Natural fiber product modified by adopting supercritical carbon dioxide technology and modification method

A natural fiber and carbon dioxide technology, which is applied in dyeing, textile and papermaking, and textile material processing, can solve the problems of low efficiency, high energy consumption, and high one-time input cost, and achieve high efficiency, uniform color, and good society. benefit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

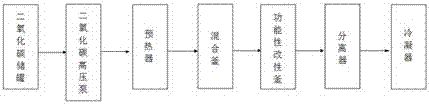

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1 A kind of method utilizing supercritical carbon dioxide technology to modify natural fiber, comprises the following steps:

[0045] 1. The addition of natural fibers, plant dyes and natural plant extracts

[0046] 200 kilograms of cotton natural fibers are loaded into the functional modification kettle, and 2kg rose dye and 1kg peppermint extract are loaded into the mixing kettle;

[0047] Described natural plant extract and plant dye can be bought on the market;

[0048] The rose dye is produced by Henan Deyu Chemical Co., Ltd., color code: #E71B64;

[0049] The mint extract is produced by Shaanxi Senfu Natural Products Co., Ltd., with a moisture content of 2.5-3%, an ash content of 0.3-0.5%, a heavy metal content of ≤3ppm, a mesh number of 200-240 mesh, and a yeast and mold content of < 20cfu / g.

[0050] 2. Preparation of supercritical carbon dioxide

[0051] Then the liquid carbon dioxide stored in the liquid carbon dioxide storage tank is injected i...

Embodiment 3

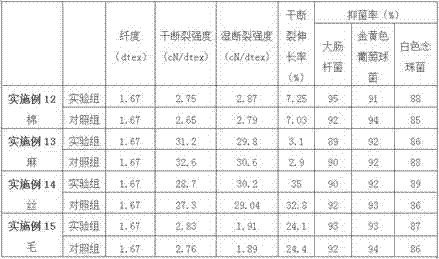

[0066] Example 3 Performance test of peppermint extract and rose dye on natural fiber modification

[0067] Cotton, silk and wool have the same physical indexes such as fineness and breaking strength before modification.

[0068] In the following examples, except that the types of natural fibers are different, other process conditions are the same as in Example 1.

[0069] The performance test results of natural fibers modified by peppermint extract listed in Table 1.

[0070] The experimental group is the functional fiber prepared by supercritical carbon dioxide technology, and the control group is the functional fiber prepared by using water as the solvent.

[0071] Table 2 Quality indicators of the experimental group and the control group

[0072]

[0073] As can be seen from the above table 2, examples 3-5 of the present invention are cotton, silk and wool natural fibers prepared by supercritical carbon dioxide technology and water as Cotton, silk, and wool natural f...

Embodiment 6

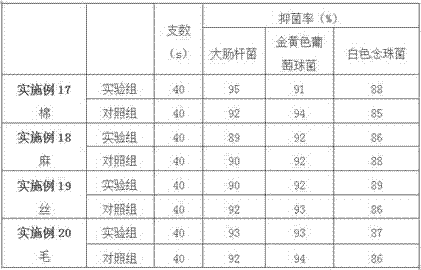

[0082] Example 6 Performance test of wormwood extract and violet dye on natural fiber modification

[0083] Cotton, linen, silk, and wool have the same physical indicators such as denier and breaking strength before modification.

[0084] In the following examples, except that the types of natural fibers are different, other process conditions are the same as in Example 1.

[0085] The performance test results of the wormwood extracts and violet dyes listed in Table 3 on the modified cotton, hemp, silk and wool natural fibers respectively. The experimental group is the natural fiber modified by supercritical carbon dioxide technology, and the control group is the fiber prepared by using water as the solvent.

[0086] Table 3 Quality indicators of the experimental group and the control group

[0087]

[0088] As can be seen from the above table 3, the examples 7-10 of the present invention are the cotton, silk, and wool natural fibers containing wormwood extract prepared b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wet breaking strength | aaaaa | aaaaa |

| Wet breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com