Patents

Literature

1626 results about "Welding defect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A welding defect is any flaw that compromises the usefulness of a weldment. There is a great variety of welding defects. Welding imperfections are classified according to ISO 6520 while their acceptable limits are specified in ISO 5817 and ISO 10042.

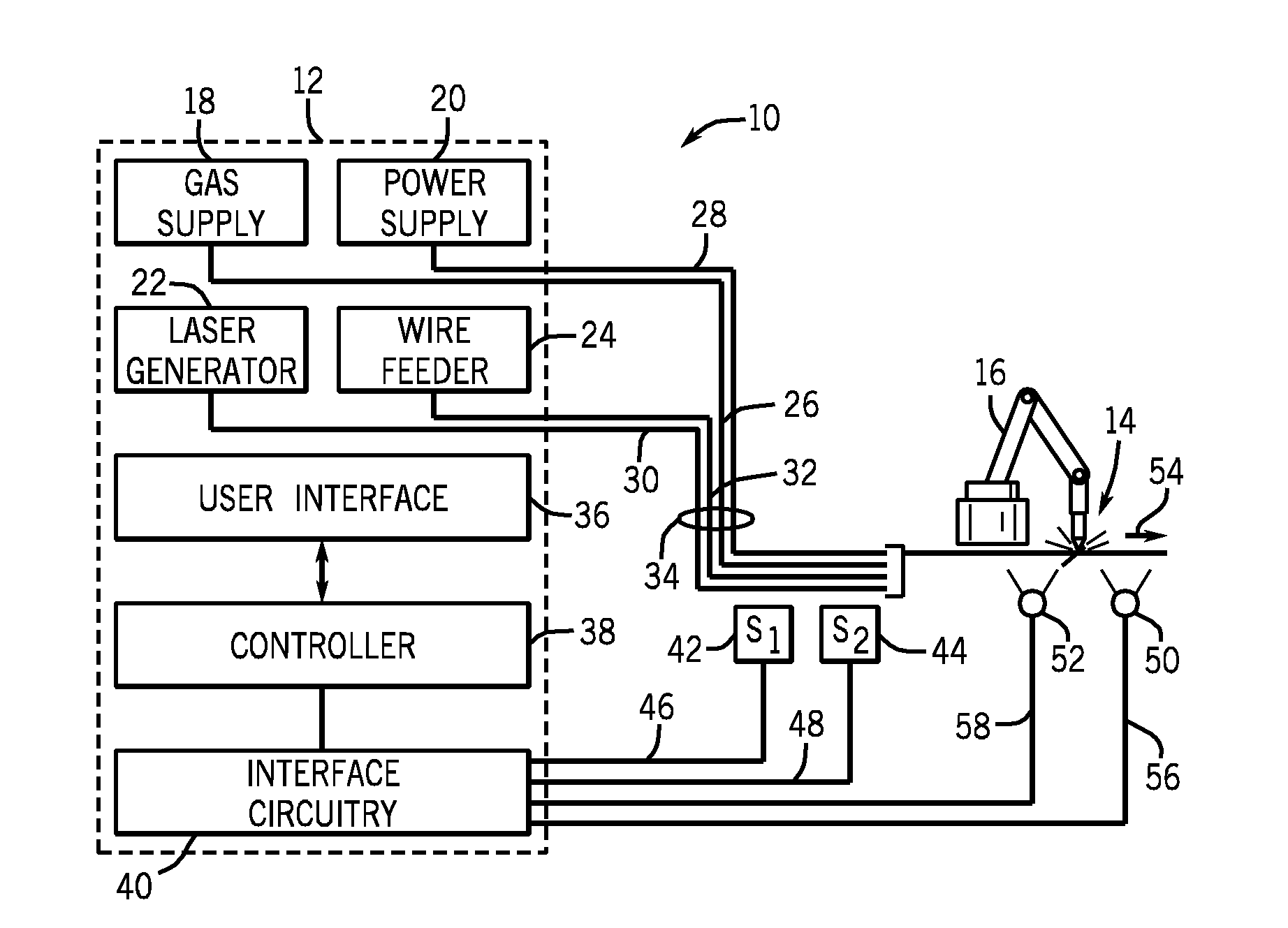

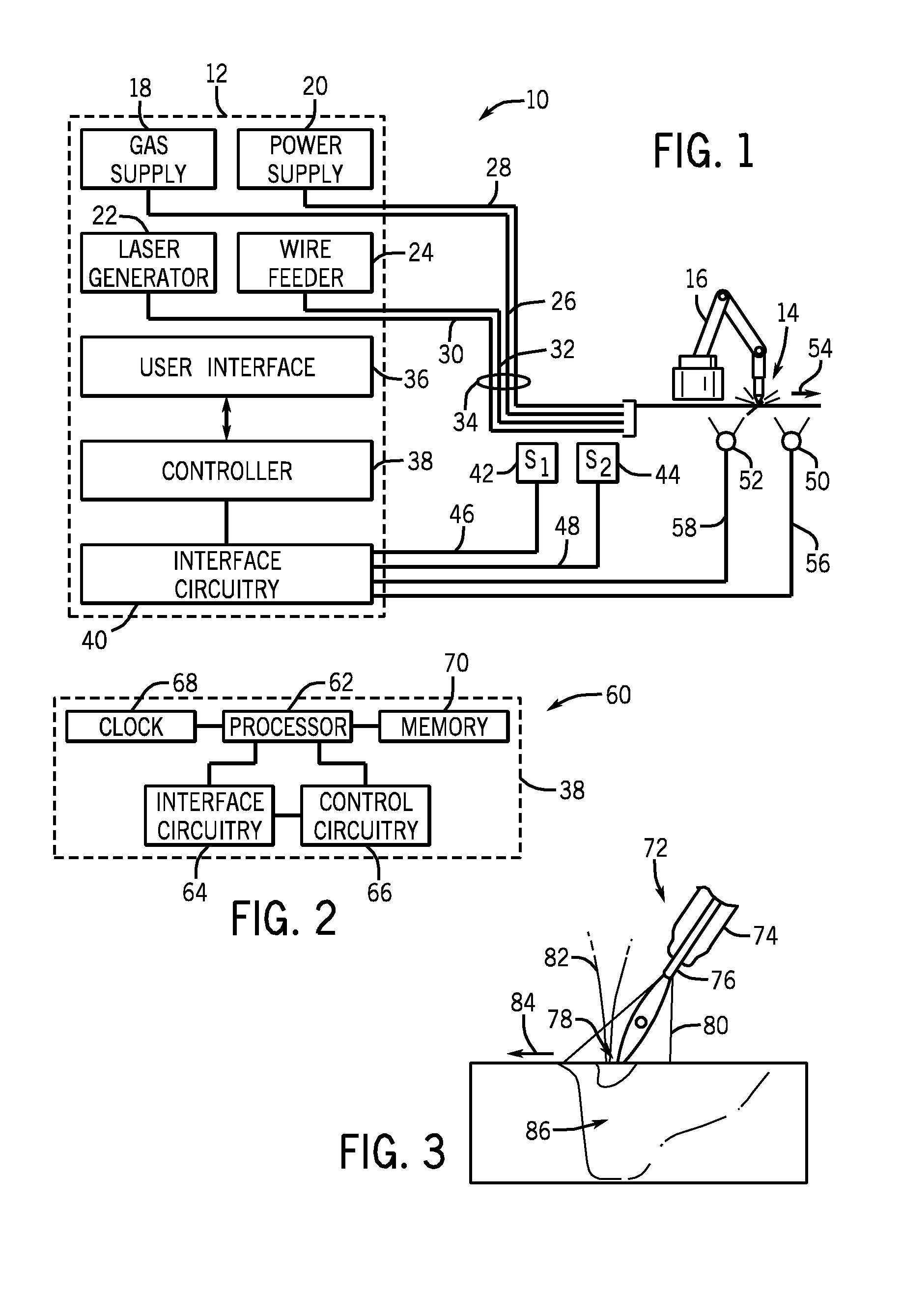

Weld defect detection systems and methods for laser hybrid welding

ActiveUS20100314362A1Welding/cutting auxillary devicesArc welding apparatusLaser-hybrid weldingPower flow

Laser hybrid welding systems adapted to identify and / or fix a weld defect occurring during a laser hybrid welding process are provided. Embodiments of the laser hybrid welding system may include one or more devices that provide feedback to a controller regarding one or more weld parameters. One embodiment of the laser hybrid welding system includes sensors that are adapted to measure the weld voltage and / or amperage during the welding process and transmit the acquired data to the controller for processing. Another embodiment of the laser hybrid welding system includes a lead camera and a lag camera that film an area directly in front of the weld location and directly behind the weld location.

Owner:ILLINOIS TOOL WORKS INC

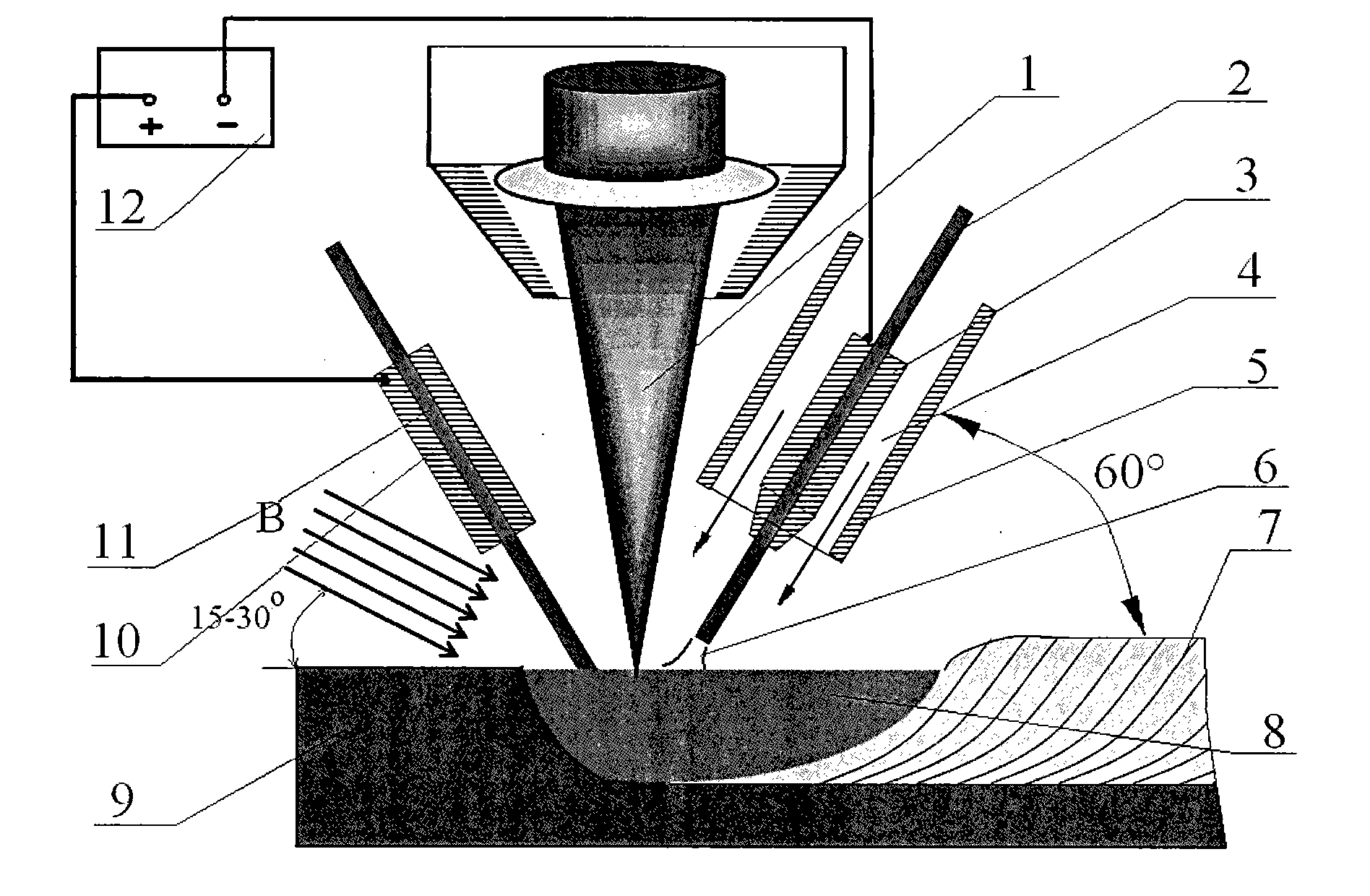

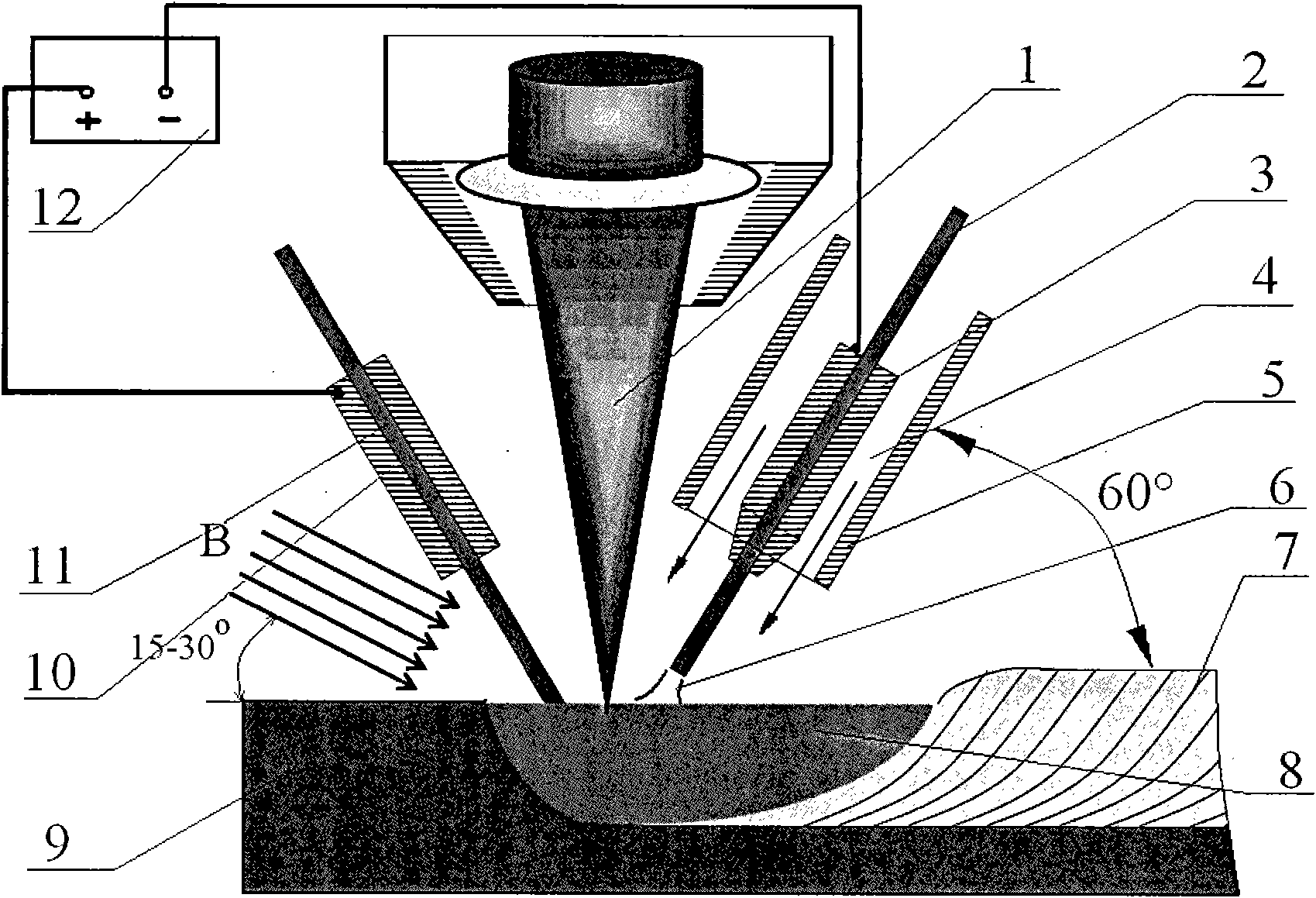

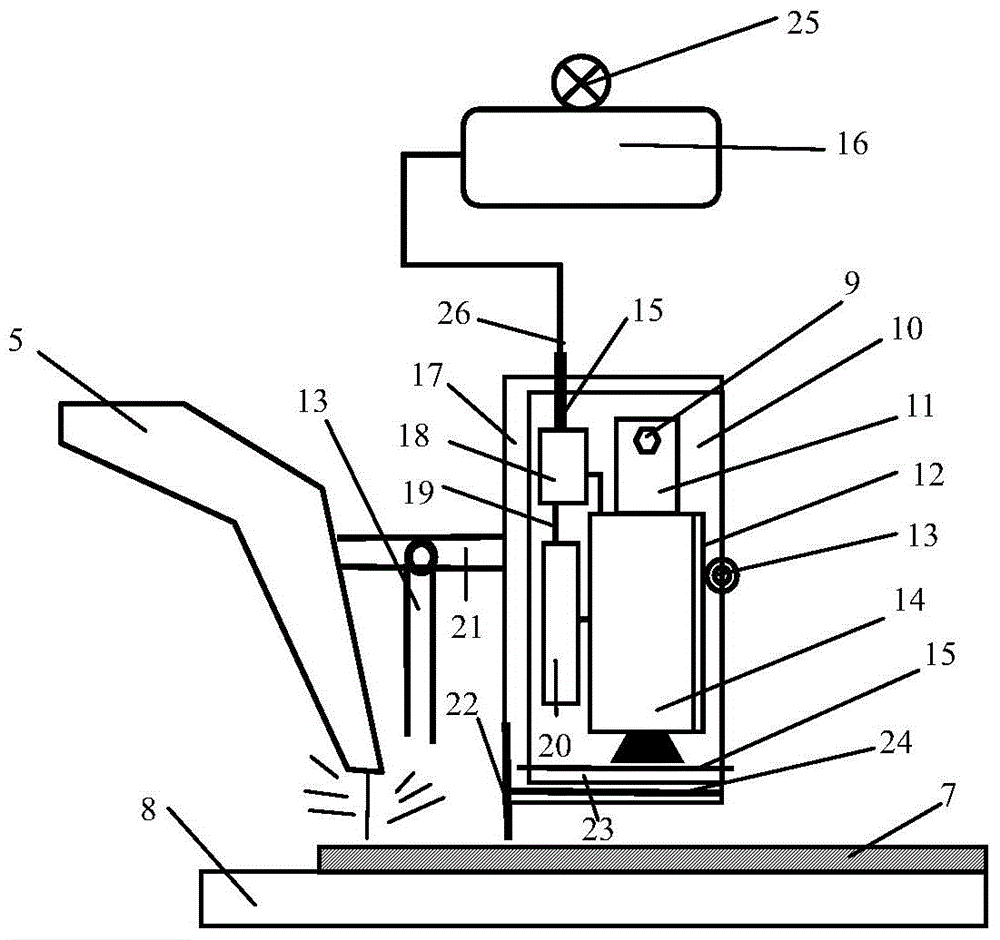

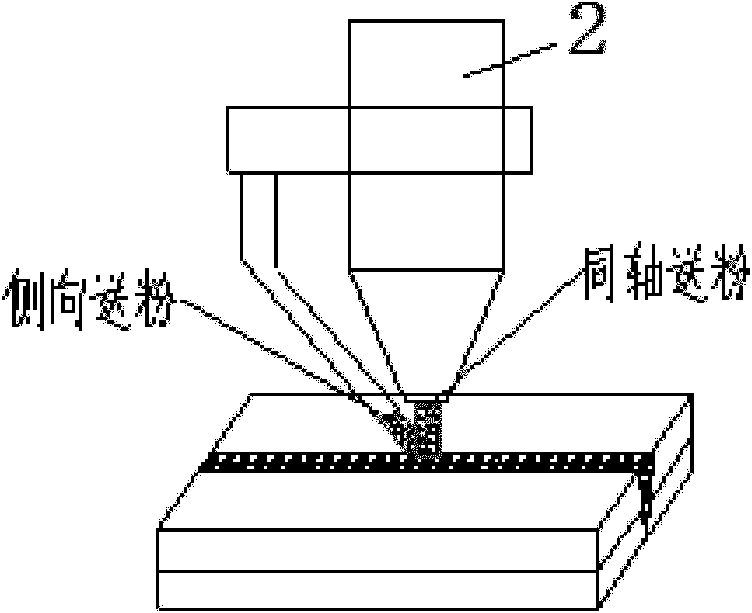

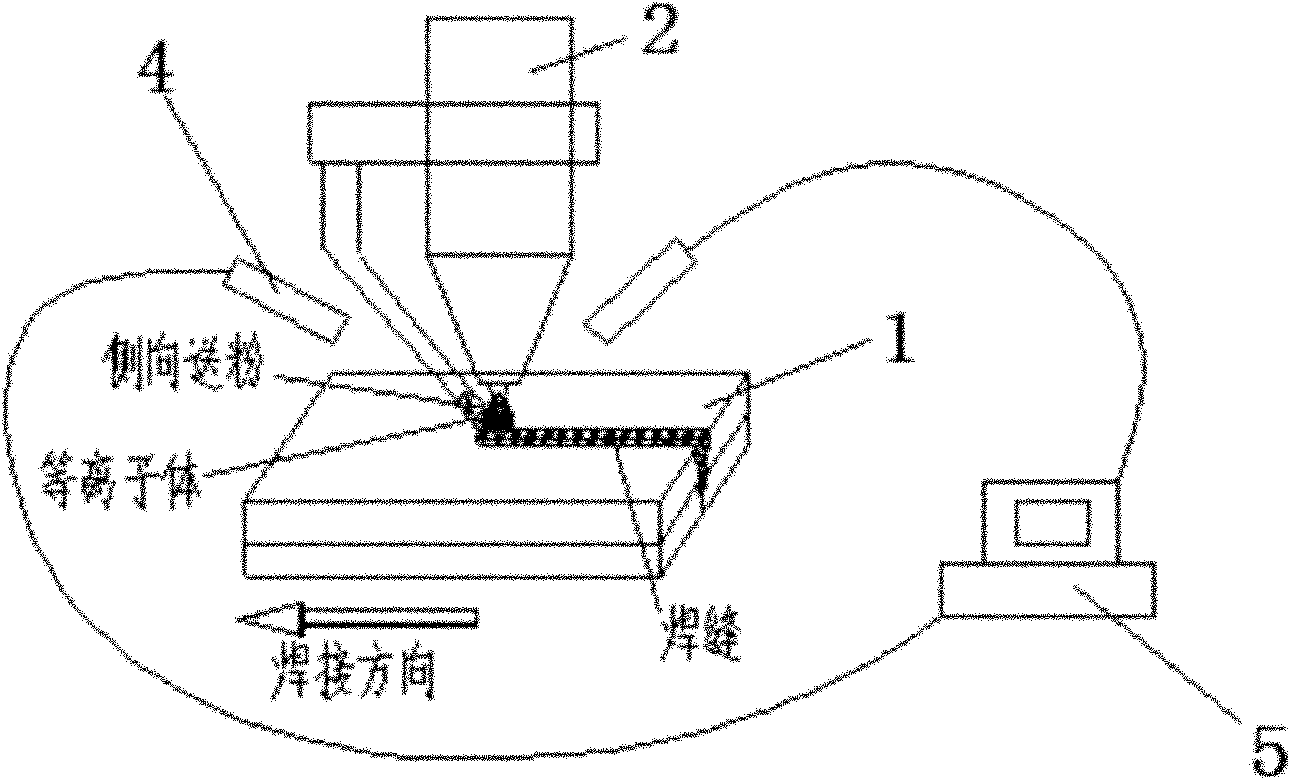

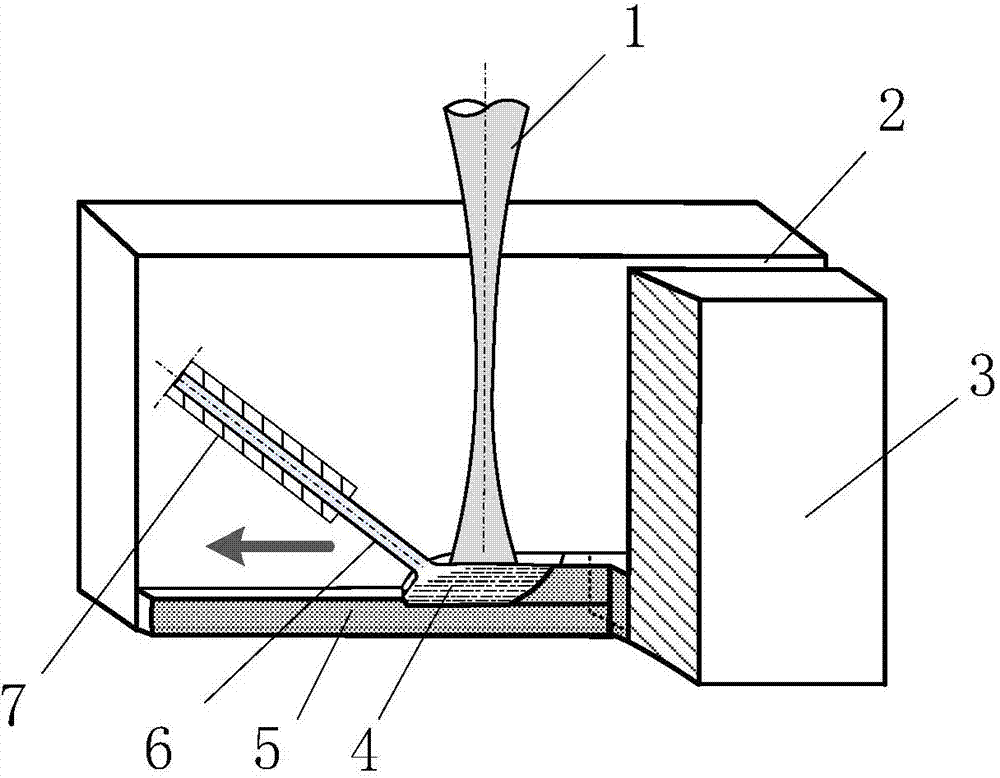

Electromagnetic current coupling field assisted hybrid melting-brazing method for laser-TIG arc and equipment

InactiveCN101862913AImprove connection qualityInhibition formationSoldering apparatusWelding apparatusMetallic materialsWelding defect

The invention discloses an electromagnetic current coupling field assisted hybrid melting-brazing method for a laser-TIG arc and equipment. In addition to the use of the welding zone, an alternating magnetic field is added to control properties of plasma formed through ionization of laser, arc and a raw material metal, thereby improving the laser utilization rate. Under the electric field assisted comprehensive effect, the weld melting depth is increased, and the assistant effect on the melting bath of the liquid-state brazing filler metal for laser-arc melting-brazing is realized through electromagnetic stirring and excitation and enhancement, thereby promoting the orderly flow of the liquid-state brazing filler metal and the rupture, wetting, spreading and proliferation of the liquid-state brazing filler metal on the surface of the high metal material, improving the full mixing of the liquid-state brazing filler metal and the base metal formed by melting the low-melting-point metal material, improving the uniformity of the components of the brazed weld, stabilizing the welding process, reducing welding defects, increasing the welding speed, improving the weld formation, optimizing the structure and performance of the brazed weld, and improving the quality of the brazed joint. Moreover, the equipment has the advantages of simple structure, flexible application, low cost, good effect and easy realization.

Owner:CHONGQING UNIV

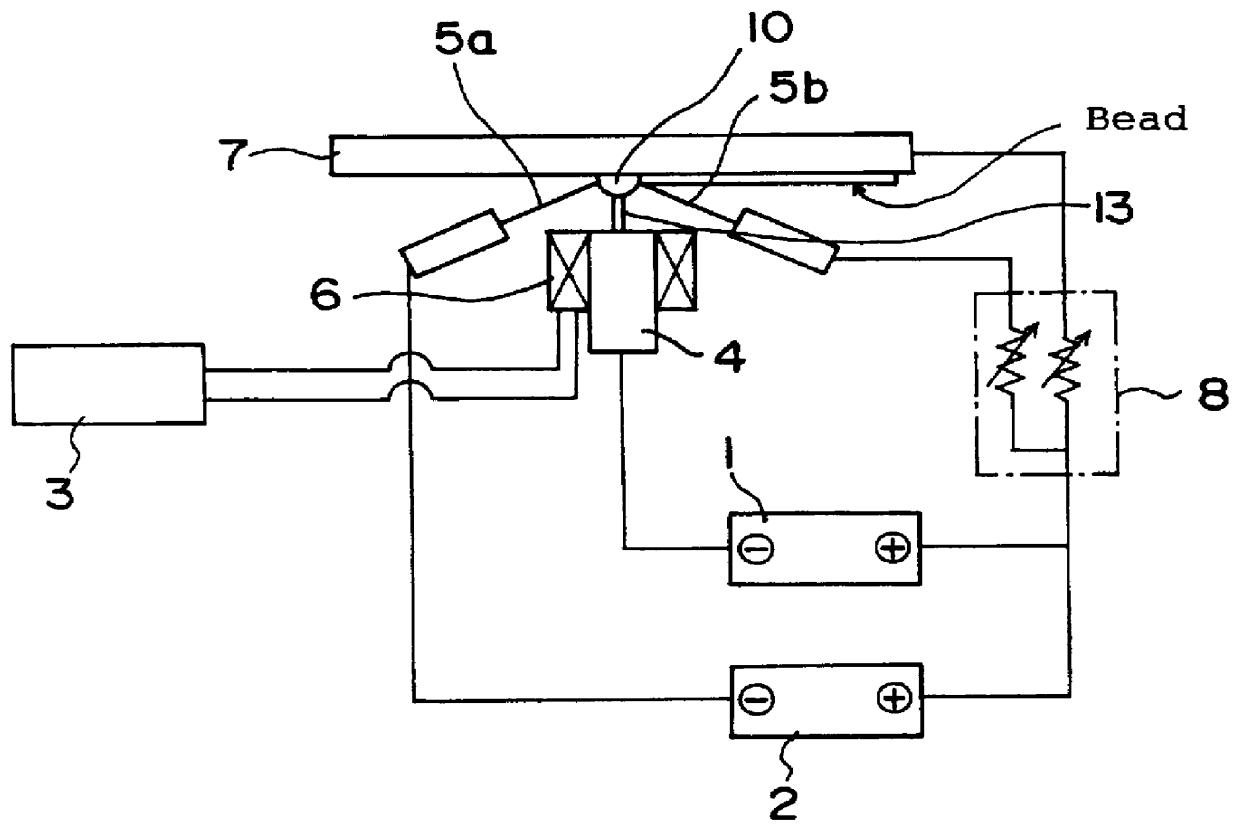

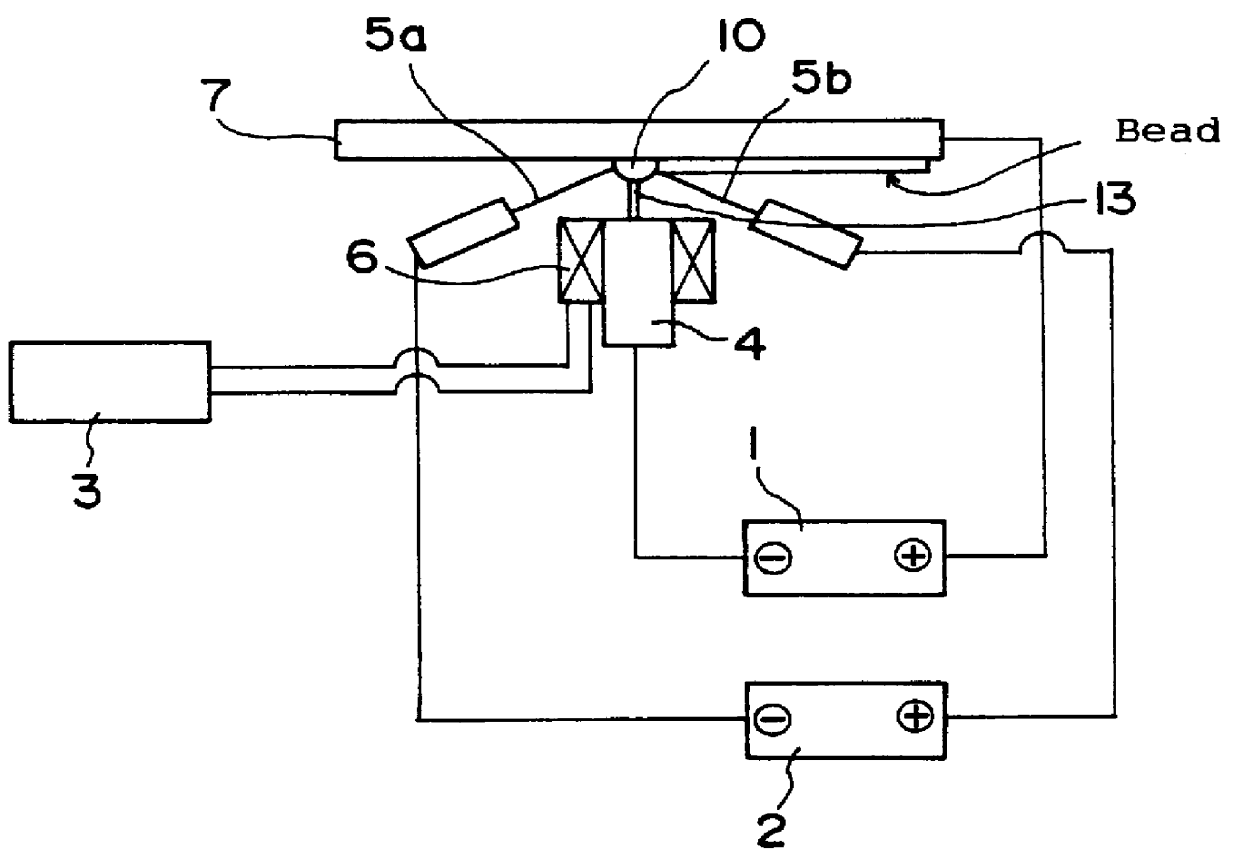

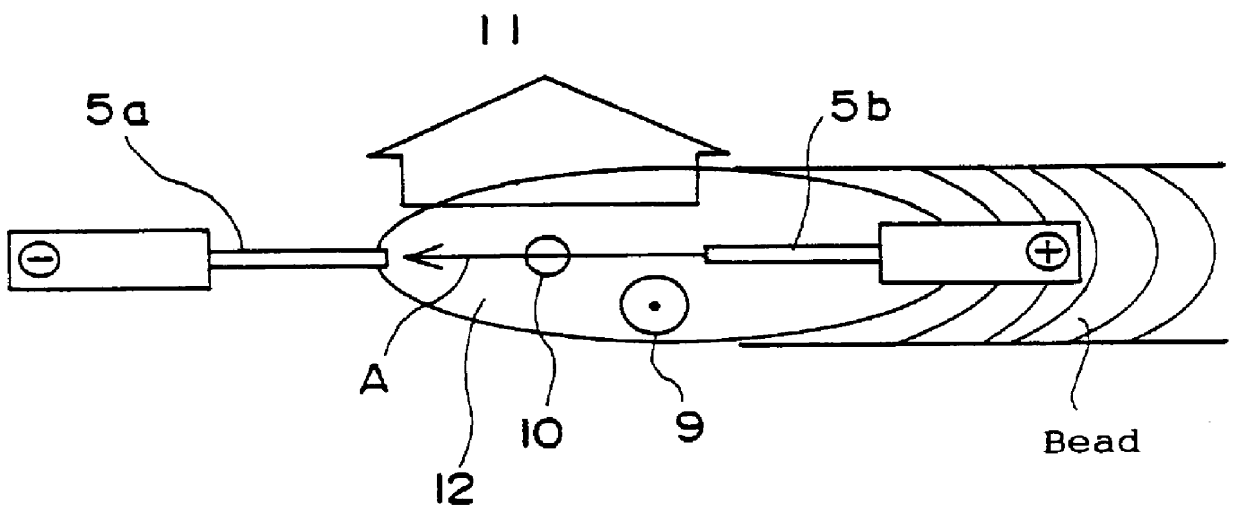

Method of welding in the horizontal position and welding apparatus therefor

InactiveUS6023043ABetter-shaped beadWelding/cutting auxillary devicesArc welding apparatusEngineeringWelding defect

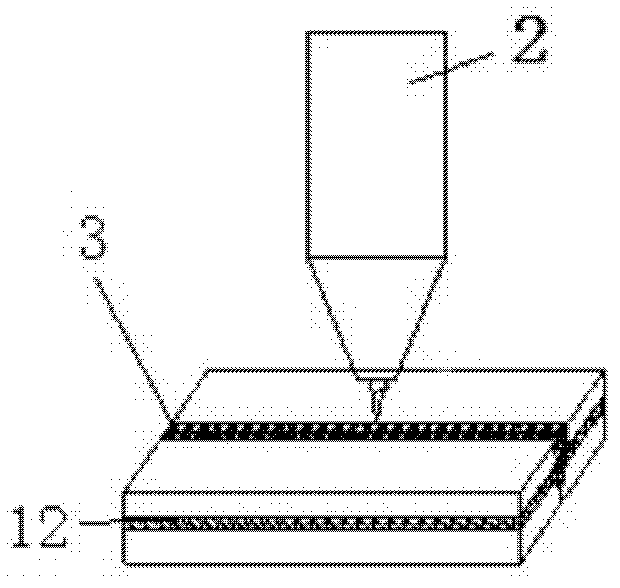

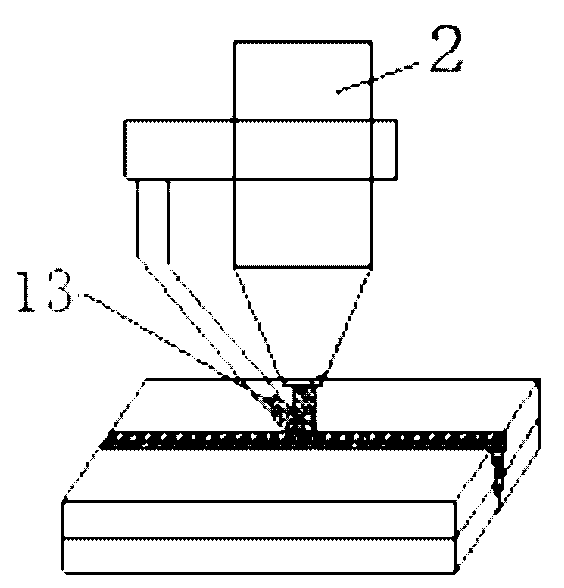

PCT No. PCT / JP97 / 01533 Sec. 371 Date Jan. 12, 1998 Sec. 102(e) Date Jan. 12, 1998 PCT Filed May 7, 1997 PCT Pub. No. WO97 / 43073 PCT Pub. Date Nov. 20, 1997The object of this invention is to prevent the occurrence of welding defects such as undercuts, overlaps and faulty angles of fusion, and to increase the efficiency of welding in the horizontal position. Auxiliary wires 5a and 5b are inserted into molten pool 12, and a unidirectional current is made to flow between them. A magnetic field 9 is induced which is approximately orthogonal to the surface of the parent material so as to generate an upward Lorentz force (opposite the pull of gravity) in molten pool 12. This force supports the molten metal and prevents it from dripping, resulting in a better-shaped bead.

Owner:MITSUBISHI HEAVY IND LTD

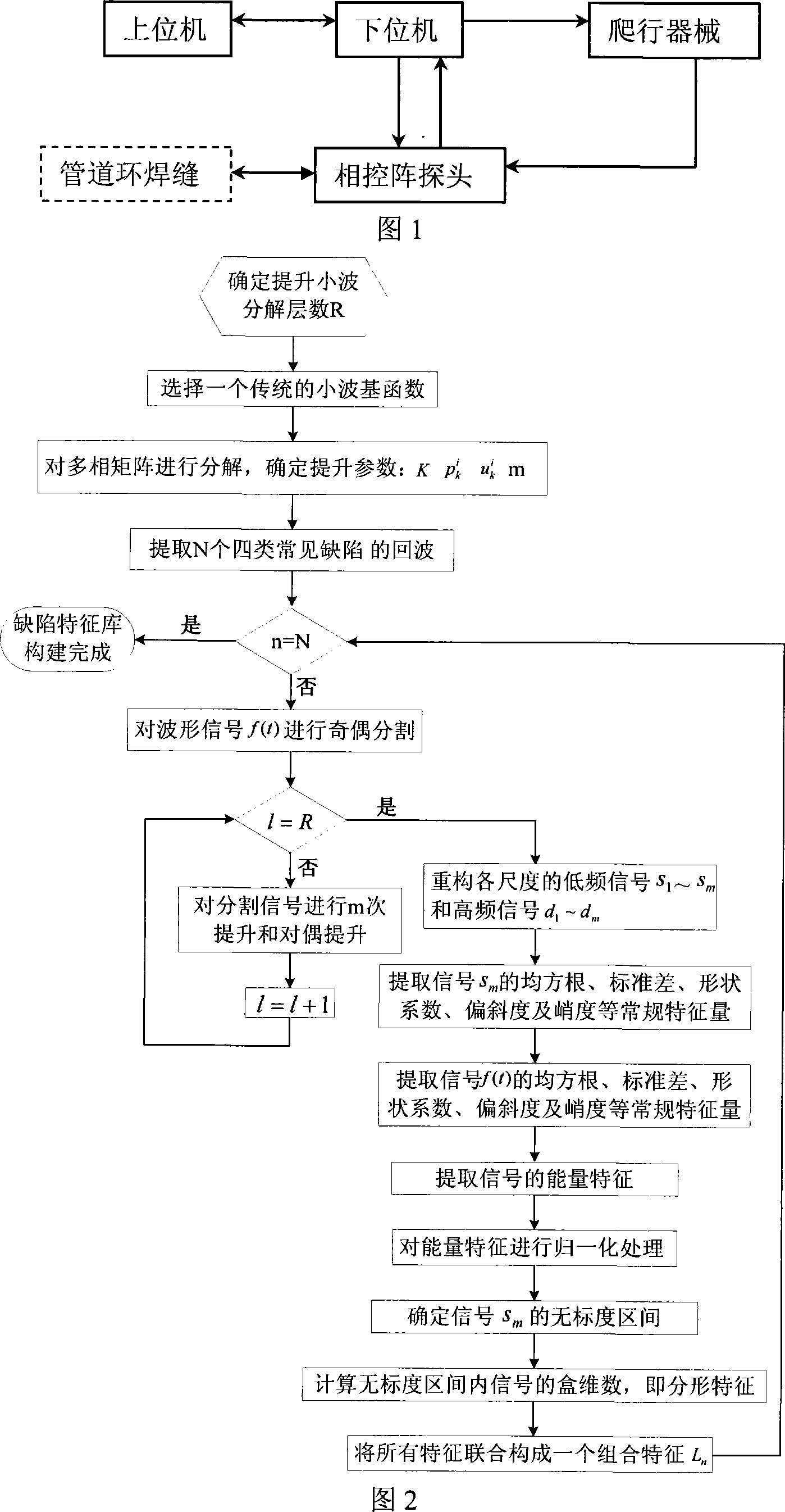

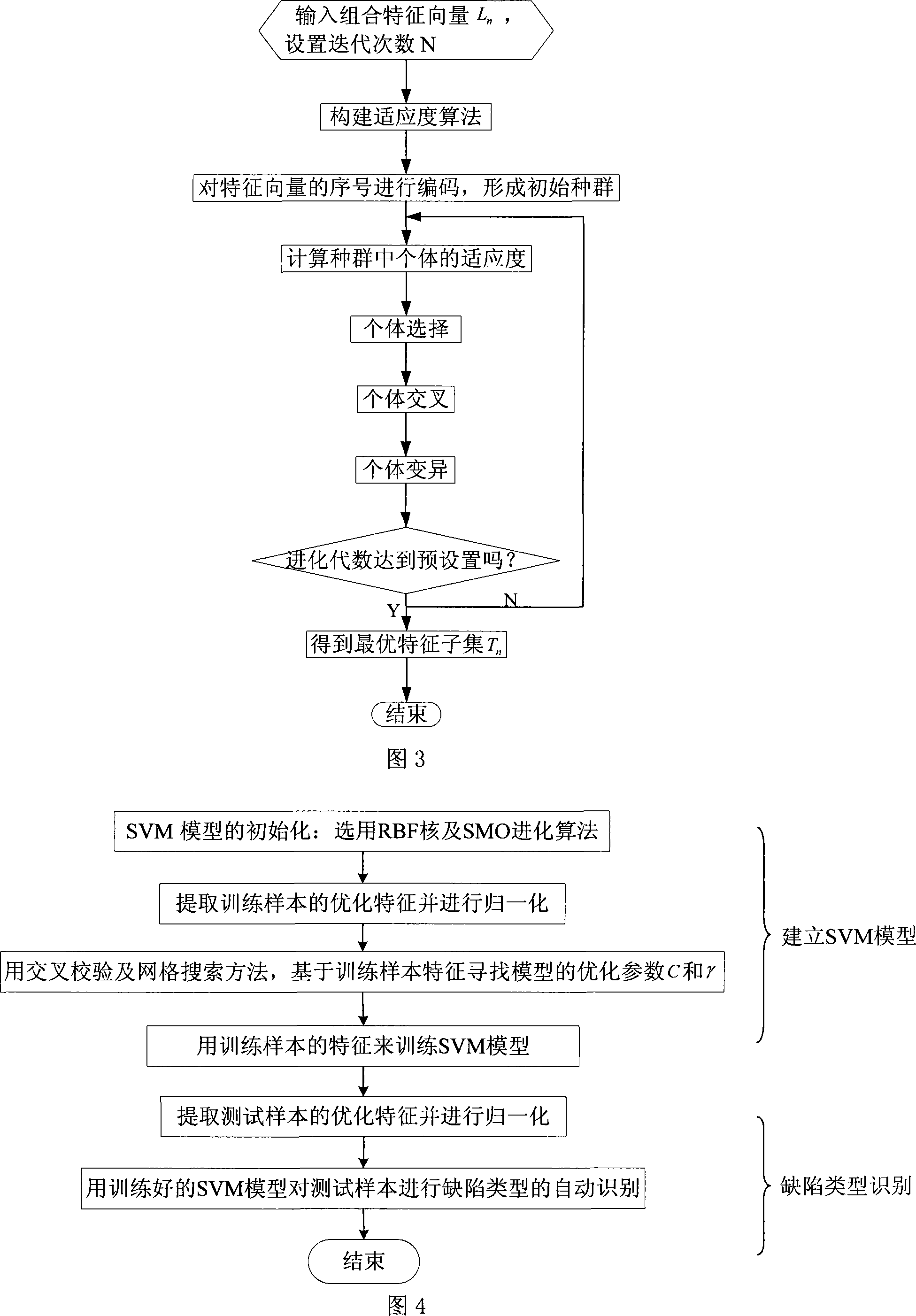

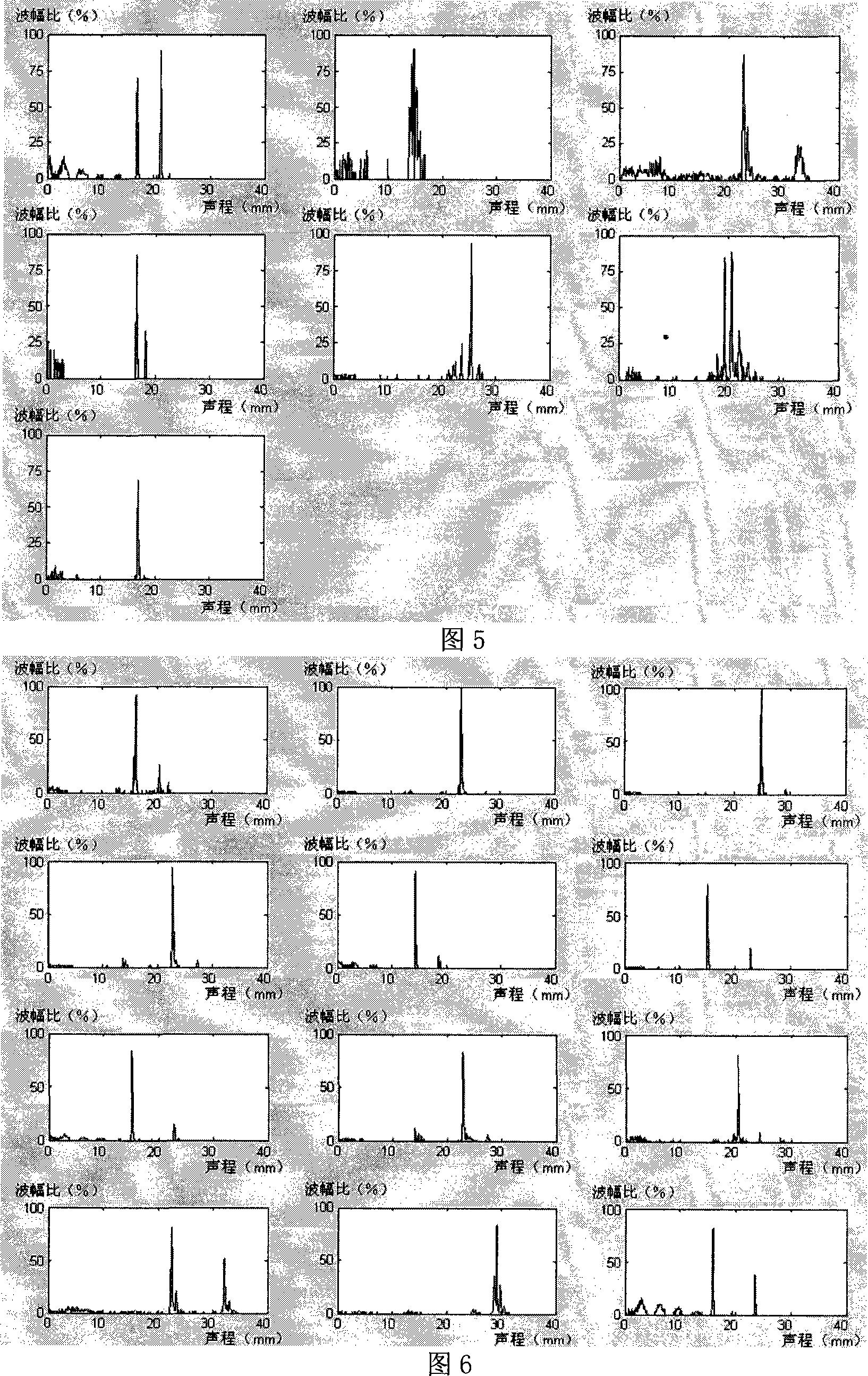

Automatic identification method for supersonic phased array for detecting oil gas pipeline girth weld defect type

InactiveCN101122585ARealize filteringReduce needProcessing detected response signalSpecial data processing applicationsSupport vector machineFeature extraction

The invention discloses an ultrasonic phased array inspection oil-gas pipe circular weld defect automatic recognition method, in particular to an ultrasonic phased array inspection oil-gas pipe circular weld defect automatic recognition method for a support vector machine, which belongs to a pipe circular weld defect type recognition technology. The recognition method includes two parts of the construction of a support vector machine model and the automatic recognition of unknown defect types in circular weld. The construction steps of the support vector machine model include artificial defect signals extraction, wavelet decomposition promotion, feature extraction, feature optimization and the training of the support vector machine model. The automatic recognition steps of unknown defect types in circular weld include defect signals extraction, optimized feature calculation and automatic recognition based on the support vector machine. The invention combines a lifting wavelet transform with a fractal technology and has the advantages of high recognition accuracy and fast recognition speed. The automatic recognition of the defect types can be realized.

Owner:TIANJIN UNIV

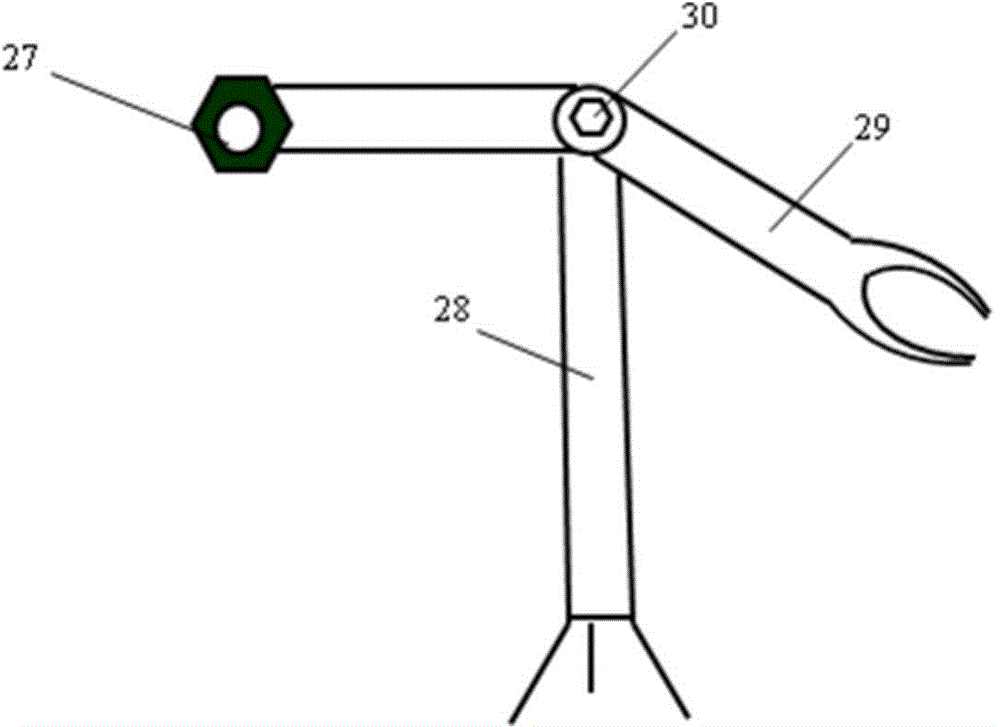

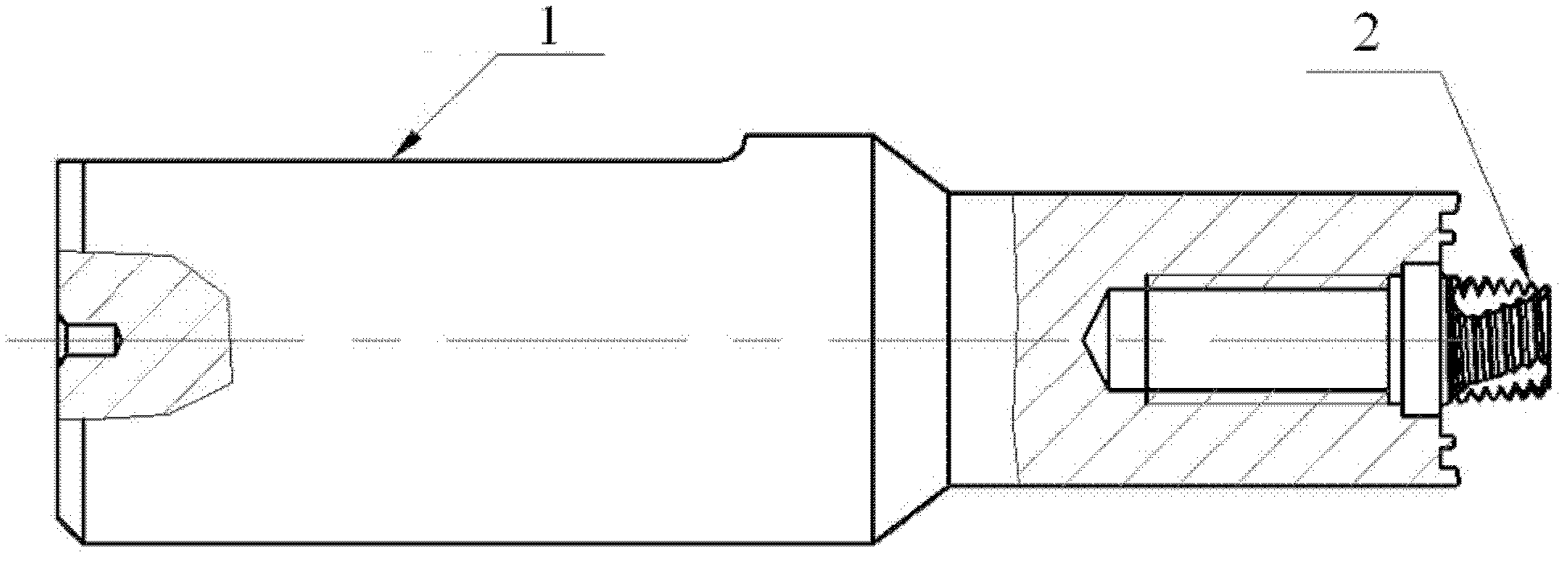

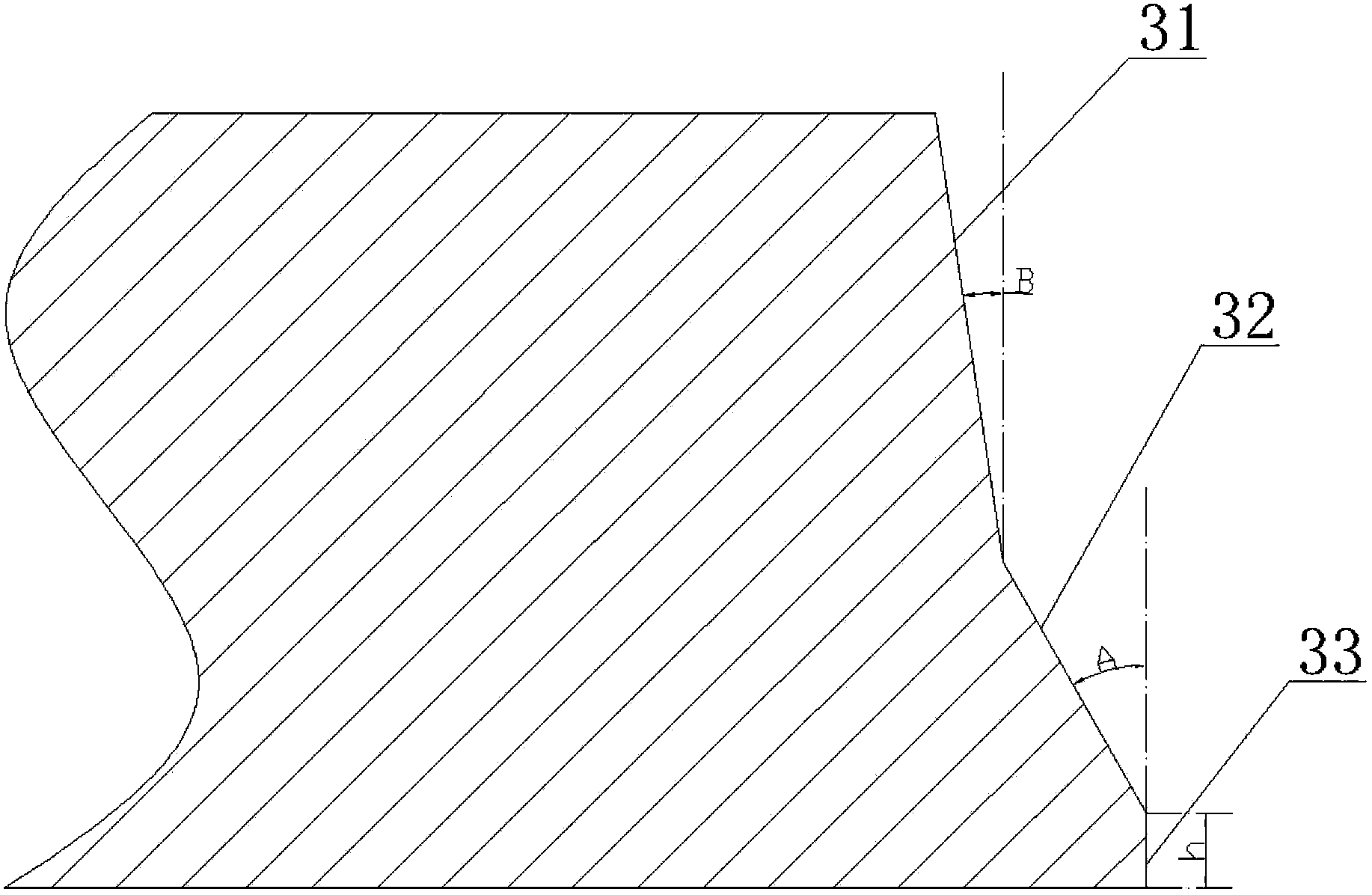

Fill type stirring friction plug repair welding method and welding tool thereof

InactiveCN101670483AReduce distortionAvoid intensityNon-electric welding apparatusFriction weldingEngineering

The invention discloses a fill type stirring friction plug repair welding method and a welding tool thereof, and relates to a stirring friction plug repair welding method and a welding tool thereof. The invention adopts fusion welding or friction plug welding for repair welding and causes the welding joints to reduce strength and have poor mechanical performance. The method comprises the followingsteps: (1) the material of a stirring pin is same as that of the part which repairs welding; (2) a conical preset hole is opened; (3) the size of the stirring pin is determined; (4) positioning is carried out; and (5) welding of the stirring friction plug is repaired. The welding tool is characterized in that the side wall of a clamping hole of a lower cylinder is provided with a thread through hole; a stirring body consists of the stirring pin and a stirring pin seat which are combined into a whole from top to bottom; the outer surface of the stirring pin seat is provided with a stirring pinclamping surface; the stirring pin is a cone; the stirring body is arranged in the clamping hole on the lower cylinder; the stirring pin clamping surface aligns to the thread through hole; and the stirring pin is exposed at the outside of the lower end surface of the lower cylinder. The invention is used for repair welding of the weld defects of stirring friction welding and keyholes.

Owner:HARBIN INST OF TECH

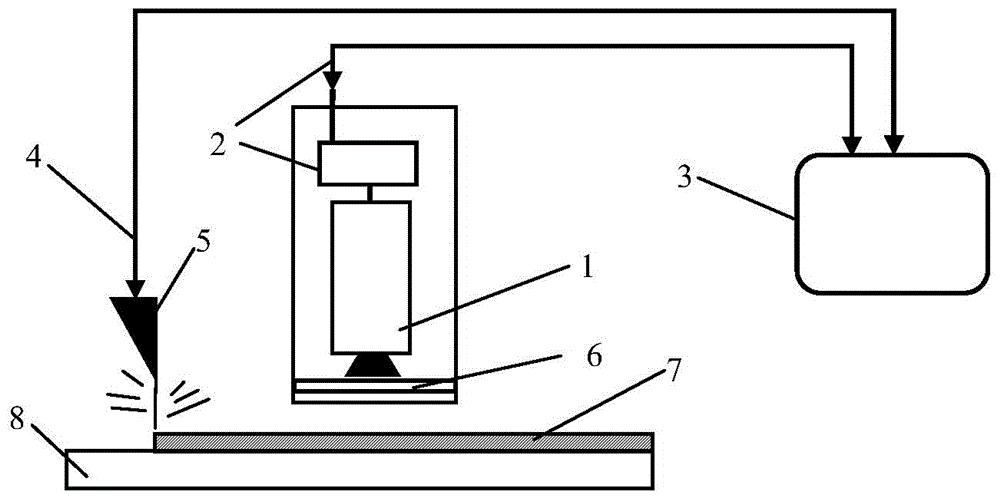

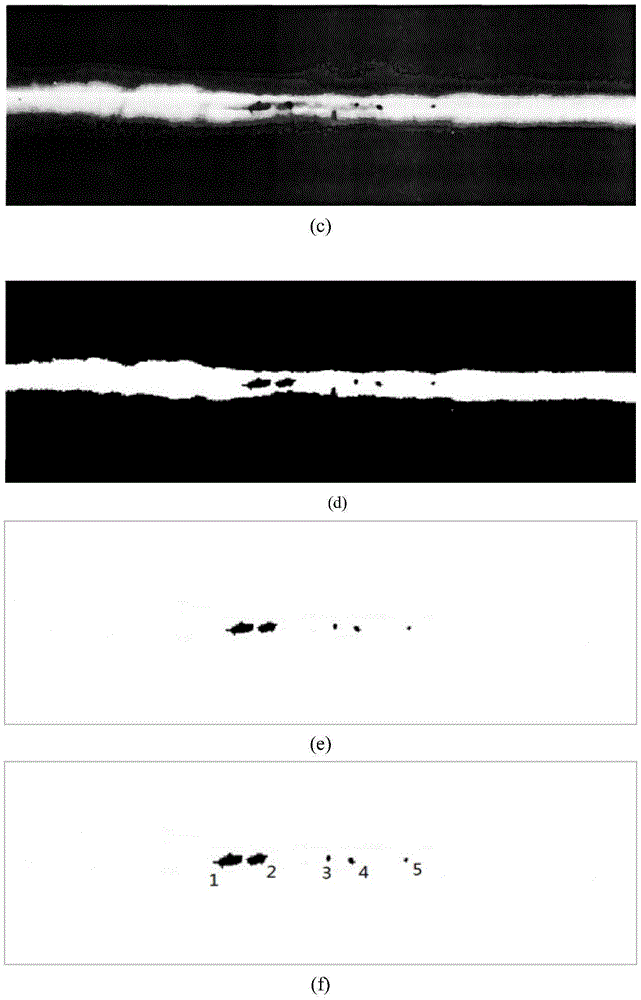

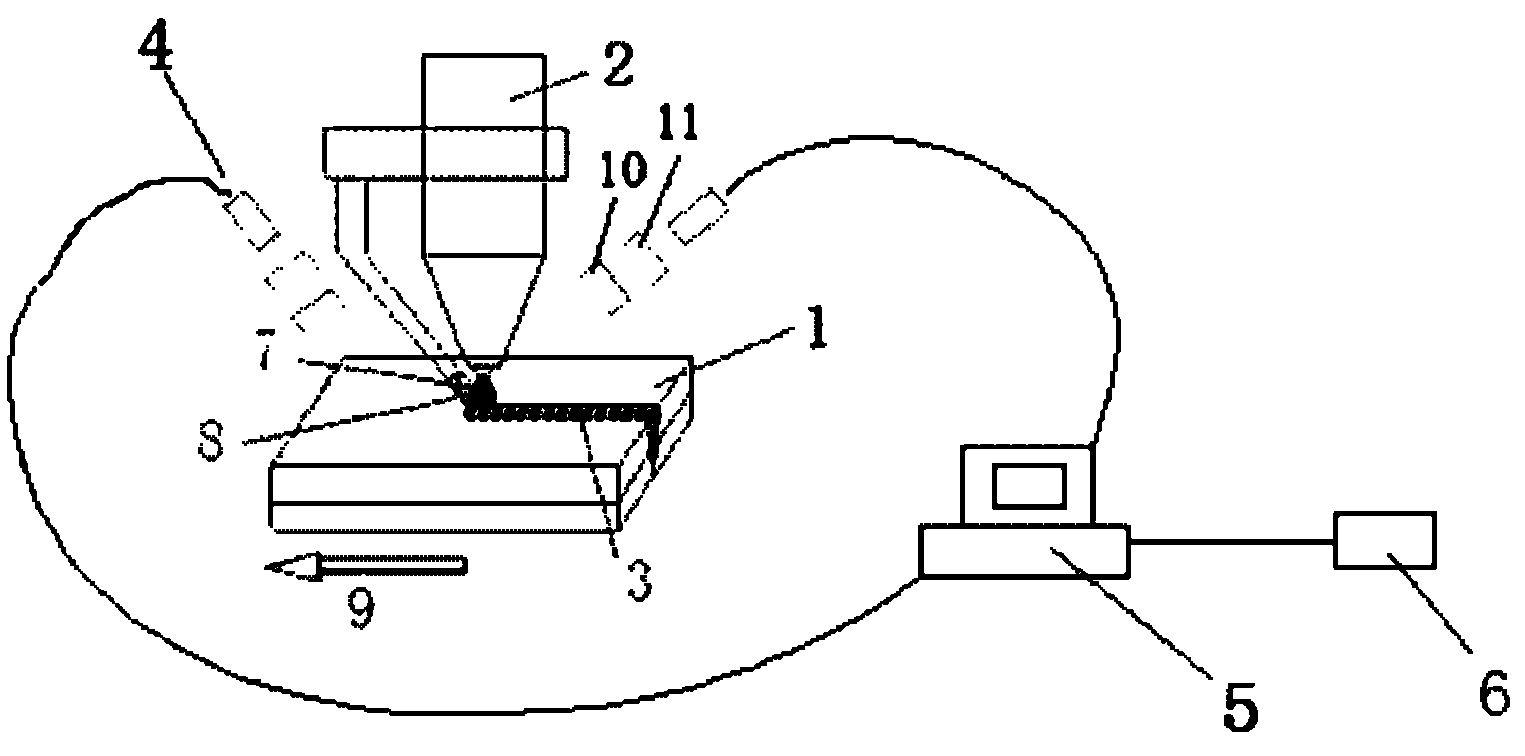

Welding quality analysis device based on infrared vision and analysis method thereof

InactiveCN104977305ALower regenerationIncrease the level of automationWelding/cutting auxillary devicesOptically investigating flaws/contaminationMelting tankVision processing

The invention discloses a welding quality analysis device based on infrared vision and an analysis method thereof. The analysis device comprises an infrared vision collecting system that is adjustably and fixedly connected to a welding facility, a vision processing system, in which welding defect intelligent recognition algorithm is embedded, and a feed control system, which can evaluate the welding quality, give an alarm, and adjust the parameters of the welding facility. The analysis method comprises the following steps: (1) collecting the infrared vision information of a molten pool or an area near a molten pool in real time through infrared sensing; (2) processing the infrared vision information by the welding defect intelligent recognition algorithm so as to obtain the weld seam positions and welding defect characteristics; (3) evaluating the welding quality in real time, and controlling the welding facility and giving an alarm aiming at different welding defects. According to the provided intelligent analysis device and intelligent analysis method, the welding process can be monitored in real time, the welding defects can be recognized, the welding seam position can be traced, the welding quality can be evaluated, the welding loss can be reduced, and the finished product yield rate can be increased.

Owner:HUAZHONG UNIV OF SCI & TECH

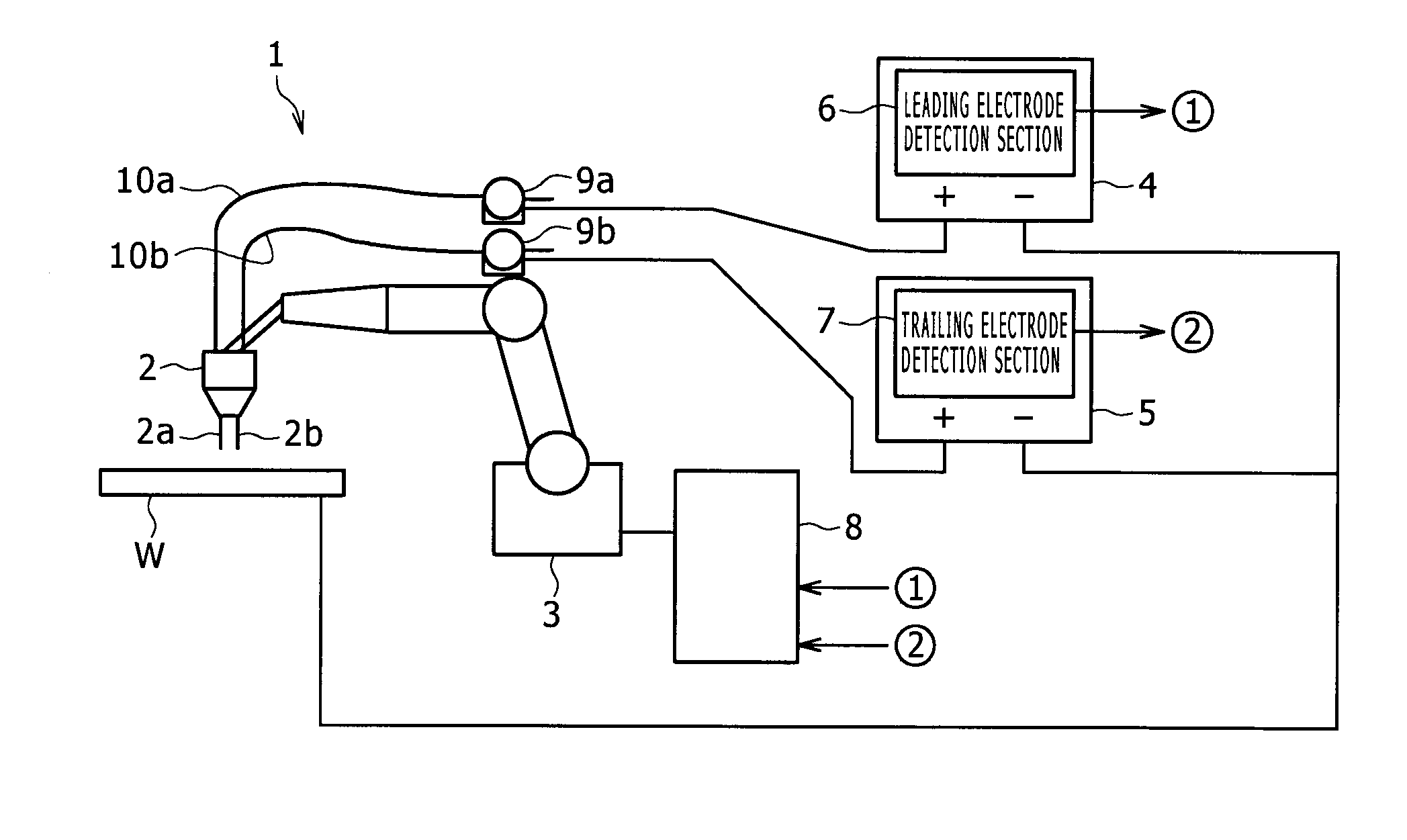

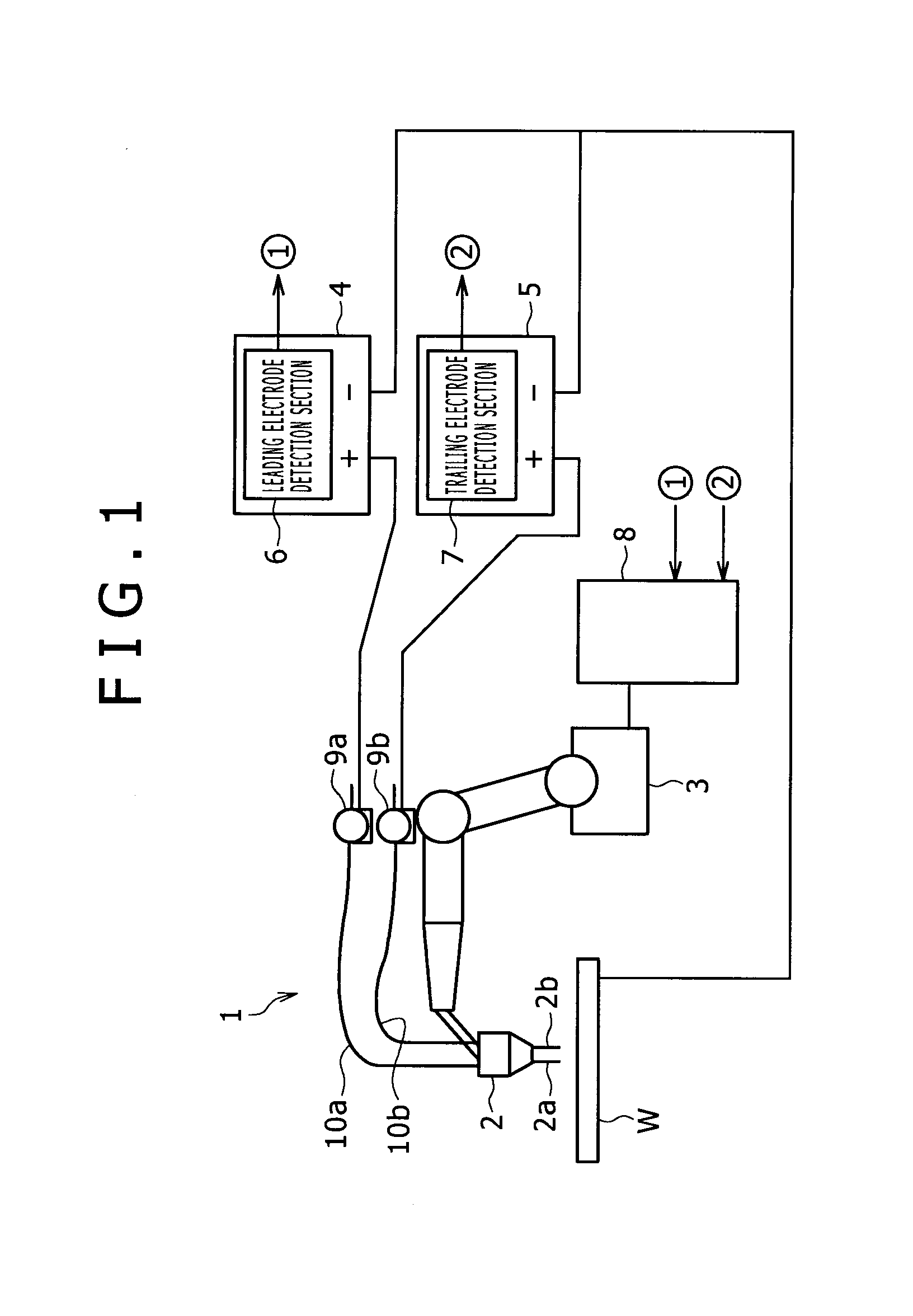

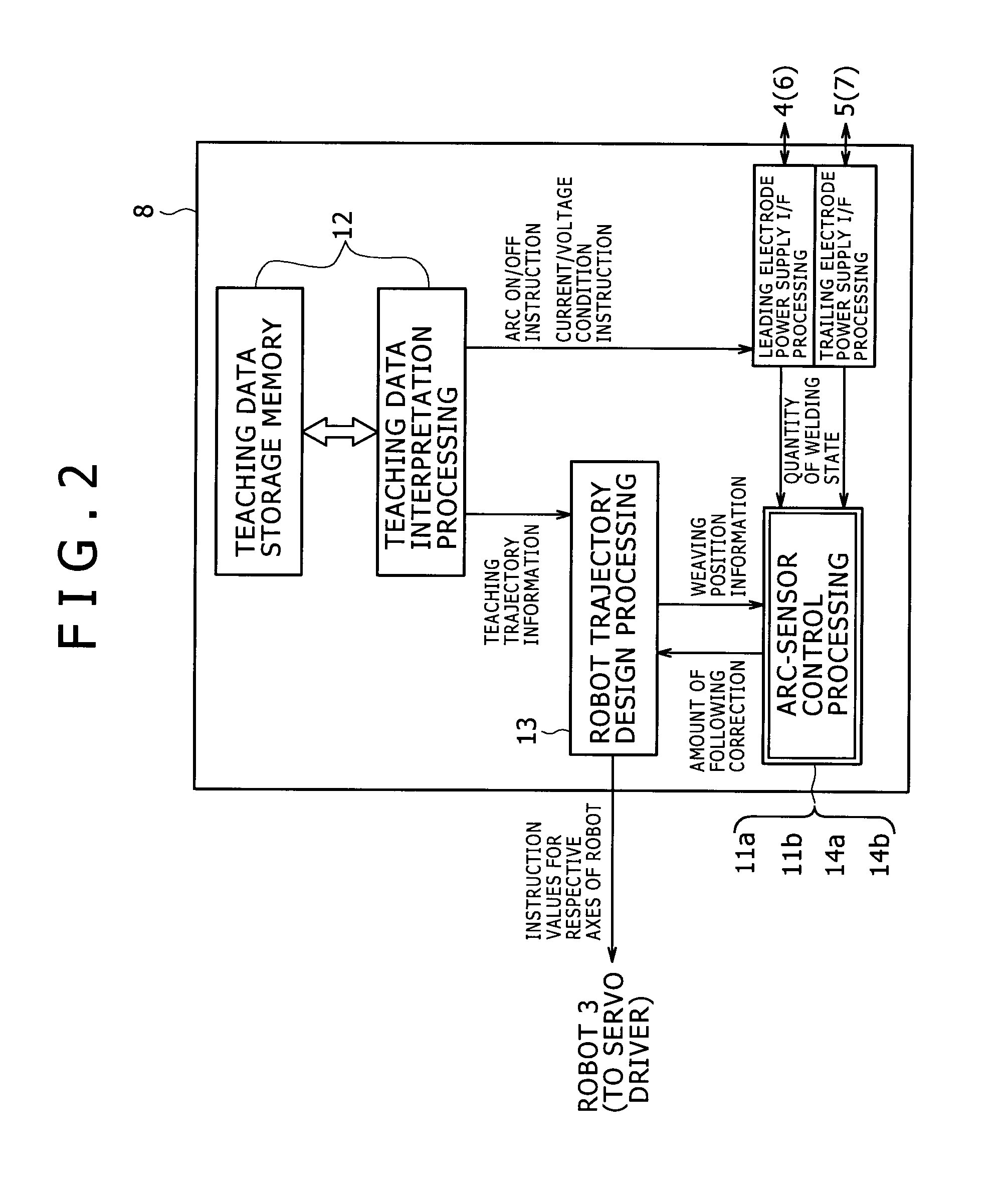

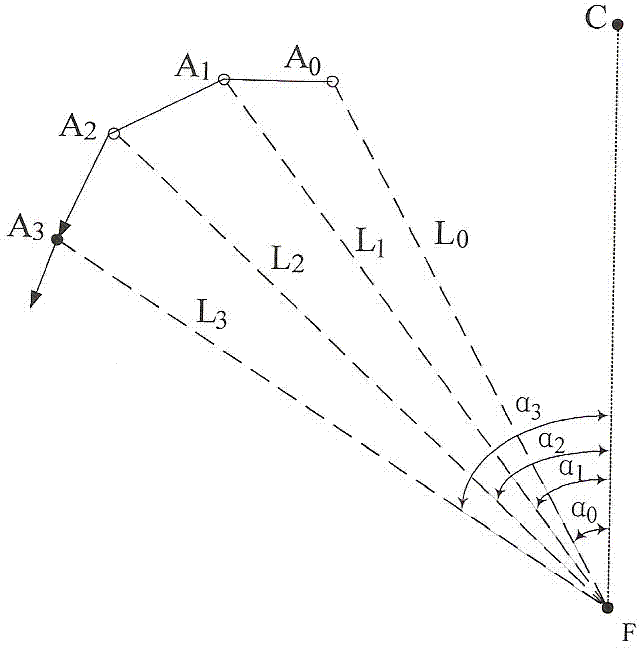

Robot control unit for controlling tandem arc welding system, and arc-sensor control method using the unit

ActiveUS20080083716A1Improve calibration accuracyImprove accuracyComputer controlSimulator controlRobot controlWelding defect

A robot control unit for controlling a tandem arc welding system, which has a welding torch, a robot for weaving the welding torch, a leading electrode power supply, and a trailing electrode power supply, includes a leading electrode detection section and a trailing electrode detection section for detecting quantity of welding state during weaving; a leading electrode processing section for calculating amounts of electrical change; a leading electrode correction section for calculating correction amounts for correcting displacement in horizontal and vertical directions from a weld line of a weaving center trajectory based on the amounts of electrical change; a trailing electrode processing section for calculating an amount of electrical change; and a trailing electrode correction section for calculating a correction amount for correcting displacement in a rotational direction from the weld line of the weaving center trajectory based on the amount of electrical change. According to the robot control unit, arc welding can be performed, which is excellent in accuracy of arc-sensor control, and hardly produces welding defects.

Owner:KOBE STEEL LTD

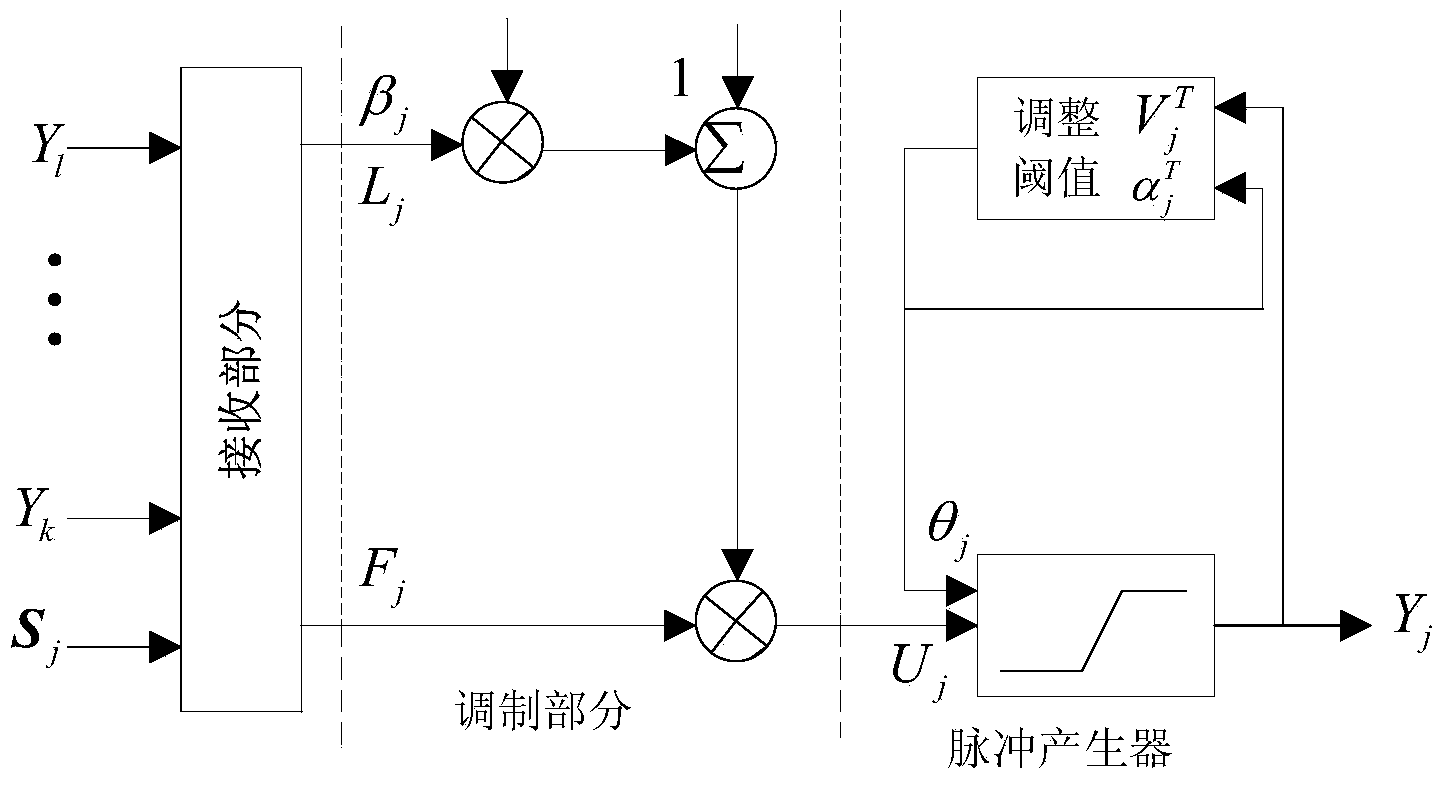

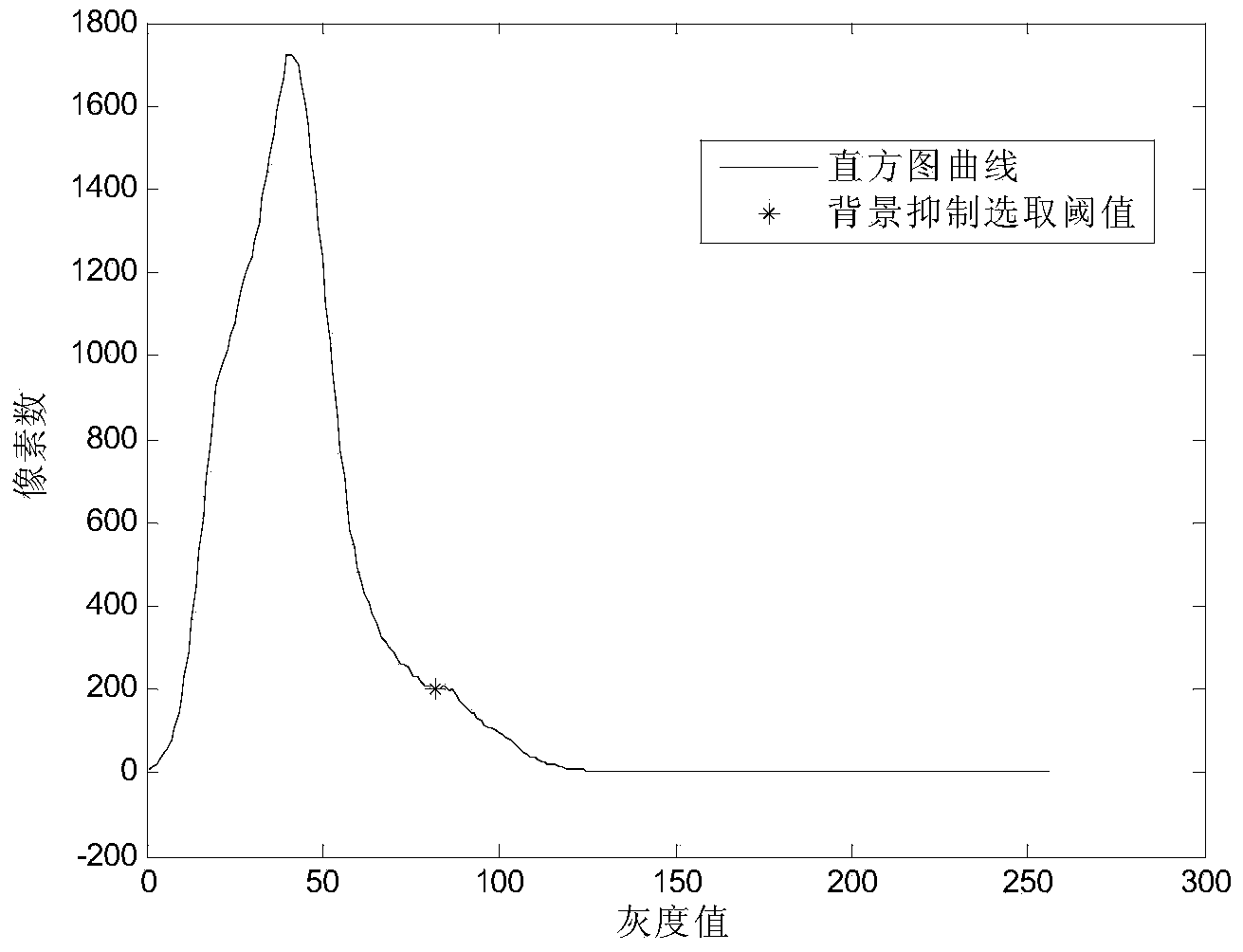

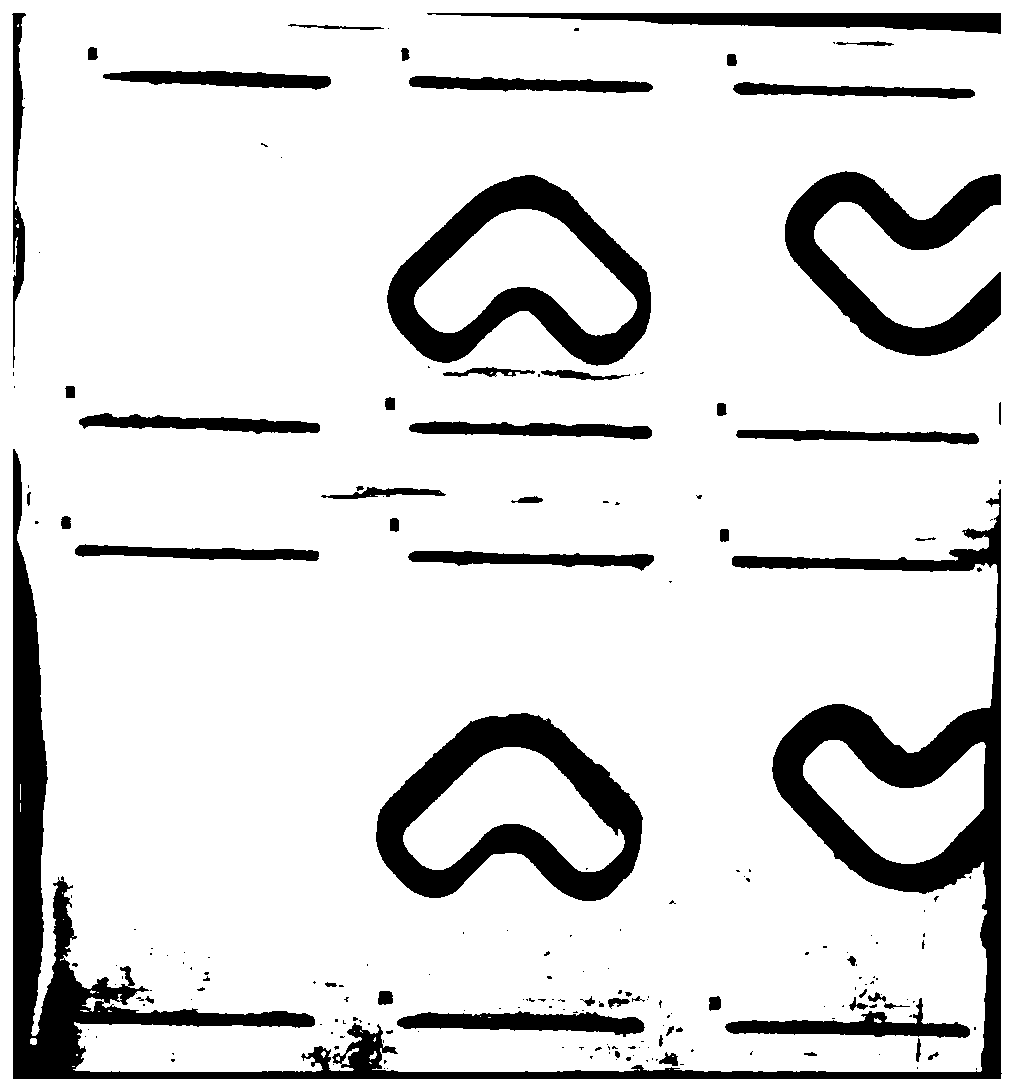

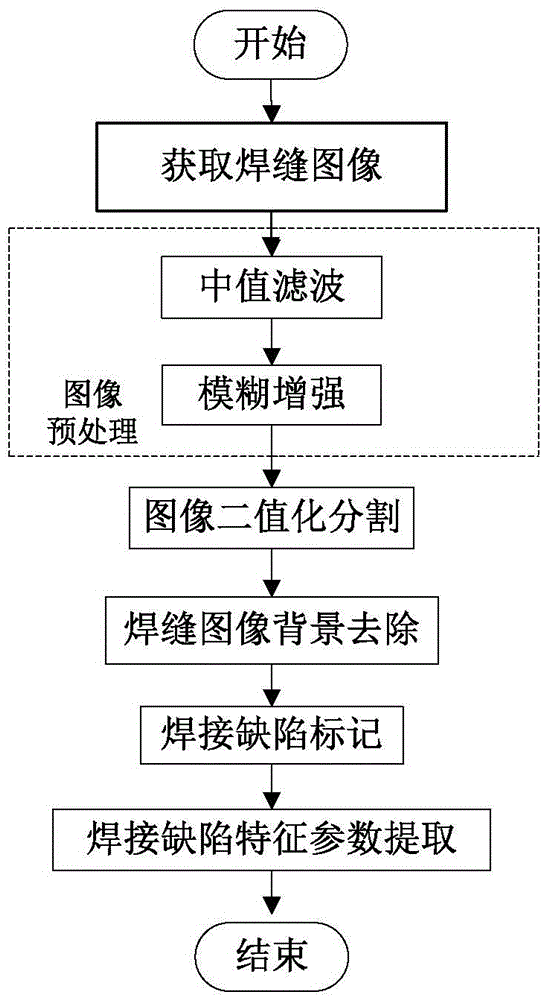

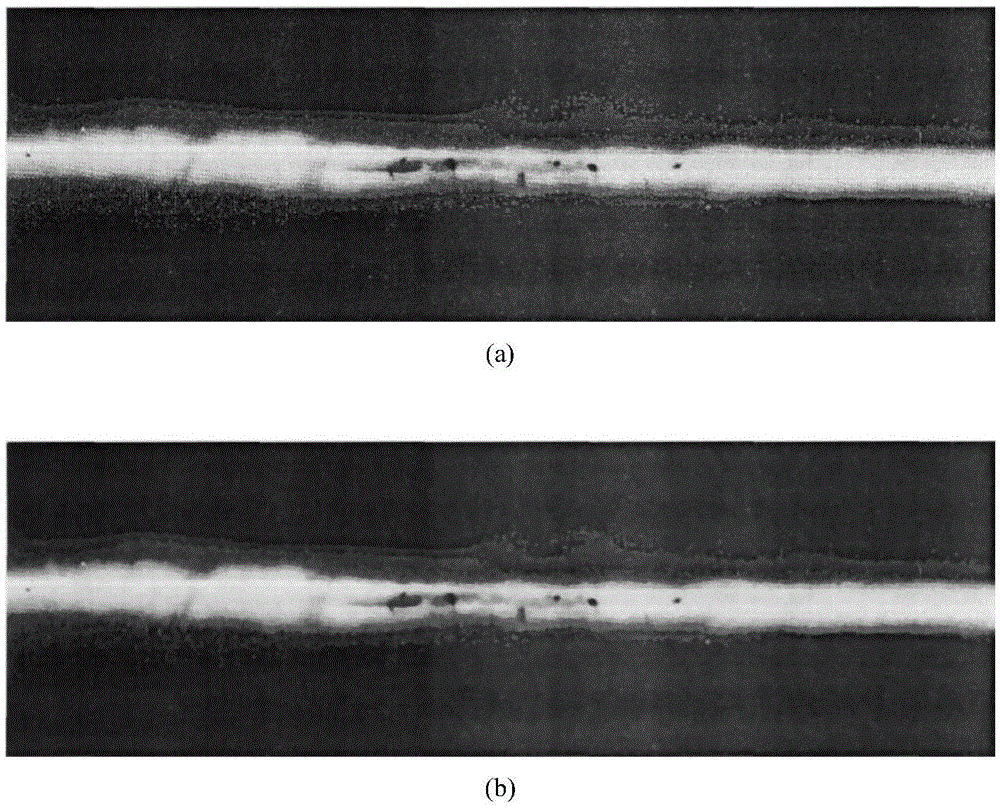

Welding defect extraction method and welding defect detection method

The invention discloses a welding defect extraction method, which belongs to the technical field that a welding technology and a digital image processing technology are crossed. According to the method, an original welding image is dissected by NSST (non-subsampled shearlet transform); for a roughly approximate low-frequency component capable of embodying a defect, the rough region of the detect is extracted by a PCNN (pulse coupled neural network); then, inverse NSST is carried out to the low-frequency component and a high-frequency component subjected to background suppression to obtain a high-frequency characteristic image; after the high-frequency characteristic image is subjected to coarse segmentation, the outline of the defect is optimized by an improved CV (Chan-Vese) model to obtain the fine edge of the defect; and finally extracted results are blended to obtain a finally-extracted defect. The invention also discloses a welding defect detection method adopting the welding defect extraction method. A welding defect structure obtained by the method disclosed by the invention has the advantages of more integral structure and clearer detail and outline, and a more reasonable and accurate reference can be provided for further processing the defect.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

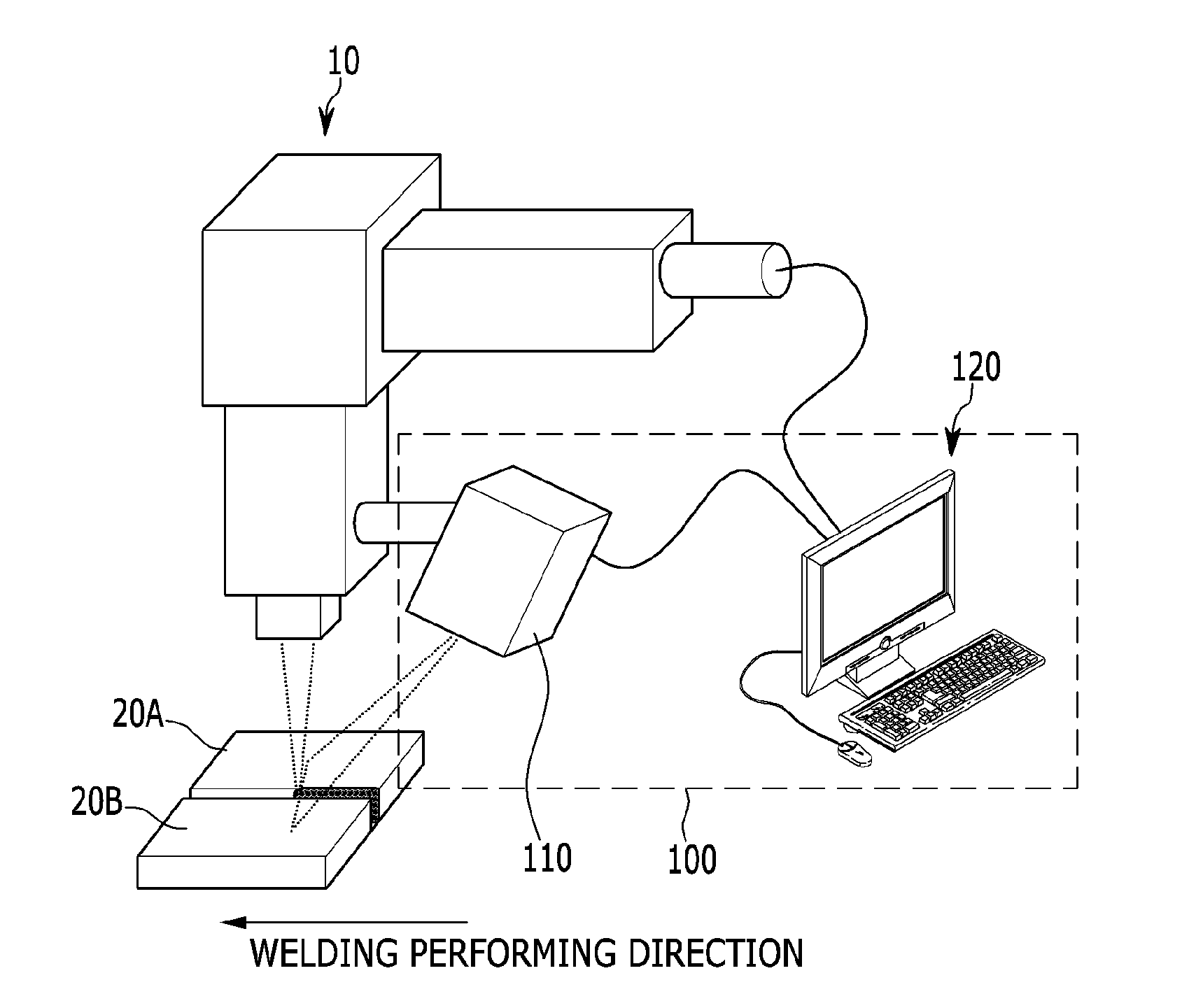

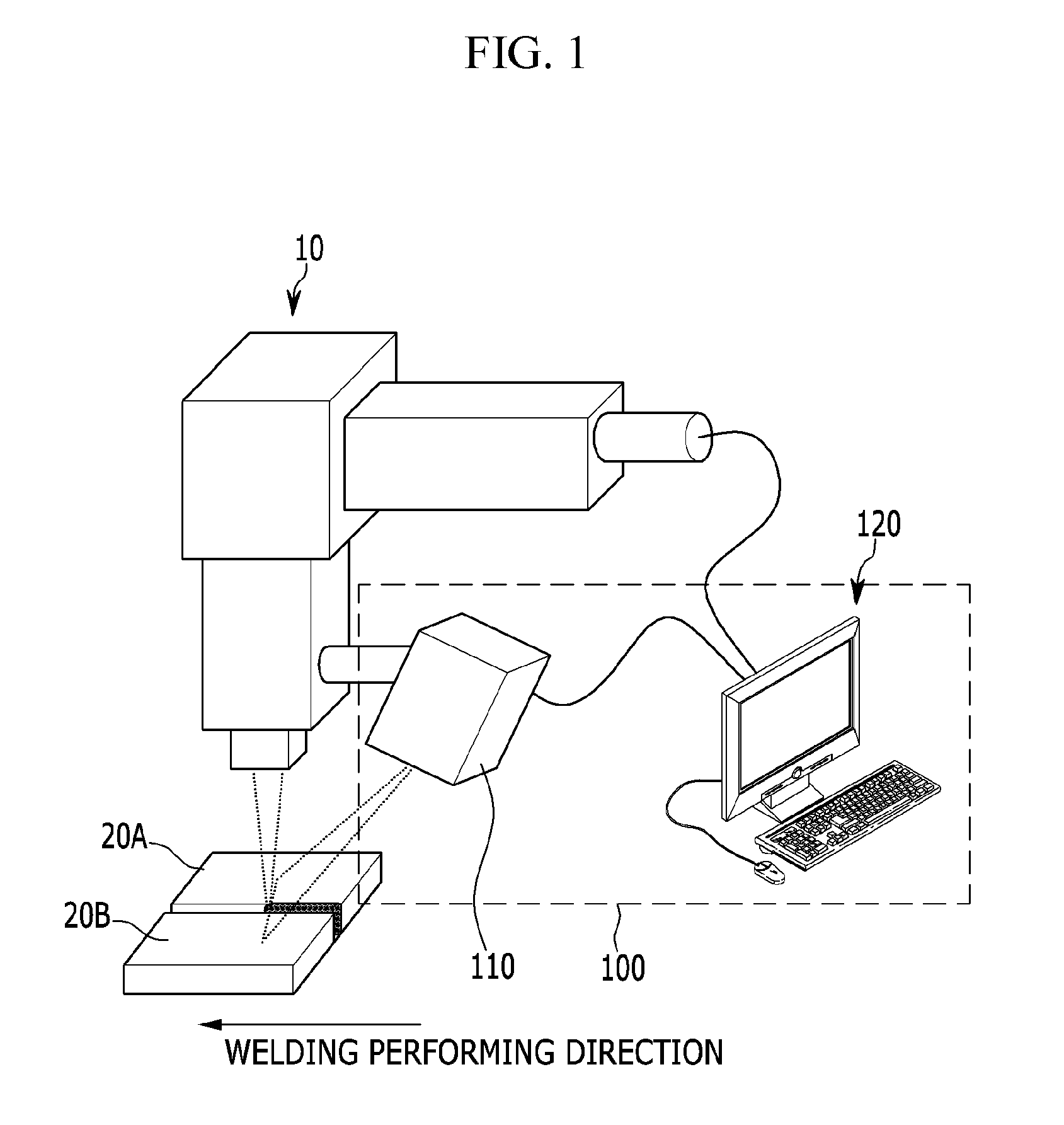

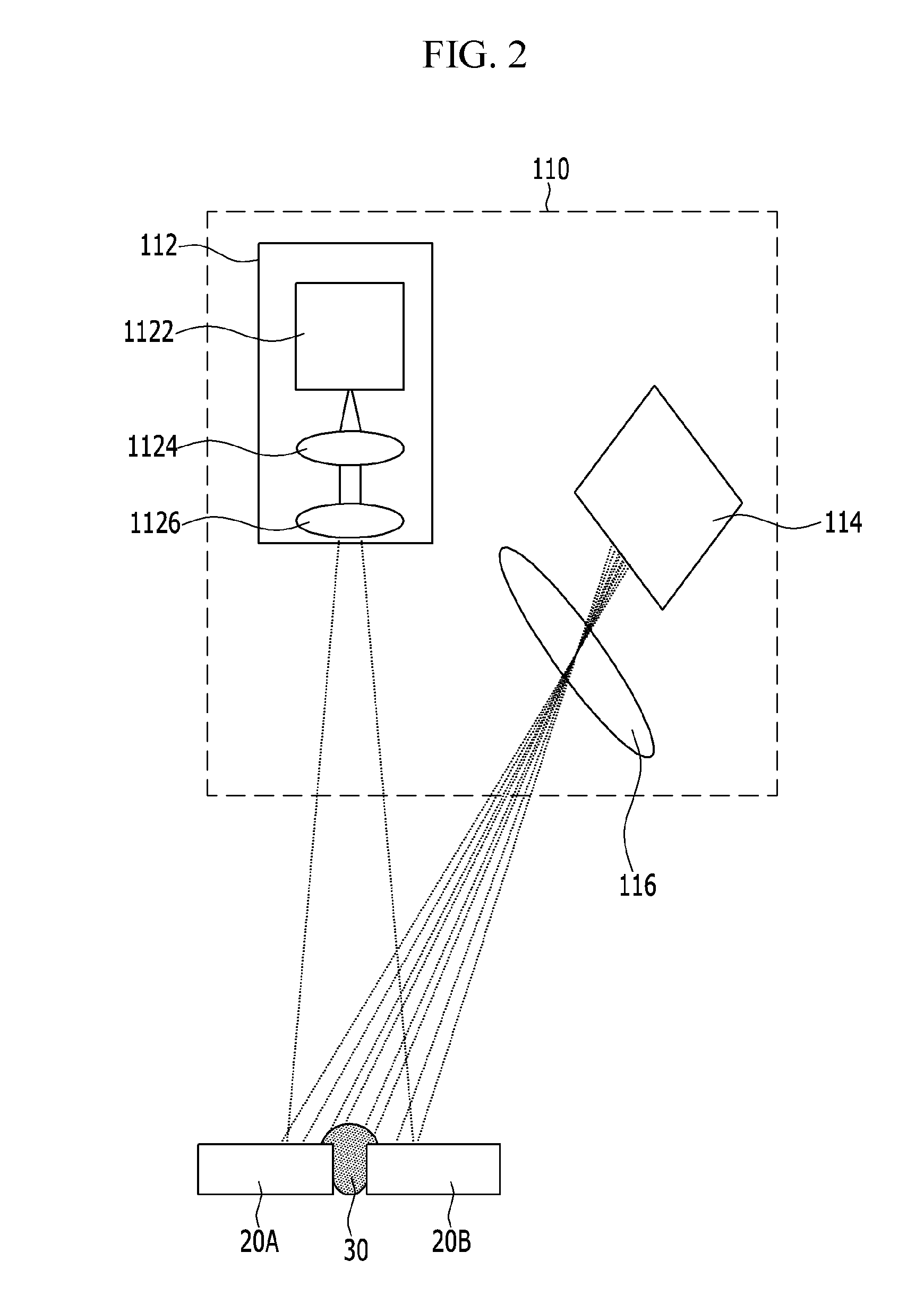

Apparatus and method for monitoring laser welding bead

ActiveUS20150001196A1Easy to manageWelding/soldering/cutting articlesLaser beam welding apparatusBead shapeEngineering

An apparatus for monitoring a laser welding bead irradiates a laser to a surface of a welding bead when welding with a laser welding machine, collects a signal reflected from the surface of the welding bead as an image signal, and then extracts at least one feature variable of a bead shape using the collected image signal. Then, the apparatus for monitoring the laser welding bead determines welding defects using the at least one feature variable, and controls an operation of the laser welding machine according to whether or not the welding defects are generated.

Owner:ELECTRONICS & TELECOMM RES INST

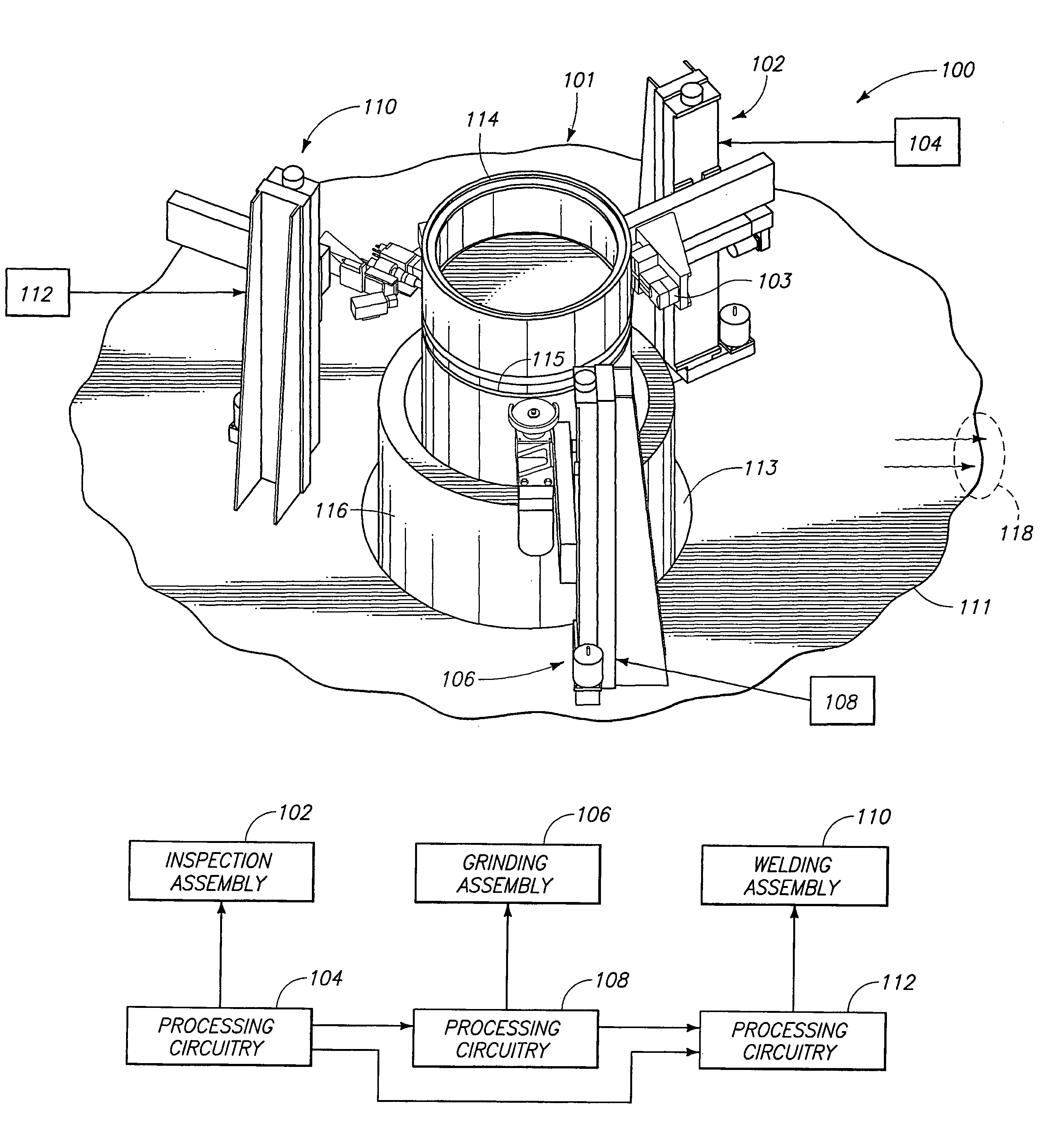

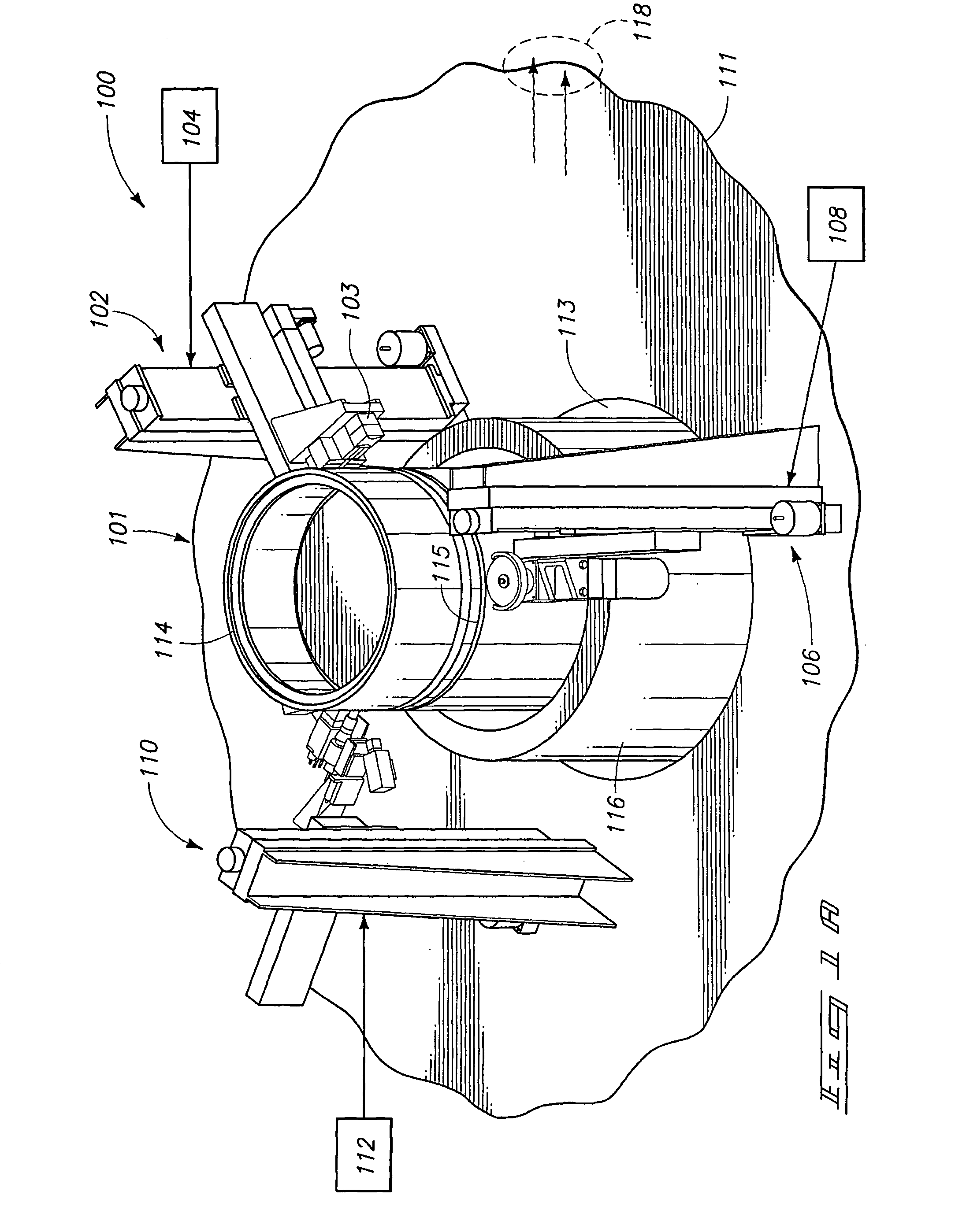

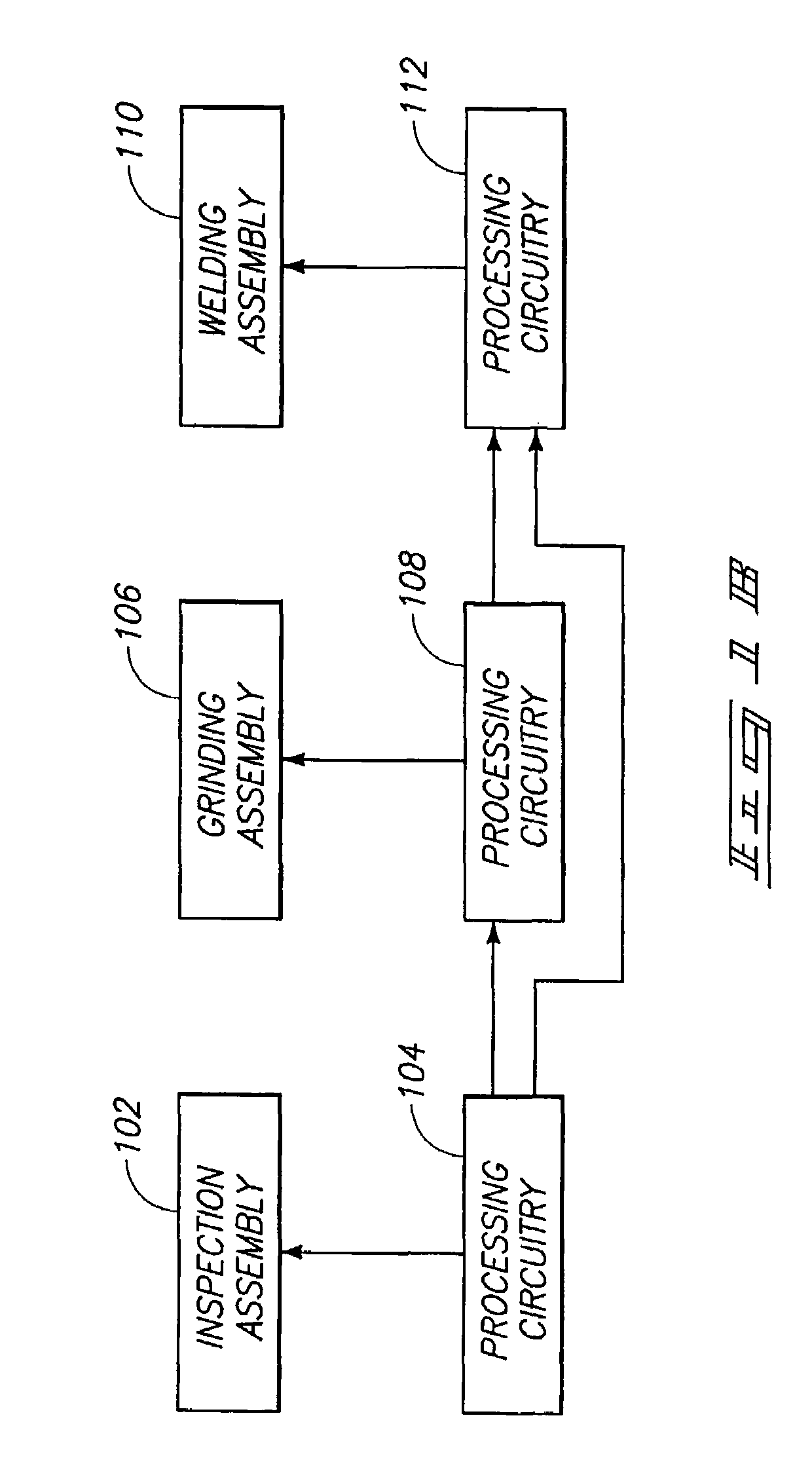

Grinding assembly, grinding apparatus, weld joint defect repair system, and methods

InactiveUS6949005B1Defect correctionPrecise positioningEdge grinding machinesRevolution surface grinding machinesDefect repairEngineering

A grinding assembly for grinding a weld joint of a workpiece includes a grinder apparatus, a grinder apparatus includes a grinding wheel configured to grind the weld joint, a member configured to receive the grinding wheel, the member being configured to be removably attached to the grinder apparatus, and a sensor assembly configured to detect a contact between the grinding wheel and the workpiece. The grinding assembly also includes a processing circuitry in communication with the grinder apparatus and configured to control operations of the grinder apparatus, the processing circuitry configured to receive weld defect information of the weld joint from an inspection assembly to create a contour grinding profile to grind the weld joint in a predetermined shape based on the received weld defect information, and a manipulator having an end configured to carry the grinder apparatus, the manipulator further configured to operate in multiple dimensions.

Owner:BATTELLE ENERGY ALLIANCE LLC

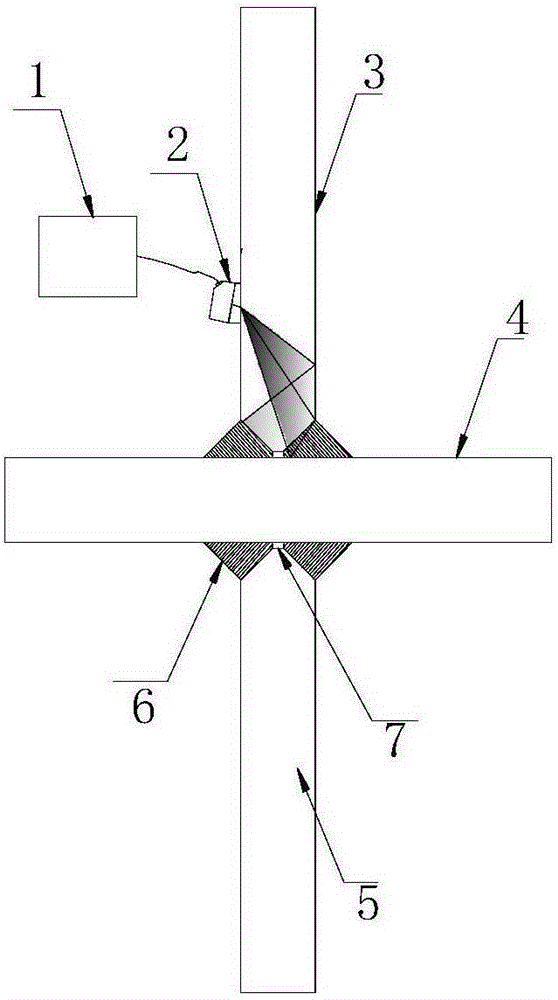

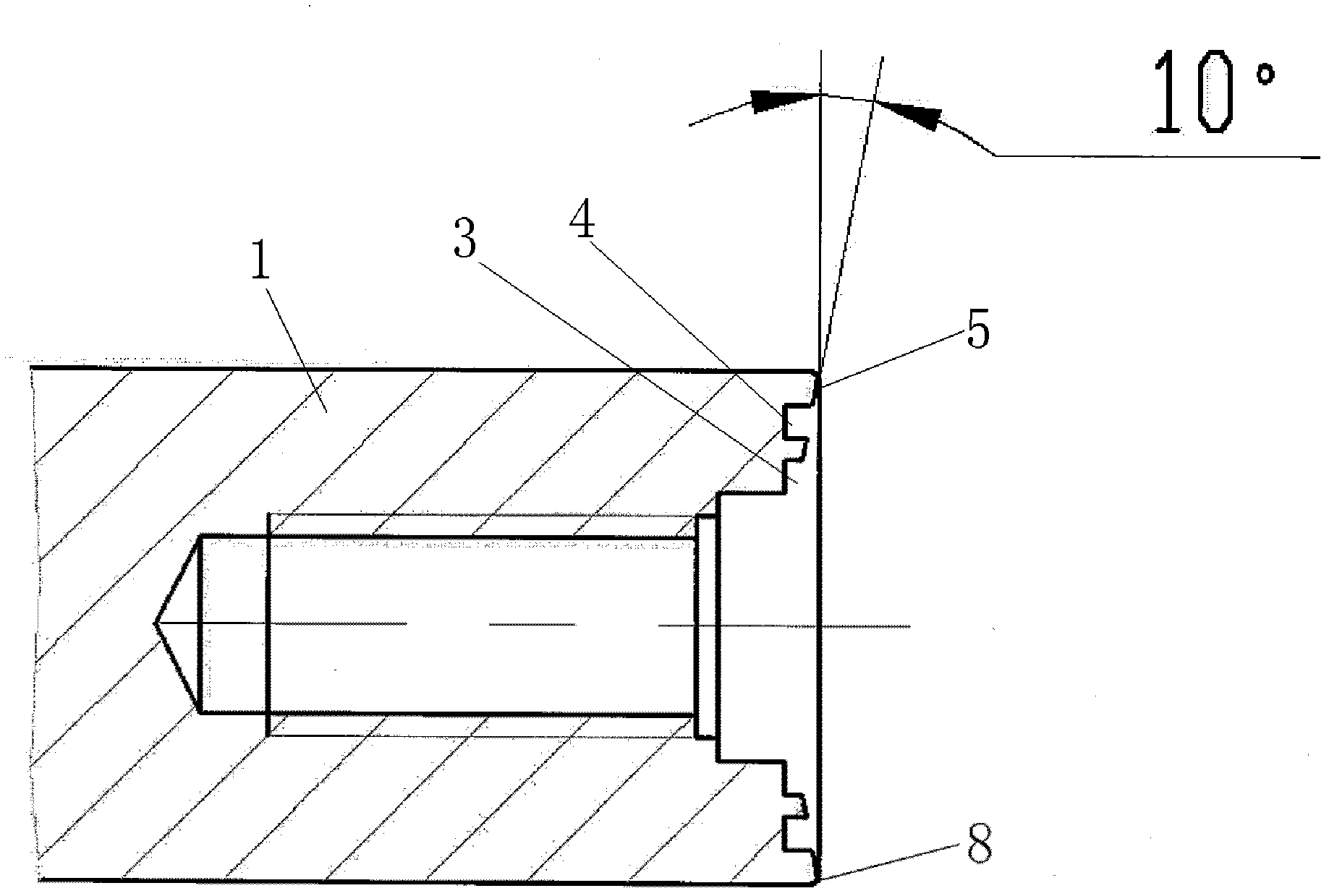

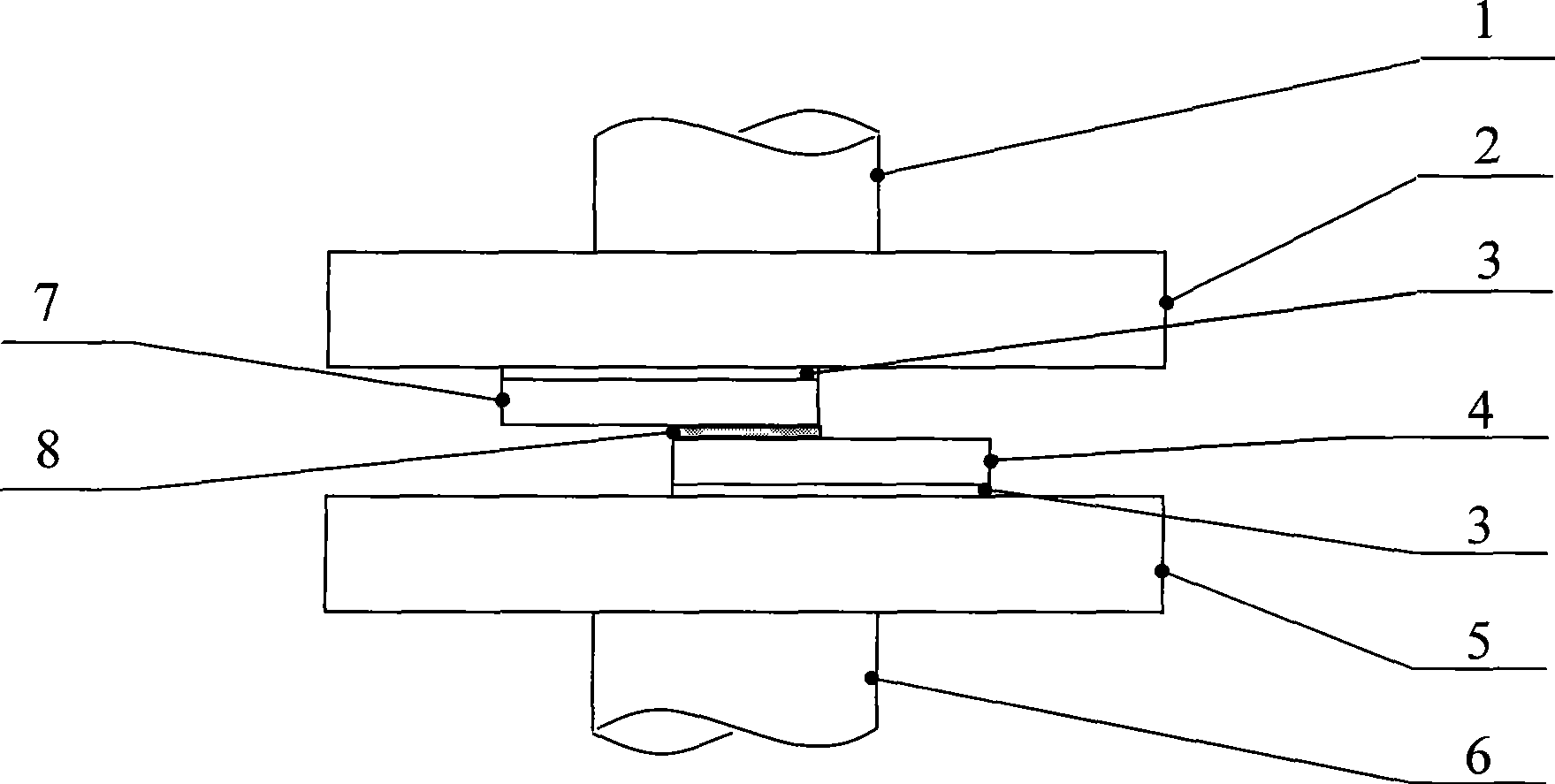

Construction steel structure weld ultrasonic phased array detection technology

ActiveCN105181798ARich non-destructive testing methods for weldsShort detection cycleAnalysing solids using sonic/ultrasonic/infrasonic wavesWelding defectPhased array

The invention relates to a construction steel structure weld ultrasonic phased array detection technology. The technology employs an ultrasonic phased array detection instrument (1) and an ultrasonic phased array probe (2) to detect the weld defect (7) in a weldment's weld (6), and consists of the steps of: 1. instrument setting; 2. instrument calibration; and 3. scanning detection. Specifically the phased array detection instrument comprises a host, the probe, software, a scanning device and accessories. According to the detection technology provided by the invention, ultrasonic phased array is employed to scan the weld only 1 to 2 times so as to finish detection, and the detection result and image are stored. The technology can effectively shorten the detection cycle, can provide beneficial reference basis for ensuring safety assessment of construction steel structure, reduces the occurrence of safety accidents, and provides reference for design to reduce conservative design, enriches construction steel structure weld nondestructive detection methods, improves work efficiency and quality, and escorts construction steel structure welding quality.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP

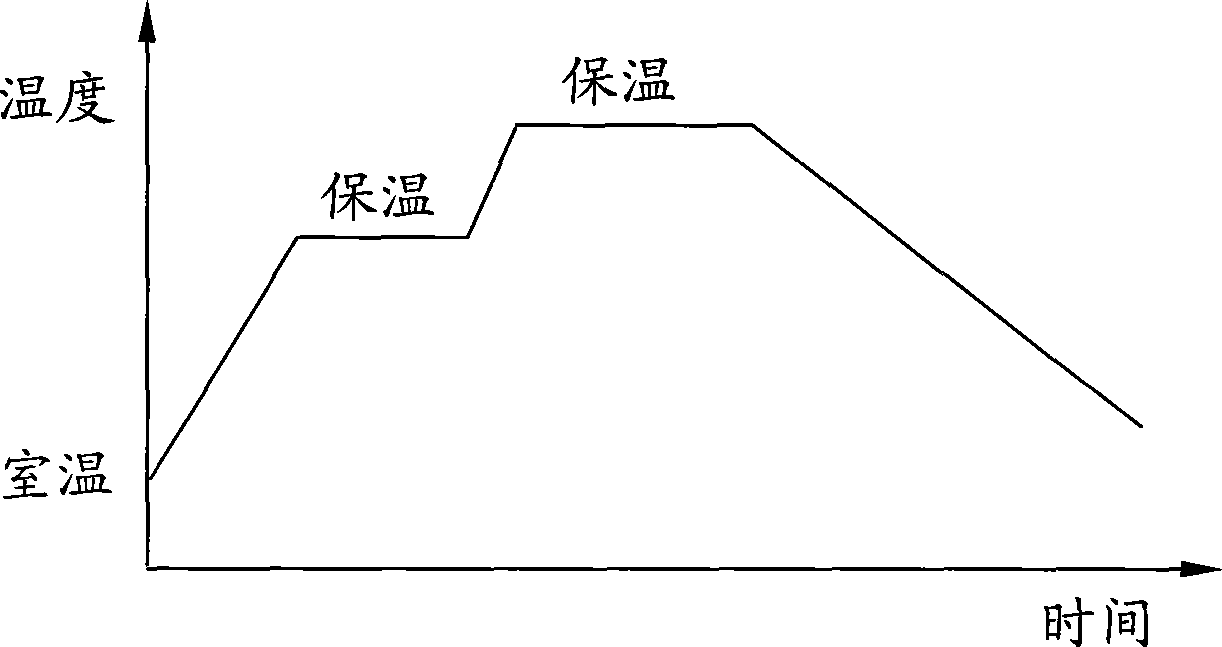

Technology for repairing surfacing of piston rod of super large marine diesel engine

InactiveCN101444881ALow roughness requirementsLow cleanliness requirementsArc welding apparatusRoom temperatureEngineering

The invention discloses a technology for repairing surfacing of a piston rod of a super large marine diesel engine, and the technology can carry out the deep repair of the surface of the piston rod. The adopted surfacing process is as follows: flaw detection and straightening are carried out on the piston rod, turning machining is carried out on the surface of the piston rod to remove a defect layer, and individual deeper cracks are manually removed by grinding; fire whirl is used for heating the piston rod twice, the first heating is carried out till 200 DEG C-250 DEG C, the heating is stopped, the race rotation is carried out for 30 minutes, the second heating is further carried out after the temperature difference between the interior and the exterior is reduced, and a surfacing machine tool is rotated after reaching 250 DEG C-300 DEG C; submerged arc welding is used for rotating dual heads of the surfacing machine tool and a 2Cr13 flux-cored welding wire for carrying out the simultaneous surfacing, and asbestos cloth is used for wrapping and keeping the temperature during the welding process; the piston rod wrapped by the asbestos cloth for slow cooling after the surfacing achieves the size requirement, when the temperature is decreased to be lower than 100 DEG C, the piston rod wrapped by the asbestos cloth is vertically placed till the temperature is decreased to the room temperature, and then the temperature-keeping cloth is removed. The surface of the piston rod after the repair by employing the method has no weld defects, the piston rod fully meets the performance requirements, and the cost is only about one fifth of the cost for fabricating a new piston rod.

Owner:DALIAN XINZHONG GRP +1

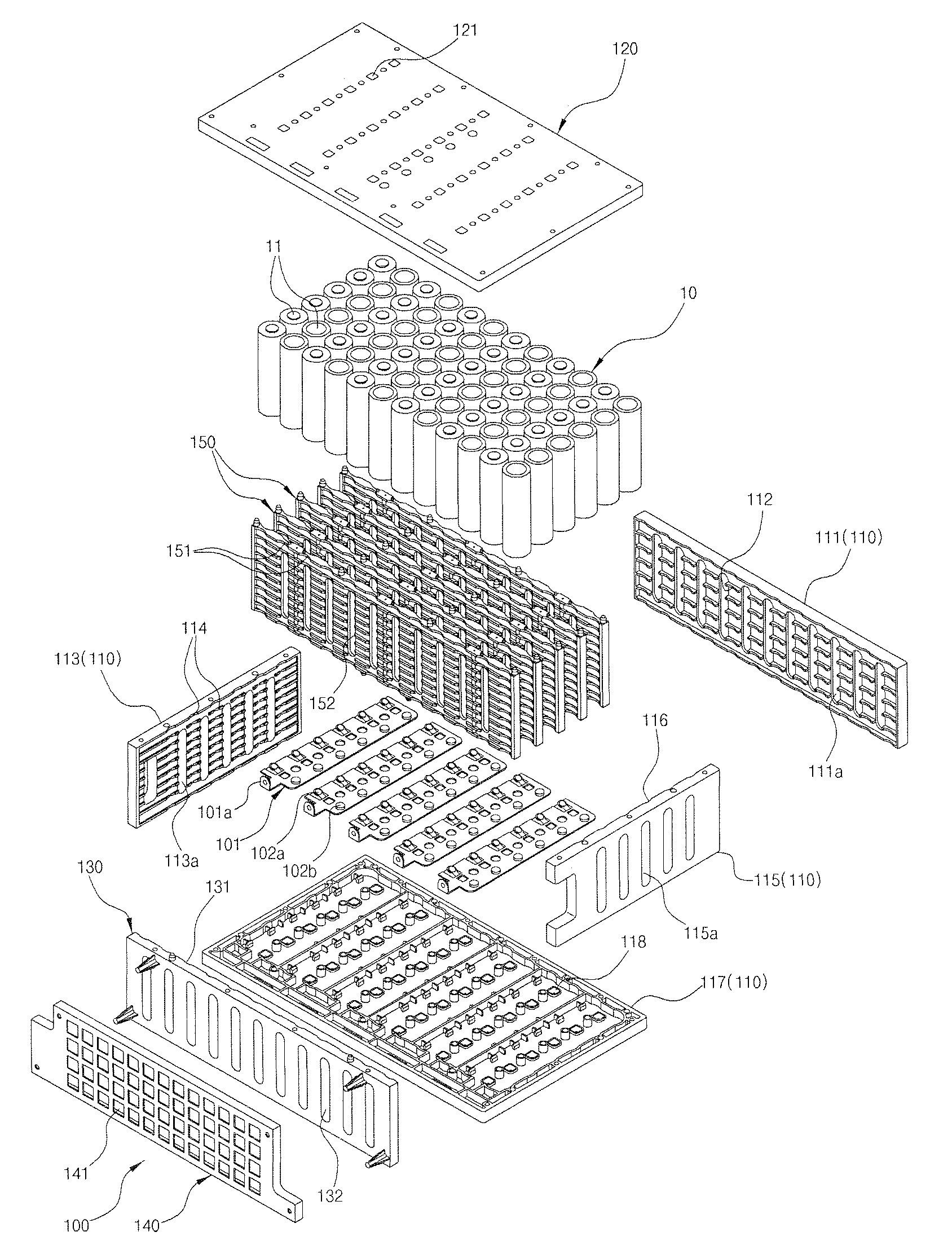

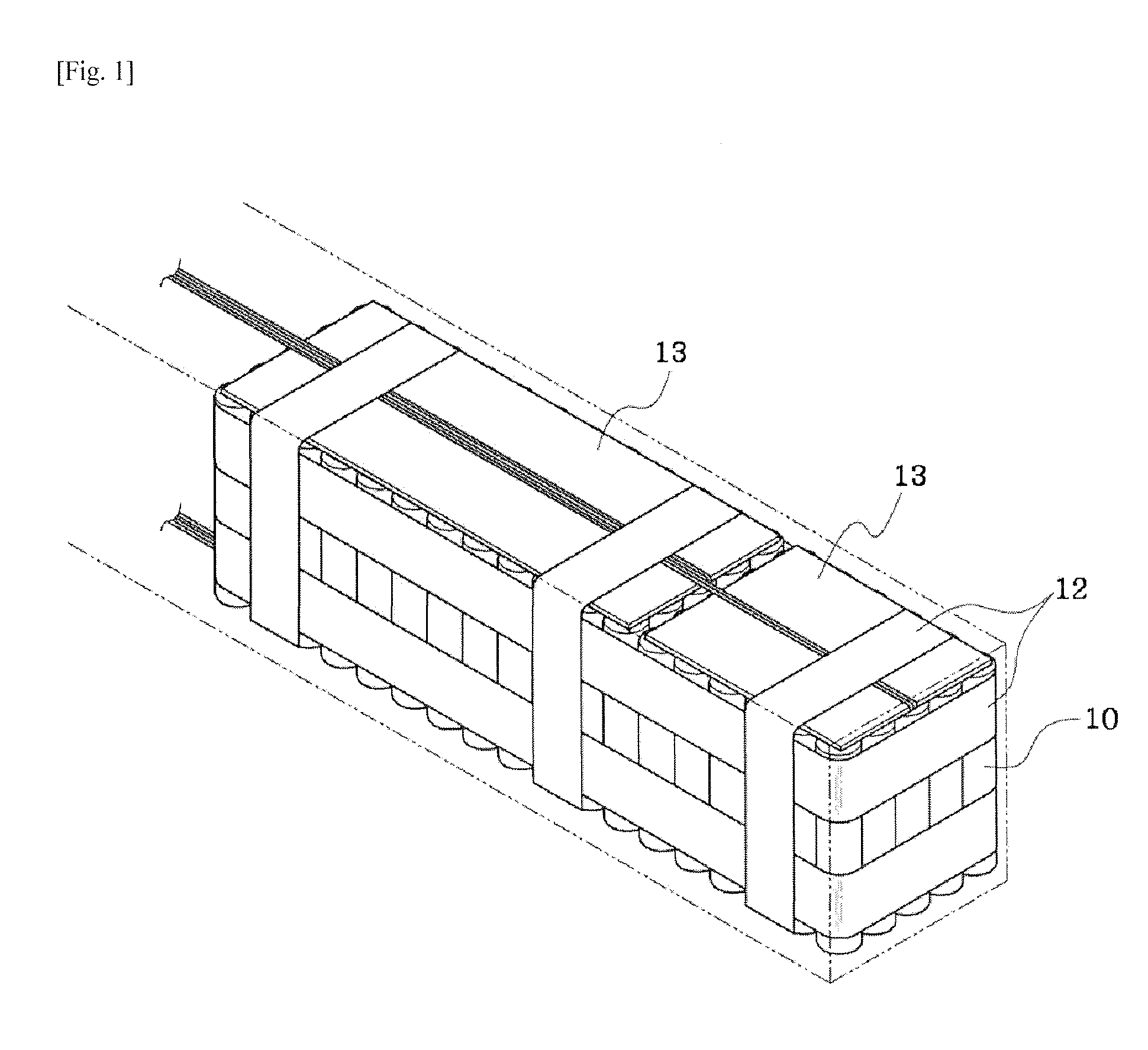

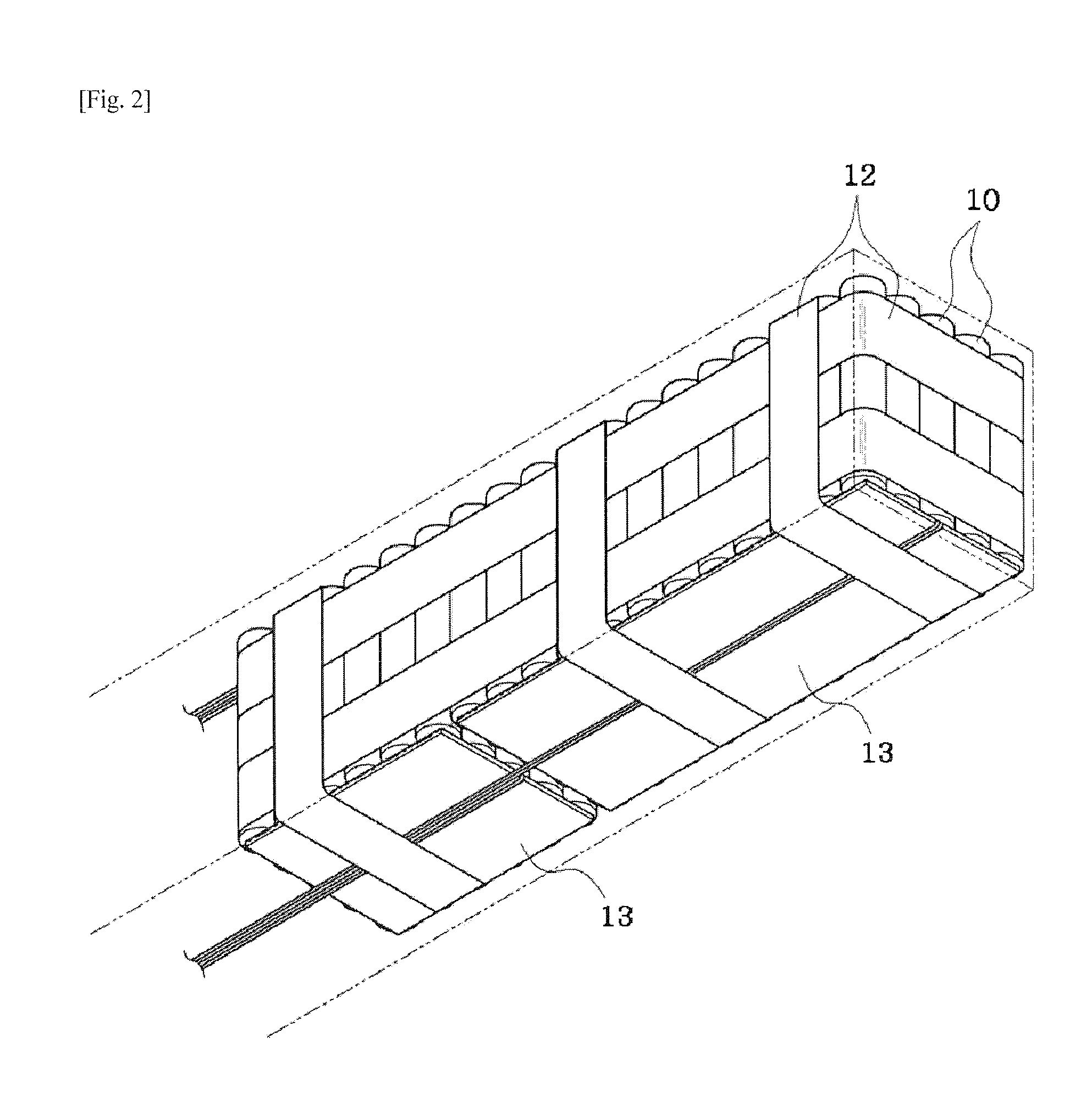

Cell Cartridge with a Composite Intercell Connecting Net Structure

InactiveUS20110287287A1Improve accuracyShorten the timePrimary cell to battery groupingSecondary cellsElectrical resistance and conductanceProduction rate

The present invention provides a cell cartridge with a composite cell interconnection network, in which plural unit cells are assembled and modularized in a case in a composite series-parallel connection manner. An object of the present invention is to provide a cell cartridge with a composite cell interconnection network, in which a plurality of unit cells can be simply assembled, as opposed to conventional methods of binding the unit cells with glass tape, for example, to shorten the time required for assembly, improve assemblability and productivity, and increase the accuracy of manufacturing standards. Moreover, another object of the present invention is to provide a cell cartridge with a composite cell interconnection network, in which a plurality of unit cells are spaced at regular intervals to prevent problems caused by direct contact between the cells and by heat generated thereby, prevent problems such as cell performance degradation and reduced battery lifespan caused by the direct contact and the generated heat, and enable mass production of standardized and modularized battery packs. Furthermore, still another object of the present invention is to provide a cell cartridge with a composite cell interconnection network, in which the structure of external terminals connected to cell terminals is modified to prevent a contact failure or excessive contact resistance between the cell terminals and the external terminals, and which can solve many other problems, caused by the welding of a nickel plate in conventional methods, such as welding defects, inconvenience of welding process, excessive assembly time due to the welding, degradation of assemblability and productivity, etc. To this end, a cell cartridge with a composite cell interconnection network is disclosed, the cell cartridge comprising: a plurality of unit cells; a case which accommodates the unit cells and is then assembled; a plurality of spacing members, each disposed between the unit cells accommodated in the case to space the unit cells a predetermined distance from each other; and a plurality of connection plates fixedly mounted on an inner side of the case and each including terminals connected to electrodes of the respective unit cells to connect the electrodes of adjacently arranged cells to each other, wherein the unit cells are connected to each other by the connection plates connected to the respective electrodes in a composite series-parallel connection manner.

Owner:ICEL SYST KOREA +1

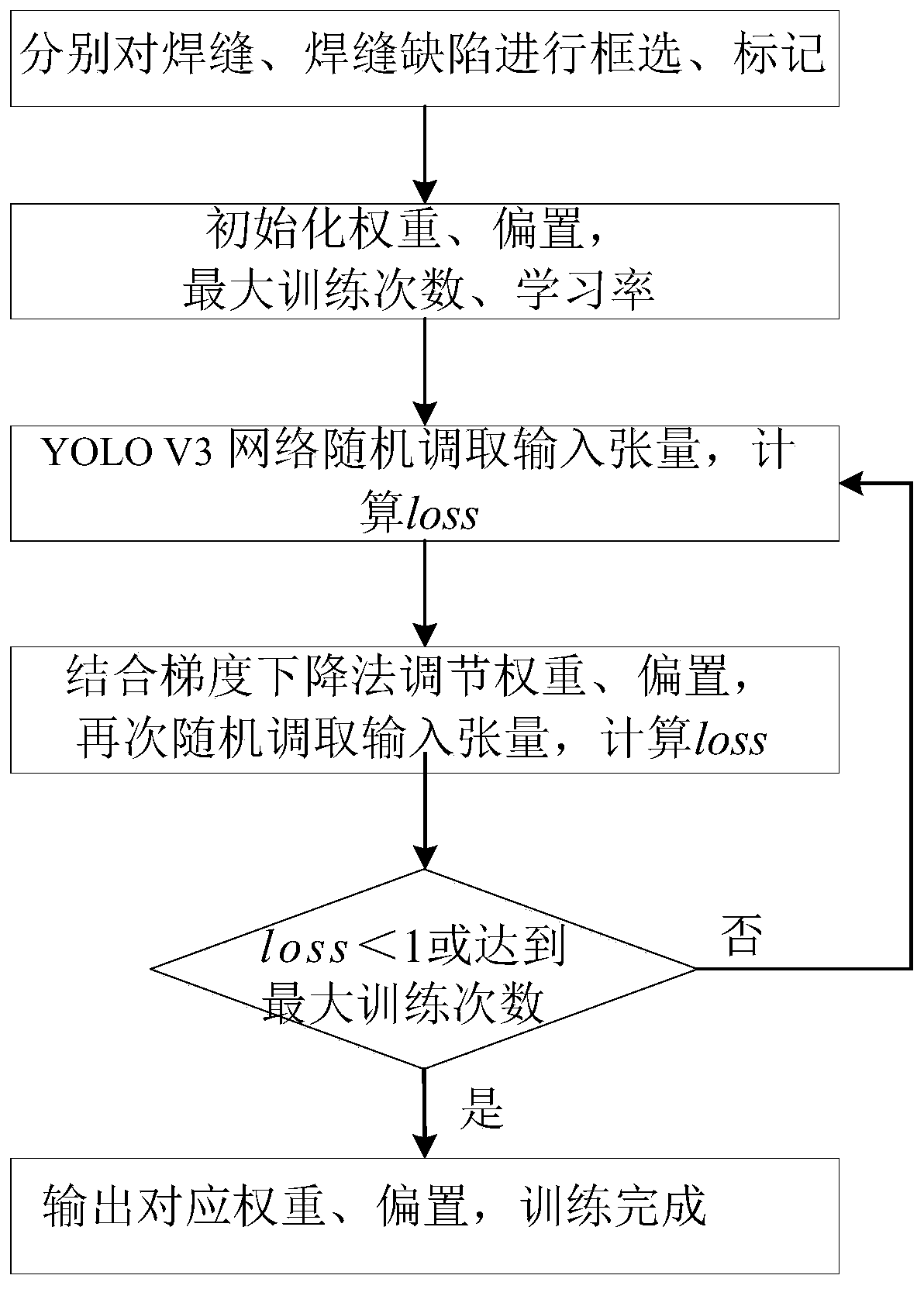

Weld seam and weld seam defect detection method based on deep learning

ActiveCN109900706AExact categoryHigh coincidenceOptically investigating flaws/contaminationPattern recognitionData set

The invention discloses a weld seam and weld seam defect detection method based on deep learning. A YOLOV3 network is used to realize weld seam and / or weld seam defect detection. A network training step comprises the following steps of using a positioning frame to select and mark the weld seams in a workpiece image and taking as a training data set; using the positioning frame to select weld defects and mark defect types in a weld seam image, and taking as a training data set I; acquiring coordinates xp and yp of the positioning frame, and width and height sizes wp and hp; initializing a network; randomly acquiring an input tensor aj for training calculation, and outputting a detection result; calculating an error function loss of a prediction result by using the detection result; and adjusting a weight W and an offset value b in combination with a gradient descent method, repeating in the way, and acquiring a trained network. The multiple weld seams and the multiple defect types can be synchronously detected, weld seam identification positioning and defect detection can be realized in one measurement, and measurement efficiency and accuracy are effectively increased.

Owner:易思维(杭州)科技有限公司

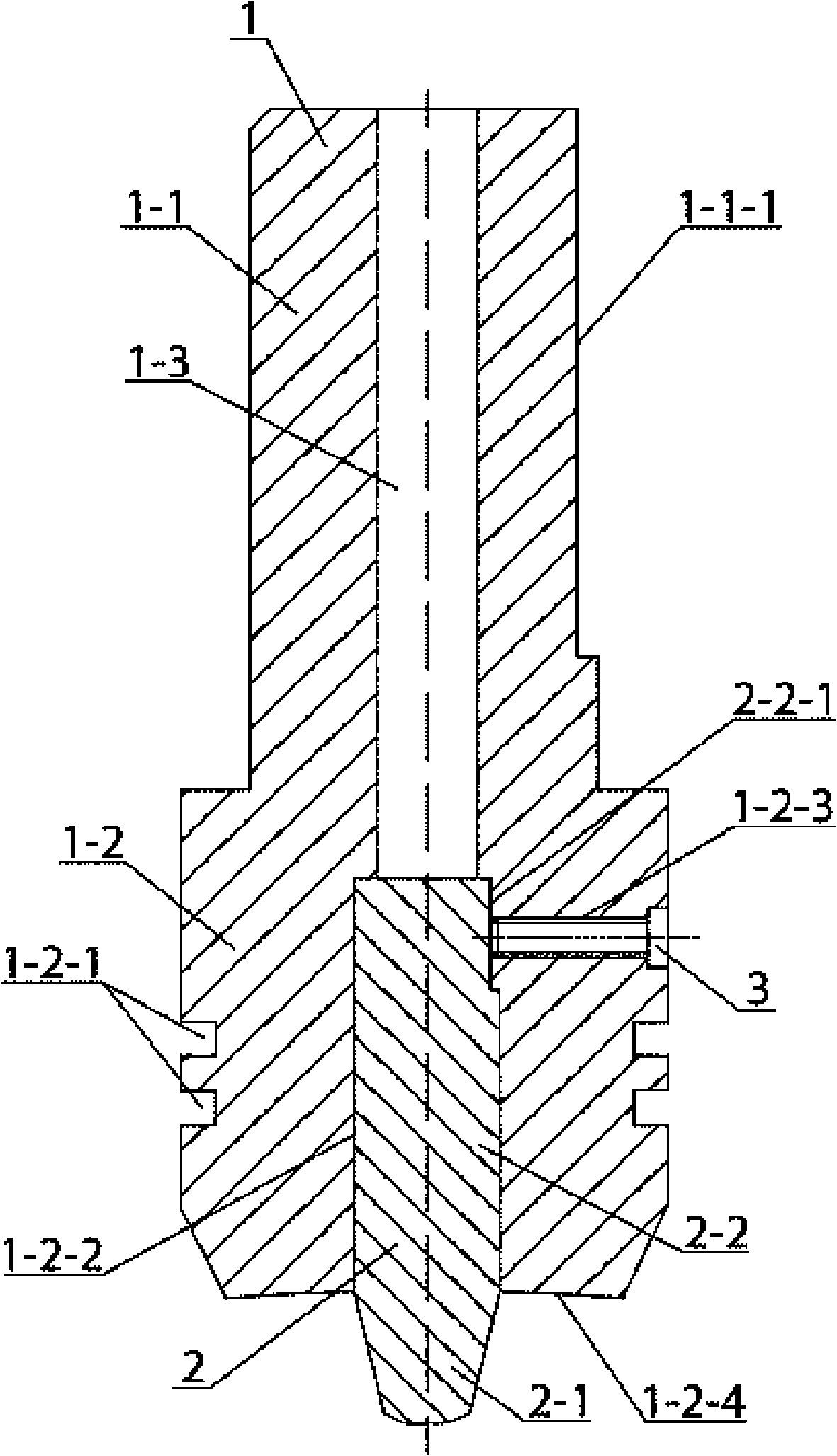

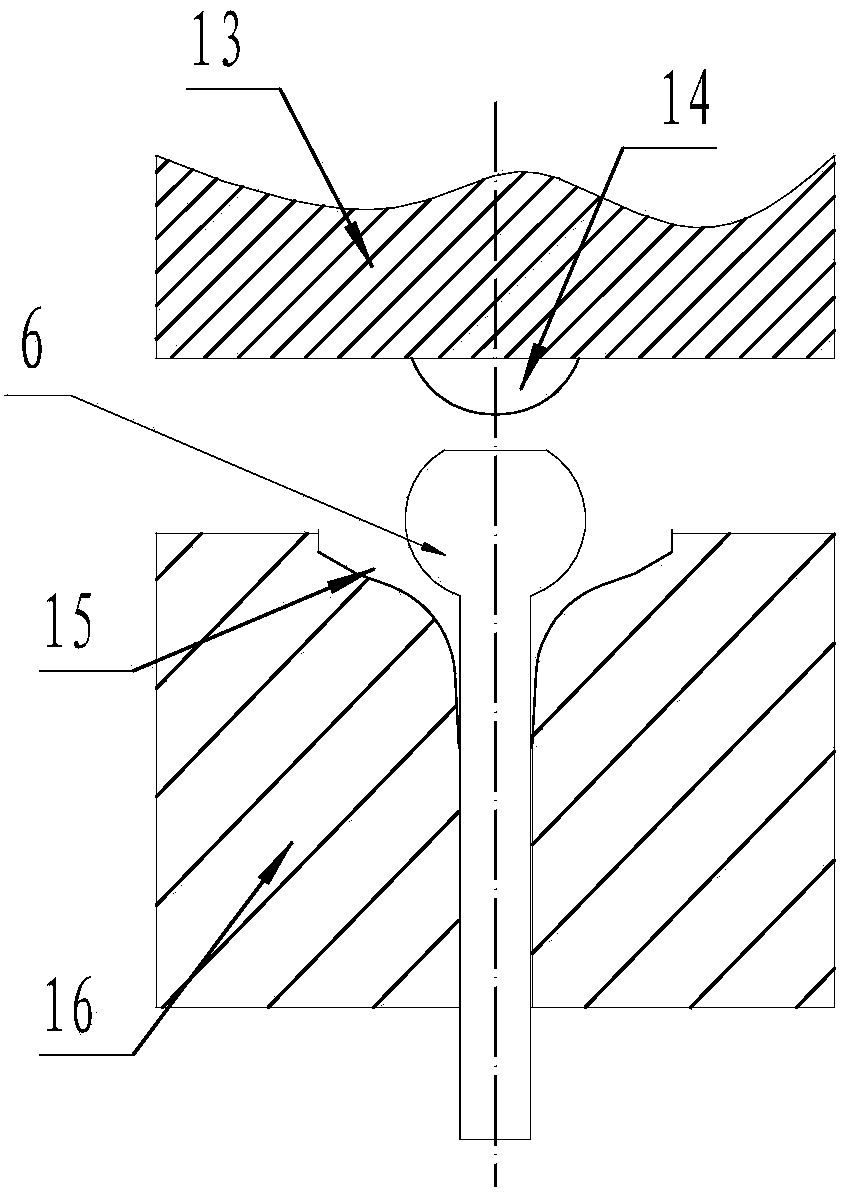

Device and method for repairing friction stir welding weld defect of storage tank for carrier rocket

ActiveCN102581476AGuarantee product qualityReduce scrapNon-electric welding apparatusFilling materialsRocket

The invention provides a device and a method for repairing a friction stir welding weld defect of a storage tank for a carrier rocket. A repair welding pin tool comprises a tool pin clamping structure and a tool pin, the end face of a shaft shoulder portion of the tool pin clamping structure is a recessed slope provided with two concentric-circle annular grooves, the front of the tool pin is of a conical thread structure, and a conical thread is circumferentially provided with three spiral grooves at intervals. The method includes the steps: firstly, manually excavating the tool pin broke at a friction stir welding weld; secondly, performing solid filling for the weld; thirdly, utilizing the repair welding pin tool to start friction stir welding from a center of the broke position of the tool pin filled with welding wires or materials to a set welding end point; and finally, continuing utilizing the repair welding pin tool to perform friction stir welding for the weld again from a welding start point to the welding end point. The method and the device are capable of guaranteeing the quality of the storage tank for the carrier rocket and decreasing scrapping of the storage tank for the carrier rocket due to the key hole type defect.

Owner:CAPITAL AEROSPACE MACHINERY +1

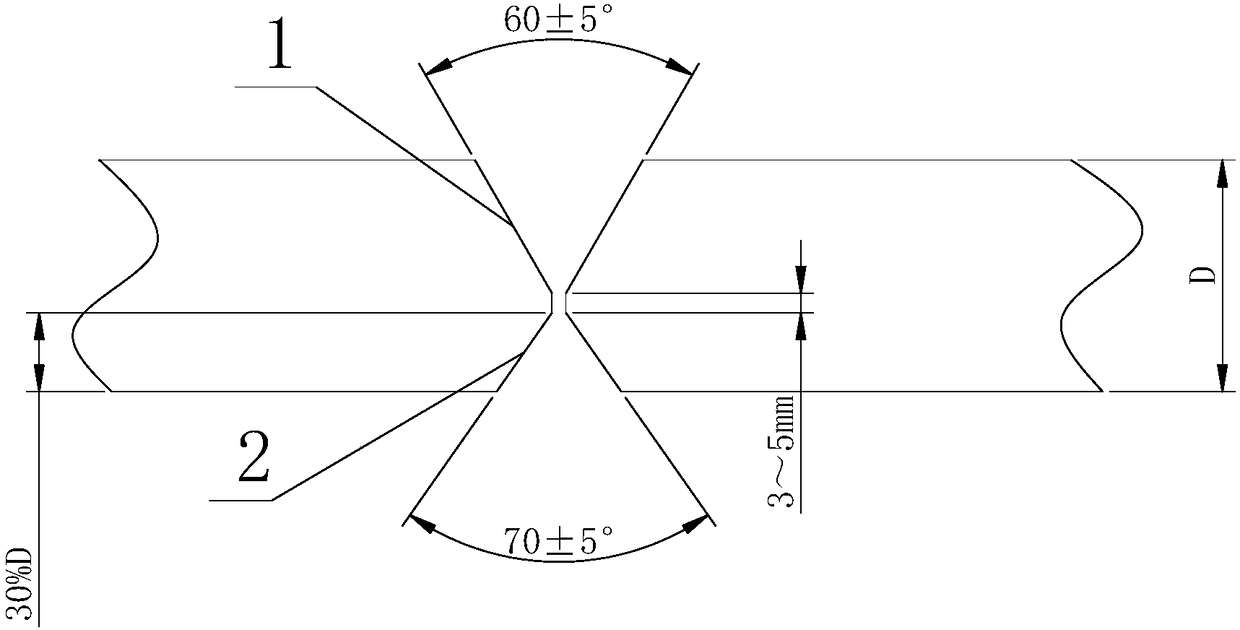

Double-wire submerged arc welding method for high heat input energy welding of high-strength super-thick steel plates

InactiveCN109014513AImprove performanceSimple methodArc welding apparatusWelding/cutting media/materialsSheet steelEngineering

The invention relates to a double-wire submerged arc welding method for the high heat input energy welding of high-strength super-thick steel plates. Double-wire submerged arc welding is carried out on the steel plates of which the thickness is larger than 50mm without carrying out preheating before welding or carrying out heat treatment after welding. The total welding heat input energy of double-wire submerged arc welding is controlled at 100+ / -5kJ / cm, interlayer temperature is controlled between 100DEG C and 150DEG C, and the welding groove type belongs to a non-symmetrical X type. The double-wire submerged arc welding method has the advantages that the method is simple, easy to operate and efficient, saves energy and is particularly suitable for guiding the building construction of a large steel structure; and the quality of welding joints is excellent, the deformation degree of the welded plates is very small, welding defects are effectively avoided, welding deformation is controlled, the welding efficiency is increased, and the welding operation intensity is reduced.

Owner:ANGANG STEEL CO LTD

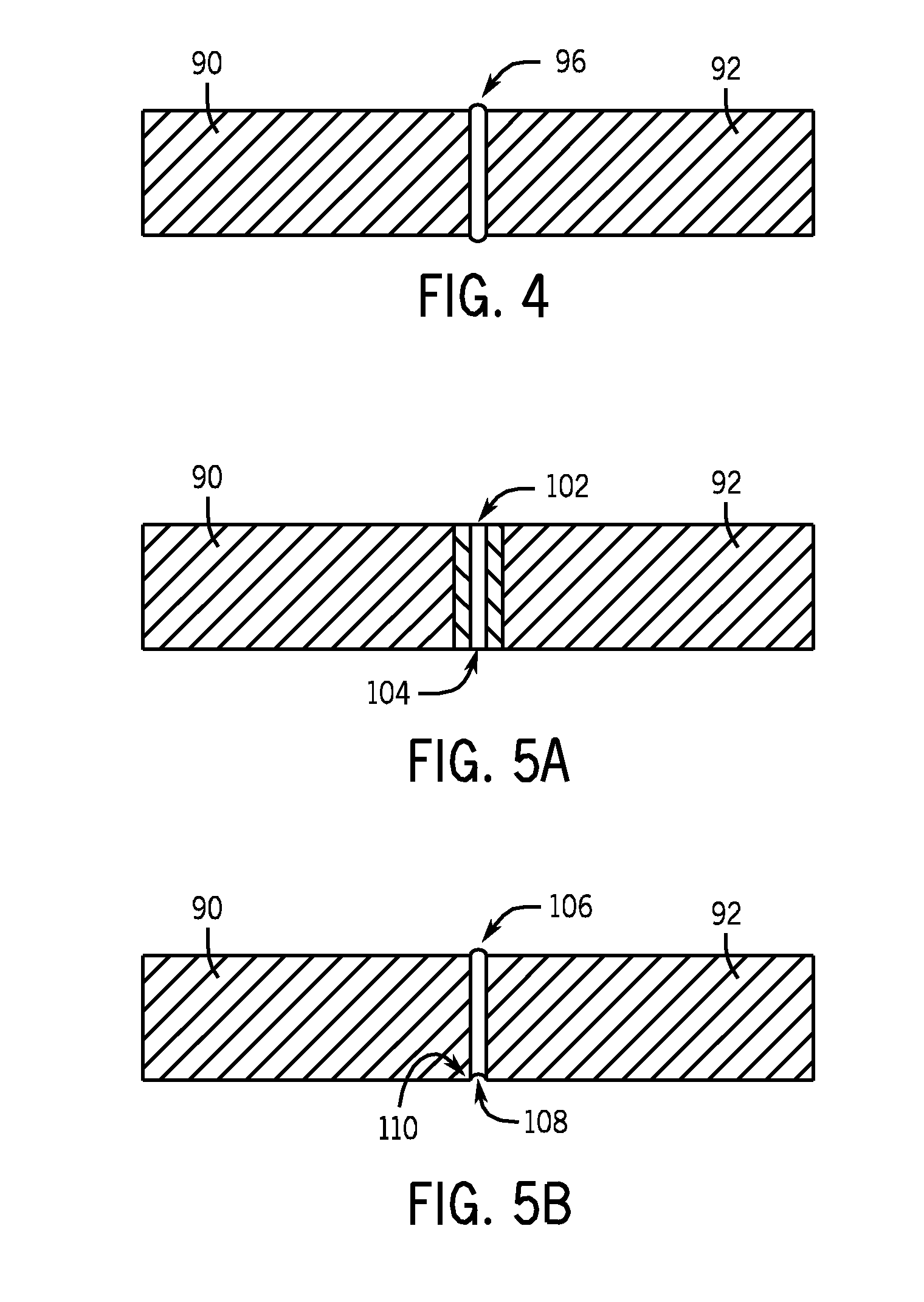

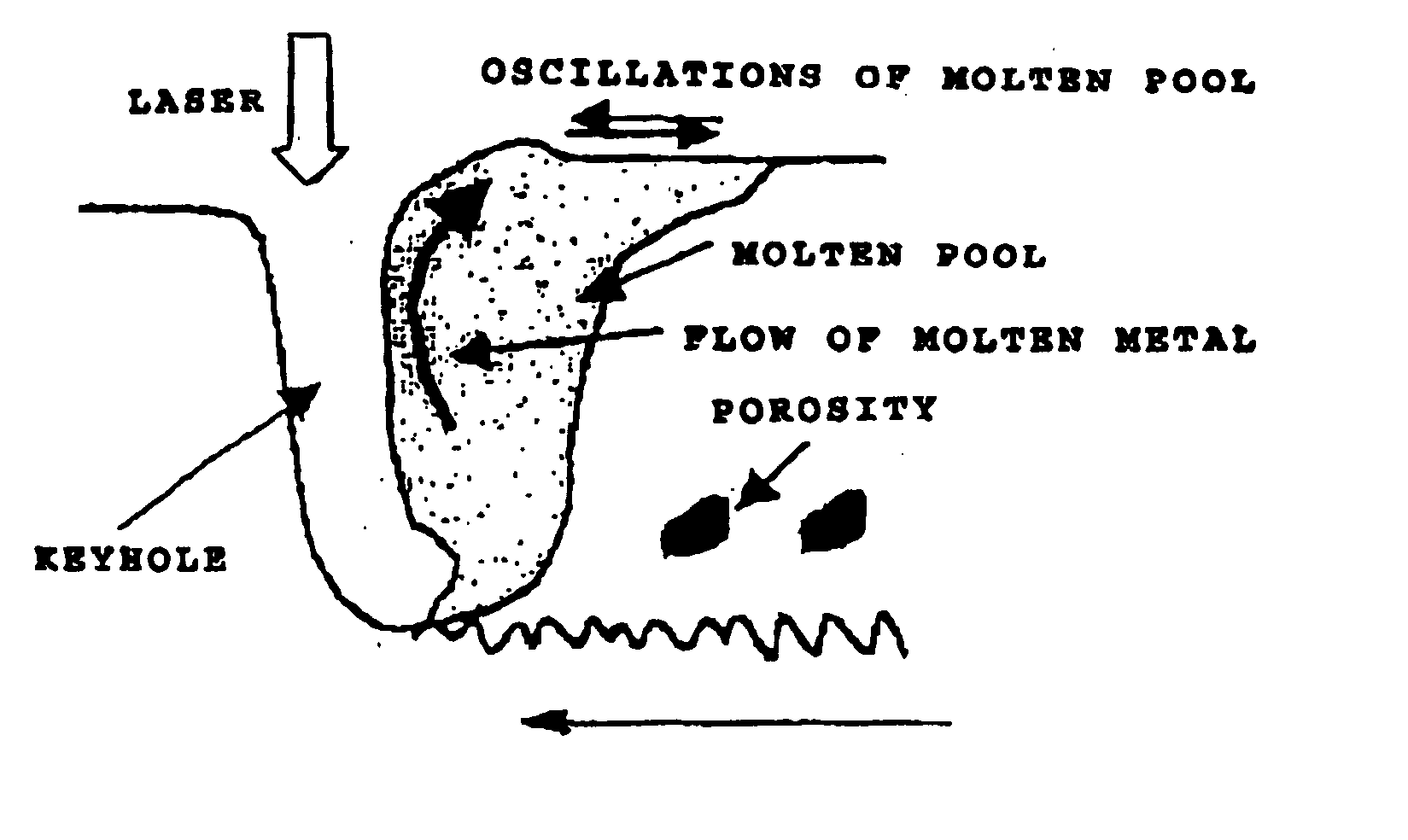

Laser welding processed

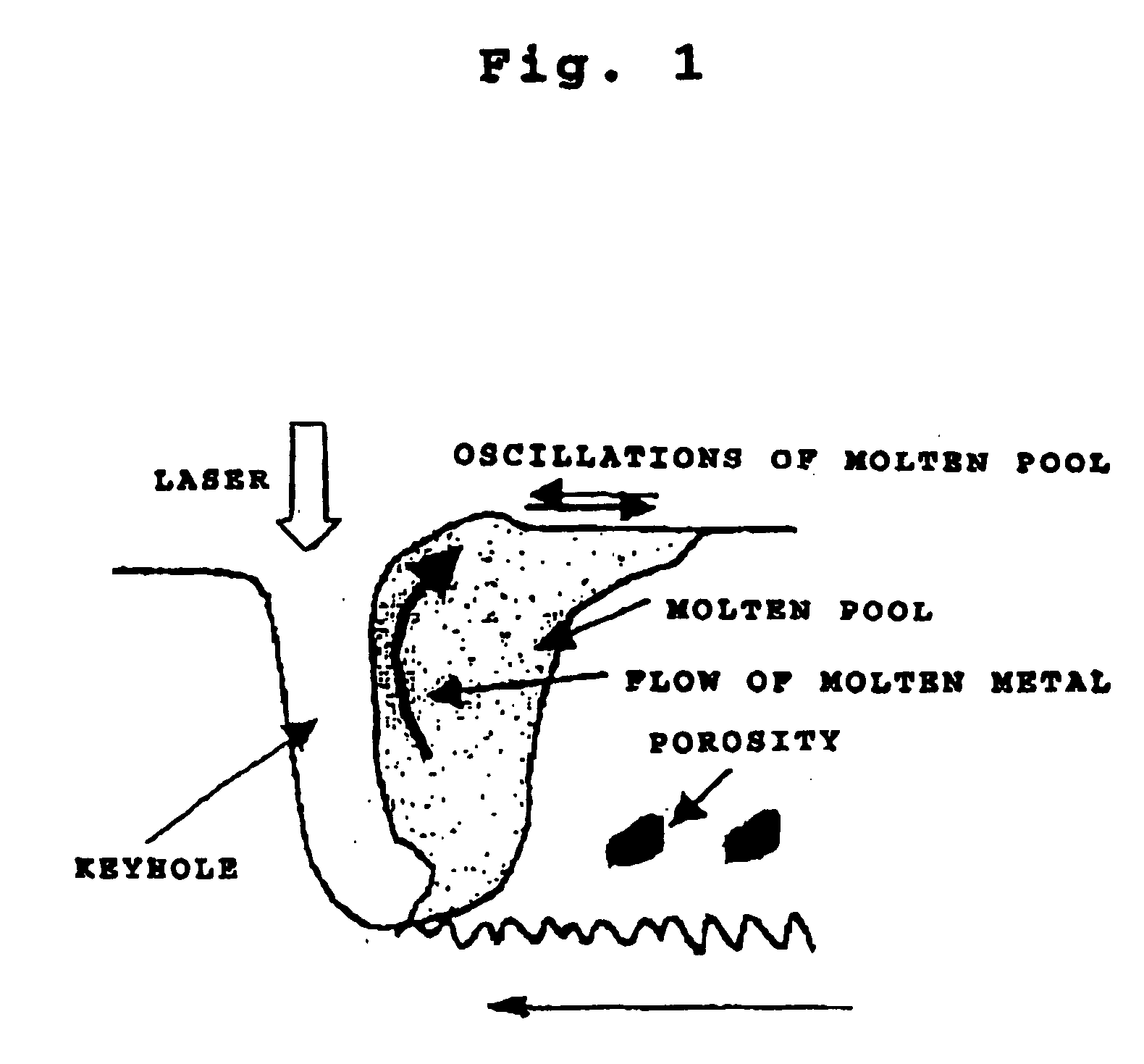

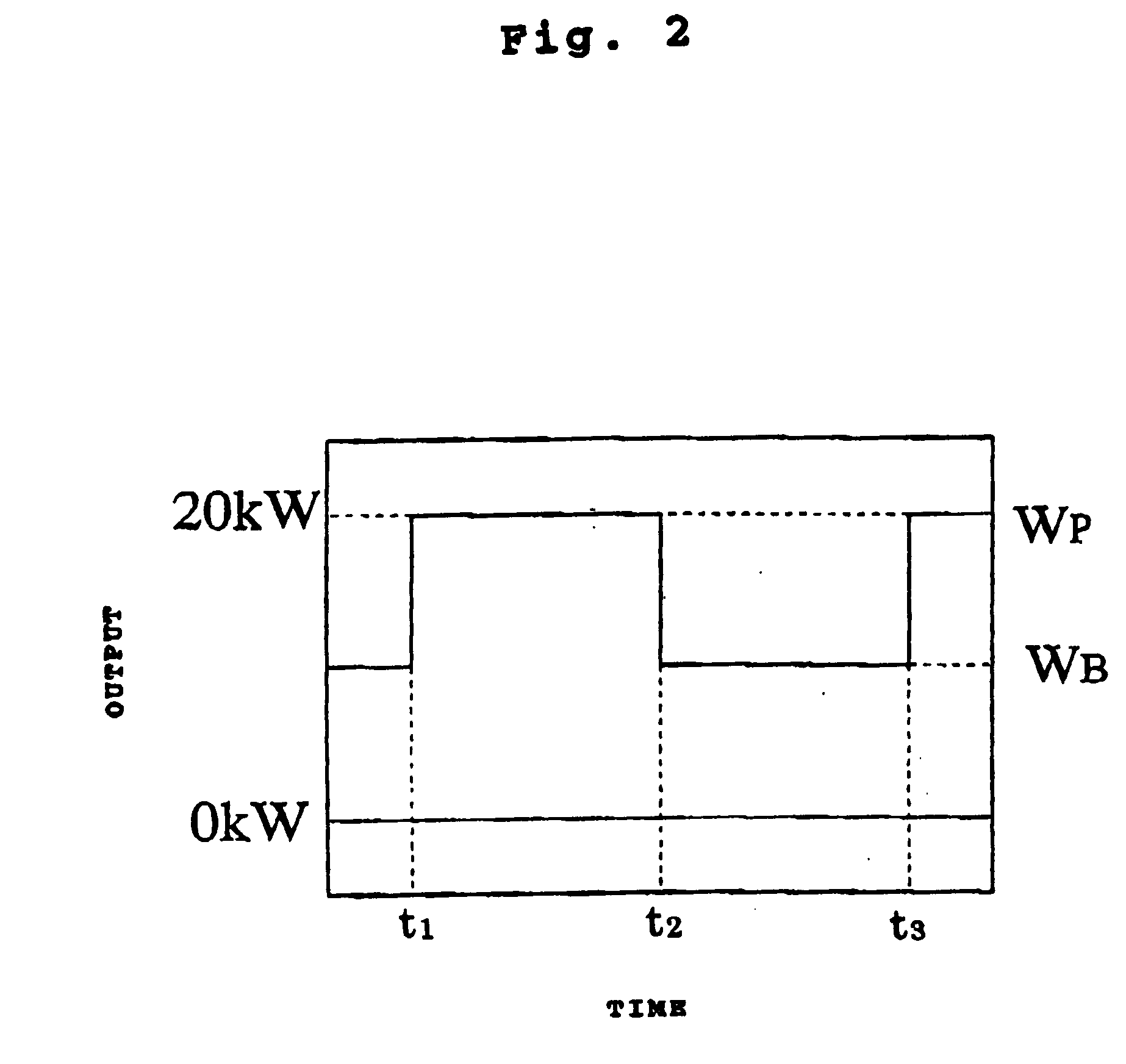

InactiveUS20040026381A1Avoid crackingInhibited porosityLaser beam welding apparatusMelting tankWelding defect

In a laser welding method, occurrence of weld defects is effectively prevented, and a high-quality weld joint is provided; and in addition, a wide range of material processes including a laser-using de p-penetration welding technique can be implemented. In keyhole welding using a laser performing output pulse modulation, the welding is conducted in accordance with a frequency conforming to a natural fr queucy of a metal molten pool.

Owner:NAT INST FOR MATERIALS SCI +1

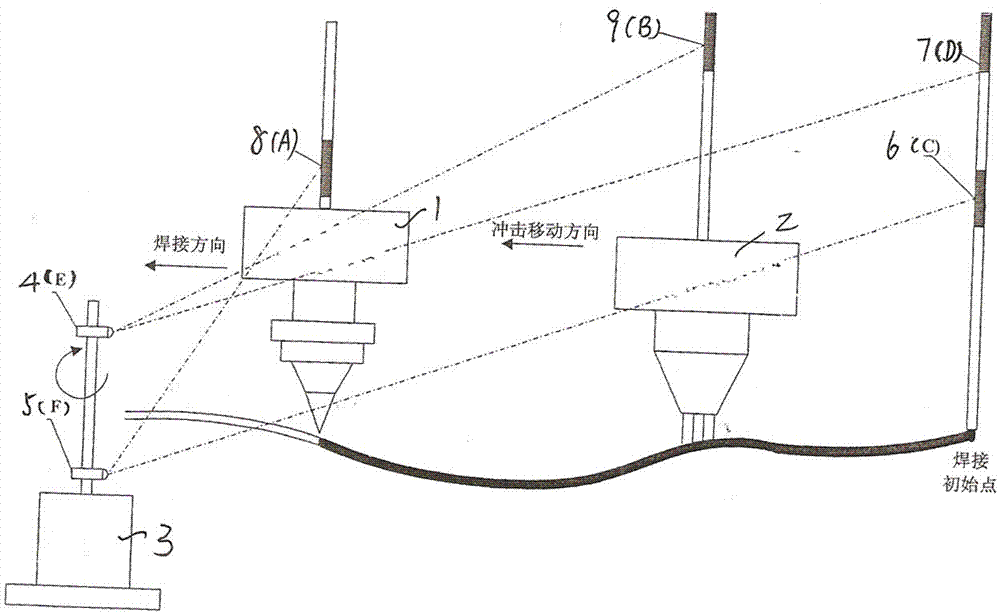

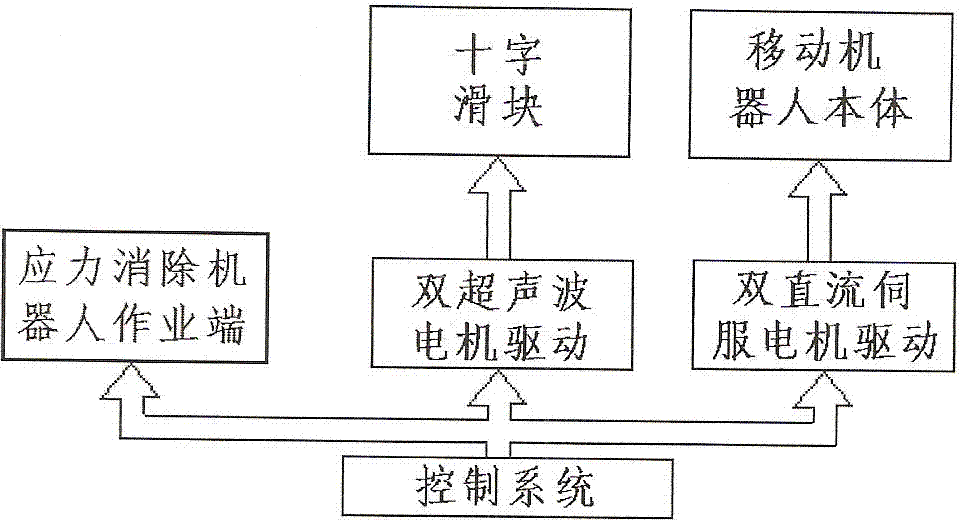

Constant-speed scanning positioning type post-welding seam tracking and residual stress removal system

ActiveCN102922147ASimple structureHigh degree of automationLaser beam welding apparatusSynchronous motorSlag

The invention discloses a constant-speed scanning positioning type post-welding seam tracking and residual stress removal system, which comprises mobile welding equipment, a welding stress removal moving robot, a synchronous motor and two reflection-type distance measuring sensors, wherein the mobile welding equipment is used for welding a welding seam, the welding stress removal moving robot is used for removing welding stress, the synchronous motor is fixedly arranged outside the welding seam and takes the axis of a synchronous motor rotation shaft as a reference point, the two reflection-type distance measuring sensors are fixed on a motor shaft, coaxially rotates with the motor and are arranged at intervals, and reflecting sheets are glued at a welding initial point, a welding nozzle of the mobile welding equipment and the operating tail end of the welding stress removal moving robot. The constant-speed scanning positioning type post-welding seam tracking and residual stress removal system is simple in structure, high in automation and high in post-welding seam tracking precision, and is free from influence of welding slag or welding defect on a post-welding seam.

Owner:NANTONG UNIVERSITY

TiNi shape memory alloy and stainless steel instant liquid-phase diffusion welding connection method

InactiveCN101362253ALess loss of shape memory propertiesSmall organizationWelding/soldering/cutting articlesNon-electric welding apparatusHeat-affected zoneSurface cleaning

The invention relates to a method for transient liquid phase diffusion bonding between TiNi shape memory alloy and stainless steel, which belongs to the technical field of the connection of dissimilar materials. In the prior art, the technology of the connection between TiNi shape memory alloy and stainless steel has the problems of welding crack, large crystal grains in the heat affected zone and poor mechanical properties. The transient liquid phase diffusion bonding between TiNi shape memory alloy and stainless steel is realized through the following steps: after the surfaces of TiNi shape memory alloy and stainless steel to be welded and the surface of AgCuTi foil is cleaned and dried, a TiNi shape memory alloy / AgCuTi metallic foil / stainless steel structure is formed, fixed through a welding clip, and then positioned in a vacuum diffusion oven, and welding pressure and temperature are applied to the structure. The method has the advantages that the welding temperature is low (relative to fusion welding), the influence to the base material is small, the connector has no welding defect, the shearing strength of the connector in the room temperature reaches 250 MPa, and the microhardness of the area near the seam section can reach 670 Hv.

Owner:BEIJING UNIV OF TECH

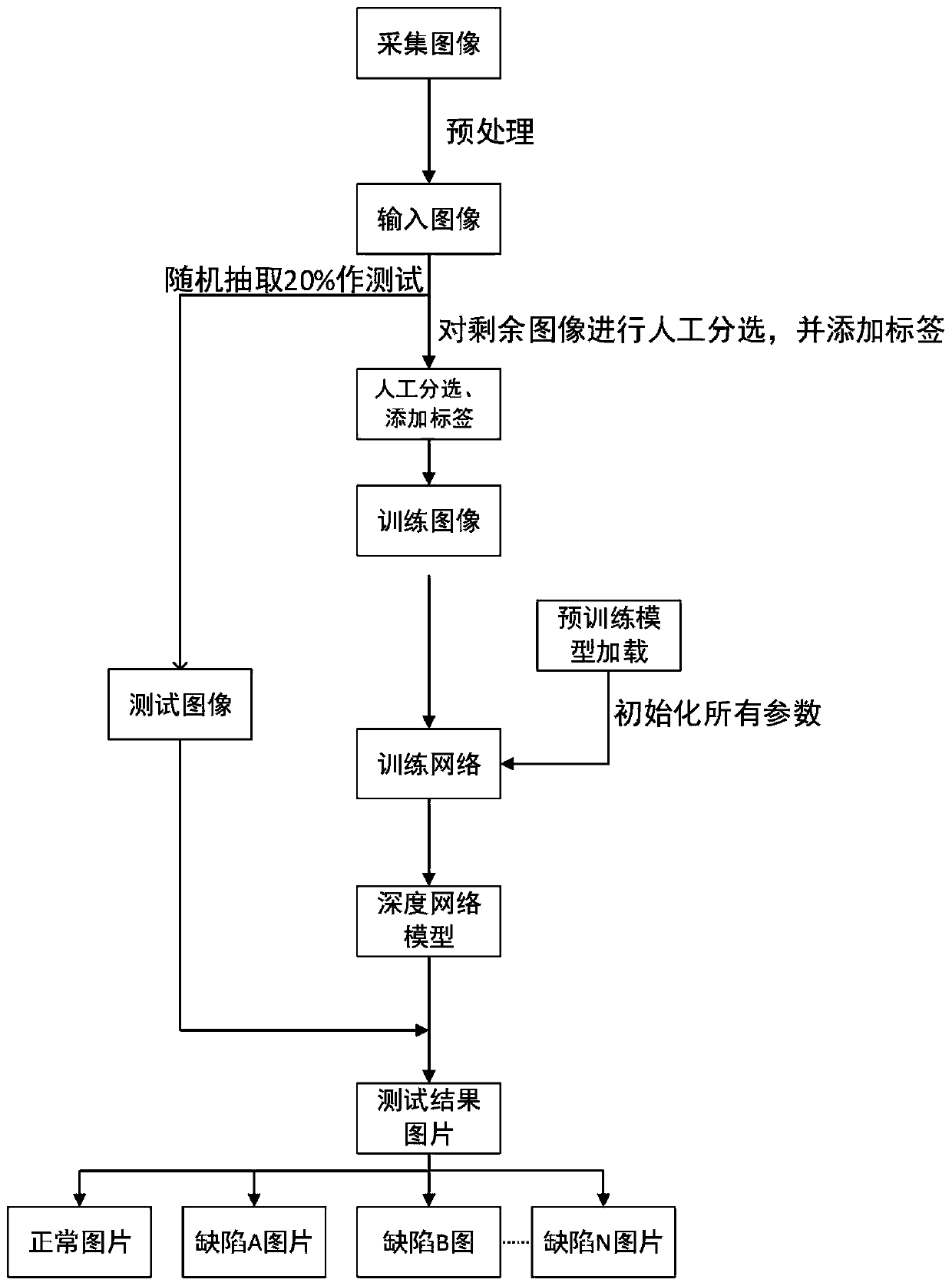

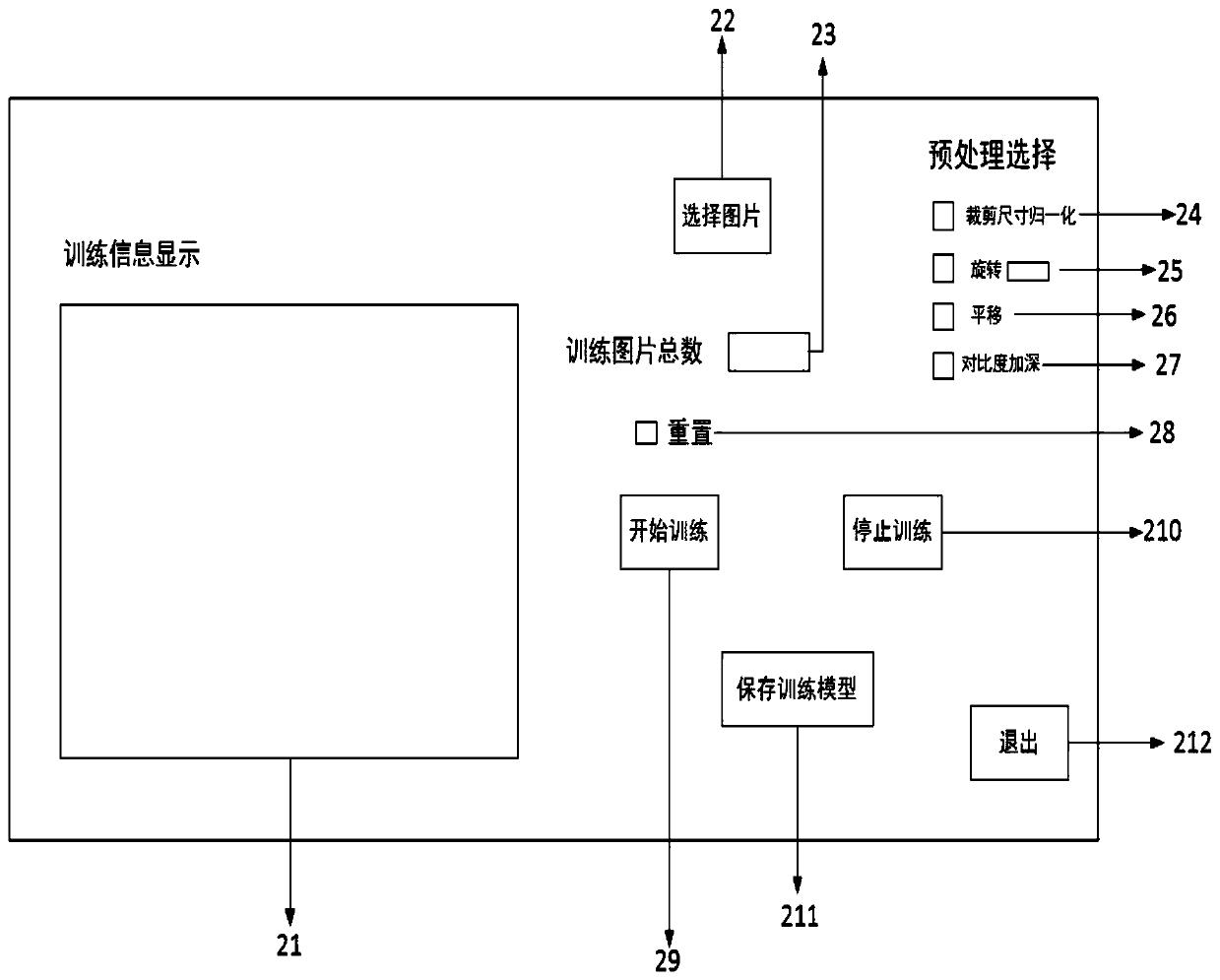

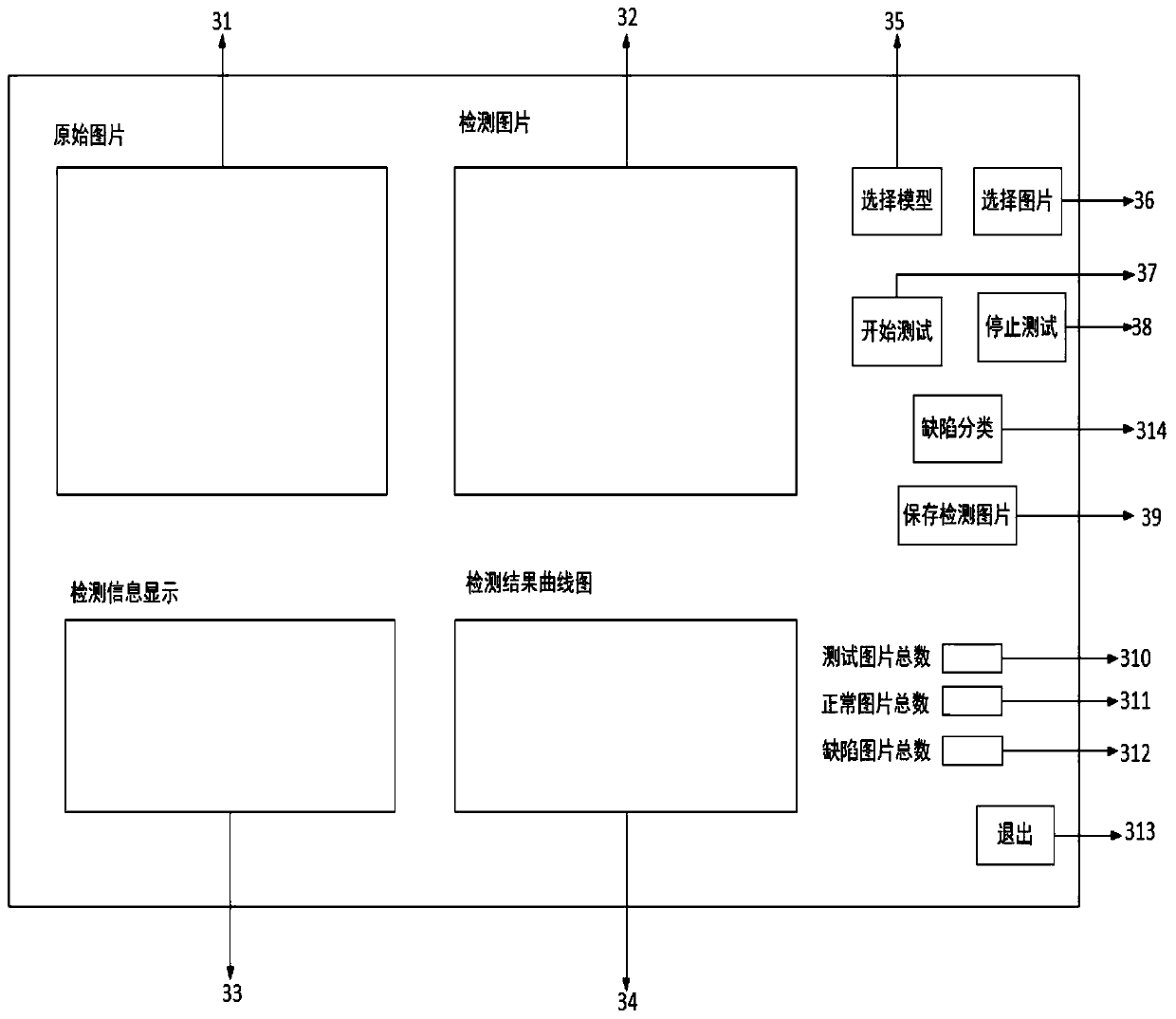

Detection method for automatically identifying and detecting weld defects

ActiveCN110570410AAvoid inefficiencyAvoid uncertaintyImage enhancementImage analysisImaging processingFeature extraction

The invention relates to a detection method for automatically identifying and detecting weld defects. Weld defects are detected based on a deep learning algorithm of a Faster R-CNN network. The methodcomprises the following steps of firstly, preprocessing collected weld defect images, randomely extracting 20% of the weld defect images for testing, manually storing residual images and adding labels for training; inputting a training sample into a Faster R-CNN neural network for training, then testing the obtained model, and finally achieving a detection effect. The Faster R-CNN network is adopted to perform feature extraction on the weld defect images, so that low efficiency and uncertainty of traditional manual feature extraction are avoided, and meanwhile, the detection process also hasrelatively high robustness. Deep learning technology and image processing technology are combined. A deep learning method is used for detecting the weld defects. When learning rate is initially set tobe 0.001, model classification accuracy reaches 99.3%, detection precision is obviously improved and detection speed is increased.

Owner:HEBEI UNIV OF TECH

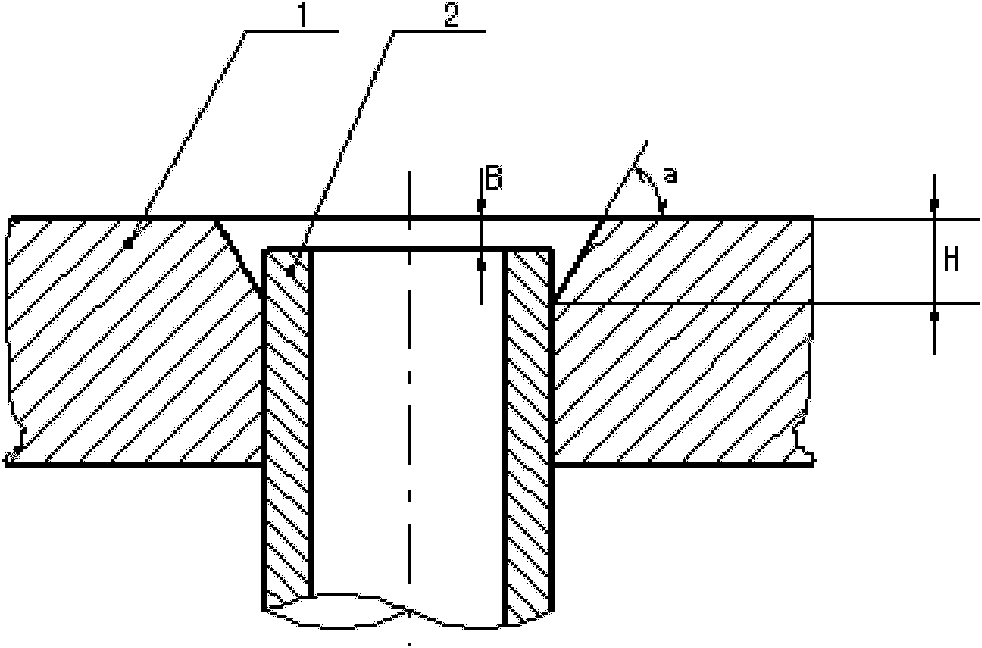

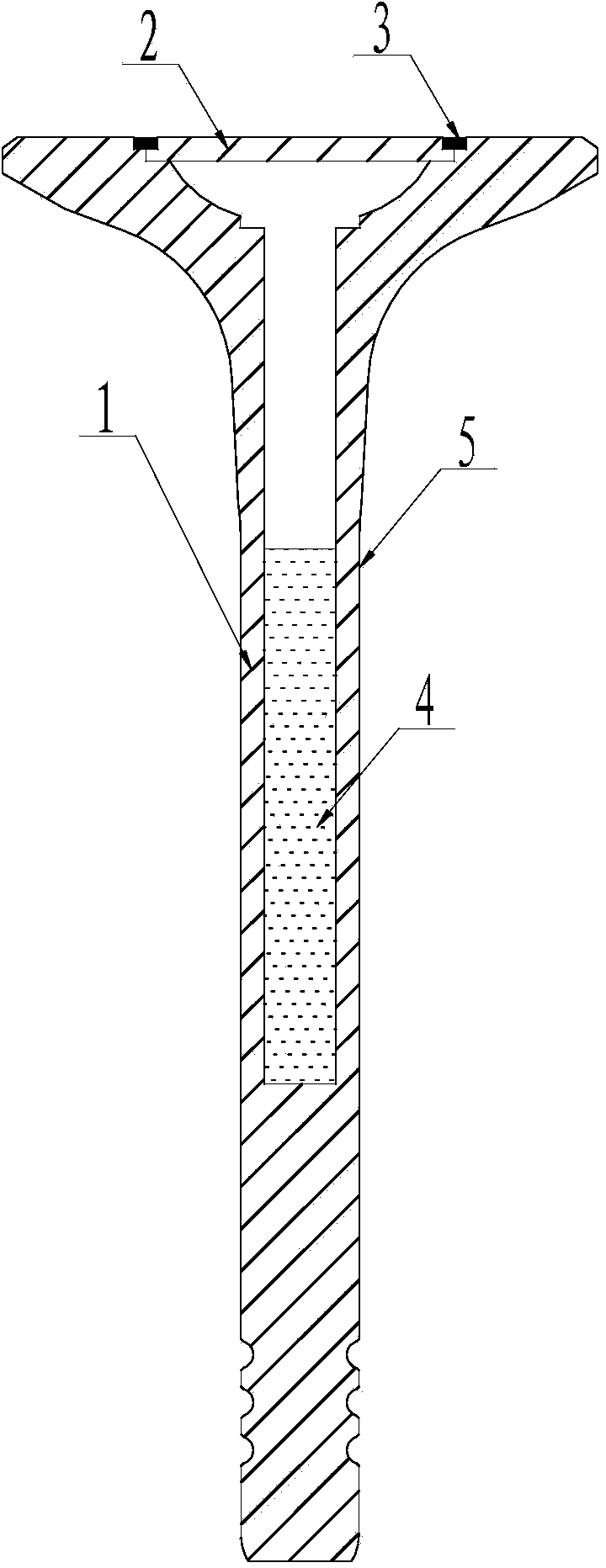

Method for welding heat exchanger tube plate and welding joint of heat exchange tube

InactiveCN102151958AInhibition retentionExtended service lifeArc welding apparatusHeat exchange apparatusEngineeringWelding defect

The invention relates to a method for welding a heat exchanger tube plate and a welding joint of a heat exchange tube. During assembling of the heat exchange tube and the tube plate, a structure which is sunken into the surface of the tube plate 0.5 to 1 millimeter is adopted; during welding, a welding sequence from bottom to top is adopted, and a 3-shaped or S-shaped welding running line is adopted; during welding, each heat exchange tube is welded with a half of a cycle, and after 8 to 10 heat exchange tubes are welded disposably without arc quenching, the tube plate is subjected to the arc quenching; and according to the same method, the other half of the cycle is welded from bottom to top. Therefore, the frequency of arc stopping and arc starting can be reduced, the welding efficiency is improved, and the number of arc starting and stopping points and the probability of generating welding defects can be reduced. During welding, a tungsten electrode can be stretched into the root part of an included angle between the heat exchange tube and the tube plate easily; during autogenous welding, an electric arc can get to a sharp corner position, and the root part can be penetrated totally without any hollow cavity, so retention of shell side corrosion media is prevented, interval corrosion is avoided and the service life of a welding line is prolonged.

Owner:TIANJIN JINBIN PETROCHEM EQUIP

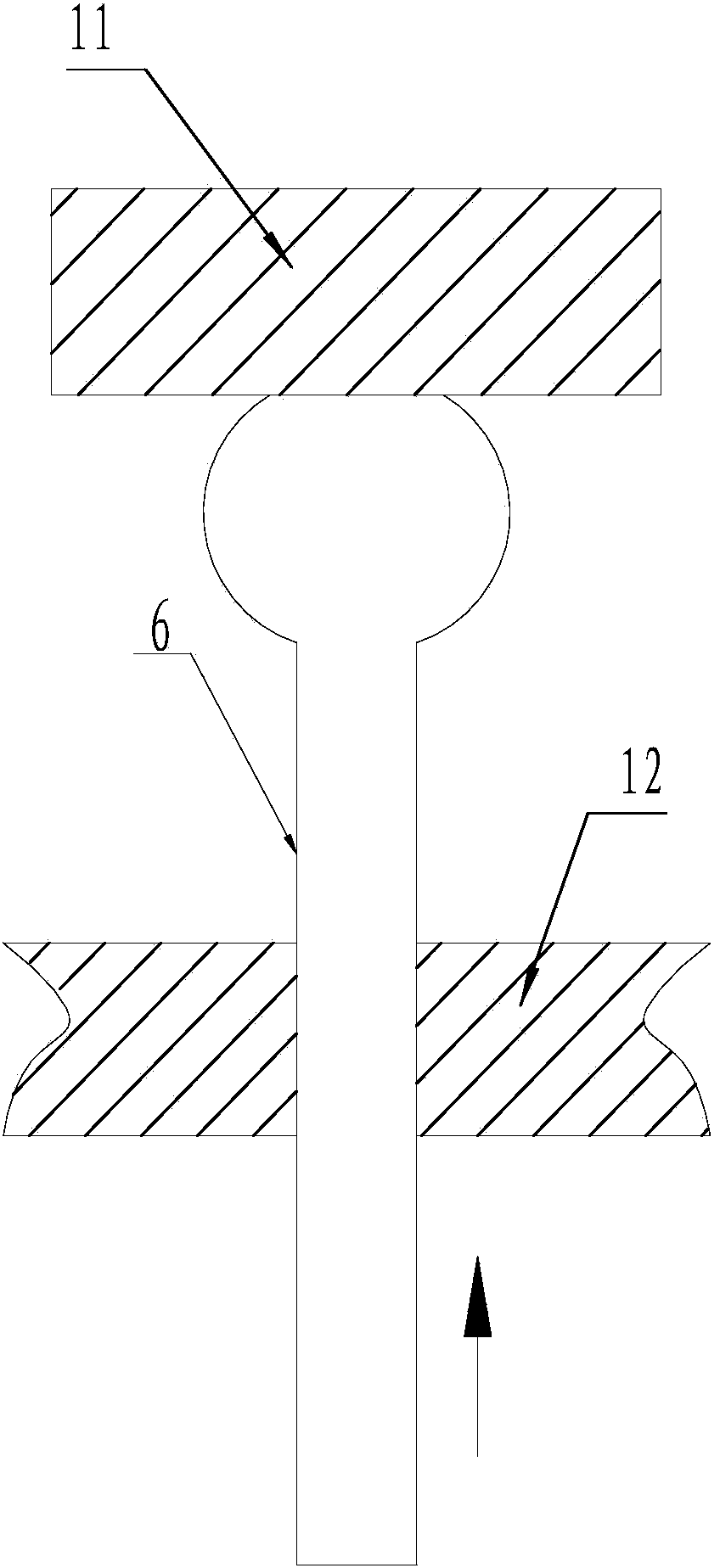

Method for manufacturing hollow sodium inflating valve with closed disc end

ActiveCN103990944AReduce uniformityGuaranteed depthMetal-working apparatusMachines/enginesGun drillWelding defect

The invention discloses a method for manufacturing a hollow sodium inflating valve with a closed disc end, belongs to a production method of valves of internal combustion engines, and particularly relates to the method for manufacturing the hollow sodium inflating valve with sodium serving as a coolant. According to the method, a pre-workblank with the end shaped like the head of garlic of a bar is formed by the thin and long bar through an electric pier; then, the valve is forged and pressed into the shape of a gas outlet valve workblank through the one-time forging and pressing process in the forging procedure, wherein the valve workblank forming process is in a high temperature state, simple in process route, low in manufacturing cost and high in efficiency. An inner hole of the valve is machined through a deep hole gun-drill, and therefore the diameter of the inner hole, the depth of the inner hole, the roughness of the inner hole, the coaxiality of the inner hole and the evenness of the wall thickness can be ensured, the machining rhythm is quick, efficiency is high, and cost is low. By means of the method of utilizing steps at the welding point of a disc end face sealing cover and the valve, welding defects are reduced, and welding strength is high.

Owner:济南沃德汽车零部件有限公司

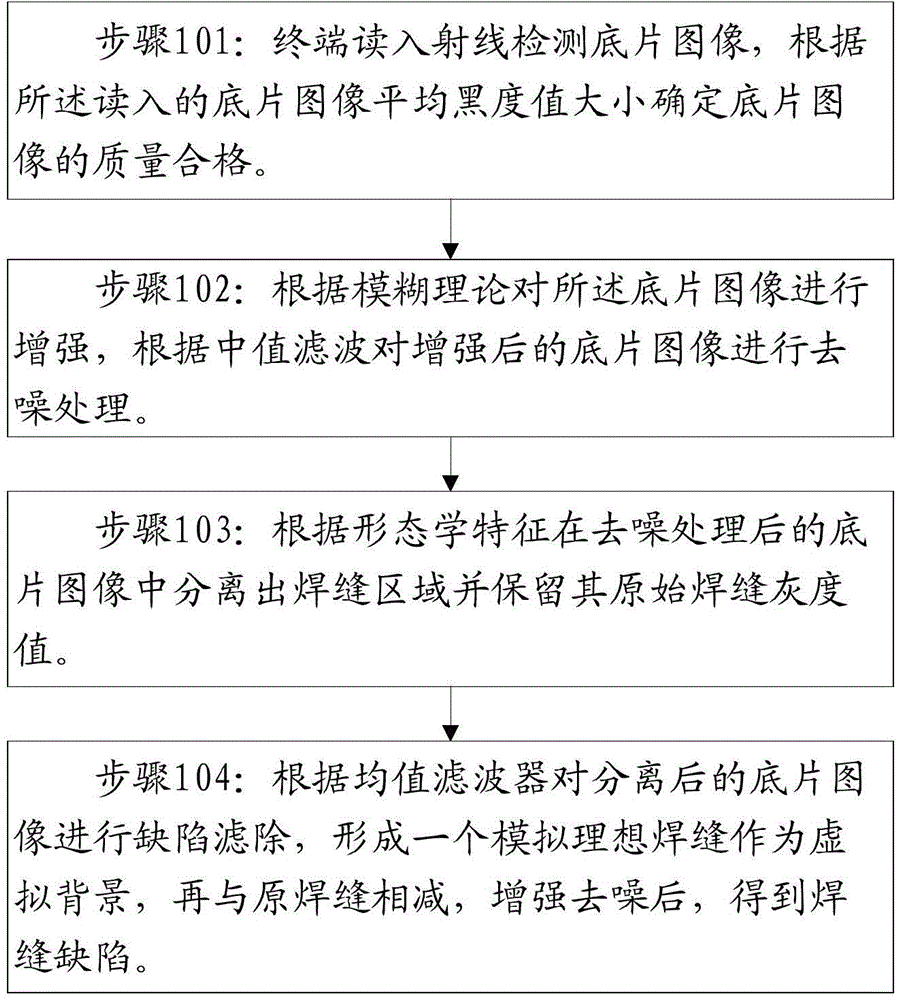

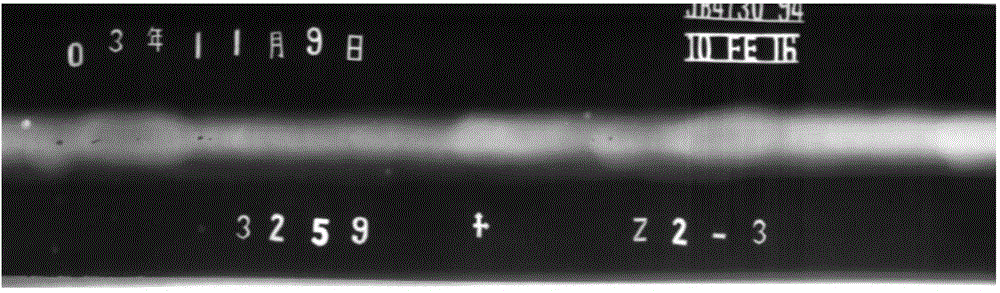

Pressure vessel weld defect identification method and device based on neural network

InactiveCN104574418AEfficient identificationReduce testing costsImage enhancementImage analysisImage averagingIdentification device

The invention discloses a pressure vessel weld defect identification method and device based on a neural network. A computer reads in a radiographic inspection negative film image, and whether the quality of the negative film image is qualified or not is determined according to the read-in average darkness value of the negative film image; the negative film image is enhanced according to a fuzzy theory, and de-noising processing is conducted on the enhanced negative film image according to median filtering; a weld joint region is separated from the negative film image obtained after de-noising processing is conducted according to the morphological feature, and an original weld joint gray value is retained; defect filtering is conducted on the separated negative film image according to a mean filter, and a simulated ideal weld joint is formed to serve as a virtual background, the virtual background is subtracted from the original weld joint, and the weld joint defect is obtained after enhancement and de-noising are conducted. The invention further discloses the pressure vessel weld defect identification device, radiographic inspection weld joint images can be identified effectively, identification accuracy reaches 92%, the detection cost can be reduced greatly, and efficiency is improved.

Owner:XIAN TECHNOLOGICAL UNIV

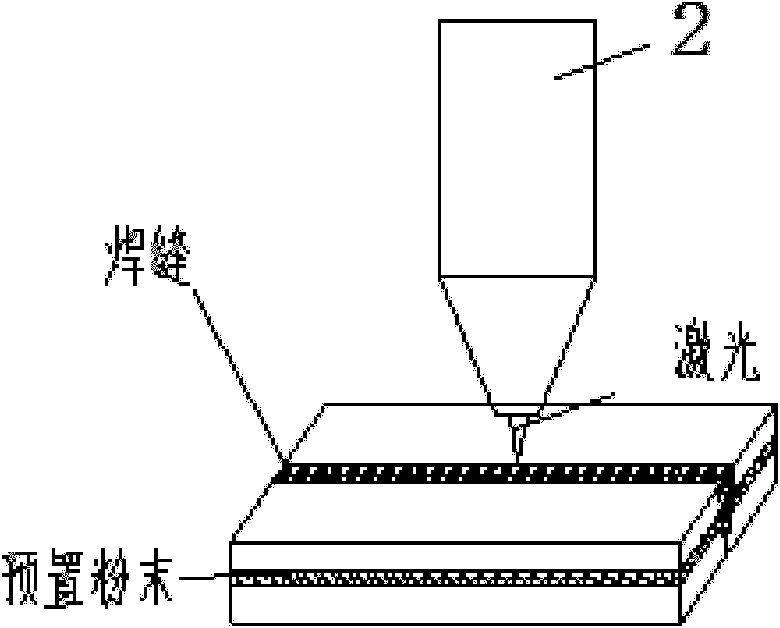

Online diagnosis method for welding defects in laser powder-adding welding process of galvanized steel based on characteristic element plasma optical signal

ActiveCN102049613ARealize online monitoringAnalysis by thermal excitationLaser beam welding apparatusDiagnosis methodsCopper

The invention discloses an online diagnosis method for welding defects in laser powder-adding welding process of galvanized steel based on a characteristic element plasma optical signal, comprising the following steps: welding the galvanized steel with a focused laser beam; simultaneously, adding copper powder at a welding part in the welding process; acquiring the characteristic element plasma optical signal in the laser powder-adding welding process of the galvanized steel by a photosensitive sensor; implementing online monitoring on types of the characteristic elements of the plasma generated by ionization of materials in the welding process and additive amount m of corresponding characteristic elements according to variation of the characteristic element plasma optical signal; and finally, obtaining relation between the characteristic element plasma optical signal and the welding defects. In the method, properties of the characteristic elements to the plasma optical signals are analyzed so as to judge whether the welding defects are generated and the generation time on line in real time, and the method can be used for online monitoring of defects in the laser welding process in practical production, and laying the foundation for online quality control of following laser welding processes.

Owner:HUNAN UNIV

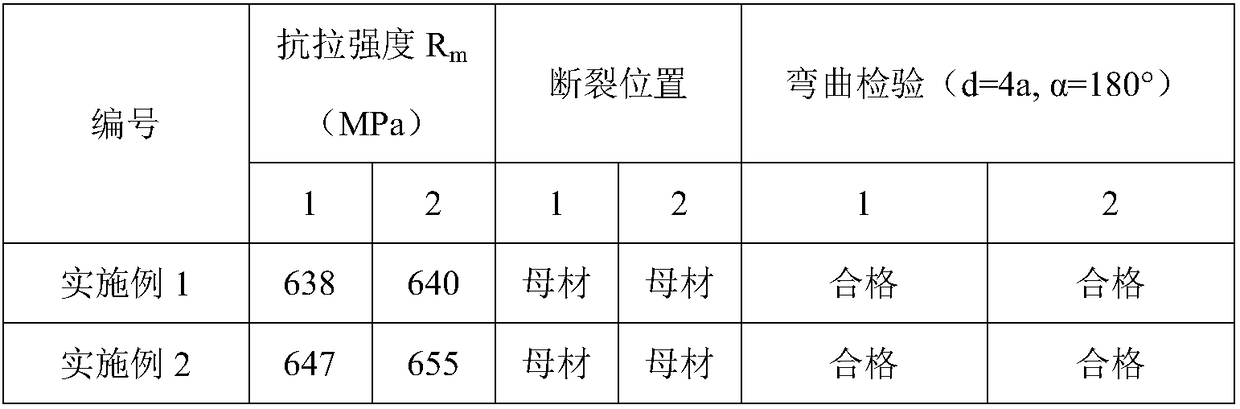

Welding method of ultra-thick and high-strength water-power steel

ActiveCN101905365ATo achieve the welding effectReduce fillingArc welding apparatusWorkpiece edge portionsEngineeringWelding defect

The invention relates to a welding method of ultra-thick and high-strength water-power steel, belonging to the welding field. Welding is realized by adopting a mixed welding mode, i.e. hand welding is adopted as a basis for filling the bottom, and gas shielded welding is adopted for a middle layer and a cover part, multilayer and multi-pass welding are adopted, a carbon arc is cropped out after a single side is filled, and the input of welding heat is controlled within 65 kJ / cm. A welding bevel adopts an asymmetric U-shaped bevel, a thick steel plate of 145-155 mm is preheated to 100 DEG C before welding, the inter-layer temperature is kept between 100 DEG C to 160 DEG C, and heat treatment stress is not carried out after welding, and the problem of reheat embrittlement of a welding joint of the high-strength water-power steel is solved. The invention needs simple welding equipment, realizes welding through a combined welding process on the basis of the traditional equipment, reduces the filling amount of welding metal, and achieves the welding effect of a narrow gap. Compared with the hand arc welding, the invention greatly improves the welding efficiency of the thick steel plate and lowers the possibility of welding defects easily generated on the hand arc welding of an ultra-thick steel plate, such as cold cracks, incomplete fusion, crisp fusion, and the like.

Owner:SHOUGANG CORPORATION +1

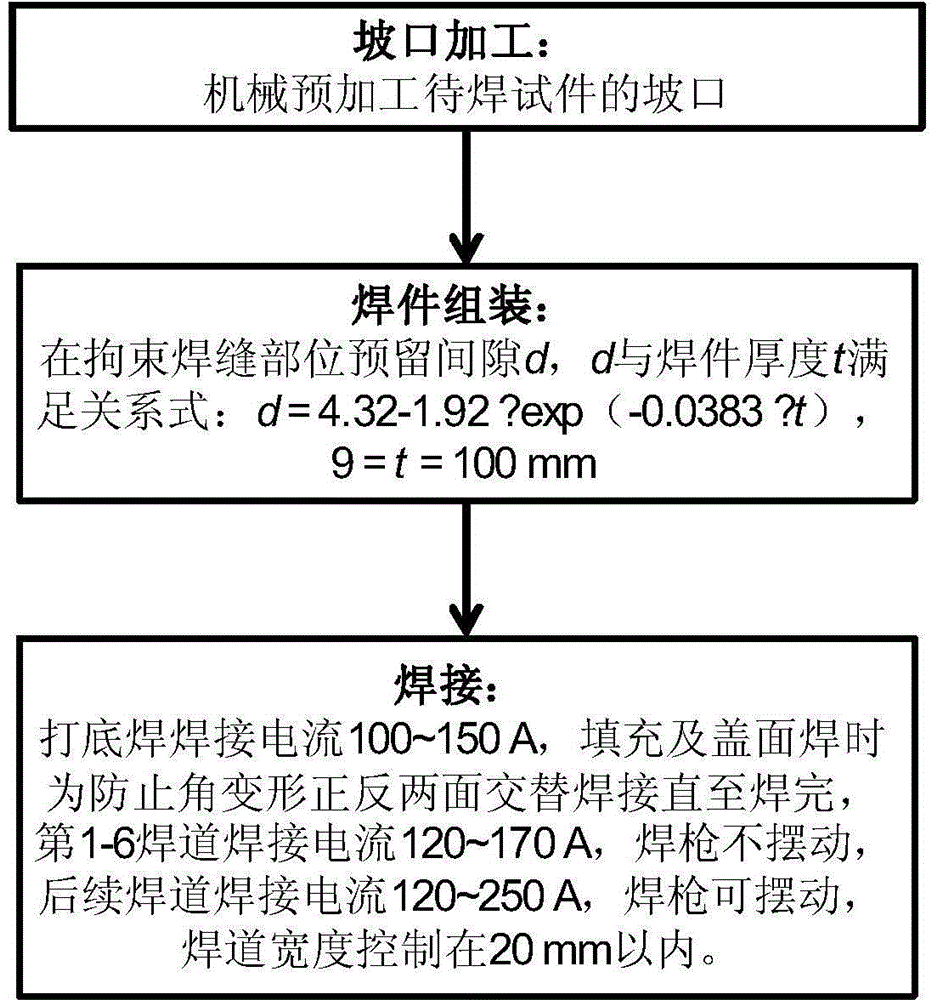

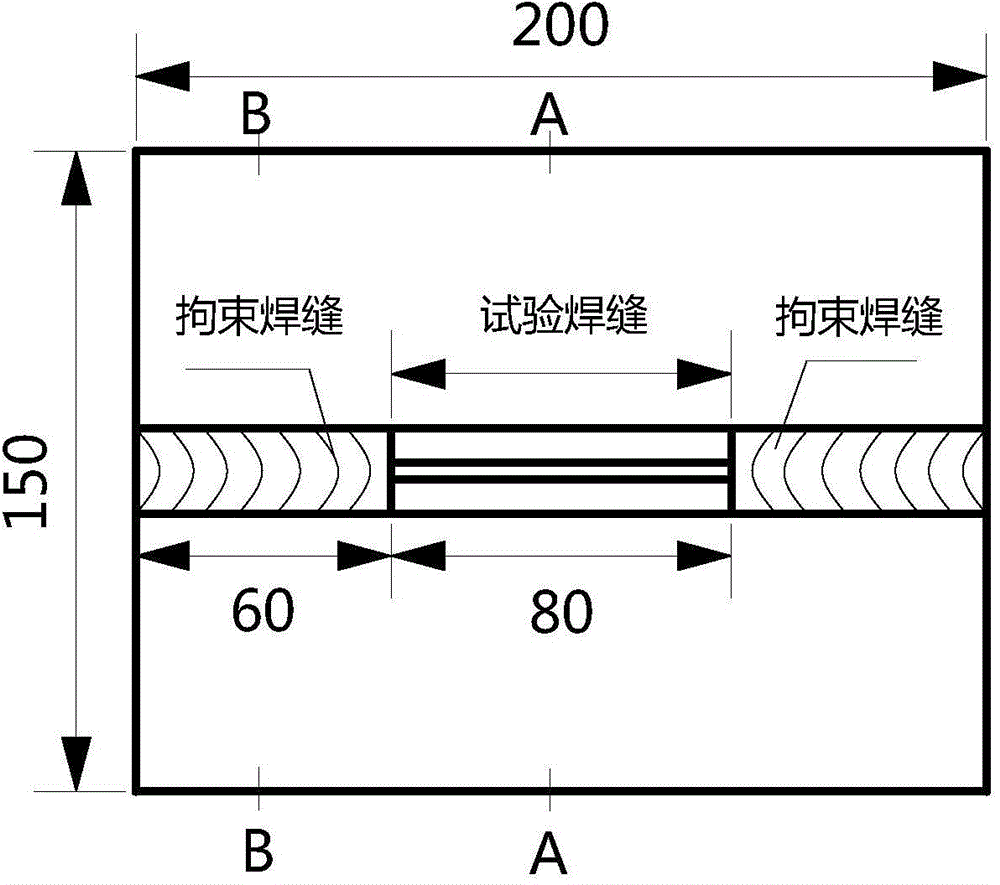

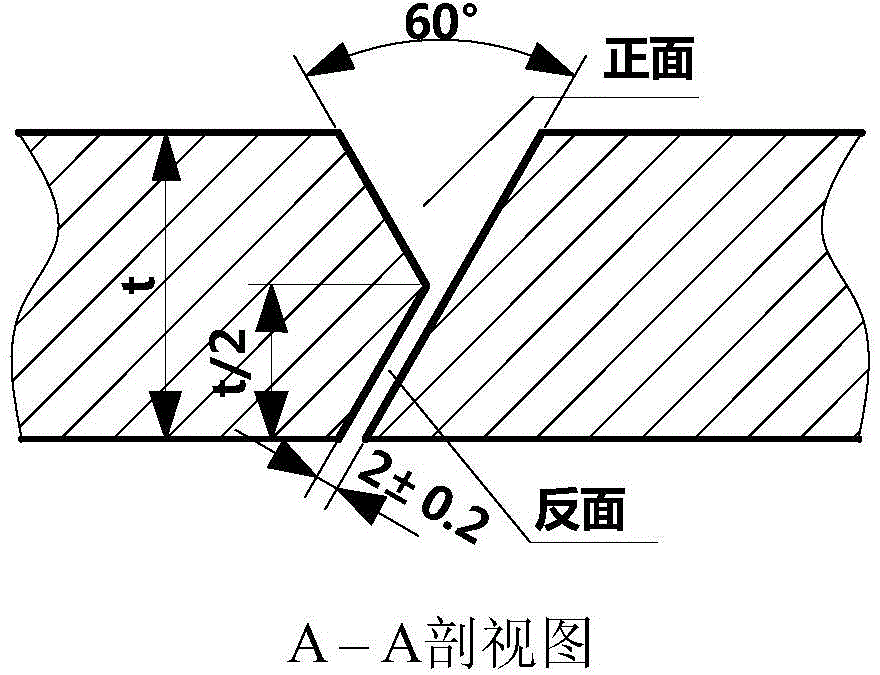

Limited welding seam manufacturing method for oblique Y-shaped groove crack welding test

ActiveCN104625456ALess heavy workReduce labor intensityArc welding apparatusWelding/soldering/cutting articlesEngineeringWeld seam

The invention discloses a limited welding seam manufacturing method for an oblique Y-shaped groove crack welding test. The method comprises the following steps that (1) groove machining: mechanical premachining is performed on a groove of a to-be-welded test piece; (2) weldment assembling: a gap d is reserved on a limited welding seam position, the d and the weldment thickness t satisfy the relation: d=4.32-1.92*exp(-0.0383*t), 9<=t<=100 mm; (3) welding: the welding currents of a backing weld range from 100 A to 150 A, when filling and cosmetic welding are performed, in order to prevent angular deformation, the front face and the back face are alternately welded until the welding is completed, the welding currents of a first weld pass to a sixth weld pass range from 120 A to 170 A, a welding gun does not swing, the welding currents of subsequent weld passes range from 120 A to 250 A, the welding gun can swing, and the width of the weld passes is controlled within 20 mm. The limited welding seam manufactured by the method has no weld defect, the weldment gap can be guaranteed without needing to insert a patch into the welding test position, the heavy work of dismantling the patch is left out, the labor intensity is reduced, and the working efficiency is improved.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

Weld defect characteristic parameter extraction method

ActiveCN105588845AFast recognitionReduce dimensionalityOptically investigating flaws/contaminationComputer visionWelding defect

Owner:美光(江苏)三维科技有限公司

Laser filler wire welding method for thick plate narrow gap

ActiveCN103801833AAvoid it happening againReduce generationWelding/soldering/cutting articlesMetal working apparatusThick plateWeld seam

The invention relates to a laser filler wire welding method for a thick plate narrow gap, and belongs to the technical field of laser material processing. The laser filler wire welding method for the thick plate narrow gap is characterized by comprising the steps that positive out-of-focus laser beams are adopted, the laser beams enter a narrow gap groove of a workpiece to be welded and act on the bottom and the side wall of the groove, and a welding pool is formed in a thermal conducting welding mode; a filler wire enters the welding pool in a wire forward feeding mode and is heated through the welding pool to be molten, the gap is filled with the molten wire to form a weld joint, and a thick plate is connected in a single-path multi-layer welding mode. According to the laser filler wire welding method for the thick plate narrow gap, the thermal conducting welding mode and the mode that the filler wire is heated through the welding pool to be molten are adopted, and the welding process is stable; meanwhile, the laser beams act on the side wall of the groove so that the welding defects such as the defect that the side wall is incompletely fused can be effectively avoided.

Owner:BEIJING UNIV OF TECH

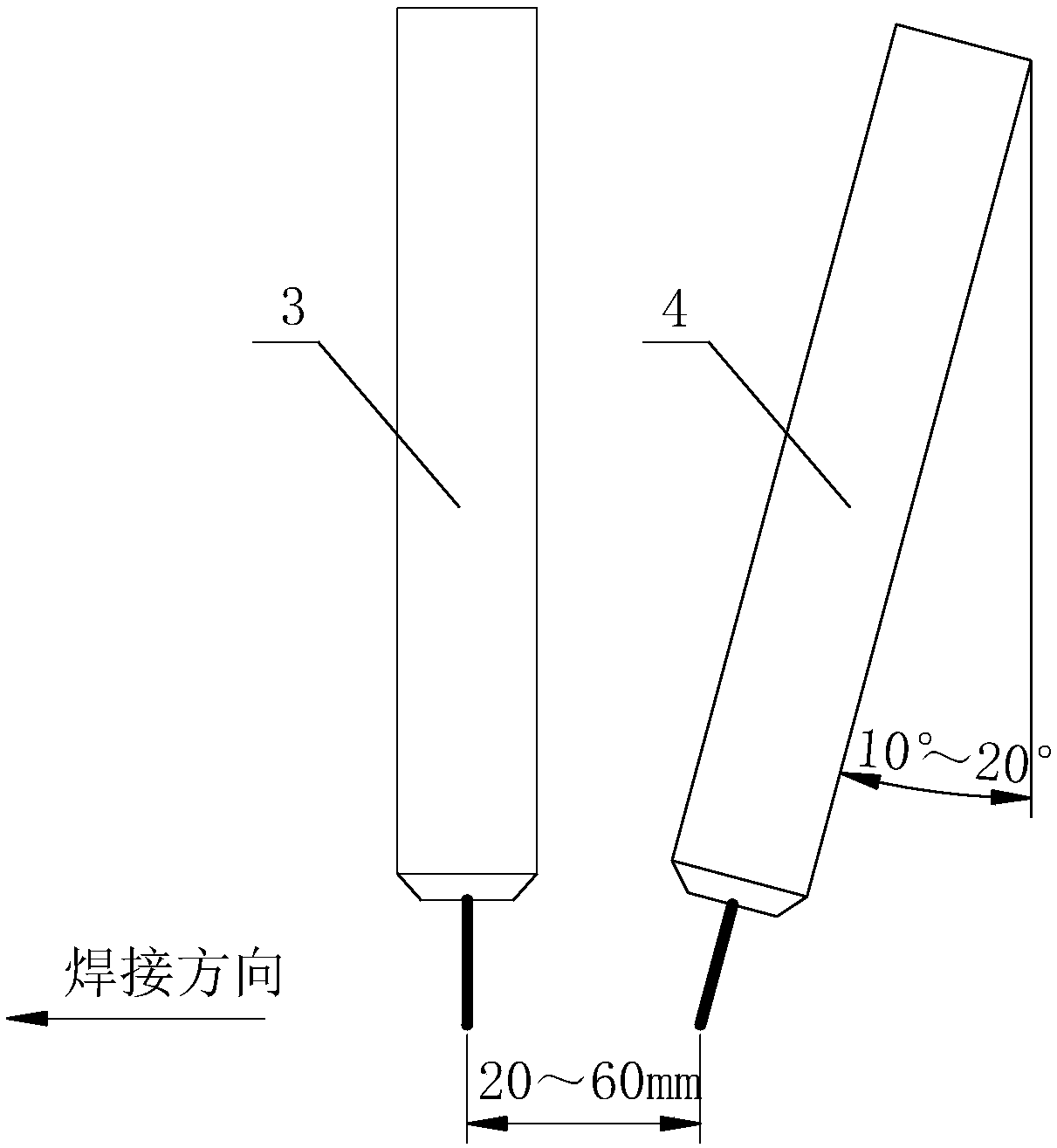

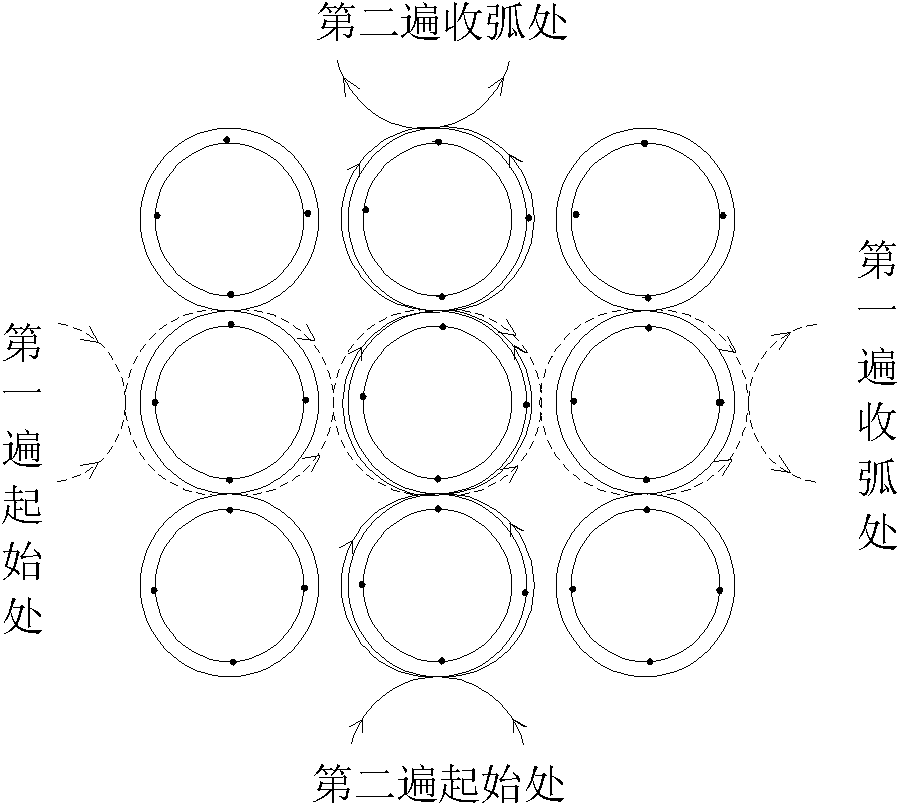

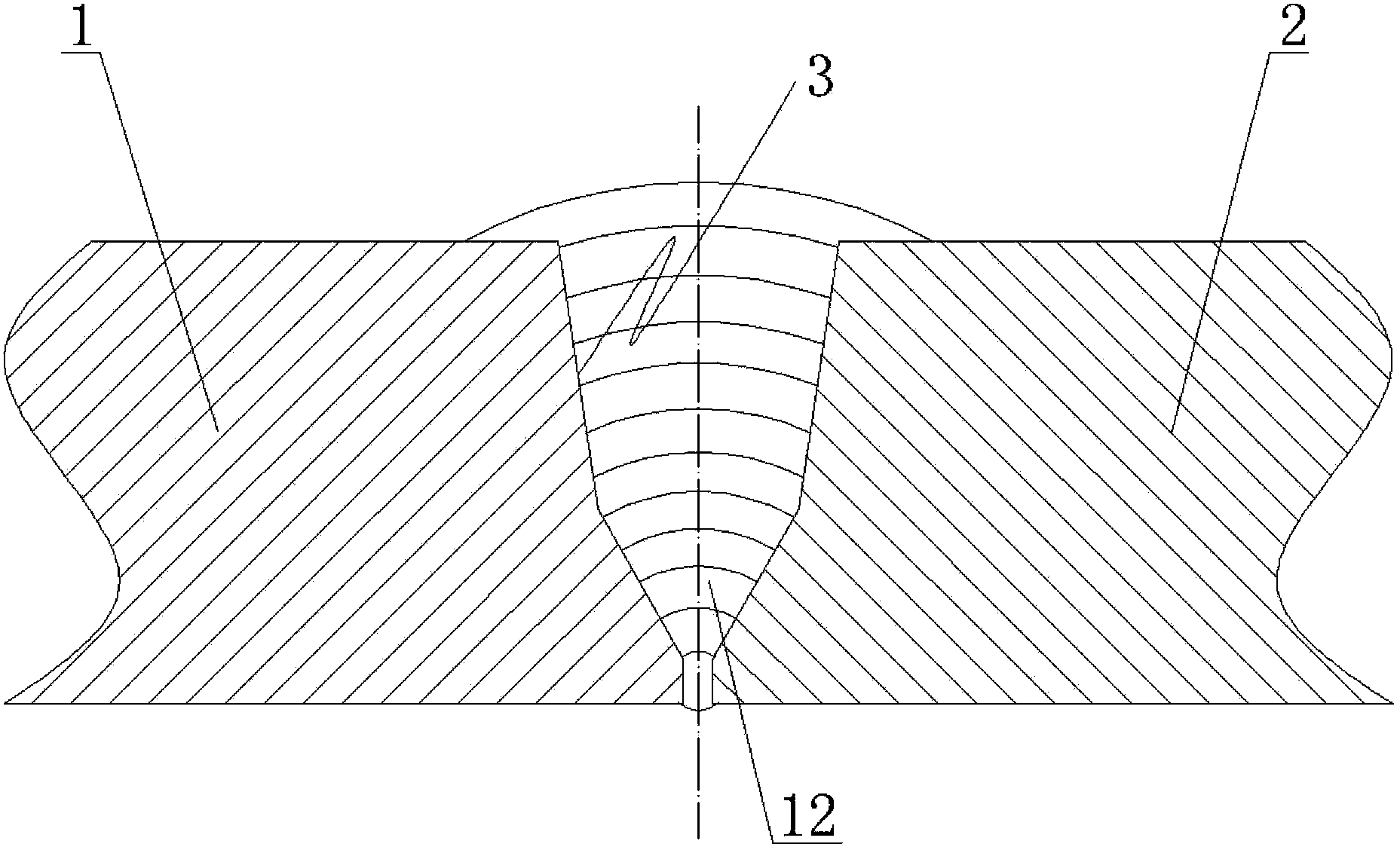

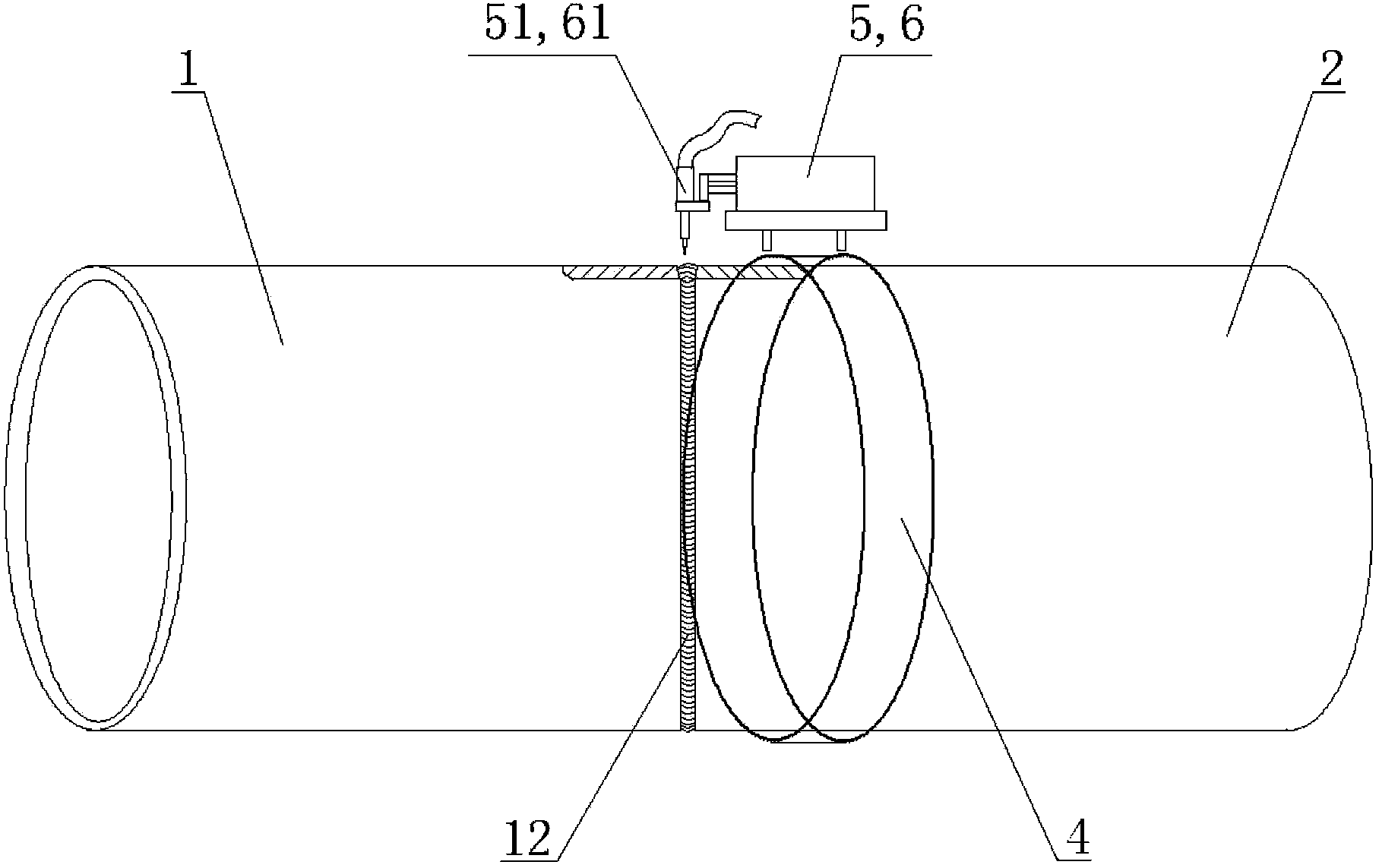

All-position automatic welding method for pipeline circumferential weld

ActiveCN103801796ALow costEasy maintenance and operationArc welding apparatusMetal working apparatusEngineeringWelding defect

The invention discloses an all-position automatic welding method for a pipeline circumferential weld and belongs to the technical field of pipeline circumferential weld welding. The method includes the following steps that firstly, steel pipes needing welding are machined to be provided with groove end faces; secondly, welding technology parameters are typed in a controller program according to the preset welding technology; thirdly, the two welded steel pipes are assembled; fourthly, one of the steel pipes is provided with a welding rail; fifthly, the welding ends of the two steel pipes are preheated before welding; sixthly, a single welding torch is used for performing root welding on grooves; seventhly, a double welding torch is used for performing hot welding, filling welding and cosmetic welding on the grooves. According to the all-position automatic welding method for the pipeline circumferential weld, due to the fact that the groove type is designed, the root welding technology, the filling welding technology and the cosmetic welding technology are adopted, the defects that in the prior art, the welding efficiency is low, a large number of welding materials are consumed, a large number of weld defects exist, the welding joint performance is poor, and the requirement for the operating skills of welders is high; or welding equipment is high in cost, and operating and maintaining are difficult are overcome.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Method for diagnosing galvanized steel laser powder addition welding defects on line based on characteristic spectrum

The invention discloses a method for diagnosing galvanized steel laser powder addition welding defects on line based on a characteristic spectrum. In order to solve the problem that various welding defects of welding seam air hole, dents and the like are easy to generate in the welding process because a zinc layer can be easily gasified to form a large amount of zinc steam in the galvanized steel laser welding process, the welding defects in the galvanized steel laser powder addition welding process are detected in real time through the intensity of a spectral line CuI 324.8nm in the welding process on the basis of preventing the zinc steam from being generated by adding copper powder; and simultaneously, the welding process is controlled by automatically adjusting process parameters, so that welding air holes are prevented from being formed. By the method, the aim of monitoring a laser powder addition welding process in real time is fulfilled, the powder addition welding quality is ensured, and a great significance is provided for actual production.

Owner:HUNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com