Patents

Literature

3966 results about "Supercritical carbon dioxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

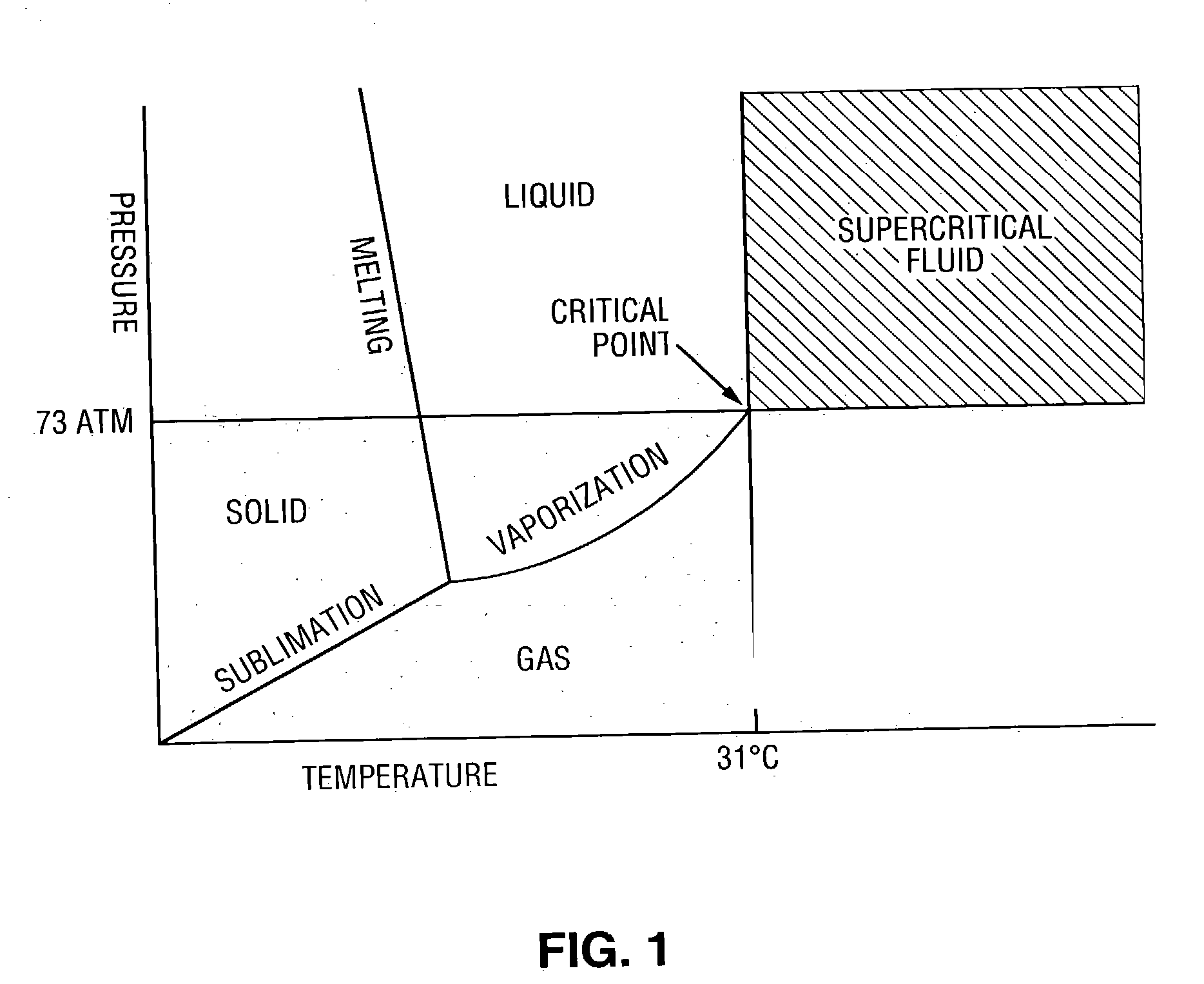

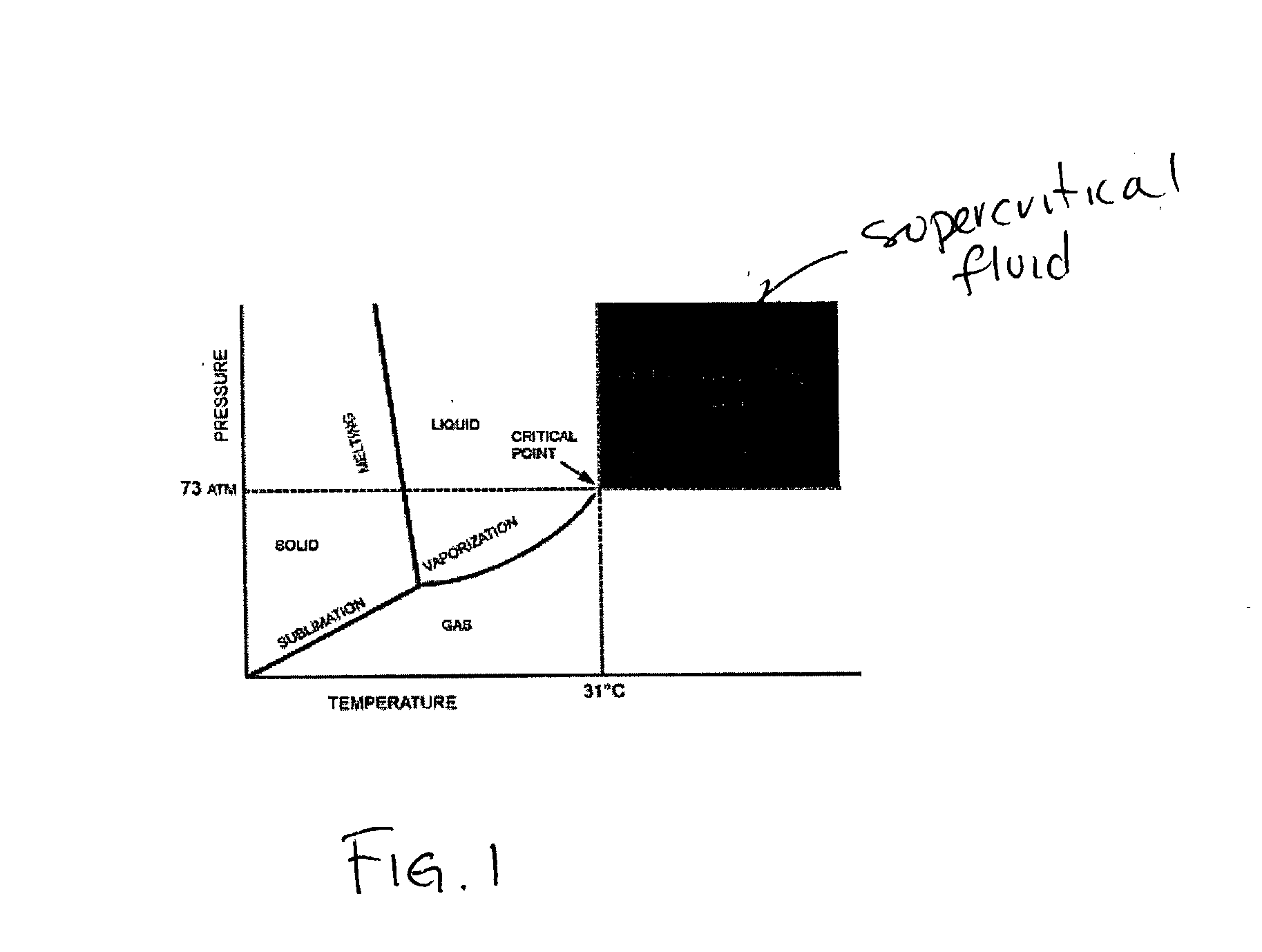

Supercritical carbon dioxide (sCO₂) is a fluid state of carbon dioxide where it is held at or above its critical temperature and critical pressure. Carbon dioxide usually behaves as a gas in air at standard temperature and pressure (STP), or as a solid called dry ice when frozen. If the temperature and pressure are both increased from STP to be at or above the critical point for carbon dioxide, it can adopt properties midway between a gas and a liquid. More specifically, it behaves as a supercritical fluid above its critical temperature (304.25 K, 31.10 °C, 87.98 °F) and critical pressure (72.9 atm, 7.39 MPa, 1,071 psi, 73.9 bar), expanding to fill its container like a gas but with a density like that of a liquid.

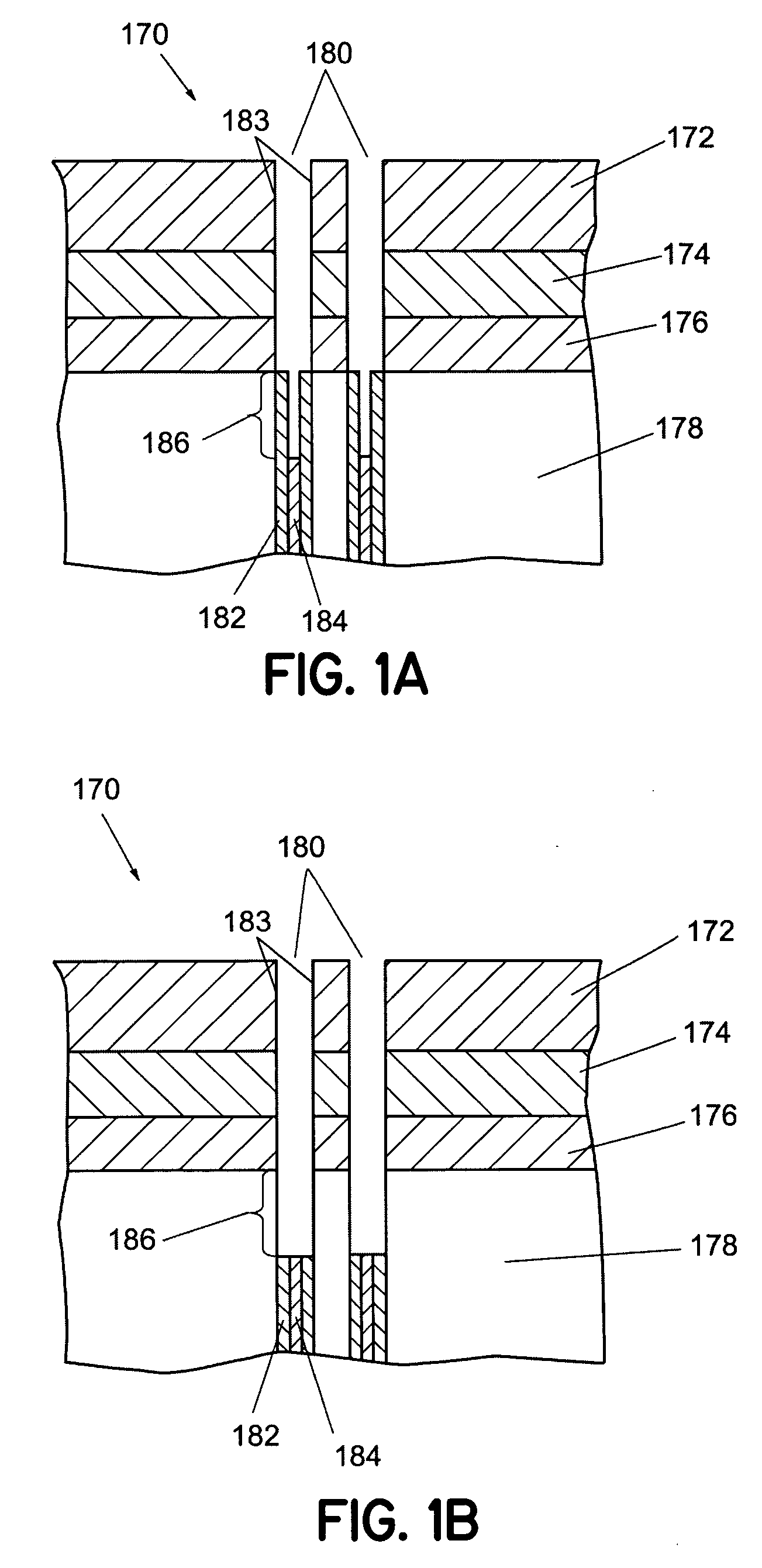

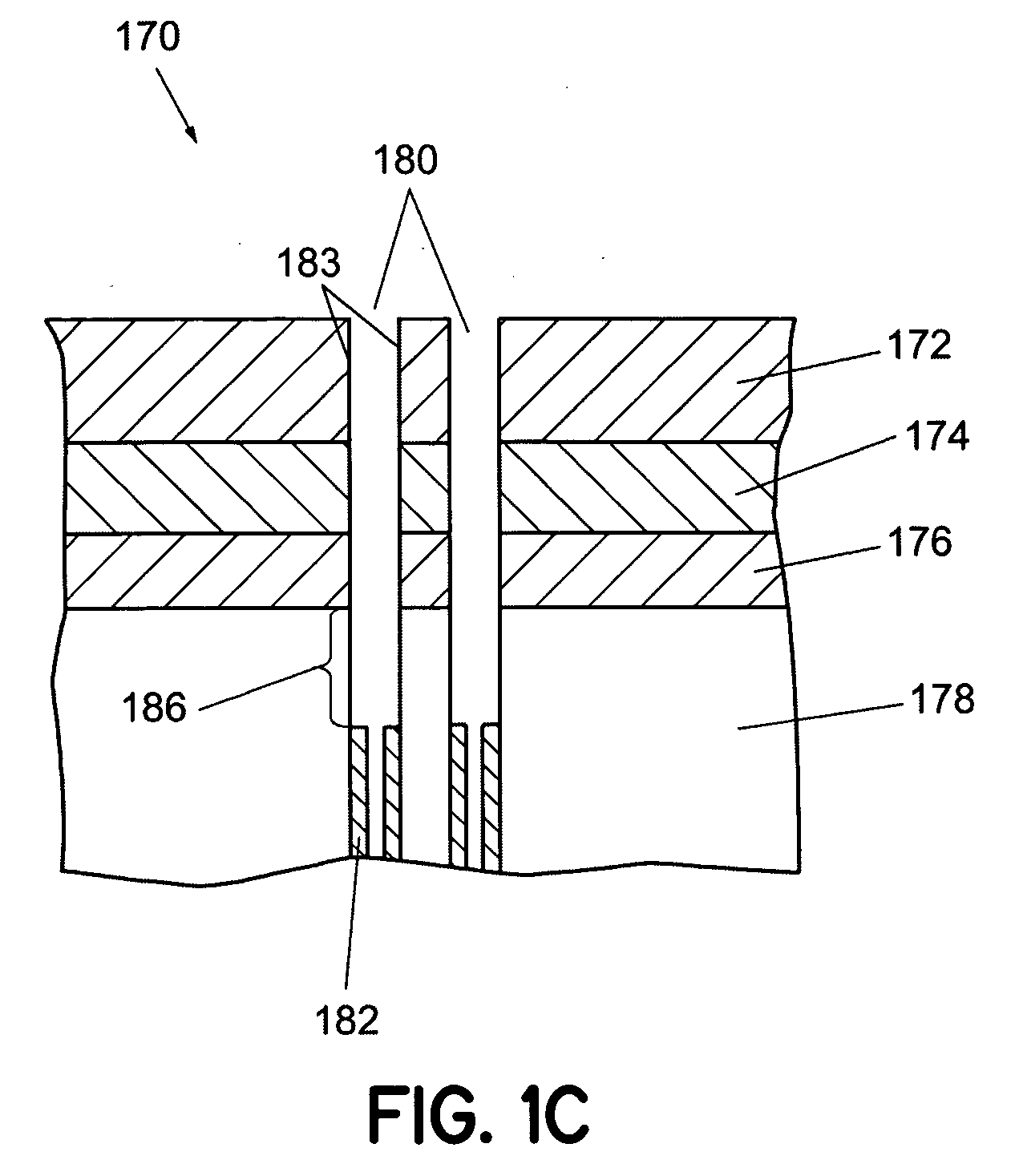

Phase change based heating element system and method

InactiveUS20060226117A1Avoid overall overheatingVacuum gauge using ionisation effectsDecorative surface effectsTemperature controlProcess engineering

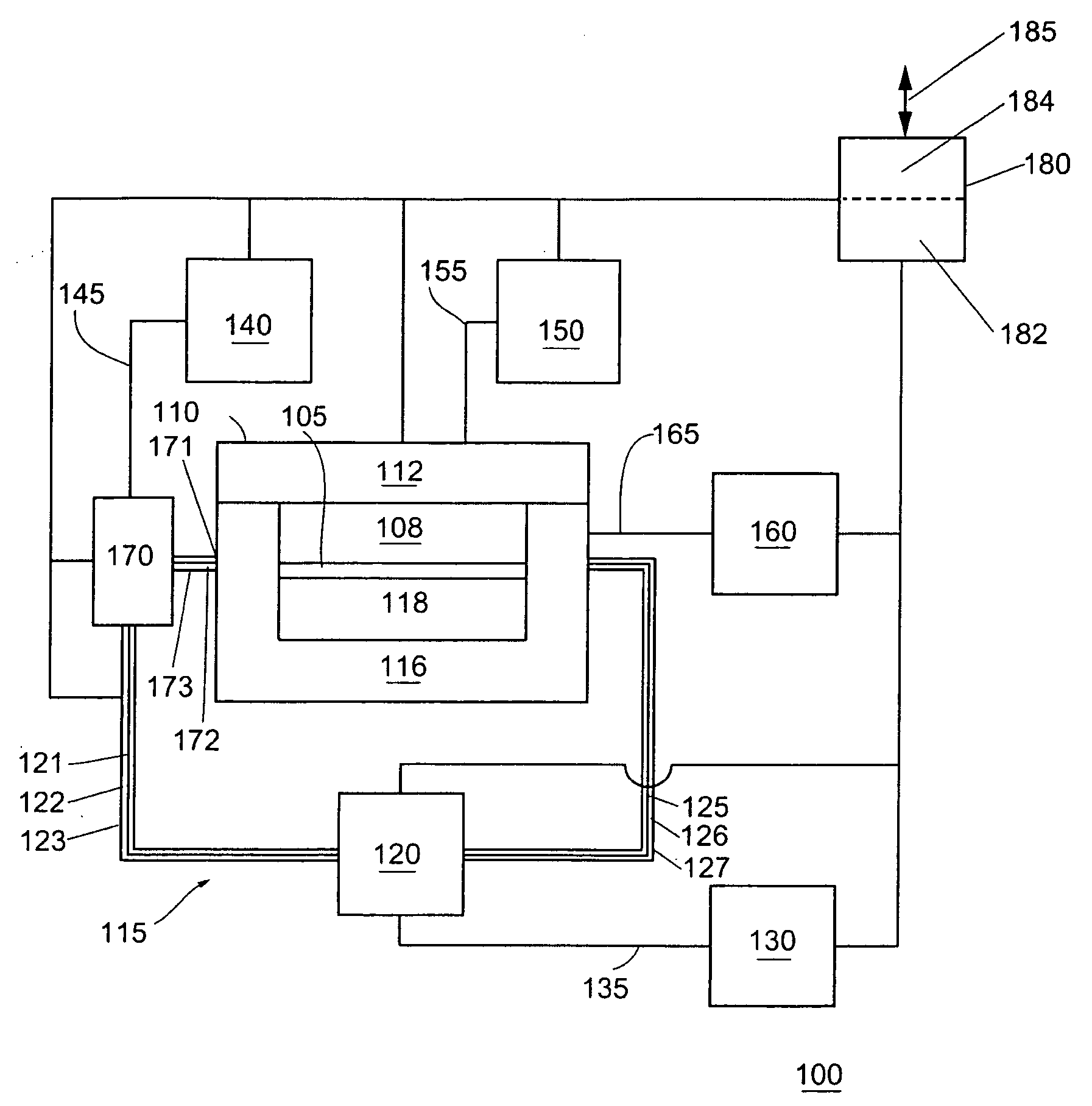

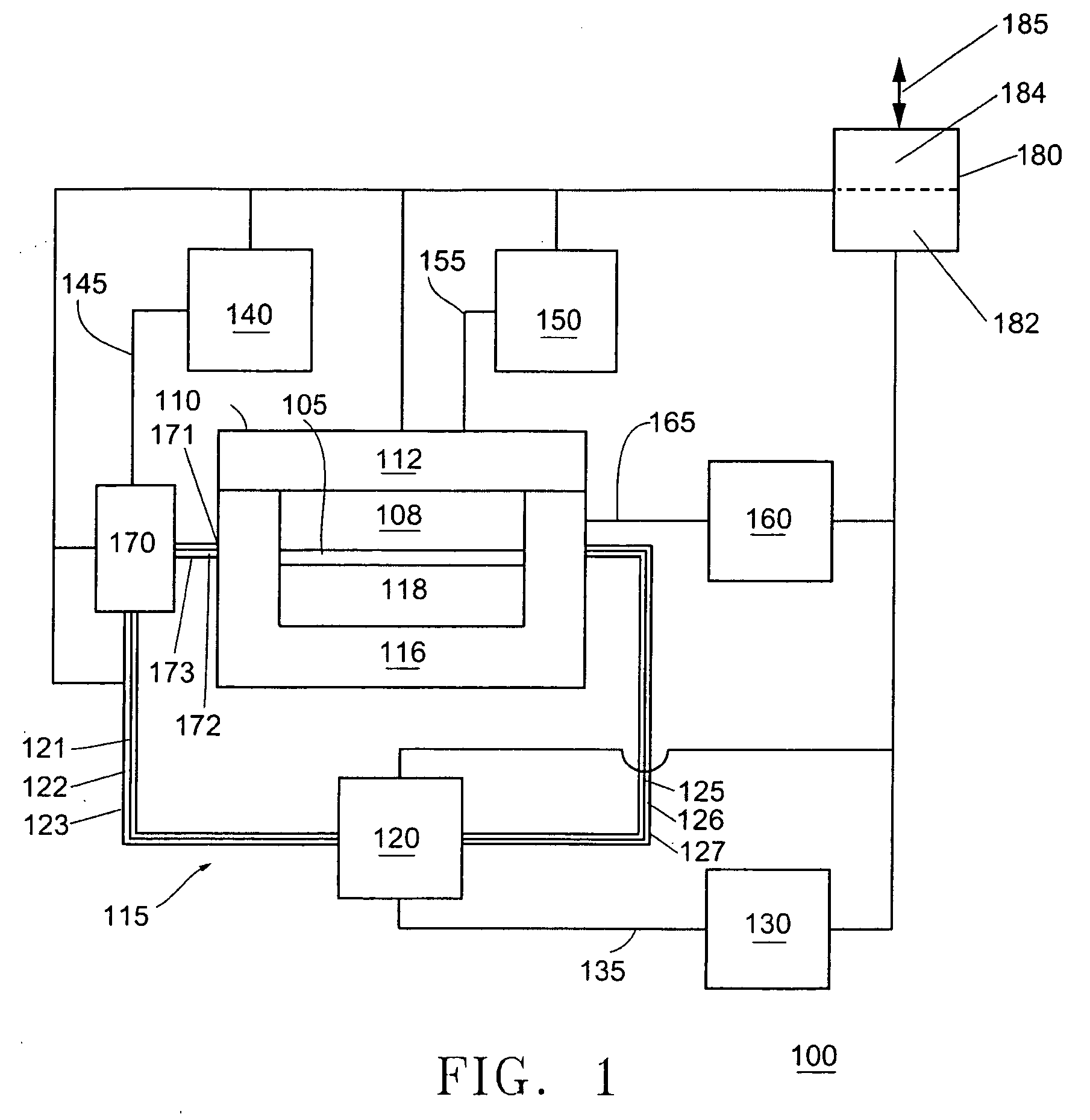

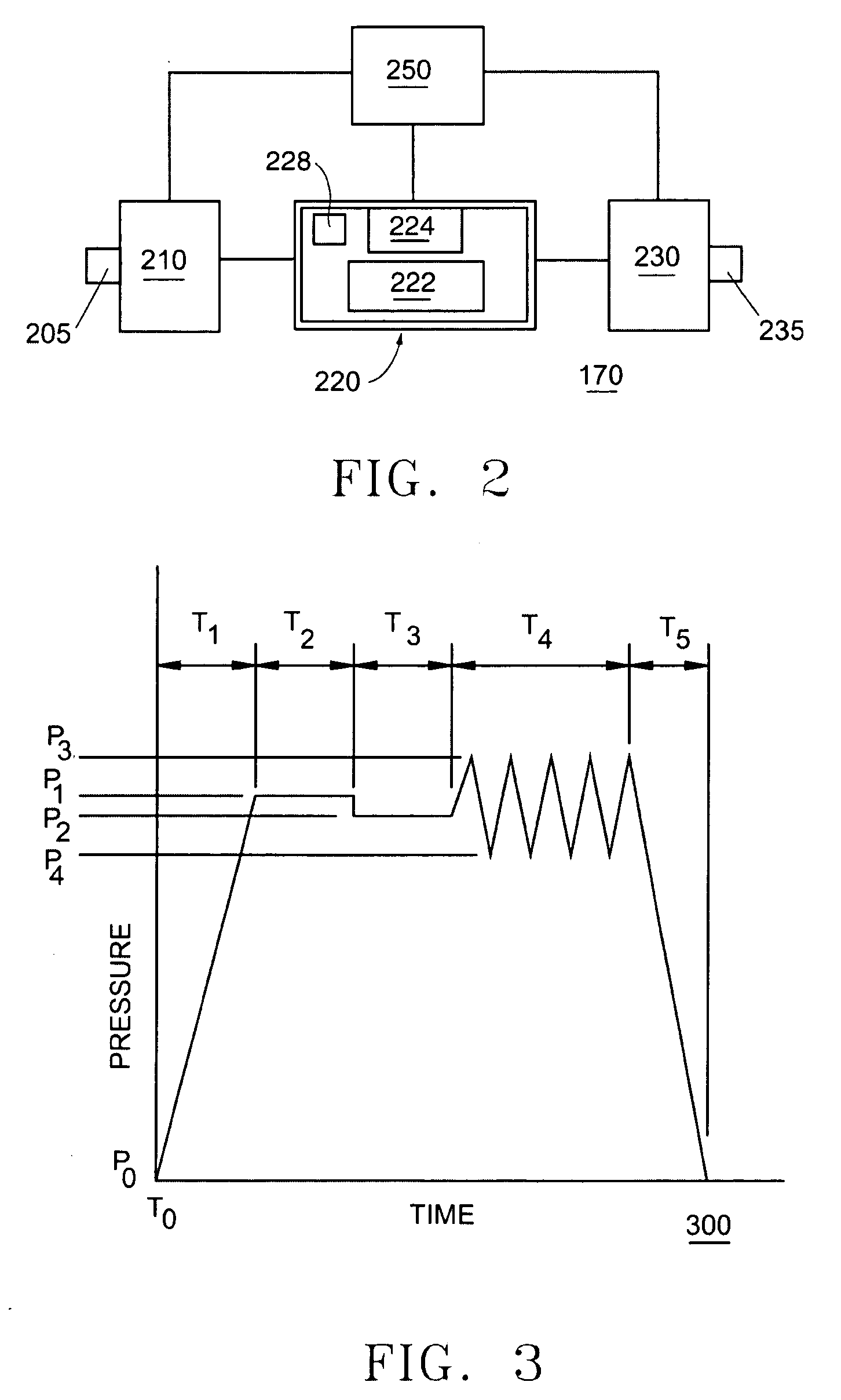

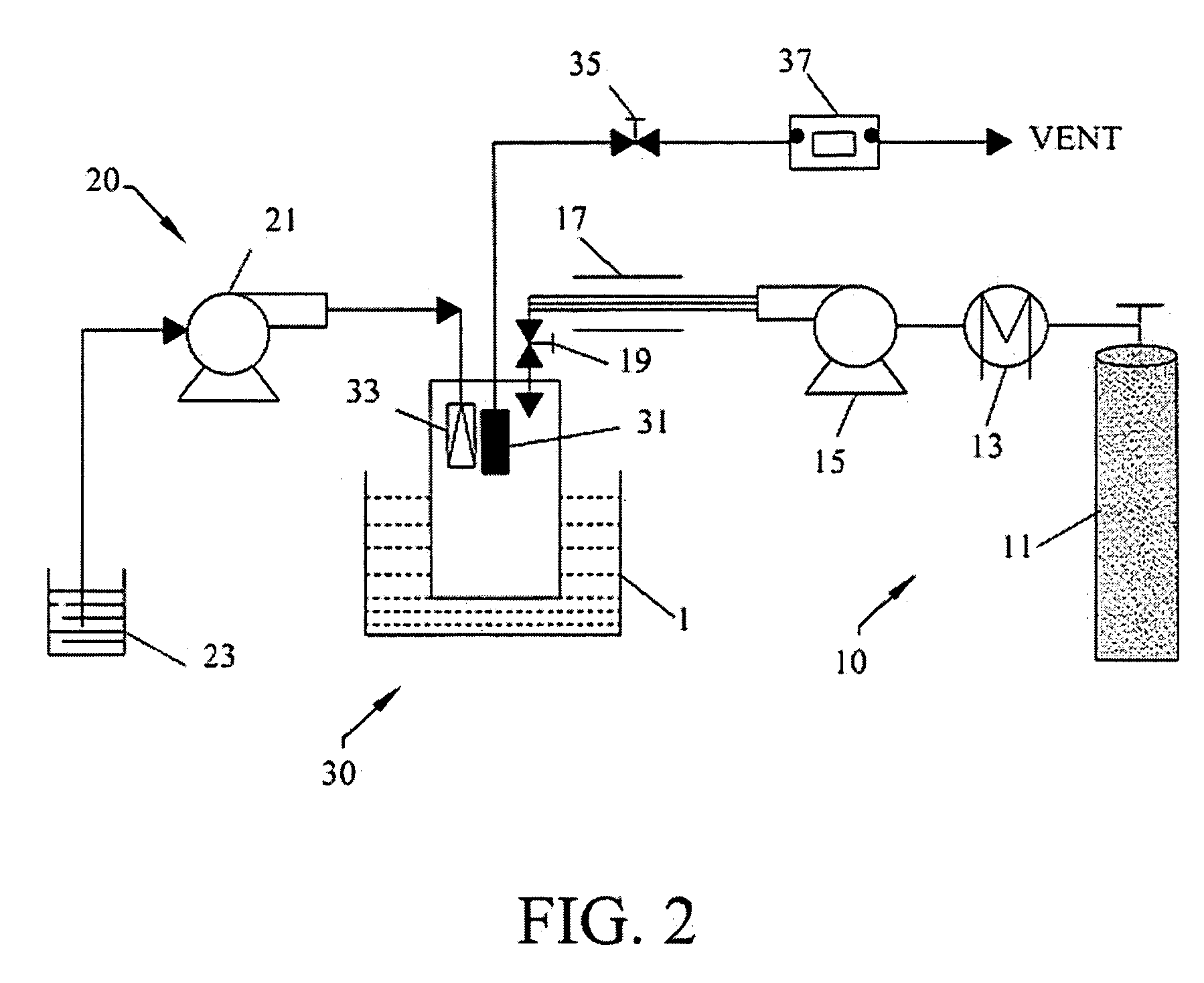

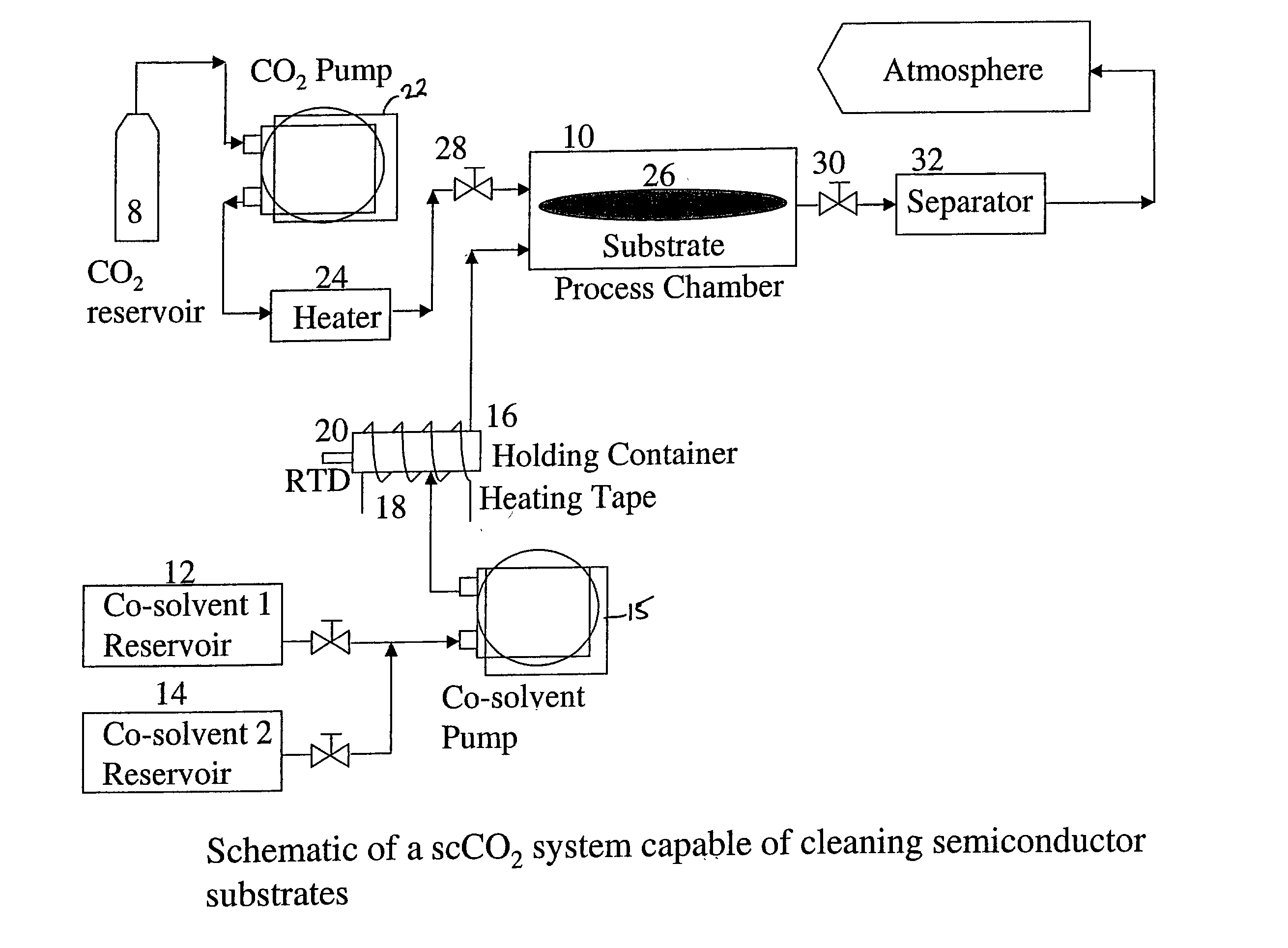

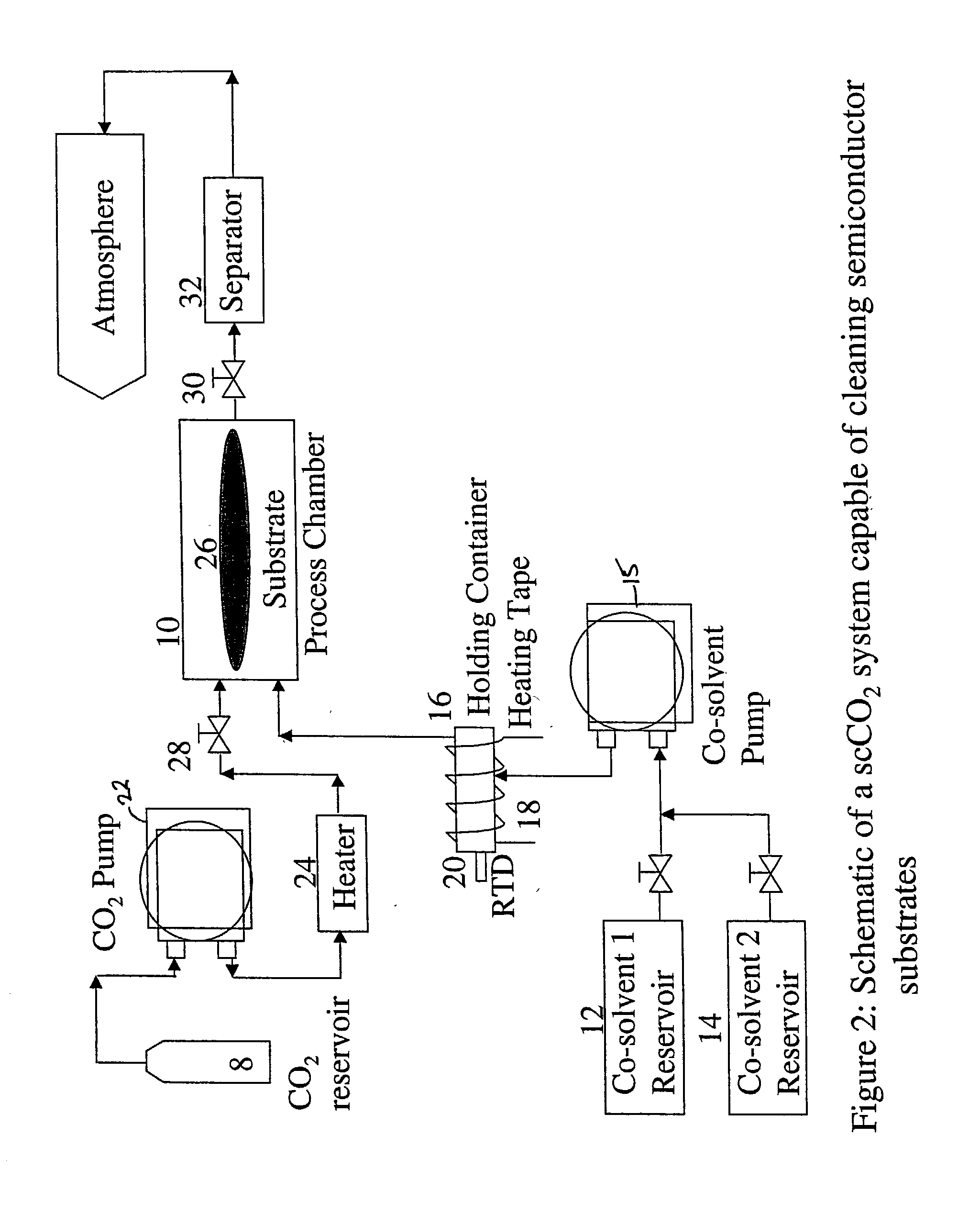

A method of and apparatus for regulating carbon dioxide using a pre-injection assembly coupled to a processing chamber operating at a supercritical state is disclosed. The method and apparatus utilize a source for providing supercritical carbon dioxide to the pre-injection assembly and a temperature control element for maintaining the pre-injection region at a supercritical temperature and pressure.

Owner:SUPERCRITICAL SYSEMS

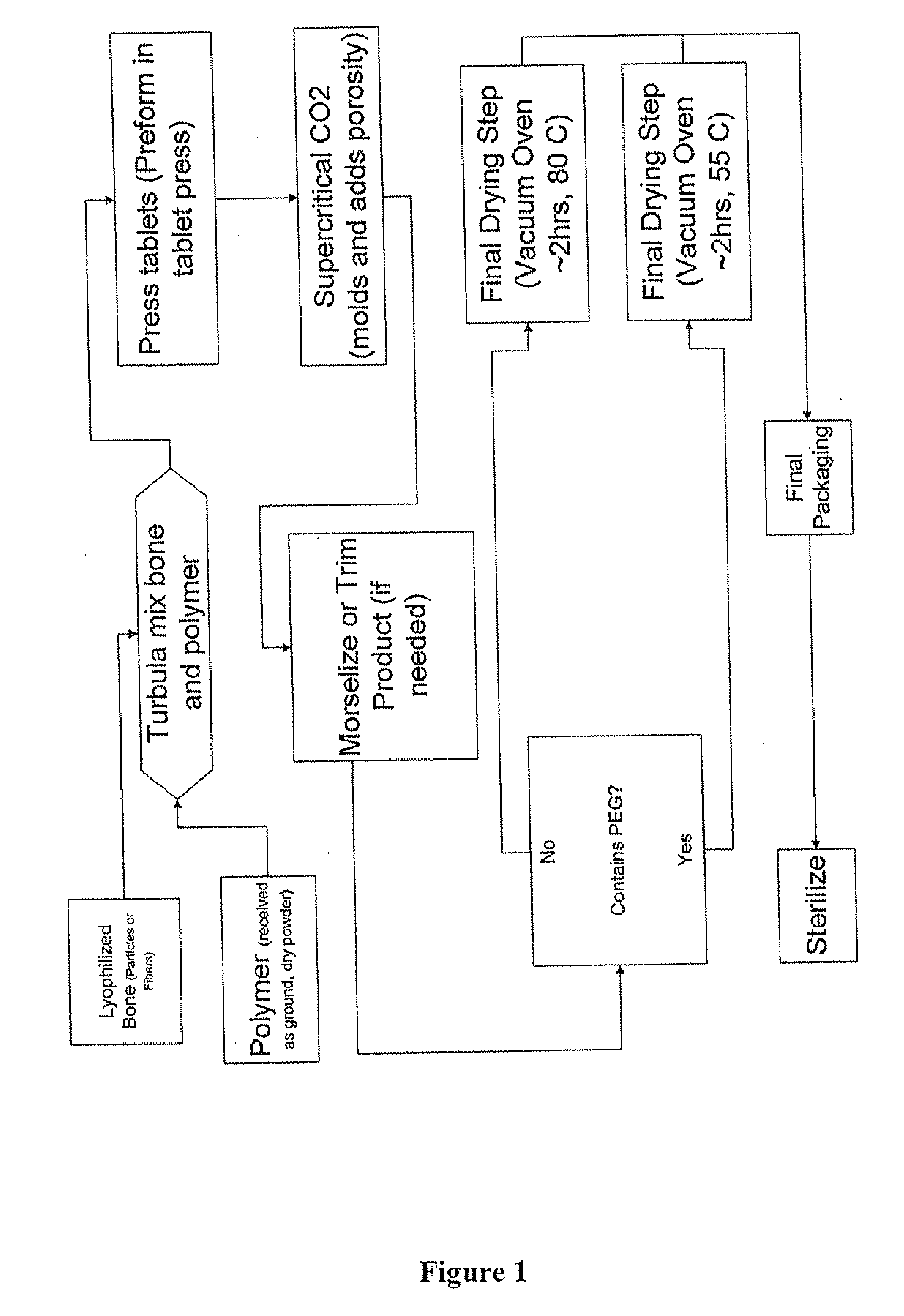

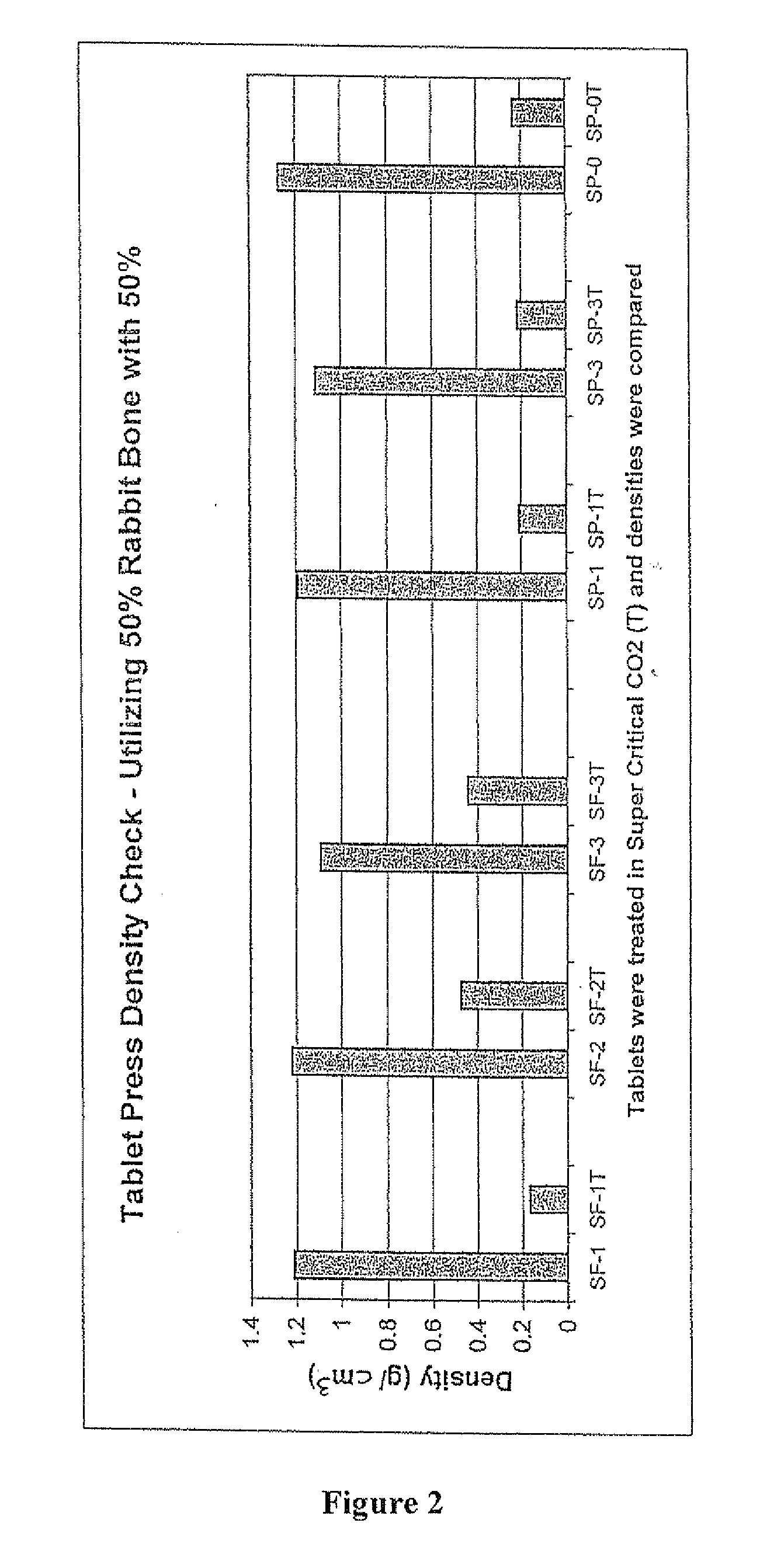

Porous osteoimplant

ActiveUS20080069852A1Accelerate the remodeling processImprove permeabilityBone implantSkeletal disorderBone growthBone defect

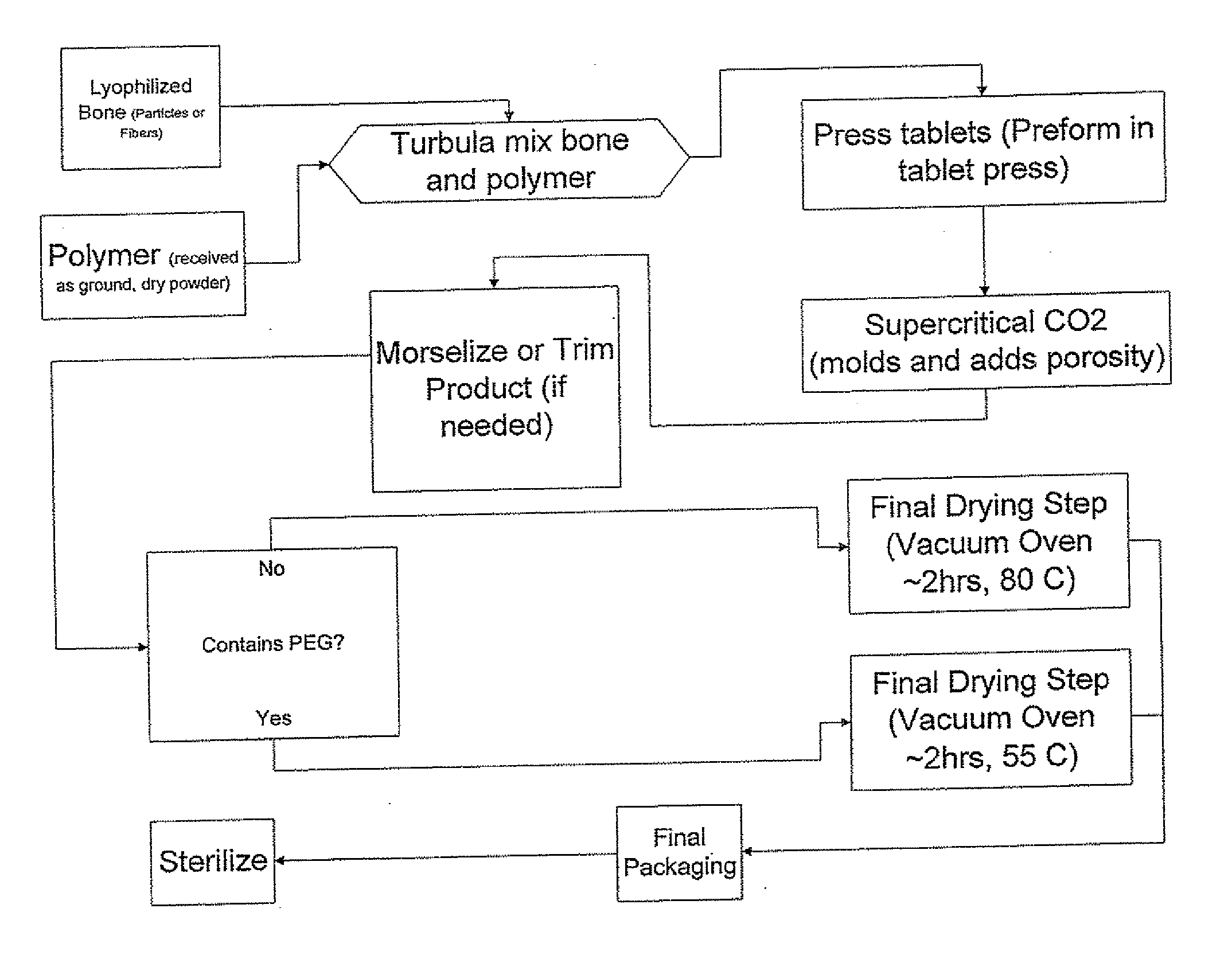

The invention is directed toward porous composites for application to a bone defect site to promote new bone growth. The inventive porous composites comprise a biocompatible polymer and a plurality of particles of bone-derived material, inorganic material, bone substitute material or composite material. In certain embodiments, the porous composites are prepared using a method that includes a supercritical fluid (e.g., supercritical carbon dioxide) treatment. The invention also discloses methods of using these composites as bone void fillers.

Owner:WARSAW ORTHOPEDIC INC

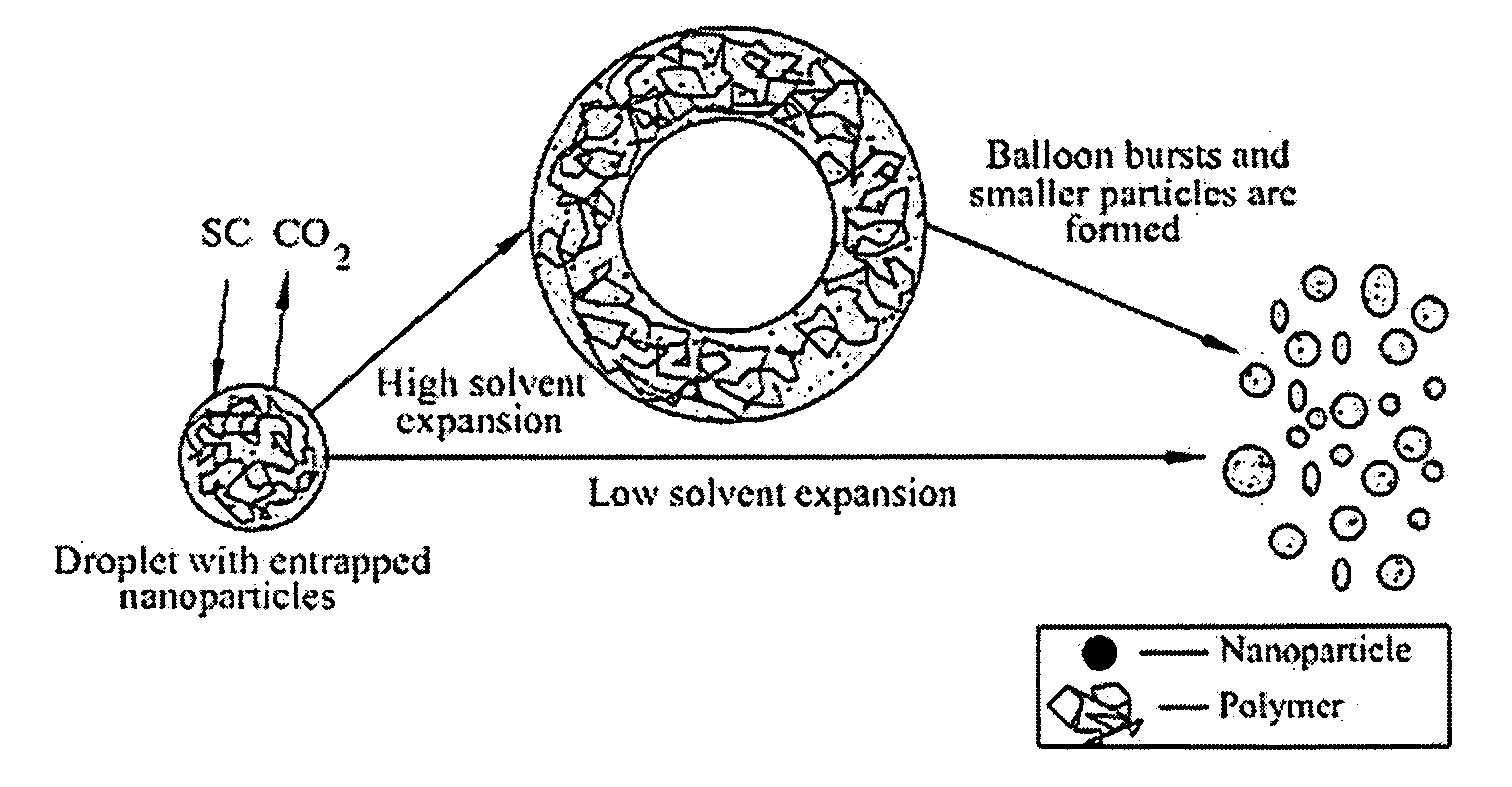

Polymer coating/encapsulation of nanoparticles using a supercritical antisolvent process

InactiveUS20050191491A1Speed up the processGranule coatingPretreated surfacesSolventSupercritical carbon dioxide

A process, method and / or system for preparing polymer-coated nanoparticles and / or other ultrafine particles utilizing a supercritical fluid, e.g., supercritical carbon dioxide (SC CO2), as an antisolvent that may be added to a solution of a polymer and an organic solvent in which insoluble nanoparticles or the like are suspended. The coating process occurs when the supercritical fluid (e.g., SC CO2) and the nanoparticle-containing suspension are combined to cause the suspended nanoparticles to precipitate as coated nanoparticles. Processing parameters for optimizing and / or enhancing the efficacy and / or efficiency of the coating process, method and / or system and for controlling the coating and / or agglomeration of coated particles are also described. The process, method and / or system has wide ranging applicability, e.g., for coating and / or encapsulation of pharmaceuticals, cosmetics, food products, chemicals, agrochemicals, pesticides, polymers, coatings, catalysts and the like.

Owner:NEW JERSEY INSTITUTE OF TECHNOLOGY

Compositions and method for removing photoresist and/or resist residue at pressures ranging from ambient to supercritical

InactiveUS20040050406A1Accelerate photoresist strippingImprove reaction kineticsNon-surface-active detergent compositionsSemiconductor/solid-state device manufacturingResistAlcohol

A method of enhancing removal of photoresist and / or resist residue from a substrate includes exposing the substrate to an environmentally friendly, non-hazardous co-solvent mixture comprising a carbonate, an oxidizer and an accelerator. The stripping process may be performed under ambient conditions, or in the presence of a supercritical fluid such as supercritical carbon dioxide with the supercritical cleaning step itself being a desirable "green" process. In one embodiment, the co-solvent mixture includes propylene carbonate, benzyl alcohol, hydrogen peroxide and an accelerator such as formic acid. If desired, supercritical carbon dioxide in combination with a second co-solvent mixture may be subsequently applied to the substrate to rinse and dry the substrate. In one embodiment, the second co-solvent mixture includes a lower alkyl alcohol such as isopropyl alcohol.

Owner:SCP GLOBAL TECH INC

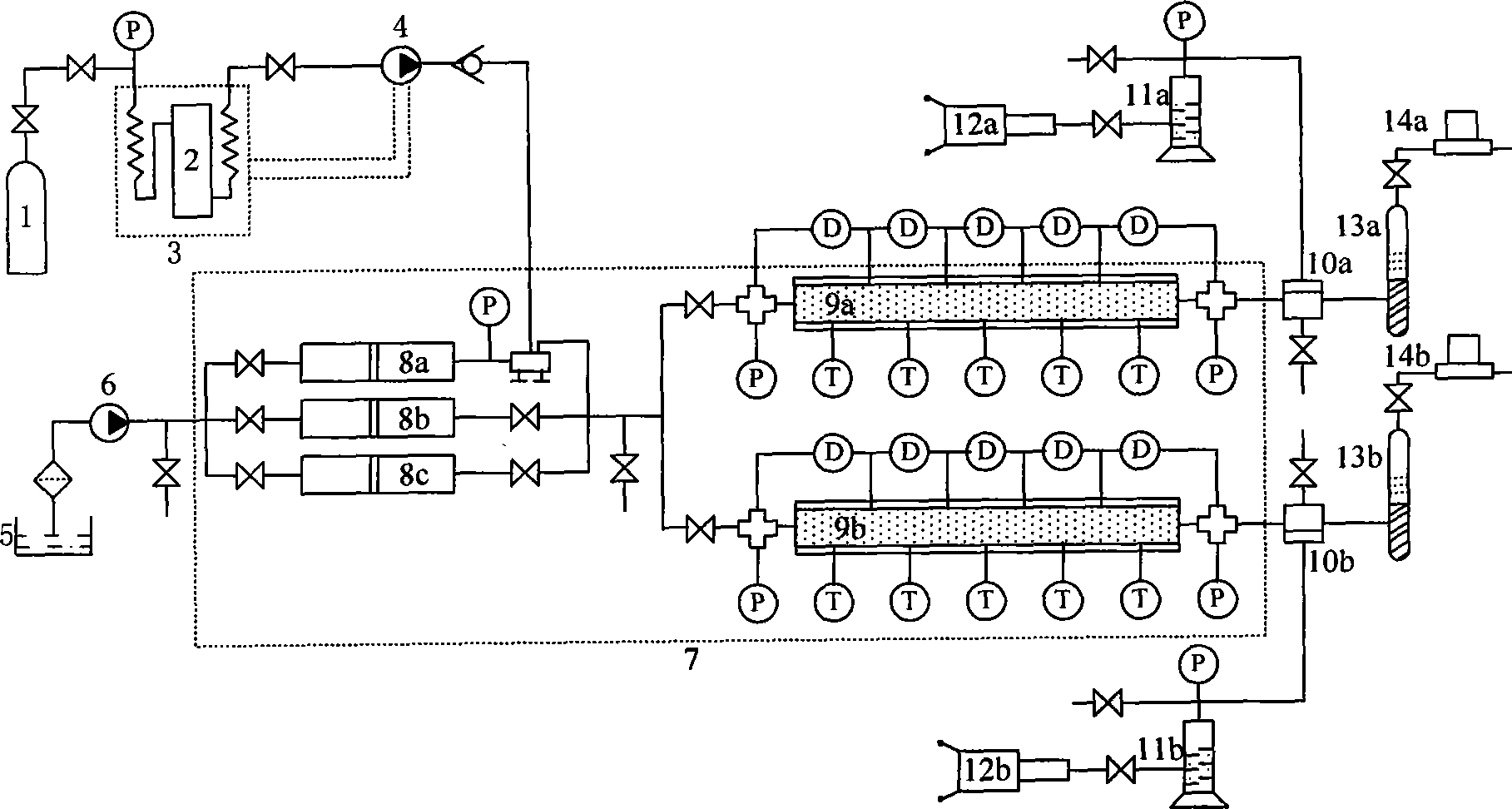

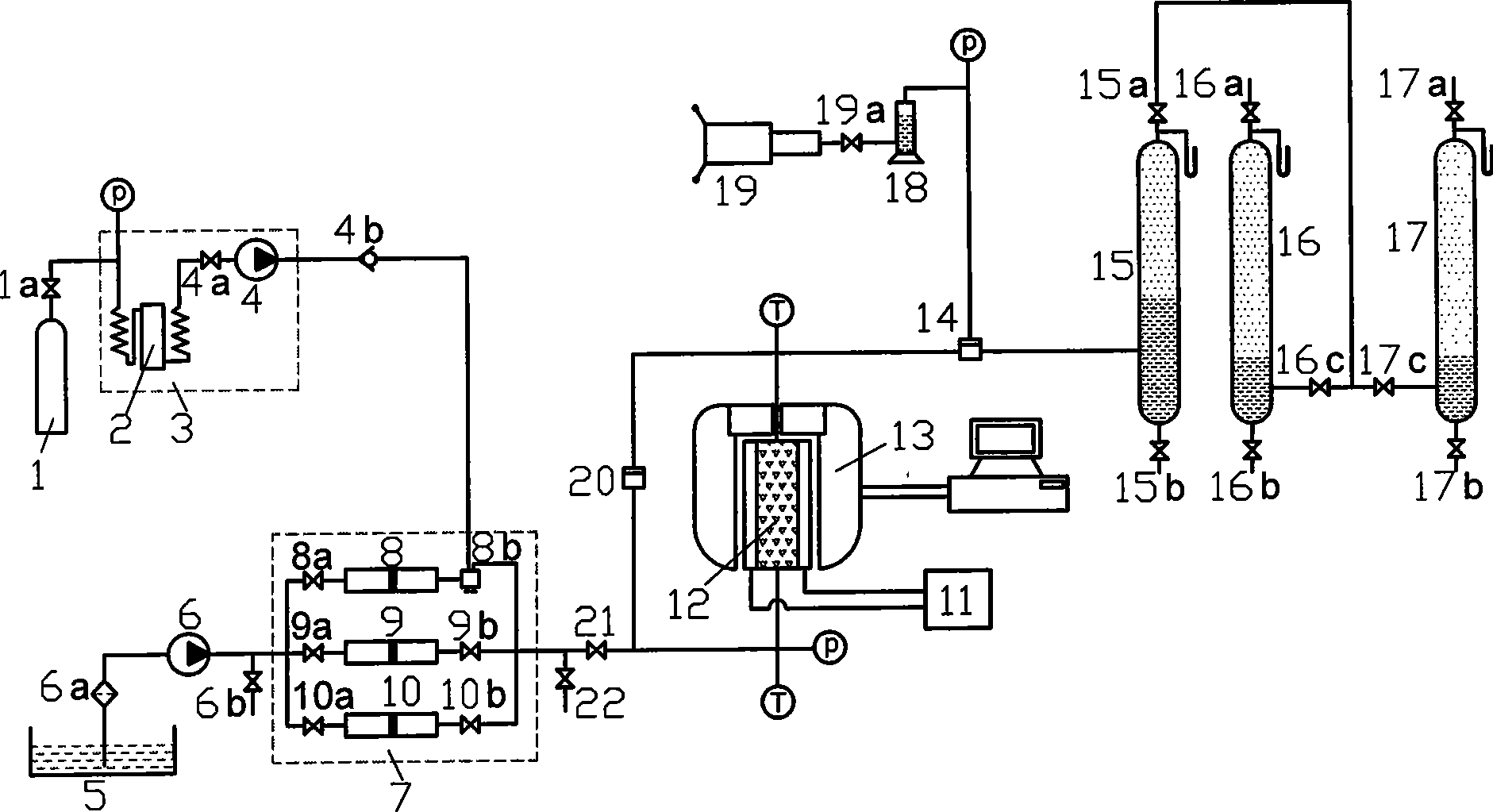

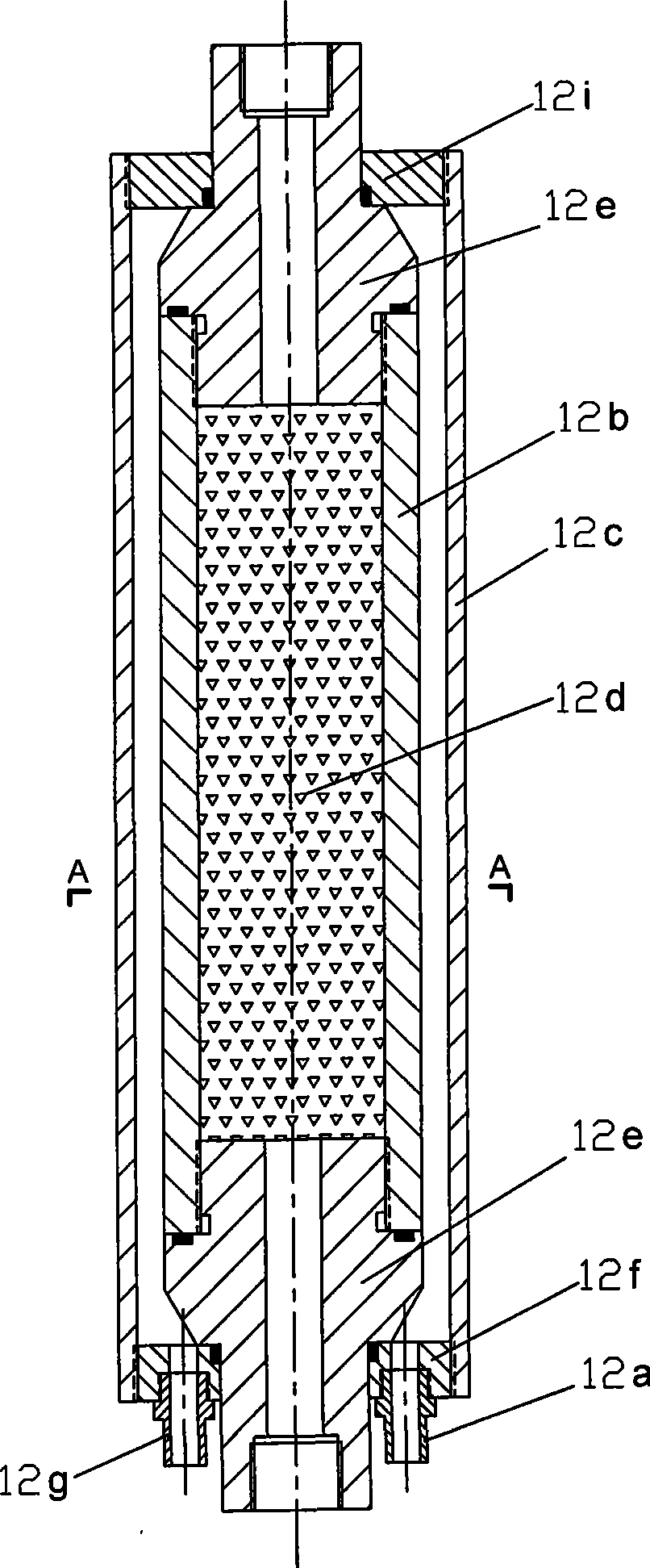

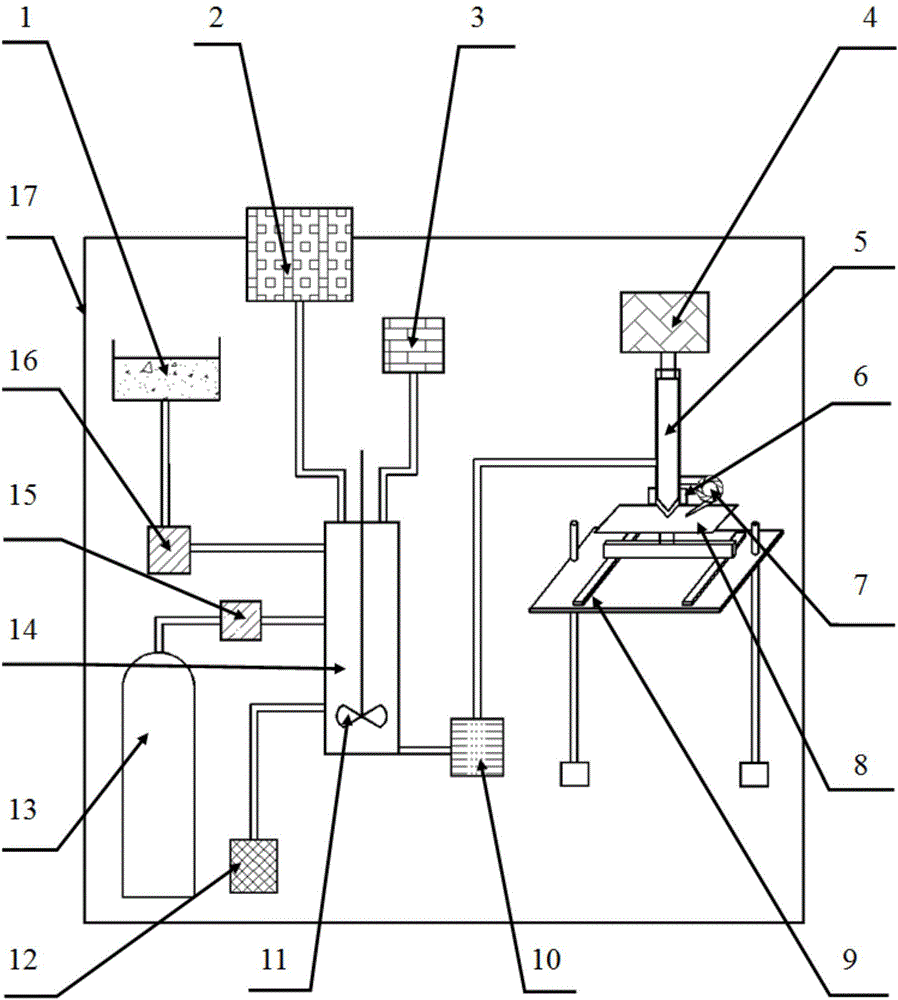

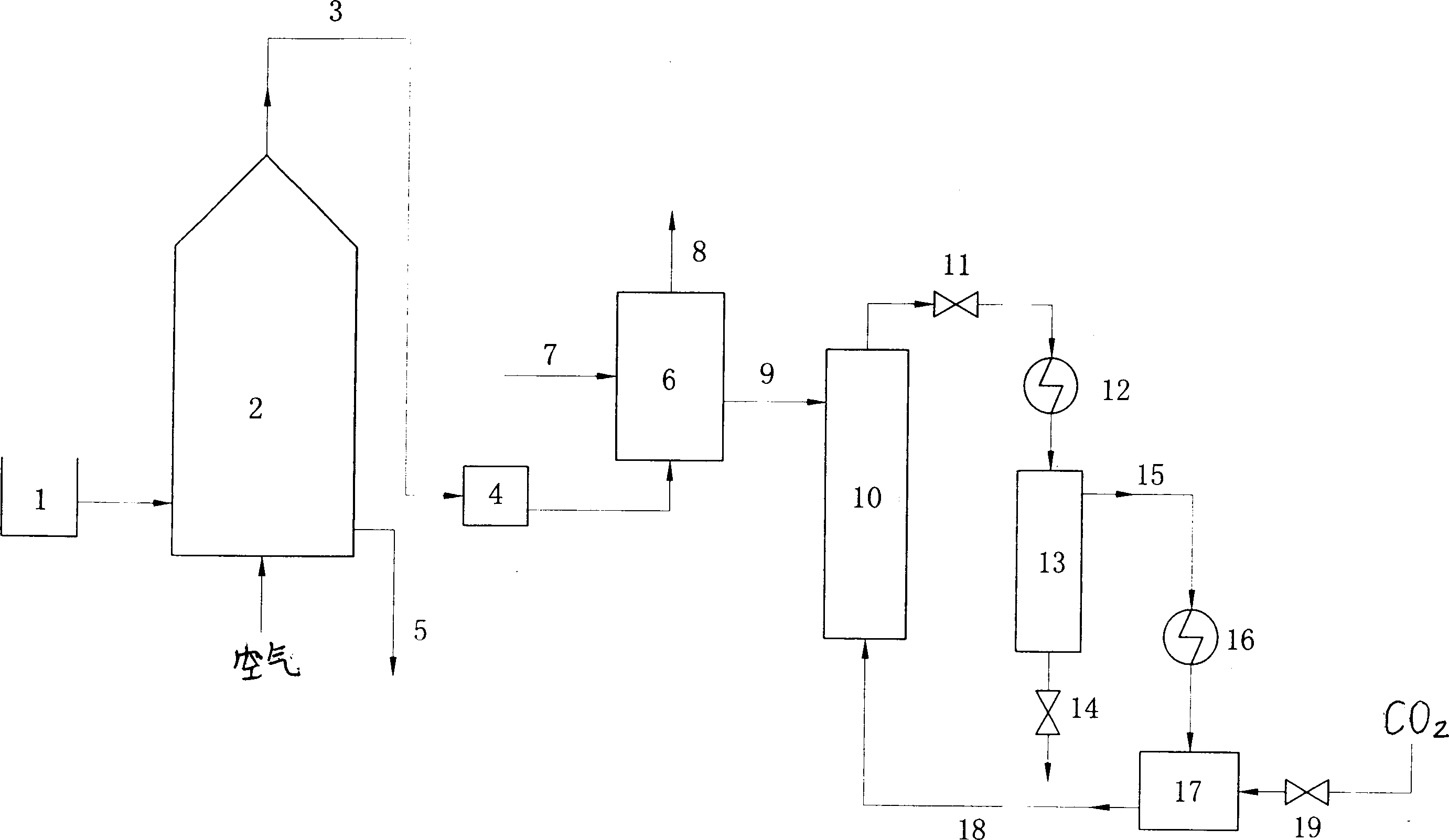

Supercritical carbon dioxide drive physical analogue device

InactiveCN101446189AEasy to achieve high temperature and high pressure supercritical stateOther gas emission reduction technologiesFluid removalRock coreDouble tube

The invention relates to a supercritical carbon dioxide drive physical analogue device, which belongs to the technical field of petroleum engineering and technology. The device adopts two paratactic simulation core devices to be connected with an injecting system, and each simulation core device is provided with an outlet measuring system; the injecting system injects formation water, crude oil and supercritical carbon dioxide to the simulation core devices, and a temperature and pressure measuring and controlling system is adopted to control the temperature set value and the pressure value of the whole system, and the outlet measuring system is adopted to measure the volumes of the carbon dioxide, the formation water and the crude oil which pass through the simulation core devices. After the CO2 gas is cooled and liquefied, the CO2 gas is pressurized and heated up to the supercriticality, and the difficulty of the accurate measurement of the injected CO2 flow; by adopting a double-tube model, the fingering and cross flow phenomenon during the driving process of the heterogeneous reservoir CO2 can be simulated; the design pressure of the device is 0 to 40 MPa, the design temperature is 0 to 180 DEG C, and the device is mainly applied to the research on supercritical CO2 miscible drive, non-miscible drive, continues gas drive or water and gas alternate drive.

Owner:DALIAN UNIV OF TECH

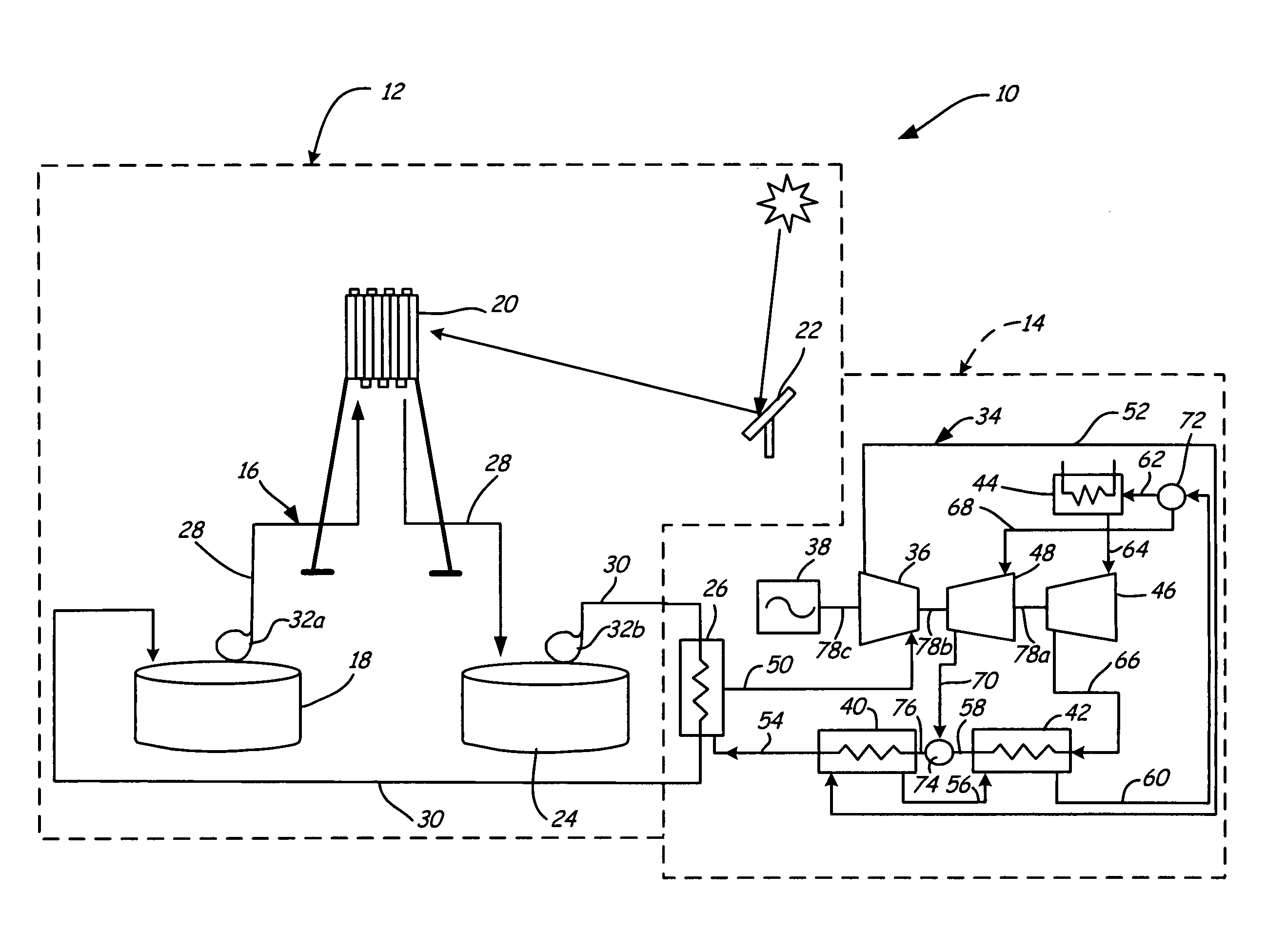

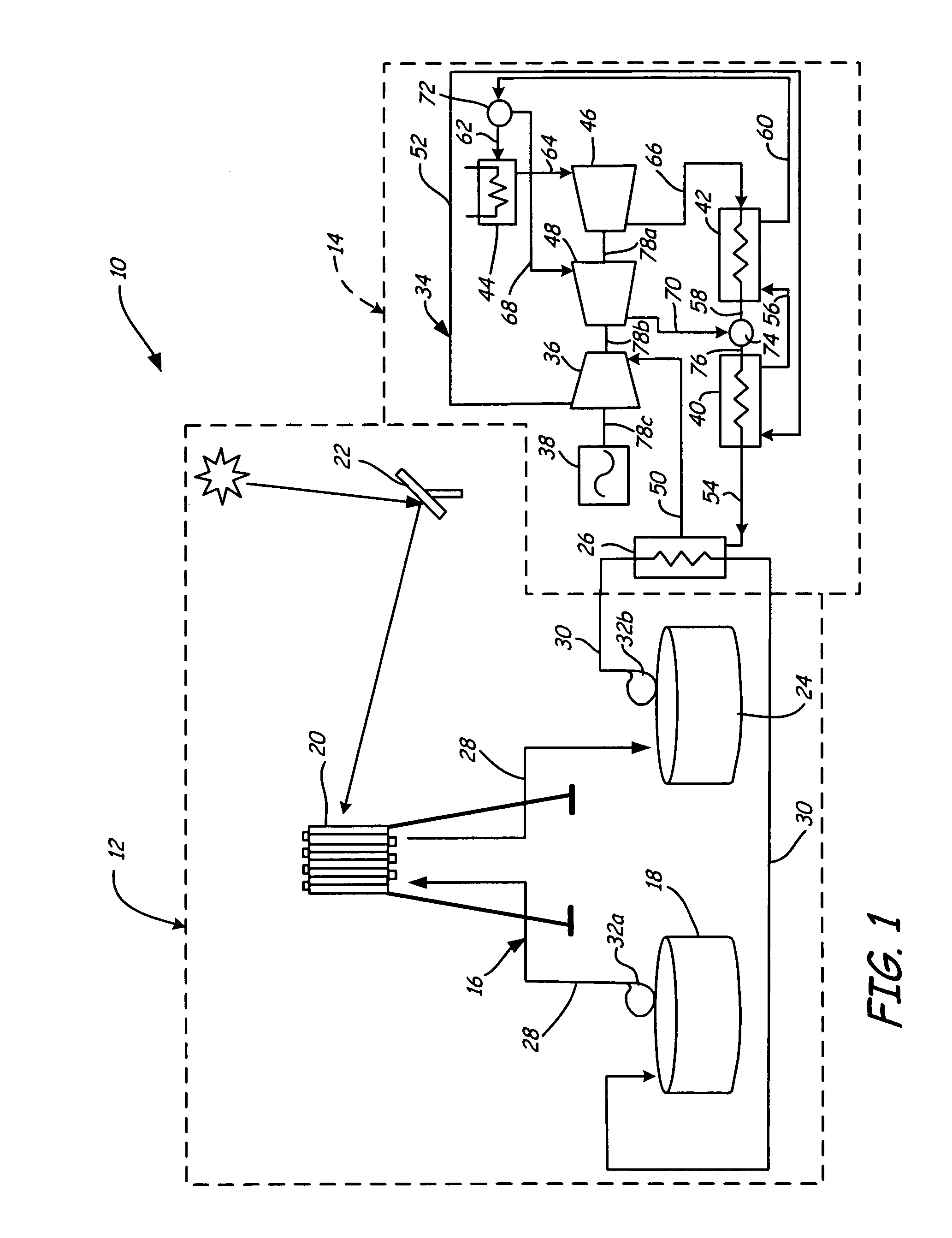

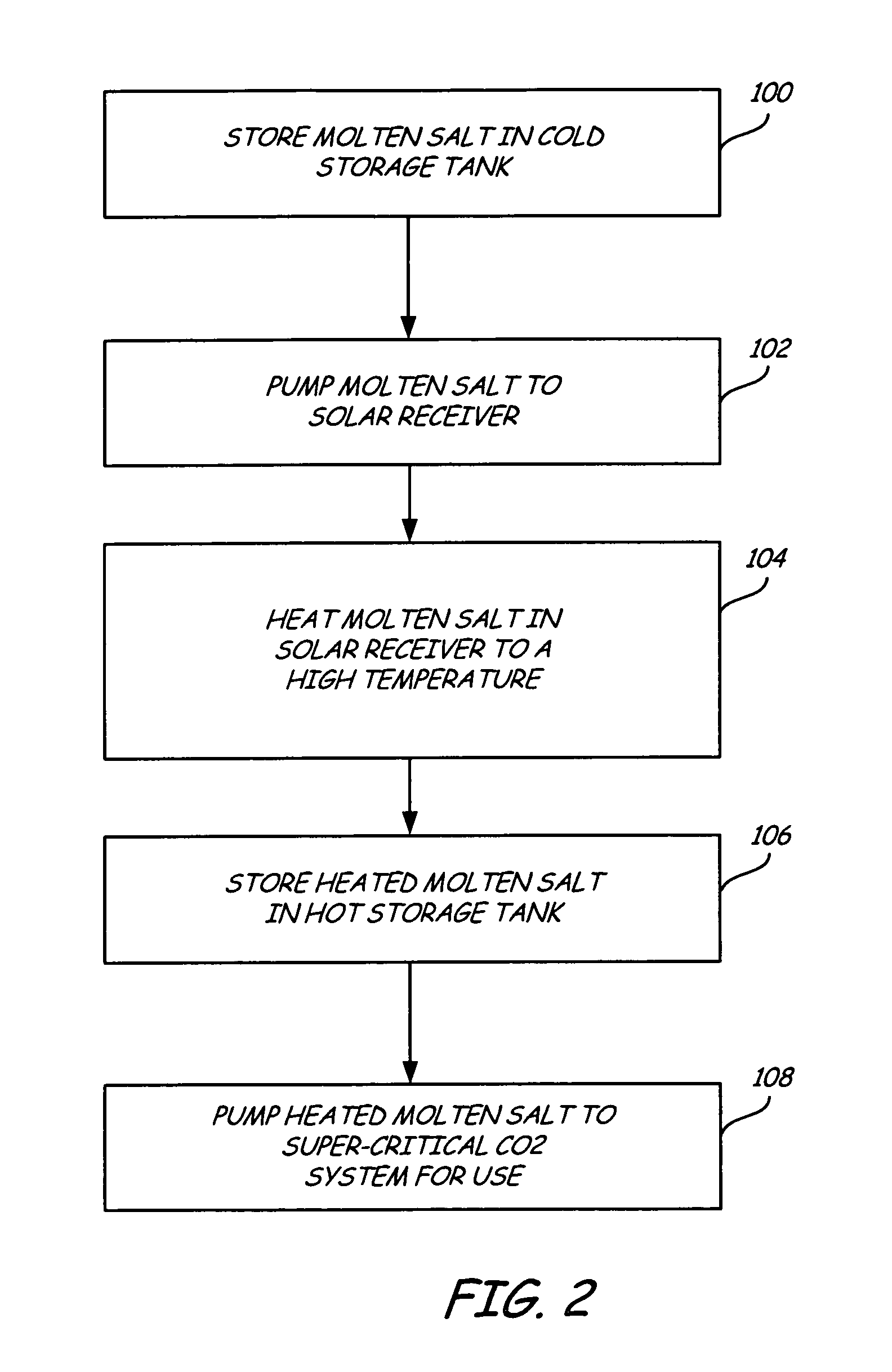

Supercritical CO2 turbine for use in solar power plants

Owner:SOLARRESERVE TECH

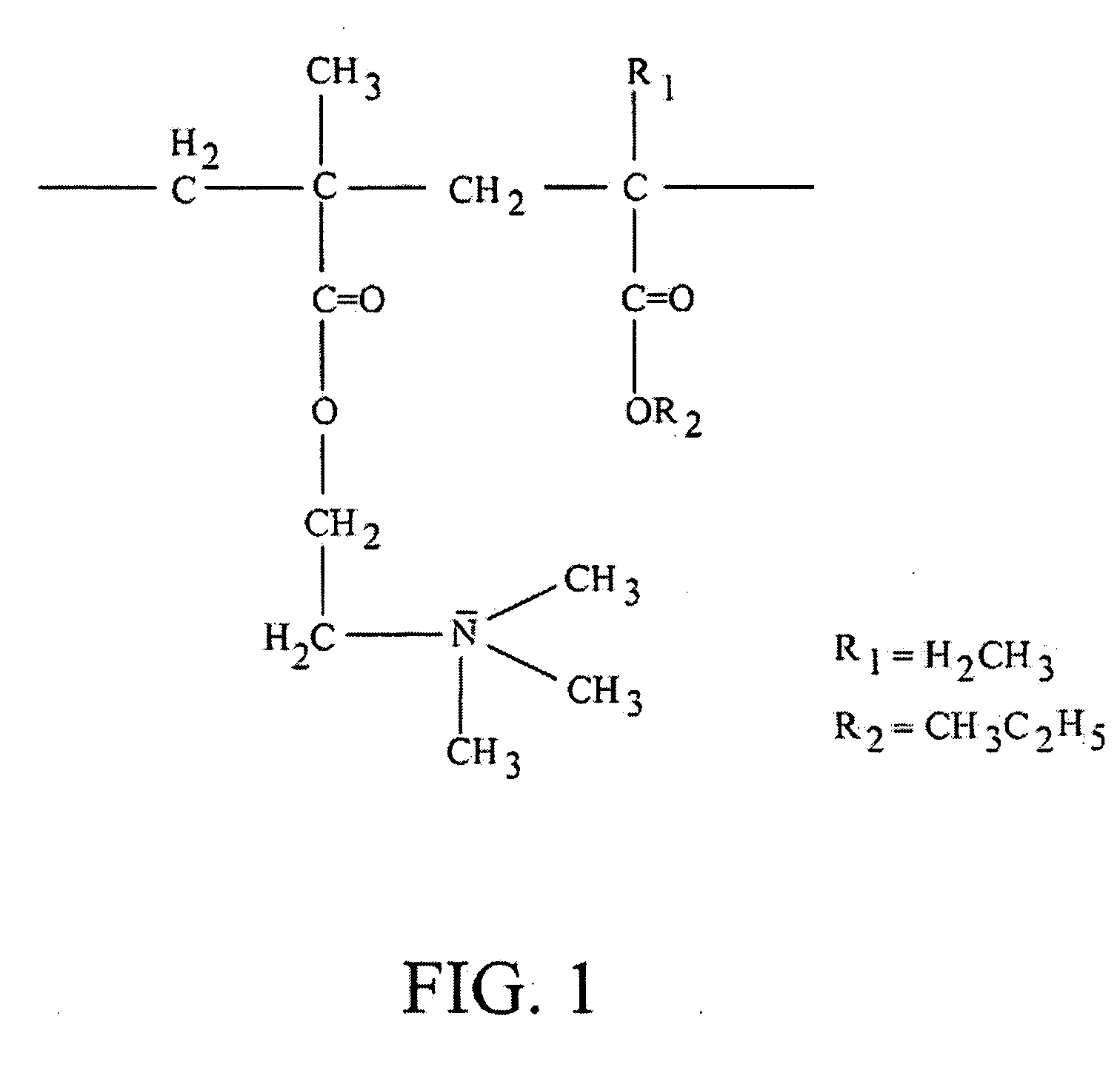

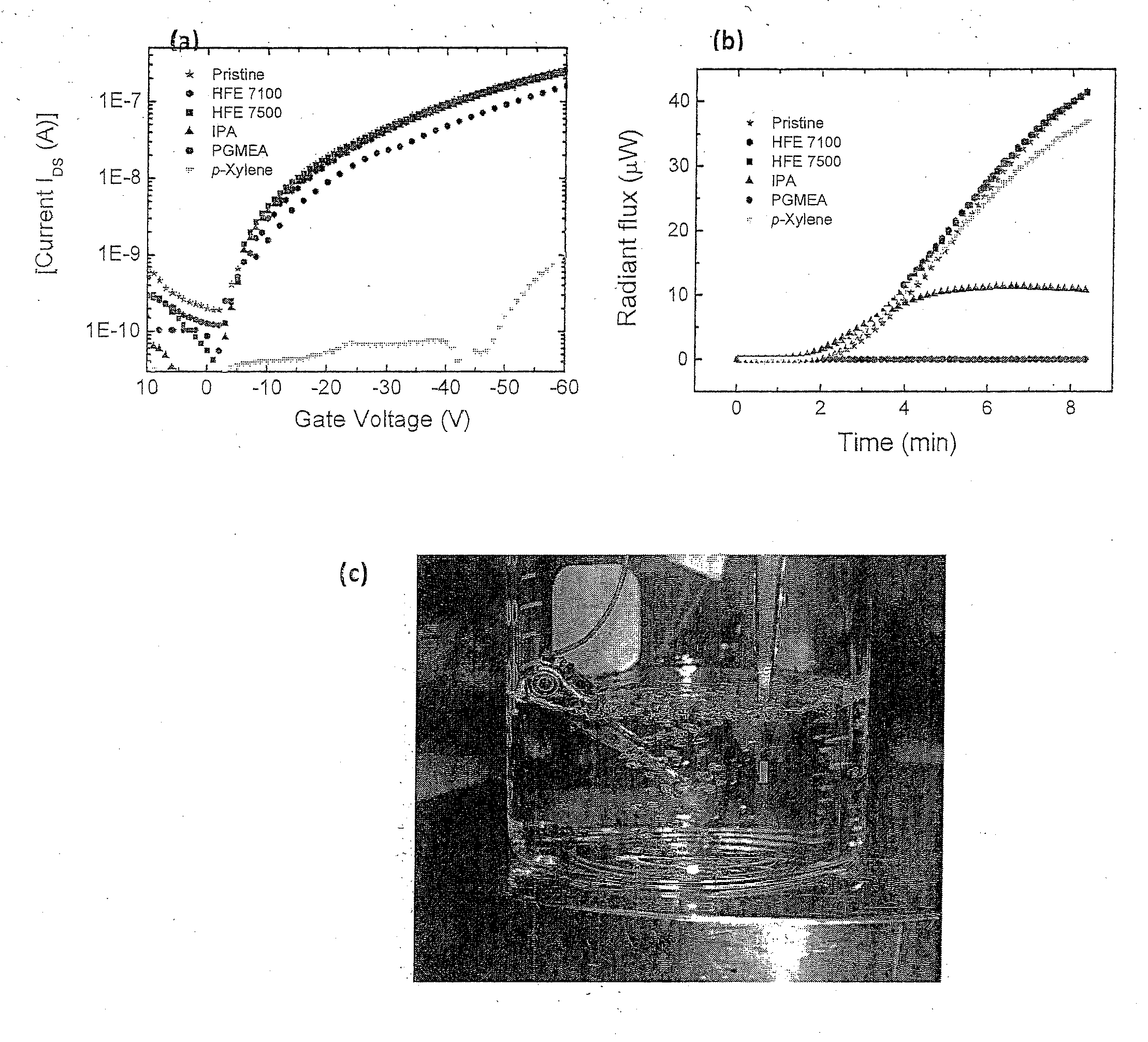

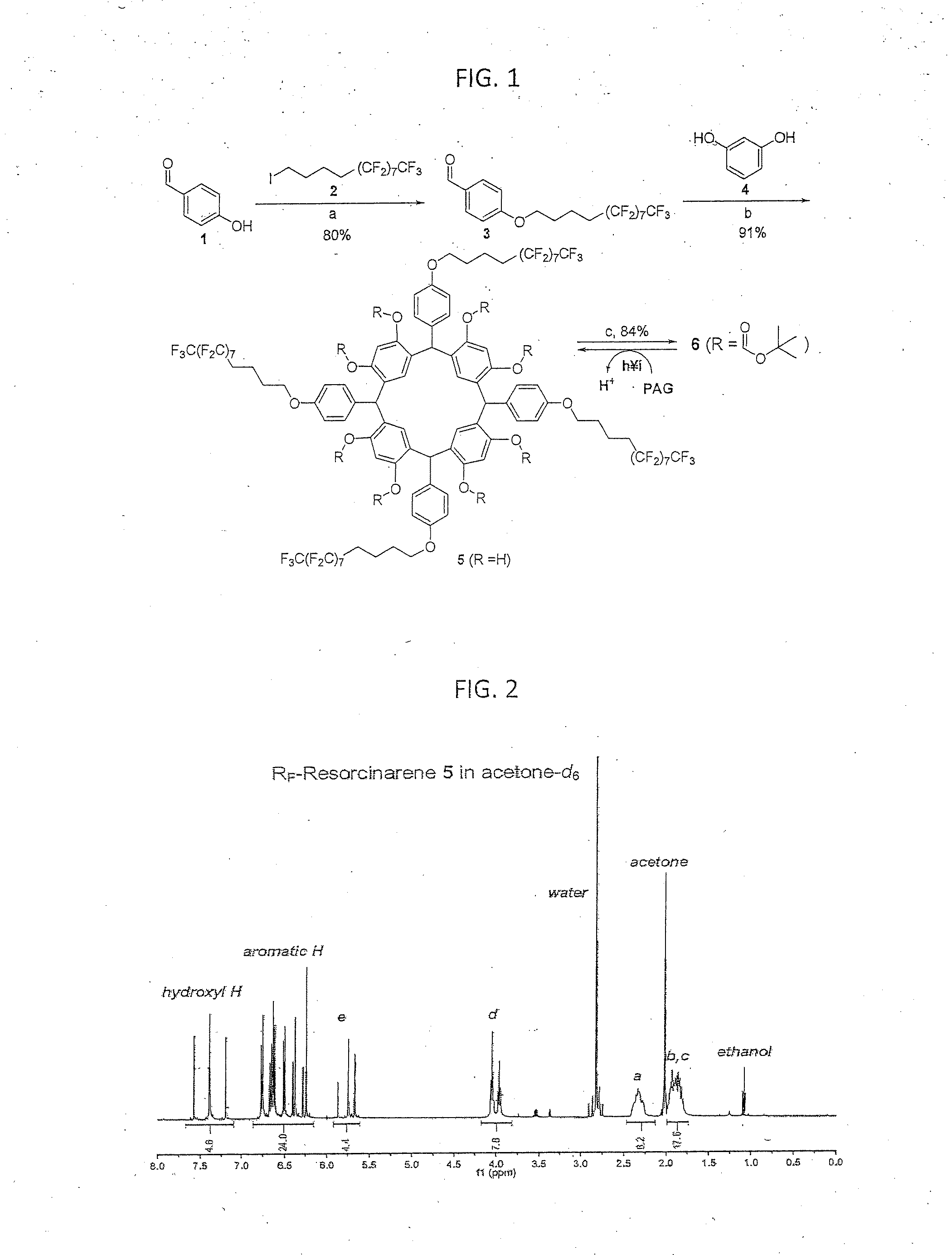

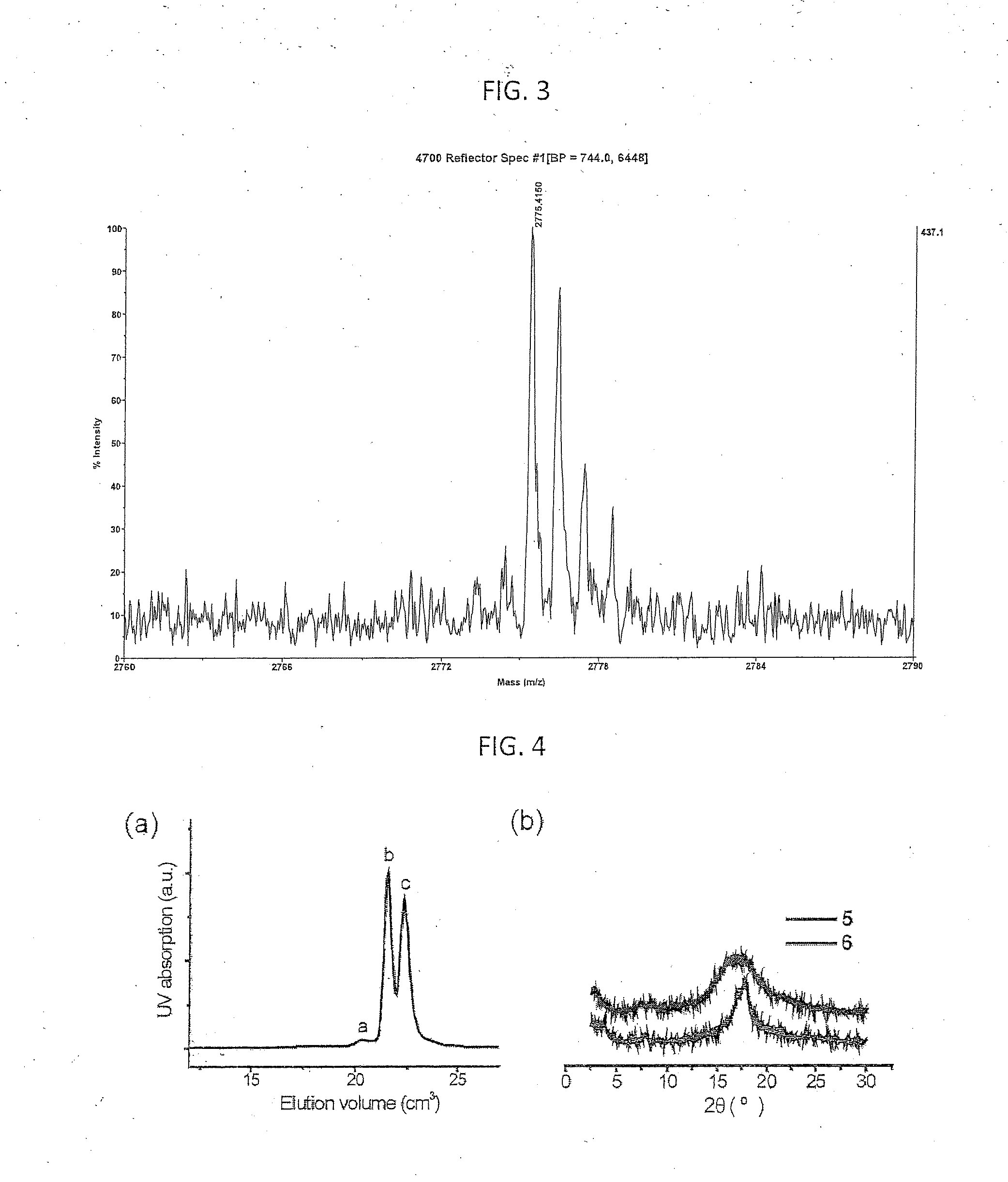

Orthogonal Procesing of Organic Materials Used in Electronic and Electrical Devices

ActiveUS20110159252A1Avoid damageImprove throughputOrganic chemistryPhotosensitive materialsOrganic structureMethacrylate

An orthogonal process for photolithographic patterning organic structures is disclosed. The disclosed process utilizes fluorinated solvents or supercritical CO2 as the solvent so that the performance of the organic conductors and semiconductors would not be adversely affected by other aggressive solvent. One disclosed method may also utilize a fluorinated photoresist together with the HFE solvent, but other fluorinated solvents can be used. In one embodiment, the fluorinated photoresist is a resorcinarene, but various fluorinated polymer photoresists and fluorinated molecular glass photoresists can be used as well. For example, a copolymer perfluorodecyl methacrylate (FDMA) and 2-nitrobenzyl methacrylate (NBMA) is a suitable orthogonal fluorinated photoresist for use with fluorinated solvents and supercritical carbon dioxide in a photolithography process. The combination of the fluorinated photoresist and the fluorinated solvent provides a robust, orthogonal process that is yet to be achieved by methods or devices known in the art.

Owner:CORNELL UNIVERSITY

Carbon dioxide oil-displacing nmr imaging detection device

InactiveCN101458218AEasy to meet high pressure strength requirementsCompact designWater resource assessmentAnalysis using nuclear magnetic resonancePorous mediumImage detection

A carbon dioxide drive nuclear magnetic resonance imaging detection device belongs to the technical field of petroleum engineering and technology. The detection device comprises: a simulation core device which is arranged in a nuclear magnetic resonance imaging device; an injection system which sequentially injects formation water, crude oil and supercritical carbon oxide into the simulation core device; a measurement and control system which is employed to control pressure and temperature of the whole system; the nuclear magnetic resonance imaging device which is employed to detect and perform quantitative analysis on an image to be tested to obtain voidage and permeability of a porous medium, and saturation seepage parameters of the supercritical carbon oxide, the formation water and the crude oil; and an output measuring system which is employed to measure volumes of the carbon dioxide gas, the formation water and the crude oil. The detection device has a design pressure of 0-40MPa and design temperature of 0-180 DEG C, and can simulate experimental studies of different displacement schemes of the supercritical CO2 under a complex petroleum reservoir condition; the simulation core device is made of a brass material, which produces no magnetism, satisfies requirements for high pressure and strength, has a compact structure, can be recycled, is conveniently operated, simple and applicable in an experimentation.

Owner:DALIAN UNIV OF TECH

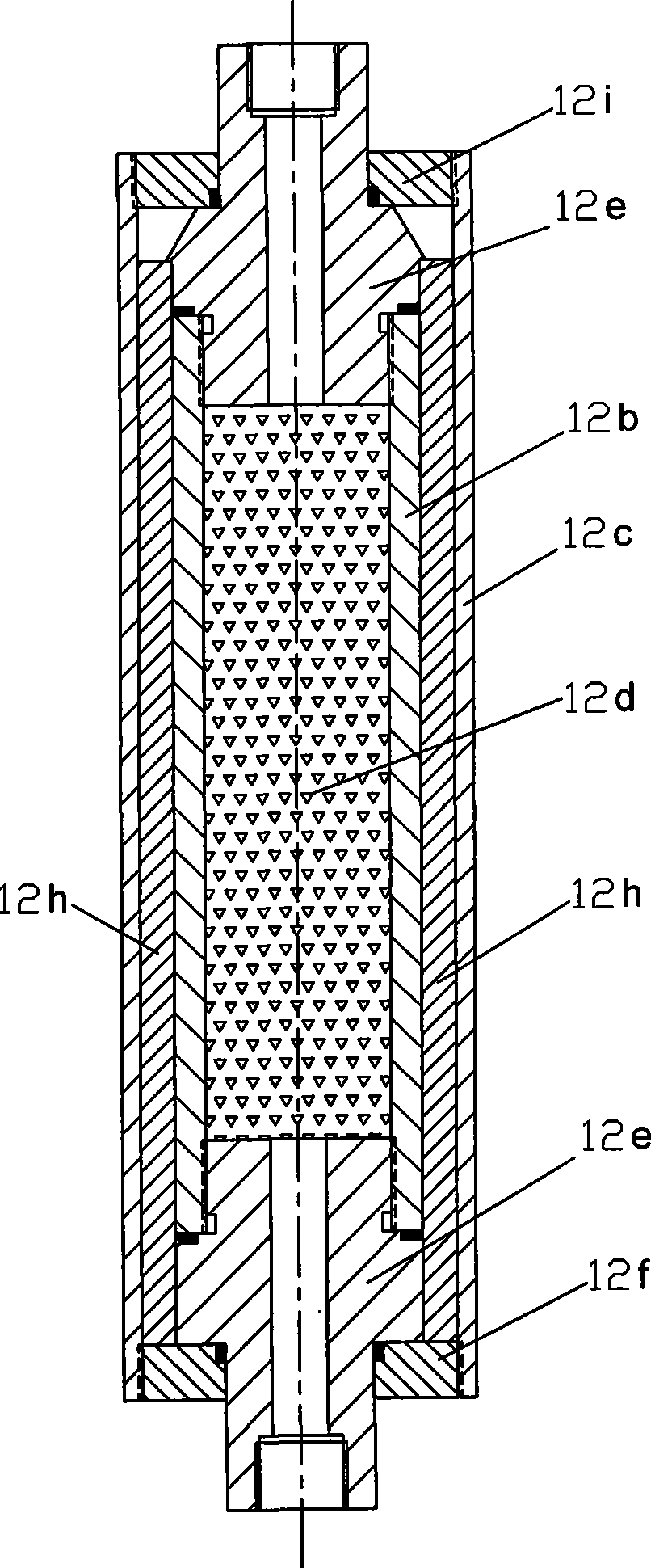

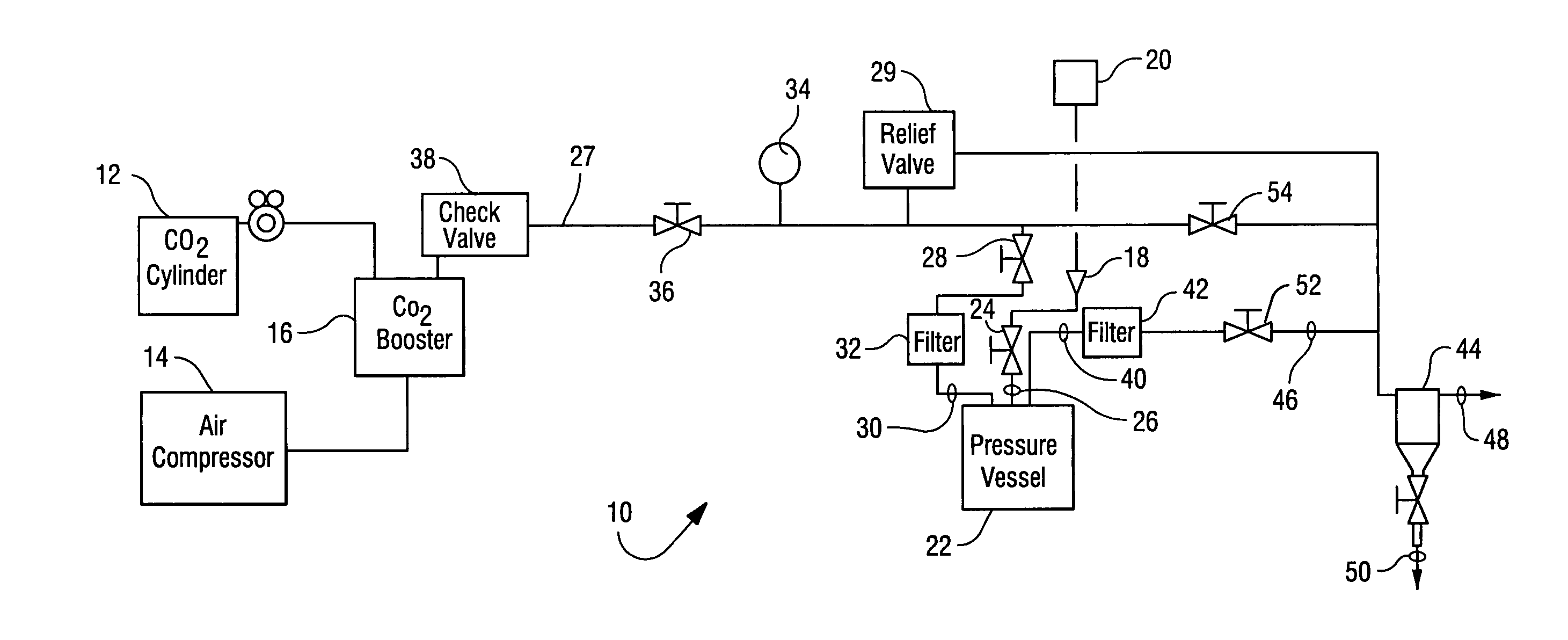

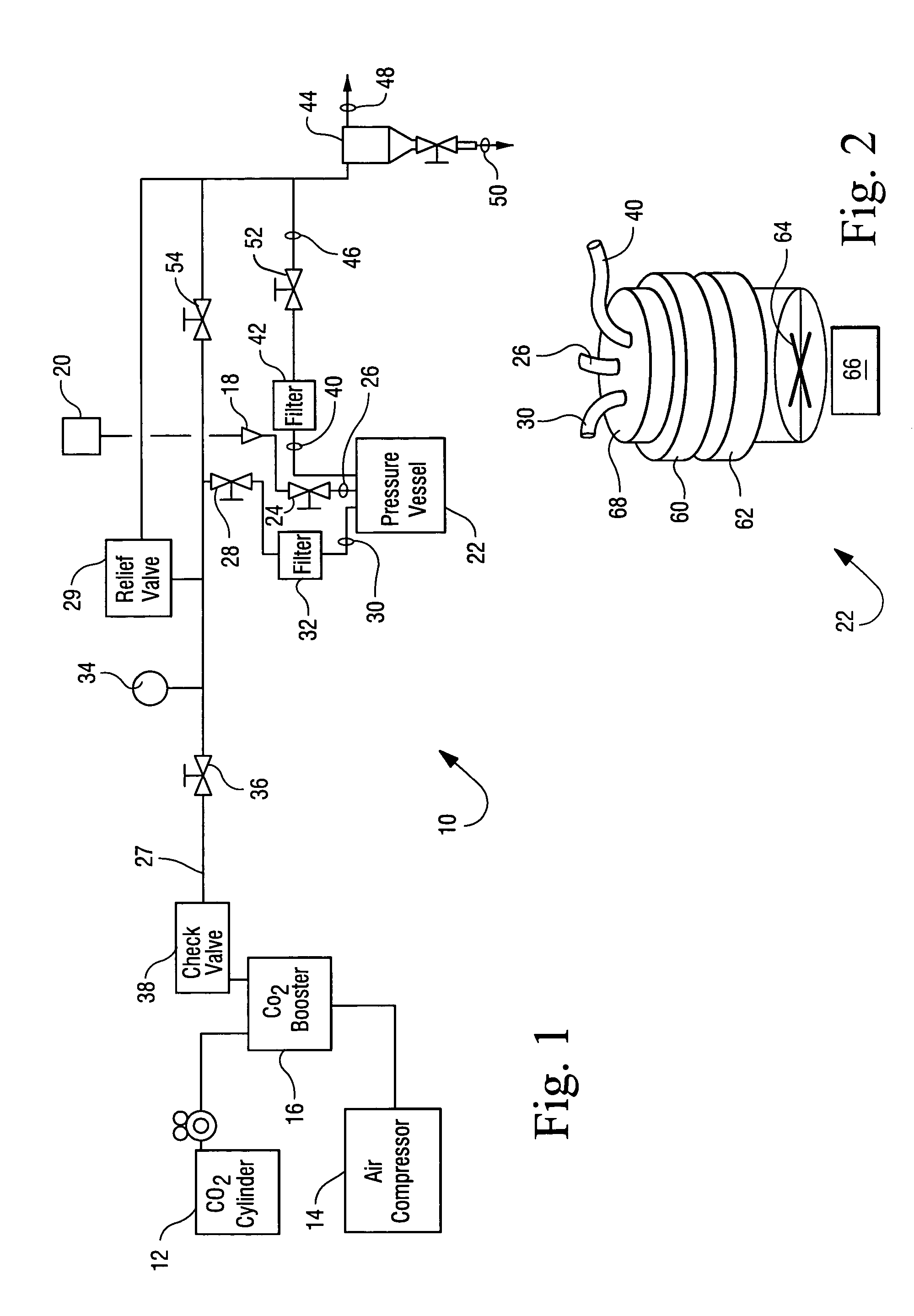

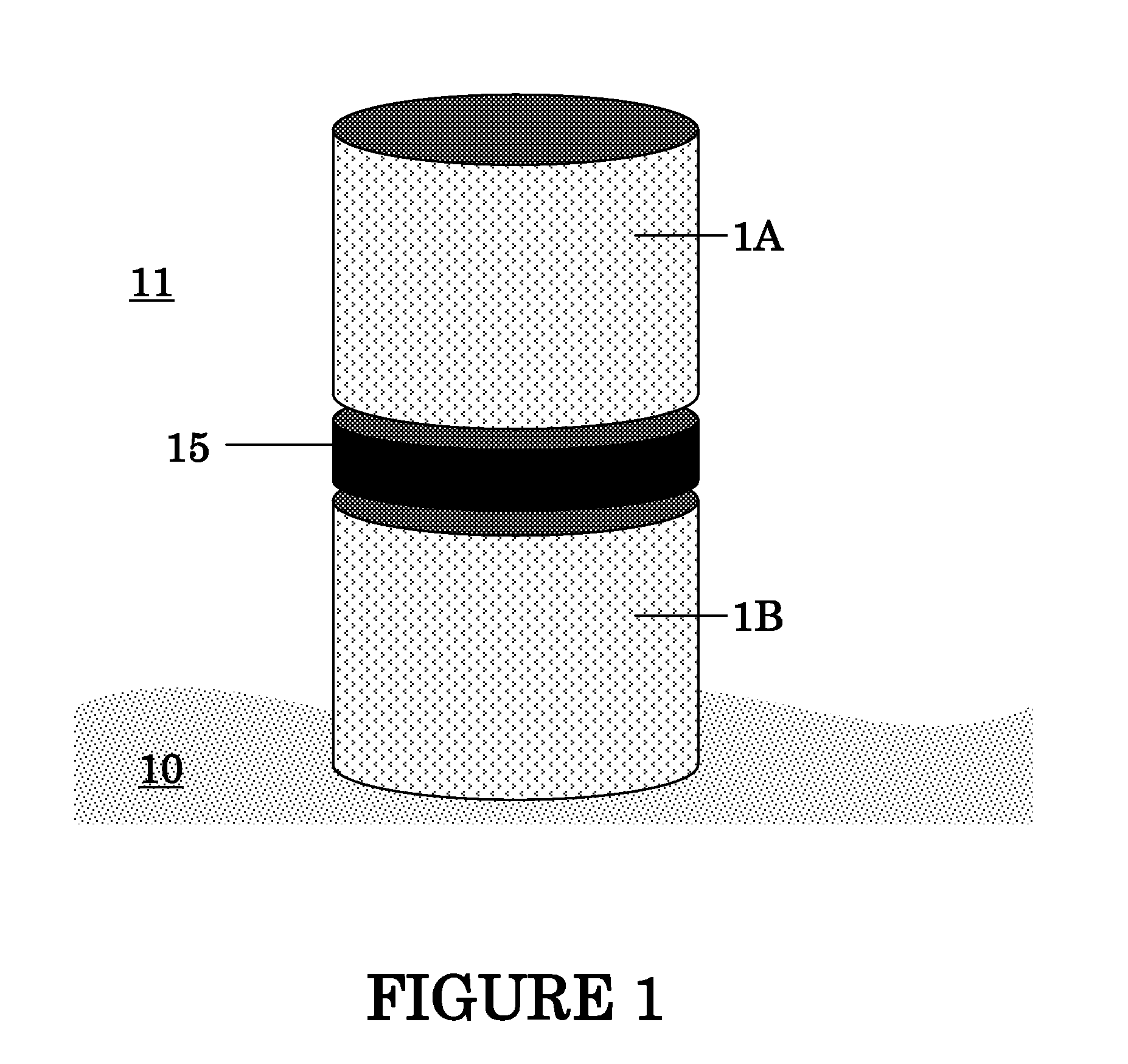

Sterialization methods and apparatus which employ additive-containing supercritical carbon dioxide sterilant

ActiveUS7108832B2Enhances mass transfer and sterilizationImprove sterilizationSamplingOther chemical processesSporePressure cycling

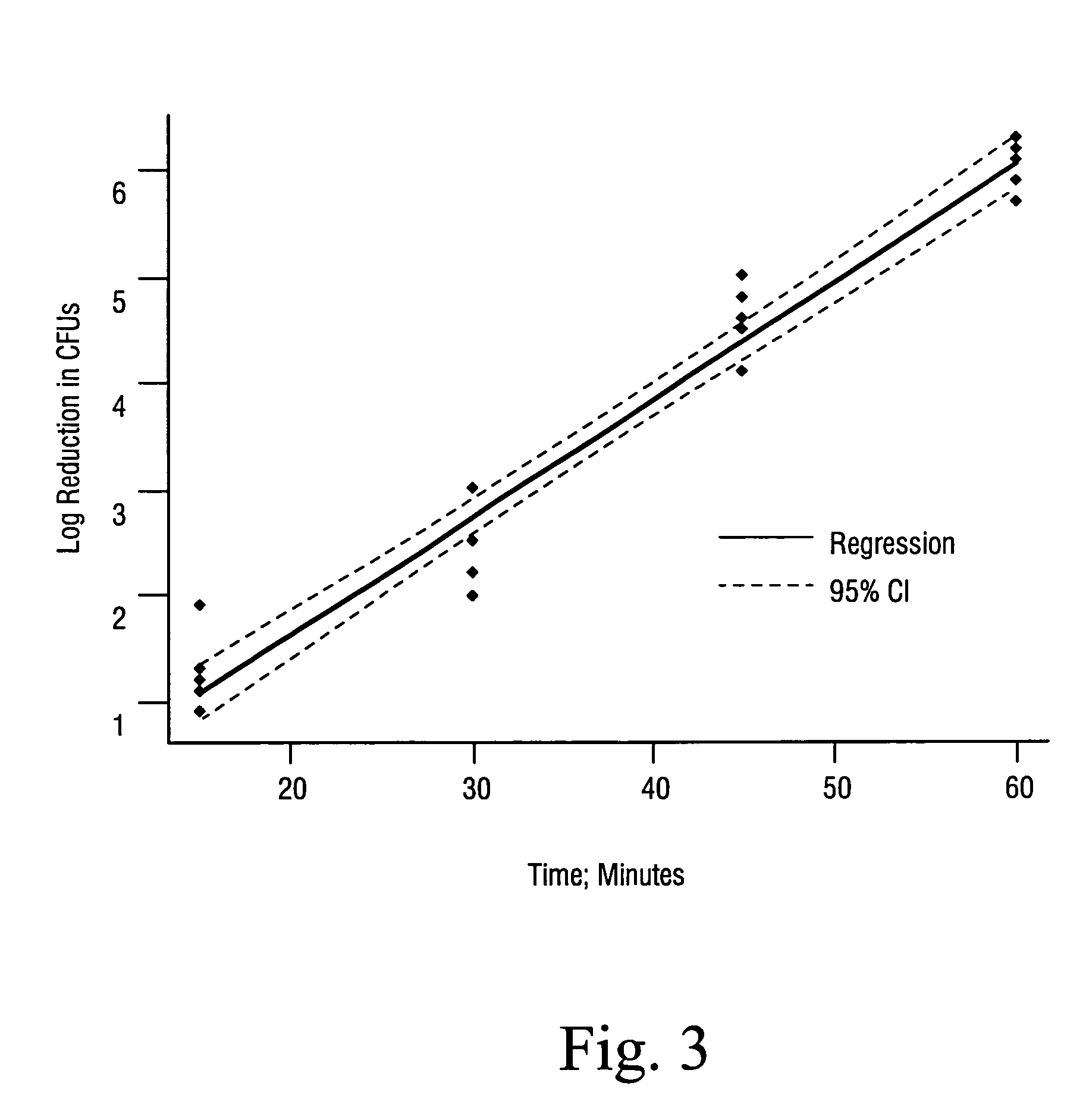

Sterilization methods and apparatus are effective to achieve a 6-log reduction in CFUs of industry standard bacteria and bacterial spores, i.e., B. stearothermophilus and B. subtilis spores, by subjecting sterilizable materials to a chemical additive-containing carbon dioxide sterilant fluid at or near its supercritical pressure and temperature conditions. Most preferably, the chemical additive-containing supercritical carbon dioxide sterilant fluid is agitated during sterilization, e.g., via mechanical agitation or via pressure cycling.

Owner:NOVASTERILIS

Composition and method for removing photoresist and/or resist residue using supercritical fluids

InactiveUS20040011386A1Non-surface-active detergent compositionsSemiconductor/solid-state device manufacturingResistOrganic solvent

A method of removing photoresist and / or resist residue from a substrate includes exposing the substrate to a supercritical fluid in combination with a co-solvent mixture comprising an organic solvent and an oxidizer. In one embodiment, the supercritical fluid is supercritical carbon dioxide and the co-solvent mixture includes 1,2-Butylene Carbonate, Dimethyl Sulfoxide and hydrogen peroxide. If desired, supercritical carbon dioxide in combination with a second co-solvent mixture may be subsequently applied to the substrate to rinse and dry the substrate. In one embodiment, the second co-solvent mixture includes isopropyl alcohol.

Owner:SCP GLOBAL TECH INC

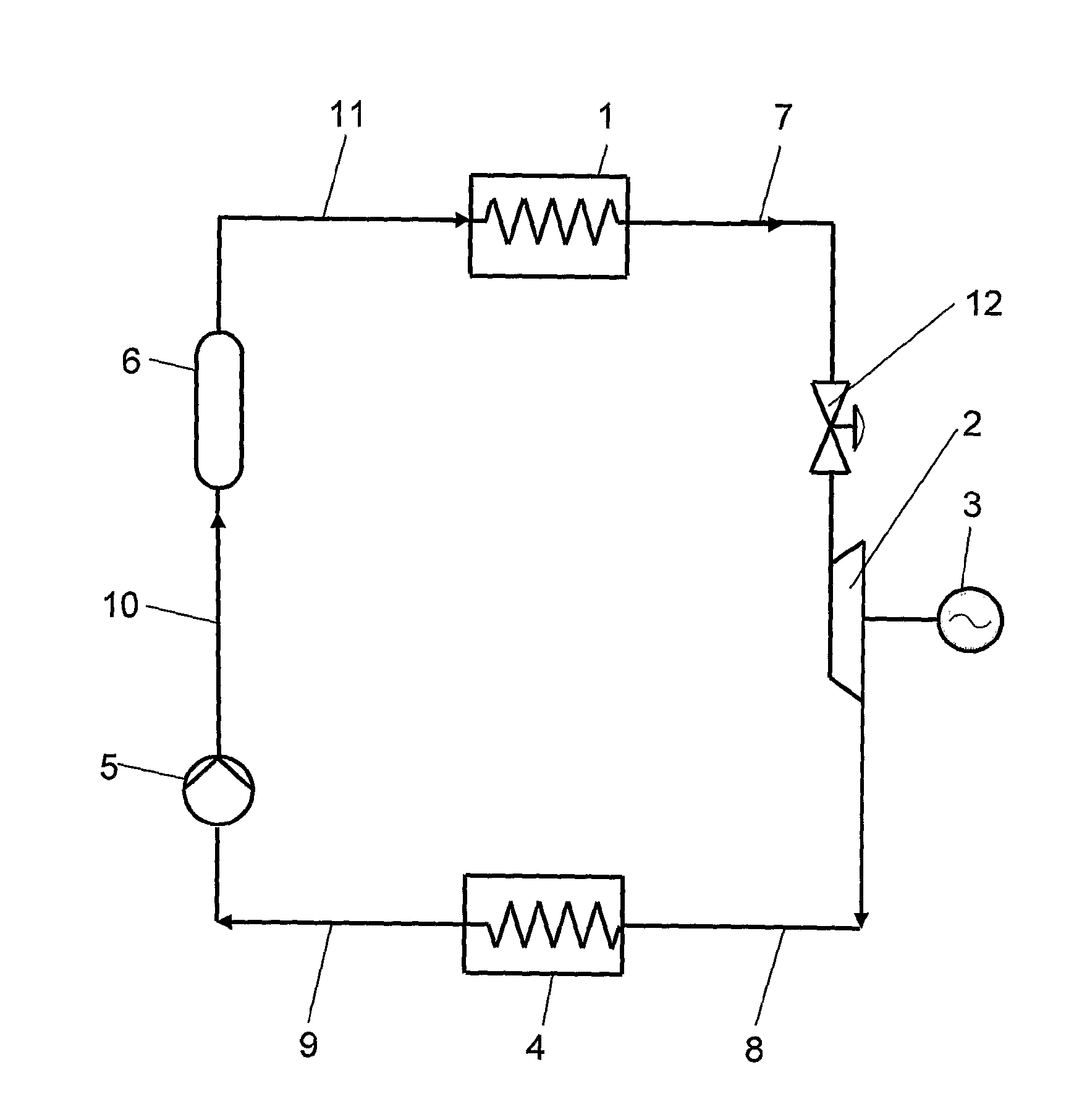

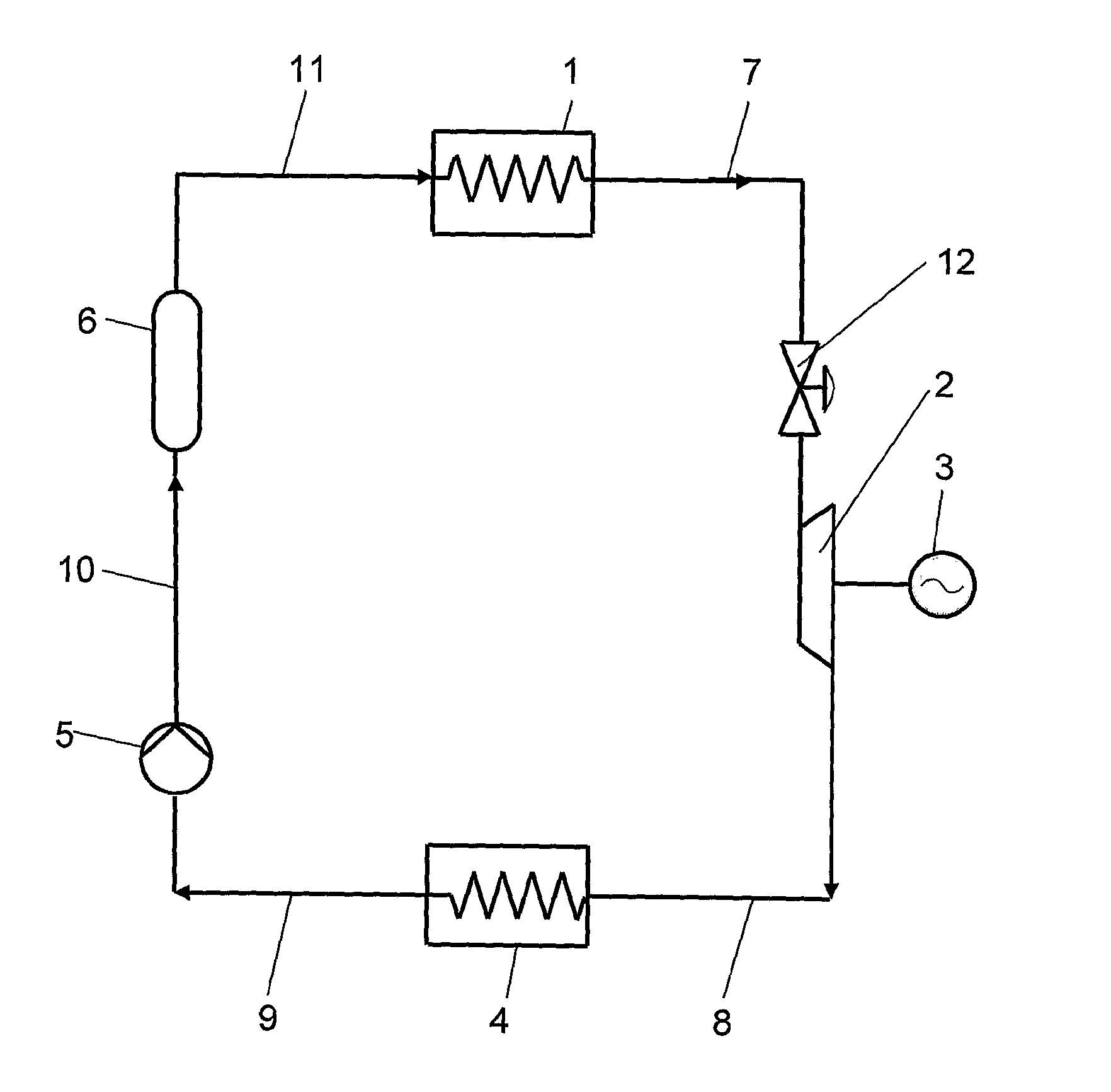

Process and device for using of low temperature heat for the production of electrical energy

The invention relates to the using of low temperature heat for the production of electrical energy by using of supercritical carbon dioxide as working fluid.It included a process and a device for process realizing with higher efficiency in relation to other known processes and with a wide temperature working range. This is related to a wider adjustability which allows an optimal operation both in summer and in winter operation without technical or constructional changes. The process is realizable without damages to the environment and is realizable with low effort. The relative emission of carbon dioxide is reduced in relation to other processes.Low temperature heat from a given heat source (1) is taken off by carbon dioxide at high supercritical pressure as heat transfer and working fluid in the process. Then the heated fluid is expanding in an expansion machine (2), which is connected with a generator (3) for the production of electric power. In this process the fluid will be cooled, then liquefied by using of a cold source (4) and in liquid state compressed to the working pressure.

Owner:TECHNIKUM CORP

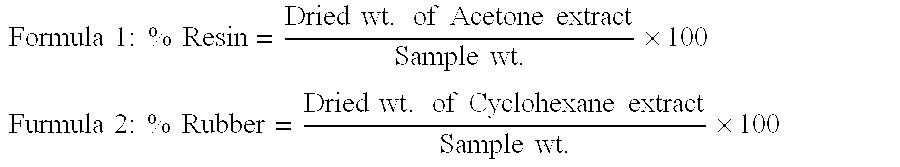

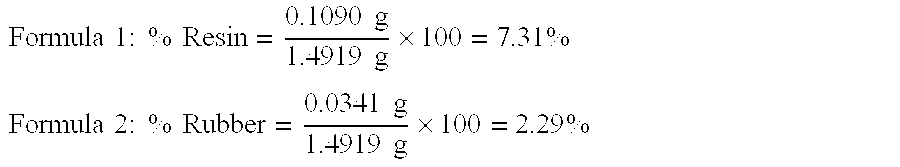

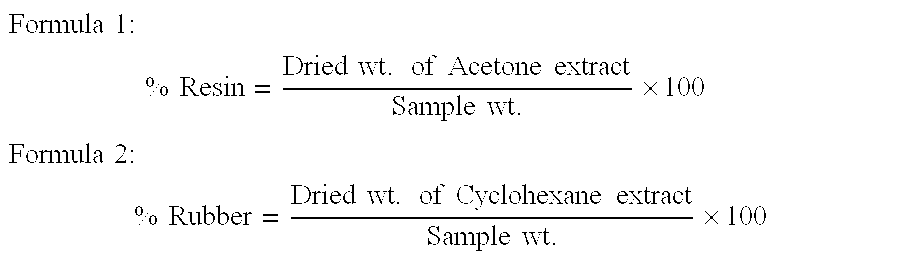

Extraction and fractionation of biopolymers and resins from plant materials

ActiveUS20060106183A1High yieldHigh purityGas current separationSolvent extractionParthenium argentatumBiopolymer

A method for the extraction, separation, fractionation and purification of biopolymers from plant materials using supercritical and / or subcritical solvent extractions is disclosed. Specifically, the process can be used for the separation of resins and rubber from guayule shrub (Parthenium argentatum), and other rubber and / or resin containing plant materials, using supercritical solvent extraction, for example supercritical carbon dioxide extraction. Additionally, polar and / or non-polar co-solvents can be used with supercritical carbon dioxide to enhance the selective extraction of resins and rubbers from the shrub.

Owner:YULEX LLC

Extraction and fractionation of biopolymers and resins from plant materials

ActiveUS7259231B2High yieldHigh purityGas current separationSolvent extractionParthenium argentatumBiopolymer

A method for the extraction, separation, fractionation and purification of biopolymers from plant materials using supercritical and / or subcritical solvent extractions is disclosed. Specifically, the process can be used for the separation of resins and rubber from guayule shrub (Parthenium argentatum), and other rubber and / or resin containing plant materials, using supercritical solvent extraction, for example supercritical carbon dioxide extraction. Additionally, polar and / or non-polar co-solvents can be used with supercritical carbon dioxide to enhance the selective extraction of resins and rubbers from the shrub.

Owner:YULEX LLC

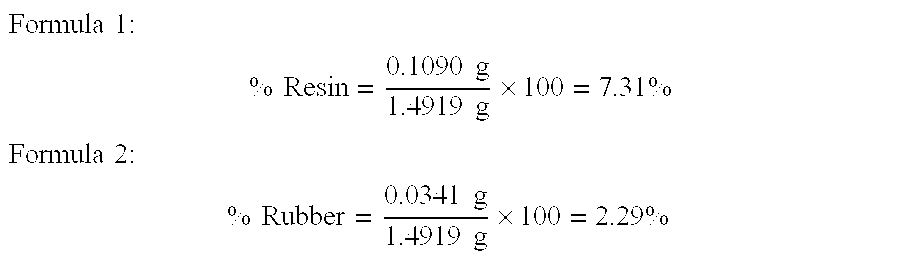

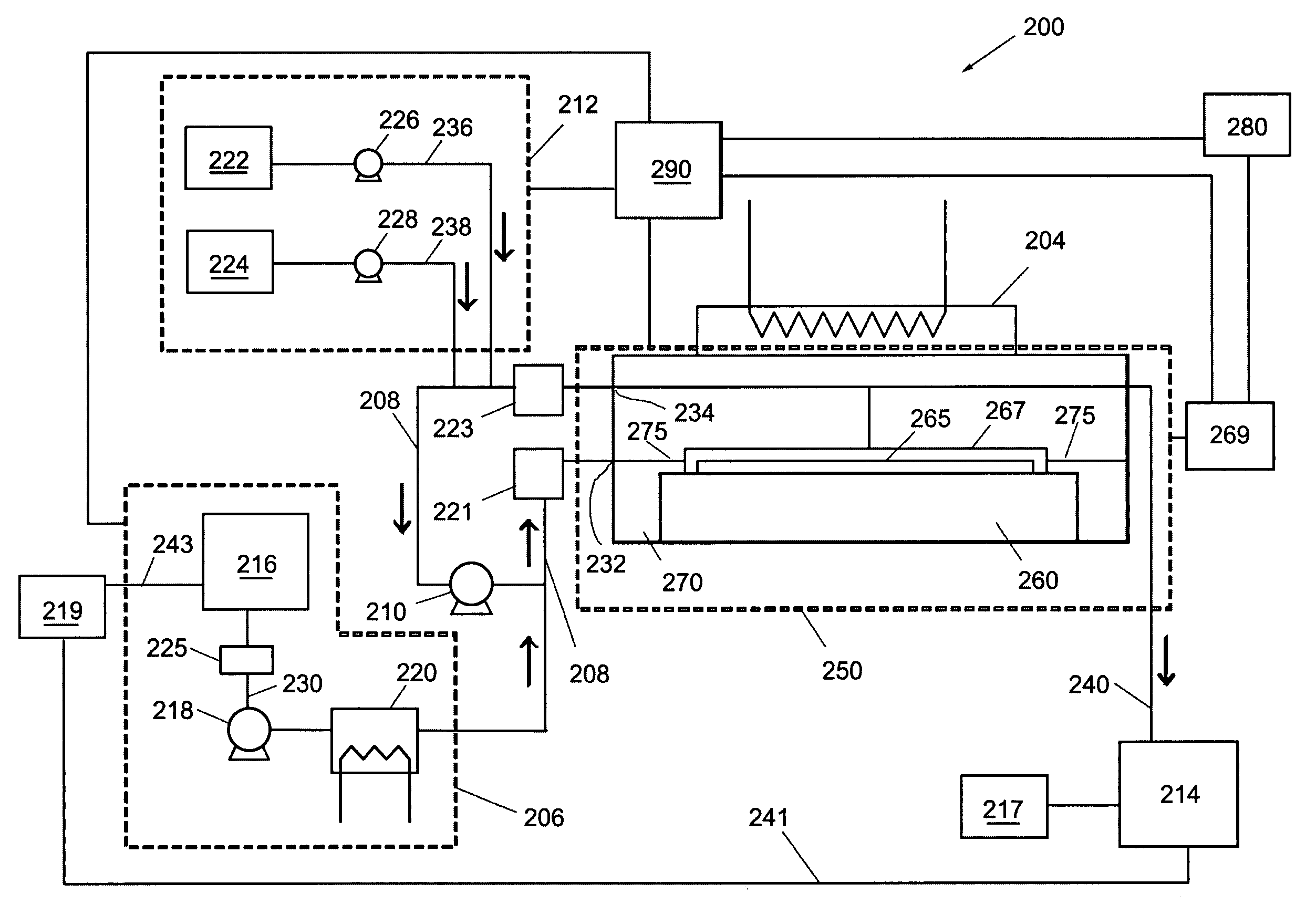

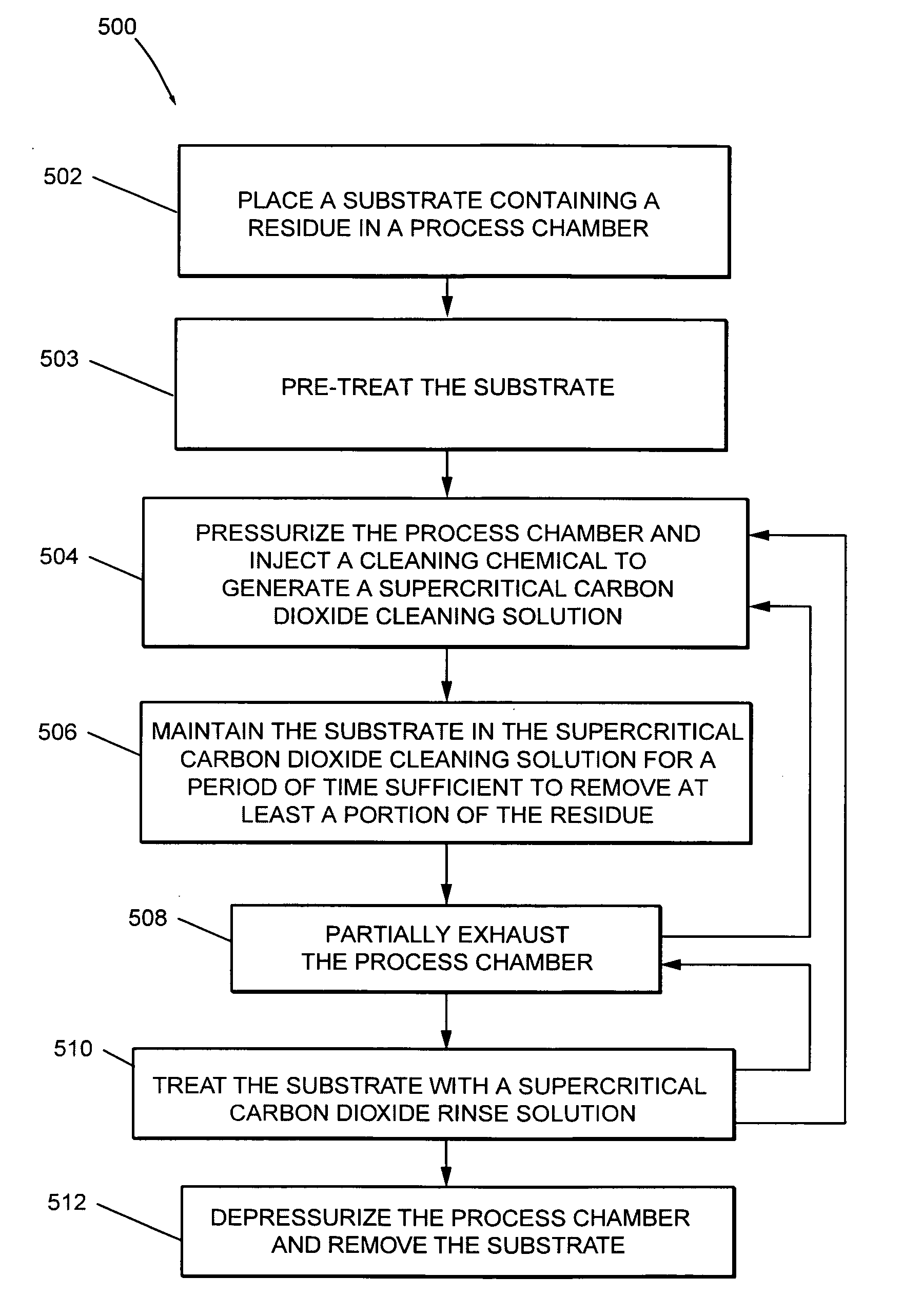

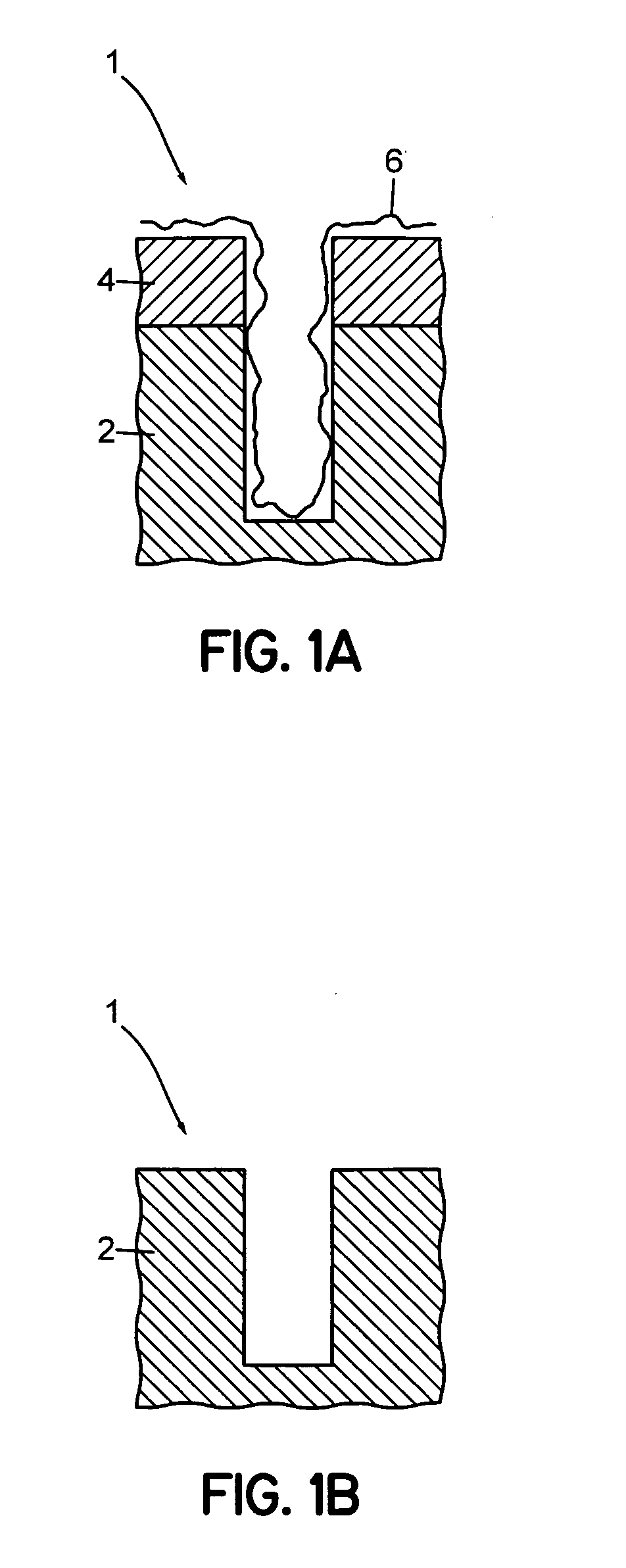

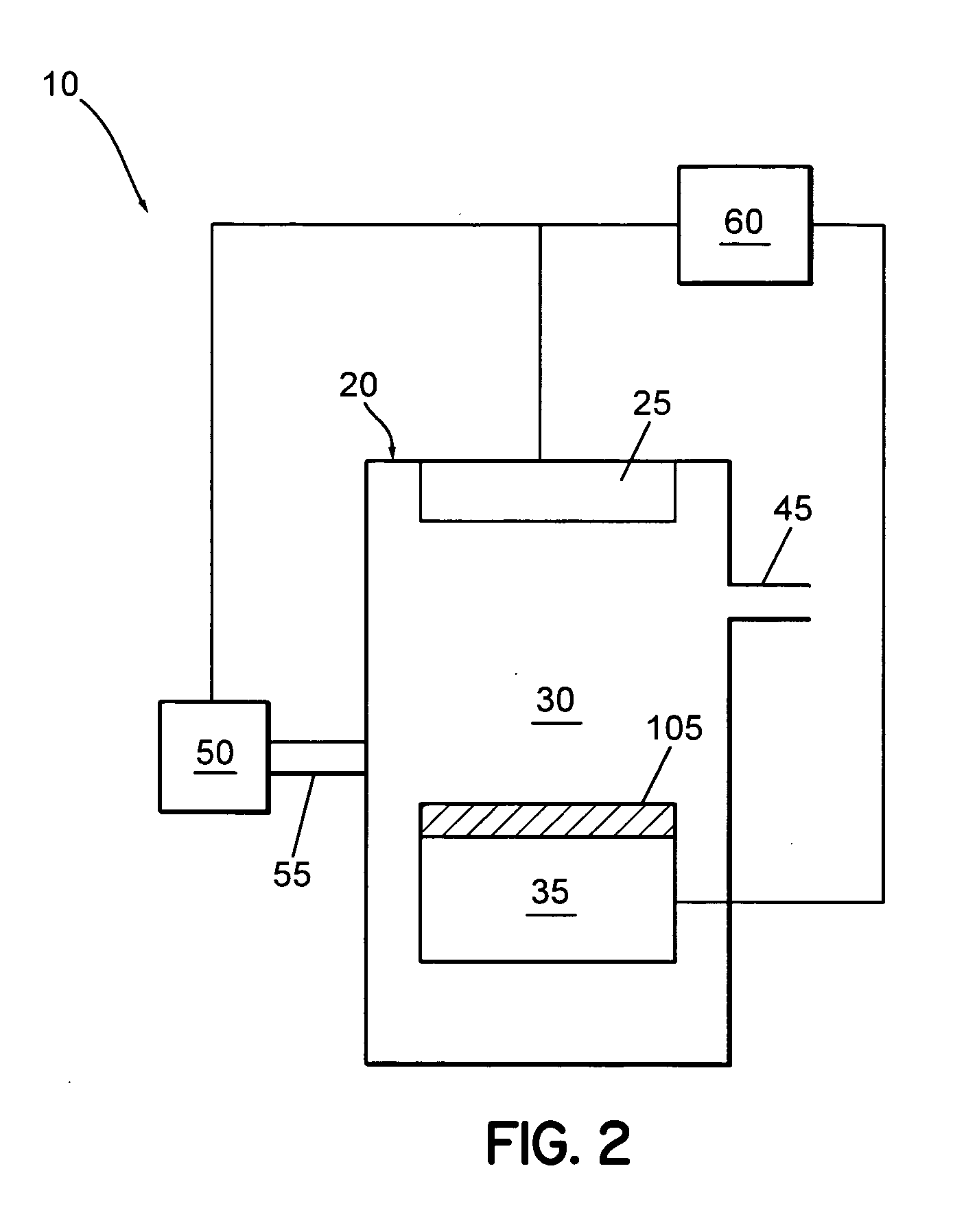

System and method for processing a substrate using supercritical carbon dioxide processing

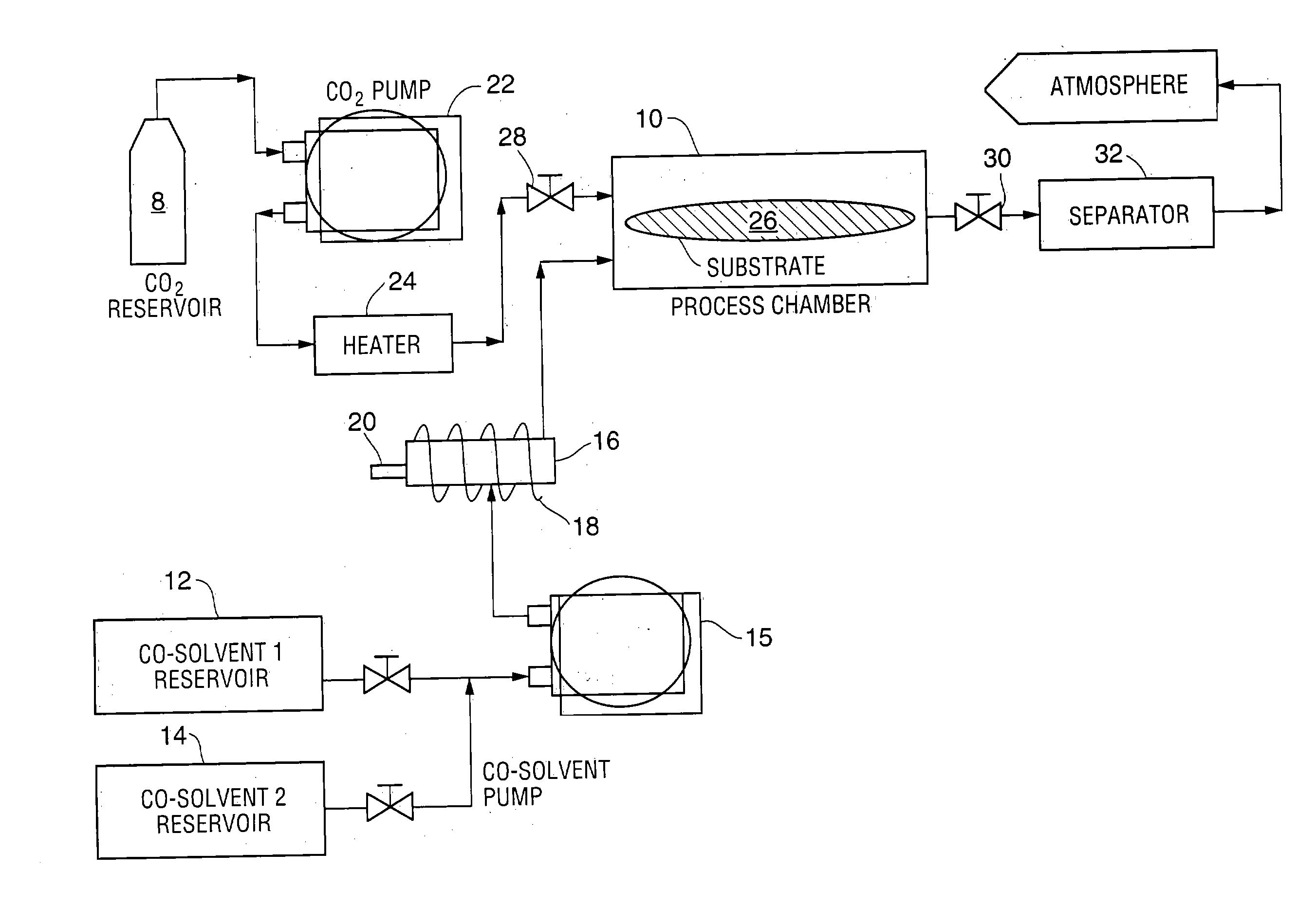

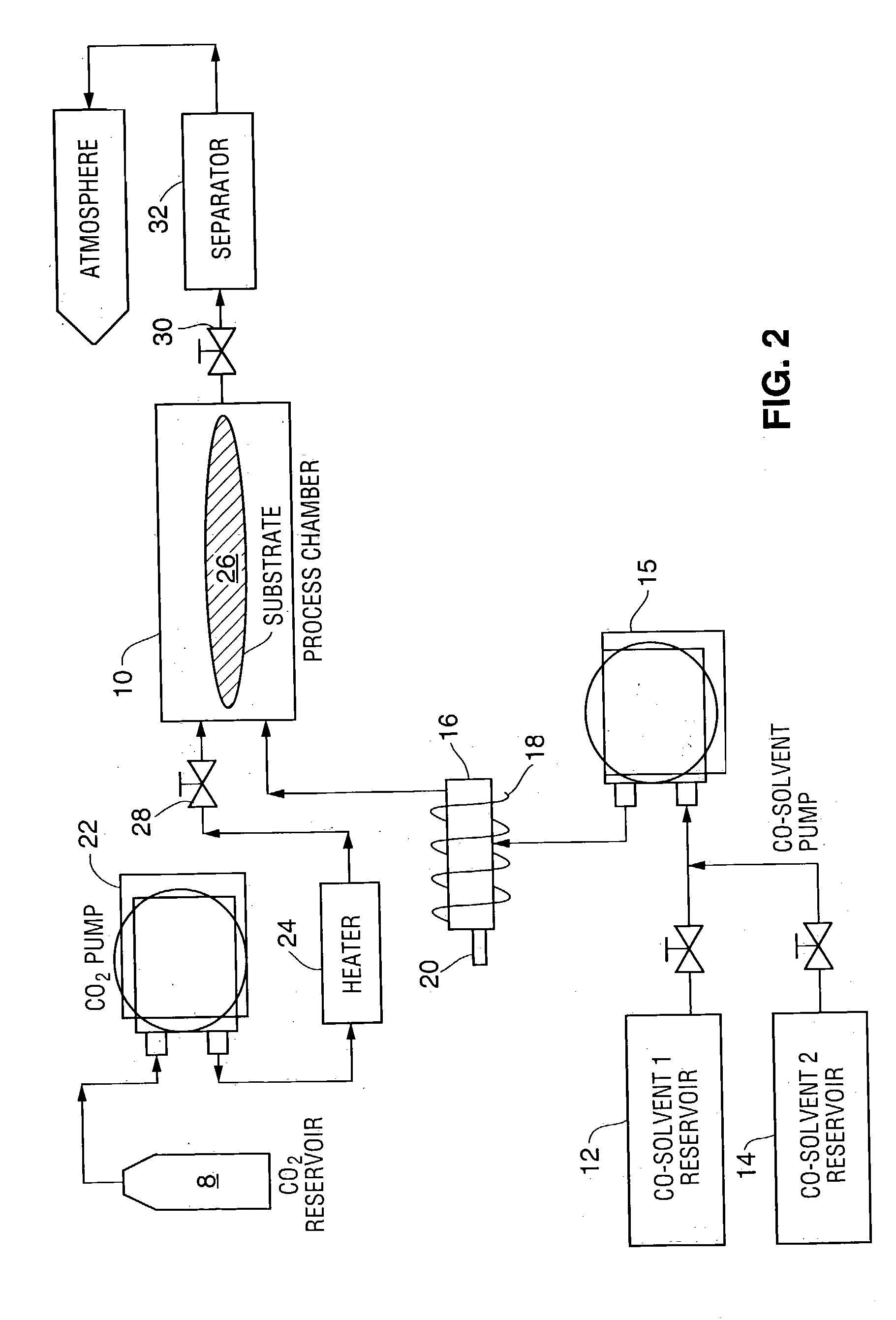

InactiveUS20060003592A1Semiconductor/solid-state device manufacturingSpecial data processing applicationsPhotoresistSupercritical carbon dioxide

A method and system for processing a substrate in a film removal system. The method includes providing the substrate in a substrate chamber of a film removal system, where the substrate has a micro-feature containing a dielectric film on a sidewall of the micro-feature and a photoresist film covering a portion the dielectric film, and performing a first film removal process using supercritical CO2 processing to remove the portion of the dielectric film not covered by the photoresist film. Following the first film removal process, a second film removal process using supercritical CO2 processing can be performed to remove the photoresist film. Alternately, wet processing can be used to perform one of the first film removal process or the second film removal process.

Owner:TOKYO ELECTRON LTD

Formation of insulator oxide films with acid or base catalyzed hydrolysis of alkoxides in supercritical carbon dioxide

Metal and / or silicon oxides are produced by hydrolysis of alkoxide precursors in the presence of either an acid catalyst or a base catalyst in a supercritical fluid solution. The solubility of the acid catalysts in the supercritical fluid can be increased by complexing the catalyst with a Lewis base that is soluble in the supercritical fluid. The solubility of the base catalysts in the supercritical fluid can be increased by complexing the catalyst with a Lewis acid that is soluble in the supercritical fluid. The solubility of water in the solution is increased by the interaction with the acid or base catalyst.

Owner:MICRON TECH INC +1

Method for preparing large-scale graphene through supercritical carbon dioxide exfoliation

ActiveCN102515155AReduce forceReduce the number of layersGrapheneBulk chemical productionMicrometerGraphite

The invention relates to a method for preparing large-scale graphene through supercritical carbon dioxide exfoliation. Supercritical carbon dioxide is adopted as an exfoliant, a surfactant is adopted as a dispersant, graphite powder and the dispersant are put in an autoclave, the carbon dioxide is pumped in the autoclave and circularly flows in a supercritical state, and then the pressure is reduced quickly to be normal pressure; the process is repeated so that the materials undergo pressure increment and pressure reduction several times; and the layers of the graphene is controlled by controlling the times of pressure increment and pressure reduction, so as to prepare the large scale graphene. Compared with the prior art, the invention has the advantages as follows: large-scale (hundreds of micrometers) high-quality graphene can be prepared; the method belongs to physical exfoliation, the treatment conditions are mild, and the quality of the graphene cannot be damaged; besides, the carbon dioxide used in the method is nontoxic, cheap and easy to obtain, and the technology is simple.

Owner:上海利物盛纳米科技有限公司

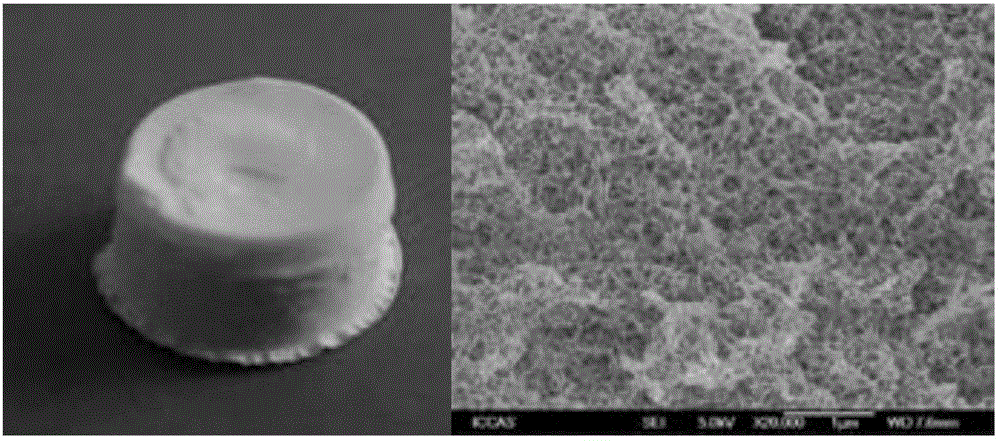

Cellulose aerogel and preparation method for hybrid aerogel thereof

The invention discloses low-cost green cellulose aerogel and a preparation method for hybrid aerogel thereof. The preparation method for the hybrid aerogel of the cellulose aerogel comprises the following steps that cellulose is dissolved into a zinc chloride aqueous solution, centrifugal deaeration is performed, and a uniform and transparent cellulose solution is obtained; the cellulose solution is formed, then the formed cellulose solution is placed into a coagulating bath to be regenerated, in addition, the regenerated cellulose solution is fully washed by use of a solvent, and cellulose solvent gel is obtained; the solvent in the cellulose solvent gel is removed by use of supercritical carbon dioxide drying or freeze drying, and the cellulose aerogel is obtained. Functional filler can be added into the cellulose solution to obtain the hybrid aerogel. By the adoption of different solution forming methods, the cellulose aerogel and the hybrid aerogel thereof in the shapes of sheets, fibers, particles and the like can be prepared. The preparation method is low in cost and is environmentally friendly, and the prepared aerogel is provided with a uniform nano-grade net porous structure.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Geopolymer composition and application for carbon dioxide storage

InactiveUS20080028995A1Enhanced pumpabilityImprove stabilityLiquid surface applicatorsSolid waste managementCo2 storageGeopolymer

The invention provides geopolymeric compositions intended for use in carbon dioxide injection or production wells or storage reservoirs and preferably in a supercritical carbon dioxide conditions. The geopolymeric composition is formed from a suspension comprising an aluminosilicate source, a metal silicate, an alkali activator, a retarder and / or an accelerator and a carrier fluid wherein the oxide molar ratio M2O / SiO2 is greater than 0.20 with M an alkali metal.

Owner:SCHLUMBERGER TECH CORP

Process for a high efficiency and low emission operation of power stations as well as for storage and conversion of energy

InactiveUS20100101231A1Improve overall utilizationReduce carbon dioxide emissionsSolidificationLiquefactionMass storageWorking fluid

The invention relates to a process and a device for process realizing to increase the efficiency of power stations by improvement of the efficiency of using the heat potentials for an electric power production by using of supercritical carbon dioxide as a working fluid and heat transfer medium as well as for the improvement of the ecological balance of power stations by minimization of the carbon dioxide emission and the total avoidance of NOx-emissions by using of pure oxygen for the burning process. Additionally the process allows the buffering of electric overcapacity energy producing mass storages for natural gas, pressed air and carbon dioxide and their effective using as well as in the continuous operation and for peak load supply of power stations.

Owner:TECHNIKUM CORP

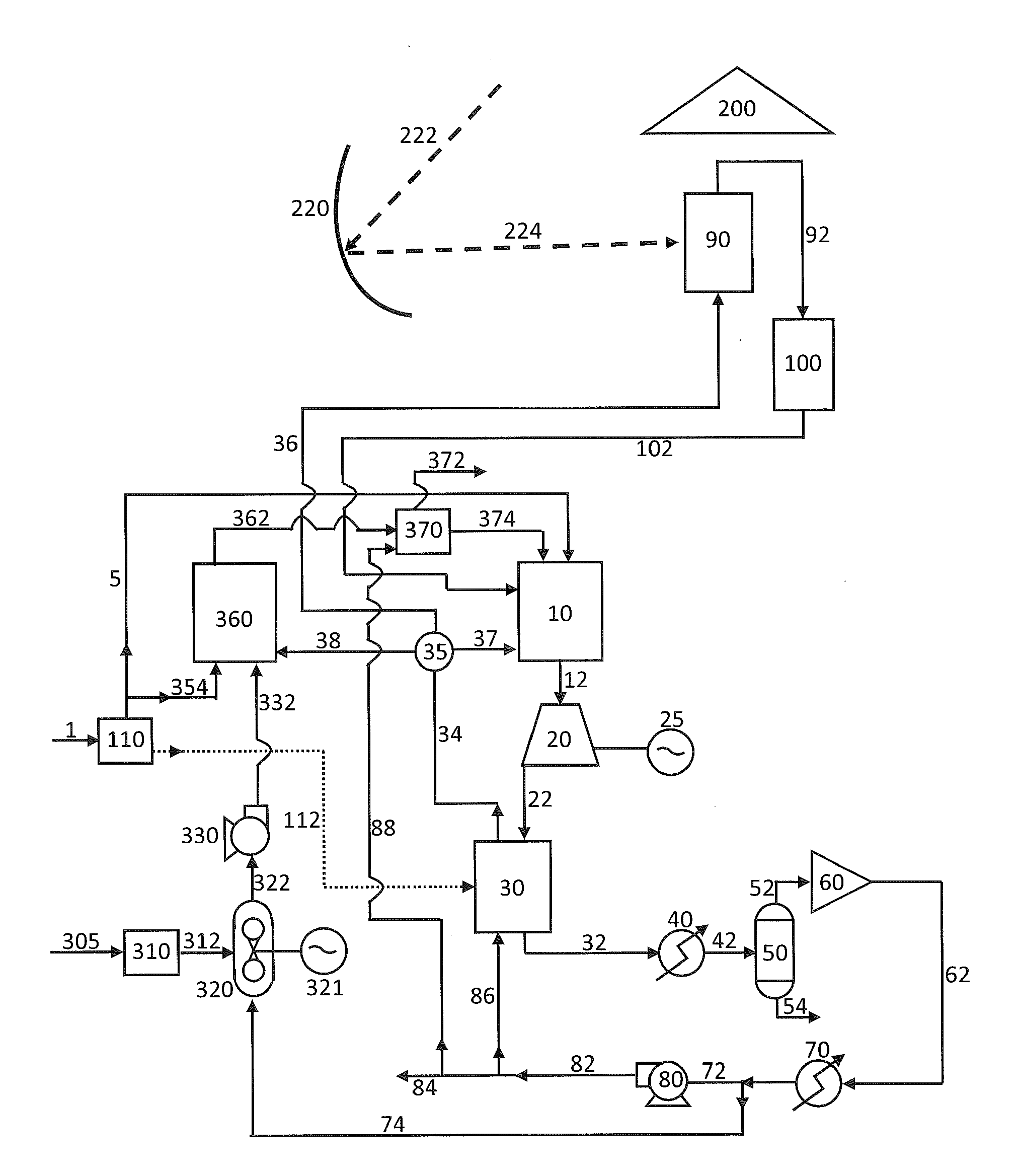

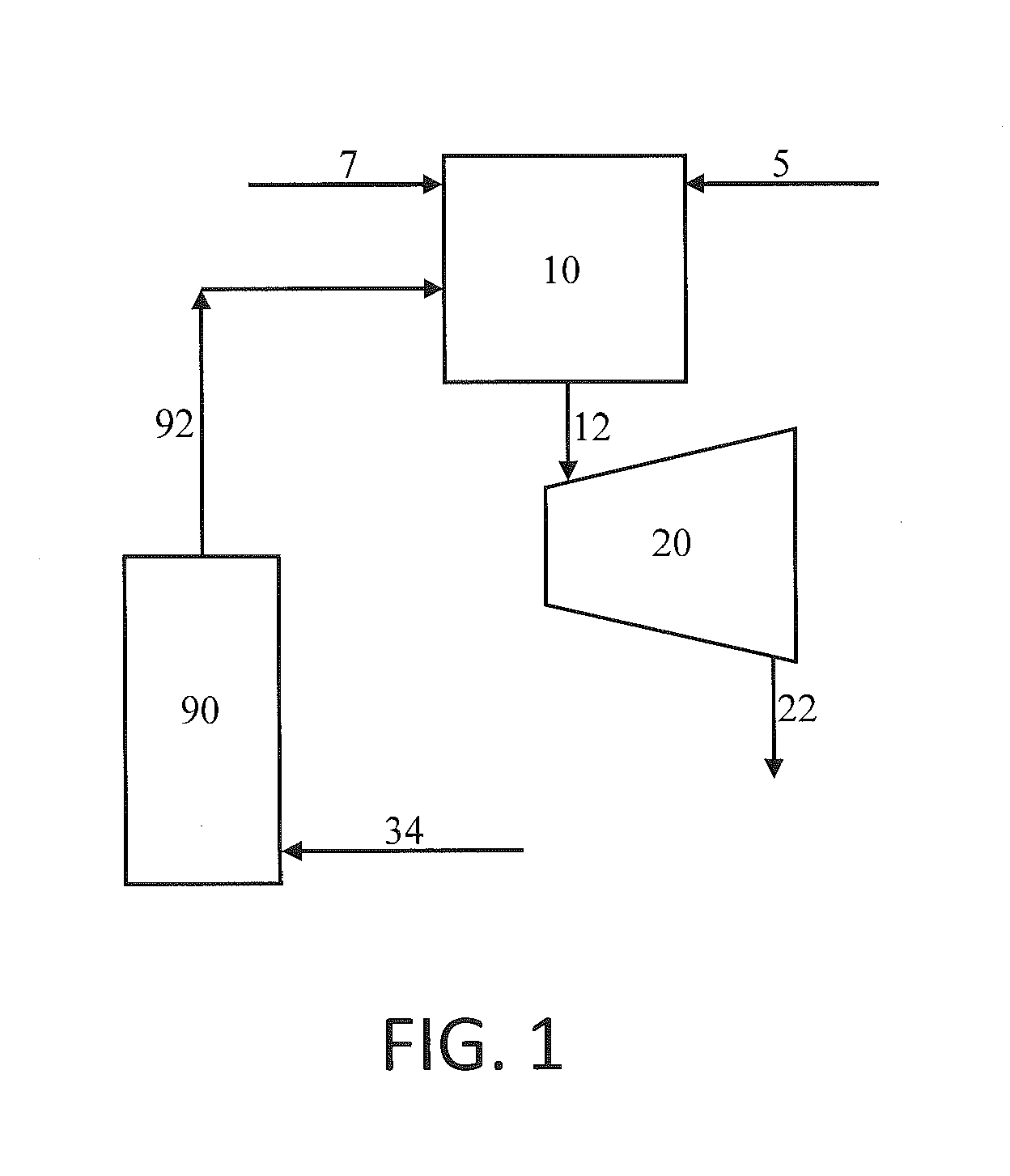

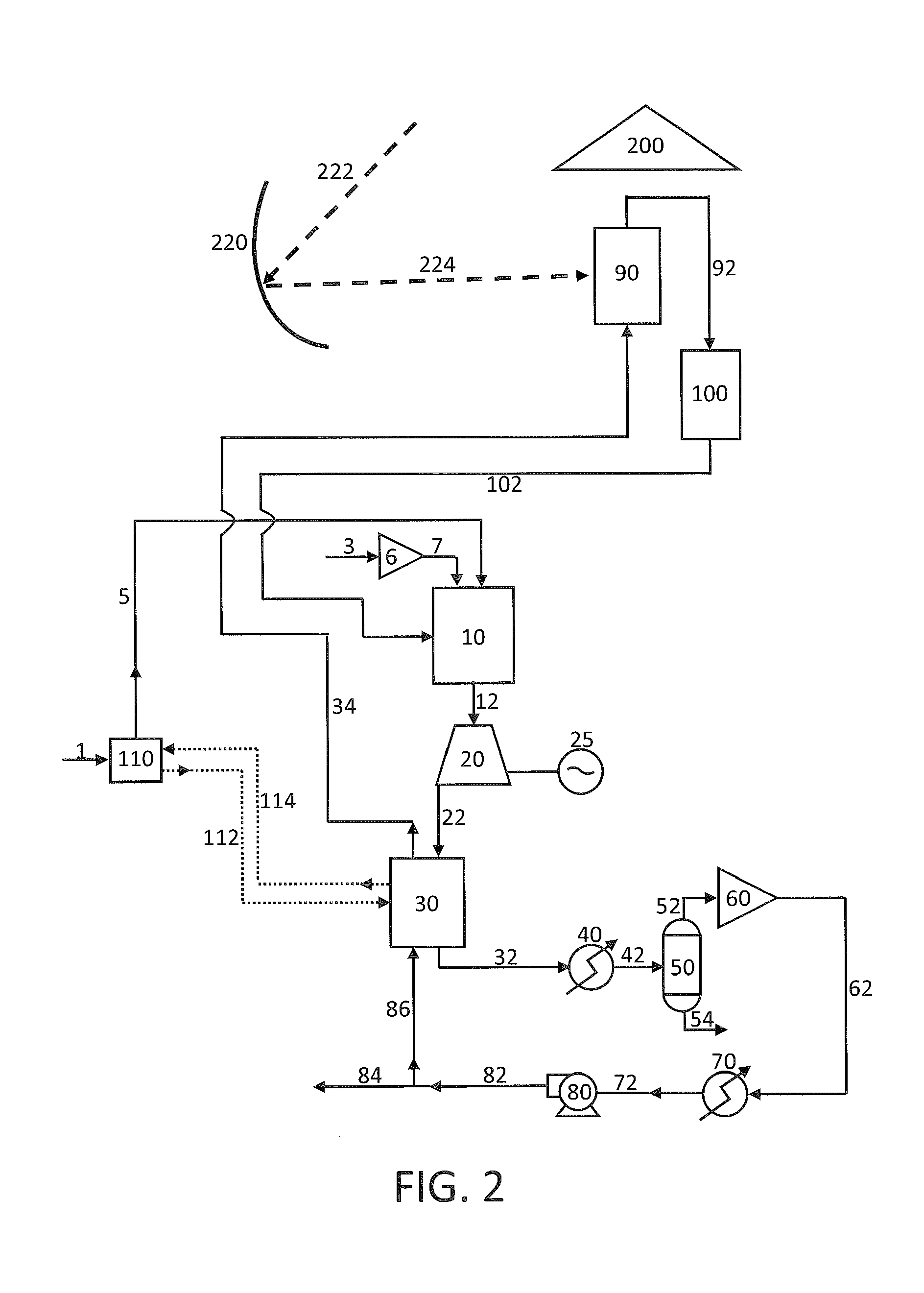

Hybrid fossil fuel and solar heated supercritical carbon dioxide power generating system and method

InactiveUS20130118145A1Improve efficiencyLow calorific valueSolar heating energyFrom solar energyCombustion systemWorking fluid

The present disclosure provides an integrated power generating system and method that combines combustion power generation with solar heating. Specifically, a closed cycle combustion system utilizing a carbon dioxide working fluid can be increased in efficiency by passing at least a portion of a carbon dioxide working fluid through a solar heater prior to passage through a combustor.

Owner:8 RIVERS CAPTTAL LLC

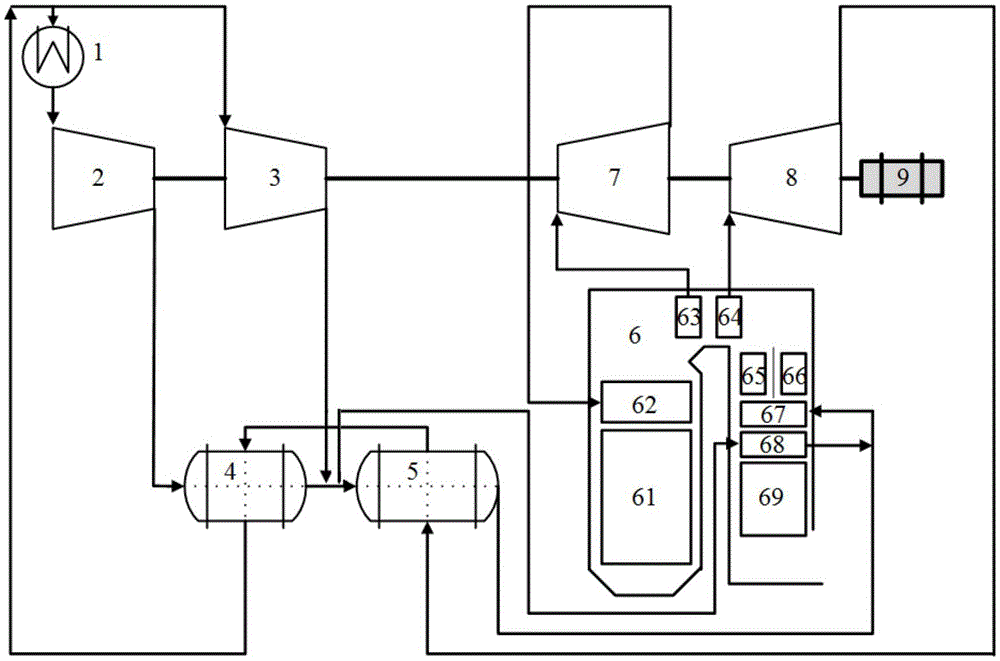

Coal-based supercritical carbon dioxide Brayton cycle double-split-flow efficient power generation system

ActiveCN105526576AReduce flue gas temperatureLower exhaust gas temperatureSteam engine plantsSteam boilersSuperheaterHigh pressure

The invention discloses a coal-based supercritical carbon dioxide Brayton cycle double-split-flow efficient power generation system which comprises a low-temperature regenerator, a precooler, a main compressor, a re-compressor, a high-temperature regenerator, a boiler, a high-pressure turbine, a low-pressure turbine and an electric generator. The boiler is composed of a combustion channel, a main heat exchange channel and a tail flue in the smoke flowing direction, wherein the combustion channel, the main heat exchange channel and the tail flue are communicated in sequence; a water-cooled wall and a reheating water-cooled wall are sequentially arranged in the combustion channel in the smoke flowing direction; a high-temperature superheater and a high-temperature reheater are sequentially arranged in the main heat exchange channel in the smoke flowing direction; a baffle, a coal economizer and a low-temperature coal economizer are sequentially arranged in the tail flue in the smoke flowing direction, and a low-temperature reheater and a lower-temperature superheater are arranged on the two sides of the baffle. According to the coal-based supercritical carbon dioxide Brayton cycle double-split-flow efficient power generation system, optimal combining of the coal-fired boiler and the supercritical carbon dioxide Brayton cycle can be achieved, and the heat exchange efficiency of the high-temperature regenerator, the thermal efficiency of the boiler and the efficiency of the power generation system are high.

Owner:XIAN THERMAL POWER RES INST CO LTD

3D printing device and 3D printing method by utilizing supercritical carbon dioxide as solvent

ActiveCN104816478AIncrease profitAvoid emissionsAdditive manufacturing apparatusGas cylinderCarbon dioxide gas cylinder E

The invention discloses a 3D printing device and a 3D printing method by utilizing supercritical carbon dioxide as a solvent. The device mainly comprises a stock unit, an ejection unit, a three-dimensional molding platform unit and a raw material recycling unit, wherein the ejection unit comprises a gas pump, a needle valve, a cooling fan and a resistive heater; the stock unit comprises high polymer material powder, a powder pump, a carbon dioxide gas cylinder, a mixing tank, a liquefied booster pump, a heater, a liquid pump and a gas pump; the three-dimensional molding platform unit comprises an aluminum alloy molding platform and a three-dimensional ball screw sliding table module; and the raw material recycling unit comprises a closed box and a recovered gas pump. According to the method disclosed by the invention, the carbon dioxide gas is turned to be in a supercritical carbon dioxide state, and after the carbon dioxide gas is completely dissolved to produce supercritical carbon dioxide solution containing a high polymer material, the solution is conveyed into the ejection unit by virtue of the liquid pump. The supercritical carbon dioxide serves as a consumable carrier, so that more kinds of high polymer materials are applied to the field of 3D printing, and the overall performances of 3D printing supplies are improved.

Owner:BEIJING UNIV OF CHEM TECH

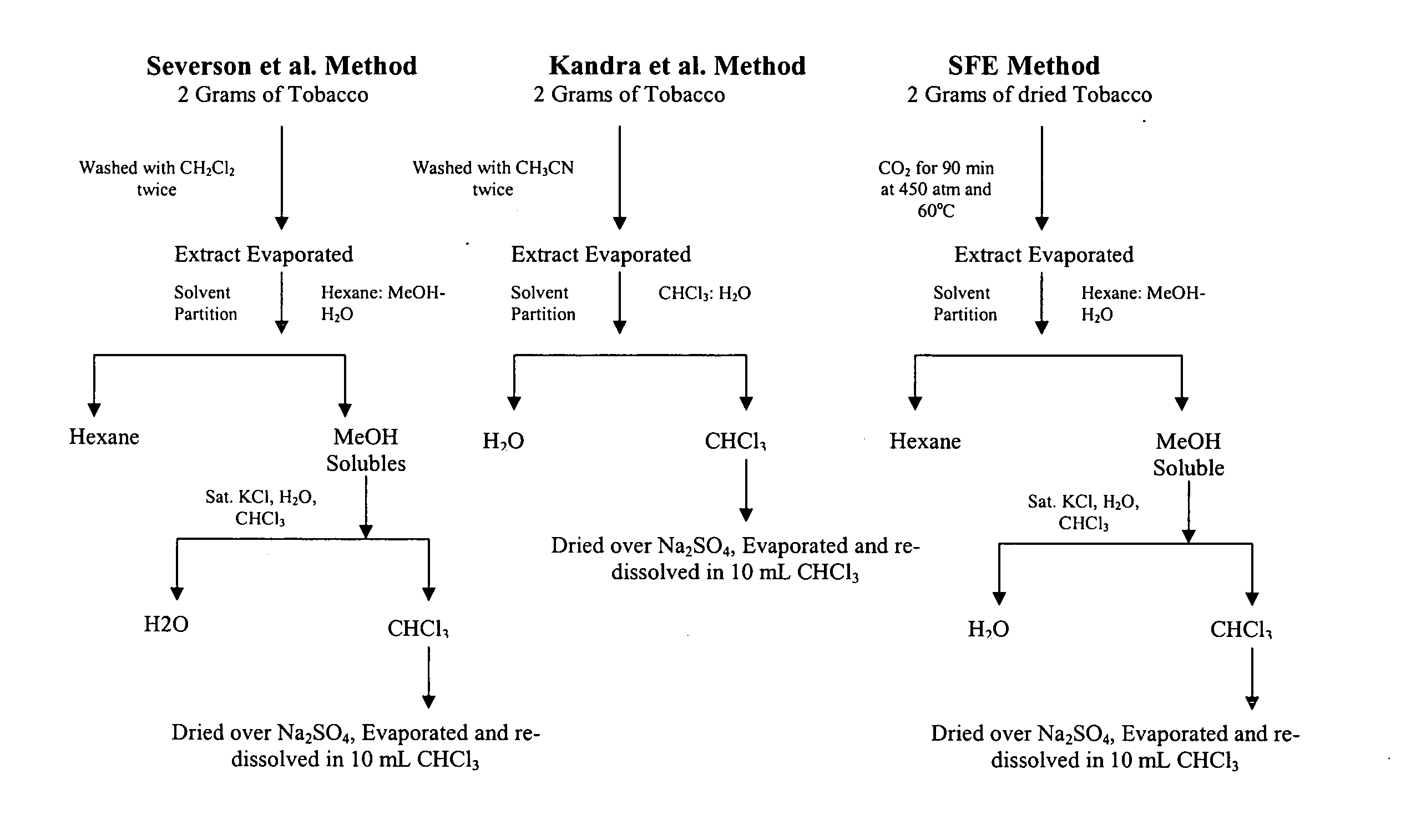

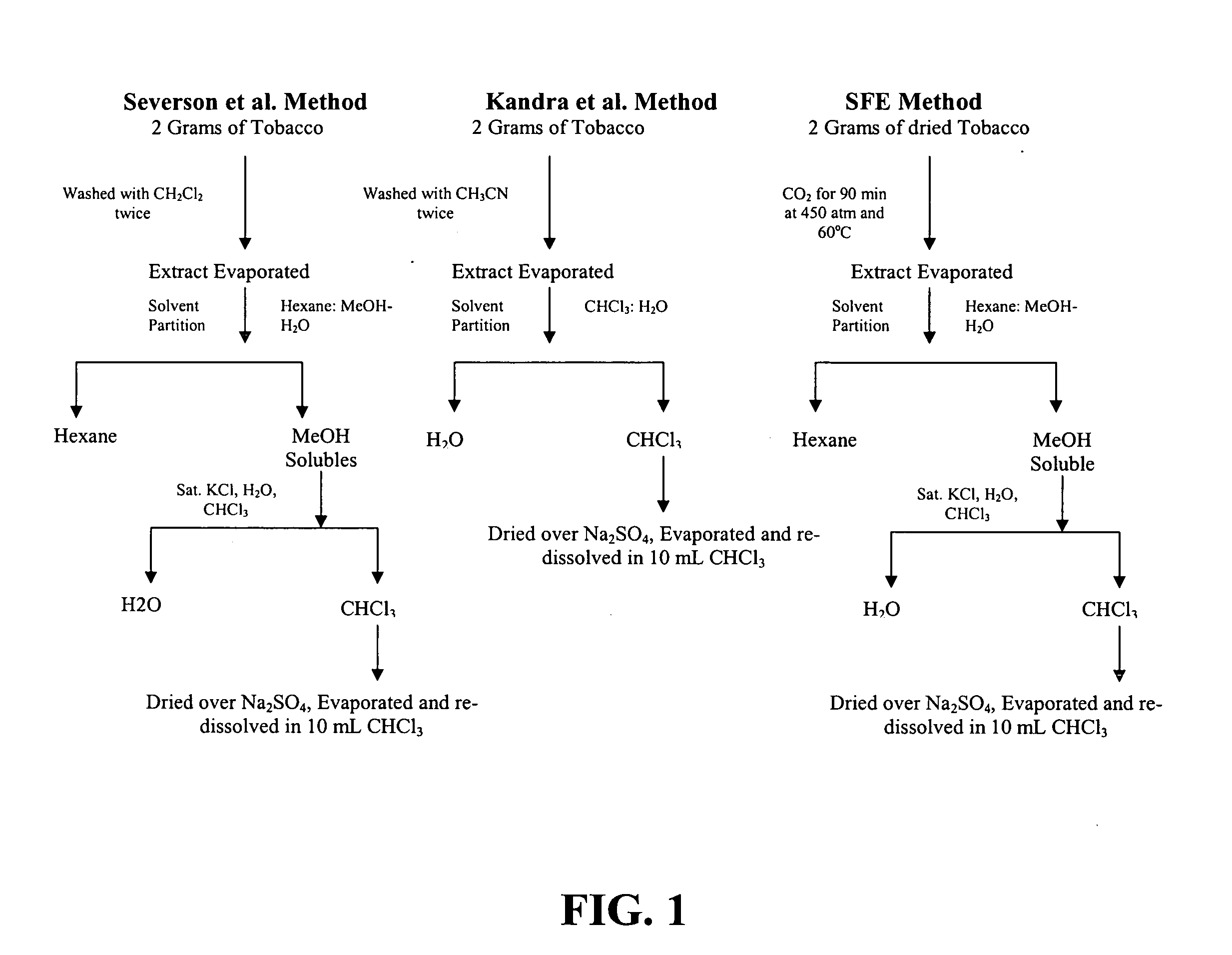

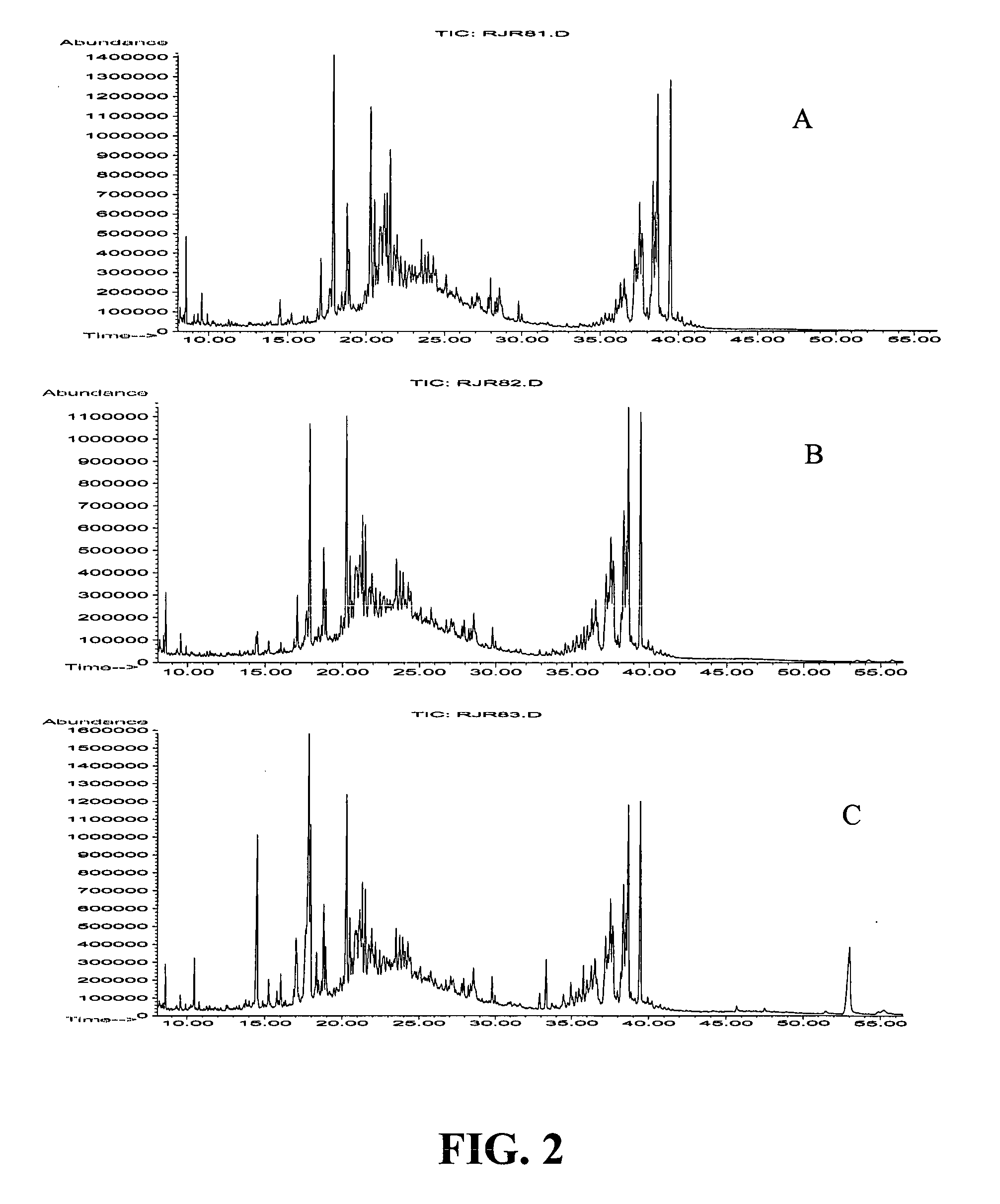

Method of extracting sucrose esters from oriental tobacco

InactiveUS20070137663A1High selectivityIncrease fluid pressureTobacco treatmentCigar manufactureSucroseNicotiana tabacum

The invention provides a method of extracting sucrose esters from Oriental tobacco, the method comprising: providing a Oriental tobacco material; contacting the solid Oriental tobacco material with a supercritical fluid, such as supercritical carbon dioxide, for a time and under conditions sufficient to extract sucrose esters from the Oriental tobacco into the supercritical fluid; and separating the supercritical fluid comprising extracted sucrose esters from the Oriental tobacco. The resulting extract can comprise more than 90% by weight of tetra-acyl sucrose esters, and can be used as a flavor additive for tobacco materials used in smoking articles.

Owner:R J REYNOLDS TOBACCO COMPANY +1

Polycarbonate block copolymers

The disclosure pertains to amphiphilic block copolymers comprising an aliphatic polycarbonate chain coupled to a hydrophilic polymer. Such amphiphilic polymers may have the formula A-L-B, where A- is a polycarbonate or polyethercarbonate chain having from about 3 to about 500 repeating units, L is a linker moiety and —B is a hydrophilic oligomer having from about 4 to about 200 repeating units. Provided copolymers are useful as surfactants capable of emulsifying aqueous solutions and supercritical carbon dioxide. Provided copolymers also have utility as additives for use in enhanced oil recovery methods.

Owner:SAUDI ARAMCO TECH CO

Method for extracting coarse oil from coix seed with hypercritical carbon dioxide

InactiveCN1485418AAcidity meetsAcidity meets requirementsFatty-oils/fats productionWater contentSupercritical carbon dioxide

A method or extracting crude oil of coix seed by supercritical carbon dioxide extraction. It comprise:1) drying, the water content of coix seed is below 10úÑú”2) pulverizing, naturally lowering temperature, after testing, pulverizing into 10-60 meshes; 3) supercritical carbon dioxide extraction, in the extracting vessel, the temperature is 30í½60degree Cú¼ the pressure is 19í½24MPaú”in the separating column, the temperature is 30í½60degree Cú¼ the pressure is 6í½15Mpaú”in the resolving vessel, the temperature is 30í½60degree Cú¼ the pressure is2í½6Mpaú”the flow rate is 10í½5000L / Hrú”the extraction time is 1í½4h.

Owner:江西康莱特新森医药原料有限公司

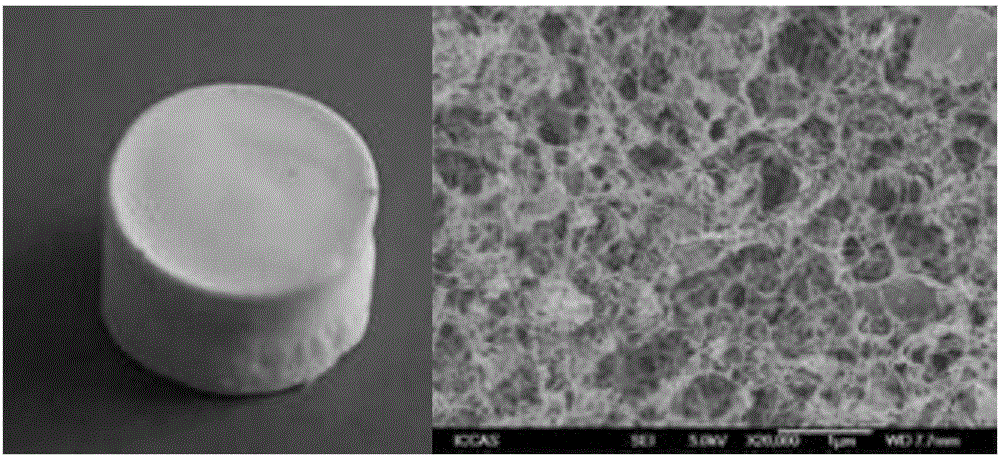

Graphene aerogel as well as preparation method and application thereof

The invention discloses graphene aerogel and a preparation method thereof. The method comprises the following steps: (1) uniformly mixing graphene oxide dispersion liquid with an amine water-soluble compound to obtain graphene oxide mixed liquid, wherein the amine water-soluble compound is selected from one or more of diethylamine, ethidene diamine, propane diamine, butane diamine, diethylene triamine, triethylene tetramine, tetraethylene pentamine, allylamine polymer and N,N'-bis(2-aminoethyl)-1,3-propane diamine; (2) irradiating the graphene oxide mixed liquid by high-energy rays under the anaerobic condition to obtain amino-modified graphene aerogel; (3) performing freeze-drying or supercritical CO2 drying to obtain the graphene aerogel. The graphene aerogel adopts a porous and macroporous structure, is relatively uniform in structure, and can be used for adsorbing an organic solvent; moreover, the preparation method is simple and environment-friendly.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

Supercritical carbon dioxide/chemical formulation for removal of photoresists

InactiveUS20040087457A1Surface-active detergent compositionsElectrostatic cleaningResistOrganic compound

A photoresist cleaning composition for removing photoresist and ion implanted photoresist from semiconductor substrates. The cleaning composition contains supercritical CO2 (SCCO2) and alcohol for use in removing photoresist that is not ion-implanted. When the photoresist has been subjected to ion implantation, the cleaning composition additionally contains a fluorine ion source. Such cleaning composition overcomes the intrinsic deficiency of SCCO2 as a cleaning reagent, viz., the non-polar character of SCCO2 and its associated inability to solubilize species such as inorganic salts and polar organic compounds that are present in the photoresist and that must be removed from the semiconductor substrate for efficient cleaning. The cleaning composition enables damage-free, residue-free cleaning of substrates having photoresist or ion implanted photoresist thereon.

Owner:ADVANCED TECH MATERIALS INC

New method for extracting jasmine oil

The present invention relates to a new extraction method for producing pure natural jasmine flower essential oil, and is characterized by that under the condition of room temp. it has no need of any solvent treatment process, only uses damp air to blow through layered jasmine flowers to carry over aromatic component sent forth by jasmine flowers, and uses a special adsorbent to trap said aromatic component, then uses supercritical CO2 fluid extraction process to recover essential oil from adsorbent.

Owner:GUANGZHOU HONSEA SUNSHINE BIOTECH CO LTD

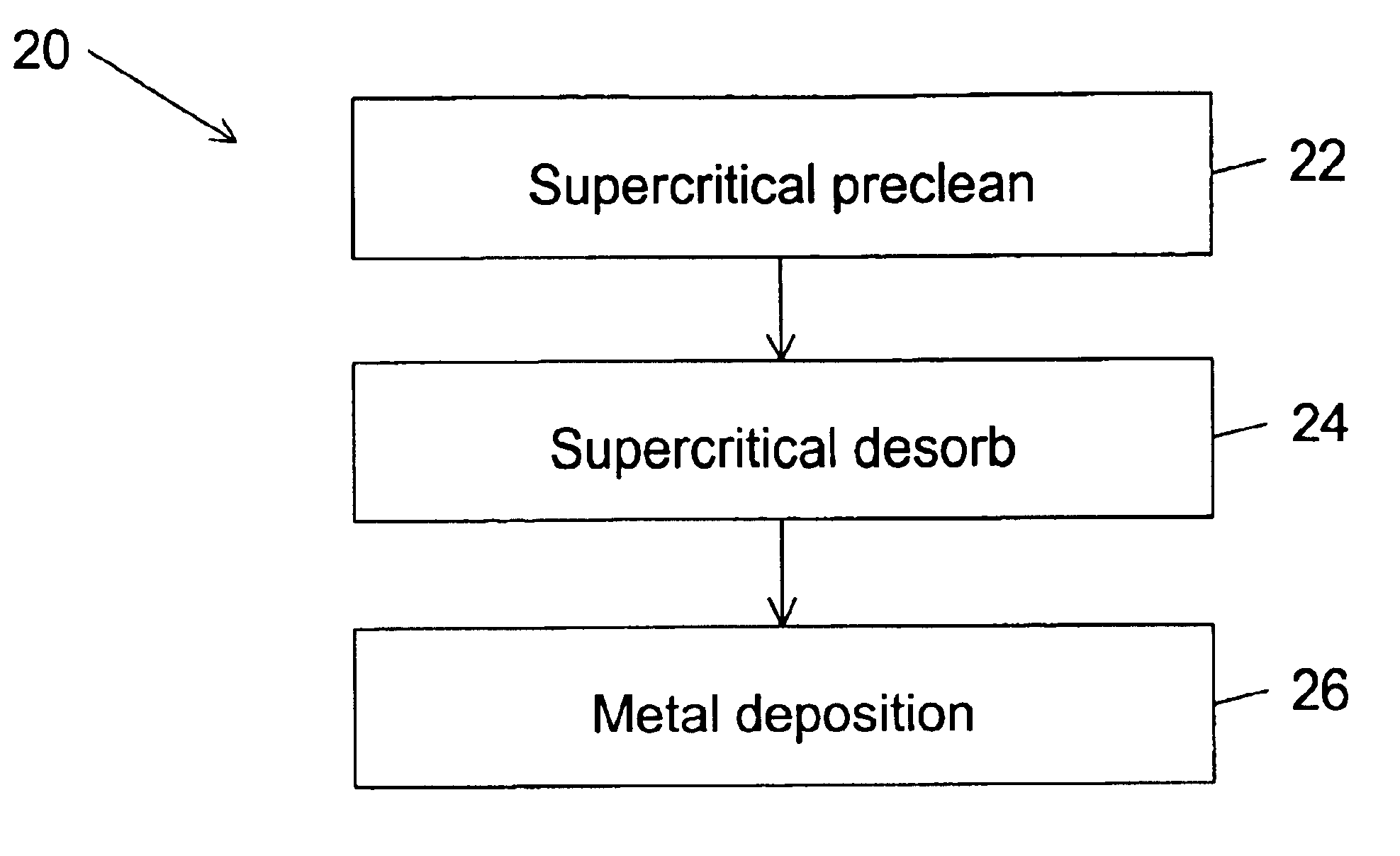

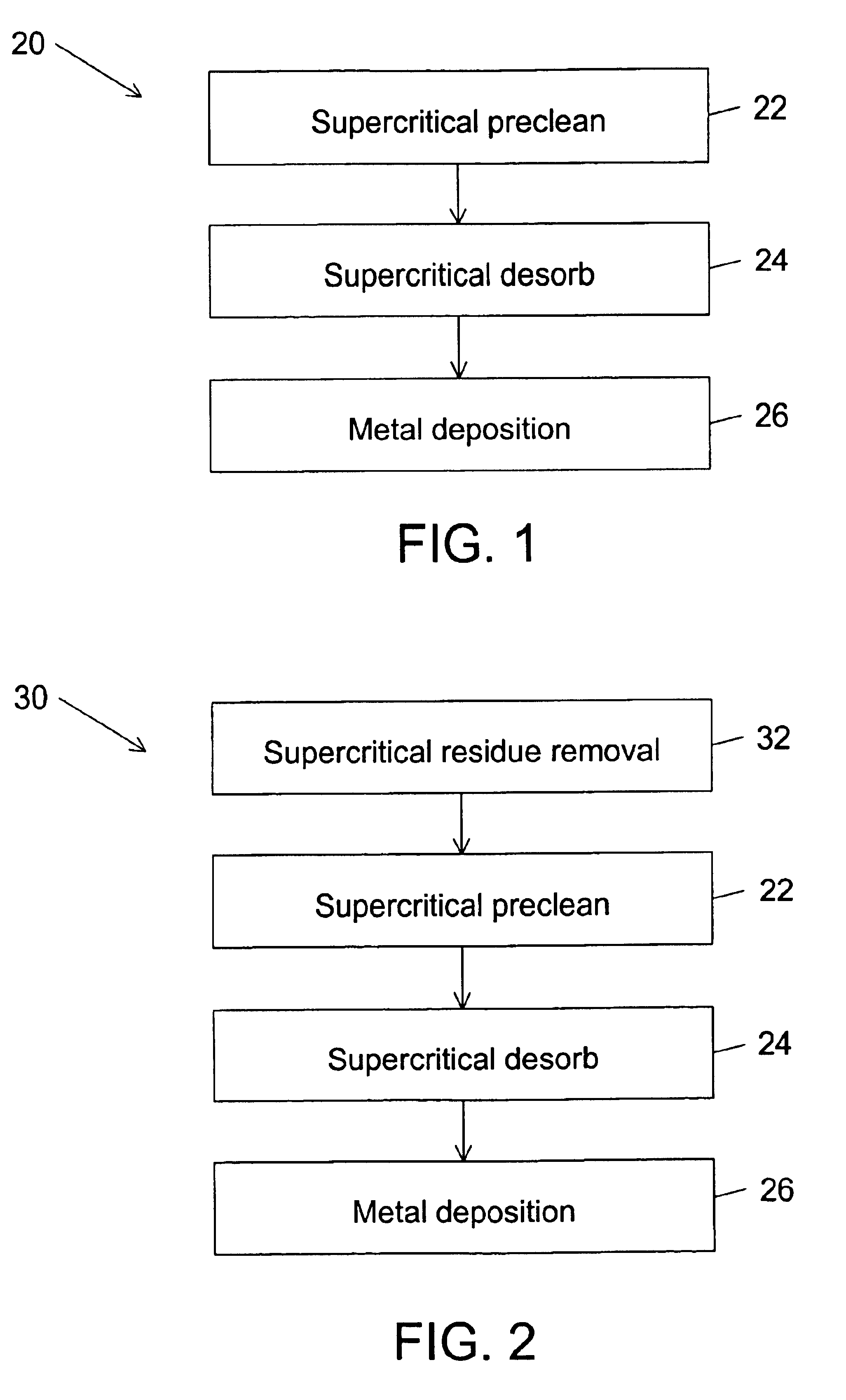

Method of depositing metal film and metal deposition cluster tool including supercritical drying/cleaning module

InactiveUS6890853B2Vacuum evaporation coatingSputtering coatingSupercritical dryingSupercritical carbon dioxide

A method of depositing a metal film on a substrate includes a supercritical preclean step, a supercritical desorb step, and a metal deposition step. Preferably, the preclean step includes maintaining supercritical carbon dioxide and a chelating agent in contact with the substrate in order to remove an oxide layer from a metal surface of the substrate. More preferably, the preclean step includes maintaining the supercritical carbon dioxide, the chelating agent, and an acid in contact with the substrate. Alternatively, the preclean step includes maintaining the supercritical carbon dioxide and an amine in contact with the oxide layer. The desorb step includes maintaining supercritical carbon dioxide in contact with the substrate in order to remove adsorbed material from the substrate. The metal deposition step then deposits the metal film on the substrate without exposing the substrate to an oxidizing material which oxidizes the metal surface of the precleaned substrate and without exposing the substrate to a nonvolatile adsorbing material which adsorbs to the substrate. An apparatus for depositing the metal film on a substrate includes a transfer module, a supercritical processing module, a vacuum module, and a metal deposition module. The supercritical processing module is coupled to the transfer module. The vacuum module couples the metal deposition module to the transfer module. In operation, the apparatus for depositing the metal film performs the supercritical preclean step, the supercritical desorb step, and the metal deposition step.

Owner:TOKYO ELECTRON LTD

System for removing a residue from a substrate using supercritical carbon dioxide processing

InactiveUS20060102208A1Photomechanical apparatusSemiconductor/solid-state device manufacturingOzone generatorSolution processed

A film removal system for cleaning a substrate containing a micro-feature having a residue thereon. The film removal system includes a supercritical fluid processing system configured for treating the substrate witha supercritical carbon dioxide cleaning solution to remove the residue from the micro-feature, and for maintaining the supercritical carbon dioxide solution at a temperature between about 35° C. and about 80° C. during the treating. The film removal system further includes an ozone generator configured for providing an ozone processing environment for treating the substrate either prior to treating with the supercritical cleaning solution or concurrently therewith, and a controller configured for controlling the ozone generator and the supercritical fluid processing system.

Owner:TOKYO ELECTRON LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com