Patents

Literature

682results about How to "Small heat affected zone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

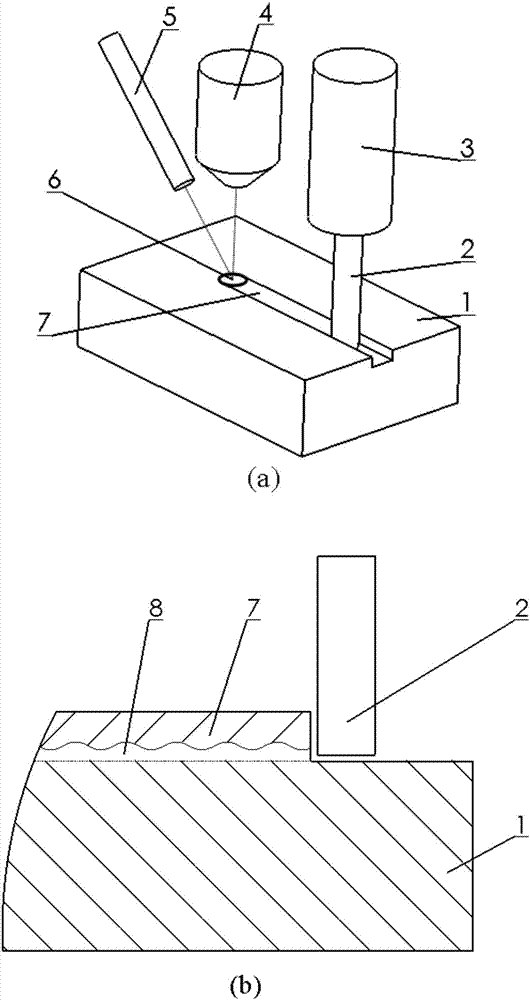

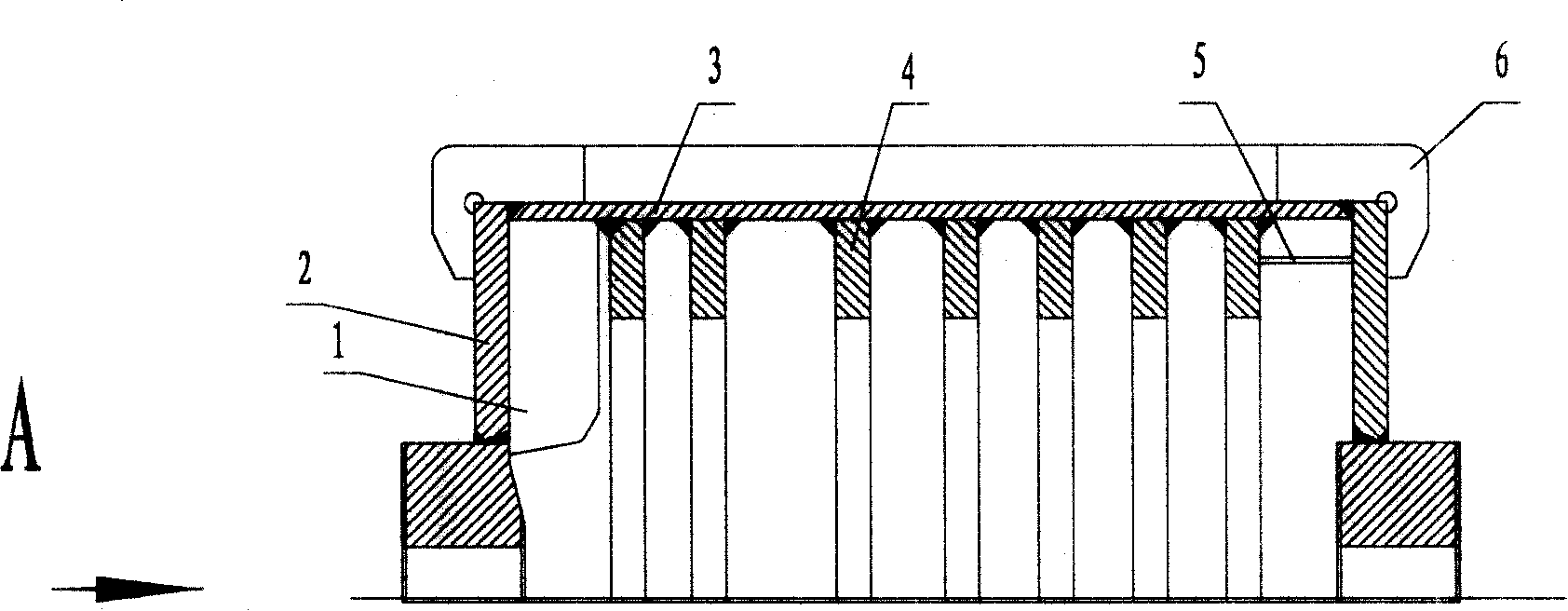

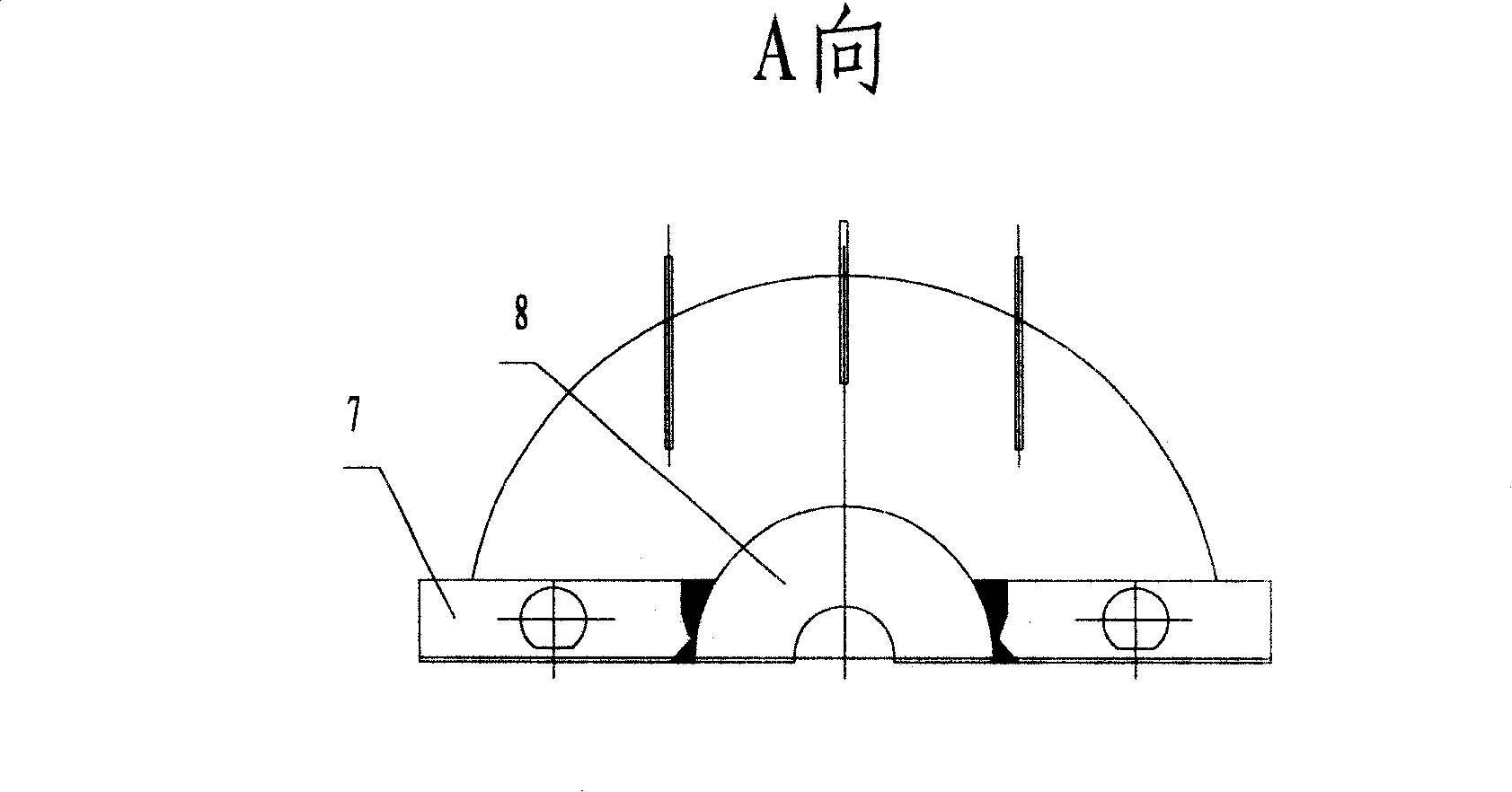

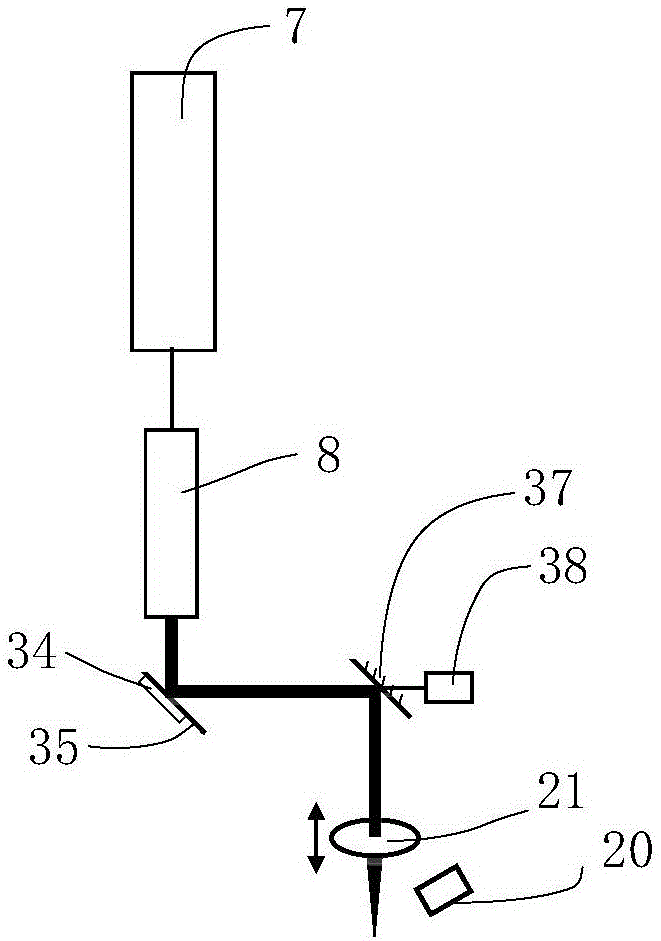

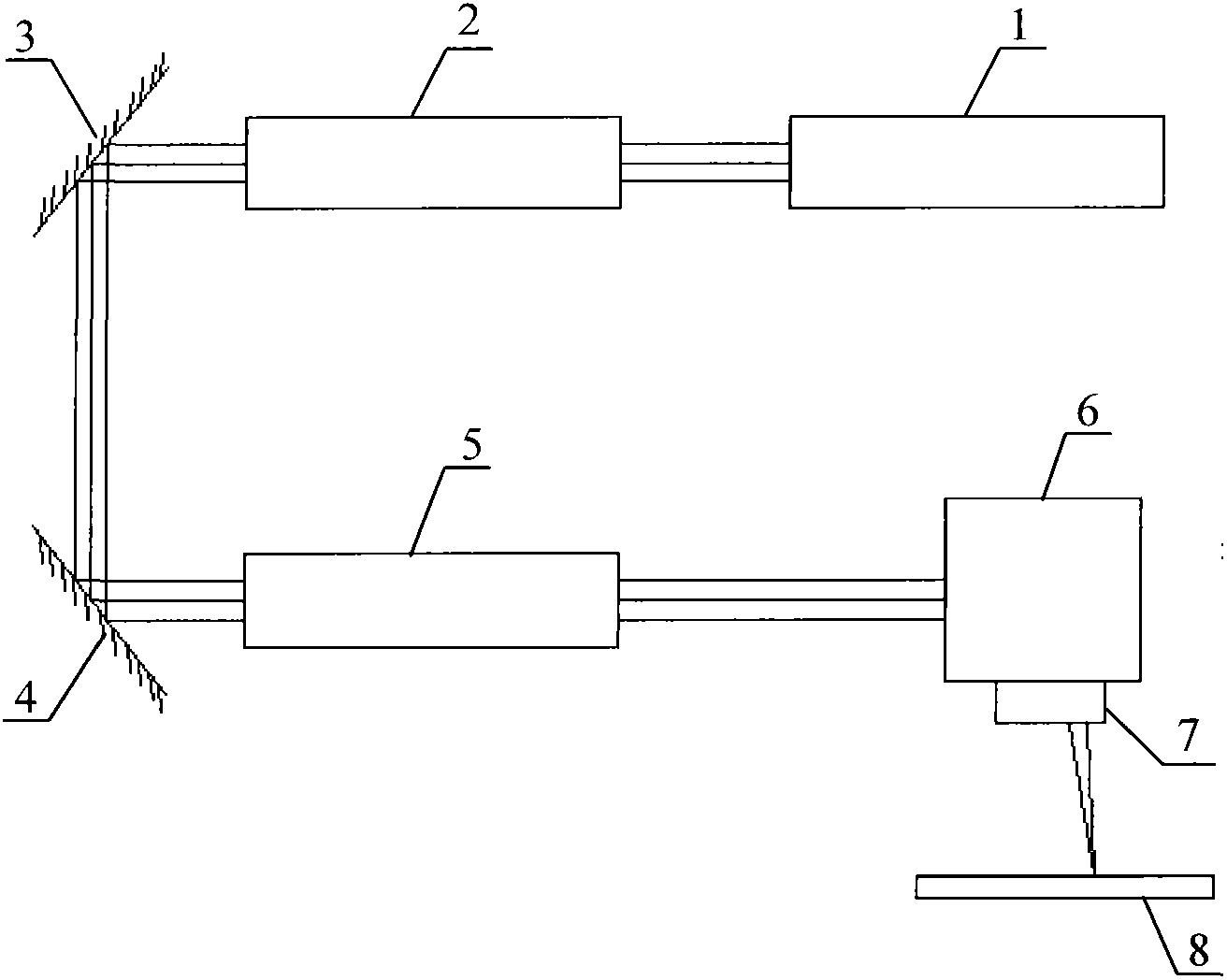

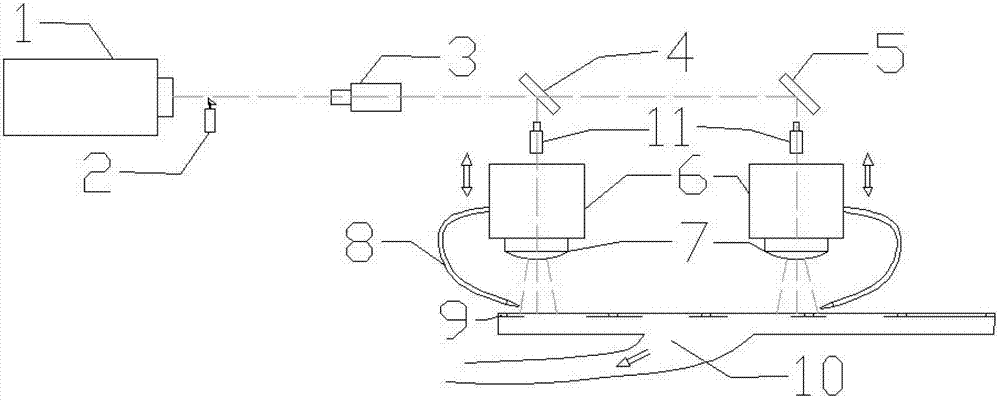

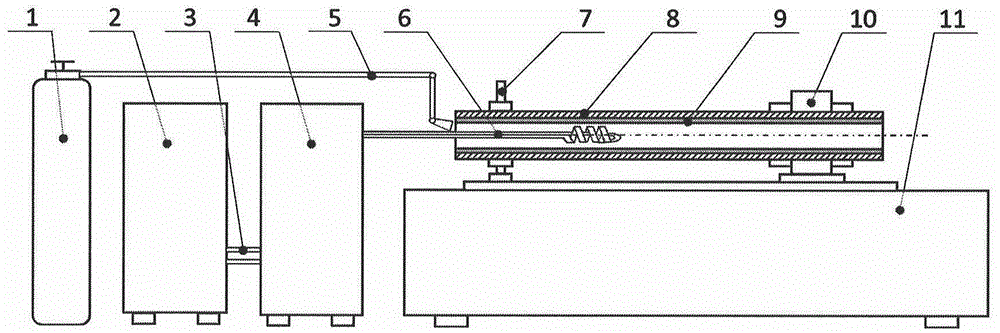

Method with functions of preheating and postheating for forming crack-free coating with high efficiency by three-light-beam laser-cladding technique

InactiveCN102383126ALow and adjustable dilution rateSmall heat affected zoneMetallic material coating processesLaser beam welding apparatusMelting tankHeat-affected zone

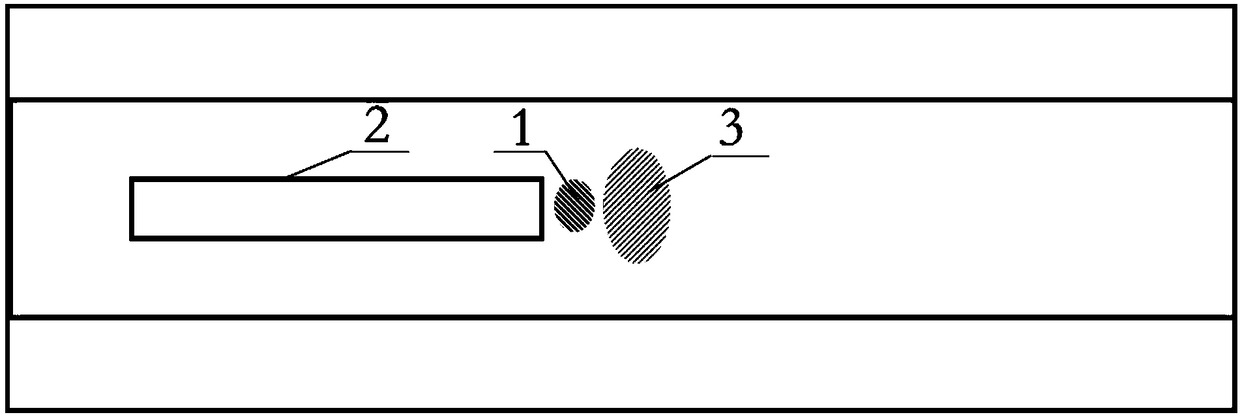

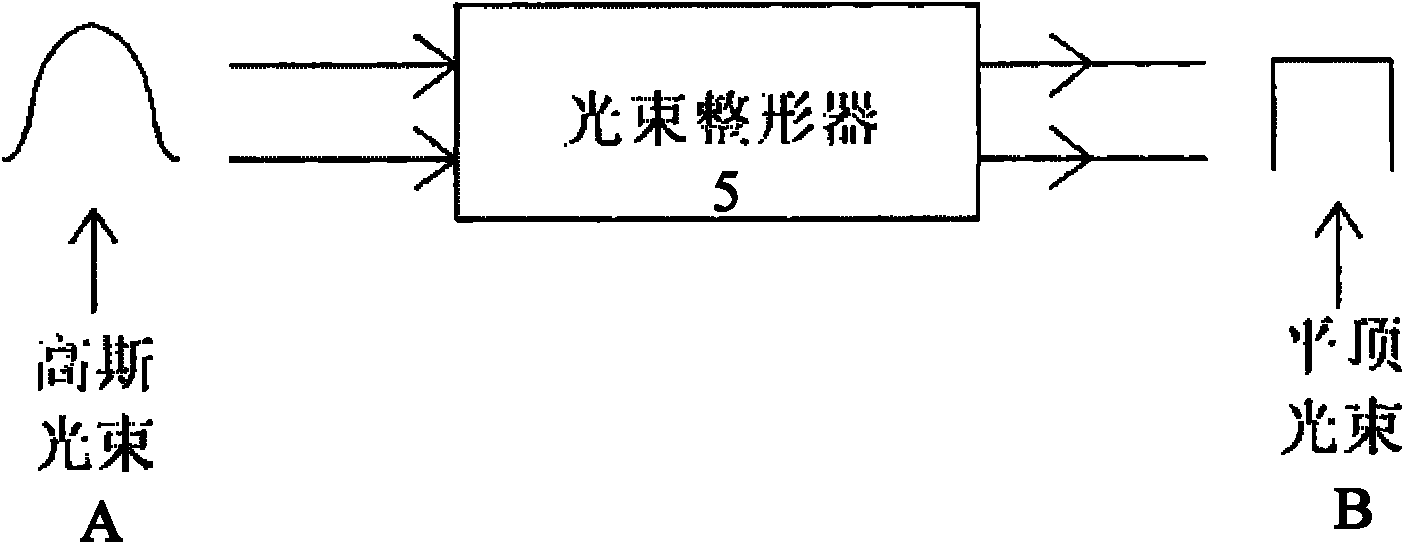

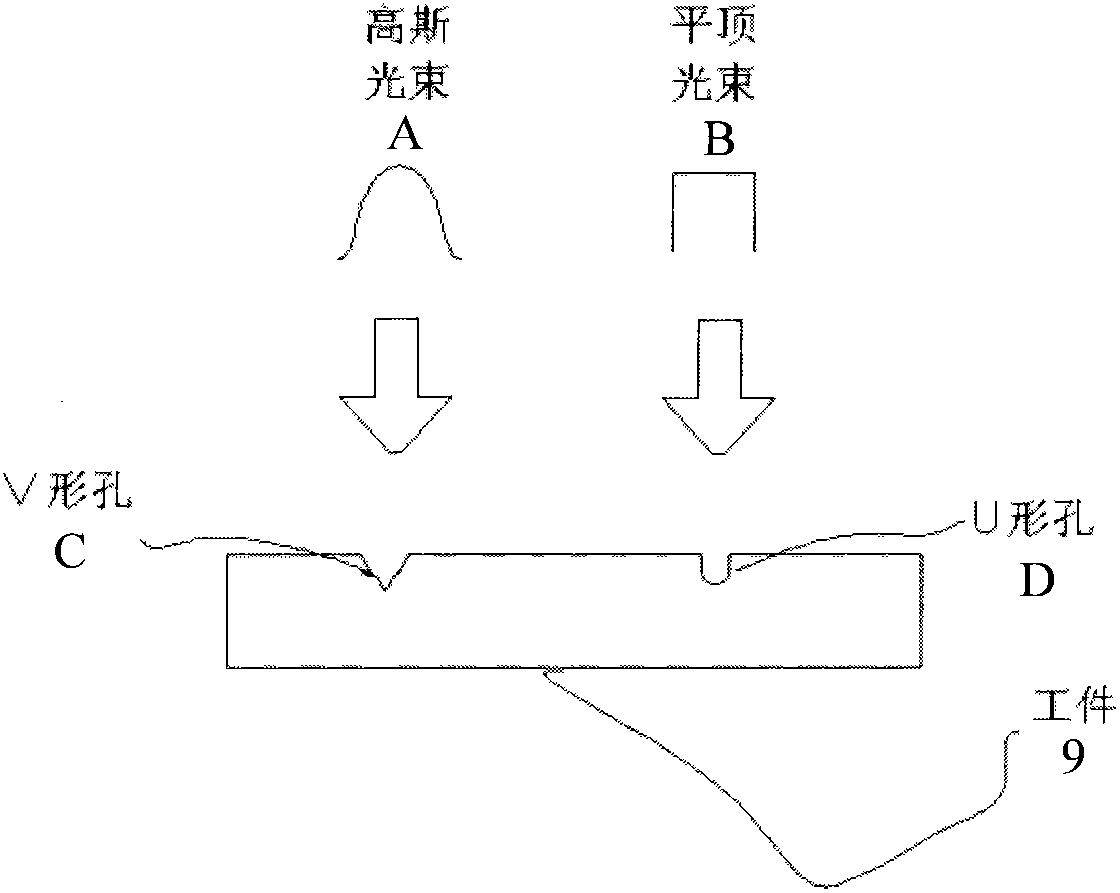

The invention discloses a method with functions of preheating and postheating for forming crack-free coating with high efficiency by a three-light-beam laser-cladding technique. The method comprises the following steps of: splitting a laser beam emitted by an Nd: YAG laser into two laser beams by using a laser beam splitter, namely a preheating laser beam for preheating the surface of a base material and a postheating laser beam for postheating the formed coating; then blowing alloy powder into a molten pool which is formed by focusing a laser beam emitted by a CO2 laser and acting the focused laser beam on the surface of the base material by using a powder nozzle, wherein after the CO2 laser beam moves away, a molten layer is cured and crystallized quickly to form the coating; and postheating the formed coating by adopting the postheating laser beam. The method has the advantages that: (1) the dilution rate of the coating is low and adjustable, and the coating is metallurgically combined with the base material, so the base material has a small thermal influence area and is deformation-free and crack-free; (2) residual inner stress in the coating can be eliminated effectively, a tissue can be improved, and the coating has high abrasion resistance, high corrosion resistance, high anti-cracking performance and high thermal shock resistance; and (3) relative to the processing efficiency in the conventional laser cladding technology, the processing efficiency in the method can be improved by 50 times to the maximum extent, so the processing cost is reduced greatly, and a large-scale industrialized application potential is realized.

Owner:NANCHANG HANGKONG UNIVERSITY

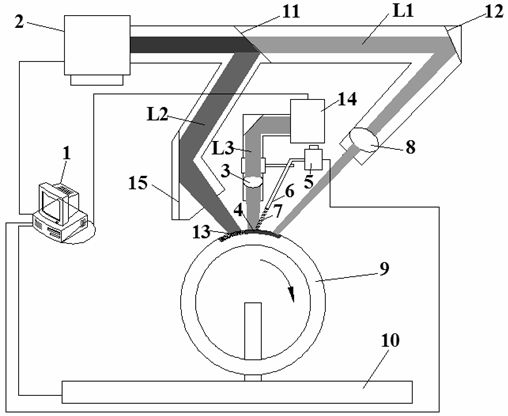

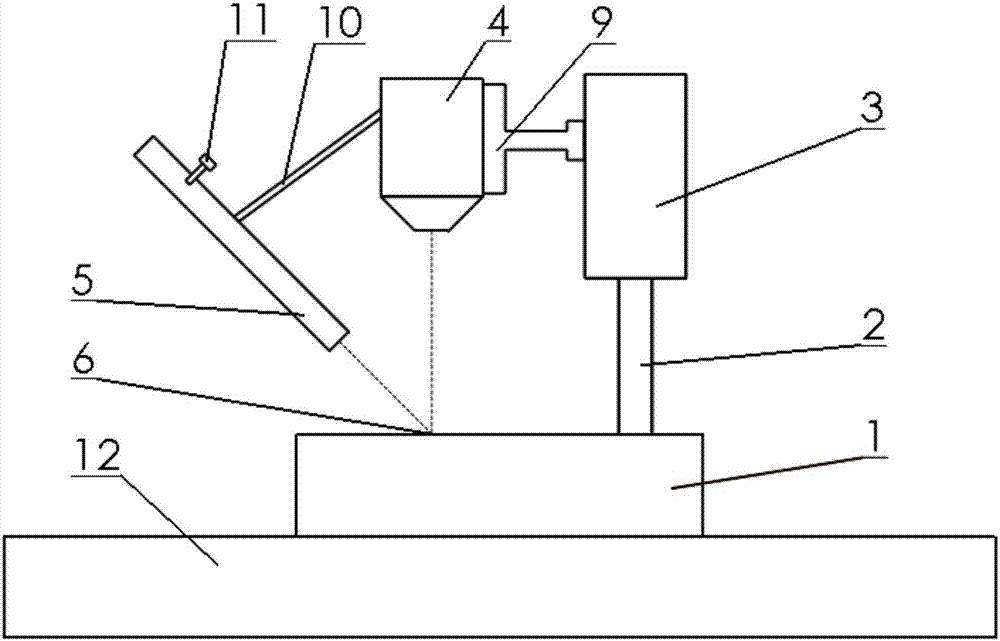

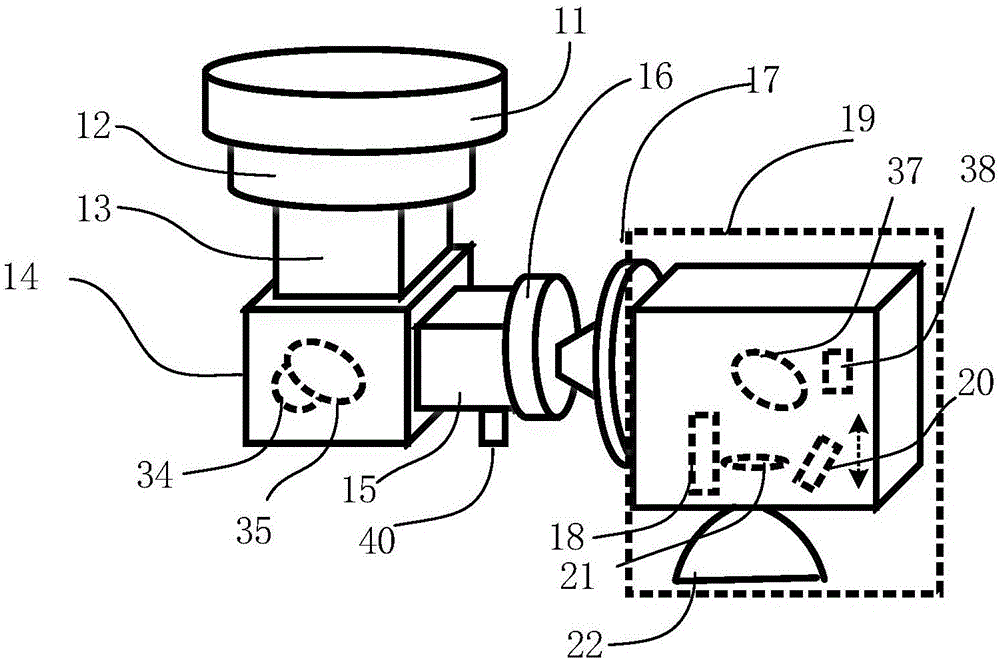

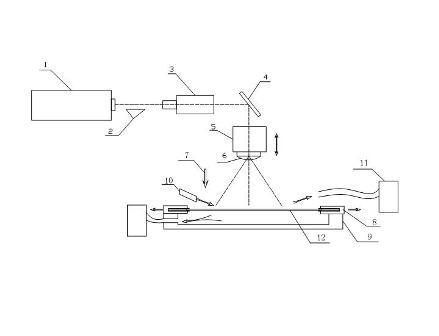

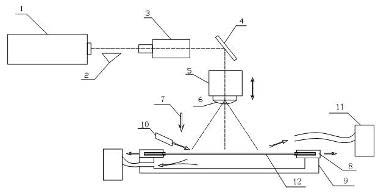

Laser micropore processor of rotating double-optical wedge

InactiveCN101670486ASmall heat affected zoneHigh precisionLaser beam welding apparatusBeam expanderHeat-affected zone

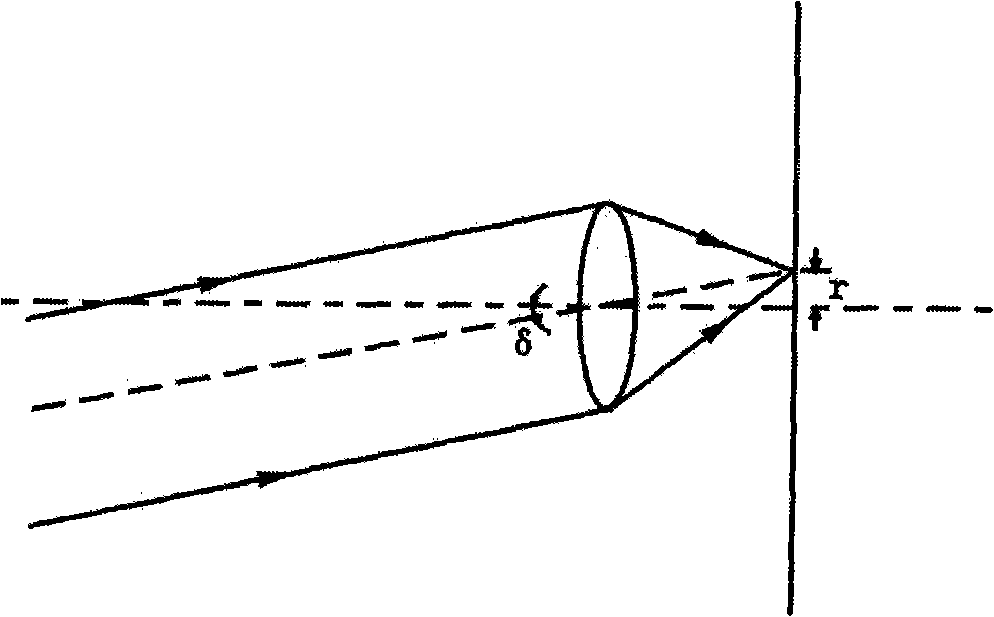

The invention discloses a laser micropore processor of a rotating double-optical wedge, comprising an ultrashort pulse laser output system consisting of a laser, a beam expander and a laser transmission system, a beam deflection system of the double-optical wedge consisting of two optical wedges, a bearing rotary mechanism of the double-optical wedge and a control system, a laser focusing system consisting of a laser focus lamp and a focuser and an adsorption location displacement system of workpieces and a computer system consisting of an installation mechanism of the workpieces and a two-dimensional displacement platform. The invention selects the DPSS laser with high-quality beam and uses the laser focusing system reaching or approaching the diffraction limit to obtain the fine focusesbeams, and then uses double-optical wedge to process the micropore in the situation of high speed revolution, therefore the invention reduces the heat affected zone of the edge of an aperture and improves caliber precision and work efficiency.

Owner:SHANGHAI INST OF LASER TECH

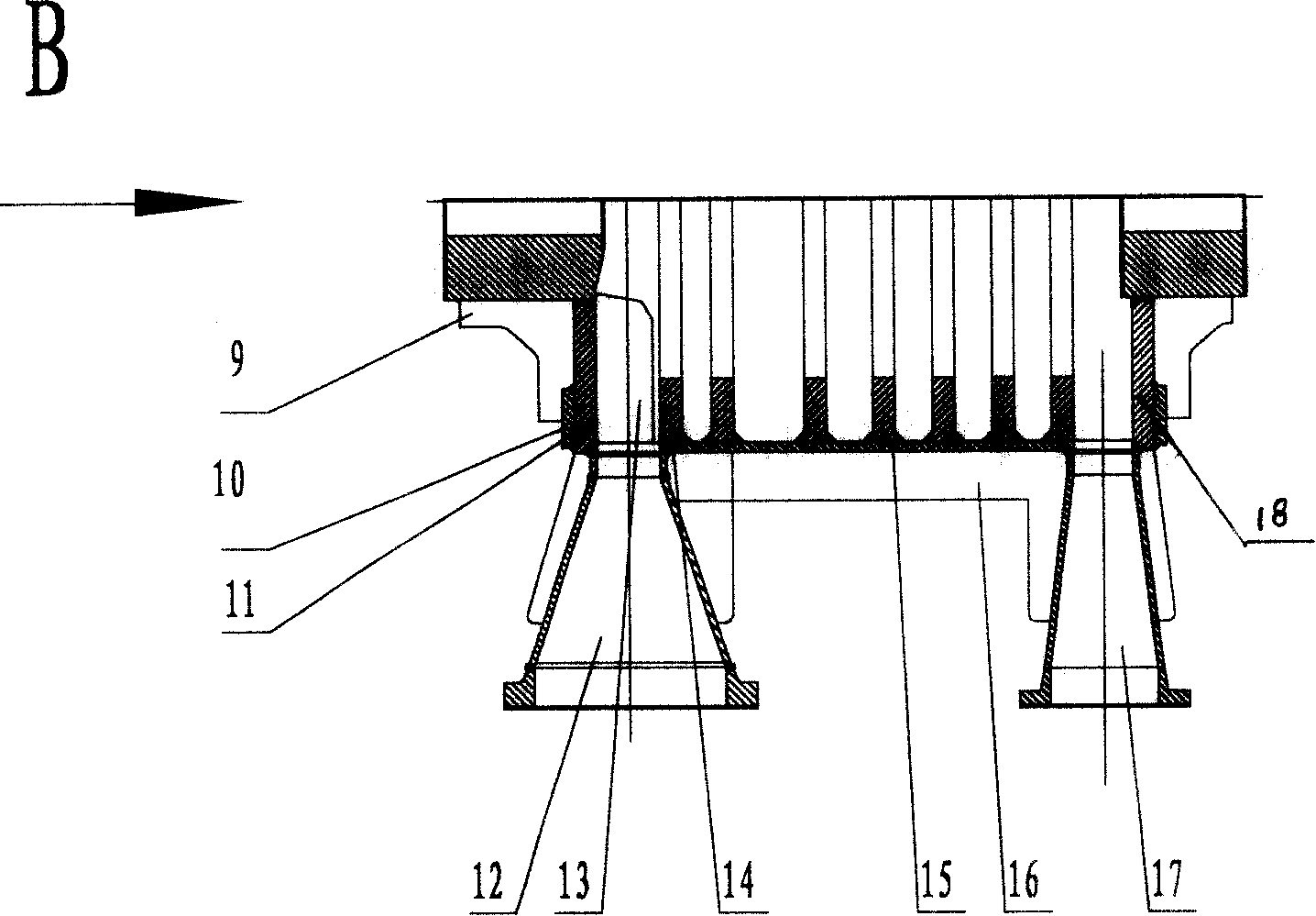

Electric power generator, steam turbine rotor spindle repaired by laser and repairing method thereof

InactiveCN1674408AMeet working conditionsHigh creep limitMagnetic circuit rotating partsPump componentsOptoelectronicsCobalt

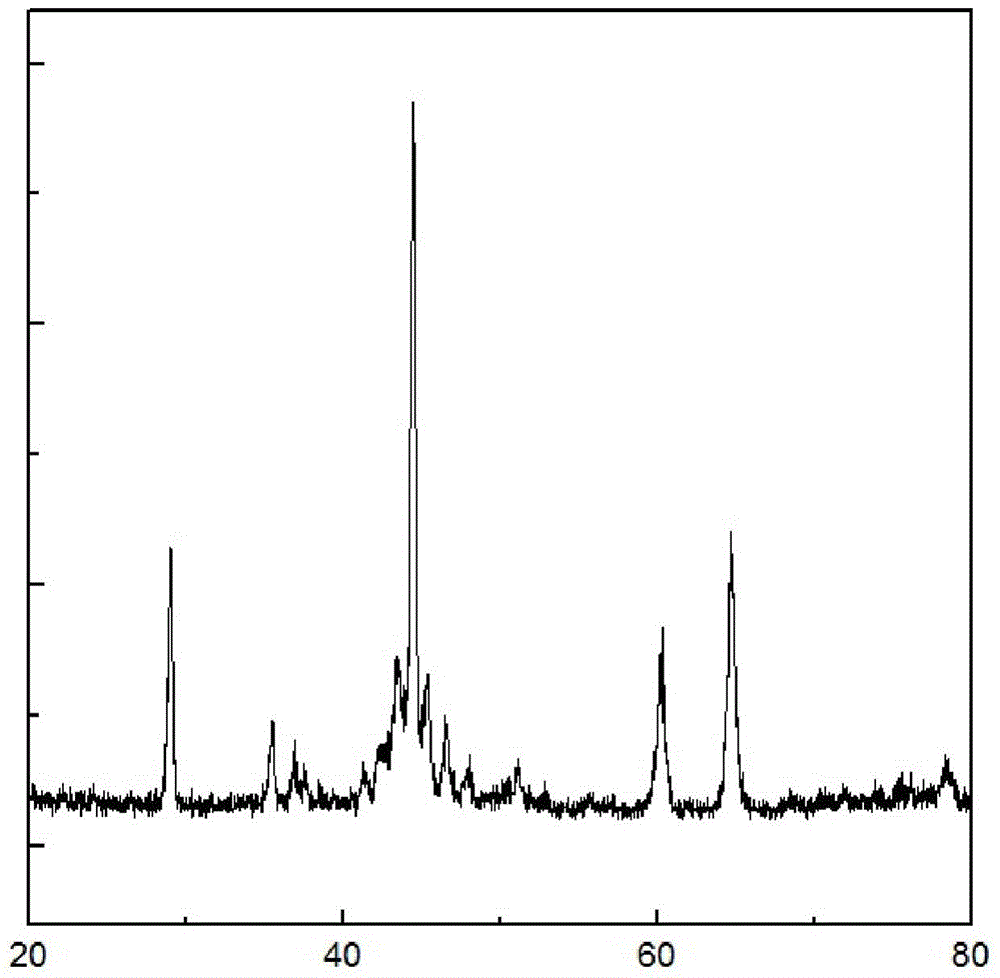

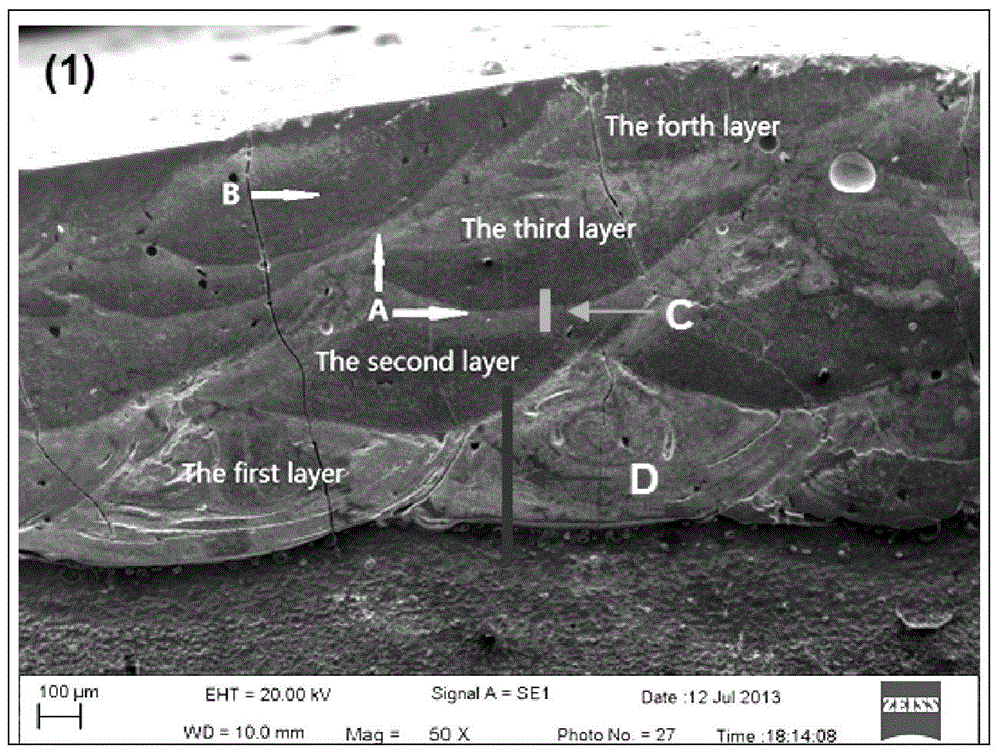

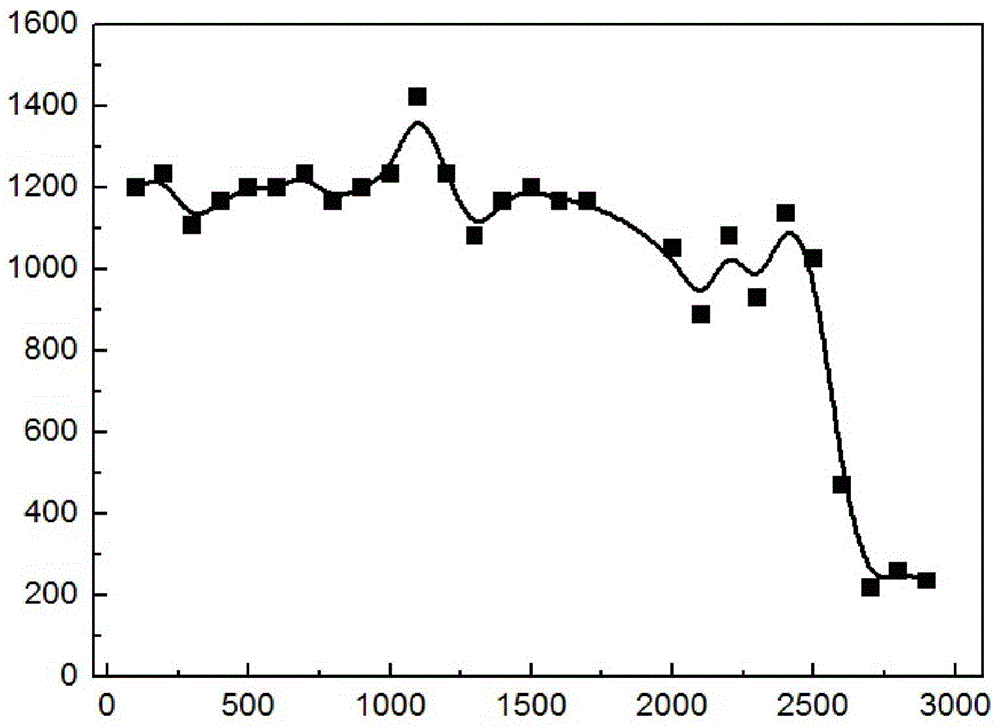

The present invention provides a laser repaired power generator and turbine rotor shaft, on its matrix surface on alloy covering layer which can be mutually merged with matrix surface and is different from matrix completely in components is formed, and on the surface where the matrix and alloy layer are connected a micromolten layer whose thickness is 0.05-0.1 mm is formed, and said alloy covering layer is nickel base, cobalt base or iron base alloy. Said invention also provides a laser repairing method of the described power generator and turbine rotor shaft. It adopts a pre-set laser melt-covering mode, and its technological parameters are: laser power 1200-2000 W, spot diameter 2-6 mm and spot moving speed 2-20 mm / s.

Owner:SHENYANG DALU LASER TECH

Laser seal welding technique for 3A21 aluminum alloy casing

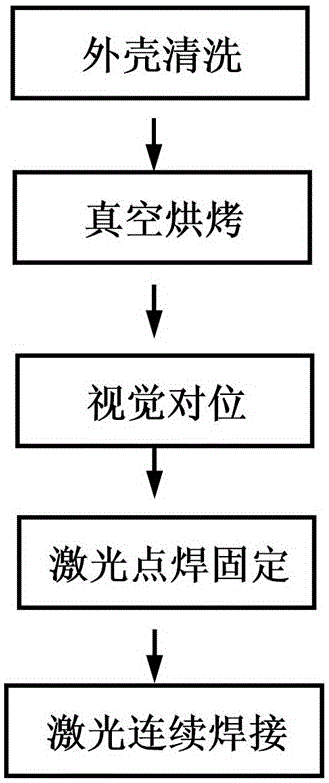

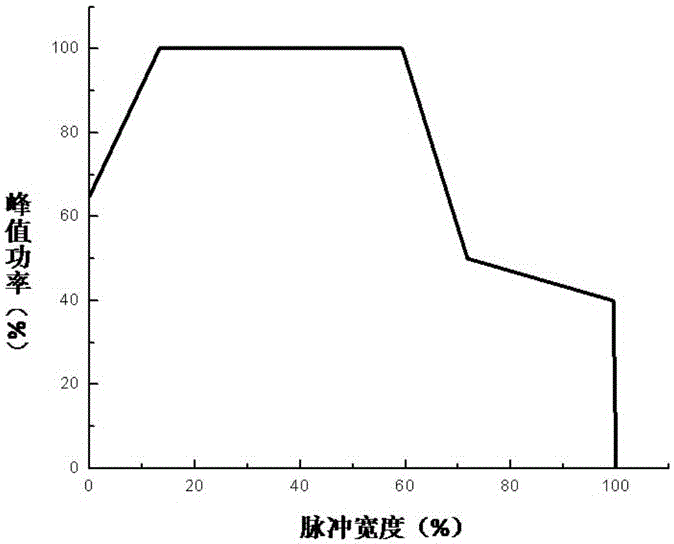

ActiveCN105081573ASmall heat affected zoneSmall thermal deformationWelding/soldering/cutting articlesMetal working apparatusWeld seamSpot welding

The invention discloses a laser seal welding technique for a 3A21 aluminum alloy casing. The laser seal welding technique comprises the following steps of visual alignment, laser spot welding location and laser seal welding. The technological parameters of the laser seal welding are that the laser pulse peak power is 3000W-3500W, the impulse waveform is preheating thermal-insulation wave, the pulse width is 4ms-8ms, the pulse repetition frequency is 10Hz-20Hz, the welding speed is 108mm / min-180mm / min, and the defocusing amount is -1mm to -2mm. The laser seal welding technique for the 3A21 aluminum alloy casing can effectively remove cracks and air holes on welding seams of laser welding of the 3A21 aluminum alloy casing. The sealed 3A21 aluminum alloy casing has the beneficial effects of being attractive in welding seam appearance, high in air tightness, high in reliability, high in efficiency and low in cost.

Owner:48TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

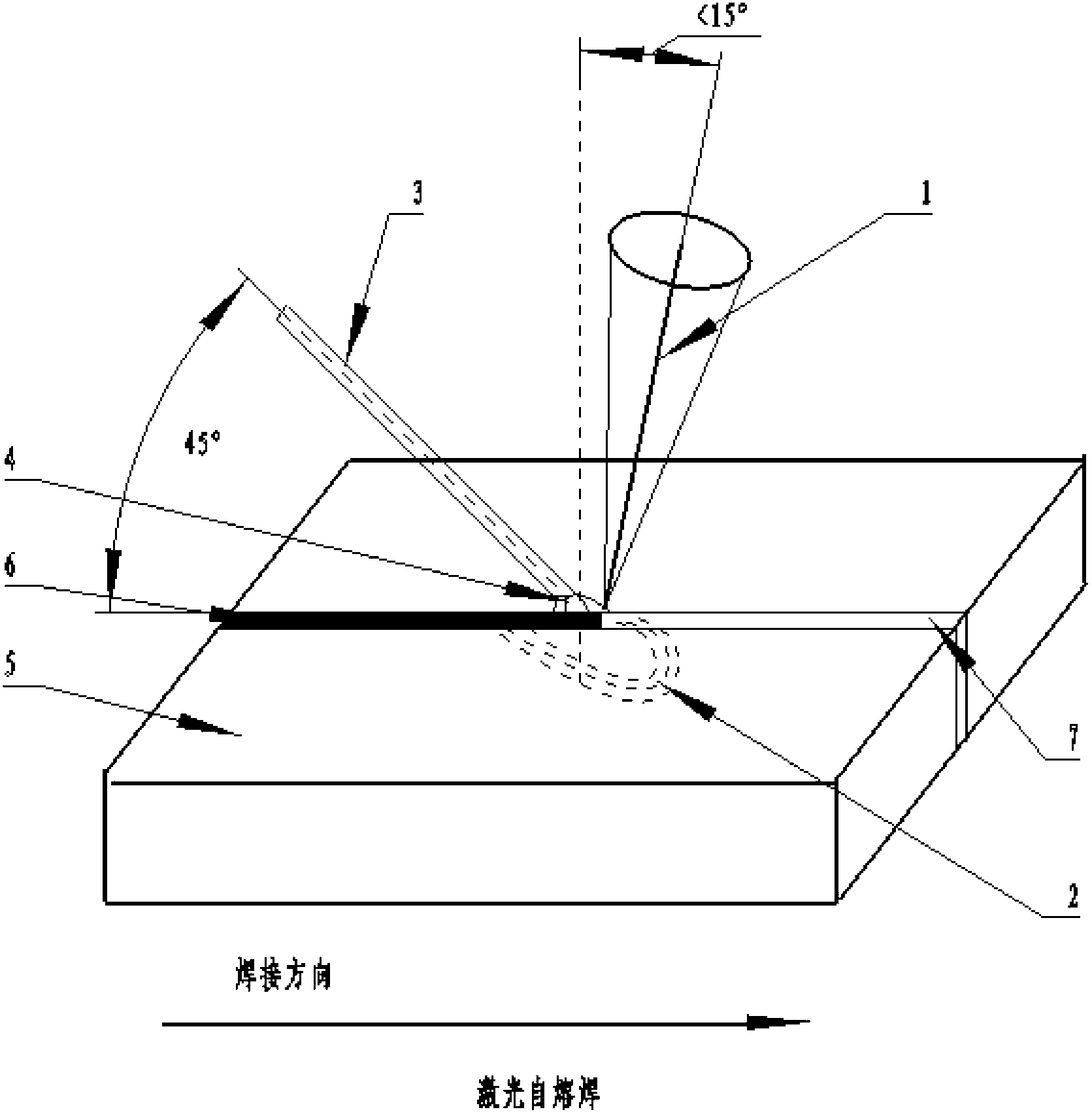

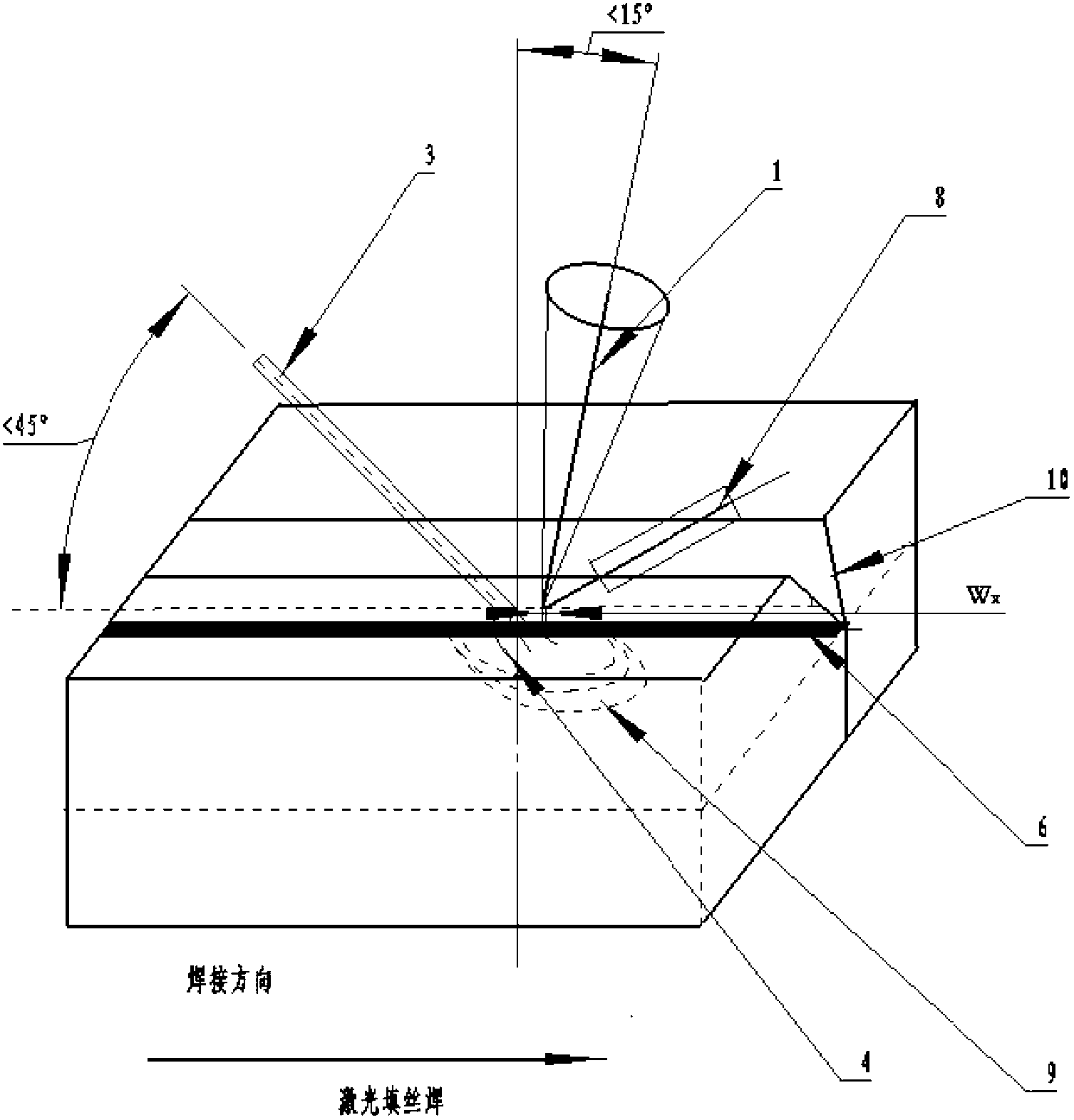

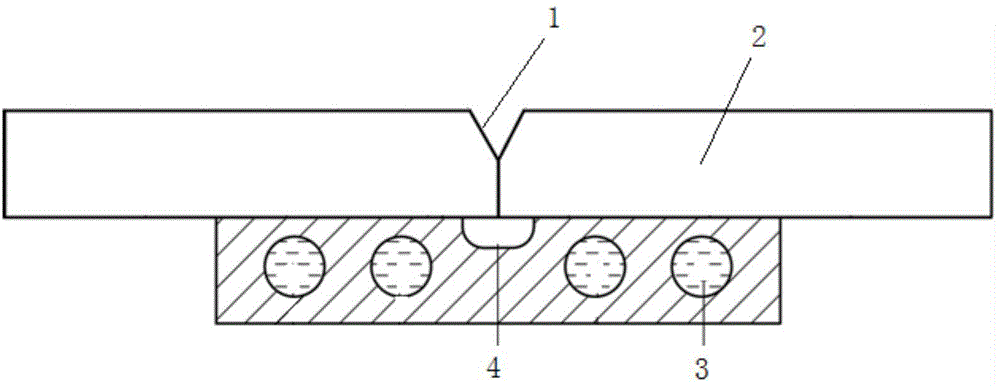

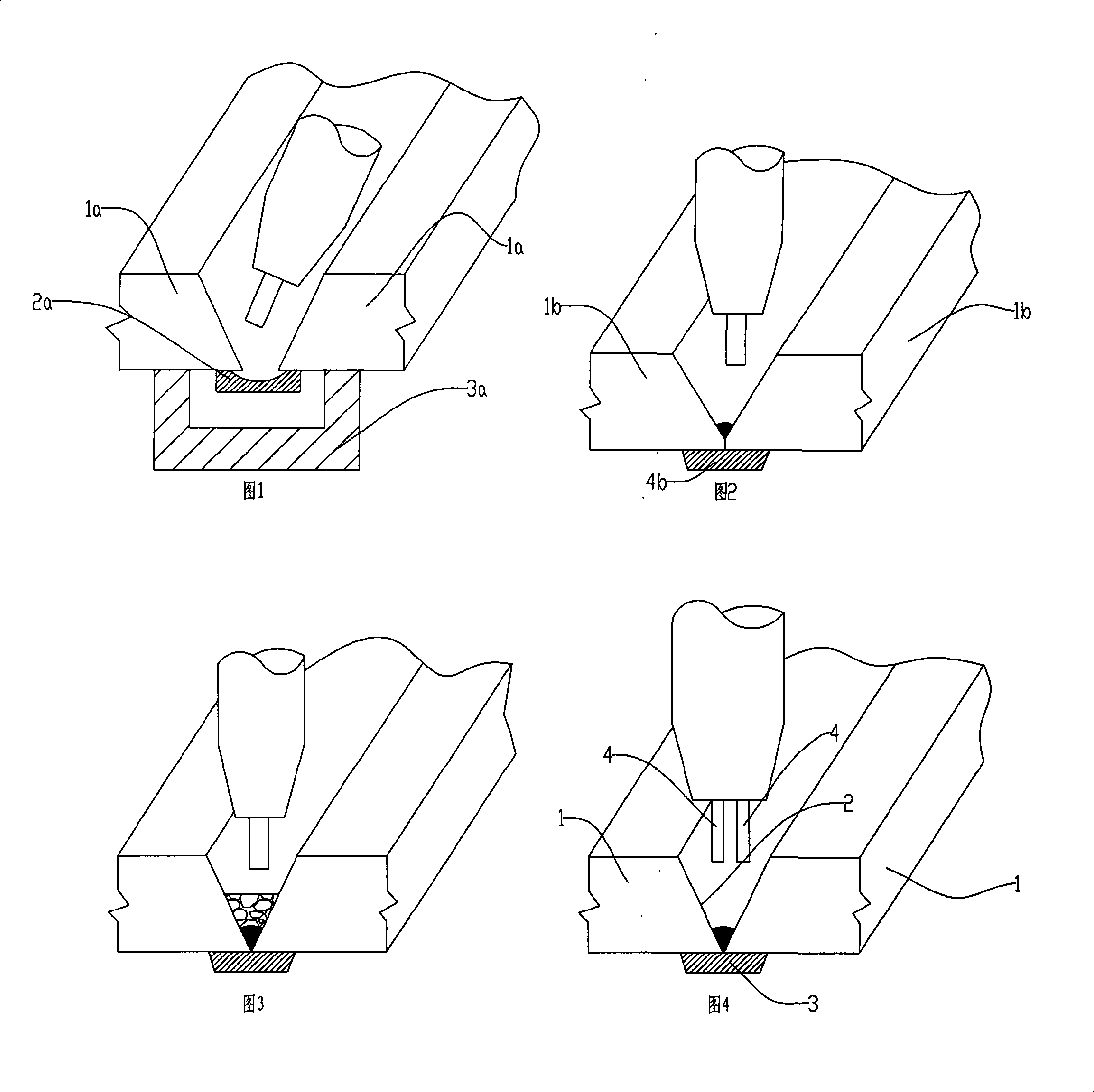

Narrow gap multi-pass laser welding method for thick plate

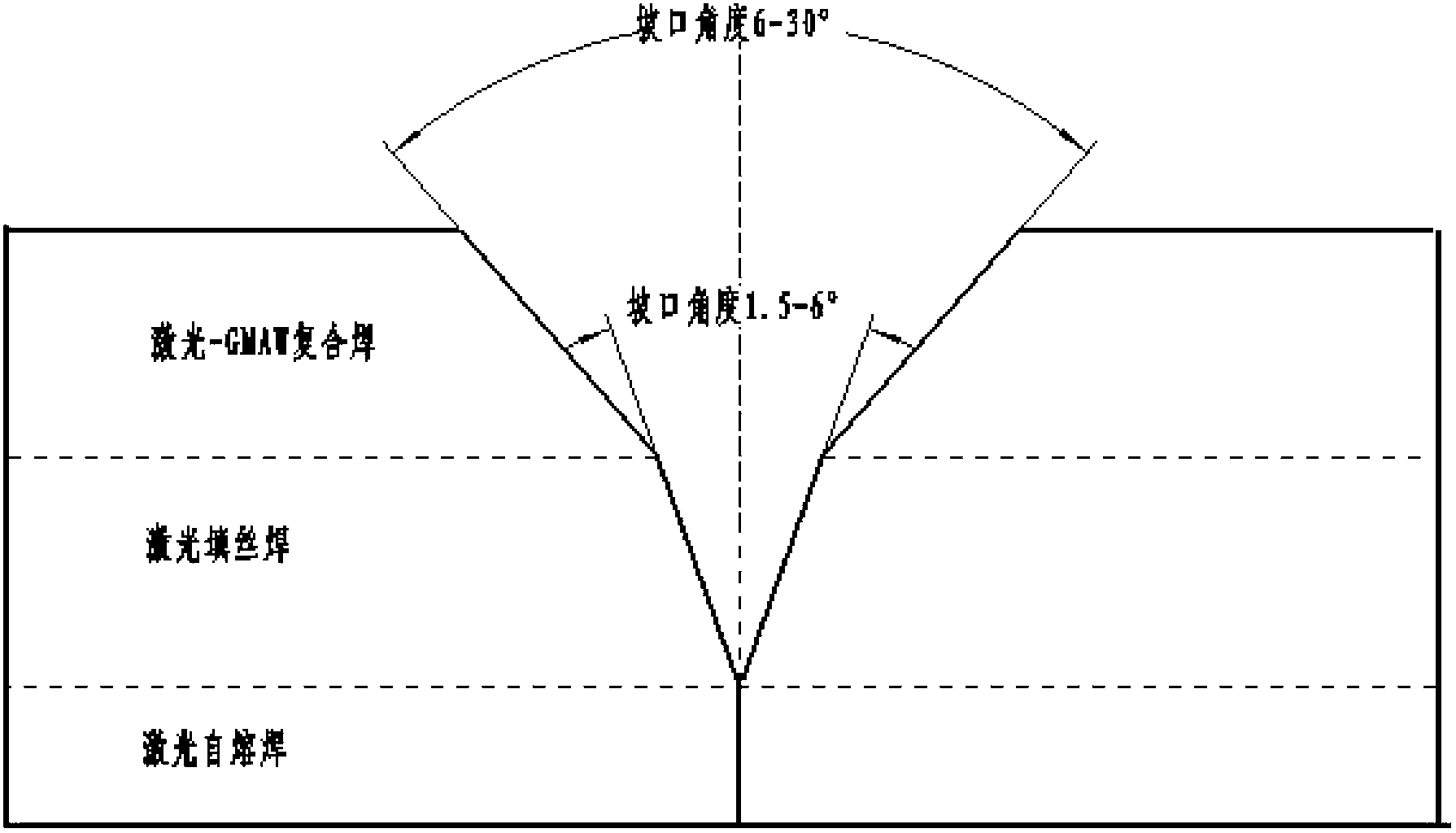

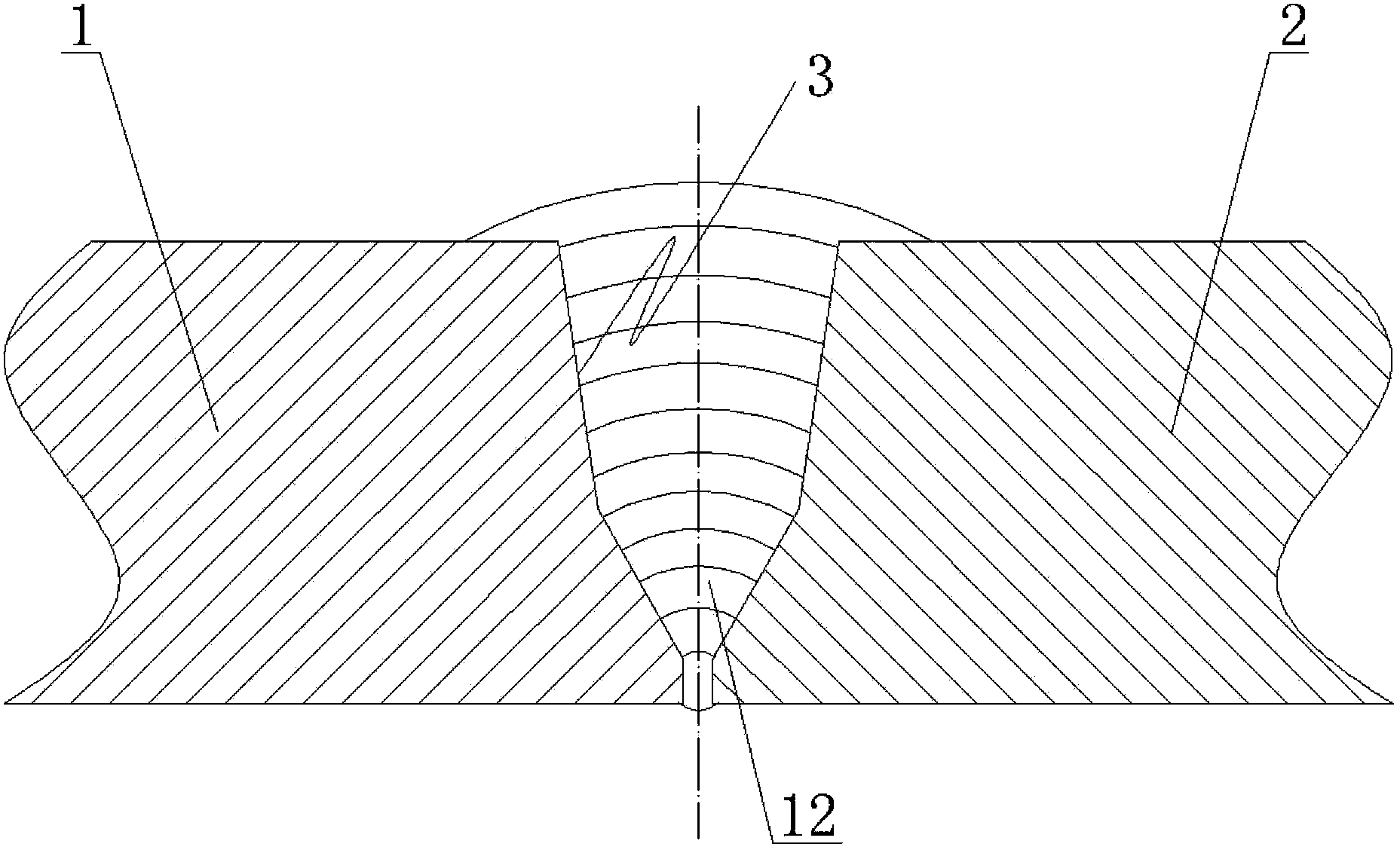

InactiveCN103008895AReduce consumptionImprove welding productivityLaser beam welding apparatusWorkpiece edge portionsThick plateGas metal arc welding

The invention discloses a laser welding method for a thick plate. A gap is reserved on the thick plate or a divided edge with a blunted edge is performed, a laser autogenous welding is adopted at the welding bead part for welding a pass for bottoming, then, the laser wire filling welding is carried out, a welding wire and a laser beam maintain an included angle being 15 degrees to 75 degrees, the welding wire extends into the divided edge gap from the front of the laser beam, when the filling wire welding cannot fully fill the divided edge gap, the laser-GMAW (gas metal arc welding) composite welding is finally carried out, and the welding of the thick plate is completed. The preserved gap value is respectively smaller than or equal to 0.5mm, the width of the performed welding bead used for the wire filling welding is smaller than or equal to 2.5mm, and the width of the performed welding bead used for the composite welding is smaller than or equal to 10mm. The laser welding method has the advantages that the problem of high-efficiency and high-quality welding of the thick plate is solved, so high-quality and efficient thick plate welding joints with small welding deformation and high gap bridging capability are obtained.

Owner:HUAZHONG UNIV OF SCI & TECH

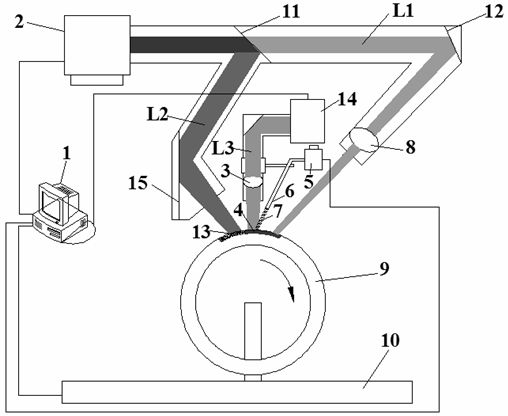

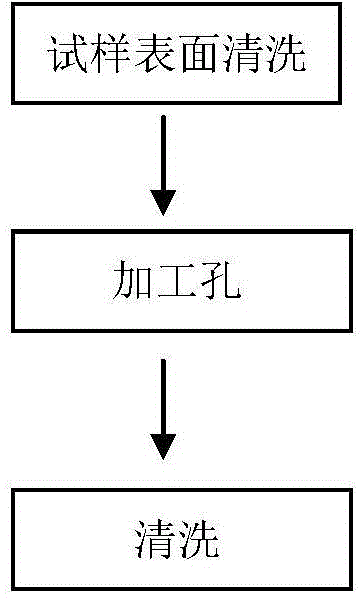

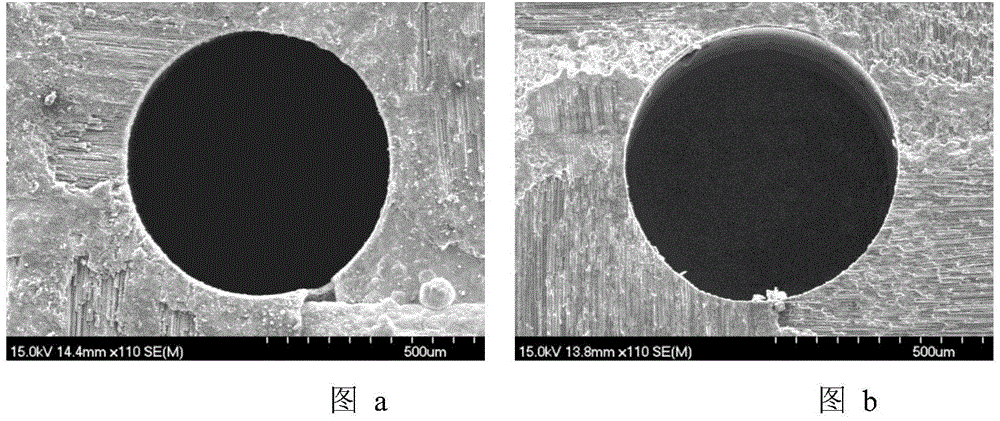

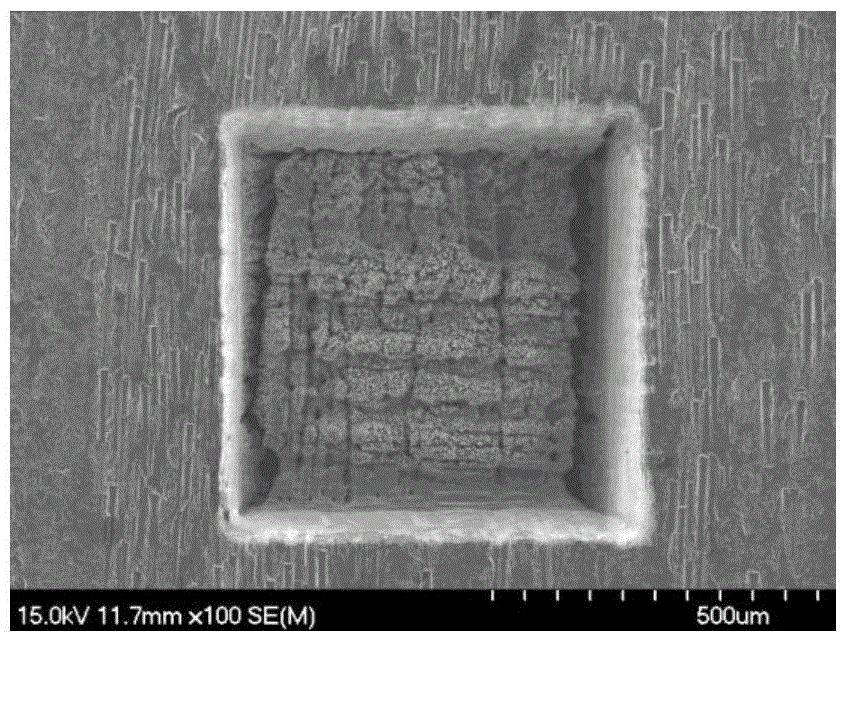

Method for machining micro holes in ceramic matrix composite through femtosecond lasers

ActiveCN104607808AHigh peak powerShort pulse widthWelding/soldering/cutting articlesLaser beam welding apparatusWavelengthLayer removal

The invention relates to a method for machining micro holes in a ceramic matrix composite through femtosecond lasers. According to the method, the silicon carbide ceramic matrix composite sample is placed on a working table and machined layer by layer in a spiral line mode through the femtosecond lasers or machined in a linear scanning mode, wherein the thickness of the sample is smaller than 3 mm; in the micro-machining process, the wave length of femtosecond laser machining ranges from 400 nm-1500 nm, the pulse width ranges from 80 fs to 500 fs, the output power of the lasers is determined according to the requirements of micro-machining and ranges from 20 mW to 20 W, and the repetition frequency of the lasers is determined according to the requirements of micro-machining and ranges from 50 K to 25 MHz; the sample is machined in a layer-by-layer removal mode, wherein the rotation speed of a machining head is 2400 rev / s. In the machining process, the method has the advantages that machining damage is small, and because material around the damage region is still in a cold state after machining, the heat effect is small; machining precision is high, energy of the femtosecond lasers is in Gaussian distribution, absorption and action of the energy in the machining process are limited within the size of which the focus center is quite small, and the machining dimension is expressed from a micro form to a sub-micro form.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Method for combined welding of austenitic stainless steel moderate thickness plate

InactiveCN104858557ALittle thermal impactNo crackWelding/soldering/cutting articlesWelding apparatusButt weldingButt joint

The invention relates to a method for combined welding of an austenitic stainless steel moderate thickness plate. The method comprises the steps of opening a V-shaped groove at the position of the to-be-welded butt joint surface of austenitic stainless steel; polishing and cleaning the surface of a to-be-welded workpiece and the position of the V-shaped groove; performing gapless tight fixed assembly of the workpiece, performing spot welding fixation on a run-on plate, an arc blowout plate and a test plate; pre-leading in protective gas prior to butt welding, guaranteeing that sufficient protective atmosphere is formed on the surface of the stainless steel groove and the bottoms of the weld joints; adopting pulsed plasma arc welding to perform bottoming welding; adopting low carbon welding wires to perform cosmetic welding of pulse wire filling argon tungsten-arc welding, performing the bottoming welding of the pulsed plasma arc welding and cosmetic welding of the pulse wire filling argon tungsten-arc welding simultaneously, and cooling the workpiece while performing the welding. The PC-PAW bottoming welding is adopted, the micropore effect is utilized to achieve one-side welding and double-sided free forming of the moderate thickness plate, the backs of the weld joints are smoothly formed and are free of cracks and edge snapping defects, the process is stable and easy to achieve, and the quality is reliable.

Owner:SHANDONG UNIV

Laser-induced oxidation auxiliary micro milling method and device thereof

InactiveCN107097072ARapid and Controlled Oxidation ReactionChanging Micromilling Removal MechanismOther manufacturing equipments/toolsMilling equipment detailsWidth ratioMicrostructure

The invention discloses a laser-induced oxidation auxiliary micro milling method and a device thereof. According to oxidable characteristics of a material to be machined, a low-power laser device is used for heating the material in the to-be-machined area, auxiliary oxidizing gas is led to serves as an oxidizing agent, instant high temperature generated by the laser is used for enabling the material in the to-be-machined area and the oxidizing agent to have the rapid controllable oxidizing reaction, through adjusting of laser and oxidizing agent parameters, the oxidizing reaction rate, the oxide microstructure and the structure are controlled, an oxidizing layer is formed on the surface of a workpiece to be machined, the micro milling removing mechanism of the material is changed, the cutting load is reduced, a micro milling cutter is used for rapidly removing the oxide layer and the small number of subsurface stratum materials, and the high-precision machined surface is formed; the higher machining efficiency and the better surface integrality are obtained, and the processing controllability is high; the machining method is used for achieving efficient and high-quality machining of high depth-to-width ratio microstructures of titanium alloy, hard alloy and other materials hard to machine.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

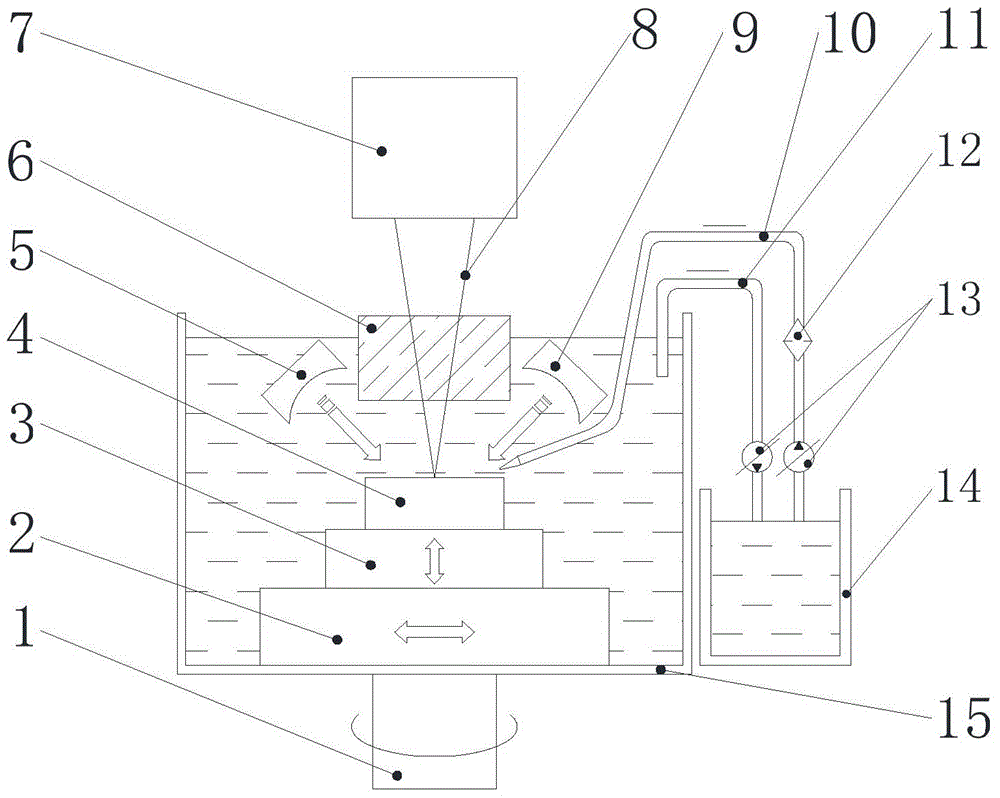

Laser micro-processing device and method thereof

InactiveCN104942442AEnhanced convectionImprove transmission efficiencyLaser beam welding apparatusSpray nozzleUltrasound

The invention relates to a laser micro-processing device and method. The laser micro-processing device comprises a rotating table and a container located on the rotating table, a lower ultrasonic vibrating table is installed at the bottom of the container, an upper ultrasonic vibrating table is fixed to the lower ultrasonic vibrating table, a workpiece is placed on the upper ultrasonic vibrating table, a laser source and a lens are arranged above the upper ultrasonic vibrating table, laser beams penetrate through the lens and reach the surface of the workpiece, an ultrasonic horn is arranged on the upper side of the upper ultrasonic vibrating table and sends ultrasonic waves to the surface of the workpiece, an outer container is connected with the container through a liquid inflow pipe and a liquid outflow pipe, and a spraying nozzle on the liquid inflow pipe faces the surface of the workpiece. When the surface of the workpiece in liquid is immersed in laser irradiation, the ultrasonic horn irradiates the surface of the workpiece or the workpiece is made to generate ultrasonic vibration in the vertical direction and the horizontal direction. Laser and the ultrasonic waves ideally act on the first surface of the workpiece at the same time, different processing effects are achieved, the ultrasonic cavitation phenomenon and the water jetting phenomenon can be intensified, the surface of the workpiece can be cleaned again, and heat-affected zones of processing, cracks and deposition of chippings are reduced.

Owner:WENZHOU UNIVERSITY

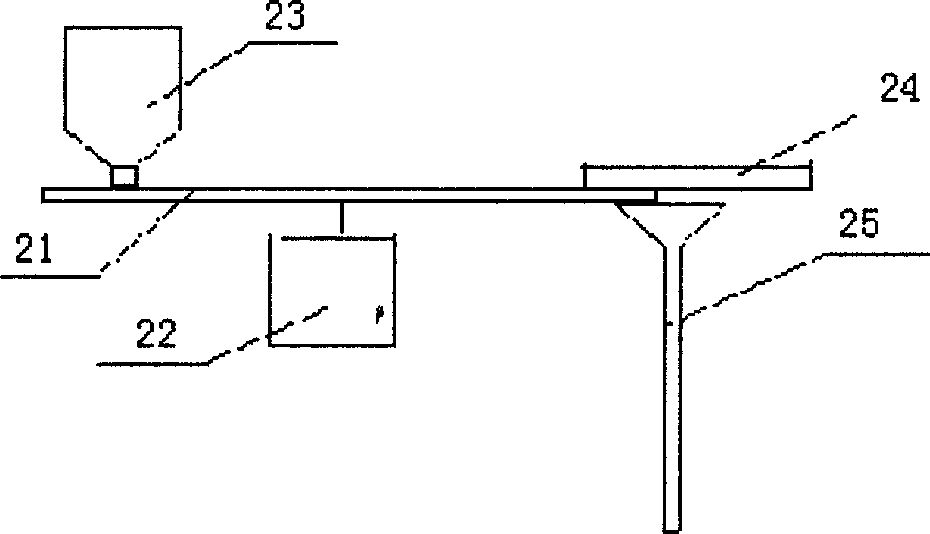

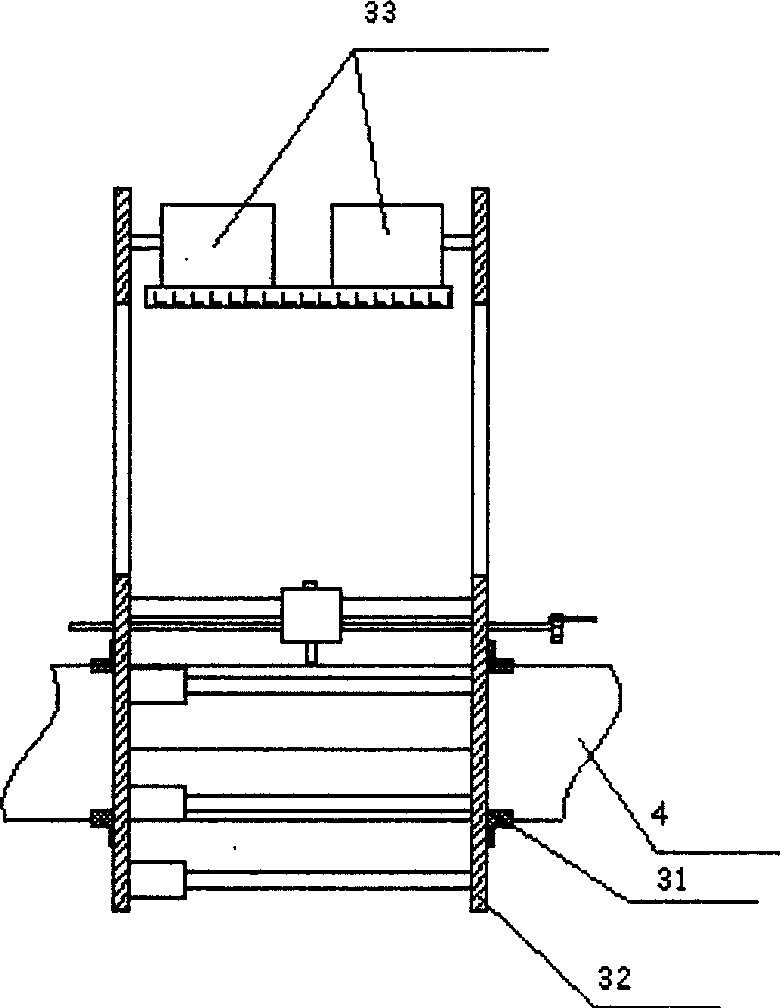

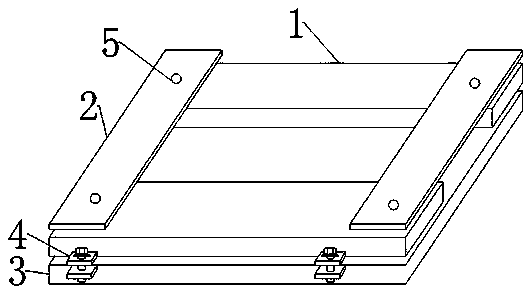

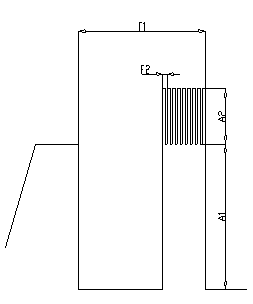

Laser method for repairing rotor shaft of generator and steam turbine and dedicated device

InactiveCN1660538AImprove controllabilityImprove automationMetallic material coating processesOther manufacturing equipments/toolsNondestructive testingElectric generator

Owner:SHENYANG DALU LASER TECH

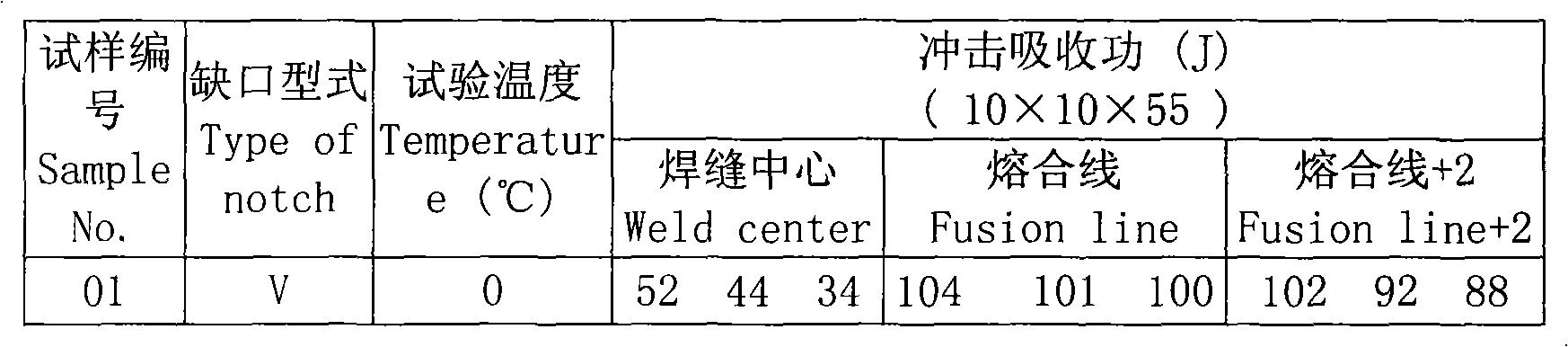

Welding process of low temperature steel welding body case

InactiveCN101209508AShorten welding cycleStable deliveryArc welding apparatusFurnace typesPower flowCurrent range

The invention relates to a welding technique in equipment manufacture industry, which is a welding speciality technique of a welding casing of an MCL-typed horizontal cutting centrifugal compressor, in particular to a welding process of the welding casing of the centrifugal compressor with low-temperature steel 09MnNiDR material at -70 DEG C. The gas protection welding is adopted; the welding wire grade is HS09MnNiDR and the diameter of the welding wire is Phi1.2mm; the polarity of the power supply is reversed DC power. The invention comprises a processing before welding, a welding process and a processing after welding; wherein, the process parameters in the welding process are that the welding current ranges from 150A to 200A, the welding voltage ranges from 24V to 28V, the protection gas is the mixed gas with 80% of Ar and 20% of CO2 according to the volume percentage, the welding speed ranges from 250mm / min to 280mm / min, the dry elongation ranges from 10mm to 15mm, and the gas flux ranges from 20L / min to 25L / min. The welding wire of the gas protection welding of the invention is not required to be dried, the welding wire is automatically fed in the welding process, and a welding rod is not required to be replaced; as the heat of the MAG melting polar gas protection welding is concentrated, the invention has the advantages of narrow thermal effect area, little deformation, beautiful forming, good quality, low cost, fast welding speed, high welding efficiency, etc.

Owner:SHENYANG BLOWER WORKS GROUP CORP

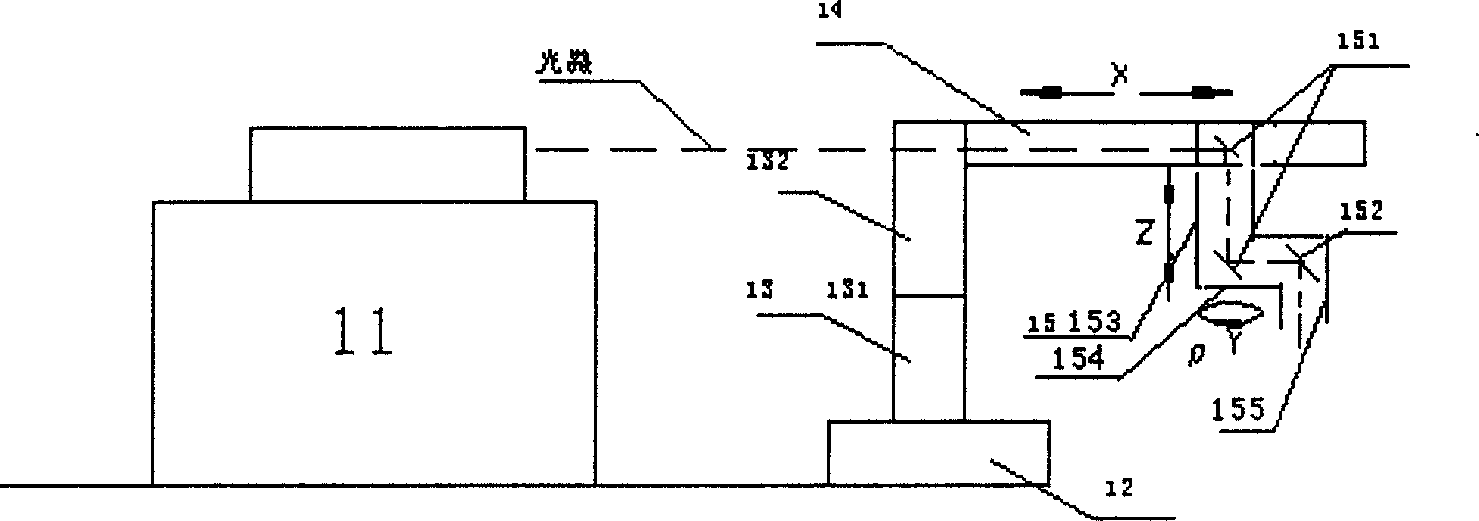

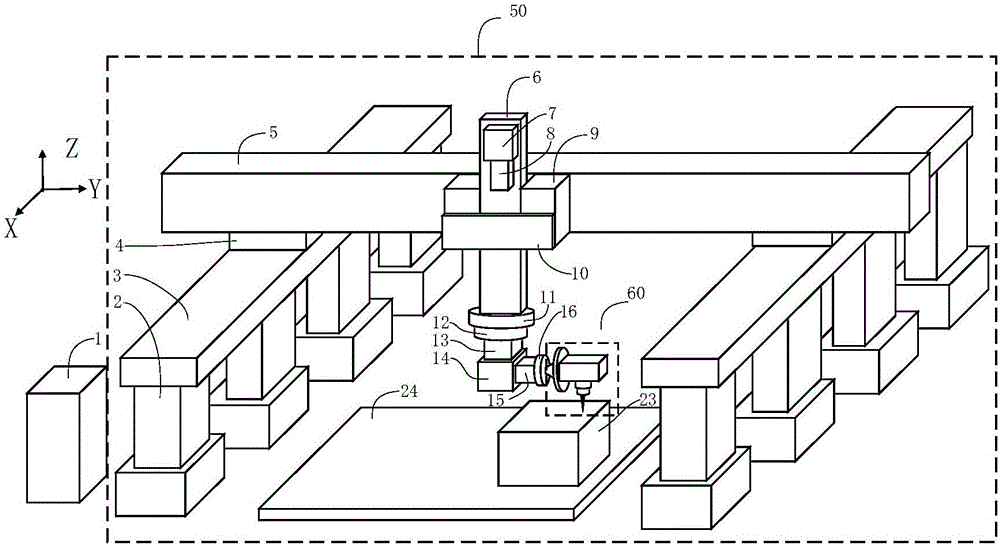

Multi-light source, multi-function and multi-axis laser processing head and apparatus

ActiveCN106563880AAchieve laser fine etchingRealize cutting processLaser beam welding apparatusNumerical controlEngineering

The present invention discloses a laser processing head and a multi-light source, multi-function and multi-axis processing apparatus comprising the same. The laser processing head includes a shell, an optical path system, a locating conical disk-shaped connecting mechanism, a laser range finder, a motor driving mechanism and a dust collection protection cover. The laser processing head has the advantages of a plurality of processing modes, flexibility in laser selection and easiness in replacement. The multi-light source, multi-function and multi-axis processing apparatus includes an apparatus control and operation system platform, a multi-axis linkage numerically-controlled machine tool and the laser processing head; the laser processing head is fixed on a high-precision multi-axis linkage machine tool through a blade handle type positioning cone device; and large-breadth and cross-scale laser fine processing only requires the switching of a laser light source, a laser optical path and the laser processing head, so that at least three kinds of large complex component fine surface processing application can be realized. The multi-light source, multi-function and multi-axis processing apparatus is especially for the aerospace field. The laser processing head and the multi-light source, multi-function and multi-axis processing apparatus comprising the same of the invention have the advantages of low manufacturing cost, wide application range, convenience in mass production and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

Method for engraving character or graphics on metal mold

InactiveCN101670490ANo extrusion stressNo mechanical stressActive medium materialLaser beam welding apparatusGraphicsHeat-affected zone

The invention discloses a method for engraving a character or a graphics on a metal mold. The method comprises the following steps: firstly, placing the metal mold on a three-dimensional work table ofa laser engraving machine, and adjusting the metal mould to a corresponding engraving position; secondly, making a character or a graphics to be engraved and adjusting the parameters of the laser engraving machine; and thirdly, scanning layer by layer to reach a required depth. The method for engraving the character or the graphics on the metal mold can solve the problems of the complex flow of the conventional CNC or EDM and liquid medicine corrosion process, simplify the structure design of the mould without generating mechanical extrusion or stress in the process and has the advantages ofsmall heat-affected region, fine process, no deformation of a workpiece, high processing efficiency, low cost and easy operation without pollution.

Owner:天津滨海雷克斯激光科技发展有限公司

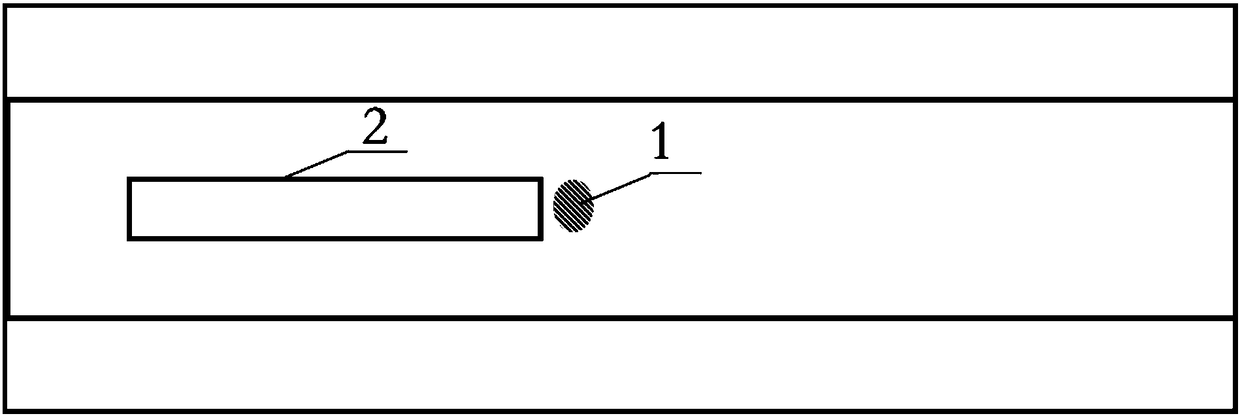

Main plate opposing connection welding method

InactiveCN101342629AFast meltingImprove deposition efficiencyArc welding apparatusButt jointActive force

The invention discloses a butt-jointing and welding method of plates. The bases of the grooves of two plates which need to be welded are butt-jointed closely and are fixed in the groove through spot welding. A ceramic pad is stuck at the bottom of the butt-jointing place by an aluminum foil. Two parallel and separated thin welding wires are used to treat welding seam by submerged arc-welding. The butt-jointing and welding method effectively shunts the welding current to the two thin welding wires, not only improves the melting efficiency of the welding wire, but also avoids the excessive concentration of the active force of electric arc, not only has high welding efficiency, but also is easier to achieve a balance state to form the welding seam under the support of surface tension and the ceramic pad.

Owner:中船海洋与防务装备股份有限公司

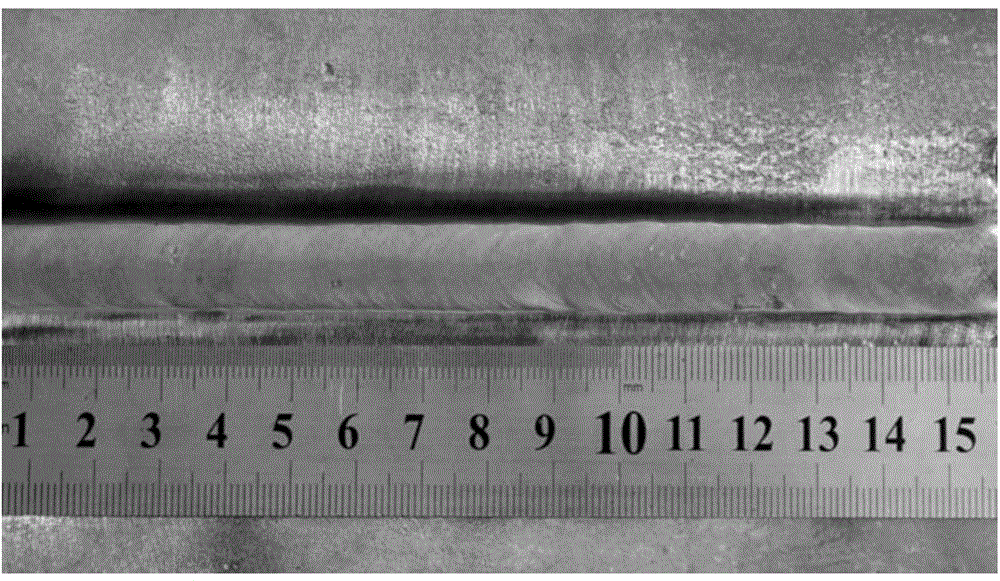

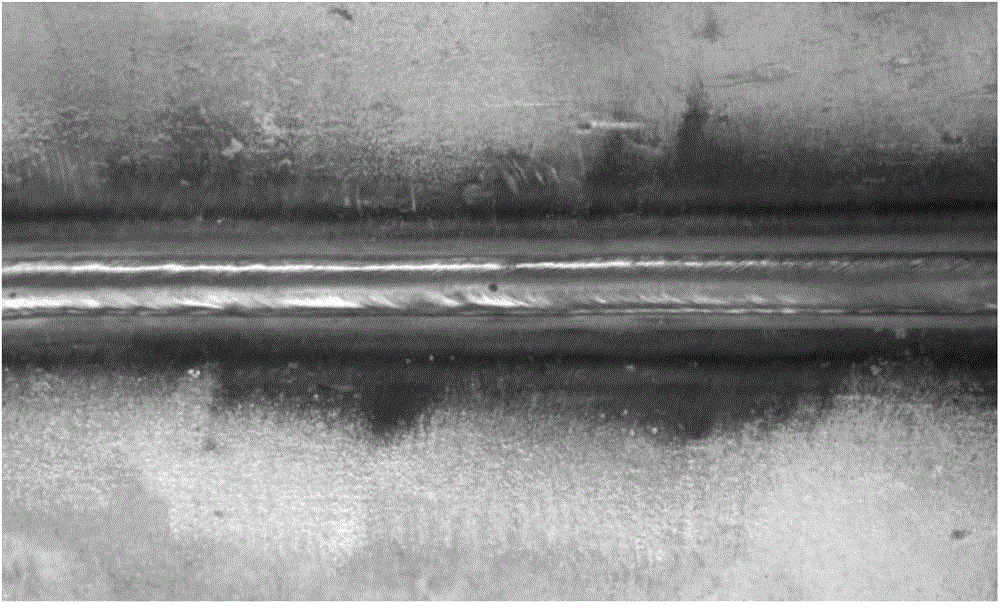

Method for efficiently compounding fusion-covering reinforced steel rail through laser and auxiliary heat source

ActiveCN108456879AReduce temperature gradientAvoid crackingFurnace typesMetallic material coating processesMelting tankHeat-affected zone

The invention discloses a method for efficiently compounding a fusion-covering reinforced steel rail through laser and an auxiliary heat source. The laser and the auxiliary heat source act on a to-be-fusion-covered area on the surface of the steel rail simultaneously, as a main heat source, the laser makes the material of a fusion-covering layer and the material on part of the base of the surfaceof the steel rail quickly fused simultaneously to form a fusion pool, the auxiliary heat source and the laser heat source move in the same direction at the same speed and preheat and / or postheat the laser fusion pool, a heat influence area and the surface layer of the base of the steel rail, the temperature gradient of the steel rail is lowered, thus the cooling speed of the steel rail is lowered,and the phenomena of transforming of a martensite in a heat influence area and cracking are avoided. Through the compounding effect, the critical cooling time for transforming an austenite to a pearlite is shortened in the heat influence area wherein the cooling time is larger than a CCT curve or a TTT curve, so that the mechanical performance among the fusion-covering layer, the heat influence area and the base is reasonably matched, the rigidity curve is smooth in distribution, and the overall fatigue performance is good. The method can fuse-cover a metal layer on the surface of a field ofa railway steel rail on line and can also achieve fuse-covering machining on the surface of the steel rail in a production workshop.

Owner:HUAZHONG UNIV OF SCI & TECH +1

All-position automatic welding method for pipeline circumferential weld

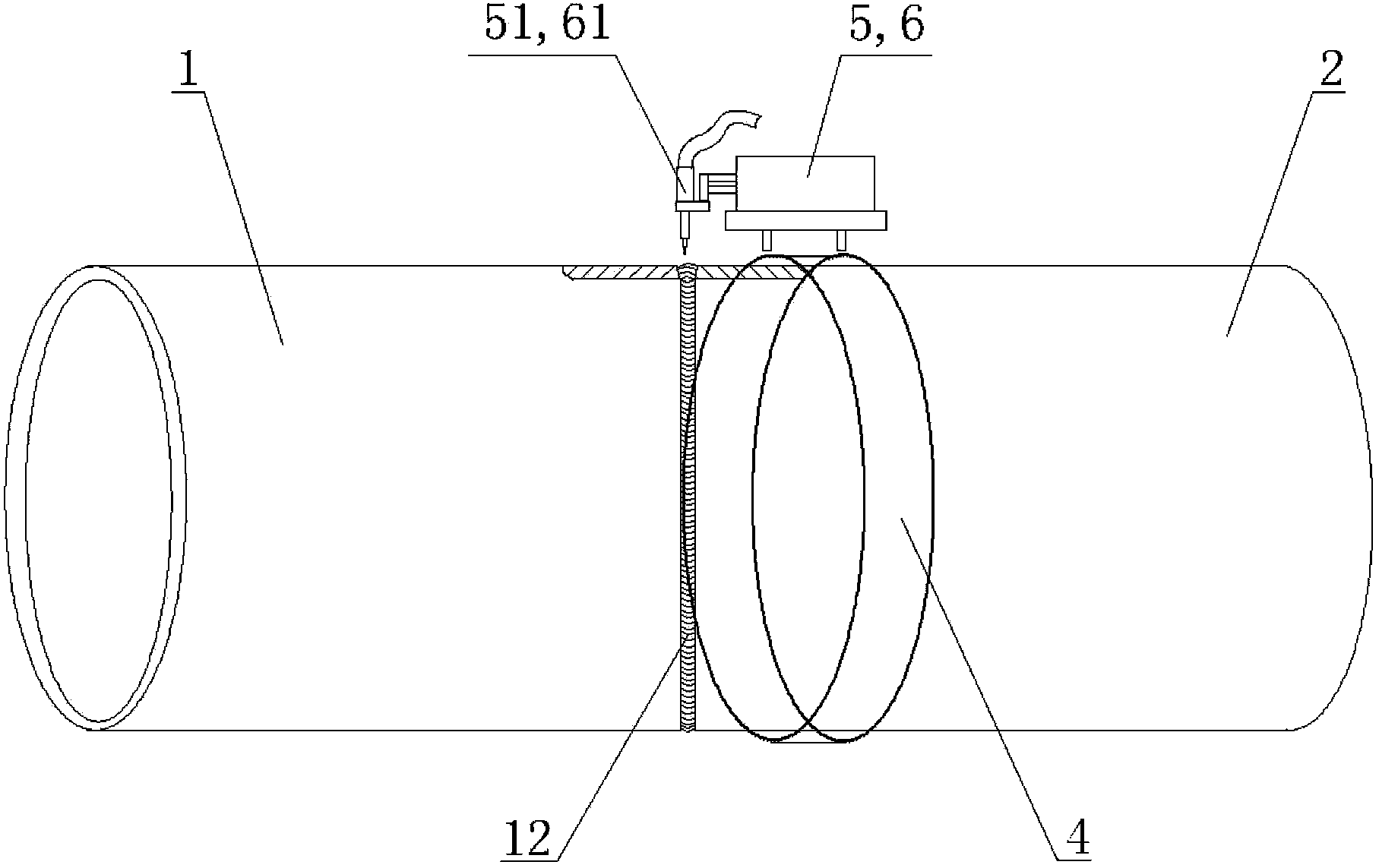

ActiveCN103801796ALow costEasy maintenance and operationArc welding apparatusMetal working apparatusEngineeringWelding defect

The invention discloses an all-position automatic welding method for a pipeline circumferential weld and belongs to the technical field of pipeline circumferential weld welding. The method includes the following steps that firstly, steel pipes needing welding are machined to be provided with groove end faces; secondly, welding technology parameters are typed in a controller program according to the preset welding technology; thirdly, the two welded steel pipes are assembled; fourthly, one of the steel pipes is provided with a welding rail; fifthly, the welding ends of the two steel pipes are preheated before welding; sixthly, a single welding torch is used for performing root welding on grooves; seventhly, a double welding torch is used for performing hot welding, filling welding and cosmetic welding on the grooves. According to the all-position automatic welding method for the pipeline circumferential weld, due to the fact that the groove type is designed, the root welding technology, the filling welding technology and the cosmetic welding technology are adopted, the defects that in the prior art, the welding efficiency is low, a large number of welding materials are consumed, a large number of weld defects exist, the welding joint performance is poor, and the requirement for the operating skills of welders is high; or welding equipment is high in cost, and operating and maintaining are difficult are overcome.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

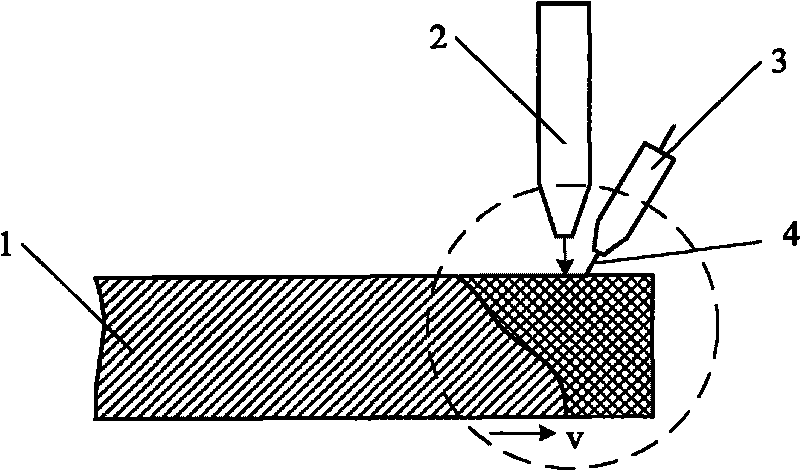

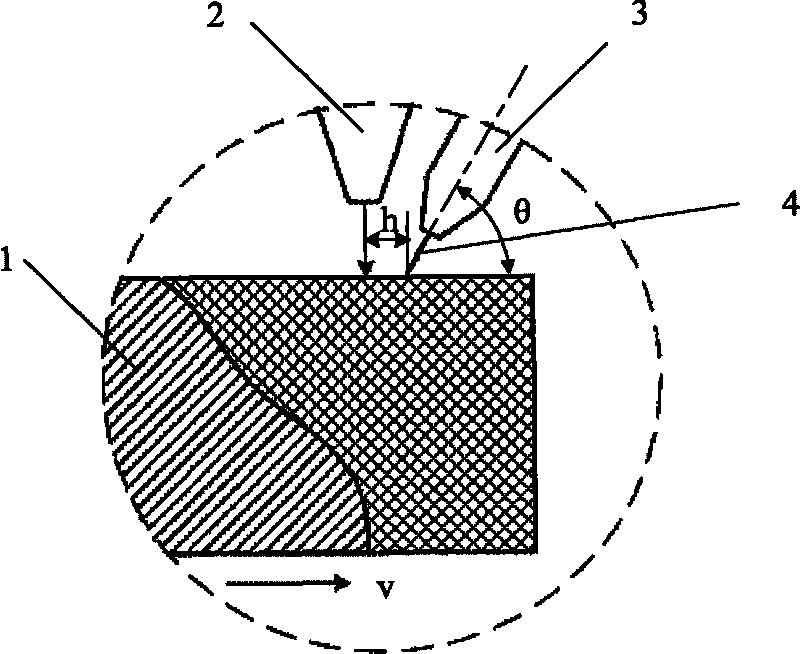

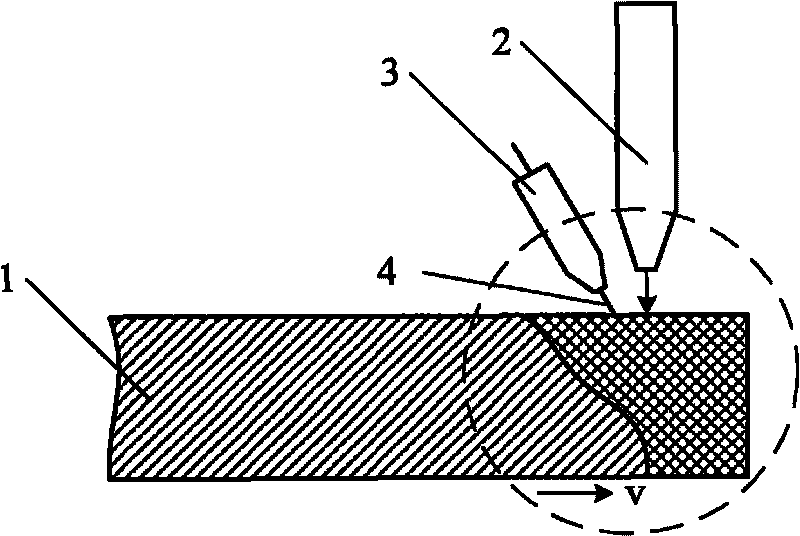

Laser-electric arc composite heat source high-speed welding method of ultrahigh strength steel

InactiveCN101733564AReduced crack susceptibilityAvoid crackingArc welding apparatusLaser beam welding apparatusLaser NozzleSpray nozzle

The invention relates to a laser-electric arc composite heat source high-speed welding method of ultrahigh strength steel, belonging to the technical field of high-strength steel welding. The traditional laser-electric arc composite heat source high-speed welding method of the high-strength or ultrahigh strength steel has overhigh welding linear energy due to low welding speed and large energy input so as to cause the deformation of a welding workpiece; in addition, chevilled silk spacing is overlarge, and stabilization action realized by a laser is reduced because the laser is adopted firstly and the electric arc is adopted subsequently so that a welding process is unstable and easy to generate splashing. The invention adopts laser-electric arc composite heat source welding; the welding workpiece is the high-strength steel or the ultrahigh strength steel; an electric arc welding gun is used for welding firstly and a laser nozzle is used for welding subsequently during welding; the current of electric arc welding is 140-180A, and the voltage of the electric arc welding is 23-25V; an included angle theta between the electric arc welding gun and the surface of the workpiece is 60-65 degrees; the laser power is 3-5kW; the welding speed v is 1-3m / minute; and the chevilled silk spacing h between a laser beam and a welding stick is determined within a range of 1-3mm. The invention realizes the welding of the ultrahigh strength steel without preheating, cold cracks or deformation.

Owner:CHANGCHUN UNIV OF SCI & TECH

Ultraviolet laser drilling device

InactiveCN102218606ASolve efficiency problemsSolution effectLaser beam welding apparatusBeam expanderLight spot

The invention relates to an ultraviolet laser drilling device. The output end of an ultraviolet Q-switched solid laser is provided with a beam expander; the output end of the beam expander is sequentially provided with a first reflecting mirror and a second reflecting mirror; the output end of the second reflecting mirror is provided with a beam shaping device; the output end of the beam shaping device is provided with a scanning galvanometer; the output end of the scanning galvanometer is connected with a focus lens; a three-dimension moving platform is arranged below the focus lens; light beams emitted from the ultraviolet Q-switched solid laser enter the beam expander; the beam expander outputs collimated light beams; the collimated light beams enter the beam shaping device through the first reflecting mirror and the second reflecting mirror; the shaped light beams enter the focus lens through the scanning galvanometer; focusing light spots, of which the energy is in a flat top distribution, are obtained at a focus position; the focus of the focused light beams is positioned on a processing workpiece of the three-dimensional moving platform. During the action of ultraviolet laser and materials, molecules are stripped off by breaking chemical bonds of the materials, a heat affected area is greatly reduced, and a good effect of processing edges is achieved.

Owner:SUZHOU DELPHI LASER +1

Laser melting rehabilitation method for titanium alloy thin-wall case

InactiveCN1966201AHigh hardnessQuality improvementLaser beam welding apparatusHeat inorganic powder coatingHydrogenThermal deformation

The invention relates to a method for using laser fusion to repair titanium alloy frame, wherein the inventive method comprises that: smoothing the abrasive area of element surface; cleaning out the solder electrolytic corrosion layer and solder vacuum anneal hydrogen removing treatment; at 750-800Deg. C, for 40-60min, 0.2-0.4MPa, using argon gas to cool down to 80Deg. C, discharging from furnace; laser fusion, while fusion frequency f=5-6Hz, time t=4-5m, under argon gas whose flux Q-4.5-5.5L / min, the fusion solder fills the abrasive part higher than 0.2-0.4mm, to cove 40-75%; abrading to needed size and roughness. The invention has simple operation and high rigidity, without thermal deformation.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

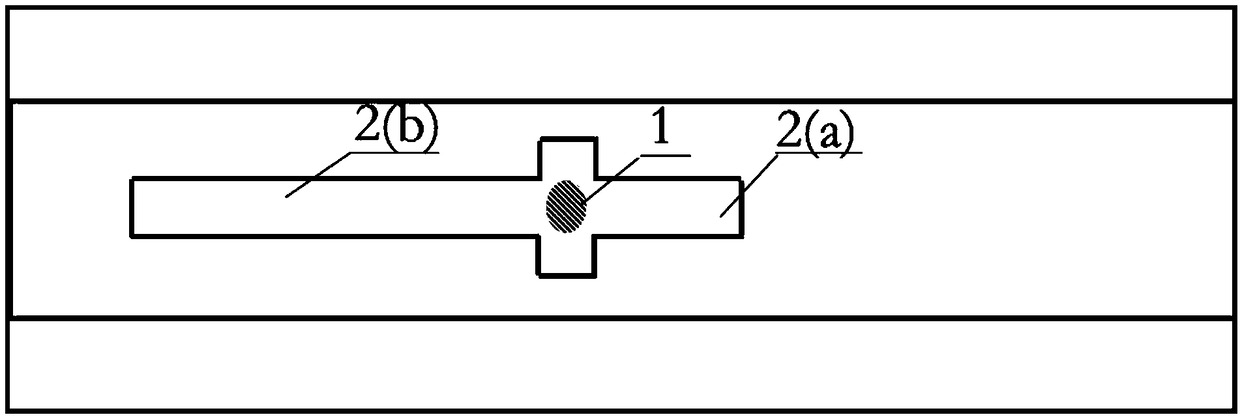

Laser and electric arc combined welding method for thick high-strength steel plates and clamp for method

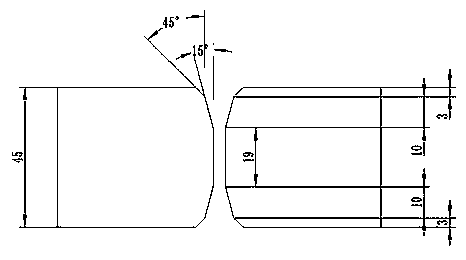

ActiveCN103406675ANo misalignmentImprove clamping efficiencyWelding/cutting auxillary devicesAuxillary welding devicesThick plateErbium lasers

The invention relates to a laser and electric arc combined welding method for thick high-strength steel plates and a clamp for the method. A 45-mm thick high-strength steel is welded with a 6-KW fiber laser and through a double-sided welding forming method, small double-sided grooves are opened, and a 1mm-1.5mm gap is reserved, accordingly, the 45-mm thick high-strength steel can be completely welded. Compared with traditional multi-layer multi-pass welding which requires at least 20 passes of welding, the combined welding method has the advantages that the progress is apparent, preheating processes are simplified, preheating time is shortened, and welded joint performances reach client required indexes; the production efficiency is improved apparently, consumption of base metal and welding wires is reduced, energy consumption is decreased, the mechanical property of welded joints is improved, the residual stress and the deformation are reduced, automation of production can be easily achieved, and the like. The special clamp is a combined clamp with four pressing plates arranged on the upper portion and a base plate used on the lower portion during welding so as to improve the efficiency and quality of the welding method. By means of the clamp, a workpiece can be positioned and fixed, the welding quality is guaranteed, and the workpiece cannot be abraded.

Owner:NANJING ZHONGKE RAYCHAM TECH

Device and method for making metal film group holes by using ultra-short pulse laser

InactiveCN102319960AEasy to processImprove surface qualityLaser beam welding apparatusOptoelectronicsObservation system

The invention relates to a device and a method for making metal film group holes by using ultra-short pulse laser. An optical shutter is arranged at the output end of a high-frequency ultra-short pulse laser device, a beam expander is arranged at the output end of the optical shutter, a 45-degree total reflector is arranged at the output end of the beam expander, a vibrating mirror and a scanning field mirror are sequentially arranged at the output end of the 45-degree total reflector, the scanning field mirror is opposite to a working platform, a charge coupled device (CCD) alignment observation system is arranged above the working platform, a group of clamping cylinders are arranged on the working platform, an air blowing system is arranged at one side of the working platform, a dust collecting system is arranged at the other side of the working platform, and a dust collecting system is also arranged below the working platform. By optical focusing of the ultra-short pulse laser device, the focal point is positioned on a metal film material, so that energy of the laser device is efficiently utilized; and by controlling the pulse number and the pulse duration of the ultra-short pulse laser device, the pulse number and the pulse time for forming each metal film aperture are modulated, so that required apertures on each metal film are sequentially machined.

Owner:SUZHOU DELPHI LASER

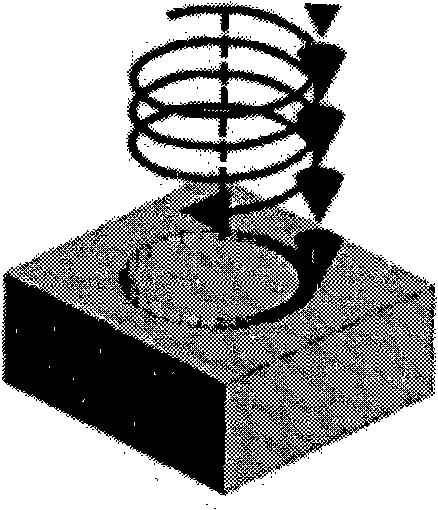

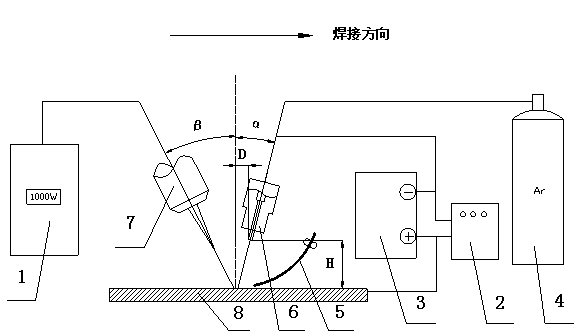

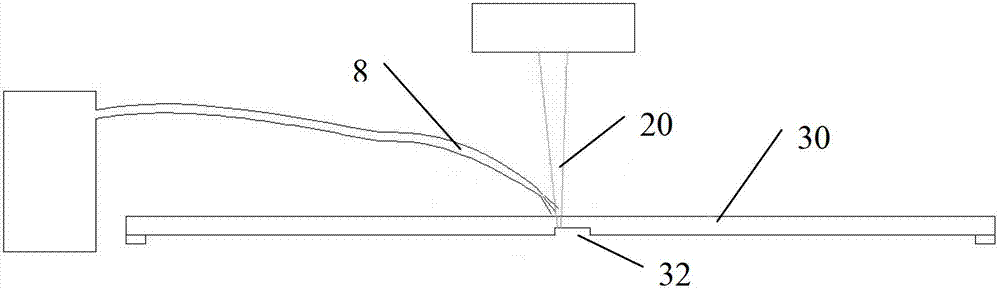

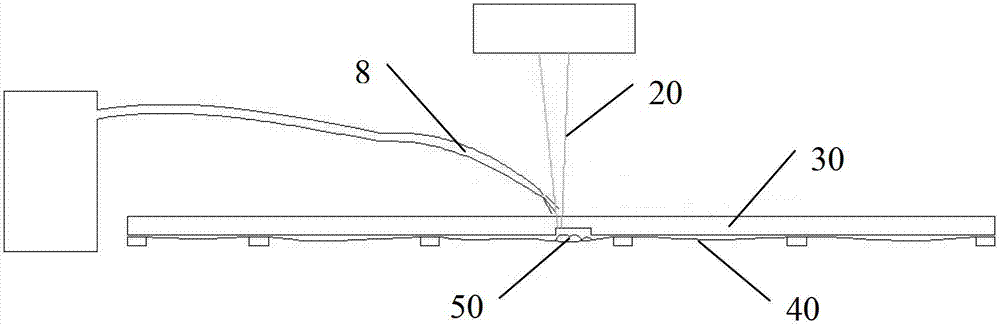

Laser high-frequency alternating-current pulse tungsten inert gas (TIG) hybrid welding process

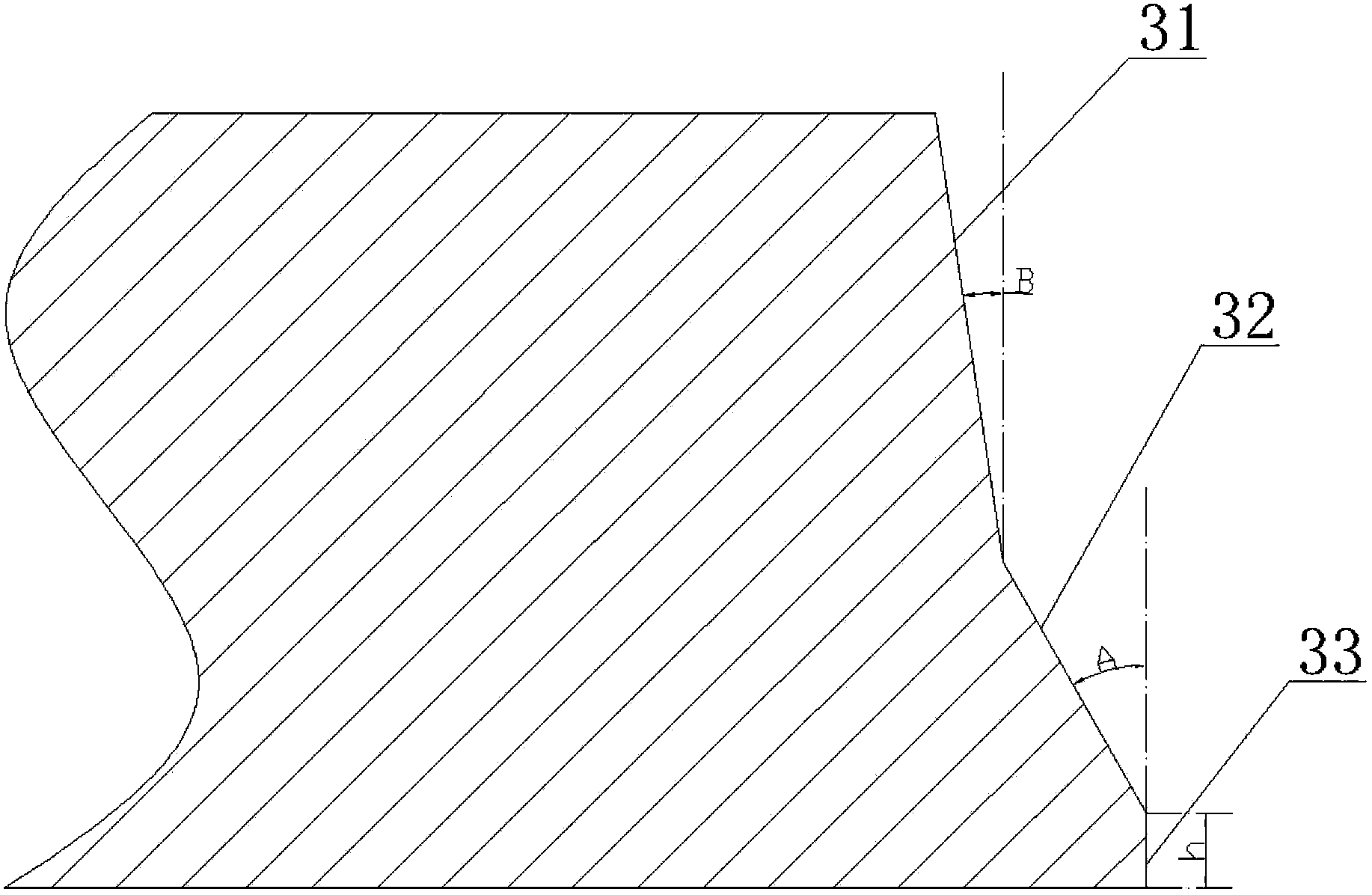

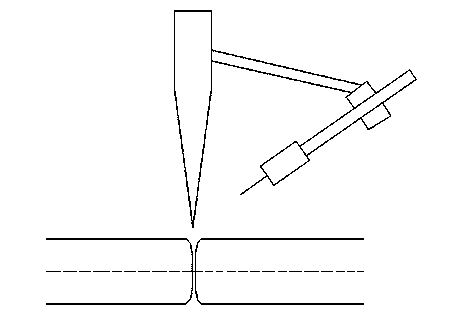

InactiveCN103192187AGood compound effectReduce laser powerWelding/soldering/cutting articlesLaser beam welding apparatusAnti stressMolten bath

The invention discloses a laser high-frequency alternating-current pulse tungsten inert gas (TIG) hybrid welding process. The process comprises the following steps of: constructing a laser high-frequency alternating-current pulse TIG hybrid welding system, and gathering an TIG arc and a semiconductor laser beam on the same welding position of a welded workpiece 8 in the same welding direction, to form a molten bath, wherein an inclined angle alpha of 10-40 degrees is formed between the TIG arc tungsten electrode tip end and a vertical direction, the semiconductor laser beam forms an included angle beta of 10-30 degrees with the vertical direction, the TIG arc tungsten electrode tip end keeps a vertical distance H of 2-4mm with the surface of the welded workpiece 8, and the TIG arc tungsten electrode tip end and the semiconductor laser beam keep a horizontal distance D of 2-5mm with an action point of the surface of the welded workpiece 8. The process disclosed by the invention can refine weld microstructure, remarkably reduce or eliminate pores in melting area and effectively improve mechanical performance and anti-stress corrosion performance of a high-strength aluminous alloy welding joint, and the process is quite practical.

Owner:SICHUAN AEROSPACE LONG MARCH EQUIP MFG CO LTD

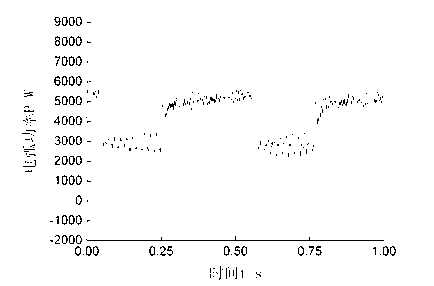

Reinforcement method of electric spark on surface of copper or copper alloy

InactiveCN1920090AEasy to useImprove surface qualityVacuum evaporation coatingSputtering coatingGas phaseShielding gas

The invention relates the method for electric spark deposition treatment on the copper or copper alloy surface. The method comprises the following steps: using copper or copper alloy as raw material, and using electric spark device to carry out deposition treatment, at the protection of argon gas, argon gas and helium. The output power is 400-1300W, the transmission voltage is 60-80V, the discharge frequency is 100-700Hz, the protection gas flow is 18-30L / min, and the deposition time is 3-15 min. The invention has not many complex devices as vapor deposition and vacuum sintering; the invention can deposit reiteratively, and has simple operation; the method has narrow heat-affected zone or no heat-affected zone; the method has not preheating before deposition and annealing treatment after deposition.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

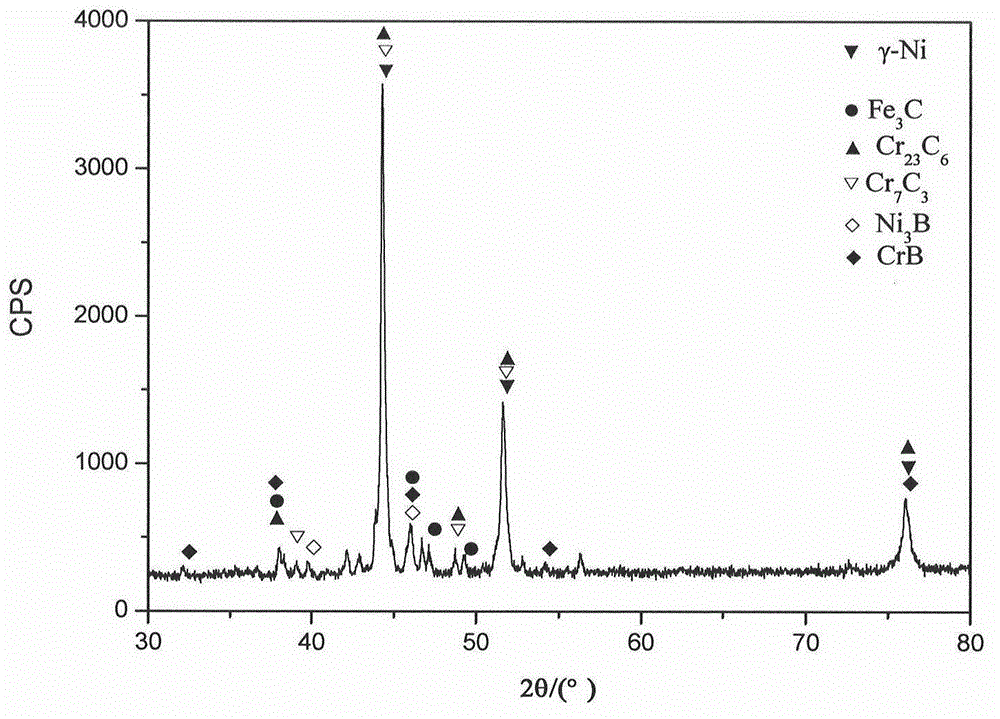

Iron-based nanocrystalline composite coating for protecting boiler tail heating surface and laser-cladding forming process of iron-based nanocrystalline composite coating

ActiveCN104357748AImprove wear and corrosion resistanceReduce corrosion wearMetallic material coating processesRare-earth elementAlloy

The invention discloses an iron-based nanocrystalline composite coating for protecting a boiler tail heating surface and a laser-cladding forming process of the iron-based nanocrystalline composite coating. The iron-based nanocrystalline composite coating comprises the following components in percentage by weight: 49.9-62.8% of Fe, 14.2-20.4% of Cr, 9.0-16.3% of Mo, 2.9-4.1% of B, 0.6-1.3% of C, 1.0-2.4% of Mn, 3.4-8.0% of W, 1.0-1.9% of Si and 0-3.9% of RE, wherein RE is a rare earth element. The forming process comprises the following steps: preparing alloy powder of the iron-based nanocrystalline composite coating; treating the surface of the boiler tail heating surface; preparing the iron-based nanocrystalline composite coating through a simultaneous powder feeding method and a laser-cladding method, wherein the laser cladding is performed for multiple times. The formed iron-based nanocrystalline composite coating is 1 mm above in thickness. The iron-based nanocrystalline composite coating can obviously enhance the wear resistance and corrosion resistance of the boiler tail heating surface, and reduce maintenance costs of worn and corroded parts and consumption of raw materials of a power plant.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

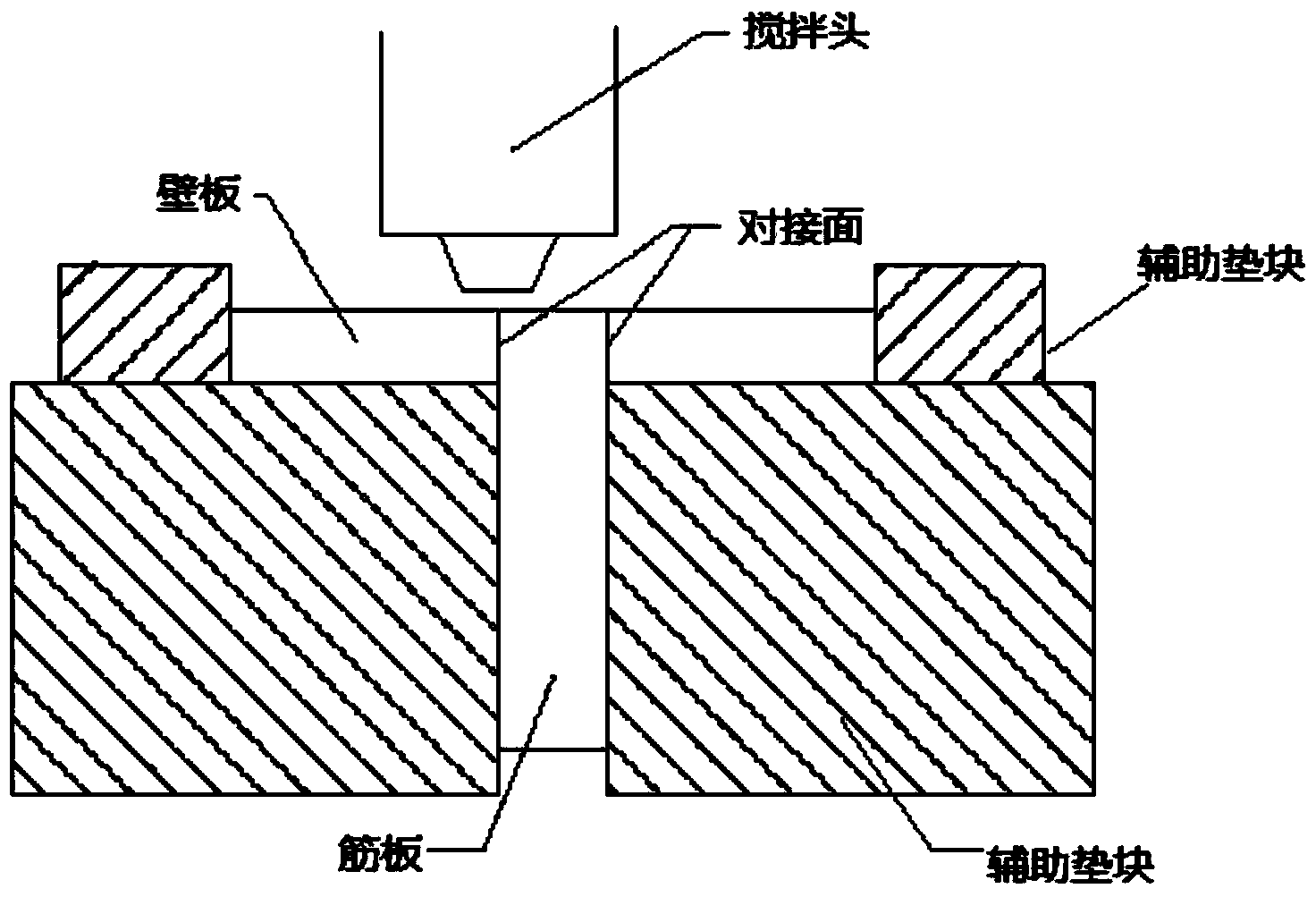

Method for T-shaped magnesium alloy section friction stir welding

InactiveCN104139239ASmall heat affected zoneSmall residual stress and deformationWelding/soldering/cutting articlesNon-electric welding apparatusCushionFriction stir welding

The invention provides a method for T-shaped magnesium alloy section friction stir welding. The method specifically comprises the following steps: alcohol is used for cleaning oil greasy dirt on alloy sections to be welded before welding; on the two sides of a magnesium alloy rib plate, a pair of auxiliary cushion blocks with a shape which is consistent with the shape of the plate is assembled; two magnesium alloy blocks with same geometric size are installed on the auxiliary cushion blocks of the rib plate as wallboards, and auxiliary cushion blocks are assembled on the two sides of the wallboards; by using a tooling, the auxiliary cushion blocks of the wallboards, three magnesium alloy sections to be welded and the auxiliary cushion blocks of the rib plates are transversely clamped on a welding bench; a main shaft of a friction stir welding machine rotates, is gradually inserted into one butting surface of the wallboards and the rib plate sections, is stopped for a while and horizontally moves to start welding, the welding is ended after the main shaft reaches an end point, and a stirring head is drawn out; parallel welding is conducted to the other butting surface, wherein the center spacing between the two weld seams is the thickness of the rib plate.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

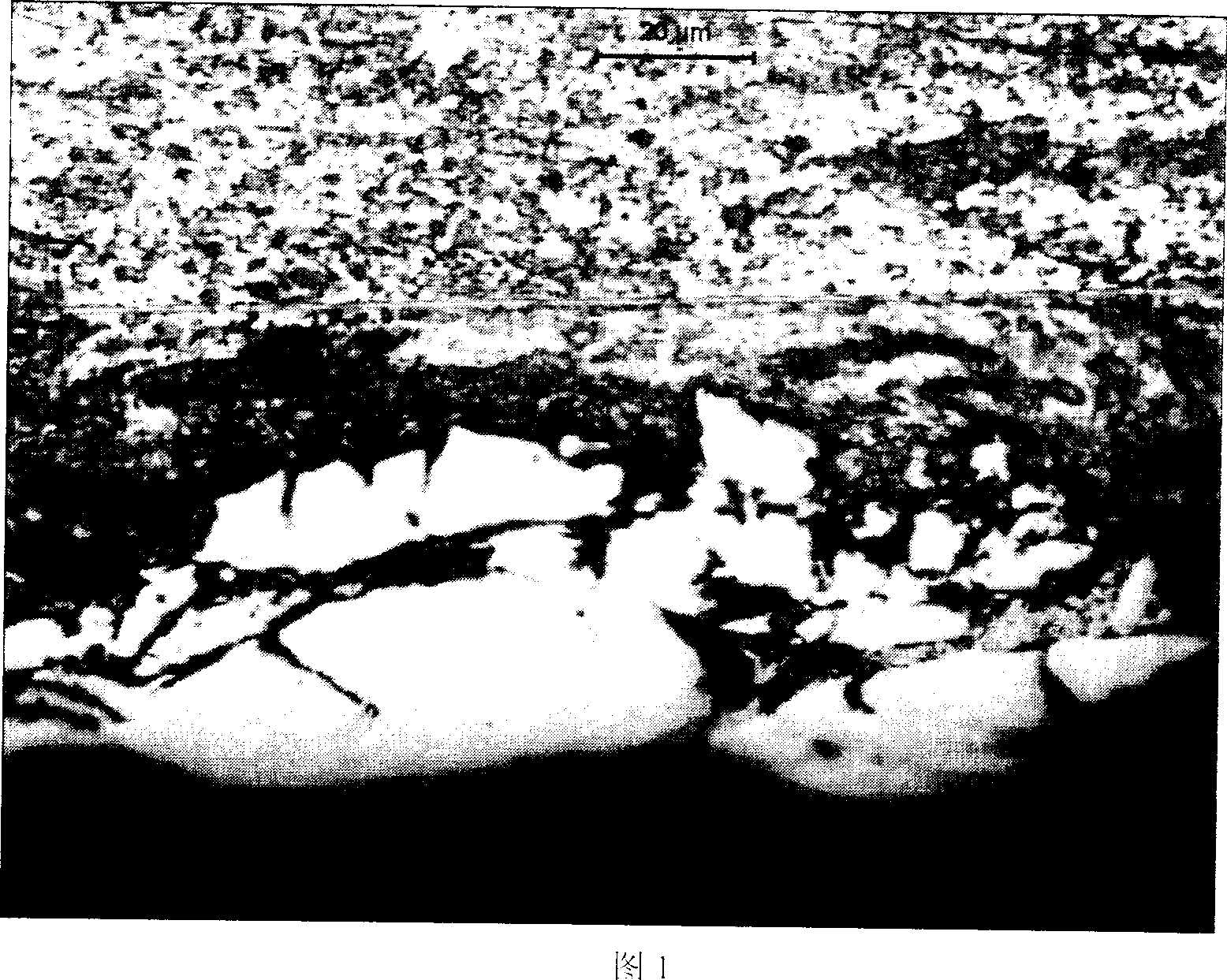

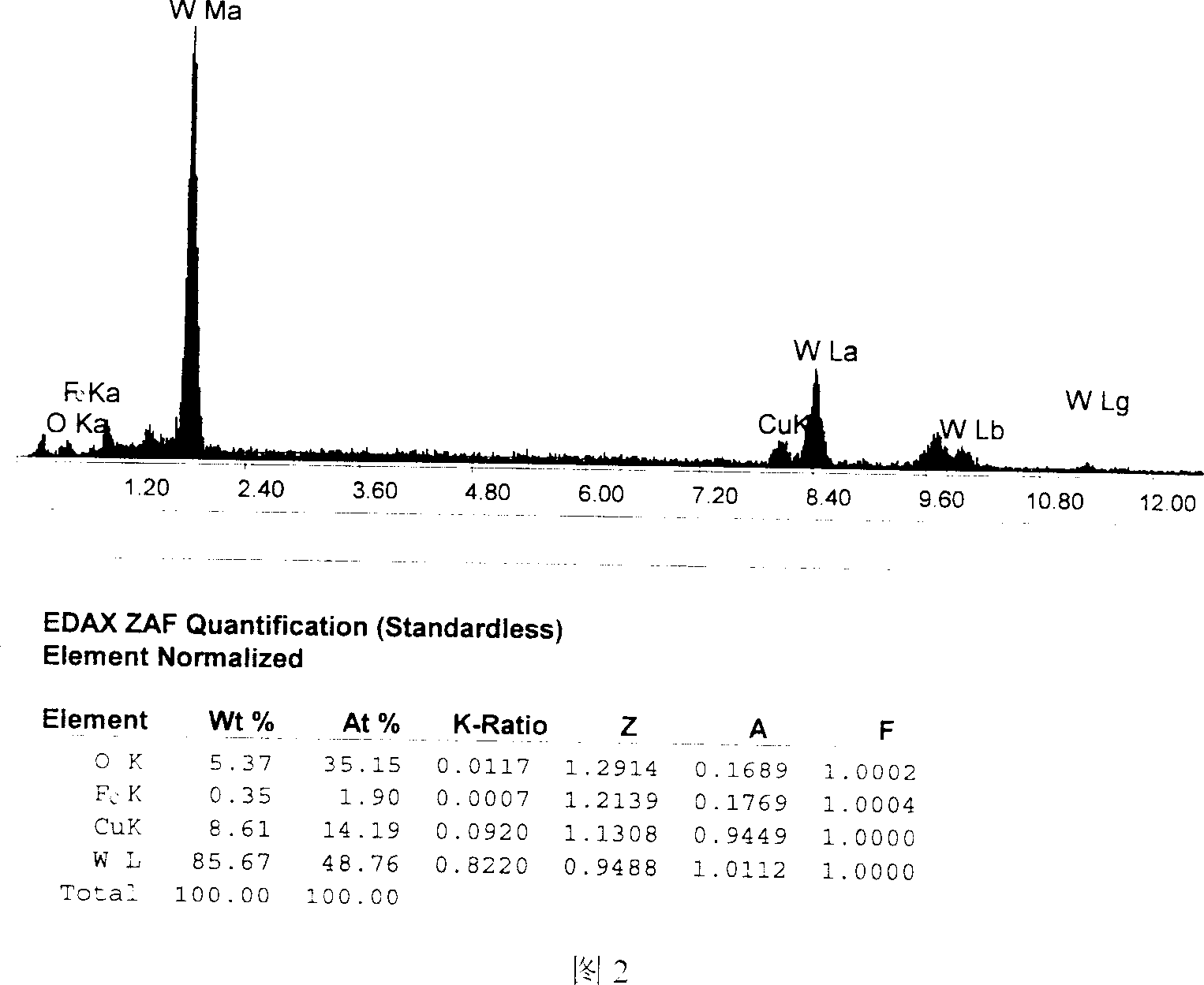

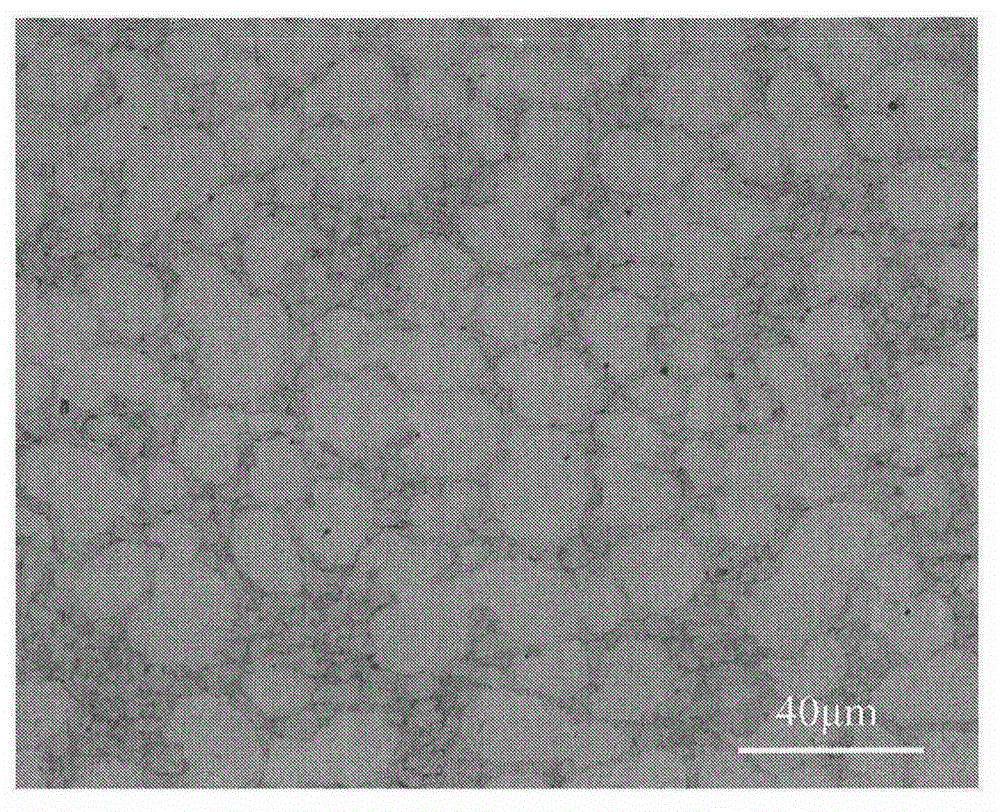

Cr12MoV cold stamping mold laser repair technology using cobalt-based tungsten carbide as fusion covering alloy

InactiveCN103911612ADense tissueSmall heat affected zoneMetallic material coating processesAlloyOptoelectronics

The invention discloses a Cr12MoV cold stamping mold laser repair technology using cobalt-based tungsten carbide as fusion covering alloy. The Cr12MoV cold stamping mold laser repair technology comprises the following steps: (1) cleaning defects on the surface of a cold stamping mold, and removing grinding racks, oil stains and microcracks on the surface; (2) using Fe316 alloy powder as a bottoming layer, and carrying out laser bottoming fusion covering; (3) using Co06+WC alloy powder as a covering layer, and after cooling the mold to 300-600 DEG C, carrying out laser fusion covering on the covering layer; and (4) carrying out mechanical machining on the surface of the fusion covering layer. According to the technology, the fusion covering layer with high interface bonding strength and compact structure and without cracks is obtained without preheating, the microhardness of the fusion covering layer reaches 58-62HRC9.8N, particularly the fusion covering layer has good abrasive resistance and can meet the production requirements, and the service life of the cold stamping mold can be prolonged.

Owner:SHANDONG UNIV

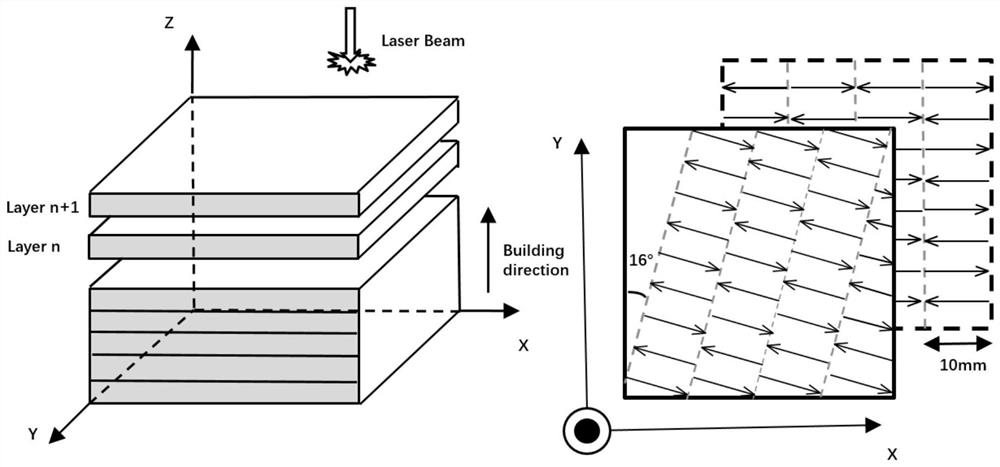

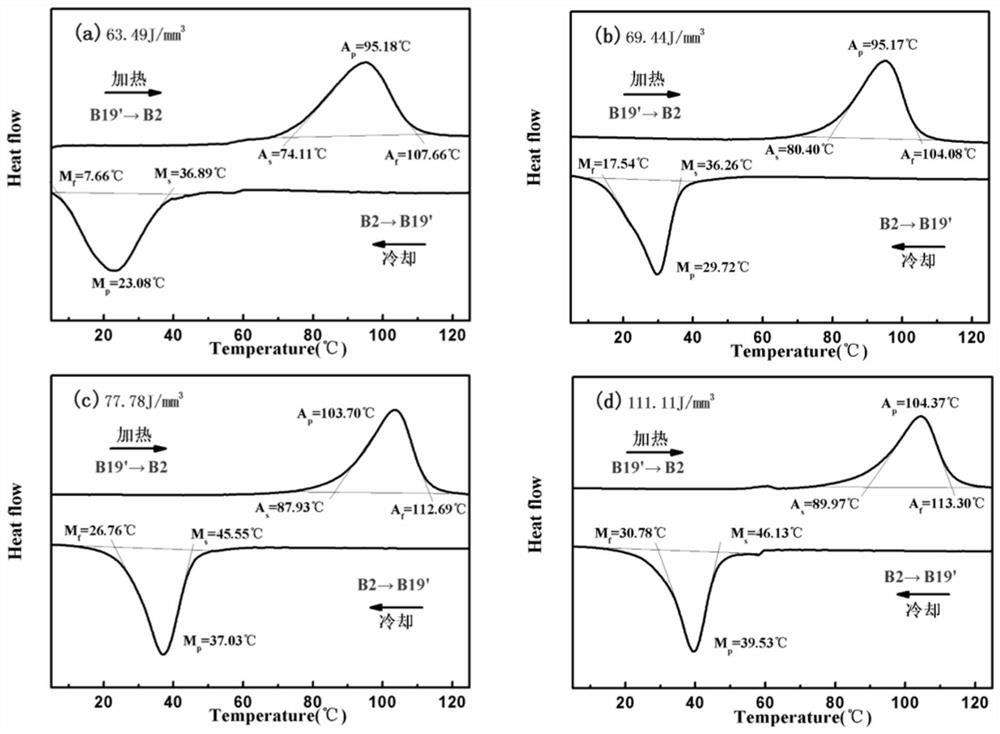

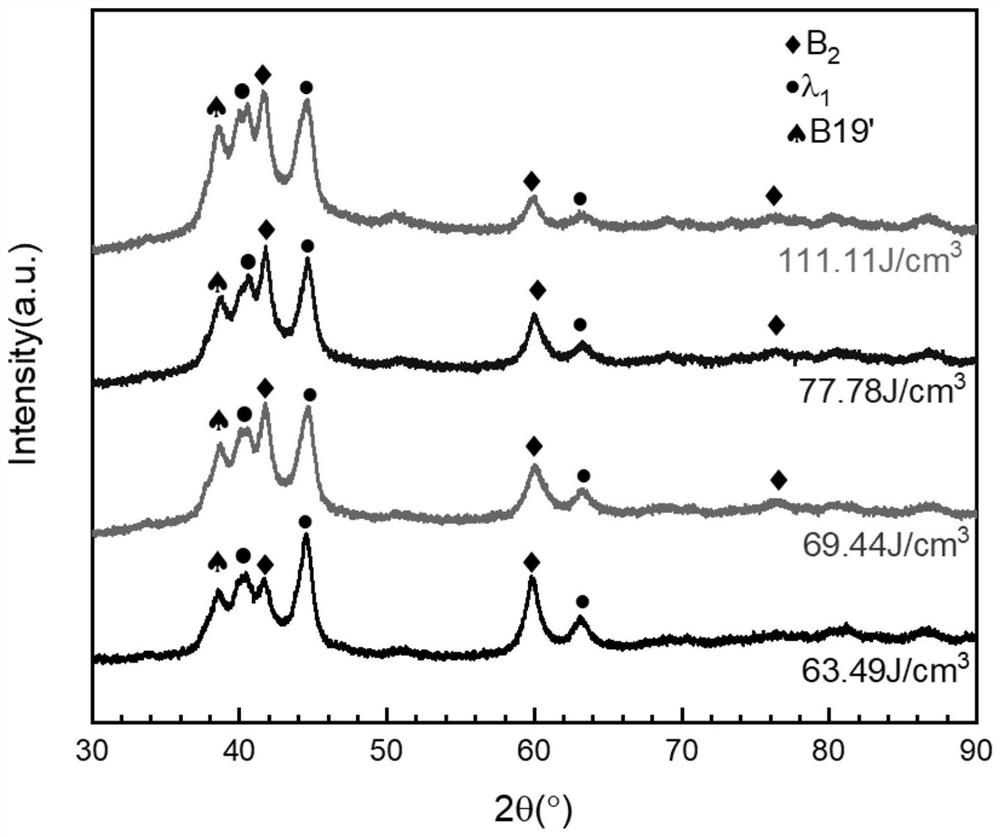

4D printing method of nickel-titanium-based ternary shape memory alloy

InactiveCN111842888AHas shape memory effectRaise the transition temperatureAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingBinary alloy

The invention belongs to the technical field of 4D printing additive manufacturing, and discloses a 4D printing method of a nickel-titanium-based ternary shape memory alloy. The 4D printing method ischaracterized in that a selective laser melting technology is adopted for printing gas atomized prefabricated NiTiZr ternary alloy powder, and a component obtained through printing has the shape memory function; and the laser energy density is changed by changing the technological parameters adopted in the selective laser melting technology, and therefore the changes of the structure and performance of the printed piece are regulated and controlled. According to the 4D printing method, the ternary component Zr is introduced into an existing nickel-titanium binary alloy, the martensite phase transformation temperature is obviously increased, the selective laser melting technology is adopted for forming, and complex parts uniform in structure and high in density can be obtained while the excellent shape memory performance and mechanical performance are guaranteed.

Owner:HUAZHONG UNIV OF SCI & TECH

Laser processing method and laser processing equipment

ActiveCN102814591AAvoid FragmentationImprove stabilityLaser beam welding apparatusMaterials scienceLaser

The invention provides a laser processing method and laser processing equipment. The laser processing method comprises the steps as follows: radiating the laser through an incident surface of a material to be processed, and colleting the light on the initial cutting surface of or close to the material to be processed so as to gasify and / or melt the material to be processed at a light collecting point and / or in an area close to the light collecting point; forming an initial thermal removing area on the initial cutting surface; continuously distributing the initial thermal removing areas on the initial cutting face along a preset path so as to form an initial thermal removing line; irradiating the laser to collect the light on the surface of or close to the material to be processed formed in the thermal removing step so as to gasify and / or melt the material to be processed at the light collecting point and / or the area close to the light collecting point, thereby forming a follow-up thermal removing area; and continuously distributing the follow-up thermal removing areas along the preset path so as to form a follow-up thermal removing line.

Owner:SUZHOU DELPHI LASER

Preparation method of metal protective coating for inner wall surface of inner bore part

InactiveCN104805435ASmall heat affected zoneFine grainMetallic material coating processesSurface engineeringHeat-affected zone

The invention discloses a preparation method of a metal protective coating for the inner wall surface of an inner bore part and belongs to the technical field of surface engineering. The metal protective coating is mainly applied to perform protective treatment on the inner wall surface of a mechanical inner bore part. The preparation method comprises the following steps: the inner wall surface of the part is subjected to cleaning, presetting a powder / binder coating, drying, high-frequency induction heating cladding, cooling and the like, and then a high-frequency induction cladding coating is prepared on the inner wall surface. The metal protective coating is not only applicable to parts made of iron, cobalt and nickel, but also applicable to ti-based, aluminium-based, copper-based and other conductive inner bore metal parts. The metal protective coating prepared on the inner wall surface of the part has the following advantages: metallurgical bonding is formed between a matrix and the coating; a heat affected zone is narrow, and thermal damage and deformation are not caused for the matrix; a cladding coating and an interface texture are compact, a crystal grain is fine and small, and defects like holes, slag inclusion and cracks are avoided; different metals or alloy powder can be selected as coating materials for preparing a wearproof, antifriction or anticorrosion coating according to the actual working condition demands of the inner wall of the part.

Owner:河北京津冀再制造产业技术研究有限公司 +2

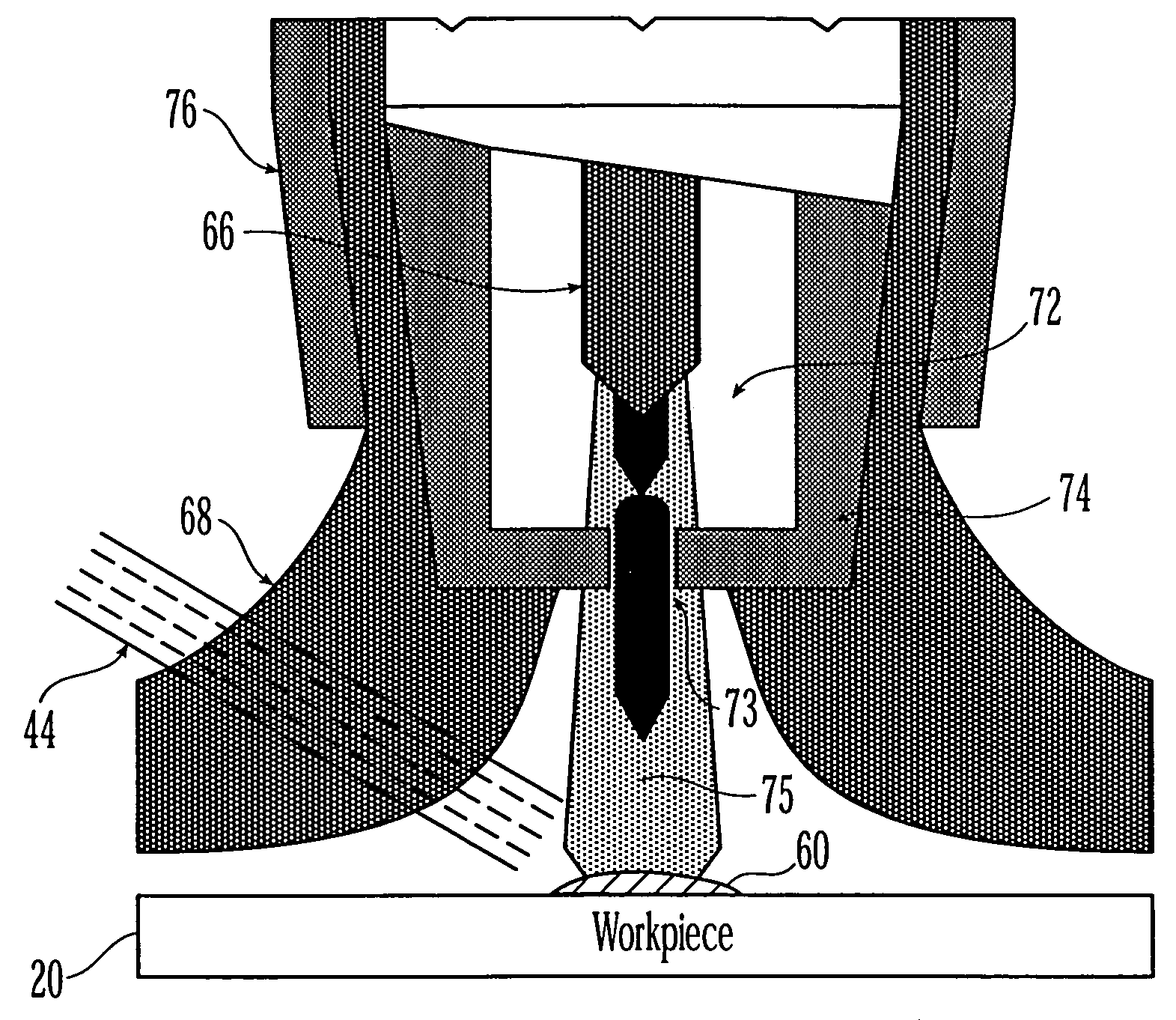

Method and apparatus for repairing superalloy components

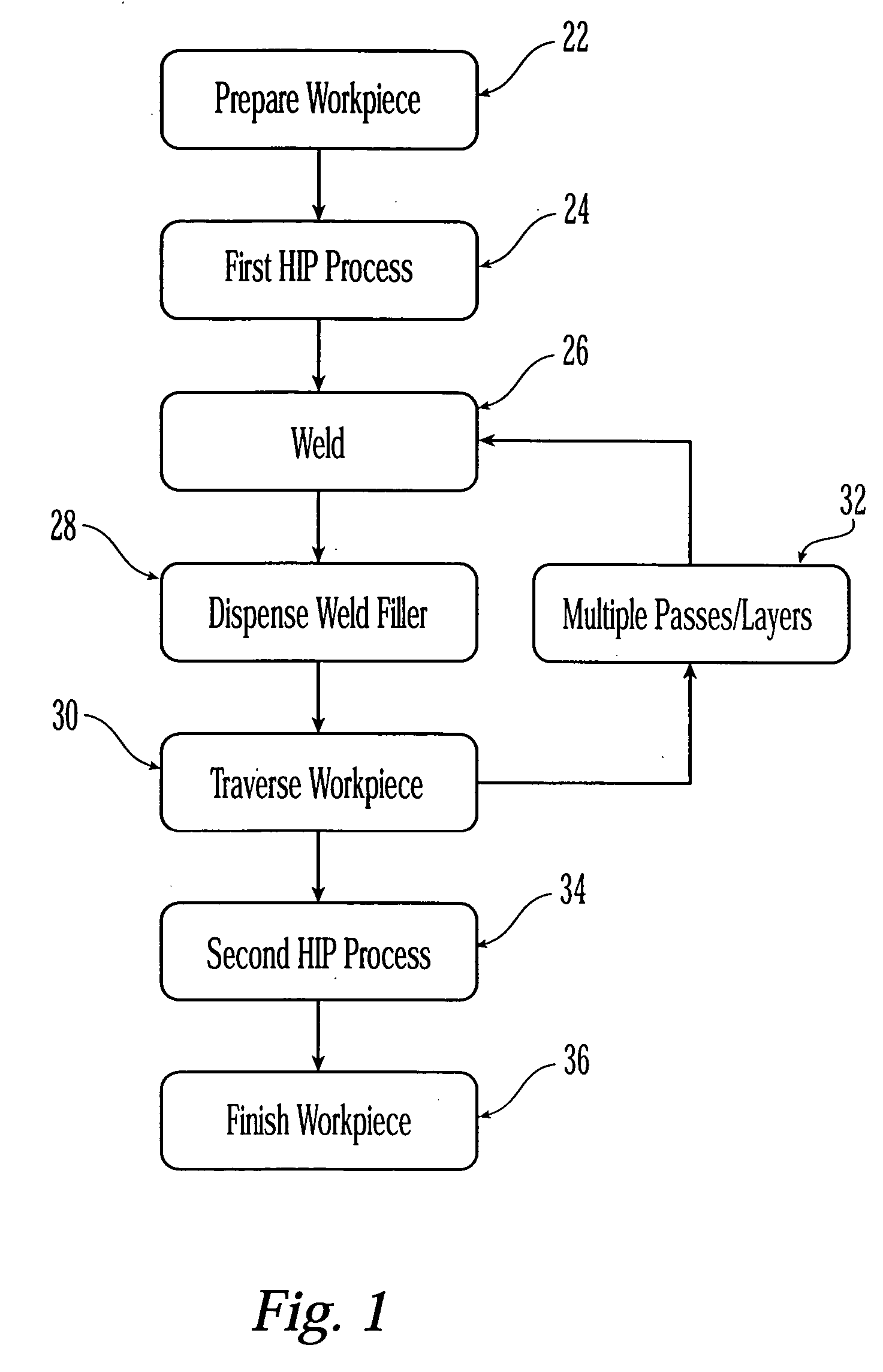

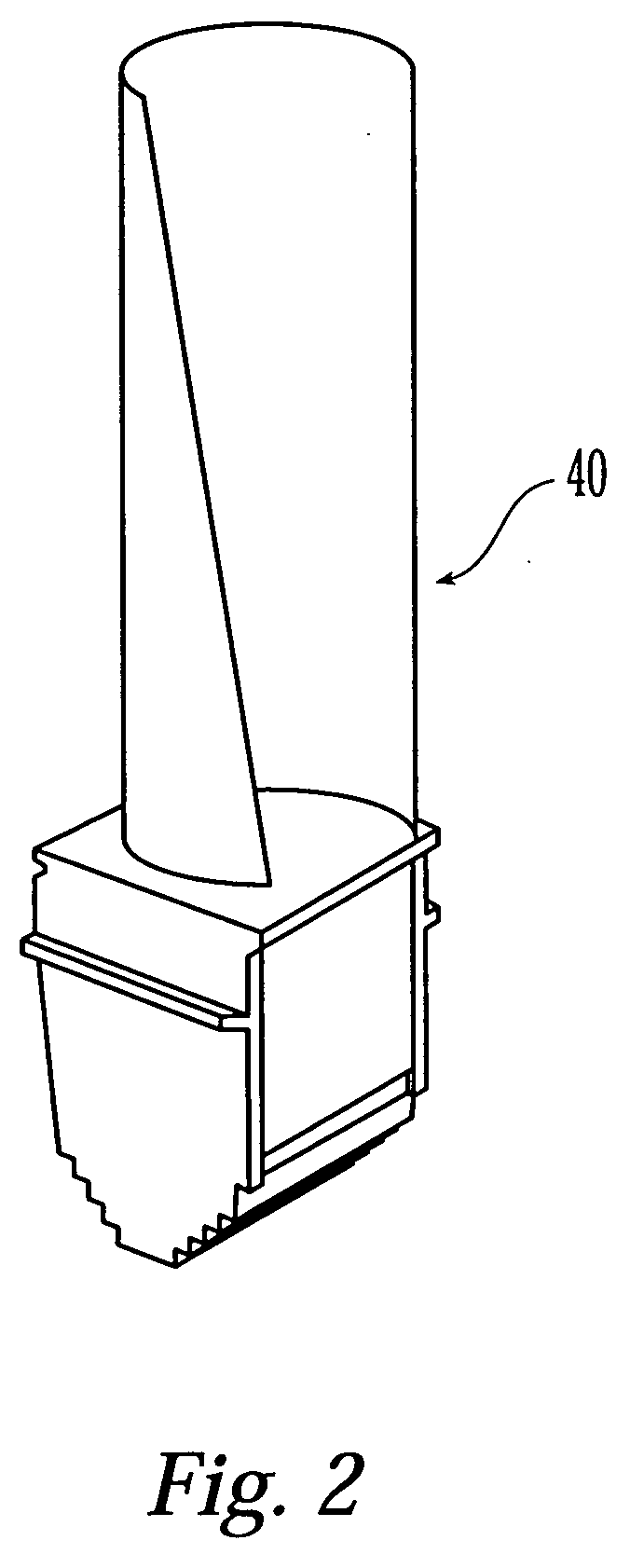

InactiveUS20050126664A1Small heat affected zoneRelieve pressureTurbinesBlade accessoriesPre-conditionRe entry

A method of repairing a metallic component, such as a superalloy turbine blade or turbine nozzle, includes the step of preparing the component by stripping the protective coatings from the component. The component is then pre-conditioned for welding by a first hot isostatic process. Once the conditioning sequence is complete, the component is welded using any of a number of welding techniques and by adding weld fillers to the weld area. After the welding step, the component is sealed by a second hot isostatic process treatment performed at conditions similar to the first hot isostatic process. The component is finally prepared for re-entry into service.

Owner:ELECTRIC POWER RES INST INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com