Patents

Literature

245 results about "Path line" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

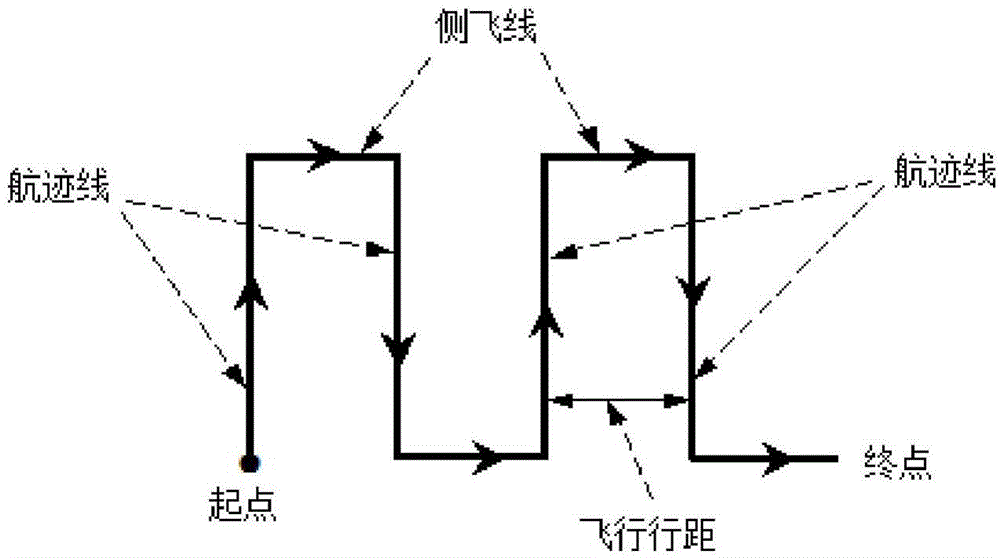

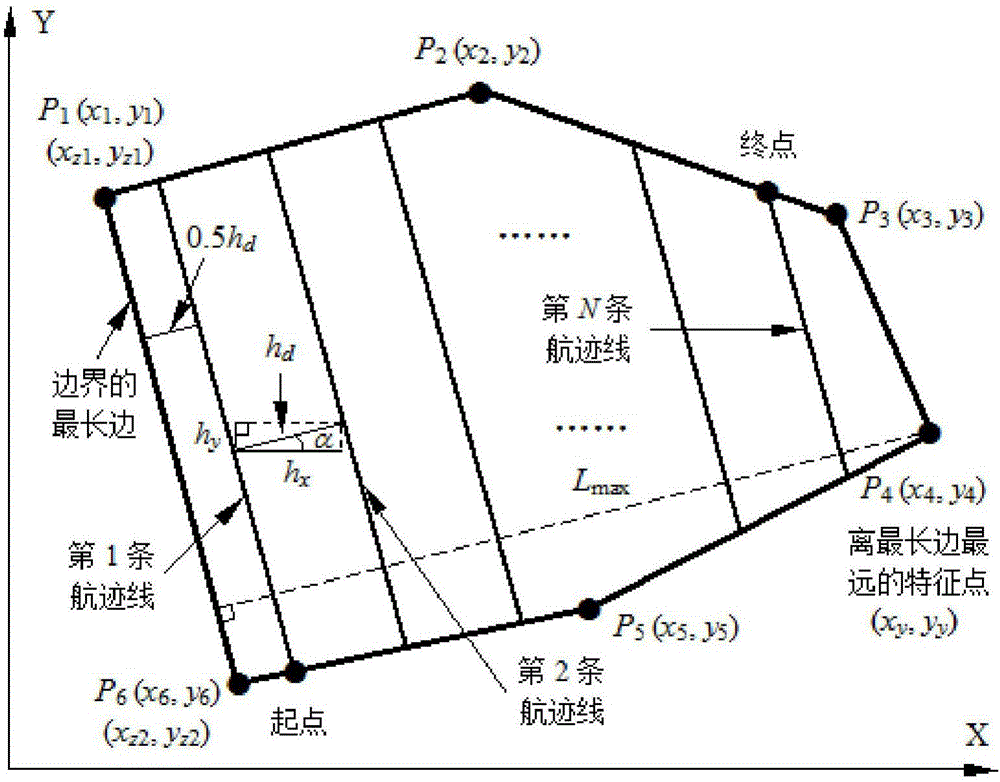

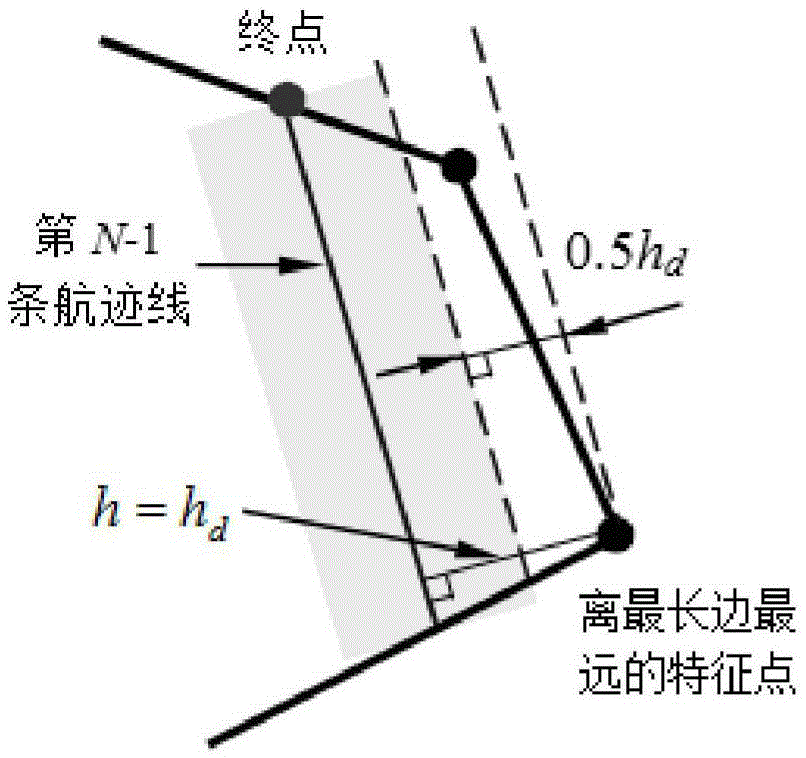

Concave convex mixed complex polygon farmland unmanned aerial vehicle spraying operation flight path planning method

ActiveCN104808660AReduce complexityReduce the difficulty of manipulationPosition/course control in two dimensionsUncrewed vehicleIntersection of a polyhedron with a line

The invention discloses a concave convex mixed complex polygon farmland unmanned aerial vehicle spraying operation flight path planning method. Starting from any feature point on the boundary of the polygon farmland, all feature points of the boundary of the polygon farmland are acquired sequentially, adjacent two points are connected by using a straight line sequentially according to the point acquisition sequence of the feature points, and an operation region of the boundary of the polygon farmland is generated; the longest edge of the boundary of the operation region is found out; a feature point farthest from the longest edge is found out; N flight path lines are drawn between the longest edge and the feature point farthest from the longest edge; coordinates of all boundary line segments crossed with the flight path lines and flight path line crossed points are obtained; the number of the crossed points between the flight path lines and the boundary line segments is judged, and when the number of the crossed points is larger than 2, flight path lines outside the operation region range are deleted; and starting from a flight path line nearest to the longest edge, the flight path lines and side flight lines are connected in sequence, and an S-shaped flight path planning line is obtained. The flight path of the concave convex mixed complex polygon farmland unmanned aerial vehicle spraying operation can be planned.

Owner:CENT SOUTH UNIV

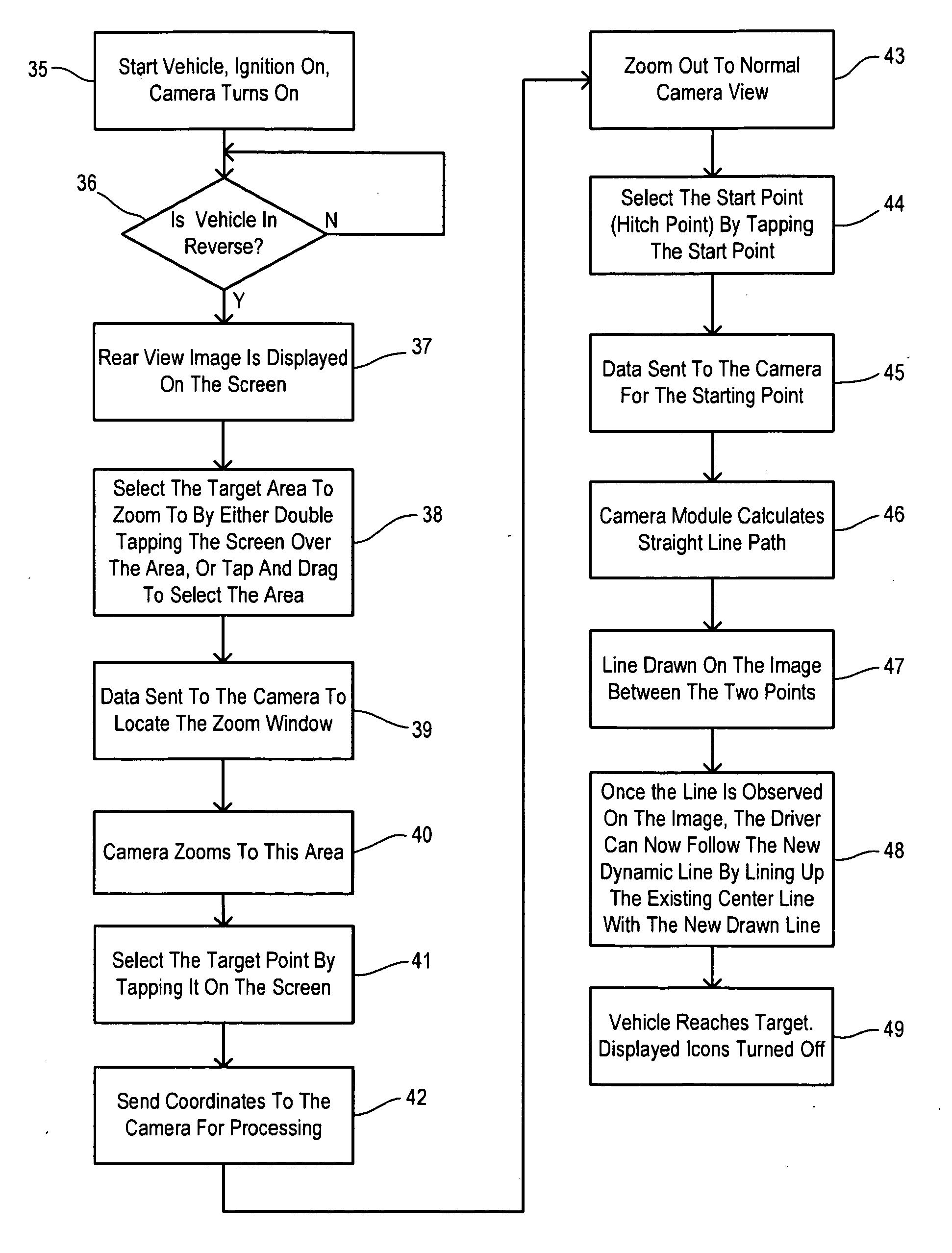

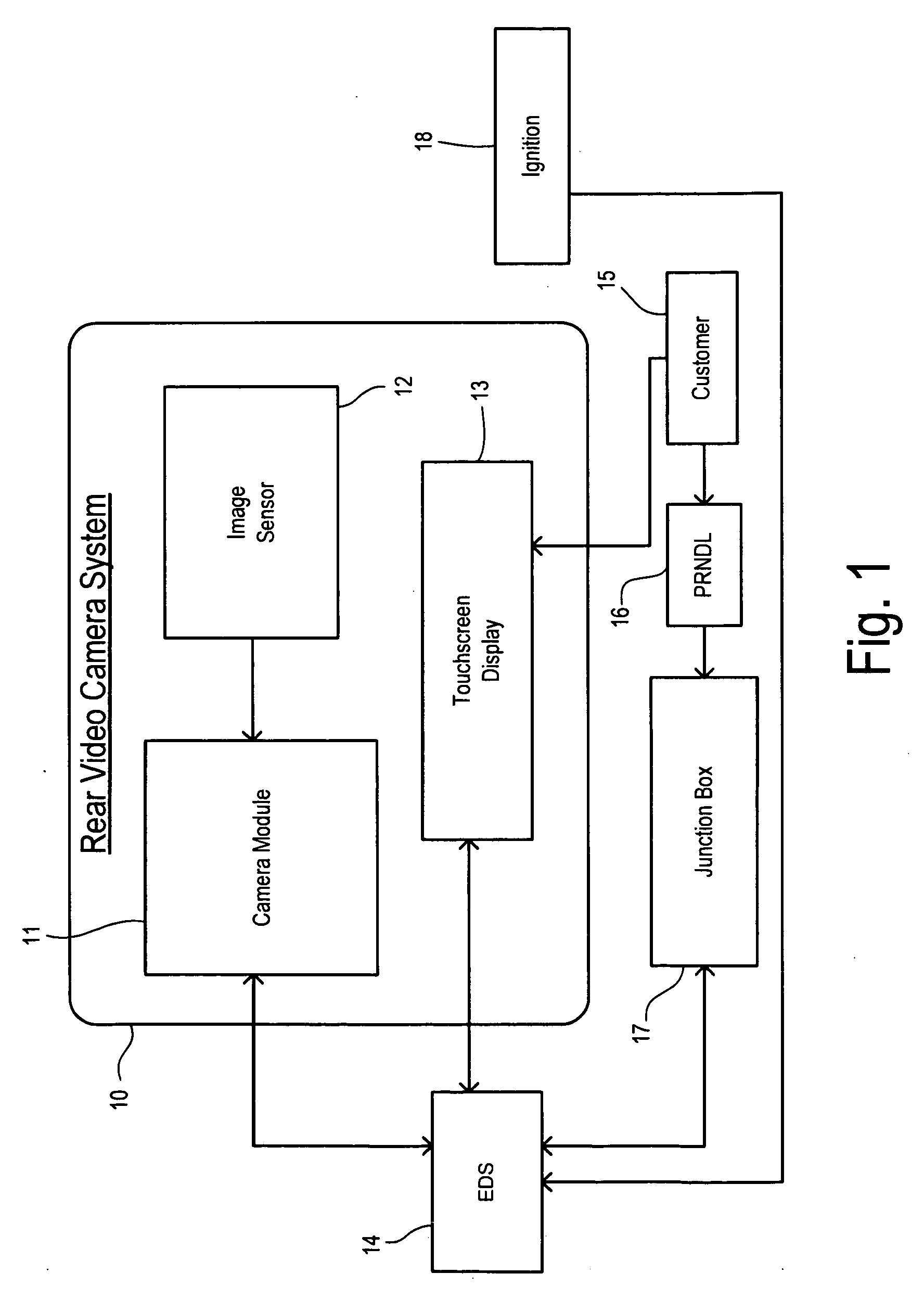

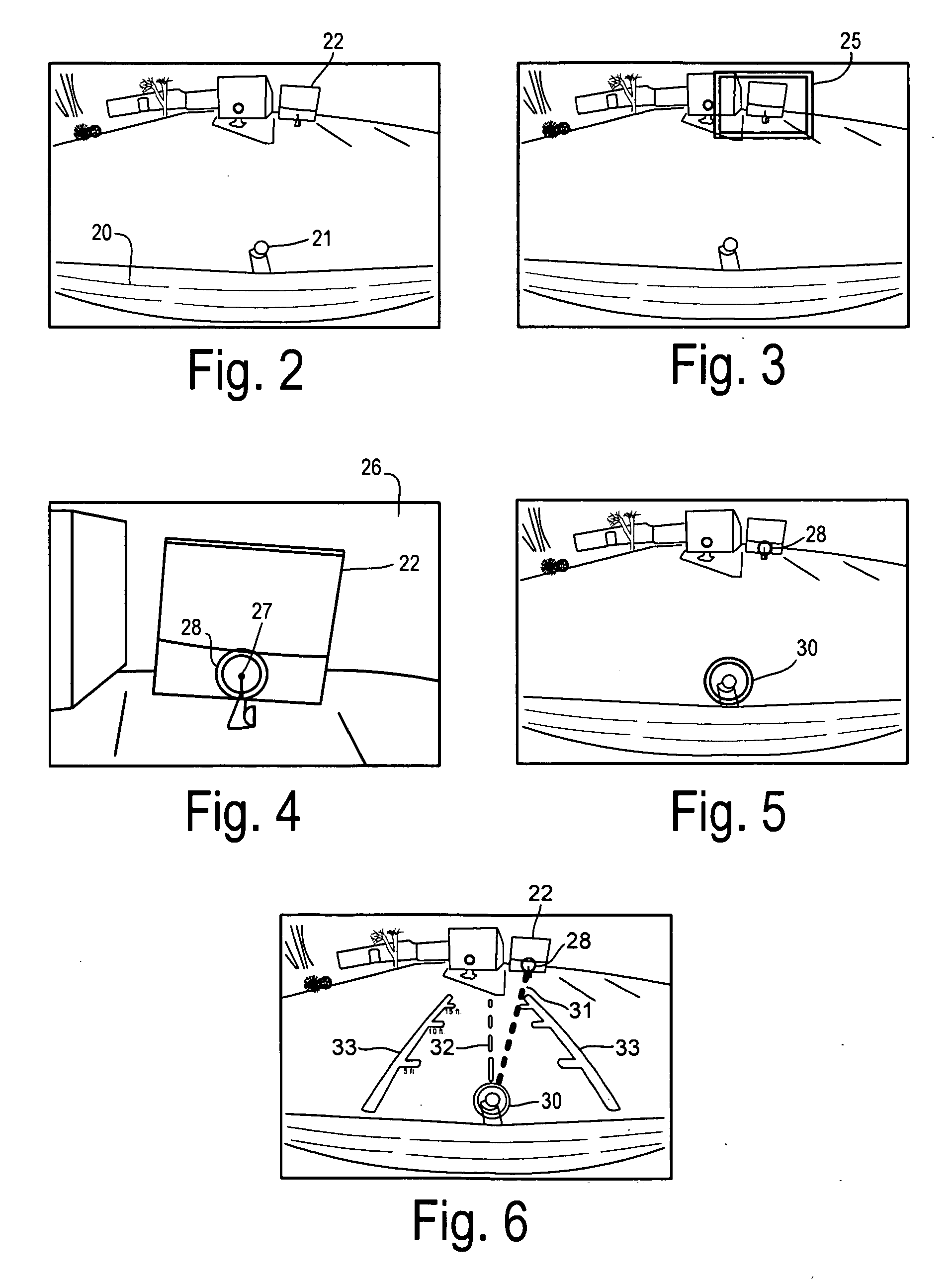

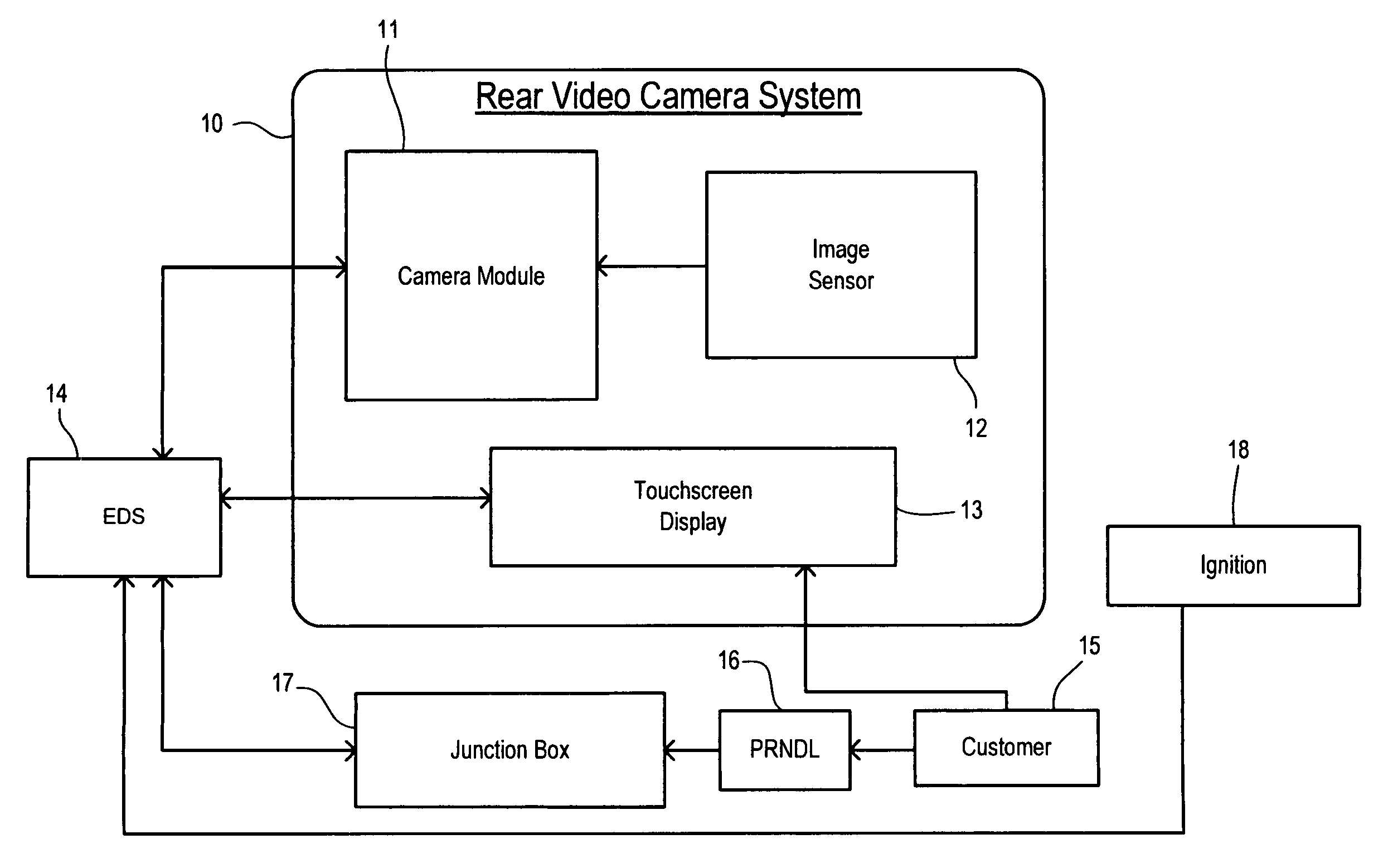

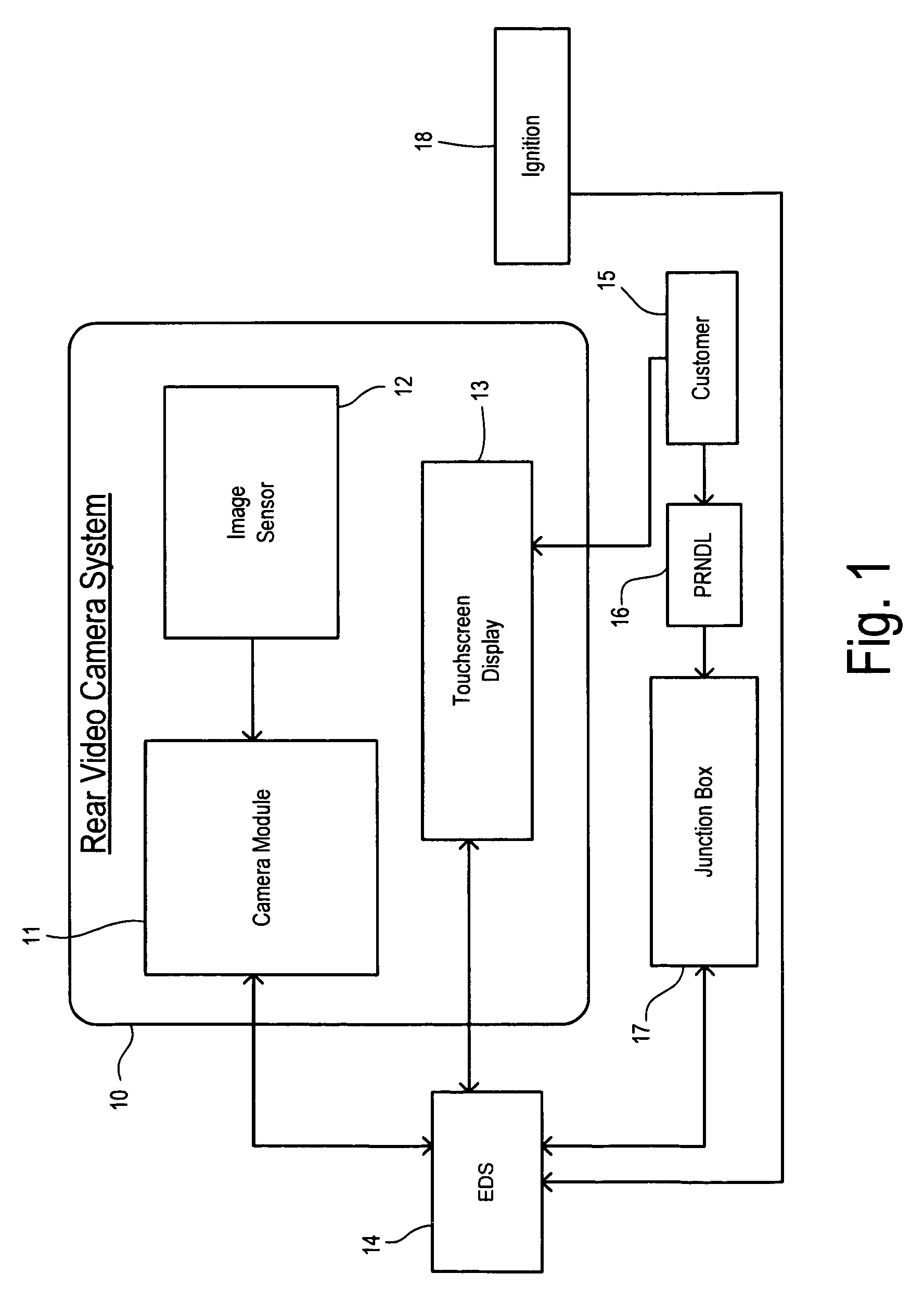

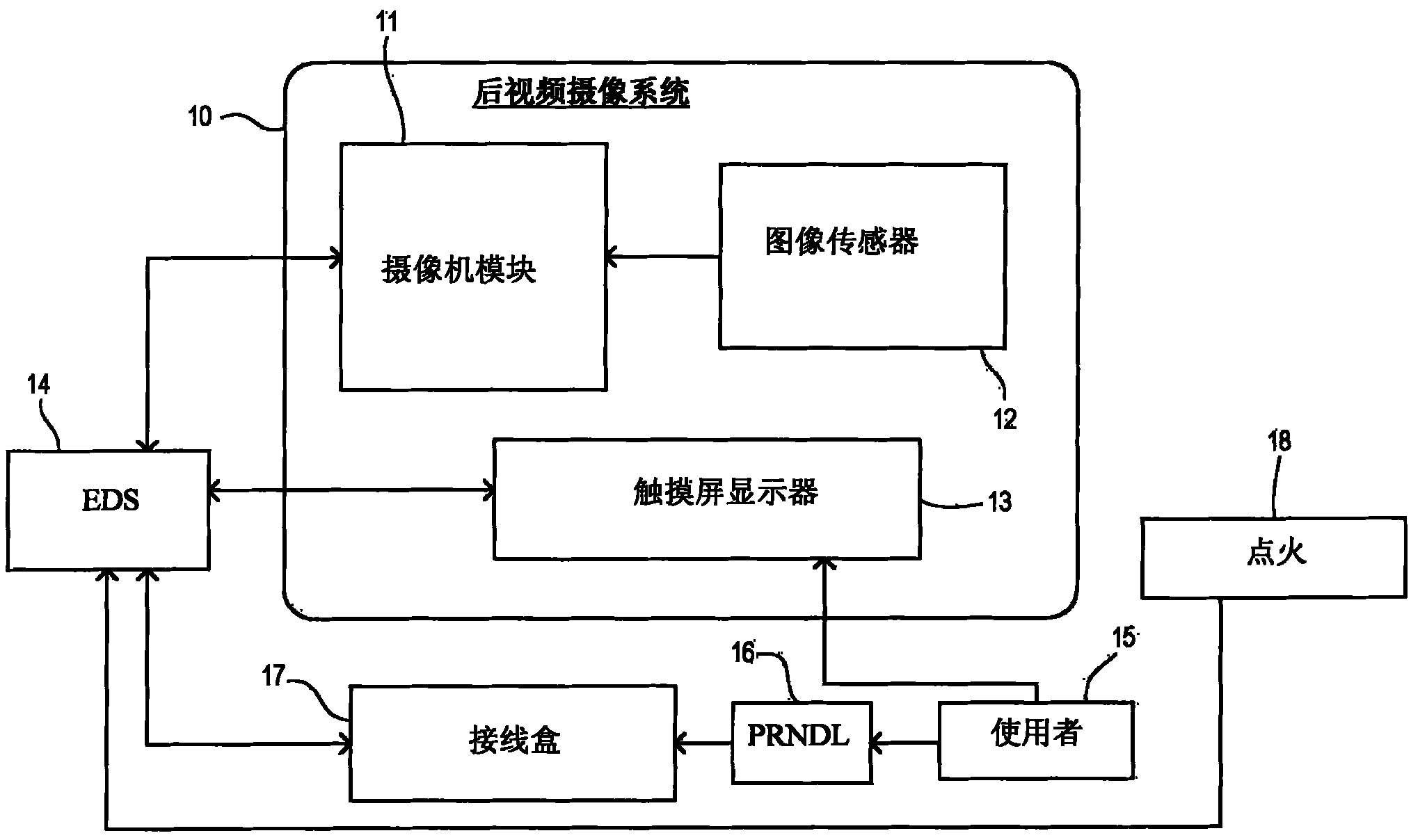

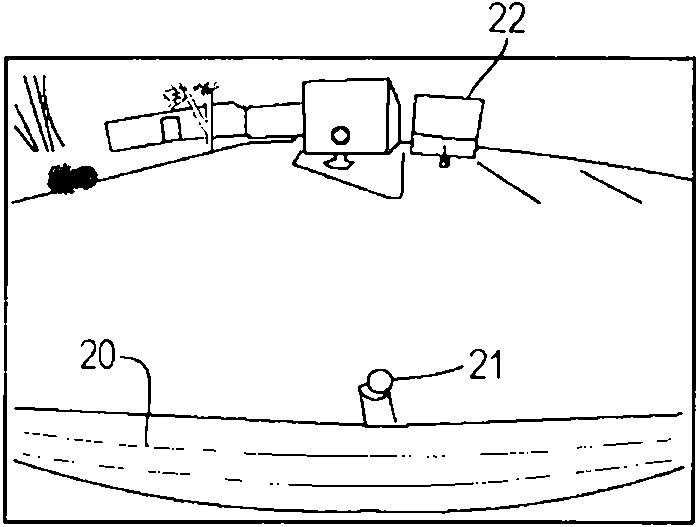

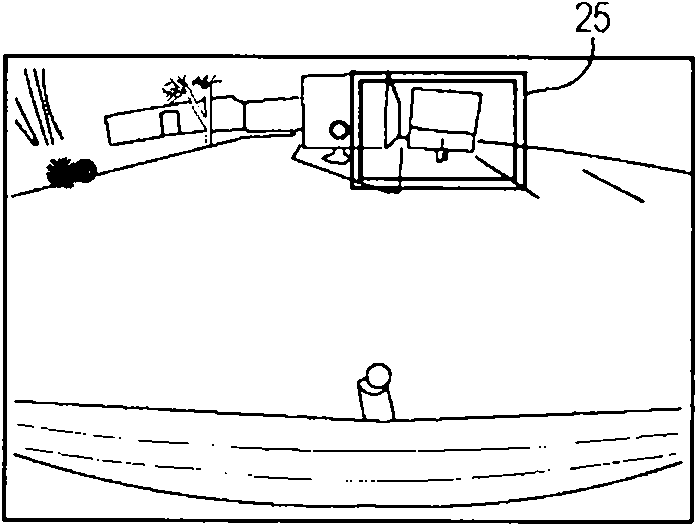

Rear Camera Backup Assistance With Touchscreen Display

InactiveUS20110001614A1Television system detailsImage analysisMobile vehicleComputer graphics (images)

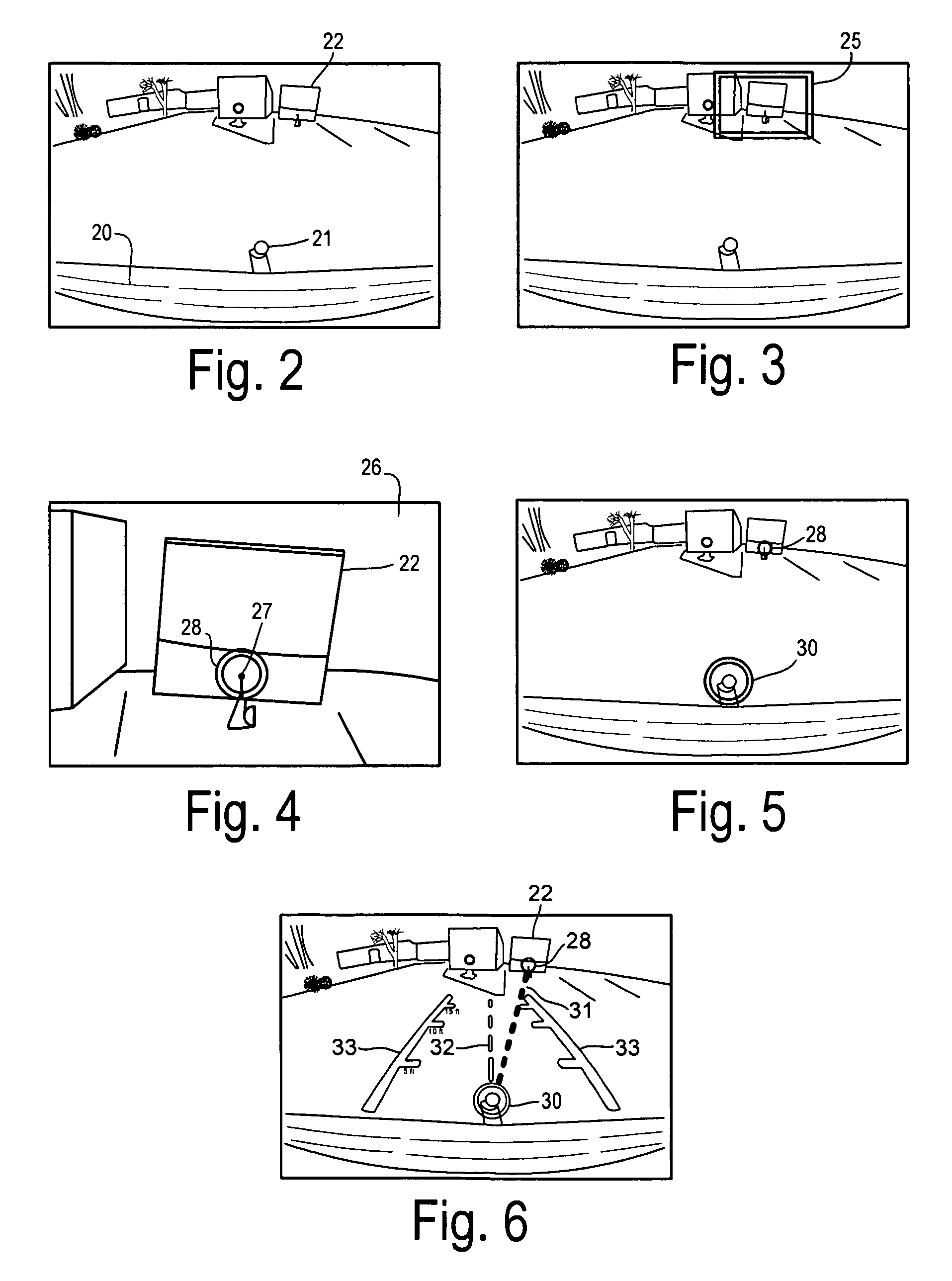

Assistance for a backup maneuver of a motor vehicle in which a first point of interest on the vehicle is moved toward a second point of interest remote from the vehicle. A rear contextual view is displayed on an electronic display obtained from a rearward directed image sensor on the vehicle. A zoom window is manually placed on the electronic display to include the second point of interest. The zoom window is enlarged, and the location of the second point of interest is manually identified within the enlarged zoom window. The identified location of the second point of interest is transformed into target positional coordinates. The rear contextual view redisplayed with a target icon at the target positional coordinates. The location of the first point of interest is manually identified on the rear contextual view and transformed into starting positional coordinates. A start icon is displayed at the starting positional coordinates in the rear contextual view. A target line is determined between the target positional coordinates and the starting positional coordinates. A path line icon is displayed in the rear contextual view corresponding to the determined target line. A bearing line is displayed in the rear contextual view extending from the start icon. The target positional coordinates are re-determined as the rear contextual view shifts during the backup maneuver. The target icon and the path line icon are updated in response to the re-determined target positional coordinates.

Owner:FORD GLOBAL TECH LLC

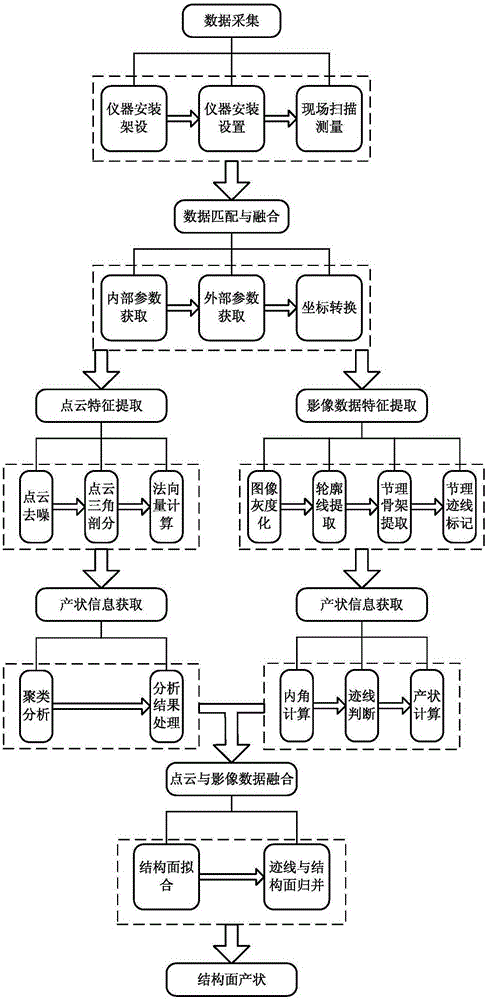

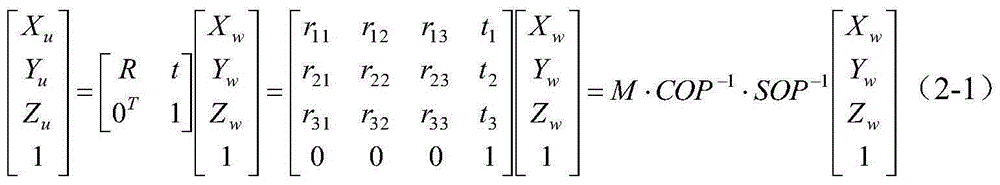

Rock structural surface occurrence measuring method integrated with laser-point cloud and digital imaging

The invention provides a rock structural surface occurrence automatic digital measuring method integrated with laser-point cloud and digital imaging. By utilization of a photogrammetric technology, a mixed global and local threshold method is employed to extract contour lines off path lines, joint path lines are extracted through skeleton extraction and path line marking, and combined with other image processing methods, and information obtaining of rock joint path line occurrence is achieved. Finally, according to the distance of the path lines to the structural surfaces, the position relations of the path lines and the structural surfaces are determined, and the path lines and the structural surfaces are subjected to combining and grouping, and occurrence of each group is employed to represent rock structural surface occurrence. Laser-point cloud and digital imaging measuring methods are integrated, rapid, efficient, non-contact and landform disregard properties of the two measuring methods are utilized fully, the measuring accuracy is raised, and the provided method has advantages of high automation degree, strong universality, comprehensive description and the like.

Owner:NANJING UNIV OF TECH

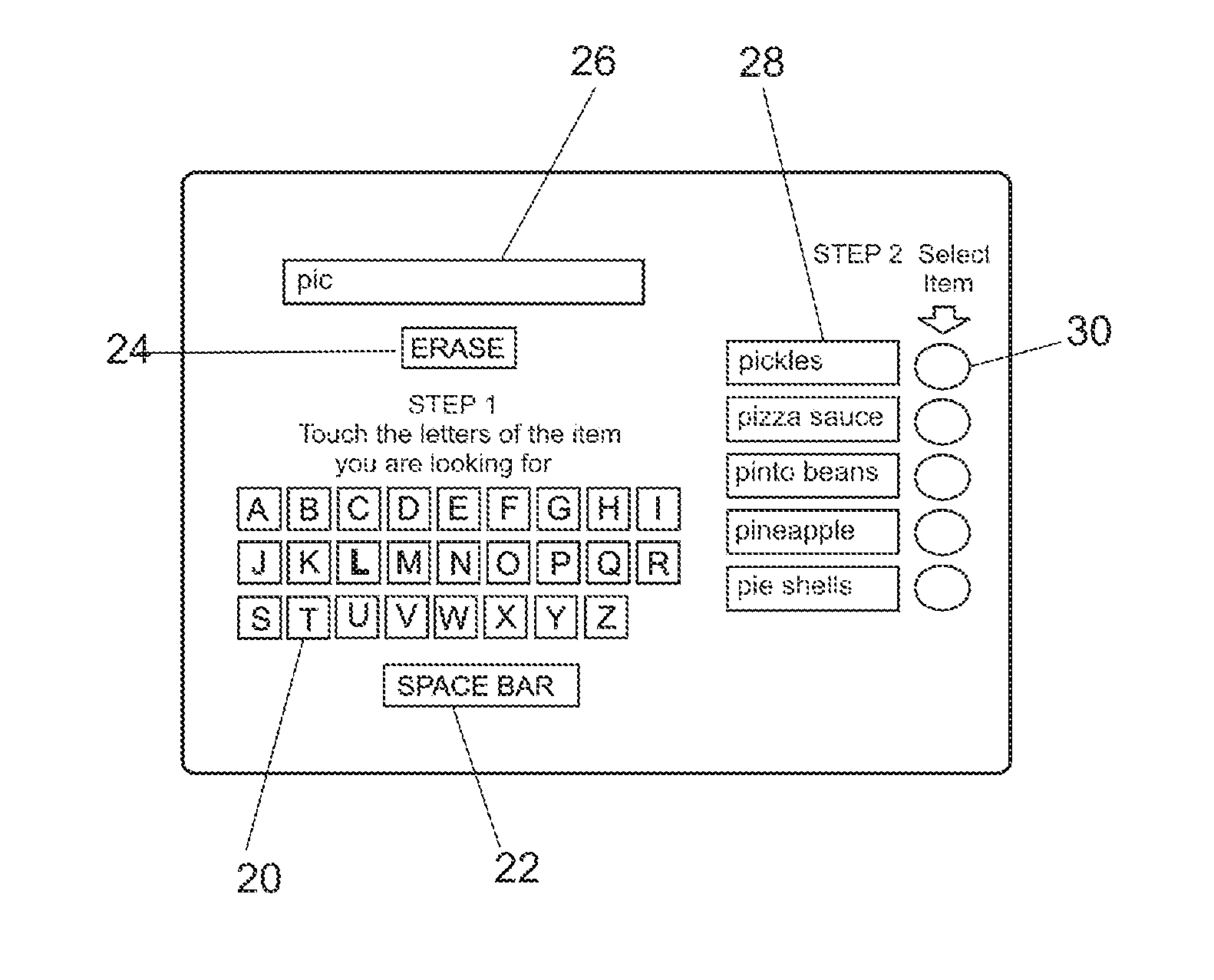

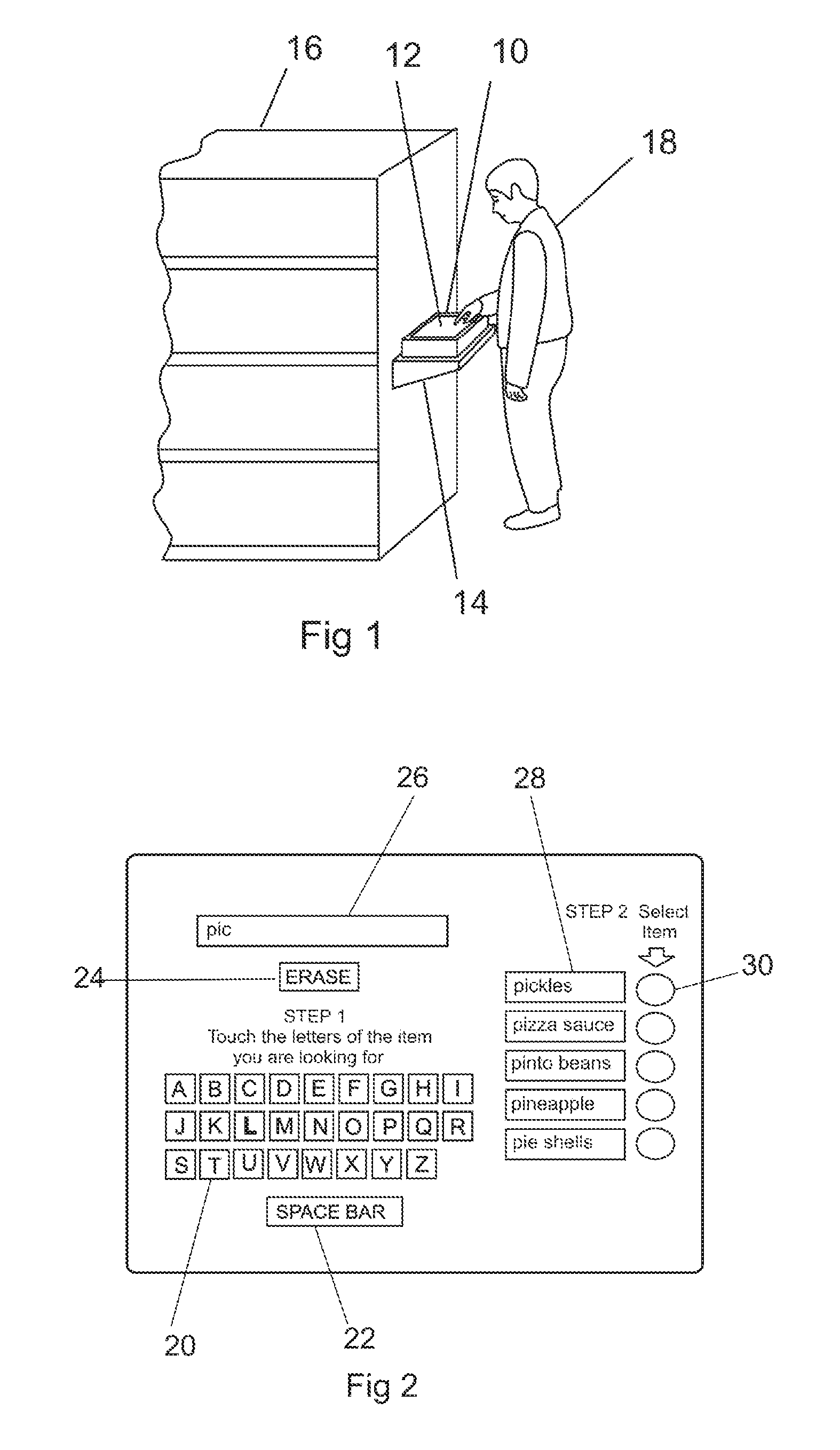

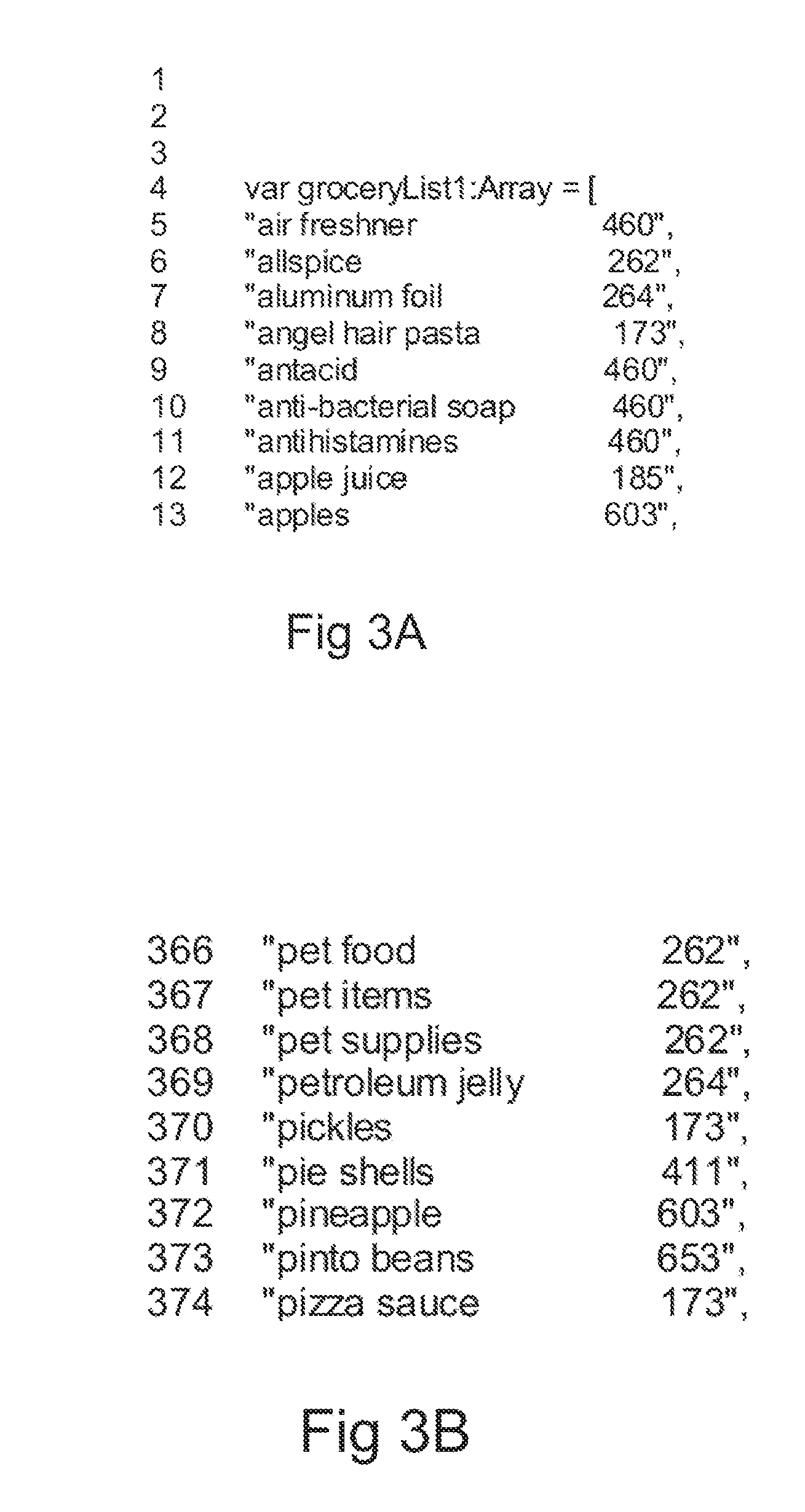

Item finder system for finding items stored in storage regions

InactiveUS20110251920A1Eliminate disadvantagesReduce disadvantagesInstruments for road network navigationRoad vehicles traffic controlGraphicsComputer science

An item finder system for situating in a retail environment for the purpose of assisting customers to find the items they wish to find has a touch-sensitive display screen. Customers enter the name of the sought item by touching letters displayed on the touch-sensitive surface which then displays a list of item names from what the customer can choose. An item name is selected from the list by touching a graphical symbol associated with the item name. The item finder system responds to the customer's touch by displaying a floor plan or layout of at least part of the store, a marker symbol representing the location of the item, for example, a section of shelf space that contains the item, and a path line extending from the customer's present location, i.e., the location of the touch-sensitive screen, to the location of the item in the store.

Owner:WATSON DOUGLAS

Rear camera backup assistance with touchscreen display using two points of interest

InactiveUS8138899B2Television system detailsInstrument arrangements/adaptationsMobile vehicleComputer graphics (images)

Assistance for a backup maneuver of a motor vehicle in which a first point of interest on the vehicle is moved toward a second point of interest remote from the vehicle. A rear contextual view is displayed on an electronic display obtained from a rearward directed image sensor on the vehicle. A zoom window is manually placed on the electronic display to include the second point of interest. The zoom window is enlarged, and the location of the second point of interest is manually identified within the enlarged zoom window. The identified location of the second point of interest is transformed into target positional coordinates. The rear contextual view redisplayed with a target icon at the target positional coordinates. The location of the first point of interest is manually identified on the rear contextual view and transformed into starting positional coordinates. A start icon is displayed at the starting positional coordinates in the rear contextual view. A target line is determined between the target positional coordinates and the starting positional coordinates. A path line icon is displayed in the rear contextual view corresponding to the determined target line. A bearing line is displayed in the rear contextual view extending from the start icon. The target positional coordinates are re-determined as the rear contextual view shifts during the backup maneuver. The target icon and the path line icon are updated in response to the re-determined target positional coordinates.

Owner:FORD GLOBAL TECH LLC

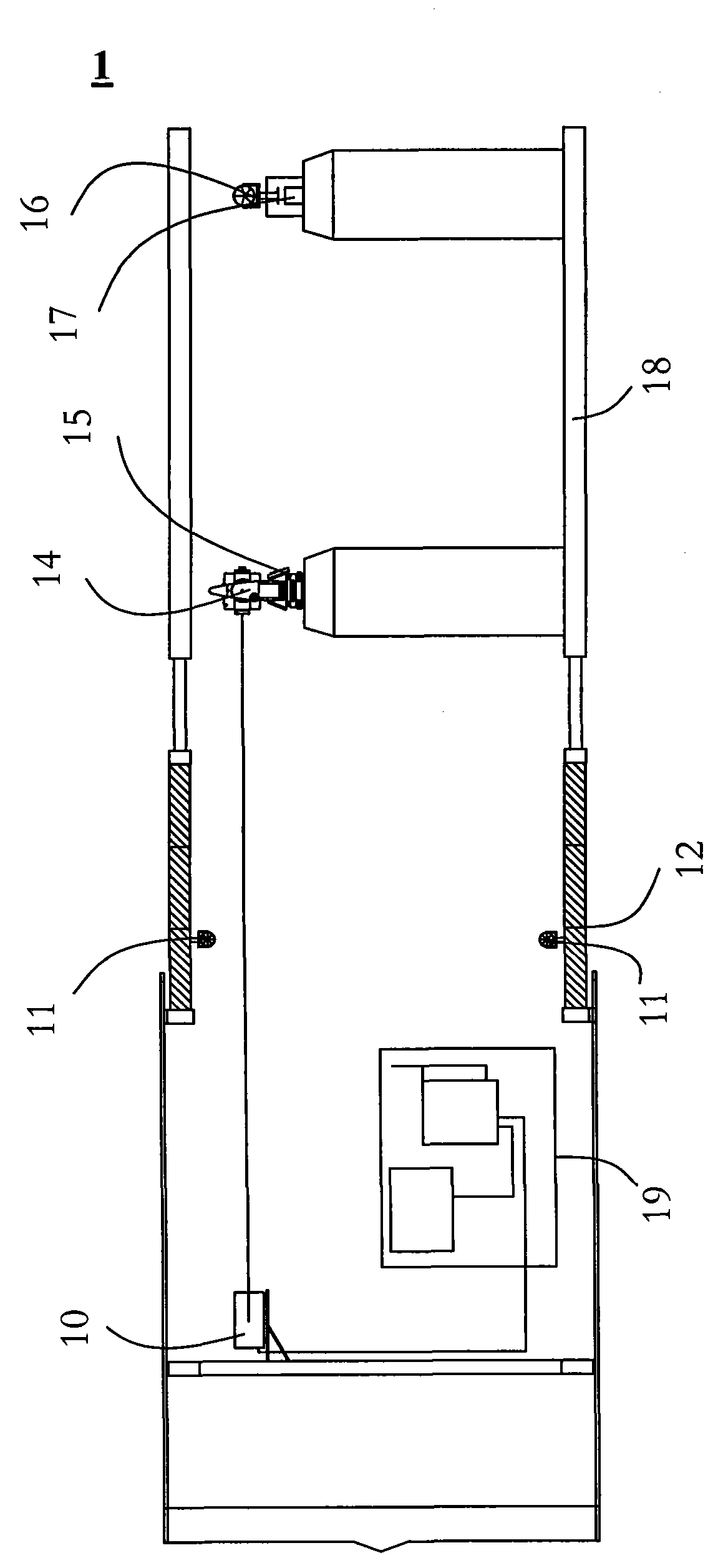

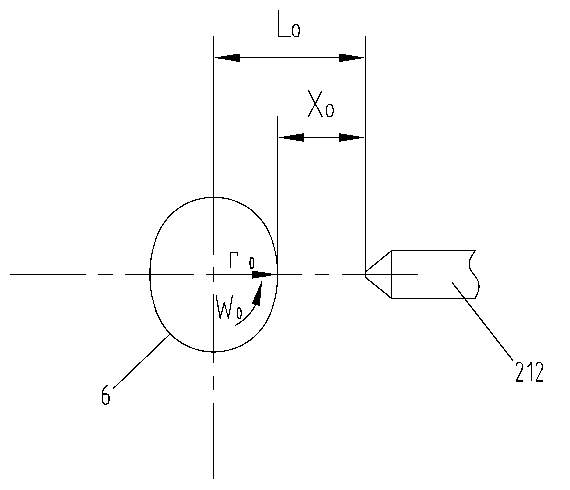

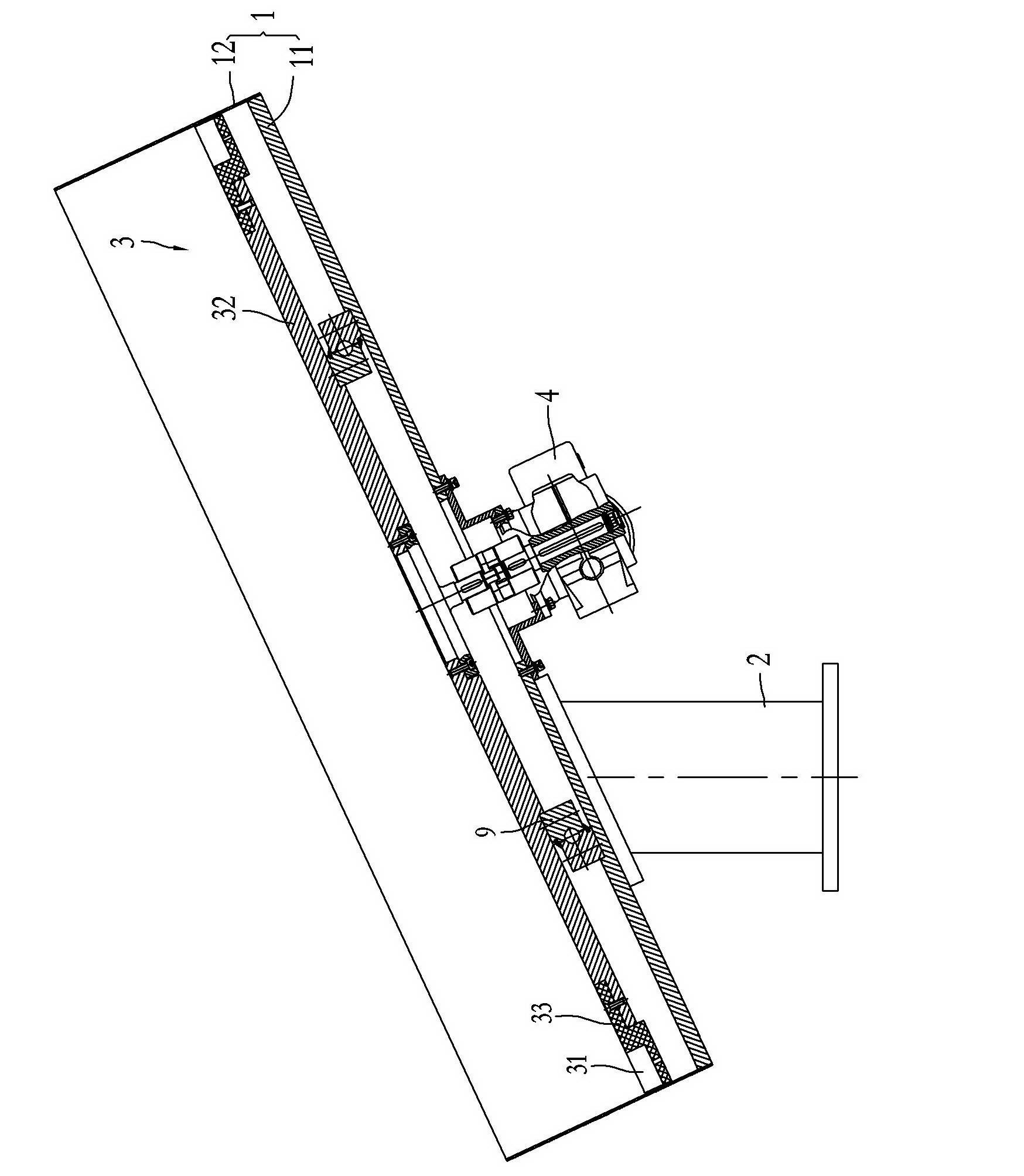

Measuring device and method of dynamic real-time measurement of position and posture of pipe pushing jack

InactiveCN103322989ASolve calculation methodAddress measurement requirementsAngle measurementSurveying instrumentsMeasurement deviceLaser target

The present invention provides a measuring device and a method of dynamic real-time measurement of position and posture of a pipe pushing jack, wherein the method comprises the steps of setting a total station and a rear view prism inside a starting shaft to obtain laser target coordinates by the total station and obtain the pipe pushing jack coordinates by the laser target coordinates, an azimuth angle, a rolling angle, and a pitch angle; installing a forward-looking prism on the pipe joint to obtain a tunnel path line; moving the total station onto the pipe joint to back calculate the real-time coordinates of the total station by the path line, and measure the position and posture of the pipe pushing jack real timely; moving the rear view prism onto the pipe joint to back calculate the real-time coordinates of the rear view prism by the path line, and measure the position and posture of the pipe pushing jack real timely. The device comprises a laser target located on the pipe pushing jack; a forward-looking prism installed on the pipe joint inside the tunnel; a forward-looking prism, a total station, and a rear view prism placed in order behind the laser target; and a controller connected with the laser target. The present invention is able to solve problems of uneasy measurement of the position coordinates caused by dynamic changes with the pipe joint moving to the pipe pushing jack.

Owner:上海米度测量技术有限公司

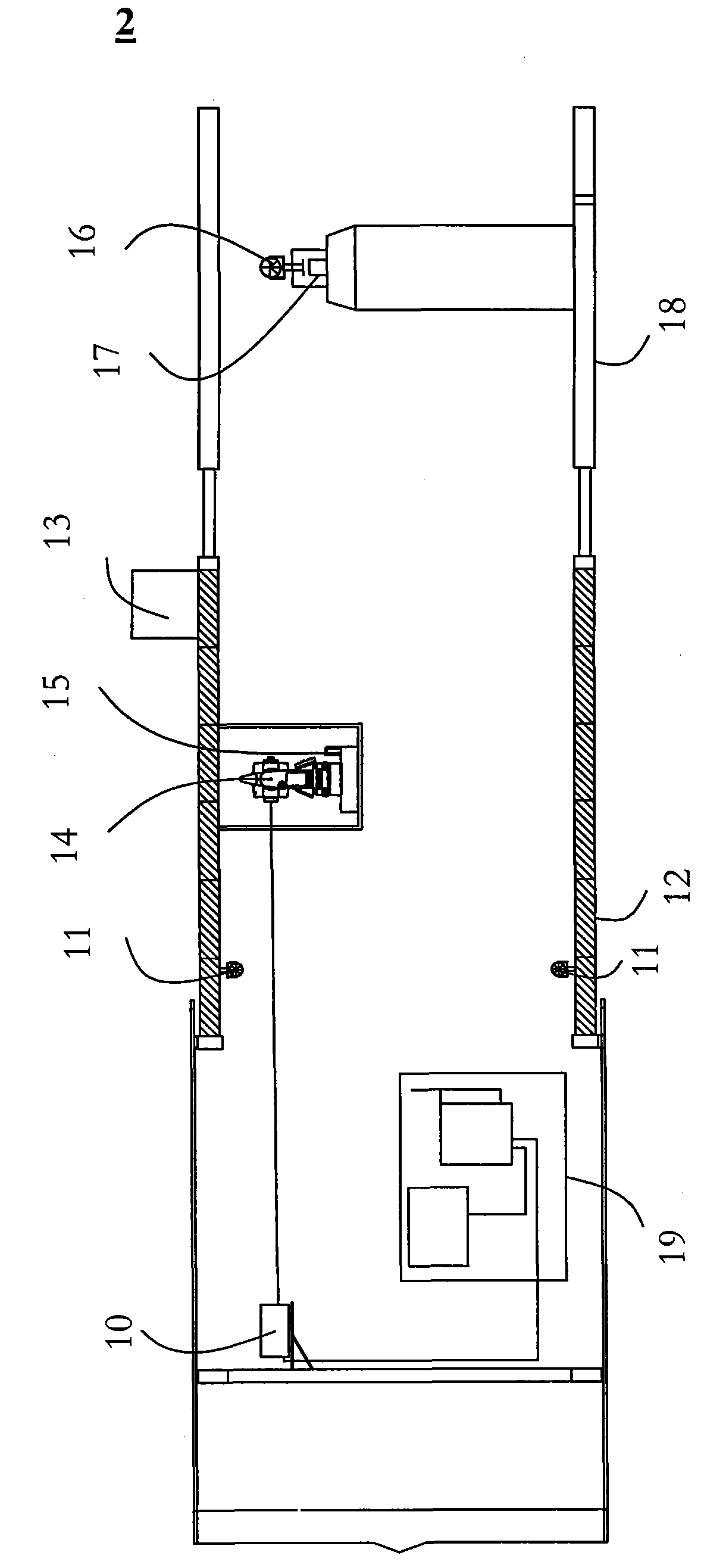

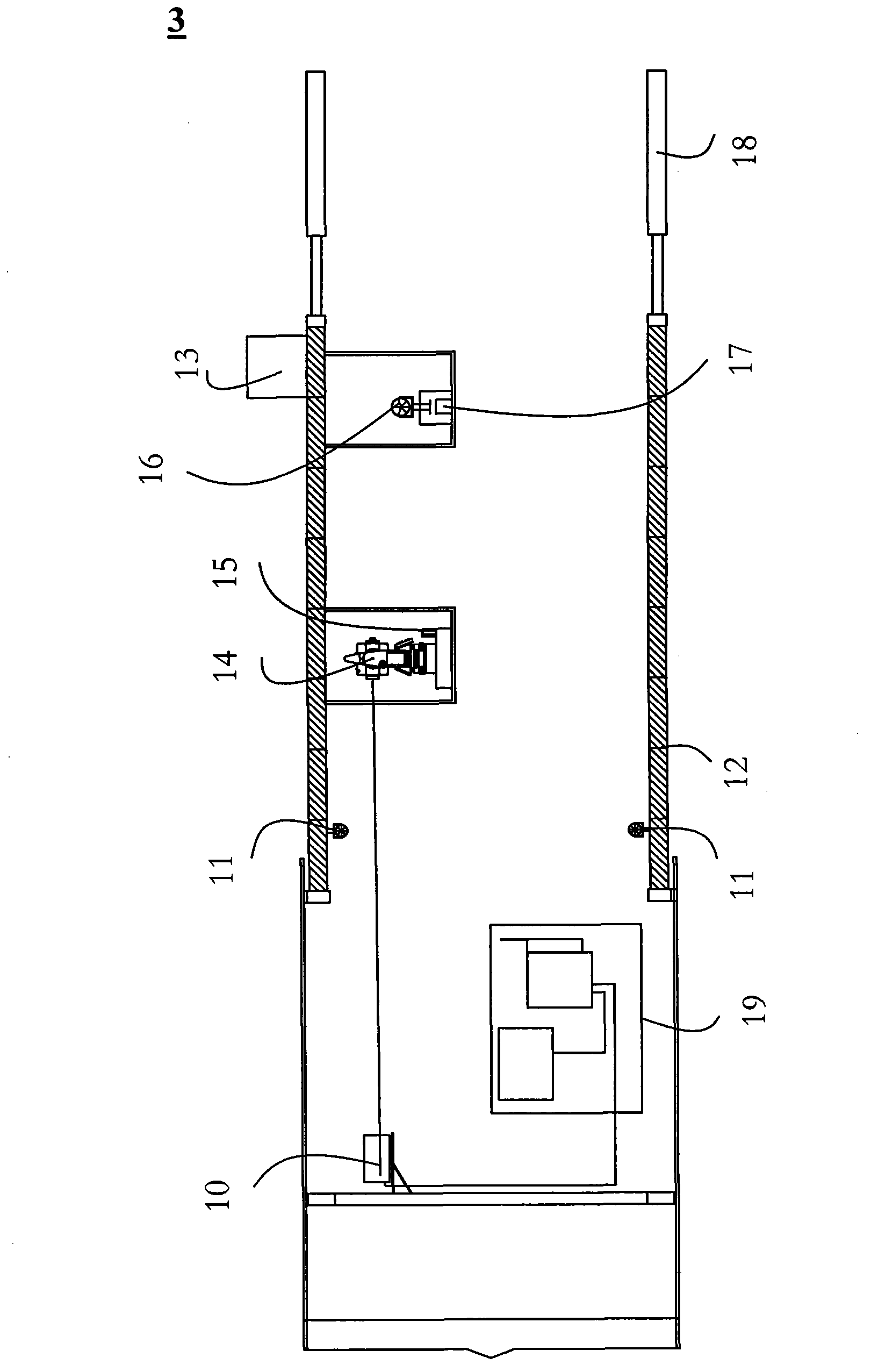

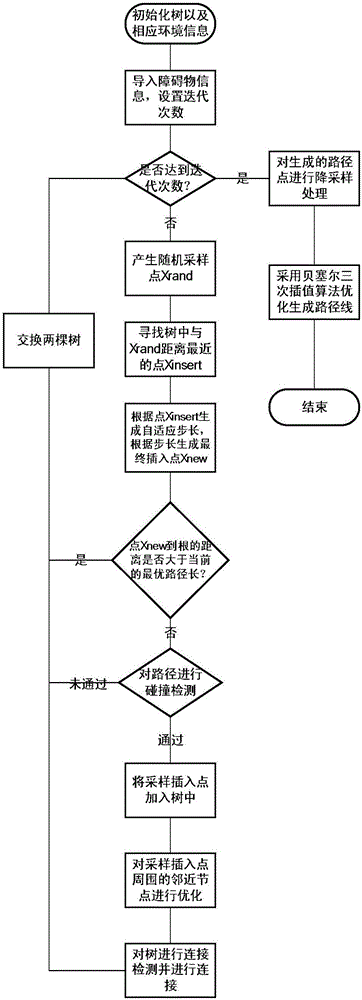

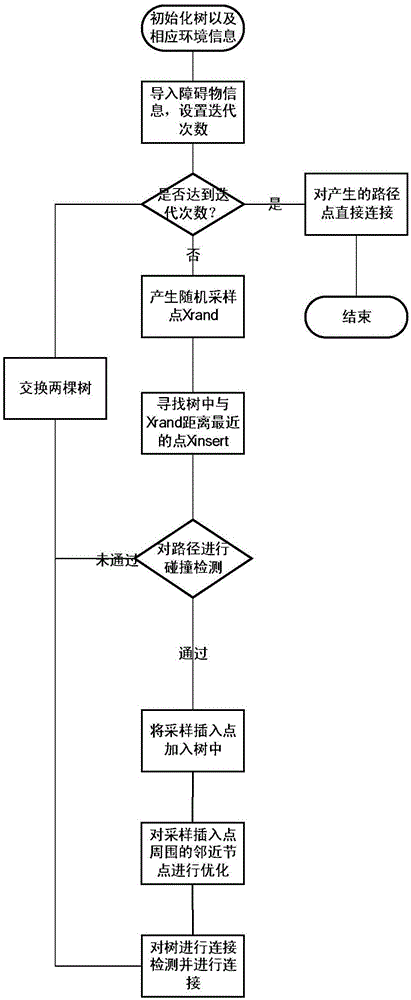

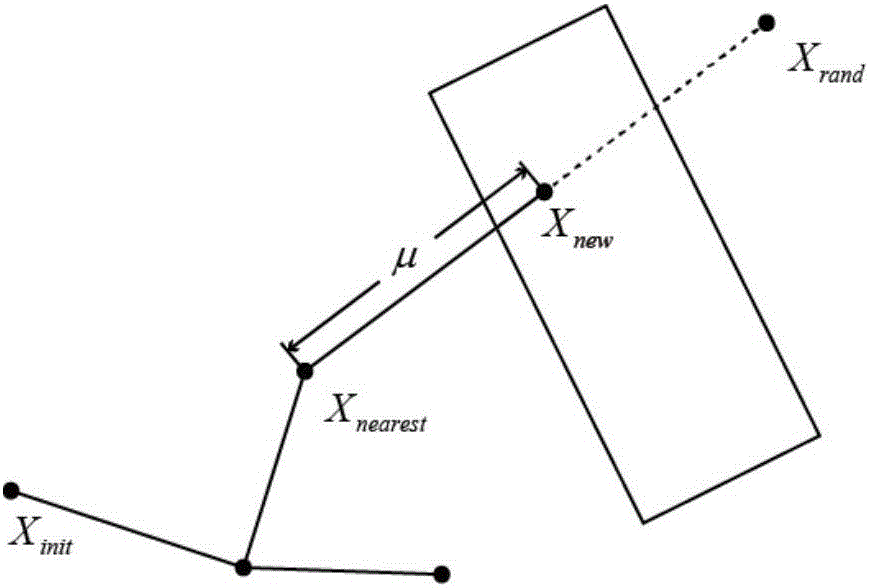

MB-RRT-based unmanned aerial vehicle two-dimensional track planning method

ActiveCN106444740AReduce memory usageAddress limitationsPosition/course control in two dimensionsPath lengthCollision detection

The invention discloses an MB-RRT-based unmanned aerial vehicle two-dimensional track planning method, comprising the steps of initializing a tree and environmental information; importing obstacle information, and setting a number of iterations; judging whether the number of iterations is arrived, if so, performing down-sampling on the generated path point and optimizing the generated path line by adopting an interpolation algorithm; otherwise, generating a random sampling point, looking for a point nearest to the random sampling point in the tree, generating an adaptive step length according to the point, generating a final interpolation point according to the step length, judging whether the distance between the interpolation point and the root is greater than the current optimal path length, if not, performing collision detection on the path, adding the interpolation point to the tree and optimizing adjacent nodes around the interpolation point; if not, performing connection detection and connection on the tree. The method is high in convergence rate and small in memory occupation space, solves the problem of limitation of growth nearby an obstacle, and can be directly applied to unmanned aerial vehicle control.

Owner:ZHEJIANG UNIV OF TECH

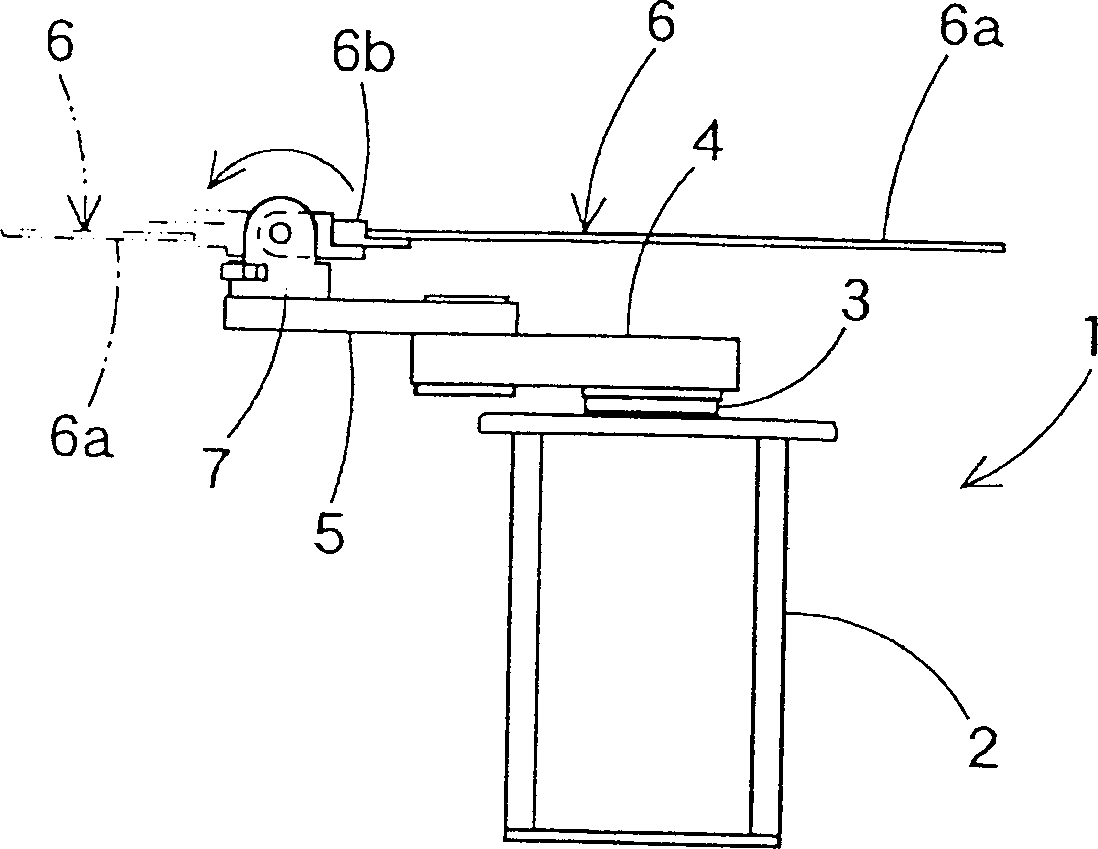

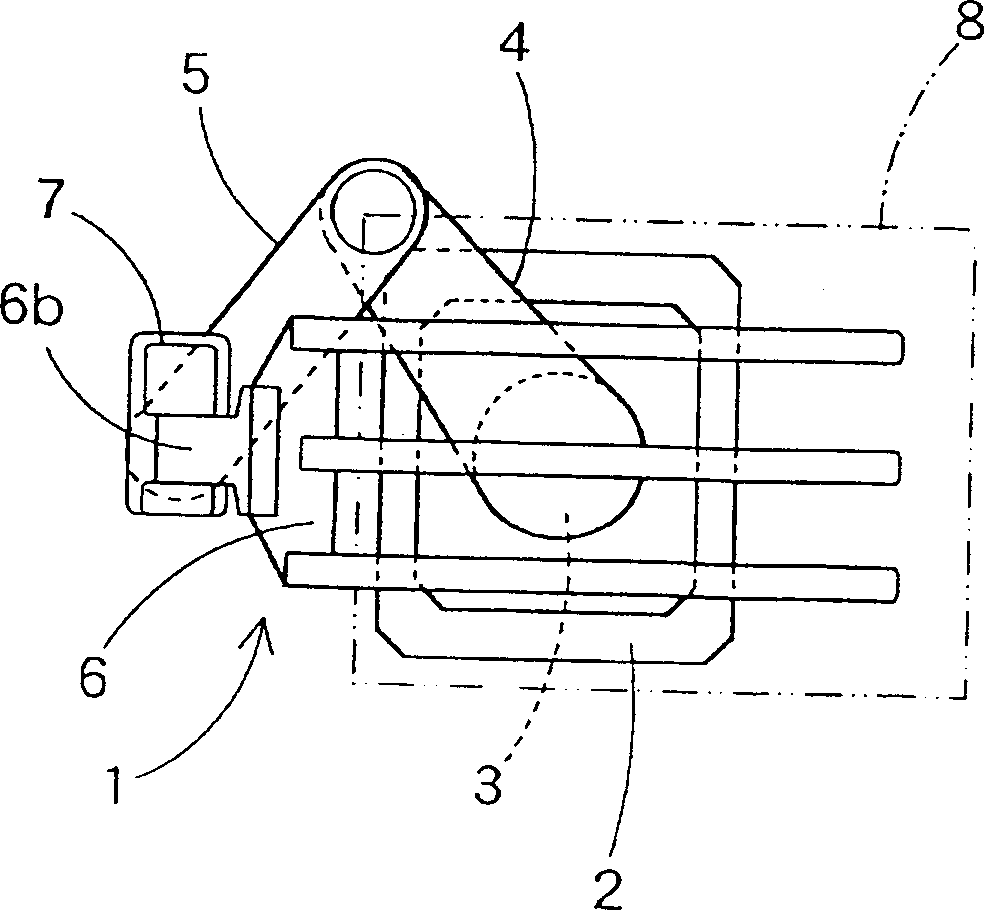

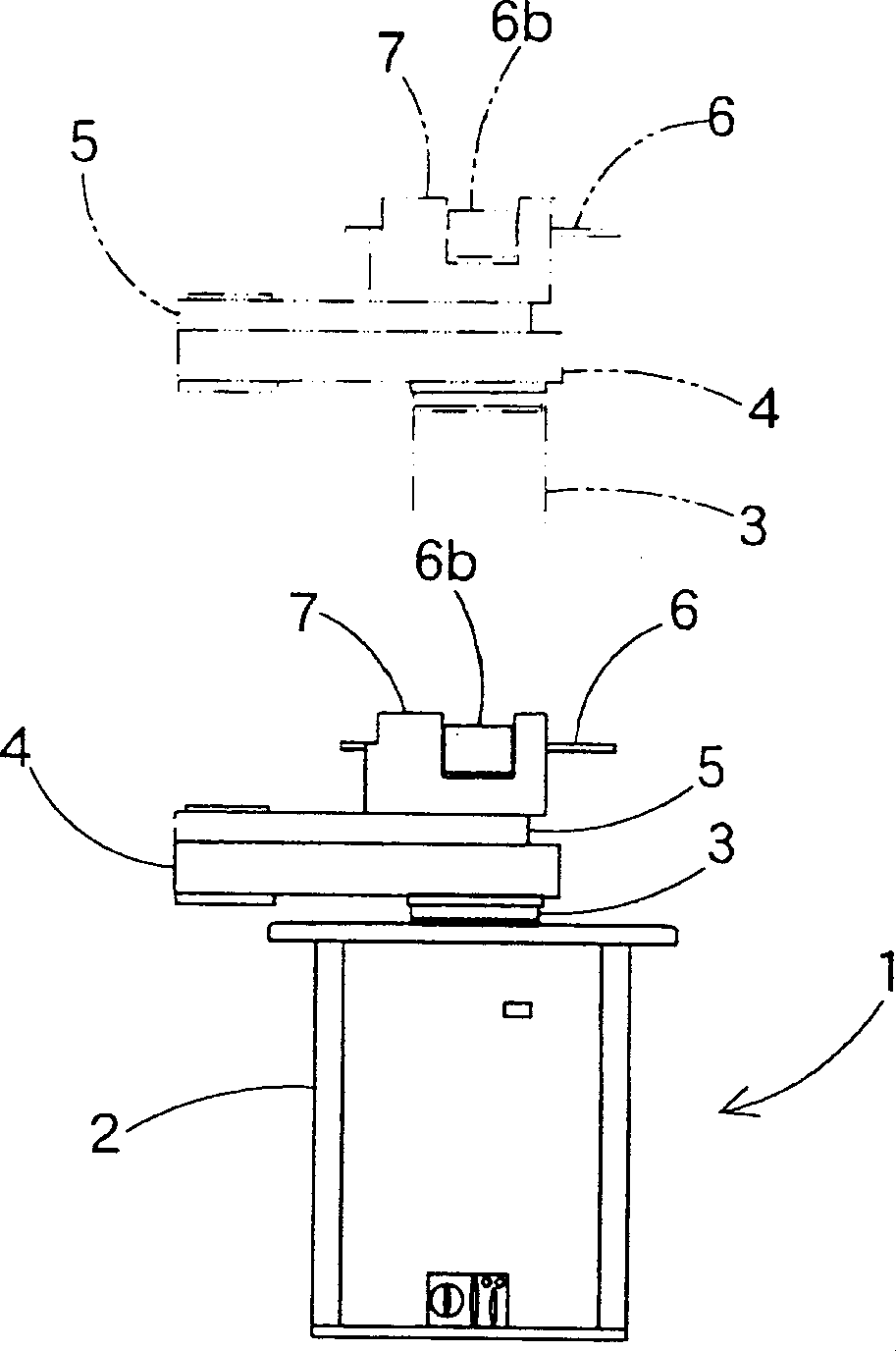

Driving gear of manipulator

PURPOSE: To minimize a footprint when a hand is reversed, to prevent a rise of circuit board path line and furthermore to enable easy application even to a double-arm robot. CONSTITUTION: A driving device of robot hand 6 is the driving device for a movable robot hand 6 that holds a thin circuit board (glass circuit board 8) and has a reversing mechanism 7 that rotates the robot hand 6 around the horizontal axis 9 that is orthogonal with the hand longitudinal direction.

Owner:AKG ACOUSTICS

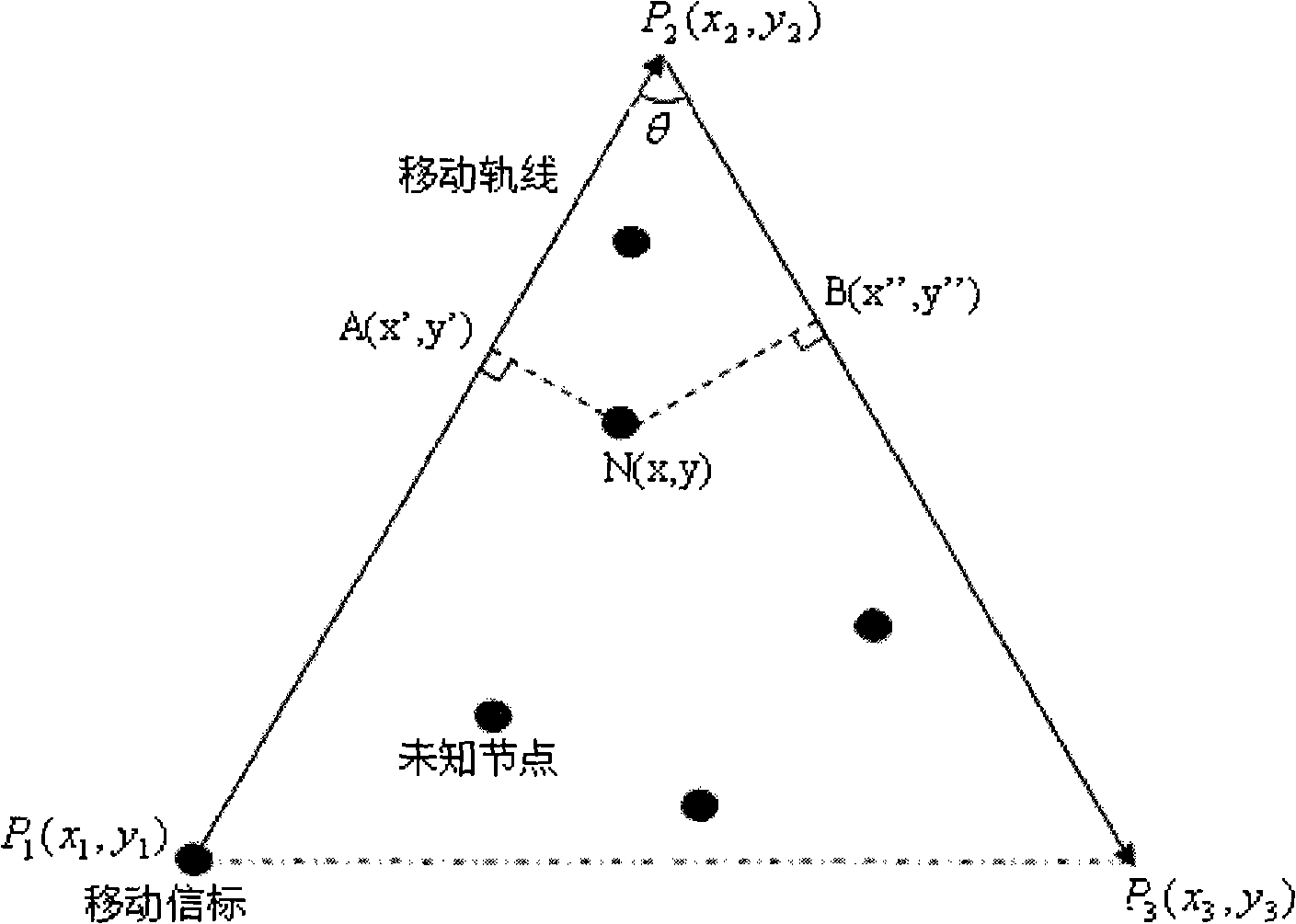

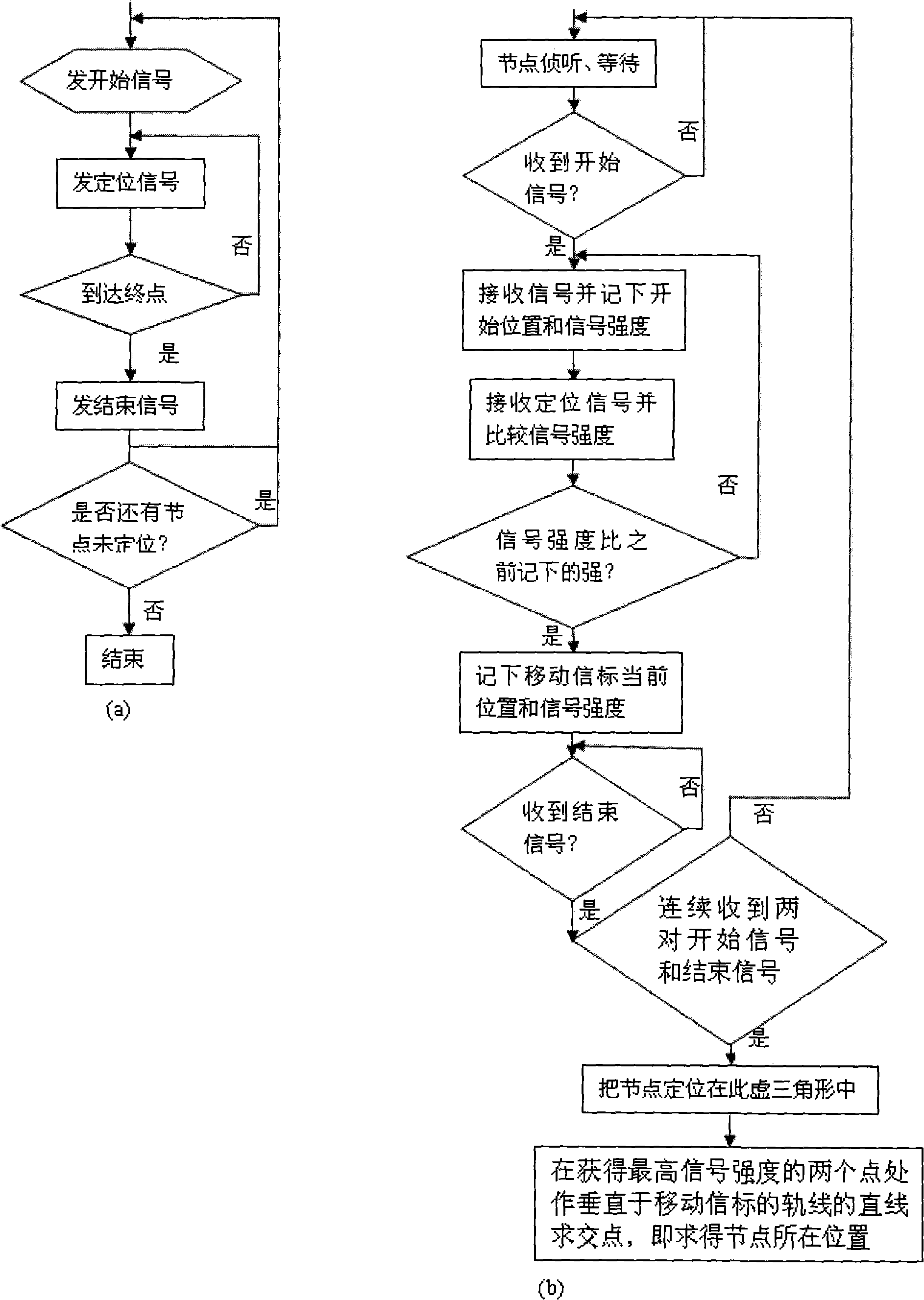

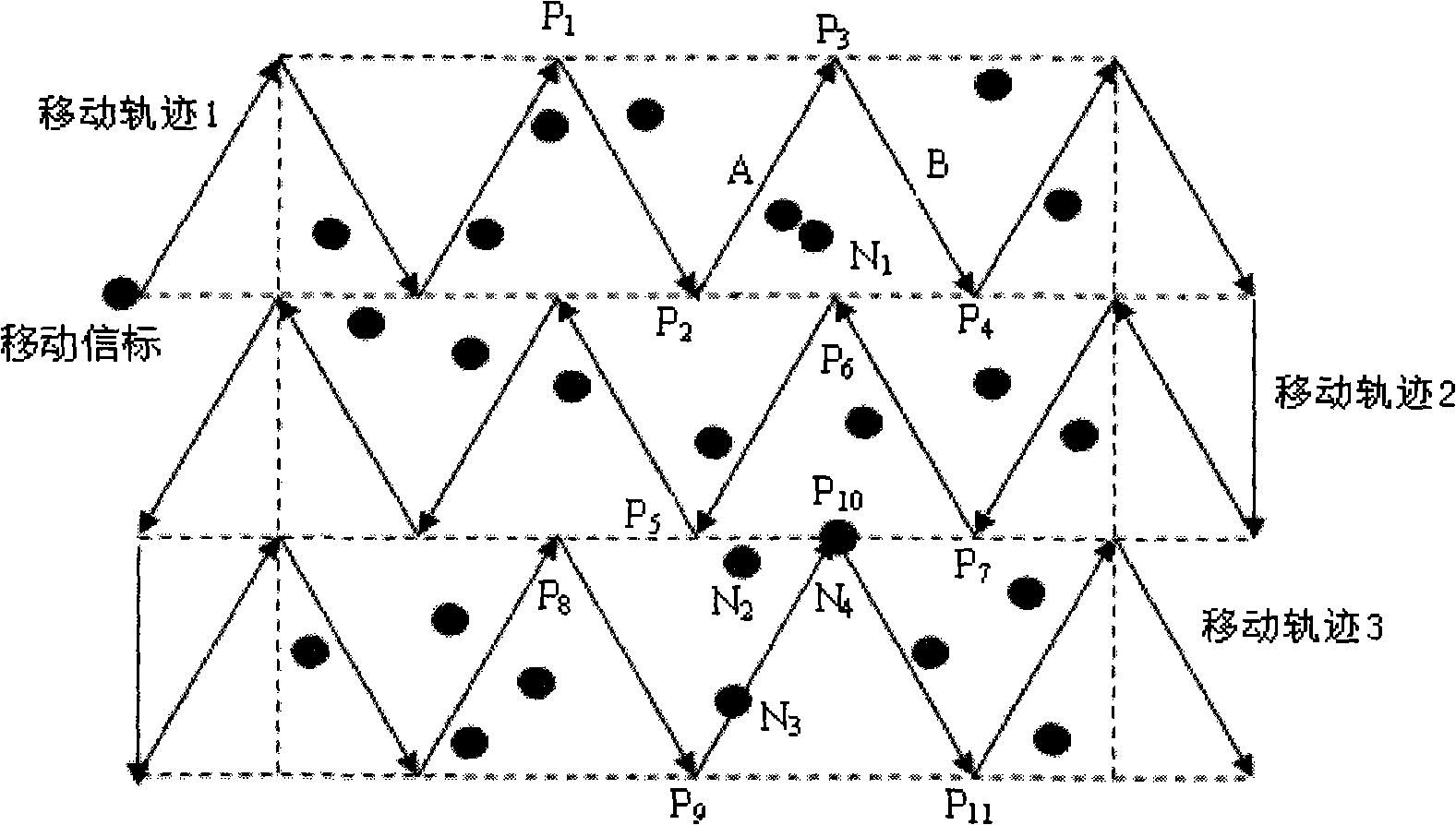

Wireless sensor network perpendicular intersection positioning algorithm

InactiveCN101285878ALower requirementImprove good performancePosition fixationData switching by path configurationExtensibilityIsoetes triquetra

A perpendicularly-crossed positioning algorithm of a wireless sensor network is used in a wireless sensor network of limited power and random distribution. The algorithm is on the premise of a mobile beacon with known self position, wherein the mobile beacon keeps broadcasting signal and current self position on a movement path line; a node records a point of highest signal intensity through comparing signal intensity, and calculates the position of the node by a geometry method according to the two points of highest signal intensity obtained from every two adjacent sides. The perpendicularly-crossed positioning algorithm requests that the path lines of the mobile beacon are two sides of an equilateral triangle and that the side length of the triangle is equal to the transmission radius R of the mobile beacon. The algorithm can accurately calculate the position of the node through using just one mobile beacon, thereby improving system extensibility and usability and reducing hardware requirement to save cost.

Owner:OCEAN UNIV OF CHINA

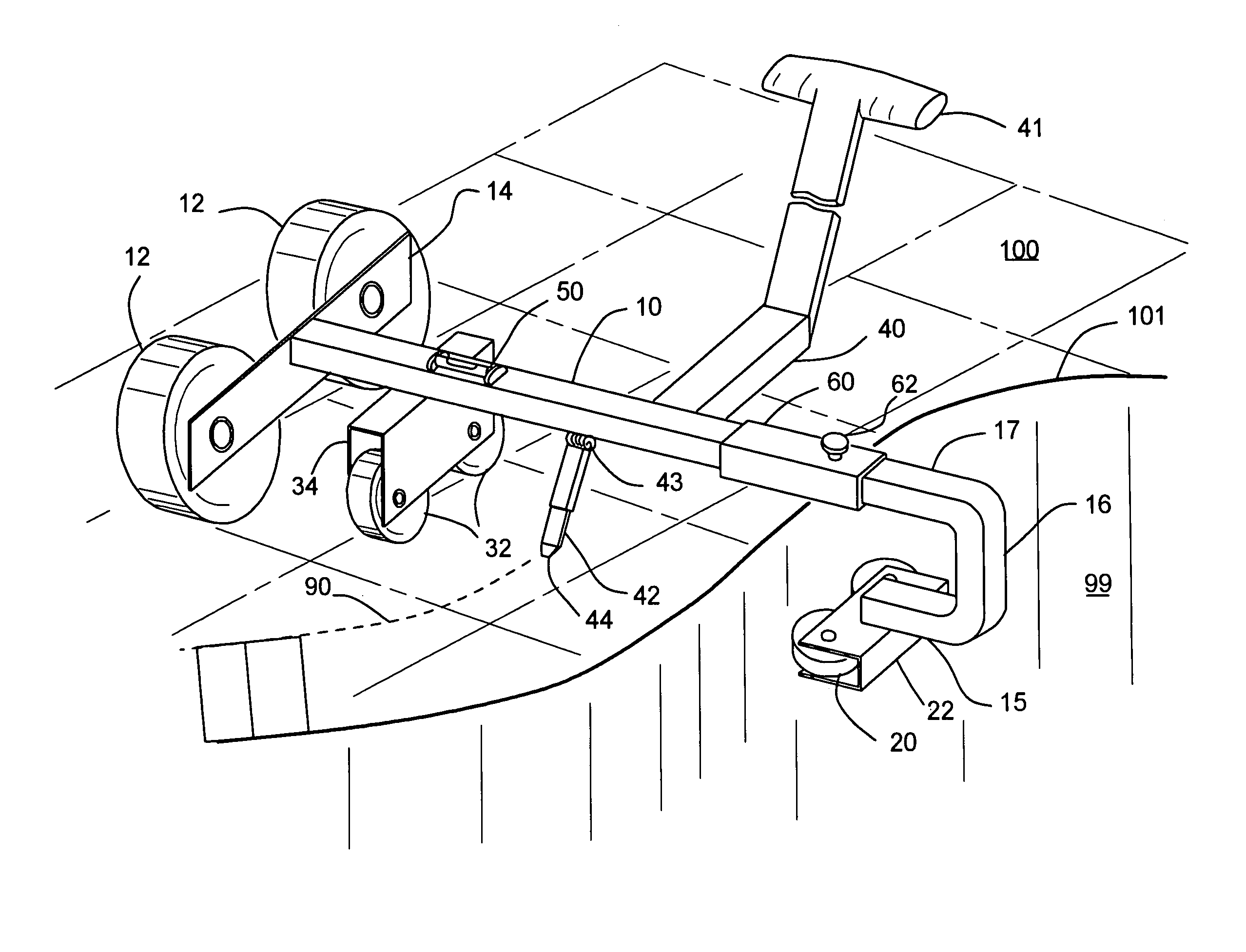

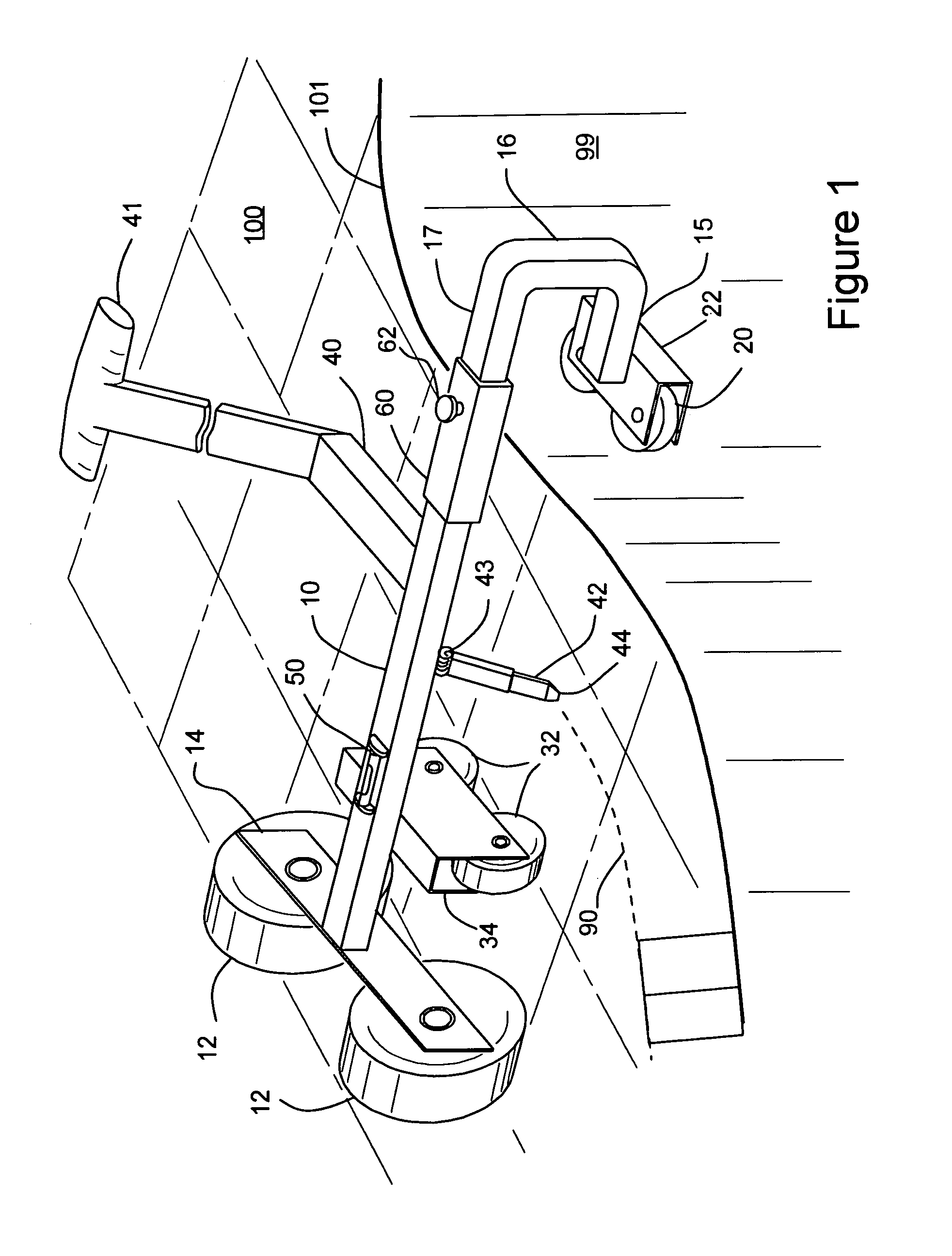

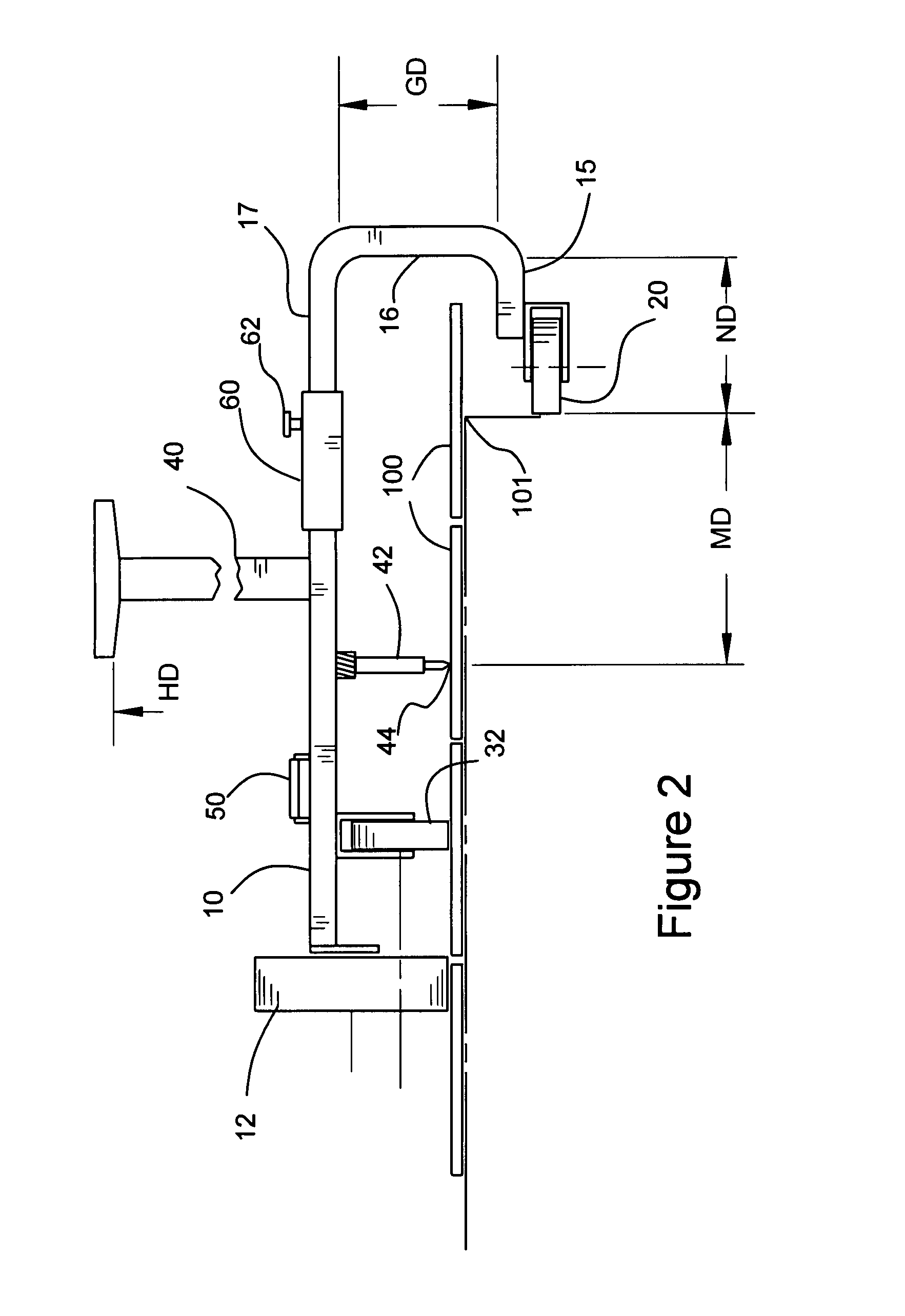

Pool deck masonry scribe

A marking device or scribe for marking masonry pieces on a horizontal deck area surrounding a pool, sauna or similar below-ground construction. The device is designed for use during construction of deck areas to enable defining a border or margin a constant distance from a curved vertical edge. This marking facilitates subsequent cutting of the marked masonry pieces for removal and construction of a more aesthetic edge border. Device guide wheels follow curved vertical walls of the pool and guide a frame and attached marker that is supported on wheels on the deck. The marking device is biased against the masonry pieces to create a path line mark as the frame and guide wheels are manually move along the edge.

Owner:LANTINEN THOMAS

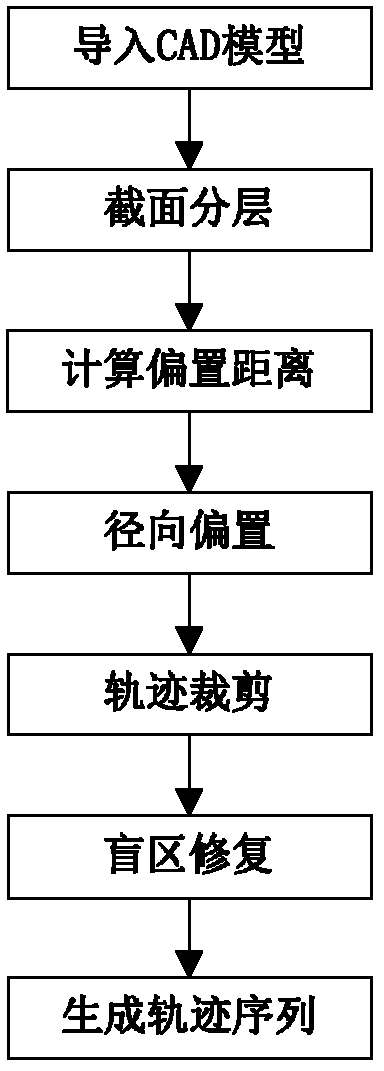

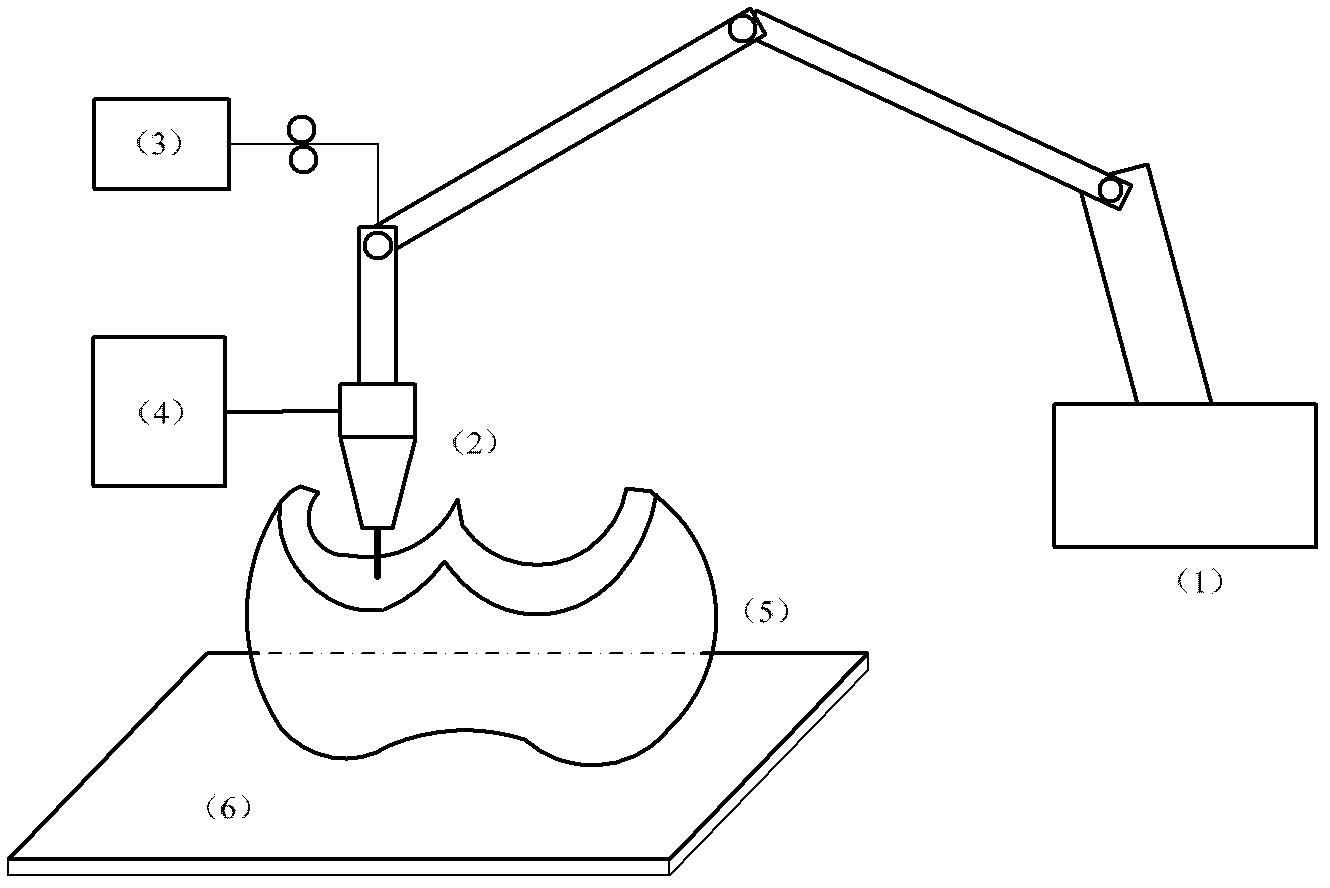

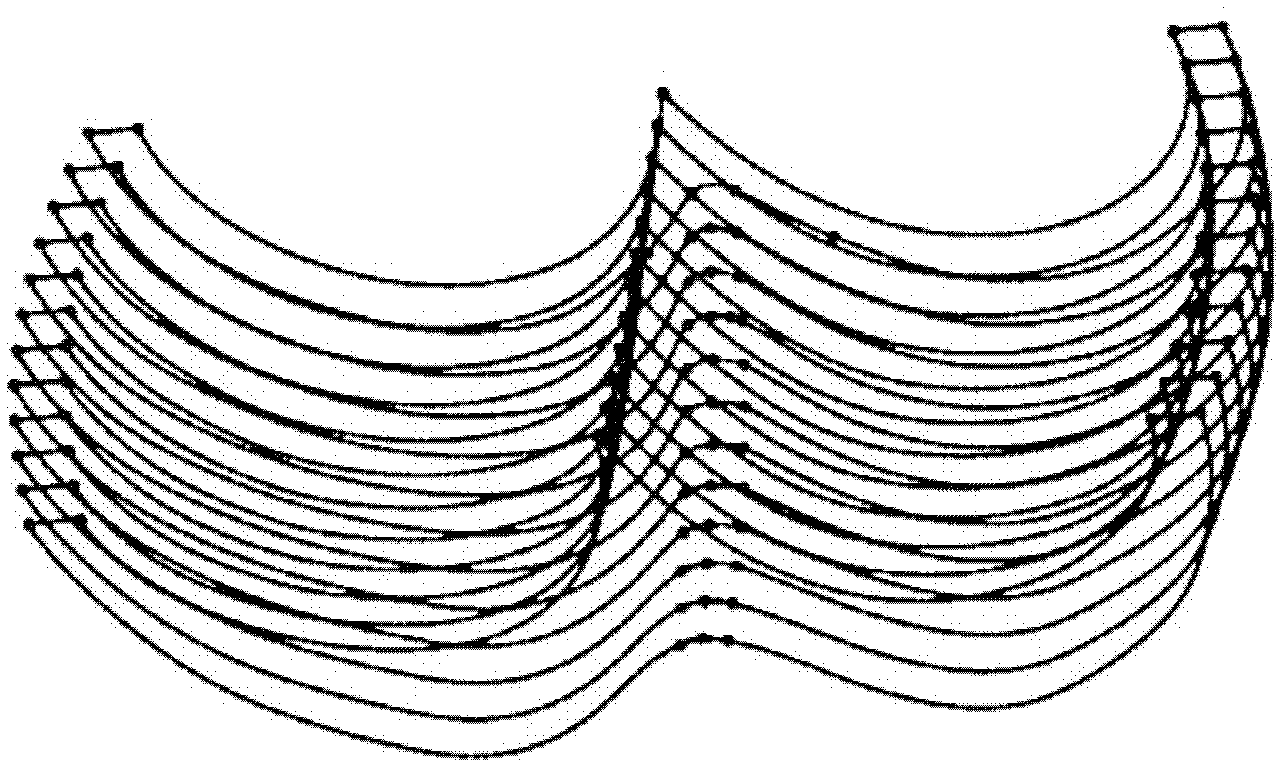

Path planning method for complicated-shape workpiece of robot bead weld based on radial bias

InactiveCN102218578AImprove efficiencyPromote generationArc welding apparatusService efficiencyWorkload

The invention relates to a path planning method for a complicated-shape workpiece of robot bead weld based on radial bias. In the method, a robot welding path is automatically planned based on a workpiece computer assisted drafting (CAD) model, contour lines on one side of the cross section of the workpiece are adopted as bias lines, contour lines on another side of the cross section are subjected to radial deflection successively, welding path lines of the cross section are automatically generated to ensure the appearance precision of the workpiece and distance between the path lines and solve the problems of self-cross of rings, straight line segment disappearance and the like. For the bias lines with excessively-changed curvature, subsection bias is performed according to curvature characteristics to adapt to complicated profile, a repair arithmetic is designed according to the requirement of a welding process and appearance characteristics of a workpiece model, the deflected path lines are adjusted to repair a dead area, and the workloads required by repairing welding and polishing are reduced. Due to the adoption of different appearances such as the complicated-shape workpiece of an arc welding robot in the method, the programming time of robot welding operation can be greatly shortened, and the service efficiency of the robot is obviously improved.

Owner:SOUTHEAST UNIV

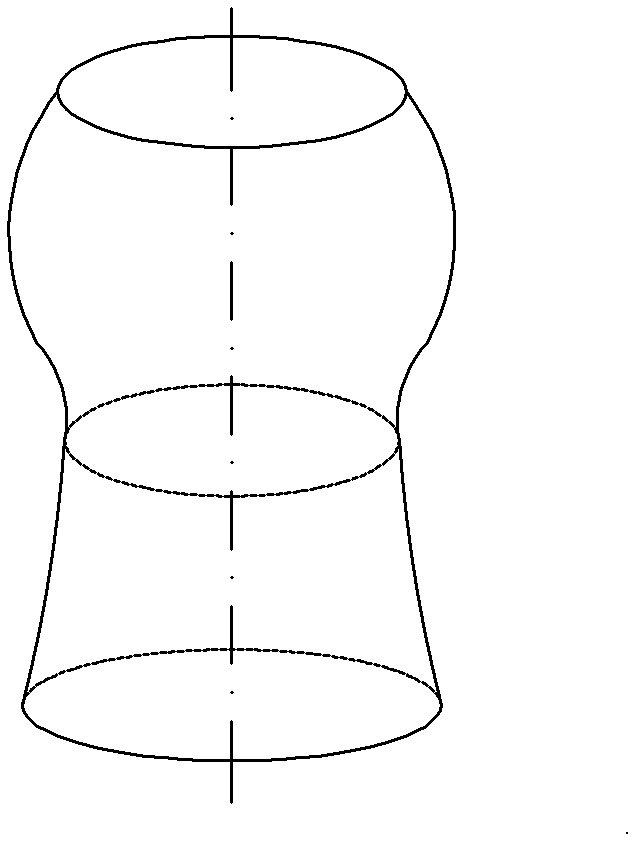

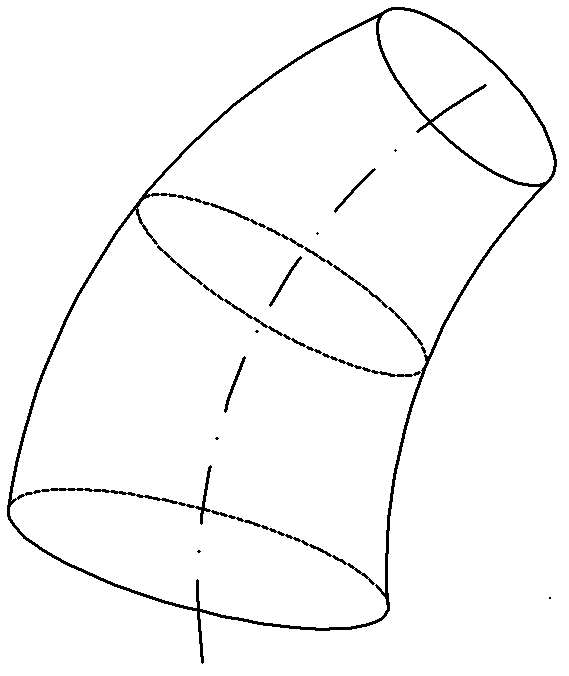

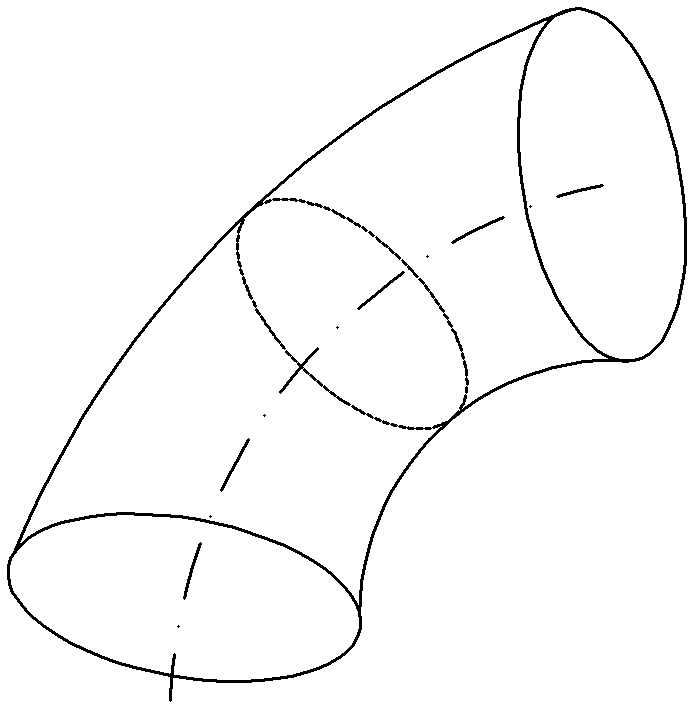

Automatic fiber laying variable-angle path planning method for non-developable curved surface part

The invention discloses an automatic fiber laying variable-angle path planning method for a non-developable curved surface part, which relates to a fiber laying path plan making method for a non-developable curved surface part and is used for solving the problem that in the complexity of a fiber laying process, the appearance accuracy and various properties of a composite material are influenced by inevitable shearing and re-conveying phenomena occurring in the automatic fiber laying process of the non-developable curved surface part. In a scheme I, the method comprises the following steps of: acquiring data information from a non-developable revolving barrel part; calculating the laying reference angle of a presoaked tow on each intersection line; determining points on an initial path; determining points on other paths; and making a path line. A scheme II is different from the scheme I in that data information is acquired from a non-developable curved surface variable-section conical shell part; and a scheme III is different from the scheme I and the scheme II in that data information is acquired from a non-developable curved surface variable-section joint part. The method is used for planning an automatic fiber laying variable-angle path on the outer surface of the non-developable curved surface part.

Owner:HARBIN INST OF TECH

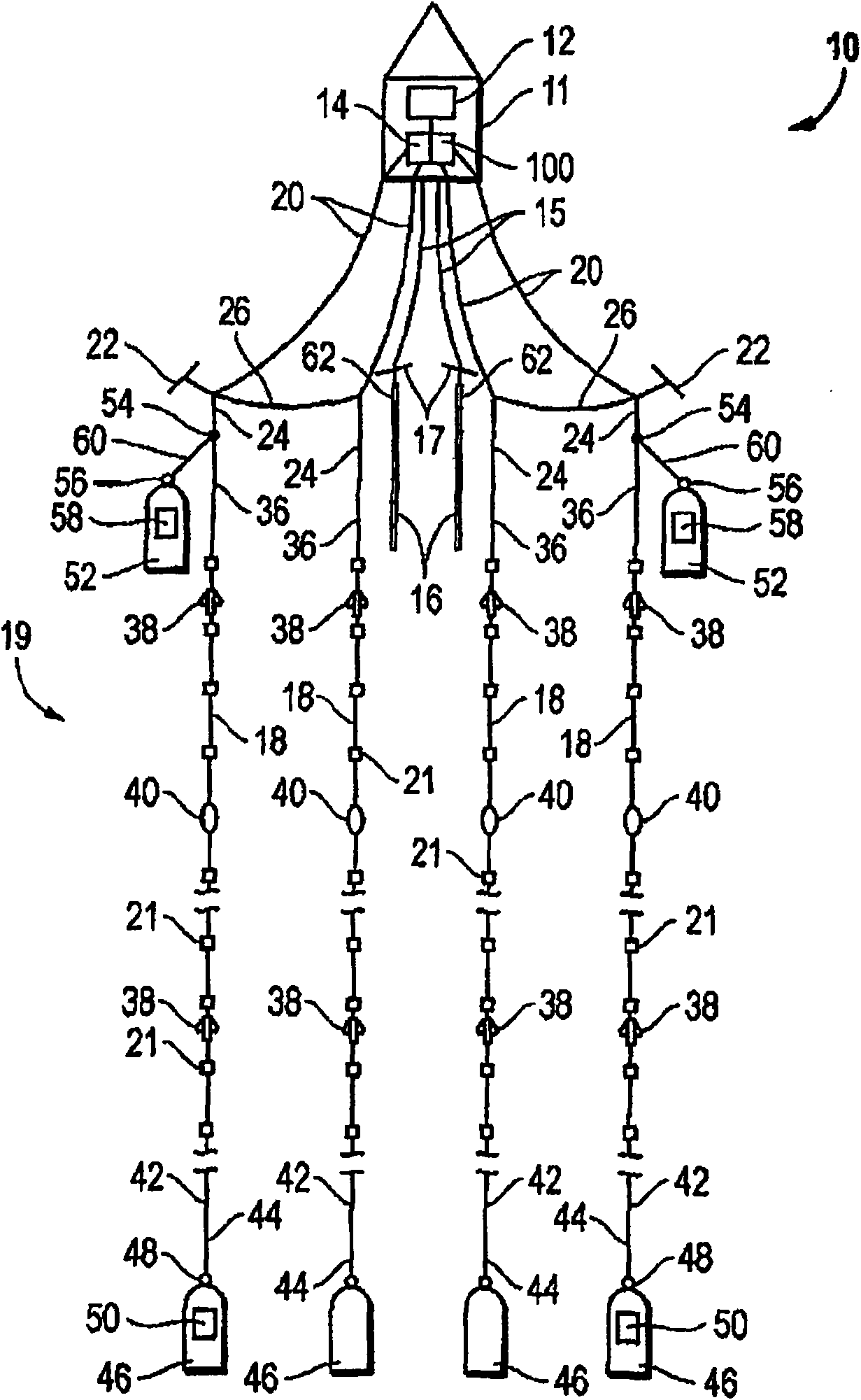

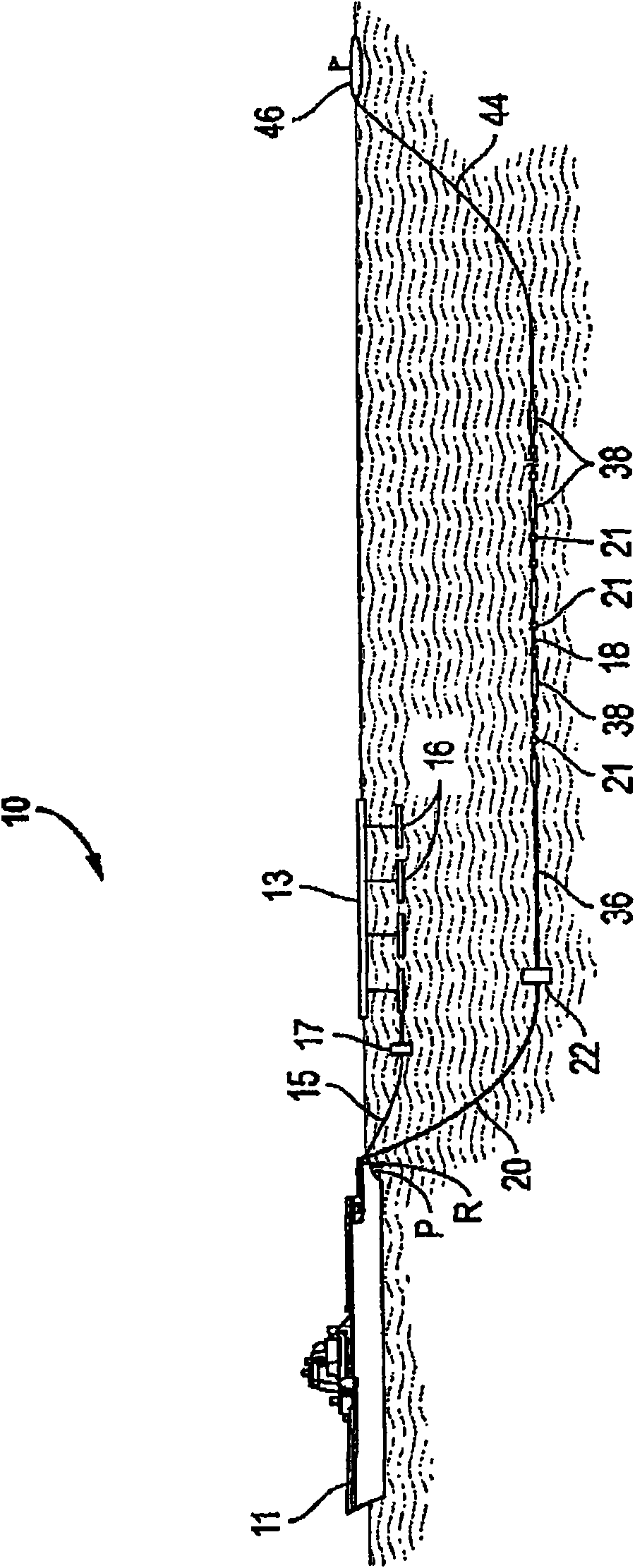

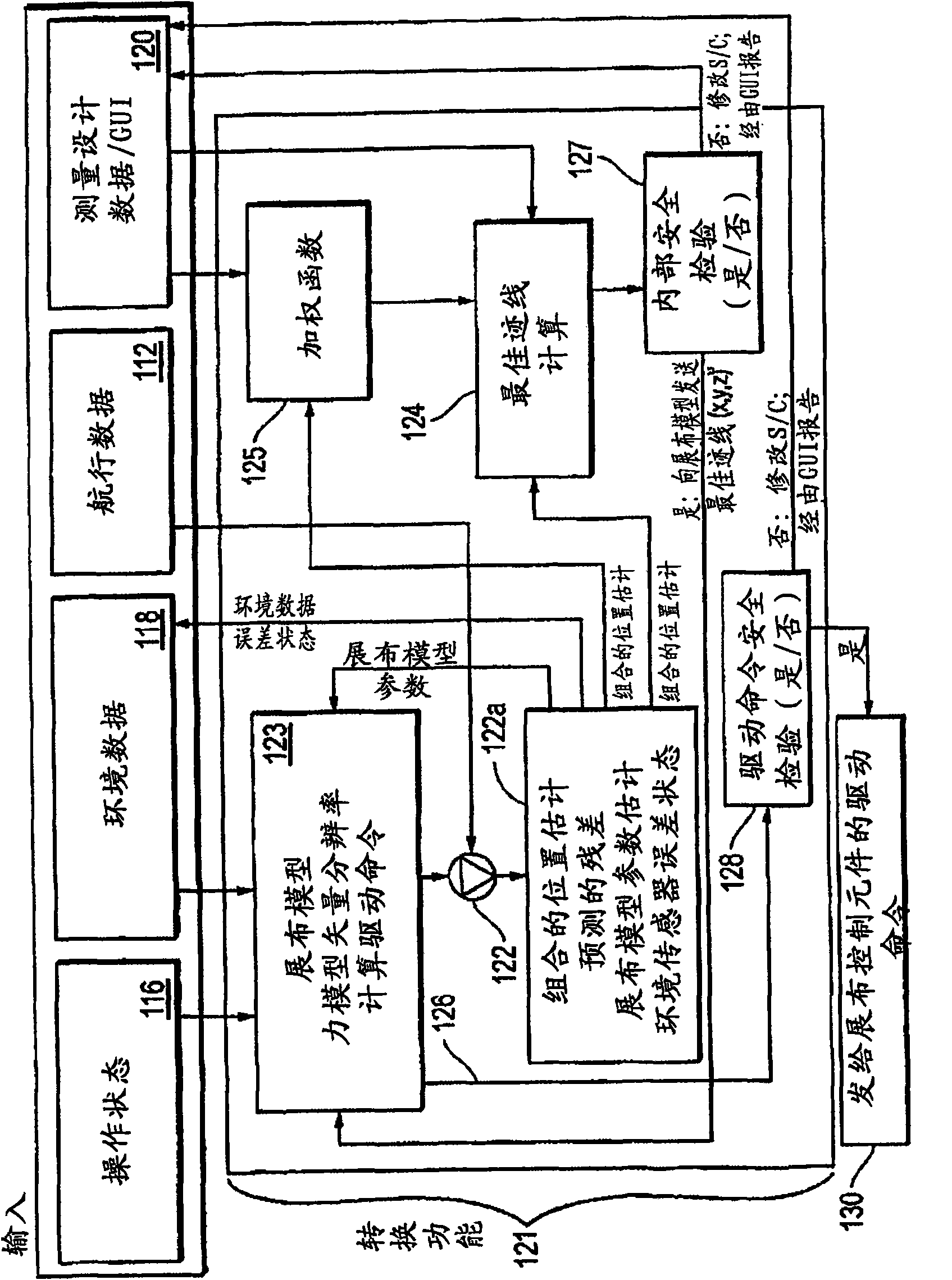

Offshore earthquake measurement method and system

The invention relates to a method for controlling an earthquake measurement spread during earthquake measurement. The spread is provided with a ship, a plurality of spread control elements, a plurality of navigation nodes, a plurality of earthquake focuses and receivers. The method comprises the step of input data collection, wherein input data comprise navigation data of the navigation nodes, operation state data generated along with a sensor of the spread control elements, measurement environment data and measurement design data. The positions of the earthquake focuses and the receivers are evaluated by using the navigation data, the operation state data and the measurement environment data. The best path lines of the earthquake focuses and the receivers are determined by utilizing the position evaluation and at least one part of input data including the measurement data. A driving instruction for at least two spread control elements is calculated by using the determined best path line. The method is realized by the system provided by the invention.

Owner:WESTERNGECO SEISMIC HLDG LTD

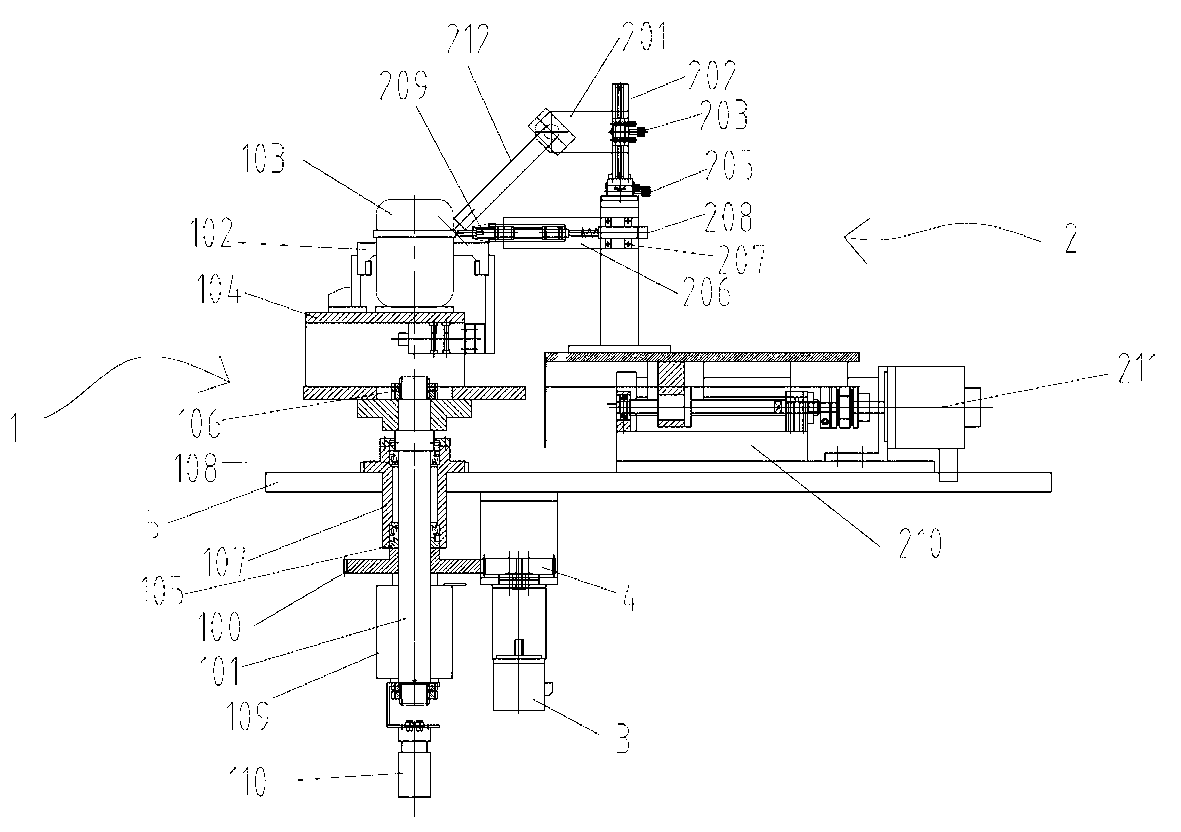

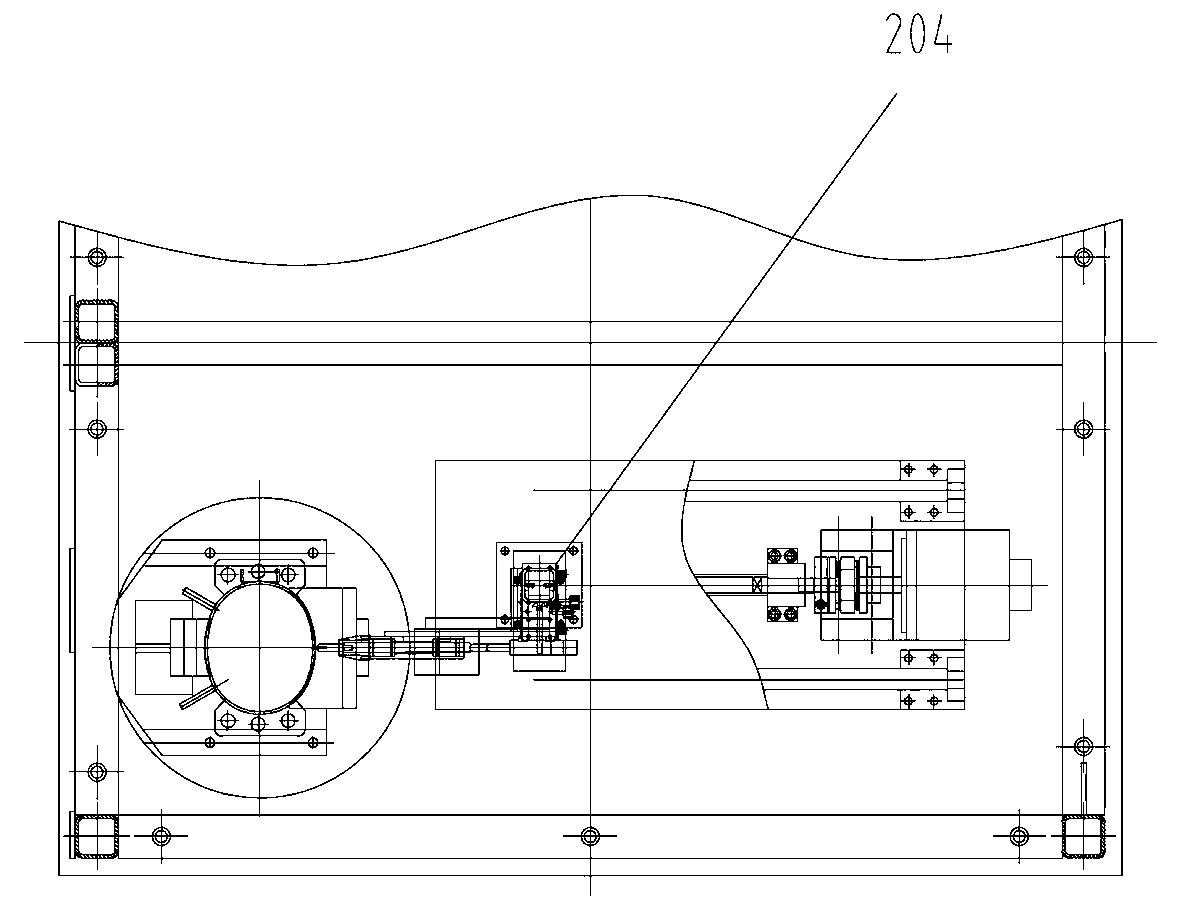

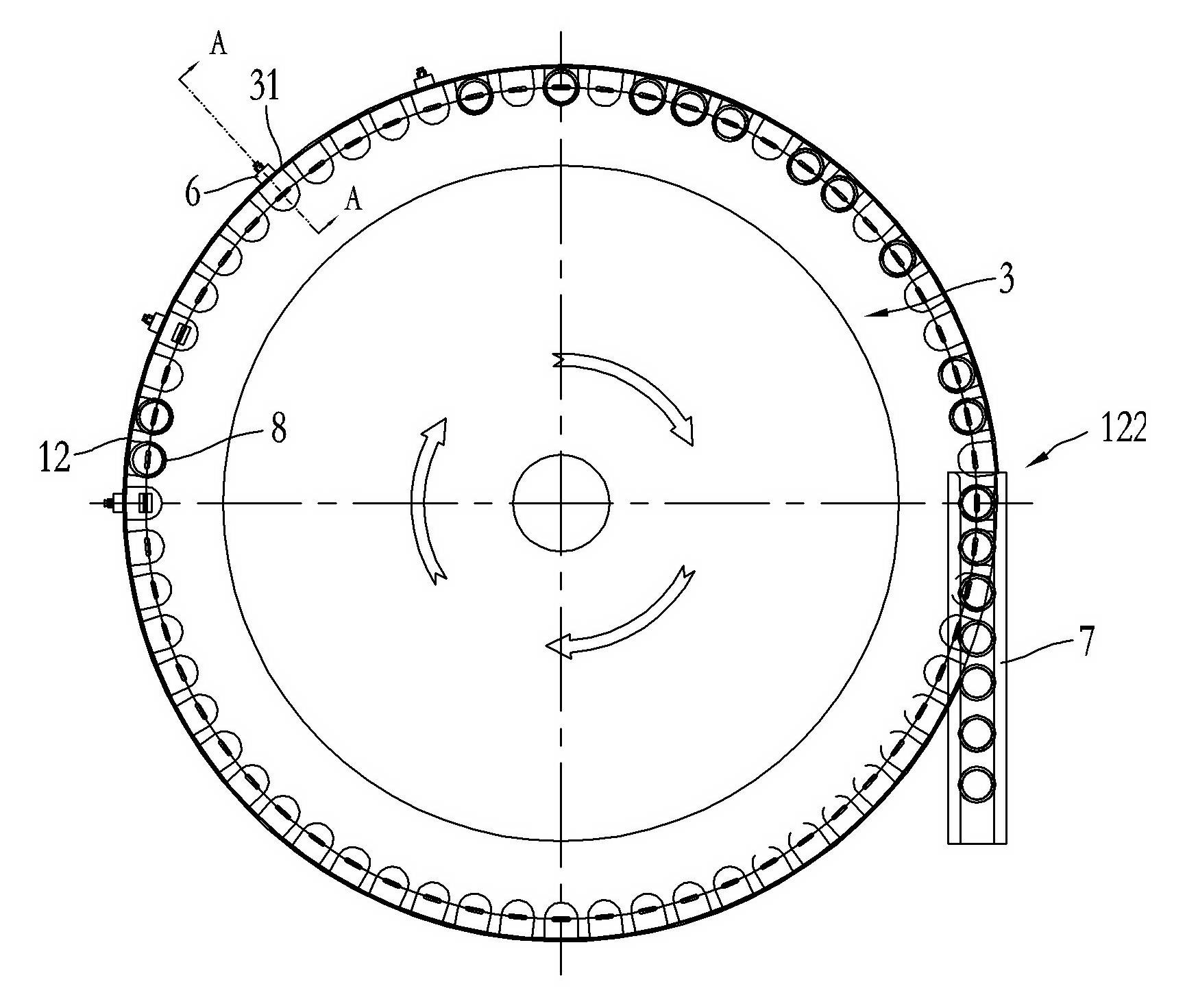

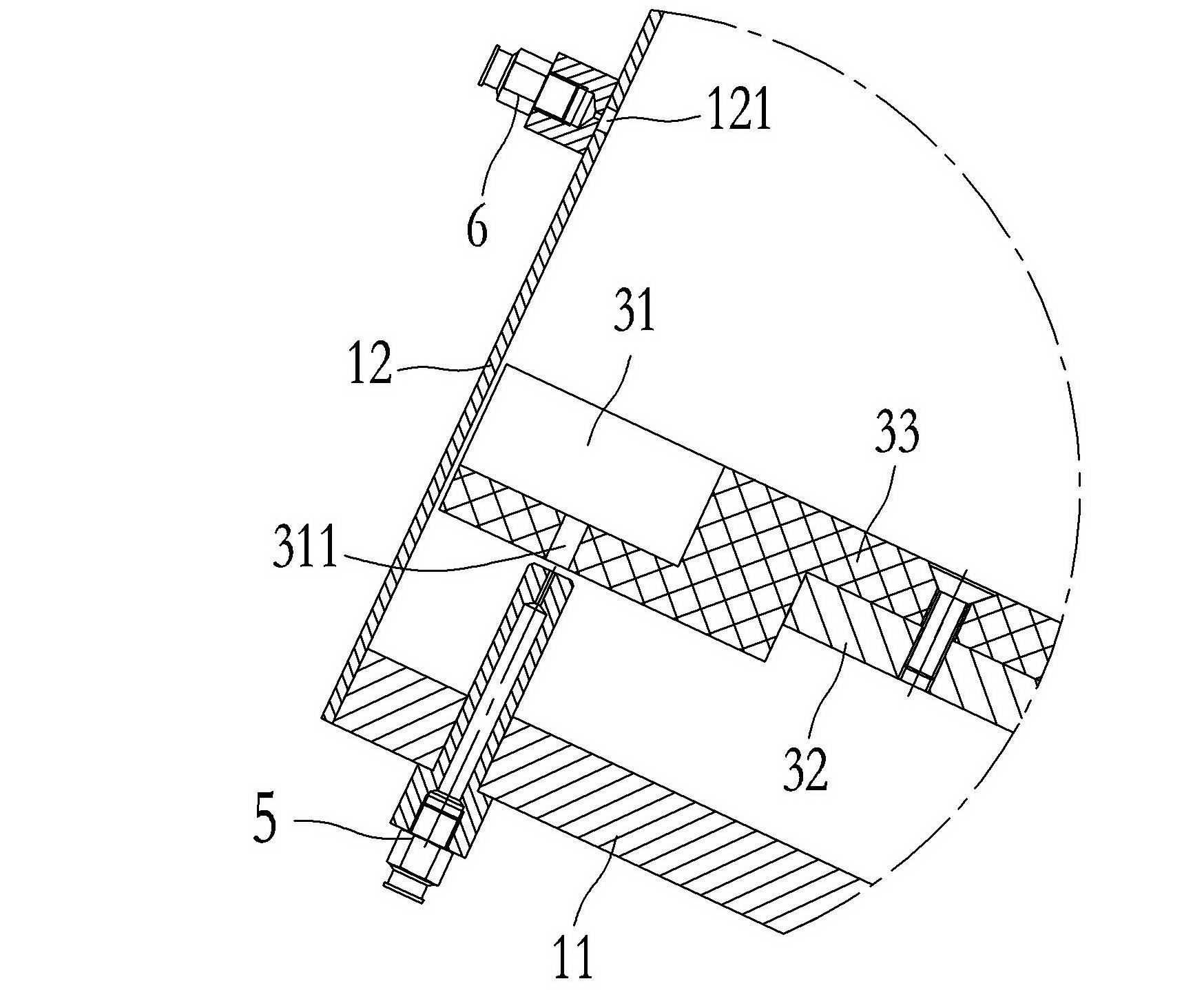

Cover sealing welding machine of compressor

ActiveCN103008935AWelding is suitable forQuality improvementWelding/cutting auxillary devicesAuxillary welding devicesClosed loopMechanical engineering

The invention relates to a cover sealing welding machine of a compressor. The cover sealing welding machine comprises a welding part and a rotary working table, wherein the welding part comprises a three-dimensional movable sliding table, a welding gun bracket, a translation servo motor, a welding gun head and a control unit; the welding gun bracket is arranged on the three-dimensional movable sliding table; the translation servo motor can be used for driving the welding bracket to slide; the control unit is used for controlling action of the translation servo motor; the rotary working table comprises a shell clamp, a rotary disc, a revolving main shaft and a revolving servo motor; the shell clamp is used for clamping a workpiece; the revolving servo motor is used for driving the revolving main shaft to rotate; the welding part is provided with a detection unit capable of measuring an outer edge parameter of a workpiece shell in real time; the detection unit is in signal connection with the control unit; an outer edge parameter signal of the workpiece shell detected by the detection unit can be timely transmitted to the control unit; and the signal is compared with a parameter pre-stored in the control unit by the control unit to control action of a next step of the translation servo motor. The welding quality is obviously improved by performing real-time measurement and closed-loop control over a cover sealing welding path line of each body.

Owner:JIANGSU BAIXUE ELECTRIC APPLIANCES

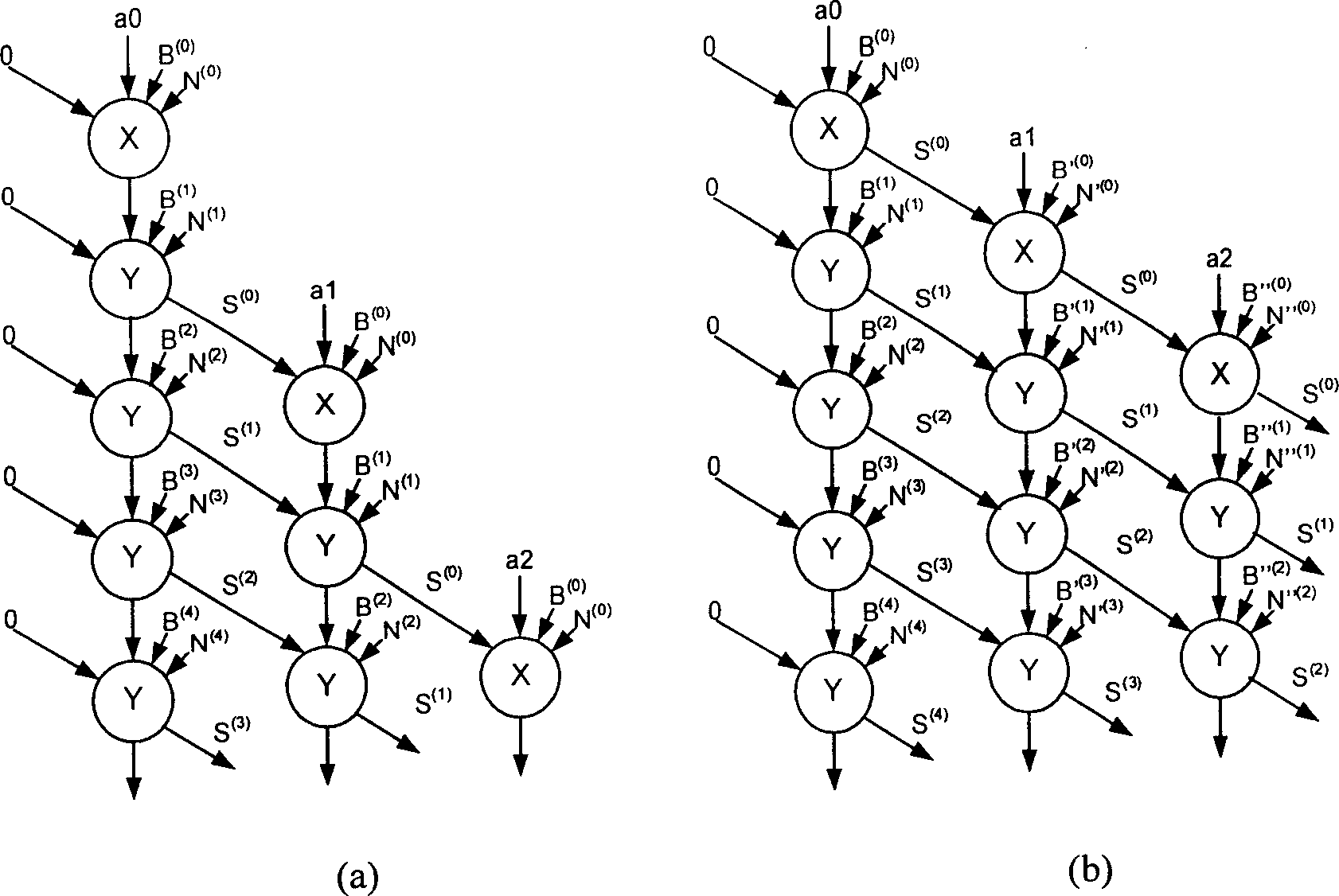

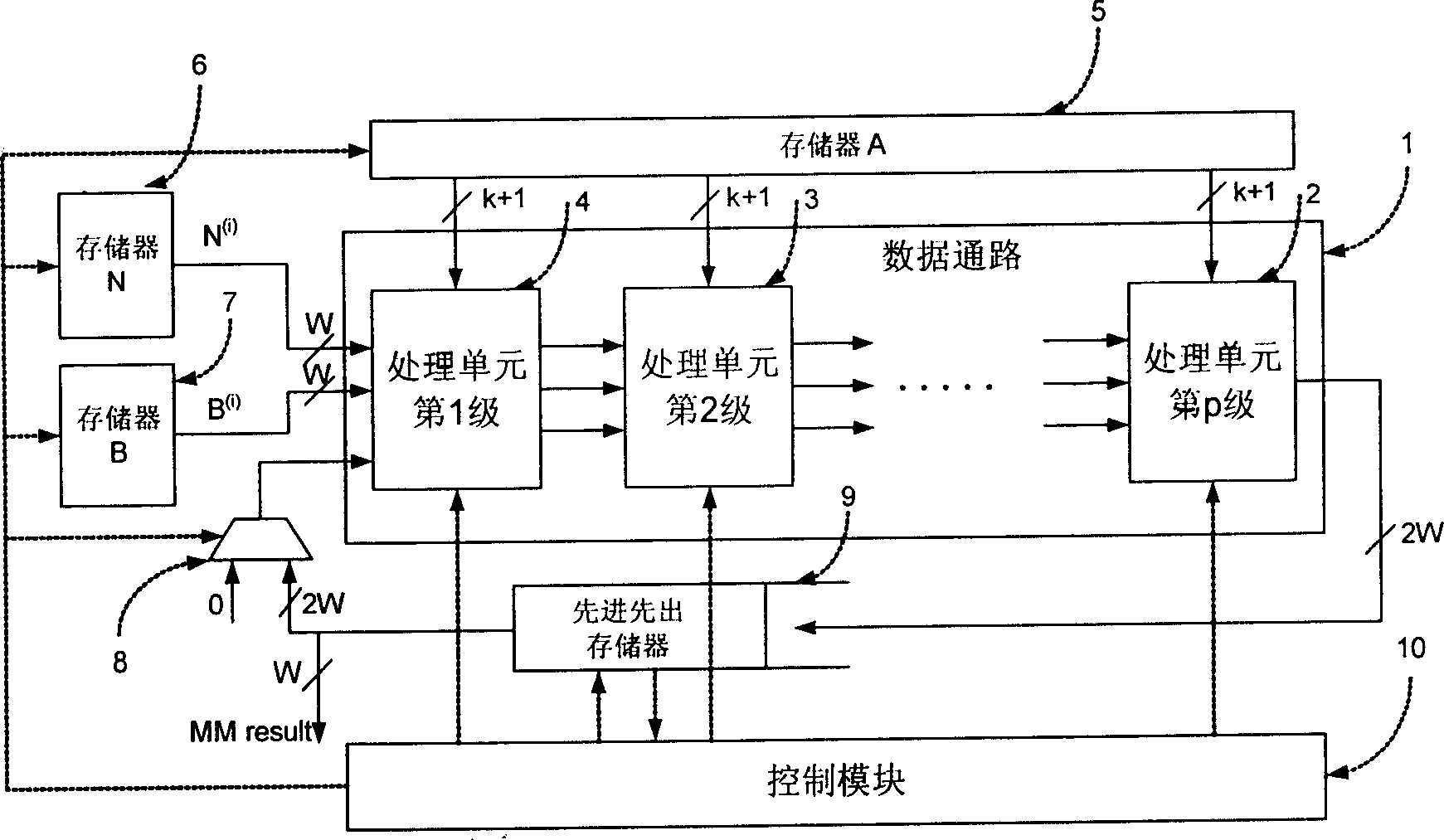

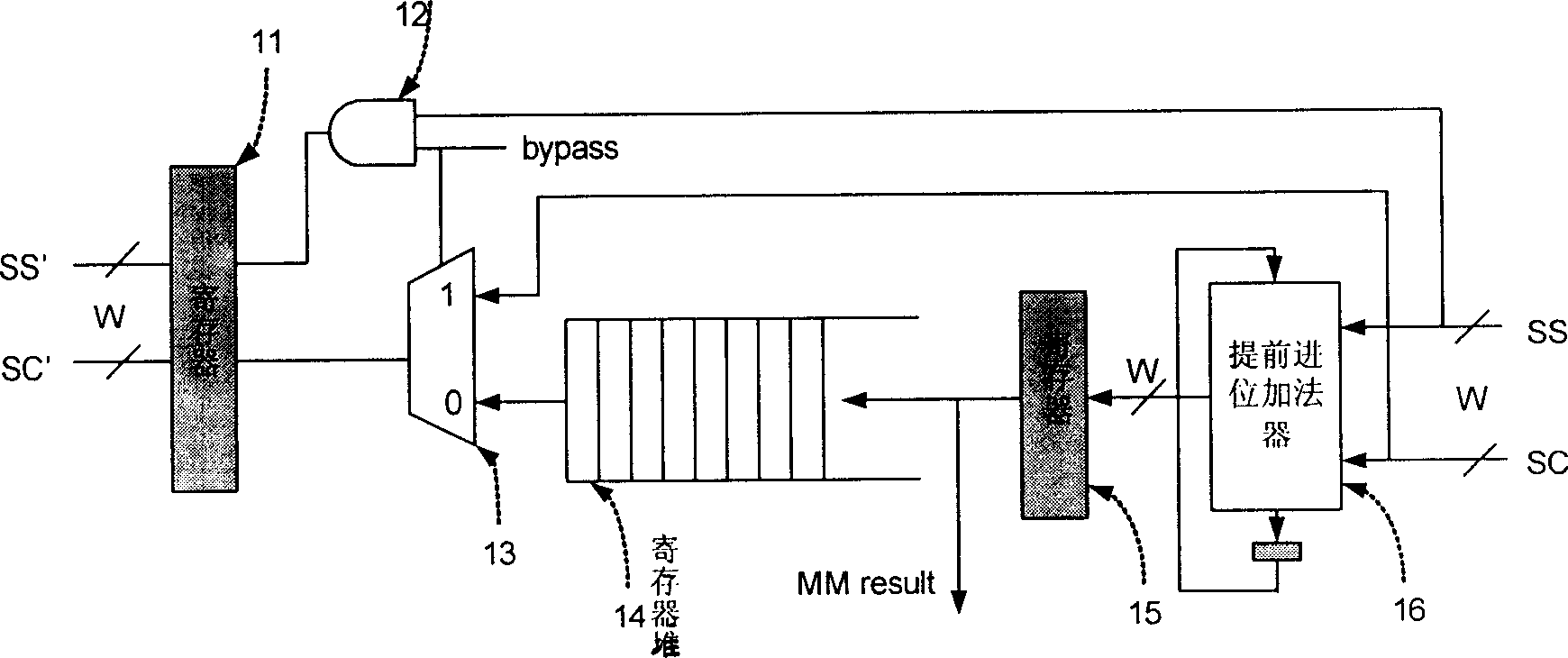

Extensible high-radix Montgomery's modular multiplication algorithm and circuit structure thereof

InactiveCN1731345AHigh speedReduce overheadComputations using residue arithmeticMontgomery reductionAnalog multiplier

The invention relates to an extended high base Montgomery analog multiplying algorithm and the circuit structure in the field of integrated circuit technology. It improves multiply characters high base Montgomery analog multiplying algorithm, wherein each step dose left shift operation to the batch N and the multiplicand B but not to the result S so that the delay between the two data path lines can de reduced from two clock weeks to one clock week. The circuit structure comprises: three storages used to store A, B and N operation numbers, a line type data path module which is formed by first stage to p stage processing units, a control module used to control the entire analog multiplier computing course and first-in first-out storage.

Owner:上海微科集成电路有限公司 +1

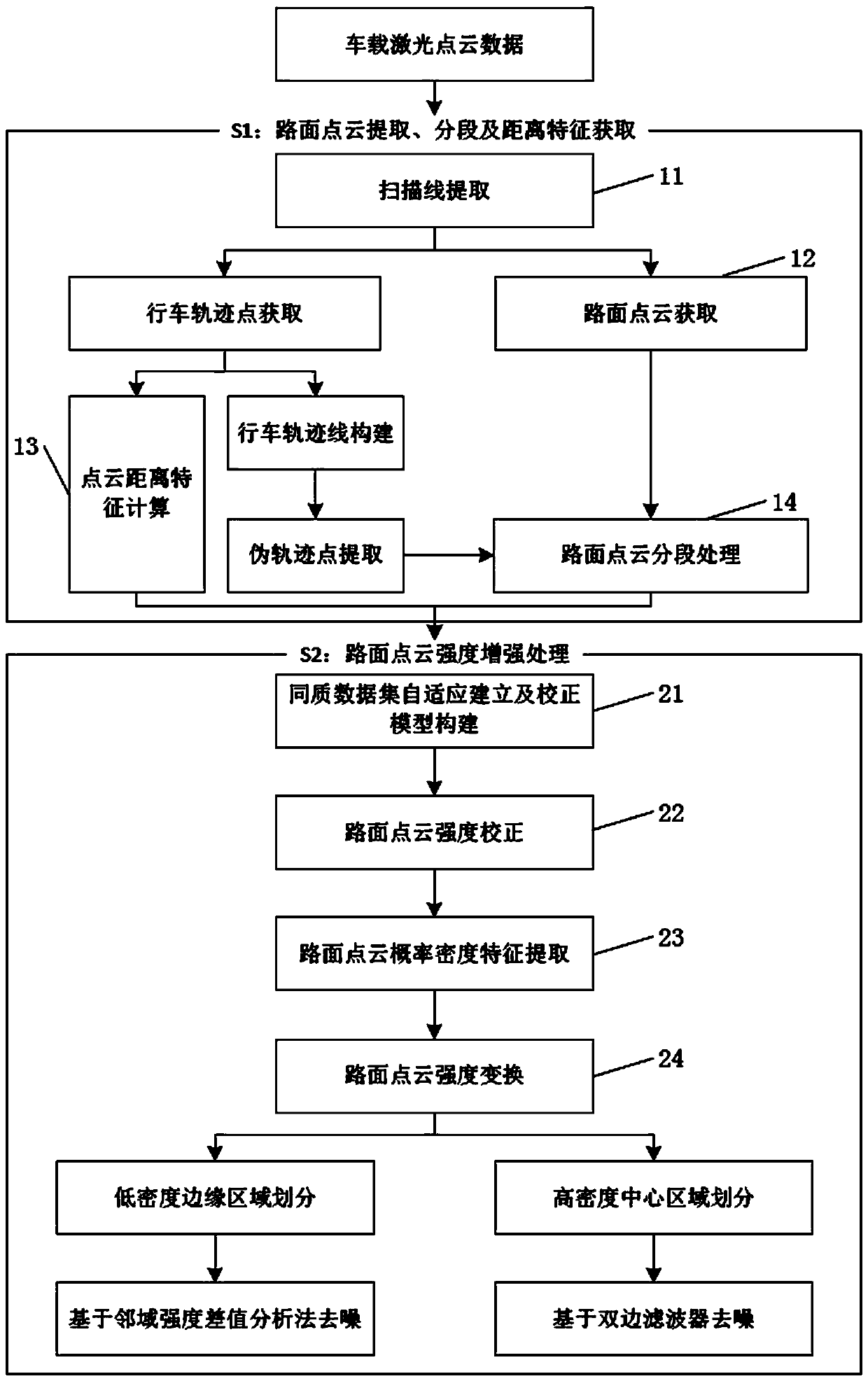

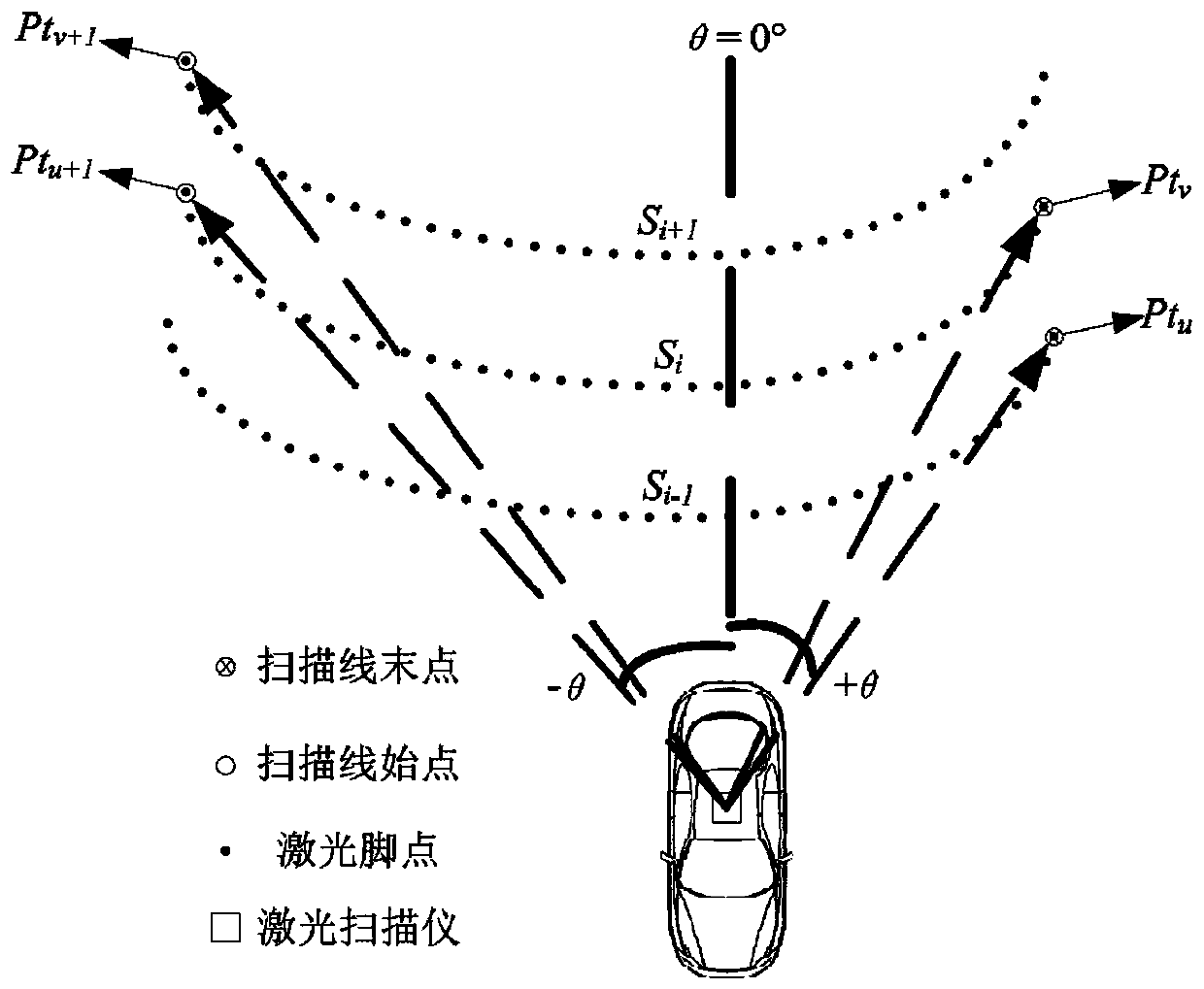

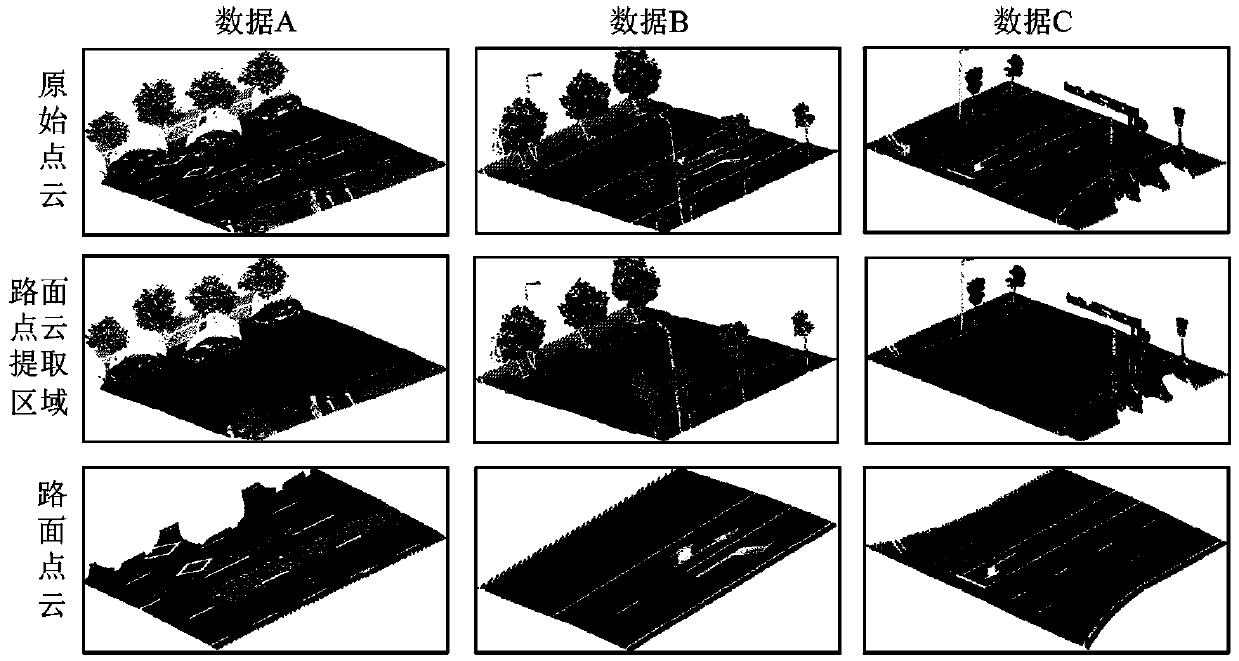

Vehicle-mounted laser scanning data-based road surface point cloud strength enhancing method

ActiveCN108681525AEnhanced Intensity VariationIncreased strength consistencyComplex mathematical operationsPoint cloudLaser scanning

The invention discloses a vehicle-mounted laser scanning data-based road surface point cloud strength enhancing method. The method comprises the following steps of: S1, obtaining a road surface pointcloud, a wheel path line and a distance from a laser point in the road surface point cloud to the wheel path line on the basis of vehicle-mounted laser scanning data, and segmenting the road surface point cloud; and S2, taking road surface point cloud segments as processing units to carry out the following steps of: 21, constructing an original distance model function and a reference distance model function, 22, carrying out strength correction on the laser point by adoption of ratio method and a difference value method, 23, carrying out strength conversion on the laser point, and 24, carryingout strength denoising on the laser point by adoption of a multi-filter integration method, so as to complete laser point strength enhancement of each road surface point cloud segment in the road surface point cloud. Compared with the prior art, the method is capable of remarkably enhancing the strength differences between different target materials of road surfaces and eliminating the strengthennoise in local homogeneous areas.

Owner:FUZHOU UNIV

Rear camera backup assistance with touchscreen display

InactiveCN101945256ATelevision system detailsInstrument arrangements/adaptationsComputer graphics (images)Display device

Assistance for a backup maneuver of a motor vehicle in which a first point of interest on the vehicle is moved toward a second point of interest remote from the vehicle. A rear contextual view is displayed on an electronic display obtained from a rearward directed image sensor on the vehicle. A zoom window is manually placed on the electronic display to include the second point of interest. The zoom window is enlarged, and the location of the second point of interest is manually identified within the enlarged zoom window. The identified location of the second point of interest is transformed into target positional coordinates. The rear contextual view redisplayed with a target icon at the target positional coordinates. The location of the first point of interest is manually identified on the rear contextual view and transformed into starting positional coordinates. A start icon is displayed at the starting positional coordinates in the rear contextual view. A target line is determined between the target positional coordinates and the starting positional coordinates. A path line icon is displayed in the rear contextual view corresponding to the determined target line. A bearing line is displayed in the rear contextual view extending from the start icon. The target positional coordinates are re-determined as the rear contextual view shifts during the backup maneuver. The target icon and the path line icon are updated in response to the re-determined target positional coordinates.

Owner:FORD GLOBAL TECH LLC

Cap sorter

The invention discloses a cap sorter, which comprises a cap bin obliquely arranged on a support. An oblique turntable is arranged on the inner side of the cap bin corresponding to the upper side of a bottom plate of the cap bin; the bottom plate is provided with a transmission device used for driving the oblique turntable to rotate; a plurality of accommodating grooves are distributed on the edge of the oblique turntable; the bottom walls of the accommodating grooves are provided with through holes; a bottom blowing air tap is fixed on the bottom plate corresponding to path lines of the through holes; a coaming of the cap bin is provided with a compressed air inlet corresponding to the upper sides of the accommodating grooves; a distance between the compressed air inlet and the bottom surfaces of the accommodating grooves is slightly longer than the height of a bottle cap; the outside of the compressed air inlet is provided with a side blowing air tap; the upper side of the coaming is provided with a bottle cap outlet corresponding to the tangential direction of the path of the accommodating grooves; and the bottle cap outlet is provided with a slideway used for conveying the bottle cap from the cap bin. By utilizing the Venturi principle, the cap sorter can sort common bottle caps, special bottle caps of which the height is greater than the outer diameter, and special caps of which the outer walls are provided with annular lugs, and the cap sorting efficiency is greatly improved.

Owner:GUANGZHOU TECH LONG PACKAGING MACHINERY CO LTD

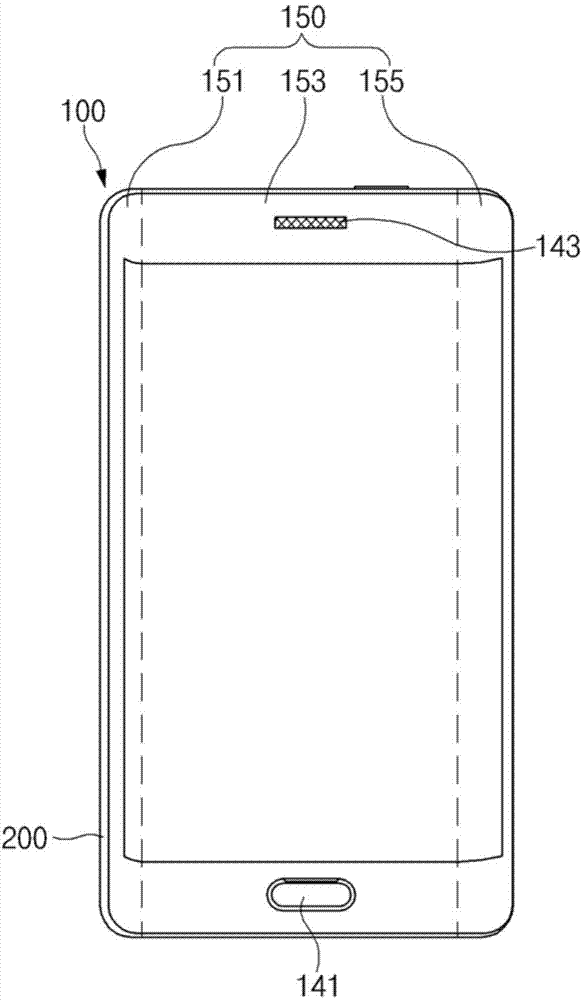

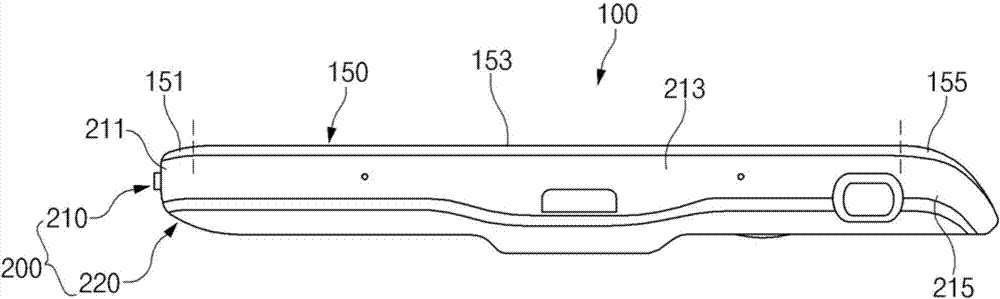

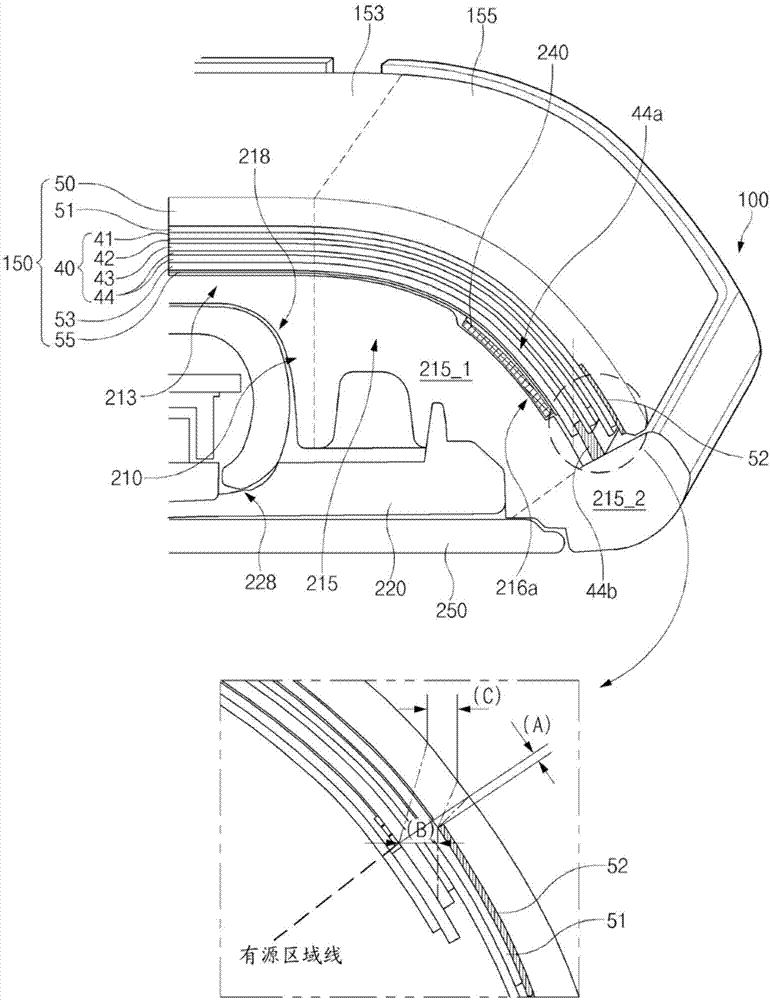

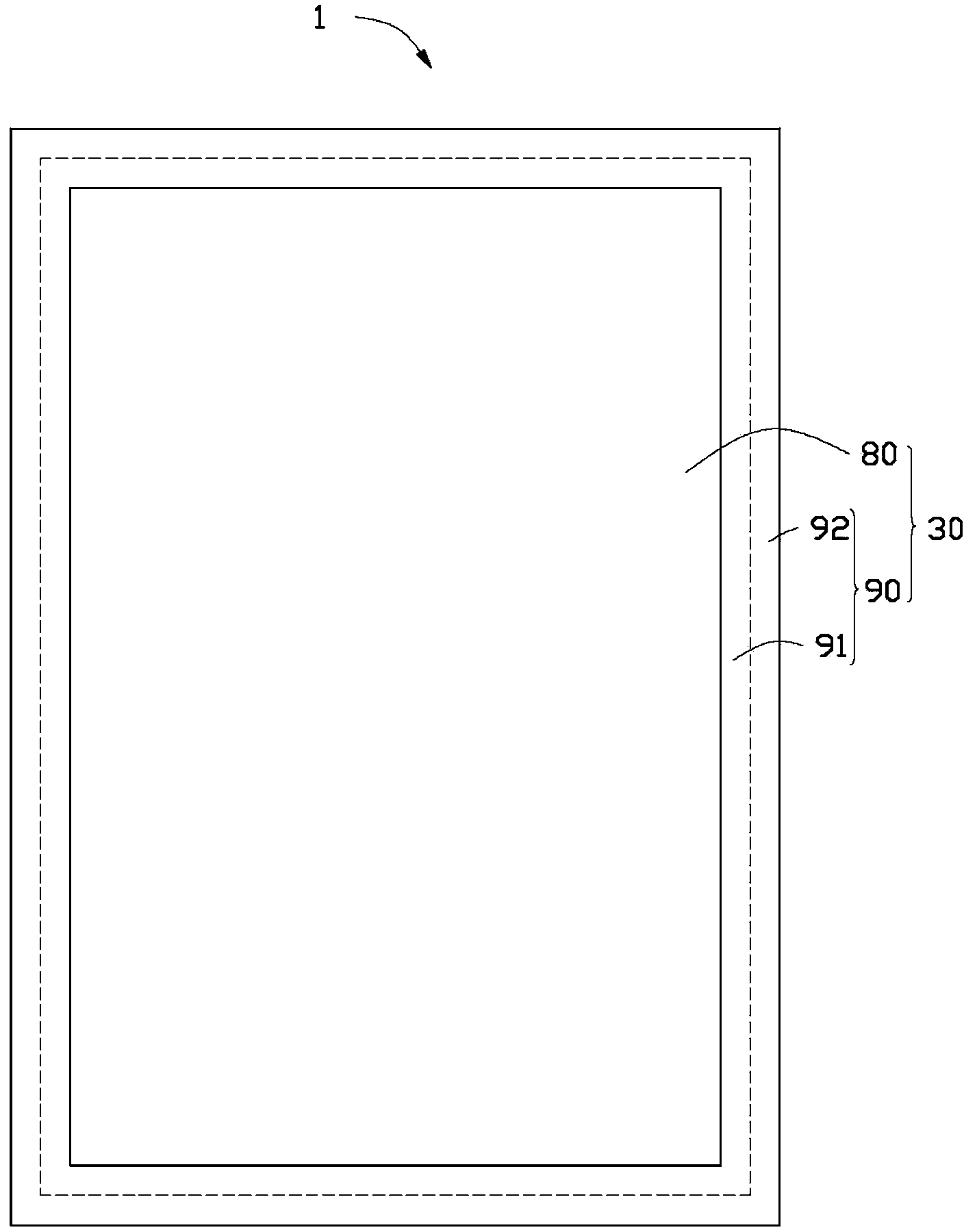

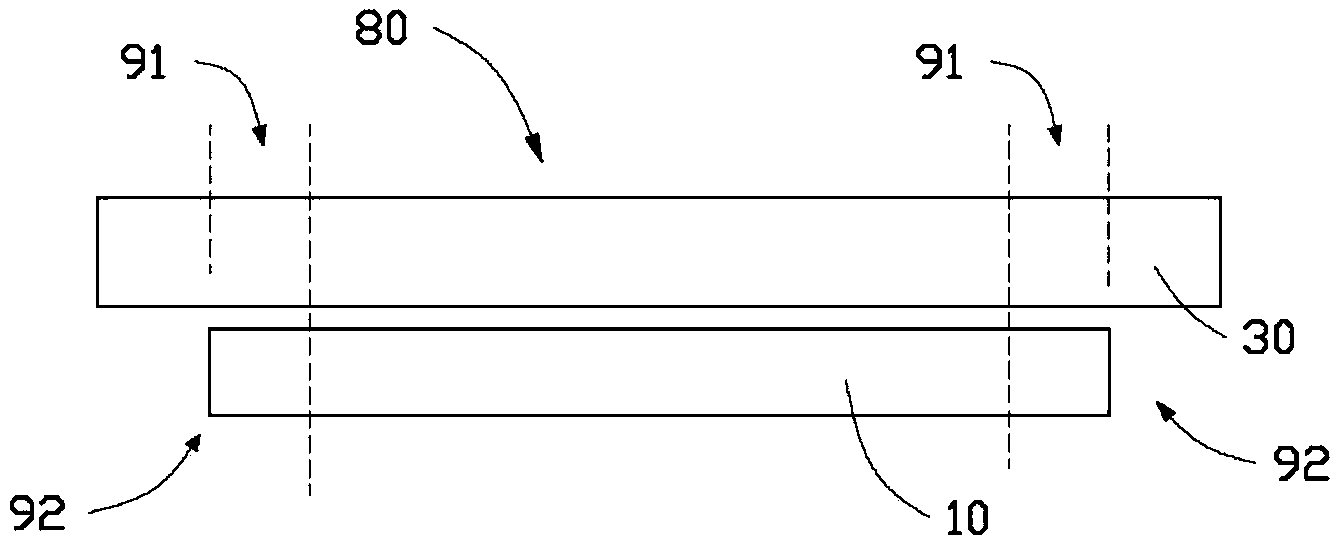

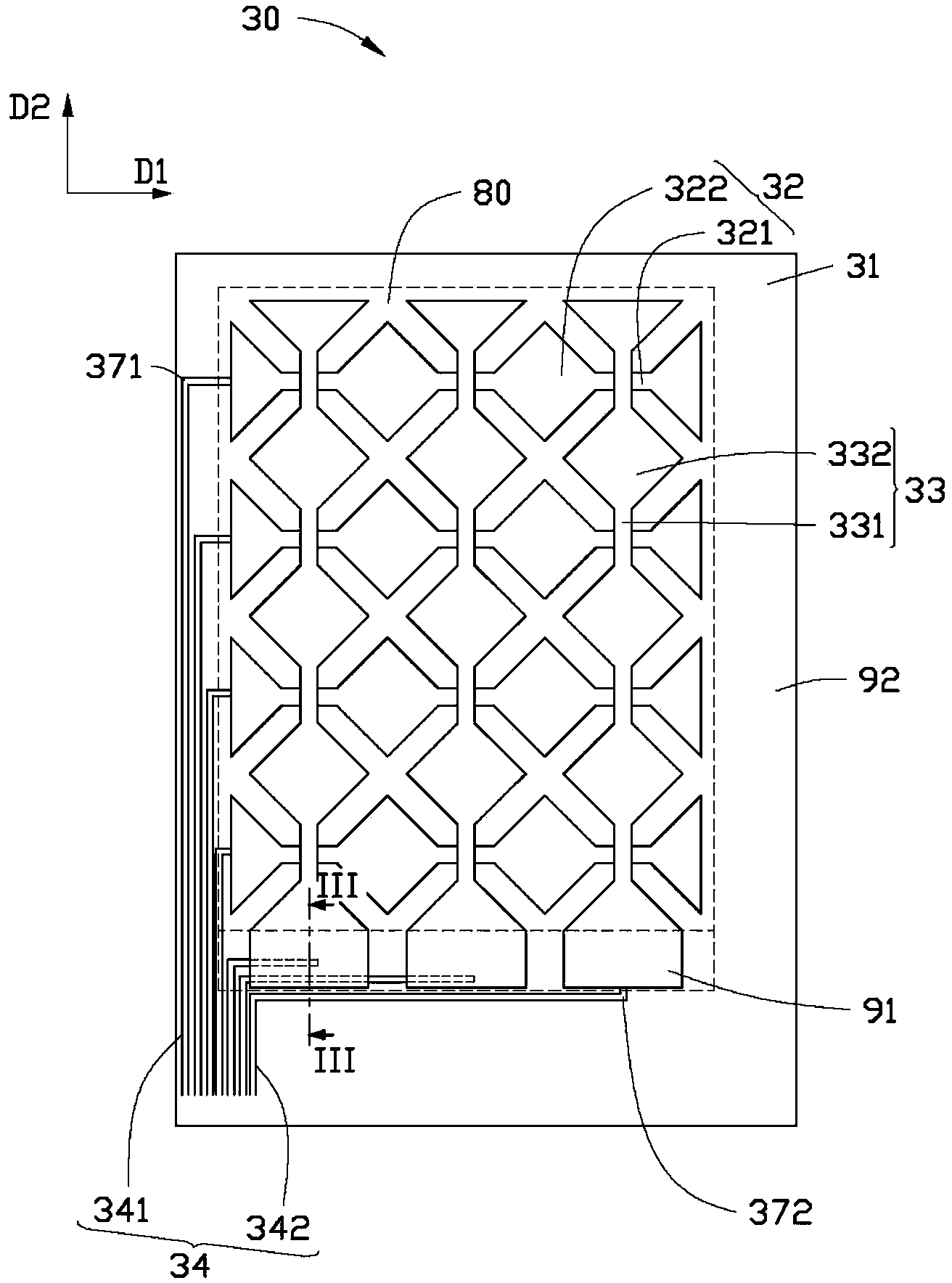

Curved display and electronic device including the same

InactiveCN104851363ACasings with display/control unitsDetails for portable computersDisplay devicePath line

The invention provides a curved display and a movable electronic device including the same. The curved display comprises an external protective layer including at least a part having an edge with certain curvature; an opaque layer arranged on the edge of the external protective layer; and a panel module layer including an electrode path line zone positioned under the opaque layer.

Owner:SAMSUNG ELECTRONICS CO LTD

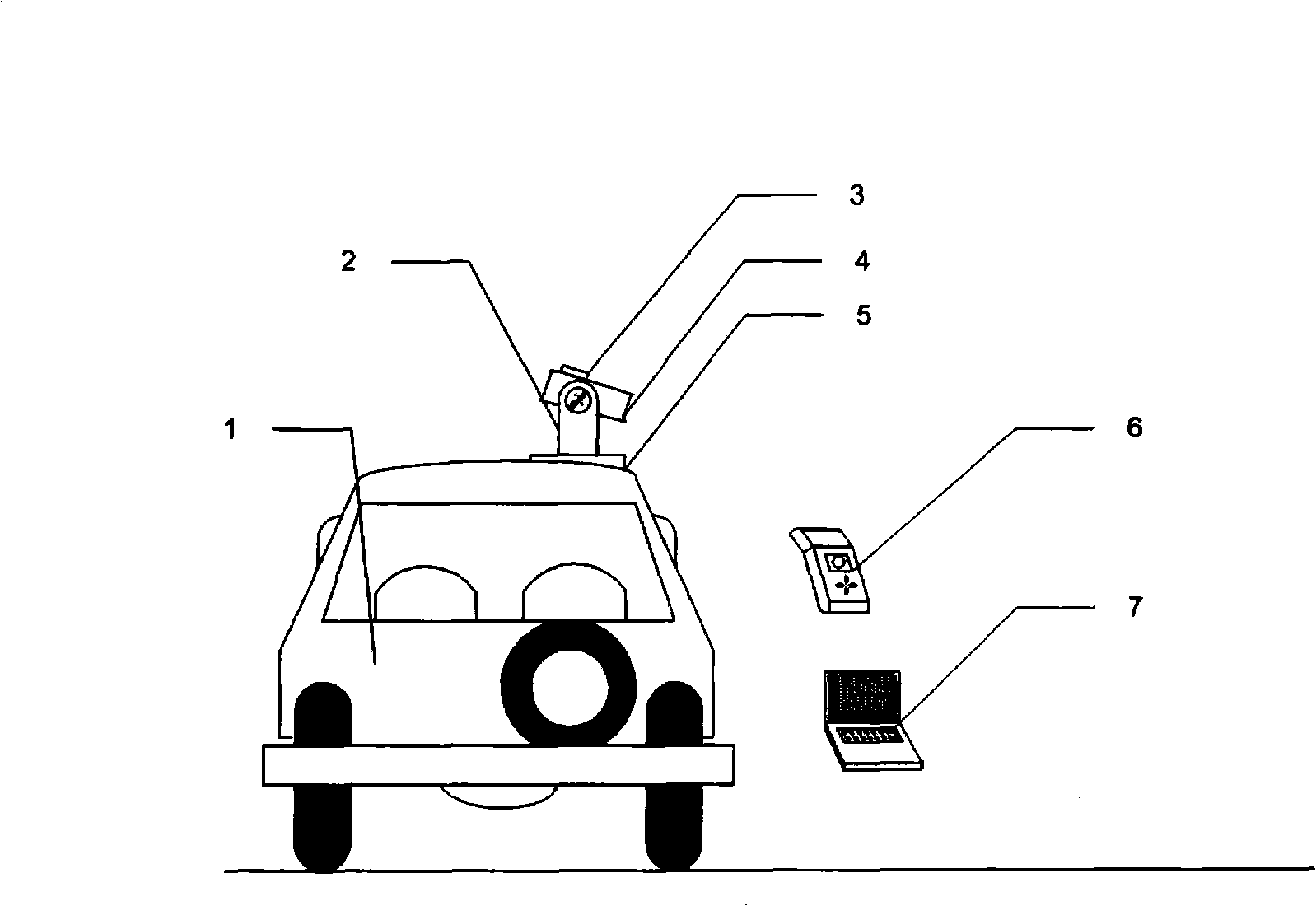

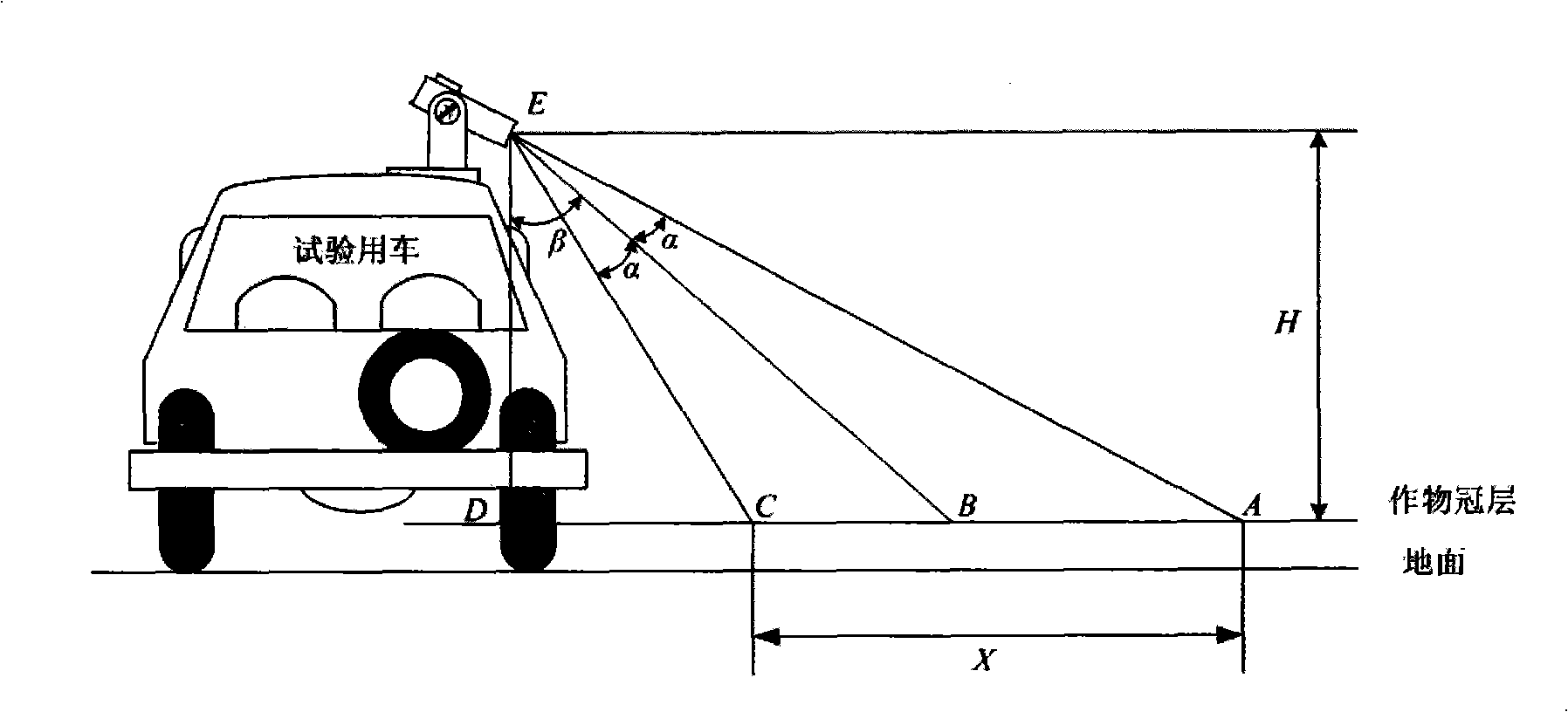

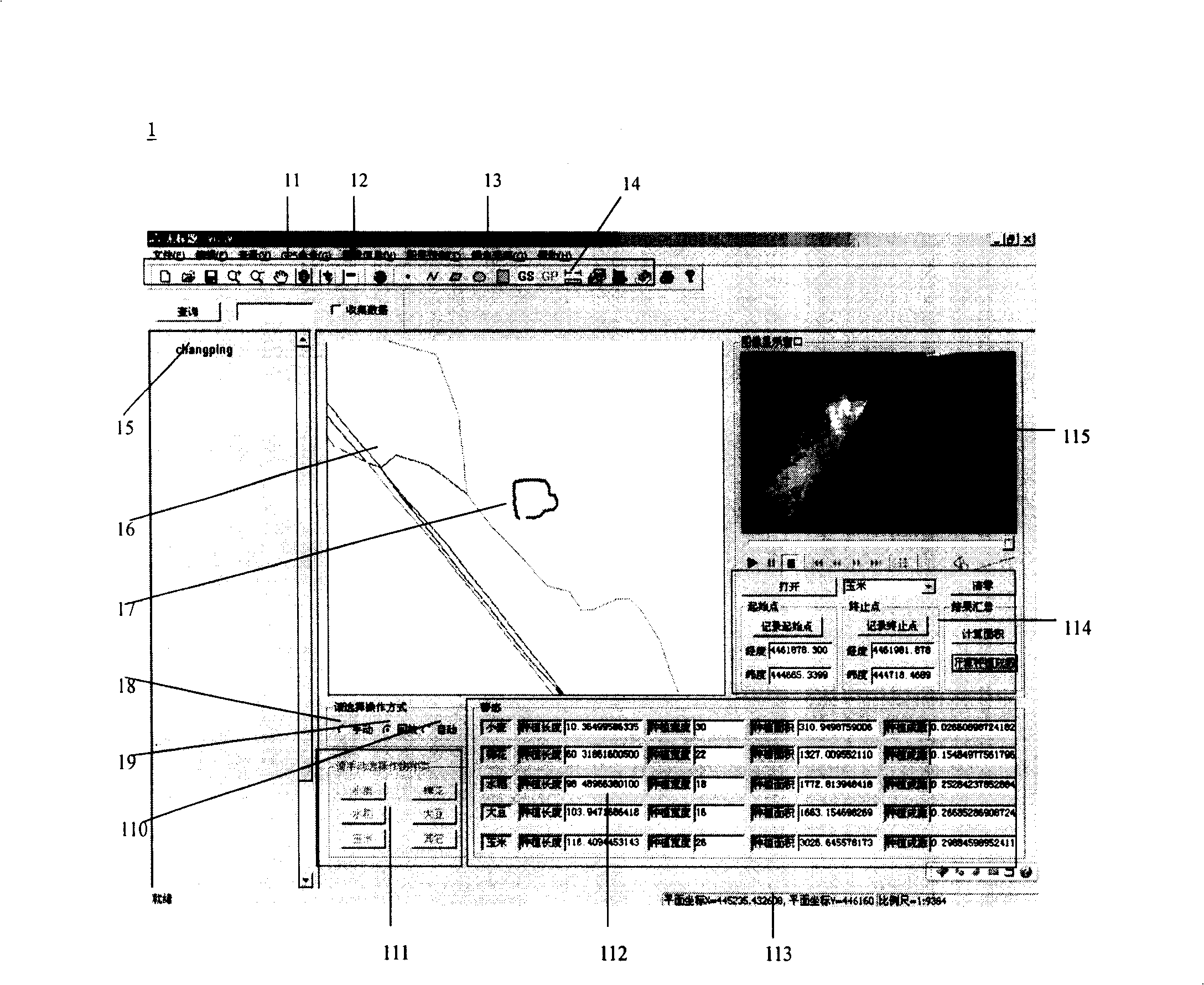

Vehicle mounted investigation method and system of large scale crops planting area

ActiveCN101349561AInvestigate planting areaReduce labor intensityPhotogrammetry/videogrammetryNavigation instrumentsVideo storageInvestigation methods

The invention discloses a large scale crop plant area vehicle-carrying investigation process and a system thereof, which comprises the matching of GPS position information and a GIS map, the matching of GPS position information and images, the decision of crop longitudinal plant width, the storage and extraction of the images, the grid algorism of the images, the identification of crop species, the storage of GPS position information and the various crops plant information and the calculation of various crops plant area and plant quotas. The process and the system can realize the drawing of vehicle navigation and path line through the GPS position information, measure the shooting angle of a camera through a dip angle sensor and control the quadrat width of a sampling, realize the video storage of the sampling and the single-frame extraction of a to-be-identified image through the image collection, and increase the real-time and the accurate ratio of identification through the grid algorism of the images, and automatically calculate the plant areas of various large scale crops through the crop identification. The system provides three ways of hand-held function, automatic function and the video playback function to calculate the plant area of crops and the plant quota.

Owner:ACADEMY OF PLANNING & DESIGNING OF THE MINIST OF AGRI +1

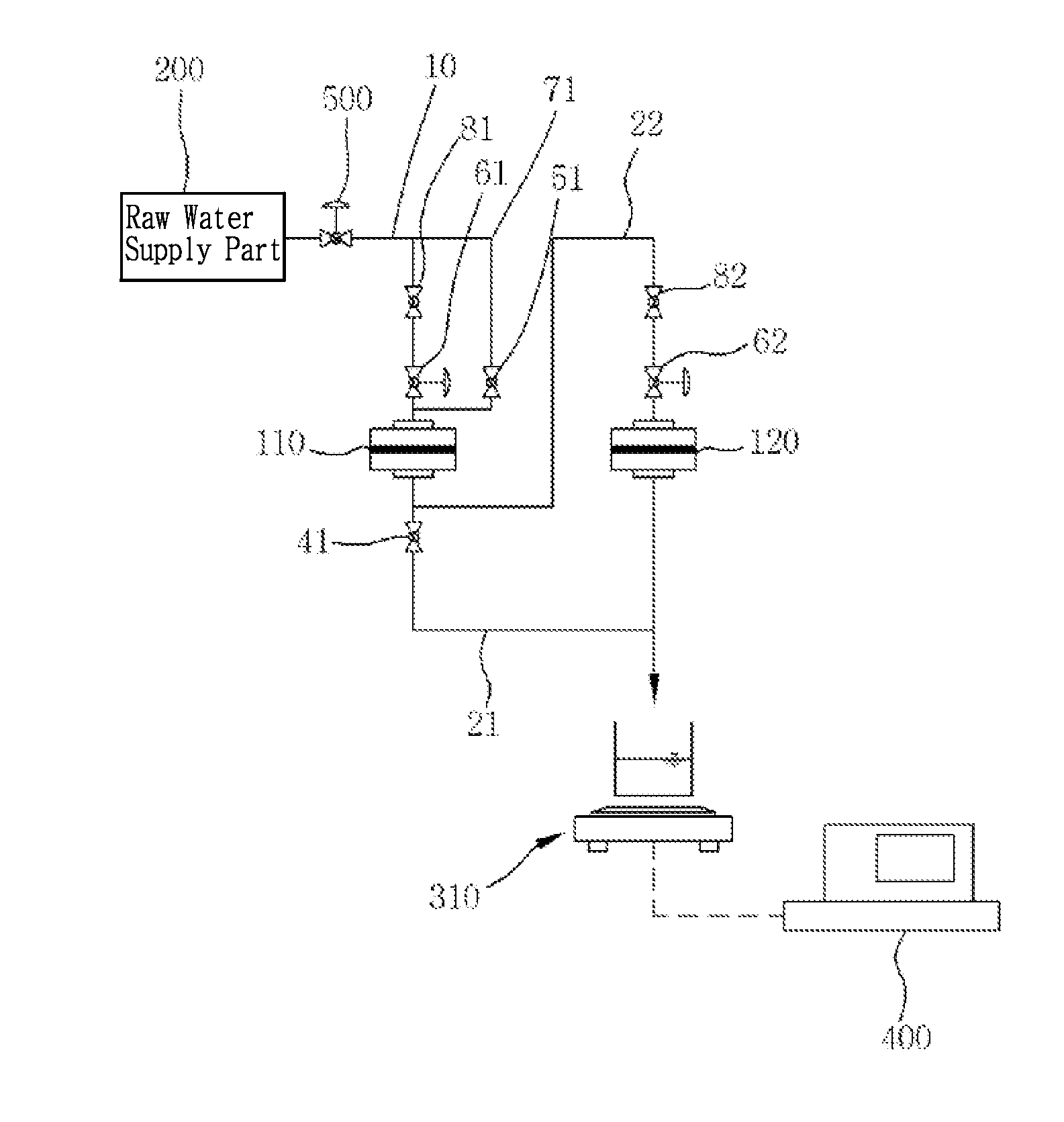

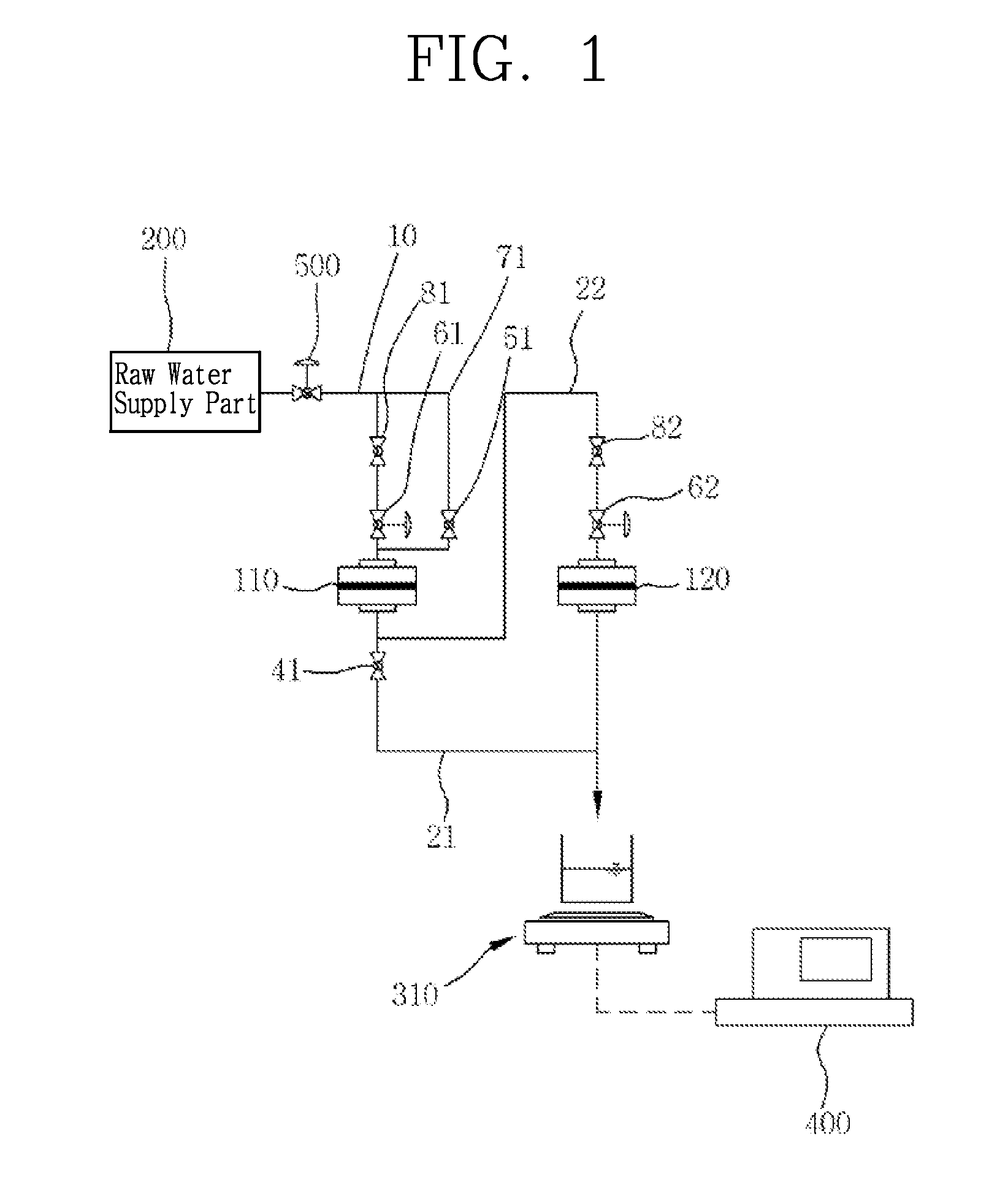

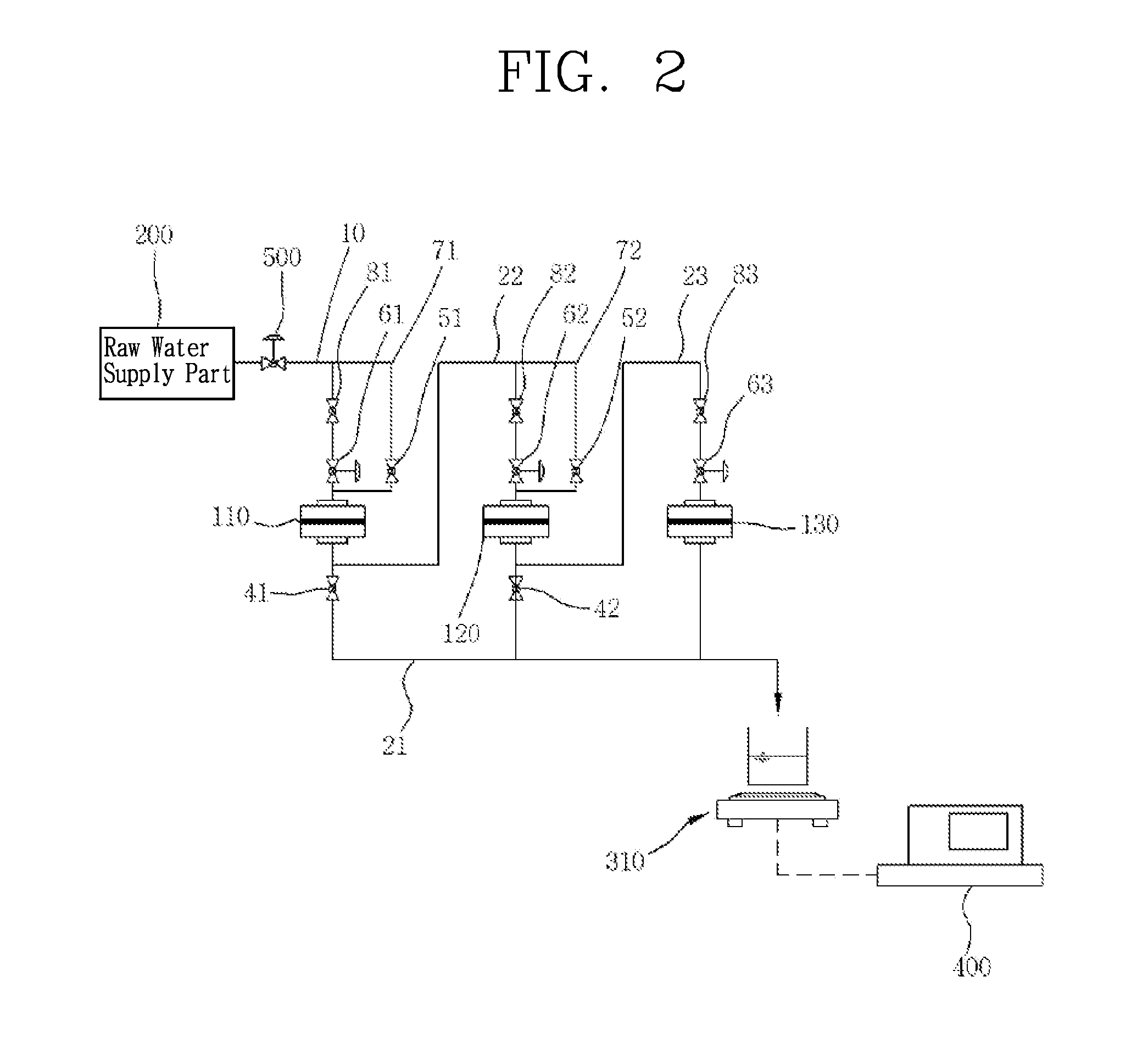

Device for measuring pollution index of filtration membrane

ActiveUS20150013434A1Simple structureEnsure measurement accuracyMembranesWater treatment parameter controlFiltration membraneDischarge measurements

A device for measuring the pollution index of a filtration membrane includes: a raw water supply part; a first filtration membrane; a raw water supply line; a first flow rate measuring part; a first path line; a second path line; a second filtration membrane having a filtration characteristic different from the first filtration membrane; a first path selection valve installed in the first path line in parallel with respect to the second filtration membrane so that a first measuring path from the raw water supply part to the first flow rate measuring part passes through the first filtration membrane and a second measuring path from the raw water supply part to the first flow rate measuring part successively passes through the first and second filtration membranes; and a pollution index measuring part measuring the pollution indexes of the first and second filtration membranes.

Owner:DOOSAN HEAVY IND & CONSTR CO LTD

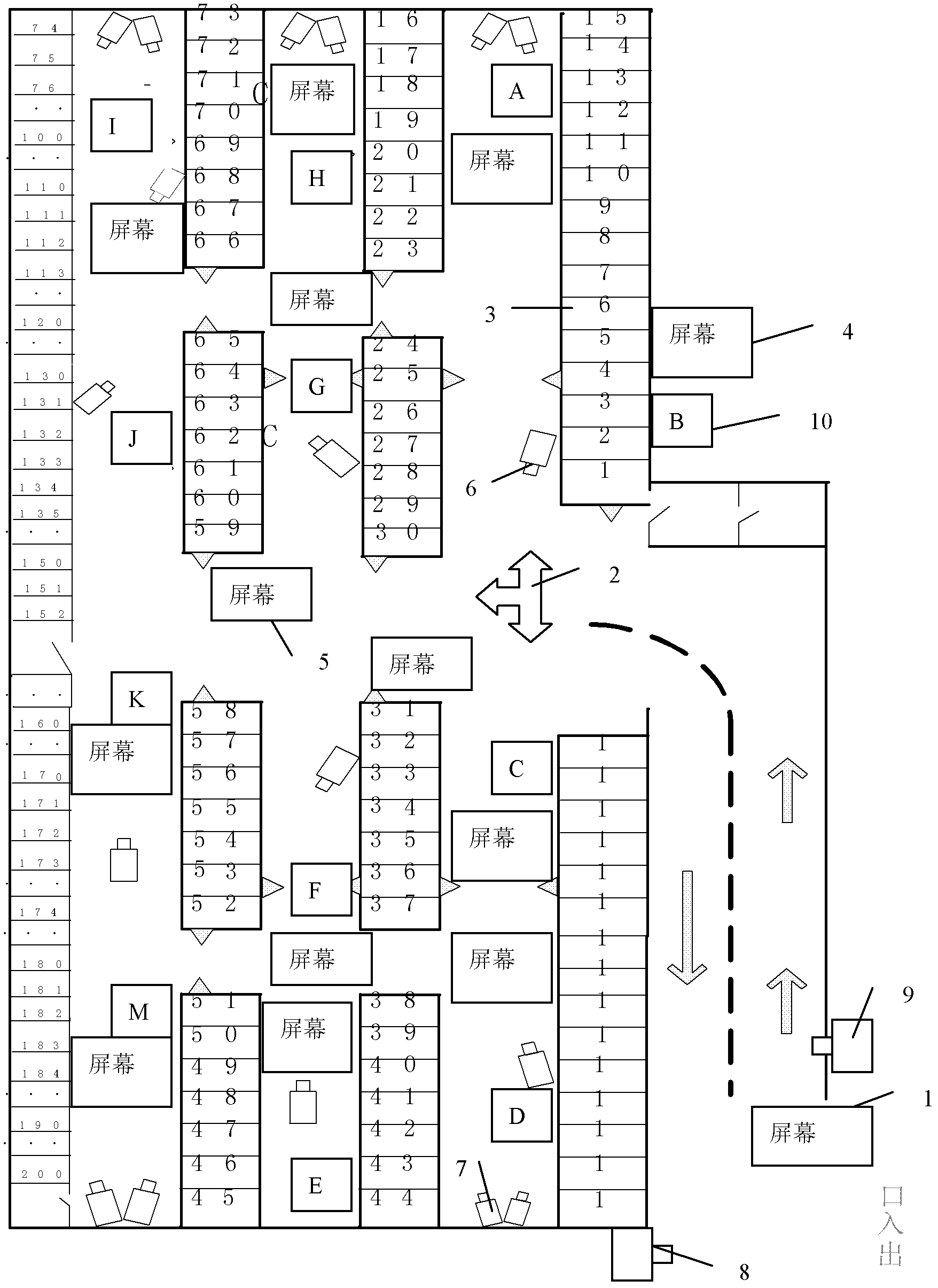

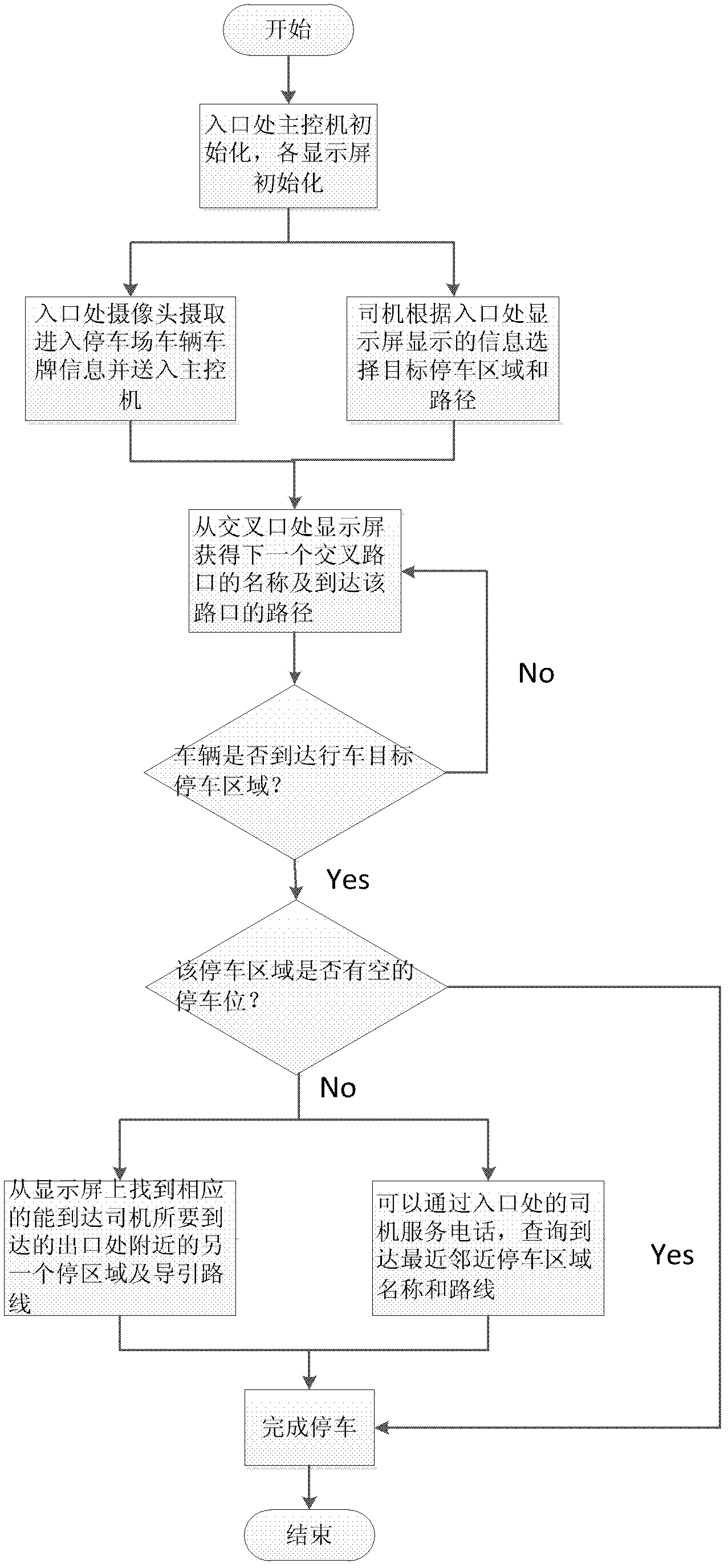

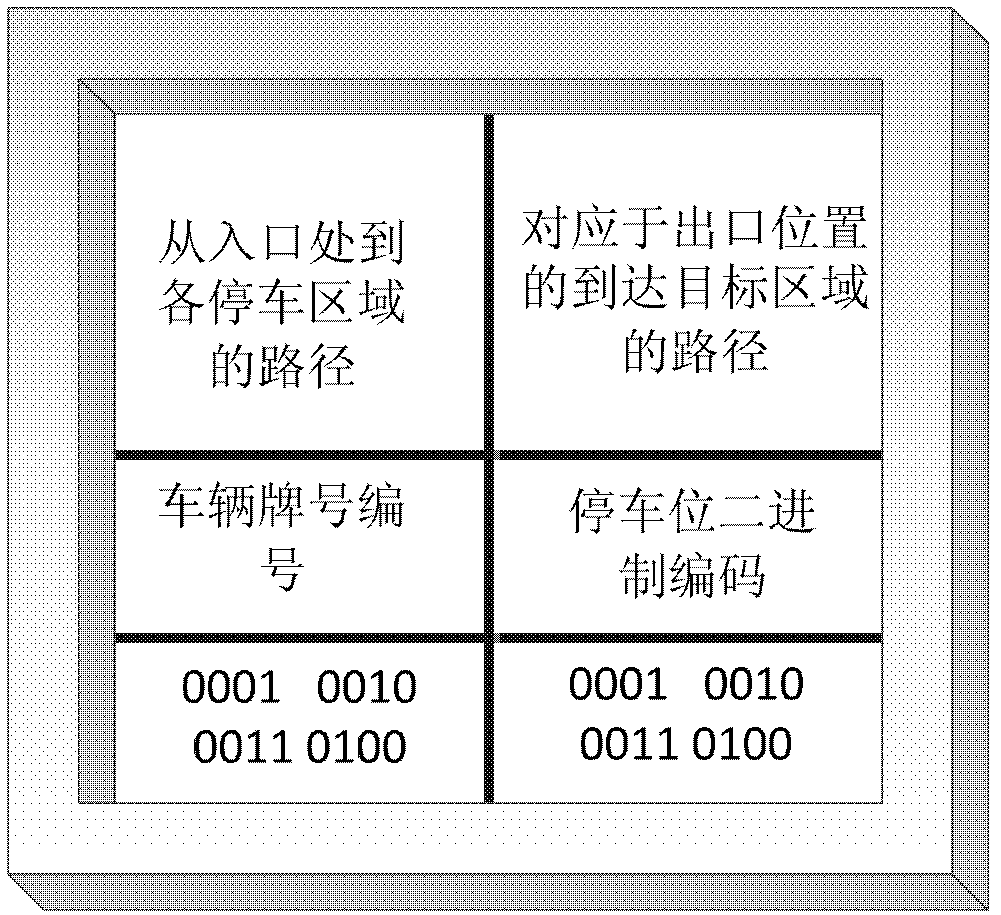

Method for guiding path corresponding to parking space of cab driving target area in parking lot

The invention relates to a method for guiding a path corresponding to a parking space of a cab driving target area in a parking lot, belonging to the technical field of the parking lot. The method is characterized in that a cap knows a parking space position, a parking area position, a position respectively reaching each corresponding exist from each parking area, and vehicle information of a parking space in each parking area according to a display screen controlled by a main controller at a parking entrance, thereby reaching a cross rod in the parking lot; and the cap knows each branch path line and a road condition map corresponding to the parking area through a display screen at each cross and reach a next cross according to a direction indicated by an electronic cursor; the steps are circularly repeated, finally the cap reaches the parking area leading to the entrance, and selectively parks according to parking information of the parking space of the parking area and parking information of each parking space in an other parking area at an exist to be reached both which are displayed on the display screen at the parking area.

Owner:嘉善罗星创业投资有限公司

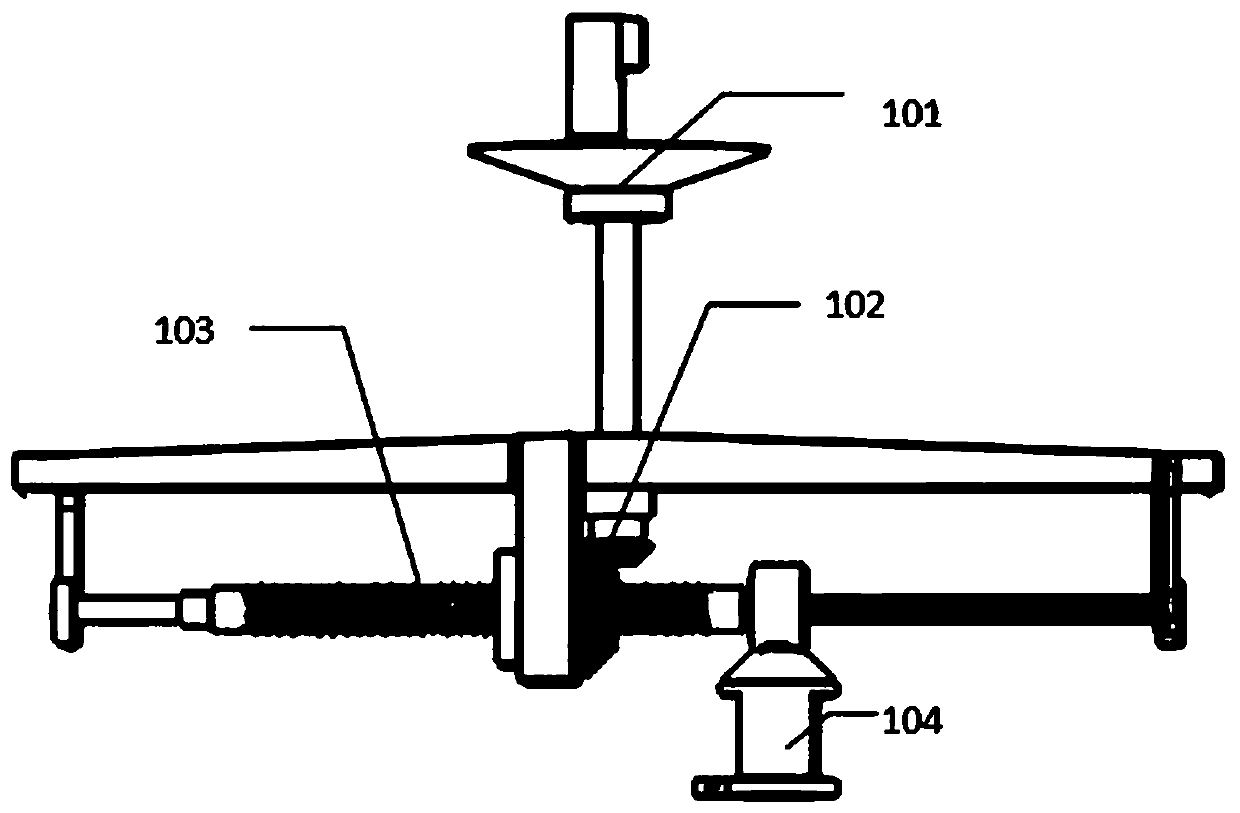

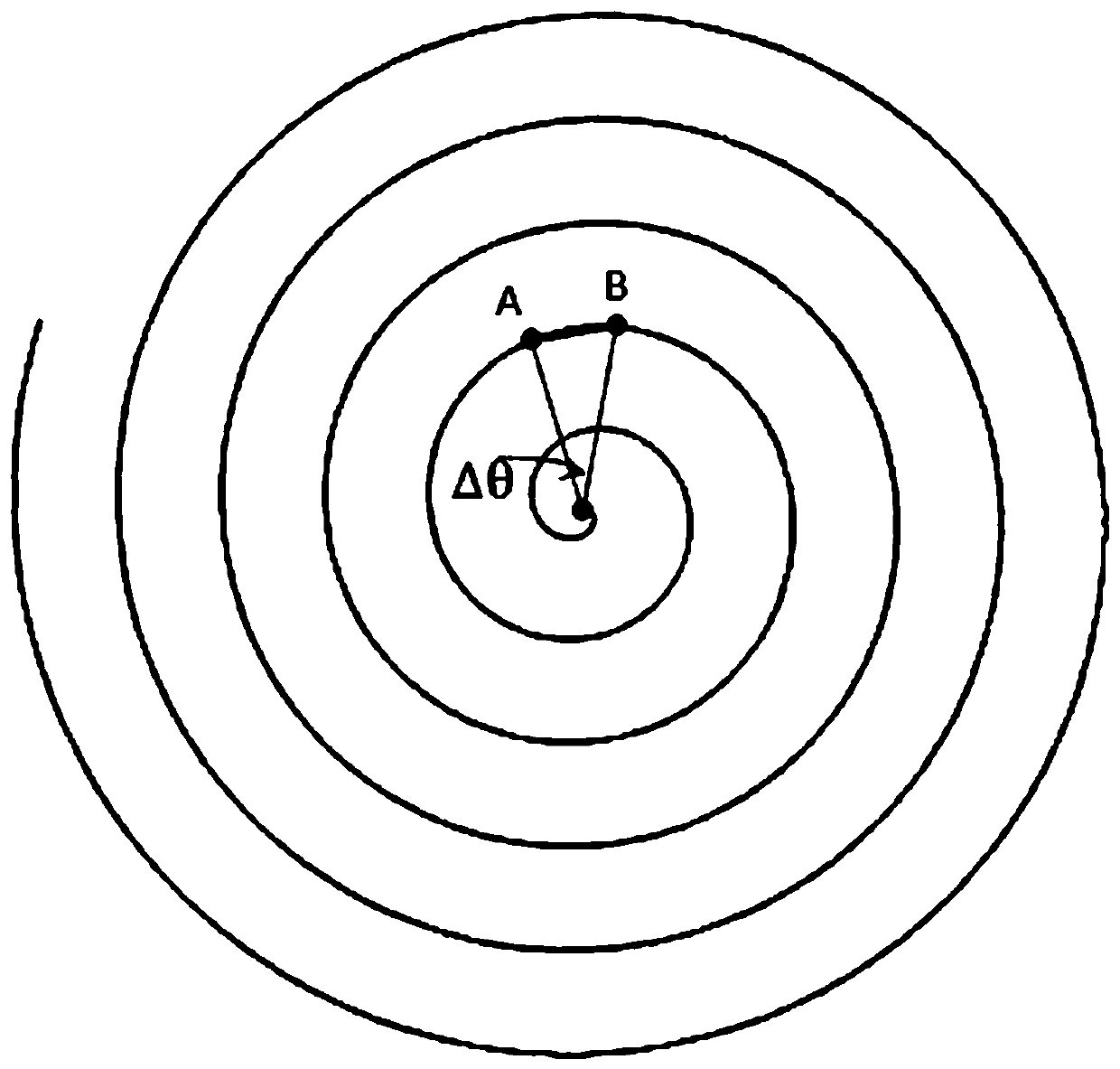

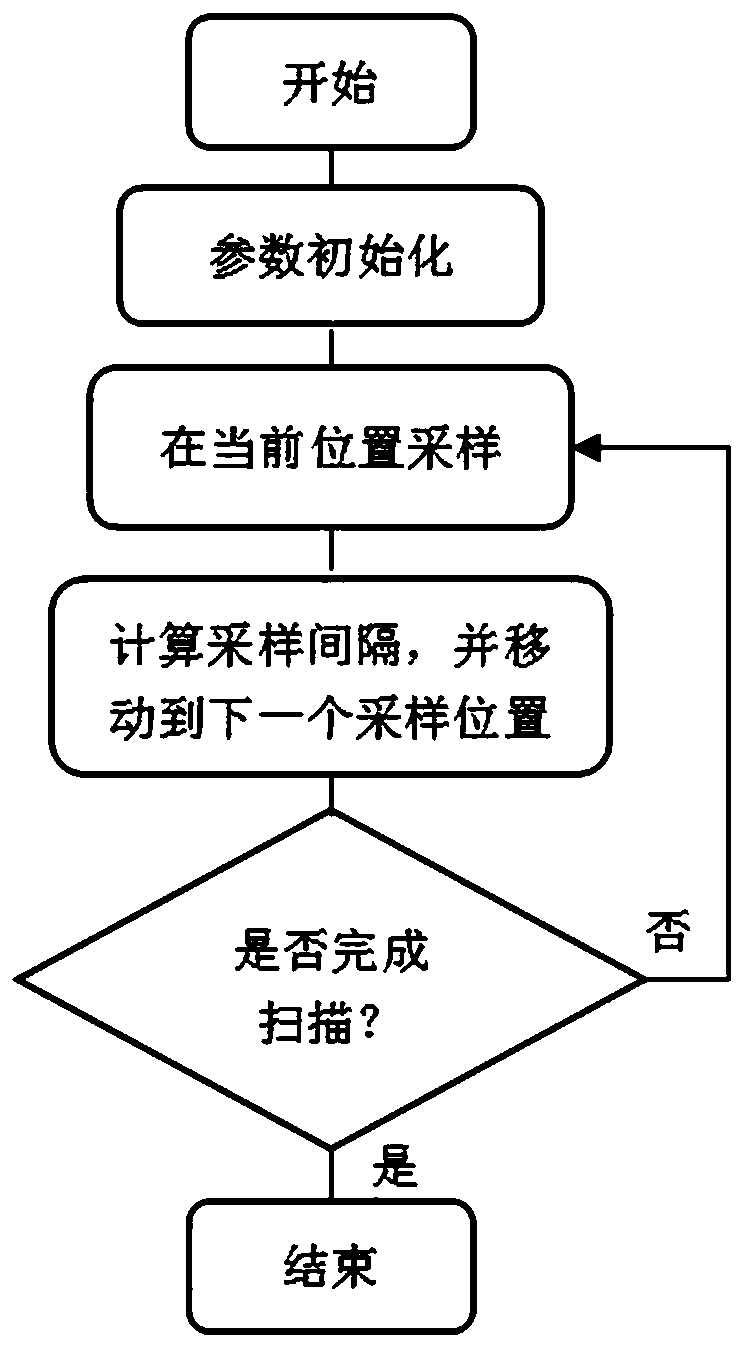

Archimedes spiral-based adjustable scanning device and method for resolution region

InactiveCN107144641AReduce complexityImprove efficiencyMaterial analysis using sonic/ultrasonic/infrasonic wavesImage resolutionTransducer

The invention provides an archimedes spiral-based adjustable scanning device and method for a resolution region. The device provided by the invention forms linkage through angular rotation and radial translation, and completes scanning of a specified region only through driving a scanning probe by a single motor along a specific archimedes spiral path. The position of the probe corresponds to the angular coordinates of the rotation one by one, so the position coordinates of the probe can be accurately known through arranging an angular transducer and a counter. According to the archimedes spiral-based polar coordinate scanning method provided by the invention, the intervals among the sampling points and the rotational speed of the motor are controlled to control the distribution of the sampling points on a path line, so that the sampling resolution is globally or locally adjustable. The archimedes spiral-based adjustable scanning device and method determine the mapping relation between the one-dimensional angle parameters and two-dimensional plane coordinates through the spiral, so scanning can be controlled to be completed by the single motor, the angular coordinates are recorded to accurately know the position coordinates of the probe, and the scanning device has simplicity of structure and reliable performance.

Owner:GUANGZHOU FENGPU INFORMATION TECH CO LTD

Touch device

InactiveCN103513825ANarrow bezelInput/output processes for data processingComputer scienceElectric signal

A touch device comprises a light-transmitting display region and a non-light-transmitting frame region located on the outer side of the display region, wherein the frame region comprises a touch region and a wiring region. The touch region is arranged between the display region and the wiring region, multiple sensing pads for sensing touch operations are distributed in the display region and the touch region according to a specific rule, and multiple connecting path lines are located in the wiring region and electrically connected with the corresponding sensing pads and are used for being connected with the sensing pads and a drive circuit so as to obtain electrical signals. The ends of at least a part of the connecting path lines electrically connected with the sensing pads extend into the touch region, the part of the connecting path lines and the sensing pads are stacked in arrangement, insulating layers are arranged between the sensing pads and the connecting path lines which are stacked, a plurality of through holes are formed in the insulating layers, and the sensing pads located in the touch region are electrically connected with the corresponding connecting path lines in the wiring region. The touch device is narrow in frame.

Owner:INTERFACE OPTOELECTRONICS SHENZHEN +1

Method for measuring flow vector of seepage liquid

ActiveCN105372167ARealize measurementImprove discriminationPermeability/surface area analysisGeomorphologyMinimum time

Provided is a method for measuring the flow vector of seepage liquid. The method includes the following steps that 1, rock is selected; 2, observation points are selected; 3, pigment is arranged on the observation points; 4, a transparent opposite face model of a rock fracture face is made; 5, the transparent opposite face model is arranged on the rock fracture face; 6, transparent sulfuric acid grid paper is placed on the upper surface of the transparent opposite face model; 7, a camera device is installed; 8, water injection is performed till seepage occurs; 9, multiple flow path lines with colors appear; 10, flow conditions are recorded; 11, a shot image is analyzed, the seepage speed of any point at the minimum time difference is calculated, and then the seepage vector of any point of the fracture face at any micro time period is measured. By means of the method for measuring the flow vector of the seepage liquid, the problem that it is impossible to trace the seepage direction of any point and calculate the seepage speed can be solved, the instant flow speed of liquid at any point in a fracture joint face can be measured, and measurement precision is high.

Owner:泰州市海通资产管理有限公司

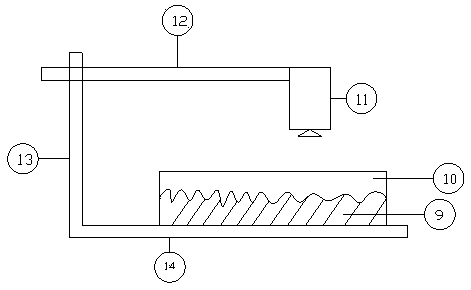

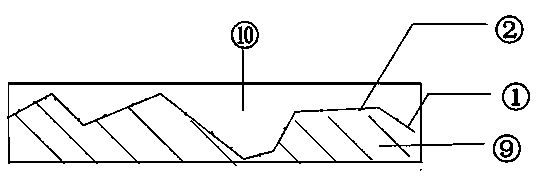

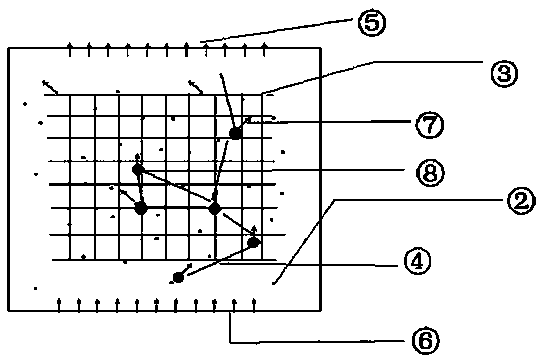

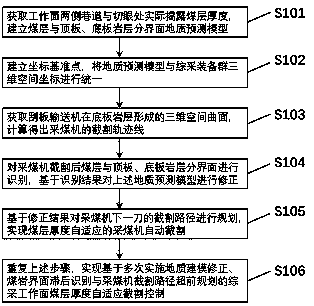

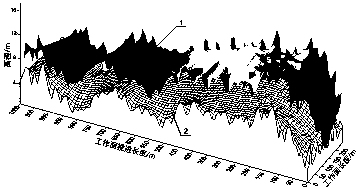

Fully mechanized mining face coal-seam thickness self-adaption cutting control method and electronic equipment

The invention discloses a fully mechanized mining face coal-seam thickness self-adaption cutting control method and electronic equipment. According to the main control process, a coal and rock seam interface geology prediction model based on a unified coordinate system and a fully mechanized coal equipment group three-dimensional space pose model are built, a cutting path line of a coal mining machine is obtained, and after the coal mining machine cuts a coal seam, identification of the coal and rock seam interface is conducted by using a video and image identification technology; based on a coal and rock identification result, the coal and rock seam interface geology prediction model is corrected; based on the corrected coal and rock seam interface, the next coal cutting path of the coalmining machine is planned in advance; fully mechanized mining face coal-seam thickness self-adaption cutting control based on multi-time real-time geology modeling correction, coal and rock interfacelagging identification and advancing planning of the cutting path of the coal mining machine is achieved. By means of the method, the problem that existing drilling, geophysical prospecting and otherdetection technology bottleneck restricts the self-adaption control of the coal mining machine is solved, self-adaption cutting under the changes of fully mechanized mining face coal-seam occurrence conditions is achieved, and the method provides a technological approach for achieving intelligentized and unmanned mining of a fully mechanized mining face.

Owner:CCTEG COAL MINING RES INST

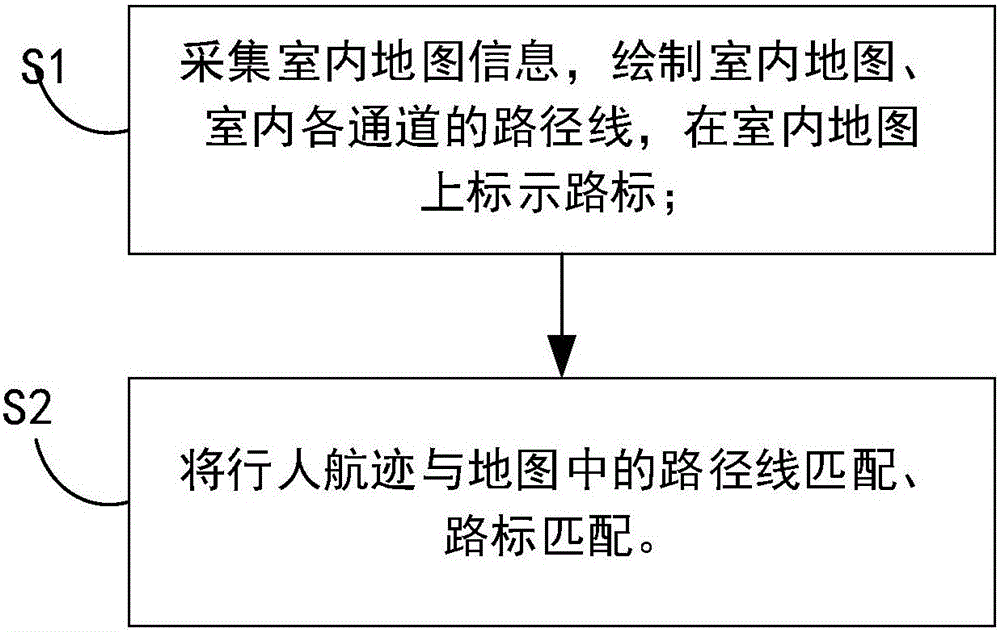

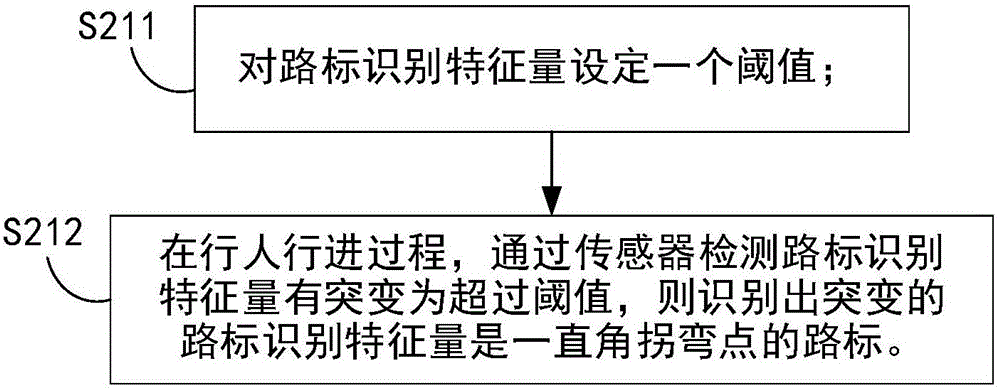

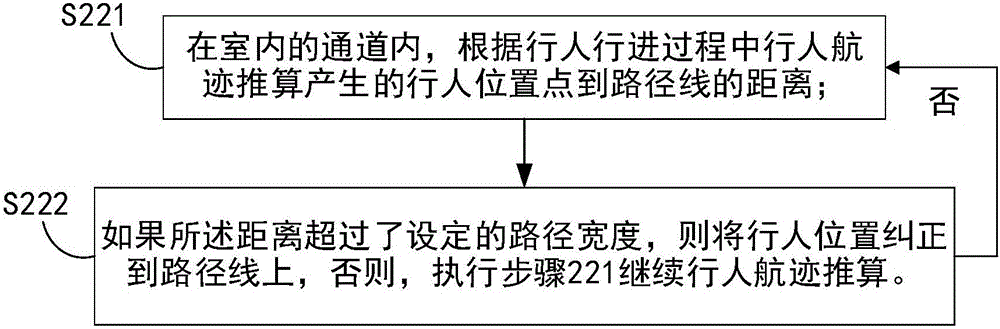

Indoor map and pedestrian track matching method

InactiveCN106289282AHigh precisionEliminate cumulative errorsInstruments for road network navigationMatching methodsComputer science

The invention relates to an indoor map and pedestrian track matching method, which comprises the following steps: S1, acquiring indoor map information, drawing an indoor map, drawing path lines of various indoor passages, and marking road signs on the indoor map; and S2, matching pedestrian track and the path lines and road signs in the map. In the map matching process, after the pedestrian position is matched to a geometrical characteristic point in the map, a new location point is considered as a new initial position of positioning; and in order to reduce accumulative errors, a sensor in a mobile phone is reinitialized at the new initial position. The thorough reinitialization is of great significance for pedestrian track calculation algorithm. Accumulative errors of position estimation layers are eliminated, and accumulative errors of course angle and step length estimation layers are also eliminated. Through path matching, through-wall behavior in narrow corridors can be avoided. With map matching on the basis of pedestrian track calculation, indoor positioning precision can be enhanced.

Owner:BEIJING FINE WAY TECH CO LTD

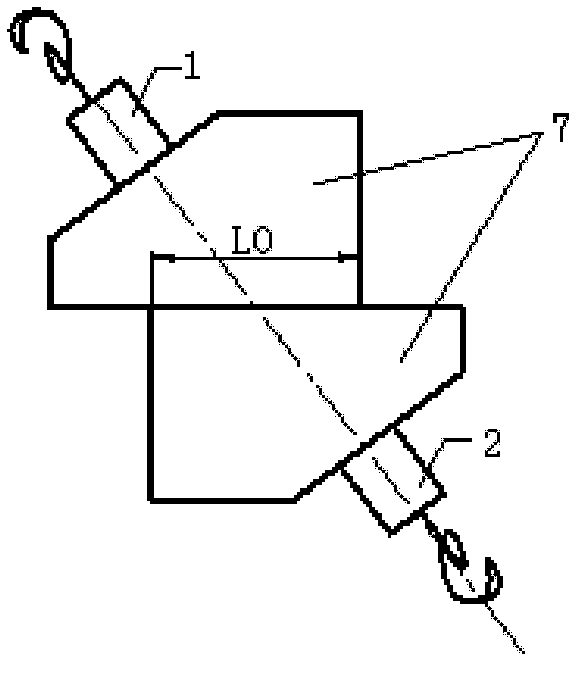

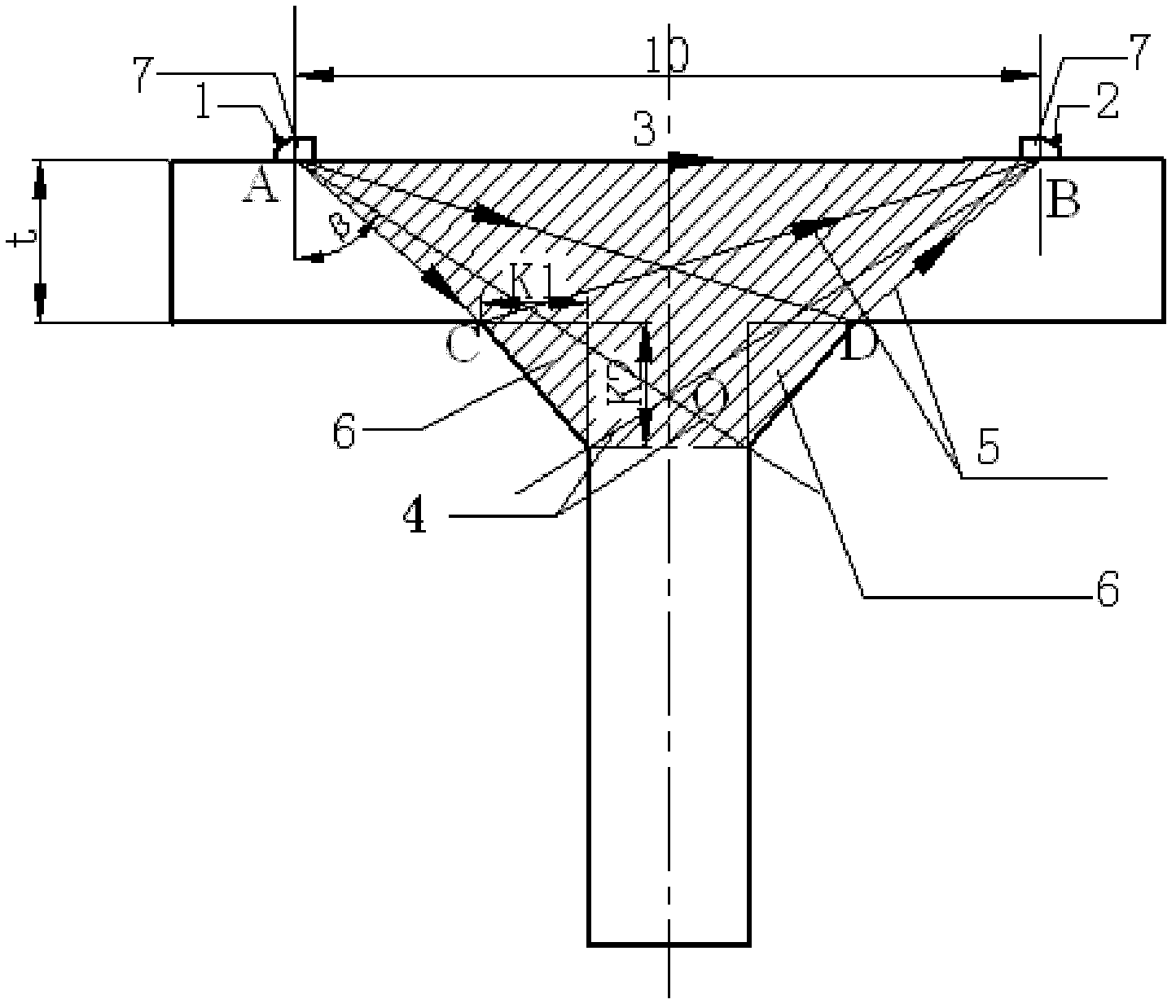

Ultrasonic TOFD (Time of Flight Diffraction) detection method for T-shaped welding joint

InactiveCN102590344AThe detection method is convenient and fastThe detection method is accurateAnalysing solids using sonic/ultrasonic/infrasonic wavesEngineeringFront edge

The invention discloses an ultrasonic TOFD (Time of Flight Diffraction) detection method for a T-shaped welding joint and relates to the field of ultrasonic waves. The ultrasonic TOFD detection method comprises the following steps of: determining the distance between every two sound incident points according to the right-angled side size of a welding angle of the detected T-shaped welding joint, the thickness of a wing plate, the thickness of a web slab and a diffuse angle of a TOFD probe; before scanning, making two scanning path lines on the wing plate symmetrical to a central line of the weld joint, wherein the spacing is the difference of the distance between every two sound incident points and the summation of front edges of two ultrasonic probes; during detection, scanning along the scanning path lines on the wing plate of the T-shaped welding joint by a probe wedged block to generate a scanning image D; and analyzing the image to obtain the internal defect characteristics of the T-shaped welding joint. According to the ultrasonic TOFD detection method disclosed by the invention, the problems that the detection efficiency and the defect detection rate are low because the detection of the T-shaped welding joint specified in the traditional detection standard is only carried out through scanning by ultrasonic wave A are solved.

Owner:天津诚信达金属检测技术有限公司

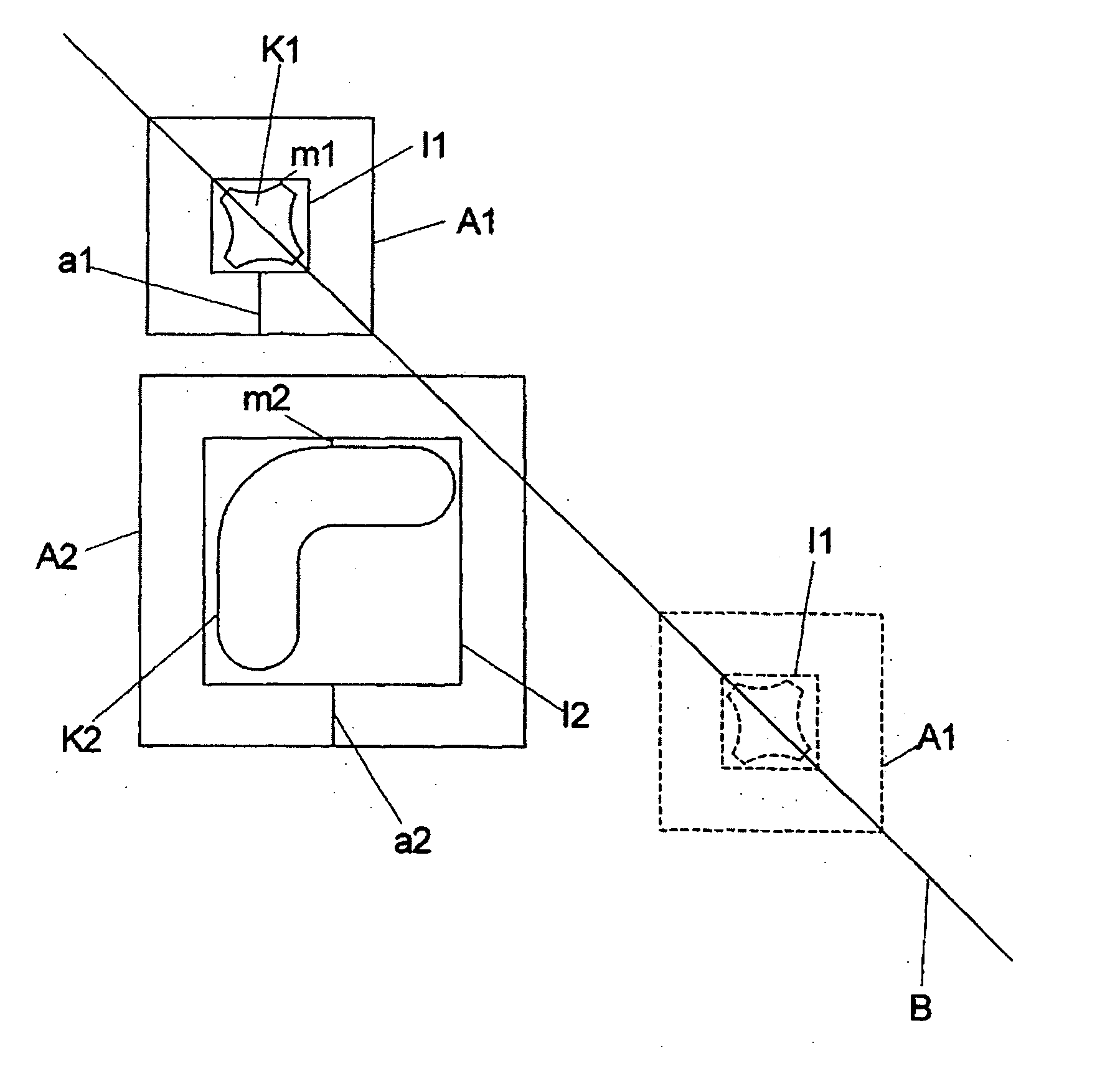

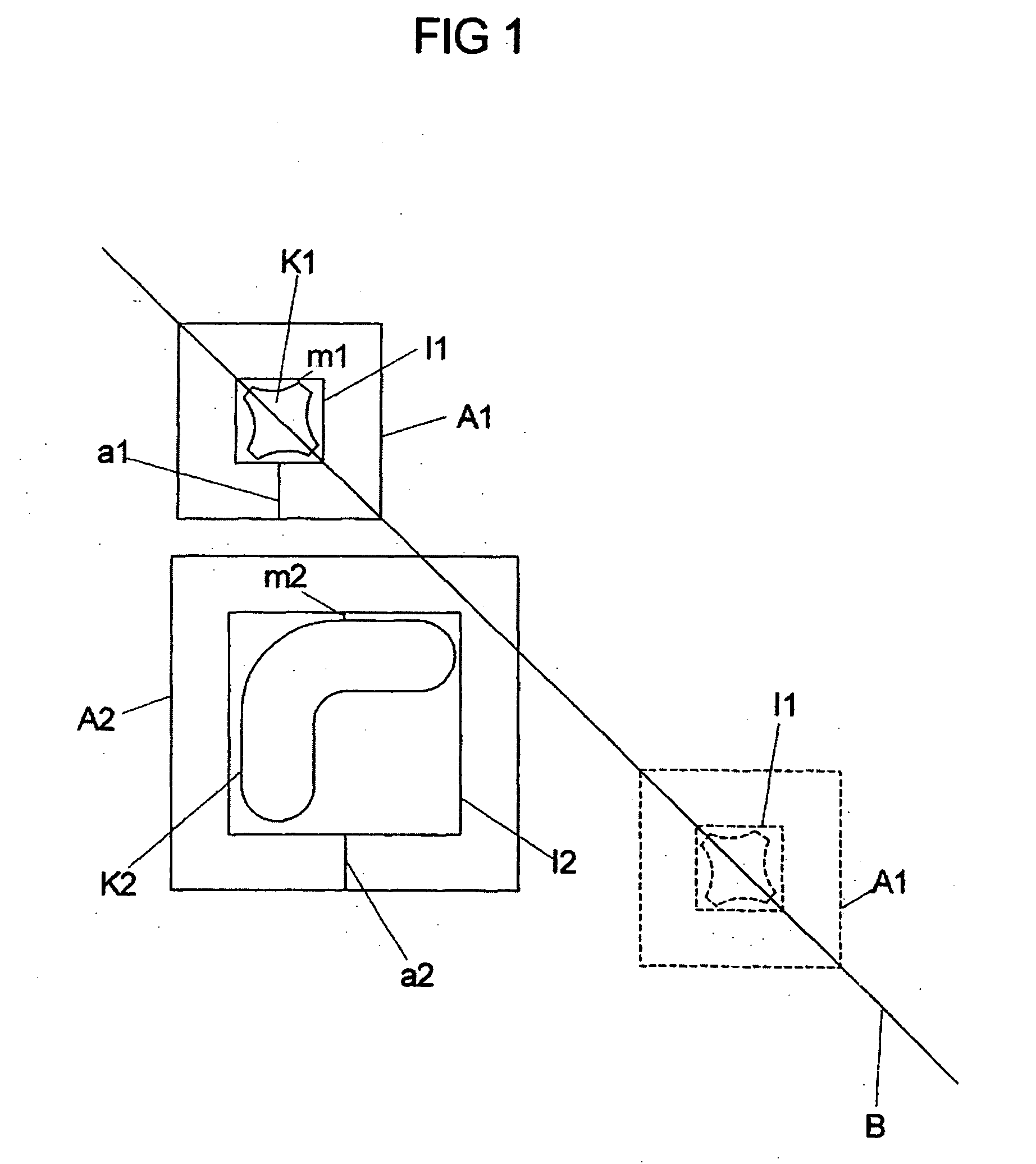

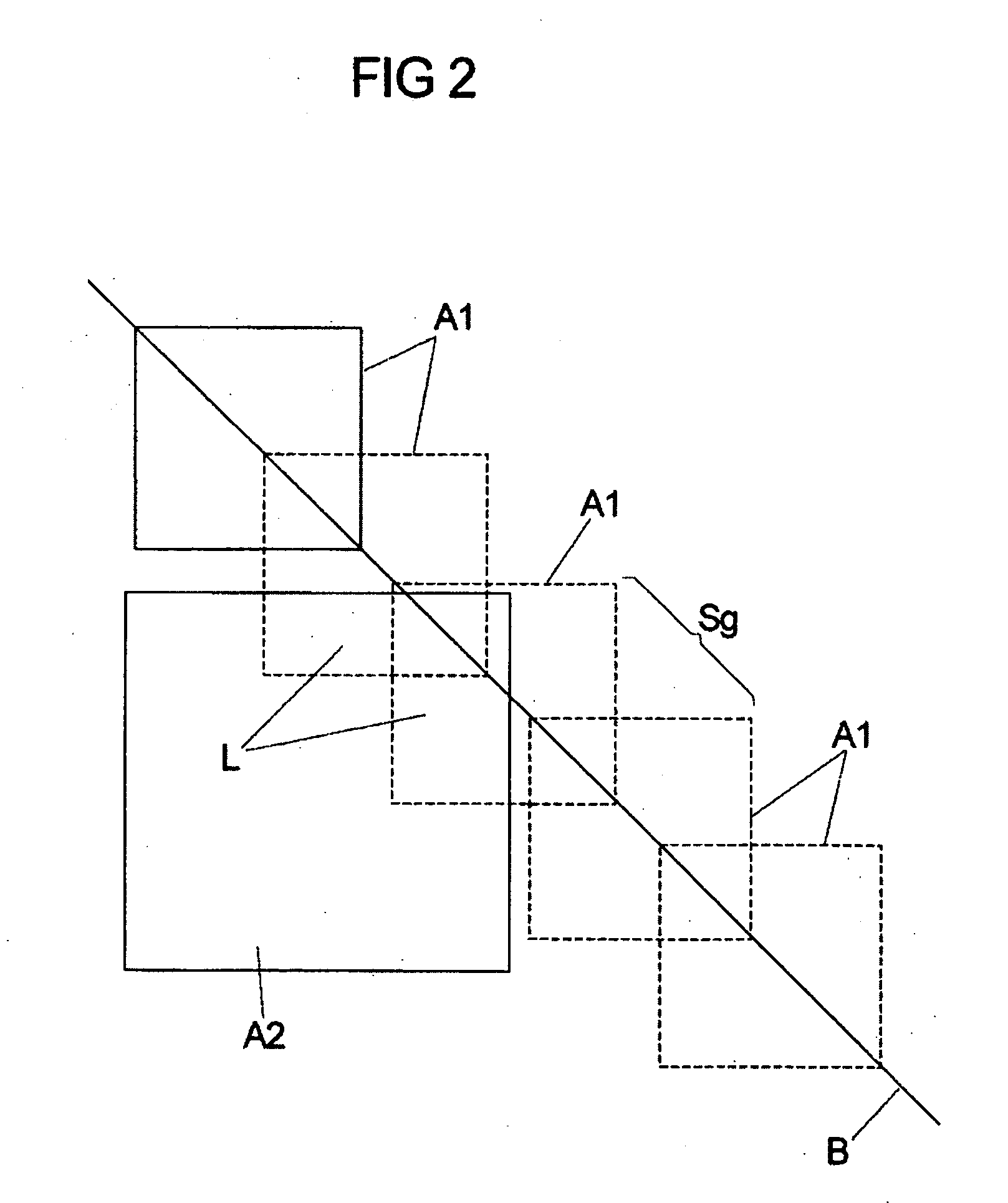

Method for detecting a possible collision of at least two objects moving with respect to each other

A method is for detecting a possible collision of at least two objects moving with respect to each other by simulating the intended relative motion of the two objects. At least one of the objects is assigned an envelope surrounding the object, the path line represents the relative motion of the objects is covered in steps of a defined step size, and the occurrence of an overlap of the objects is detected for ascertaining a possible collision of the objects. For at least one object, the outer contour of the corresponding envelope is used as a datum for detecting an overlap. At least one object is assigned an inner and an outer envelope, of which the inner envelope surrounds the object and the outer envelope surrounds the inner envelope. The outer envelope is used as a datum for detecting an overlap of the two objects, and when an overlap is detected in a segment of the path line, the segment of the path line is re-traversed using a smaller, second step size. When the segment of the path line is re-traversed, the inner envelope of at least one of the objects is used as a datum for detecting an overlap.

Owner:DR JOHANNES HEIDENHAIN GMBH

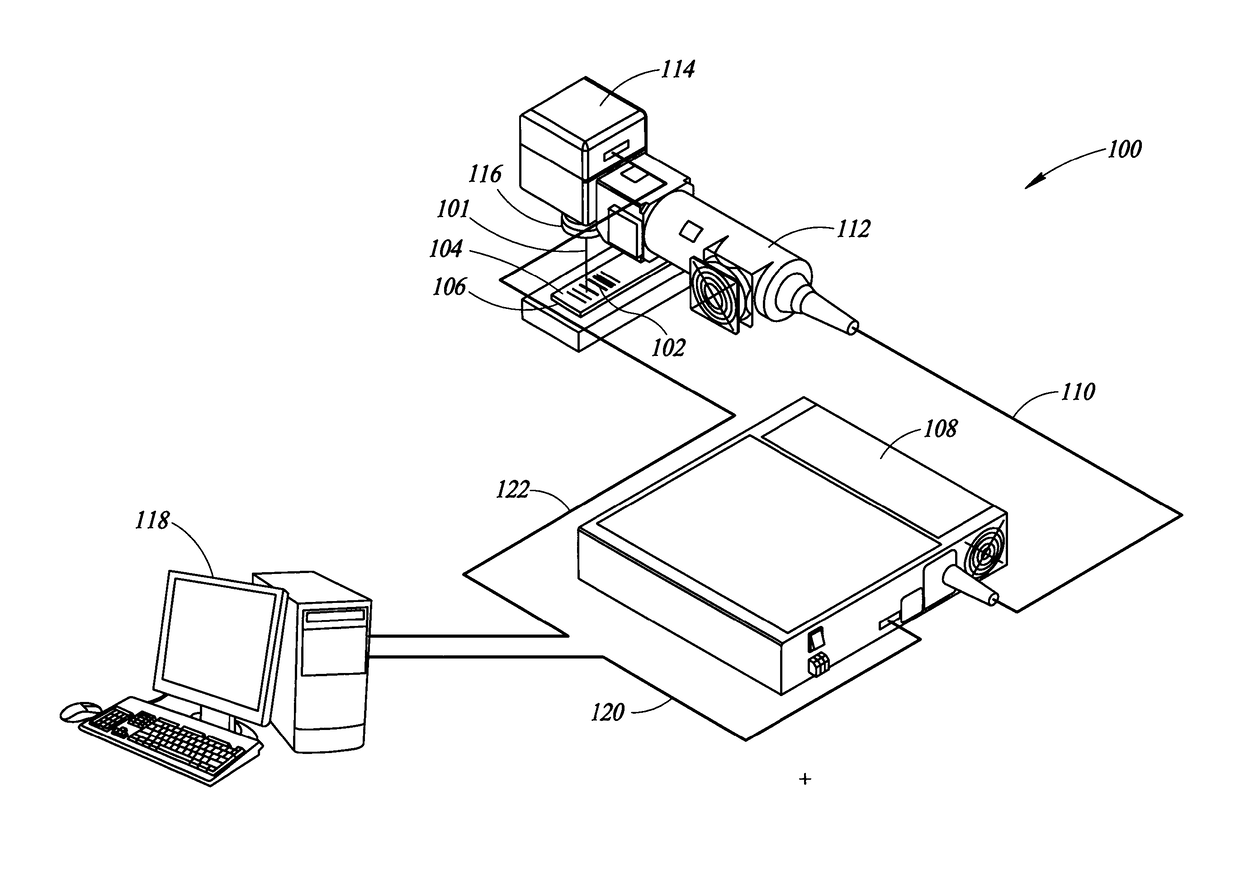

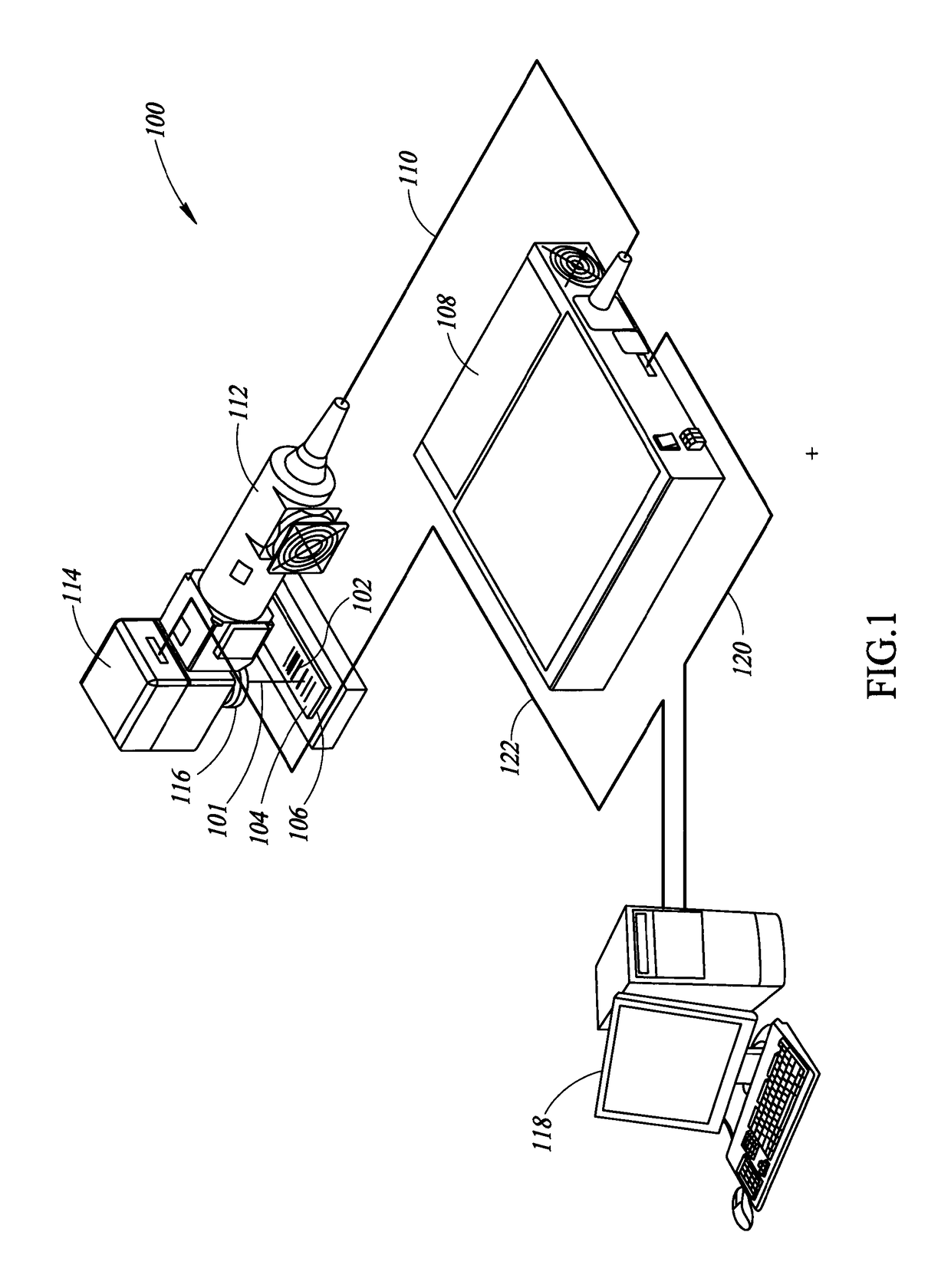

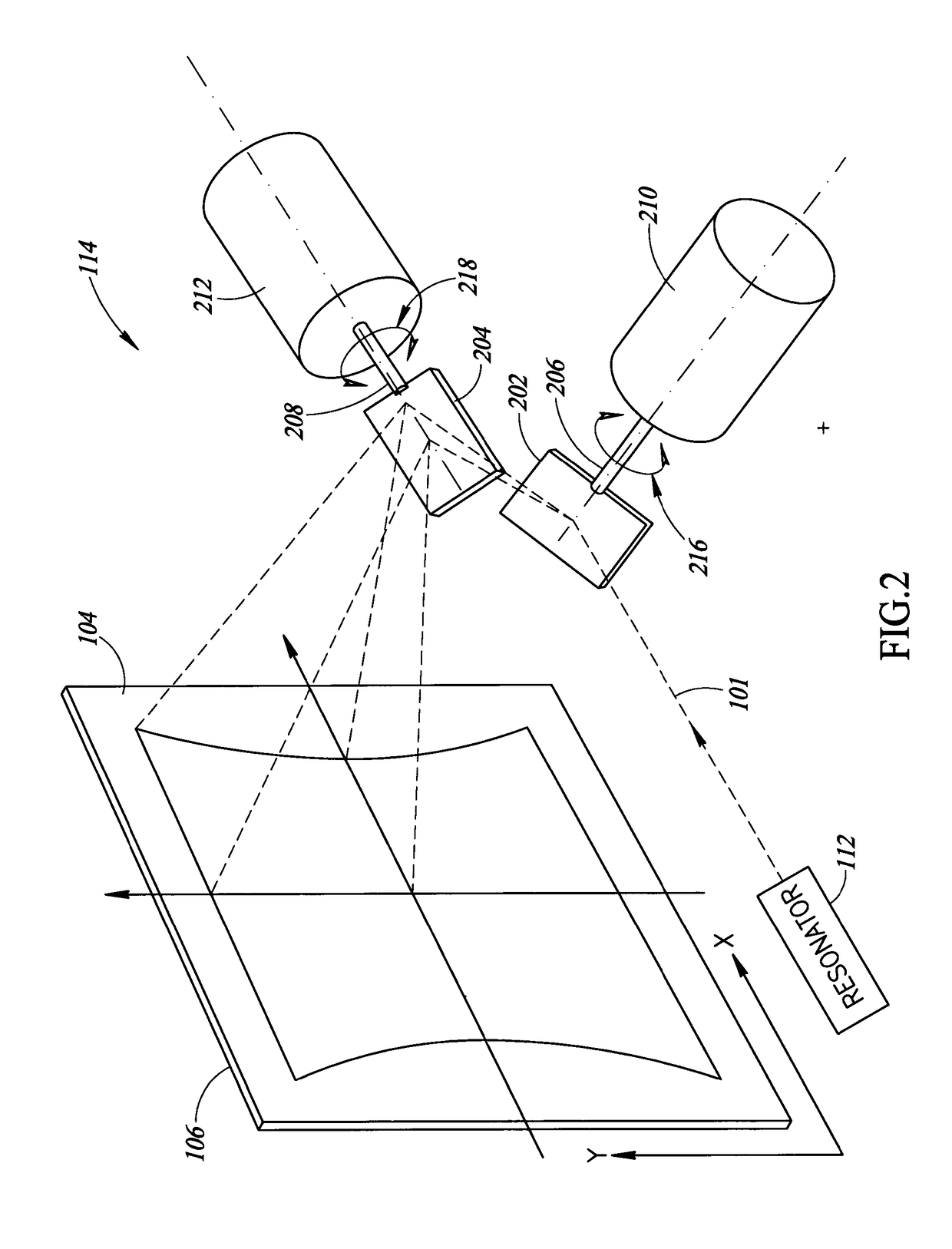

Systems, methods, and articles for laser marking machine-readable symbols

Systems and methods for generating machine-readable symbols on surfaces of objects using laser marking systems and processes. A specialized contour fill pattern for a laser beam path may be used that combines modules of a machine-readable symbol into bounded blocks or islands according to adjacencies and / or according to role (e.g., finder pattern, timing pattern, encoded payload data). In some implementations, the islands of modules may be filled using a laser beam path that traverses contour path lines from inner path lines to outer path lines. Once the islands have been generated during pre-processing, they are sorted to reduce the required time for the laser to “jump” (i.e., move with the laser turned off) from one island to a subsequent island to be filled. A filling pattern for bounded areas with sharp corners (e.g., squares, rectangles) may be simplified by rounding corners to optimize speed while maintaining suitable marking quality.

Owner:DATALOGIC IP TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com