Patents

Literature

65 results about "Ultrasonic drilling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

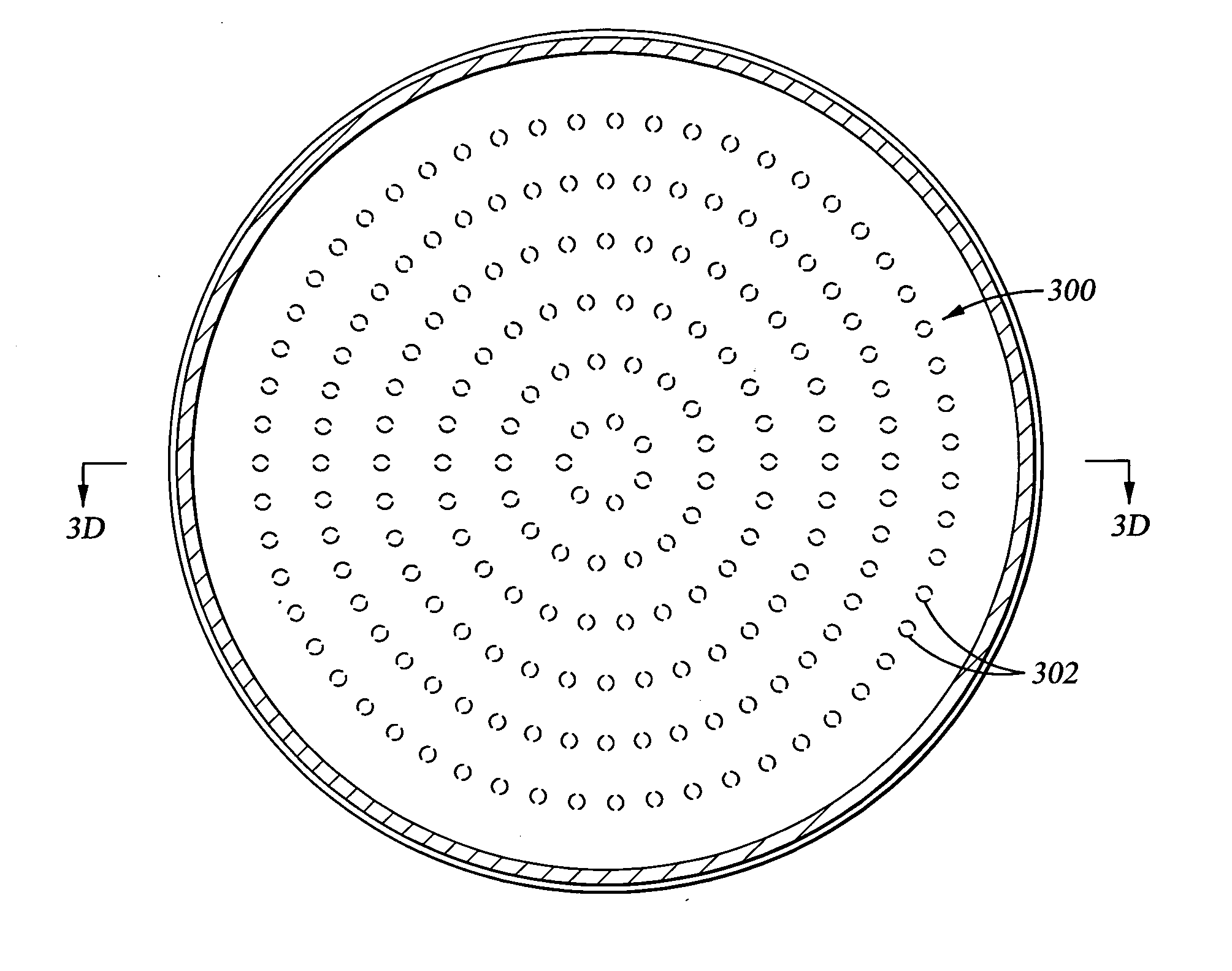

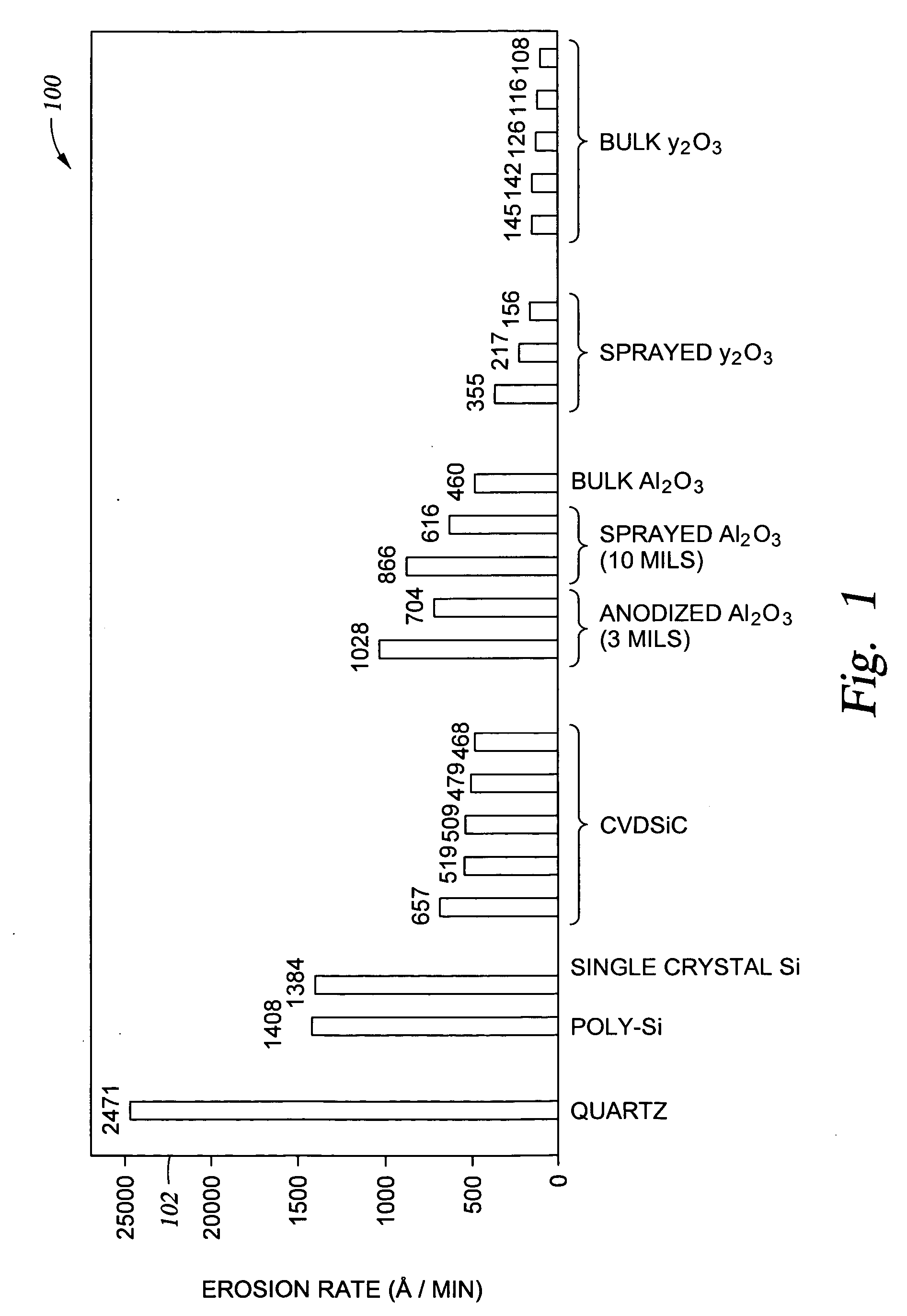

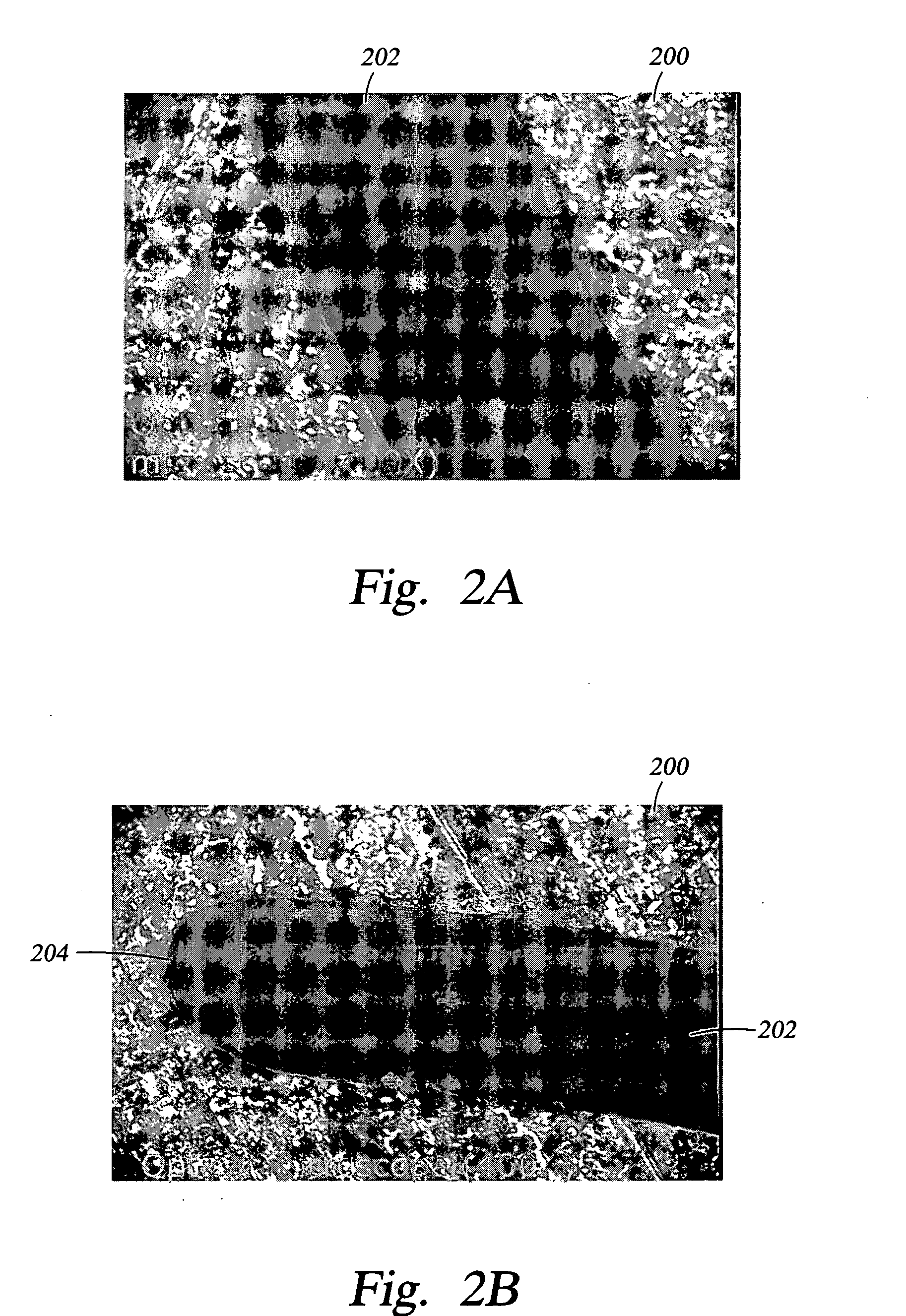

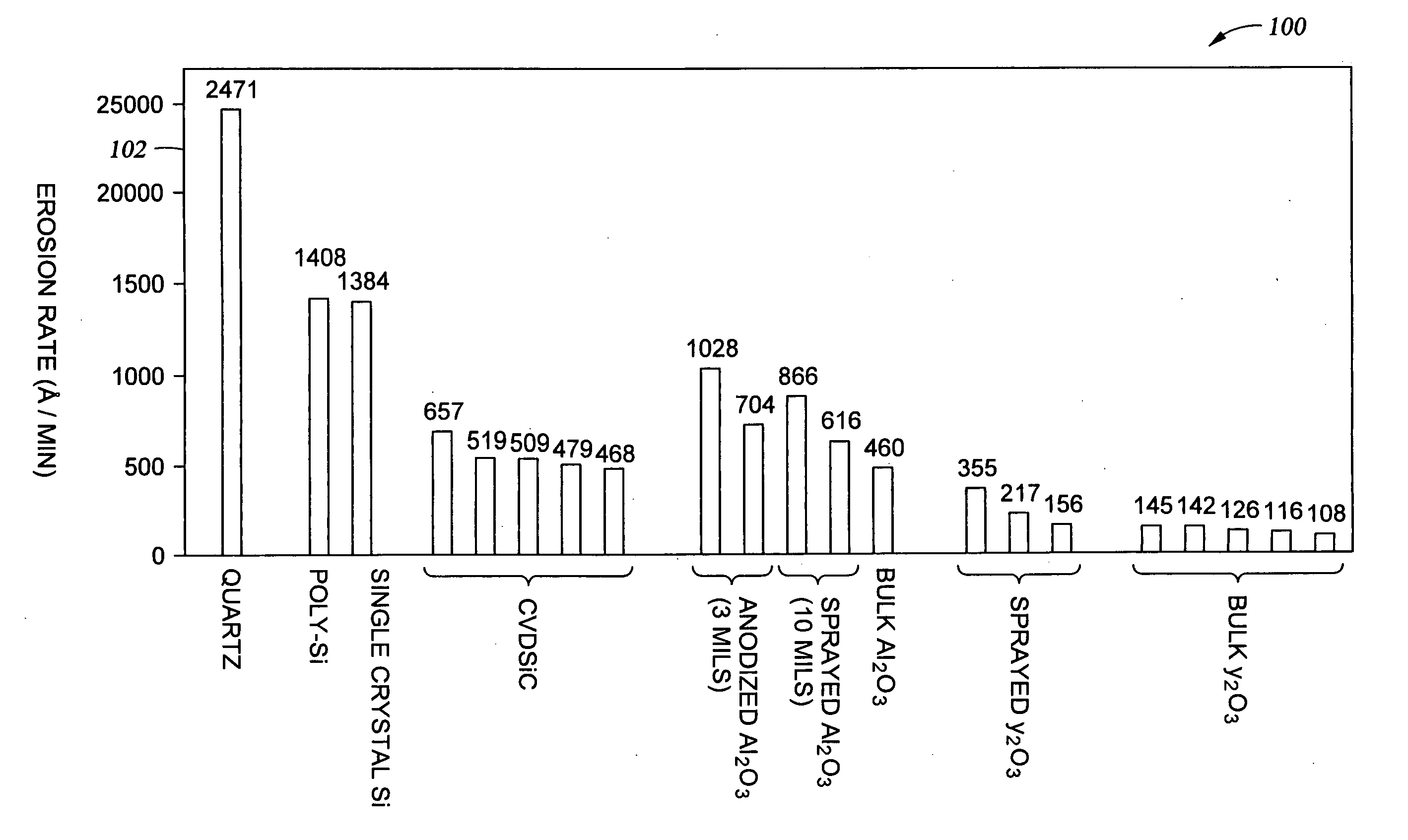

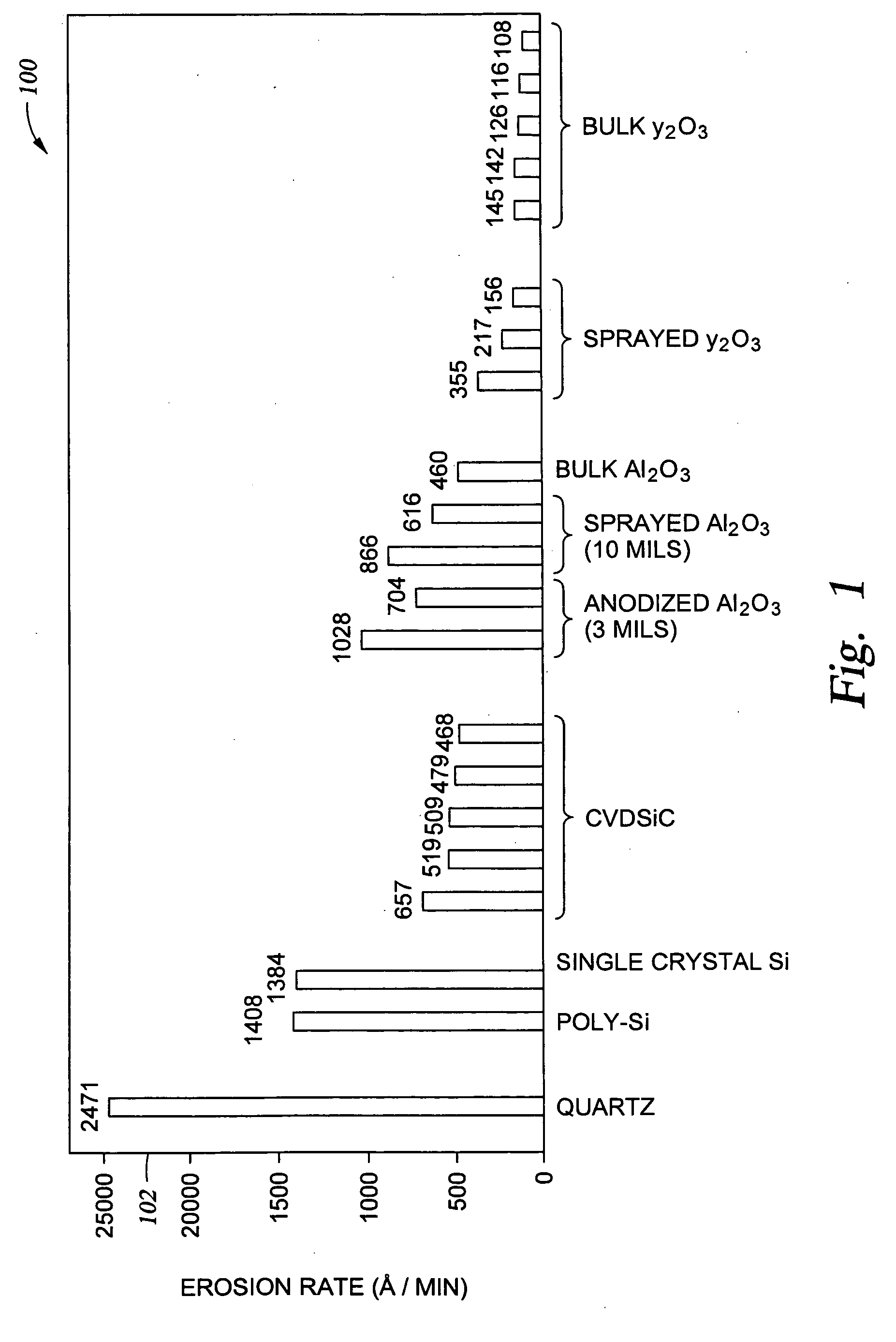

Gas distribution plate fabricated from a solid yttrium oxide-comprising substrate

InactiveUS20050056218A1Extended service lifePromote resultsAfter-treatment apparatusElectric discharge tubesVolumetric Mass DensityYttrium

Disclosed herein is a gas distribution plate for use in a gas distribution assembly for a processing chamber, where the gas distribution plate is fabricated from a solid yttrium oxide-comprising substrate, which may also include aluminum oxide. The gas distribution plate includes a plurality of through-holes, which are typically crescent-shaped. Through-holes which have been formed in the solid yttrium oxide-comprising substrate by ultrasonic drilling perform particularly well. The solid yttrium oxide-comprising substrate-typically comprises at least 99.9% yttrium oxide, and has a density of at least 4.92 g / cm3, a water absorbency of about 0.02% or less, and an average grain size within the range of about 10 μm to about 25 μm. Also disclosed herein are methods for fabricating and cleaning the yttrium oxide-comprising gas distribution plate.

Owner:APPLIED MATERIALS INC

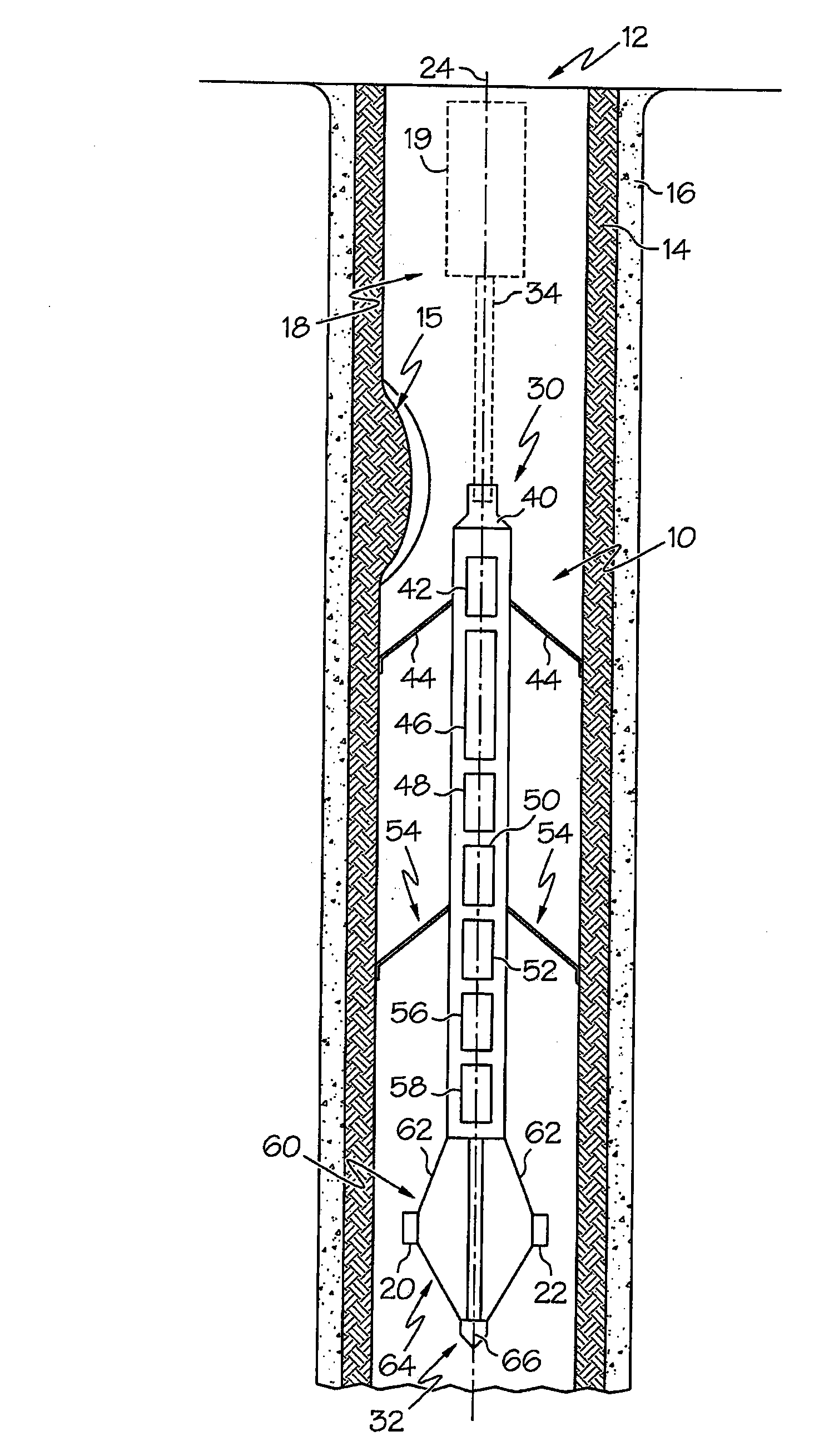

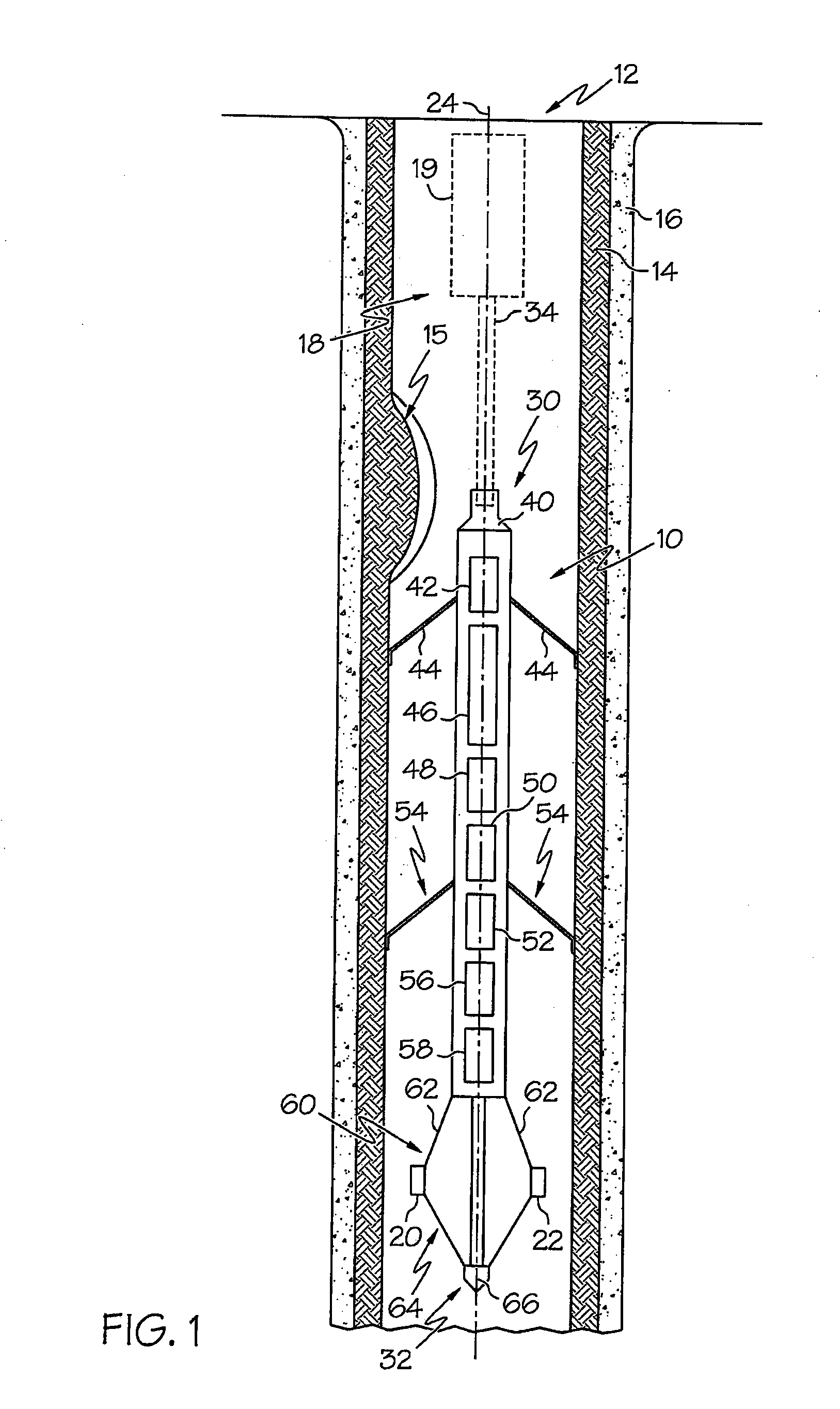

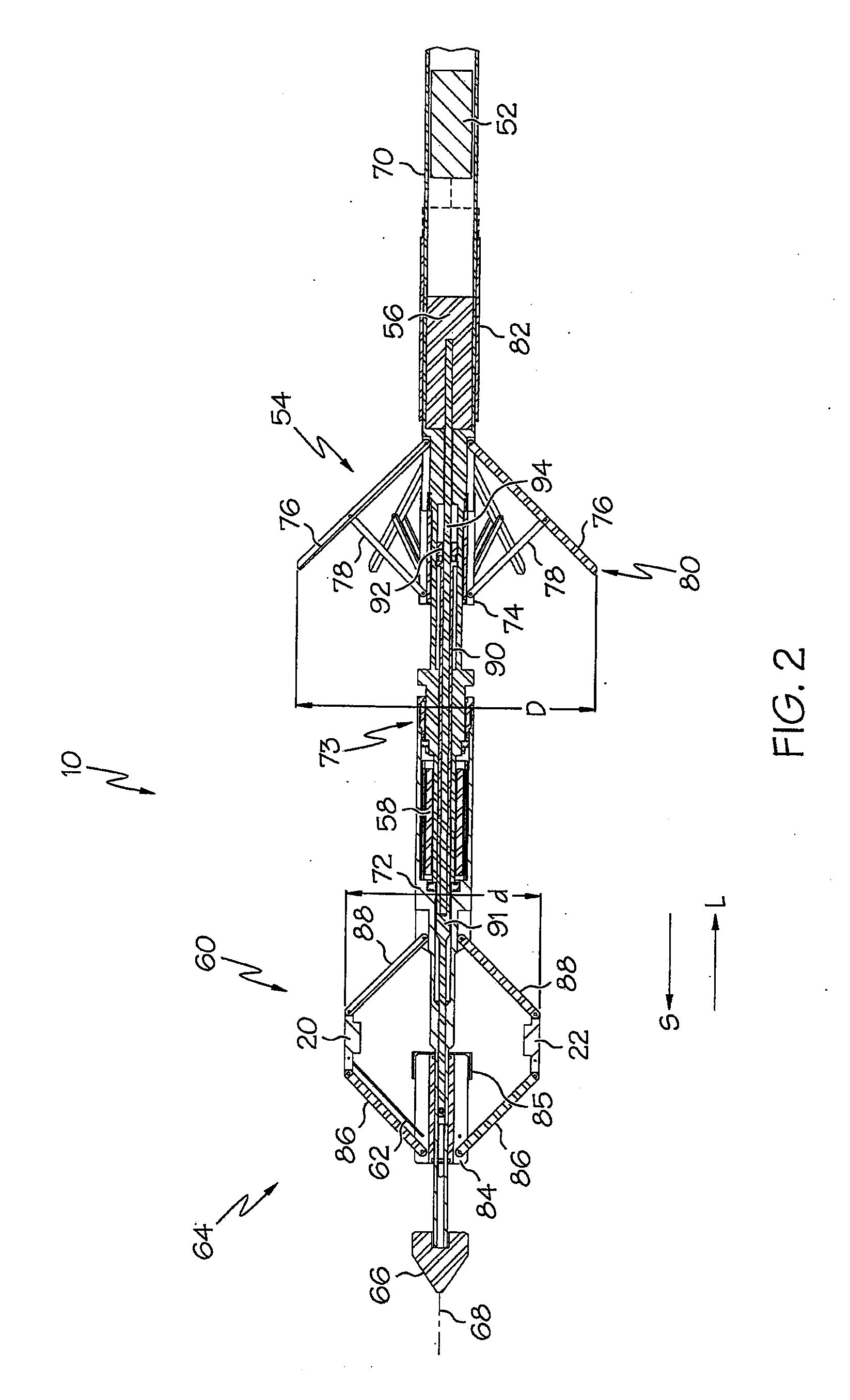

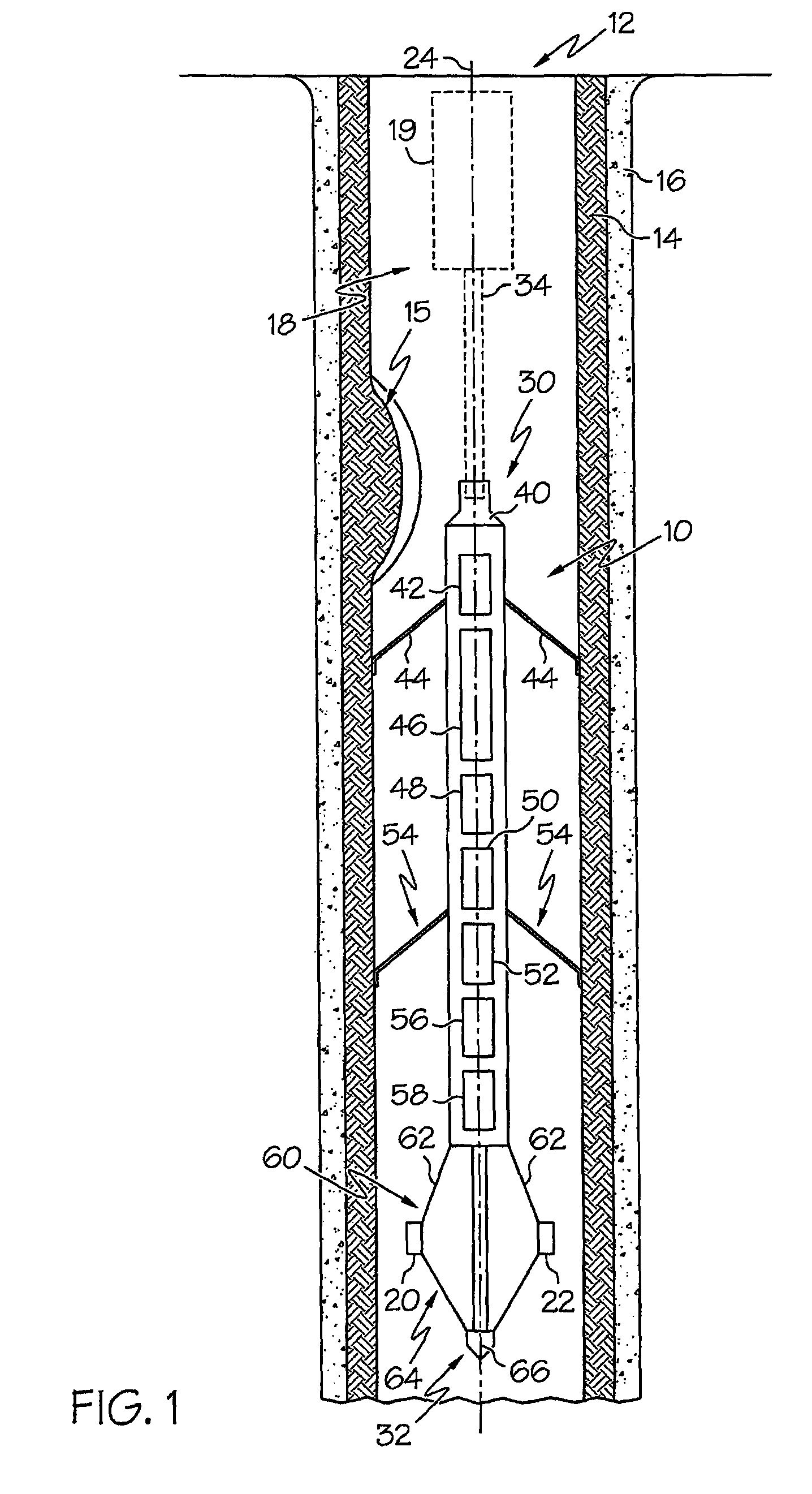

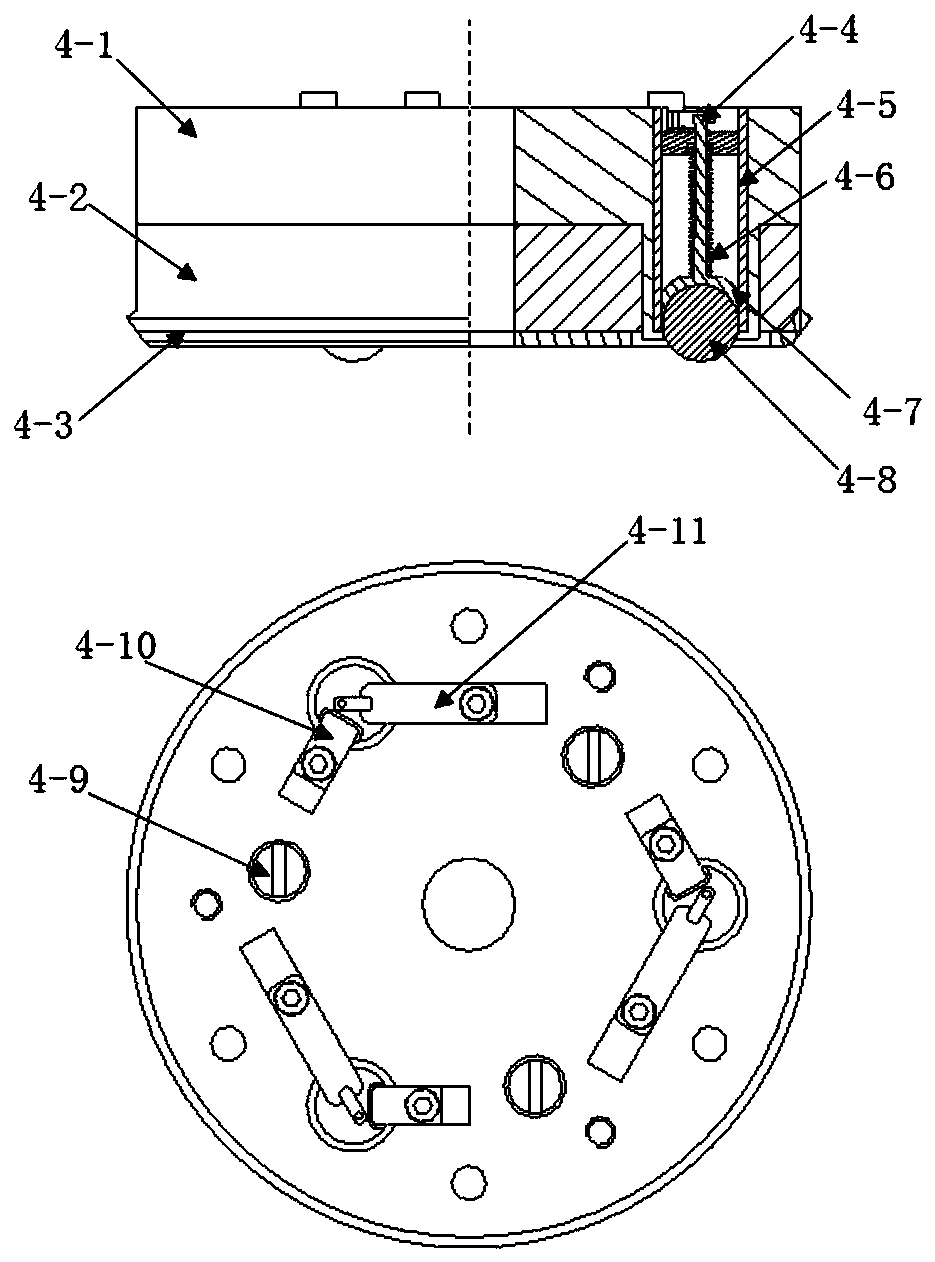

Folding ultrasonic borehole imaging tool

A borehole logging tool includes a housing oriented along a longitudinal axis, and a centralizer assembly that positions the housing substantially at the center of the borehole. In one example, the centralizer assembly includes a plurality of centralizer arms radially extendable outward from the longitudinal axis. The borehole logging tool further includes a scanning head that rotates a plurality of scanning sensors axially within the borehole about the longitudinal axis. The scanning head further includes a plurality of linkage arms coupled to the plurality of scanning sensors such that the scanning sensors are radially extendable outward from the longitudinal axis. The borehole logging tool further includes an extension assembly adapted to substantially concurrently control the radial extension of the centralizer arms and the plurality of sensors.

Owner:BAKER HUGHES OILFIELD OPERATIONS LLC

Cleaning method used in removing contaminants from a solid yttrium oxide-containing substrate

InactiveUS20070151581A1Extended service lifePromote resultsAfter-treatment apparatusElectric discharge tubesEngineeringVolumetric Mass Density

Disclosed herein is a gas distribution plate for use in a gas distribution assembly for a processing chamber, where the gas distribution plate is fabricated from a solid yttrium oxide-comprising substrate, which may also include aluminum oxide. The gas distribution plate includes a plurality of through-holes, which are typically crescent-shaped. Through-holes which have been formed in the solid yttrium oxide-comprising substrate by ultrasonic drilling perform particularly well. The solid yttrium oxide-comprising substrate typically comprises at least 99.9% yttrium oxide, and has a density of at least 4.92 g / cm3, a water absorbency of about 0.02% or less, and an average grain size within the range of about 10 μm to about 25 μm. Also disclosed herein are methods for fabricating and cleaning the yttrium oxide-comprising gas distribution plate.

Owner:APPLIED MATERIALS INC

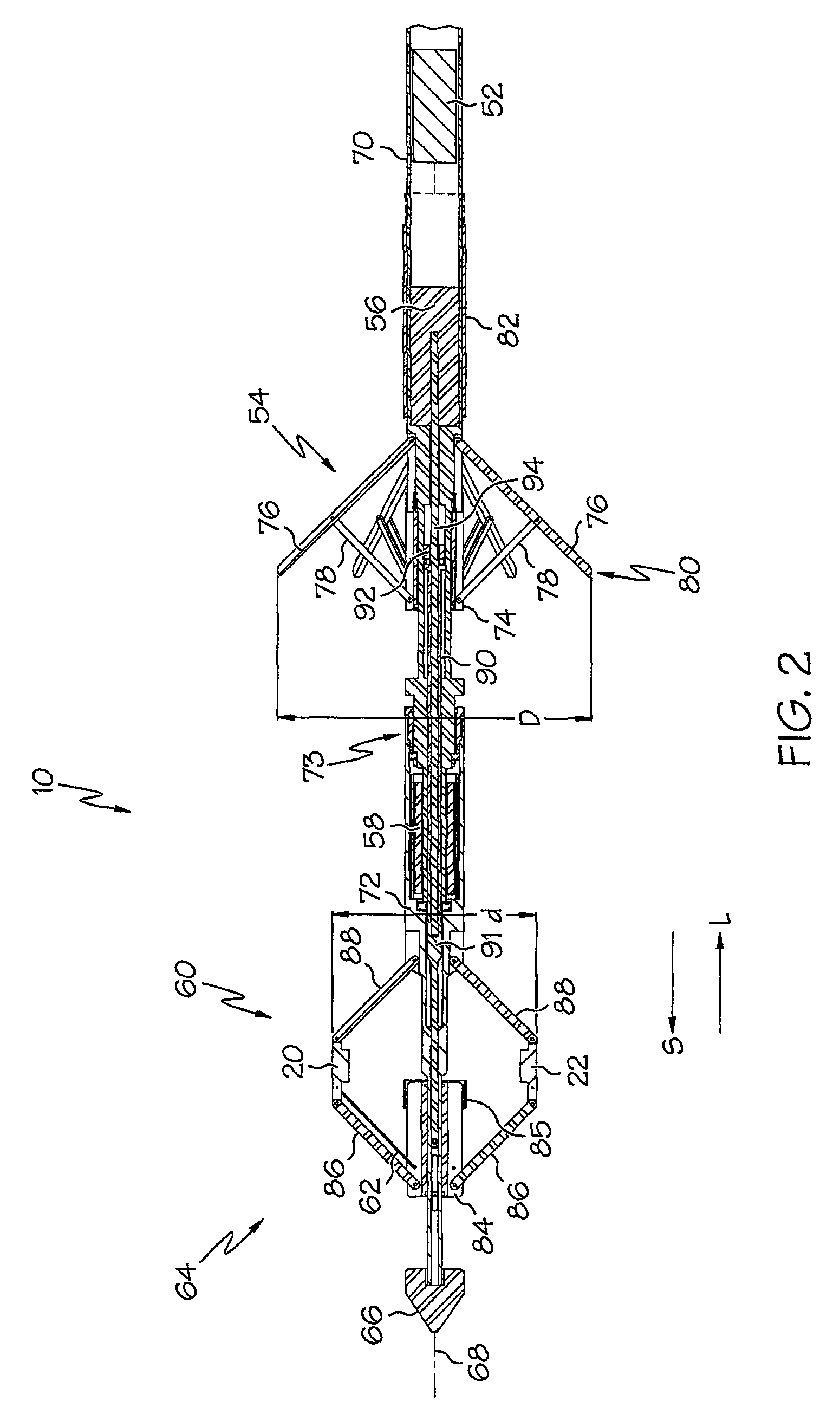

Ultrasonic/sonic mechanism of deep drilling (USMOD)

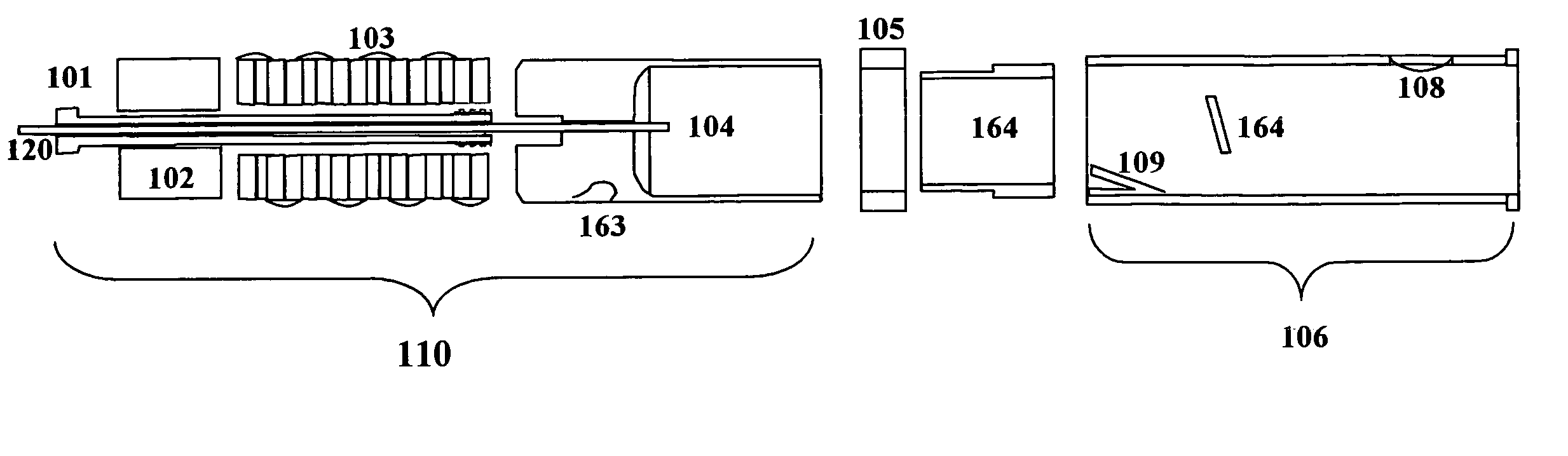

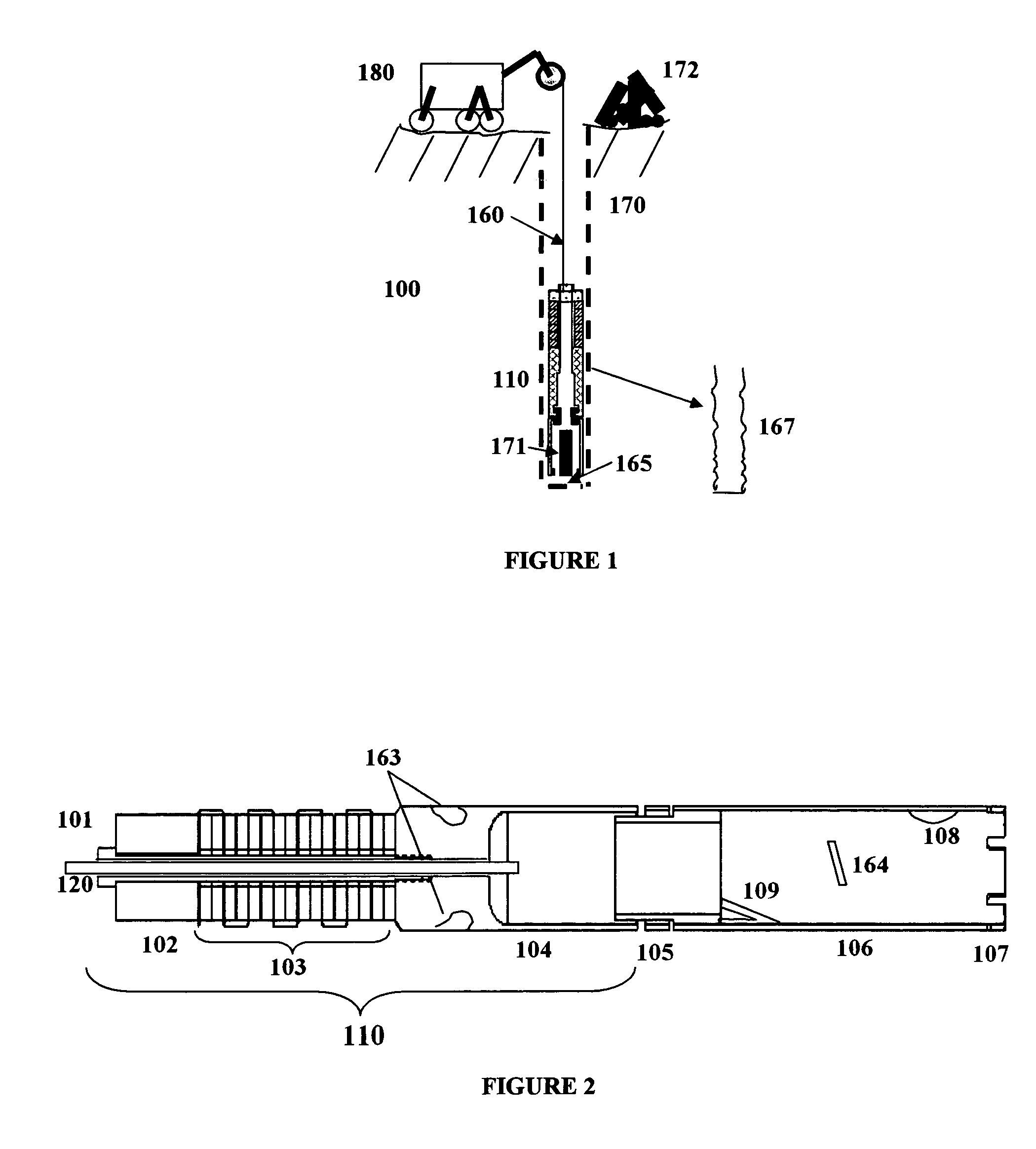

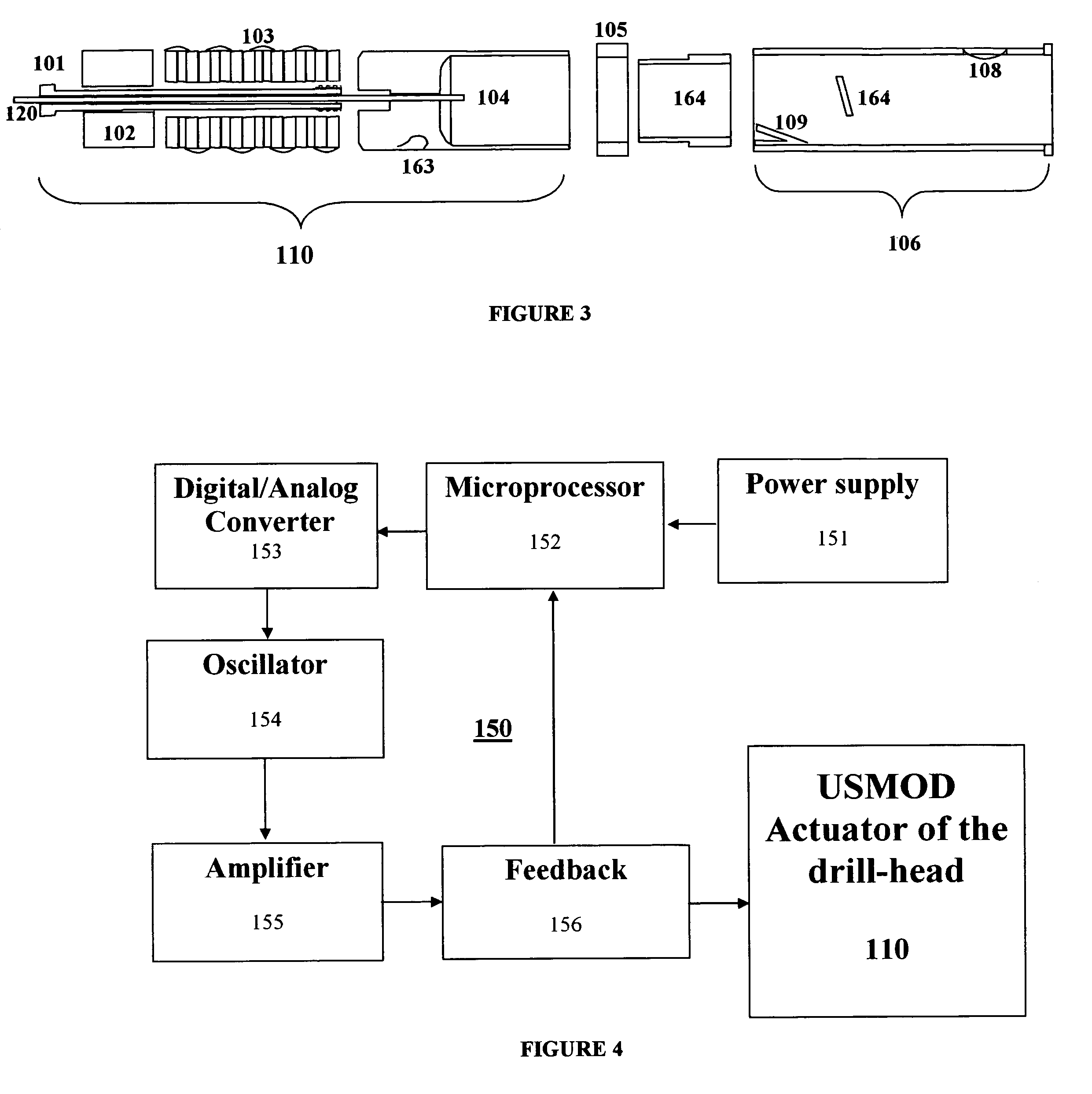

The present invention provides an ultrasonic and sonic mechanism of deep drilling (USMOD) that is driven by a vibrating actuator and operates in a similar manner to the gopher with regards to drilling debris removal. The actuator induces vibration in the form of a hammering actuation. The mechanism consists of a penetration bit with a diameter that is the same or larger than the actuator. The embodiment of the invention that is disclosed herein emulates a gopher. This ultrasonic gopher is lowered down into the produced borehole, cores the medium, breaks and holds the core, and finally extracts and deploys the core.A USMOD device consists of power drive and a drill-head. The power driver generates ultrasonic pulses to activate the USMOD mechanism and it allows optimized use of power by duty cycling the signal. The drill-head consists of an actuator, free mass and a penetration bit. The actuator consists of a vibration source and a horn that amplifies the amplitude of the vibration. The horn has a cylindrical cross-section to produce a drill-head that has cylindrical configuration and eliminate undesirable trapping of extracted soil and powdered cuttings. A cavity inside the tubular-shape horn provides space for packaging miniature instrumentation and sensors. The actuator activates an integrated free-mass that hammers the penetration bit, where the free-mass operates as a transformer to lower the vibration frequency to produce the hammering action. In one implementation of the USMOD it is designed to contain a trap for collection of upward traveling dust, debris and powdered cuttings.

Owner:BAR COHEN YOSEPH +4

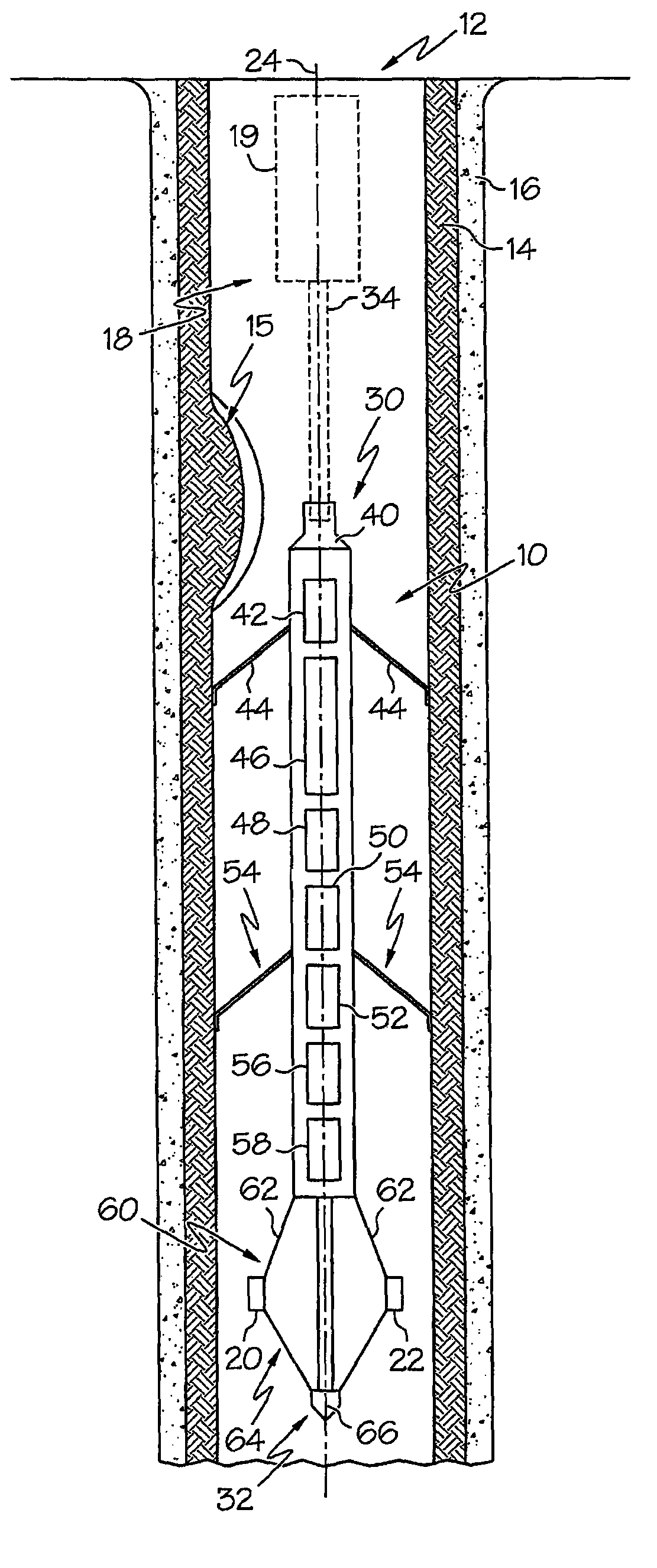

Folding ultrasonic borehole imaging tool

A borehole logging tool includes a housing oriented along a longitudinal axis, and a centralizer assembly that positions the housing substantially at the center of the borehole. In one example, the centralizer assembly includes a plurality of centralizer arms radially extendable outward from the longitudinal axis. The borehole logging tool further includes a scanning head that rotates a plurality of scanning sensors axially within the borehole about the longitudinal axis. The scanning head further includes a plurality of linkage arms coupled to the plurality of scanning sensors such that the scanning sensors are radially extendable outward from the longitudinal axis. The borehole logging tool further includes an extension assembly adapted to substantially concurrently control the radial extension of the centralizer arms and the plurality of sensors.

Owner:BAKER HUGHES OILFIELD OPERATIONS LLC

Design of main shaft of rotary ultrasonic machine

InactiveCN102452131AImprove surface qualityDoes not change chemical/electrical propertiesStone-like material working toolsDevice formEngineering

The invention relates to a design of a main shaft of a rotary ultrasonic machine, in particular to an efficient device formed by combining an ultrasonic machine tool and a general machine tool. The efficient device can finish the drilling and tapping of ceramic materials. According to the characteristics of ultrasonic vibration, the main shaft of the rotary ultrasonic machine is designed referring to the structure and working principle of the existing machine tool, and the working principle and rotary ultrasonic drilling material removing principle of the rotary ultrasonic machine are analyzed to enable the rotary ultrasonic machine to finish the drilling and tapping of ceramic materials. Ultrasonic waves are applied to a wire saw, and materials are removed by the instantaneous impact of abrasive materials, so that the surface quality of the workpiece cut by the wire saw is superior to that of the workpiece cut by a common wire saw.

Owner:褚桂君

All-electric ultrasonic drilling machine and drilling method thereof

PendingCN107503687AQuick responseLarge outputPiezoelectric/electrostriction/magnetostriction machinesConstructionsElectricityHigh energy

The invention discloses an all-electric ultrasonic drilling machine and a drilling method thereof. The all-electric ultrasonic drilling machine comprises a rotating mechanism, a feeding mechanism, an ultrasonic vibrating mechanism, a supporting mechanism and a control system. According to the destruction by ultrasonic frequency vibrational impact and rock resonance, ultrasonic frequency vibrating force, pressure and rotational force are combined so that cracks of rock propagate at higher speed to arrive at resonance-fatigue breaking, and this mode has the advantages of higher rock-breaking efficiency, higher energy utilization rate and low slurry usage. The ultrasonic frequency vibrational force generated by piezoelectric ceramic is applied to rock through the ultrasonic vibrating mechanism, rock-breaking efficiency of the drilling machine is greatly improved, the service life of a drill bit is greatly extended, and ultrasonic frequency vibrational drilling is achieved. In normal rotational vibrational drilling, the all-electric ultrasonic drilling machine of the invention can provide stable resonance-fatigue destruction under a frequency the same the inherent frequency of rock, hard rock breaking strength is reduced, bulk breaking is achieved, drilling speed is greatly increased, and drilling cost is greatly reduced.

Owner:JILIN UNIV

Rotary ultrasonic drilling transverse vibration stability domain predicting method

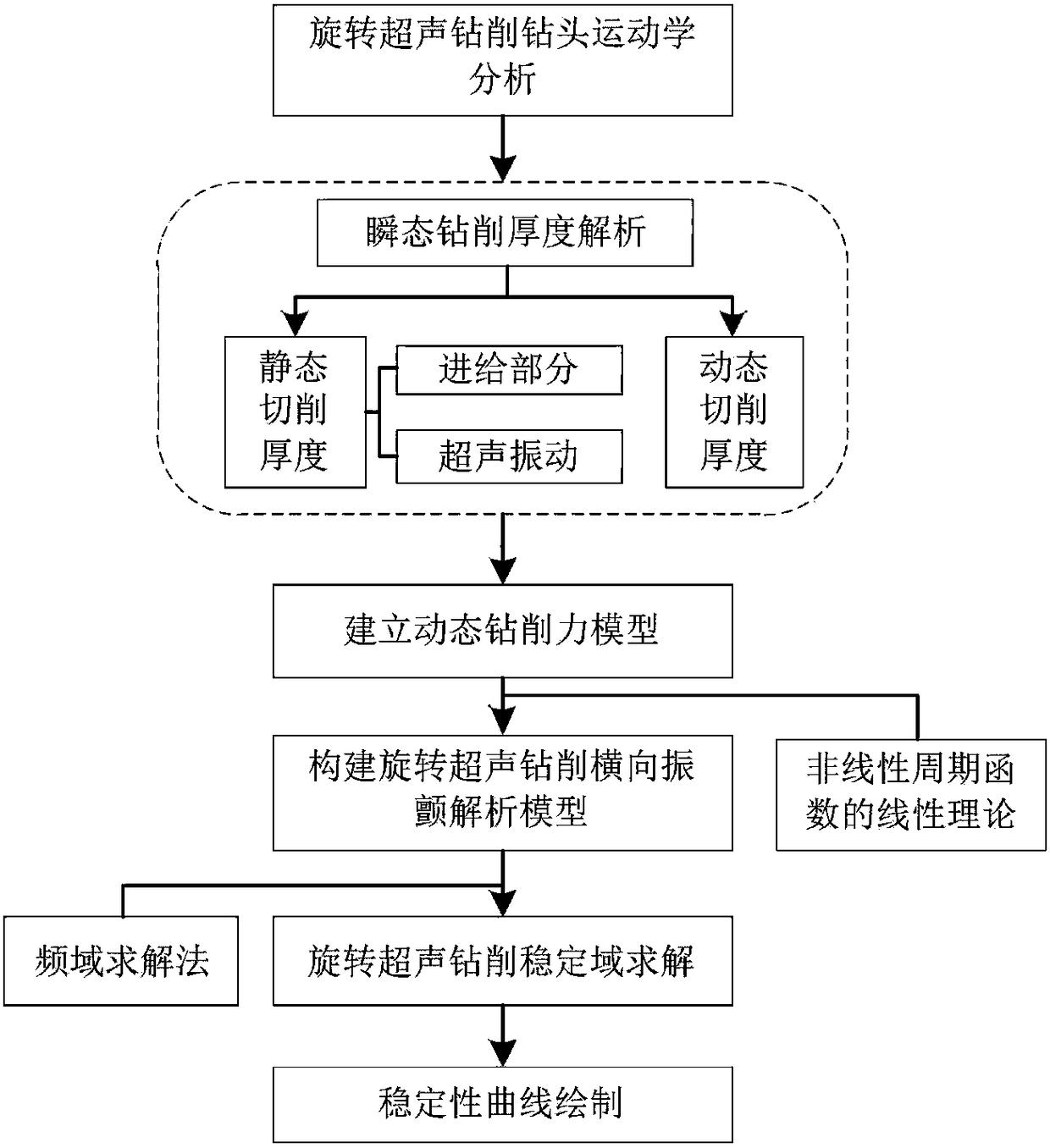

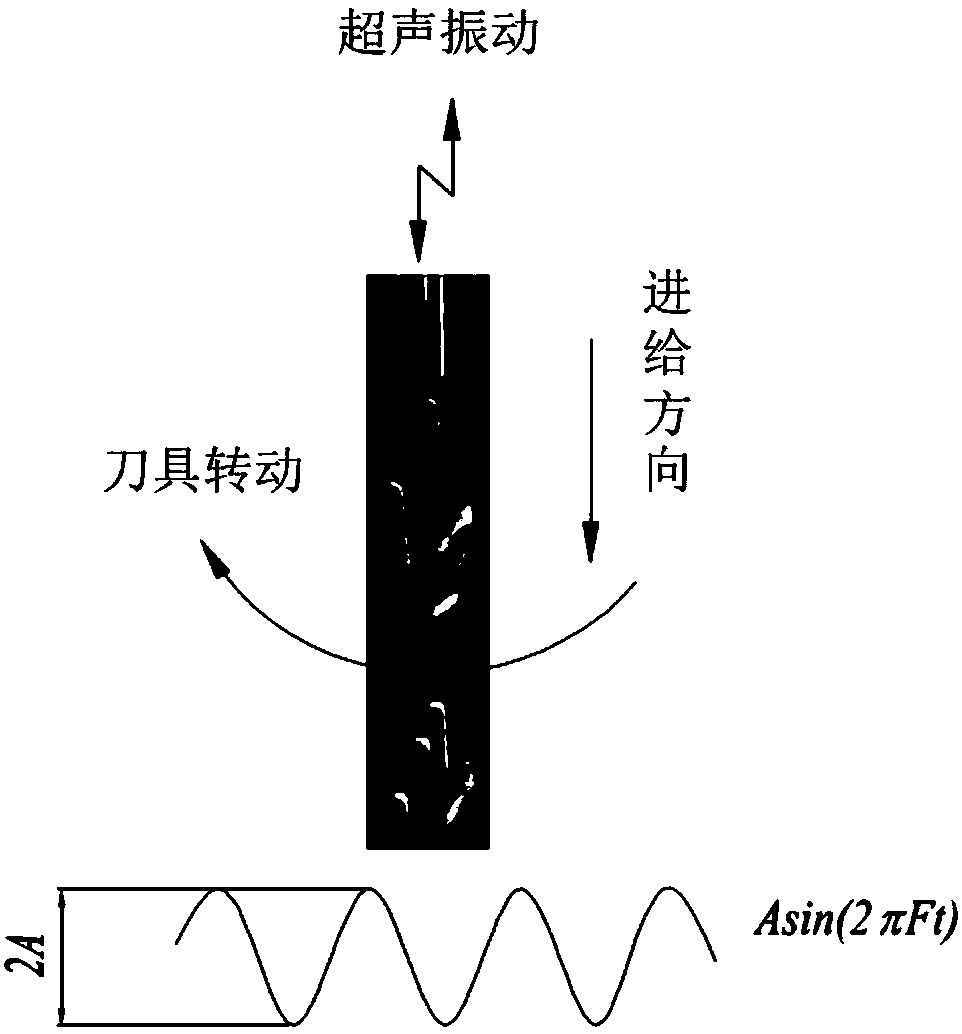

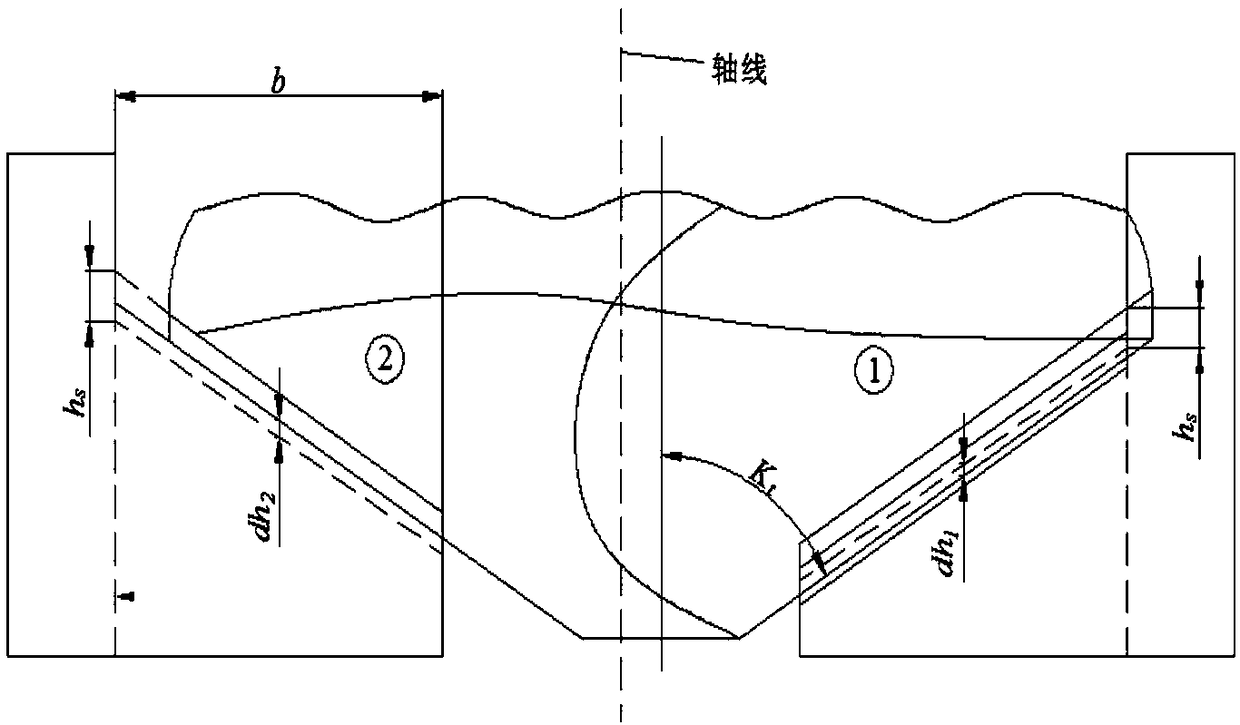

ActiveCN108256273ASolve the problem that there is no solution method for the stable domain of rotary ultrasonic drillingAchieving Lateral Flutter Stability Domain PredictionGeometric CADDesign optimisation/simulationKinematicsUltrasonic vibration

The invention provides a rotary ultrasonic drilling transverse vibration stability domain predicting method. The method includes the steps of firstly, acquiring the expression of axial feeding and ultrasonic vibration parts in static drilling thickness on the basis of rotary ultrasonic drilling bit kinematics analysis, and using dynamic drilling thickness to build a transient drilling thickness model; secondly, using a drilling thickness exponential function method to build a dynamic drilling force relation; thirdly, according to the linear theory of a nonlinear periodic function, building a transverse vibration analysis model under the machining manner; fourthly, using a frequency domain solving method to solve the models above to obtain the expression of a critical drilling depth and corresponding rotation speed; fifthly, using MATLAB software to program and draw a rotary ultrasonic drilling transverse vibration stability curve to achieve stability domain predicting.

Owner:NANJING UNIV OF SCI & TECH

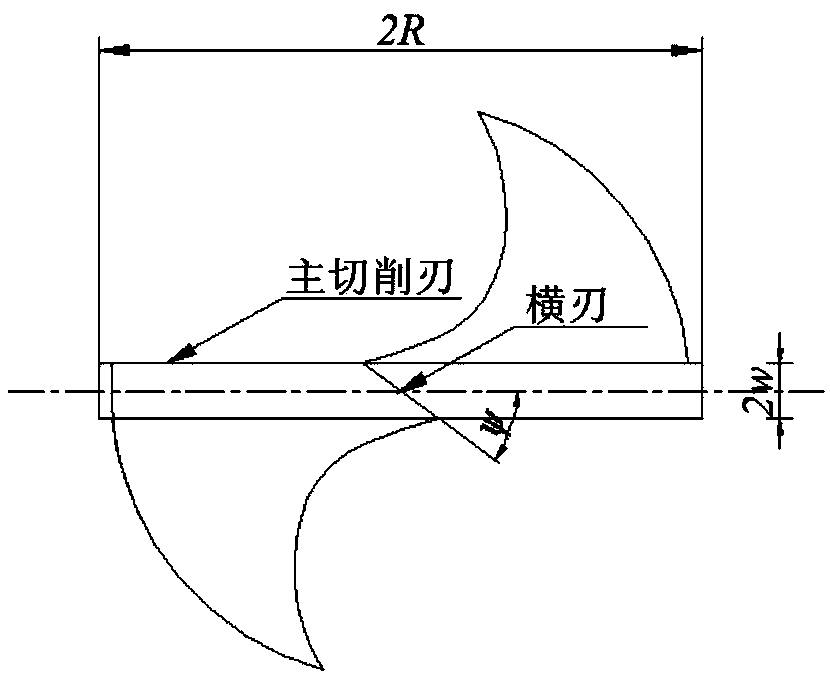

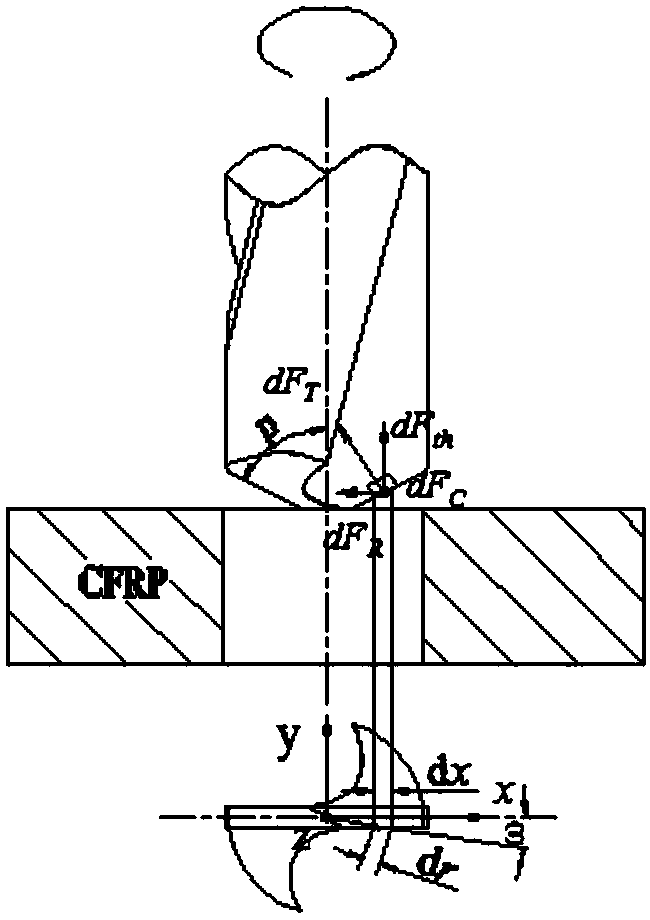

Method for predicting axial force of whole process of rotary ultrasonic drilling of CFRP/Al laminated structure

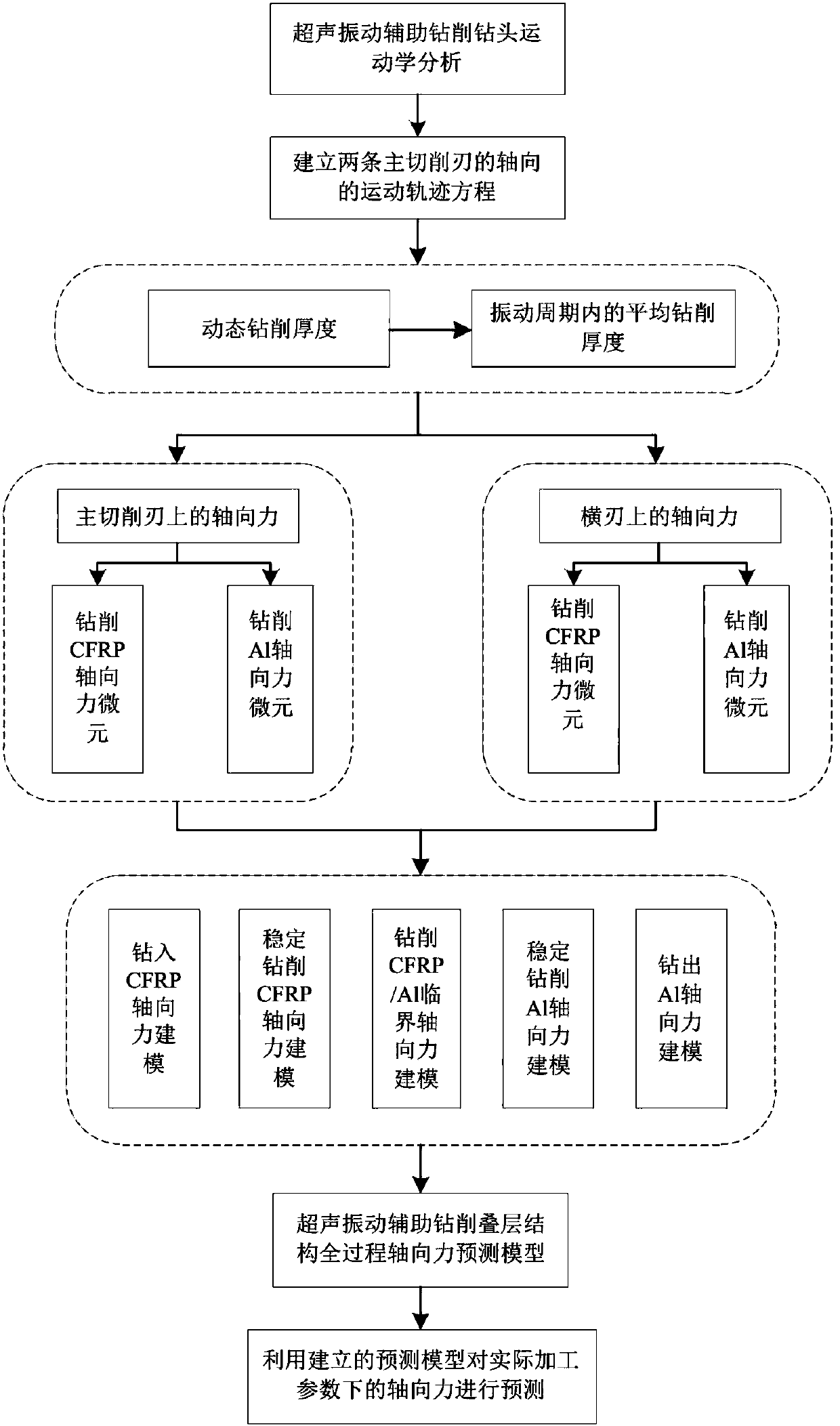

InactiveCN107932188AIn line with the actual processing conditionsImprove forecast accuracyMeasurement/indication equipmentsEngineeringAxial force

The invention provides a method for predicting axial force of the whole process of rotary ultrasonic drilling of a CFRP / Al laminated structure. The method comprises the steps that firstly, an axial motion trajectory equation of two main cutting edges is established, and a dynamic drilling thickness in the drilling process and an average drilling thickness in a vibration period are obtained; secondly, the axial force on the main cutting edges and the axial force on a transverse edge are analyzed and calculated, infinitesimal expressions of the axial force on the main cutting edges and the axialforce on the transverse edge during CFRP drilling and infinitesimal expressions of the axial force on the main cutting edges and the axial force on the transverse edge during Al drilling are established correspondingly; and then the drilling whole process is divided into a drilling-in CFRP stage, a stable CFRP drilling stage, a CFRP / Al drilling critical stage, a stable Al drilling stage and a drilling-out Al stage, aiming at machining characteristics of all the stages, axial force prediction models of five stages are established correspondingly, and finally, predicting of the axial force of the whole process of rotary ultrasonic drilling of the CFRP / Al laminated structure is achieved.

Owner:NANJING UNIV OF SCI & TECH

Preparation method of doped polarization-maintaining optical fiber

InactiveCN106082628AImprove flatnessHigh Laser Slope EfficiencyGlass shaping apparatusCoatingsPolarization-maintaining optical fiberSolid particle

The invention discloses a preparation method of a doped polarization-maintaining optical fiber. The method includes the following specific steps of adding nanopore silicon dioxide powder to a rare earth and co-doped ion inorganic salt solution to form a suspension, centrifugally separating solid particles and liquid at high speed, conducting drying, dewatering and granulating to form ion adsorption silicon dioxide particles, conducting isostatic compaction and the like to obtain a cylindrical rare earth doped silicon oxide core bar, conducting drilling, grinding and polishing, and establishing a uniform porous silicon dioxide thin film layer on the inner wall of a core bar tube through a nanometer assembling technology. Silicon dioxide nanometer particles and doping ions are mixed in a solution, the uniformity of the doping ions in the radial direction and the axial direction of the core bar is quite high, the fiber core refraction rate profile has high flatness, the fiber core numerical value aperture precision can be adjusted, the optical fiber has high laser slope efficiency, the stress area of the rare earth ion doped optical fiber prefabricated bar in the ultrasonic drilling process can be effectively reduced by means of a multi-drilling method, and machining precision is high.

Owner:YANSHAN UNIV

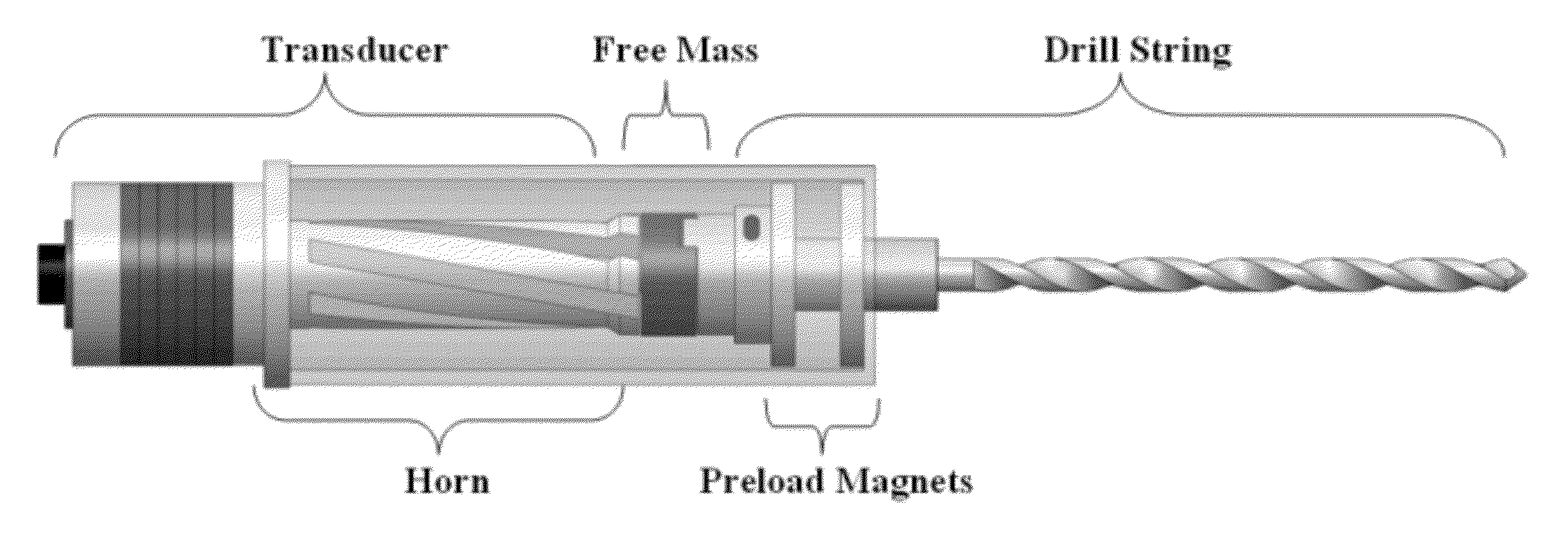

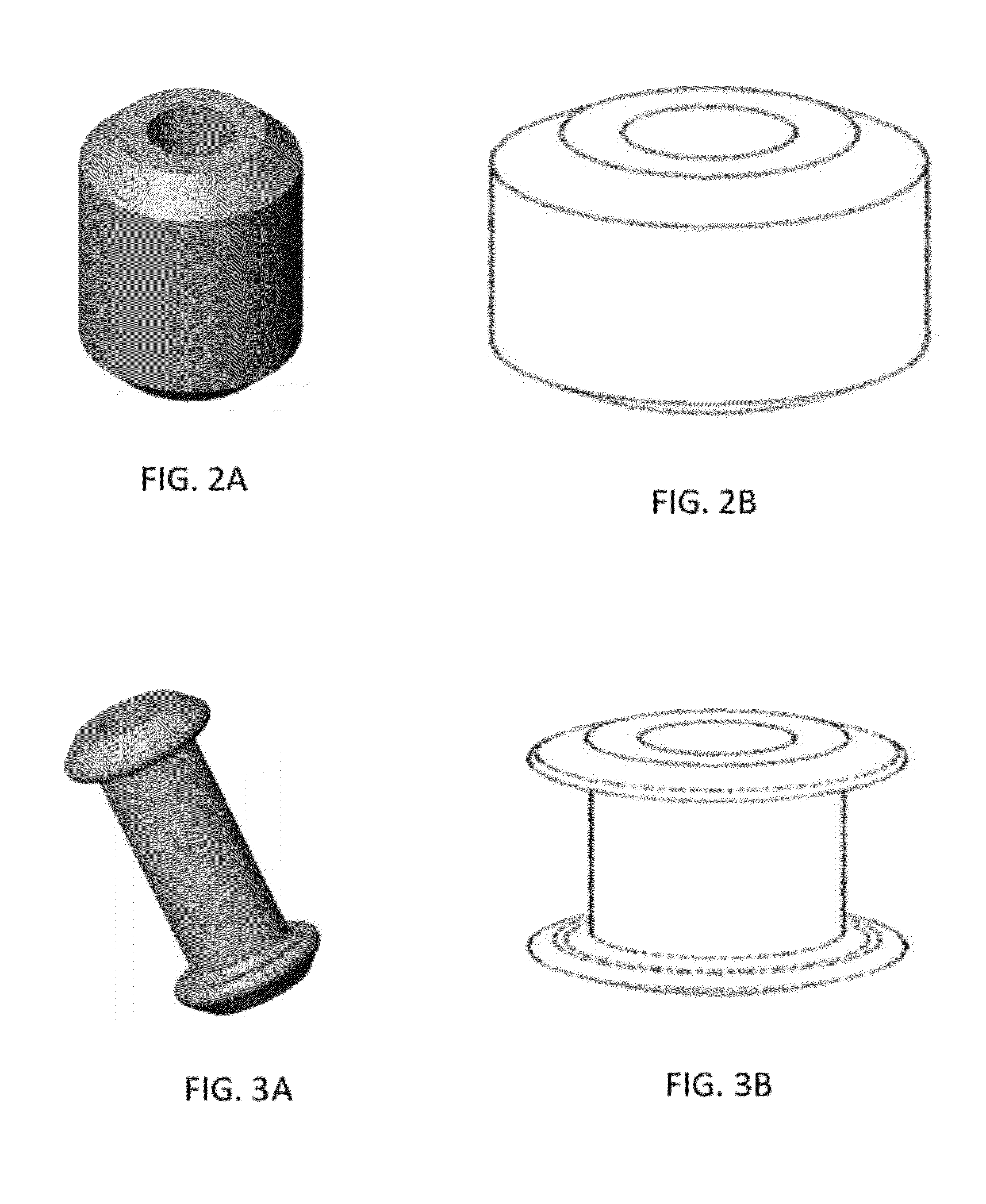

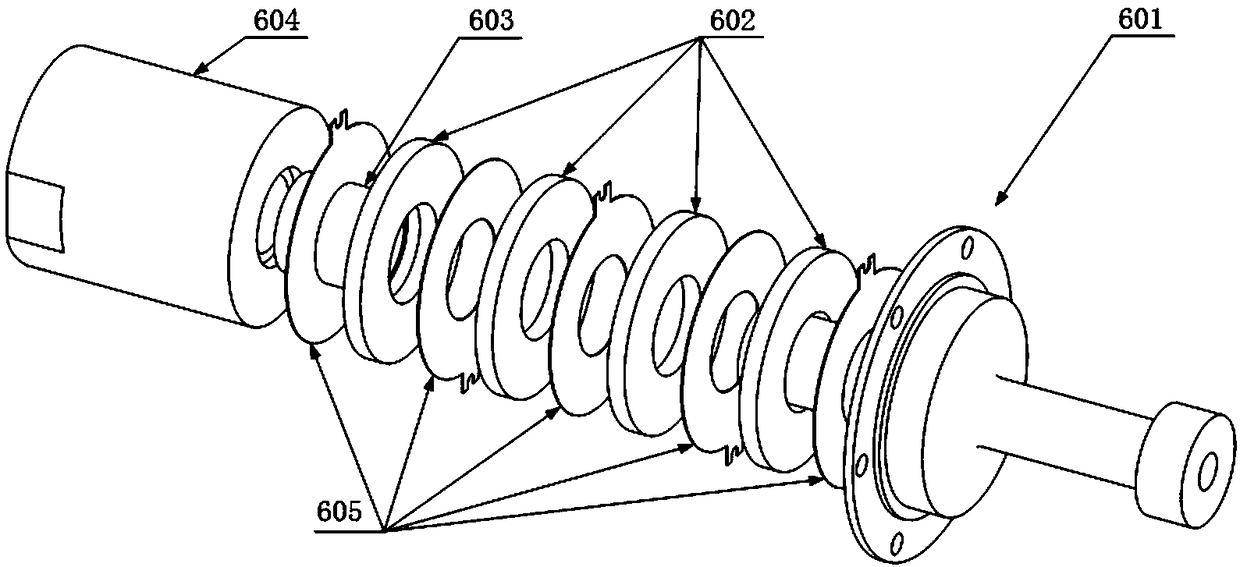

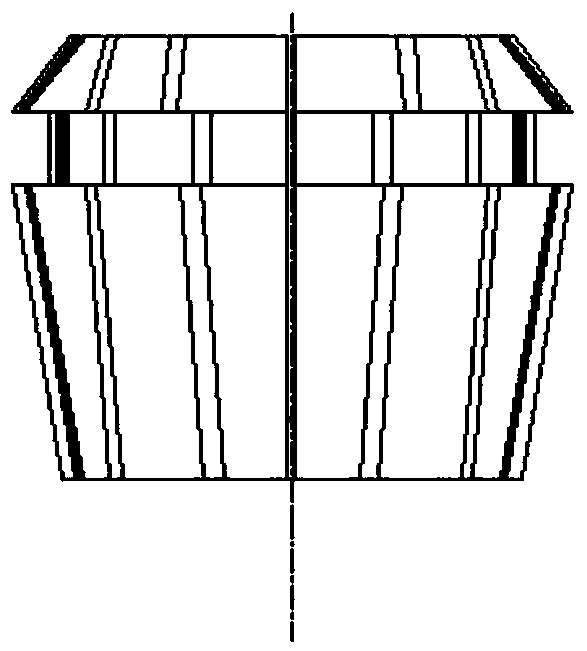

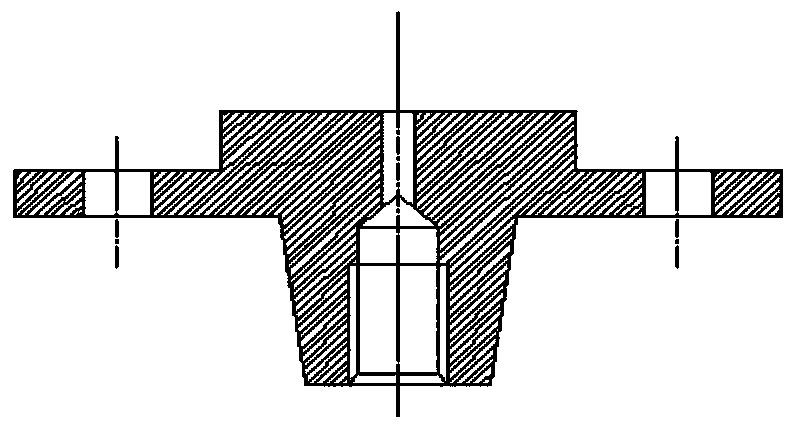

Free-mass and interface configurations of hammering mechanisms

InactiveUS20120037390A1Reduce distractionsMinimize jammingConstructionsReciprocating drilling machinesTransducerUltrasonic drilling

The design of the free-mass in an ultrasonic driller / corer (USDC) has been refined in order to improve the performance and operational reliability of the system. In one embodiment, the improvements in performance and operational reliability include decreasing the impact surface area of the free-mass to increase the transfer of impact energy from the piezoelectric transducer and reductions in the likelihood that the system will jam.

Owner:CALIFORNIA INST OF TECH

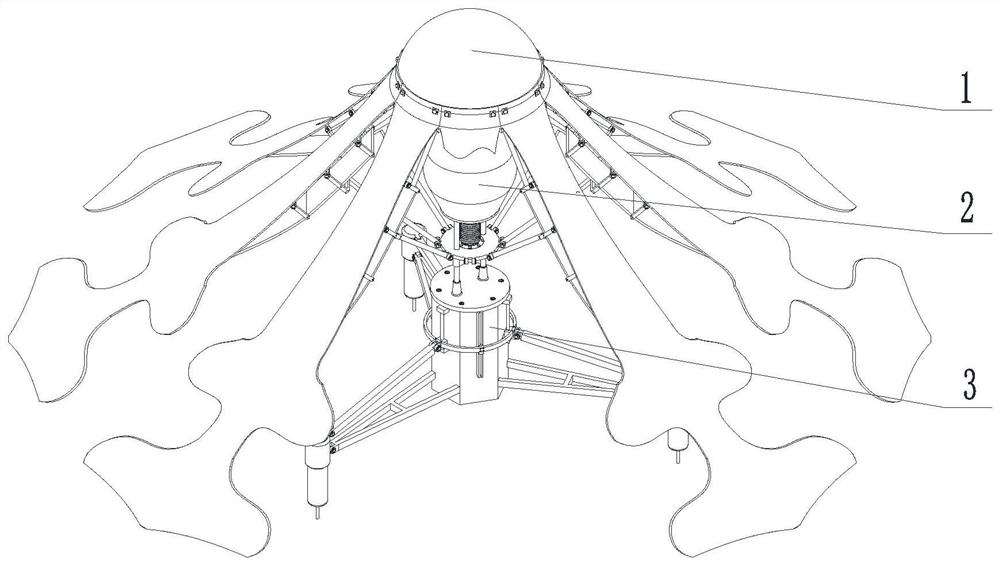

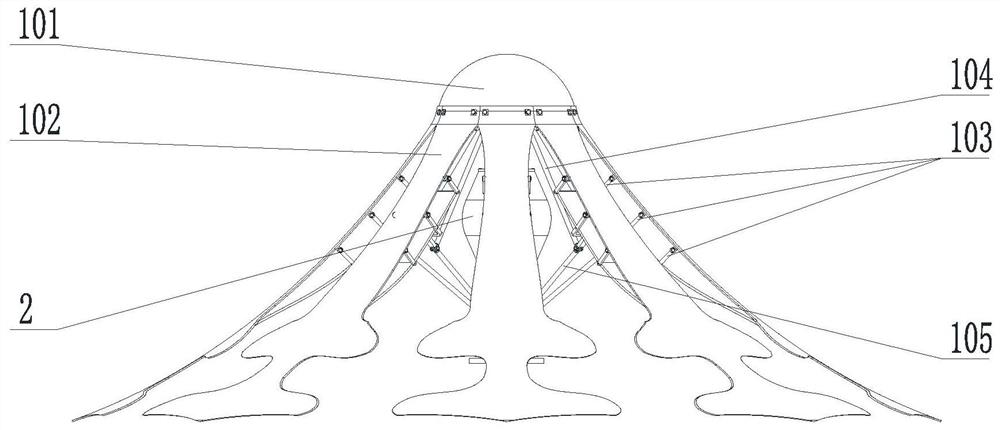

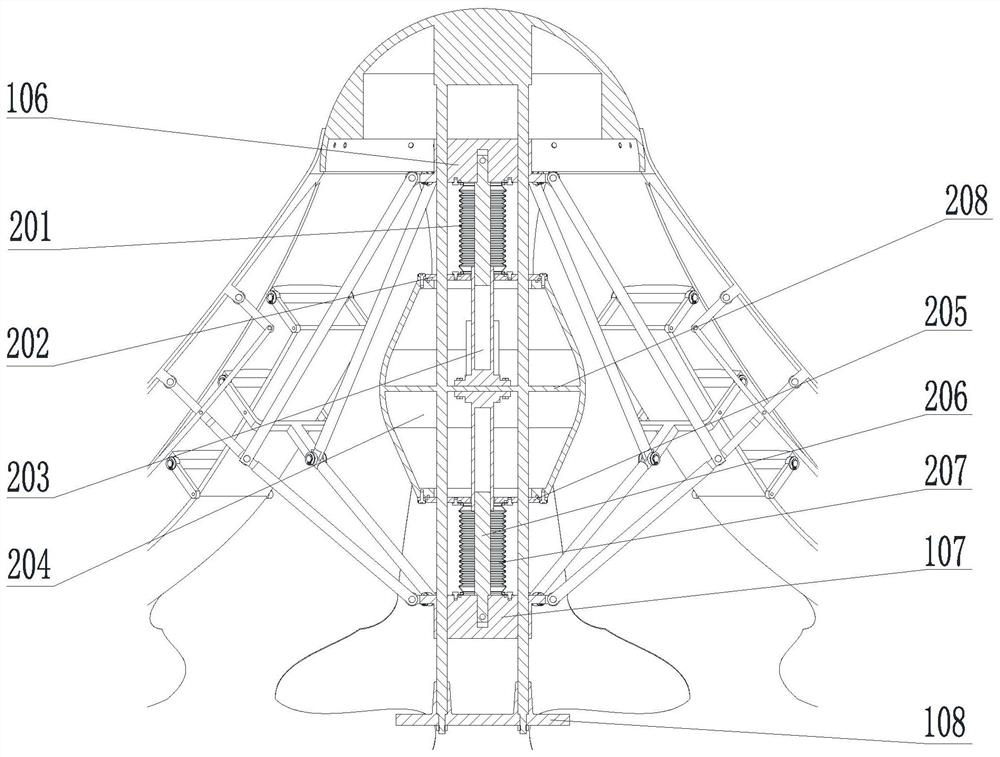

Jellyfish imitating swimming type seabed ultrasonic drilling sampling robot

ActiveCN112193389AAchieve swimmingEasy to adaptWithdrawing sample devicesPropulsive elements of non-rotary typeWhole bodyElectric machinery

A jellyfish imitating swimming type seabed ultrasonic drilling sampling robot comprises a jellyfish imitating swimming device, a central power cabin and an anchoring drilling device. The jellyfish imitating swimming device is similar to jellyfishes in appearance, the central power cabin is fixed to the middle of the jellyfish imitating swimming device, and the anchoring drilling device is fixed tothe lower portion of the jellyfish imitating swimming device. Two electric push rods in the central power cabin drive flexible tentacles on the outer side of the jellyfish imitating swimming device to swing so as to achieve swimming of the drilling sampling robot. When the anchoring drilling device moves, the anchoring drilling device is in a folded state; after the drilling sampling robot reaches a seabed rock bed, a linear motor on the outer side of the anchoring device adjusts an anchoring mechanism to enable the anchoring mechanism to be in a triangular supporting state, and an anchoringultrasonic drill penetrates into the seabed rock bed to enable the whole body to be anchored to the seabed. The drilling ultrasonic drill extends downwards to be close to a seabed to carry out sampling work. The robot has a stable and flexible biomorphic structure and an efficient drilling sampling mechanism with strong adaptability, and can flexibly adapt to complex submarine topographic environments.

Owner:SHANDONG UNIV OF SCI & TECH

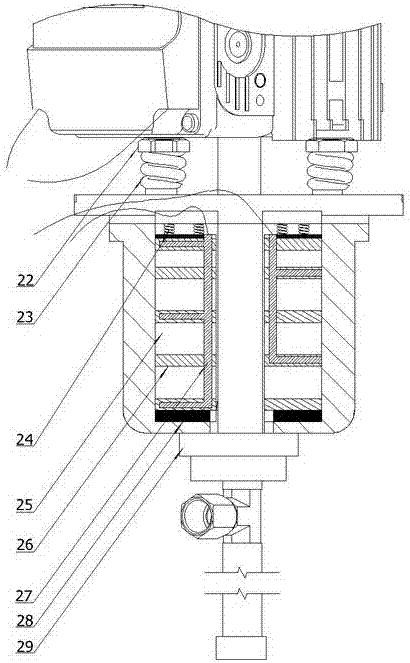

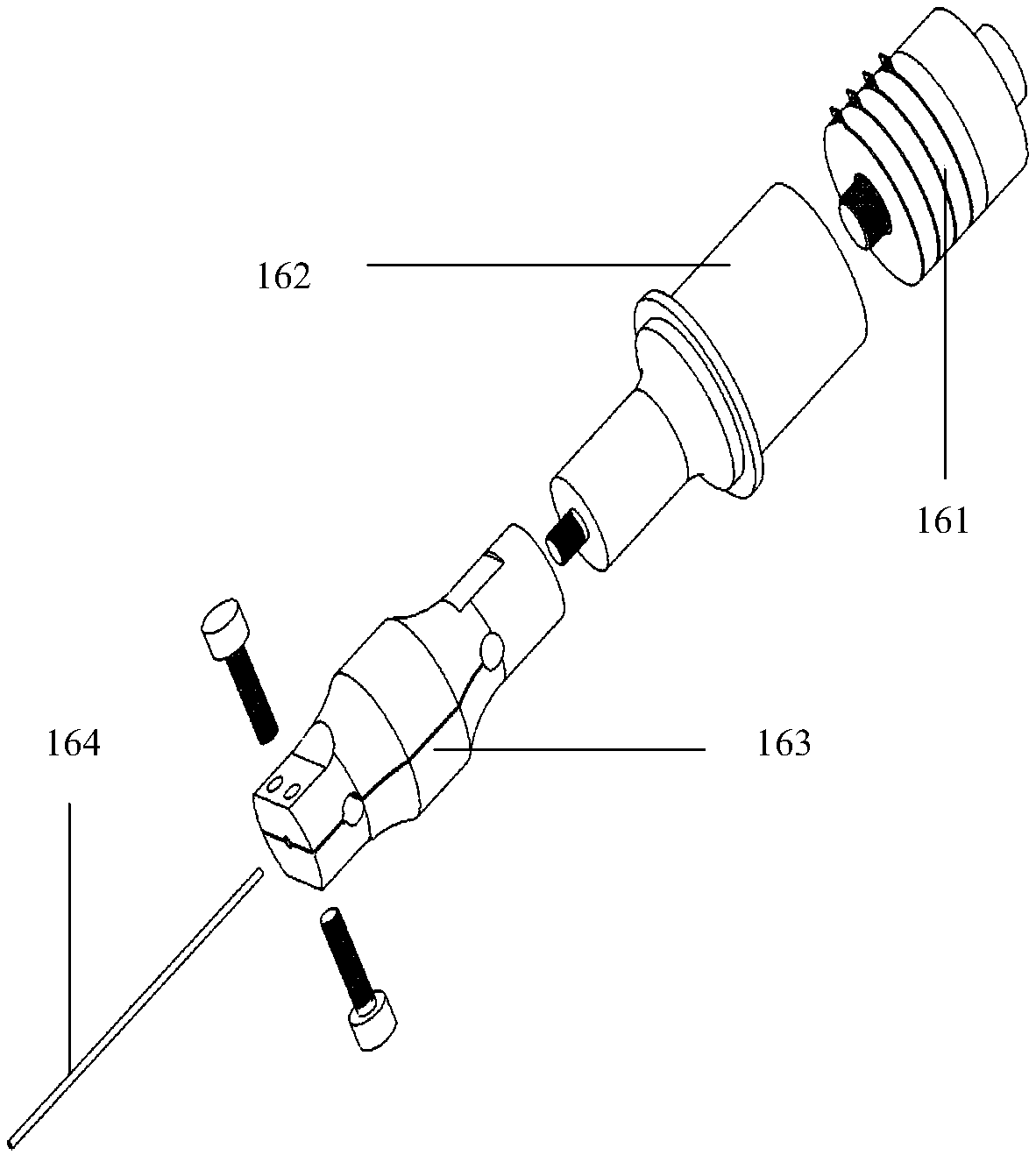

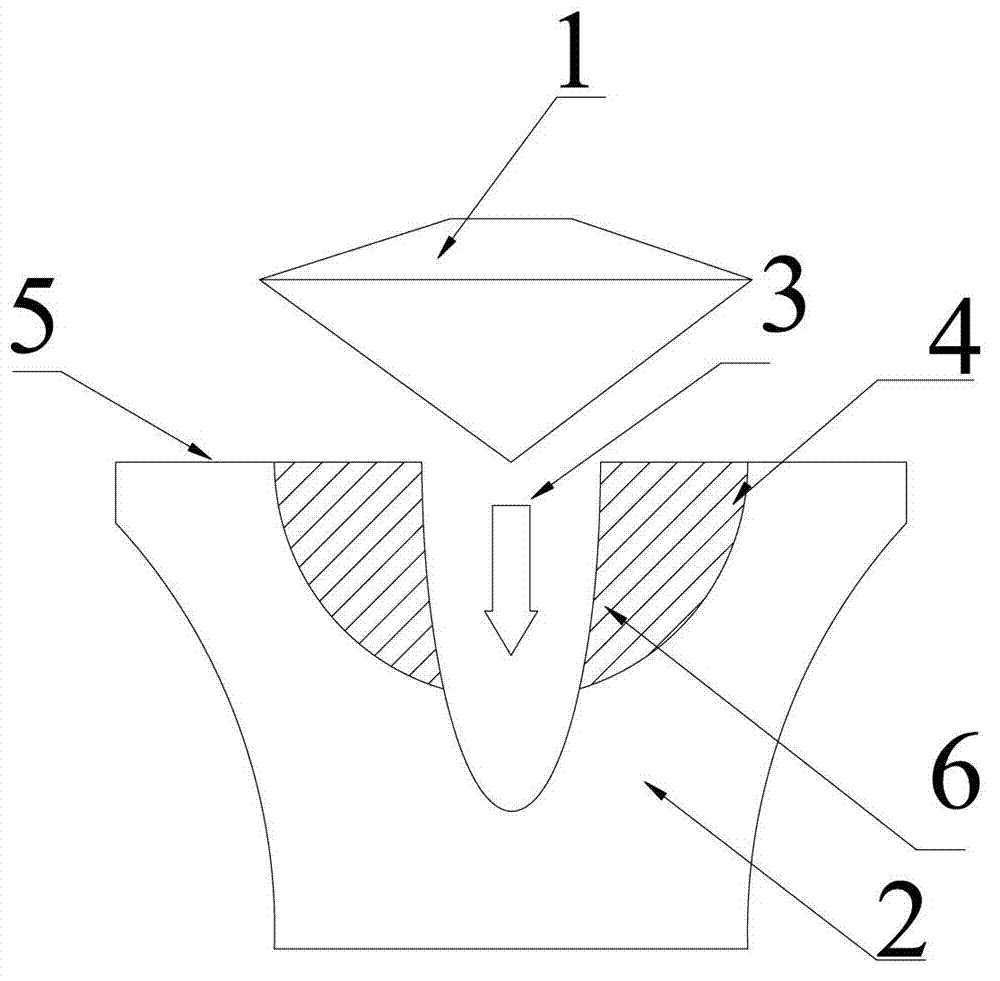

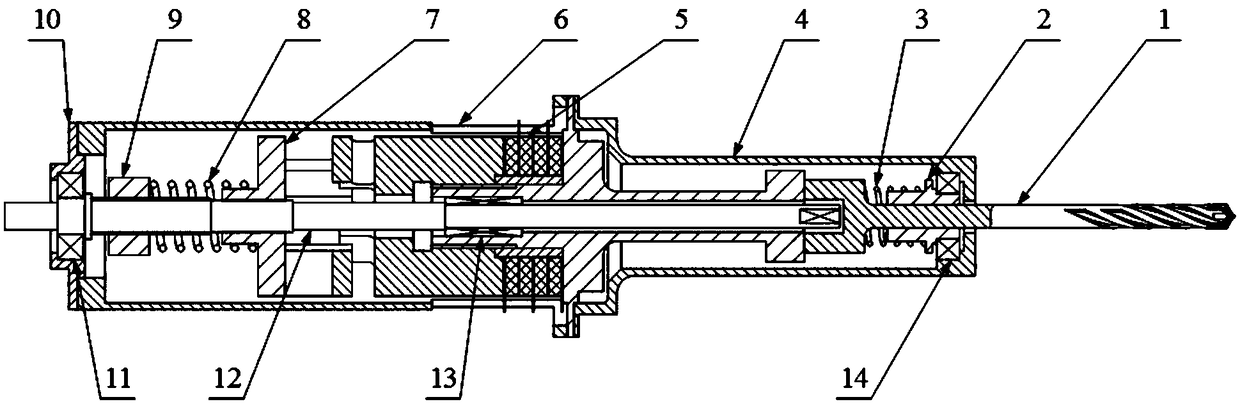

Electromagnetic motor-assisted rotary impact type ultrasonic drilling device

ActiveCN108999571AScientific and reasonable structure designReduce power consumptionEarth drilling toolsDrilling rodsDrive shaftTransducer

The invention provides an electromagnetic motor-assisted rotary impact type ultrasonic drilling device, which is characterized in that a driving shaft of the drilling device is fixedly connected witha sampling drilling tool, the periphery of the driving shaft is sleeved with a sandwich piezoelectric transducer and a free mass block, the free mass block is located between the sandwich piezoelectric transducer and the sampling drilling tool, a front shell and a rear shell are connected to form a shell, a rotary motor is located behind the rear shell and is connected with the driving shaft; andthe tail end of the sampling drilling tool is sleeved with a restoring spring and a bearing sleeve, the restoring spring is connected with the bearing sleeve and used for providing a restoring force in the moving process of the sampling drilling tool, and the sampling drilling tool penetrates through the head of the front shell. The electromagnetic motor-assisted rotary impact type ultrasonic drilling device solves the problems of low drilling efficiency and poor chip removal performance of an impact type ultrasonic drilling device, and the drilling tool is driven to perform rotary movement byusing the electromagnetic motor. Provided by the invention is an electromagnetic motor-assisted rotary impact type ultrasonic drilling device, and the rotary impact type ultrasonic drilling device has higher drilling efficiency and more excellent chip removal performance compared with the impact ultrasonic drilling device.

Owner:HARBIN INST OF TECH

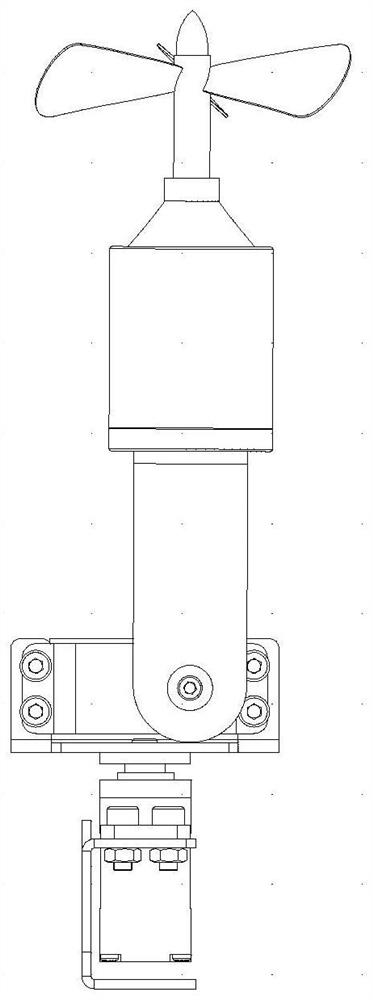

Handheld ultrasonic drilling machine

The invention belongs to the field of exploration tools and discloses a handheld ultrasonic drilling machine. A rotary shaft of a motor is connected with an output shaft through a shaft coupler; a conducting sliding ring is fixed on the output shaft; an end face of the conducting sliding ring is in electric contact and sliding connection with a carbon brush; the tail end of the output shaft is connected with a flange disc on an ultrasonic transducer; a control switch is used for controlling a rotary speed of the motor and the frequency of the ultrasonic transducer. According to the handheld ultrasonic drilling machine disclosed by the invention, drilling and sampling are carried out by adopting a manner of combining high-frequency (20000Hz or more) vibration with rotation, and a high-frequency vibration force generated by the ultrasonic transducer acts on a drilling bit so that the drilling bit is drilled into a stratum in a cutting, shearing and breaking manner; meanwhile, the vibration frequency of the transducer is close to inherent frequency of rocks to realize resonance drilling. The handheld ultrasonic drilling machine can be used for obtaining a relatively high mechanical drilling speed under relatively small drilling pressure and the drilling efficiency in hard rocks can be extremely improved, so that the labor intensity of workers is reduced and the working cost is reduced.

Owner:JILIN UNIV

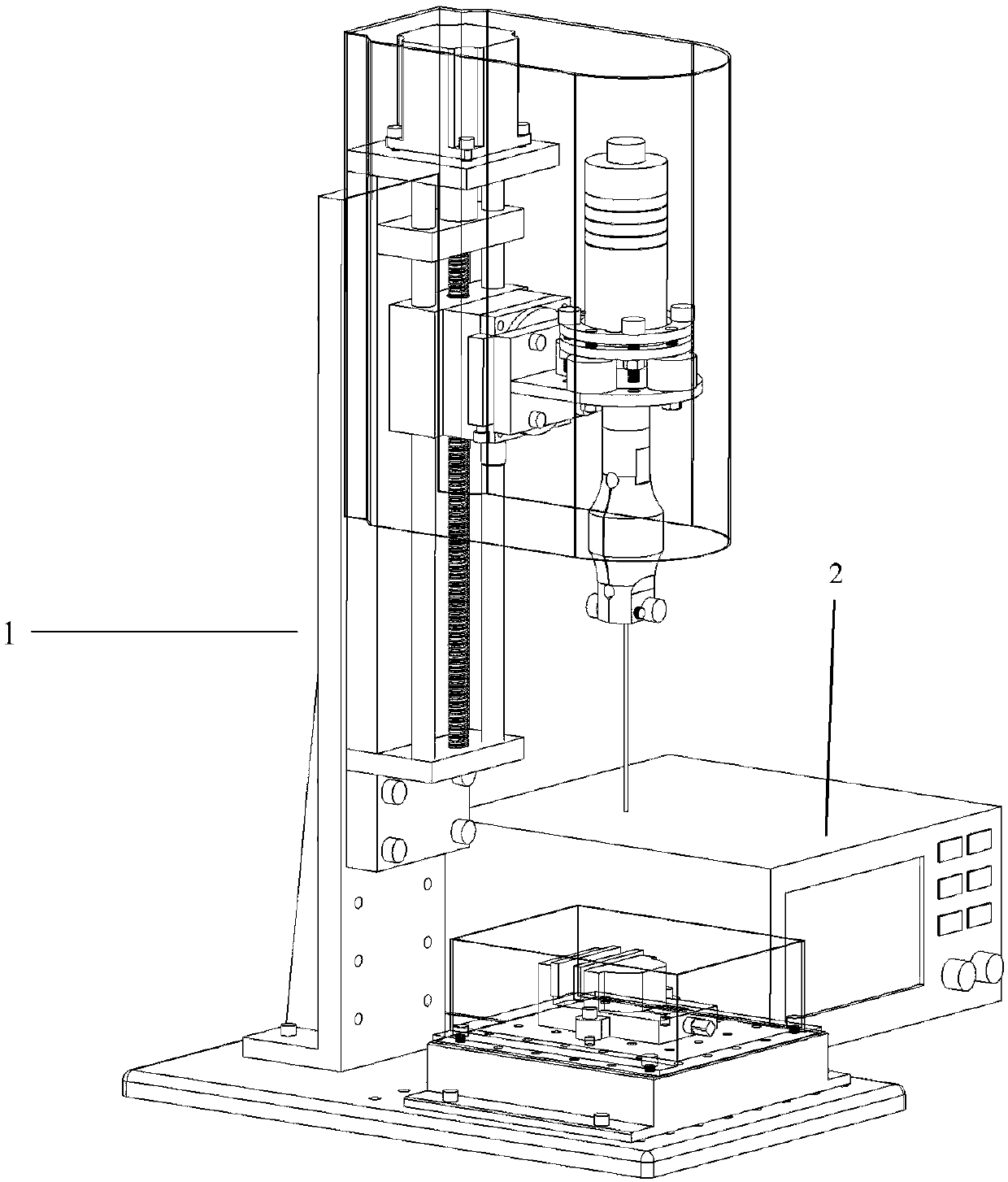

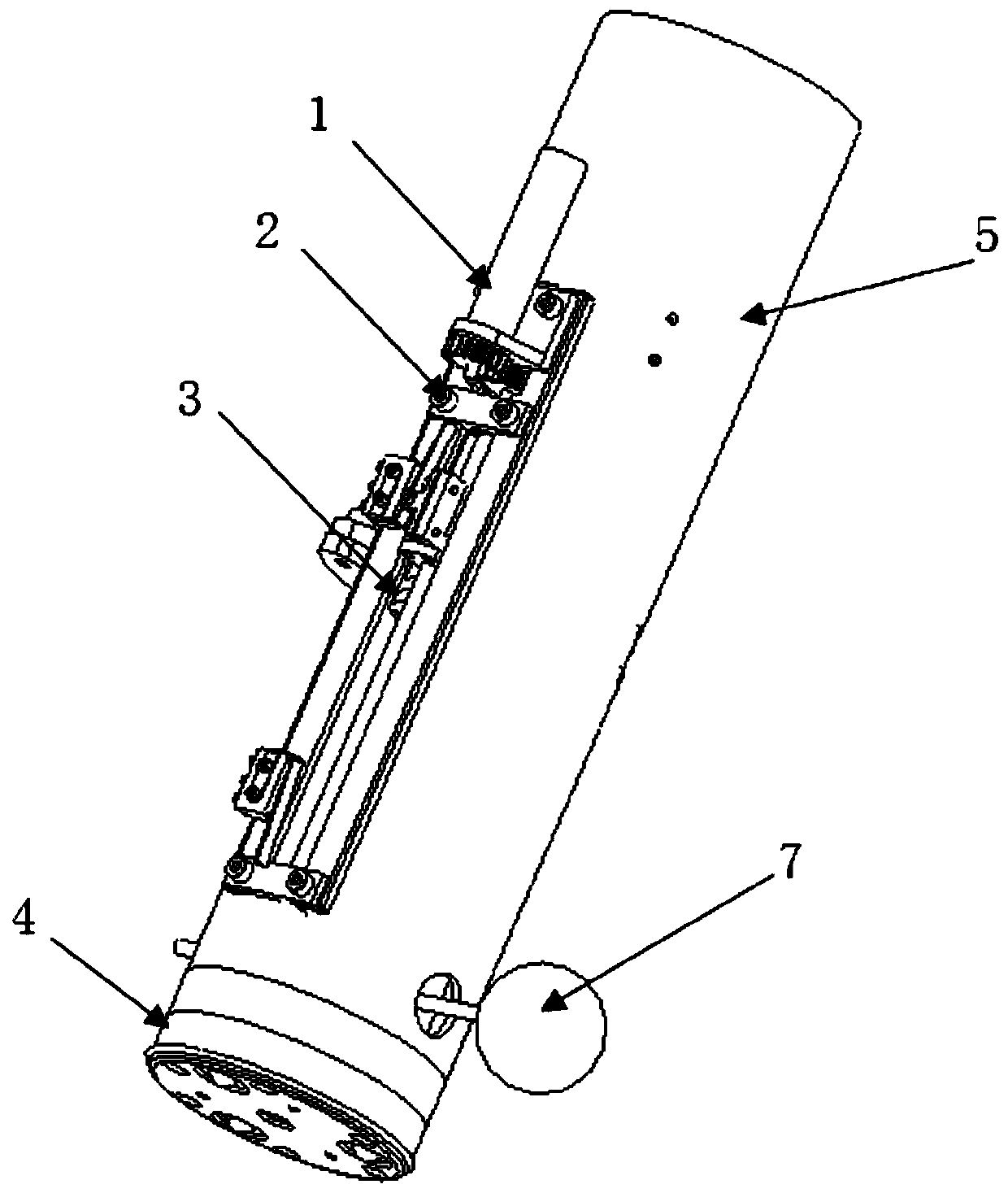

Hard-brittle material large-depth-diameter-ratio tiny-special-shaped-hole precise ultrasonic drilling

PendingCN107775722AAvoid bendingAvoid breakingMetal working apparatusControl systemElectric machinery

The invention discloses a hard-brittle material large-depth-diameter-ratio tiny-special-shaped-hole precise ultrasonic drilling machine which comprises a machine tool body and a control system. The machine tool body comprises a workbench, an upright, a sliding rail, a slider, a stepping motor and an angle adjusting device, an electric displacement platform is mounted on the workbench, the steppingmotor is connected with the slider, an ultrasonic vibration device is connectedly mounted on the angle adjusting device which is connectedly mounted on the slider, a pressure sensor is mounted on theultrasonic vibration device, and the control system is connected with the electric displacement platform, the pressure sensor, the stepping motor, the angle adjusting device and the ultrasonic vibration device. The control system adjusts axis position of a tool head by controlling the slider and the angle adjusting device, so that parallelism between axis of the tool head and moving direction isensured, and bending or breaking of the tool head due to the fact that angle of the tool head and drilling direction are not parallel is avoided. The control system adjusts processing pressure throughthe pressure sensor, so that the tool head and a workpiece are protected, and controlling of hole wall coarseness is facilitated.

Owner:HUAQIAO UNIVERSITY

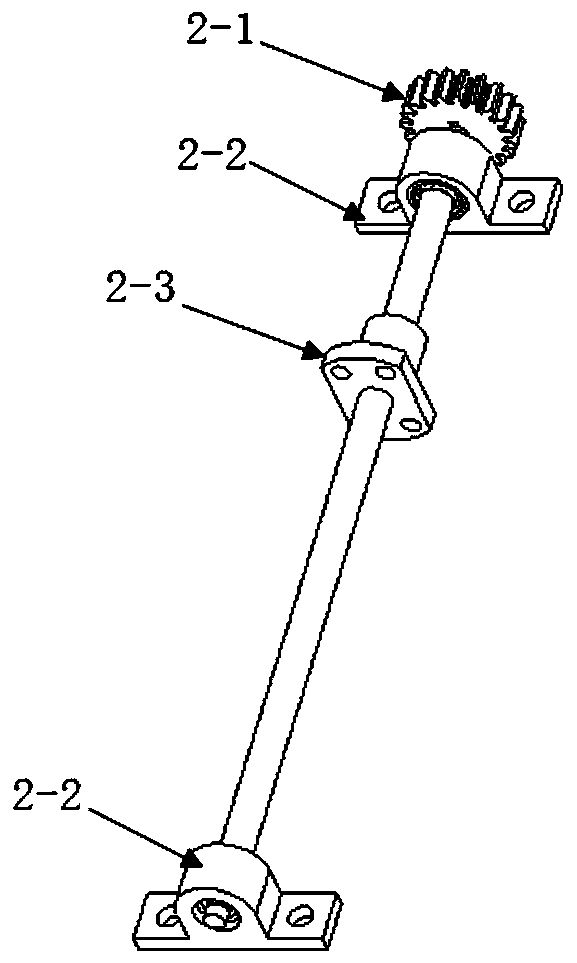

Ultrasonic vibration cord coring drill tool

InactiveCN105507804AIncrease drilling speedImprove drilling efficiencyConstructionsReciprocating drilling machinesRock coreResonance

The invention discloses an ultrasonic vibration cord coring drill tool. The ultrasonic vibration cord coring drill tool is characterized in that power can be supplied to a piezoelectric ceramic vibrator by a battery of the ultrasonic vibration cord coring drill tool, high-frequency voltages with different frequencies can be provided, and accordingly the piezoelectric ceramic vibrator can be excited to ultrasonically vibrate; generated ultrasonic vibration is transmitted to rock via an outer tube and a drill bit, and resonance breaking can be carried out on the rock; single-action characteristics of rock core tubes are kept among the battery, the piezoelectric ceramic vibrator and a solid shaft by the aid of bearings. The ultrasonic vibration cord coring drill tool has the advantages that the ultrasonic vibration cord coring drill tool is convenient to replace, the application range of ultrasonic drilling can be greatly expanded, the drilling periods can be shortened, and the cord coring drilling speeds can be increased.

Owner:JILIN UNIV

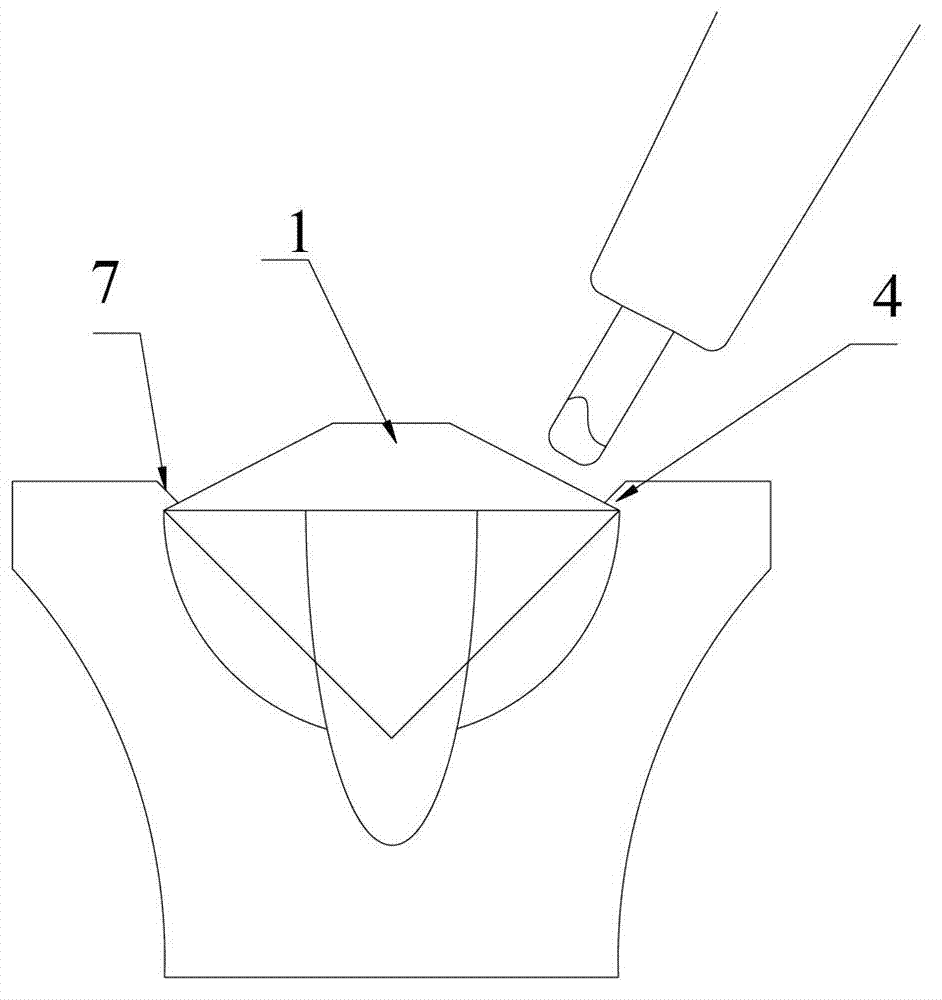

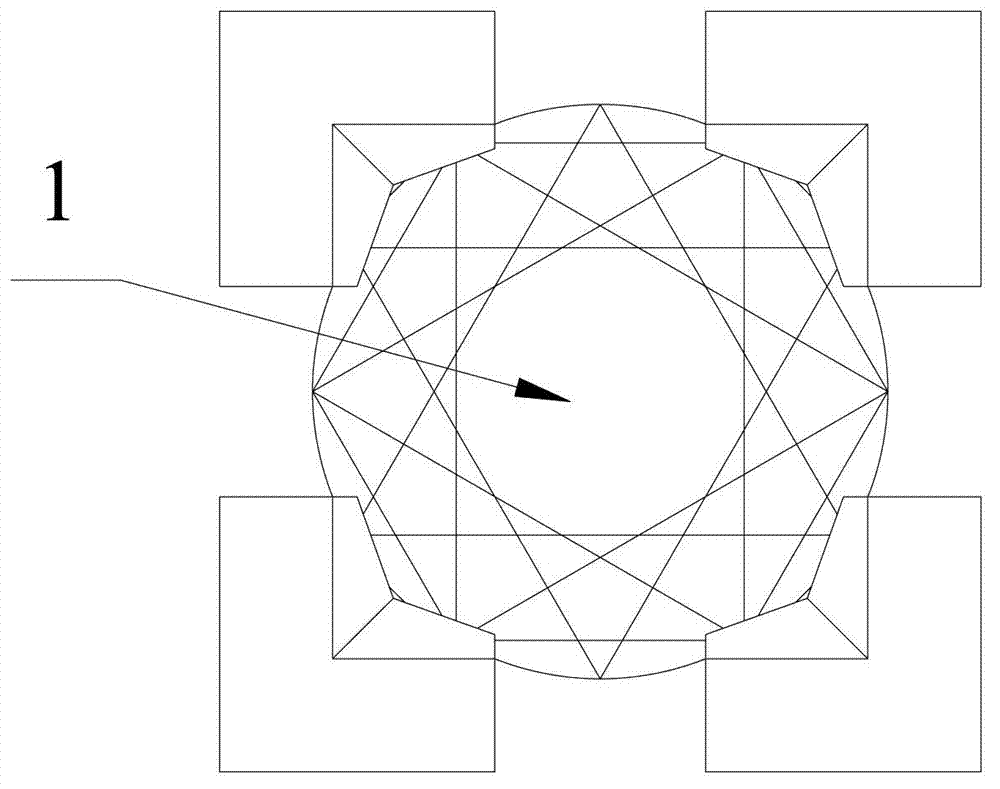

Inlaying method for gem ornament

The invention relates to an inlaying method for a gem ornament. The inlaying method comprises the following steps: polishing an inlaying body after demoulding of the inlaying body; carrying out primary cleaning and polishing; filing away the top of the inlaying body by using a flat file to ensure an inlaying opening of the inlaying body to be smooth and uniform; adjusting and calibrating the inlaying opening to an appropriate size by using an ultrasonic drilling rod with a moderate size corresponding to the size of the gem ornament; carving a pit which is 1.5 mm far away from the inlaying opening on the inlaying body and inlaying the gem ornament into the pit; filing away the periphery of the inlaying opening by using the flat file; then wetting a small cloth wheel with a polishing wax and carrying out polishing; shoveling an angled bevel edge corresponding to an edge of an inlaying ornament from the edge of the inlaying ornament to the top of the gem ornament by using a flat shovel; and finally clearing needless gold fillings and carrying out polishing. According to the invention, after stable inlaying is realized, the flat shovel is used to shovel the angled bevel edge corresponding to an edge of a prong on the inlaying body from the edge of the prong to the top of the gem ornament, which enables a diamond to be brighter and bonding between the inlay ornament and the gem ornament to be firmer.

Owner:HENGXIN XILI IND

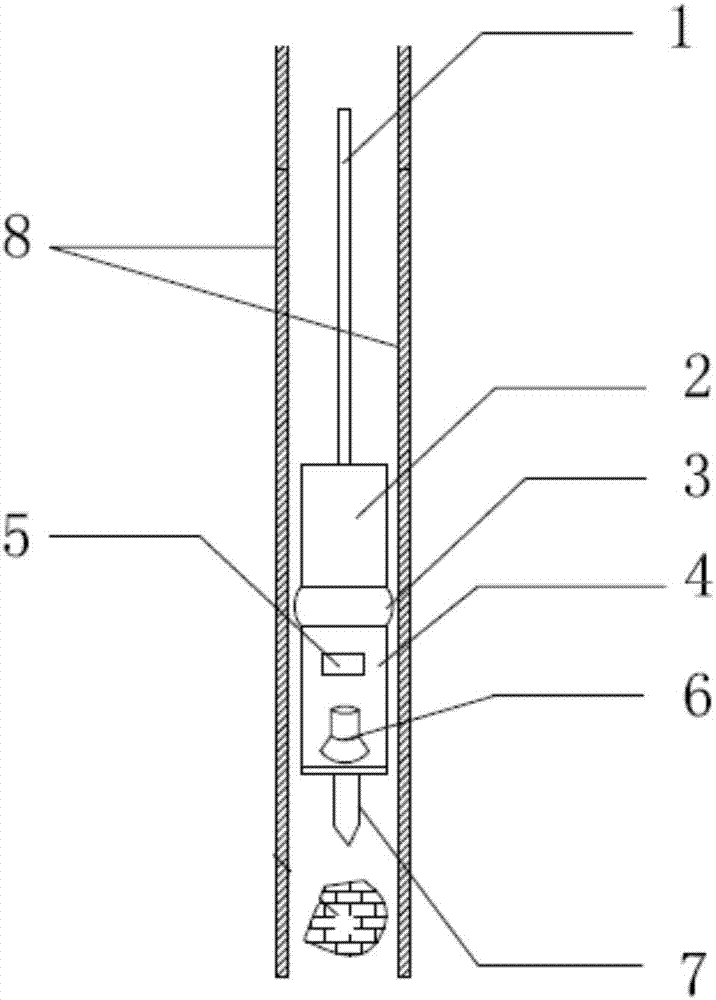

Pile measuring hole obstacle clearing device based on ultrasonic drill bit

The invention discloses a pile measuring hole obstacle clearing device based on an ultrasonic drill bit. The device comprises a cable, a counterweight block and an ultrasonic drilling machine; the ultrasonic drill bit is arranged at the front end of the ultrasonic drilling machine; an ultrasonic generator and a piezoelectric ceramic ultrasonic transducer are arranged in the ultrasonic drilling machine; the ultrasonic generator is electrically connected with the cable; the ultrasonic generator is electrically connected with the piezoelectric ceramic ultrasonic transducer through a control circuit; and the cable, the counterweight block and the ultrasonic drilling machine are all positioned in a pile measuring hole. The pile measuring hole obstacle clearing device based on the ultrasonic drill bit can effectively clear the blocked pile measuring hole, fills the blank on the clearing aspect of the pile measuring hole, solves the difficulty of incapability of measuring the pile measuring hole due to blockage, and is convenient in use, safe and efficient.

Owner:昂徕博智能科技(昆山)有限公司

Processing method of rare earth ion doped optical fiber perform

ActiveCN105502916AReduce the stress areaReduce the degree of deviationGlass making apparatusRare earth ionsChemical vapor deposition

The invention relates to a processing method of a rare earth ion doped optical fiber perform. The method comprises steps as follows: a preform containing a rare earth ion doped core layer is deposited with the MCVD (modified chemical vapor deposition) technology; the preform is cut off in a preset position, sizes and positions of two holes are designed reasonably, and multiple small holes are designed in the two holes; a large drill is determined according to the diameter of the holes and a small drill is determined according to the diameter of the small holes; drilling: holes are drilled in the positions of the small holes with the small drill firstly, positions of the multiple small holes are required to overlap with the contact surface of the large drill and the preform, and after the multiple small holes are drilled, the large drill is used for drilling holes in the position of the large drill; after drilling, inner walls of the holes are polished until the inner holes reach designed sizes. The processing method has the advantages as follows: the stress area of the rare earth ion doped optical fiber preform in the ultrasonic drilling process can be effectively decreased with a repeated drilling method, and damage caused by mechanical external force to the optical fiber preform can be further weakened; the processing accuracy of the rare earth ion doped optical fiber perform can be further improved.

Owner:CHINA ELECTRONICS TECH GRP NO 46 RES INST

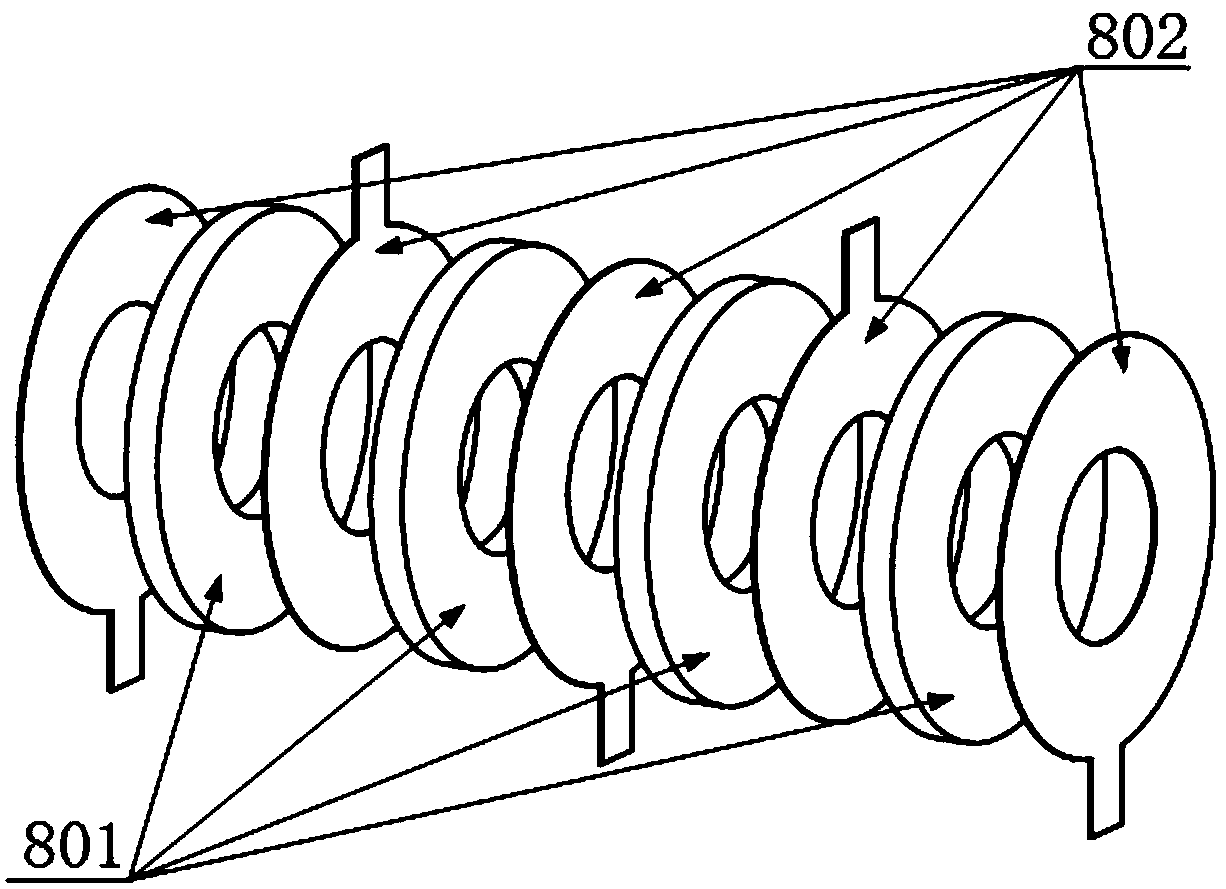

Ultrasonic drilling device

InactiveCN108856779AReduce wearFast processingMechanical vibrations separationPositioning apparatusTransformerTransducer

The invention discloses an ultrasonic drilling device. The device is mainly composed of a sleeve cup, an induction coil set, a cooling system, a transducer, an amplitude transformer and a drill pipe,the top of the sleeve cup is connected with a machine tool main shaft through a clamping mechanism, and the lower portion of the sleeve cup is open. The induction coil set matched with the transduceris wound on the outer wall of the sleeve cup; the cooling system and the transducer are arranged in the open end of the sleeve cup; the driving end of the transducer is connected with the input end ofthe amplitude transformer, the amplitude transformer is fixed to the end face of the open end of the sleeve cup through a connecting bolt, and the output end of the amplitude transformer is connectedwith the upper end of the drill pipe; and a cutter is arranged at the lower end of the drill pipe. The ultrasonic drilling device has the beneficial effects that the ultrasonic drilling device is connected with the machine tool main shaft through the clamping mechanism, rotation of the machine tool main shaft and longitudinal vibration of the transducer form longitudinal-torsion composite vibration, and then a workpiece can be drilled; the cooling system is integrated in the ultrasonic drilling device, the transducer and the workpiece can be simultaneously cooled, and an external cooling system is not needed; and the ultrasonic drilling device is high in machining speed, high in machining precision, good in machining quality and small in abrasion of the drill pipe.

Owner:WUHAN UNIV OF TECH

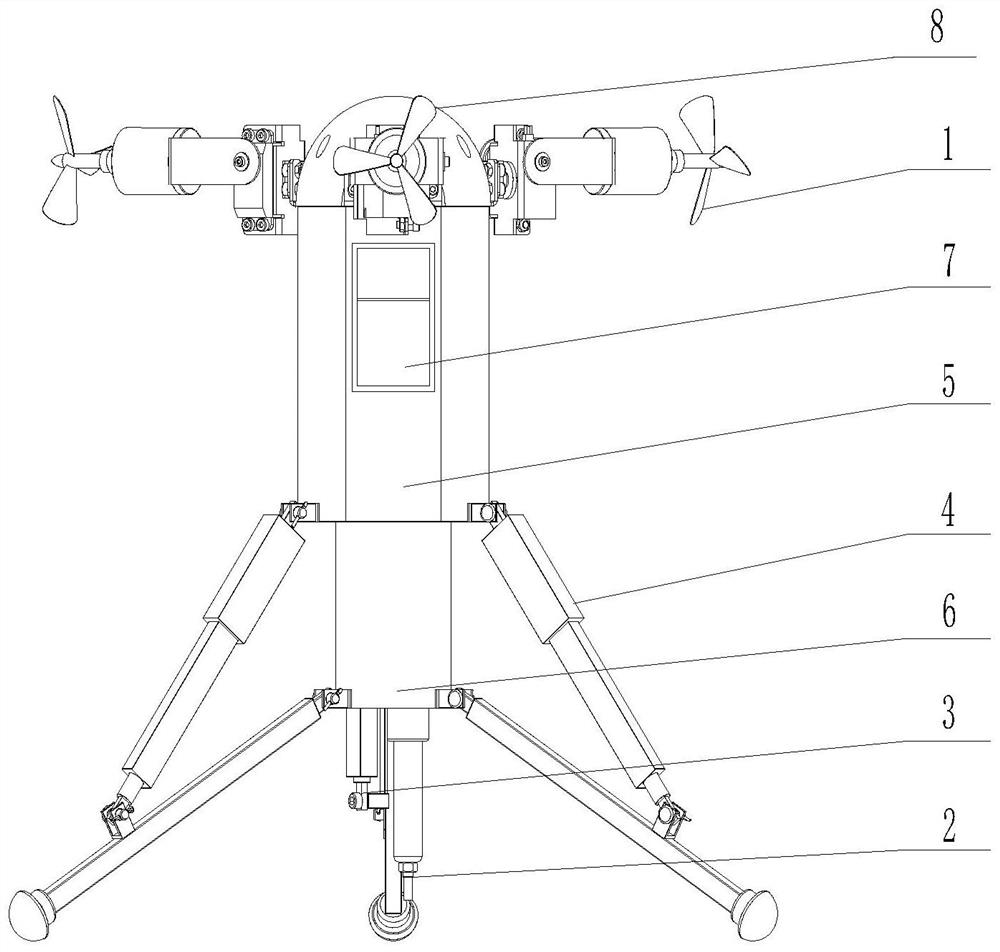

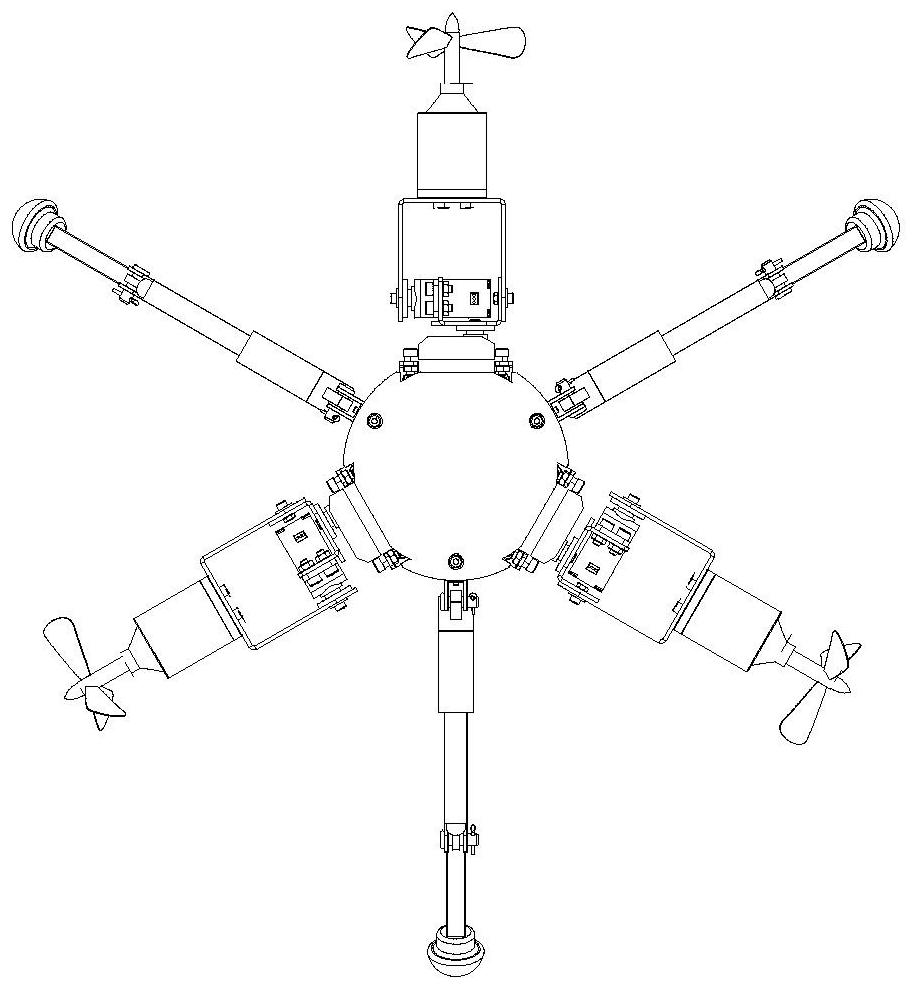

Underwater vector propulsion type ultrasonic drilling robot and using method thereof

PendingCN114544231AFlexible movementImprove efficiencyConstructionsReciprocating drilling machinesSupersonic wavesStructural engineering

The invention discloses an underwater vector propulsion type ultrasonic drilling robot which comprises a vector propeller, an ultrasonic drilling device, a drilling device fixing device, a base supporting and adjusting mechanism, a sealed cabin, a hollow cylindrical shell, a lithium battery and a hemispherical shell. Three groups of vector propellers are uniformly arranged at the top of the spherical shell, each group of propeller has two degrees of freedom, a lithium battery is arranged in the sealed cabin, a hollow cylindrical shell is arranged at the lower part of the sealed cabin, and a drilling device fixing device and an ultrasonic drilling device are arranged in the hollow cylindrical shell; a hollow cylindrical shell is installed on the lower portion of the sealed cabin, the sealed cabin is hinged to a base supporting and adjusting mechanism, and the base supporting and adjusting mechanism is hinged to the hollow cylindrical shell. The seabed rock sampling device can realize seabed rock sampling work, and can stably take a rock sample to the water surface by means of the device.

Owner:SHANDONG UNIV OF SCI & TECH

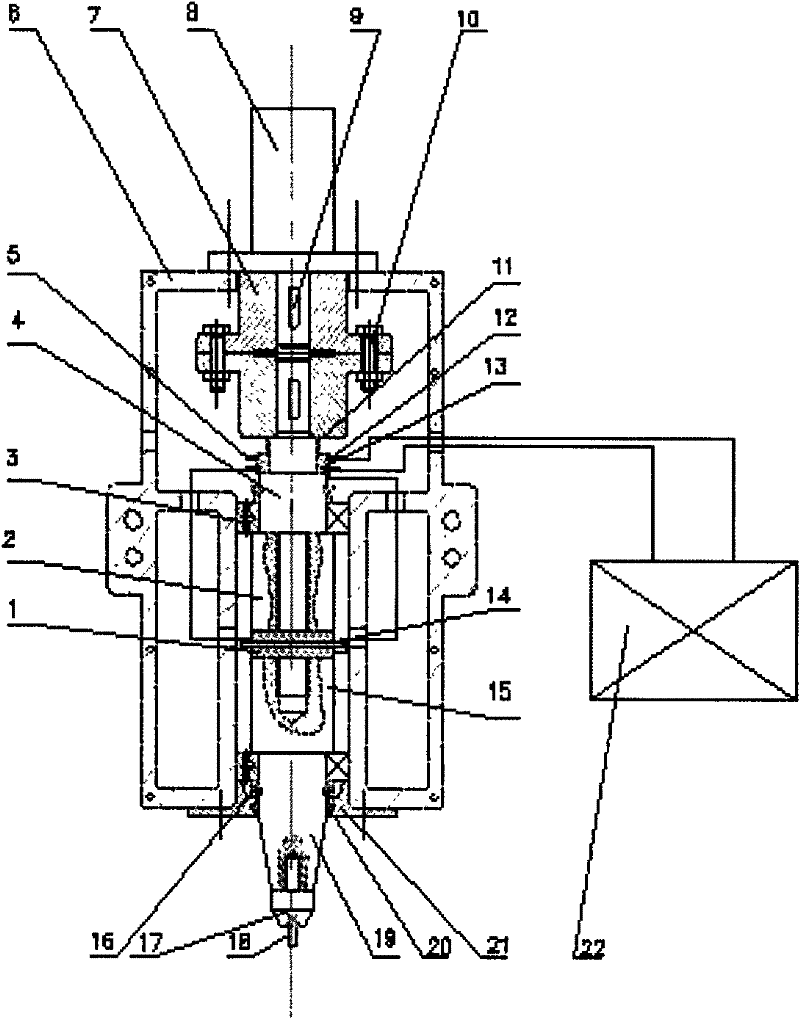

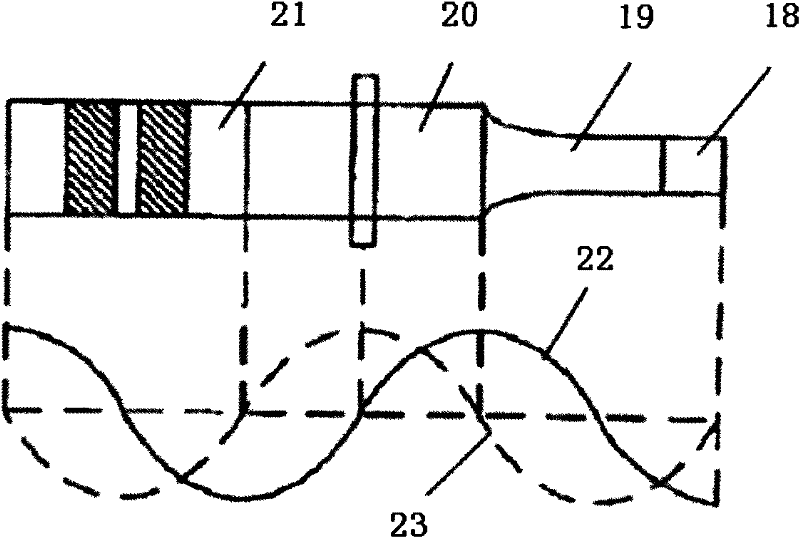

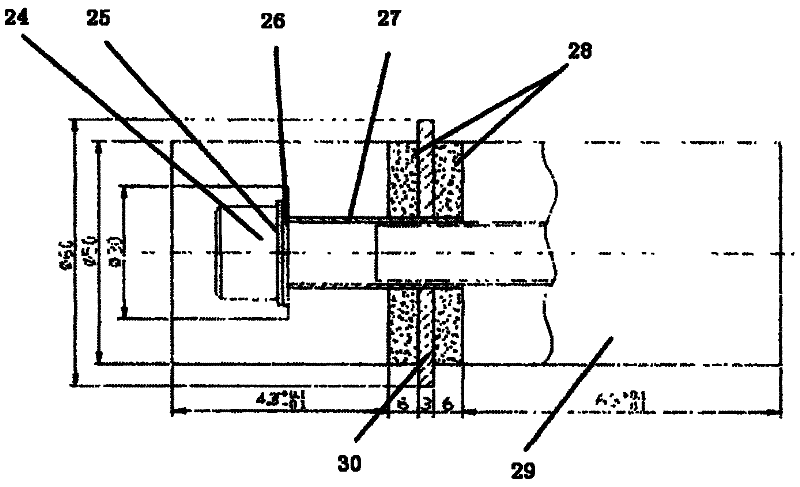

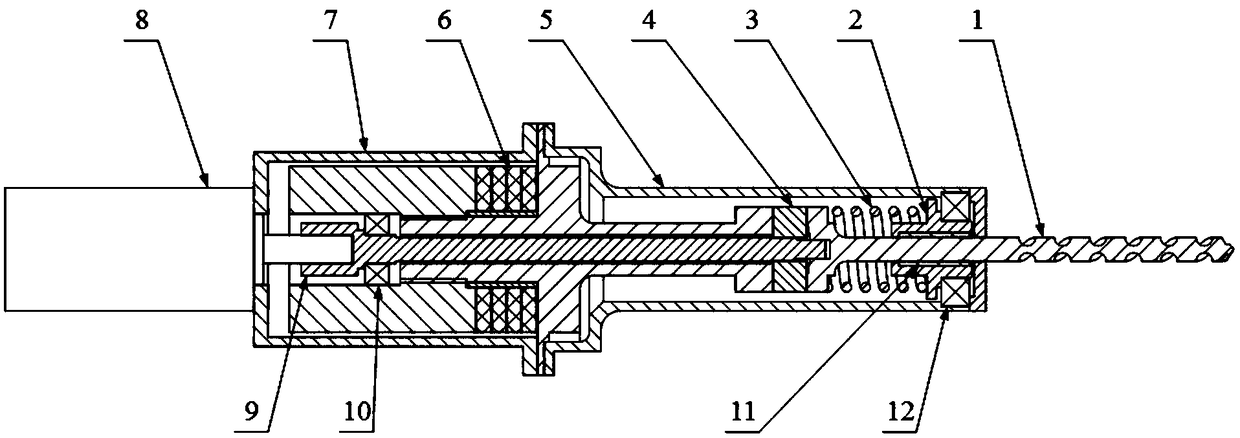

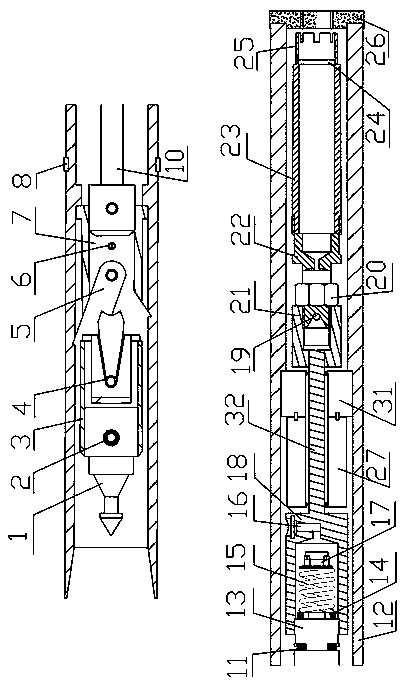

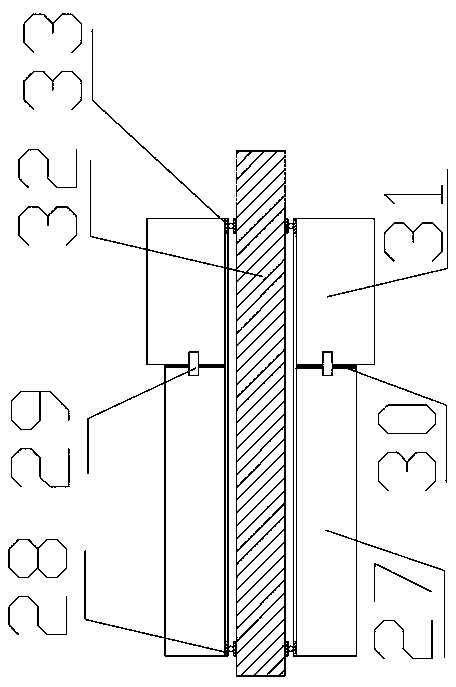

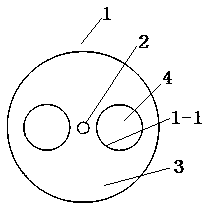

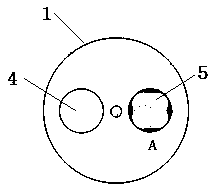

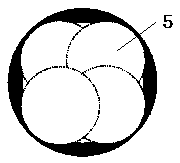

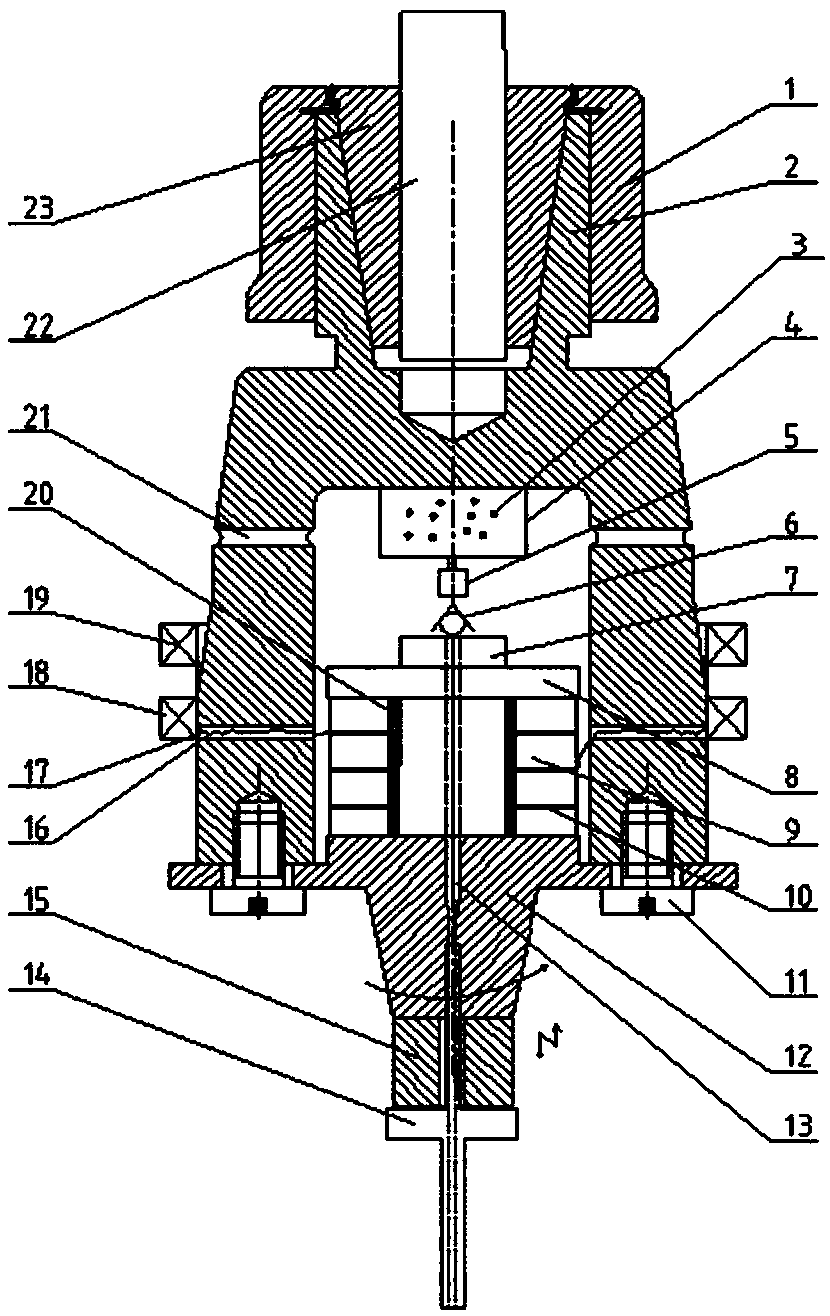

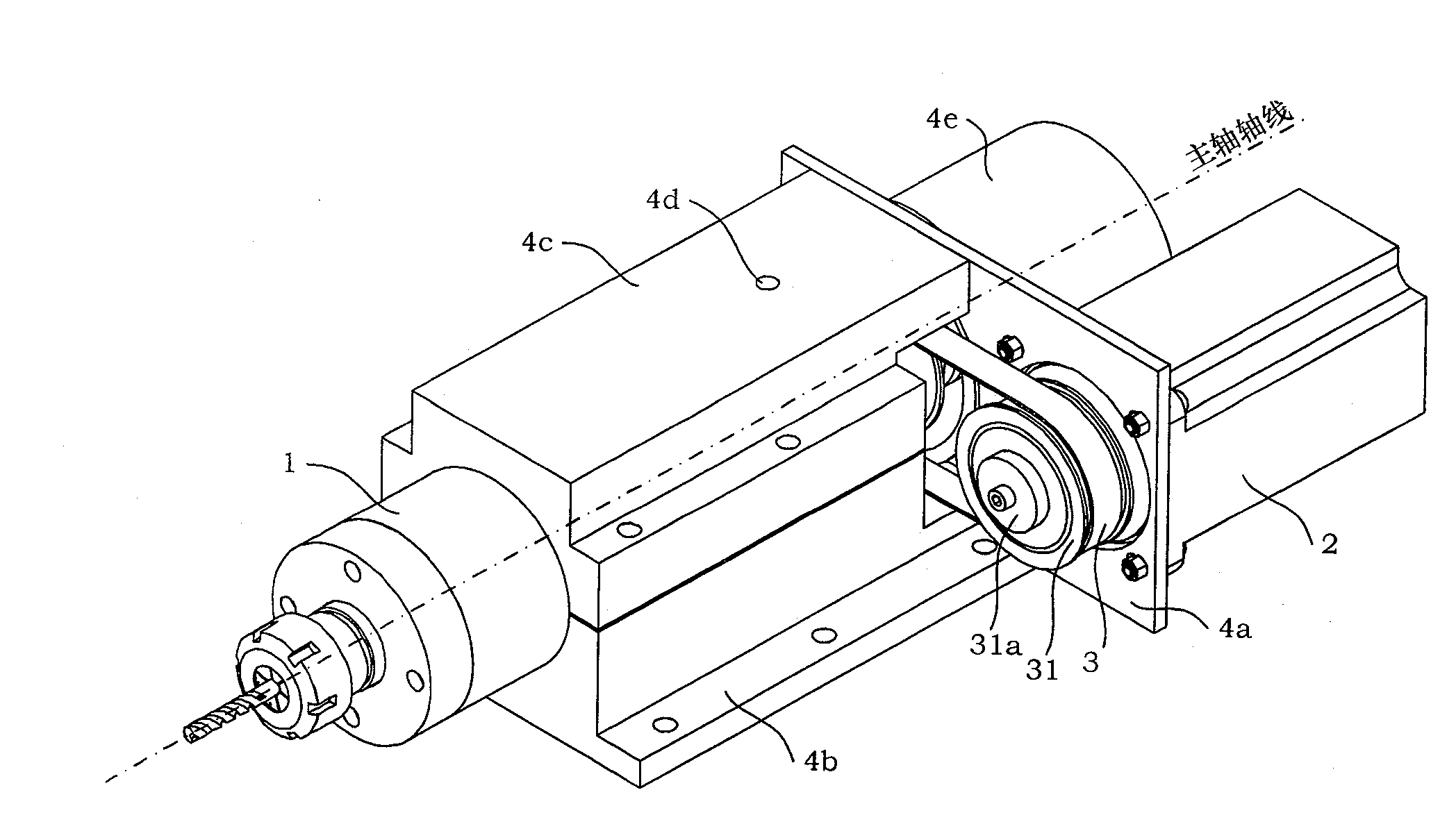

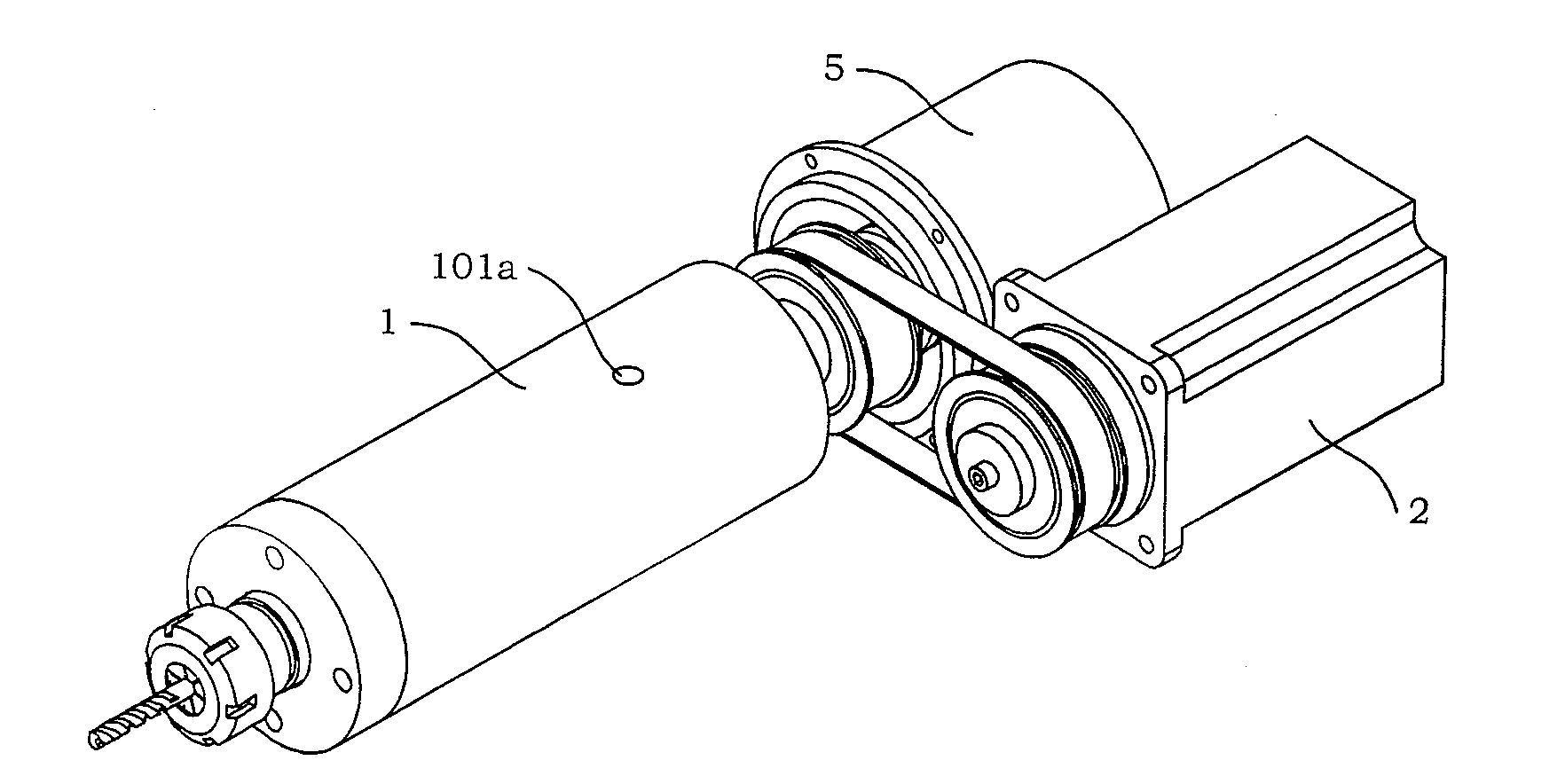

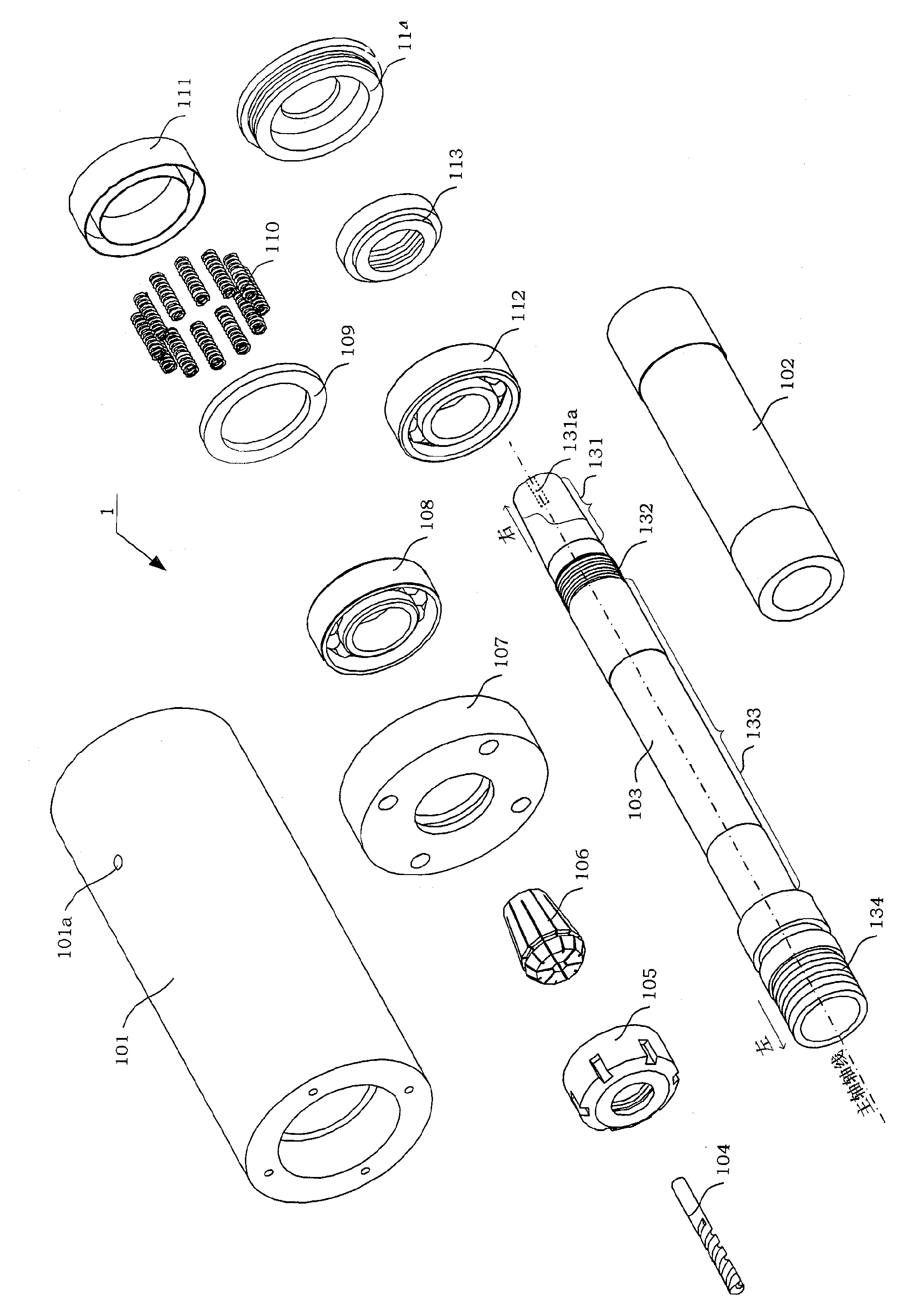

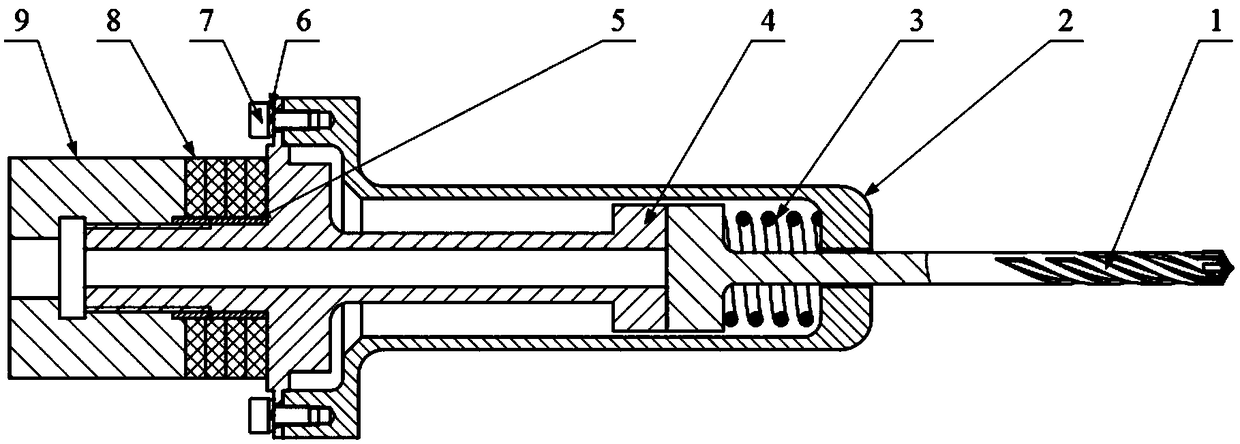

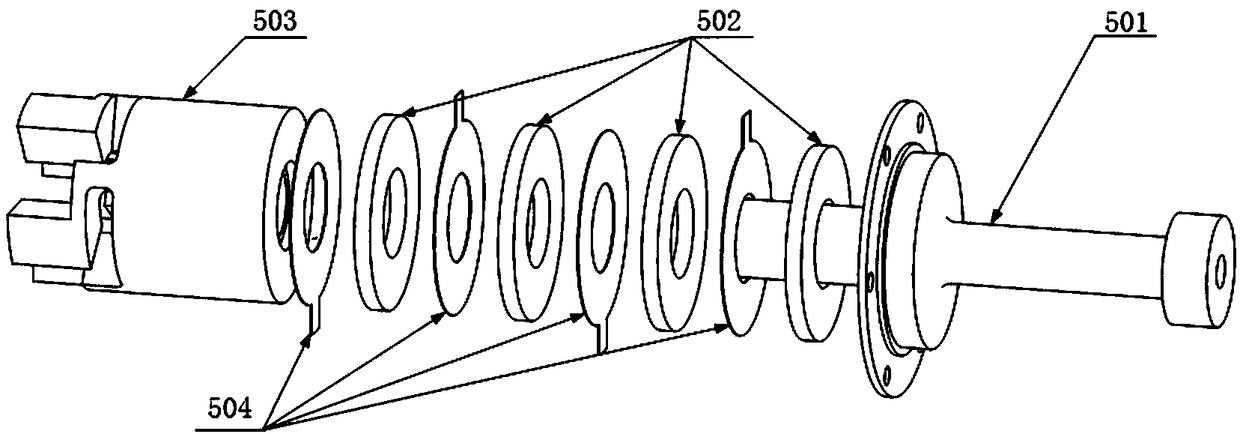

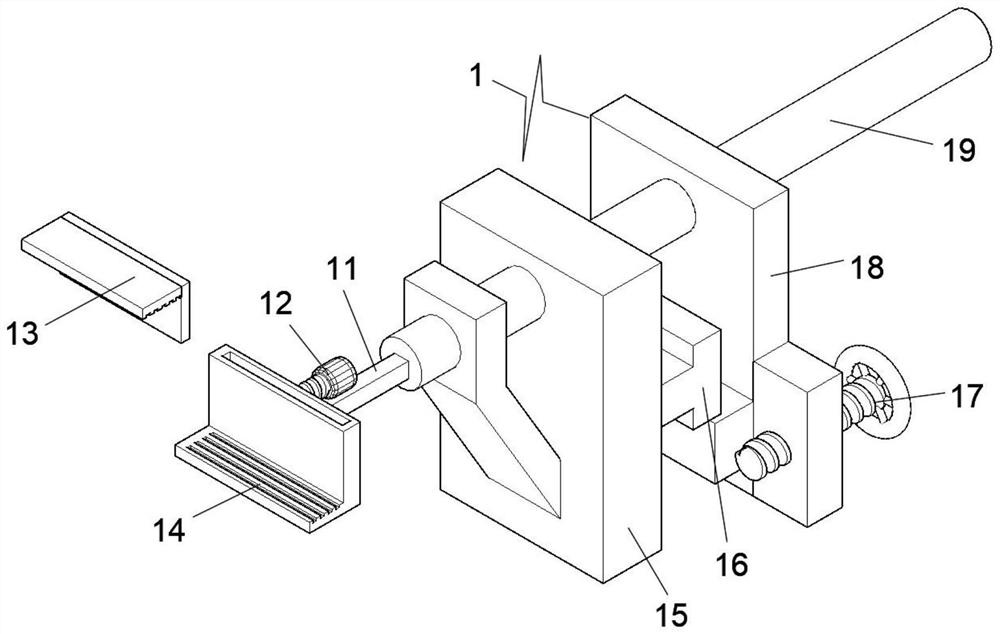

Rotary type transducer main shaft device of supersonic vibrated drill

InactiveCN100566894CAchieved by ultrasonic vibrationGuaranteed rotation accuracyMechanical vibrations separationMotor driveTransducer

The invention discloses a rotary transducer spindle device for ultrasonic vibration drilling. The rotary transducer spindle device consists of a spindle assembly (1), a motor drive assembly, a transducer power supply assembly (5), and a housing assembly Composition; the compression screw (510) of the transducer power supply assembly (5) is connected in the threaded hole (131a) of the main shaft (103) of the main shaft assembly (1); the driven pulley (32) of the motor drive assembly is socketed On the main shaft (103) of the main shaft assembly (1), the driving pulley (31) and the driven pulley (32) are connected through a transmission belt (3). The spindle device of the rotary ultrasonic transducer of the present invention can be installed on a table-type drilling machine, and the workpiece can be processed by adding a feed control component. Make the motor in the system work, use the slip ring (502a) to supply power to the ultrasonic transducer, realize the high-speed rotation of the main shaft (103) and generate ultrasonic vibration in the axial direction of the main shaft, and superimpose to obtain the composite motion of the rotational ultrasonic vibration. Clamping a drill bit or reamer at the end of the spindle can realize rotary ultrasonic vibration drilling or reaming.

Owner:BEIHANG UNIV

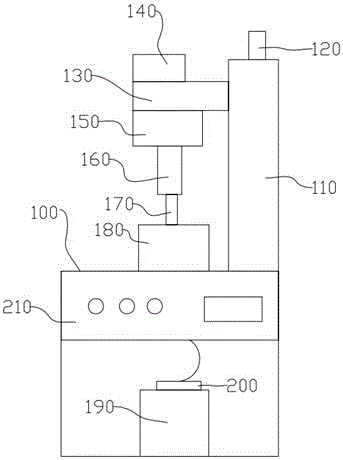

Ultrasonic drilling machine

InactiveCN104943002ASimple structureFunction increaseWorkpiecesTurning toolsLocking mechanismEngineering

The invention discloses an ultrasonic drilling machine which comprises a working table, wherein a steel upright is mounted on one side of the working table; a lifting hand wheel for controling the extension of the steel upright is arranged at the top of the steel upright; a wave head mounting barrel is mounted above a connection rod of the steel upright; a cooling fan is arranged at the top of the wave head mounting barrel; a locking mechanism is arranged at the bottom of the wave head mounting barrel, and connected with a tool head by an ultrasonic amplitude-change pole; a water tank is arranged below the tool head; and an ultrasonic generator panel is mounted on the surface of the working table. The ultrasonic drilling machine is suitable for mass production of small and medium-sized carving crafts, jade hanging pieces and jade pendants. The ultrasonic drilling machine has the multiple advantages that a line is elegant, a texture is clear, and a three dimensional sense is strong; a product produced by the ultrasonic drilling machine has uncomparable realistic degree than that is handmade; and the ultrasonic drilling machine can completely replace hand carving, is excellent in practical performance and automation performance, novel in design, good and innovative, and has market popularization prospects.

Owner:CHANGZHOU JINHAIJI MACHINERY MFG

Impact-type ultrasonic drilling device free of free mass blocks

InactiveCN108979521ASave the collision linkScientific and reasonable structure designConstructionsReciprocating drilling machinesEnergy transferDrill

The invention provides an impact-type ultrasonic drilling device free of free mass blocks. A sampling drill is mounted at the front end of an variable-amplitude rod of the drilling device. A shell ismounted on the peripheries of the tail ends of the variable-amplitude rod and the sampling drill. A return spring is located in the shell and sleeves the tail end of the sampling drill. A rear cover plate is mounted on the periphery of the tail end of the variable-amplitude rod, and is connected with the shell. A elastic gasket is mounted between the rear cover plate and the shell, a piezoelectricceramic stack is located between the variable-amplitude rod and the rear cover plate, the rear end of the variable-amplitude rod passes through the piezoelectric ceramic stack, and an insulating sleeve is disposed between the piezoelectric ceramic stack and the variable-amplitude rod. The impact-type ultrasonic drilling device has the advantages that the problems that ultrasonic drilling devicesin the prior art are all provided with the free mass blocks, need to complete two contact collisions and cause energy loss are solved; according to the impact-type ultrasonic drilling device free of the free mass blocks, the free mass blocks are omitted, and only one collision needs to be completed, so that the energy transfer efficiency of the ultrasonic drilling device is improved; the ultrasonic drilling device has low weight, low drilling pressure and low power consumption.

Owner:HARBIN INST OF TECH

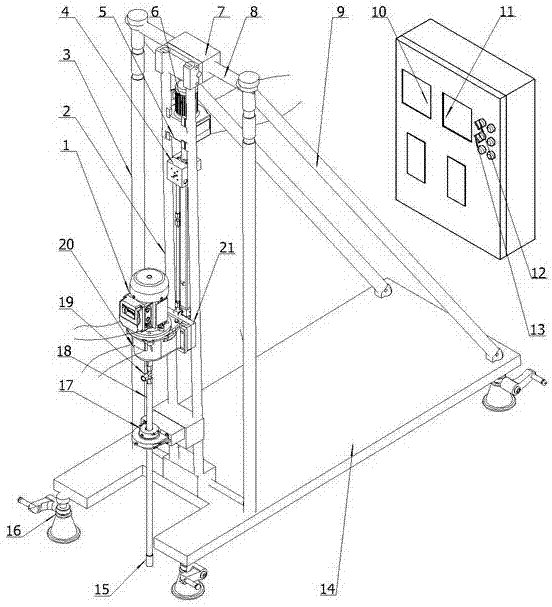

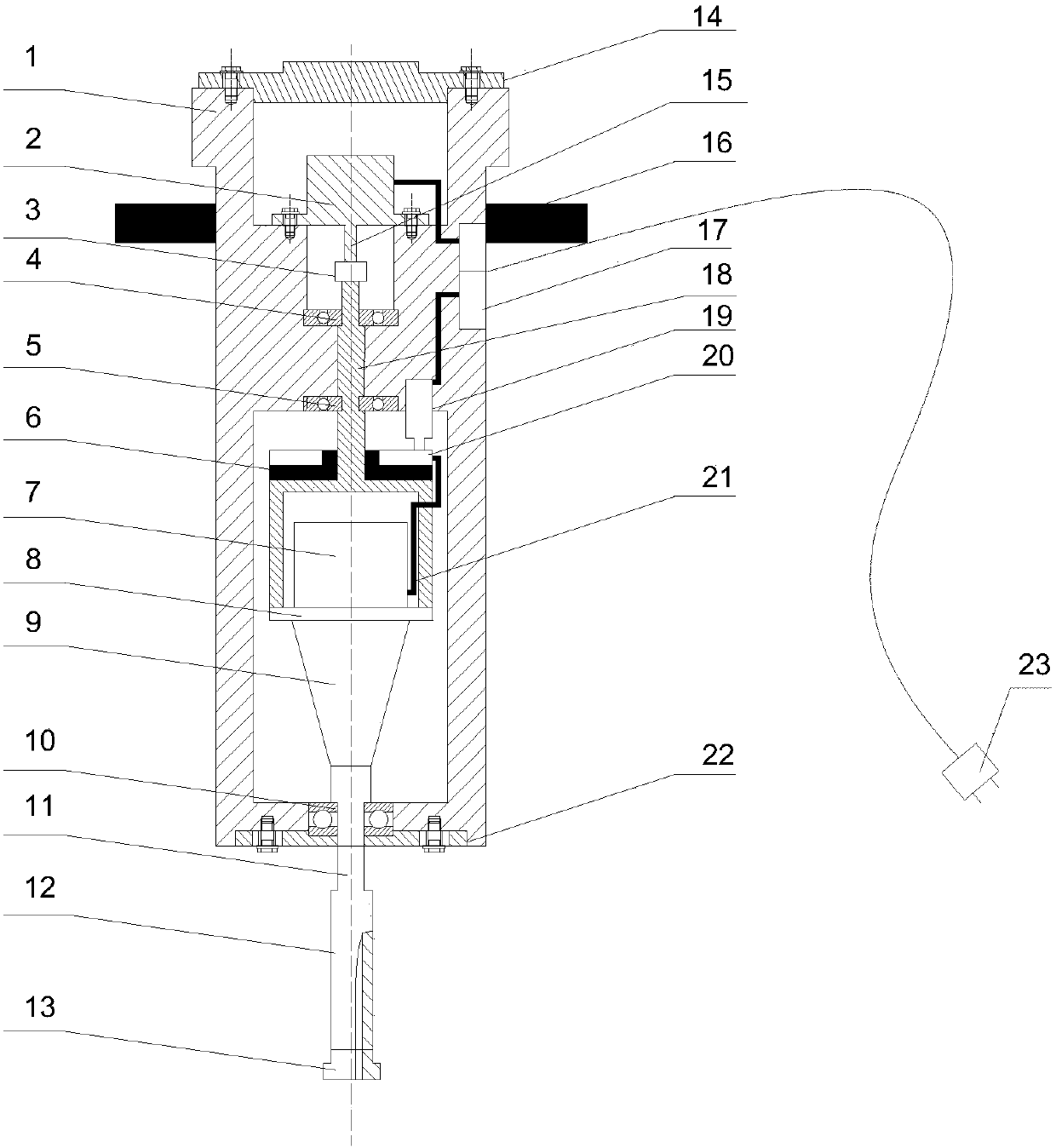

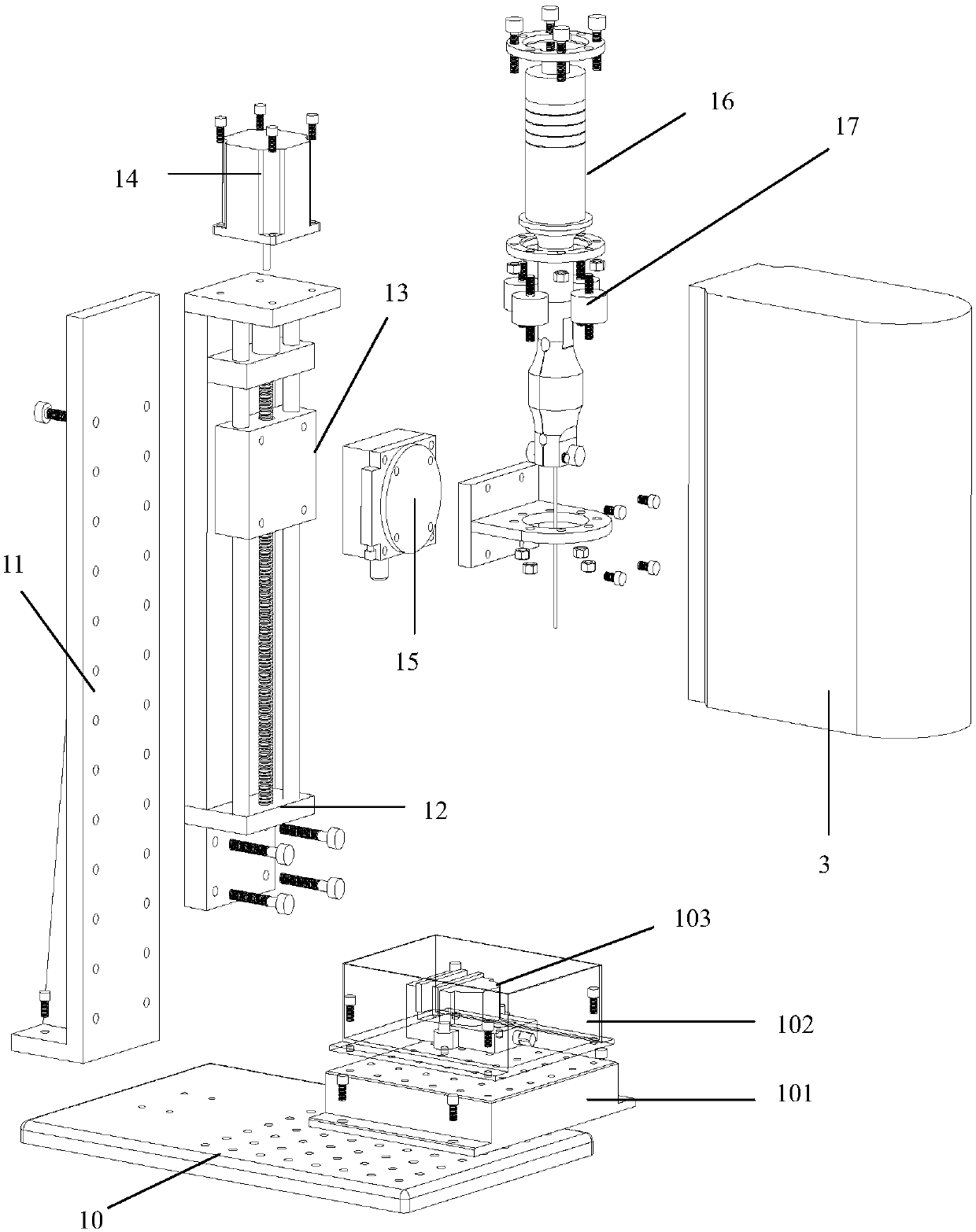

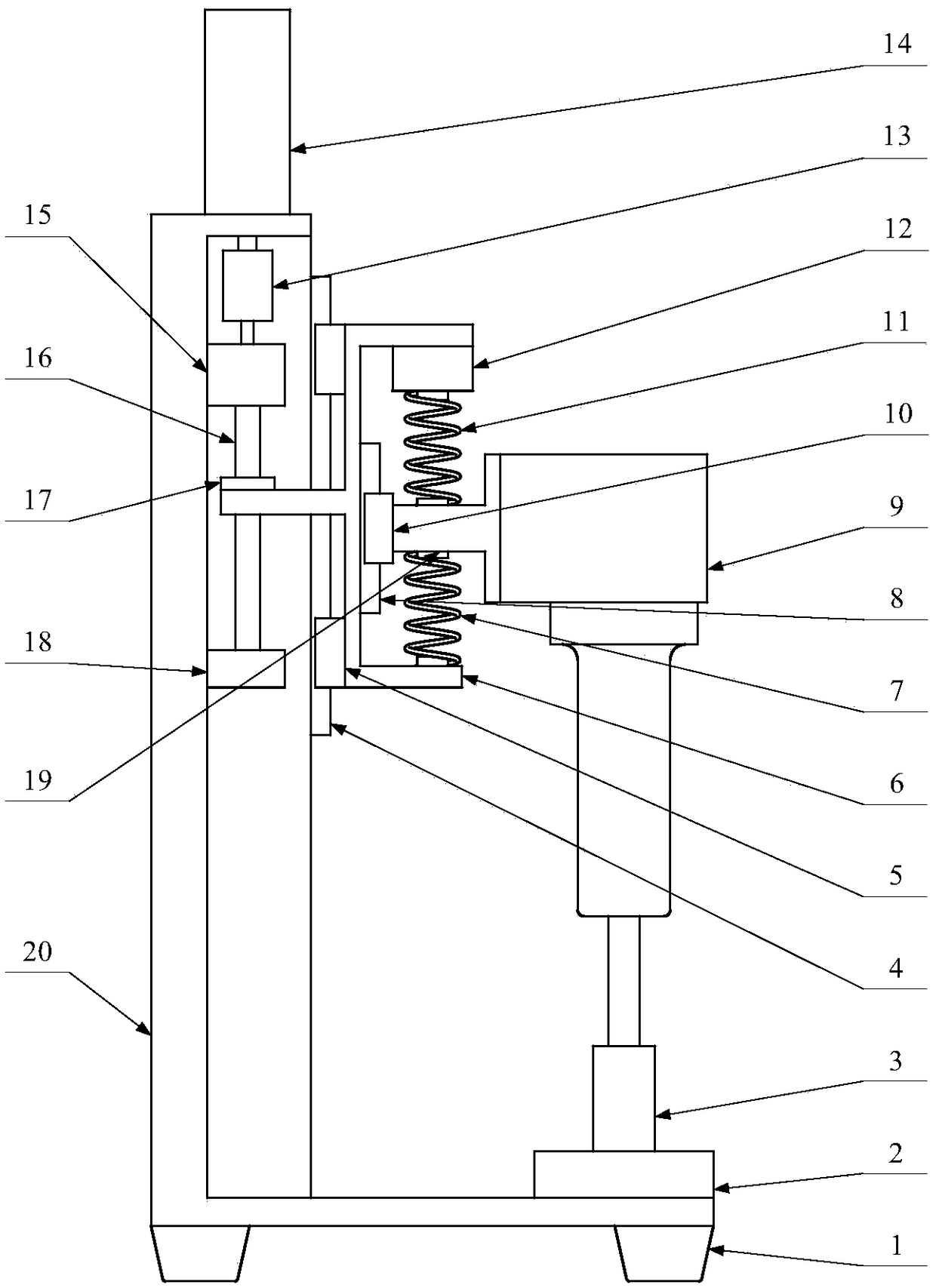

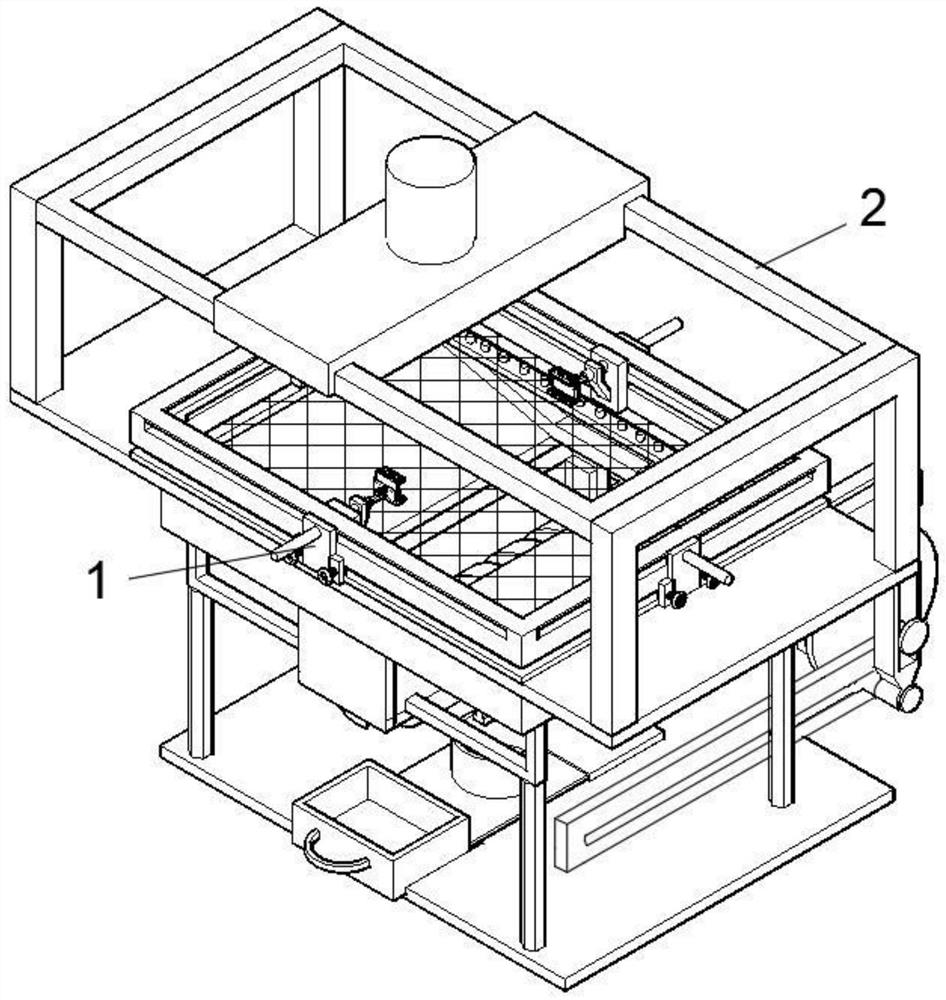

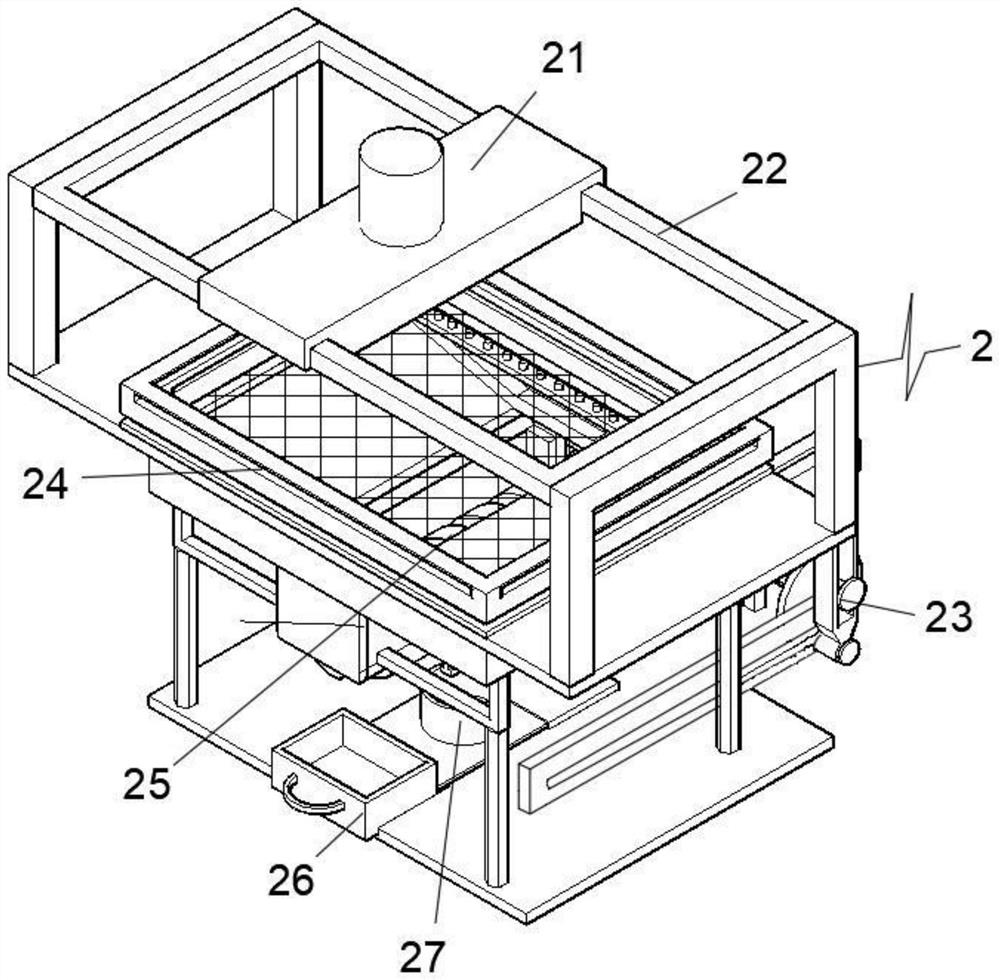

Test bench for testing comprehensive performances of ultrasonic drilling device

ActiveCN108871831AEffective use of ultrasonic vibration efficiencyReduce impactStructural/machines measurementMotor driveBall screw

The invention provides a test bench for testing the comprehensive performances of an ultrasonic drilling device. The frame of the test bench is shaped like L, and an impact force sensor is mounted onthe bottom surface of the frame. A rock sample is fixedly mounted on the impact force sensor, and the ultrasonic drilling device is vertically placed on the upper surface of the rock sample. The ultrasonic drilling device is fixedly connected with a loading platform, and the loading platform is fixedly connected with an adjusting mechanism. A rotating motor is mounted on a vertical column of the frame, and a ball screw is fixed inside the vertical column of the frame through a screw fixed end support seat and a screw movable end support seat. The rotating motor drives the ball screw to rotatethrough a shaft coupler, and a screw nut is fixed on the ball screw in a sleeved manner and is fixedly connected with the adjusting mechanism. The test bench solves a problem that the parameters, suchas the load spring stiffness, the loading force, the return spring stiffness and the restoring force, cannot be measured in the prior art, and proposes the test bench for testing the comprehensive performances of the ultrasonic drilling device, which can perform the testing of the influence of the above parameters on the drilling efficiency.

Owner:HARBIN INST OF TECH

Rotary-impact-type ultrasonic drilling device without free mass block

InactiveCN108952562ATurn aroundRealize impactWithdrawing sample devicesDrilling drivesDrive shaftTransducer

The invention provides a rotary-impact-type ultrasonic drilling device without a free mass block. A sampling drilling tool and a transmission shaft of the rotary-impact-type ultrasonic drilling machine are connected, and the periphery of the transmission shaft is sleeved with a longitudinal-longitudinal torsion composite piezoelectric transducer. A front shell, a rear shell and a rear bearing endcover are connected sequentially. The tail portion of the transmission shaft penetrates out of the rear bearing end cover. A rotor is connected with a loading spring, and the compression amount of theloading spring is adjusted by adjusting the position of a nut on the transmission shaft. The tail end of the longitudinal-longitudinal torsion composite piezoelectric transducer makes contact with the rotor. The tail end of the sampling drilling tool is sleeved with a return spring and a rotary shaft sleeve, the return spring and the rotary shaft sleeve are connected, and the sampling drilling tool penetrates out of the head portion of the front shell. Through the rotary-impact-type ultrasonic drilling device without the free mass block, the problem that ultrasonic drilling machines in the prior art are all provided with free mass blocks, two times of contact collision needs to be completed, and consequently, energy is lost is solved, the free mass block is omitted, collision only needs to be completed once, and thus the energy transmitting efficiency of the ultrasonic drilling machine is improved.

Owner:HARBIN INST OF TECH

Drilling mechanism for small celestial body star catalogue

The invention relates to a drilling mechanism for a small celestial body star catalogue, belongs to the technical field of aerospace deep space exploration, and aims at carrying out automatic drillingand sample collection tasks on a small celestial body surface layer sample. A weak-gravitation star catalogue drilling mechanism for deep space exploration adopts an ultrasonic drill for drilling, and can realize small-feeding-force and large-hardness sample drilling; in the drilling process, the samples are concentrated together, and after the samples are drilled to the specified depth, the sample collecting container can be closed. The protection points are a weak gravity star catalogue drilling mechanism design scheme, a working principle, a grounding assembly design and an ultrasonic drilling and sample collection integrated design scheme.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

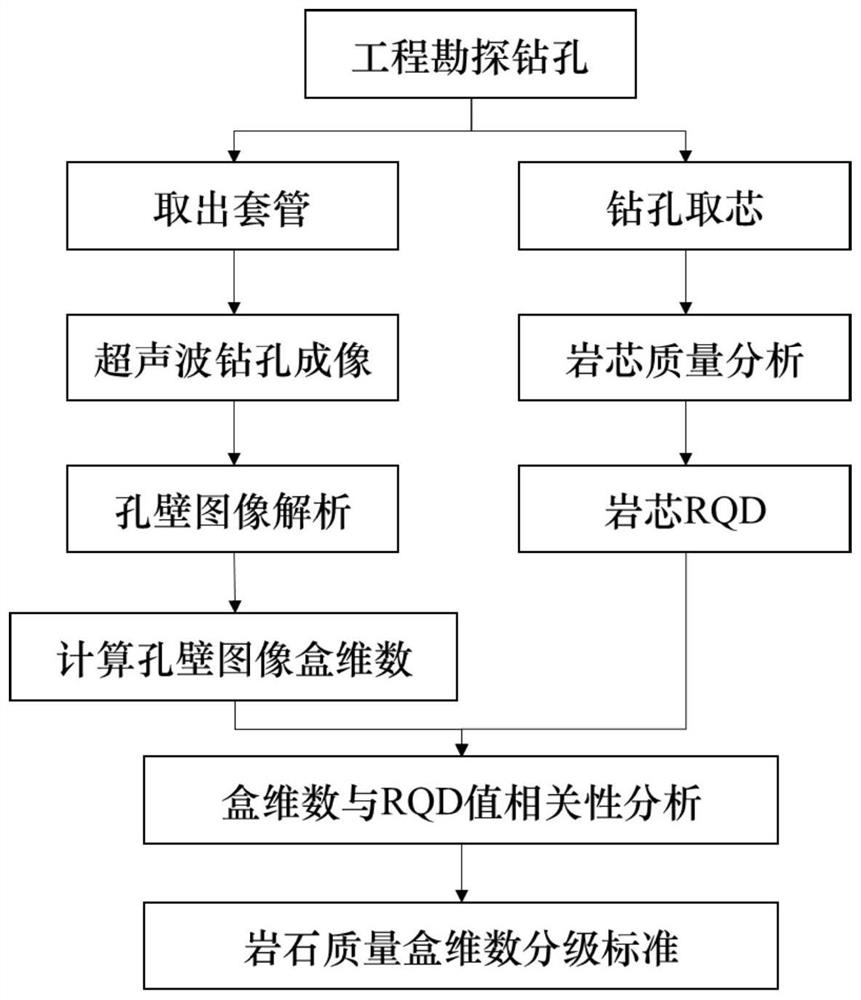

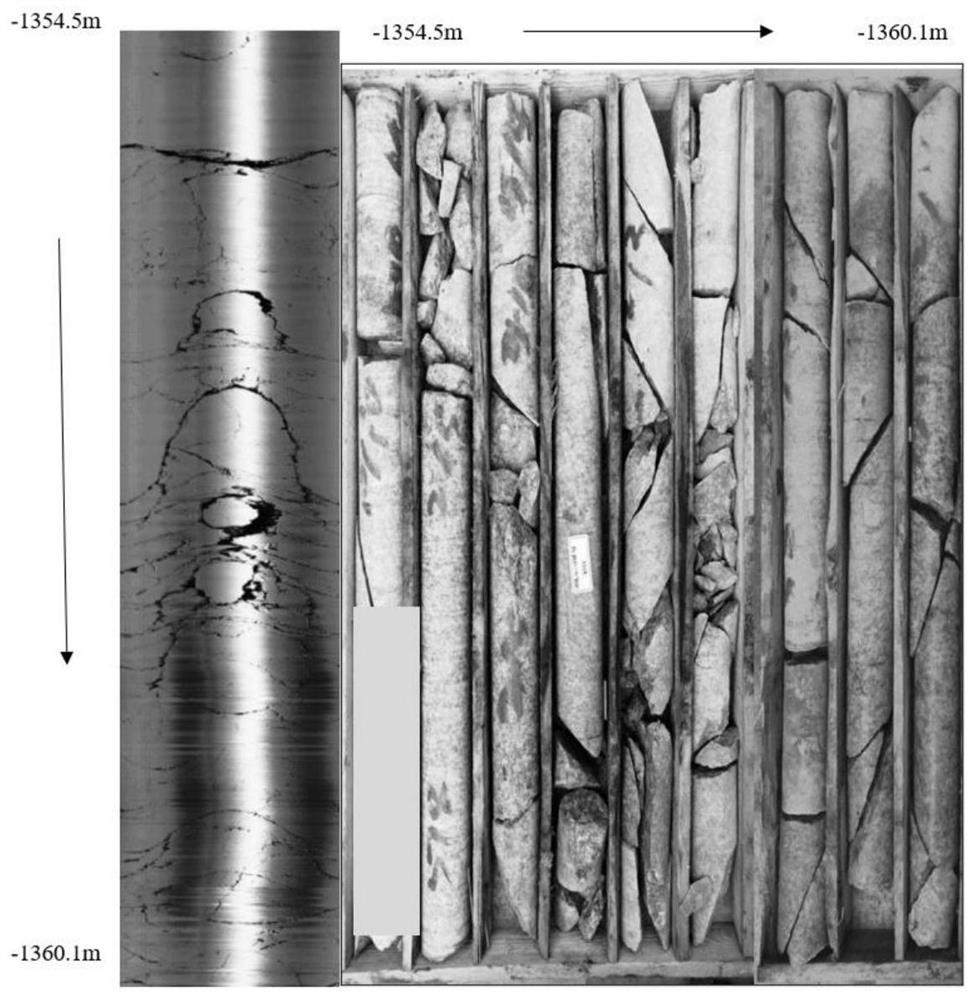

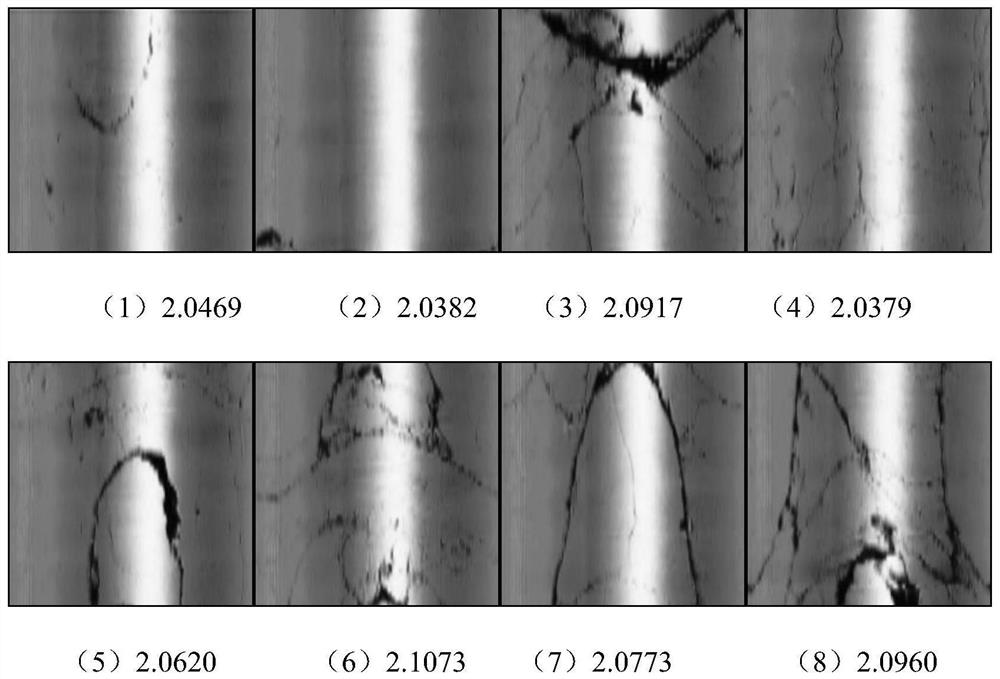

Rock mass quality evaluation method based on ultrasonic drilling imaging technology and fractal method

The invention provides a rock mass quality evaluation method based on an ultrasonic drilling imaging technology and a fractal method, and belongs to the technical field of engineering investigation. The method comprises the steps that firstly, a drill hole is formed in a stratum or a rock mass through a drilling technology; then a hole wall image of the drill hole is obtained in situ through the ultrasonic drilling imaging technology, and due to the self-similar characteristics of an internal structural surface of the rock mass, a fractal box dimension value of the hole wall image can be obtained by utilizing the fractal method according to the characteristics; and then a quantitative relation between the fractal box dimension value of the hole wall image and the rock quality is established, so that the rock quality in the detected stratum is rapidly and accurately evaluated without taking a rock core, the construction period is shortened, and especially the exploration efficiency is improved in a deep construction process.

Owner:UNIV OF SCI & TECH BEIJING

Numerical control ultrasonic drilling machine tool

InactiveCN114226780AAvoid stockpilingSpeed up dischargeCleaning using toolsPositioning apparatusNumerical controlEngineering

The invention relates to the field of drilling machine tools, in particular to a numerical control ultrasonic drilling machine tool which comprises a supporting storage device, fixed limiting claws are symmetrically inserted into the supporting storage device in a sliding mode, and each fixed limiting claw comprises an inserting rod, a fastening screw, a fixed clamping plate, a fixed bottom plate, a movable clamping plate, a sliding key, a fixing screw, a limiting plate and an air cylinder. The fixing screws are symmetrically inserted into the side end of the limiting plate in a threaded mode, the air cylinder is fixedly connected to the top end of the interior of the limiting plate and the top end of the interior of the movable clamping plate, the sliding key is fixedly welded to the end, close to the limiting plate, of the movable clamping plate, and the inserting rod is slidably inserted into the air cylinder. Workpieces of different thicknesses can be clamped through the arrangement of the fixed limiting claw, the fixed limiting claw can move in the supporting and storing device, the workpieces can be moved without disassembling the fastening device, and through the arrangement of the supporting and storing device, chippings generated during work of the device can be stored and treated in time.

Owner:项城林

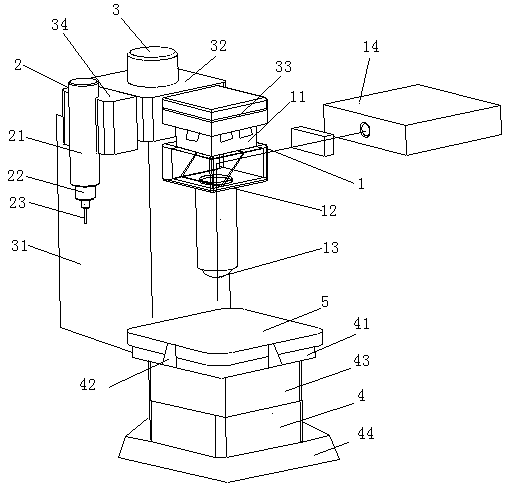

A laser and ultrasonic composite drilling processing system and processing method thereof

InactiveCN106513986BQuality improvementHigh precisionLaser beam welding apparatusLaser processingUltrasonic machining

The invention relates to the machining field of drilling holes in hard and brittle materials, in particular to a laser and ultrasound combined type drilling system and a machining method thereof. According to the laser and ultrasound combined type drilling system, the hard and brittle materials can be protected, high-speed machining can be realized and locating can be accurate. The laser and ultrasound combined type drilling system mainly comprises a laser machining system, an ultrasonic machining system, a precision rotating and locating mechanism and an axis aligning system, wherein the laser machining system and the ultrasonic machining system are installed on the precision rotating and locating mechanism to regulate locating. The axis aligning system mainly comprises a locating panel, locking structures, a gravity center sensor, a distance sensor, an oriented adjusting structure, a movement adjusting base and a drive control device, and the locating panel is a thin supporting panel loading work-pieces to be machined. Through a combined drilling method, the hard and brittle work-pieces can be machined at high speed and high precision. The laser machining system and the ultrasonic machining system are adopted for combined machining procedures, and therefore pre-drilling can be carried out in advance, high-speed operation can be realized, the quality of the work-pieces can be protected, and the surface machining precision can be improved.

Owner:DONGGUAN UNIV OF TECH +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com