Patents

Literature

3142 results about "Contour line" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A contour line (also isoline, isopleth, or isarithm) of a function of two variables is a curve along which the function has a constant value, so that the curve joins points of equal value. It is a plane section of the three-dimensional graph of the function f(x, y) parallel to the (x, y)-plane. In cartography, a contour line (often just called a "contour") joins points of equal elevation (height) above a given level, such as mean sea level. A contour map is a map illustrated with contour lines, for example a topographic map, which thus shows valleys and hills, and the steepness or gentleness of slopes. The contour interval of a contour map is the difference in elevation between successive contour lines.

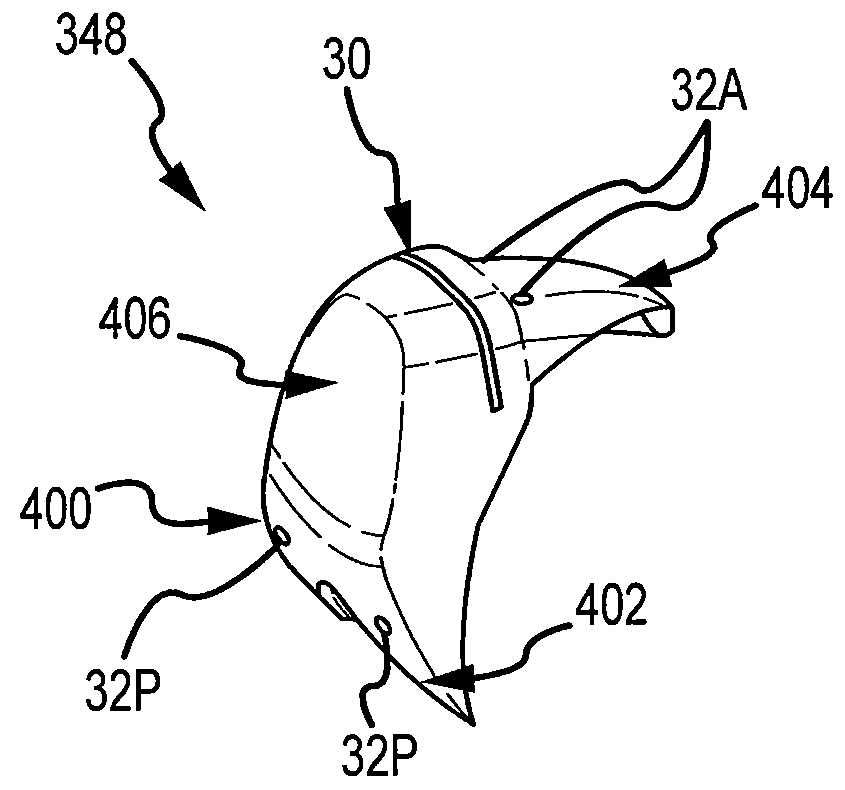

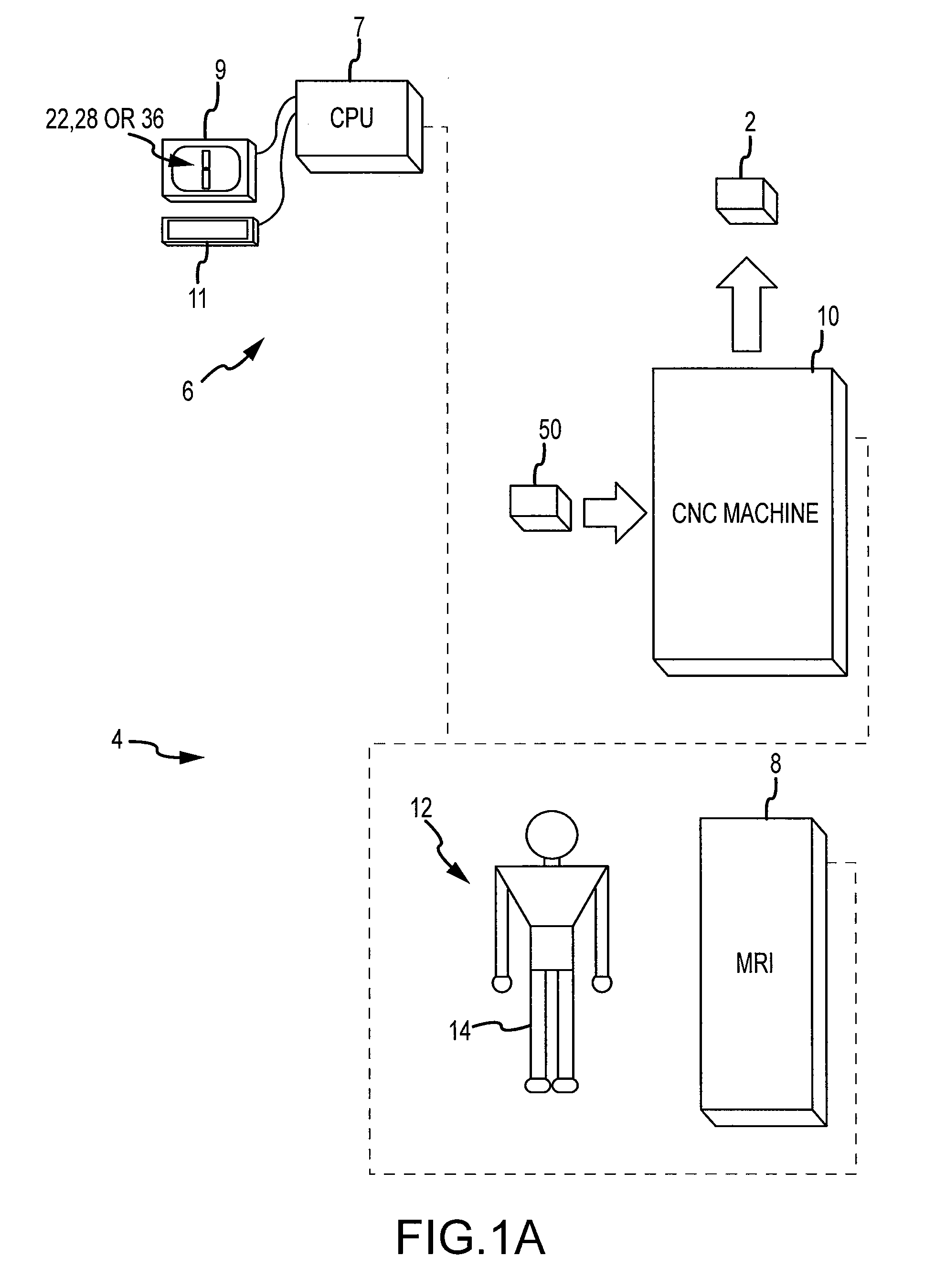

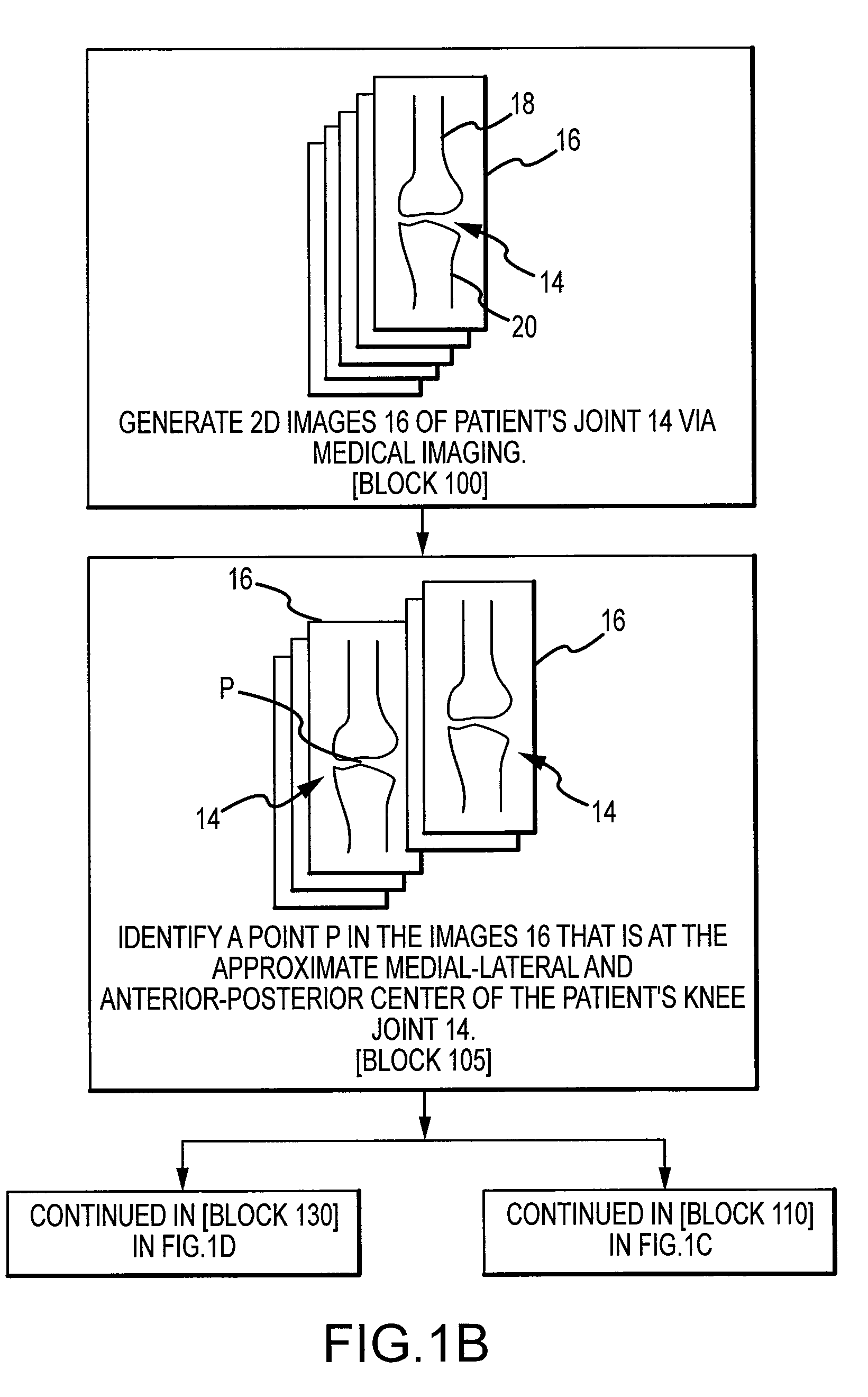

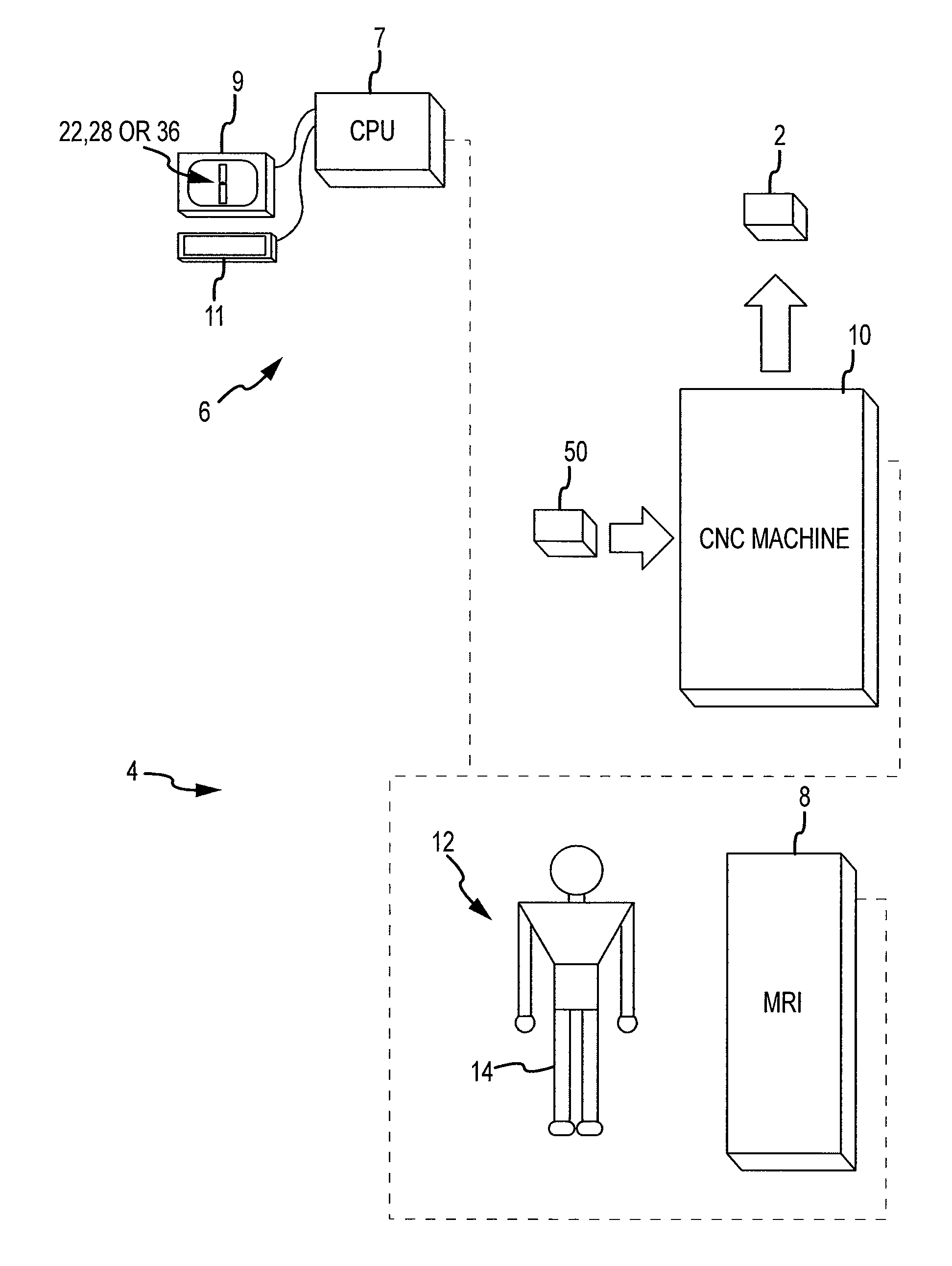

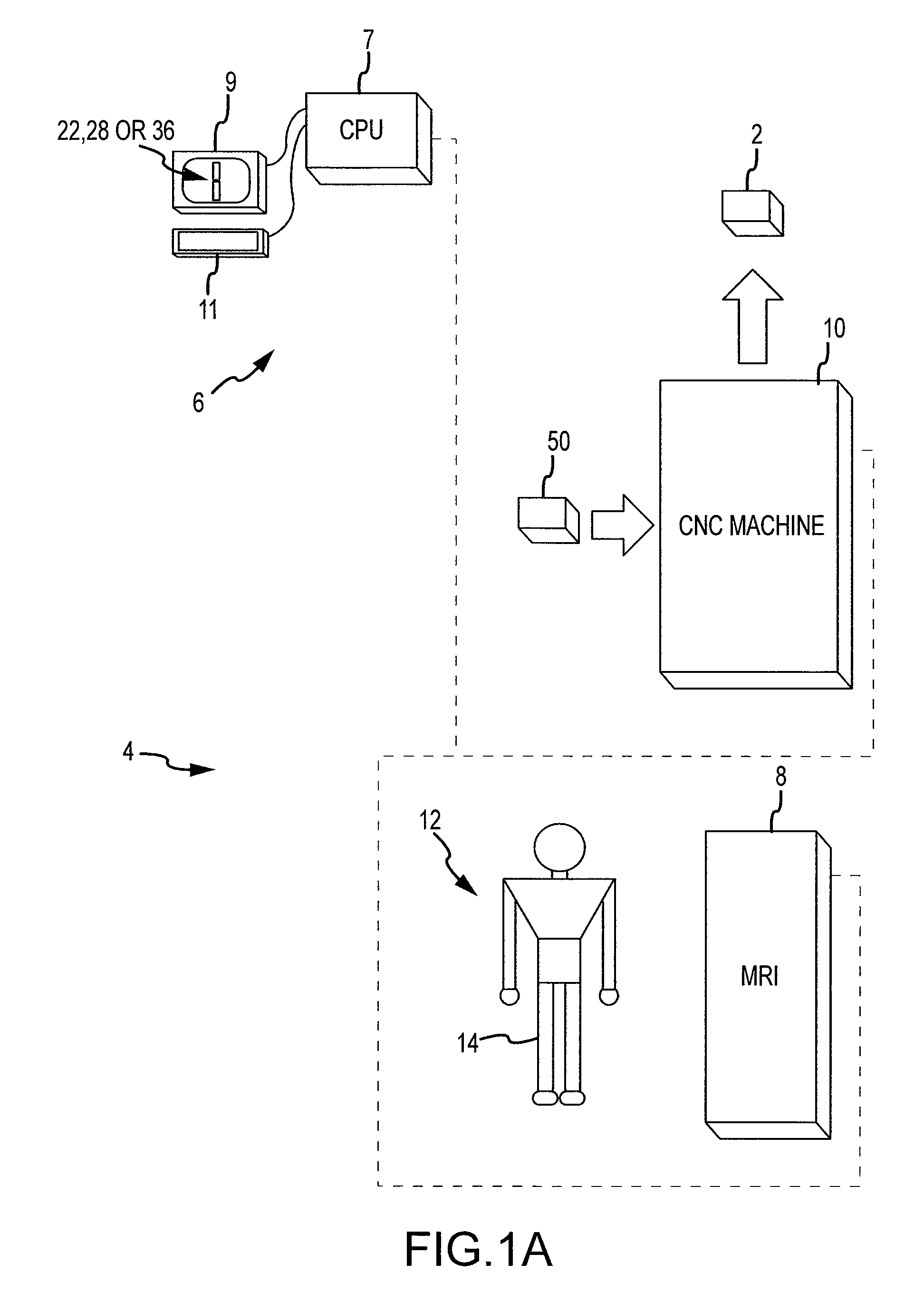

System and method for manufacturing arthroplasty jigs having improved mating accuracy

ActiveUS20100023015A1Facilitate arthroplasty implantsDiagnosticsComputer-aided planning/modellingSacroiliac jointOrthodontics

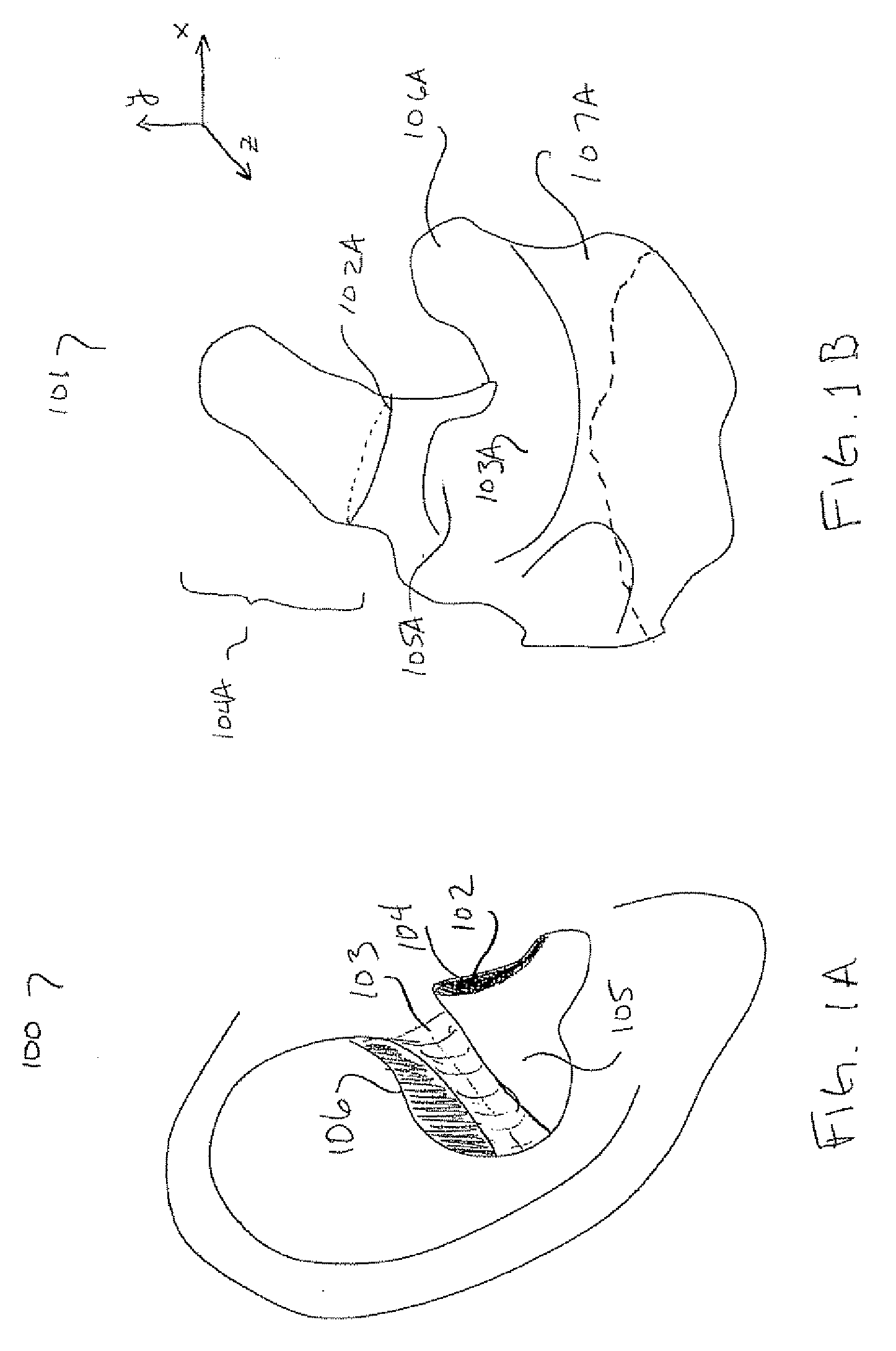

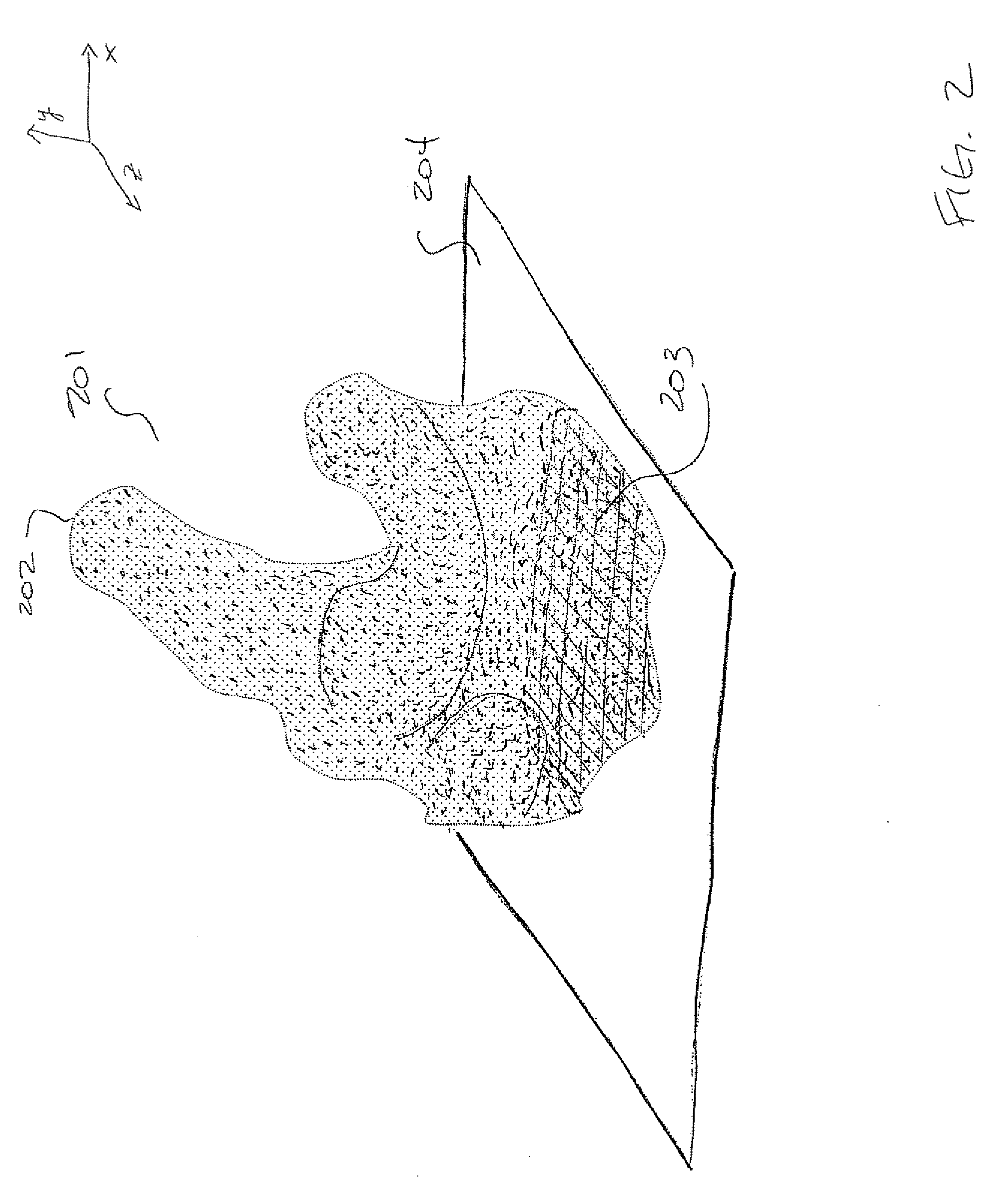

Disclosed herein is a method of defining a mating surface in a first side of an arthroplasty jig. The mating surface is configured to matingly receive and contact a corresponding patient surface including at least one of a bone surface and a cartilage surface. The first side is oriented towards the patient surface when the mating surface matingly receives and contacts the patient surface. The method may include: a) identifying a contour line associated with the patient surface as represented in a medical image; b) evaluating via an algorithm the adequacy of the contour line for defining a portion of the mating surface associated with the contour line; c) modifying the contour line if the contour line is deemed inadequate; and d) employing the modified contour line to define the portion of the mating surface associated with the contour line.

Owner:HOWMEDICA OSTEONICS CORP

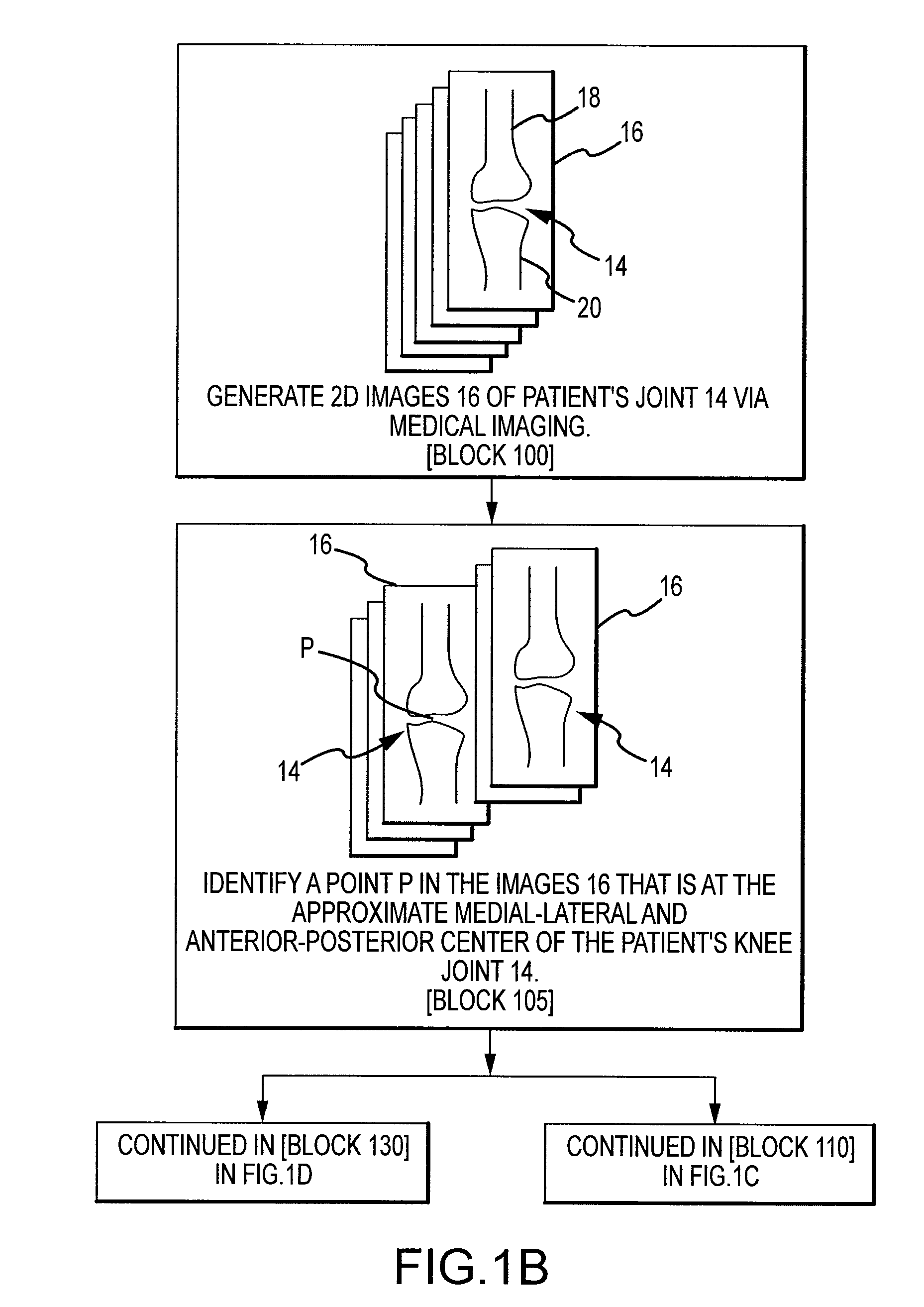

System and method for manufacturing arthroplasty jigs

ActiveUS8221430B2Facilitate arthroplasty implantsCharacter and pattern recognitionComputerised tomographsBone formingSacroiliac joint

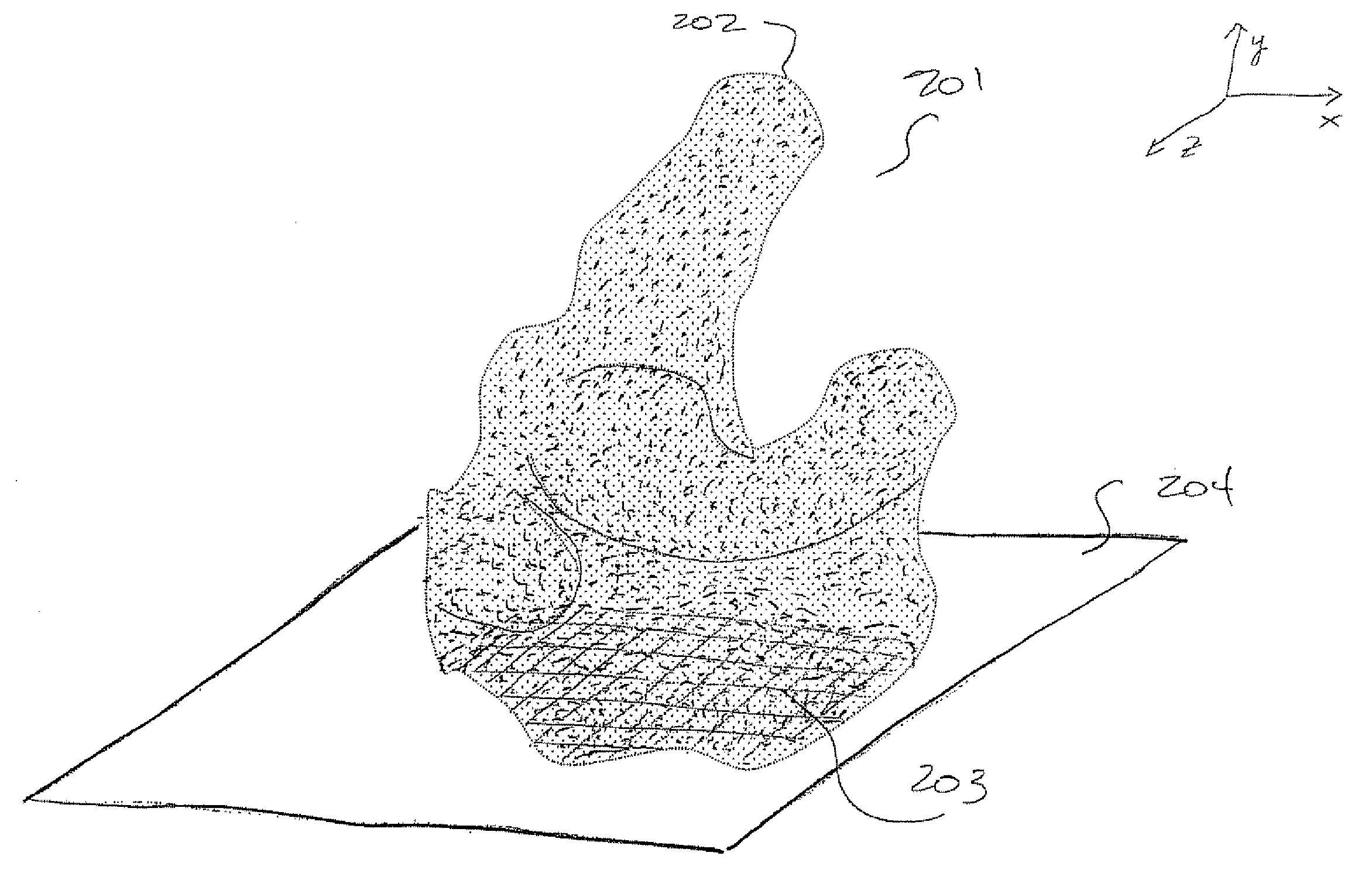

Disclosed herein is a method of computer generating a three-dimensional surface model of an arthroplasty target region of a bone forming a joint. The method may include: generating two-dimensional images of at least a portion of the bone; generating an open-loop contour line along the arthroplasty target region in at least some of the two-dimensional images; and generating the three-dimensional model of the arthroplasty target region from the open-loop contour lines.

Owner:HOWMEDICA OSTEONICS CORP

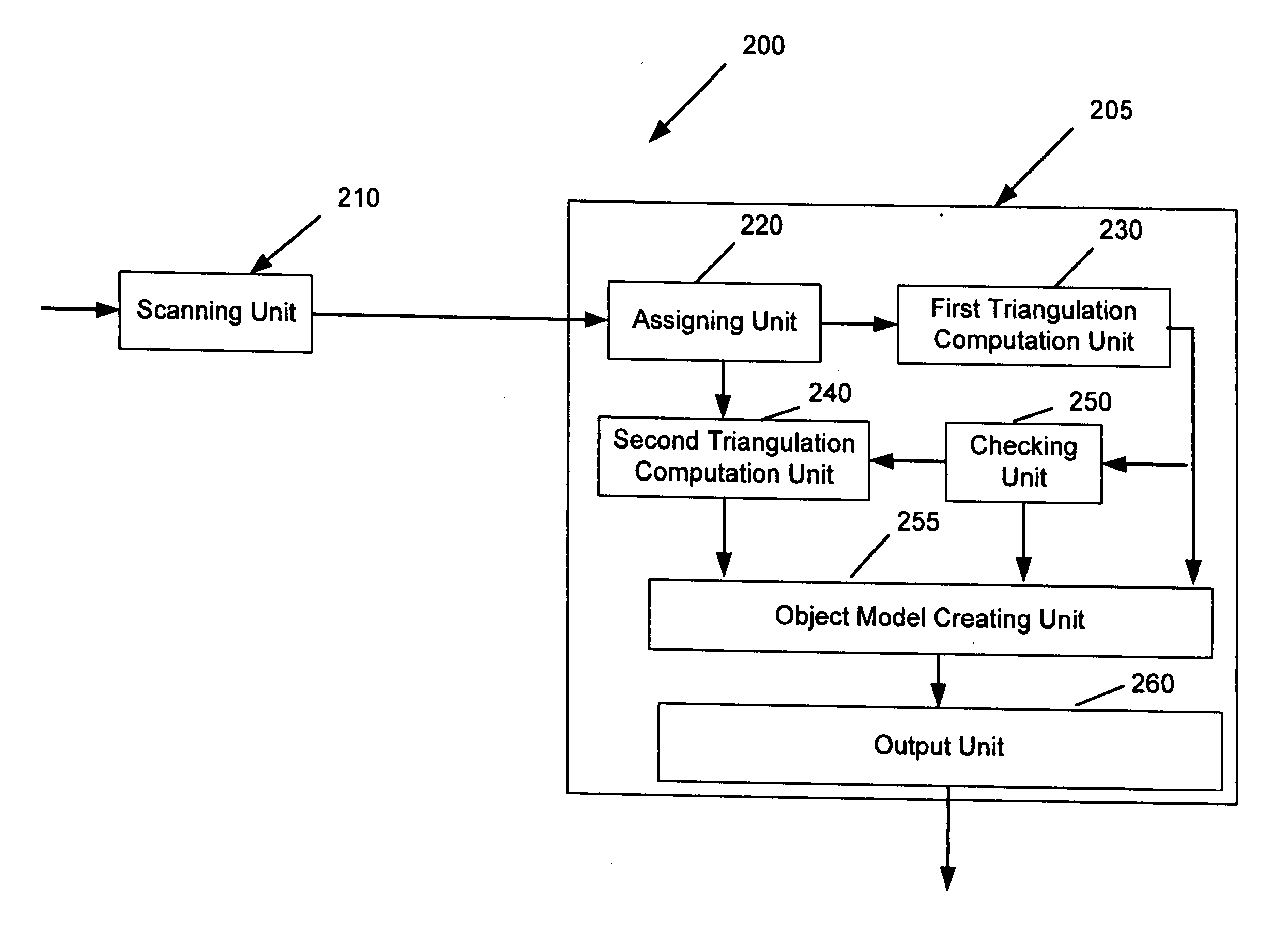

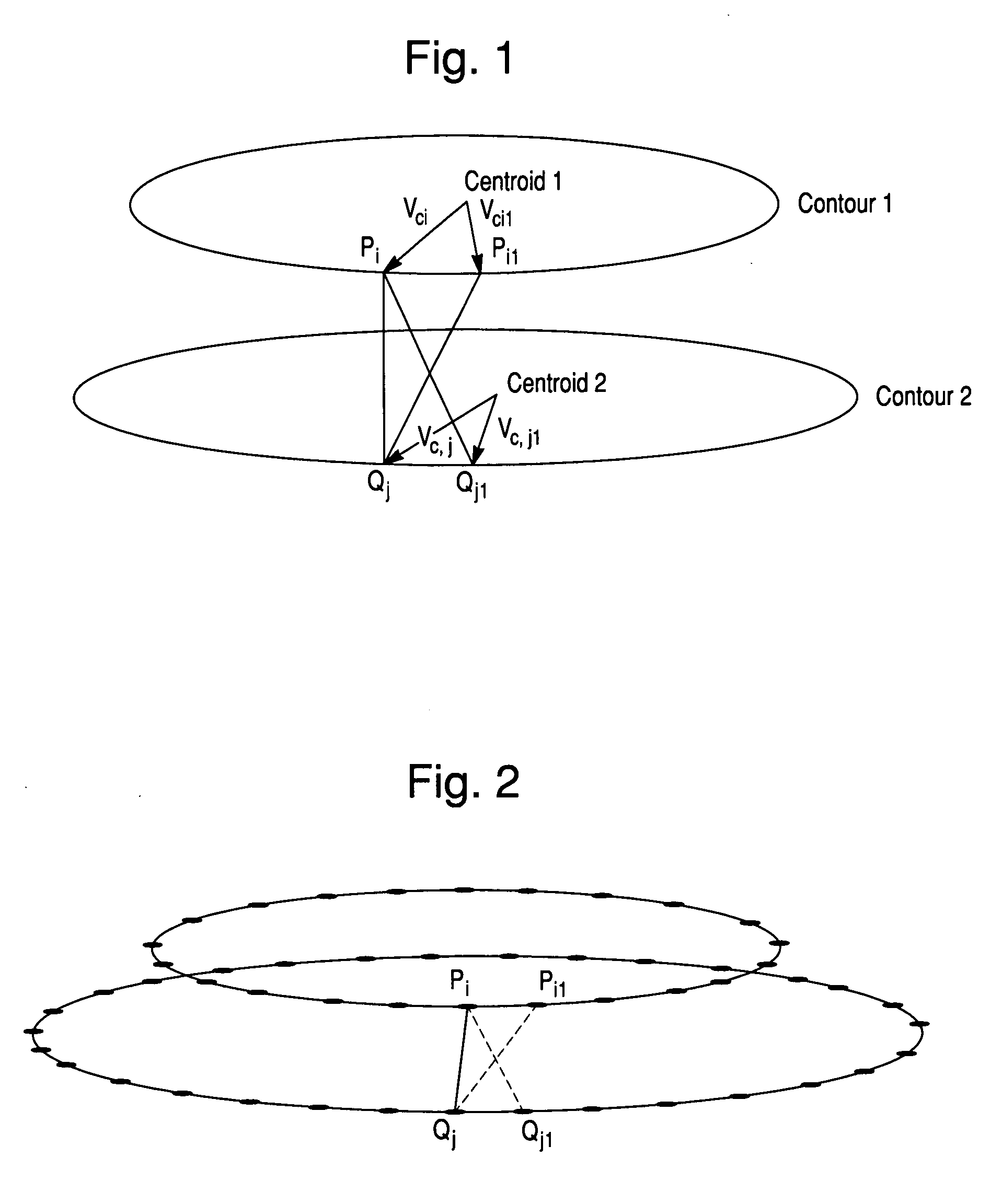

Contour triangulation system and method

ActiveUS20070253617A1Investigating moving sheetsCharacter and pattern recognitionTriangulationComputer vision

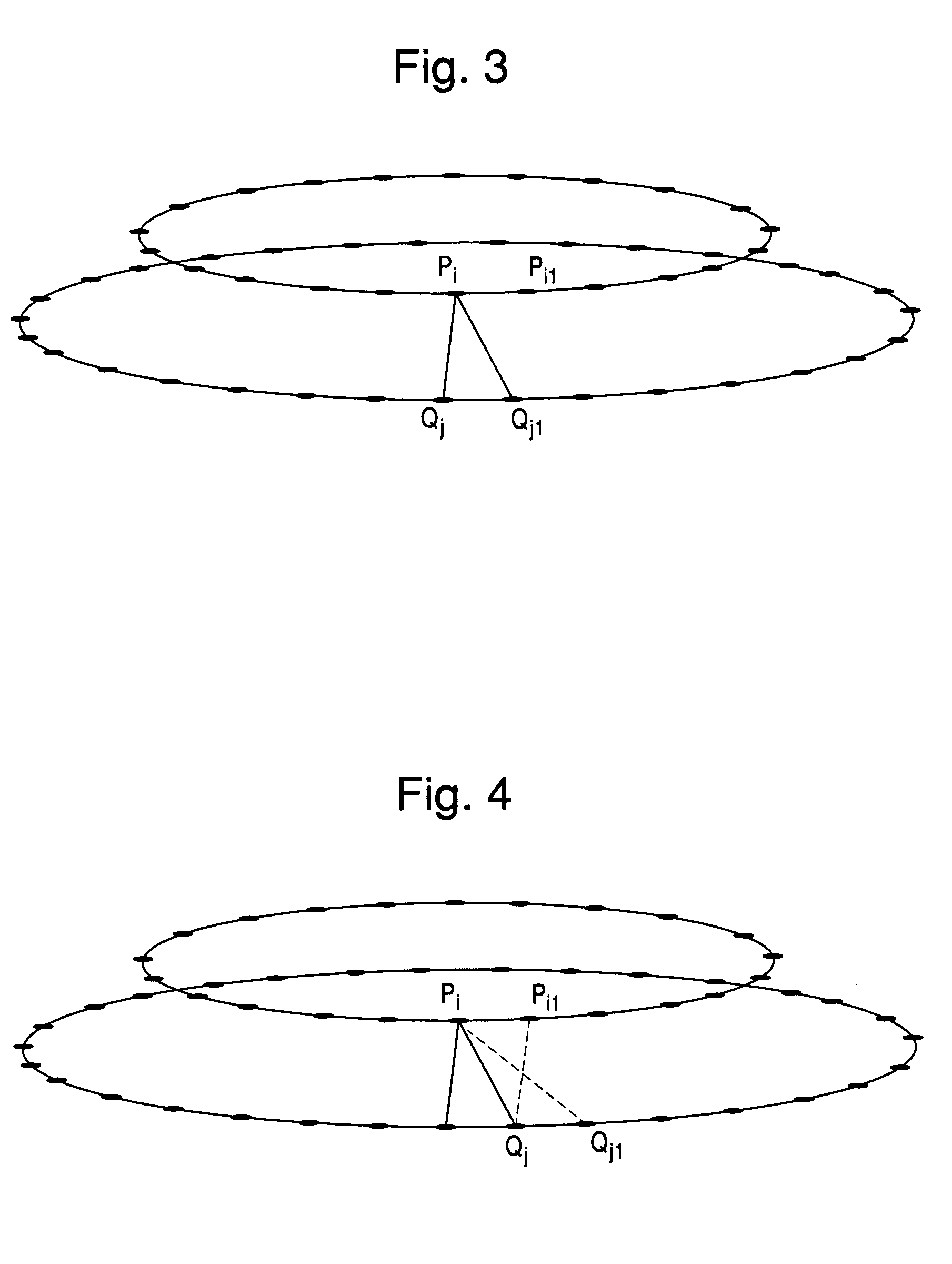

A method and apparatus for reconstructing a surface shape of an object having contour lines, includes assigning points to each contour line. A first triangulation scheme is performed with respect to respective points on two adjacently-positioned contour lines, to determine a first surface shape for a portion of the object corresponding to the two contour lines. The first surface shape is checked to determine if the first surface shape is in error. If the first surface shape is not in error, the first surface shape is outputted for the portion of the object as determined by the first triangulation scheme, as a reconstructed surface shape for that portion of the object. If the first surface shape is in error, a second triangulation scheme is performed with respect to the respective points on the two contour lines, to determine a second surface shape for that portion of the object, and the second surface shape is outputted for that portion of the object as determined by the second triangulation scheme, as a reconstructed surface shape.

Owner:MAKO SURGICAL CORP

System and method for mapping complex fractionated electrogram information

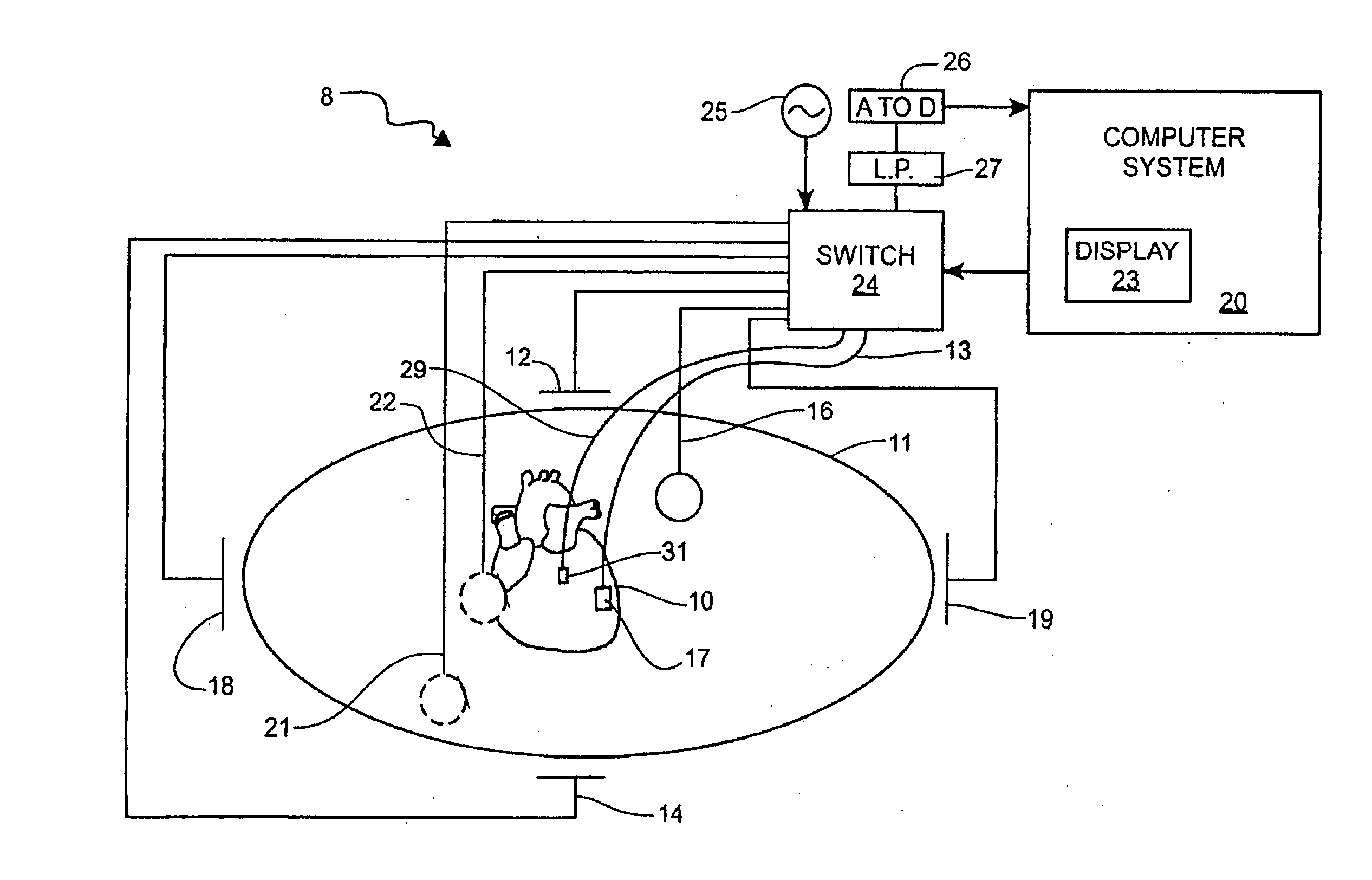

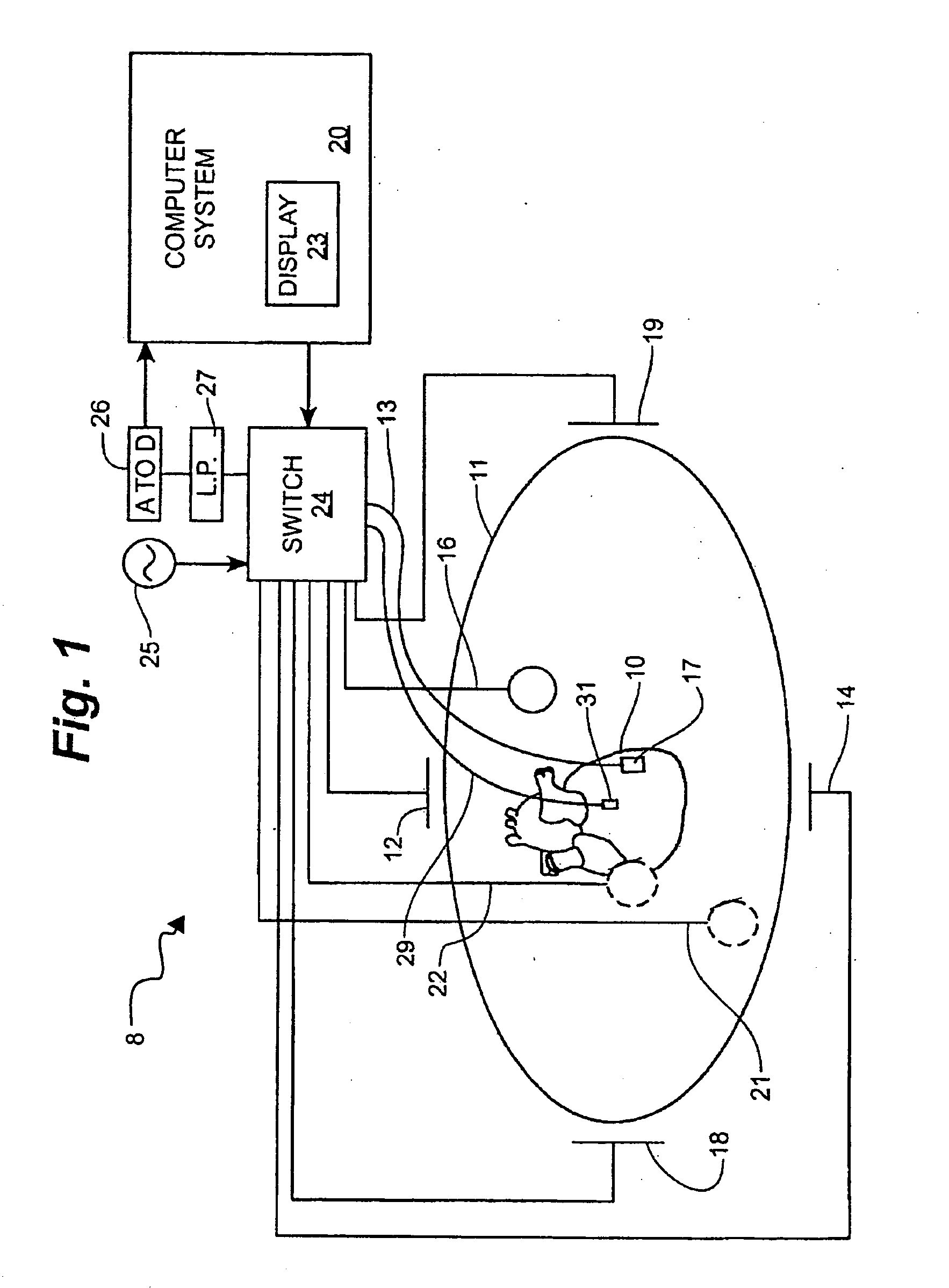

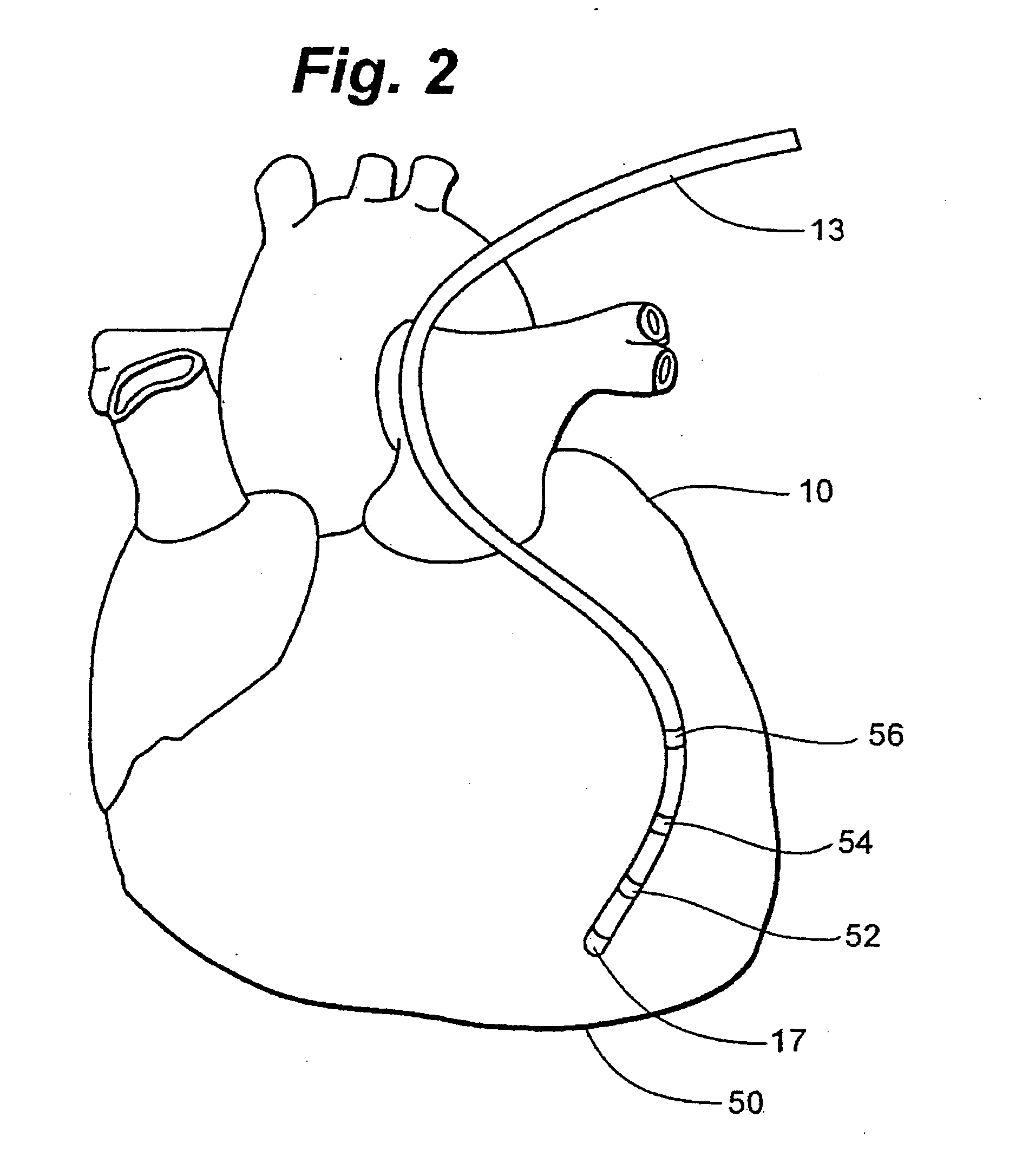

A system for presenting information representative of patient electrophysiological activity, such as complex fractionated electrogram information, includes at least one electrode to measure electrogram information from the heart surface, at least one processor coupled to the at least one electrode to receive the electrogram information and measure a location of the at least one electrode within the heart, and a presentation device to present the electrogram information as associated with the location at which it was measured on a model of the patient's heart. A memory may also be provided in which to store the associated electrogram information and measured location. Data may be analyzed using both time-domain and frequency-domain information to create a three-dimensional map. The map displays the data as colors, shades of color, and / or grayscales, and may further utilize contour lines, such as isochrones, to present the information.

Owner:ST JUDE MEDICAL ATRIAL FIBRILLATION DIV

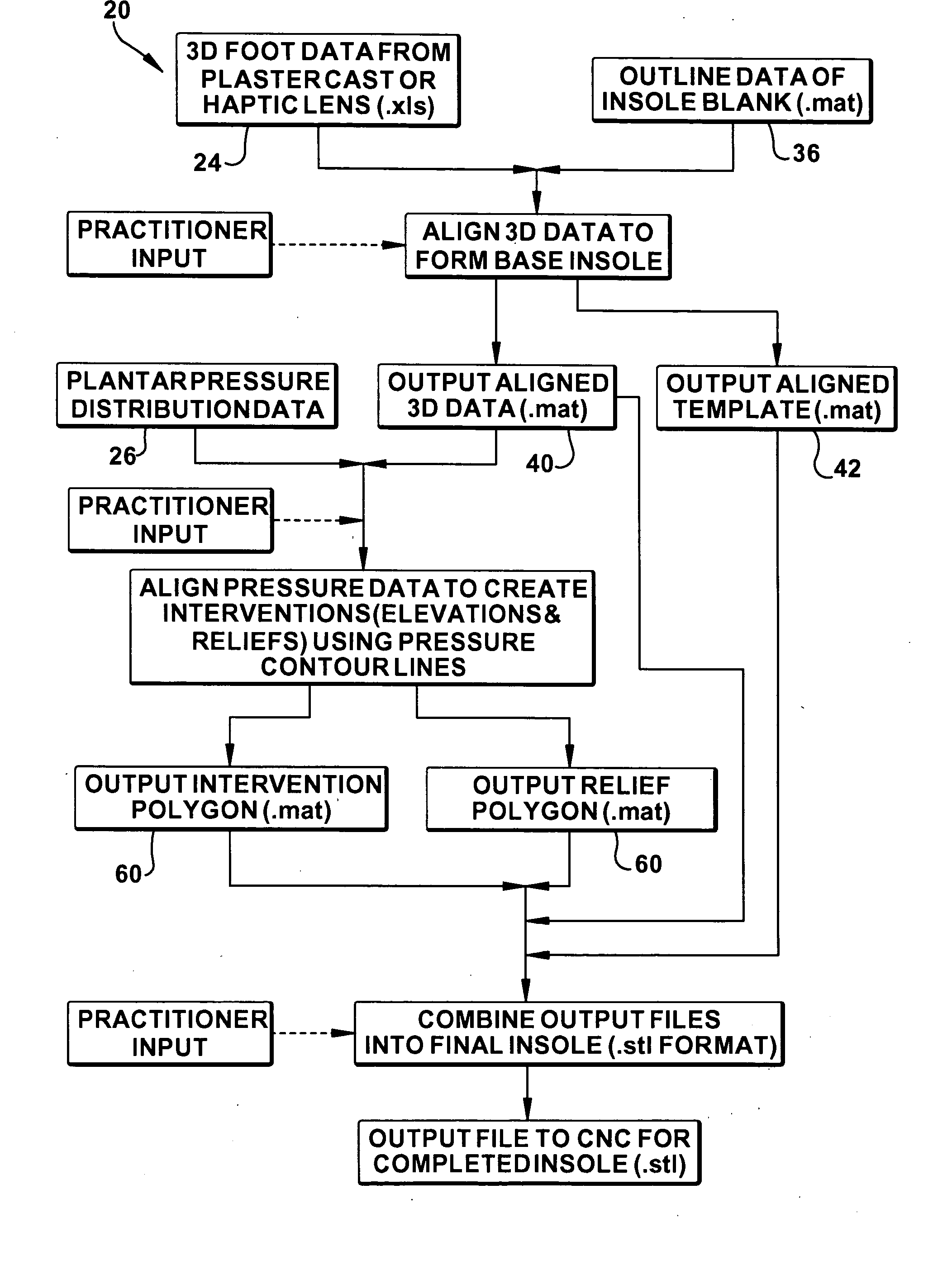

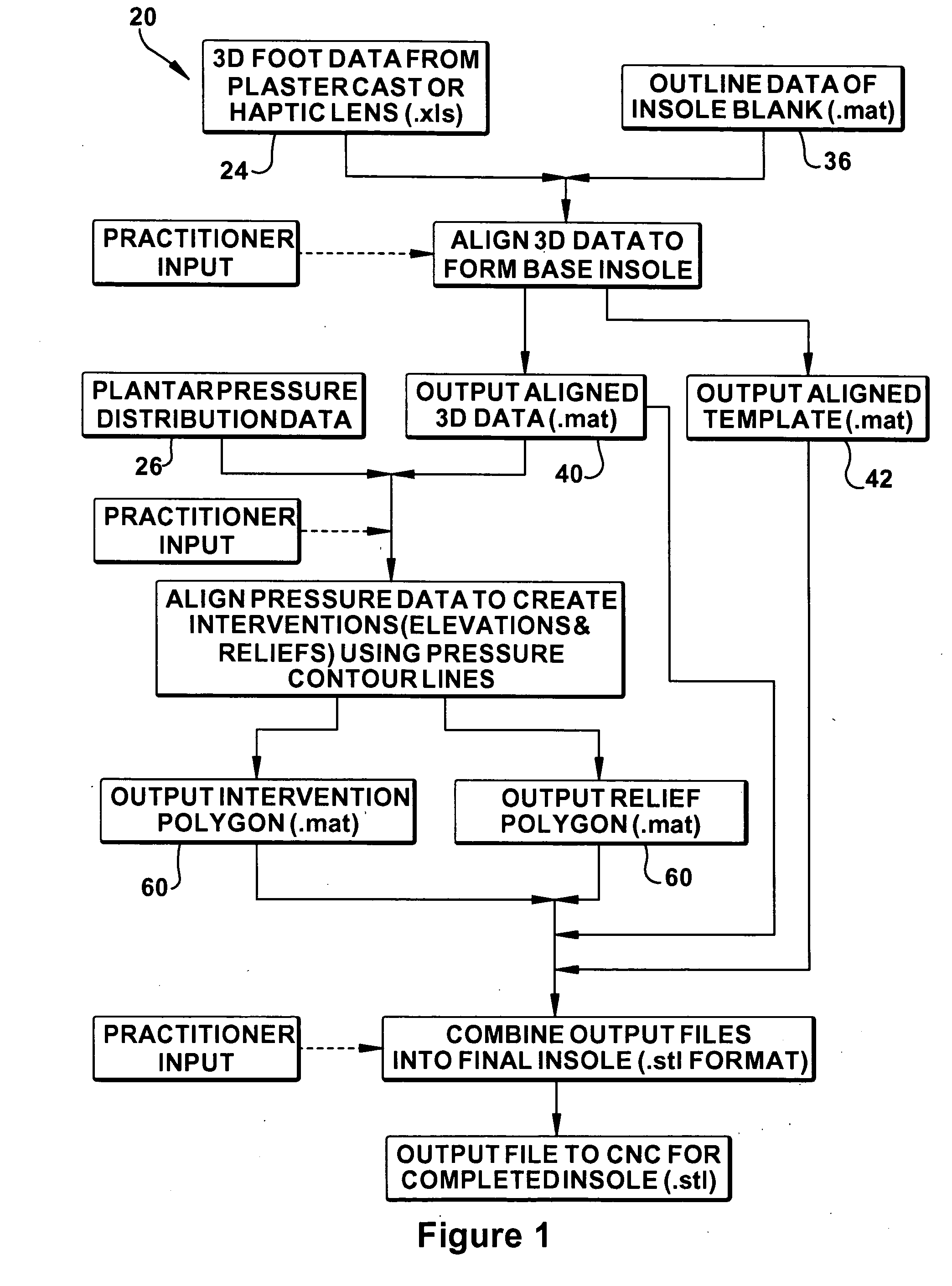

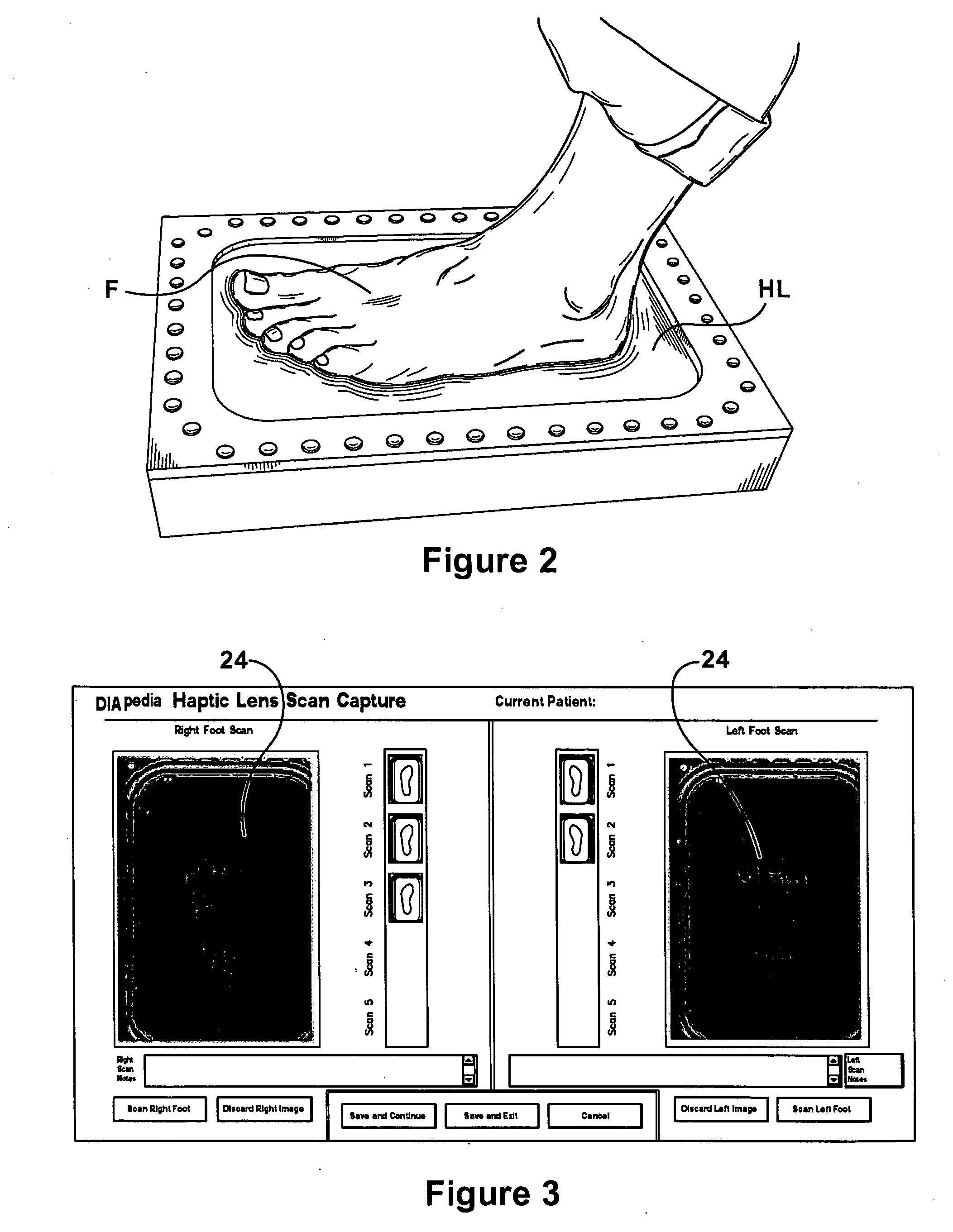

Method for Design and Manufacture of Insoles

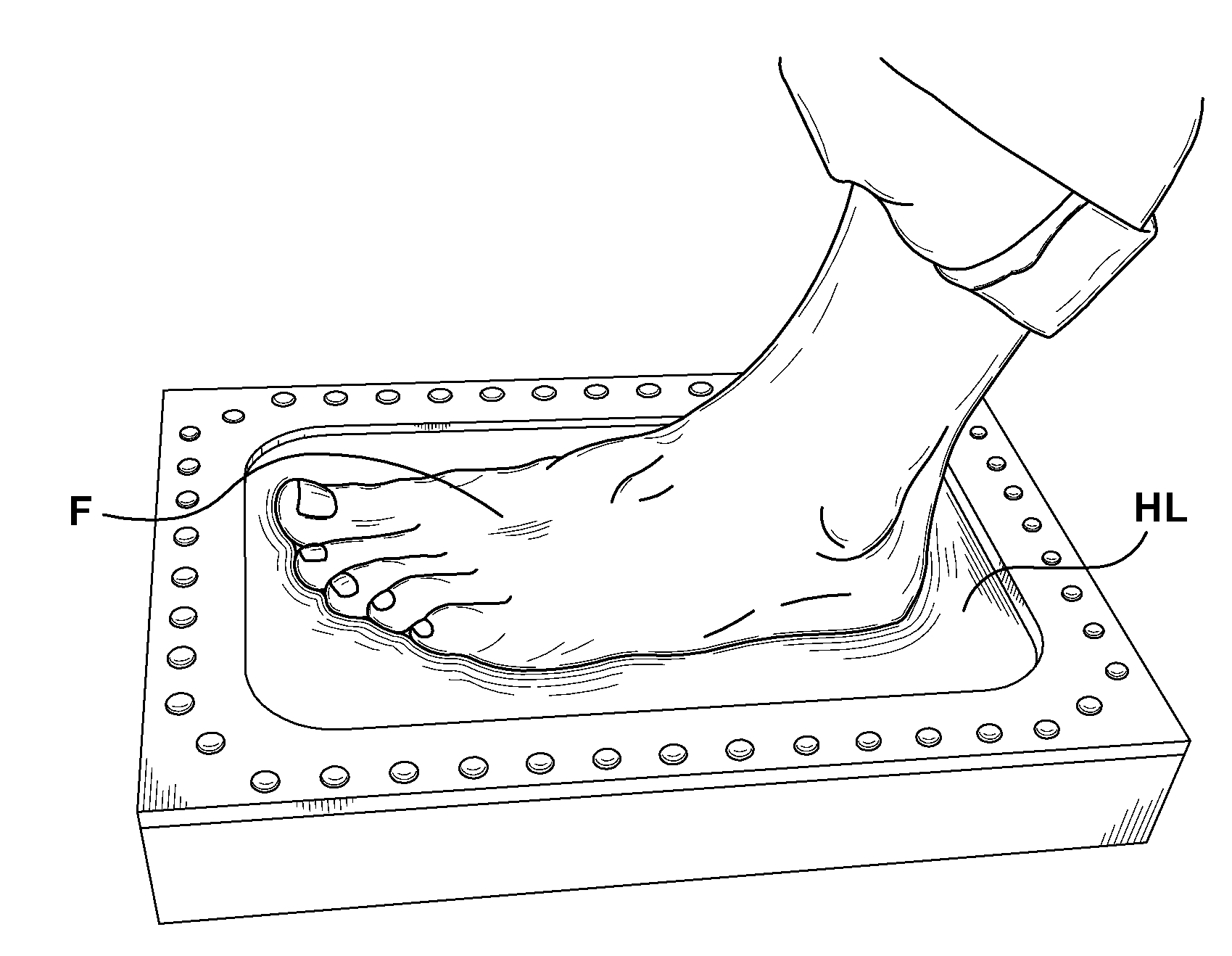

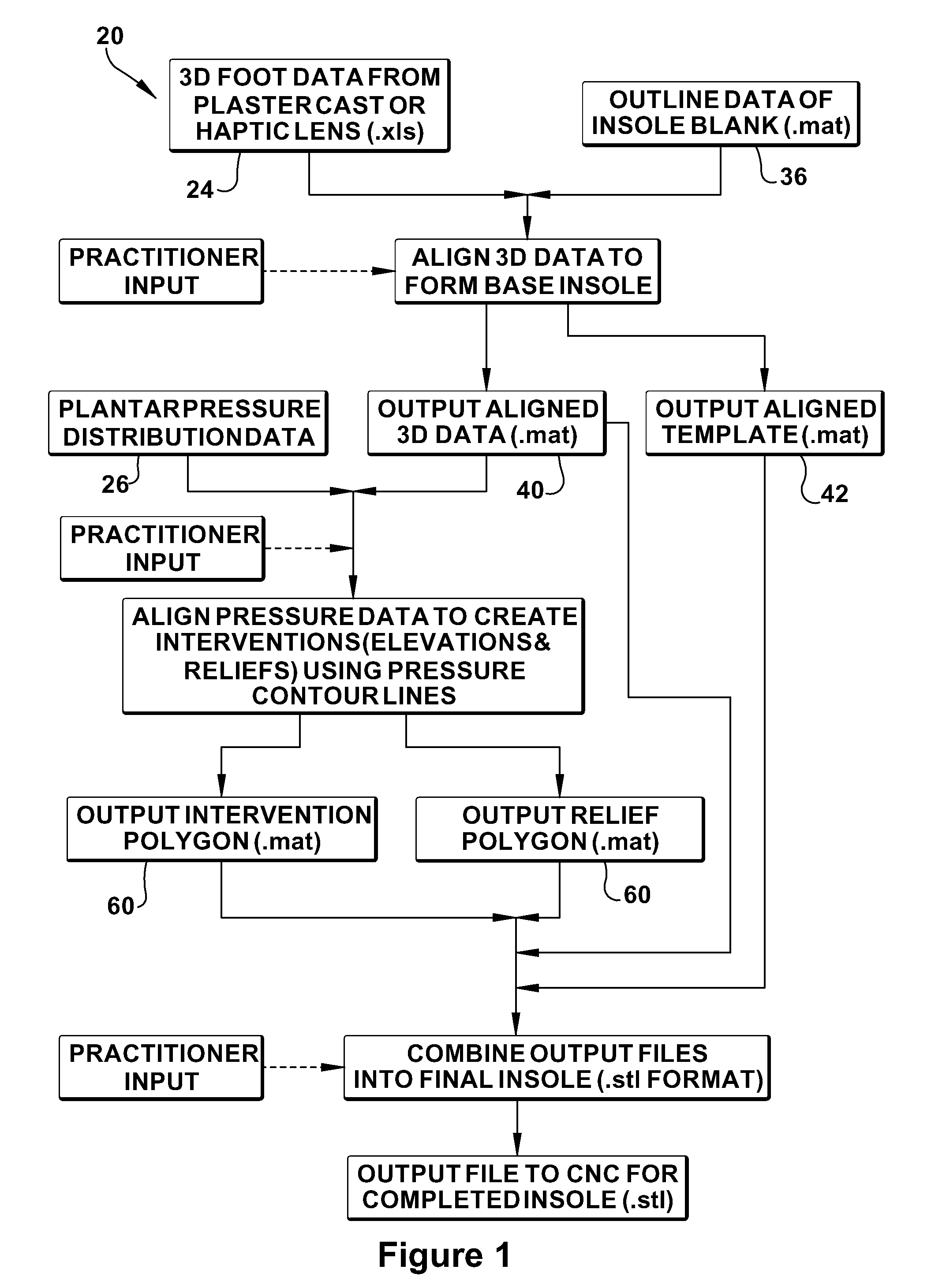

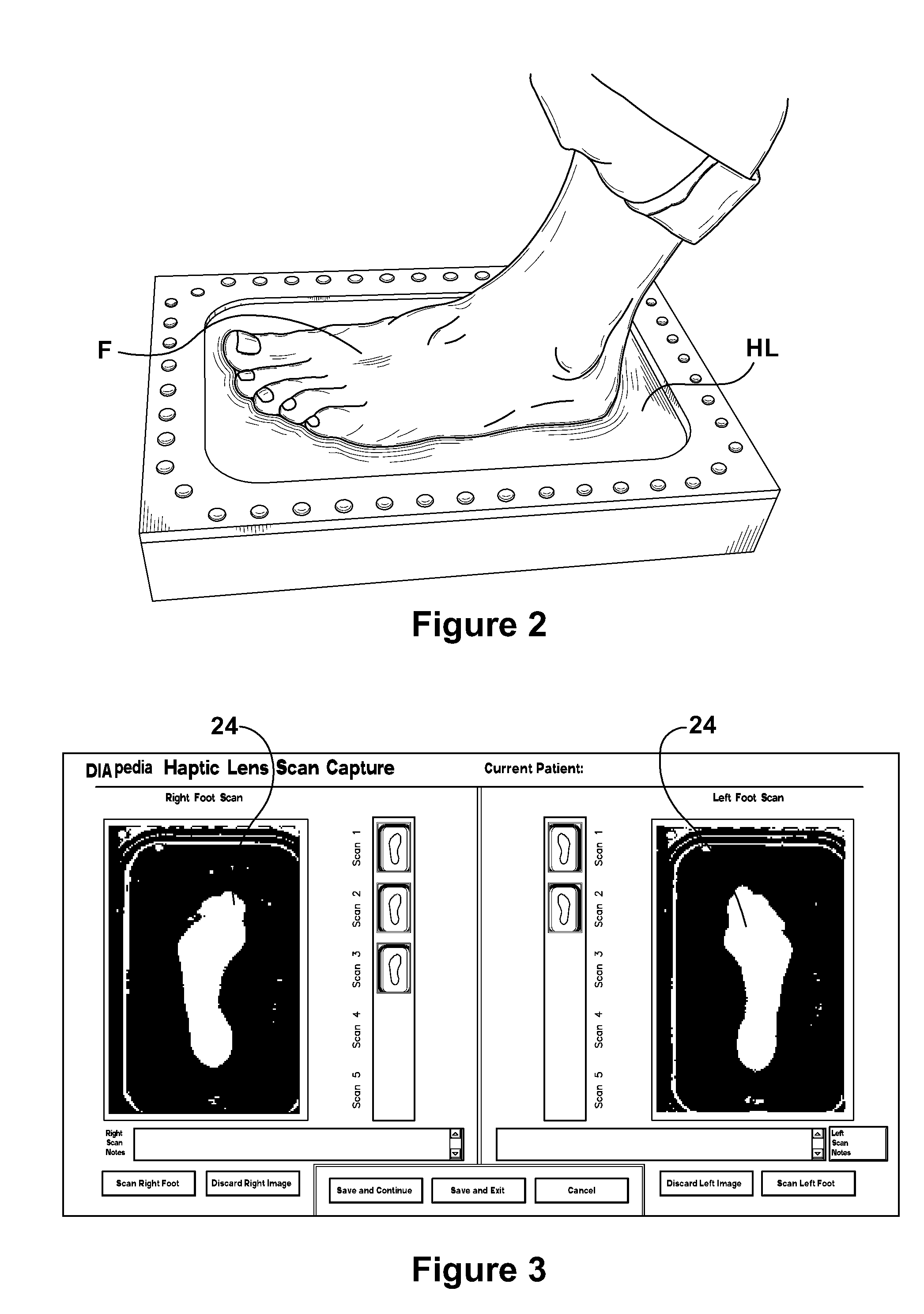

InactiveUS20070163147A1Increase pressureReduce pressureFoot measurement devicesSoles3d imageEngineering

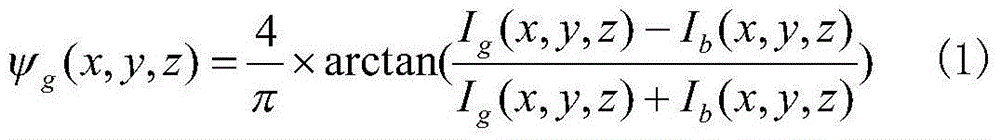

A method for the design and production of improved pressure reducing therapeutic shoe insoles for a person. The method includes the steps of measuring a three dimensional image of a foot and the distribution of plantar pressures applied by a person's foot being measured for a pressure reducing insole. Selecting a shoe insole outline or template which best fits or corresponds to the shape of a foot being measured. A foot display is generated which combines and aligns the three dimensional foot shape and the plantar pressure distribution. A three dimensional insole display is generated which combines and aligns the foot shape and plantar pressure distribution, and includes modifications based upon selected pressure contour lines identified within the foot display which are above predetermined pressure thresholds.

Owner:DIAPEDIA

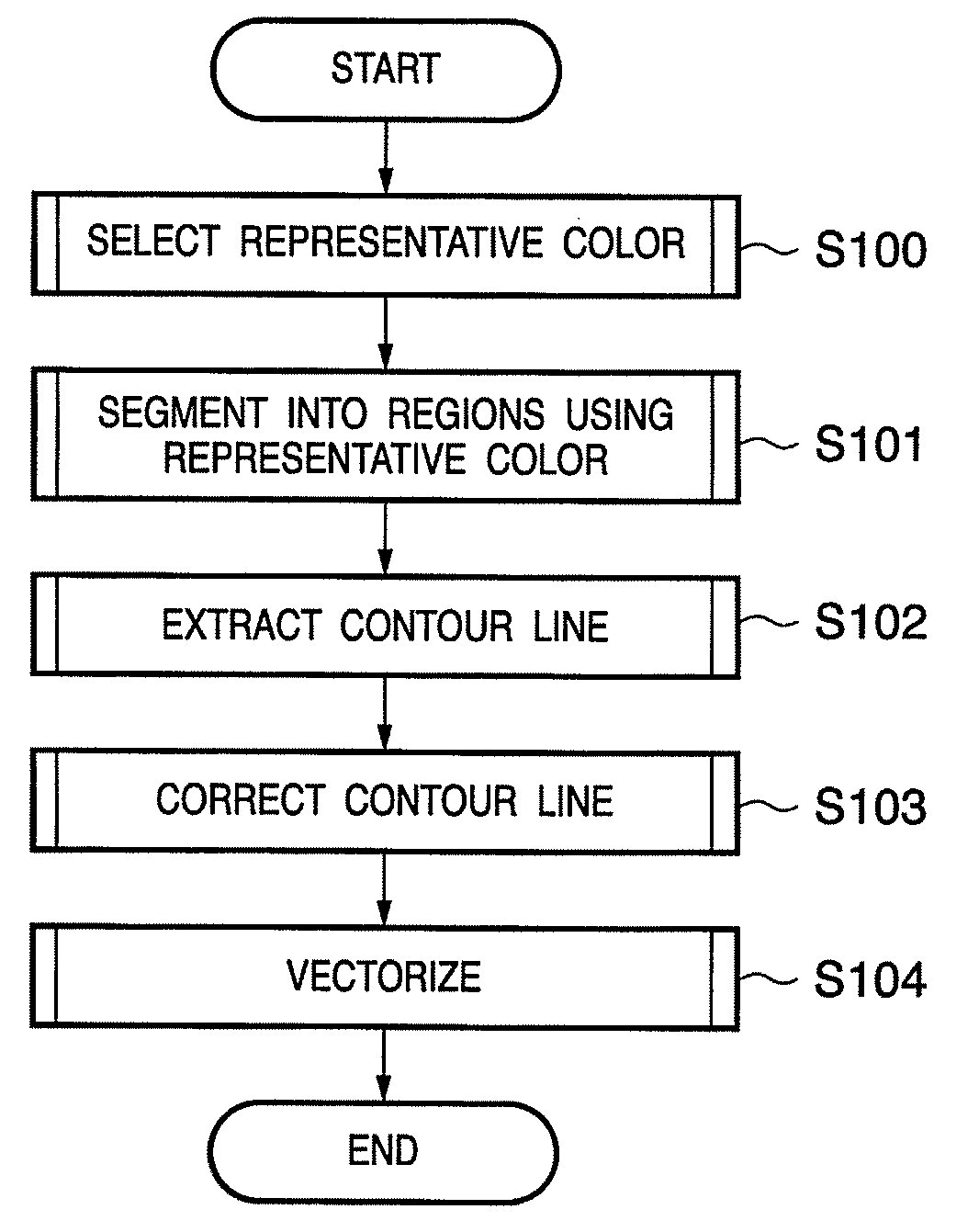

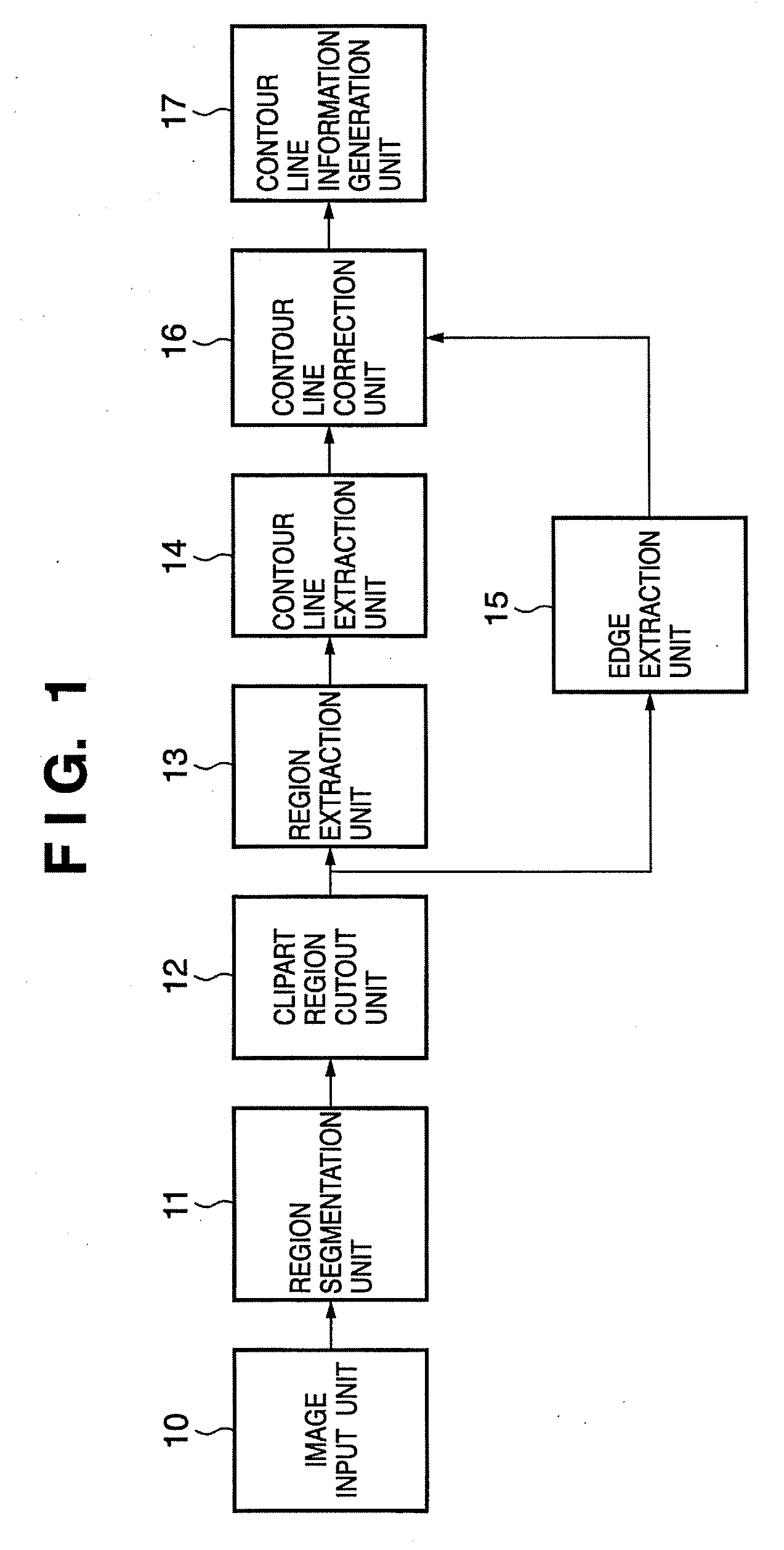

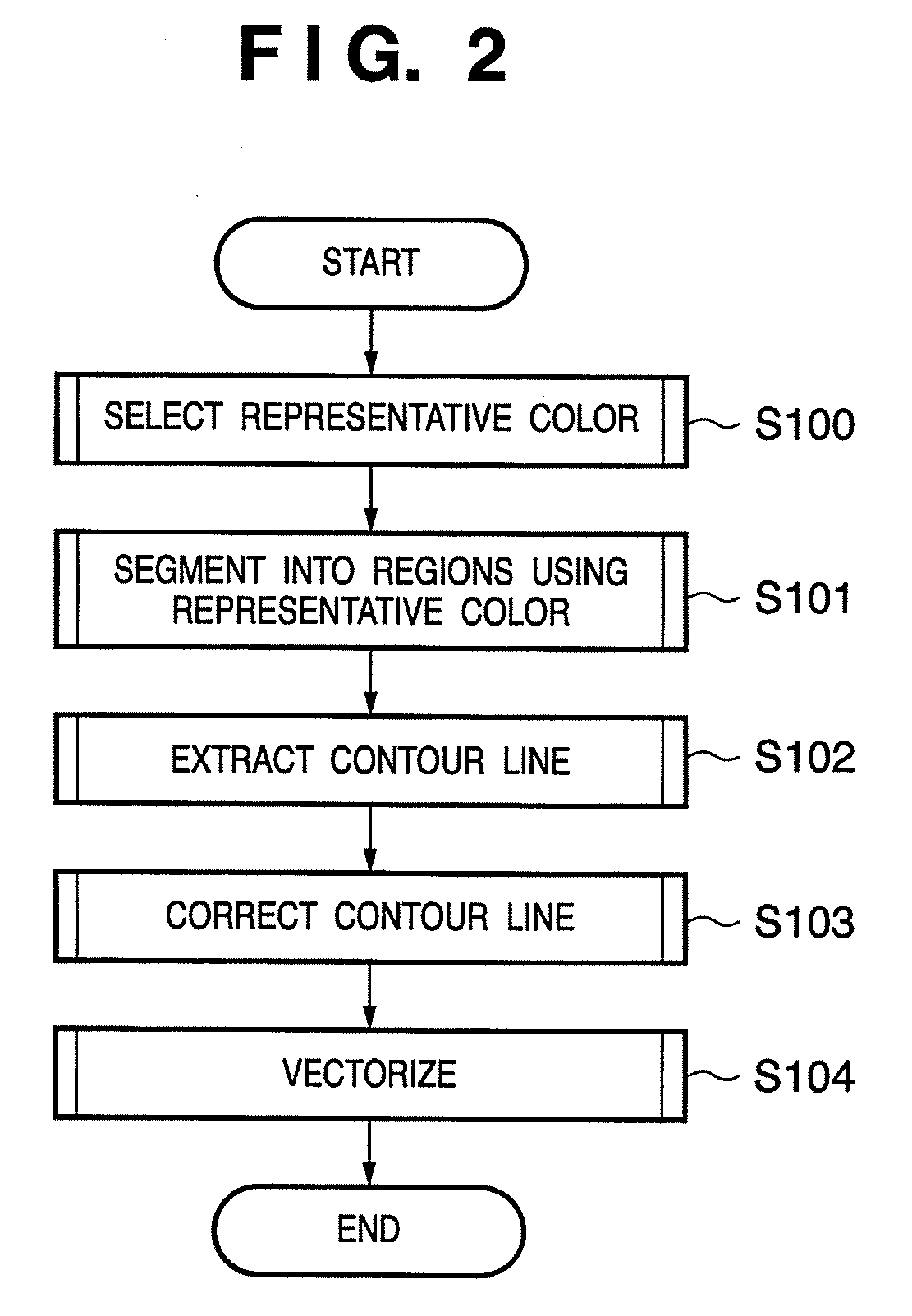

Image processing apparatus, image processing method, and program

An image processing apparatus, image processing method, and program which enable generation of vector data capable of replicating a clipart region of a raw image as faithfully as possible are provided. To accomplish this, a raw image is segmented into region images according to attributes. From the segmented region images, a region image having a predetermined attribute is cut out from the raw image. At least one representative color which configures the predetermined region image is decided based on an appearance color of the cut out predetermined region image. A color image having the decided representative color is extracted from the predetermined region image. A contour line of the extracted color image is extracted. An edge image within the predetermined region image is extracted. The extracted contour line is corrected based on the extracted edge image. Using the corrected contour line, vector data of the predetermined region image is generated.

Owner:CANON KK

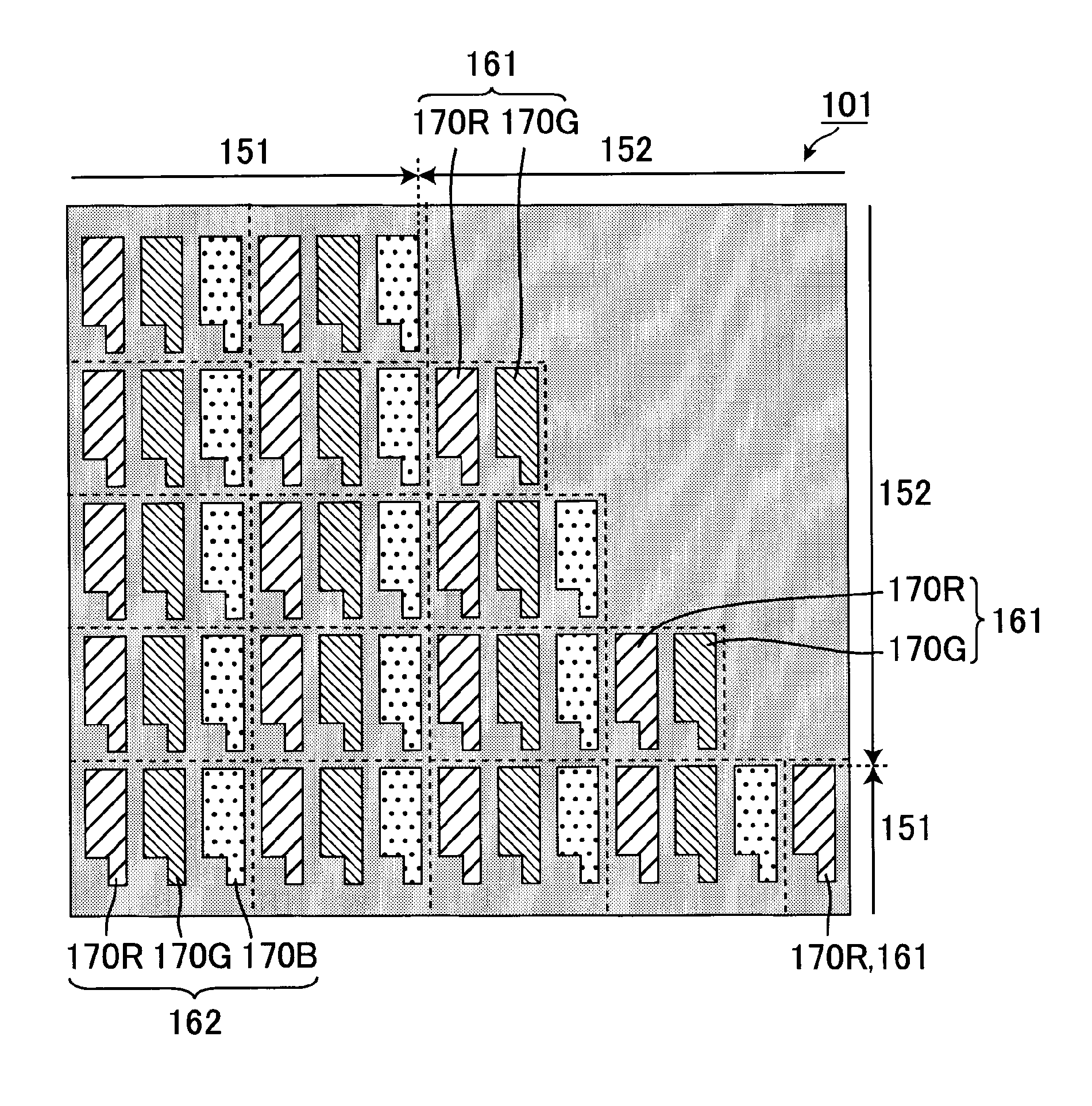

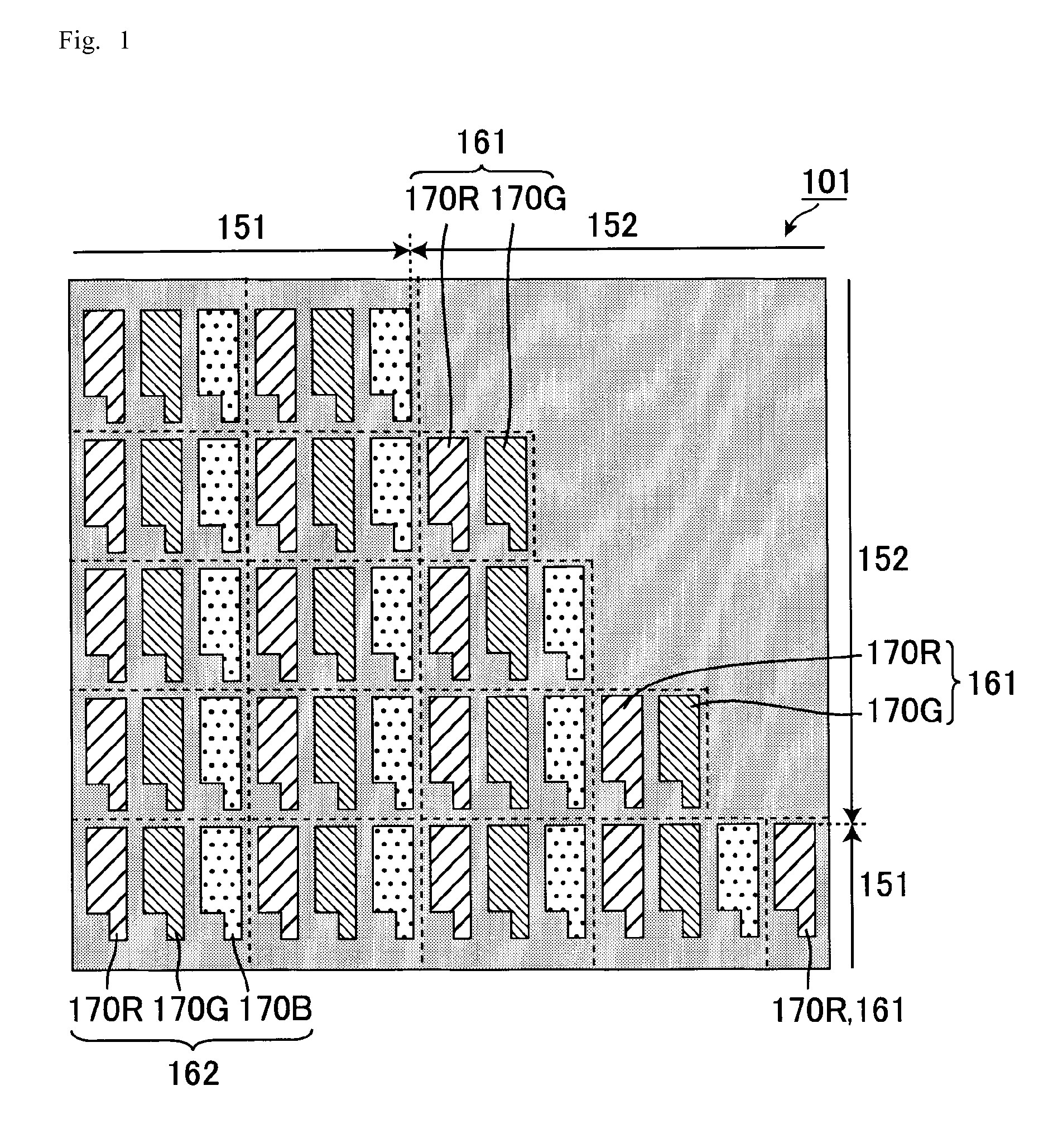

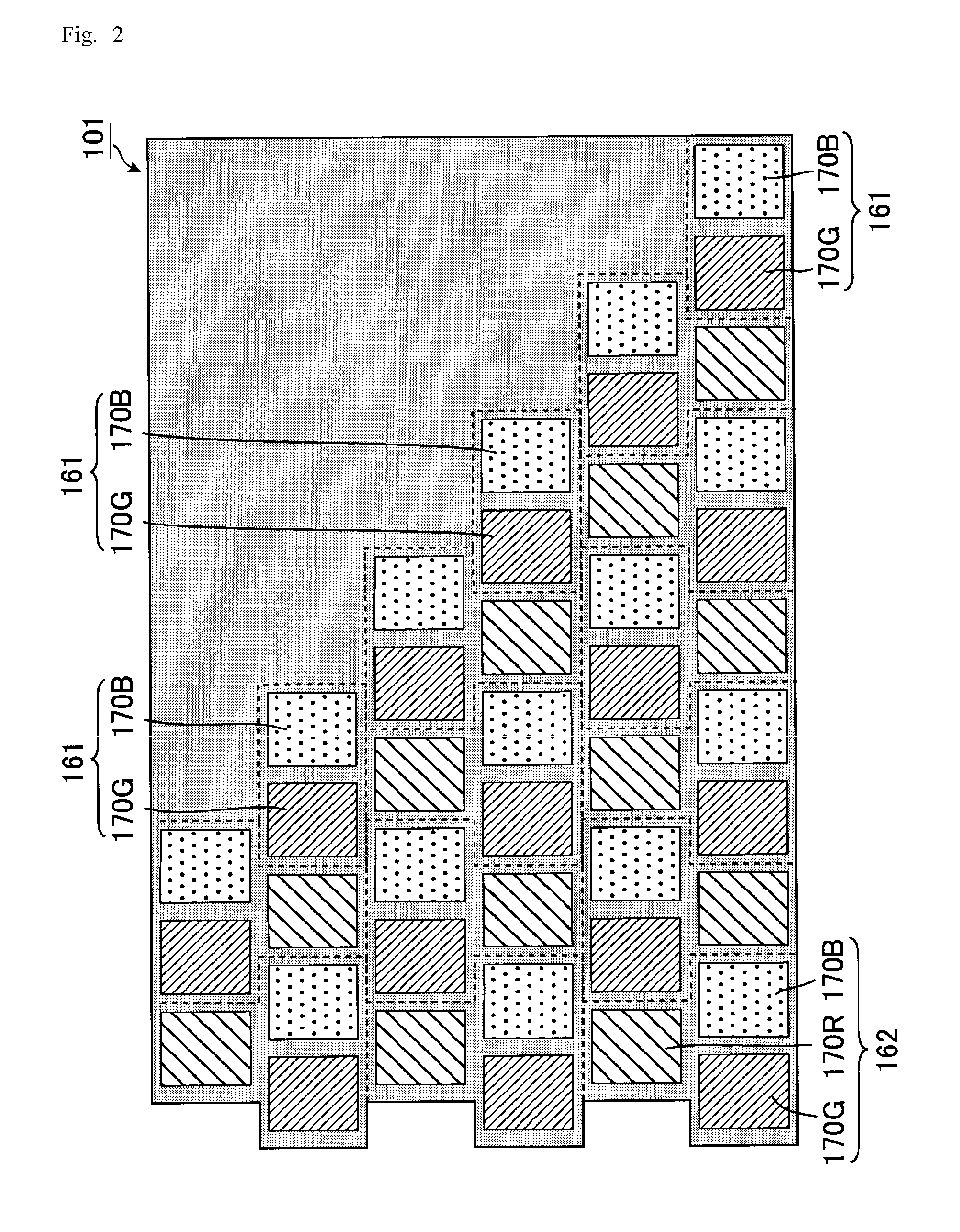

Display panel and display apparatus

ActiveUS20100214195A1Good lookingSimple designCathode-ray tube indicatorsNon-linear opticsShape displayContour line

Owner:SHARP KK

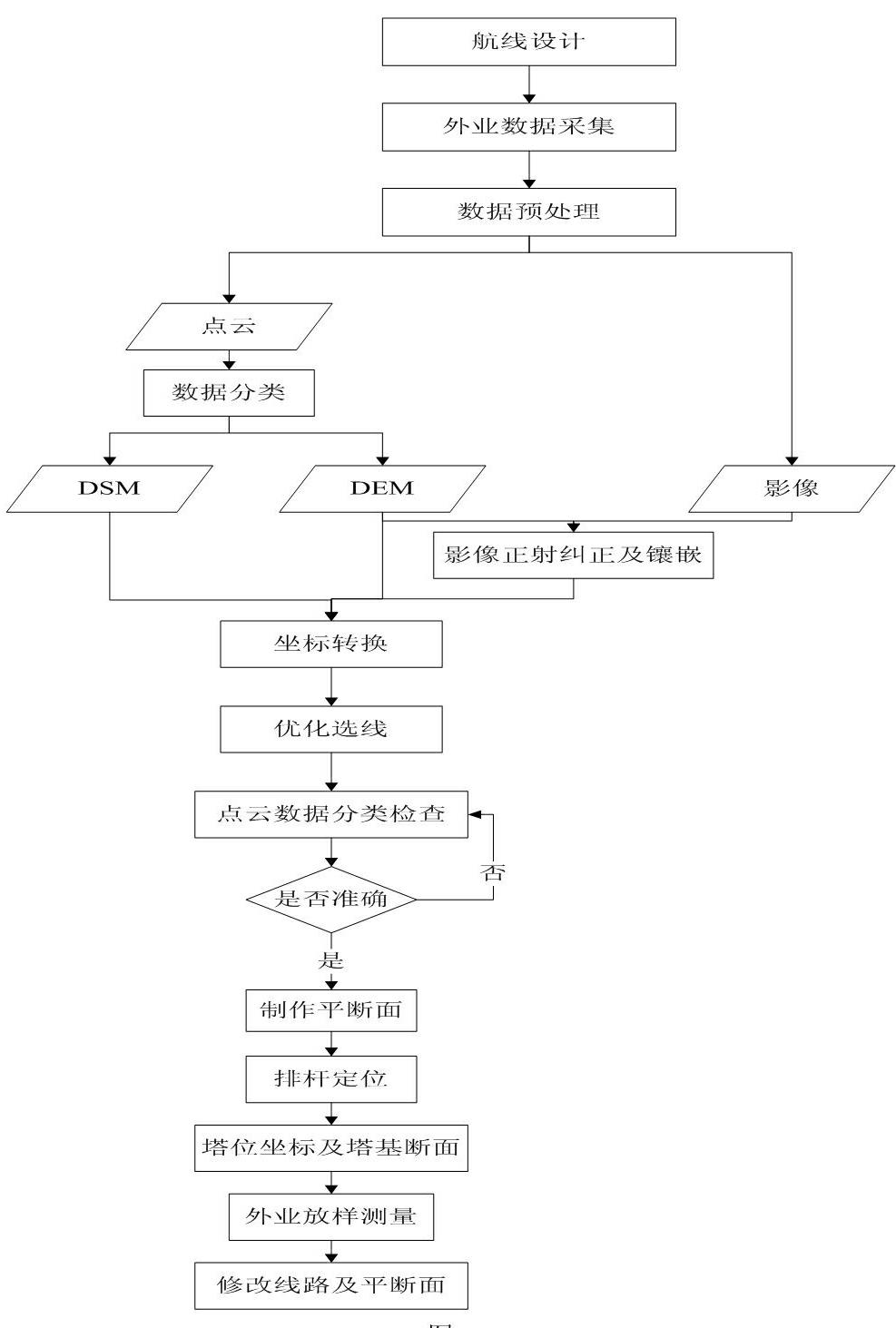

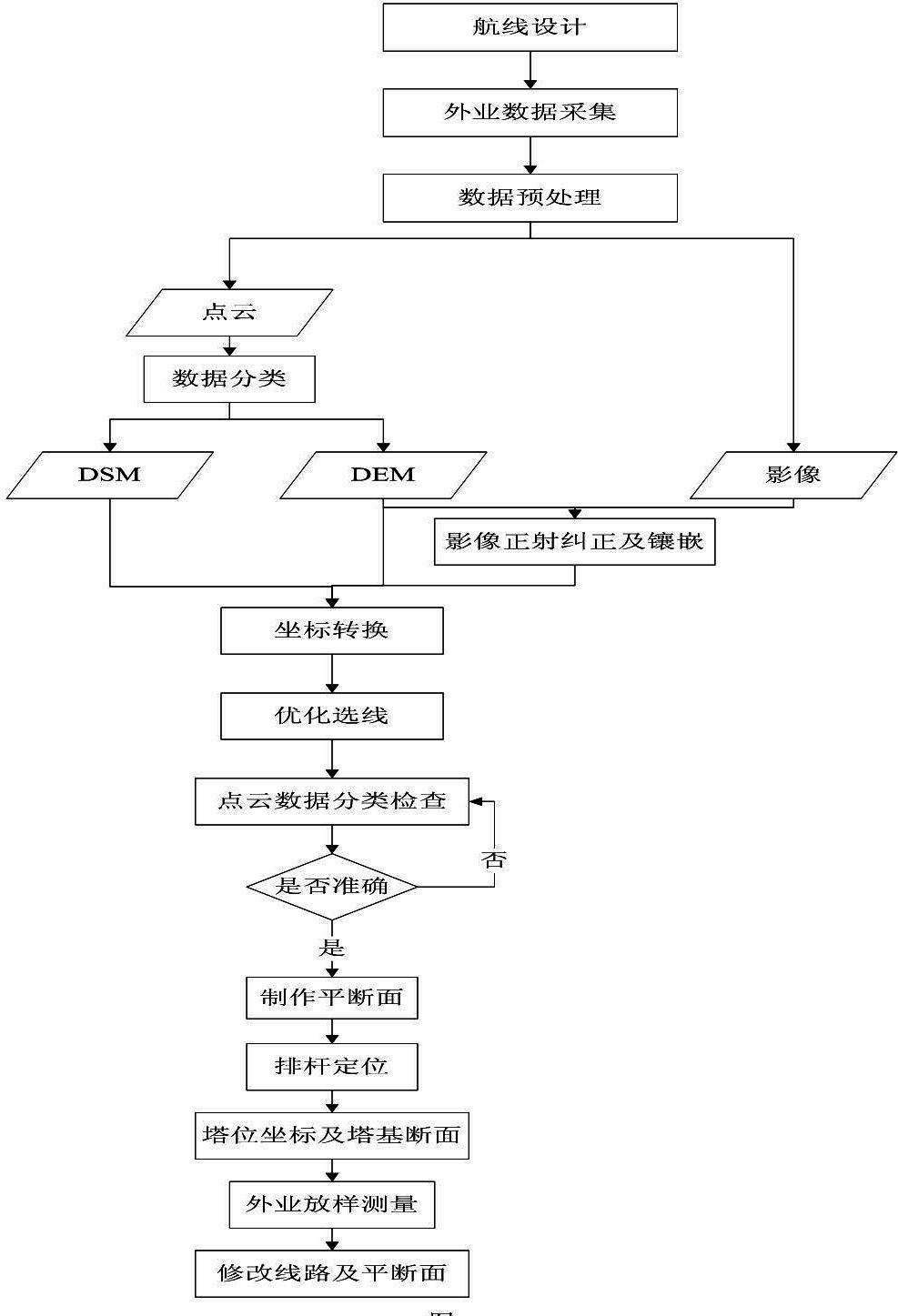

Three-dimensional optimizing route selection method based on airborne laser radar

InactiveCN102662179AIncrease sampling densityRealize high-precision measurementElectromagnetic wave reradiationData acquisitionSelection system

The invention discloses a three-dimensional optimizing route selection method based on an airborne laser radar. The method comprises the following steps of: carrying out flight design according to a feasible route of a line, and acquiring flight field data by the laser radar according to design parameters; carrying out united computation on laser ranging data and POS system positioning data to obtain laser point cloud data through pre-processing the data; post-processing the data to obtain a point cloud classification map, a digital elevation model (DEM), a digital surface model (DSM), a contour line and a digital orthoimage map (DOM); importing into a three-dimensional optimizing route selection system, selecting a line route, checking peripheral landform of a line corridor, and carrying out optimization design on the line; combining with a three-dimensional image and a plane section, carrying out operations of pre-arranging poles and arranging poles in a route selection software, and outputting an image route diagram; and drawing the plane section of the route, and carrying out alignment survey. The method utilizes the section view and the orthoimage in the three-dimensional optimizing route selection system to realize the operations of pre-arranging the poles and arranging the poles, so as to generate a plane section diagram needed by power industry department, and the operation efficiency of route selection is improved.

Owner:MIANYANG SKYEYE LASER TECH

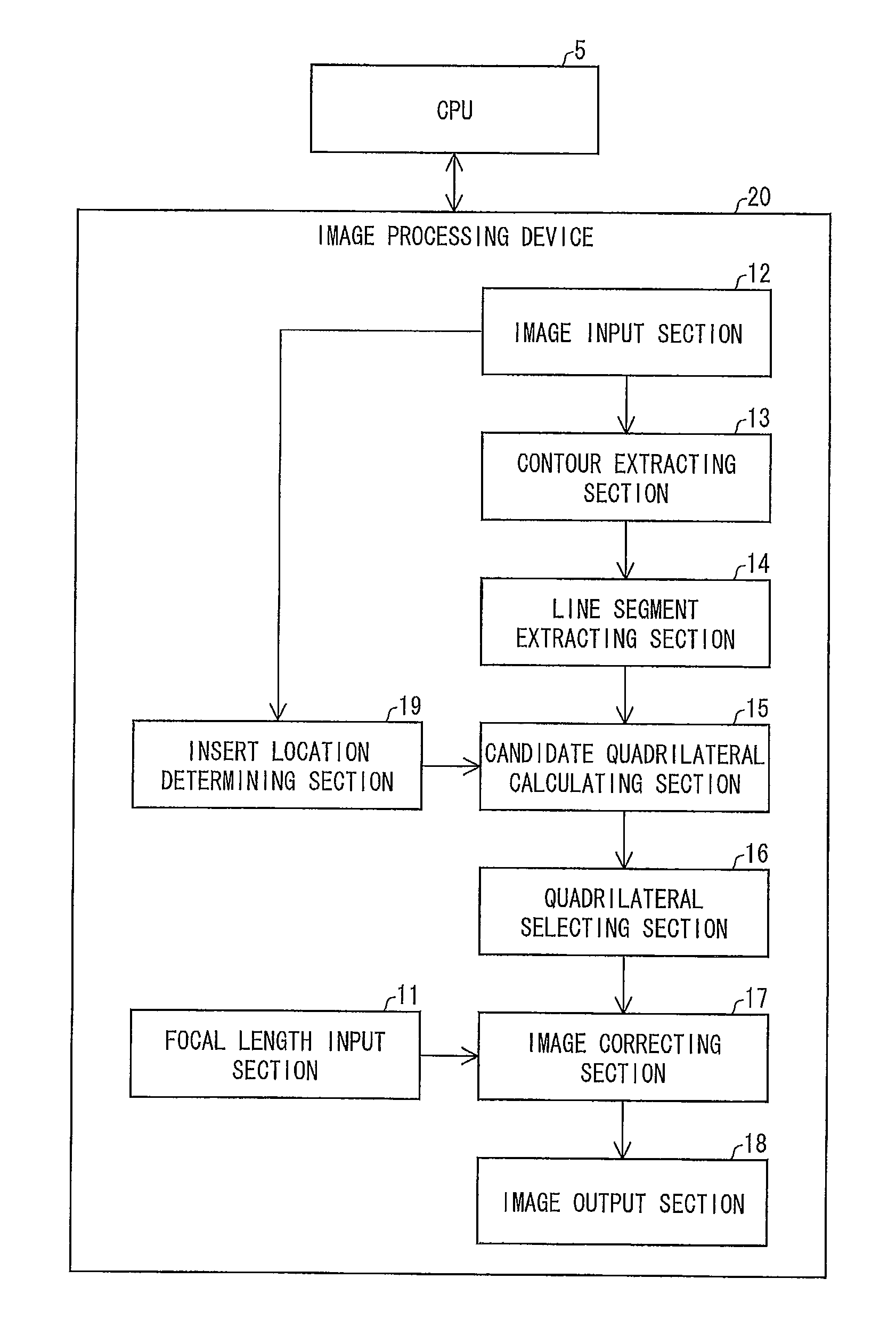

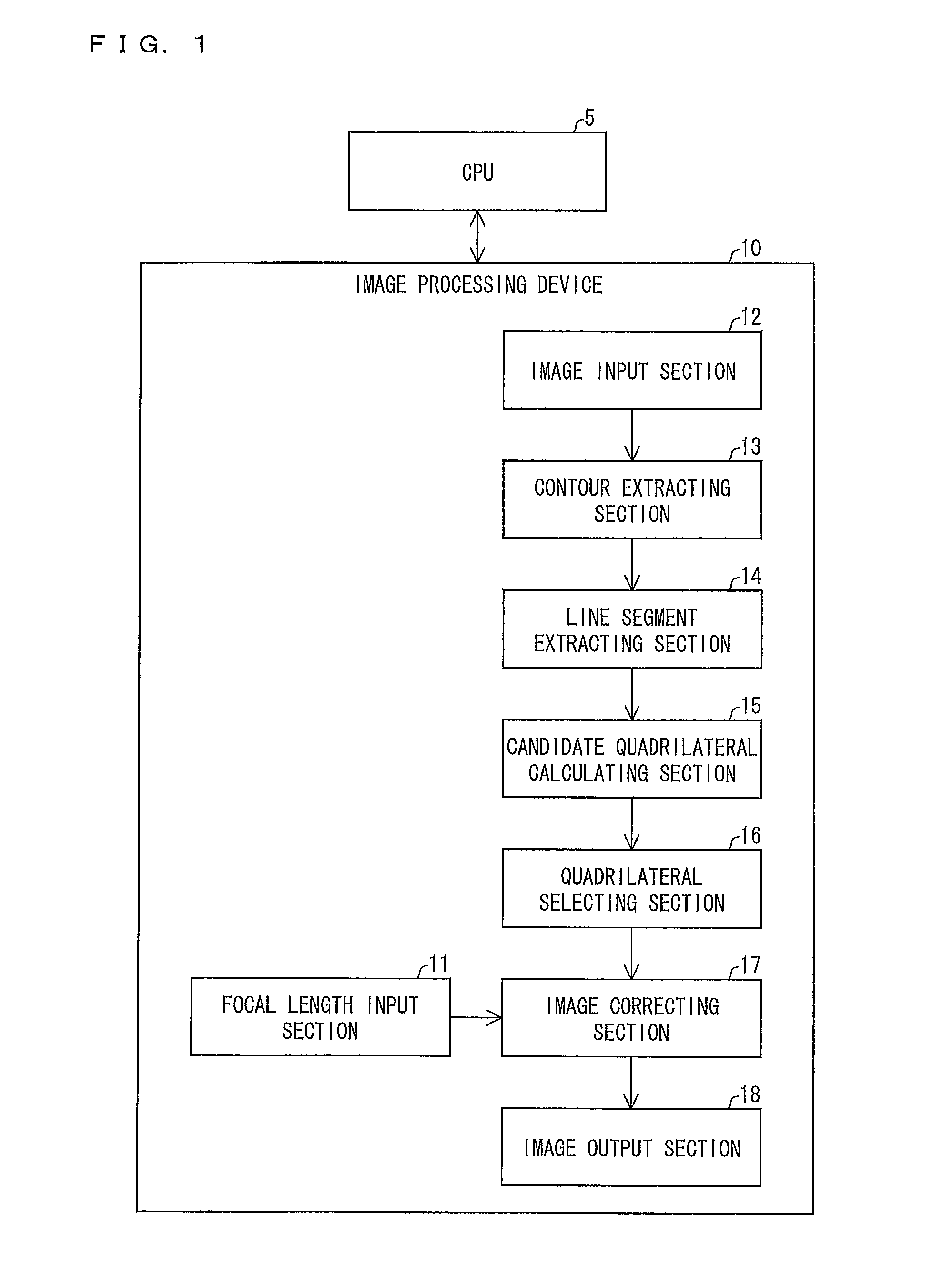

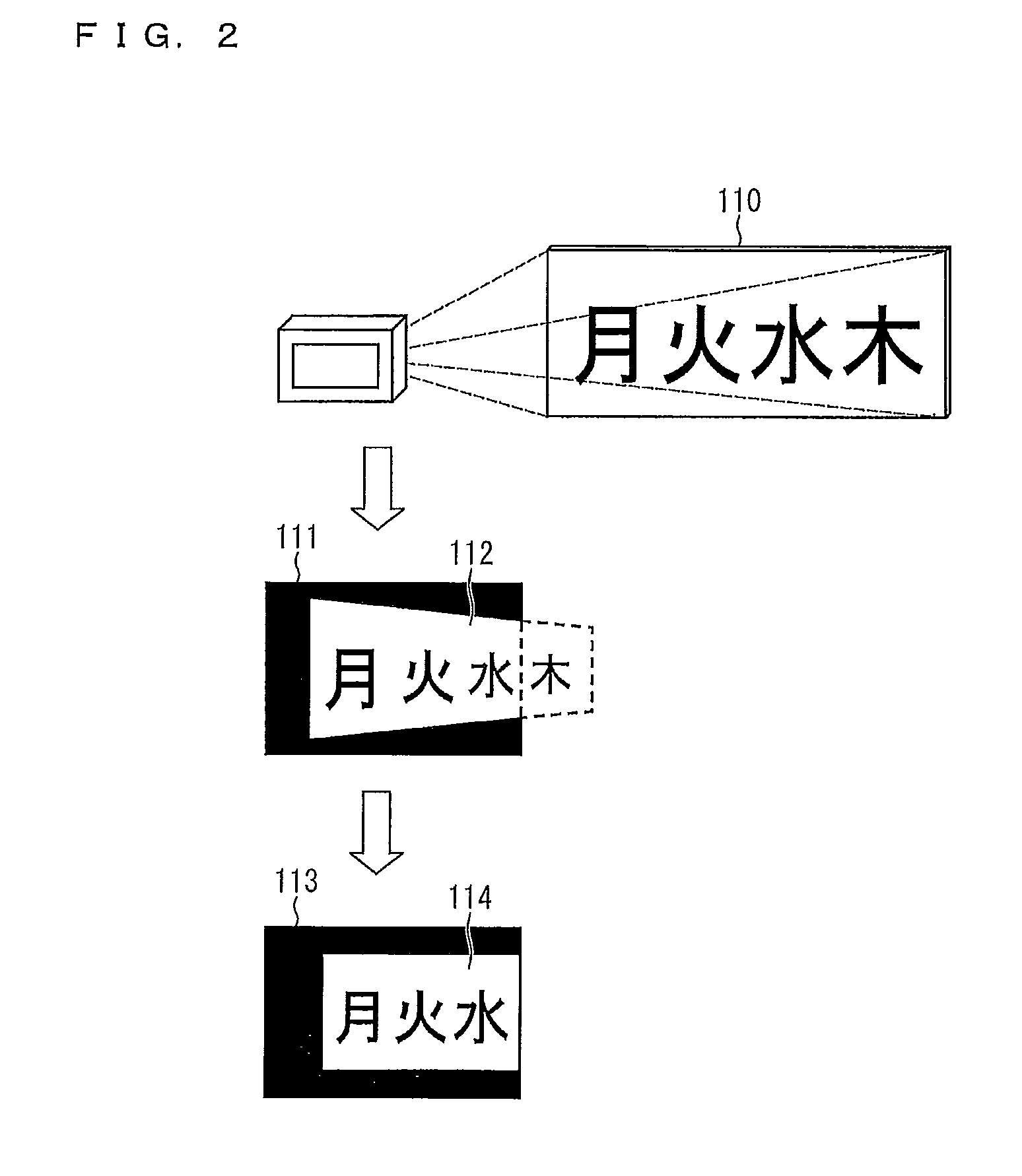

Image processing device, image processing method, image processing program, and recording medium with recorded image processing program

ActiveUS8731321B2Correct distortionImage enhancementTelevision system detailsImaging processingComputer graphics (images)

An image processing device (10) includes: a line segment extracting section (14) for generating a line segment image obtained by extracting contour line segments contained in a contour of a subject in a captured image; a candidate quadrilateral calculating section (15) for (i) putting at least one virtual line segment in the line segment image (ii) selecting four line segments from a set containing the at least one virtual line segment and the contour line segments, and (iii) identifying a quadrilateral defined by four straight lines containing respective selected four line segments; and an image correcting section (17) for correcting a distortion in perspective transformation of the captured image based on the quadrilateral identified by the candidate quadrilateral calculating section (15). With the configuration, the distortion of the subject can be corrected without manually adjusting a degree of correction, even in a case where the subject having sides is partially not contained in the captured image or the subject is not a document image.

Owner:SHARP KK

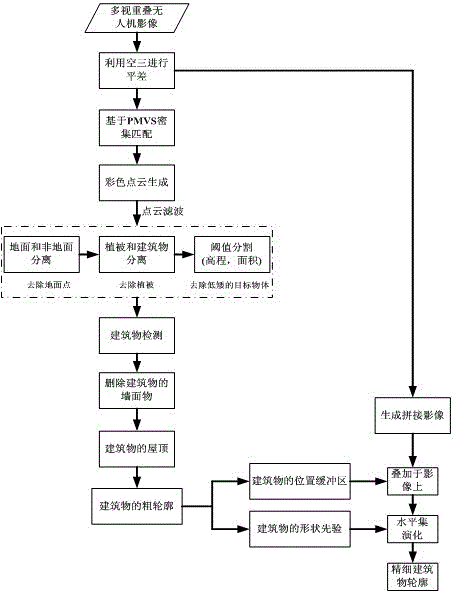

Unmanned aerial vehicle multi-overlapped-remote-sensing-image method for extracting building contour line

ActiveCN104484668AHigh precisionReduce complexityImage analysisCharacter and pattern recognitionPoint cloudPrior information

The invention discloses an unmanned aerial vehicle multi-overlapped-remote-sensing-image method for extracting a building contour line. The unmanned aerial vehicle multi-overlapped-remote-sensing-image method includes the steps that three-dimensional point cloud is generated with an aerial-triangulation and dense-matching combined method and filtered, and a building is detected from the point cloud; after the walls of the detected building are canceled, the general contour of the building is extracted from building top face information; the general contour of the building serves as a buffering area to be overlapped on spliced images and serves as shape prior information, evolution is carried out in the buffering area with a level set algorithm, and finally an accurate contour of the building is obtained. By means of the unmanned aerial vehicle multi-overlapped-remote-sensing-image method, as point cloud three-dimensional information generated by the multiple overlapped images is sufficiently used, and meanwhile the high-accuracy geometrical information of the high-resolution remote sensing images is used in a combined mode, the building contour extracting accuracy is remarkably improved, and the complexity of the method is lowered.

Owner:WUHAN UNIV

Method for design and manufacture of insoles

ActiveUS20060070260A1Increase pressureReduce pressureMedical simulationFoot measurement devices3d imageEngineering

A method for the design and production of improved pressure reducing therapeutic shoe insoles for a person. The method includes the steps of measuring a three dimensional image of a foot and the distribution of plantar pressures applied by a person's foot being measured for a pressure reducing insole. Selecting a shoe insole outline or template which best fits or corresponds to the shape of a foot being measured. A foot display is generated which combines and aligns the three dimensional foot shape and the plantar pressure distribution. A three dimensional insole display is generated which combines and aligns the foot shape and plantar pressure distribution, and includes modifications based upon selected pressure contour lines identified within the foot display which are above predetermined pressure thresholds.

Owner:DIAPEDIA

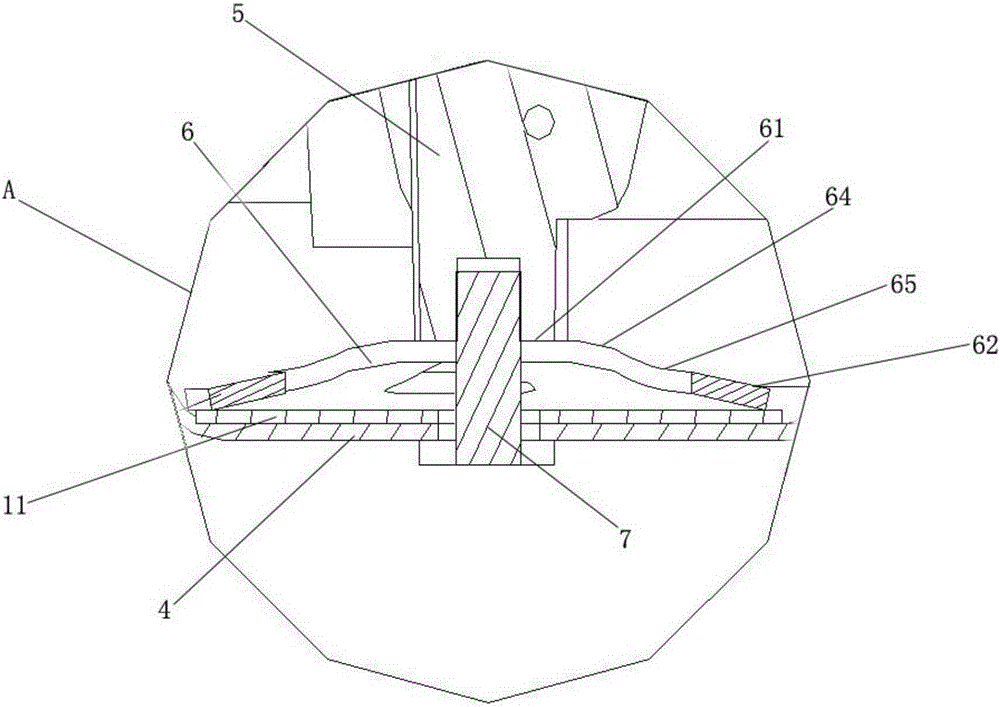

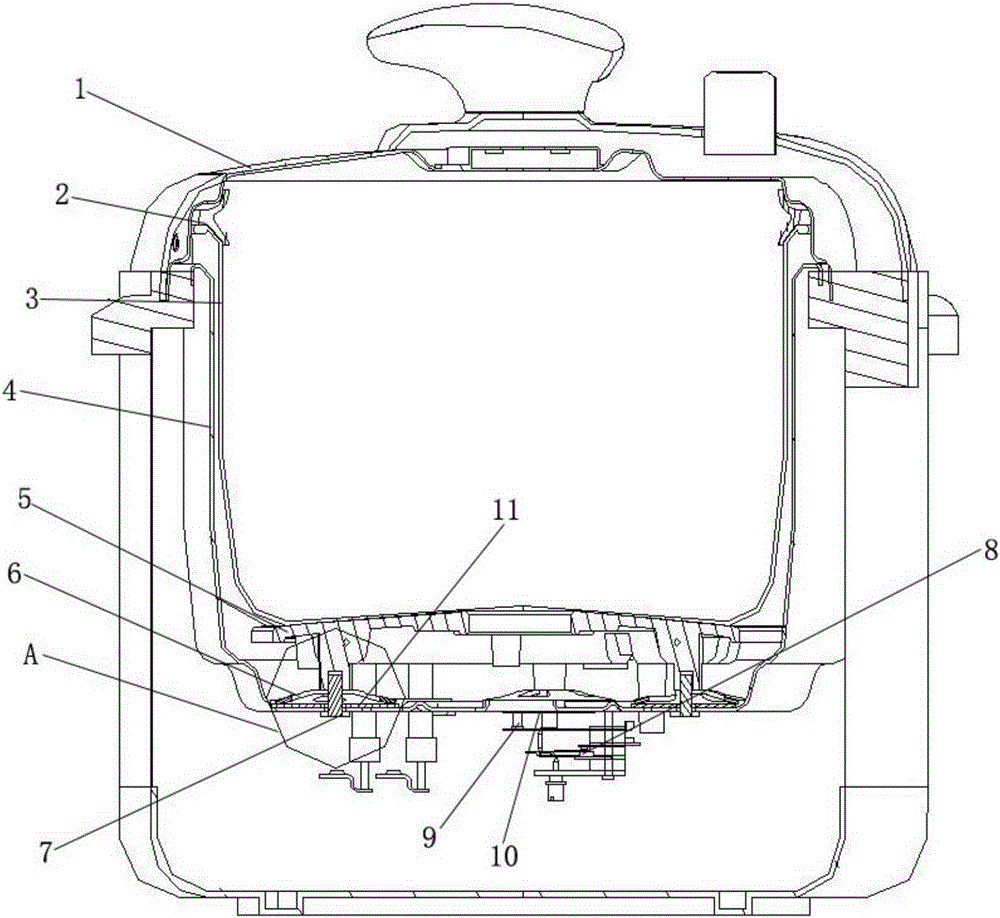

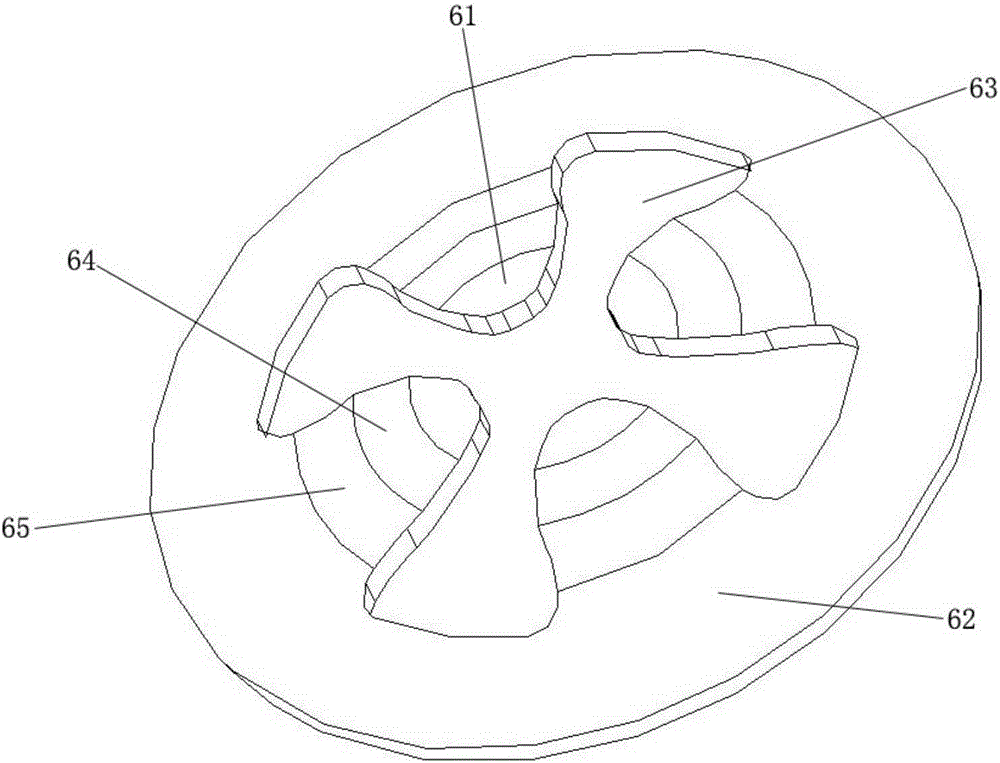

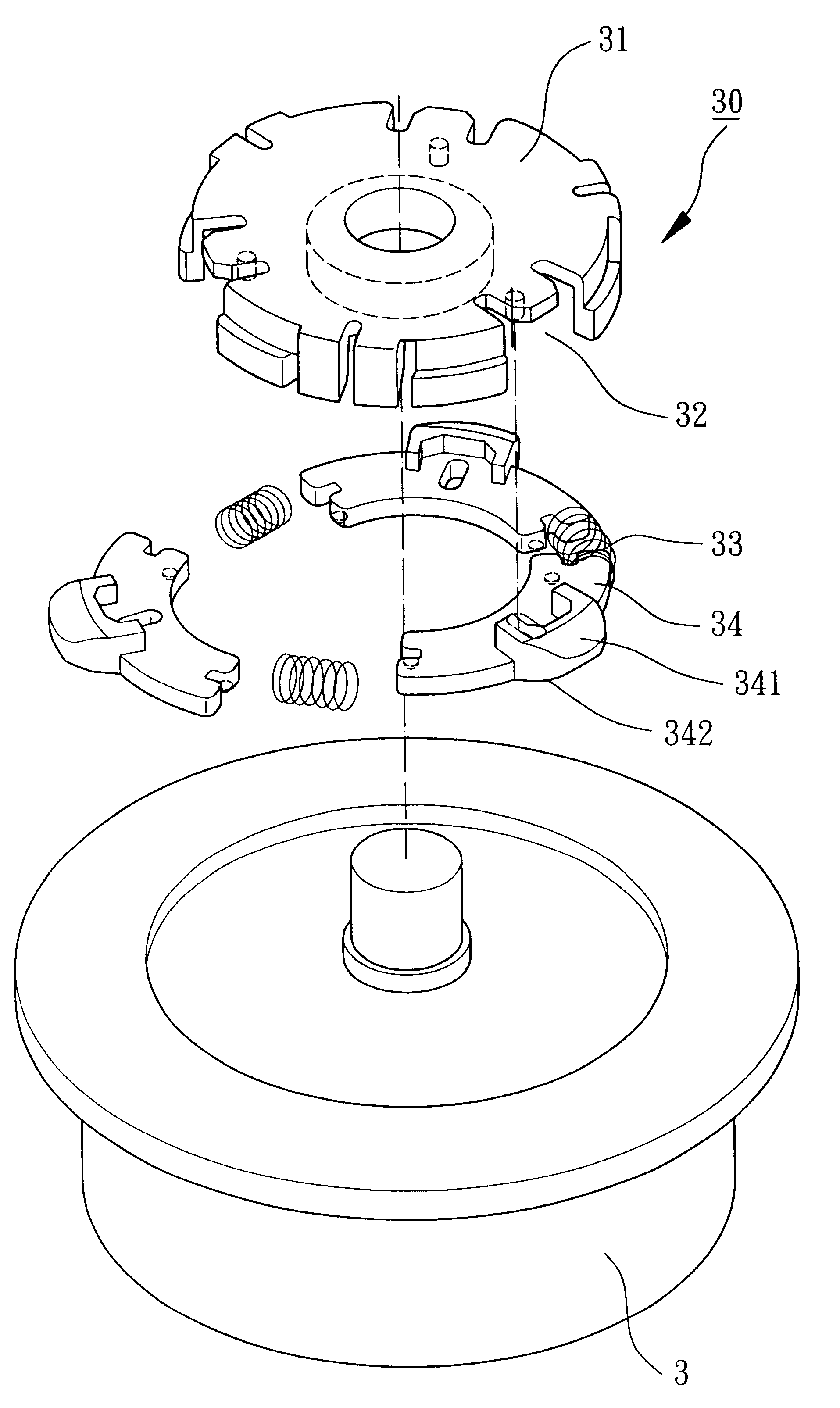

Pressure-control type electric pressure cooker

ActiveCN105286498AImprove stability and securitySimple structurePressure-cookersEngineeringPressure controlled ventilation

The invention discloses a pressure-control type electric pressure cooker. A sealed body is formed by sequentially connecting a pot cover, a seal ring, an inner pot and an outer pot; a plurality of belleville springs, which are provided with opening grooves, are arranged between a heating plate and the outer pot; upper supporting rings are formed by horizontally flanging the small-diameter ends of the belleville springs towards inner sides, and lower supporting rings are formed by the big-diameter ends of the belleville springs; an elastic deformation area is formed by a conical wall parts between each of the upper supporting rings and each of the lower supporting rings; the elastic deformation areas penetrate through the upper supporting rings in a radial direction and extend to conical body parts, and the opening grooves that contour lines projected on a horizontal plane are in a cross form are formed; the opening grooves are of gradually expanded structures with upsides smaller than downsides from openings to bottoms; the lower supporting rings are supported on the bottom of the outer pot; the upper supporting rings are propped against supporting legs of the heating plate; and the supporting legs and the belleville springs are integrally positioned with and connected to the outer pot by virtue of fixed screws. The amount of elastic deformation of the electric pressure cooker is effectively improved by virtue of the belleville springs, and the change in induction pressure of a pressure detection device is more conveniently to be detected, so that the precision and the safety stability of pressure control are improved.

Owner:HANGZHOU YONGYAO TECH

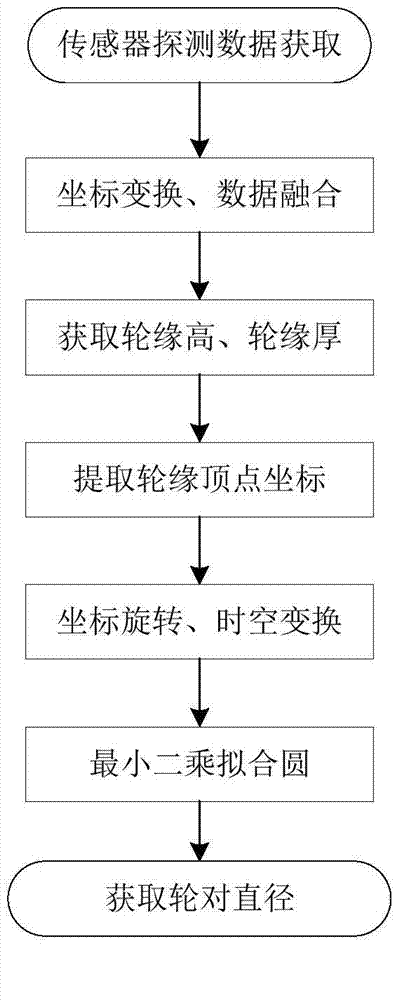

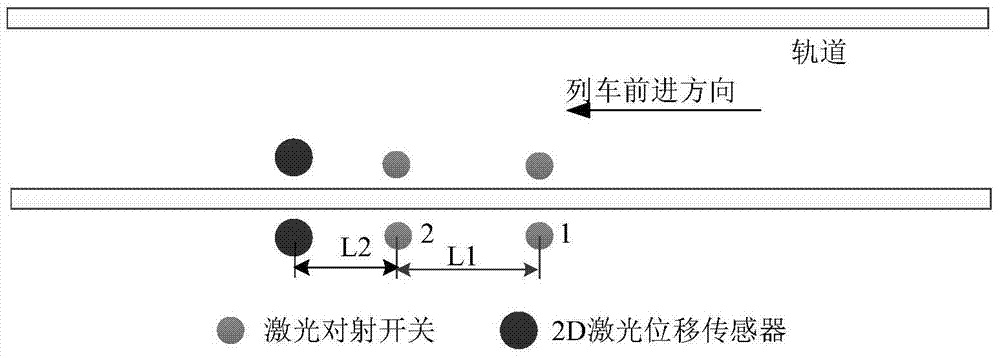

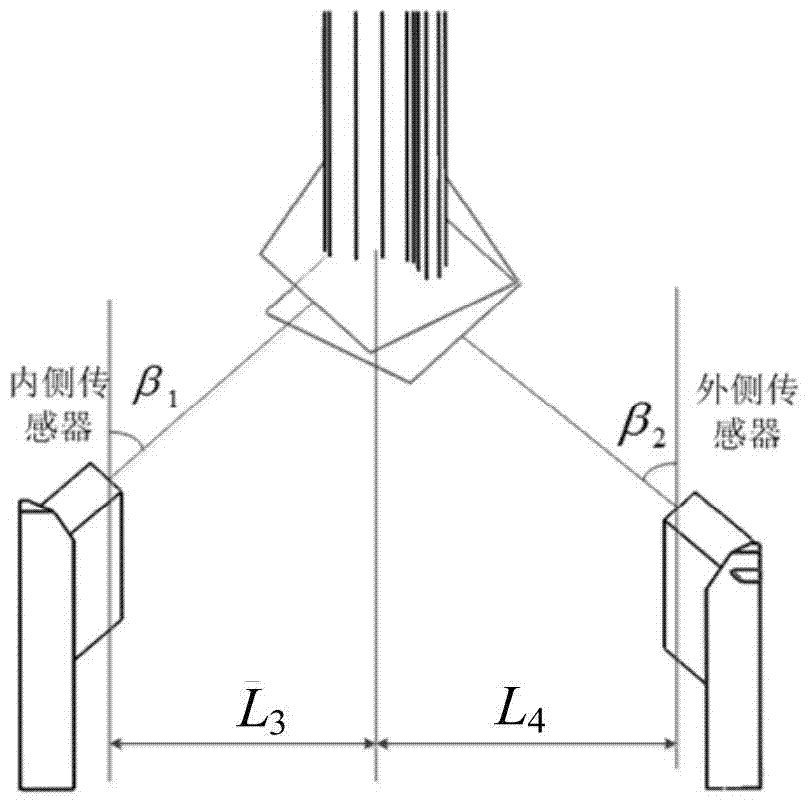

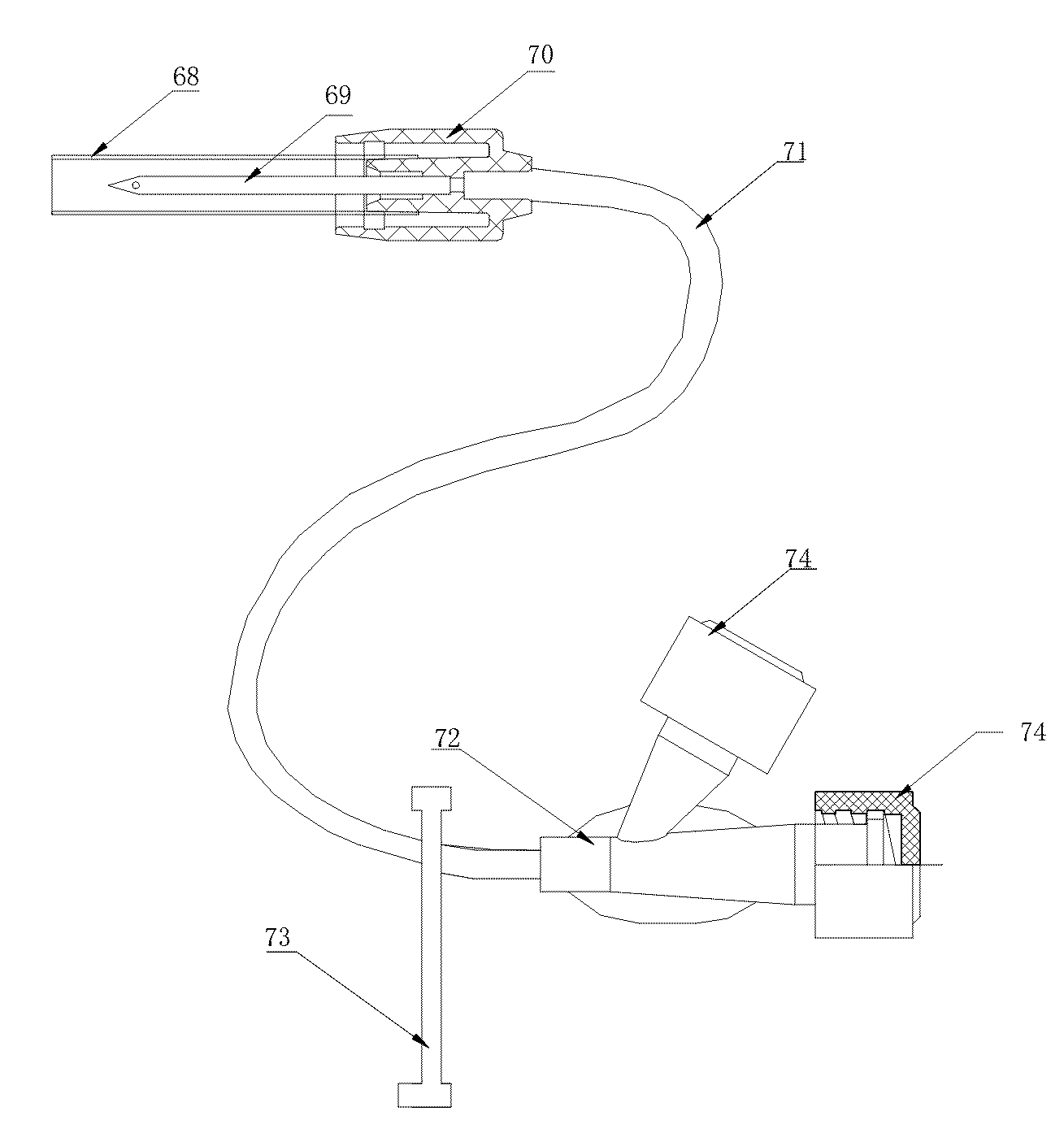

Method and device for online detection of size of city rail train wheel set

ActiveCN104228875ALow costEasy to operateWheel-rims surveying/measuringGeometric relationsContact type

The invention discloses a method and device for online detection of the size of a city rail train wheel set. A system is mainly comprises two 2D laser displacement sensors arranged along a train rail in a mirror symmetric mode, and two laser bijection switches arranged on the two sides of the same rail in a certain geometrical relation. The 2D laser displacement sensors detect and obtain tread contour lines, and the two laser bijection switches detect the wheel passing speed. The rim height and the rim thickness are worked out by extracting the tread contour lines of wheels passing through a detection system according to the geometrical relation. The coordinates of the lowest rim points of the detected tread contour lines of the wheels at different moments are extracted, the coordinates at the different moments are restored to coordinate values at the same moment on the condition that the speed is given, so that the circle where the top points of the rims of the wheels are located is fitted out, the two times of the height of the rims is subtracted from the diameter of the circle of the top points of the rims, and thus the diameters of the wheels are obtained. The method and device for online detection of the size of the city rail train wheel set are low in cost, simple in operation and high in non-contact type measurement precision.

Owner:NANJING UNIV OF SCI & TECH +1

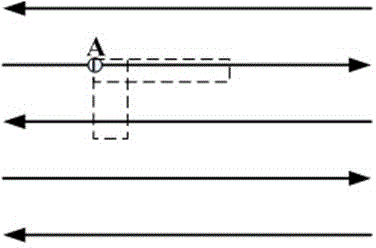

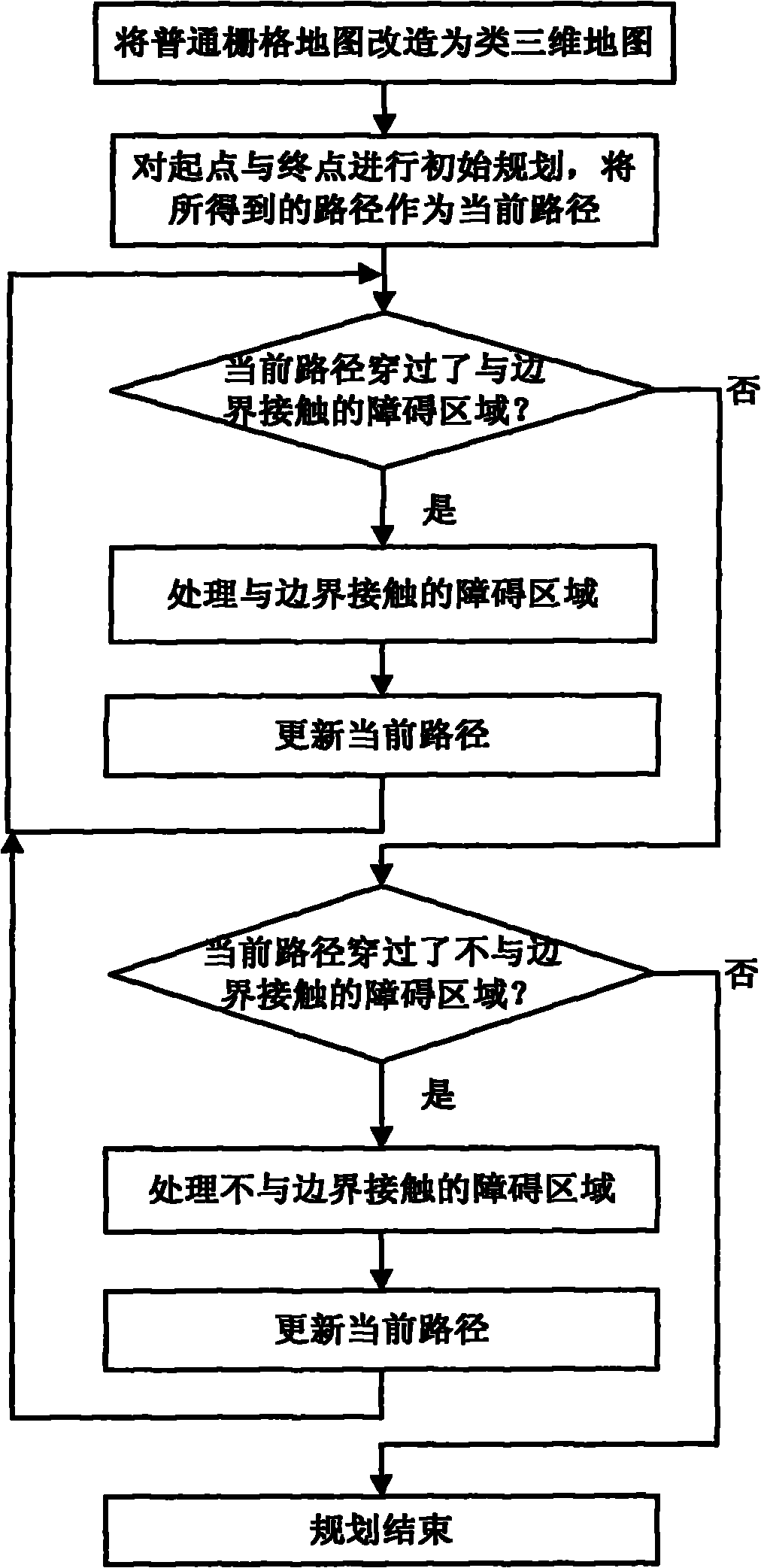

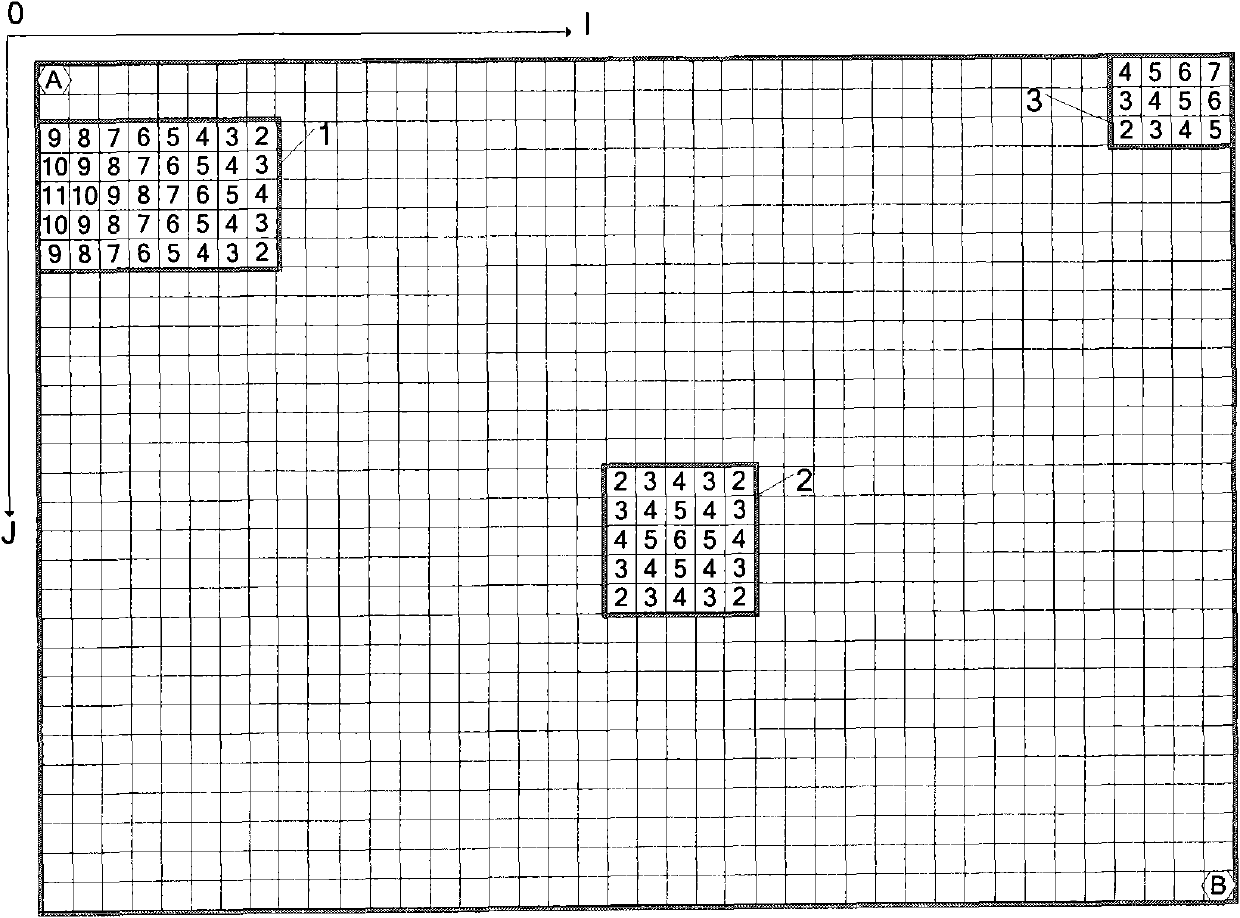

Quasi three-dimensional map-based mobile robot global path planning method

ActiveCN101769754AOvercome the shortcoming that the topology map is very complicatedAvoid disadvantagesInstruments for road network navigationPlanning methodComputer science

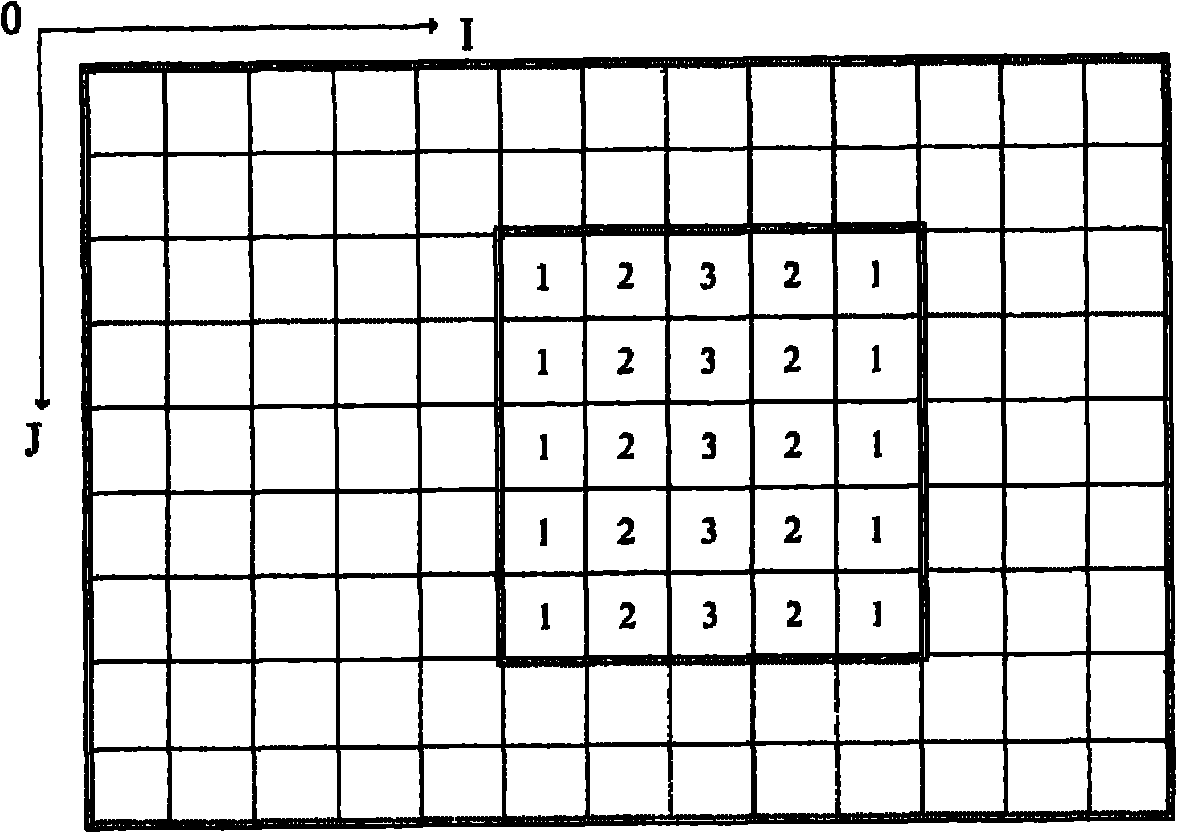

The invention discloses a quasi three-dimensional map-based mobile robot global path planning method. The method comprises the following steps: 1, reforming a common grid map to a quasi three-dimensional map based on the contouring principle; 2, initially planning: connecting the starting point and the finishing point of a mobile robot into a straight line serving as a current path; 3, scanning the grid passed by the current path, changing to step 6 if a barrier cannot be scanned, or changing to step 4 or step 5 according to the type of a barrier if the barrier is found by scanning; 4, processing the barrier contacted with the boundary, updating the current path, and returning to the step 3; 5, processing barriers which are not contacted with the boundary, updating the current path, and returning to the step 3; and 6, outputting the current path to complete the global path planning. The method sufficiently explores the information of the barriers, improves the execution efficiency of a program, is easy for implementation, and meets the real-time requirement of the mobile robot global path planning.

Owner:湖南湘江时代机器人研究院有限公司

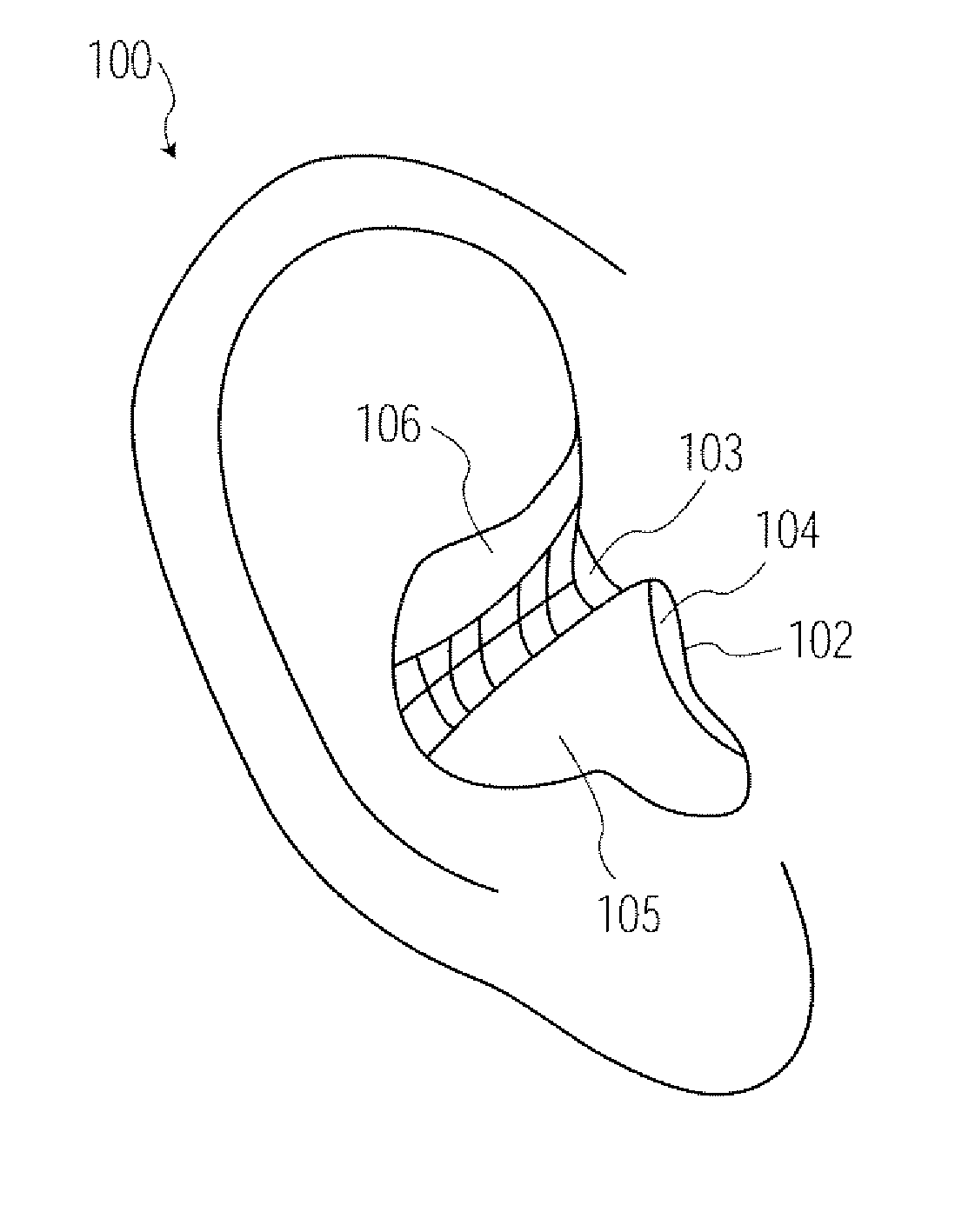

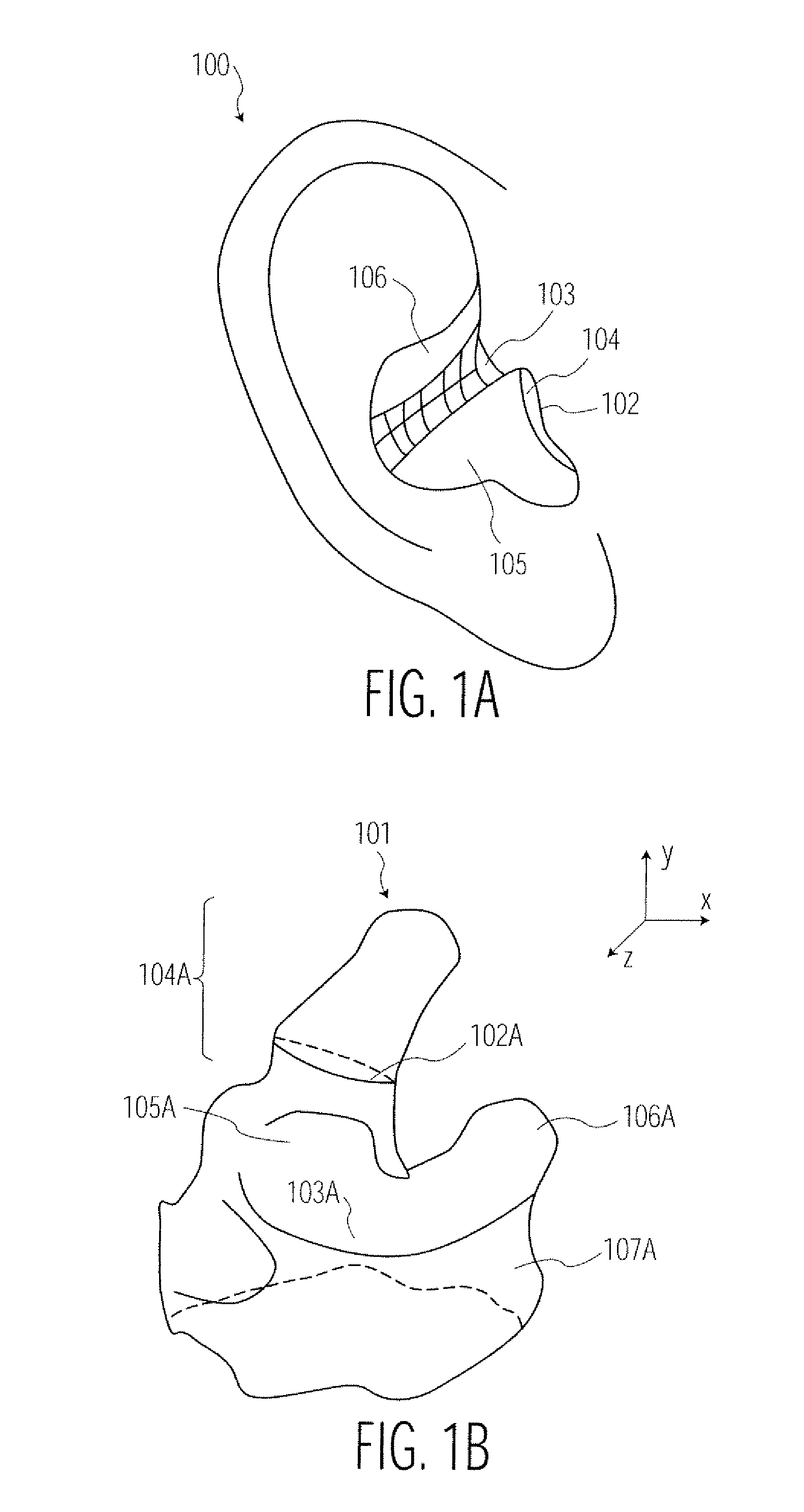

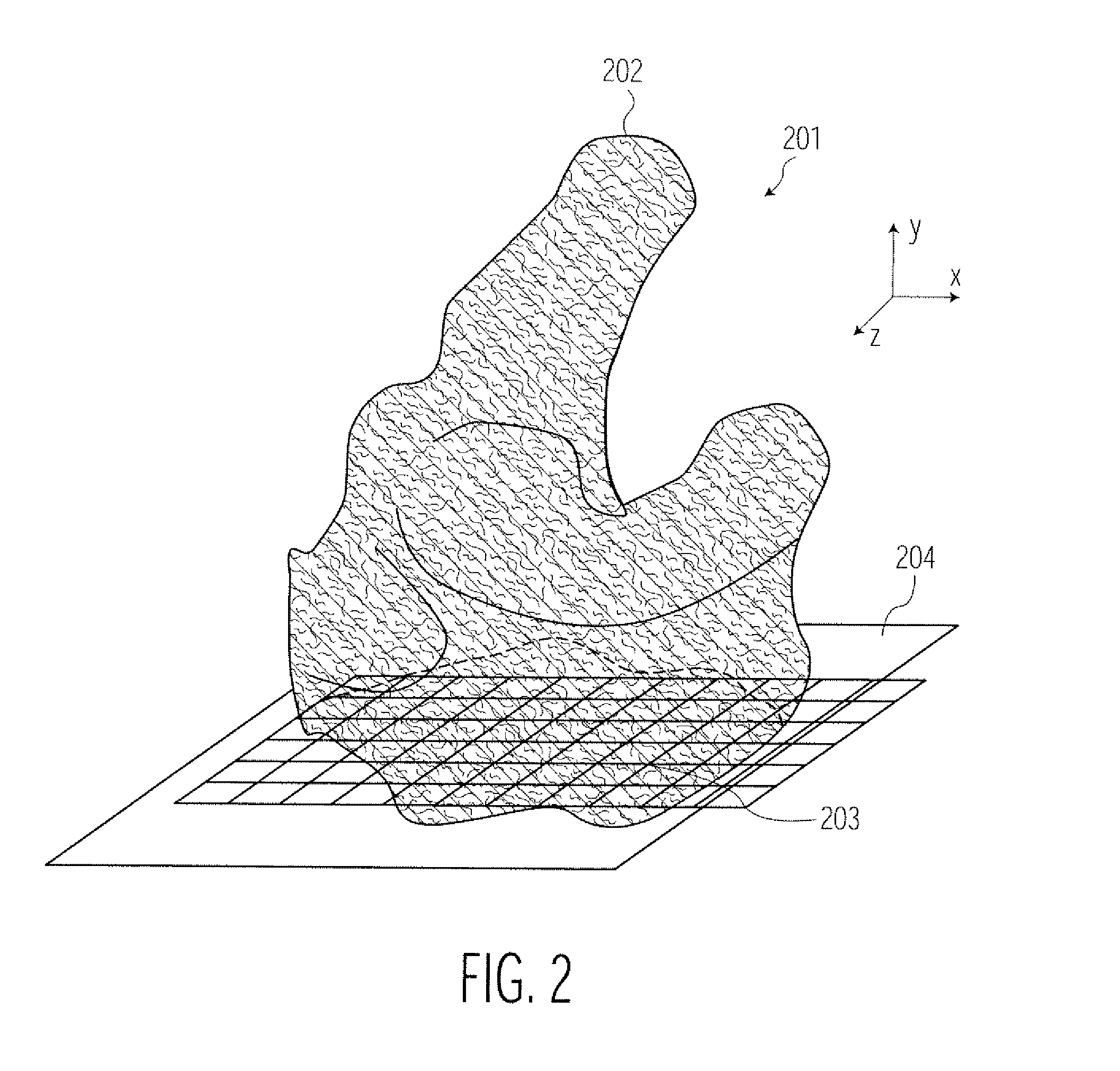

Method and Apparatus for Ear Canal Surface Modeling Using Optical Coherence Tomography Imaging

ActiveUS20070127756A1Avoid spendingSimple methodUltrasonic/sonic/infrasonic diagnosticsCatheterMedicine3d image

A method and apparatus for generating a three dimensional representation of an ear canal are disclosed whereby an ear canal of a patient is imaged using optical coherence tomography (OCT). In a first embodiment, cross-section images of an ear canal are taken by, for example, rotating an OCT imaging sensor about a predetermined axis at each of a plurality of positions. In accordance with another embodiment, a contour line is then identified in each of the cross section images and a flow algorithm is used to identify the boundary of the ear canal cross section. Once the boundaries of each cross section have been identified, all of the cross section images are combined to generate a three dimensional image of the ear canal.

Owner:SIEMENS CORP

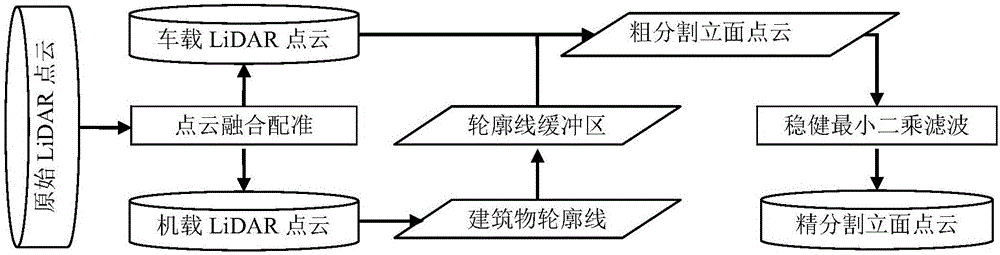

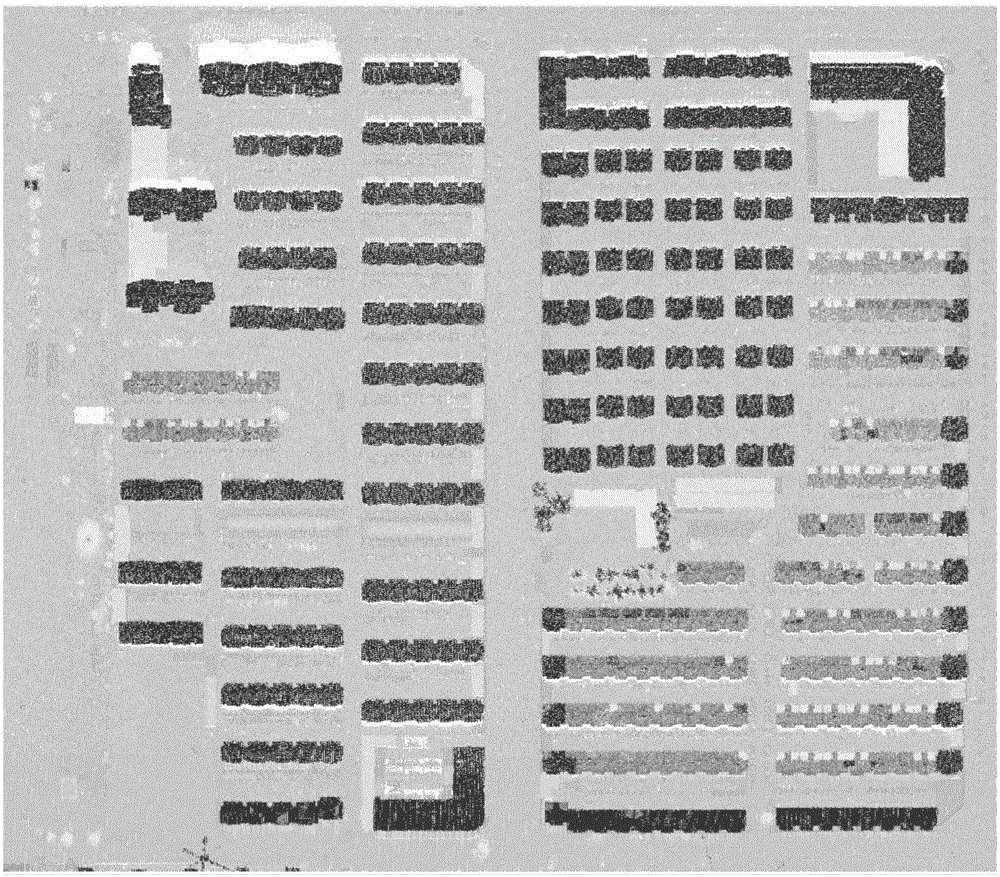

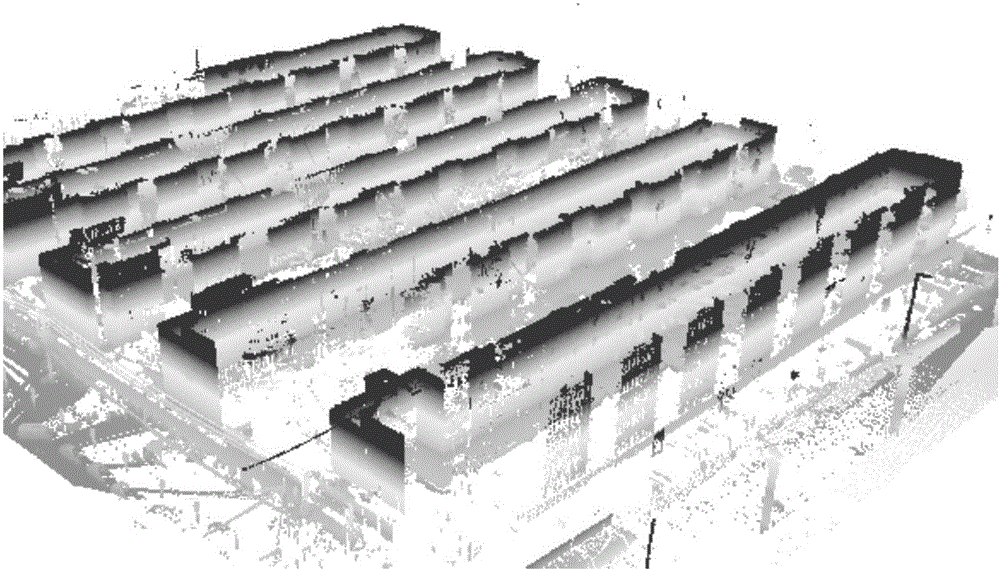

Automatic segmentation method for point cloud of facade of large scene city building

ActiveCN105844629AHigh precisionAccurate segmentationImage enhancementImage analysisAutomatic segmentationPoint cloud

The invention discloses an automatic segmentation method for a point cloud of a facade of a large scene city building. The method comprises steps of (1) performing fusion registration on airborne LiDAR point cloud data and on-vehicle LiDAR point cloud data, (2) extracting airborn LiDAR building point cloud data from the airborne LiDAR point cloud data which goes through registration in the step (1), (3) performing segmentation on the point cloud data of a single building based on the airborne LiDAR point cloud data extracted from the step (2), (4) performing contour tracking on the single building segmented by the step (3), (5) performing simplification and normalization processing on a contour line extracted from the step (4), (6) performing rough segmentation on the point cloud of the facade of the building based on the contour line which goes through the simplification and normalization processing in the step (5), and (7) performing fine segmentation on the building facade point cloud which is roughly segmented in the step (6). The automatic segmentation method of the invention can fast and accurately separate the building facade point cloud from the on-vehicle LiDAR point cloud.

Owner:HENAN POLYTECHNIC UNIV

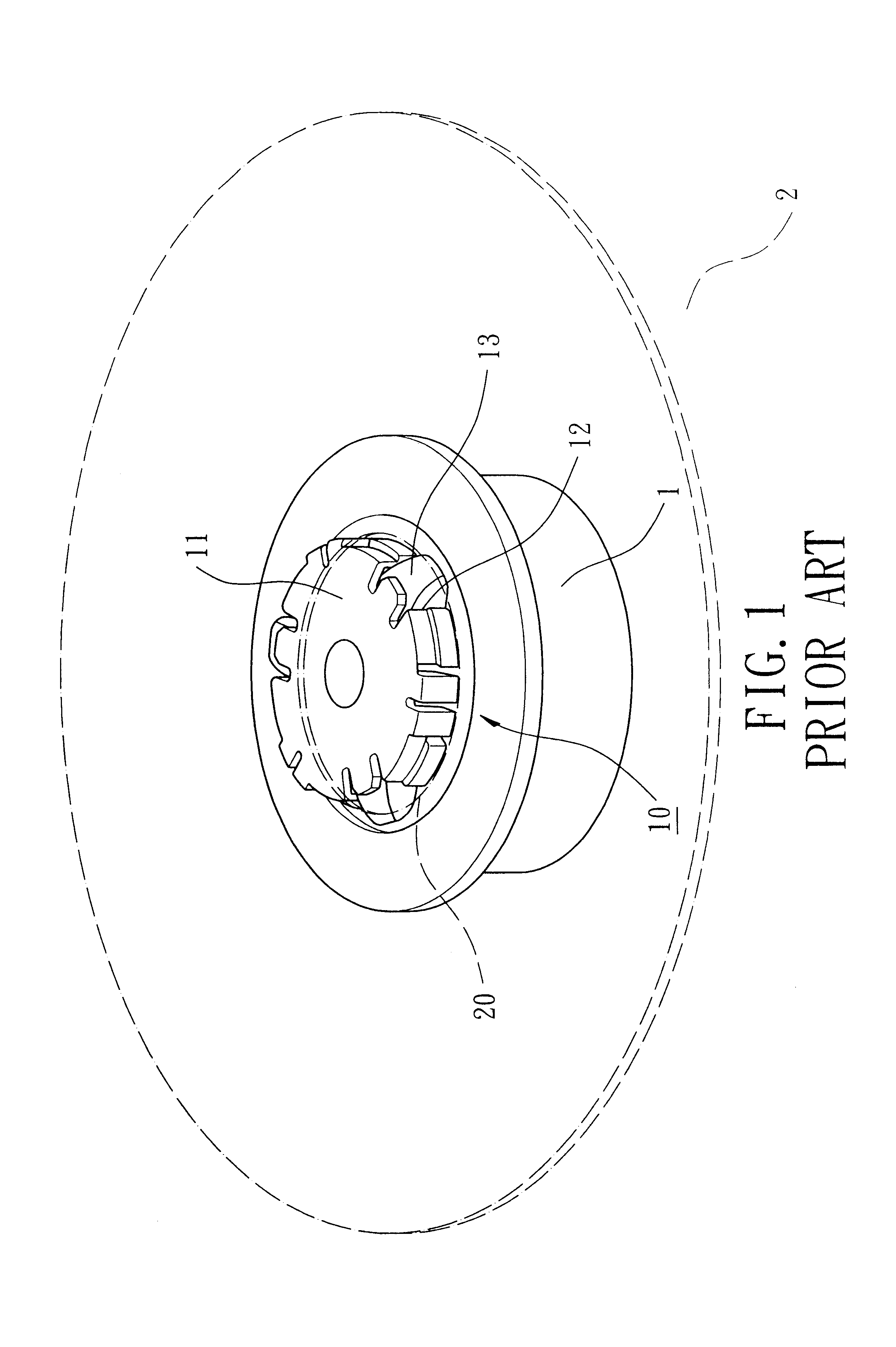

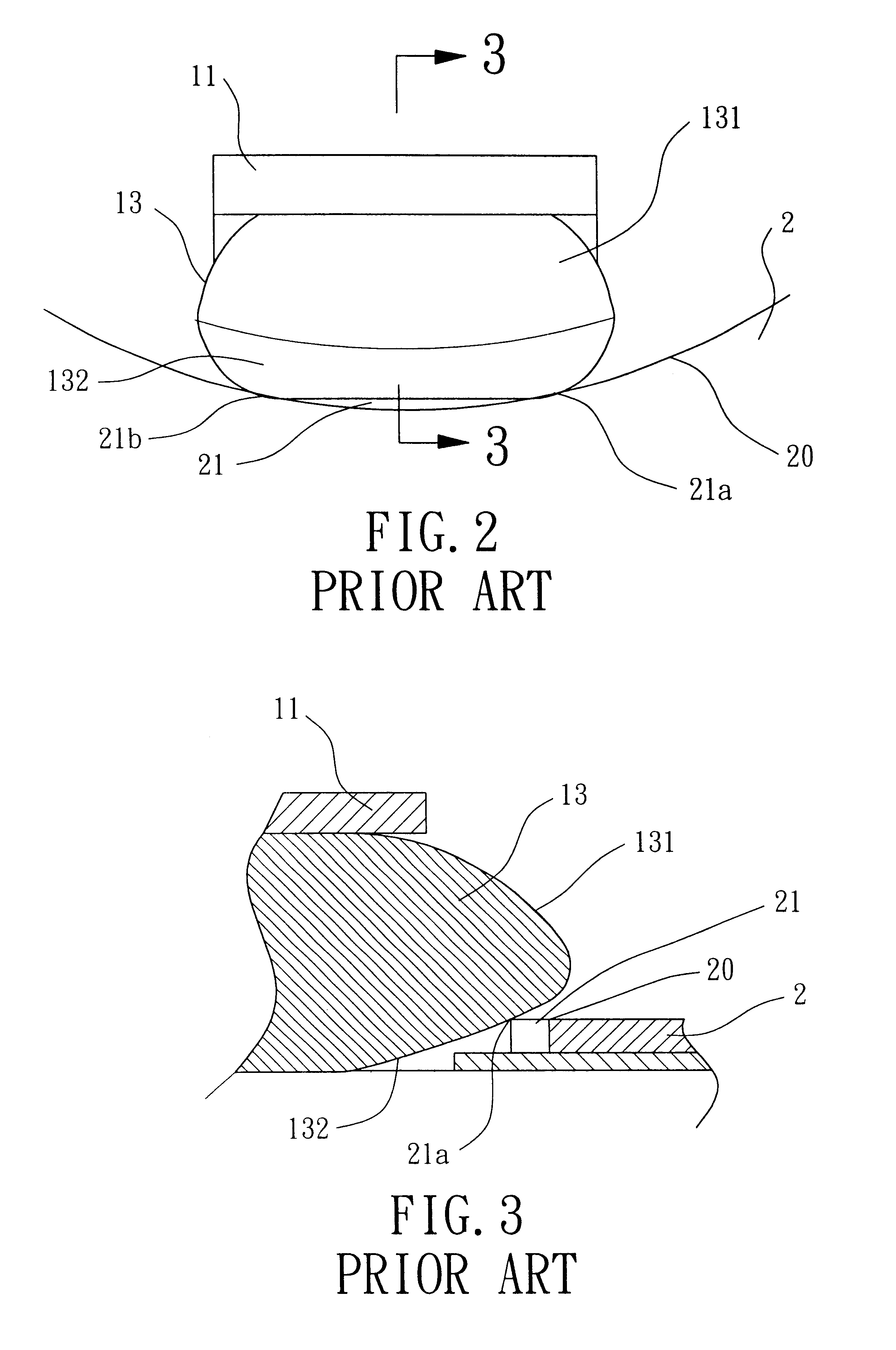

Device with spring-loaded curved tongues for holding an optical disk around a rotary shaft of a motor

InactiveUS6845512B2Prevent movementRecord information storageRecording on magnetic disksEngineeringContour line

A device includes a casing having a plurality of equispaced openings formed around, and a plurality of spring-loaded radial tongues partially extended out from and retractable into the openings. Each of the radial tongues has a lower curved surface with a constant curvature in any imaginary contour line throughout at least one area of the lower curved surface. Furthermore, the constant curvature is exactly the same as the curvature of the rounded inner edge of the optical disk to be held.

Owner:SUNONWEALTH ELECTRIC MACHINE IND

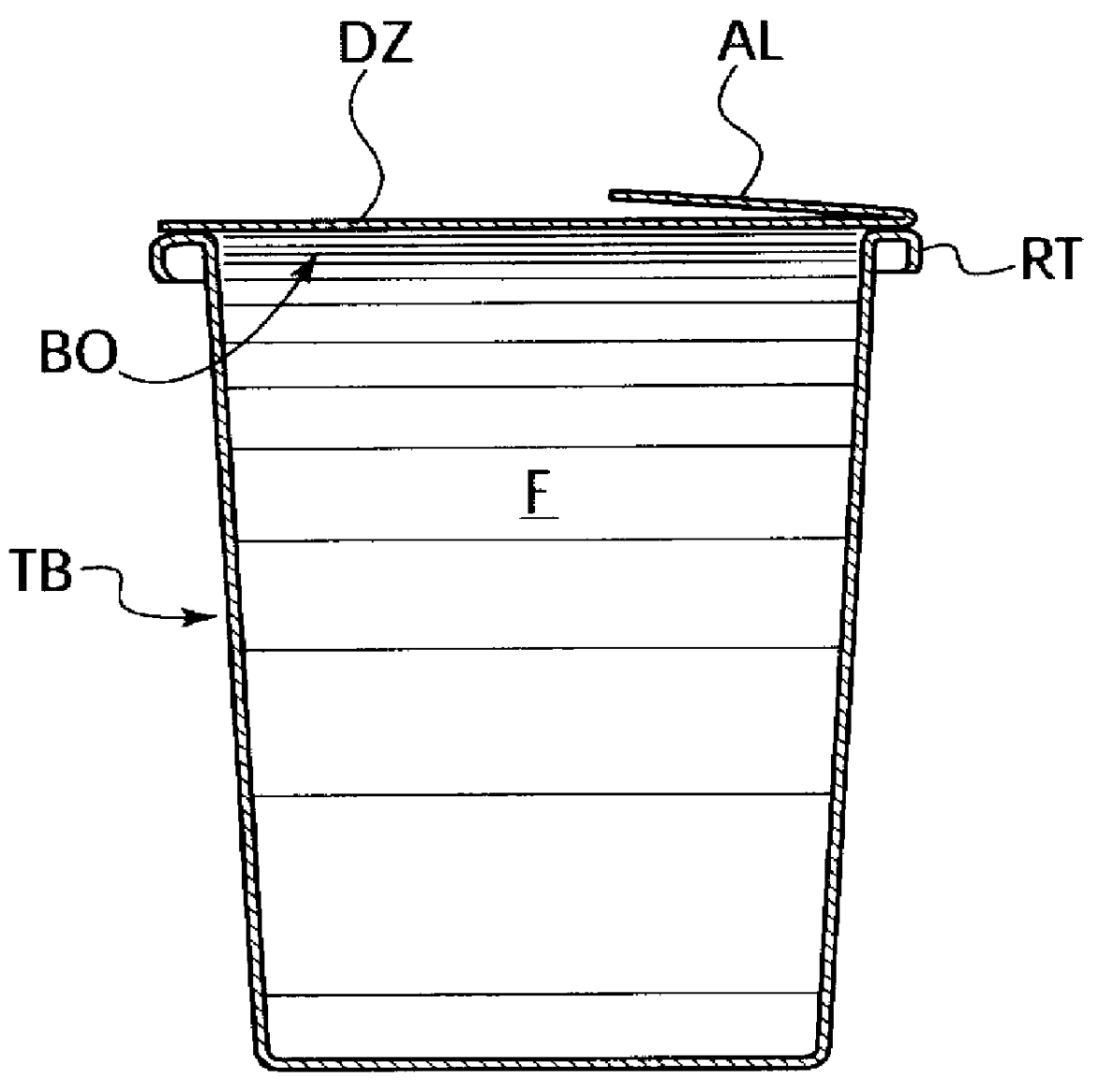

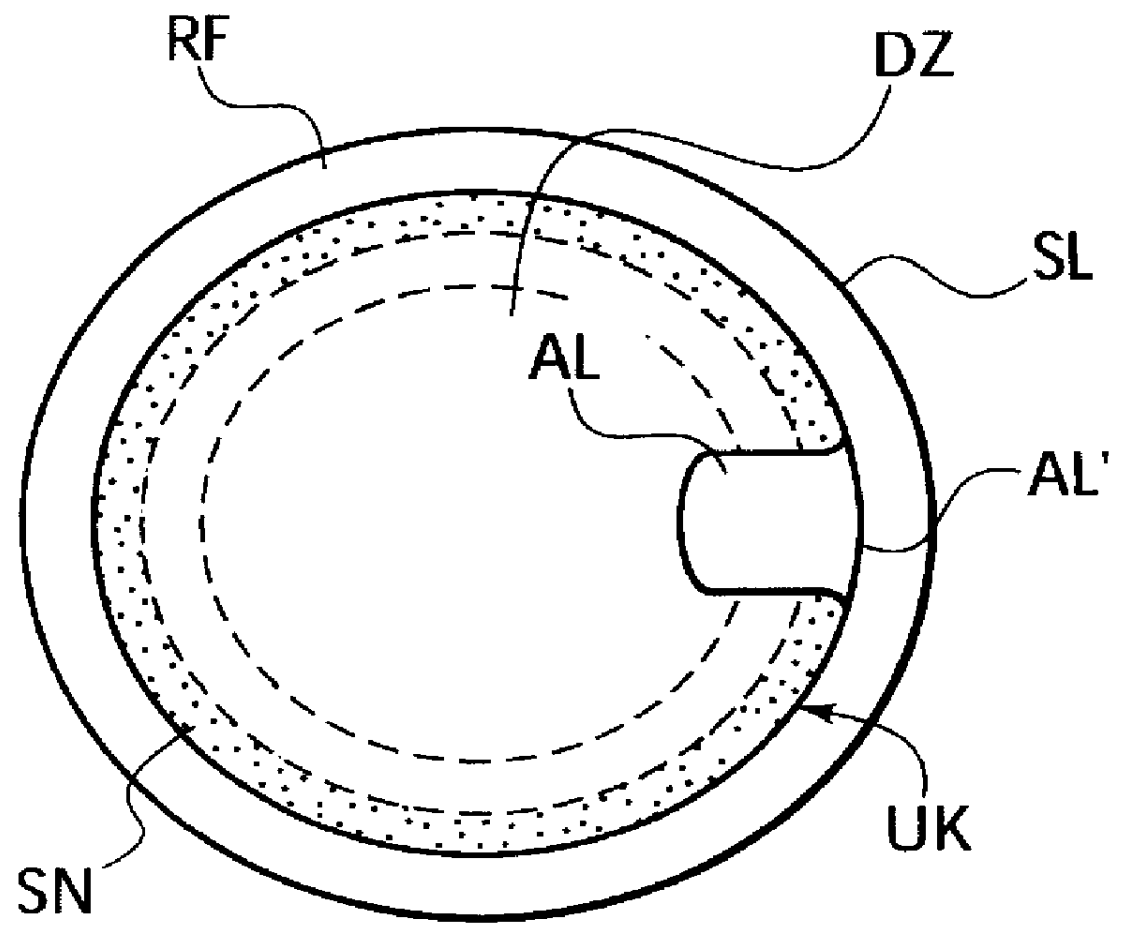

Process and packing machine for manufacturing filled drinking cups

InactiveUS6161367AReduce mechanical forceMinimized cover foil wasteCapsFlanged caps applicationPack materialEngineering

The invention is concerned with a process of manufacturing filled drinking cups closed by cover foil blanks heat-sealed thereto and formed by deep-drawing from a thermoplastic packing material strip, comprising a beaded peripheral flange, with the cover foil blanks being provided with a pull flap. According to the invention the method includes the following steps: cyclically feeding the packing material strip loaded with the deep-drawn and filled cups underneath a cover foil blank transfer means; taking up the cover foil blanks from the transfer means, with the pull flaps, during transfer of the cover foil blanks to the packing material strip, being positioned in a direction substantially vertical to the extension plane of the blanks, and the blanks with the upright pull flaps above the cup openings being applied to the packing material strip; sealing the margins of the cover foil blanks to the unmolded areas of the packing material strip about the cup openings; bending the upright flaps during the advance movement of the packing material strip; punching the cups from the packing material strip along a punching contour line extending in parallel to and at a space from the circumferential contour of the cover foil blanks; and transferring the punched cups into a beading means wherein the peripheral flange portion projecting relative to the cover foil blanks is downwardly beaded.

Owner:HASSIA VERPACKUNGSMASCHEN

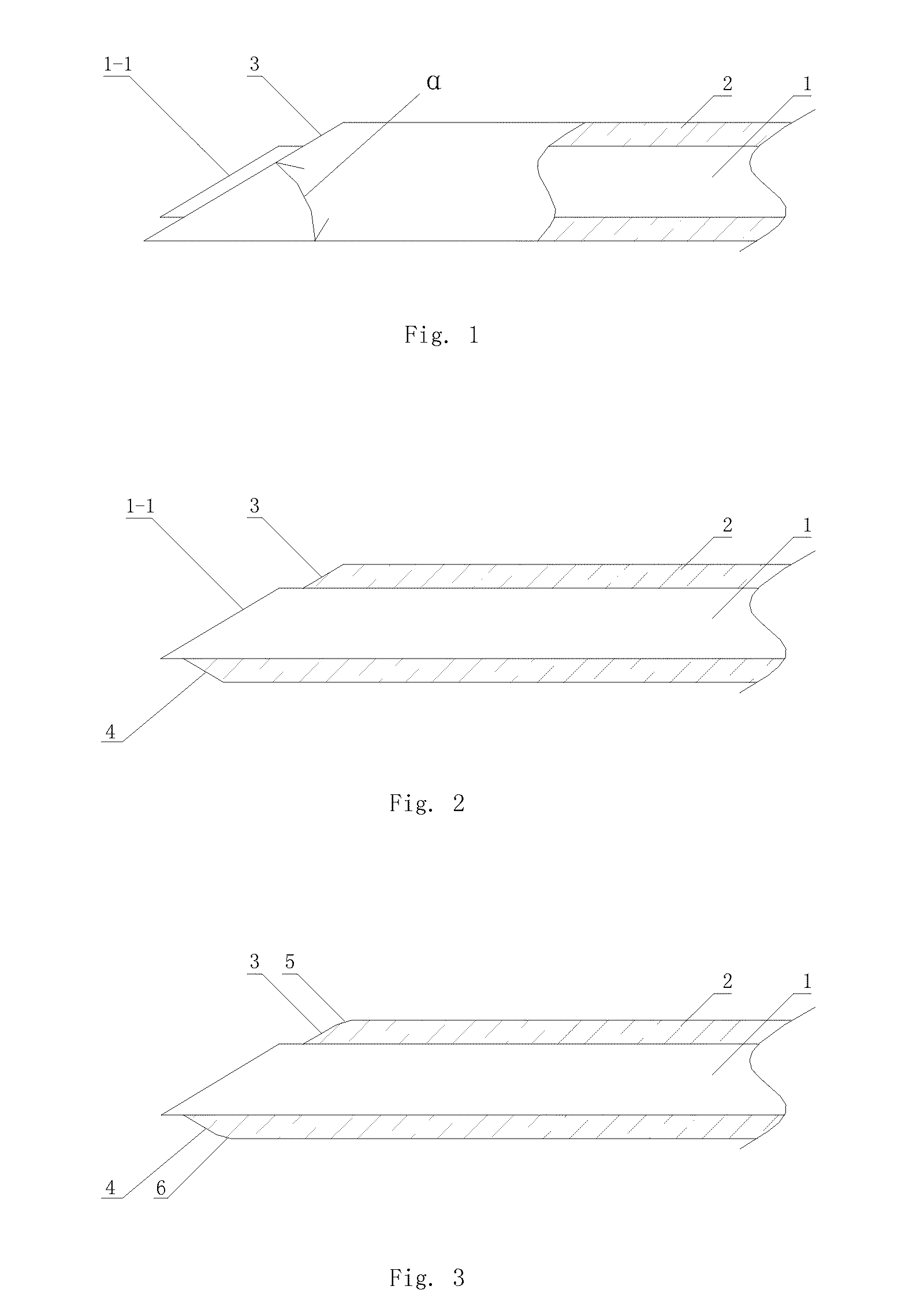

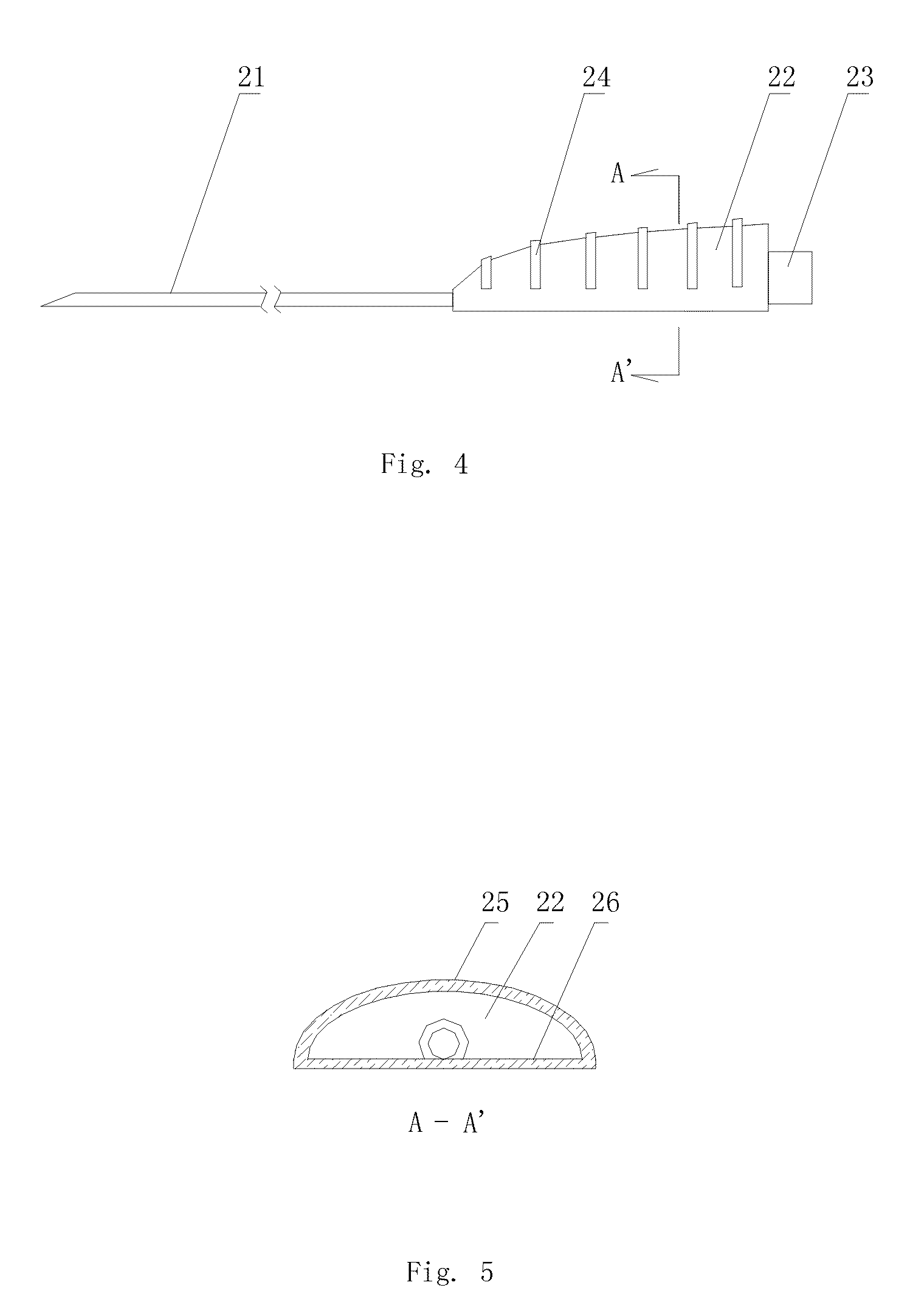

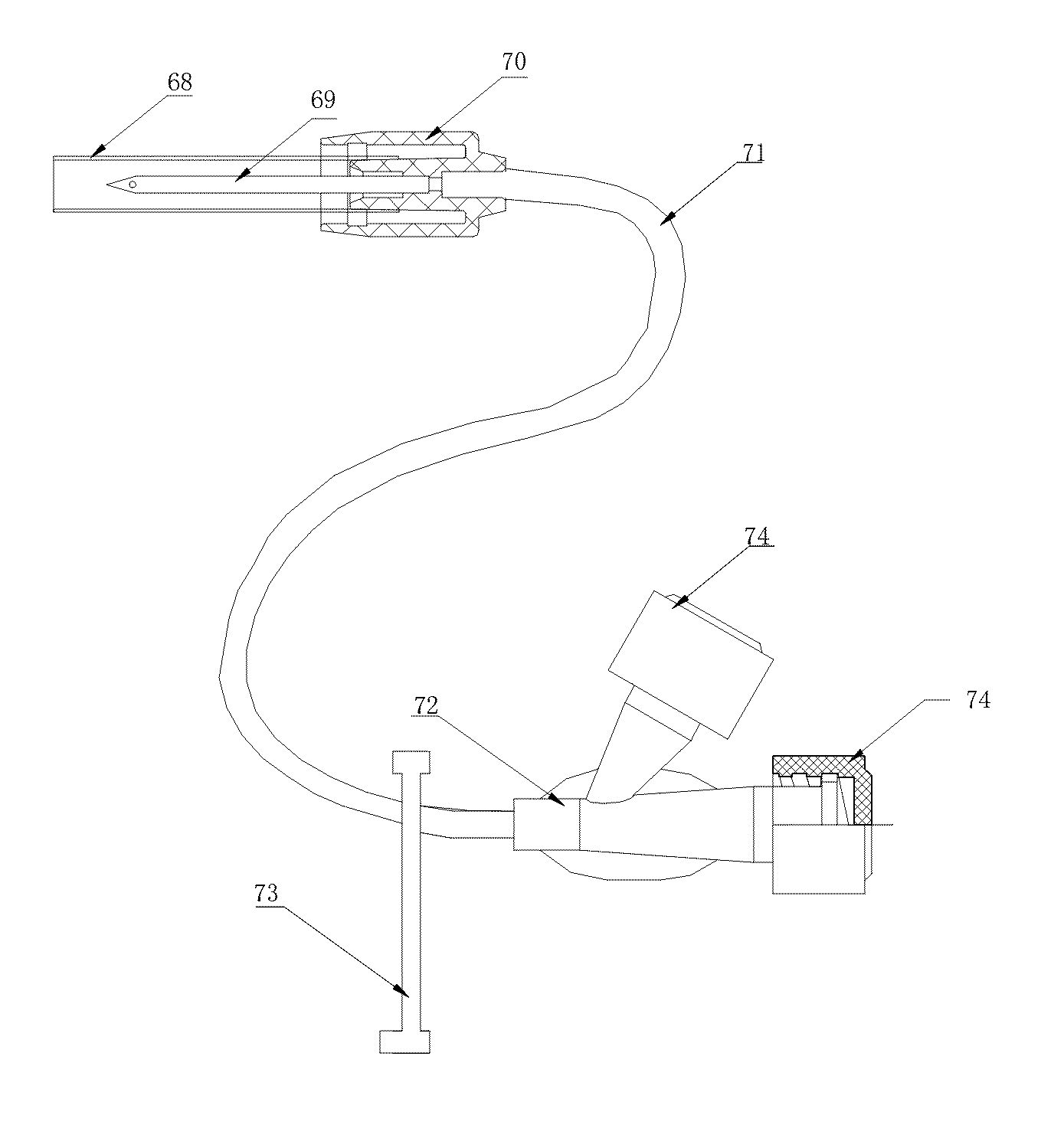

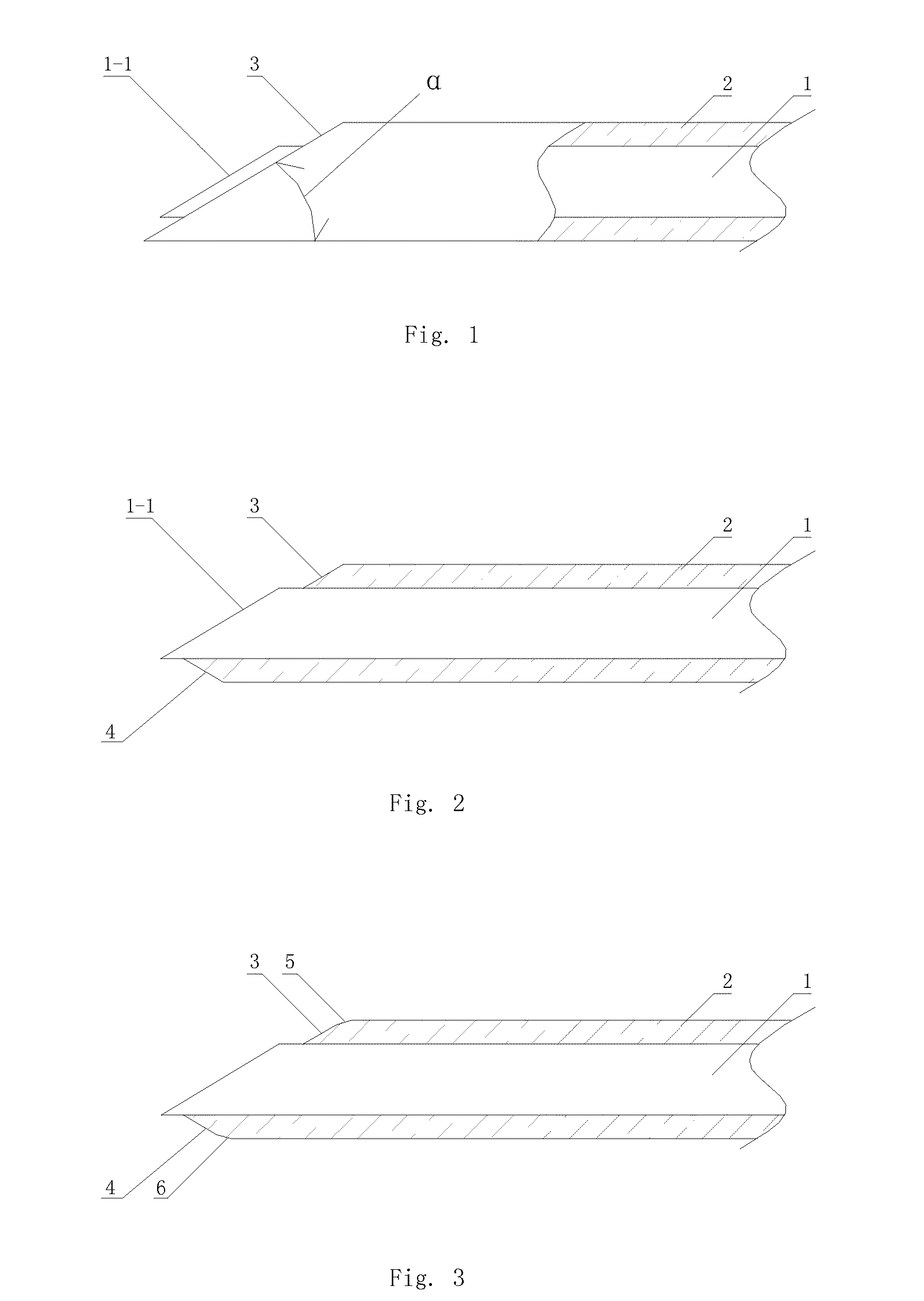

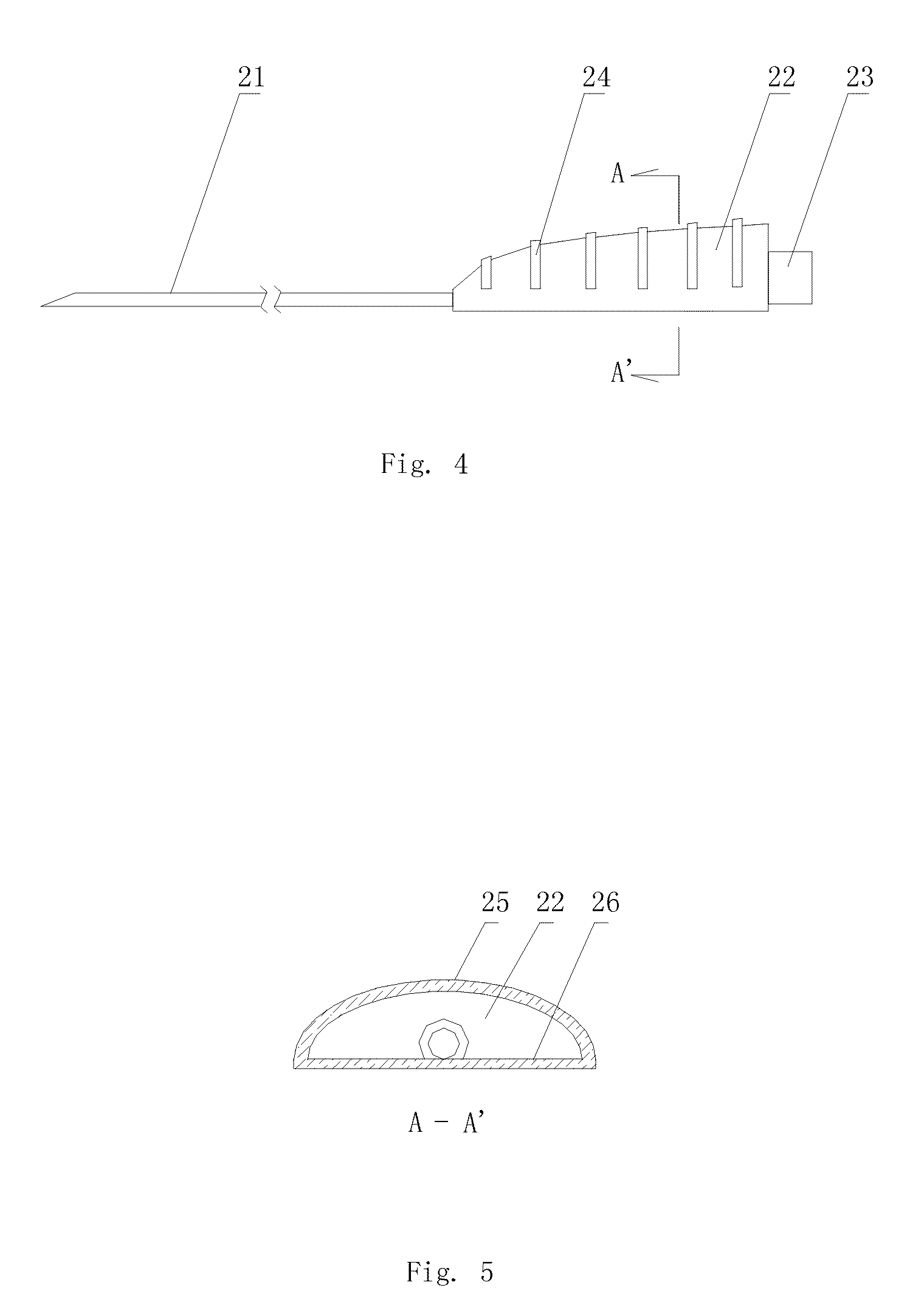

Safety Transfusion Catheter

InactiveUS20100036331A1Easy to moveMinimize injuryGuide needlesHaemostasis valvesInfusion catheterEngineering

A safety transfusion catheter includes a flexible retention tube (2) fitted over a metal guiding needle (1). The flexible retention tube (2) is provided with a needle handle (22; 22′) connected with it. The angle between the end (3) of the flexible retention tube (2) and its longitudinal axis or longitudinal tube wall is less than 90°. The cross section of the needle handle (22; 22′) has an outer contour line of a closed curve formed with a curve (5, 25) intersecting a beeline (6; 26). A further safety transfusion catheter includes a flexible retention tube (39) fitted over a metal guiding needle (32), a transfusion connecting tube (38) in fluid communication with flexible retention tube (39) and a rubber casing cap (42) at the end of the flexible retention tube (39). The transfusion connecting tube (38) and flexible retention tube (39) form a T-shaped or an oblique Y-shaped structure.

Owner:SUN MEDICAL SCI SHANGHAI

Hard rock tunnel non-blasting digging blocking method and construction method

The invention relates to a hard rock tunnel non-blasting digging blocking method and a construction method. According to the method, a hole drilling core taking technology is utilized, mutually engaged cutting peripheral holes are formed along a tunnel digging contour line, so that a hole wall-shaped digging free face is formed on the periphery of a tunnel face; a hydraulic splitting machine splitting technology is used, in addition, the characteristic that the tensile intensity and the shearing-resistant intensity of rock are much smaller than the pressure-resistant intensity is utilized, the tunnel face digging blocking is firstly carried out, in each digging block, the synchronous splitting digging splitting surfaces do not exceed two, in addition, the two splitting surfaces are in large-angle obtuse angle intersection, in addition, at least one digging free face vertical to the tunnel face is included, then, the digging construction sequence from the lower side to the upper side and from the periphery to the middle is adopted, and the smaller splitting force is used for carrying out rock pulling cracking and shearing cutting splitting digging on the tunnel face along the splitting surface. The hard rock tunnel non-blasting digging blocking method has the advantages that the adverse influence of vibration, noise and dust in the hard rock digging construction can be eliminated, and the utilization rate of tunnel hole slag as building stone materials can be improved.

Owner:FUZHOU PLANNING DESIGN & RES INST

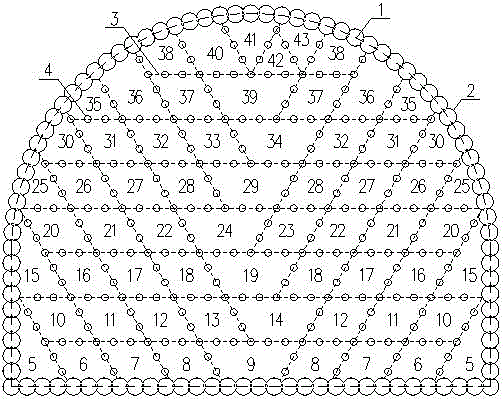

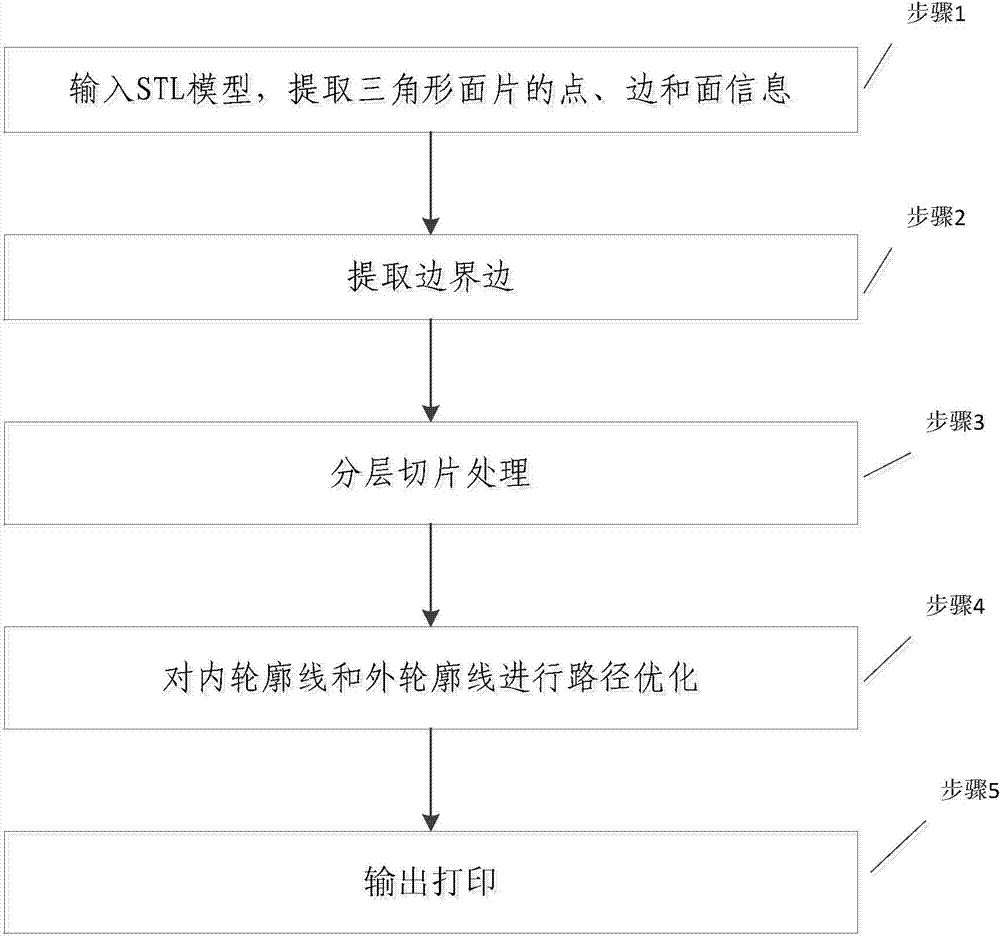

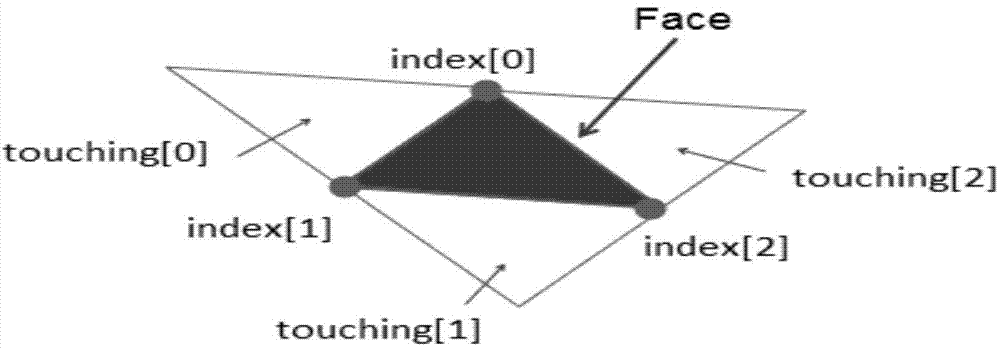

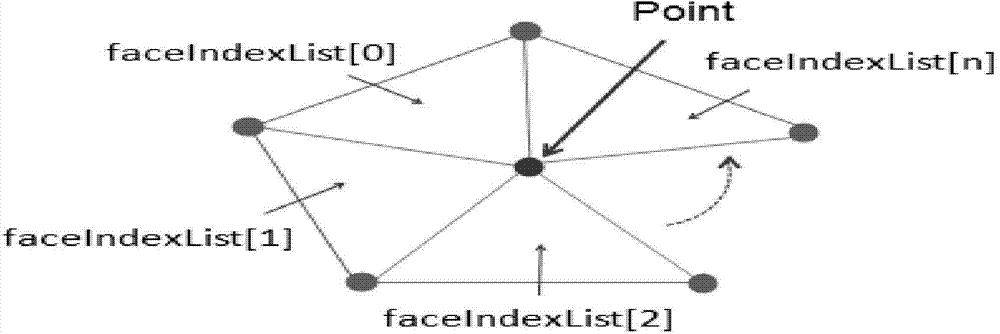

Slicing processing method aiming at non-closed STL model with boundaries

InactiveCN104331555ATroubleshoot slice handling issuesImprove molding efficiencySpecial data processing applicationsComputer graphics (images)3d printer

The invention discloses a slicing processing method aiming at a non-closed STL model with boundaries for a 3D (three-dimensional) printer. The method comprises the following steps that point, edge and surface information of triangles in an STL model are extracted, and in addition, the topology relationship among the point, edge and surface information is built; all boundary edges are extracted according to the boundary edge judging rule; lamination slicing processing is carried out on non-closed lattices to obtain non-closed 2D polygons; printable inner and outer contour lines obtained after the deflection processing on the polygons are subjected to path optimization for reducing idle strokes; a slicing file is used for outputting universal Gcode files which are read and printed by the 3D printer. The invention provides the slicing method aiming at non-closed STL model input from the boundary extraction aspect for the first time, and breaks through the limitation that the traditional 3D printer can only carry out the slicing processing on the closed STL model, and the slicing processing on the non-closed STL model with the boundaries is realized, so that the non-closed STL model can be directly printed and formed.

Owner:上海极臻三维设计有限公司

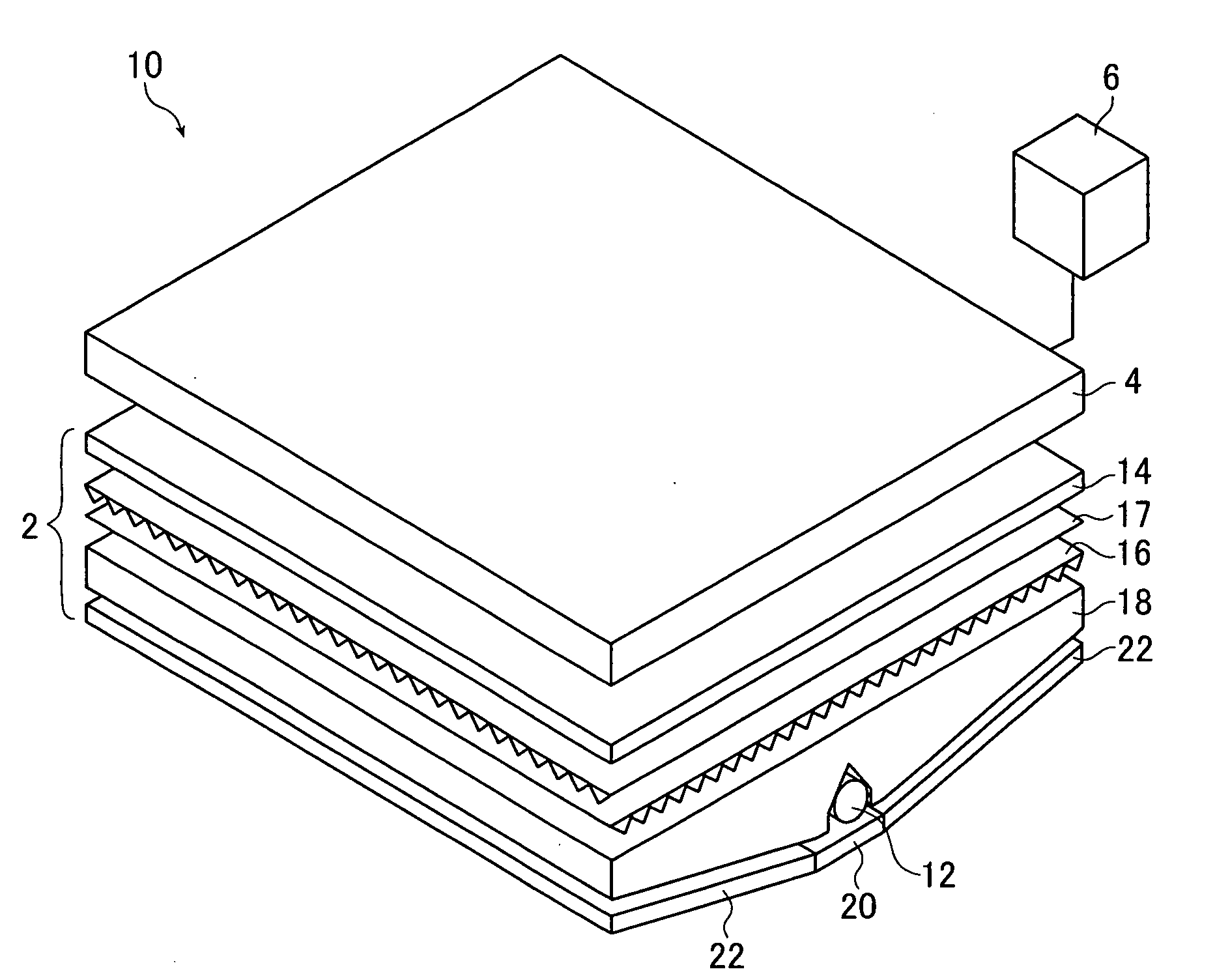

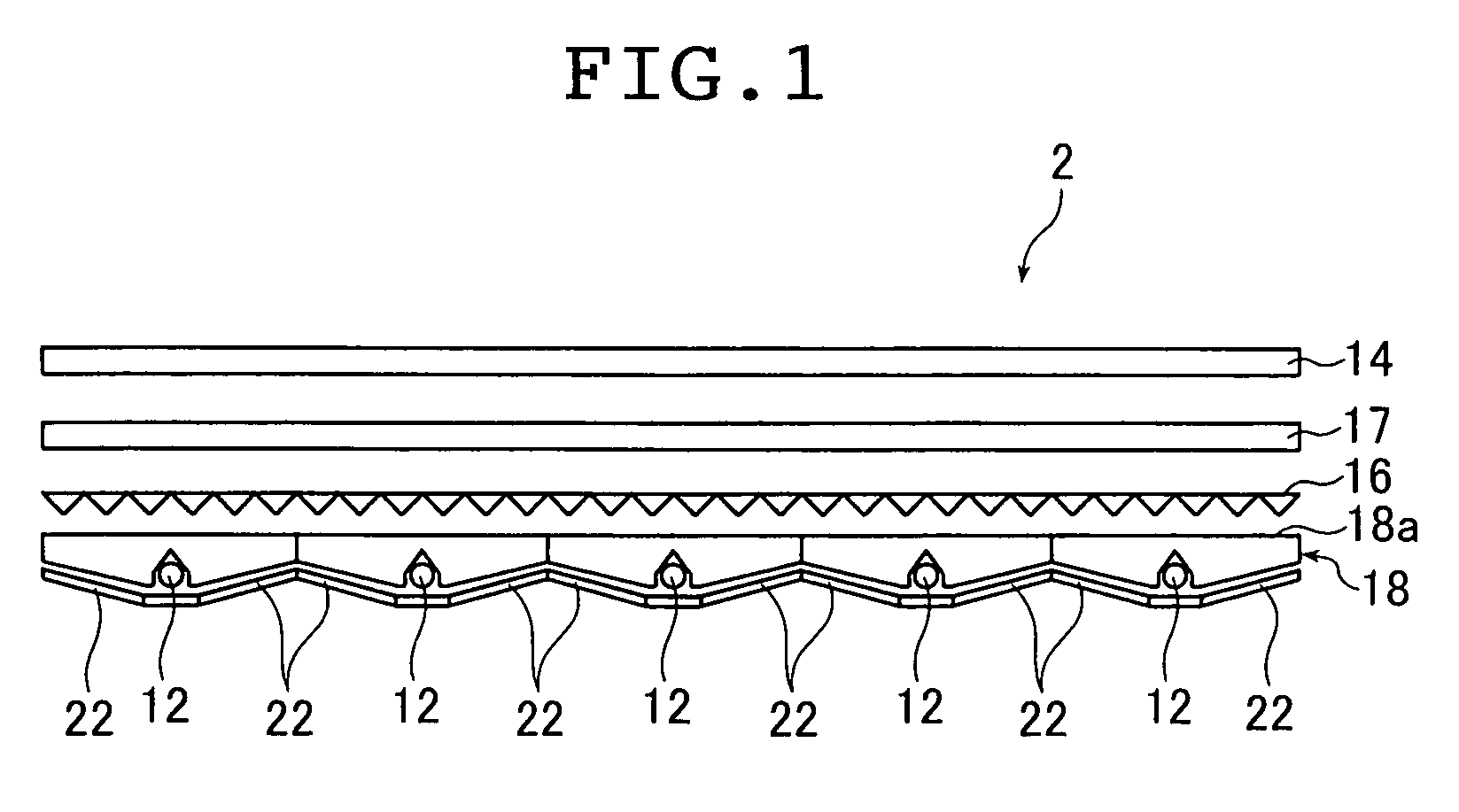

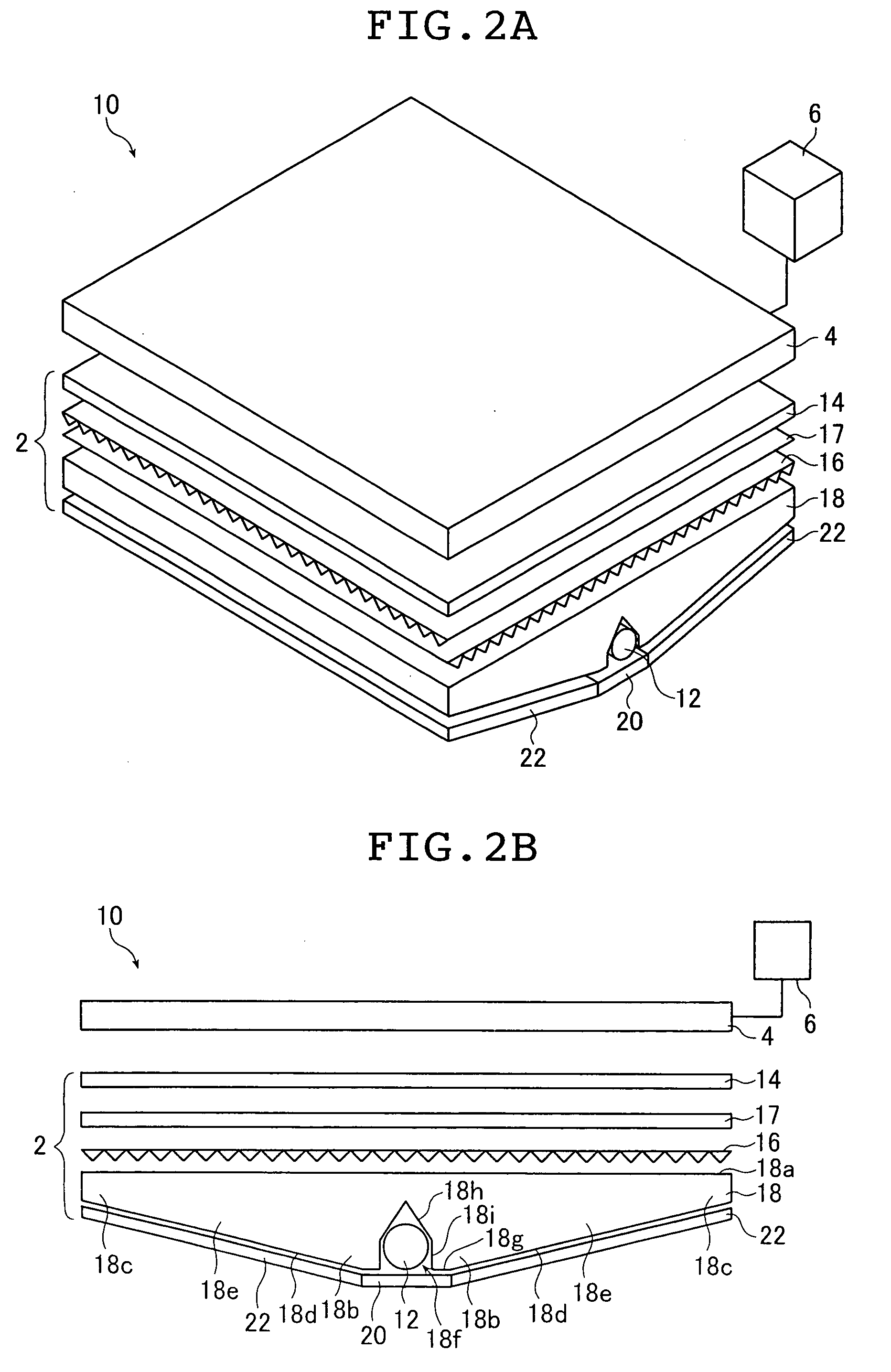

Light Guide Plate, and Planar Lighting Device and Liquid Crystal Display Device Using Such Light Guide Plate

InactiveUS20080137004A1Improve light utilization efficiencyReduce unevennessMechanical apparatusPlanar/plate-like light guidesLiquid-crystal displayLight guide

A parallel groove of a light guide place for accommodating a light source has, in a perpendicular cross section, a shape composed of a pair of contour lines that approach each other toward a light emitting plane, cross at a peak, and has a part where an inclination angle to a line vertical to the light emitting plane changes, and the inclination angle at a base end side far from the peak is sharper than that at a tip end side close to the peak. Thus, uniform and high brightness light can be emitted.

Owner:FUJIFILM CORP

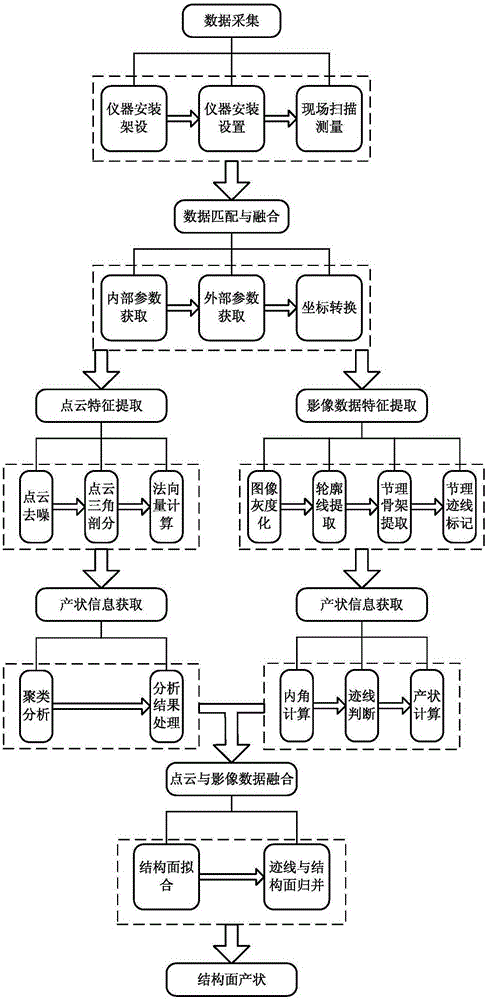

Rock structural surface occurrence measuring method integrated with laser-point cloud and digital imaging

The invention provides a rock structural surface occurrence automatic digital measuring method integrated with laser-point cloud and digital imaging. By utilization of a photogrammetric technology, a mixed global and local threshold method is employed to extract contour lines off path lines, joint path lines are extracted through skeleton extraction and path line marking, and combined with other image processing methods, and information obtaining of rock joint path line occurrence is achieved. Finally, according to the distance of the path lines to the structural surfaces, the position relations of the path lines and the structural surfaces are determined, and the path lines and the structural surfaces are subjected to combining and grouping, and occurrence of each group is employed to represent rock structural surface occurrence. Laser-point cloud and digital imaging measuring methods are integrated, rapid, efficient, non-contact and landform disregard properties of the two measuring methods are utilized fully, the measuring accuracy is raised, and the provided method has advantages of high automation degree, strong universality, comprehensive description and the like.

Owner:NANJING UNIV OF TECH

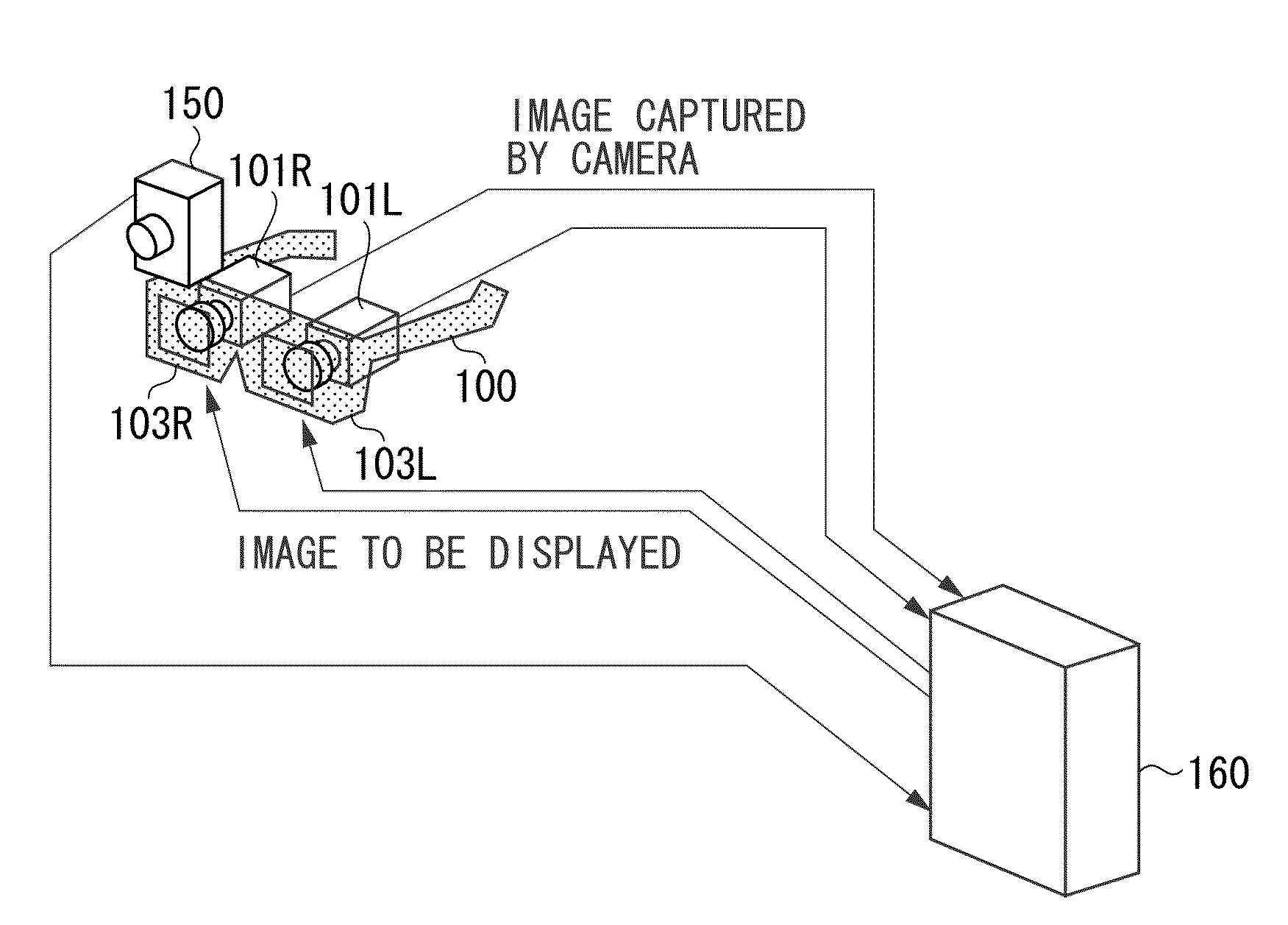

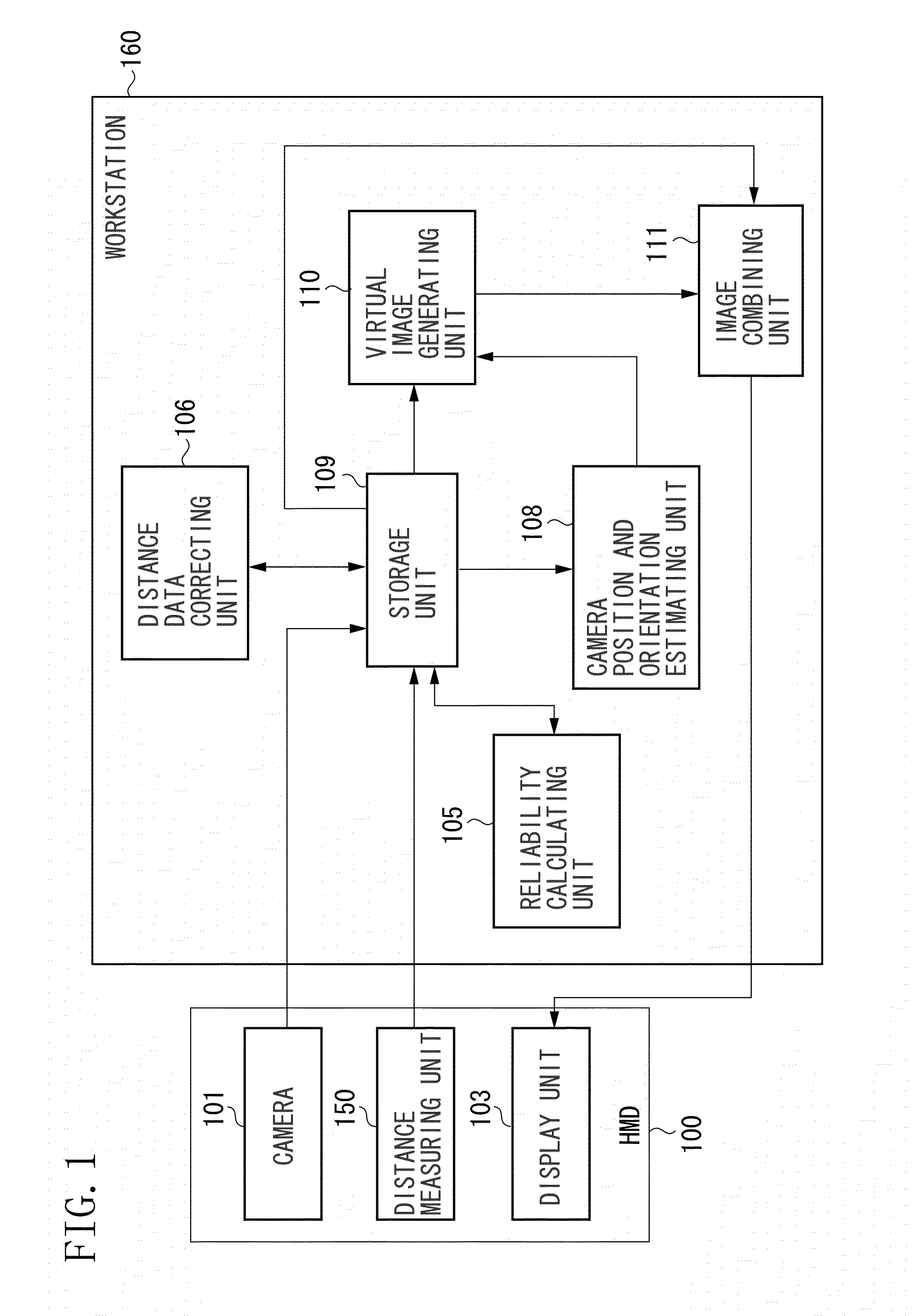

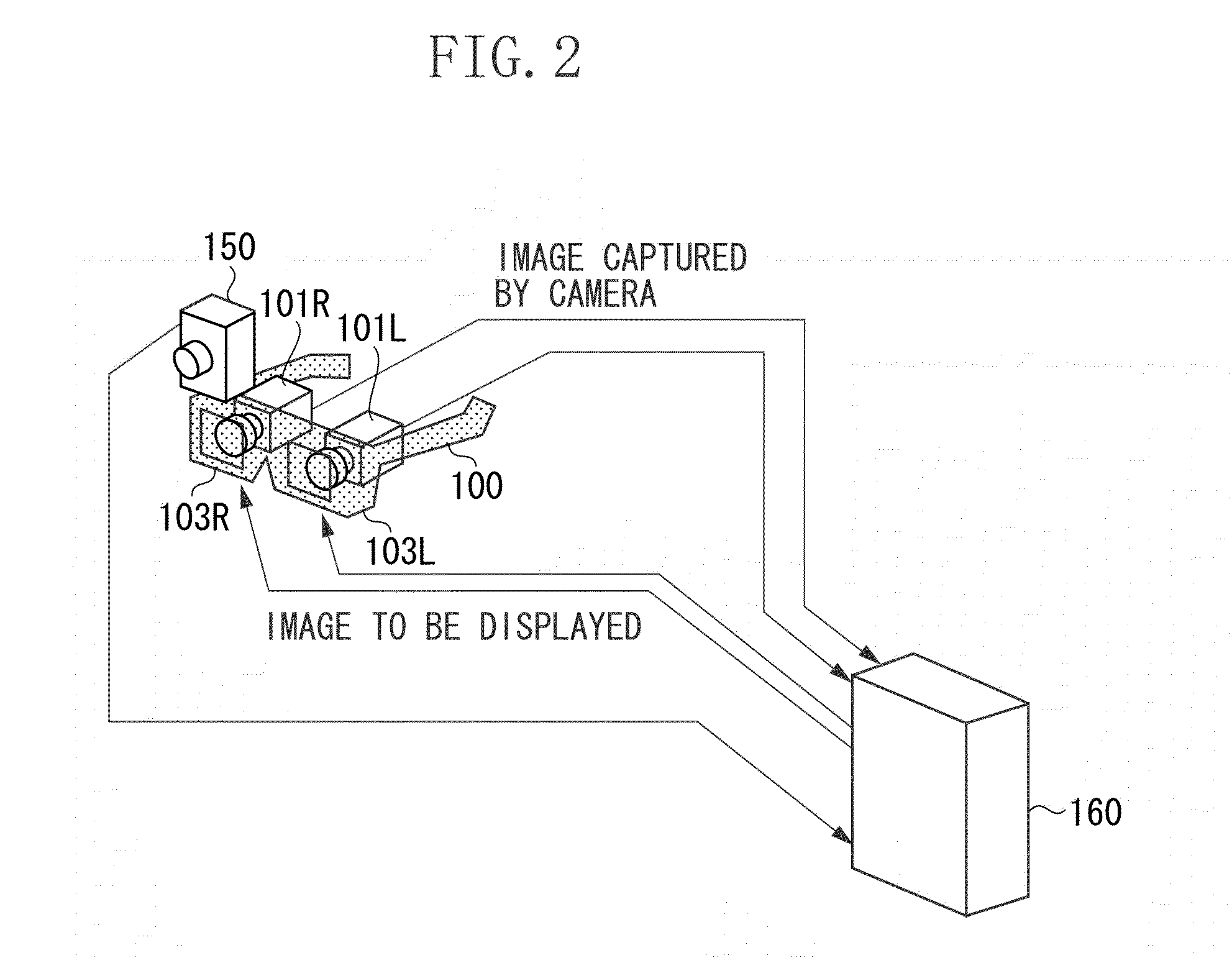

Image processing apparatus capable of generating object distance data, image processing method, and storage medium

InactiveUS20140140579A1Reduce errorsImprove reliabilityImage enhancementImage analysisImaging processingContour line

An image processing apparatus includes a distance measuring unit configured to measure a distance from a target object and generate a distance image, a camera configured to acquire a captured image including the target object, a reliability calculating unit configured to calculate a reliability level with respect to a measurement value of the generated distance image based on the captured image and the distance image and generate a reliability image, and distance data correcting unit configured to generate a high reliability distance image using the reliability image and the distance image and generate a corrected distance image by interpolating or extrapolating the high reliability distance image up to a region including a contour line.

Owner:CANON KK

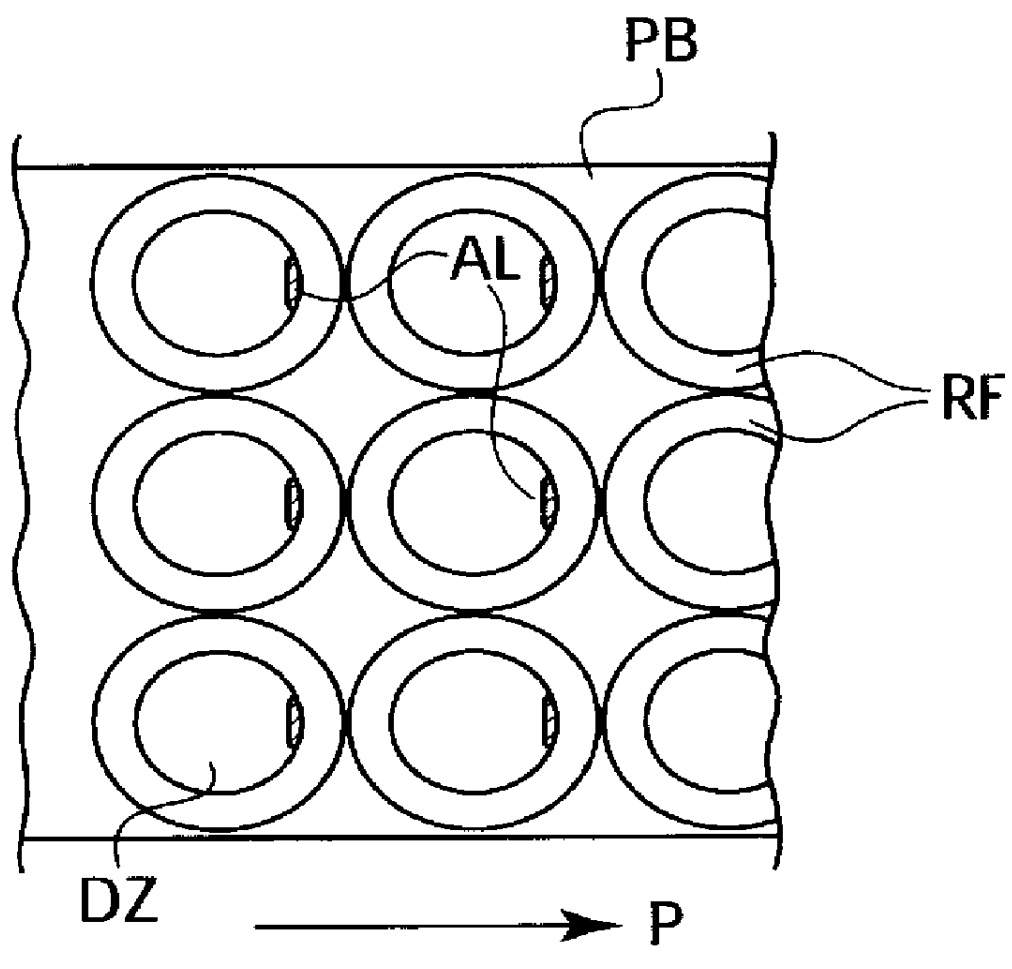

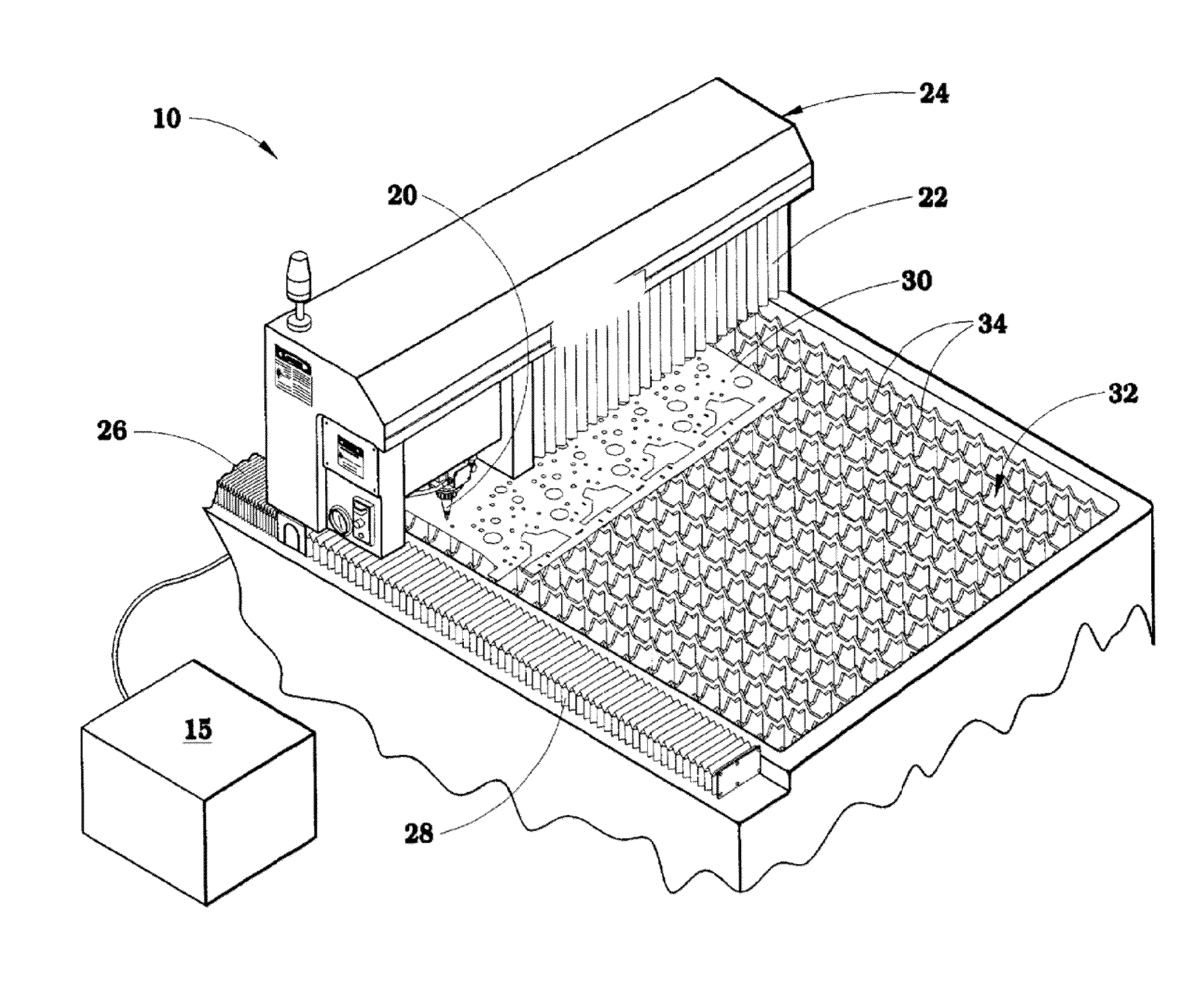

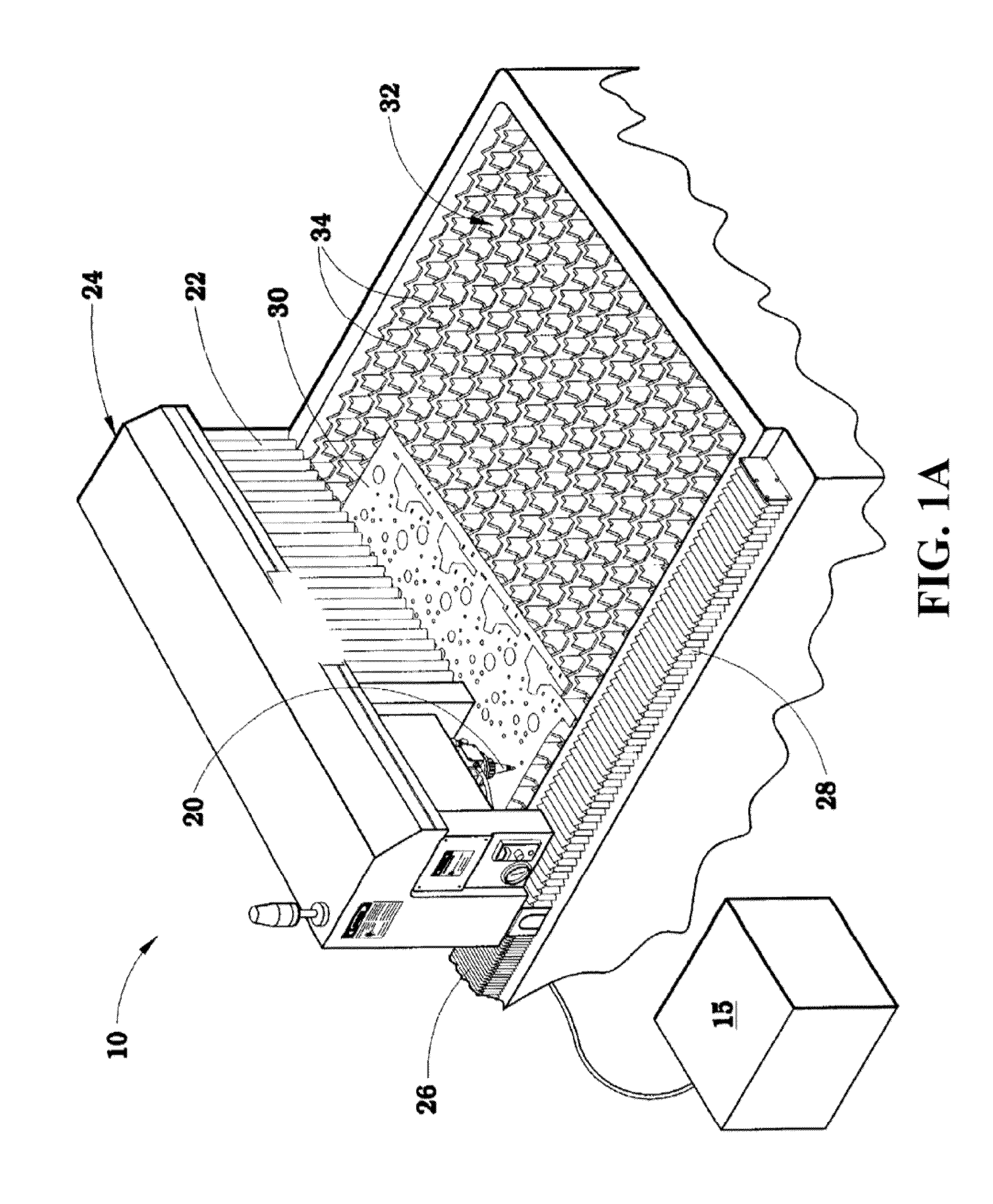

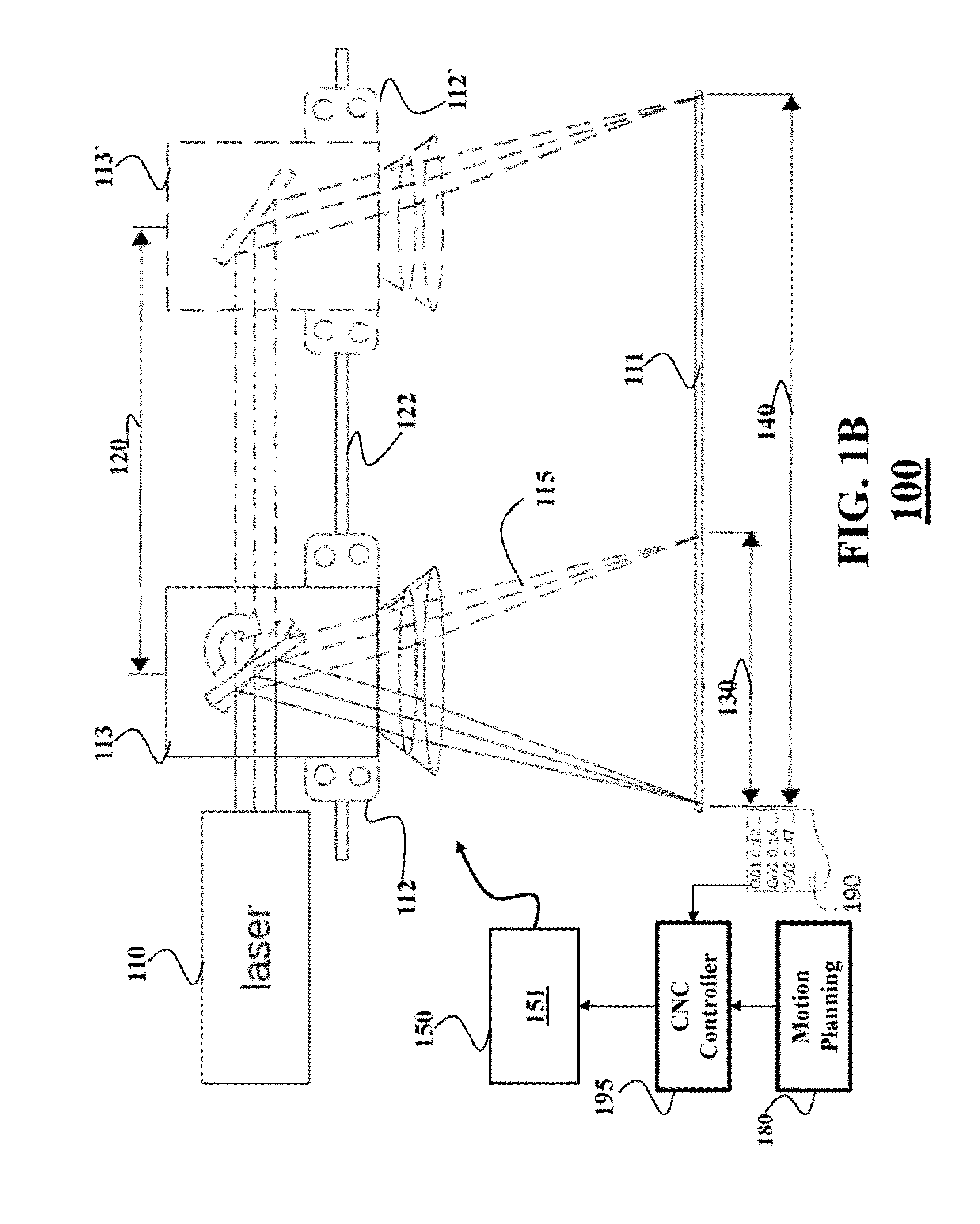

System and Method for Controlling Machines According to Pattern of Contours

A set of costs representing operations of a machine along a set of trajectories connecting a set of exit and entry points on contours of a pattern is determined. Each trajectory represents an operation of the machine proceeding from an exit point with an exit velocity to an entry point with an entry velocity according to dynamics of the machine. The set of trajectories includes at least one trajectory representing the operation along a contour with non-zero velocities at corresponding exit and entry points, and at least one trajectory representing the operation between different contours with non-zero velocities at the corresponding exit and entry points. A sequence of the trajectories optimizing a total cost of operation of the machine tracking the pattern is determined based on the costs, and a set of instructions for controlling the machine is determined according to the sequence.

Owner:MITSUBISHI ELECTRIC RES LAB INC

Safety transfusion catheter

A safety transfusion catheter includes a flexible retention tube fitted over a metal guiding needle. The flexible retention tube is provided with a needle handle connected with it. The angle between the end of the flexible retention tube and its longitudinal axis or longitudinal tube wall is less than 90.degree. The cross section of the needle handle has an outer contour line of a closed curve formed with a curve intersecting a beeline. A further safety transfusion catheter includes a flexible retention tube fitted over a metal guiding needle, a transfusion connecting tube in fluid communication with flexible retention tube and a rubber casing cap at the end of the flexible retention tube. The transfusion connecting tube and flexible retention tube form a T-shaped or an oblique Y-shaped structure.

Owner:SUN MEDICAL SCI SHANGHAI

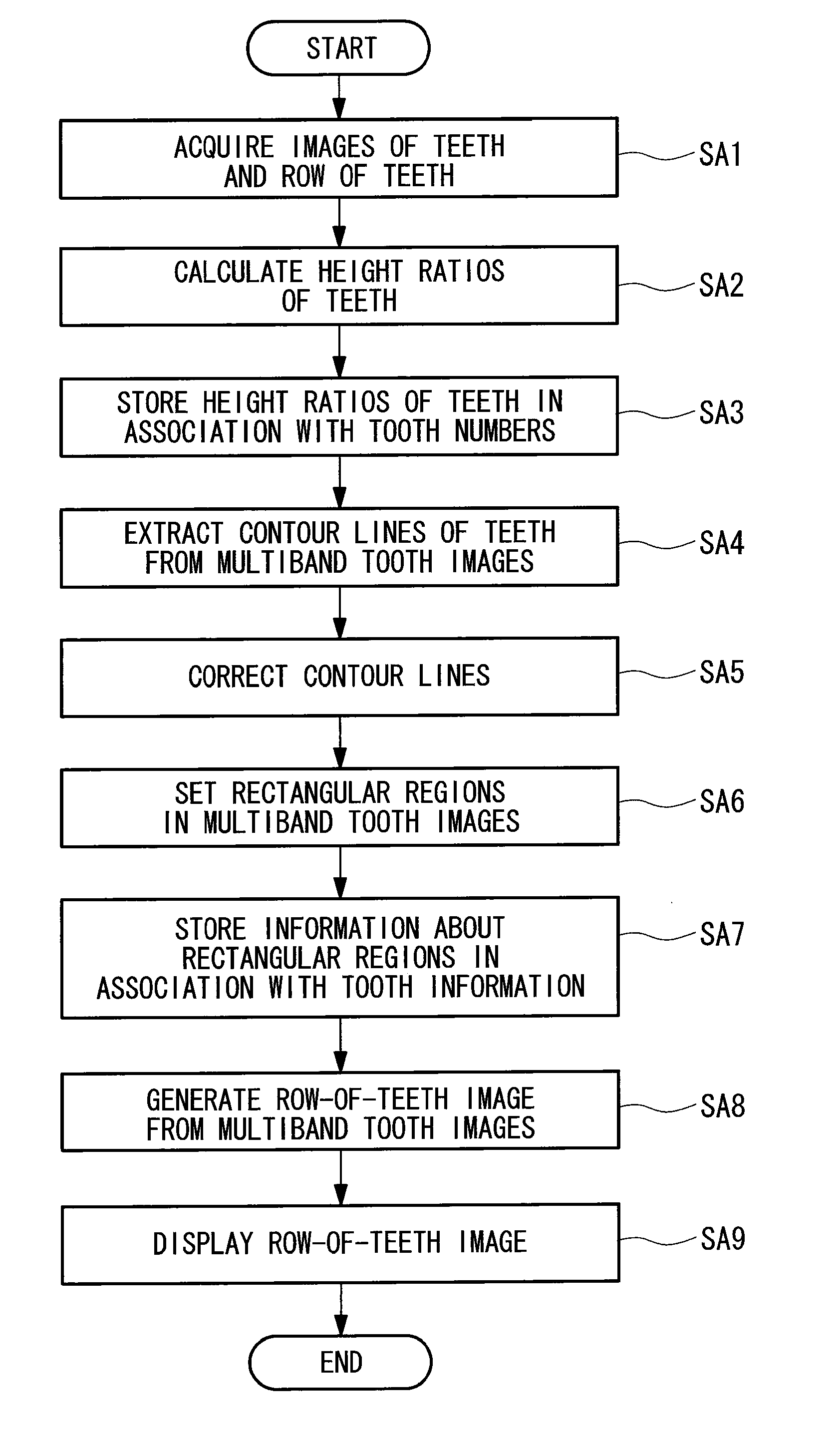

Dental colorimetry apparatus

InactiveUS20090322868A1Color balance of an entire row of teeth can be checkedMaterial analysis using wave/particle radiationCharacter and pattern recognitionComputer scienceColorimetry

A dental colorimetry apparatus that allows the color balance of an entire row of teeth to be checked is provided. The invention provides a dental colorimetry apparatus 2 including a multiband-image storing section 21 storing images of teeth in association with information about the positions of the teeth in row of teeth; a contour-line extracting section 25 for extracting contour lines of the teeth from the images of the teeth; a rectangle-setting section 27 for setting rectangles in the images of the teeth so as to include the contour lines extracted by the contour-line extracting section 25 and so as to circumscribe at least both sides of the teeth; and an image-generating section 29 for generating a row-of-teeth image by arranging the images of the teeth based on the information about the positions of the teeth in the row of teeth so that the rectangles adjoin each other.

Owner:OLYMPUS CORP

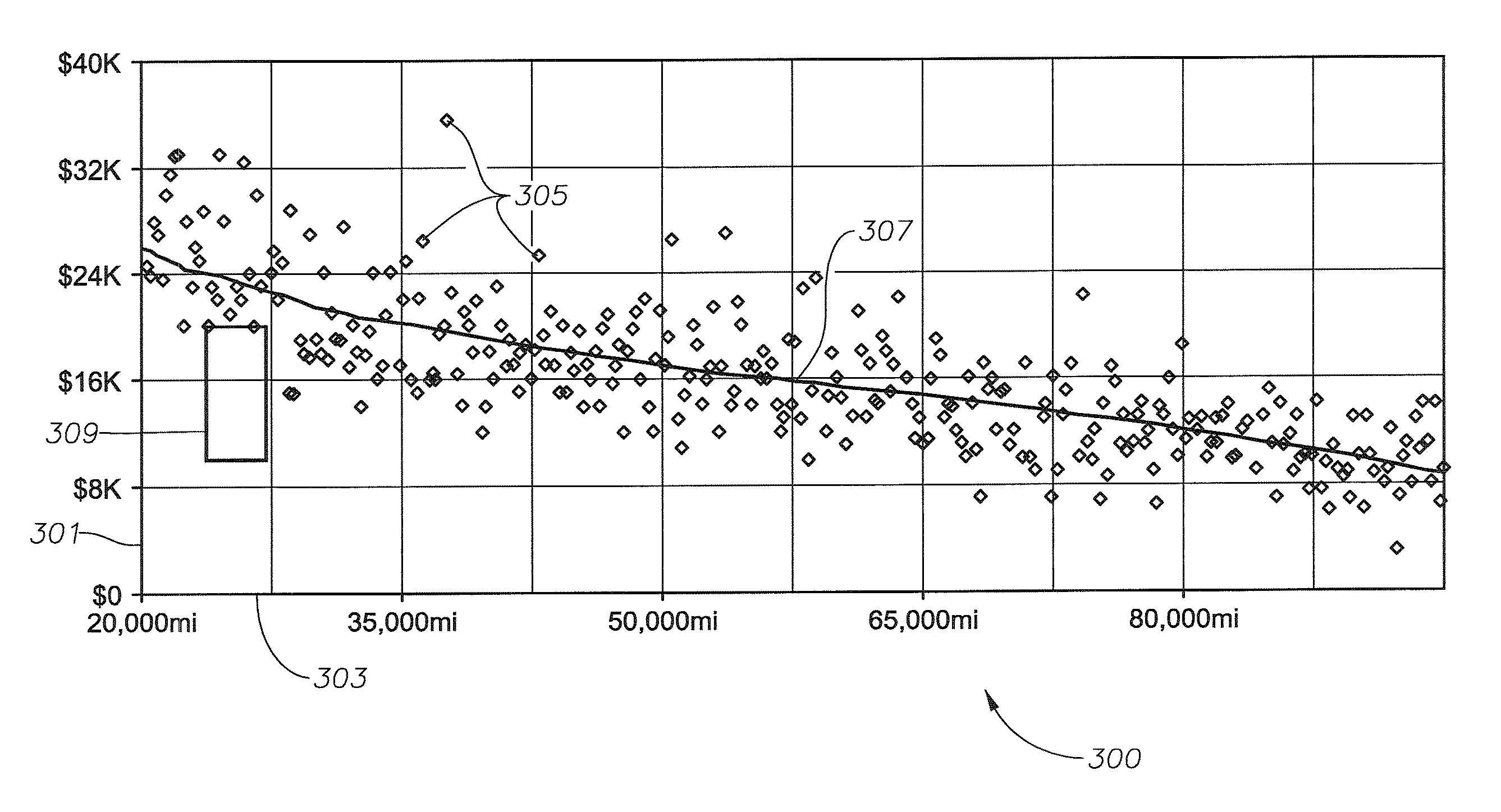

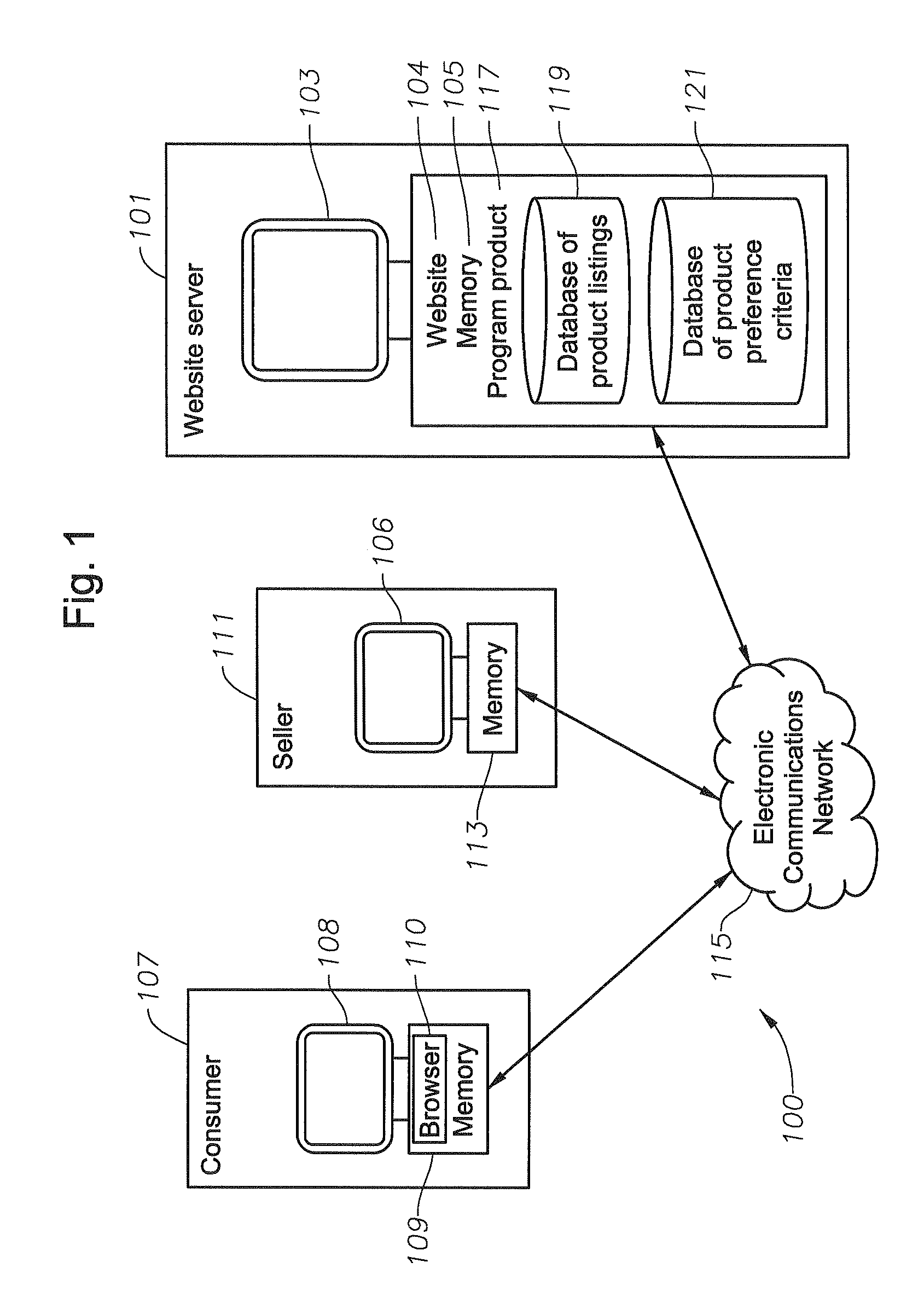

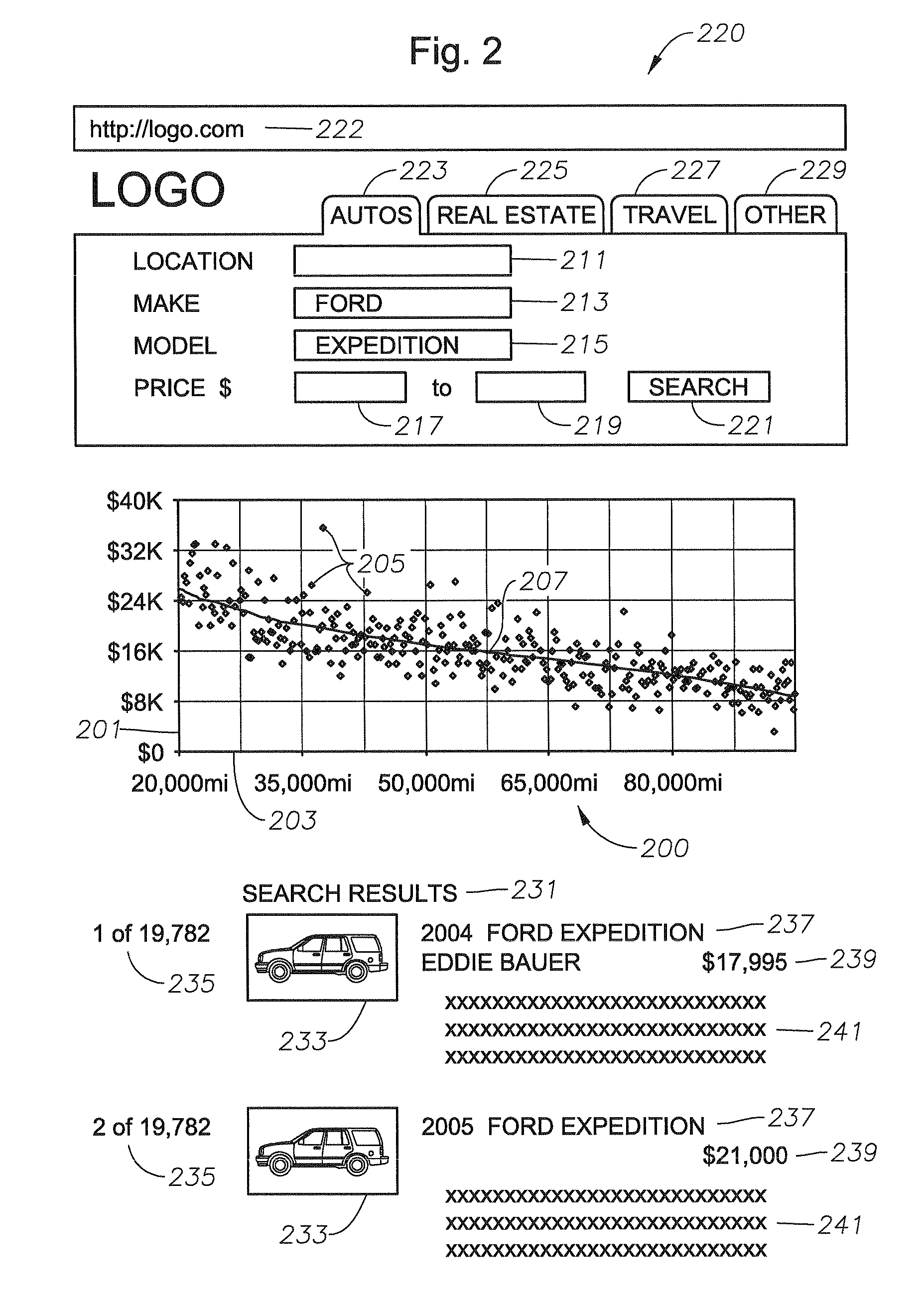

Positioning E-commerce product related to graphical imputed consumer demand

ActiveUS8326662B1Large possible marketEfficiently provideFinanceProduct appraisalTwo-dimensional graphGraphics

Example embodiments provide program products, systems, and associated methods of presenting a seller with a graphical representation of demand for a potential product listing so that the seller can intelligently price and position the product. A website server associated with a website of product listings captures in a database product preference criteria for a consumer, including, for example, price information. The website server aggregates the captured product preference criteria for a plurality of consumers and determines an imputed consumer demand for a potential product listing. The website server displays on a display device associated with a computer of a seller a multi-dimensional graph of demand for the potential product listing so that the seller can gauge market demand prior to listing a product for sale. Embodiments further include two-dimensional graphs plotting demand versus price, contour lines for the demand imposed on pricing graphs, and color-coded demand heat maps.

Owner:OVERSTOCK COM

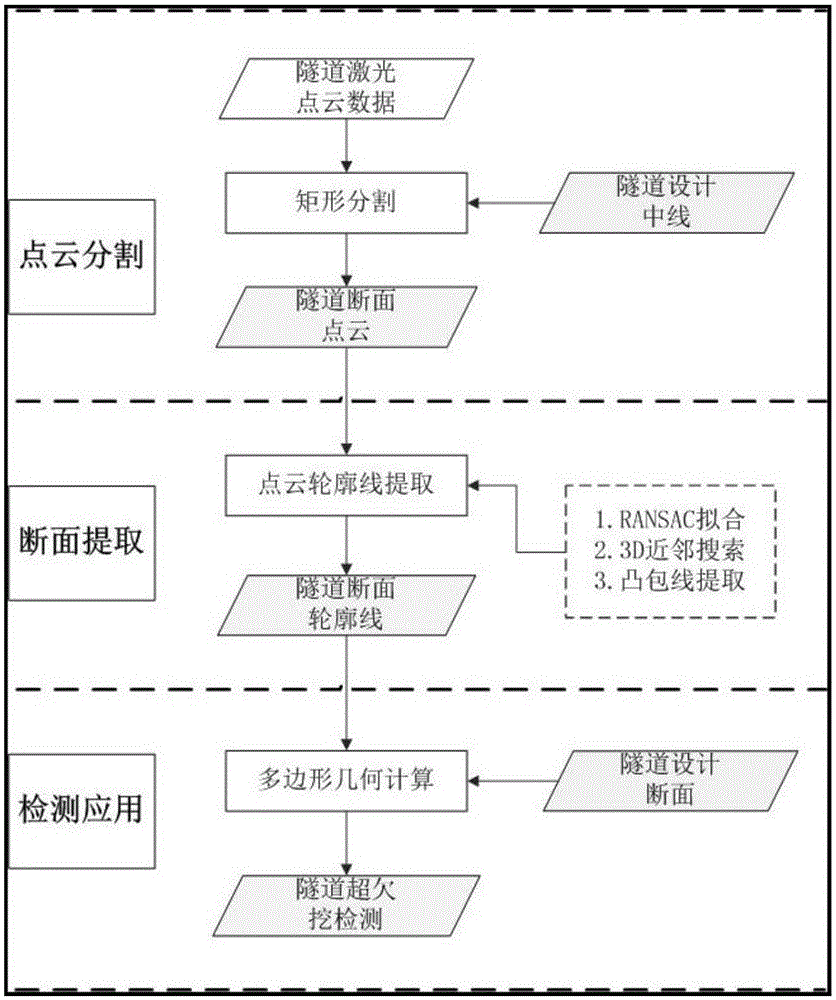

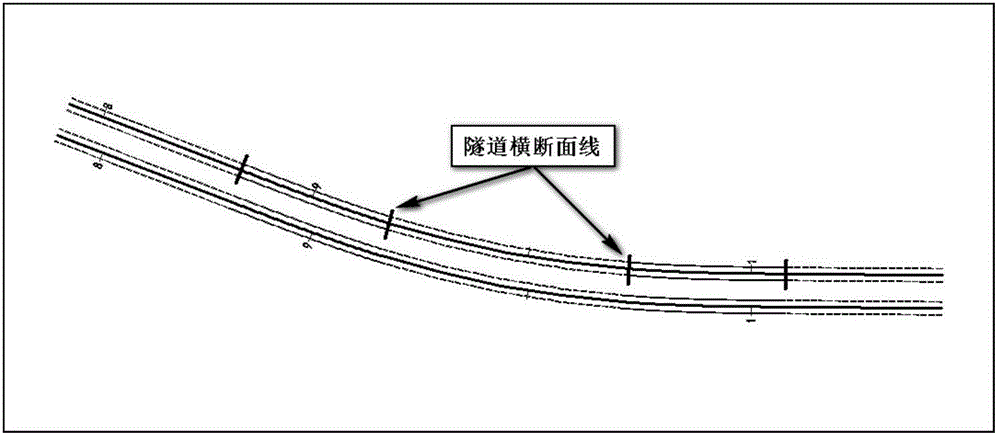

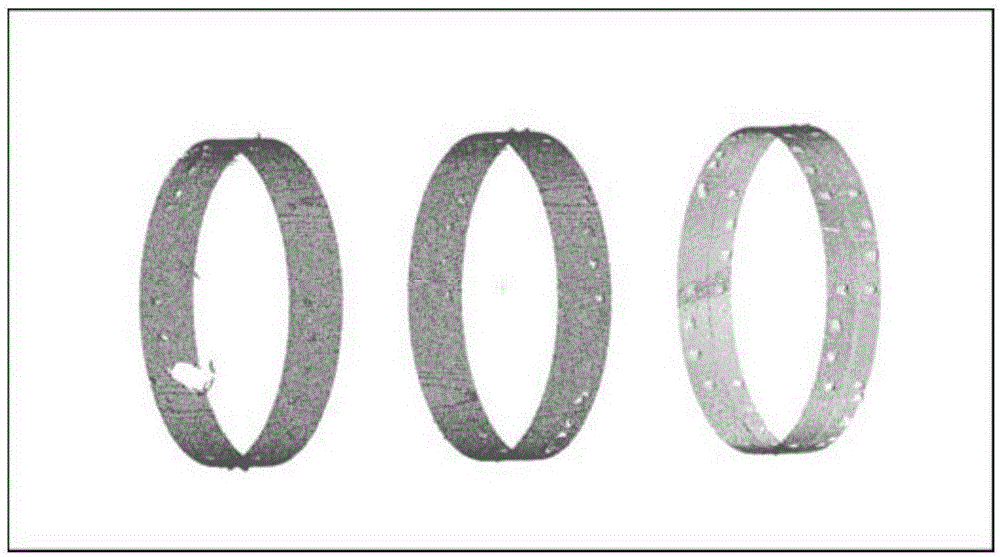

Tunnel back-break detection method based on laser-point cloud

The invention discloses a tunnel back-break detection method. The method includes the following steps that S1, according to center line data of a tunnel line, the thickness value and width value of a section are set, and tunnel section point cloud automatic partitioning is carried out; S2, the partitioned section point cloud is projected to the XOY plane, and a convex hull extraction method is adopted for carrying out automatic extraction of a section point cloud contour lines to obtain a measured section line; and S3, the tunnel design section is utilized, the distances between feature points of the tunnel design section and the measured section line and the locations of the feature points are calculated, and back-break automatic detection is carried out. Tunnel back-break detection is carried out by utilizing three-dimensional laser-point cloud data, and rapid partitioning of the section point cloud is achieved by adopting radius searching and a rectangular partitioning algorithm; on the basis of back-break area statistics of a polygonal intersection algorithm, the method is suitable for back-break detection of various types of tunnels; and compared with a traditional total-station section measurement mode, the detection efficiency is high, results are comprehensive and full and accurate, and the measurement precision meets the back-break detection requirement.

Owner:CHINA RAILWAY DESIGN GRP CO LTD

Method and Apparatus for Aperture Detection of 3D Hearing Aid Shells

InactiveUS20070201713A1Shorten the timeImage enhancementImage analysisHearing aidArtificial intelligence

A method identifying apertures of ear impressions is disclosed. A plurality of contour lines associated with an ear impression are determined and a difference value between a value of a characteristic, such as the diameter, of each contour line and that characteristic of an adjacent contour line is determined. The aperture is identified as being that contour line having the greatest difference value. The contour lines are determined by identifying where a plane intersects the surface of the graphical representations. In another embodiment, the contour lines are assigned a weight. A contour index is then calculated for each contour line as a function of the difference value and these weights. According to this embodiment, the aperture is identified as being a contour line that is adjacent to that contour line having the greatest contour index.

Owner:SIEMENS HEARING INSTRUMENTS +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com