Coal-based supercritical carbon dioxide Brayton cycle double-split-flow efficient power generation system

A technology of Brayton cycle and carbon dioxide, applied in steam generation, machine/engine, steam engine device, etc., can solve the problems of reducing the heat transfer efficiency of the regenerator and increasing the temperature difference of heat transfer, so as to reduce the heat loss of exhaust gas, Reduce heat transfer temperature difference and improve heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is described in further detail below in conjunction with accompanying drawing:

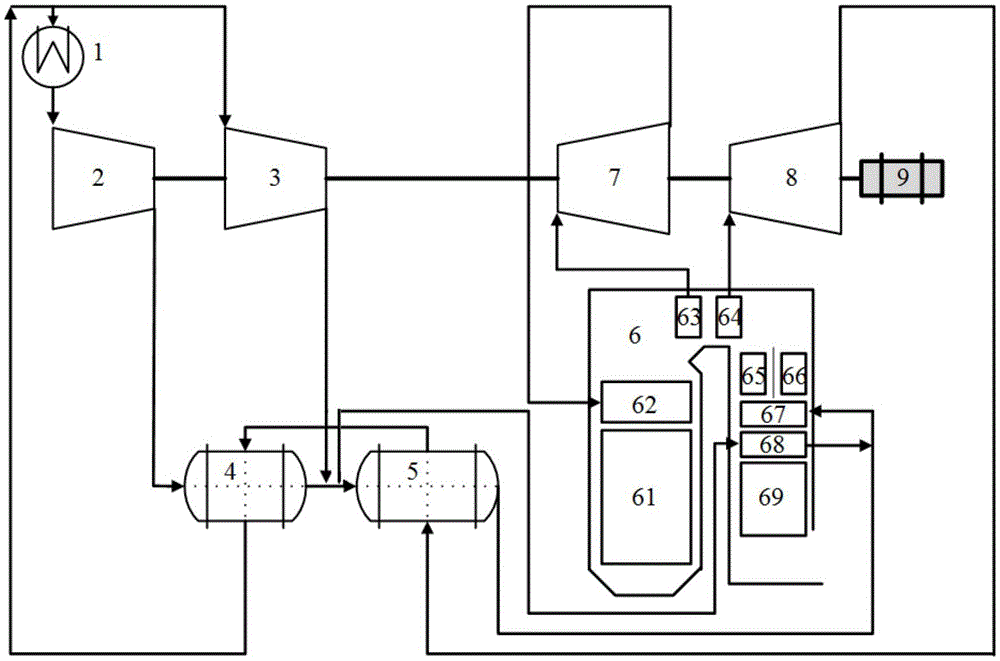

[0016] refer to figure 1 The coal-based supercritical carbon dioxide Brayton cycle double-split high-efficiency power generation system described in the present invention includes a low-temperature regenerator 4, a precooler 1, a main compressor 2, a recompressor 3, a high-temperature regenerator 5, a boiler 6, The high-pressure turbine 7, the low-pressure turbine 8, the boiler 6 and the generator 9; the boiler 6 is composed of a combustion channel, a main heat exchange channel and a tail flue connected in sequence along the flue gas flow direction, wherein the combustion channel is connected along the flue gas In the direction of channel flow, a water-cooled wall 61 and a reheated water-cooled wall 62 are arranged in sequence. In the main heat exchange channel, a high-temperature superheater 63 and a high-temperature reheater 64 are arranged in sequence along the dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com