Patents

Literature

325results about How to "With energy saving and emission reduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

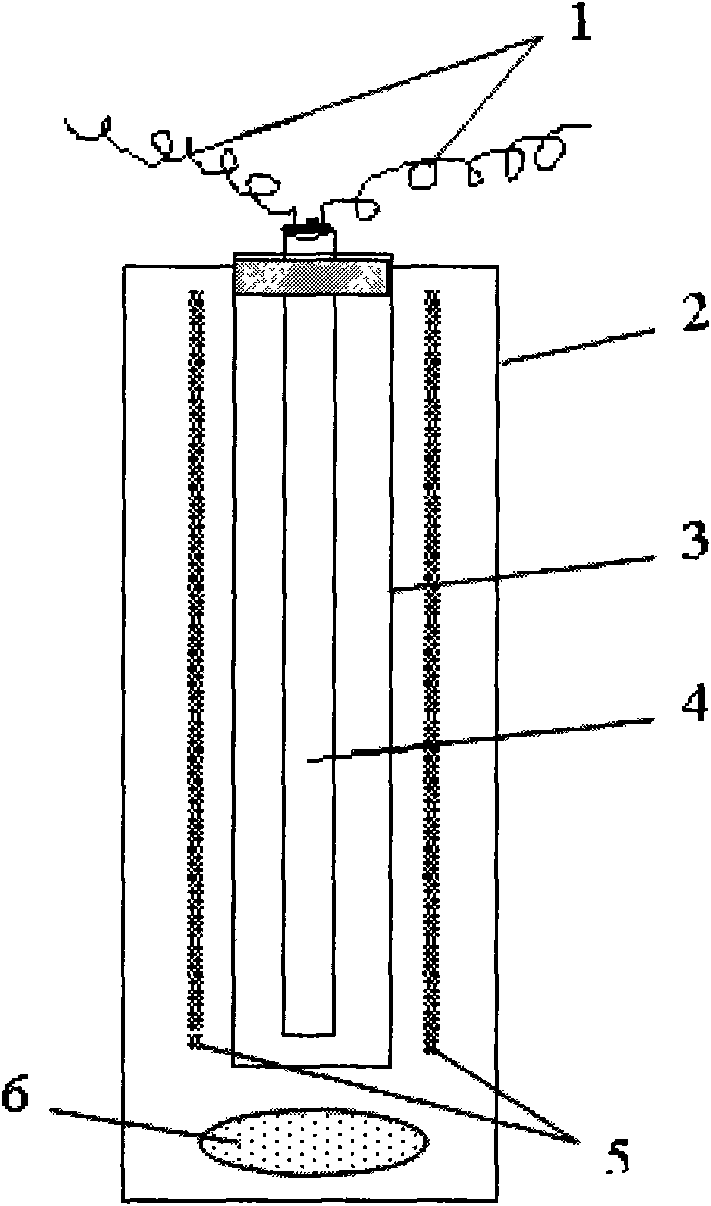

Aluminum electrolysis inert anode

InactiveCN103757661AAvoid consumptionWith energy saving and emission reductionElectrolysisHigh entropy alloys

The invention provides an aluminum electrolysis inert anode of which the material is a high-entropy alloy. The high-entropy alloy contains 5-10 alloy elements of which the mole ratio can be identical or different; and the atomic percent of each main element is 5-35%. The high-entropy alloy inert anode has the characteristics of favorable high-temperature oxidation resistance, high aluminum electrolysis salt corrosion resistance, high electric conductivity and the like. The high-entropy alloy prepared by the smelting method has the advantages of simple technique and low cost, and is easy for connection. When being used for aluminum electrolysis, the high-entropy alloy can avoid the consumption of the carbon anode and the emission of the CO2 gas, and has the advantages of energy saving and emission reduction.

Owner:FUJIAN UNIV OF TECH

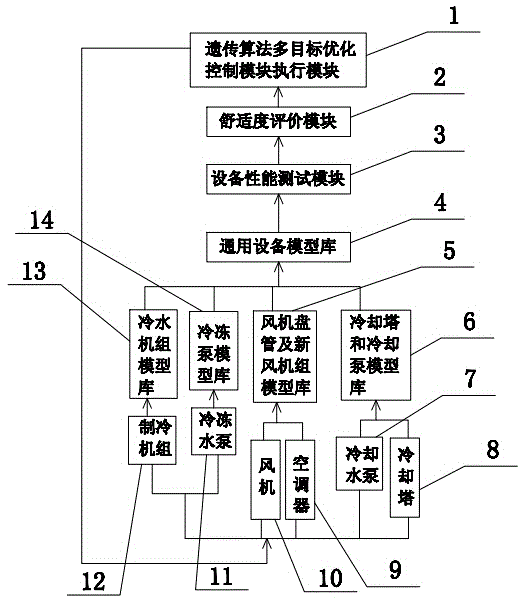

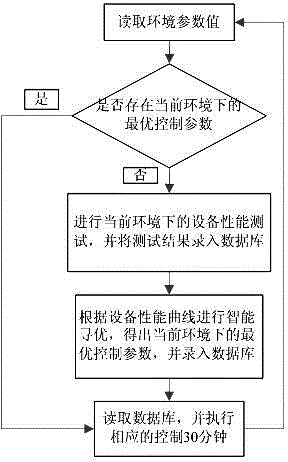

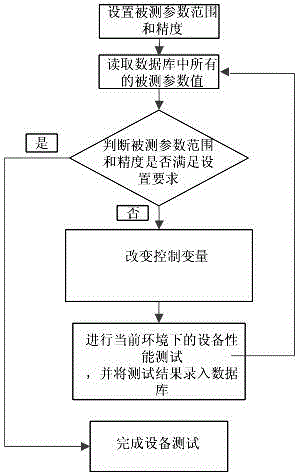

Central air-conditioning control system and control method thereof

InactiveCN104566868AIntelligent adjustment of measurement accuracyIntelligent adjustment of sampling frequencyMechanical apparatusSpace heating and ventilation safety systemsTransition seasonBehavior recognition

The invention provides a central air-conditioning control system and a control method thereof, and belongs to the technical field of air-conditioning systems. The central air-conditioning control system comprises a universal equipment model library, an equipment performance testing module, a comfort level evaluating module, a genetic algorithm multi-objective optimization control module and an execution module. An actual measured method is used, a system model is established, and the central air-conditioning control system is high in precision and high in reliability and is adaptive; a genetic algorithm is used, multi-objective optimizing can be realized, the optimizing efficiency is high, the comfort level is high, energy is saved, and the cost is low; whether a user feels comfortable or not can be intelligently judged by a user behavior recognition mode, and control objectives are adjusted in time; and the control method can be optimal on the basis of environmental change, particularly at the transition season, the equipment efficiency can be greatly improved, and energy conservation and emission reduction are realized.

Owner:ZHEJIANG LUTE ENERGY TECH

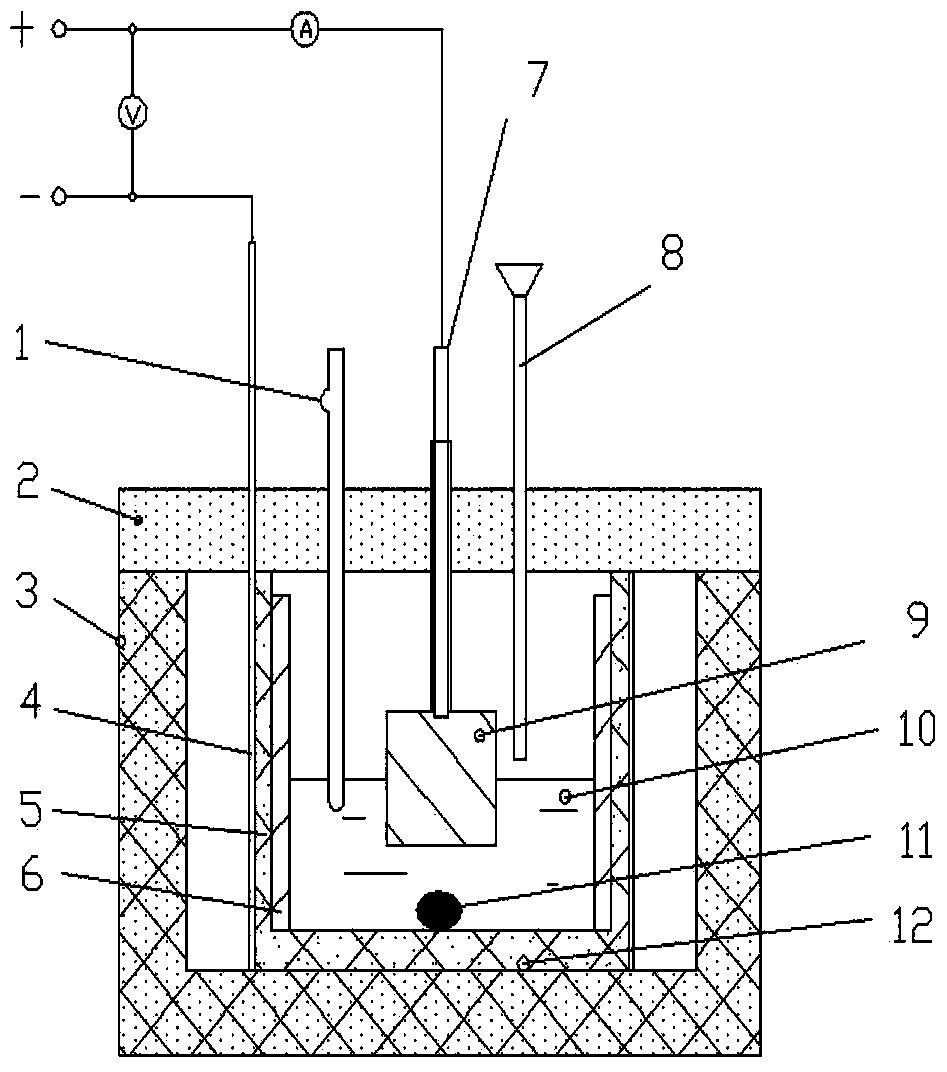

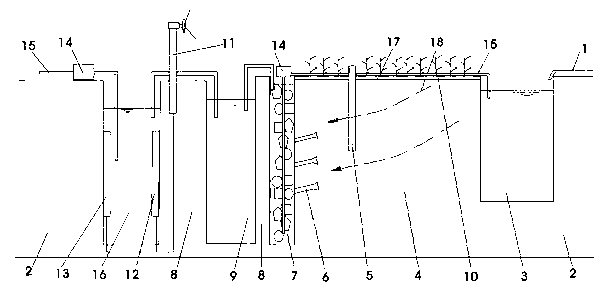

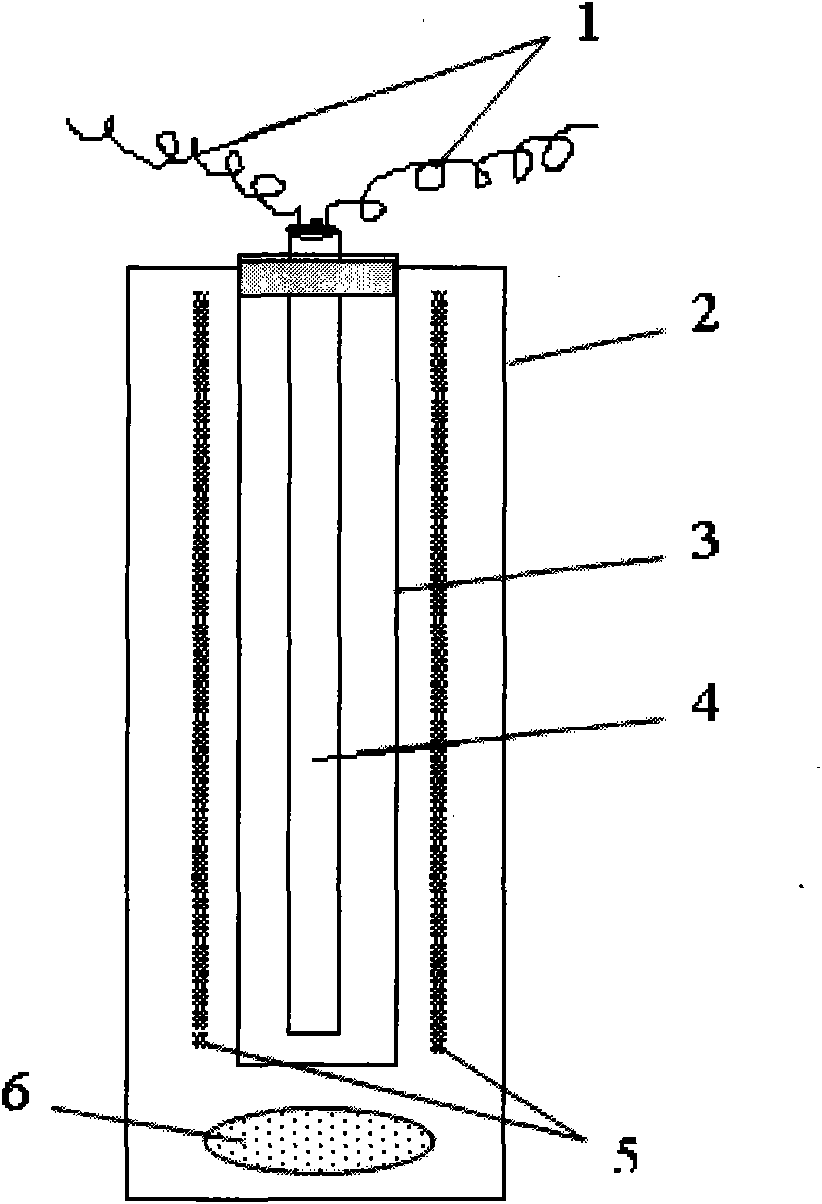

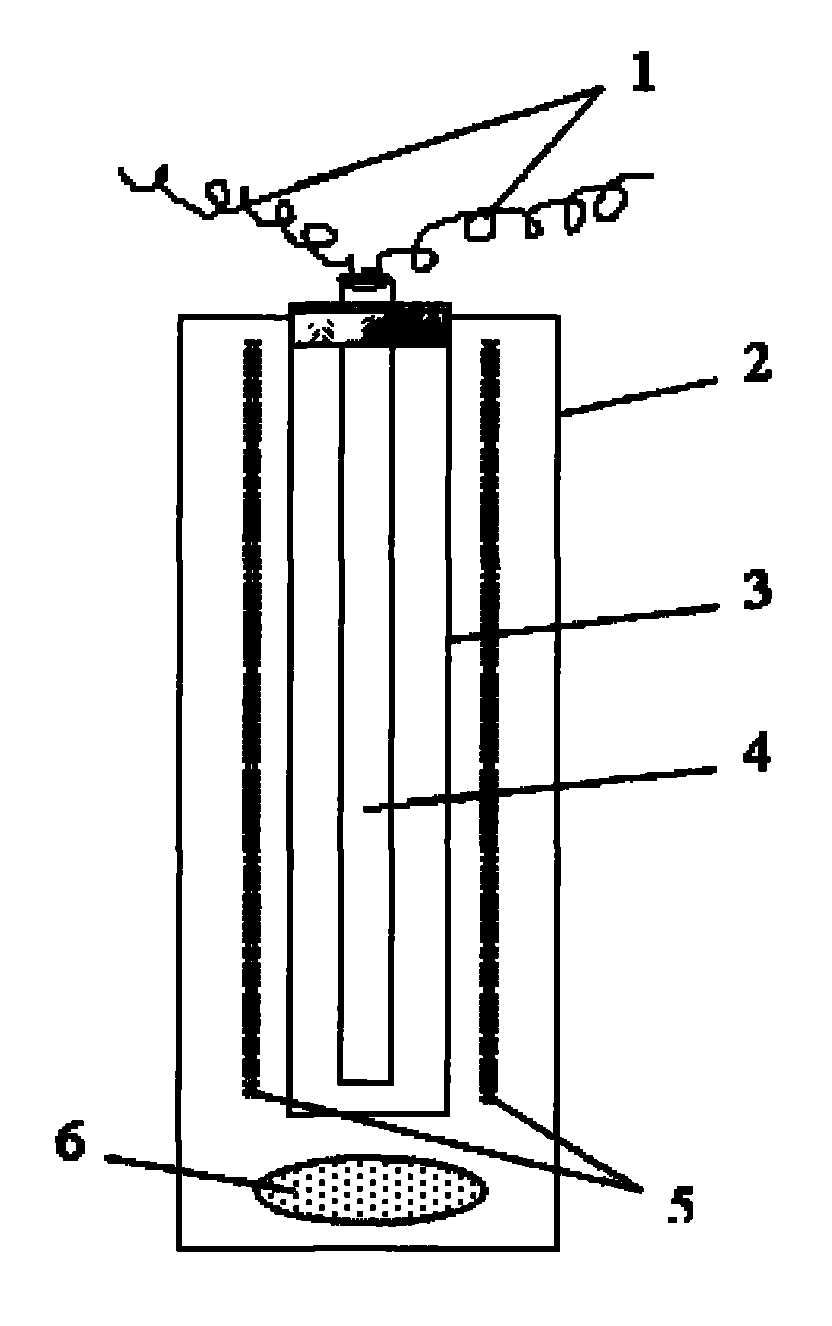

In-situ rainwater leaching repair system for contaminated soil

The invention relates to an in-situ rain leaching repair system for contaminated soil. The in-situ rain leaching repair system at least comprises three parts, namely a rain collection part, a leaching repair part and a waste water treatment part, wherein the rain collection part is provided with water guiding pipes, a water collecting tank and canals, the leaching repair part is provided with an observation well, water collecting pipes and plants planted for the soil phytoremediation, the observation well is built in a middle-upper layer of contaminated soil, and the water collecting pipes are in the middle-lower layer; and the waste water treatment part is provided with a filter tank, a microorganism putting tank, an electric separation tank, a wind power generating set and the like, leaching waste water is firstly filtered by the filter tank, and is then repaired by the microorganism putting tank, and finally, the leaching waste water passes through the electric separation tank to process heavy metal so as to obtain the purified liquid. The in-situ rain leaching repair system establishes a complete contaminated soil simulated repairing system for the soil in an aeration zone, and combines repair technologies of leaching, plants, microorganisms, electric separation and the like. The in-situ rain leaching repair system has the characteristics of energy conservation, emission reduction and no secondary pollution, and is suitable for repairing the soil in a large-area aeration zone with little pollution.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Methanol gasoline for vehicle

The invention discloses an energy-efficient, environment-friendly and high-efficient and low-cost automobile methanol gasoline. The methanol gasoline consists of (calculated by weight percent) gasoline (20-48 percent), methanol (30-70 percent), light hydrocarbon (5-15 percent) and additives (5-7 percent); the additives in the automobile methanol gasoline consists of (calculated by weight percent) solubilizer (1.5-5 percent), anti-oxidant (0.05-0.2 percent), antifreezing agent (0.5-1.0 percent), heat-value increasing agent (0.5-1.0 percent), plasticizer (0.05-0.5 percent), antioxidant (0.05-0.2 percent), stabilizer (0.2-0.8 percent) and antiseptic agent (0.2-1.0 percent). The raw materials required by the automobile methanol gasoline are available from extensive resources and the price is low; suitable for mass production and the production process is very simple; besides, the production is not restricted by seasons or scale.

Owner:上海龙津石油有限公司

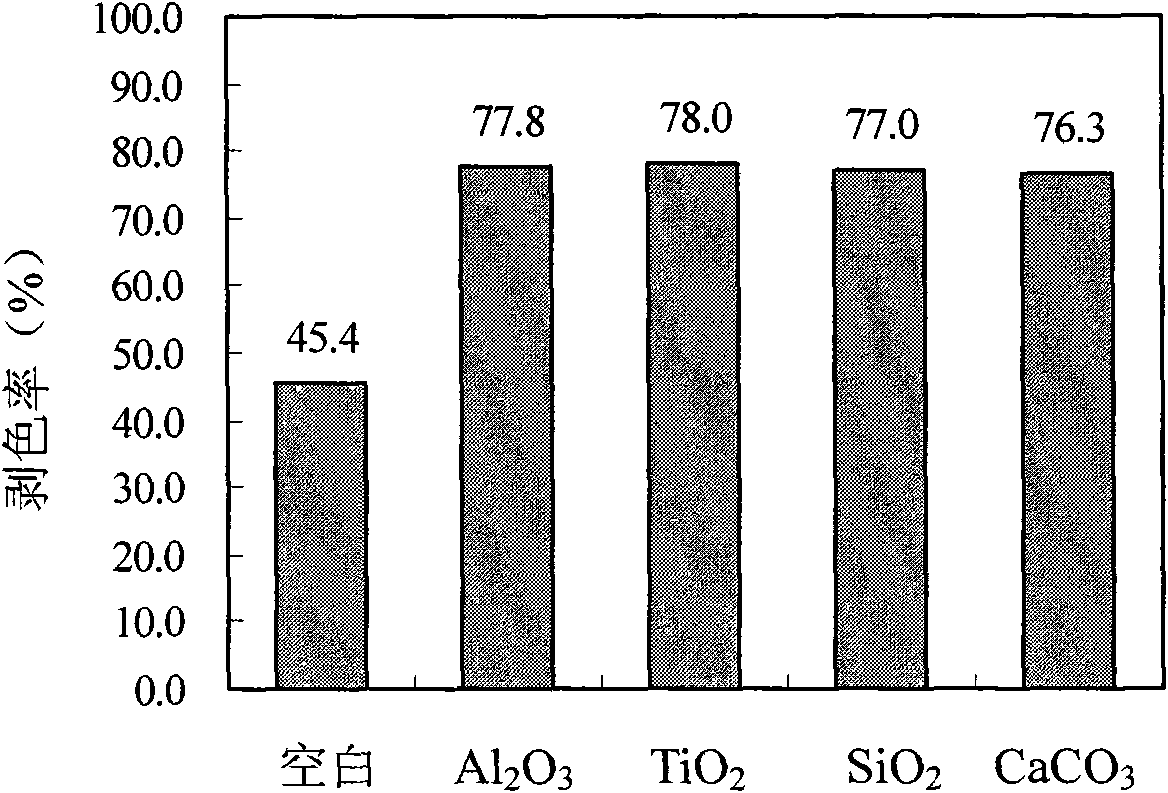

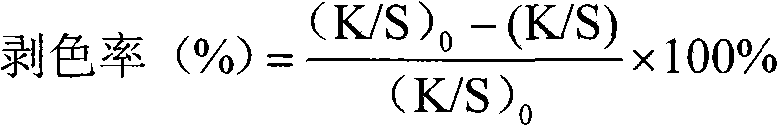

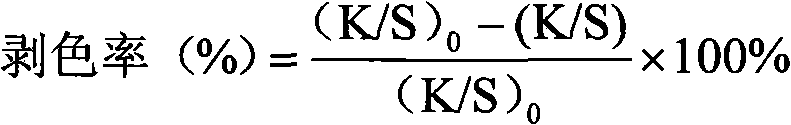

Stripping treatment method for dyed textiles

The invention discloses a stripping treatment method for dyed textiles. The method comprises the following steps: using nanometer material as a catalyst, treating the dyed textiles, in particular to defective dyed products, under ultraviolet light in oxygen at 10-100 DEG C so as to reach different required dye effects and repair or redye the textiles; and meanwhile, adding an accelerant to a stripping bath to accelerate or enhance the dye effect. The method adopts strong oxidative free radicals, and the like generated by nanometer material photocatalysis as stripping agents, can obtain satisfactory stripping effect under normal temperature and normal pressure, avoids using a great amount of reducing agents, oxidants, and the like as in a traditional stripping method and can repeatedly usethe nanometer material stripping bath. The stripping technology has clean process, no pollutant generation, good environmental-protection ecological property, simple equipment and process, short flows, high efficiency, energy reduction and consumption and emission reduction.

Owner:SUZHOU UNIV

Low-temperature cocoon cooking method for mulberry cocoon with little sericin

InactiveCN101831714AImprove efficiencyWith energy saving and emission reductionSilk filament obtainingSocial benefitsEconomic benefits

The invention discloses a low-temperature cocoon cooking process for a mulberry cocoon with little sericin, which comprises a step of soaking dry mulberry cocoon with little sericin in water at the temperature of 35 DEG C under vacuum, wherein the water temperature of the I soaking section on an upper groove of a cocoon cooking machine is 35 DEG C; the water temperature of the II soaking section is 45 DEG C; the cooking temperature is 80 DEG C; the temperatures of a middle section, a vibrating section and a statically cooking section on a cooking part are 50 DEG C, 40 DEG C and 30 DEG C respectively; the temperature of an outlet part is 30 DEG C; the cocoon cooking time is 14 minutes; and the difference between the reelability percentage of the low-temperature cocoon cooking process and the reelability percentage of a high-temperature cocoon cooking process is no more than 5 percent. Matched with the popularization of new products of the mulberry cocoon with little sericin, the low-temperature cocoon cooking process realizes energy conservation and emission reduction in a reeling process and has direct economic benefit and wide social benefit for creating an energy-saving and emission-reducing 'low-carbon' society.

Owner:SUZHOU UNIV

Stripping processing method of textile printing defective items

InactiveCN101787644AHas strong oxidizing propertiesReductiveBleaching apparatusDyeing processTextile printerUltraviolet lights

The invention discloses a stripping processing method of textile printing defective items, which implements stripping processing on printing defective items and particularly on dyeing defective items by using an active material which is generated by initiating and catalyzing an oxidant or a reducing agent under ultraviolet light and low temperature and has strong oxidability or reducibility as a stripping agent so as to be convenient for the rehandling or redyeing of textiles. Because of the adoption of various active materials which are generated by ultraviolet light initiation and optical catalysis as the stripping agent, the method can obtain an approving stripping effect under normal pressure and temperature, thereby avoiding the consumption of a large amount of energy sources in a traditional high-temperature stripping method and the use of a large amount of reducing agent, oxidant and the like. The stripping technology of the invention has the advantages of high efficiency, energy saving, emission reduction, simple equipment and process and short procedures.

Owner:SUZHOU UNIV

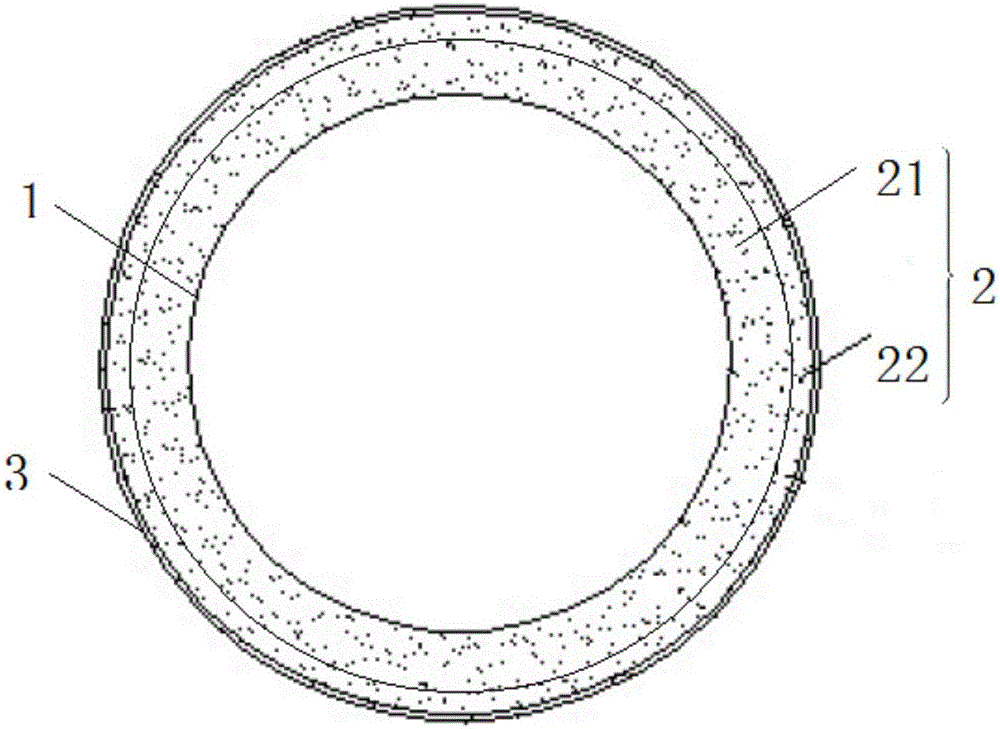

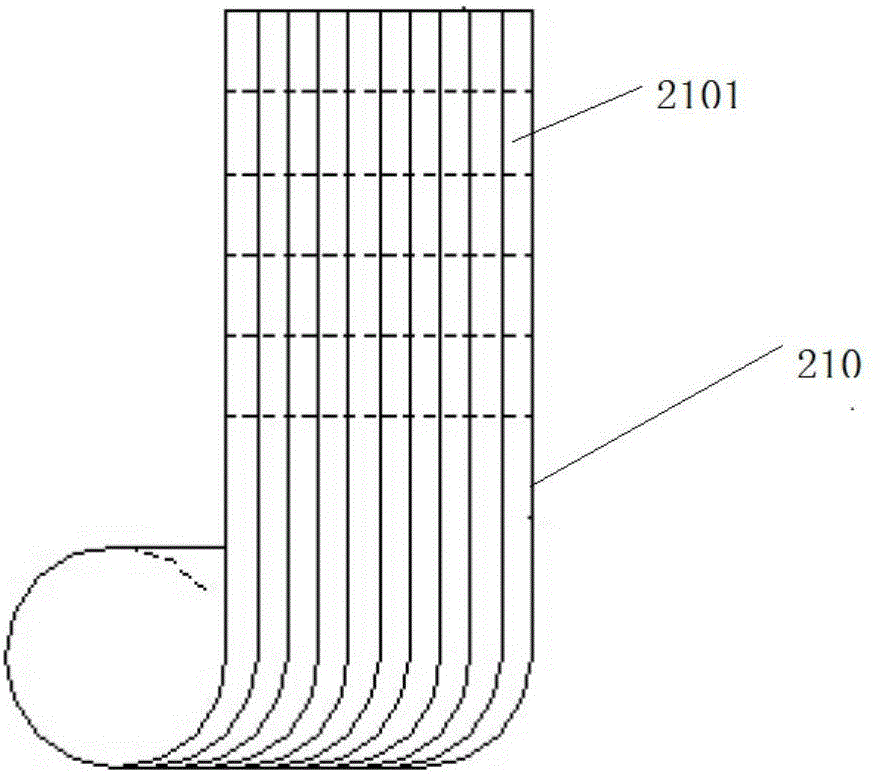

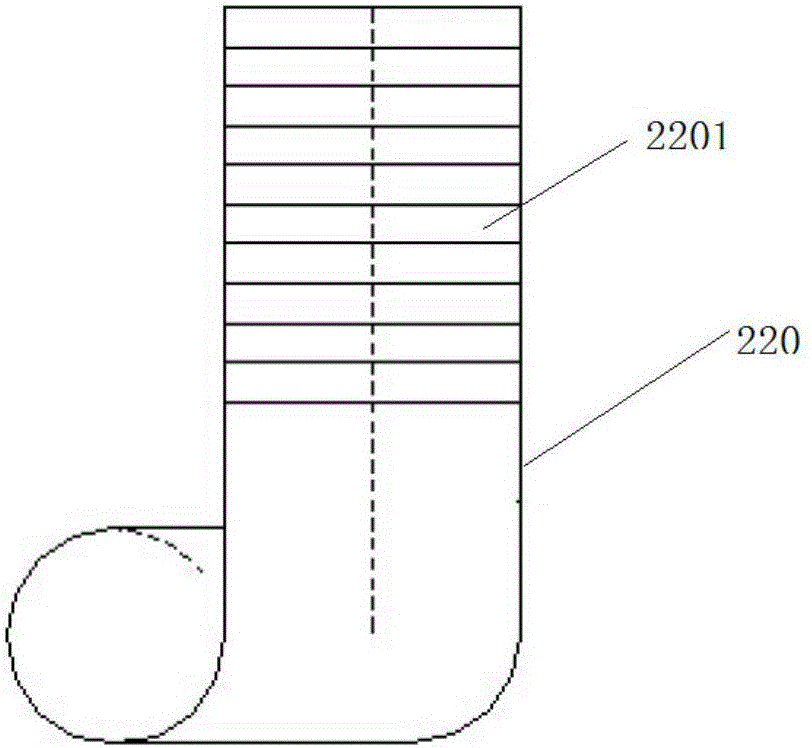

Ultra-large-diameter bamboo winding composite tube and manufacturing method thereof

ActiveCN105715881AImprove axial strengthEnhanced bending and impact resistanceRigid pipesTubular articlesStress distributionFiber

The invention belongs to the related field of composite tubes, and discloses an ultra-large-diameter bamboo winding composite tube. The bamboo winding composite tube comprises a lining layer, a composite strengthening layer and an outer protection layer from inside to outside, and the lining layer is made of fiber blankets or non-woven fabrics with anticorrosive resin in an adhesion manner; the composite strengthening layer is formed in a manner that two different types of bamboo skin curtains are wound outside the lining layer in a layer-by-layer manner according to the proper layer number and the thickness proportion wholly in the ring direction, the bamboo skin curtains are sprayed with the resin in a liquid-leaching manner while winding is carried out, and then bonding curing is carried out; and the outer protection layer is cured on the outer surface of the strengthening layer in a coating manner, and the effects of water prevention, corrosion prevention, radiation prevention and the like are achieved. The invention further discloses a corresponding manufacturing method. Through the ultra-large-diameter bamboo winding composite tube and the manufacturing method, even under the tube diameter obvious expanding condition, the characteristic that the whole structure of the bamboo winding composite tube is free of stress distribution defect can be well kept, and meanwhile comprehensive properties of pressure resistance, ring stiffness, long-term use quality stability and the like can be obviously improved.

Owner:ZHEJIANG XINZHOU BAMBOO BASED COMPOSITES TECH +1

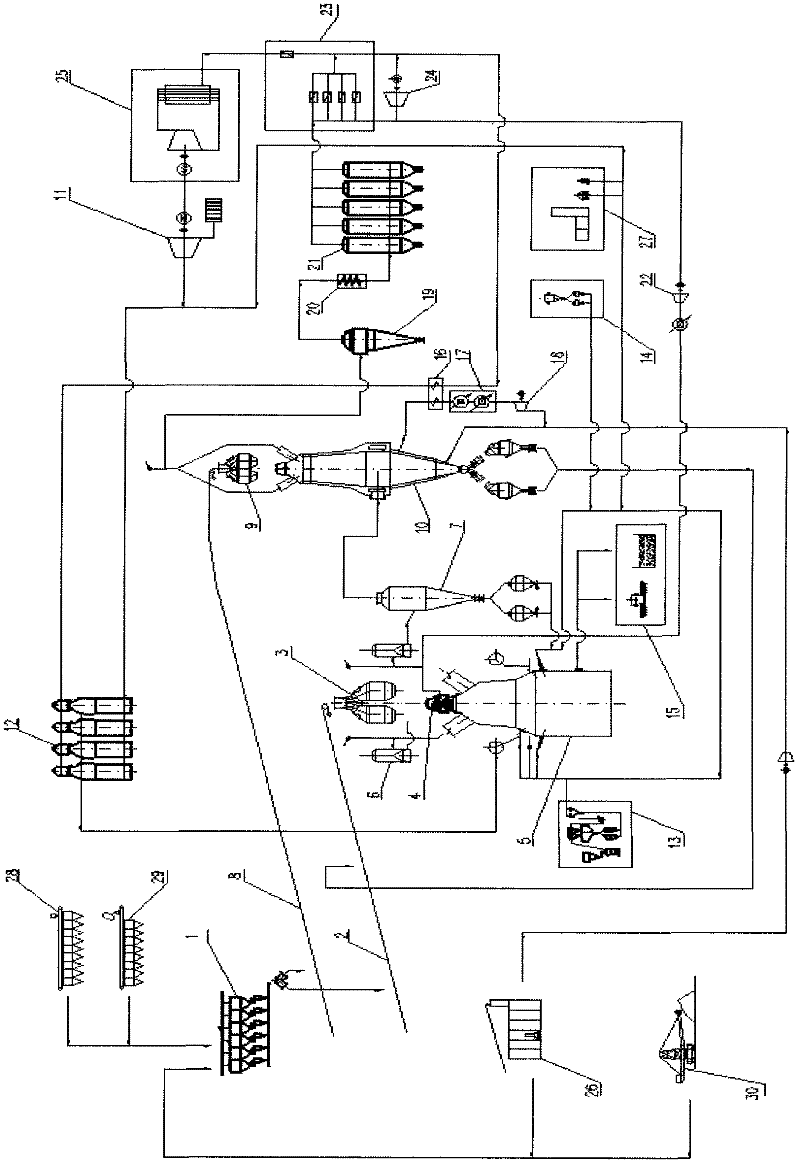

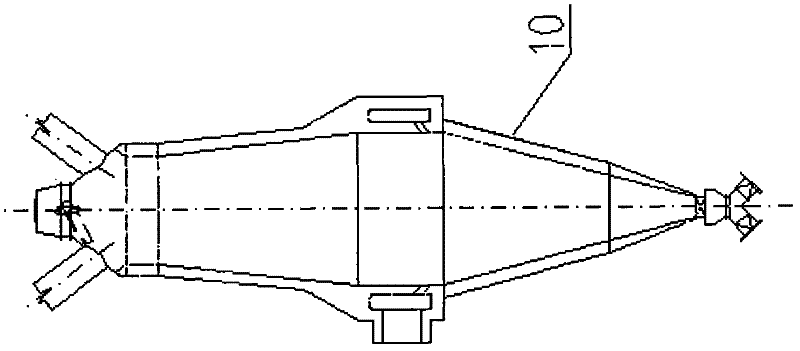

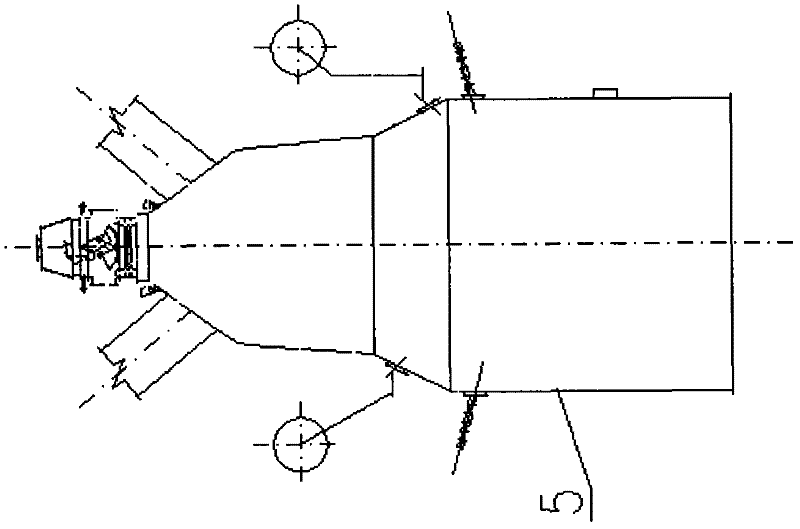

High-wind-temperature rotational flow injection disturbance melting reduction and prereduction combination device and method

ActiveCN102337369AGood for high pressure operationGood for material level controlShaft furnaceMetallurgyCogeneration

The invention discloses a high-wind-temperature rotational flow injection disturbance melting reduction and prereduction combination device and a method, which belong to the technical field of melting reduction. The device comprises a raw material system, a furnace top material charging and distributing system, a melting reduction furnace, a furnace top high-temperature gas system, a prereduction furnace, a semicoke gas recycling system, a coal dust preparing and spraying system, a molten iron desulfurizing agent preparing and jetting device, an oxygen and nitrogen supplying system, a residual iron treating system, a high-wind-temperature hot blast furnace, a melting reduction furnace blower, a furnace top gas dedusting and recycling system and a gas cogeneration device. The method comprises the following steps of: introducing high-temperature gas which is generated in a high-wind-temperature rotational flow injection disturbance melting reduction furnace into the prereduction furnace; directly reducing an iron-containing raw material in a solid phase state into a prereduction furnace material with a certain metallization rate; cooling, and then adding the cooled material and semicoke which serve as the furnace material and a fuel respectively into the melting reduction furnace; and finally producing molten iron by reduction. The device and the method have the advantages of high production efficiency and low energy consumption, are easy to operate and make industrialization easily realized.

Owner:BEIJING SHOUGANG INT ENG TECH

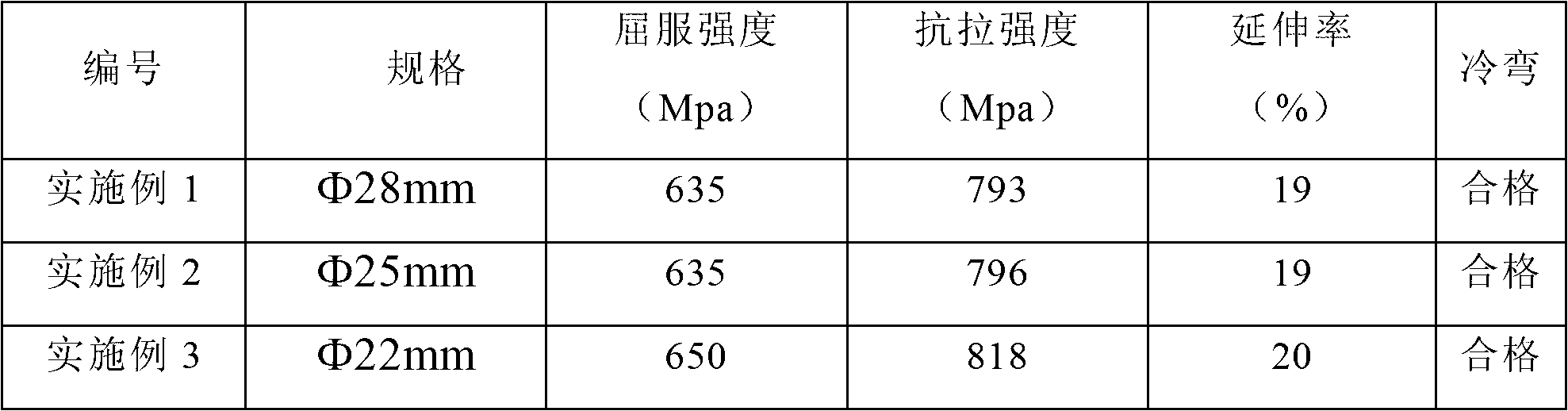

HRB600E vanadium-containing high-strength hot-rolled earthquake-resistant reinforced bar and production method thereof

The invention discloses an HRB600E vanadium-containing high-strength hot-rolled earthquake-resistant reinforced bar and a production method thereof. The reinforced bar comprises the following chemical components in percentage by weight: 0.23-0.30% of C, 0.5-0.8% of Si, 1.20-1.60% of Mn, 0.15-0.20% of V, no more than 0.035% of P, no more than 0.030% of S, 0.015-0.025% of N and the balance of Fe and inevitable impurities. The production method comprises the following steps: performing converter or electric furnace smelting, performing external refining, performing continuous casting, heating a casting blank, rolling and performing air cooling on a cooling bed. According to the invention, the V and N contents in steel are controlled, thereby promoting formation and precipitation of V (C, N) fine particles; steel making and steel rolling process parameters are strictly controlled, thereby obviously enhancing the strength of the reinforced bar and having certain hydrogen corrosion resistance; indicators of the reinforced bar meets the requirements of an earthquake-resistant reinforced bar; and the reinforced bar has the practical meanings of energy saving, emission reduction, high safety and environment friendliness.

Owner:HEBEI IRON AND STEEL

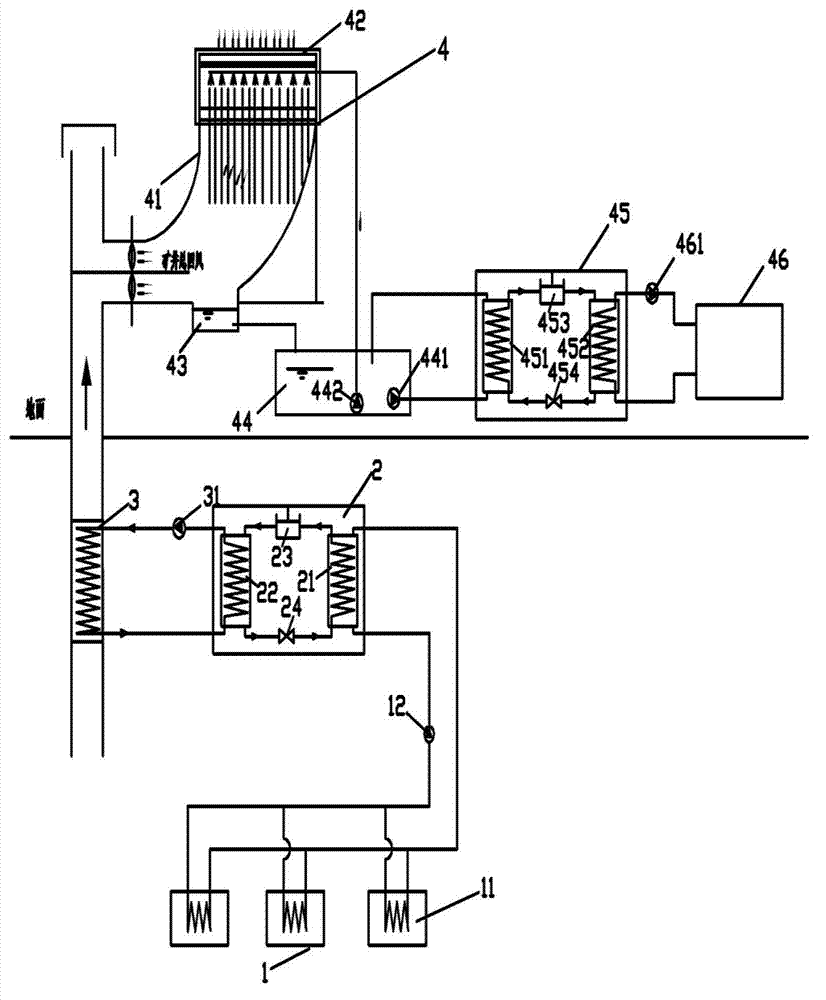

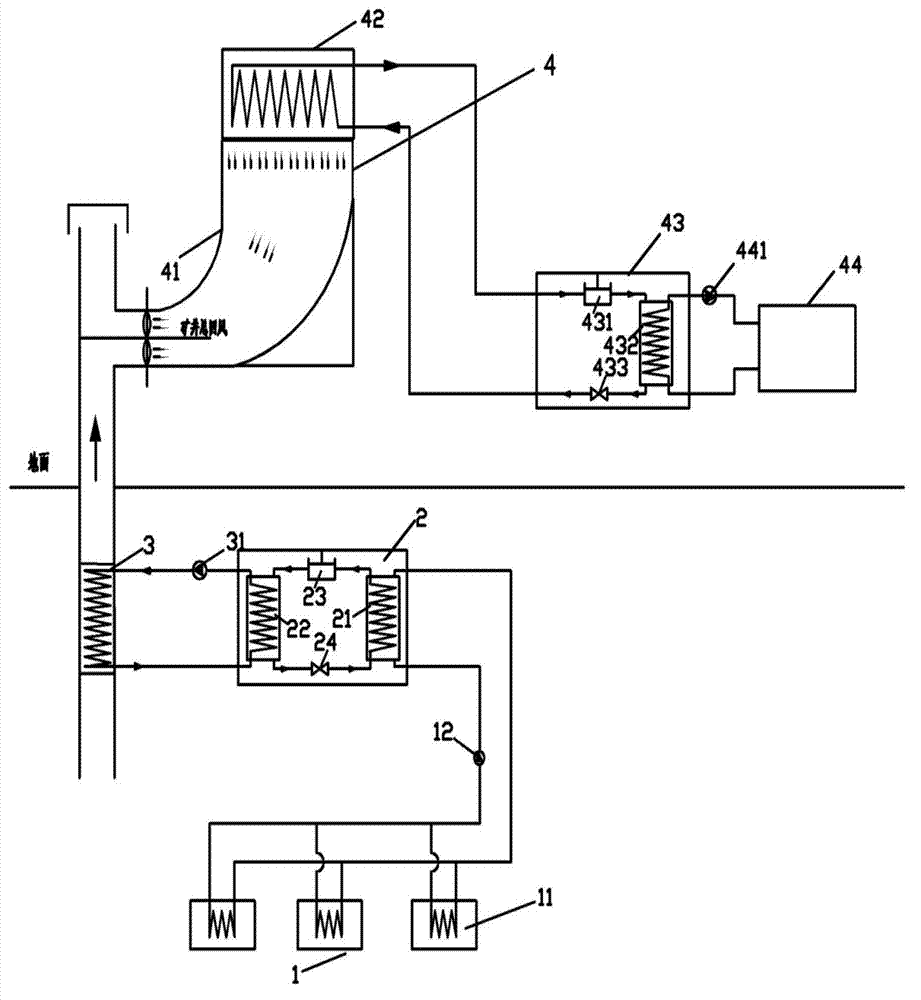

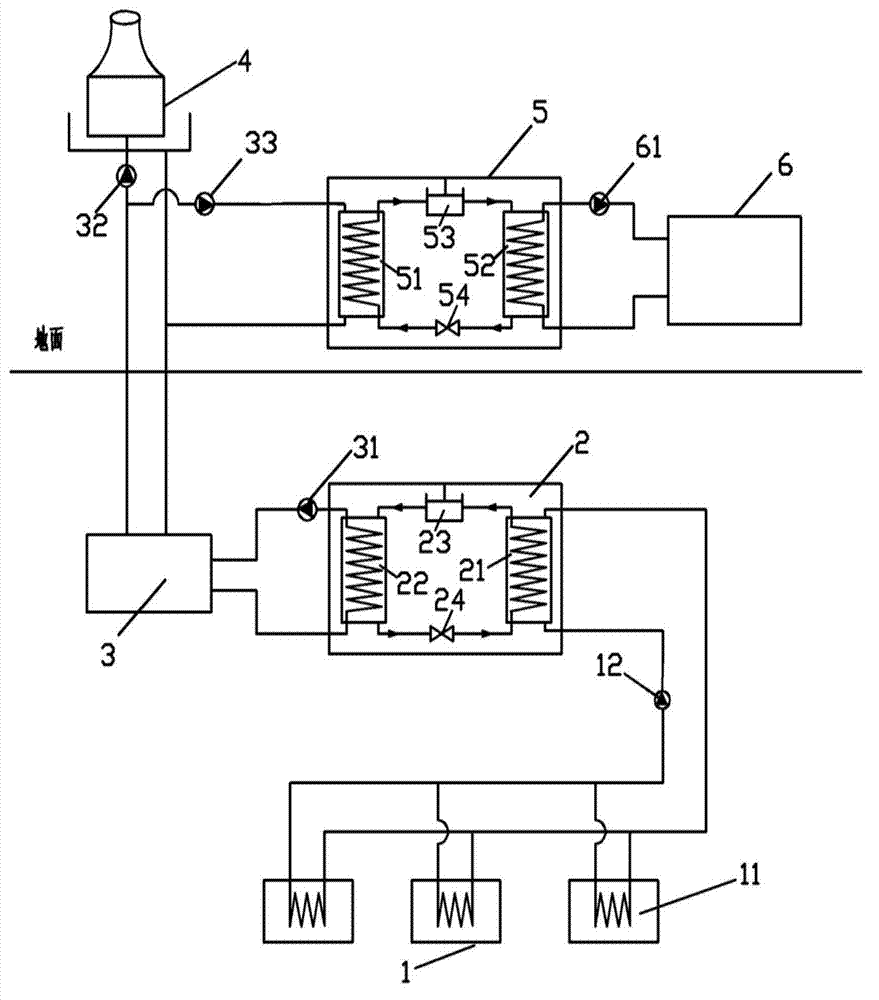

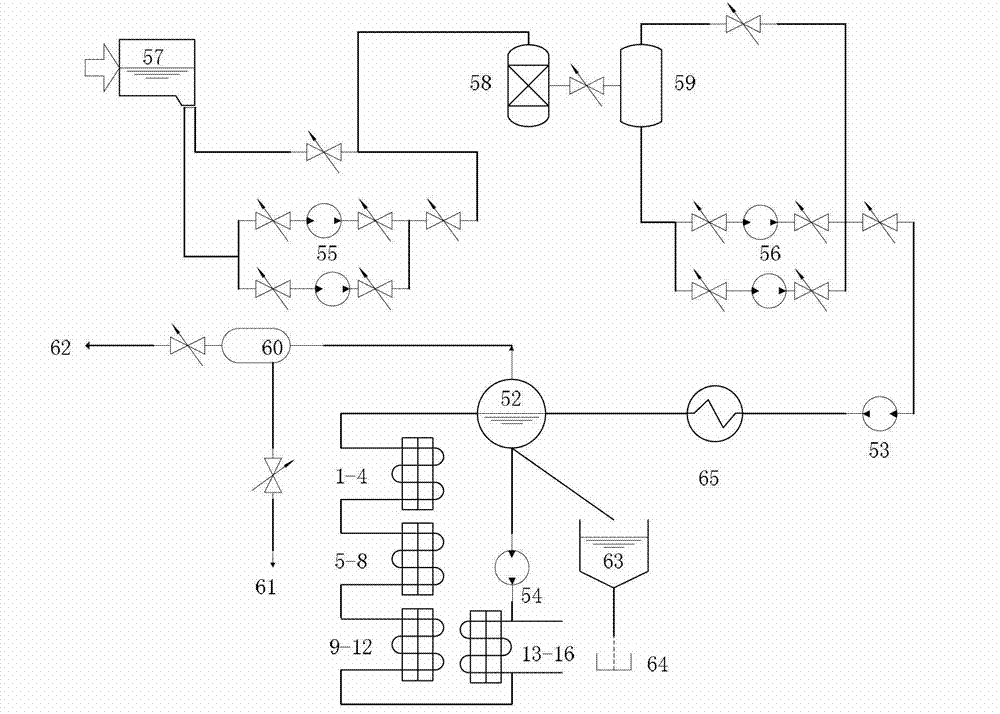

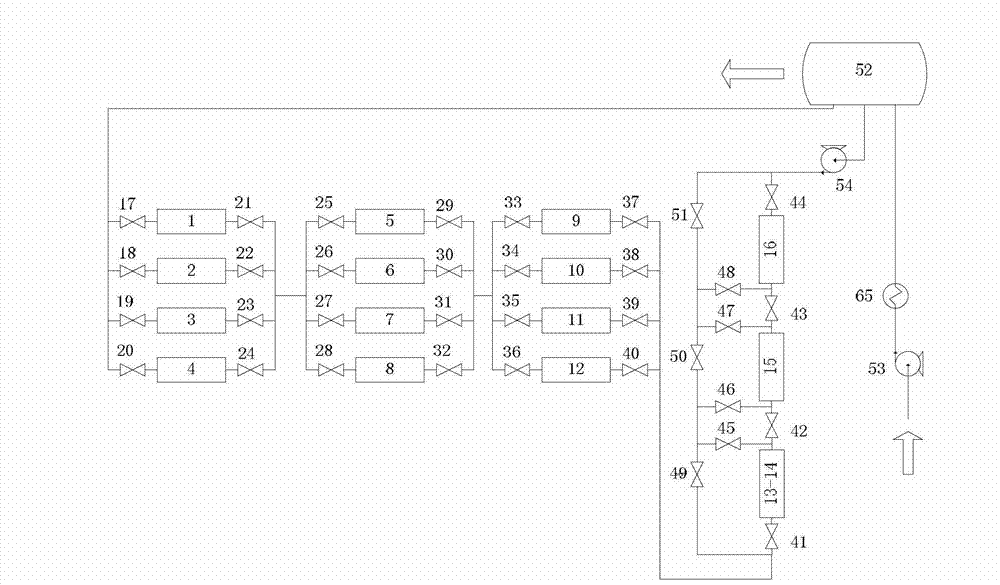

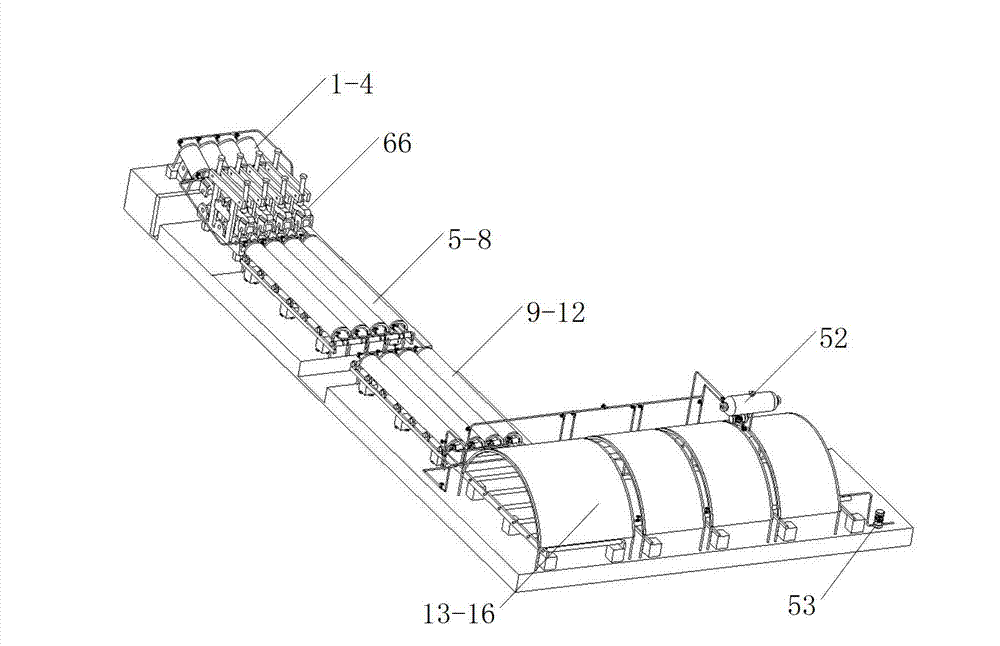

Mine underground cooling and waste heat recycling system

ActiveCN102733840AImprove economic and environmental benefitsFlexible and diverseHeat pumpsTunnel/mines ventillationCoalChiller

The invention relates to a mine underground cooling and waste heat recycling system, comprising an air cooler unit, a cooling set unit, a heat pump set unit and a user equipment unit, and a mine return air heat pump system or a cooling tower. According to specific implementation requirements, different combined connections are used for forming multiple heat exchange circulation loops, by the multiple heat exchange circulation loops, the underground high-temperature waste heat is recycled and provided for corresponding user equipment, so that the mine underground cooling is realized, and the requirement on heat usage for production and living of the coal mine is satisfied. The mine underground cooling and waste heat recycling system can be widely used in the mine underground cooling and waste heat recycling process.

Owner:北京矿大节能科技有限公司

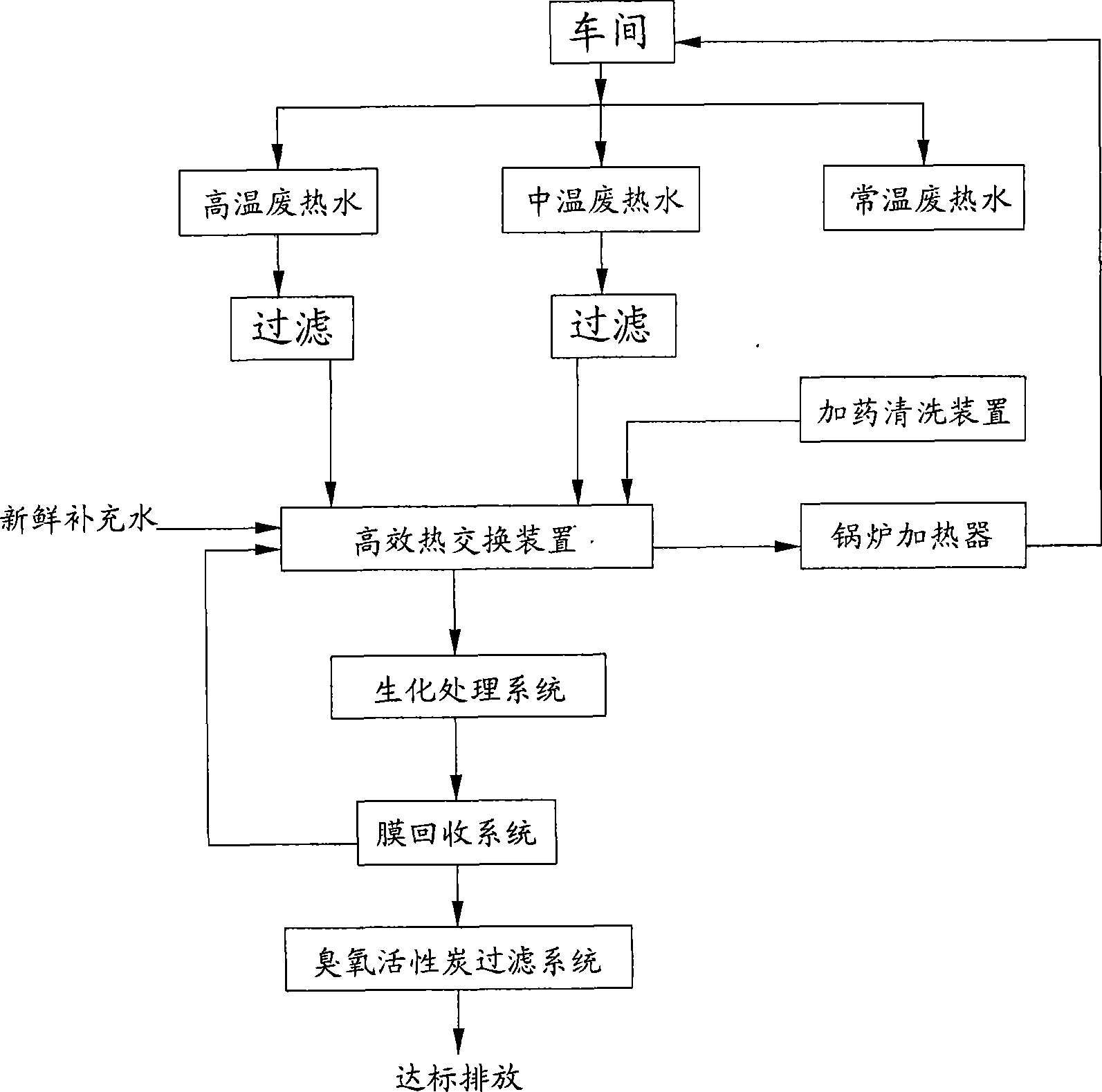

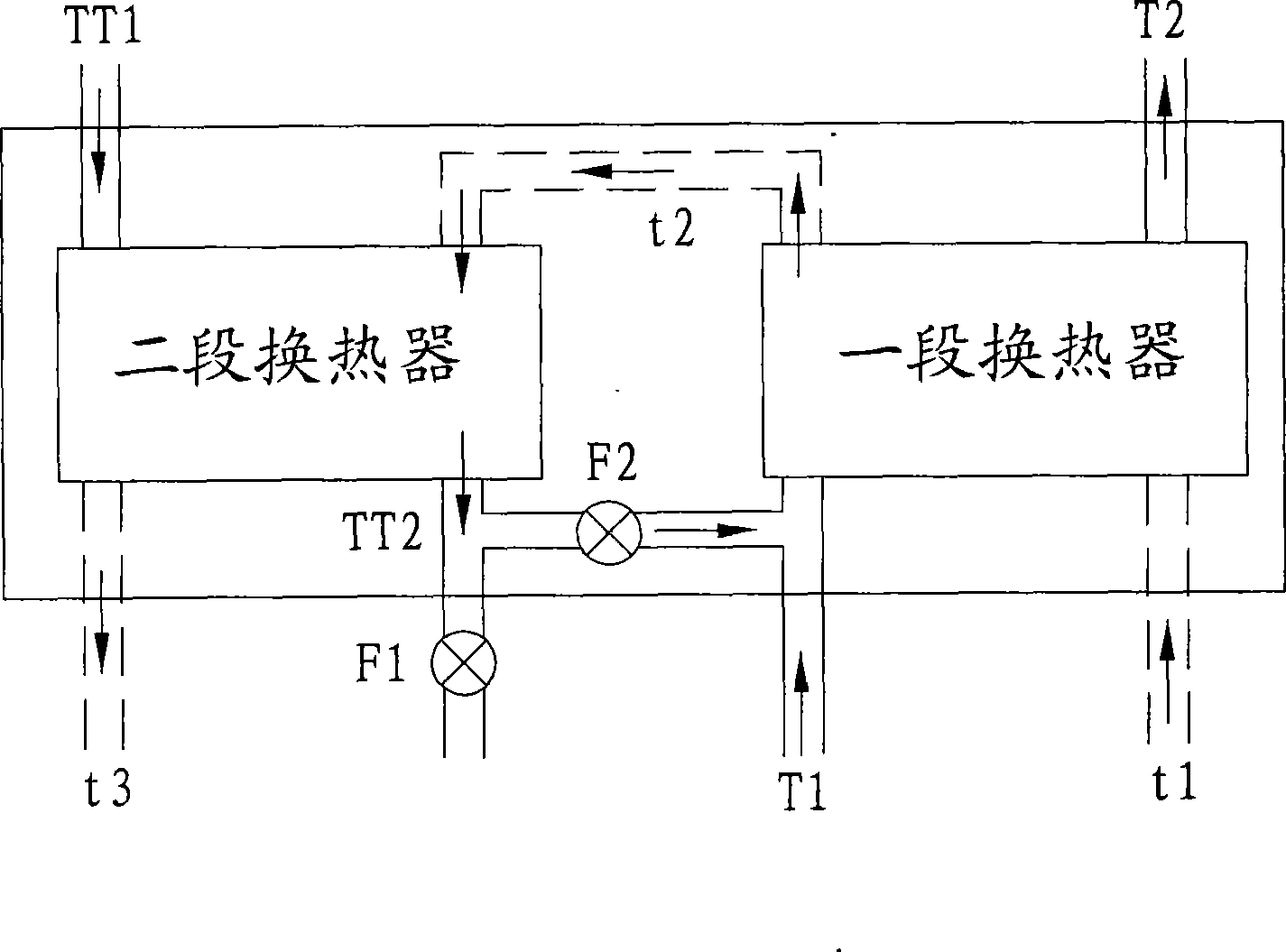

Comprehensive recovery method for heat energy and water from printing and dyeing industry wastewater and heat-exchanging system

InactiveCN101462809AReduce consumptionReduce the temperatureWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentRecovery methodThermal energy

The invention discloses an integrated recovery method and a heat exchanger for the heat energy and water in the wastewater of the printing and dyeing industry. The invention belongs to the technical field of the wastewater treatment in the printing and dyeing industry. The integrated recovery method for the heat energy and water in the wastewater of the printing and dyeing industry comprises the following steps: dividing the printing and dyeing wastewater emitted by a workshop into three types, namely normal temperature water, moderate temperature water and high temperature water, and treating the three types of water separately; after respectively removing impurities through filtration treatment, leading the moderate temperature wastewater and the high temperature wastewater into a high efficiency heat exchange device to carry out the heat exchange with a cold water source and increase the temperature of the cold water source in advance before the cold water source enters a boiler heating room, simultaneously reducing the temperature of the hot wastewater, mixing the high temperature wastewater and moderate temperature wastewater undergoing the heat exchange with the normal temperature wastewater, and then leading the water into a subsequent membrane treatment system for treatment; and taking the membrane system penetrating water and fresh compensation water together as the cold water source which is sent to the high efficiency heat exchange device, and realizing the emission up to the standards after the treatment of the enriched water. The invention can not only reclaim heat energy, but also have the advantages of energy conservation and emission reduction, improvement of equipment service life, convenient equipment maintenance, and the like.

Owner:VISBE XIAMEN ENVIRONMENT TECH CO LTD

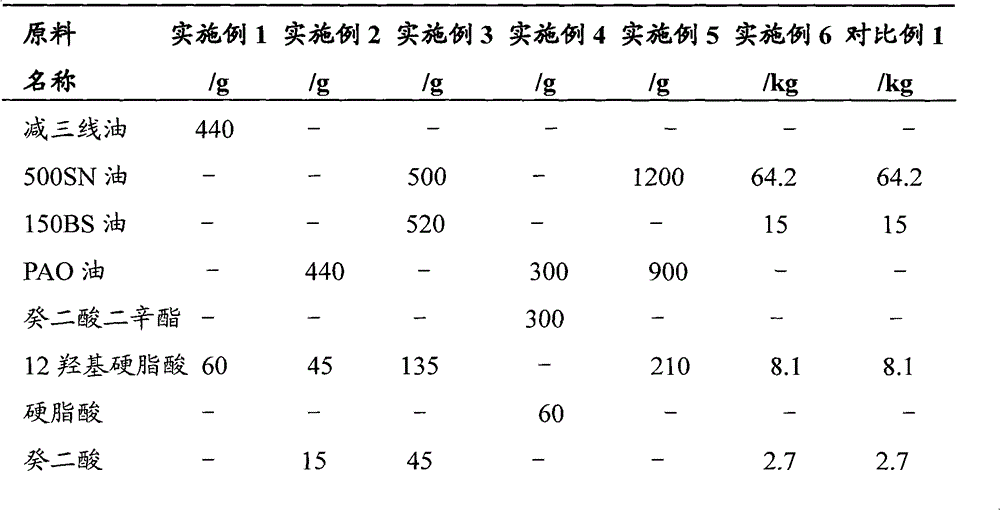

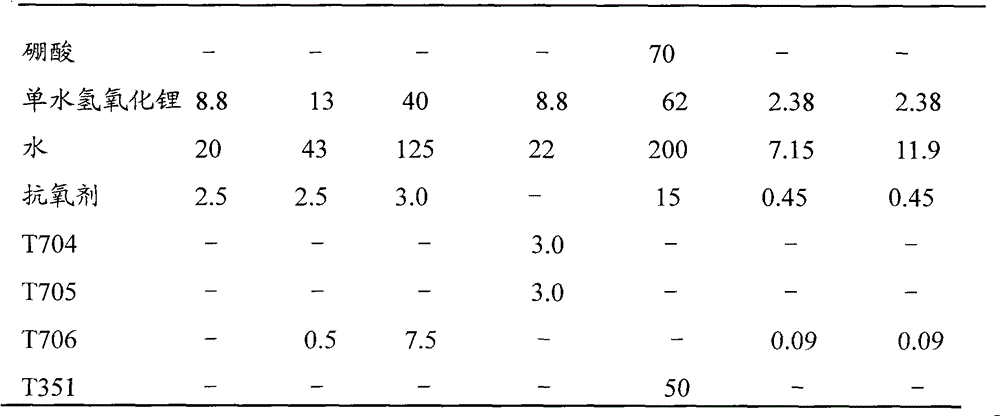

Method for preparing lithium lubricating grease

ActiveCN102796603AWith energy saving and emission reductionReduce energy consumptionLubricant compositionBase oilAqueous solution

The invention provides a method for preparing lithium lubricating grease. The method comprises the following steps of: 1) adding one third to one second of the weight of the entire base oil into a grease kettle, adding a calculated amount of monobasic acid or monobasic acid and at least one kind of dibasic acid or polybasic acid, raising the temperature, and stirring to ensure that the acid and the base oil are fully mixed; 2) raising the temperature to 40 to 80 DEG C, adding one third to one second of a calculated amount of lithium hydroxide monohydrate crystals under stirring, and fully mixing; 3) raising the temperature to 82 to 120 DEG C, and adding an aqueous solution of residual lithium hydroxide monohydrate for saponification reaction; and 4) after full saponification reaction, raising the temperature and dehydrating, continuing to raise the temperature to 200 to 220 DEG C, adding the residual base oil serving as quenching oil, reducing the temperature and cooling, adding necessary additives, homogenizing, grinding, and degassing to obtain finished lubricating grease. The method for preparing the lithium lubricating grease has the advantages of energy conservation, emission reduction and energy consumption reduction, can be used for lithium or complex lithium lubricating grease, and is particularly suitable for a process for preparing the lithium or complex lithium lubricating grease in an atmospheric kettle.

Owner:CHINA PETROLEUM & CHEM CORP +1

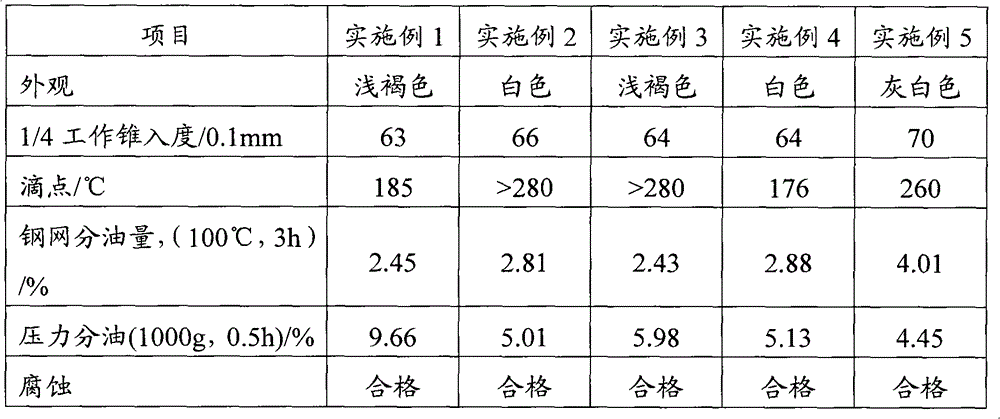

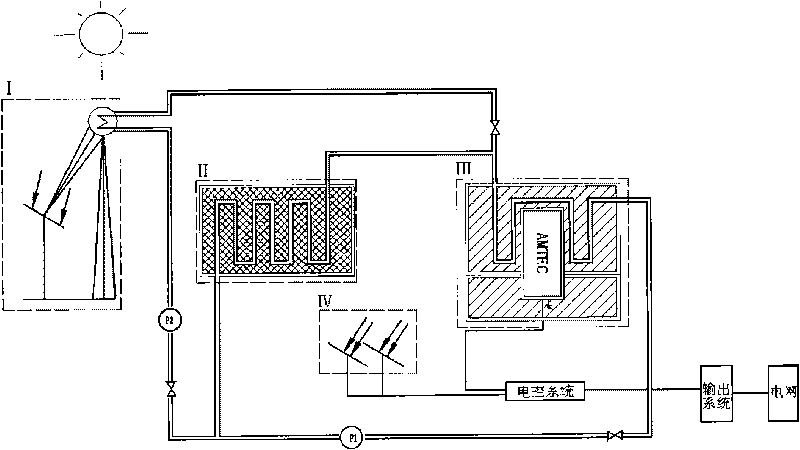

Solar energy high temperature storage type thermal power generation method and device

InactiveCN101702597AExtended use timeReduce dependenceSolar heat devicesPV power plantsHigh temperature storageThermal energy

The invention provides a solar energy high temperature storage type thermal power generation method and device. The solar energy high temperature storage type thermal power generation device comprises a solar energy tower thermal collection module I, a high temperature phase change thermal storage module II, a thermoelectric conversion module III and a photovoltaic power generation module IV. A solar energy photovoltaic power generation system directly changes the solar energy to electrical energy; a solar thermal power generation absorbs the solar energy through the solar energy tower thermal collection module I under the enough sunshine, the absorbed solar energy passes through the heat transferring media in the form of heat, one part of the solar energy is transmitted to the phase change thermal storage module II, the heat storage material of the phase change thermal storage module II is heated to perform phase change so as to store the heat, the other part the solar energy passes through the thermoelectric conversion module III to directly change the heat energy to the electrical energy; when the sunshine is not enough, the heat storage material releases heat to be as the heat source of the thermoelectric conversion module III. The power generation method of the invention used as a new energy and renewable energy development technology with huge development potentiality, adopts thermal storage technology to ensure effective use and provide time delay so as to transform a part of peak loads of the day to valley loads of the night.

Owner:HARBIN ENG UNIV

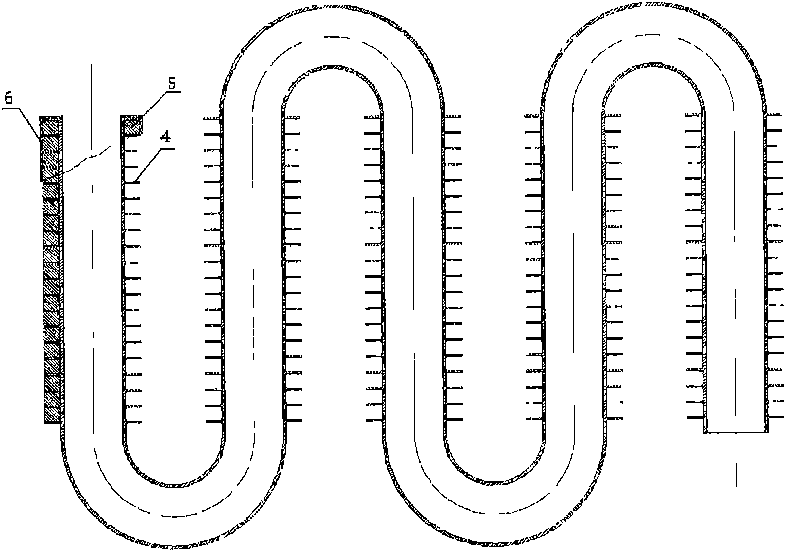

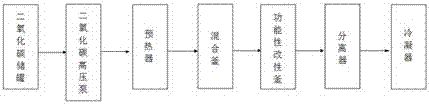

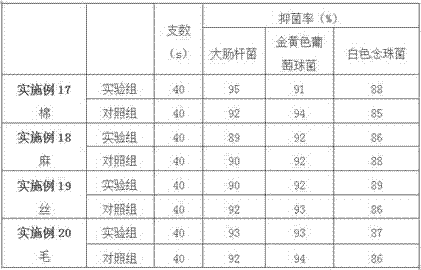

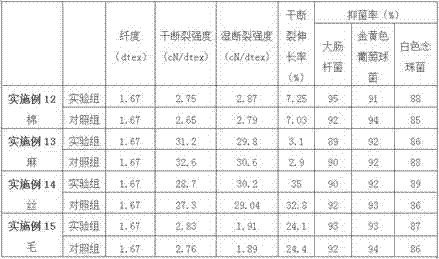

Natural fiber product modified by adopting supercritical carbon dioxide technology and modification method

The invention provides a natural fiber product modified by adopting a supercritical carbon dioxide technology. The modified natural fiber product is a cotton, hemp, silk or wool natural fiber or a yarn, fabric or clothing prepared from the natural fiber. The invention further provides a method for modifying the natural fiber product by adopting the supercritical carbon dioxide technology. The method comprises the step of adding the natural fiber and a vegetable dye and a natural plant extract; the natural fiber is modified by innovatively adopting the supercritical carbon dioxide technology; water or other reagent is not utilized as a solvent, no wastewater or waste is generated or discharged, and the method has the characteristics of ecological environment protection and wide adaptability of fabric varieties and belongs to an environment-friendly functional modification technology. The natural fiber which is functionally modified by adopting the supercritical carbon dioxide technology is uniform in color and luster, extremely good in reproducibility and free of an injury to the natural fiber.

Owner:BESTEE MATERIAL (TSINGTAO) CO LTD

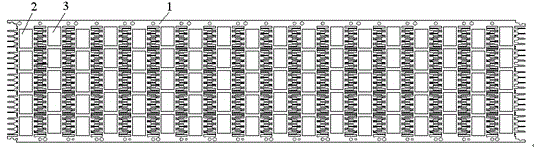

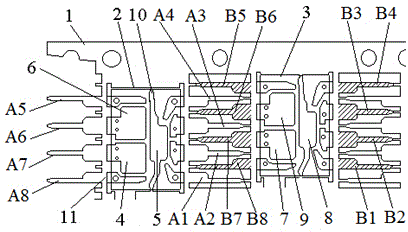

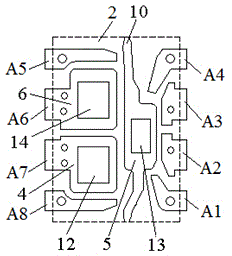

Lead wire framework based on DIP multiple substrates and method of using lead wire framework to manufacture packaging part

ActiveCN104934405ANovel structureLow costSemiconductor/solid-state device detailsSolid-state devicesStructural engineeringLead frame

Provided is a lead wire framework based on DIP multiple substrates and a method of using the lead wire framework to manufacture a packaging part. The lead wire framework comprises a framework body with a plurality of rows of first framework unit sets and a plurality of rows of second framework unit sets, and the two kinds of framework unit sets are arranged at intervals. A framework unit is provided with three substrates, wherein two substrates are in connection with four inner pins of the framework unit through a dam bar, and are located between a third substrate and the dam bar; the third substrate is in connection with the frame of the framework body through a tie bar; the inner pin in the framework unit towards an adjacent framework unit and the inner pin of the adjacent framework unit towards the framework unit are interlaced. A wafer is thinned and sawed, and a chip is adhered to the lead wire framework according to requirements to obtain a packing part through processes including pressure welding, post curing, plastic package, etc. The lead wire framework is conductive to increasing product function integration, and improving product packaging yield, quality and reliability; in addition, the lead wire framework can be extended to multi-row matrix type packaging, and is not limited to a DIP packaging form.

Owner:TIANSHUI HUATIAN TECH

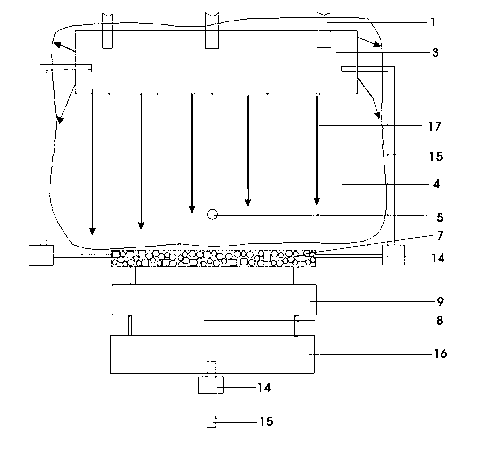

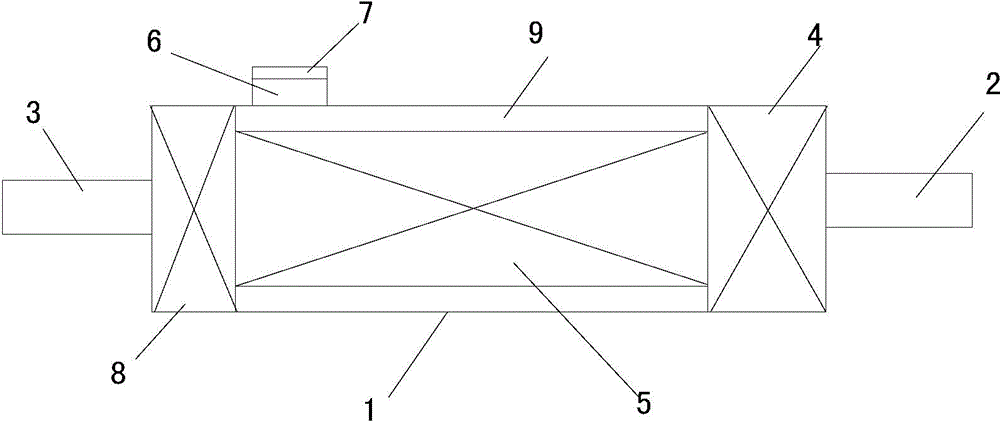

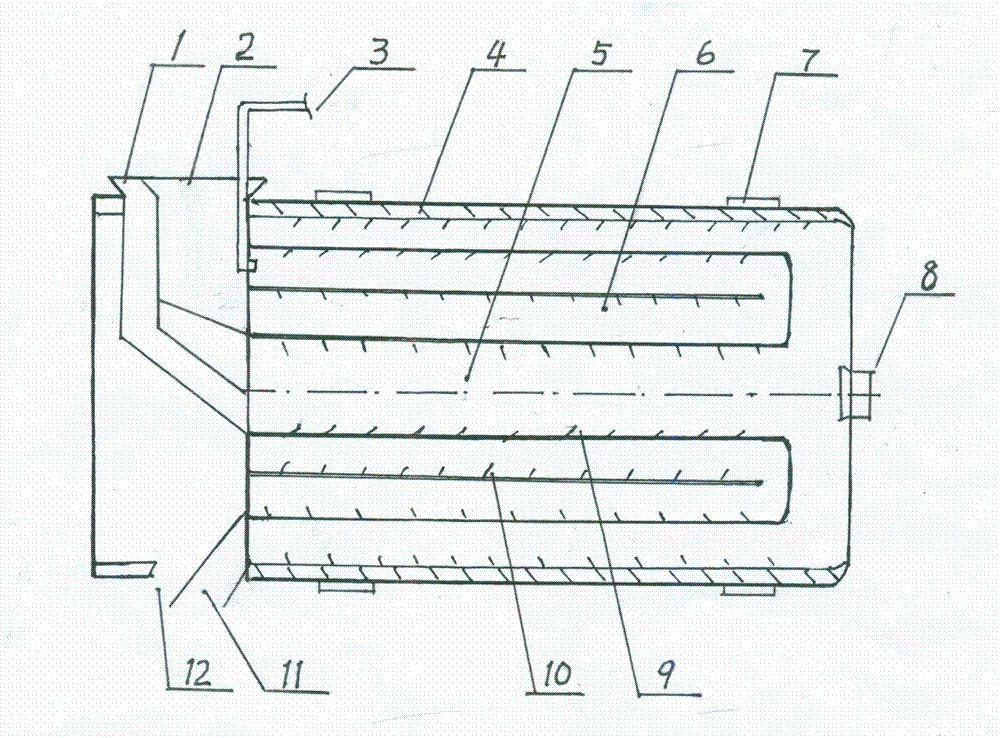

Methanol steam reforming hydrogen production reactor for fuel cell car

InactiveCN104157889AEvenly heatedImprove energy efficiencyHydrogenFuel cell auxillariesSteam reformingFuel cells

A methanol steam reforming hydrogen production reactor for a fuel cell car comprises a casing, wherein a methanol and water solution inlet pipe is arranged at the right end of the casing, a produced hydrogen outlet pipe is arranged at the left end of the casing, and the inside of the casing is divided into a right cavity, a middle cavity and a left cavity by two baffles; an evaporator is arranged in the right cavity; a catalyst is arranged in the middle cavity, a waveguide communicated with the middle cavity is mounted on the pipe wall of the middle cavity, and an electromagnetic pipe is arranged on the waveguide; a condenser is arranged in the left cavity. As a reactant is heated by microwave radiation, the inner side and the outer side of the reactant can be simultaneously heated, the system is uniformly heated, the occurrence of partial high temperature zones and cold points is avoided, the energy efficiency of the system can be improved, and the double effects of energy conservation and emission reduction are realized.

Owner:SHANGHAI UNIV OF ENG SCI

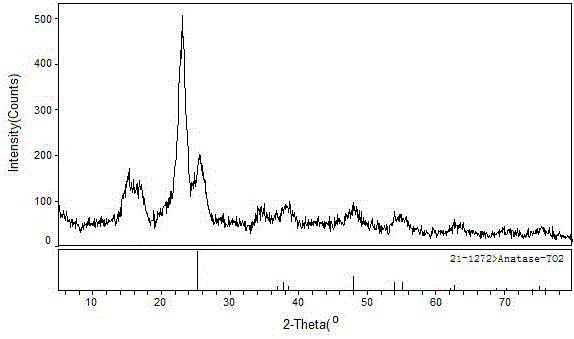

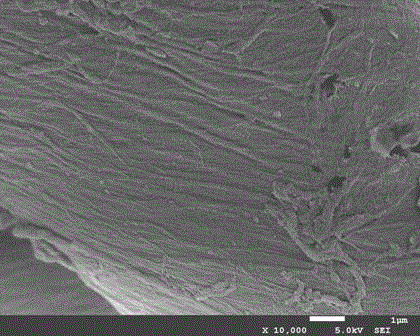

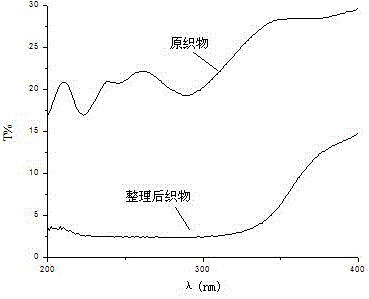

Arranging method for loading nanometer titanium dioxide on textiles

ActiveCN105696308AGood dispersionImprove bindingLight resistant fibresVegetal fibresWater bathsUltraviolet

The invention discloses an arranging method for loading anatase type nanometer titanium dioxide on textiles. The arranged textiles have a photocatalytic self-cleaning function and an ultraviolet resisting function. The method specifically includes the following process steps and conditions of firstly, conducting textile pretreatment, wherein the textiles are boiled to remove impurities and auxiliaries and then sufficiently dried for standby application; secondly, preparing working liquid, wherein titanate type precursors and alcohol solvent are rapidly stirred and evenly mixed to prepare the working liquid; thirdly, soaking the dry textiles obtained in the first step in the working liquid obtained in the second step, or spraying the working liquid obtained in the second step on the single faces or double faces of the dry textiles obtained in the first step; fourthly, putting the textiles in the third step in a water bath to be subjected to water heating or steaming, and taking out the textiles to be washed and dried. The arranging method is simple in process, little in medicine consumption, and capable of saving time and energy, the arranged textiles have photocatalytic performance and excellent ultraviolet resistance under ultraviolet and visible light, and loaded nanometer titanium dioxide and textiles have good combining firmness.

Owner:SICHUAN UNIV

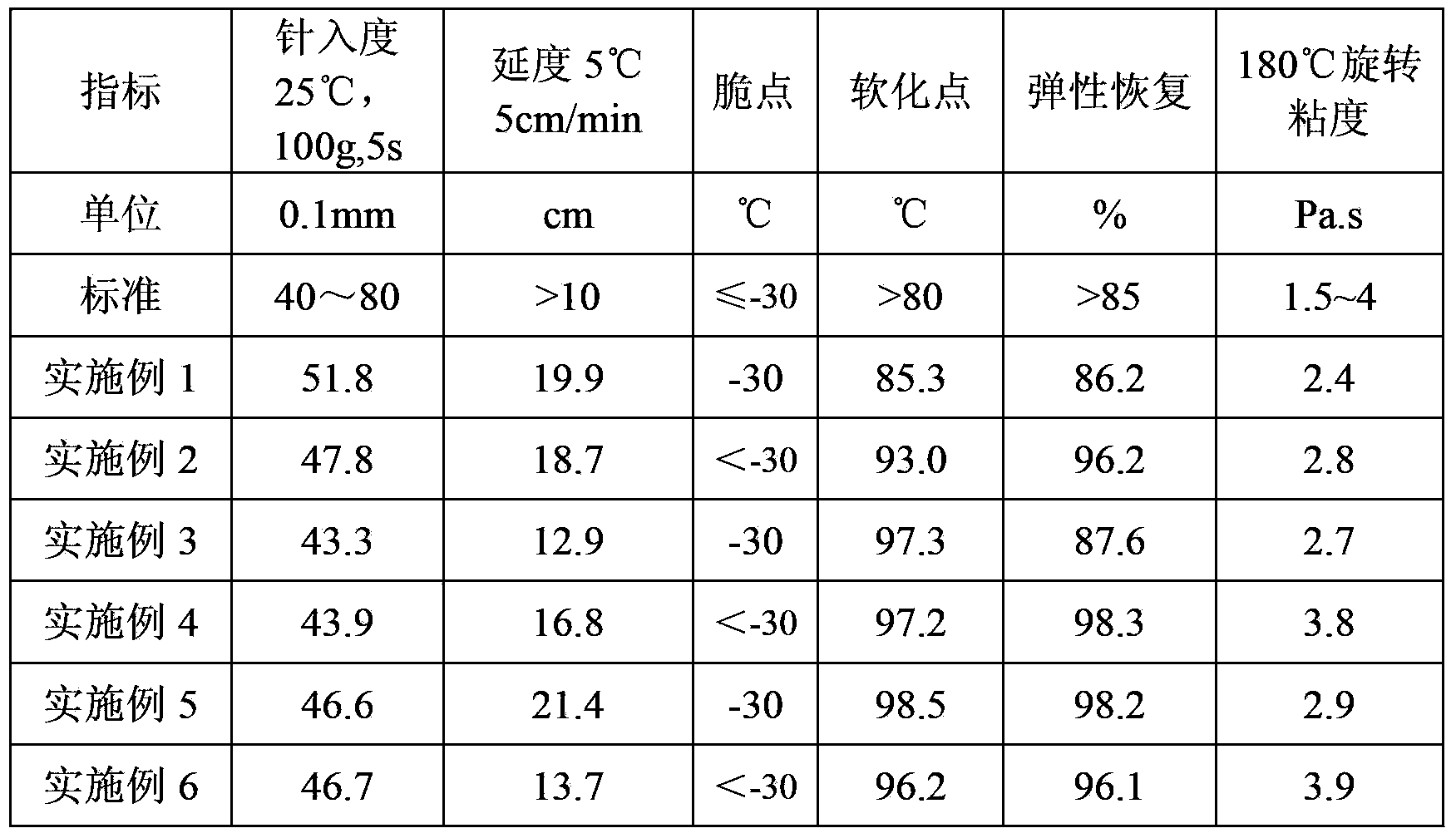

High-performance modified asphalt and preparation method thereof

InactiveCN103408956AImprove high temperature stabilityGood low temperature stabilityBuilding insulationsPolymer scienceButadiene-styrene rubber

The invention relates to high-performance modified asphalt. The high-performance modified asphalt is prepared from the following ingredients: asphalt, thermoplastic rubber, glue powder, an additive and a stabilizer, wherein the asphalt is heavy-traffic-road petroleum asphalt or cycloalkyl petroleum asphalt, the thermoplastic rubber is styrene-isoprene-styrene block copolymer (SIS) or styrene-butadiene-styrene (SBS), the glue powder is rubber powder which is formed through grinding waste and old tires prepared through normal temperature methods, the additive is volcanic ash or silicon powder or fly ash, and the stabilizer is rosin or rosin resin. The high-performance modified asphalt has better high-temperature stability, the softening point capable of reaching above 80 DEG C, better low-temperature stability, the brittle point being below -30 DEG C, relatively high elasticity, the elasticity recovery reaching over 90% and better adhesivity reaching over the level IV. The waste of energy and resources is reduced through using industrial and domestic wastes as much as possible, so that the preparation method has the advantages of energy saving, emission reduction, simple production process and low cost.

Owner:周乃承

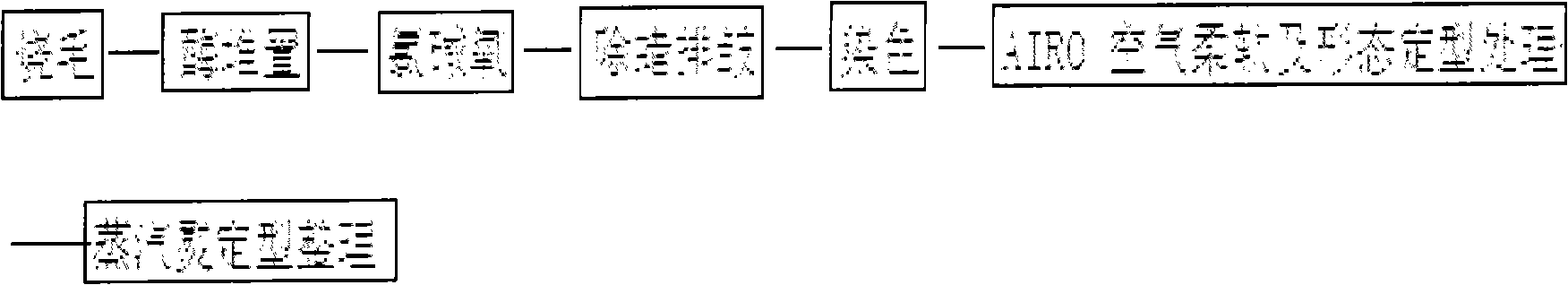

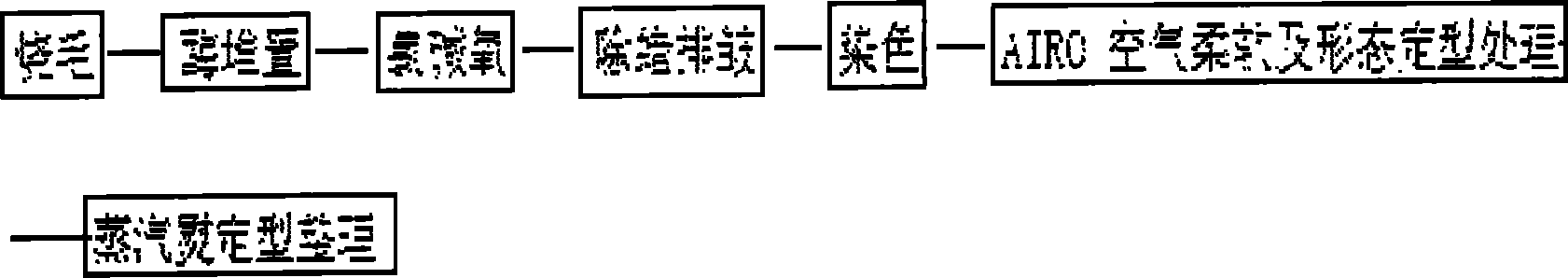

Dyeing and finishing process of pure-flax Huashu textile fabric

ActiveCN102021840AWith shape memory functionMaintain the shape of micro-creasesBiochemical fibre treatmentBleaching apparatusWaxWater resources

The invention relates to a dyeing and finishing process of a pure-flax Huashu textile fabric, comprising the following steps of: singeing fabrics, stacking enzymes, oxidizing chlor-alkali, removing wax and crimples, dyeing, softening by AIRO air, shaping and ironing and finishing by steam. The pure-flax Huashu textile fabric not only maintains the original excellent characteristics of pure-flax fabrics, but also has good drapability, skin intimacy, low strength loss and high dye fastness, has the functions of shaping details and remembering small folds, eliminates itchy feeling and expands the use field of fabrics. The invention has reasonable process design, is environment-friendly and greatly reduces the use of energy and water resources.

Owner:安徽中天新材料科技股份有限公司

Process for dyeing silk interwoven jacquard fabric

ActiveCN104018369AShorten process timeIncrease productivityDyeing processColour fastnessPolymer science

The invention discloses a process for dyeing a silk interwoven jacquard fabric, belonging to the field of silk interwoven jacquard fabric dyeing technology. The process comprises the steps of dye fixing, primary washing, soaping, secondary washing and cylinder discharge and drying, wherein in the dye fixing step, the pretreated silk interwoven jacquard fabric is put into an active dye solution and dyed by adopting a jig dyeing method at 80-85 DEG C for 60-200 minutes; the active dye solution is obtained by mixing 1-5% owf of lanasol dye, 1-5% owf of HE type dye, 20-50g / L of anhydrous sodium sulphate, 5-20g / L of sodium carbonate and water. The process disclosed by the invention can be used for realizing bath dyeing when silk fibers and cellulose fibers in the silk interwoven jacquard fabric are dyed with different colors respectively, the color fastness of the obtained silk interwoven jacquard fabric with the double-color effect can reach the two-bath dyeing fastness, meanwhile, energy is saved, emission is reduced, and the process time is obviously shortened.

Owner:ZIBO DARANFANG SILK GRP

Total-nutrient kelp oligosaccharide biological synergistic fertilizer and preparation method thereof

InactiveCN102584432AWith energy saving and emission reductionCombination of medicine and fertilizerFertilizer mixturesDiseaseLyase

The invention relates to a total-nutrient kelp oligosaccharide biological synergistic fertilizer and a preparation method thereof. The preparation method comprises the steps of: firstly soaking kelps in water and filtering soaking water; crushing the soaked kelps, adding kelp powder into the filtered soaking water and adding alginic acid lyase for enzymolysis; and after the enzymolysis is completed, conducting low-temperature concentration to enzymatic hydrolyzate to complete the preparation of liquid fertilizer. Since the temperature in the whole production process is controlled to be below 50 DEG C and any chemical is not used, the total-nutrient kelp oligosaccharide biological synergistic fertilizer has the characteristics of environmental friendliness, ecological and environmental protection, energy saving and emission reduction, natural plant growth promoting factors in the kelps are fully reserved, compositions such as iodine, alginic acid oligosaccharide, mannitol and fucoidan capable of resisting diseases and adversity, preserving water and moisture and resisting ionizing radiation, ultraviolet radiation and nuclear radiation are added and the efficacy that medicine and the fertilizer are combined together is obtained.

Owner:青岛丰泰海洋生物科技有限公司 +1

U-shaped internal-combustion rotating limekiln capable of recovering CO2

The invention belongs to the field of kiln, and provides a u-shaped internal-combustion rotating limekiln capable of recovering CO2. The limekiln is characterized in that the rotary kiln is horizontal, a u-shaped muffle heating furnace and a u-shaped calcining chamber are adjacently arranged inside the rotary kiln, blades are arranged on the inner wall of the muffle heating furnace and the inner wall of the calcining chamber, and a carbon dioxide collector is arranged through a limestone feeding inlet to communicate with the calcining chamber. Compared with present muffle rotary limekilns, the u-shaped internal-combustion rotating limekiln capable of recovering CO2 has significant advantages of reasonable structure, energy conservation, and emission reduction, and can recover and utilize materials and improve product quality.

Owner:赵光辉

A kind of Pleurotus eryngii culture material

The invention relates to a Pleurotus eryngii culture medium which is prepared from the following raw materials in parts by mass: 40-60 parts of bacterial dreg, 30-40 parts of corn cob, 10-15 parts of bran and 0.9-1.1 parts of lime. By using the bacterial dreg instead of wood dust and cottonseed hull, the bacterial dreg is recycled, thereby enhancing the bioavailability of the effective constituents in the bacterial dreg; and thus, the invention solves the problem of raw material resources, effectively utilizes the agricultural leftovers, changes wastes into valuable substances and lowers the raw material cost and transportation expenses, thereby lowering the production cost of the Pleurotus eryngii and having favorable economical and ecological effects.

Owner:广西中农食品有限公司

Baking-free brick made by the Yellow River mud and production method thereof

The invention relates to a burn-free brick and a production method thereof, particularly to a burn-free brick produced with the Yellow River silt and a production method thereof. The burn-free brick is produced by the extrusion of press machines after mixing the raw materials at a weight ratio as follows: 50-70% Yellow River silt; 20-30% fluoride gypsum powder; 5-10% cement; 3-5% aluminum potassium sulfate and 2-5% construction-used acrylic rubber powder. The invention makes full use of waste fluoride gypsum and a large number of Yellow River silt and is energy-saving and emission reducing and can prevent environmental pollution to meet ecological environmental protection requirements. The burn-free bricks have the advantages of low cost, high strength and good comprehensive performance and each performance are much higher than the relevant national standards of bricks for construction. The production method of has advantages of simple process and convenient production.

Owner:李浩

HRB600E reinforcement steel bar and production method thereof

The invention discloses a HRB600E reinforcement steel bar and a production method thereof. The reinforcement steel bar consists of the following elements in percentage by weight: 0.20-0.28 percent of C, 1.30-1.60 percent of Mn, 0.30-0.80 percent of Si, 0.80-0.12 percent of V, less than or equal to 0.020 percent of S, less than or equal to 0.030 percent of P, 0.05-0.40 percent of Cr and the balance of Fe and inevitable impurities. The production method comprises a smelting procedure, a continuous casing procedure and a steel rolling procedure. In the smelting procedure, molten steel in a ladle is alloyed, so that the molten steel contains 0.08-0.12 percent by weight of V and 0.05-0.40 percent by weight of Cr. The vanadium content of the reinforcement steel bar is reduced by about 30-40 percent than the vanadium content of a reinforcement steel bar with the same level of yield strength, and the reinforcement steel bar has the advantages of high yield strength, high tensile strength, high yielding-to-tensile ratio, high specific elongation and the like.

Owner:LAIWU IRON & STEEL GRP

Waste heat recovery device for billets produced by continuous casting machine

InactiveCN102861883AEfficient recyclingImprove working environmentWaste heat recovery unitWorking environment

The invention provides a waste heat recovery device for billets produced by a continuous casting machine. The device comprises a withdrawal and straightening unit front section radiant heating surface, a pre-cutting section radiant heating surface, a post-cutting section radiant heating surface, and a pusher section radiant heating surface through modular design, a forced circulating water pump, a steam-water separation unit and the like. The arrangement mode of the withdrawal and straightening unit front section radiant heating surface, the pre-cutting section radiant heating surface and the post-cutting section radiant heating surface which are at a higher temperature is that an arch-shaped cover type radiant heating surface is arranged independently for each roller table. Shielding type radiant heating surfaces are arranged for the withdrawal and straightening unit front section, the pre-cutting roller section, the post-cutting roller section and the pusher section respectively; and high-temperature billets are isolated from the environment while radiation heat of the billets is absorbed, heat radiation of the high-temperature billets to the environment is cut off thoroughly, therefore workshops can be cooled effectively, and the working environment is improved substantially.

Owner:SOUTHEAST UNIV

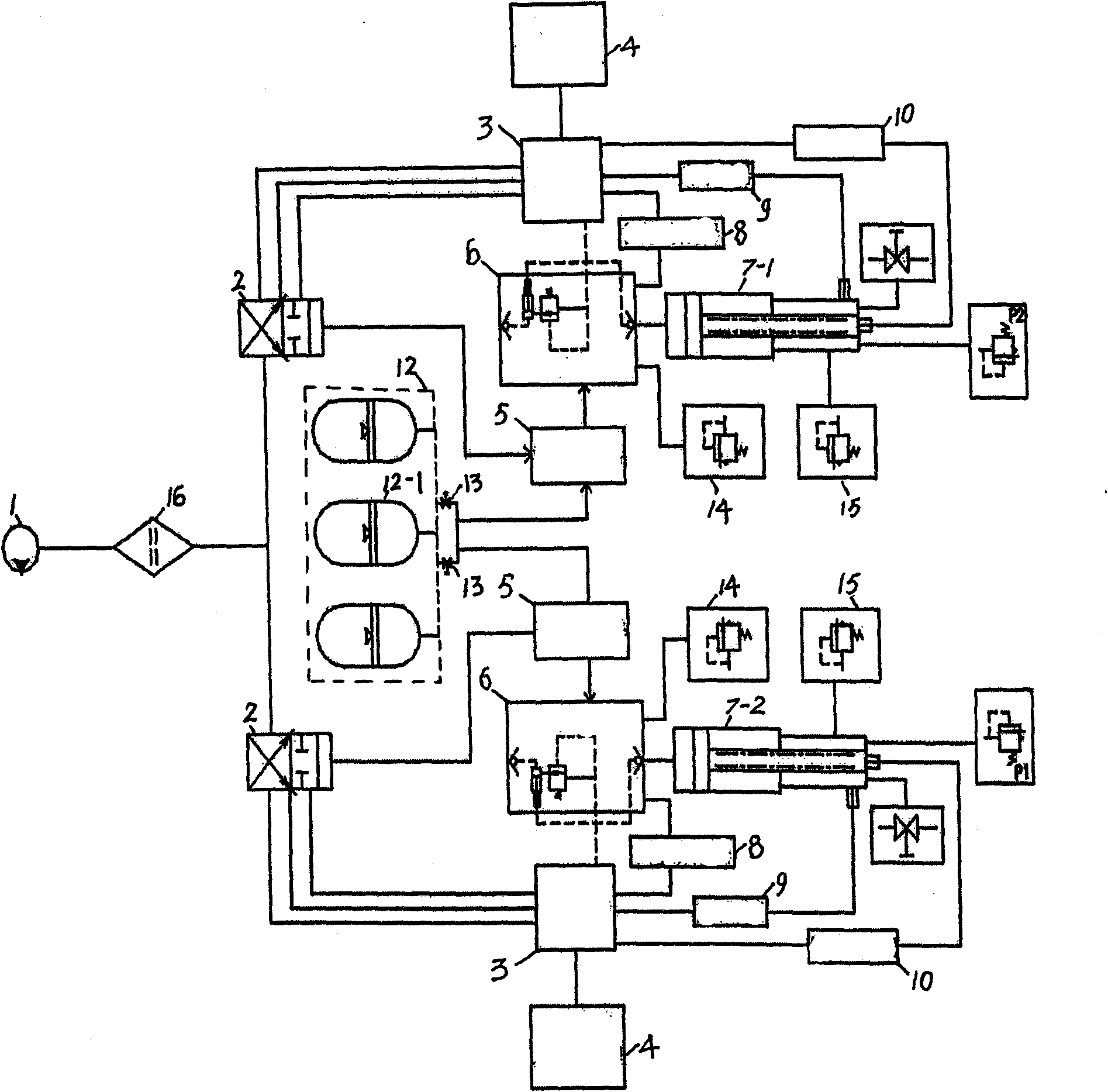

Impact resistance test device of high-flow safety valve

InactiveCN101788375AGood for observing dynamic stabilitySolve the problem of high pressure pump without large flowShock testingData processing systemMicrocomputer

The invention relates to an impact resistance test device of a high-flow safety valve, which comprises a high-pressure pump station, a microcomputer data acquiring machine and a microcomputer measurement control / data processing system, wherein the microcomputer data acquiring machine is connected with the microcomputer measurement control / data processing system; the high-pressure pump station branches two paths by a precise filter and the two paths are respectively connected with two electromagnetic valves; the electromagnetic valves are connected with liquid source adapters; the liquid source adapters are connected with liquid control devices; the liquid control devices are connected with superchargers; the microcomputer data acquiring machine is connected with the electromagnetic valves, connected with the liquid control devices by energy accumulating pressure sensors, connected with the supercharger by a high-pressure sensor and the supercharger by a displacement sensor; the supercharger in one path is a large supercharger, and the supercharger in the other path is a medium supercharger; and energy accumulator groups are respectively connected with the two liquid source adapters. The invention simulates the dynamic process under the condition of working condition sinking and instant impact of an underground hydraulic bracket vertical column of the high-flow safety valve and tests the characteristic parameters of the safety valve.

Owner:温州市基安机械有限公司

Wood-like co-extruded ASA modified material and preparation method thereof

The invention provides a wood grain-imitated co-extruded ASA modified material. The material mainly comprises the following compositions by weight percentage: 50 to 90 percent of ASA background material and 10 to 50 percent of ASA grain material. Plastic steel doors and windows produced from the wood grain-imitated co-extruded ASA modified material have strong three- dimension effect and vivid wood grain; the wood grain-imitated co-extruded ASA modified material can realize wood replacement by plastic, saves valuable forest resource, has excellent weather resistance, broadens application and development of a wood grain-imitated material, can be applied to the preparation of doors and windows both indoors and outdoors, guardrails, decorative plates, earth foot lines, furniture and the like. The invention also provides a method for preparing the modified material; the method comprises the steps of weighing, mixing and extrusion; and the wood grain-imitated co-extruded ASA modified material has a simple preparation method, wide source of raw materials, low cost of a finished product and wide popularization and application value.

Owner:DONGGUAN JINFULIANG PLASTIC & RUBBER TECH CO LTD

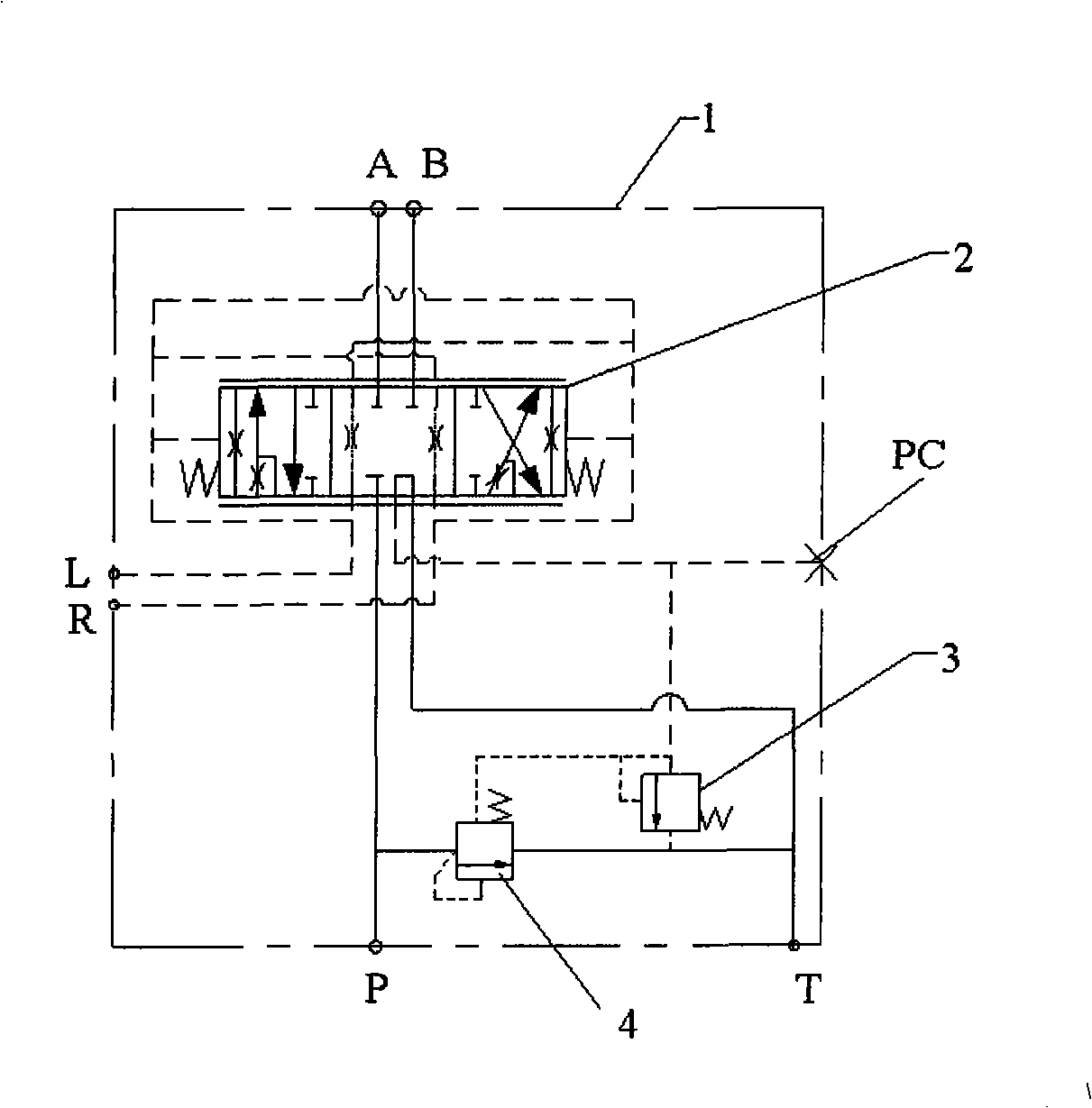

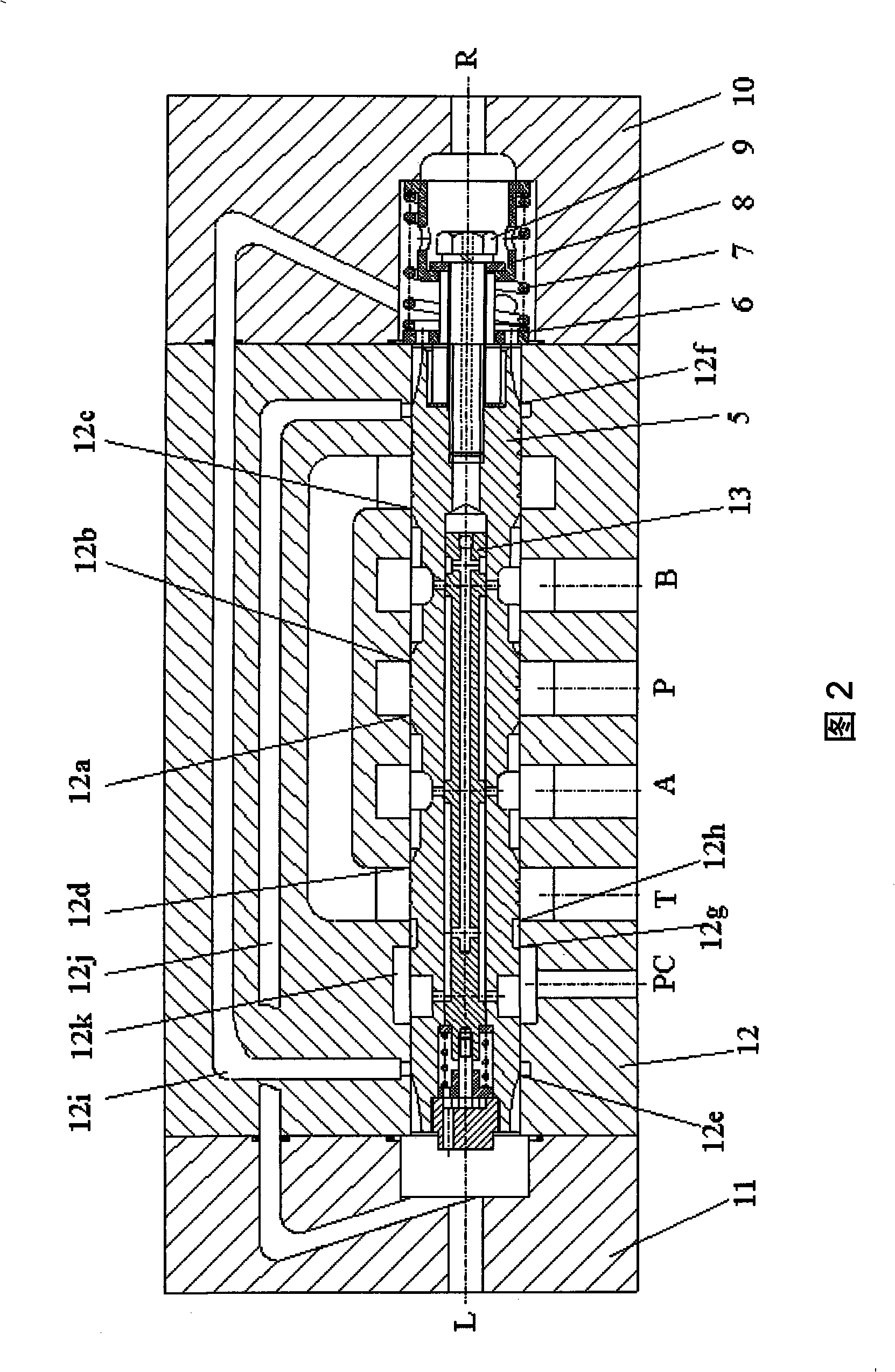

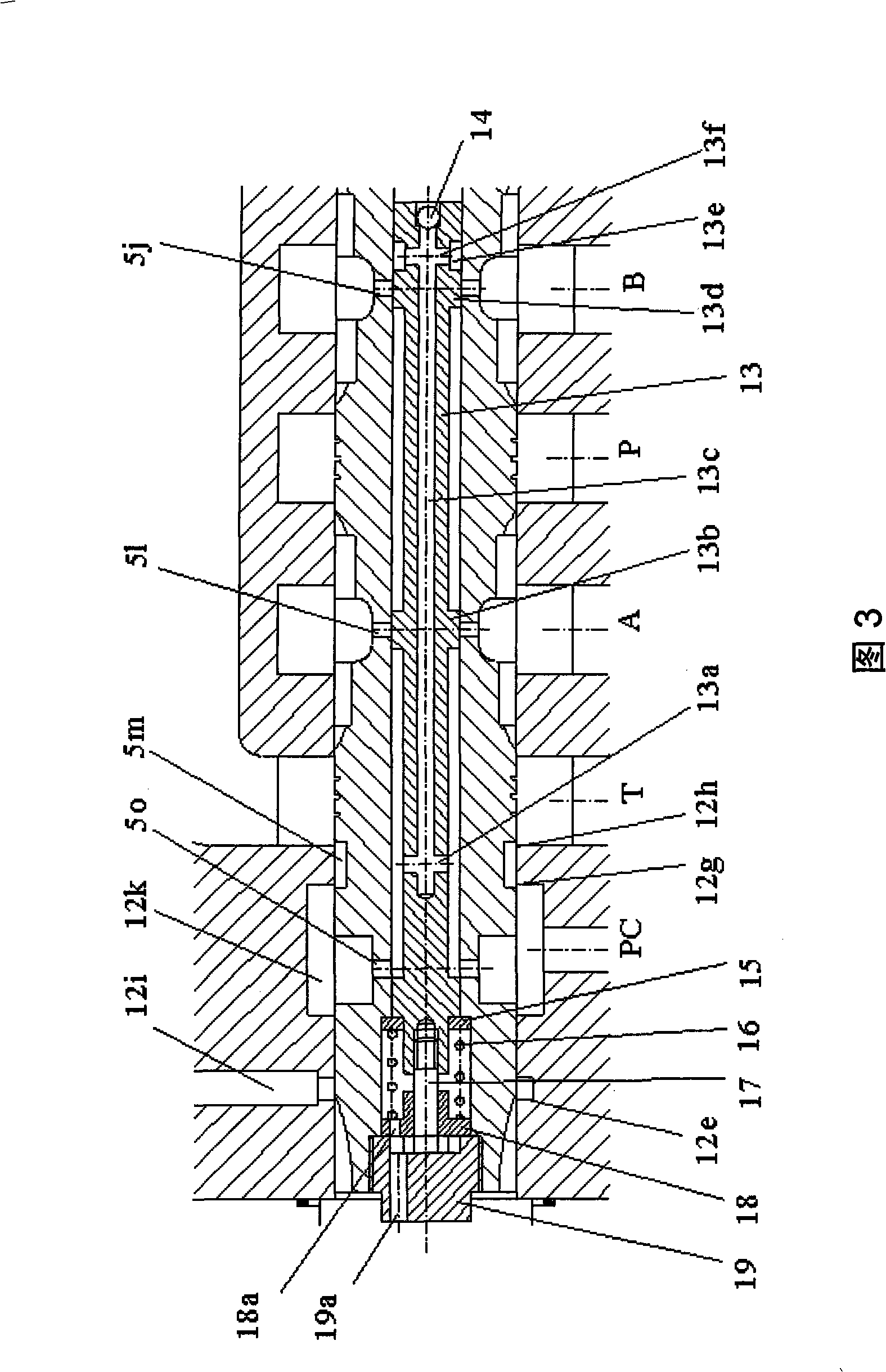

Energy-saving vibration-reduction type flux amplification valve

InactiveCN101255878AWith non-steering condition unloading functionWith energy saving and emission reductionServomotor componentsExternal connectionPilot valve

The present invention provides an energy-saving damping type amplificative valve. Four throttling groove groups are symmetrical with midline of the main valve core 5, the throttling groove groups on two sides of midline comprise a first oil trough 5a, a second oil trough 5b, a third oil trough 5c and a fourth oil trough 5d in pair respectively, the other two throttling groove groups comprise a first oilreturning groove 5e, a second oilreturning groove 5f, a third oilreturning groove 5g and a fourth oilreturning groove 5h in pair respectively, four throttling groove groups form four main valve port respectively with the first oil intake throttling edge 12a, the second oil intake throttling edge 12b, the first oilreturning throttling edge 12c, the second oilreturning throttling edge 12d, the pilot valve throttling grooves 5i on two ends of the main valve core 5 form two pilot valve port with the first pilot valve throttling edge 12e and the second pilot valve throttling edge 12f on two ends of valve body 12 respectively, the first ring groove 5m and the second ring groove 5n are provided on the left of the main valve core 5, an oil guide ring groove 12k are arranged on the corresponding position of the valve body 12, the first unloading edge 12g and the second unloading edge 12h are provided on the valve body 12 corresponding the position of the first ring groove 5m, seven external connection oil ports are provided on the valve body 12.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com