Device and method for making metal film group holes by using ultra-short pulse laser

An ultra-short pulse laser, metal thin film technology, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of easy to produce consumables selectivity, low processing efficiency, weak, etc. The effect of a small area of influence and good surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The invention utilizes an optical path focusing system that modulates the pulse of a pulsed laser to carry out a group hole process on the metal thin film, so as to obtain a stable and efficient metal film group hole product.

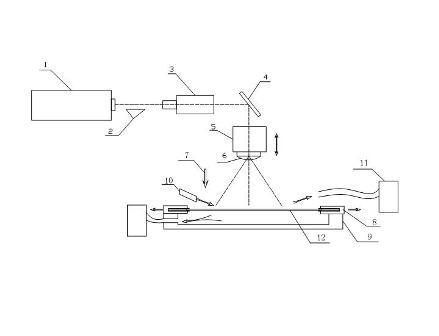

[0017] Such as figure 1 As shown, the device for making metal thin film group holes with ultrashort pulse laser, the output end of high frequency short pulse laser 1 is arranged with optical gate 2, and the high frequency short pulse laser has a wavelength of <355nm ultraviolet or deep ultraviolet and a pulse width between 100fs ~ 100ns, frequency 10KHz ~ 50MHz laser, the output end of the shutter 2 is provided with a beam expander mirror 3, the output end of the beam expander mirror 3 is arranged with a 45-degree total reflection mirror 4, and the output end of the 45-degree total reflection mirror 4 A vibrating mirror 5 and a scanning field mirror 6 are arranged in sequence. The scanning field mirror 6 is facing the working platform 9. A CCD al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com