Adjustable feed water heat regenerative system for turbo generator unit

A technology of steam turbine generator set and heat recovery system, which is applied in the direction of feed water heater, steam generation, machine/engine, etc. It can solve the problems of affecting the service life of equipment, the reduction of average heat absorption temperature of boilers, and the reduction of feed water temperature, etc., and achieve economical Improved performance and safety, increased average endothermic temperature, and improved average endothermic temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

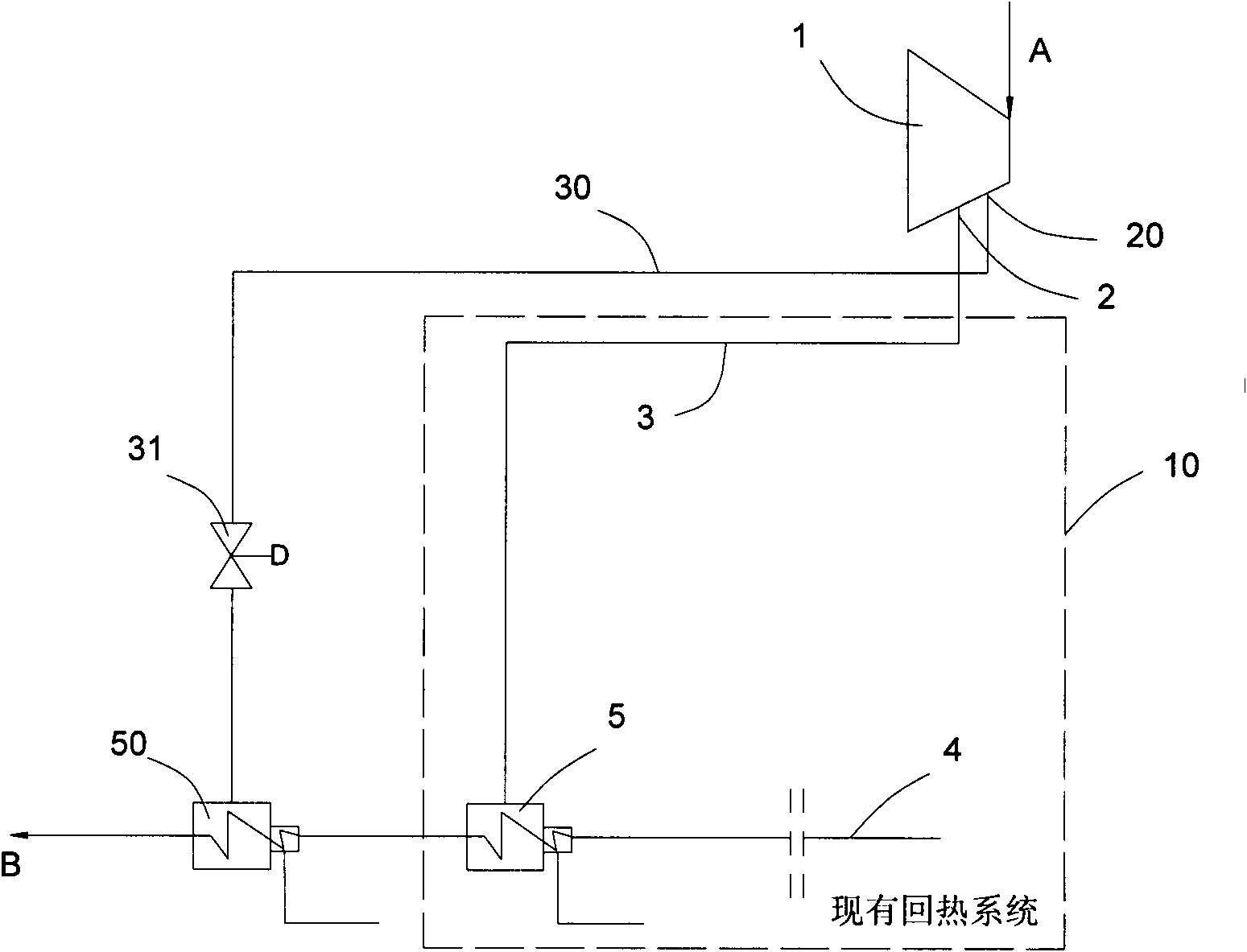

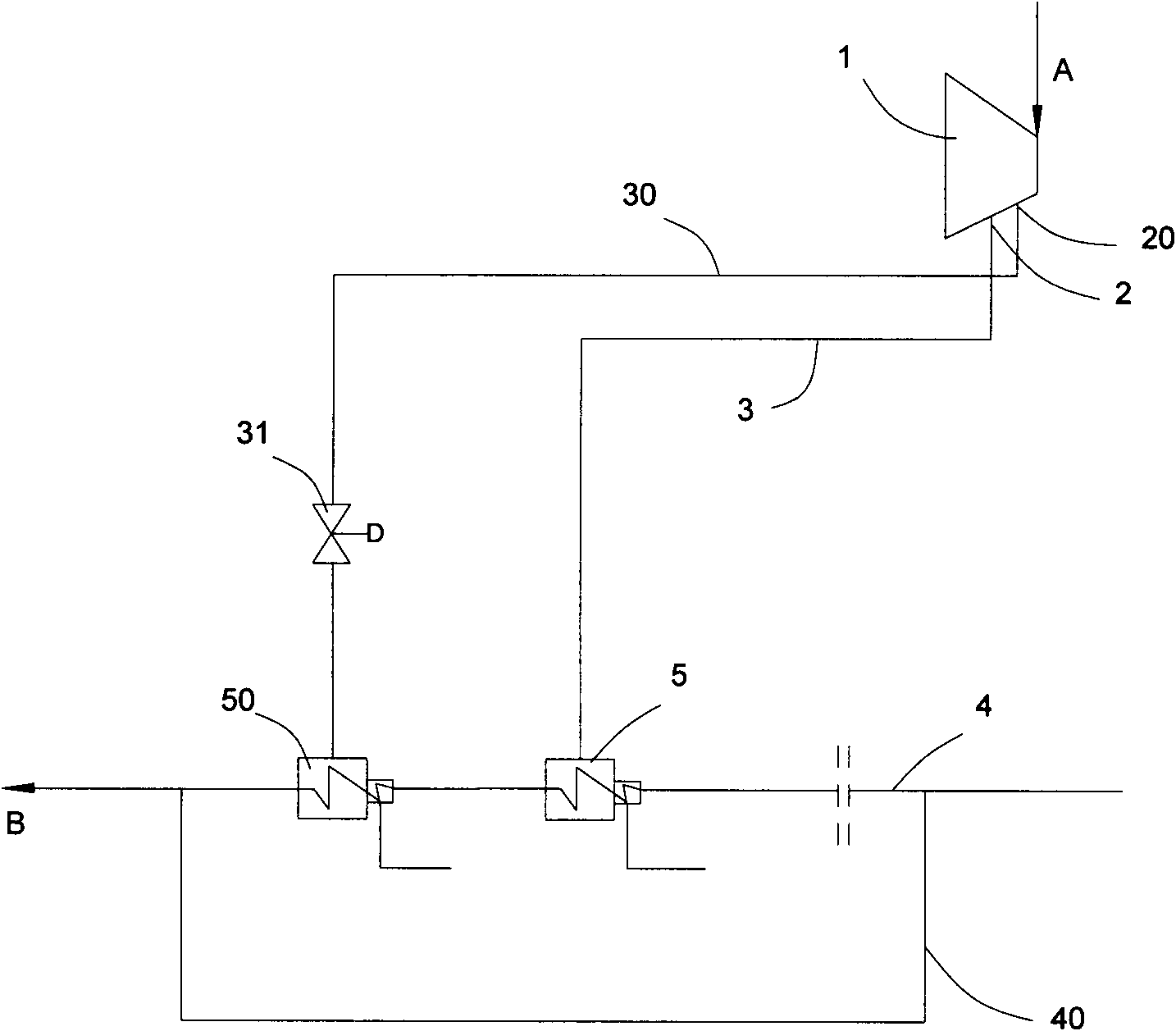

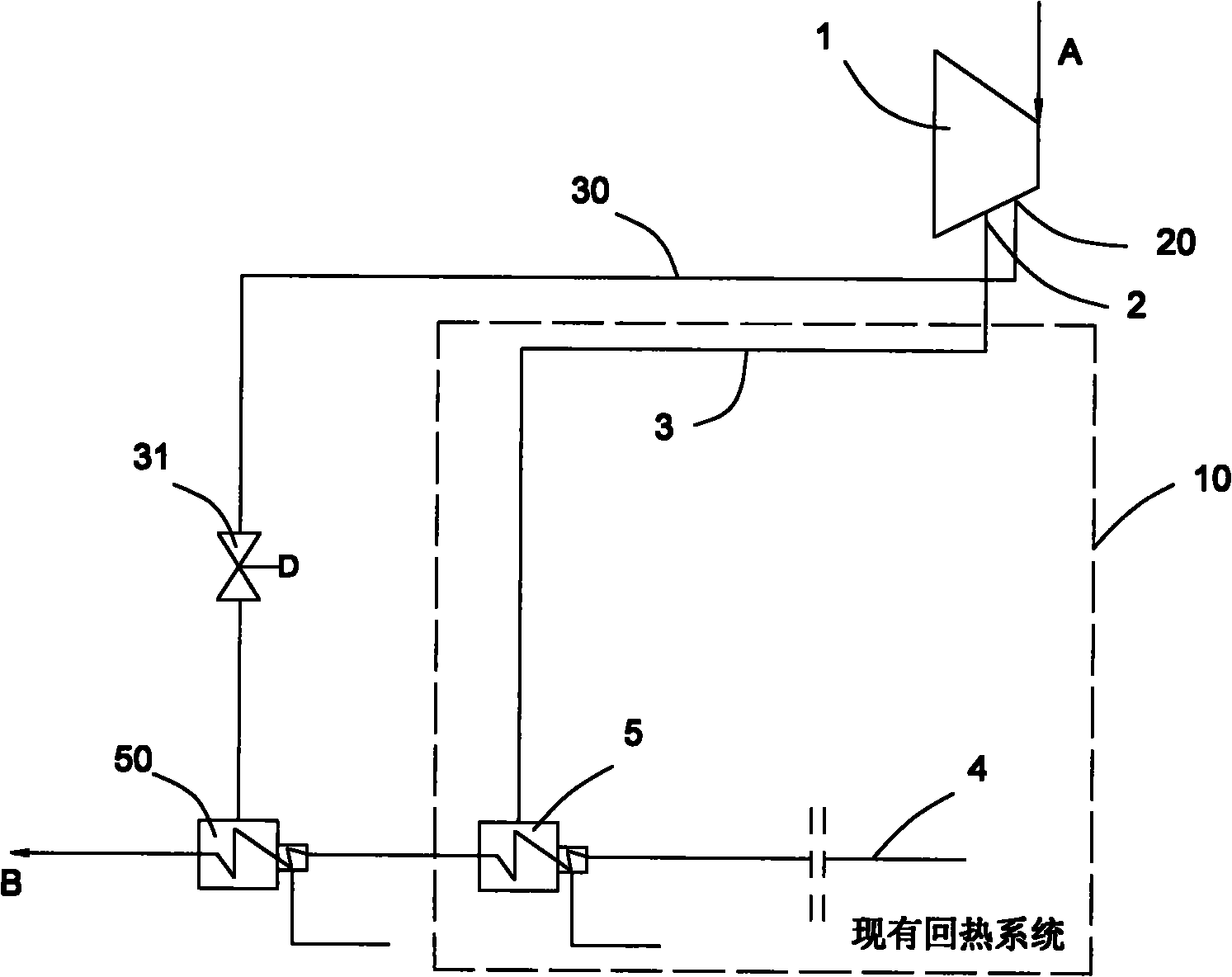

[0021] The elastic heat recovery system of the present invention is based on the existing heat recovery system by adding an extraction port with a higher extraction pressure to the high-pressure cylinder, a corresponding extraction pipe, and a high-pressure feedwater heater. The system introduces a part of the steam that has done work to the feedwater heater through the additional extraction pipe to heat the boiler feedwater, and its drain flows to the forward feedwater heater, and an extraction pipe is installed on the additional extraction pipe. The steam control valve adjusts the extraction steam, and can keep the pressure after the extraction steam control valve basically unchanged within the usual load change range to maintain the feed water temperature basically unchanged. The present invention numbers the order of the feedwater heaters according to the flow direction of the feedwater, so the high-pressure feedwater heater is also called the final stage feedwater heater. C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com