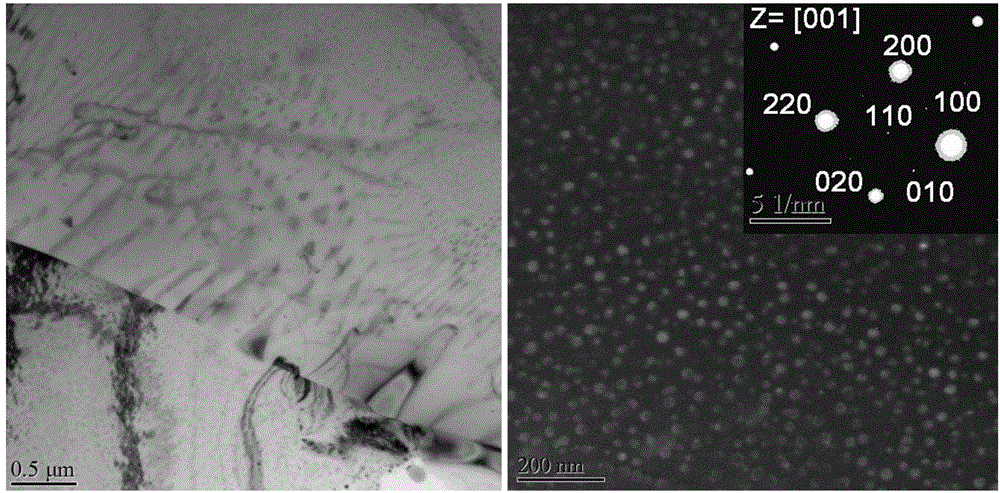

High-entropy alloy with dispersion nano-sized precipitate strengthening effect and preparing method thereof

ActiveCN104694808AWide range of ingredientsControl mechanical propertiesElectric arc furnaceHigh entropy alloys

The invention discloses high-entropy alloy with the dispersion nano-sized precipitate strengthening effect and a preparing method thereof. The method comprises the steps of removing oxidized skin of a metal material, and then conducting weighing and burdening accurately according to a ratio; conducing smelting in an electric-arc furnace in an argon shield atmosphere of titanium absorbed oxygen to obtain an initial high-entropy alloy ingot, and conducting cold rolling, wherein rolling reduction is 20-50%; placing the ingot in a heat treatment furnace with a temperature ranging from 900 DEG C to 1000 DEG C for heat preservation for 0.5-2 hours, and conducting quenching; placing the ingot in a heat treatment furnace with a temperature ranging from 700 DEG C to 800 DEG C for heat preservation for 2-18 hours, and conducting quenching. By means of precipitation strength, on the premise that high plasticity is kept, yield strength and tensile strength are improved greatly. The room-temperature tensile strength of (FeCoNiCr)94Ti2Al4 in the final state reaches 1094 MPa, plastic elongation is 35%, work hardening effect is remarkable, comprehensive room-temperature mechanical property is prominent, high-temperature tensile strength can reach 400 MPa at the temperature of 800 DEG C and strain rate of 10<-3>, steady creep rate is smaller than or equal to 10<-8> under the stress of 100 MPa and at the temperature of 750 DEG C, and high-temperature tensile strength and creep mechanical property are excellent.

Owner:UNIV OF SCI & TECH BEIJING

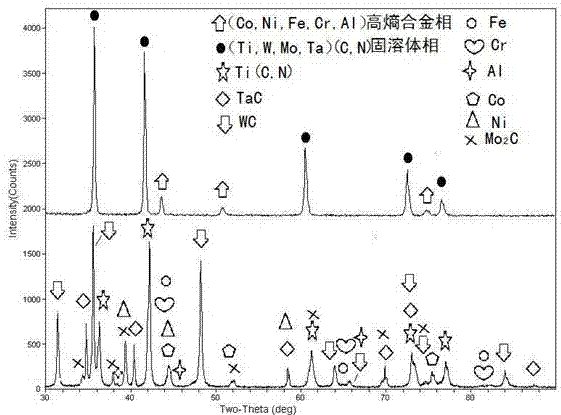

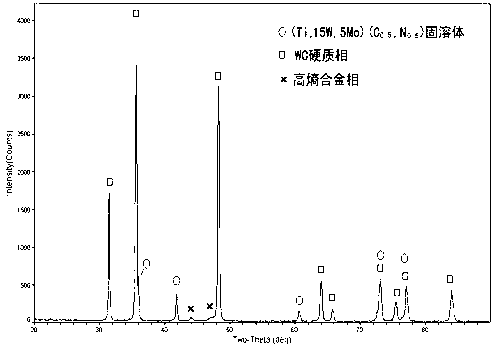

Titanium carbonitride based metal ceramic based on high-entropy alloy binder phase and preparation method of metal ceramic

InactiveCN102787266AImprove corrosion resistanceImprove wear resistanceRare-earth elementHigh entropy alloys

Disclosed is a titanium carbonitride based metal ceramic material based on a high-entropy alloy binder phase. The binder phase of the titanium carbonitride based metal ceramic material is high-entropy alloy, the hard phase of the titanium carbonitride based metal ceramic material is carbonitride solid solution, the high-entropy alloy binder phase includes at least four of ferrum, cobalt, nickel, chromium, aluminum, vanadium, titanium, copper, zirconium, molybdenum, manganese and rare earth elements, and the molar content ratio of each element ranges from 5% to 35%. In a preparation method, the titanium carbonitride based metal ceramic material based on the high-entropy alloy binder phase comprises raw materials including, in weight percent, 3-30% of the high-entropy alloy binder phase, 0-30% of second carbide powder and the balance carbonitride solid solution powder, the carbonitride solid solution powder includes at least one of Ti (Cx, N1-x), (Ti, M1...) and (Cx, N1-x), the M1 component of the (Ti, M1...) and (Cx, N1-x) includes at least one of W, Mo, Ta, Nb, V, Cr, Zr, Hf, Y and lanthanide, and 0<x<1 in the Ti (Cx, N1-x), (Ti, M1...) and (Cx, N1-x). The preparation method includes the process steps of (1) ball-milling mixing, (2) forming and (3) low-pressure sintering.

Owner:SICHUAN UNIV

Superhard composite material and method for preparation thereof

The invention relates to a super-hard composite material. The preparation method for the composite material comprises the step of mixing ceramic phase powder and multi-element high-entropy alloy powder to form a mixture, a pressed mixture and a sintered mixture, so as to prepare the super-hard composite material. The multi-element high-entropy alloy is an alloy containing 5 to 11 main elements, and each main element accounts for 5 to 35 molar percent of the multi-element high-entropy alloy.

Owner:IND TECH RES INST

High-entropy alloy powder used for spraying

InactiveCN102828139AImprove self-fluxingImprove spraying effectMolten spray coatingHigh entropy alloysWear resistance

The invention discloses high-entropy alloy powder used for spraying, belonging to the technical field of alloy materials. The high-entropy alloy powder comprises five or more than five metal elements and non-metal elements Si and B, wherein addition amount of each metal element accounts for 5-35mol% of the total mole number of the high-entropy alloy powder, content of the added non-metal element Si accounts for 1-20mol% of the total mole number of the high-entropy alloy powder, and the content of the added non-metal element B accounts for 1-10mol% of the total mole number of the high-entropy alloy powder. The high-entropy alloy powder disclosed by the invention and a coating prepared by the high-entropy alloy powder after solidification can avoid precipitation of massive brittle phases after the traditional multi-element alloy is solidified, the coating has a simple fcc or bcc solid solution phase structure, brittleness of the multi-element alloy can be greatly reduced, the coating has multiple excellent performances such as high hardness, thermostability, wear resistance and corrosion resistance, and the high-entropy alloy powder can be applied to multiple surface coating technologies such as thermal spraying and laser cladding and has a wide application prospect.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Precipitation Hardening High Entropy Alloy and Method of Manufacturing the Same

High-entropy alloy, particularly a precipitation hardening high entropy alloy, is provided as a component material used in electromagnetic, chemical, shipbuilding, mechanical, and other applications, a component material used in extreme environments requiring high strength and good corrosion resistance, and the like.

Owner:THE IND & ACADEMIC COOPERATION & CHUNGNAM NAT UNIV

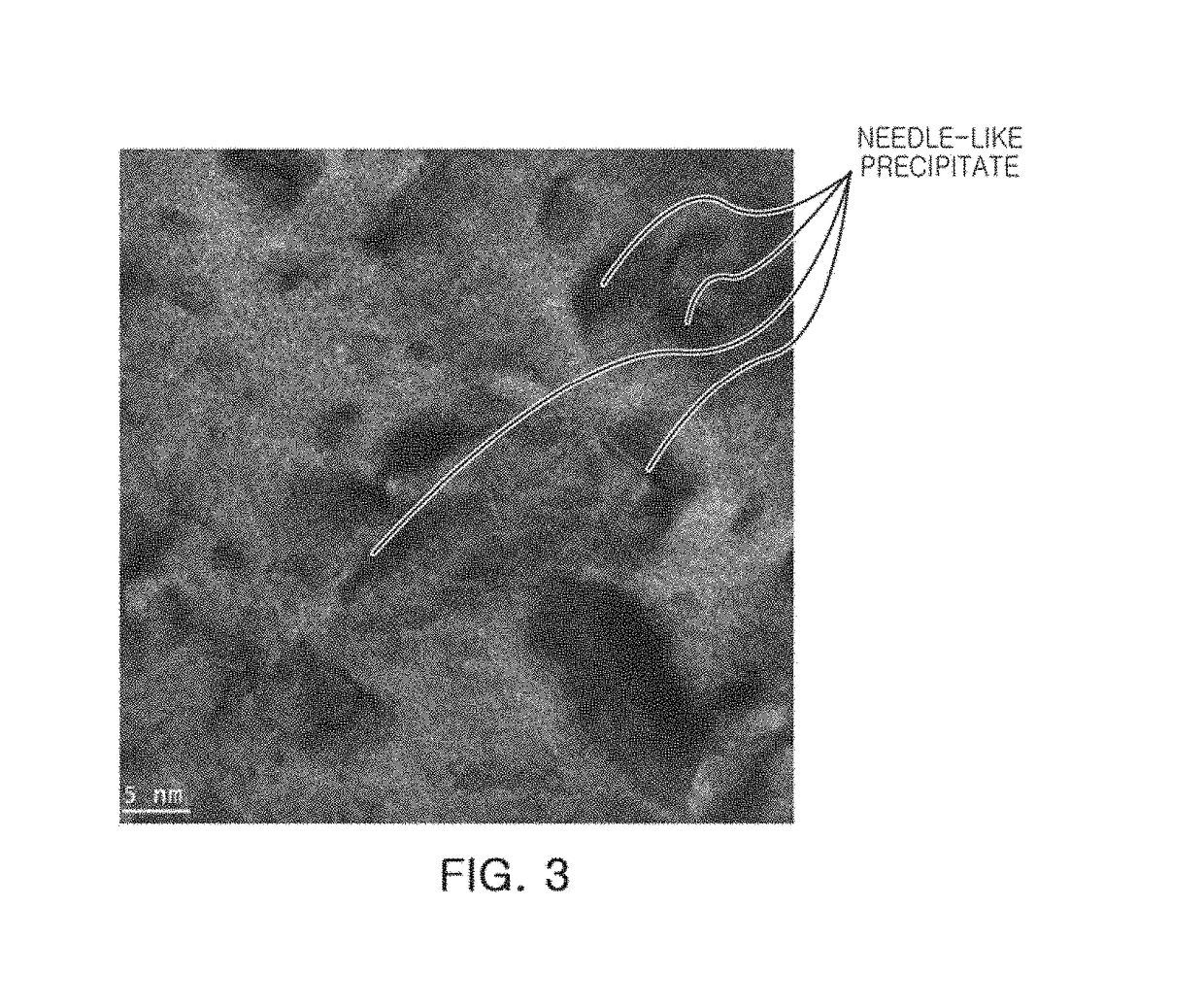

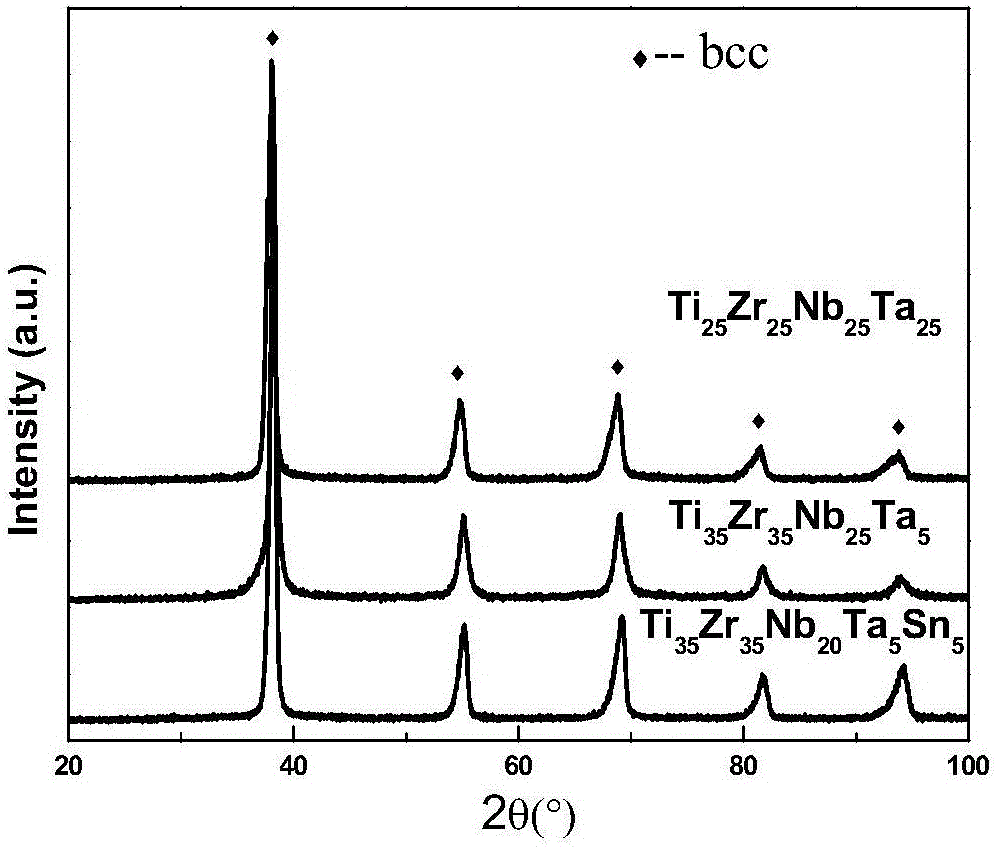

Biomedical TiZrNbTa high-entropy alloy and preparation method thereof

The invention discloses a biomedical TiZrNbTa high-entropy alloy and a preparation method thereof. The high-entropy alloy has a chemical formula of (TiaZrb)x(NbcTad)yMz; the atomic percents of all components are as follows: a not more than 35 at% and not less than 0, b not more than 35 at% and not less than 0, c not more than 35 at% and not less than 0, d not more than 35 at% and not less than 0, a+b=x, c+d=y, x not more than 70 at% and not less than 5, y not more than 70 at% and not less than 5, M is any one or more in V, Mo, Sn, W, Mn, Al, Fe, Co, Ni, Cu, Cr and Zn, z not more than 35 at% and not less than 0, and x+y+z=100. The alloy is higher in strength, excellent in plasticity and low in Young modulus; the components of the alloy is free of poison on human bodies, or are low-toxicity elements to satisfy the biomedical demands; and the high-entropy alloy is broad in application prospect in the aspect of biomedical materials.

Owner:UNIV OF SCI & TECH BEIJING

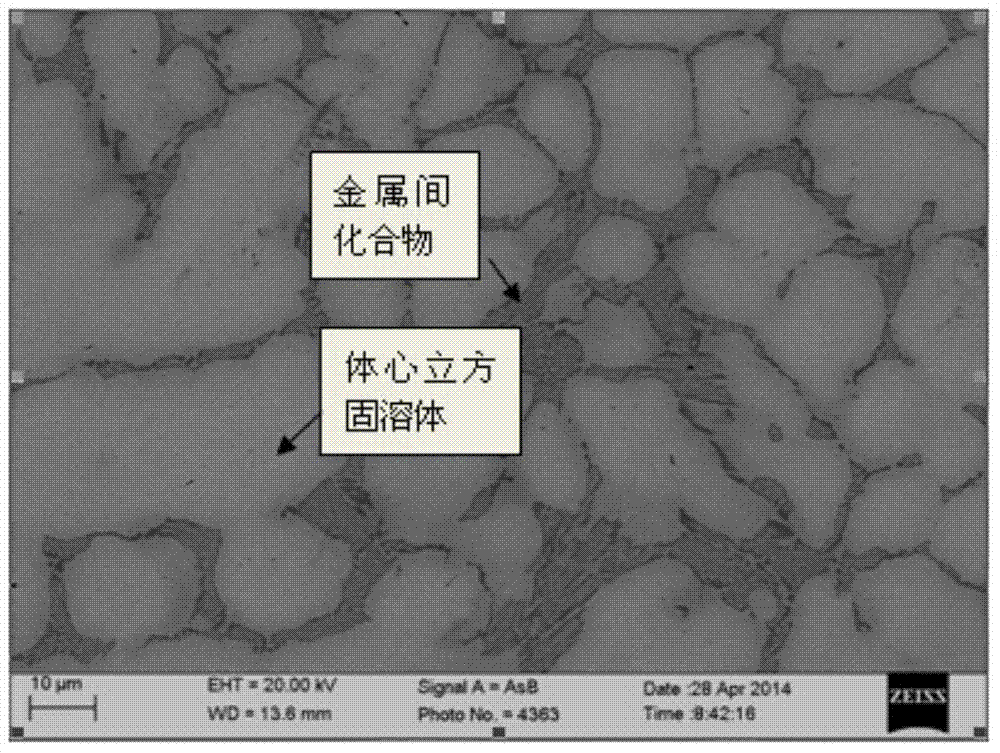

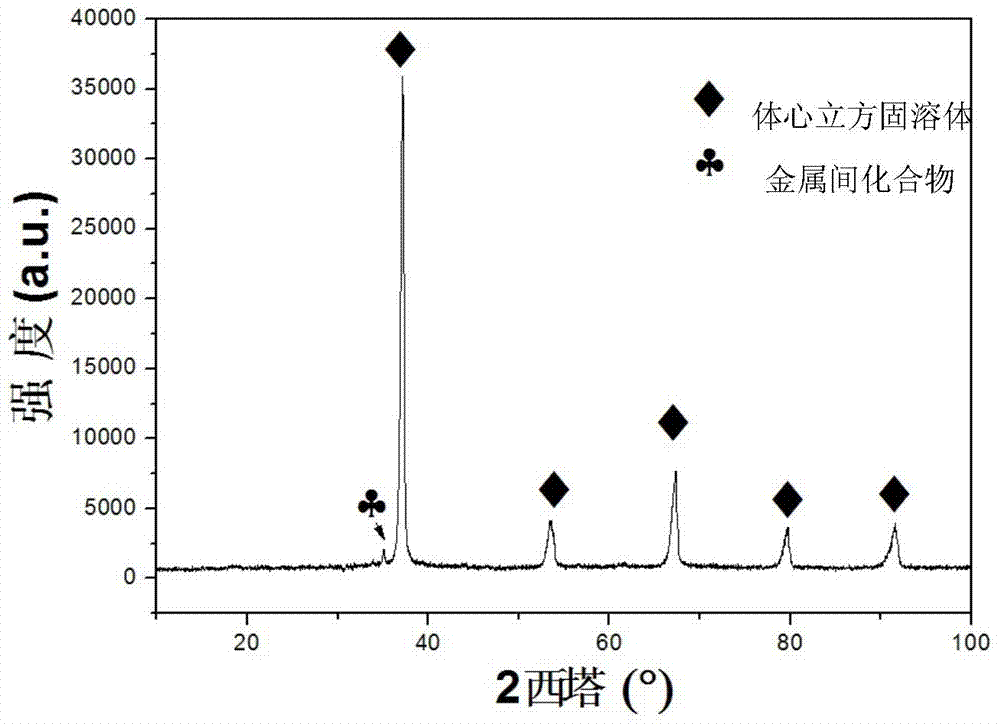

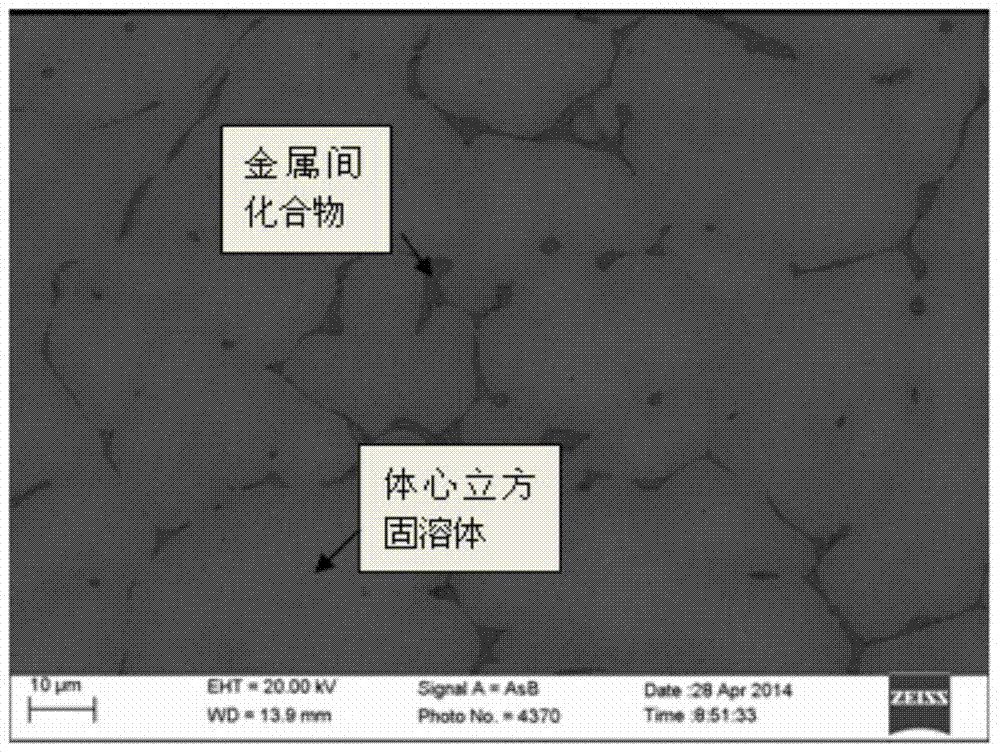

Low thermal expansion coefficient NaMxAlySiz high entropy alloy and preparation method thereof

The invention relates to a low thermal expansion coefficient NaMxAlySiz high entropy alloy and a preparation method thereof, the chemical components of the alloy are as follows: 75 <= a <= 100%, 0 <= x <= 10%, 0<= y<= 10%, 0<= z<= 5%, N is arbitrary three or more than three of Ta, Nb, Hf, Zr, Ti, Mo and W, and M is any one or more than one of V, Mn, Fe, Co, Ni and Cr. The alloy phase structure is as follows: a body centered cubic solid solution and an intermetallic compound. The alloy is prepared by arc melting method in three stages. The NaMxAlySiz high entropy alloy has a low thermal expansion coefficient at the temperature in the range of room temperature to 1000 DEG C, the change rate is less than 20%, and the alloy has a broad application prospect in the high temperature industrial field.

Owner:UNIV OF SCI & TECH BEIJING

High-entropy alloy-base composite material and preparation method thereof

The invention provides a high-entropy alloy based composite material and a method for preparation, which relates to an alloy composite material and a method for preparation. The invention provides the high-entropy alloy based composite material and a method for preparation, and a composite material whose comprehensive performance is better than high-entropy alloy. The high-entropy alloy based composite material is made from 1-45 percent of reinforced phase and 55-99 percent of high-entropy alloy base according to the volume percentage. The high-entropy alloy based composite material is prepared by an in-situ spontaneity method or a non- in-situ spontaneity method, and the reinforced phase is prepared in an original position in the high-entropy alloy base or is added from the outer portion. The invention further improves the mechanical properties of materials basing on original high-entropy alloy, and is capable of playing the potentiality of the high-entropy alloy base in maximum limit. The high-entropy alloy based composite material of the invention is capable of being used by various preparation processes, the operation is easy and is easy to operate.

Owner:HARBIN INST OF TECH

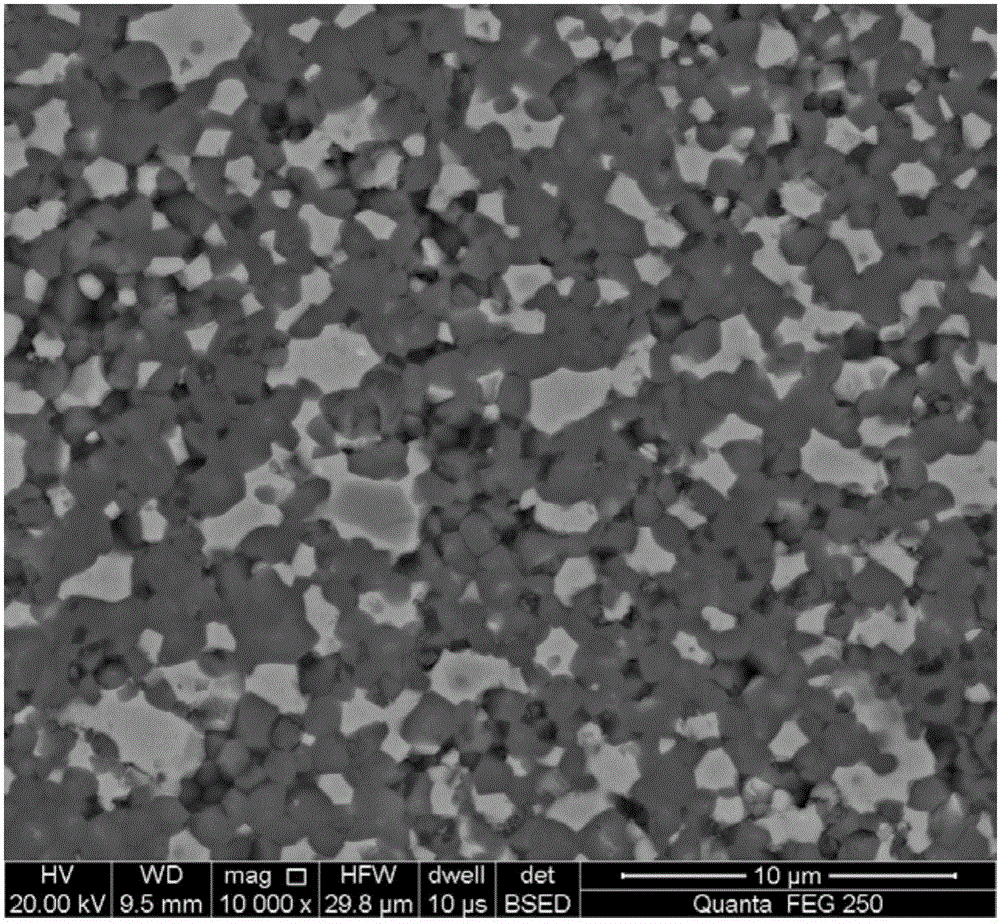

Refractory high-entropy alloy/titanium carbide composite and preparation method thereof

The invention discloses a refractory high-entropy alloy / titanium carbide composite. A refractory high-entropy alloy serves as a matrix phase, and titanium carbide serves as a wild phase; and elements in the refractory high-entropy alloy are selected from at least four kinds of elements of W, Mo, Ta, Nb, V, Ti, Zr, Hf and Cr. A preparation method of the refractory high-entropy alloy / titanium carbide composite comprises the steps that at least four kinds of carbonization metal powder in tungsten carbide, molybdenum carbide, tantalum carbide, niobium carbide, vanadium carbide, the titanium carbide, hafnium carbide, zirconium carbide and chromium carbide are selected and mixed according to the equal molar ratio or the ratio close to the equal molar ratio to form high-entropy matrix powder; and after the high-entropy matrix powder and titanium powder are mixed, alloy mechanization is carried out, then spark plasma sintering or hot-press sintering is carried out, and the refractory high-entropy alloy / titanium carbide composite is obtained. The density and cost of the composite are reduced while the hardness of the composite is improved, excellent high-temperature performance is achieved, and the requirement for manufacturing a high-temperature structural component is met.

Owner:江西咏泰粉末冶金有限公司

Nitrogen-strengthened TiZrHfNb-based high-entropy alloy and preparation method thereof

ActiveCN105671392AThe scope of application of large ingredientsBroad preparation conditionsCrucibleHigh entropy alloys

Owner:UNIV OF SCI & TECH BEIJING

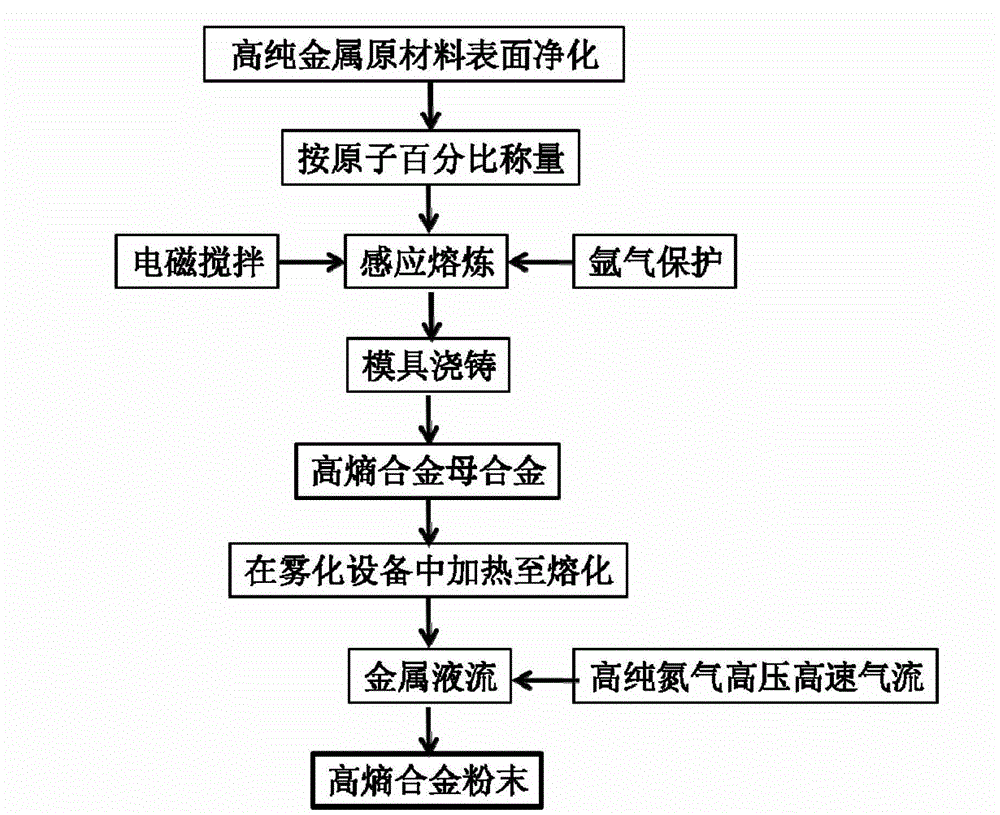

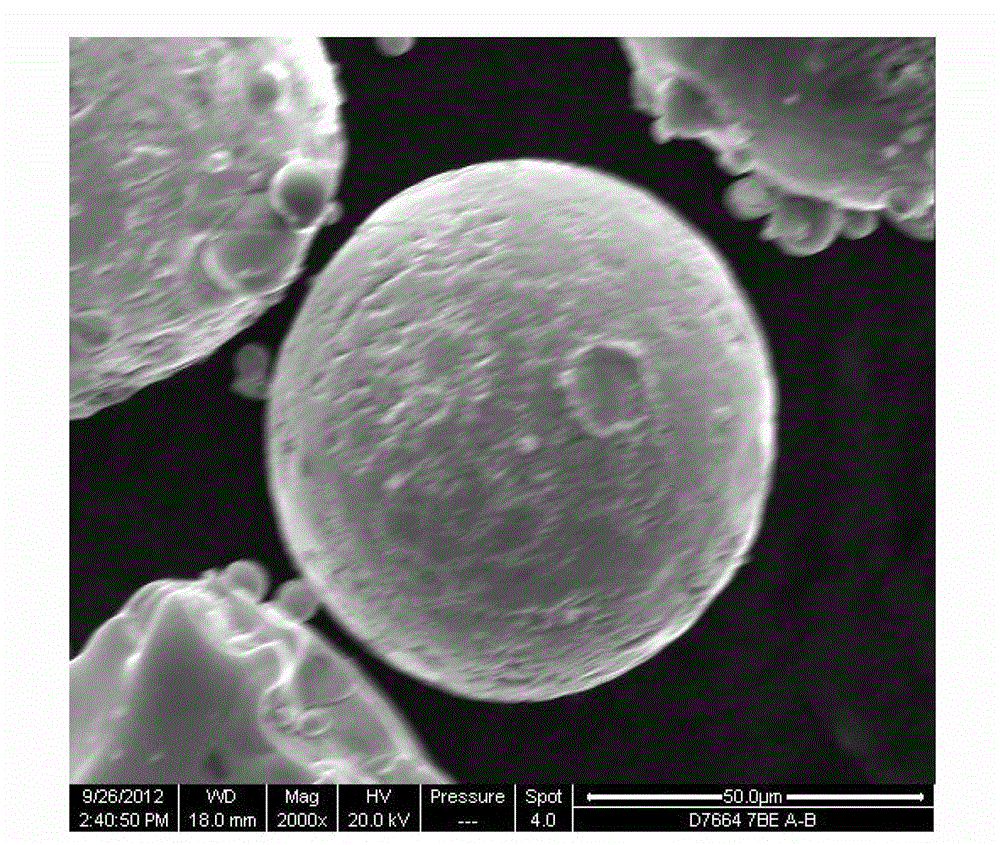

High-entropy alloy powder material for supersonic spraying and manufacturing method thereof

ActiveCN103056352AImprove organizationImprove performanceMolten spray coatingHigh entropy alloysOxygen content

The invention relates to a high-entropy alloy powder material for supersonic spraying and a manufacturing method thereof. The high-entropy alloy powder material for the supersonic spraying can be obtained and is characterized in that the high-entropy alloy powder material comprises, by atomic percent, 10-20% of Al, 15-20% of Fe, 15-20% of Co, 15-20% of Ni, 15-20% of Cr and 15-20% of Cr, and total percent is 100%. The high-entropy alloy powder material is made by a gas atomization rapid solidification process. Particles of high-entropy alloy powder are spherical or ellipsoidal, a phase structure is composed of a solid solution phase with a simple face-centered cubic or body-centered cubic structure, ingredients and tissues are even, alloy solid solubility is high, and segregation is small. The manufacturing method of the high-entropy alloy powder material is controllable in powder size, good in mobility, low in oxygen content, small in environment pollution, high-entropy alloy coating with excellent combination property or a block high-entropy alloy material with more excellent performance can be obtained through a supersonic spraying process.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

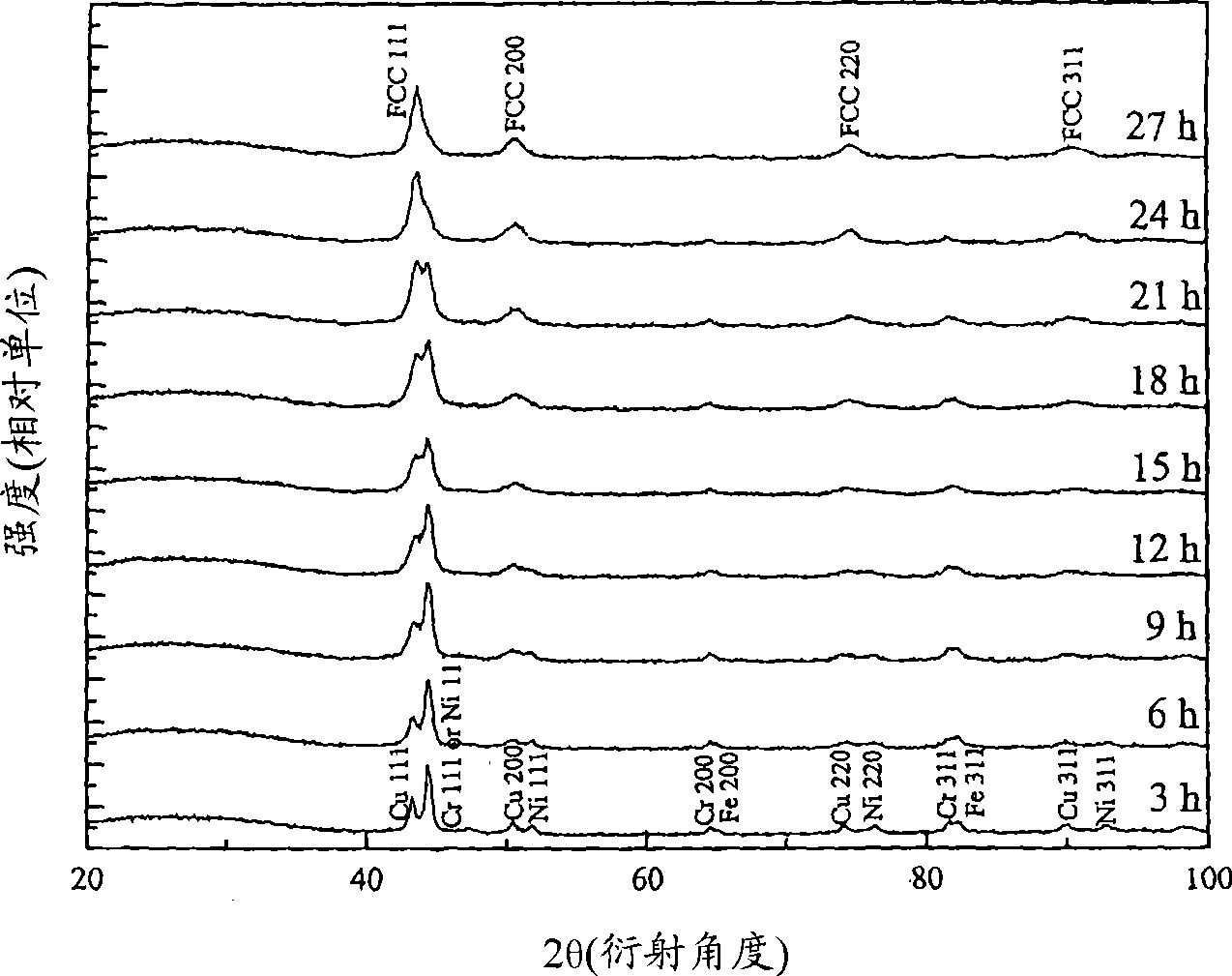

Preparation method of ultra-fine grain high-entropy alloy

The invention belongs to the technical field of metal materials and machining and relates to a preparation method of an ultra-fine grain high-entropy alloy. Firstly, smelting is conducted, an FeCoCrNiMn series high-entropy alloy is compounded to be an intermediate alloy composed of pure metal with the purity being higher than 99.5% or alloy elements, a vacuum furnace is adopted for smelting, and the furnace casting temperature is 1550-1600 DEG C; then after cast ingots are subjected to homogenization heat treatment at the temperature of 1000-1350 DEG C, strong deformation asynchronous and synchronous mixed cold rolling treatment is conducted, continuous rolling is conducted through single-pass large percent reduction, the total rolling quantity is no smaller than 85%, and alloy structure nanocrystallization is achieved; and the rolled alloy is subjected to annealing treatment under the temperature of 450-800 DEG C, and the high-entropy alloy of an ultra-fine grain structure is obtained. Compared with the prior art, the preparation method is simple in technique, easy to achieve on a plate rolling production line, high in production efficiency and low in cost; and the size of the prepared ultra-fine grain high-entropy alloy is large, the comprehensive mechanical performance is excellent, and the preparation method can be applied to the fields of engineering machinery, aeronauticsand astronautics, military industry, electronics, instruments and the like.

Owner:SHANGHAI JIAO TONG UNIV

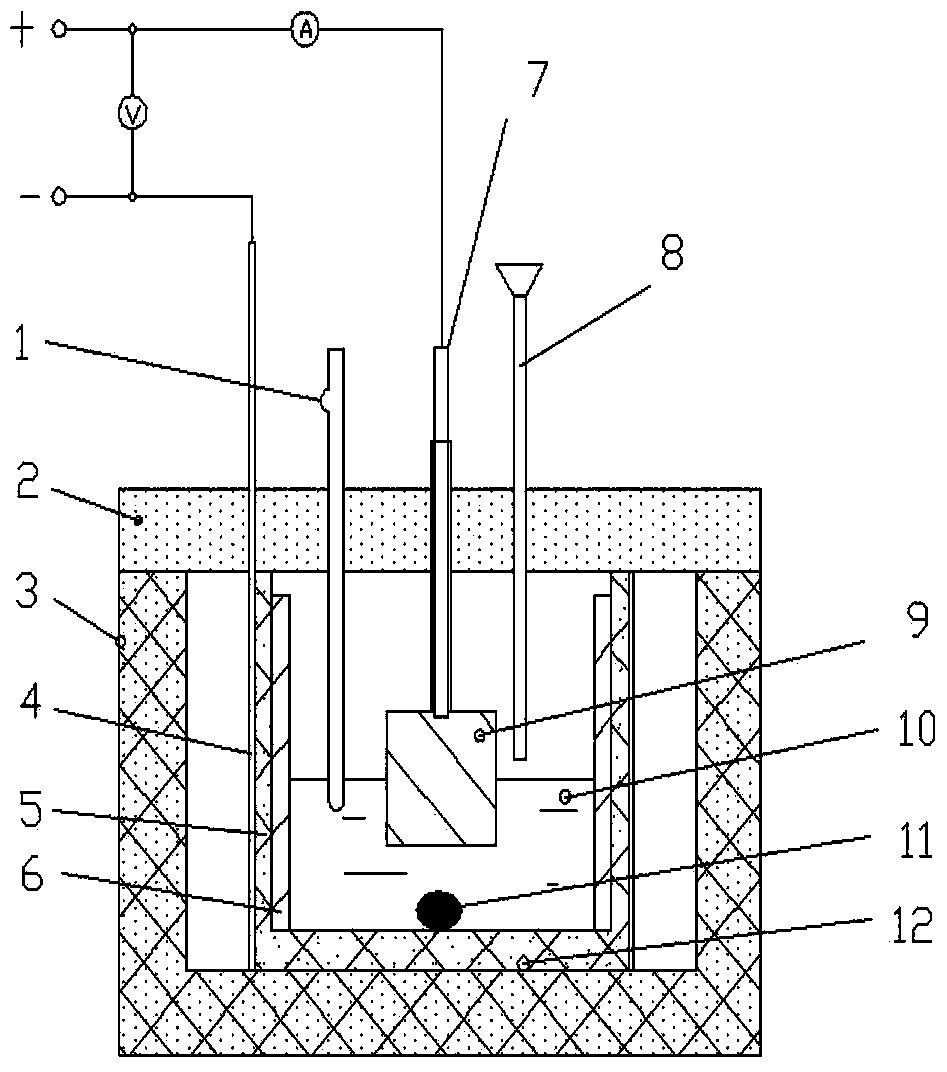

Aluminum electrolysis inert anode

InactiveCN103757661AAvoid consumptionWith energy saving and emission reductionElectrolysisHigh entropy alloys

The invention provides an aluminum electrolysis inert anode of which the material is a high-entropy alloy. The high-entropy alloy contains 5-10 alloy elements of which the mole ratio can be identical or different; and the atomic percent of each main element is 5-35%. The high-entropy alloy inert anode has the characteristics of favorable high-temperature oxidation resistance, high aluminum electrolysis salt corrosion resistance, high electric conductivity and the like. The high-entropy alloy prepared by the smelting method has the advantages of simple technique and low cost, and is easy for connection. When being used for aluminum electrolysis, the high-entropy alloy can avoid the consumption of the carbon anode and the emission of the CO2 gas, and has the advantages of energy saving and emission reduction.

Owner:FUJIAN UNIV OF TECH

High-entropy alloy binder phase-based nitrogen-containing hard alloy and preparation method thereof

The invention discloses a high-entropy alloy binder phase-based nitrogen-containing hard alloy, wherein the binder phase of the nitrogen-containing hard alloy is high-entropy alloy, and the hard phase of the nitrogen-containing hard alloy is uniformly distributed WC (Wolfram Carbide) and carbon nitride solid solution; the high-entropy alloy binder phase is at least four of iron, cobalt, nickel, chromium, aluminum, vanadium, titanium, copper, zirconium, molybdenum and manganese; the molar ratio of content of each element is 5-35 percent; the carbon nitride solid solution is at least one of Ti(Cx, N1-x) and (Ti, M1, ......)(Cx, N1-x); and M1 component in the (Ti, M1, ......)(Cx, N1-x) is at least one of W, Mo, Ta, Nb, V, Cr, Zr, Hf, Y and lanthanides. According to a preparation method of the high-entropy alloy binder phase-based nitrogen-containing hard alloy, the alloy comprises the raw material components in percentage by weight: 3-25 percent of high-entropy alloy binder phase, 45-96.9 percent of WC powder and 0.1-30 percent of carbon nitride solid solution powder, wherein the nitrogen element in the nitrogen-containing hard alloy is introduced through the carbon nitride solid solution. The preparation method of the multi-element composite carbon nitride solid solution-based nitrogen-containing hard alloy comprises the following steps of: (1) mixing through ball milling; (2) shaping; and (3) performing low-pressure sintering.

Owner:SICHUAN UNIV

Multi-Component Solid Solution Alloys having High Mixing Entropy

A multi-component high-entropy alloy includes a composition selected from the following group: VNbTaTiMoWRe, VNbTaTiMoW, VNbTaTiMoRe, VNbTaTiWRe, VNbTaMoWRe, VNbTiMoWRe, VTaTiMoWRe, NbTaTiMoWRe, VNbTaTiMo, VNbTaTiW, VNbTaMoW, VNbTiMoW, VTaTiMoW, NbTaTiMoW, VNbTaTiRe, VNbTaMoRe, VNbTiMoRe, VTaTiMoRe, NbTaTiMoRe, VNbTaWRe, VNbTiWRe, VTaTiWRe, NbTaTiWRe, VNbMoWRe, VTaMoWRe, NbTaMoWRe, VTiMoWRe, NbTiMoWRe, TaTiMoWRe, wherein relative amounts of each element vary by no more than ±15 atomic %.

Owner:UT BATTELLE LLC

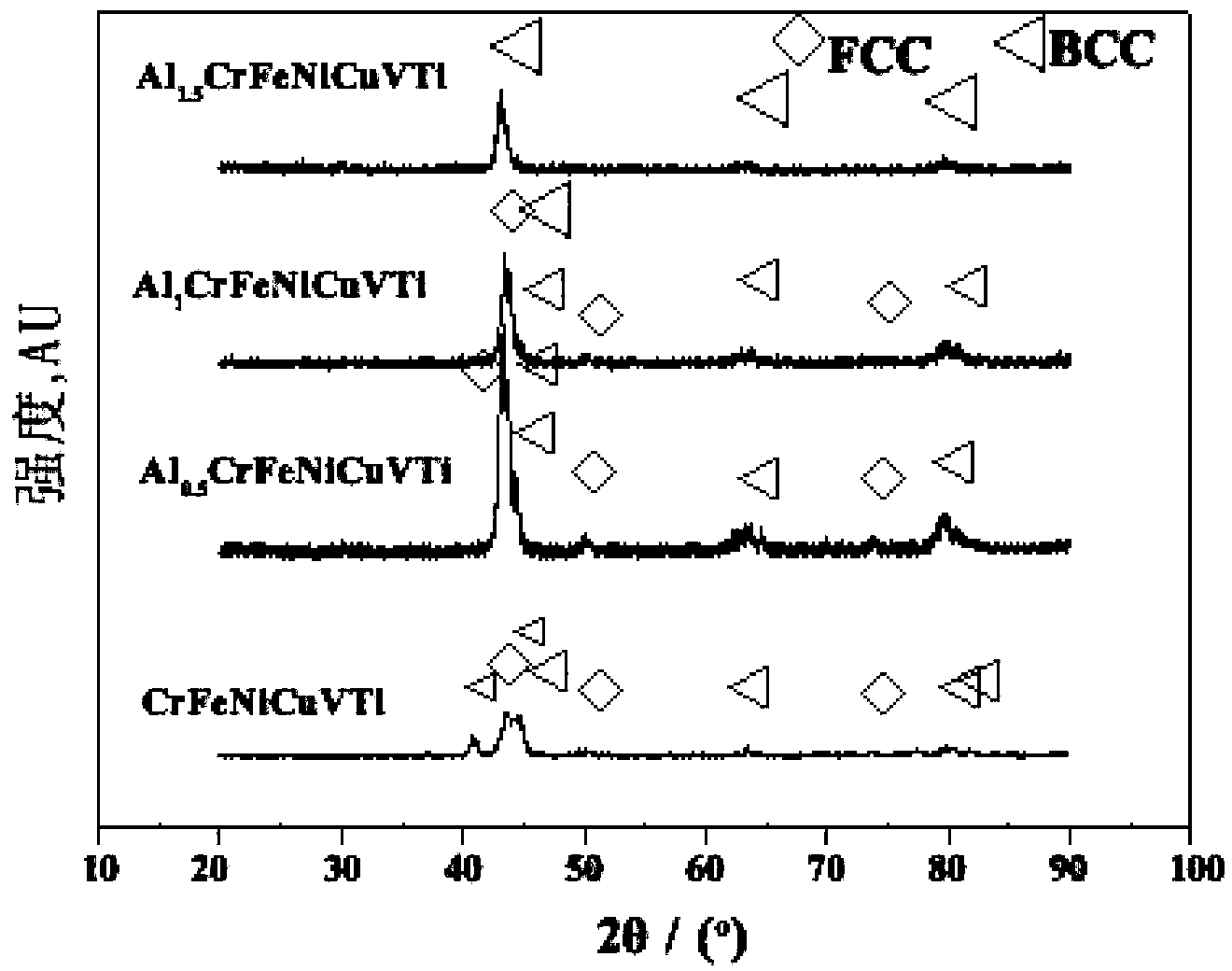

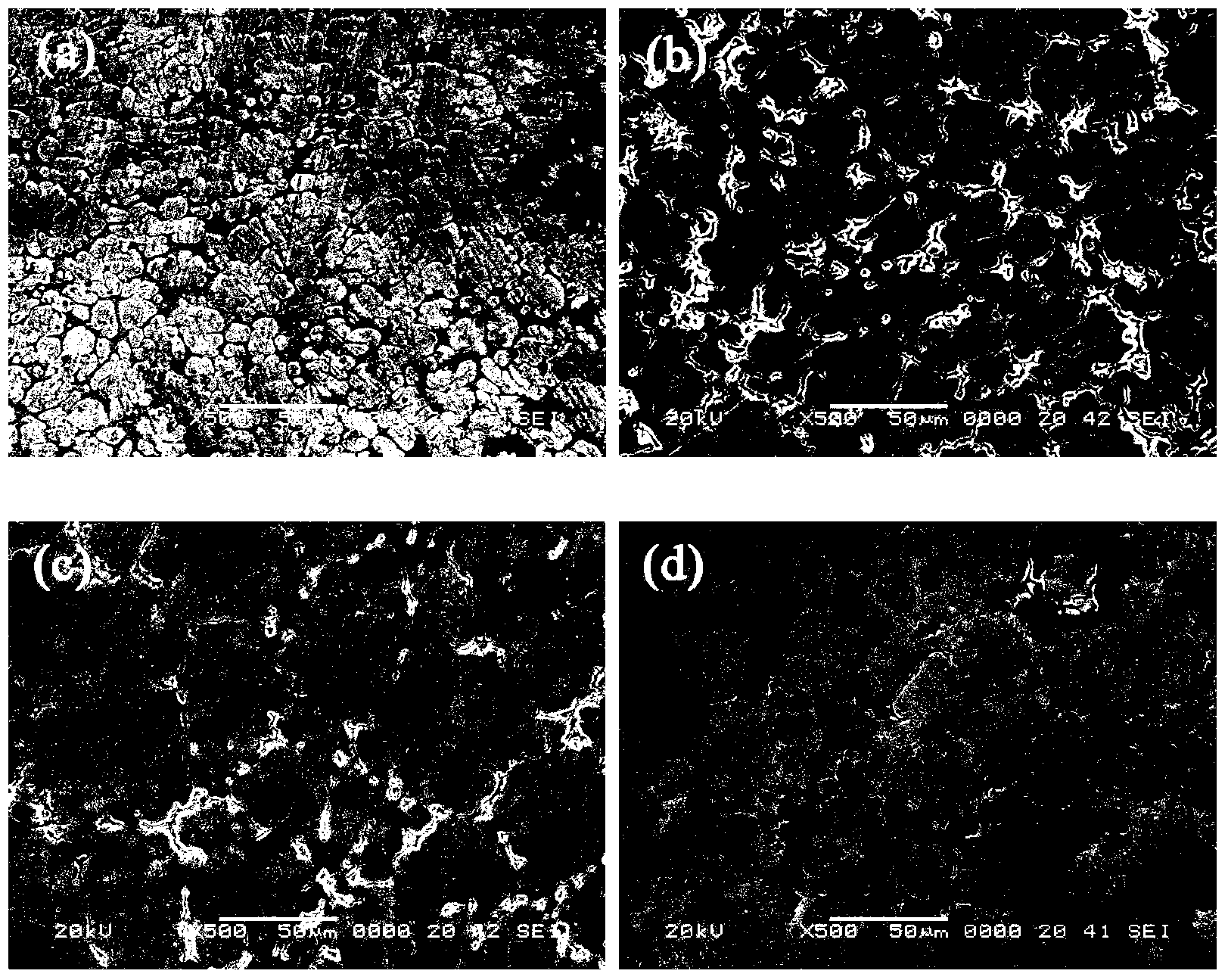

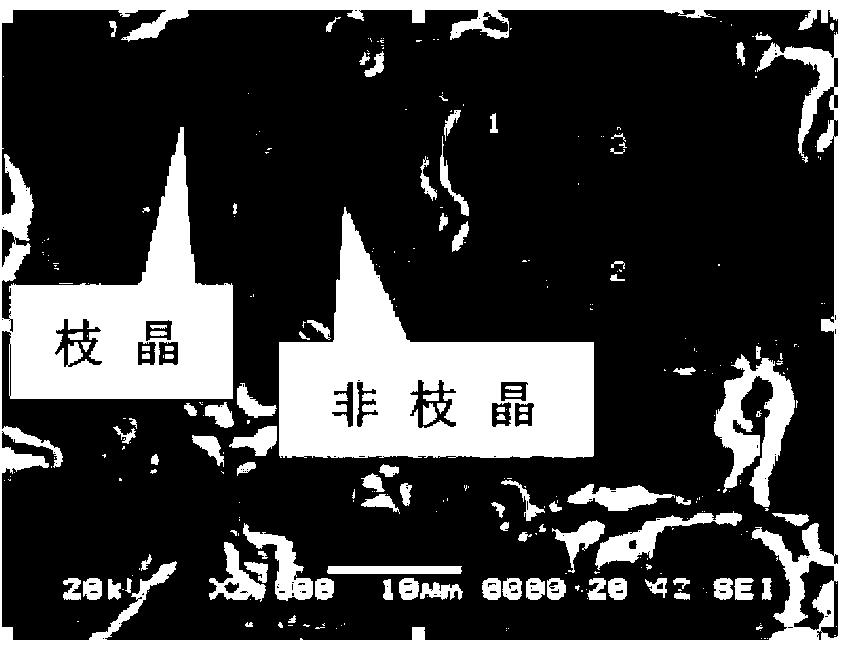

AlxCrFeNiCuVTi high-entropy alloy material and preparation method thereof

The invention relates to an AlxCrFeNiCuVTi high-entropy alloy material and a preparation method thereof. The high-entropy alloy comprises a component of AlxCrFeNiCuVTi, wherein x is a molar ratio, and the value range of x is 0.5-1.5. The preparation method of the alloy material comprises the following steps of: putting raw materials into a solution including acetone and ethanol, cleaning for 23-30 minutes by using an ultrasonic oscillator, and then drying in a 50DEG C drying oven for 6 hours; weighing alloys according to a molar ratio, and putting the alloys into a water-cooling copper crucible; when the air pressure in a furnace body reaches 3*10<-3>Pa, introducing high-purity argon to clean for 3-5 times; introducing high-purity argon to ensure that the air pressure in a furnace chamber is kept to be 0.8-0.9 atmospheric pressure, and then electrifying, wherein the smelting striking current is 30-40A, the current after stabilization is 90A, the time for smelting the alloys once is 10 seconds, and a sample needs to be smelted for 5 times repeatedly; and when the components of a smelted sample are uniformly cooled, taking the alloy out of the furnace. Compared with a conventional crystal alloy, the AlxCrFeNiCuVTi high-entropy alloy material has higher hardness, strength, high temperature stability, corrosion resistance and work hardening capacity.

Owner:梧州漓佳铜棒有限公司

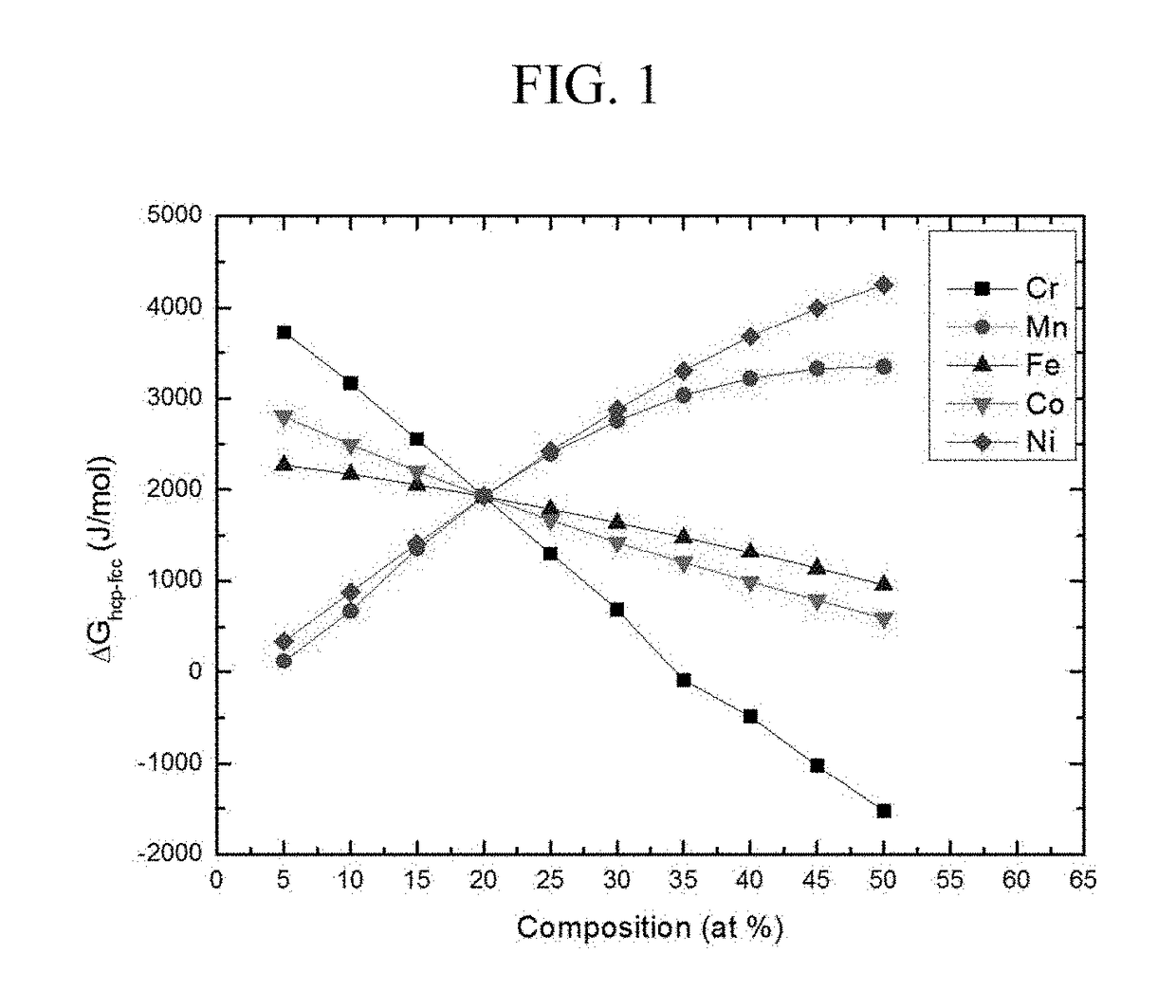

High entropy alloy having twip/trip property and manufacturing method for the same

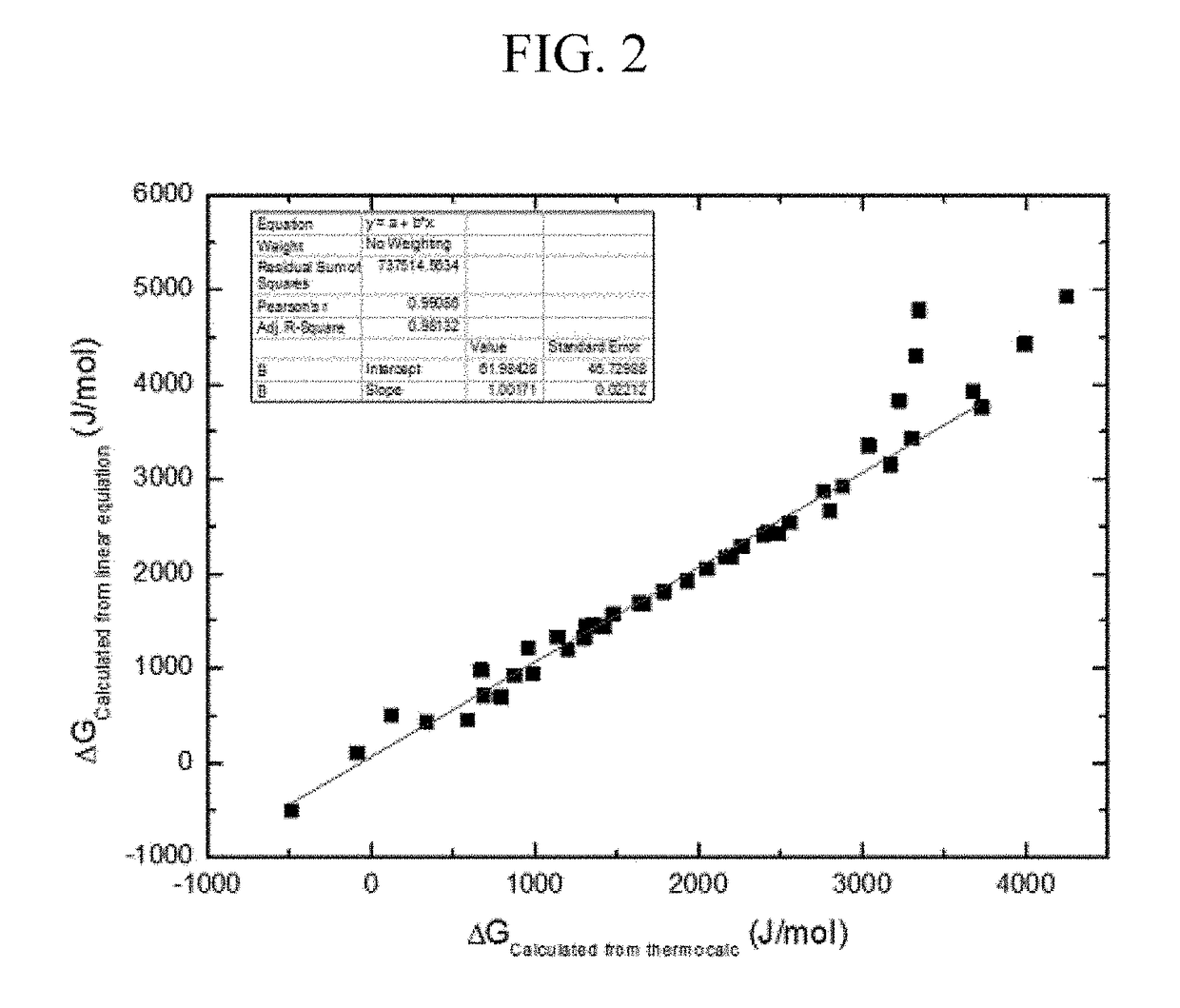

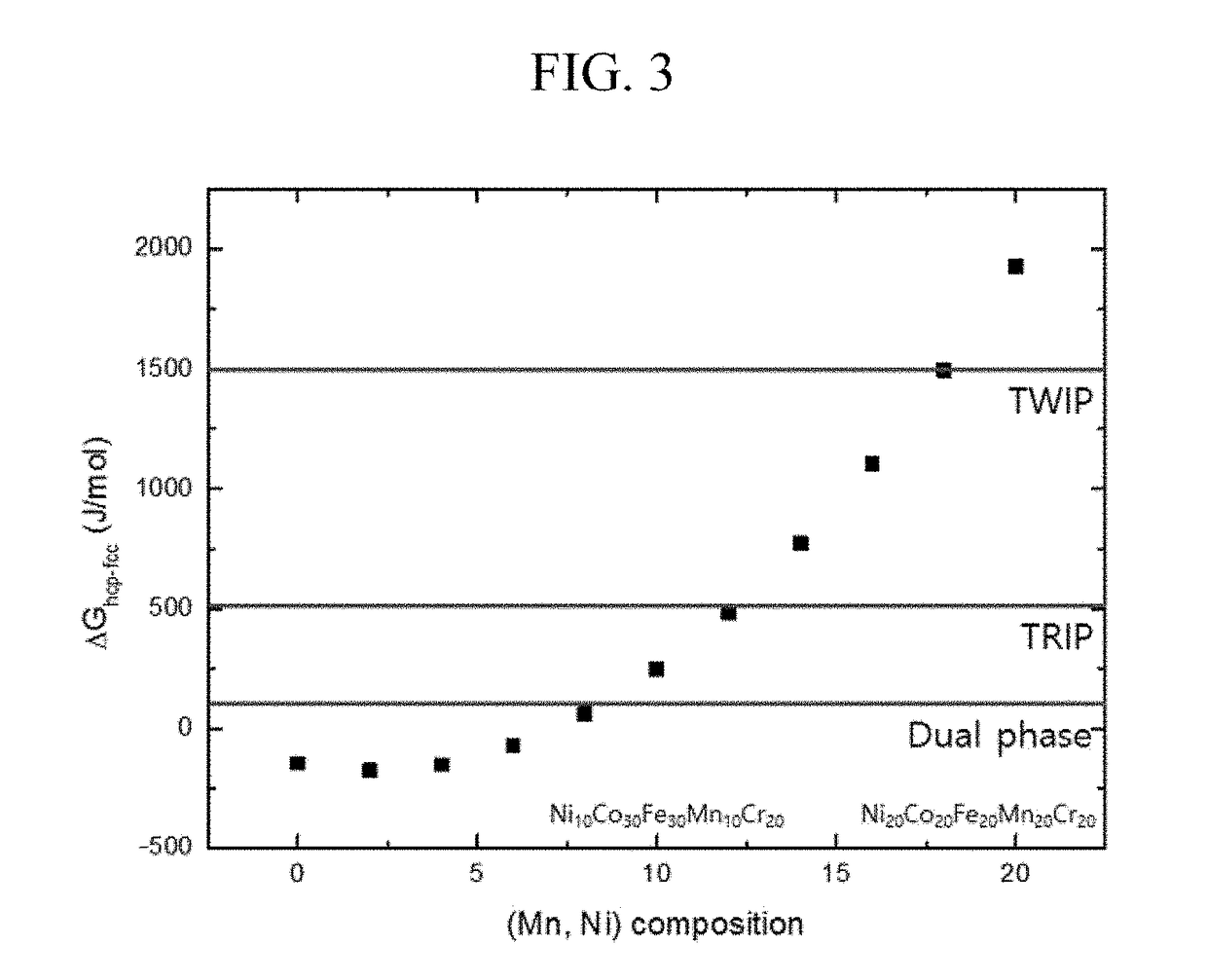

The present invention relates to a high entropy alloy having more improved mechanical properties by controlling contents of additive elements in a NiCoFeMnCr 5-element alloy to control stacking fault energy, thereby controlling stability of a γ austenite phase to control a transformation mechanism, wherein the stacking fault energy is controlled in a composition range of NiaCobFecMndCre (a+b+c+d+e=100, 1≦a≦50, 1≦b≦50, 1≦c≦50, 1≦d≦50, 10≦e≦25, and 77a−42b−22c+73d−100e+2186≦1500), and thus, the γ austenite phase exhibits a twin-induced plasticity (TWIP) property or a transformation induced-plasticity (TRIP) property in which the γ austenite phase is subjected to phase transformation into an ε martensite phase or an α′ martensite phase, under stress, thereby having improved strength and elongation at the same time to have excellent mechanical properties.

Owner:SEOUL NAT UNIV R&DB FOUND

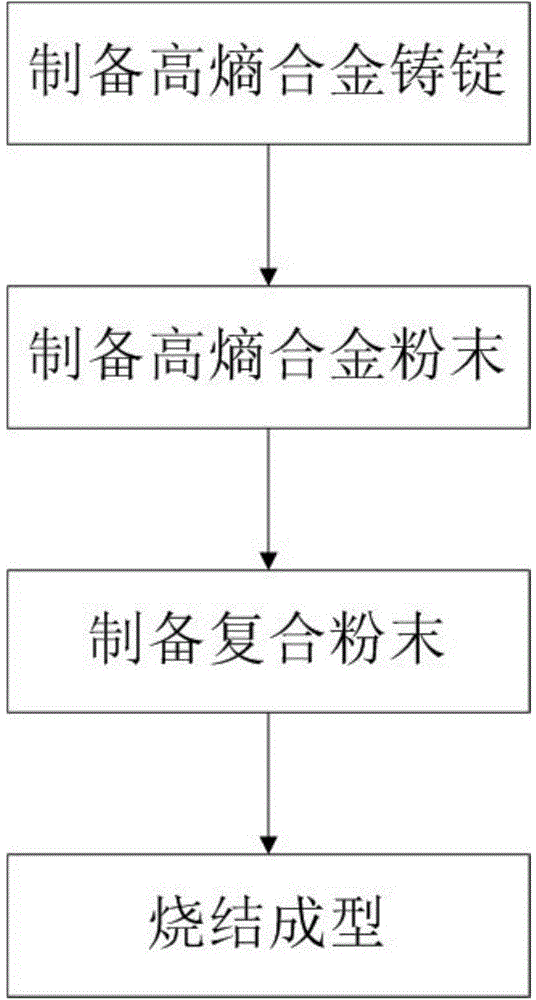

High-entropy alloy particle-reinforced aluminum-based composite material and preparation method thereof

The invention discloses a high-entropy alloy particle-reinforced aluminum-based composite material and a preparation method thereof, and belongs to the field of preparation of composite materials. The problems of influence on material densification and difficulty in the simultaneous improvement of strength and plasticity of the composite material due to own brittleness of a conventional metal-based reinforcement phase and limitation to sintering temperature are solved. The aluminum-based composite material is formed by the ball-milling mixing and sintering forming of a matrix phase and a reinforcement phase, wherein the volume ratio of the matrix phase aluminum and the reinforcement phase high-entropy alloy particles AlCoCrFeNiTi0.5 is 1: 4 to 1: 9. The preparation method for the high-entropy alloy particle-reinforced aluminum-based composite material comprises a step of preparing a high-entropy alloy ingot, a step of preparing high-entropy alloy powder, a step of preparing composite powder and a sintering forming step. According to the high-entropy alloy particle-reinforced aluminum-based composite material and the preparation method thereof, a process is simple, lower in energy consumption and cost and easy to implement, the tensile strength of the prepared high-entropy alloy particle-reinforced aluminum-based composite material is strengthened by 32.4 to 90.1 percent, the elongation of the high-entropy alloy particle-reinforced aluminum-based composite material is improved by 29.6 to 52.0 percent, and the comprehensive performance of the aluminum-based composite material is improved.

Owner:HUAZHONG UNIV OF SCI & TECH

Microalloyed Ti-Zr-Hf-V-Nb-Ta refractory high-entropy alloy and preparation method thereof

The invention relates to a microalloyed Ti-Zr-Hf-V-Nb-Ta refractory high-entropy alloy and a preparation method thereof, and belongs to the technical field of metal materials. The refractory high-entropy alloy is endowed with good plasticity and high strength mainly by adjusting the ratio of main components and adding a small amount of microalloyed elements, and the density can be adjusted in a relatively wide range; in addition, during a preparation process, Hf, Nb, Ta and microalloyed elements other than Al at high melting points are pre-alloyed and smelted first, and then Ti, Zr, V and Al are added for final alloying smelting, thereby facilitating uniform mixing of a plurality of components with large differences in melting point, and ensuring the excellent comprehensive performance ofthe prepared refractory high-entropy alloy.

Owner:北京中辰至刚科技有限公司

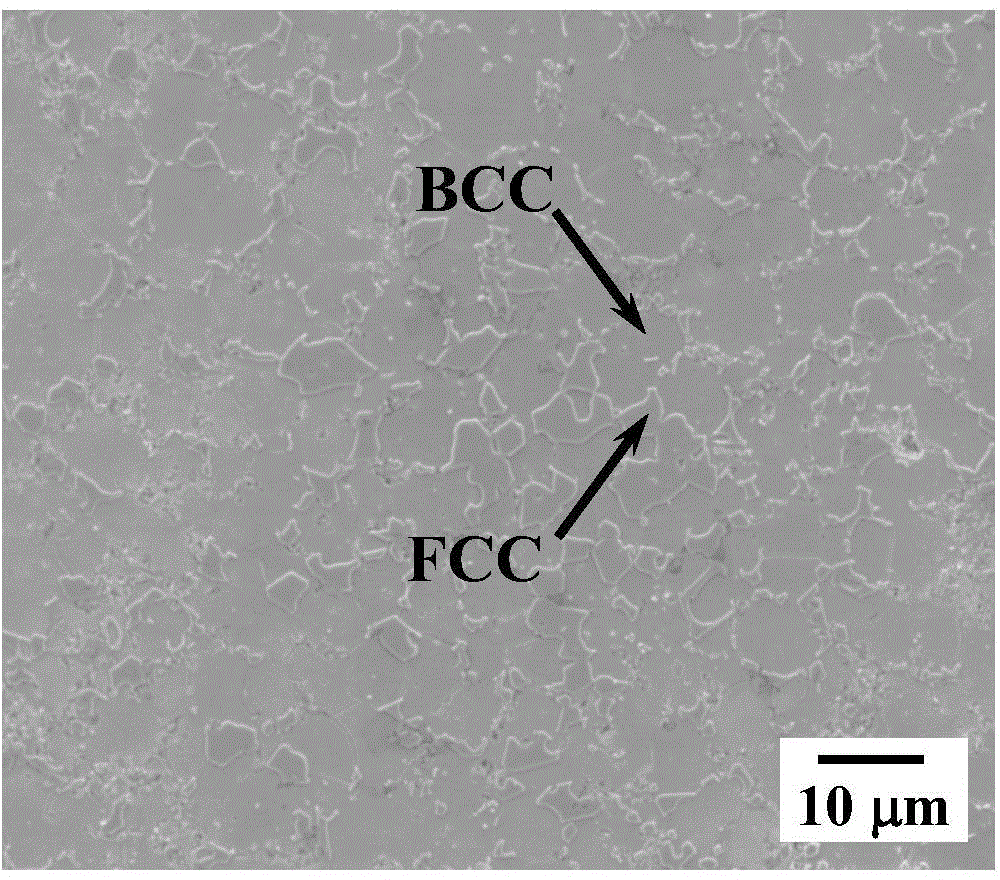

Multiphase high-entropy alloy and preparation method thereof

ActiveCN109252083AImprove bindingImprove high temperature oxidation resistanceHigh entropy alloysThermal treatment

The invention belongs to the field of high-entropy alloy, and relates to multiphase high-entropy alloy with excellent high-temperature corrosion resistance and mechanical performance. The multiphase high-entropy alloy with the excellent high-temperature corrosion resistance and mechanical performance is prepared from the chemical components in percentage by mass(at.%): 5-40% of Fe, 2-30% of Cr, 15-45% of Ni, 3-25% of Al and 0.2-2.0% of Nb; meanwhile, one or more following element can be added: 0-0.5% of C, 0-4% of Mo, 0-35% of Mn, 0-35% of Cu, 0-35% of Co, 0-2.0% of Si, 0-1.0% of Ti, 0-1.0% ofV, 0-0.8% of W and 0-0.5% of Y; through treatment of the high-purity raw materials, blending, smelting in a vacuum induction furnace, moulding shaping and thermal treatment, the multiphase high-entropy alloy is obtained. By adjusting the element contents, a microstructure of FCC, a small amount of BCC and a second phase is achieved, and the comprehensive performance of the high-entropy alloy is obviously superior to the comprehensive performance of existing high-entropy alloy.

Owner:ANYANG INST OF TECH +1

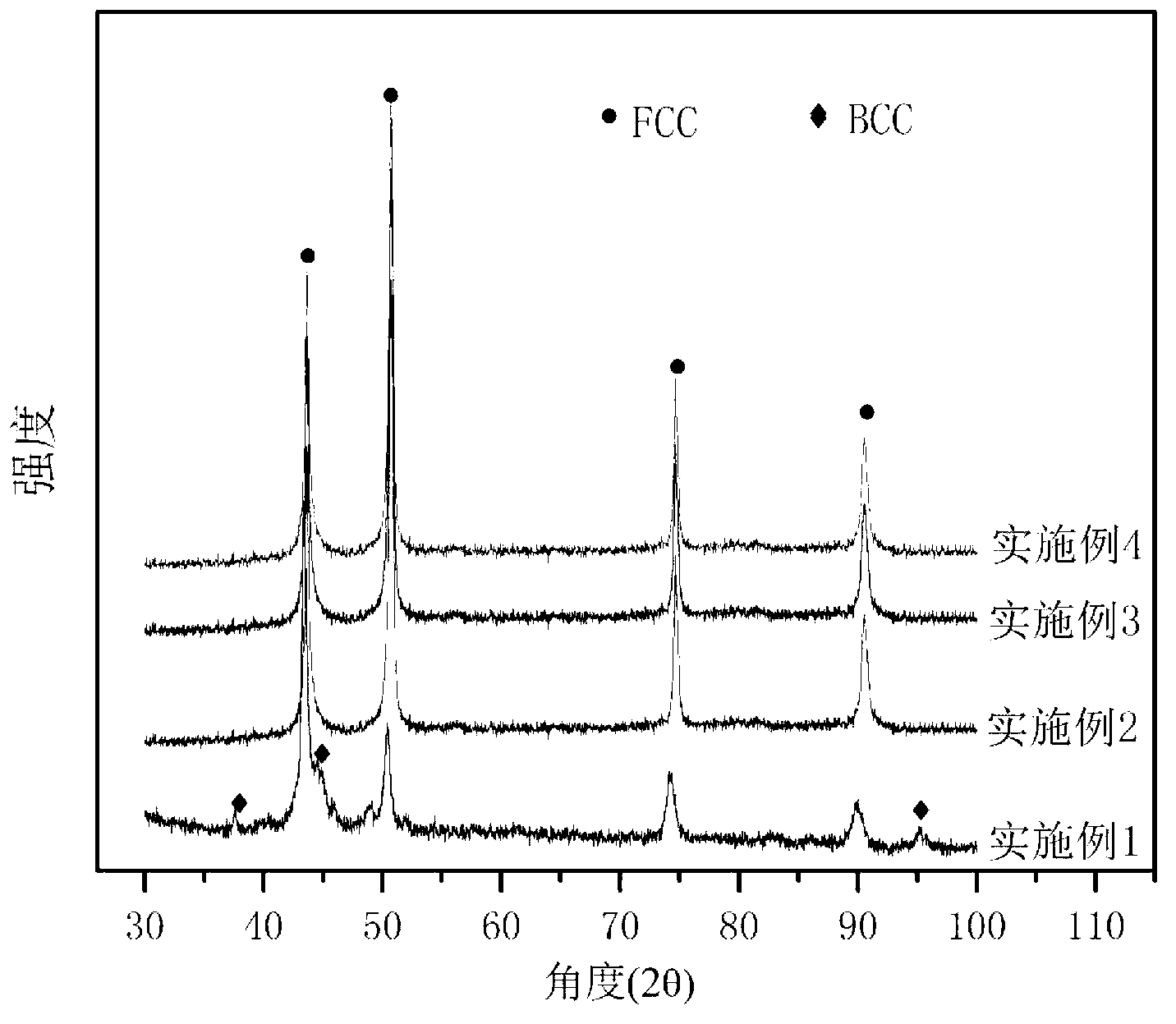

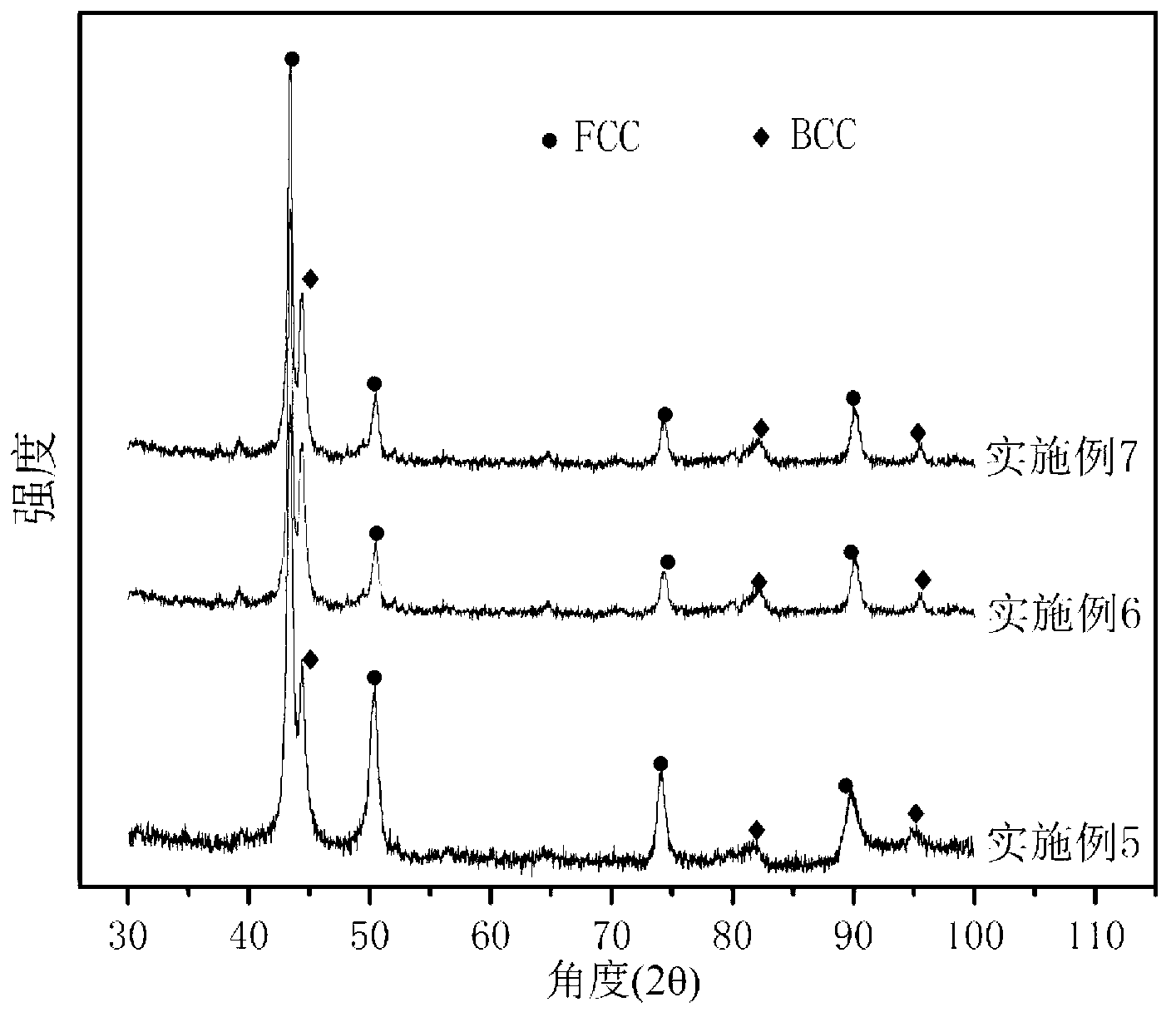

High-strength high-toughness ultrafine-grained high-entropy alloy and preparation method thereof

The invention belongs to the technical field of alloy material, and discloses a high-strength high-toughness ultrafine-grained high-entropy alloy and a preparation method thereof. The high-strength high-toughness ultrafine-grained high-entropy alloy is composed of the following elements according to the atomic percentage: 20%-25% of Ni, 18%-20% of Fe, 18%-22% of Co, 18%-20% of Cr, and 20%-24% of Al; the microstructure takes a body-centered cubic disordered solid solution phase rich in Ni and Al elements as a matrix phase, and takes a face-centered cubic disordered solid solution phase rich in Fe and Cr elements as a reinforcing phase. The preparation method of the alloy comprises the steps: elemental powders with the atomic percentages are subjected to powder mixing and high-energy ball milling to prepare an amorphous composite powder, and the amorphous composite powder is sintered to obtain the high-strength high-toughness ultrafine-grained high-entropy alloy. The prepared high-entropy alloy has the advantages of large size and good comprehensive mechanical properties, and can be used in the fields of aeronautics and astronautics, military industry, electrons, instruments and apparatuses and the like.

Owner:SOUTH CHINA UNIV OF TECH

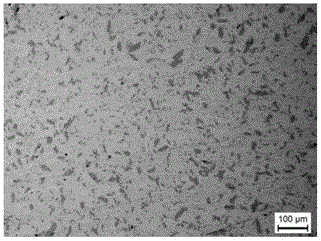

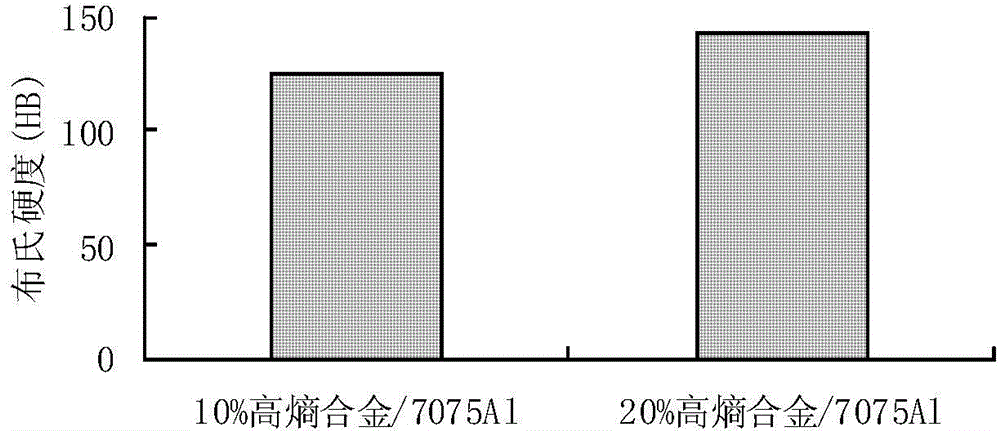

High-entropy alloy reinforced aluminum-based composite material and preparation method thereof

ActiveCN104388764AImprove the bonding strength of the interfaceImprove the state of the interfaceHigh entropy alloysRoom temperature

The invention belongs to the technical field of composite materials and discloses a high-entropy alloy reinforced aluminum-based composite material and a preparation method thereof. The composite material takes high-entropy alloy as a reinforcing phase and takes aluminum alloy as a base body. The preparation method of the composite material comprises the following steps: packaging high-entropy alloy particles and aluminum alloy powder into a ball milling tank, sealing and mixing the powder for 5-25 hours to obtain a mixed material; packaging the mixed material into a bag; applying a pressure of 5MPa to 15MPa at room temperature to compact the mixed material in the bag to obtain a semi-finished product; putting the compacted semi-finished product into thermal extruding equipment, preheating the semi-finished product to 400-480 DEG C, preheating a mold to 200-400 DEG C, keeping the temperature of the semi-finished product and the mold for 1-3 hours to finish the preheating process, and then performing hot extrusion formation at an extrusion pressure of 5MPa to 15MPa and at an extrusion ratio of 4 to 25 to obtain the high-entropy alloy reinforced aluminum-based composite material.

Owner:GUANGDONG XINGFA ALUMINUM +1

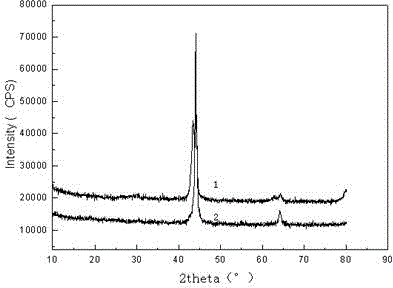

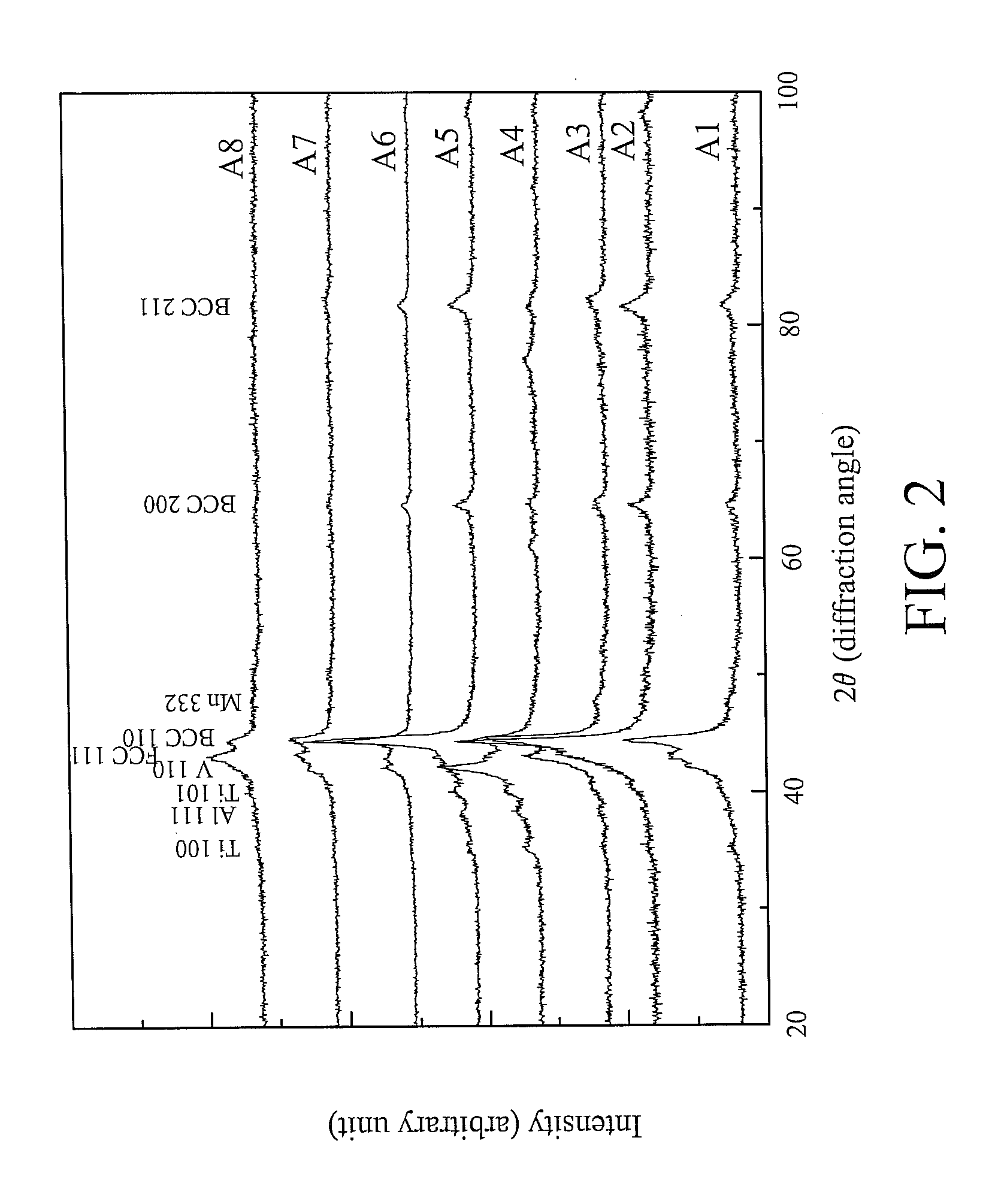

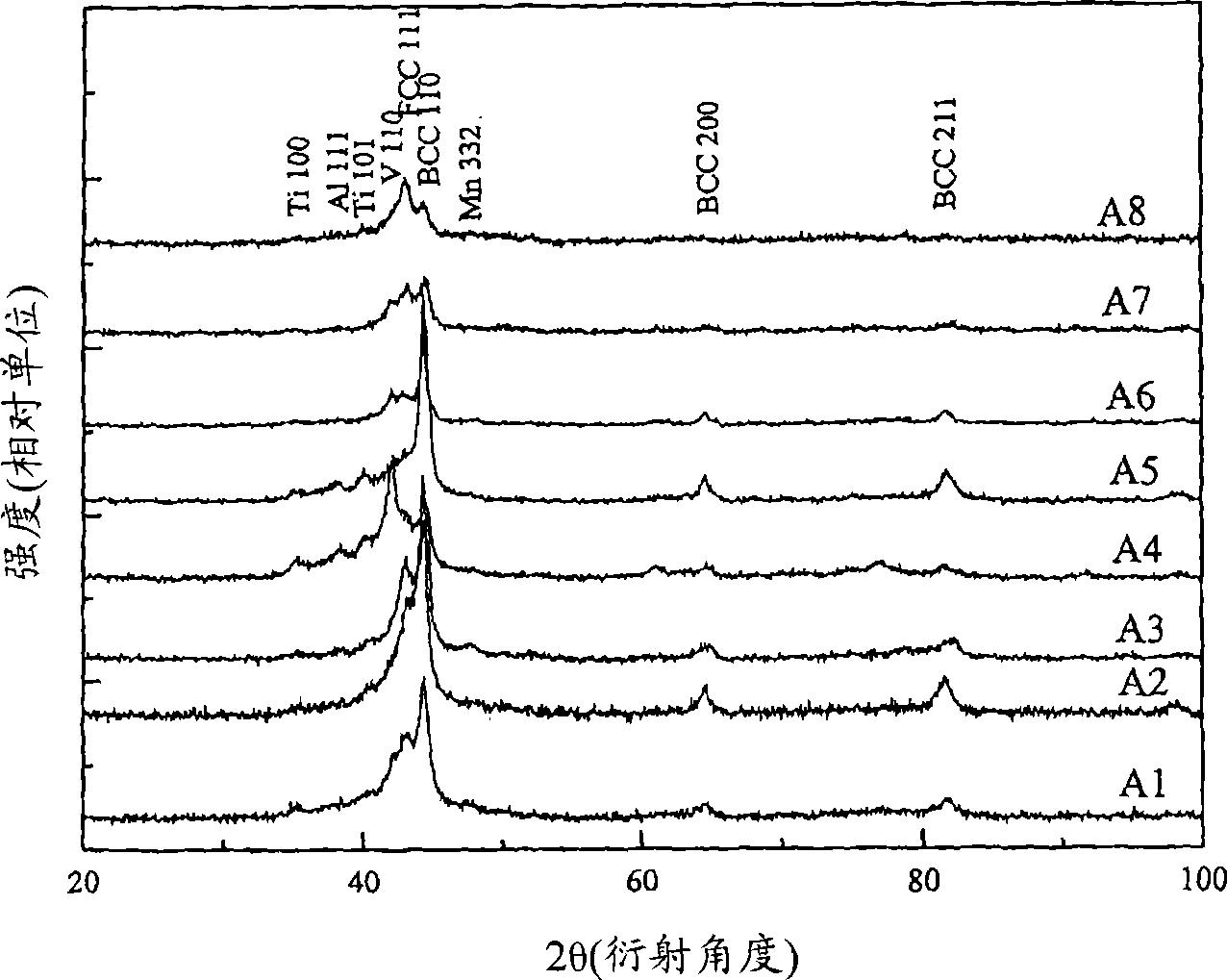

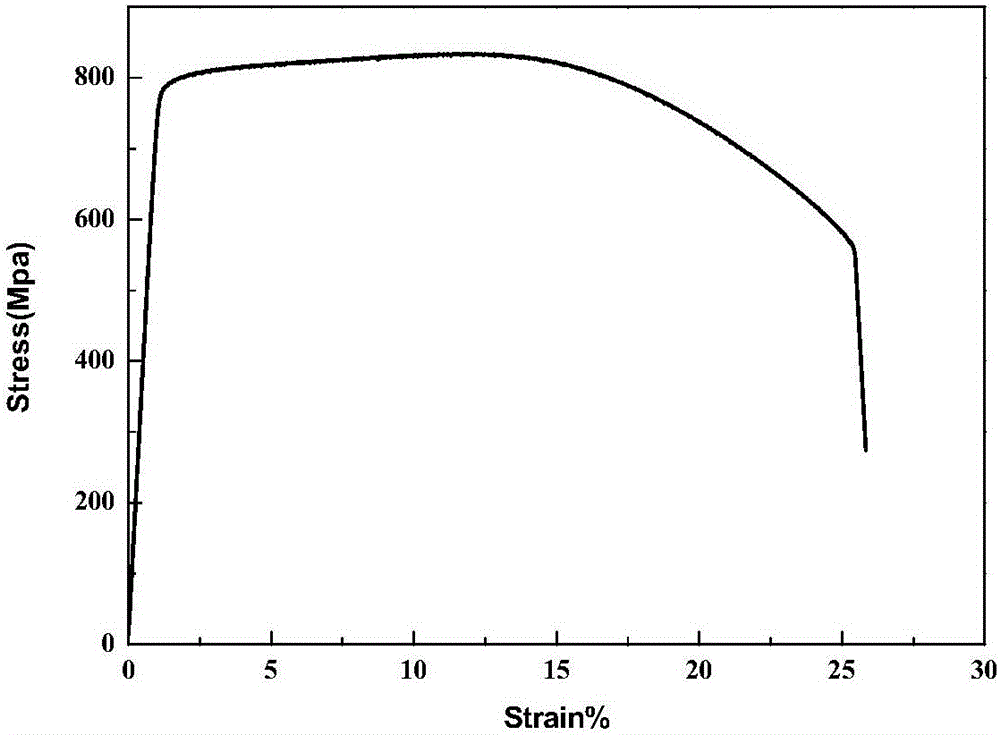

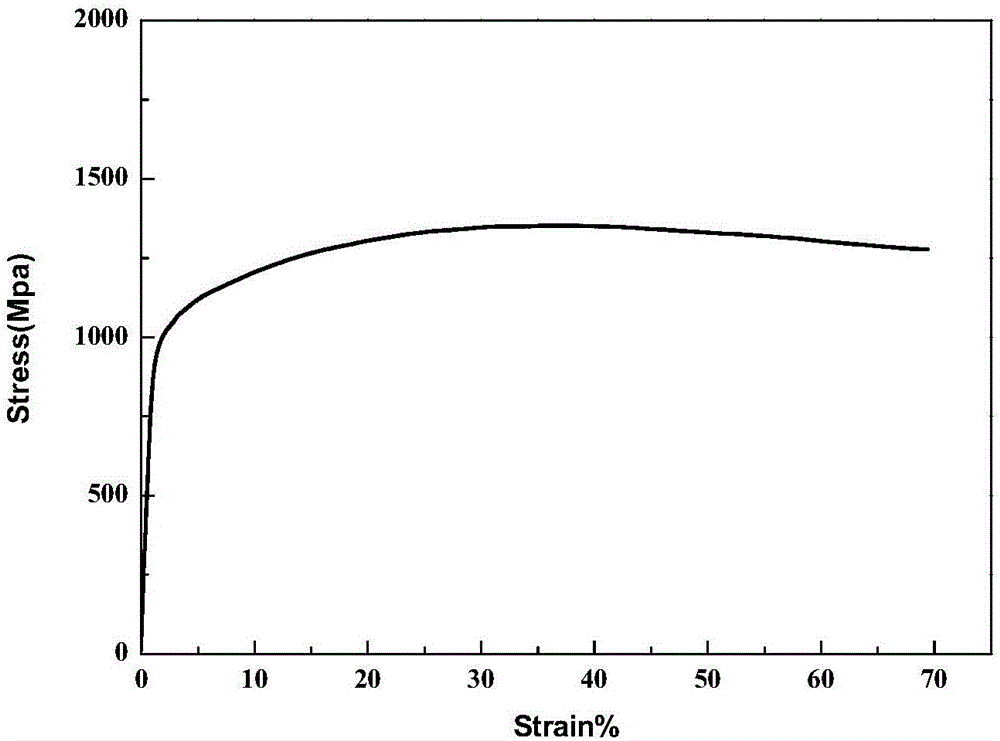

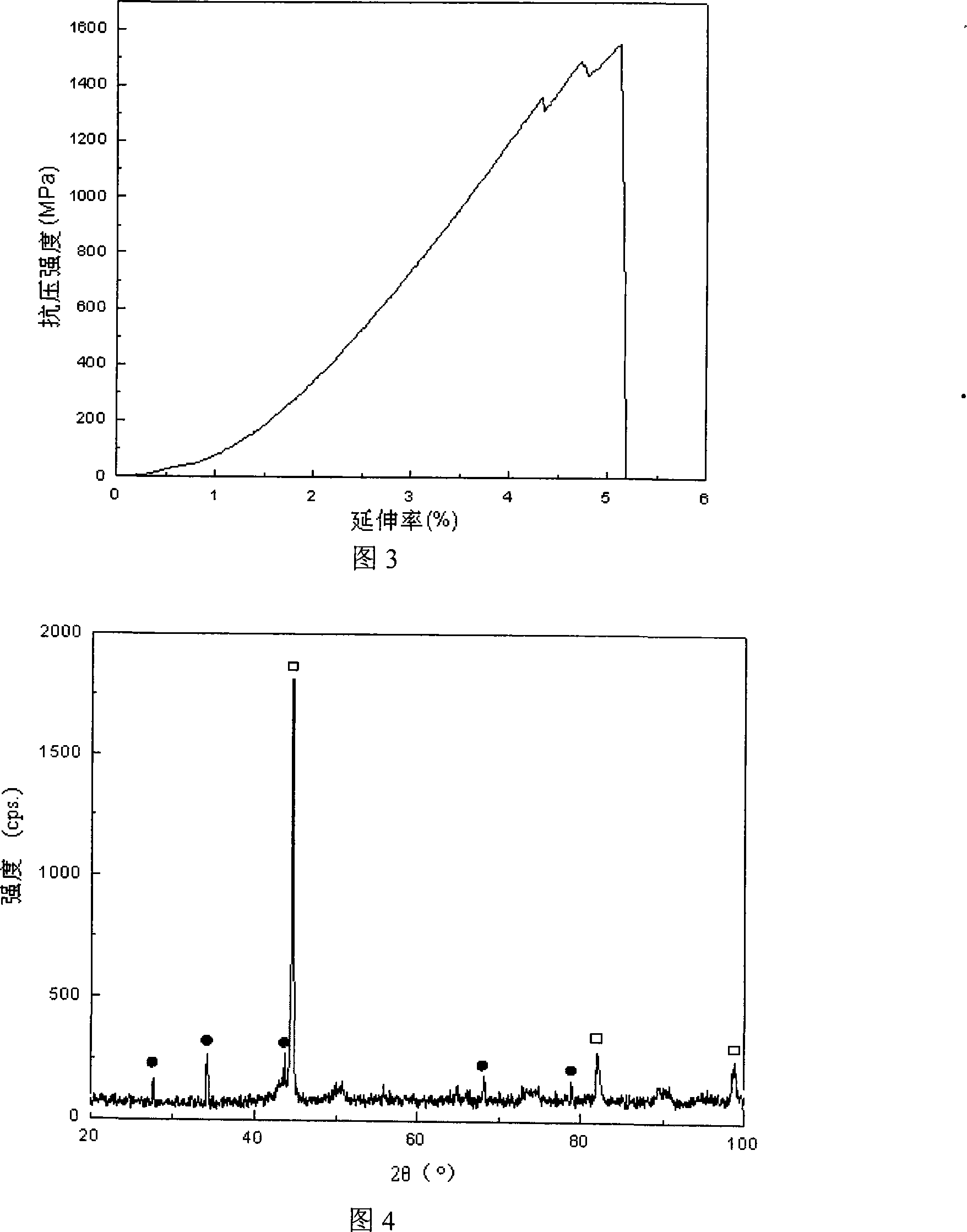

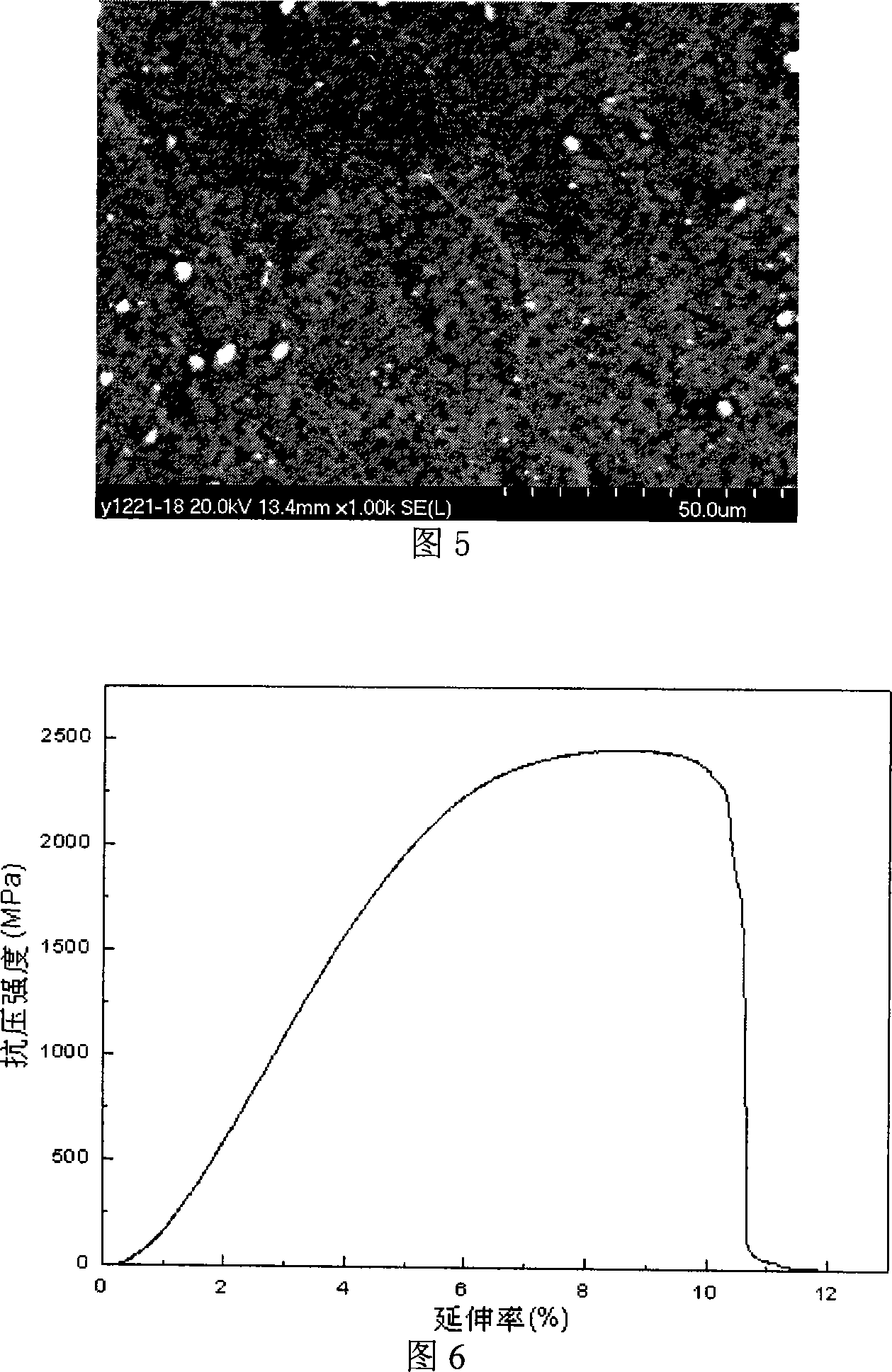

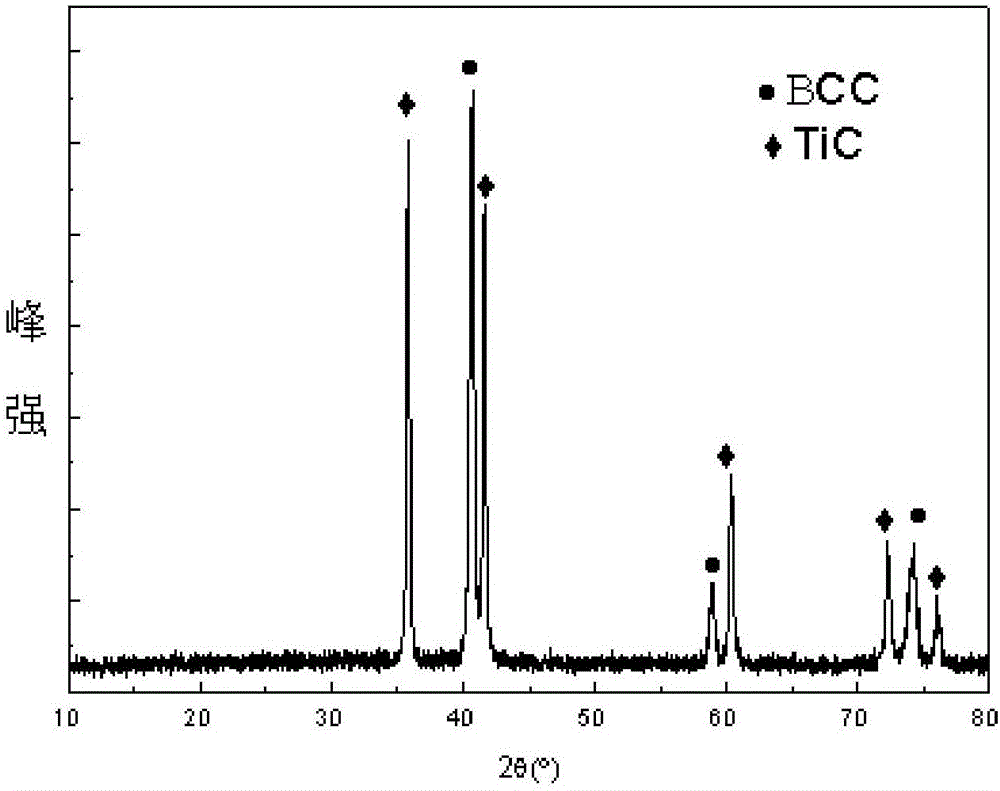

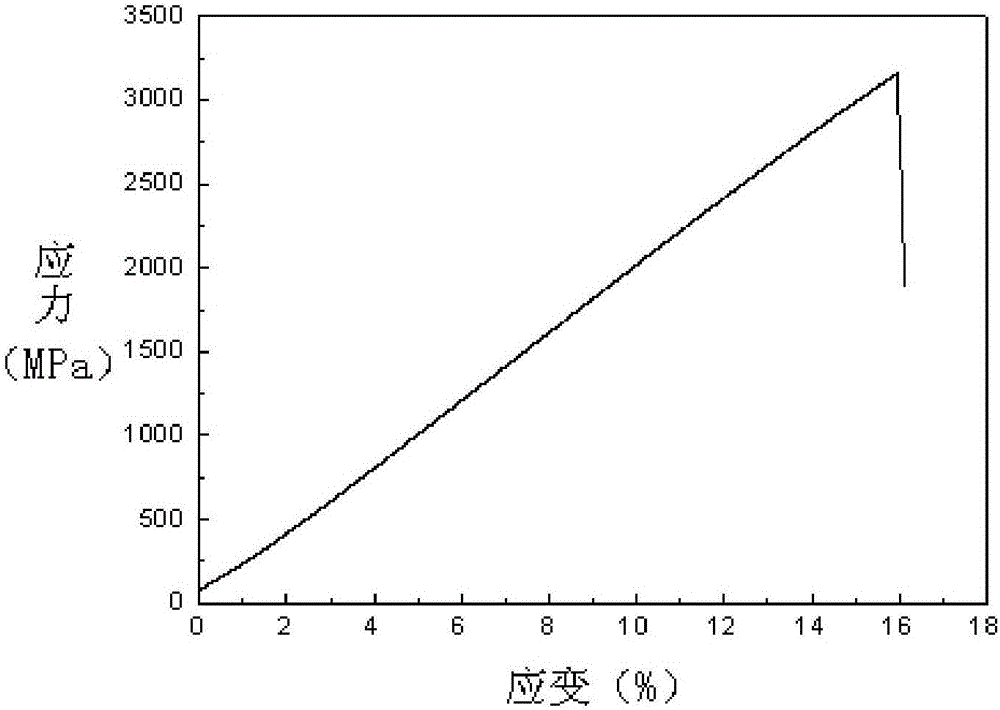

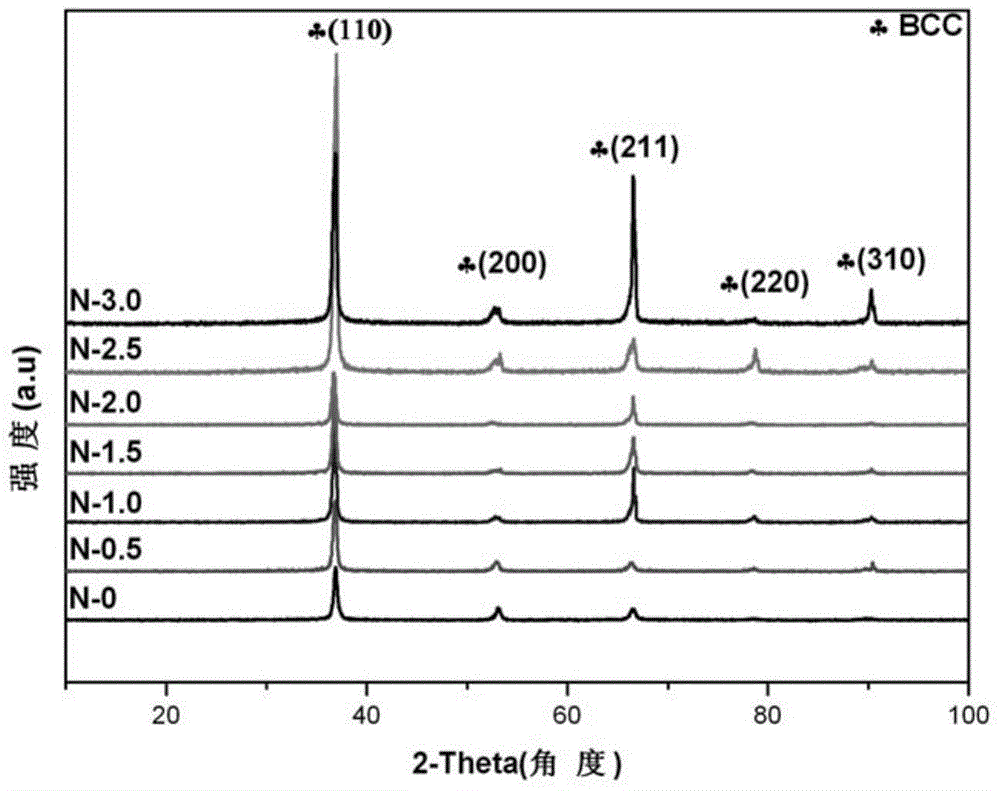

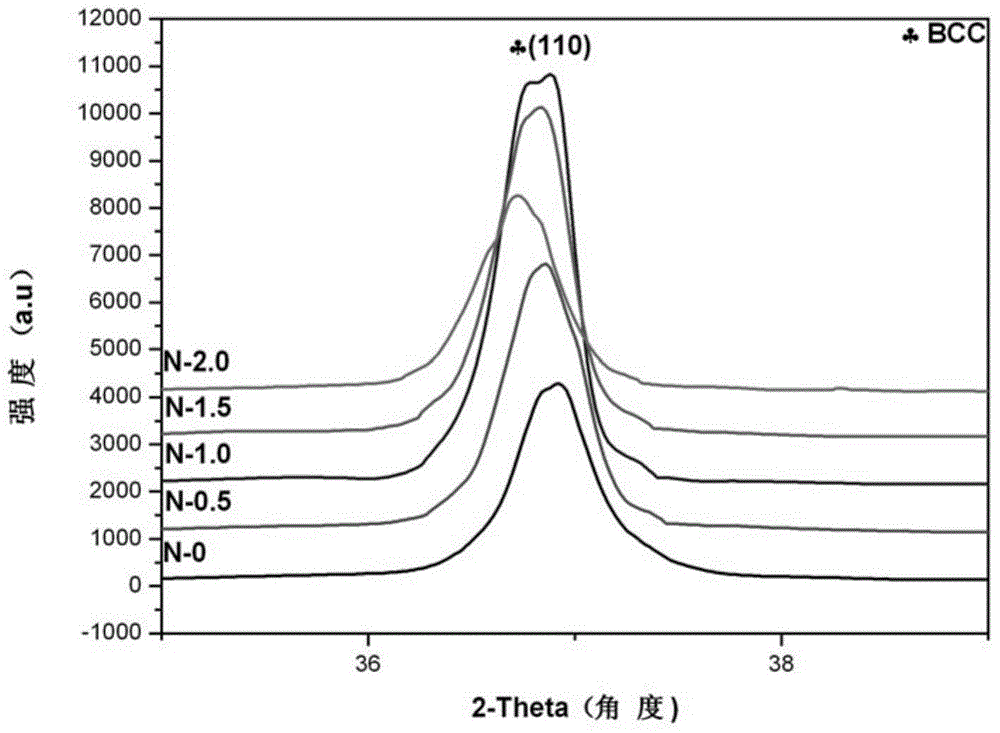

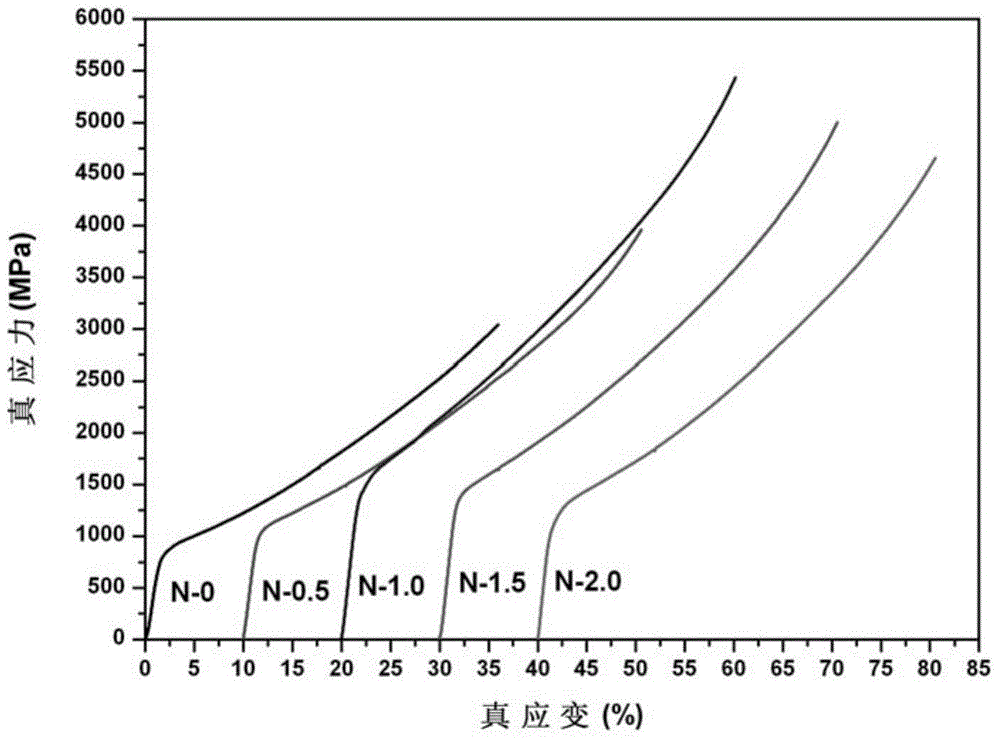

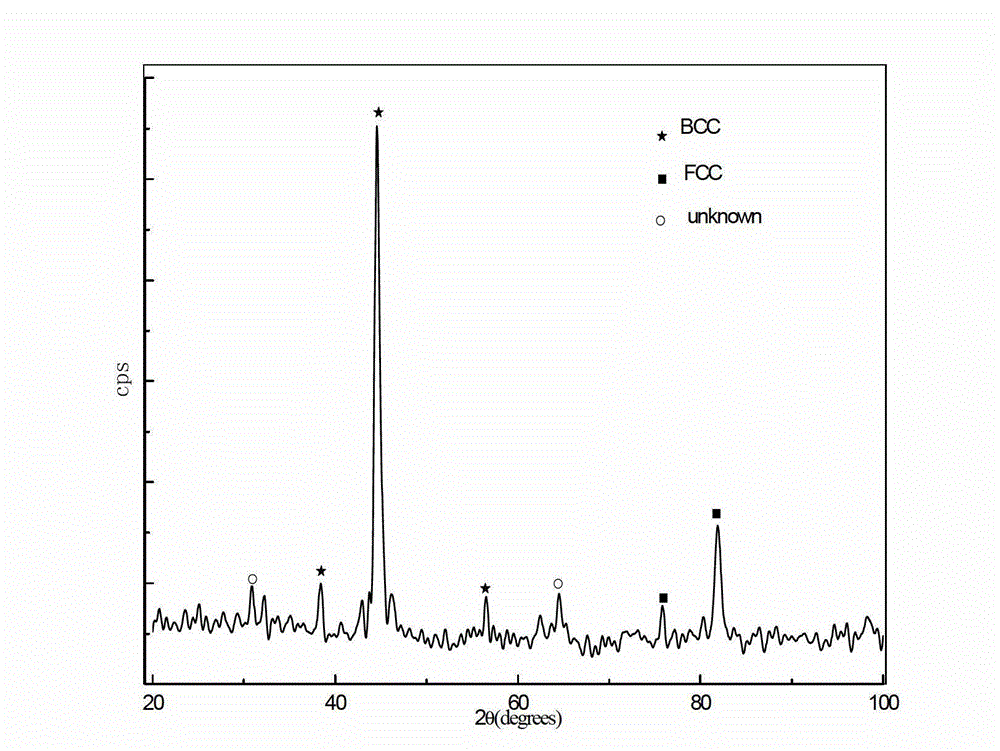

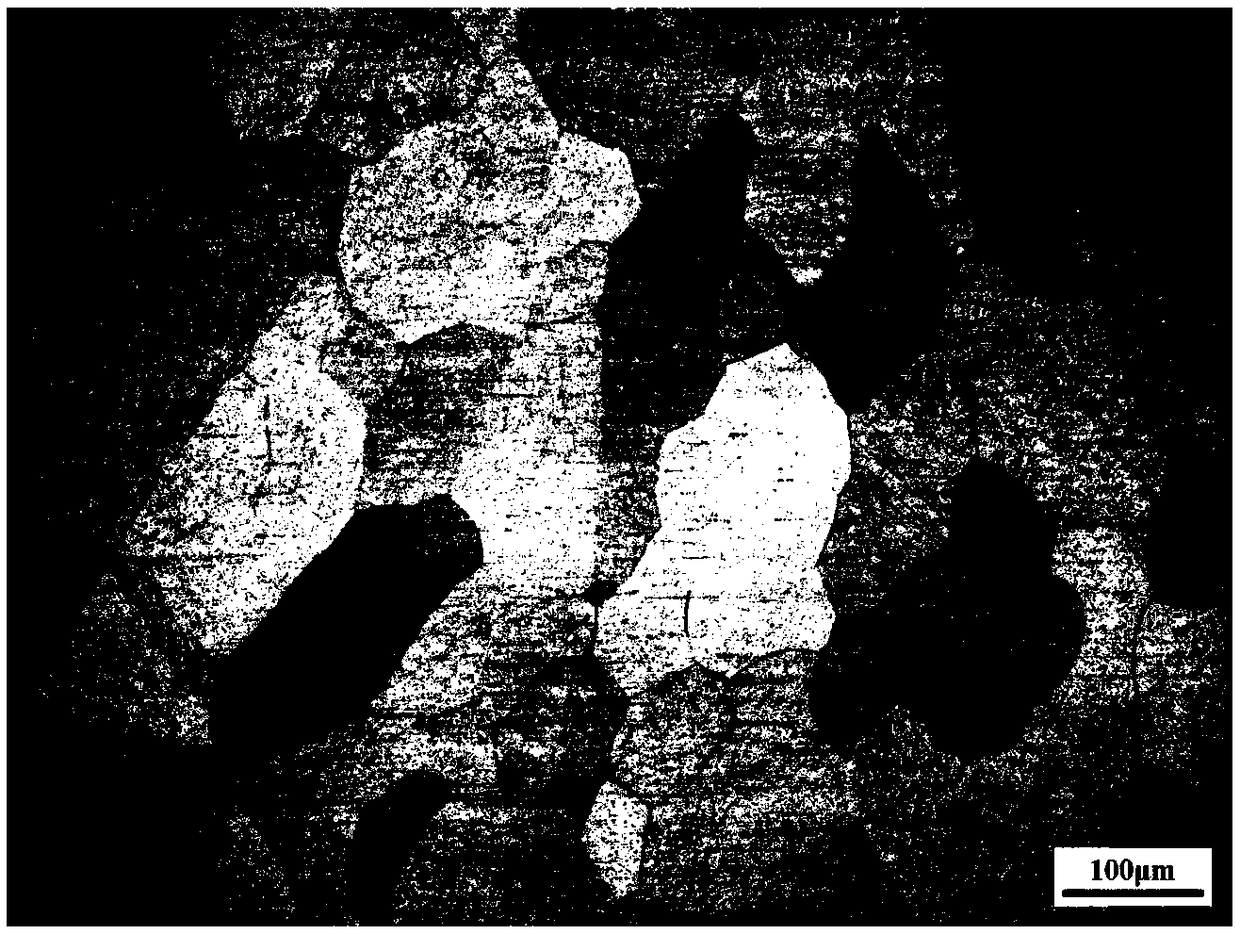

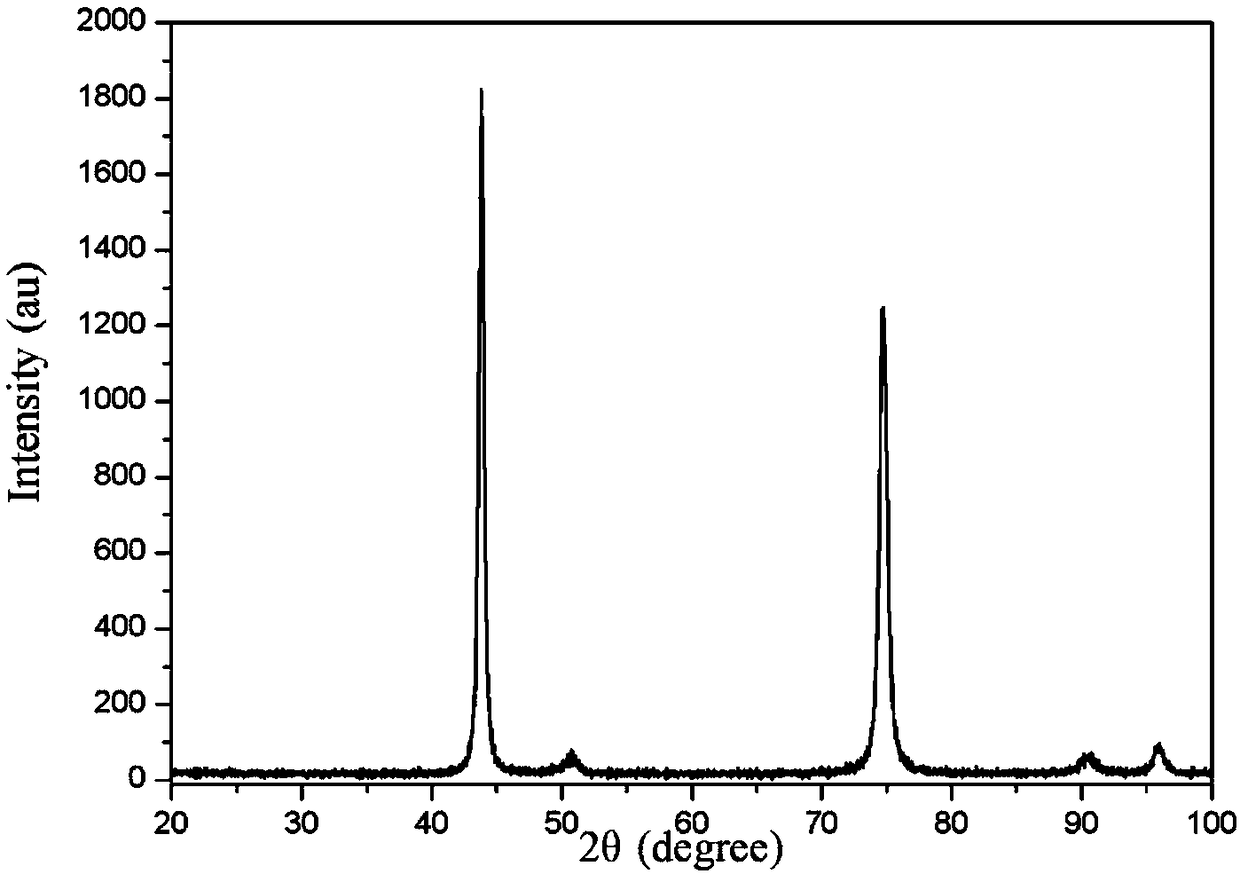

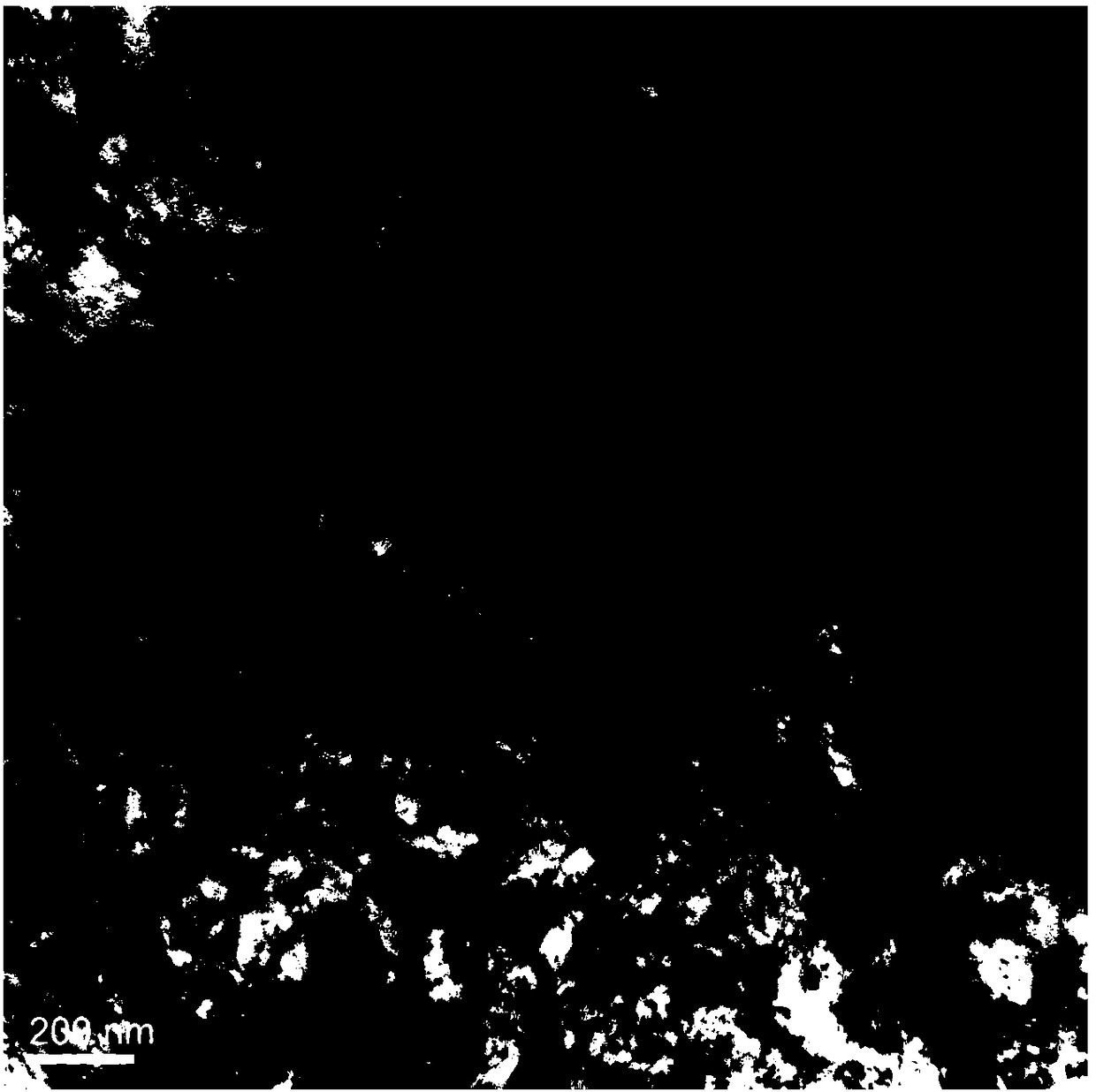

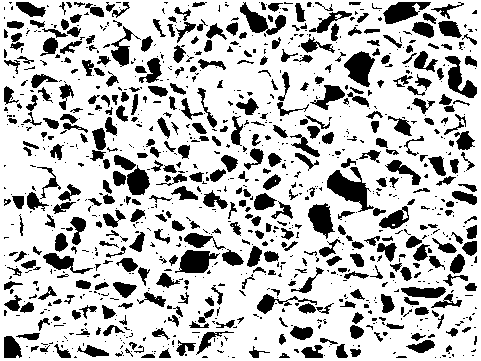

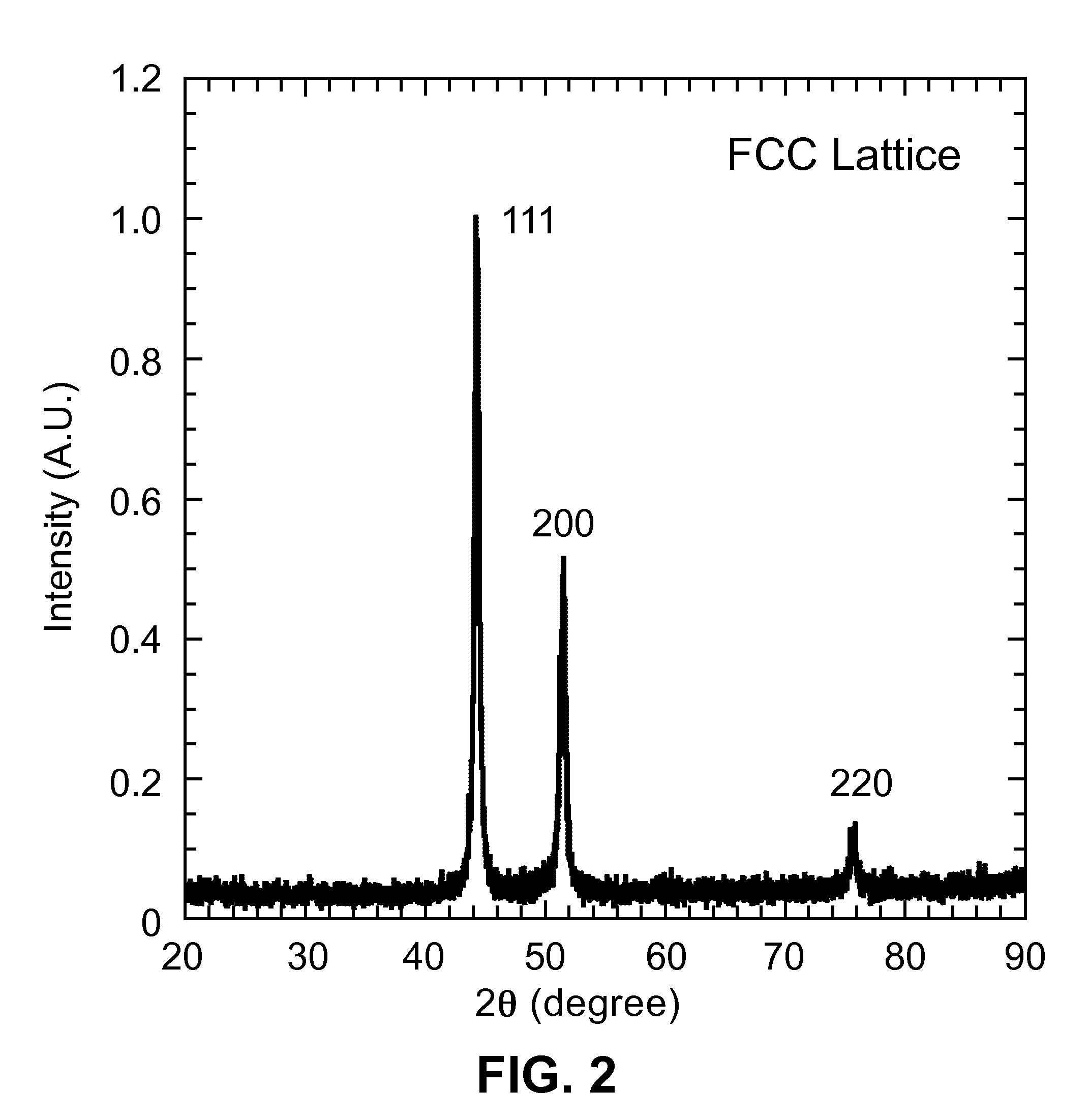

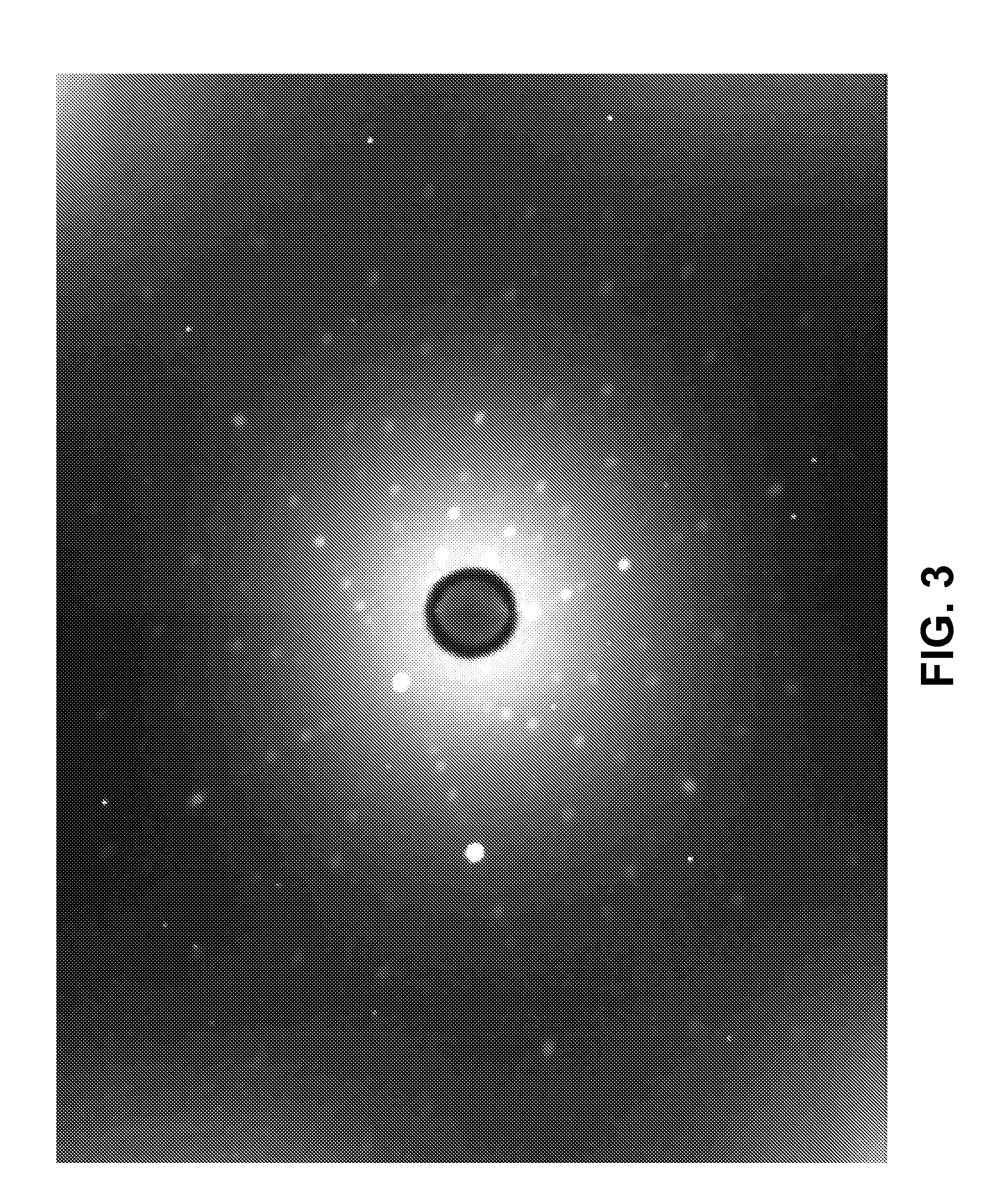

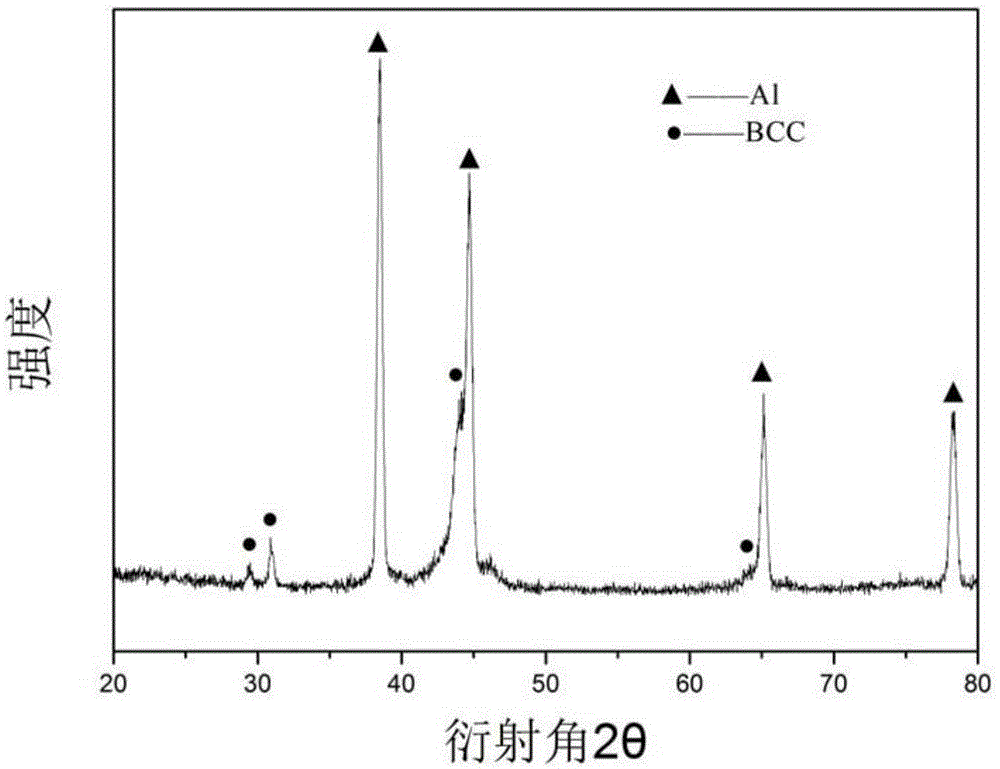

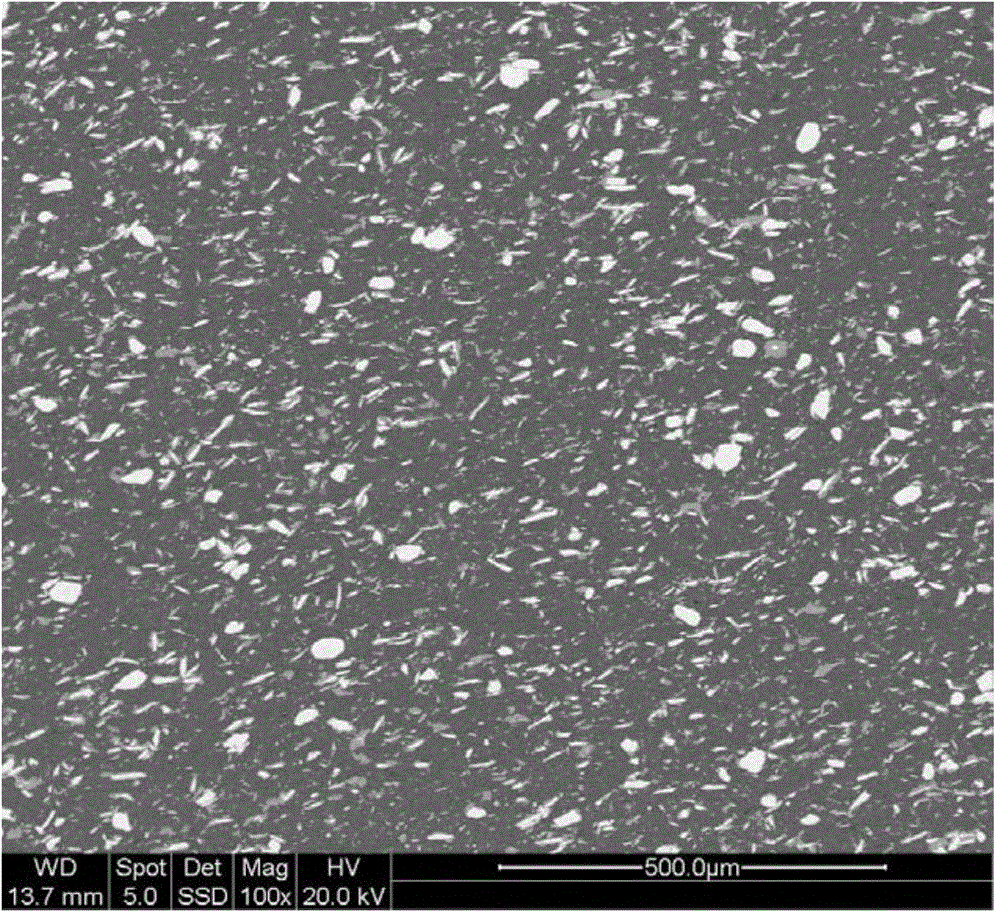

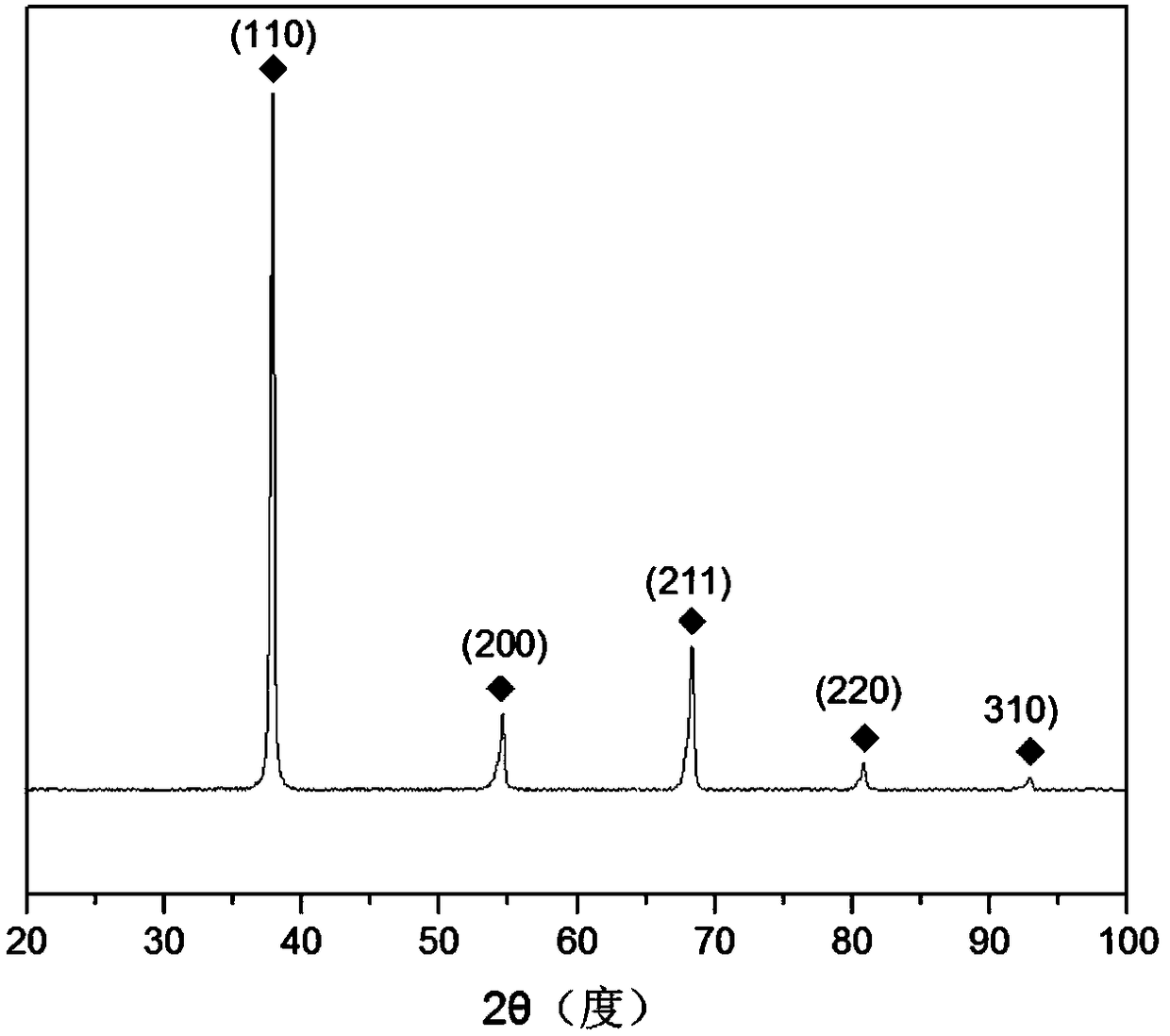

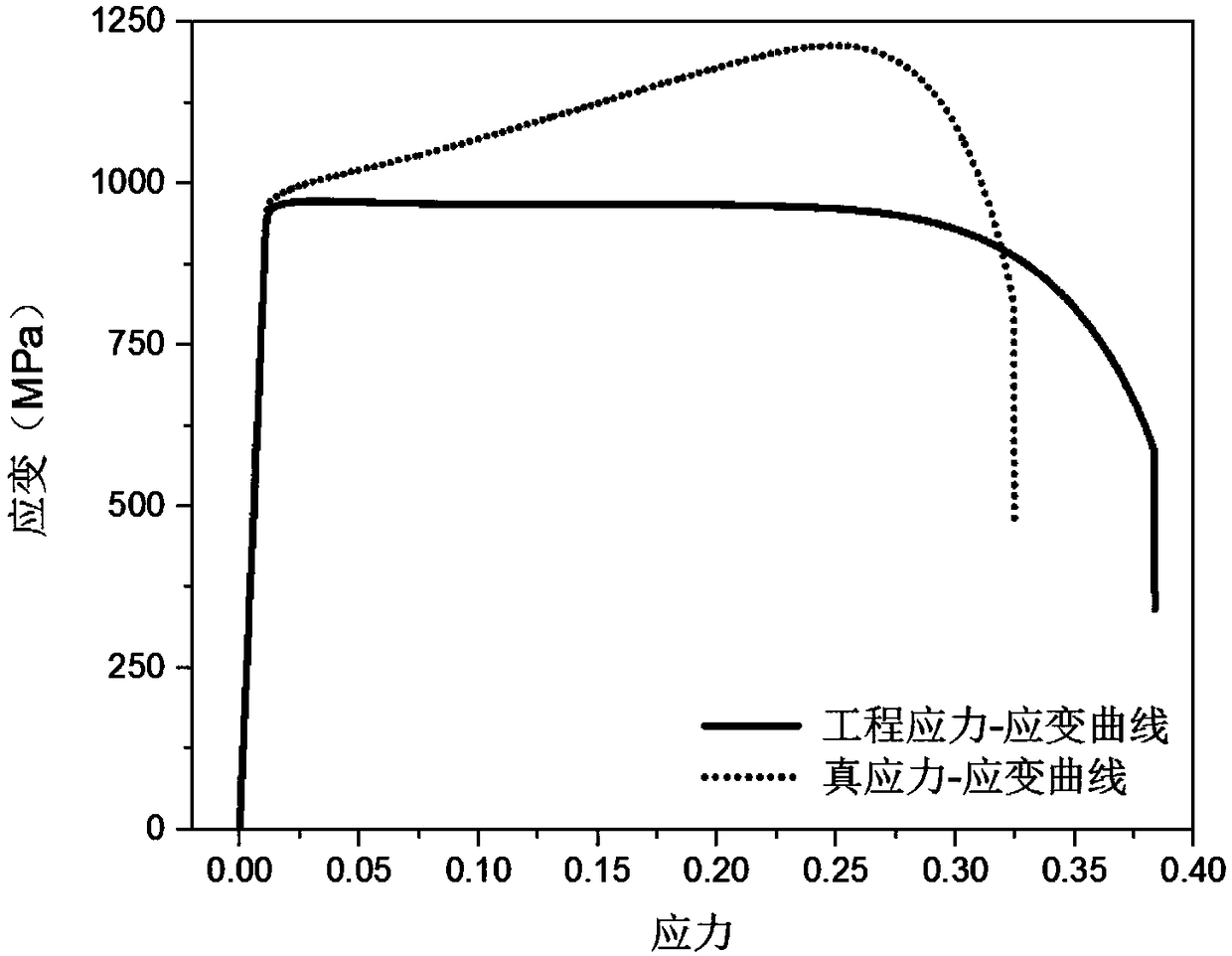

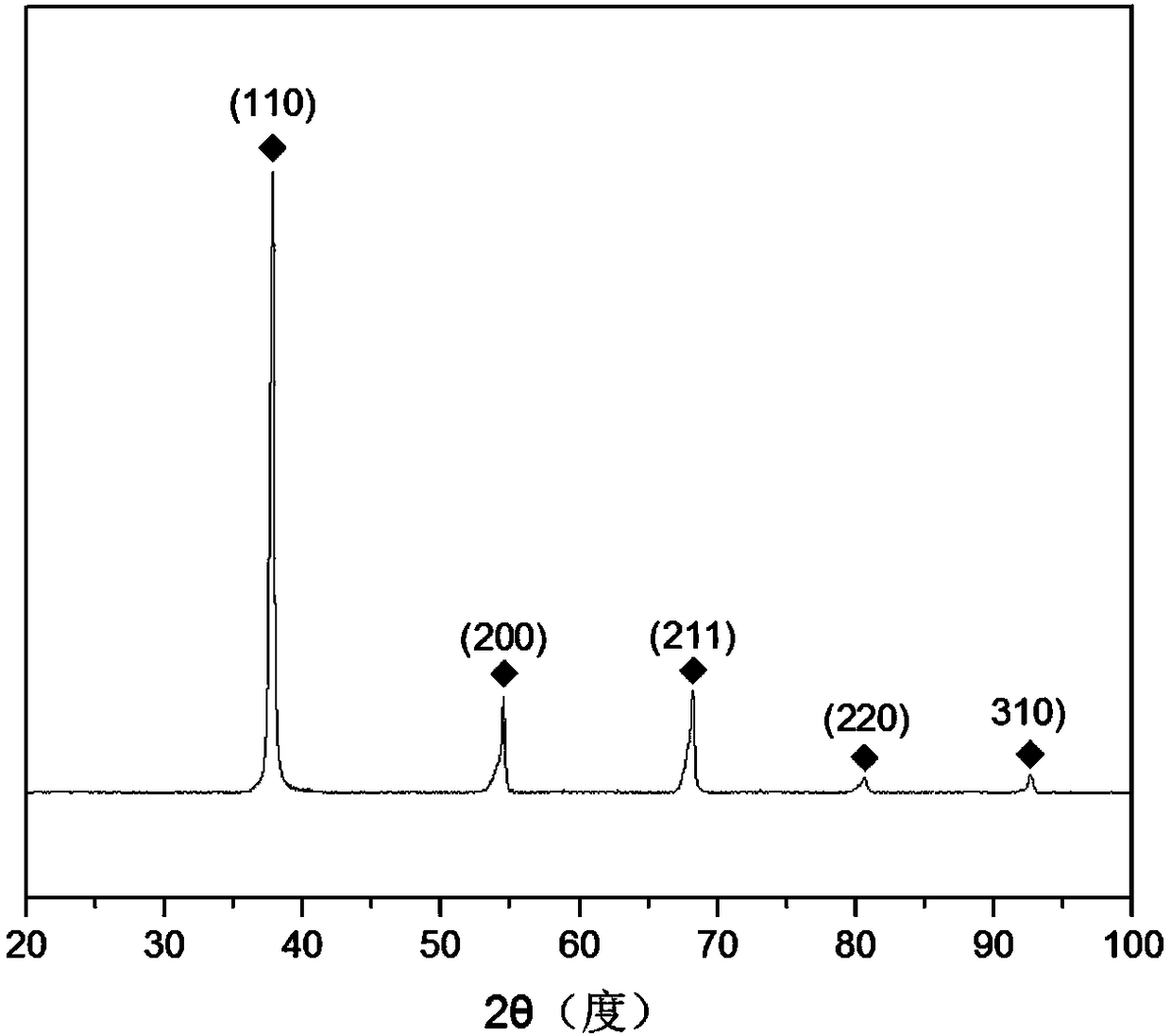

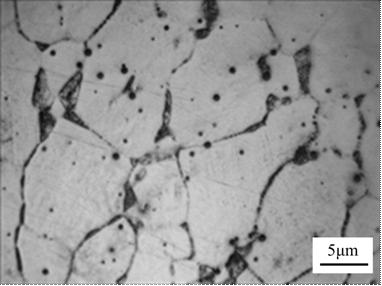

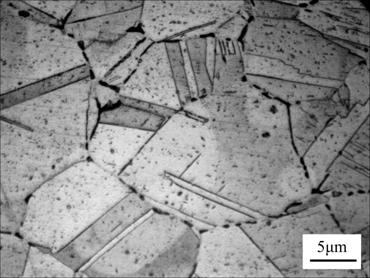

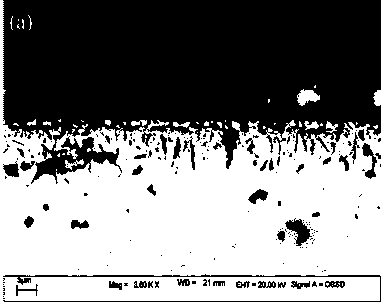

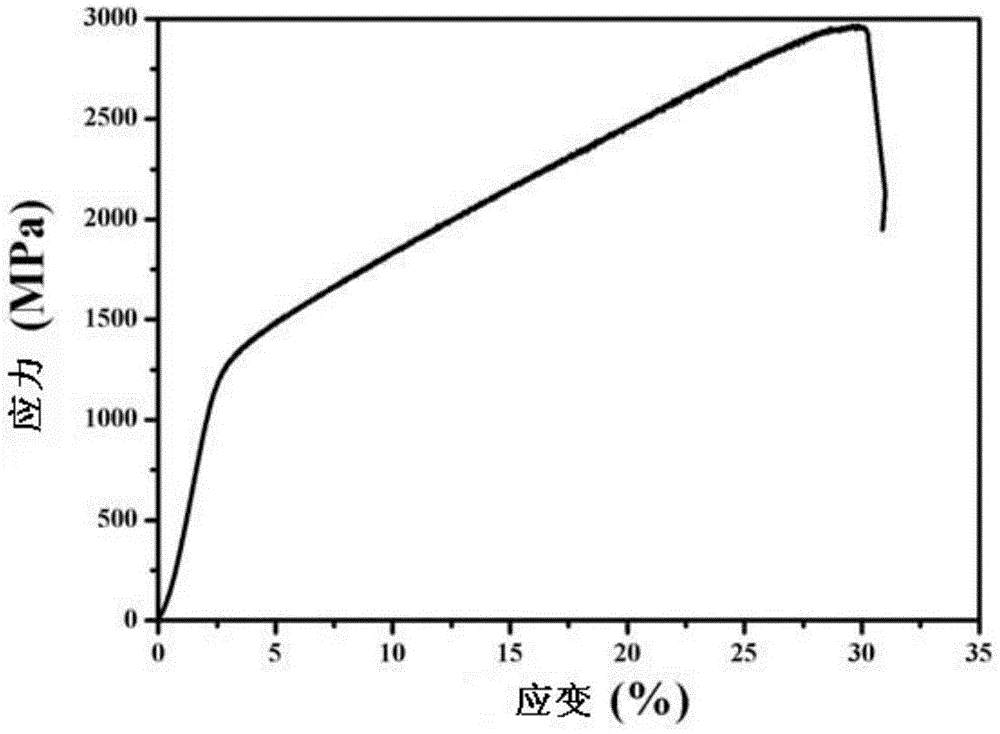

TiZrNbVMo[x] high entropy alloy and preparation method thereof

The invention relates to a high entropy alloy material and a preparation method thereof, the high entropy alloy composition is TiZrNbVMo[x], wherein x is the molar ratio with a value range of x = 0 ~ 1.0. The preparation method comprises the following steps: using a mechanical method to remove oxide skin of metallurgical raw materials of Ti, Zr, Nb, V and Mo elements, then accurately weighing according to the molar ratio; respectively melting intermediate alloys of MoTi and TiZrNbV in a non self-consumable vacuum electric-arc furnace or a cold crucible suspension furnace, finally putting the intermediate alloys together to melt into target alloys, melting each alloy for more than 3 times to ensure uniformity of the composition; taking a specific mass of a master alloy to preparing a rod or plate sample by use of vacuum suction casting or pouring equipment. Compared with traditional crystal materials, the high entropy alloy disclosed by the invention exhibits high hardness, yield strength and fracture strength, and compared with other high-strength body-core-structure high entropy alloys, the high entropy alloy disclosed by the invention has better plastic deformation ability.

Owner:UNIV OF SCI & TECH BEIJING

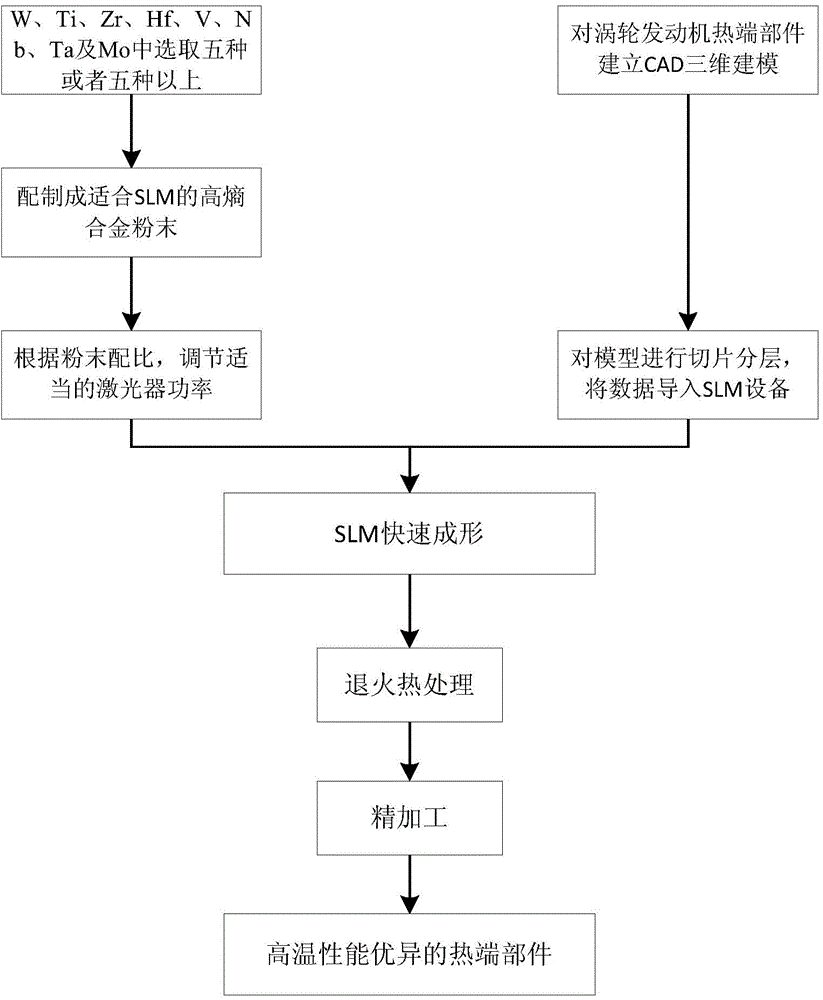

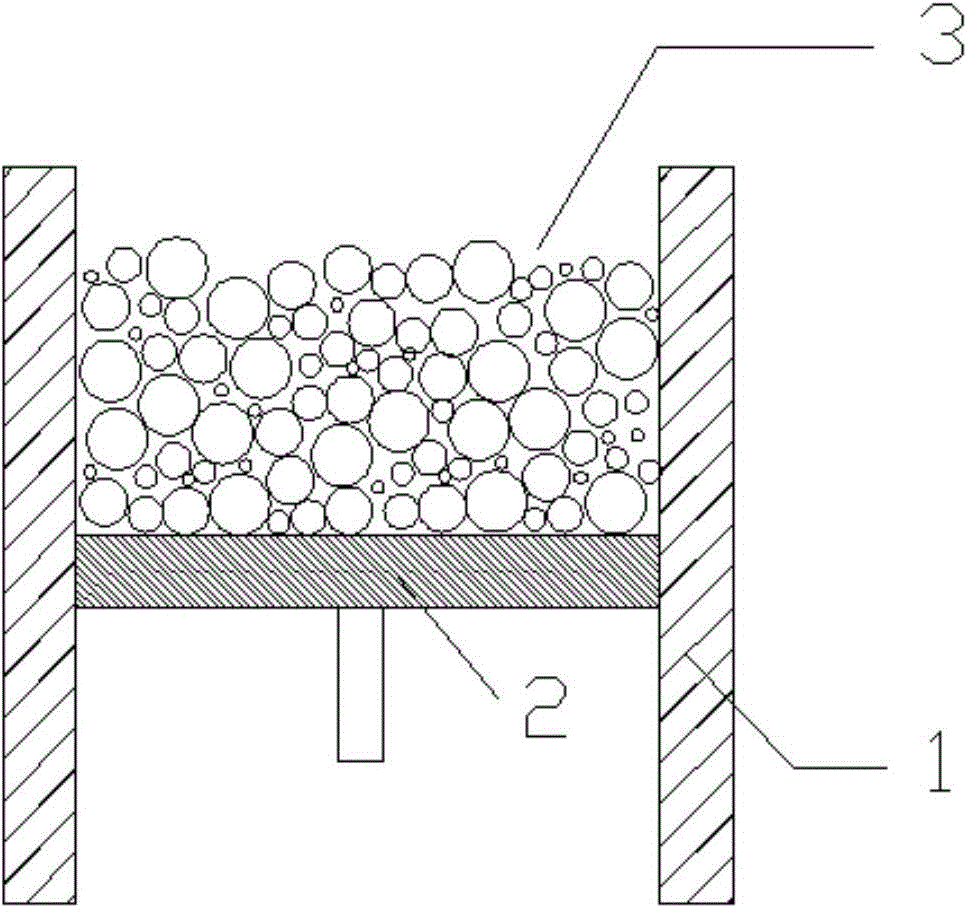

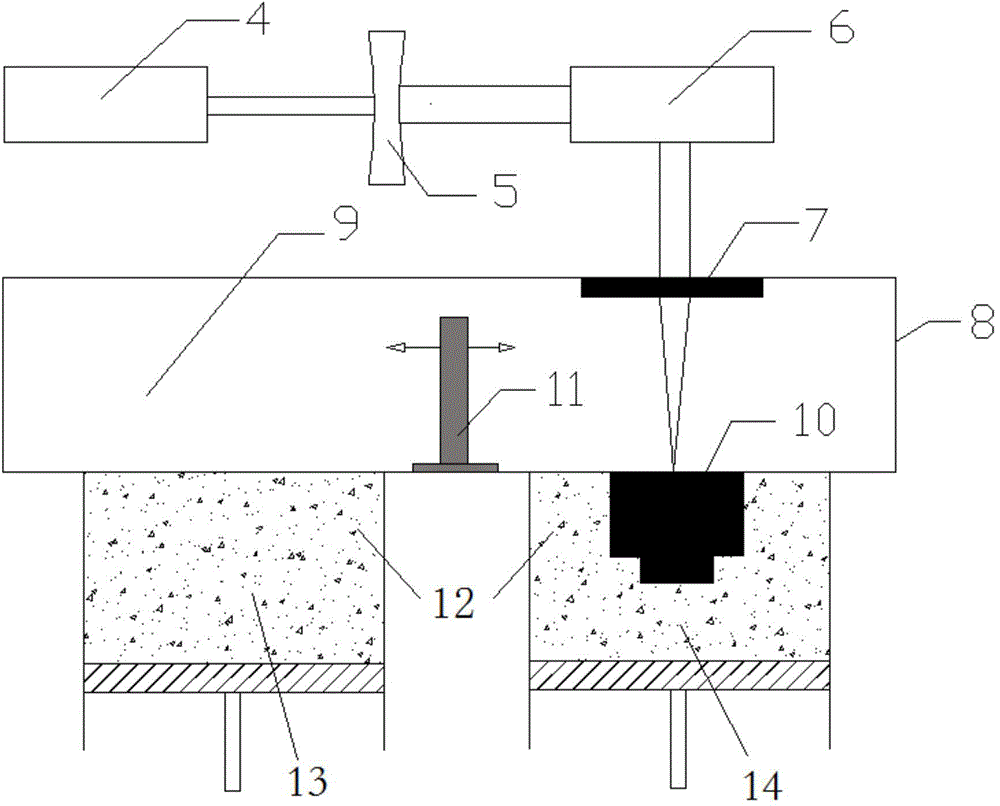

High-entropy alloy hot-end part manufacturing method of turbine engine on basis of selective laser melting

ActiveCN104308153AMeet the requirements of gas temperature to form a large thrustSatisfy the requirement of increasing the gas temperature to form a large thrustTurbinesIncreasing energy efficiencySelective laser meltingSelective laser sintering

The invention discloses a high-entropy alloy hot-end part manufacturing method of a turbine engine on the basis of selective laser melting and belongs to the technical field of manufacture of hot-end parts of the turbine engine. The high-entropy alloy hot-end part manufacturing method includes firstly selecting five or more of eight kinds of high-melting metal powder of tungsten, titanium, zirconium, hafnium, vanadium, niobium, tantalum and molybdenum, and mixing the powder uniformly according to a certain mole ratio to obtain high-entropy alloy powder; setting up a three-dimensional solid model of a hot-end part of the turbine engine, slicing and layering by software to obtain profile data of various sections, and importing the data into a quick forming device; quickly forming a hot-end part blank of the turbine engine by the SLM technology; thermally treating and finely processing the blank to obtain the high-temperature high-entropy alloy hot-end part of the turbine engine. The formed hot-end part of the turbine engine has high compactness and excellent high temperature performance, has high forming accuracy and surface accuracy and can be quickly and accurately manufactured.

Owner:XI AN JIAOTONG UNIV

High-entropy alloy powder for spray coating and preparation method thereof, as well as composite material and preparation method thereof

InactiveCN104561878APurify the meltReduce oxygen contentMolten spray coatingRare-earth elementHigh entropy alloys

The invention provides high-entropy alloy powder for spray coating. The high-entropy alloy powder is composed of CraFebCocNidAleMfRg, wherein a, b, c, d, e, f, g are atomic percentages, a, b, c, d, e, f are nearly equal atomic percentages, g is larger than 0 and is smaller than 1, and a+b+c+d+e+f+g is equal to 100; M is at least one of Ti, HF, Mn and Cu; and R is at least one of rare earth elements. The invention further provides a preparation method of the high-entropy alloy powder, a composite material obtained by spray coating of the high-entropy alloy powder and a preparation method of the composite material. The high-entropy alloy coating provided by the invention has the advantages of high strength and low manufacturing cost, and has hardness and excellent adhesive force much better than those of traditional alloys, thereby being an excellent wear-resistant material and having a great application prospect.

Owner:BYD CO LTD

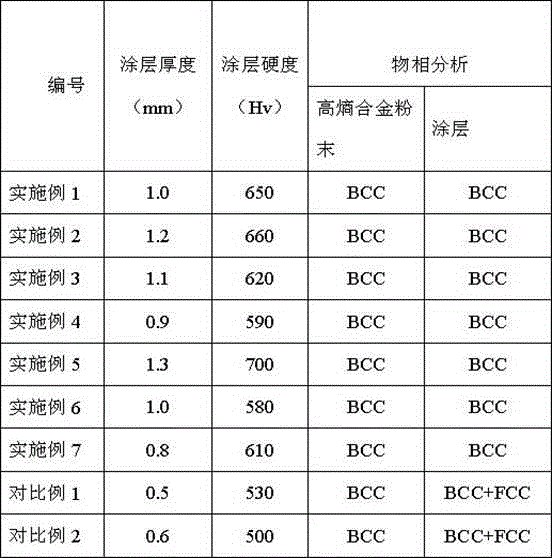

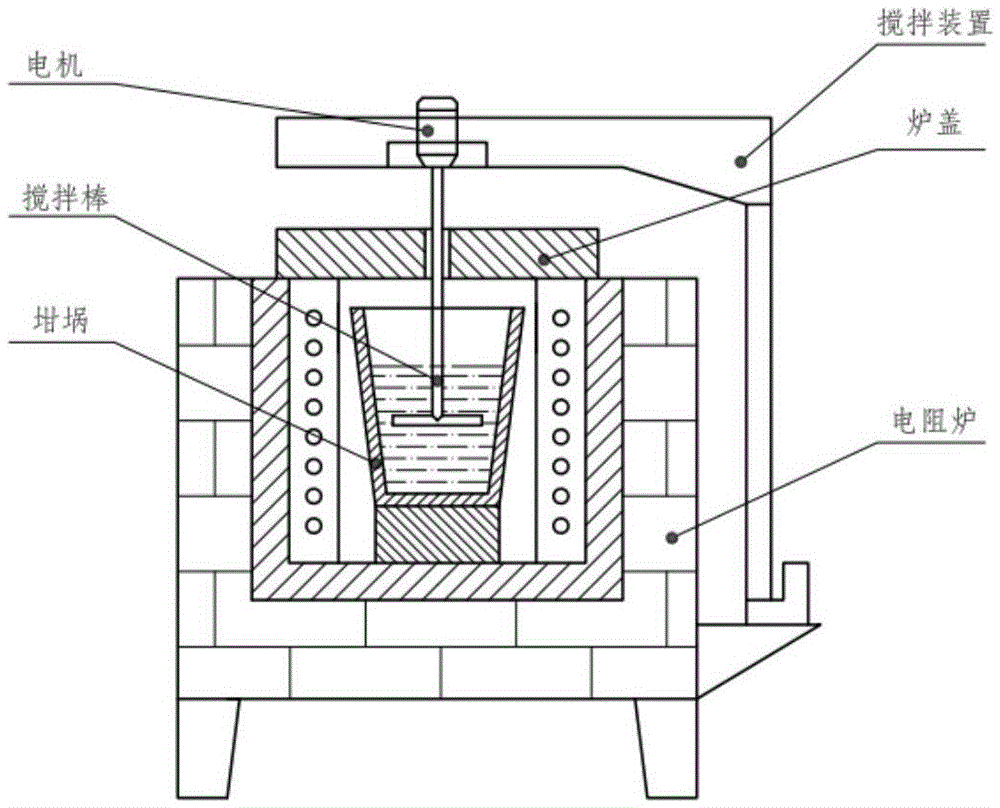

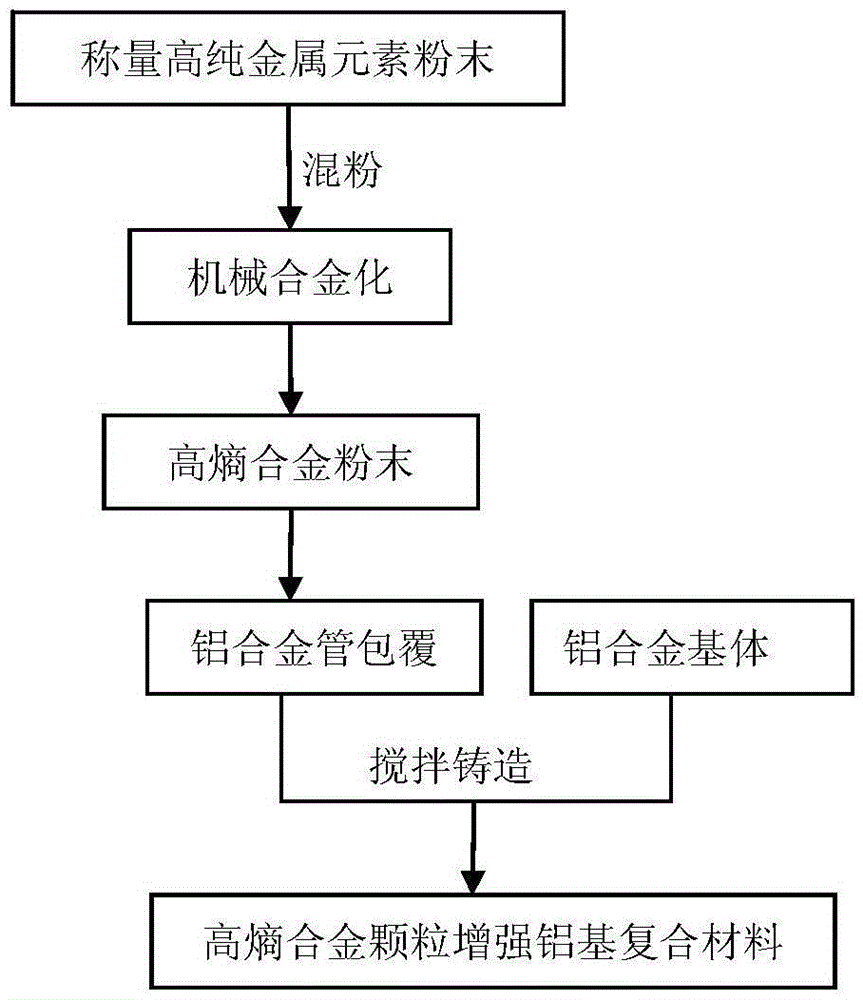

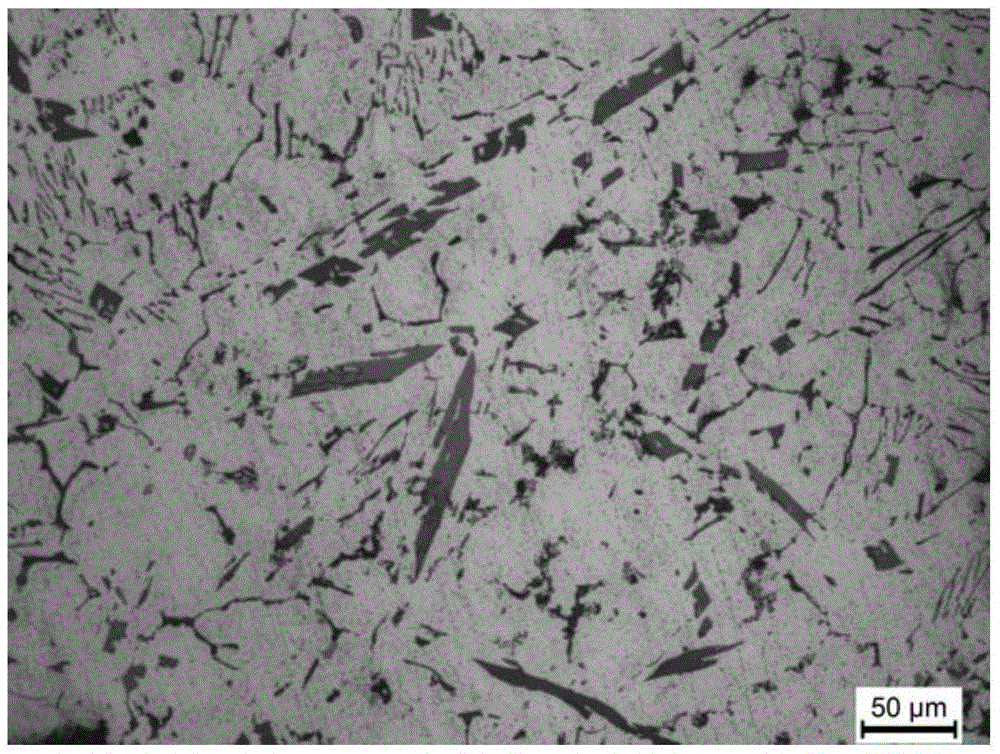

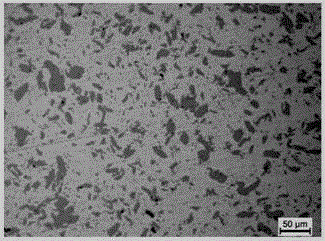

High-entropy alloy particle reinforced aluminum base composite material and stirring casting preparation process thereof

The invention discloses a high-entropy alloy particle reinforced aluminum base composite material and a stirring casting preparation process thereof. The preparation process adopts mechanical alloying to prepare high-entropy alloy powder and screen to obtain high-entropy alloy particles; the high-entropy alloy particles are sealed by adopting an aluminum alloy pipe having the same material with a basal body; the aluminum alloy pipe weighed in a segmented manner is added in the molten basal body; the high-entropy alloy particles are dispersed by a stirring mode; and the high-entropy alloy particle reinforced aluminum base composite material is prepared by a casting process. The high-entropy alloy particles are 0.1-35%; aluminum alloys are 65-99.9%; and the sum of the two is 1. The high-entropy alloy particles in the structure of the prepared composite material are uniformly dispersed; the high-entropy alloy and aluminum alloy interface bonding compatibility is excellent; the strength and the toughness are excellent; the preparation process is simple; the powder has no need to be treated; the cost is low; the stability is good; and the composite material is suitable for large-batch production and standard production, and is excellent in promotion and application prospect.

Owner:GUANGDONG XINGFA ALUMINUM +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

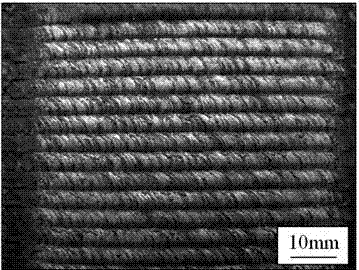

![TiZrNbVMo[x] high entropy alloy and preparation method thereof TiZrNbVMo[x] high entropy alloy and preparation method thereof](https://images-eureka.patsnap.com/patent_img/2902361d-51ee-4238-b4c1-5d60d73103a3/HDA0000405578970000011.PNG)

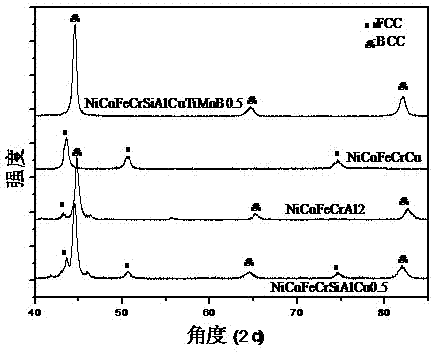

![TiZrNbVMo[x] high entropy alloy and preparation method thereof TiZrNbVMo[x] high entropy alloy and preparation method thereof](https://images-eureka.patsnap.com/patent_img/2902361d-51ee-4238-b4c1-5d60d73103a3/HDA0000405578970000021.PNG)

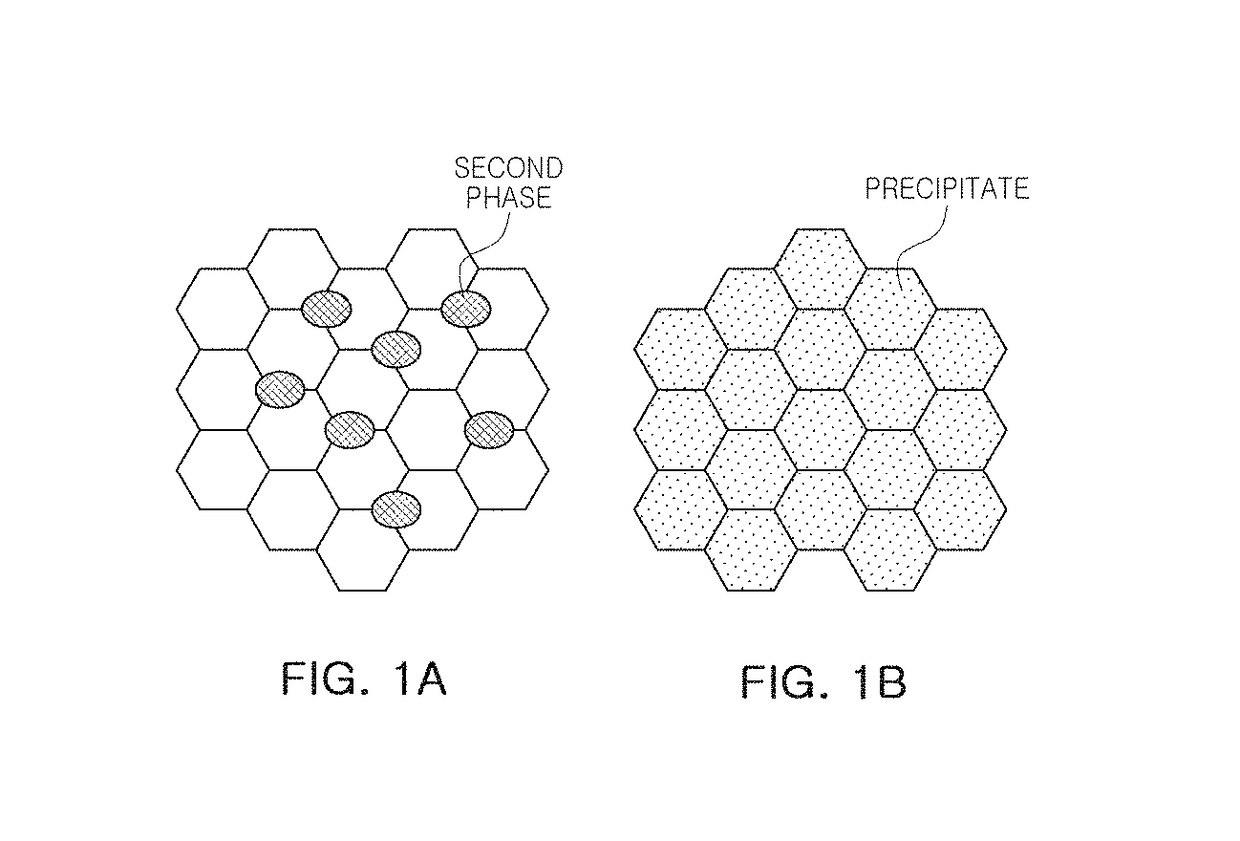

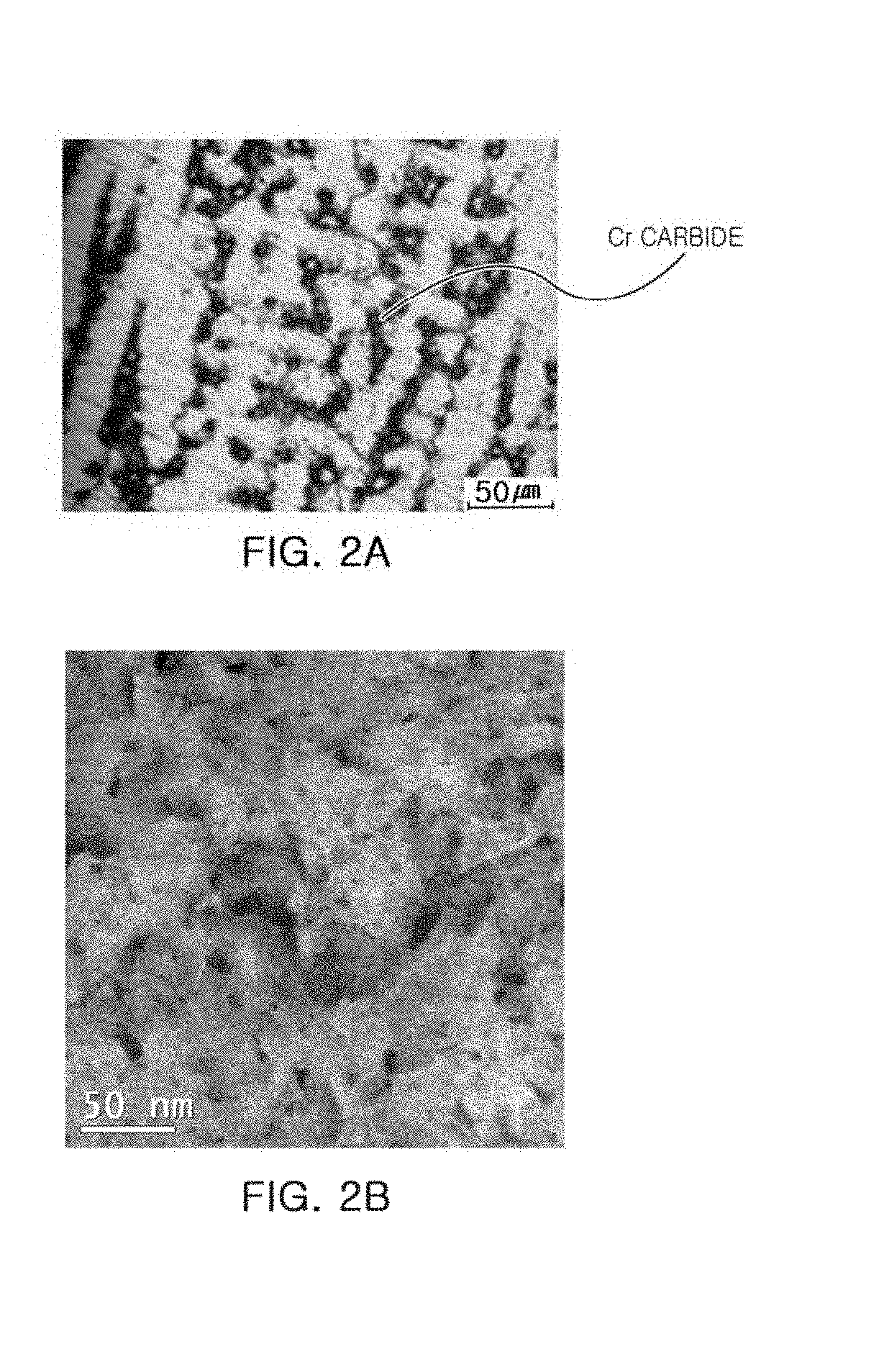

![TiZrNbVMo[x] high entropy alloy and preparation method thereof TiZrNbVMo[x] high entropy alloy and preparation method thereof](https://images-eureka.patsnap.com/patent_img/2902361d-51ee-4238-b4c1-5d60d73103a3/HDA0000405578970000031.PNG)