Patents

Literature

61 results about "Blind side" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

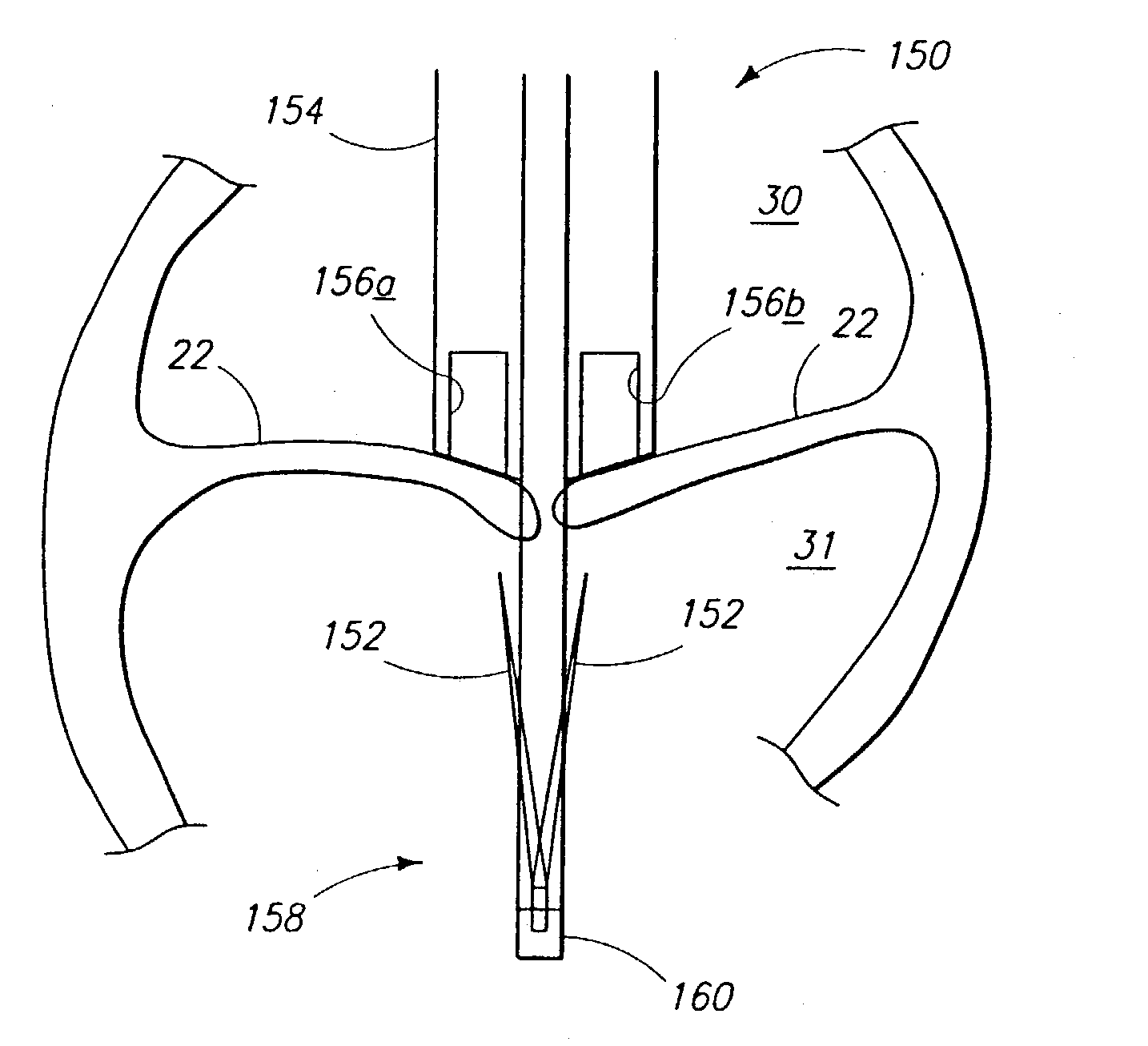

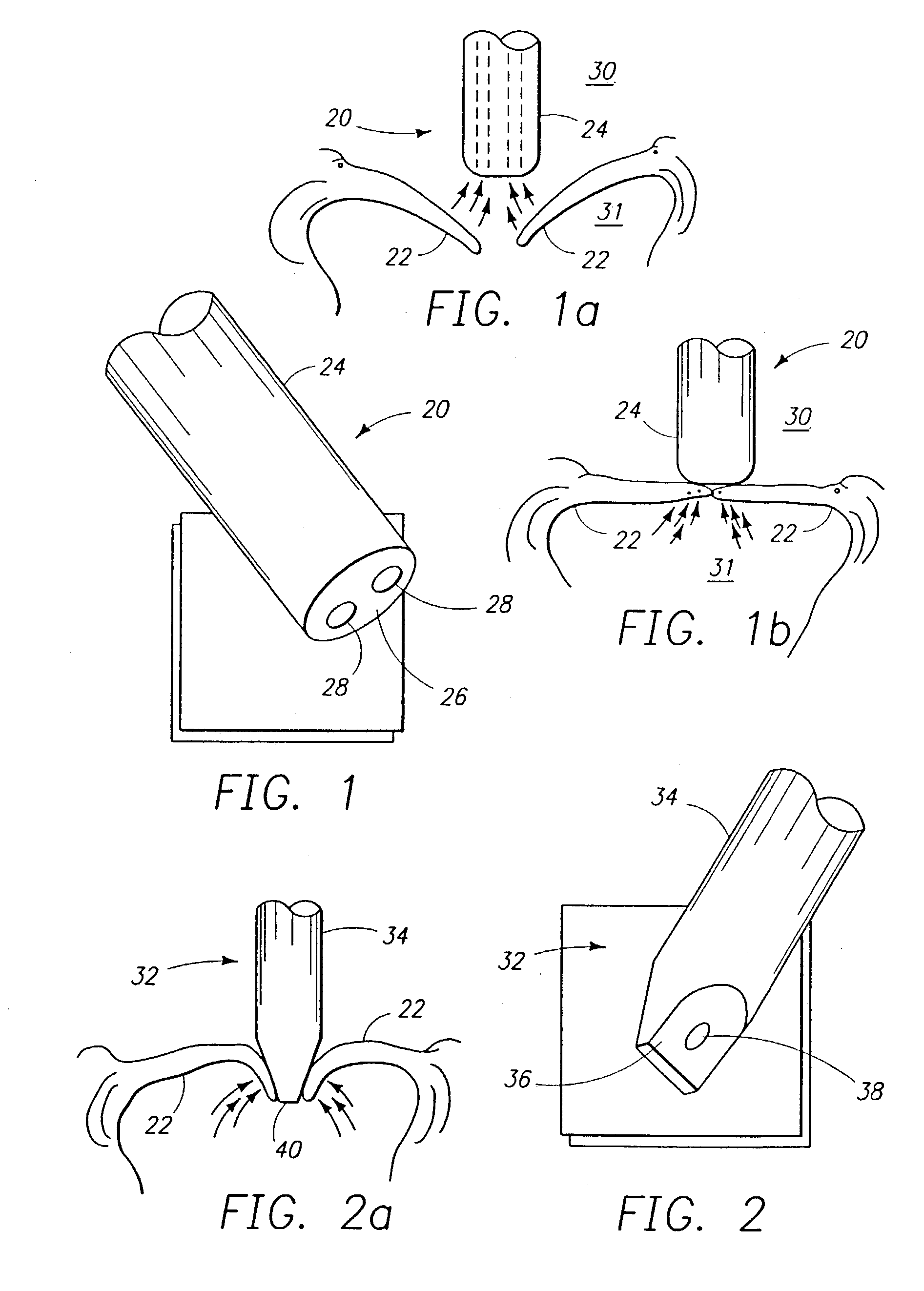

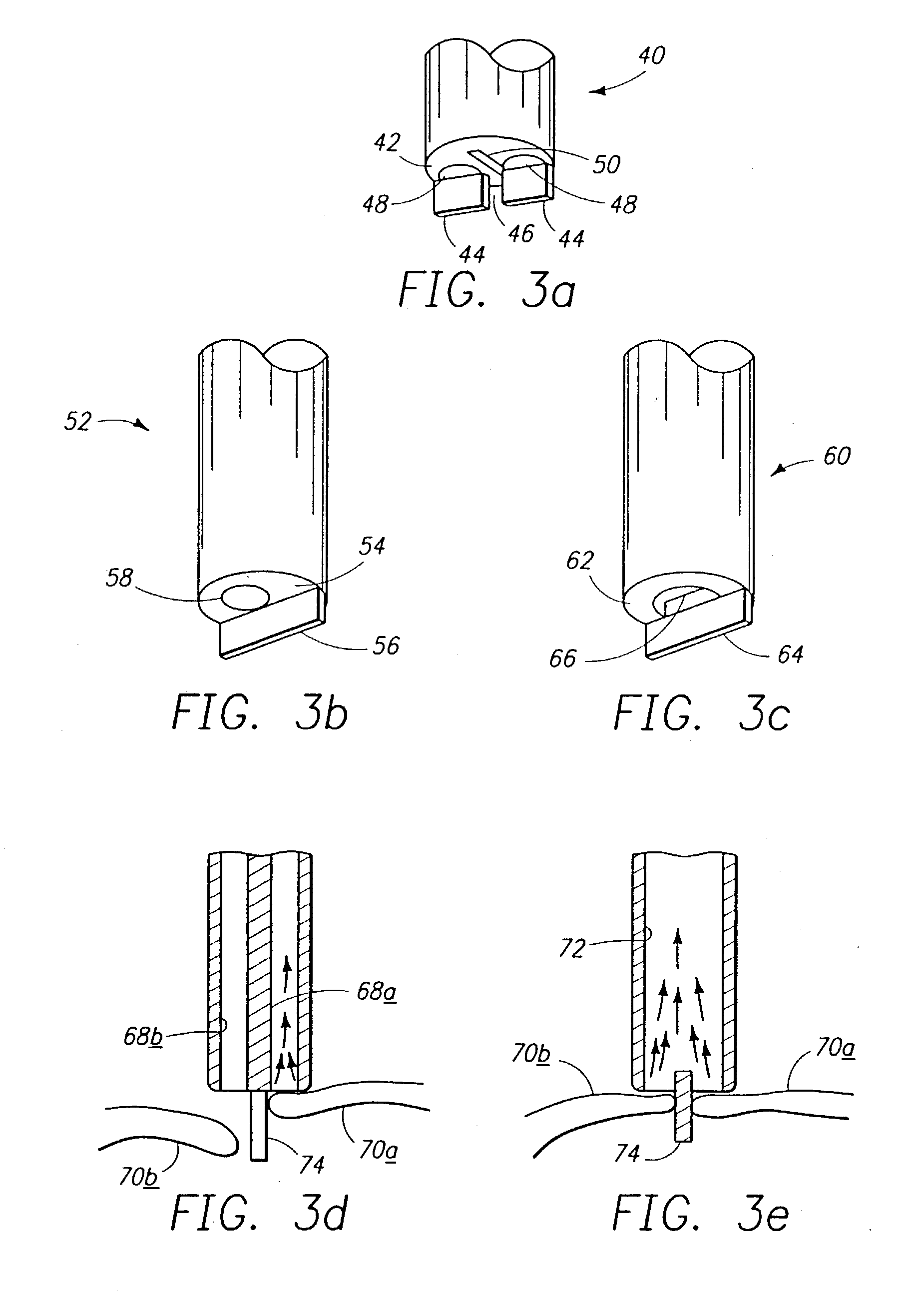

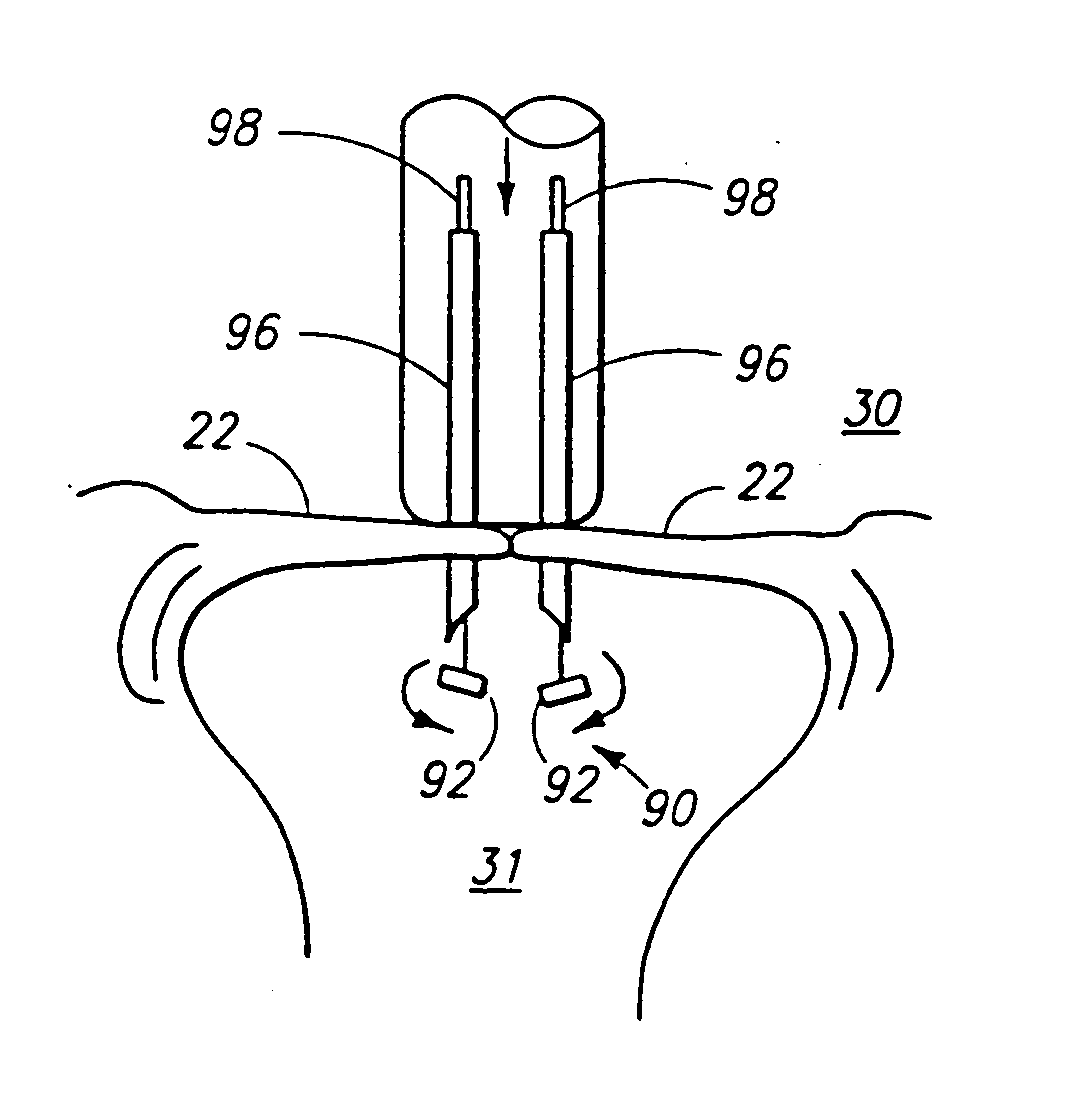

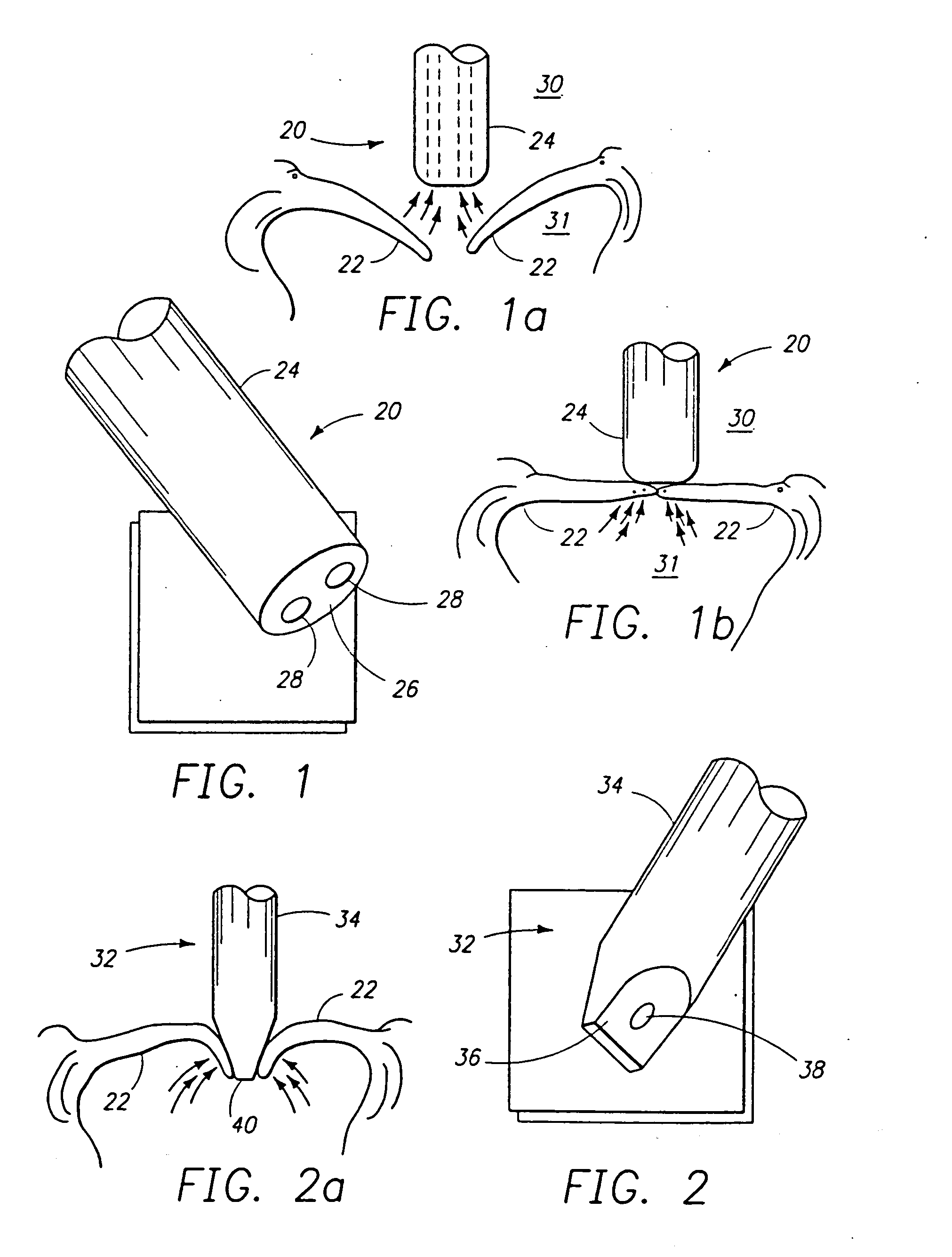

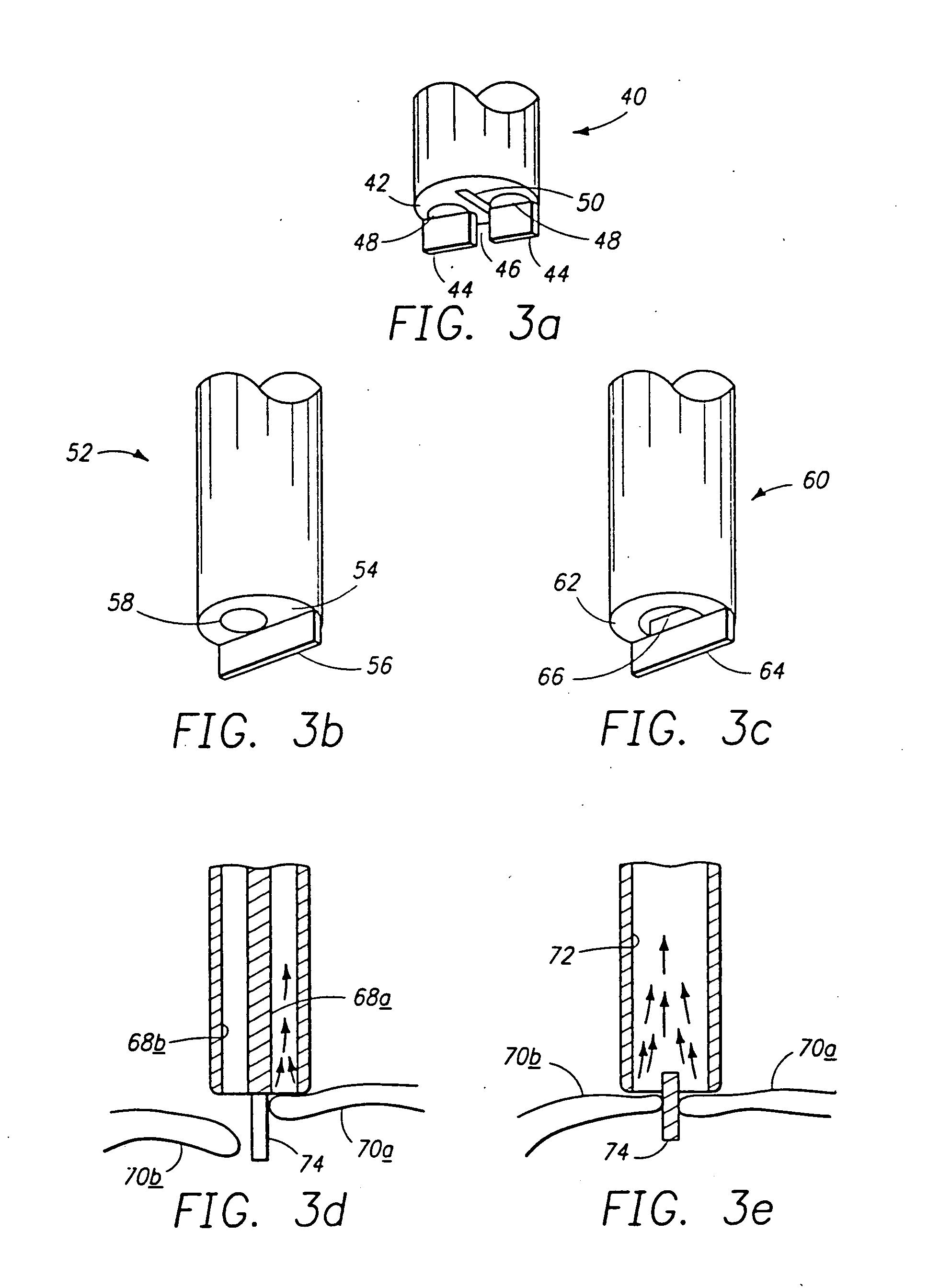

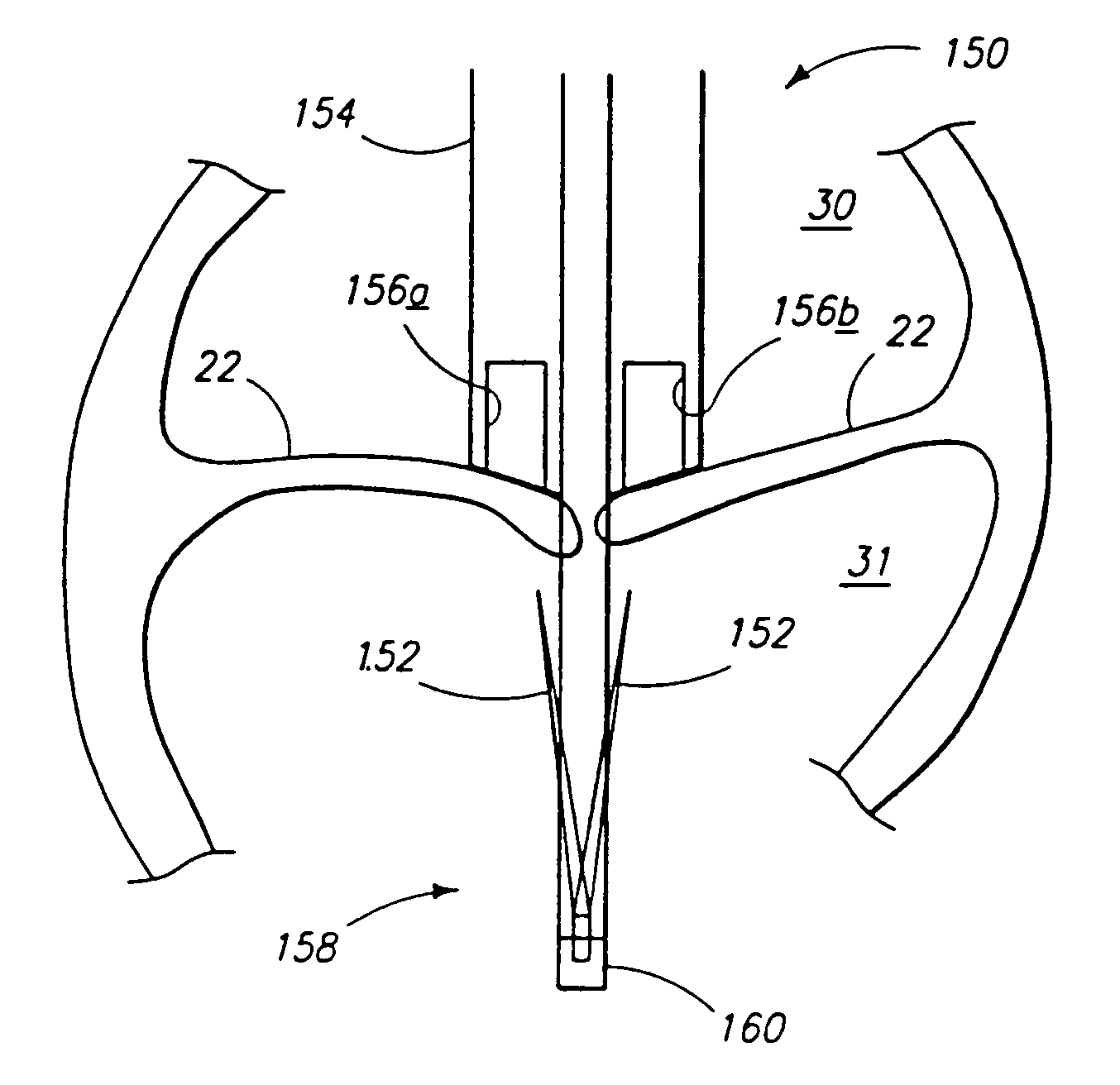

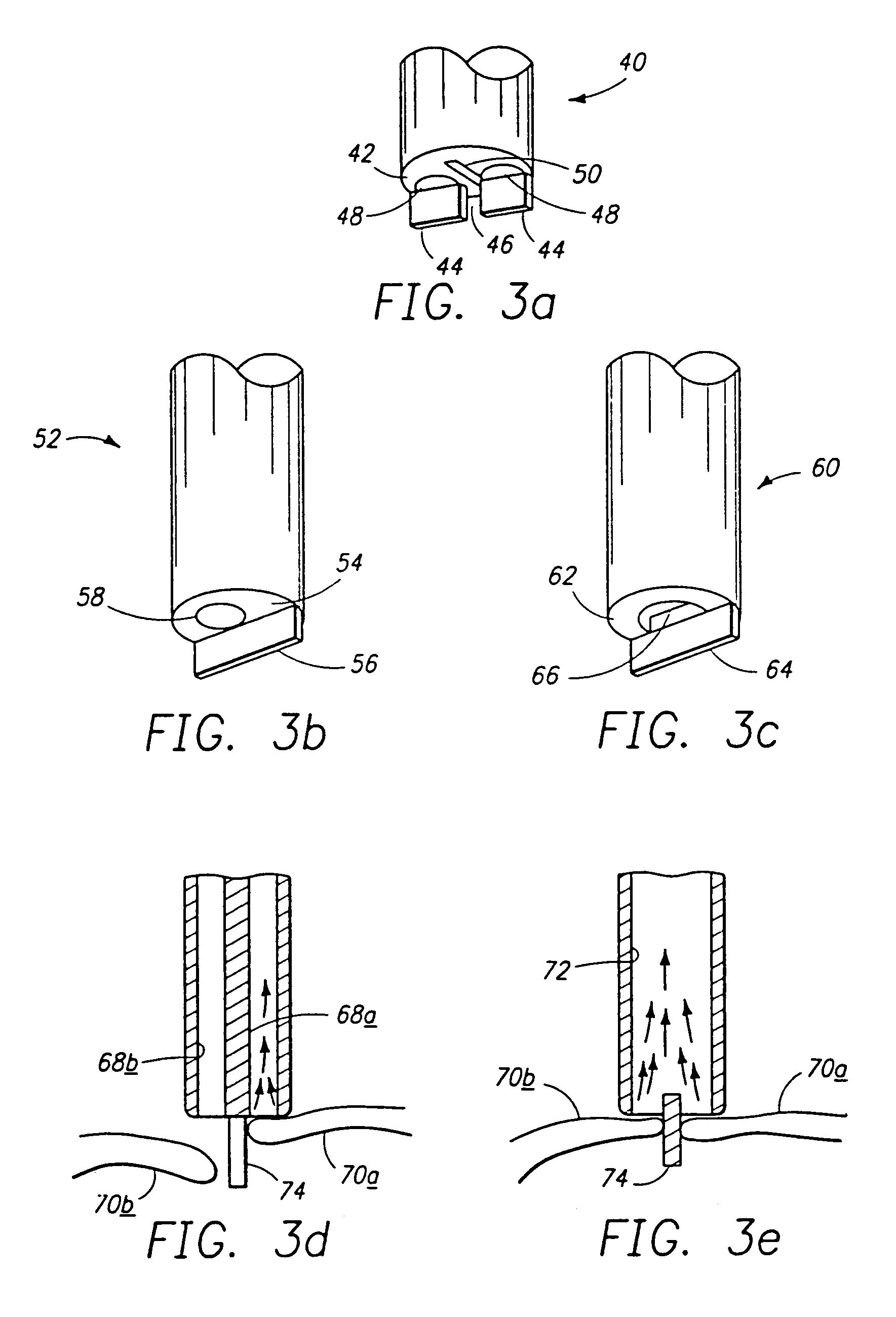

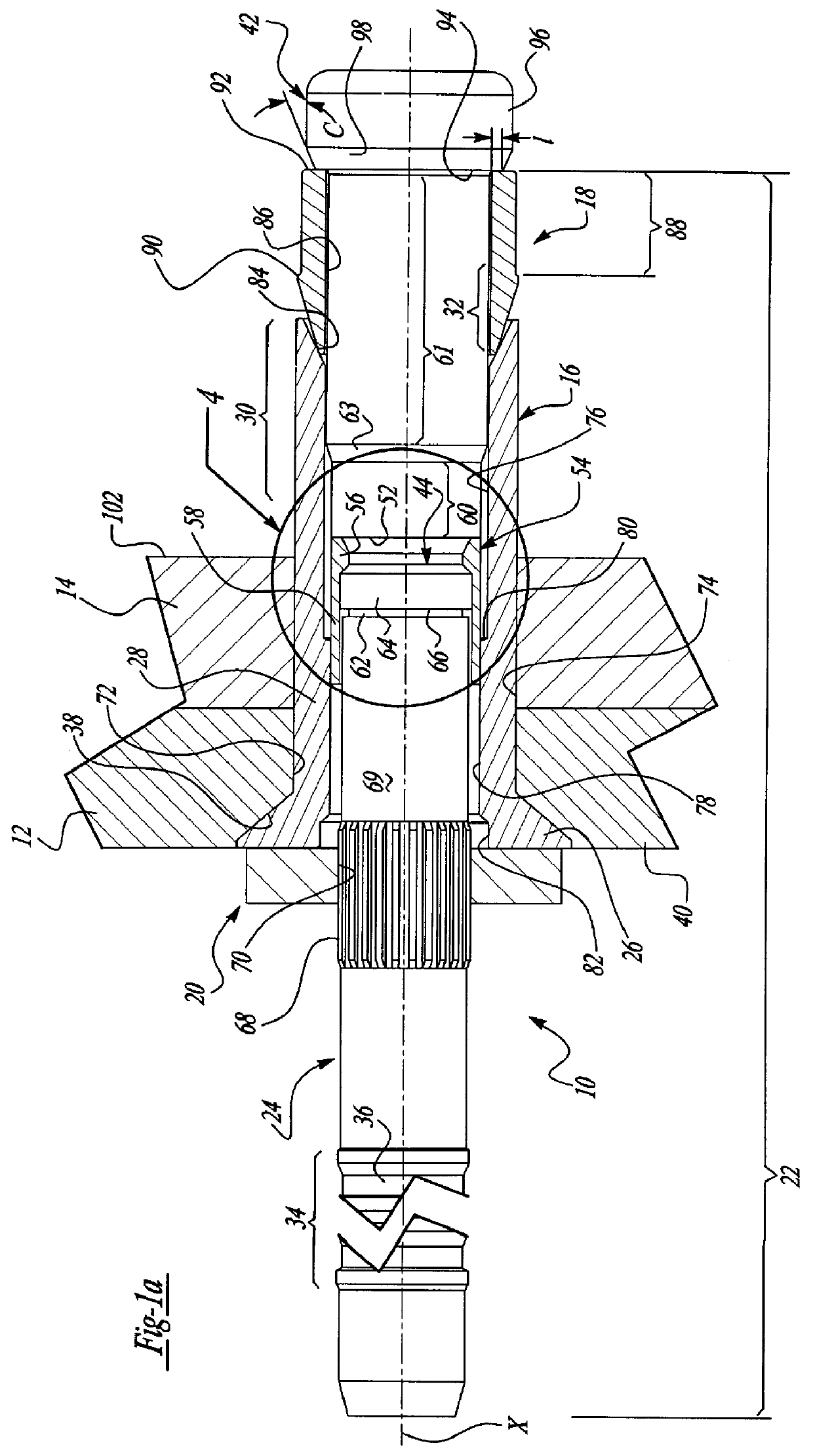

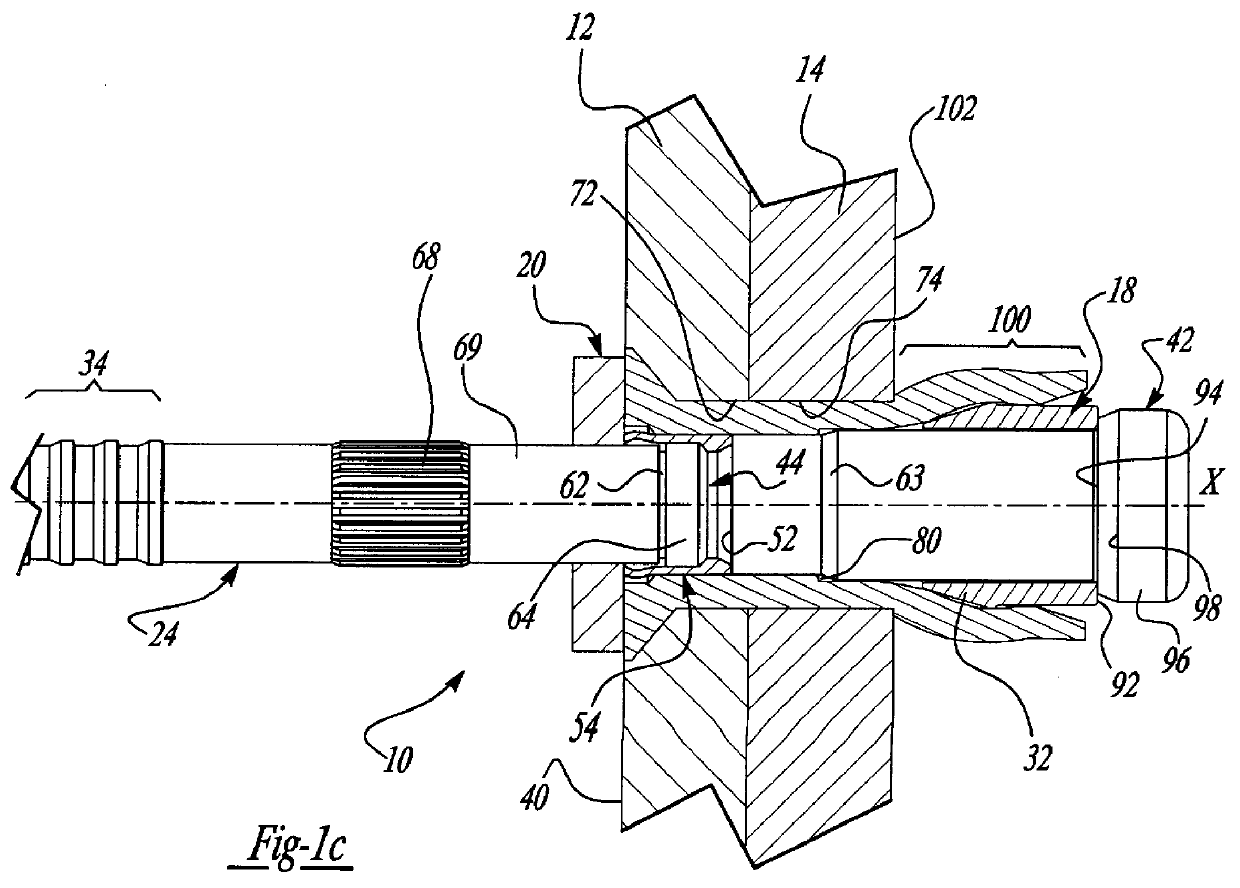

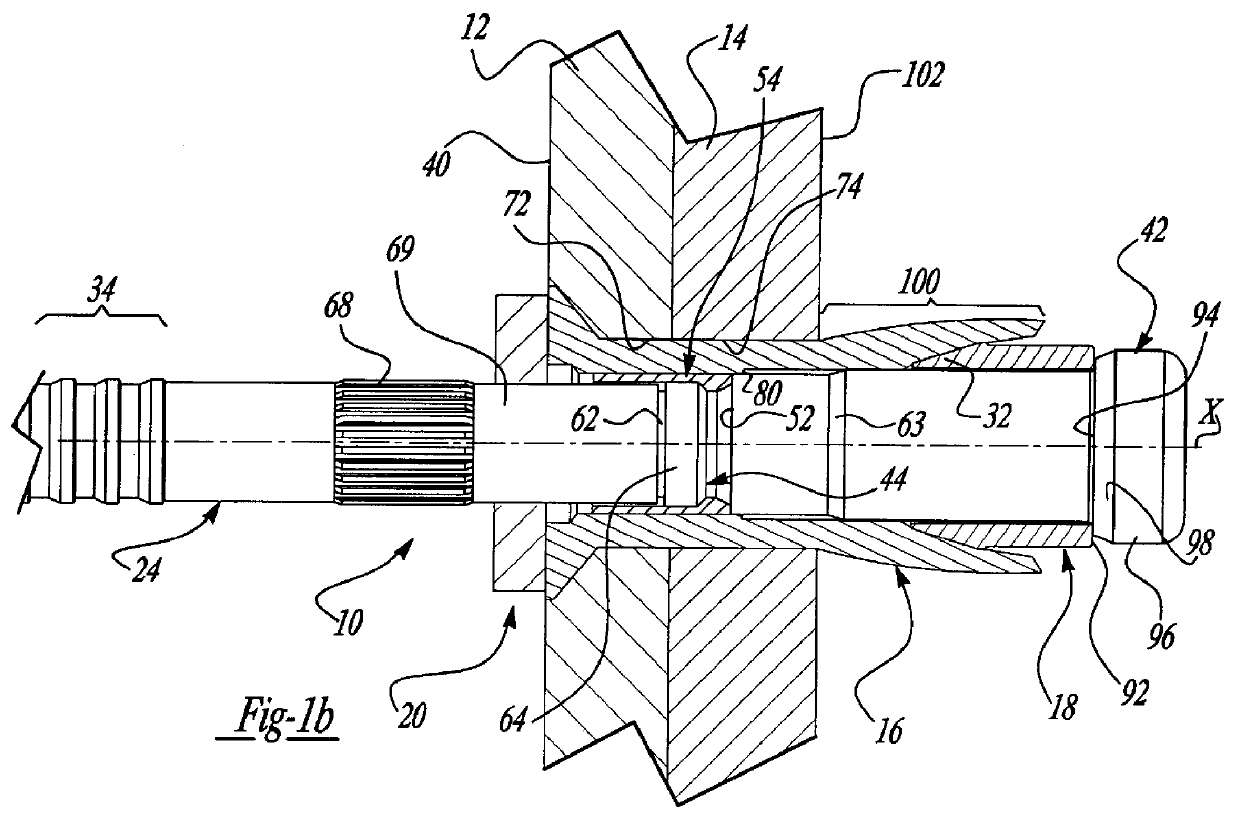

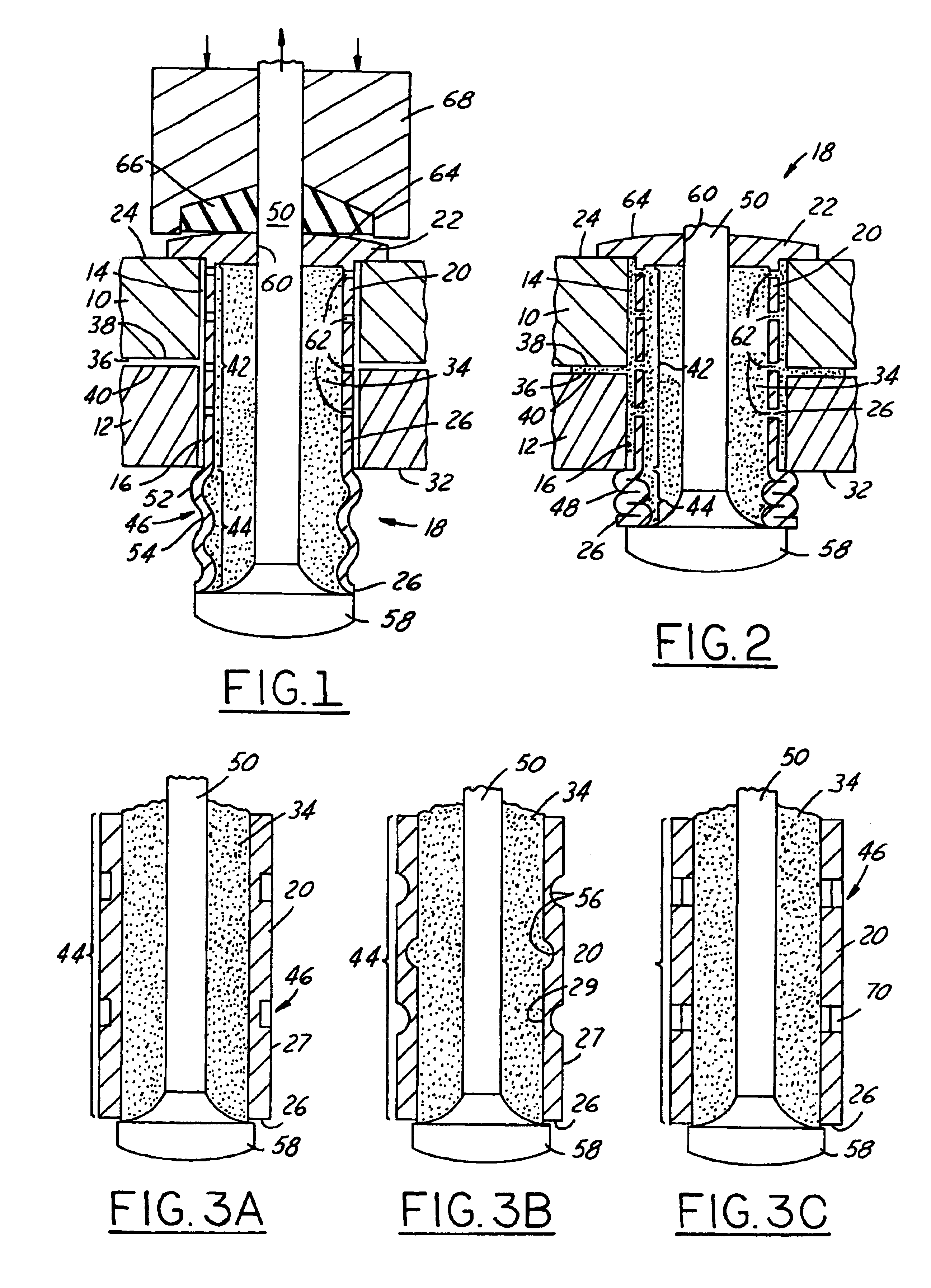

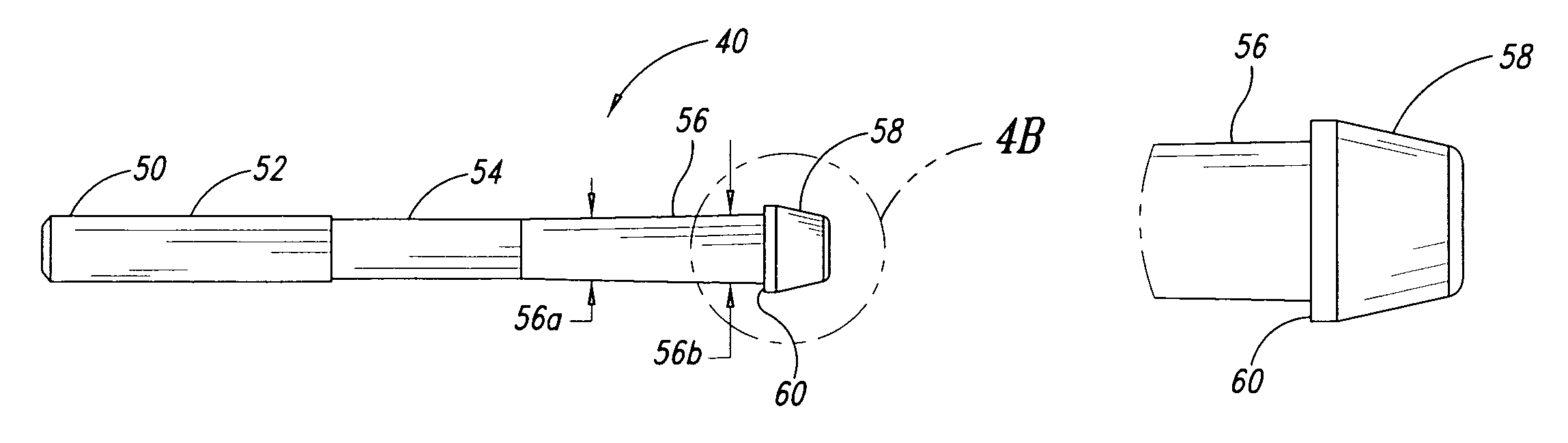

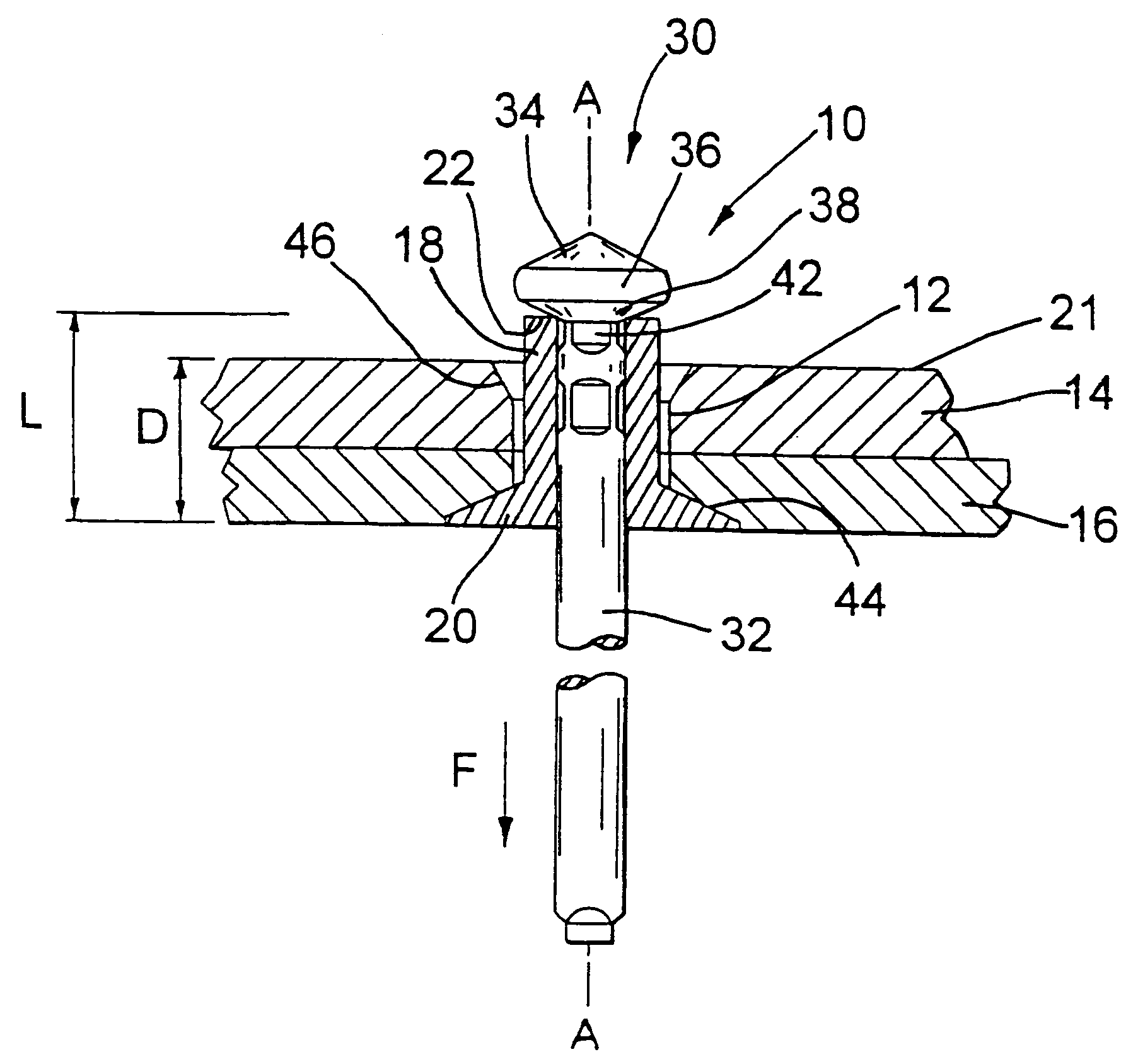

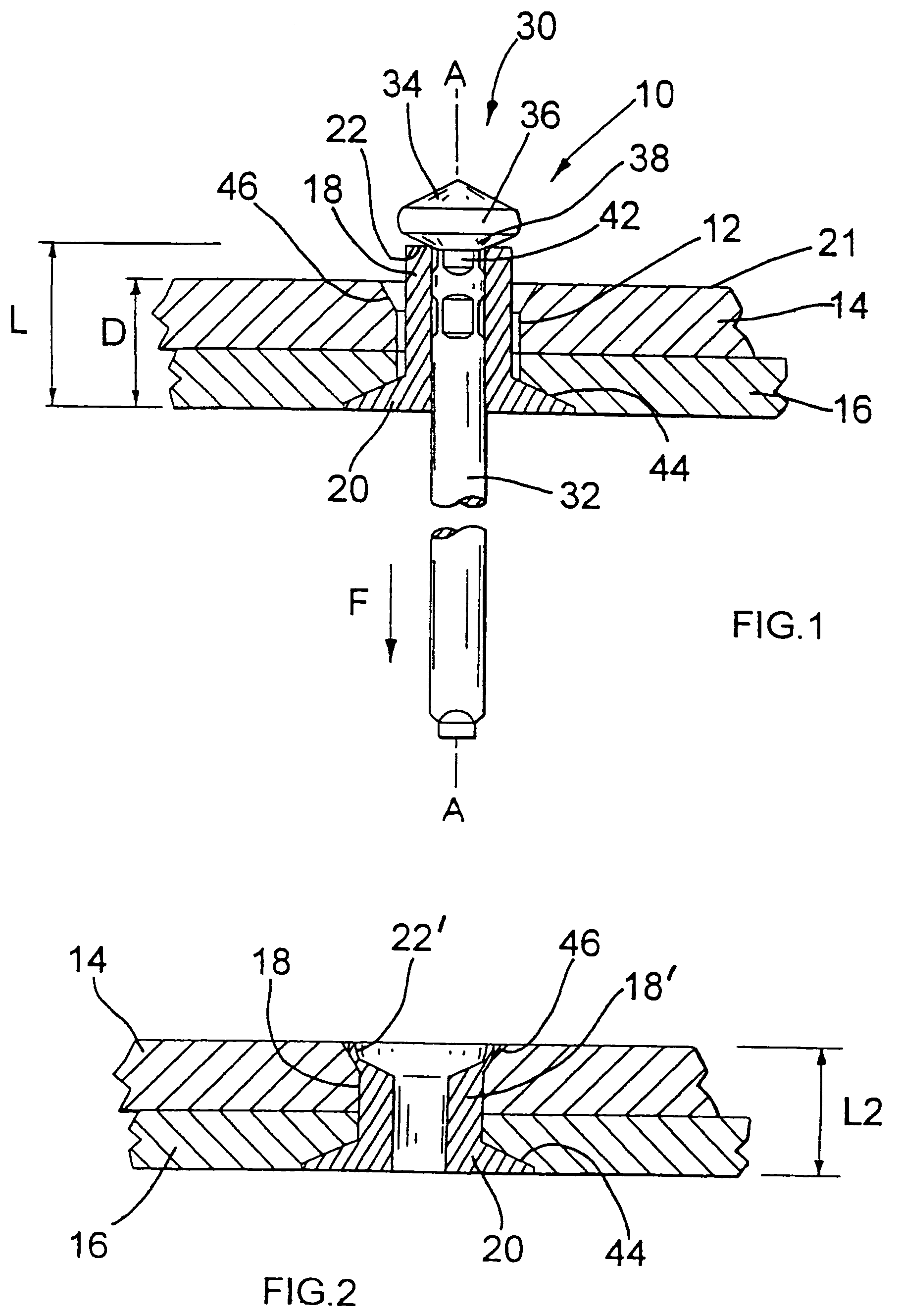

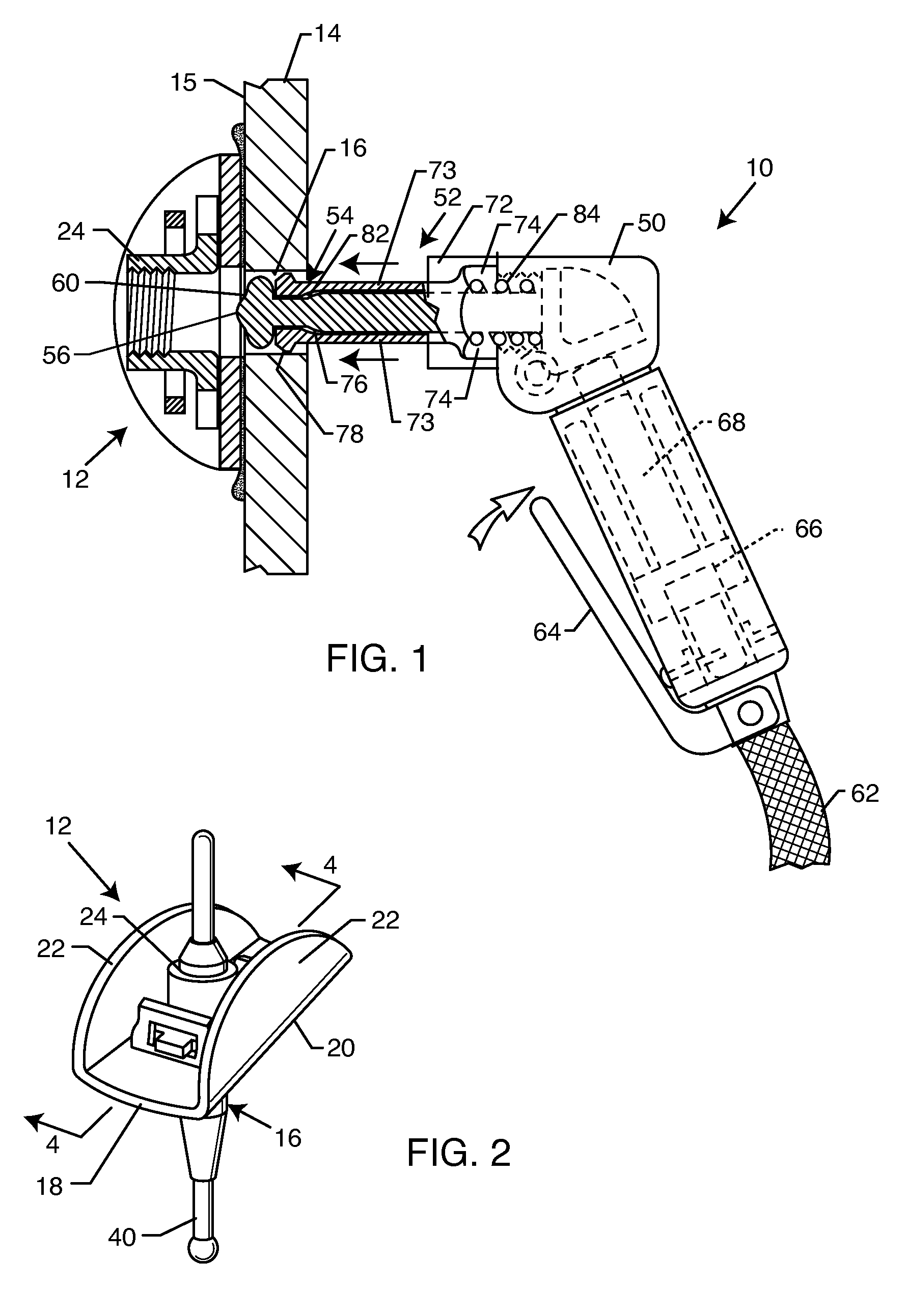

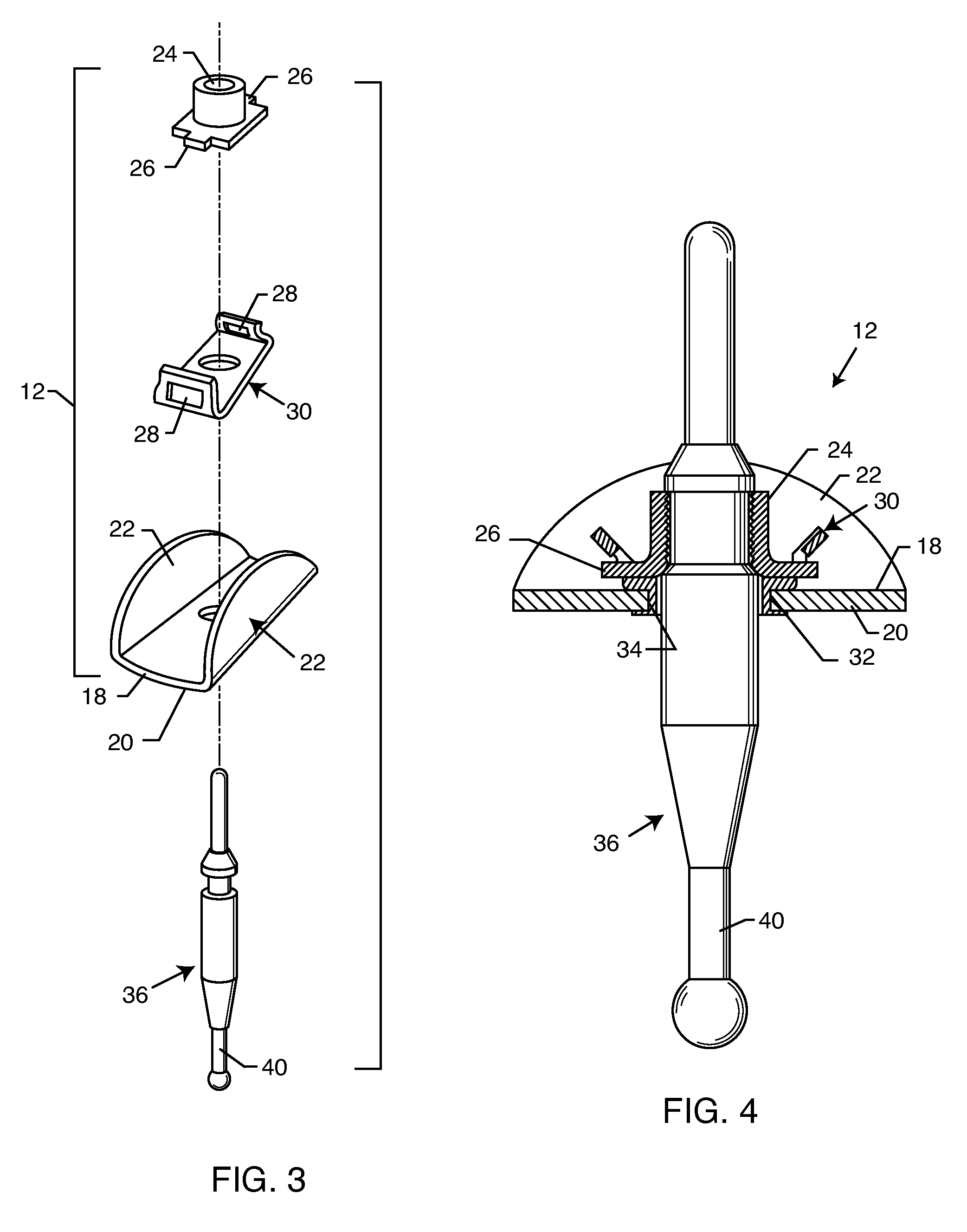

Minimally invasive mitral valve repair method and apparatus

The present invention is directed to an apparatus and method for the stabilization and fastening of two pieces of tissue. A single device may be used to both stabilize and fasten the two pieces of tissue, or a separate stabilizing device may be used in conjunction with a fastening device. The stabilizing device may comprise a probe with vacuum ports and / or mechanical clamps disposed at the distal end to approximate the two pieces of tissue. After the pieces of tissue are stabilized, they are fastened together using sutures or clips. One exemplary embodiment of a suture-based fastener comprises a toggle and suture arrangement deployed by a needle, wherein the needle enters the front side of the tissue and exits the blind side. In a second exemplary embodiment, the suture-based fastener comprises a needle connected to a suture. The needle enters the blind side of the tissue and exits the front side. The suture is then tied in a knot to secure the pieces of tissue. One example of a clip-based fastener comprises a spring-loaded clip having two arms with tapered distal ends and barbs. The probe includes a deployment mechanism which causes the clip to pierce and lockingly secure the two pieces of tissue.

Owner:EDWARDS LIFESCIENCES CORP

Minimally invasive mitral valve repair method and apparatus

The present invention is directed to an apparatus and method for the stabilization and fastening of two pieces of tissue. A single device may be used to both stabilize and fasten the two pieces of tissue, or a separate stabilizing device may be used in conjunction with a fastening device. The stabilizing device may comprise a probe with vacuum ports and / or mechanical clamps disposed at the distal end to approximate the two pieces of tissue. After the pieces of tissue are stabilized, they are fastened together using sutures or clips. One exemplary embodiment of a suture-based fastener comprises a toggle and suture arrangement deployed by a needle, wherein the needle enters the front side of the tissue and exits the blind side. In a second exemplary embodiment, the suture-based fastener comprises a needle connected to a suture. The needle enters the blind side of the tissue and exits the front side. The suture is then tied in a knot to secure the pieces of tissue. One example of a clip-based fastener comprises a spring-loaded clip having two arms with tapered distal ends and barbs. The probe includes a deployment mechanism which causes the clip to pierce and lockingly secure the two pieces of tissue.

Owner:EDWARDS LIFESCIENCES CORP

Minimally invasive mitral valve repair method and apparatus

The present invention is directed to an apparatus and method for the stabilization and fastening of two pieces of tissue. A single device may be used to both stabilize and fasten the two pieces of tissue, or a separate stabilizing device may be used in conjunction with a fastening device. The stabilizing device may comprise a probe with vacuum ports and / or mechanical clamps disposed at the distal end to approximate the two pieces of tissue. After the pieces of tissue are stabilized, they are fastened together using sutures or clips. One exemplary embodiment of a suture-based fastener comprises a toggle and suture arrangement deployed by a needle, wherein the needle enters the front side of the tissue and exits the blind side. In a second exemplary embodiment, the suture-based fastener comprises a needle connected to a suture. The needle enters the blind side of the tissue and exits the front side. The suture is then tied in a knot to secure the pieces of tissue. One example of a clip-based fastener comprises a spring-loaded clip having two arms with tapered distal ends and barbs. The probe includes a deployment mechanism which causes the clip to pierce and lockingly secure the two pieces of tissue.

Owner:EDWARDS LIFESCIENCES CORP

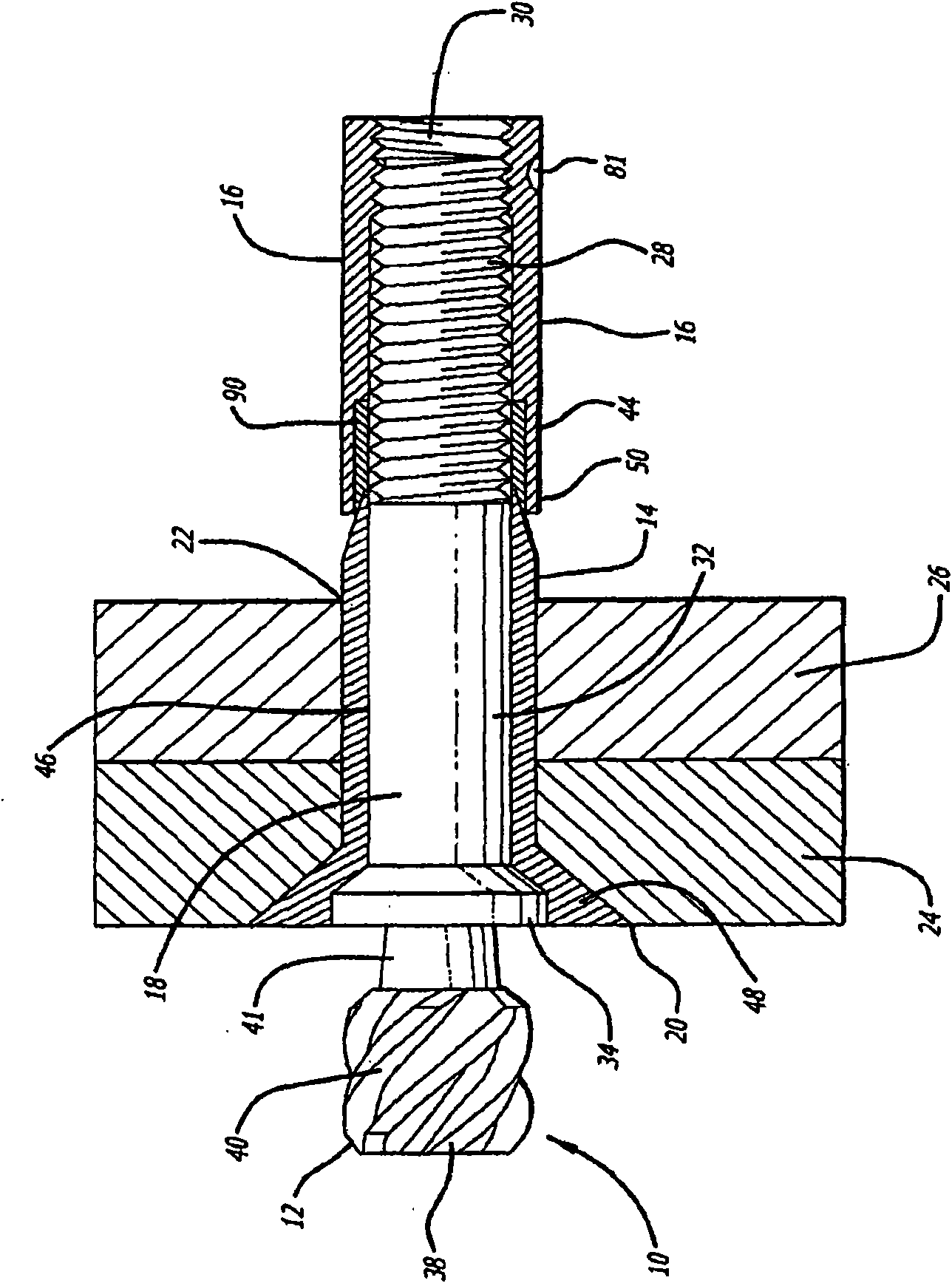

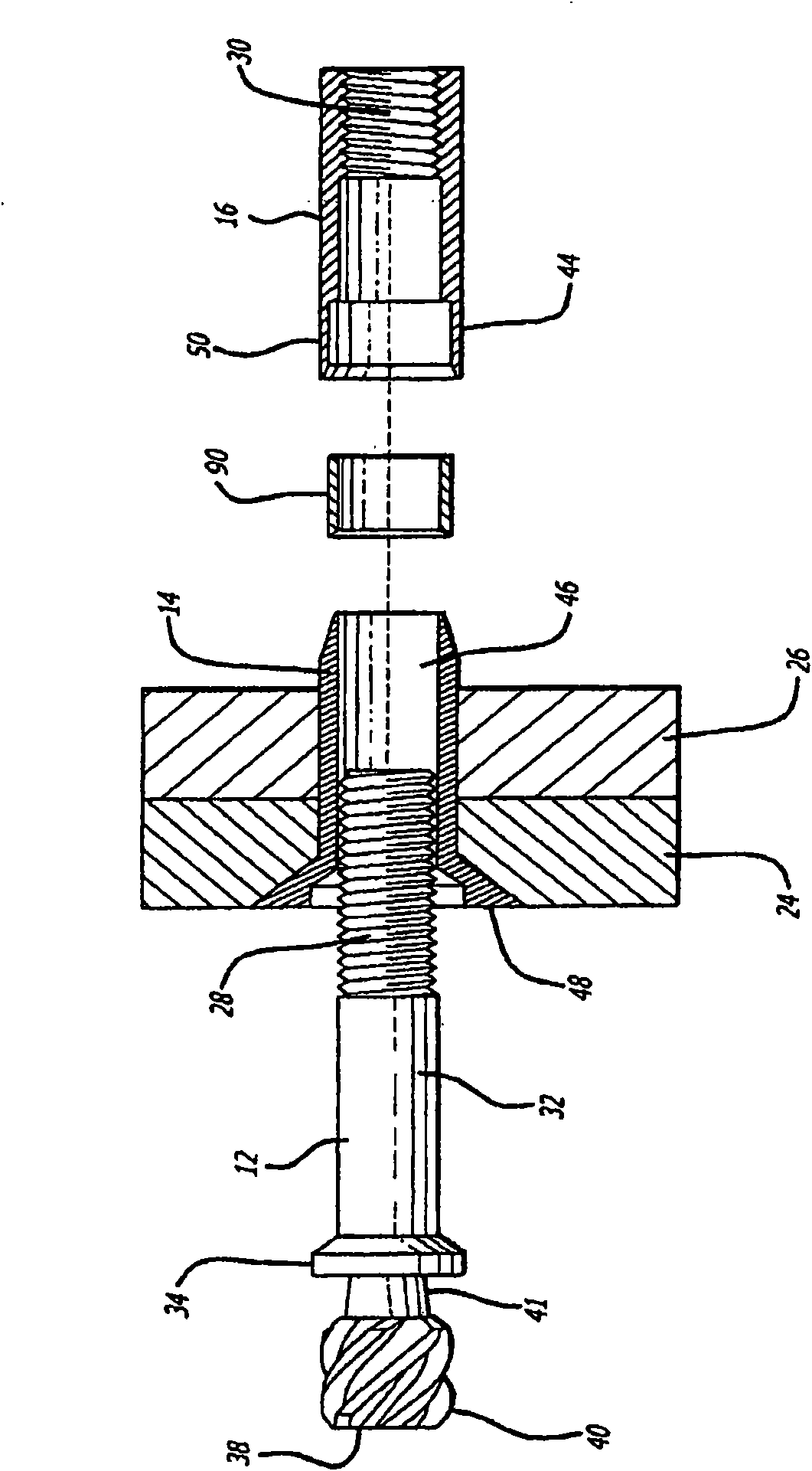

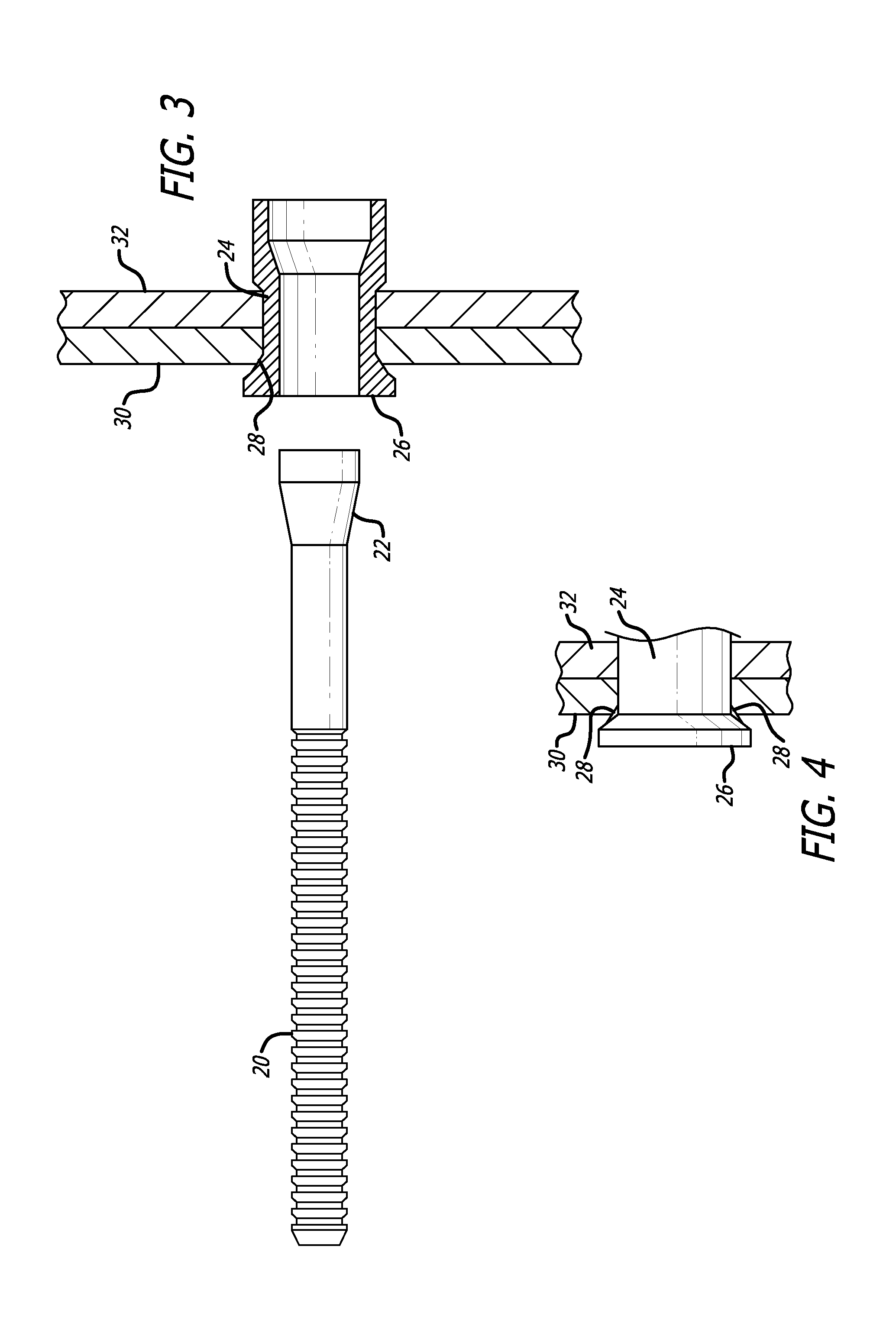

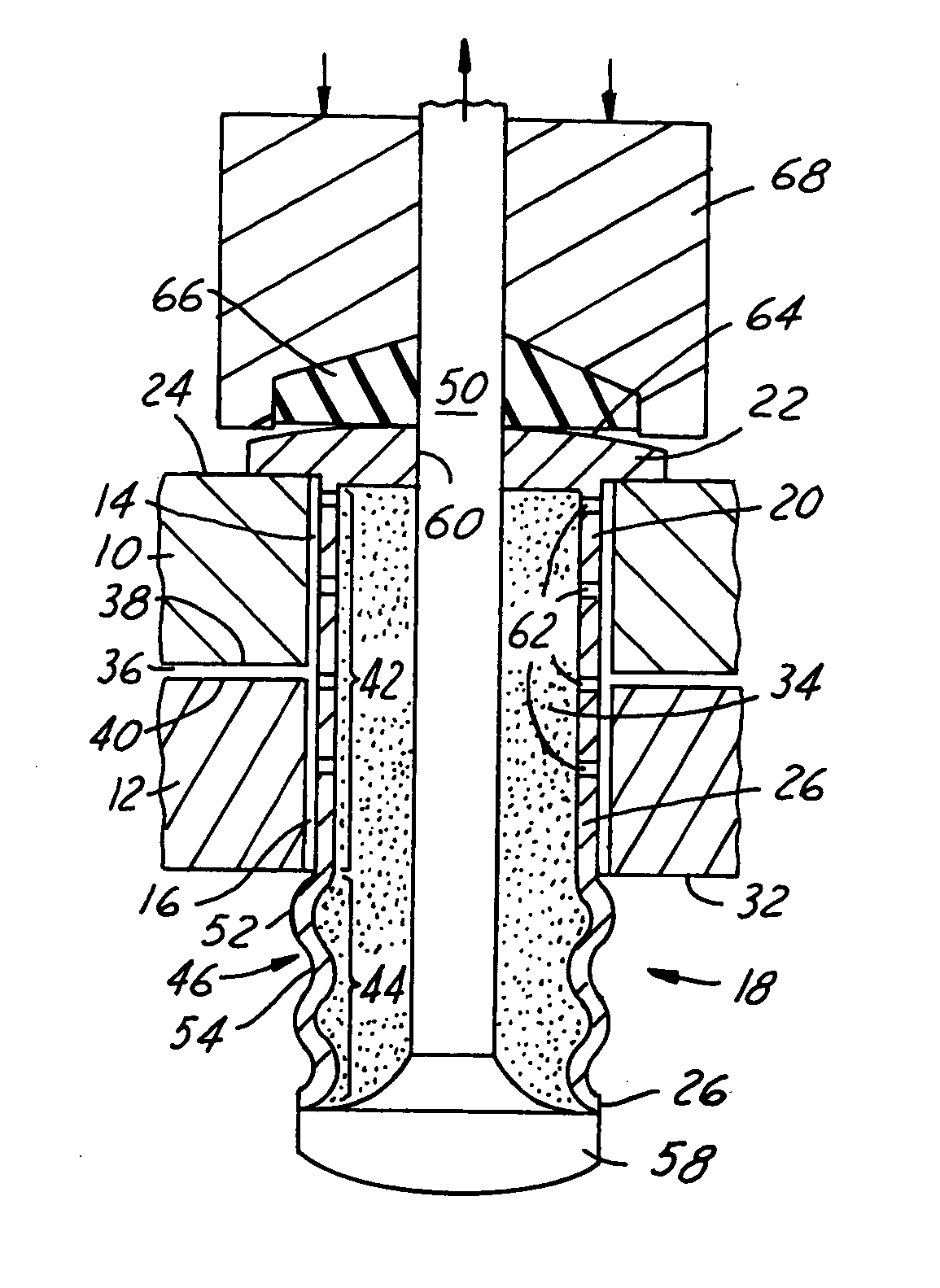

Blind fastener with high strength blind head and high clamp and high shear load resistance

A blind fastener with a pin having a pin shank which extends through a cylindrical main sleeve and expansion sleeve whereby it can be gripped and pulled by an installation tool with the pin having an enlarged pin head at the blind end of the pin shank. The expansion sleeve is located between the pin head and the inner end of the main sleeve and is adapted to move into the inner or blind end of the main sleeve to form a first tulip shaped blind head for clamping workpieces together in response to a relative axial force applied between the sleeves and pin by engagement of the pin head with the expansion sleeve. As the axial force is increased the pin head is moved into the expansion sleeve to form a second tulip head to further clamp the workpieces and to secure the pin, main sleeve and expansion sleeve together at that end and is moved closely adjacent the workpiece surface at the blind side to form a high strength blind head.

Owner:HUCK INT INC

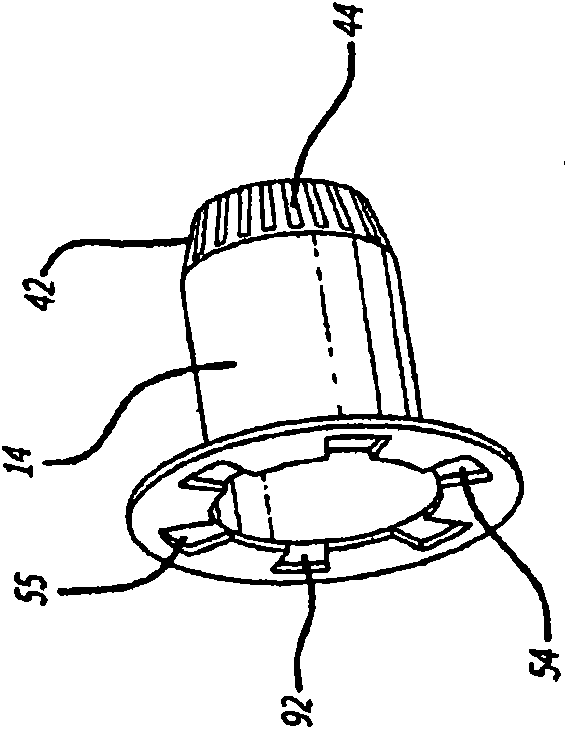

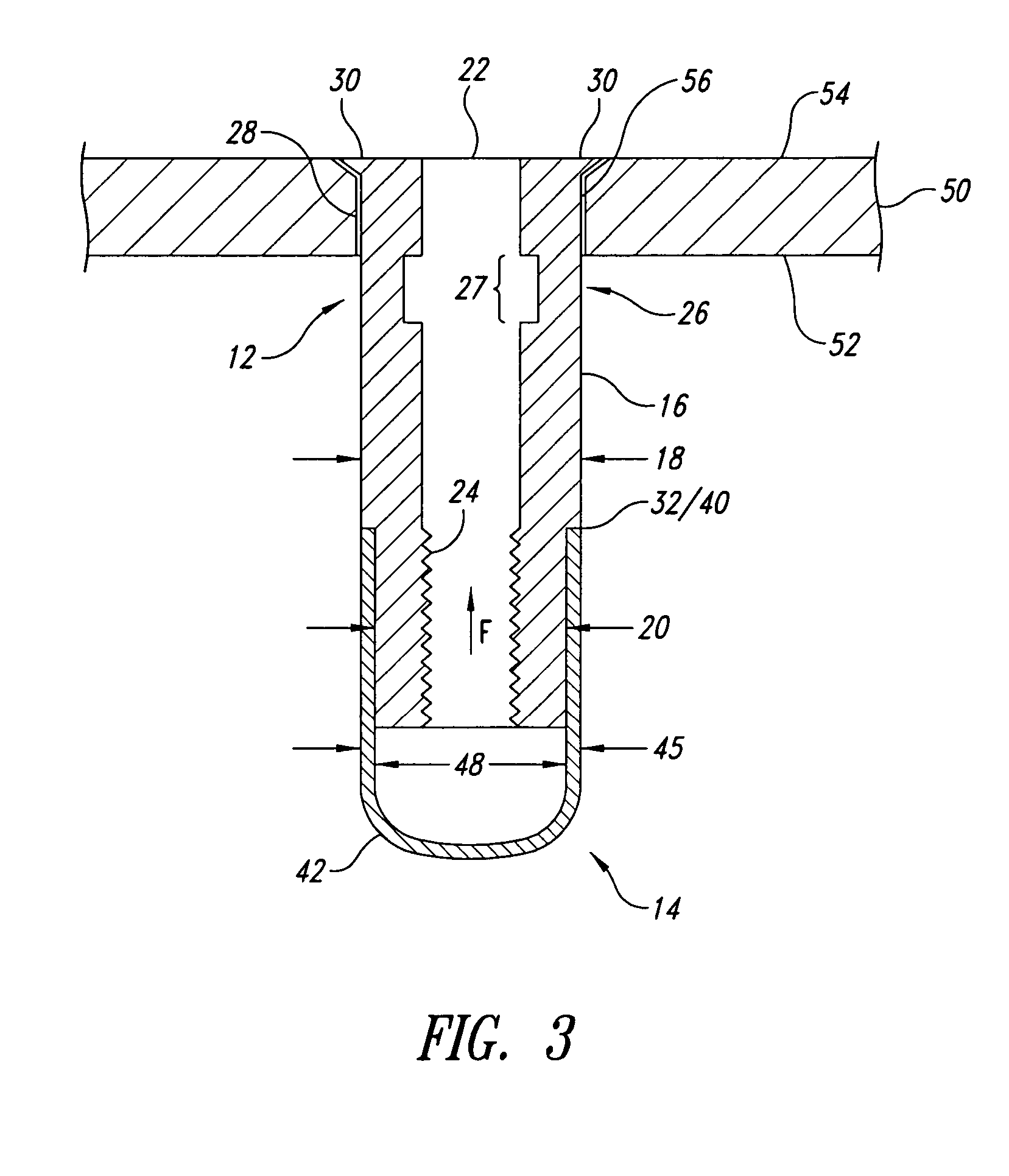

Sealed, blind fastener assembly

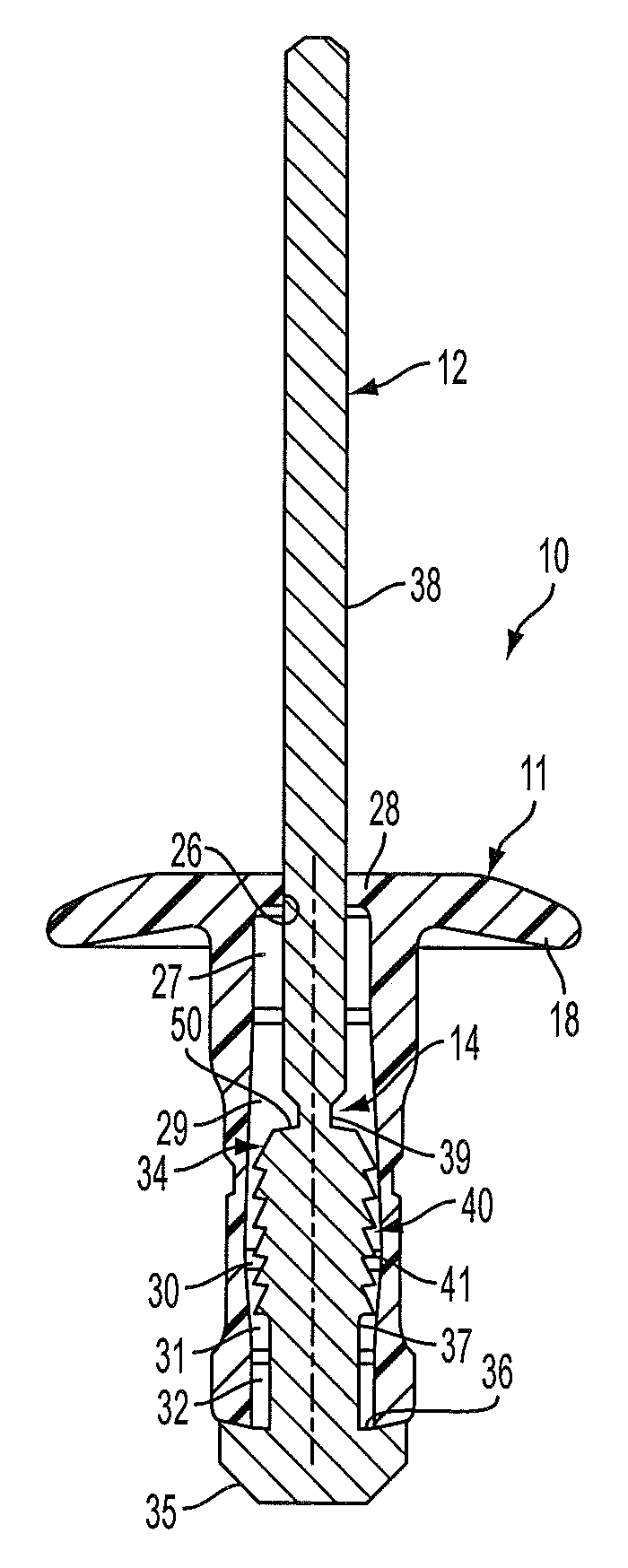

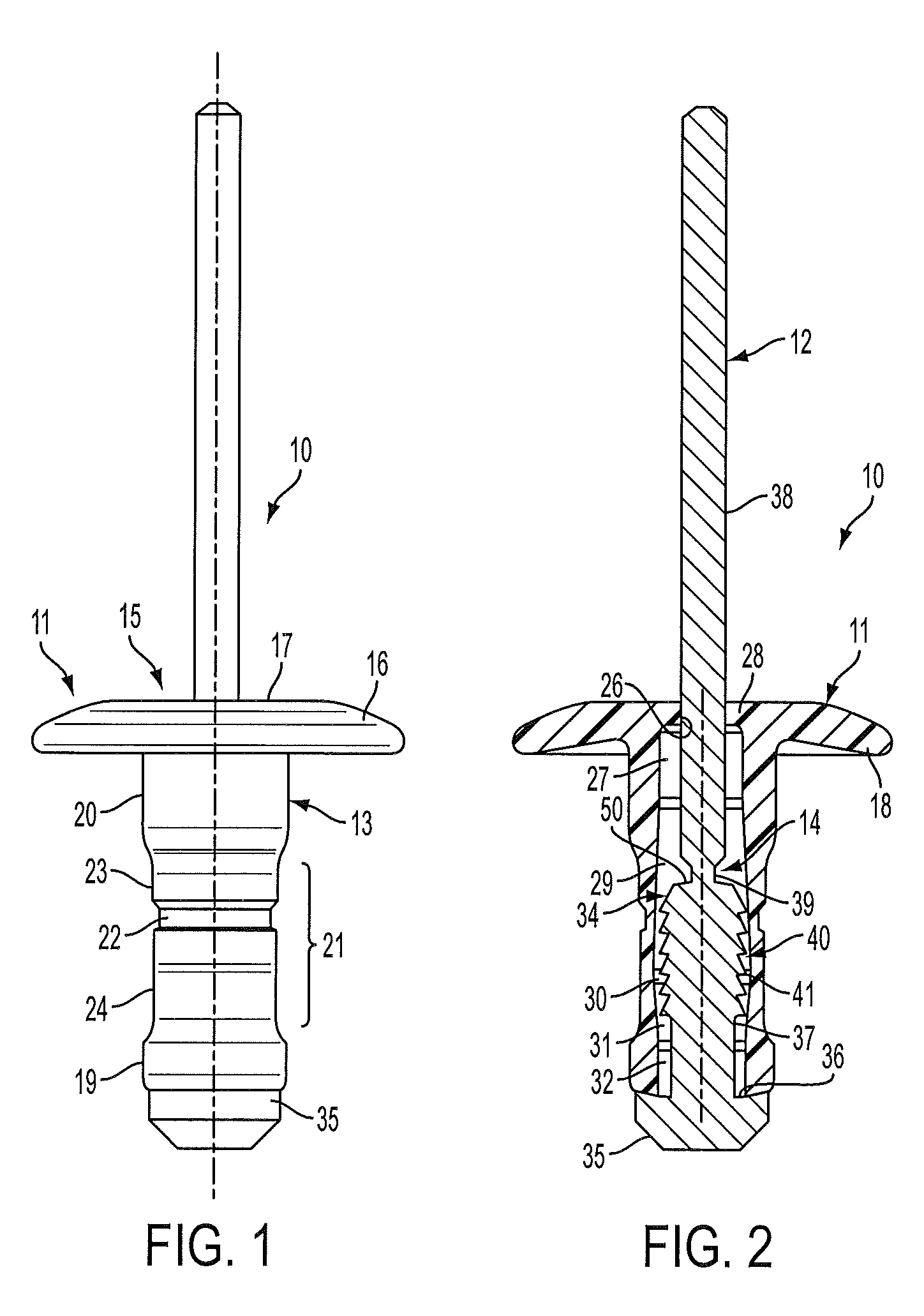

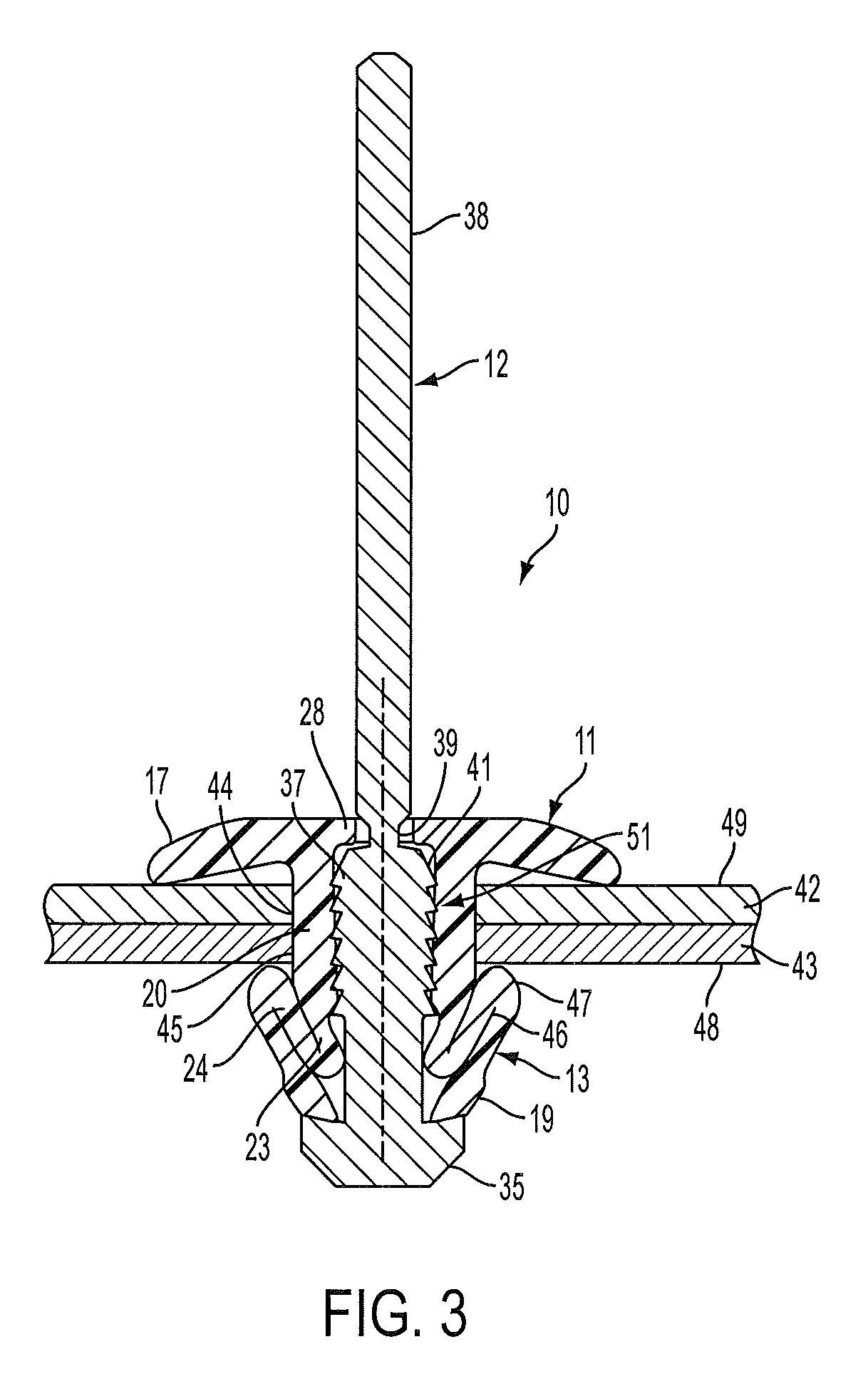

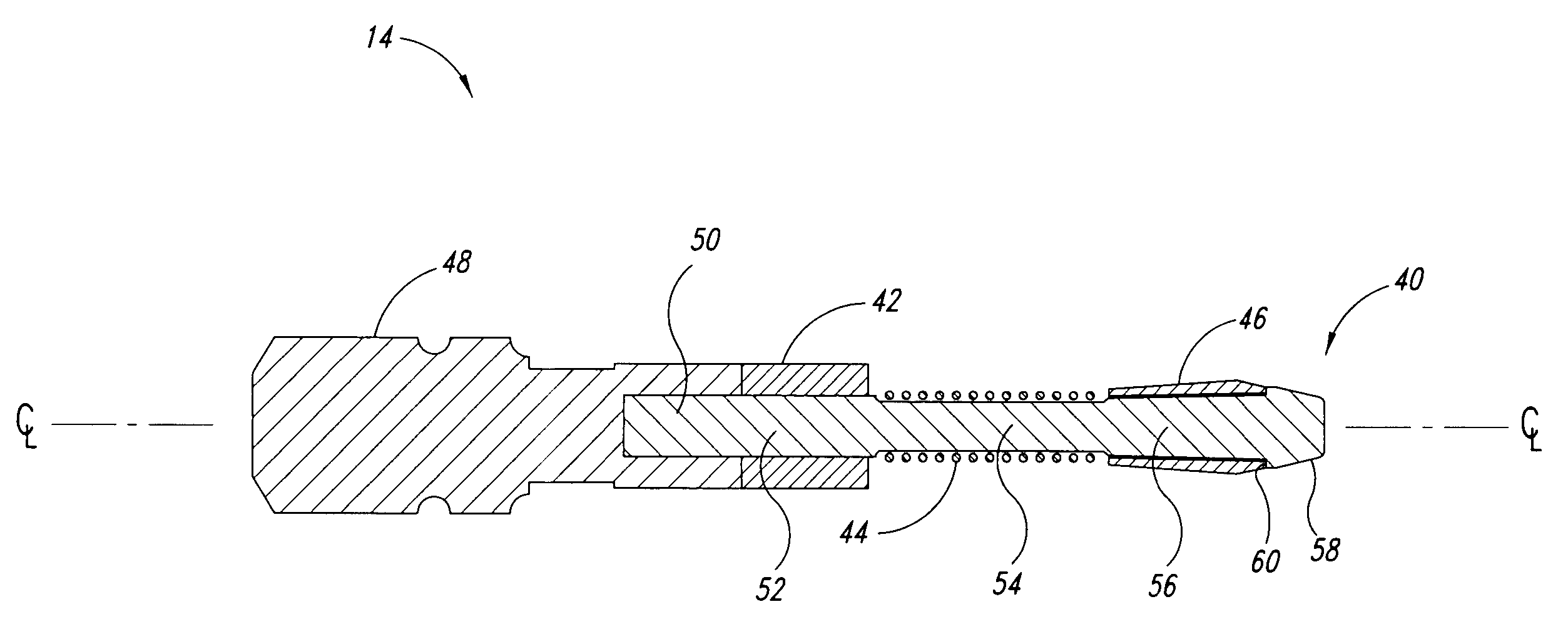

A sealed attachment fastener assembly with a receiving member and a cap that can be inserted into an opening in a work piece and fixed therein from only one side of the work piece. A portion of the fastener assembly on the blind side of the work piece is collapsible into a flange. In addition, another portion of the fastener assembly is contemporaneously radially expandable within the opening of the work piece to at least rotationally secure the fastener assembly with respect to the work piece. The radial expansion will result in a high interference fit of the fastener in the work piece, which may enhance the fatigue of the installation. A cap completes the fastener assembly to substantially prevent fluid from leaking through the fastener assembly opening. The cap can be assembled with the receiving member after the internal threads within the receiving member have been machined.

Owner:FATIGUE TECH

Blind rivet with extended adhesive reservoir

This invention provides a design of an adhesive encapsulated blind rivet for joining an assembly of overlying parts having an accessible side and an inaccessible side. The rivet comprises a rivet head and tubular rivet body. A mandrel is inserted through the open end of the tubular rivet body and through a mandrel hole in the rivet head. A mandrel head engages the end of the tubular body. The tubular body is filled with a mass of latent adhesive around the mandrel. The rivet body is longer than the thickness of the parts to be joined to accommodate a substantial amount of adhesive for expulsion through holes in the rivet body located within the thickness of the assembled parts. The portion of the rivet body extending beyond the blind side of the assembled parts is weakened in a pattern of corrugations or other bands for folding of the end of the tubular body in setting the blind side of the rivet and expelling the larger quantity of adhesive against and between the riveted parts.

Owner:GM GLOBAL TECH OPERATIONS LLC

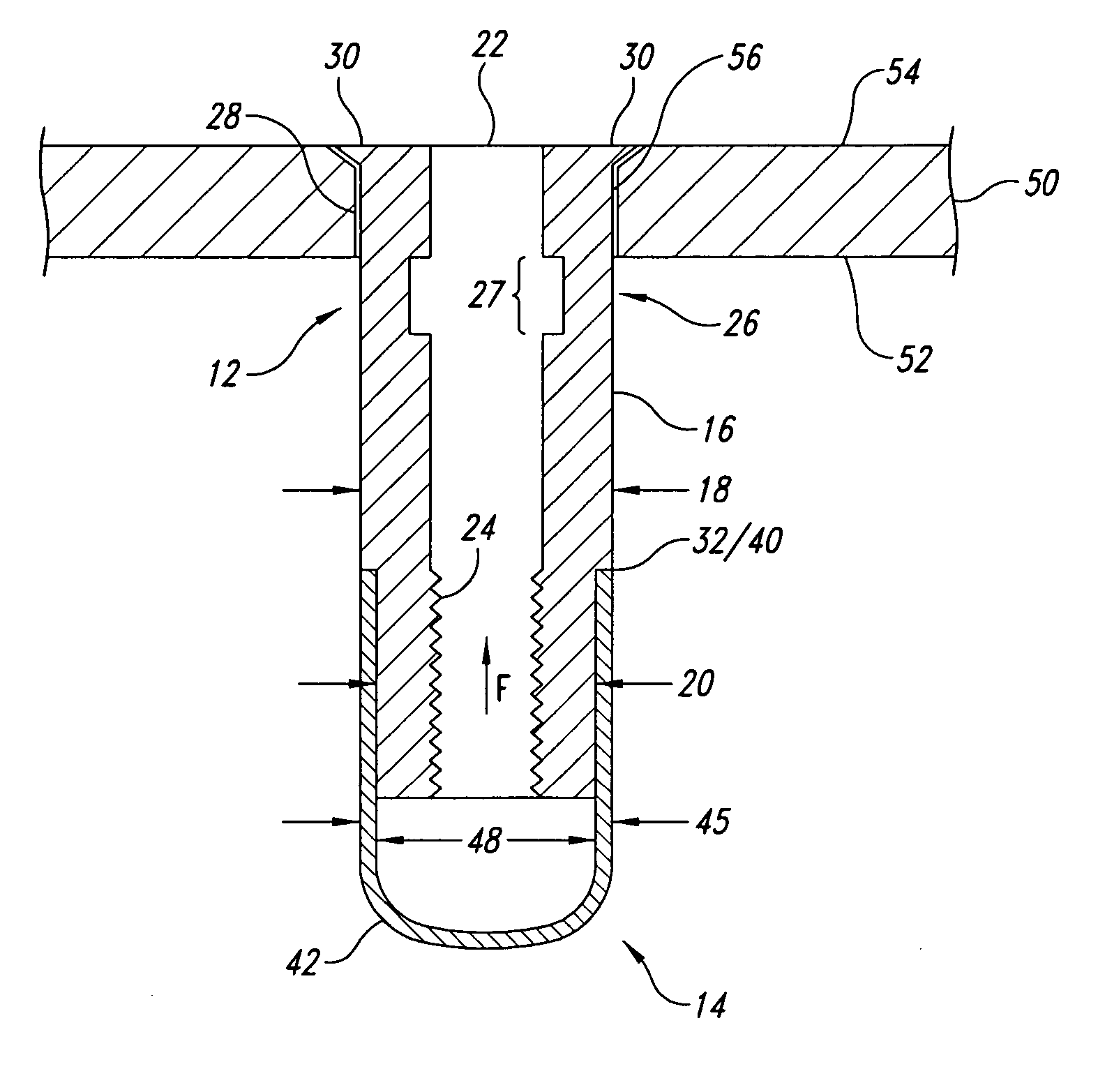

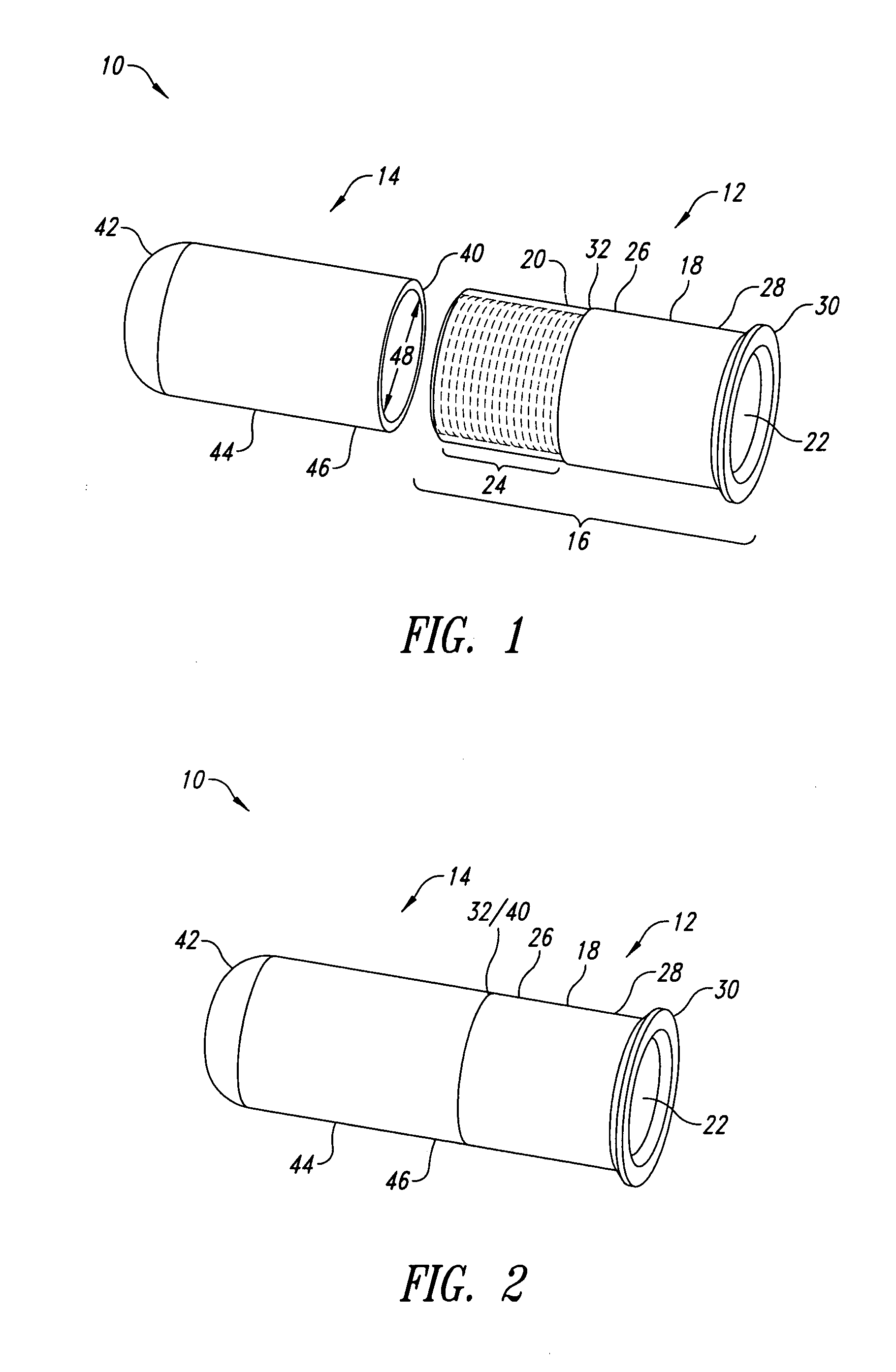

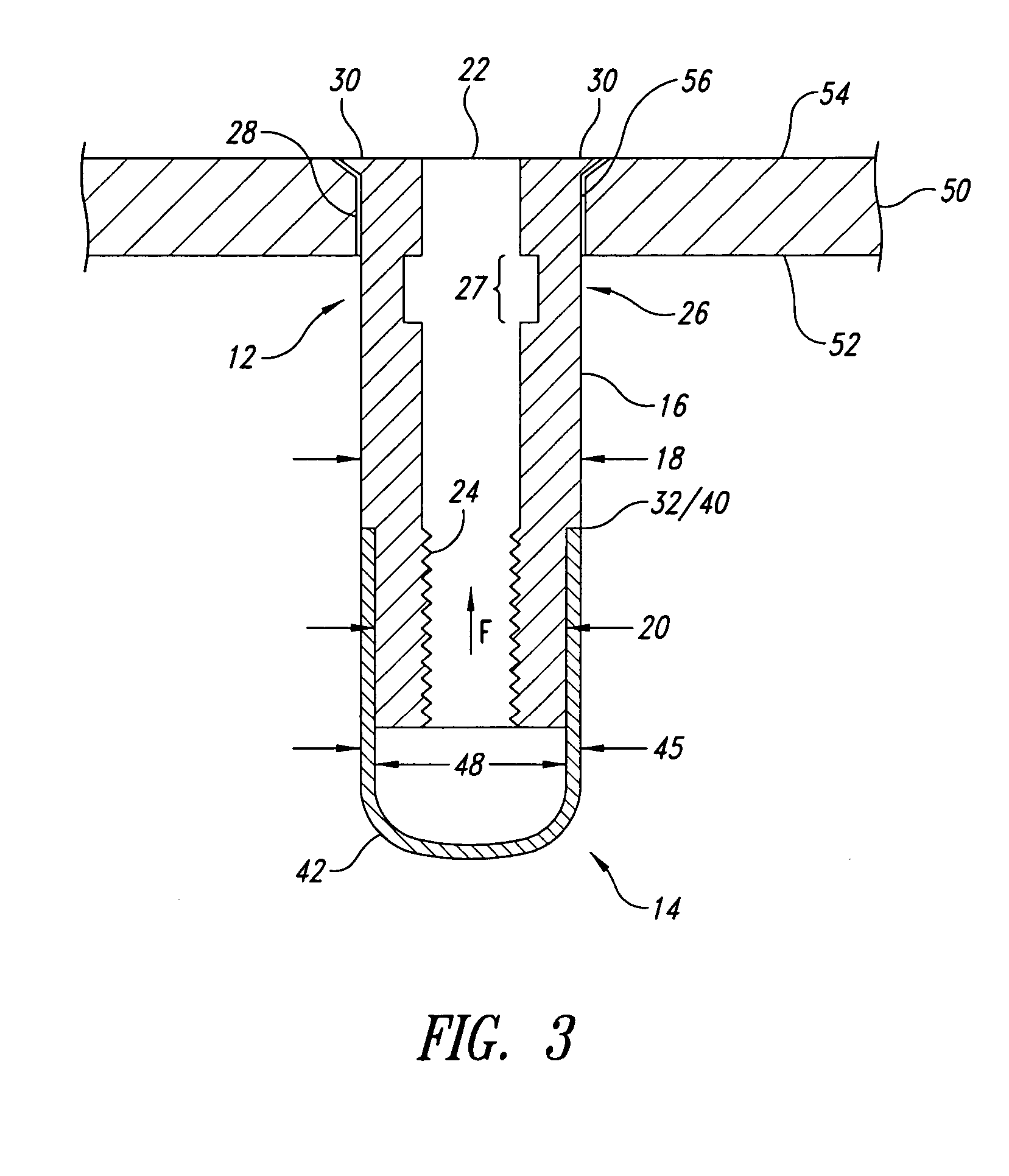

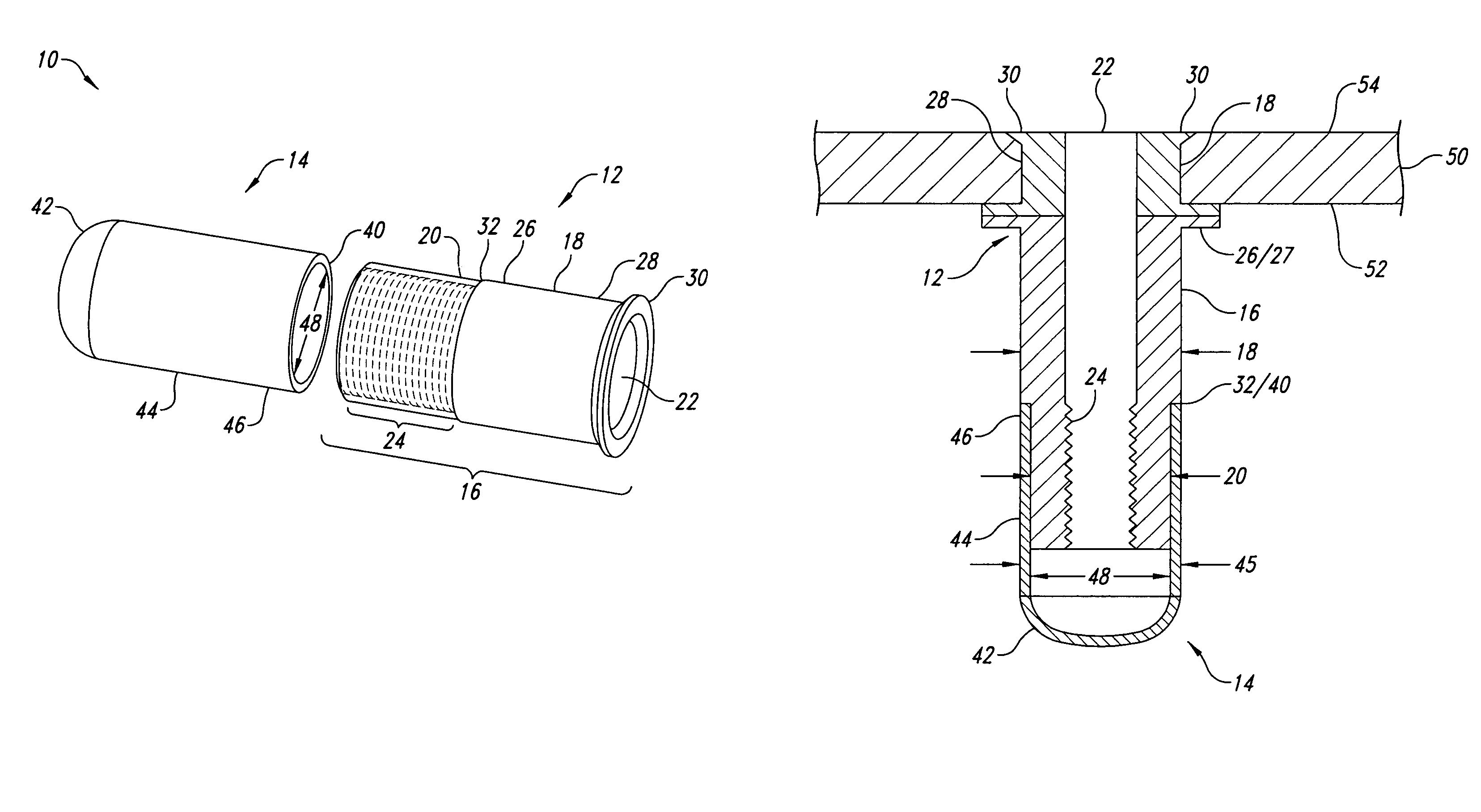

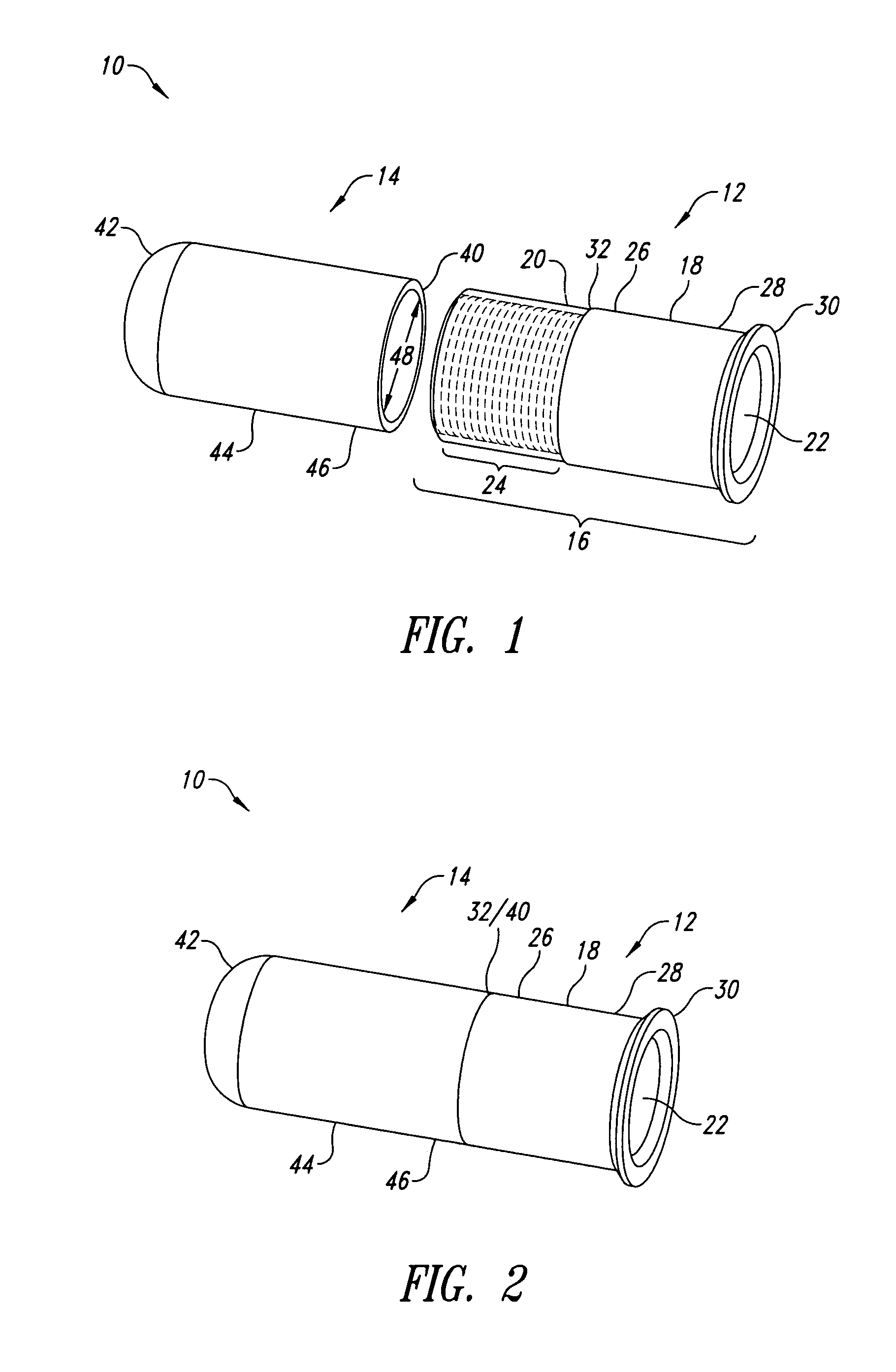

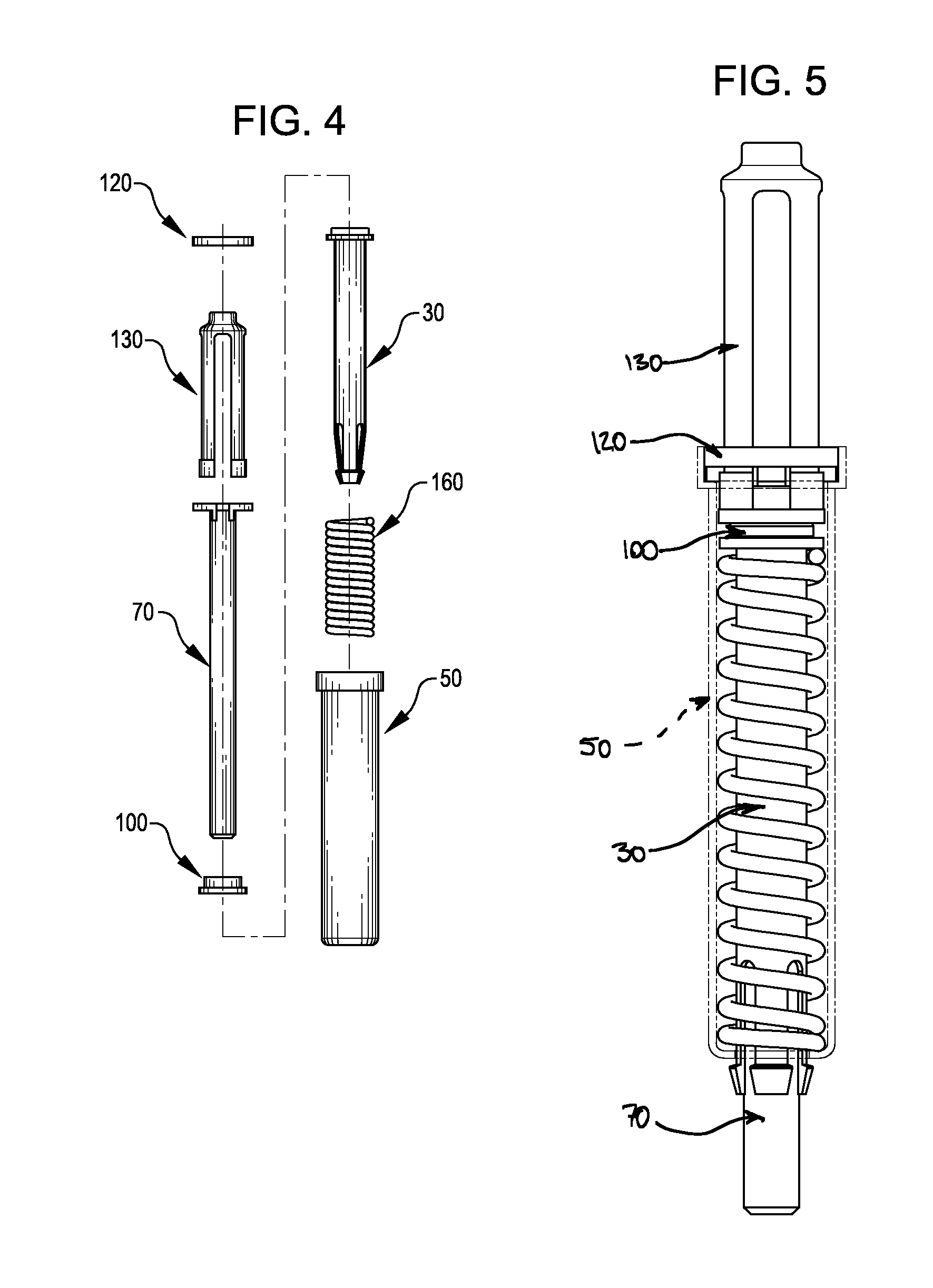

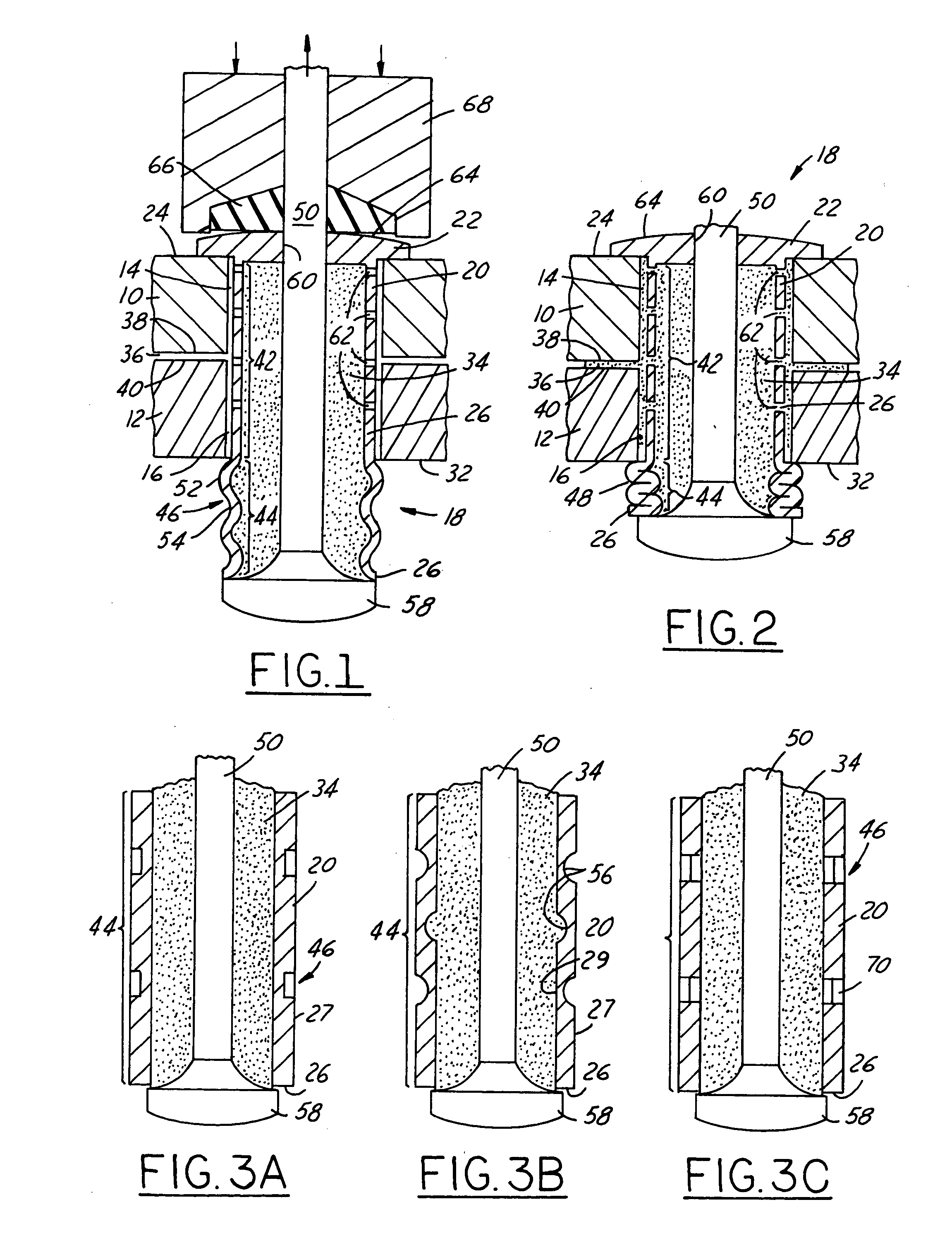

Mandrel assembly and method of using the same

ActiveUS7509829B2Restrict movementExtrusion mandrelsForging/hammering/pressing machinesEngineeringMechanical engineering

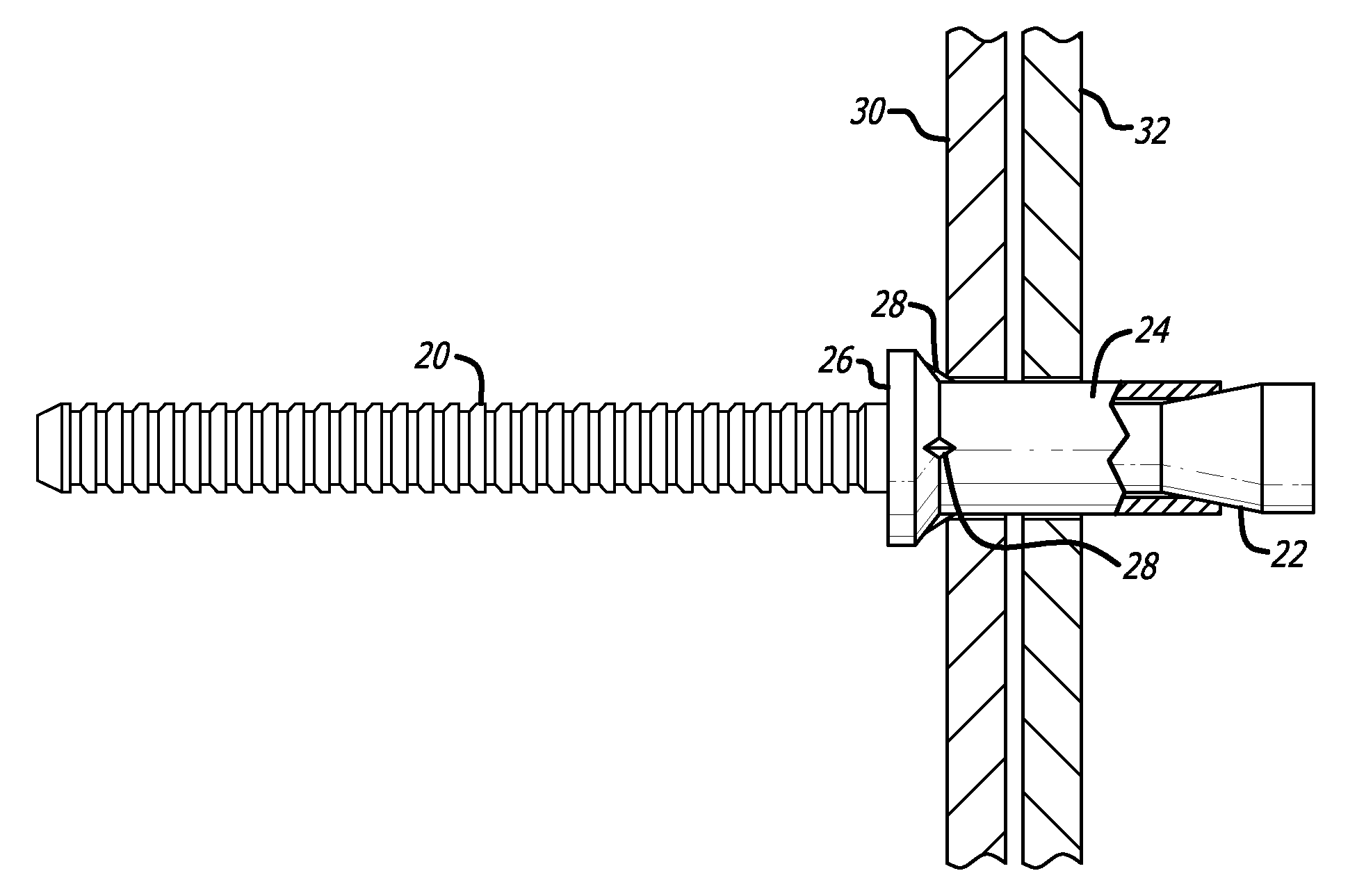

A mandrel assembly has a mandrel, a biasing member, and a outer member. The biasing member biasly maintains the outer member in a first position, which corresponds to a contoured portion of the mandrel, when the outer member is either on the access or the blind side of a workpiece. The biasing member is compressible to allow the outer member to move into a second position as the outer member is moved through an opening in the workpiece. In the first position, the outer member includes a maximum outer circumference that is larger than the opening of the structural workpiece. In the second position, the outer member includes a maximum outer circumference that fits within the opening of the structural workpiece.

Owner:FATIGUE TECH

Blind fastener and nose assembly for installation thereof

Owner:ALCOA GLOBAL FASTENERS

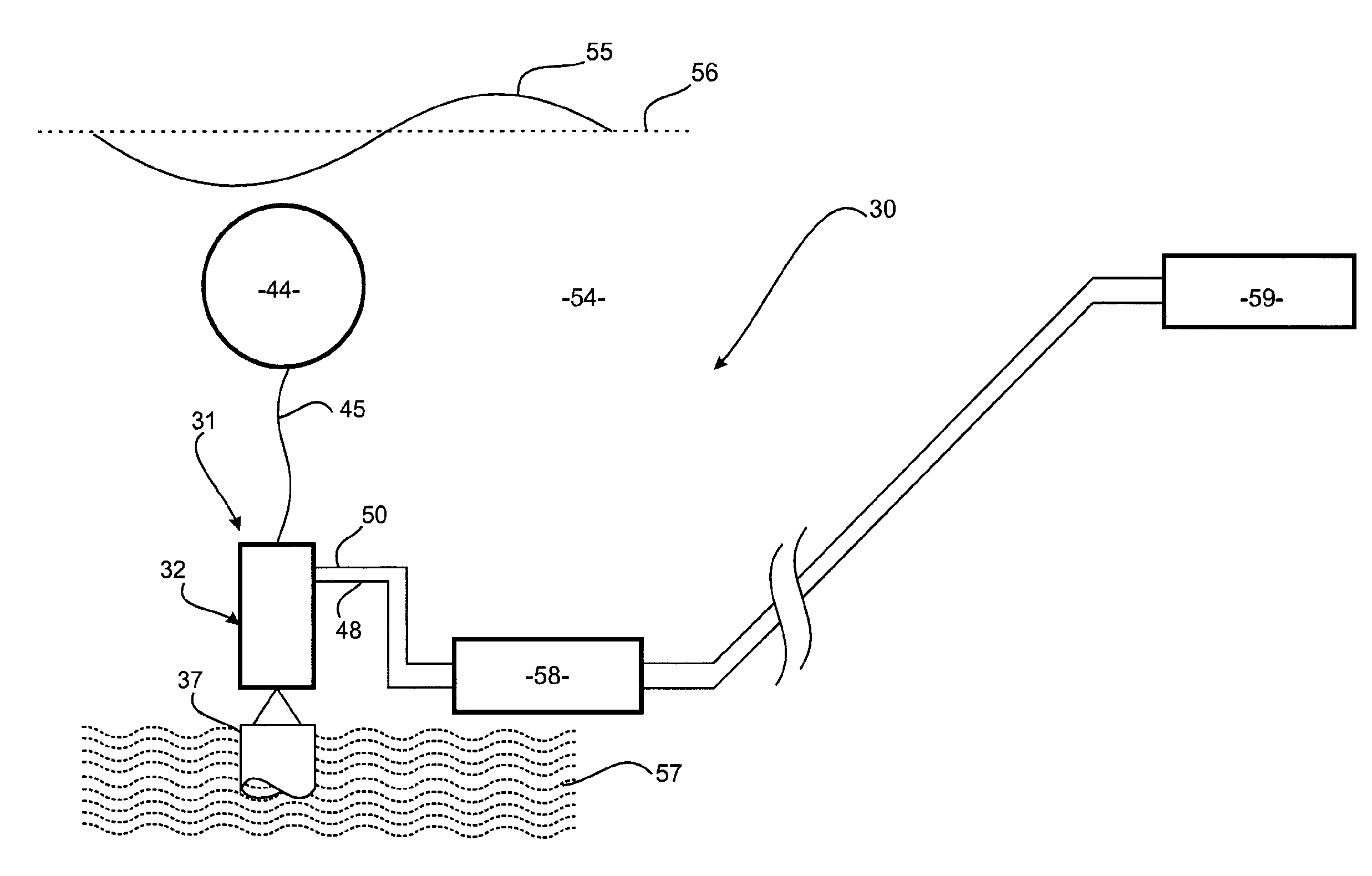

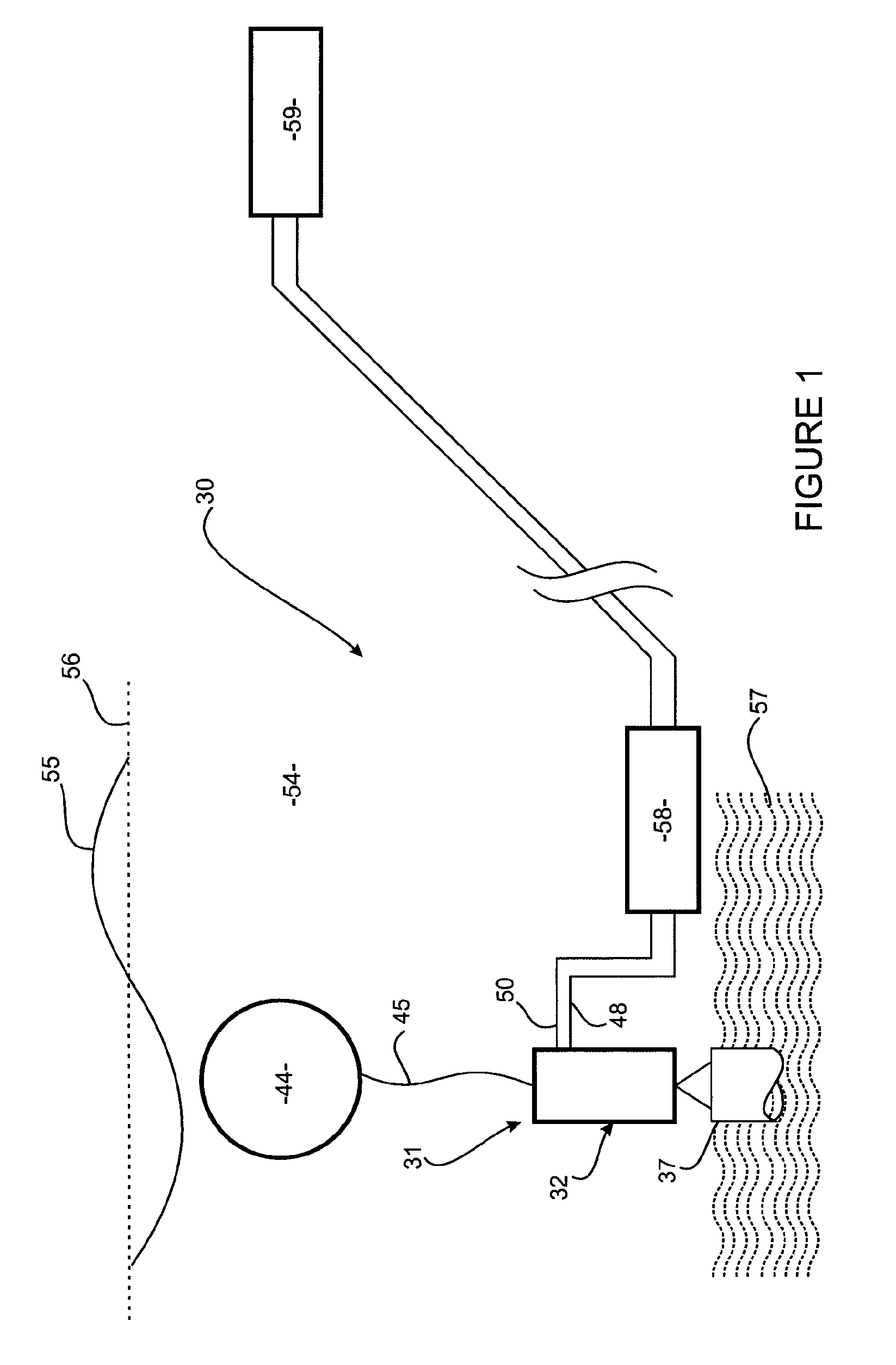

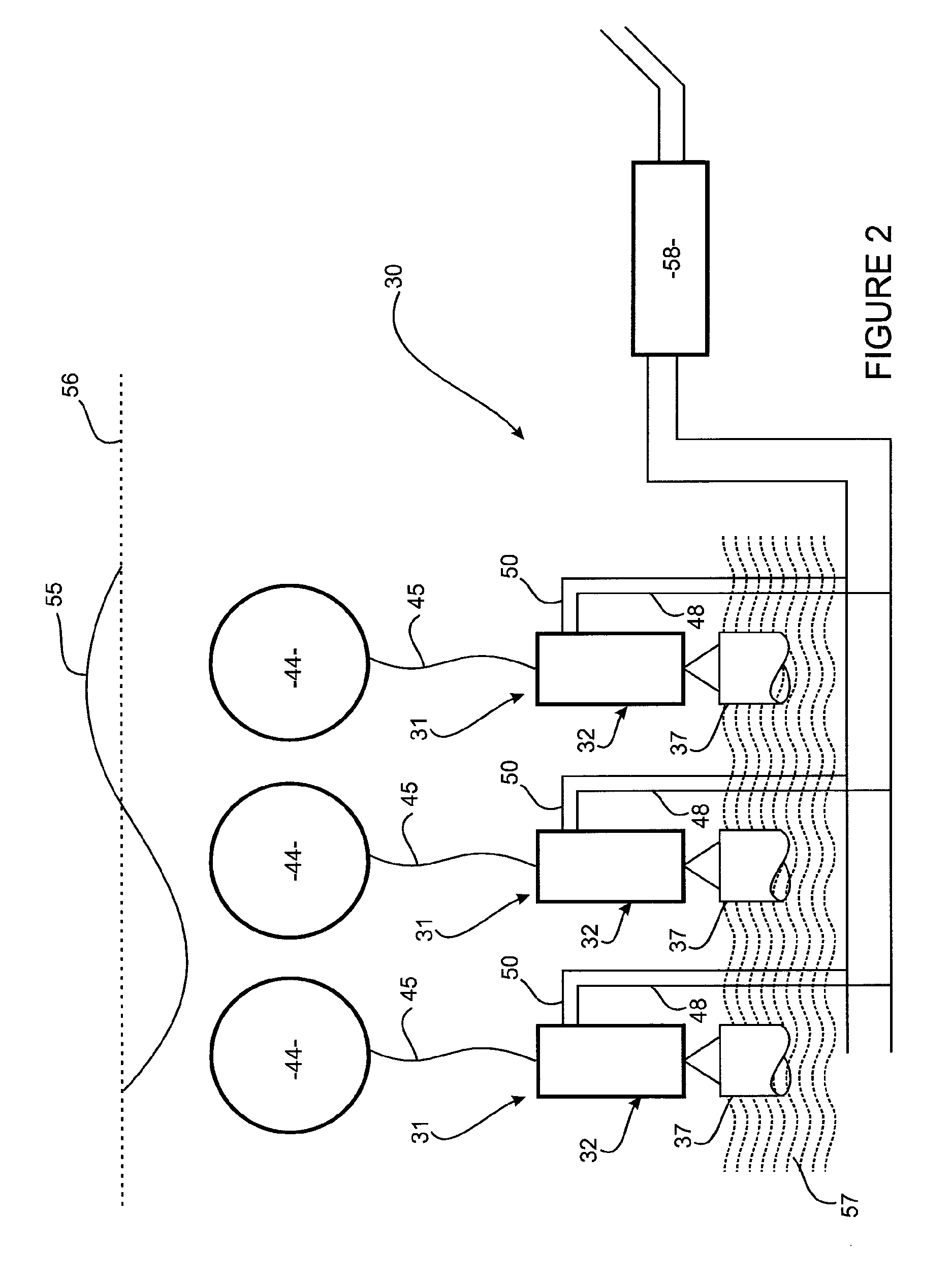

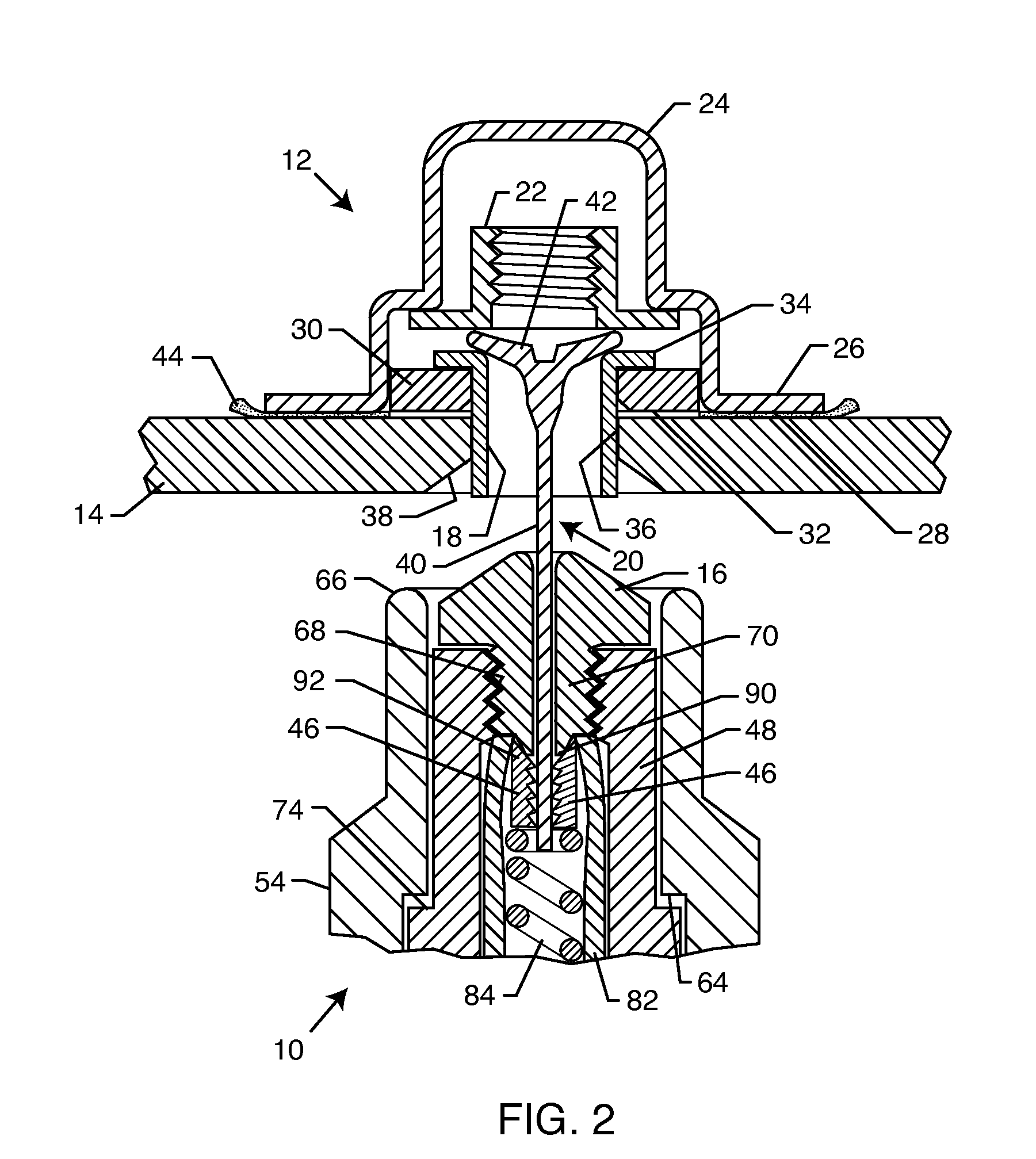

Hydraulic apparatus

A closed-loop hydraulic apparatus 200 for converting wave energy comprises a pump 201 for pumping a fluid through the apparatus 200. The pump 201 includes a body 202 defining a chamber 203, and a piston 207 that partitions the chamber 203 into a working side 208 and a blind side 209. A buoyant actuator is connected to the piston 207. An inlet 64 is connected to the working side 208 of the chamber 203 so that the fluid is able to flow from the inlet 64 and into the working side 208 of the chamber 203. An outlet 63 is connected to the working side 208 of the chamber 203 so that the fluid is able to flow from the working side 208 of the chamber 203 to the outlet 63. A hydraulic controller 102 is operable to control the pump 201 by controlling the pressure of the fluid at the inlet 64 and the outlet 63 so as to optimise the output of the pump 201 in response to tidal variations and / or sea state. The pressure of the fluid at the inlet 64 and the outlet 63 is controlled in accordance with a control algorithm.

Owner:CETO IP

Sealed, blind fastener assembly

Owner:FATIGUE TECH

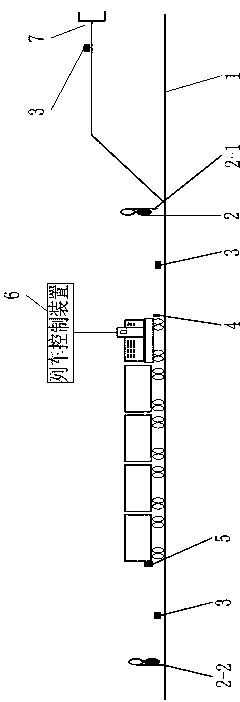

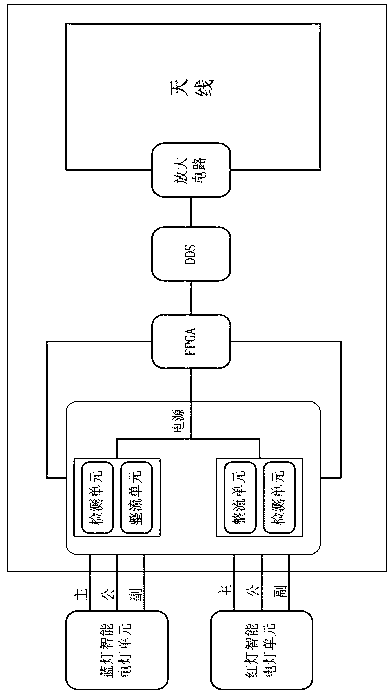

Shunting automatic protection system and automatic shunting method

ActiveCN103171593AAccurate acquisitionPossess the ability to judge the direction of train movementRailway signalling and safetyProtection systemAutomatic testing

The invention discloses a shunting automatic protection system. At least two ground devices are arranged between a front shunting signal machine and a back shunting signal machine of each station track. The ground devices collect shunting state signals of the shunting signal machines and engine driving state signals and send the collected signals to an engine device. The signals are sent to a train control device after being processed by the engine device. The shunting automatic protection system has the advantages that shunting signal machine states and current positions can be acquired timely and accurately when the front end of a car row or the back end of the car row is close to the shunting signal machine for certain distance. Current positions of the front end of the car row or the back end of the car row can be acquired timely and accurately when the front end of the car row or the back end of the car row is close to a blind siding bottom gear position for certain distance. The shunting signal machine states and the positions of the front end of the car row or the back end of the car row are sent to a train control device timely so as to provide conditions for forced automatic stop movement taken by the train control device.

Owner:HENAN LANXIN TECH

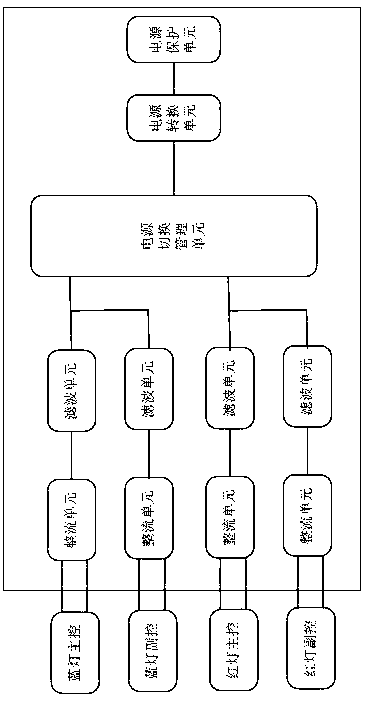

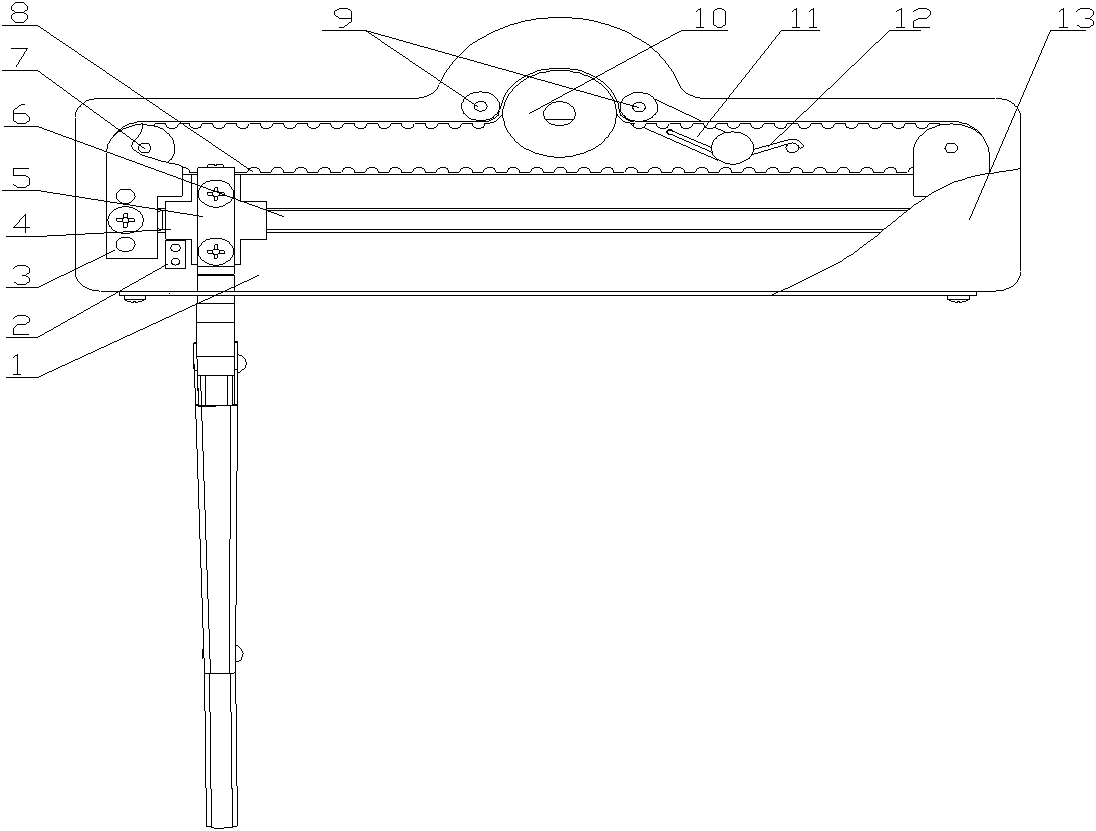

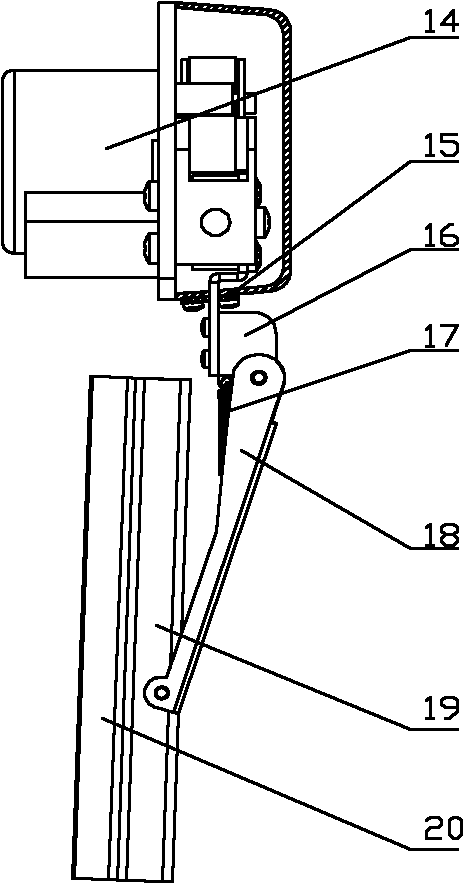

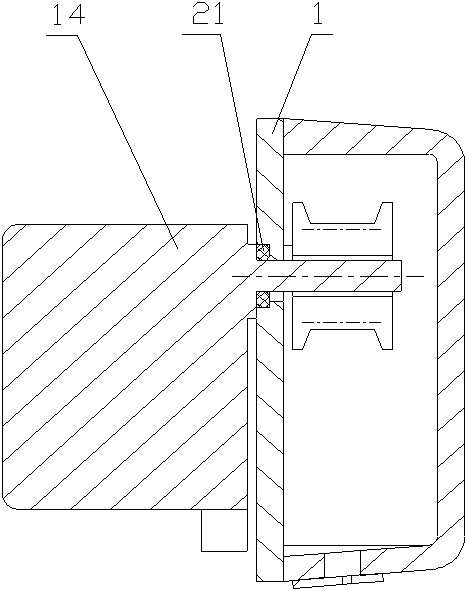

Rain wiper of camera protective cover and video monitoring system

ActiveCN102123240AIncrease working areaEliminate dead spotsTelevision system detailsColor television detailsVideo monitoringFixed frame

The invention belongs to the field of video monitoring, and provides a rain wiper of a camera protective cover and a video monitoring system; the rain wiper comprises a substrate, a reflective optical coupler, a fixing frame, a sliding block, a connecting sheet, a guide rail, a driven wheel, a belt, a pinch roller, a belt wheel, a pressing sheet, a spring, a shell, a motor, a sealing rubber bar, a large rain wiper arm, a small rain wiper arm, a rubber bar clamping plate and a rubber bar; the connecting sheet and the sliding block are fixed together; the connecting sheet is used for clamping the belt; the sliding block is sheathed on the guide rail; the connecting sheet is connected with the large rain wiper arm; the large rain wiper arm is connected with the small rain wiper arm; the small rain wiper arm is connected with the rubber bar clamping plate; the rubber bar clamping plate is connected with the rubber bar; and the spring is further connected between the large rain wiper arm and the small rain wiper arm. In the invention, the structure such as a reflective optical coupler is adopted so that the work area is rectangular and the view window blind side splodge is effectively eliminated; and the belt torque is born on the motor shaft so that the damage rate of the rain wiper is reduced.

Owner:TIANJIN YAAN TECH CO LTD

Installation tool for use with a liner sleeve attachment

Owner:PHYSICAL SYST

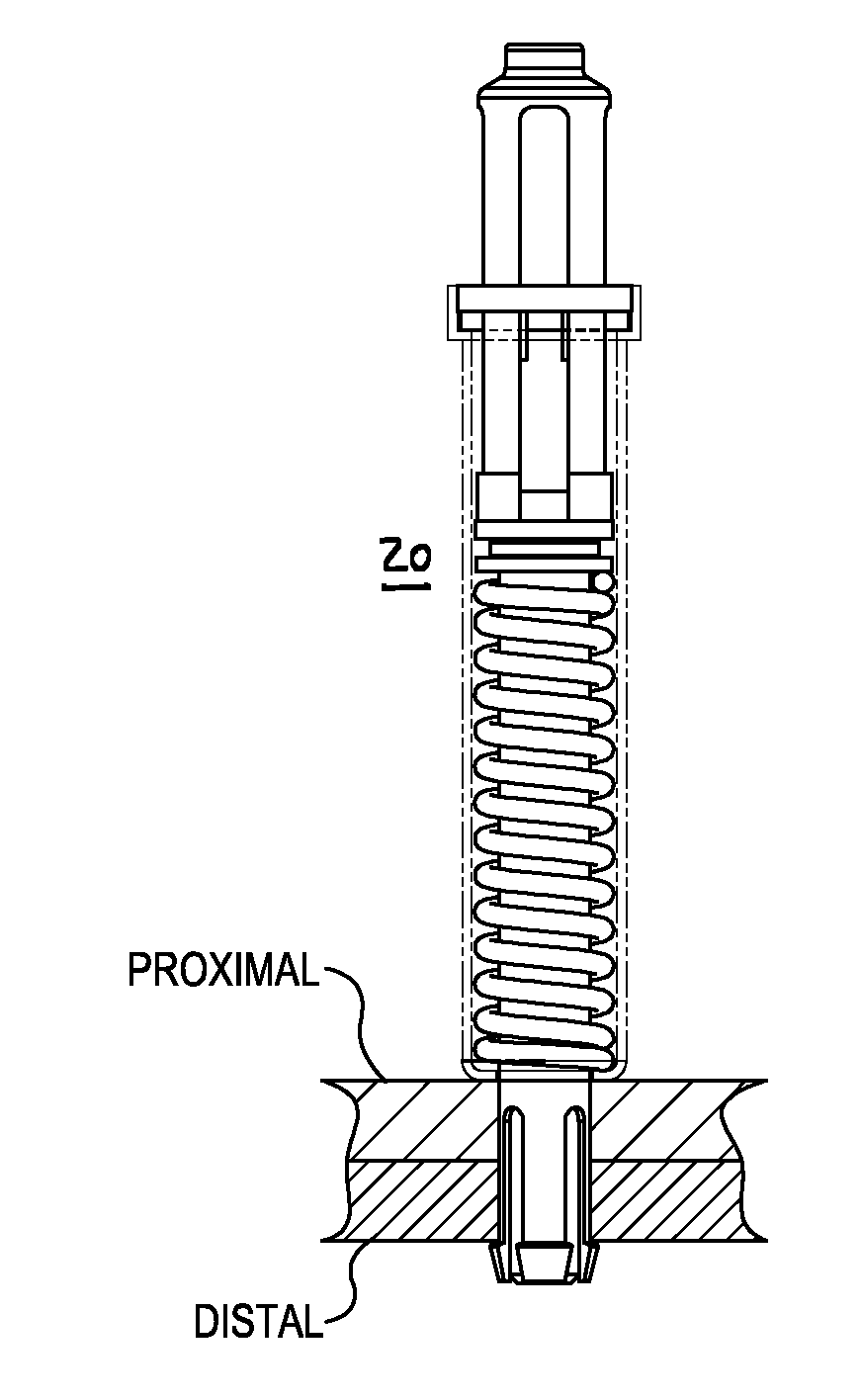

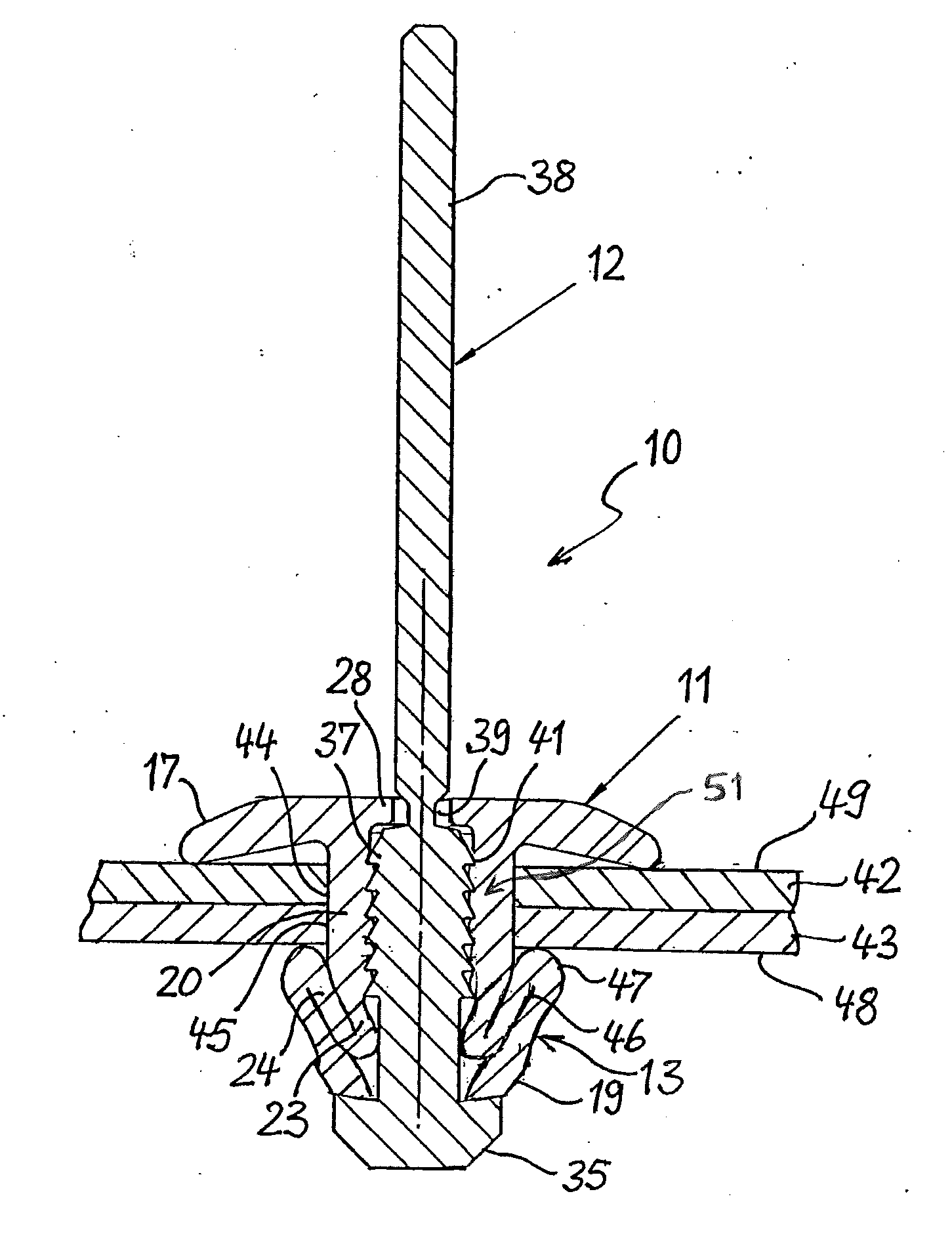

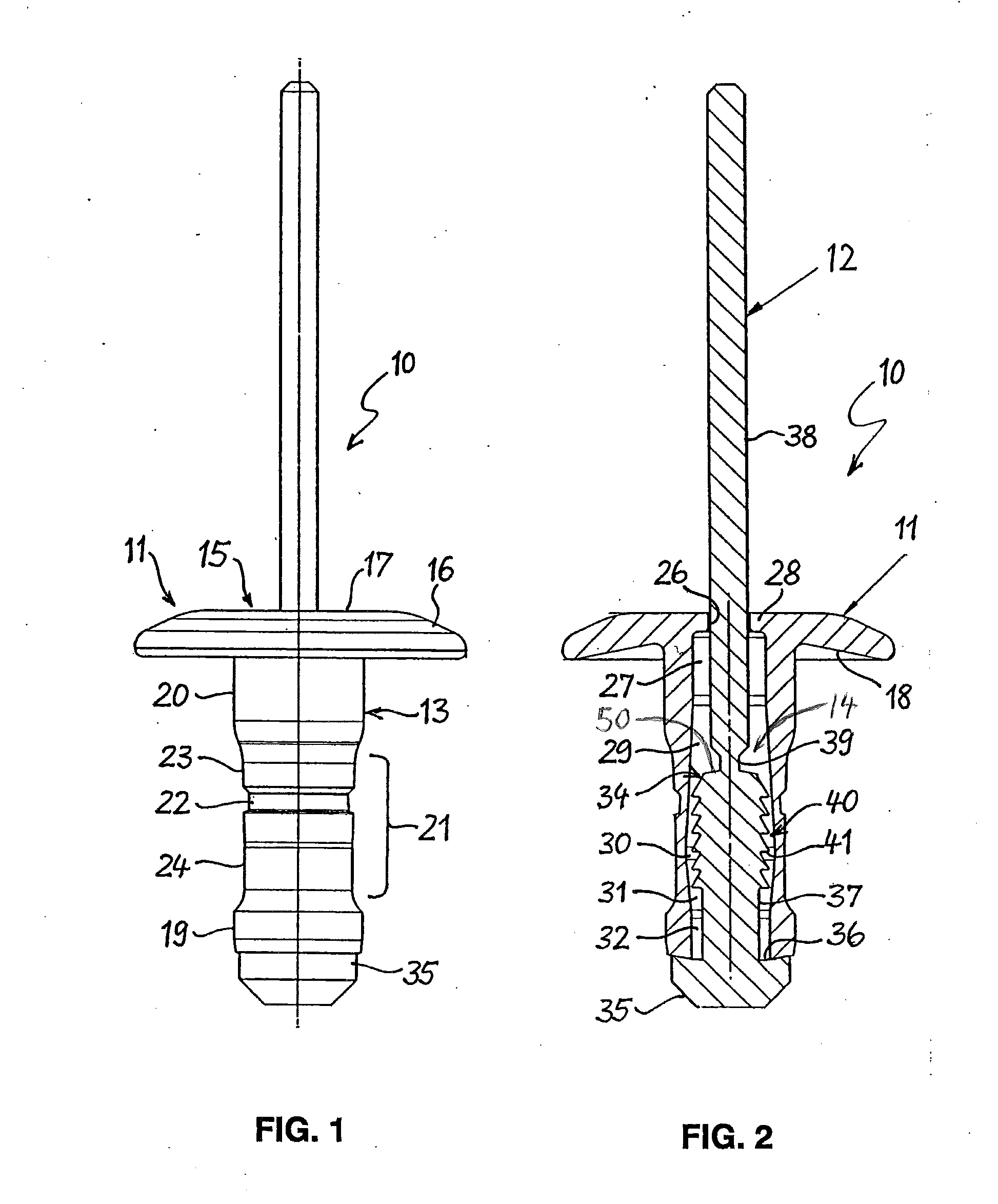

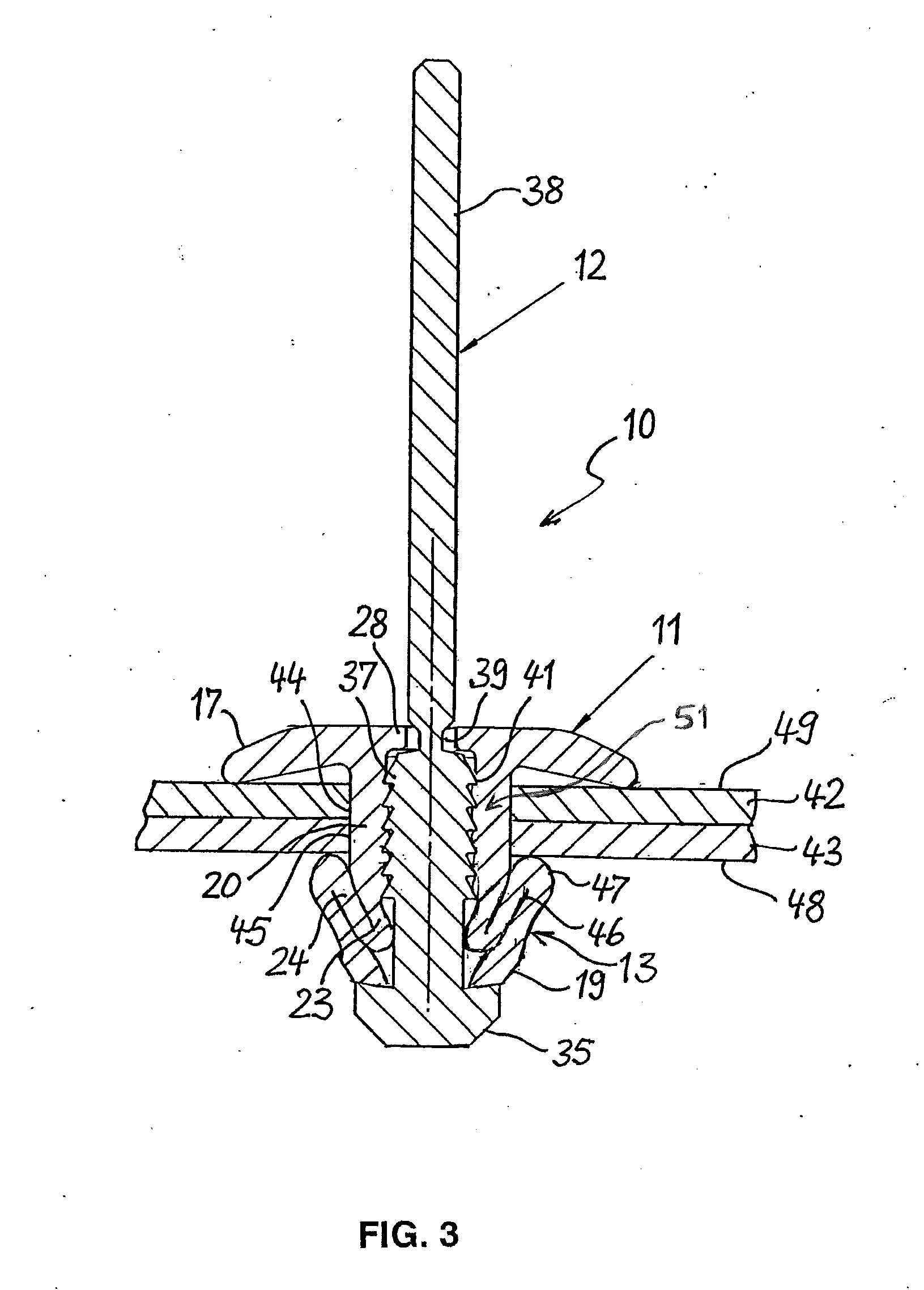

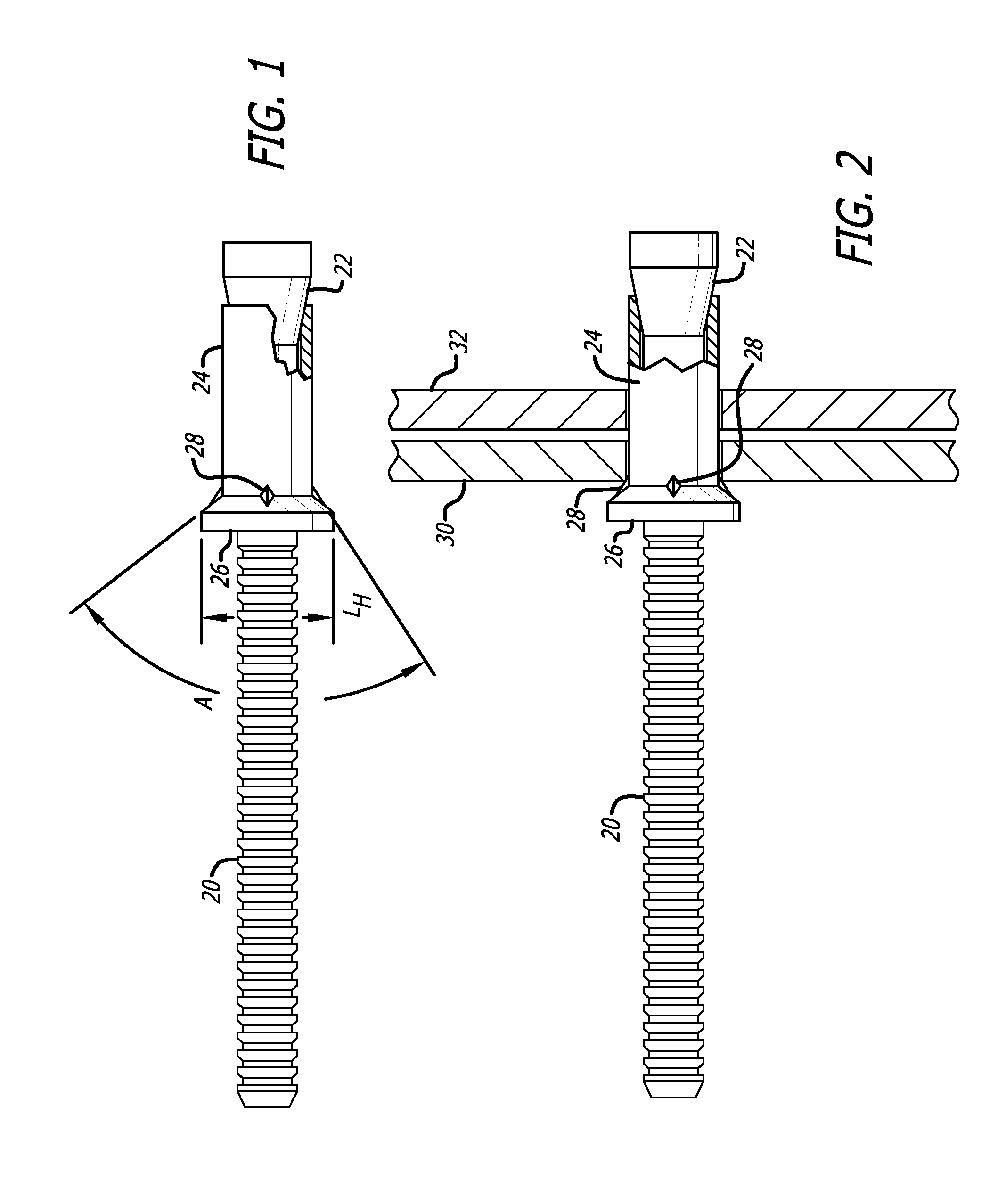

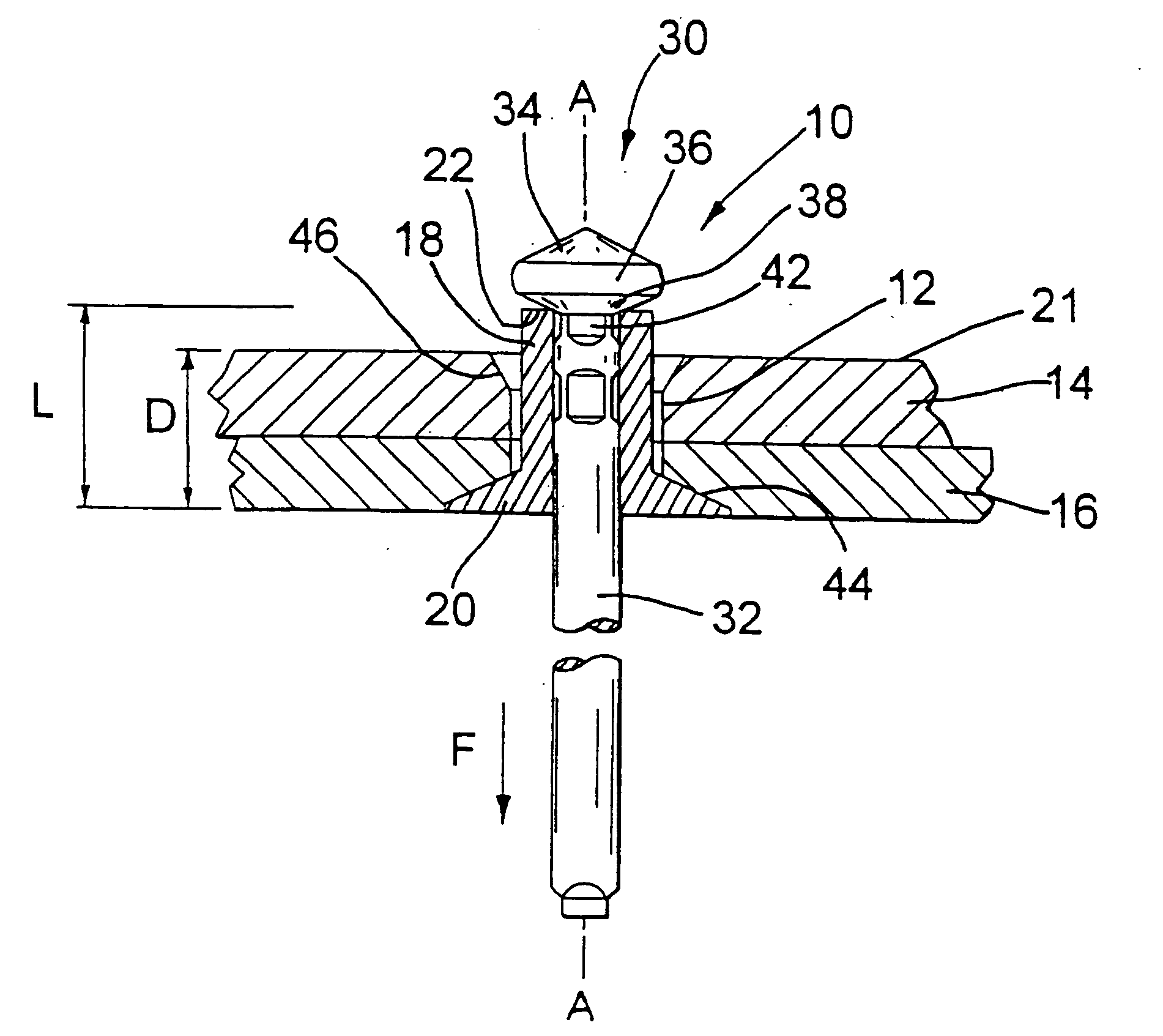

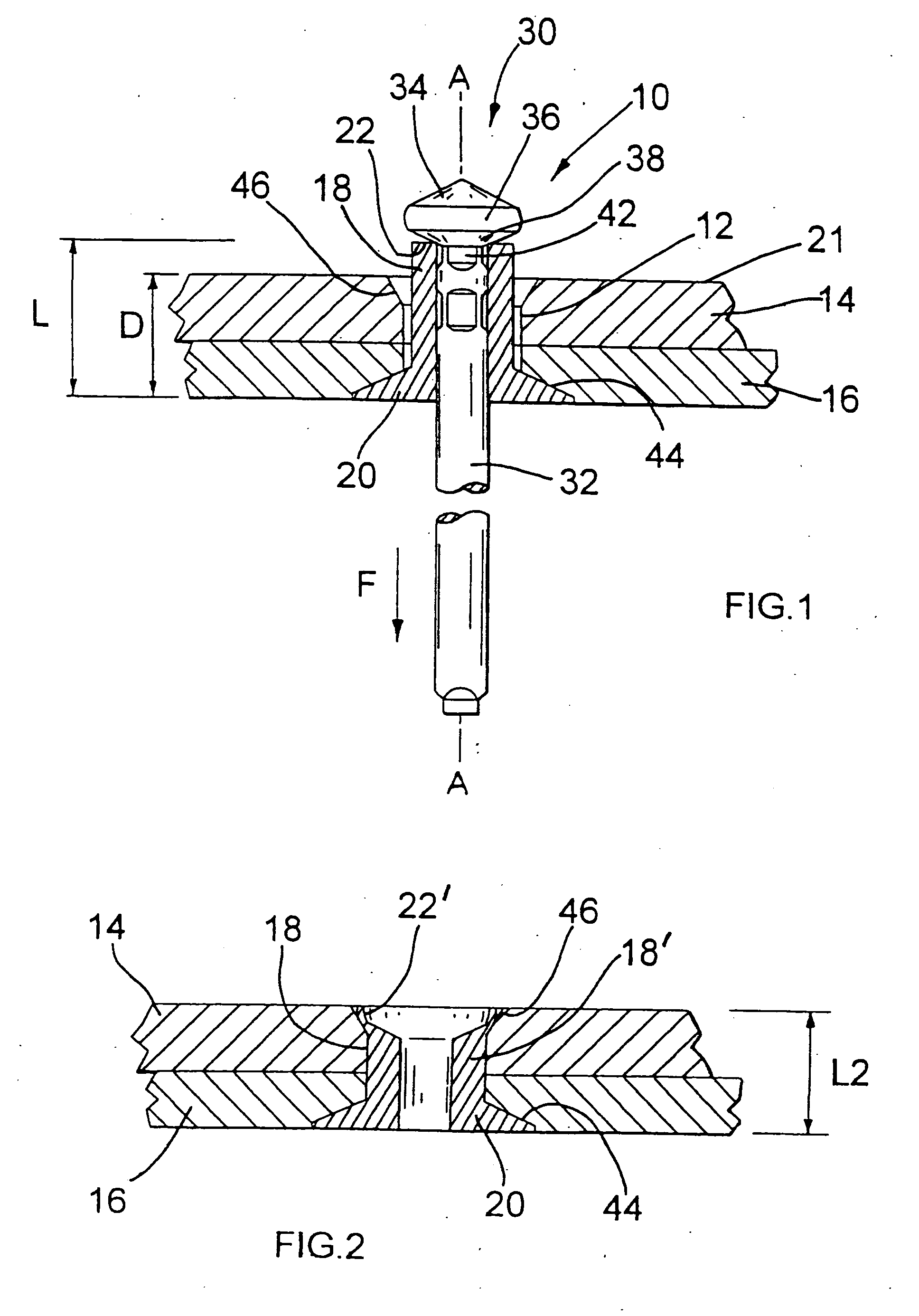

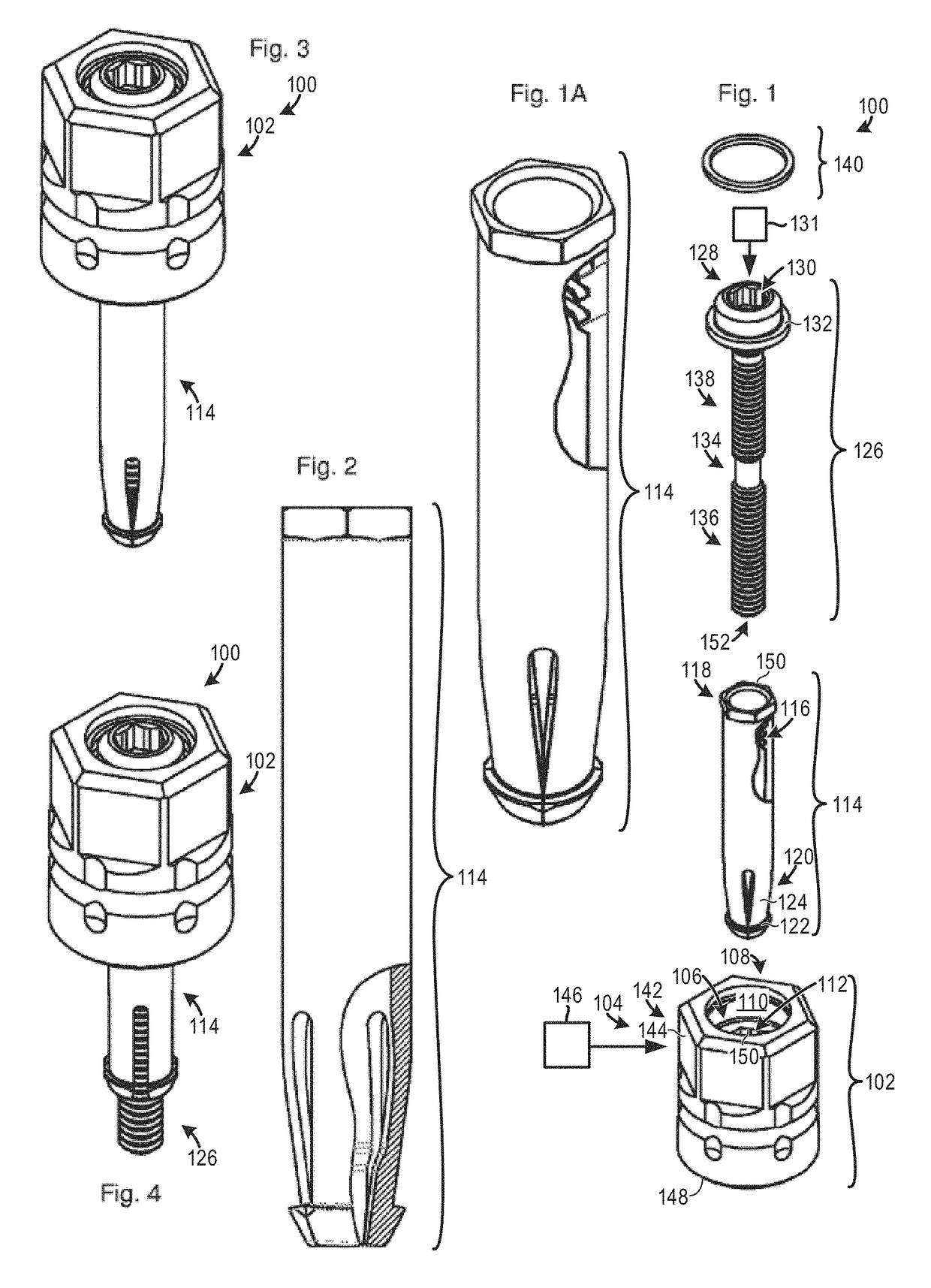

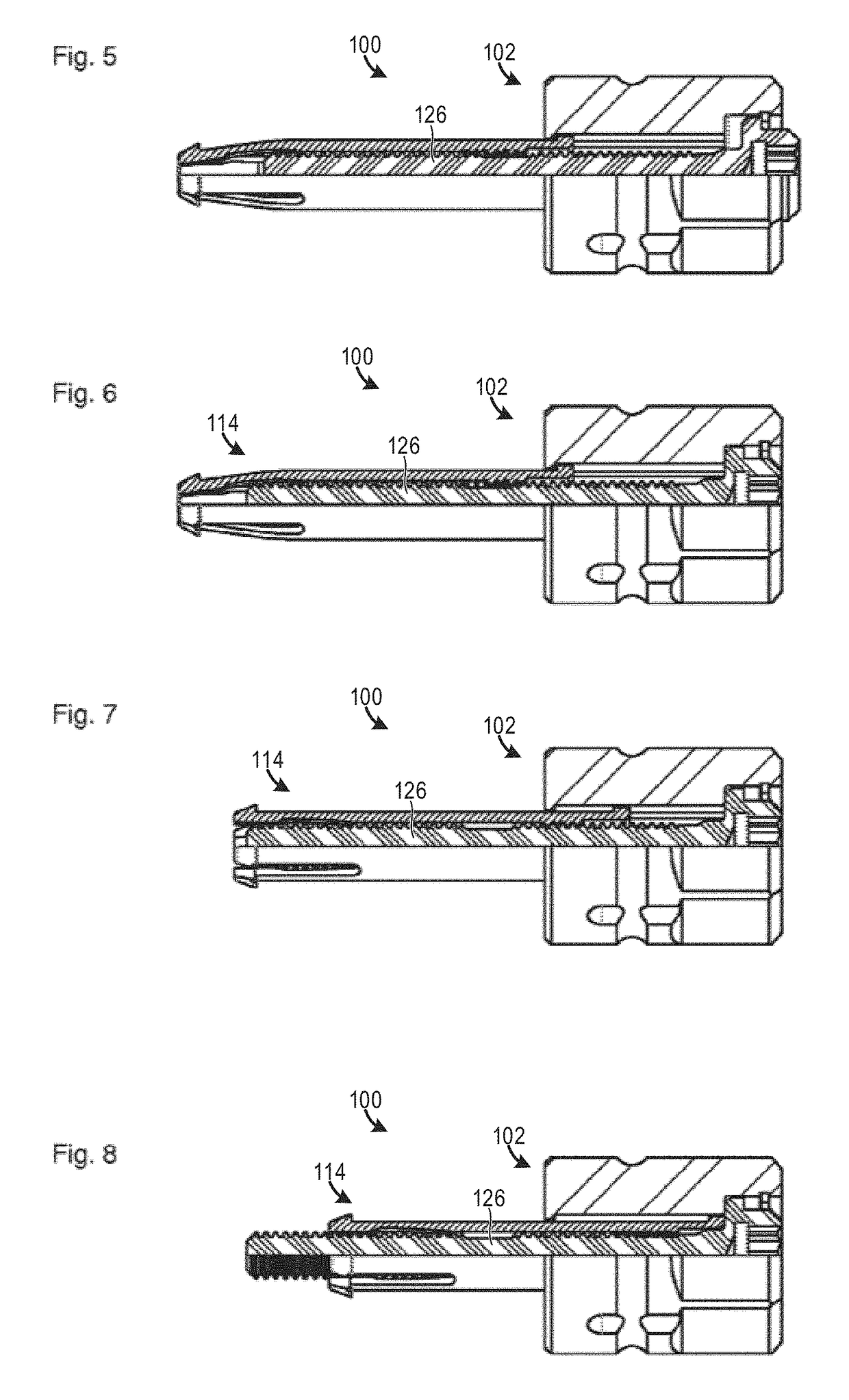

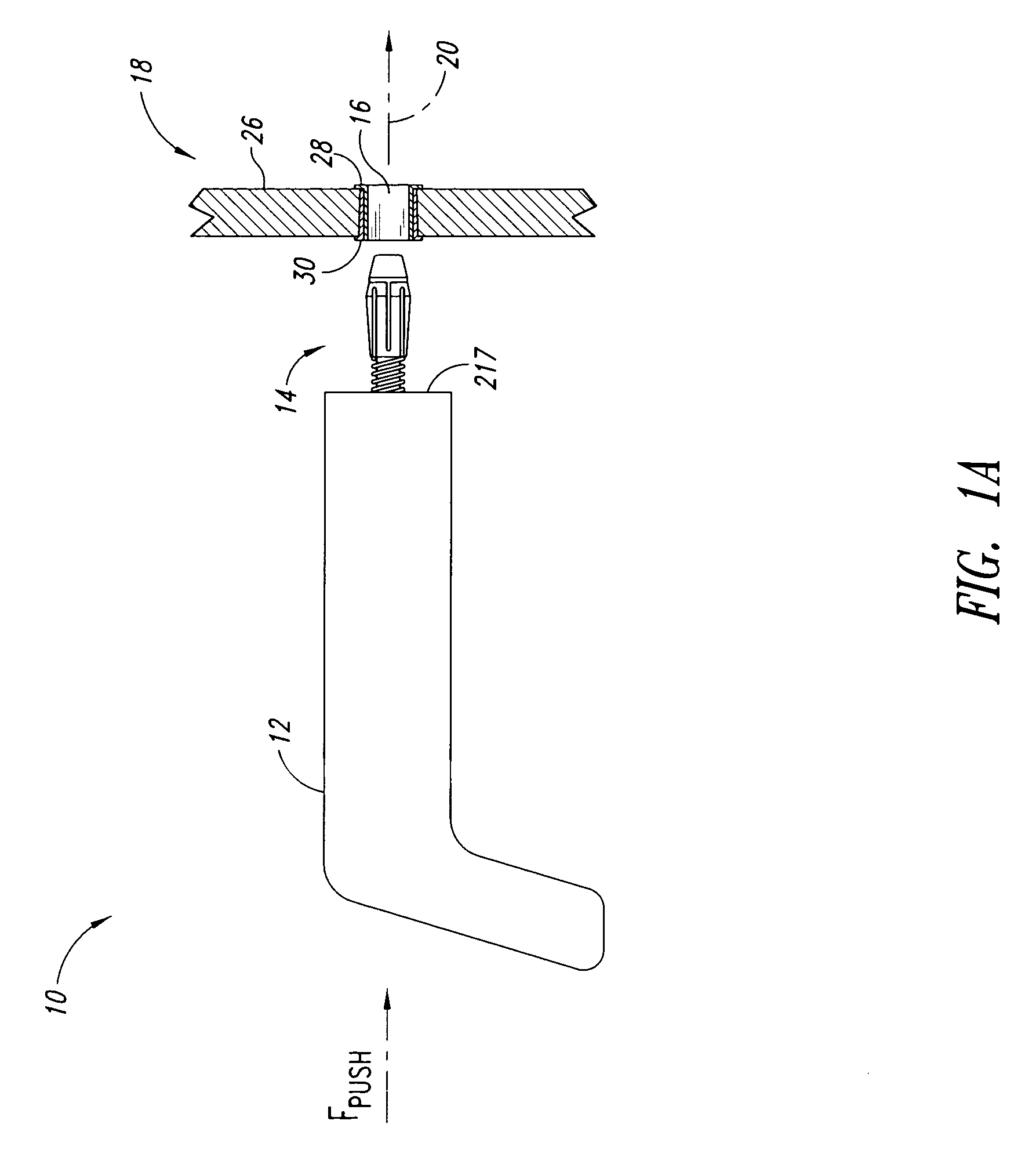

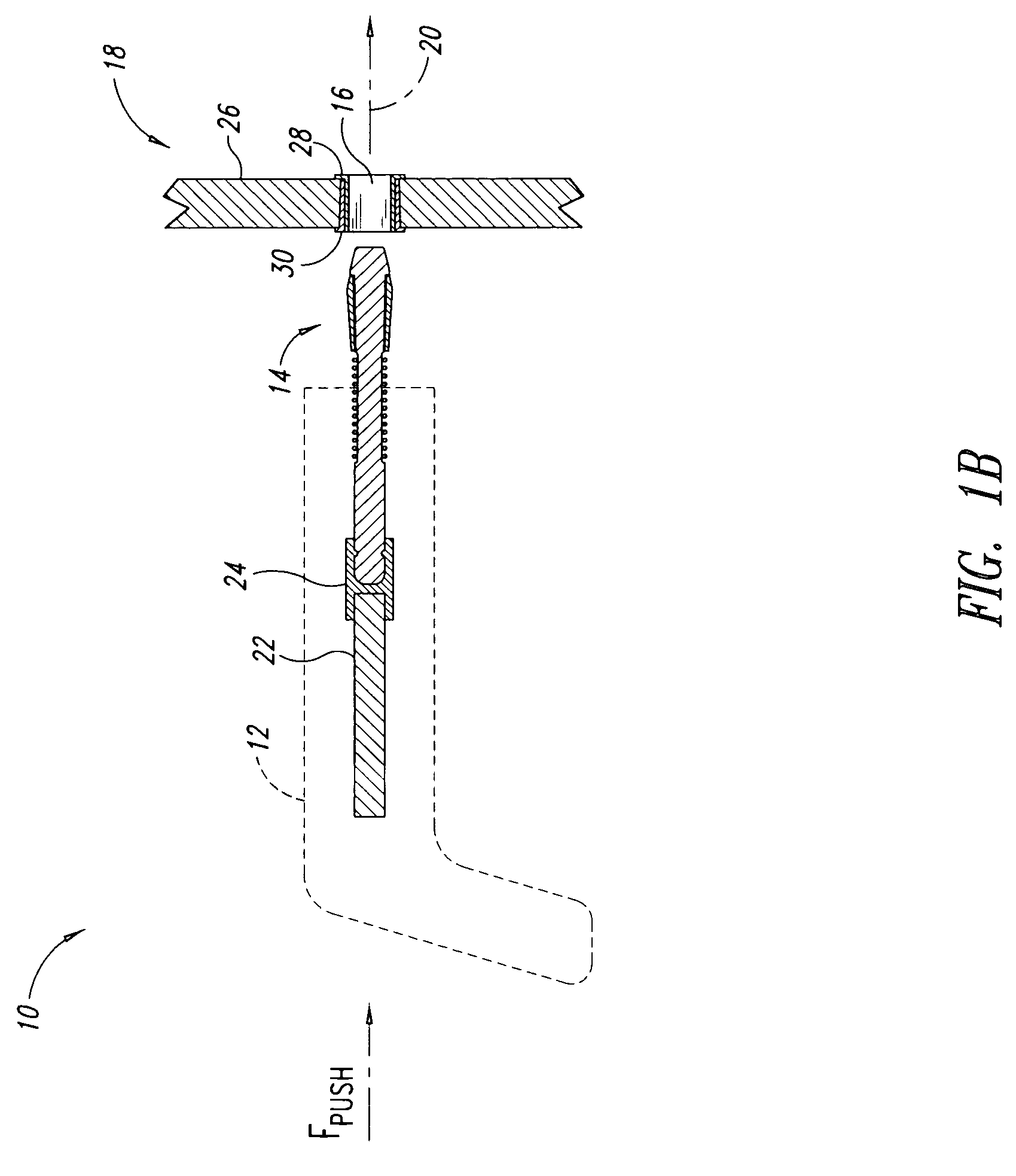

Biased blind side temporary fasteners, systems and methods

ActiveUS20130084130A1High level of workEasy to manufactureSnap-action fastenersSheet joiningEngineeringBlind side

Biased blind side fasteners and related methods for temporarily securing together at least two work pieces that each define a hole through which at least a portion of the fastener may pass. Fastener embodiments include an elongate, hollow case for substantially housing a generally cylindrical collet body and a bias element for urging the collet body into the case, and at least partially housing a central rod having a proximal end linked to a proximal portion of the case by a web element and a distal end extending from the case. Such embodiments further include a translatable plunger for temporarily overcoming the urging of the bias element and causing extension of the collet body away from the case, thereby permitting insertion of a fastener into the work pieces' holes, wherein the plunger is formed to substantially translatably pass through the web element.

Owner:CENTRIX

Blind rivet with a plastic rivet body

A blind rivet made of plastic, the shank of the body has a first region located between the head and the foot end, and the first region has a reduced first wall thickness. Within the first region is located a second region with a second wall thickness further reduced as compared to the first region. The first and second regions are arranged such that, as a result of the rivet setting process, the wall of the shank forms a roll fold with an annular bead that is pressed axially against the blind side of the workpiece.

Owner:NEWFREY

Blind rivet method

There is provided a blind rivet including an axially extending hollow tubular body having a tail end face at one end and a pre-formed radially enlarged flange at the other end, together with a mandrel having a stem which extends co-axially though the body and having enlarged head adjacent the tail end of the body, the stem having a weakened region immediately adjacent the head. There is also provided a method of fastening at least two workpieces using such a blind rivet, including providing the blind side of the workpieces with a countersunk region to accommodate the conically deformed tail end of the body after setting, substantially flush therewith.

Owner:NEWFREY

Temporary Rivet

A temporary fastener or temporary blind rivet having a cylindrical sleeve and a sleeve head thereon, the region where the sleeve and sleeve head mate having a plurality of local protrusions thereon, with a stem passing through the sleeve head and sleeve, the stem having an enlarged stem head thereon adjacent the end of the sleeve opposite the sleeve head, the stem for pulling relative to the sleeve head to cause the enlarged stem head to form a blind side head on the sleeve, to pull the workpieces together, to cause the local protrusions to make depressions in, and to fill the depressions in, an outer edge of the hole in the adjacent workpiece, and to pull through the sleeve and sleeve head to expand the sleeve into a tight fit in the hole in the workpieces. The protrusions make indentations in the edge of the hole in the adjacent workpiece to provide increased resistance to spinning when the temporary blind rivet is drilled out for a permanent fastener.

Owner:ALLFAST FASTENING SYST

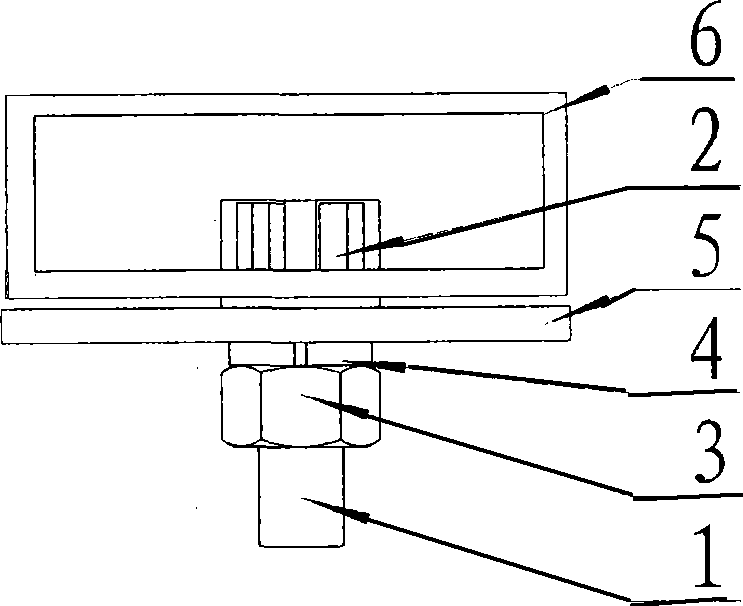

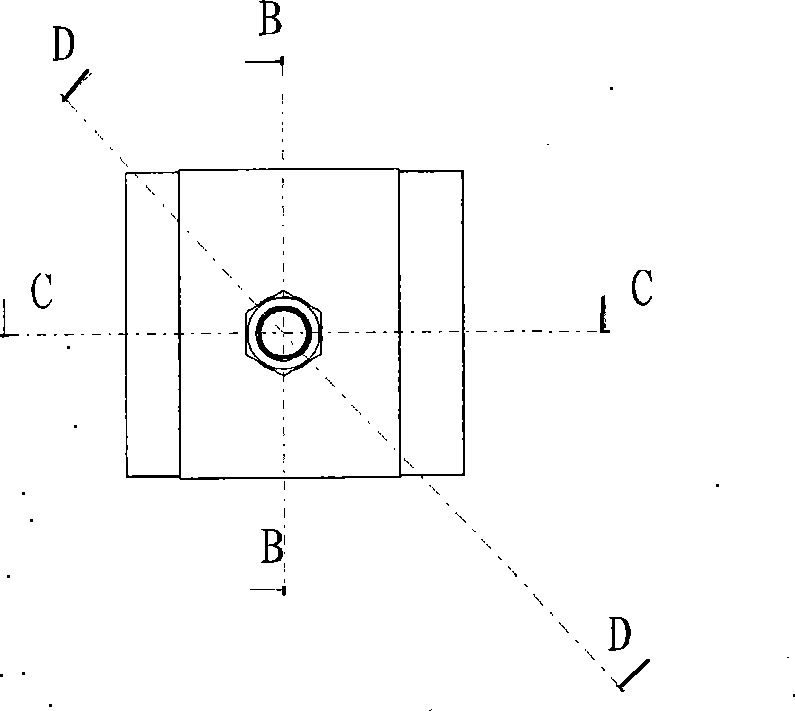

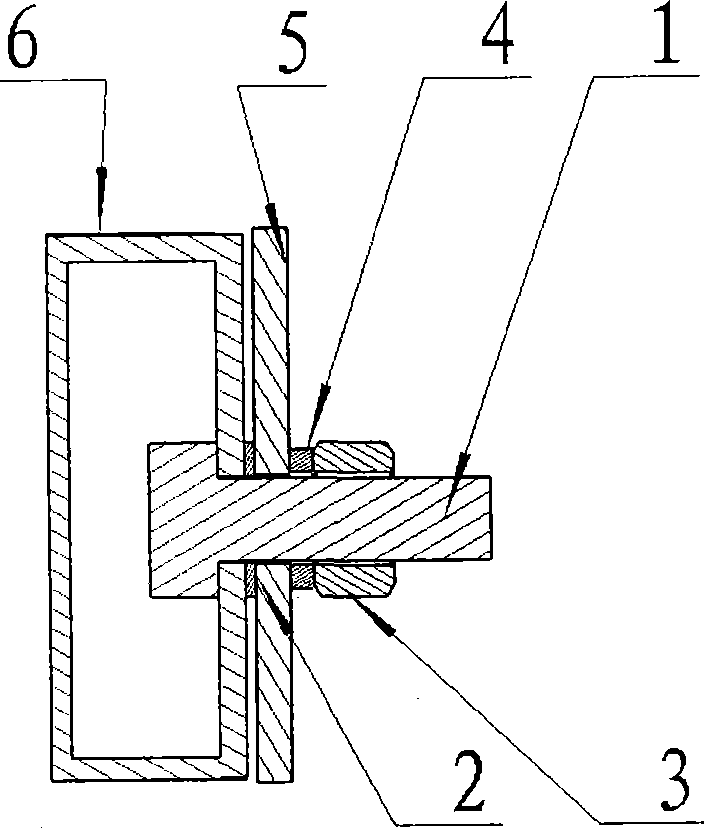

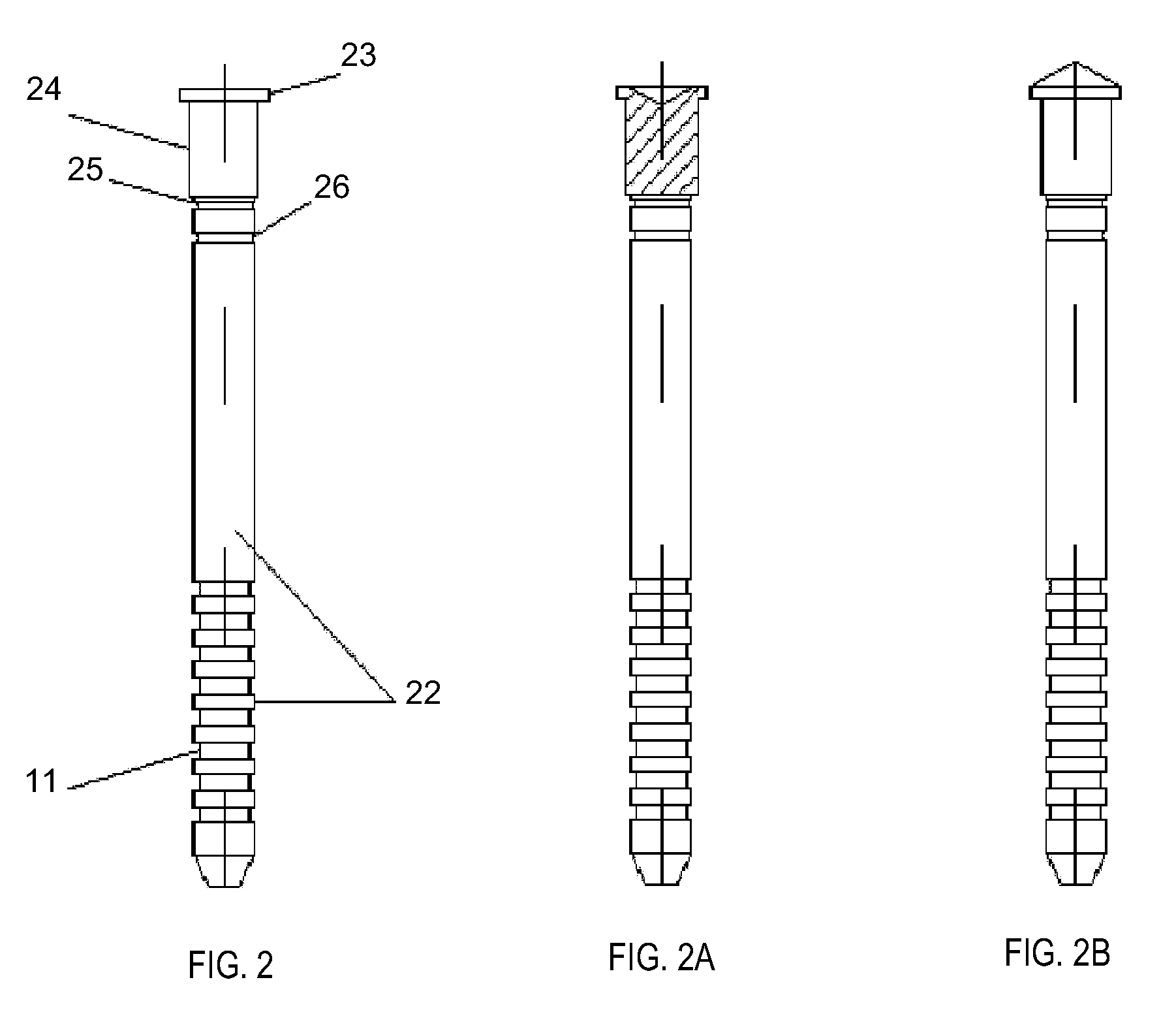

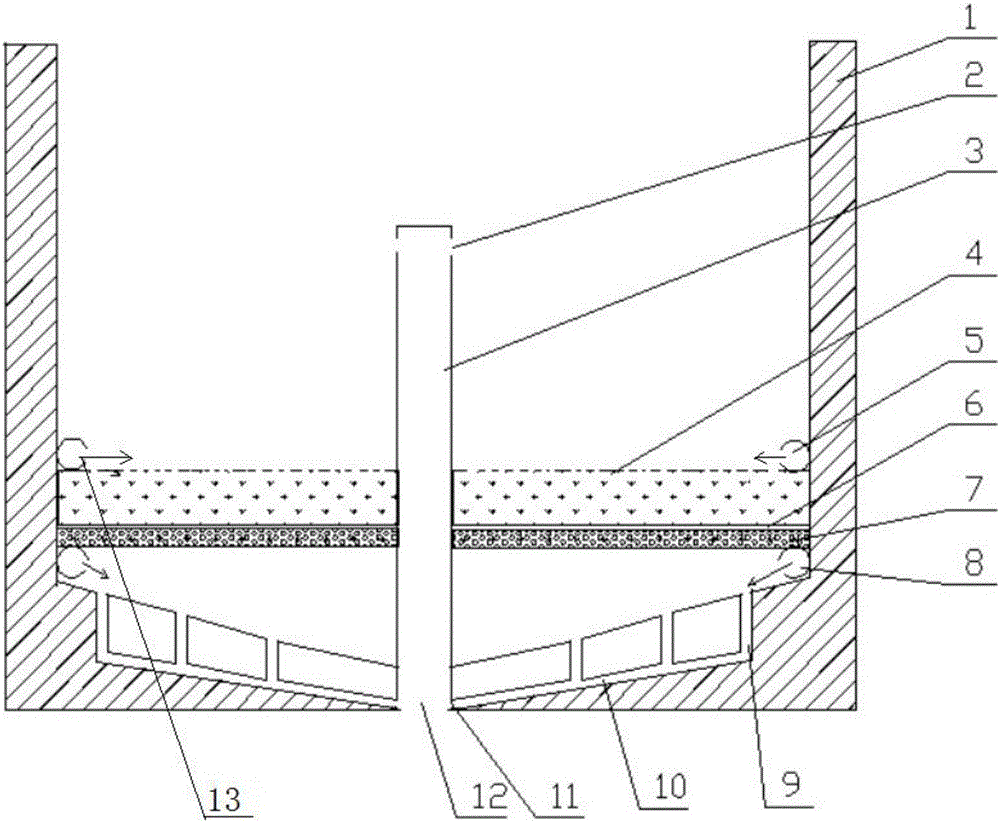

Single side mounting bolt connecting component, bolt gasket and mounting method thereof

The invention discloses a unilateral mounting bolt connector, a bolt gasket and an installation method thereof. The bolt connector comprises a screw and a bolt head at one end of the screw, wherein a contour line of the cross section of the bolt head is a closed pattern in shape of concavo-convex intervals. The bolt gasket comprises a base with holes and upright posts which are arranged on the base, wherein the upright posts are arranged on the base at intervals along a rotary plane. The bolt connector and the bolt gasket with the structures and the installation method break the structures of the prior bolt connector and the gasket and the prior installation method. When a blind hole is provided with a bolt, the method can finish installation operation on one side, and can conveniently detach a bolt component repeatedly. The method solves the problems that the prior bolt structure can not achieve repeated usage of detachment at the blind side and the method does not break a connected element during detachment. The method prolongs service life of the connected element, and saves cost greatly.

Owner:DONGFENG MOTOR CORP HUBEI

Blind rivet method

There is provided a blind rivet comprising an axially extending hollow tubular body having a tail end face at one end and a pre-formed radially enlarged flange at the other end, together with a mandrel having a stem which extends co-axially though the body and having enlarged head adjacent the tail end of the body, the stem having a weakened region immediately adjacent the head, whereby the mandrel head having an outer diameter greater than an outer diameter of said body, usually by between 4% and 9%, and which has a uniform conical shoulder extending between said outer diameter of the head and the stem, so as to exert a setting force having an axial component for compressing the rivet body axially and an angular component effecting conical deformation of the tail end radially. There is also provided a method of fastening at least two workpieces using such a blind rivet, including providing the blind side of the workpieces with a countersunk region to accommodate the conically deformed tail end of the body after setting, substantially flush therewith.

Owner:NEWFREY

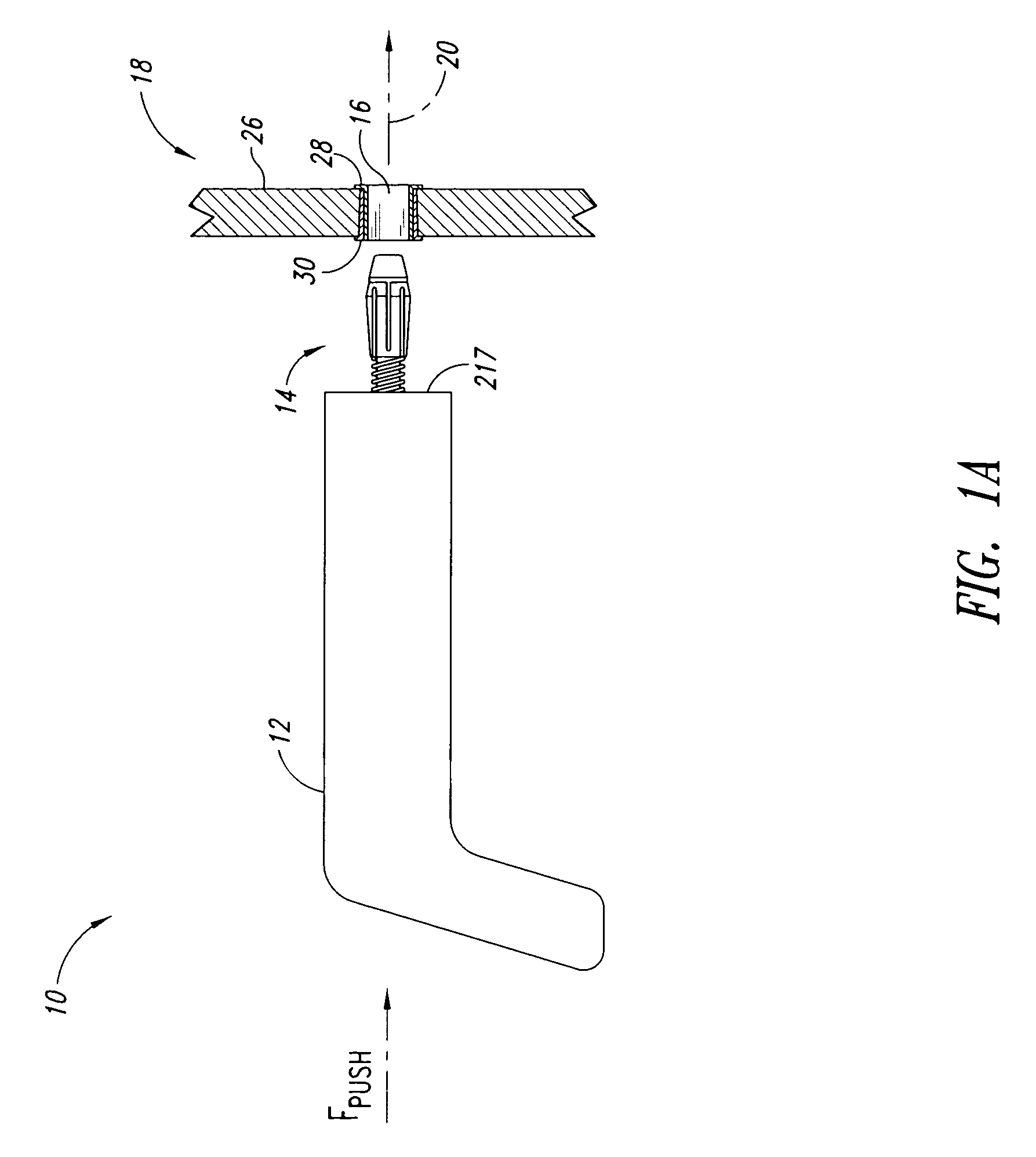

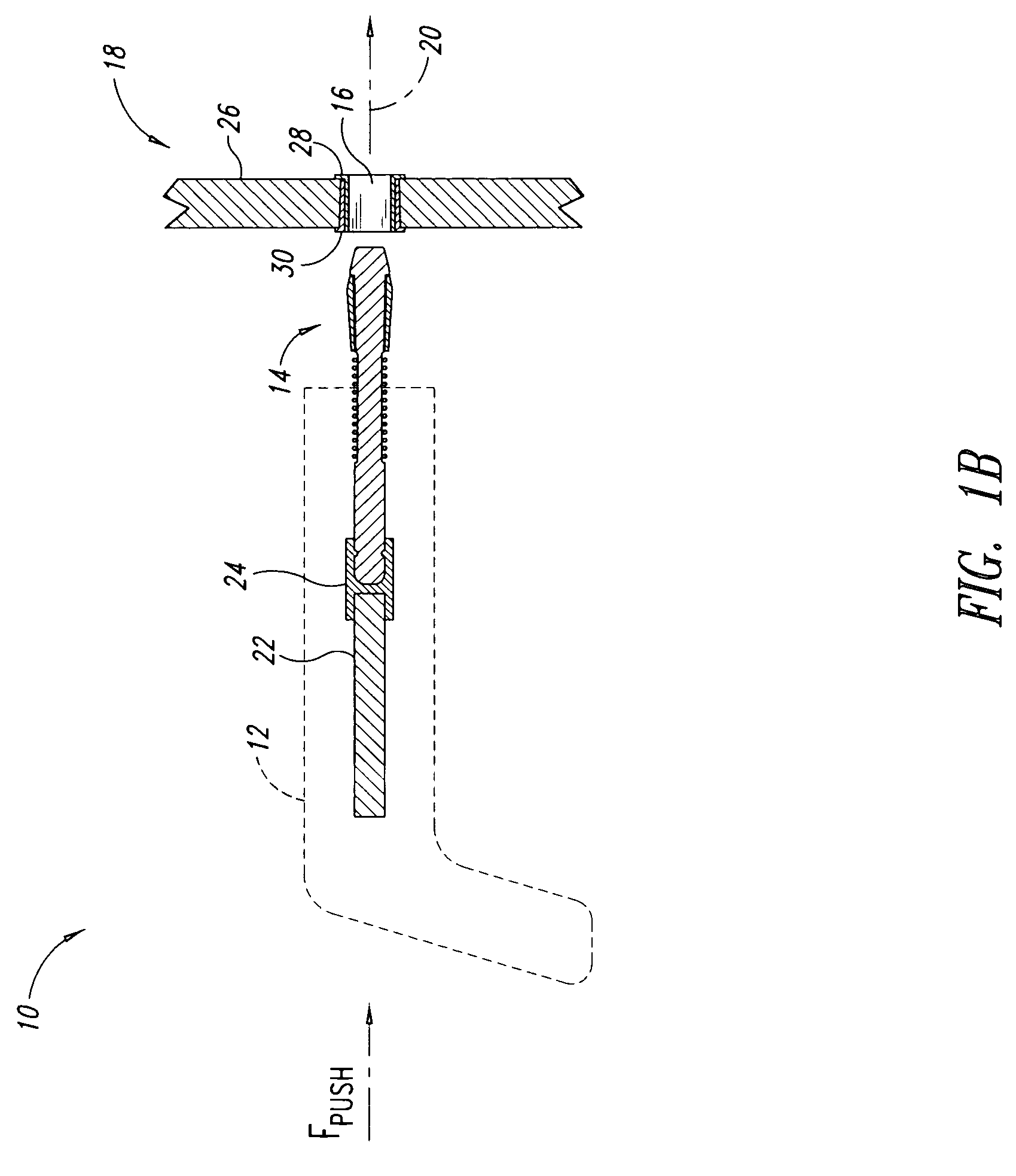

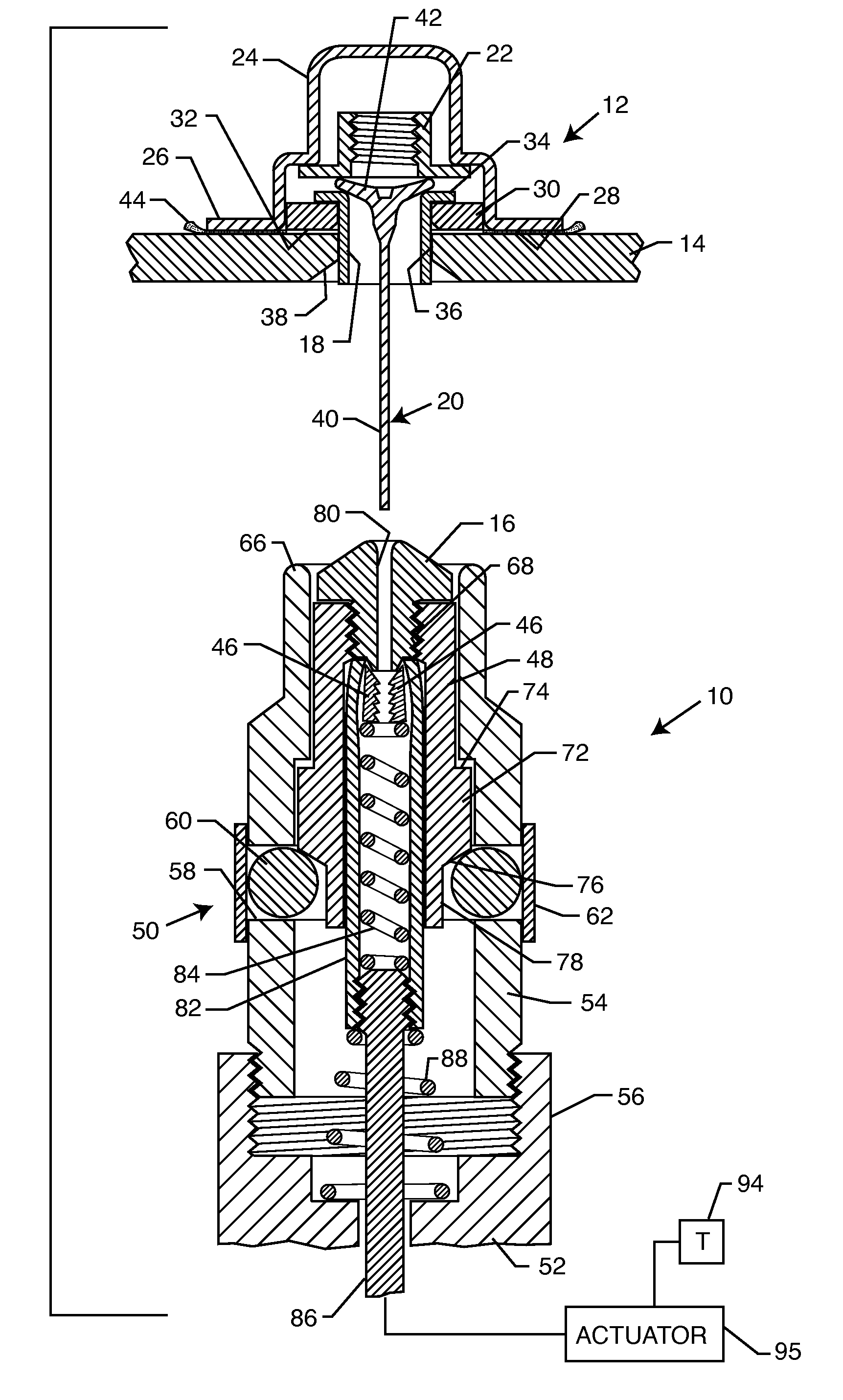

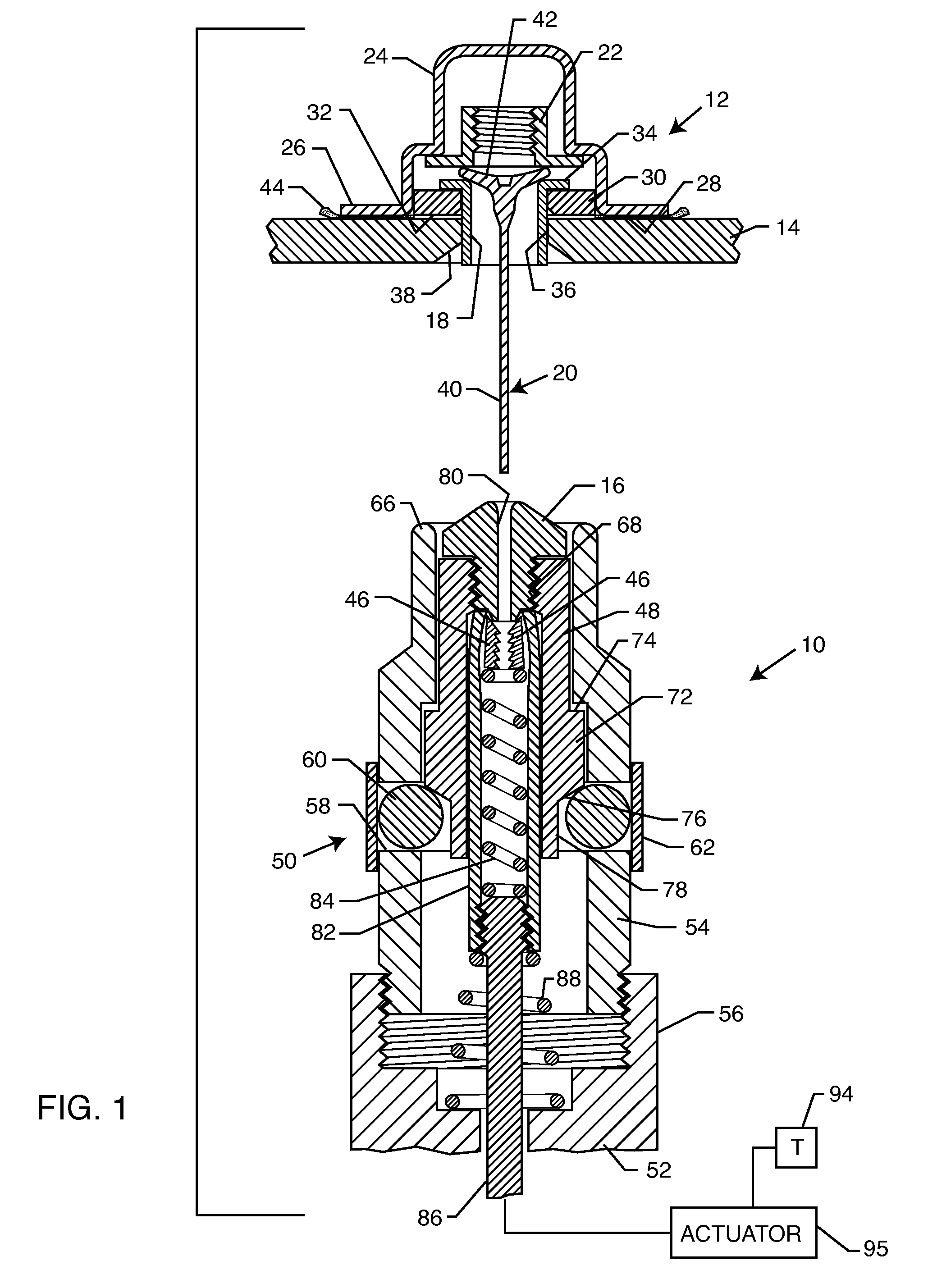

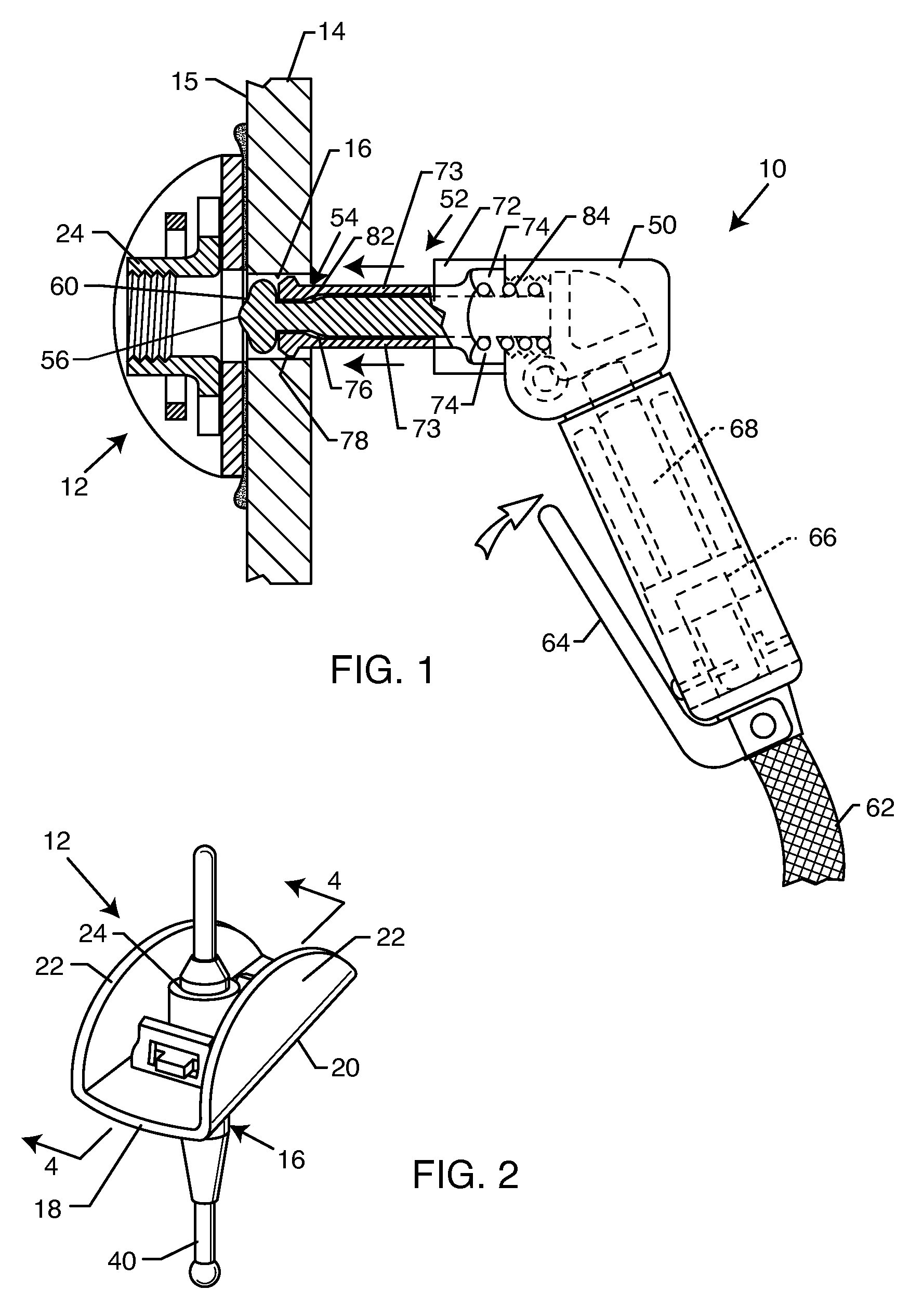

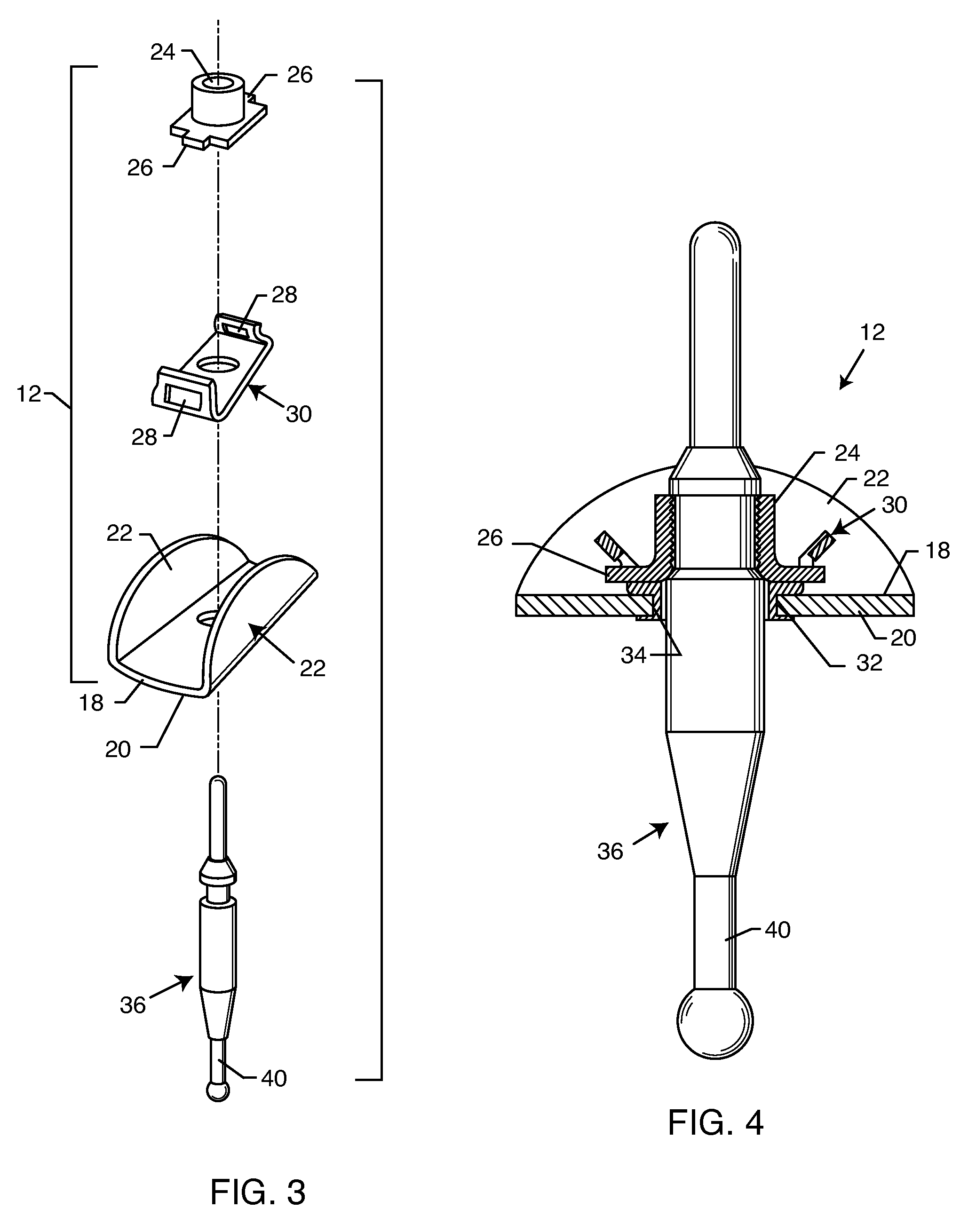

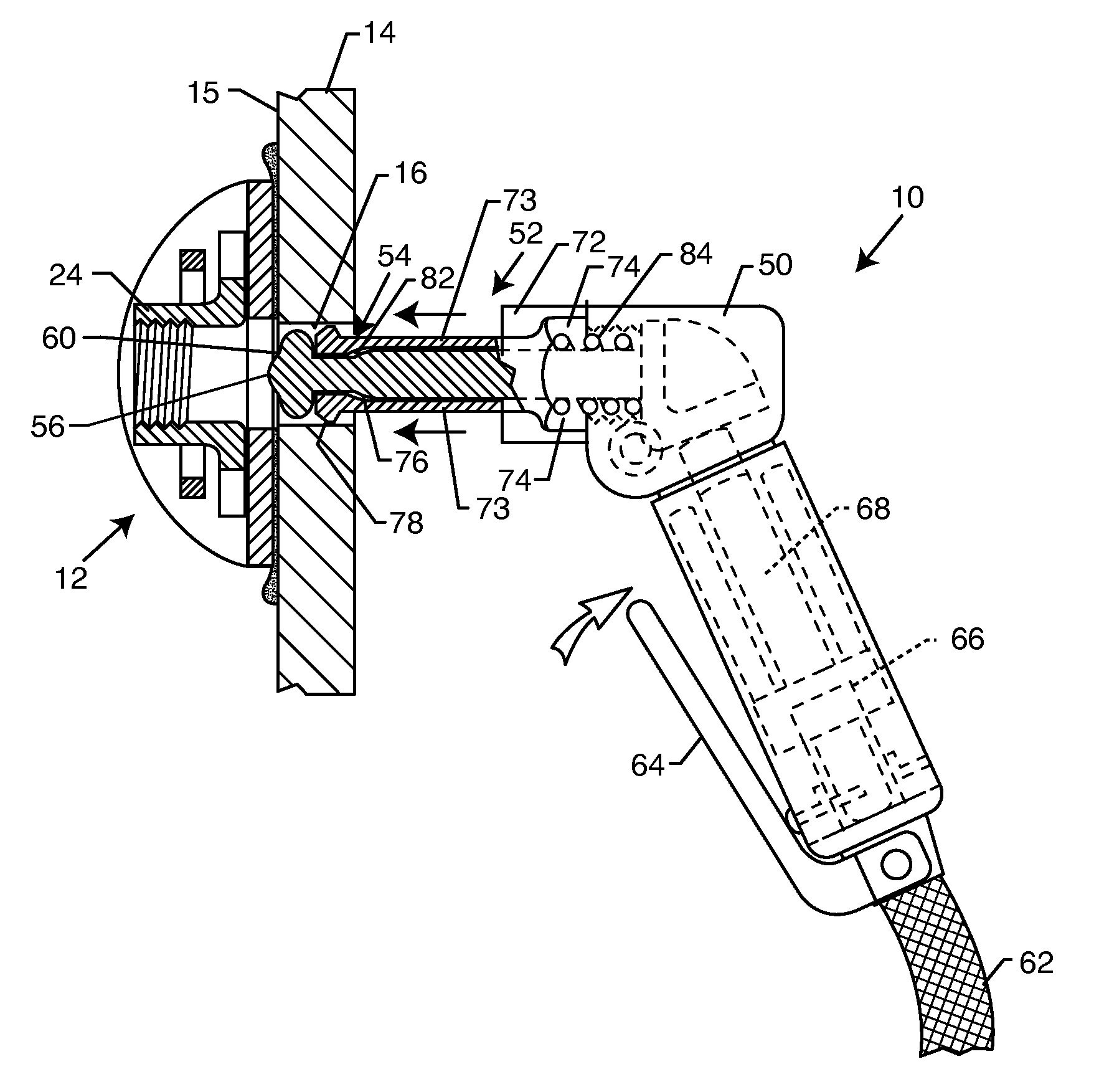

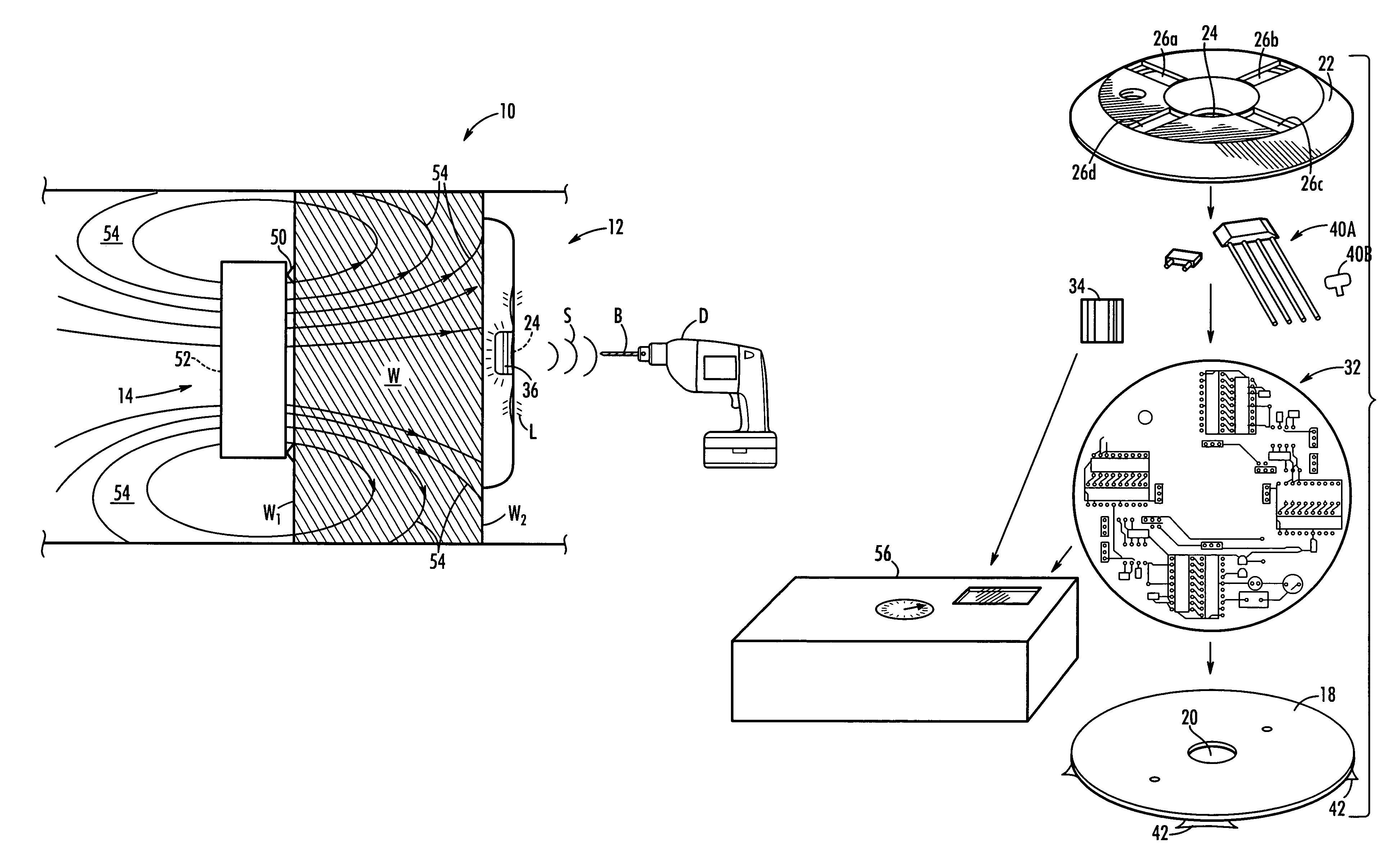

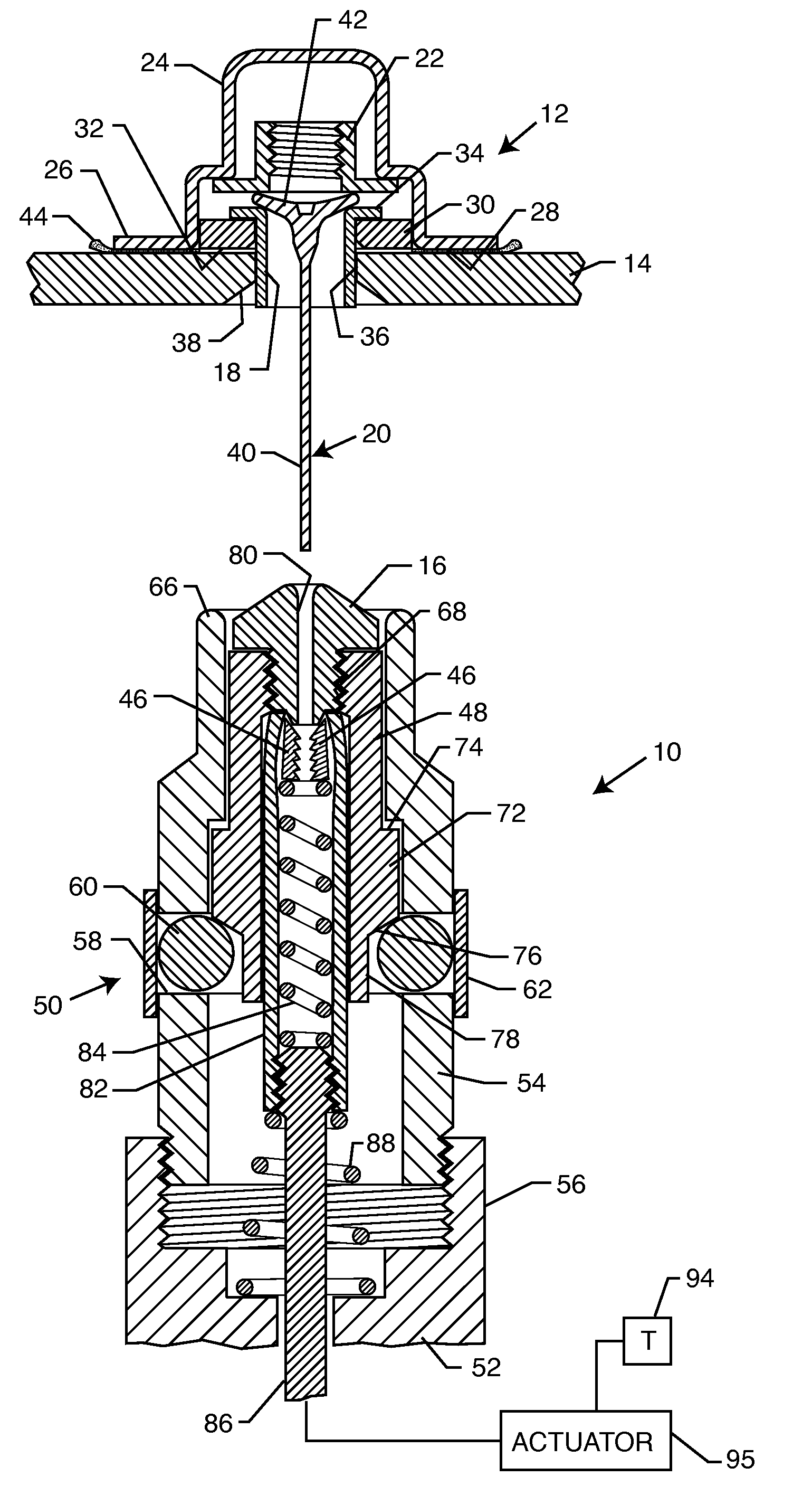

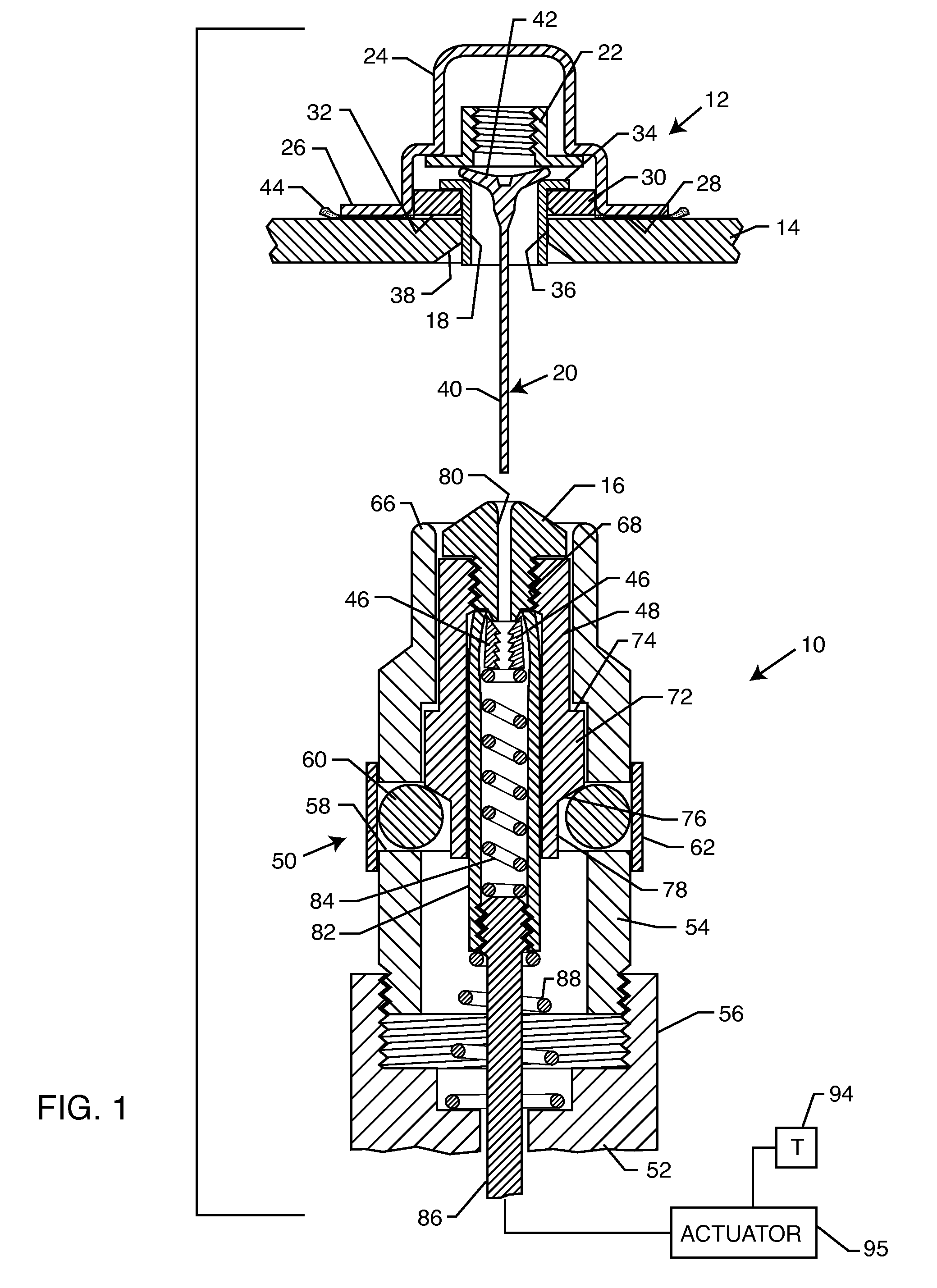

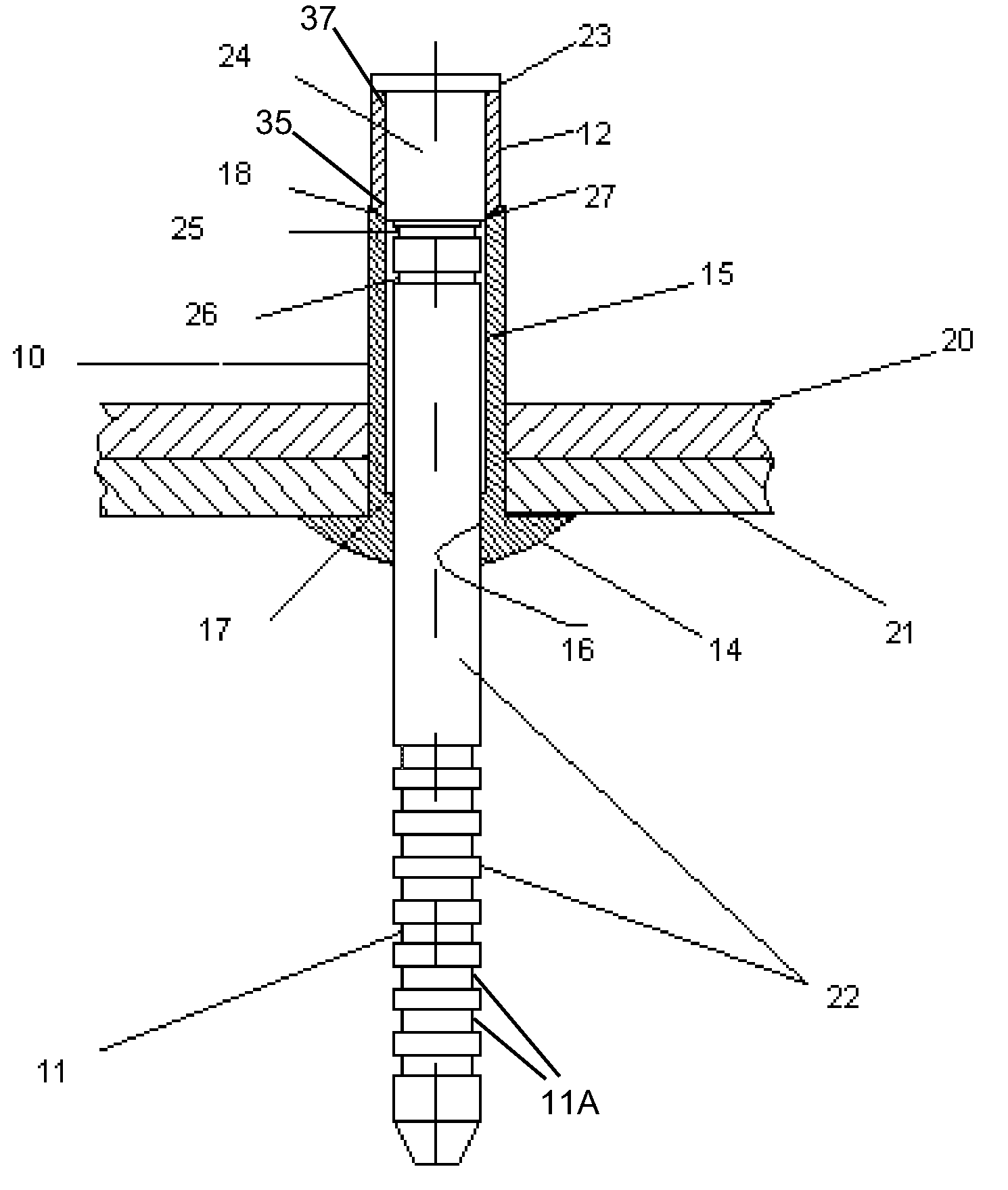

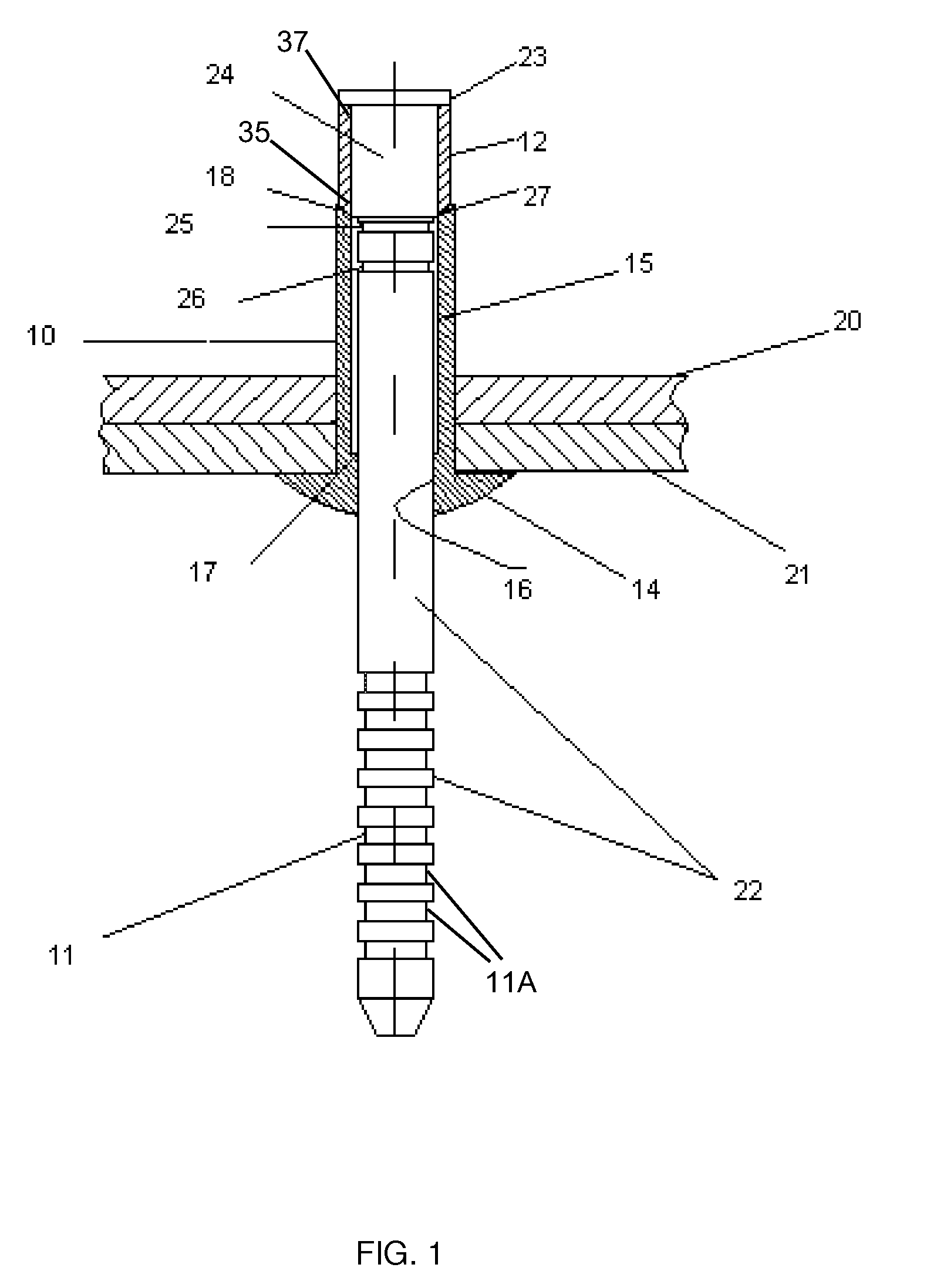

Nutplate bond strength tester unit

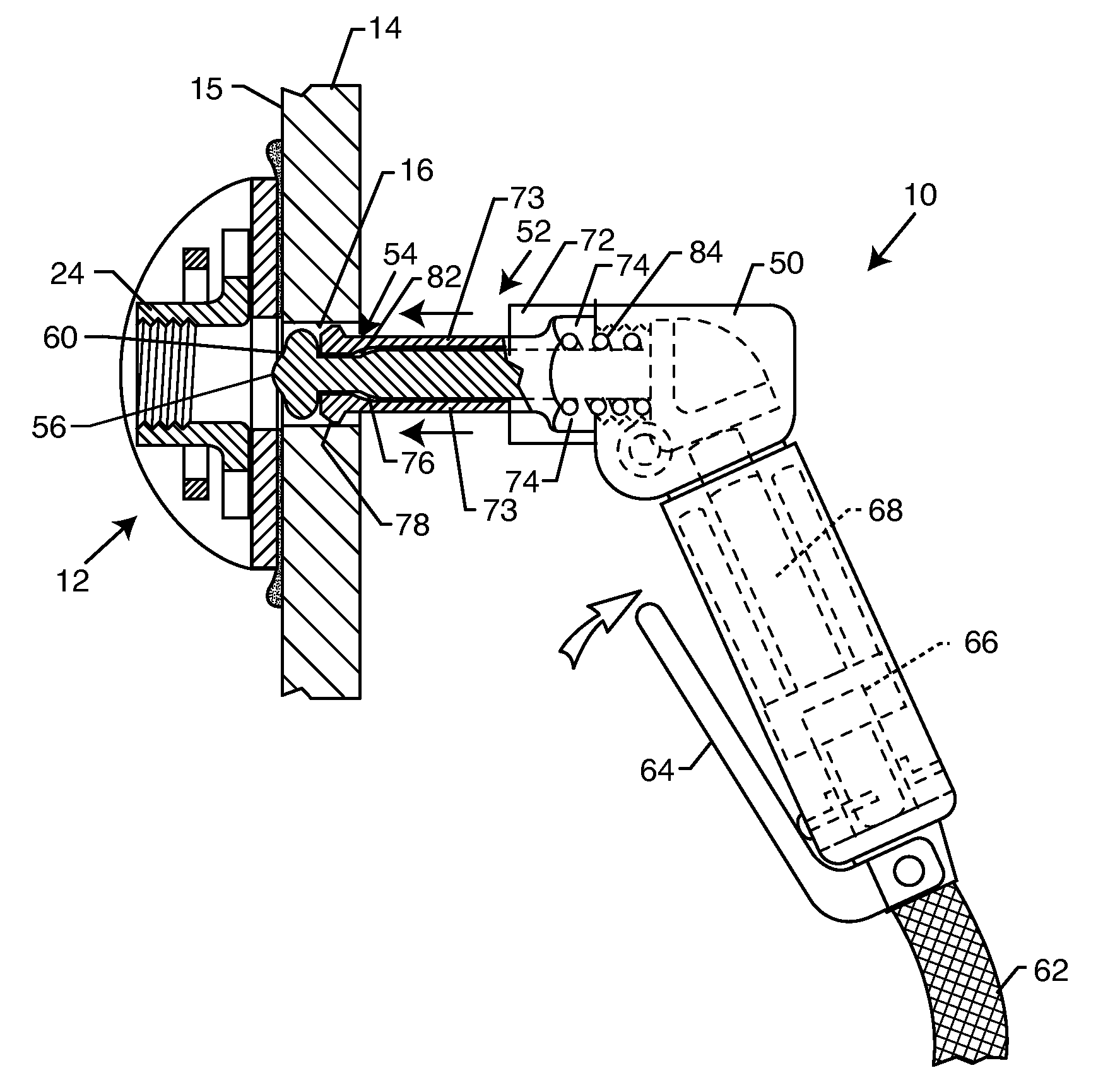

ActiveUS7389698B2For quick replacementHigh bonding strengthMaterial strength using tensile/compressive forcesUsing mechanical meansEngineeringActuator

A bond strength tester unit is provided for testing adhesive bond strength of a nutplate or the like attached to a substrate, such as by adhesive bonded attachment to a blind side of the substrate in substantial alignment with a substrate opening. The nutplate may be constructed according to U.S. Pat. No. 5,013,391, and carries a fastener element such as a threaded nut or the like for subsequent connection with a mating fastener element such as a threaded bolt or the like passed through the substrate opening. The tester unit includes a tool tip having a reaction head for engaging the substrate, in combination with an actuator pin for applying a test force of selected magnitude against the adhesively bonded nutplate. In the event of inadequate bond strength, the actuator pin will separate the nutplate from the substrate.

Owner:PHYSICAL SYST

Nutplate bond strength tester unit

ActiveUS20070044569A1For quick replacementHigh bonding strengthMaterial strength using tensile/compressive forcesUsing mechanical meansActuatorUltimate tensile strength

A bond strength tester unit is provided for testing adhesive bond strength of a nutplate or the like attached to a substrate, such as by adhesive bonded attachment to a blind side of the substrate in substantial alignment with a substrate opening. The nutplate may be constructed according to U.S. Pat. No. 5,013,391, and carries a fastener element such as a threaded nut or the like for subsequent connection with a mating fastener element such as a threaded bolt or the like passed through the substrate opening. The tester unit includes a tool tip having a reaction head for engaging the substrate, in combination with an actuator pin for applying a test force of selected magnitude against the adhesively bonded nutplate. In the event of inadequate bond strength, the actuator pin will separate the nutplate from the substrate.

Owner:PHYSICAL SYST

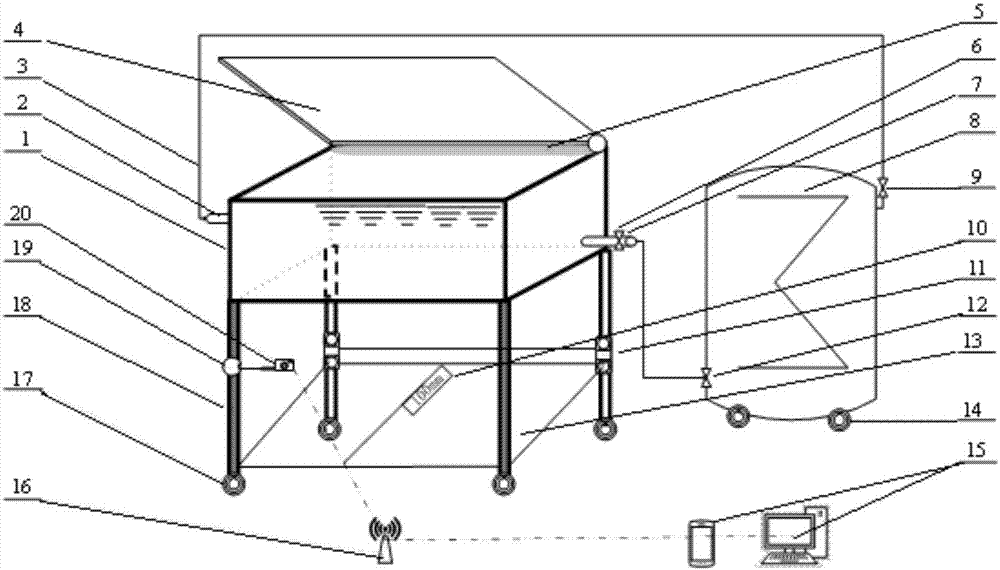

Fish-experiment biology observation instrument and using method

ActiveCN107372281AEasy to assemble and disassembleEasy to transportPisciculture and aquariaTemperature controlWireless transmission

The invention discloses a fish-experiment biology observation instrument and a using method and belongs to the field of fish biology. The observation instrument comprises an aquarium, a support, a reflection observation device, a shooting device, a measurement device, a wireless transmission device, an image data receiving terminal and a temperature control system; the aquarium is installed on the support and is communicated with the temperature control system; the reflection observation device is installed on four supporting legs of the support, and the measurement device is mounted on the reflection observation device; the shooting device with the wireless transmission function is installed on one of the supporting legs of the support, wireless communication with the image data receiving terminal is achieved through the wireless transmission device, and thus data and images are transmitted in time; the temperature control system is connected with the aquarium to guarantee the appropriate temperature of water in the aquarium; thus, observation and recording of the blind side body color of an experiment fish and measurement of biological characters such as the total length, body length, body height, head length can be facilitated, stress influences, caused by manual operation, on the experiment fish can be drastically reduced, the experiment success rate is increased, the work efficiency is improved, and the labor cost is saved.

Owner:宁德市富发水产有限公司 +1

Blind rivet with extended adhesive reservoir

This invention provides a design of an adhesive encapsulated blind rivet for joining an assembly of overlying parts having an accessible side and an inaccessible side. The rivet comprises a rivet head and tubular rivet body. A mandrel is inserted through the open end of the tubular rivet body and through a mandrel hole in the rivet head. A mandrel head engages the end of the tubular body. The tubular body is filled with a mass of latent adhesive around the mandrel. The rivet body is longer than the thickness of the parts to be joined to accommodate a substantial amount of adhesive for expulsion through holes in the rivet body located within the thickness of the assembled parts. The portion of the rivet body extending beyond the blind side of the assembled parts is weakened in a pattern of corrugations or other bands for folding of the end of the tubular body in setting the blind side of the rivet and expelling the larger quantity of adhesive against and between the riveted parts.

Owner:GM GLOBAL TECH OPERATIONS LLC

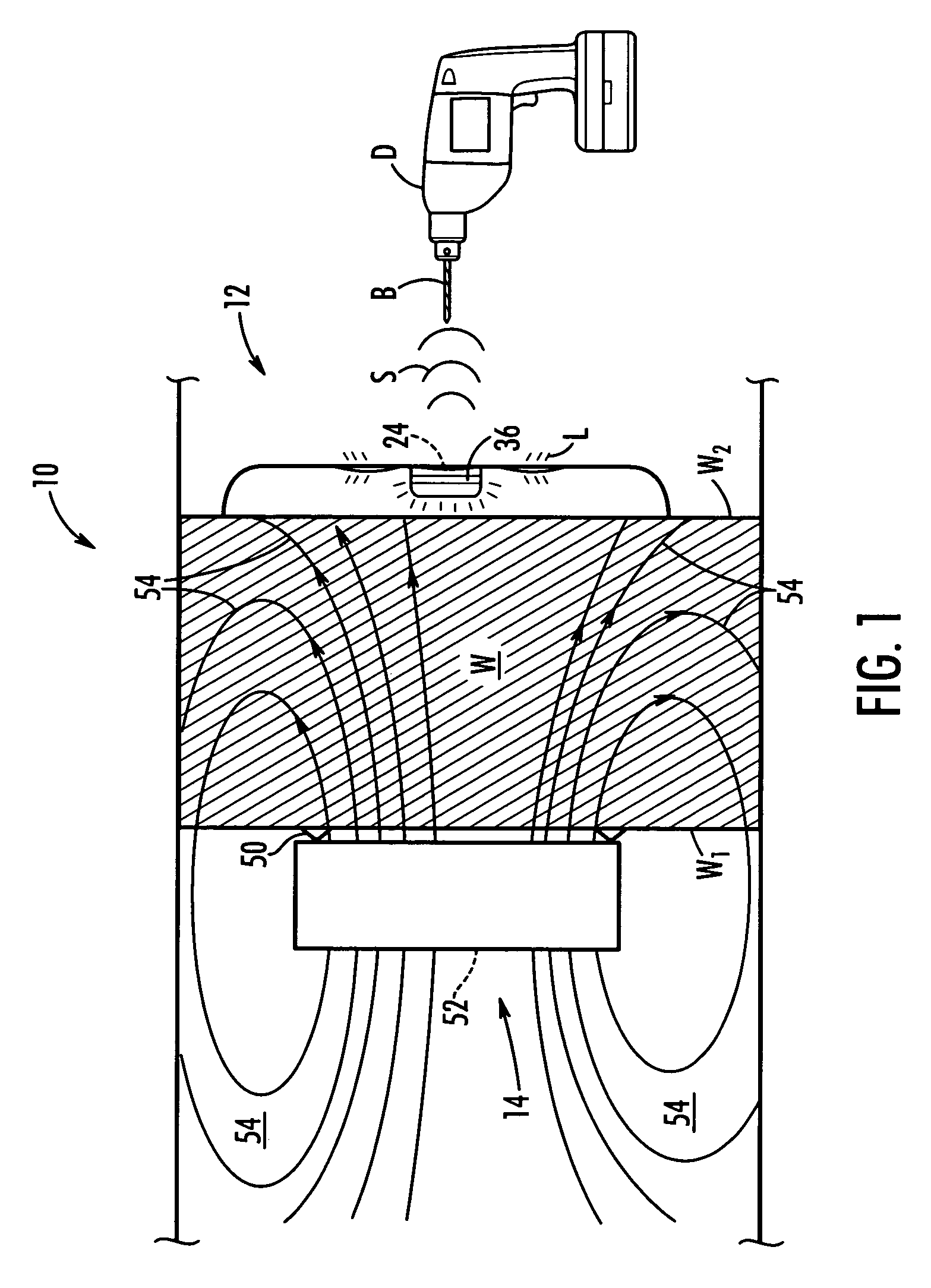

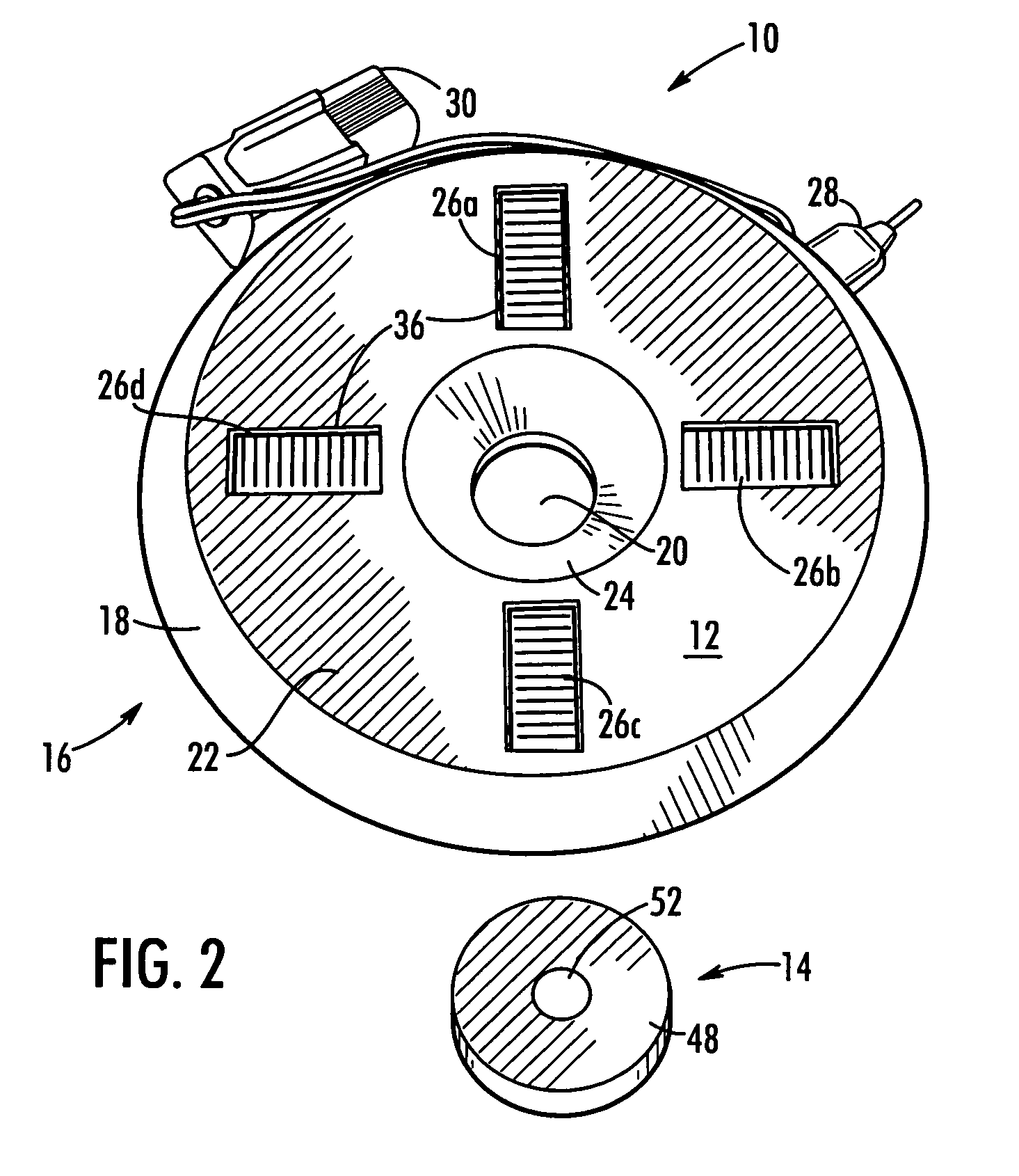

Device for establishing a cutting point from a blind side of a structure

InactiveUS7385390B1Simple and economical to manufacture and assembleMark accuratelyCurrent/voltage measurementSolid-state devicesElectronic communicationEngineering

A blind spot targeting system for establishing a cutting point includes a locator with a housing having an indicator and a signal-sensing device. The housing has a hole therethrough, and the indicator is in electronic communication with the signal-sensing device for indicating a cutting point on a first side of a structure. A transmitter is also included, which has a complementary hole therethrough. The transmitter is for placement on a second side of the structure for emitting a signal, which the signal-sensing device senses. The indicator in communication with the signal-sensing device indicates alignment of the hole and the complementary hole to establish the cutting point for cutting through the hole into the first side of a structure and possibly through the second side of the structure in a direction of the complementary hole.

Owner:GASQUE JR SAMUEL N

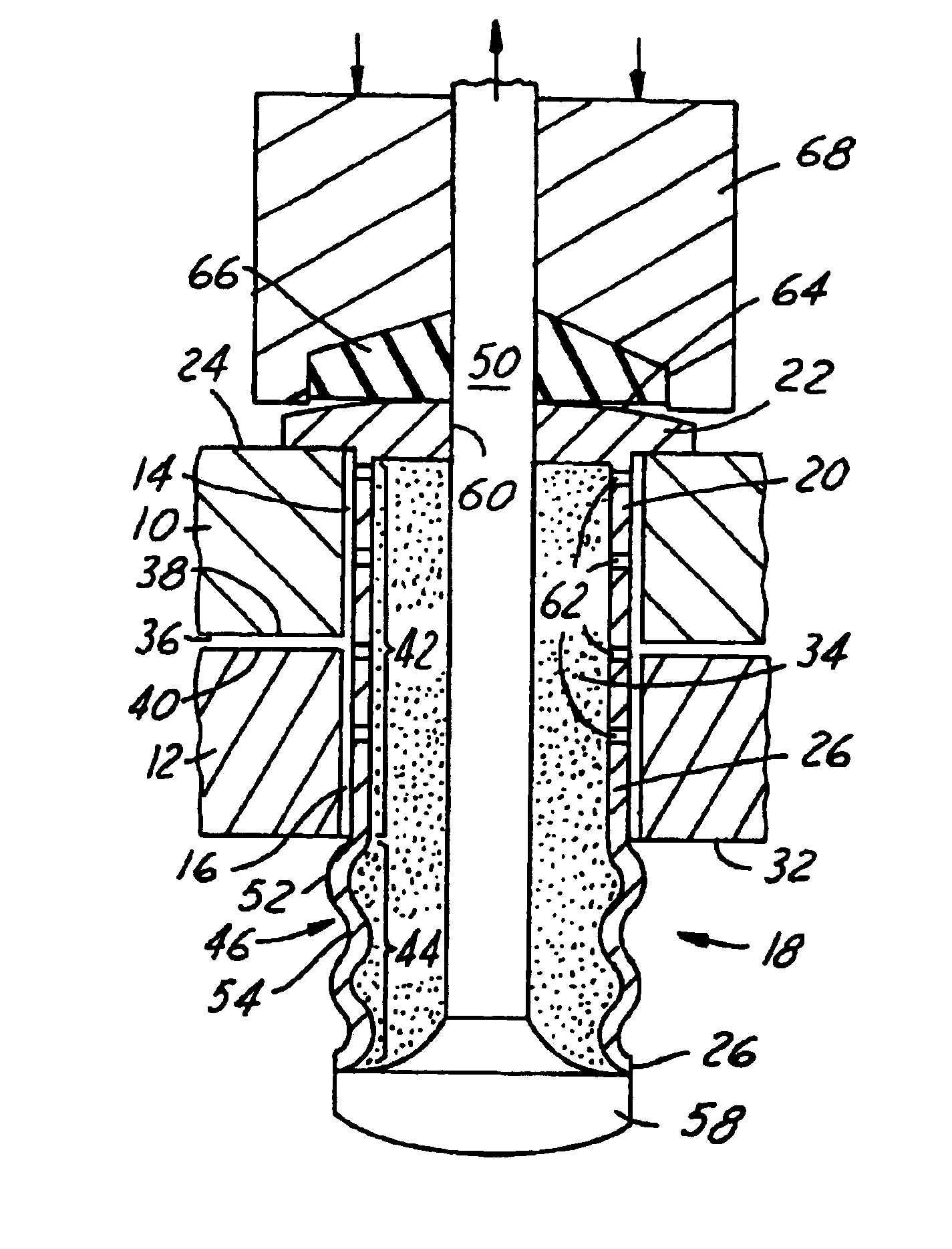

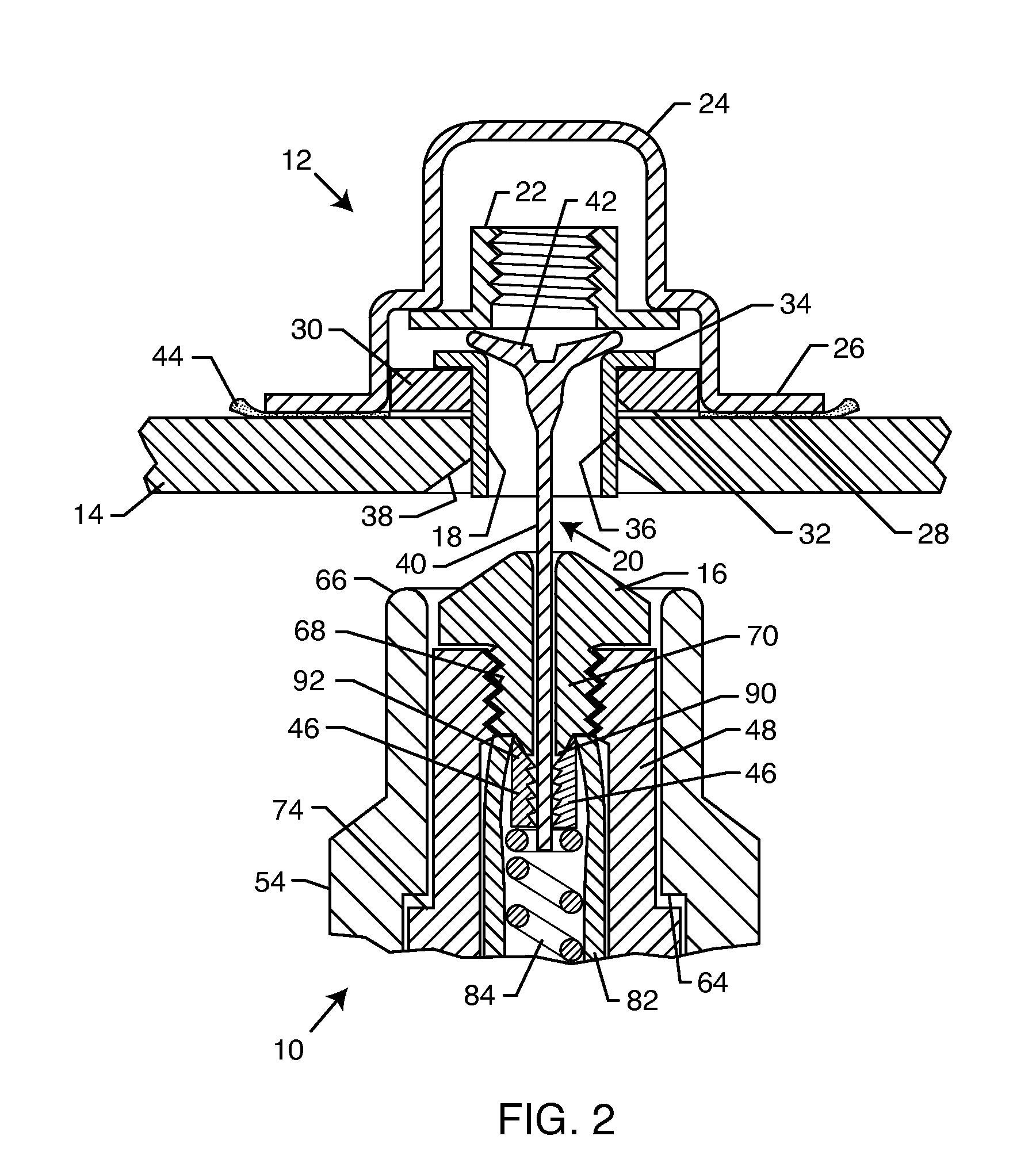

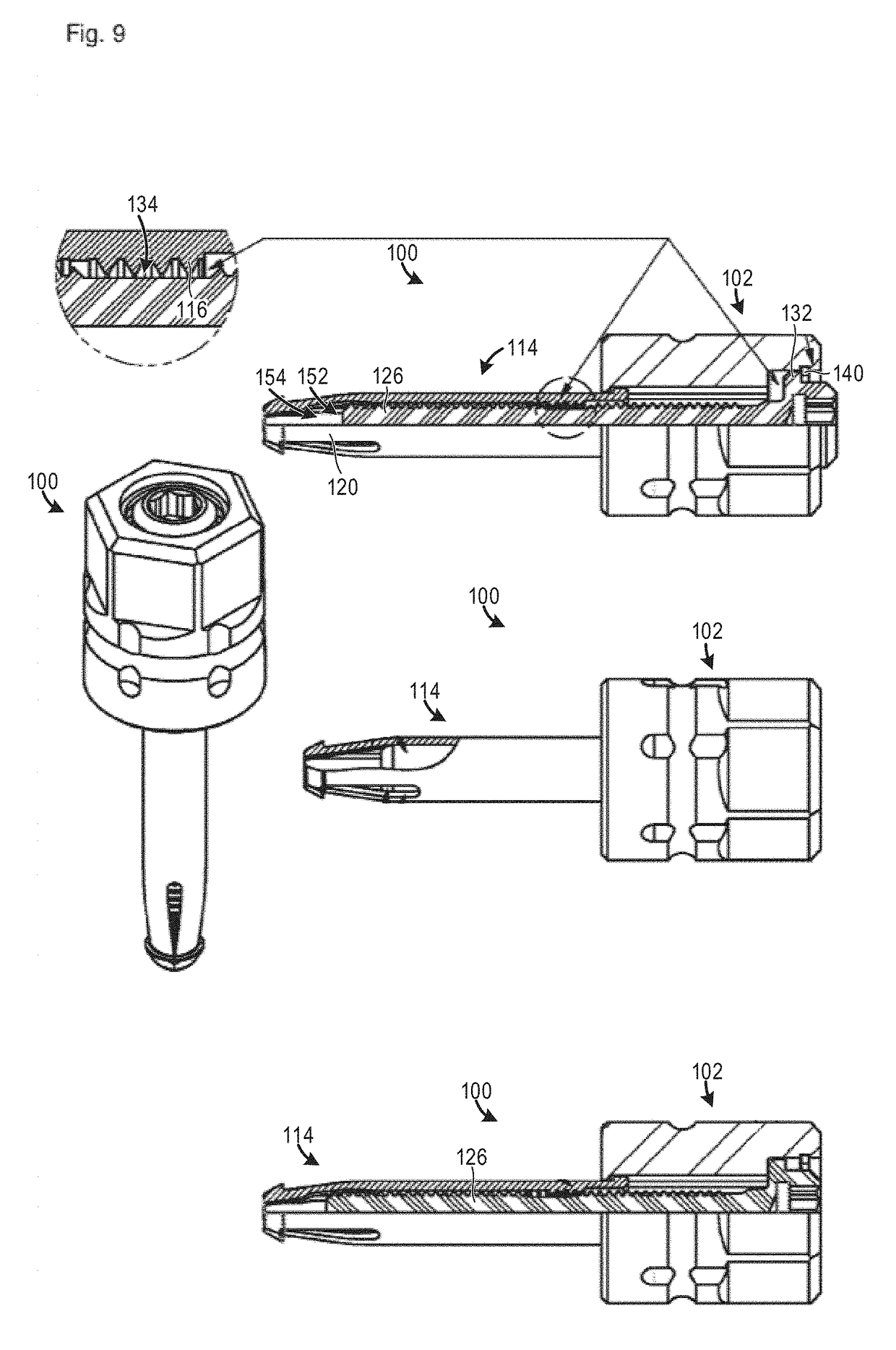

Installation tool for use with a liner sleeve attachment

An installation tool for use with a liner sleeve attachment, such as a nutplate assembly for mounting onto a substrate blind side as disclosed in U.S. Pat. No. 5,704,747. The installation tool includes retractable grip jaws for gripping and pulling a fixture pin protruding from the attachment, for initially advancing a tapered tool nose piece into deforming engagement with an attachment liner sleeve leading end to flare and / or expand the liner sleeve to lock the liner sleeve onto the substrate. Continued pulling action exerts a sufficient force to collapse a fixture pin head and thereby permit pull-removal of the fixture pin from the attachment. The nose piece is carried by a retractable inner housing normally retained in an advanced position for deforming the liner sleeve, and thereafter movable to a retracted position spaced from the liner sleeve to accommodate substantially unobstructed fixture pin separation from the attachment.

Owner:PHYSICAL SYST

One piece screws for, and methods for making and using, blind side fasteners and systems with free spin feature

A fastener with a freely translatable collet body, which at least partially translates within an auxiliary structure, and further comprise a captive threaded screw for rotationally engaging with the collet body to transform rotational movement into translational movement through substantial arresting of collet body rotation by way of an anti-rotation means. The screw comprises a free-spin feature that functionally, but not physically, decouples a drive tool from the collet body.

Owner:CENTRIX

Blind rivet with a plastic rivet body

A blind rivet made of plastic, the shank of the body has a first region located between the head and the foot end, and the first region has a reduced first wall thickness. Within the first region is located a second region with a second wall thickness further reduced as compared to the first region. The first and second regions are arranged such that, as a result of the rivet setting process, the wall of the shank forms a roll fold with an annular bead that is pressed axially against the blind side of the workpiece.

Owner:NEWFREY

Mandrel assembly and method of using the same

ActiveUS20070180885A1Restrict movementForging/hammering/pressing machinesForging press detailsEngineeringMechanical engineering

A mandrel assembly has a mandrel, a biasing member, and a outer member. The biasing member biasly maintains the outer member in a first position, which corresponds to a contoured portion of the mandrel, when the outer member is either on the access or the blind side of a workpiece. The biasing member is compressible to allow the outer member to move into a second position as the outer member is moved through an opening in the workpiece. In the first position, the outer member includes a maximum outer circumference that is larger than the opening of the structural workpiece. In the second position, the outer member includes a maximum outer circumference that fits within the opening of the structural workpiece.

Owner:FATIGUE TECH

Blind rivet assembly

A blind rivet assembly for securing workpieces having aligned bores with the workpieces having an open surface at an open side and a blind surface at a blind side, the blind rivet assembly including a tubular shell having an enlarged shell head adapted to be in engagement with the open surface of the workpieces, a stem having an elongated shank with a stem head at the far end of the shank and having gripping means at the opposite end adapted to be gripped by an installation tool for application of an axial pulling force, and a placement ring having an near end and a far end, and having a pre-installation orientation and a post-installation orientation, wherein in the pre-installation orientation the placement ring is disposed around a ring receiving portion of the elongated shank, and the post-installation orientation is created by axially pulling the stem towards the open side of the workpieces with an axial pulling force that forces the placement ring into a through bore which causes the shell to deform outwards and form a blind head, and wherein upon continued axial pulling of the stem, the stem progressively moves into the shell until the stem encounters a stop shoulder, whereupon material of the stop shoulder is moved into a locking portion to arrest further movement of the stem, and whereupon increased axial force on the stem shears a portion of the stem on the open side at a shearable break-groove.

Owner:SARIV

Industrial culture device capable of simulating flounder paralichthys wild benthic environment

Owner:TIANJIN BOHAI SEA FISHERIES RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com