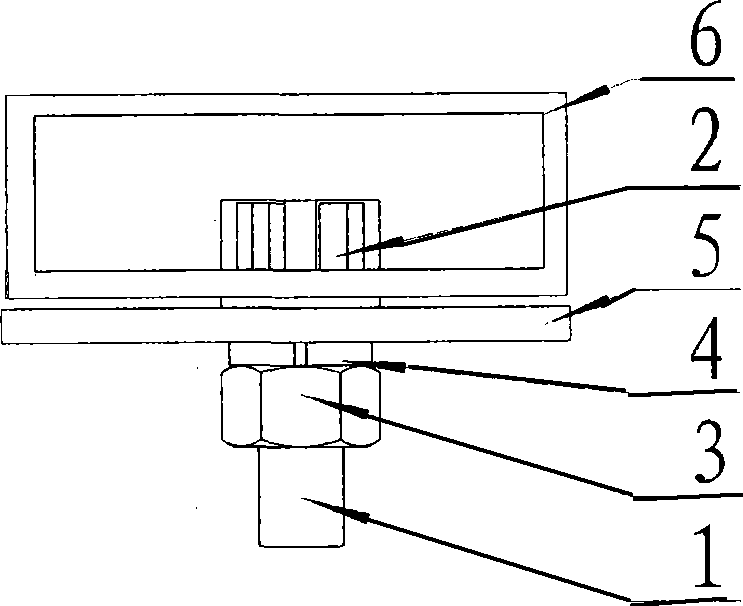

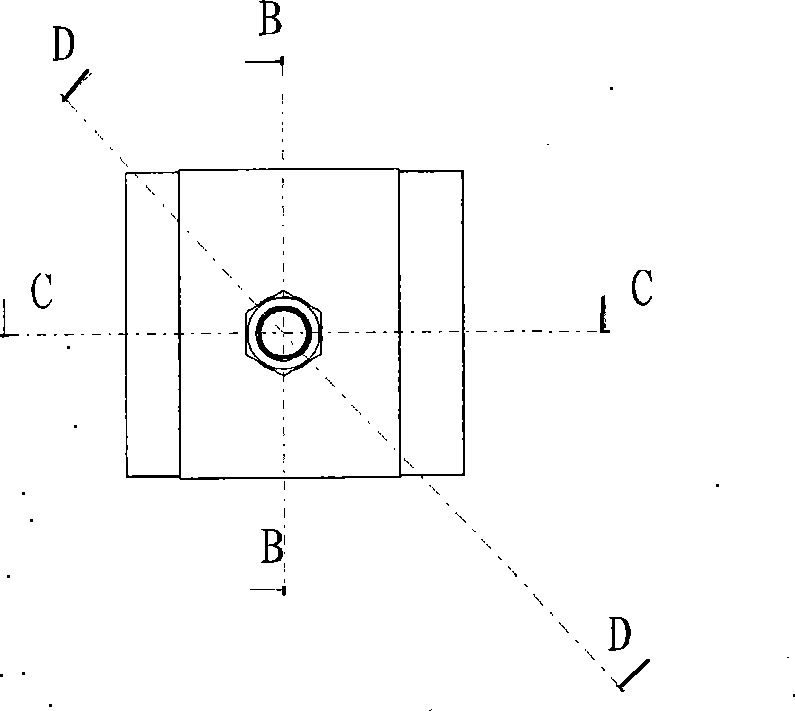

Single side mounting bolt connecting component, bolt gasket and mounting method thereof

A technology for installing bolts and connectors, applied in the direction of connecting components, bolts, threaded fasteners, etc., can solve the problems of inconvenient disassembly, damage to the structure of the connected parts, and the connected parts cannot be reused, so as to save costs and prolong the service life. The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

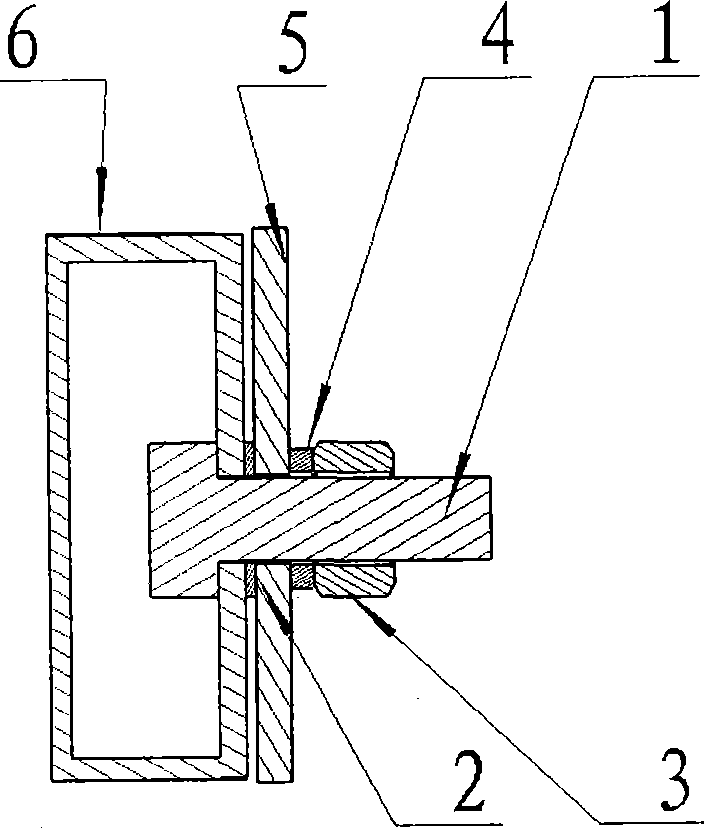

[0037] This embodiment is used to explain the claims, and the scope of protection of the present invention is not limited to the description of the following structures. What those skilled in the art do based on the suggestiveness and indication of the technical solution proposed in this claim is different from that of this embodiment. Structures all belong to the protection scope of the present utility model.

[0038] The contour line of the cross section of the bolt head is a closed figure with concave and convex shapes, and the closed figure with concave and convex shapes of the bolt head can be a closed figure connected by multiple arcs and straight lines, or a closed figure connected by multiple arcs A closed figure, or a closed figure connected by multiple straight line segments. The contour line of the cross-section of the bolt head is a closed figure in the shape of concavo-convex intervals, which includes a groove. Three sets of projections and grooves, four sets of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com