Patents

Literature

82results about How to "Improved Strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

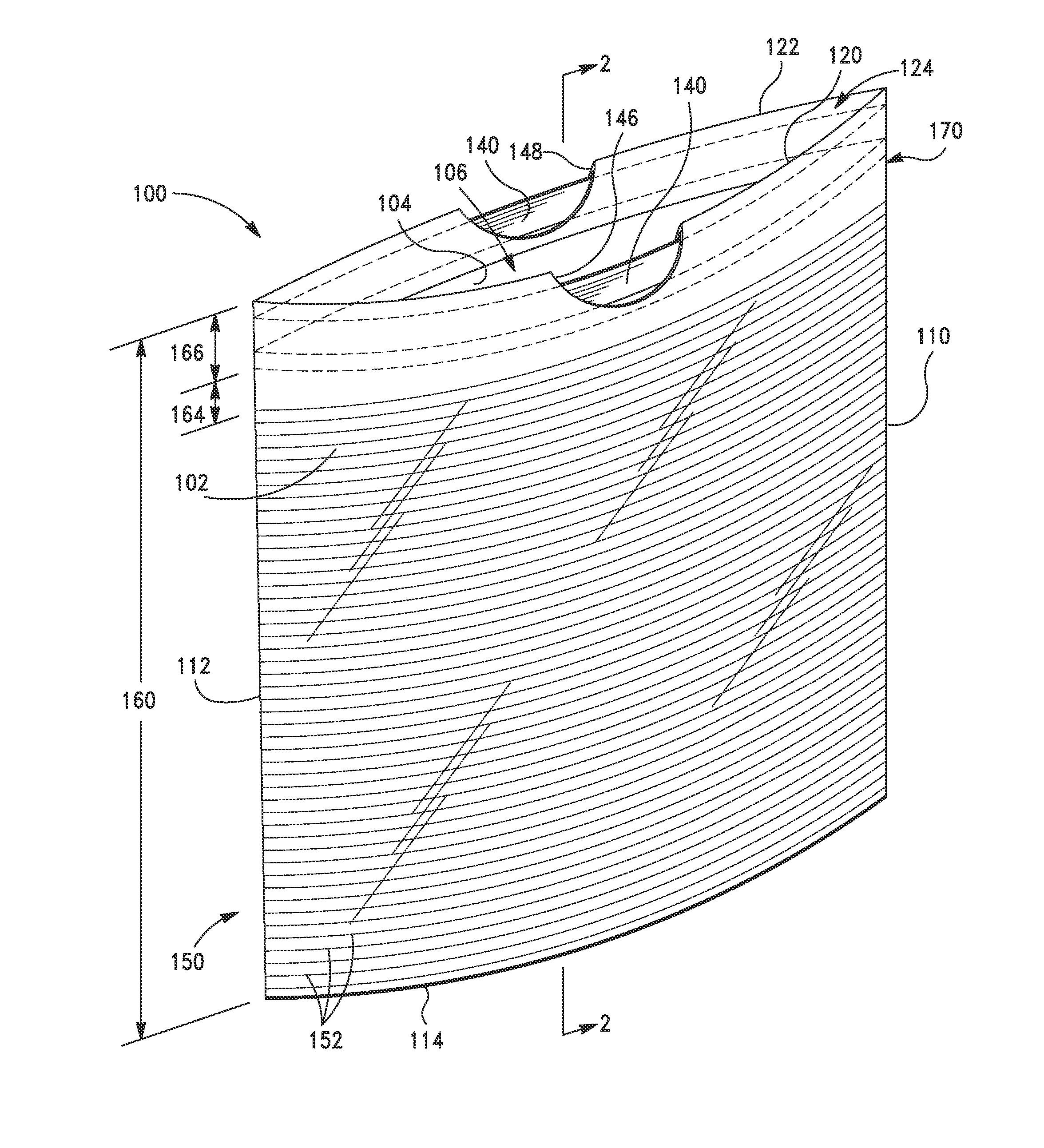

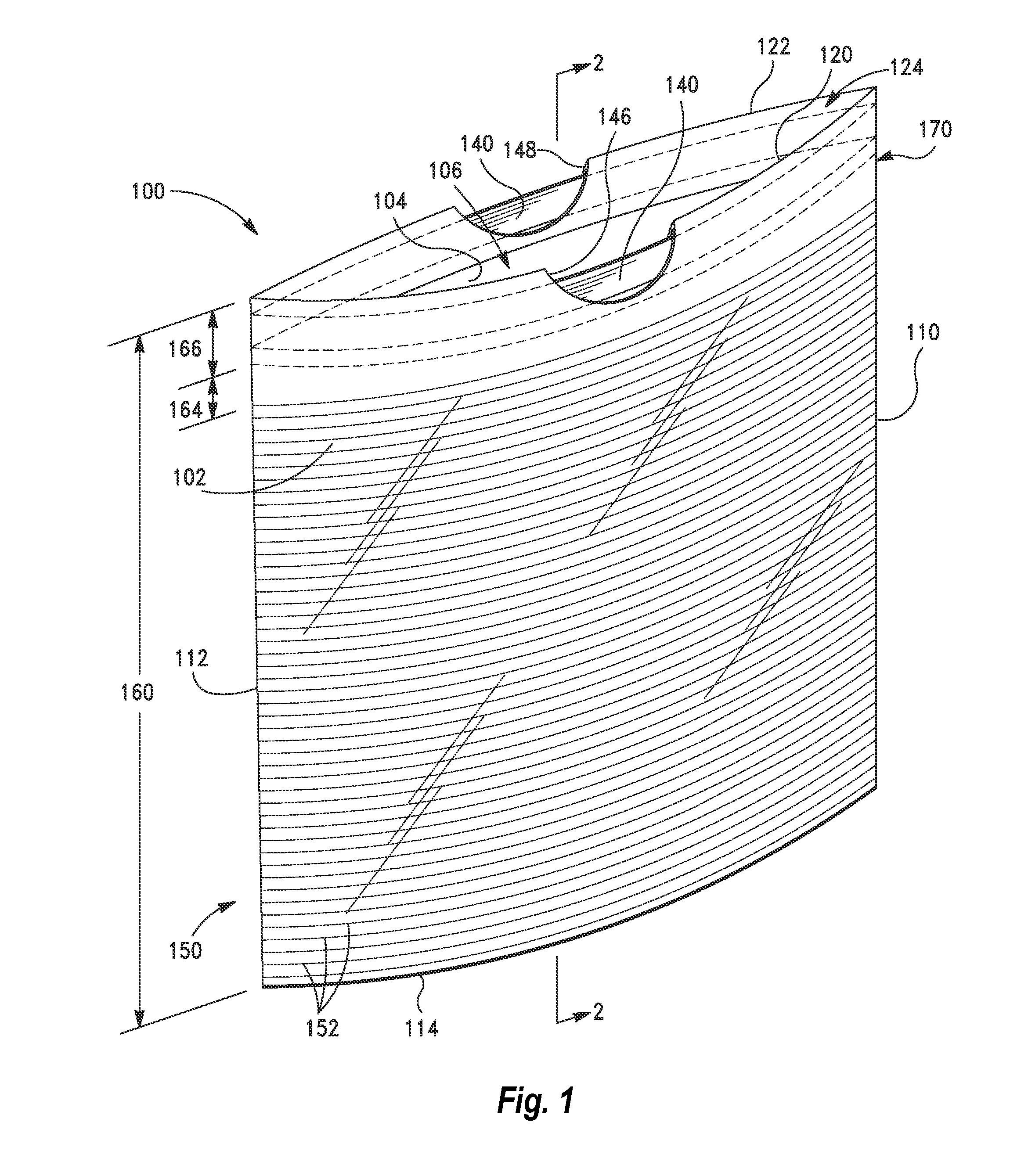

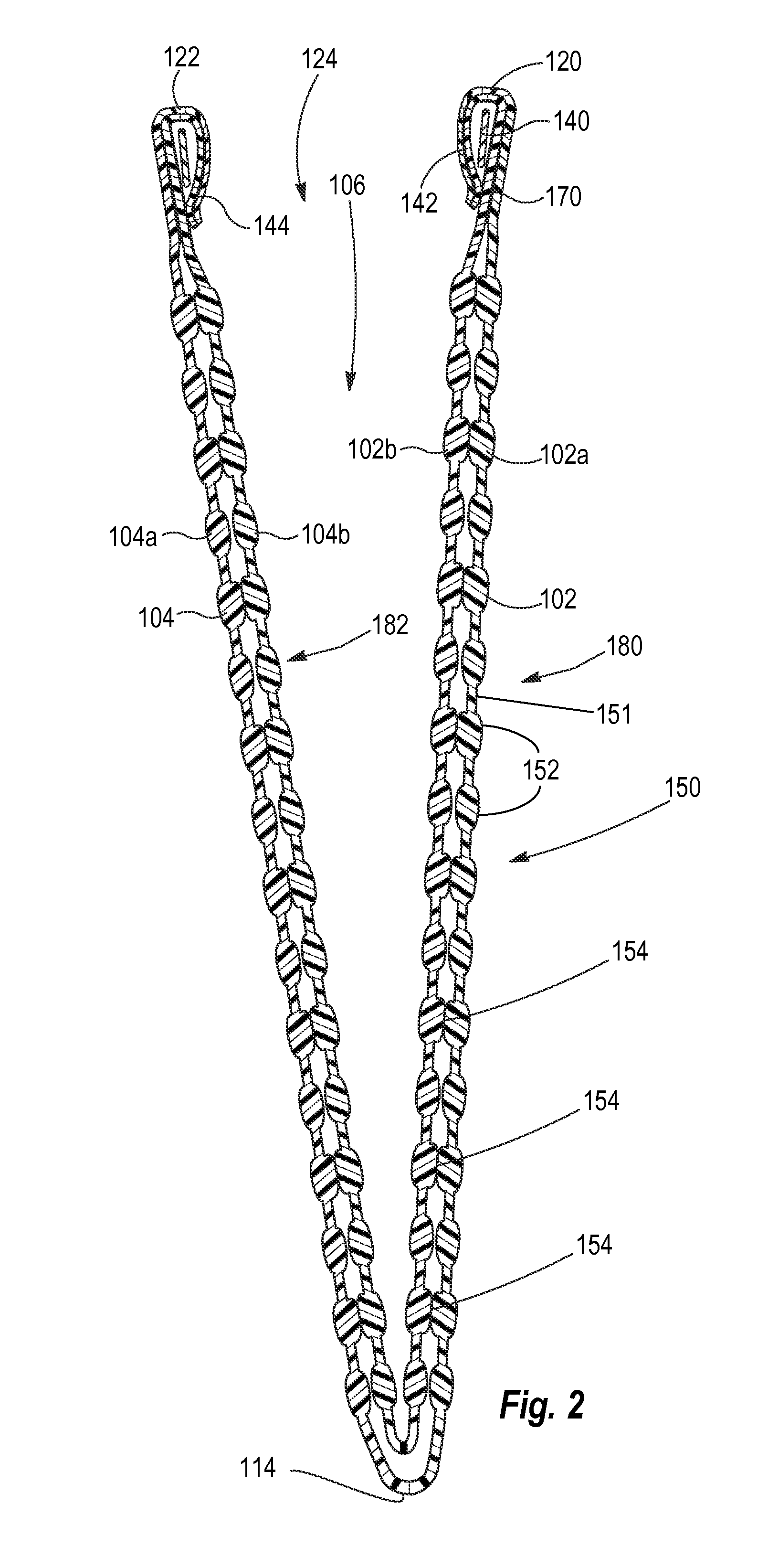

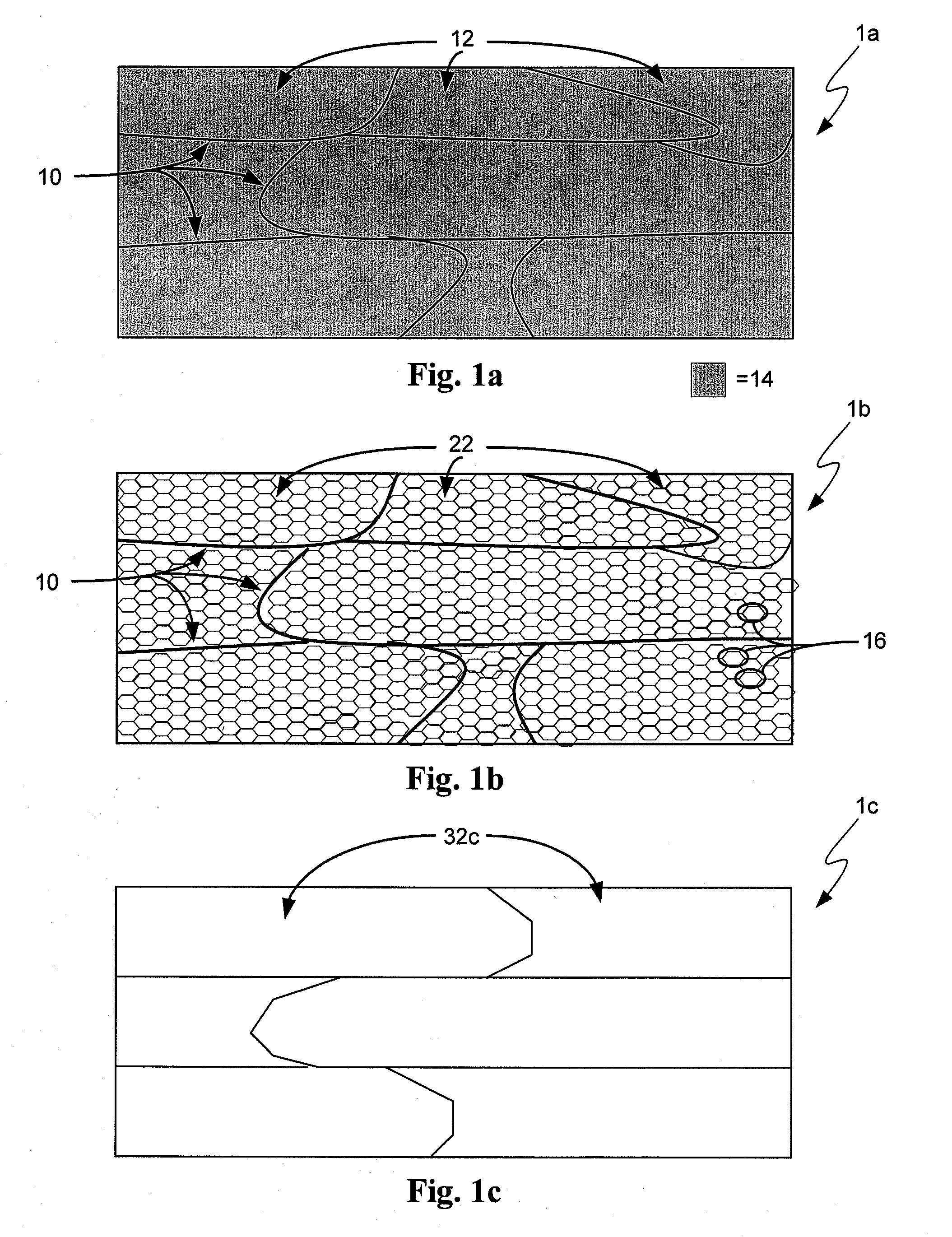

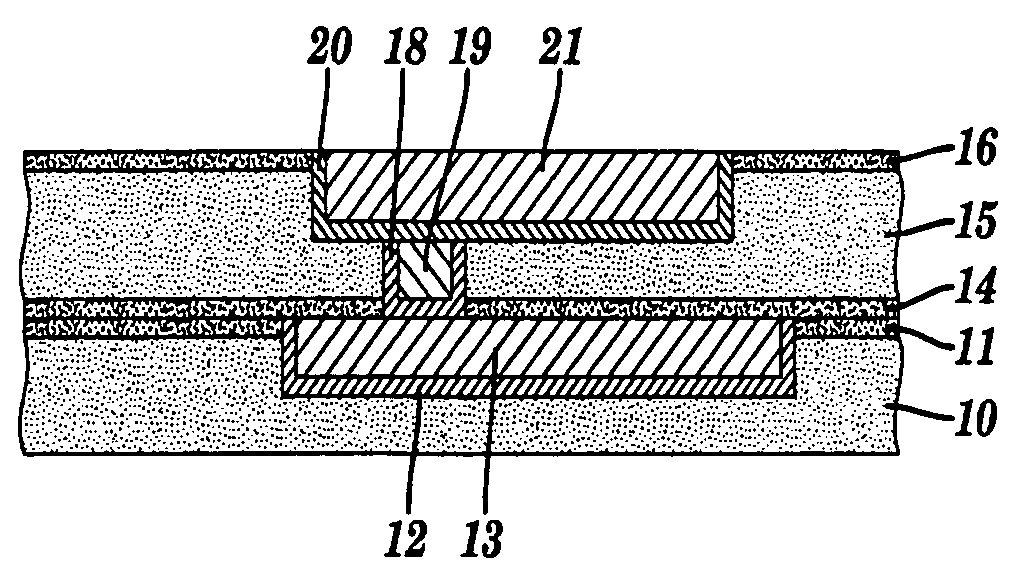

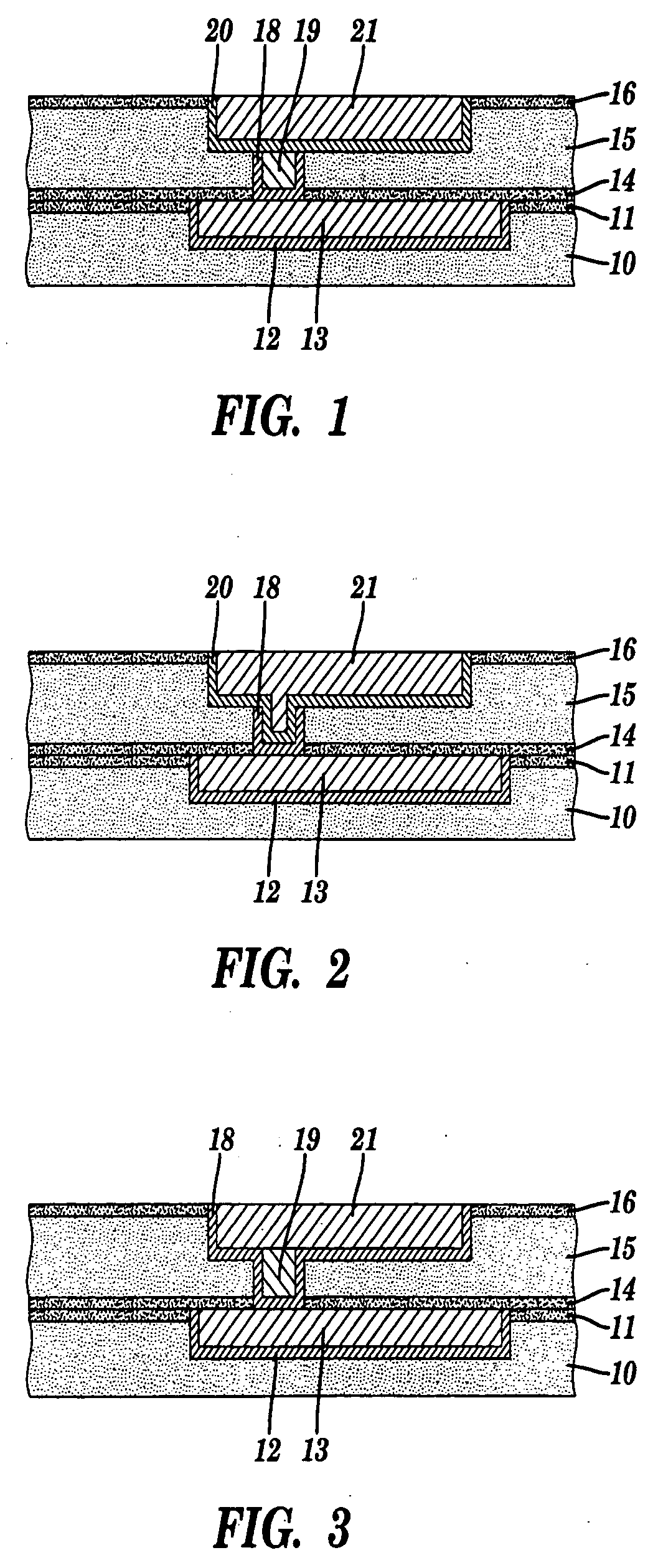

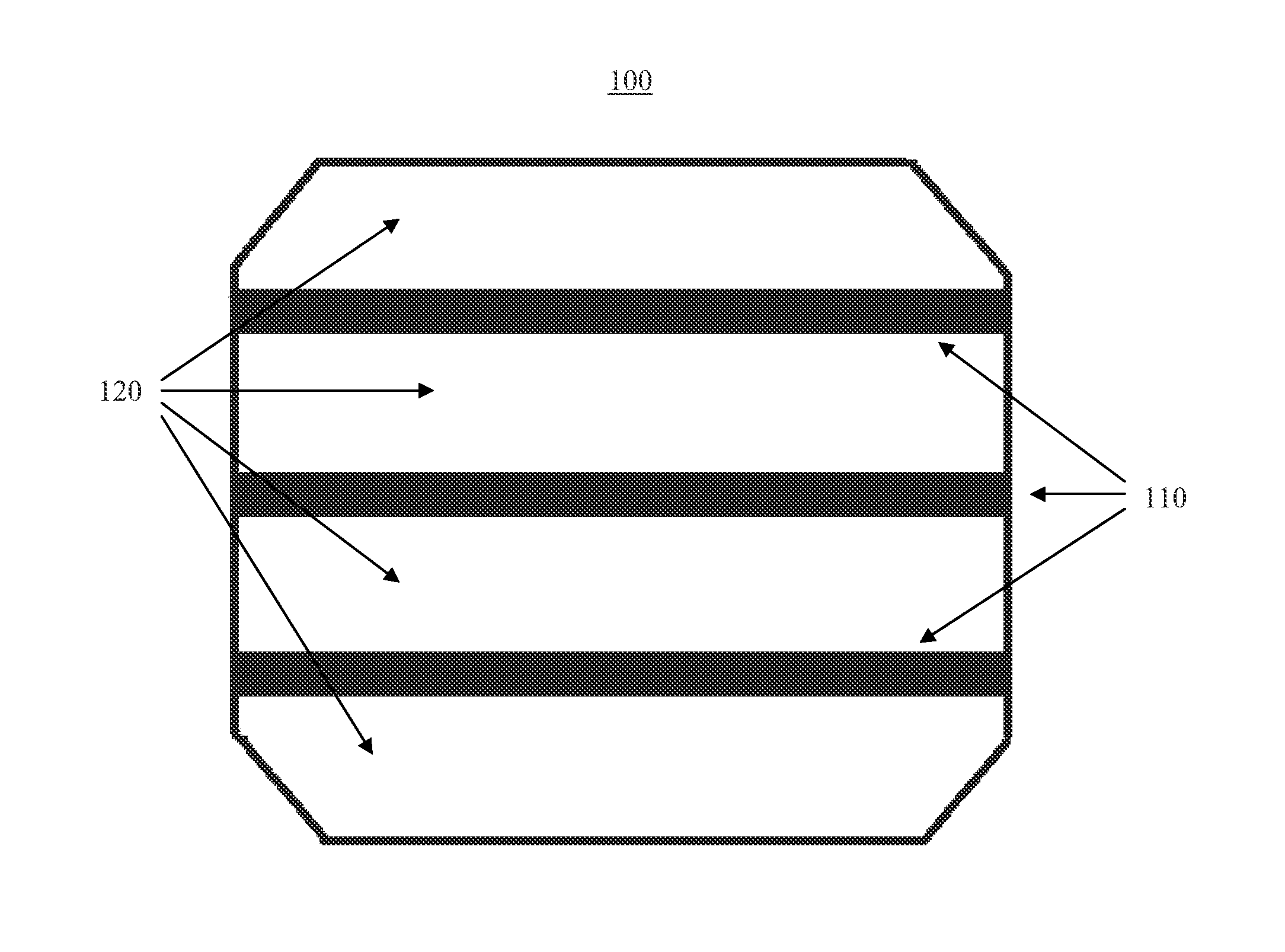

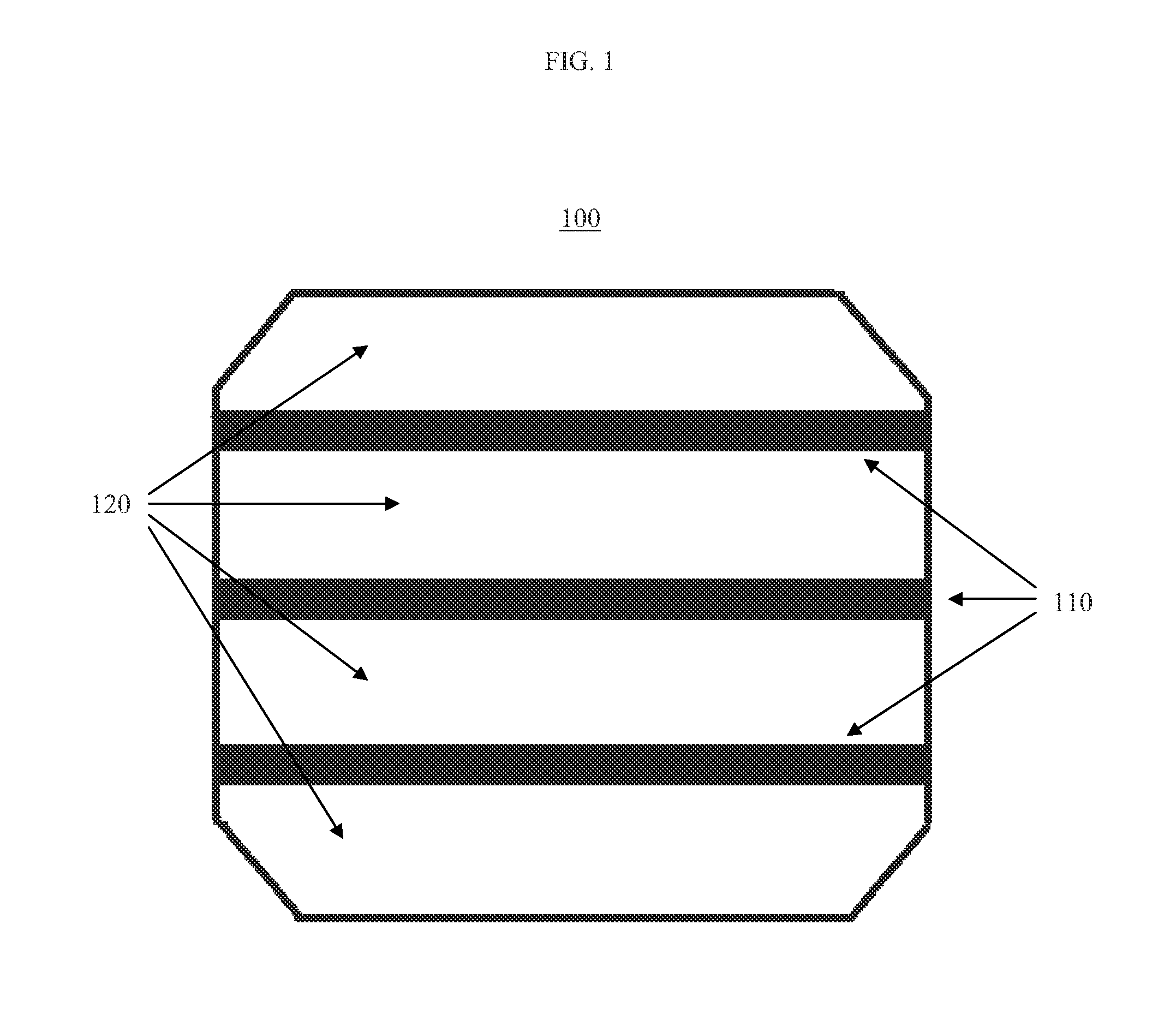

Non-Continuously Laminated Multi-Layered Bags With Ribbed Patterns And Methods of Forming The Same

ActiveUS20120134606A1Enhance propertyImproved strengthBag making operationsBagsEngineeringNetwork pattern

Methods for creating multi-layered bags with increased or maintained strength involve forming a ribbed pattern in one or more film layers of a multi-layered bag. The method also includes non-continuously laminating the film layers of the multi-layered bag together. In one or more implementation, a transverse direction ring rolling process forms the ribbed pattern and bonds the film layers together. In one or more additional implementations, the ribbed pattern and lamination are formed separately. Still further implementations include forming network patterns one or more film layers of a multi-layered bag. Multi-layered bags formed in accordance with one or more implementations of the present invention include one or more of increased strength or reduced basis weight.

Owner:THE GLAD PROD CO

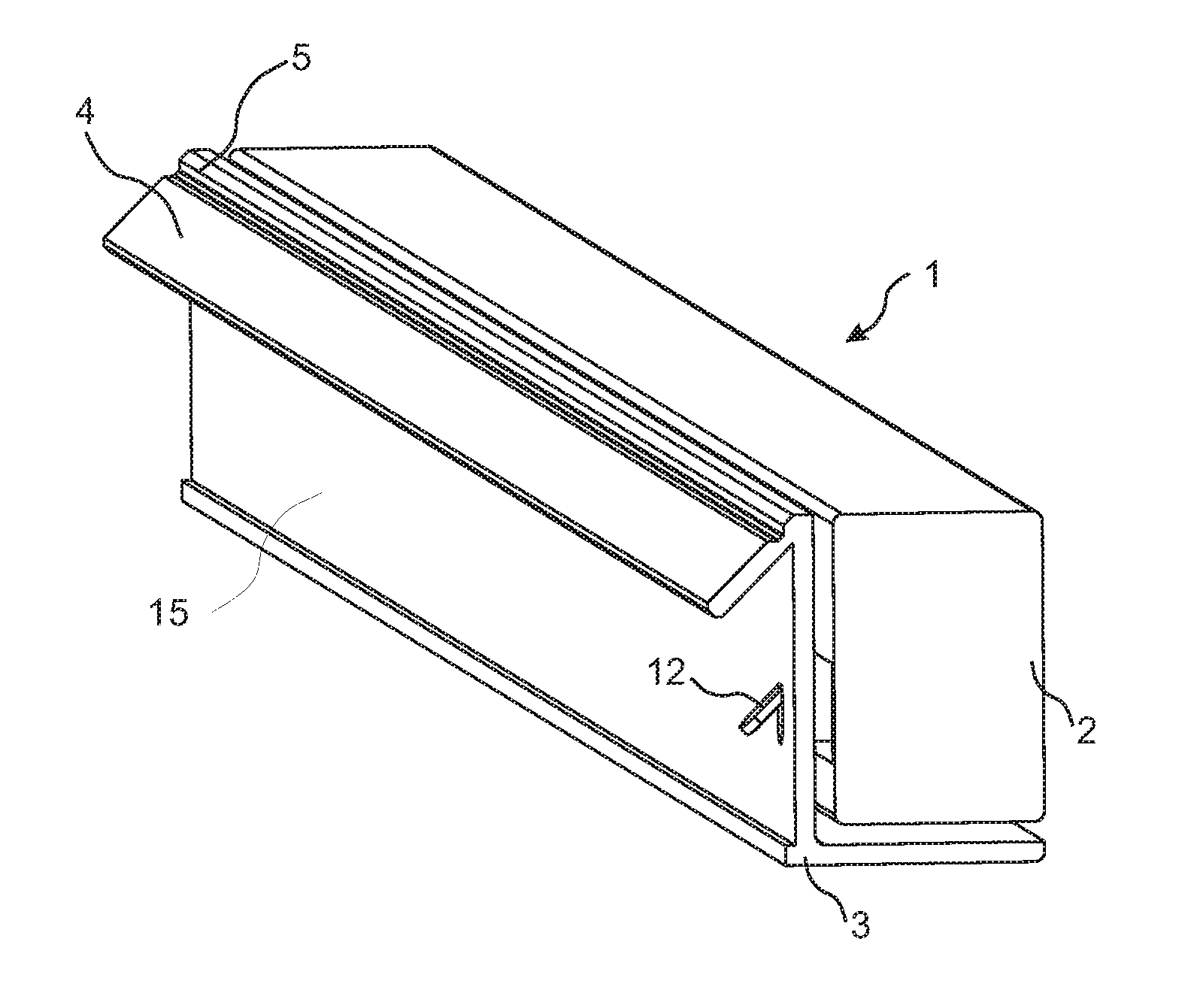

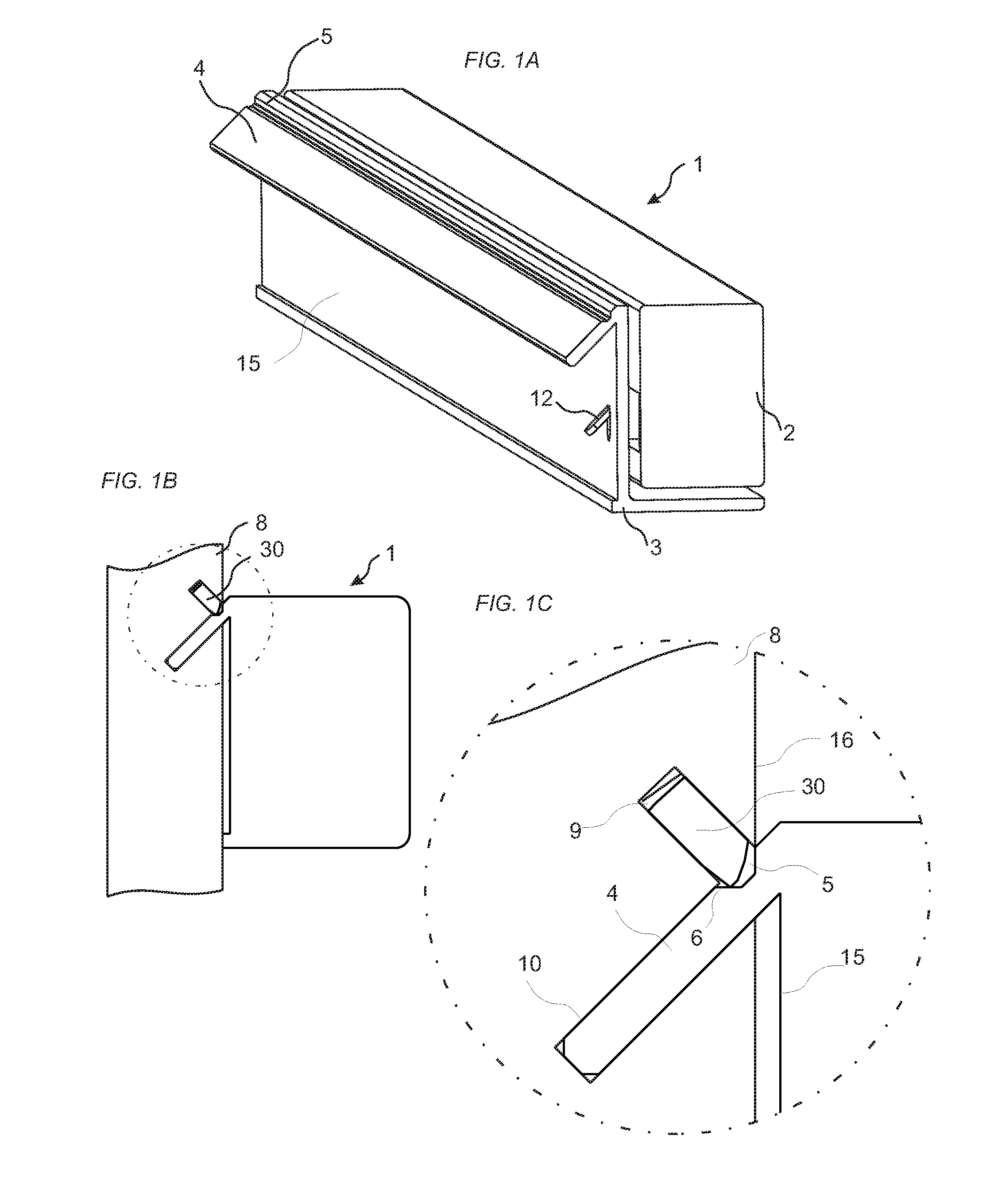

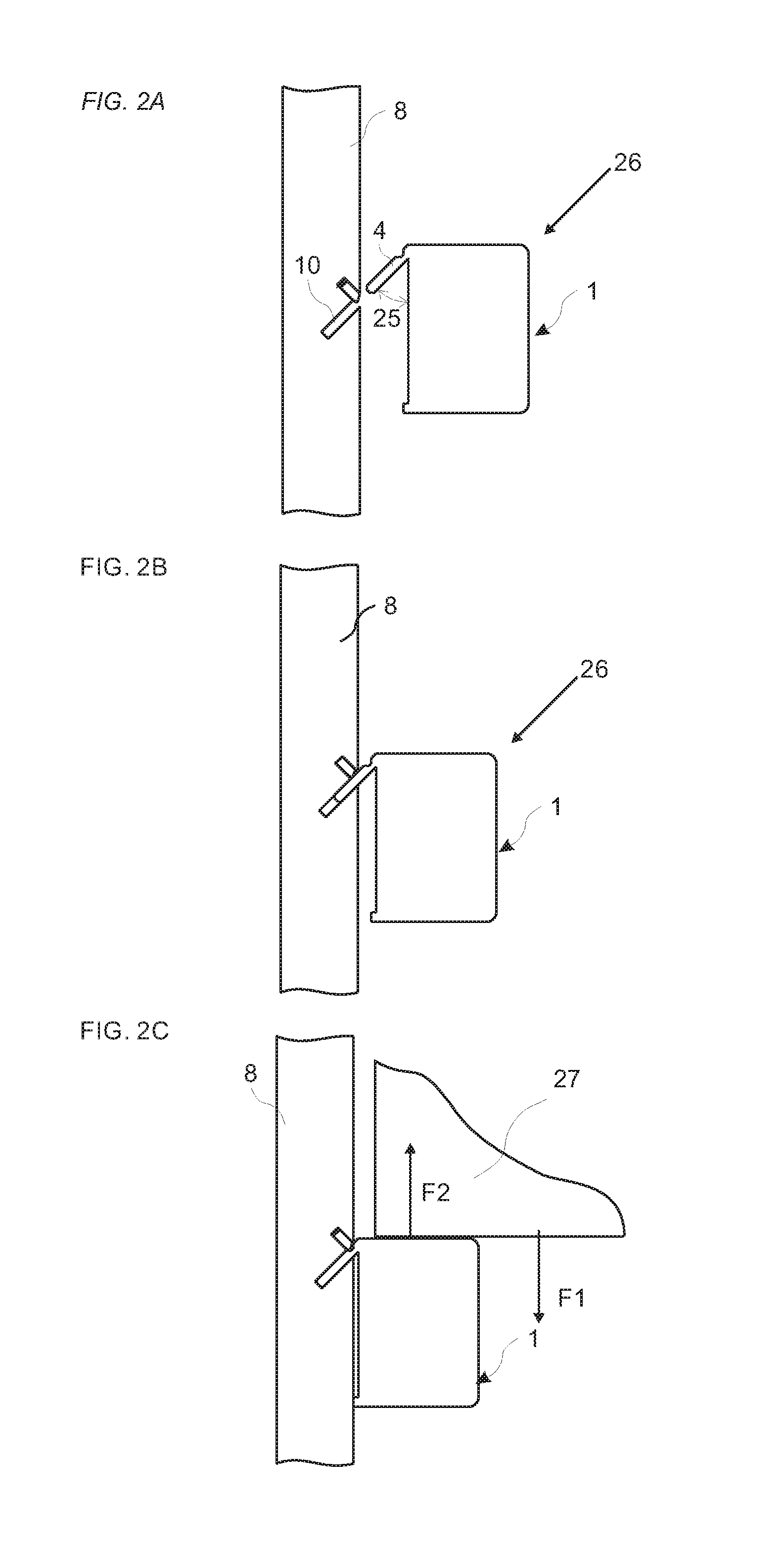

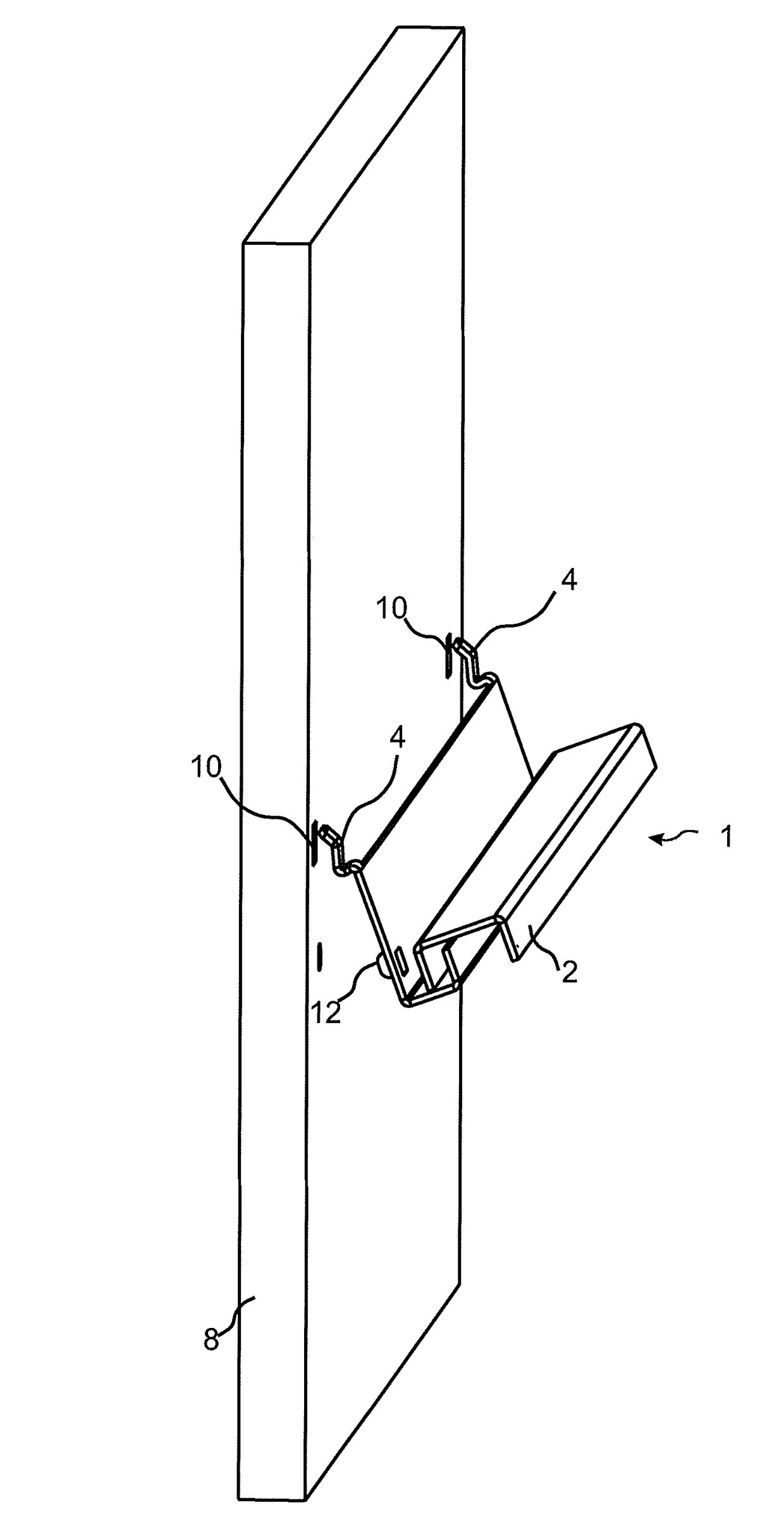

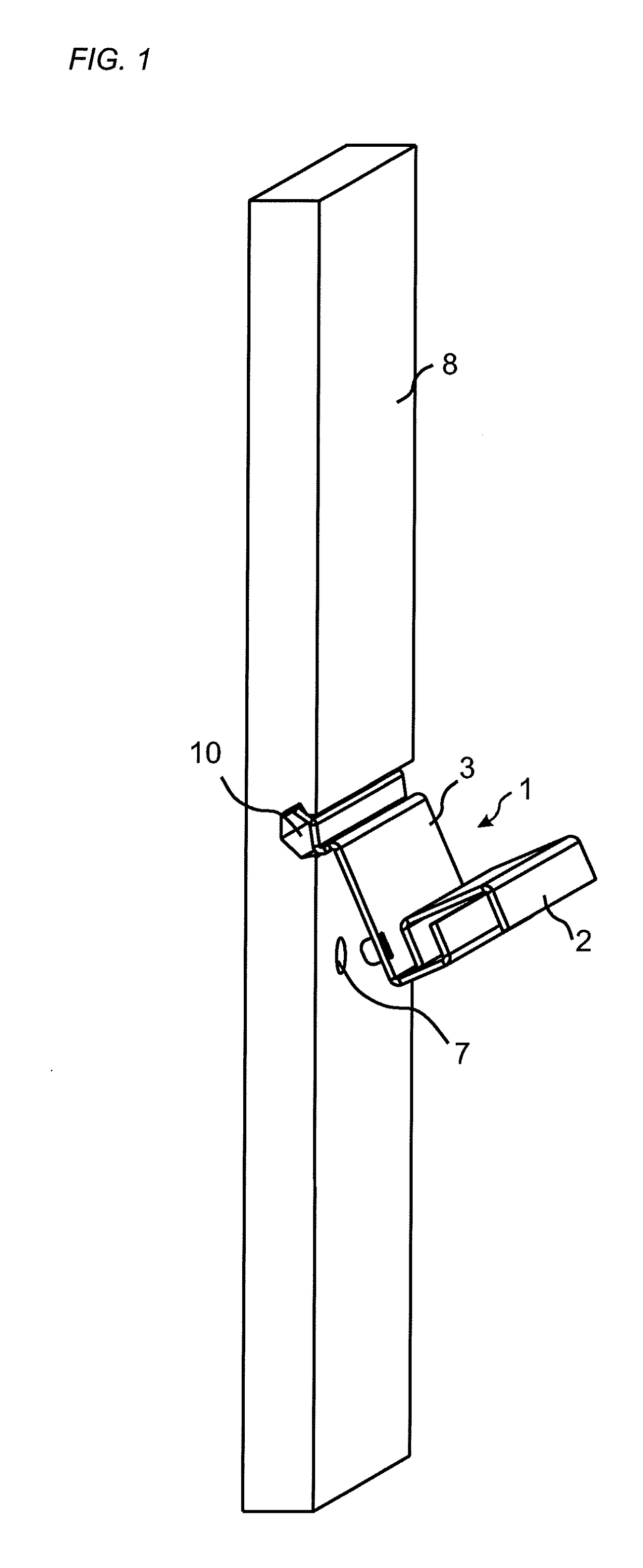

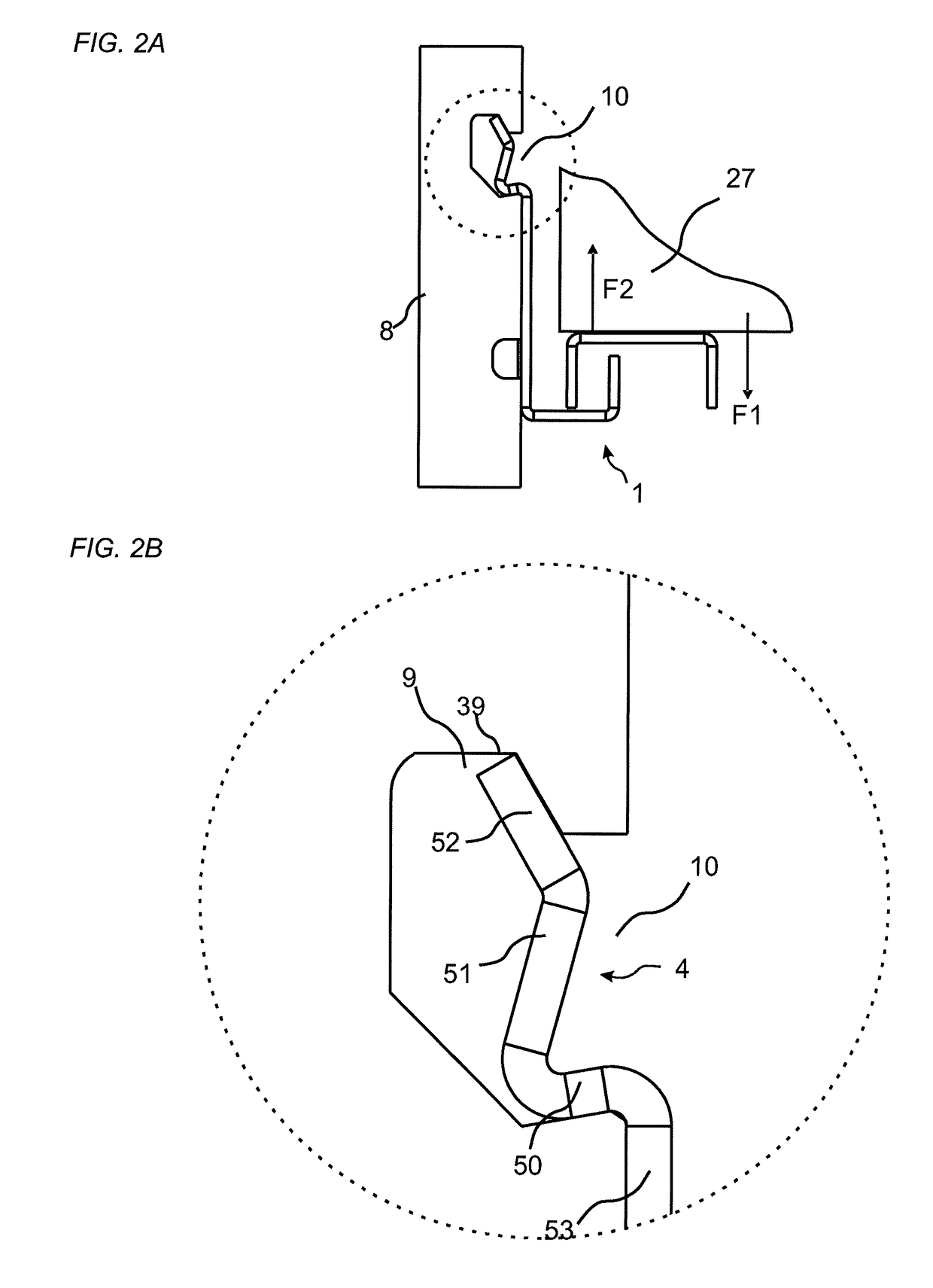

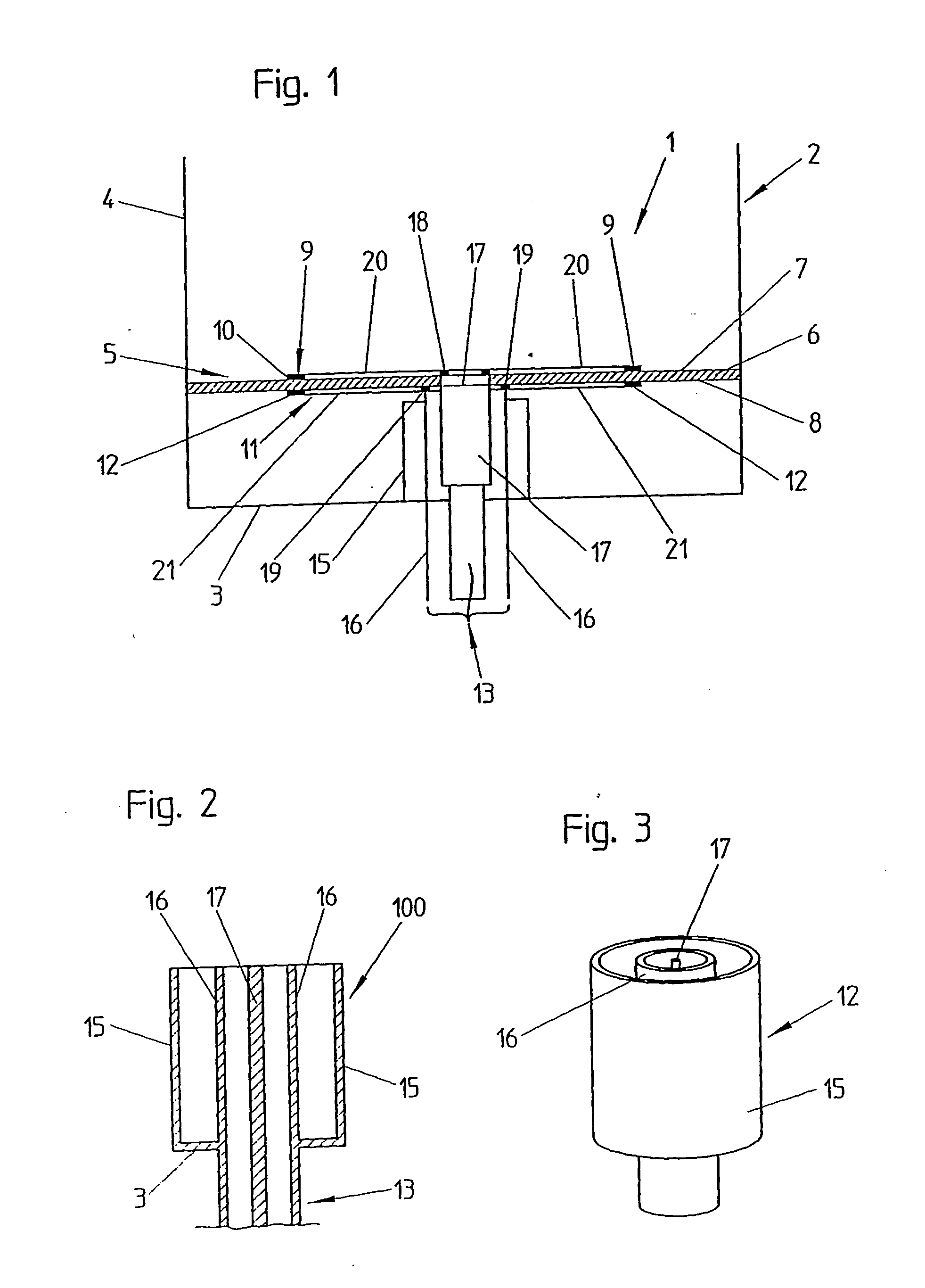

Panel with a slider

A panel provided with a slider. The slider including a first surface and the panel including a second surface, the slider is being configured to be assembled to the panel with the first surface facing the second surface. The second surface is provided with an insertion groove and a displacement groove, which are of a longitudinal shape. A first angle, which is between the second surface and the insertion groove, is an acute angle. A strip protrudes from the first surface. A second angle, which is between the strip and the first surface, is an acute angle. The strip is configured to be inserted into the insertion groove when the slider is assembled to the panel. A displaceable tongue is arranged in the displacement groove. A locking surface of the displaceable tongue is configured to cooperate with a locking surface of the strip for locking the strip to the panel.

Owner:VÄLINGE INNOVATION AB

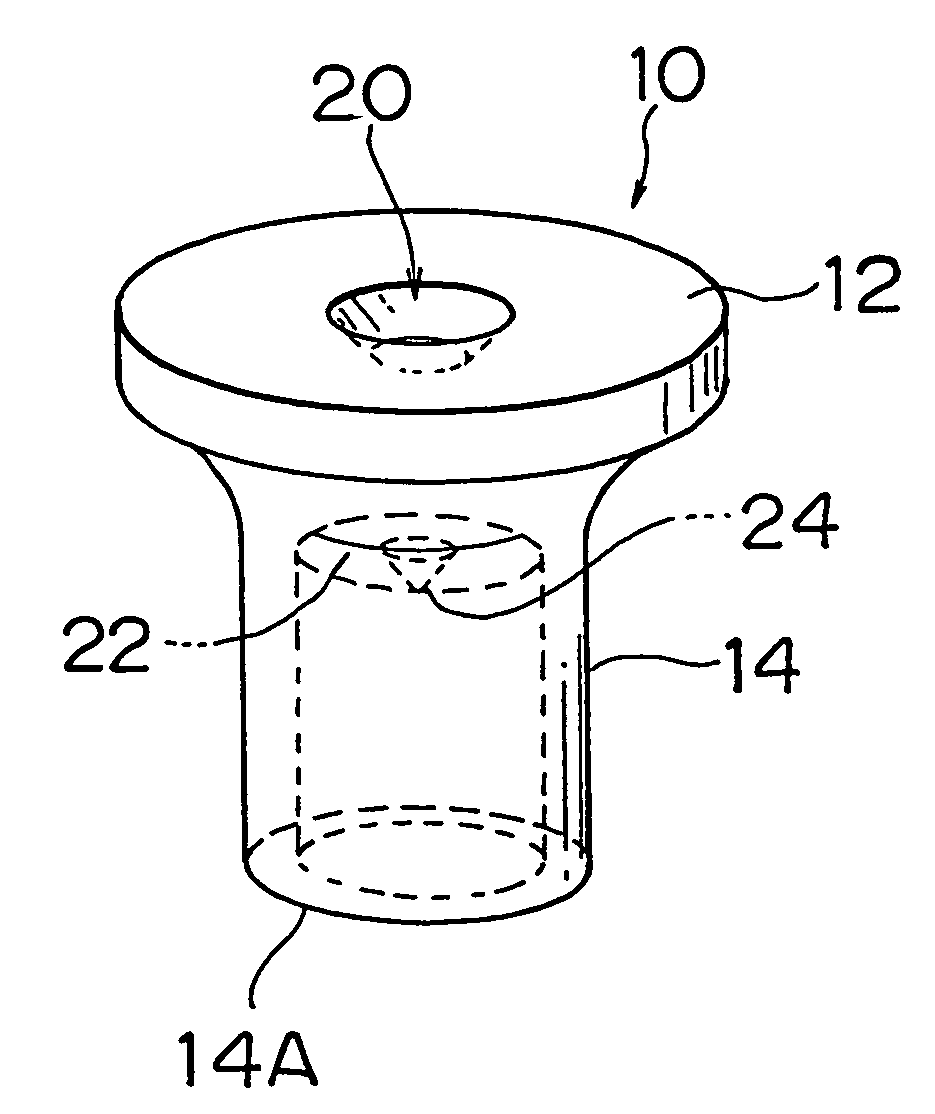

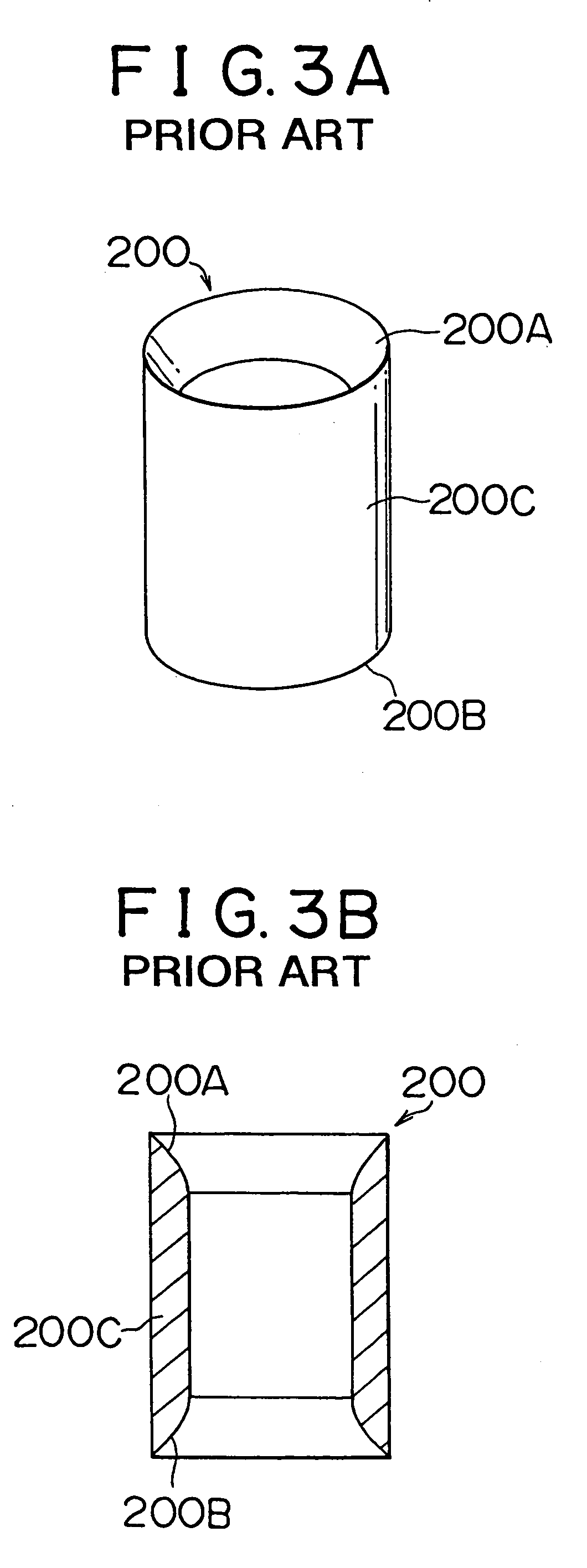

Rivet, riveted joint structure riveting apparatus, and riveting method

InactiveUS6988862B1Improved strengthImprove fastening strengthRivetsSheet joiningExtremity PartEngineering

A rivet is provided which includes axially opposite end portions at least one of which is more likely to be deformed radially outwards than a remaining portion thereof, and the remaining portion is more resistant to a load applied in an axial direction of the rivet than the axially opposite end portions. As one example, the rivet includes a head portion and a cylindrical portion that extends from the head portion, and a recess is formed in the head portion so as to be open to a top surface of the head portion.

Owner:TOYOTA JIDOSHA KK

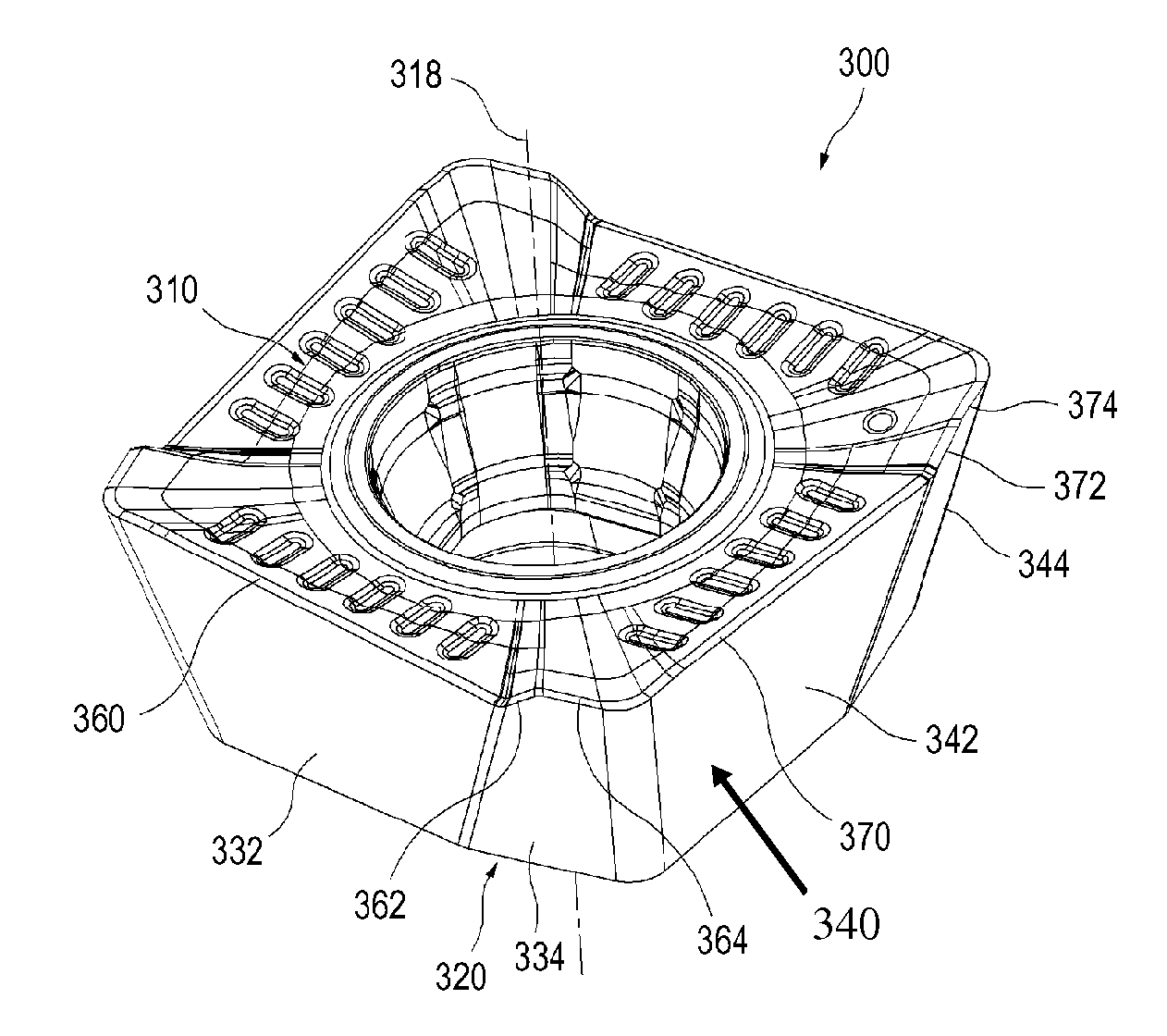

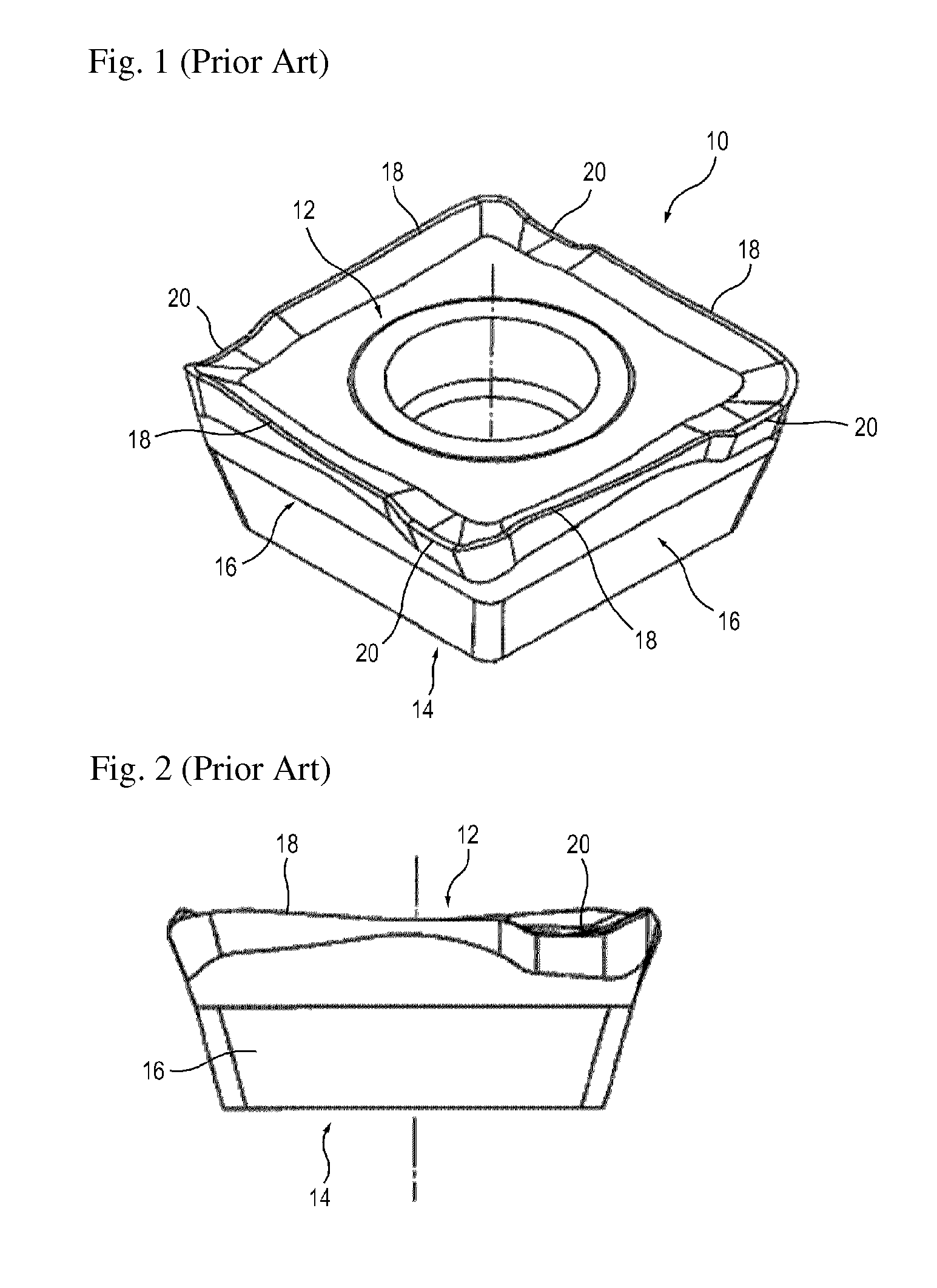

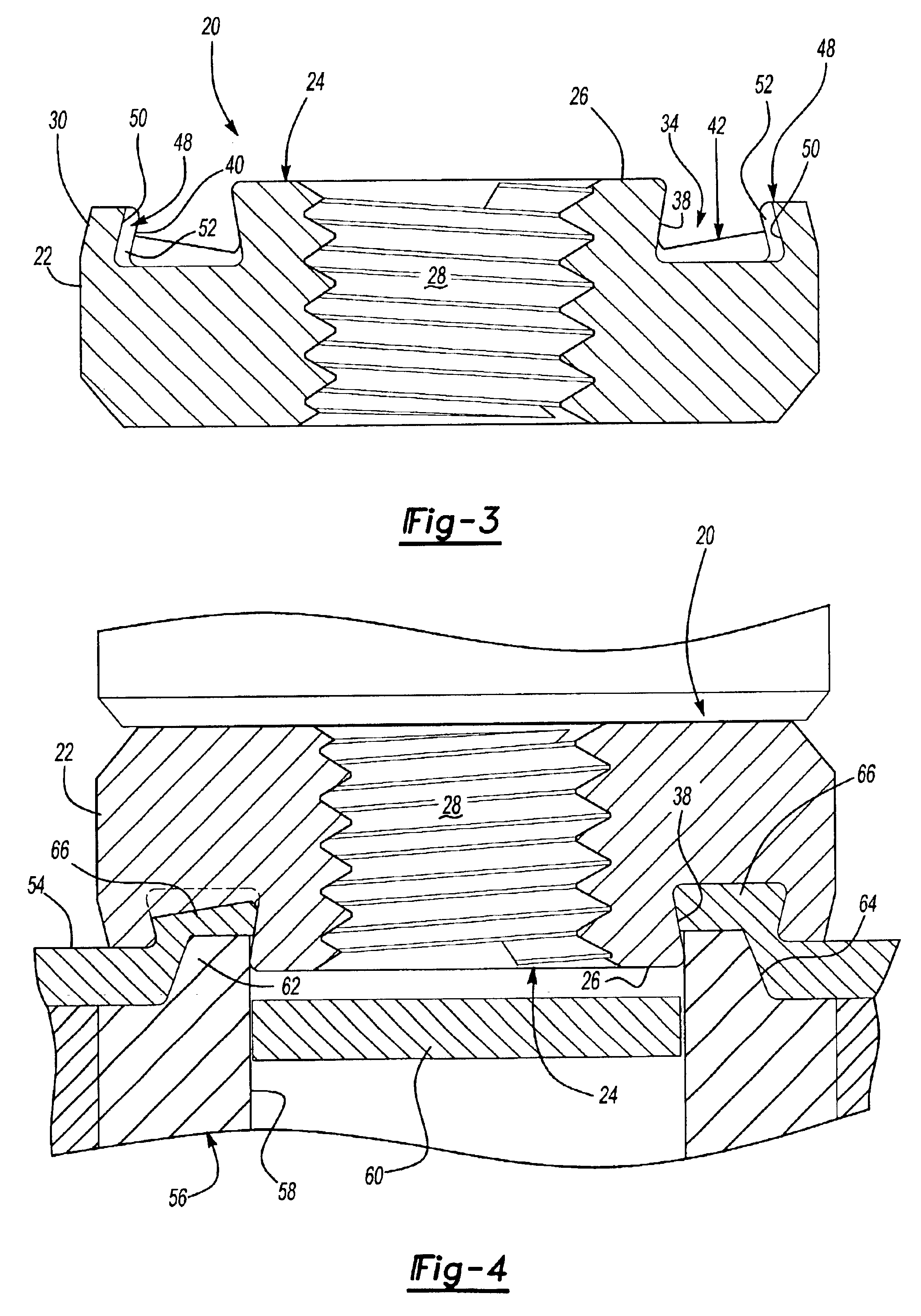

Cutting Insert

ActiveUS20120070242A1Improved strengthEasy to performMilling cuttersShaping cuttersAcute angleMechanical engineering

A cutting insert has a top surface, a bottom surface, a plurality of side surfaces that connect the top and bottom surfaces. The side surfaces form an obtuse angle with the bottom surface as well as an acute angle with the top surface. The side surfaces include a first side surface and a second side surface, which form an obtuse angle with each other when seen from the above. A main cutting edge is formed at an intersection between the first side surface and the top surface. An inclined cutting edge, which is only for ramp milling, and a minor cutting edge are formed at an intersection between the second side surface and the top surface. An obtuse angle, which the second side surface forms with the bottom surface, is greater than that which the first side surface forms with the bottom surface.

Owner:TAEGUTEC

Panel with a slider

A set including a panel and a slider, such as a drawer slider. The slider including a slider surface and the panel comprising a panel surface. The slider is configured to be assembled to the panel with the slider surface facing the panel surface. The panel surface is provided with an insertion groove and an undercut groove, which are of a longitudinal shape. A strip protrudes from the slider surface, and the strip is configured to be inserted into the insertion groove and the undercut groove by an angling motion.

Owner:VÄLINGE INNOVATION AB

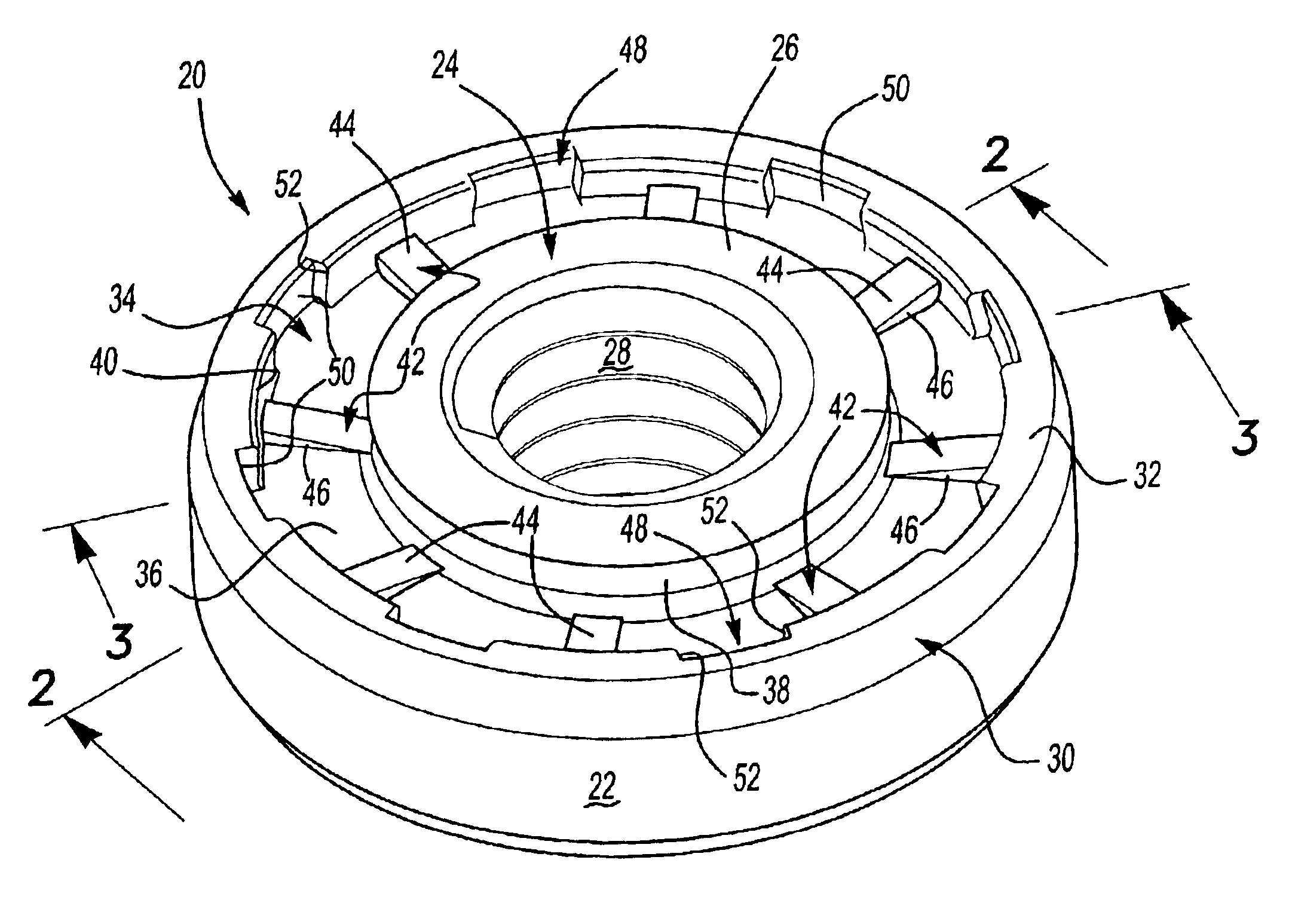

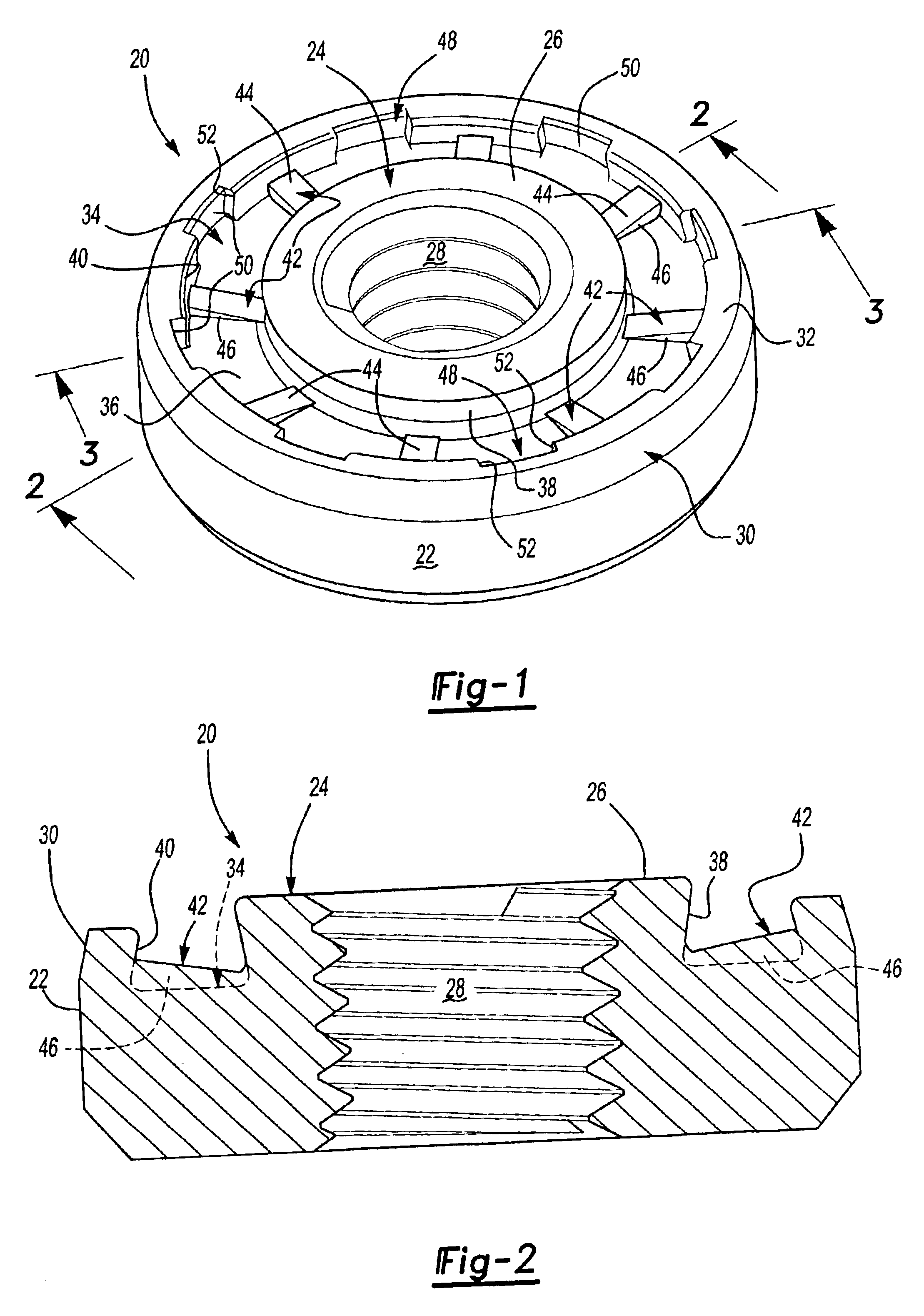

Self-attaching female fastener and method of installation

A self-attaching nut having an annular pilot, an annular flange surrounding the pilot and an annular groove in the bearing surface surrounding the pilot, wherein the bottom wall of the groove has inclined rectangular protuberances and the outer wall of the groove has radial channel-shaped grooves spaced between the radial protuberances. During installation, panel metal is driven against the inclined radial protuberances, driving panel metal under the inclined outer wall of the groove and into the radial grooves in the flange.

Owner:WHITESELL FORMED COMPONENTS

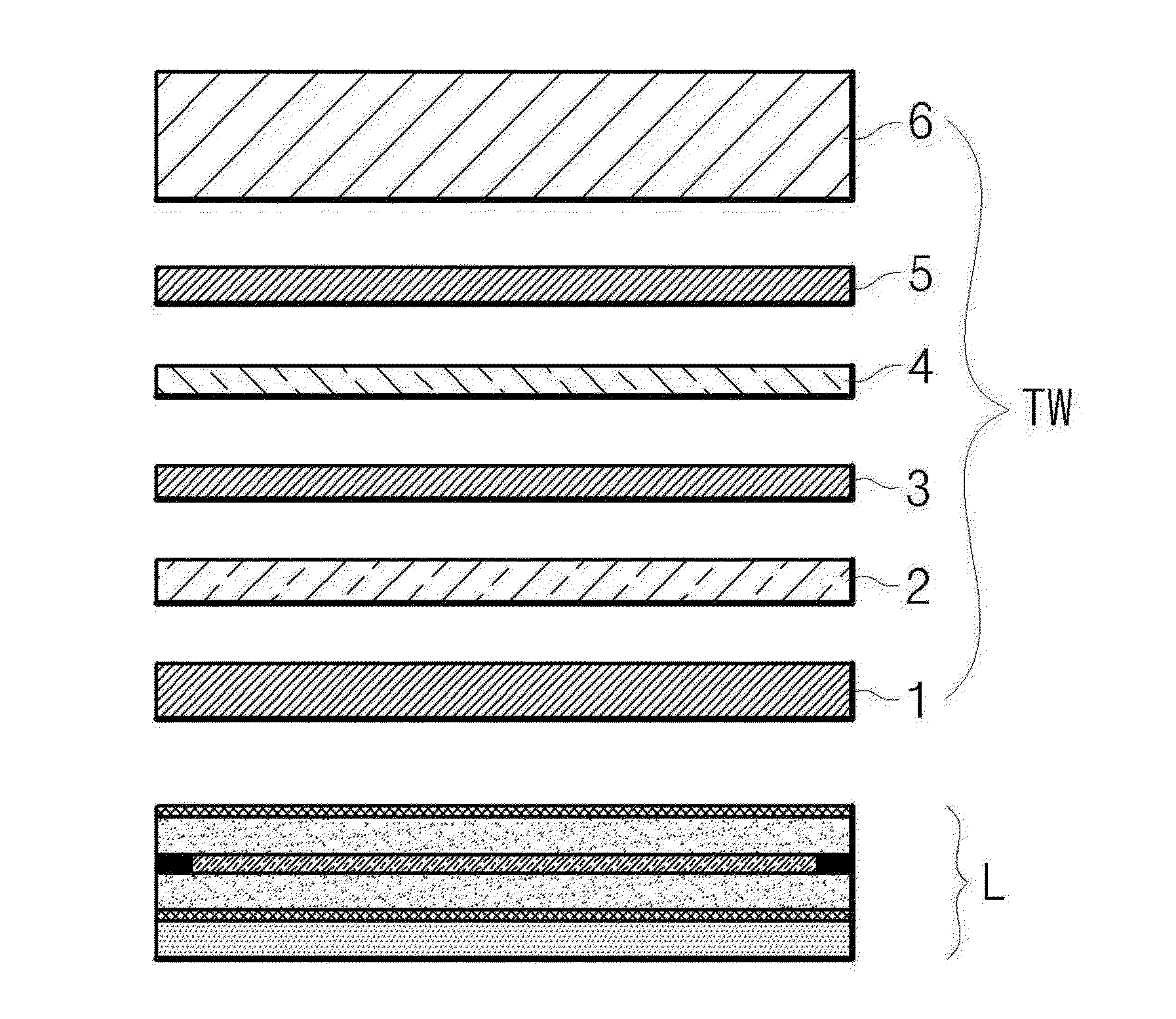

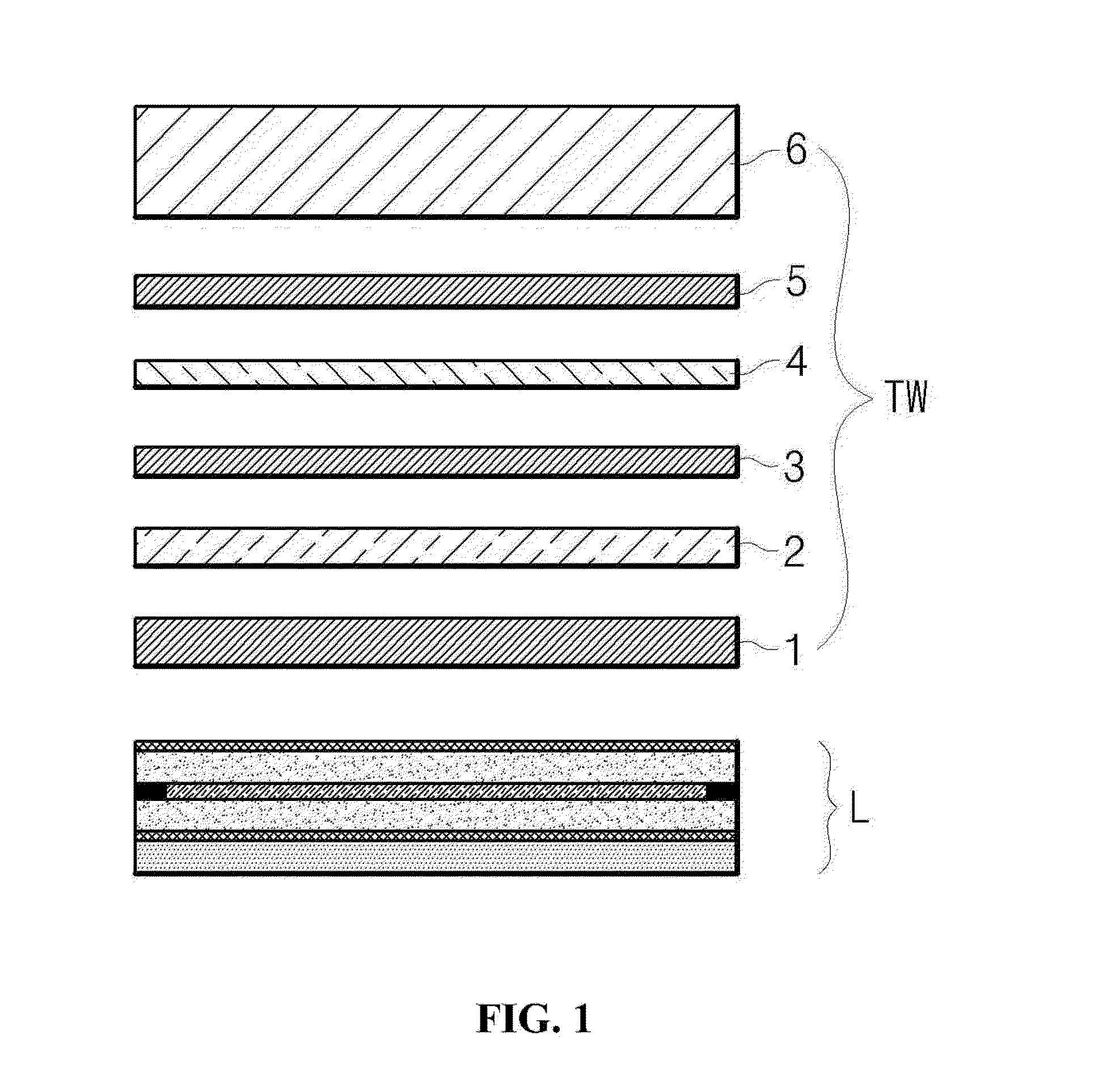

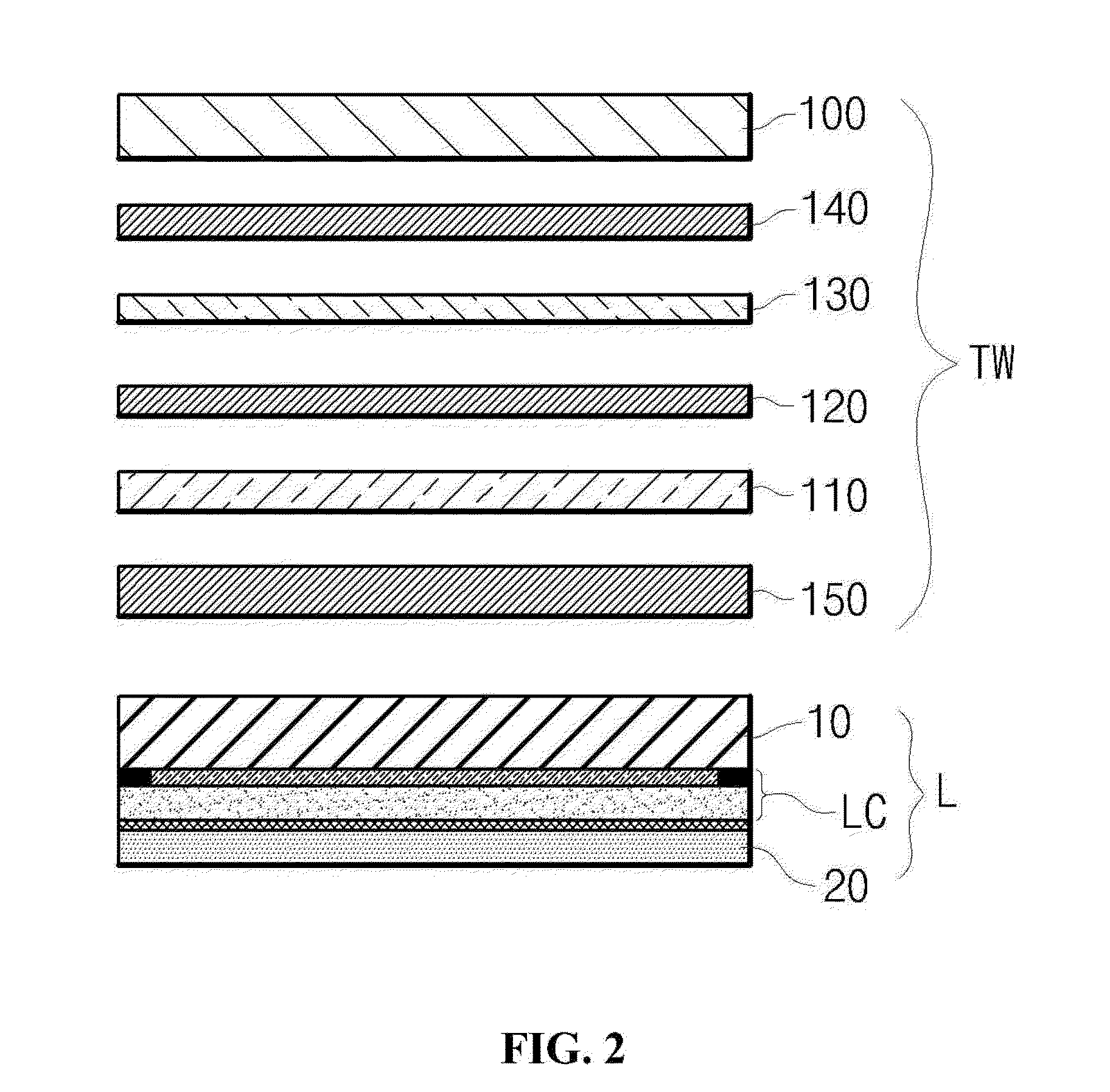

Integrated touch screen

ActiveUS20120313877A1Improved strengthSimplify processStatic indicating devicesLayered productsLiquid-crystal displayLiquid crystal

Disclosed is a structure of a touch screen which is integrally implemented with a liquid crystal panel. In the structure, a touch sensor module is integrally implemented with the liquid crystal panel, a substrate of the liquid crystal panel is formed of two side strengthened glass, and the touch sensor module is integrally implemented on the two strengthened glass, thereby being capable of improving strength of the whole touch sensor module and simplifying a process.

Owner:LG INNOTEK CO LTD

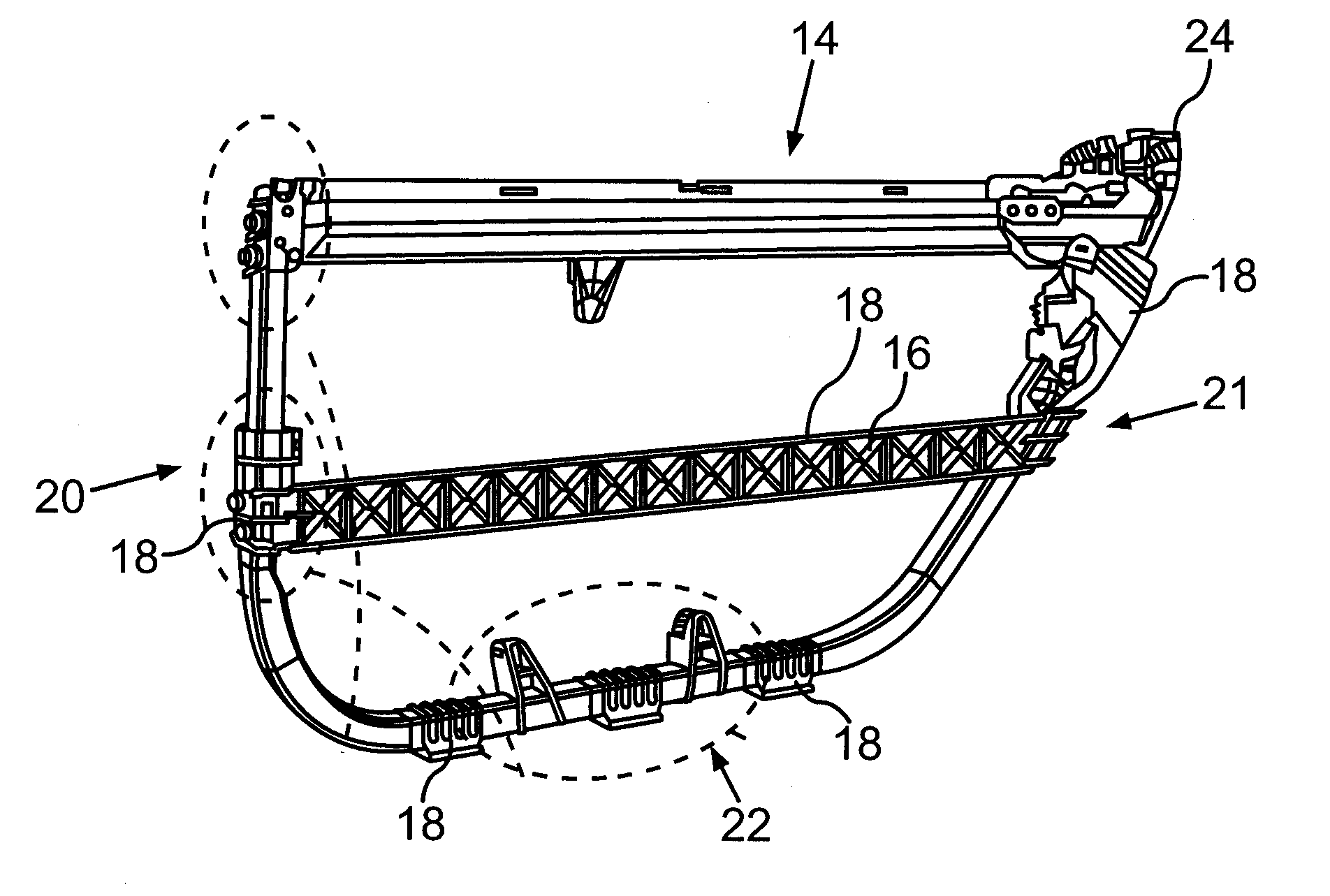

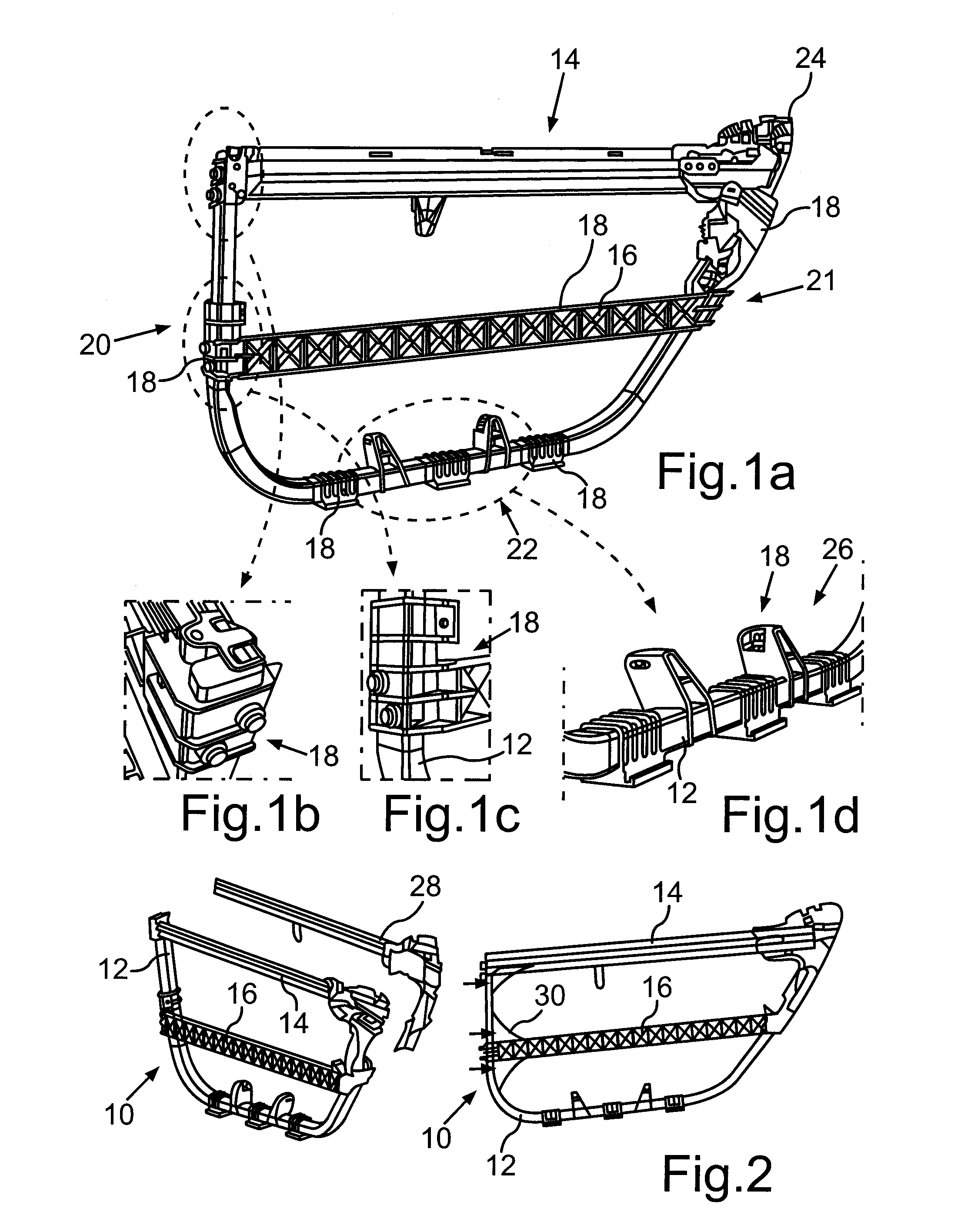

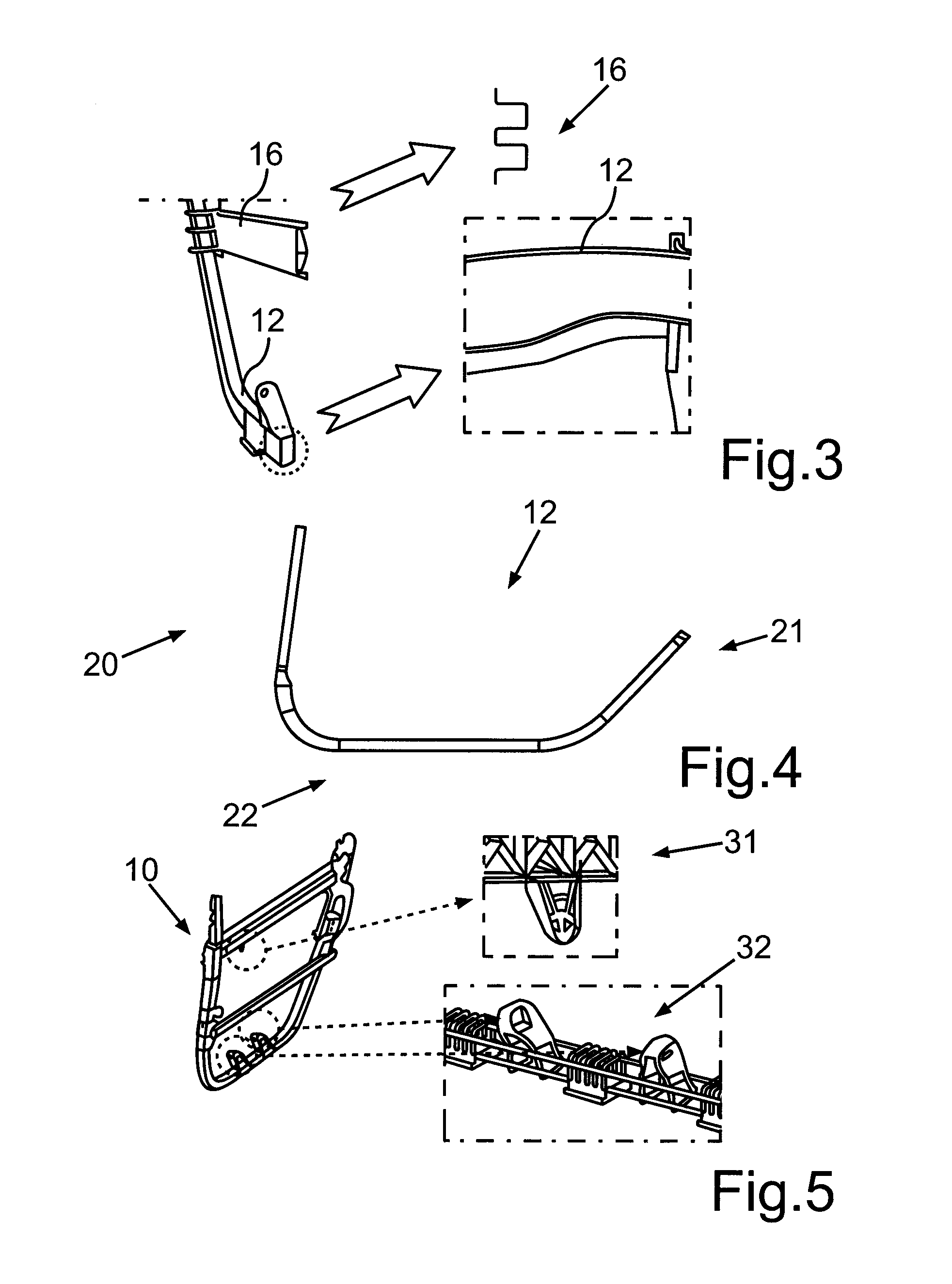

Door for a Motor Vehicle and Method for the Production Thereof

InactiveUS20130057018A1Simply designImproved strengthMetal rolling stand detailsDomestic articlesEngineeringHigh pressure

A door for a motor car includes a door support with at least one metal carrier element at least partially provided with plastic. The at least one metal carrier element is formed as an internal high pressure formed part. At least one metal reinforcement part and / or support part is / are attached to the metal carrier element.

Owner:DAIMLER AG

Flocculation of cell material

InactiveUS6967085B1High shearImproved strengthMicrobiological testing/measurementMicroorganism based processesIonCell material

A process of flocculating microbial cell material from a suspending medium which contains cell material, comprising adding to the suspending medium a first polymeric material which is cationic and has intrinsic viscosity of not more than 2 dl / g, and subsequently or simultaneously adding to the suspending medium a second polymeric material which is cationic or substantially non-ionic and has intrinsic viscosity of at least 4 dl / g, and allowing the cell material to flocculate.

Owner:CIBA SPECIALTY CHEM WATER TRATMENTS

Packaging pouch

InactiveUS20110058755A1Improved strengthEasy to operateDispensing apparatusBagsTowelettesEngineering

The disclosure aims at improving the strength of a bag for the packing of products such as moist towelettes. For this purpose, the invention provides to add an upper gusset linking the front and back faces of the packing back and to make integral the flap with such upper gusset through an opening provided on the front face of the packing bag. According to one exemplary embodiment, the packing bag having the general shape of an envelope, more particularly including a back face and a front face, the front face being provided with a dispensing opening which can be closed by a flap, the upper edges of the back and front faces being sealed on the internal layer of an upper gusset, said upper gusset, the flap and the front face being integral. Besides, the upper edge of the front face has at least one cut through which at least a part of the internal layer of the upper edge of the flap is sealed on a part of the internal layer of the upper gusset.

Owner:UNKNOWN

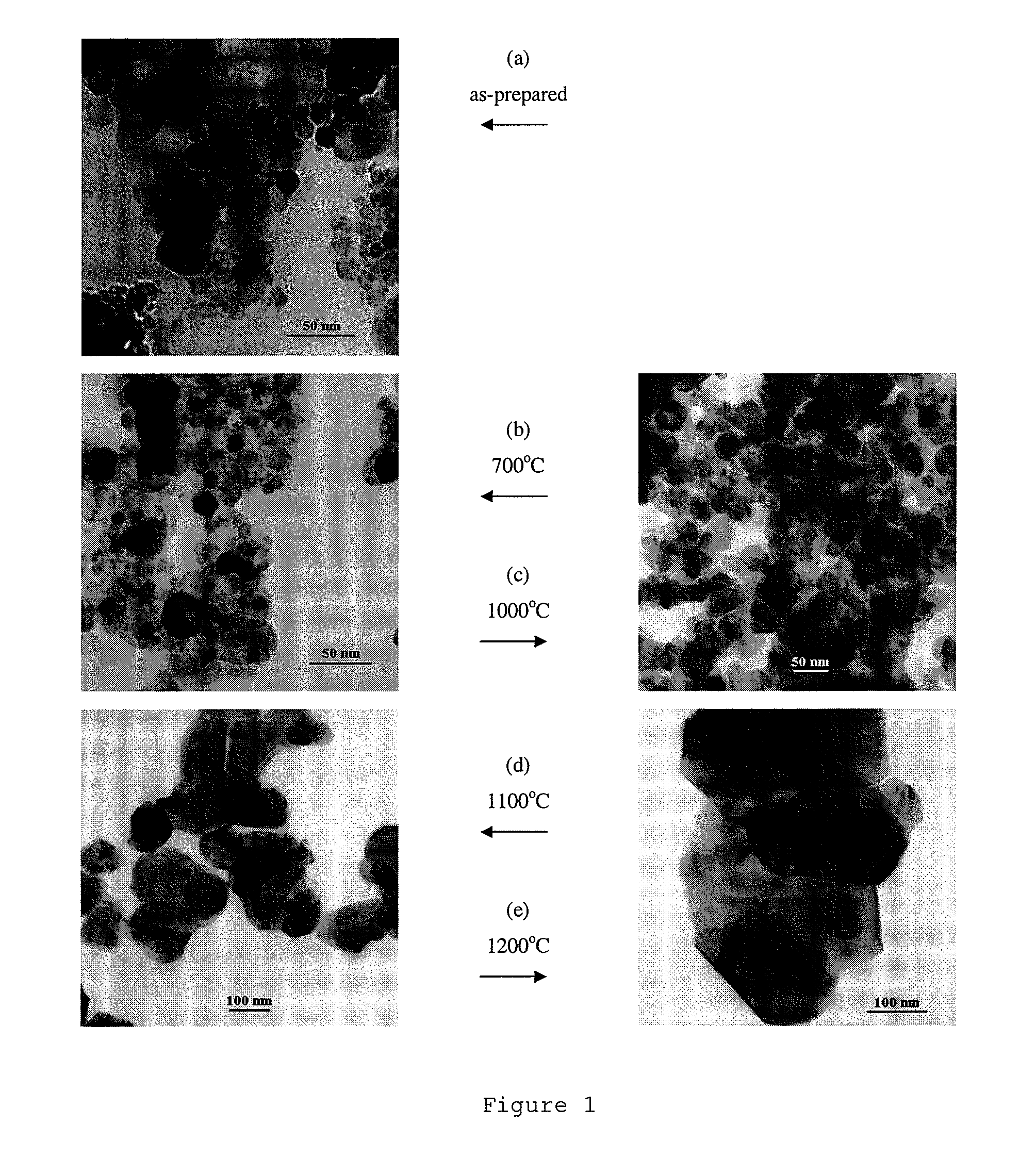

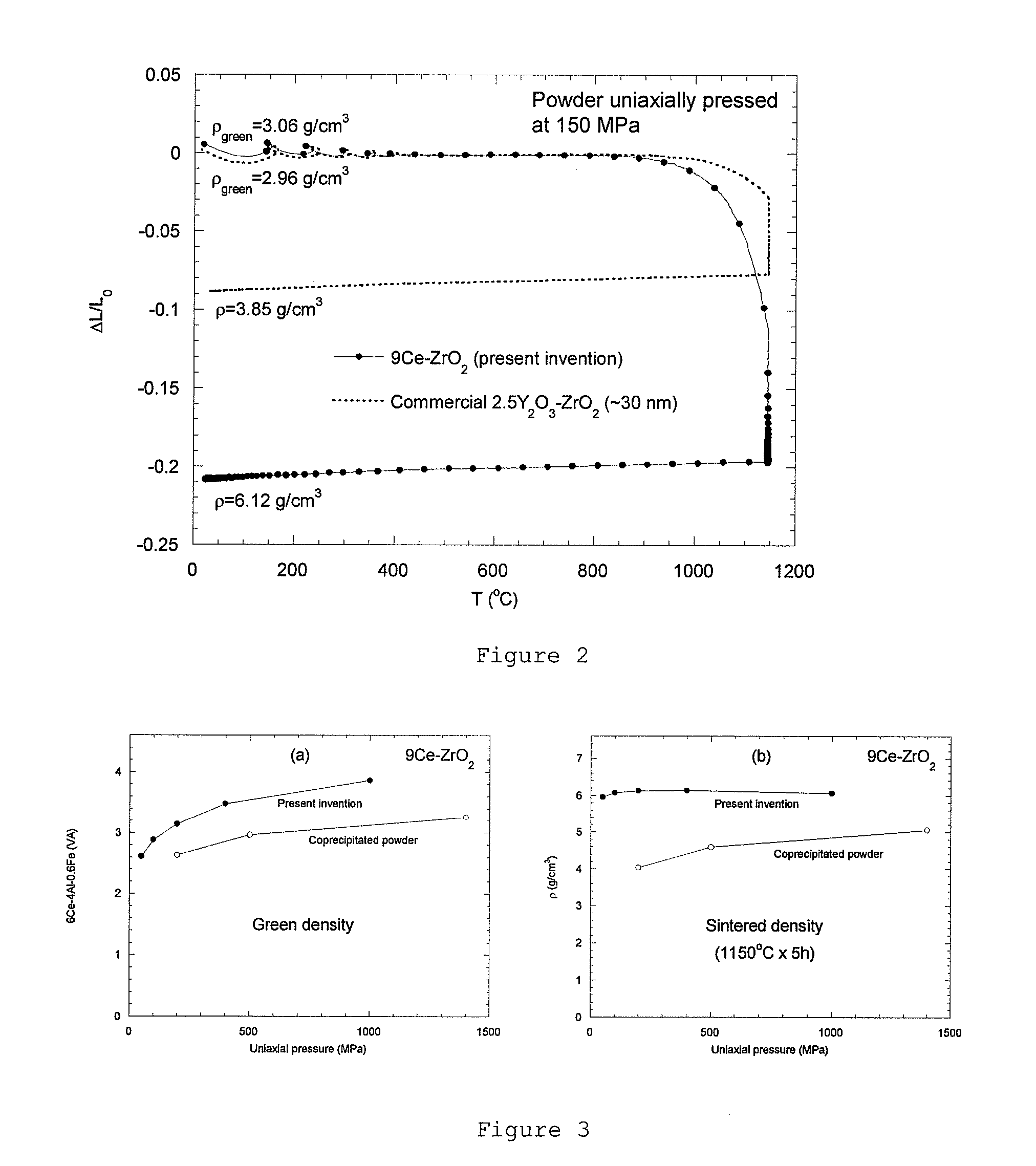

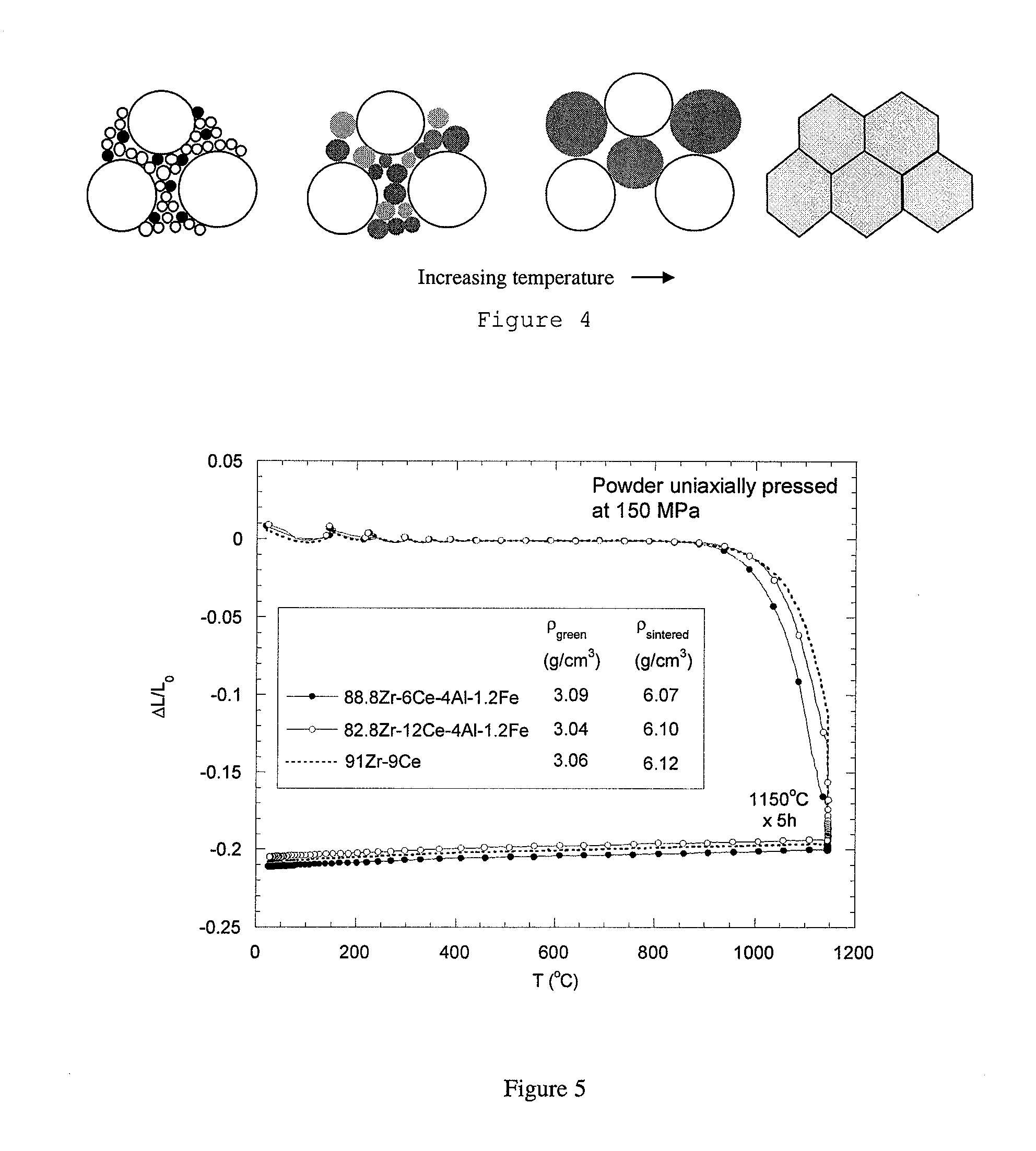

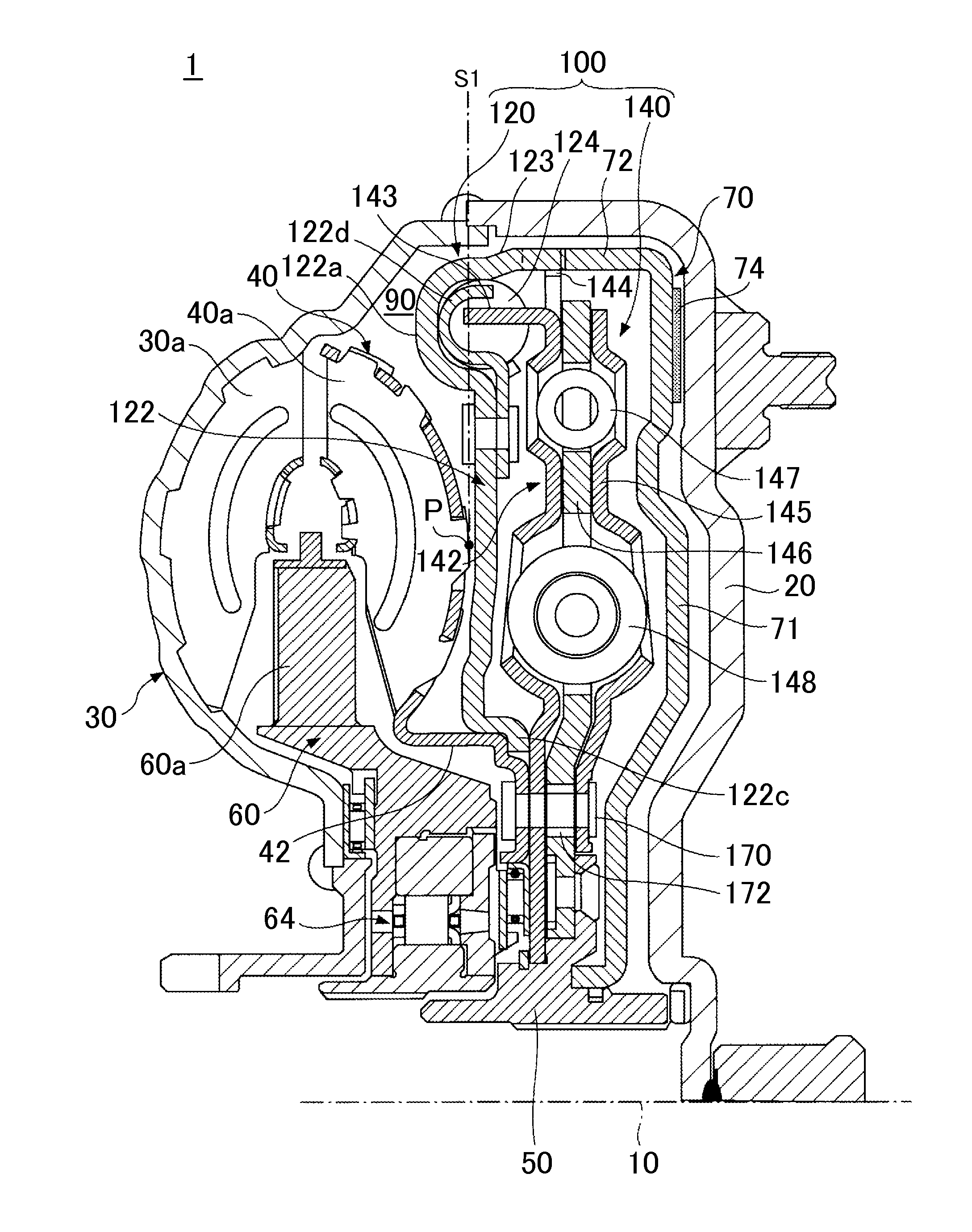

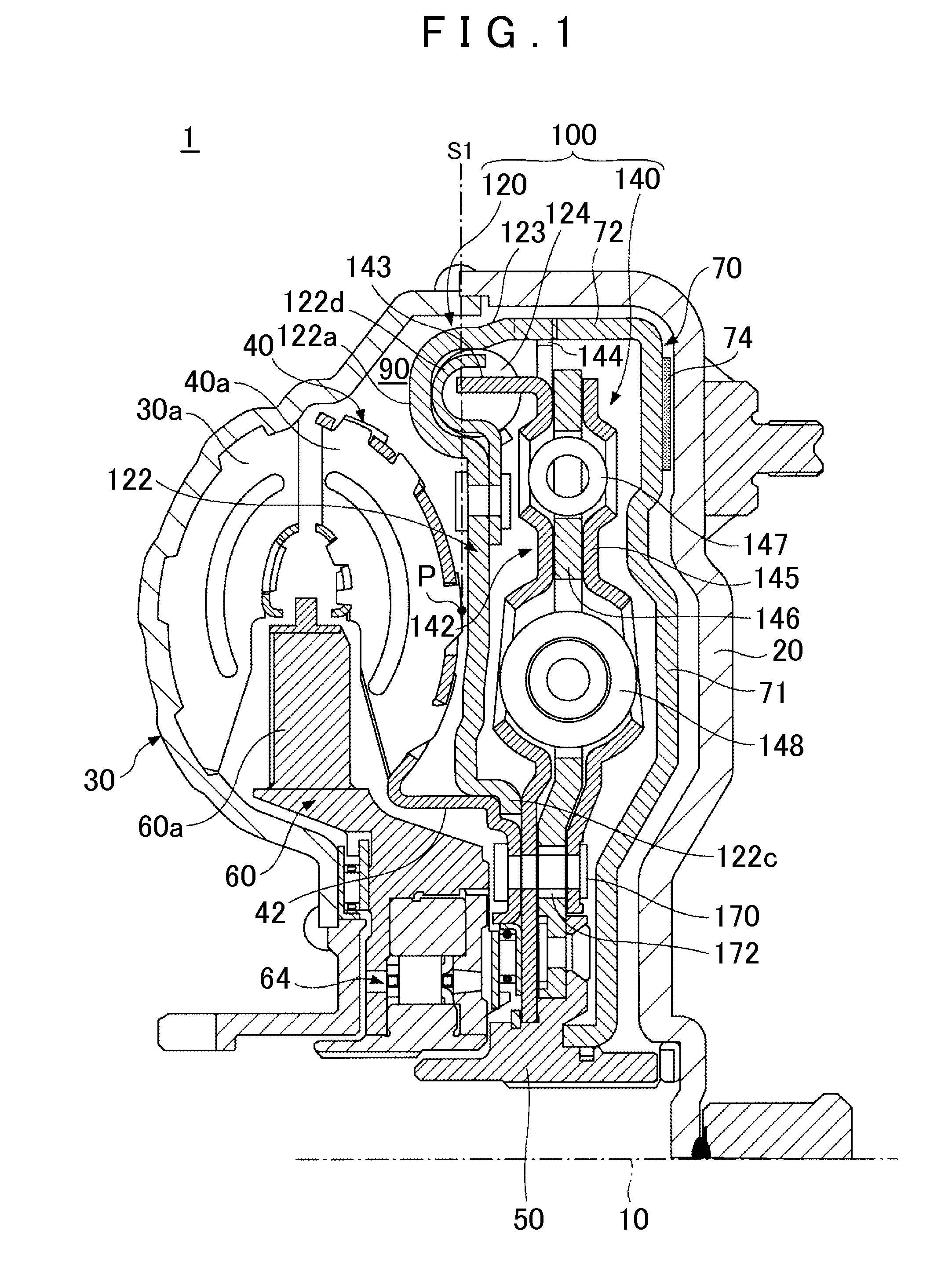

Zirconia Ceramic

InactiveUS20070179041A1Improved strengthHigh strengthMaterial nanotechnologyIndividual molecule manipulationNano sized particleMetallurgy

A multi-component powder is described for consolidation to form a sinterable green body for a zirconia ceramic. The multi-component powder comprises at least 80% by volume of nano-sized particles of zirconia and up to 20% by volume of a stabilising agent which may form a coating around the nano-sized particles of zirconia and is optionally in particulate form. A multi-component slurry formed by suspending the powder in a liquid is also described as well as a green body formed from either the slurry or the powder. A zirconia ceramic formed by sintering the green body is also described.

Owner:ADVANCED NANO TECH

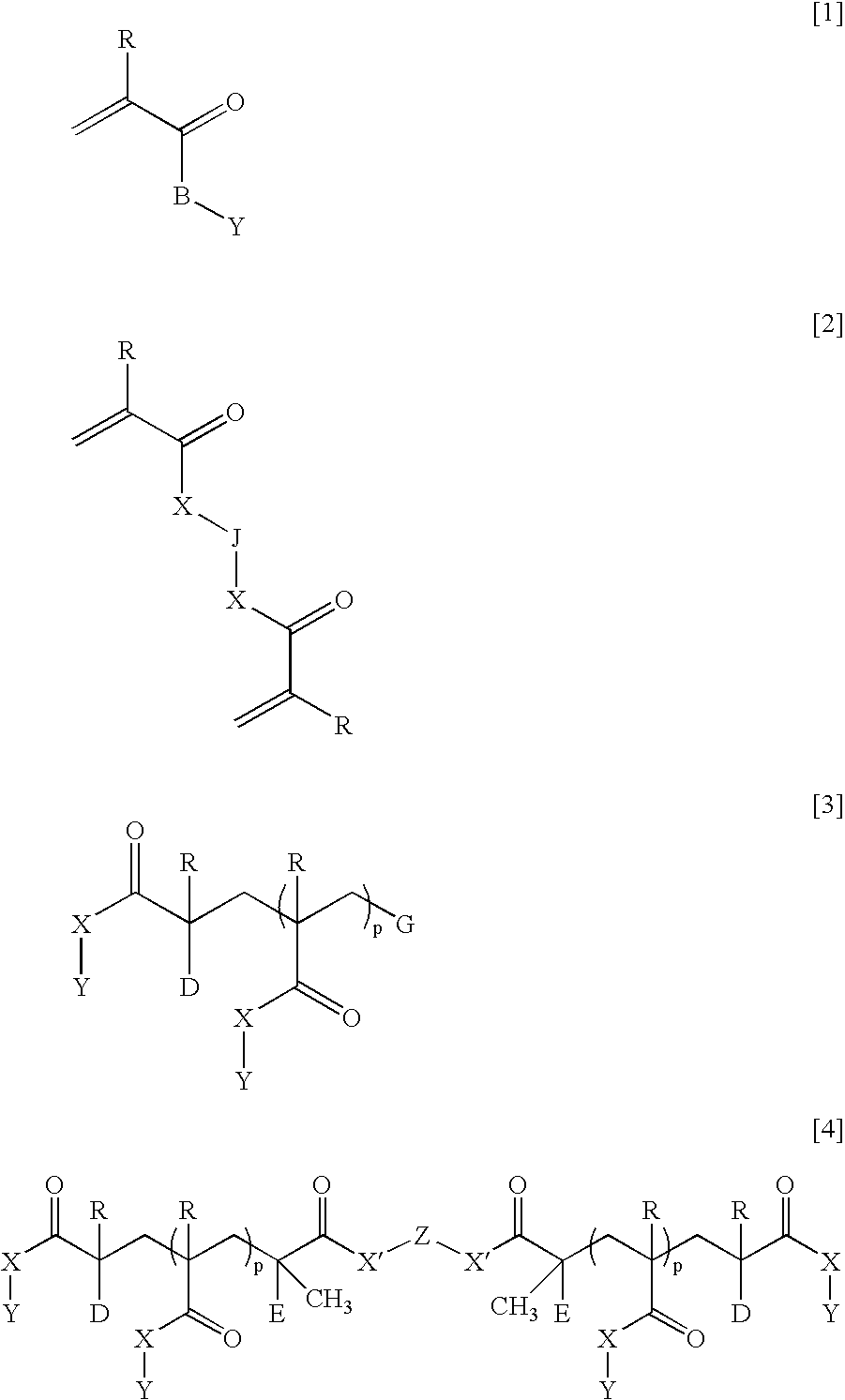

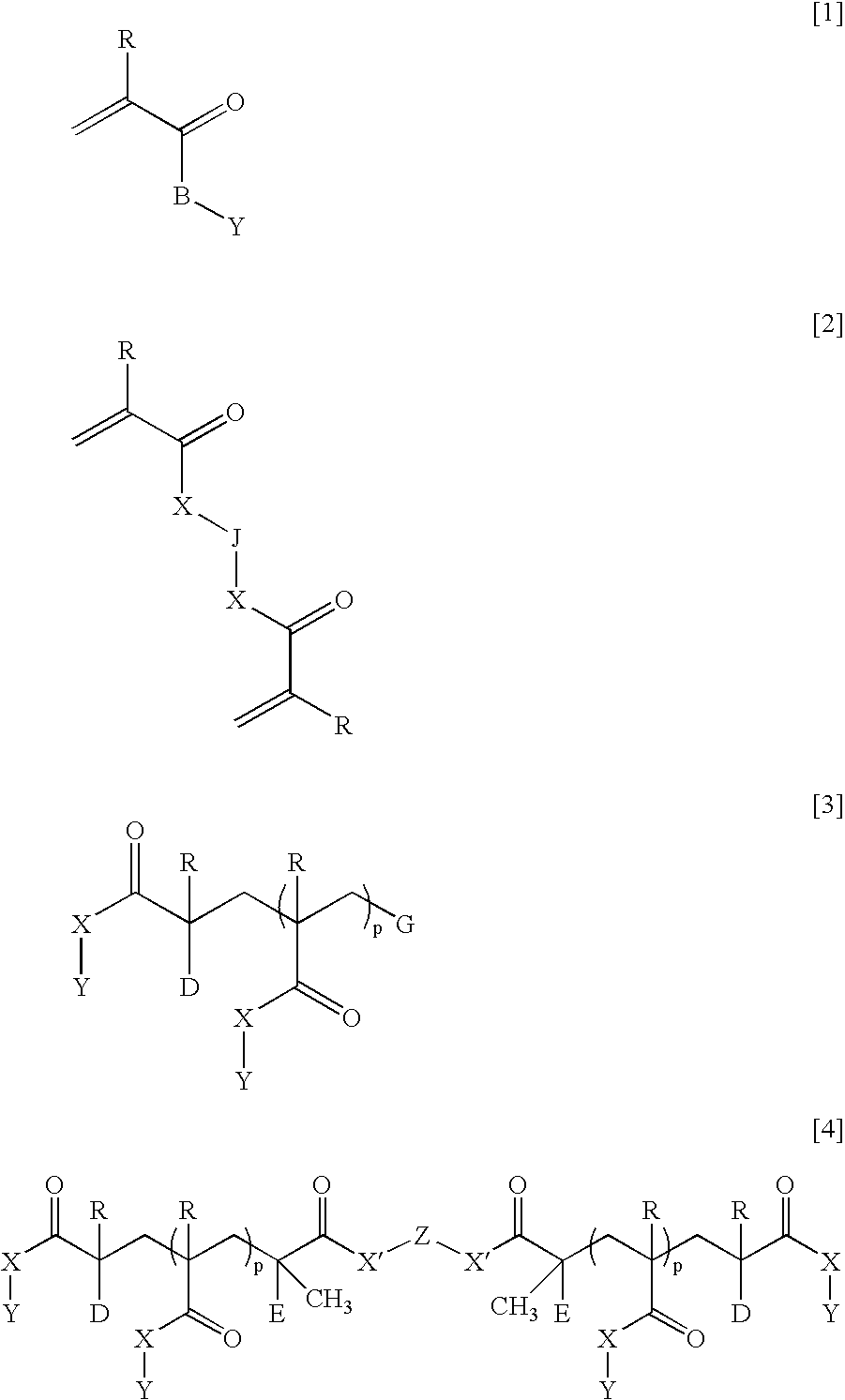

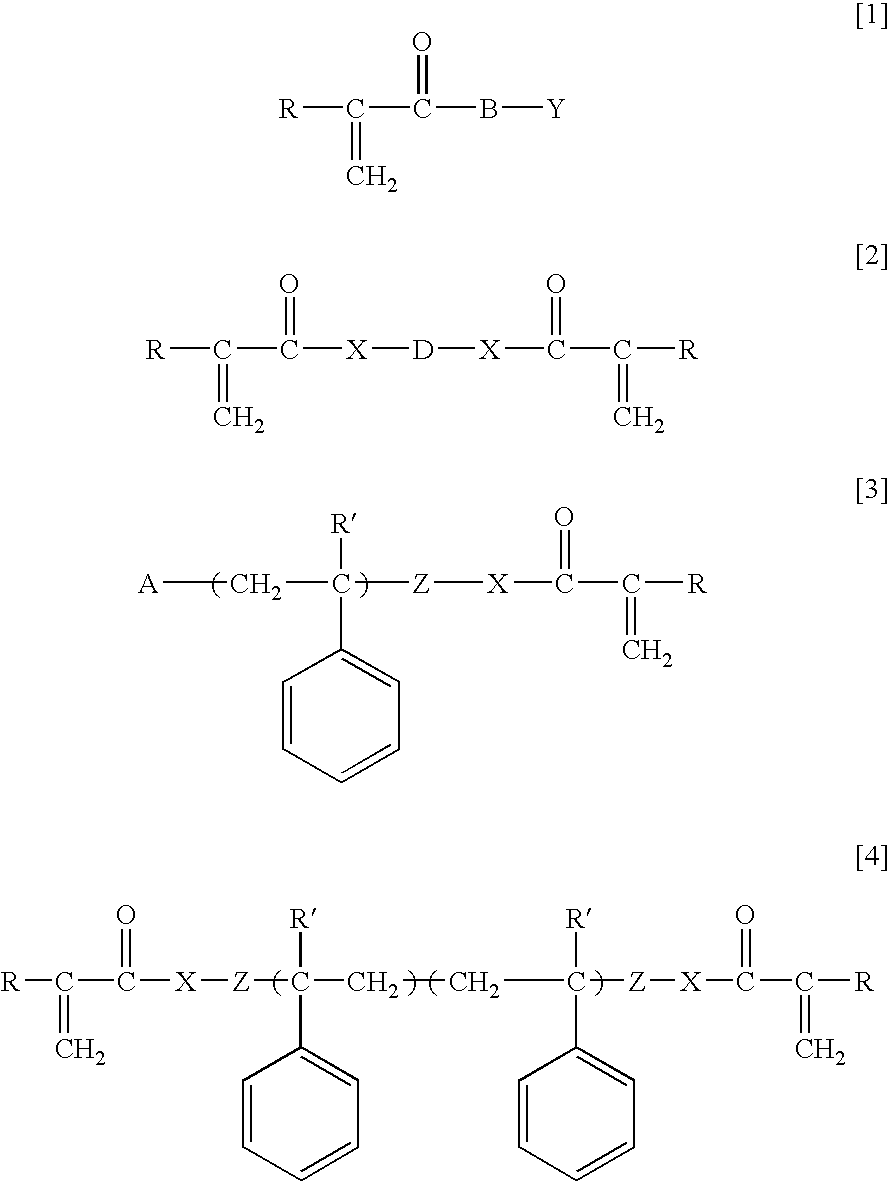

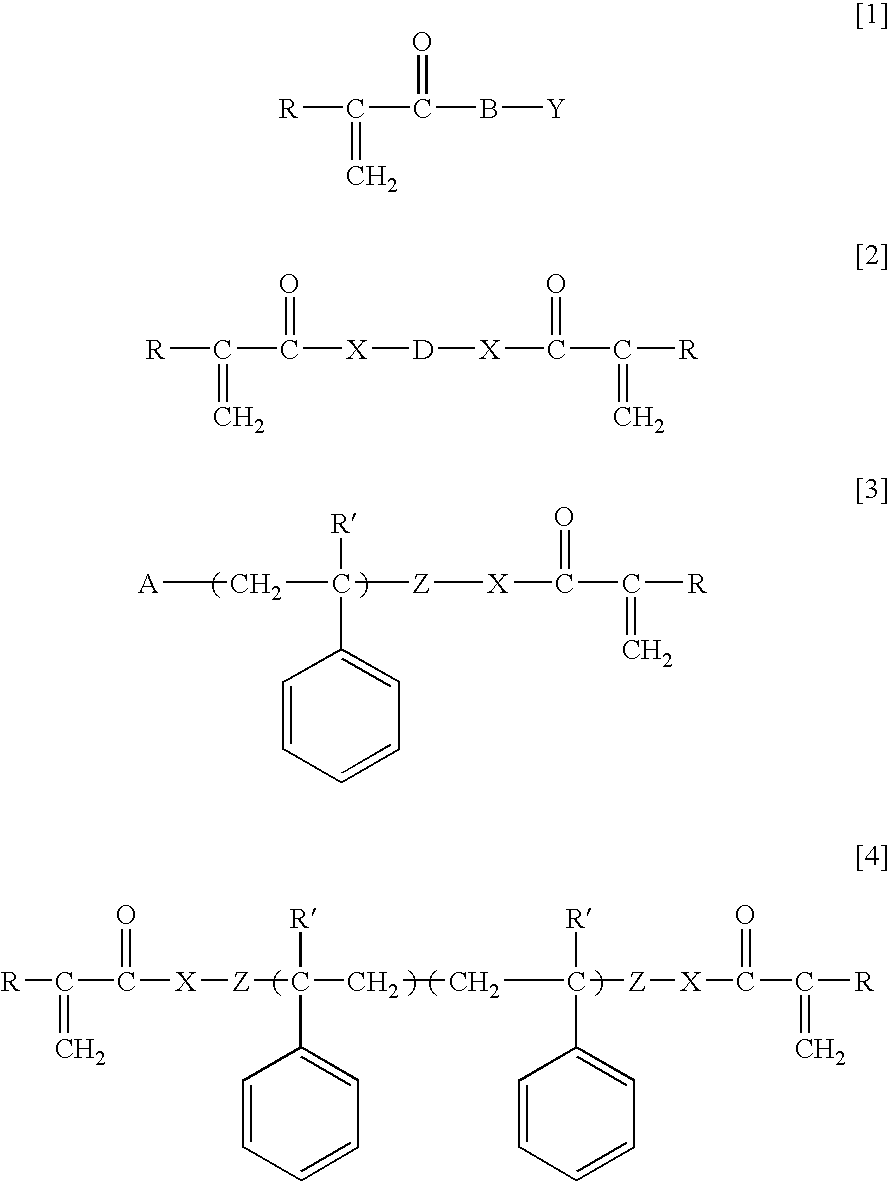

Polymers for paper and paperboard coatings

InactiveUS20050261394A1Improved strengthHigh strengthSynthetic resin layered productsCellulosic plastic layered productsWater solublePolymer

The invention is directed to the composition and use of substantially water-soluble amphoteric (co)polymers as co-binders for paper and paperboard coating applications.

Owner:CIBA SPECIALTY CHEM WATER TRATMENTS

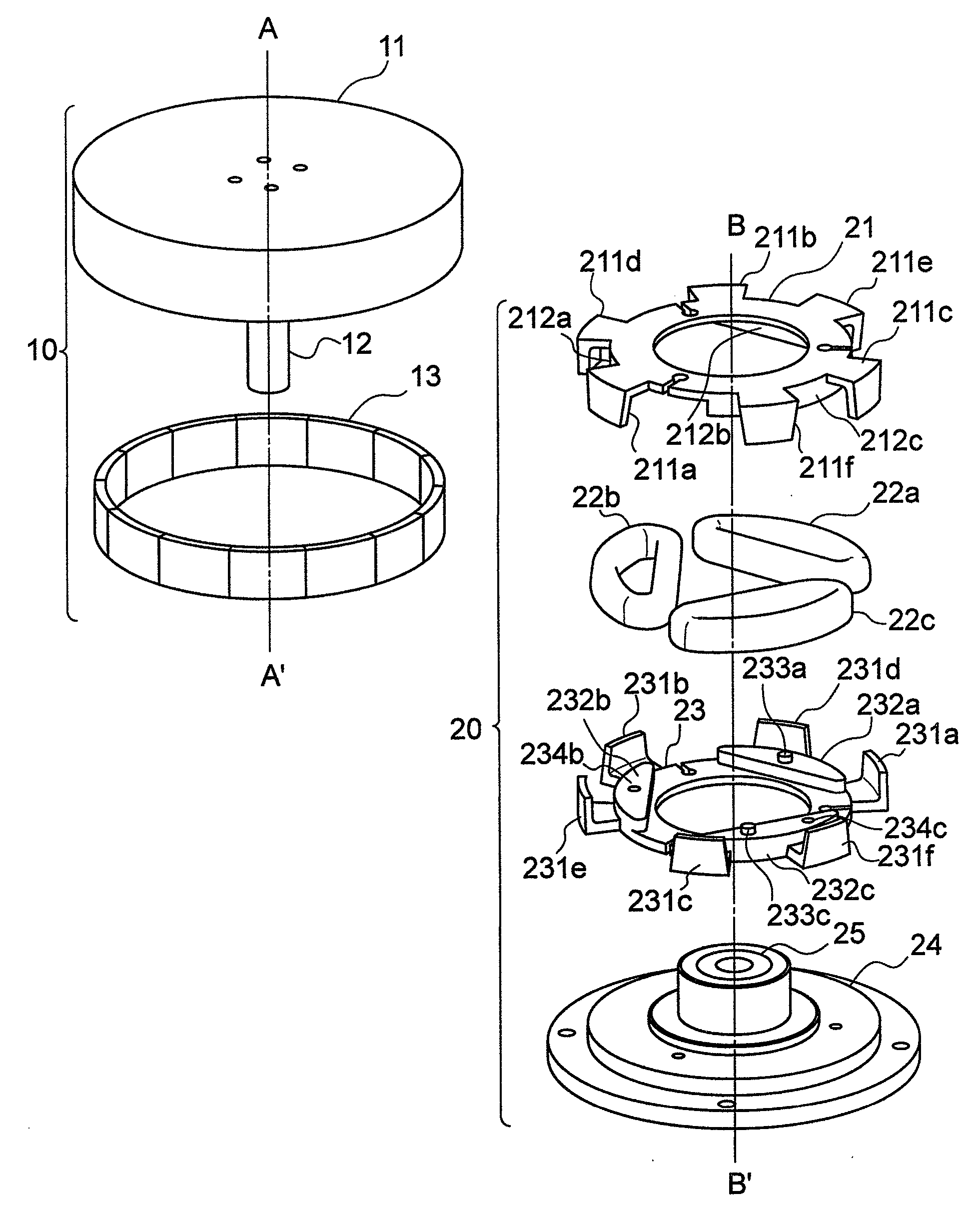

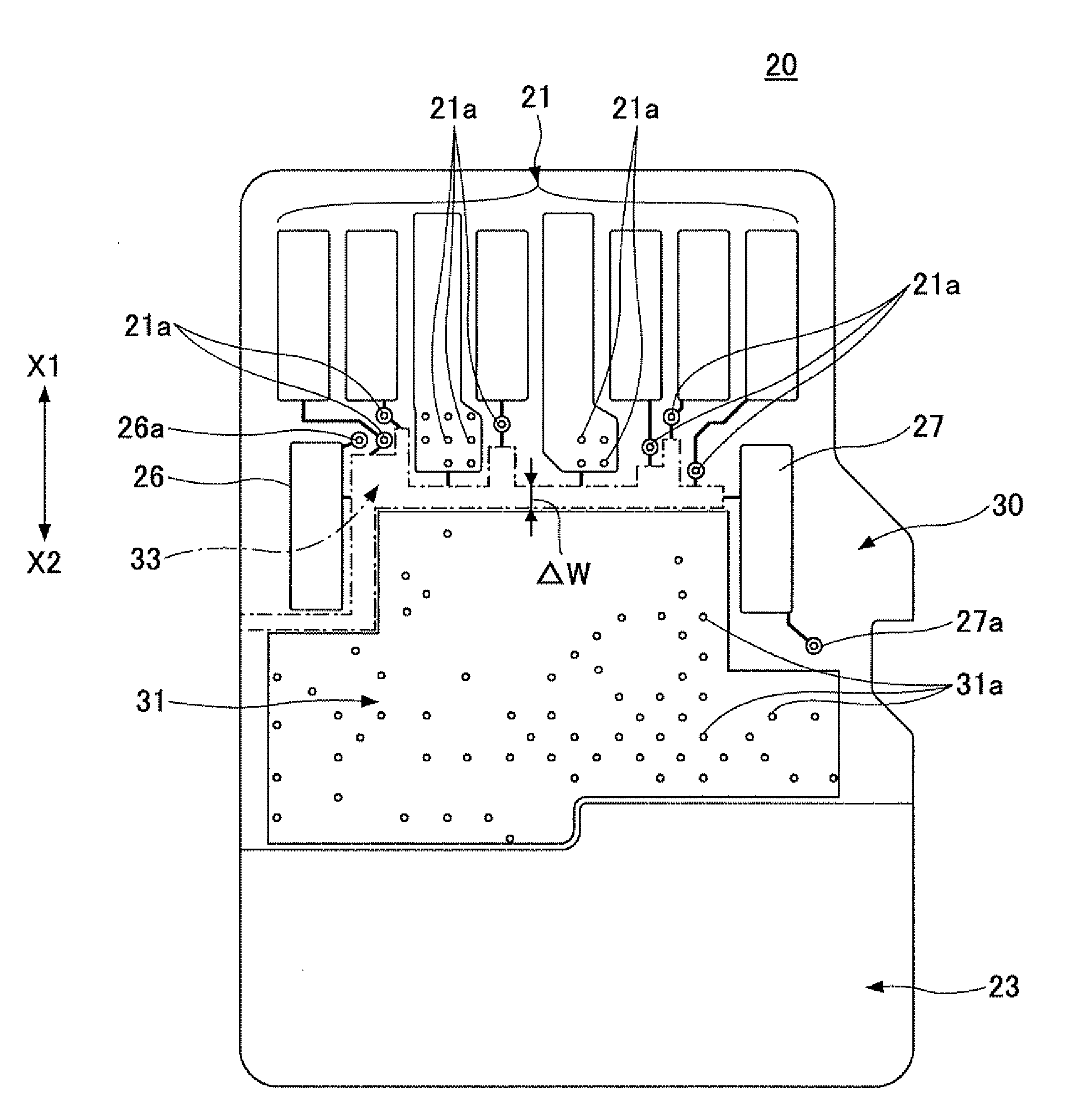

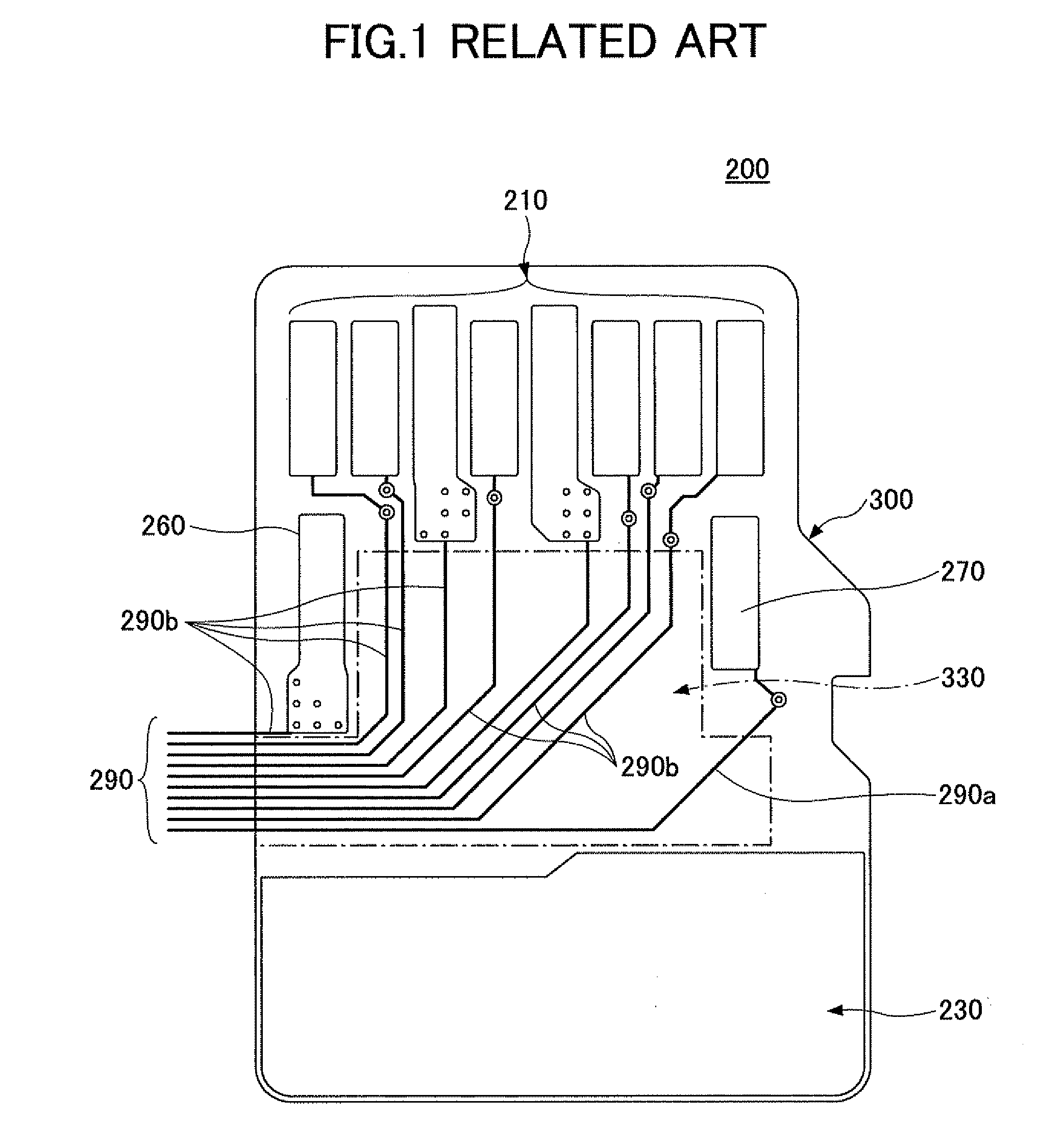

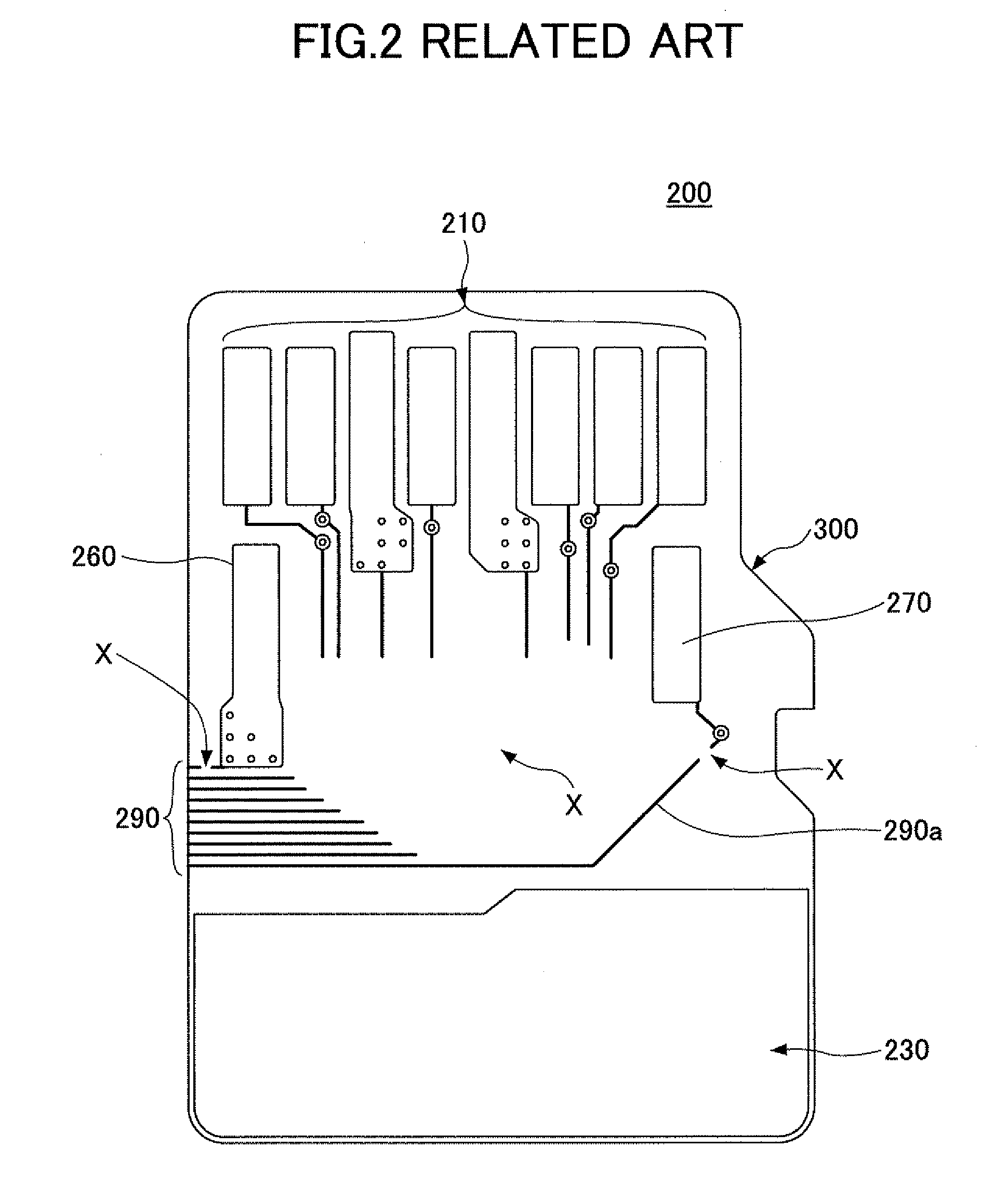

Starting device and damper device for use therein

ActiveUS20120111683A1Improved strengthEffectively utilizedRotary clutchesFluid gearingsClutchEngineering

A starting device includes: a lock-up clutch mechanism; a fluid coupling; a spring damper including a spring, a power transfer portion transferring power from the lock-up clutch mechanism to the spring, and a power output portion transferring power from the spring to an input shaft; and a pendulum damper including a pendulum and a pendulum power transfer portion transferring power from the spring damper to the pendulum. The output portion of the lock-up clutch, the pendulum damper, the spring damper, and the fluid coupling are arranged sequentially in this order from a motor in the axial direction. The lock-up clutch mechanism output and the spring damper output are connected to each other on the outer circumferential side of the pendulum damper, and the spring damper output and the pendulum power transfer portion are connected to each other on the inner circumferential side of the pendulum.

Owner:AISIN AW CO LTD

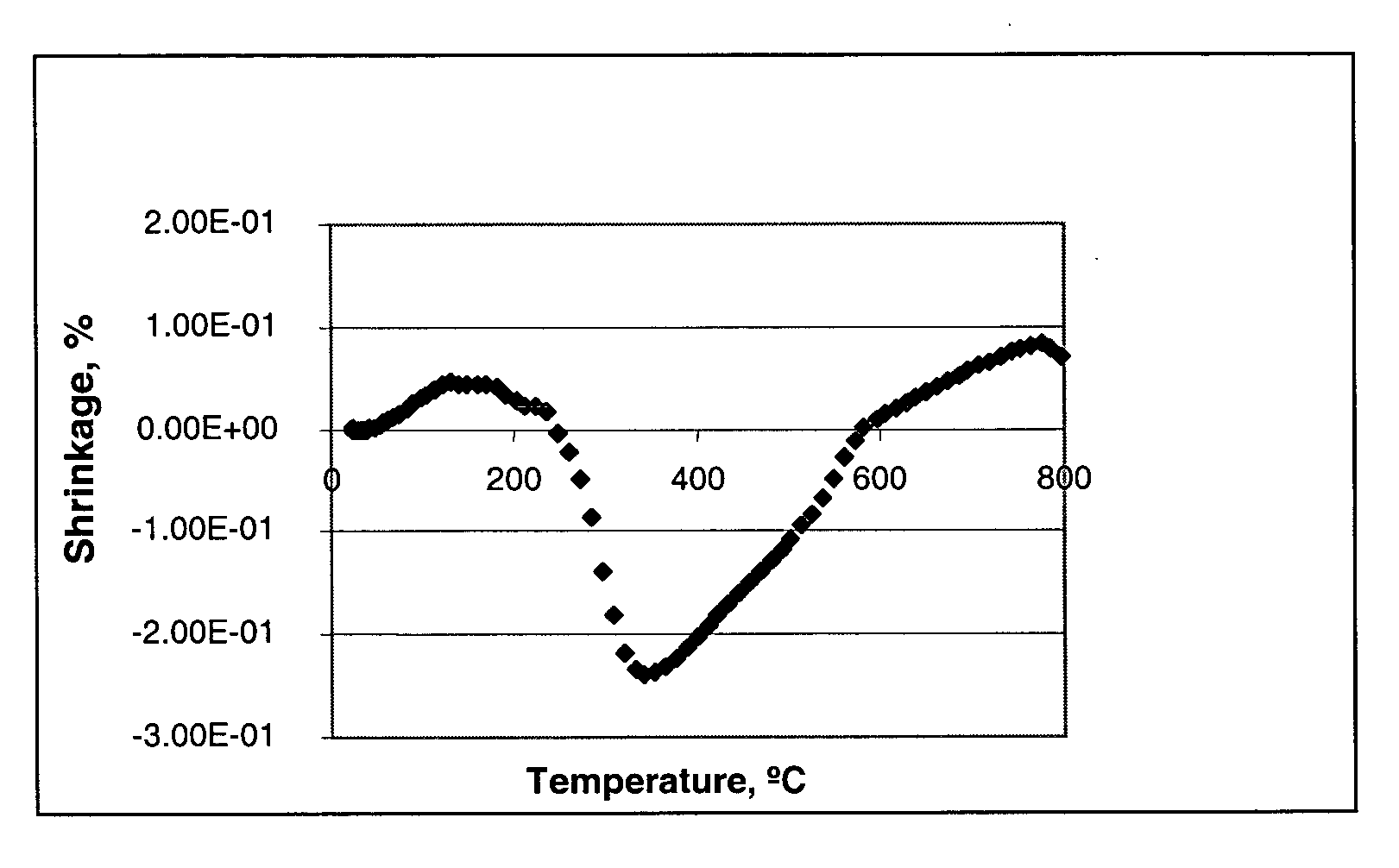

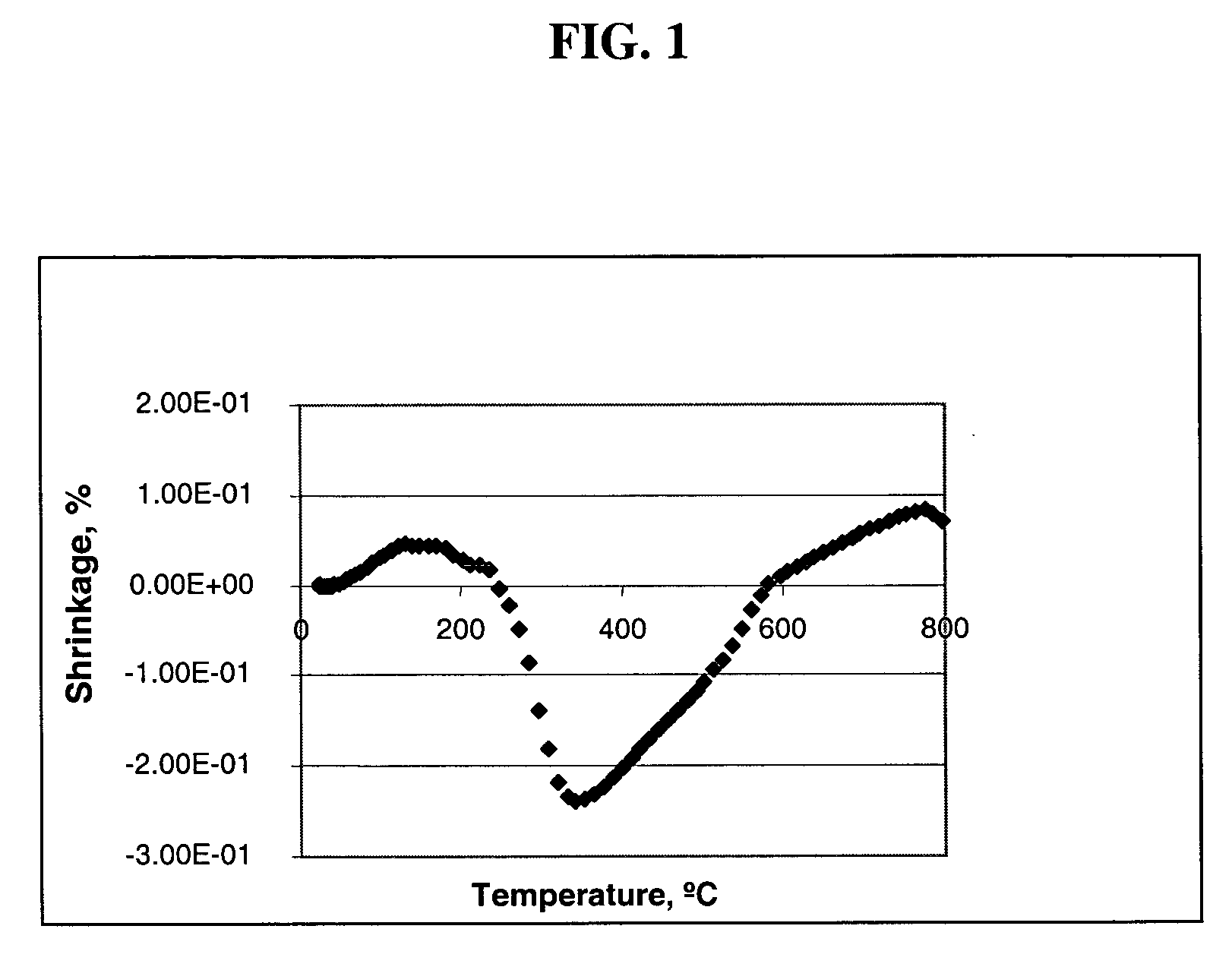

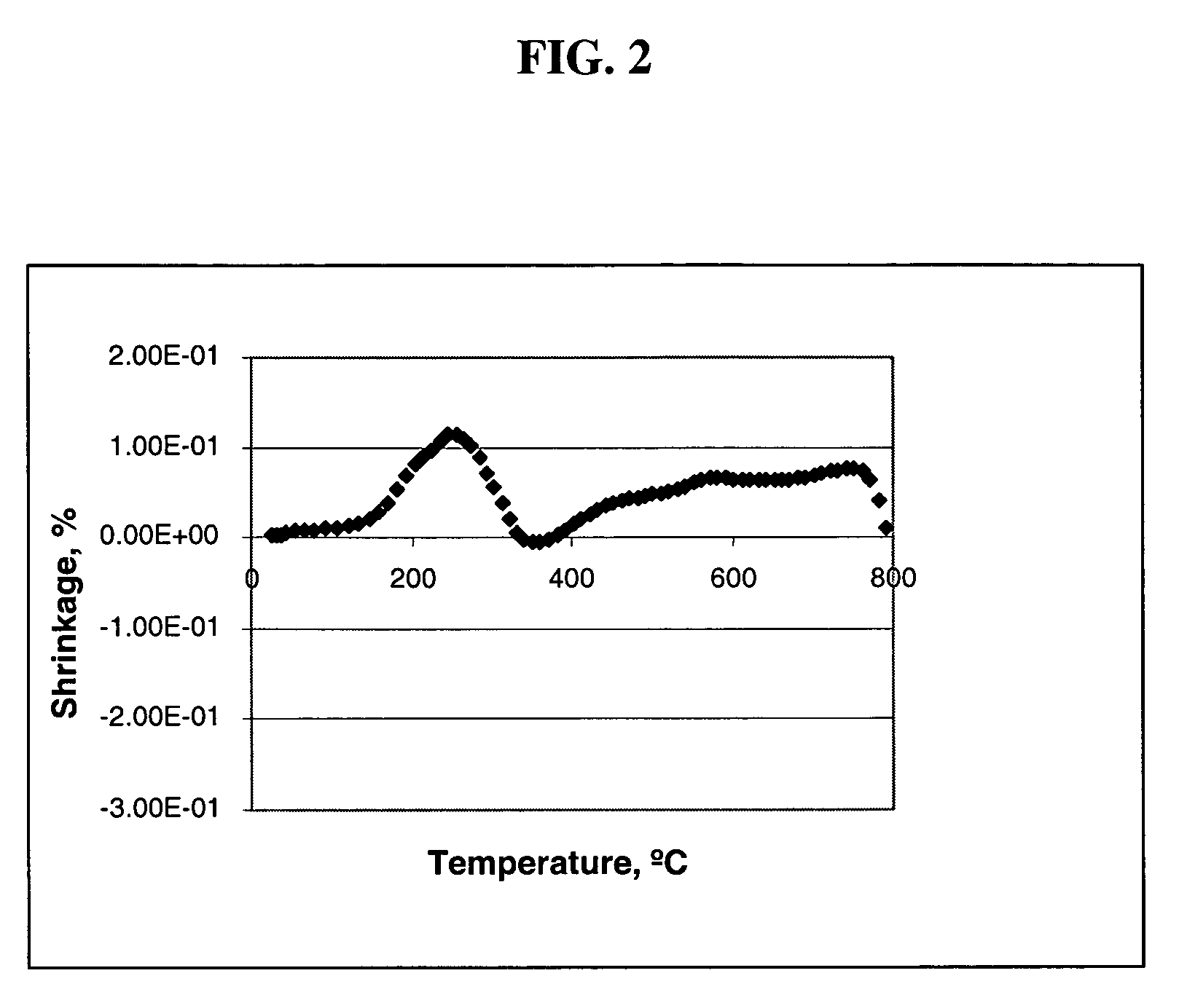

Method for fabricating ceramic articles

InactiveUS20060027951A1Improved strengthMore resistantCeramic shaping apparatusClaywaresSolventWater soluble

A method for fabricating a ceramic article which includes providing a batch comprising components of (i) a mixture of inorganic raw materials comprising talc, alumina, and silica; (ii) a binder comprising a water-soluble organic binder and a fibrous silicate mineral having a high aspect ratio in combination with a large surface area that is highly charged and has a strong interaction with a polar solvent, and is further characterized by a median particle size of 1-2 microns; and (iii) a polar solvent; mixing the batch components to form a homogenous and plasticized mass; shaping the plasticized mass into a green body wherein the green body has improved strength in a temperature region between 300°-900° C. to resist cracking during subsequent sintering; and, sintering the green body by heating to a temperature and for a time to initiate and sufficiently achieve conversion of the green body into a fired ceramic article.

Owner:CORNING INC

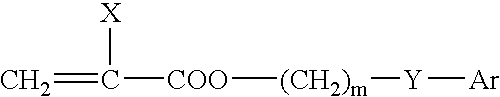

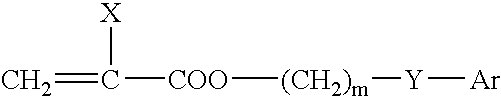

Ophthalmic and otorhinolaryngological device materials

ActiveUS20060282163A1Improved strengthHigh strengthTissue regenerationIntraocular lensRefractive indexMethacrylate

Disclosed are soft, high refractive index device materials having improved strength. The materials contain a monofunctional or difunctional, acrylate or methacrylate terminated aromatic functional methacrylic or acrylic macromer.

Owner:ALCON INC

Recrystallized aluminum alloys with brass texture and methods of making the same

A recrystallized aluminum alloy having brass texture and Goss texture, wherein the amount of brass texture exceeds the amount of Goss texture, and wherein the recrystallized aluminum alloy exhibits at least about the same tensile yield strength and fracture toughness as a compositionally equivalent unrecrystallized alloy of the same product form and of similar thickness and temper.

Owner:ARCONIC TECH LLC

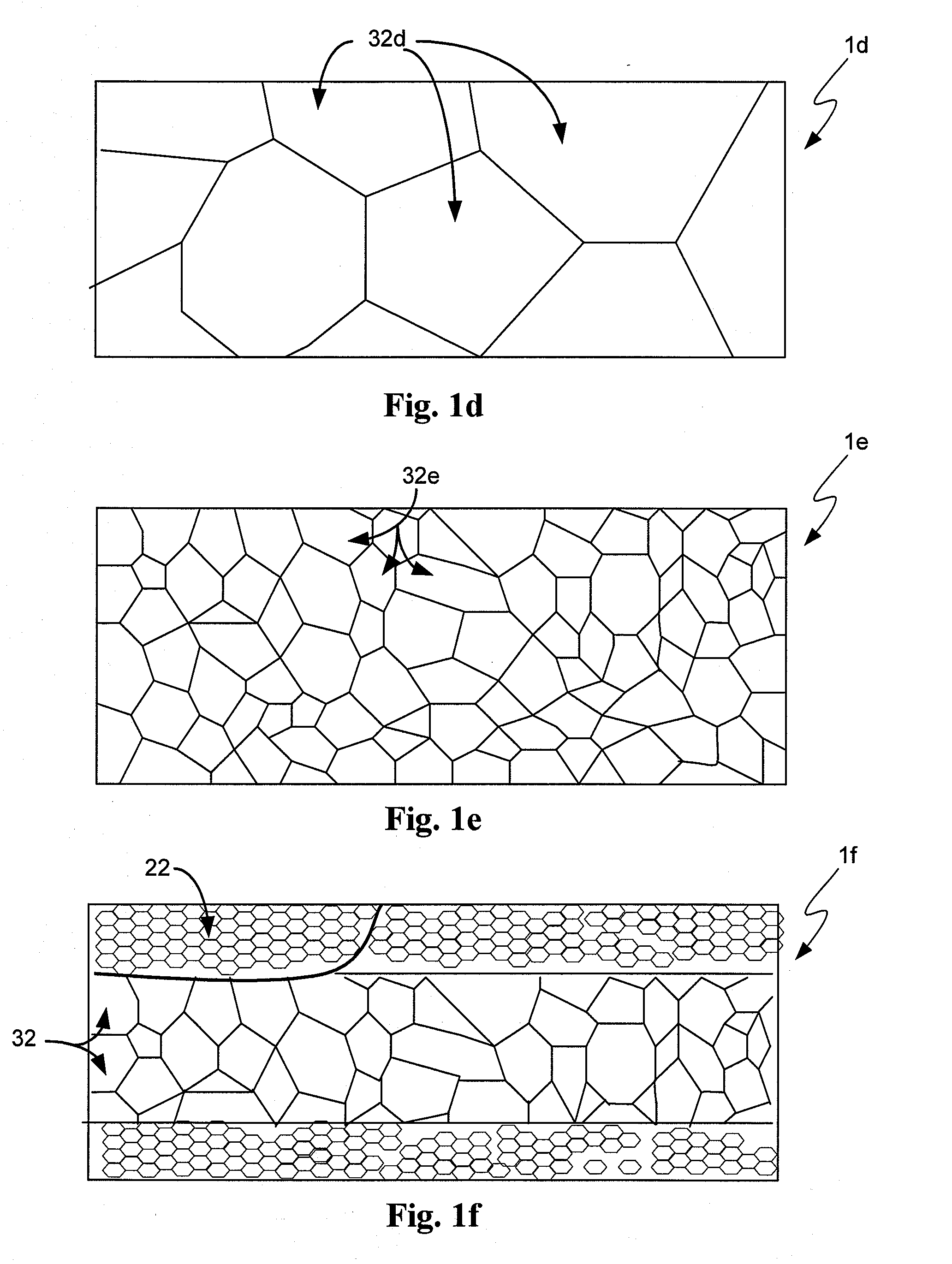

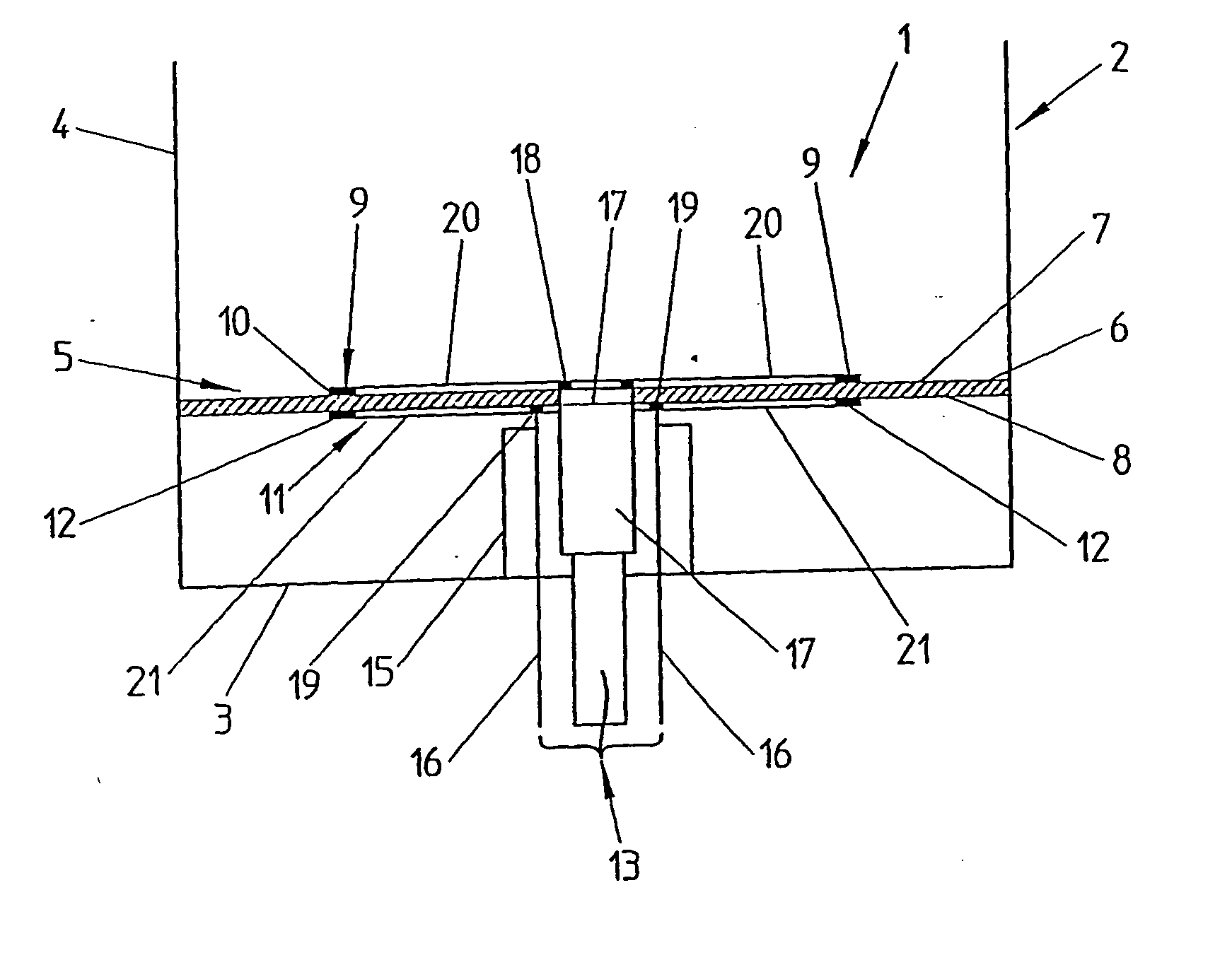

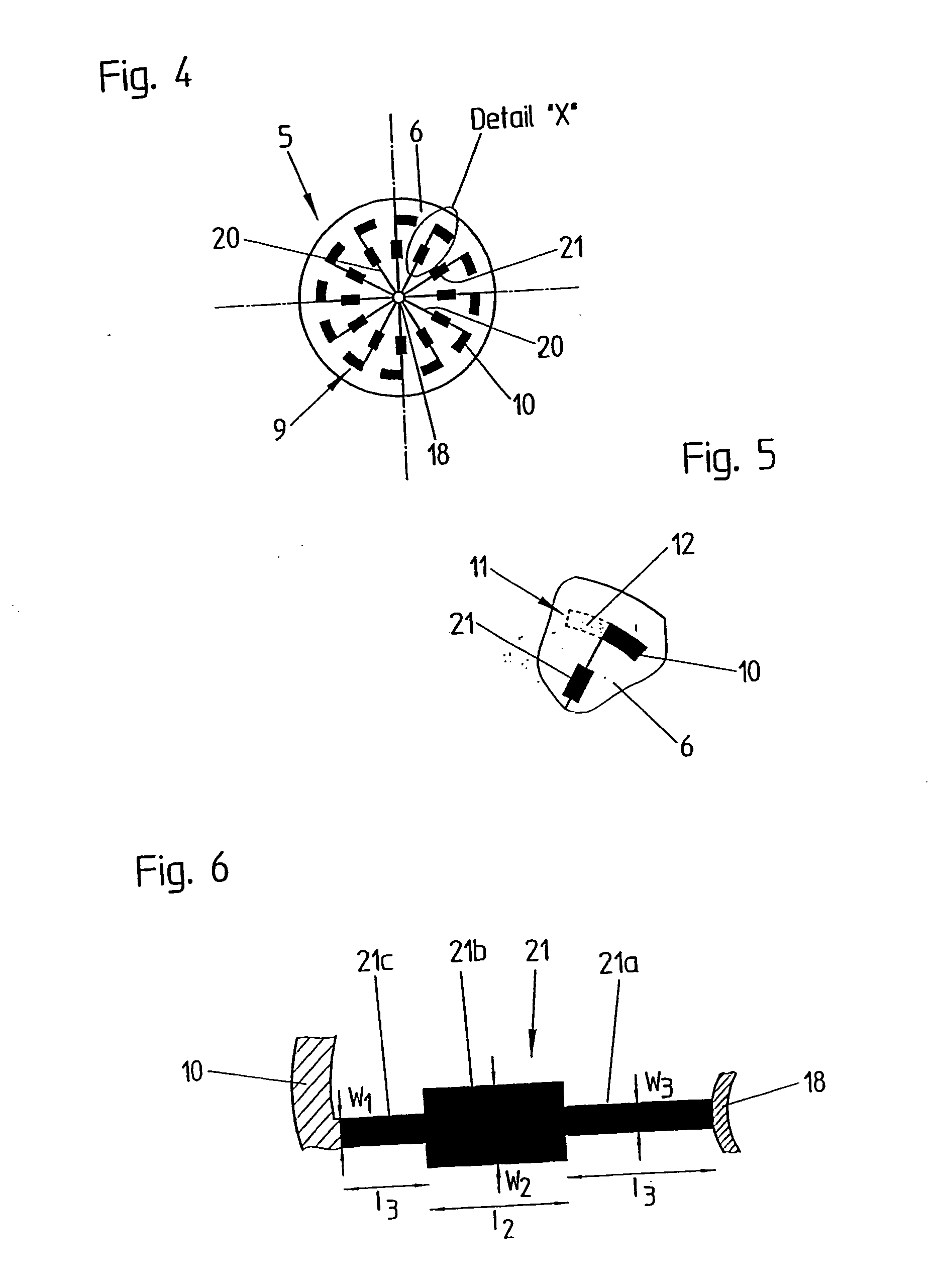

Planar antenna and antenna system

InactiveUS20050184920A1Improved strengthEasy to manufactureWaveguide mouthsAntenna supports/mountingsPhysicsCylindrical waveguide

The present invention relates to a planar antenna (1) for excitation of the TE01-mode of an electromagnetic wave and adapted to be arranged in a waveguide tube (2). The planar antenna comprises a substrate (6) of dielectric material having a first surface (7) intended to face towards a filling good surface and a second surface (8) facing in an opposite direction. A first group (9) of a plurality of dipole arms (10) is arranged on the first surface (7) or the second surface (8) on a perimeter of a circle with a predetermined radius. A second group (11) of a plurality of dipole arms (12) is arranged on the first surface (7) or the second surface (8) on the perimeter of the circle with the predetermined radius. The dipole arms (10) of the first group (9) extend in a first direction and the dipole arms (12) of the second group (11) extend in a direction opposite the first direction. Furthermore, the present invention relates to an antenna system comprising a cylindrical waveguide tube (2) having a bottom plate (3) and a tube portion (4) and a planar antenna (1) as mentioned above.

Owner:VEGA GRIESHABER GMBH & CO

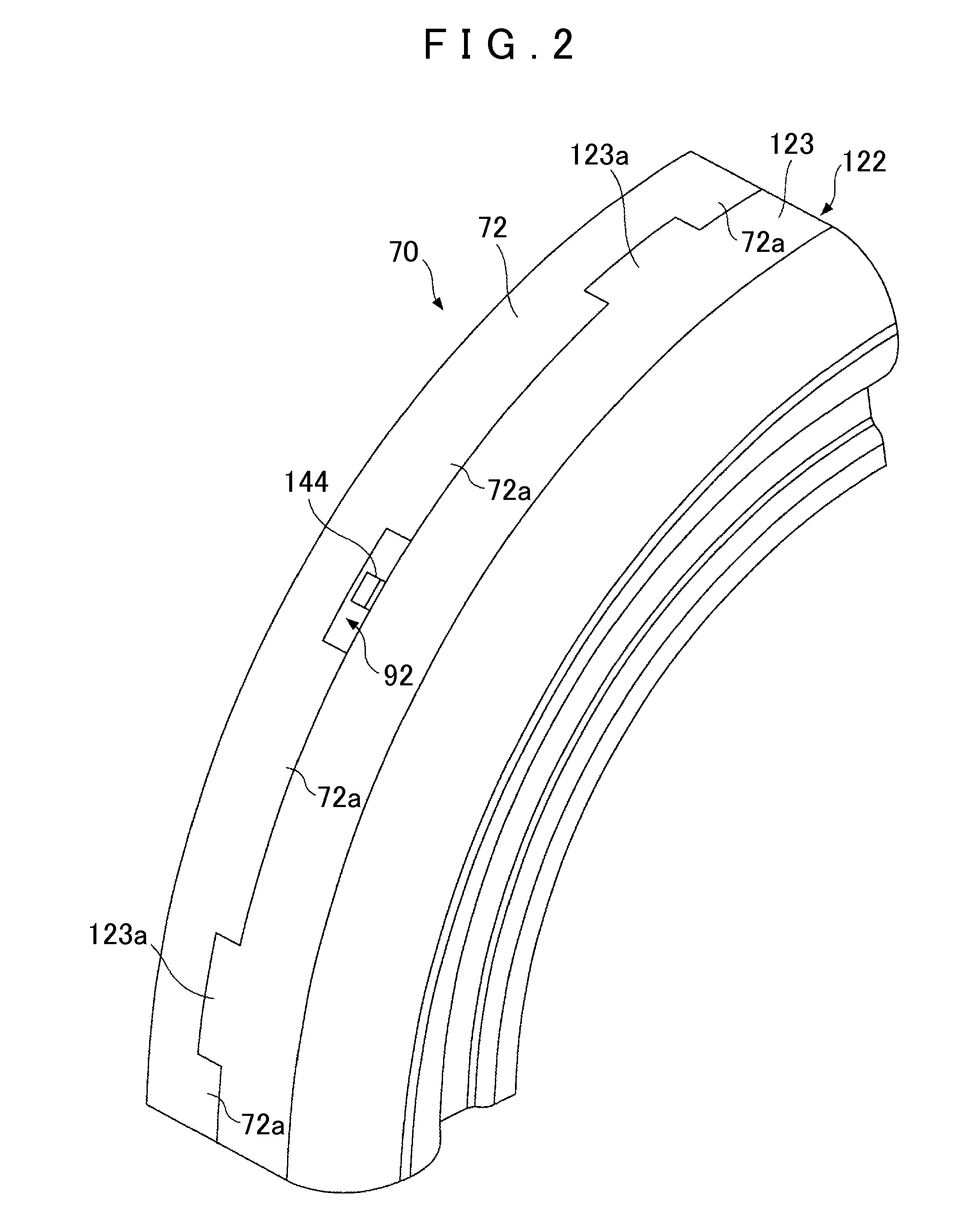

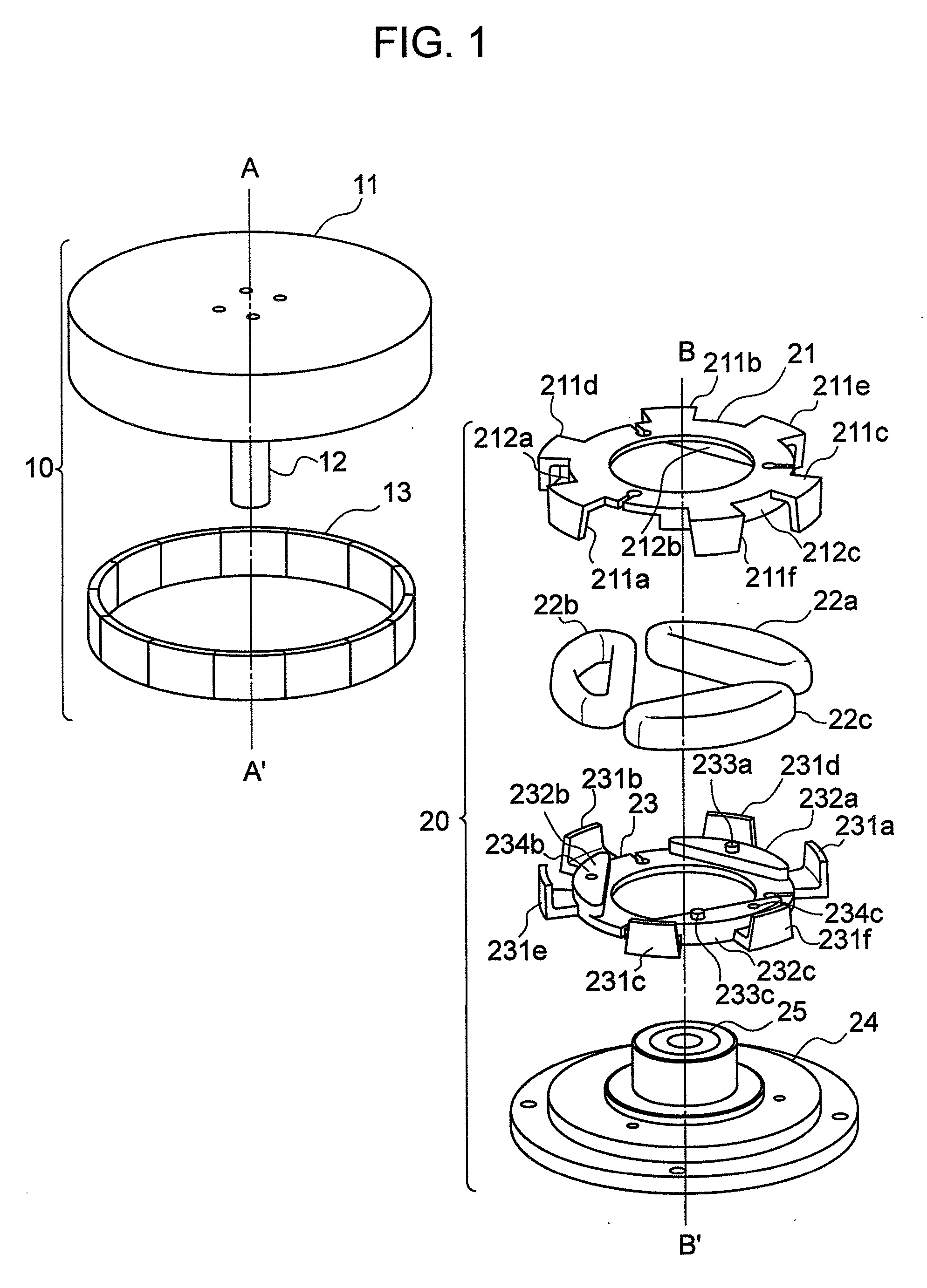

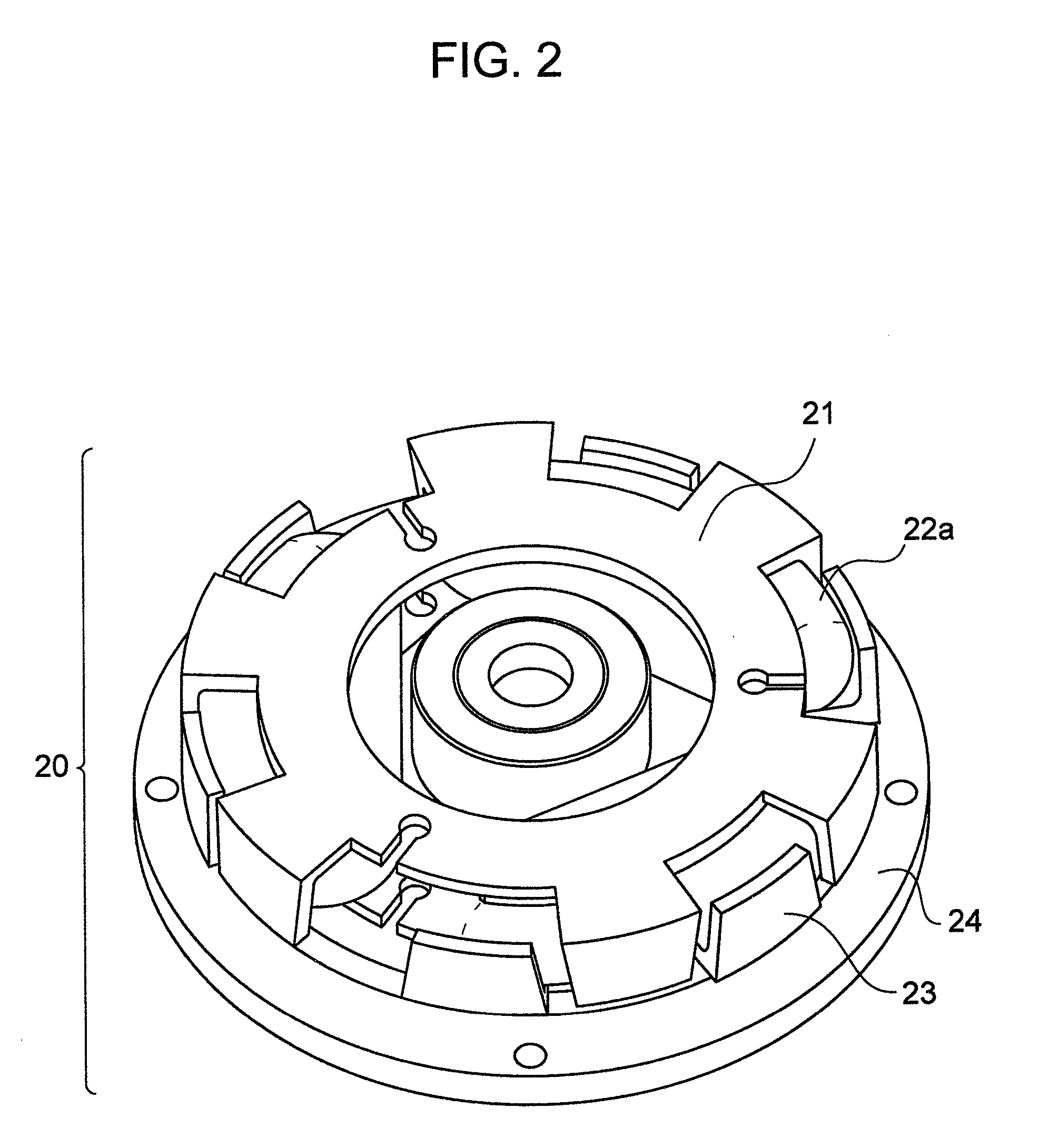

Motor and fan device using the same

ActiveUS20080069686A1Easily assembleImproved strengthPump componentsMagnetic circuit stationary partsMagnetic fluxStator

The present invention provides a motor which includes a stator including a plurality of one-phase stators composed of a pair of stator cores having claw-type teeth and a coil for generating magnetic flux at the claw-type teeth, and a rotor for generating torque at a rotary shaft, wherein the stator core includes a plurality of split cores having the same shape, and the split cores are formed to have a recessed portion and a projected portion to be fitted in the recessed portion. Thereby, by using a plurality of the split cores having the same shape, one stator core is formed. On this occasion, the shape of the split cores is molded so that the recessed portion and the projected portion of one stator core are disposed at positions at which those are fitted to the projected portion and the recessed portion of the opposing stator core, respectively.

Owner:HITACHI IND EQUIP SYST CO LTD

Ophthalmic and otorhinolaryngological device materials

InactiveUS20060281888A1Improved strengthHigh strengthTissue regenerationProsthesisChemistryComposite material

Disclosed are soft, high refractive index device materials having improved strength. The materials contain a polystyrene macromer.

Owner:ALCON INC

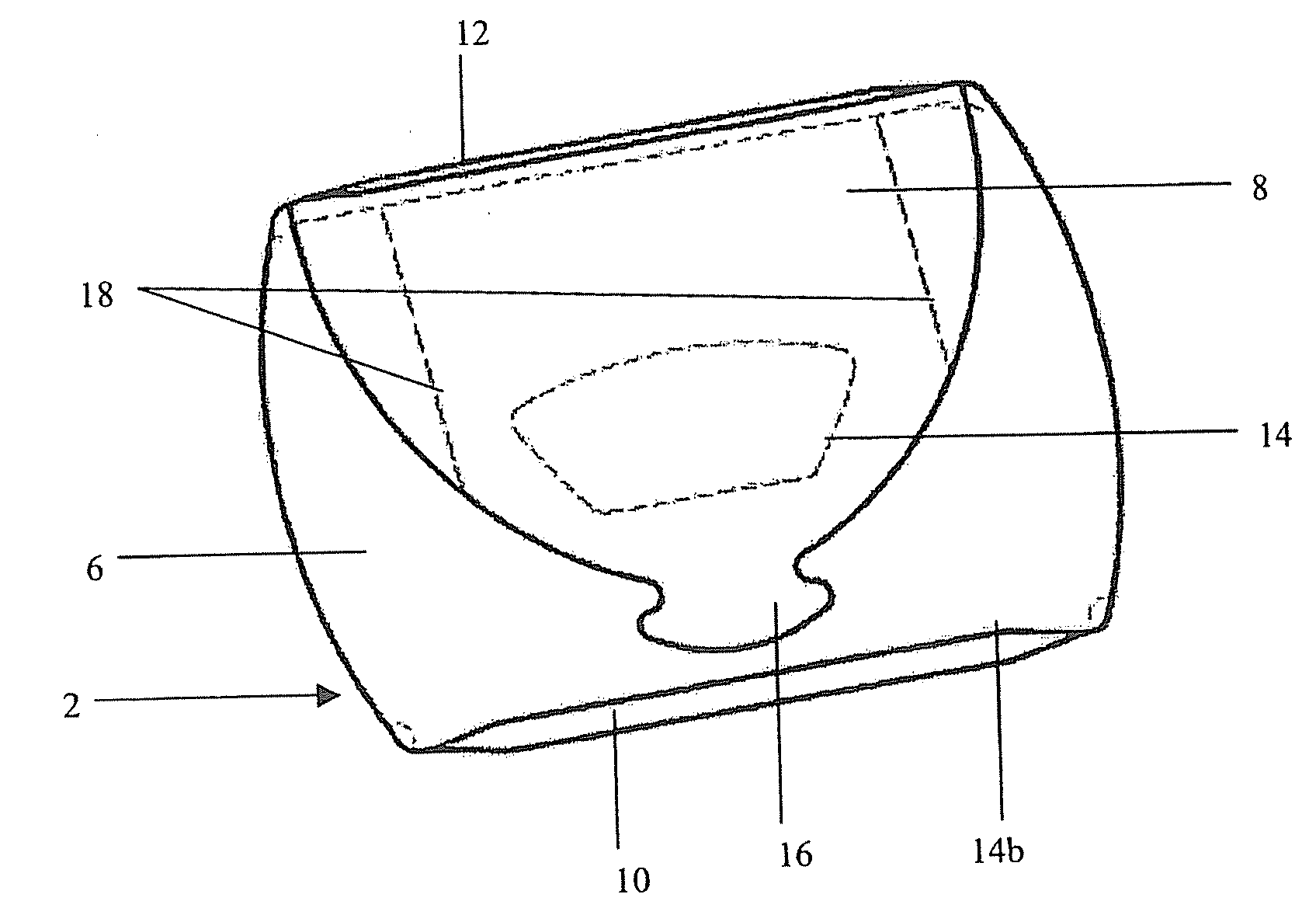

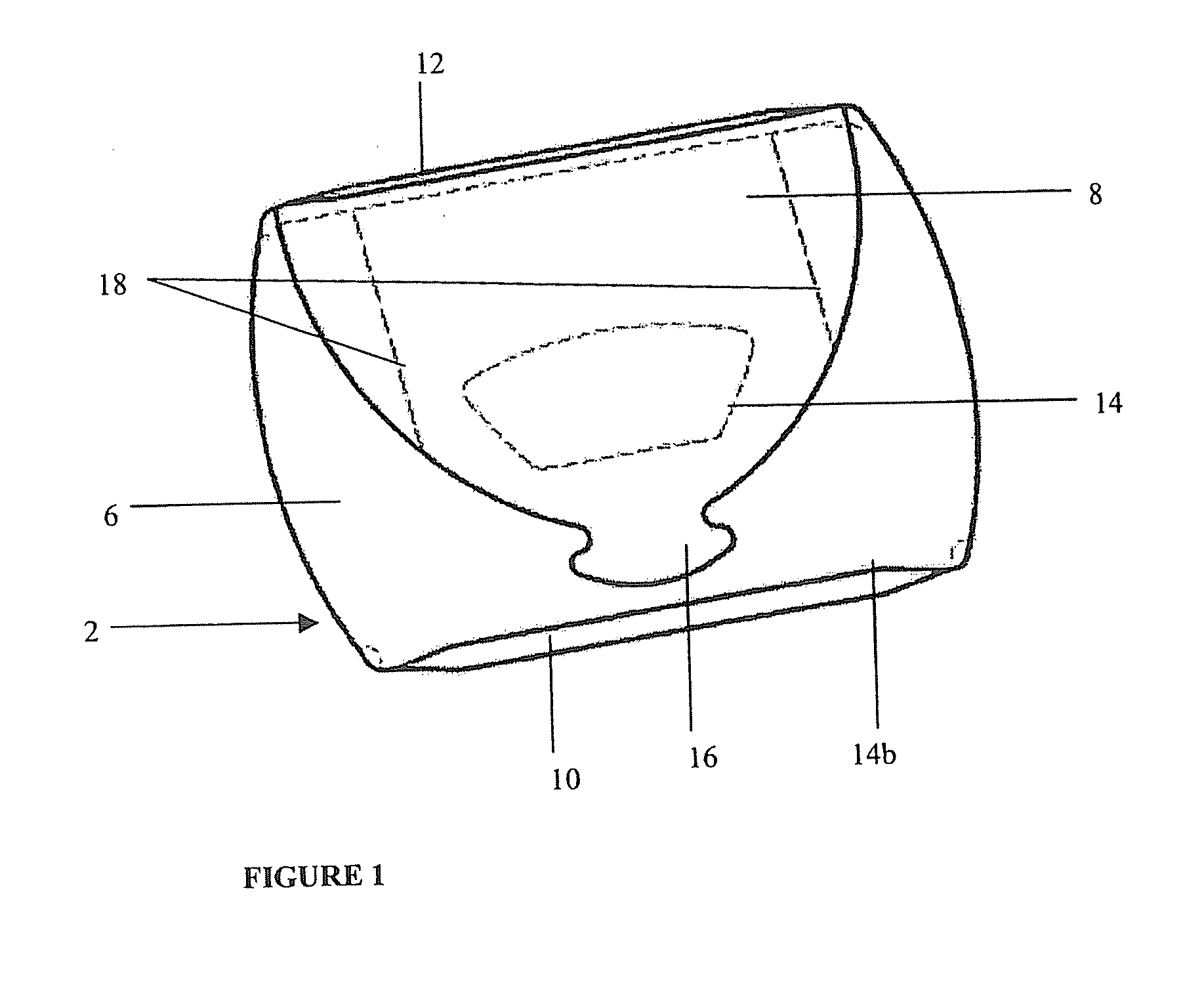

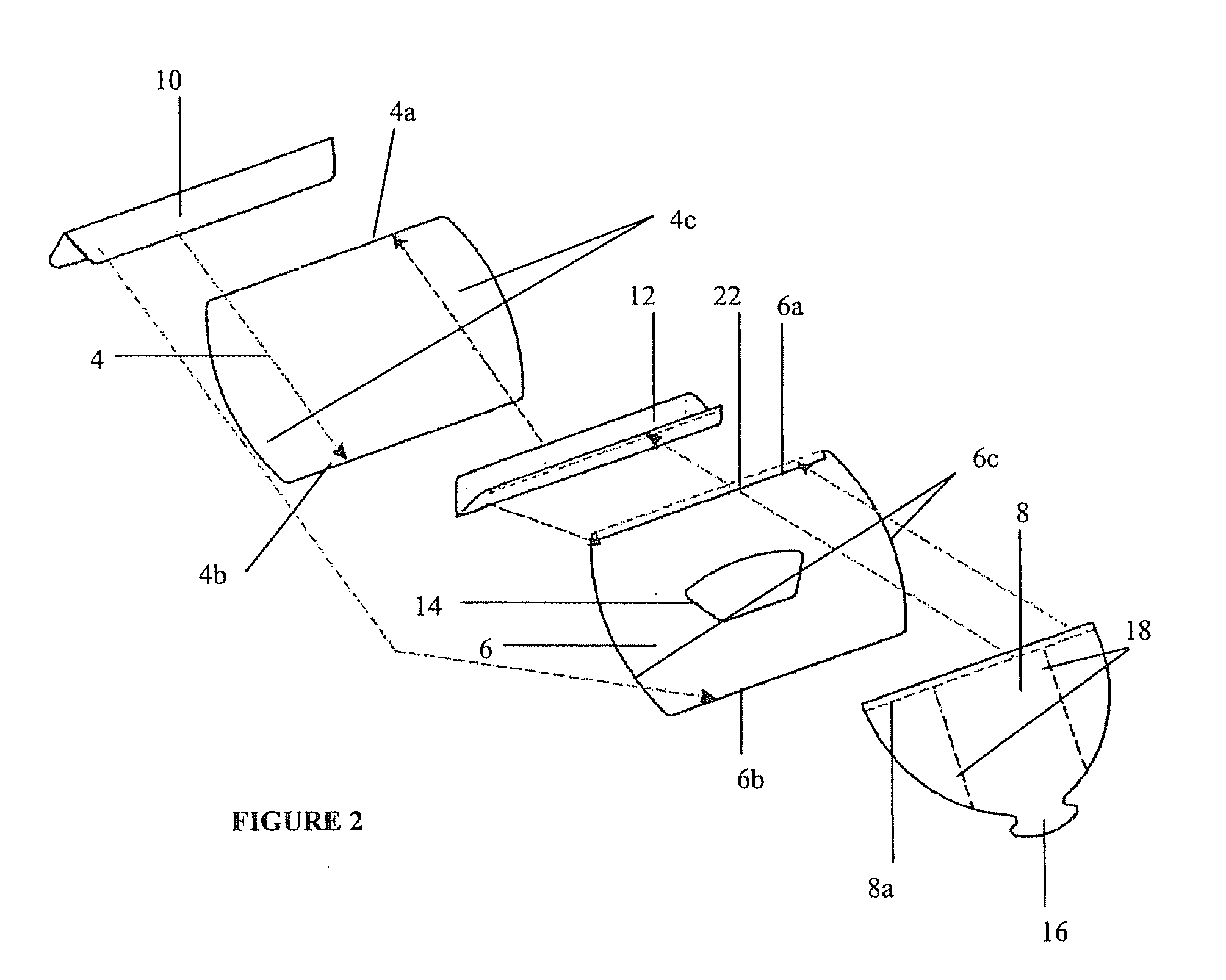

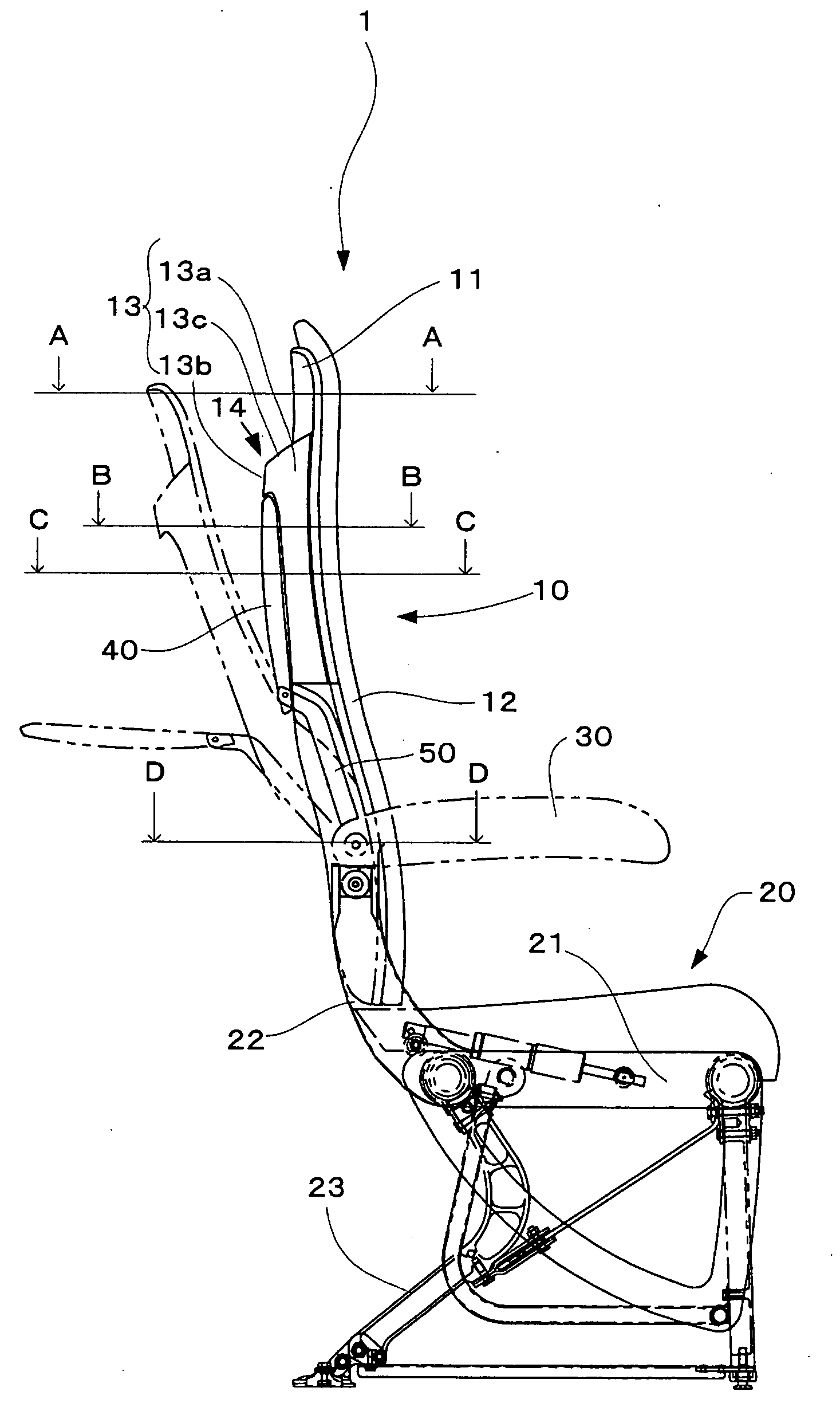

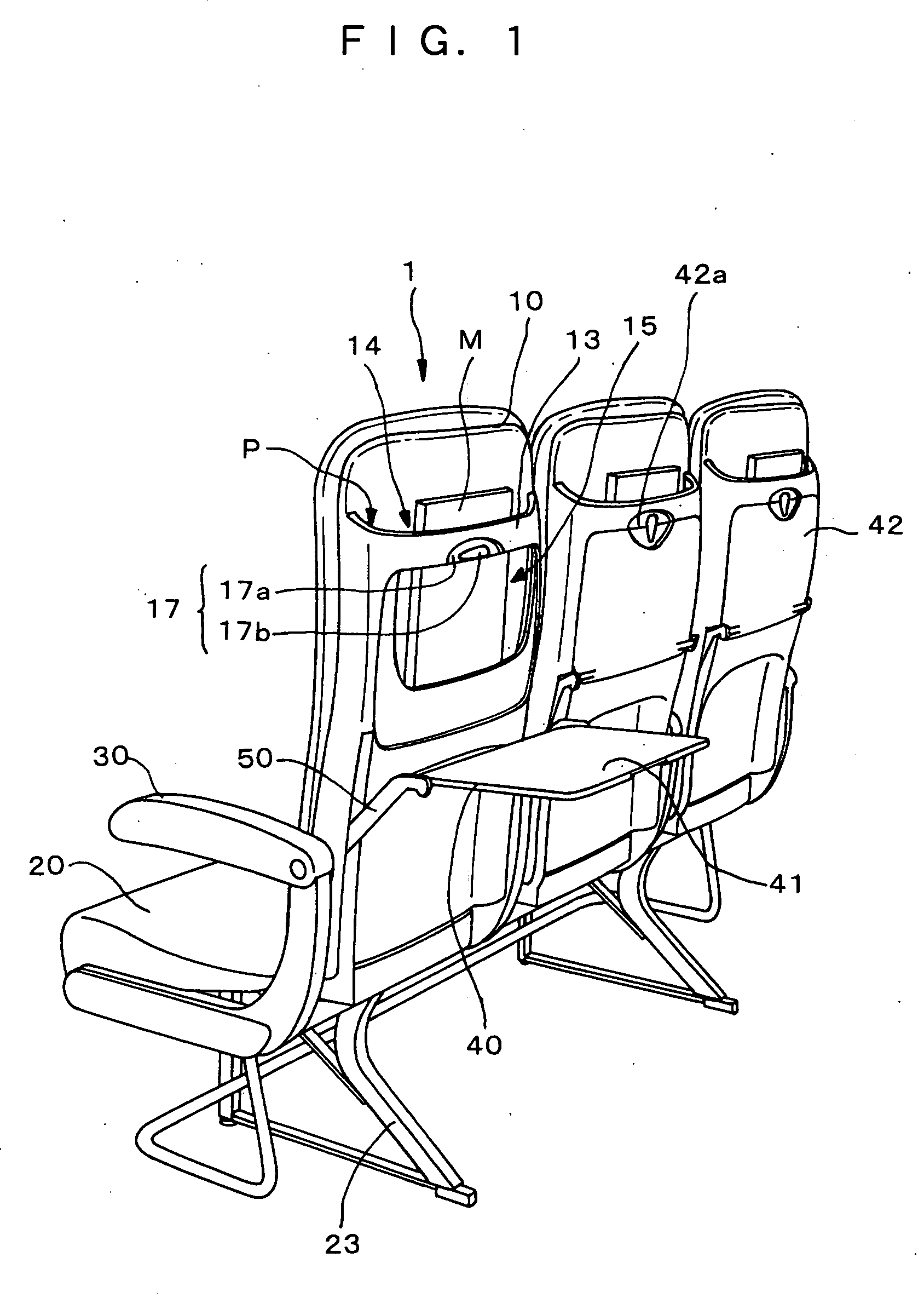

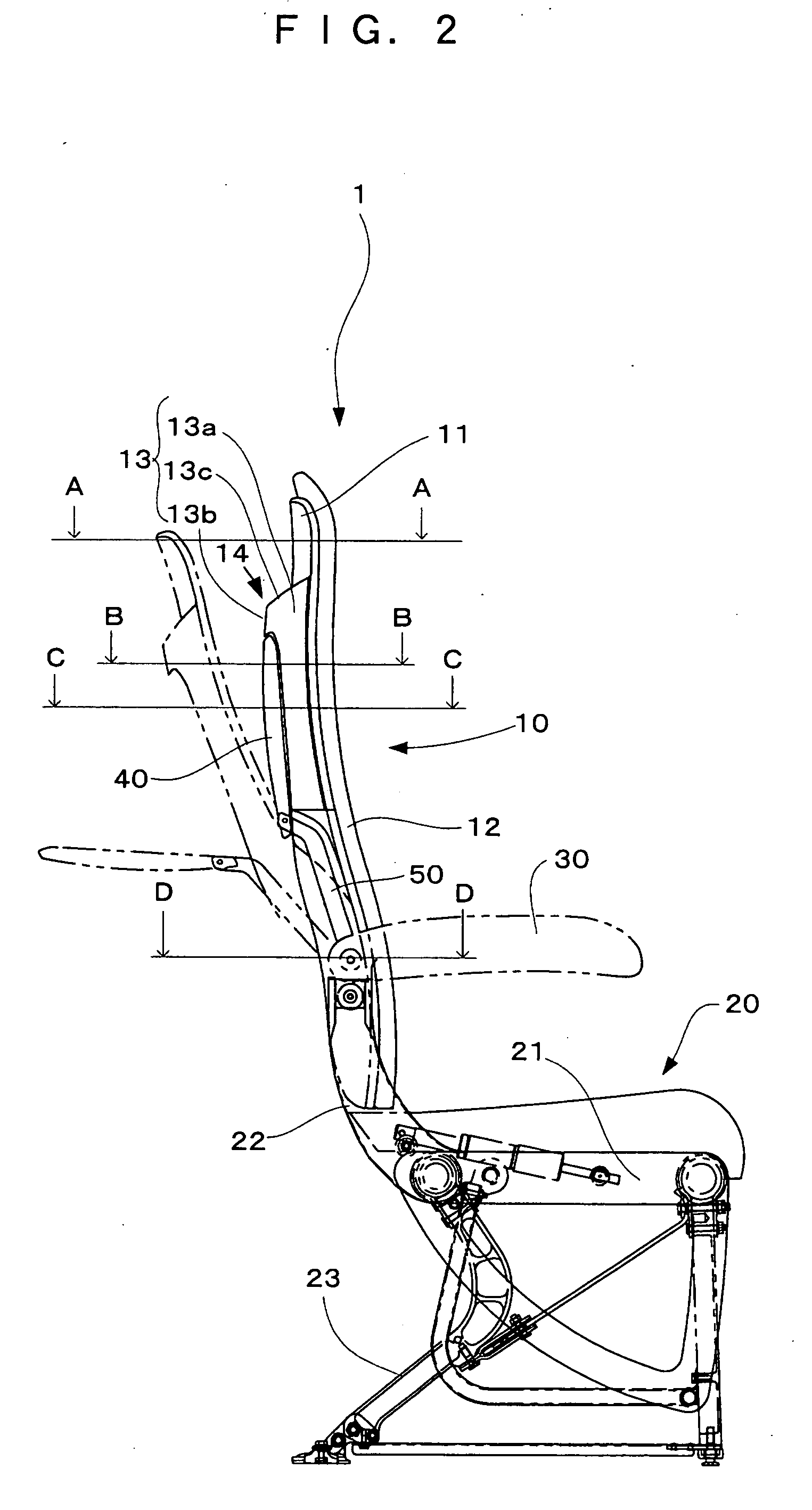

Aircraft Seat

ActiveUS20100155536A1Improved strengthIncrease weightVehicle seatsSeating arrangementsAirplaneCushion

An aircraft seat which can receive the load of a sitting person with only a back plate member, using no seat back frame, thus eliminating the need for sacrificing the sitting space, which results from the existence of the seat back frame, and at the same time, allowing the weight of the seat to be reduced, is provided. The aircraft seat (1) on which an aircraft passenger is to sit comprises a seat back (10) made up of a back plate member (11) that a cushion (12) is installed onto a front face (11a) thereof for receiving the back of a sitting person, and a reinforcing member (13) which is disposed on the rear face (11b) of the back plate member (11) for reinforcing the back plate member (11), and said back plate member (11) is formed in the shape of a curved surface which enhances the surface rigidity.

Owner:KI HOLDINGS

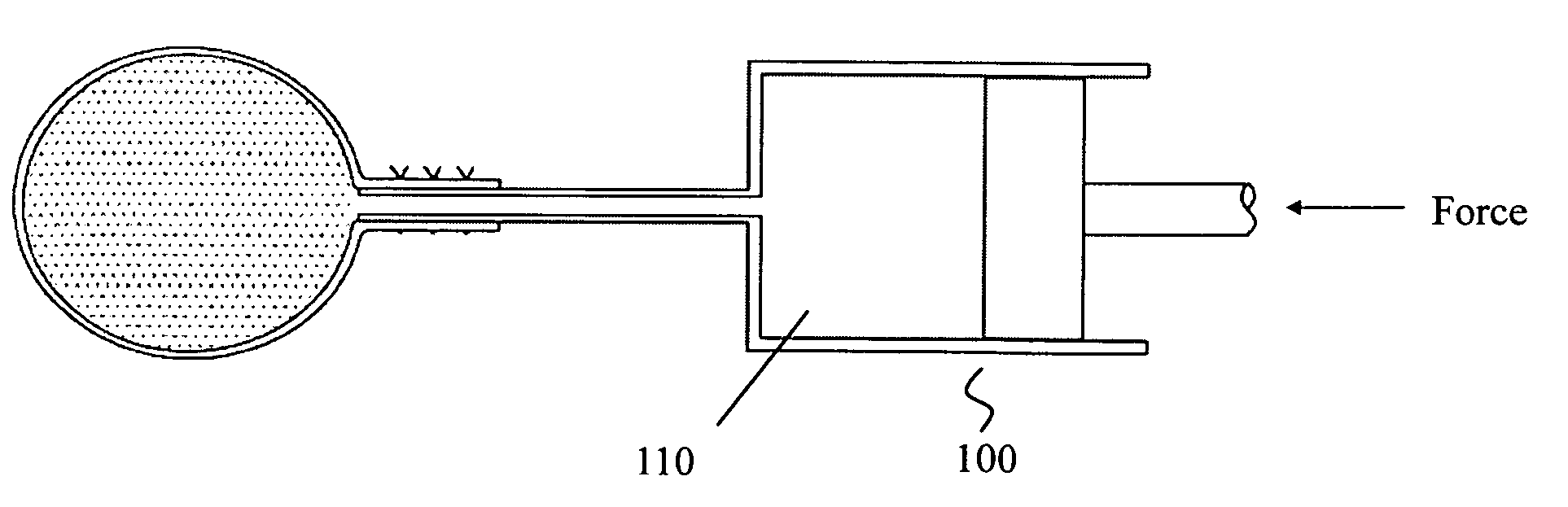

Perforated balloon and method for forming a hardened orthopaedic paste in a bone using same

The present invention discloses a technique for forming a hardened orthopaedic paste in a bone cavity, which involves a forced-feeding balloon rupture mechanism. This mechanism includes continuously or intermittently injecting a liquid or gas into a perforated balloon containing a hardened orthopaedic paste therein in a bone cavity until the perforated balloon is dilated to exceed a critical size, and thus ruptures.

Owner:JOY MEDICAL DEVICES CORP

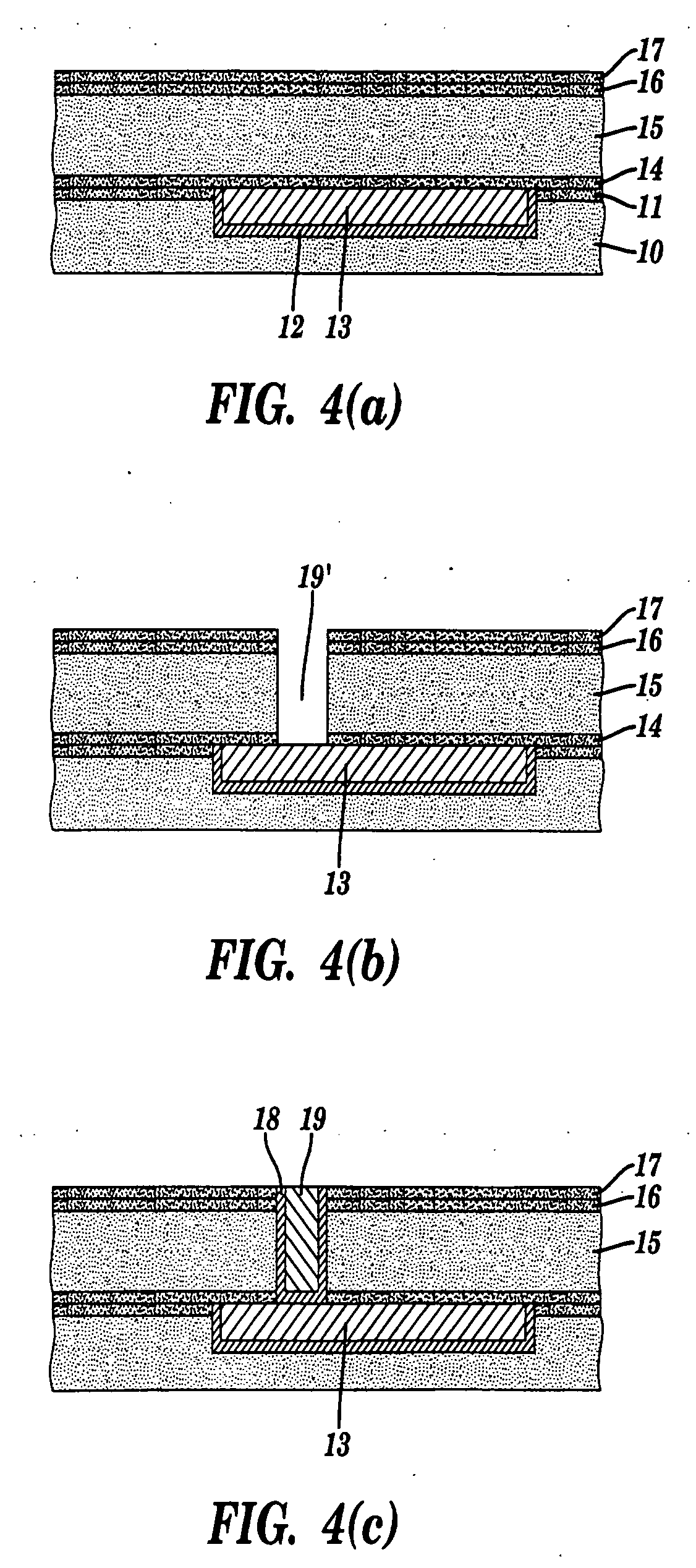

Dual damascene interconnect structures having different materials for line and via conductors

ActiveUS20040262764A1Improved strengthHigh strengthSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorMetal

Methods are disclosed for forming dual damascene back-end-of-line (BEOL) interconnect structures using materials for the vias or studs which are different from those used for the line conductors, or using materials for the via liner which are different from those used for the trench liner, or having a via liner thickness different from that of the trench liner. Preferably, a thick refractory metal is used in the vias for improved mechanical strength while using only a thin refractory metal in the trenches to provide low resistance.

Owner:AURIGA INNOVATIONS INC

Sintered Silicon Wafer

InactiveUS20100330325A1Improved strengthImprove yield rateLayered productsVacuum evaporation coatingCrystalliteMonocrystalline silicon

Provided is a sintered silicon wafer in which the maximum crystal grain size is 20μm or less and the average crystal grain size is 1μm or more but not more than 10μm; specifically, provides is a sintered silicon wafer having the following mechanical properties measured by collecting a plurality of test samples from the sintered silicon wafer having a diameter of 400mm or more, namely, the average deflecting strength based on a three-point bending test of 20kgf / mm2 or more but not more than 50kgf / mm2, the average tensile strength of 5kgf / mm2 or more but not more than 20kgf / mm2, and the average Vickers hardness of Hv 800 or more but not more than Hv 1200. The provided sintered silicon wafer is a sintered compact wafer having a fixed strength and mechanical properties similar to those of single-crystal silicon even when it is a sintered silicon wafer of large-size disk shape.

Owner:JX NIPPON MINING& METALS CORP

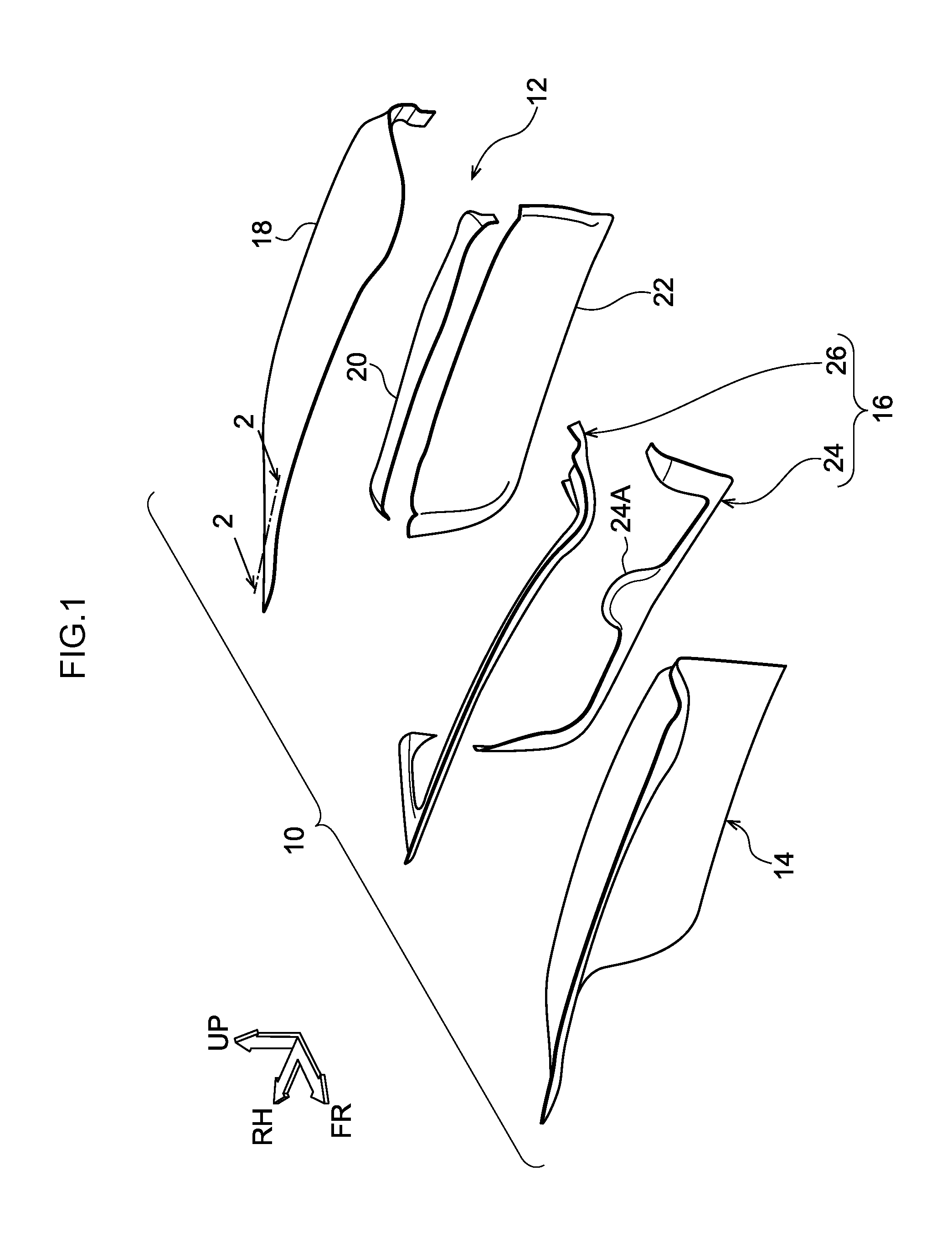

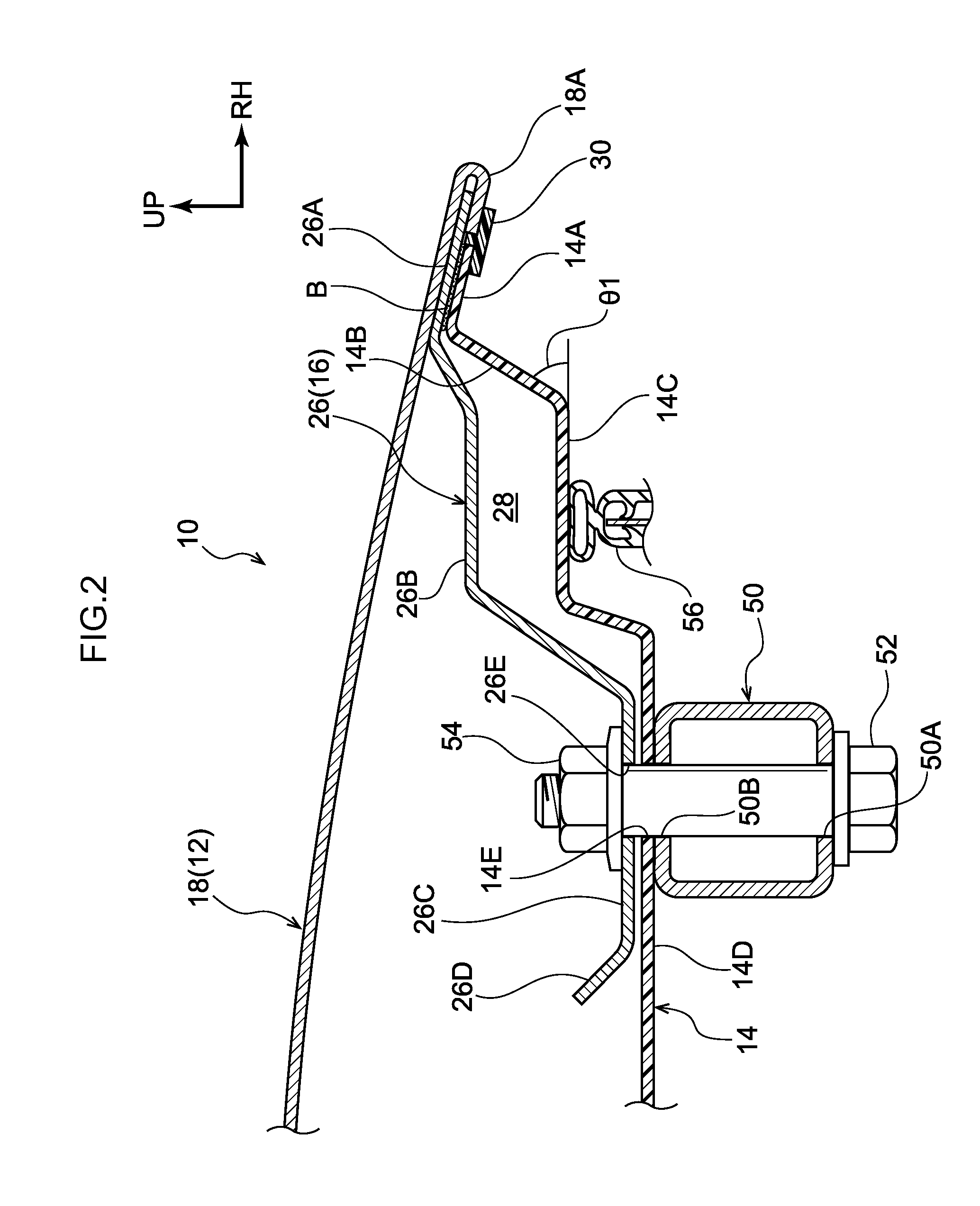

Vehicle panel structure and manufacturing method of vehicle panel structure

ActiveUS20160229464A1Improved strengthAdvantageous effectSuperstructure subunitsVehiclesEngineeringSurface plate

The present invention includes a metal outer panel configuring an outer panel of a vehicle, a metal reinforcing member that is disposed at an end portion of the outer panel and that is joined to the outer panel further toward an inner side of the vehicle than the outer panel, and a resin inner panel that is disposed further toward an inner side of the vehicle than the reinforcing member and that is joined to the reinforcing member, wherein a closed cross-section is formed between the inner panel and the reinforcing member.

Owner:TOYOTA JIDOSHA KK

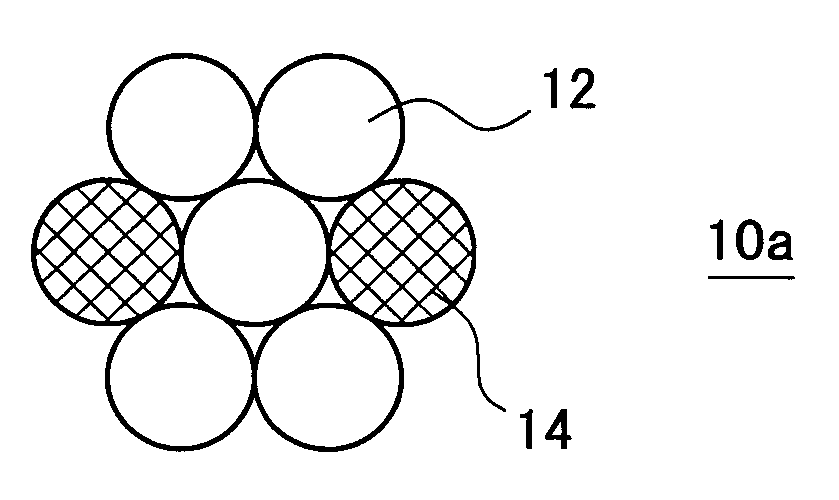

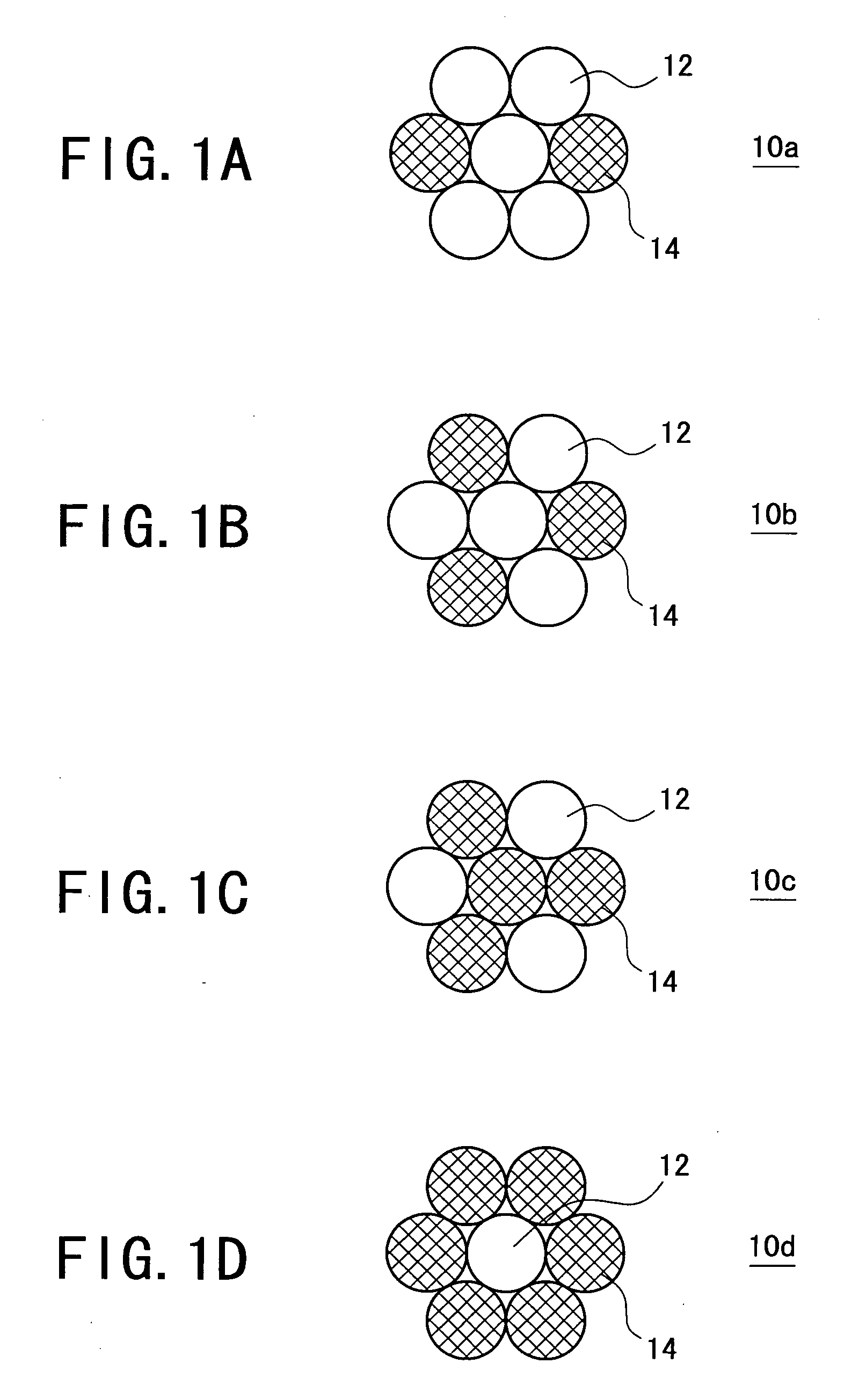

Conductor of an electric wire, and an insulated wire

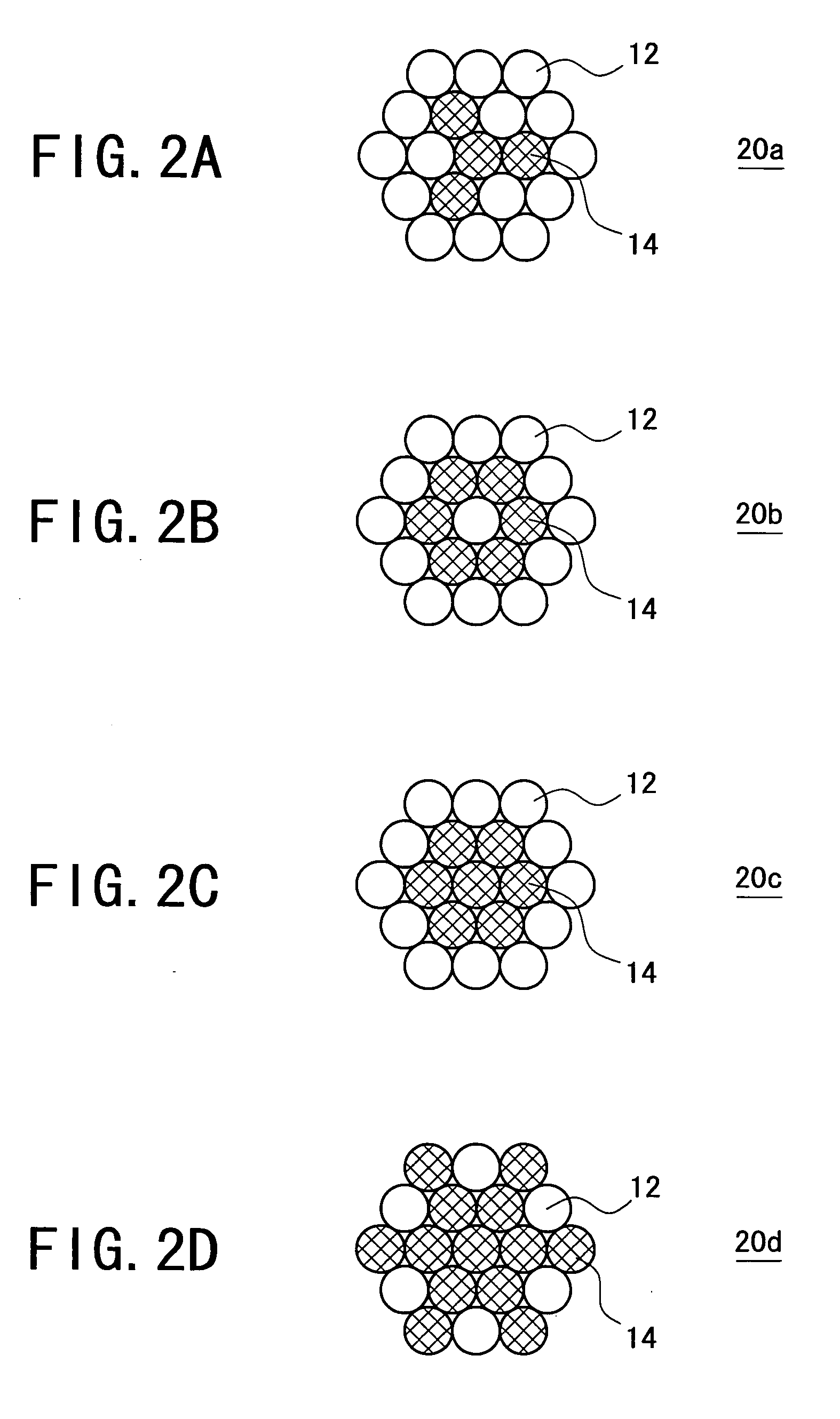

InactiveUS20100018745A1Low conductor resistanceImproved strengthNon-insulated conductorsConductive materialCorrosionElectrical conductor

A conductor of an electric wire, and an insulated wire which are excellent in corrosion resistance and recyclability, of which the strength which is decreased by weight reduction and diameter reduction is improved. The conductor includes a strand which includes a first elemental wire made from pure copper and a second elemental wire made from a copper alloy. In the conductor, a cross-sectional area of the first elemental wire as a percentage of a cross-sectional area of the conductor is preferably within a range of 10 to 90%. Examples of the copper alloy include a Cu—Ni—Si alloy, and a copper alloy containing Sn, Ag, Mg, or Zn. The conductor may be compressed concentrically. The insulated wire is prepared by covering the conductor with an insulator.

Owner:AUTONETWORKS TECH LTD +2

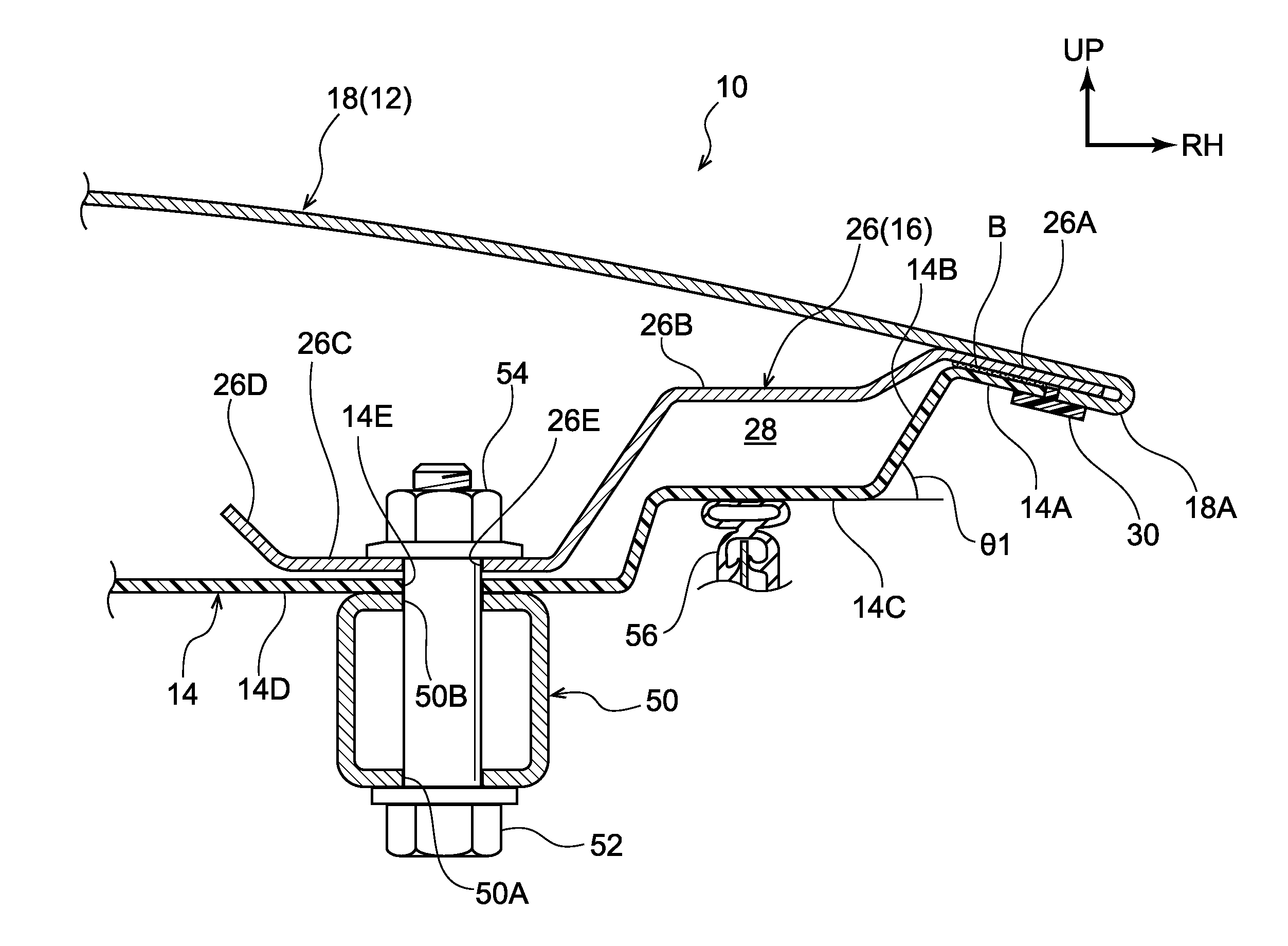

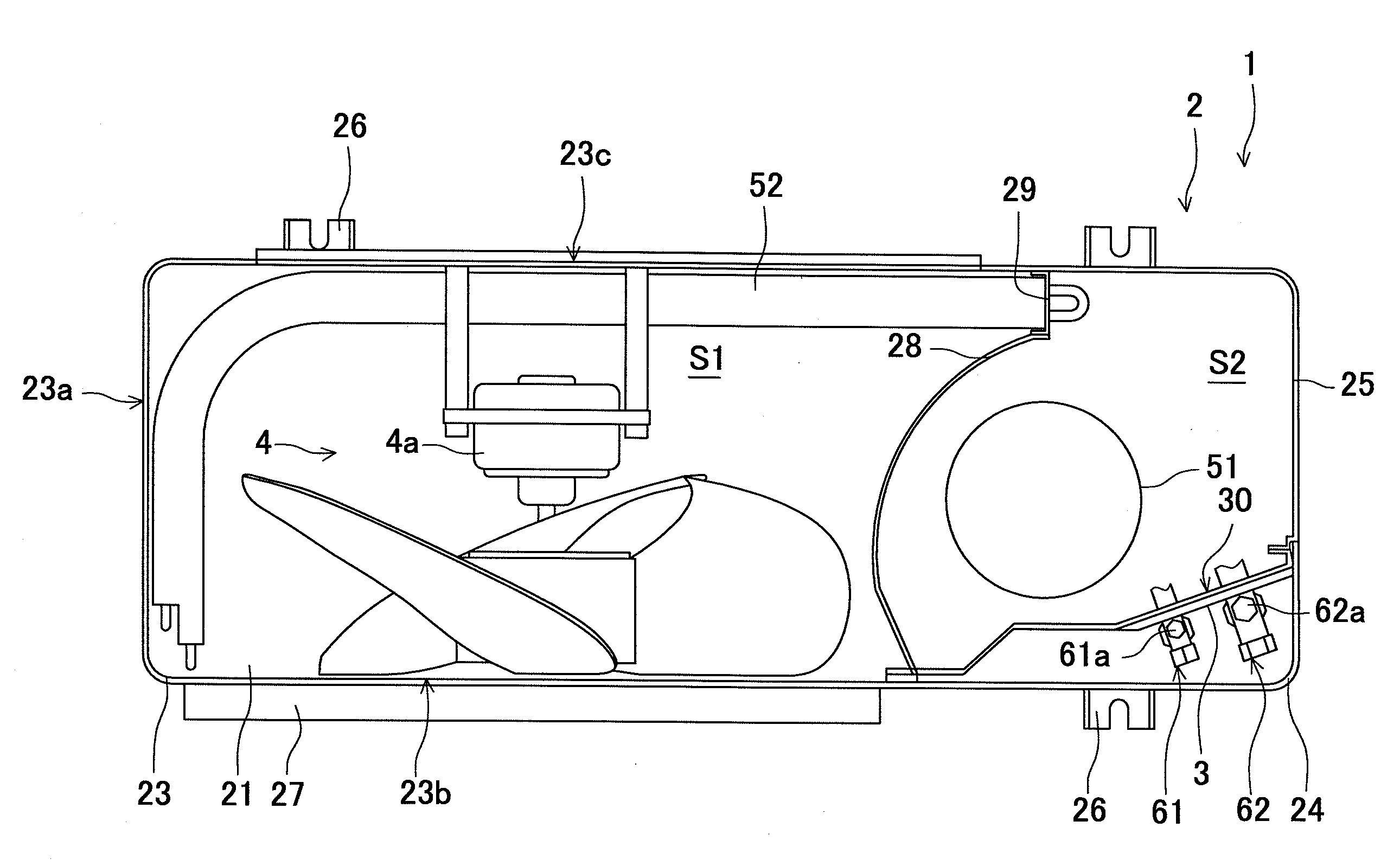

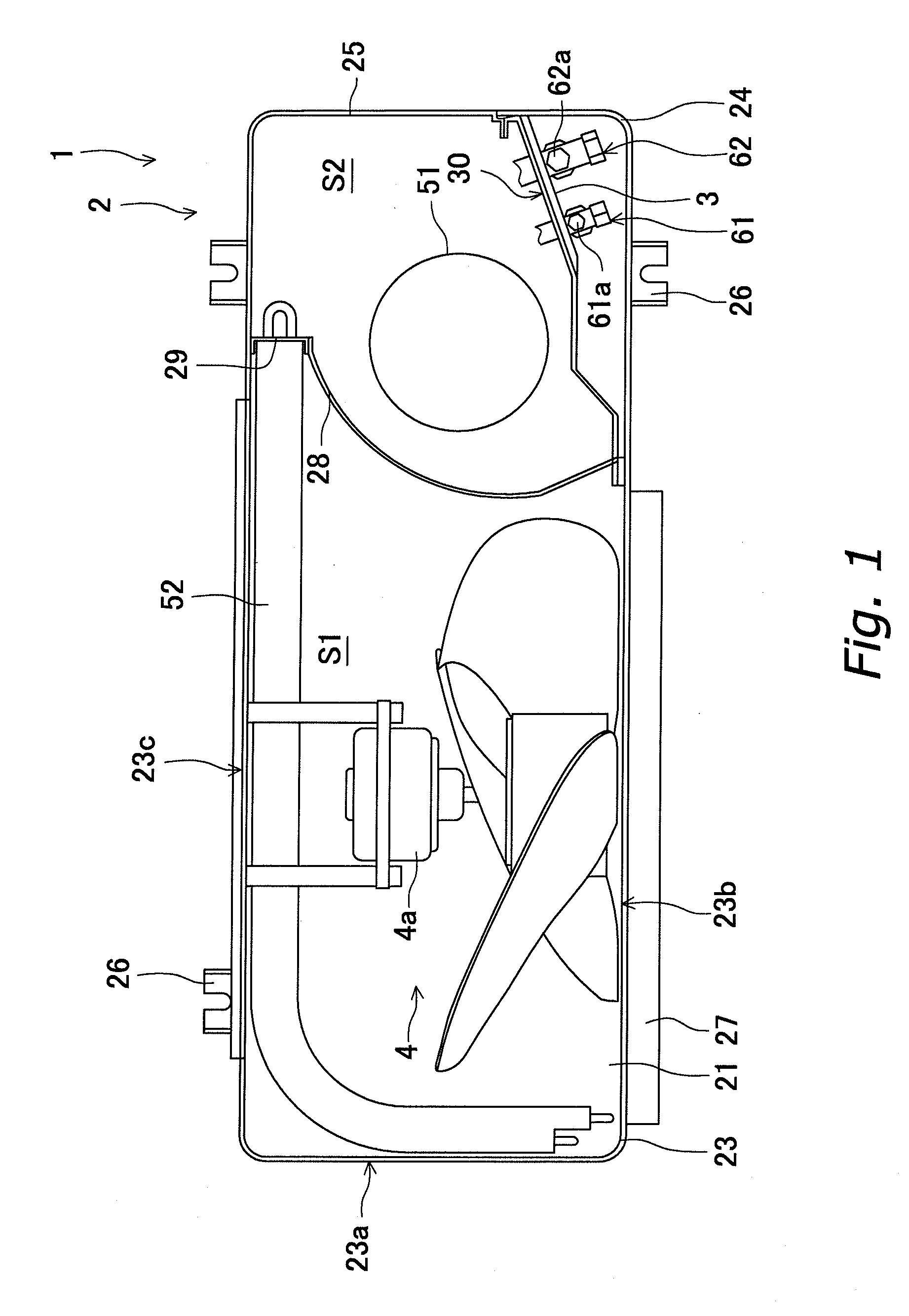

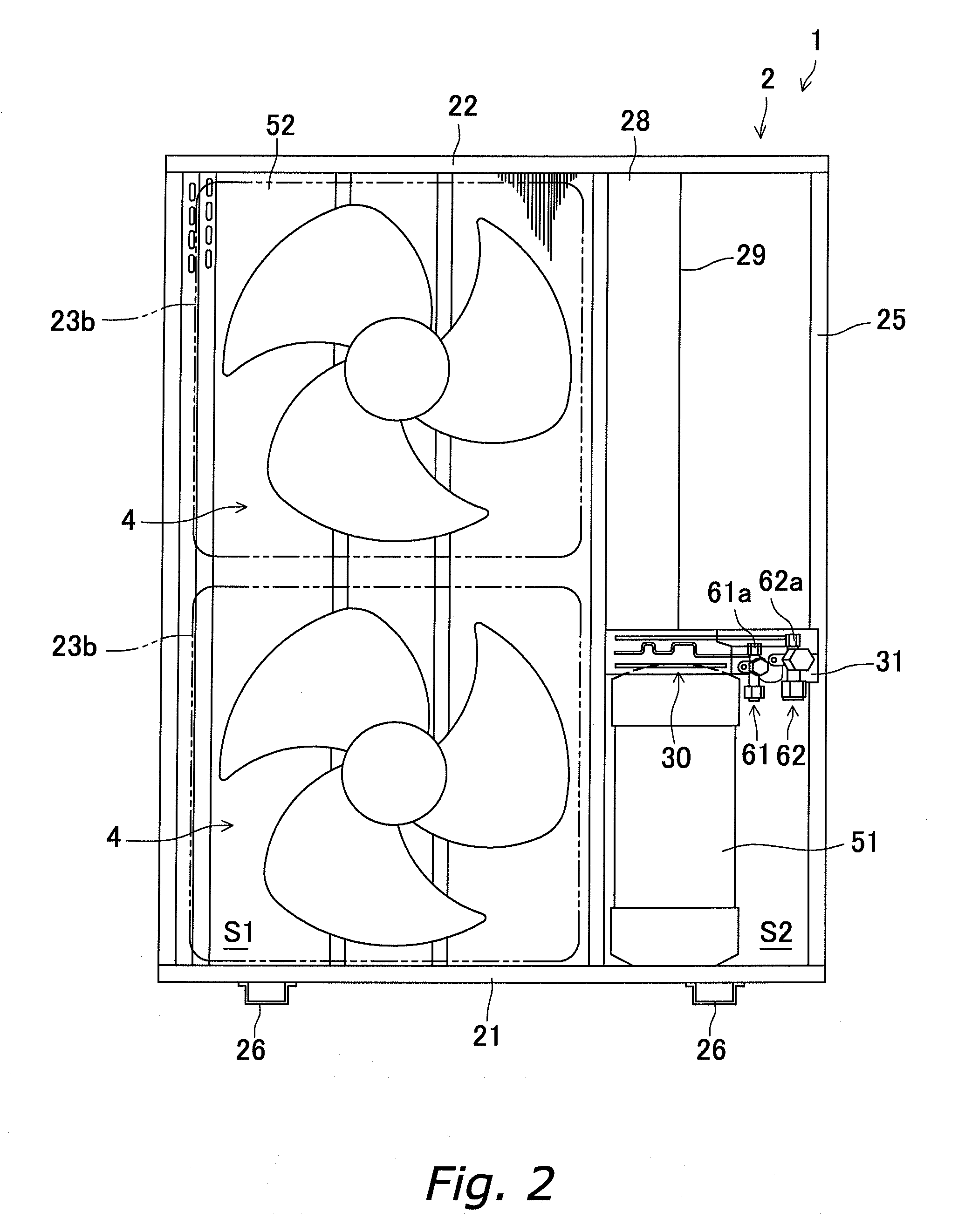

Shut-off valve support member and outdoor unit of air conditioner provided with the same

InactiveUS20090044554A1Improved strengthHigh strengthDomestic cooling apparatusRefrigerantsRefrigerantEngineering

In a plate shaped shut-off valve support member configured to support a shut-off valve to which a refrigerant pipe on an indoor unit side is connected, and configured to be extended across a first fixing portion and a second fixing portion of an outdoor unit, the operability of a service port of the shut-off valve is ensured and the strength of the shut-off valve support member is improved. A shut-off valve support member (30) comprises an attachment portion (35), an interference prevention portion (36), and a stepped portion (37). A shut-off valve (61, 62) is attached to the attachment portion (35) with a service port (61a, 62a) of the shut-off valve (61, 62) protruding in a direction perpendicular to a longitudinal direction of the shut-off valve support member. The interference prevention portion (36) is located at a position opposite to the attachment portion (35) when viewed in the longitudinal direction, away from the service port (61a, 62a) in a thickness direction of the shut-off valve support member, and is disposed so as to overlap with the service port (61a, 62a) when viewed in the thickness direction. The stepped portion (37) is formed between the attachment portion (35) and the interference prevention portion (36).

Owner:DAIKIN IND LTD

Card type wireless communication module

InactiveUS20110128207A1Frequency characteristic be degradeImproved strengthPrinted circuit detailsAntennas earthing switches associationEngineeringElectroplating

A card type wireless communication module, includes a board; a plurality of terminals formed on the board, the terminals including an external antenna terminal, the terminals having a plating process applied thereto; and a ground pattern formed on the board; wherein a feeding wiring pattern arrangement area is formed between forming positions of the terminals on the board and a forming position of the ground pattern, the feeding wiring pattern arrangement area has a feeding wiring pattern formed thereon, the feeding wiring pattern feeds power to the terminals at the time of an electrolytic plating process, and the feeding wiring pattern is removed after the electrolytic plating process is completed.

Owner:MITSUMI ELECTRIC CO LTD

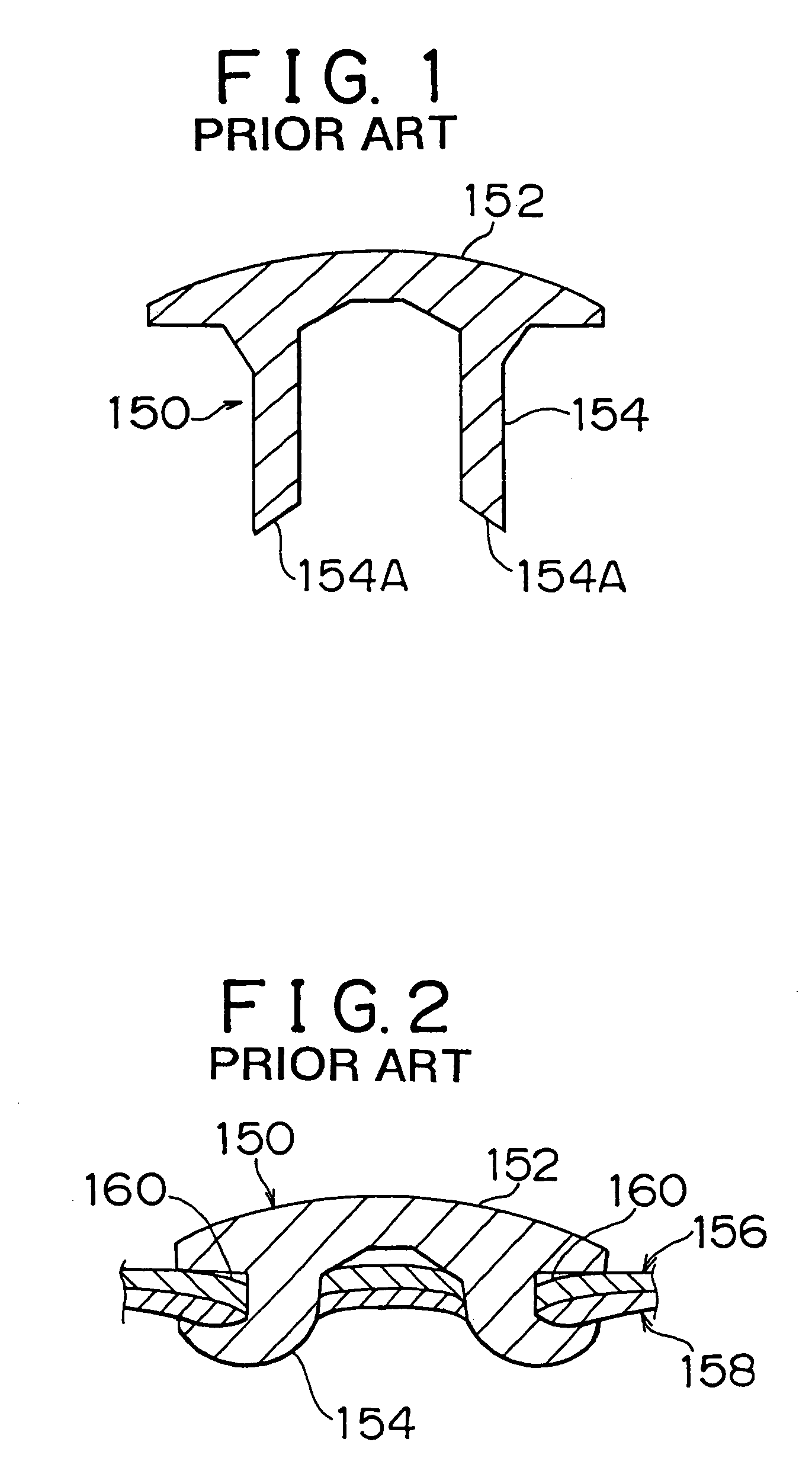

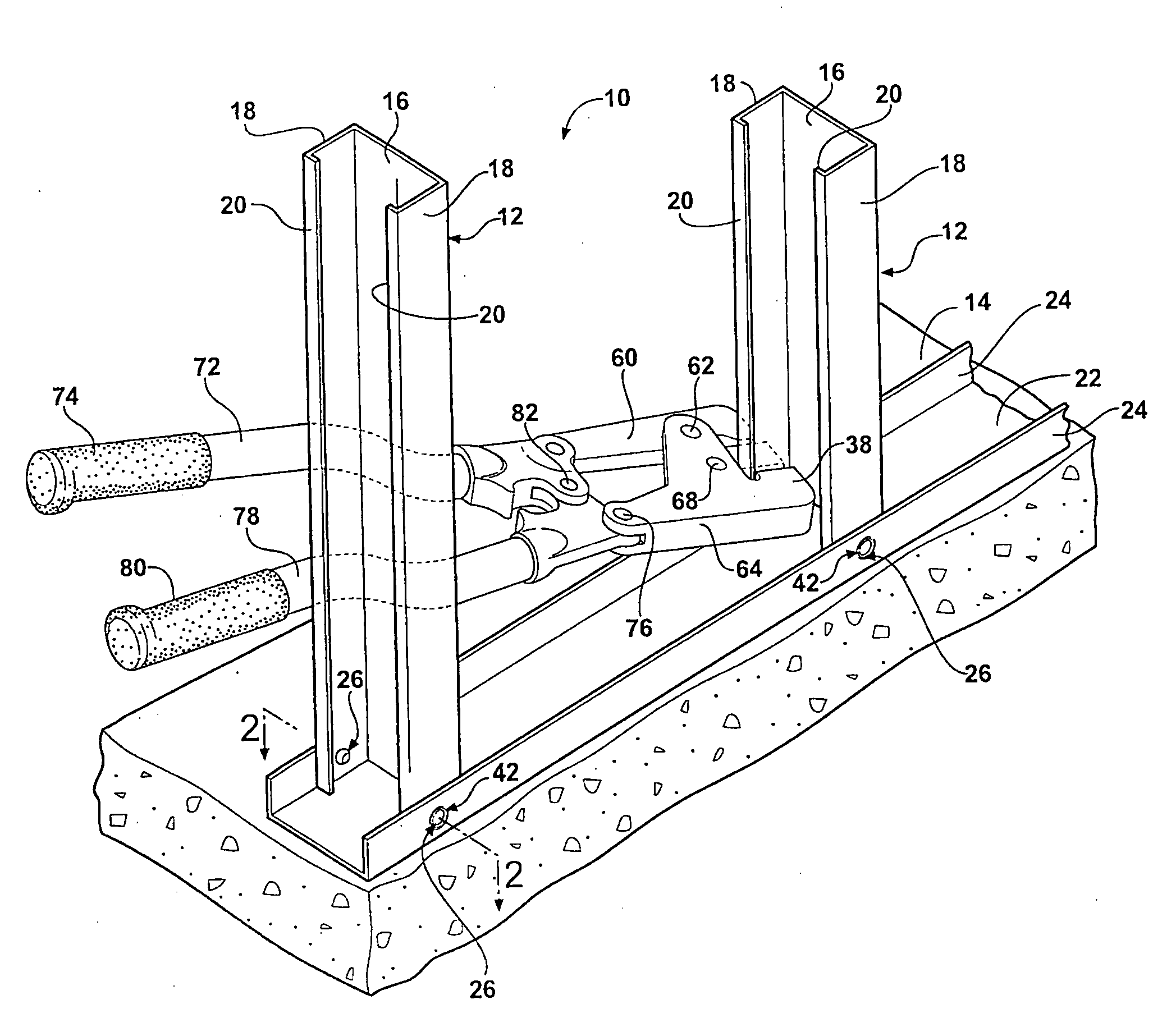

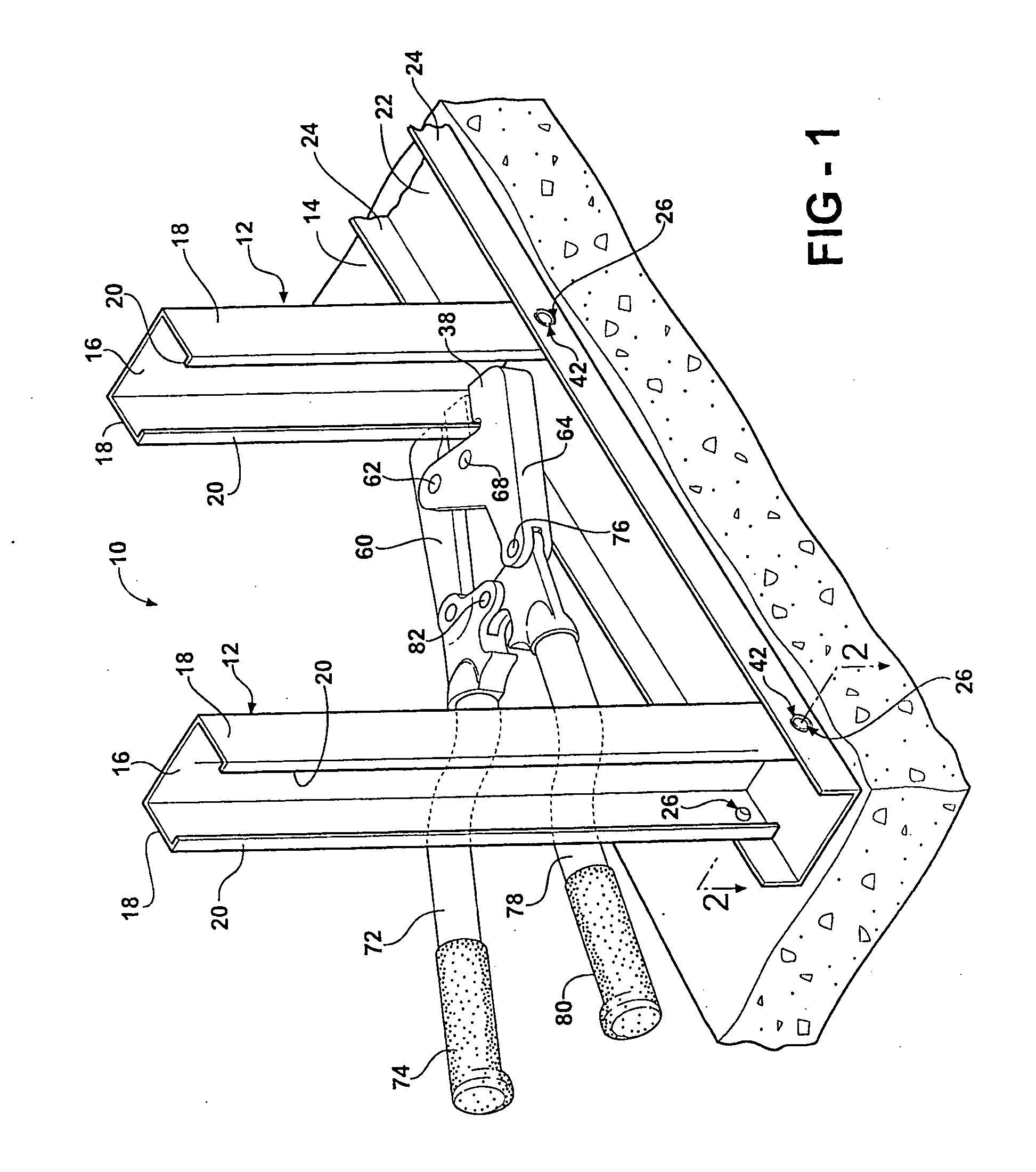

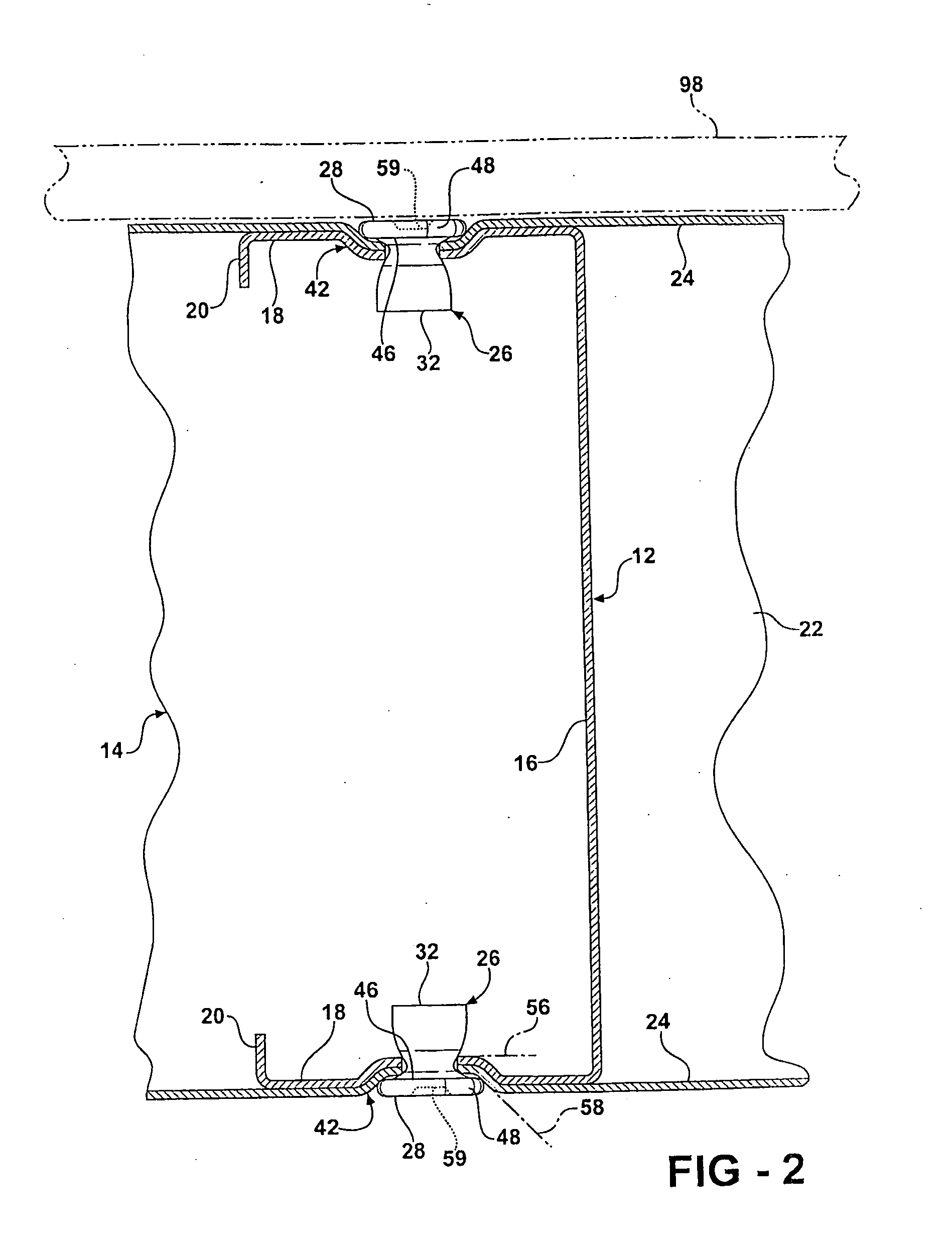

Rivet tool for steel studs

An improved method for constructing a steel stud frame wall (10) or other sheet metal joining applications using self-punching rivet fasteners (26). The steel stud frame wall includes discrete members to be joined, such as studs (12) connected to a bottom (or top) track (14). A rivet (26) is driven from the outside and staked on the inner, blind side of the overlapping regions of sheet metal. A leading tip (32) of the rivet (26) punches a chad (54) and is then deformed in a die cavity (40) of a setting tool to lock the formed steel pieces in position. The head (28) of the rivet (26) is pressed into the sheet metal during the setting operation so that a pocket (42) is formed out of the surrounding sheet metal, the pocket (42) having at least two distinct contours (56, 58) formed around the rivet head (28). The pocket (42) allows the rivet head (28) to seat into the outer surface of the sheet metal, thus facilitating a subsequent covering operation with wallboard (98) or the like. The multiple distinct contours (56, 58) of the pocket (42) substantially enhances the joint integrity in both sheer and rotational directions. The punched chad (54) helps avoid the introduction of stress cracks in the sheet metal, thereby enhancing joint integrity. A tool for setting the rivet (26) can be actuated mechanically, pneumatically, hydraulically, electrically, by combustion or any other known process.

Owner:HASSENZAHL ROBERT D

Electroconductive paste with adhesion enhancer

InactiveUS20150155401A1Improved strengthHigh bonding strengthConductive materialSemiconductor/solid-state device manufacturingTellurium dioxideTungsten

The present invention relates to an electroconductive paste useful in the manufacture of silicon solar cells and solar cell modules, especially for the backside of the silicon wafer. The electroconductive paste comprises metallic particles, glass frit, organic vehicle, and an adhesion enhancer. The adhesion enhancer comprises a metal or a metal oxide, or any other metal compound that will convert to metal or metal oxide at firing temperature. The adhesion enhancer comprises at least one metal selected from the group consisting of tellurium, tungsten, molybdenum, vanadium, nickel, antimony, magnesium, zirconium, silver, cobalt, cerium, and zinc, or oxides thereof. Preferably, the adhesion enhancer is tellurium or tellurium dioxide, and may be present in an amount of about 0.01-5 wt. % (based upon 100% total weight of the paste). The glass frits can be leaded or lead-free and may be present in an amount of about 1-10 wt. %. The metallic particles can be any of silver, aluminum, gold or nickel, or any alloys thereof, and can be present in an amount of about 40-75 wt. %. Another aspect of the present invention relates to a solar cell printed with an electroconductive paste composition on its backside, as well as an assembled solar cell module. Another aspect of the present invention relates to soldering pads formed by the present invention electroconductive paste composition on a silicon substrate, wherein the pull force required to remove the soldering pad from the silicon substrate is above 1 Newton. An additional aspect of the present invention relates to a method of producing a solar cell.

Owner:HERAEUS PRECIOUS METALS NORTH AMERICA CONSHOHOCKEN

Chromia-alumina refractory

ActiveUS20100019419A1Improved strengthLowering of permeabilityCeramic shaping apparatusClaywaresMaterials scienceRefractory

A refractory composition comprising at least 50 weight percent chromic oxide (Cr2O3), as measured by chemical analysis. The composition includes fused chromia-containing grain, powdered chromic oxide and sintered chromia-containing grain. The fused chromia-containing grain and the sintered chromia-containing grain comprise at least 50 weight percent chromia oxide, as measured by chemical analysis.

Owner:HARBISON WALKER REFRACTORIES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com