Patents

Literature

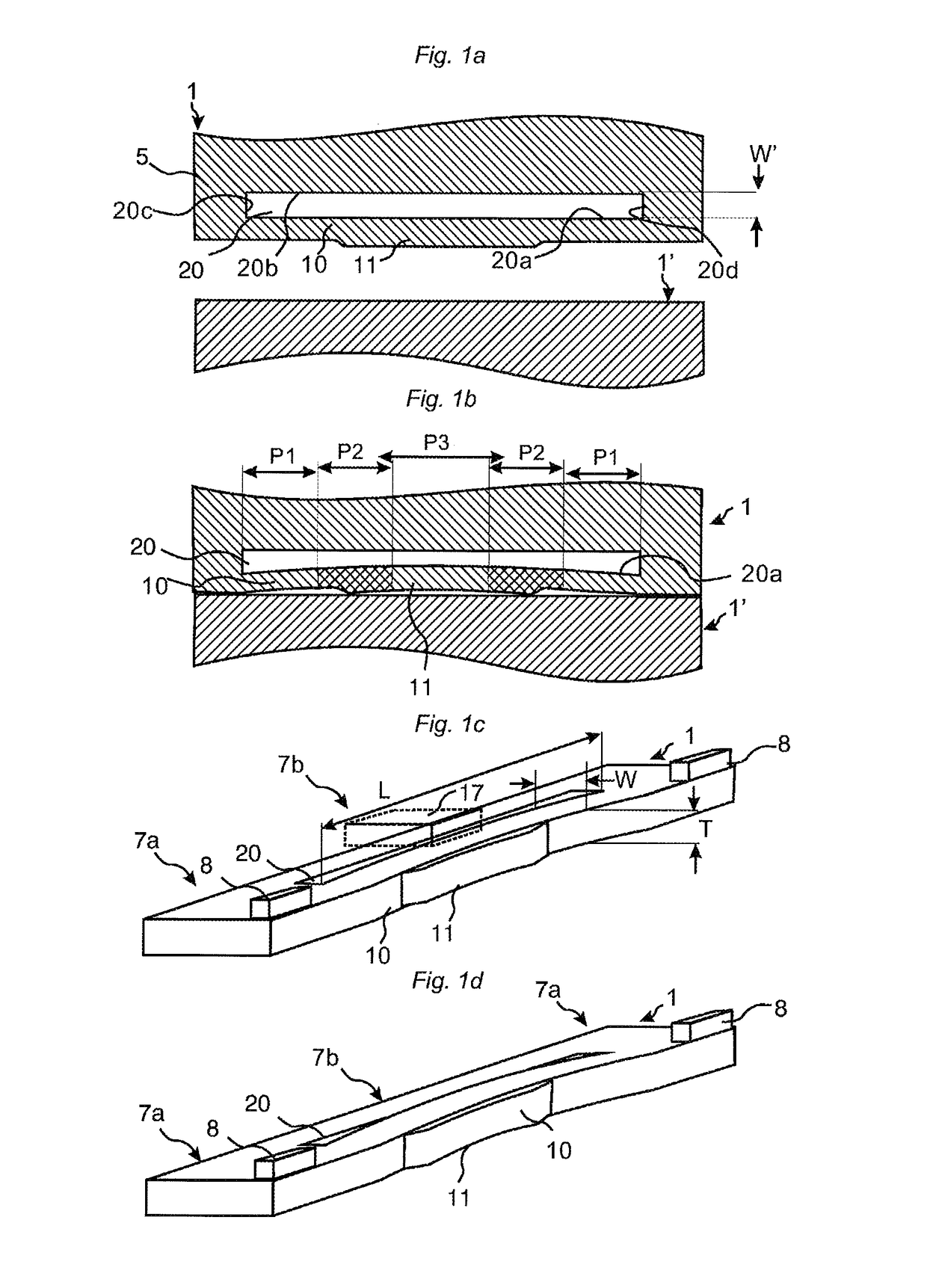

230results about How to "High locking strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

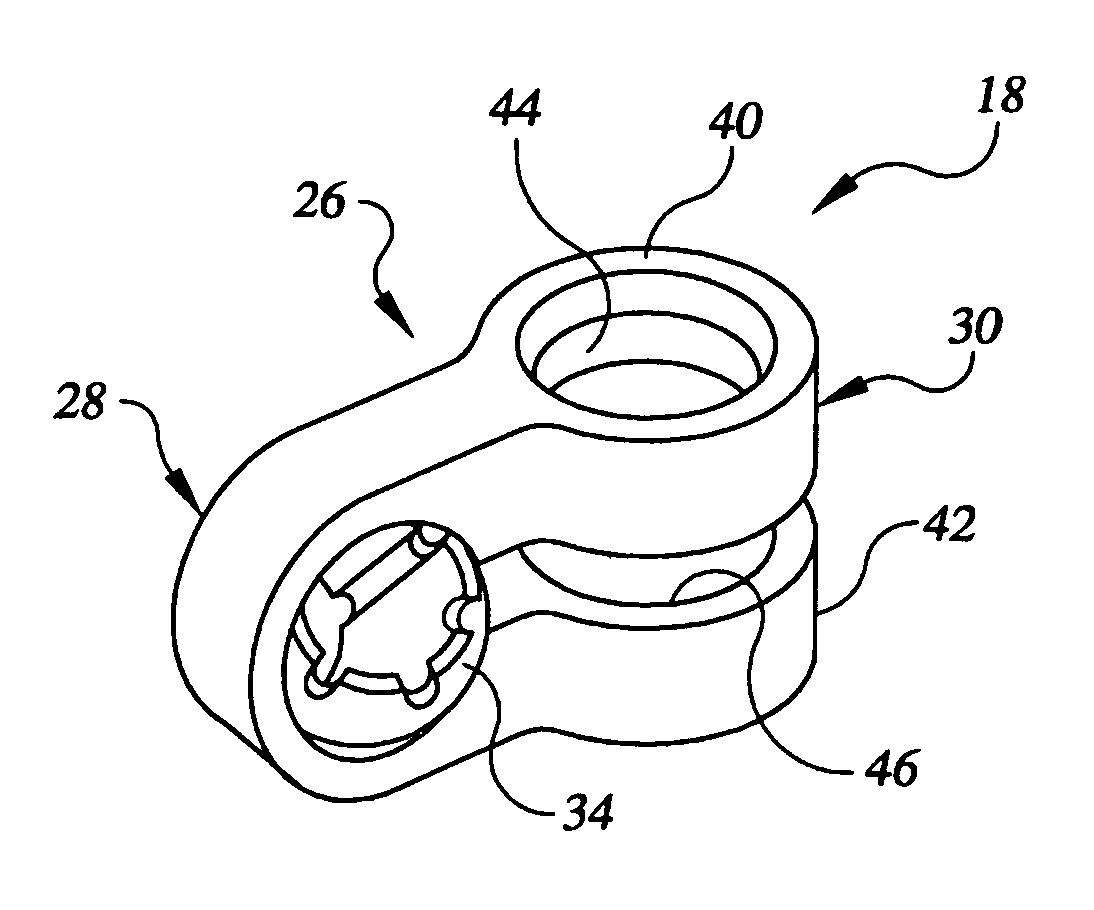

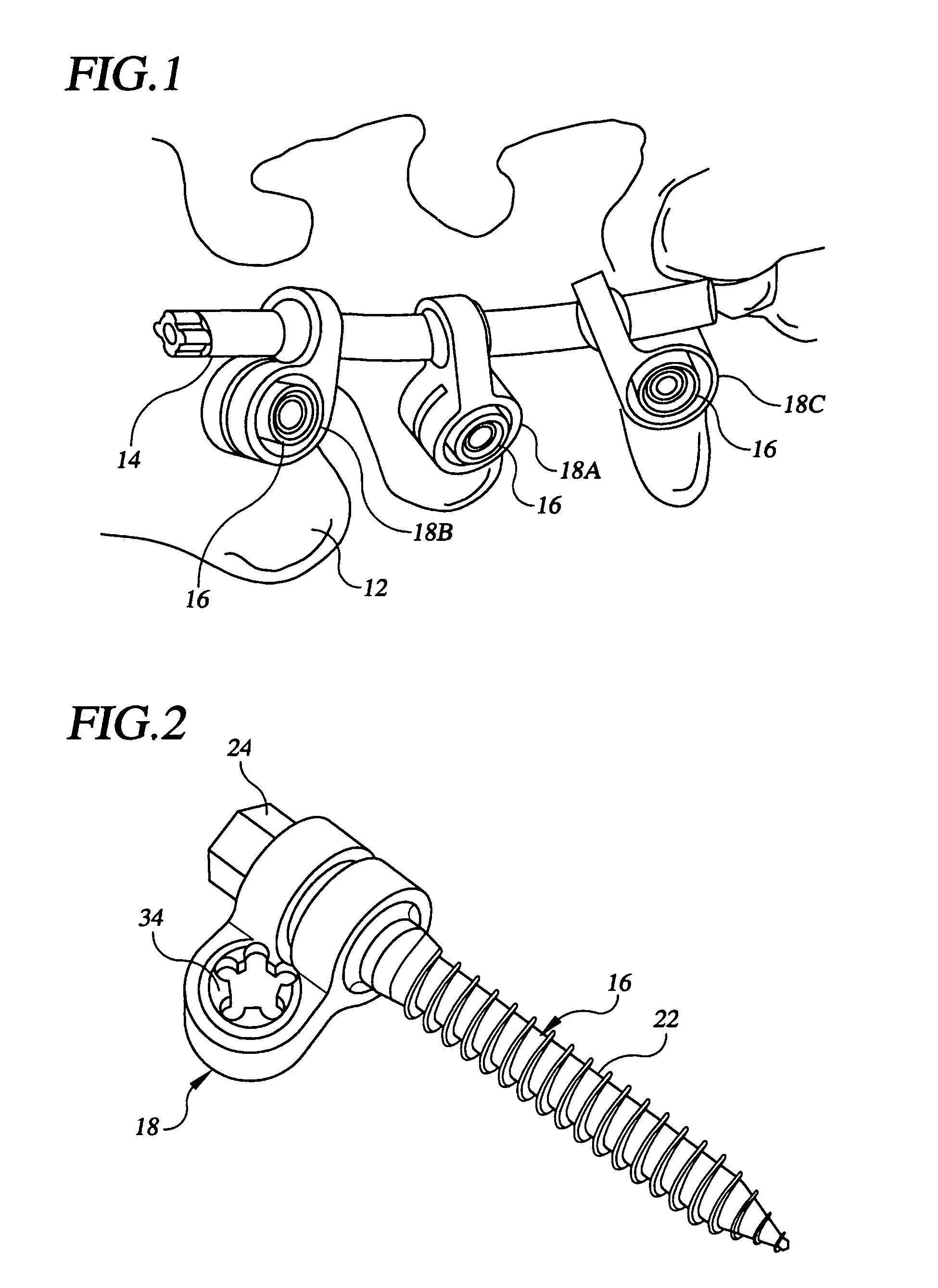

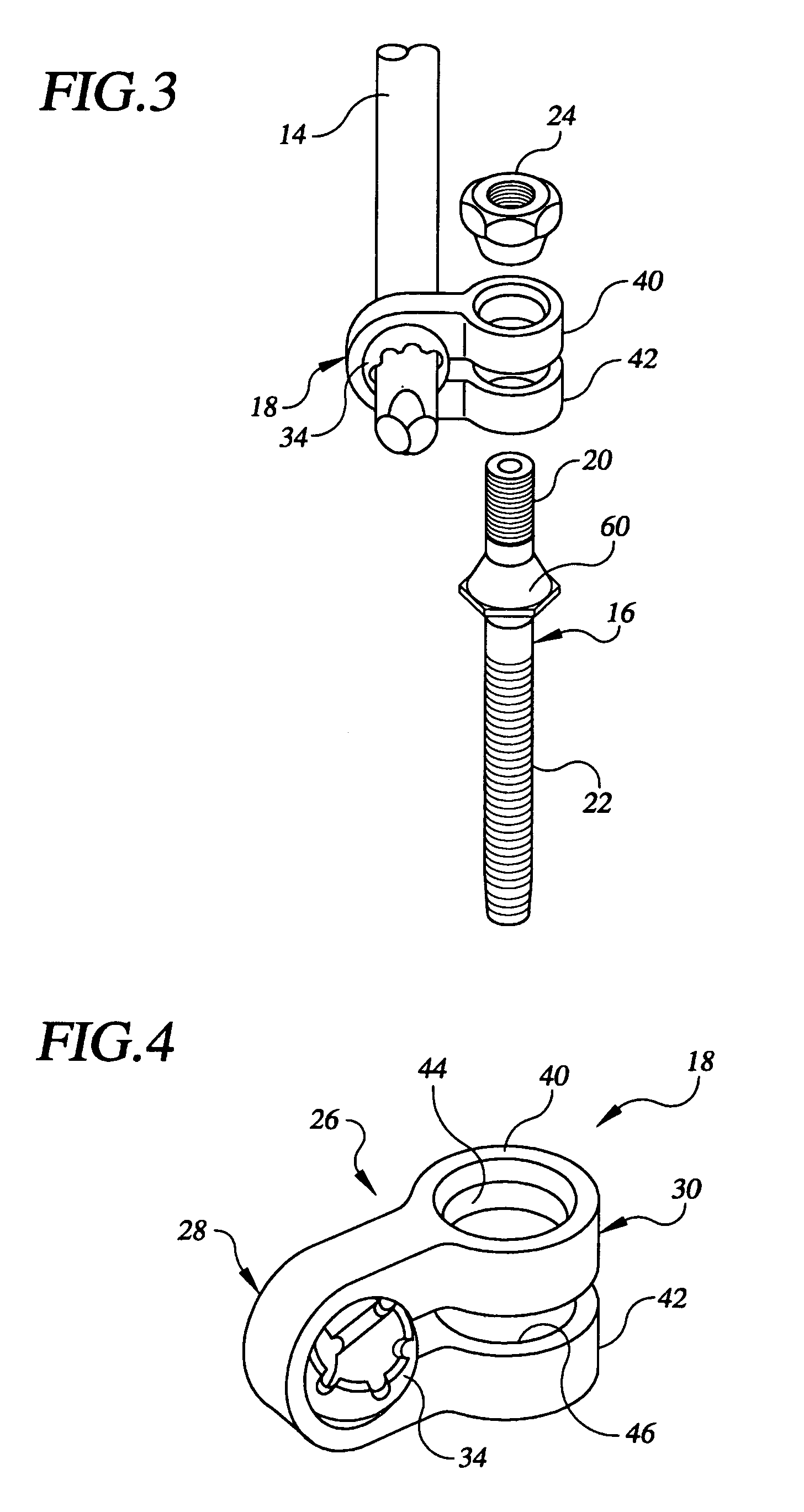

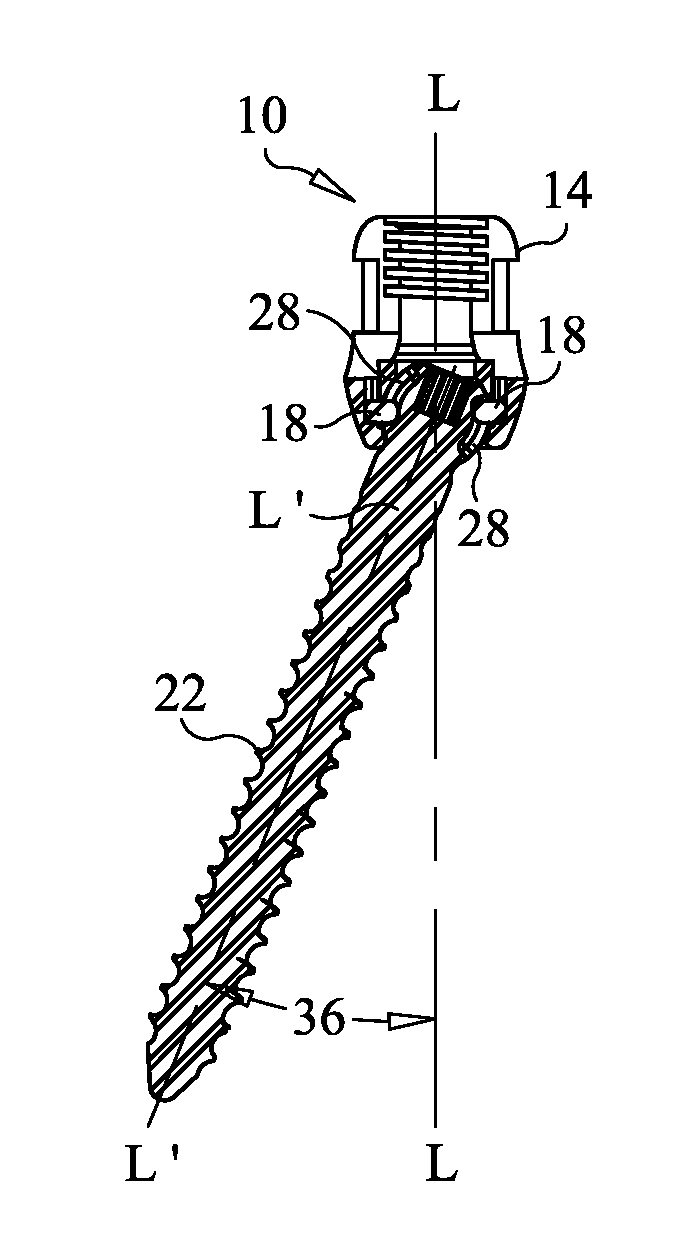

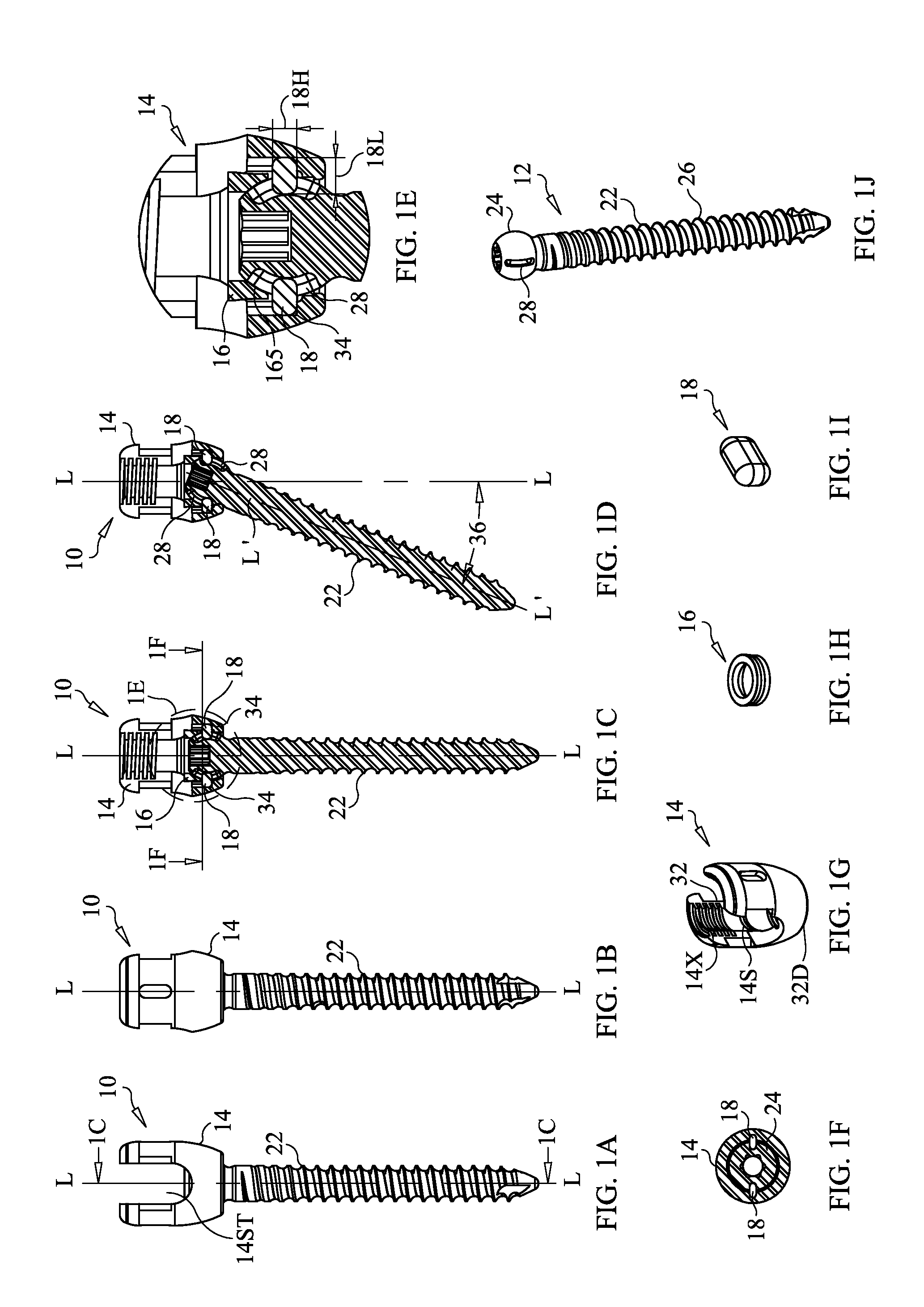

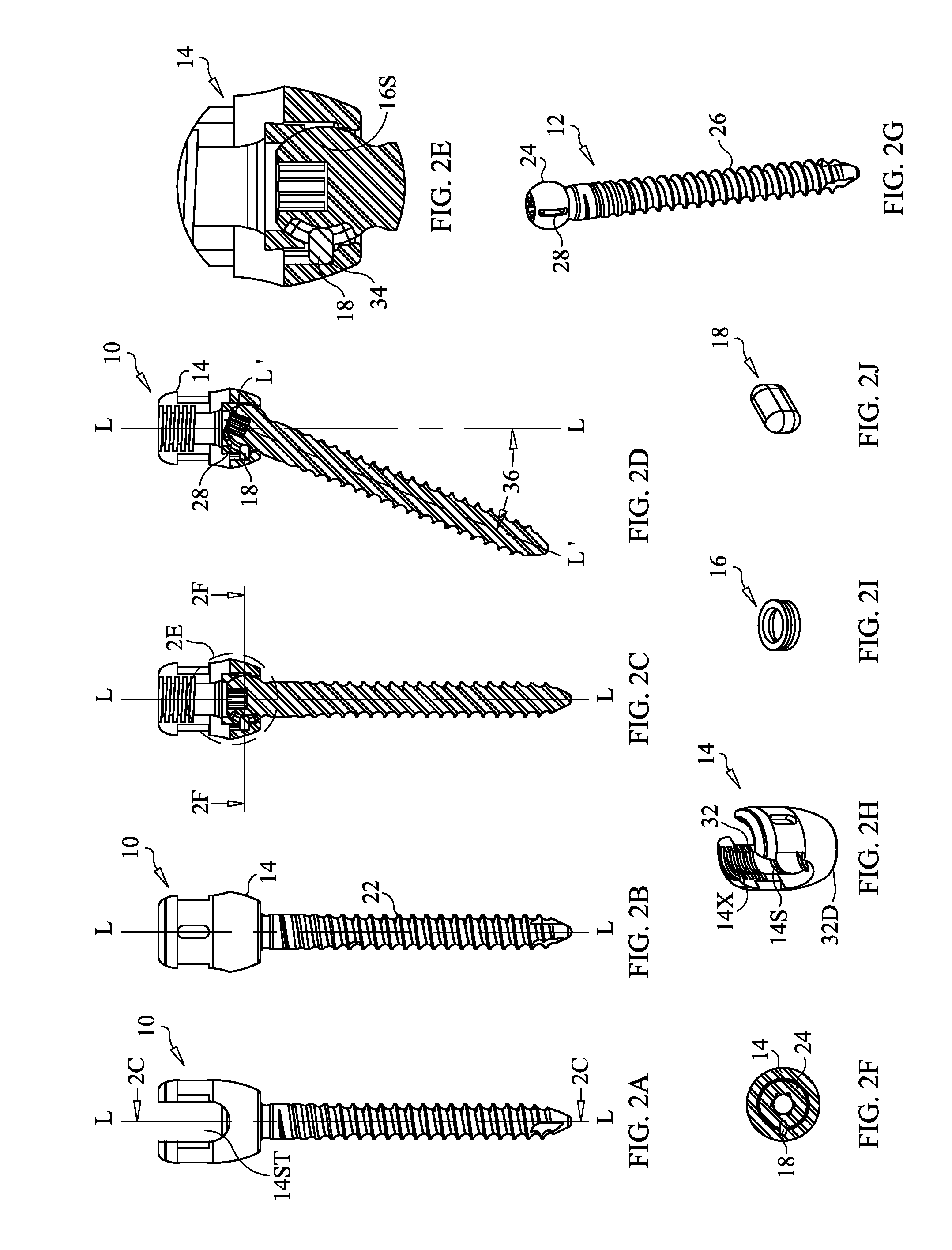

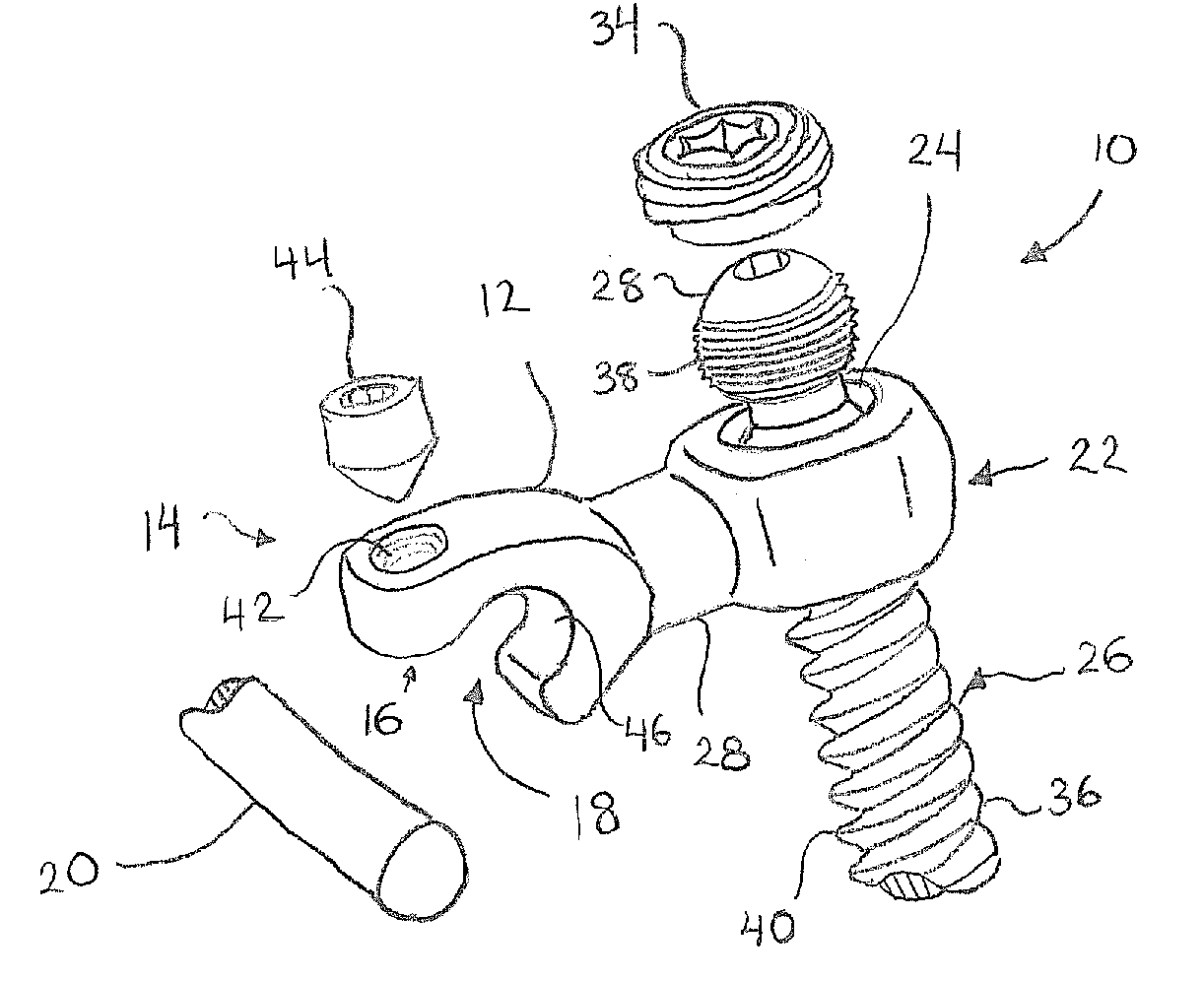

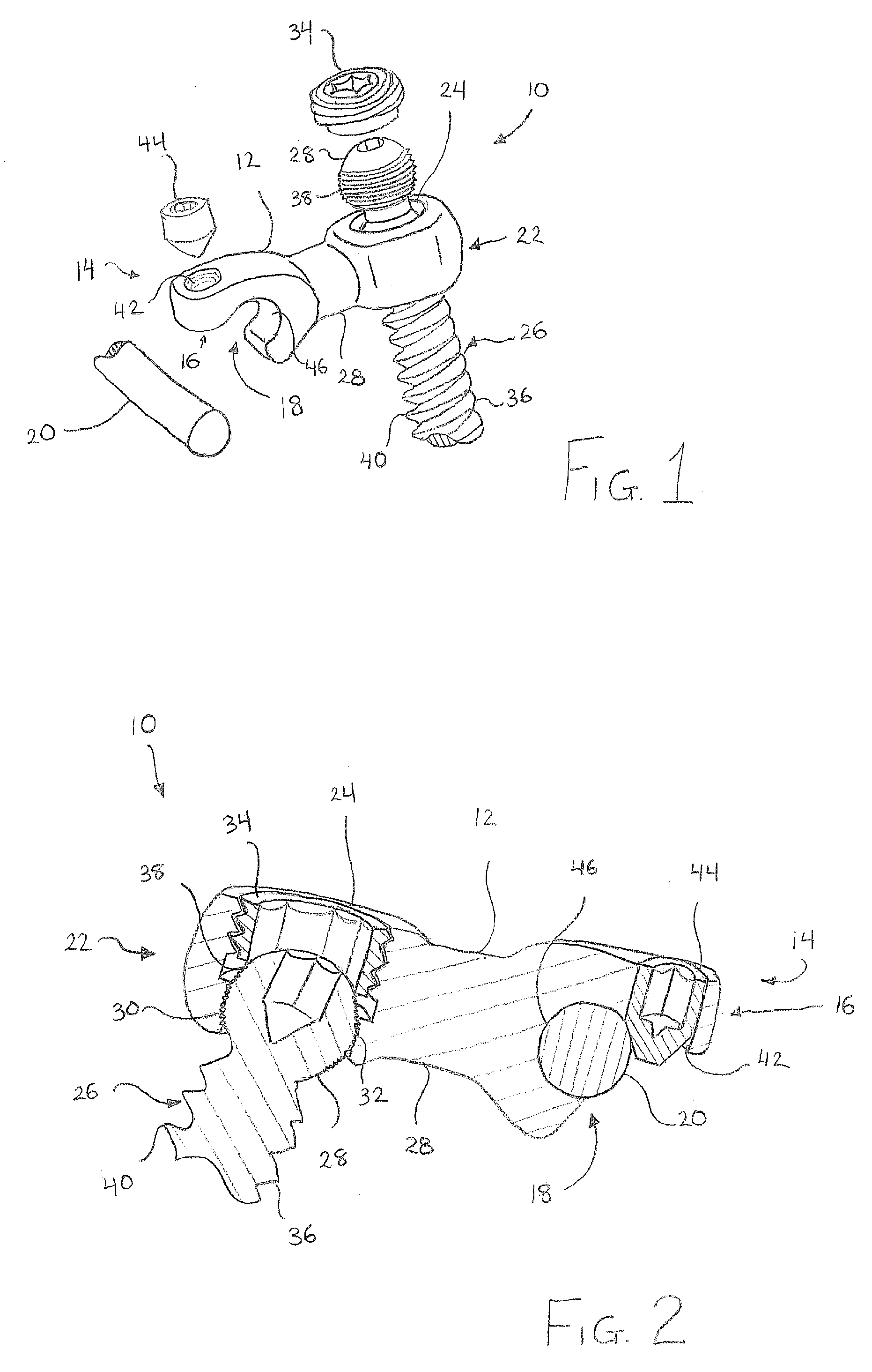

Spinal fixation system

ActiveUS7104992B2Uniform collapseHigh locking strengthInternal osteosythesisJoint implantsScrew threadBiomedical engineering

A spinal fixation system includes a rod, an anchor, and a clamp assembly. The anchor is adapted to engage a bone. The clamp assembly secures the anchor to the rod. The clamp assembly includes a first portion with first and second flanges for receiving the anchor. A compressible ball is carried by the second portion of the clamp assembly. The ball has a through hole receiving the rod. The through hole is defined by a generally cylindrical inner surface having at least one relieved channel. The first and second flanges include first and second opposing surfaces, respectively. The first and second opposing surfaces are normally angled relative to one another. A nut which threadably engages an upper shaft of the fastener is tightened to draw together the first and second flanges to a position in which they are generally parallel to one another. At least a portion of the through hole tapers from one of the first and second ends towards a center of the ball.

Owner:ZIMMER BIOMET SPINE INC

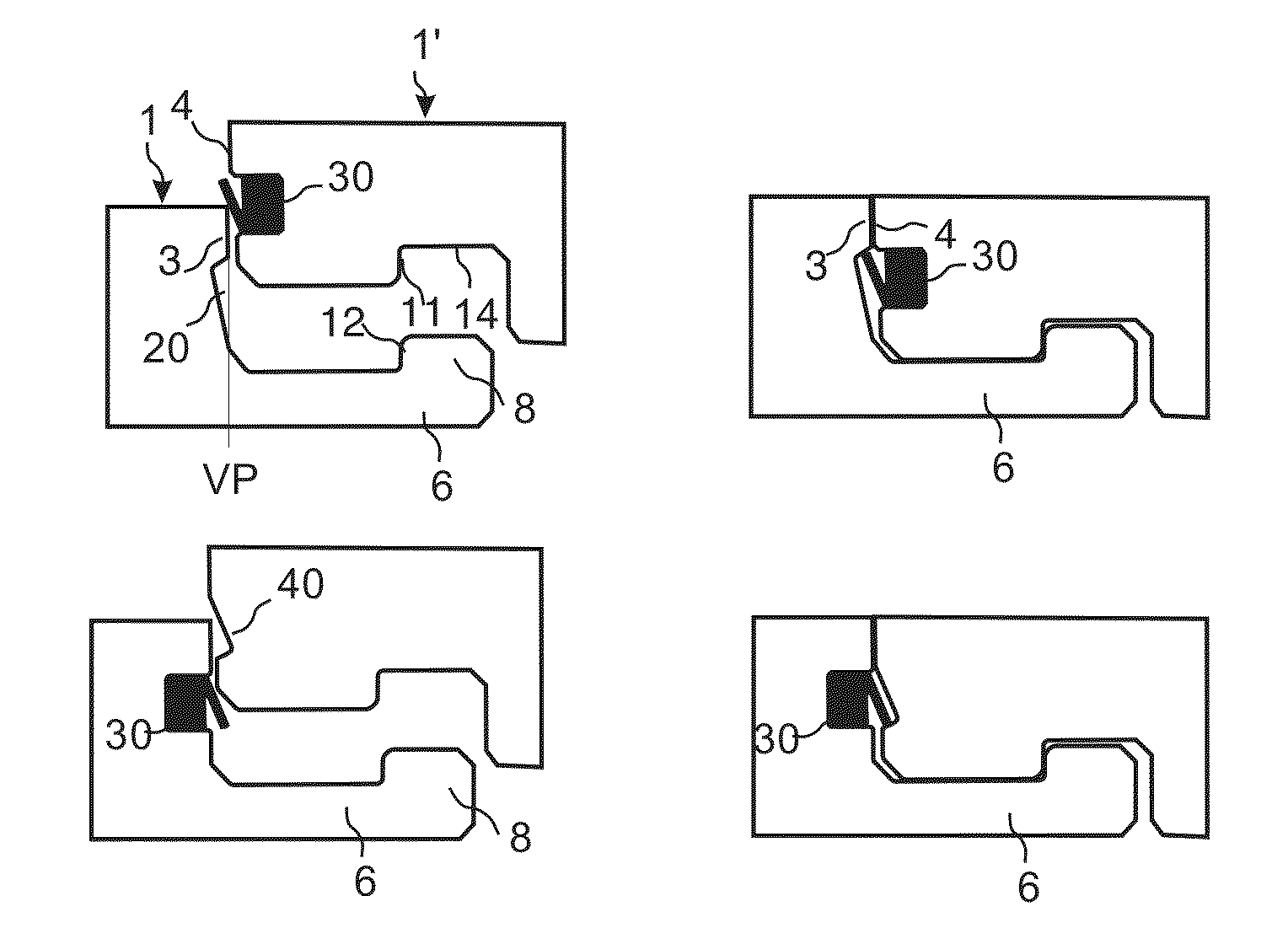

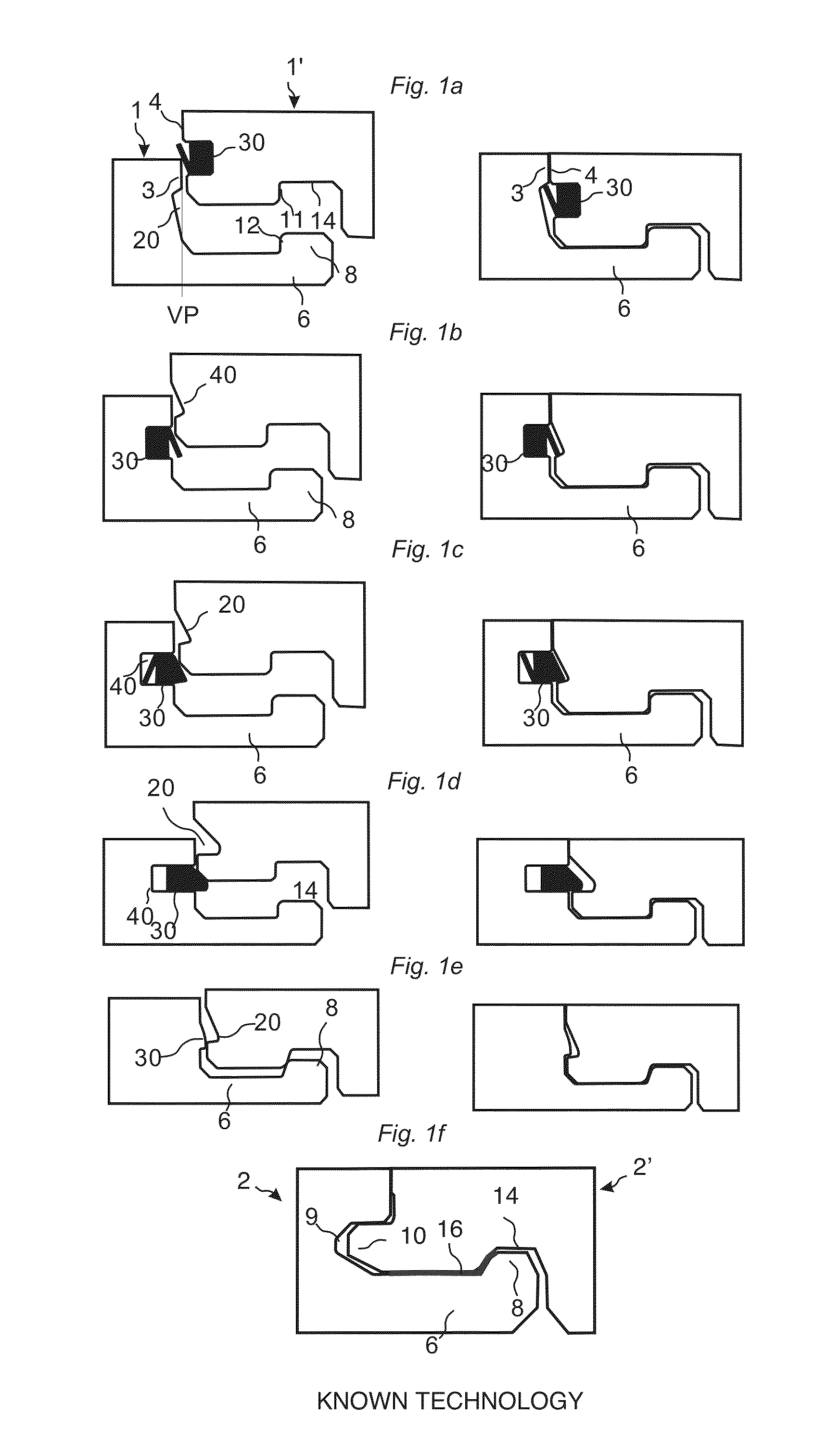

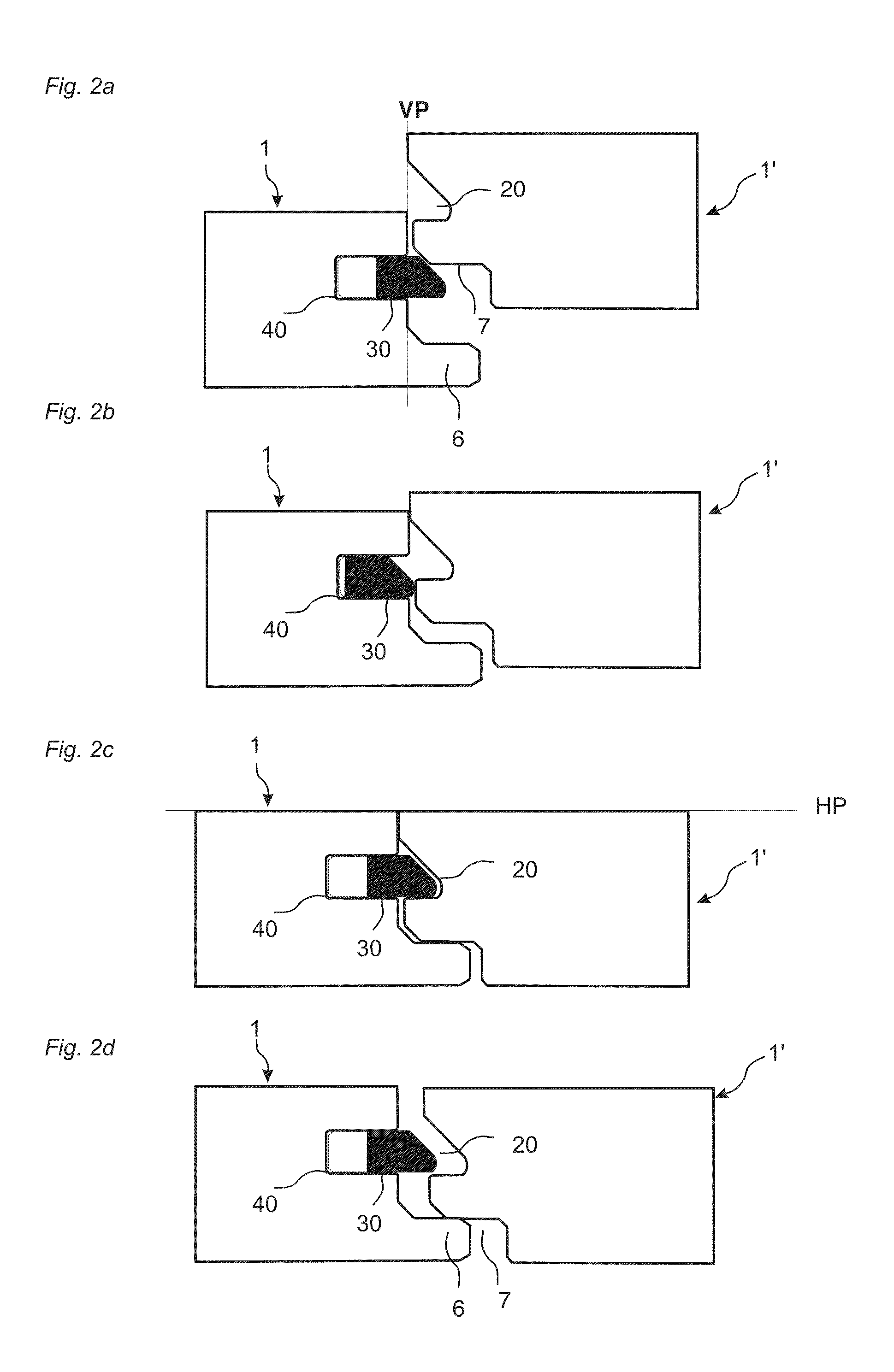

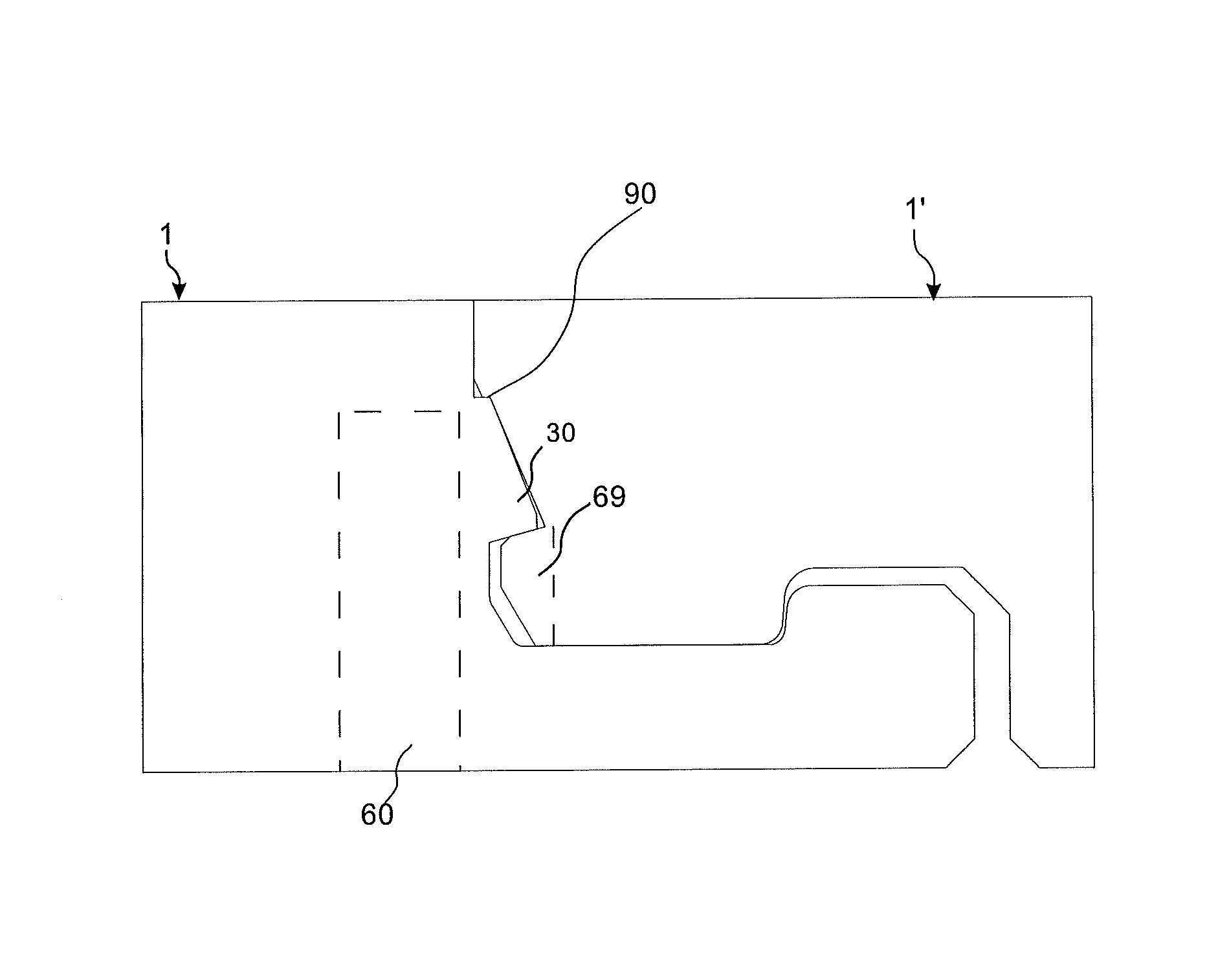

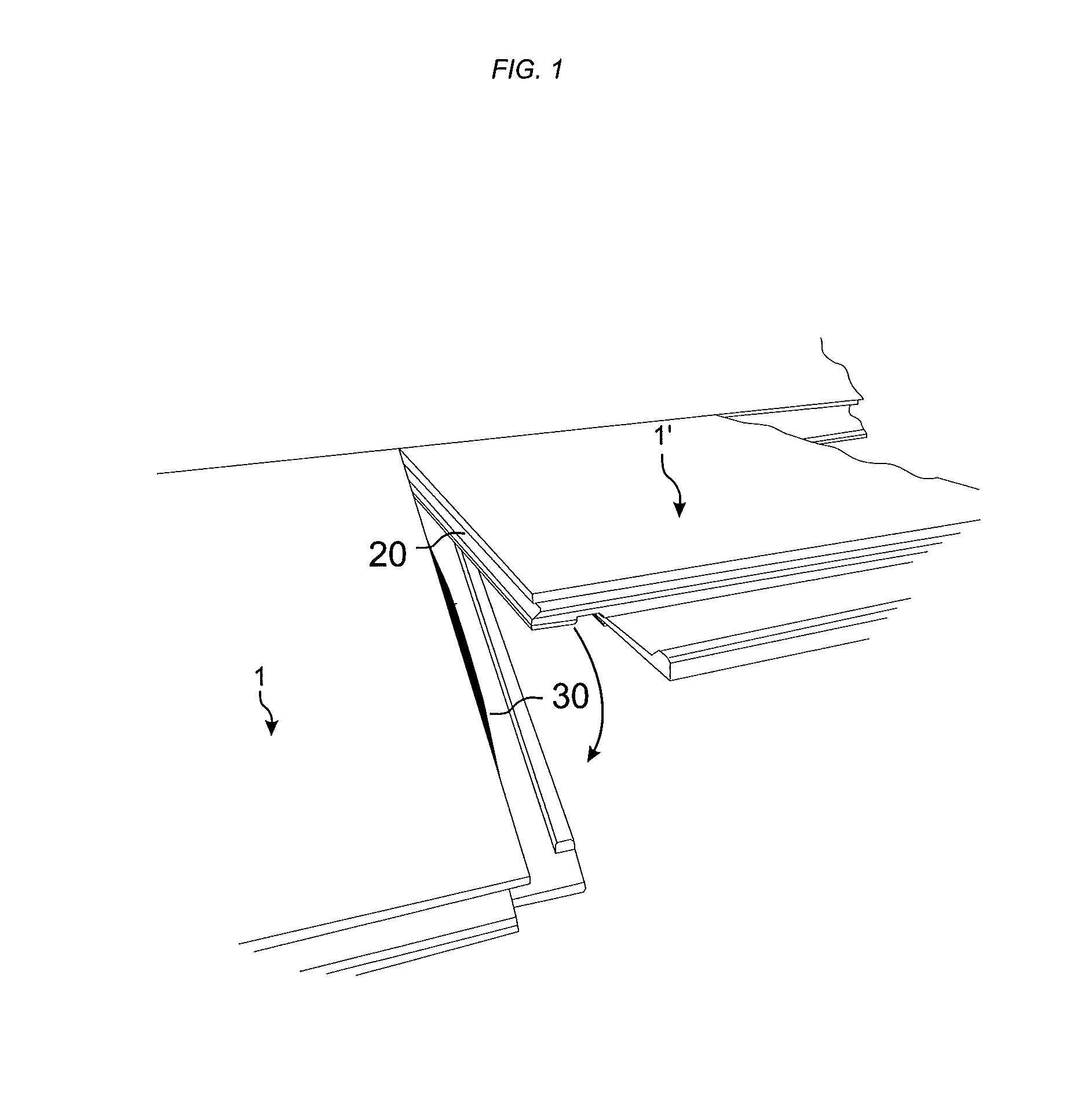

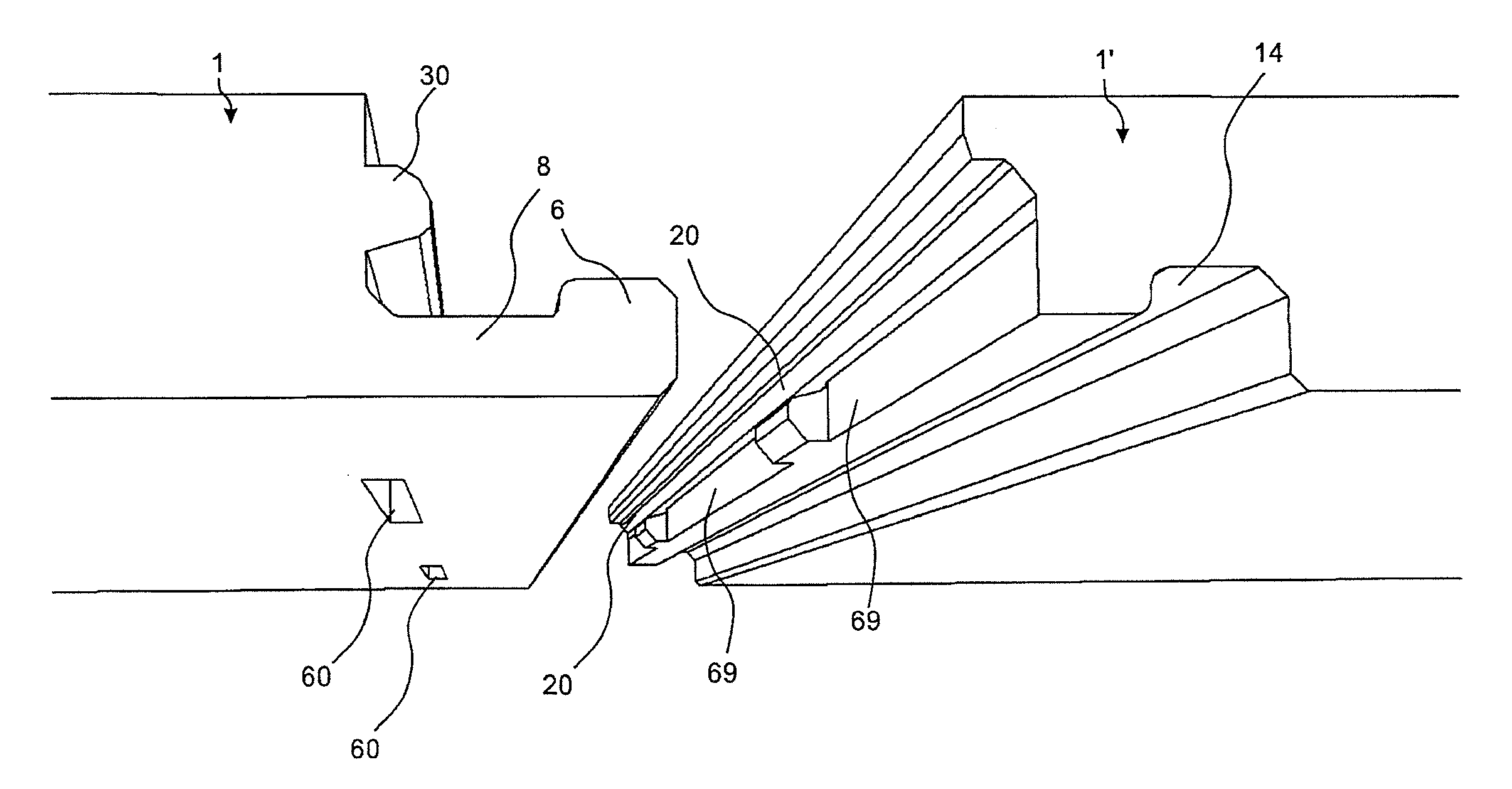

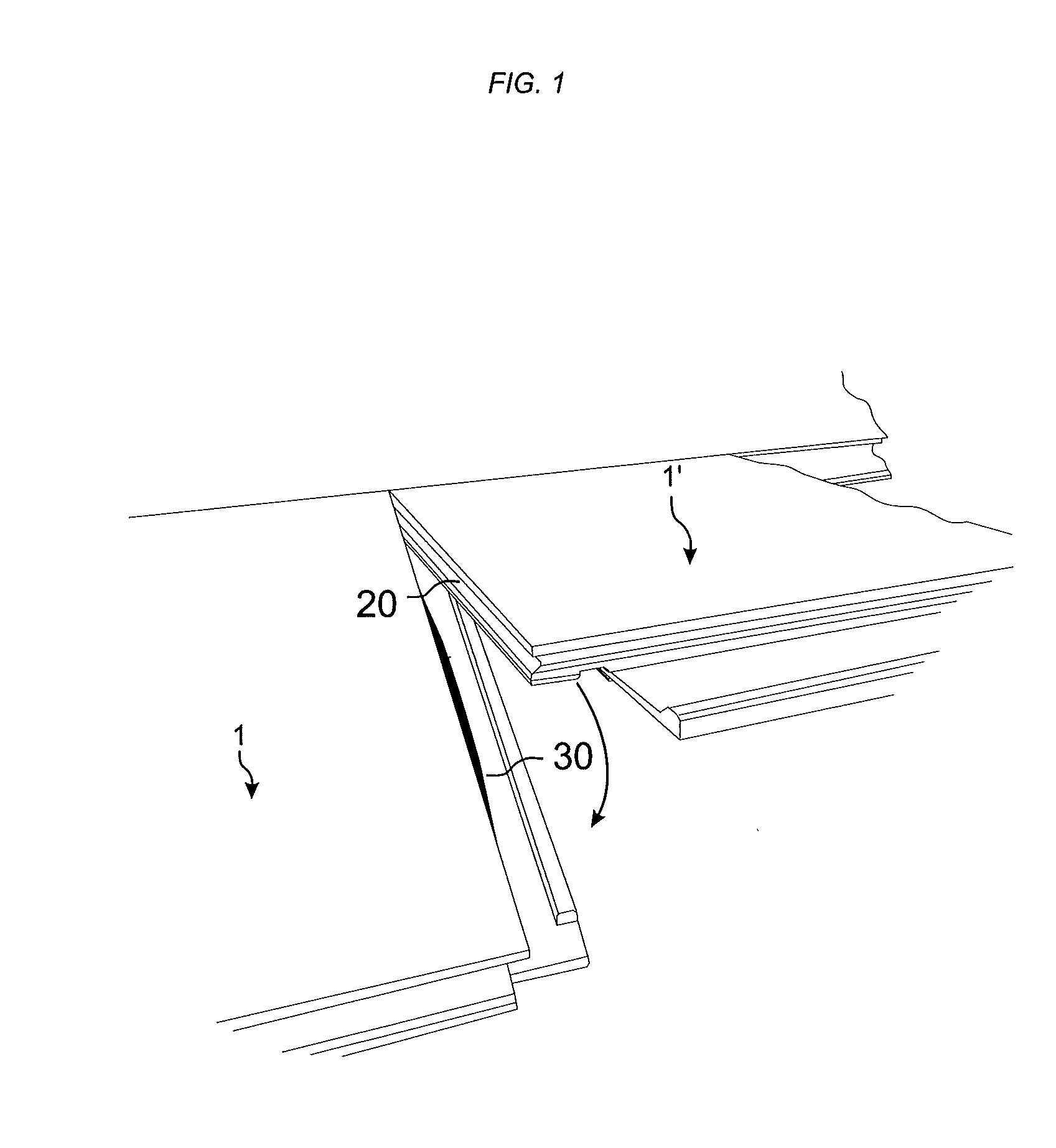

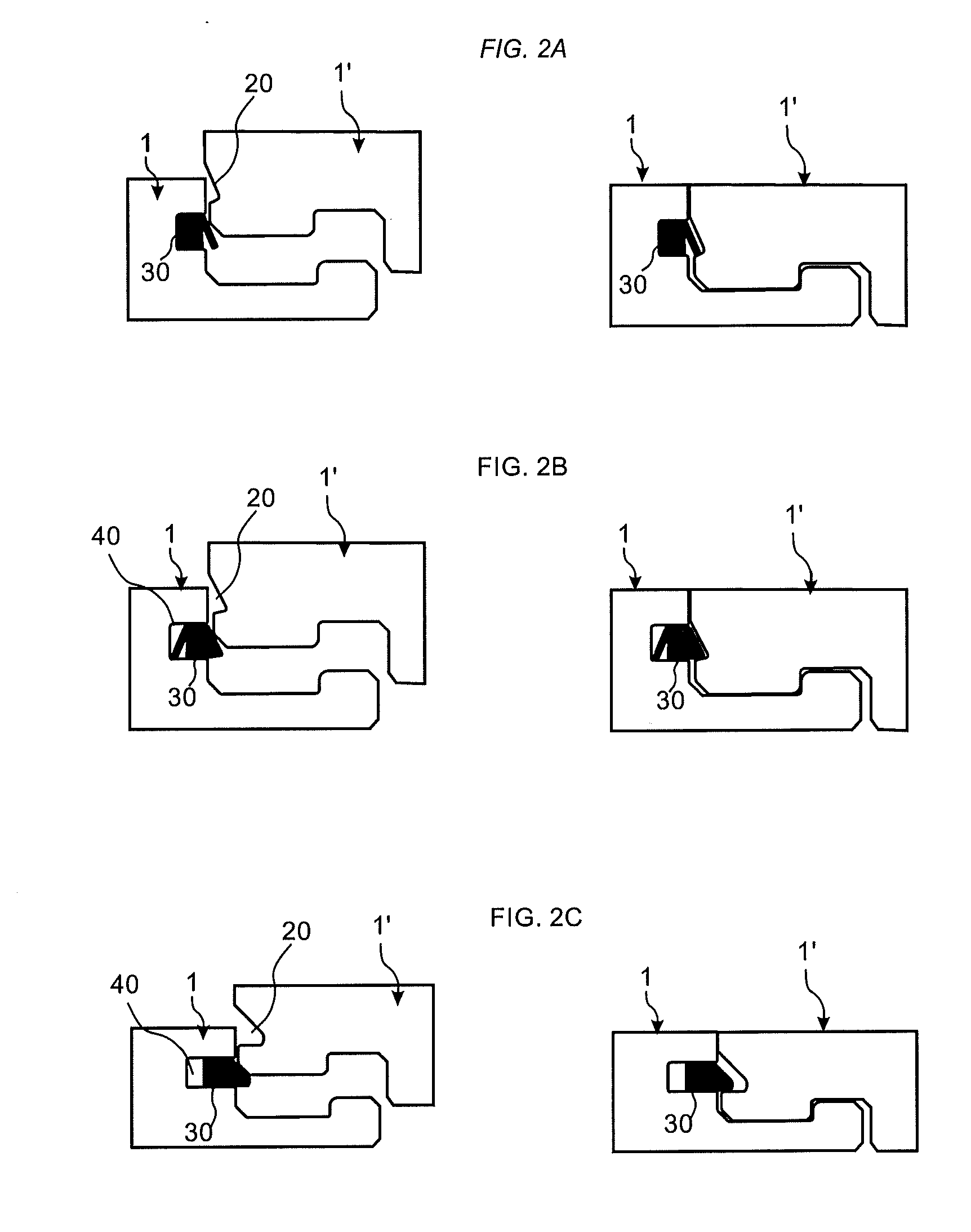

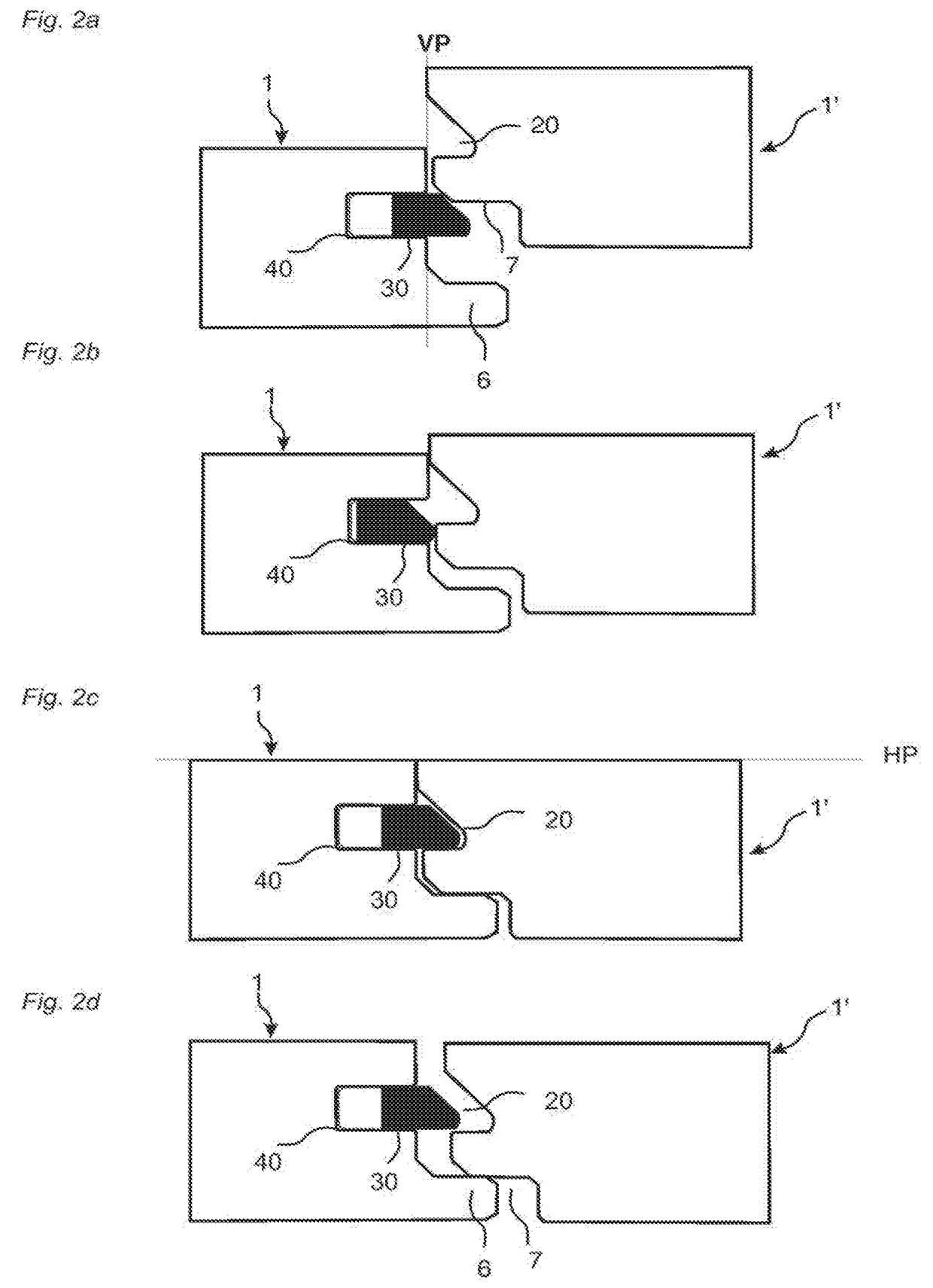

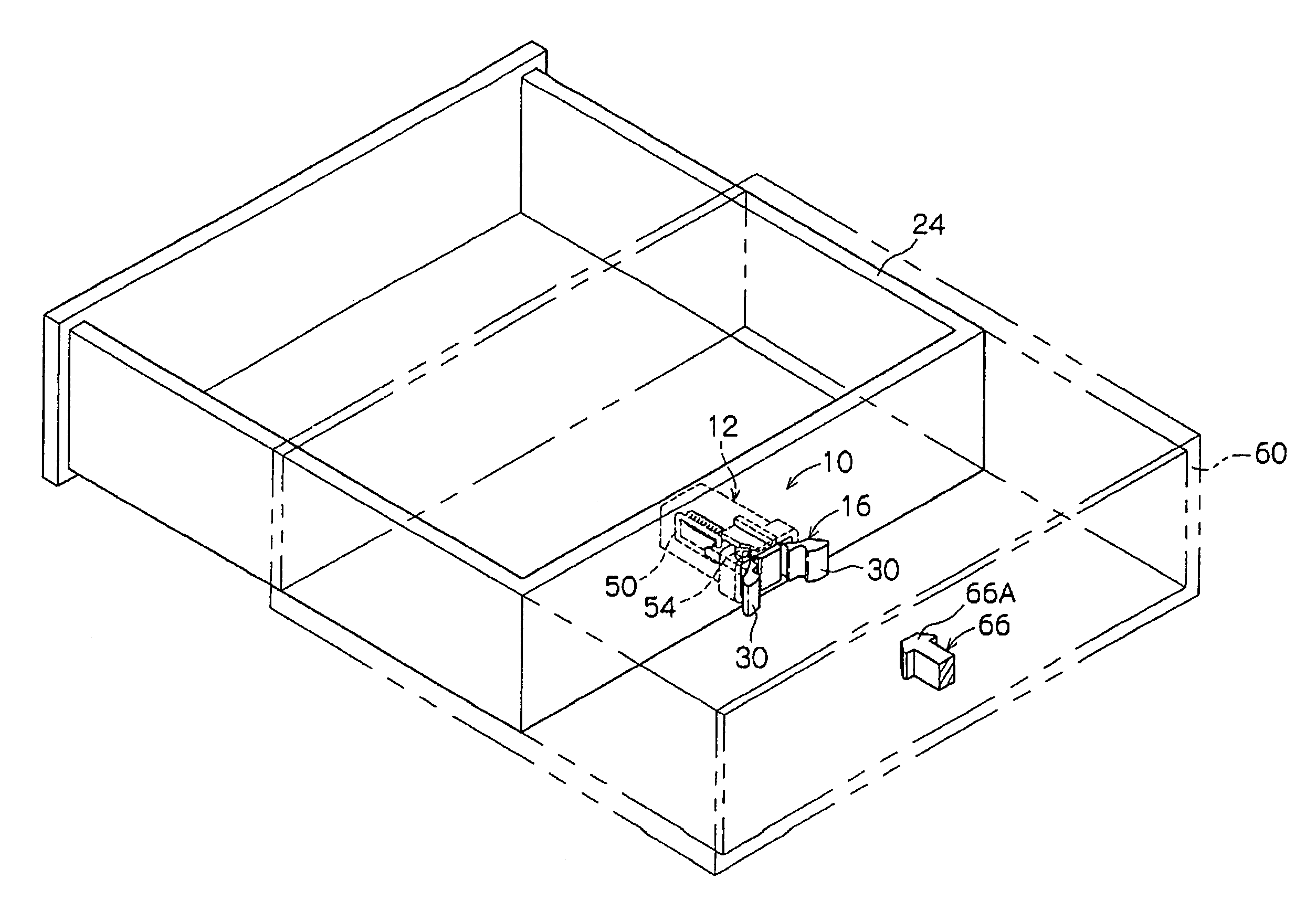

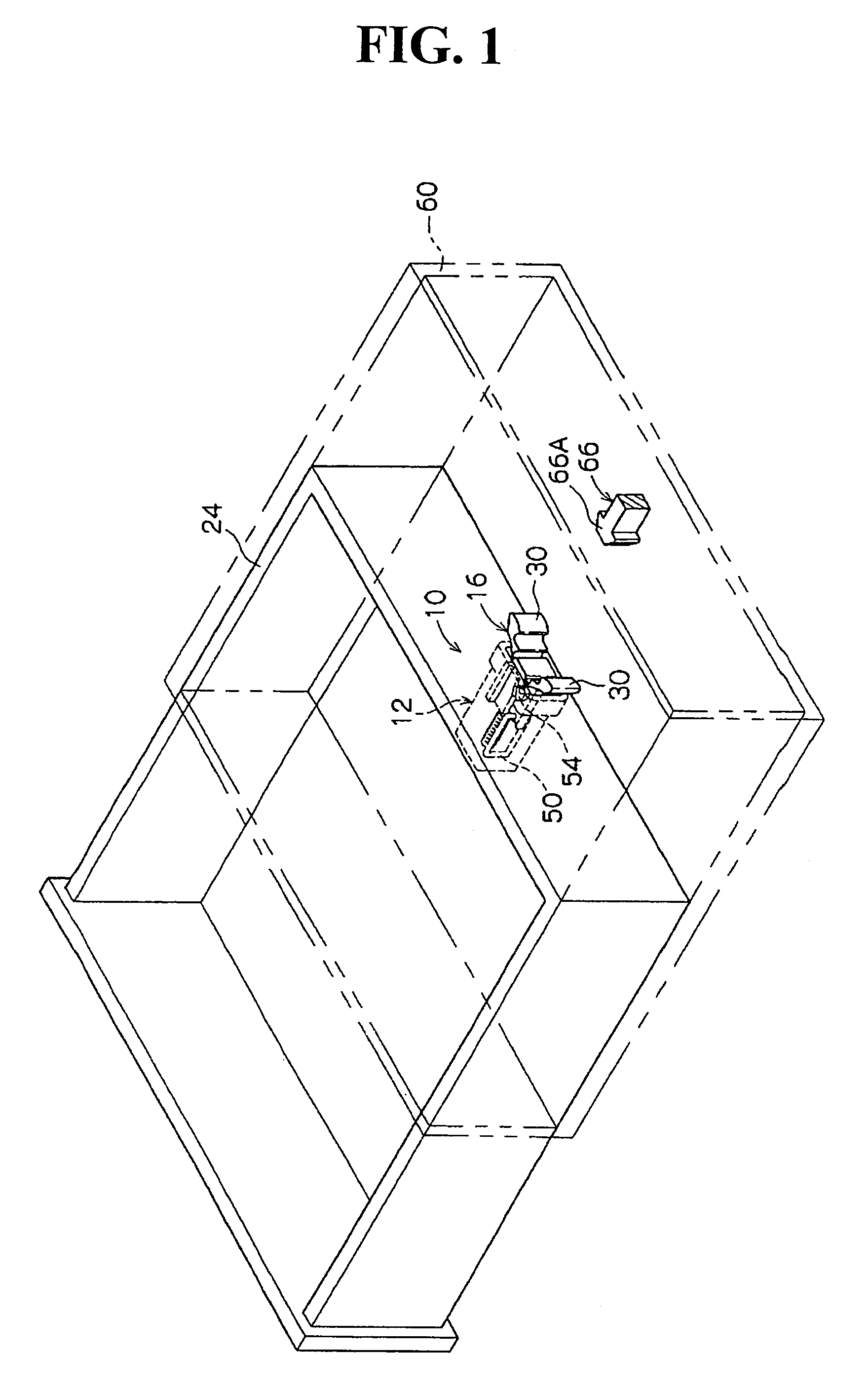

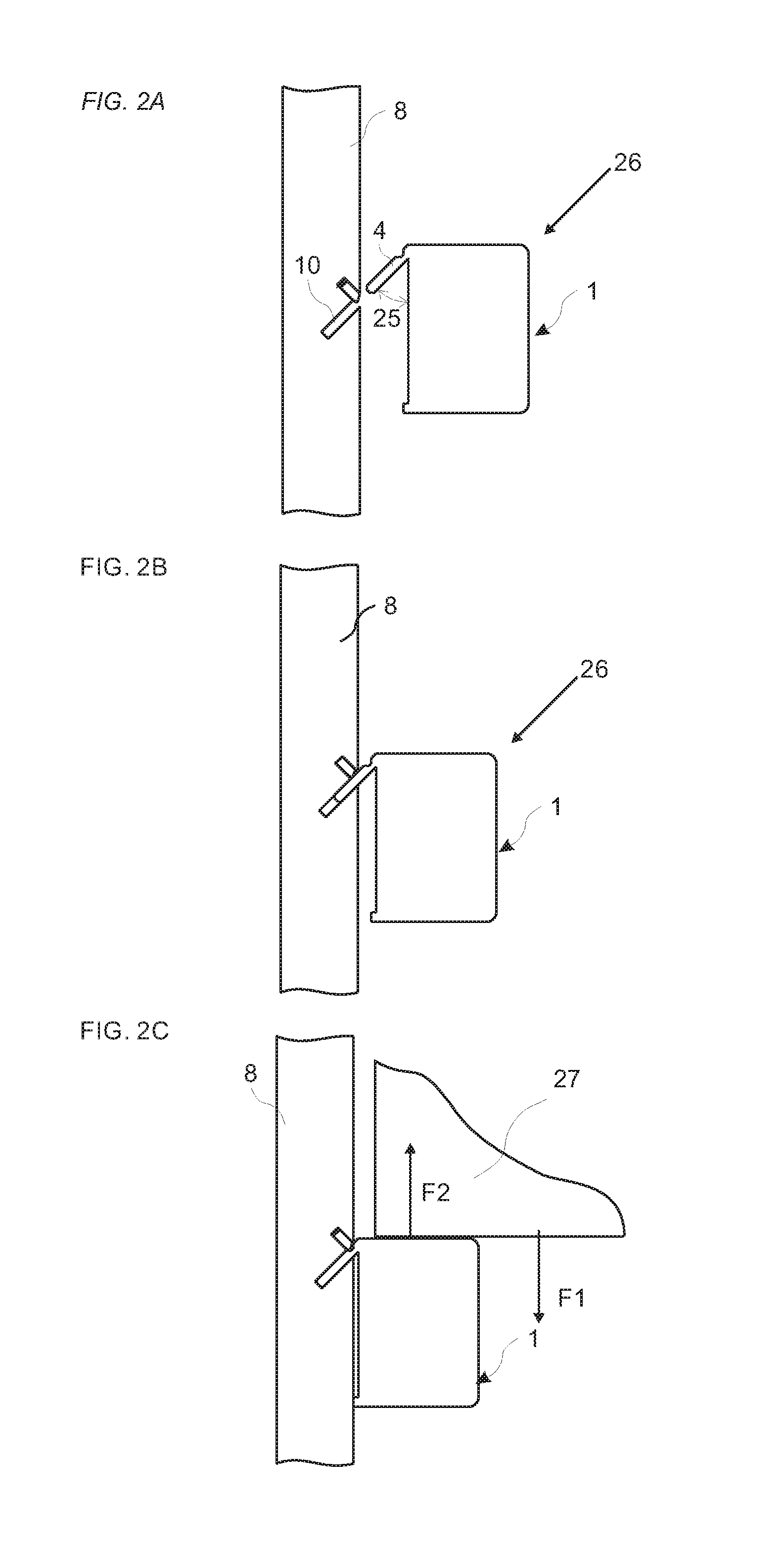

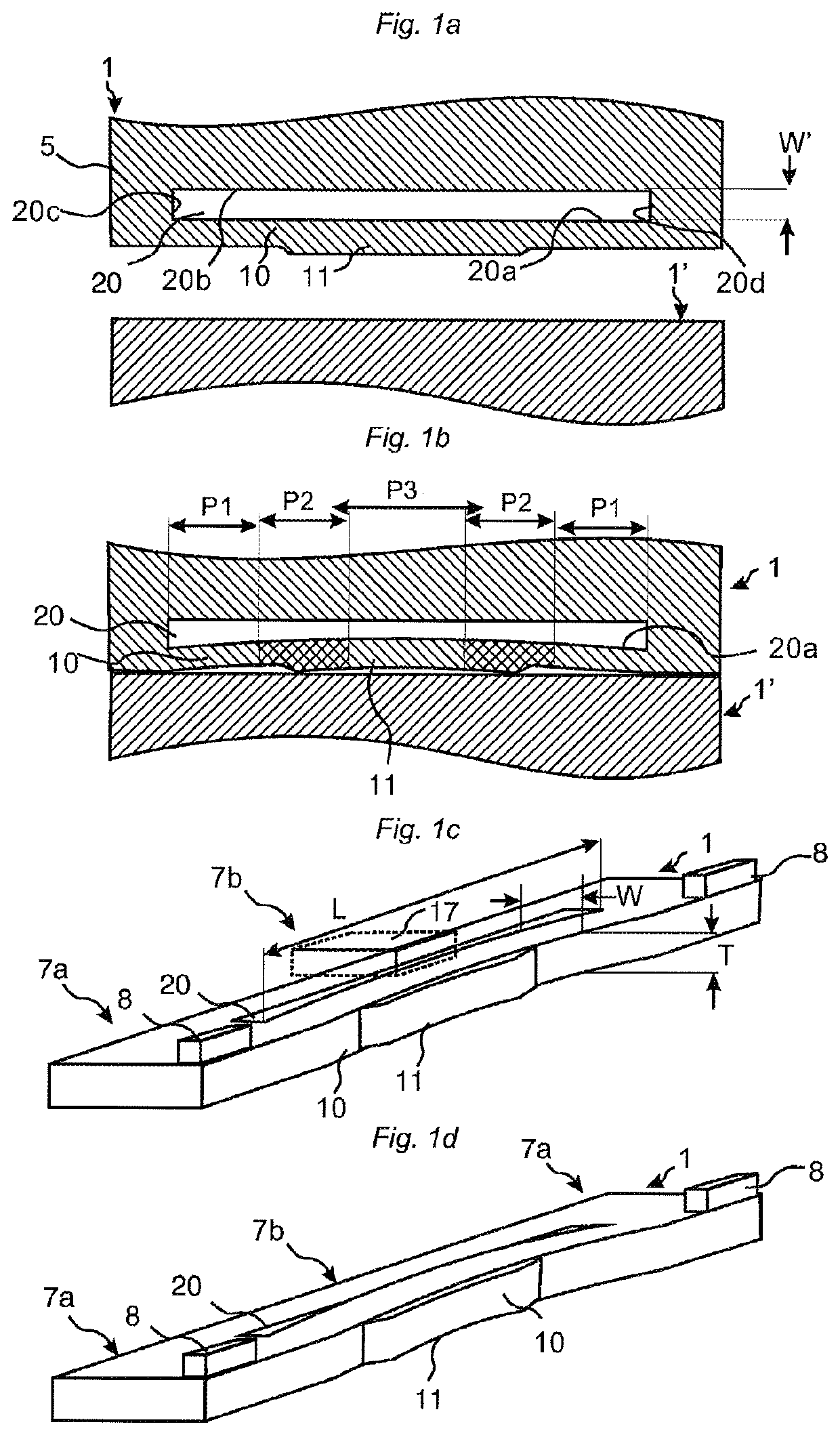

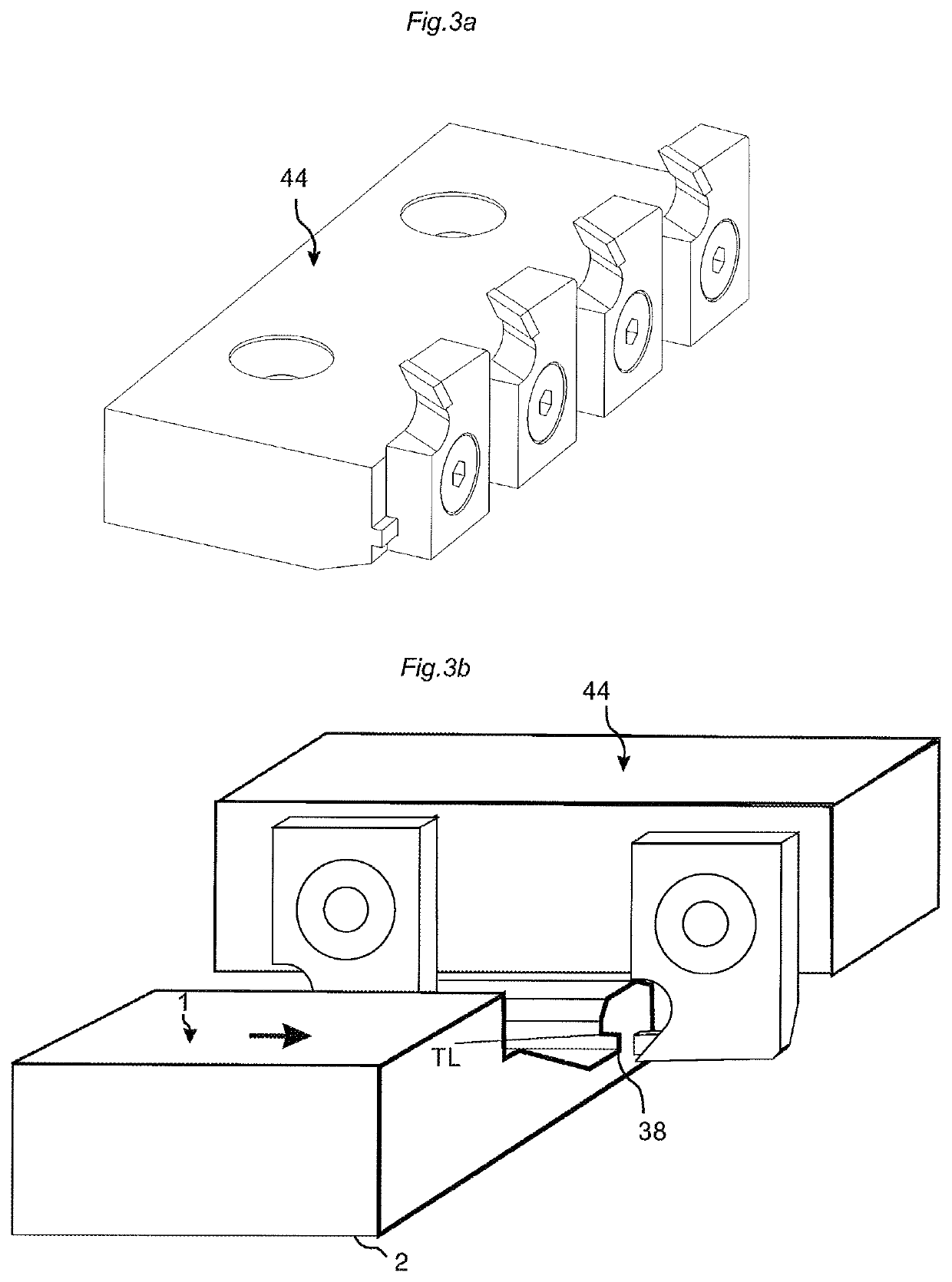

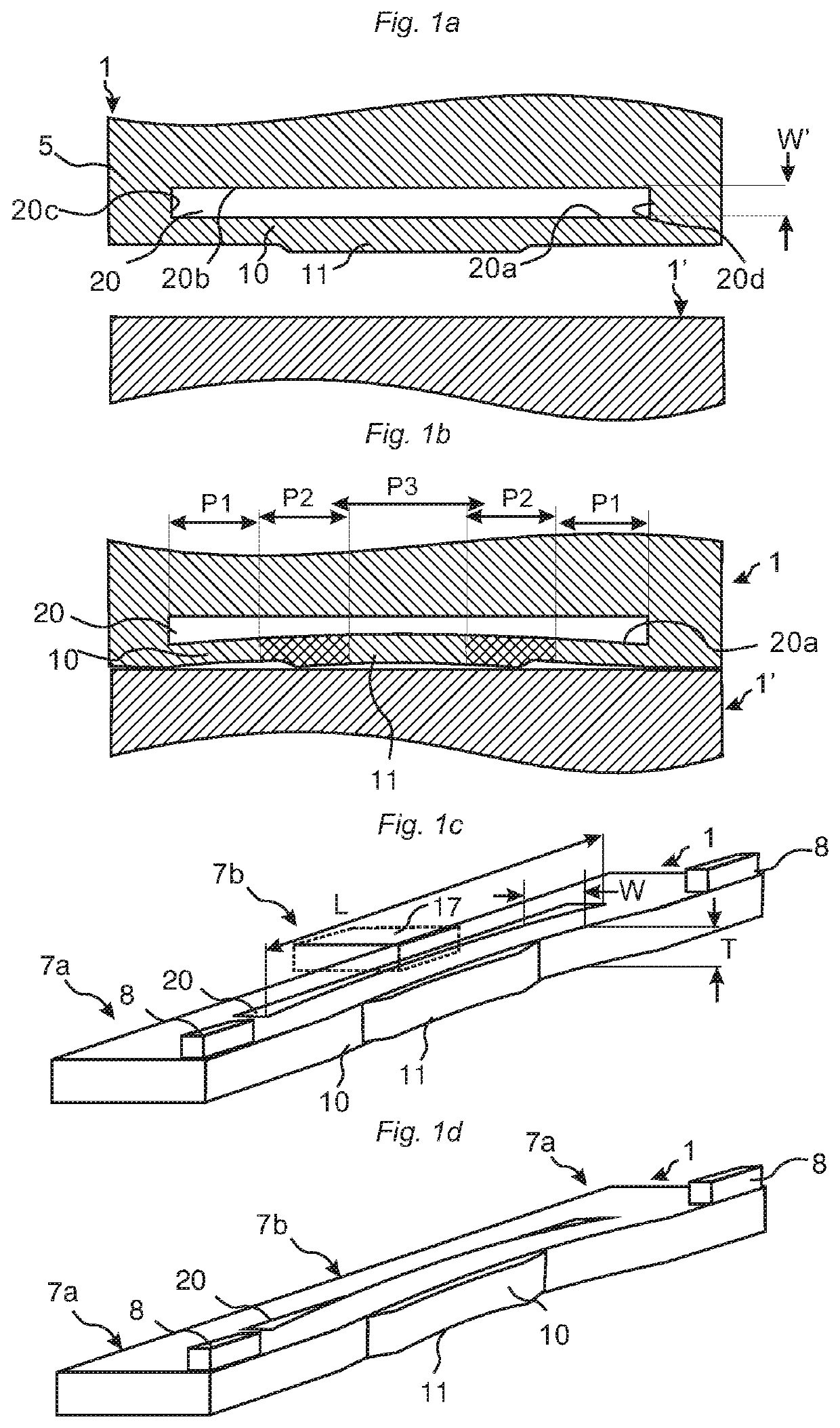

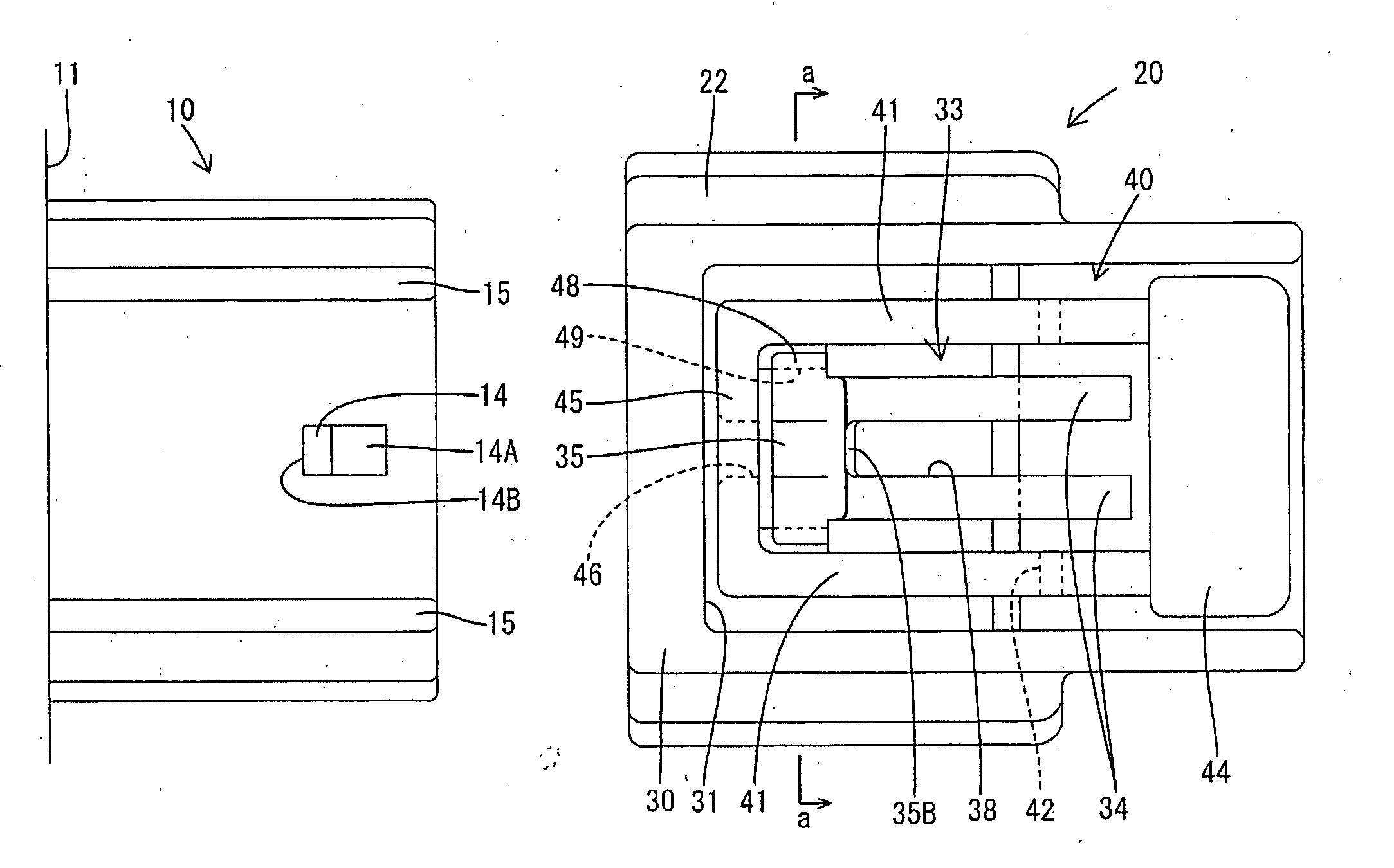

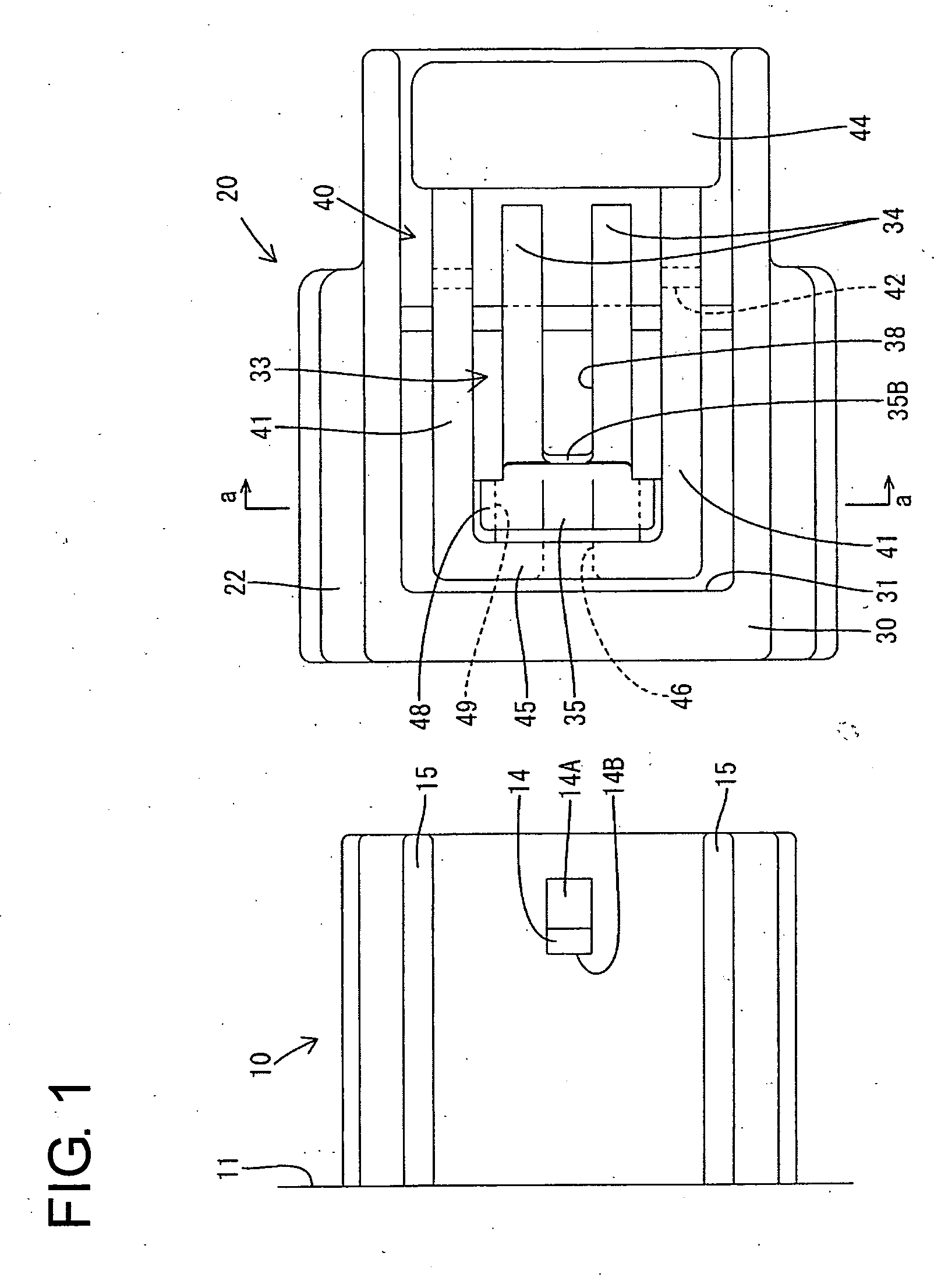

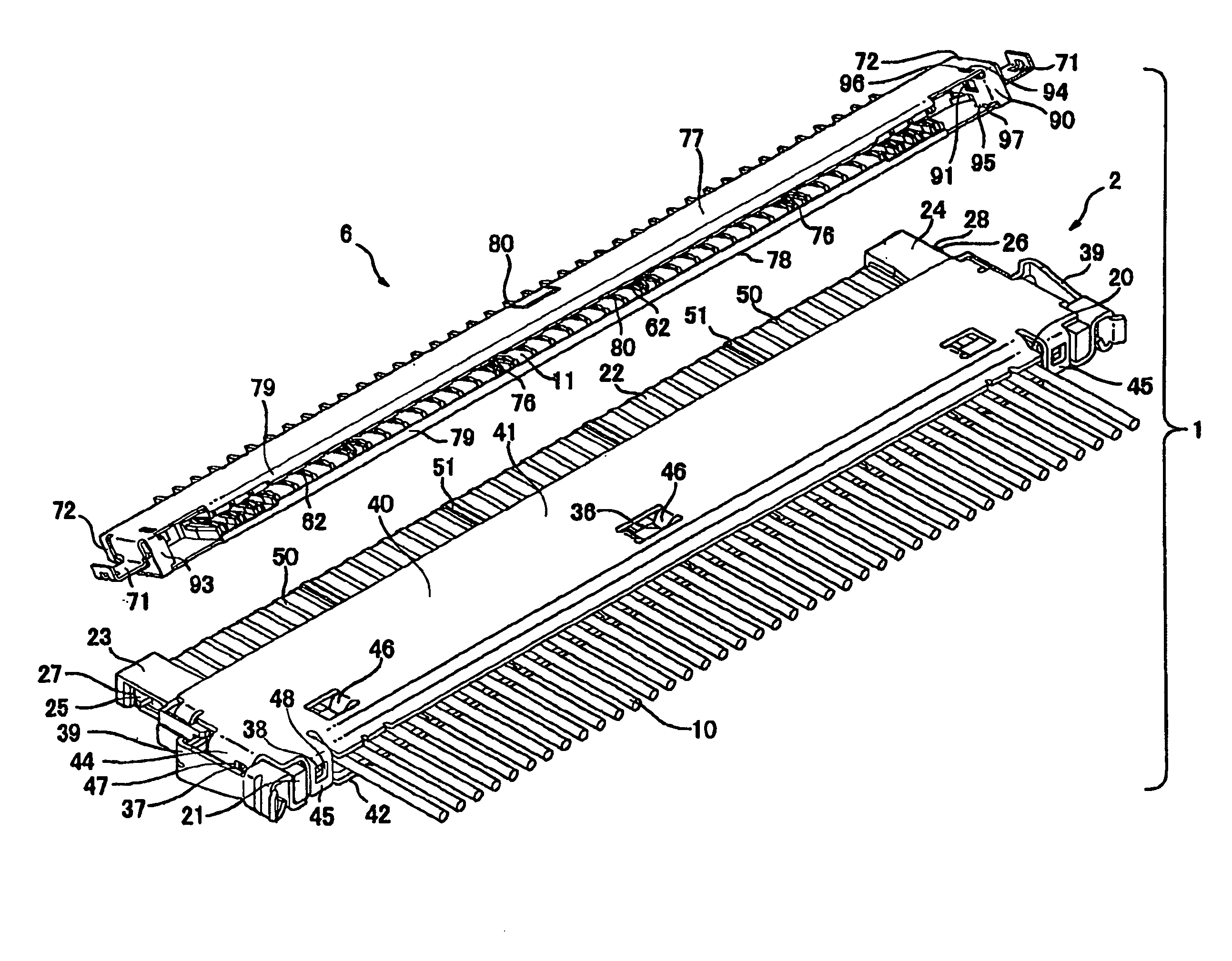

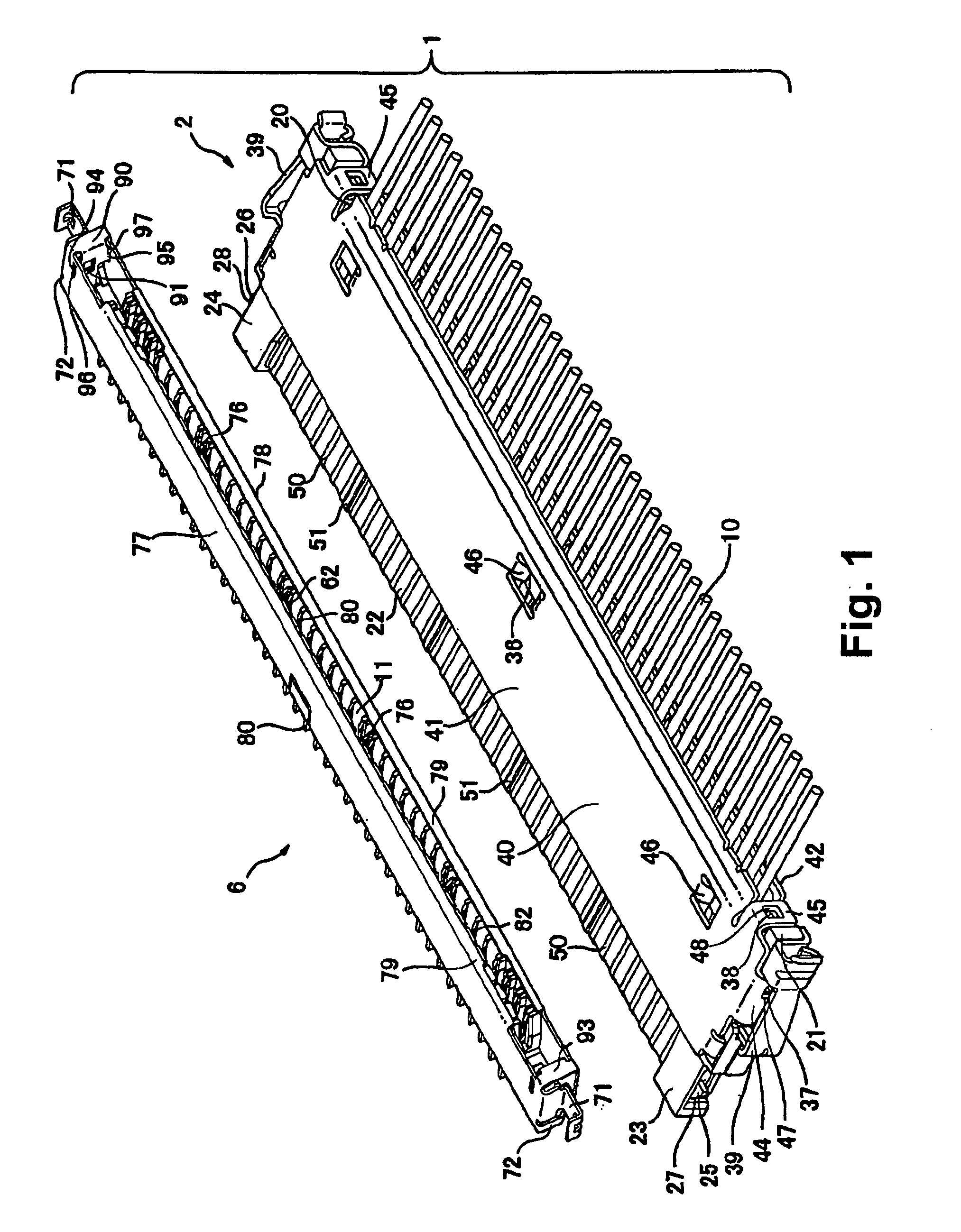

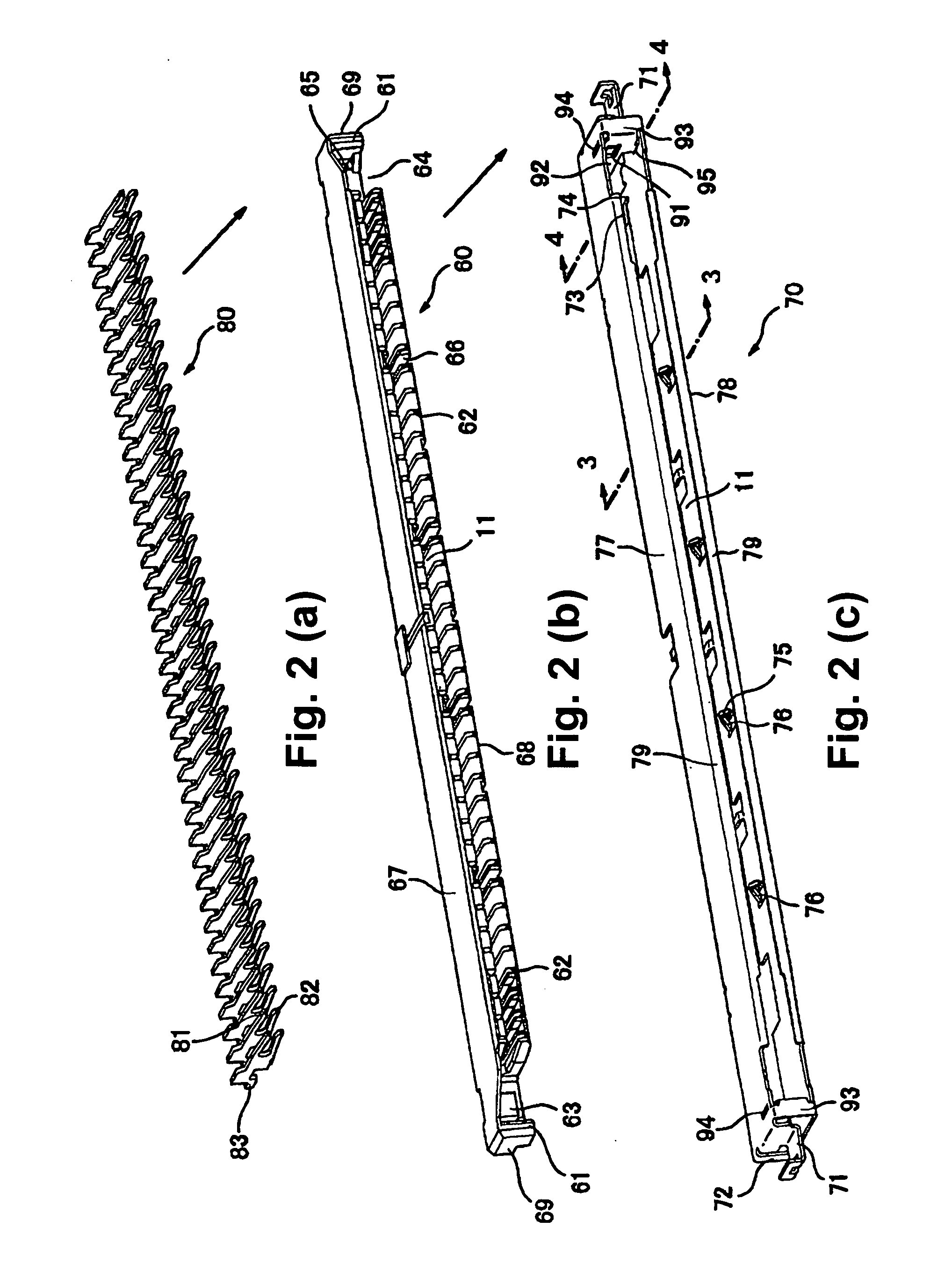

Building panel with a mechanical locking system

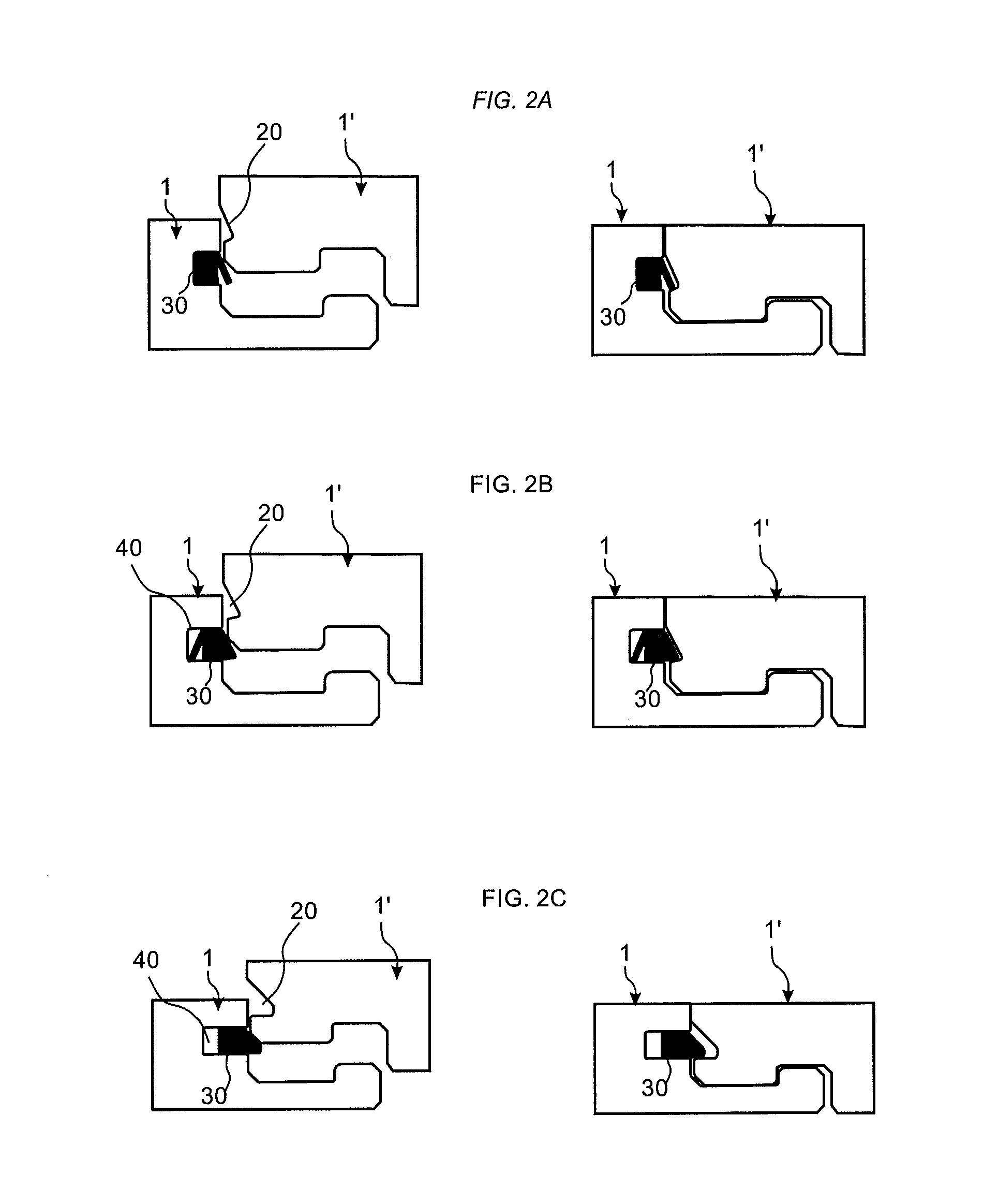

ActiveUS8596013B2Easy to manufactureHigh locking strengthCovering/liningsBuilding componentsStructural engineeringSystem building

Building panels 1, 1′ provided with a mechanical locking system including a tongue 30, at an edge of a first panel 1, cooperating with a tongue groove 20, at an edge of an adjacent second panel 1′, for vertical locking of the building panels. The edge of the first panel is provided with a displacement groove 60, which is downwardly open, and includes an inner wall 61, an outer wall 62, and an upper wall 67. The tongue 30 is formed out of the edge of the first panel. A resilient and displaceable and part 66 of the tongue 30 is displaceable into the displacement groove 60.

Owner:VÄLINGE INNOVATION AB

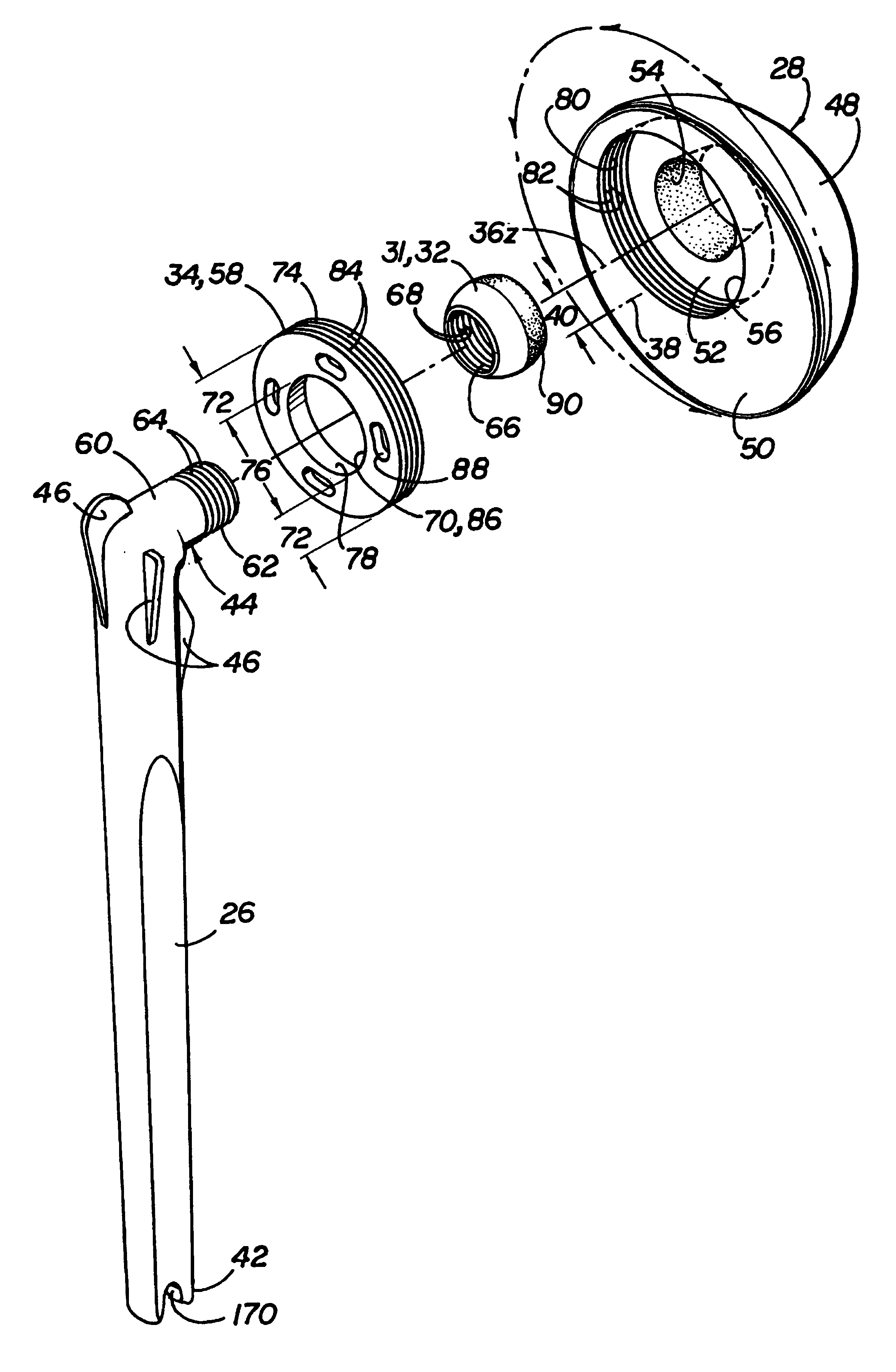

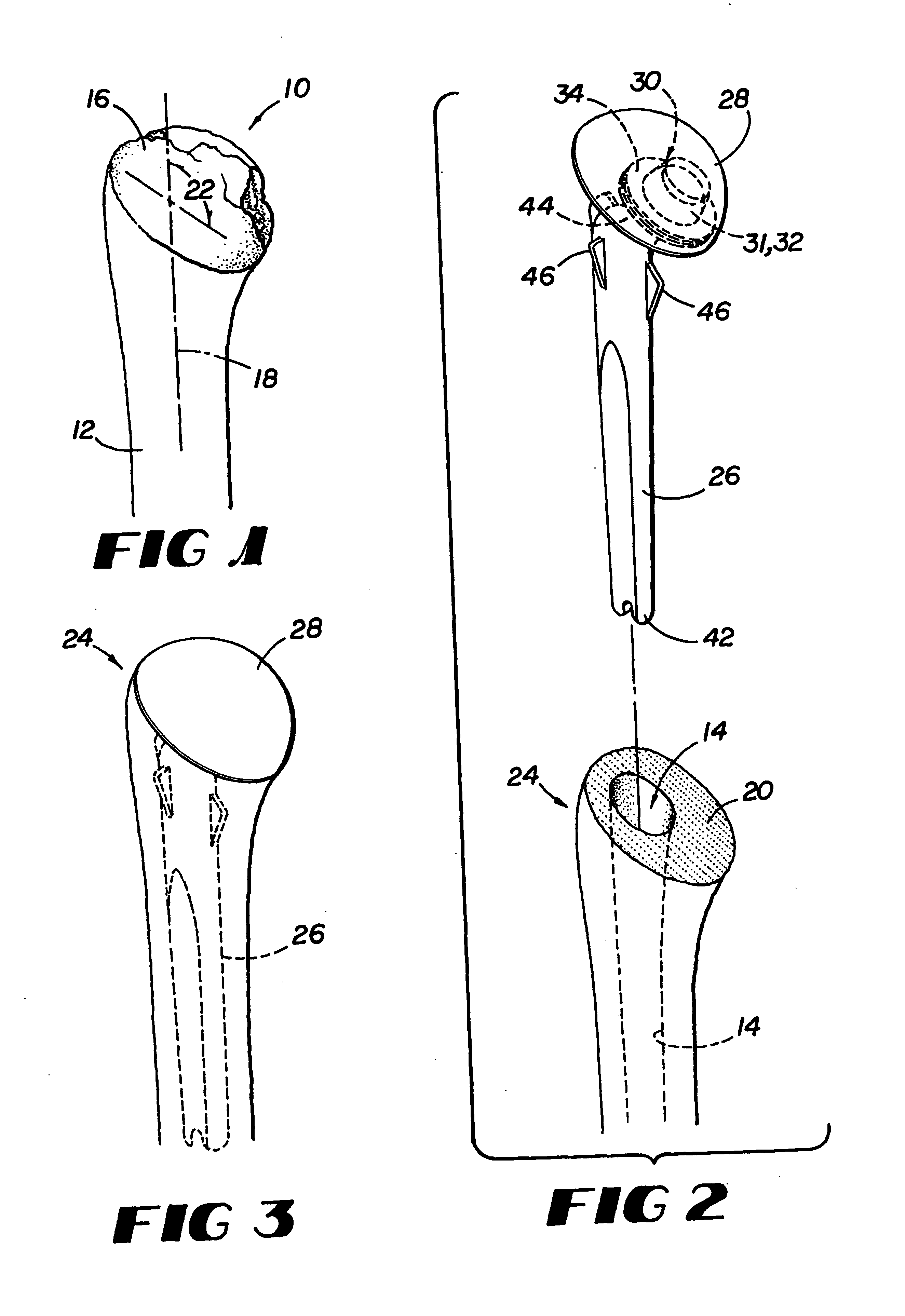

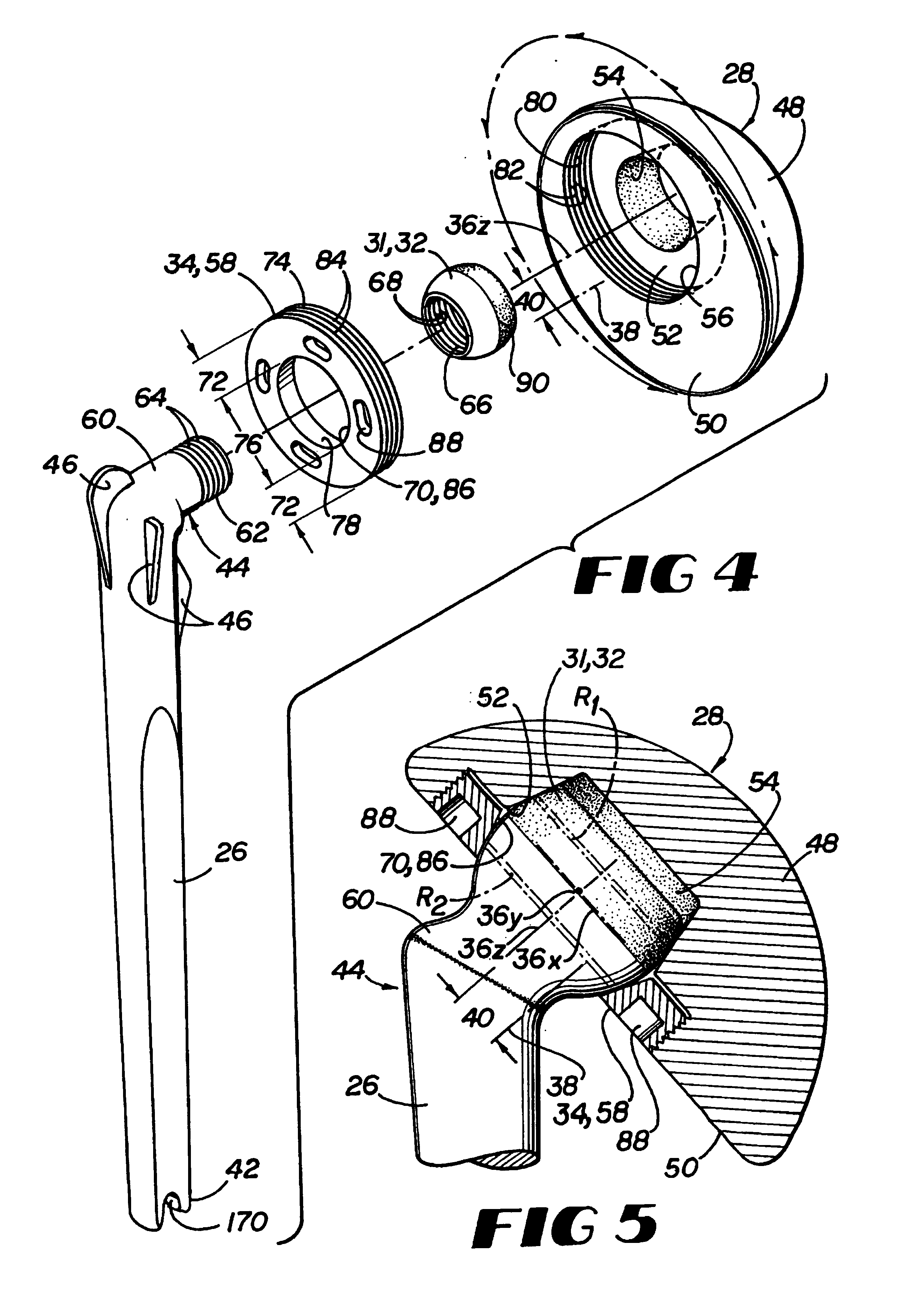

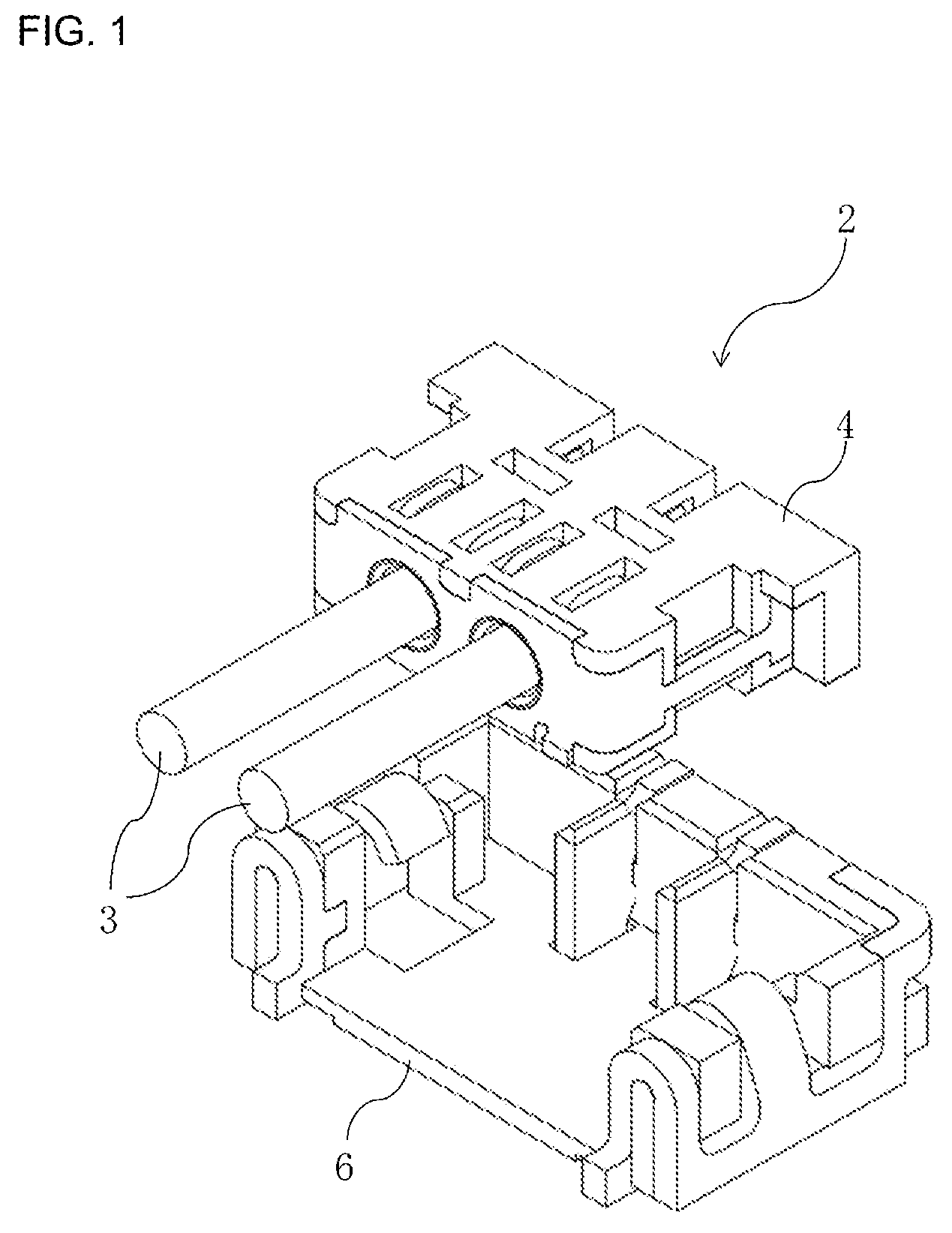

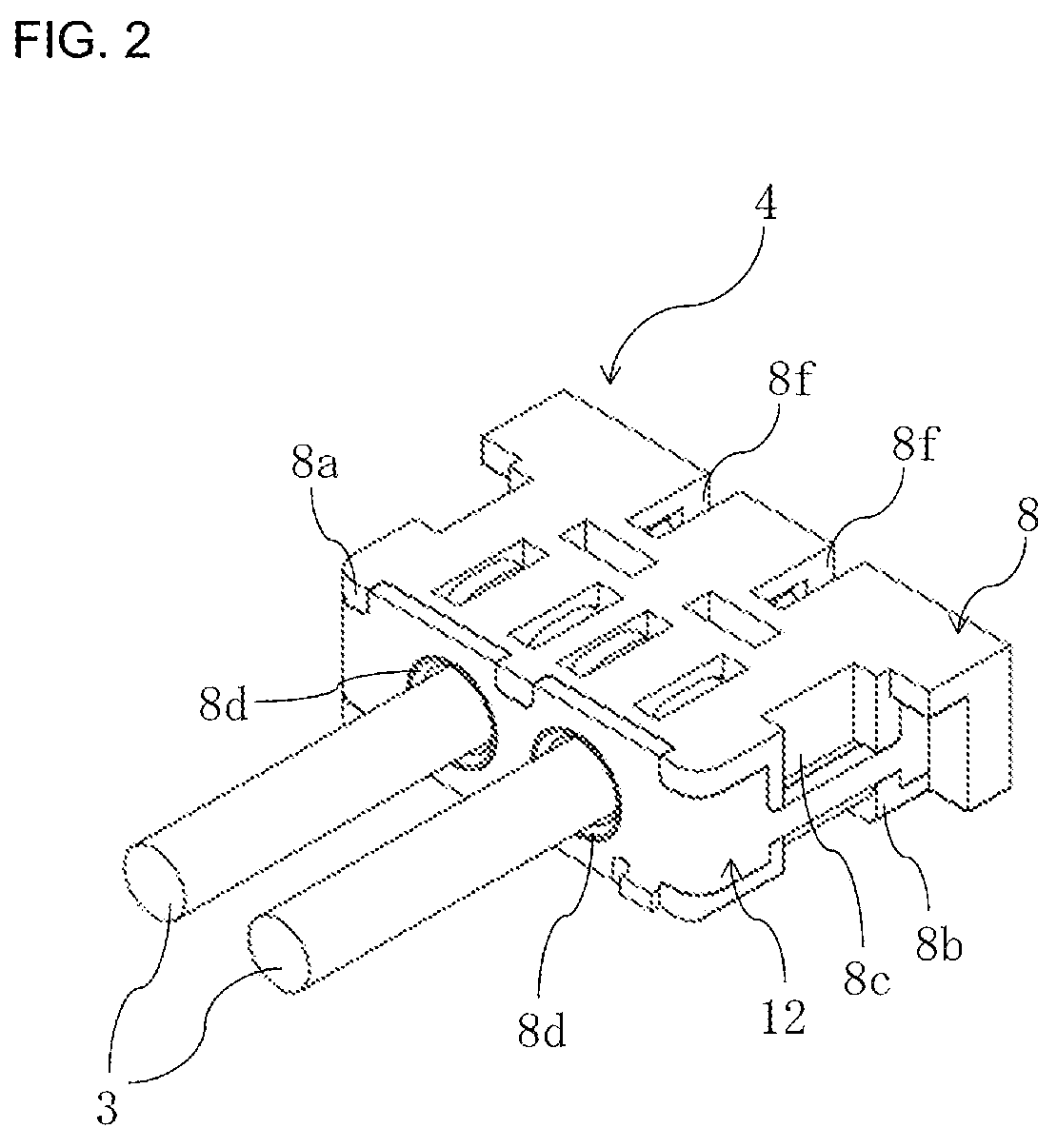

Modular prosthesis system with novel locking mechanism

InactiveUS7097663B1Reliable lockingReduce the risk of infectionJoint implantsShoulder jointsLocking mechanismSurgical repair

A modular prosthesis for replacement of a joint articulating surface of a bone, where the modular prosthesis generally comprises a head with a recessed socket, an elongate stem, and a connecting member including a patrix member having a generally spherical surface and adapted to be attached to an end of the stem and to be received in the head, and a locking member adapted to lock the head to the stem in a desired orientation; a system for use in surgical repair of a joint including a selection of components for assembling the modular implant prosthesis, a selection of components for assembling a trial prosthesis, and a transfer device for arranging the components of the implant prosthesis in the same orientation as the components of the trial prosthesis; and methods of using the modular prosthesis and system of the invention.

Owner:SMITH & NEPHEW INC

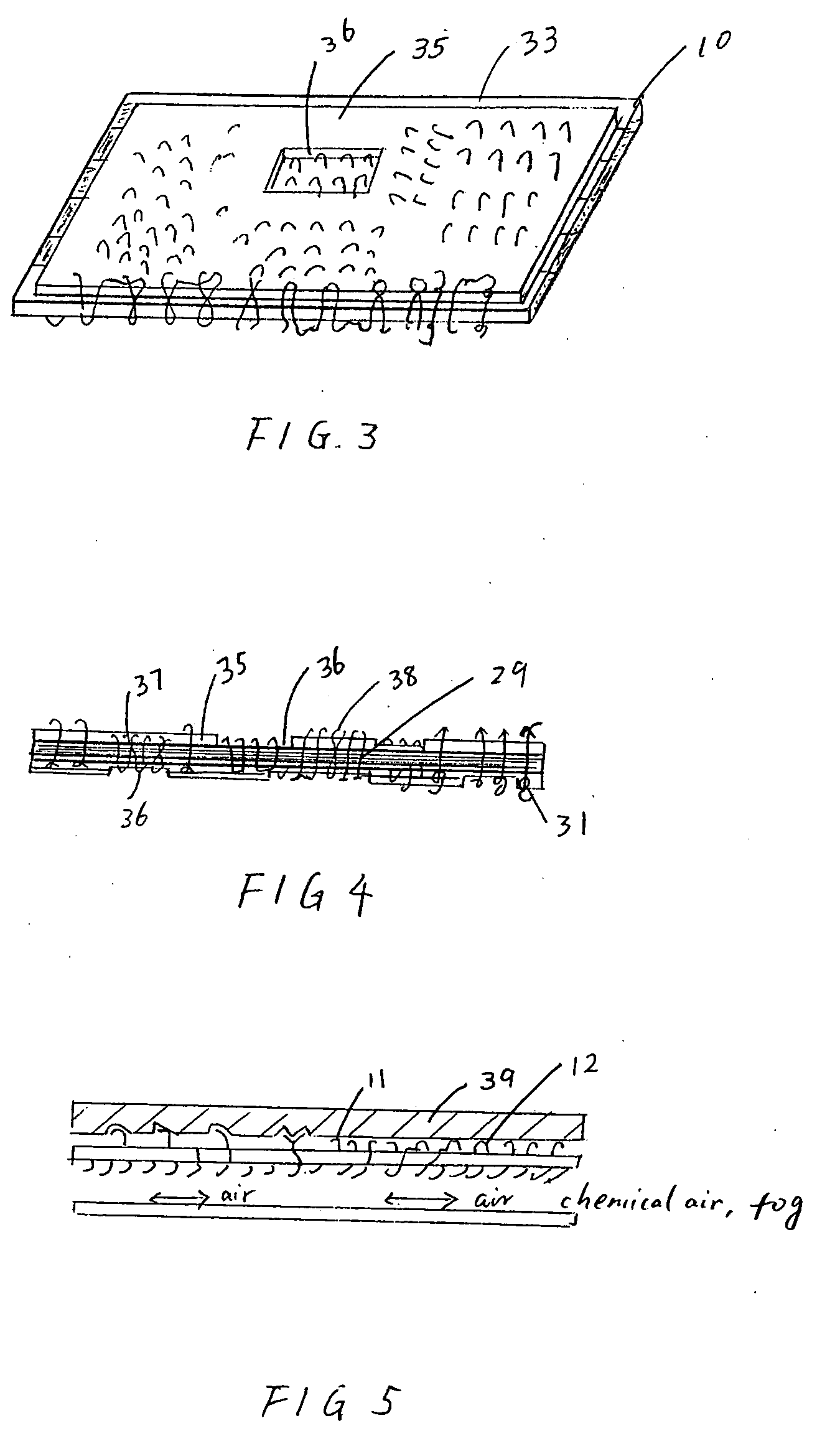

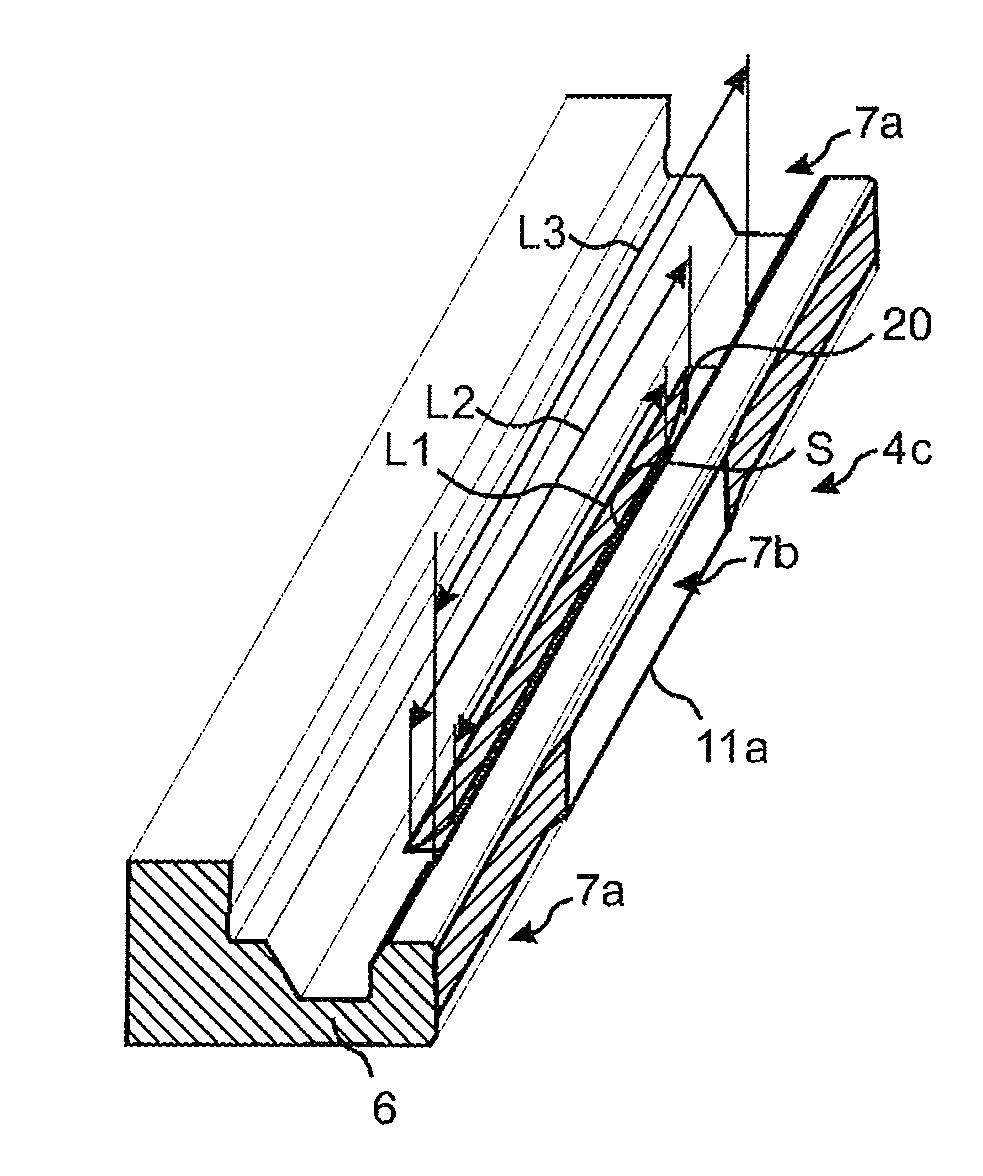

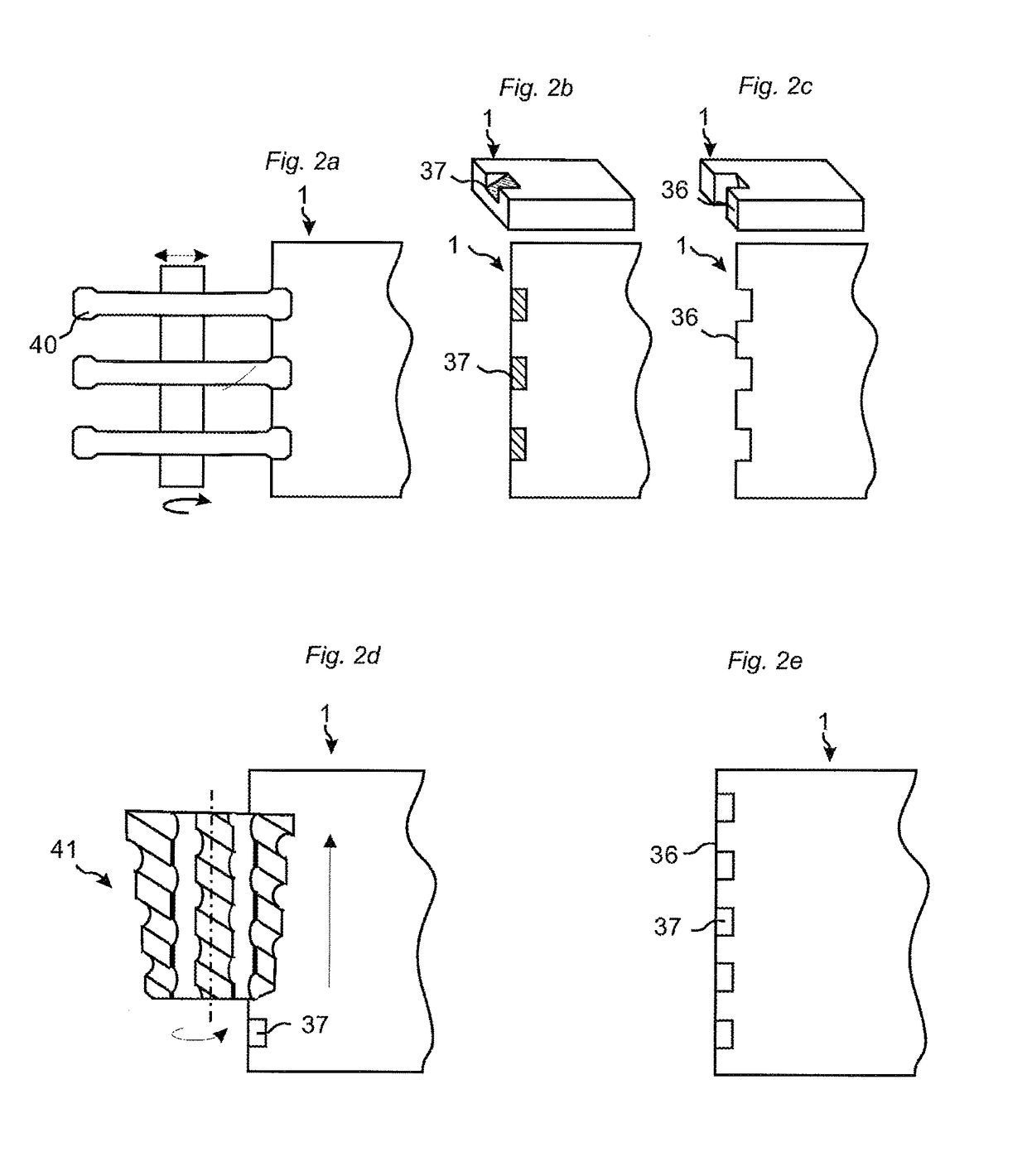

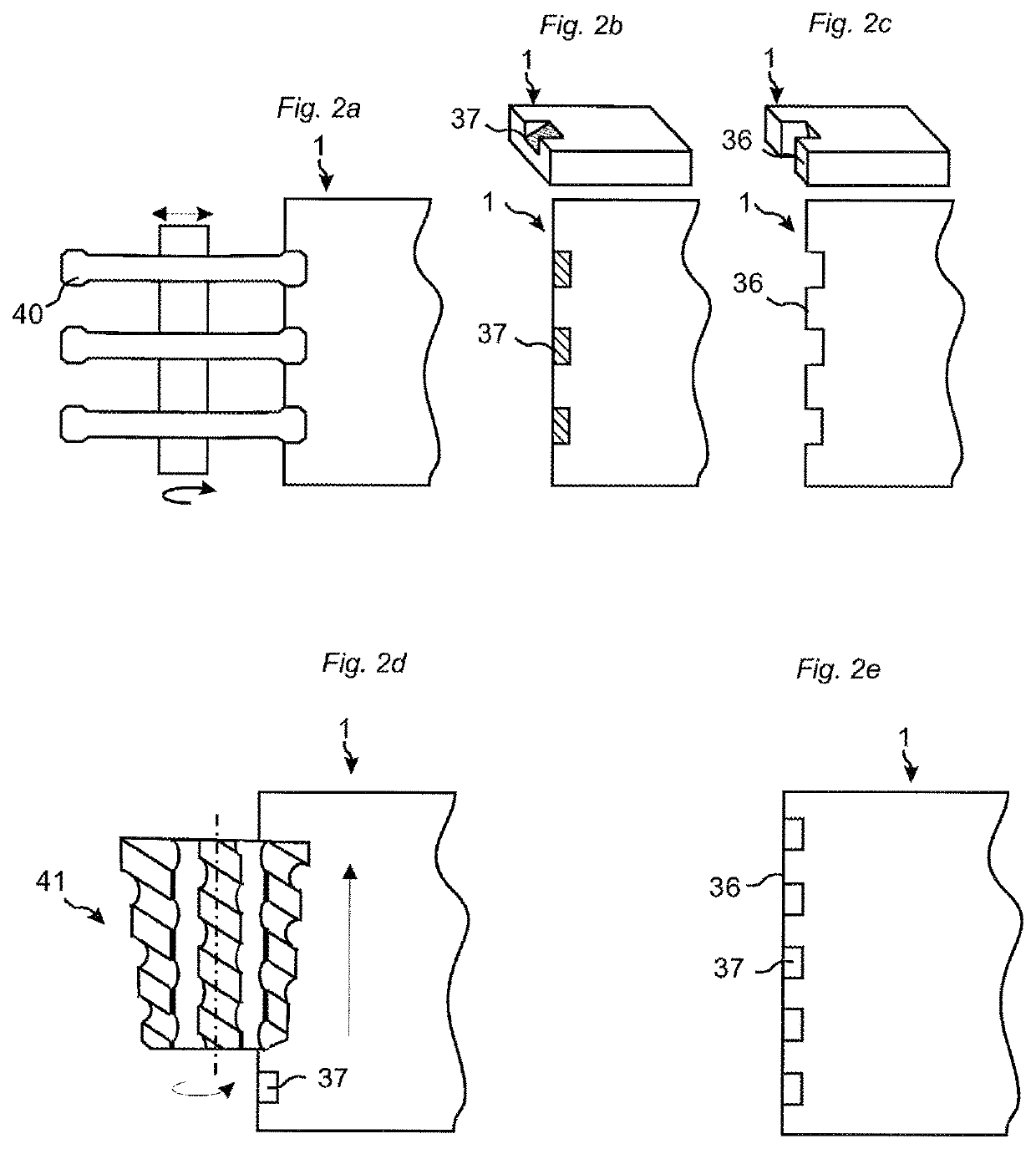

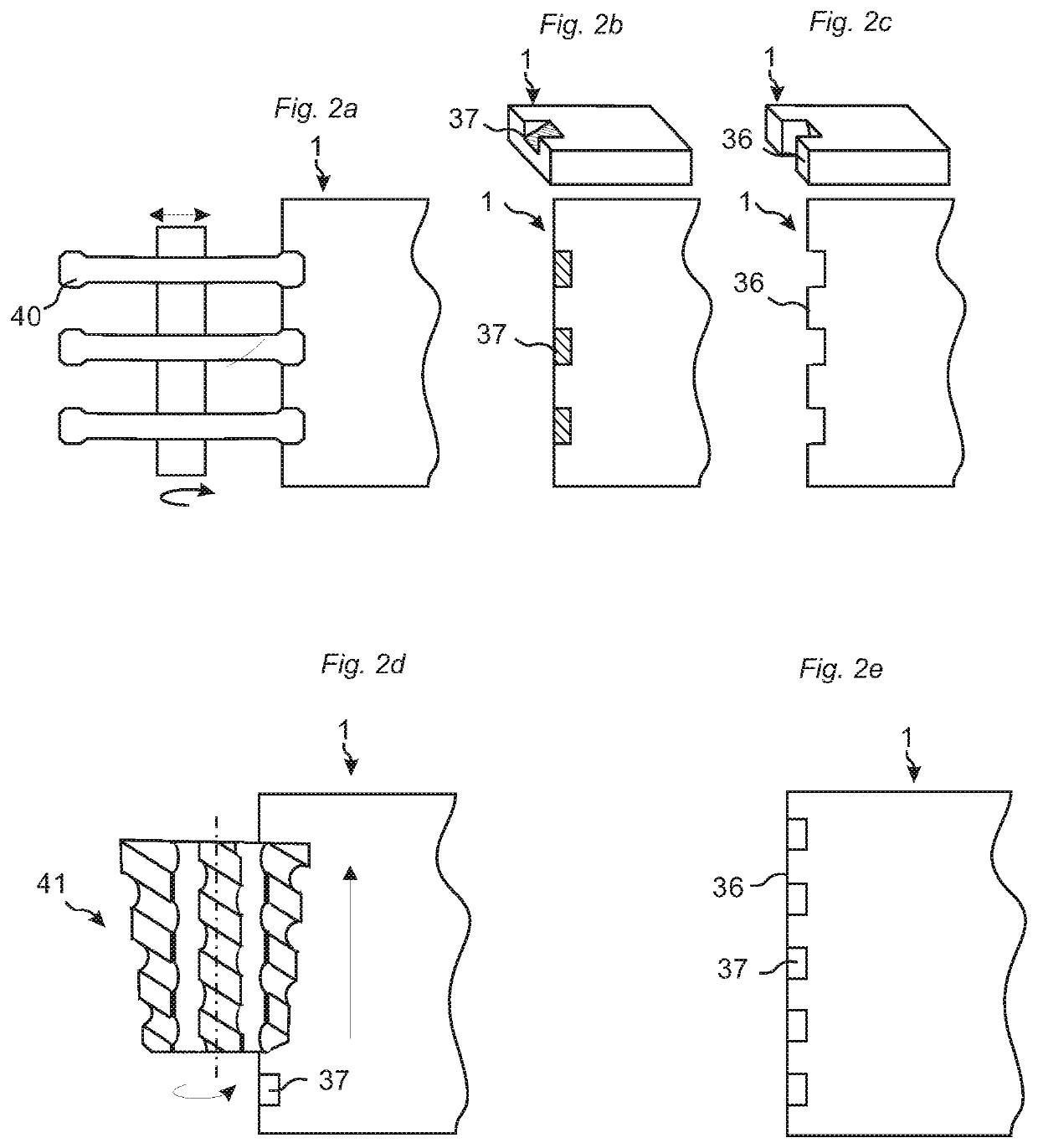

Building panel with a mechanical locking system

ActiveUS20130263547A1Easy to manufactureHigh locking strengthCovering/liningsBuilding componentsStructural engineeringSystem building

Building panels 1, 1′ provided with a mechanical locking system including a tongue 30, at an edge of a first panel 1, cooperating with a tongue groove 20, at an edge of an adjacent second panel 1′, for vertical locking of the building panels. The edge of the first panel is provided with a displacement groove 60, which is downwardly open, and includes an inner wall 61, an outer wall 62, and an upper wall 67. The tongue 30 is formed out of the edge of the first panel. A resilient and displaceable and part 66 of the tongue 30 is displaceable into the displacement groove 60.

Owner:VÄLINGE INNOVATION AB

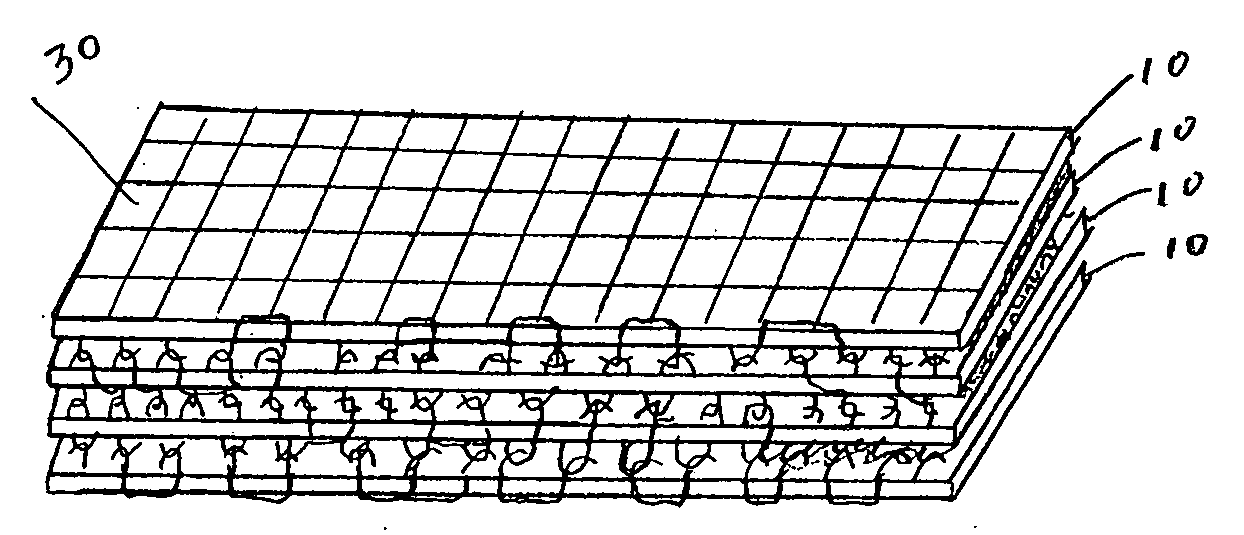

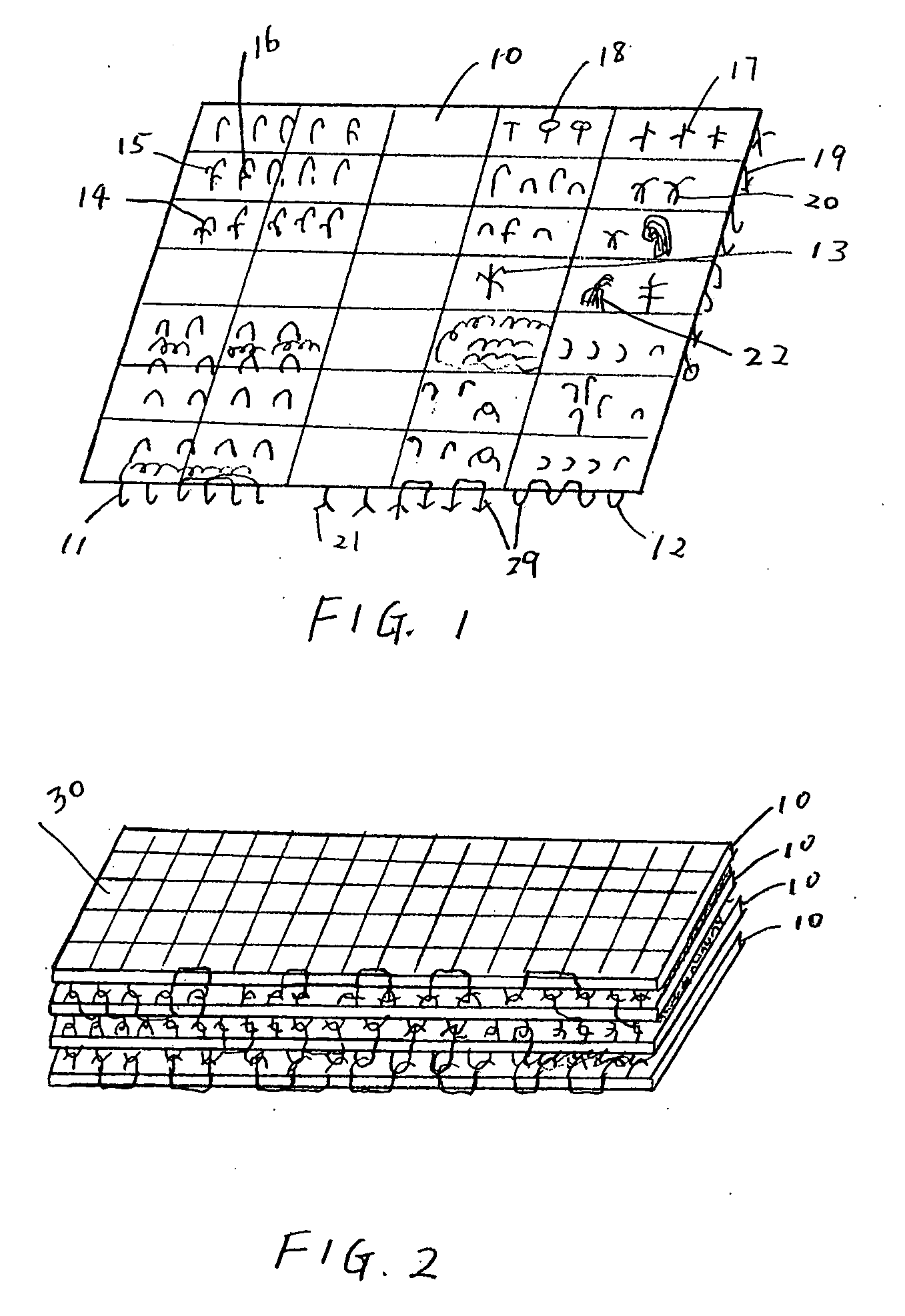

Fiber Products, Prepregs, Composites and Method of Producing Same

InactiveUS20080193709A1Increase strength and interface strengthIncreased strengthSlide fastenersLayered productsFastenerYarn

The present invention is to provide methods to increase composite interlaminate strength and interface strength, and make 3D fibers products, prepregs and composites, by using trans-interface and / or trans-fiber products such as trans-plies, strands and / or yarns fastening components selected from the group comprising of hooks and loops (velcro), hooks and hooks, zipper heads, fish hook shape hooks, staples, arrow heads, forks and mushroom heads. One ply of fibers has one or multiple of the above fasteners on at least one side. Lay-up the plies with said fastening components on its one or two sides to obtain a 3D fiber products with those fastening components locked together. The plies can be separated if need re-lay-up. A thread or a yarn have the fastening components around 0-360 degree on its surface. Lay the threads together or intercross each other to get a 3D fiber products. In those 3D fiber products, two parts of the fastening components lock each other if they meet and engage. A 3D composite can be made using the 3D fiber products.One fiber ply with the fasteners on its at least one side, is impregnated or protruded with matrix materials, a piece of the prepreg with the fasteners prepreg with the fasteners are made. Lay and press the prepreg together fastening components will lock each other if they meet and engage. In most of production processes, the matrix materials might soften and meld, and the fastening components will further interlock each other. So a 3D composite structure is made by the said 3D prepregs. Those fastening components may stay just partially or fully in matrix at matrix surface. The fastening components increase the interface strength when two matrix materials meet just by crossing interface even if they are not locked and without fiber products in matrix.

Owner:HAN NANLIN

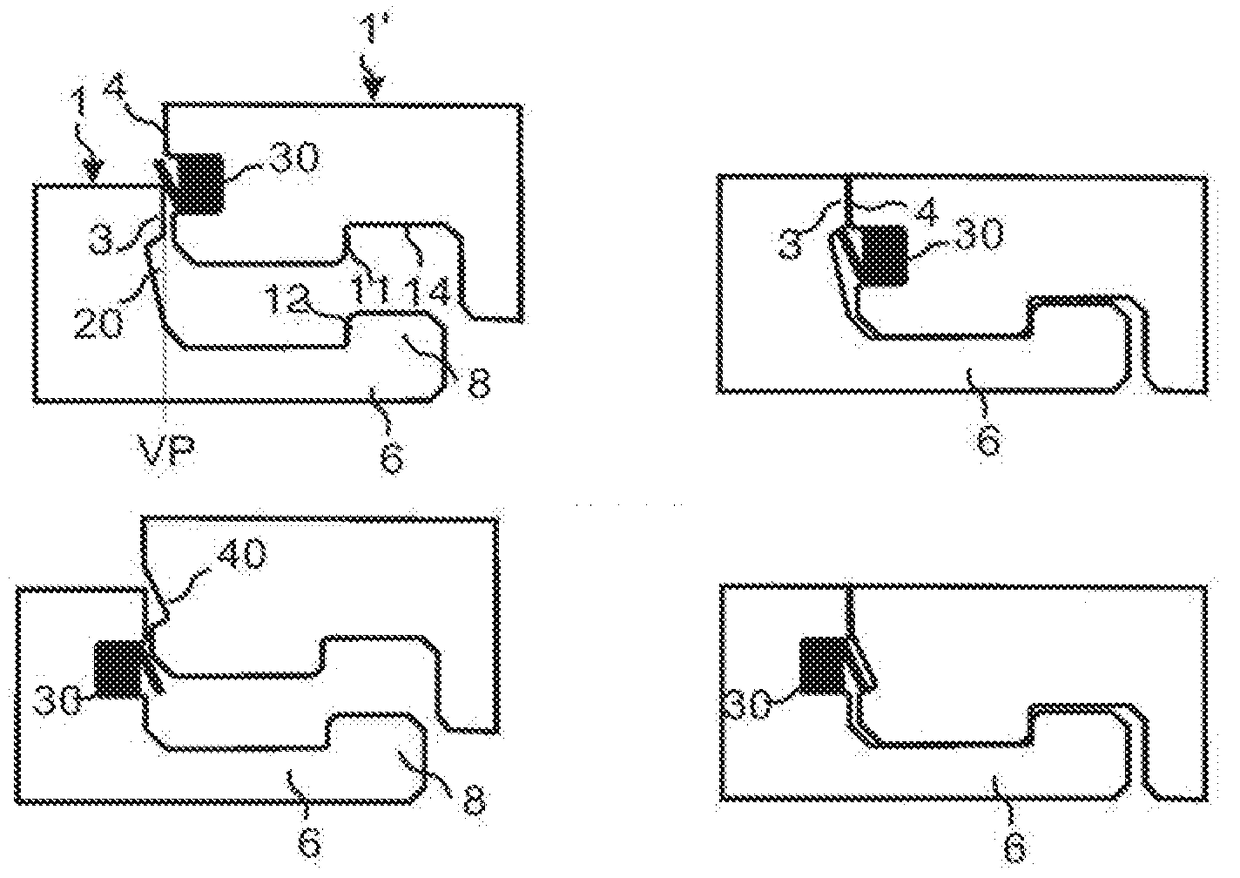

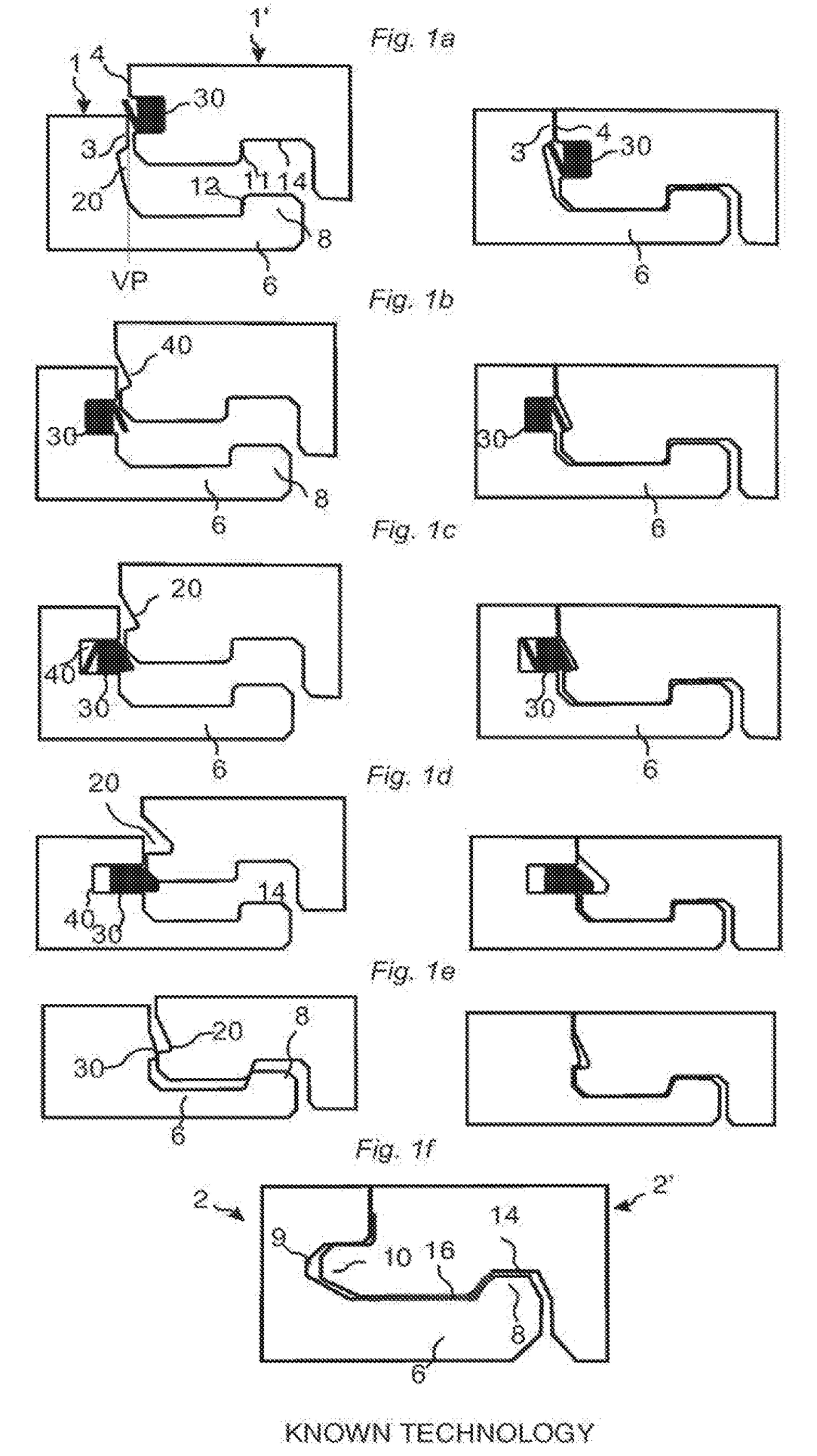

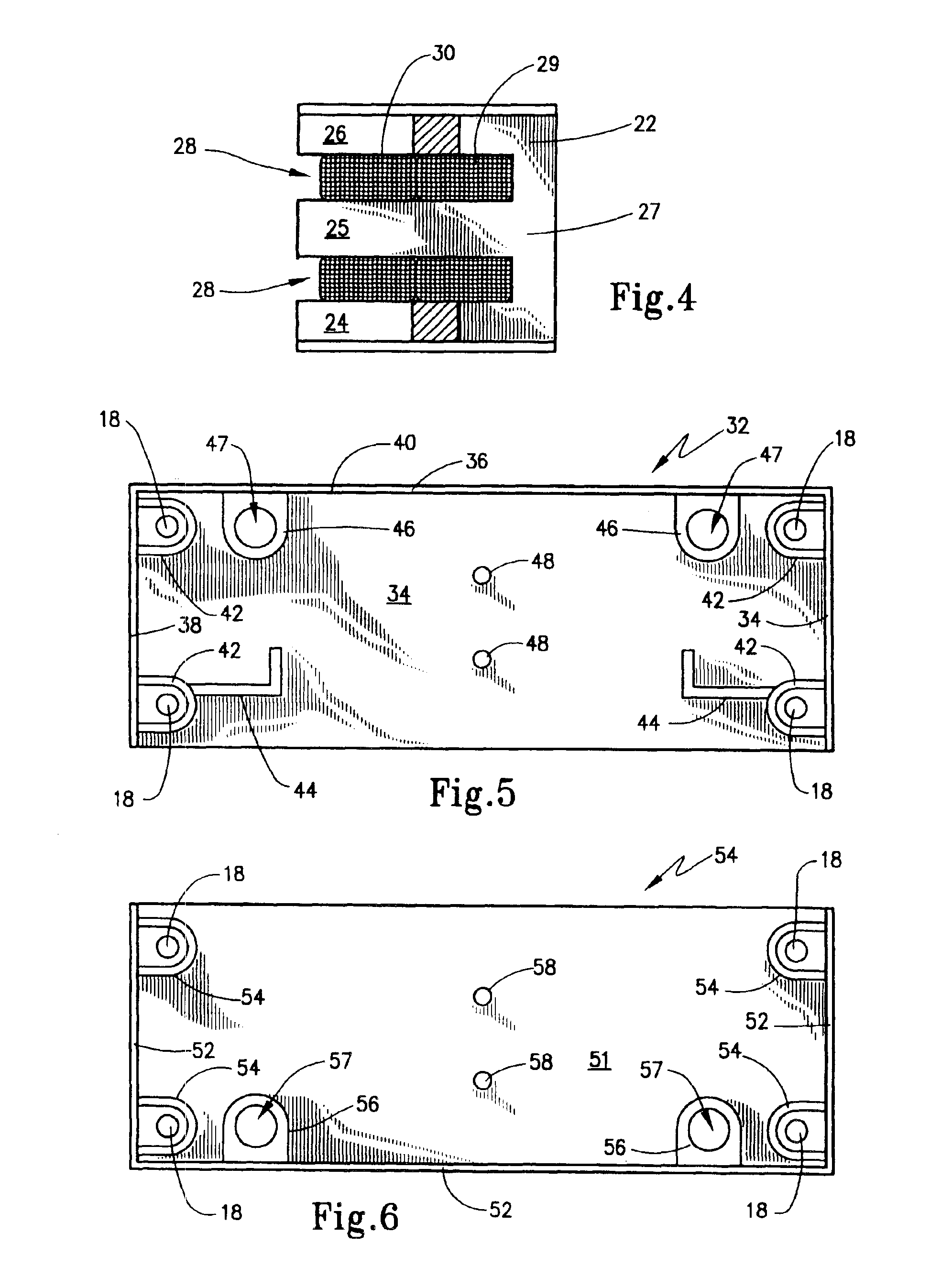

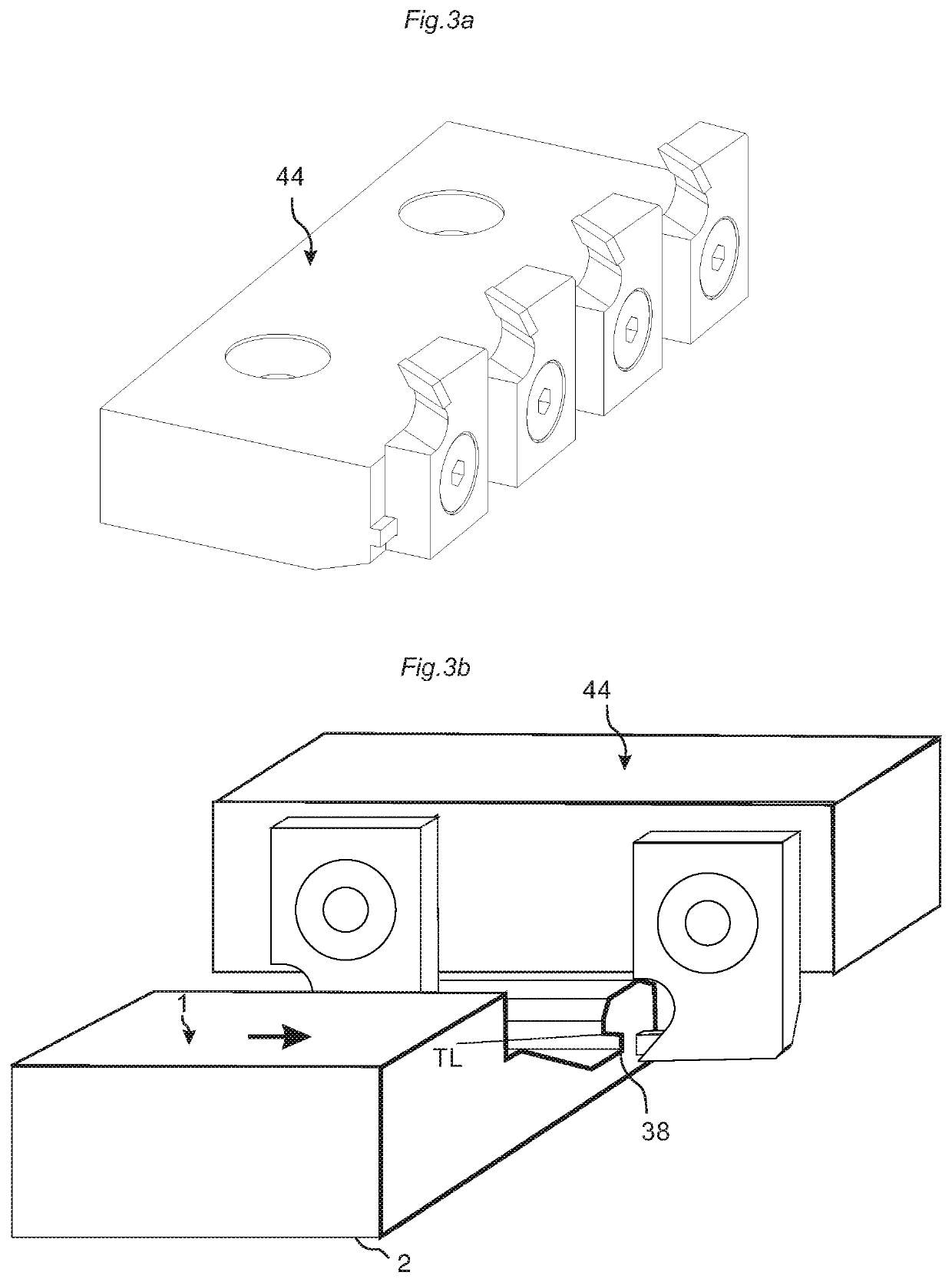

Mechanical locking system for floor panels

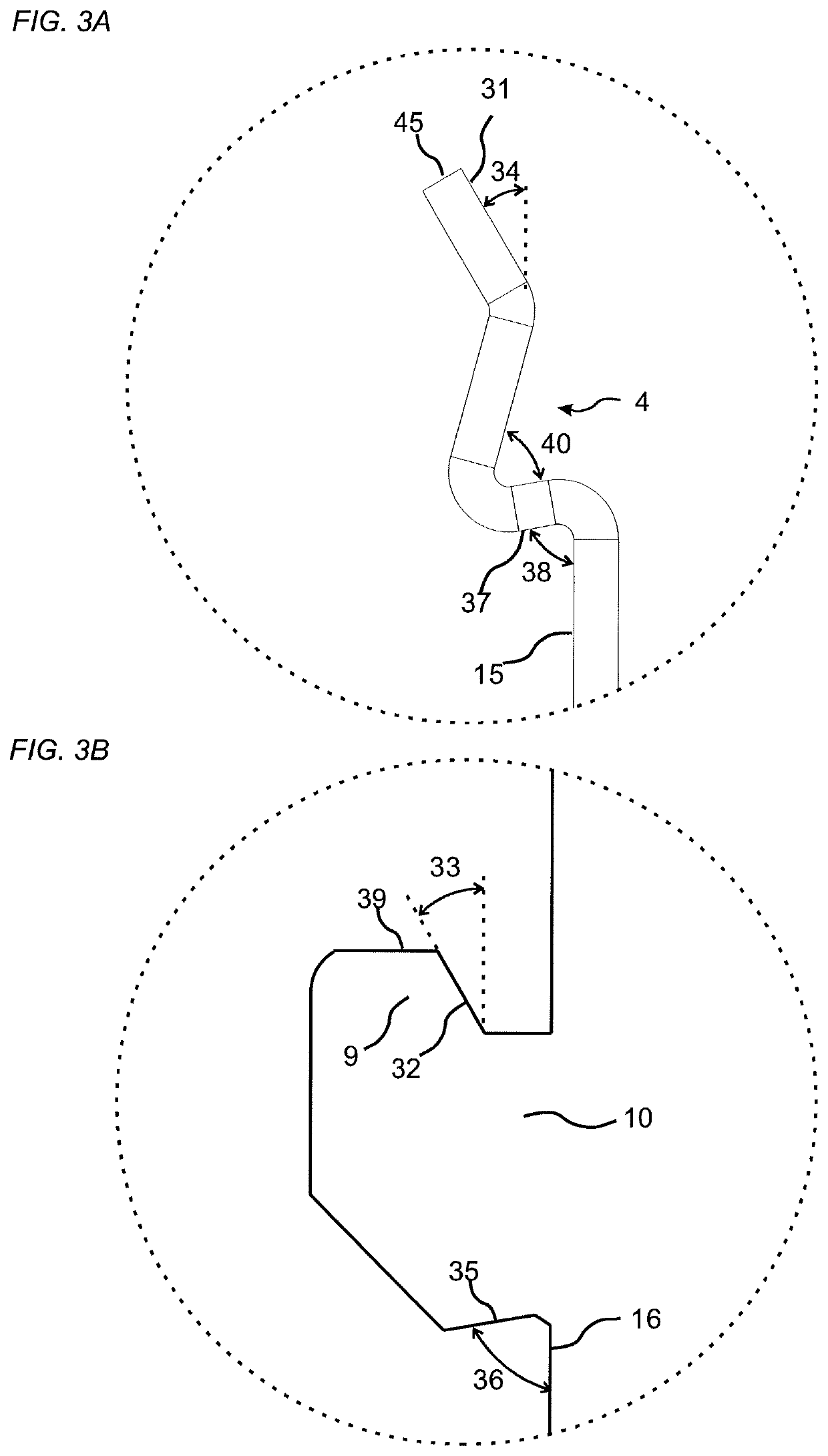

ActiveUS20180002933A1Prevent upward bendingHigh locking strengthFlooringEngineeringVertical displacement

Floor panels are shown, which are provided with a mechanical locking system that may be locked with a vertical displacement of a first panel against a second panel. The locking system includes a first rigid and a second flexible joint edge section with different locking functions. The first edge section provides a horizontal locking and the second section provides a vertical locking.

Owner:CERALOC INNOVATION AB

Mechanical locking system for floor panels

Floor panels are shown, which are provided with a vertical folding locking system on short edges that only locks vertically and a mechanical locking system on long edges that prevents displacement along the long edges. A locking system for primarily rectangular floor panels with long and short edges installed in parallel rows, which allows that the short edges may be locked to each other with a vertical movement without a horizontal connection and that such horizontal connection is accomplished by the locking system on the long edges including a first and second horizontal locking perpendicular to the edges and along the edges.

Owner:CERALOC INNOVATION AB

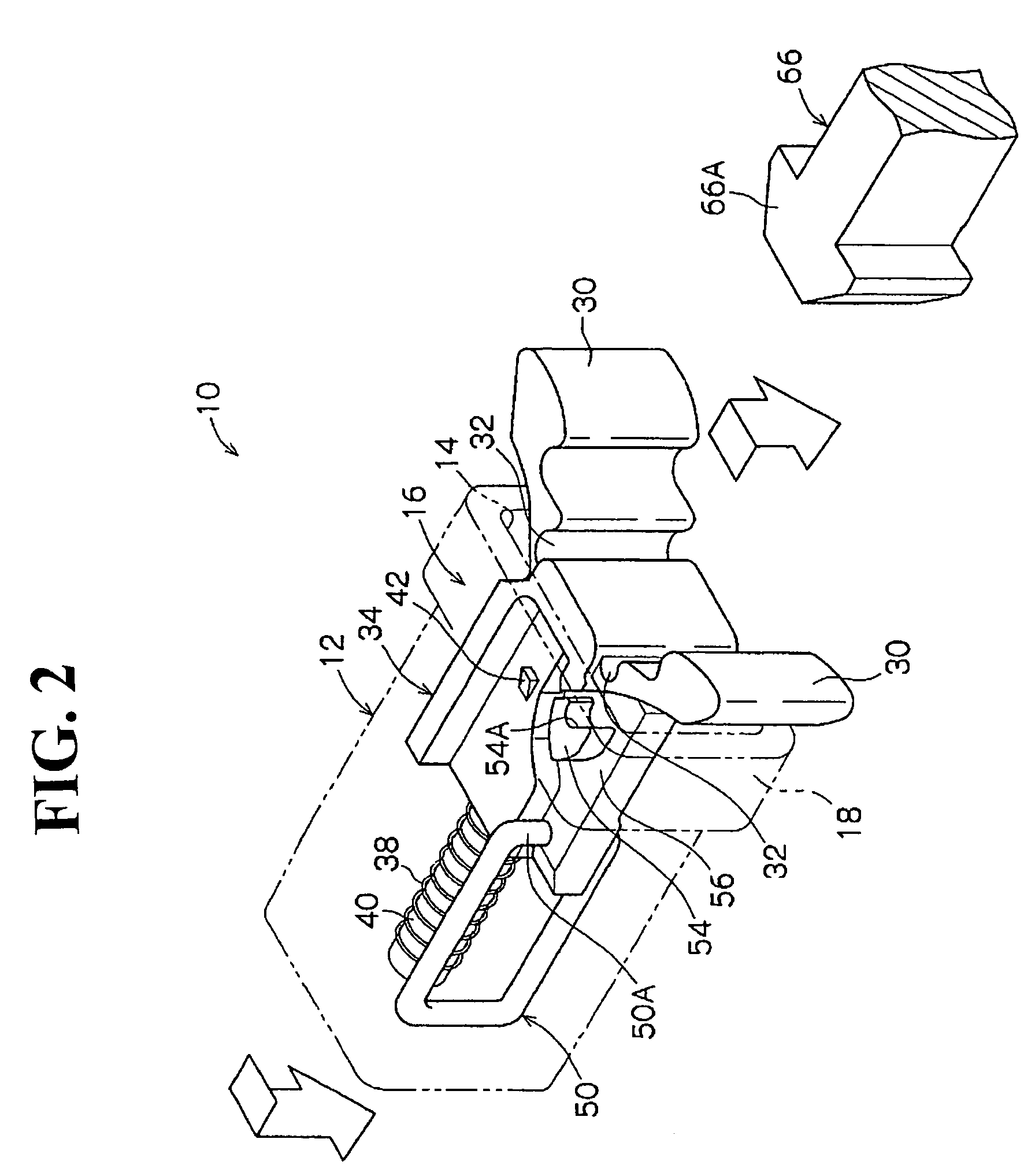

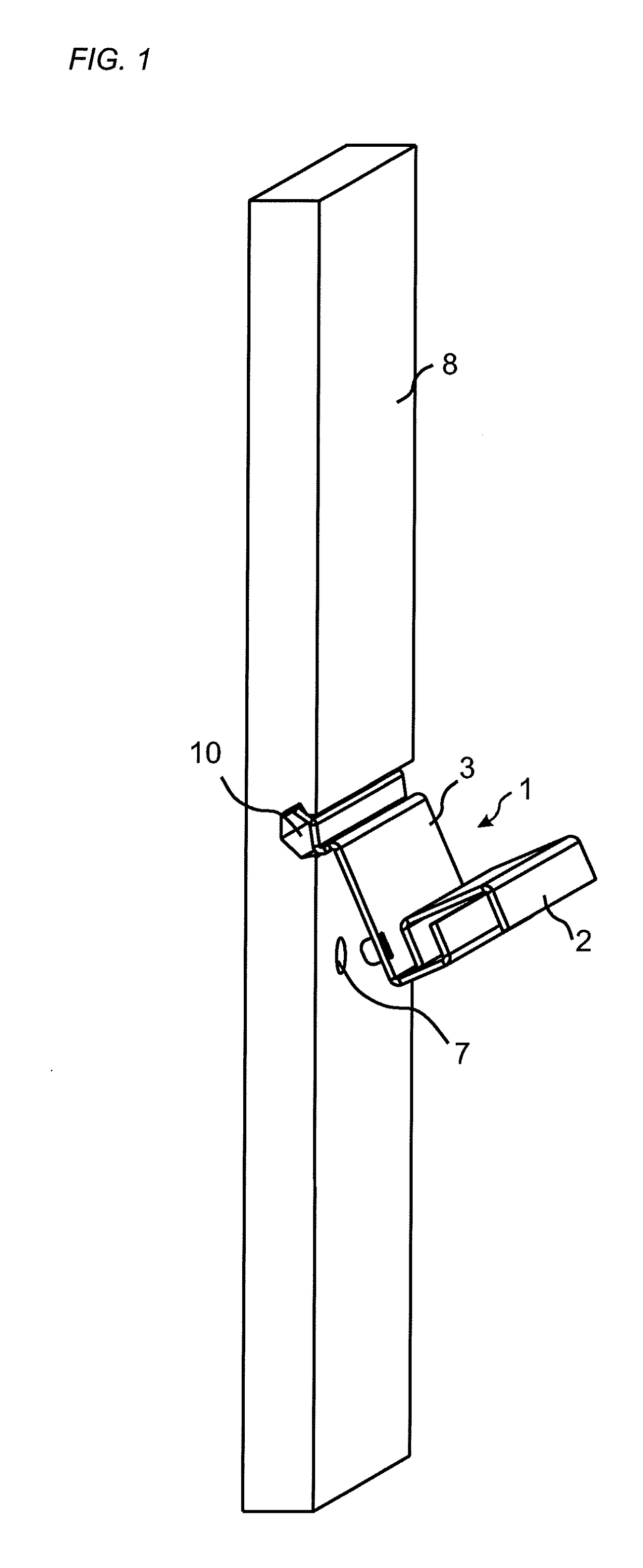

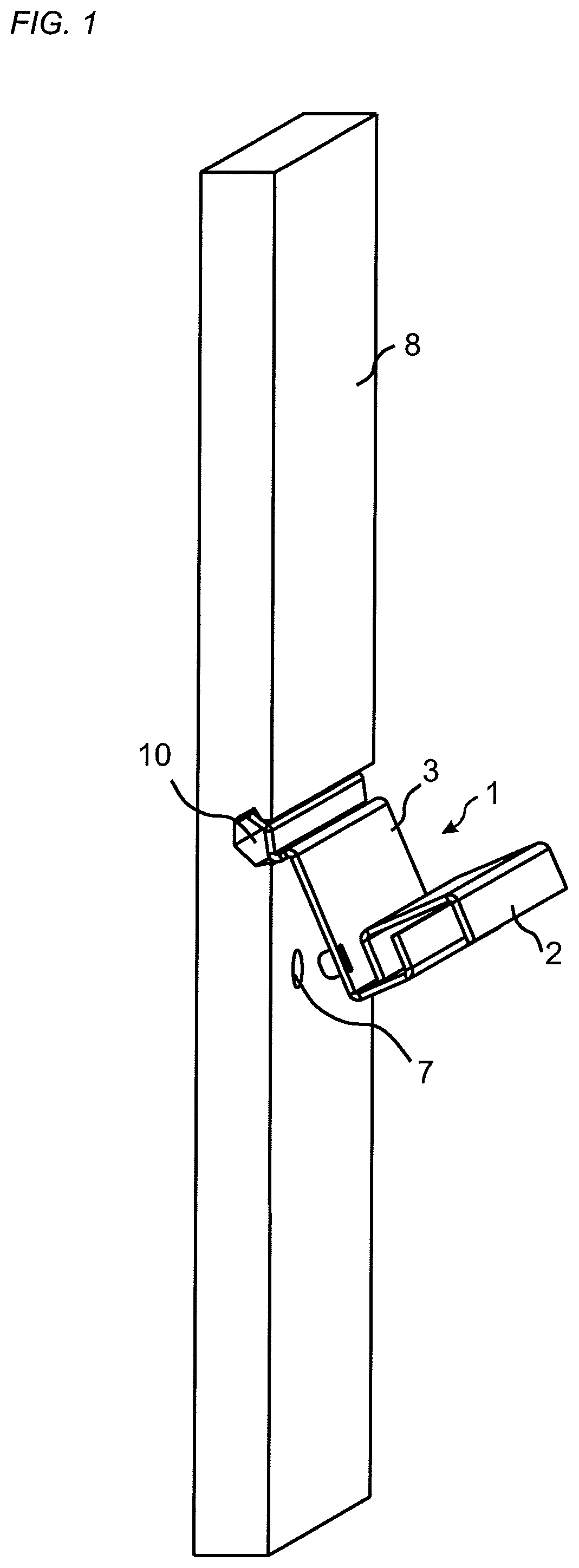

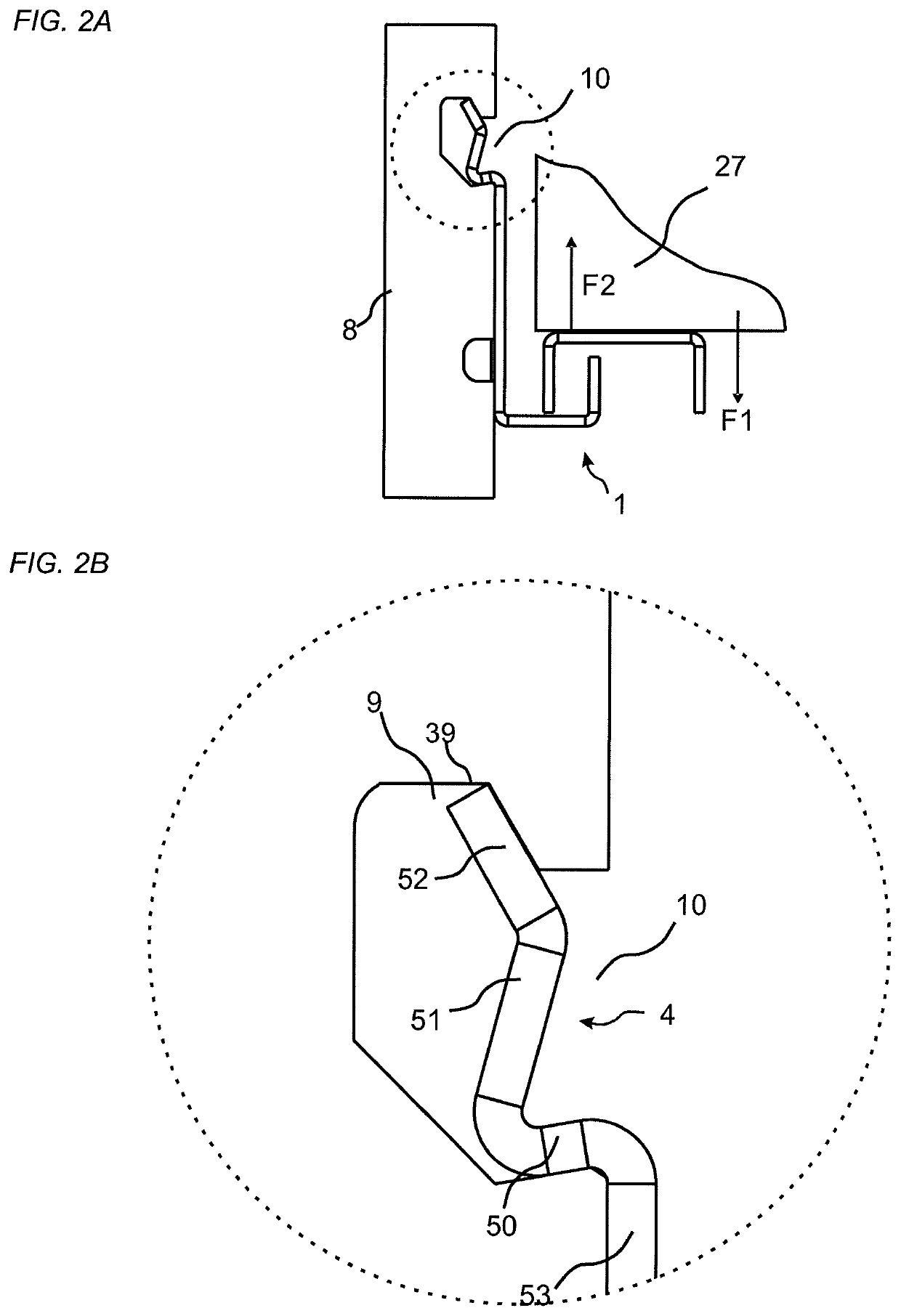

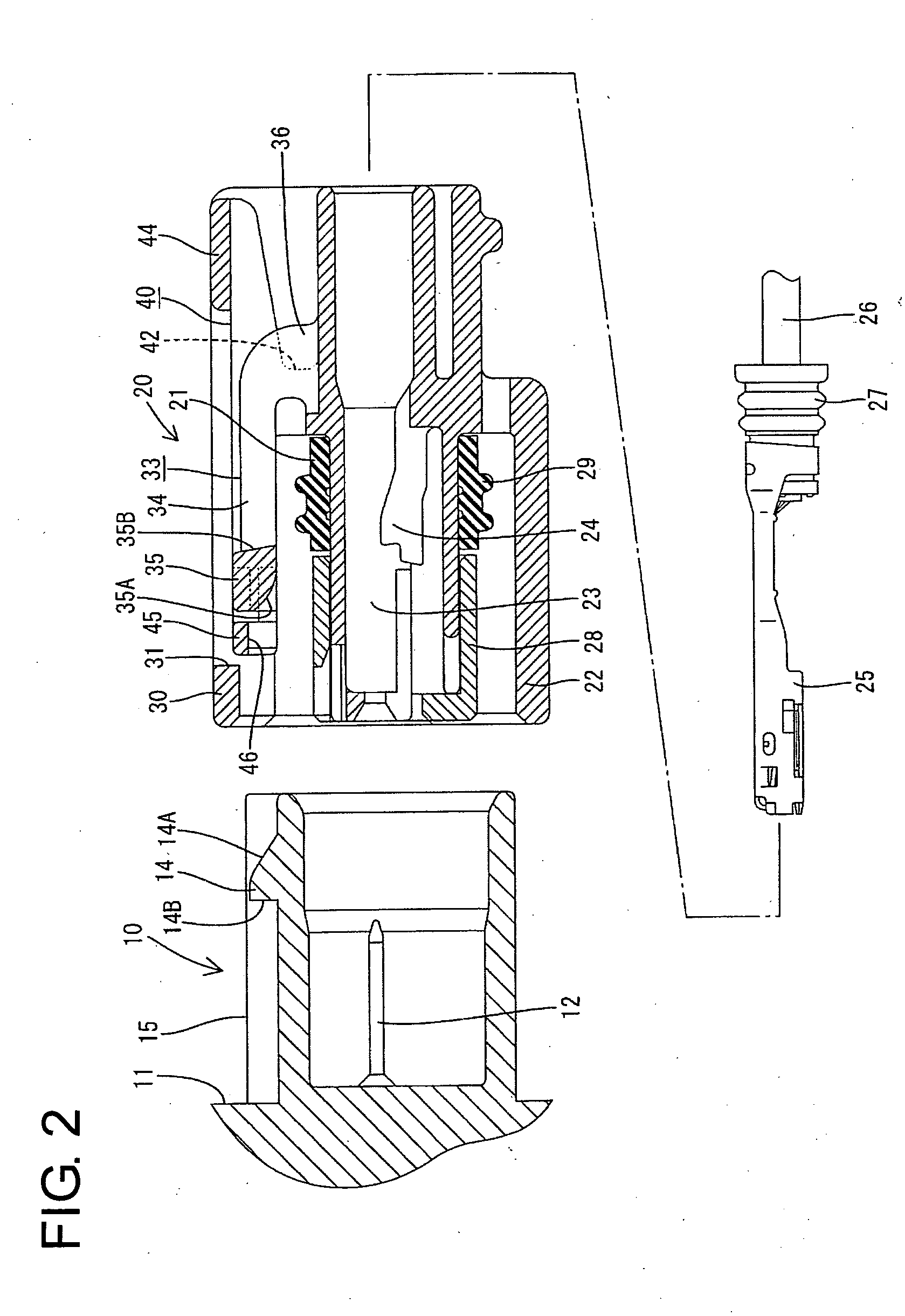

Lock mechanism and latch device

ActiveUS7393026B2Easy to measureReduce expensesBuilding locksWing fastenersLocking mechanismEngineering

A lock mechanism holds a moving member on a main body immovably in a locked state and allows movement in an unlocked state. The lock mechanism includes a circulating cam groove formed on the main body or the moving member, and a trace member having an angle bracket shape with one and the other trace parts to sway on the main body or moving member. The one trace part circulates along the circulating cam groove in each approaching and moving away operation of the moving member, and locks the moving member in a state having coupled with the coupling part. A wall surface is formed on the main body or moving member to be disposed in a different position from the circulating cam groove so that the other trace part of the trace member is operable to contact the wall surface only in the locked state of the moving member.

Owner:NIFCO INC

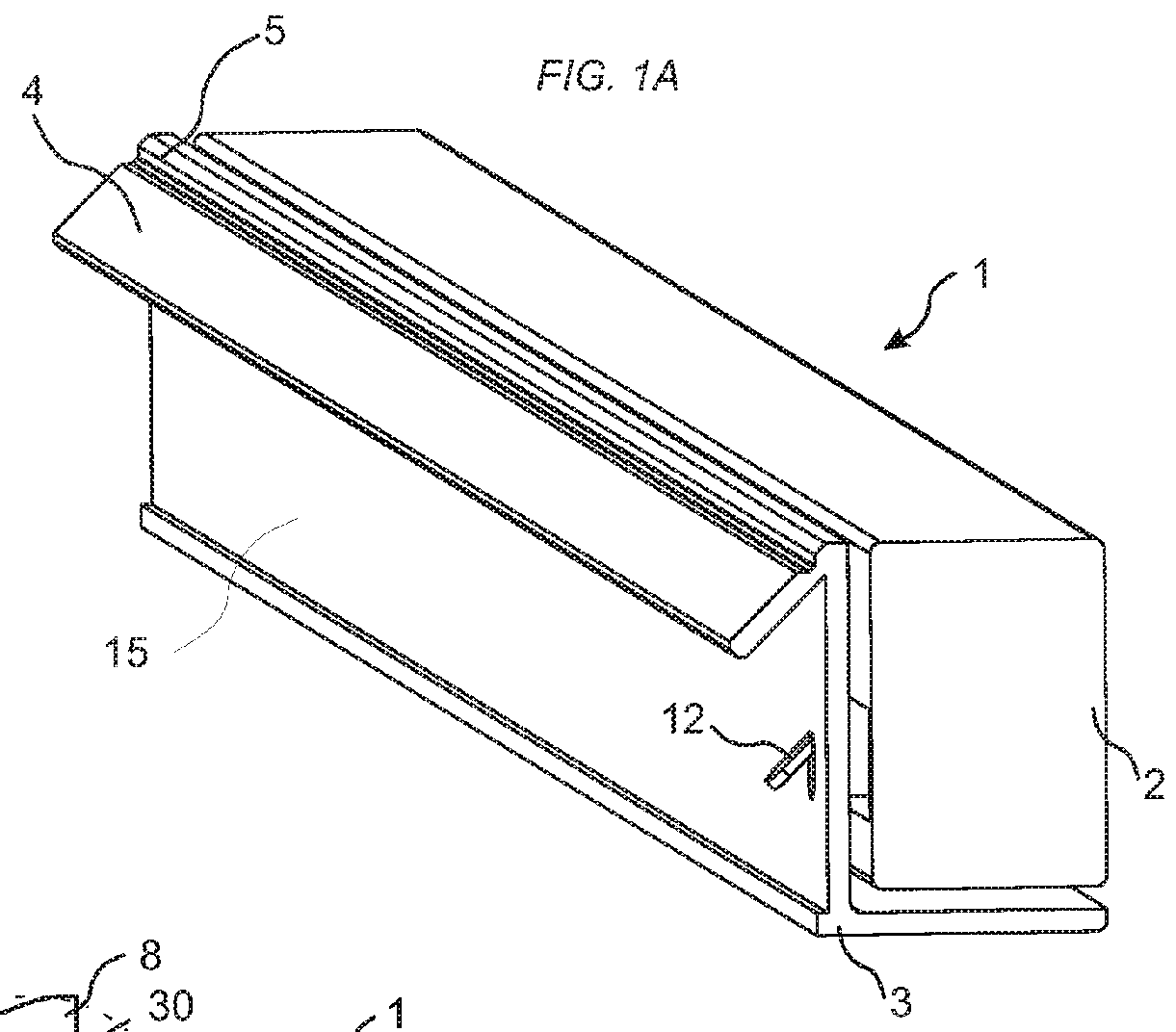

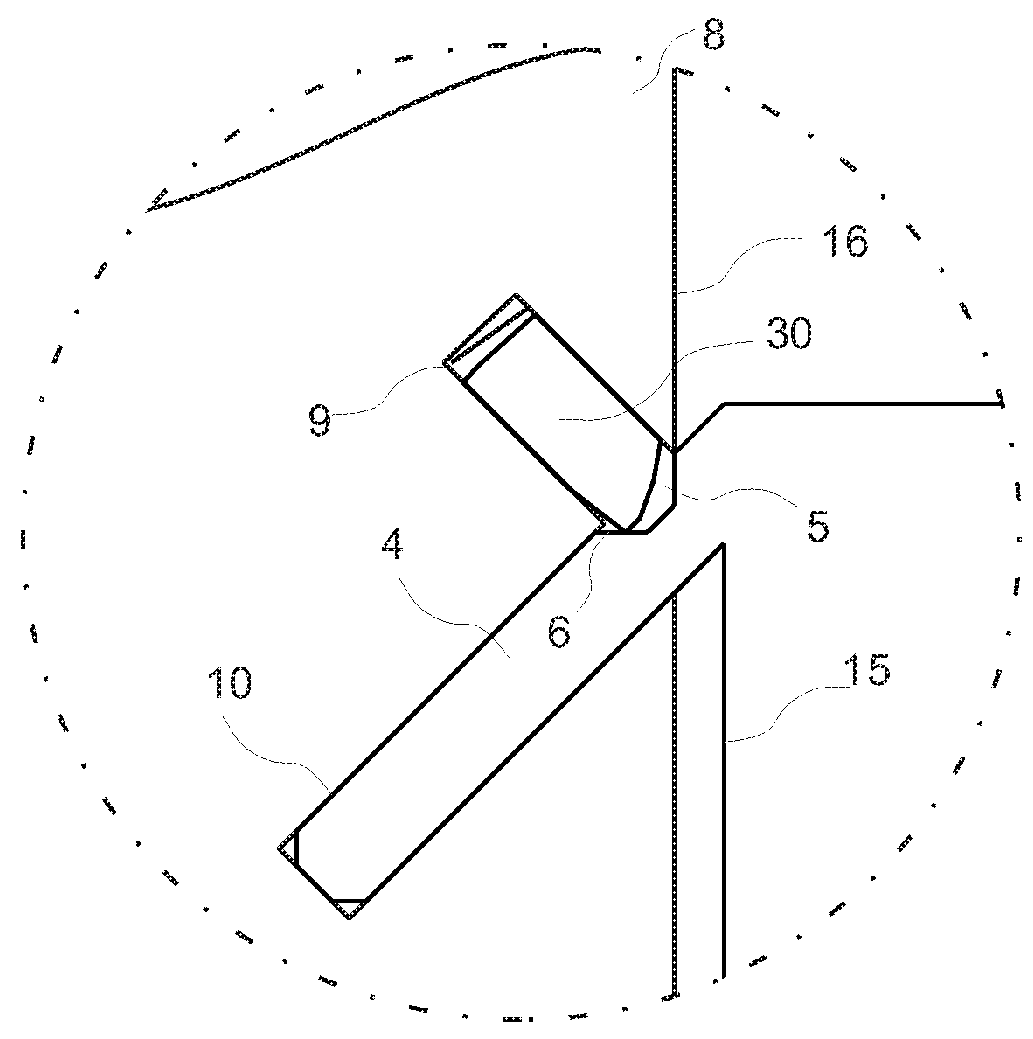

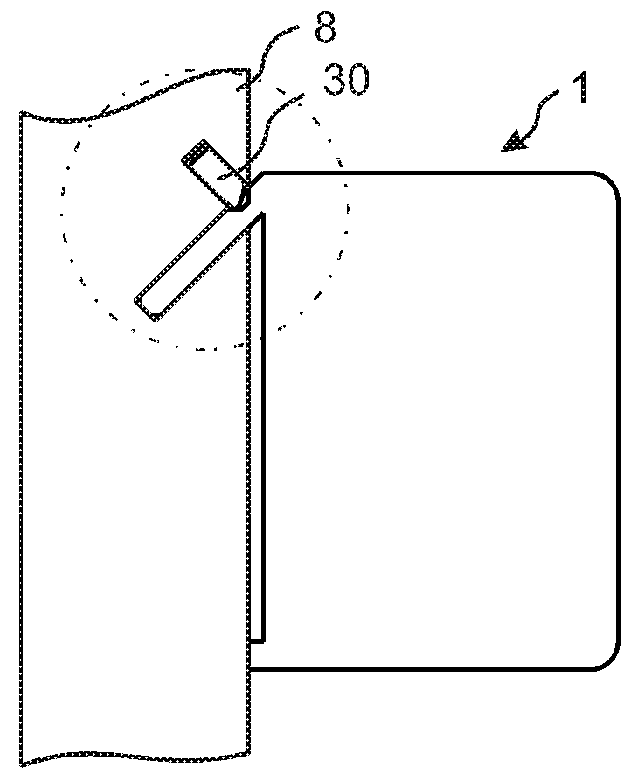

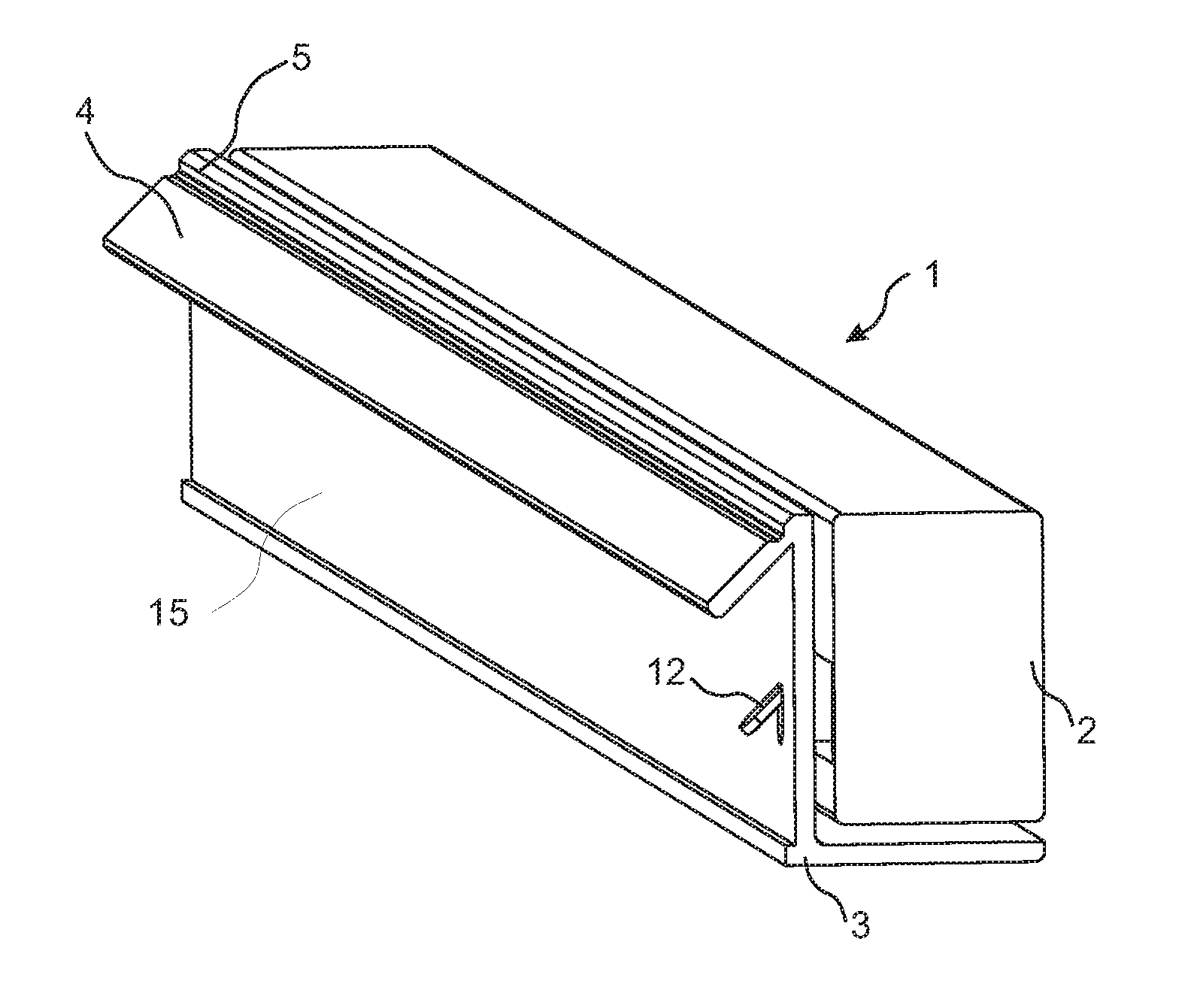

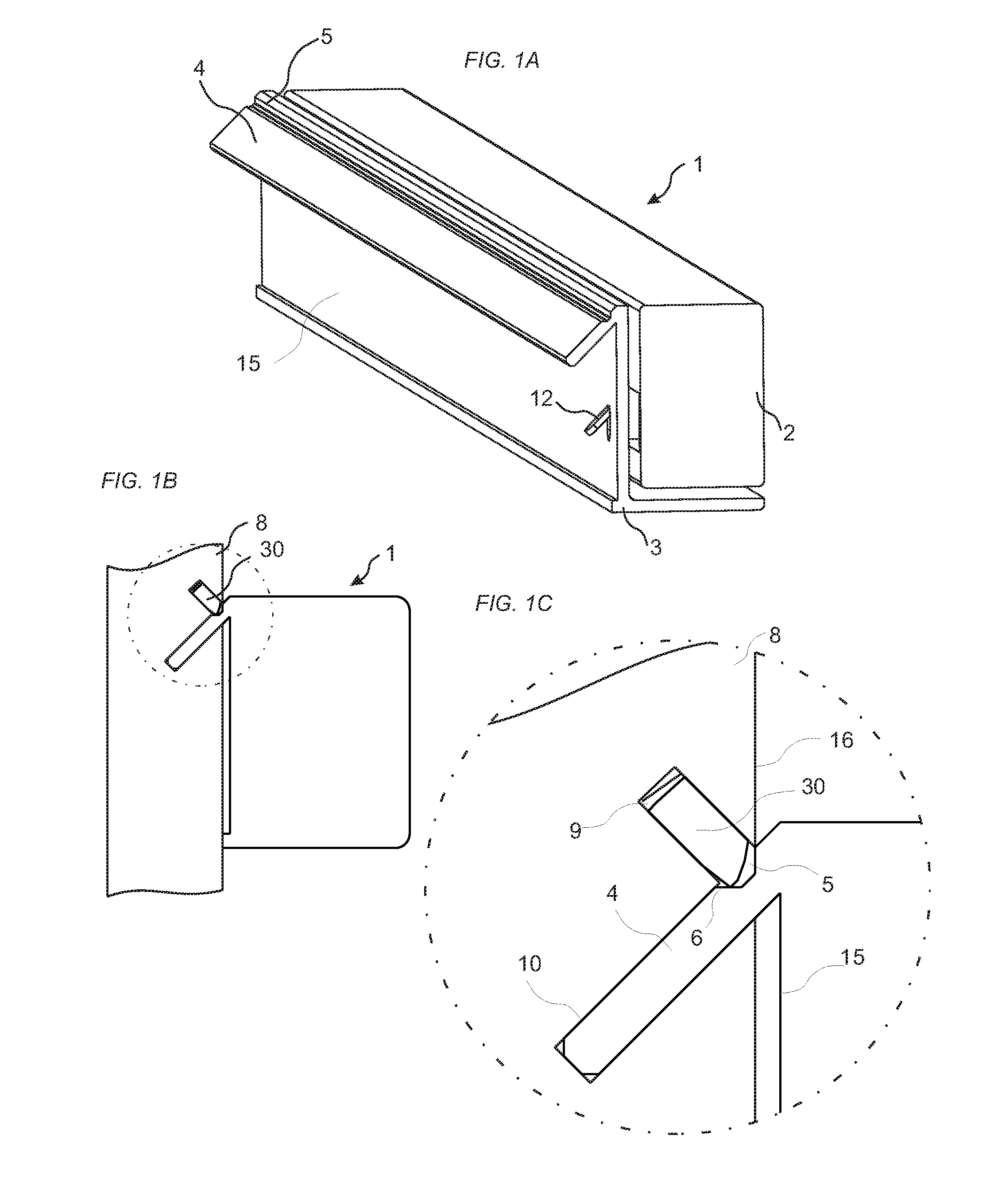

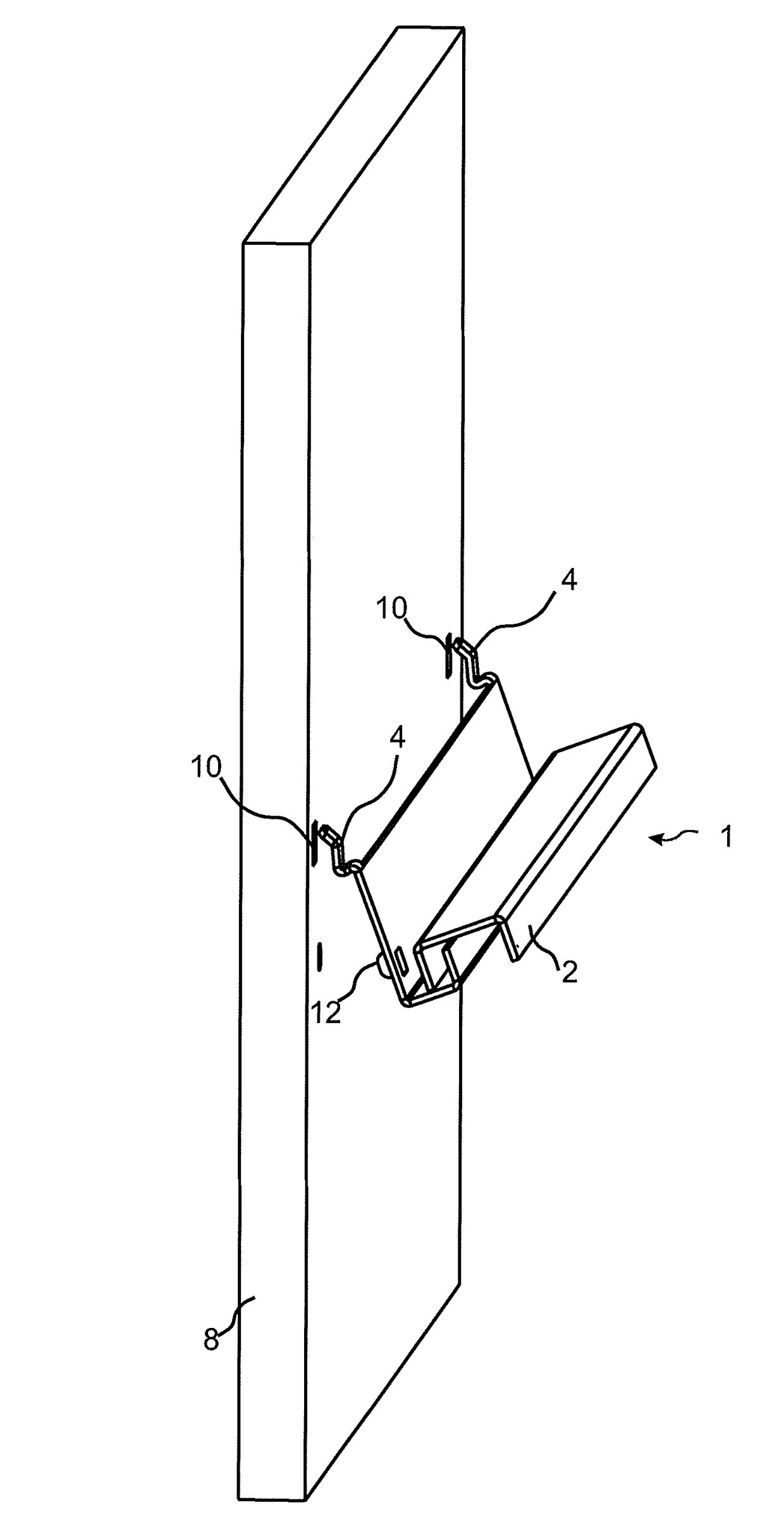

Panel with a slider

A panel provided with a slider. The slider including a first surface and the panel including a second surface, the slider is being configured to be assembled to the panel with the first surface facing the second surface. The second surface is provided with an insertion groove and a displacement groove, which are of a longitudinal shape. A first angle, which is between the second surface and the insertion groove, is an acute angle. A strip protrudes from the first surface. A second angle, which is between the strip and the first surface, is an acute angle. The strip is configured to be inserted into the insertion groove when the slider is assembled to the panel. A displaceable tongue is arranged in the displacement groove. A locking surface of the displaceable tongue is configured to cooperate with a locking surface of the strip for locking the strip to the panel.

Owner:VÄLINGE INNOVATION AB

Panel with a slider

A panel provided with a slider. The slider including a first surface and the panel including a second surface, the slider is being configured to be assembled to the panel with the first surface facing the second surface. The second surface is provided with an insertion groove and a displacement groove, which are of a longitudinal shape. A first angle, which is between the second surface and the insertion groove, is an acute angle. A strip protrudes from the first surface. A second angle, which is between the strip and the first surface, is an acute angle. The strip is configured to be inserted into the insertion groove when the slider is assembled to the panel. A displaceable tongue is arranged in the displacement groove. A locking surface of the displaceable tongue is configured to cooperate with a locking surface of the strip for locking the strip to the panel.

Owner:VÄLINGE INNOVATION AB

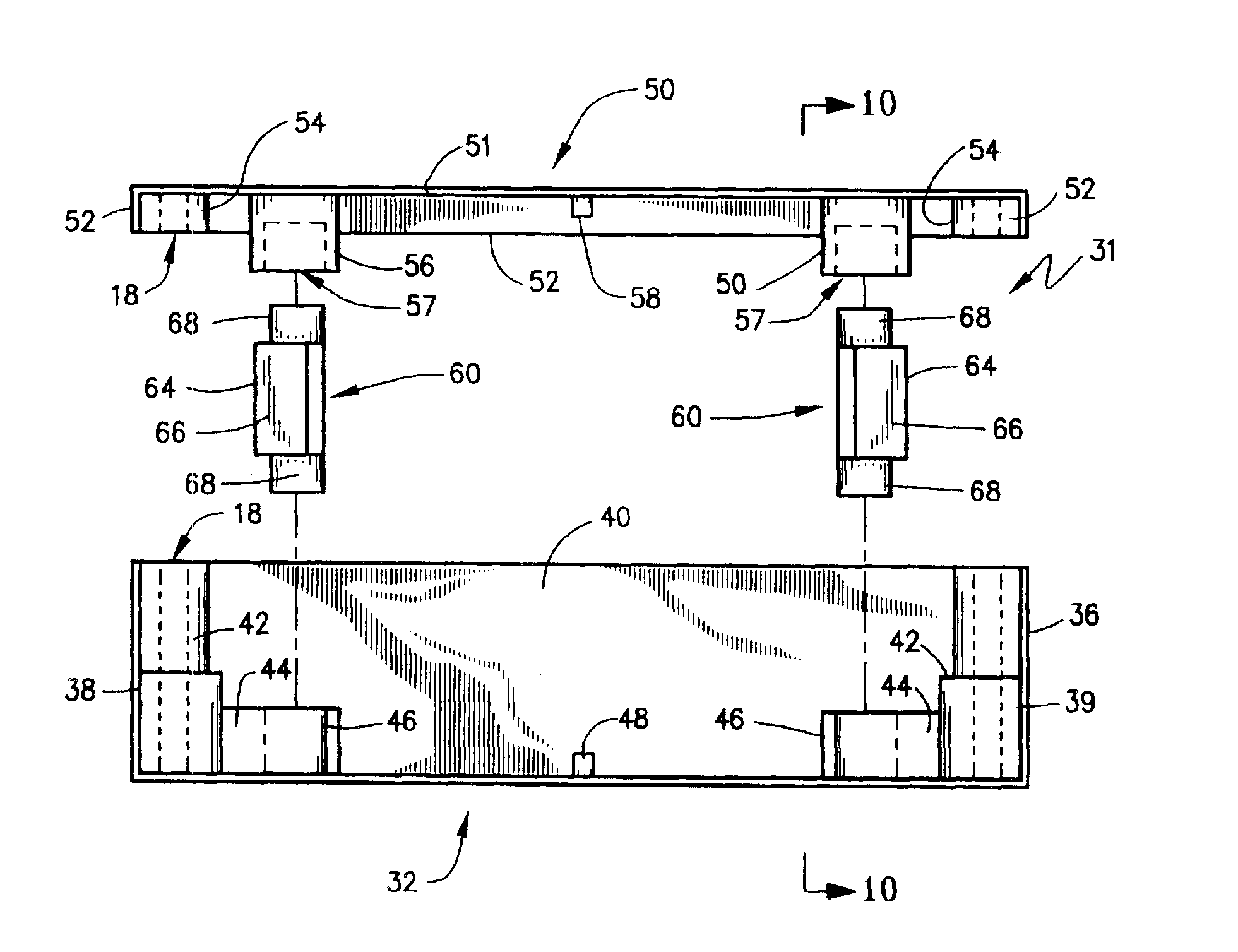

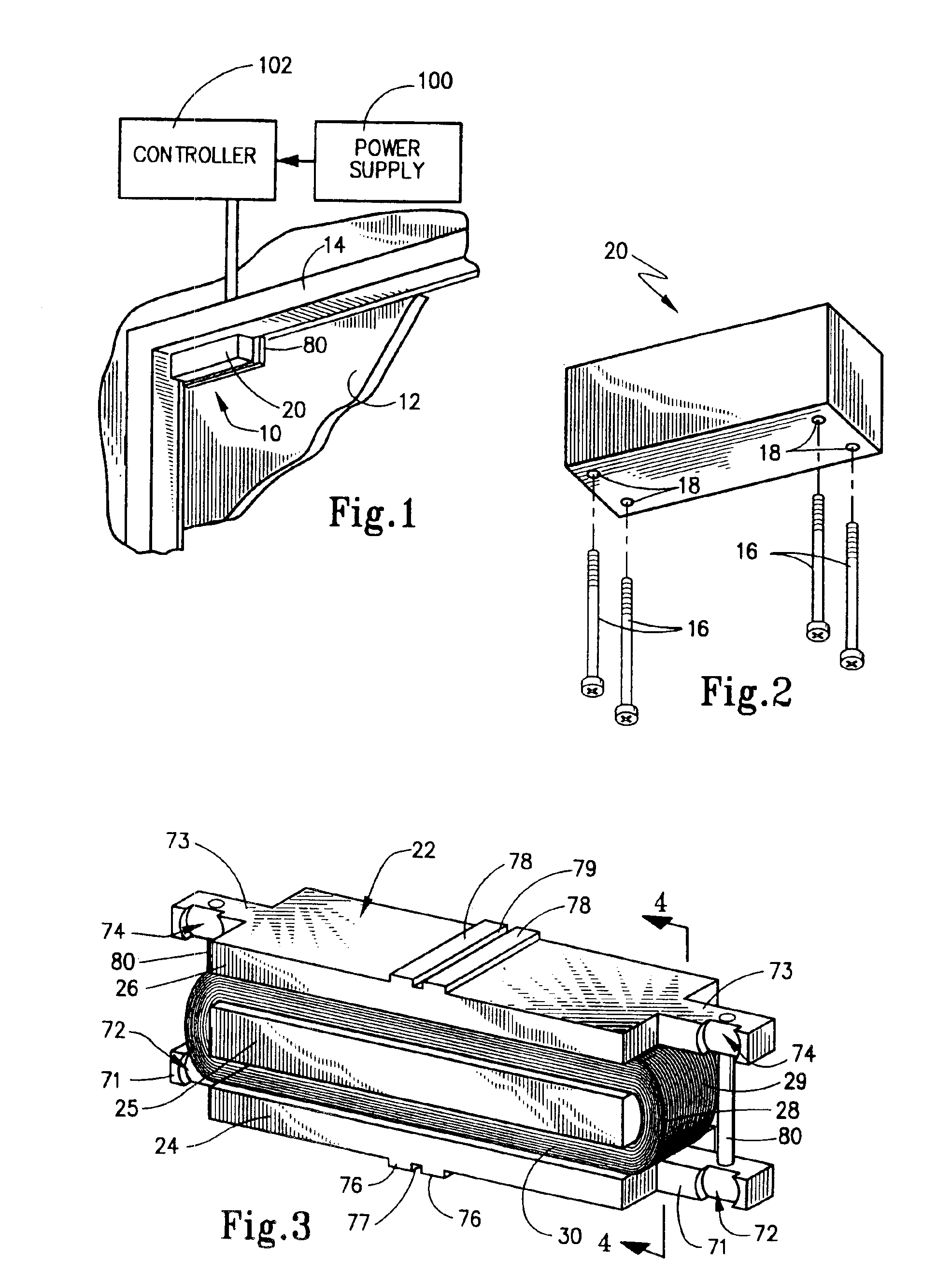

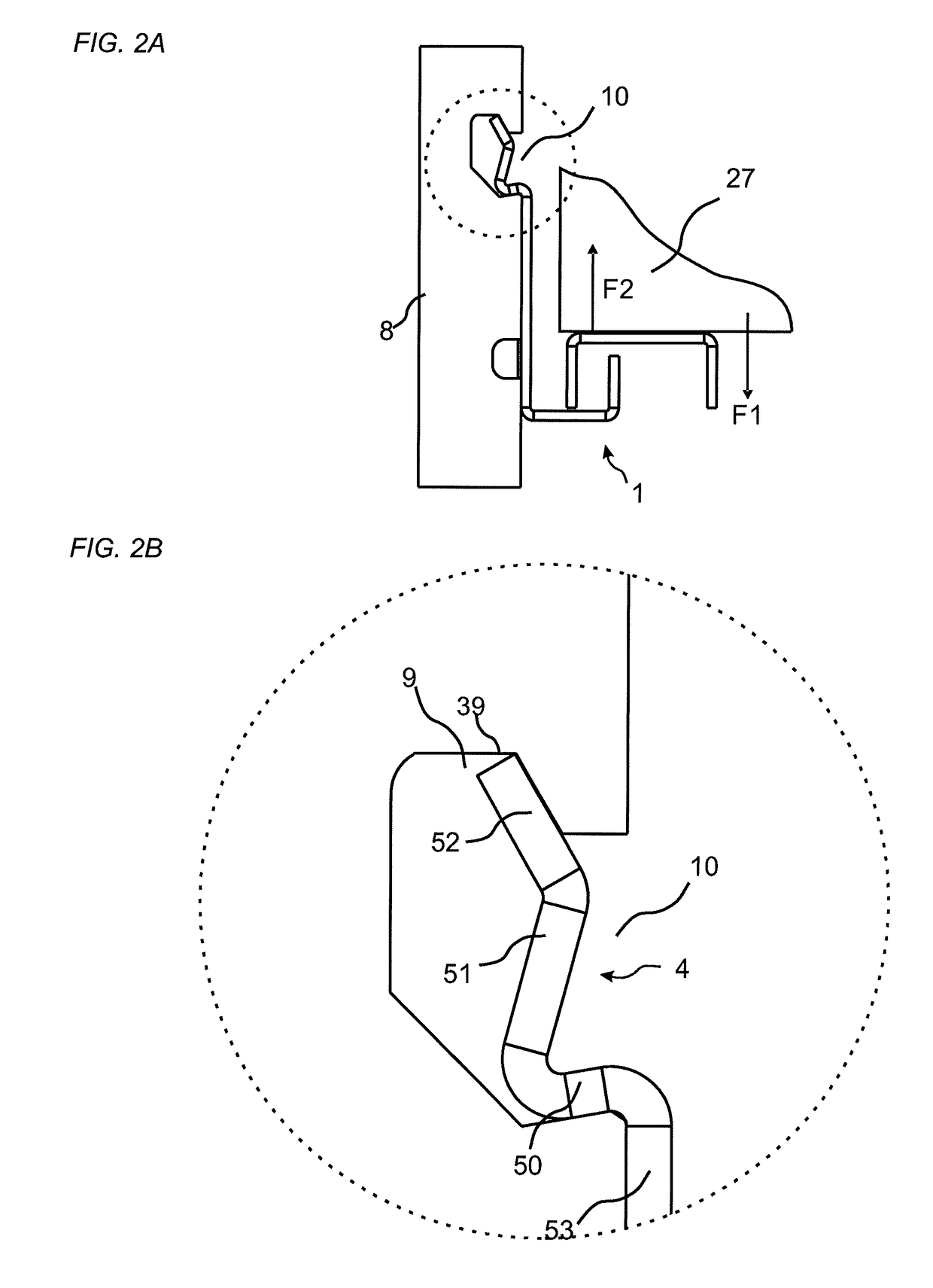

Electromechanical locking method and device

InactiveUS6902214B2Reduced size and costHigh locking strengthBuilding locksWing fastenersCatch and releaseMechanical engineering

An electromechanical lock includes a latching assembly secured to a first structure, a catch piece secured to a second structure, and an electromechanical device. The latching assembly includes at least one latch element movable between a capture and release states to mechanically engage and disengage the catch piece, an arming member movable between a first and second positions wherein the latch element is released and captured, and a biasing element to urge the arming member into the first position. When the electromagnetic device is switched “on”, it magnetically engages the arming member with sufficient force to overcome the biasing force whereby movement of the catch piece away from the received state results in the latch element moving into the capture state to prevent separation of the first and second structures; when the electromagnetic device is switched “off”, the first and second structures may be separated.

Owner:SMITH JERRY R

Panel with a slider

A set including a panel and a slider, such as a drawer slider. The slider including a slider surface and the panel comprising a panel surface. The slider is configured to be assembled to the panel with the slider surface facing the panel surface. The panel surface is provided with an insertion groove and an undercut groove, which are of a longitudinal shape. A strip protrudes from the slider surface, and the strip is configured to be inserted into the insertion groove and the undercut groove by an angling motion.

Owner:VÄLINGE INNOVATION AB

Mechanical locking system for floor panels

Floor panels are shown, which are provided with a mechanical locking system that may be locked with a vertical displacement of a first panel against a second panel. The locking system includes a first rigid and a second flexible joint edge section with different locking functions. The first edge section provides a horizontal locking and the second section provides a vertical locking.

Owner:CERALOC INNOVATION AB

Mechanical locking system for floor panels

ActiveUS20200109569A1Prevent upward bendingHigh locking strengthFlooringClassical mechanicsEngineering

Owner:CERALOC INNOVATION AB

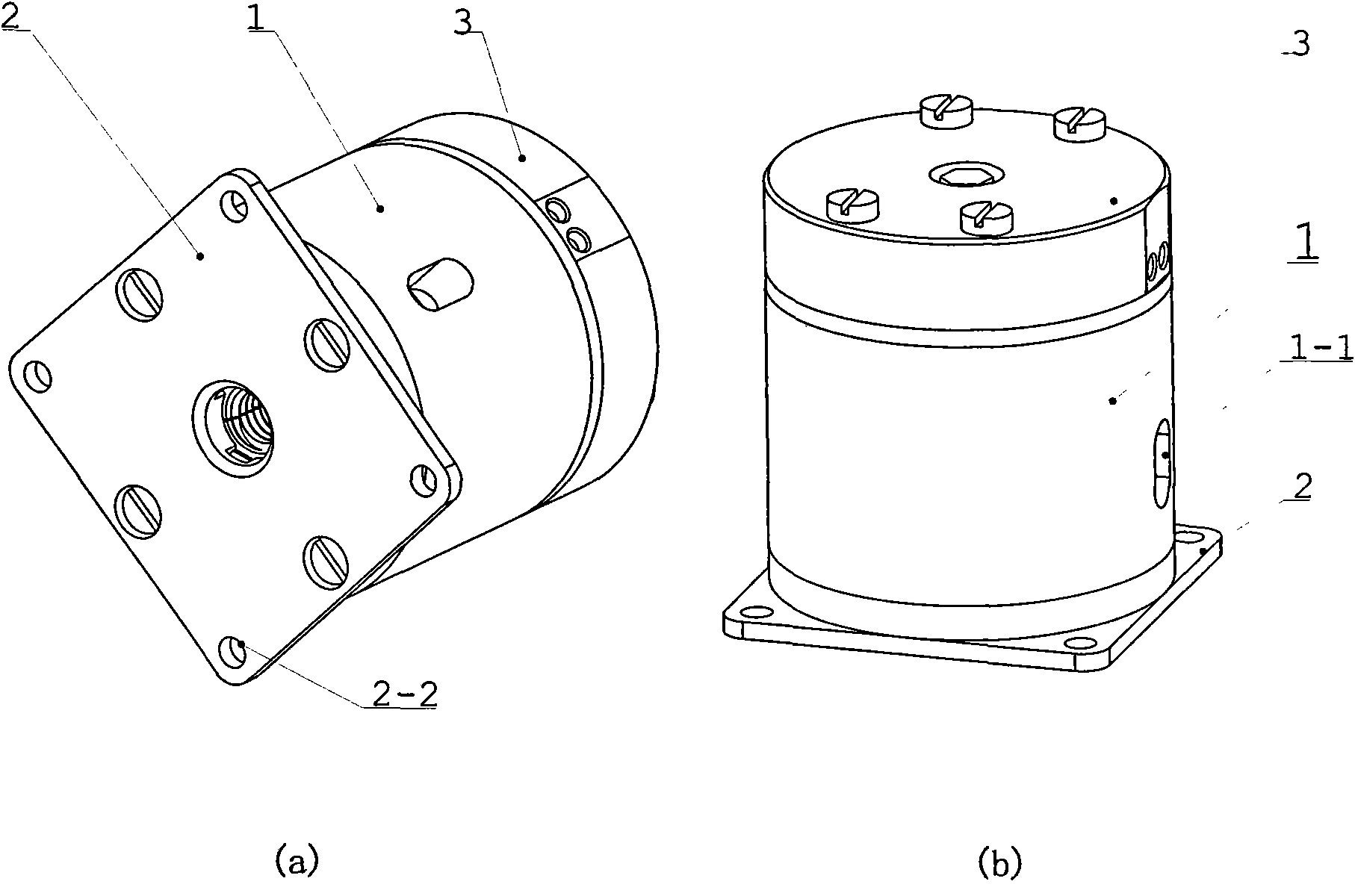

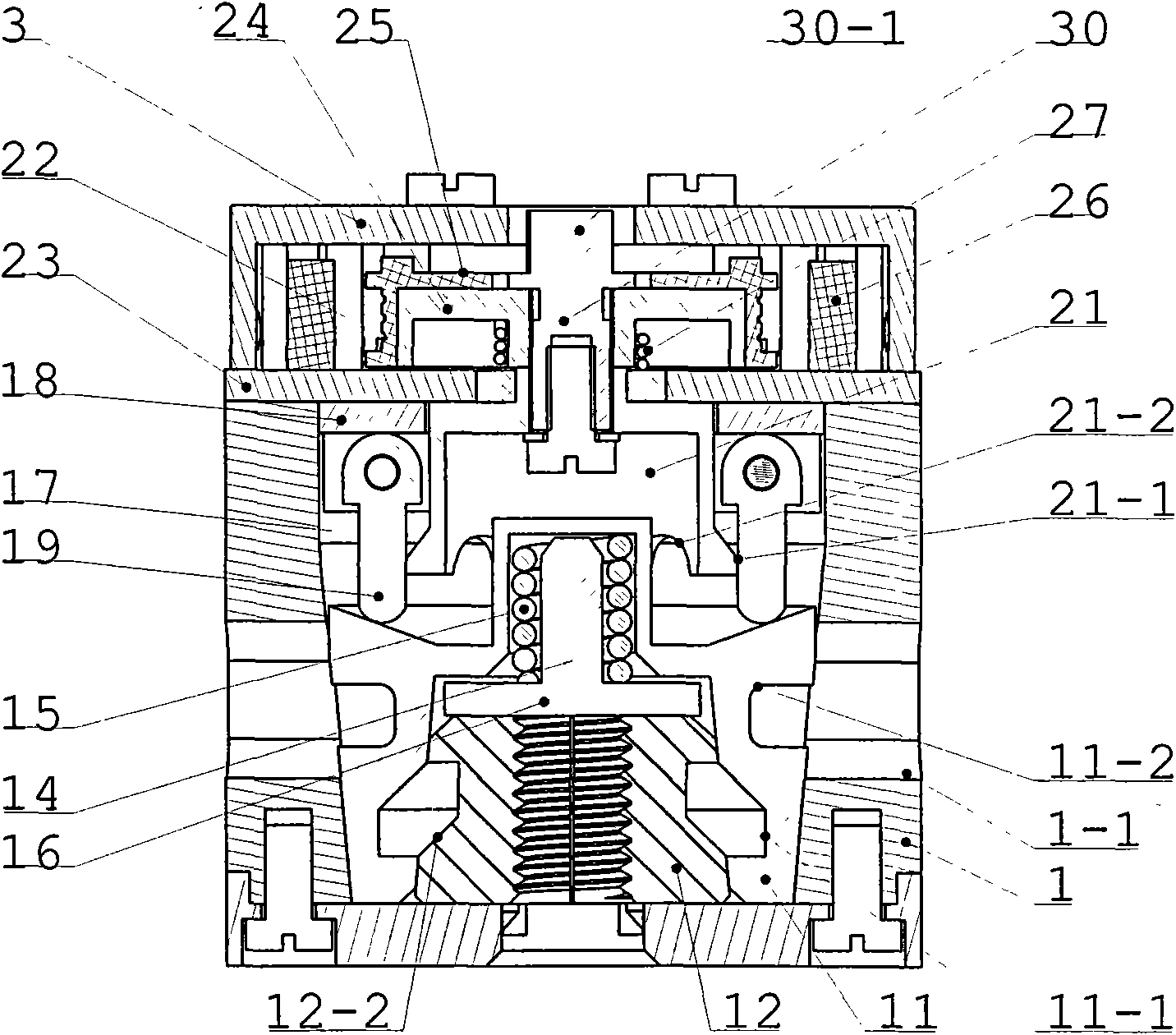

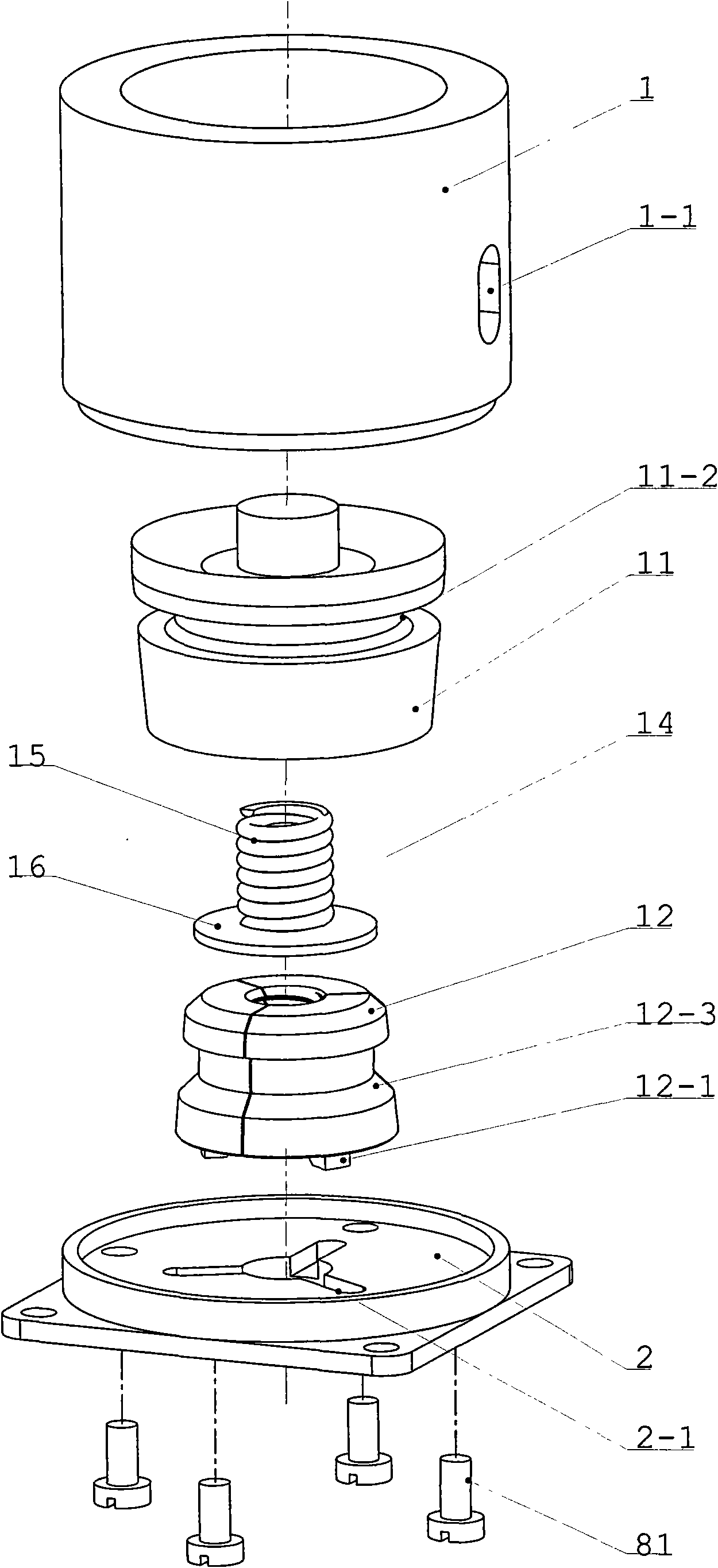

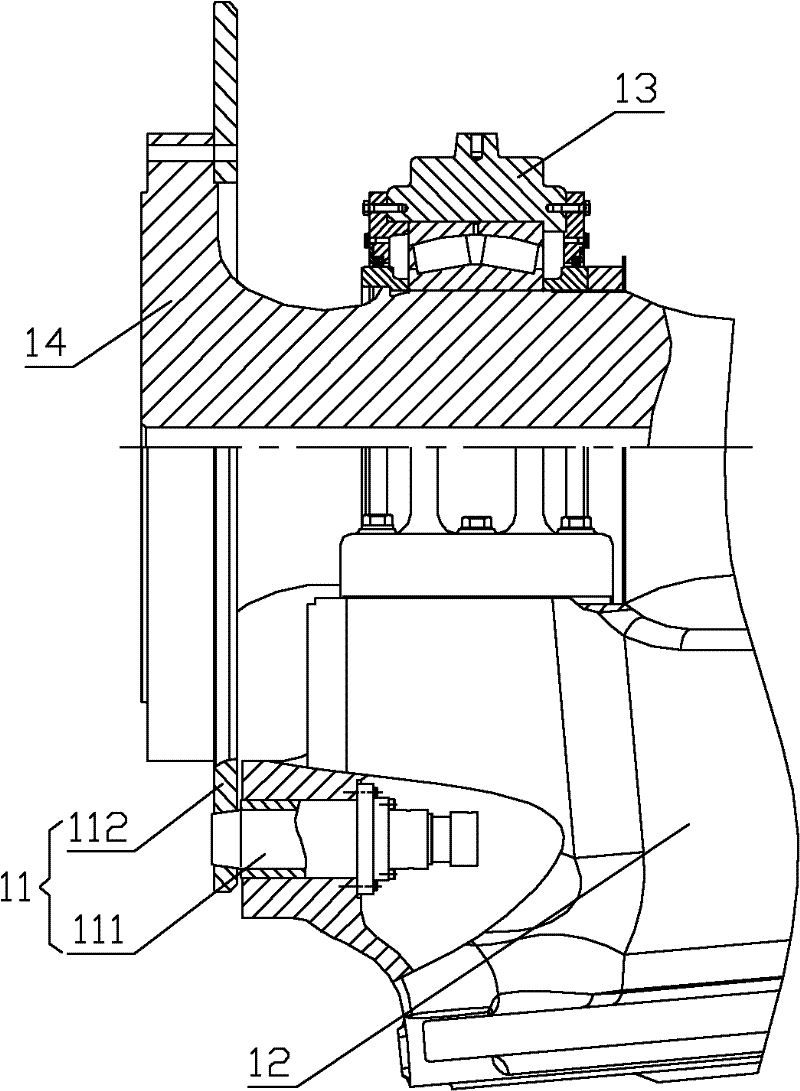

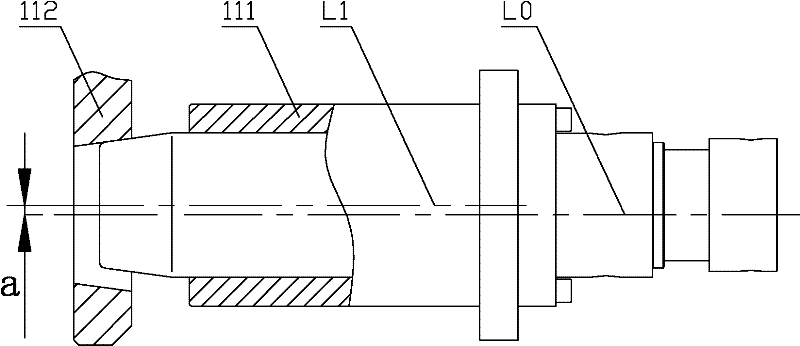

Locking-unlocking device driven by two-stage redundancy

InactiveCN101913436AHigh locking strengthReliable lockingCosmonautic component separationEngineeringElectrical and Electronics engineering

The invention relates to a locking-unlocking device driven by two-stage redundancy, belonging to the technical field of locking and unlocking between two structures. The device is characterized by comprising a cylindrical shell with two open ends, a shell base, a shell top cover, a split nut, a ferrule 11, a primary drive, a primary stop dog, a switching device and a secondary drive, wherein the shell base and the shell top cover are respectively connected with the two ends of the shell, and through holes are respectively arranged in the centers of the shell base and the shell top cover; the split nut is arranged on the inner axial line of the shell, the ferrule is sleeved at the periphery of the split nut, and one end of the collar is closed; and the primary drive, the primary stopdog, the switching device and the secondary drive are arranged in the shell. The device has the advantages of reliable locking and unlocking, little unlocking impact force, strong bearing capacity, fast resetting operation, compact structure, small volume, diversified installation interfaces, and the like.

Owner:郑钢铁 +1

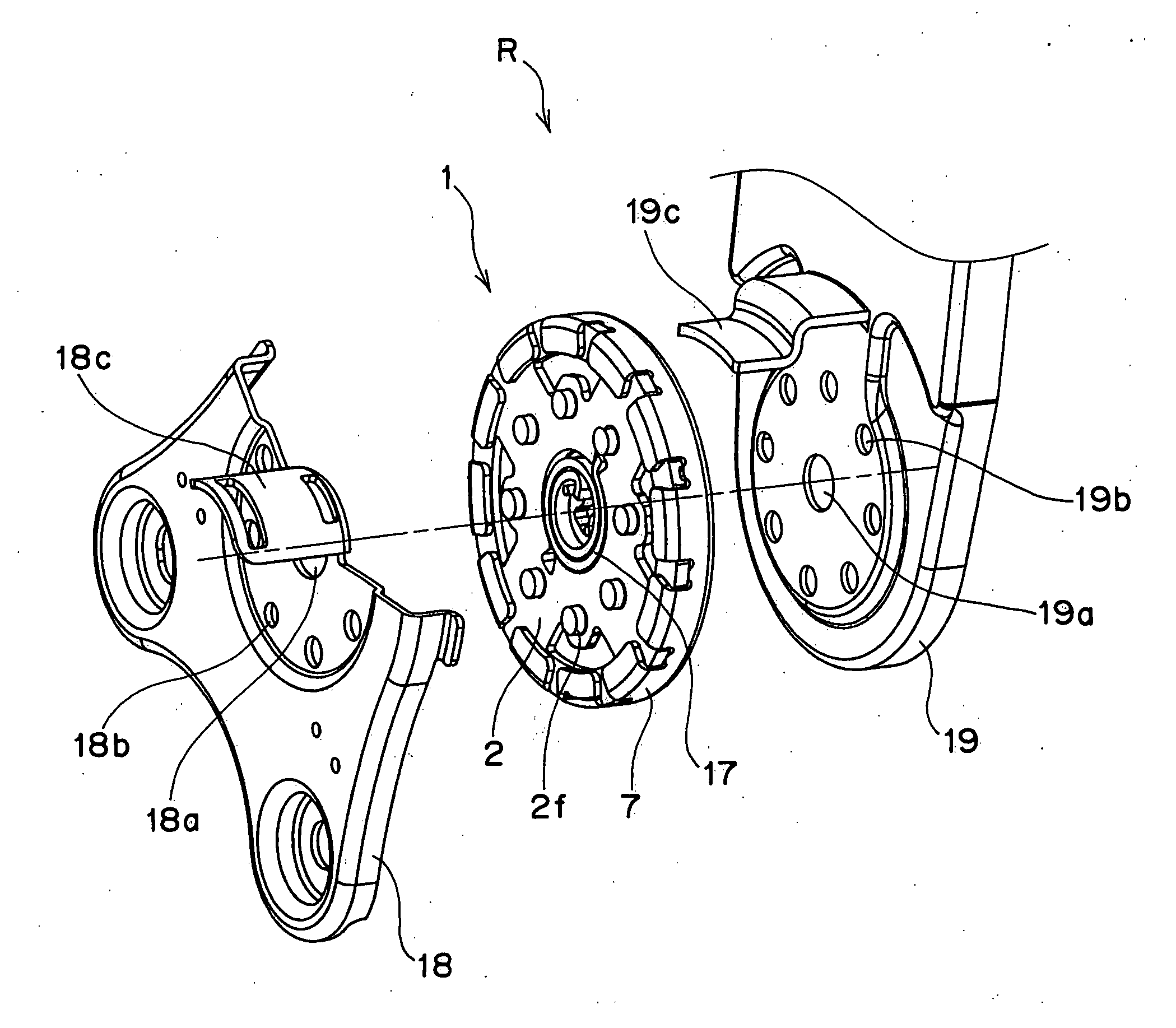

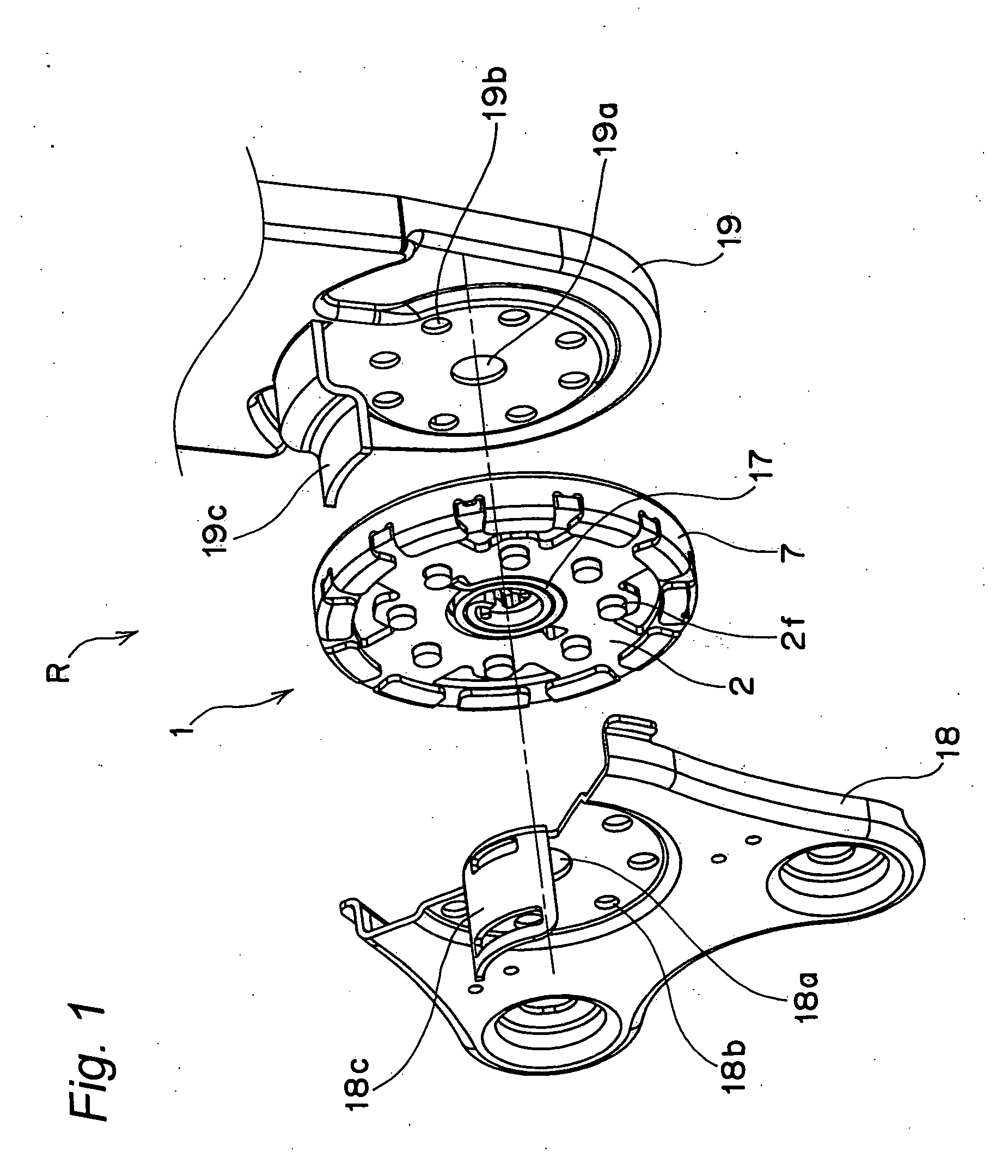

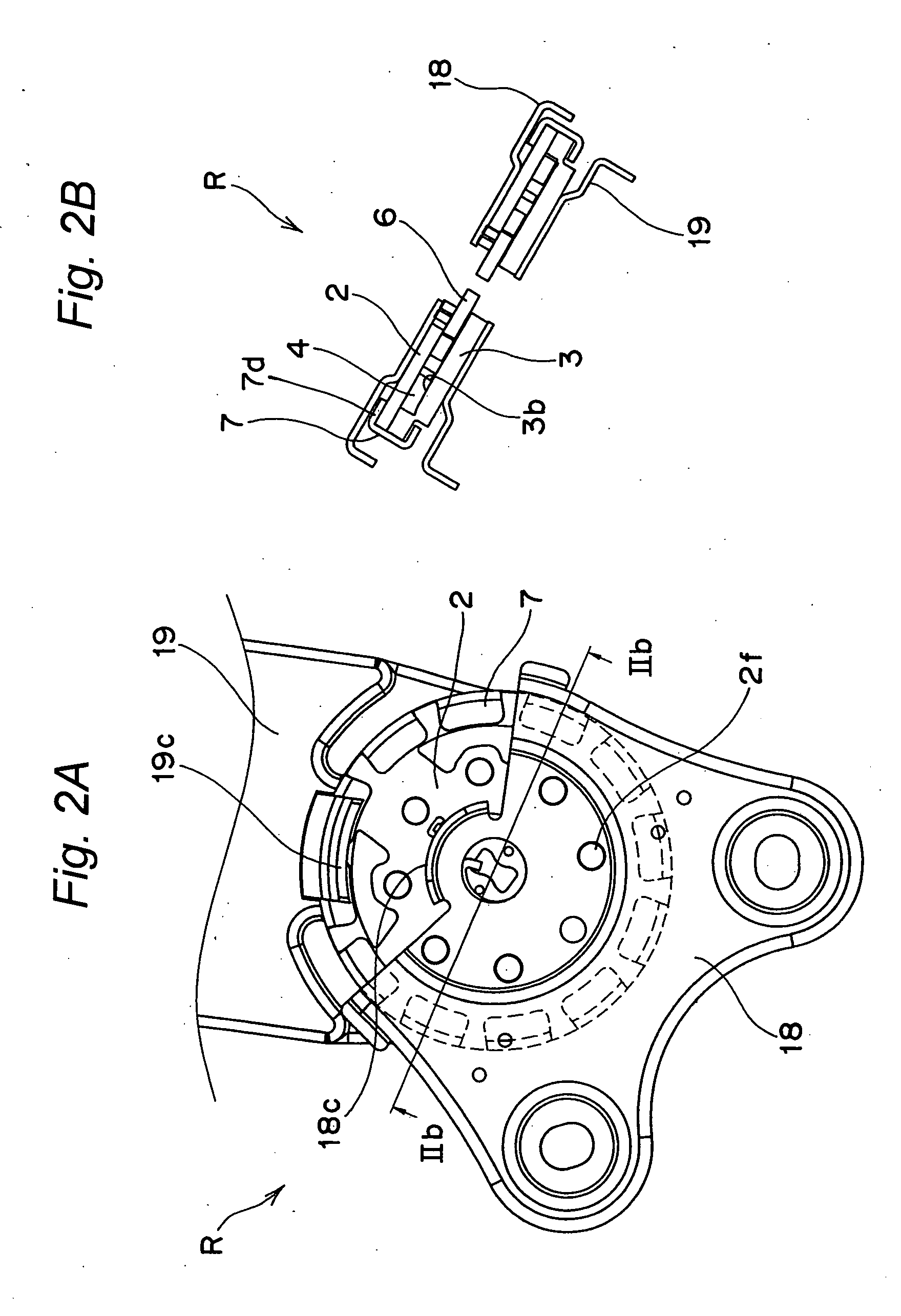

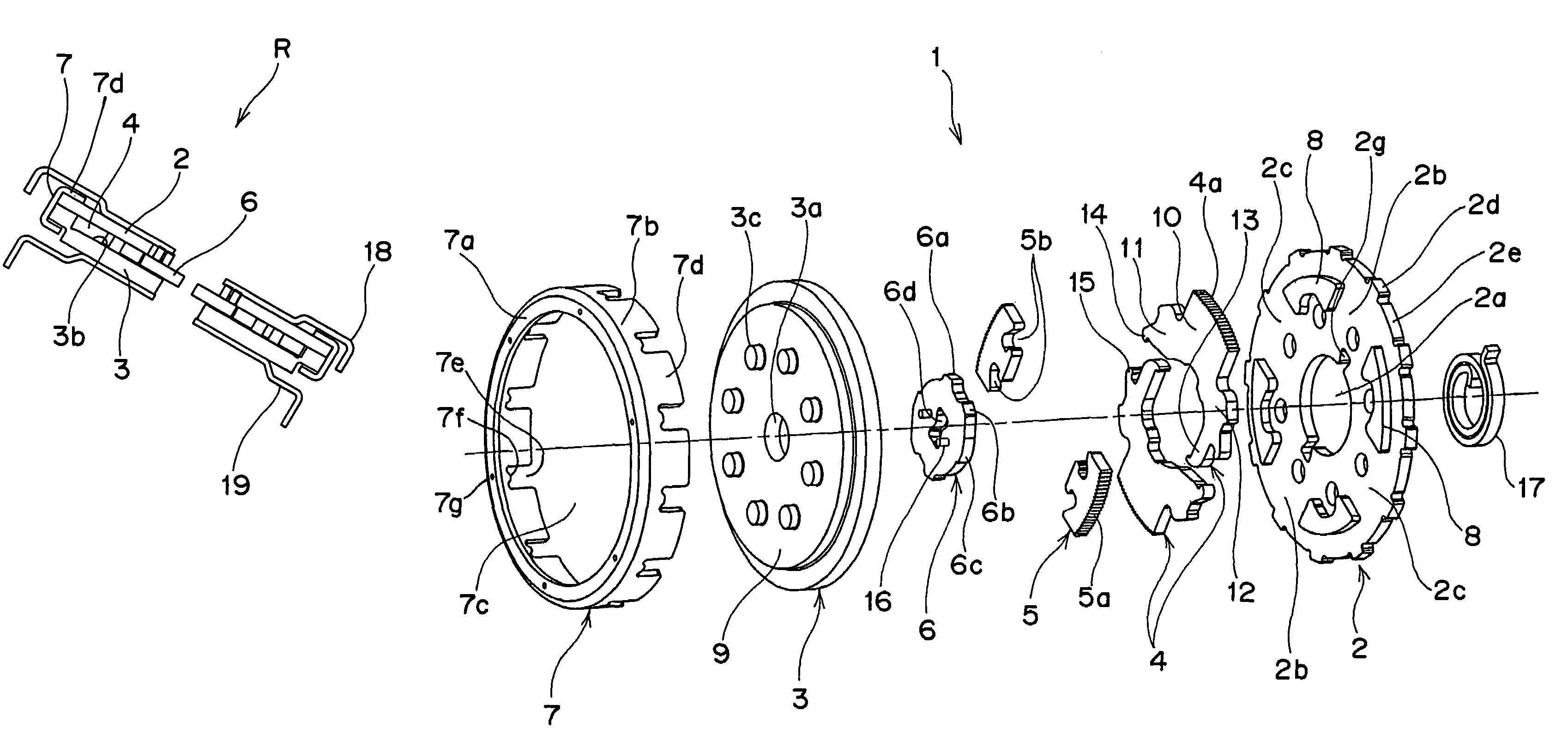

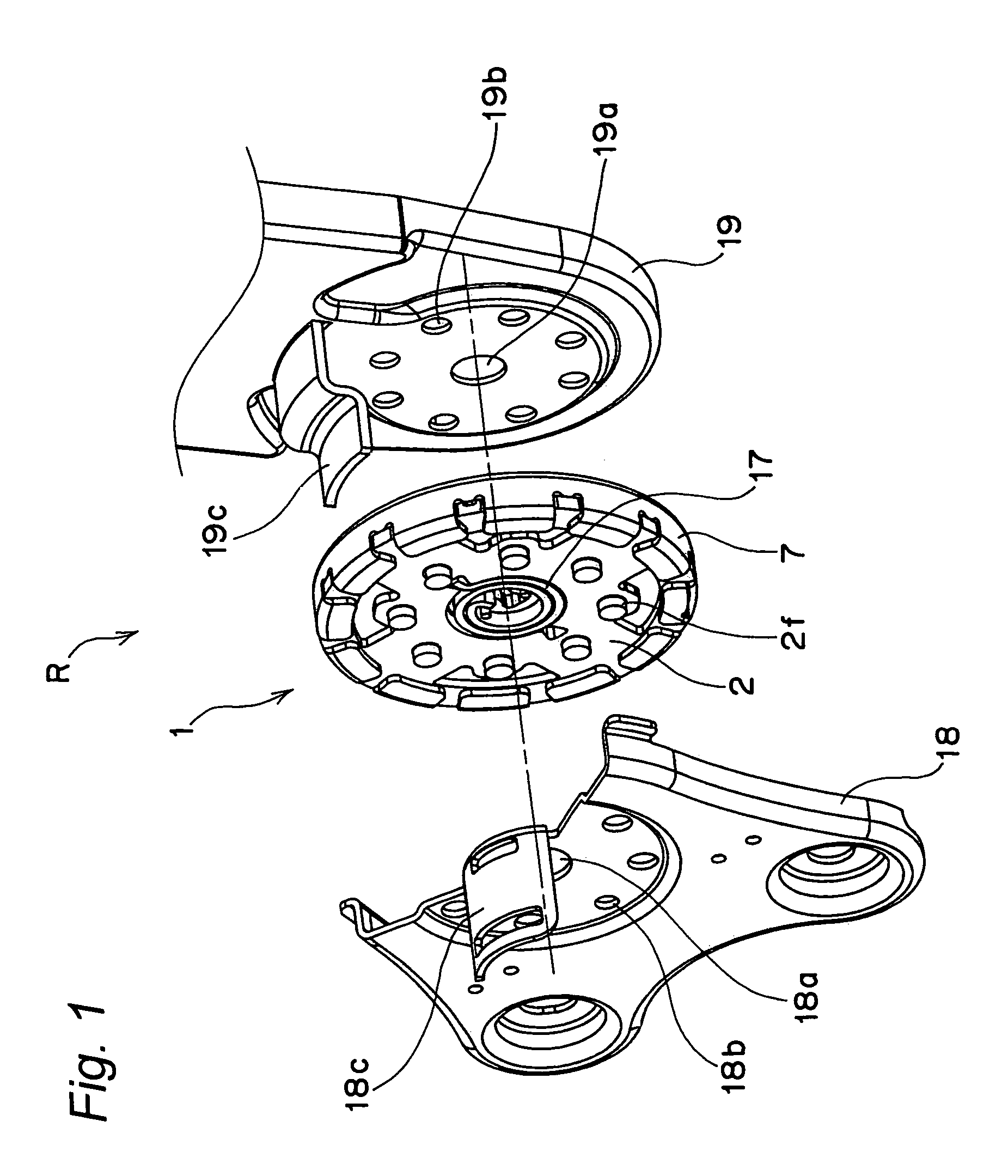

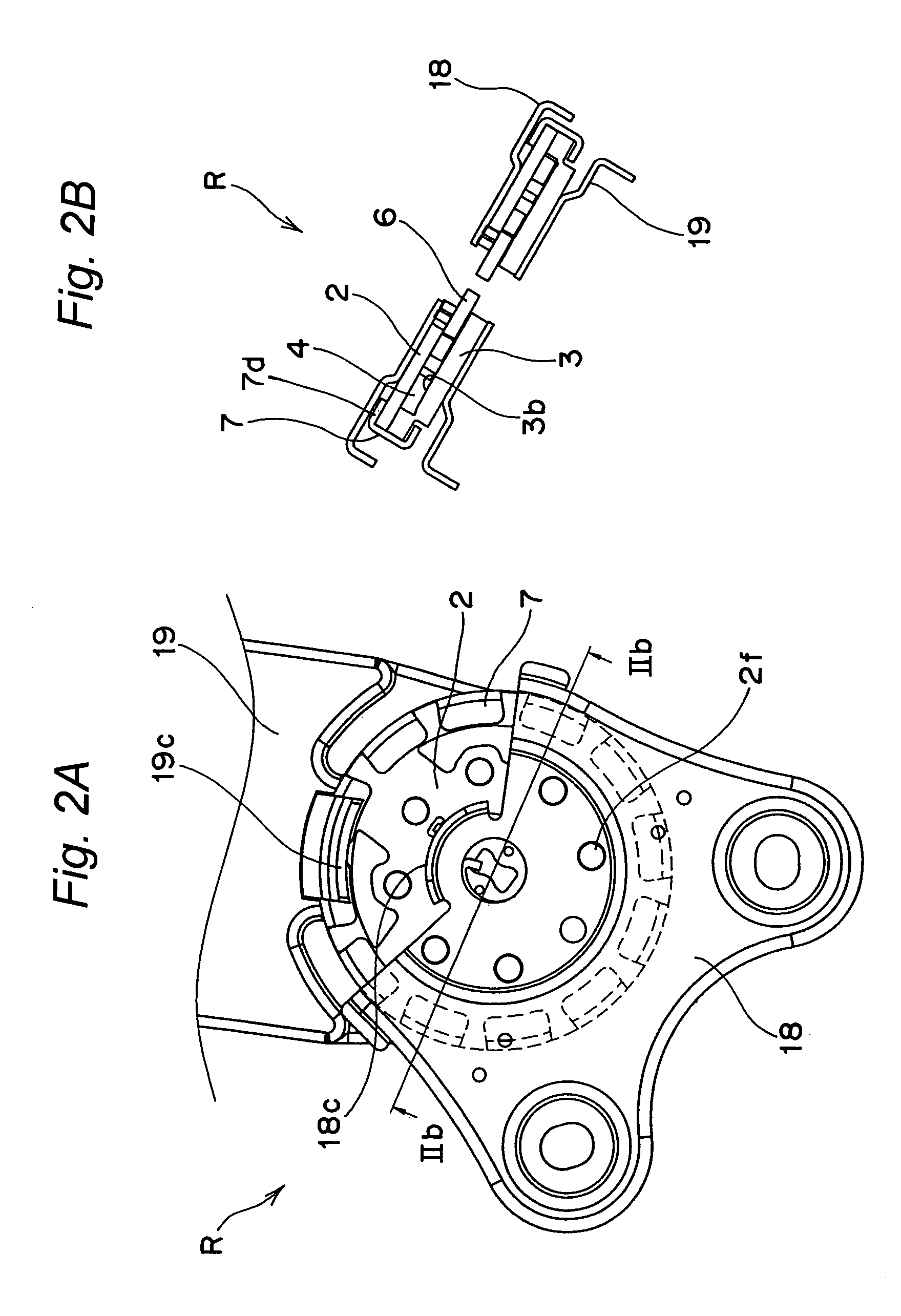

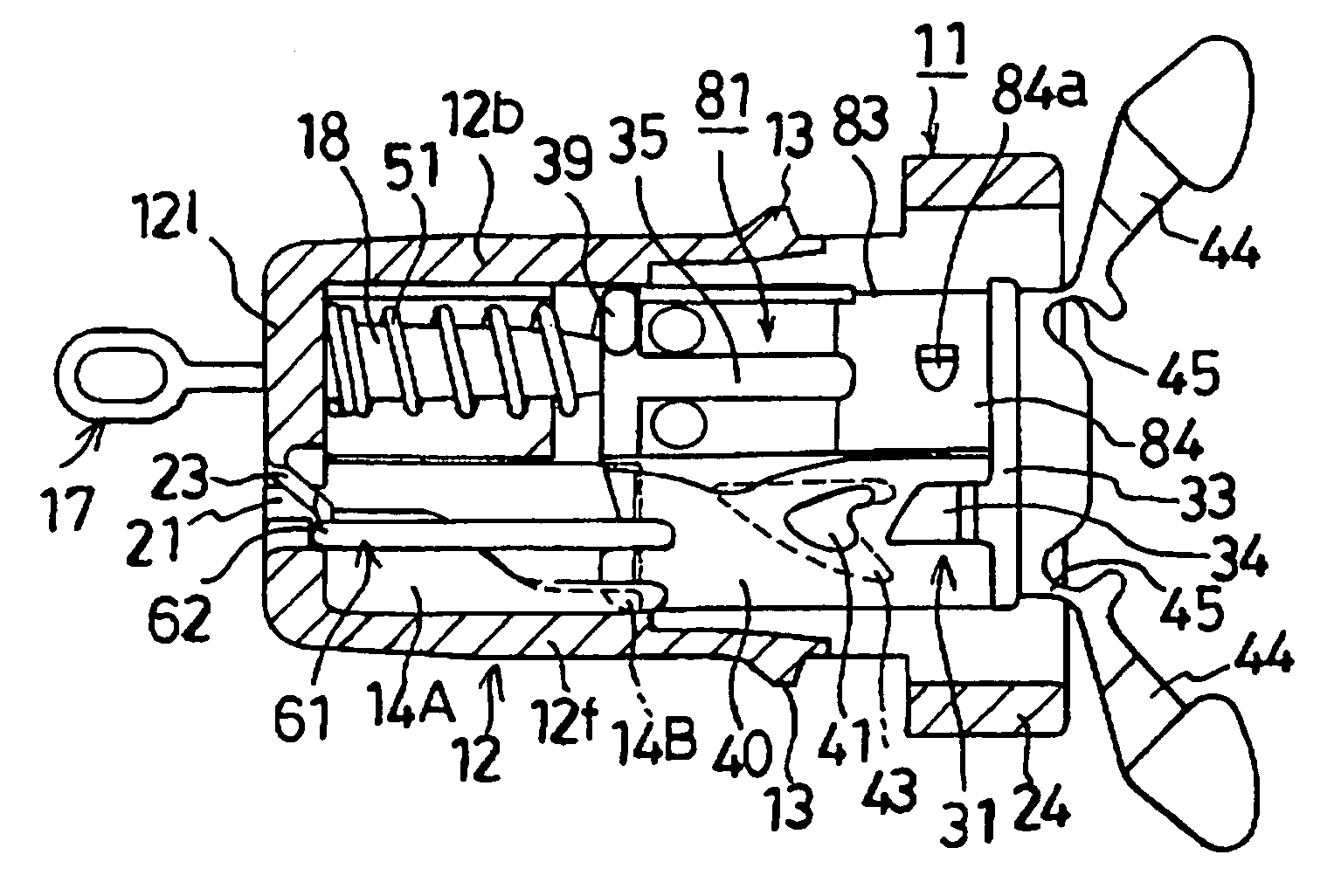

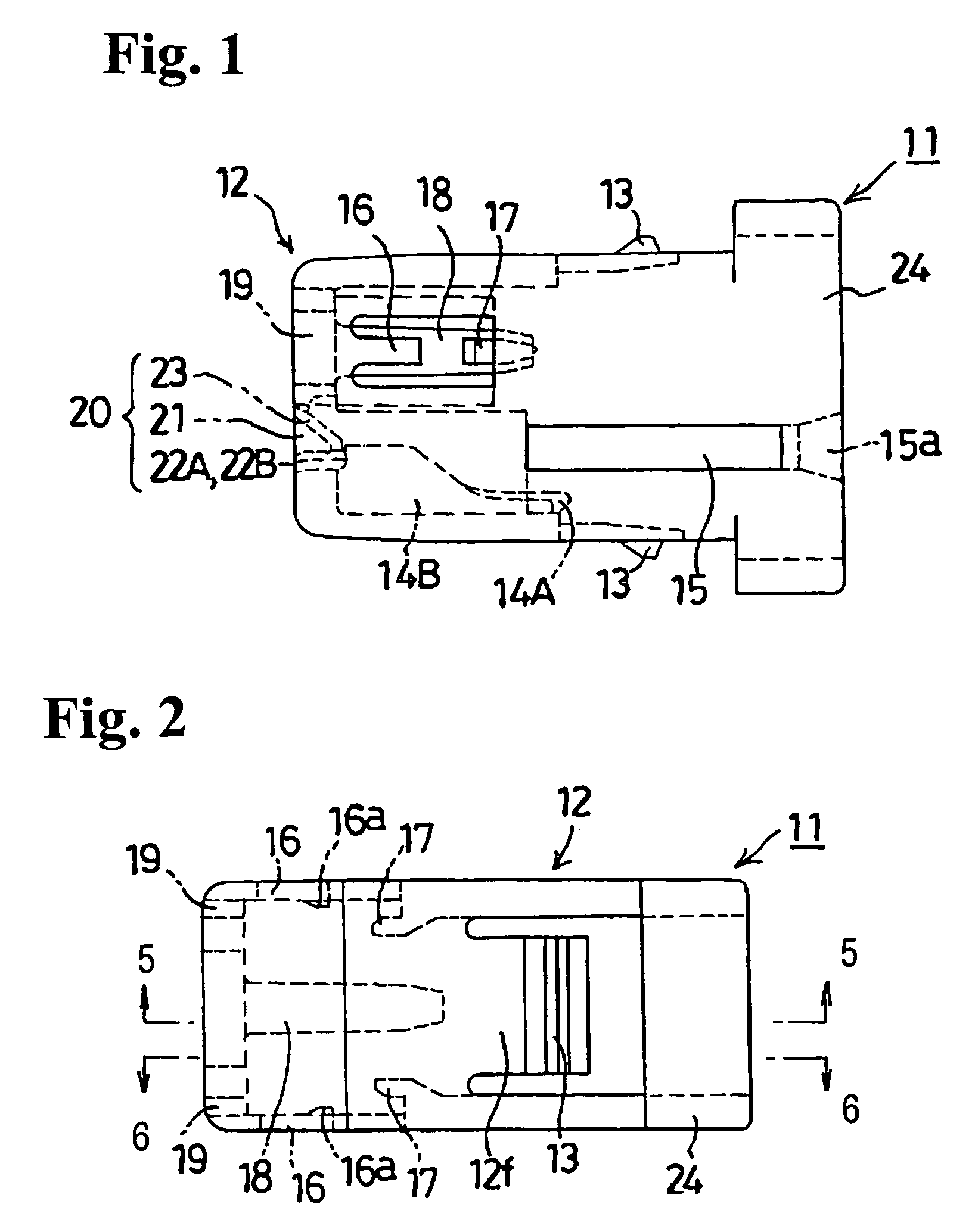

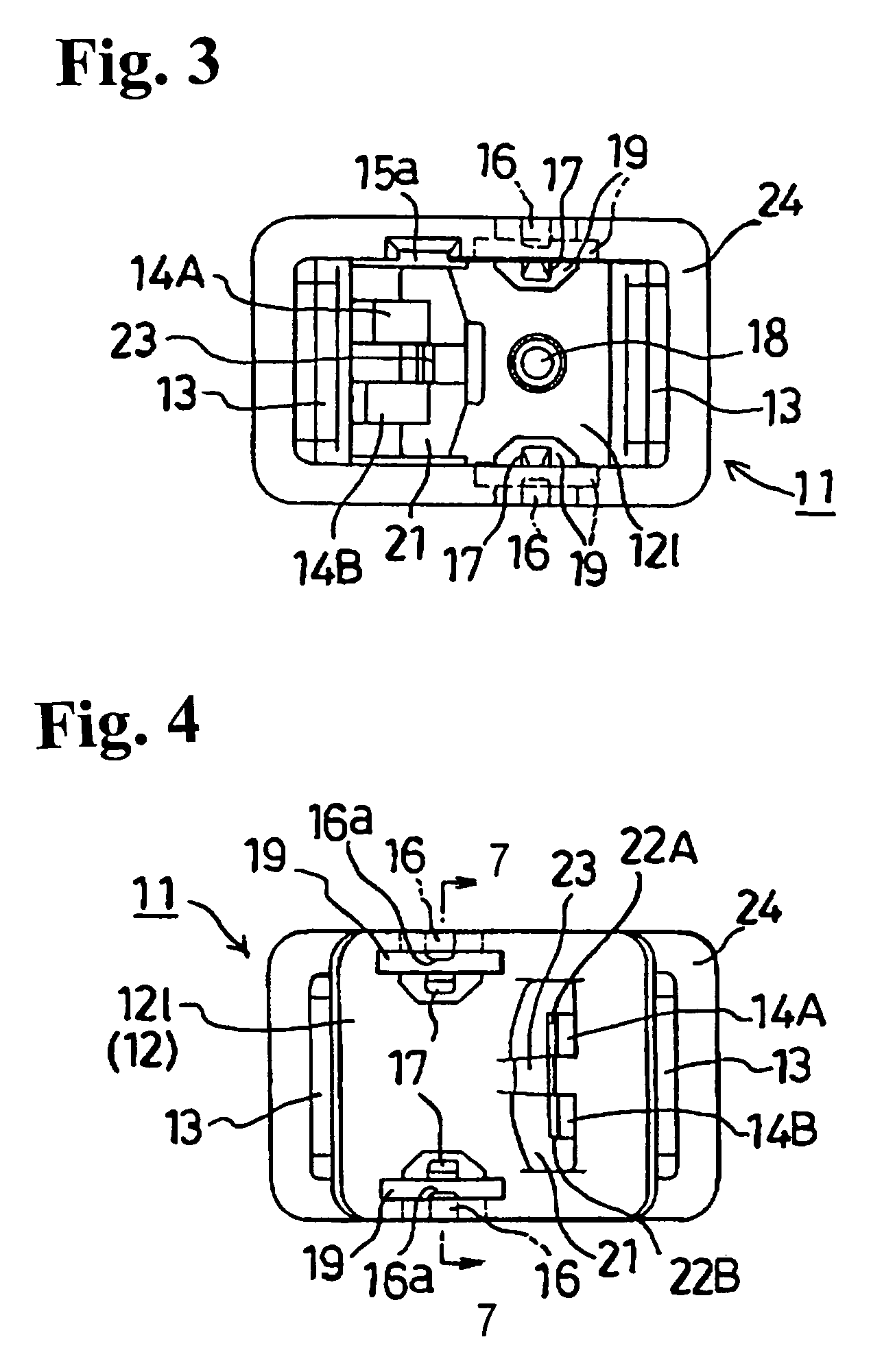

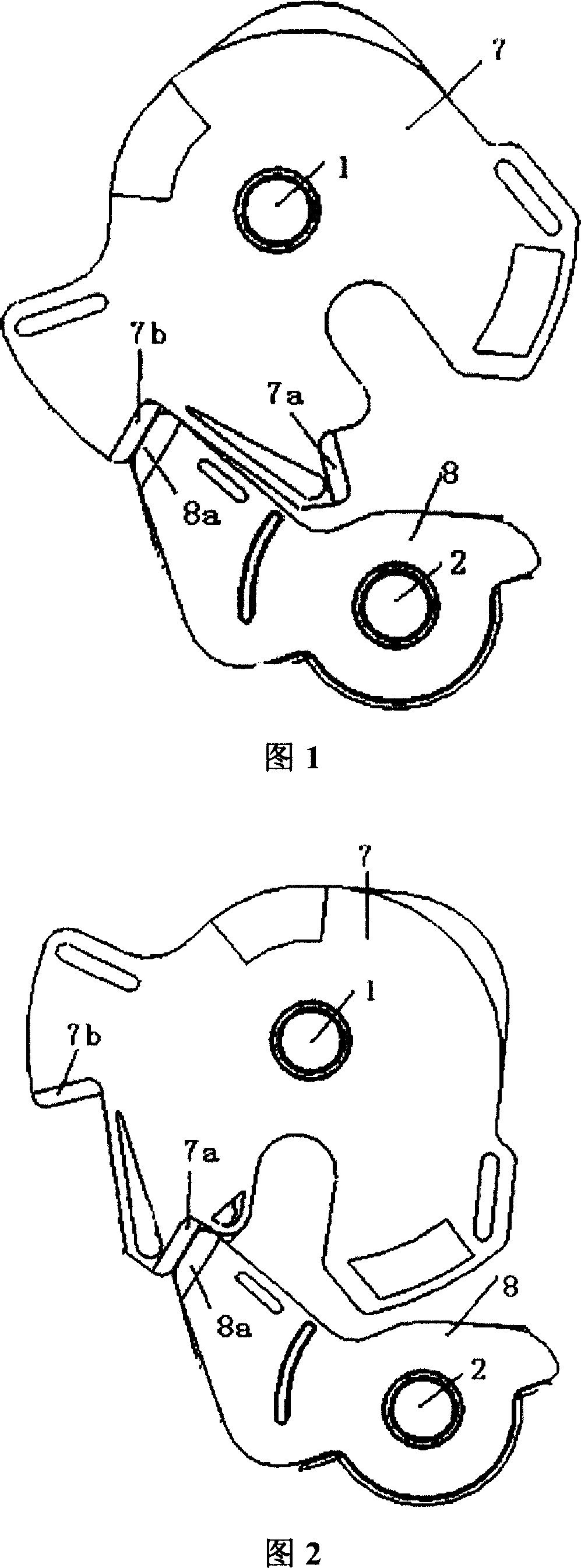

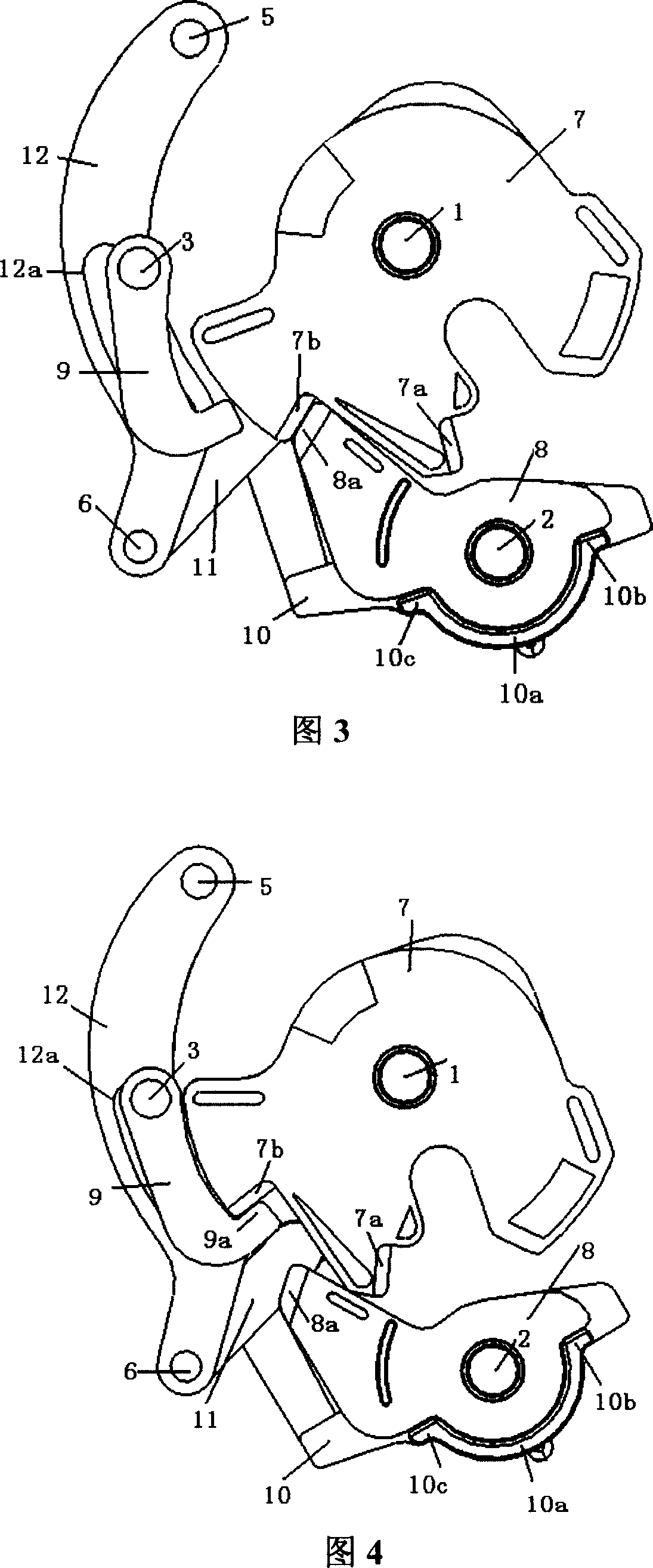

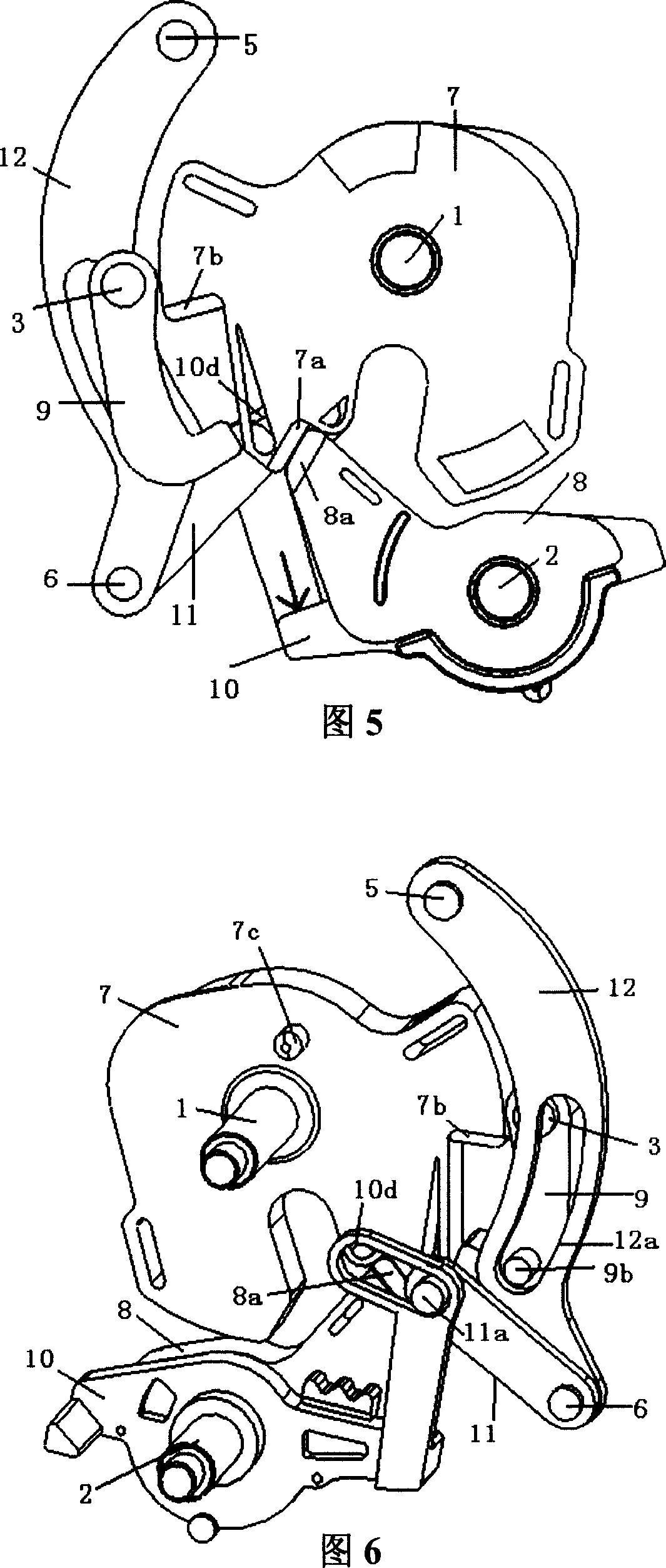

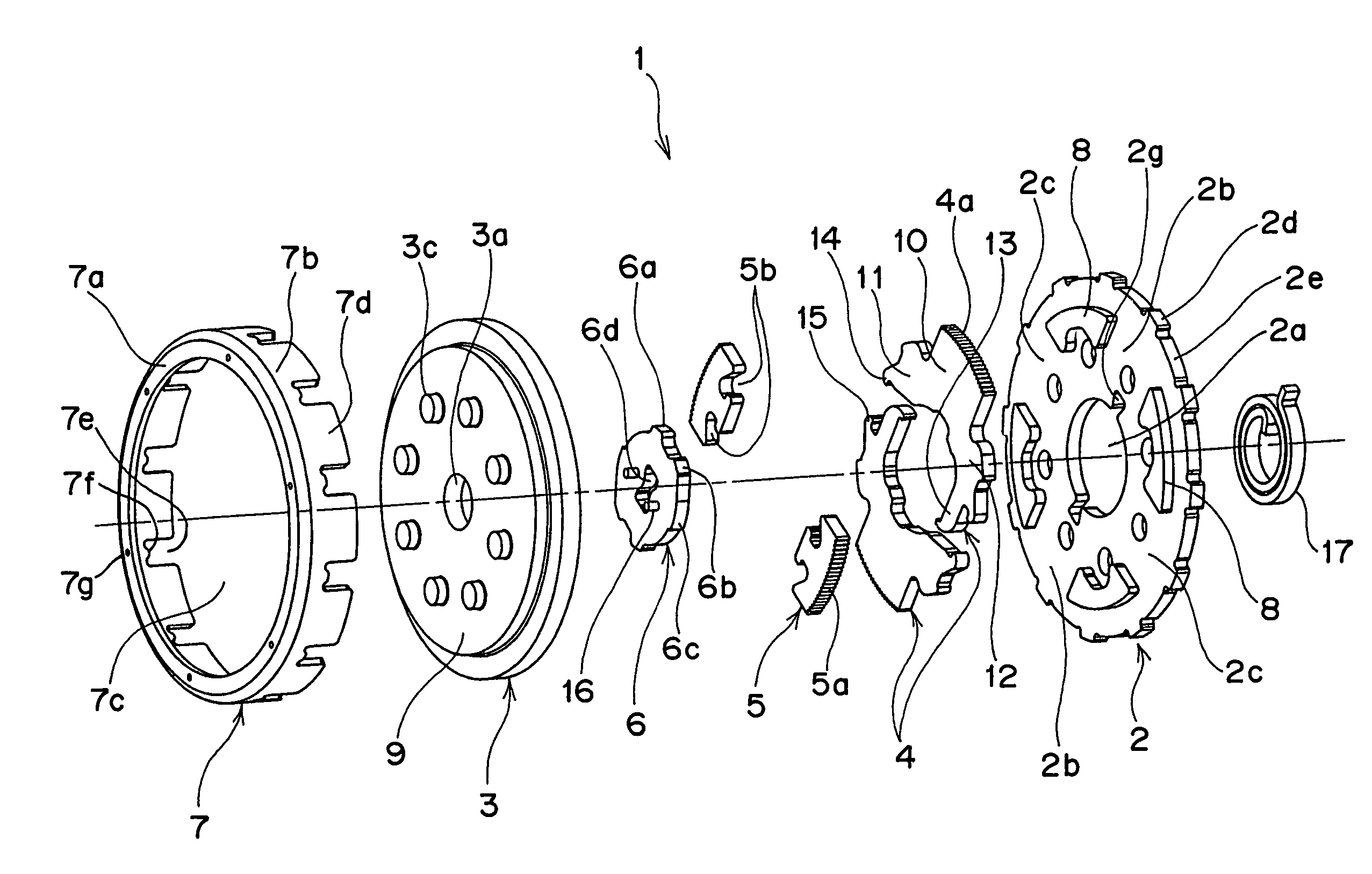

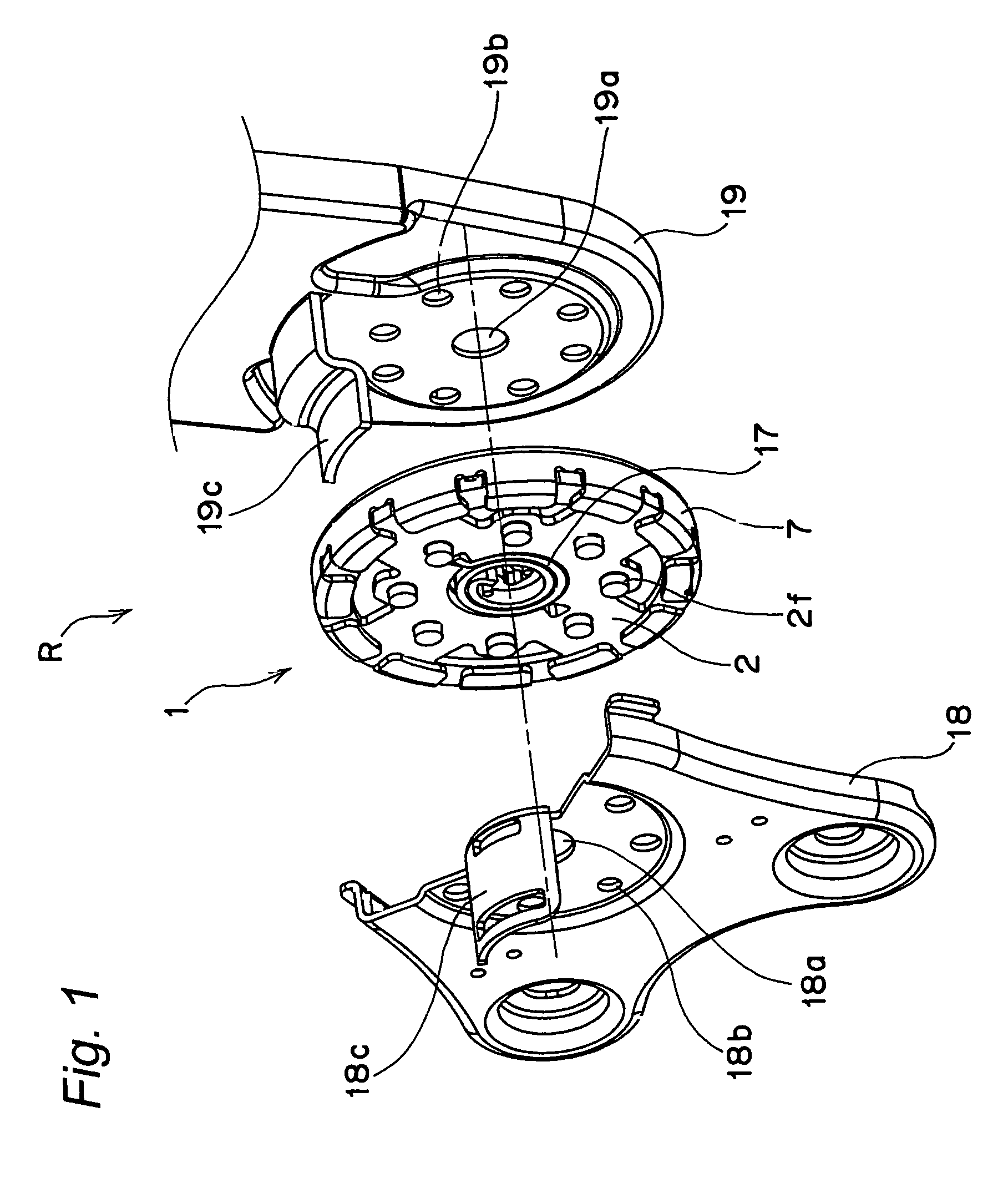

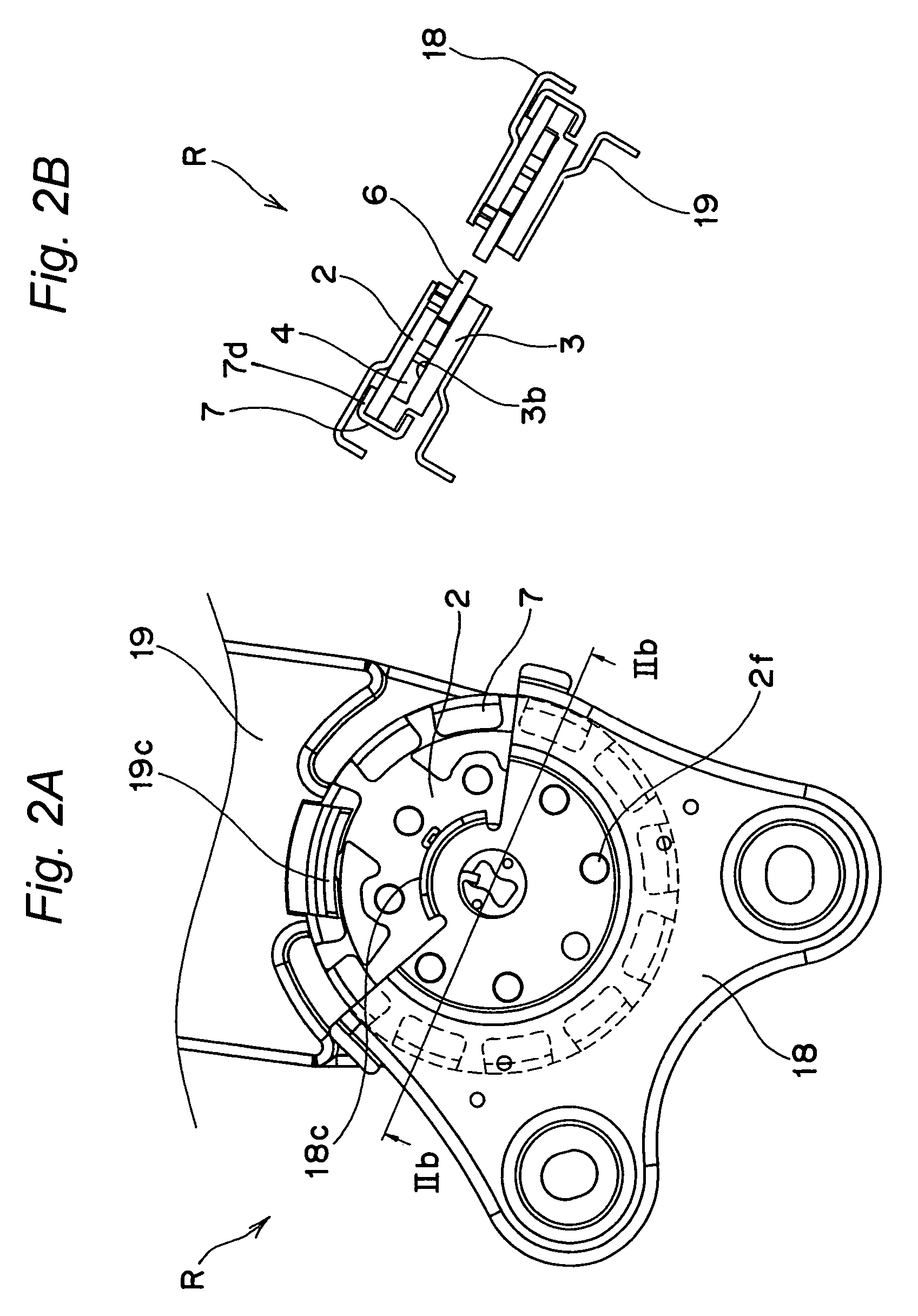

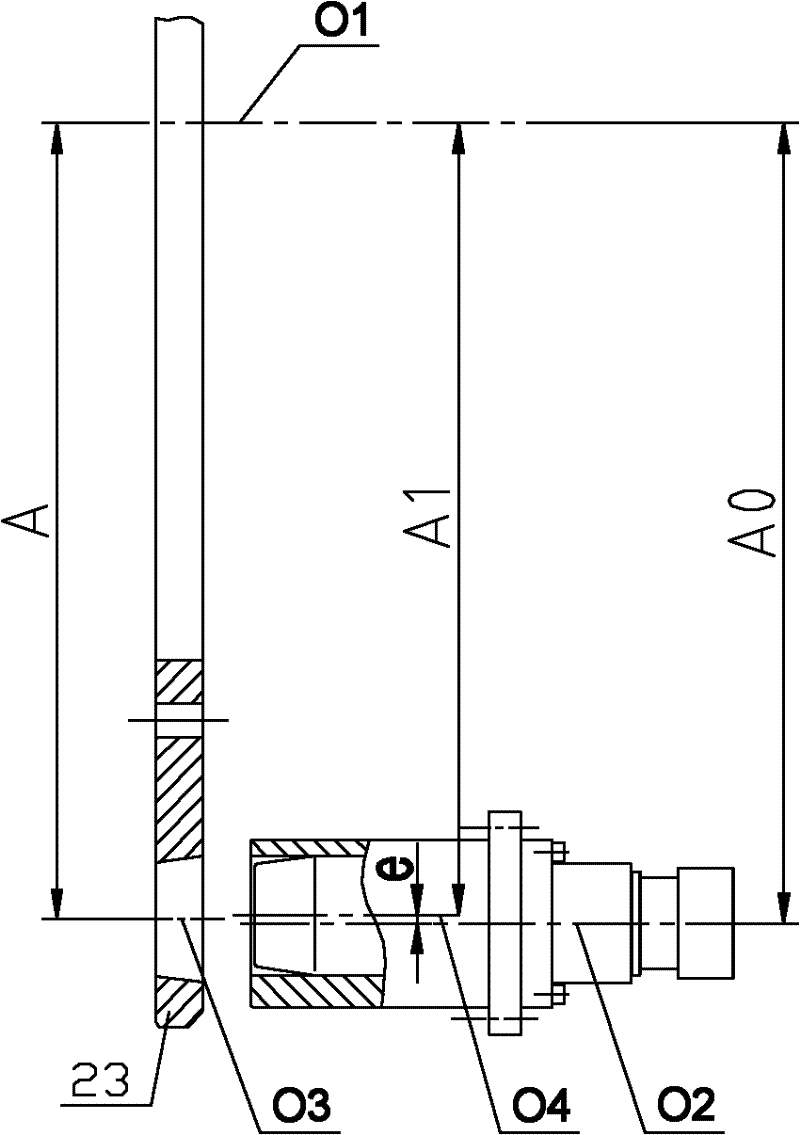

Recliner adjuster

InactiveUS20070040436A1Internal diameter can be increasedHigh locking strengthMovable seatsEngineeringCam

A recliner adjuster for adjusting an inclination of a seat back with respect to a seat cushion includes a guide bracket to be secured to one of the seat cushion and the seat back, an internal gear to be secured to the other of the seat cushion and the seat back, a cam interposed between the guide bracket and the internal gear, a pair of lock gears interposed between the guide bracket and the internal gear so as to be radially slidable in association with movement of the cam, and a mounting ring for mating the guide bracket and the internal gear with each other with the cam and the pair of lock gears accommodated therein. The mounting ring has a generally flat annular portion, a cylindrical side portion, and a plurality of bent portions formed at a distal end of the cylindrical side portion. The guide bracket and the internal gear are sandwiched between the generally flat annular portion and the plurality of bent portions of the mounting ring, and an outer peripheral surface of the internal gear is held in sliding contact with an inner surface of the cylindrical side portion of the mounting ring, thereby radially positioning the internal gear.

Owner:DELT IND

Recliner adjuster

A recliner adjuster for adjusting an inclination of a seat back with respect to a seat cushion includes a guide bracket to be secured to one of the seat cushion and the seat back, an internal gear to be secured to the other of the seat cushion and the seat back, a cam interposed between the guide bracket and the internal gear, a pair of lock gears interposed between the guide bracket and the internal gear so as to be radially slidable in association with movement of the cam, and a mounting ring for mating the guide bracket and the internal gear with each other with the cam and the pair of lock gears accommodated therein. The mounting ring has a generally flat annular portion, a cylindrical side portion, and a plurality of bent portions formed at a distal end of the cylindrical side portion. The guide bracket and the internal gear are sandwiched between the generally flat annular portion and the plurality of bent portions of the mounting ring, and an outer peripheral surface of the internal gear is held in sliding contact with an inner surface of the cylindrical side portion of the mounting ring, thereby radially positioning the internal gear.

Owner:DELT IND

Panel with a slider

ActiveUS10670064B2Reduce assemblyHigh locking strengthDrawersFurniture joiningClassical mechanicsStructural engineering

A set including a panel and a slider, such as a drawer slider. The slider including a slider surface and the panel comprising a panel surface. The slider is configured to be assembled to the panel with the slider surface facing the panel surface. The panel surface is provided with an insertion groove and an undercut groove, which are of a longitudinal shape. A strip protrudes from the slider surface, and the strip is configured to be inserted into the insertion groove and the undercut groove by an angling motion.

Owner:VÄLINGE INNOVATION AB

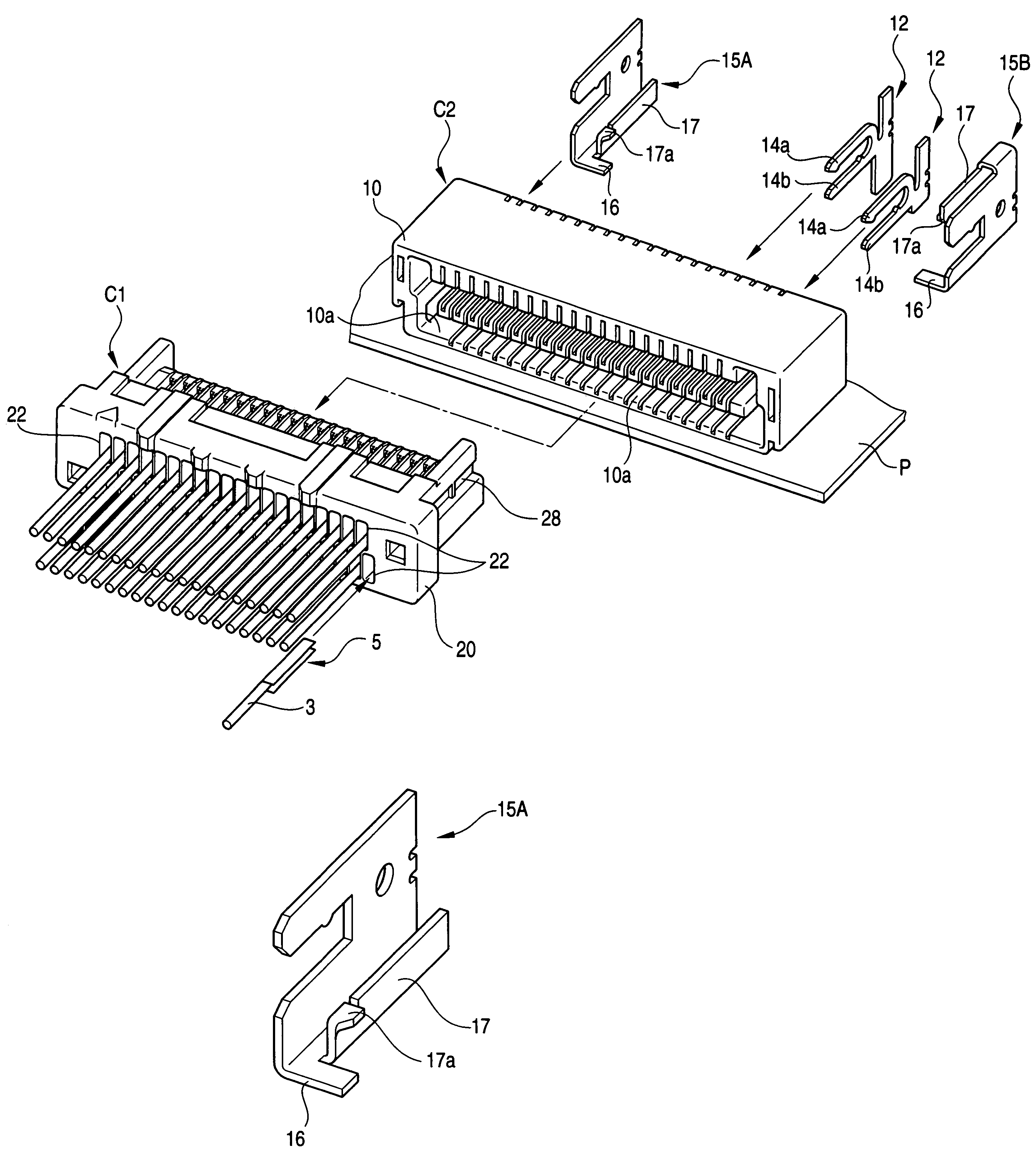

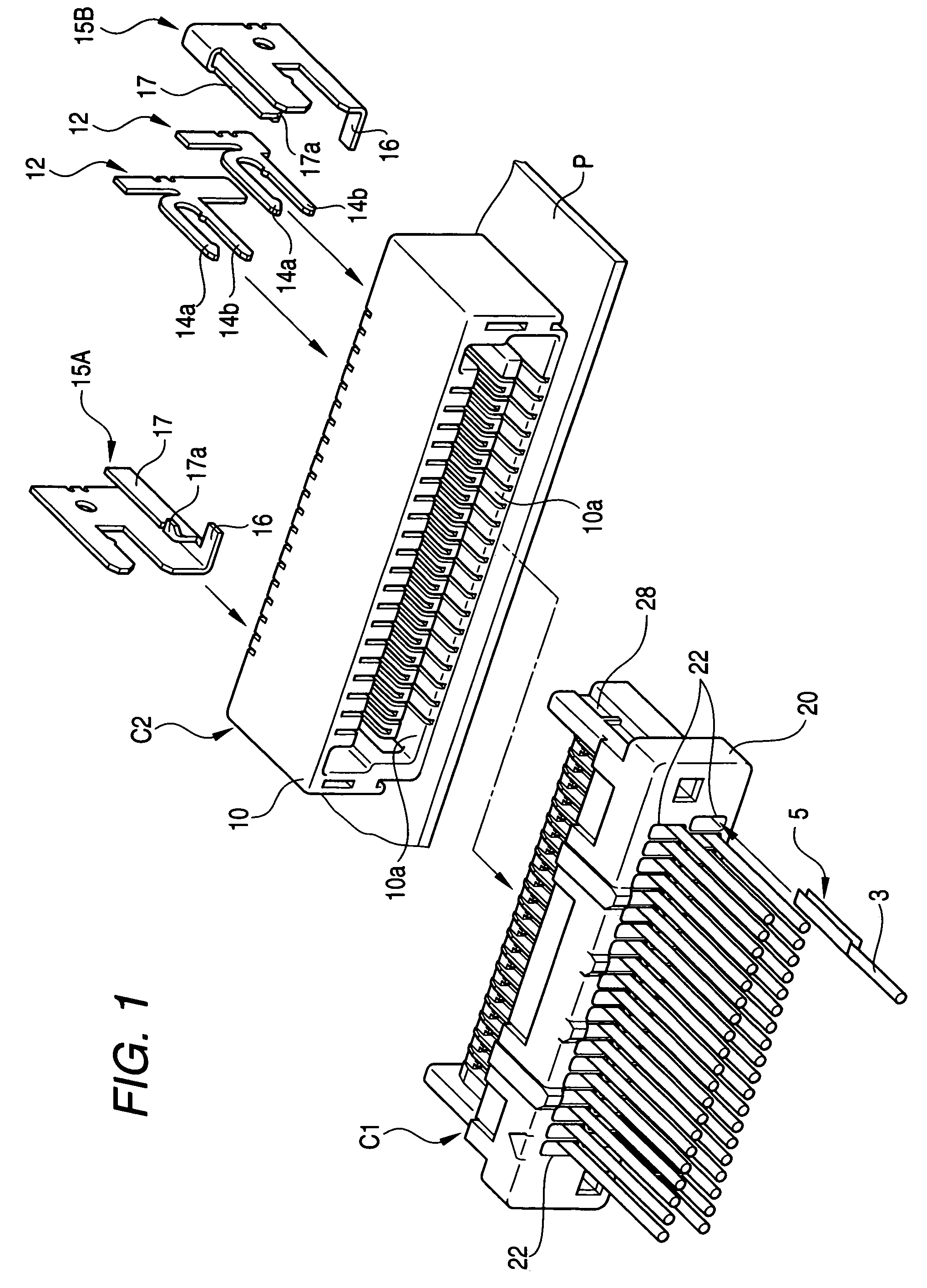

Connector locking construction

InactiveUS20050082840A1Increase the areaHigh locking strengthIncorrect coupling preventionConstruction fastening devicesEngineeringMechanical engineering

Owner:SUMITOMO WIRING SYST LTD

Latch device

ActiveUS6986535B2High locking strengthMade smallContact driving mechanismsBuilding locksLocking mechanismEngineering

Owner:NIFCO INC

Connector

InactiveUS20080032540A1High locking strengthReduce in quantityCoupling protective earth/shielding arrangementsCoupling device detailsMating connectionLocking mechanism

A connector is provided with a lock mechanism for locking with a mating connector when the mating connector is fitted in the connector. The connector includes a housing and a metal shell for covering an upper surface, a lower surface, and side surfaces of the housing. The metal shell includes a fitting lock piece on a side portion of a fitting opening, and the fitting lock piece is arranged along a fitting direction with respect to the mating connector. The fitting lock piece includes a corresponding lock member for locking with a locking member of the mating connector when the mating connector is fitted in the connector through the fitting opening. The fitting lock piece engages an upper plate and a lower plate of the metal shell covering the upper surface and the lower surface of the housing, respectively.

Owner:HIROSE ELECTRIC GROUP

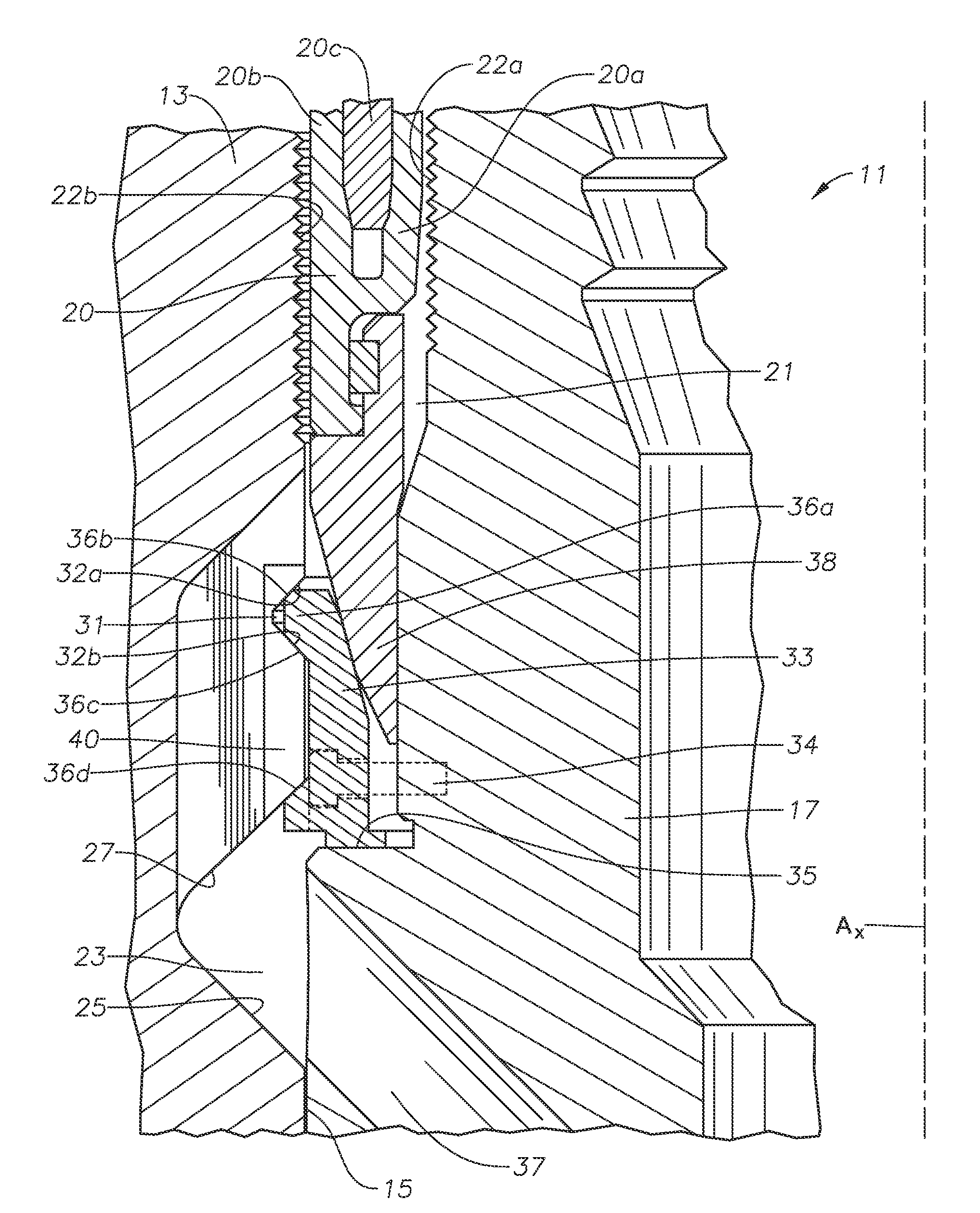

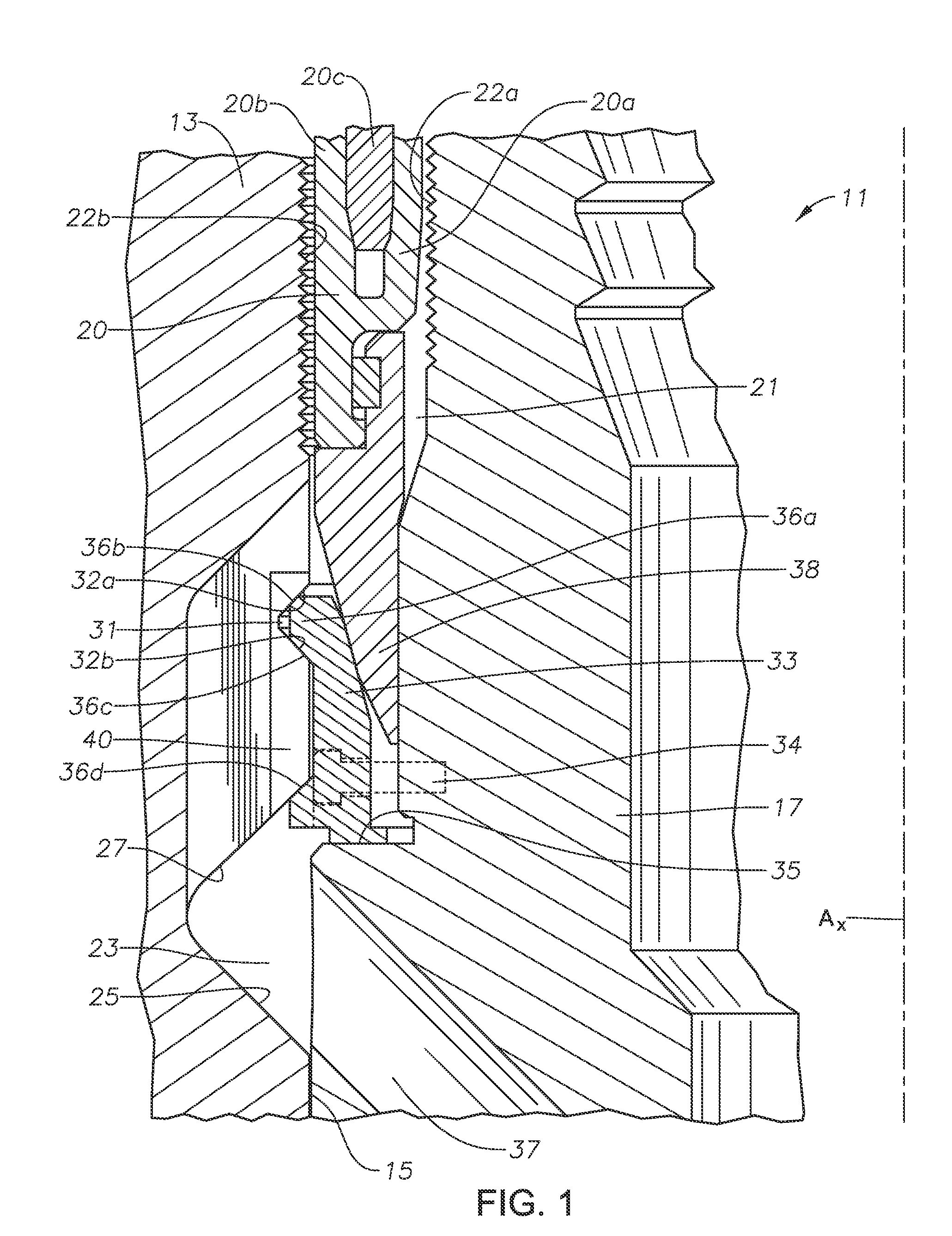

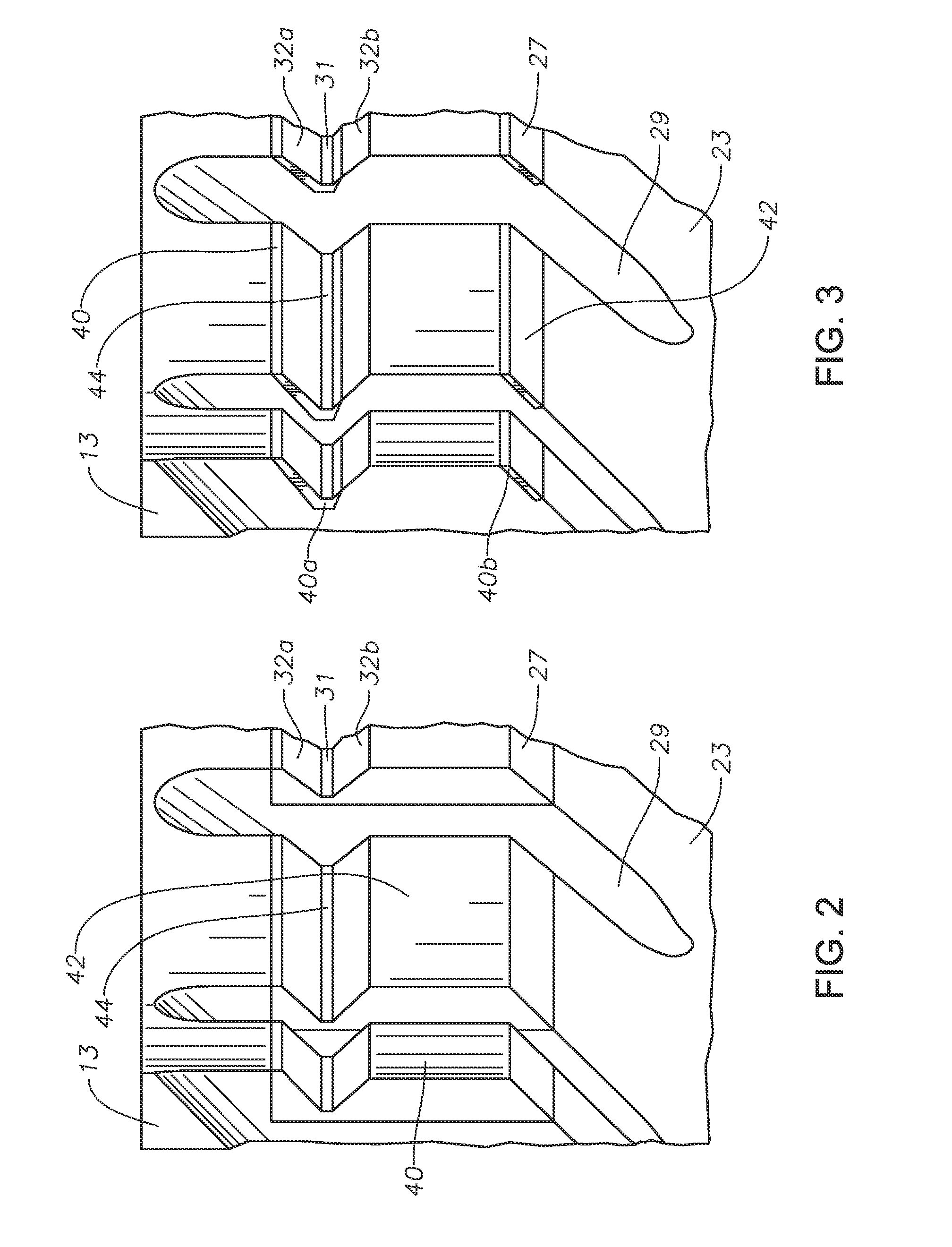

Staged Locking of Surgical Screw Assembly

ActiveUS20140046374A1Reducing diameter of boreReduce the overall diameterSuture equipmentsInternal osteosythesisBearing surfaceFastener

A surgical screw assembly including: a fastener including an elongate shaft having a proximal end and a distal end and a head at the proximal end. A tulip having a an internal bearing surface is provided. A distal end of the tulip has a bore therethrough defining the internal bearing surface. Locking enhancement features are configured to cooperate with the head, such that, in an unlocked configuration, the head is movable relative to the tulip; in a provisionally locked configuration, the locking enhancement features engage the head with a first polyaxial grip strength; and in a finally locked configuration, the locking enhancement features engage the head with a second polyaxial grip strength greater than the first polyaxial grip strength.

Owner:SPINECRAFT

Automobile door lock

ActiveCN1987028AHigh locking strengthNon-mechanical controlsPower-actuated vehicle locksElectrical and Electronics engineeringDetent

Owner:BYD CO LTD

High Strength Inlay to Improve Lock-Down Capacity in a Wellhead

ActiveUS20150114667A1Improve locking effectHigh strengthDrilling rodsFluid removalEngineeringMechanical engineering

A wellhead assembly includes a wellhead housing having a bore and a locking profile including a gallery slot, and an annular notch. An inner wellhead assembly is selectively landed in the bore of the wellhead housing, the inner wellhead assembly having a lock ring with a lock ring profile that engages the locking profile. The engaging surface is a sloped downward facing surface at an axially upper end of the gallery slot. The annular notch has a notch engaging profile with a downward facing notch upper shoulder and an upward facing notch lower shoulder. The locking profile includes an inlay, the inlay being located on the notch upper shoulder and the engaging surface.

Owner:VETCO GRAY

Recliner adjuster having main and auxiliary lock gears

A recliner adjuster for adjusting an inclination of a seat back with respect to a seat cushion includes a guide bracket to be secured to one of the seat cushion and the seat back, an internal gear to be secured to the other of the seat cushion and the seat back, a cam rotatably mounted between the guide bracket and the internal gear, a pair of lock gears interposed between the guide bracket and the internal gear so as to be radially slidable in association with rotation of the cam, and a pair of auxiliary lock gears interposed between the guide bracket and the internal gear so as to be radially slidable in association with the pair of lock gears. The rotation of the cam causes the pair of lock gears to radially slide between respective engaging positions, at which engaging teeth thereof are held in engagement with internal teeth of the internal gear, and respective engagement released positions at which the engagement of the engaging teeth of the pair of lock gears with the internal teeth of the internal gear is released. A radial sliding movement of the pair of lock gears between the engaging positions and the engagement released positions causes the pair of auxiliary lock gears to radially slide between respective engaging positions, at which the engaging teeth thereof are held in engagement with the internal teeth of the internal gear, and respective engagement released positions at which the engagement of the engaging teeth of the pair of auxiliary lock gears with the internal teeth of the internal gear is released.

Owner:DELTA KOGYO CO LTD

Spinal Implant Connection Assembly

ActiveUS20100234893A1High locking strengthConnection securityInternal osteosythesisJoint implantsSpinal columnUltimate tensile strength

The present invention provides a connection assembly that can be used to securely connect a spinal implant to a bone anchor. In particular, the present invention preferably provides a spinal implant connection assembly that is able to securely connect the spinal implant to the anchors even when there is a variance in the angle and position of the anchors with respect to the spinal implant. Furthermore, the present invention provides a connection assembly with structure to increase the locking strength of the connection assembly.

Owner:GLOBUS MEDICAL INC

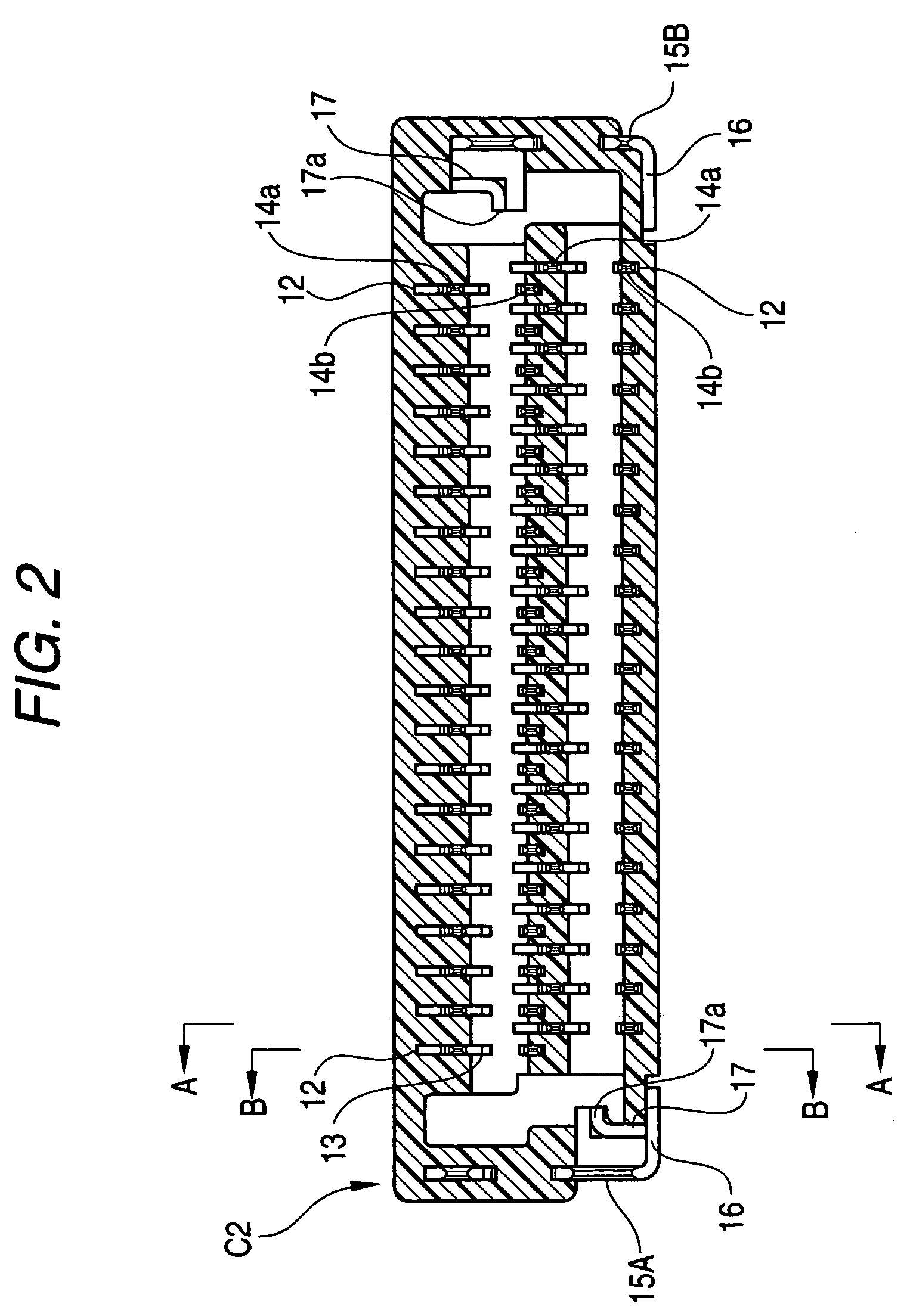

Board mounting type connector with metal fastening member

InactiveUS7258567B2Reliable miniaturizationHigh locking strengthCoupling device detailsConnections effected by permanent deformationEngineeringFastener

A board mounting type connector includes: a housing being made of a resin, the housing holding a plurality of terminals, each terminal being arranged in parallel and connected to a circuit board; and a metal fastening member being fixed to both ends of the housing in a widthwise direction of the housing in which the terminals are arranged, the metal fastening member being mounted to the circuit board, and each metal fastening member having an engaging portion which engages with a housing of a counterpart connector fitted into the board mounting type connector so that the connectors are engageable to each other in a fitted state.

Owner:AUTONETWORKS TECH LTD +2

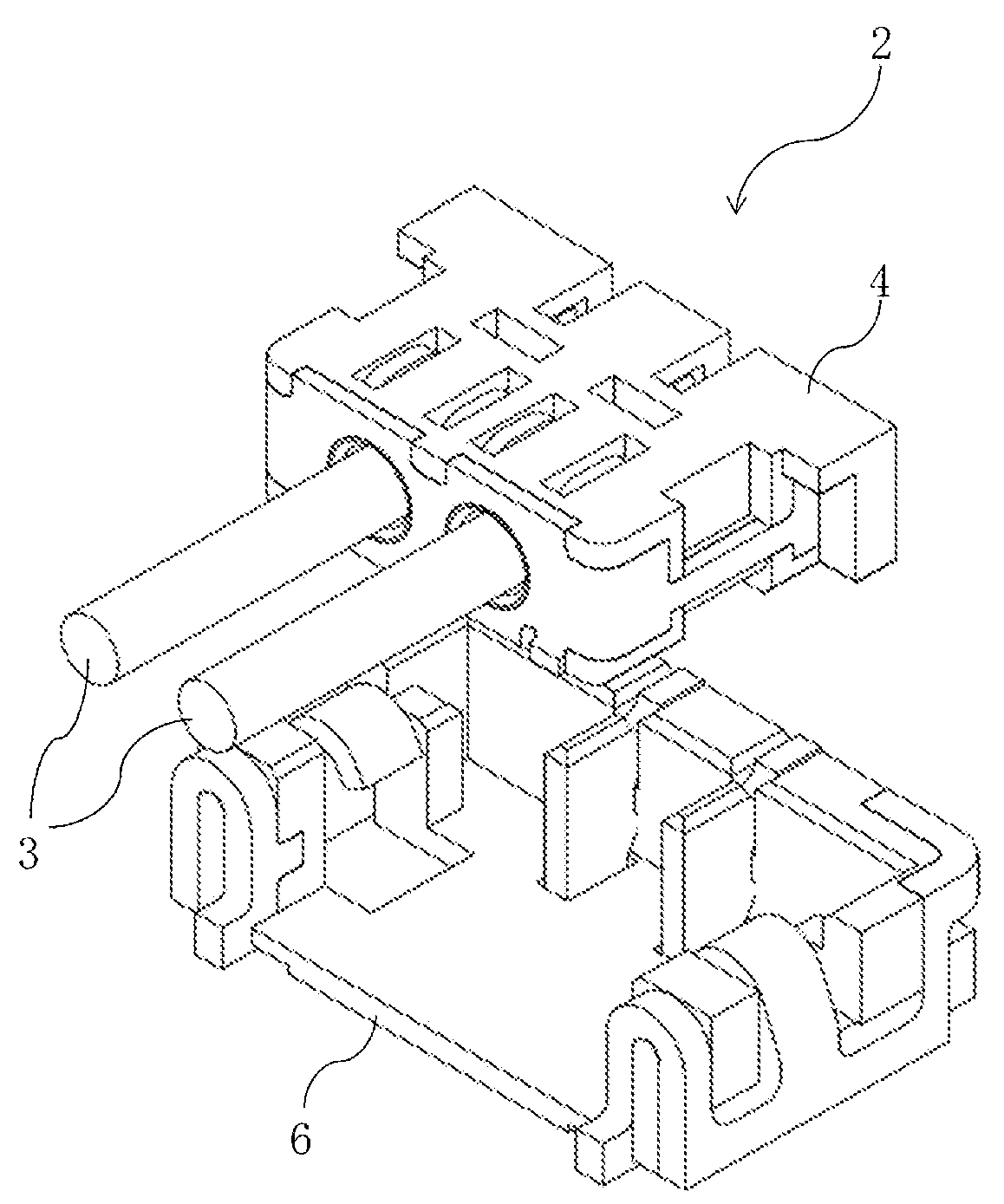

Electric connector

An electric connector includes a first connector, and a second connector, wherein the first connector includes a first housing, a plurality of first contacts, and first lock metal fittings, the second connector includes a second housing, a plurality of second contacts, and a second lock metal fitting, an electric wires are inserted into the second connector in a direction parallel to a circuit board surface, and in a direction perpendicular to an arranging direction of the second contacts, and the second lock metal fitting includes lock engaging portions provided at both ends of the arranging direction of the second contacts of the second housing, and a coupling portion coupling the lock engaging portions at least at a side of a removing direction of the second connector of the electric wires at an insertion side of the electric wires of the second housing.

Owner:ACES ELECTRONICS CO LTD

Fan and wind wheel locking device thereof

ActiveCN102251936AHigh locking strengthExtended service lifeWind energy generationWind motor componentsWind forceEngineering

The invention discloses a fan and a wind wheel locking device thereof. The disclosed wind wheel locking device comprises a lock body and a locking disk, wherein the lock body is arranged on a rack of the fan; the locking disk is fixedly connected with a wind wheel of the fan; a lockpin is arranged in a cavity of the lock body; a locking hole cooperated with the lock pin is arranged in the lockingdisk; axial center lines of the lock body and the lockpin are mutually parallel and spaced by a preset distance; the lock body and the lockpin can synchronously rotate around the center line of the lock body; and the lock body and the rack are provided with at least two fixed connection positions. The wind wheel locking device has the advantages of obviously increasing the locking reliability of the wind wheel and prolonging the service life of the wind wheel; in the mean time, under wind action, the back-and-forth rocking range of the wind wheel is obviously decreased; and therefore, the reliability of the wind wheel is increased, the service life of the wind wheel is prolonged and the potential safety hazard of a unit and maintenance personnel is reduced.

Owner:ZHEJIANG WINDEY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com