Laser filler wire welding method for thick plate narrow gap

A technology of laser wire filling and welding method, which is applied to laser welding equipment, welding equipment, welding/welding/cutting objects, etc., can solve the problems of small received energy on the side wall, small melting amount, unfused side wall and bottom, etc. Achieve the effect of avoiding welding porosity and spatter, small heat affected zone, and increasing the thickness range of weldable plates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

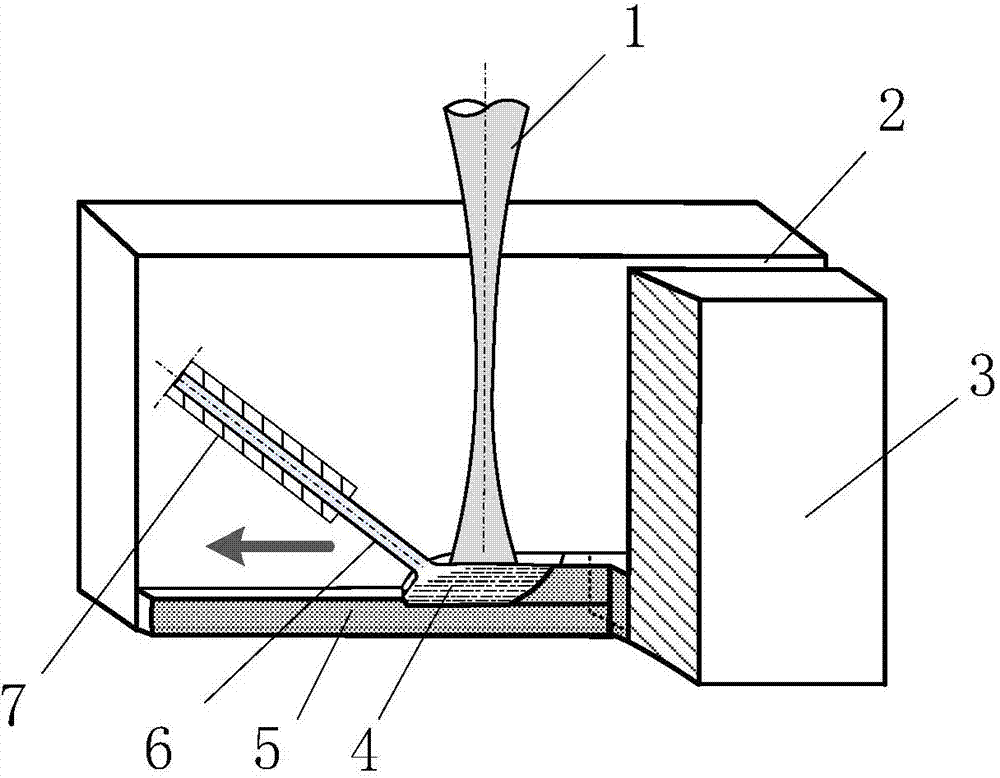

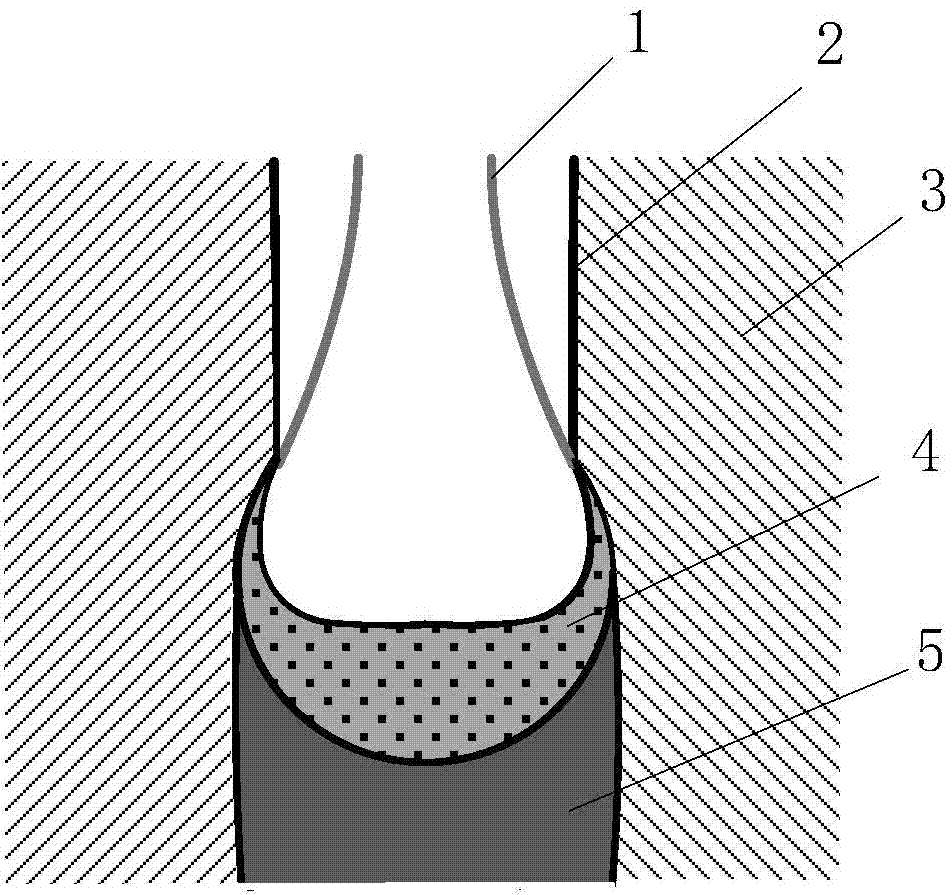

[0016] In this example, the workpiece is two 60mm thick 304 stainless steel plates that are butted, the groove width is 3.5mm, the blunt edge thickness is 2mm, and the groove depth is 58mm. Stainless steel welding wire ER347 with a diameter of 1mm is used. Using IPG company YLS-6000 fiber laser. The welding parameters are: welding speed 0.36m / min, welding power 4200W, wire feeding speed 3.1m / min, defocus distance 54mm, spot diameter 4mm. The distance between the welding wire and the beam is 2mm. The side-blowing gas protection form is adopted, the flow rate of the protection gas is 25L / min, the protection gas is argon with a purity of 99.9%, and the diameter of the protection gas nozzle is 7mm. The welded joint of the example of the present invention is well formed, and the width of the weld seam is 3.8 mm. No defects such as unfused side walls and welding pores are found in the cross section of the weld seam.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com