Patents

Literature

124results about How to "Simply formed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

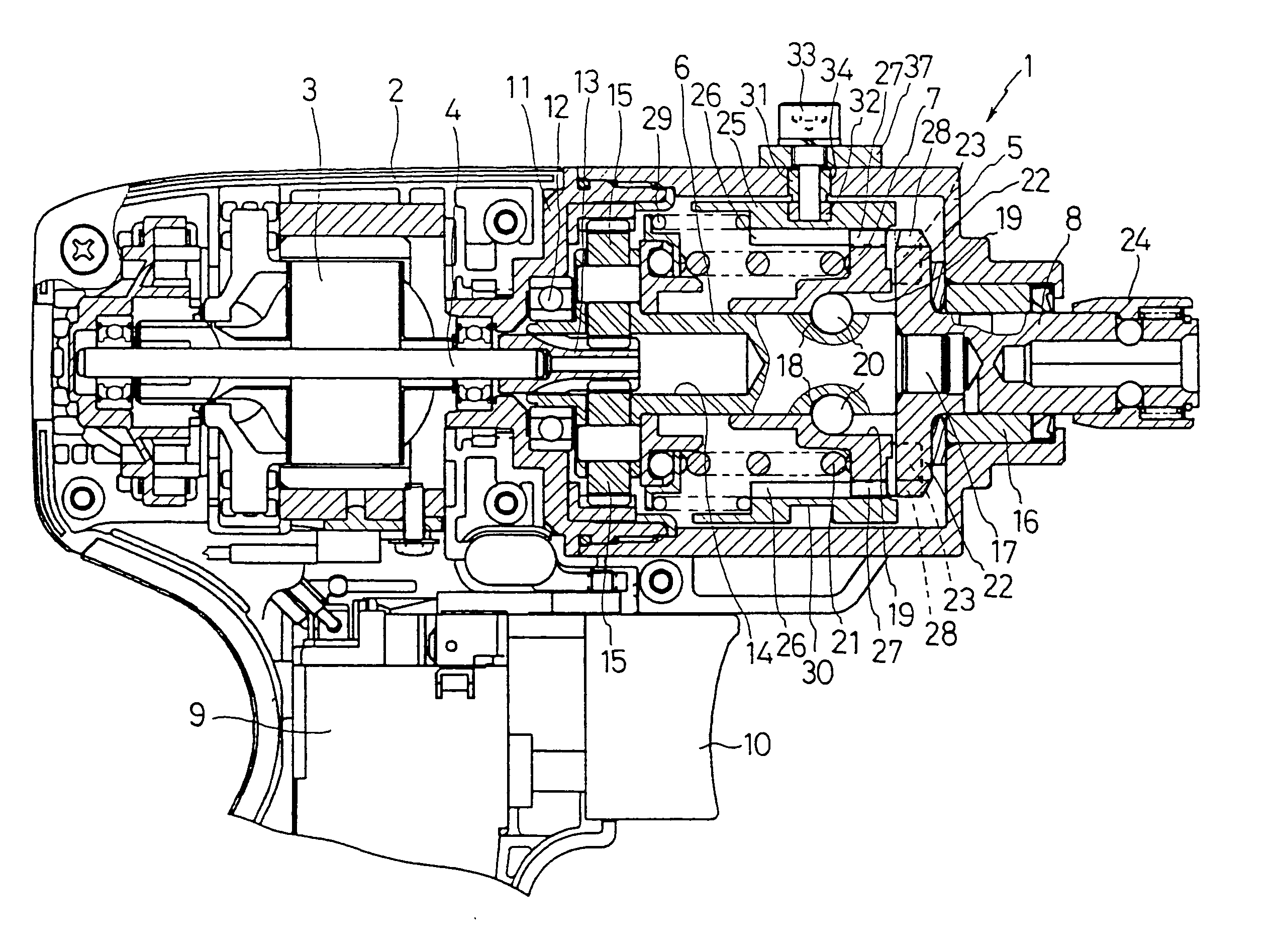

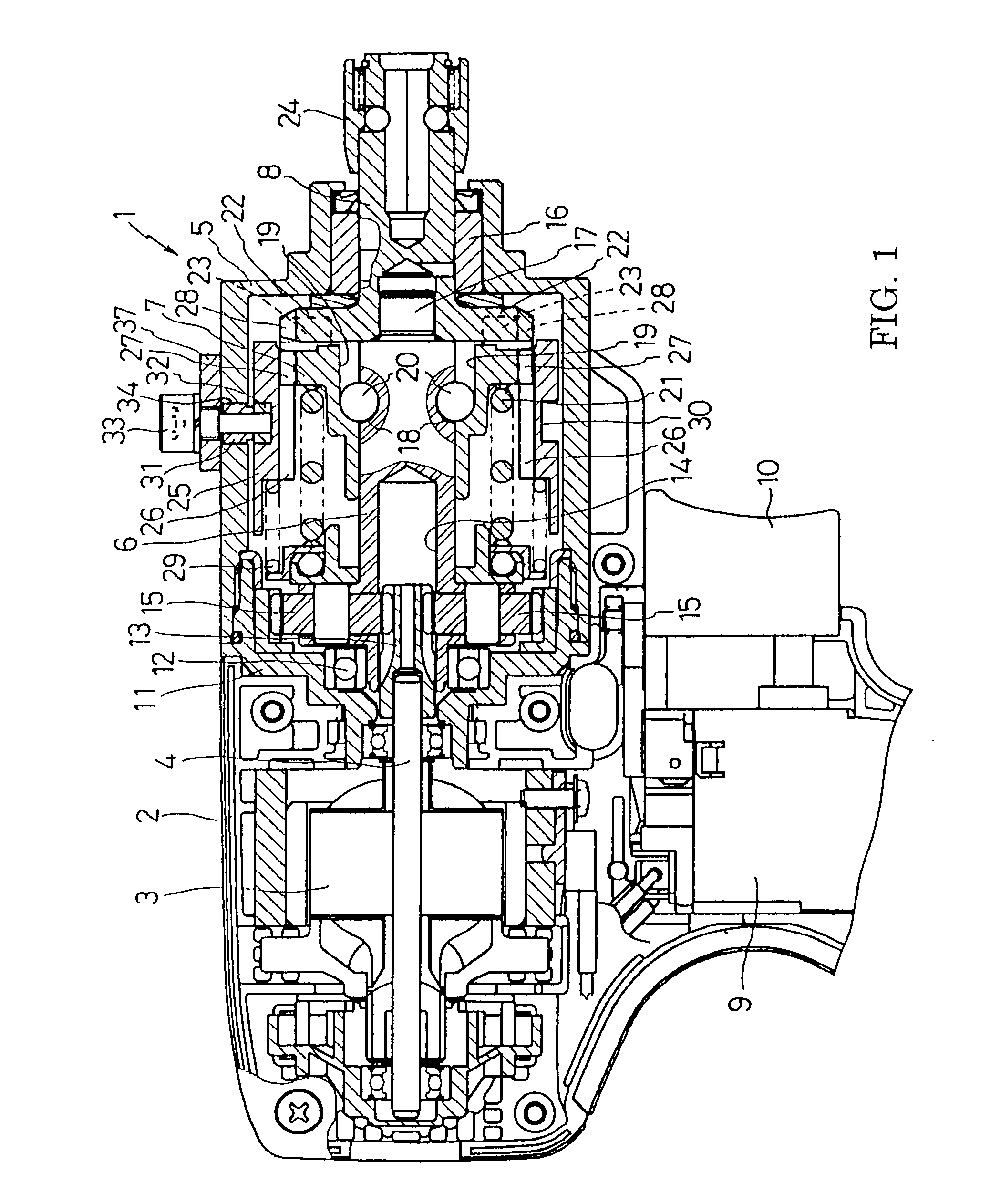

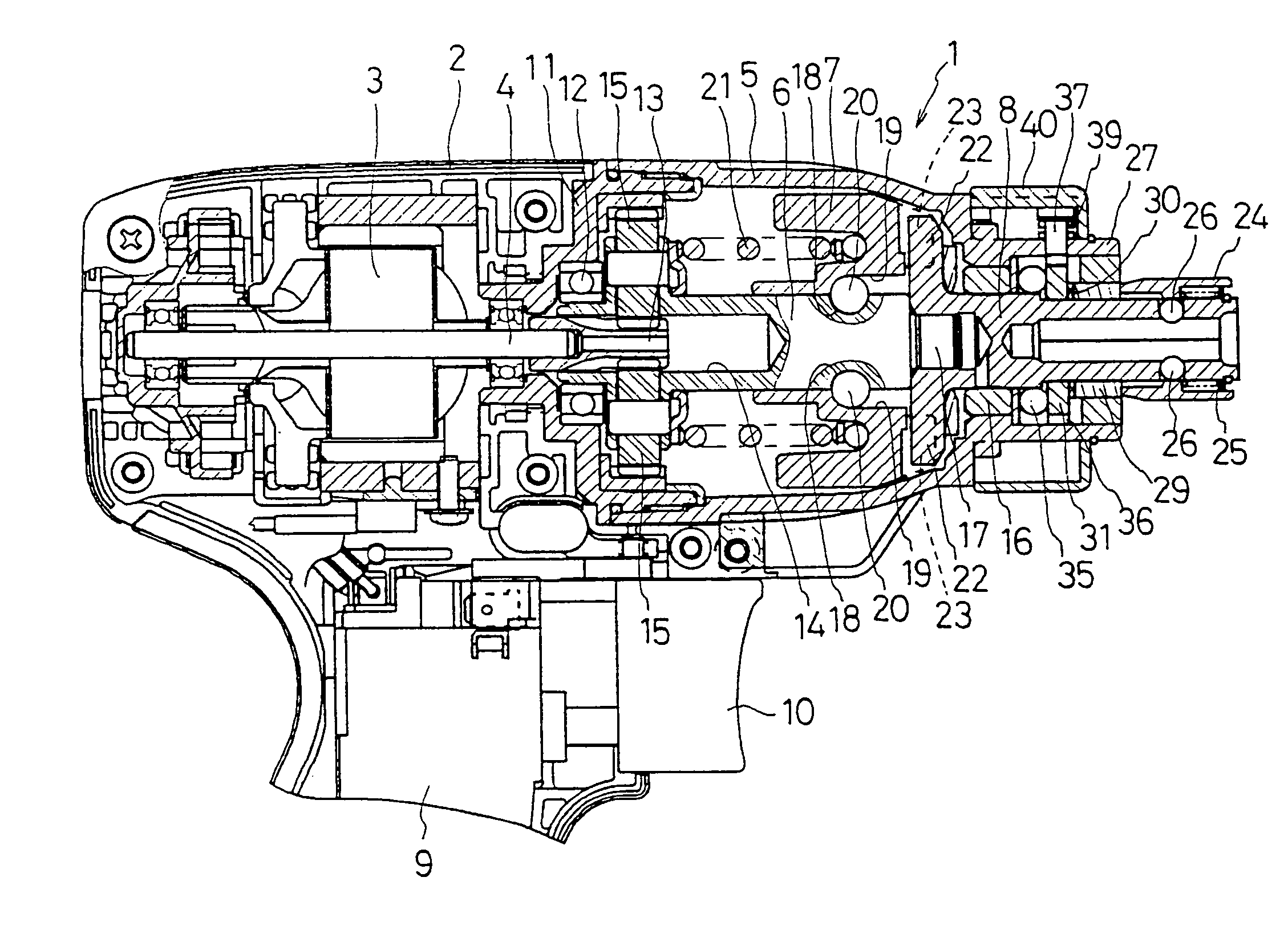

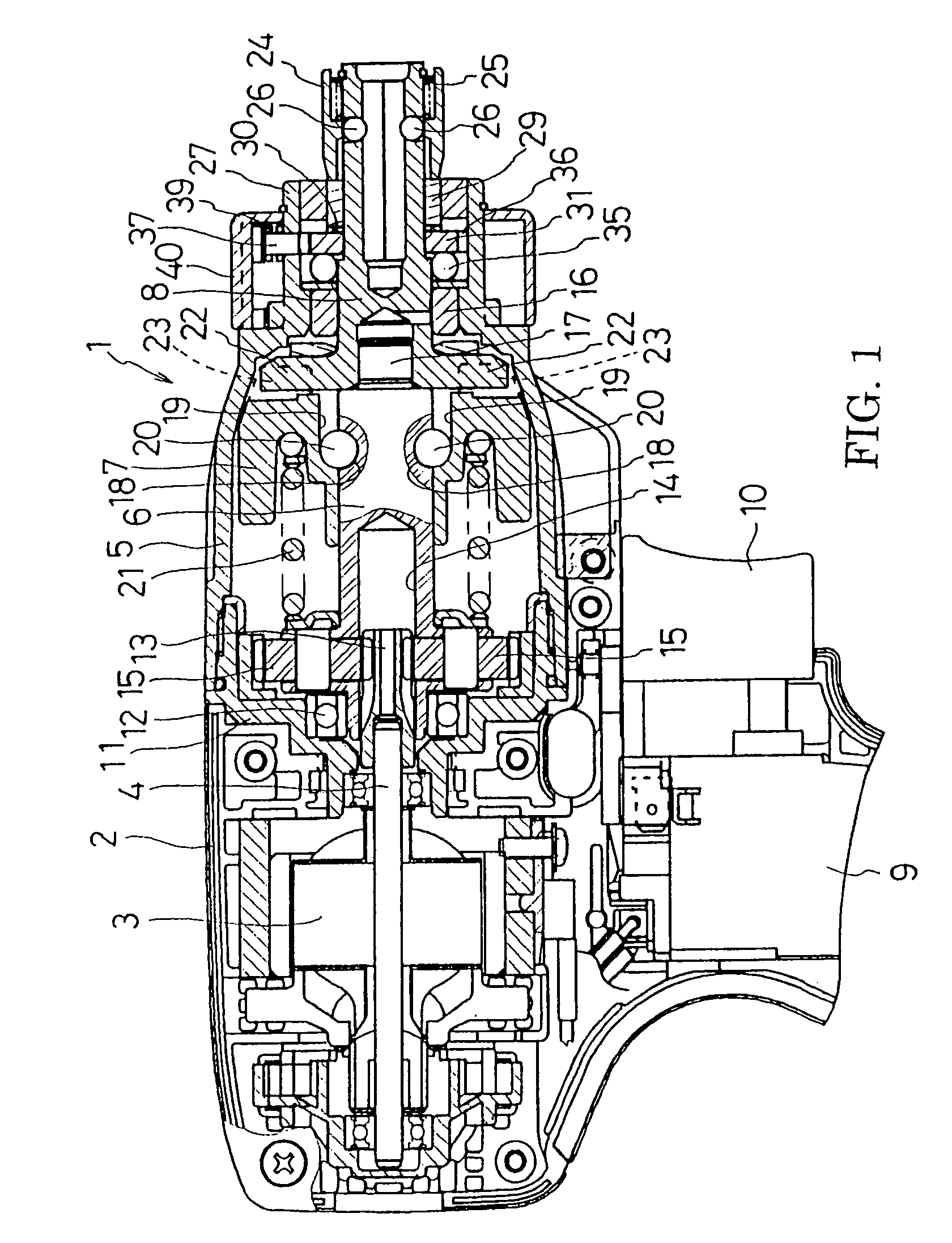

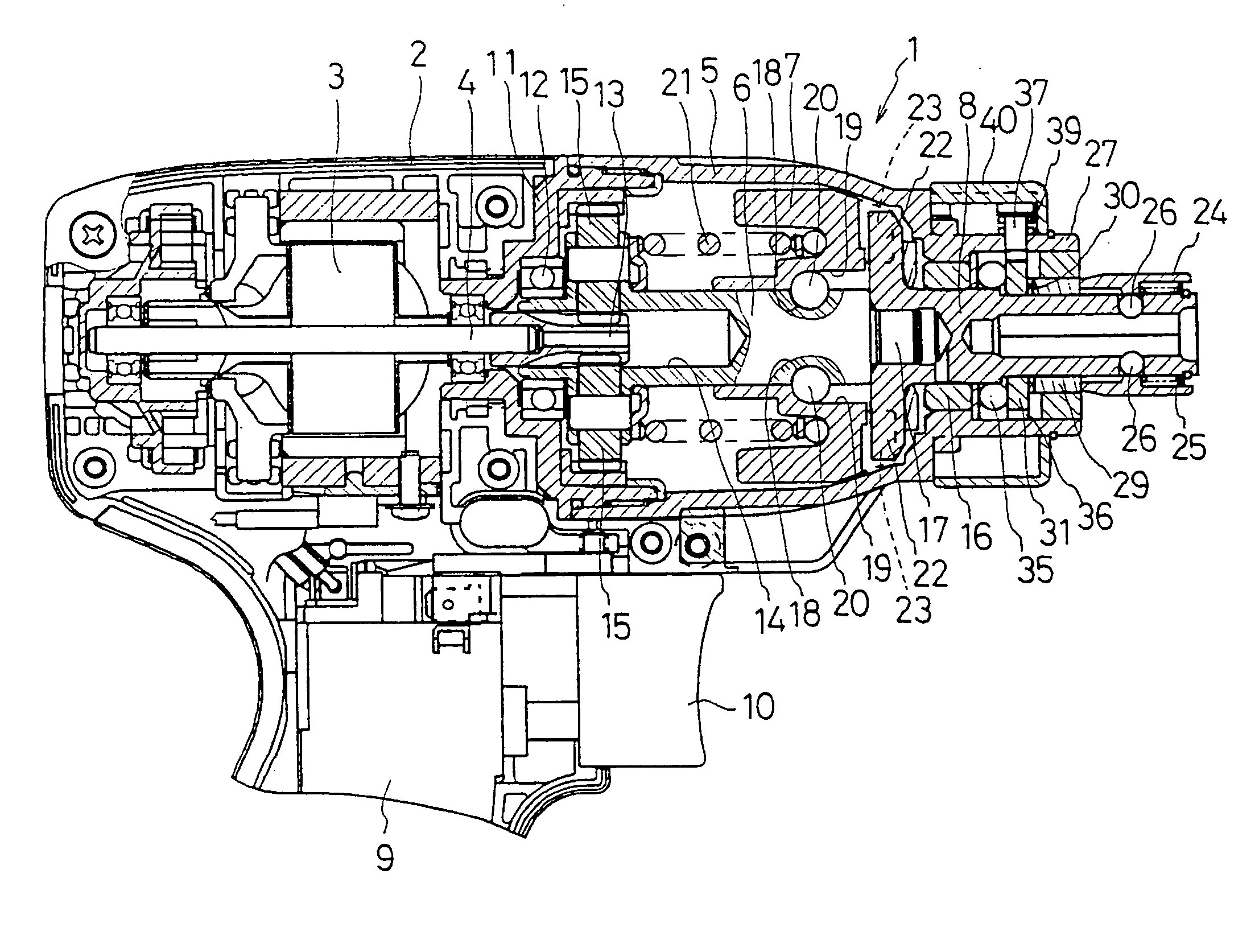

Impact driver having an external mechanism which operation mode can be selectively switched between impact and drill modes

ActiveUS7124839B2Simple structureImprove usabilityReciprocating drilling machinesPortable percussive toolsOperation modeEngineering

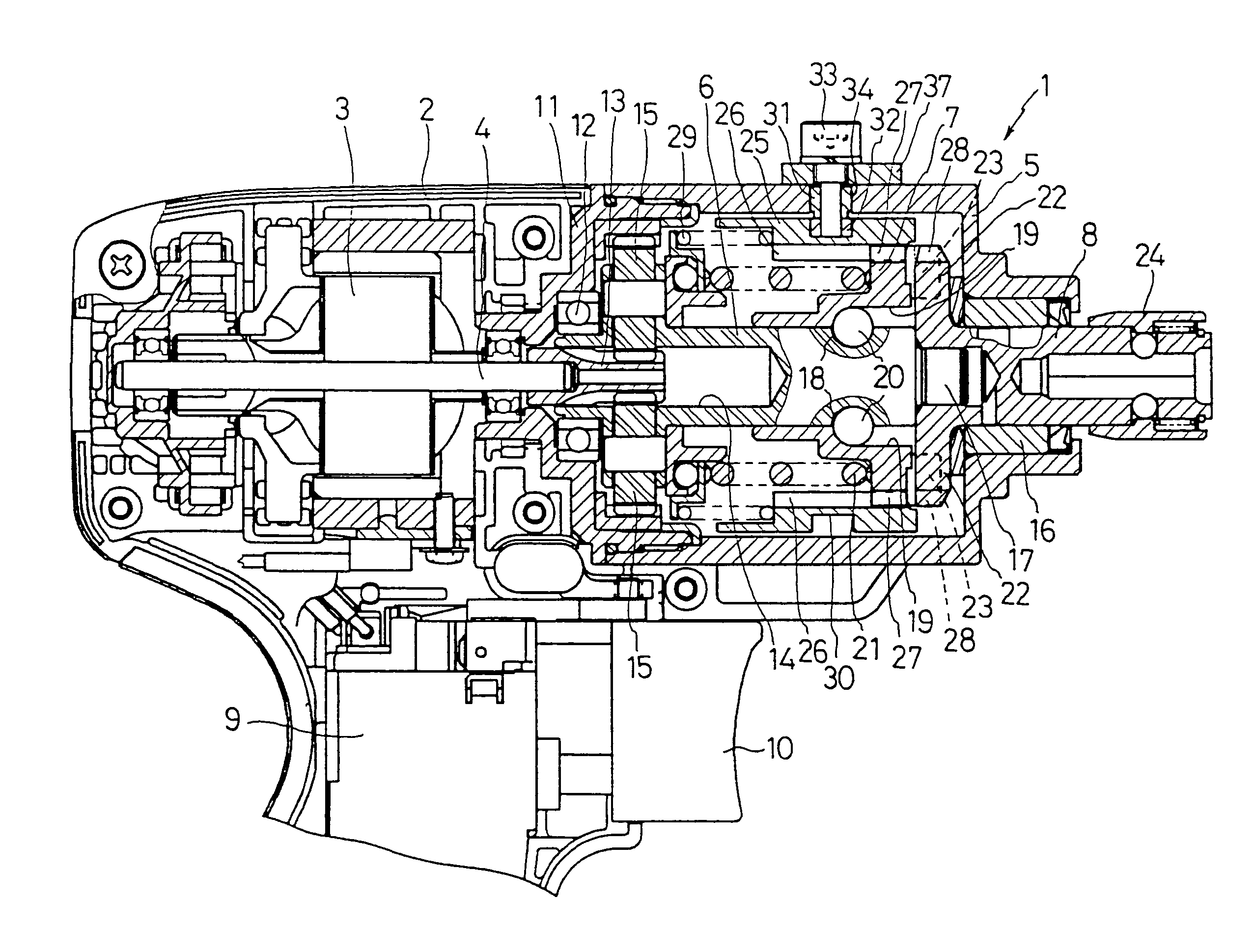

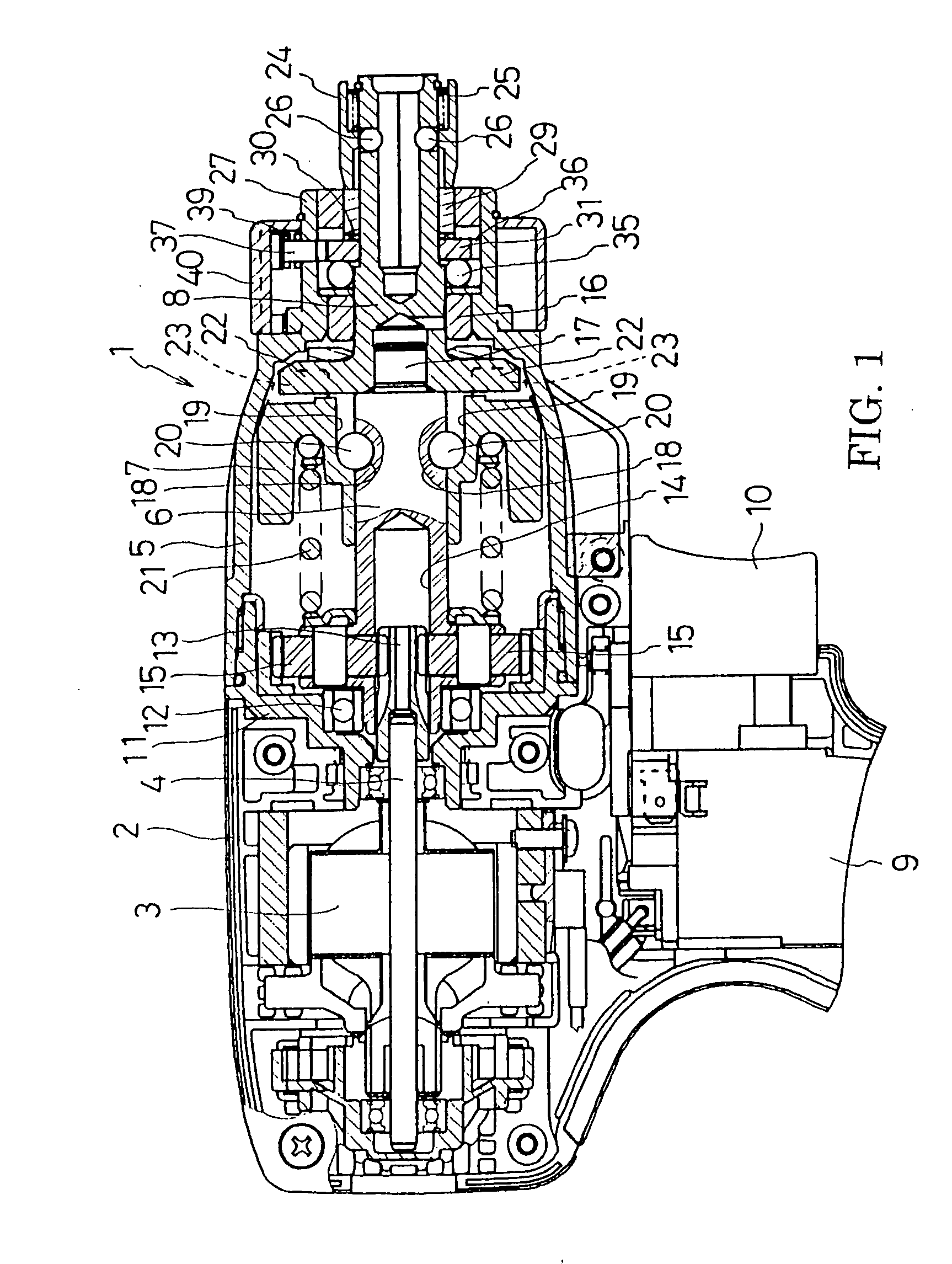

An impact driver in which a drill mode can be selected without fail is provided. In a hammer case, a connecting sleeve is provided so as to be slidable back and forth. At the backward position, the connecting sleeve engages with only a first engaging tooth provided on the outer circumference of the hammer for rotating integrally. At the forward position, it engages with both the first engaging tooth of the hammer and a second engaging tooth of an anvil for rotating integrally with both of them, and thus a drill mode is obtained. Further, an operating bolt is provided in the hammer case to be inserted into a concave groove of the connecting sleeve through a guide groove formed in the hammer case. The operating bolt slides the connecting sleeve to the forward or backward position by its movement in the guide groove.

Owner:MAKITA CORP

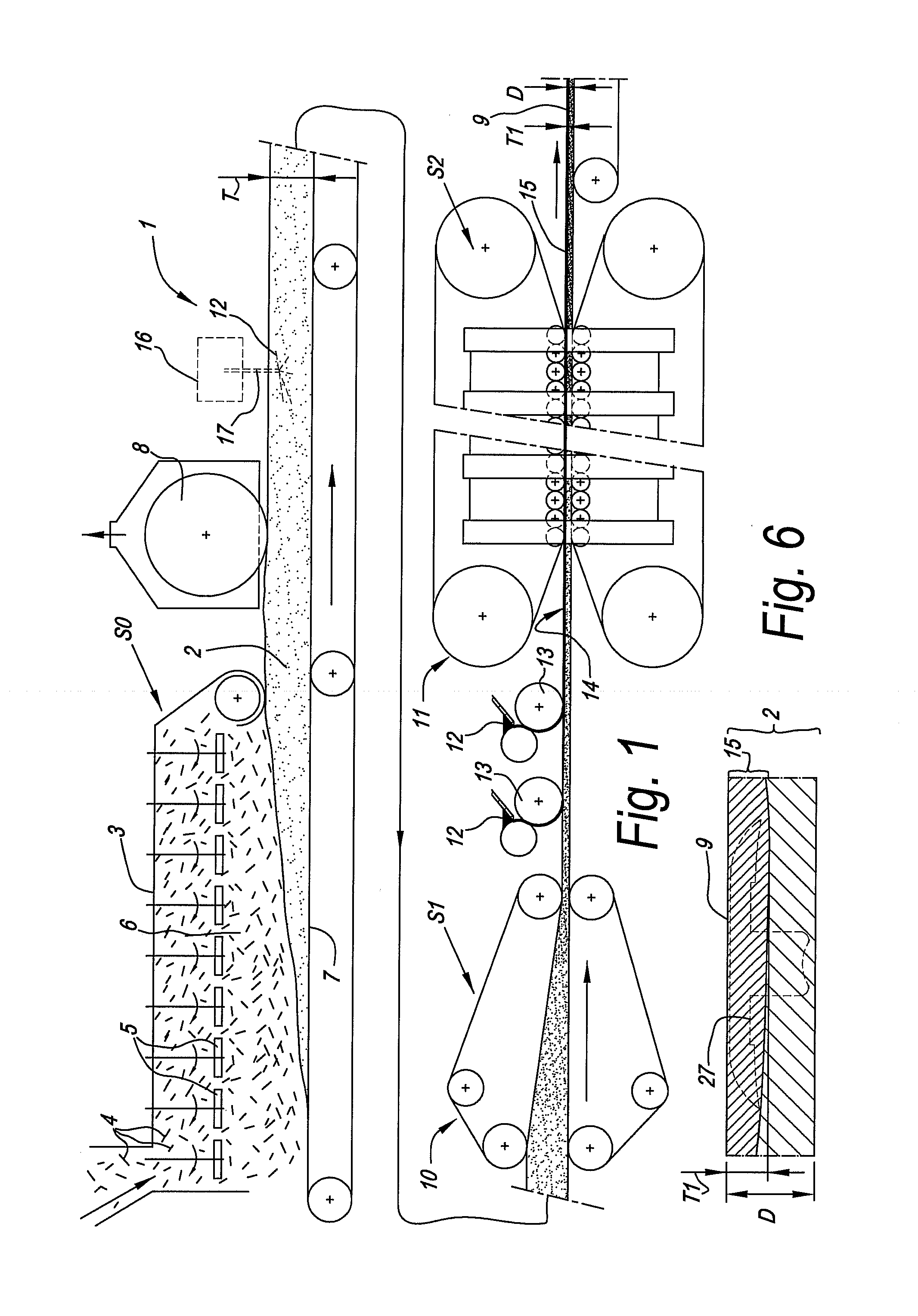

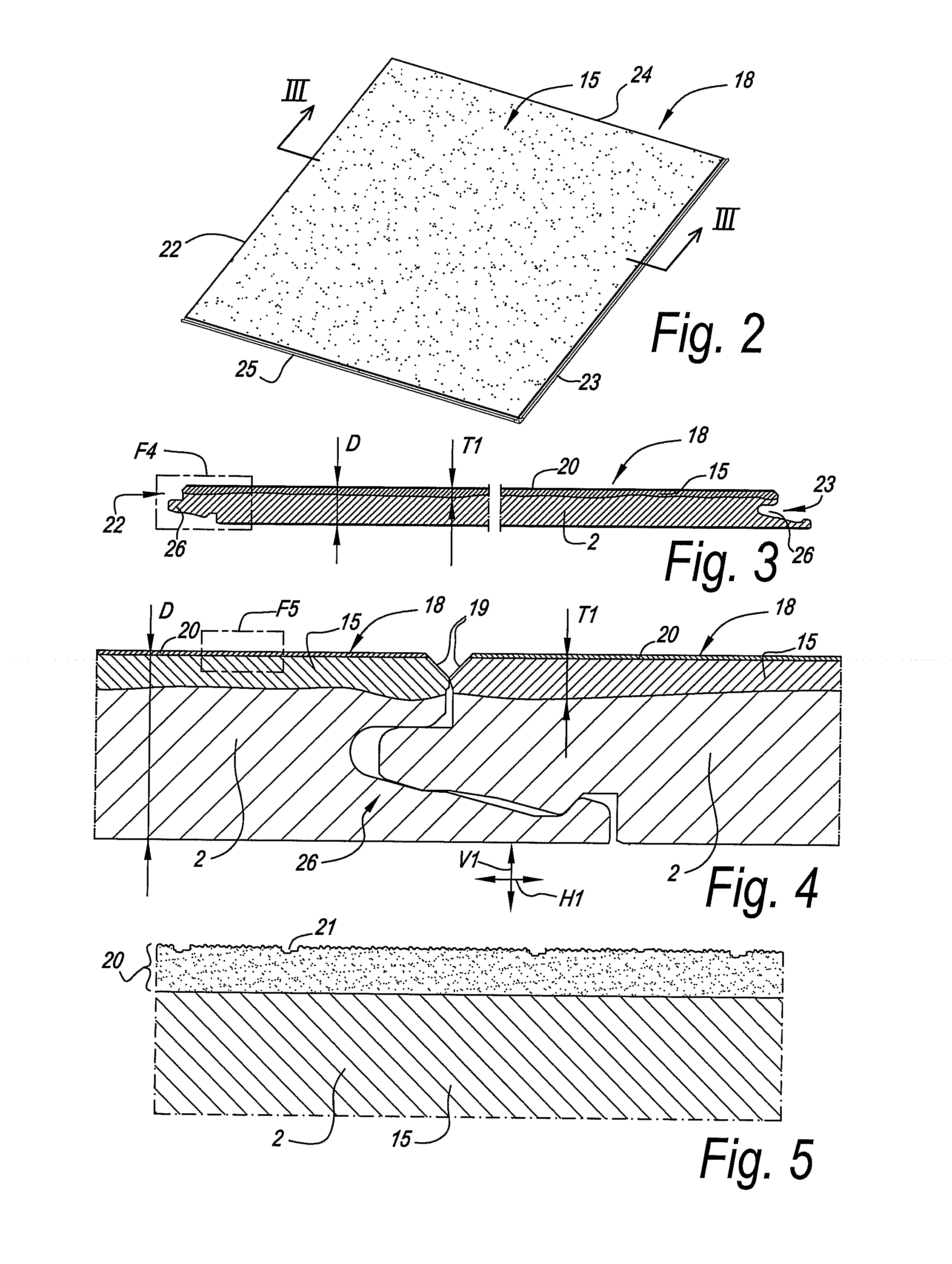

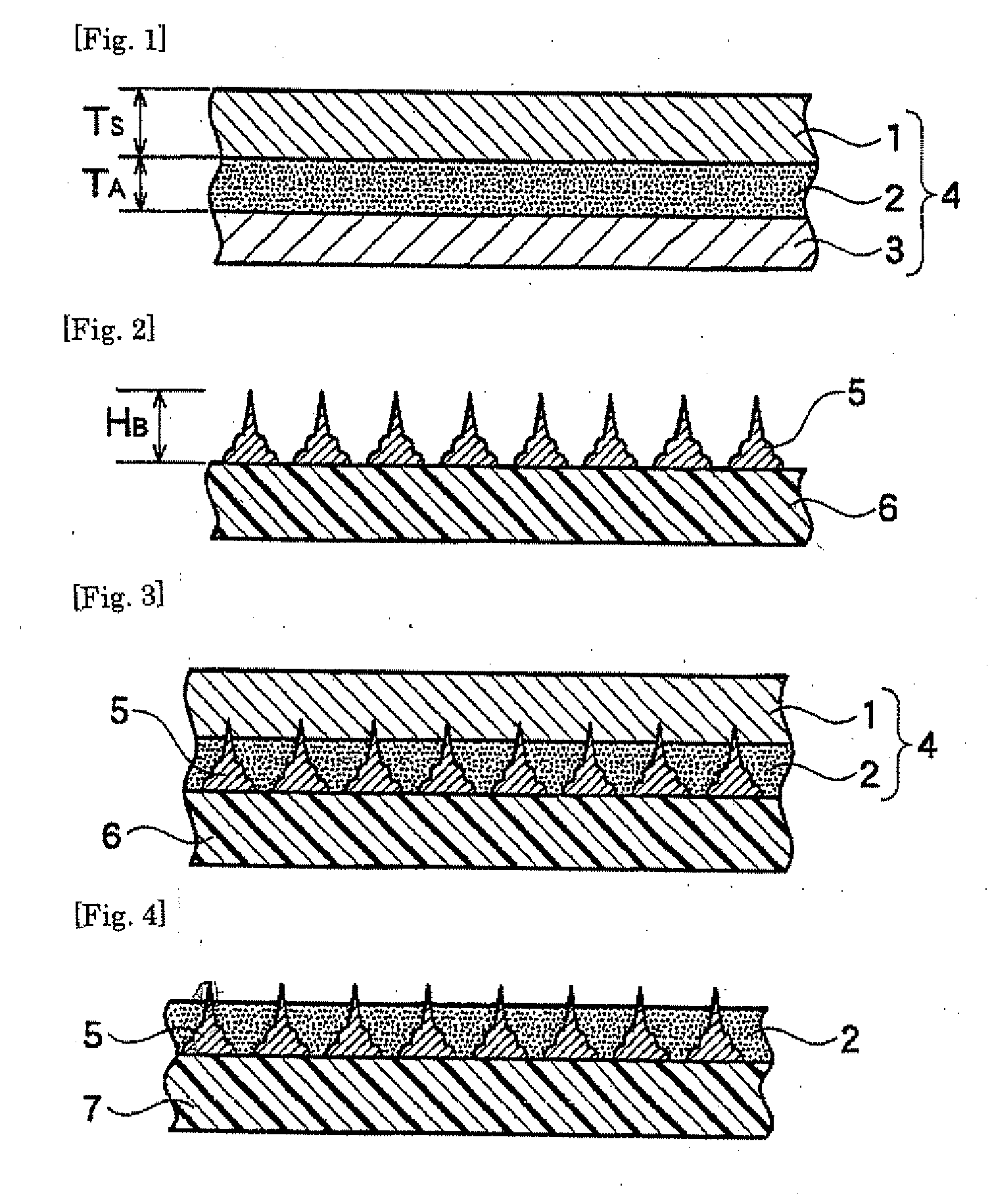

Method for manufacturing panels and panels obtained hereby

InactiveUS20110311806A1Simply formedFine surfaceLayered productsMonocomponent cellulose artificial filamentVolumetric Mass DensityEngineering

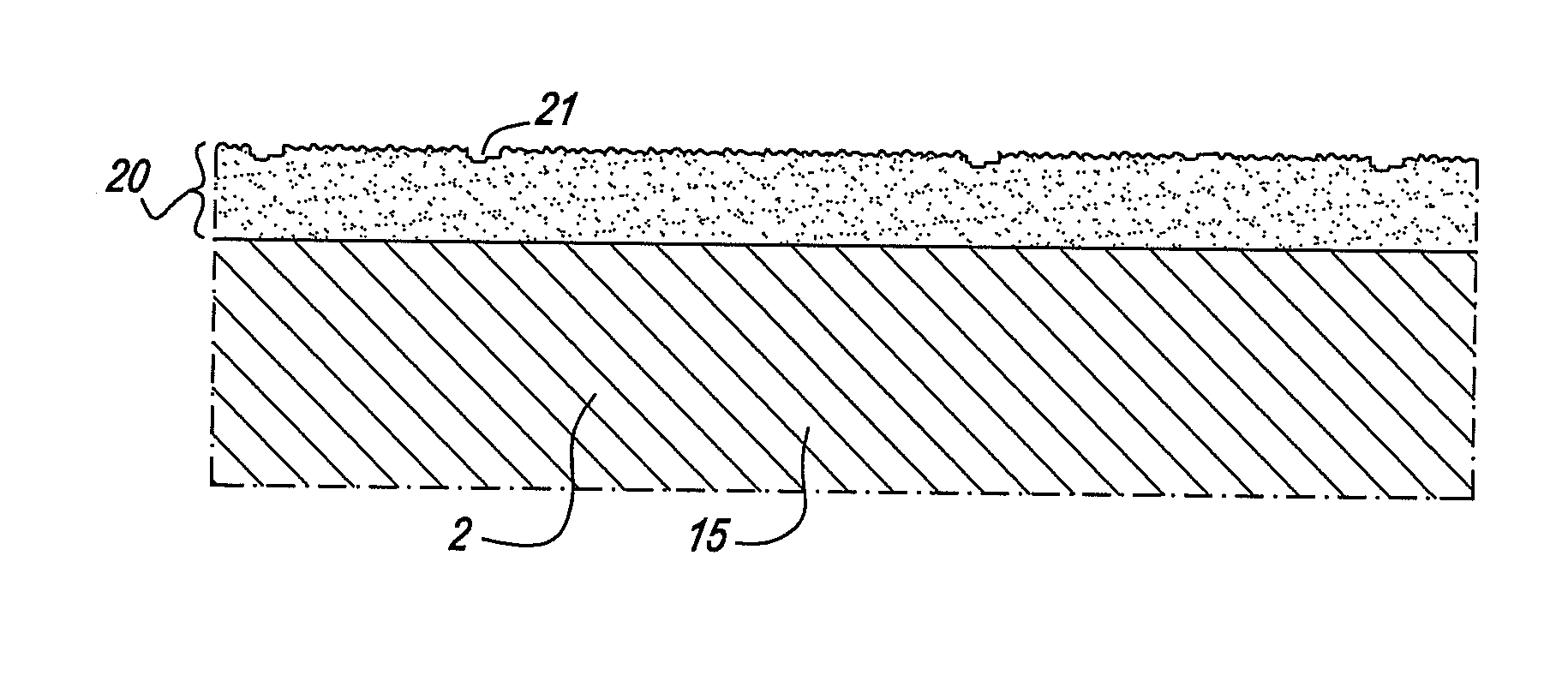

A method for manufacturing panels including a substrate on the basis of a pressed material mass, whereby it is started from a material mass to be densified, wherein the density of this material mass, in one or more densifying steps, is at least doubled. Prior to one or more of these densifying steps, a colorant is added to the material mass.

Owner:FLOORING IND LTD

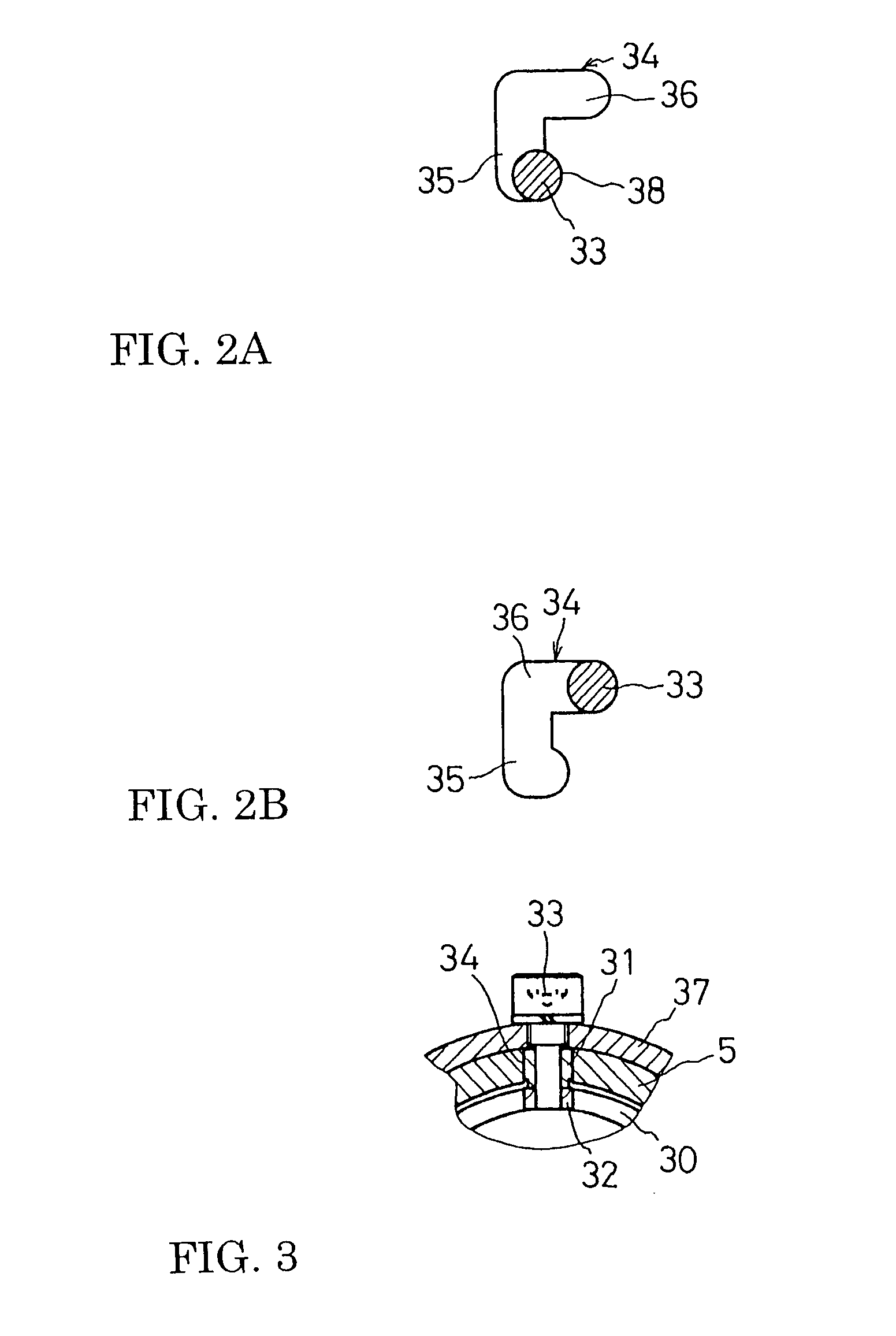

Impact driver

ActiveUS20050199404A1Simple structureImprove usabilityReciprocating drilling machinesPortable percussive toolsEngineeringMechanical engineering

An impact driver in which a drill mode can be selected without fail is provided. In a hammer case, a connecting sleeve is provided so as to be slidable back and forth. At the backward position, the connecting sleeve engages with only a first engaging tooth provided on the outer circumference of the hammer for rotating integrally. At the forward position, it engages with both the first engaging tooth of the hammer and a second engaging tooth of an anvil for rotating integrally with both of them, and thus a drill mode is obtained. Further, an operating bolt is provided in the hammer case to be inserted into a concave groove of the connecting sleeve through a guide groove formed in the hammer case. The operating bolt slides the connecting sleeve to the forward or backward position by its movement in the guide groove.

Owner:MAKITA CORP

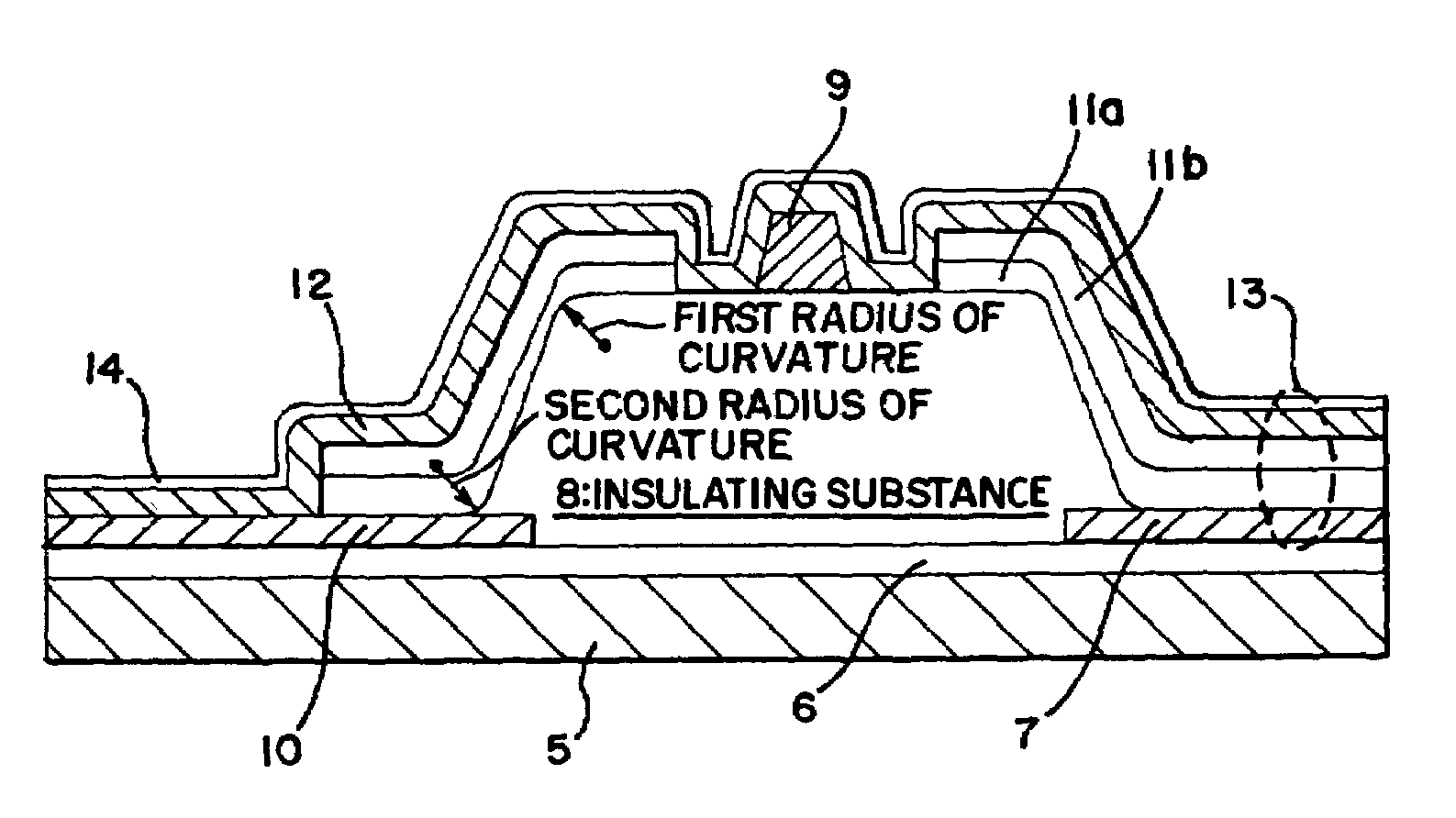

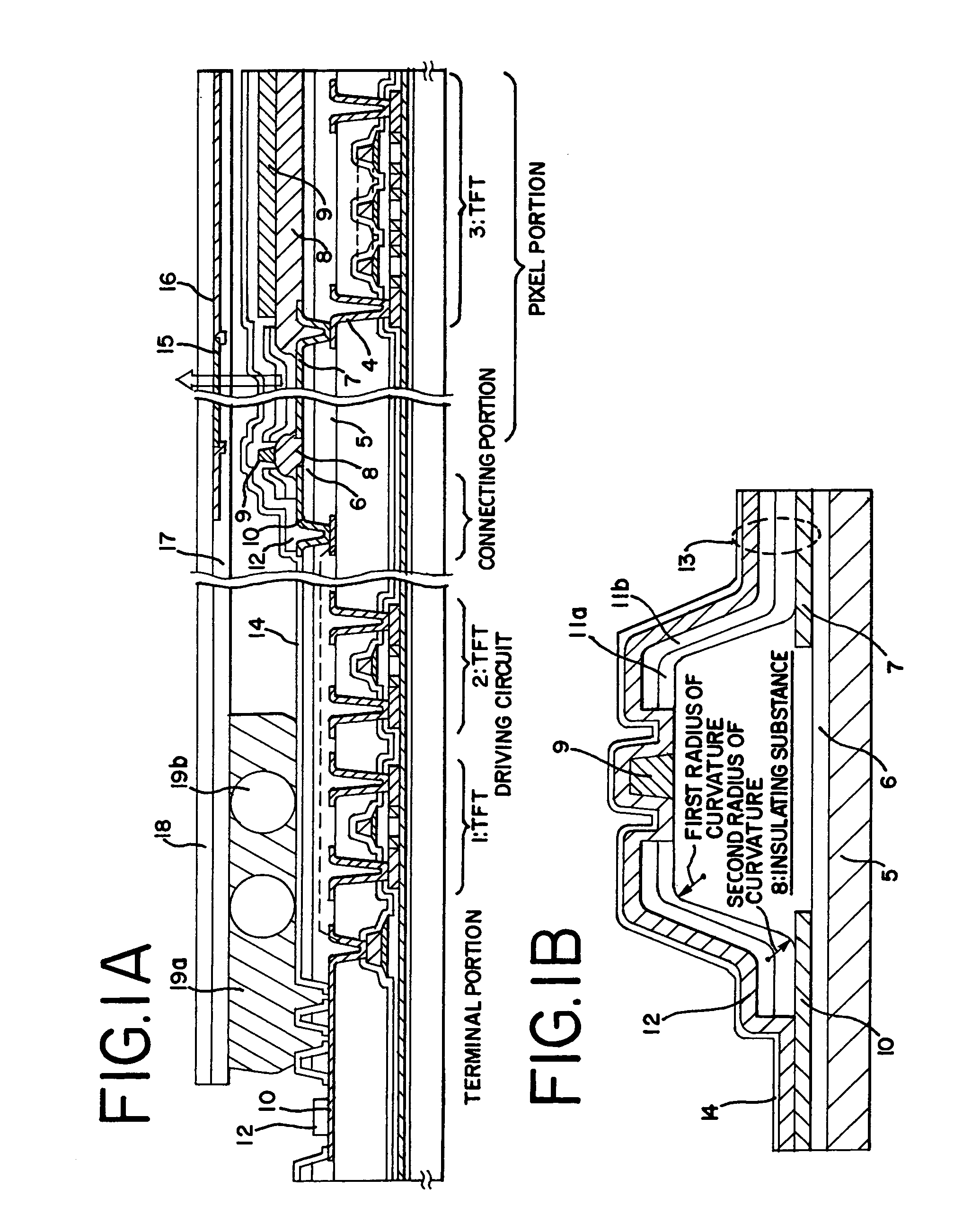

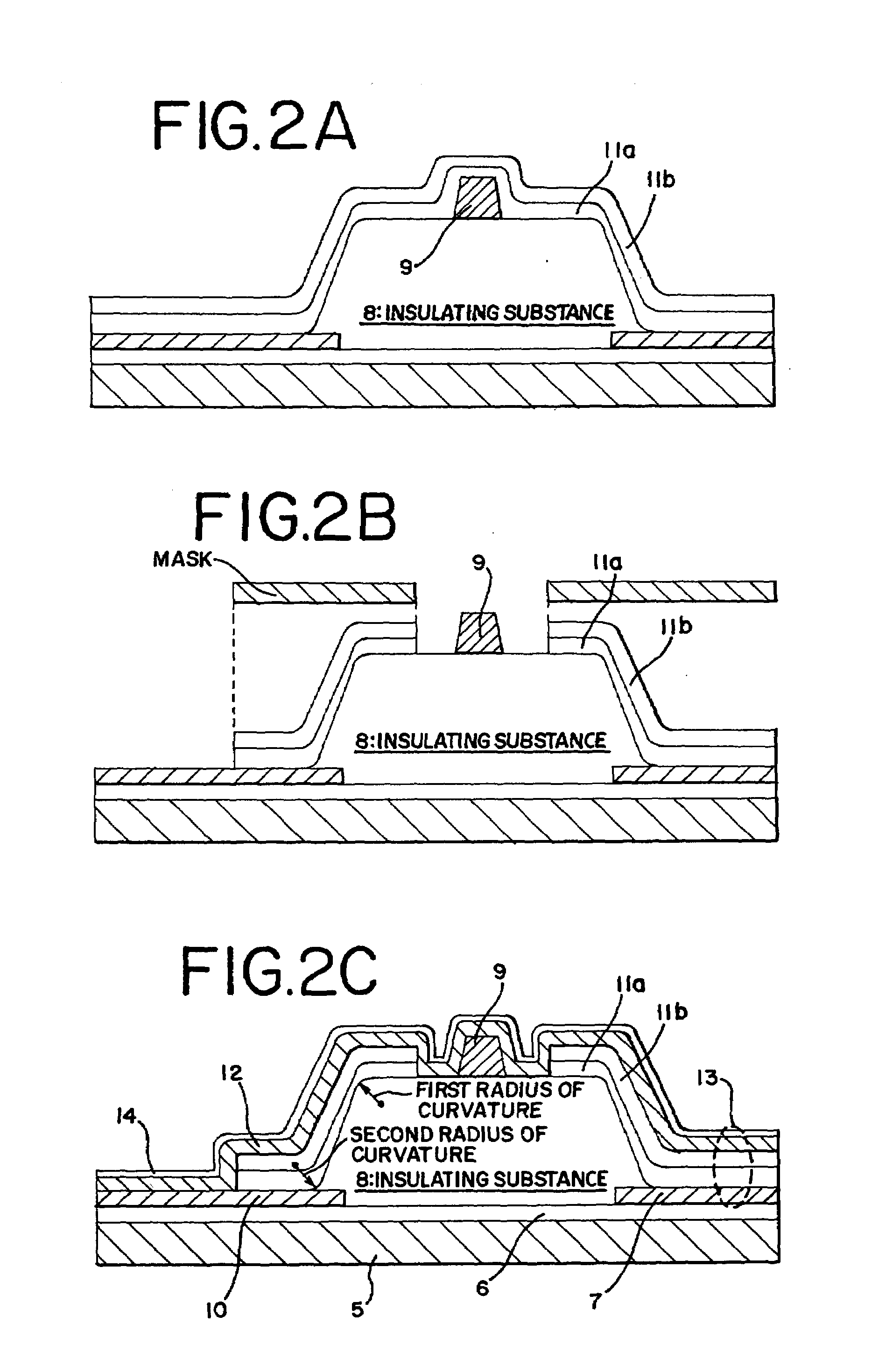

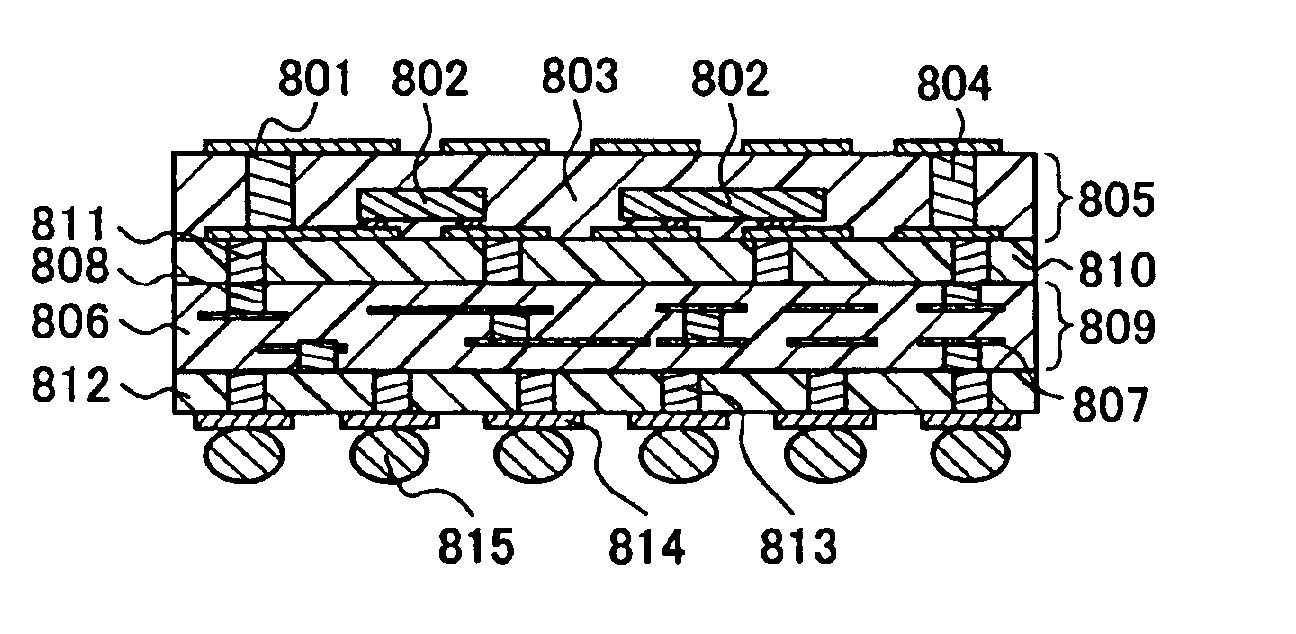

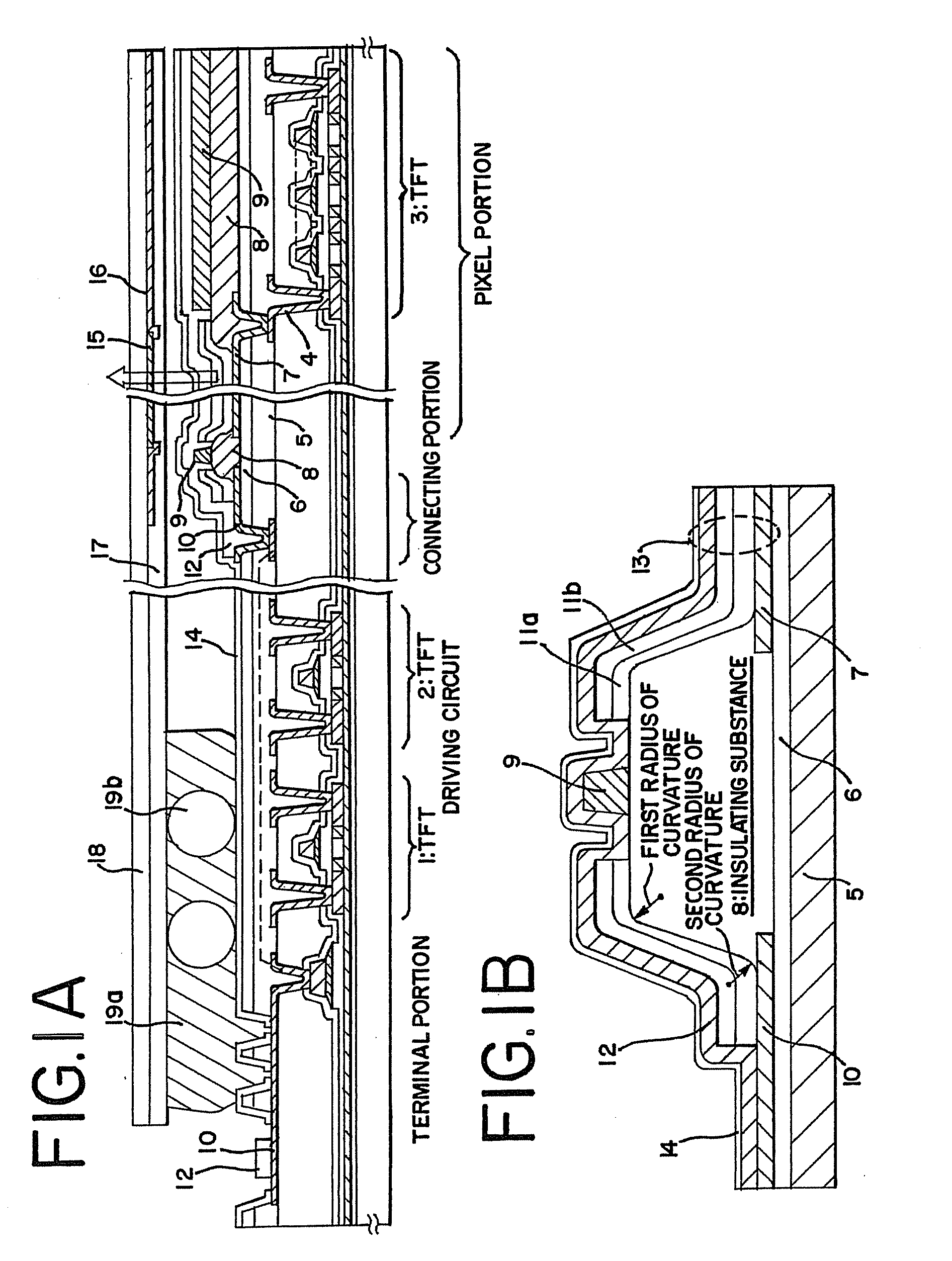

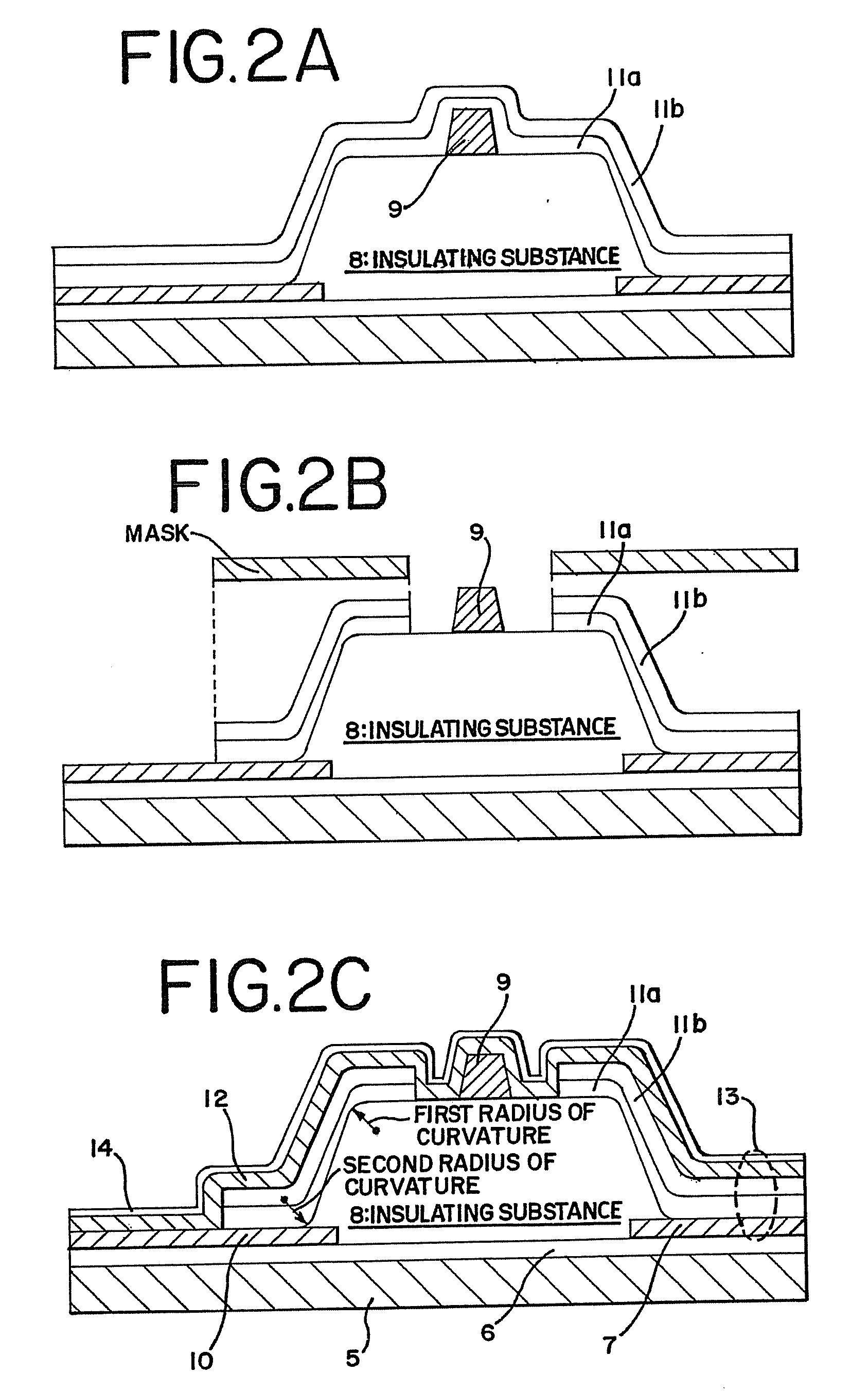

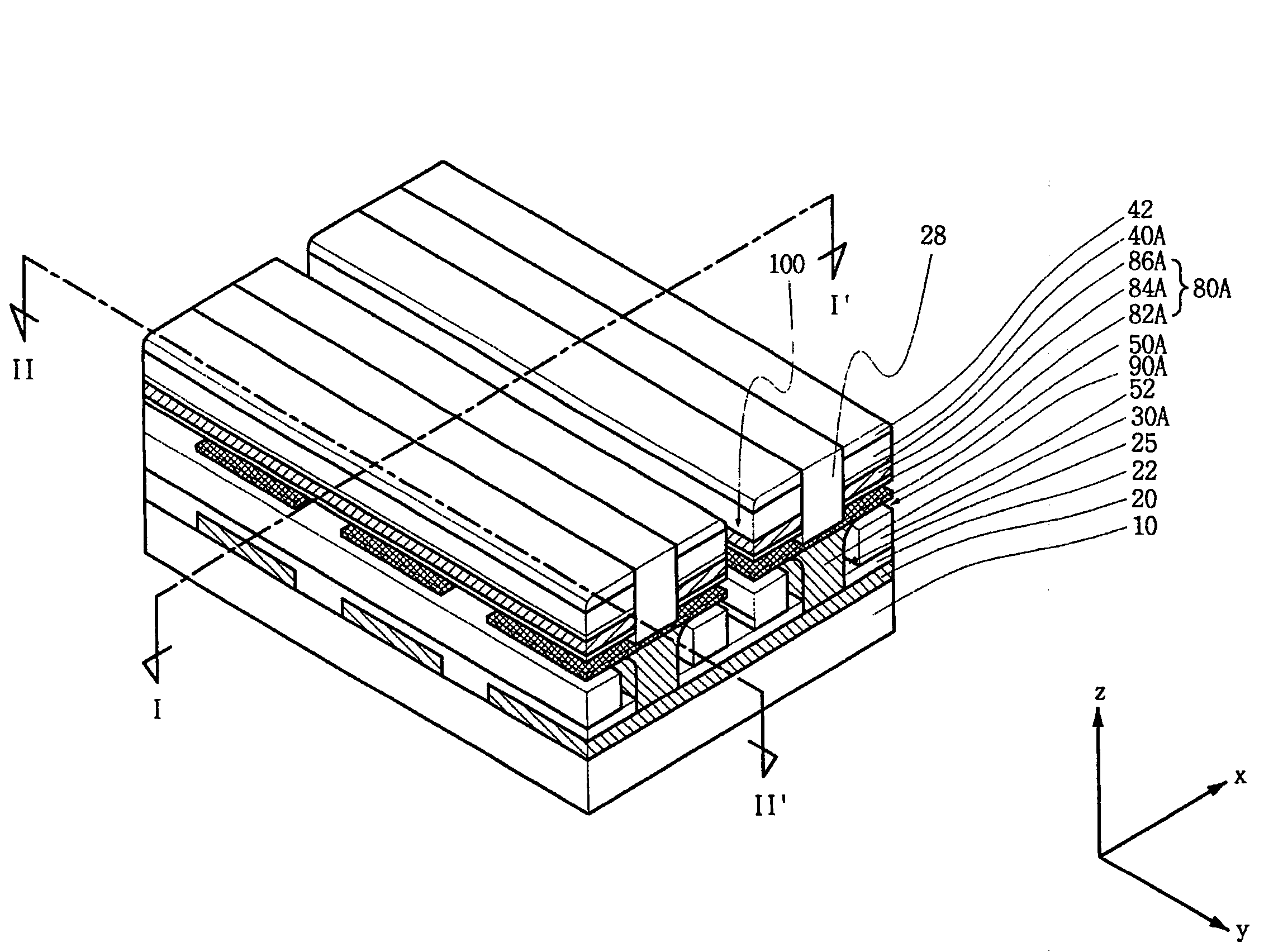

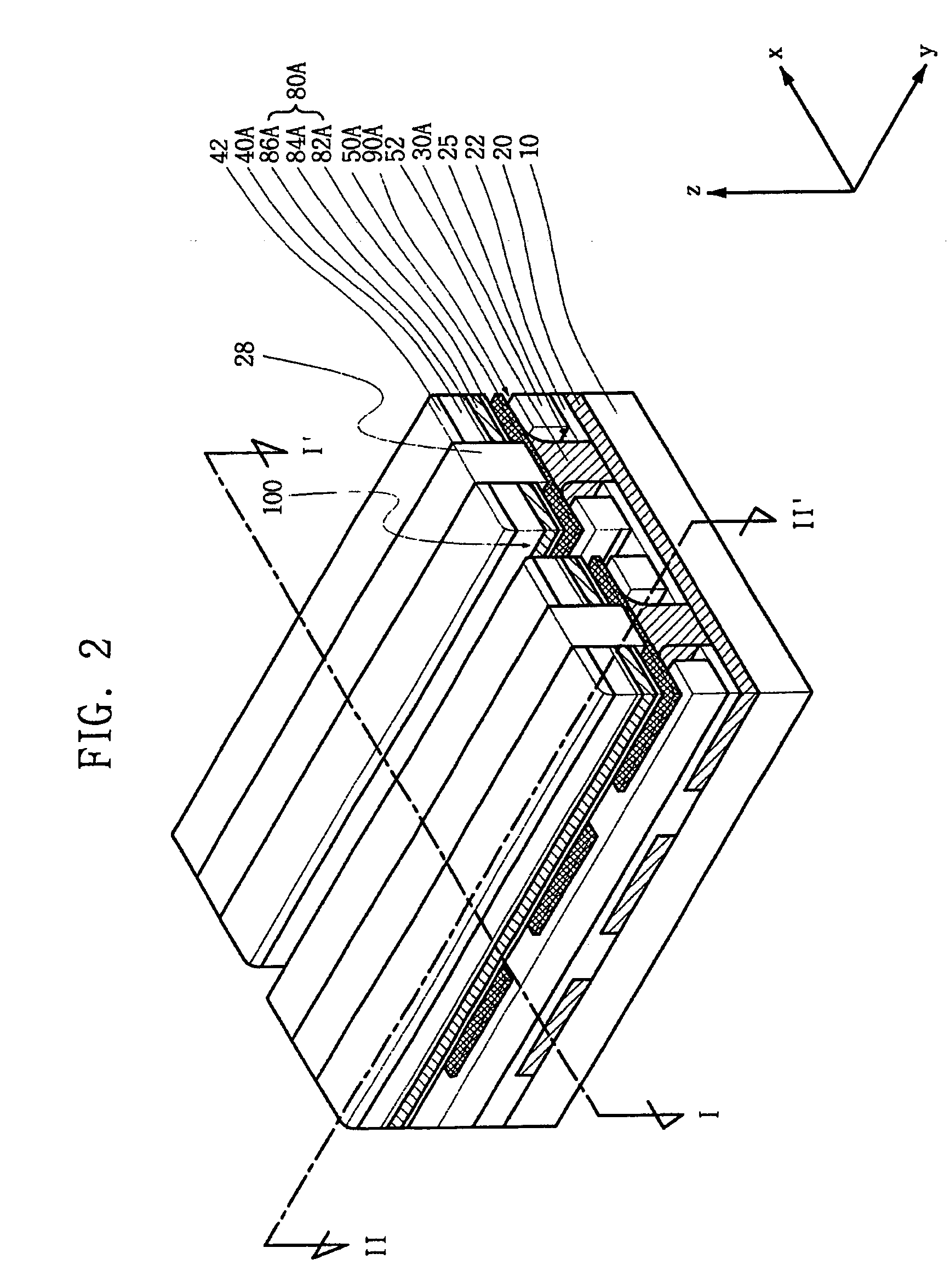

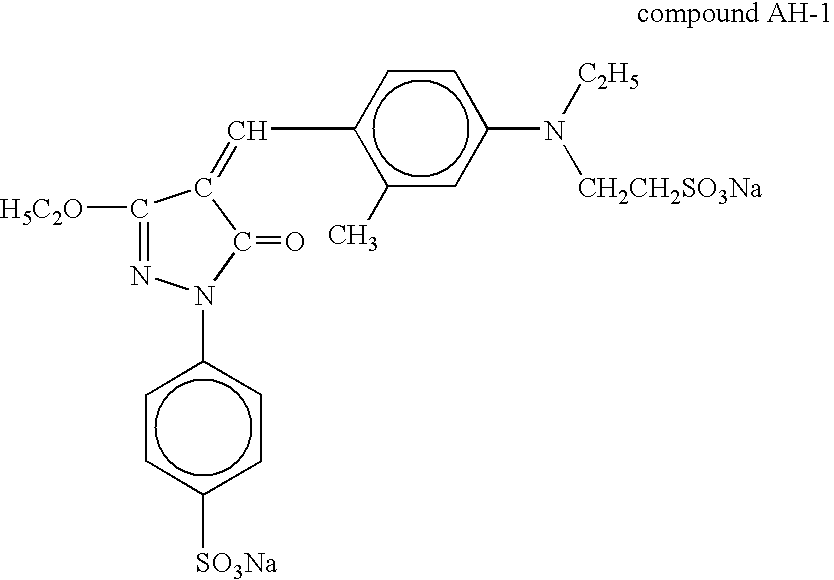

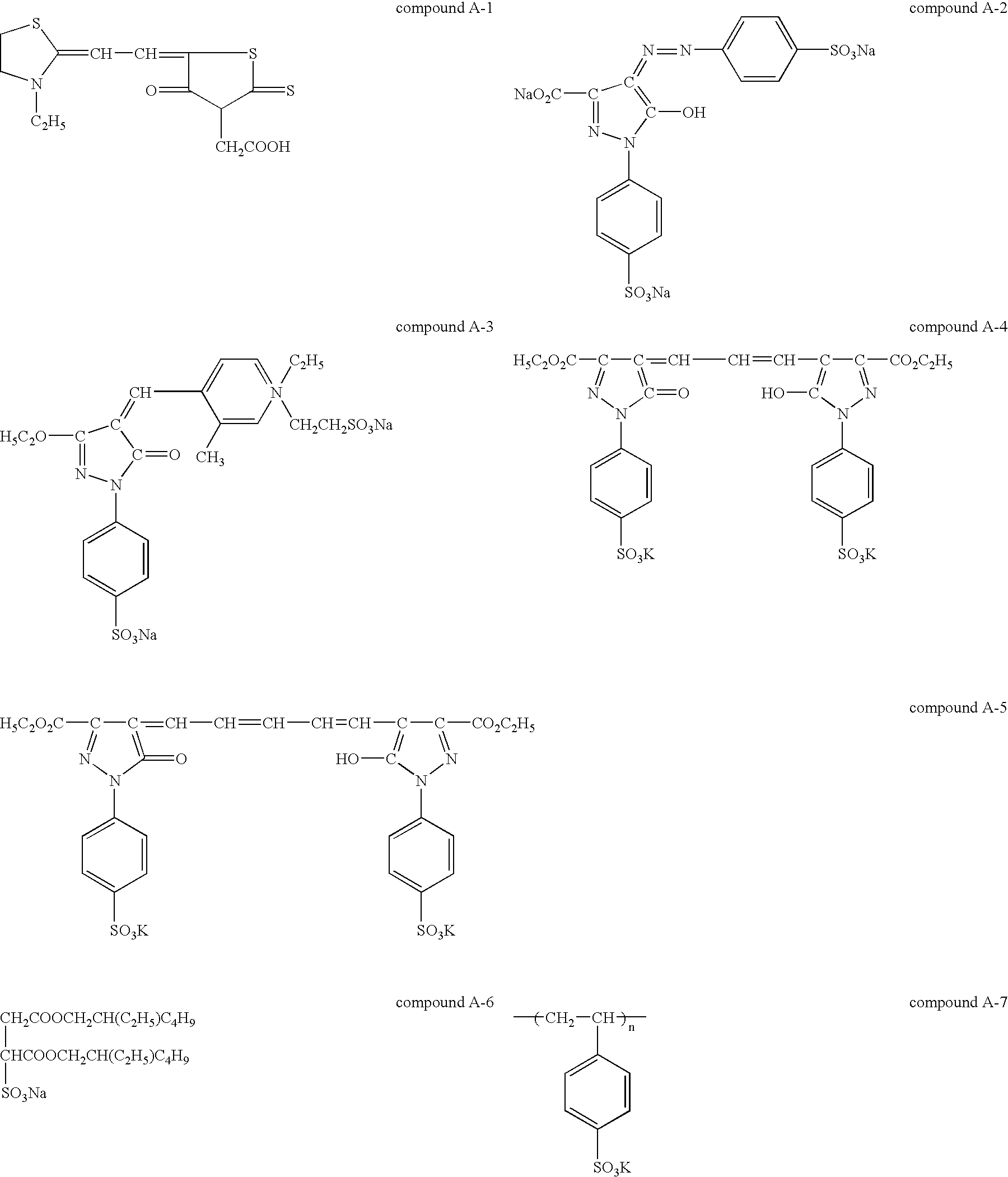

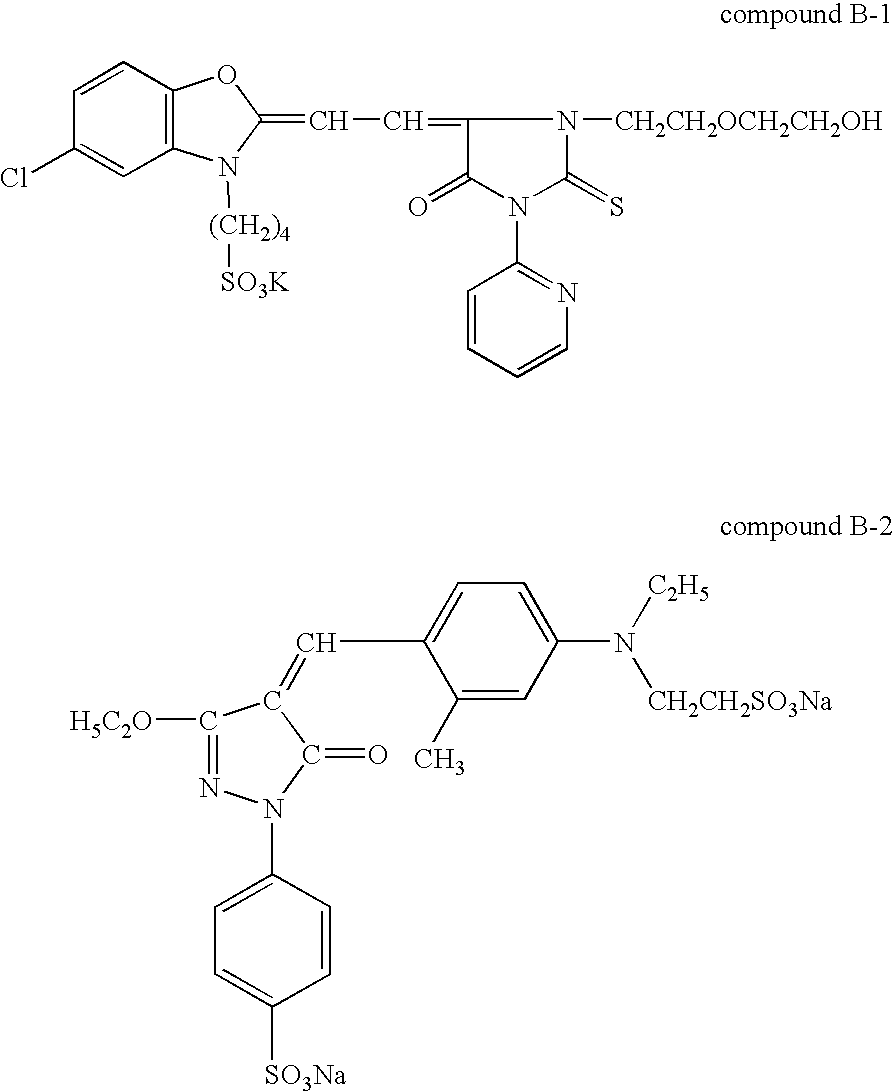

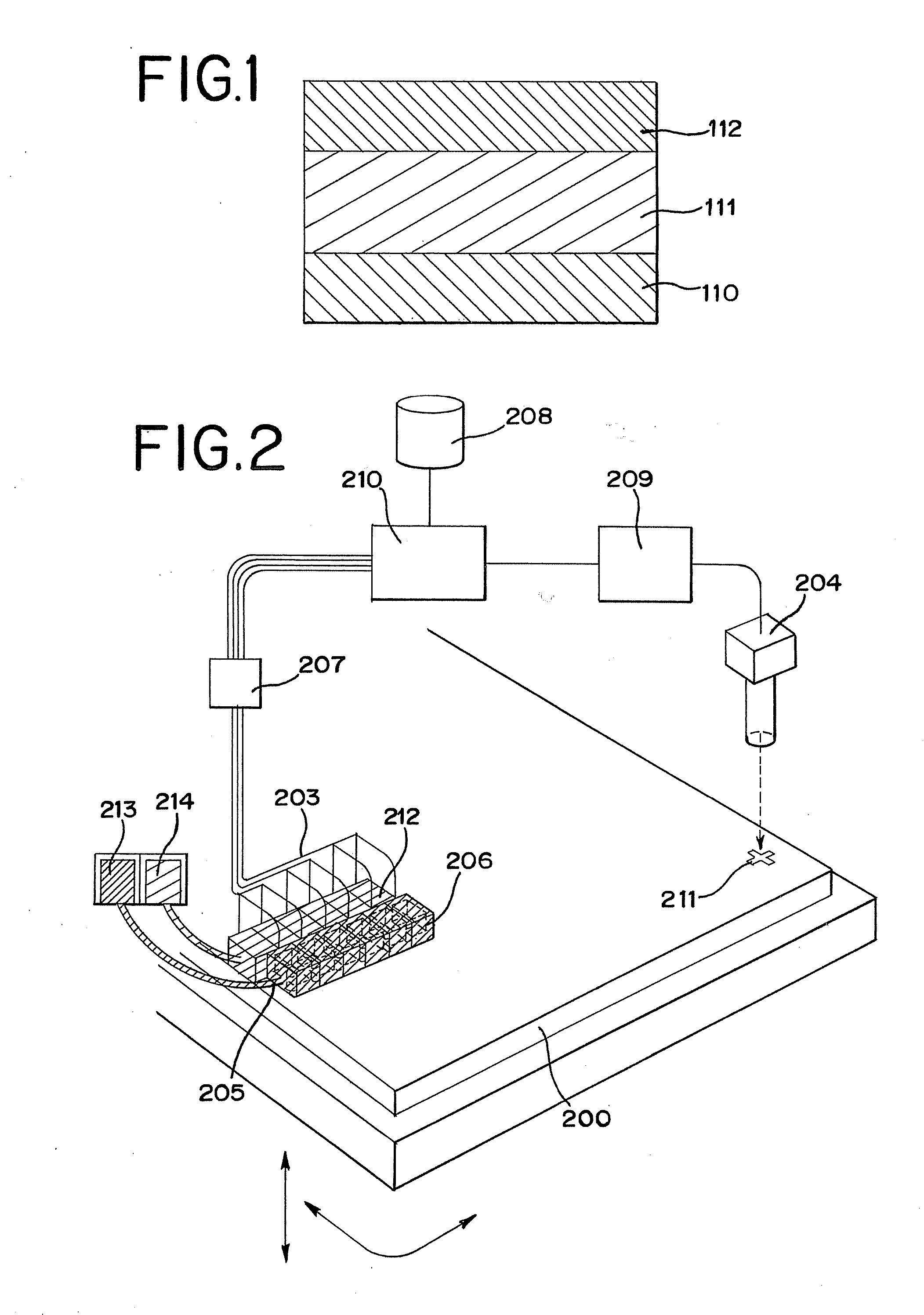

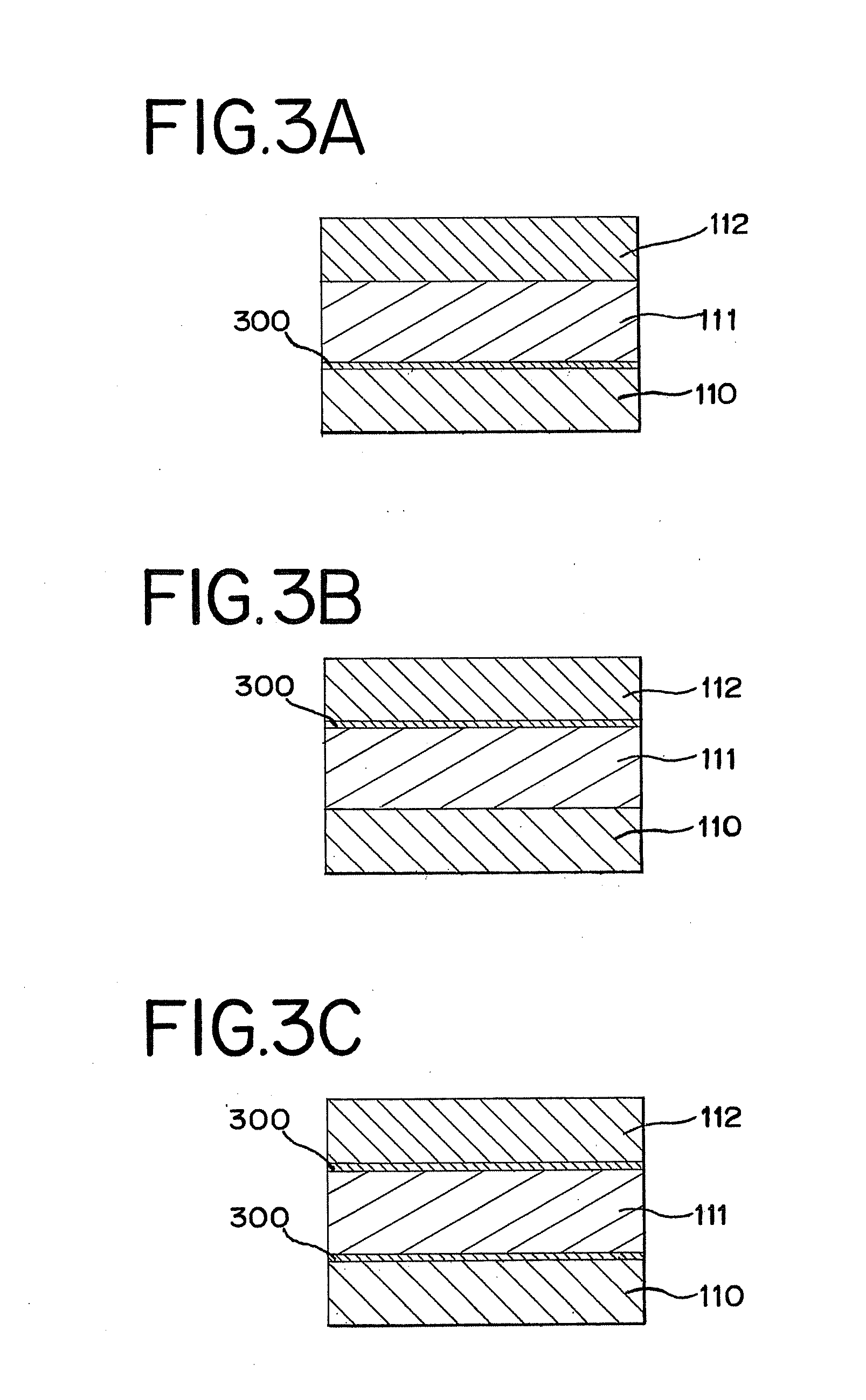

Light emitting apparatus and method of fabricating the same

InactiveUS7402945B2Simply formedEliminate failure in coverageDischarge tube luminescnet screensElectroluminescent light sourcesChemistryOrganic compound

Although an ink jet method known as a method of selectively forming a film of a high molecular species organic compound, can coat to divide an organic compound for emitting three kinds (R, G, B) of light in one step, film forming accuracy is poor, it is difficult to control the method and therefore, uniformity is not achieved and the constitution is liable to disperse. In contrast thereto, according to the invention, a film comprising a high molecular species material is formed over an entire face of a lower electrode connected to a thin film transistor by a coating method and thereafter, the film comprising the high molecular species material is etched by etching by plasma to thereby enable to selectively form a high molecular species material layer. Further, the organic compound layer is constituted by a material for carrying out luminescence of white color or luminescence of single color and combined with a color changing layer or a coloring layer to thereby realize full color formation.

Owner:SEMICON ENERGY LAB CO LTD

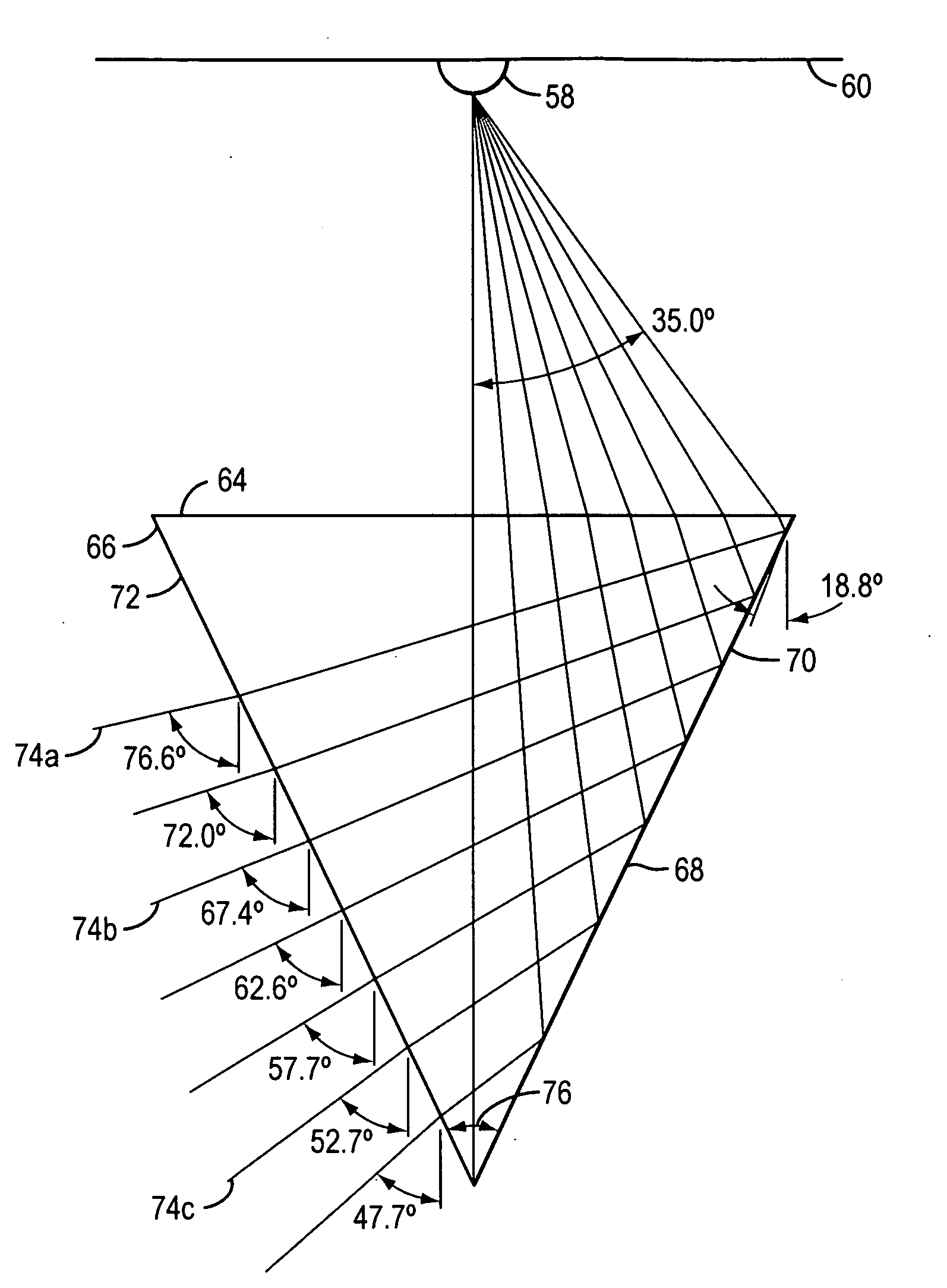

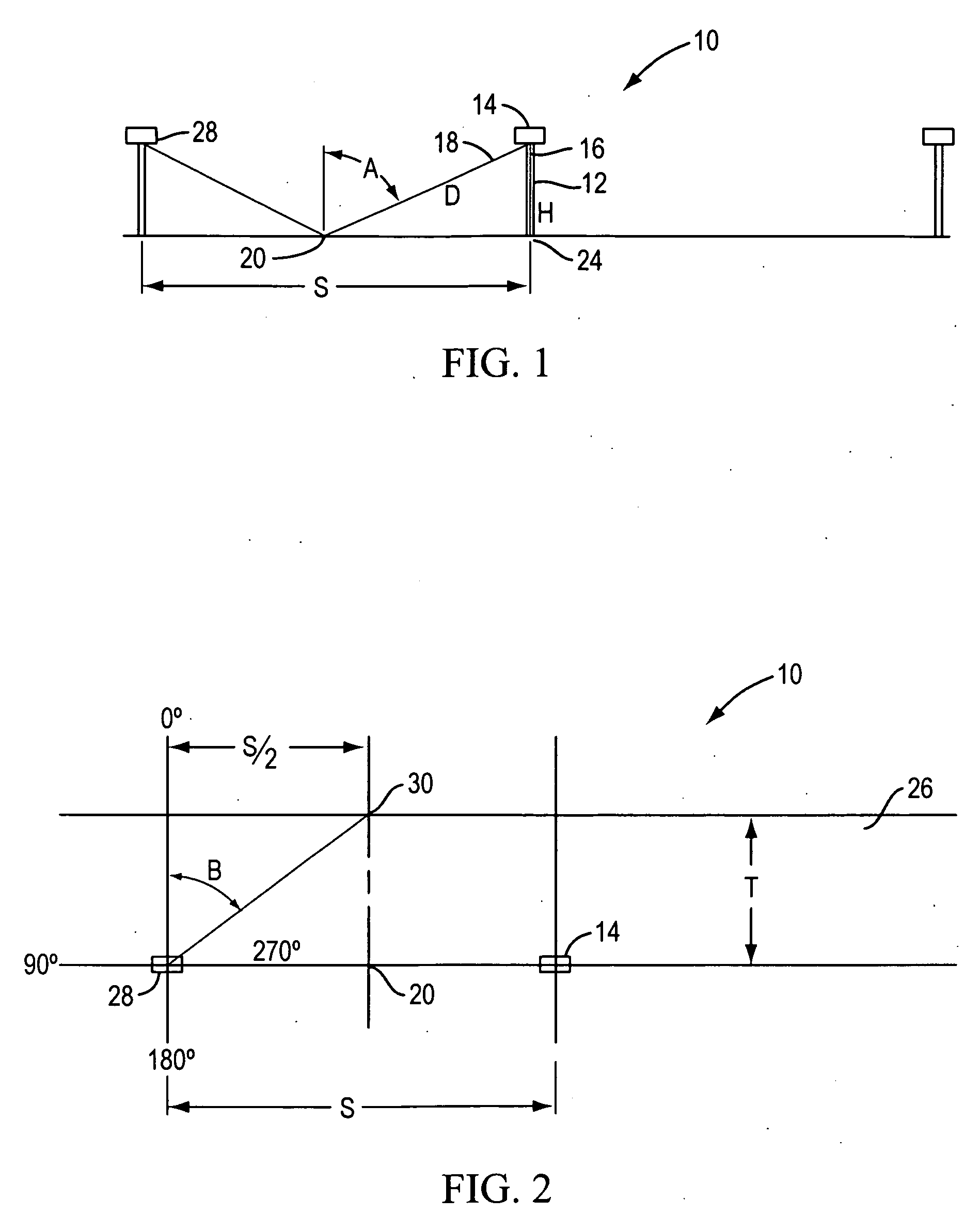

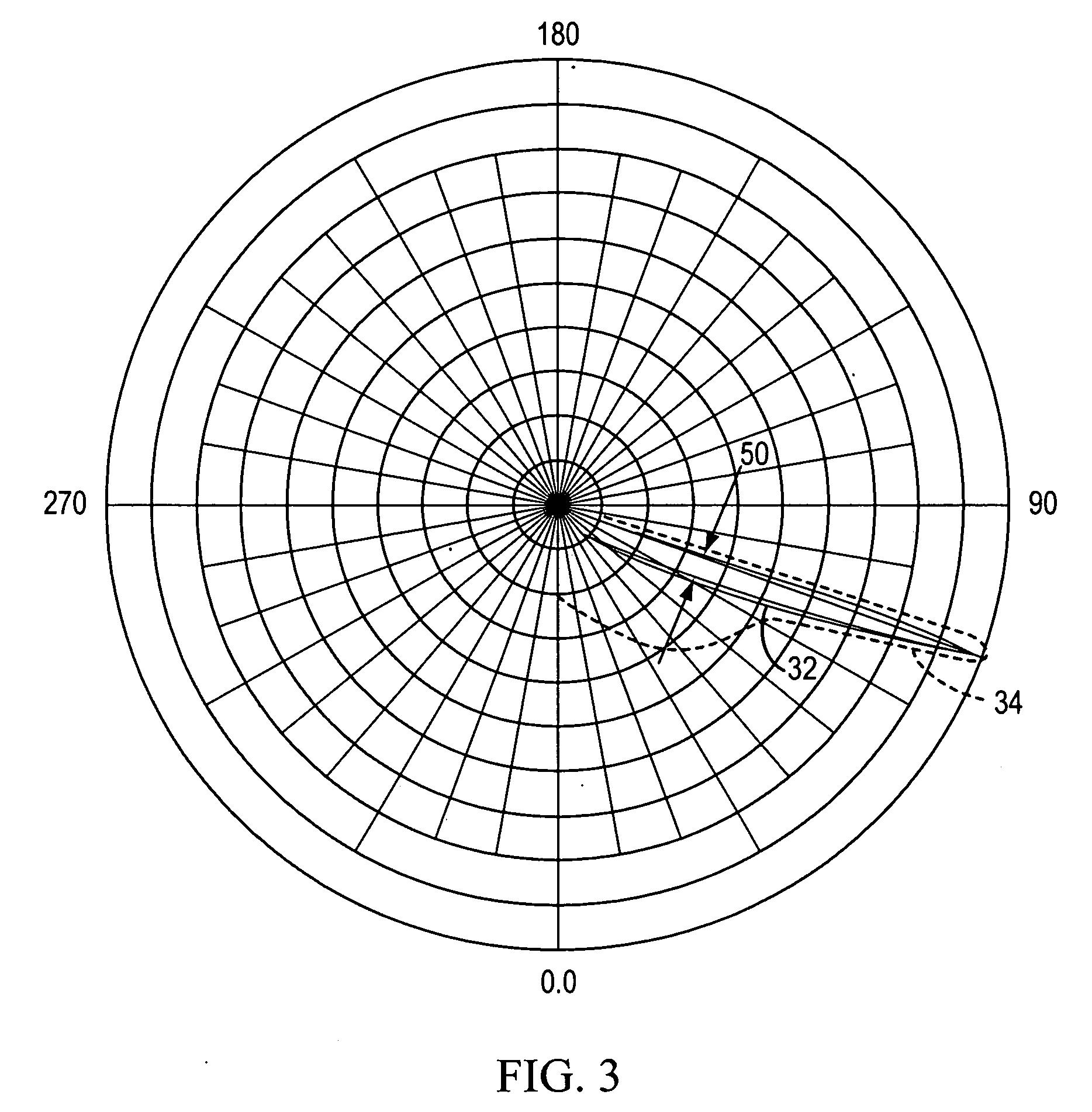

Lens for Solid-State Light-Emitting Device

InactiveUS20100073927A1Emission reductionConvenient lightingNon-electric lightingPoint-like light sourceCamera lensLight equipment

A lens is provided for use with a solid-state light-emitting device, typically a light-emitting diode. The lens may be used in luminaries for roadway lighting and other applications. In one embodiment the lens includes a conical structure proximate the light-emitting source of the light-emitting device.

Owner:LEWIN IAN +1

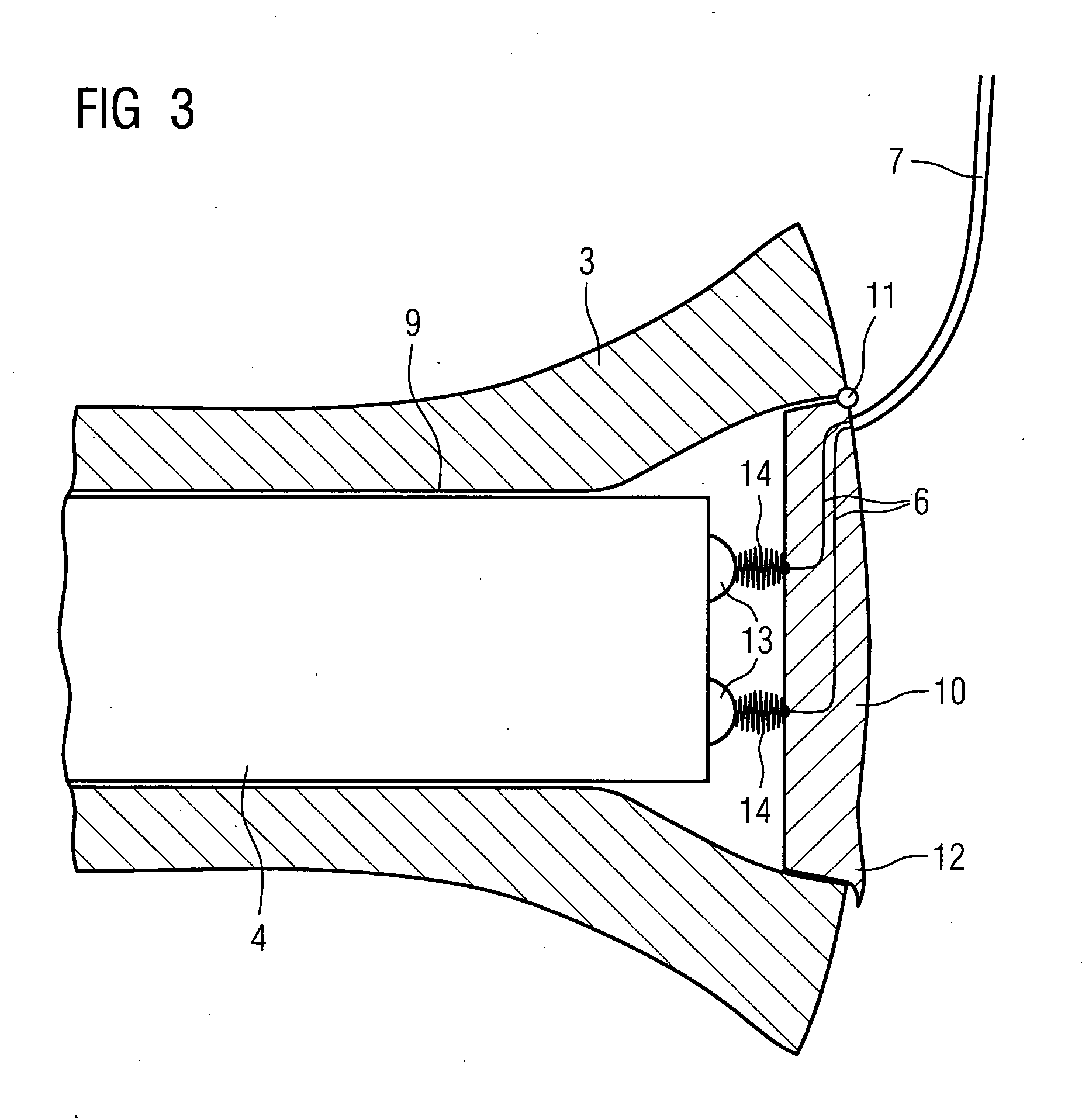

Impact driver having a percussion application mechanism which operation mode can be selectively switched between percussion and non-percussion modes

InactiveUS7131503B2Boring by percussion easilyImprove usabilityDrilling rodsWrenchesEngineeringOperation mode

Owner:MAKITA CORP

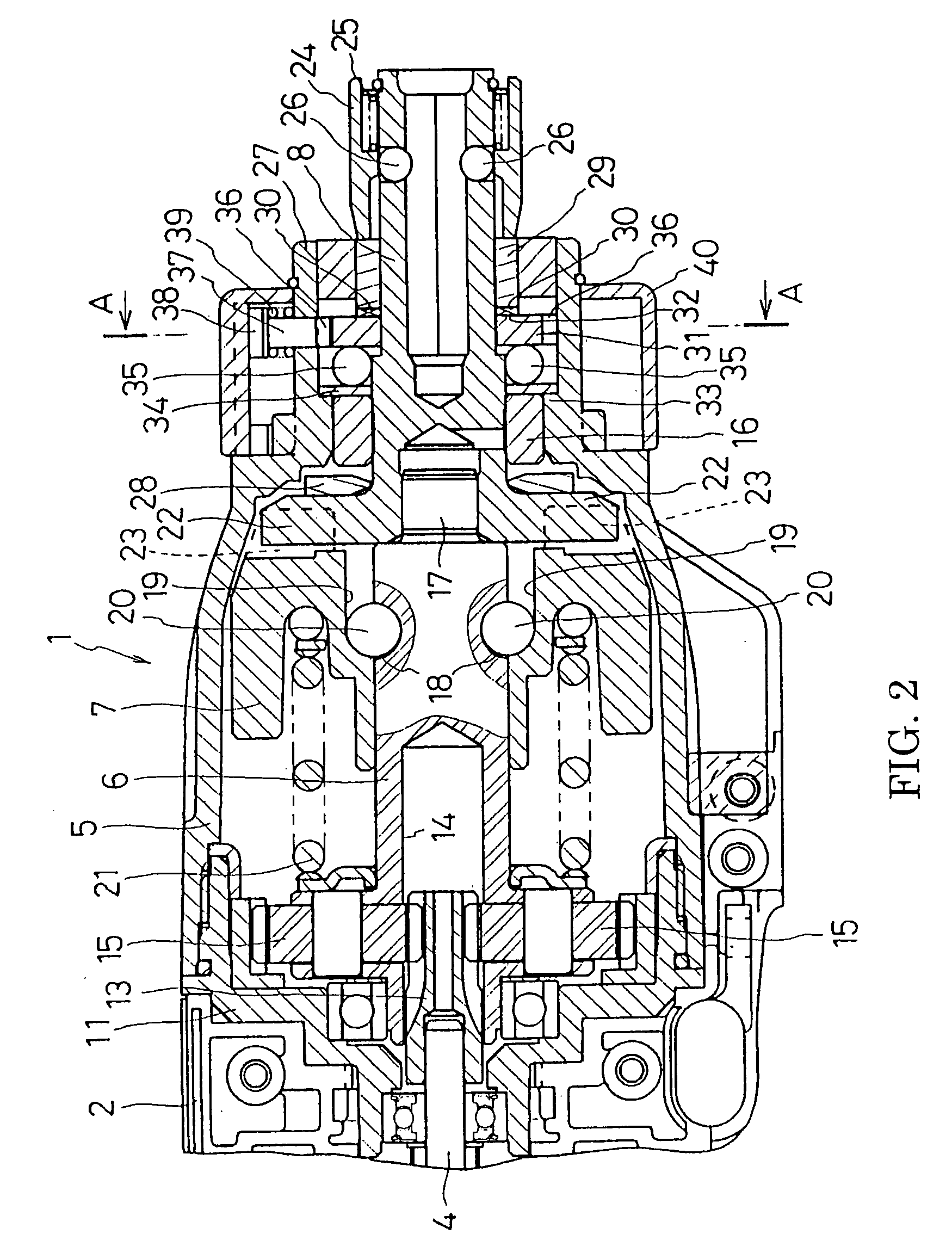

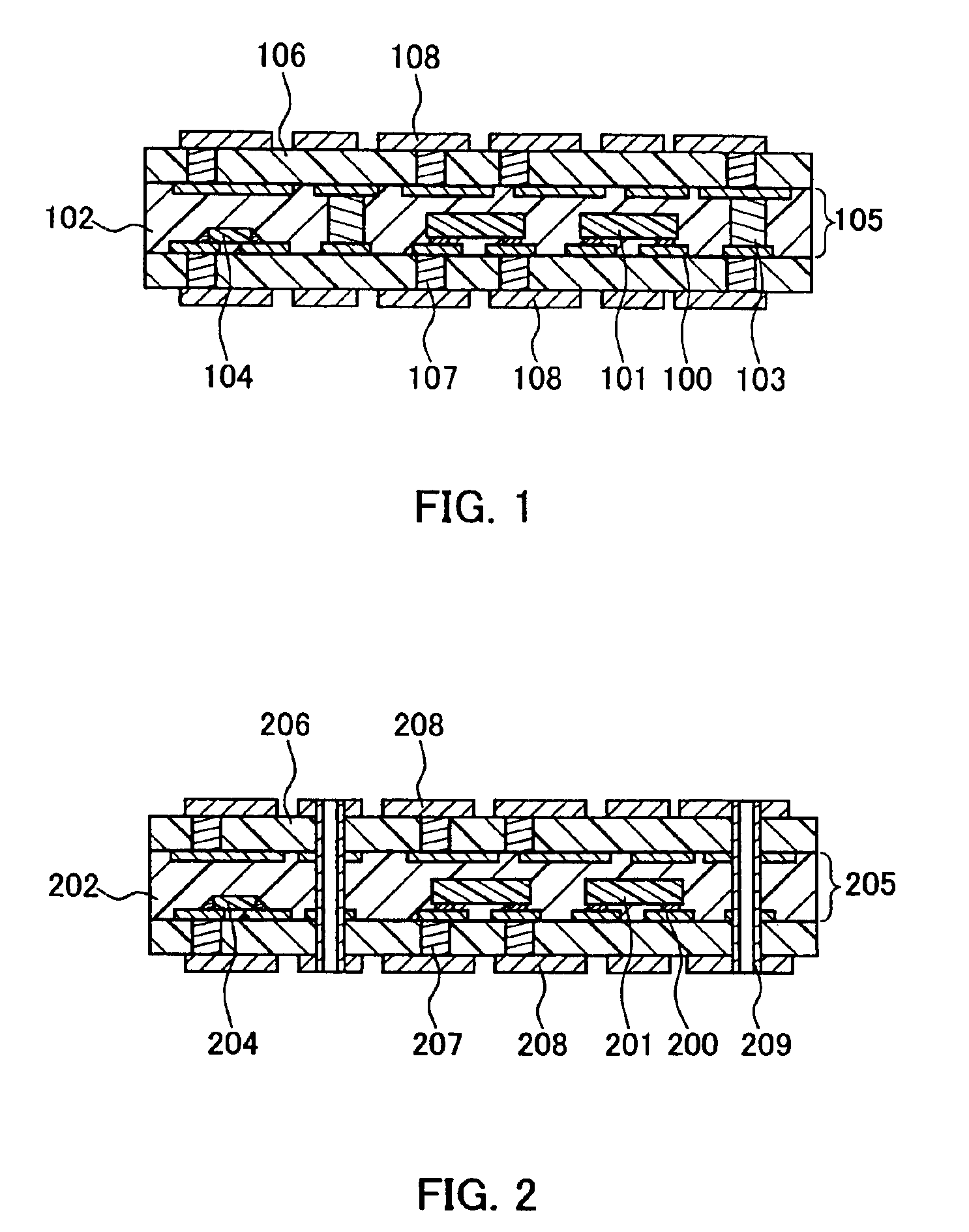

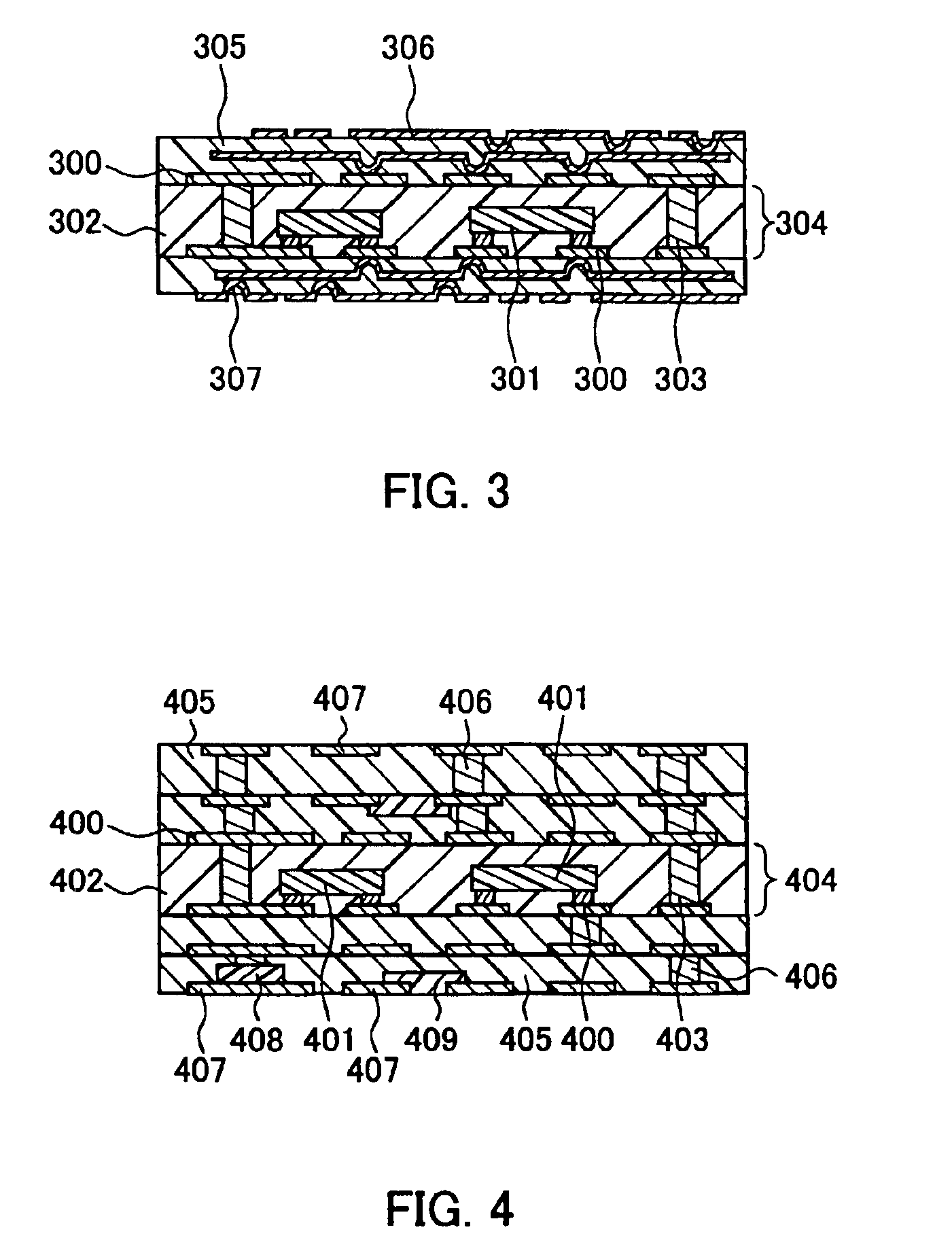

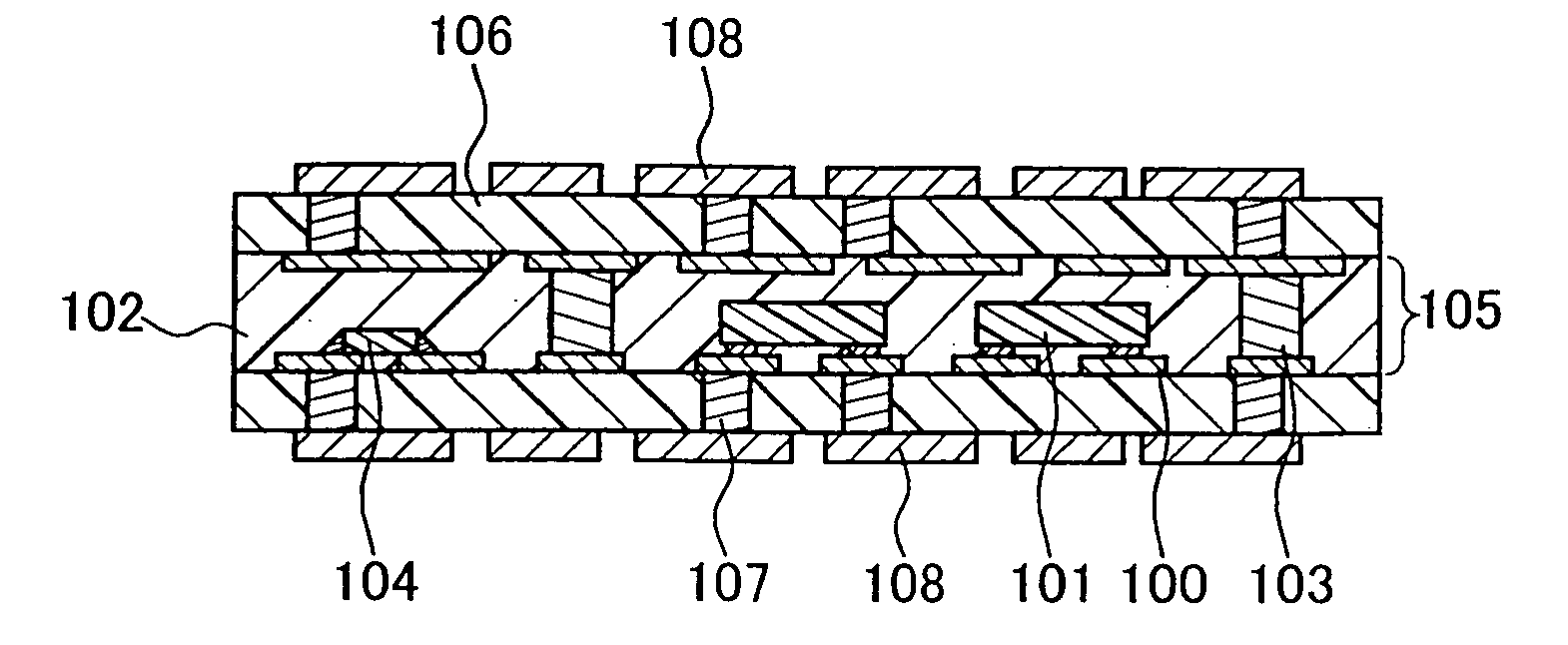

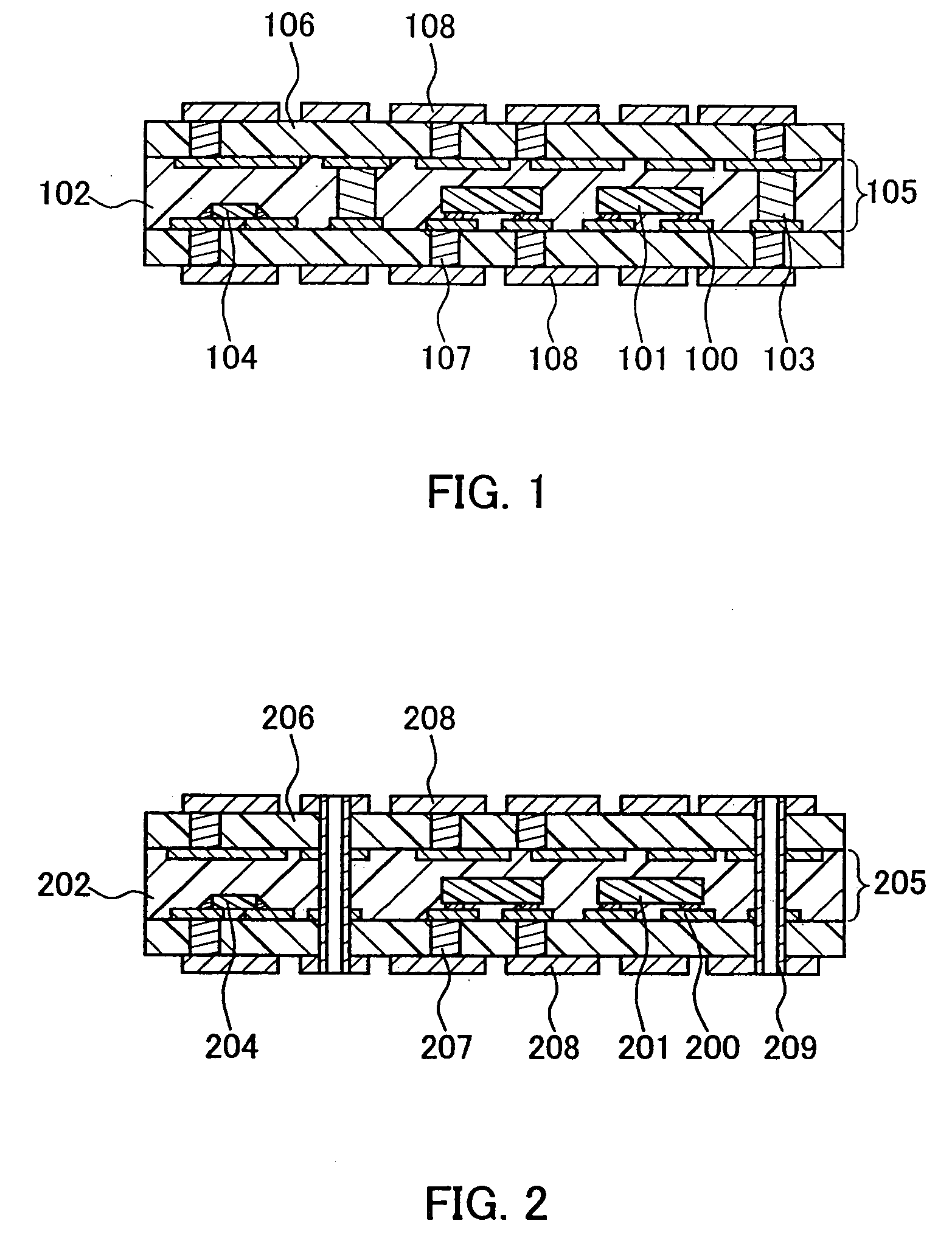

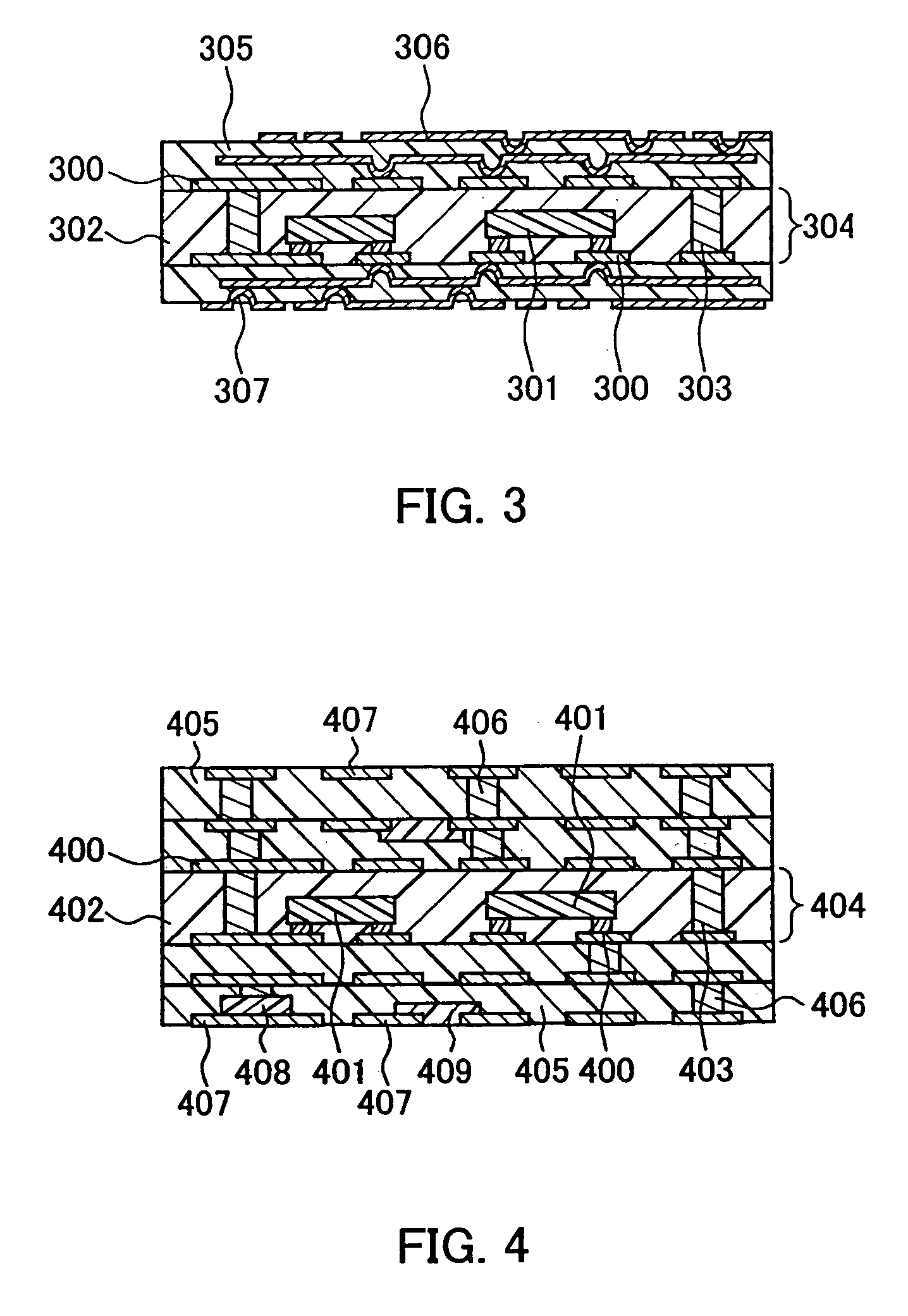

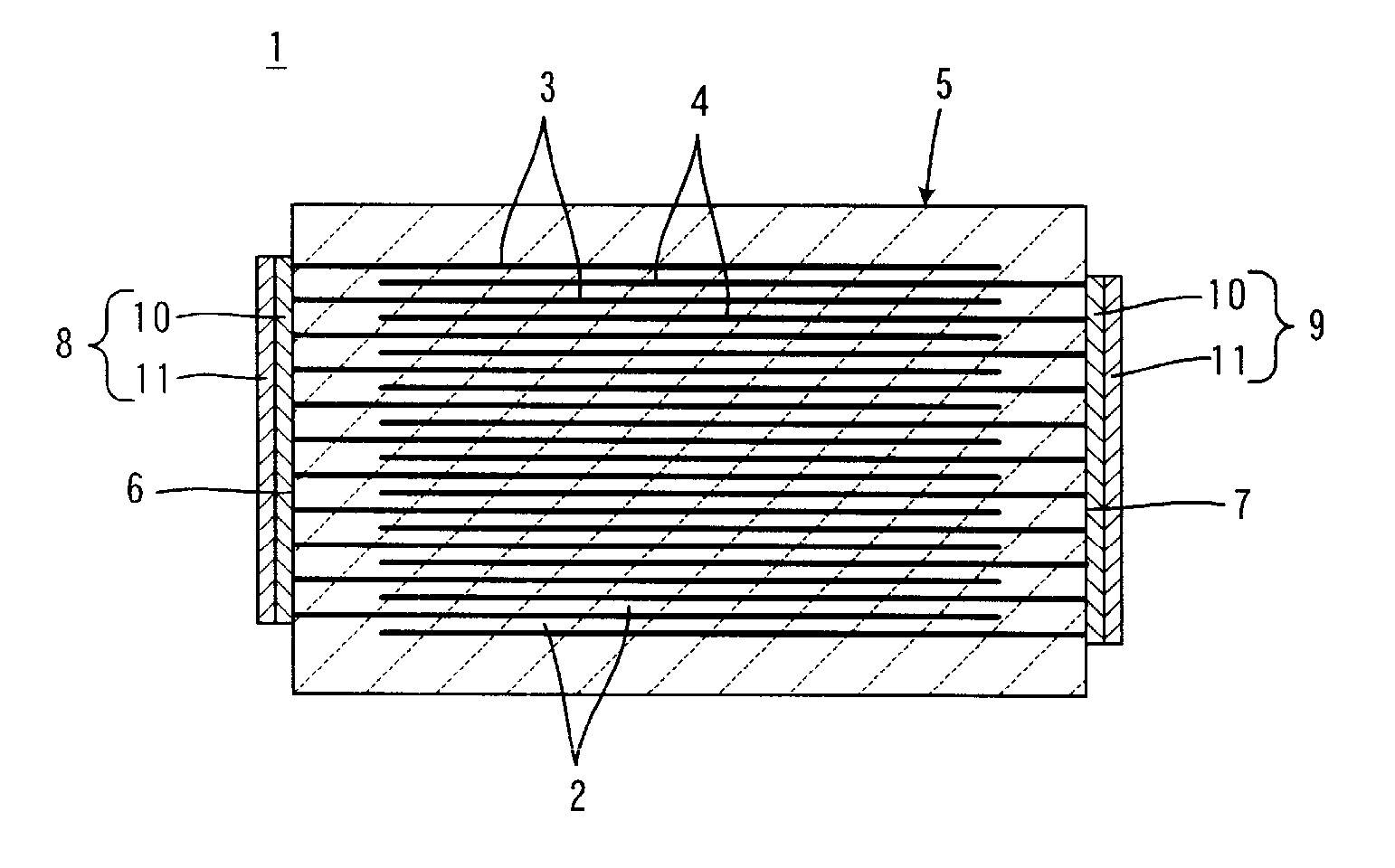

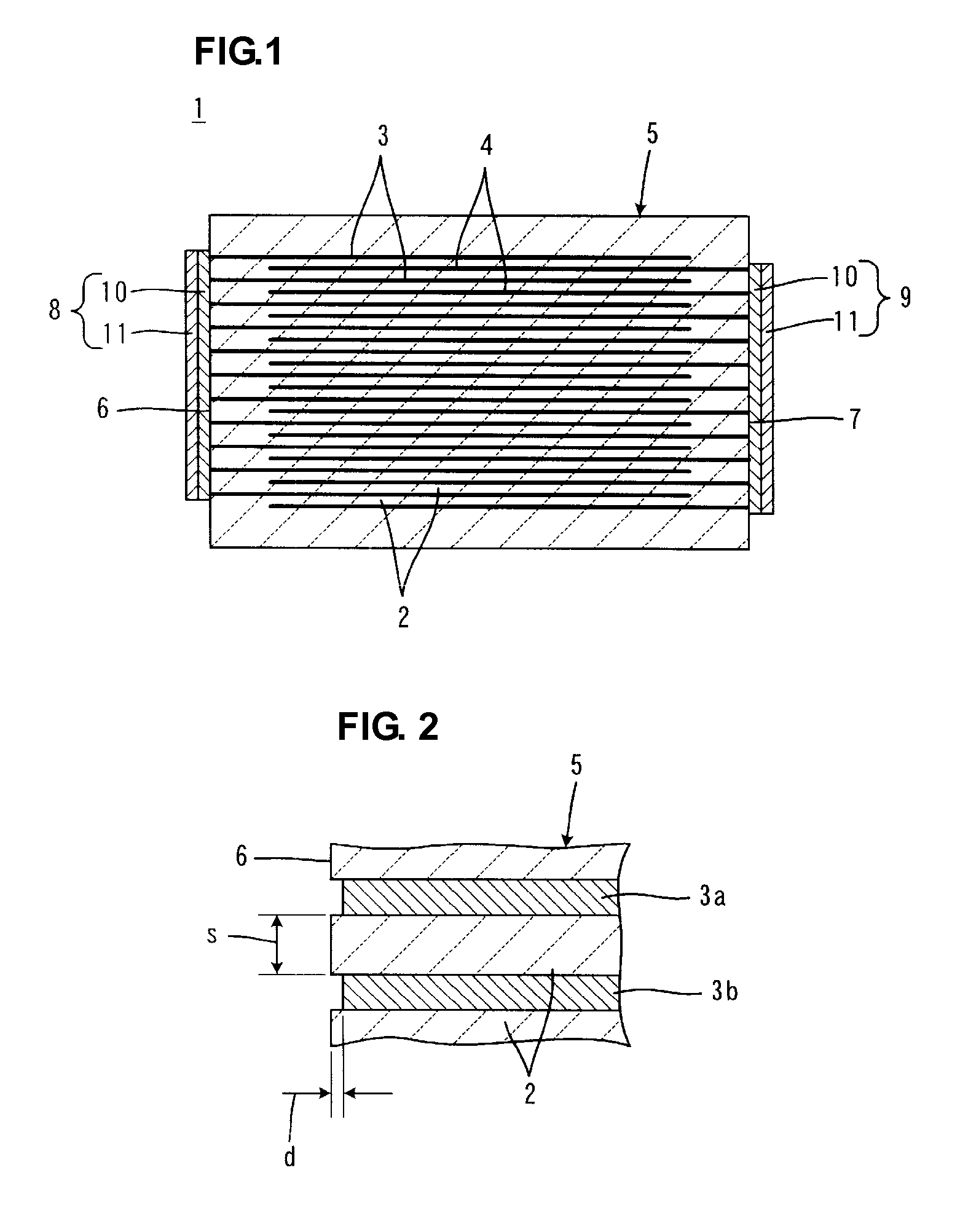

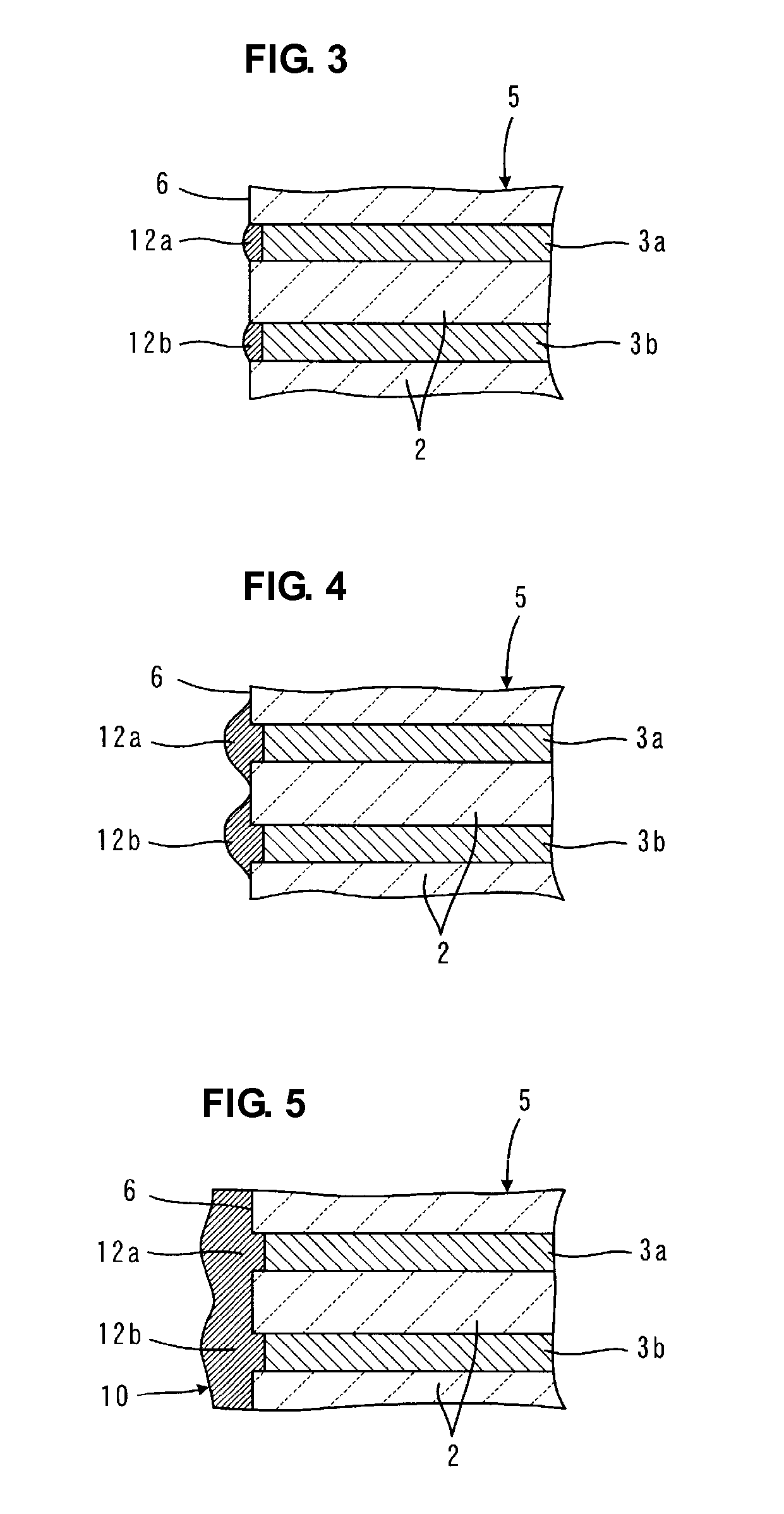

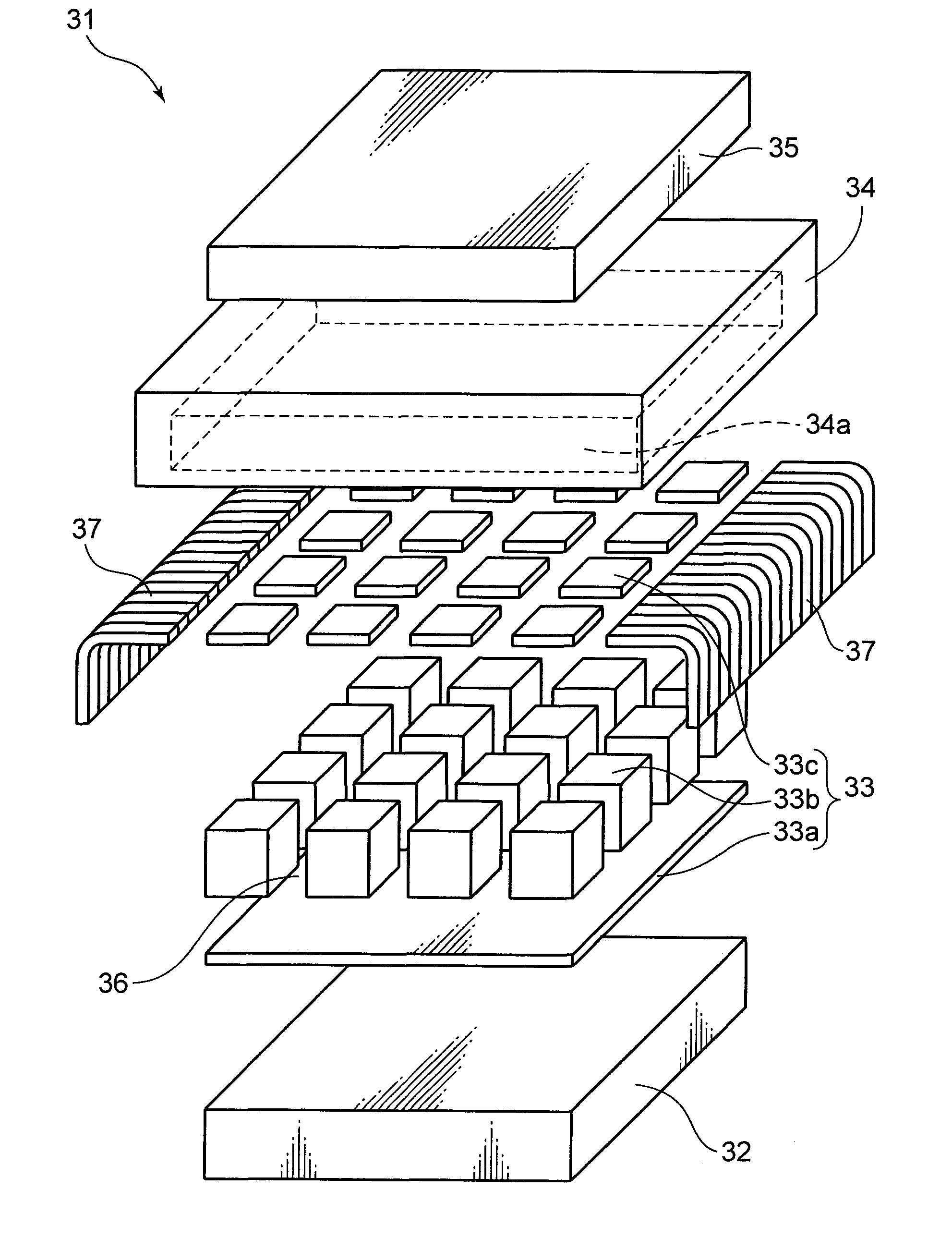

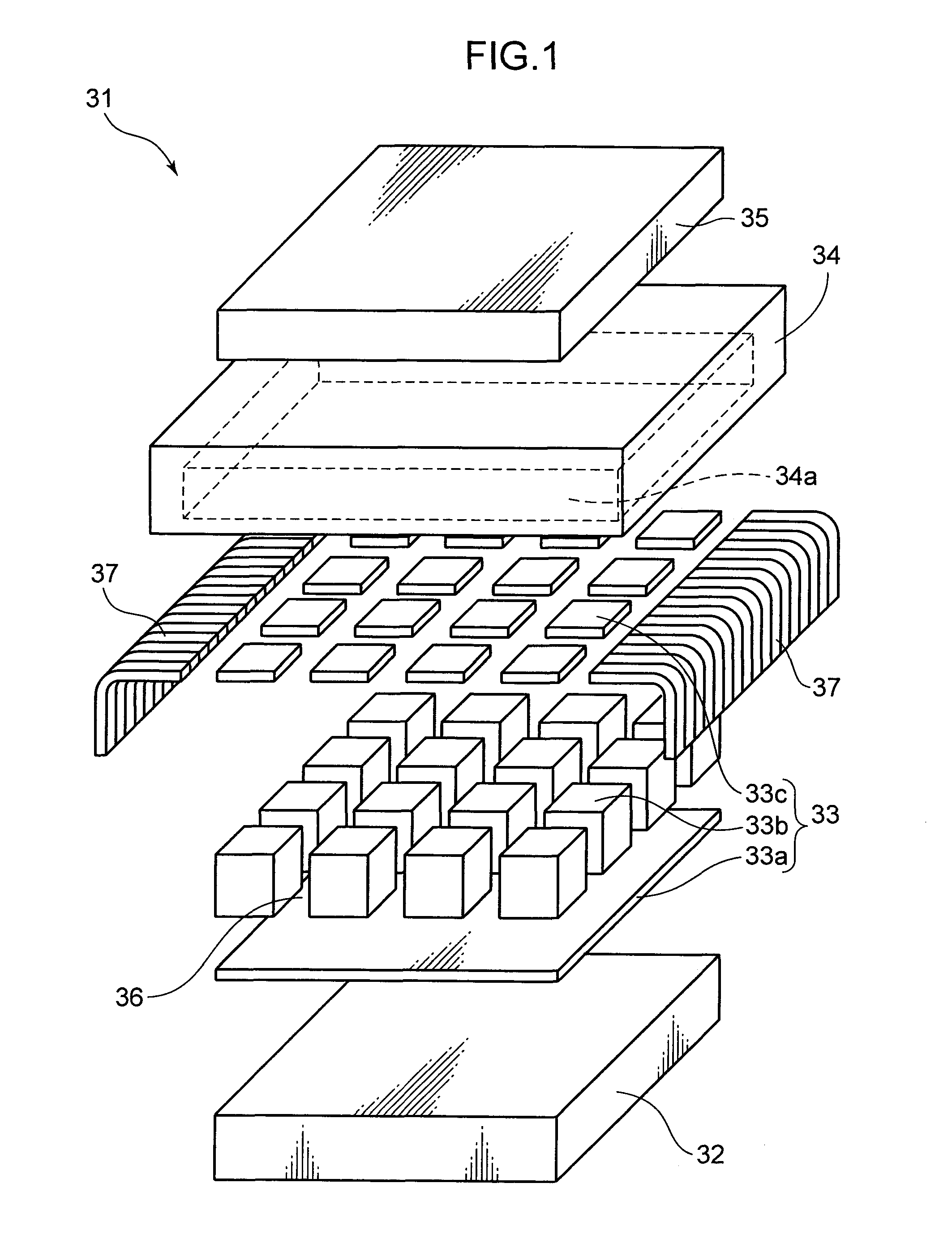

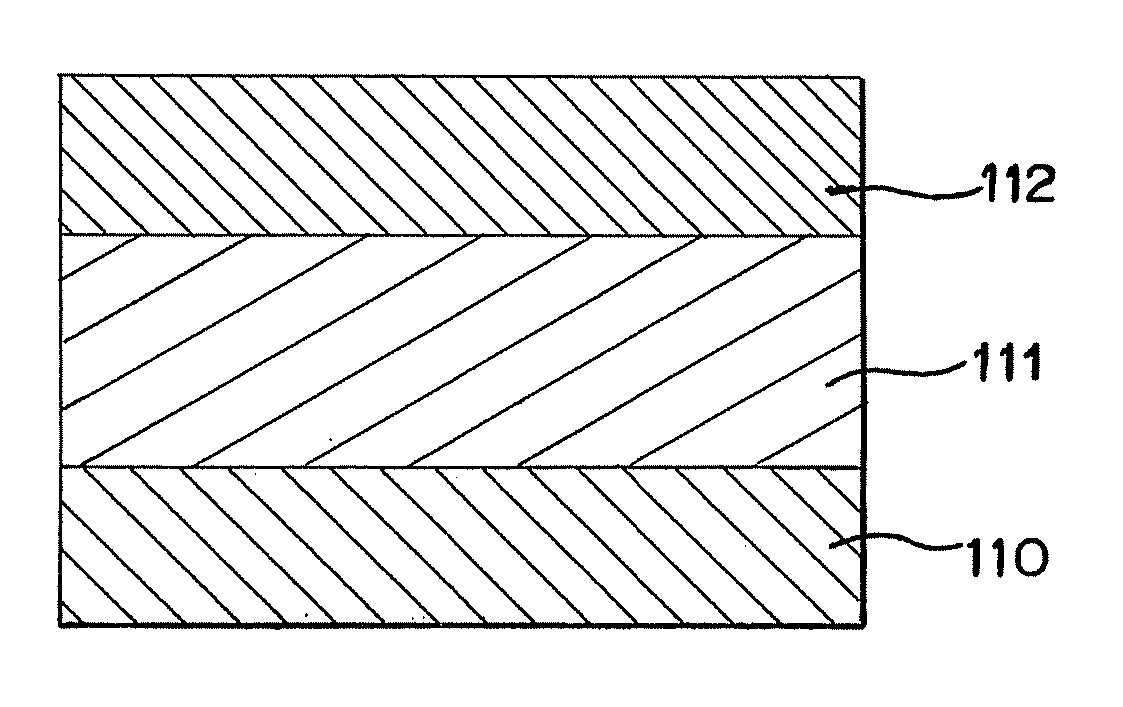

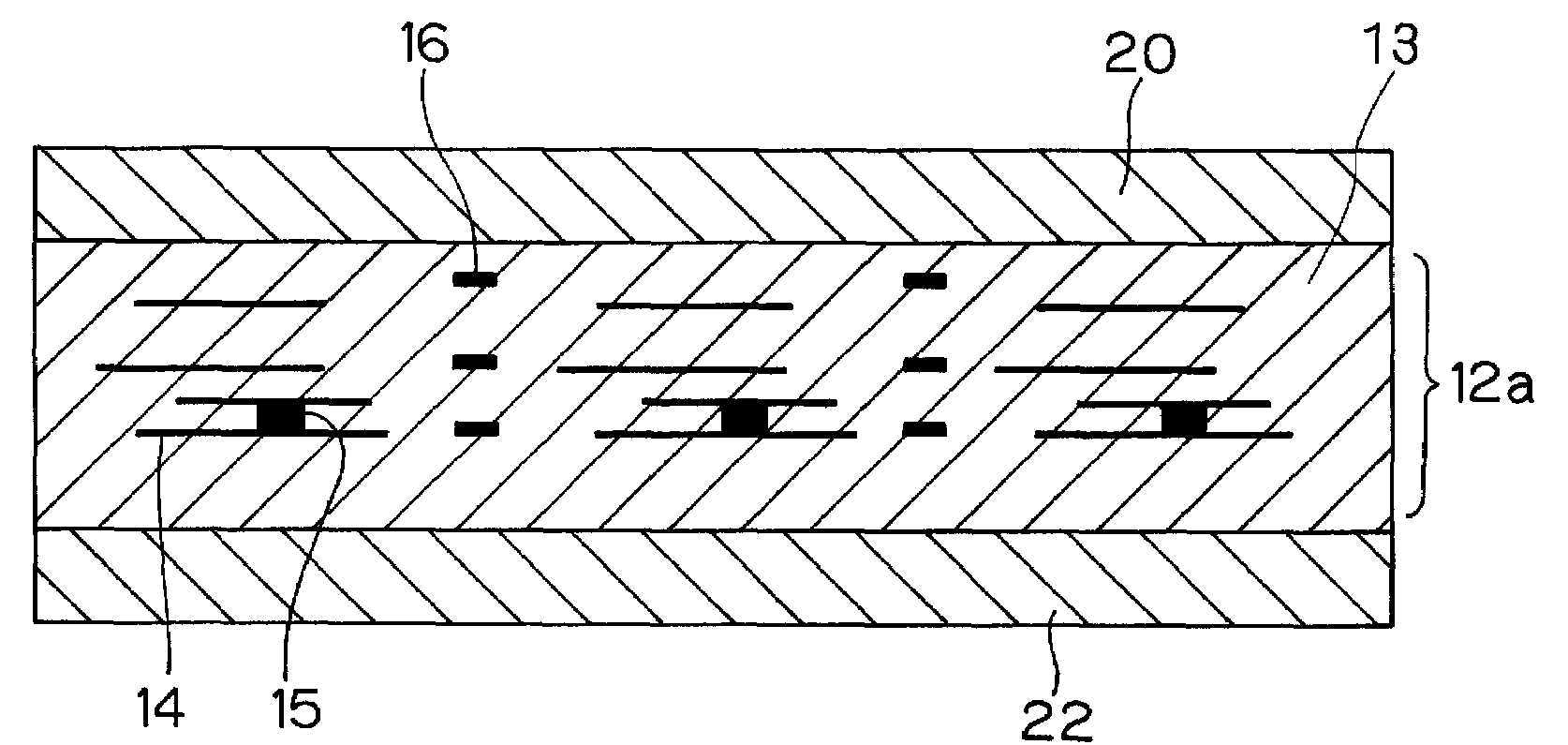

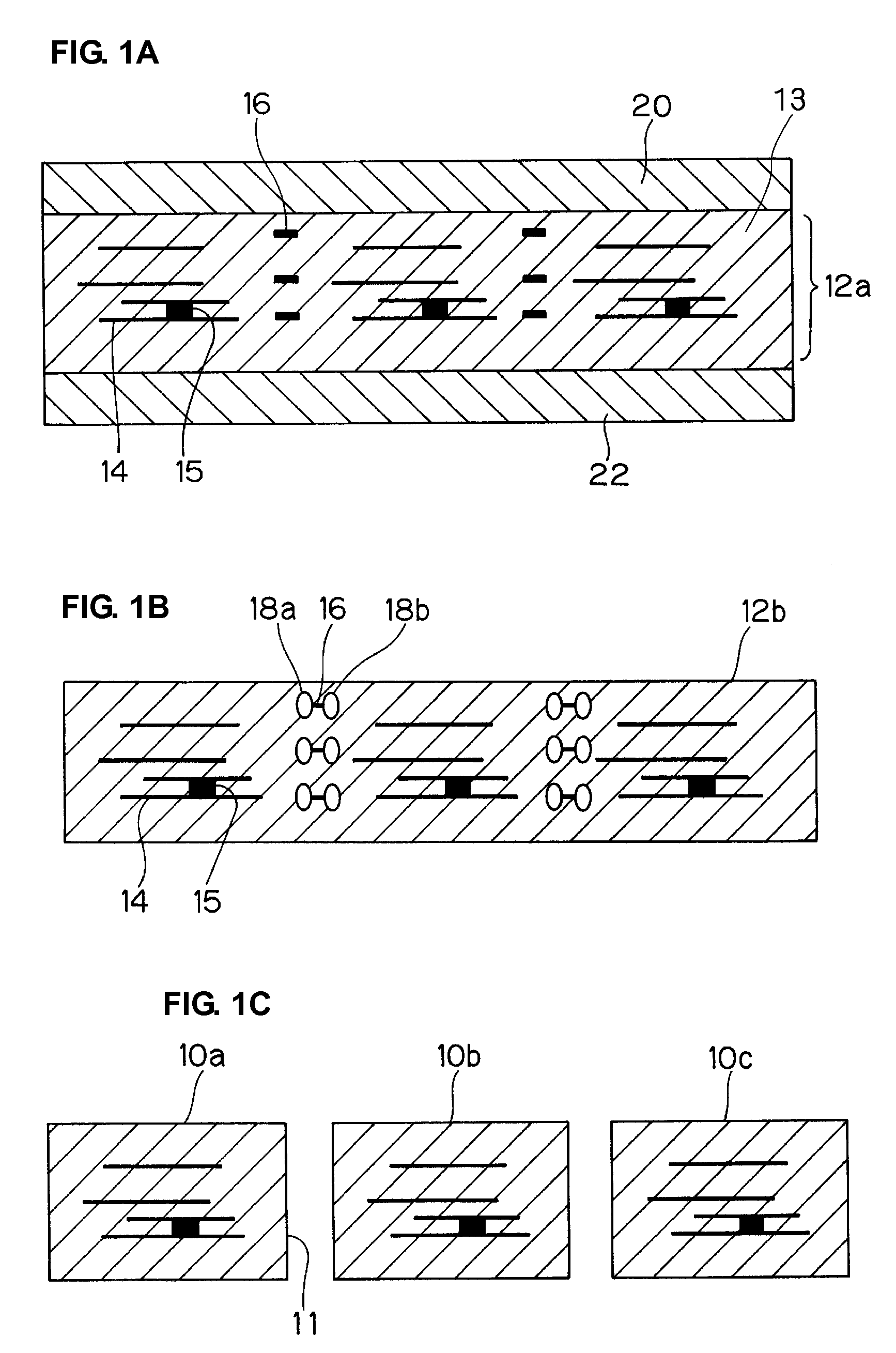

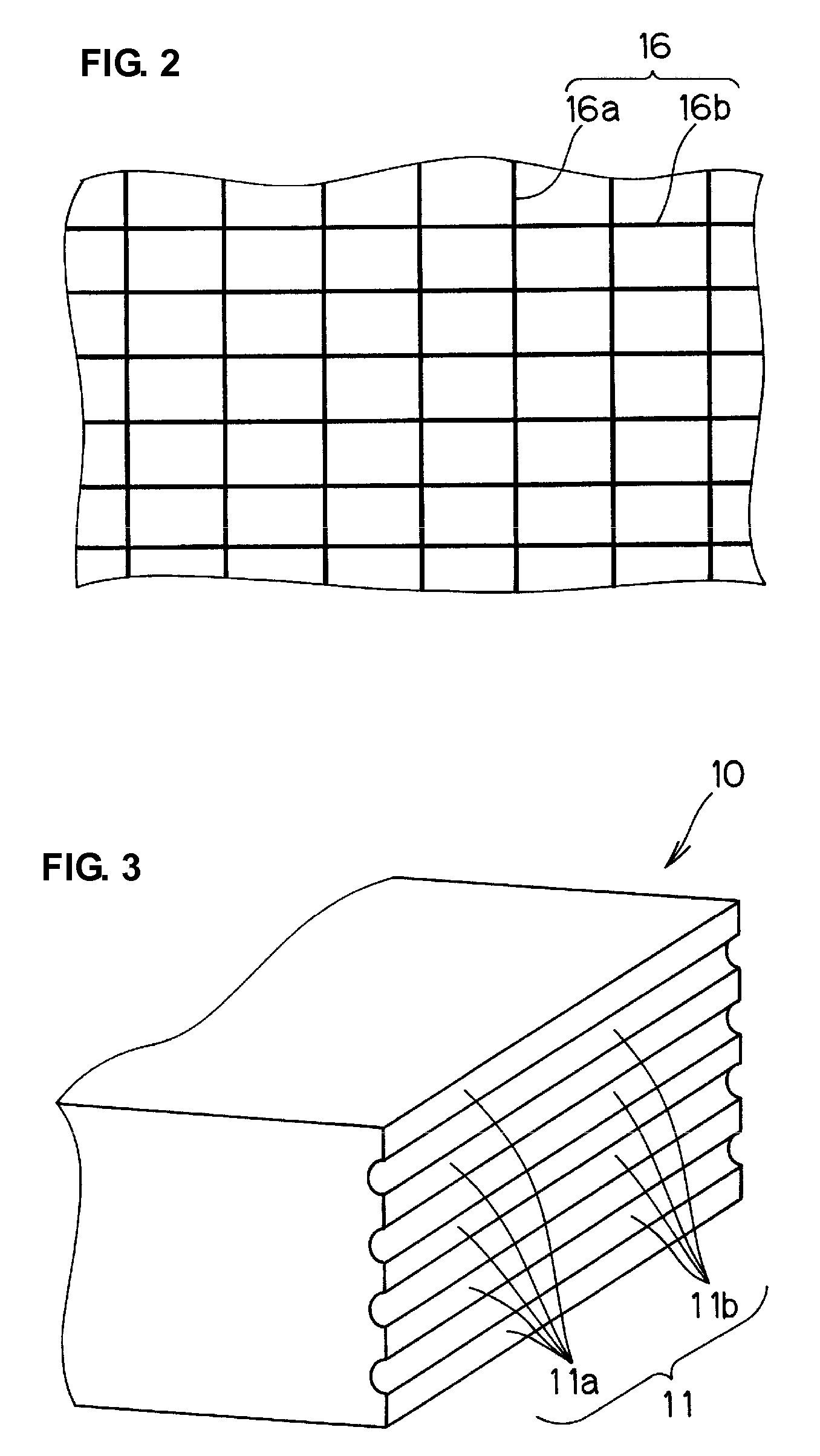

Component built-in module and method for producing the same

InactiveUS6939738B2Excellent in thermal radiation property and dielectric propertySimply formedSemiconductor/solid-state device detailsPrinted circuit aspectsHigh densityActive component

A component built-in module including a core layer formed of an electric insulating material, and an electric insulating layer and a plurality of wiring patterns, which are formed on at least one surface of the core layer. The electric insulating material of the core layer is formed of a mixture including at least an inorganic filler and a thermosetting resin. At least one or more of active components and / or passive components are contained in an internal portion of the core layer. The core layer has a plurality of wiring patterns and a plurality of inner vias formed of a conductive resin. The electric insulating material formed of the mixture including at least an inorganic filler and a thermosetting resin of the core layer has a modulus of elasticity at room temperature in the range from 0.6 GPa to 10 GPa. Thus, it is possible to provide a thermal conductive component built-in module capable of filling the inorganic filler with high density; burying the active component such as a semiconductor etc. and the passive component such as a chip resistor, a chip capacitor, etc. in the internal portion of the substrate; and simply producing a multilayer wiring structure.

Owner:PANASONIC CORP

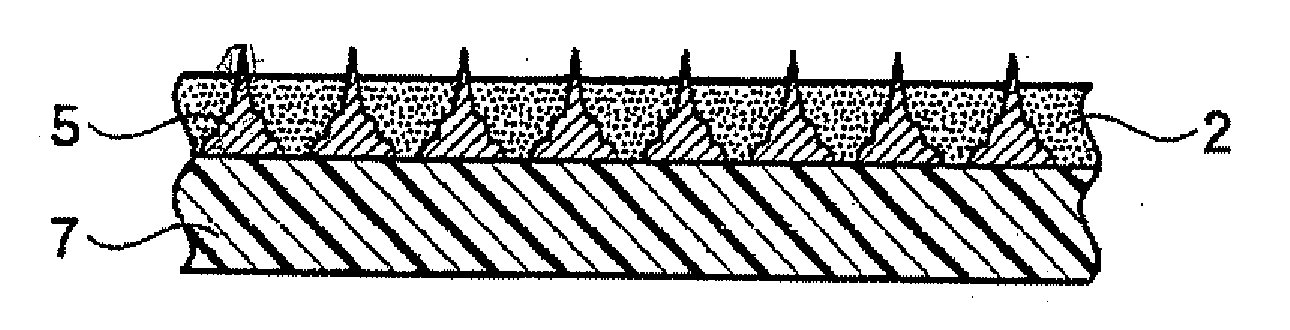

Sheet-Like Underfill Material and Semiconductor Device Manufacturing Method

InactiveUS20090075429A1Simply formedSemiconductor/solid-state device detailsSolid-state devicesFilling materialsYoung's modulus

A sheet-like underfill material includes a base and adhesive layer provided peelably on the base for use in a flip chip mounting process in the manufacture of a semiconductor device. The process includes laminating a sheet-like underfill material onto a circuit face of a semiconductor wafer having bumps on its circuit face and, simultaneously, allowing the bumps to pierce the adhesive layer and allowing the tops of the bumps to penetrate the base. The base has a storage elastic modulus of 1.0×106 Pa to 4.0×109 Pa, a breaking stress of 1.0×105 Pa to 2.0×108 Pa, and a Young's modulus of 1.0×107 Pa to 1.1×1010 Pa. The adhesive layer has a storage elastic modulus of 1.0×104 Pa to 1.0×107 Pa and a breaking stress of 1.0×103 Pa to 3.0×107 Pa.

Owner:LINTEC CORP

Impact driver

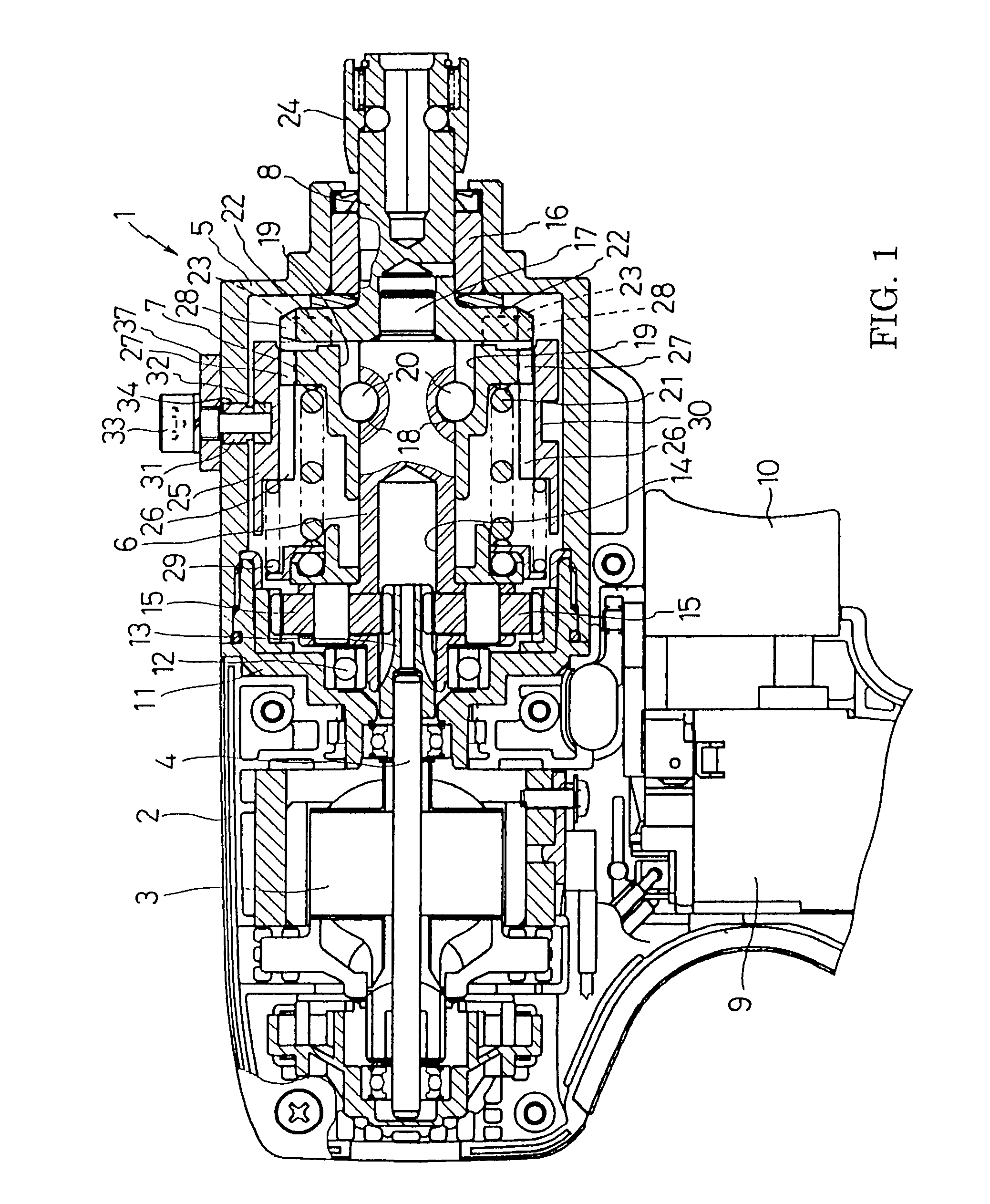

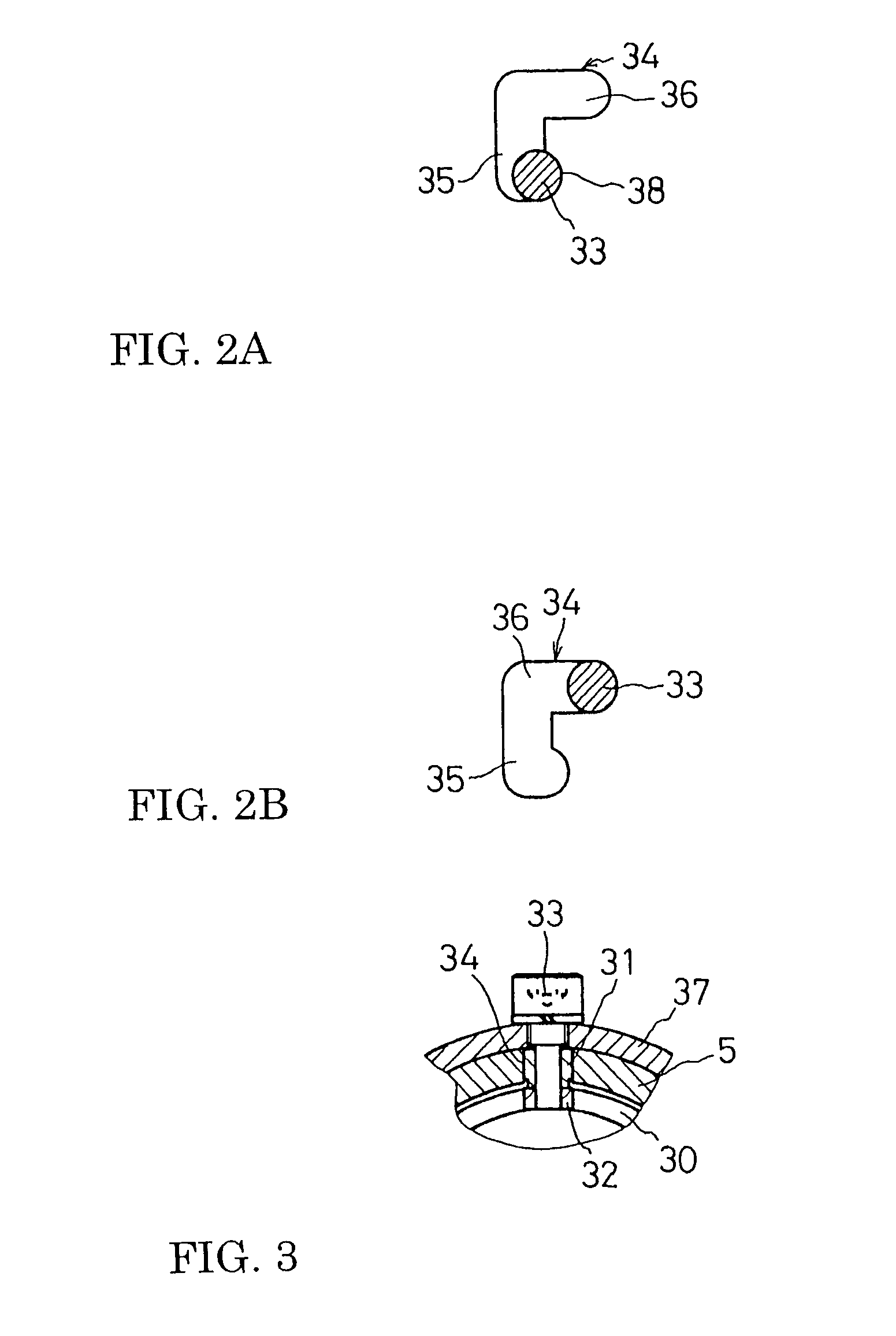

InactiveUS20050173139A1Simply formCost reductionDrilling rodsReciprocating drilling machinesEngineeringMode change

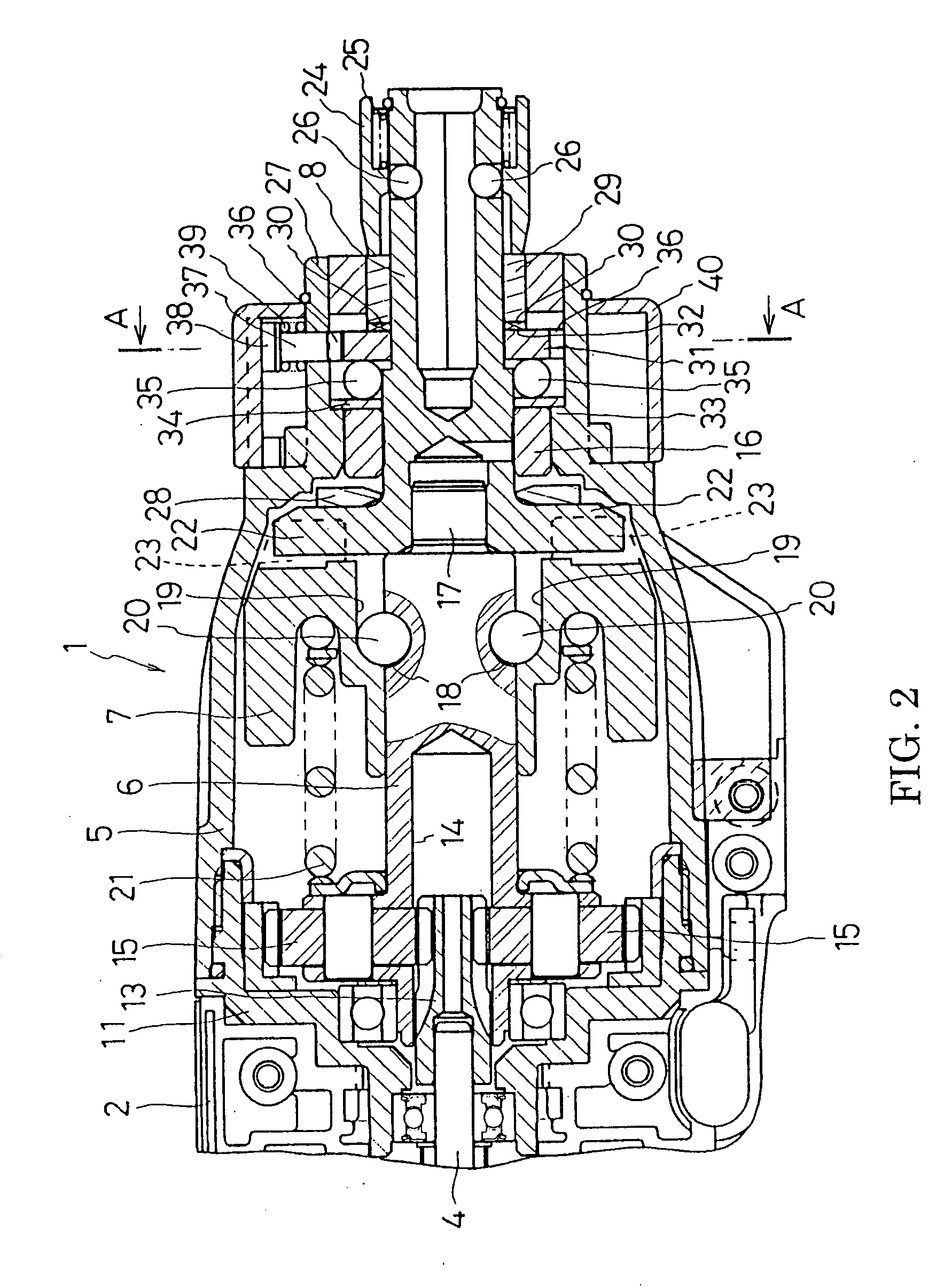

An impact driver capable of boring and having an excellent usability is provided. An anvil(8) is arranged so as to slightly move in the axial direction. A first cam(29) having cam gears(30, 30 . . . ) is externally provided at the anvil so as to be integral with the anvil(8). At the rear of the first cam(29), a second cam(31) having cam gears(32, 32 . . . ) and further having cam gears(36, 36 . . . ) at its outer circumference is externally provided to the anvil(8) so as to be rotatable. At the backward position of the anvil(8), the cam gears(30, 32) contacts with each other. On the other hand, in the cylindrical portion(27) of the hammer case(5), an engaging pin(37) capable of engaging with an engaging gear(36) of the second cam(31) is provided. The engaging pin(37) can change its location by the rotative operation of a mode-change ring(40), whereby a percussion mode and a non-percussion mode is selected.

Owner:MAKITA CORP

Ear insert for hearing aids

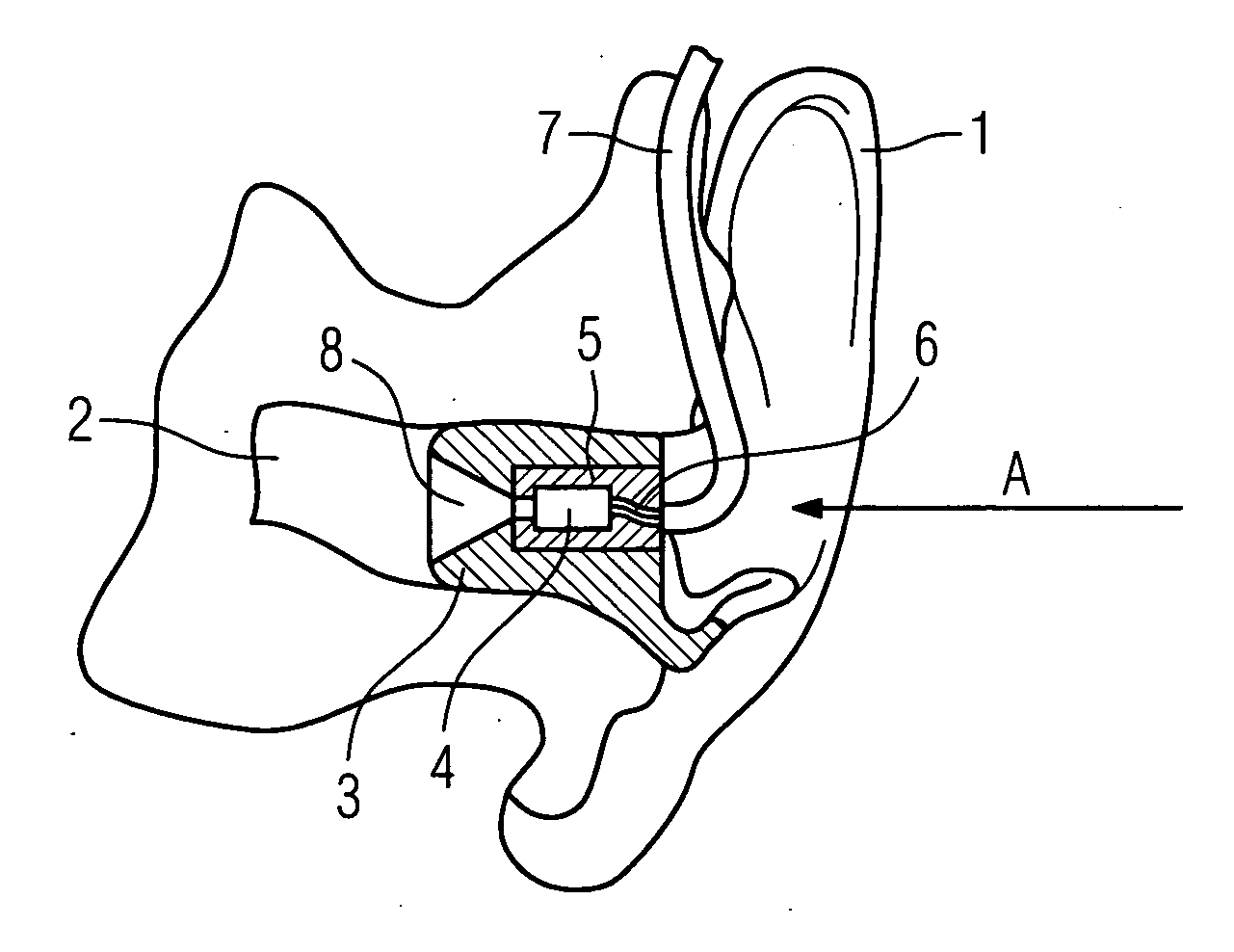

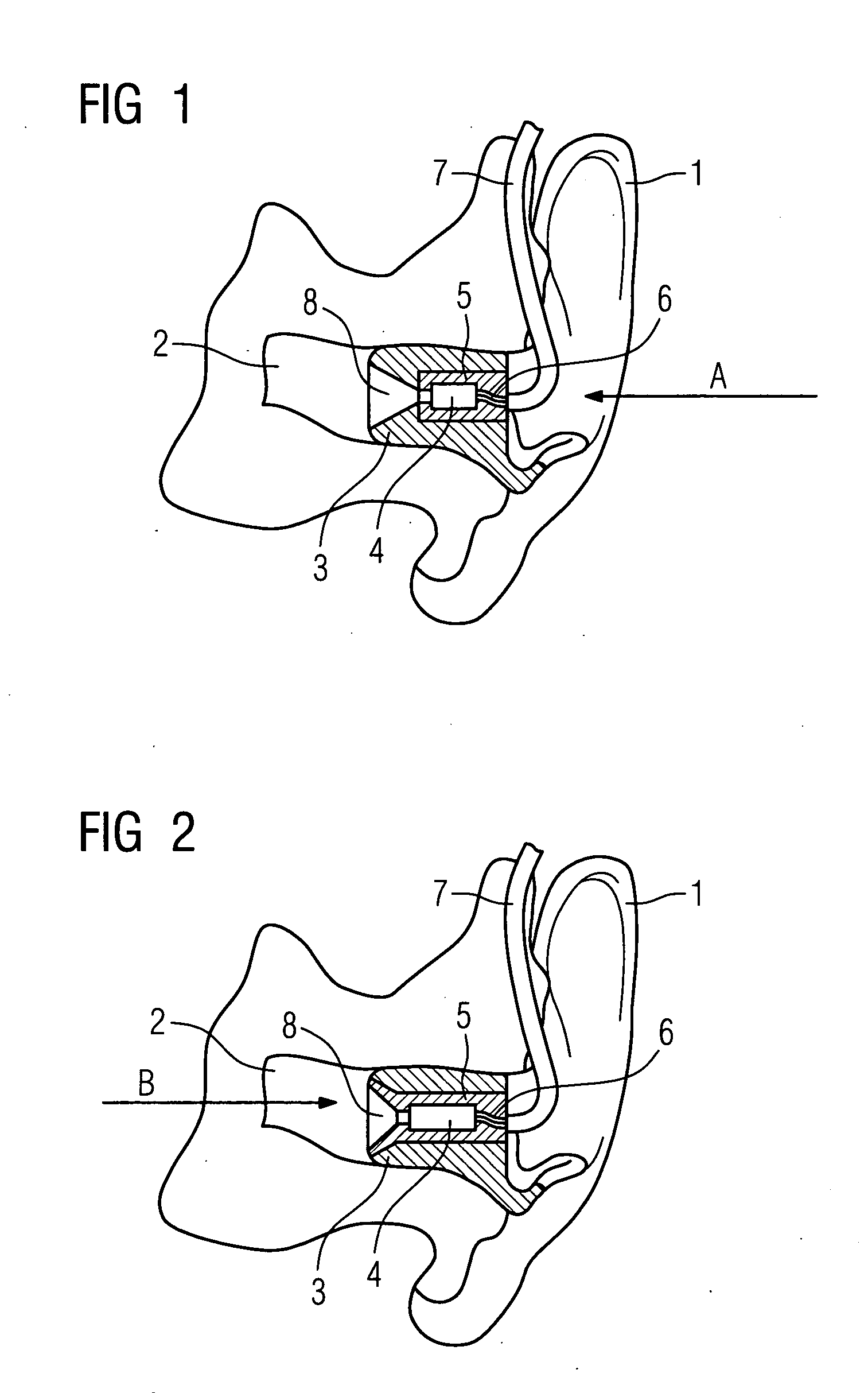

InactiveUS20050190940A1Improve acoustic propertiesReduce manufacturing costEar supported setsDetails for specific frequency responseEar AuricleEngineering

Owner:SIVANTOS PTE LTD

Component built-in module and method for producing the same

InactiveUS20050230848A1Excellent in thermal radiation property and dielectric propertySimply formedSemiconductor/solid-state device detailsPrinted circuit aspectsHigh densityActive component

A component built-in module including a core layer formed of an electric insulating material, and an electric insulating layer and a plurality of wiring patterns, which are formed on at least one surface of the core layer. The electric insulating material of the core layer is formed of a mixture including at least an inorganic filler and a thermosetting resin. At least one or more of active components and / or passive components are contained in an internal portion of the core layer. The core layer has a plurality of wiring patterns and a plurality of inner vias formed of a conductive resin. The electric insulating material formed of the mixture including at least an inorganic filler and a thermosetting resin of the core layer has a modulus of elasticity at room temperature in the range from 0.6 GPa to 10 GPa. Thus, it is possible to provide a thermal conductive component built-in module capable of filling the inorganic filler with high density; burying the active component such as a semiconductor etc. and the passive component such as a chip resistor, a chip capacitor, etc. in the internal portion of the substrate; and simply producing a multilayer wiring structure.

Owner:PANASONIC CORP

Image-transfer medium, production process of transferred image, and cloth with transferred image formed thereon

InactiveUS6871950B2Great easeSimply formedTransfer printing processCoatingsImage transferComputer science

Owner:CANON KK

Method of manufacturing multilayer electronic component

InactiveUS20080145551A1Increase the effective volume ratioImprove reliabilityFixed capacitor dielectricStacked capacitorsElectronic componentElectrochemistry

An electroless plating step for forming external electrodes includes preparing a plating solution including a reducing agent and metal ions having a more electochemically positive deposition potential than the oxidation-reduction potential of the reducing agent, placing a laminate for a multilayer electronic component together with a conductive medium having catalytic activity for an oxidation reaction of the reducing agent in a vessel, and stirring the laminate and the conductive medium in the plating solution by rotation, shaking, inclination, or vibration. Electroless plating proceeds to connect each other plating deposits deposited on the ends of a plurality of internal electrodes.

Owner:MURATA MFG CO LTD

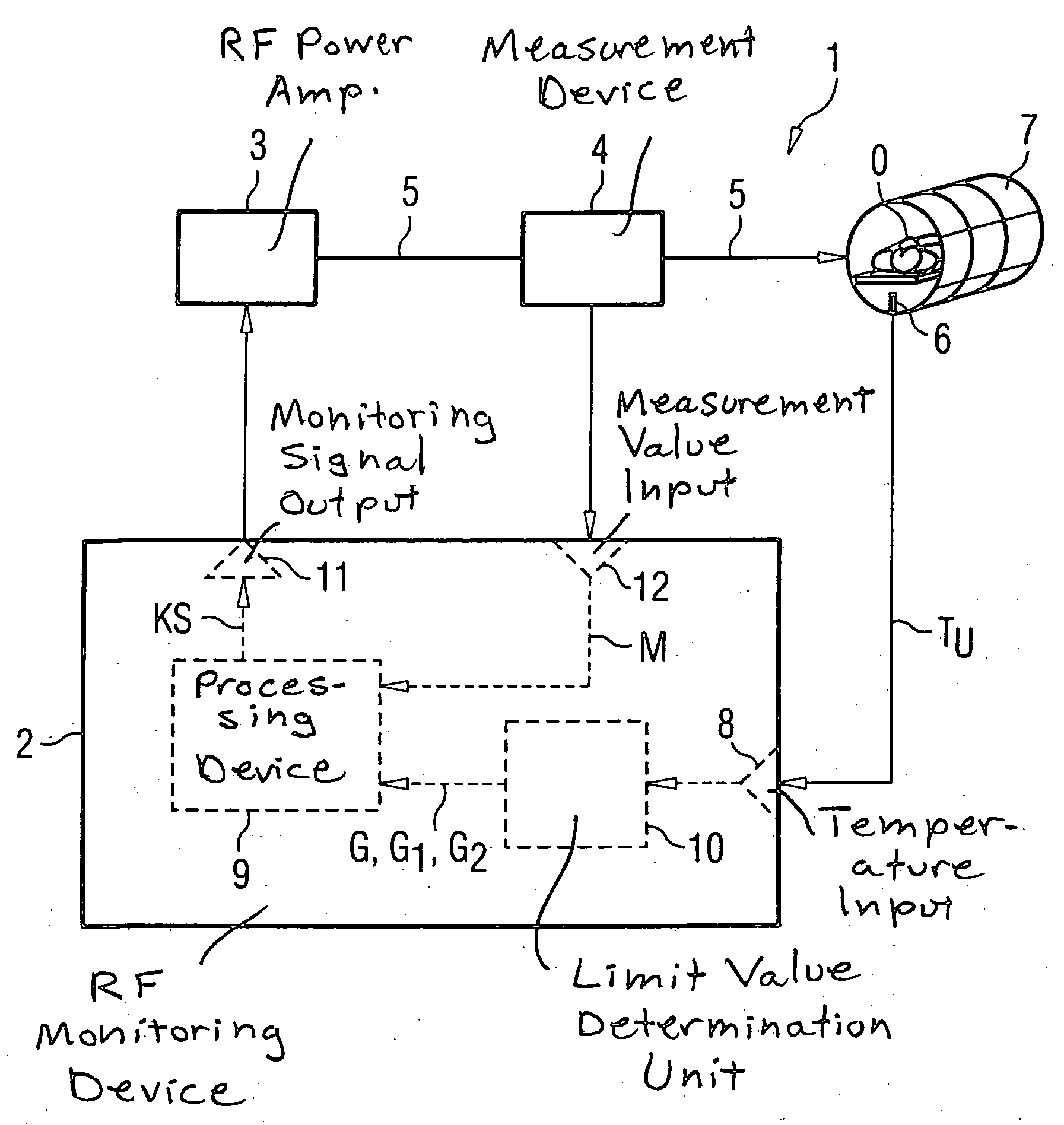

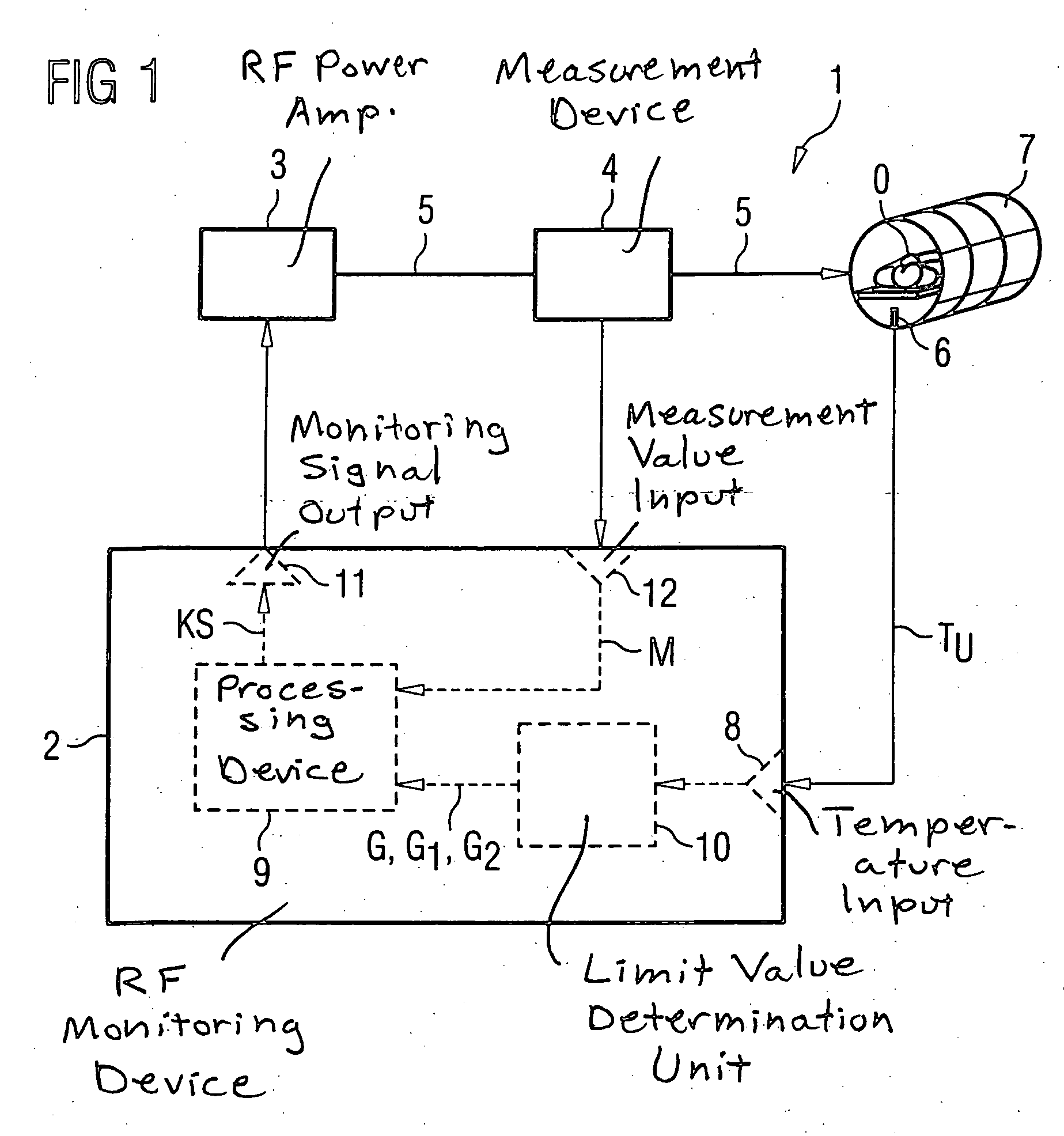

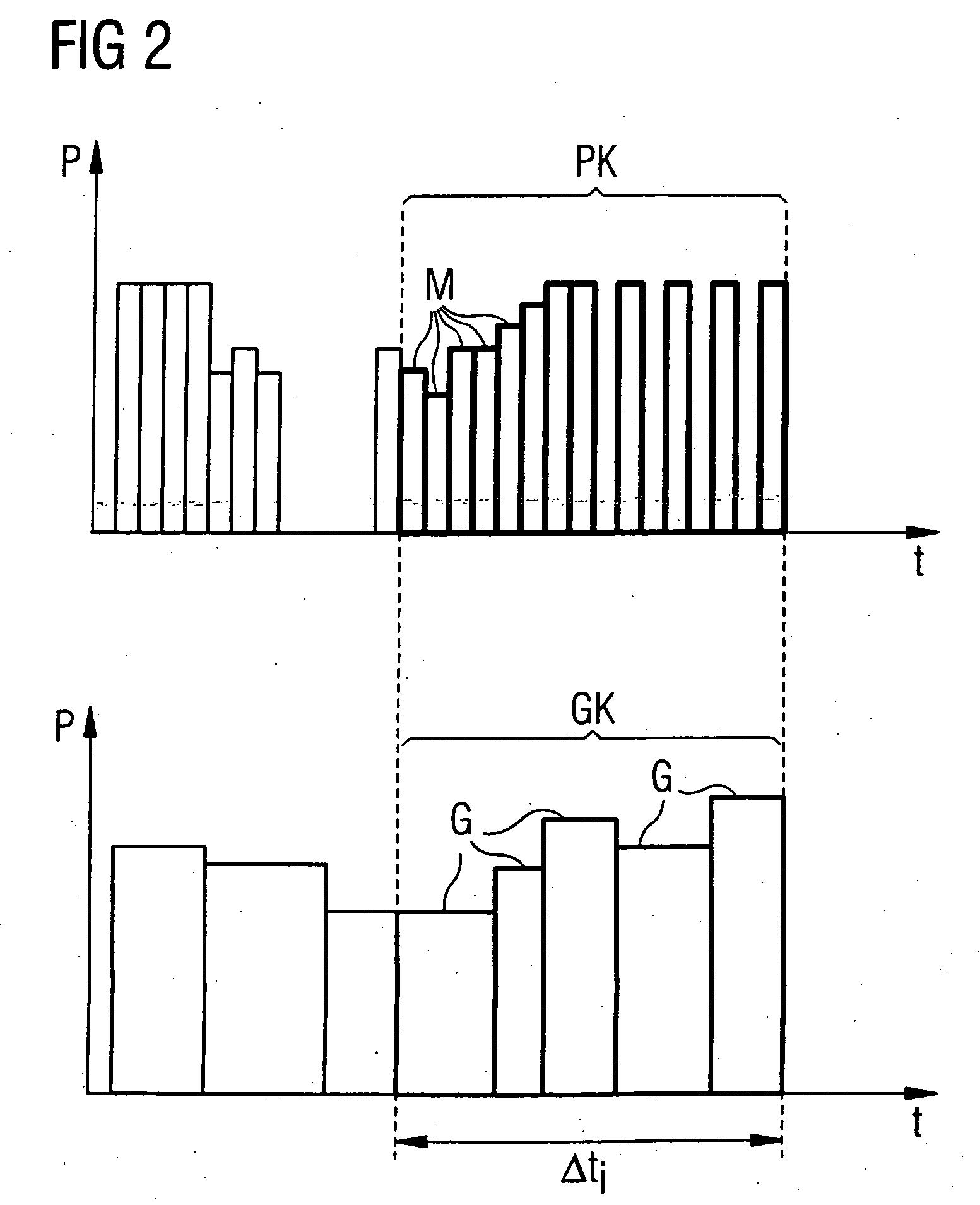

Method for monitoring an RF power amplifier, and an RF device, a monitoring device, and an MR system corresponding thereto

ActiveUS20050197077A1Reduce transmit powerSimply formedResonant long antennasGain controlAudio power amplifierResonance

In a method for monitoring of a radio frequency power amplifier and a radio frequency device, a radio frequency monitoring device and magnetic resonance tomography system operable according to the method, radio frequency pulses emitted by a radio frequency power amplifier and are transmitted into a human subject by a transmission coil at temporal intervals. Measurement values that represent the power of the radio frequency pulses are measured at temporal intervals, and varying, predetermined power limit values are determined at temporal intervals. A control value representing the radio frequency dose emitted in a time window is determined based on a number of measurement values measured in the time window. Likewise, a limit control value representing a dose limit value allowed in the appertaining time window is determined based on the power limit values determined in the appertaining time window. The radio frequency power amplifier is limited in operation if and when the control value reaches or exceeds the limit control value.

Owner:SIEMENS HEALTHCARE GMBH

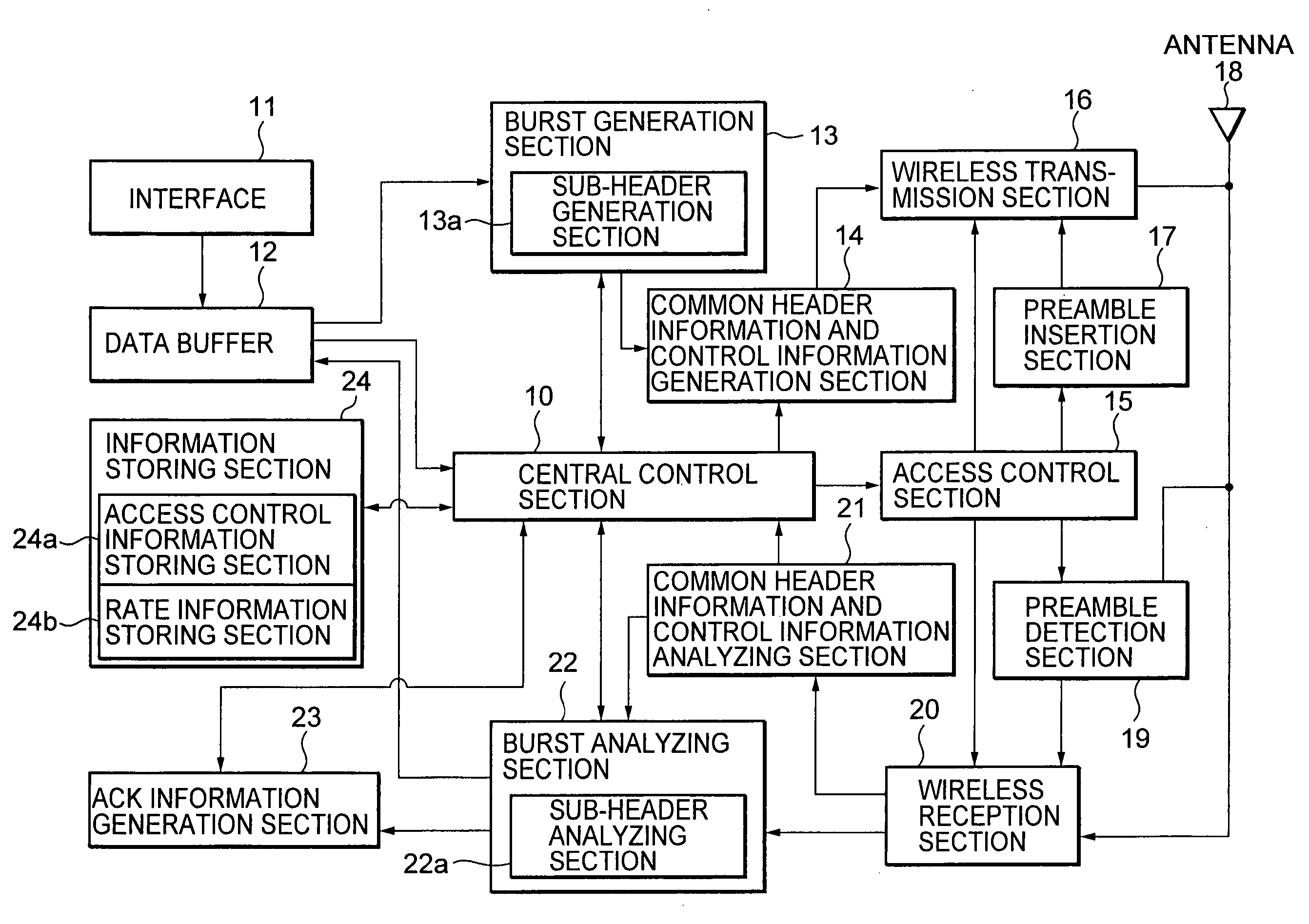

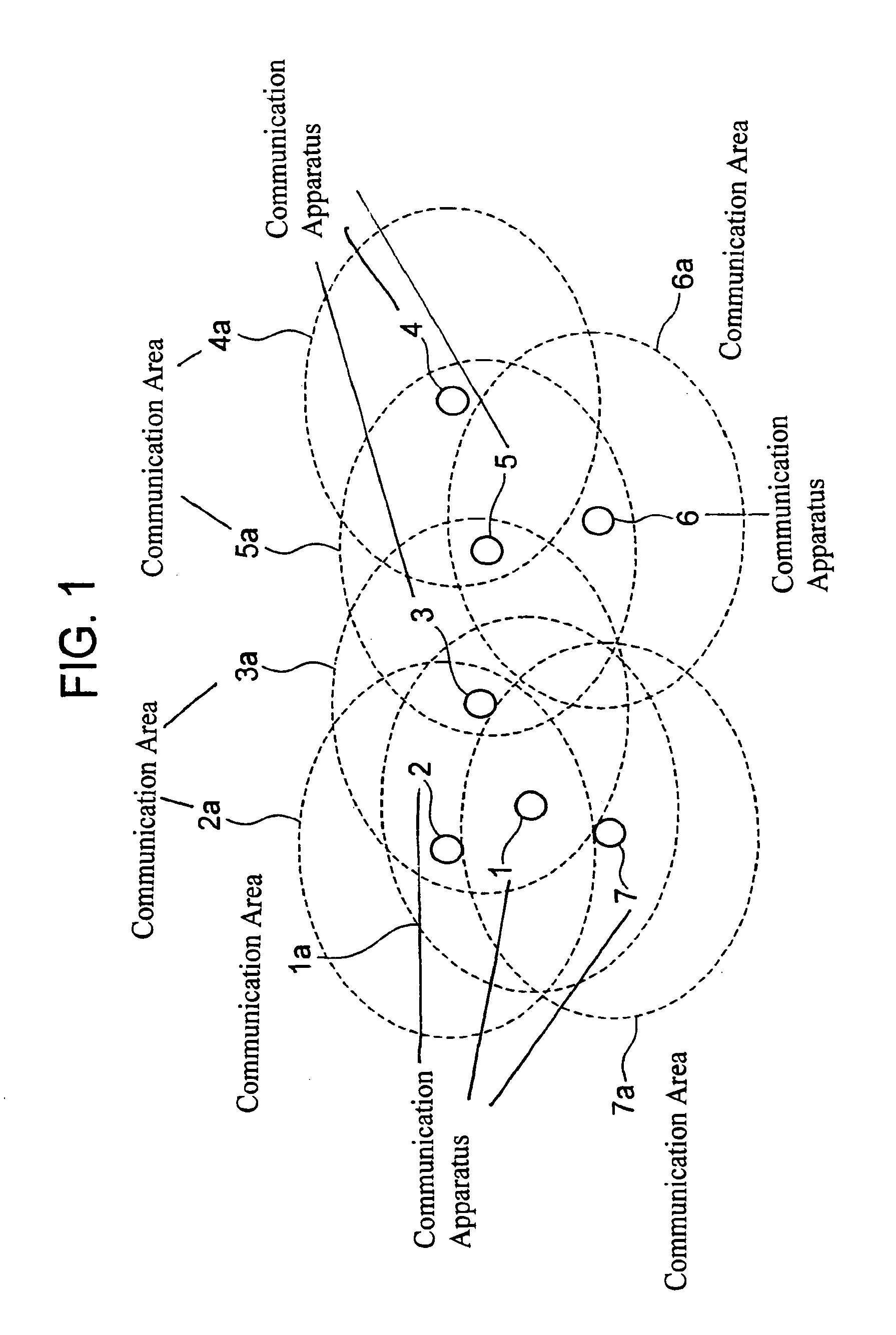

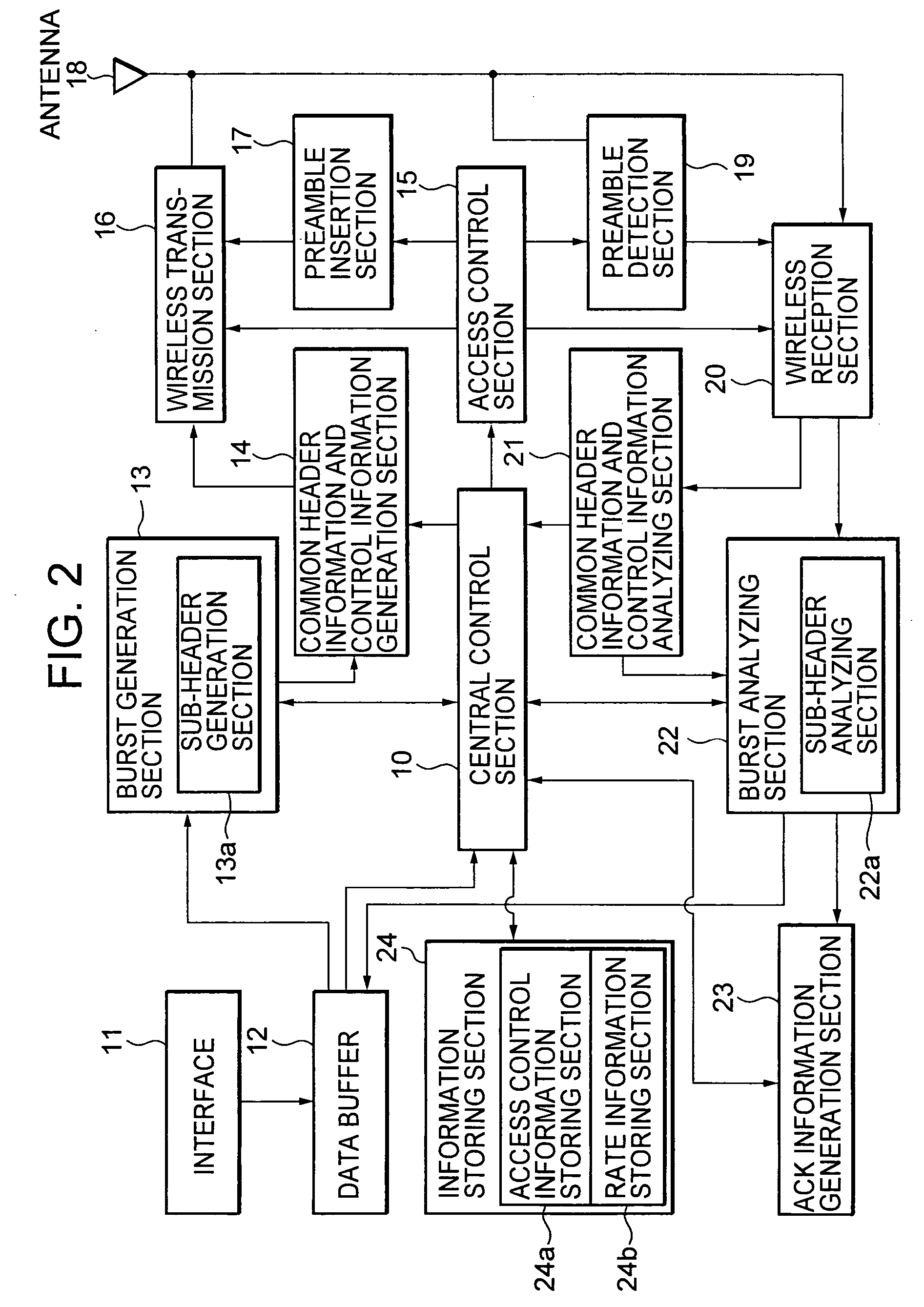

Wireless communication apparatus, a method of wireless communication, and a program for wireless communication

ActiveUS7746842B2Avoid mistakesEasy to reuseError prevention/detection by using return channelNetwork traffic/resource managementTelecommunicationsStructure of Management Information

In wireless communication with another communication apparatus in a predetermined wireless network, overhead information defined in a media access control layer is divided into a header of information necessary for the common access control and a header of information necessary for each payload. Address information is added to the header of information necessary for the common access control in order to transmit the generated header attached to the transmission data. In the case of forming a physical burst in which a plurality of data payloads are combined into one, a frame structure is provided without needless repetition of address information.

Owner:SONY CORP

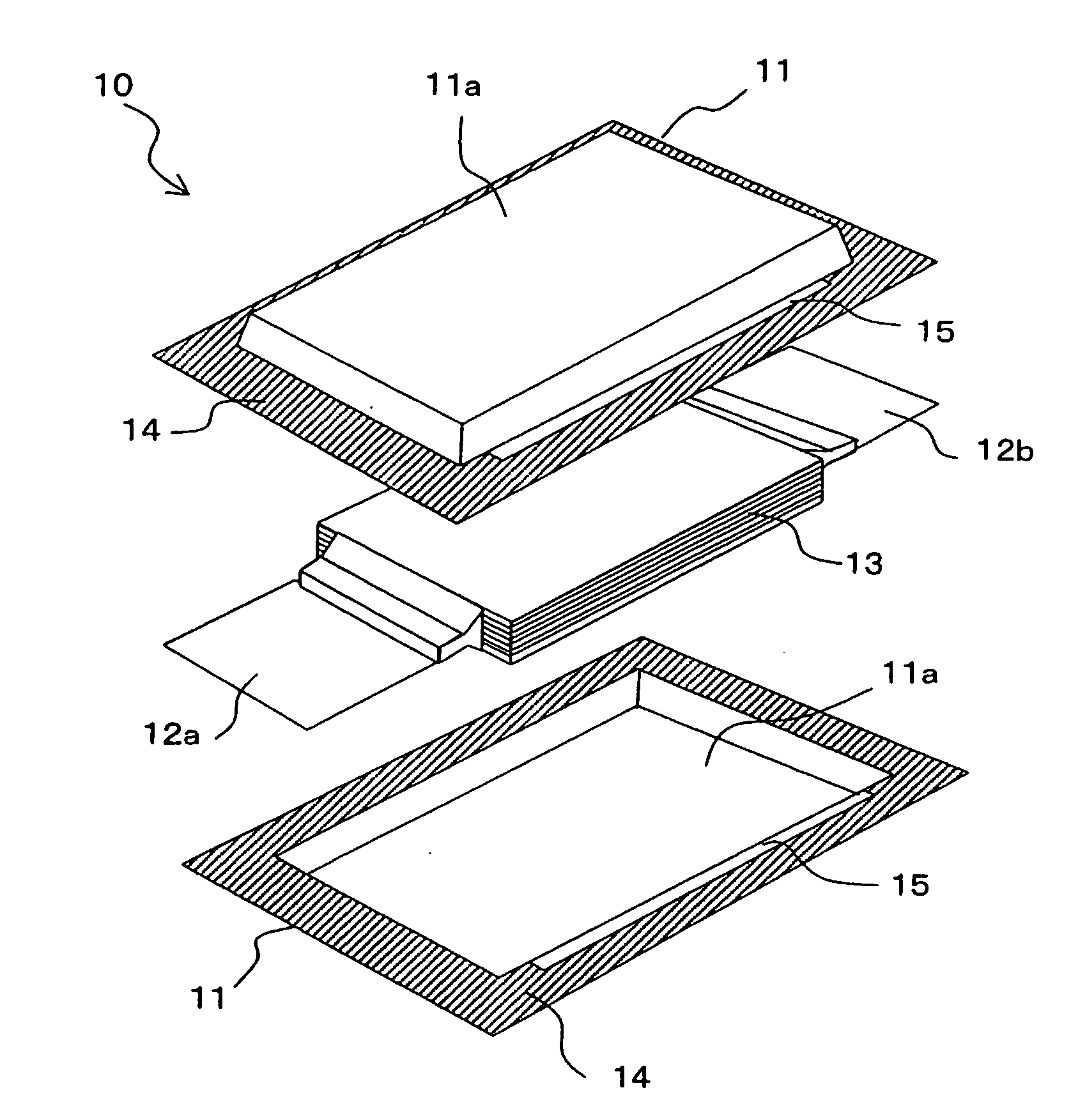

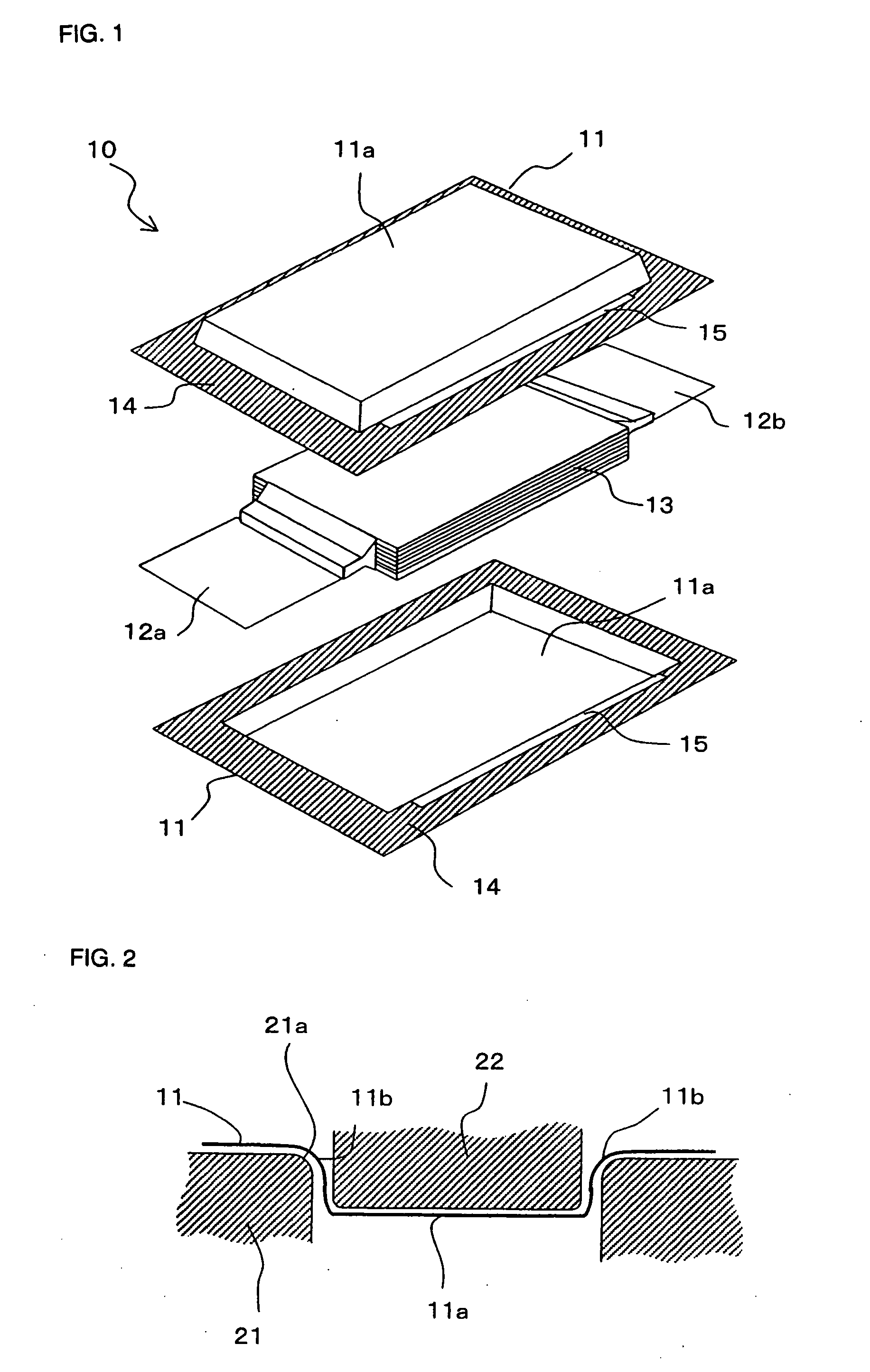

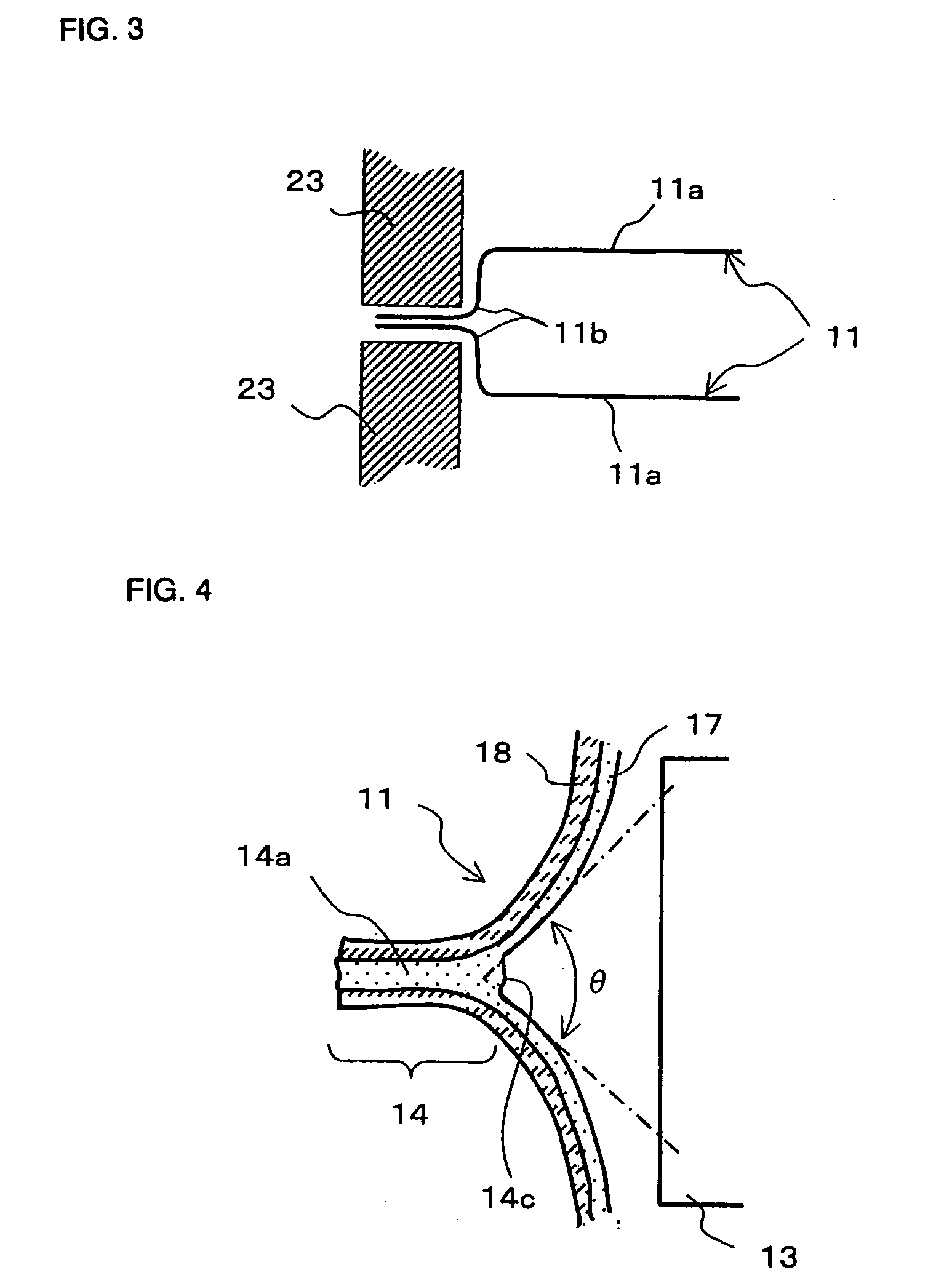

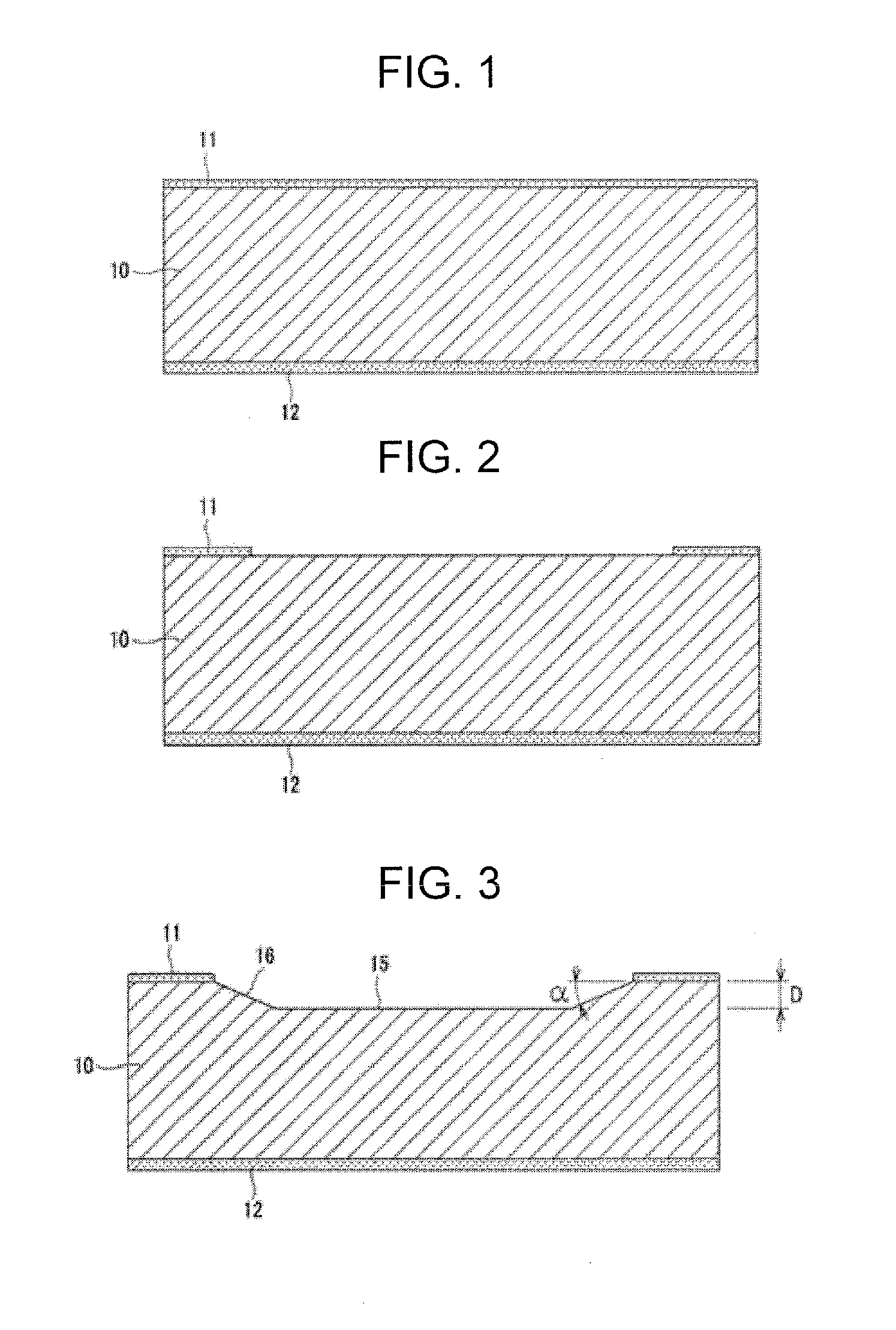

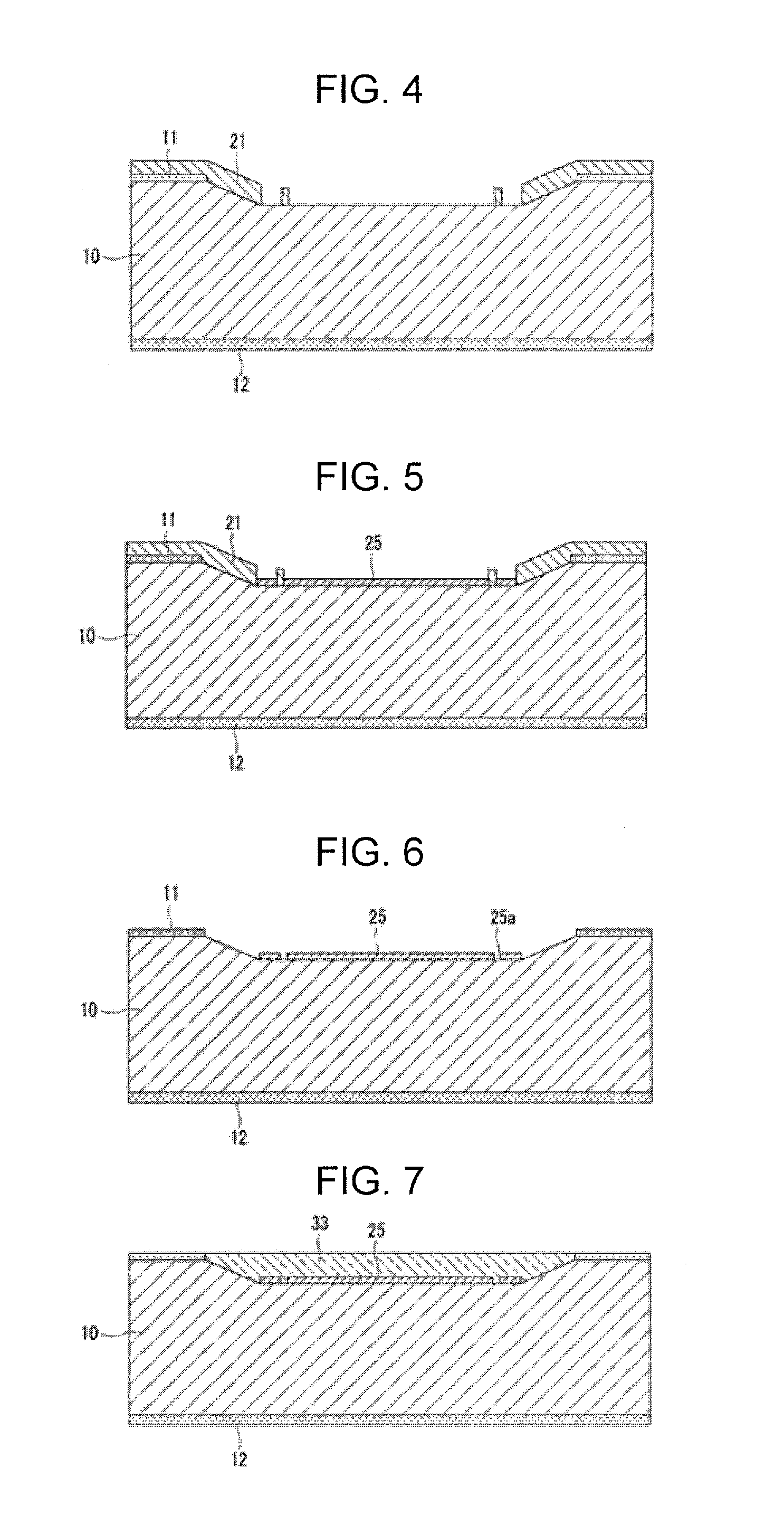

Film-packaged electric device and its manufacturing method

ActiveUS20060210872A1Blocking may occurSimply formedFinal product manufactureSmall-sized cells cases/jacketsEngineeringClose contact

The occurrence of micro-crack is prevented at the root of a thermally sealed area of casing materials even if a thick electric device element is sealed. Film covered battery 10 has cell element 13 to which leads 12a, 12b are connected, and casing films 11 for sealing cell element 13 with leads 12a, 12b extended therefrom. Casing films 11 are thermally sealed along the periphery to seal cell element 13. Thermally sealed area 13 of casing films 11 is positioned between both surfaces of cell element 13 in the thickness direction of cell element 13. On a side of casing films 11 from which leads 12a, 12b are not extended, close contact zone 15, in which casing films 11 are not thermally sealed to each other but are in close contact with each other, is formed continuously to a space which receives cell element 13. Close contact zone 15 has a length of one-half or more of the distance from one end to the other end of an inner edge of thermally sealed area 14.

Owner:NEC CORP

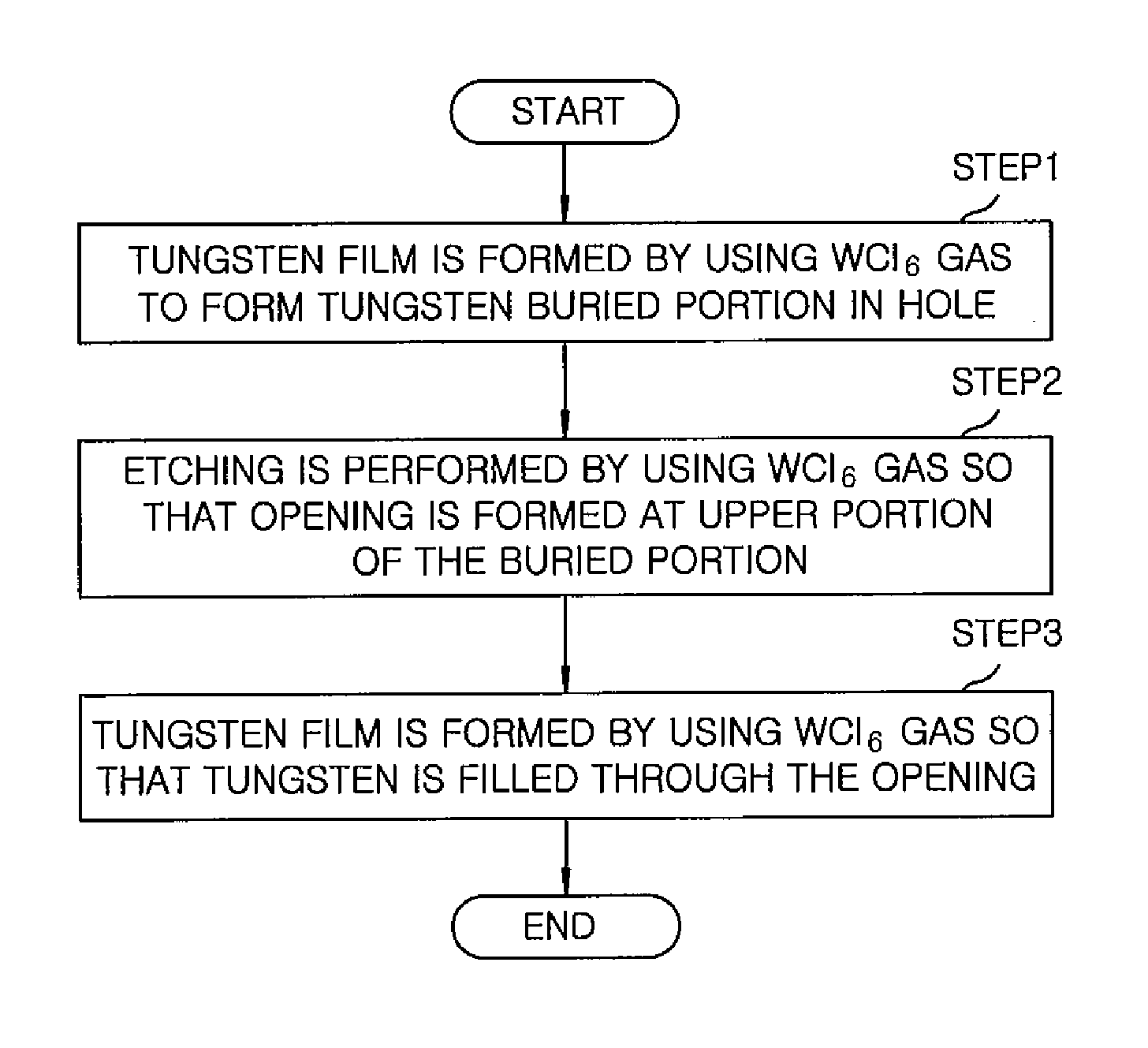

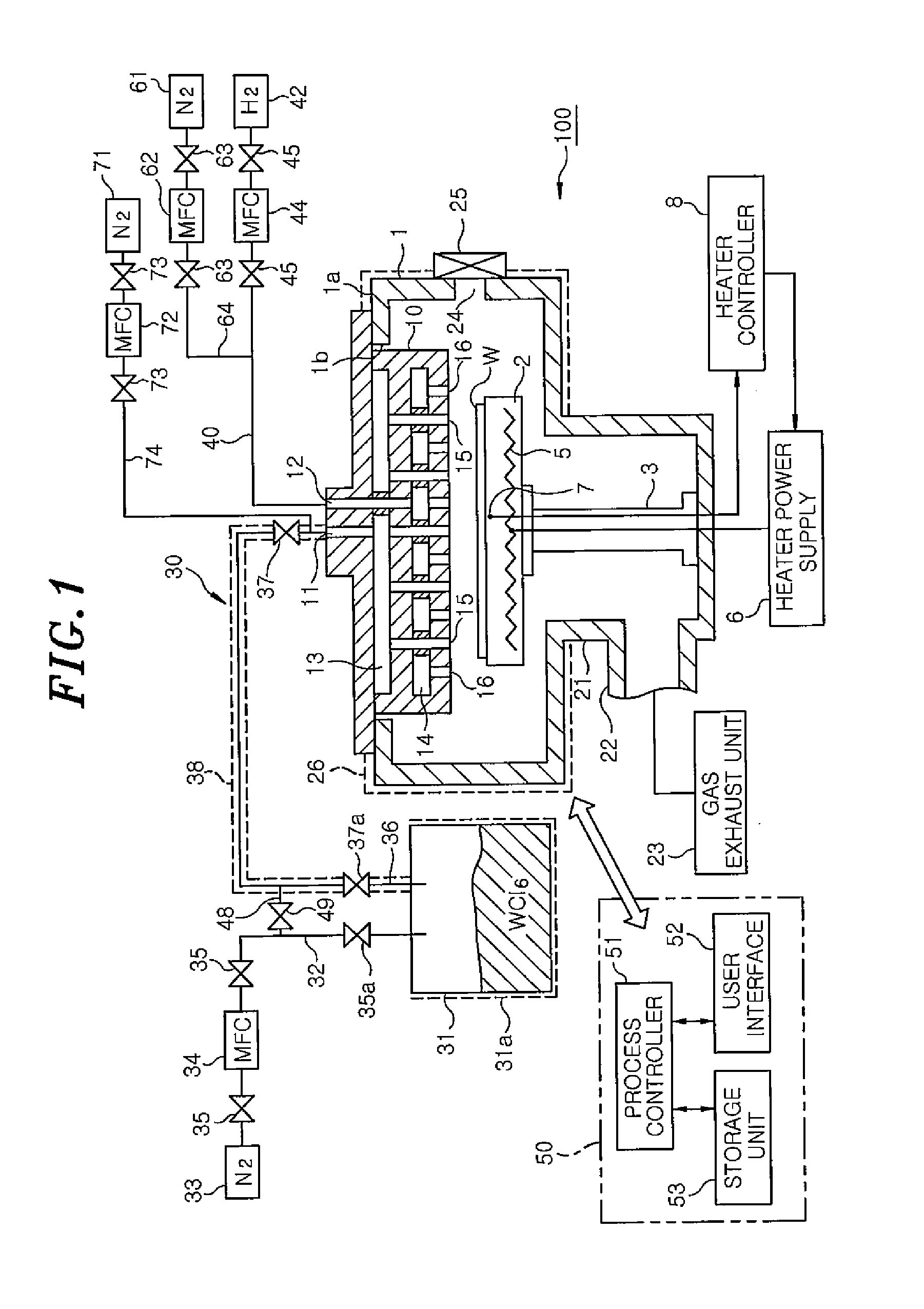

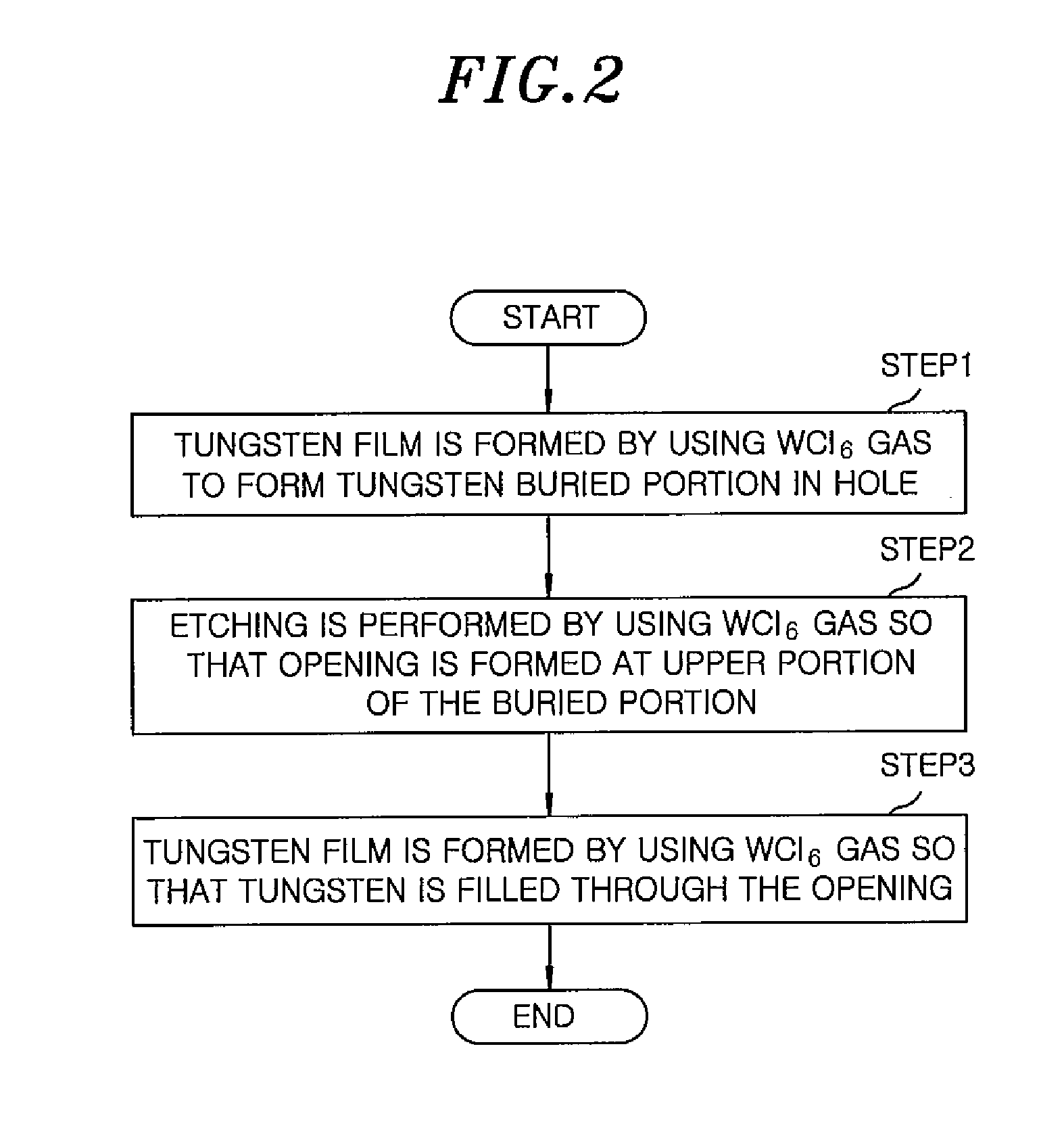

Tungsten film forming method

ActiveUS20150279736A1High throughputSimply formedSemiconductor/solid-state device detailsSolid-state devicesTungsten film

In a tungsten film forming method, a substrate having a recess is provided in a processing chamber, and a first tungsten film is formed on the substrate to fill the recess with a tungsten by simultaneously or alternately supplying WCl6 gas as a tungsten source and a reducing gas under a depressurized atmosphere of the processing chamber, and by reacting the WCl6 gas with the reducing gas while heating the substrate. Then, an opening is formed in the tungsten filled in the recess by supplying WCl6 gas into the processing chamber and etching an upper portion of the tungsten. Thereafter, a second tungsten film is formed on the substrate having the opening by simultaneously or alternately supplying the WCl6 gas and the reducing gas into the processing chamber, and by reacting the WCl6 gas with the reducing gas while heating the substrate.

Owner:TOKYO ELECTRON LTD

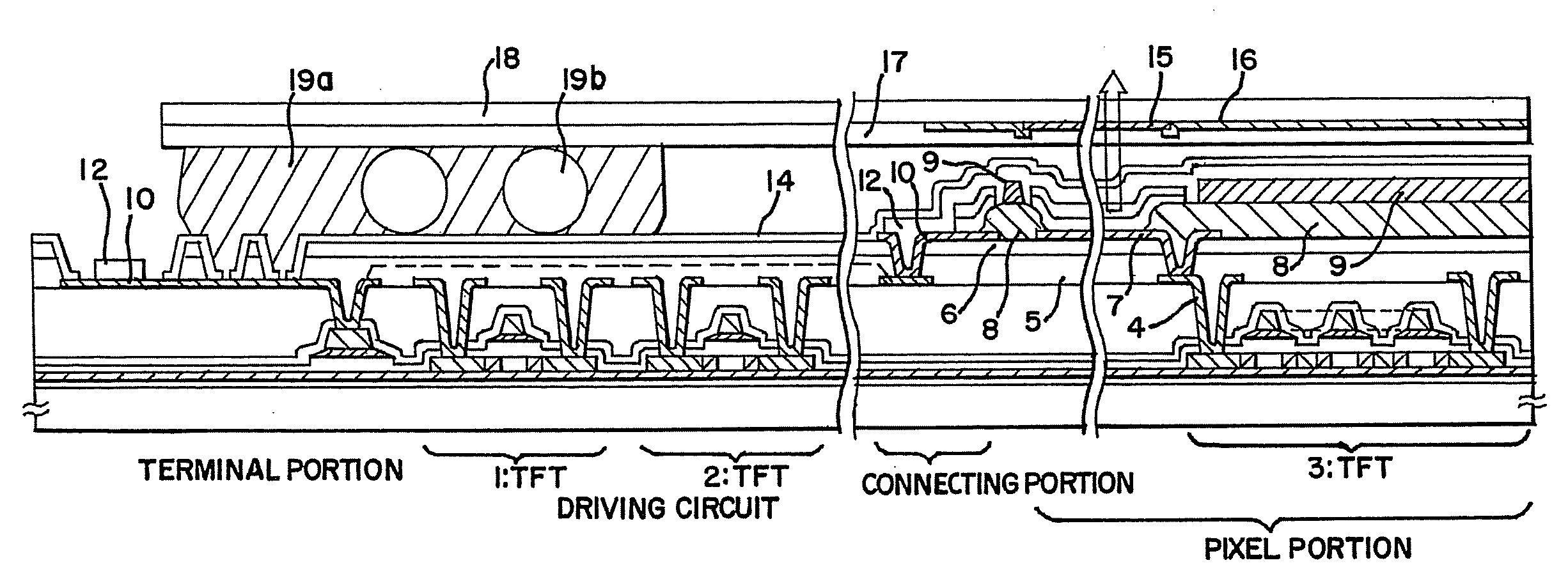

Light Emitting Apparatus and Method of Fabricating the Same

InactiveUS20090061551A1Simply formedEliminate failure in coverageElectroluminescent light sourcesSolid-state devicesColor changesEntire face

Although an ink jet method known as a method of selectively forming a film of a high molecular species organic compound, can coat to divide an organic compound for emitting three kinds (R, G, B) of light in one step, film forming accuracy is poor, it is difficult to control the method and therefore, uniformity is not achieved and the constitution is liable to disperse. In contrast thereto, according to the invention, a film comprising a high molecular species material is formed over an entire face of a lower electrode connected to a thin film transistor by a coating method and thereafter, the film comprising the high molecular species material is etched by etching by plasma to thereby enable to selectively form a high molecular species material layer. Further, the organic compound layer is constituted by a material for carrying out luminescence of white color or luminescence of single color and combined with a color changing layer or a coloring layer to thereby realize full color formation.

Owner:SEMICON ENERGY LAB CO LTD

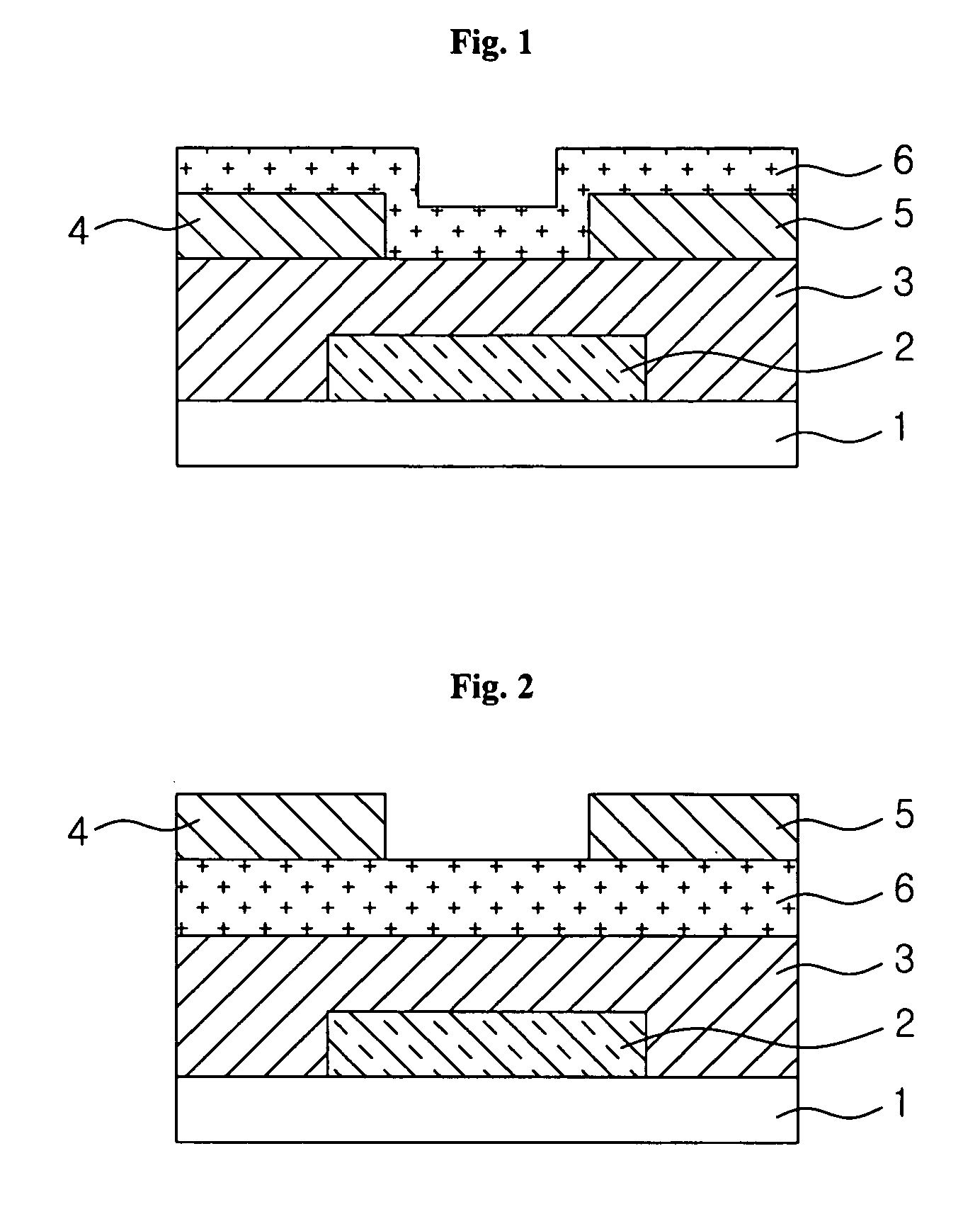

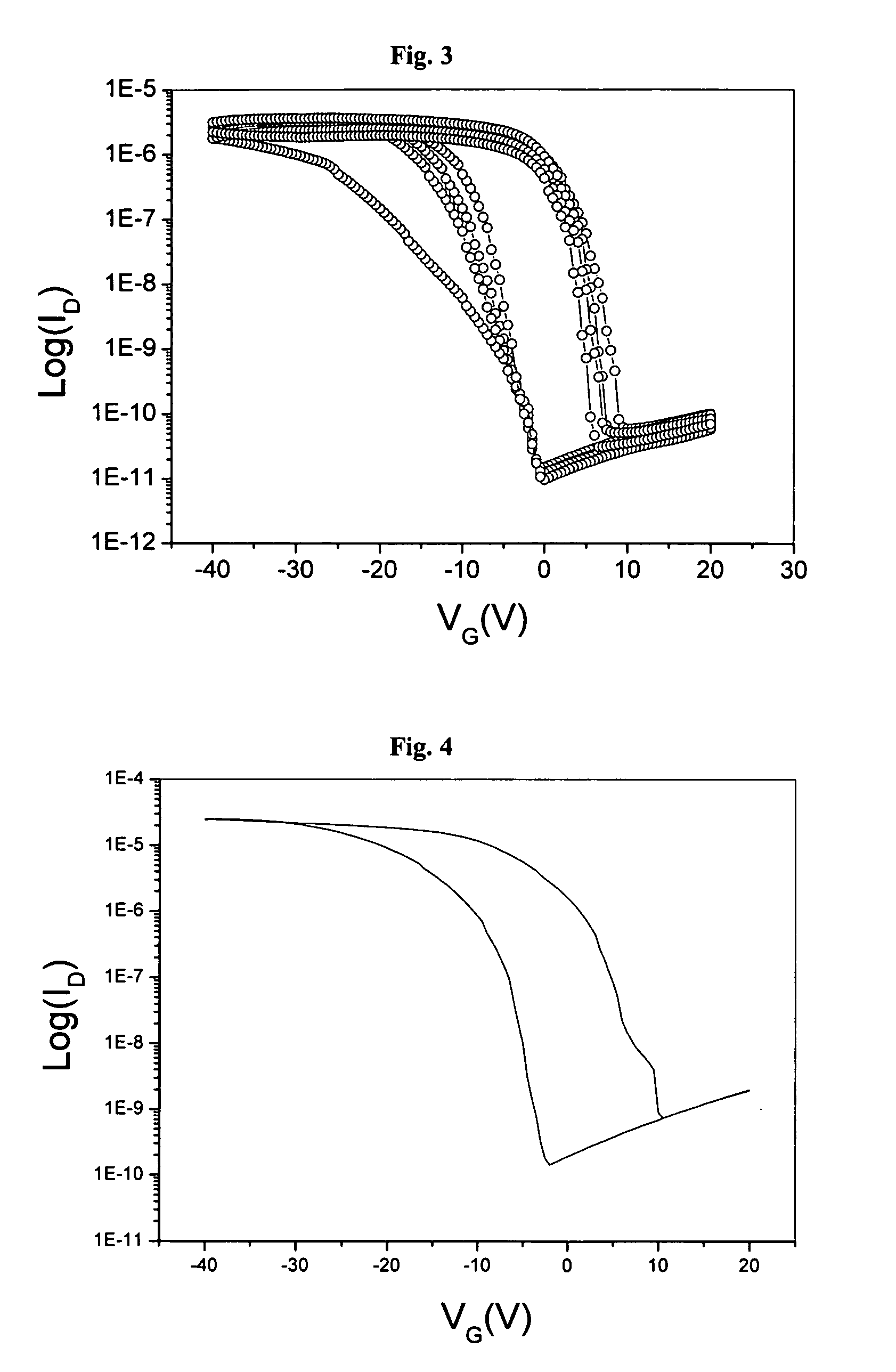

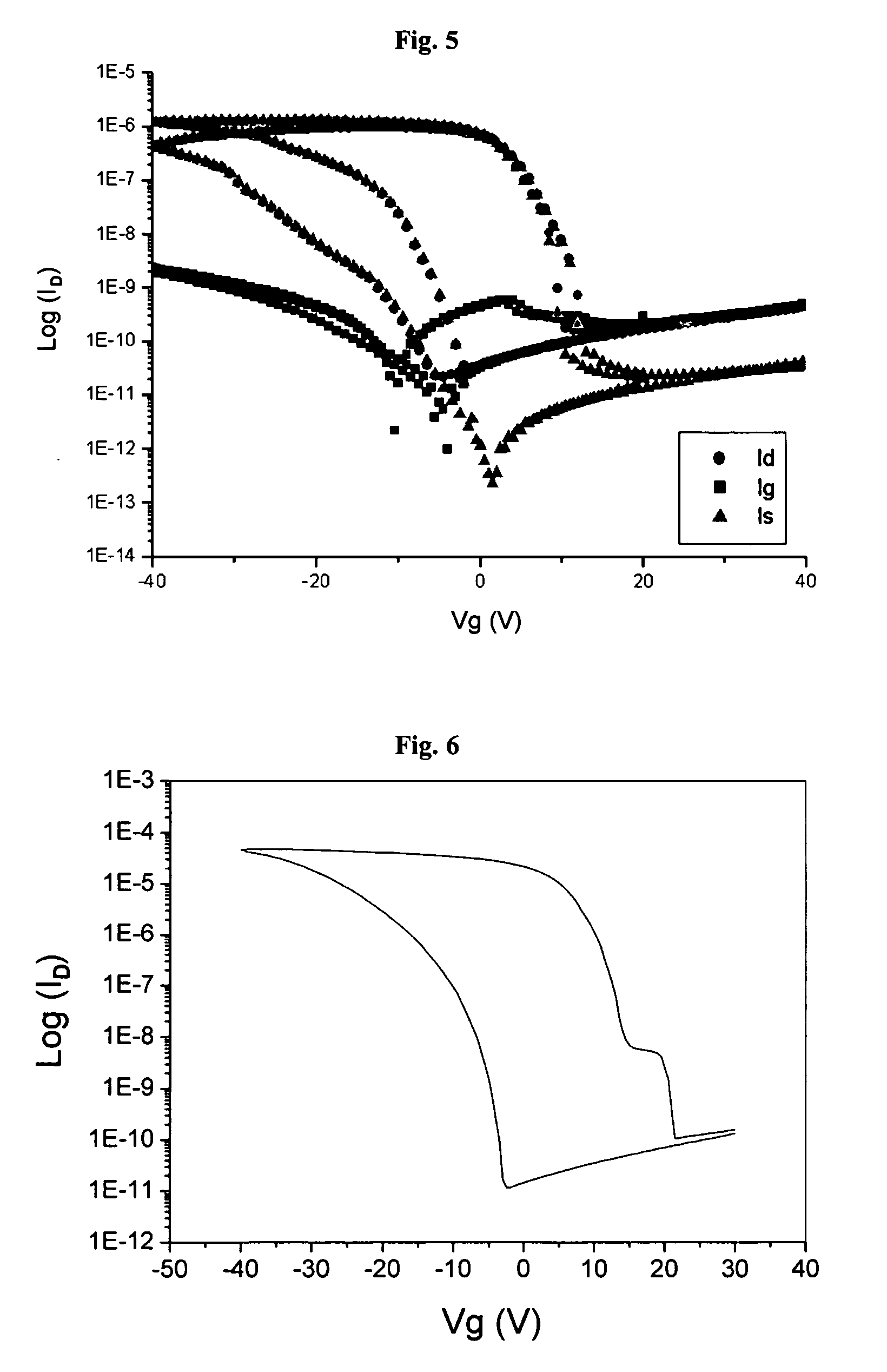

Organic insulator composition, organic insulating film having the same, organic thin film transistor having the same and electronic device having the same and methods of forming the same

ActiveUS20070129473A1High carrier mobilitySimple formatGroup 4/14 element organic compoundsLiquid organic insulatorsHysteresisSilane compounds

Example embodiments of the present invention relate to an organic insulator composition, an organic insulating film having the organic insulator composition, an organic thin film transistor having the organic insulating film, an electronic device having the organic thin film transistor and methods of forming the same. Other example embodiments of the present invention relate to an organic insulator composition including a fluorinated silane compound that may be used to improve the charge carrier mobility and hysteresis of an organic thin film transistor. An organic insulator composition including a fluorinated silane compound and an organic thin film transistor using the same is provided. The hysteresis and physical properties, e.g., threshold voltage and / or charge carrier mobility, of the organic thin film transistor may be improved by the use of the organic insulator composition. The organic thin film transistor may be effectively used in the manufacture of a variety of electronic devices including liquid crystal displays (LCDs) and / or photovoltaic devices.

Owner:SAMSUNG ELECTRONICS CO LTD

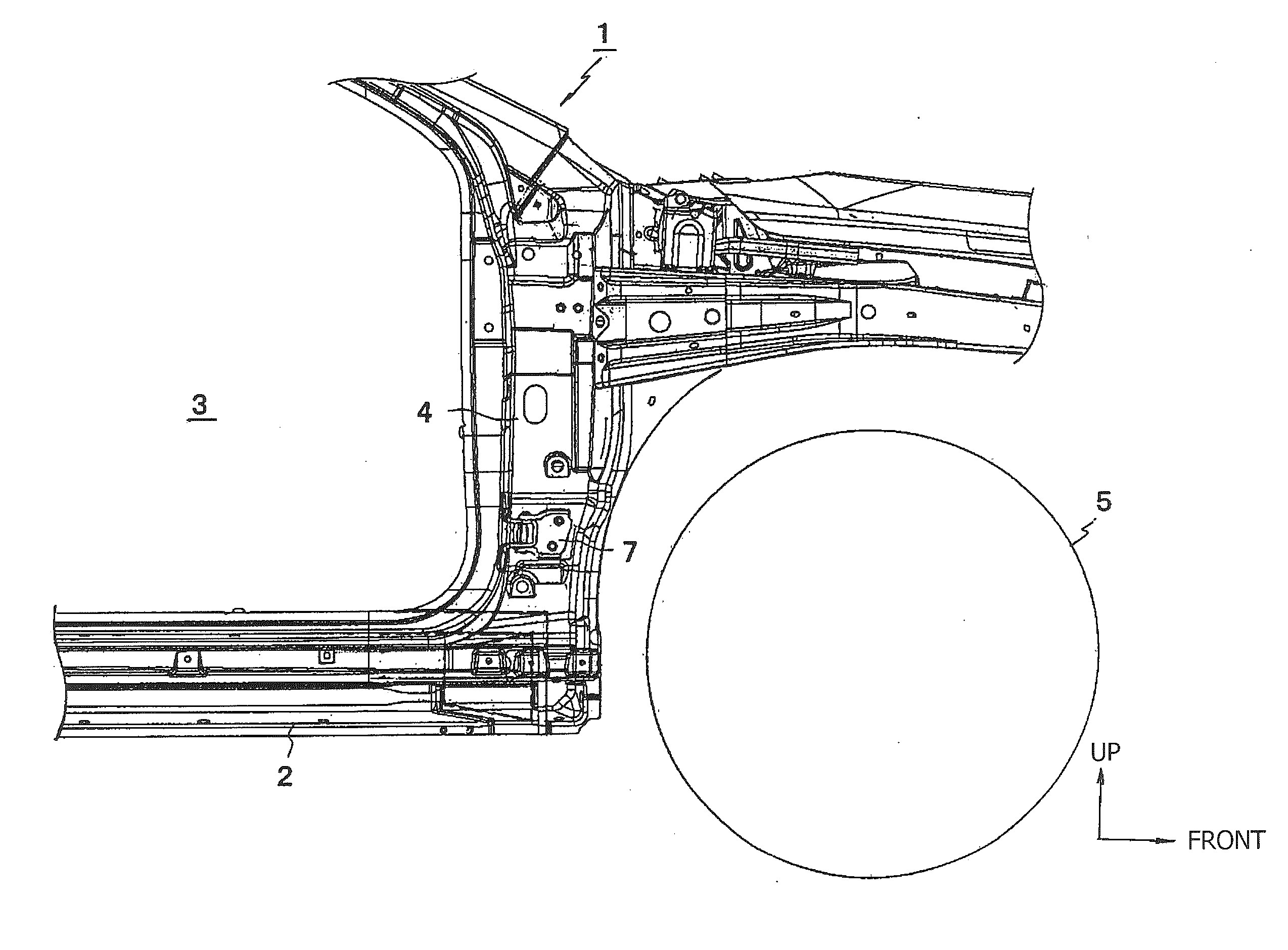

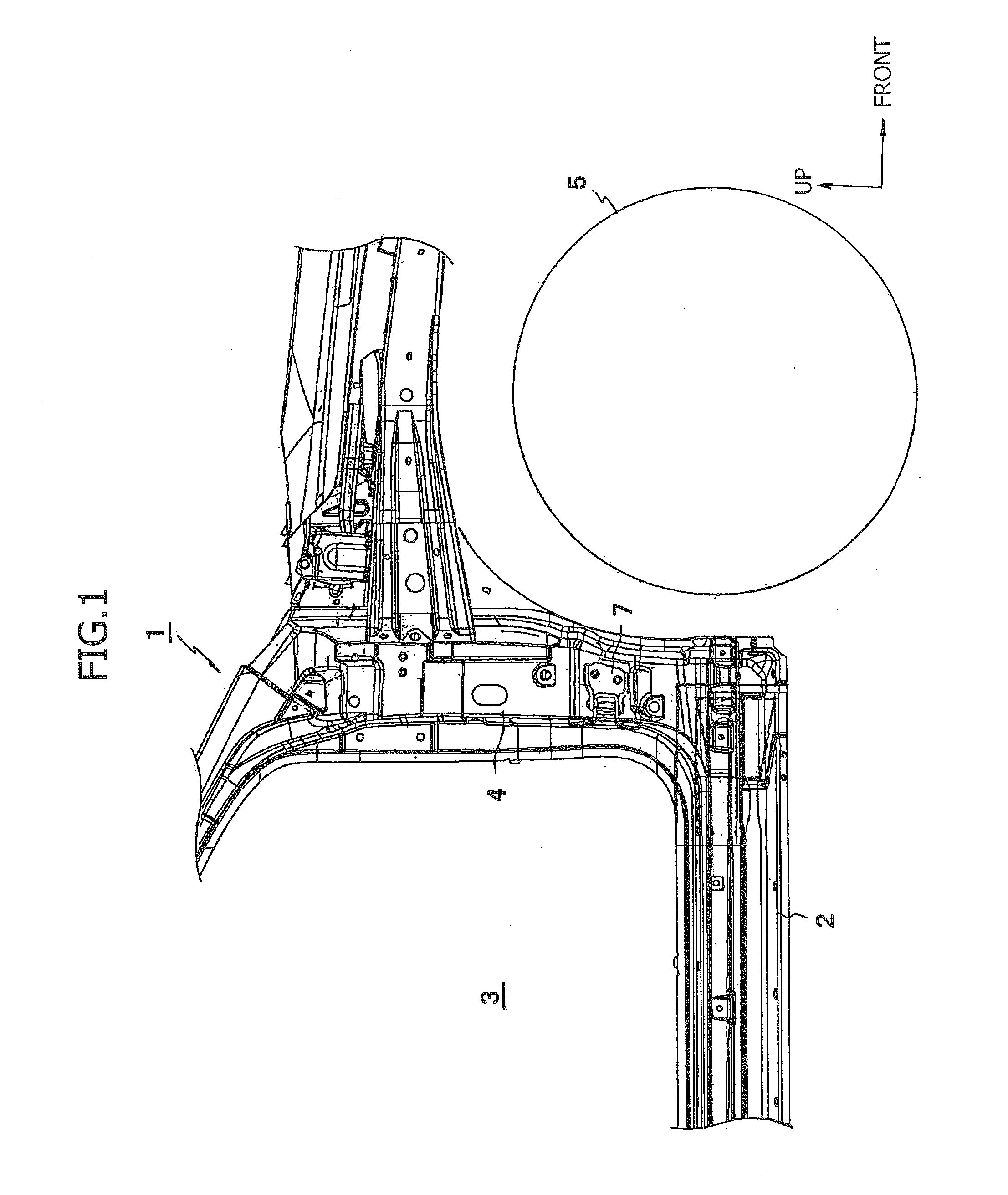

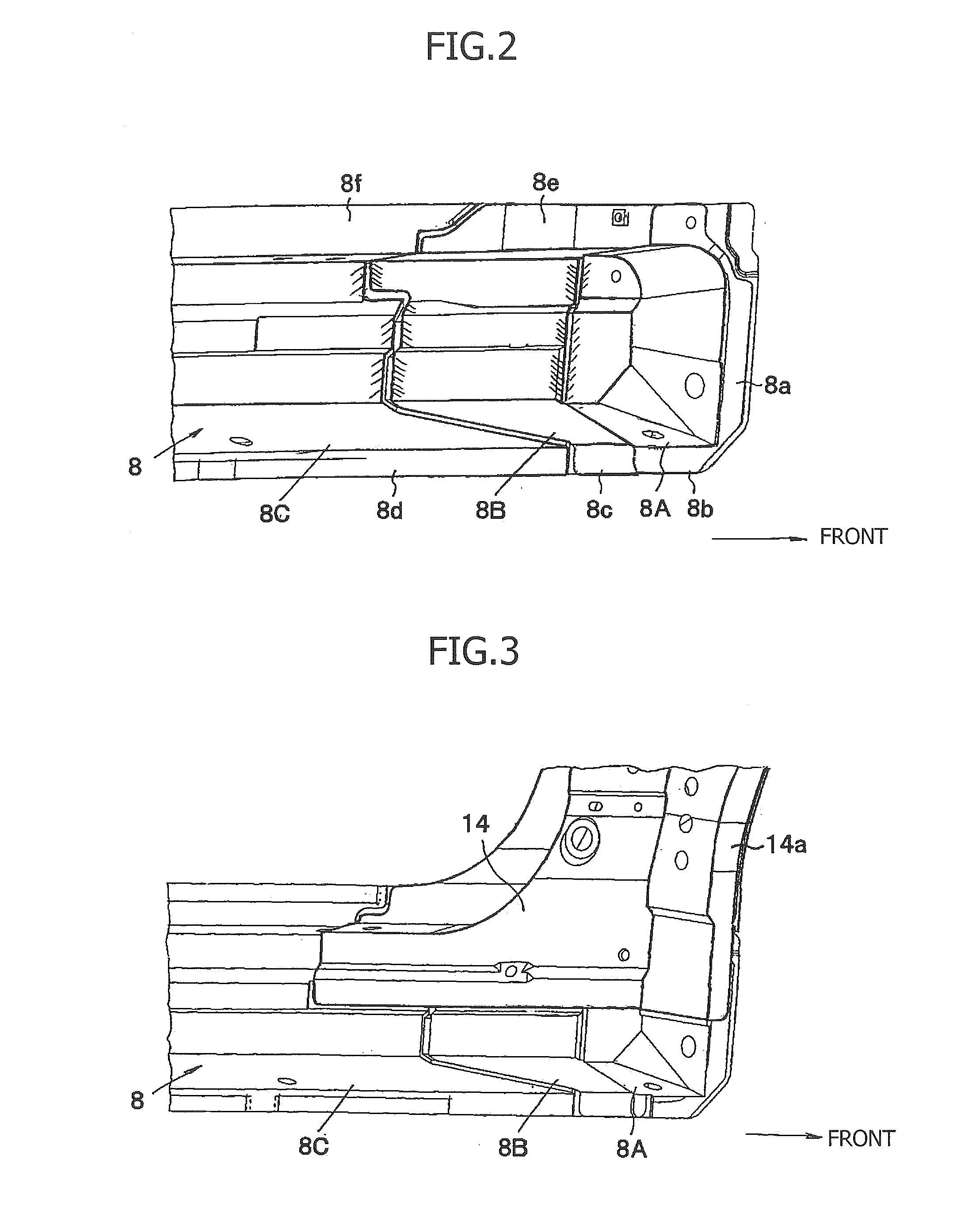

Lower structure of vehicle front pillars

InactiveUS20100295336A1Good molding effectImprove workabilityVehicle seatsSuperstructure subunitsEngineeringMechanical engineering

Owner:SUZUKI MOTOR CORP

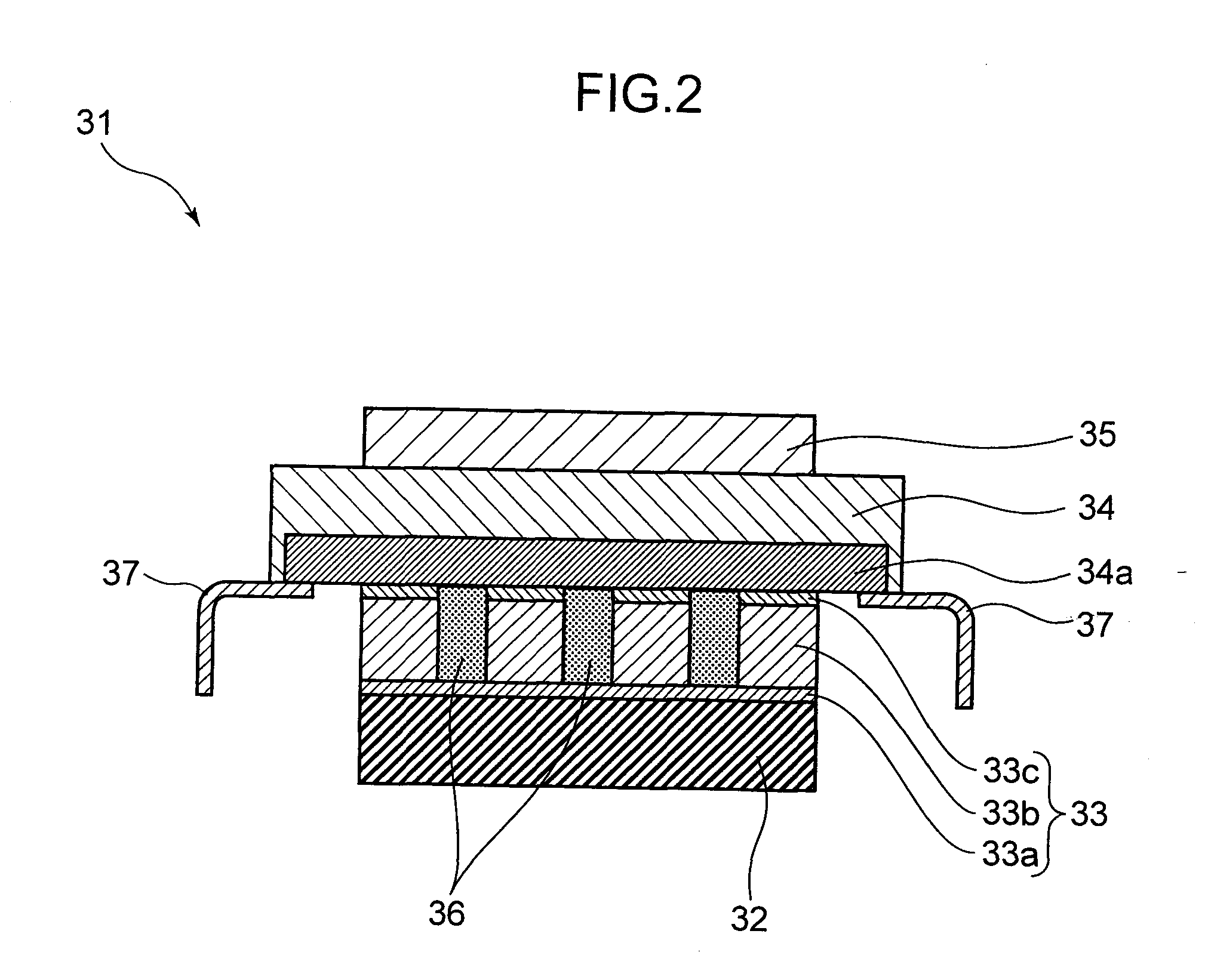

Array-type ultrasonic vibrator

ActiveUS20110198968A1Simply formedUltrasonic/sonic/infrasonic diagnosticsPiezoelectric/electrostriction/magnetostriction machinesAcousticsAcoustic impedance

An array-type ultrasonic vibrator according to the present invention has an acoustic matching layer that has a plate-like body made of a material having a lower acoustic impedance than a plurality of piezoelectric elements. Signal wiring is formed on the plate-like body of the acoustic matching layer. Accordingly, for this array-type ultrasonic vibrator, the signal wiring can be easily formed without using additional components.

Owner:KONICA MINOLTA MEDICAL & GRAPHICS INC

MEMS microphone and method for manufacturing same

InactiveUS20110316100A1Reduce in quantityAvoid crackingMicrophonesLoudspeakersMems microphoneEngineering

A micro electro mechanical systems (MEMS) microphone, and a method of manufacturing the MEMS microphone having an interval between a membrane and a back plate, the interval being correctly adjusted by forming the membrane and the back plate after an air-gap forming portion on a silicon substrate. Since the membrane and / or the back plate are / is formed by electroless plating, a sacrificial layer is easily planarized, and a residual stress is easily removed or controlled. The MEMS microphone includes a silicon substrate in which a back chamber is formed and on which an air-gap forming portion is formed above the chamber by etching the silicon substrate to a predetermined depth above the chamber; a membrane formed on the air-gap forming portion of the silicon substrate or the silicon substrate; and a back plate that is formed on the air-gap forming portion or the silicon substrate so as to be spaced apart from the membrane, wherein an air gap is formed between the membrane and the back plate.

Owner:BSE CO LTD

Multibit electro-mechanical memory device and method of manufacturing the same

InactiveUS20090097315A1Highly integratedShorten the cantilever lengthSolid-state devicesRead-only memoriesBit lineEngineering

A multibit electro-mechanical memory device comprises a substrate, a bit line on the substrate, a first interlayer insulating film on the bit line, first and second lower word lines on the first interlayer insulating film, the first and second lower word lines separated horizontally from each other by a trench, a spacer abutting a sidewall of each of the first and second lower word lines, a pad electrode inside a contact hole, first and second cantilever electrodes suspended over first and second lower voids that correspond to upper parts of the first and second lower word lines provided in both sides on the pad electrode, the first and second cantilever electrodes being separated from each other by the trench, and being curved in a third direction that is perpendicular to the first and second direction; a second interlayer insulating film on the pad electrode, first and second trap sites supported by the second interlayer insulating film to have first and second upper voids on the first and second cantilever electrodes, and first and second upper word lines on the first and second trap sites.

Owner:SAMSUNG ELECTRONICS CO LTD

Translucent electromagnetic shield film, producing method therefor and emulsifier

InactiveUS20060008745A1Easily forming fine line patternImprove shielding effectPhotomechanical exposure apparatusPrinted circuit manufactureEmulsionElectroplating

A producing method for a translucent electromagnetic shield film comprising exposing a photosensitive material having an emulsion layer containing a silver salt and a dye on a substrate, then executing a development process to form a metallic silver portion and a light transmitting portion respectively in an exposed area and an unexposed area, and applying a physical development and / or a plating process to the metallic silver portion thereby causing the metallic silver portion to carry a conductive metal. The producing method allows to inexpensively mass produce a translucent electromagnetic shield film without a moiré pattern, having a high EMI shield property and a high transparency at the same time.

Owner:FUJIFILM CORP +1

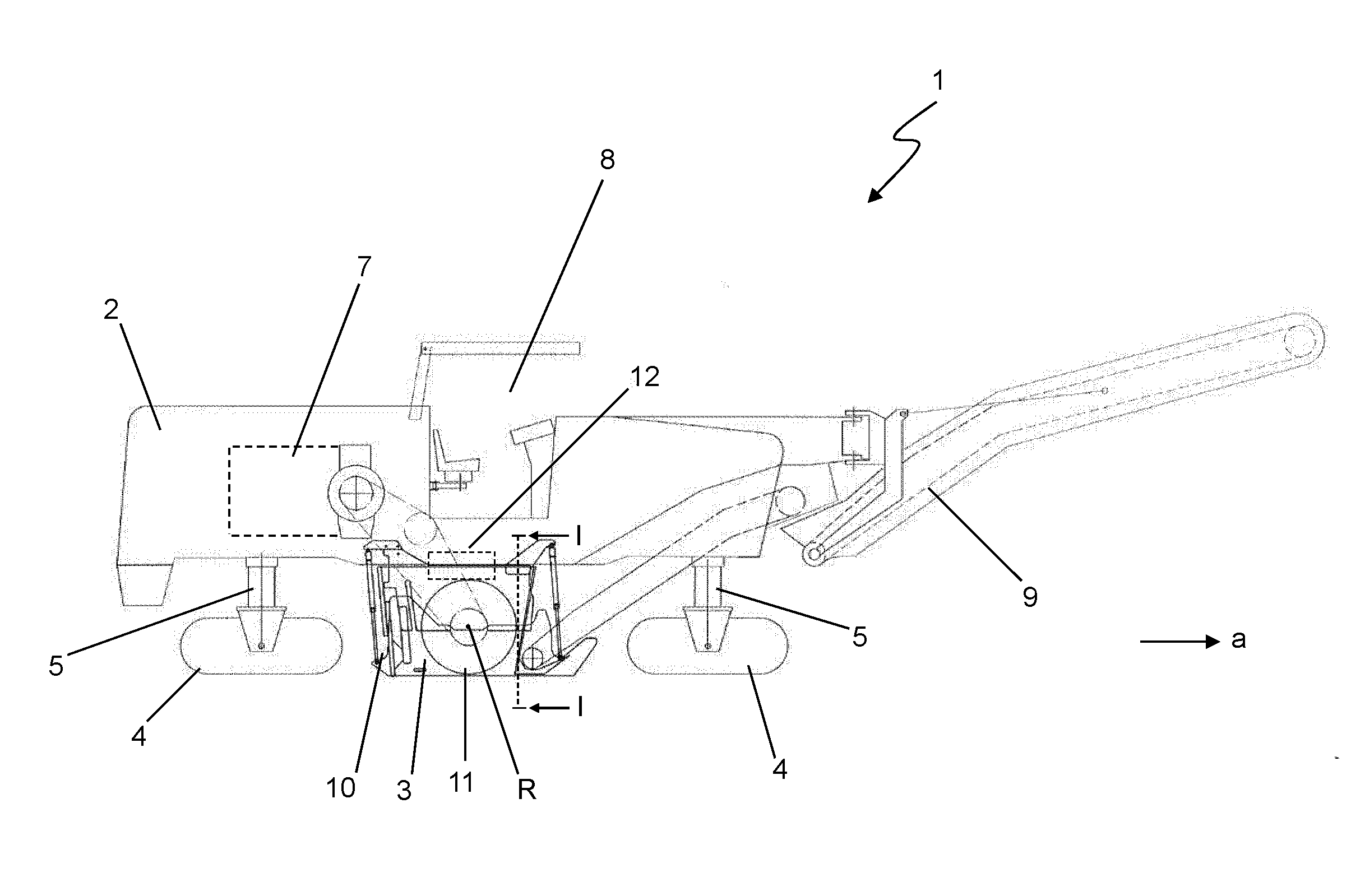

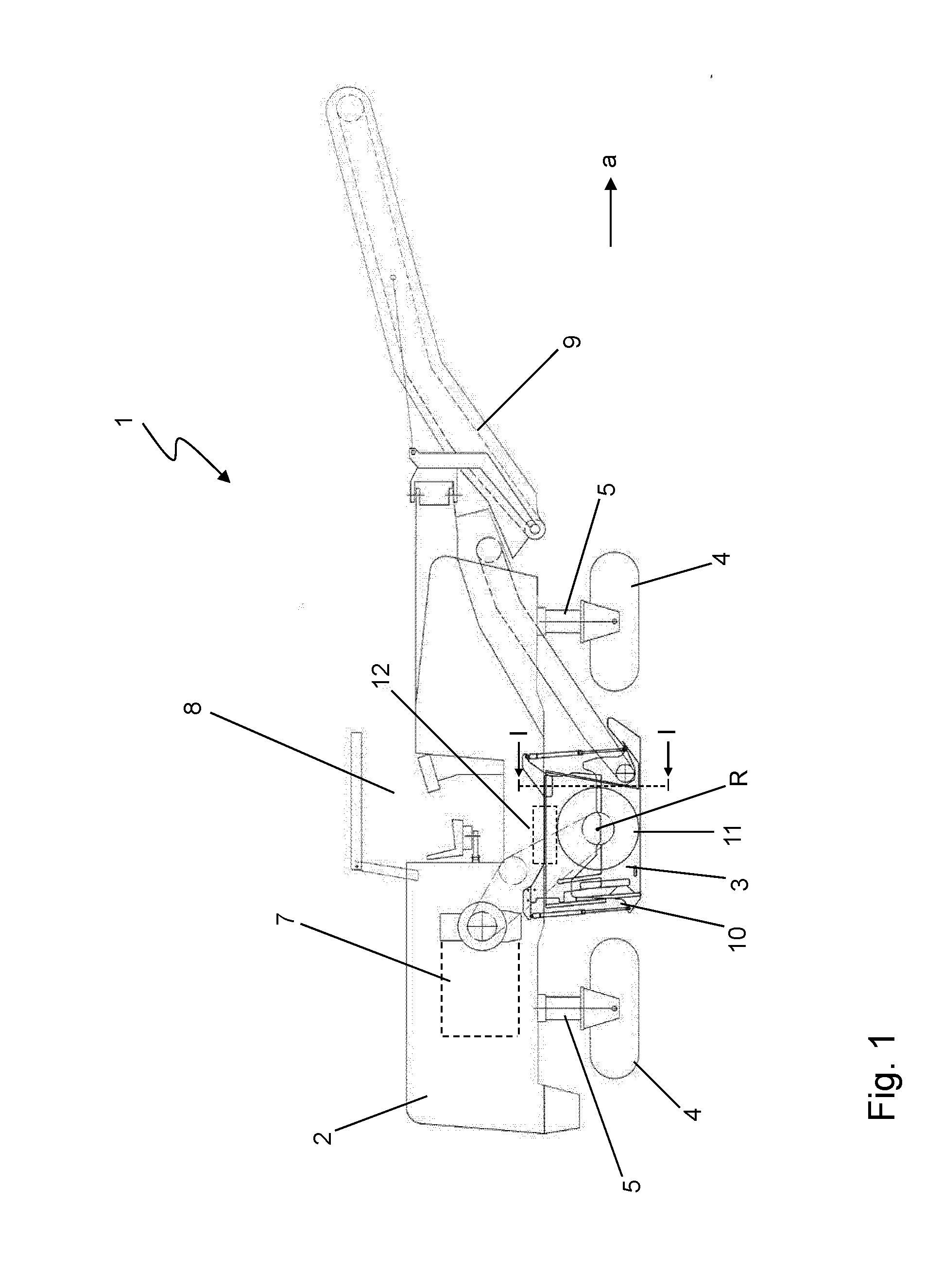

Ground Milling Machine Having A Replaceable Milling Part And Method For Replacing A Milling Part Of A Ground Milling Machine

ActiveUS20160040371A1Stable positionMore cost-effectiveRoads maintainenceMetal working apparatusMachine partsAgricultural engineering

The present invention relates to a ground milling machine, in particular, a road cold milling machine, having a replaceable milling drum unit. To make this replacement procedure easier, the present invention proposes a fastening device between the milling part and the machine part of the ground milling machine. The present invention furthermore relates to a method for replacing a milling part on the ground milling machine, a fastening device being used for this purpose.

Owner:BOMAG

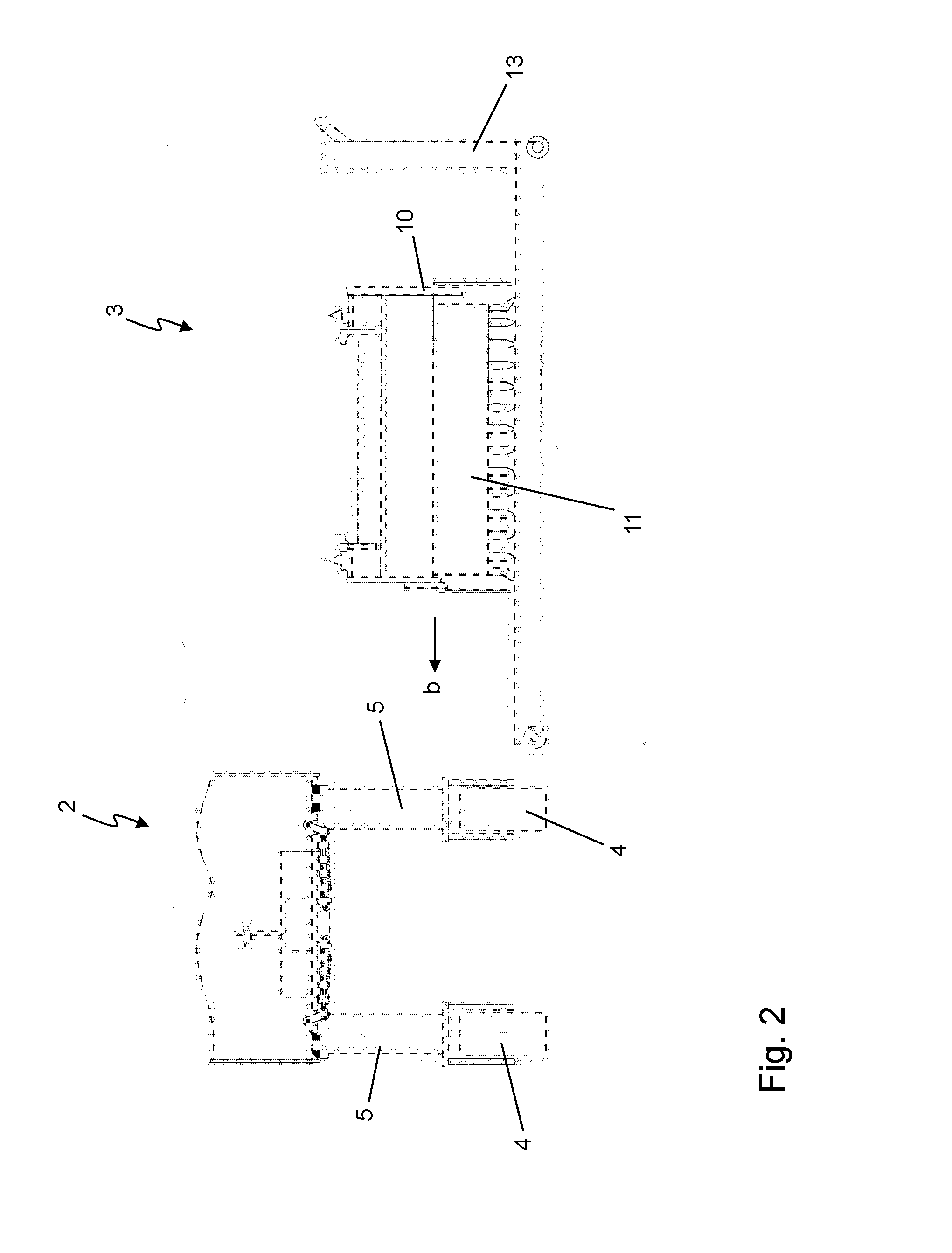

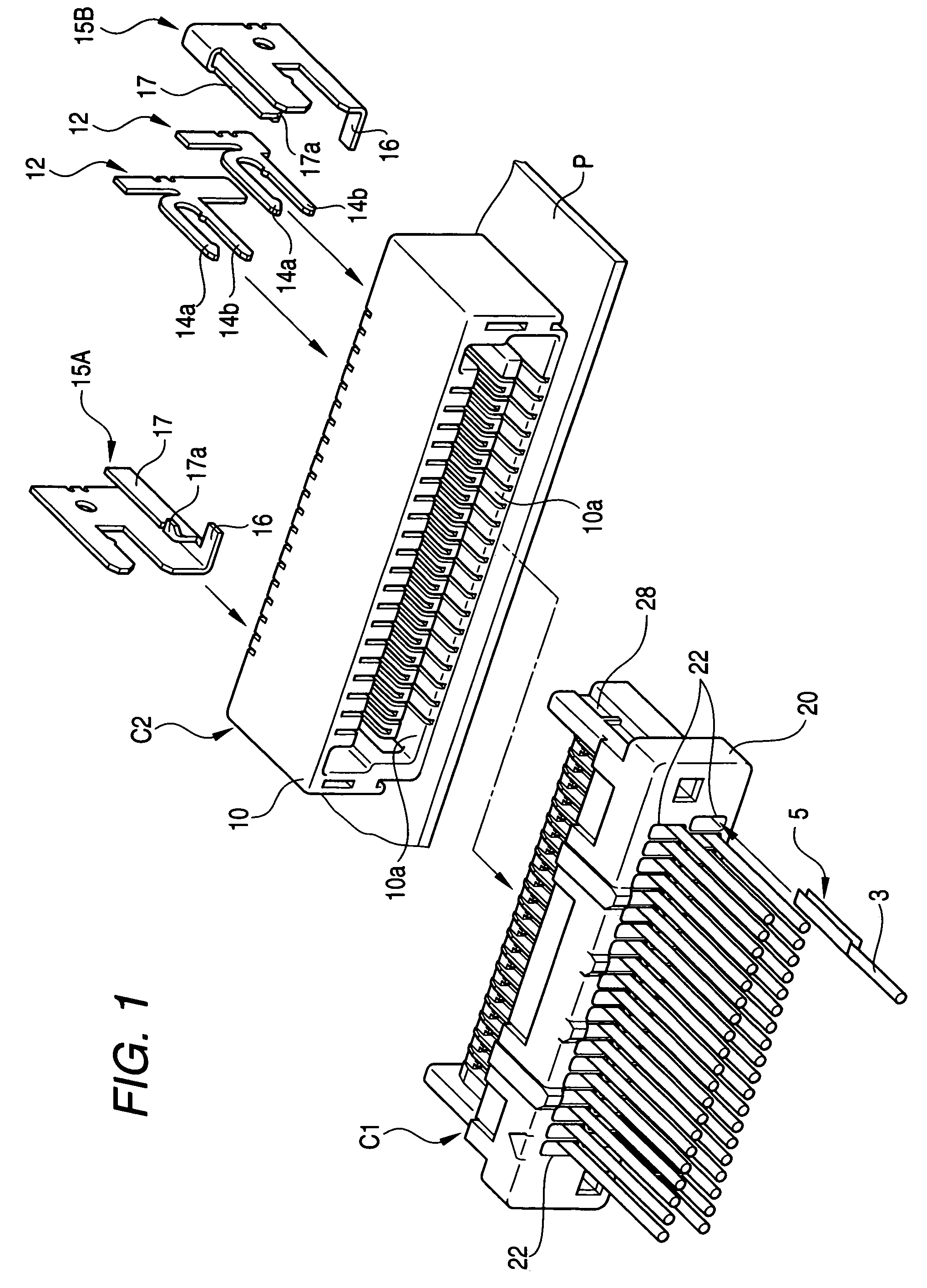

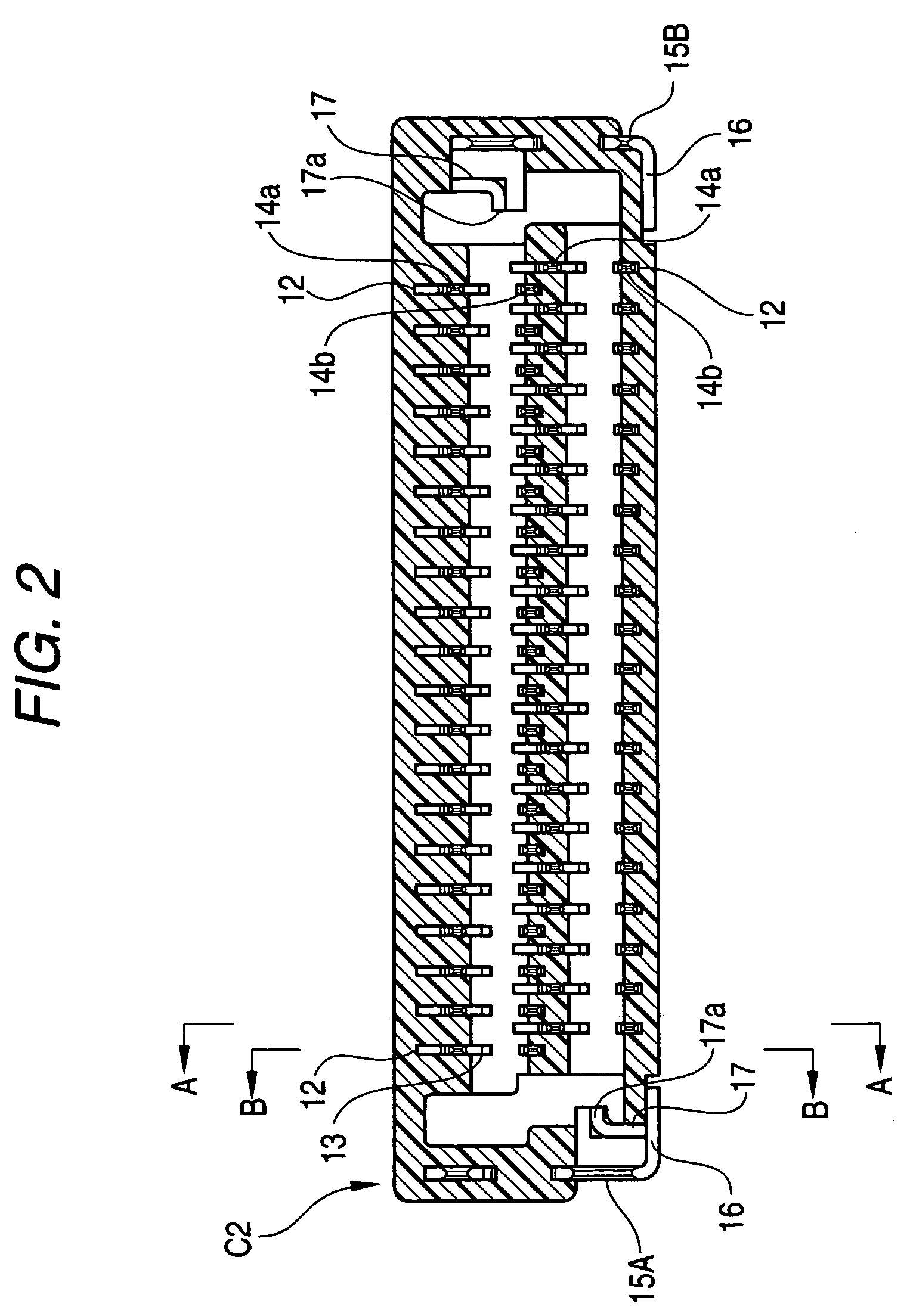

Board mounting type connector with metal fastening member

InactiveUS7258567B2Reliable miniaturizationHigh locking strengthCoupling device detailsConnections effected by permanent deformationEngineeringFastener

A board mounting type connector includes: a housing being made of a resin, the housing holding a plurality of terminals, each terminal being arranged in parallel and connected to a circuit board; and a metal fastening member being fixed to both ends of the housing in a widthwise direction of the housing in which the terminals are arranged, the metal fastening member being mounted to the circuit board, and each metal fastening member having an engaging portion which engages with a housing of a counterpart connector fitted into the board mounting type connector so that the connectors are engageable to each other in a fitted state.

Owner:AUTONETWORKS TECH LTD +2

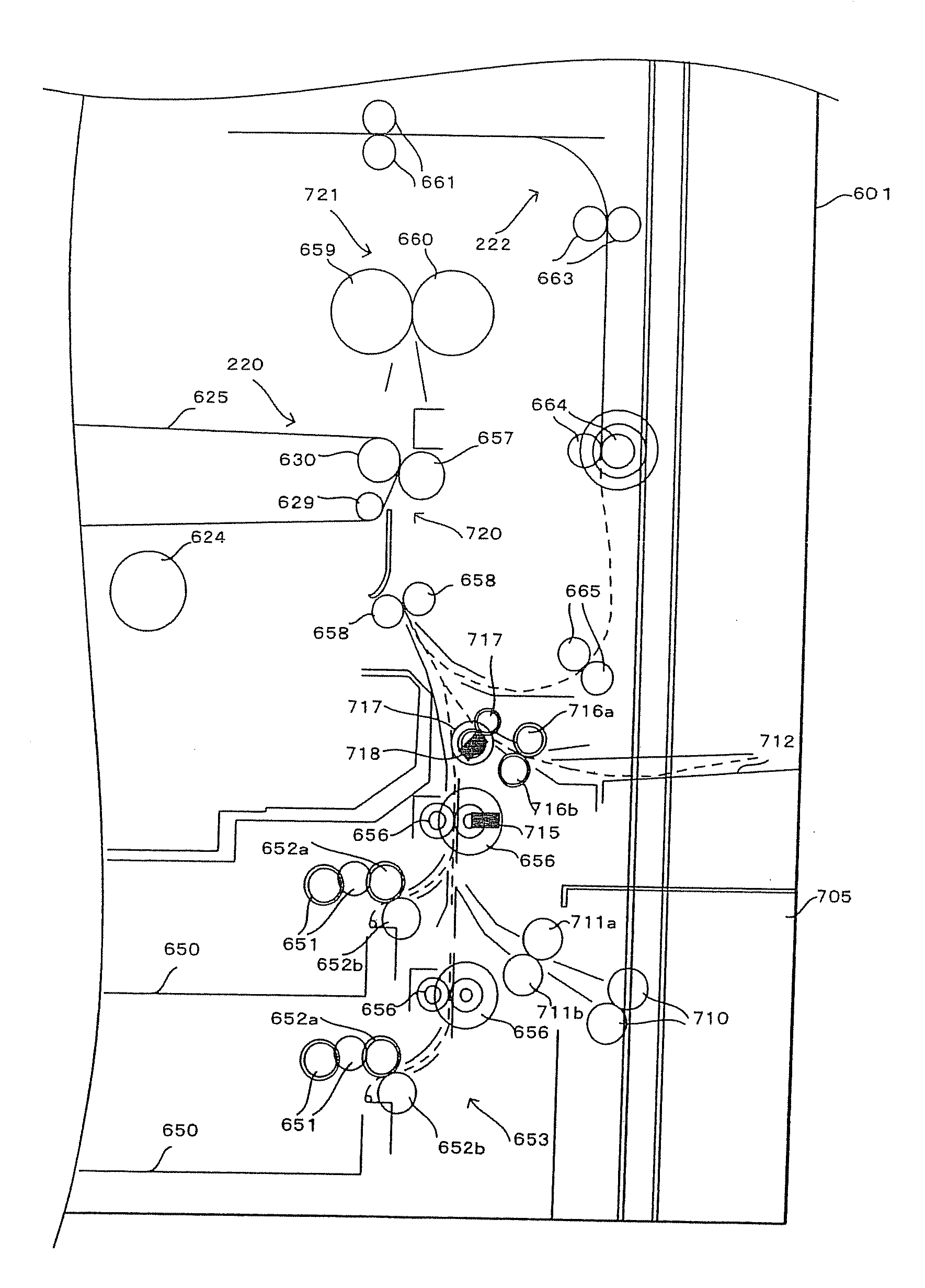

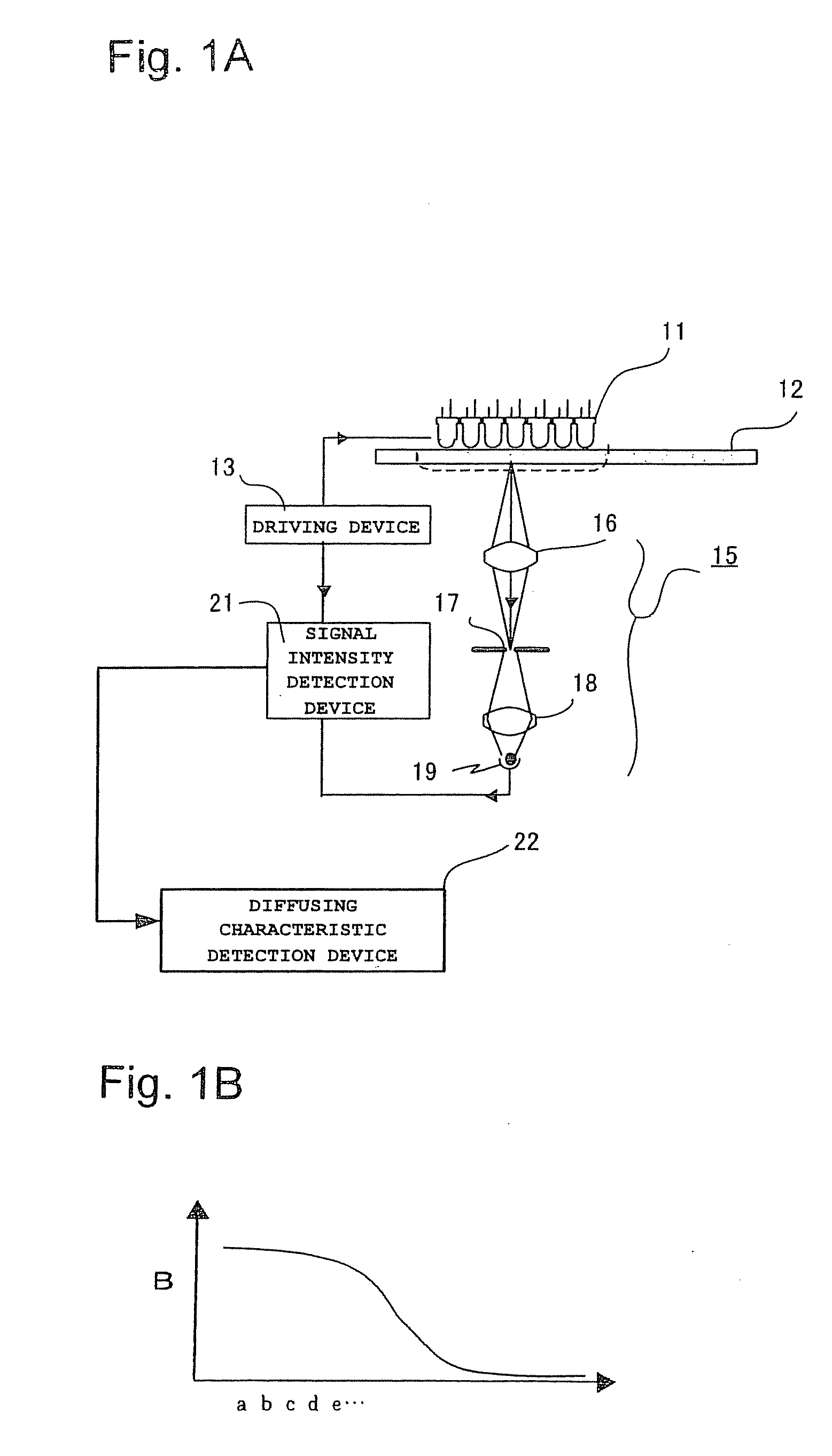

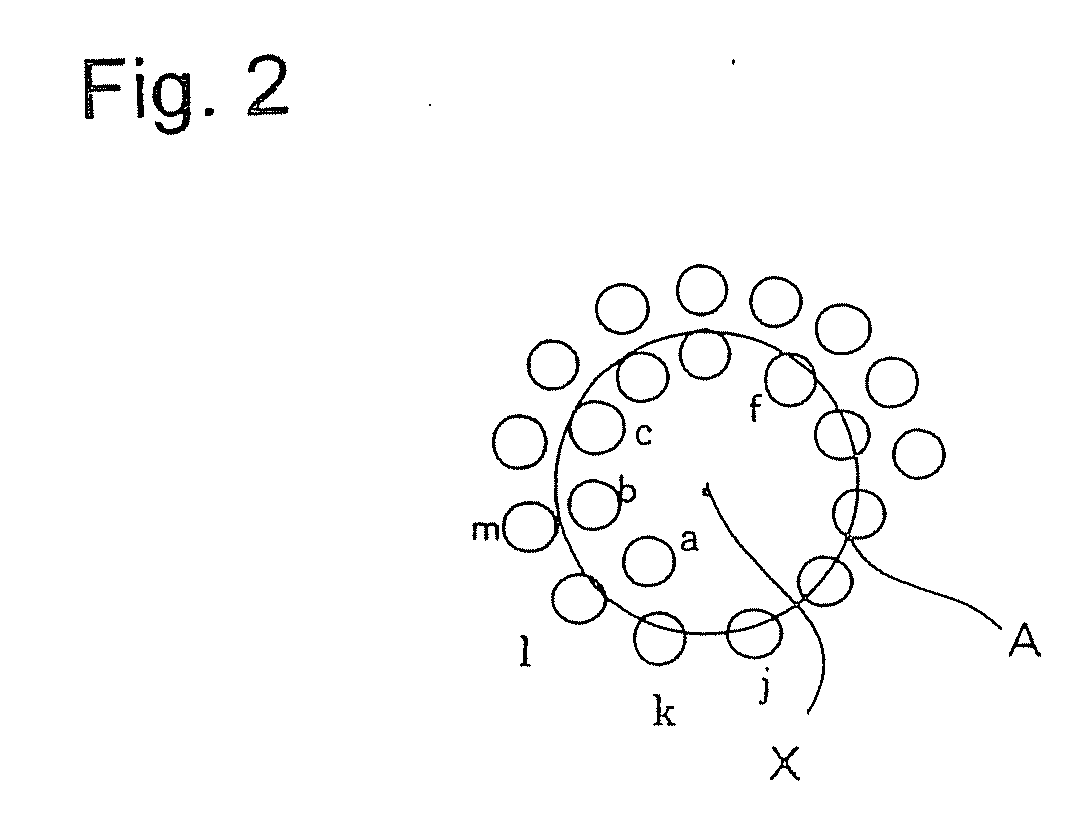

Paper type determination device

A paper type determination device of the invention drives plural light emitting points different from one another and having sequentially increasing distances from a reference point to emit light in such a manner that each is identified for irradiating one surface of a sheet of paper subjected to determination. A photodetection device set at a specific detection field of view having the center at the reference point is disposed on the other surface side of the sheet of paper, and it receives light having passed through the sheet of paper from the respective light emitting points at positions on inside and outside of the detection field of view to detect intensity of light for each light emitting point. A diffusing characteristic of the sheet of paper is obtained on the basis of the intensity of light from each light emitting point detected by the photodetection device, and a paper type is determined on the basis of the diffusing characteristic.

Owner:KK TOSHIBA +1

Memory Element and Method for Manufacturing the Same, and Semiconductor Device

InactiveUS20100283024A1Easy to makeImprove performanceTransistorNanoinformaticsNanoparticleConductive materials

The memory element has a structure at least including a first conductive layer, a second conductive layer, and a memory layer disposed between the first conductive layer and the second conductive layer. The memory layer is formed by a droplet discharge method using nanoparticles of a conductive material each of which is coated with an organic thin film. Specifically, a composition in which nanoparticles of a conductive material each of which is coated with an organic thin film are dispersed in a solvent is discharged (ejected) as ink droplets, and the solvent is dried to be vaporized to form the memory layer. Accordingly, a memory element can be formed simply. In addition, efficiency in the use of materials can be improved and yield is also improved, so that the memory element can be provided at low cost.

Owner:SEMICON ENERGY LAB CO LTD

Method for producing multilayer ceramic substrate

ActiveUS20080135155A1Easily and accurately producedWell formedPrinted circuit aspectsCircuit fluid transportCeramic substrateSintered ceramic

In a method for producing a multilayer ceramic substrate, a green ceramic laminate includes green conductive patterns arranged on a plurality of ceramic green sheets and portions to be formed into a plurality of multilayer ceramic substrates. Boundary-defining conductive patterns are arranged on the ceramic green sheets and along boundaries of the multilayer ceramic substrates. The boundary-defining conductive patterns have firing shrinkage characteristics that are different from those of the ceramic green sheets. During firing of the green ceramic laminate, cavities adjacent to edges of the boundary-defining conductive patterns are formed. A sintered ceramic laminate is divided at edges passing through the cavities.

Owner:MURATA MFG CO LTD

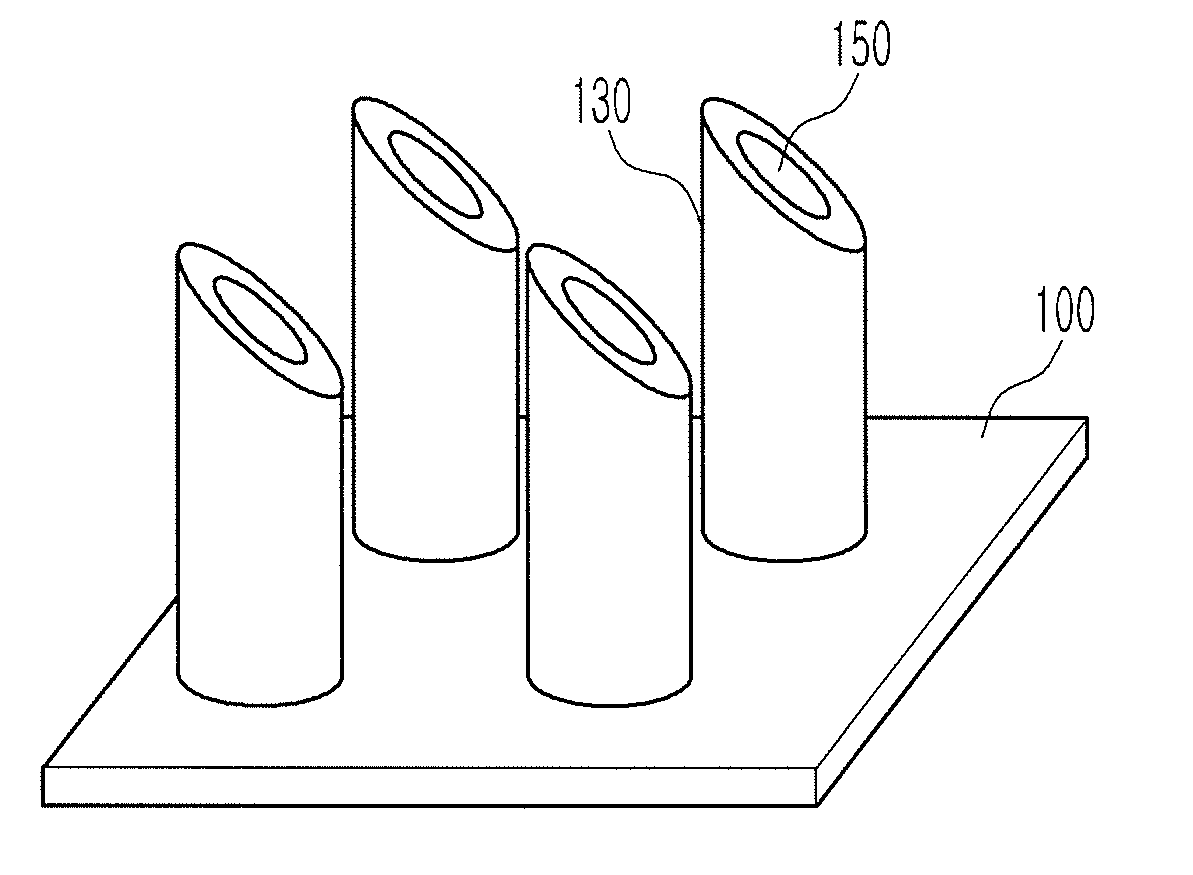

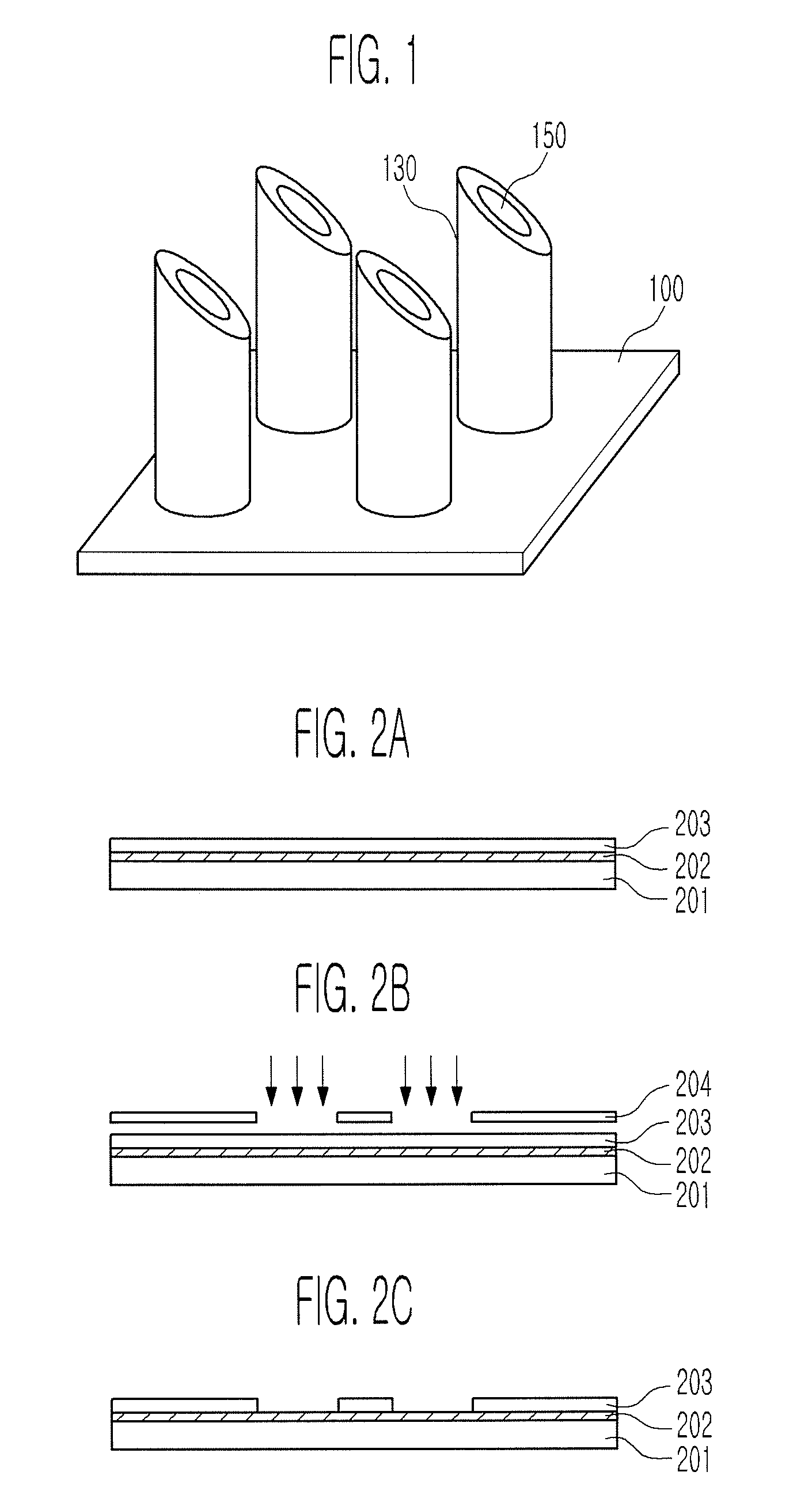

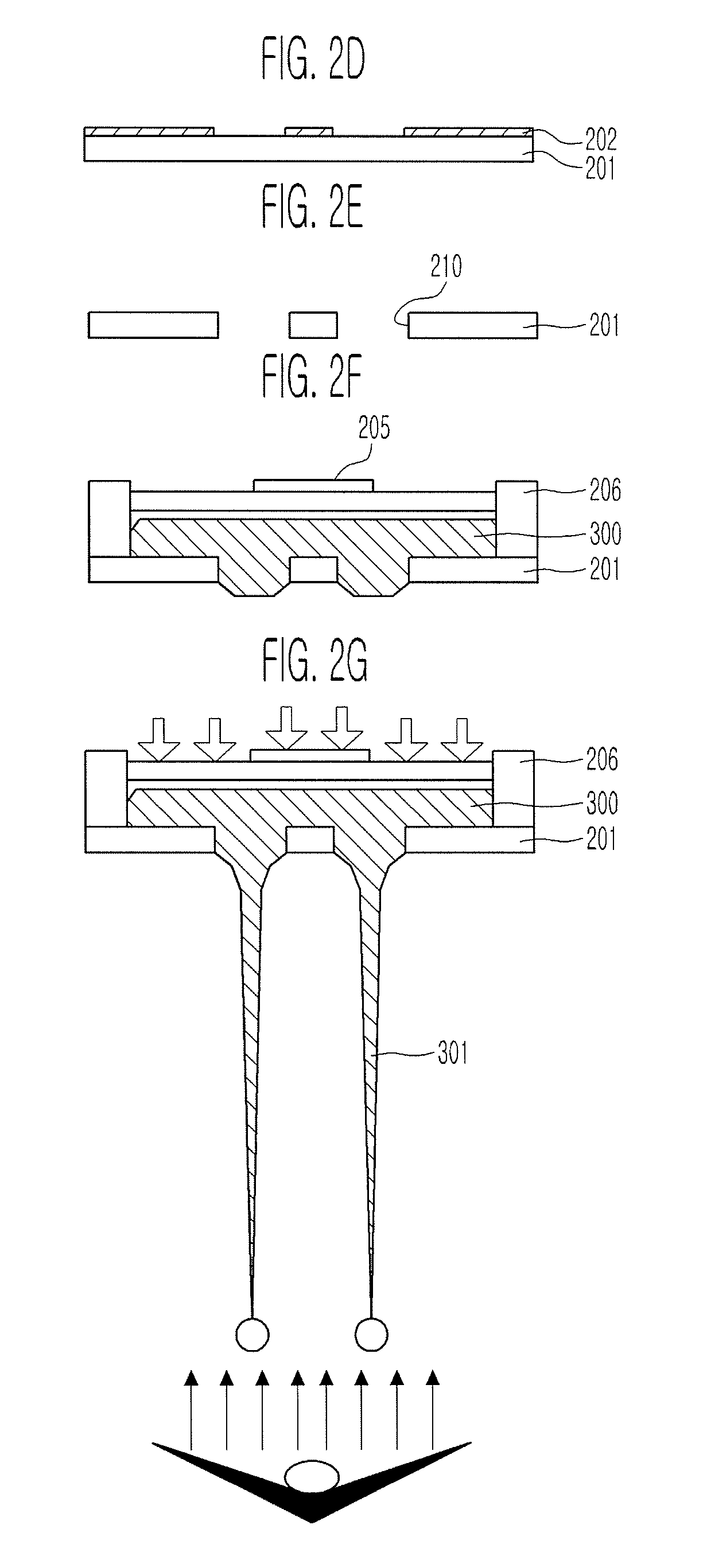

Method of manufacturing hollow microneedle structures

ActiveUS20110011827A1Prevent hardeningSimply formedFruit and vegetables preservationInfusion syringesPhotoresistResist

Provided is a method of manufacturing a hollow microneedle structure. The method includes forming an injection mold having a through hole, filling the injection mold with a photoresist formed of a viscous material, and extruding the photoresist from the injection mold through the through hole, solidifying the extruded photoresist to form a needle-type photoresist structure, forming a seed layer on the surface of the photoresist structure, forming a metal plated layer on the seed layer, inclining an end tip of the photoresist structure having the metal plated layer, and removing the photoresist from the metal plated layer to form a hollow. Thus, the hollow microneedle structure can be manufactured to have such diameter, length, hardness, and inclination angle as to minimize pain. The hollow microneedle structure can be combined with an apparatus for detecting a biomaterial or injecting cosmetic substances or medicines, and variously applied.

Owner:ELECTRONICS & TELECOMM RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com