Cover sealing welding machine of compressor

A welding machine and compressor technology, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problem of high-precision, high-strength welding technology for compressor covers, and compressor shell compensation. and correction, large size dispersion and other problems, to achieve the effect of light weight, improved quality, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below by specific embodiment the present invention is described in further detail:

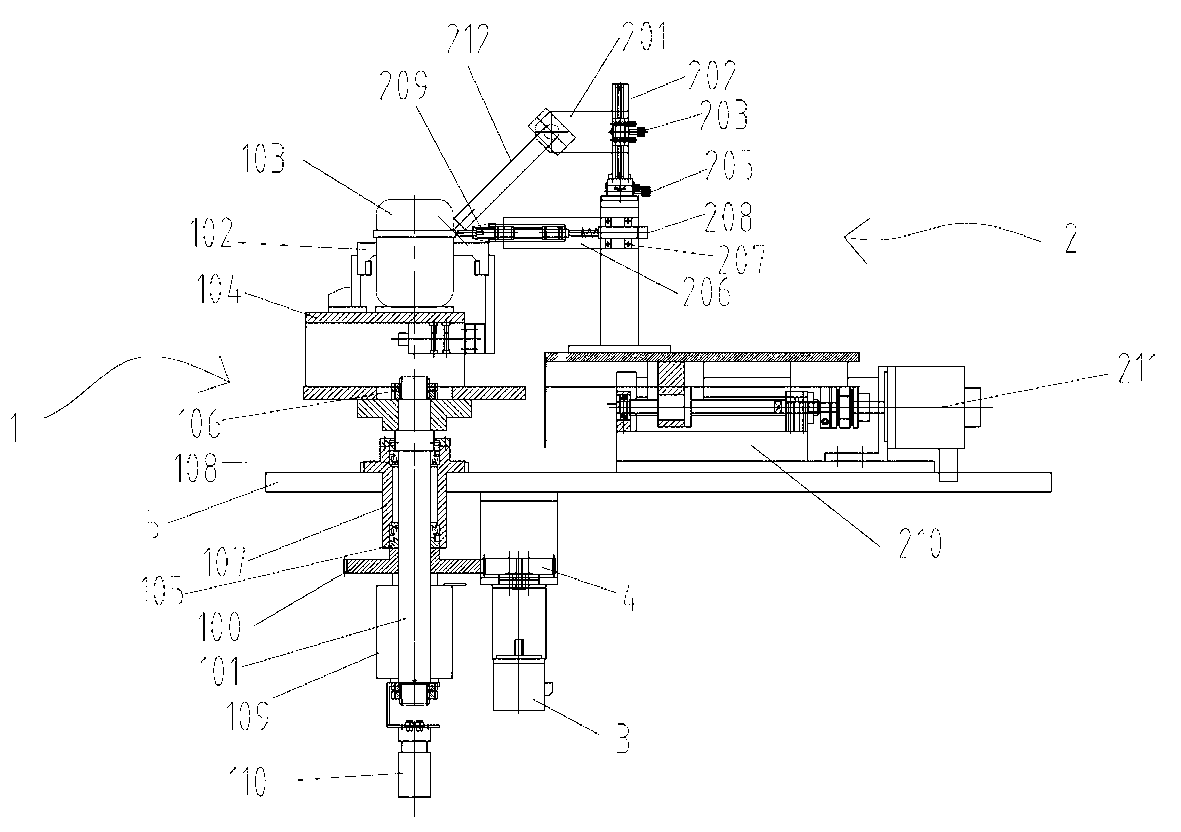

[0023] Such as figure 1 The front view of the welding machine shown is mainly composed of a rotary table 1 and a welding part 2. The rotary table 1 is driven to rotate by a rotary servo motor 3. The rotary servo motor 3 is installed at the lower end of the horizontal platform 5, and through gears 4 and The driven gear 100 on the rotary table 1 is connected, and the driven gear 100 is installed on the stepped rotating main shaft 101 through a key (not shown in the figure). There is a shell clamp 102 on the top of the rotary table 1, which is used to tighten the cylinder head 103 of the compressor. The size of the cavity of the housing fixture 102 can be adjusted to meet the requirements of workpieces of different sizes (ie, cylinder heads of compressors). The housing fixture 102 is installed in the cavity of the rotary disc 104, and the rotary disc 104 is connected to the stepped rotar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com