Patents

Literature

3095results about "Feed-water heaters" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

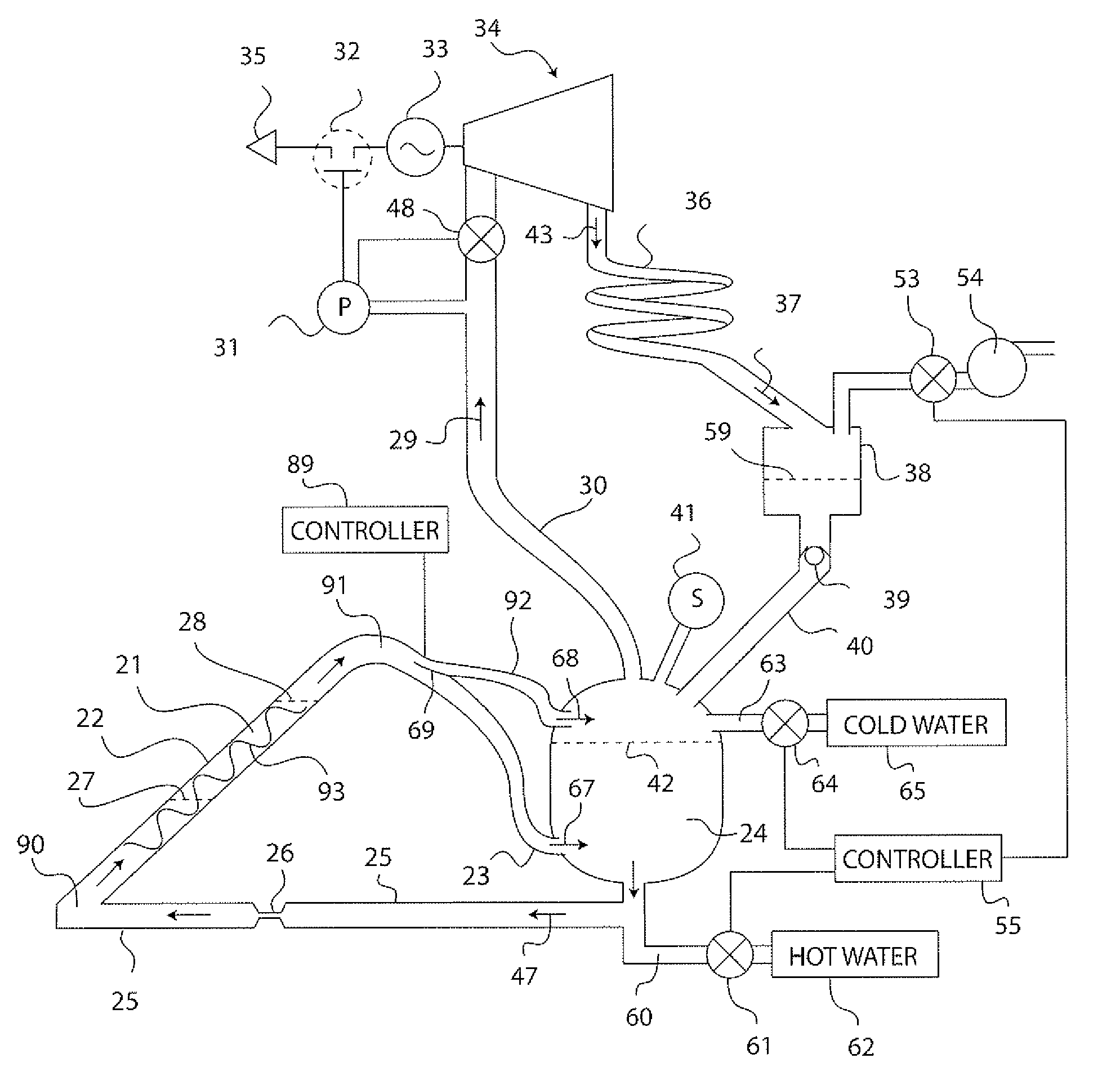

Method of measurement, control, and regulation for the solar thermal hybridization of a fossil fired rankine cycle

InactiveUS20090125152A1Guaranteed uptimeReduce capacityAuxillary drivesLevel controlBiological activationHeat transfer fluid

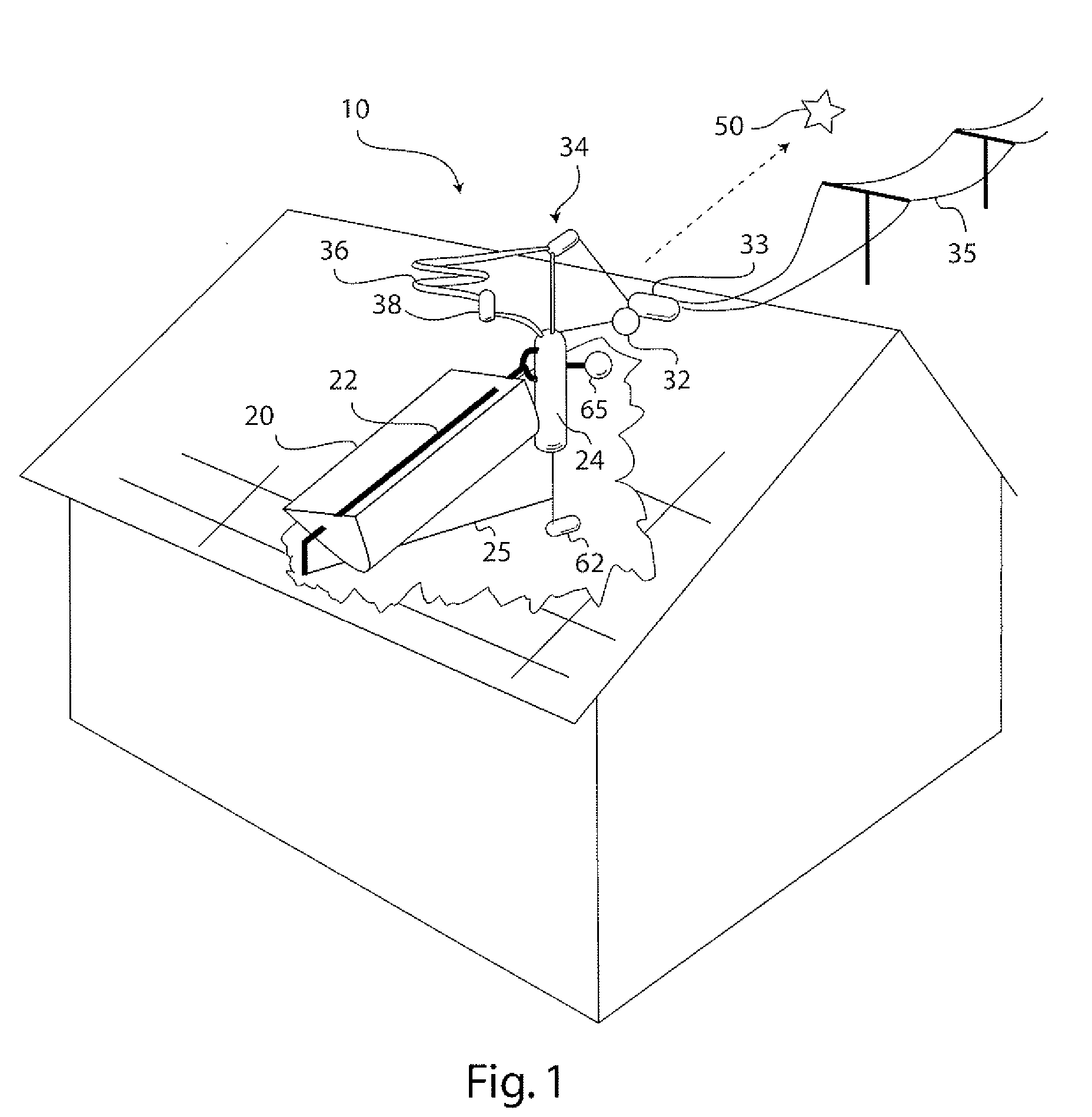

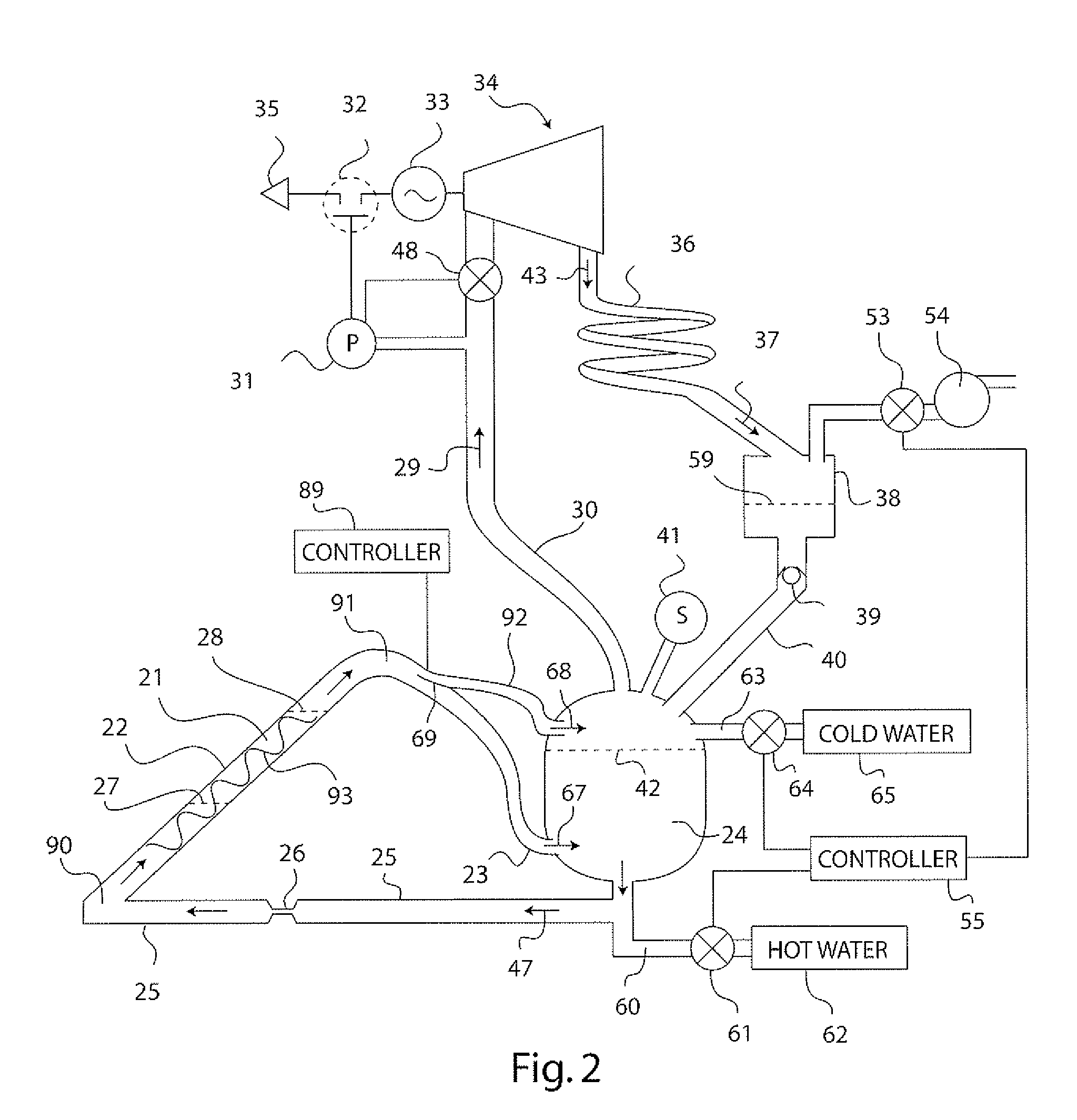

A method of measurement, control, and regulation for a solar integrated Rankine cycle power generation system can include a central processing unit (CPU) which receives input from an operator and / or sensors regarding load forecast, weather forecast, system cost, and capacity or efficiency needs. The method can include activation, in various sequencing, of heat transfer fluid control valves, storage control valves, and at least one turbine control valve.

Owner:MARKRON TECH

Solar Thermal Power System

InactiveUS20090199557A1Simple efficiencyTechnology being suitableAuxillary drivesSteam separation arrangementsThermal energy storageEngineering

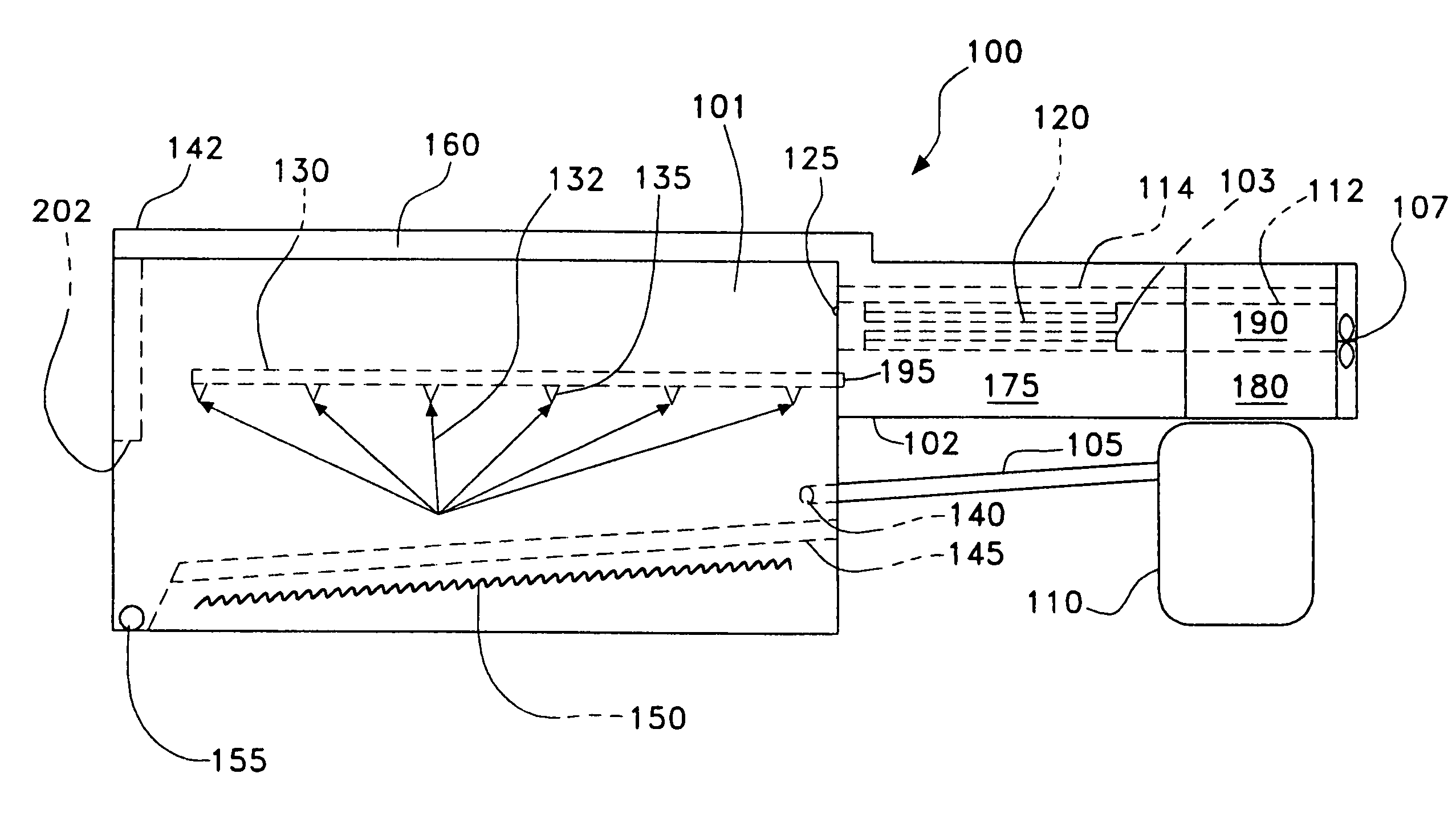

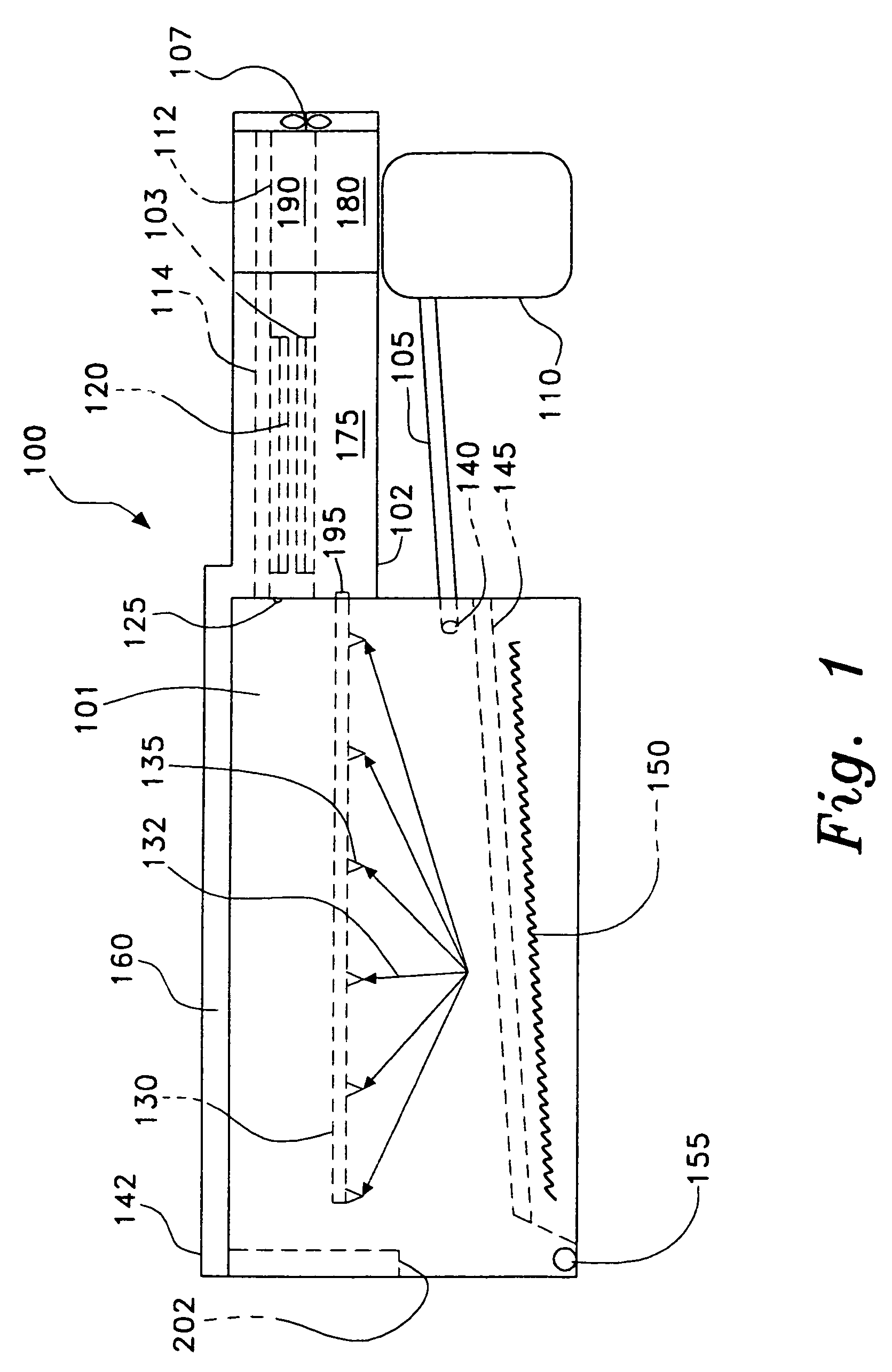

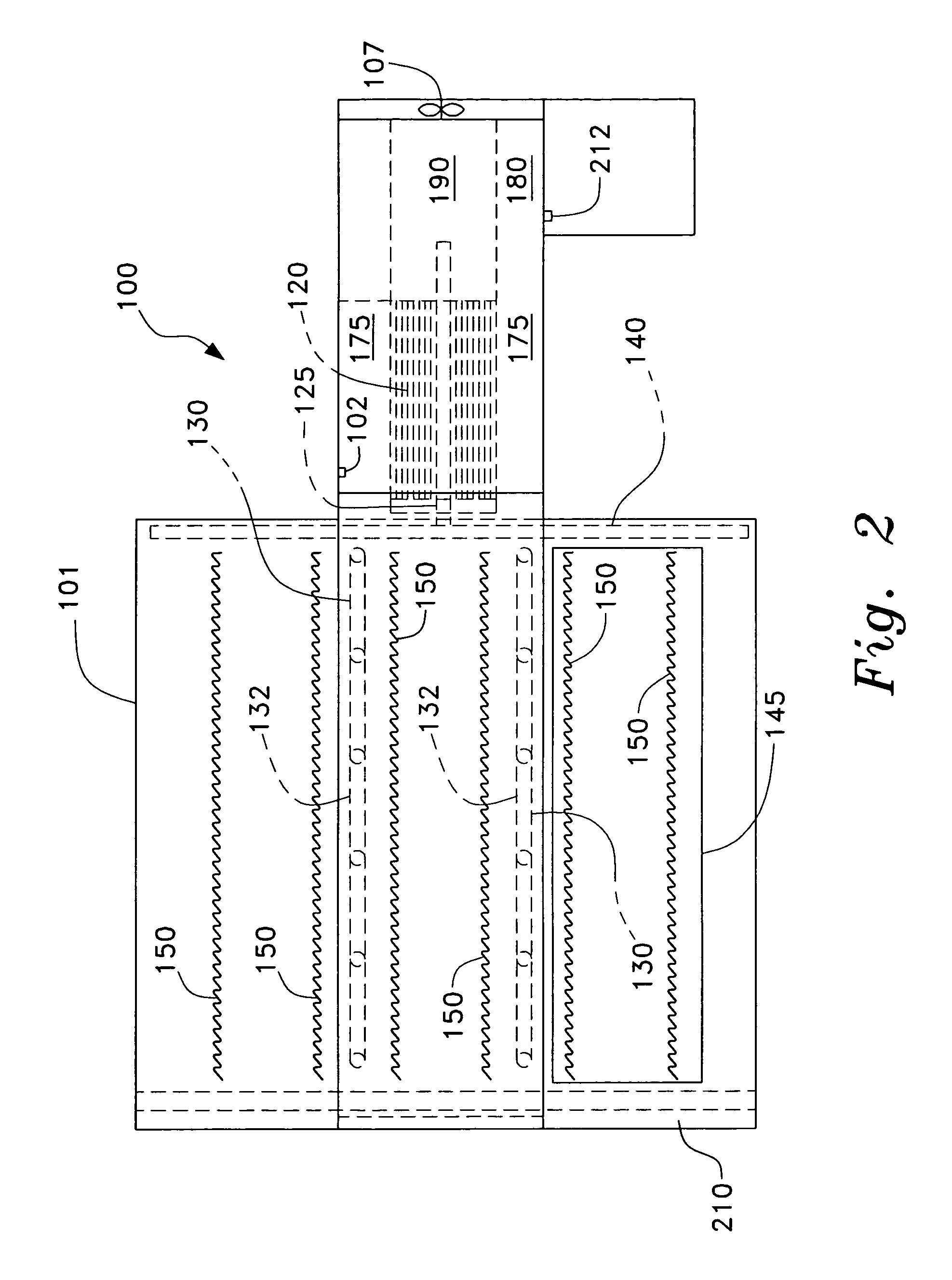

A solar thermal power generator includes an inclined elongated boiler tube positioned in the focus of a solar concentrator for generating steam from water. The boiler tube is connected at one end to receive water from a pressure vessel as well as connected at an opposite end to return steam back to the vessel in a fluidic circuit arrangement that stores energy in the form of heated water in the pressure vessel. An expander, condenser, and reservoir are also connected in series to respectively produce work using the steam passed either directly (above a water line in the vessel) or indirectly (below a water line in the vessel) through the pressure vessel, condense the expanded steam, and collect the condensed water. The reservoir also supplies the collected water back to the pressure vessel at the end of a diurnal cycle when the vessel is sufficiently depressurized, so that the system is reset to repeat the cycle the following day. The circuital arrangement of the boiler tube and the pressure vessel operates to dampen flow instabilities in the boiler tube, damp out the effects of solar transients, and provide thermal energy storage which enables time shifting of power generation to better align with the higher demand for energy during peak energy usage periods.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

Method and device of turbine submerged combustion boiler

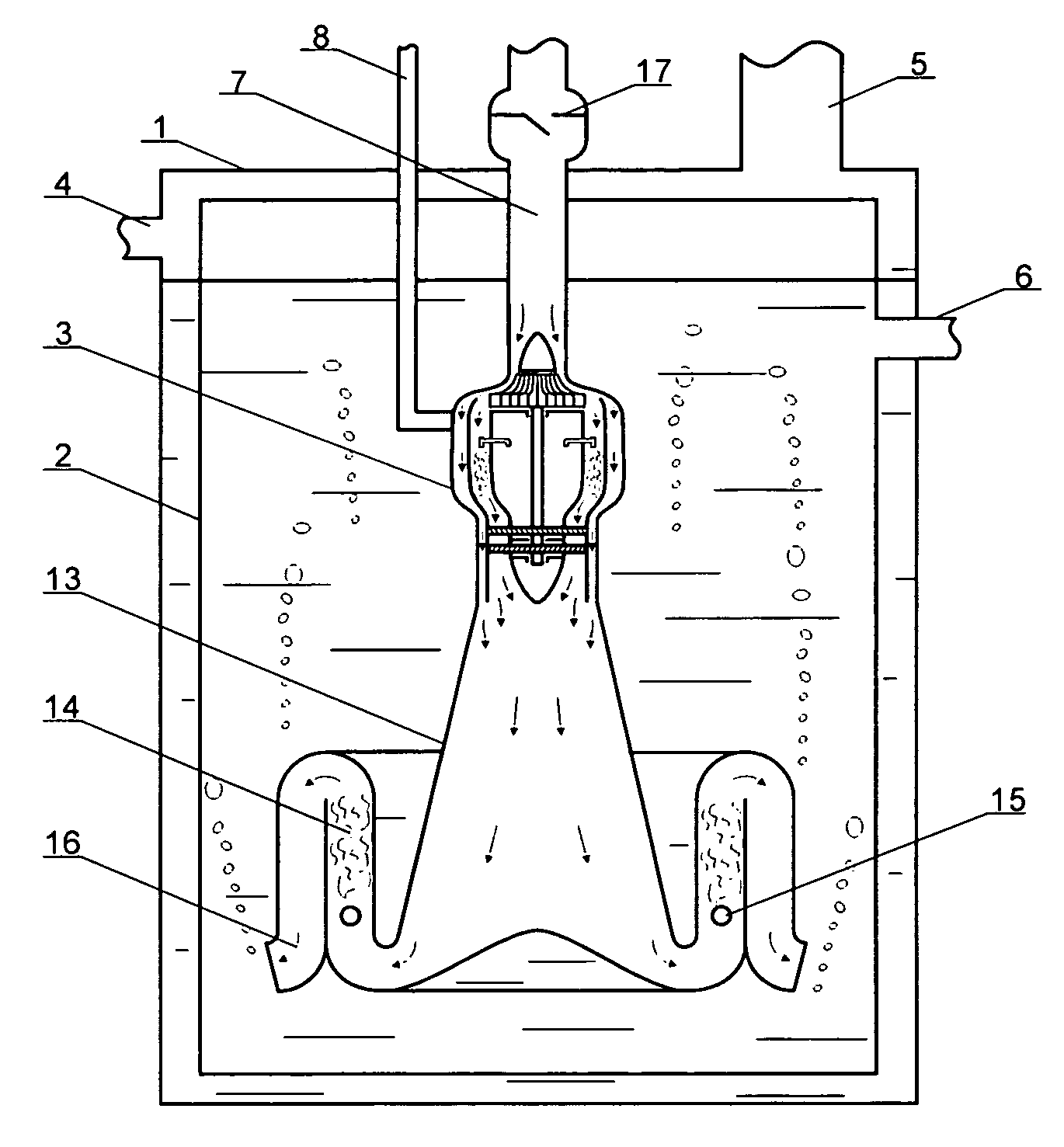

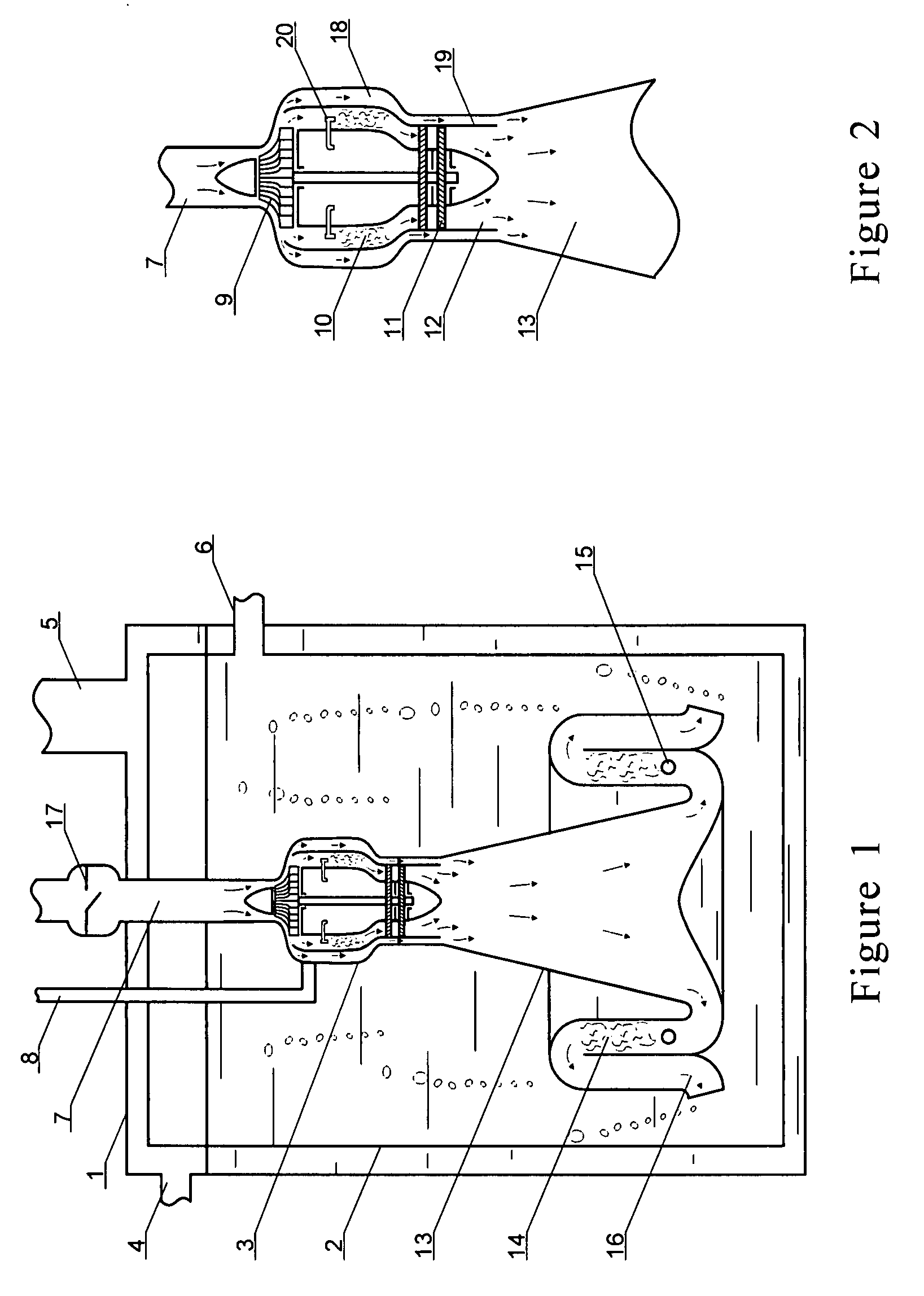

InactiveUS20080035078A1Improve energy efficiencySteam generation using pressureGas turbine plantsComing outHigh energy

The invention is about a submerged combustion method and the device; in details, it is a submerged combustion method and the device utilizing turbine heat engine principle. In the invention, turbine power combustion means is used and substituted conventional submerged combustion system that must equip air blowing means. The high temperature gases generated from the combustion within the turbine power combustion means will do works on turbine, which will drive the air compressor means of the turbine power combustion means to induce air for combustion, and will drive the second-time complete combustion of high temperature gases and the complement fuel, and then the gases will come out from water bottom against tank water pressure and carry out heat interchange with tank water. The turbine submerged combustion boiler device of the invention need not equip air blowing means additionally which would consume energy. So it has high energy efficiency and a simple system structure. And it has features of high heat interchange rate, stable long term heat efficiency, environmental protection, etc.

Owner:LI WEICHENG

Boiler water blowdown control system

InactiveUS6655322B1Constant flowThe process is simple and accurateBoiler cleaning apparatusMachines/enginesControl systemEngineering

The present invention relates to a method for automatically maintaining the concentration of scale forming minerals in boiler water for boiler systems utilizing bimodal feedwater pumps that deliver a substantially constant feedwater flow to the boiler drum when activated. According to the present invention, the feedwater supply pump and blowdown rate control valve are synchronized to remove boiler water at a predetermined rate when the feedwater pump is activated. The present invention thereby provides a simplified and less expensive method for controlling the concentration of dissolved solids in boiler water despite variations in the steam loads and / or other boiler operation parameters.

Owner:CHEMTREAT

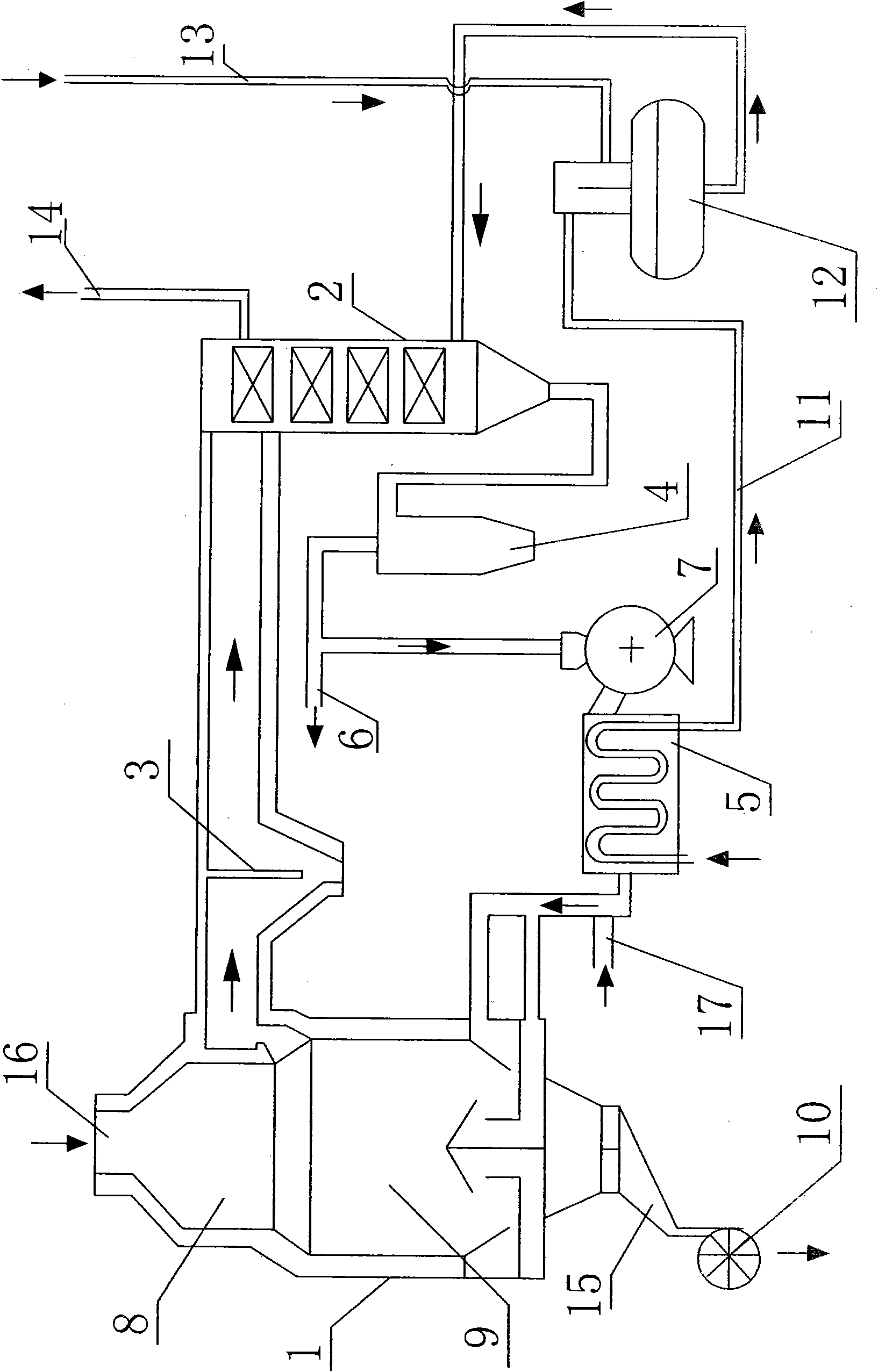

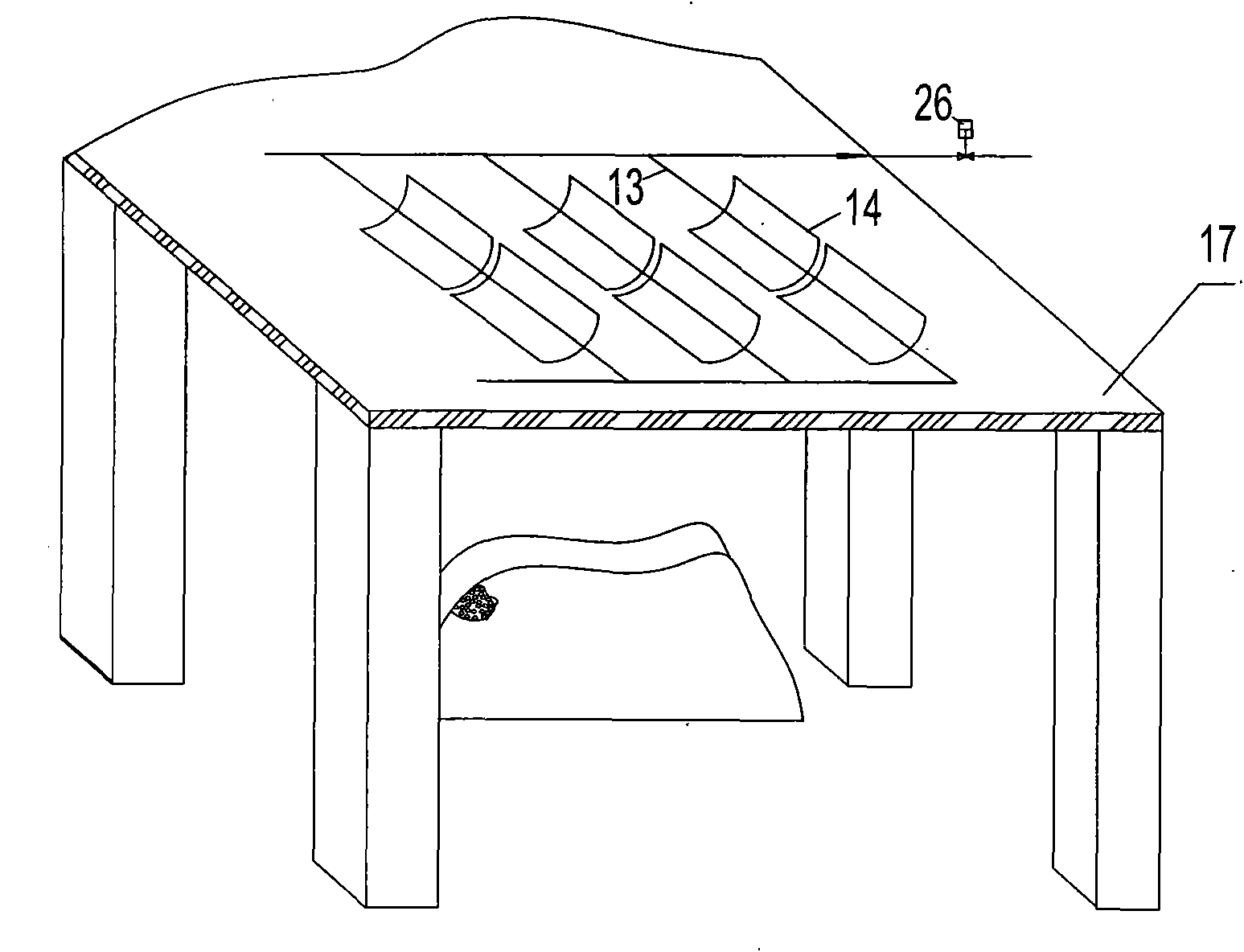

Grading recycling and cascade utilization method of residual heat resources in sintering process and device thereof

ActiveCN101655320AOvercome congenital deficienciesSolve the problem of air leakageLiquid degasificationIncreasing energy efficiencyThermodynamicsEngineering

The invention relates to a method for effectively recycling and utilizing residual heat resources in a sintering process and a device thereof. The invention has the main contents that a fiery sinter ore is filled in a vertical and sealed tank body, air is led from the tank body so as to cool the sinter ore, sensible heat of the sinter ore is almost totally carried by the air and is exhausted fromthe top of the tank body at the same time; and hot air is led into a residual heat boiler to generate steam to synchronously generate power. Compared with the prior sintering residual heat recycling and utilization technology, the invention has higher residual heat recycling utilization ratio, effectively reduces the energy consumption of the sintering procedure with reasonable and effective method, simple apparatus and easy operation, and is relatively favorable for popularization and application in the technical field of residual heat resource recycling and utilization in a metallurgy process.

Owner:NORTHEASTERN UNIV

Salt water distillation system

The salt water distillation system includes a sprinkler to form a mist of salt water over a distillation plate. The distillation plate is heated by applying electrical current to a heating coil. The steam is transferred to a condensation chamber and condensed fresh water is collected. During the desalination process, salt impurities are deposited on the hot distillation plate. A sludge remover, i.e., a steam head and movable ram, is provided to clean the distillation plate of the salt impurities. An exhaust fan is provided to cool fresh water condensate and lower air pressure in the system. Heat transferred from the steam during condensation is used to pre-heat the salt water to increase efficiency of the system.

Owner:RIVES MICHAEL L +1

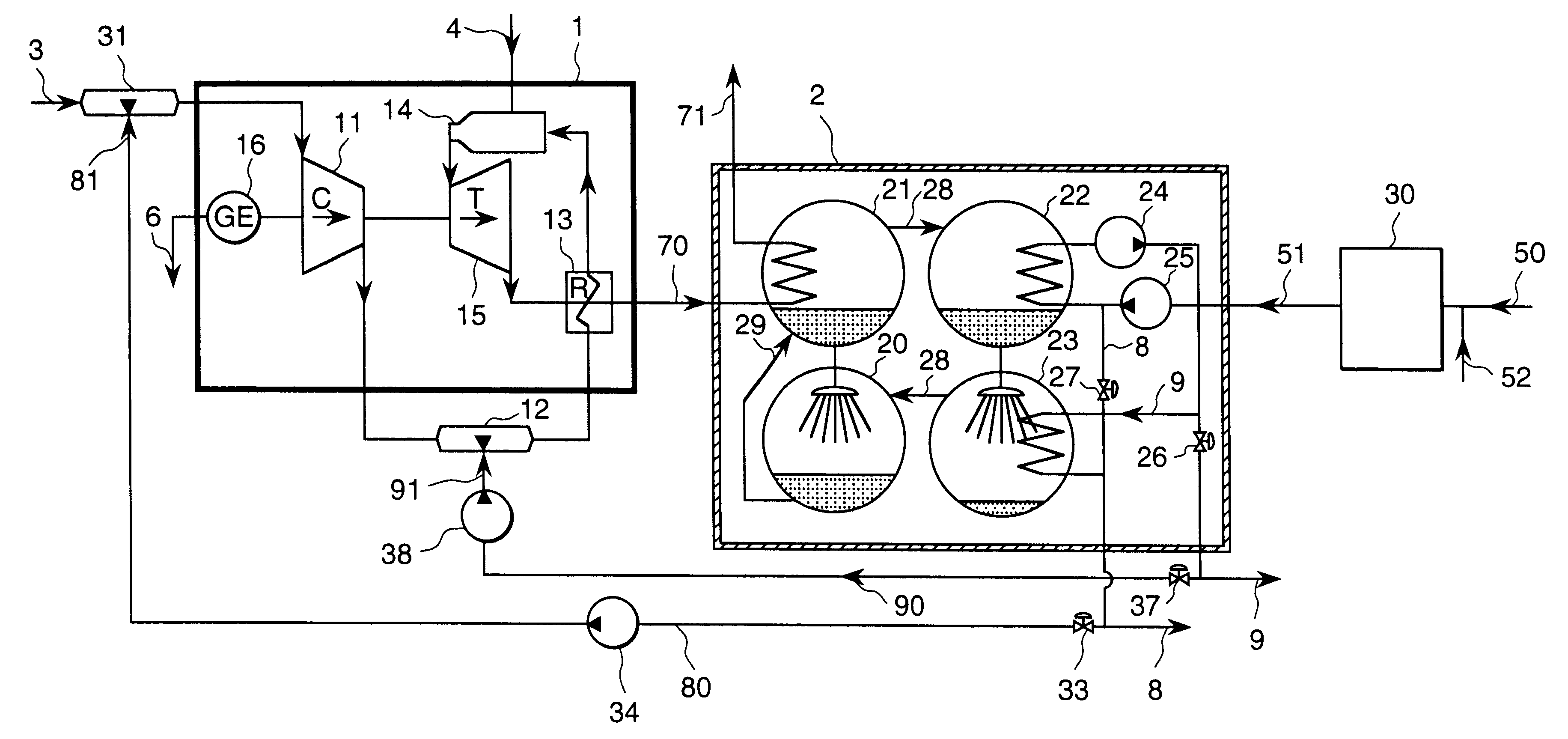

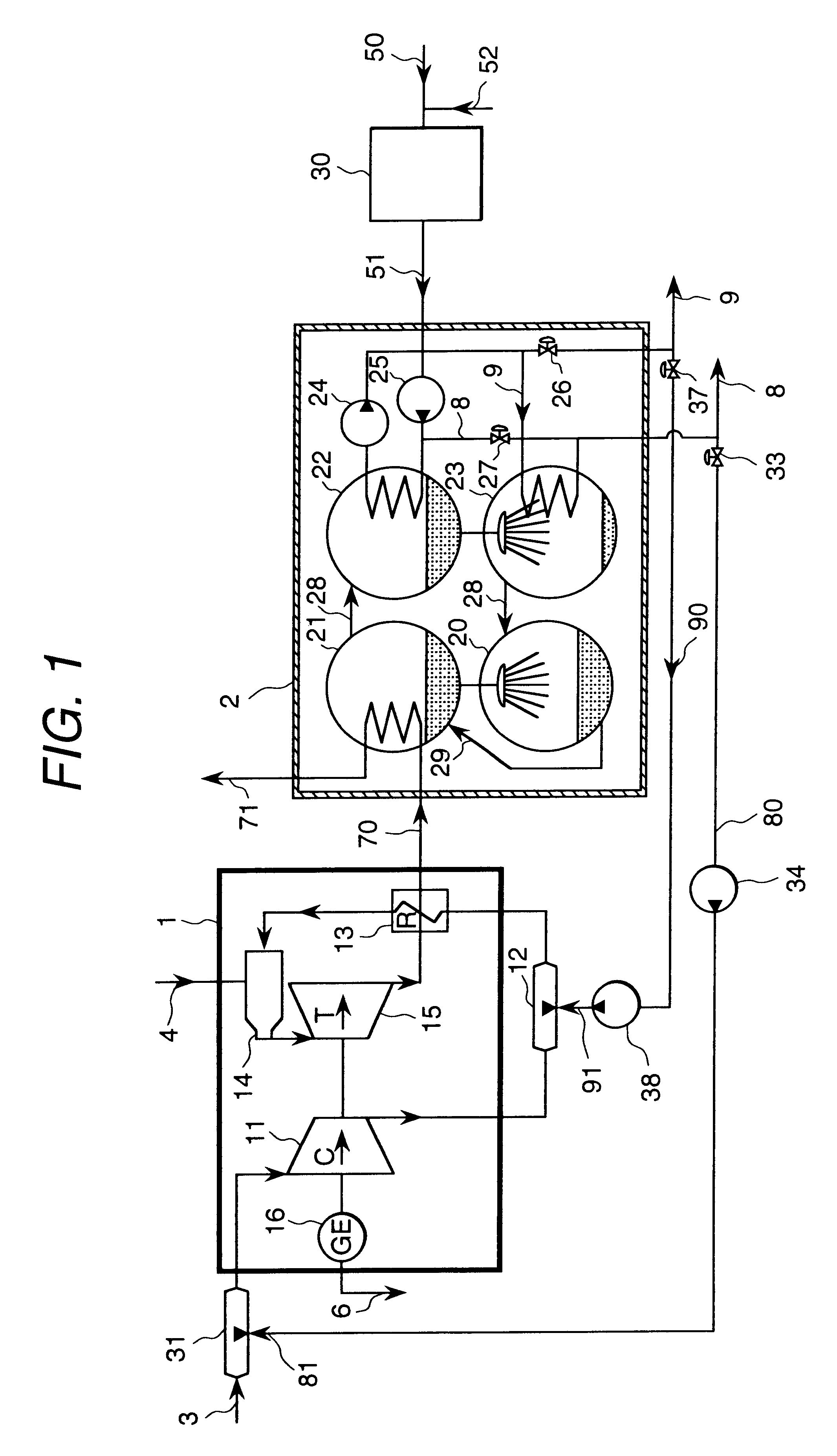

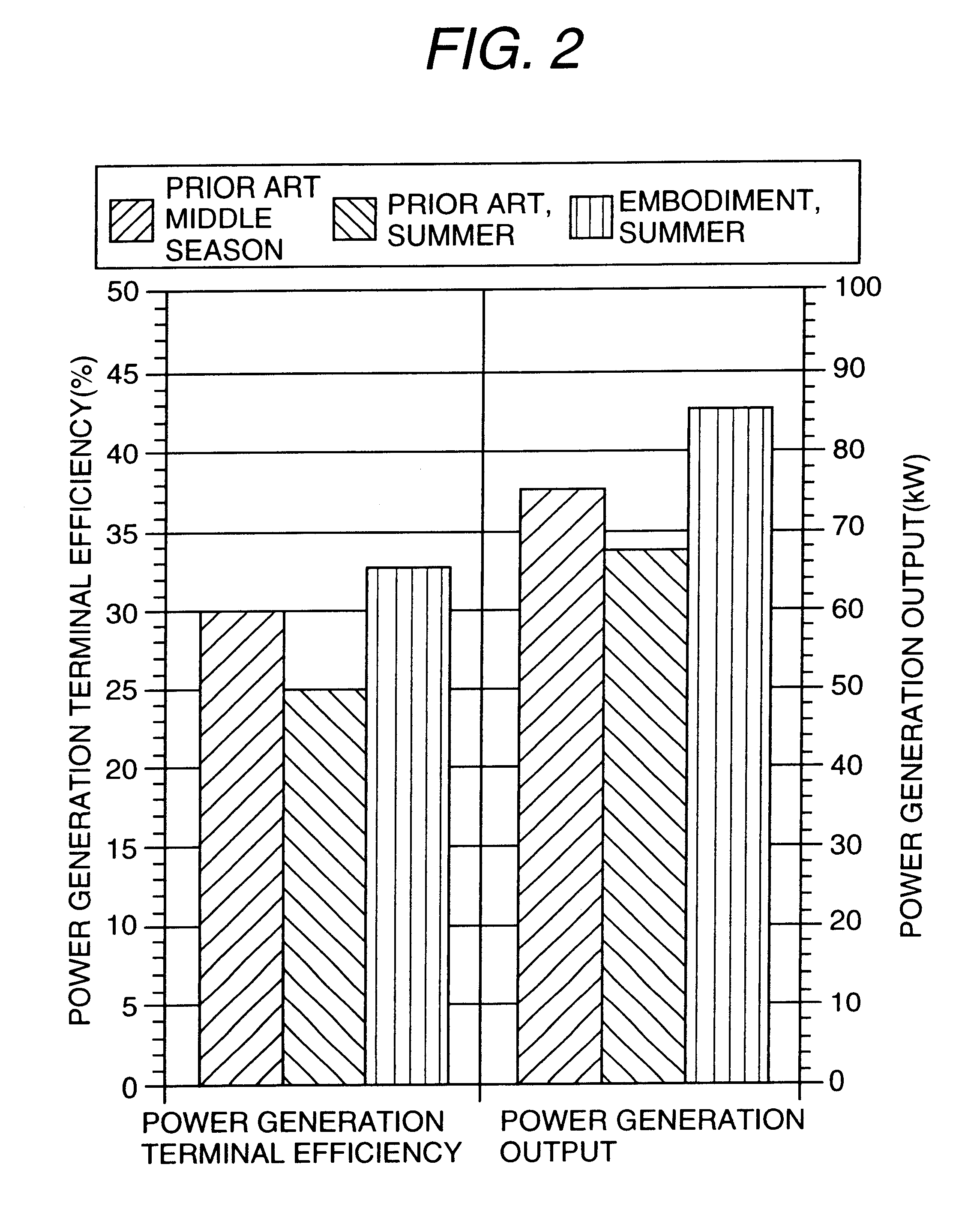

Heat and electric power supply system and operation method thereof

A heat and electric power supply system includes a regenerative gas turbine and an adsorption refrigerator recovering exhaust heat of exhaust gas from the gas turbine and is provided with inlet air cooling equipment including a spray device for spraying cold water from the adsorption refrigerator into an air-intake port of the regenerative gas turbine and a humidifier effecting humidification by hot water injection from the refrigerator into a compressor delivery port of the regenerative gas turbine. The cooling by cold water and humidification by hot water injection are effected according to operational conditions.

Owner:MITSUBISHI HITACHIPOWER SYST LTD

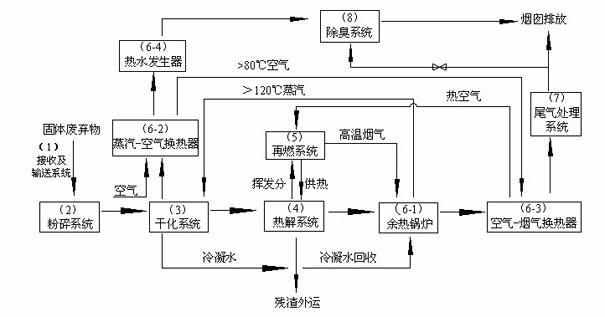

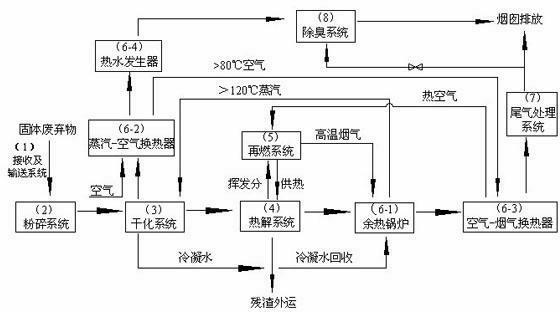

Novel process for pyrolysis of solid wastes

InactiveCN102537973AHas waste heat utilization valueAvoid consumptionSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisCombustionRoom temperature

The invention discloses a novel process for pyrolysis of solid wastes. According to the existing pyrolysis technology, the solid wastes with low calorific values and high moisture content are difficult to treat, and effects of being completely harmless, reduced and recycled cannot be achieved. The novel process provided by the invention comprises the following steps of: uniformly crushing the solid wastes by a crushing system and conveying the crushed solid wastes to a drying system to be dried; carrying out the pyrolysis in a pyrolysis system and treating a pyrolyzed product by a re-burning system to provide energy needed by the pyrolysis system; conveying high-temperature smoke into a residual heat boiler to generate saturated vapor with a temperature which is higher than 1000 DEG C; carrying out heat exchange on the vapor by a vapor-air heat exchanger; after raising the temperature of normal-temperature air, conveying the air into the vapor-air heat exchanger to carry out the heat exchange with output smoke of the residual heat boiler; conveying the hot air into the pyrolysis system and carrying out processes of cooling combustion smoke, de-acidifying and removing dust on the smoke of the residual heat boiler through an exhaust gas treatment system; receiving uncondensed gas in condensed odor vapor by the deodorization system, carrying out final treatment on the uncondensed gas and exhausting. According to the invention, the residual heat value of the high-moisture solid wastes is sufficiently utilized and the utilization is not limited by types of the solid wastes, so that the energy source and the operation cost are saved.

Owner:ZHONGCHANG ENVIRONMENT PROTECTION GROUP +1

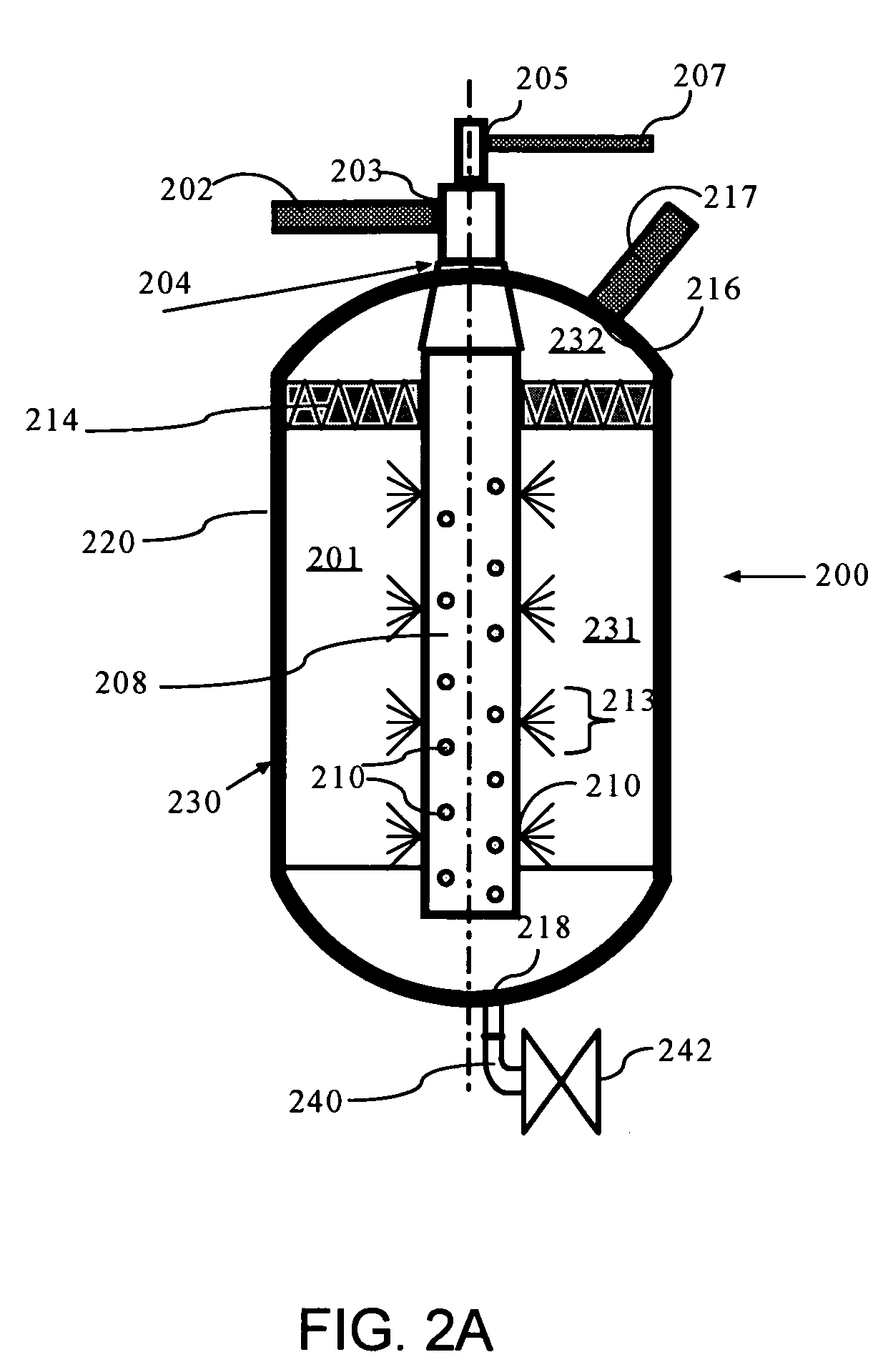

Hot to cold steam transformer for turbine systems

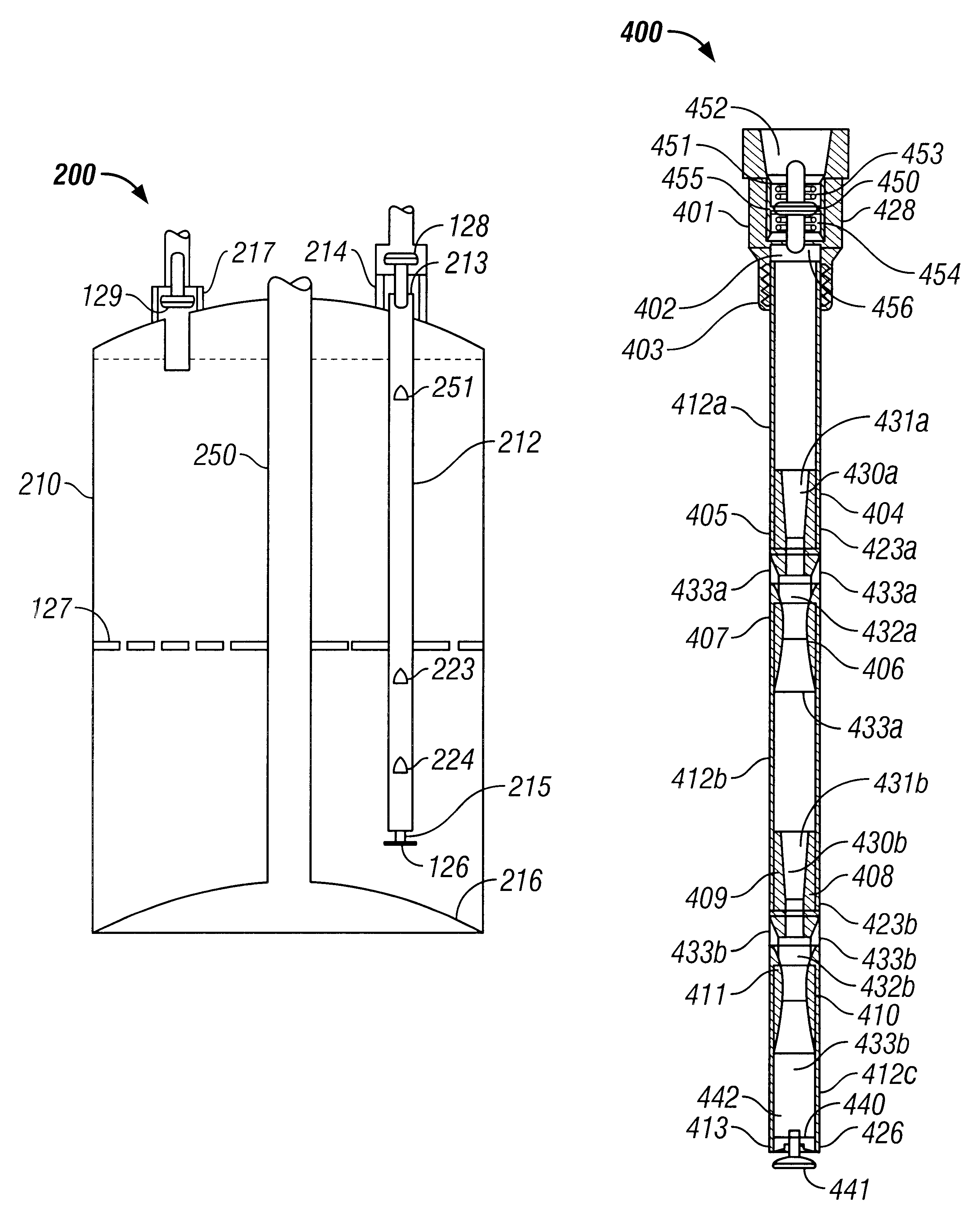

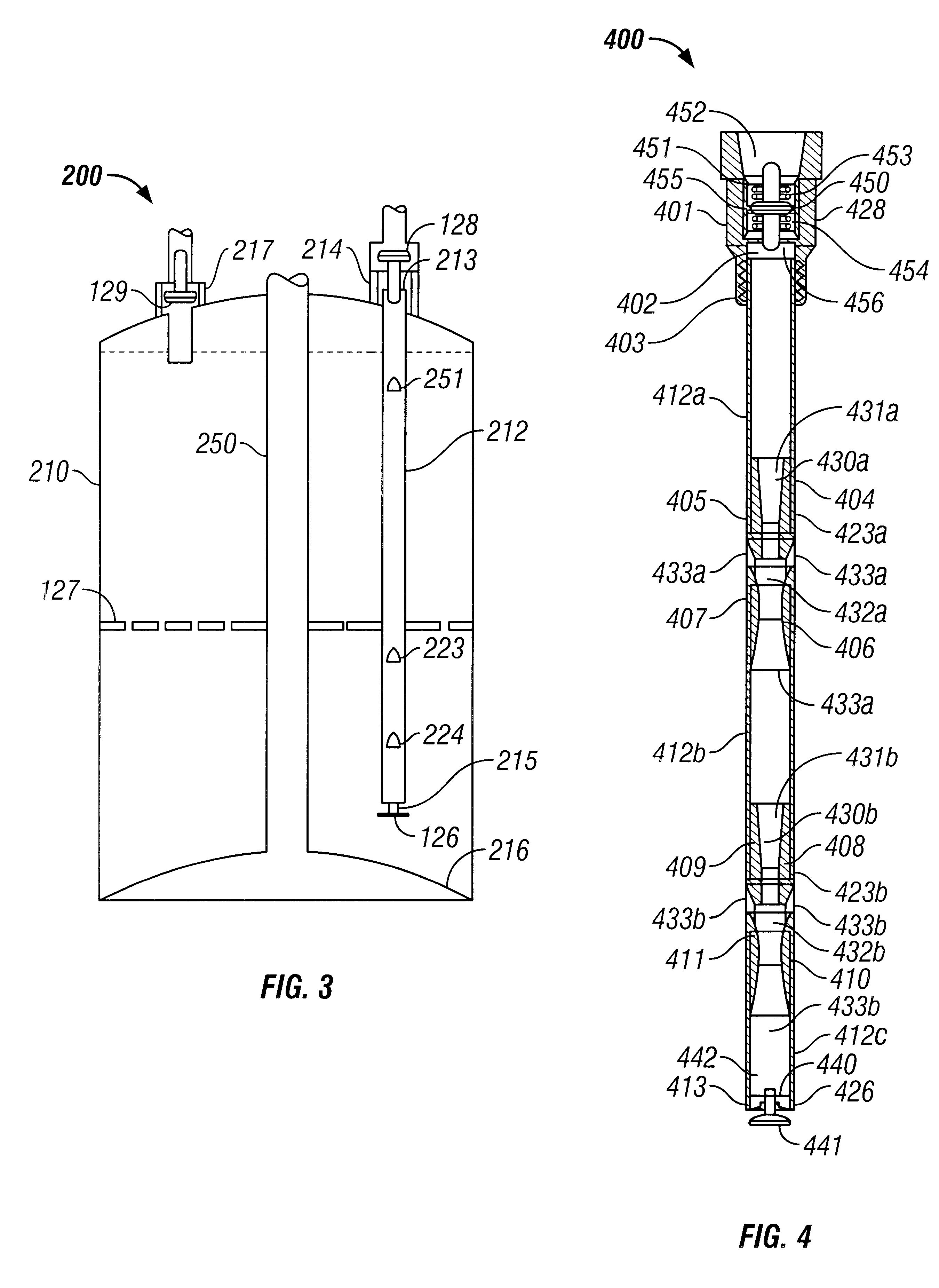

A steam transformer (200) receives steam through a steam inlet (203), and the steam is mixed in a mixing zone (231) with water entering through a water inlet (205). Steam cooled by contact with the water exits the steam transformer through a cold steam outlet (216). Between the mixing zone (231) and the cold steam outlet (216) is positioned a demister (214) that restricts the passage of water droplets.The steam transformer (200) is used to condition the steam temperature in steam turbine and combined cycle turbine facilities when adjustment of steam temperature is required, such as for cold starts of turbines. The steam transformer (200) may be installed into a bypass circuit or directly inline. A number of differing configurations and designs are disclosed.

Owner:SIEMENS ENERGY INC

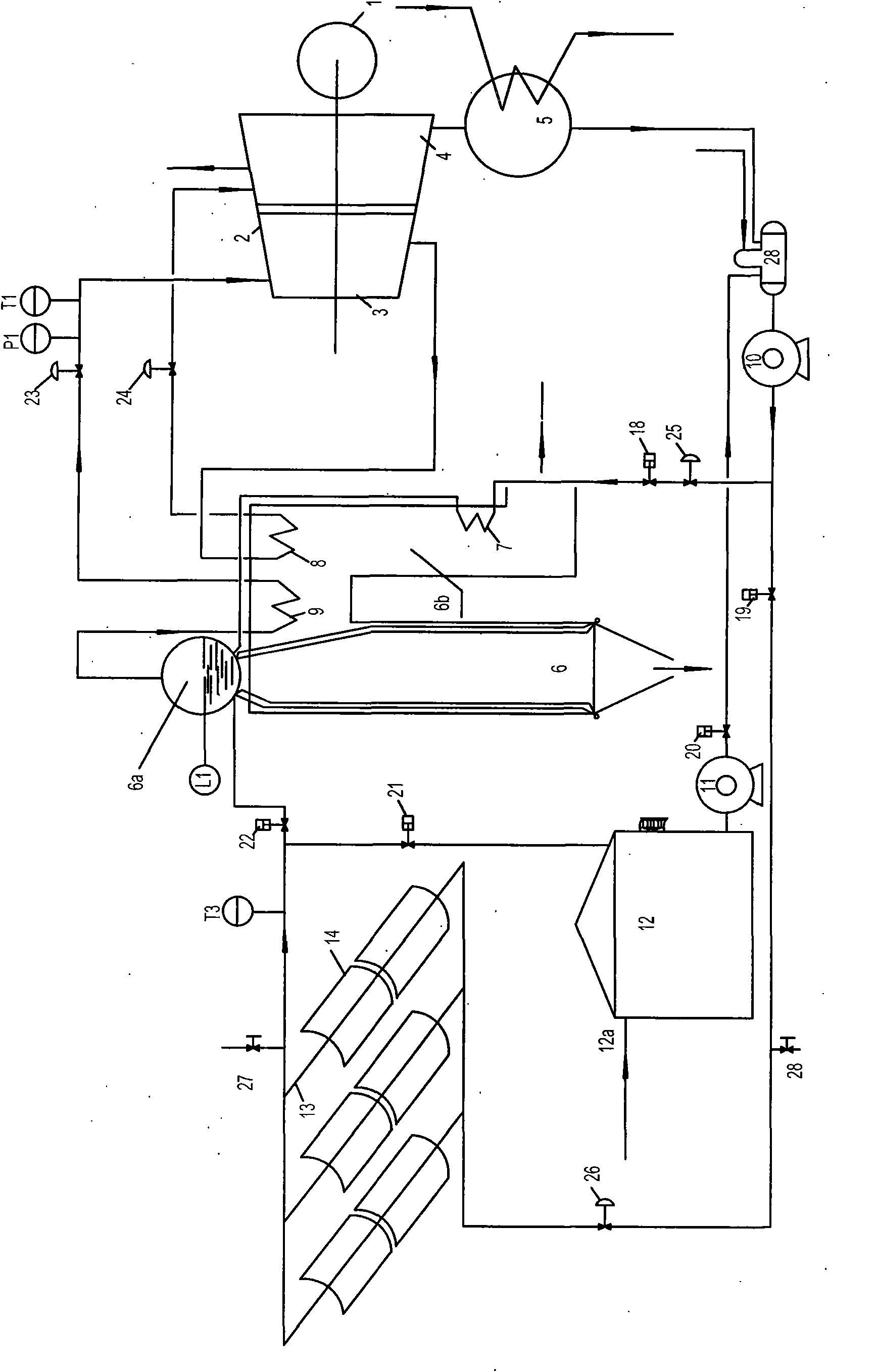

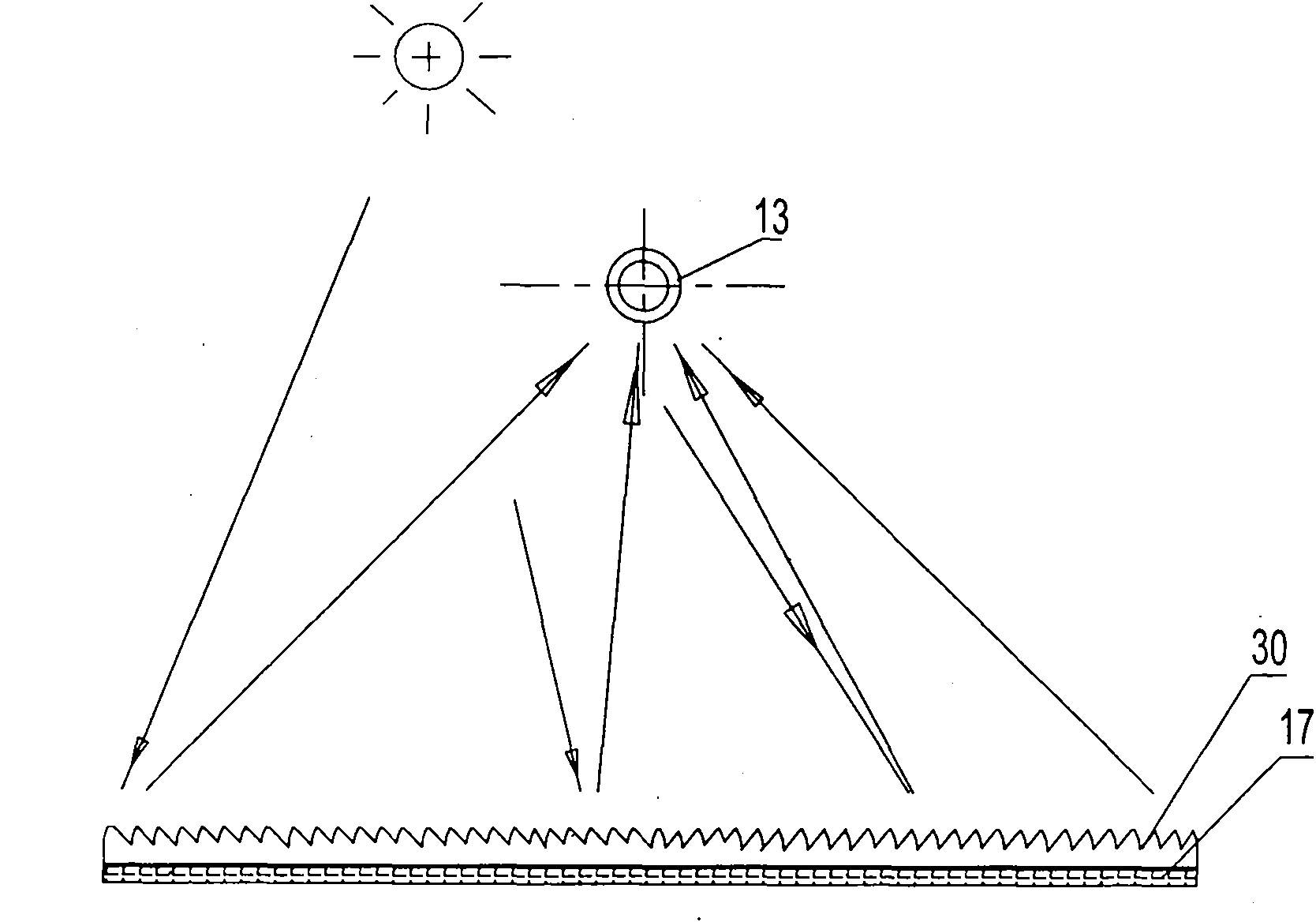

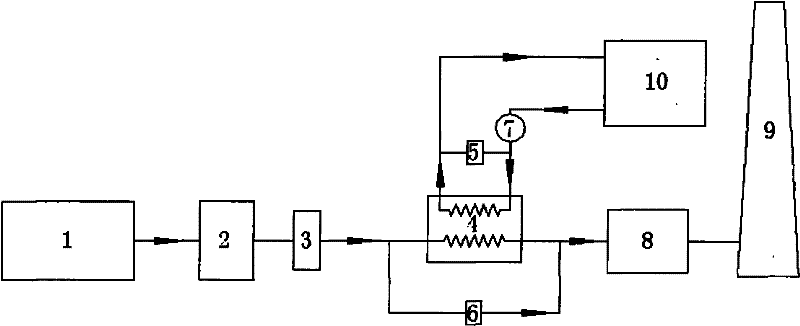

Solar power generation method and system taking biomass boiler as auxiliary heat source

ActiveCN101968041ASolve the problem of antifreeze in winterHigh thermal efficiencySolar heating energyFrom solar energyWater storage tankEngineering

The invention discloses a solar power generation method and a solar power generation system taking a biomass boiler as an auxiliary heat source. The system comprises a solar condensation heat collecting device, a biomass boiler device and a steam turbine generator system, wherein the solar condensation heat collecting device takes water as a medium and is combined by adopting medium-pressure solar vacuum heat collecting pipes in a series-parallel matrix; the outlet of the solar condensation heat collecting device is communicated with the bottom of a steam pocket of the biomass boiler; and the steam outlet of the steam pocket of the biomass boiler is connected with a cylinder of a steam turbine generator. A de-aerator and a water supply pump are connected in series in the water inlet pipeline of the solar condensation heat collecting device. A steam re-heater is connected in series in the connected pipeline of the steam outlet of the steam pocket of the biomass boiler and the cylinder of the steam turbine generator; the steam re-heater is connected to the cylinder of the steam turbine generator; and the steam re-heater is placed in a flue of the biomass boiler. A water supply tank is a desalting water storage tank, and the desalting water storage tank is connected with the de-aerator through the water supply pump and connected with the outlet of the solar condensation heat collecting device through a first control valve.

Owner:WUHAN KAIDI ENG TECH RES INST CO LTD

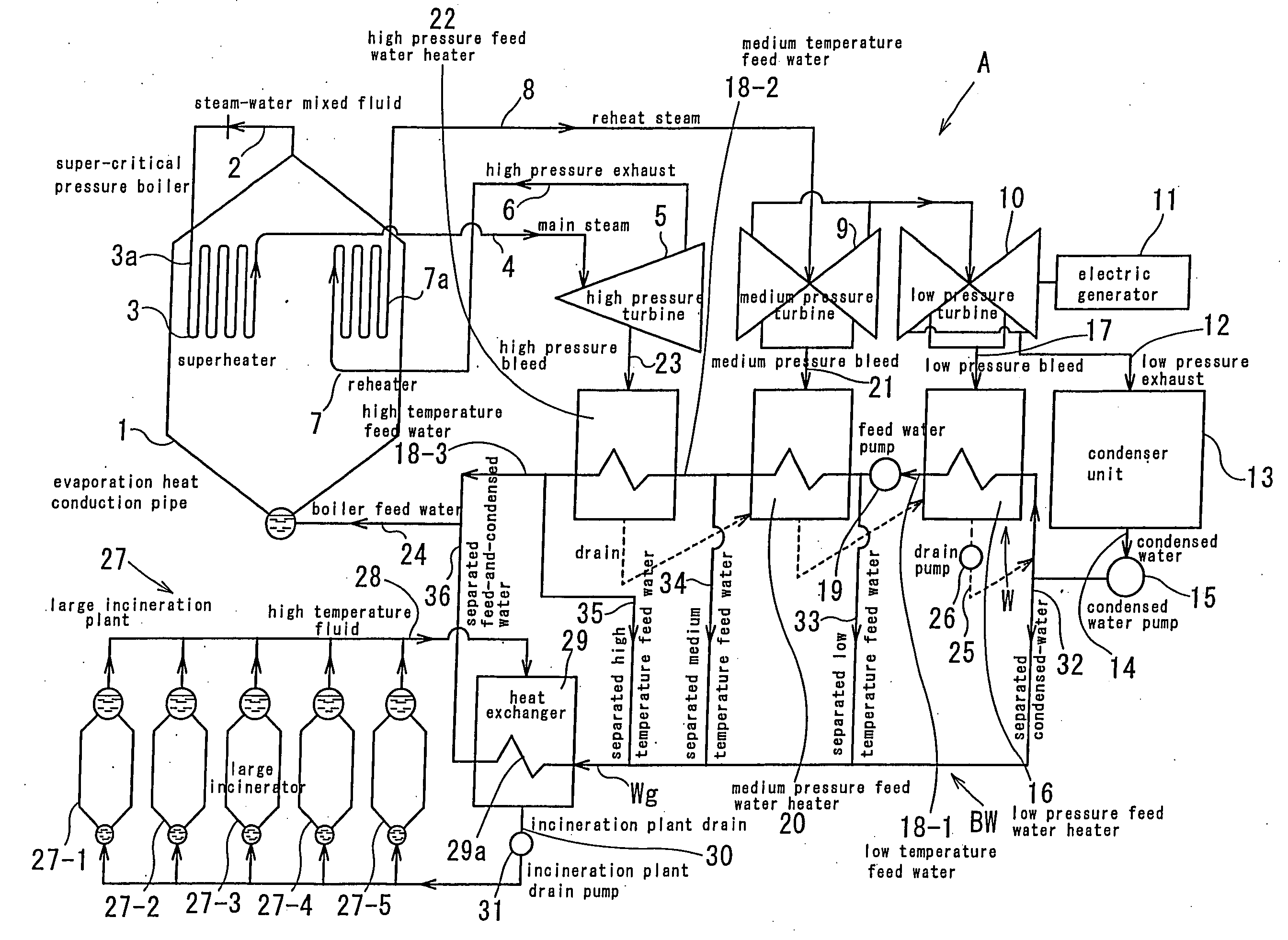

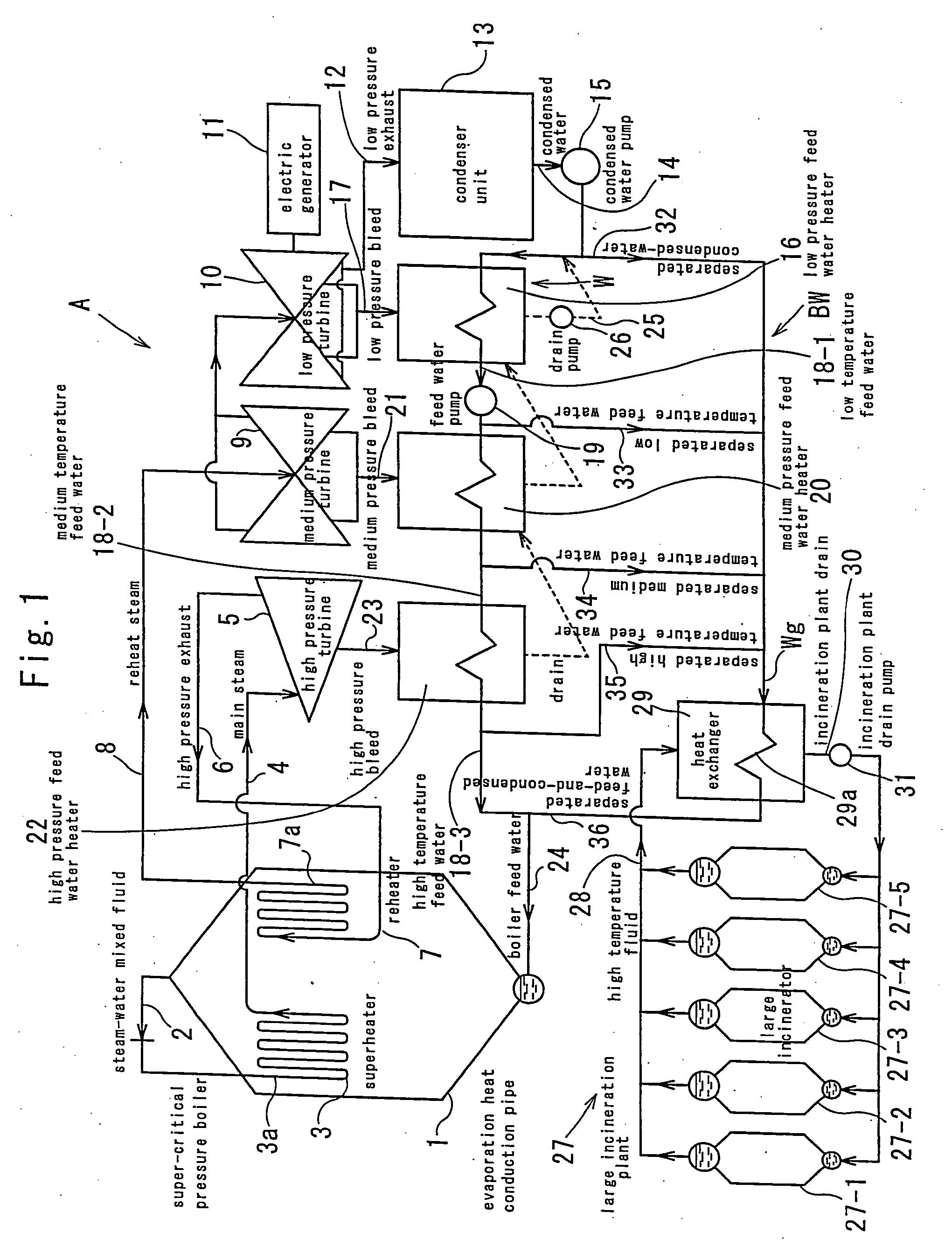

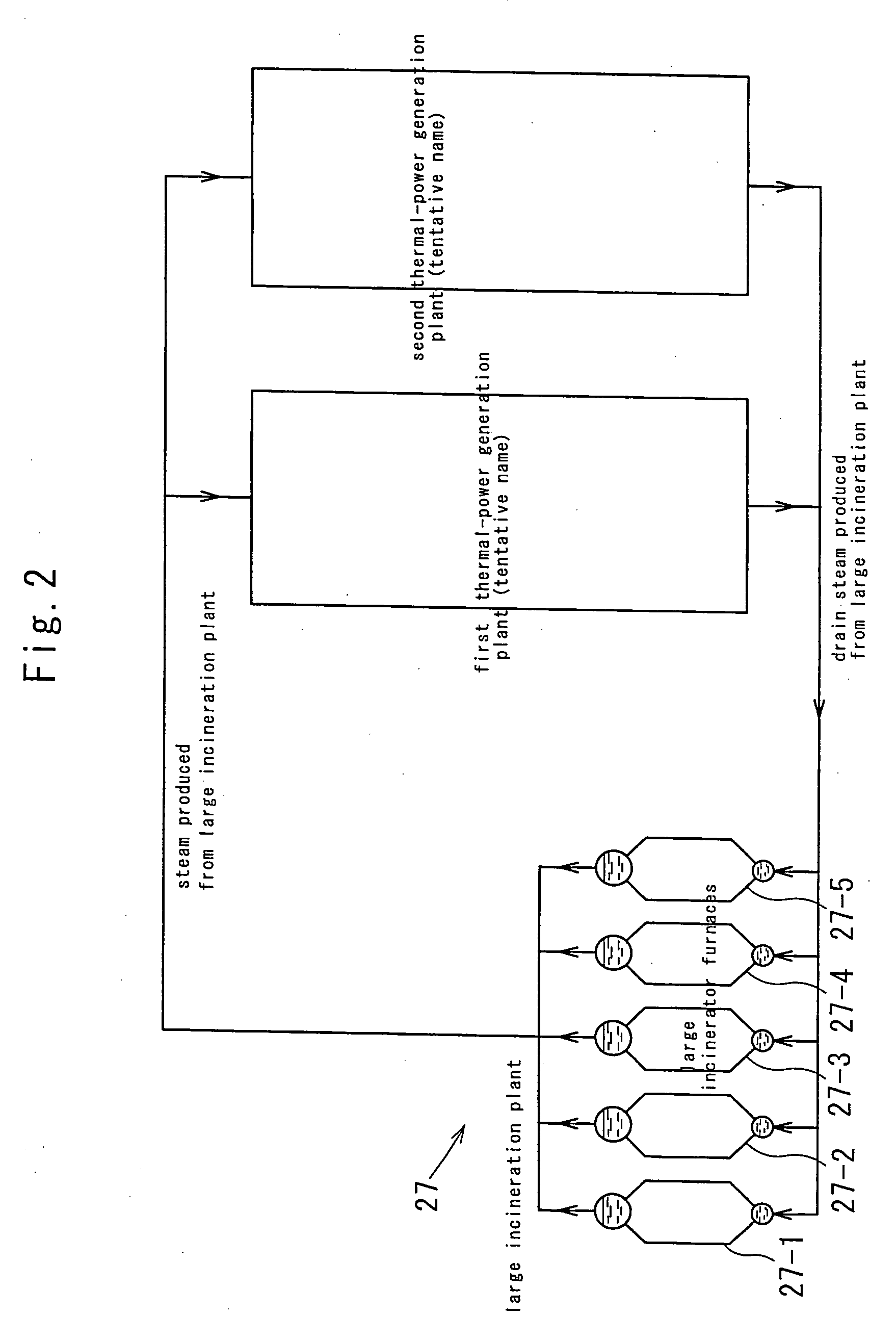

Reheat/regenerative type thermal power plant using rankine cycle

InactiveUS20060254251A1Reducing thermic efficiencyEasy to useEnergy industryGas turbine plantsIncinerationThermoelectric Power Plants

A reheat-and-regenerating type thermal power plant (A) using Rankine cycle has a water feed bypass (BW) which suppies high temperature fluid (28) produced in a large incineration plant (27) to a heat exchanger (29) and by which confluent feed water (Wg) resulting from the confluence of separated condensed-water (32), separated low temperature feed water (33), separated medium temperature feed water (34) and separated high temperature feed water (35) is supplied to a superheat conduction pipe (3a) through a heat exchanger conduction pipe (29a). The water feed bypass (BW) is installed separately from a feed water path (W), thus insuring an efficient use of the high temperature fluid (28) produced upon incinerating a huge amount of combustible wastes in the large incineration plant (27).

Owner:OGAWA KIICHIRO

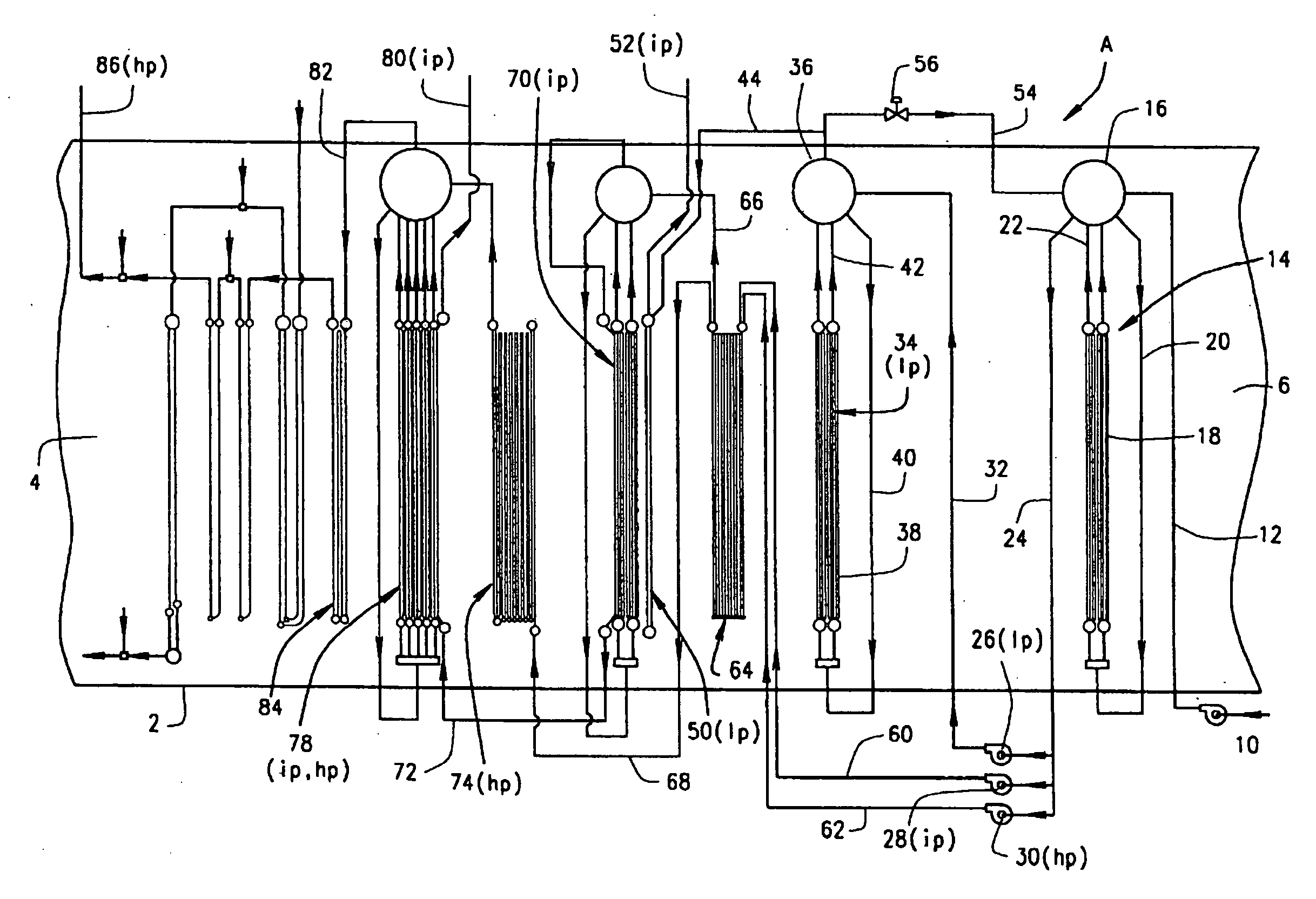

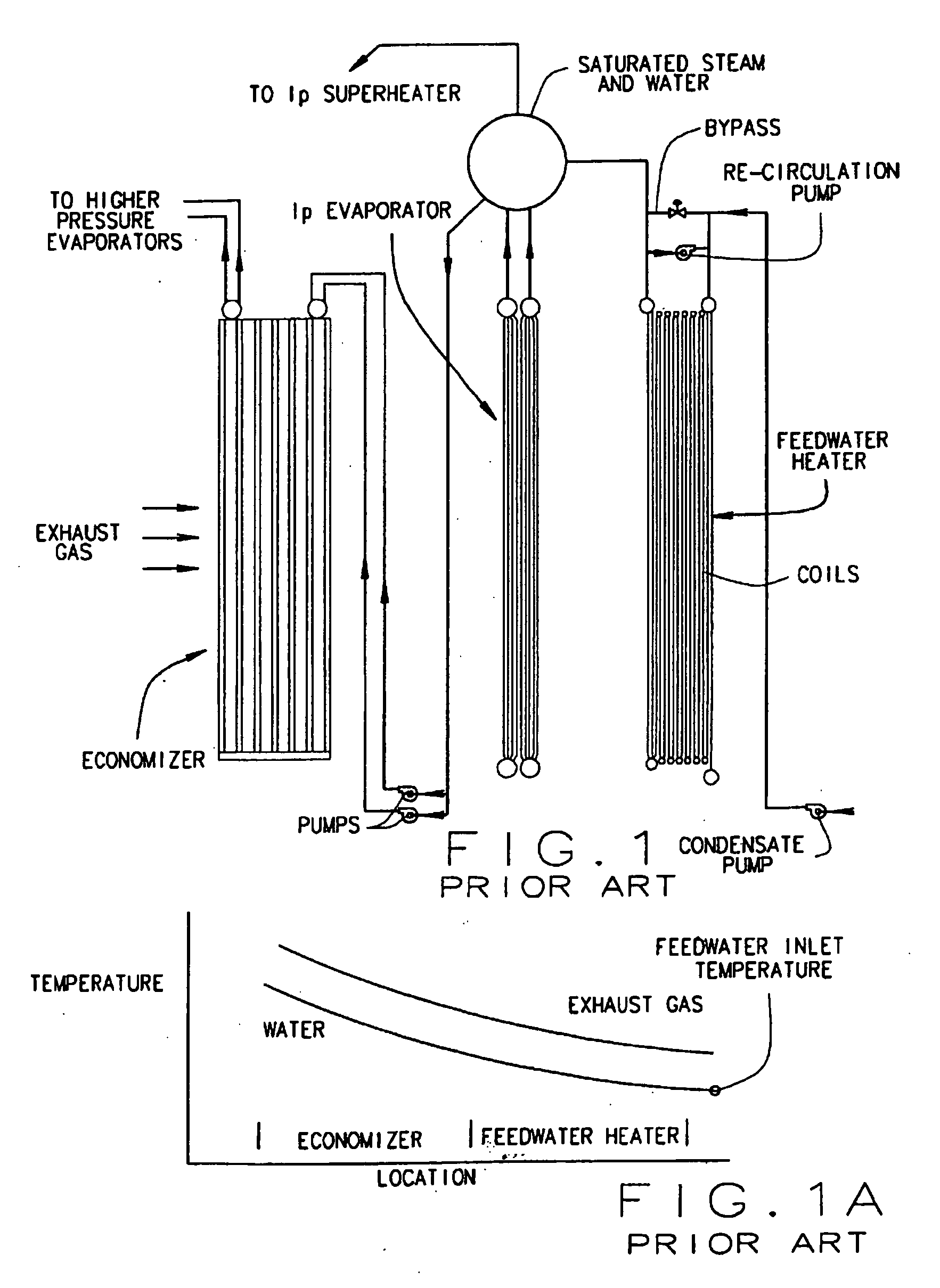

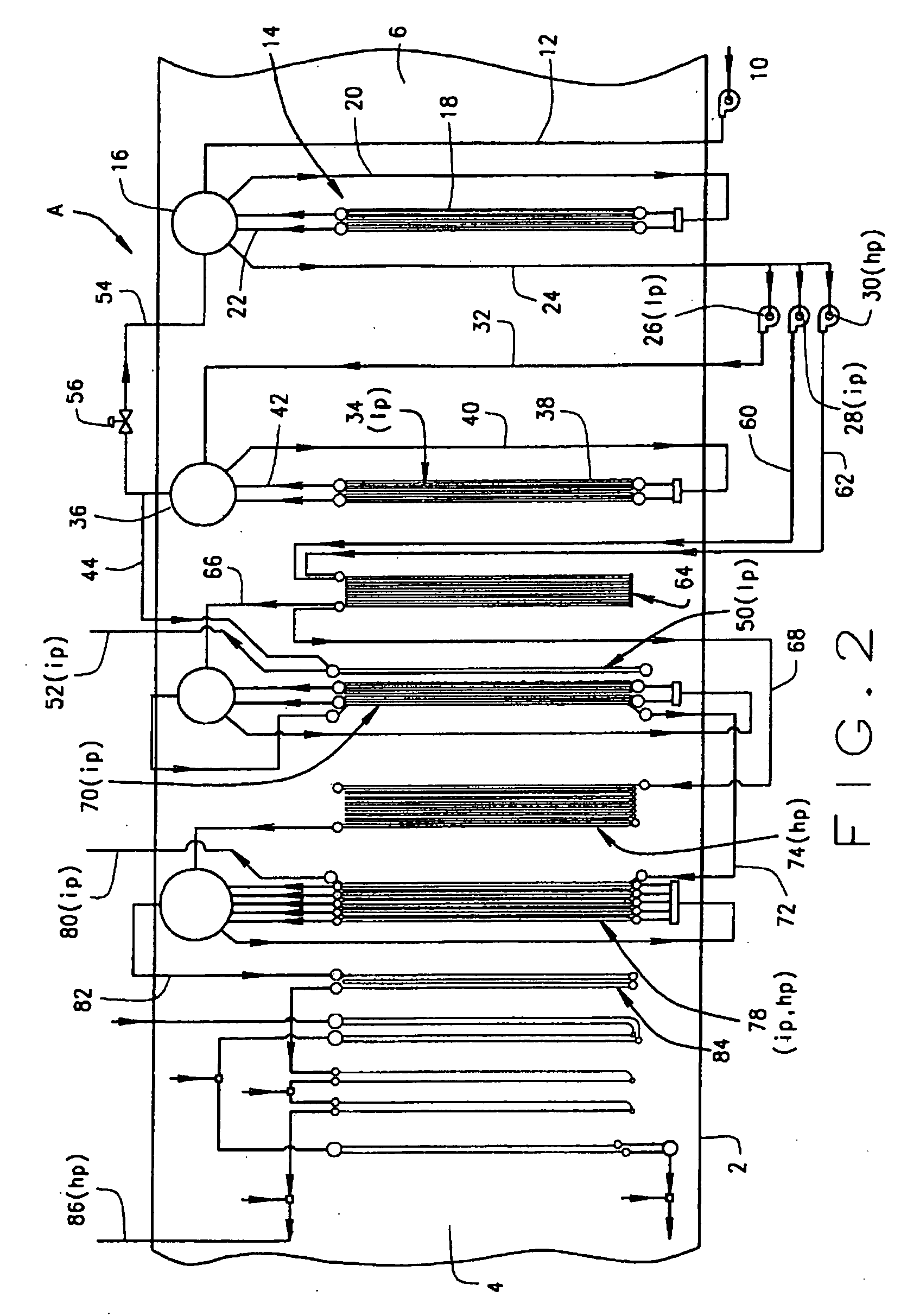

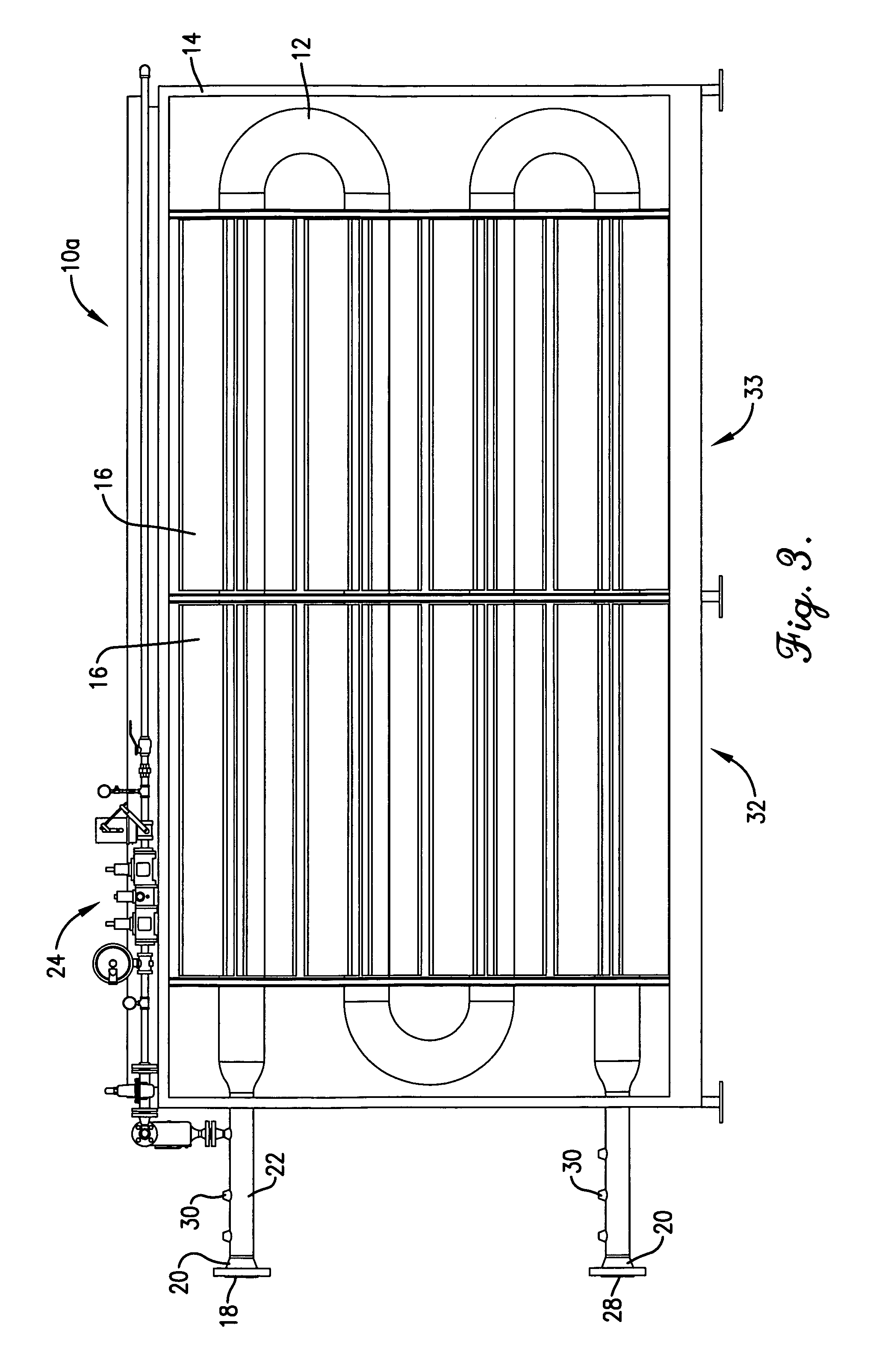

Process and apparatus for heating feedwater in a heat recovery steam generator

InactiveUS20120312019A1Steam generation heating methodsSteam accumulatorsCorrosive acidExhaust fumes

A feedwater heater (14) in a heat recovery steam generator (A,B) lies within a flow of hot exhaust gas. The feedwater heater (14) converts subcooled feedwater into saturated feedwater water, the temperature of which is only lightly above the acid dew point temperature of the exhaust gas so that corrosive acids do not condense on coils (18) of the feedwater heater (14). Yet the temperature of the saturated feedwater lies significantly below the temperature of the exhaust gas at the coils (18), so that the coils (18) operate efficiently and require minimal surface area. Pumps (26, 28, 30) elevate the pressure of the saturated feedwater and direct it into an economizer (64, 90) where, owing to the increase in pressure, the water is again subcooled. The economizer (64, 90) elevates the temperature still further and delivers the higher pressure feedwater to evaporators (34, 70, 78) that convert it into saturated steam that flows on to the superheaters (50, 78, 84). Higher pressure pegging stem admitted to the feedwater heater (14) controls the pressure—and temperature—of saturated steam and water in the feedwater heater (14).

Owner:NOOTER ERIKSEN INC

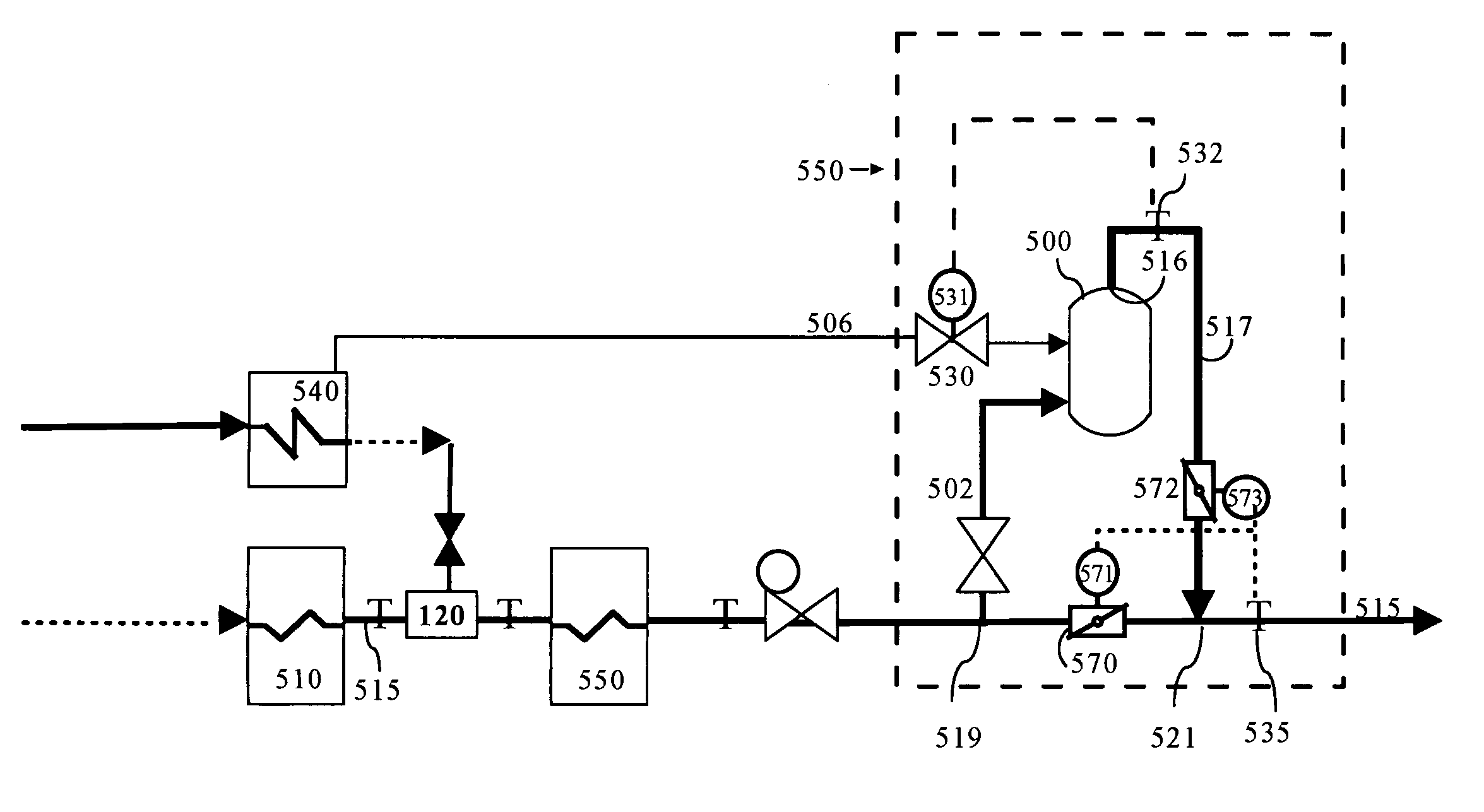

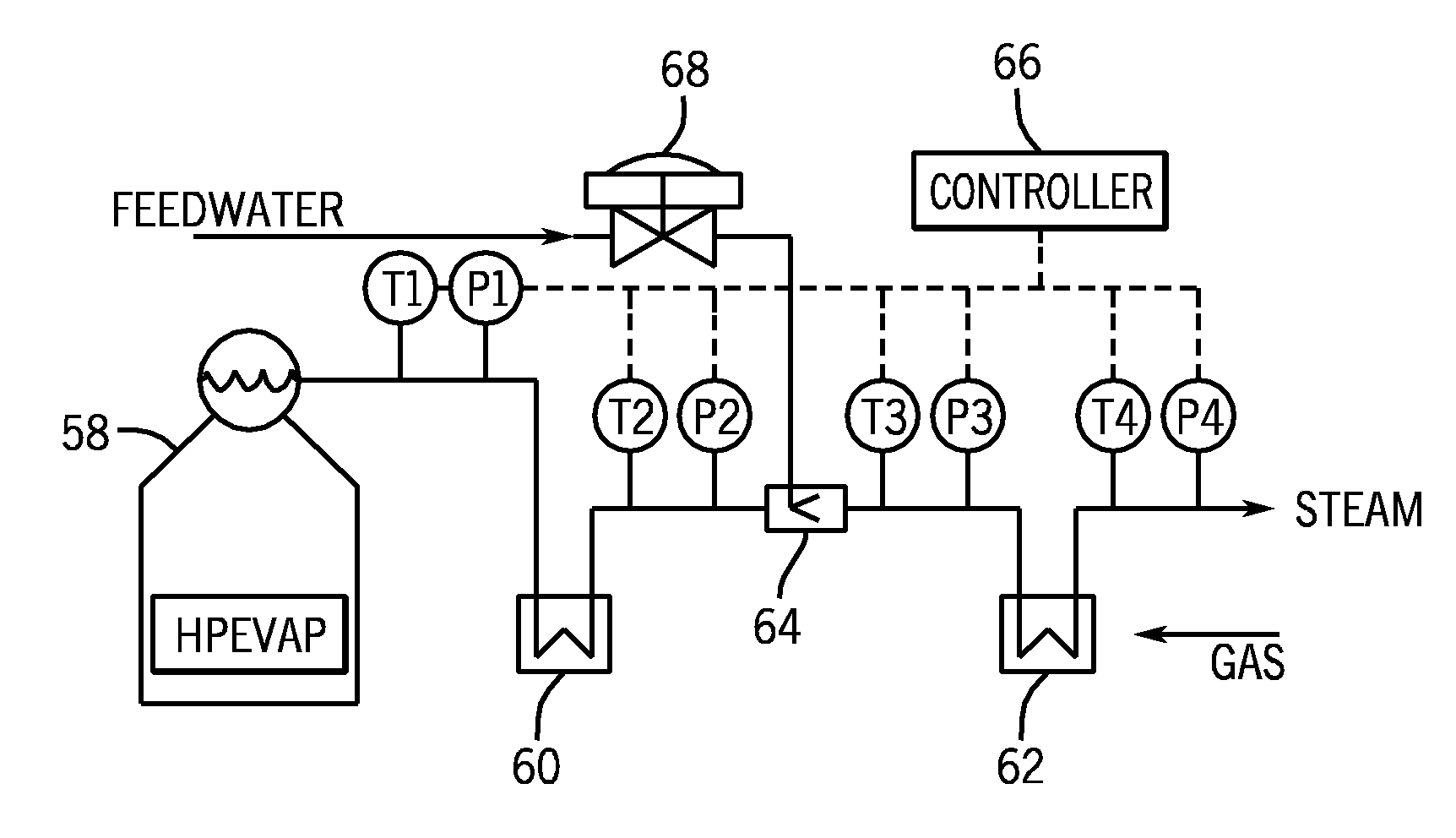

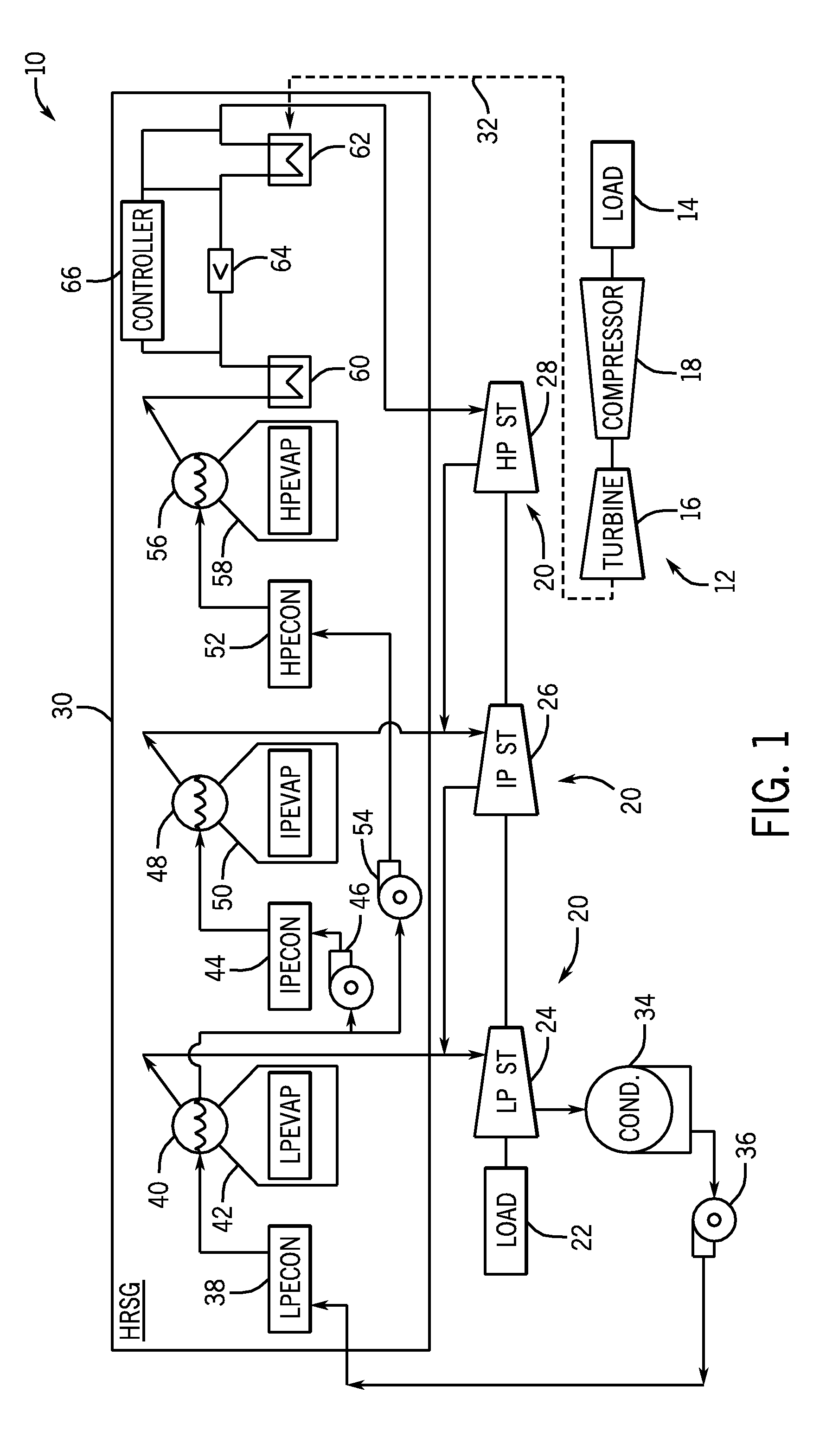

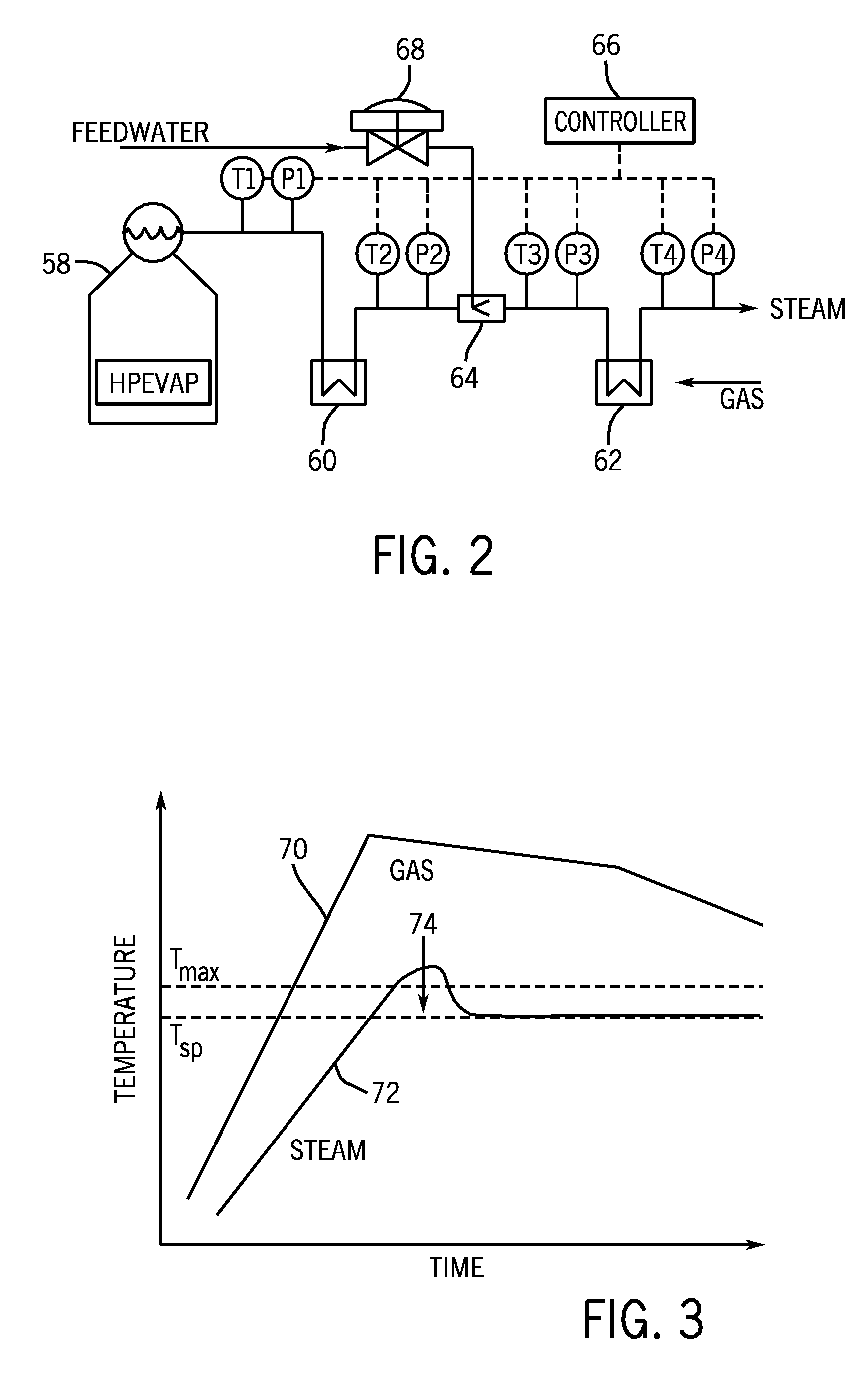

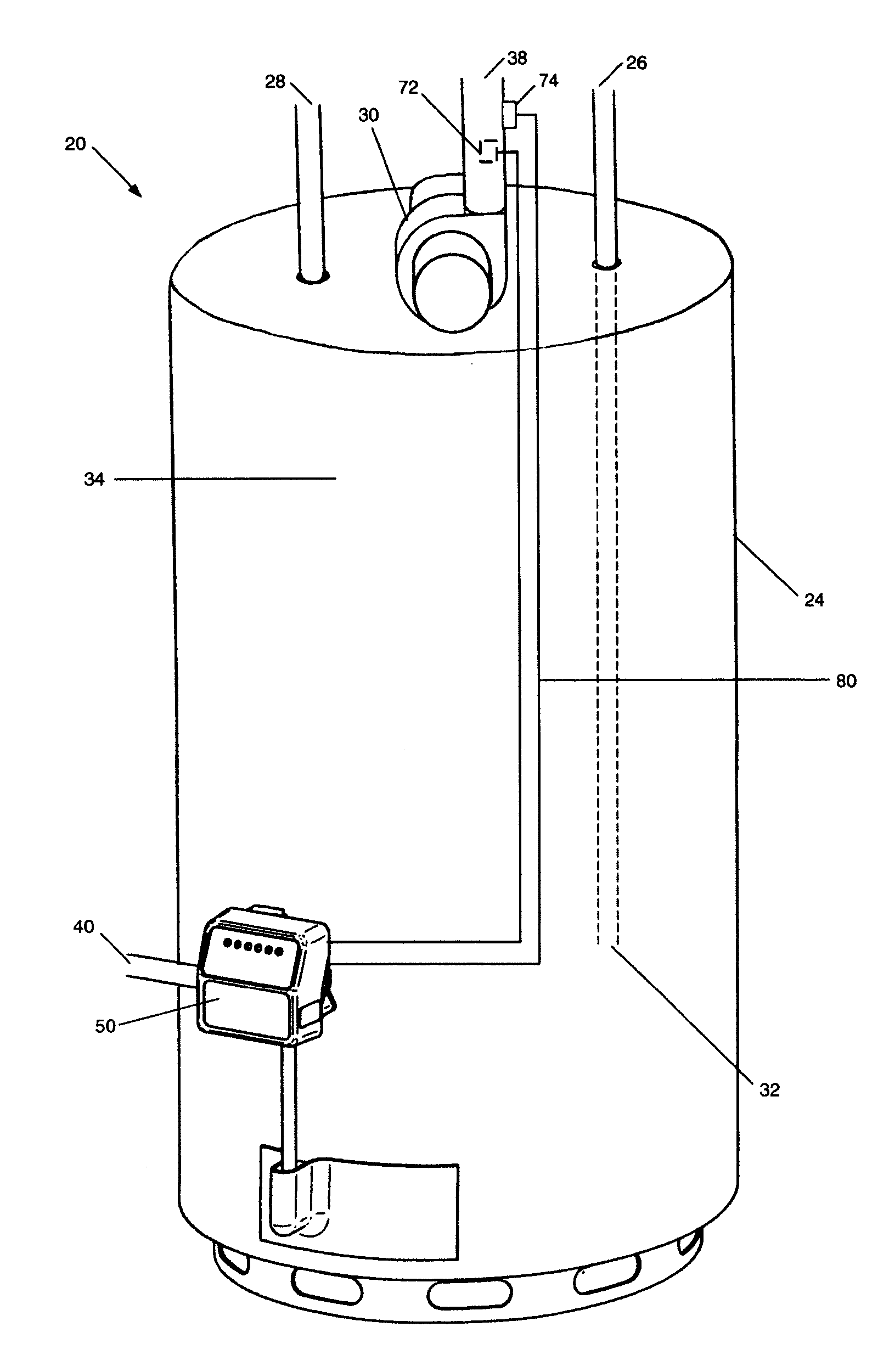

Inter-stage attemperation system and method

Systems and methods for controlling exhaust steam temperatures from a finishing superheater are provided. In certain embodiments, the system includes a controller which includes control logic for predicting an exhaust temperature of steam from the finishing superheater using model-based predictive techniques (e.g., based on empirical data or thermodynamic calculations). Based on the predicted exhaust temperature of steam, the control logic may use feed-forward control techniques to control the operation of an inter-stage attemperation system upstream of the finishing superheater. The control logic may determine if attemperation is required based on whether the predicted exhaust temperature of steam from the finishing superheater exceeds a set point temperature as well as whether the inlet temperature of steam into the finishing superheater drops below a set point temperature of steam. The attemperation system may include a characterizing function to linearize the valve operation controlled by the control logic to inject cooled, high-pressure feedwater into the steam upstream of the finishing superheater, which may, in turn, control the exhaust temperature of steam from the finishing superheater. The disclosed embodiments may also be applied to any systems where an outlet temperature of a fluid from a heat transfer device may be controlled.

Owner:GENERAL ELECTRIC CO

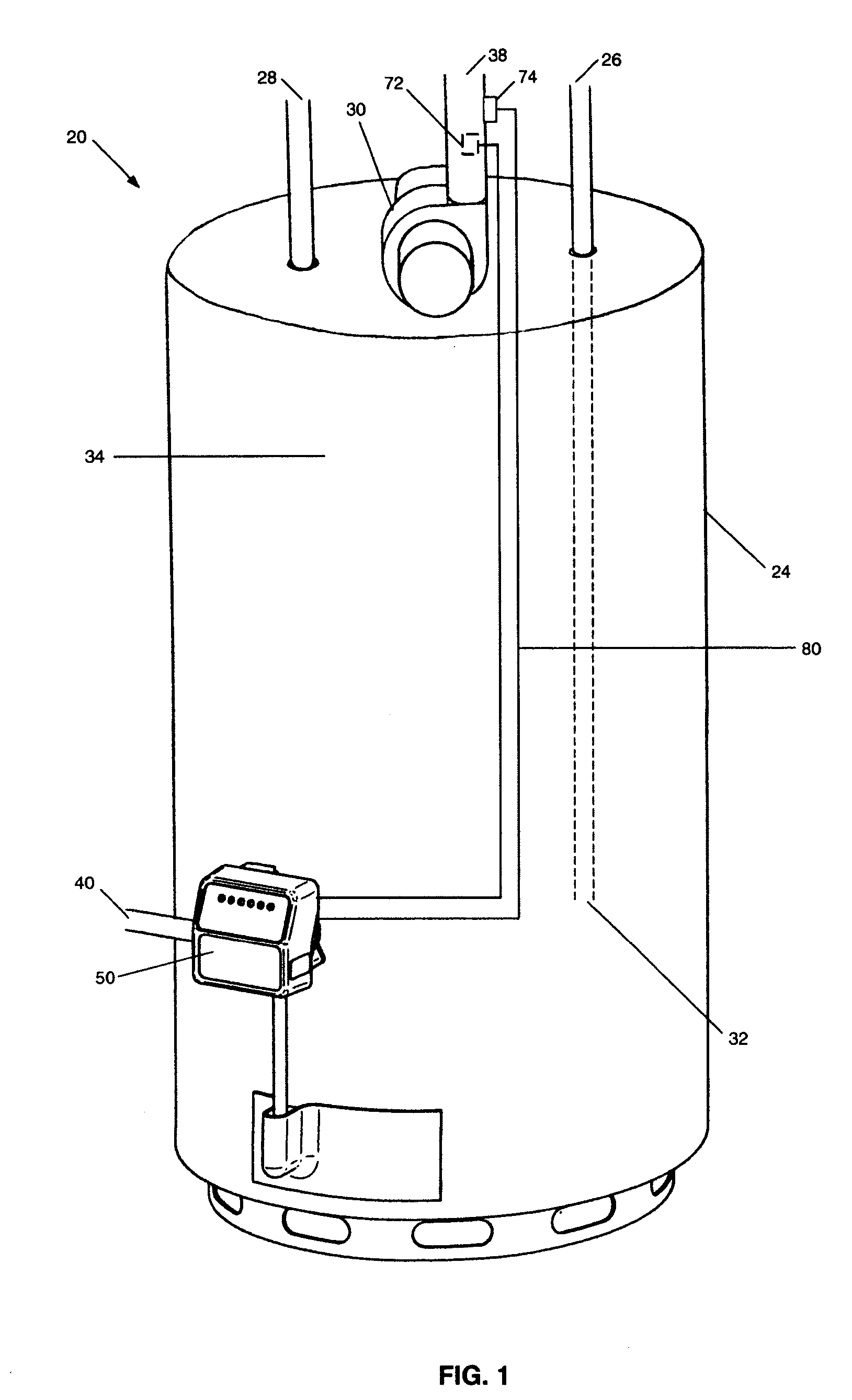

System and methods for controlling a water heater

A control for a water heater is provided that comprises a pressure switch for sensing a predetermined level of airflow sufficient for maintaining proper burner operation, and a temperature sensing means for sensing the temperature of the water in the tank. The control further comprises a processor for controlling the operation of the burner to maintain the water temperature above a predetermined value. When the processor receives a signal from the pressure switch indicating an insufficient level of airflow, the processor shuts down the burner and subsequently attempts to restart the burner. The processor will also lock-out further burner operation after a predetermined number of consecutive shut downs occurs before the water is heated to a desired temperature during a single call for heating.

Owner:COPELAND COMFORT CONTROL LP +1

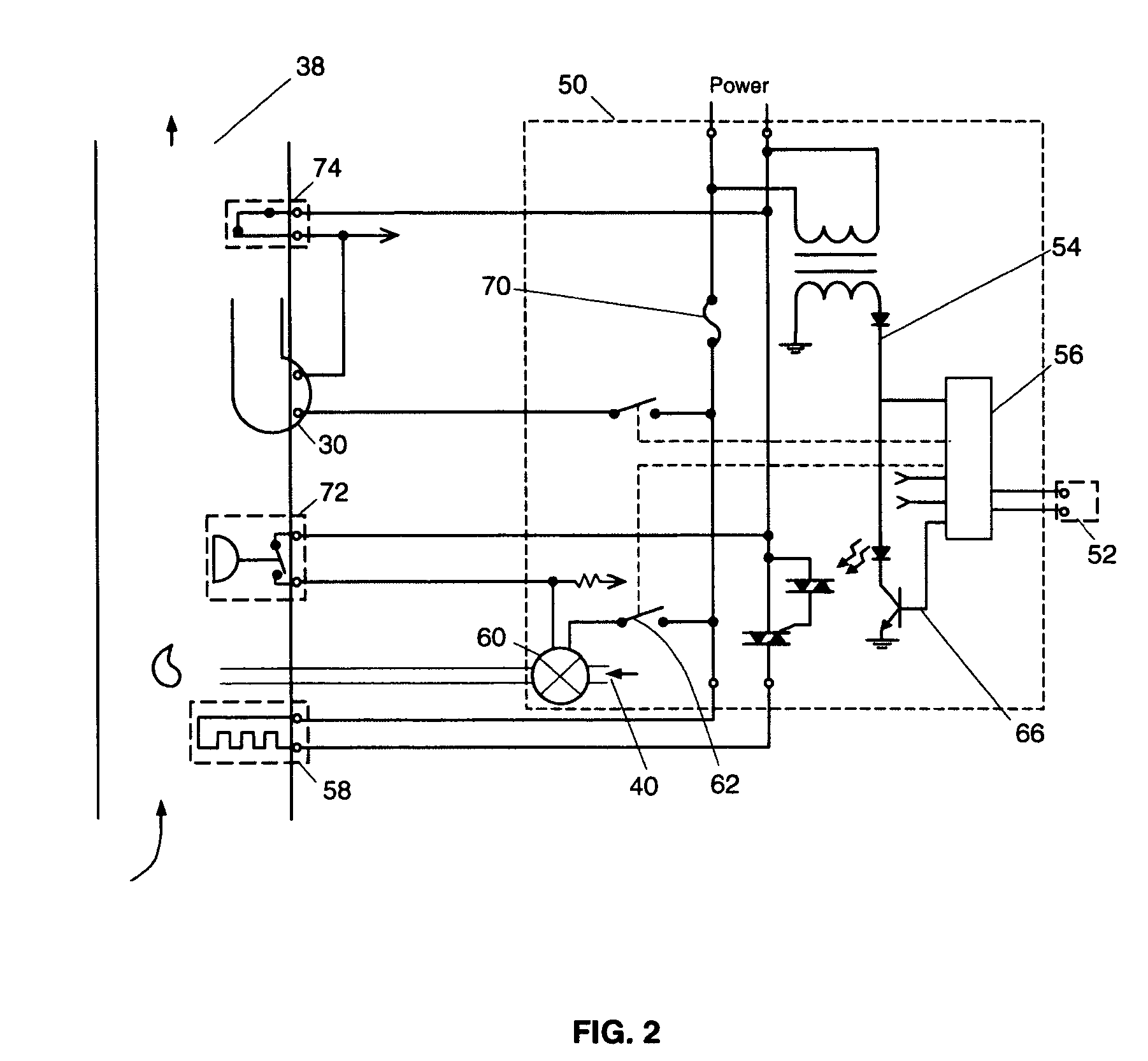

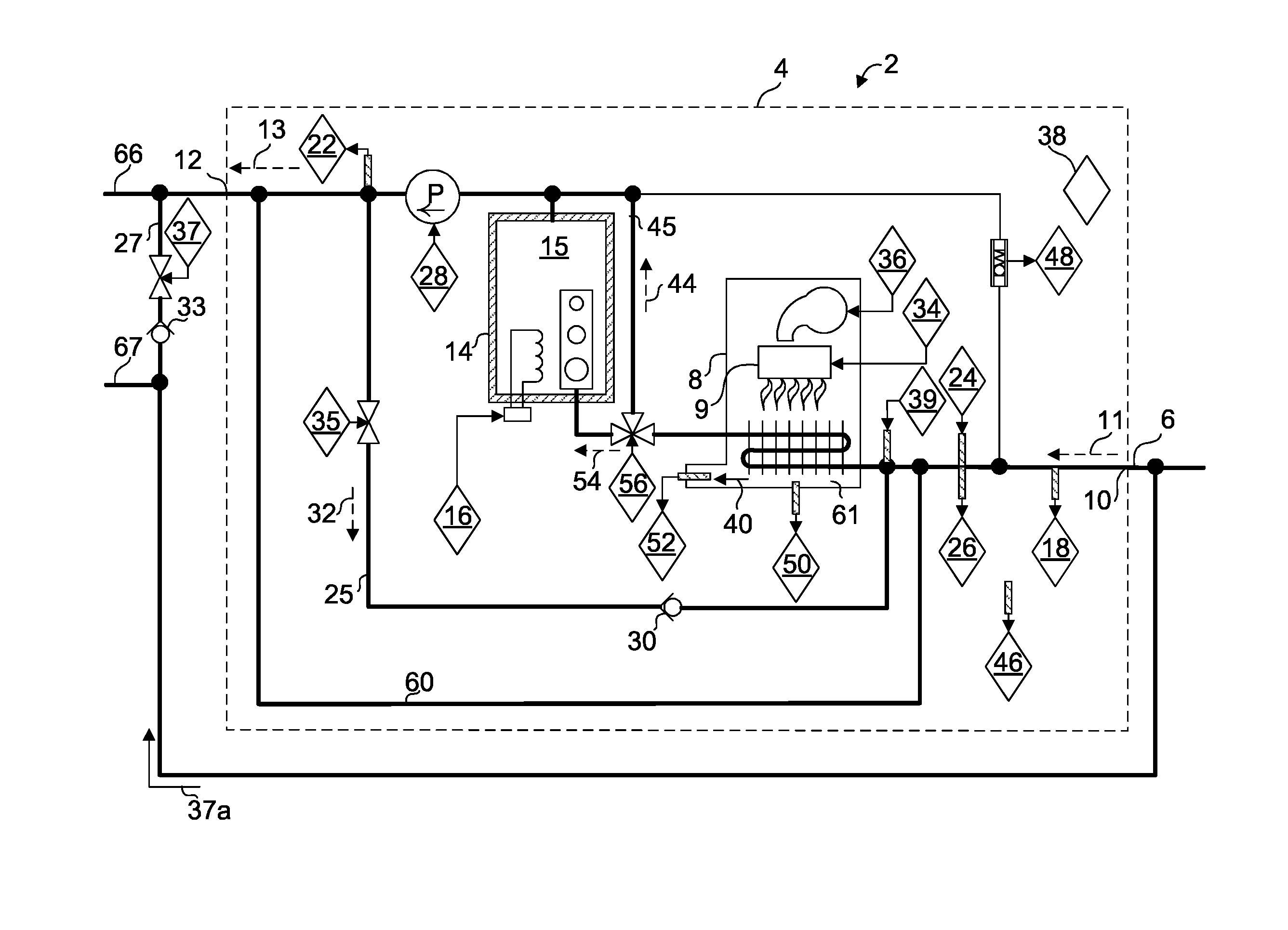

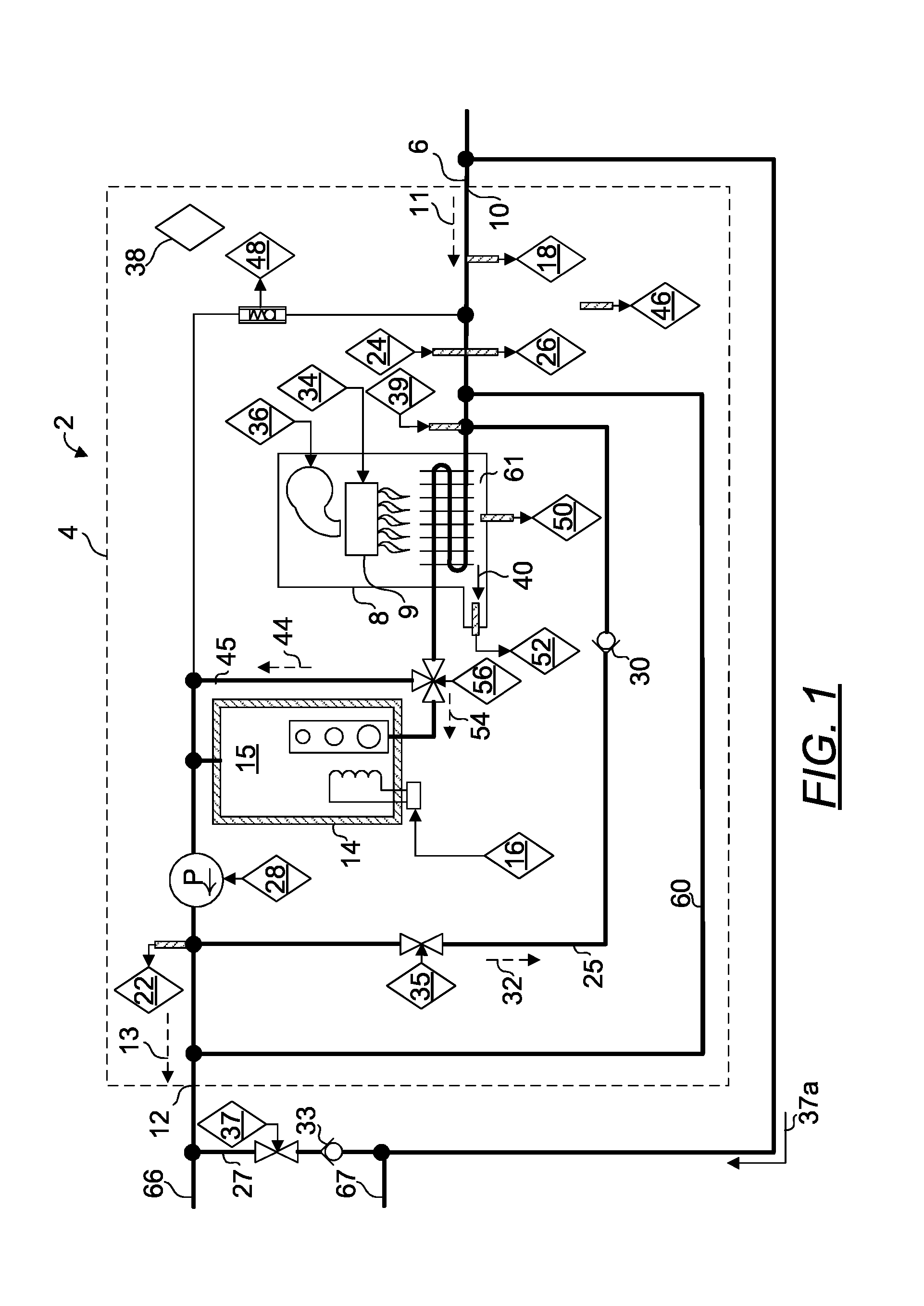

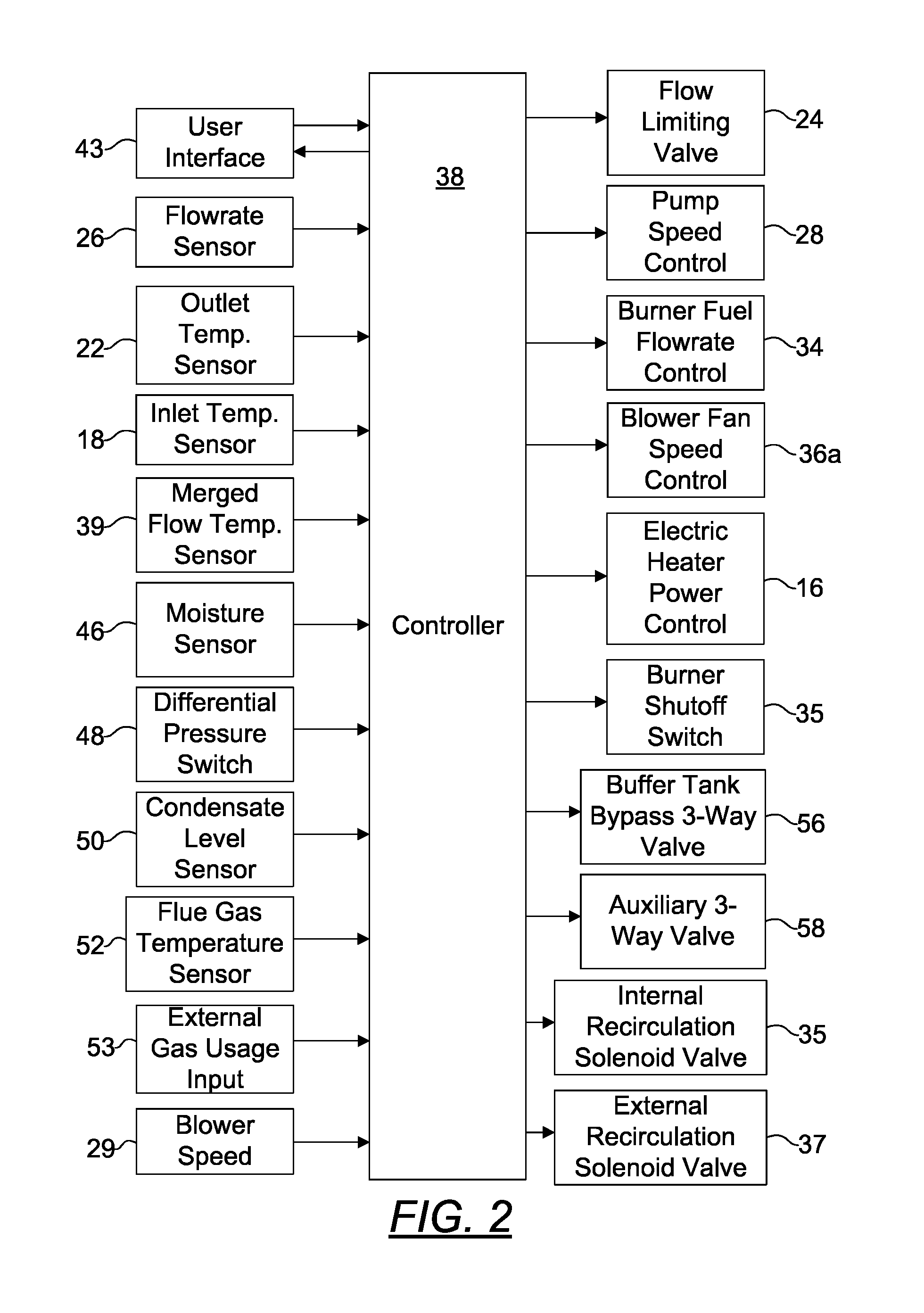

Apparatus and control method for a hybrid tankless water heater

ActiveUS20130312671A1Quick checkAvoid delayCentral heating componentsTemperatue controlTemperature responseBuffer tank

An on demand tankless water heater system that is capable of quickly delivering water within a desired temperature range. The tankless water heater provides a hybrid heating method that contains a primary heating system and a secondary heating system disposed in a buffer tank that cooperate to facilitate control of output water temperature during water usage. A pressure differential switch detects low flow demand and allows the secondary heating system to provide immediate heating to the water. This secondary heating system provides a faster temperature response and fine tuning of output water temperature.

Owner:INTELLIHOT

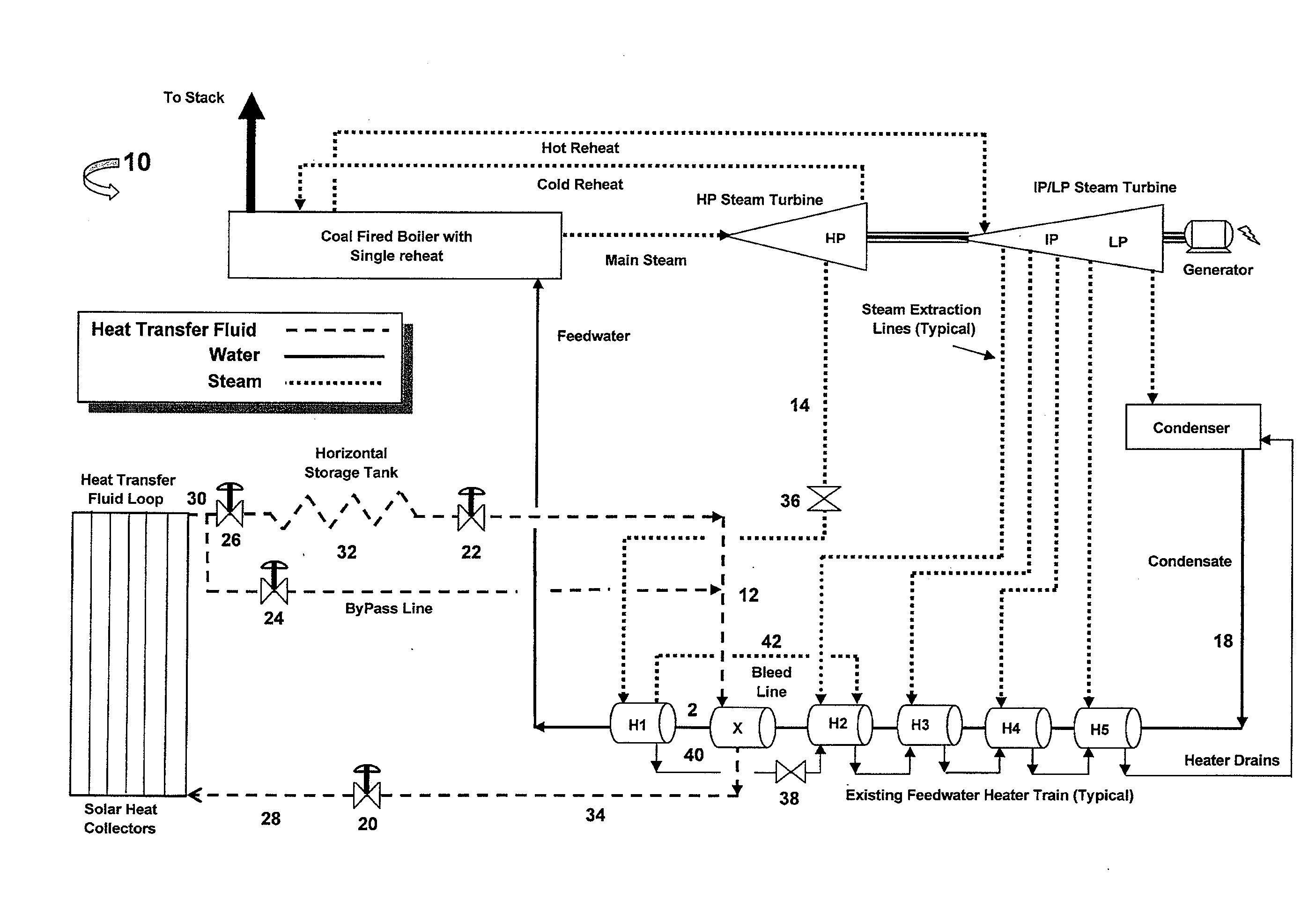

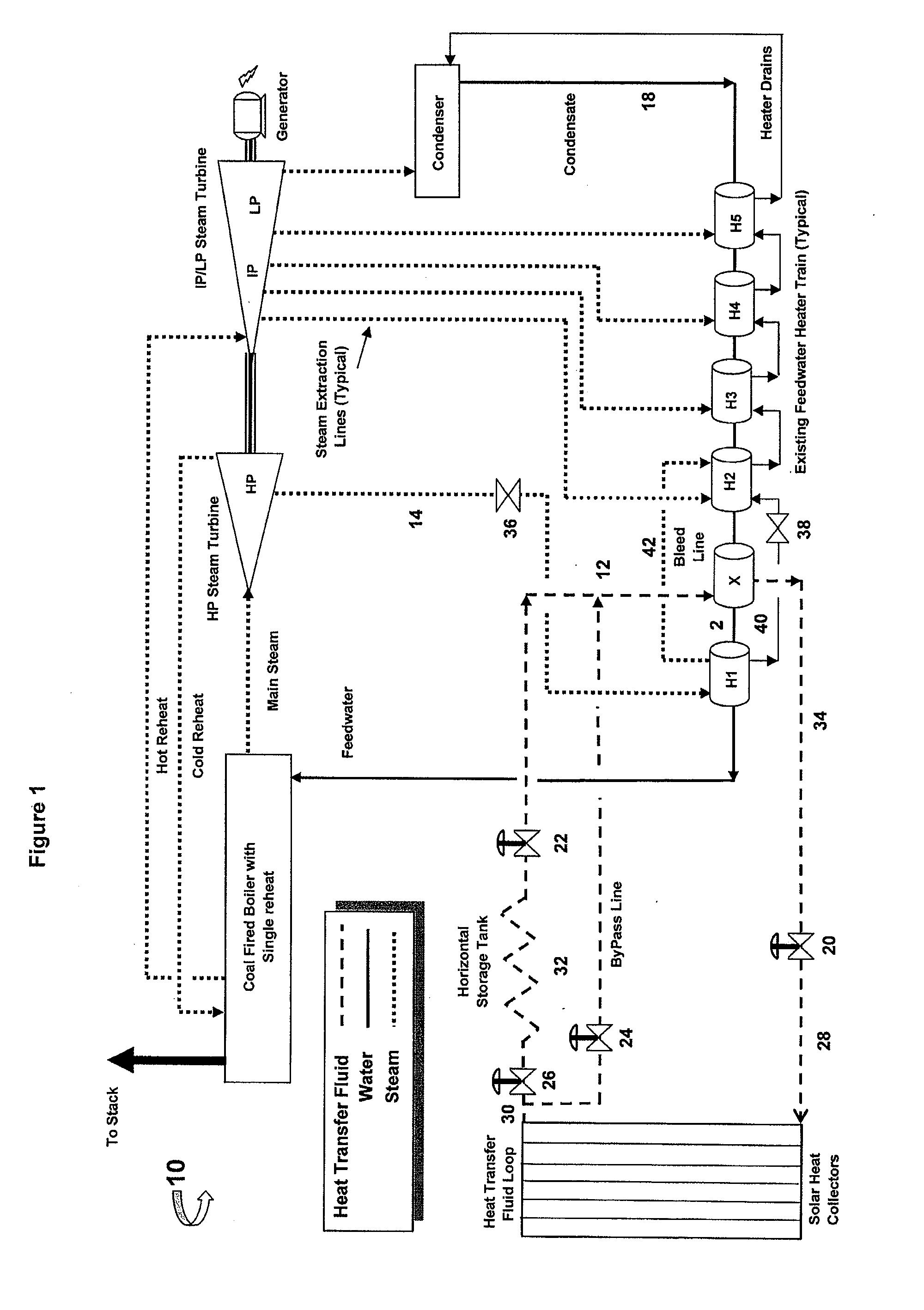

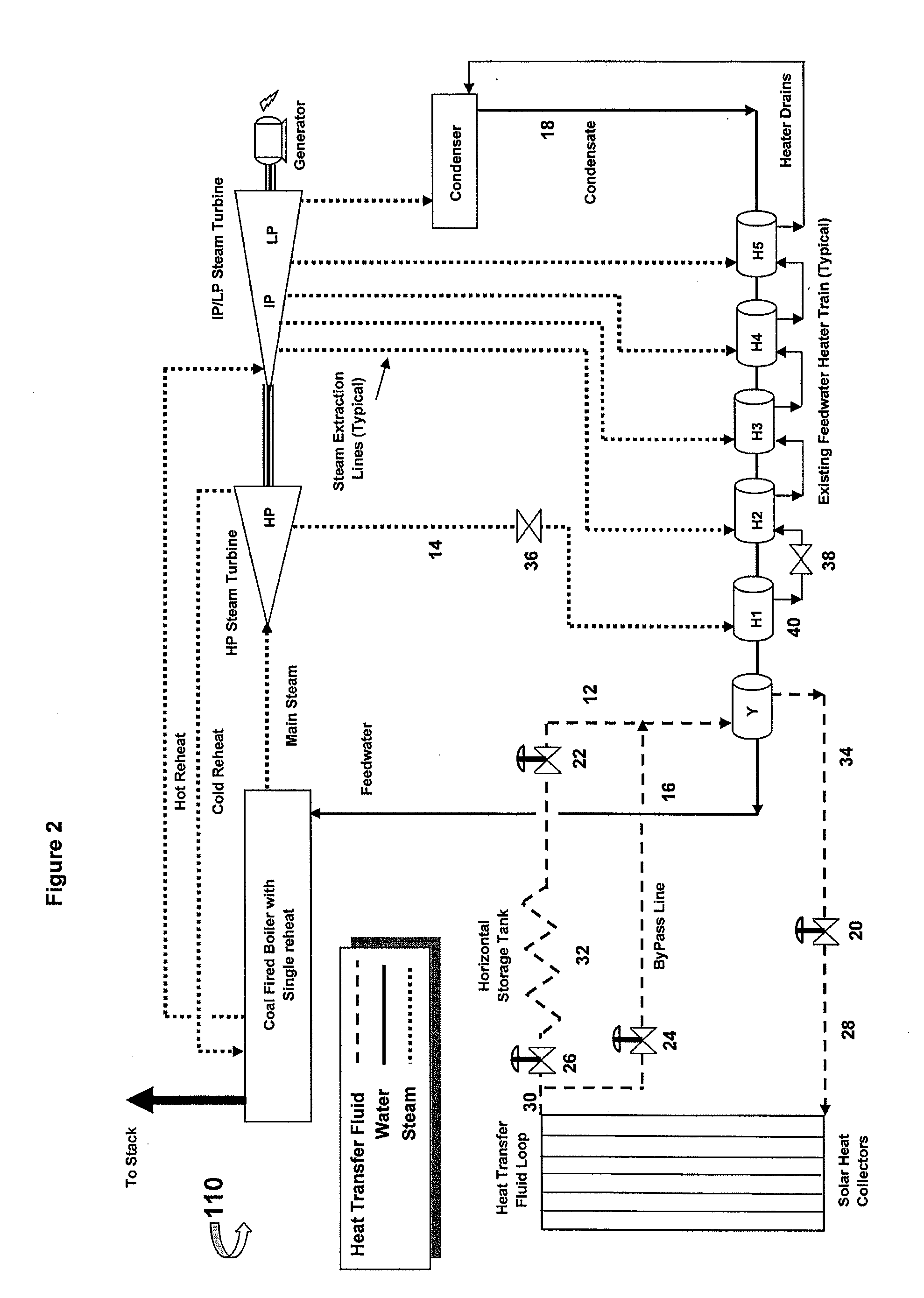

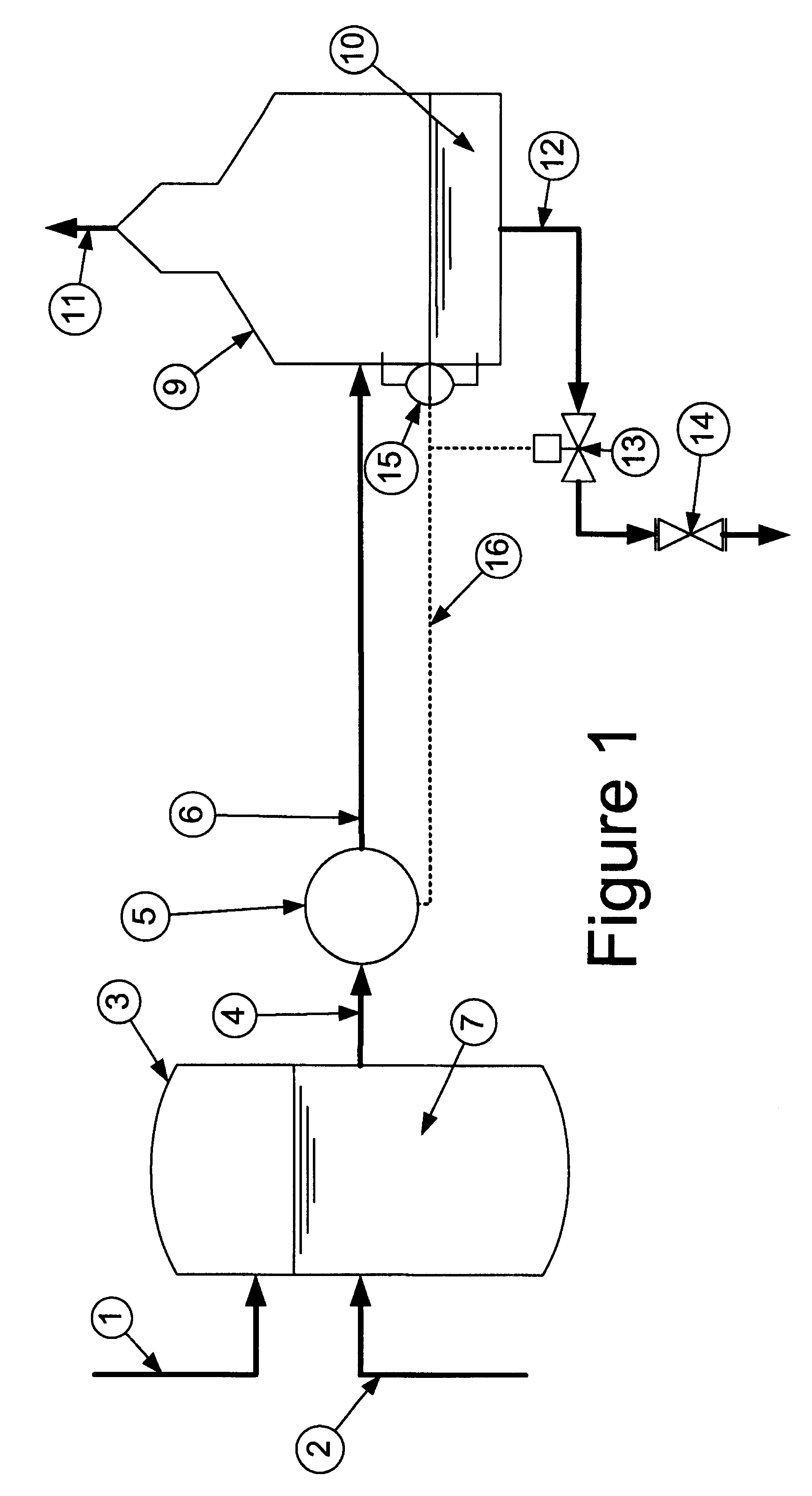

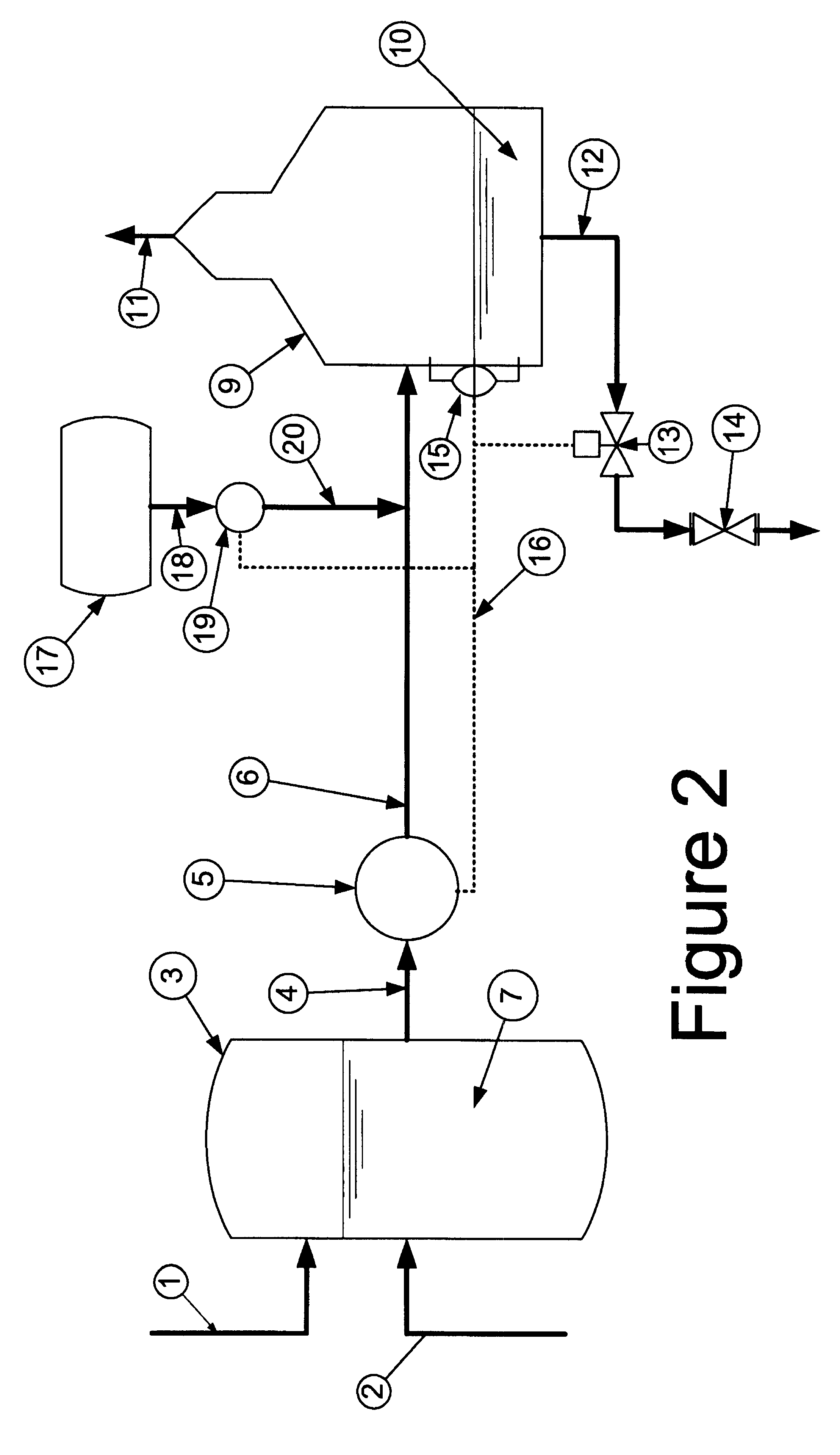

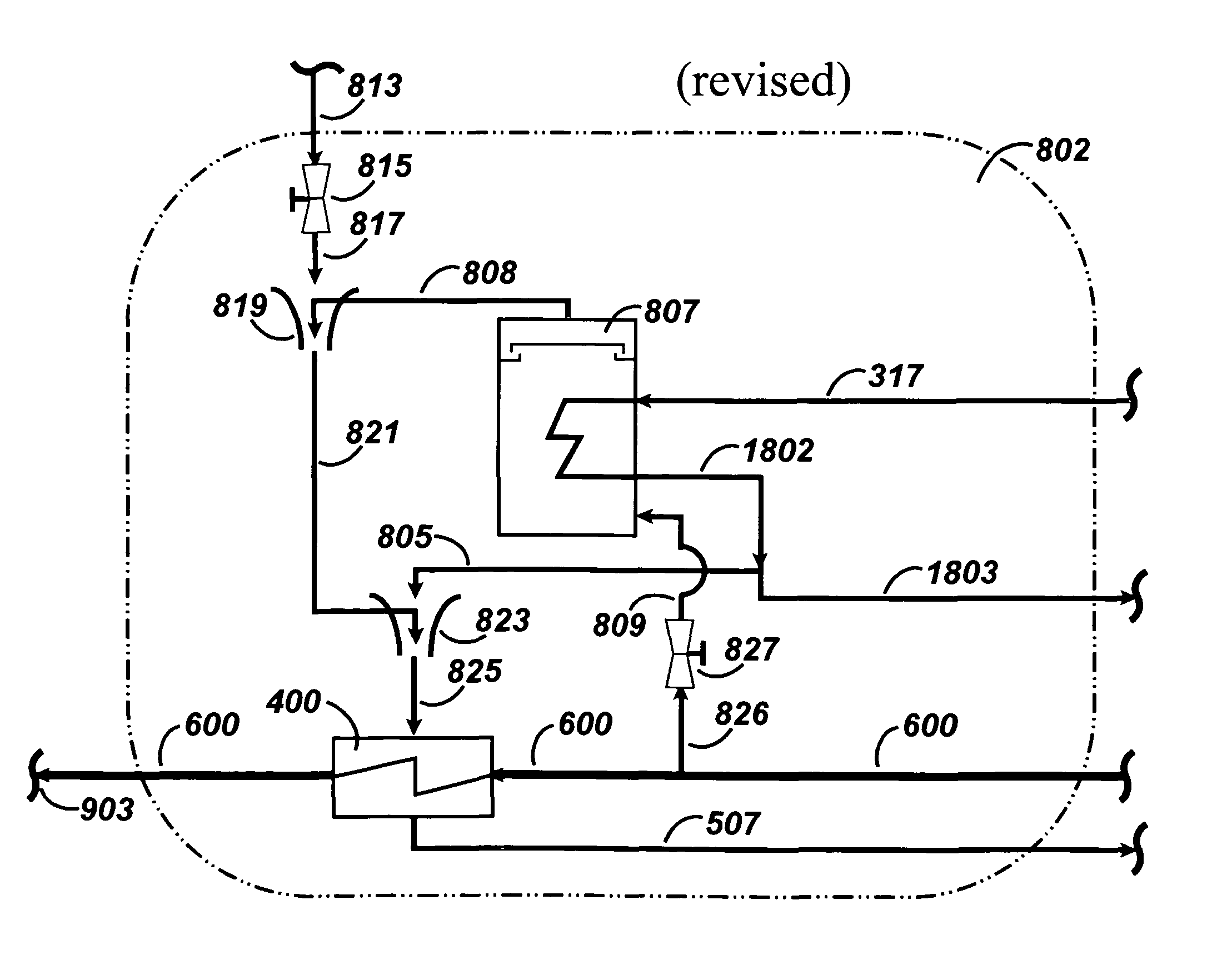

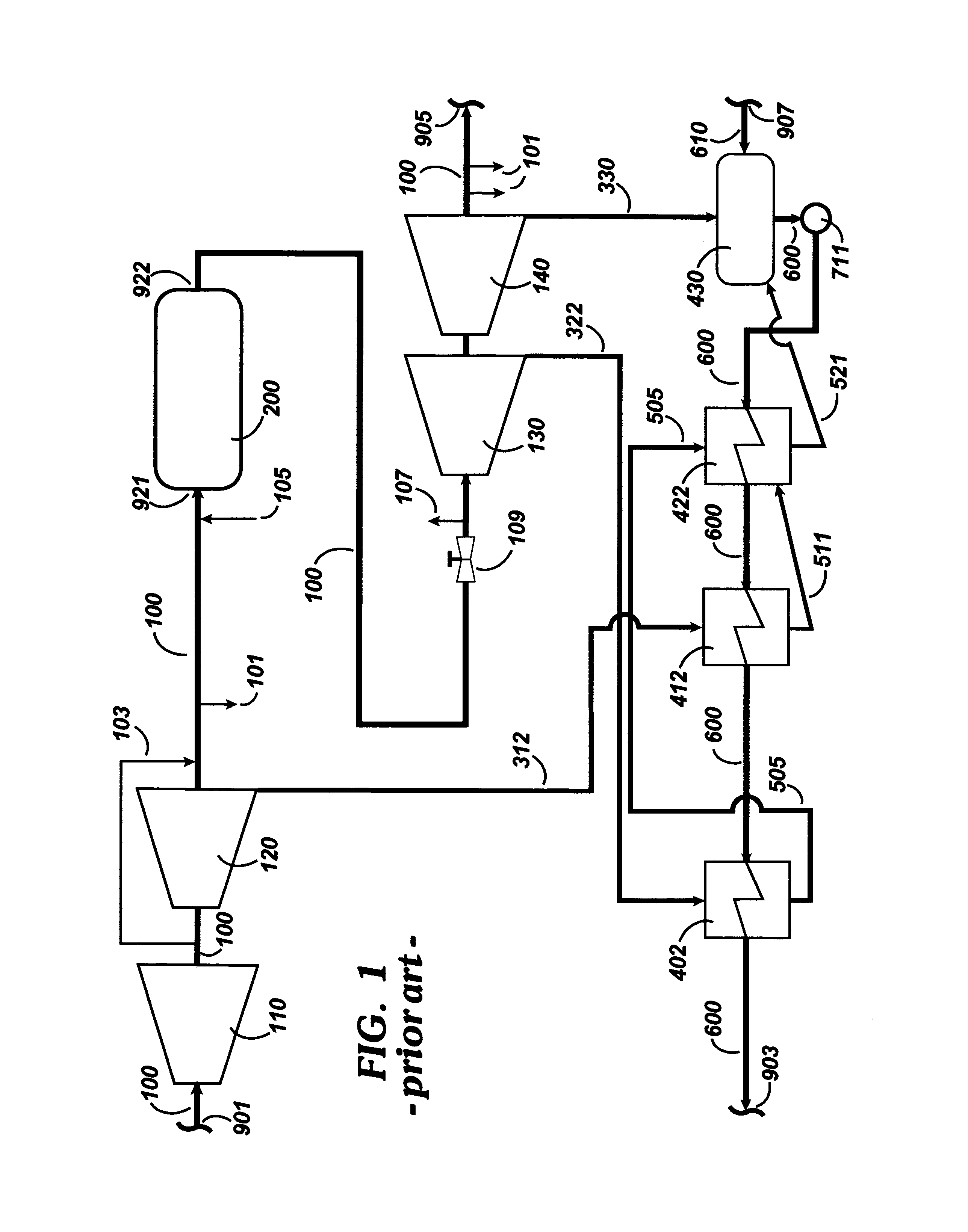

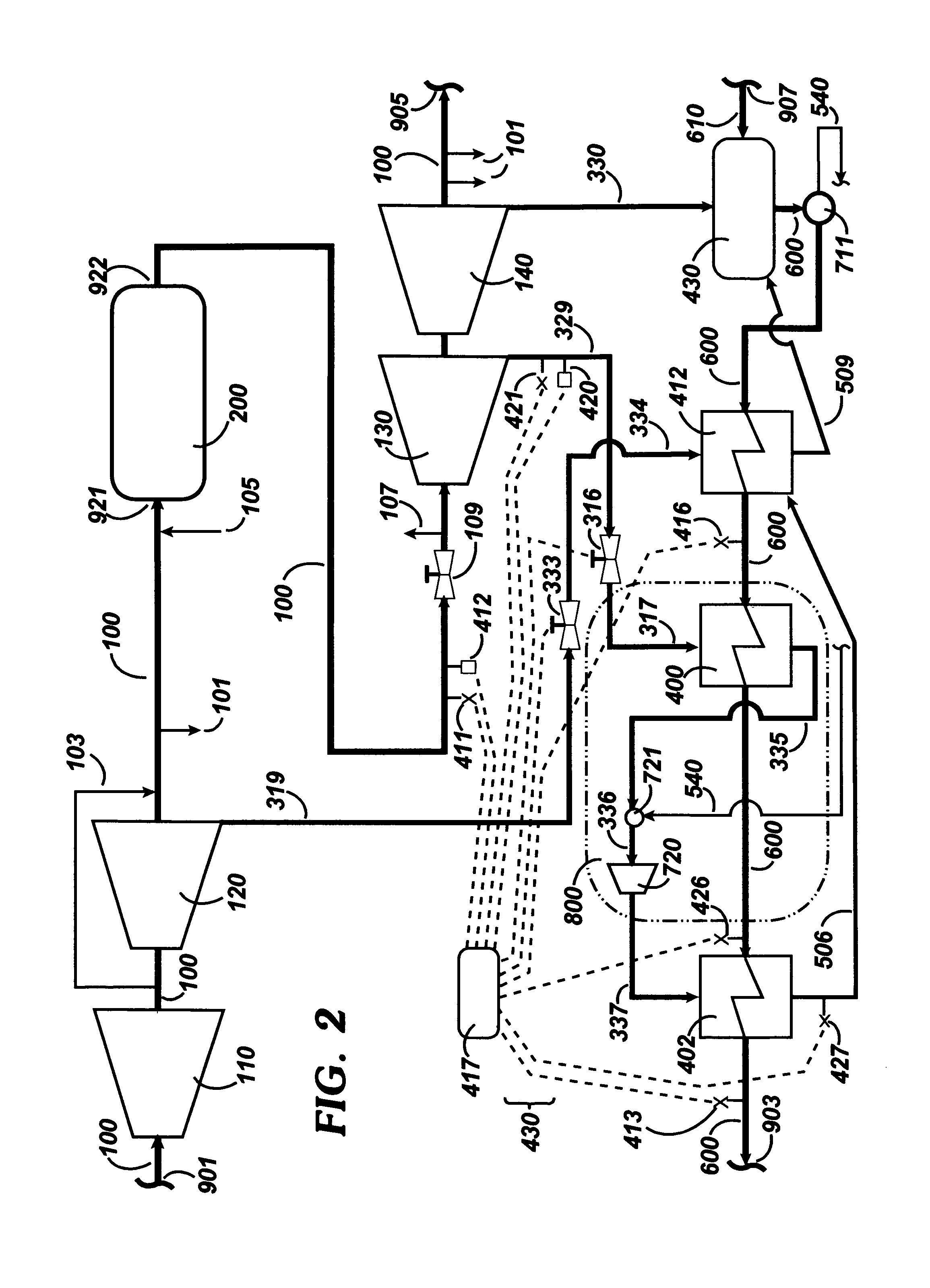

Method and apparatus for controlling the final feedwater temperature of a regenerative Rankine cycle using an exergetic heater system

ActiveUS8091361B1Power Loss MinimizationImprove system reliabilitySteam regenerationSteam useWorking fluidPower station

This invention relates to a method and apparatus for increasing the final feedwater temperature associated with a regenerative Rankine cycle, said cycle commonly used in thermal systems such as conventional power plants, whose steam generators are fired with a fossil fuel and whose regenerative Rankine cycle employs a reheating of the working fluid. This invention involves the placement of an Exergetic Heater System in the feedwater path of the regenerative Rankine cycle. The Exergetic Heater System conditions and heats feedwater such that the temperature of the cycle's final feedwater as it enters the steam generator has reached a desired value. The Exergetic Heater System receives its driving steam from an Intermediate Pressure turbine extraction.

Owner:EXERGETIC SYST

Method for recovery and utilization of waste heat from low temperature flue gas

InactiveCN102269401AReduce heatIncreasing energy efficiencyHot-water central heatingThermal energyBoiler feedwater pump

The invention discloses a method for recovering and utilizing waste heat from low-temperature flue gas. An air-water heat exchanger (4) is connected in series or in parallel in the flue at the rear of the induced draft fan or booster fan (3) of the existing boiler or kiln (1). The inlet port of the hot side of the air-water heat exchanger is connected with the induced draft fan or booster fan (3), the outlet port of the hot side is connected with the desulfurization absorption tower (8) or the chimney (9), and the inlet port of the cold side is circulated with the heat user The outlet pipe or condensate pipe of the water or boiler softened water system is connected, the cold side outlet is connected with the hot user circulating water supply or the boiler feed water pump, and a waterway is connected between the hot side outlet pipe and the cold side inlet pipe of the air-water heat exchanger A bypass pipe, and a waterway bypass regulating valve (5) is arranged on the pipe; a flue gas bypass pipe between the induced draft fan or booster fan and the desulfurization absorption tower (8), and a flue gas bypass pipe A flue bypass regulating valve (6) is arranged on it. By connecting a gas-water heat exchanger in series or in parallel in the flue behind the induced draft fan of the boiler or kiln, the purpose of saving heat energy can be achieved.

Owner:LUOYANG BLUE SEA INDAL

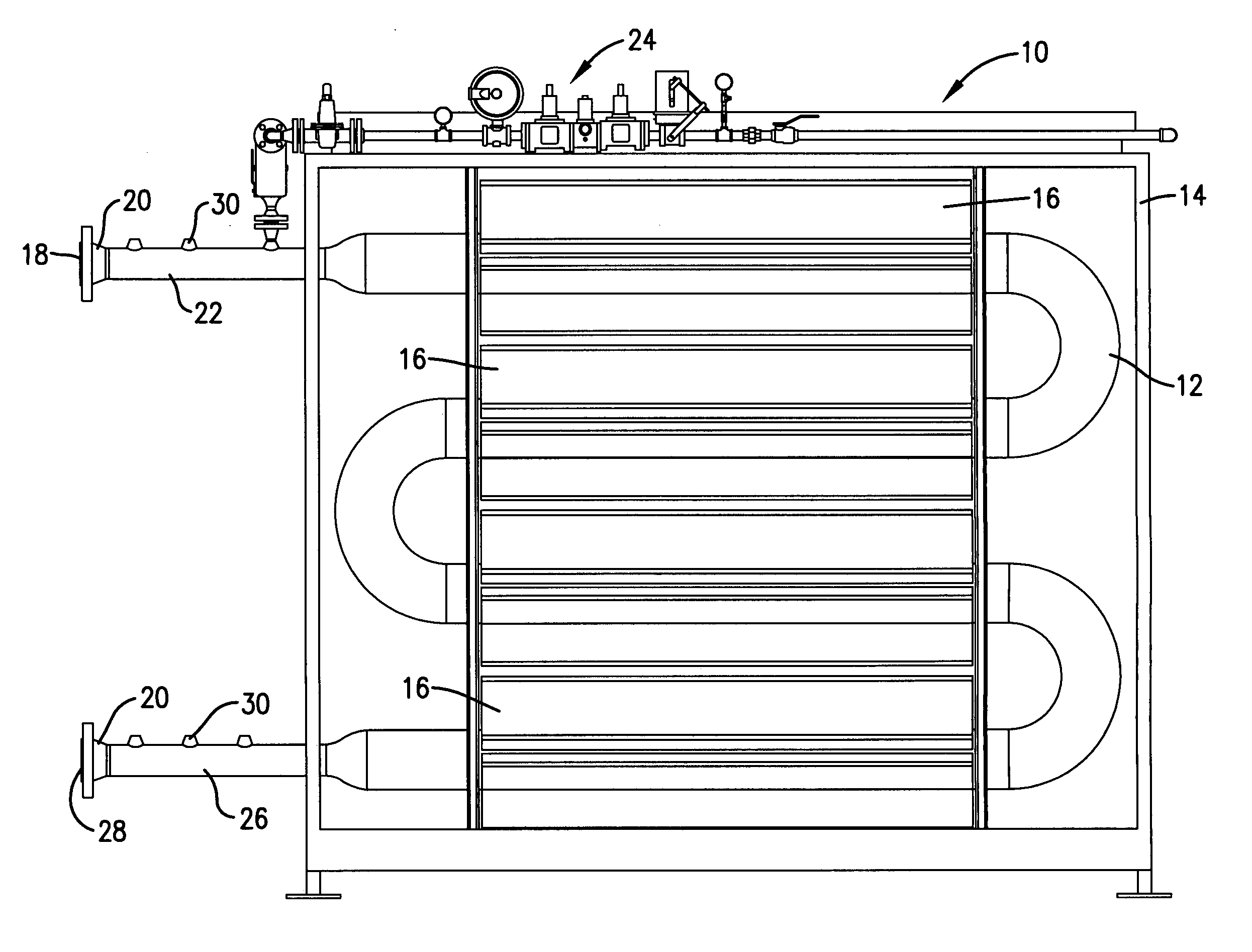

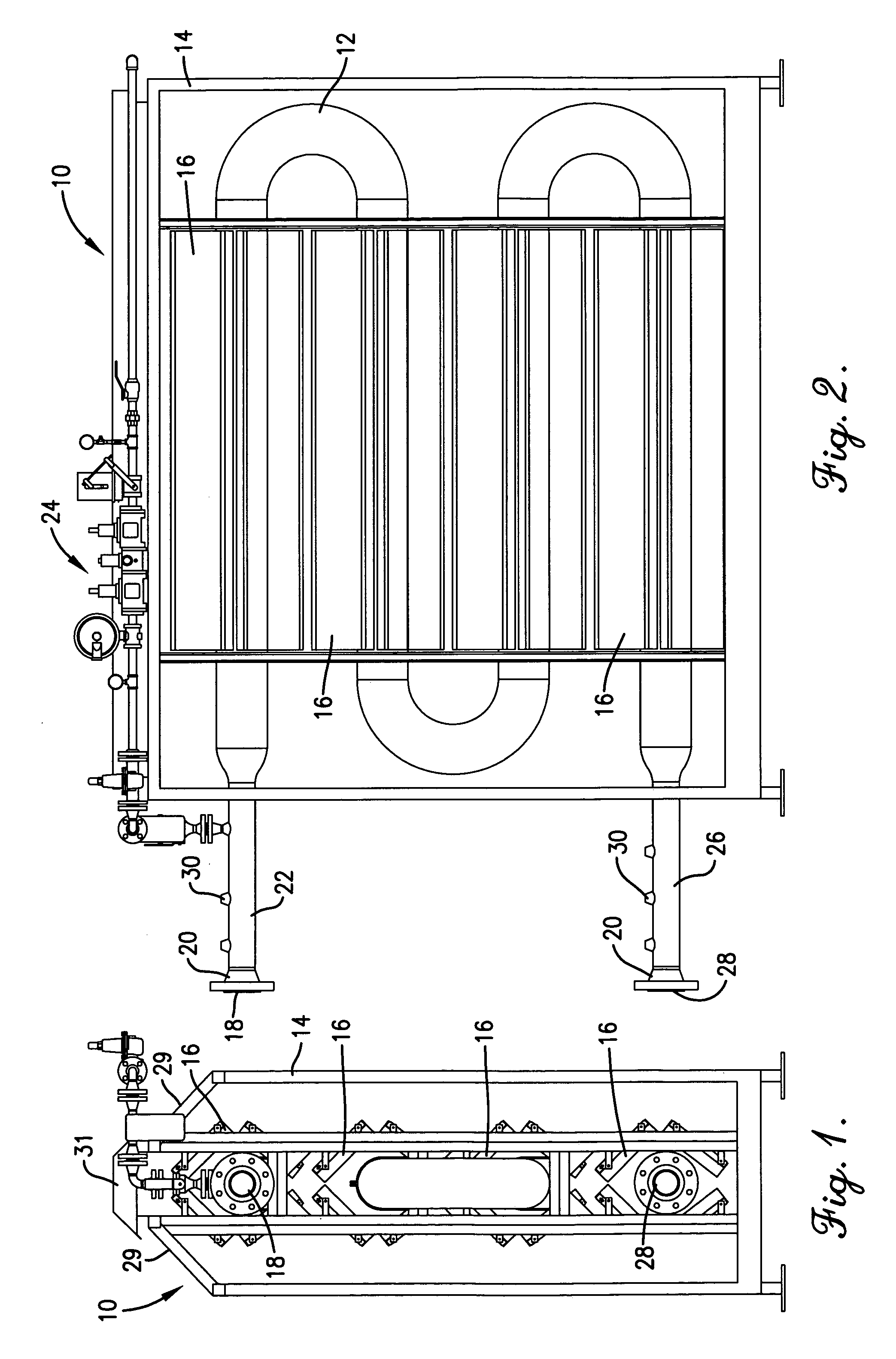

Pipeline heater

ActiveUS7066730B2Extended stayImprove heat transfer performanceOther heat production devicesSteam generation using pressureEngineeringResidence time

A pipeline heater comprising a plurality of flameless catalytic IR emitters positioned about a section of pipe in a substantially diamond-shaped configuration, the diameter of the pipe section being greater than the diameters of the heater inlet and outlet manifolds in order to increase the residence time of the fluid within the heater. The pipeline heater may comprise a single or multiple passes of the pipe section therethrough, each pass having a plurality of catalytic emitters positioned thereabout in a substantially diamond-shaped configuration.

Owner:CATALYTIC INDAL GROUP

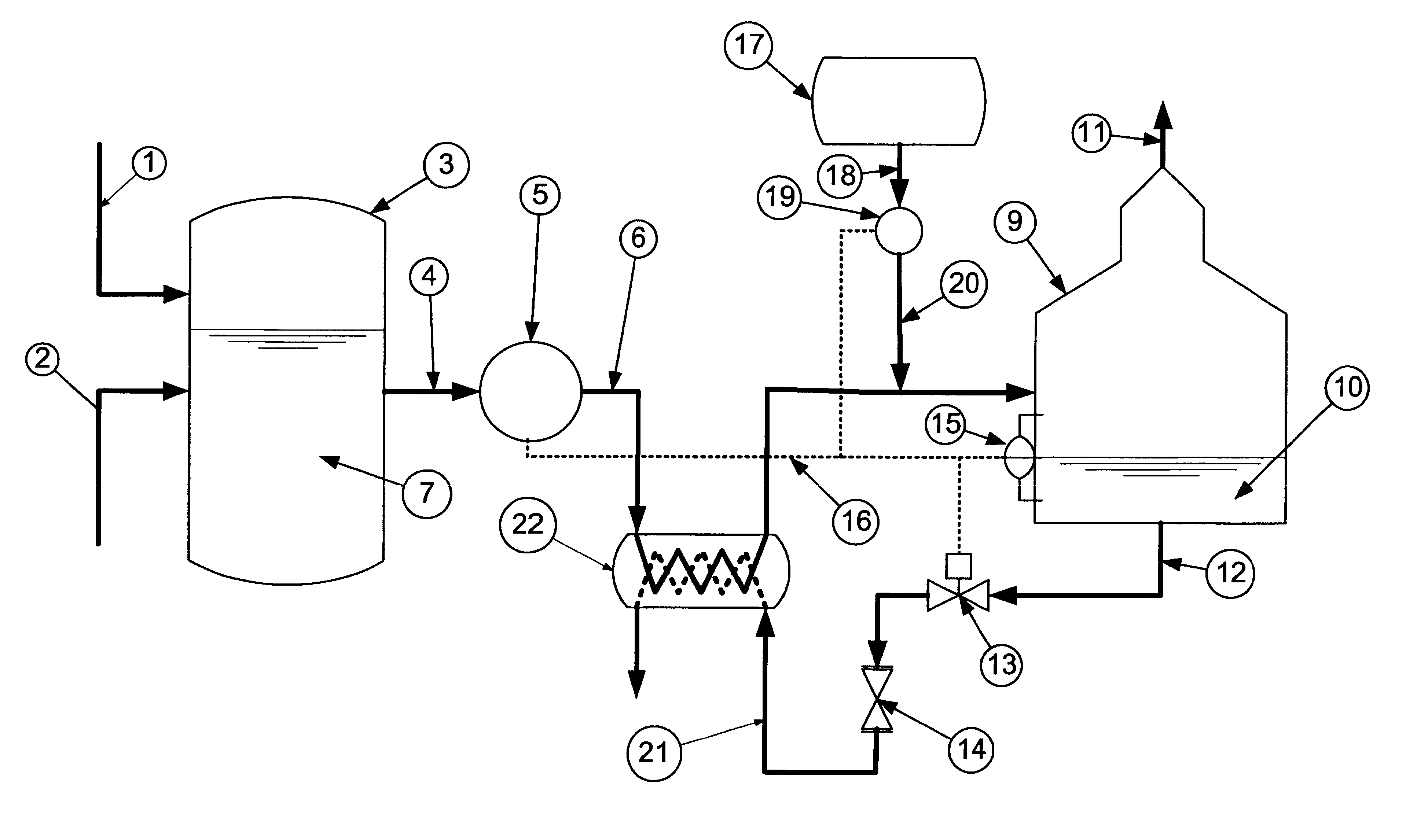

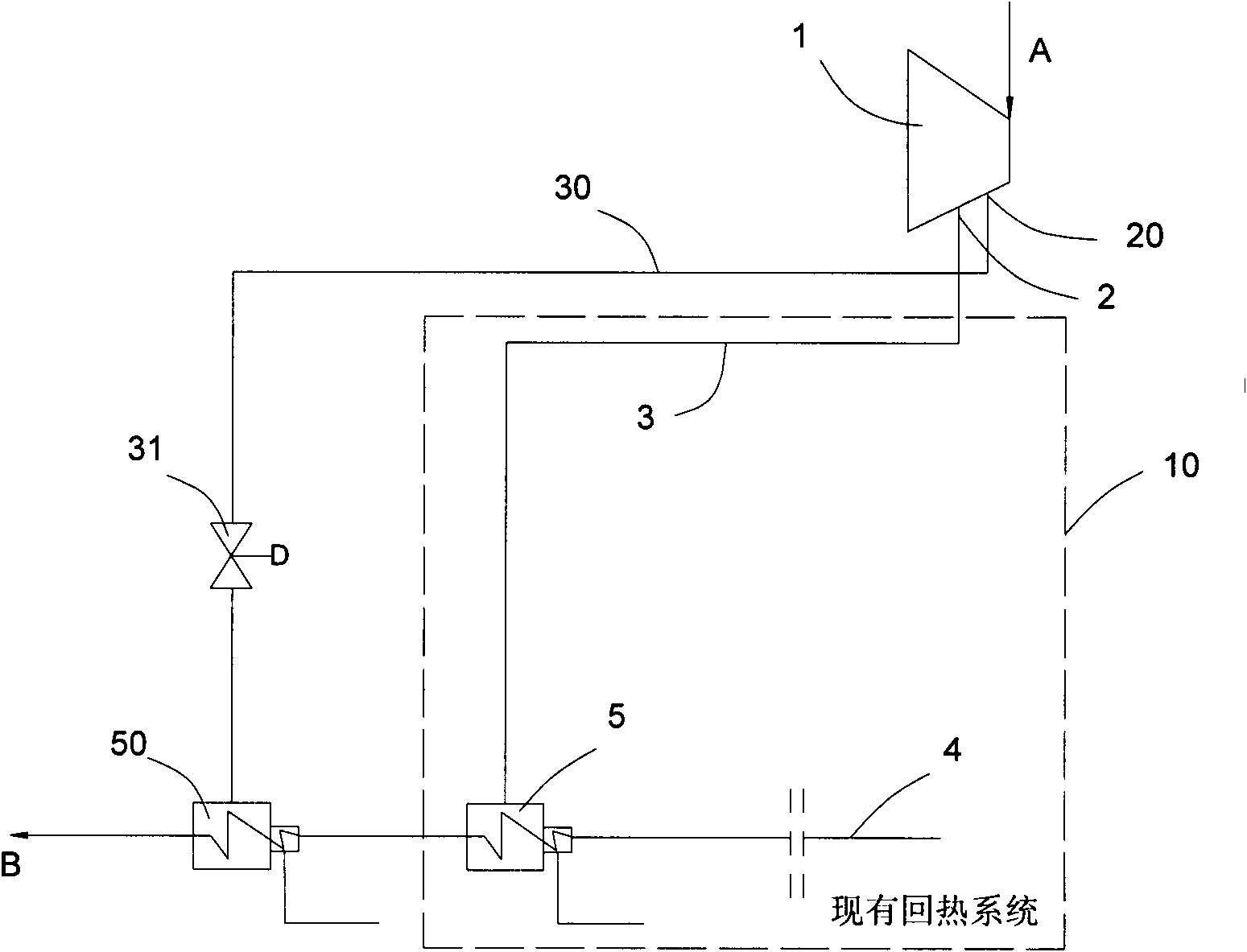

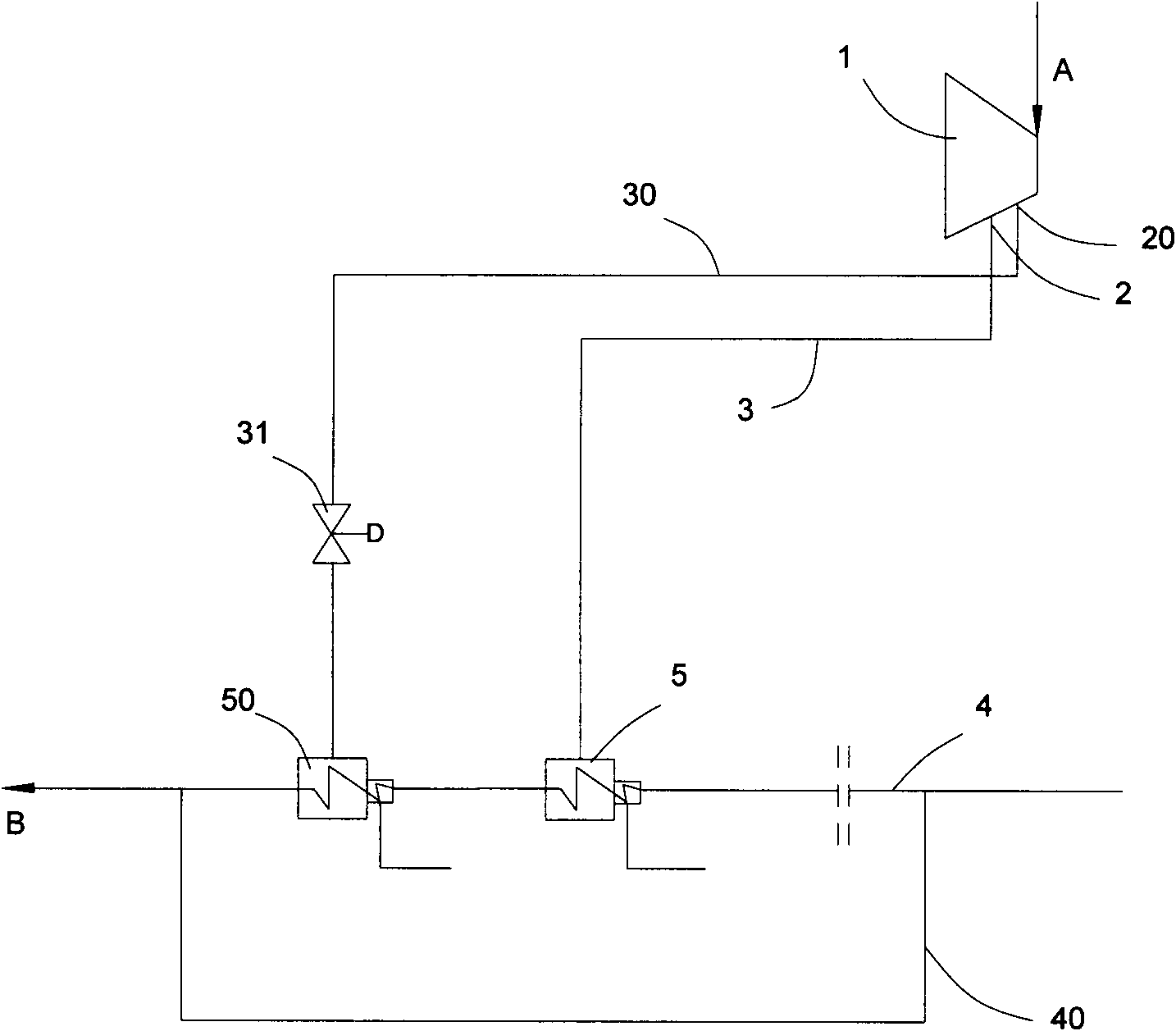

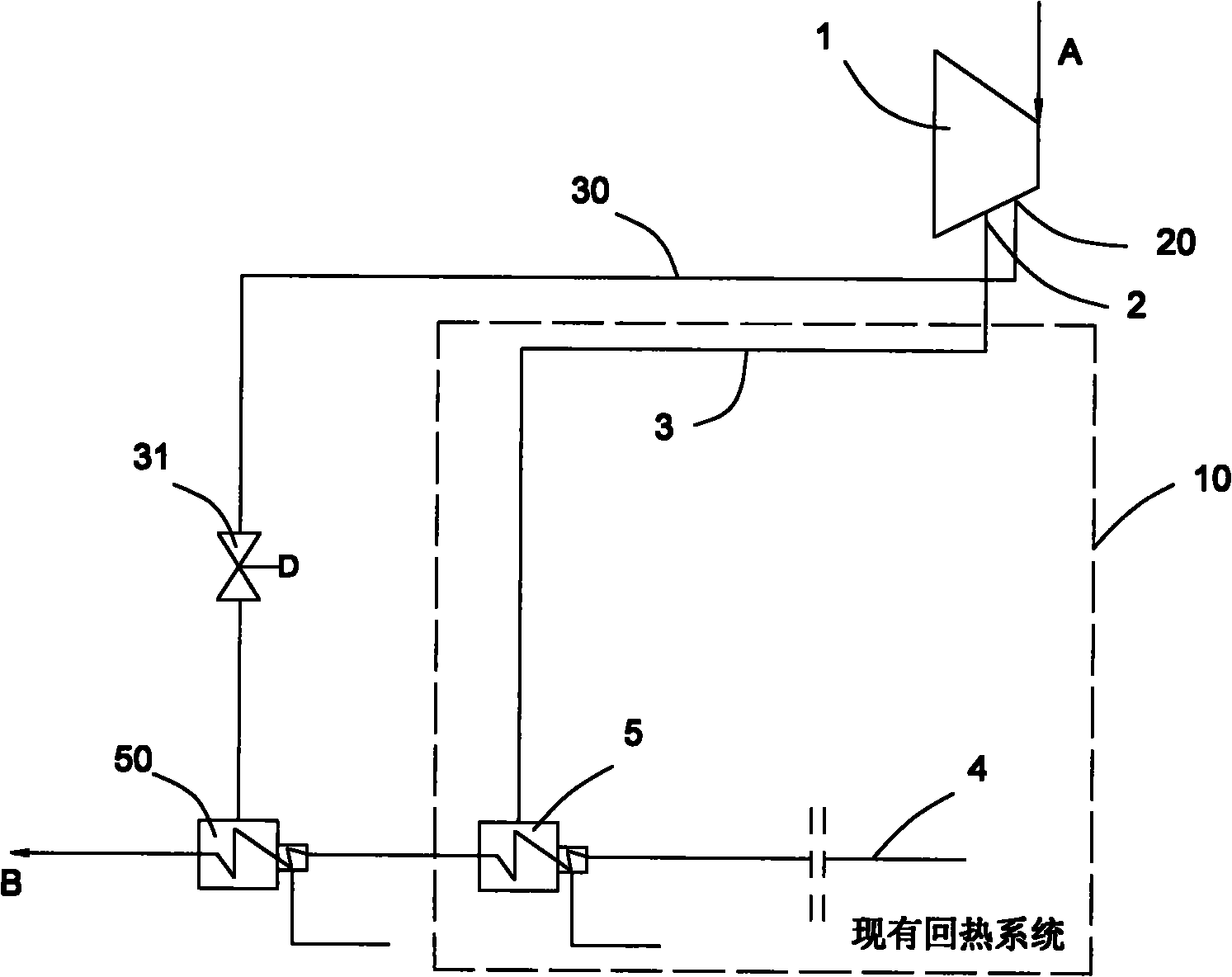

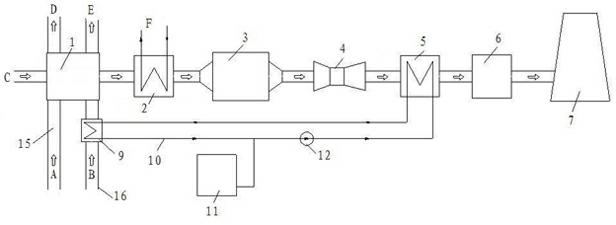

Adjustable feed water heat regenerative system for turbo generator unit

ActiveCN102537933APromote environmental protectionImprove economyMachines/enginesFeed-water heatersEngineeringHigh pressure

The invention provides an adjustable feed water heat regenerative system for a turbo generator unit, which comprises a high pressure cylinder of a steam turbine, a final-stage extraction opening, a final-stage feed water heater, a steam extraction pipe and a regulating valve, wherein the final-stage extraction opening is additionally arranged on the high pressure cylinder; the steam extraction pressure of the final-stage extraction opening is much higher than the common highest extraction pressure; additionally extracted steam is used as a heat source of the final-stage feed water heater; the steam extraction pipe is connected with the final-stage extraction opening and the final-stage feed water heater; and the regulating valve is arranged on the steam extraction pipe. Part of steam which does work is guided to the feed water heater through the final-stage steam extraction pipe so as to further heat feed water of a boiler. The heat regenerative system provided by the invention is an elastic heat regenerative system. The temperature of the feed water can be maintained or changed under the variable load condition of the unit, so that the environmental friendliness, the economy and the safety of the unit are improved and the frequency modulation characteristic is perfected.

Owner:冯伟忠

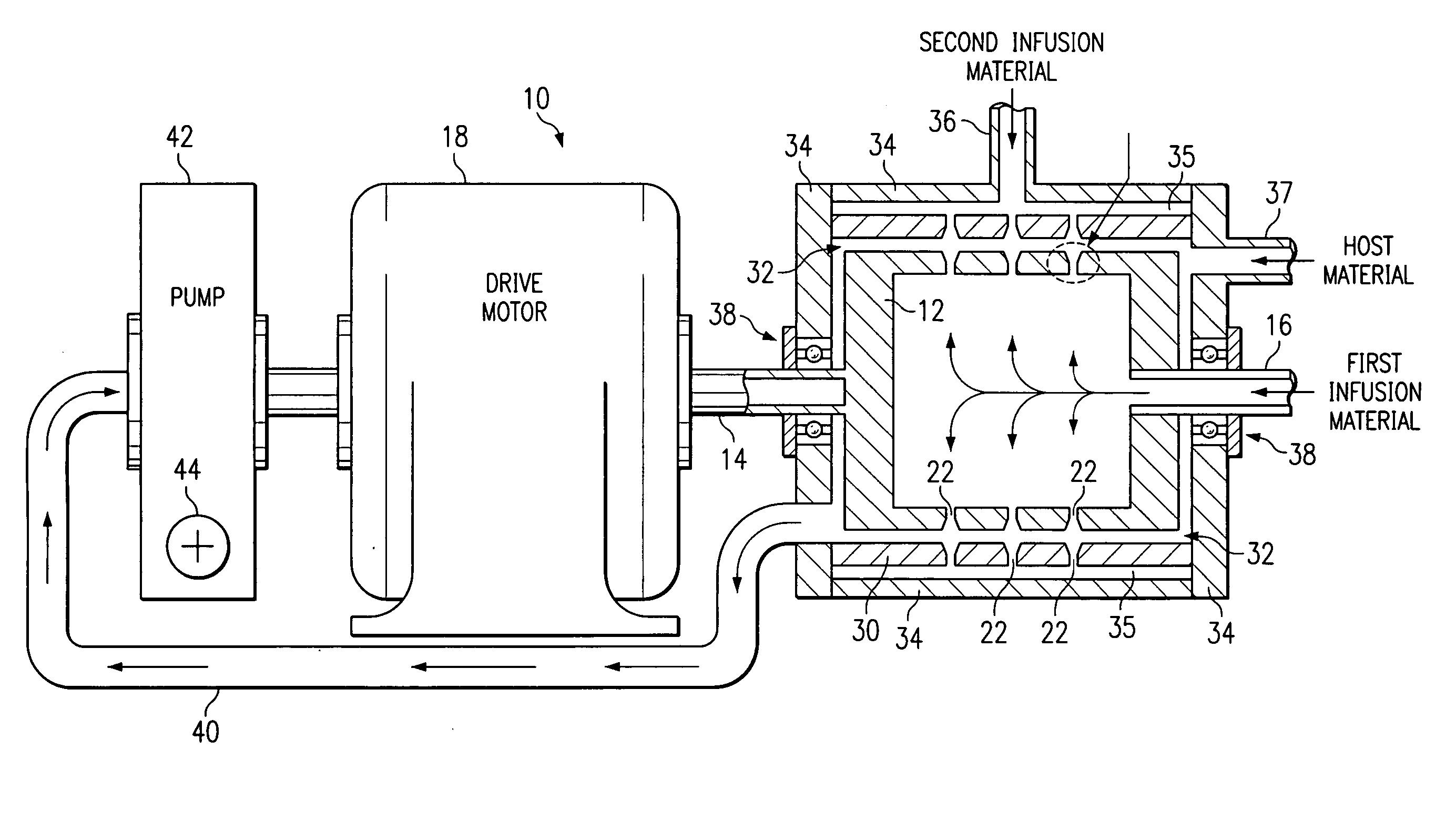

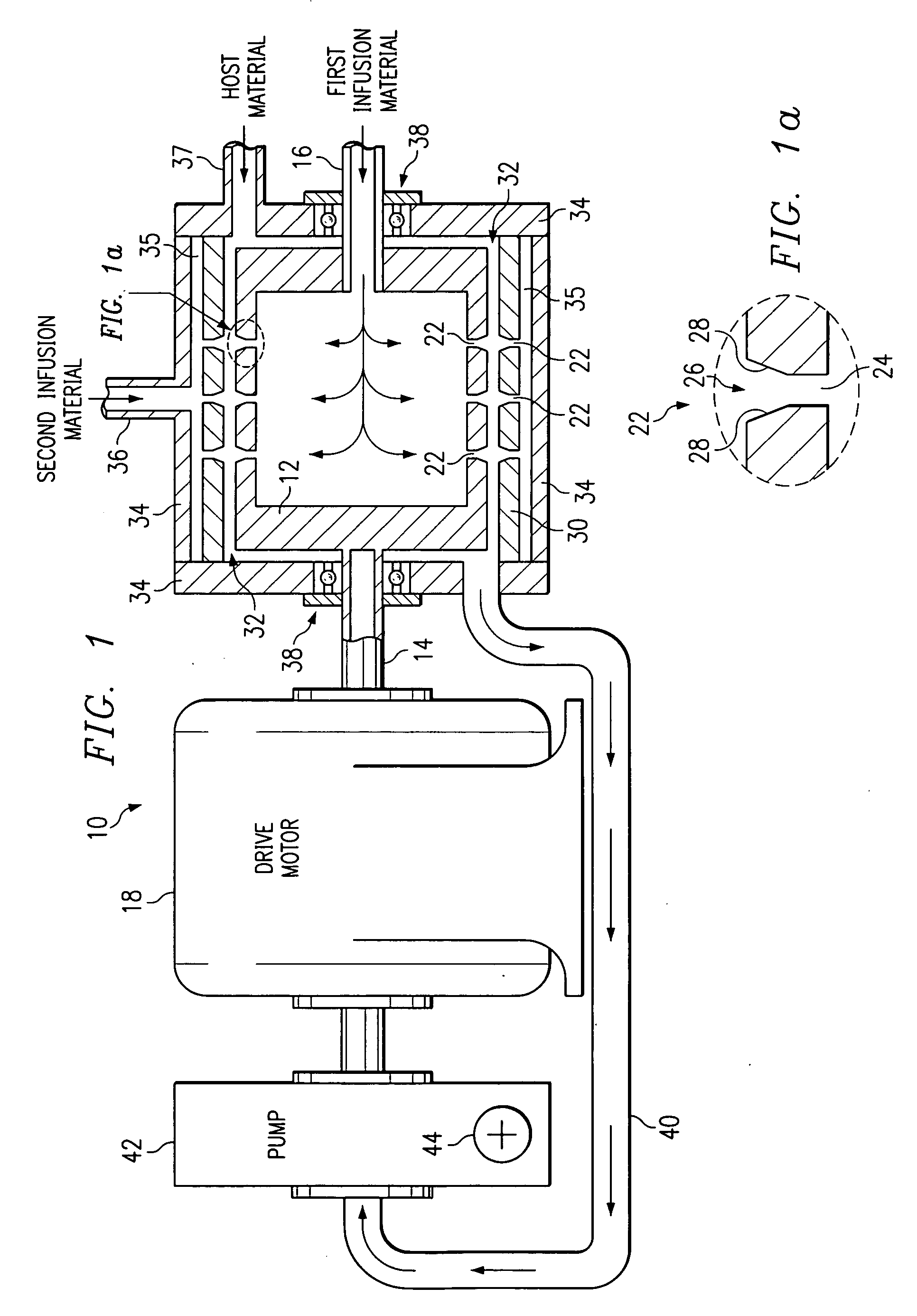

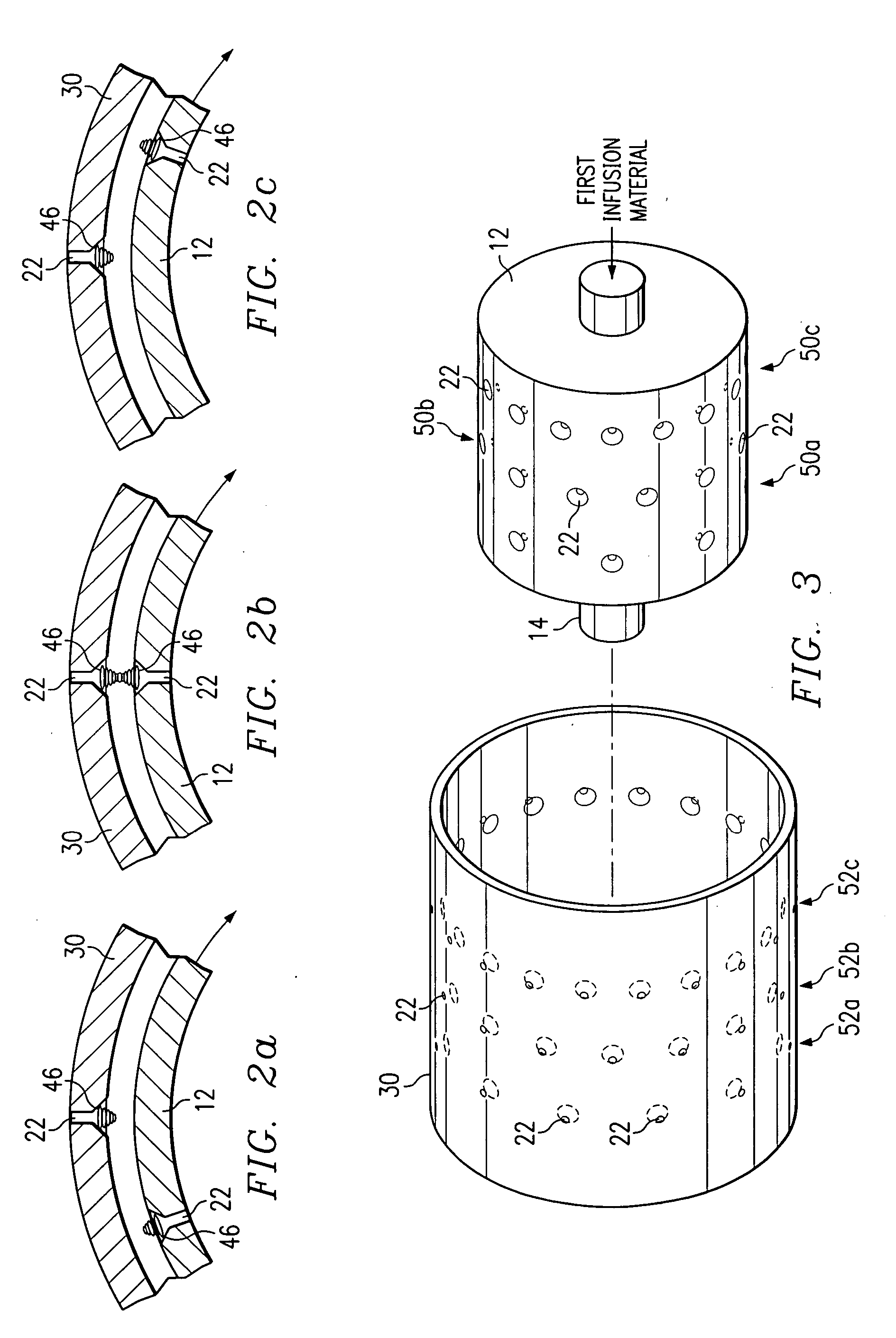

Diffuser/emulsifier for aquaculture applications

Owner:REVALESIO CORP

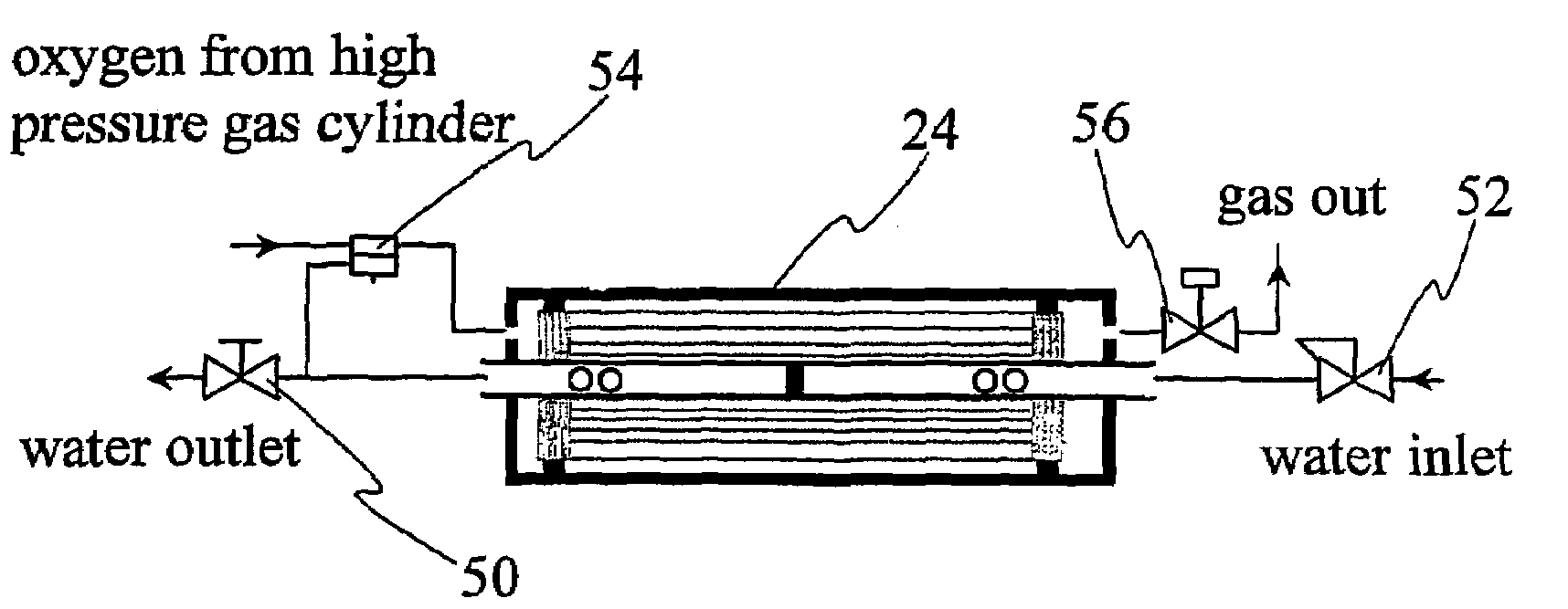

Controlled atmosphere gas infusion

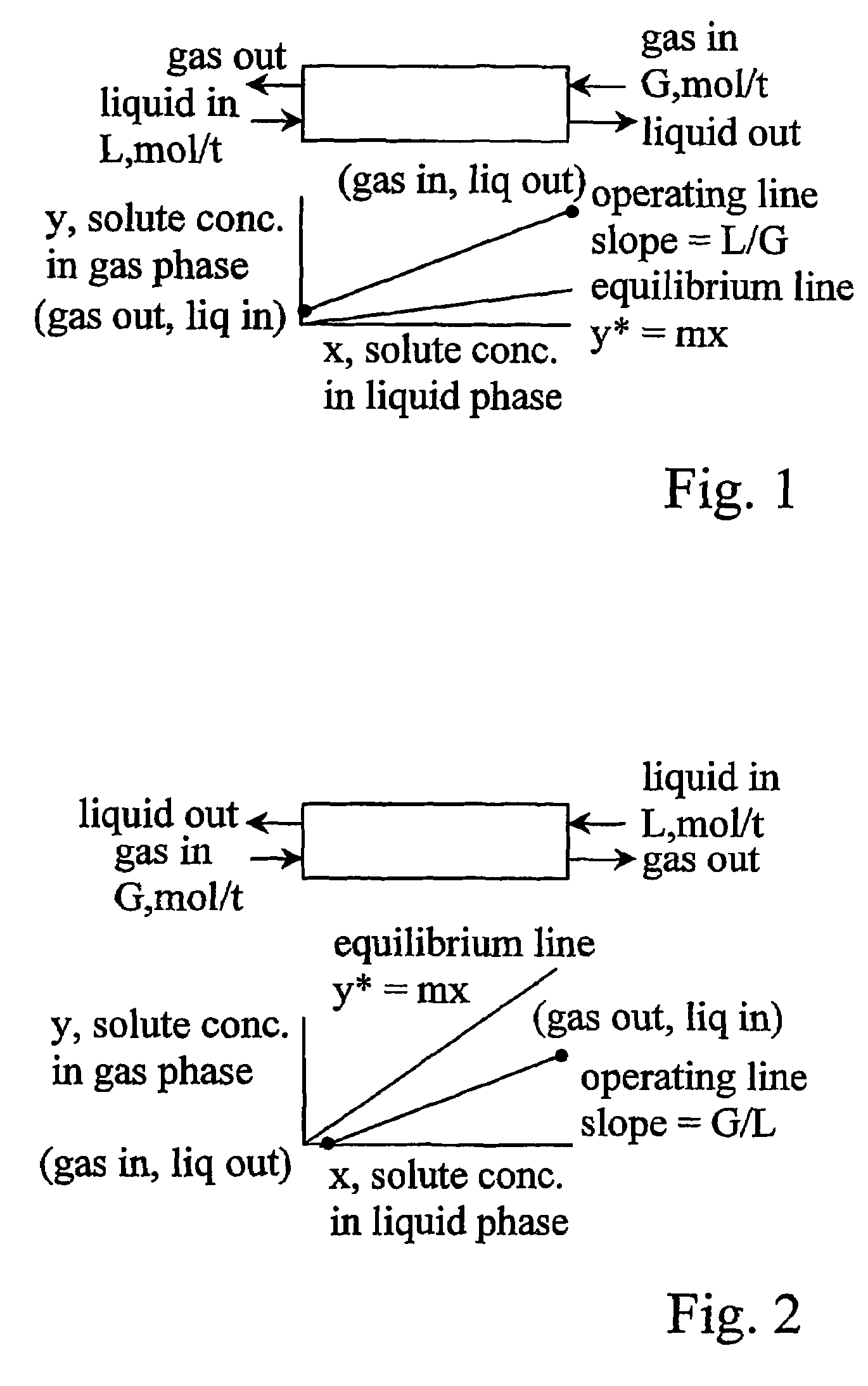

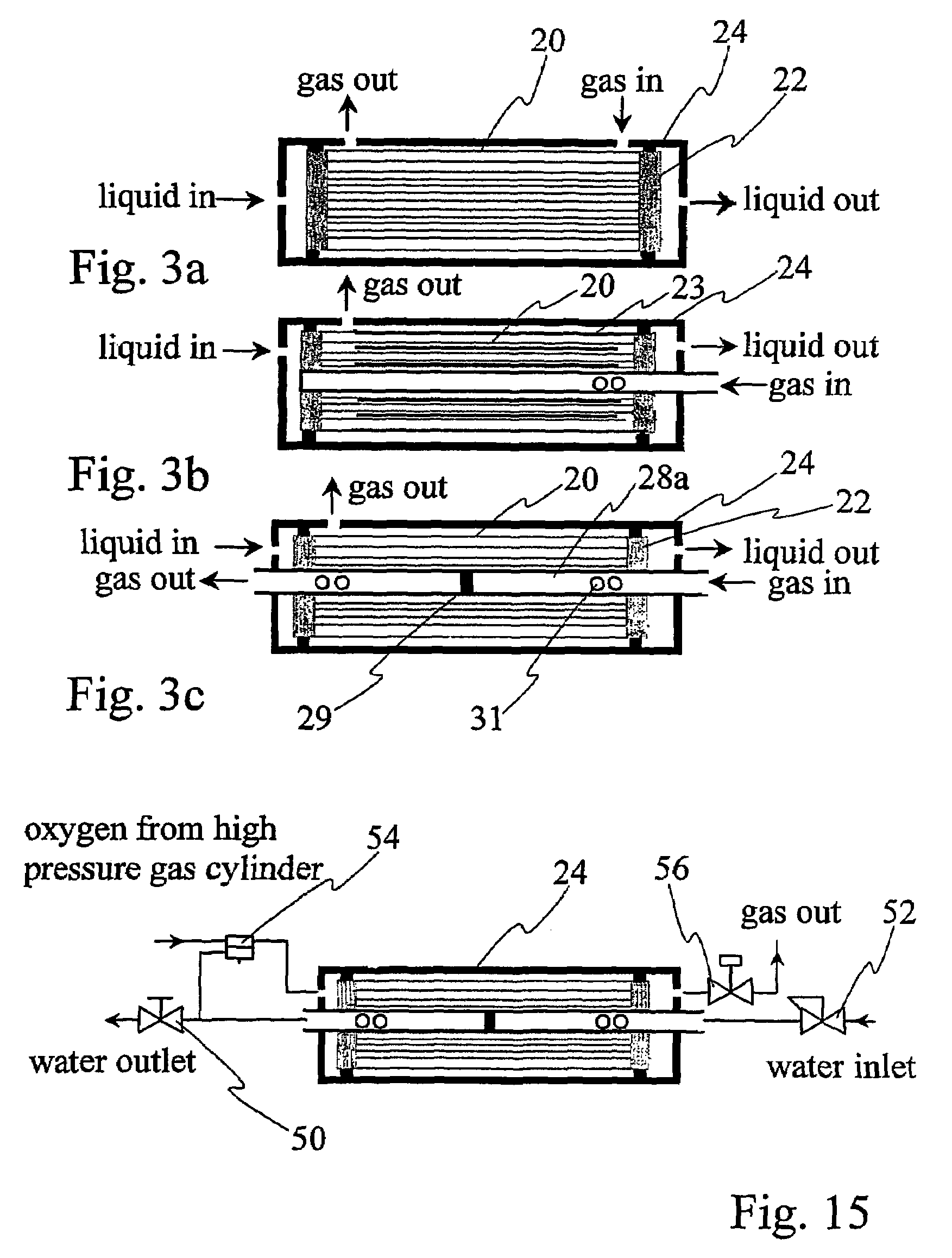

ActiveUS7537200B2Reduce gas contentLowering total dissolved gas pressure(TG)Treatment using aerobic processesFlow mixersFiberHollow fibre membrane

The invention disclosed relates to a method and apparatus for controlling the dissolved gas content of aqueous liquid containing a dissolved gas by providing a microporous hydrophobic hollow fibre membrane, to provide at equilibrium a stable interface between an aqueous liquid phase containing dissolved gas on one side of the membrane and a gaseous phase on the other side of the membrane, and controlling the aqueous phase and gaseous phase pressures, such that in operation the gaseous phase pressure is up to but not exceeding the aqueous phase pressure, and flowing the gaseous and liquid phases across the membrane, to provide simultaneous mass transfer through the membrane of a first gas in the gaseous phase into the liquid phase and of a second gas dissolved in the aqueous liquid into the gaseous phase, whereby the gas content of the first gas in the aqueous phase is increased, the gas content of the second gas in the gaseous phase is decreased and the total dissolved gas pressure (TG) of the aqueous phase is altered.

Owner:CANZONE

Water mixing system for water heaters

InactiveUS6553947B2Temperature control without auxillary powerSteam generation heating methodsEngineeringStorage type

Disclosed herein are storage type water heaters having means for improved mixing of cold water supply with water stored in the water tank of a water heater, means for limiting surges of water into and out of a water tank, and means for disrupting formation and propagation of convection currents and water streamers in a water tank.

Owner:BRADENBAUGH KENNETH A

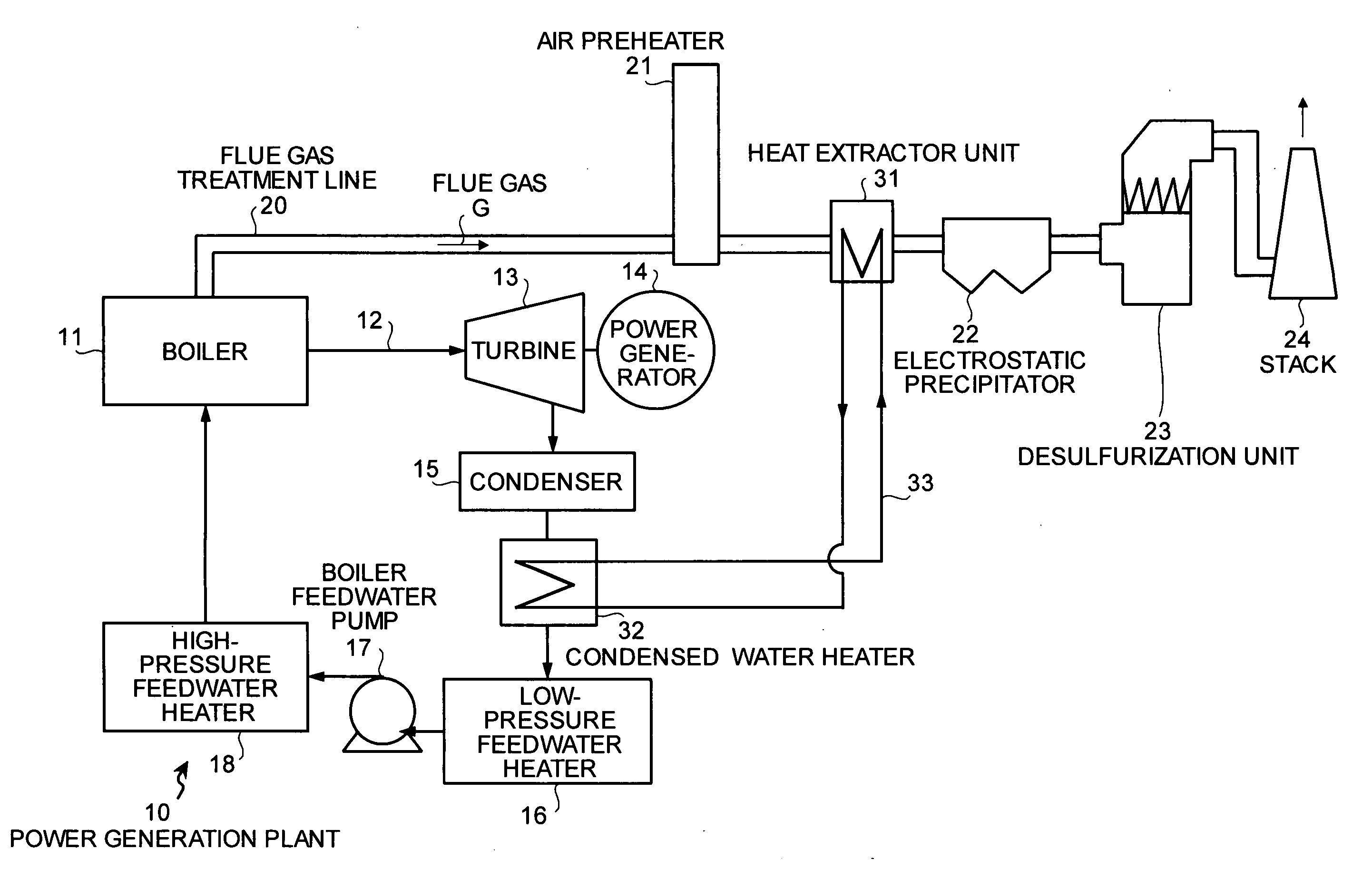

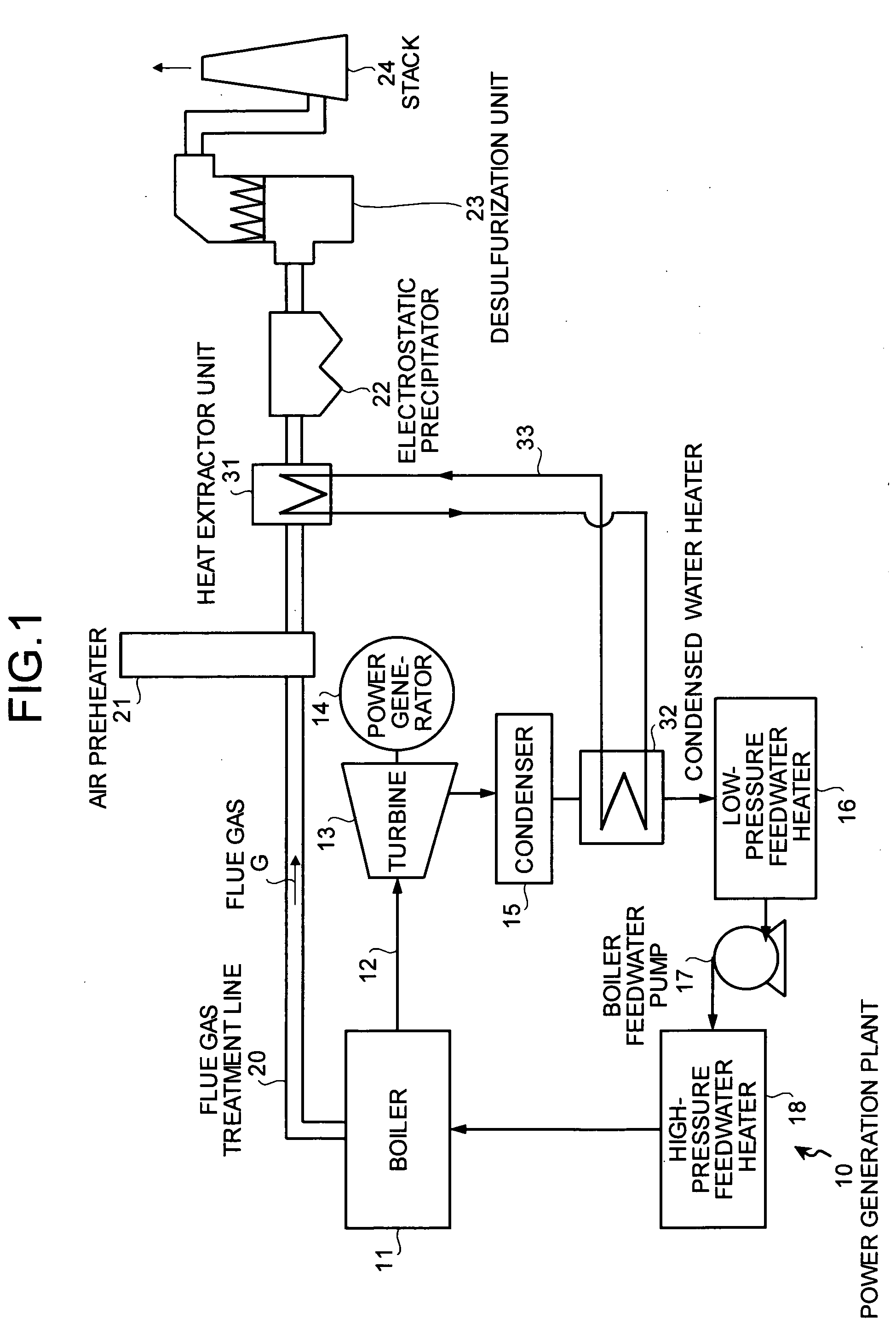

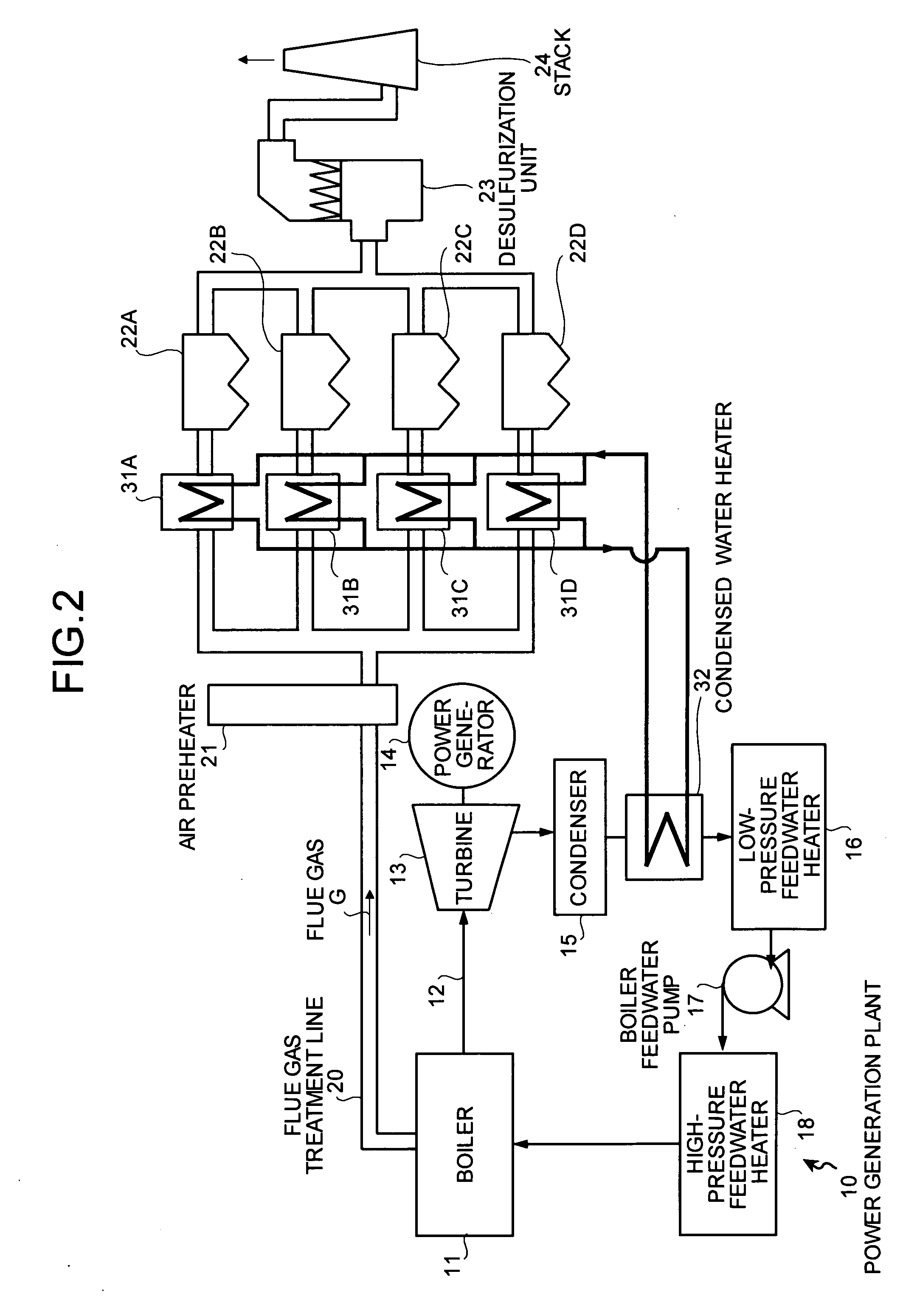

Heat recovery equipment

Heat recovery equipment recovers heat from flue gas. The heat recovery equipment includes a power generation plant that drives a steam turbine by superheated steam produced in a boiler, and an exhaust-gas treatment line that treats flue gas output from the boiler. The exhaust-gas treatment line includes a first air preheater, a heat extractor unit, and a dry electrostatic precipitator. The power generation plant includes a condensed water line. The condensed water line includes a condenser, a condensed water heater, and a low-pressure feedwater heater. The condensed water heater heats water condensed by the condenser with the heat recovered by the heat extractor unit.

Owner:MITSUBISHI POWER LTD

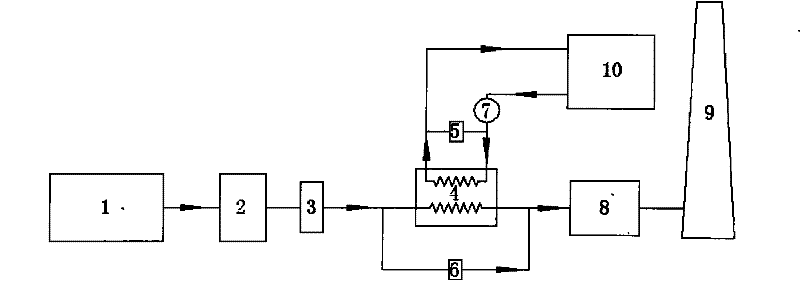

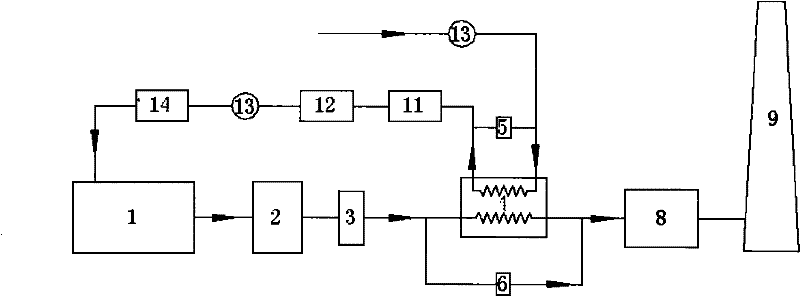

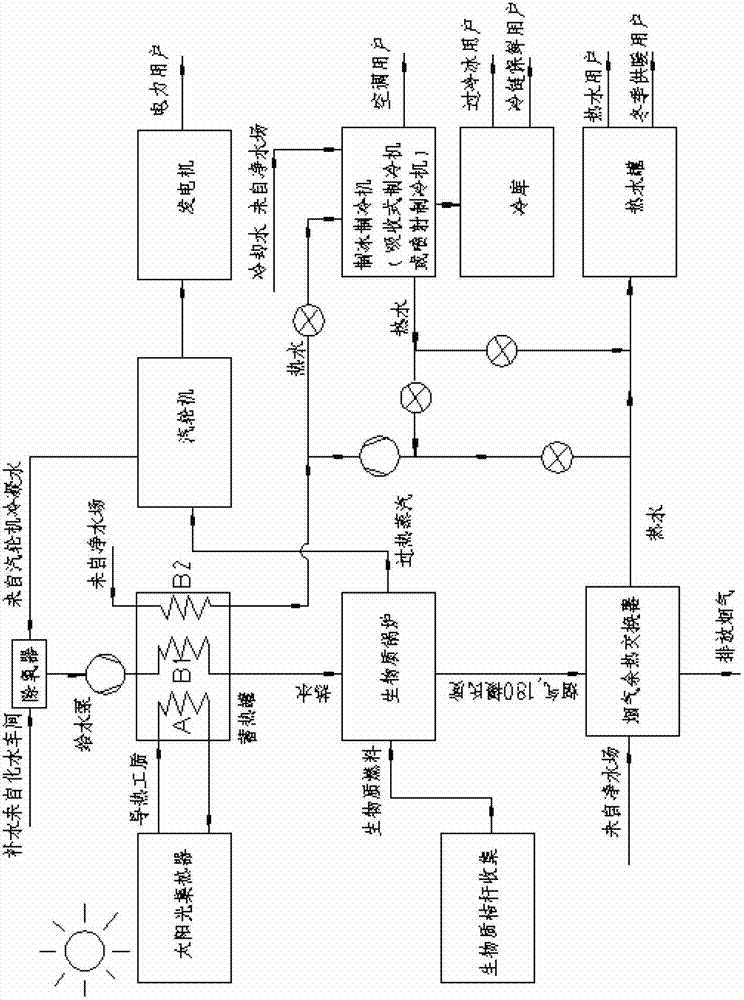

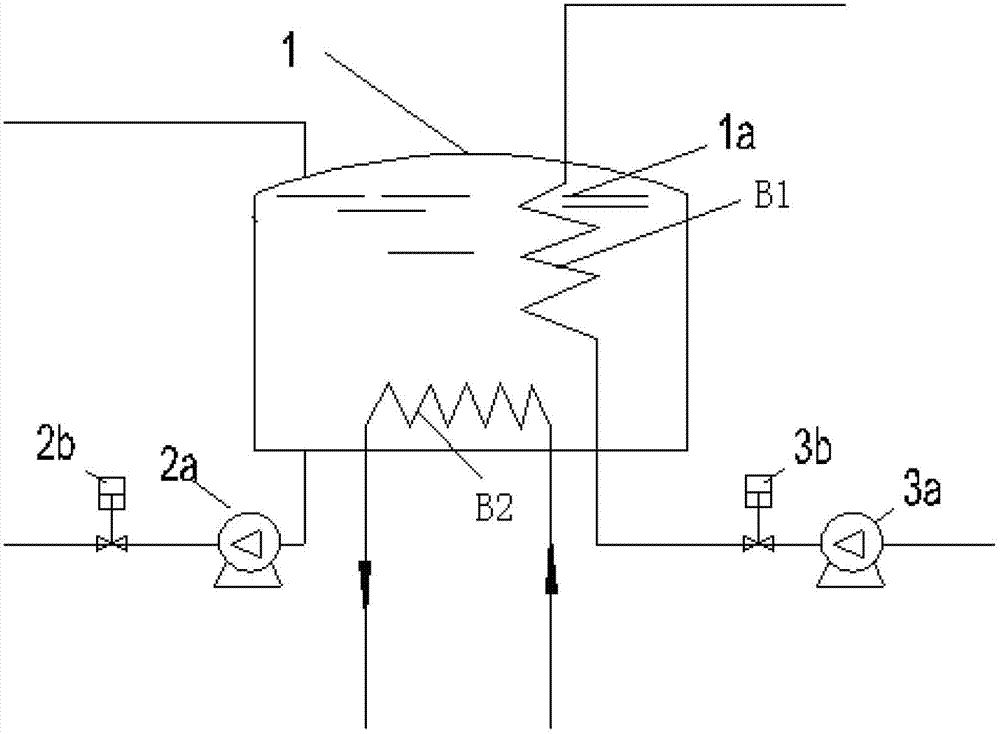

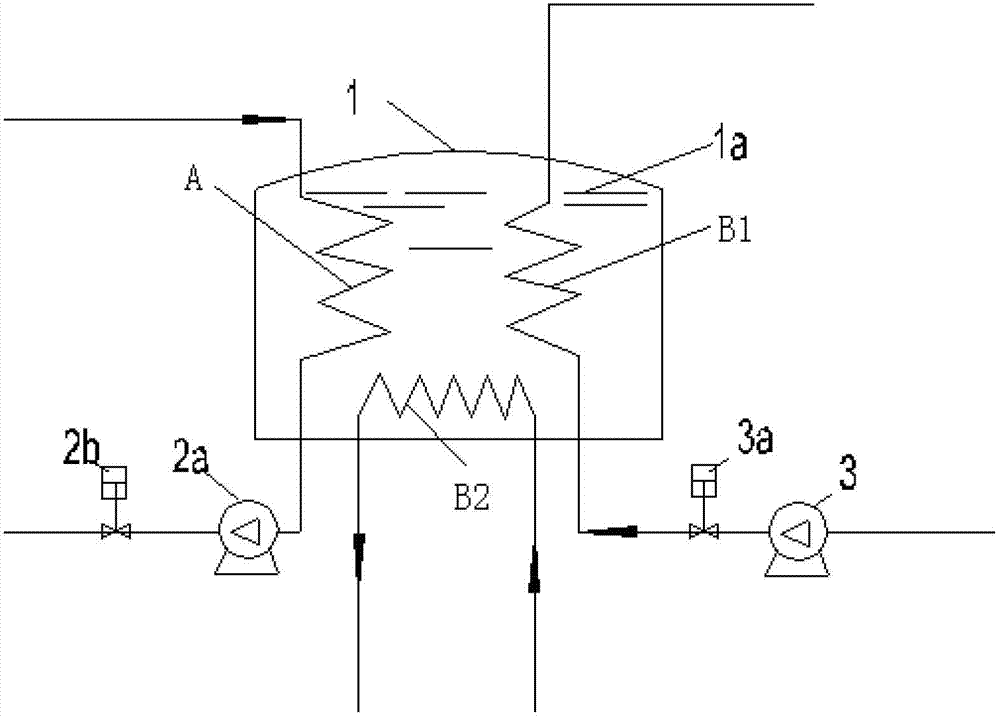

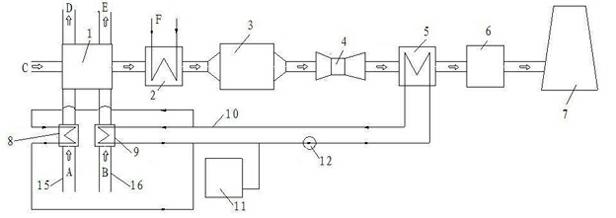

Thermal power system with complementation between solar energy and biomass energy

InactiveCN102967080AEnergy saving and environmental protection use energy modeSolve instabilitySolar heating energySpace heating and ventilationThermal energySolar light

The invention provides a thermal power system with complementation between solar energy and biomass energy. The thermal power system comprises a solar light condensing device, a solar heat storage kettle, a biomass heat power station, a combined refrigerating and icing device for intensive cooling, and a hot water system for intensive heating, wherein the solar light condensing device is connected with the solar heat storage kettle through a pipeline, the inlet of a first output heat exchanger B1 of the solar heat storage kettle is connected with the outlet of a water supply pump of a biomass boiler, and the outlet of the B1 is connected with the inlet of a water supply system of the biomass boiler; an inlet pipeline of a second output heat exchanger B2 of the solar heat storage kettle is connected with an output pipeline of a water purification plant, and the outlet of the B2 is connected with a heat input pipeline of the combined refrigerating and icing device; the heat input pipeline can supply heat for refrigerating and icing; and work cooling water of the combined refrigerating and icing device is connected to a hot water kettle of the heat supply system to intensively supply heat to users. The solar heat storage kettle is a two-medium or three-medium double-circulation heat storage kettle, and the heat storage medium is heat transfer oil and fused salt.

Owner:ZHONGYING CHANGJIANG INTERNATIONAL NEW ENERGY INVESTMENT CO LTD

Smoke waste heat utilization system

ActiveCN102759096AIncrease profitReduce heat consumptionCombustion processIndirect carbon-dioxide mitigationAir preheaterPollutant emissions

The invention discloses a smoke waste heat utilization system, wherein two condensation heat exchangers are added between a desulfurizing tower and a CO2 catching system, so as to absorb smoke heat and lower exhaust smoke temperature; and the absorbed heat is used for condensation water heating and municipal heating respectively. Two smoke coolers are arranged between an electric precipitator and the desulfurizing tower, and the heat recovered from the smoke is used for boiler primary air heating and further condensation water heating respectively. An air heater is arranged between an air inlet and an air preheater, and the heat recovered from the smoke by the smoke coolers is used for boiler primary air heating. The smoke waste heat utilization system can facilitate energy conservation and efficiency improvement for a power plant, and is particularly important for a running power plant which is difficult to improve the back-heating efficiency through increasing a steam parameter. Through optimizing running parameters of a unit, increasing condensation water heating bypasses and raising the temperature of the boiler primary air entering the air preheater, the heat consumption of a whole heating device can be lowered, the pollutant emission is reduced, and the energy utilization is improved.

Owner:XI AN JIAOTONG UNIV

Method for starting a continuous steam generator and continuous steam generator for carrying out said method

The invention relates to a continuous steam generator provided with an evaporator through flow heating surface which is disposed in a heating gas channel which can be cross flown in an approximately vertical manner in a heating gas device, said evaporator through flow heating surface comprising a plurality of parallel connected steam generating pipes enabling a flow medium to flow through, and an overheating heating surface which is arranged downstream from the evaporator through flow heating surface comprising a plurality of parallel connected overheating pipes enabling the evaporated flow medium to flow through, also enabling production and operational costs to be reduced and enabling the temperature of the steam on the outlet of the overheating heating surface to be controlled in a comparatively simple and flexible manner. The steam end-point of the flow medium is displaced to the overheating pipe, if required. The continuous heating surfaces and the overheating heating surfaces are combined to form one functional unit such that the overheating heating surface can be used as a steam heating surface in a continuous steam generator which is particularly suitable for carrying out said method.

Owner:SIEMENS AG

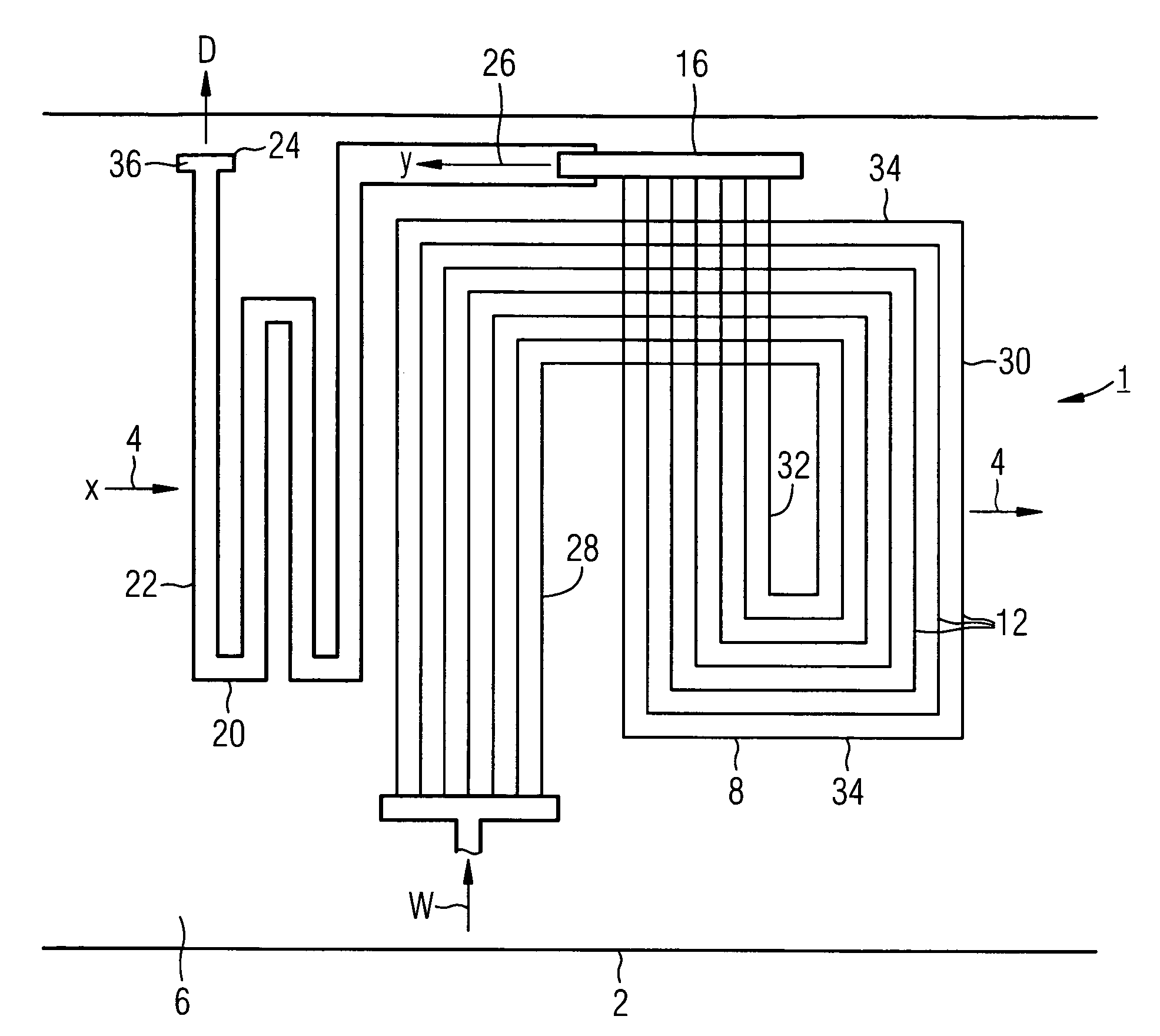

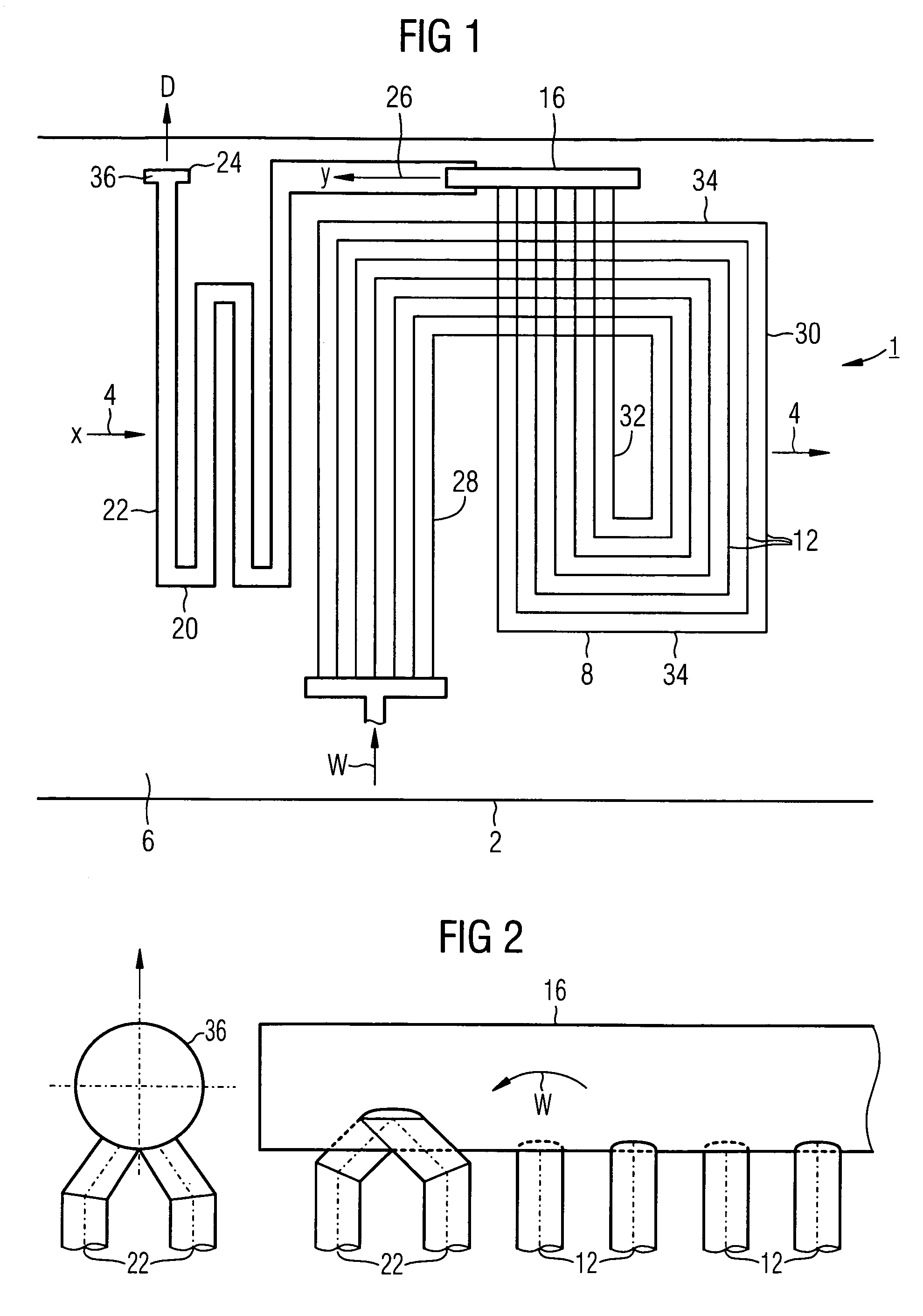

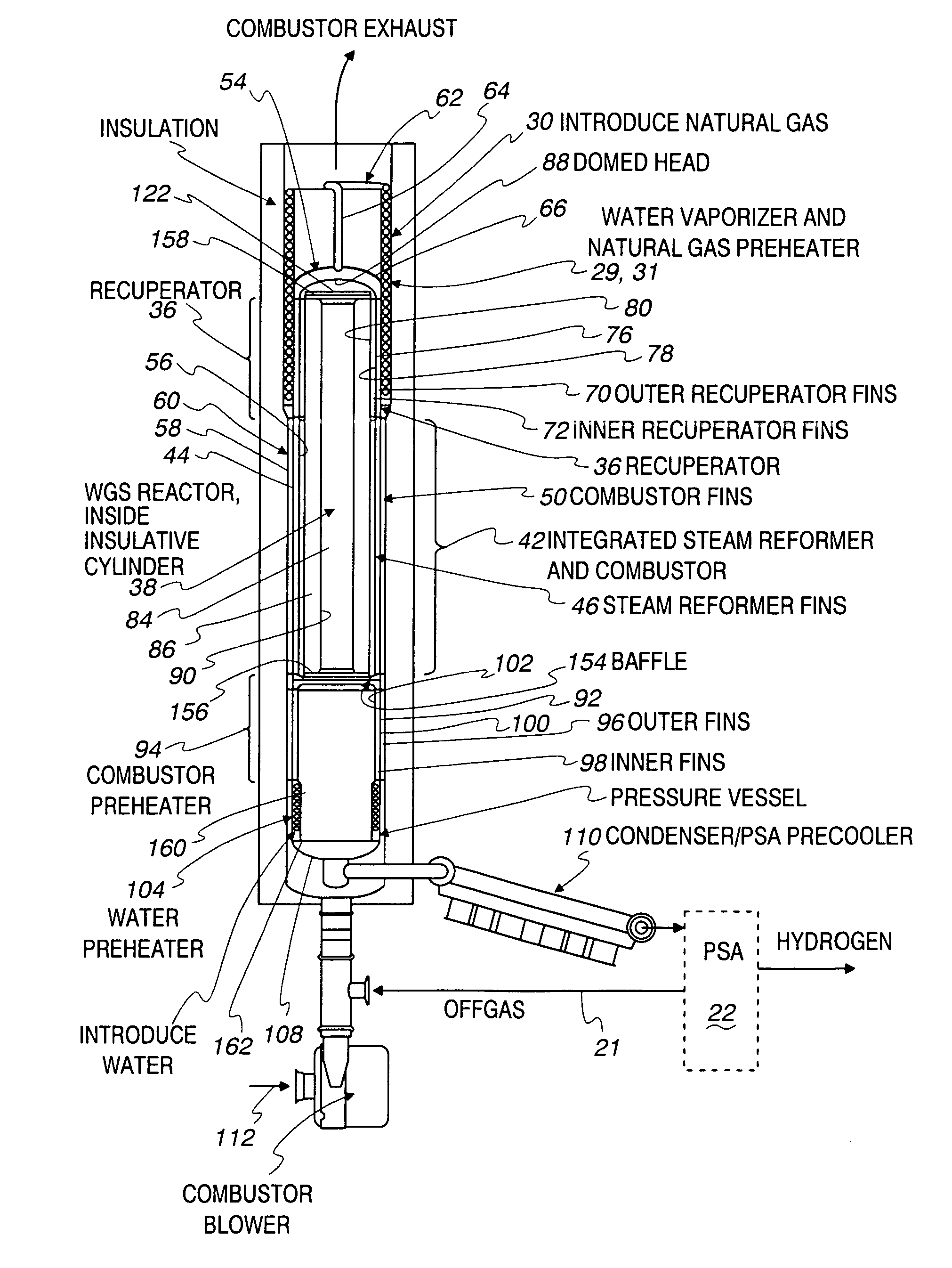

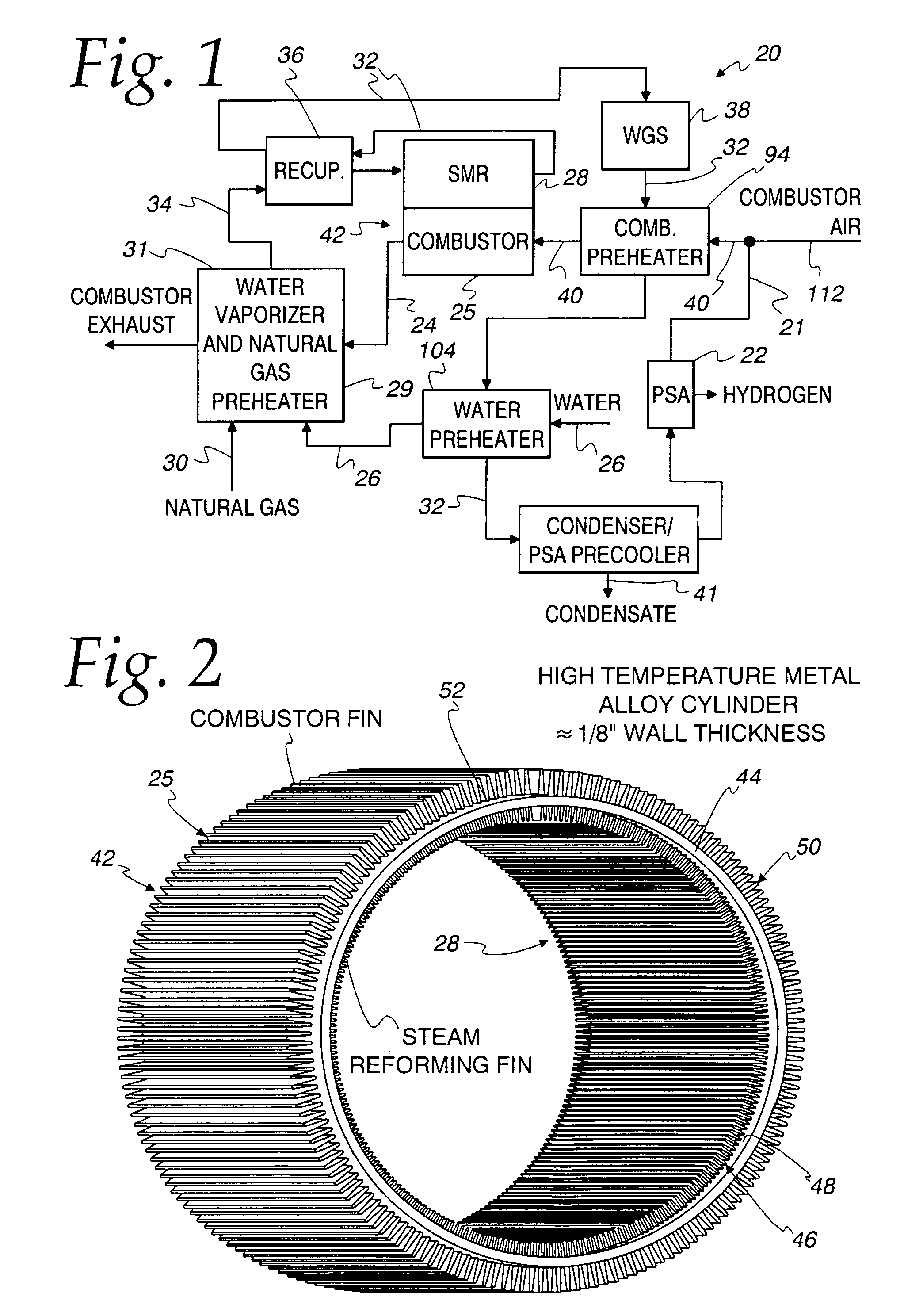

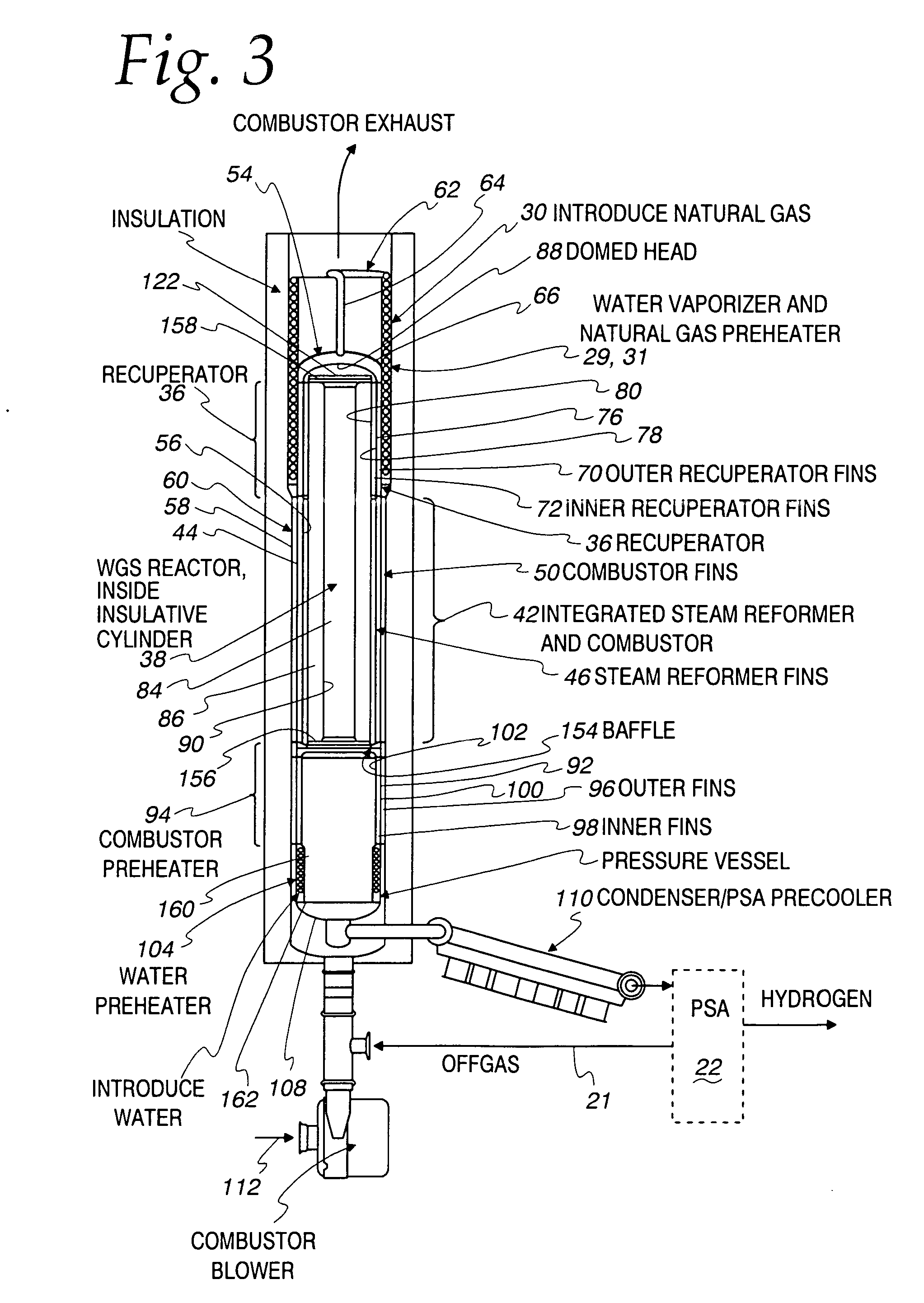

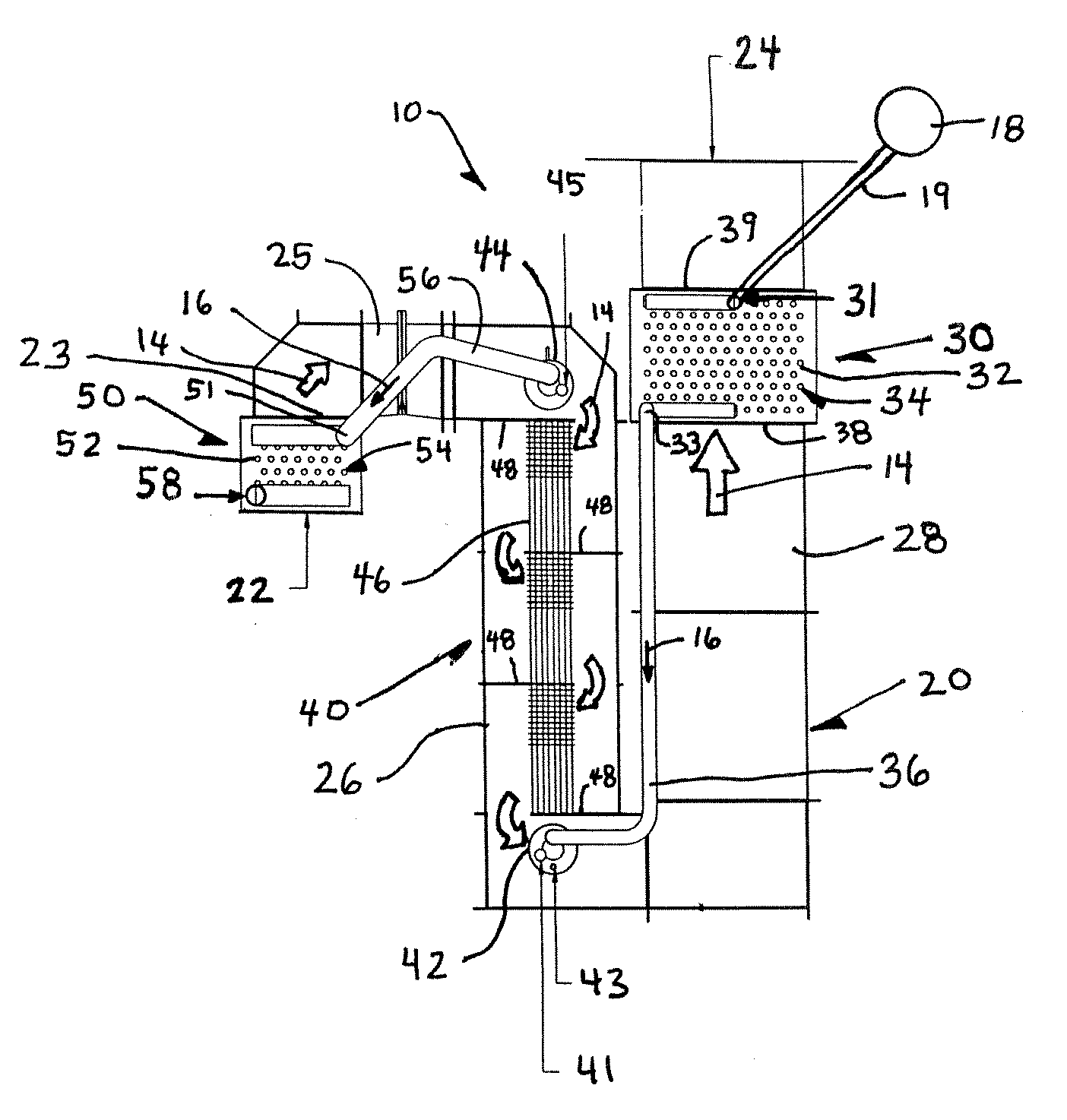

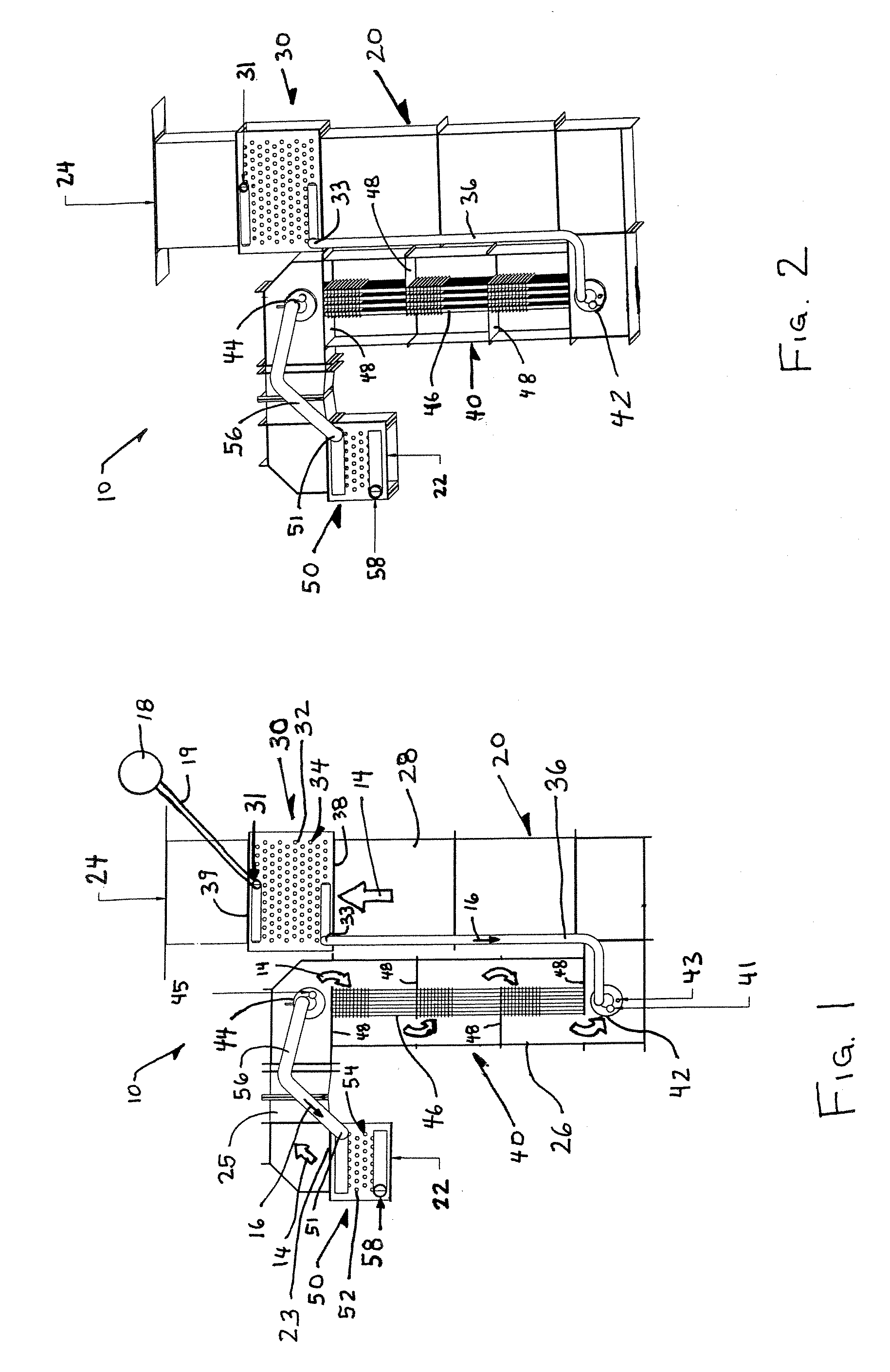

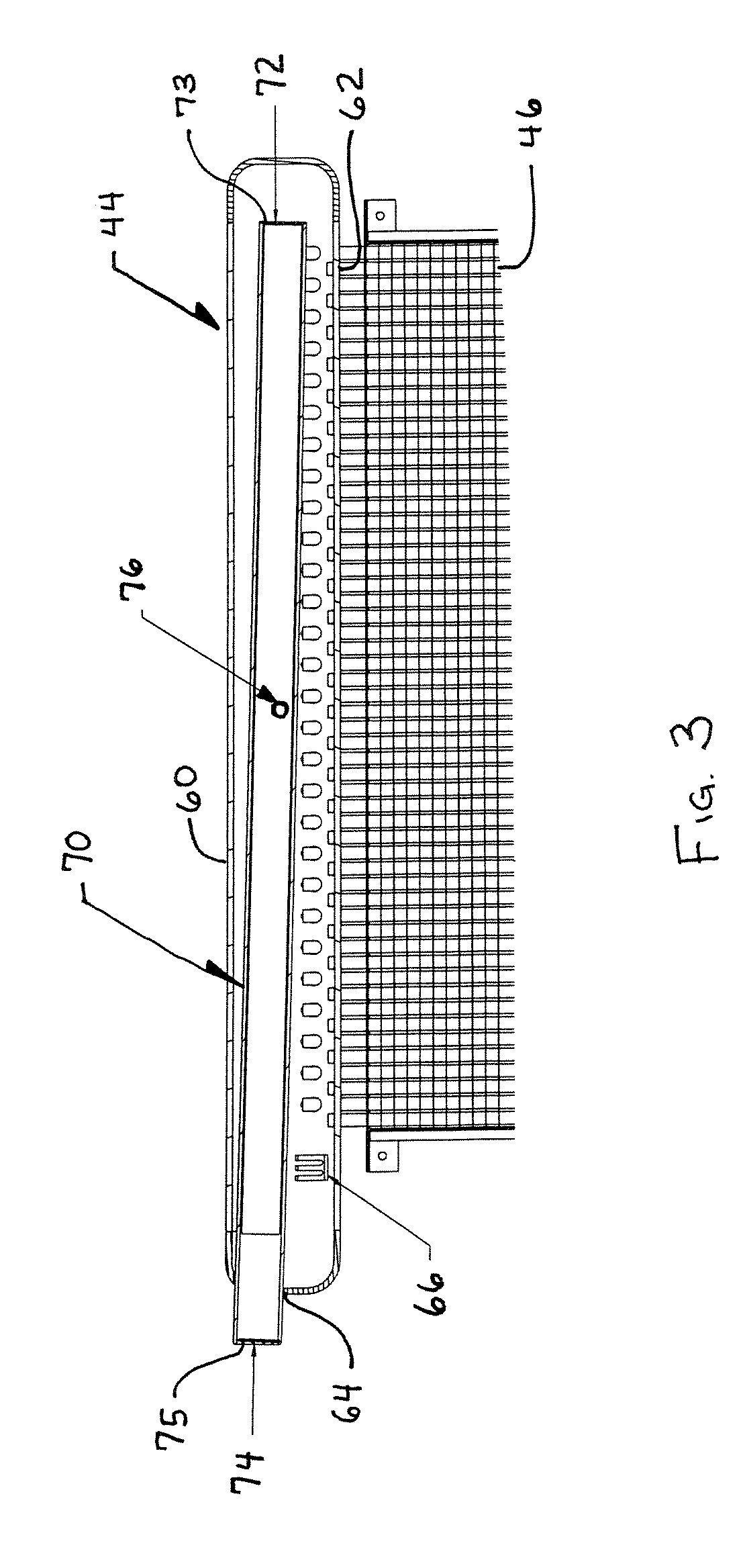

Highly integrated fuel processor for distributed hydrogen production

InactiveUS20050178063A1High purity hydrogenHigh level of hydrogen product efficiencyMuffle furnacesFuel cell auxillariesSteam reformingCombustor

A fuel processing system is provided wherein heat is transferred from a reformate flow (32) downstream from a water-gas shift (38) to both a) a combustor feed flow (40) that is supplied to a combustor (25); and b) a water flow (26) that is supplied to a reformer feed mix (34) for a steam reformer (28).

Owner:MODINE MFG CO

Heat exchanger having a counterflow evaporator

An evaporator including a lower drum, an upper drum, and at least one tube extending between the lower drum and the upper drum. The plurality of tubes have fluid passageways therein extending from the lower drum to the upper drum. A duct is provided having a heating gas passageway provided therein. The at least one tube extends through the heating gas passageway. The fluid passageways define an overall flow path from the lower drum to the upper drum extending in a direction substantially counter-current to an overall flow path defined by the heating gas passageway extending from a gas inlet of the heating gas passageway to a gas outlet thereof.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

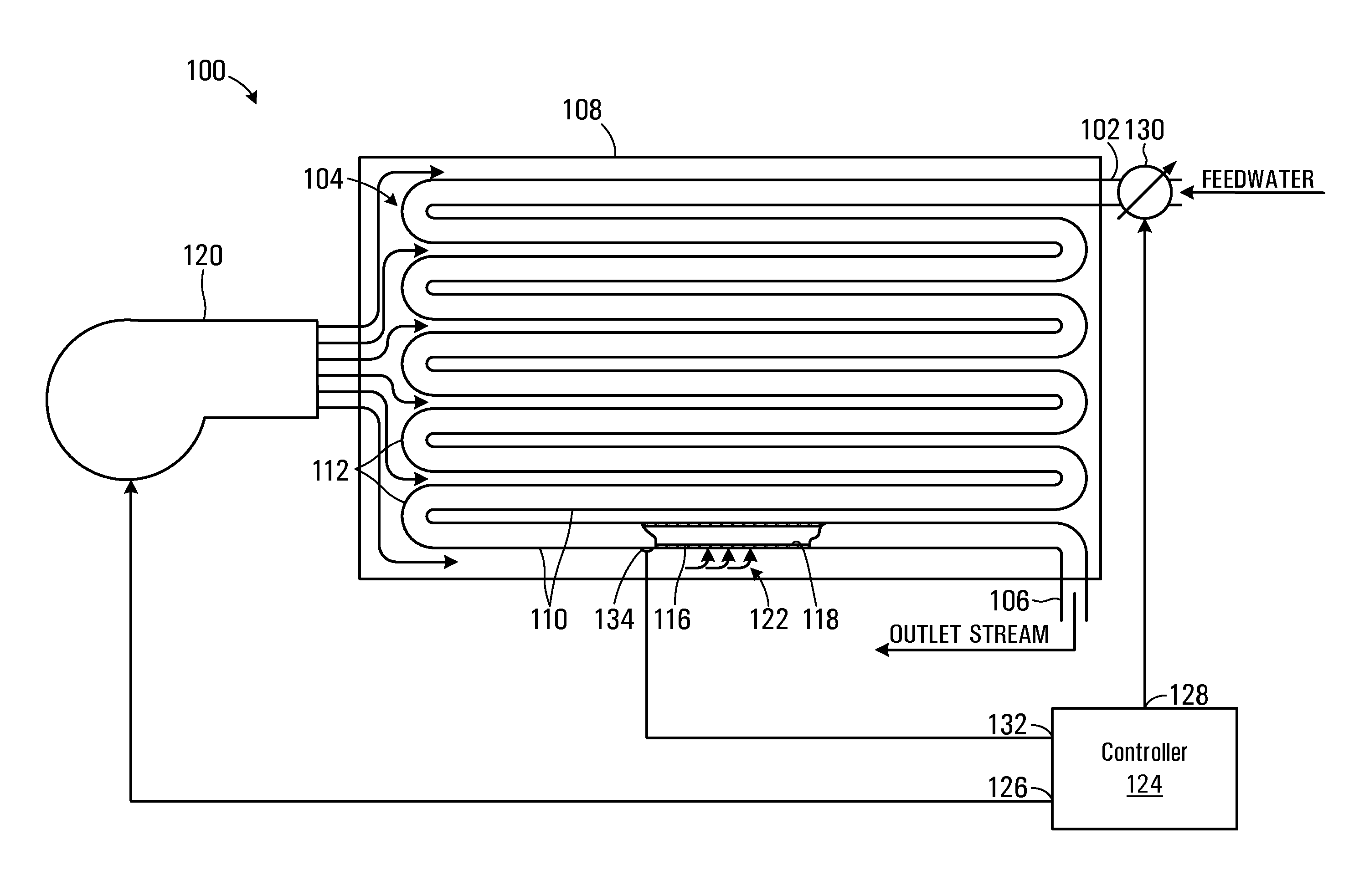

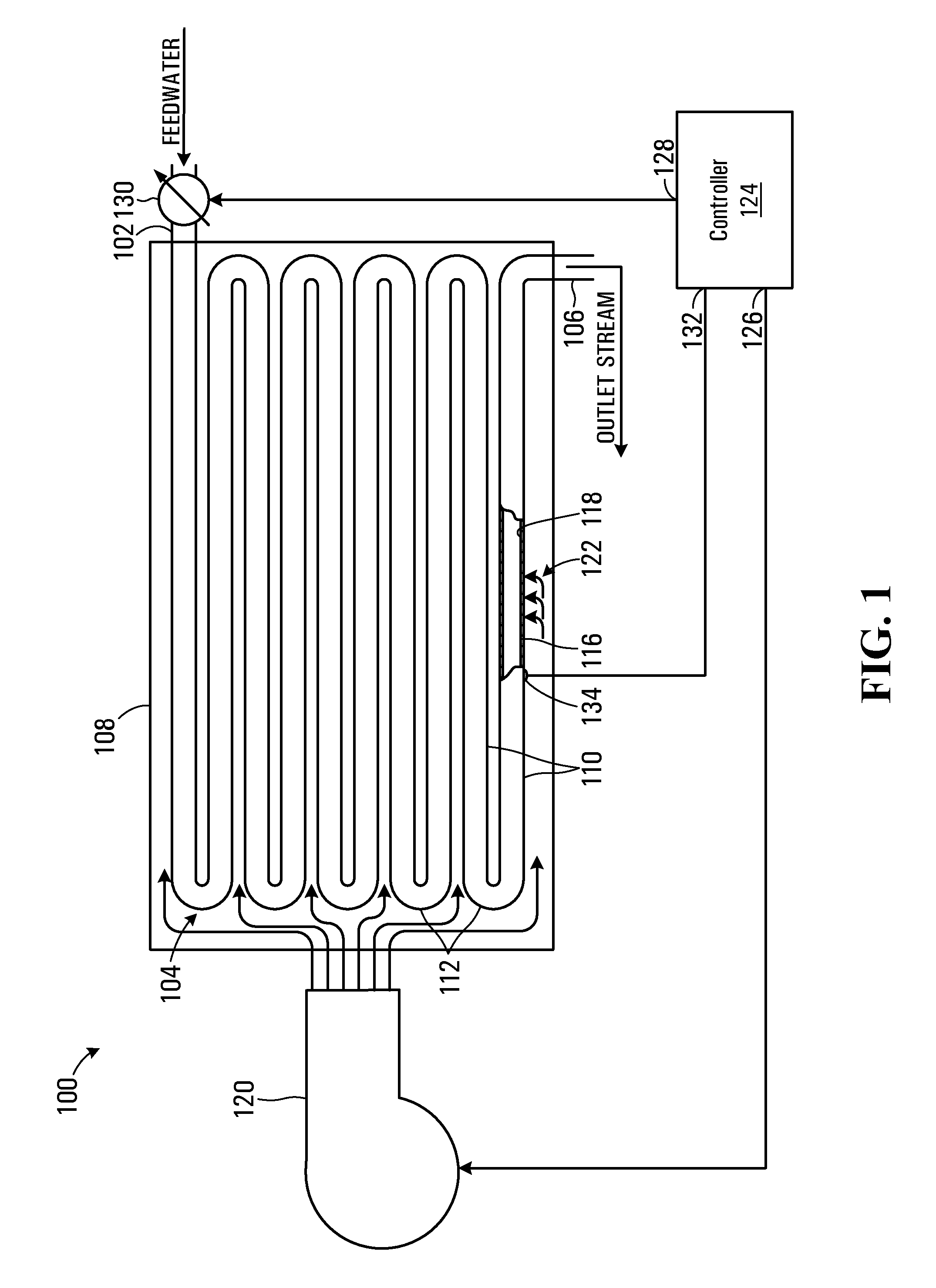

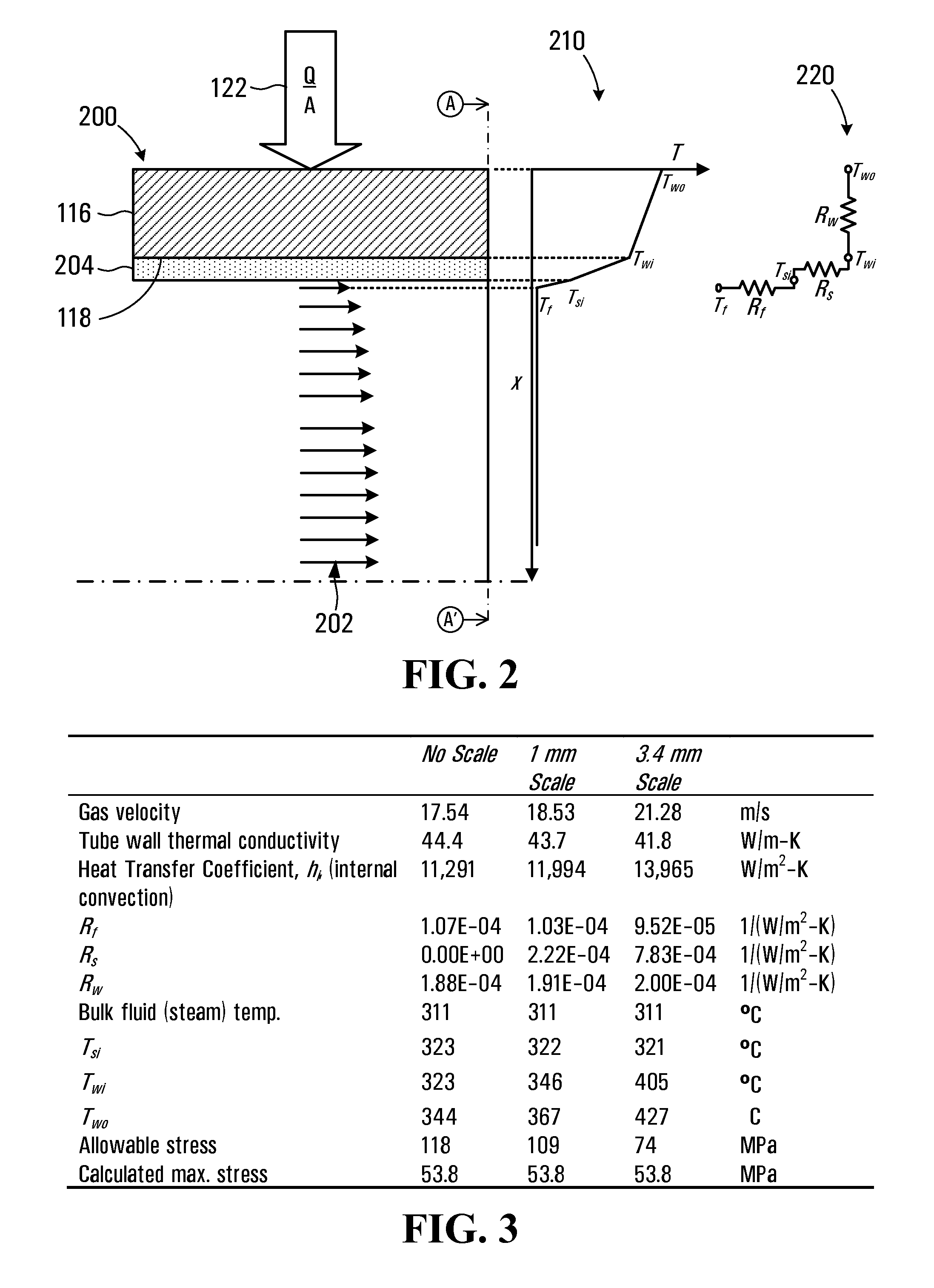

Steam generator and method for generating steam

ActiveUS20130161009A1Improve cooling effectReduce problem sizeBoiler water tubesBoiler cleaning apparatusHeat fluxEvaporation

A method for generating steam from a feedwater inlet stream including impurities is disclosed. The method involves receiving the feedwater inlet stream at an inlet of a steam generator and causing the feedwater stream to flow through a tubing circuit to an outlet of the tubing circuit, the tubing circuit having a substantially un-rifled bore defined by a metal wall. The method also involves delivering a heat flux to the feedwater stream through the metal wall of the tubing circuit to generate steam by causing evaporation of feedwater within the tubing circuit, and controlling at least one of a flow rate of the feedwater stream and the heat flux to cause generation of an outlet stream at the outlet includes a steam portion and liquid phase portion, the steam portion being greater than about 80% of the outlet stream by mass. The steam portion provides sufficient cooling of the metal wall to maintain a wall temperature at less than a threshold temperature.

Owner:FCCL PARTNERSHIP

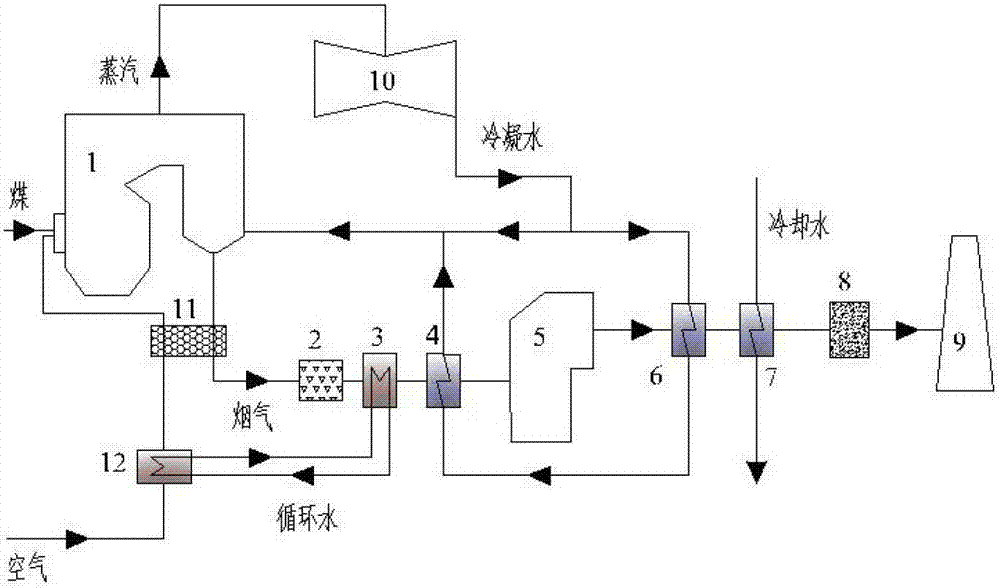

Exhaust gas waste heat recovery and emission reduction comprehensive application system for coal-fired boiler in thermal power plant

ActiveCN102305413AImprove dust removal efficiencyImprove performanceCombustion processIndirect carbon-dioxide mitigationAir preheaterExpansion tank

The invention discloses an exhaust gas waste heat recovery and emission reduction comprehensive application system for a coal-fired boiler in a thermal power plant. In the invention, along the flow direction of flue gas, an air preheater, a first low temperature economizer, a low temperature dust collector, a draught fan, a second low temperature economizer and a desulfuration island are sequentially arranged on a pipe between the boiler and a chimney, wherein, the inlet of the air preheater is respectively communicated with a cold primary air pipe and a cold secondary air pipe; the cold secondary air pipe is provided with a secondary air heater; the secondary air heater is communicated with the second low temperature economizer via a coal-water pipe; the coal-water pipe is provided with an expansion tank and a water pump; and the low temperature economizer is divided into two segments, wherein, one segment is used for heating condensed water, and the other section is used for heating the cold secondary air at the inlet of the air preheater by virtue of a water medium. The exhaust gas waste heat recovery and emission reduction comprehensive application system has the beneficial effects of maximally utilizing the gas waste heat, reducing heat consumption of a machine set, lowering energy consumption of equipment such as the dust collector, the draught fan, a blower and the like, reducing the power consumption rate of the thermal power plant, improving the economical efficiency of the thermal power plant, more efficiently saving the energy consumption, and benefiting construction of the lowcarbon society.

Owner:SOUTHWEST ELECTRIC POWER DESIGN INST OF CHINA POWER ENG CONSULTING GROUP CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com