Patents

Literature

1189results about "Monocomponent cellulose artificial filament" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

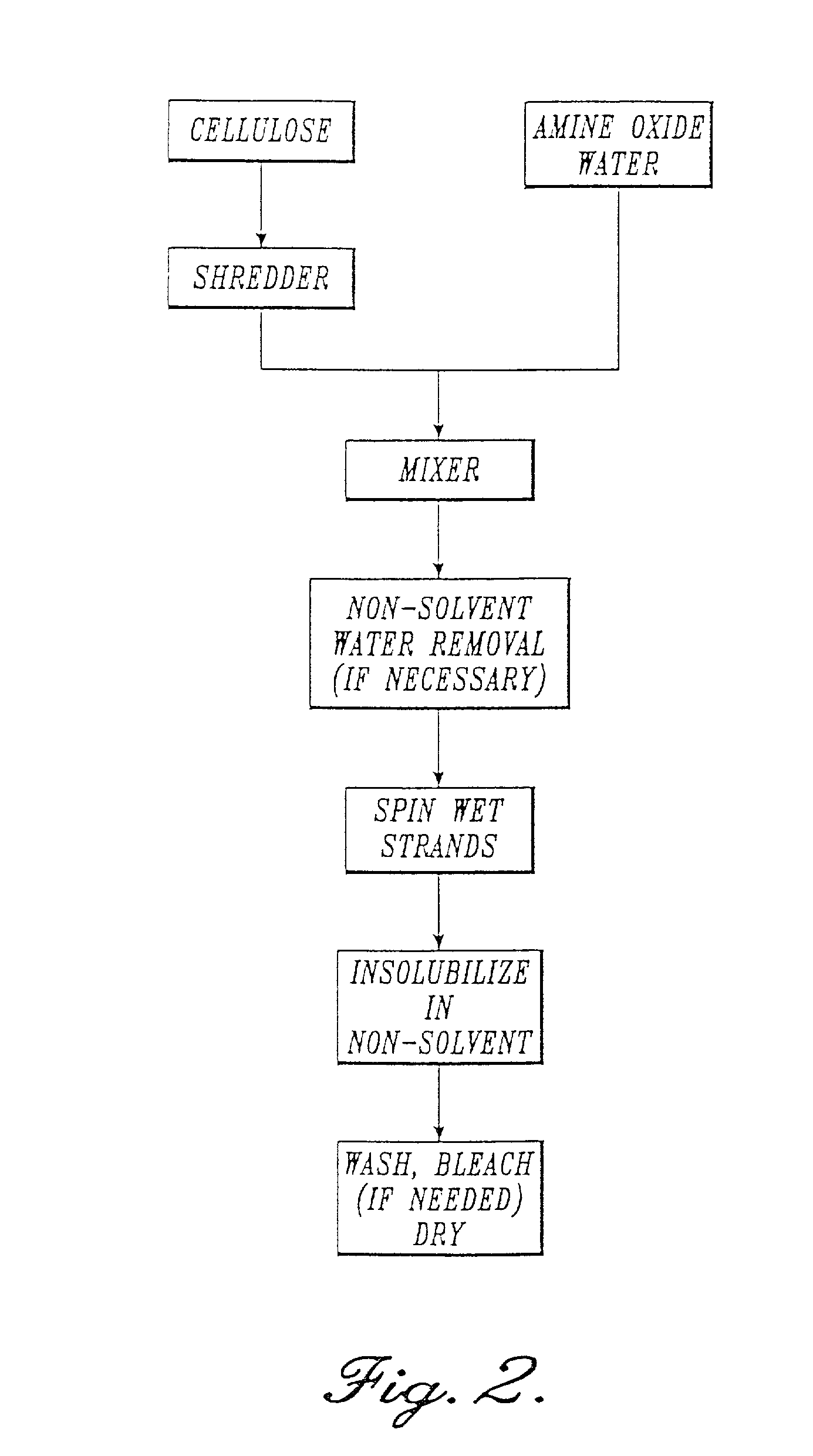

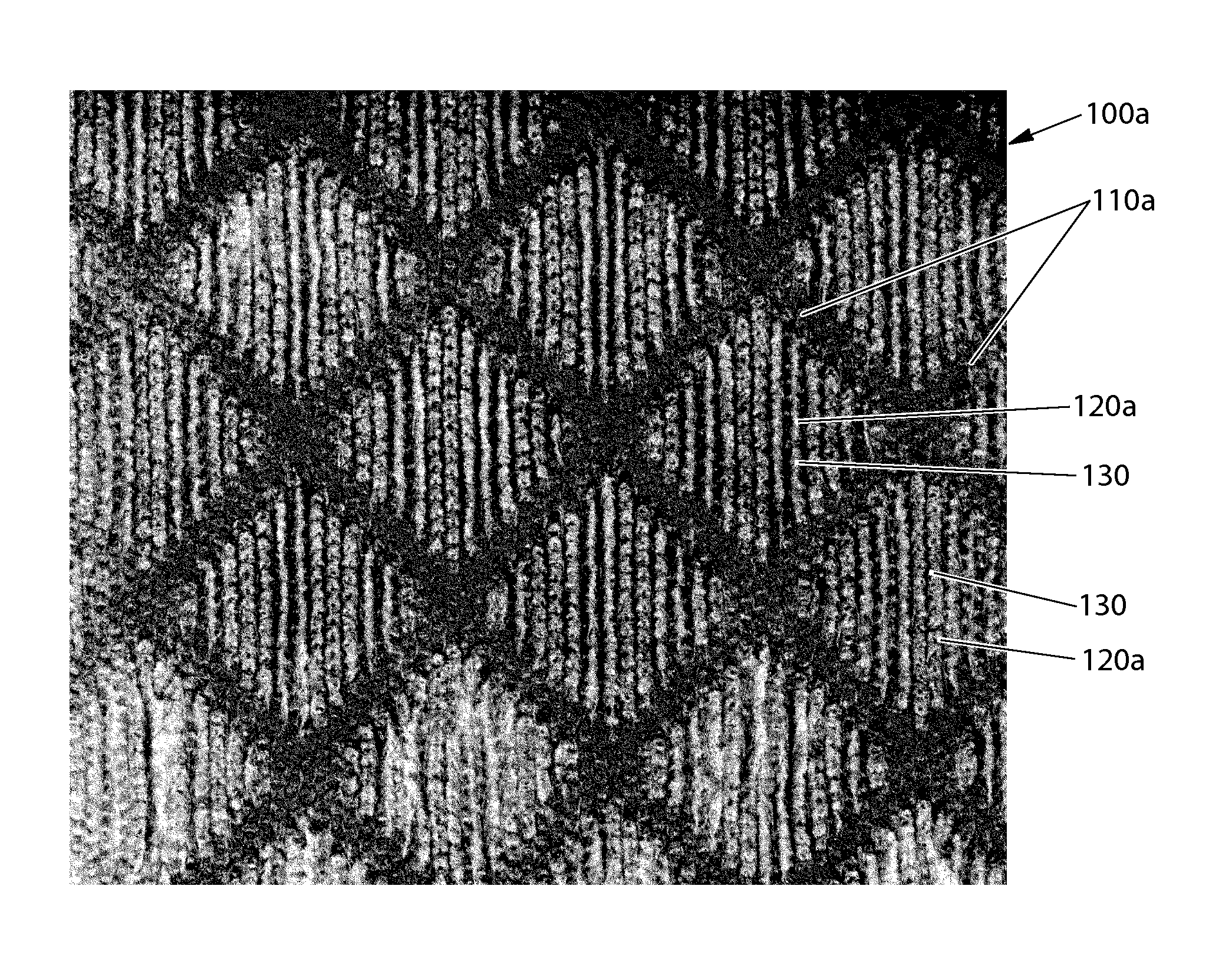

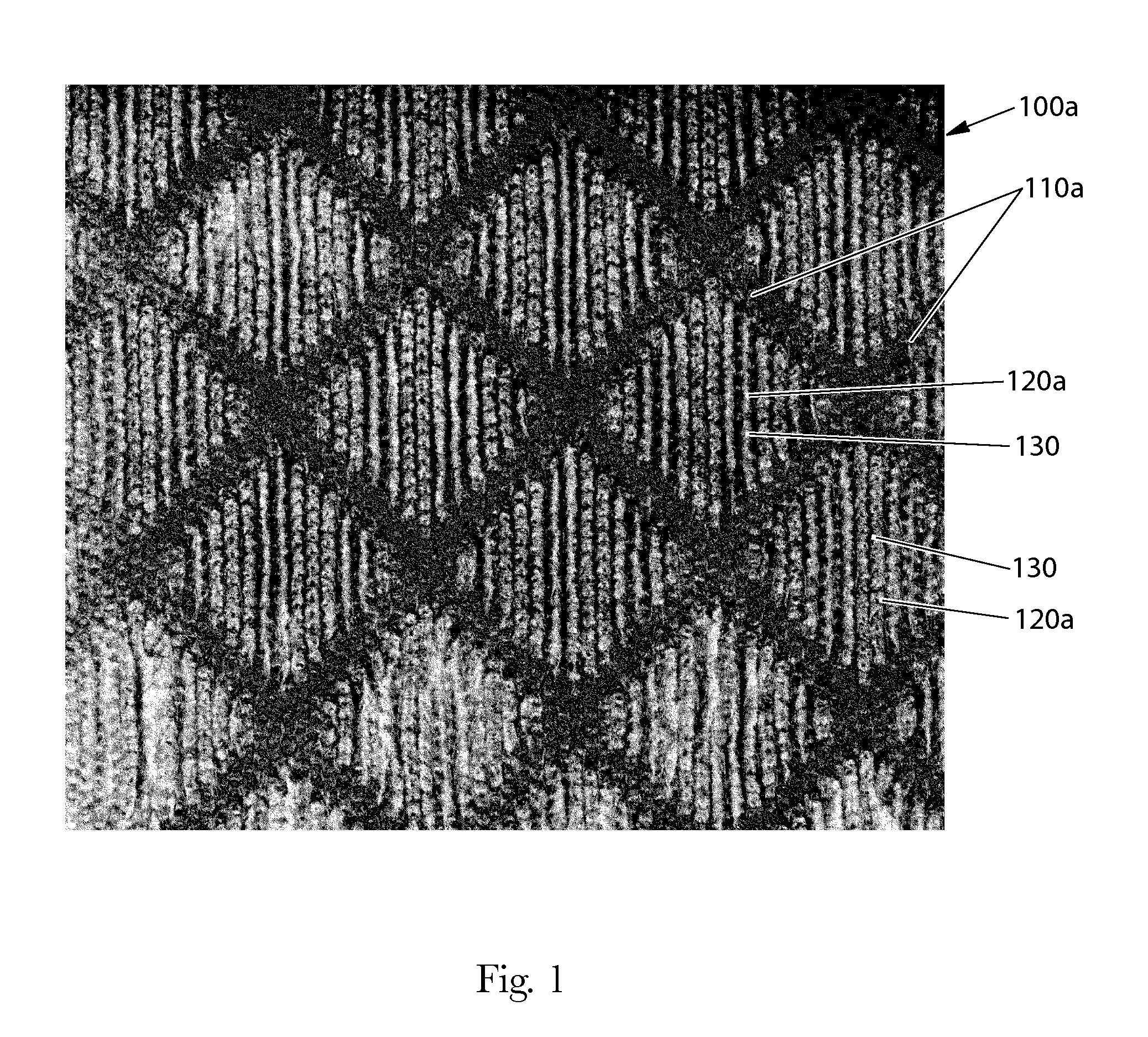

Lyocell nonwoven fabric

InactiveUS7067444B2Powerful solventLow tendency to fibrillatePulp properties modificationMonocomponent cellulose artificial filamentMelt blowingNonwoven fabric

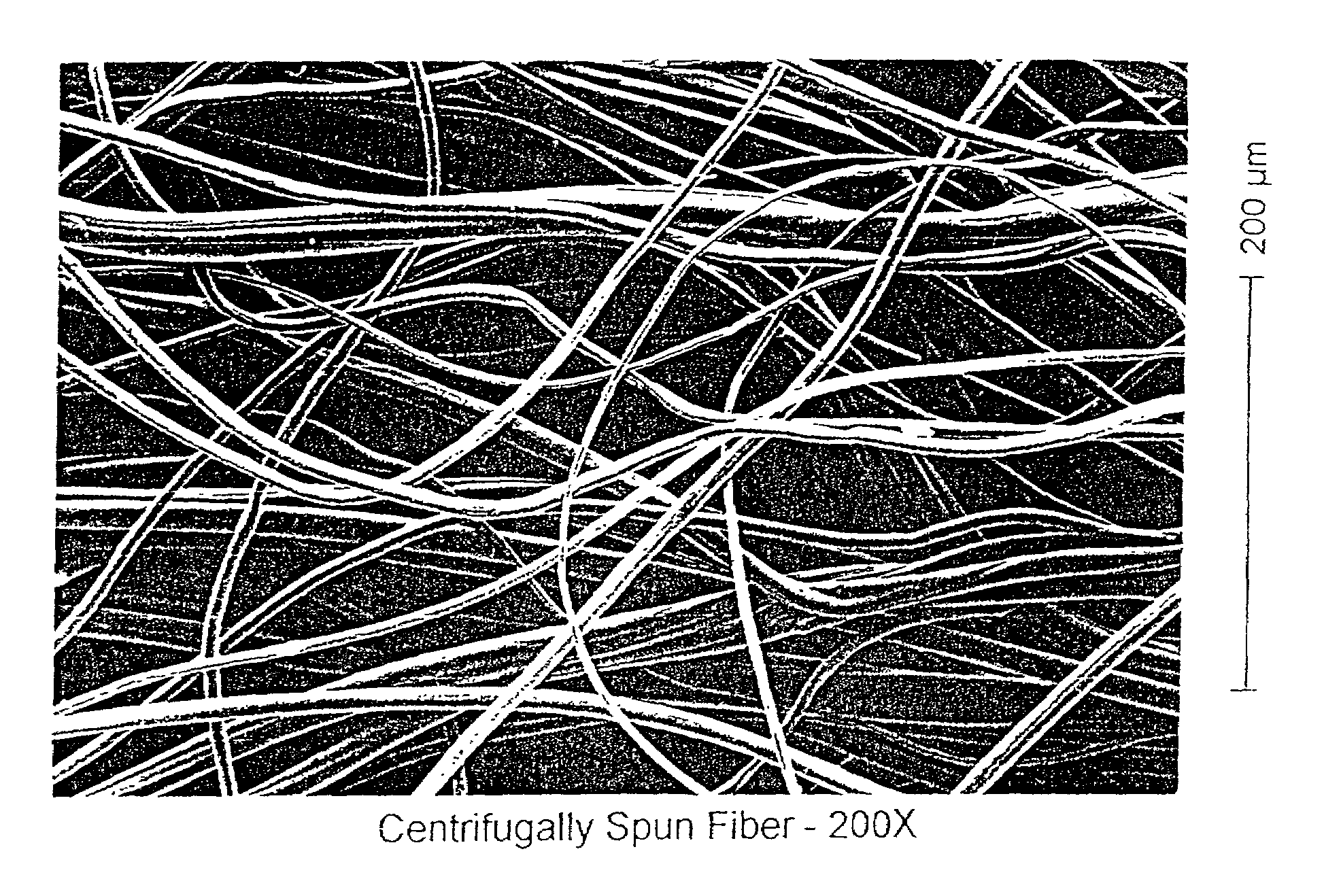

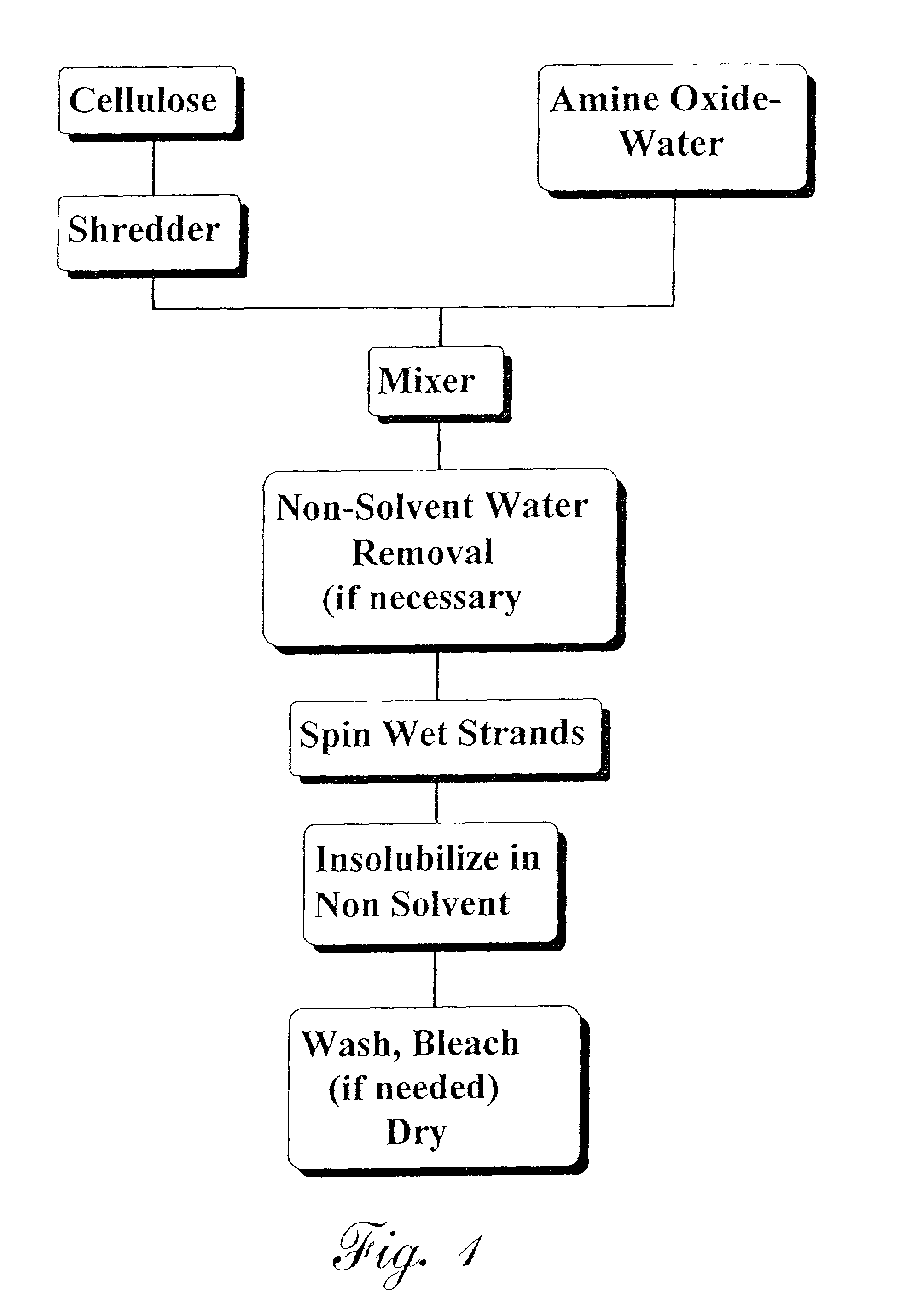

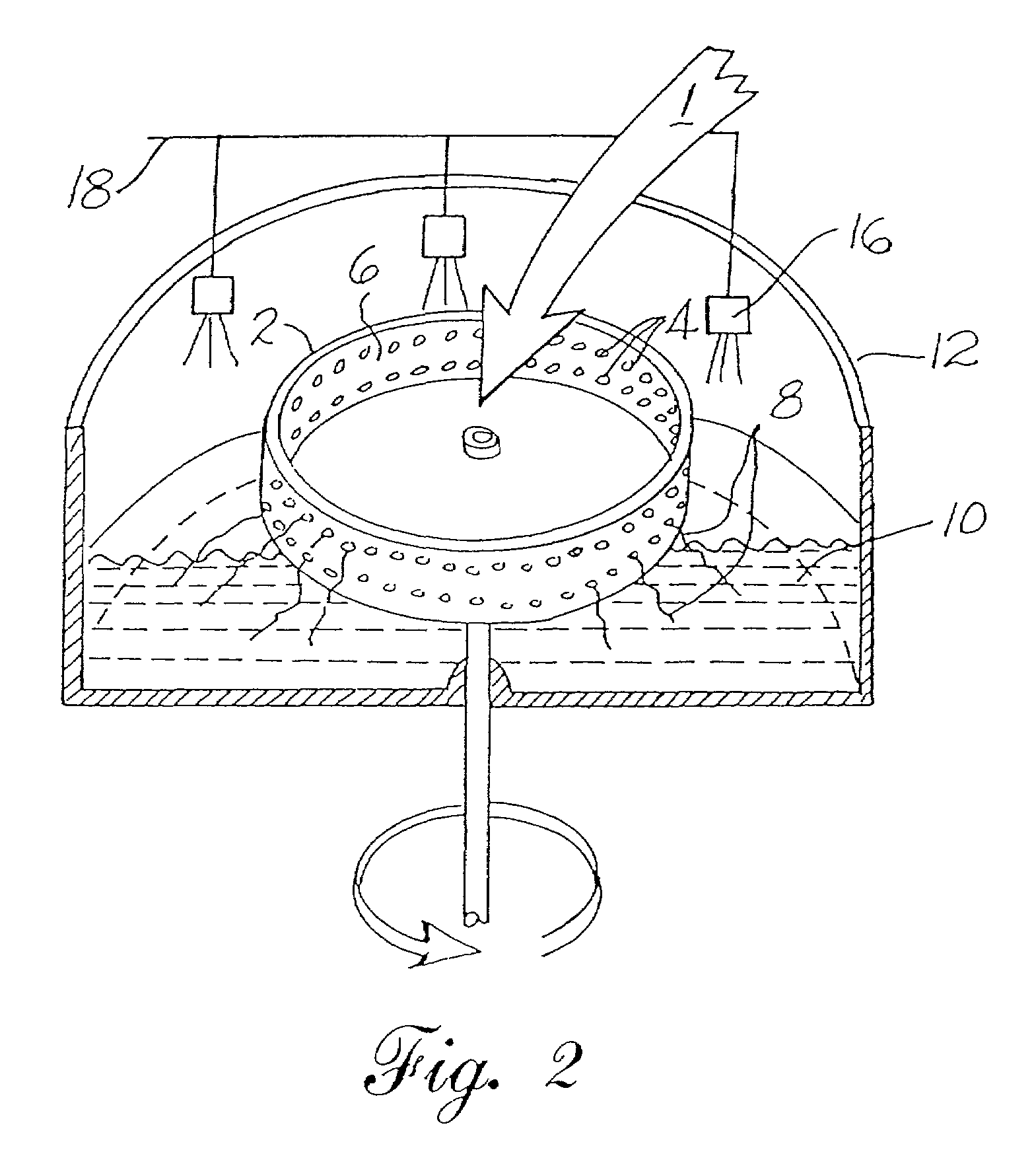

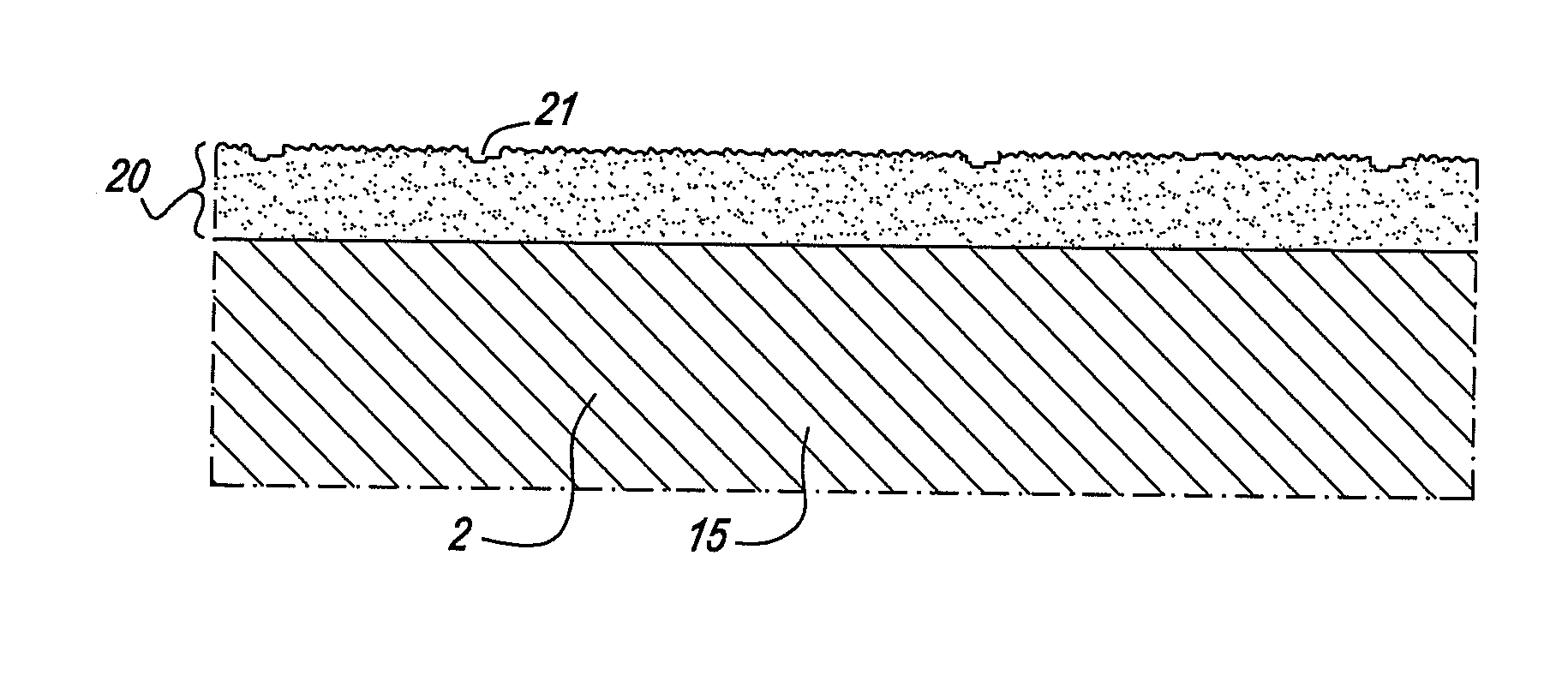

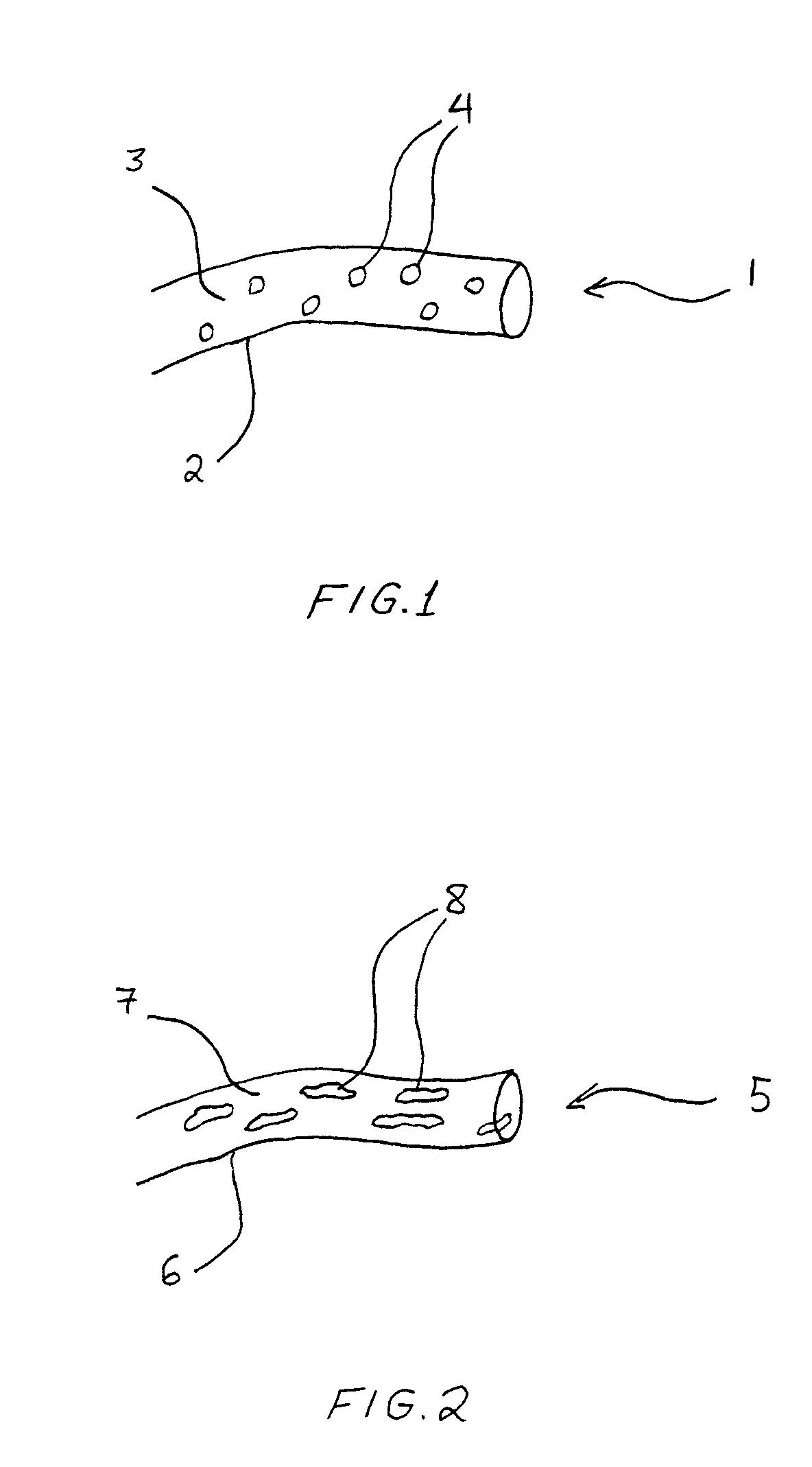

A lyocell nonwoven fabric having fibers characterized by pebbled surfaces and variable cross sections and diameters along the fibers and from fiber to fiber, is disclosed. The lyocell nonwoven fabric is produced by centrifugal spinning, melt blowing or spunbonding. The lyocell nonwoven fabric has fibers that can be made in the microdenier range with average weights as low as one denier or less. The lyocell nonwoven fabric has fibers with low gloss, a reduced tendency to fibrillate and have enhanced dye receptivity.

Owner:INT PAPER CO

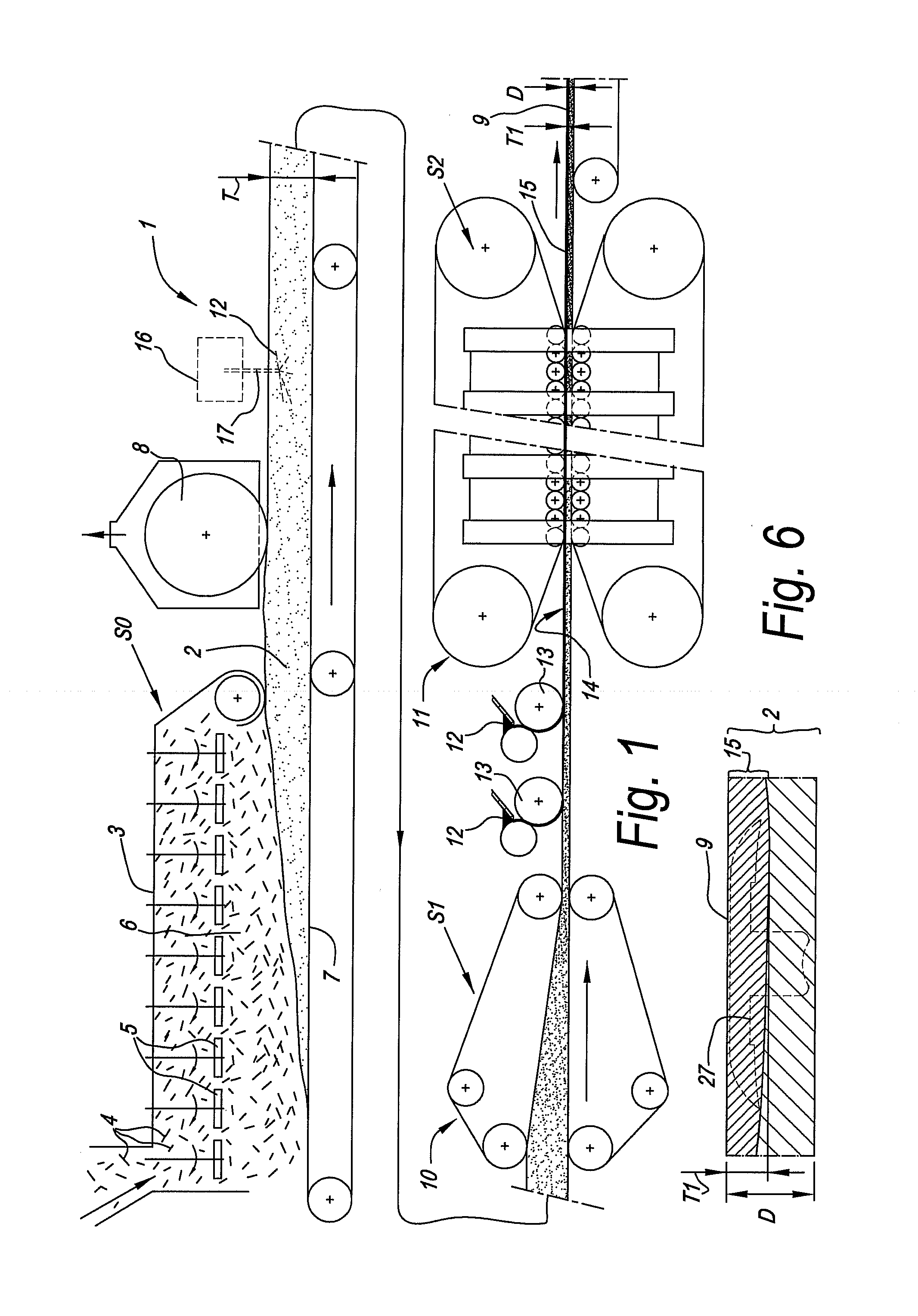

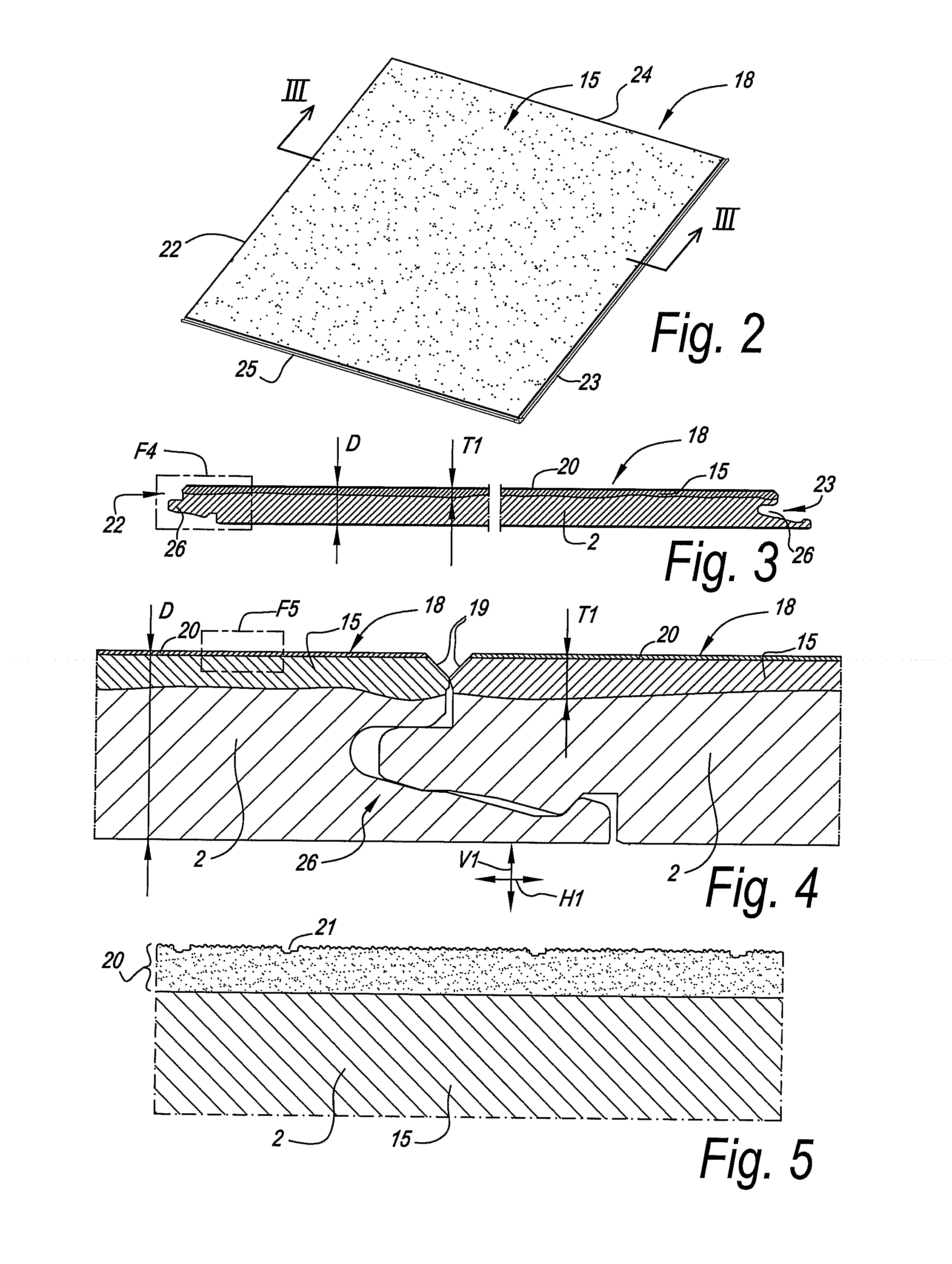

Method for manufacturing panels and panels obtained hereby

InactiveUS20110311806A1Simply formedFine surfaceLayered productsMonocomponent cellulose artificial filamentVolumetric Mass DensityEngineering

A method for manufacturing panels including a substrate on the basis of a pressed material mass, whereby it is started from a material mass to be densified, wherein the density of this material mass, in one or more densifying steps, is at least doubled. Prior to one or more of these densifying steps, a colorant is added to the material mass.

Owner:FLOORING IND LTD

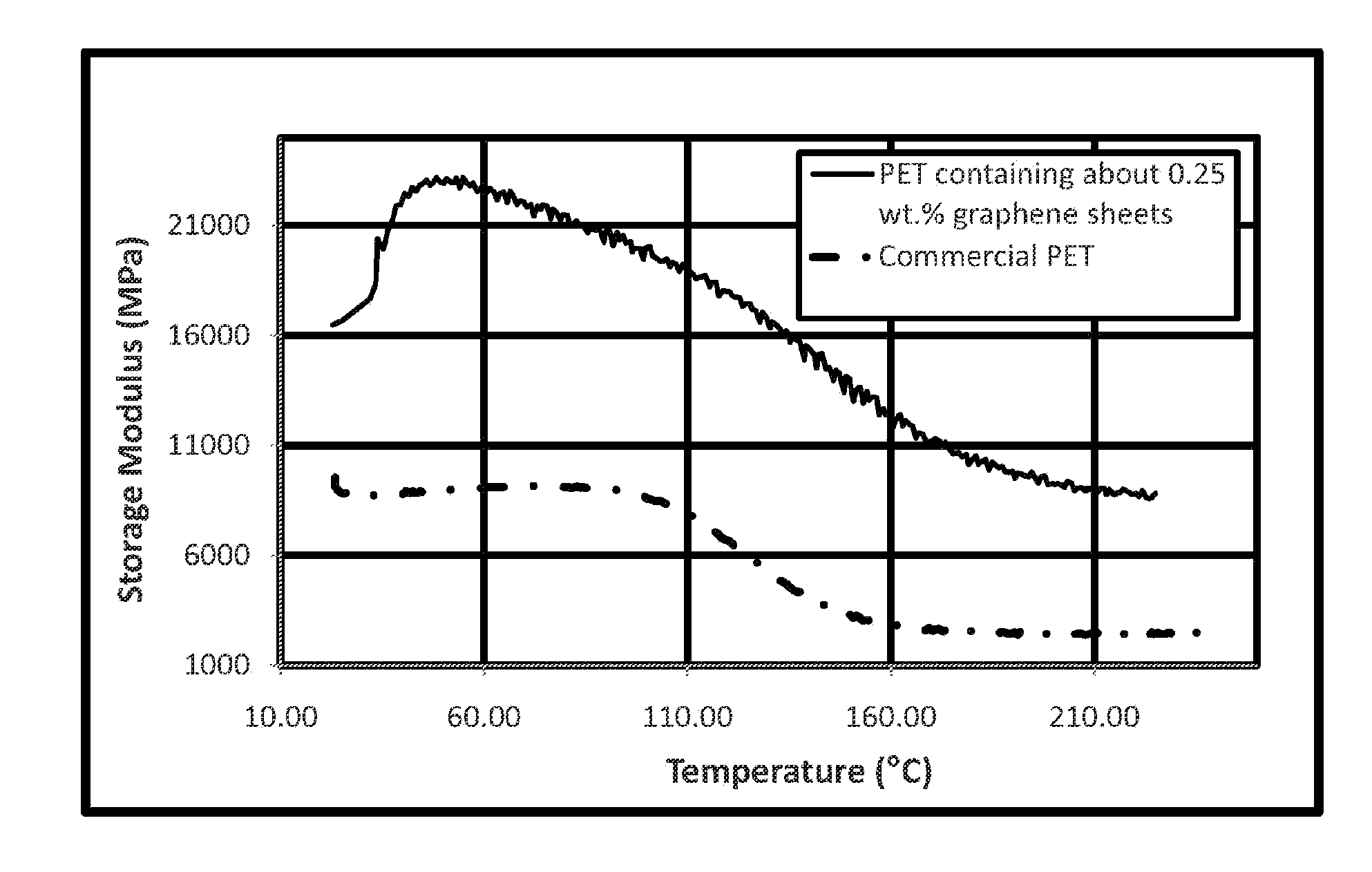

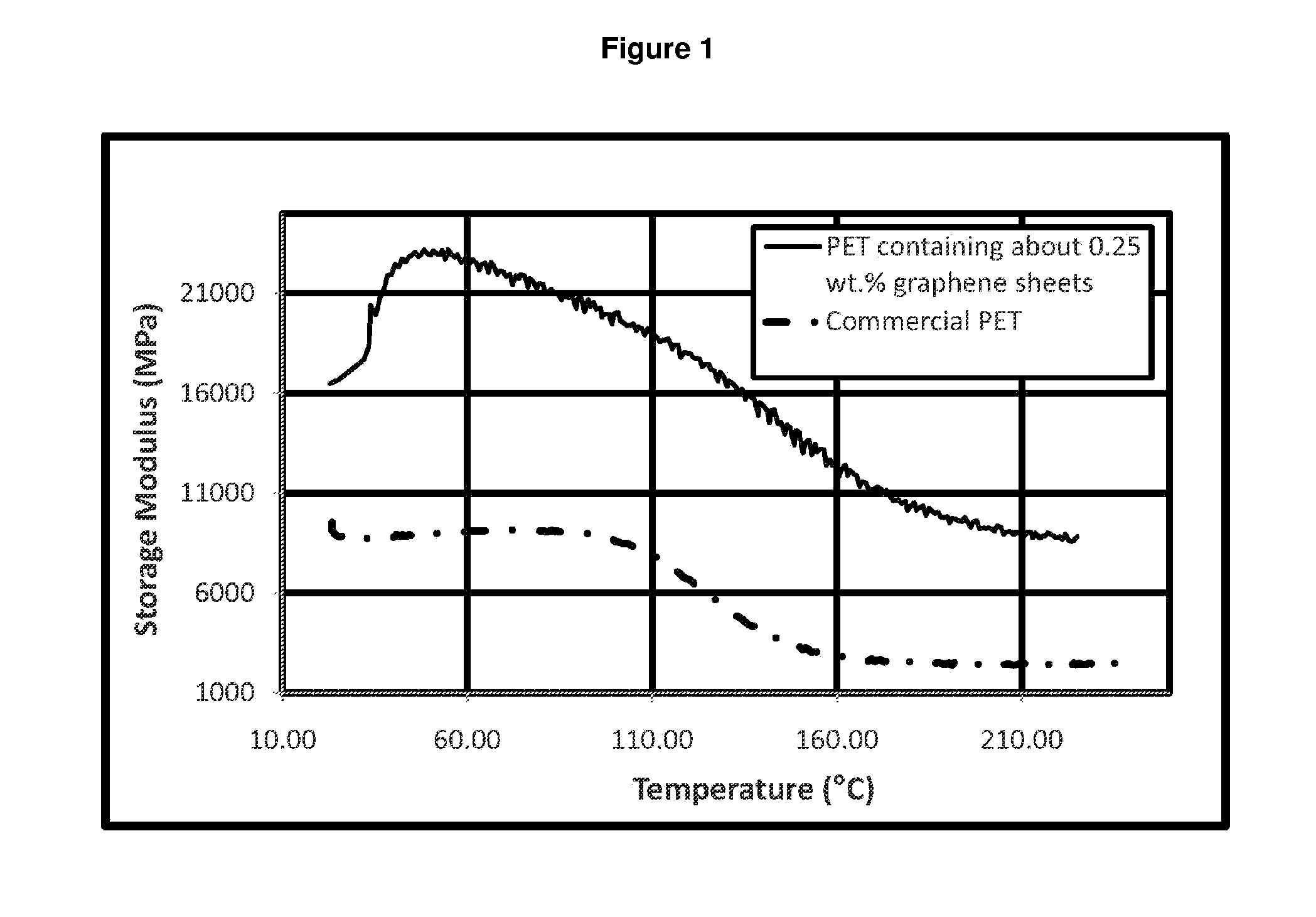

Polymeric fibers and articles made therefrom

InactiveUS20120244333A1Electric discharge heatingMonocomponent cellulose artificial filamentPolyesterYarn

Fibers described herein comprise a composition including a polymer and graphene sheets. The fibers can be further formed into yarns, cords, and fabrics. The fibers can be in the form of polyamide, polyester, acrylic, acetate, modacrylic, spandex, lyocell fibers, and the like. Such fibers can take on a variety of forms, including, staple fibers, spun fibers, monofilaments, multifilaments, and the like.

Owner:VORBECK MATERIALS CORP +1

Transfer method and transfer apparatus

InactiveUS20060243377A1Simple structureReduce capacityElectrical apparatusDecorative surface effectsOptoelectronics

A transfer method includes the steps of placing a donor substrate including a support base and a transfer layer provided on the support base onto a receptor substrate such that the transfer layer faces the receptor substrate, evacuating a space between the receptor substrate and the donor substrate that are placed one on the other, and transferring the transfer layer onto the receptor substrate by applying a radiant ray onto the donor substrate in an evacuated atmosphere.

Owner:SONY CORP

Temperature regulating cellulosic fibers and applications thereof

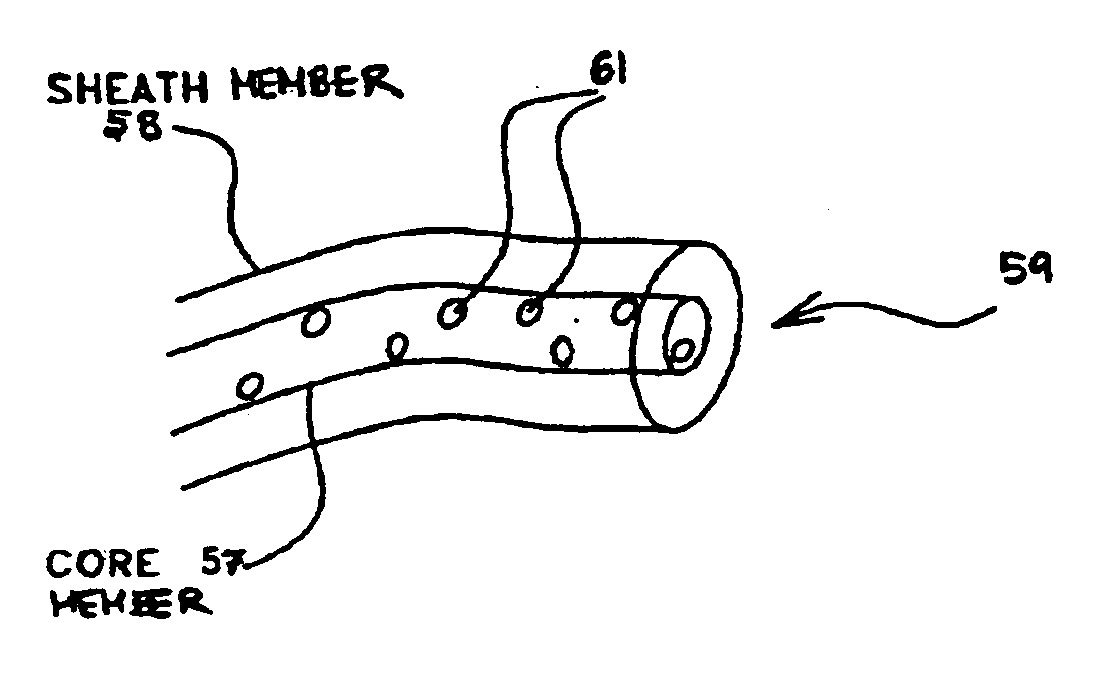

InactiveUS20070026228A1Monocomponent cellulose artificial filamentGlass/slag layered productsCellulose fiberPhase-change material

Cellulosic fibers having enhanced reversible thermal properties and applications of such cellulosic fibers are described. In one embodiment, a cellulosic fiber includes a fiber body including a cellulosic material and a set of microcapsules dispersed in the cellulosic material. The set of microcapsules contain a phase change material having a latent heat of at least 40 J / g and a transition temperature in the range of 0° C. to 100° C., and the phase change material provides thermal regulation based on at least one of absorption and release of the latent heat at the transition temperature. The cellulosic fiber can be formed via a solution spinning process, and can be used in various products where thermal regulating properties are desired.

Owner:OUTLAST TECH GMBH

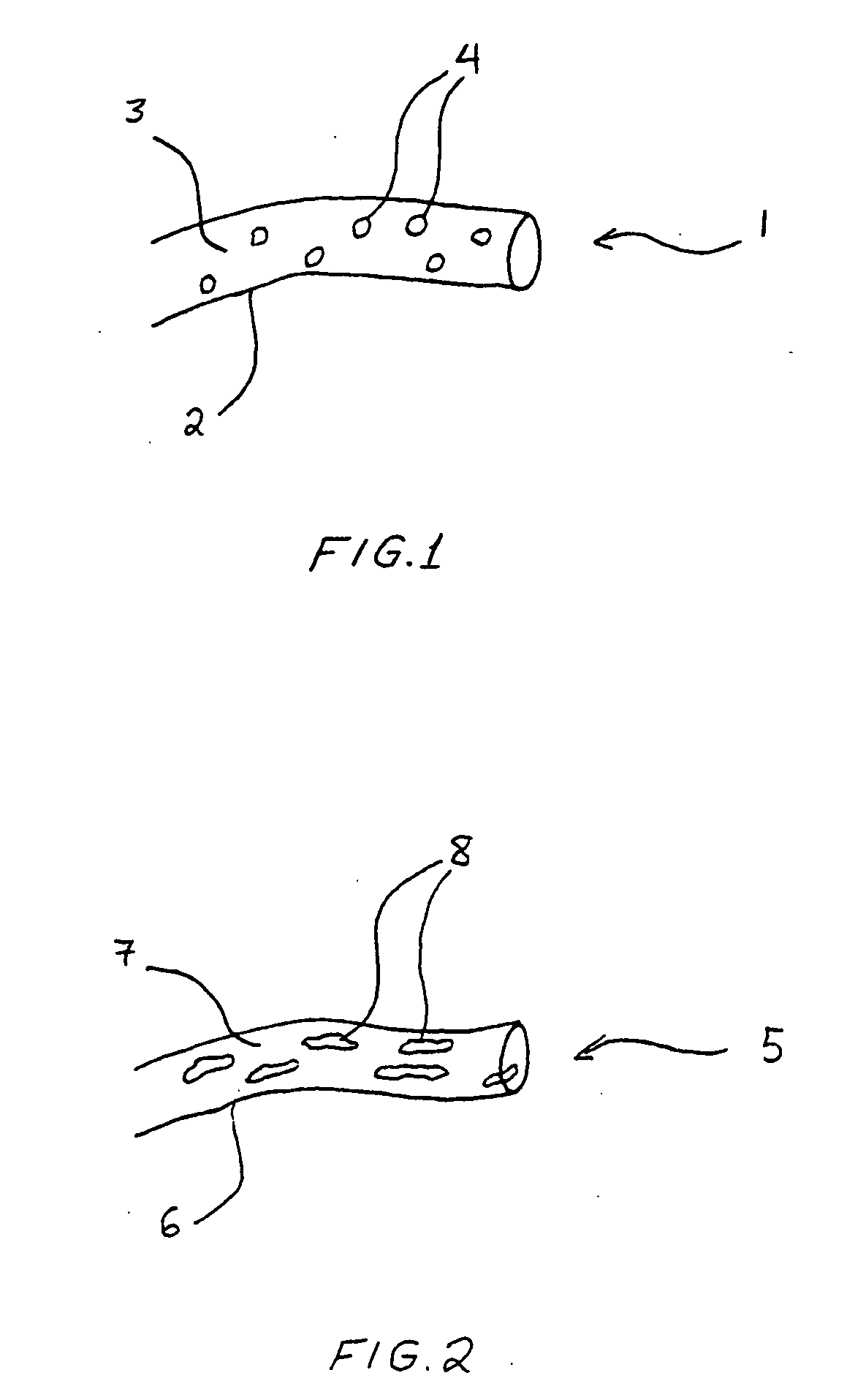

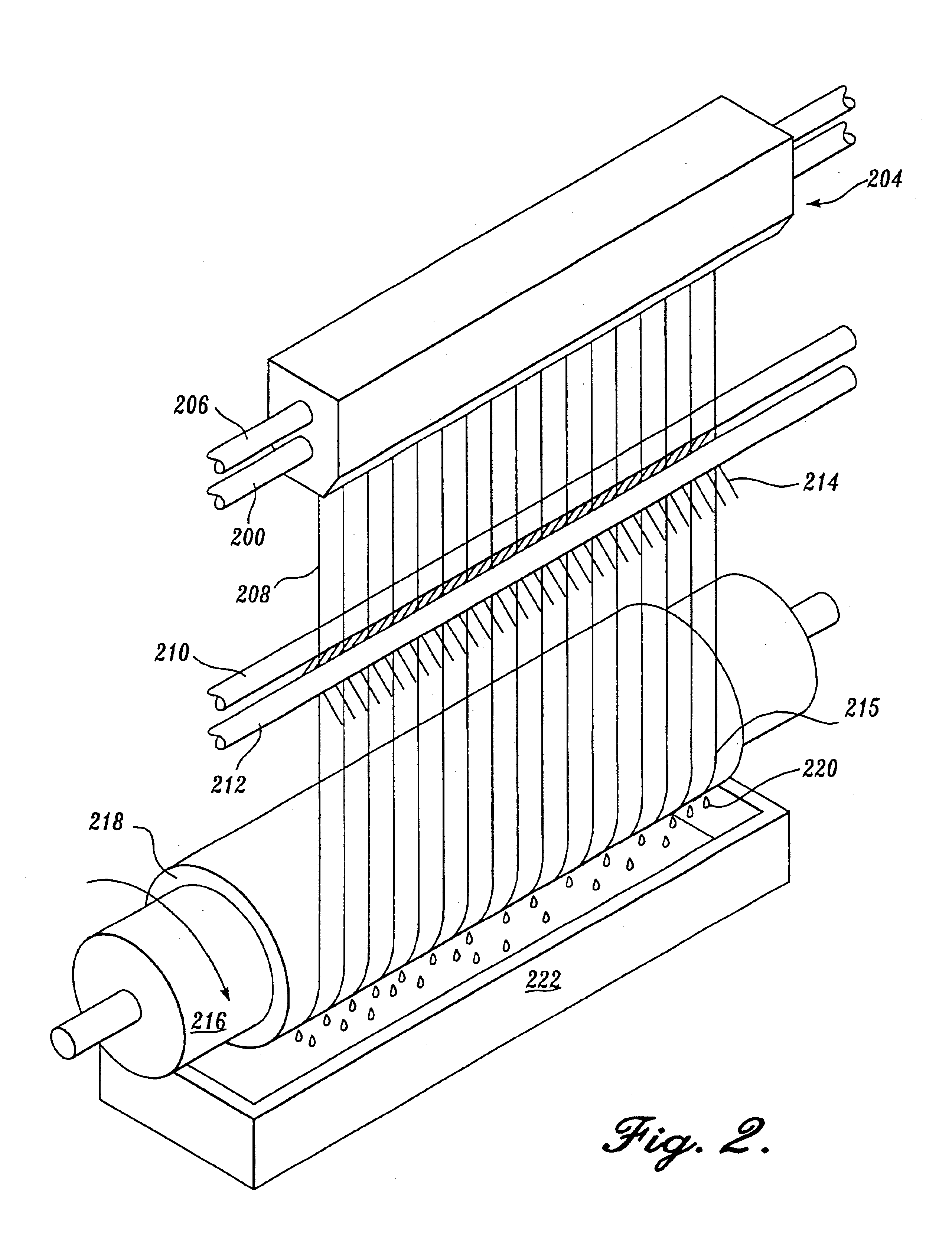

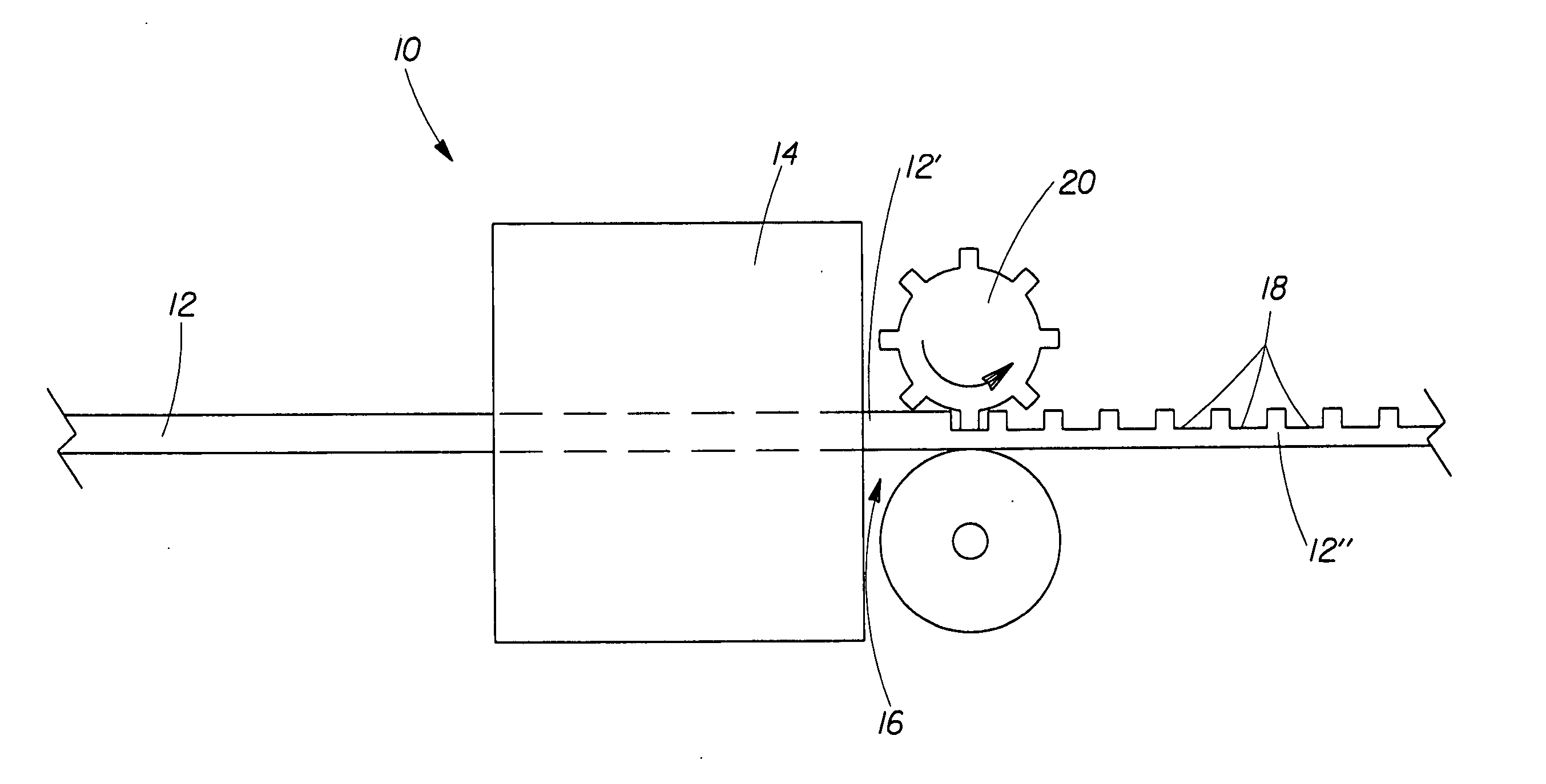

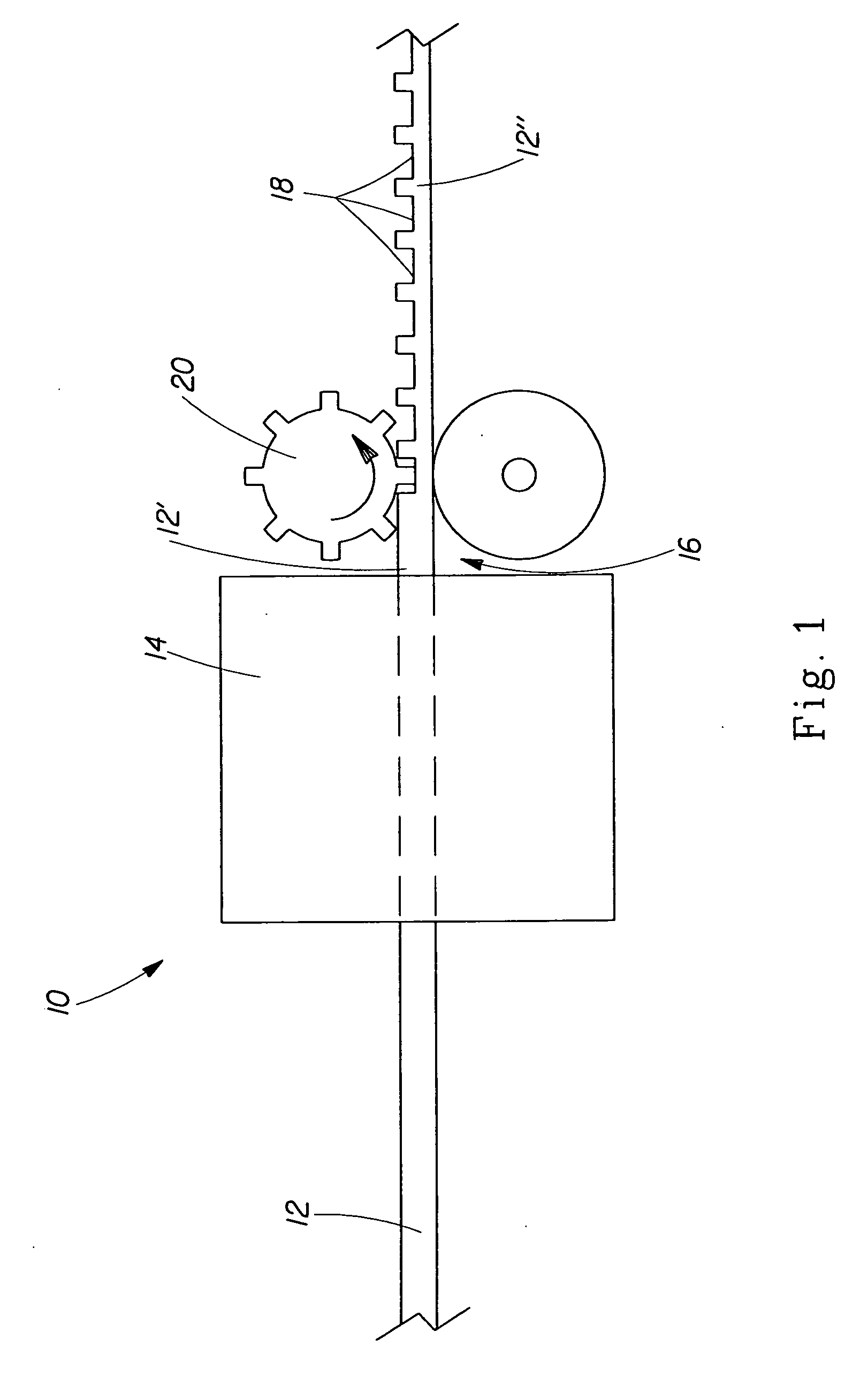

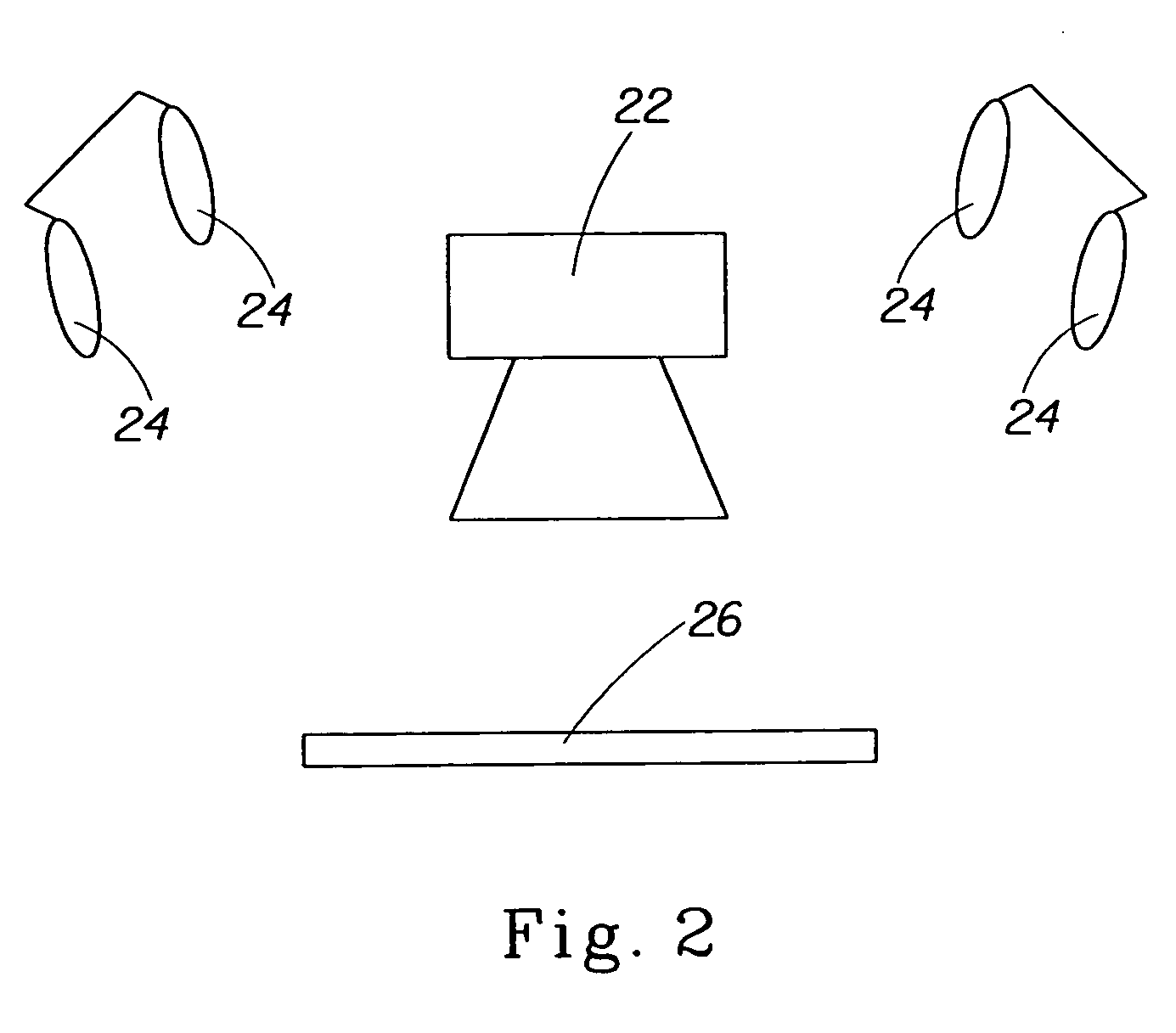

Meltblown process with mechanical attenuation

InactiveUS6773648B2High speed spinningImprove productivityPulp properties modificationArtificial filament physical treatmentCelluloseUltrasound attenuation

Owner:WEYERHAEUSER NR CO

Fiber composite

InactiveUS20100272980A1High transparencyLow water absorptionMonocomponent cellulose artificial filamentRecord information storageThermal expansionCellulose fiber

To provide a cellulose fiber composite having high transparency, low water absorption and low coefficient of linear thermal expansion.A fiber composite which comprises fibers having an average fiber diameter of at most 30 nm and a matrix material and which has a haze of at most 5 according to JIS K-7136 when the fiber composite has a thickness of 100 μm.

Owner:MITSUBISHI CHEM CORP

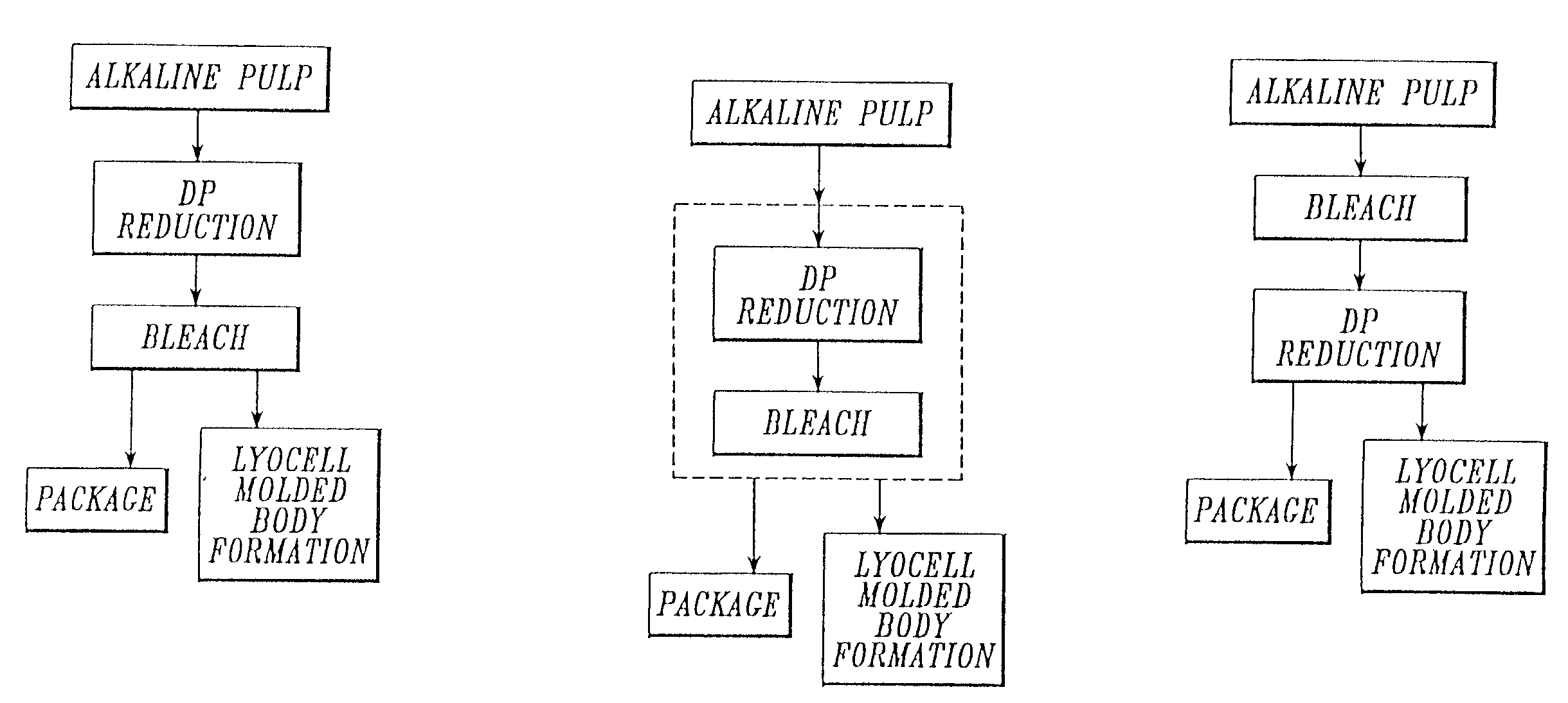

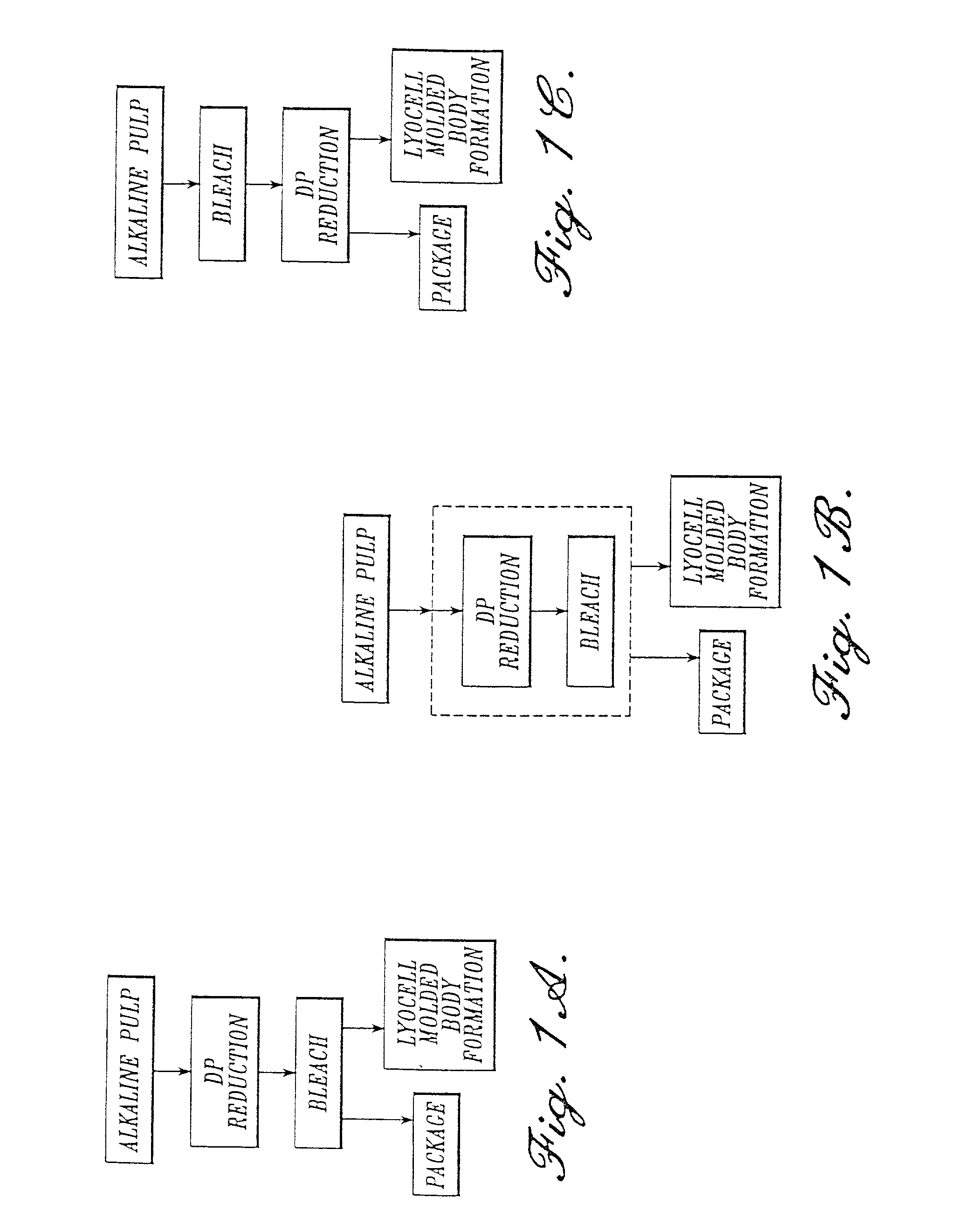

Process for making a composition for conversion to lyocell fiber from an alkaline pulp having low average degree of polymerization values

InactiveUS7083704B2Reducing hemicellulose contentIncreasing copper numberPulp properties modificationMonocomponent cellulose artificial filamentHemicelluloseLyocell

The present invention provides compositions, useful for making lyocell fibers, having a high hemicellulose content, a low copper number and including cellulose that has a low average degree of polymerization (D.P.) and a narrow molecular weight distribution. Further, the present invention provides processes for making compositions, useful for making lyocell fibers, by contacting an alkaline pulp having a high hemicellulose content of at least about 7% with an oxidant sufficient to reduce the average degree of polymerization to about 200 to 1100 without substantially reducing the hemicellulose content or increasing the copper number of the pulp.

Owner:INT PAPER CO

Cellulosic fibers having enhanced reversible thermal properties and methods of forming thereof

Cellulosic fibers having enhanced reversible thermal properties and methods of forming such cellulosic fibers are described. In one embodiment, a cellulosic fiber includes a fiber body formed of an elongated member. The elongated member includes a cellulosic material and a temperature regulating material dispersed within the cellulosic material. The temperature regulating material includes a phase change material having a transition temperature in the range of −5° C. to 125° C. The cellulosic fiber can be formed via a solution spinning process and can be used in various products where thermal regulating properties are desired. For example, the cellulosic fiber can be used in textiles, apparel, footwear, medical products, containers and packagings, buildings, appliances, and other products.

Owner:OUTLAST TECH GMBH

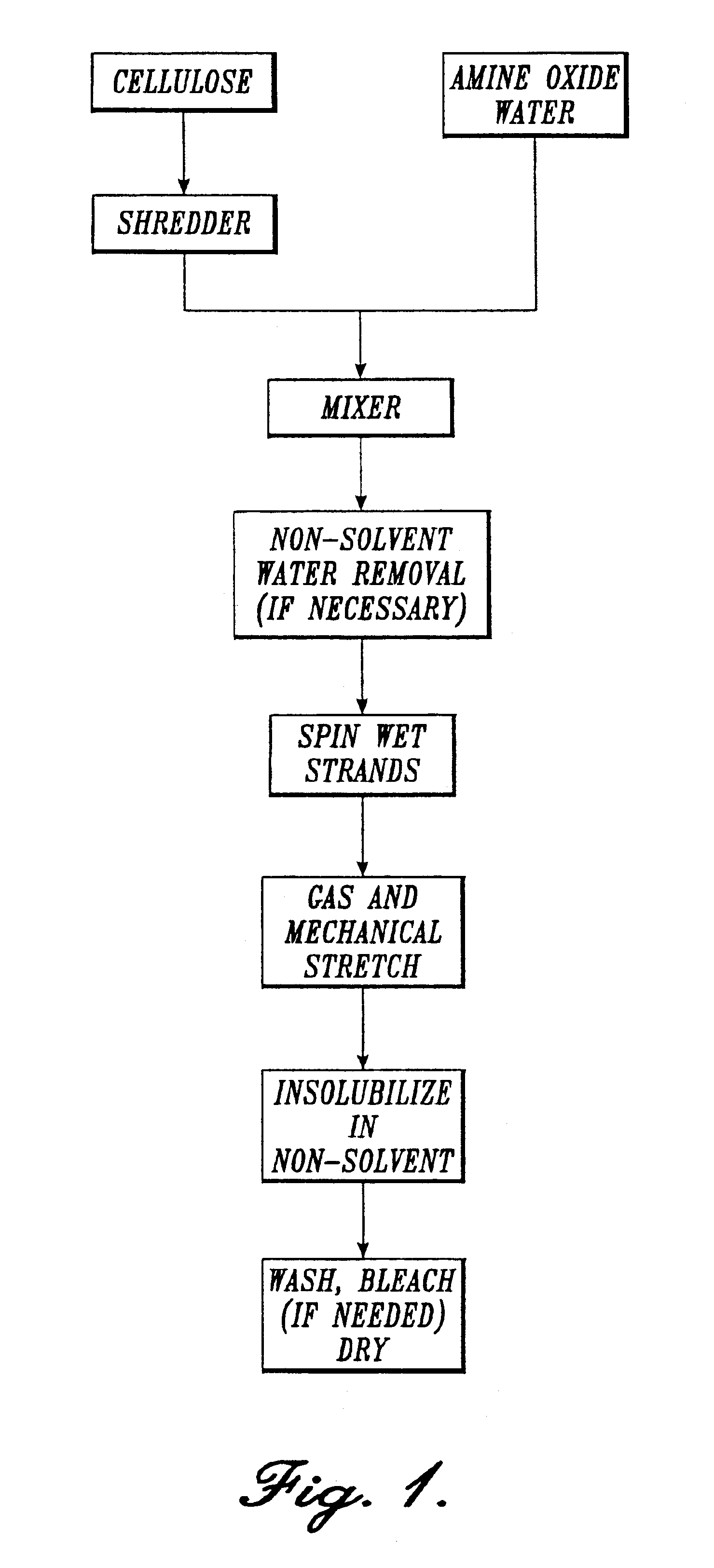

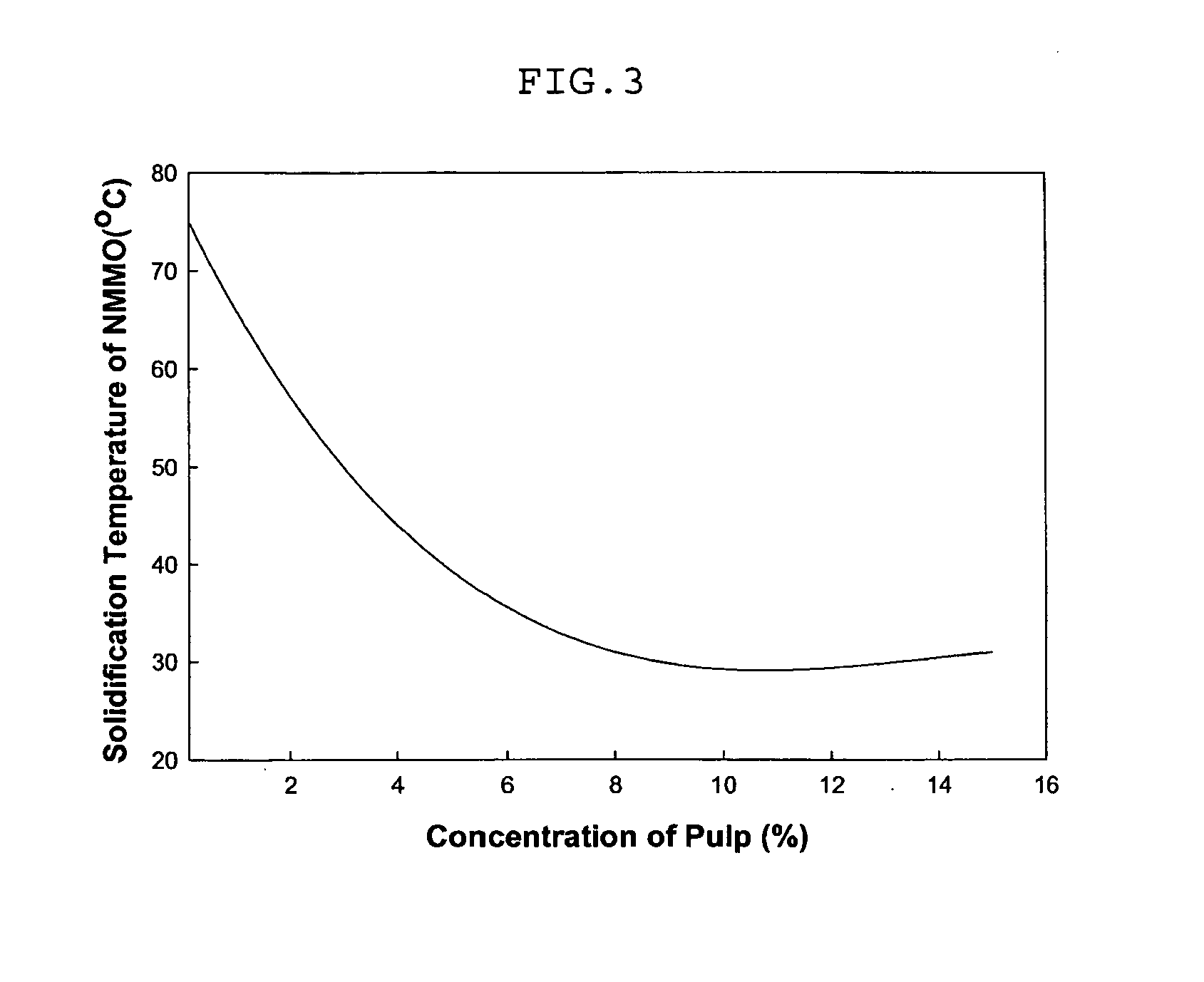

Solution containing cellulose dissolved in n-methylmorpholine-n-oxide and high tenacity lyocell multifilament using the same

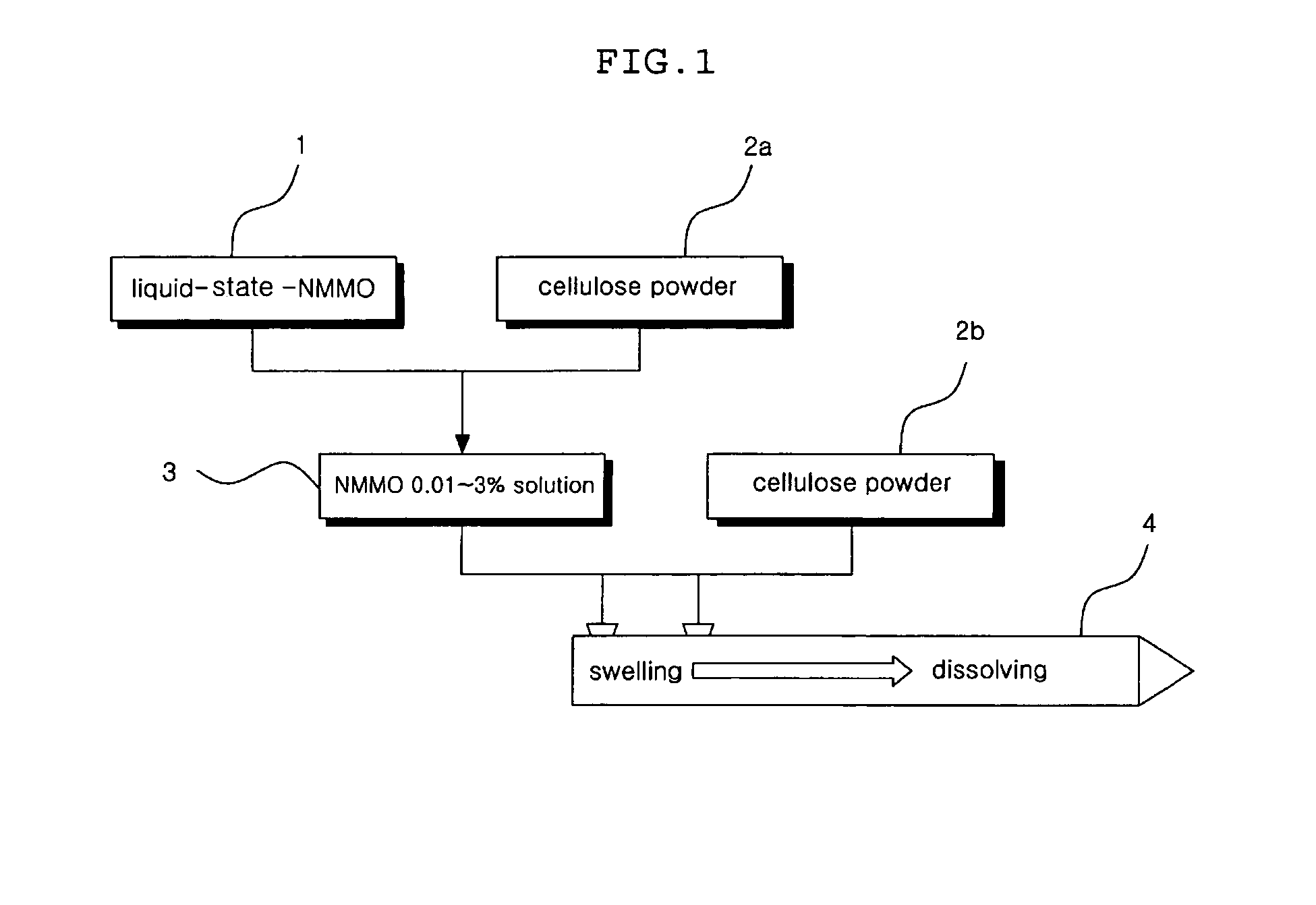

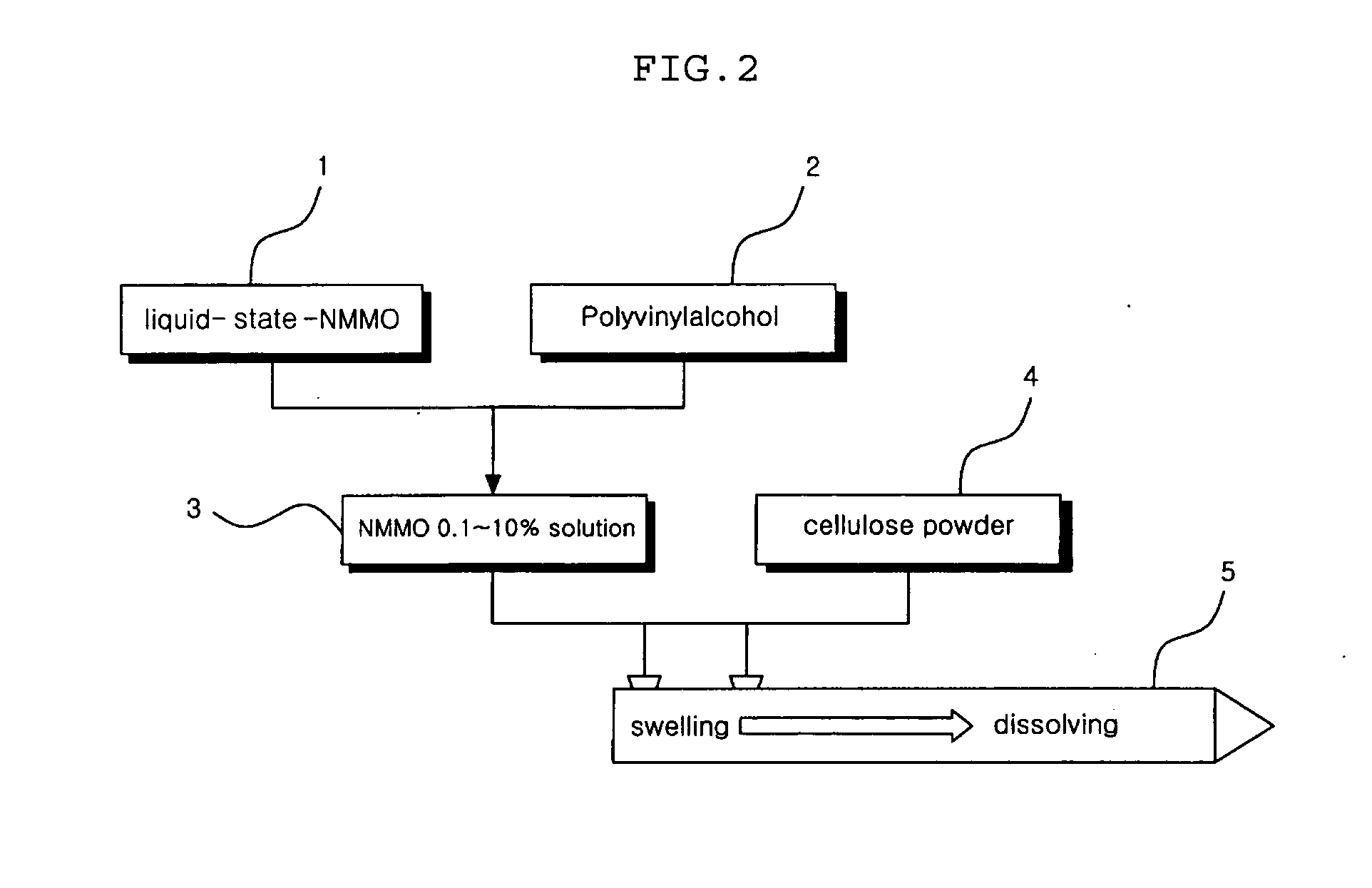

ActiveUS20050154093A1Solidifying temperatureIncrease flexibilityNon-fibrous pulp additionMonocomponent cellulose artificial filamentLiquid stateLyocell

This invention relates to a method of preparing cellulose solution which is homogeneous at relatively low temperature, in which a small amount of cellulose powder or polyvinylalcohol is dissolved in the liquid-state, concentrated N-methylmorpholine-N-oxide (hereinafter, referred to as ‘NMMO’) so as to lower the solidifying temperature of NMMO, and then, the resulting solution and cellulose powder are fed into an extruder so as to be mixed, swollen and melted in the extruder.

Owner:HYOSUNG ADVANCED MATERIALS CORP

Polymeric structures and method for making same

InactiveUS20050275133A1Monocomponent cellulose artificial filamentMonocomponent synthetic polymer artificial filamentFiberMaterials science

Owner:THE PROCTER & GAMBLE COMPANY

Rotary spinning processes for forming hydroxyl polymer-containing fibers

InactiveUS7655175B2Monocomponent protein artificial filamentElectric discharge heatingFiberMaterials science

Owner:THE PROCTER & GAMBLE COMPANY

Methods and systems for manufacturing the manufacture of layered three-dimensional forms

ActiveUS20080237933A1Efficiently reclaim and re-useEfficient use ofAdditive manufacturing apparatusArtificial filament recoveryParticulatesBiological activation

New methods and systems for manufacturing a three-dimensional form, comprising steps of providing a plurality of particulates; contacting the particulates with an activation agent; contacting particulates having the activation agent with a binder material that is activatable by the activation agent; at least partially hardening the binder for forming a layer of the three-dimensional form; and repeating these steps to form the remainder of the three-dimensional form. Following sequential application of all required layers and binder material to make the form, the unbound particles are appropriately removed (and optionally re-used), to result in the desired three-dimensional form. The invention also contemplates a novel method for preparing a form, where unbound particulates free of binder material are re-claimed.

Owner:EXONE

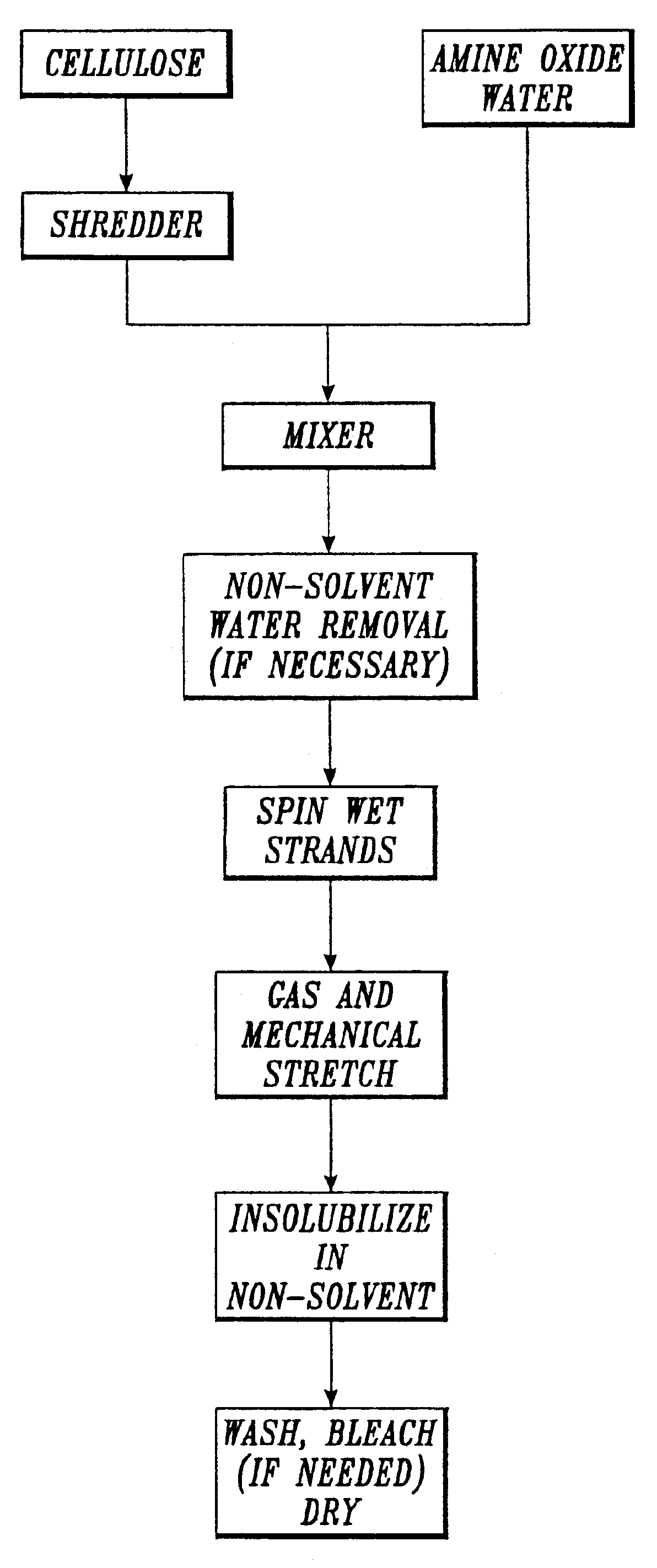

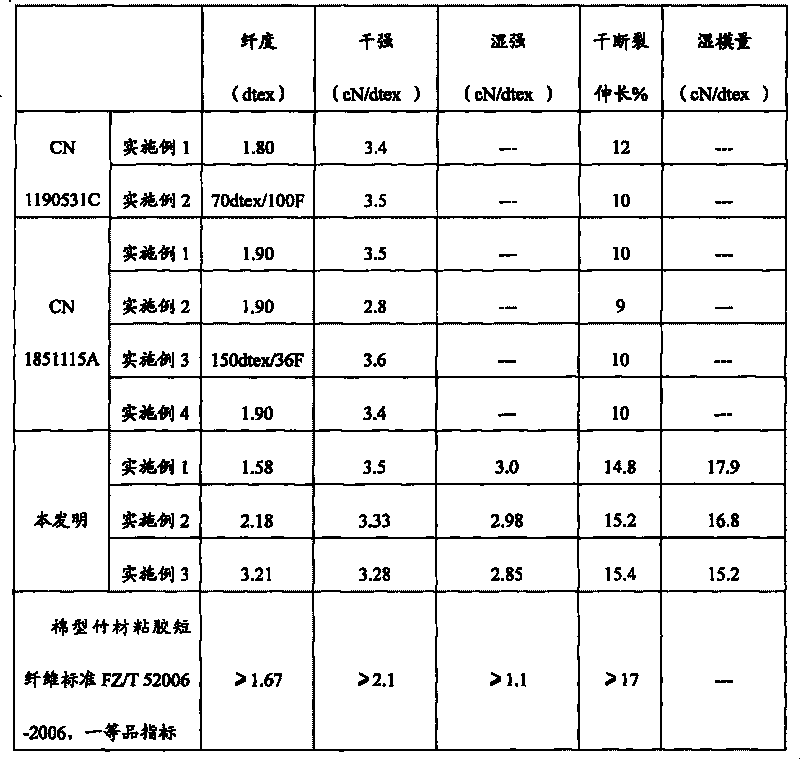

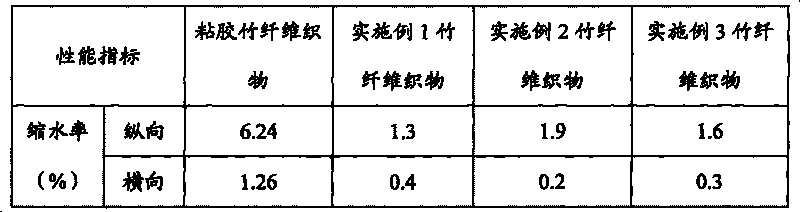

Solvent method high-wet-modulus bamboo fiber and preparation method thereof

ActiveCN101694019AEasy to operateReduce energy consumptionMonocomponent cellulose artificial filamentVegetable materialFiberCellulose

The invention discloses a solvent method high-wet-modulus bamboo fiber and a preparation method thereof. The preparation method of the bamboo fiber comprises the following steps: activation, adding bamboo pulp into deionized water, adjusting the pH value, adding cellulase for activation, and then adding alkali to adjust the pH value; squeezing, vacuum dewatering and squeezing; pre-dissolving, adding water solution containing 50-88% of N-methyl morpholine-N-oxide; dissolving, entering a dissolving machine, heating, vacuumizing, dehydrating, dissolving, homogenizing and defoaming; spinning, spraying through a spinneret plate, and molding by adopting a dry wet spinning; washing; whitening; oiling; and drying. The preparation method has simple operation, no industrial pollution, low energy consumption and high safety performance, and is applicable to manufacturing the solvent method bamboo fiber by large-scale industrialized continuous production; furthermore, the bamboo fiber prepared by the method not only maintains the natural physical and chemical properties of the bamboo fiber, but also generates no harmful chemical residue and has higher wet modulus.

Owner:SHANGHAI LYOCELL FIBER DEV

Method of Producing a Web Substrate Having Activated Color Regions in Deformed Regions

Owner:THE PROCTER & GAMBLE COMPANY

High-strength transparent cellulose material and preparation method thereof

ActiveCN101880410AGood mechanical propertiesImprove thermal stabilityMonocomponent cellulose artificial filamentSpinning solutions preparationSupercritical dryingCellulose

The invention discloses a transparent high-strength fiber material. The preparation method comprises the following steps that: cellulose is dissolved in NaOH-urea aqueous solution or LiOH-urea aqueous solution which is pre-cooled at low temperature to obtain a cellulose solution, and different thicknesses of cellulose hydrogels are prepared by the cellulose solution; water in the cellulose hydrogel is replaced into an organic solvent to obtain a cellulose organic gel; the cellulose hydrogel or the cellulose organic gel is subject to supercritical drying, ambient pressure drying or freeze drying to remove a liquid medium so as to obtain a cellulose aerogel; and the cellulose hydrogel, the organic gel or the aerogel are autoclaved at a temperature of 30-200 DEG C under the pressure of 10-160Mpa to obtain the high-strength transparent cellulose material. The cellulose material prepared by the invention has excellent mechanical properties, thermal stability and optical permeability.

Owner:WUHAN UNIV

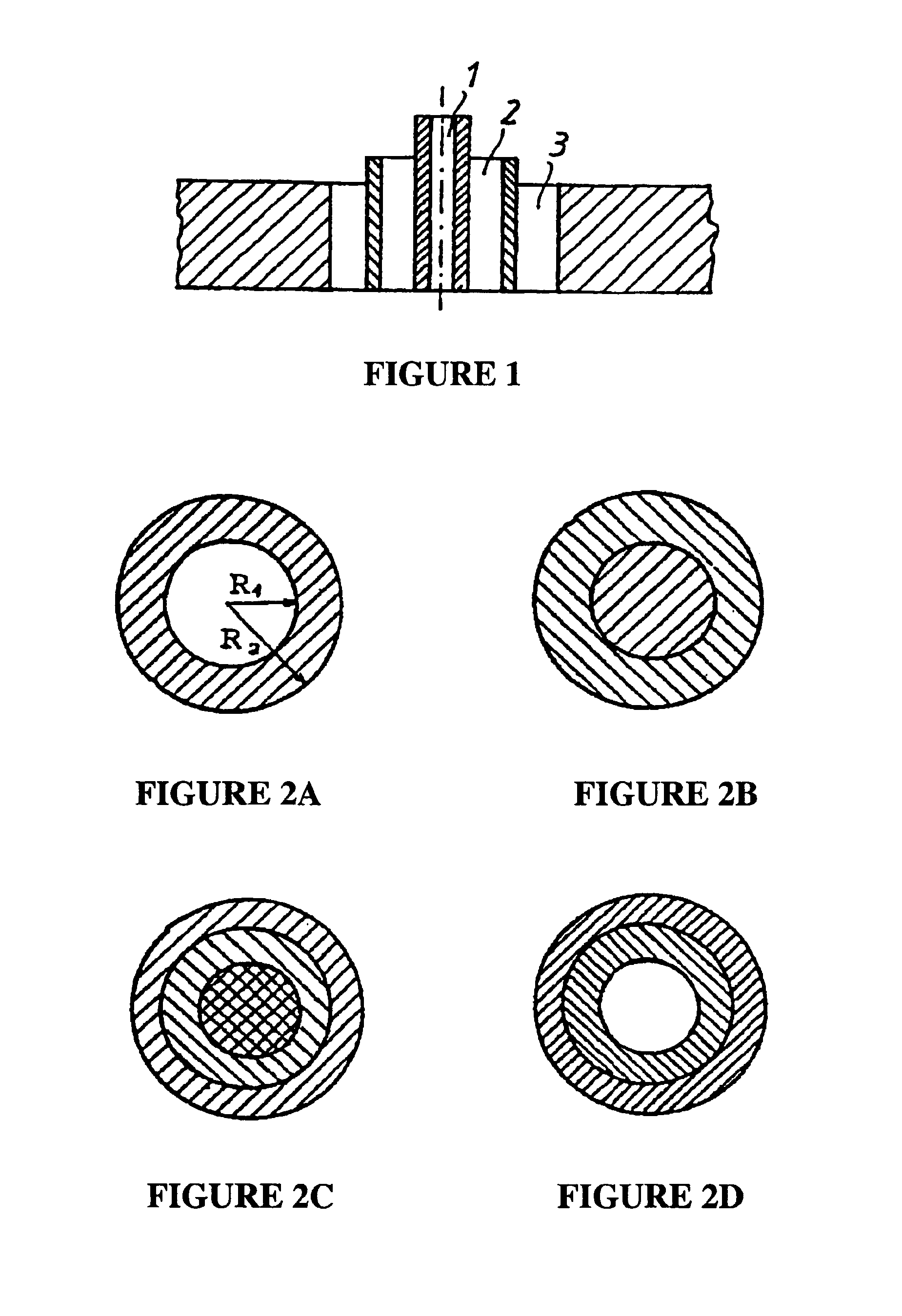

Method for producing shaped bodies

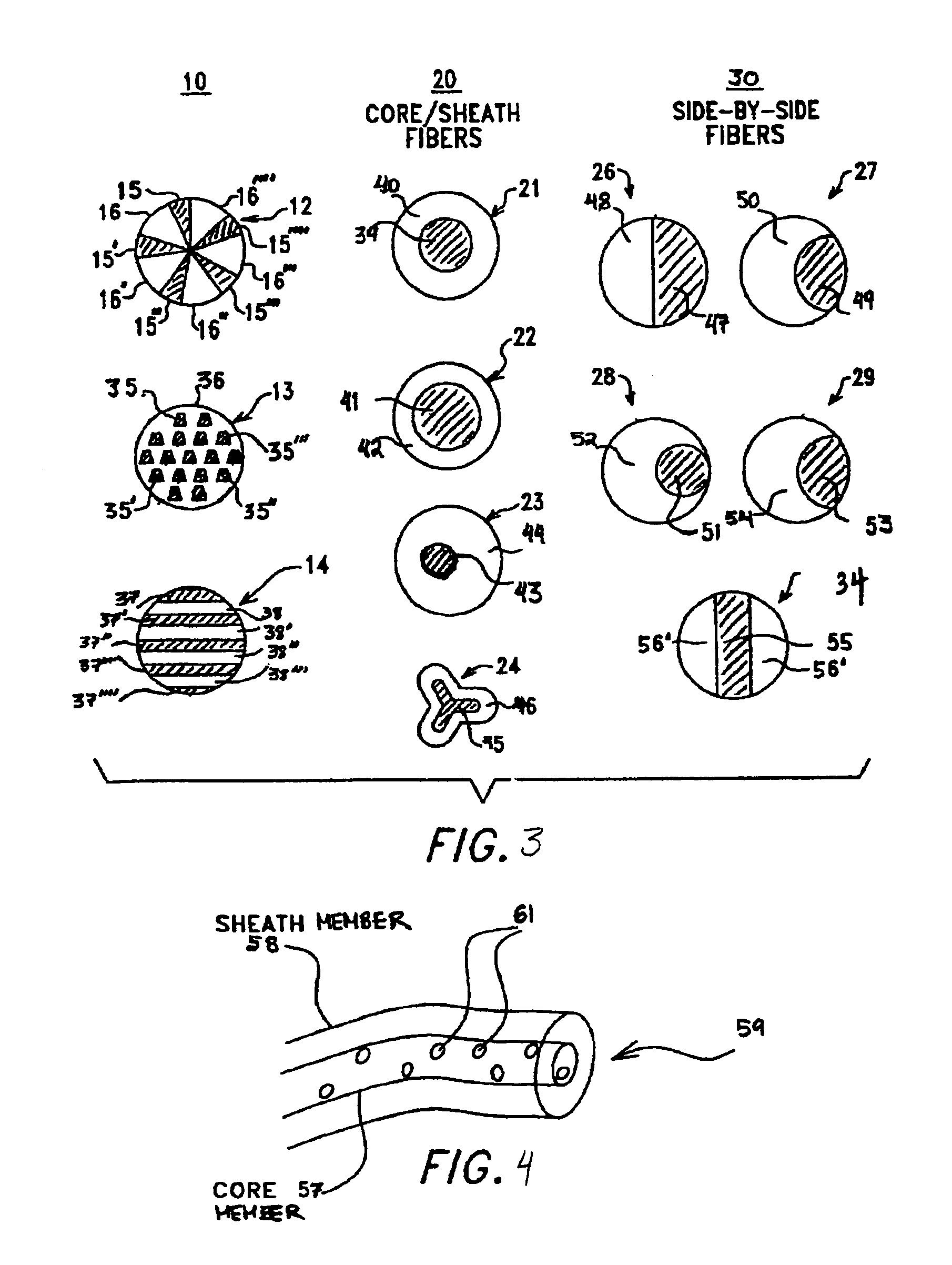

InactiveUS6881361B1Monocomponent cellulose artificial filamentConjugated cellulose/protein artificial filamentsPolyvinyl alcoholSolvent

The invention relates to a method for producing shaped bodies, especially threads or foils, from at least one polymer of the groups consisting of polysaccharide, polysaccharide derivative or polyvinyl alcohol by forming a solution of the polymer that contains an additive in a solvent containing amine-N-oxide, extruding the solution and precipitating the extrudate by contacting with a coagulant. The invention is characterized in that at least two polymeric solutions are formed. At least one of the two polymeric solutions contains one or more finely distributed additives and the at least two polymeric solutions are simultaneously extruded forming a combined extrudate.

Owner:OSTTHURINGISCHE MATERIALPRUFGES FUR TEXTIL & KUNSTE

Bamboo-charcoal viscose fiber and method for making same

InactiveCN1607271AStrong ability to absorb odorMonocomponent cellulose artificial filamentWet spinning methodsEmulsionEngineering

Said invention discloses a bamboo charcoal viscose fiber and producing method. The bamboo charcoal is finely selected, coarse cracked, dust removed, trash extracted, and pulverized to less than 0.5 micrometer, the bamboo charcoal micropowder and dispersant are put in water to made into aqueous emulsion slurry, filtered four times by two-layer of poplin filter fabric, respectively spinning in filament spinning machine and shorts spinning machine to obtain said bamboo charcoal viscose fiber which has bacteriostasis and antibiotic effect.

Owner:XINXIANG CHEM FIBER

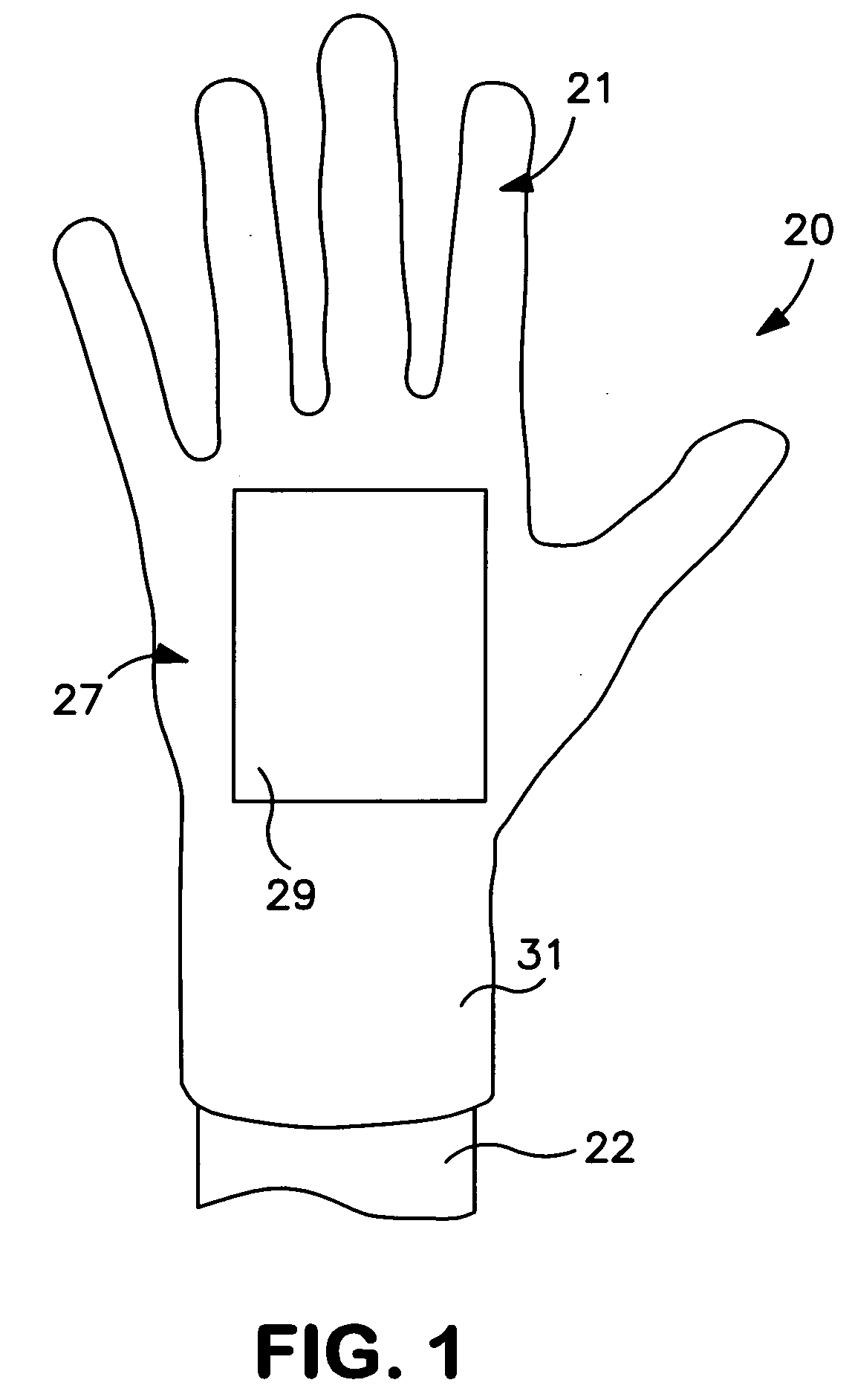

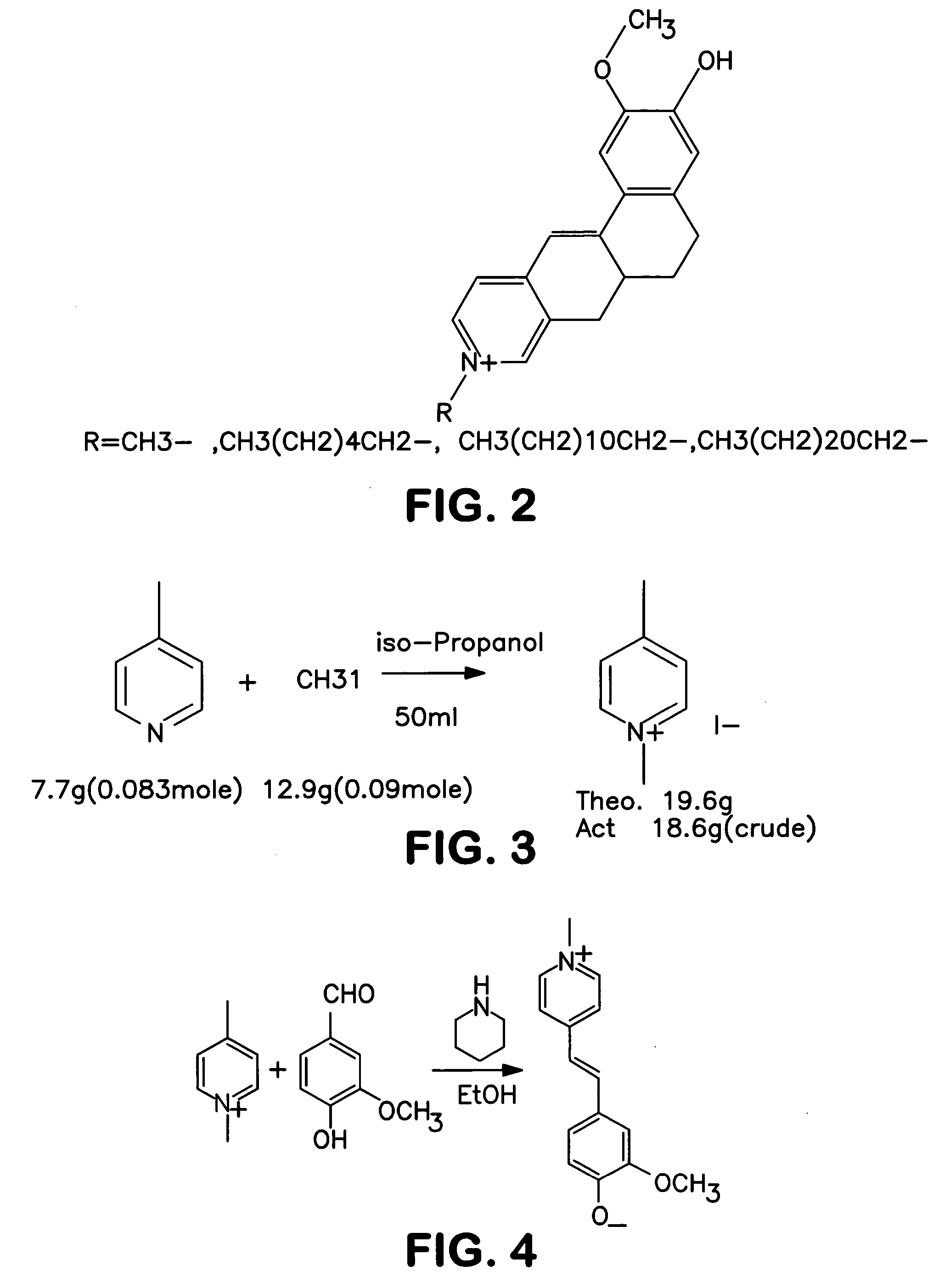

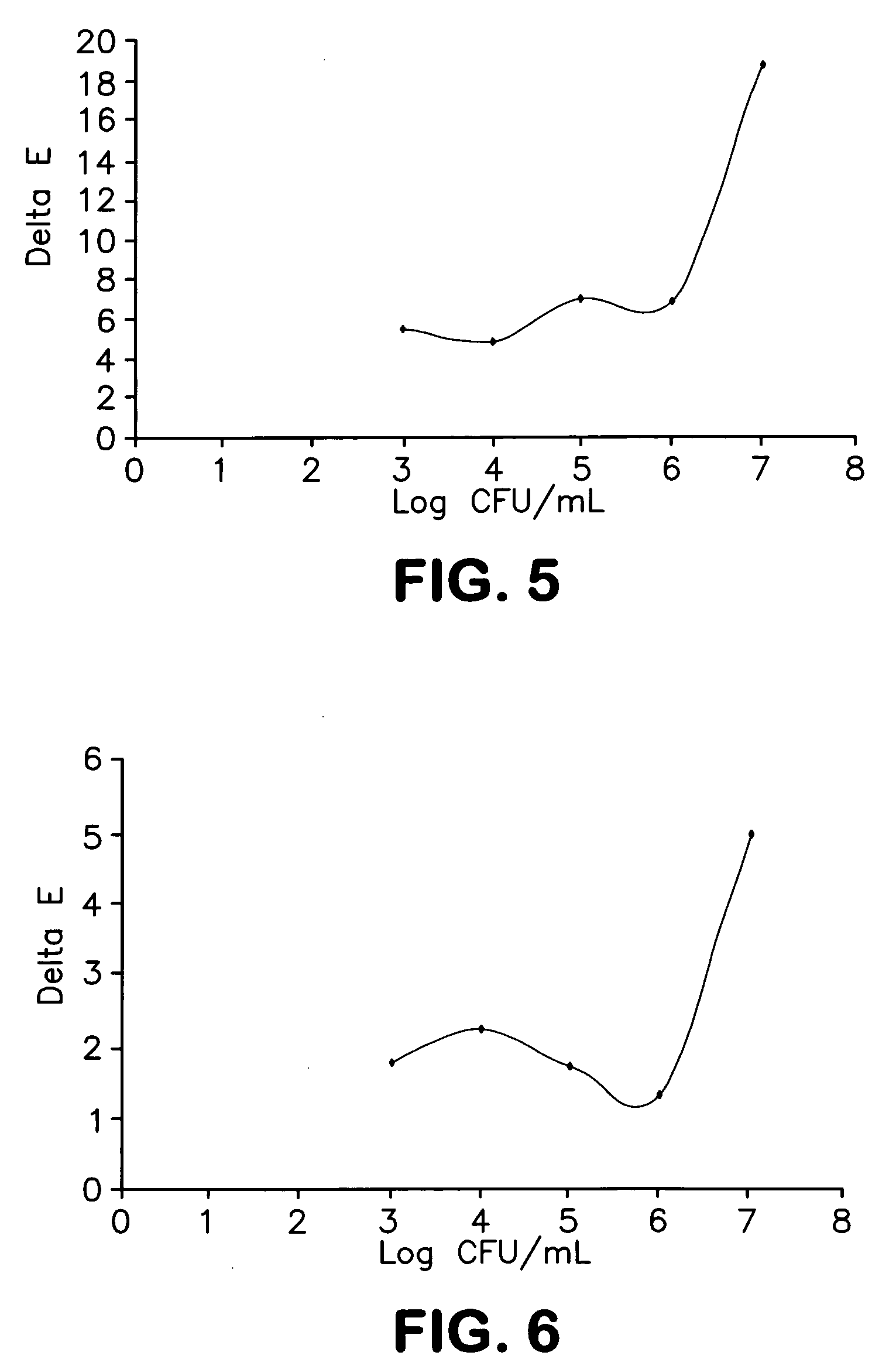

Detection of microbe contamination on elastomeric articles

ActiveUS20060134613A1Bioreactor/fermenter combinationsBiological substance pretreatmentsMicroorganismOxidation-Reduction Agent

An elastomeric article that contains a chromogen that undergoes a detectable change in color in the presence of one or more microbes is provided. For example, in one embodiment, the chromogen is a solvatochromic dye (e.g., Reichardt's dye) that undergoes a color change in the presence of bacteria or other microbes. More specifically, such dyes may respond to differences in polarity between microbe components (e.g., cell membrane, cytoplasm, etc.) and the environment outside the cell. Alternatively, other mechanisms may be wholly or partially responsible for the interaction between the dye and the microbe, such as acid-base reactions, redox reactions, and so forth.

Owner:O&M HALYARD INC

Bamboo charcoal viscose fiber and manufacturing method thereof

InactiveCN1807711ASoft touchComfortable to wearMonocomponent cellulose artificial filamentEmulsionViscose fiber

The invention discloses a bamboo charcoal viscose and preparing method, wherein the bamboo charcoal viscose consists of bamboo charcoal micro powder and bamboo vinegar liquid. The method consists of preparing rubber process and spinning process, wherein it is characterized by the following: preparing viscose solution and bamboo charcoal powder emulsion; adding in disperser and bamboo charcoal powder emulsion in deionized water; mixing up to get bamboo charcoal micro powder emulsion; mixing up viscose solution and bamboo charcoal micro powder emulsion; sending to spinning machine to prepare fiber.

Owner:上海恒加纺织有限公司

Nanocomposites of cellulose and clay

InactiveUS20050051054A1Improve thermal stabilityIncreased degradation temperatureMaterial nanotechnologyFibre treatmentCelluloseNanometre

This invention relates to a process of forming a nanocomposite of cellulose with a clay material that is used as the nanofiller material. The nanocomposites show significant improvements in thermal properties when compared to unbleached cotton and cotton processed under conditions for nanocomposite preparation. The degradation temperature of these nanocomposites is significantly increased over that of unbleached cotton.

Owner:US SEC AGRI

Process of forming a non-woven cellulose web and a web produced by said process

ActiveUS20090258562A1Economical and efficientMonocomponent cellulose artificial filamentWoven fabricsCellulose fiberEngineering

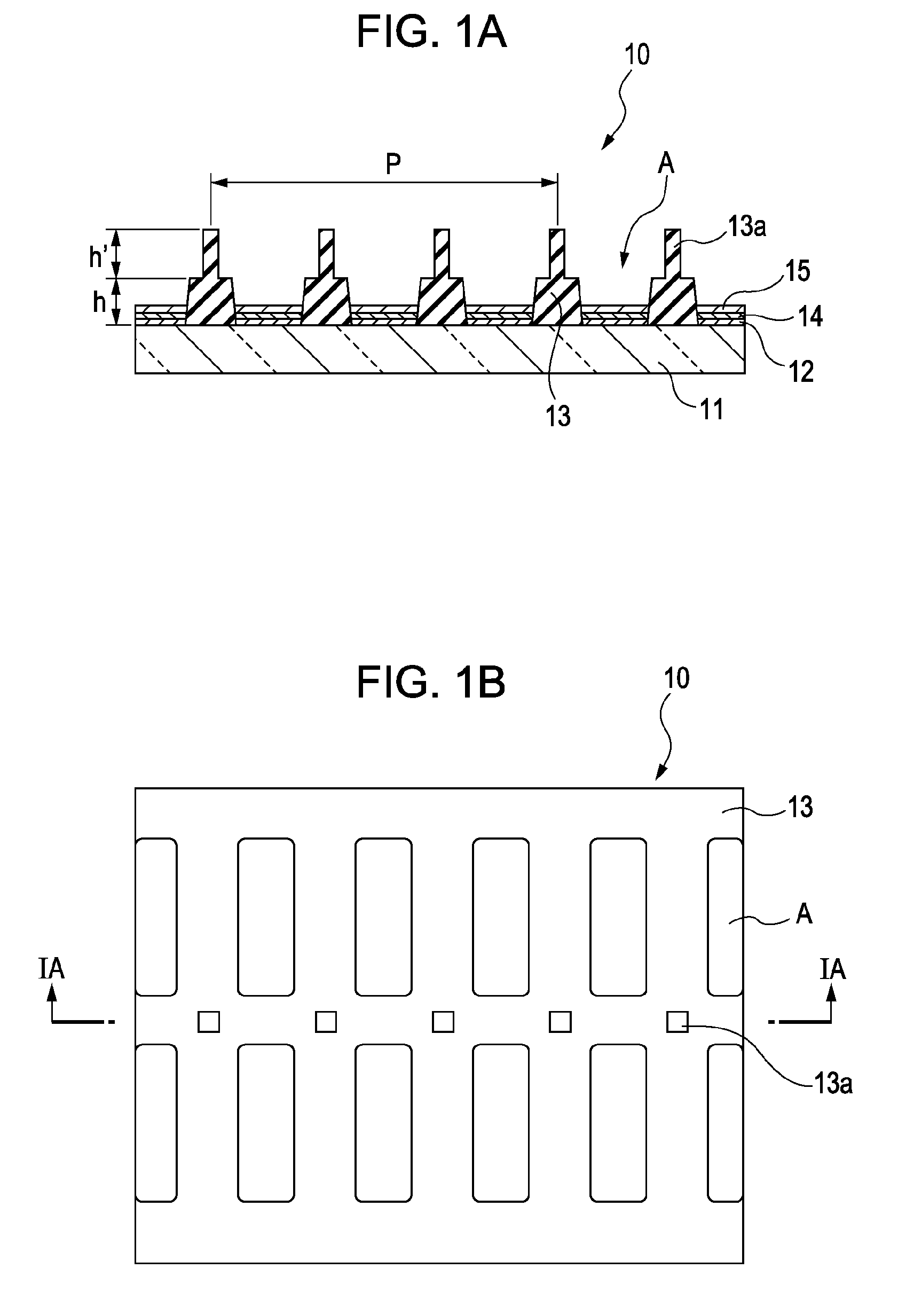

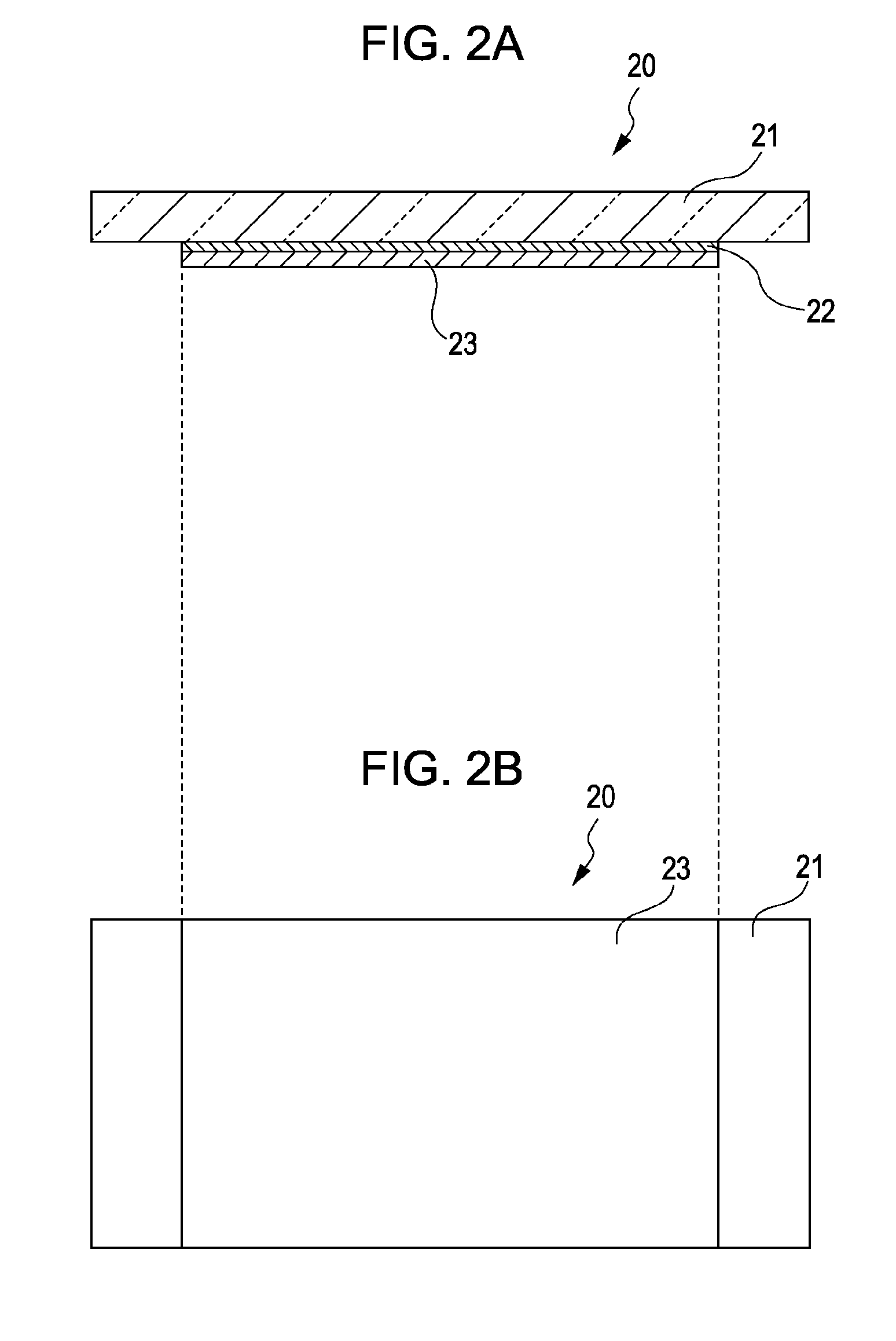

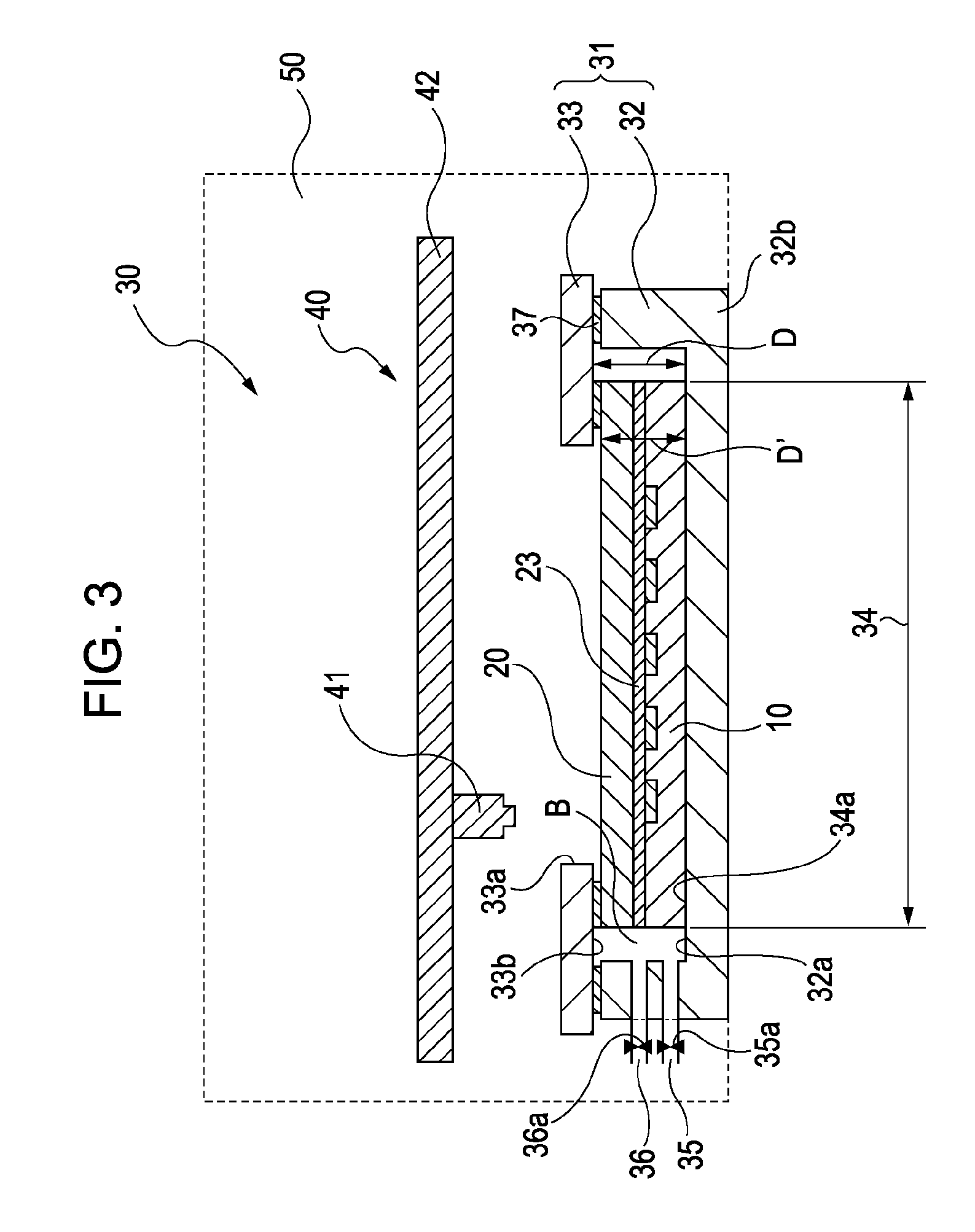

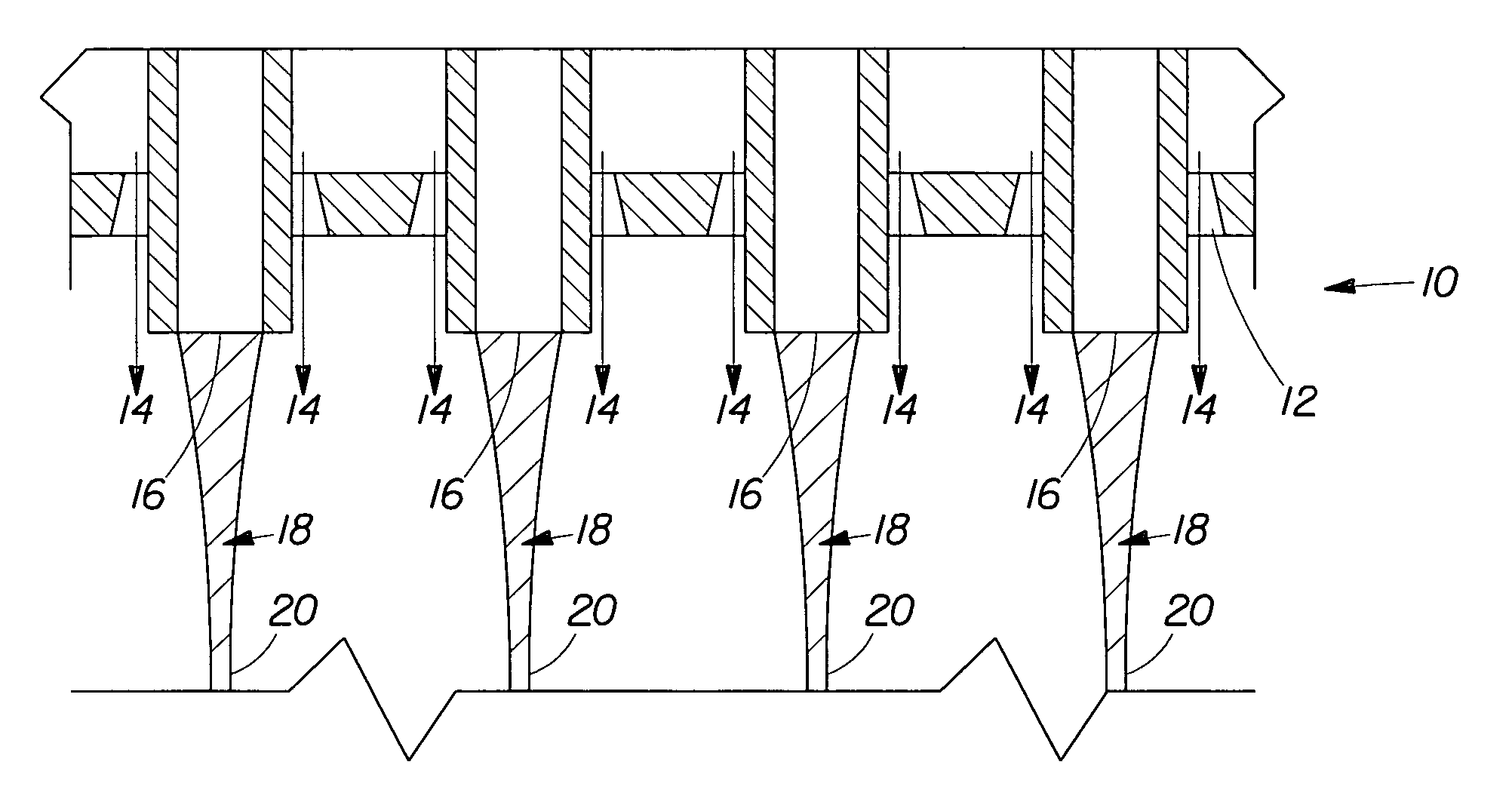

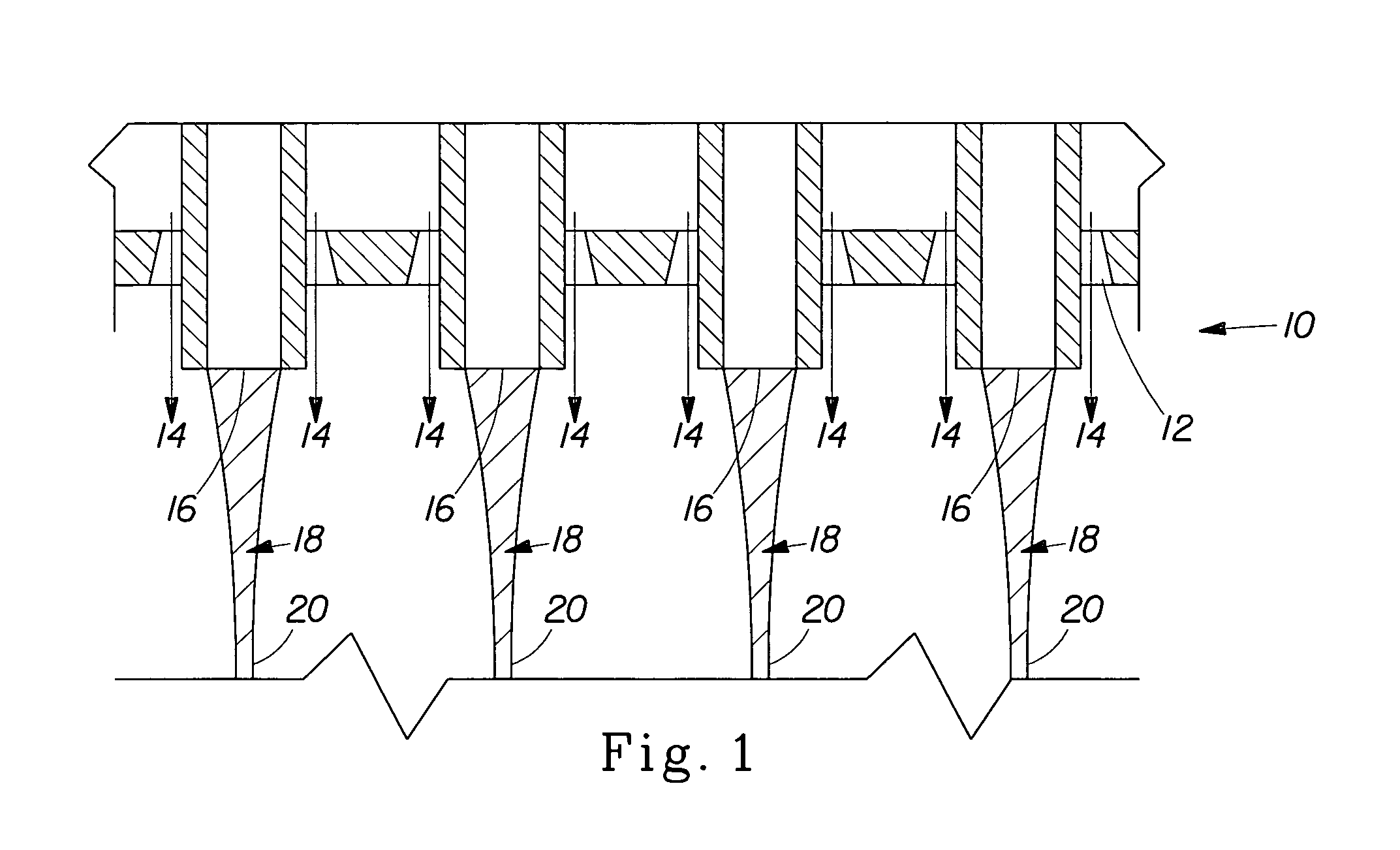

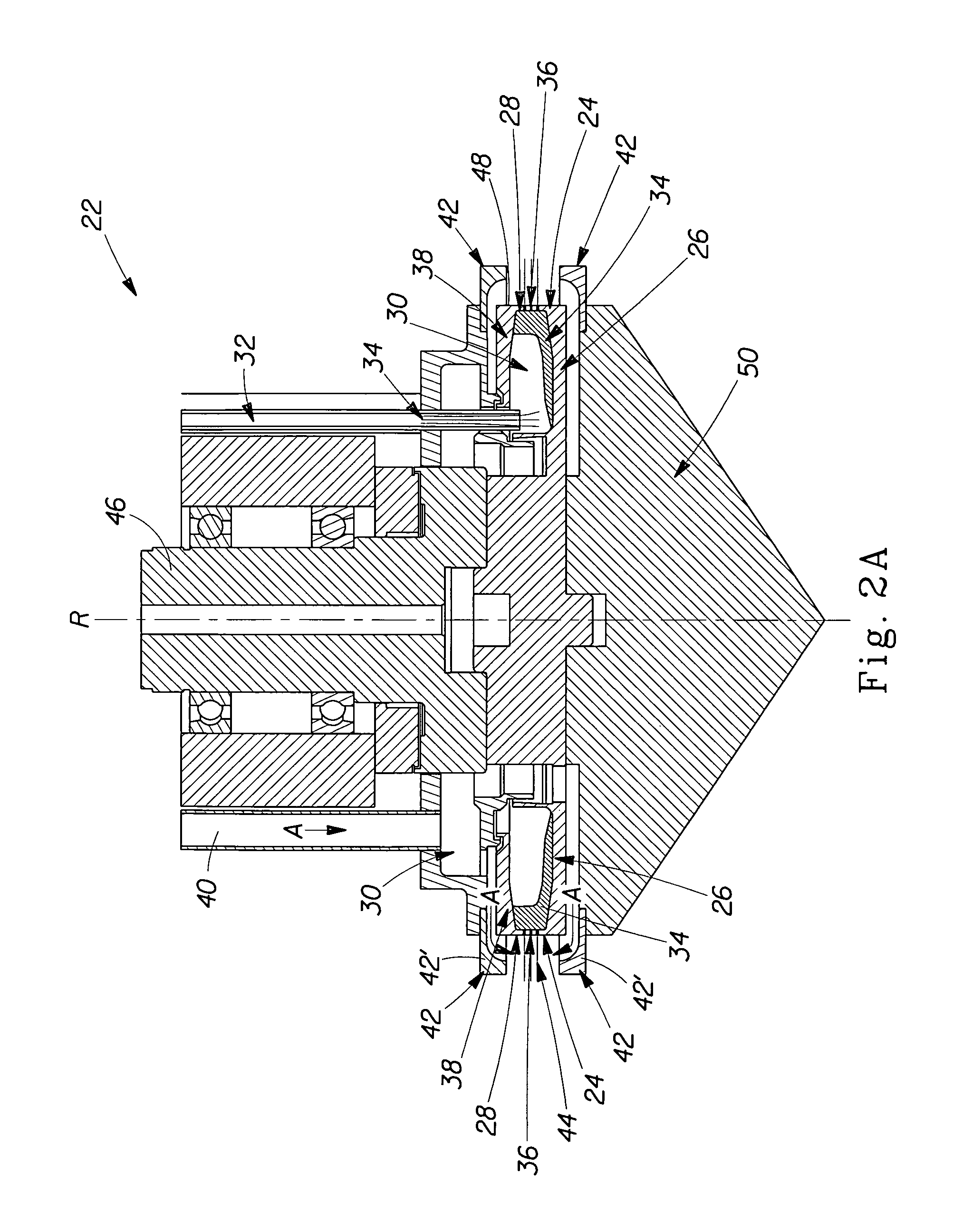

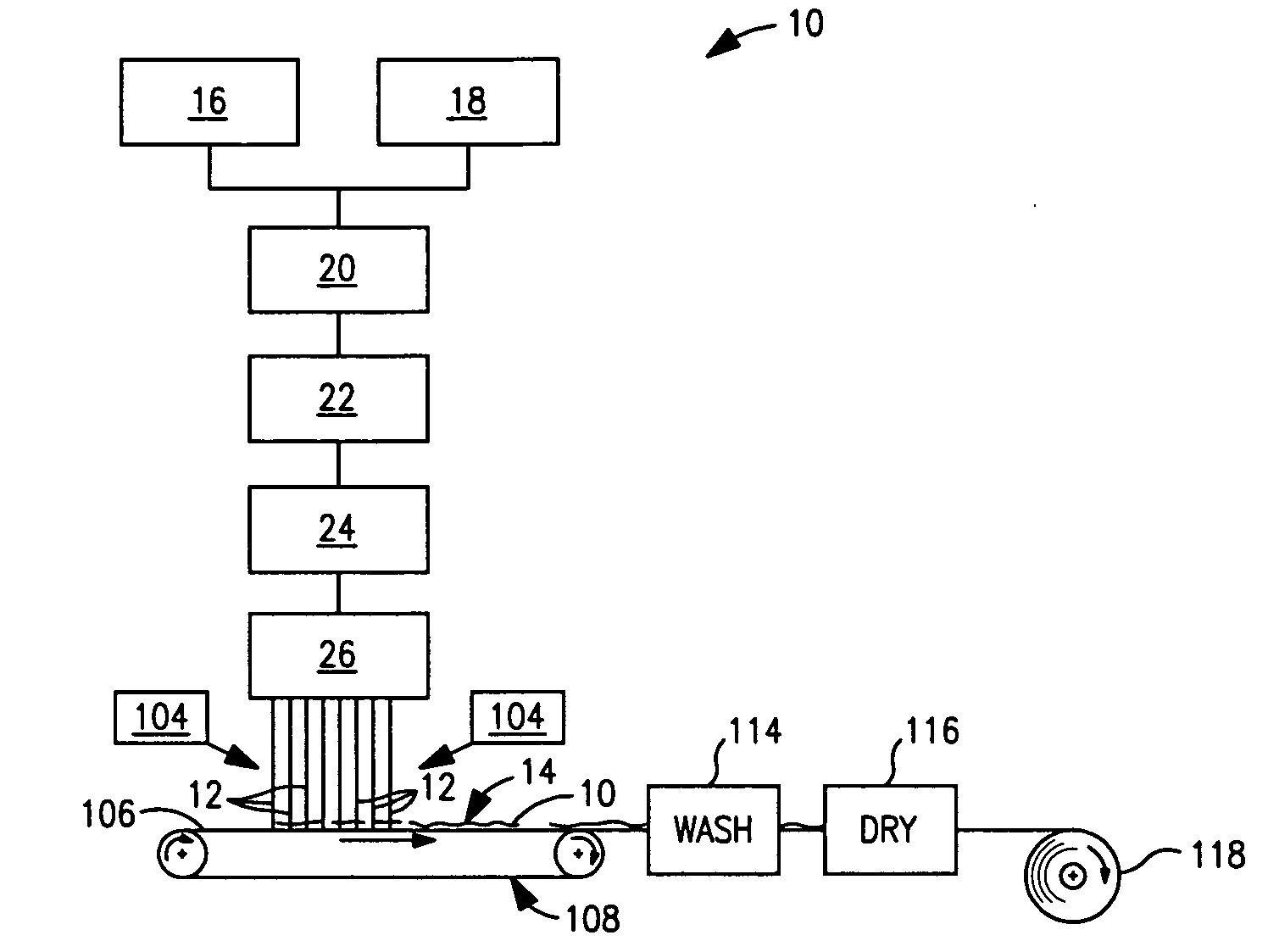

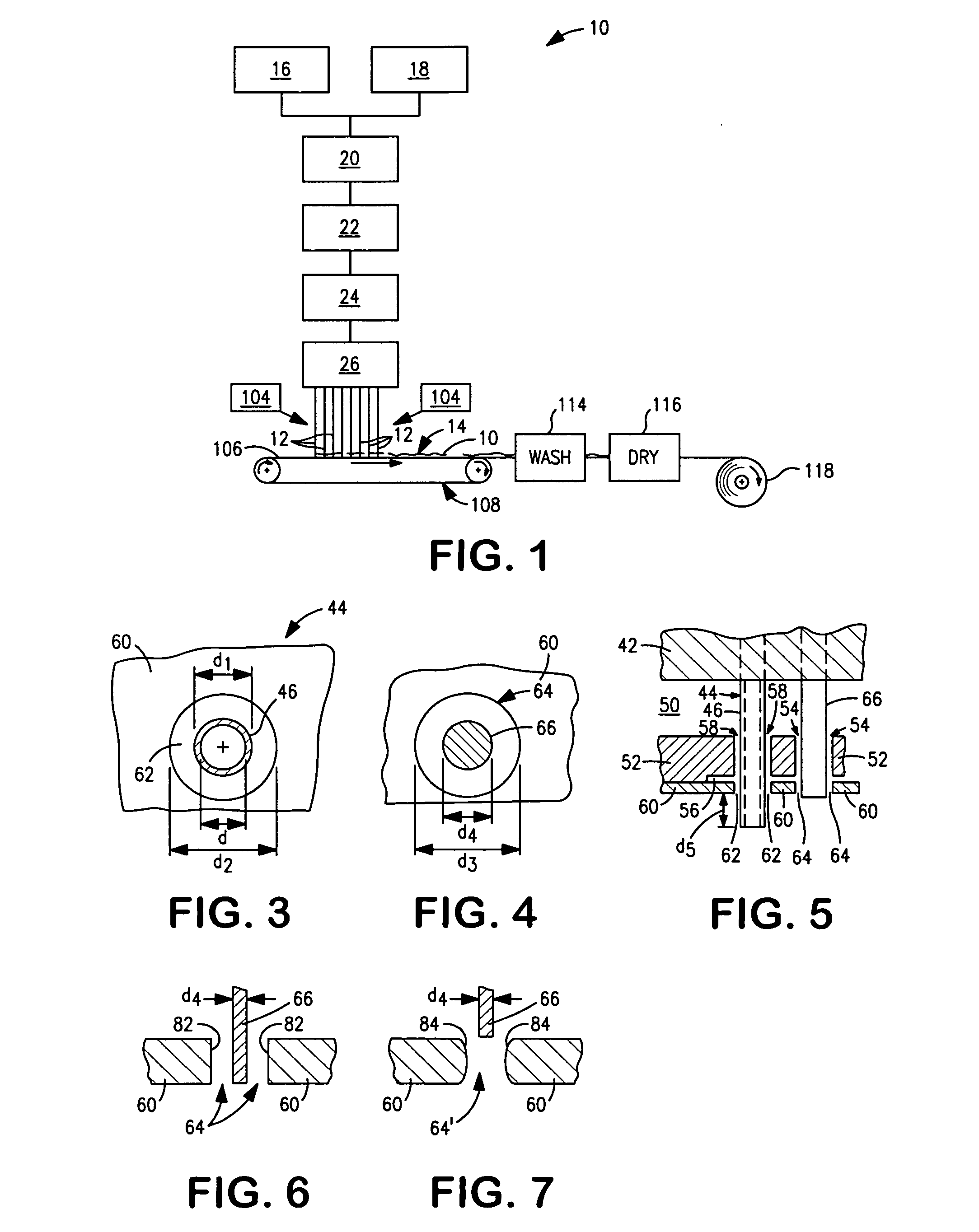

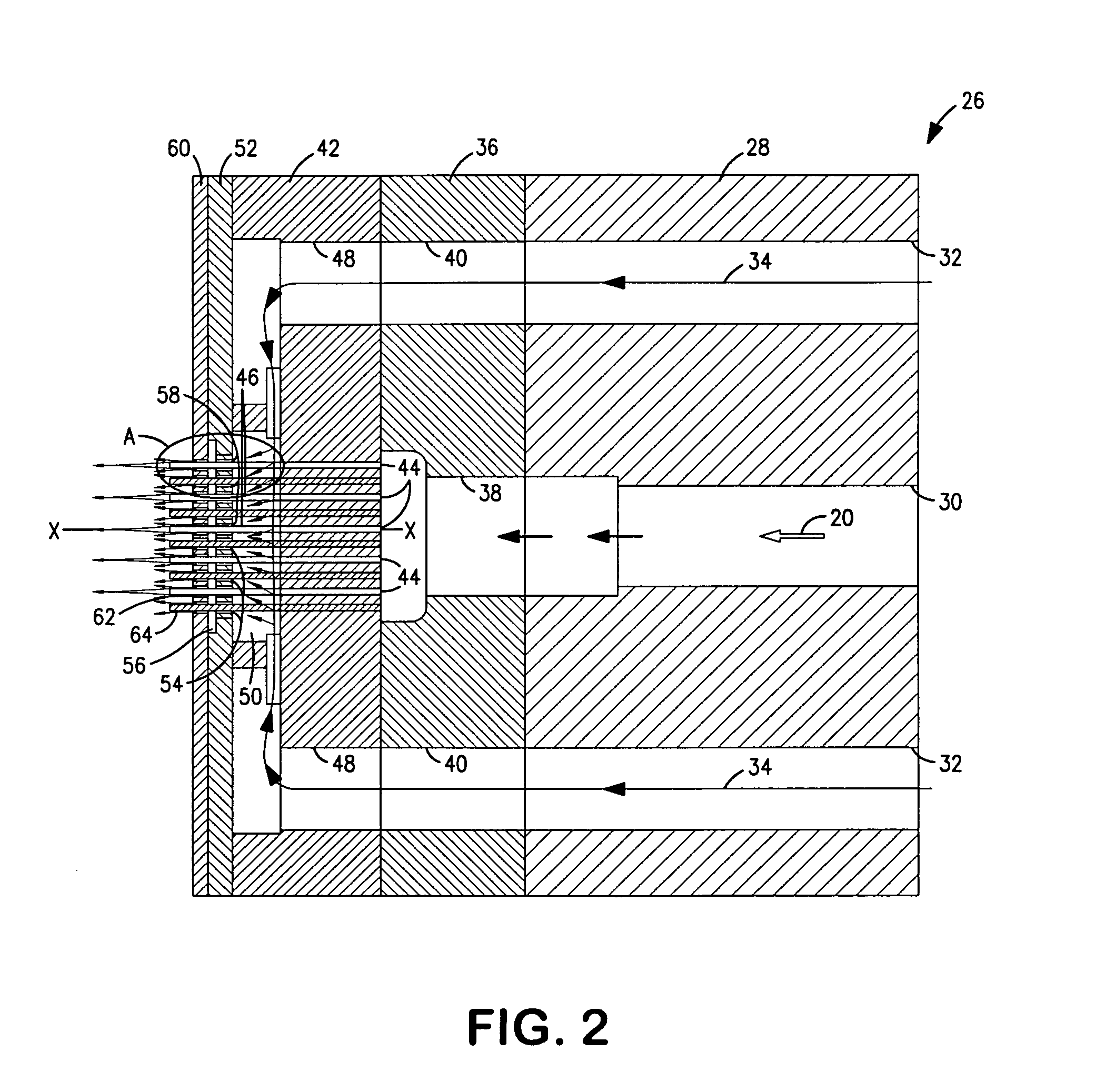

A process is disclosed of forming cellulose fibers. The process includes extruding an aqueous solution of cellulose and a solvent through a first member to form molten filaments. The first member has multiple rows of first and second openings with a nozzle positioned in each of the first openings. At least one of the nozzles in one row is staggered from at least one of the nozzles in an adjacent row. At least a portion of each of the molten filaments is shrouded in a pressurized gas emitted through each of the first openings. Each of the molten filaments is contacted with a liquid to remove some of the solvent and transform each of the molten filaments into a continuous solid fiber. The continuous solid fibers are then collected on a moving surface to form a non-woven cellulose web.

Owner:REIFENHAUSER GMBH & CO

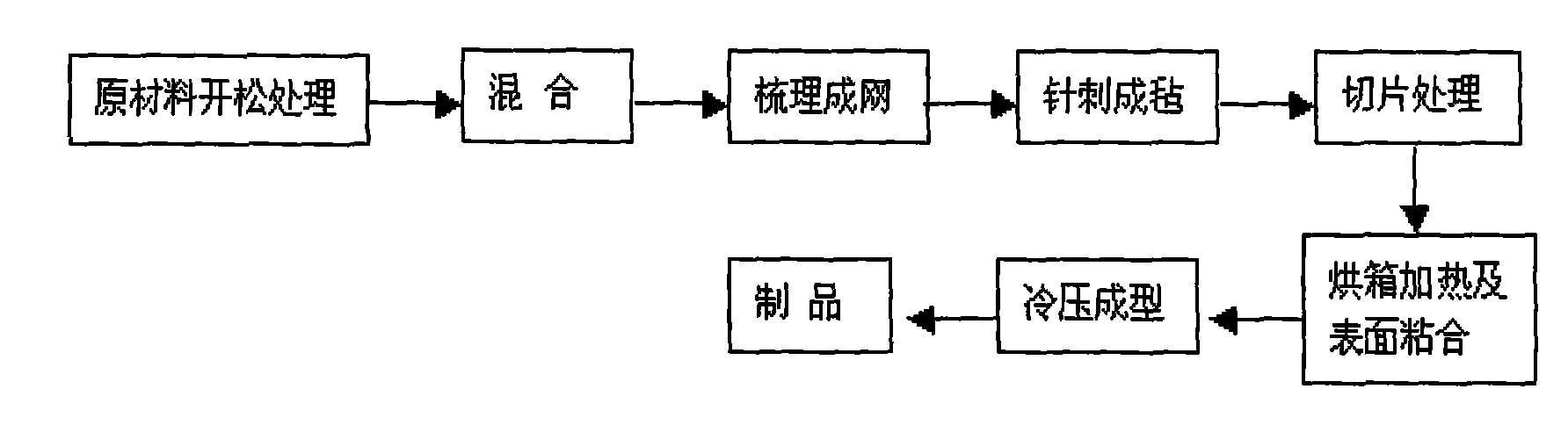

Fibrilia automobile inner decoration member and method of manufacturing the same

ActiveCN101549671ANo pollution in the processReduce lossMonocomponent cellulose artificial filamentSuperstructure subunitsRaw materialPolypropylene fiber

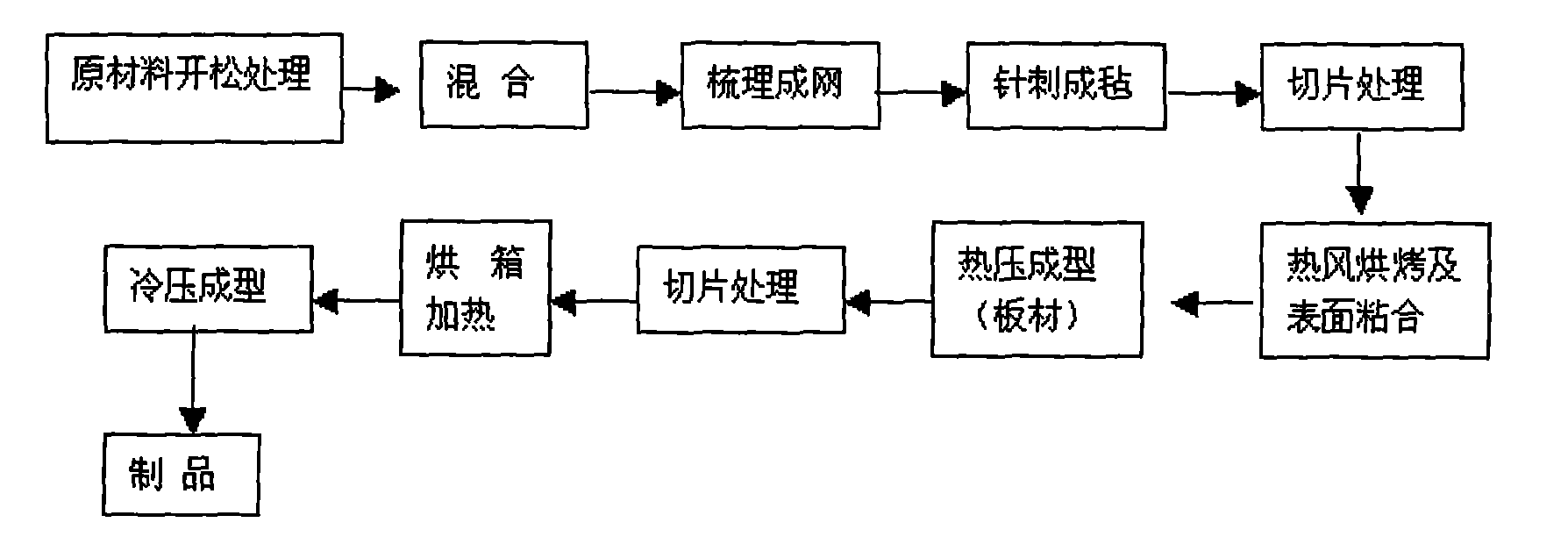

The present invention relates to a fibrilia automobile inner decoration member and a method of manufacturing the same, the steps is that implementing a opening treatment to packaged raw material, mixing jute fiber and polypropylene fiber according to proportionality in a cotton opener, and fiber netting simultaneously; then needling to form a felt by a needle machine, and implementing a sliced sheet treatment to the product after felting; baking and heating the felt directly in a baking oven to bond the surface, the baking temperature is from 180 to 200 DEG C; then cold press molding by a product mold, finally manufacturing a finished product; or preparing the belt into a sheet material to store, then baking and heating the sheet material, and a corresponding product molding according to requirements.

Owner:CHERY AUTOMOBILE CO LTD

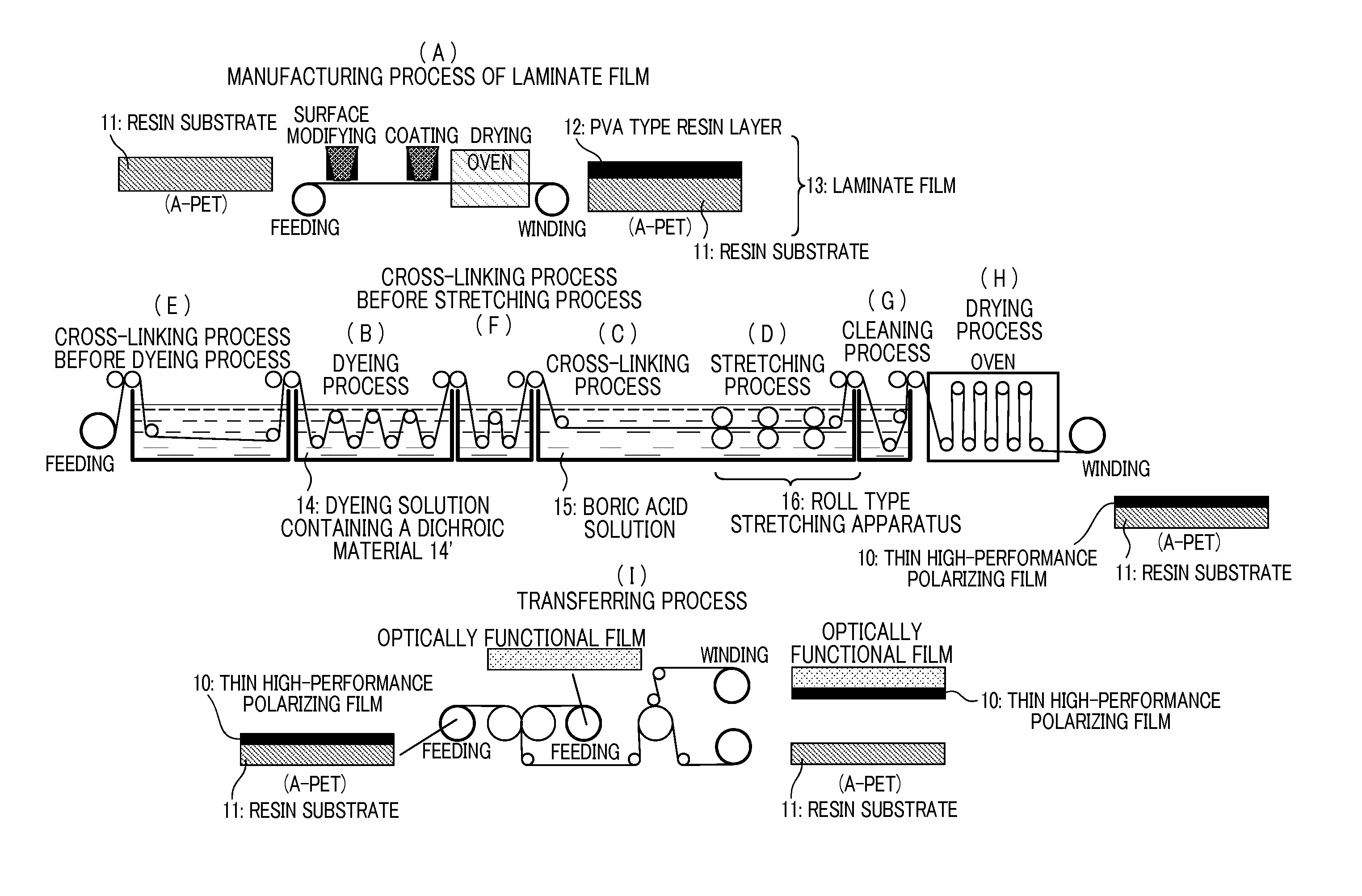

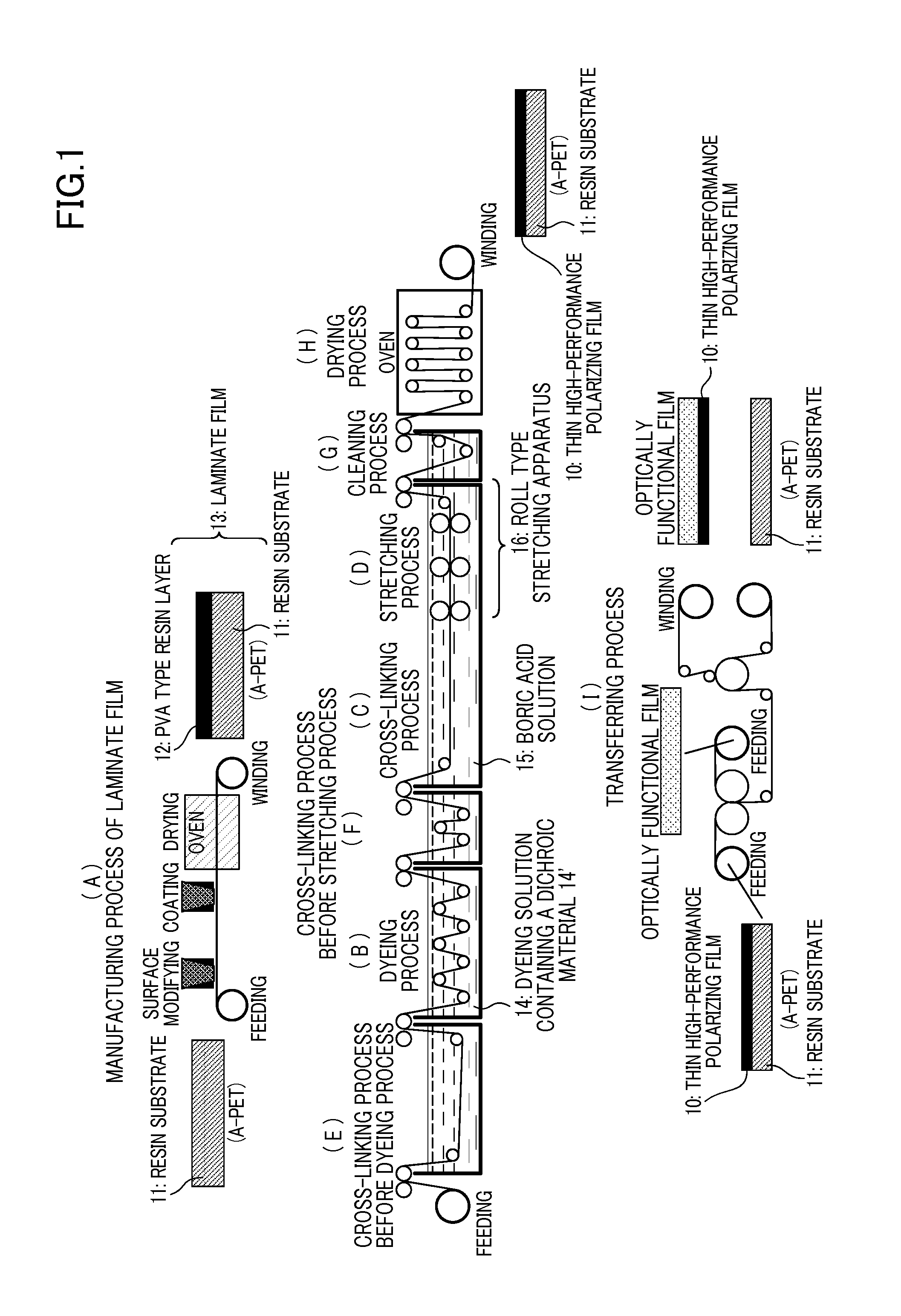

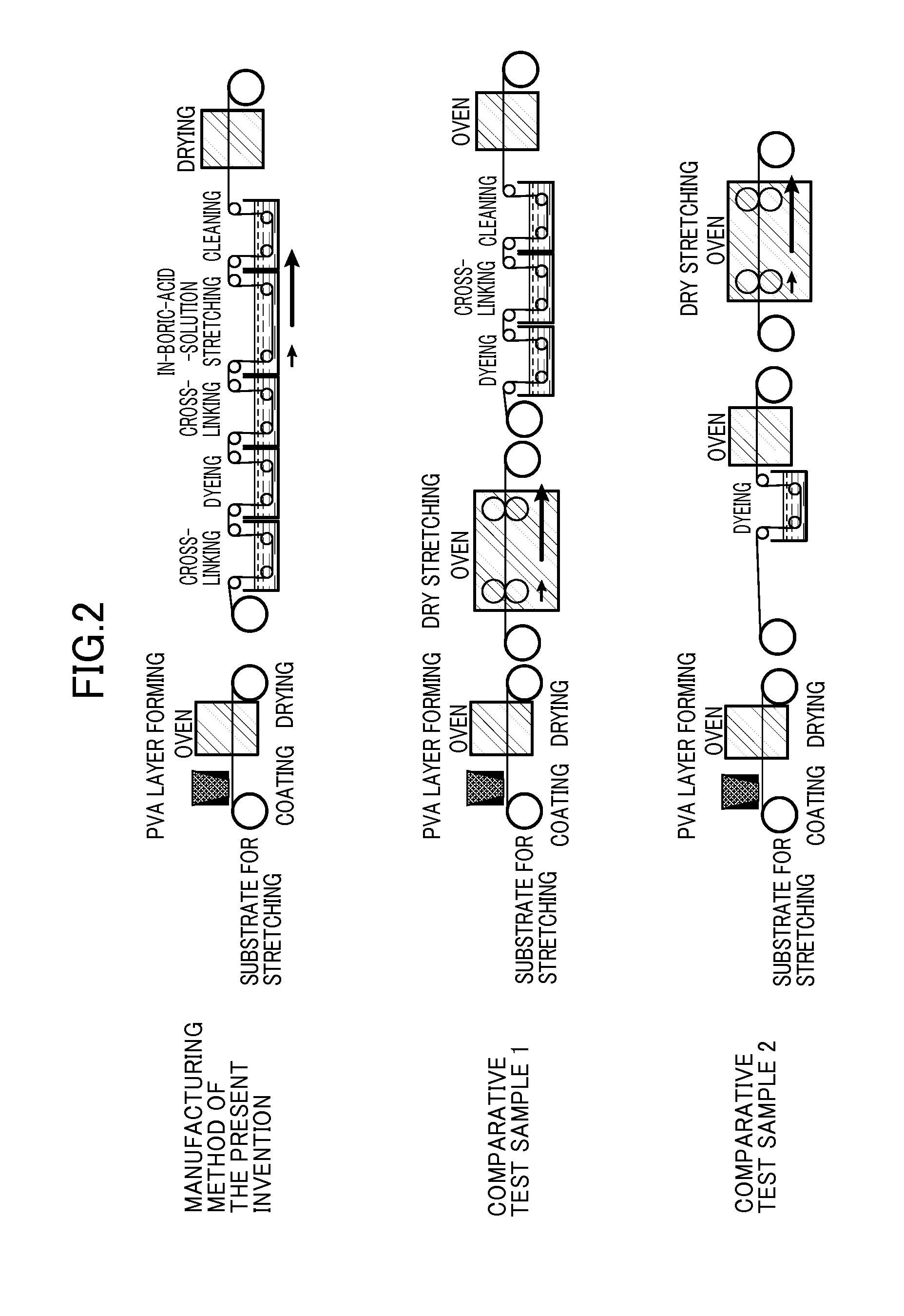

Thin high-performance polarizing film and method for manufacturing the same

InactiveUS20110315306A1High magnificationReduced optical performanceMonocomponent cellulose artificial filamentPolarising elementsStretch ratioBoric acid

A method for manufacturing a thin high-performance polarizing film includes coating a polyvinyl alcohol type resin on a resin substrate having a thickness of at least 20 μm and then drying the resin to thereby form a polyvinyl alcohol type resin layer, immersing thus produced polyvinyl alcohol type resin layer in a dyeing solution including a dichroic material to thereby have the dichroic material impregnated in the polyvinyl alcohol type resin layer, stretching the polyvinyl alcohol type resin layer having the dichroic material impregnated therein together with the resin substrate in a boric acid solution such that a total stretching ratio of 5.0 or more of the original length is achieved.

Owner:NITTO DENKO CORP

Flame retardant cellulose fiber and preparation method thereof

InactiveCN101608348ASuitable for processingEasy to useFlame-proof filament manufactureMonocomponent cellulose artificial filamentMass ratioCellulose fiber

The invention discloses a flame retardant cellulose fiber and a preparation method thereof. The fiber has the components of fire retardant and cellulose which have the mass ratio of 10-25:100; wherein the fire retardant is novel phosphorus fire retardant having the average grain diameter being less than 1mum; the cellulose is wood pulp or cotton pulp having the polymerization degree of 400-1000 and alpha-cellulose content being more than or equal to 90%. According to the components with the mass ratio of the fiber, the preparation method of the fiber comprises the technique as follows: 1. preparation of flame retardant spinning solution as the following: according to the mass ratio, firstly adding the fire retardant into ionic liquid at the normal temperature, and leading the fire retardant to be uniformly dispersed in the ionic liquid under mechanical agitation; then adding the cellulose into the mixed ionic liquid to be fully dissolved with the dissolving temperature of 70-110 DEG C to prepare flame retardant spinning solution; ensuring the mass ratio between the cellulose and the ionic liquid to be 5-35:95-65: 2. preparation of the flame retardant cellulose fiber: preparing the flame retardant cellulose fiber according to the conventional spinning process flow.

Owner:TIANJIN POLYTECHNIC UNIV

Nano wave-absorption fibre and method for making same

InactiveCN101135071AImprove absorbing performanceInfluence of absorbing performanceMonocomponent protein artificial filamentMonocomponent cellulose artificial filamentFiberMaterials science

The present invention belongs to the field of radiation resisting technology, and is especially one kind of nanometer wave absorbing fiber. The nanometer wave absorbing fiber consists of nanometer wave absorbing particle of 1-100 nm diameter of fine fiber of 30-2000 nm diameter in the weight ratio of 3-35 to 65-97. The nanometer wave absorbing fiber has wide wave absorbing range, powerful wave absorbing capacity, lasting wave absorbing effect and high flexibility. It has wave absorbing function, as well as antistatic, bacteriostasis, biochemical protection and other functions.

Owner:上海兰度科技有限公司

Lithium hydrate and carbamide composition solvent for dissolving cellulous fiber and its use

InactiveCN1546556AHigh strengthWide range of usesMonocomponent cellulose artificial filamentSpinning solutions preparationAcid waterLithium hydroxide

The invention relates to a dissolvent for cellulose dissolution through freezing-unfreezing method or direct dissolution method, and process for preparing the regenerated cellulose fibers and films by utilizing the dissolvent, wherein the dissolvent is the water solution of lithium hydroxide and urea whose compositions are 3.0-7.0wt% of lithium hydroxide, 4.0-30.0.0wt% of urea, the rest is water. The water solution of lithium hydroxide and urea can directly dissolve cellulose through freezing-unfreezing method or by pre-cooling the dissolvent in advance to -10 deg. C - -4 deg. C. It can be used to obtain high dissolvability transparent concentrated cellulose solution. By using the concentrated cellulose solution and through 3-5wt% diluted acid water solution coagulation, regeneration, regenerated cellulose films and fibers can be prepared.

Owner:WUHAN UNIV

Element-negative-ion-releasing sterilizing mite-preventing electromagnetic-wave-preventing fire-retarding nano-grade fabric used in vehicles

InactiveCN102400238AMonocomponent protein artificial filamentMonocomponent cellulose artificial filamentTextile fiberSlurry

The invention relates to element-negative-ion-releasing sterilizing mite-preventing electromagnetic-wave-preventing fire-retarding nano-grade fabric used in vehicles. The invention belongs to the technical field of textile fiber fabric production of vehicle-use nano-grade decorative fabric with functions of refreshing and air-purifying. The fabric is a nano-grade functional healthy textile. The nano-grade fabric provided by the invention is produced form chitosan, which is a natural high polymer extracted from shells of shellfishes, crabs and shrimps; a natural antibiotic humectant SCJ-920; a high-efficiency mite-preventing antibacterial agent SCJ-998; nano-grade negative-ion powder SCJ-900; negative-ion far infrared healthcare slurry 700; a fire retarding finishing agent ATF; an aromatic finishing agent SCM; electromagnetic-wave-preventing ferrites Fe2O3, Fe3O4, and Fe; substances such as TiO2, Al2O3, and ZnO used for providing far infrared radiation; an Ag-embedded nano-TiO2 (AT) antibacterial agent; nano-grade selenium or organic selenium which is rare on earth; organic germanium, Chinese herbal medicines, essential oil, maifanite, tourmaline nano-grade powder and other materials. A mixture of the materials is added to cotton, linen, wool, silk, polyamide fiber, acrylic fiber, terylene or viscose fiber spinning liquid, and the nano-grade fabric is produced through weaving.

Owner:丁一

Viscose fibre with tea anti-bacterial anti-foul function and its preparing method

InactiveCN1944720AWith antibacterial and deodorant functionComfortable to takeMonocomponent cellulose artificial filamentArtifical filament manufactureAnti bacterialViscose fiber

The present invention provides one kind of viscose fiber with antibacterial and antifouling tea component, and the viscose fiber contains antiseptic comprising at least one of natural tea pigment, tea polyphenol and catechin. The powder or solution of at least one of natural tea pigment, tea polyphenol and catechin in the amount of 1-10 wt% is added into viscose spinning fluid to result in lasting antibacterial and antifouling functions. The viscose fiber has also the fragrance of tea, dyeing effect and no side effect on human body, and is suitable for use in making underwear, other costumes and bedding.

Owner:秦如涛

Superabsorbent cellulosic fiber and method of making same

InactiveUS6844066B2Good absorption rateHigher efficient graftingMonocomponent cellulose artificial filamentDisinfectionCellulose fiberUnsaturated monomer

Owner:RAYONIER PERFORMANCE FIBERS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com