Patents

Literature

438results about How to "Speed up discharge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

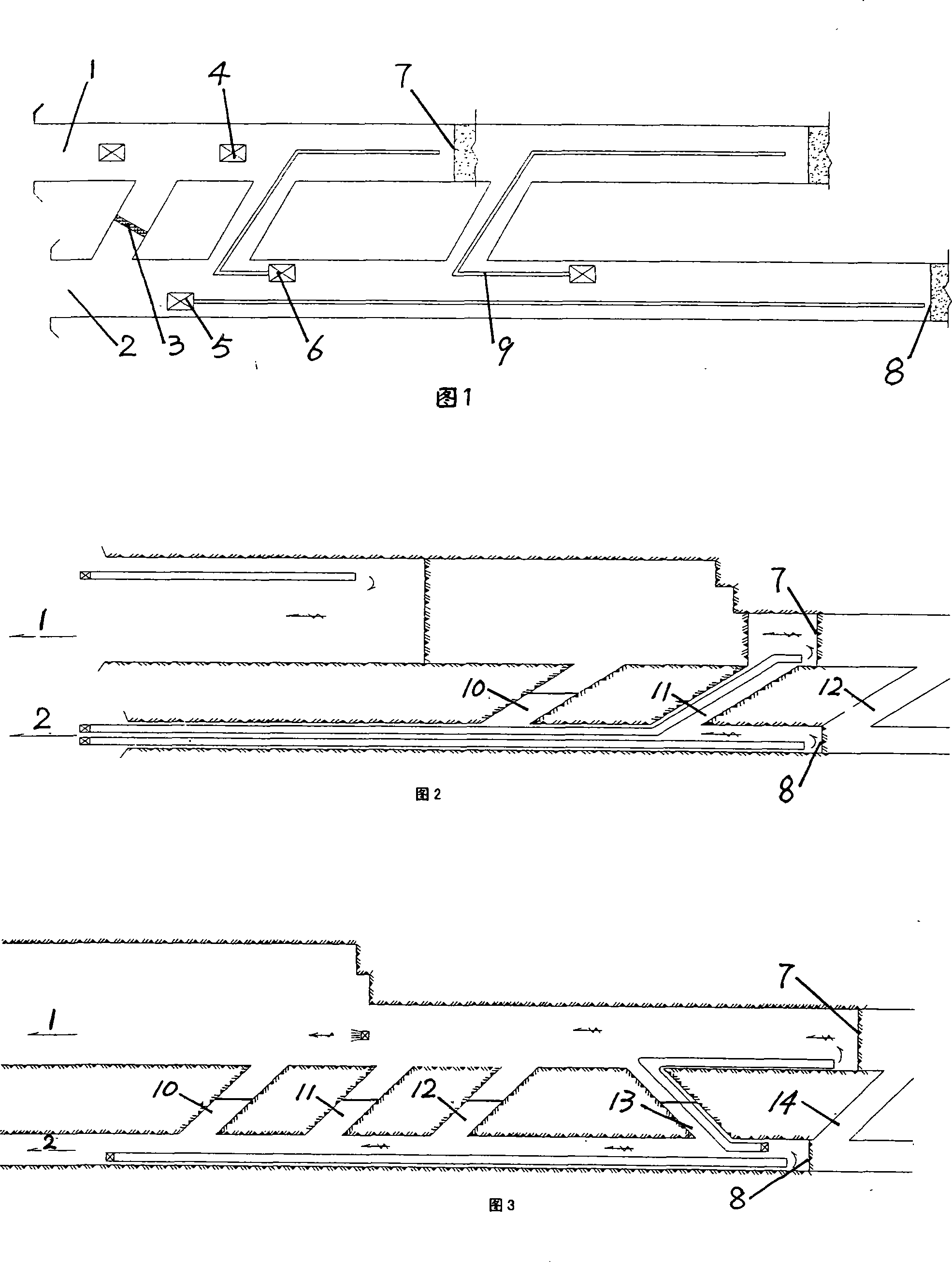

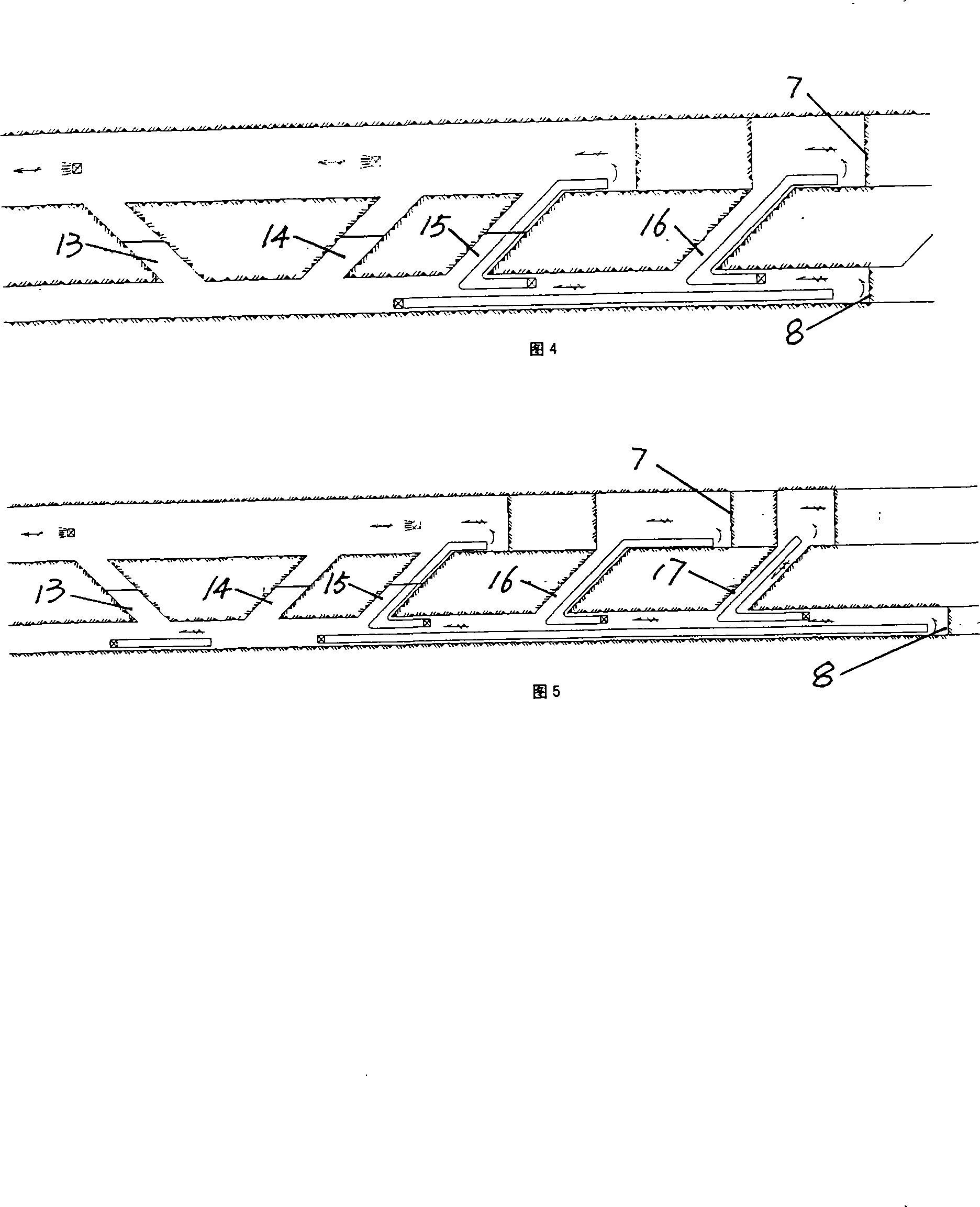

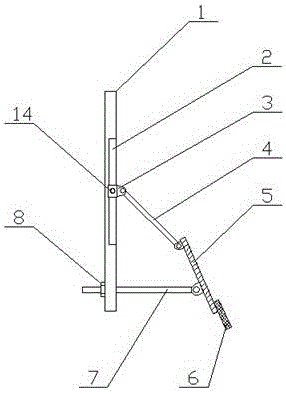

Laneway type ventilating technique for long and large tunnel

The invention relates to a long tunnel gallery ventilation technique, solving the problems that poor ventilation performance, high construction cost and hindering construction of the prior art, belonging to the field of tunnel construction technique, which is characterized in that an exhaust fan is arranged in the main tunnel to pump the foul air; the flat tunnel mouth has no plugging obstacle, and a plurality of blowers are arrange at the position having fresh air entering from the flat tunnel mouth; the blower transfers fresh air to different working positions via a blowing ventilator. The long tunnel gallery ventilation technique has the advantages that: 1. saving the length of laying air duct, in particular to long tunnel with considerable amount of ducts; 2. using low power jet blower instead the main blower to save electricity; 3. speeding up the discharge of the foul air, having good visible condition and enough oxygen content; 4. the smoke of working position is exhausted in short time which speeds up the construction; 5. the flat tunnel has no air dampers which realizes no obstacle plugging and the improvement of the traffic environment.

Owner:THE 4TH ENG CO LTD OF CHINA RAILWAY 17TH BUREAU GRP

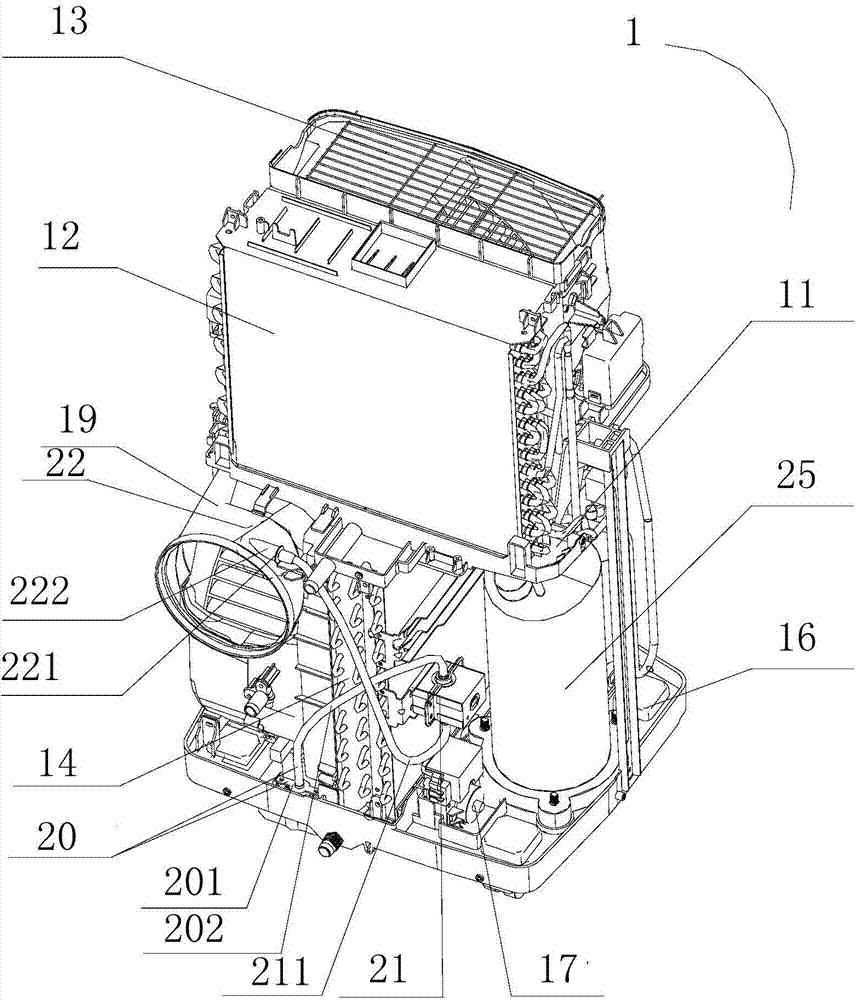

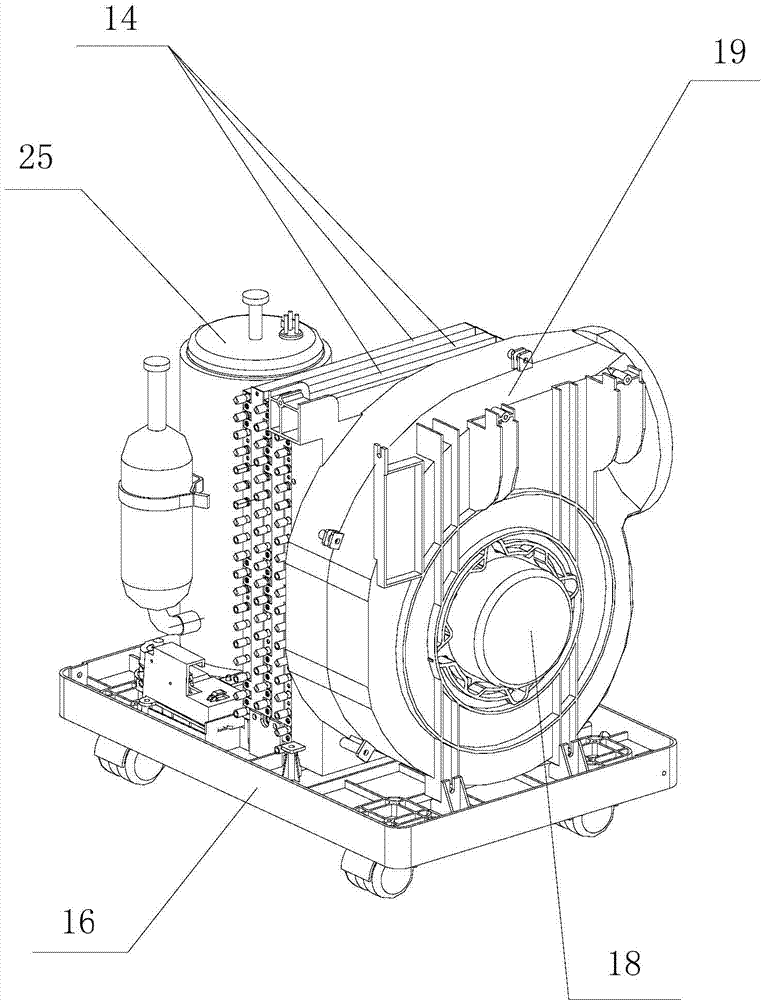

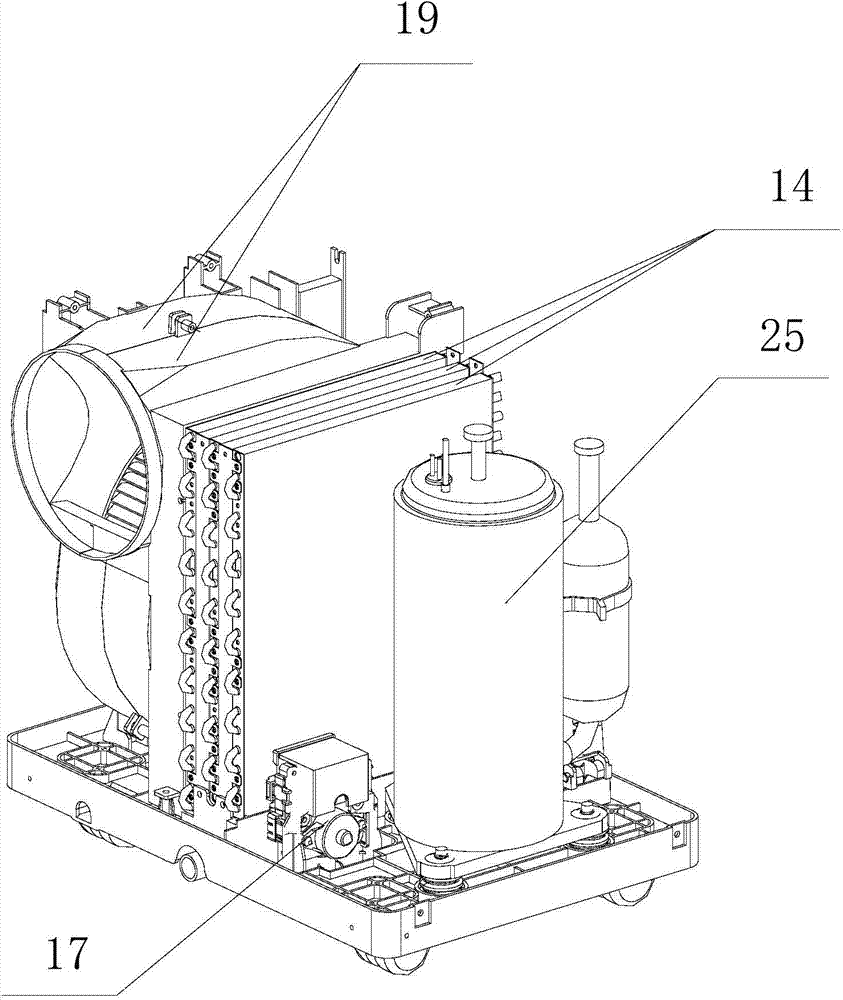

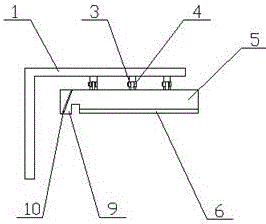

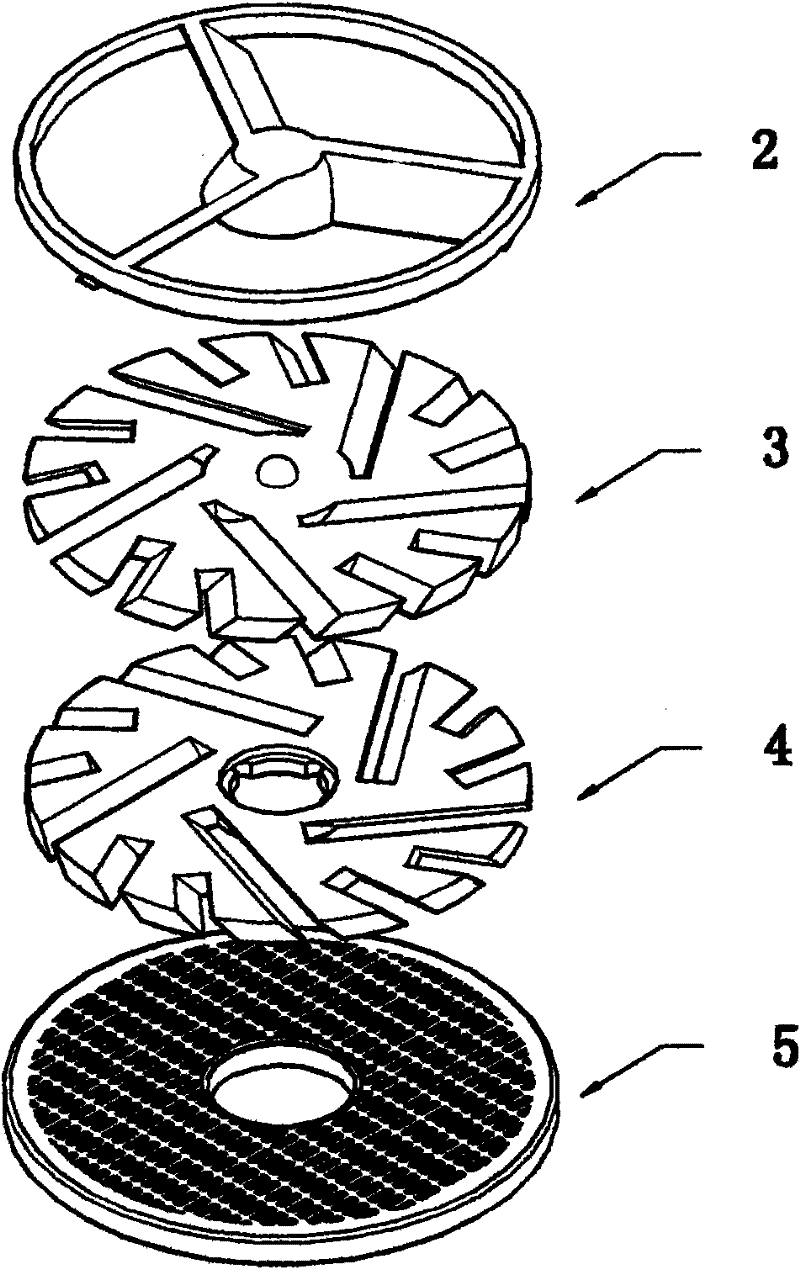

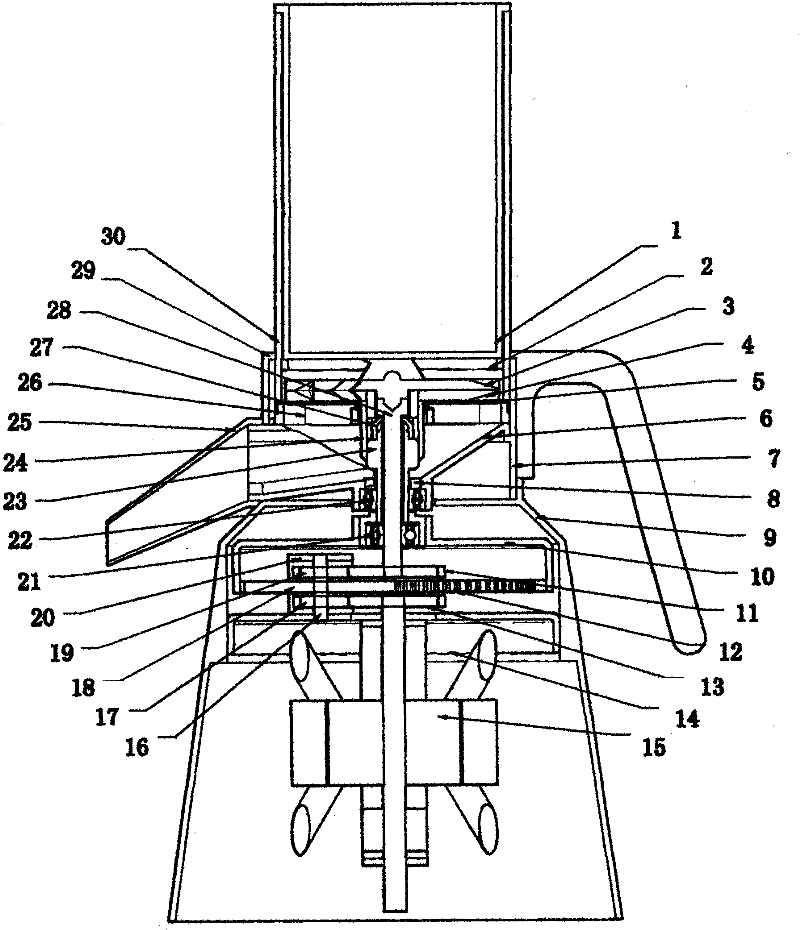

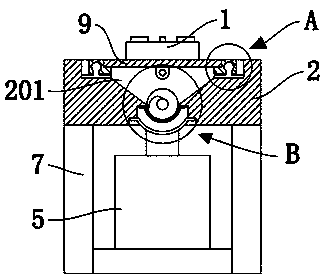

Integrated air conditioner and condensed water processing method for integrated air conditioner

ActiveCN104764095AImprove human needsFully recycleCondensate preventionLighting and heating apparatusEnvironmental engineeringWater processing

The invention discloses an integrated air conditioner and a condensed water processing method for the integrated air conditioner. The integrated air conditioner comprises an indoor water receiving plate, a drainage device connected with the indoor water receiving plate and used for leading the condensed water in the indoor water receiving plate to the outer side walls of multiple rows of condensers of the integrated air conditioner, the multiple rows of condensers used for heating condensed water on the outer side walls to at least vaporize part of the condensed water, a water tank arranged on a chassis of the integrated air conditioner and used for receiving non-vaporized condensed water on the outer side wall, and a water beating motor which comprises a plurality of water beating wheels and is used for beating the non-vaporized condensed water to the outer side walls of the condensers through the water beating wheels so as to enable the multiple rows of condensers to vaporize the non-vaporized condensed water again. By means of the technical scheme, the condensed water in the integrated air conditioner can be discharged automatically, and a user is protected from manually discharging the condensed water.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

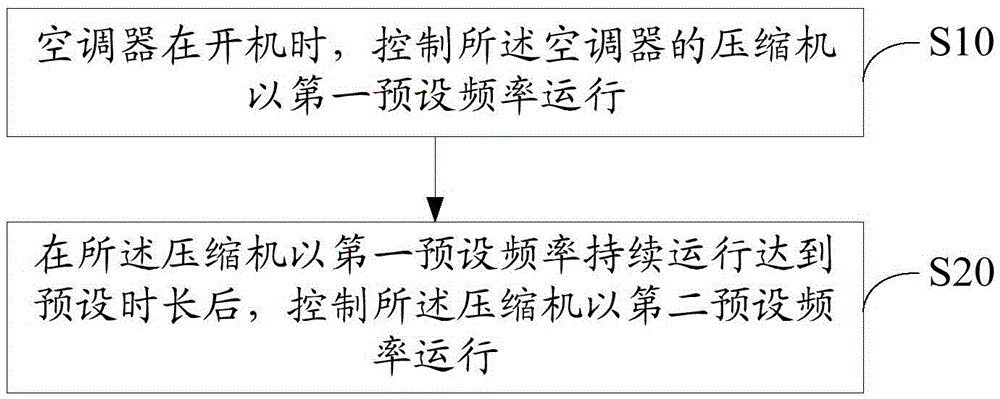

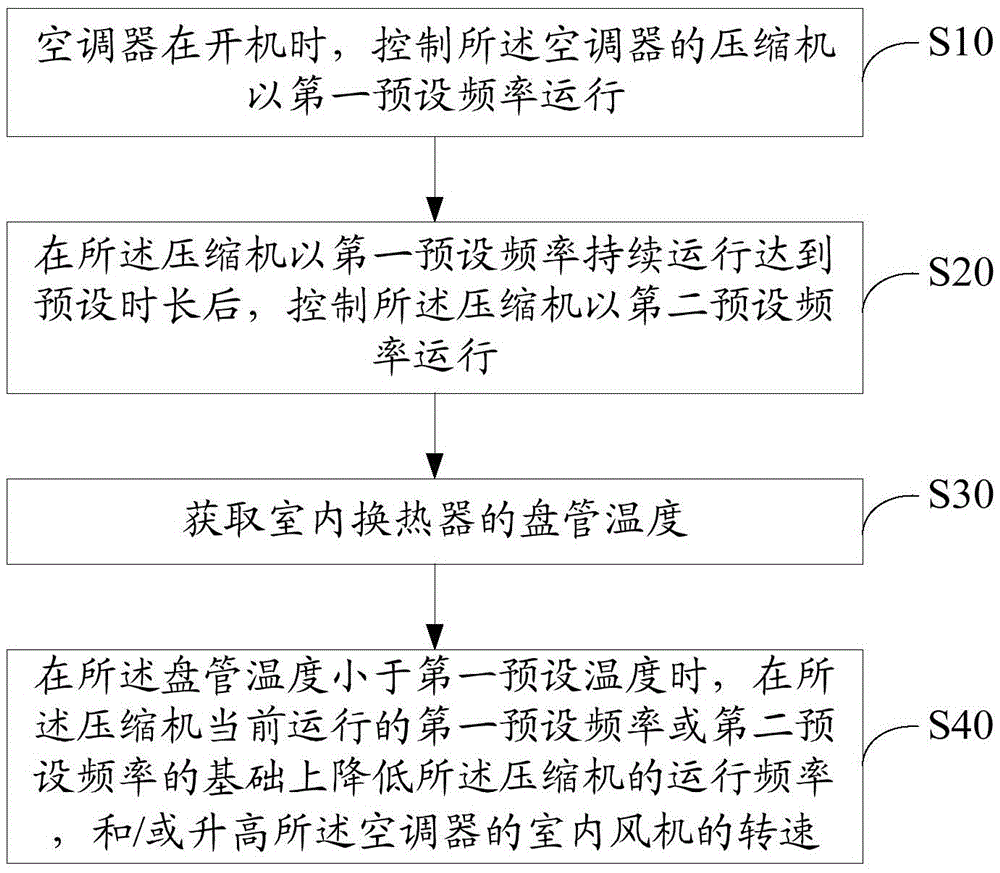

Water blowing prevention control method for air conditioner and air conditioner

InactiveCN105571084AReduce the amount of condensateSpeed up dischargeCondensate preventionSpace heating and ventilation safety systemsControl theoryPrevention control

The invention discloses a water blowing prevention control method for an air conditioner. The water blowing prevention control method comprises the following steps: when the air conditioner is switched on, controlling a compressor of the air conditioner to operate at a first preset frequency; after the compressor is kept operating at the first preset frequency for preset time, controlling the compressor to operate at a second preset frequency, wherein the first preset frequency is smaller than the second preset frequency. The invention further discloses the air conditioner. According to the water blowing prevention control method and the air conditioner, the amount of condensed water produced when the air conditioner is just switched on can be effectively reduced; furthermore, the condensed water discharging speed can be increased after the air conditioner is switched on for preset time, thus effectively preventing the water blowing phenomenon.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

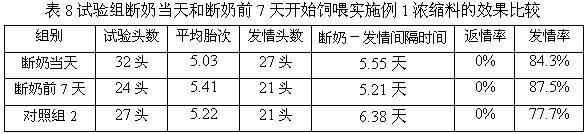

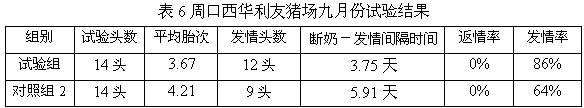

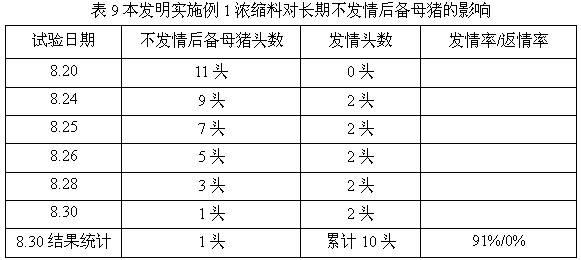

Concentrated feed for barren sows

ActiveCN102038114AChange in adhesionSpeed up dischargeAnimal feeding stuffAccessory food factorsSodium bicarbonateAnimal science

The invention relates to a concentrated feed for barren sows, and per 1,000 parts by weigh of the concentrated feed comprises the following raw materials in parts by weight: 490 to 510 parts of puffed bean pulps, 240 to 260 parts of puffed soybeans, 70 to 90 parts of fish meals, 3 to 5 parts of microbial ecological agents, 15 to 25 parts of glucoses, 35 to 45 parts of mountain flour, 35 to 45 parts of calcium hydrophosphate, 10 to 20 parts of table salt, 3 to 4 parts of sodium bicarbonate, 3 to 7 parts of composite trace elements, 0.6 to 0.7 parts of chromium picolinate, 5 to 8 parts of compound amino acid, 0.006 to 0.01 parts of folic acid, 0.9 to 1.5 parts of boar composite many-dimensions, 0.3 to 0.4 parts of vitamin E, 1 to 2 parts of vitamin C, 0.9 to 1.5 parts of beta-carotene, 1 to 2 parts of flavoring agents, 0.09 to 0.15 parts of phytase, 1 to 2 parts of ethoxy quinoline, 2 to 3 parts of choline chloride, and the balance of carriers. In case of adding 30 percent of the concentrated feed into daily fodders for sows, the interval time from ablactation to oestrus can be shortened, thereby improving the oestrous rate, litter size and the like of the sows.

Owner:河南雄峰科技股份有限公司

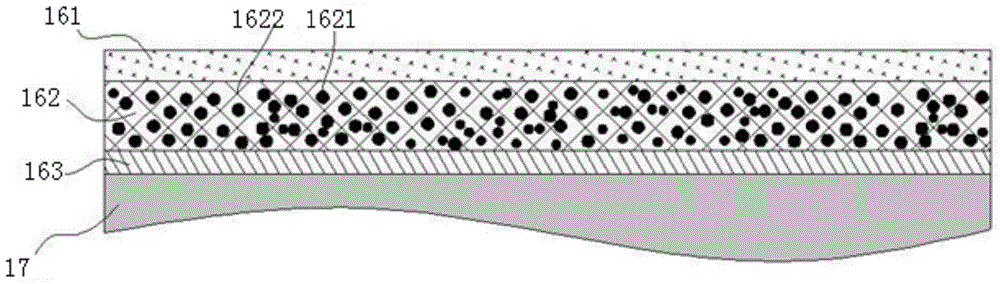

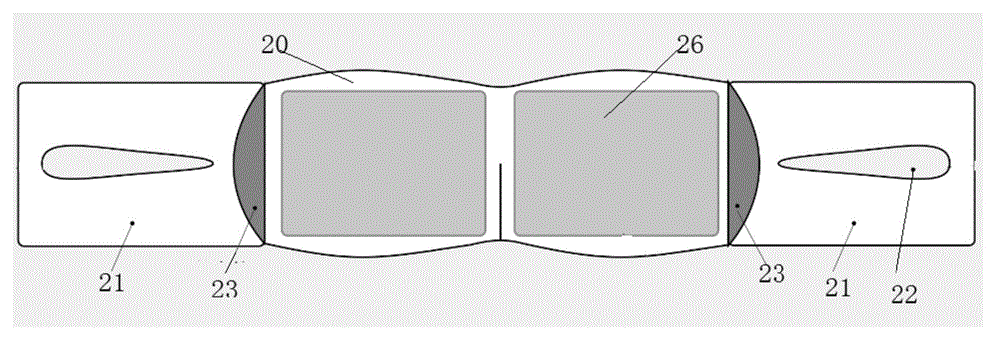

Spontaneous-heating thermal insulation eye mask

ActiveCN104127280ASpeed up dischargePromote absorptionTherapeutic coolingTherapeutic heatingThermal insulationEnvironmental resource

The invention discloses a spontaneous-heating thermal insulation eye mask. The parts corresponding to the eyes of a human body respectively have at least three layers of structures. At each part, the three layers of structures comprise an outer layer formed by breathable materials, a heating layer and a thermal insulation layer made of waterproof thermal insulation materials, wherein the heating layer is provided with a heating compound which can conduct heating by making contact with air and an upper cover which at least makes contact with the outer layer and is made of breathable materials. The spontaneous-heating thermal insulation eye mask is simple in structure and cannot be limited by environmental resources, the situation that external resources supply energy to the spontaneous-heating thermal insulation eye mask is avoided, and the spontaneous-heating thermal insulation eye mask can conduct heating safely, stably and evenly, effectively prolong the heating time and reduce the heating peak temperature. The spontaneous-heating thermal insulation eye mask can improve blood circulation of the eyes and enables skin pores to be enlarged so as to discharge sweat and dirt oil. When the spontaneous-heating thermal insulation eye mask is used together with a traditional skin care product, the spontaneous-heating thermal insulation eye mask can improve absorption of effective components of the traditional skin care product, can further increase the skin care effect while reducing the use amount of the skin care product, and is safe and sanitary to use and low in cost.

Owner:HANDY TECH ZHUHAI LTD

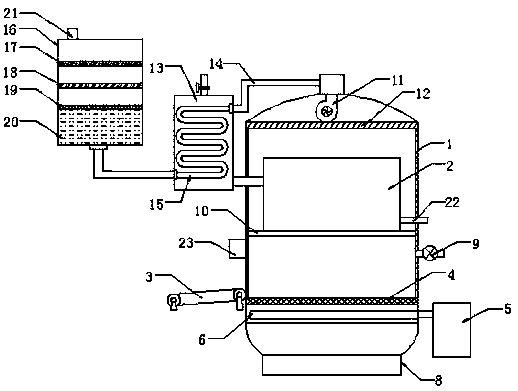

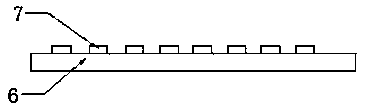

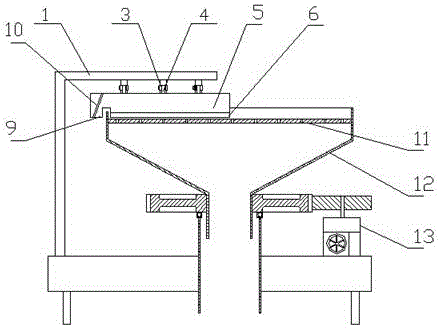

Environment friendly type industrial smoke overall treatment boiler and using method thereof

InactiveCN108645021ABurn evenlyBurn fullySolid fuel combustionCombustion technology mitigationCoalEngineering

The invention discloses an environment friendly type industrial smoke overall treatment boiler which comprises a boiler body, a heat exchange box and a purification box. A base is arranged at the bottom end of the boiler body, a burning cavity is arranged inside the boiler body, a burning separating plate is arranged at the lower end of the burning cavity, a fuel gas pipe is arranged below the burning separating plate, one end of the fuel gas pipe is connected with a fuel gas device, a feeding opening is formed in one side of the burning cavity, a conveying belt is arranged on the outer side of the feeding opening, a combustion-supporting pump is arranged on one side of the burning cavity, a supporting plate is arranged above the burning cavity and supports a water tank, and water in the water tank is heated to be discharged through a water discharging pipe; and the heat exchange box is arranged, heat of smoke in a smoke pipe is transferred to water in the heat exchange box, the waterin the heat exchange box is preheated, the water heating speed is increased, the heat energy is sufficiently used, the using amount of fire coal can be reduced, and energy conservation and emission reduction are achieved. The environment friendly type industrial smoke overall treatment boiler is reasonable in design, practical, feasible, more user-friendly and suitable for application and popularization.

Owner:王连会

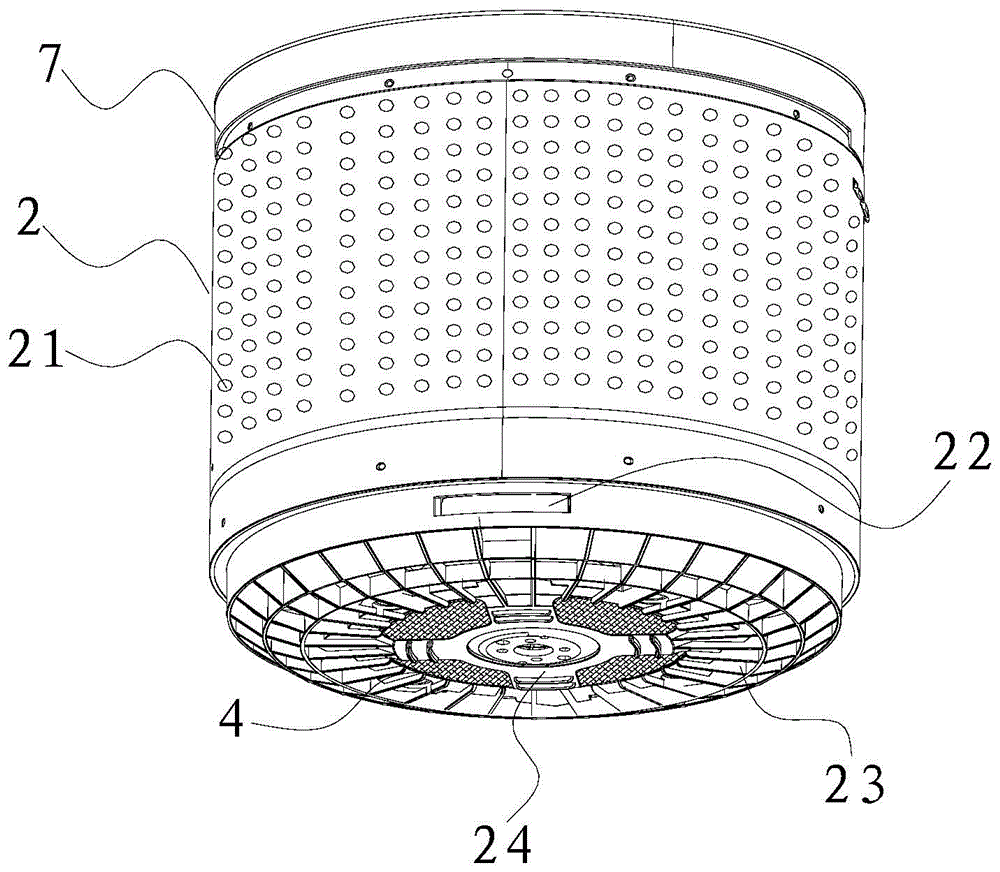

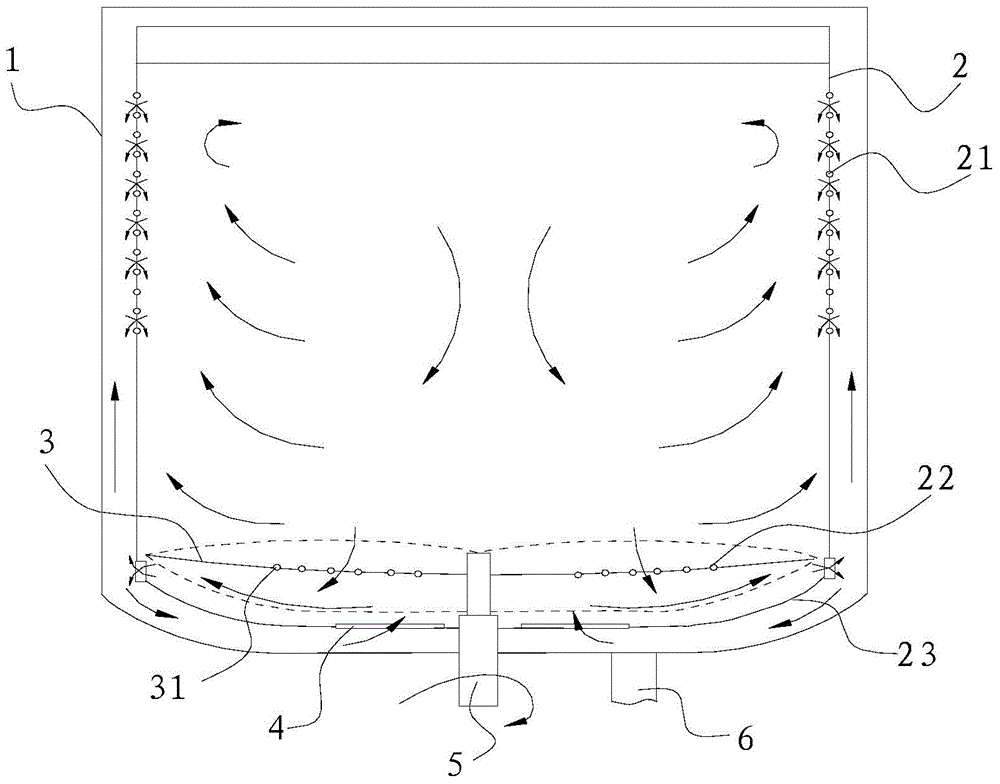

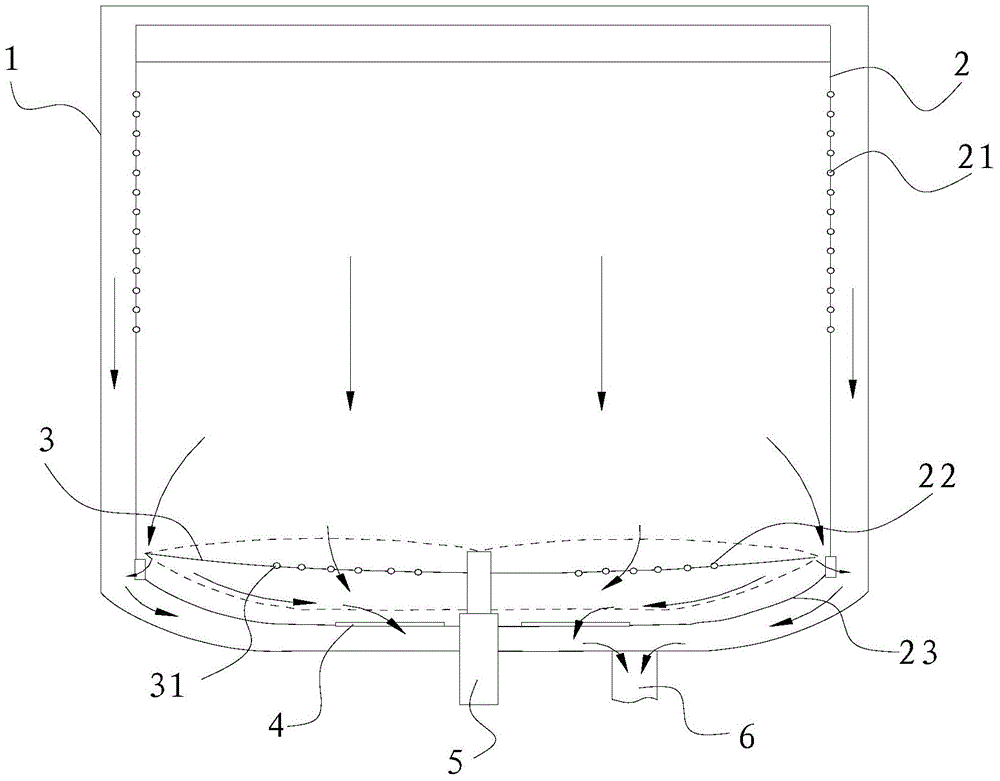

Washing machine drainage control method

ActiveCN105088643ASpeed up dischargeIncrease flushing powerControl devices for washing apparatusTextiles and paperImpellerWater flow

The invention provides a washing machine drainage control method and belongs to the field of washing device control. The invention aims to solve the problem of poor automatic cleaning effect of filter screens of the conventional washing machines. The washing machine drainage control method is characterized in that the rotating speed of an inner barrel and / or an impeller is controlled in a drainage process and the flow speed of washing liquor is controlled by controlling the rotating speed of the inner barrel and / or the impeller to clean a filter screen through back flushing. The washing machine drainage control method improves the filter screen cleaning effect; the rotation of the inner barrel and / or the impeller increases the discharge speed of the washing liquor, so that the filter screen cleaning effect can also be improved. When the water level is relatively low, the inner barrel and / or the impeller rotate(s) at a relatively high speed and wave-like high speed rotating water flow containing a large number of bubbles is generated in the inner barrel; the high speed wave-like bubble water flow can wash thread residues attached to the filter screen away, so that the filter screen is cleaned automatically.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

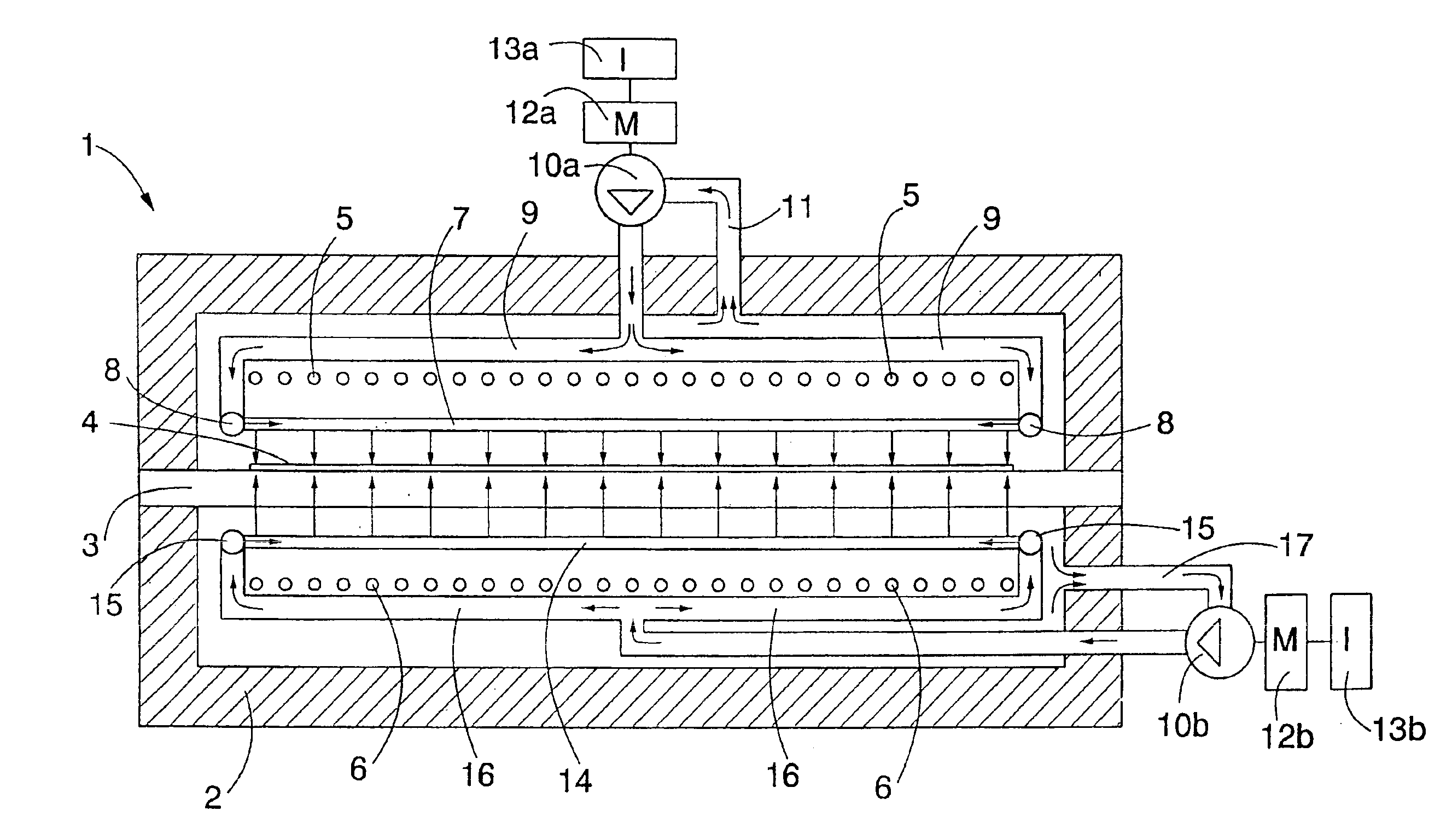

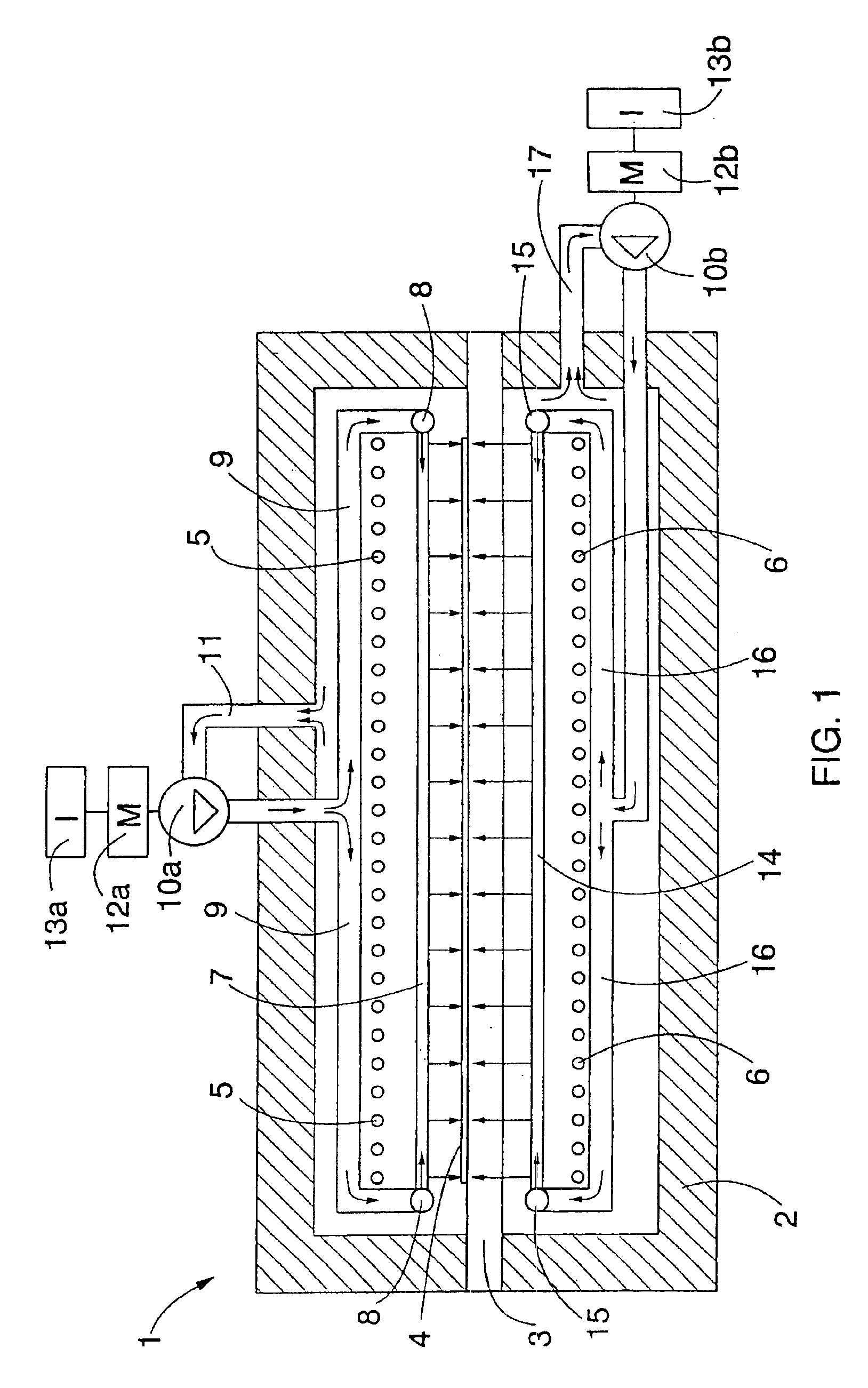

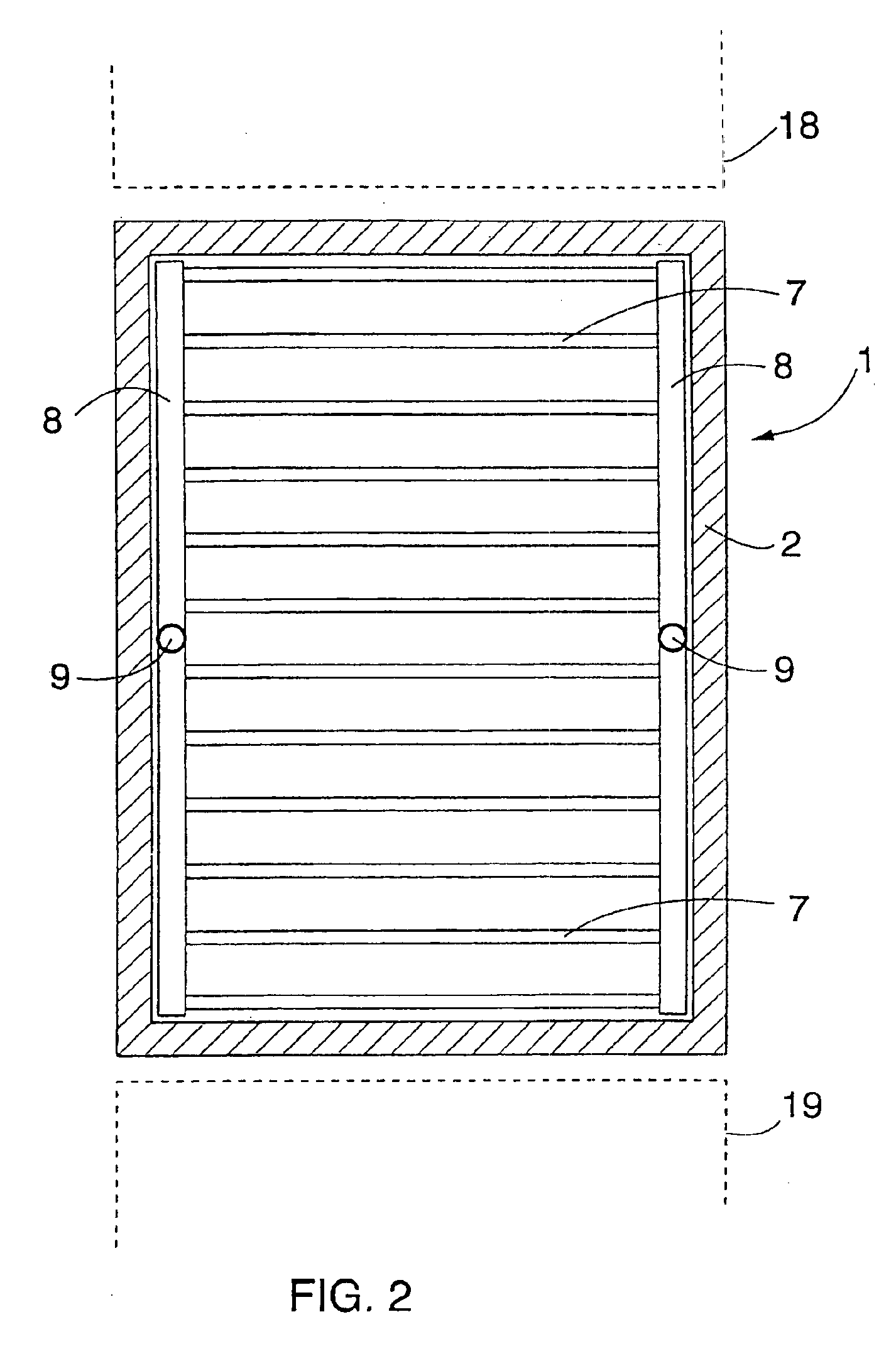

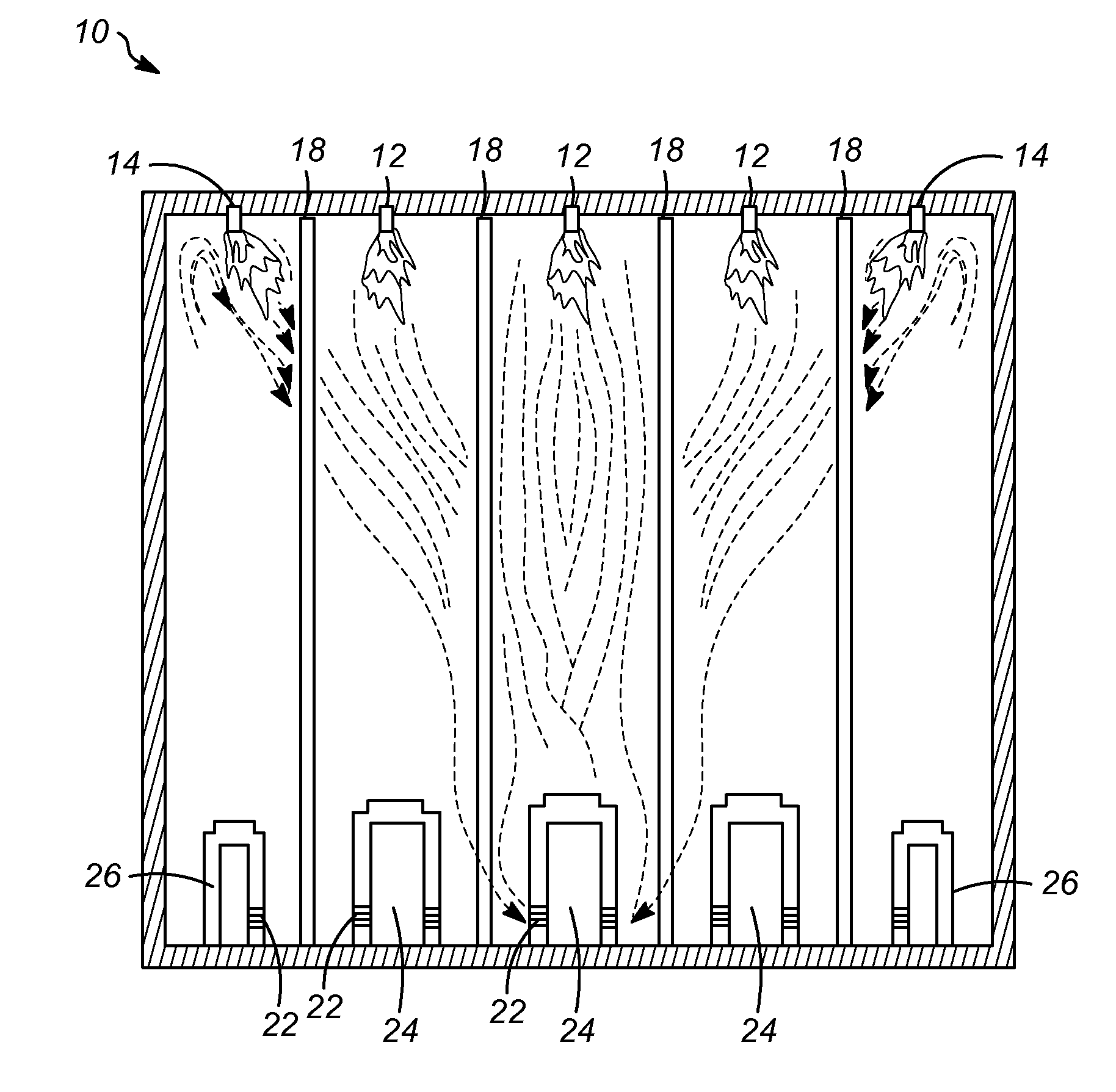

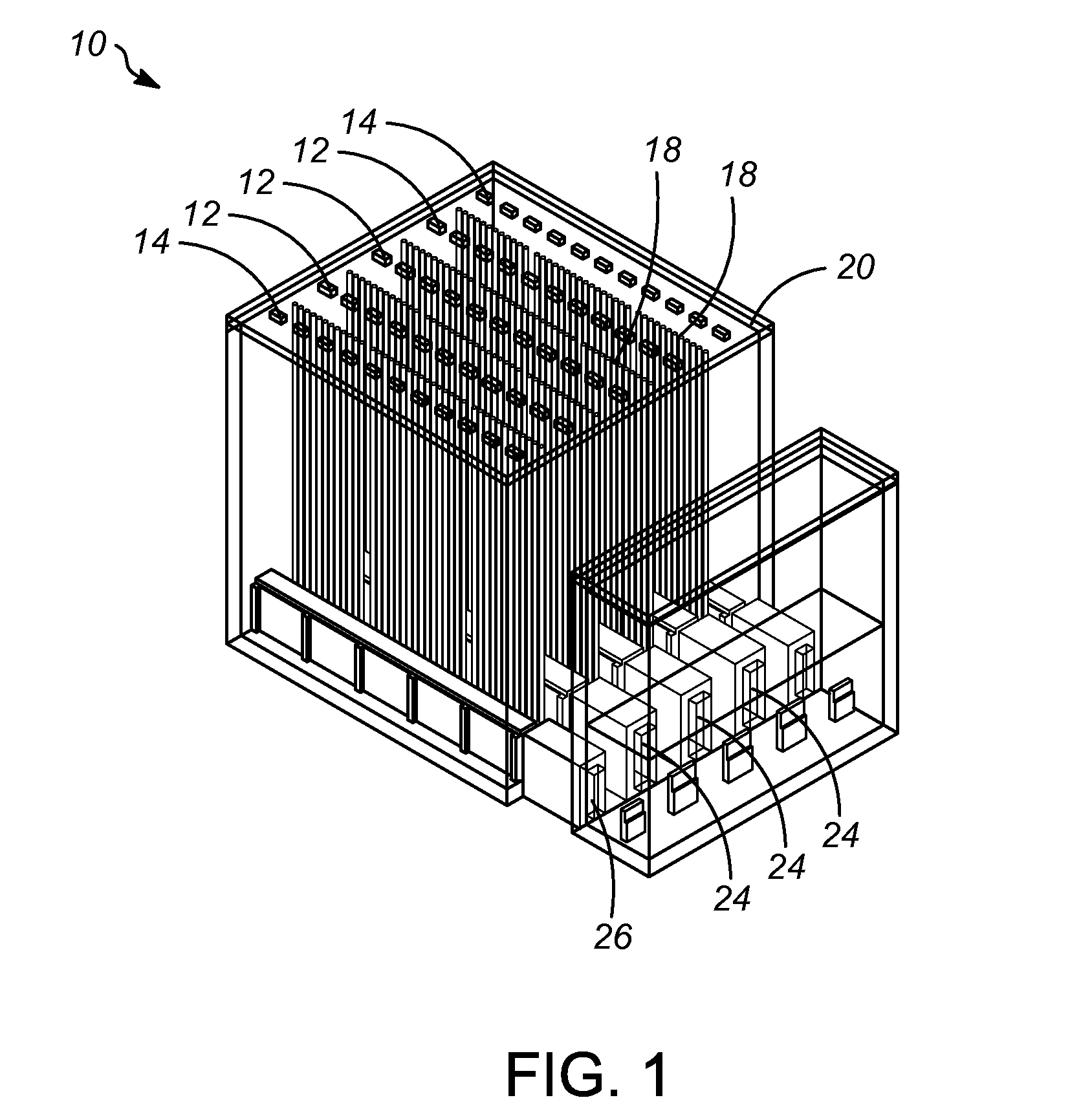

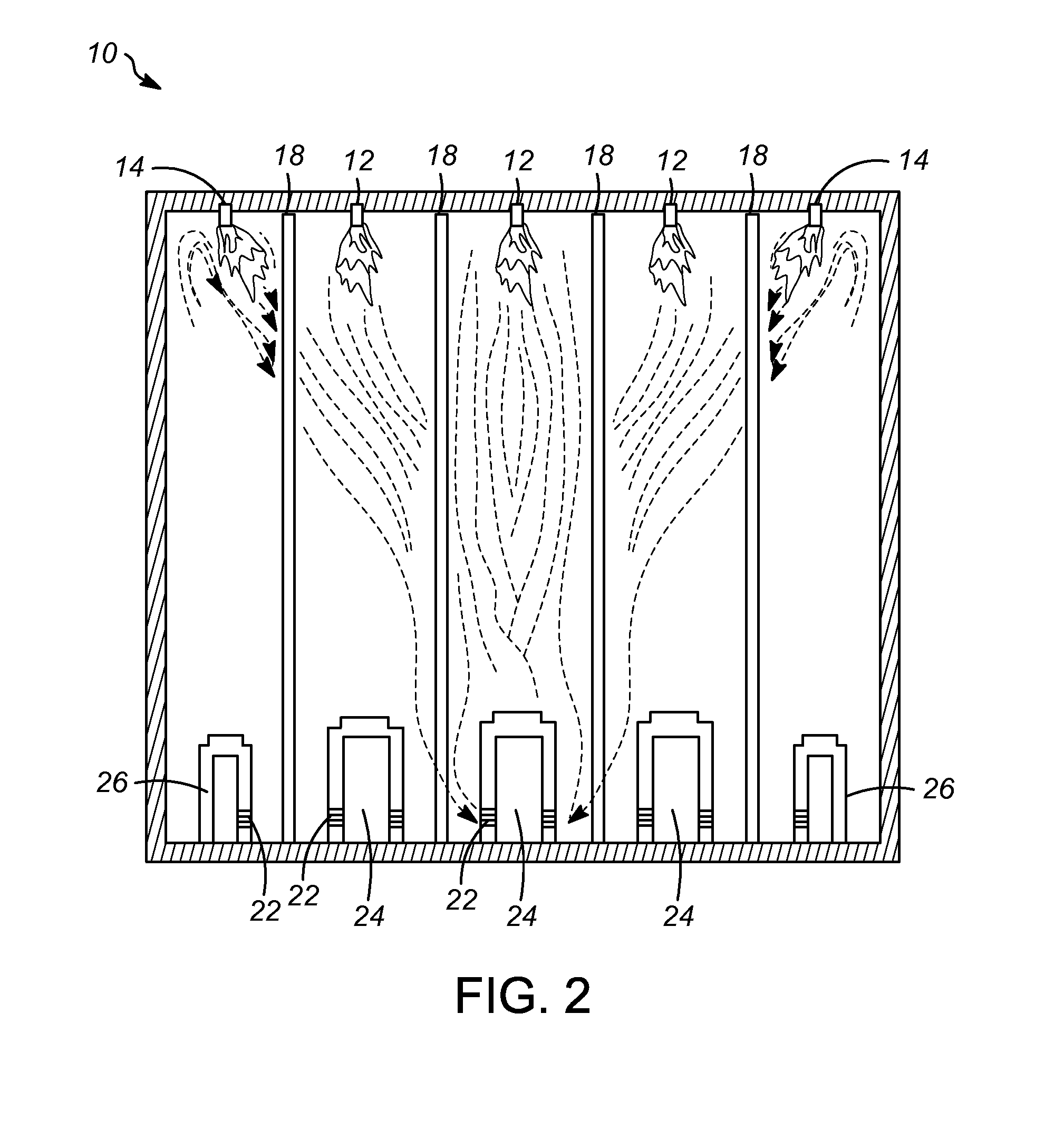

Method and apparatus for heating glass

InactiveUS6881931B2High discharge velocityHigh coefficientGlass drawing apparatusBaking ovenEngineeringHeatable glass

A method and apparatus for heating glass, in which glass (4) is heated upon rollers (3) in a tempering furnace (1) from above and below of the glass (4). At least the upper surface of the glass (4) is heated with hot air jets directed substantially perpendicularly relative to the surface of the glass (4). The air jets have been provided by sucking air mainly from the inside of the furnace and by pressurizing the air taken from the inside of the tempering furnace (1) to an overpressure of over 0.1 bar relative to the pressure in the tempering furnace (1).

Owner:UNIGLASS ENG

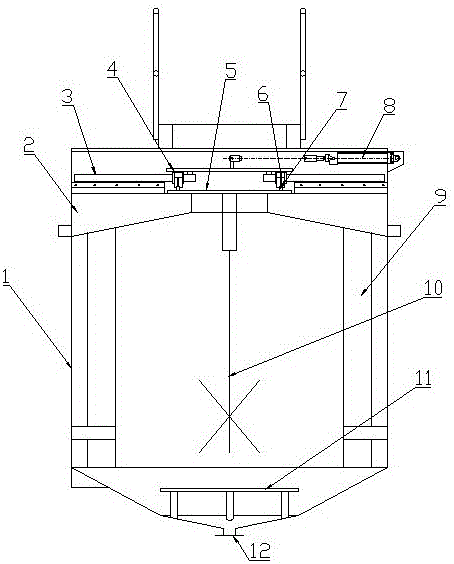

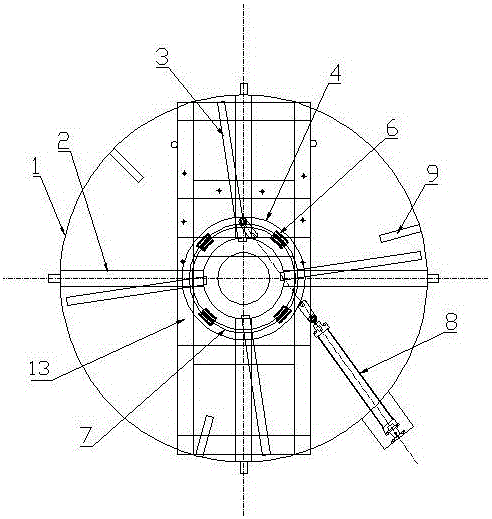

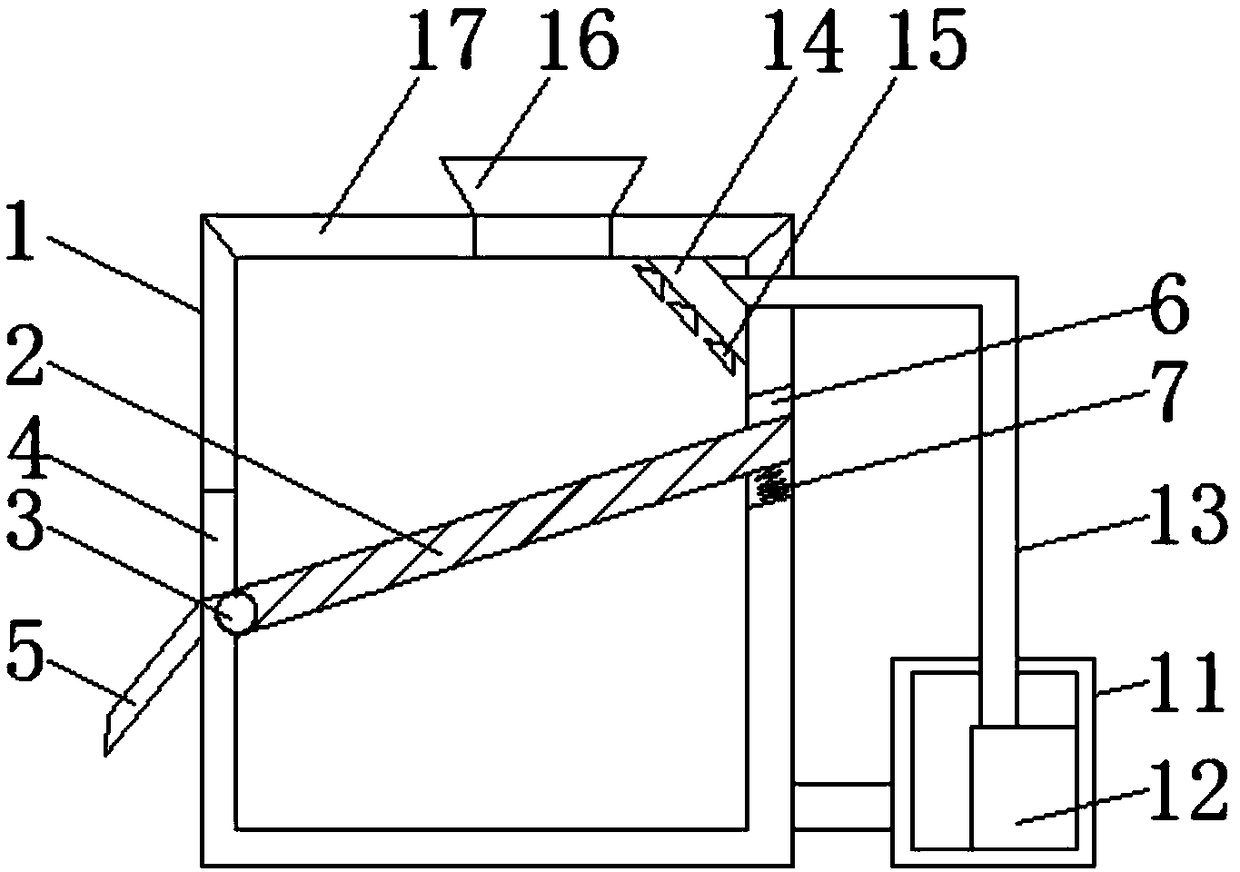

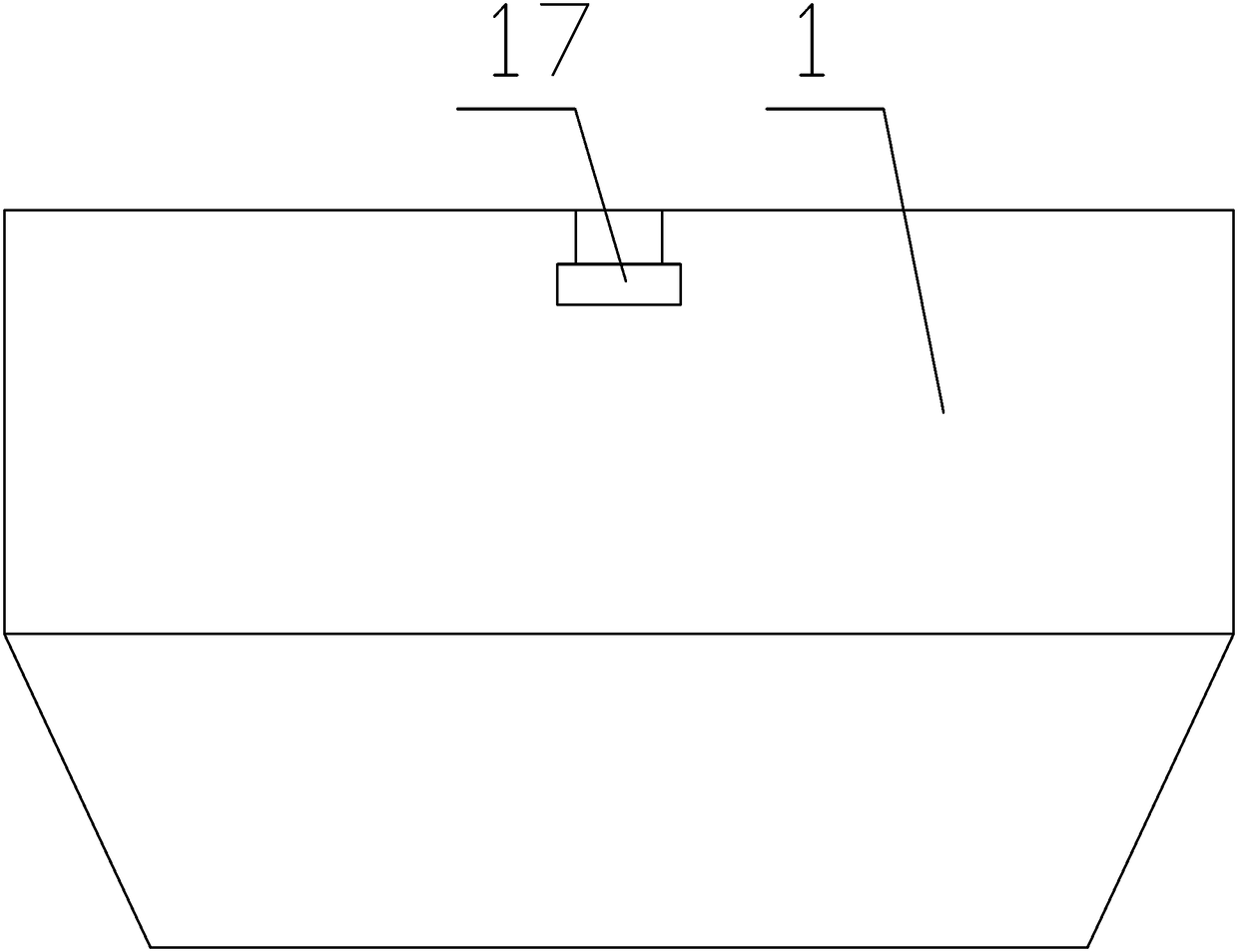

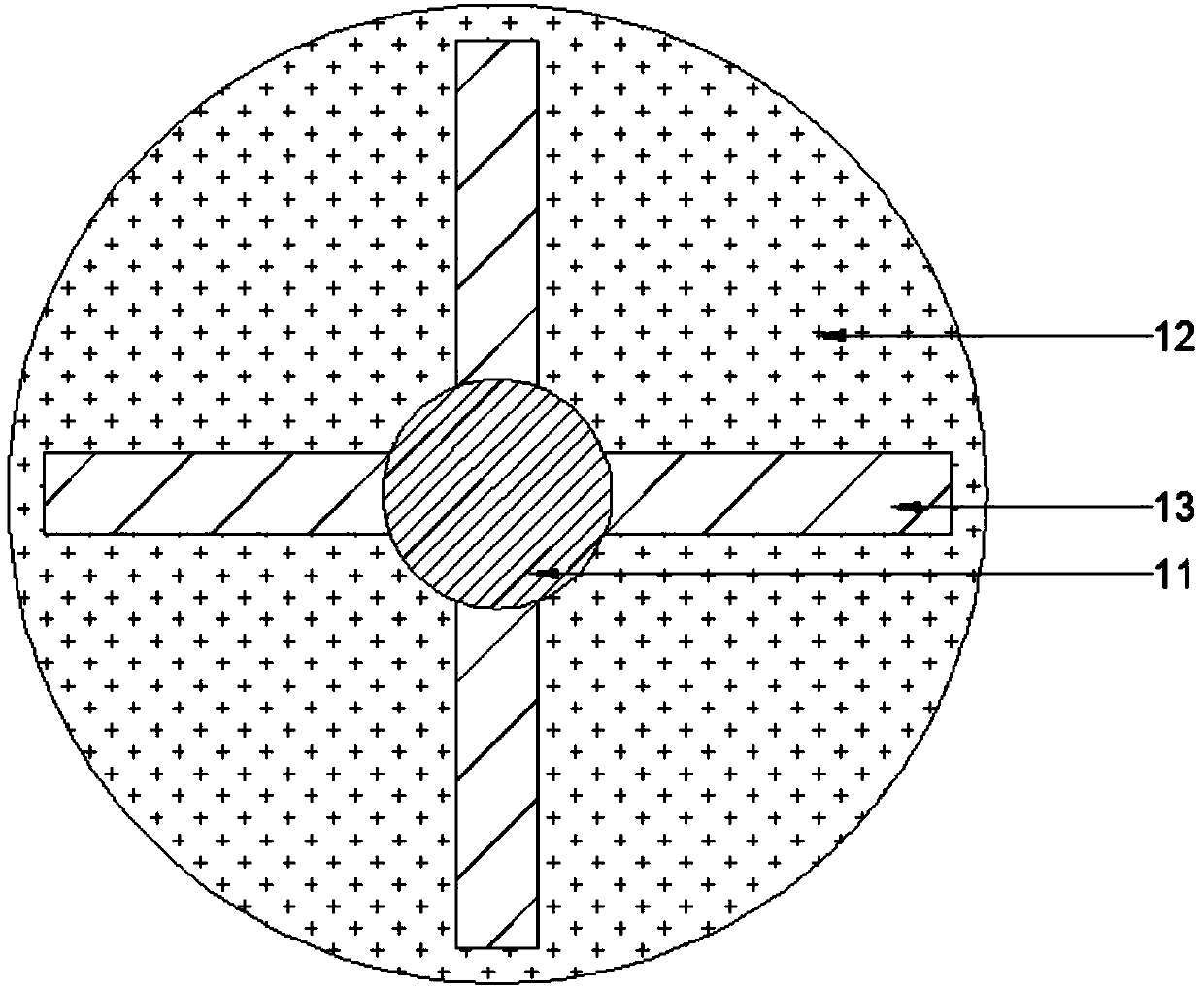

Flotation device and method for removing free carbon in silicon carbide powder

The invention relates to a flotation device and method for removing free carbon in silicon carbide powder. The device comprises a tank and a stirring device. The stirring device is connected with the tank through a fixed frame. A material inlet is arranged at the top of the tank, and a material outlet is arranged at the bottom of the tank. A foam scraping-away device is arranged at the position, between the inner wall of the tank and the stirring device, close to the material inlet, and comprises a foam collecting tank arranged in the radial direction of the tank and a rotary scraping plate matching the foam collecting tank. The outer end of the foam collecting tank is connected with the side wall of the tank, and a foam output opening is formed in the connecting position. The inner end of the foam collecting tank is connected with a fixed seat at the bottom of the fixed frame. A rotary seat is arranged on the fixed seat and provided with the rotary scraping plate. The foam collecting tank and the rotary scraping plate are arranged, so that foam with free carbon on a liquid face is removed smoothly in time, and flotation efficiency is improved. The foam output opening is arranged, so that automatic discharge is achieved. The rotary seat is arranged to avoid dead corner scraping. A power mechanism is arranged, so that the automation degree is high, good stability is achieved, and the flotation efficiency is improved.

Owner:连云港龙塔研磨材料有限公司

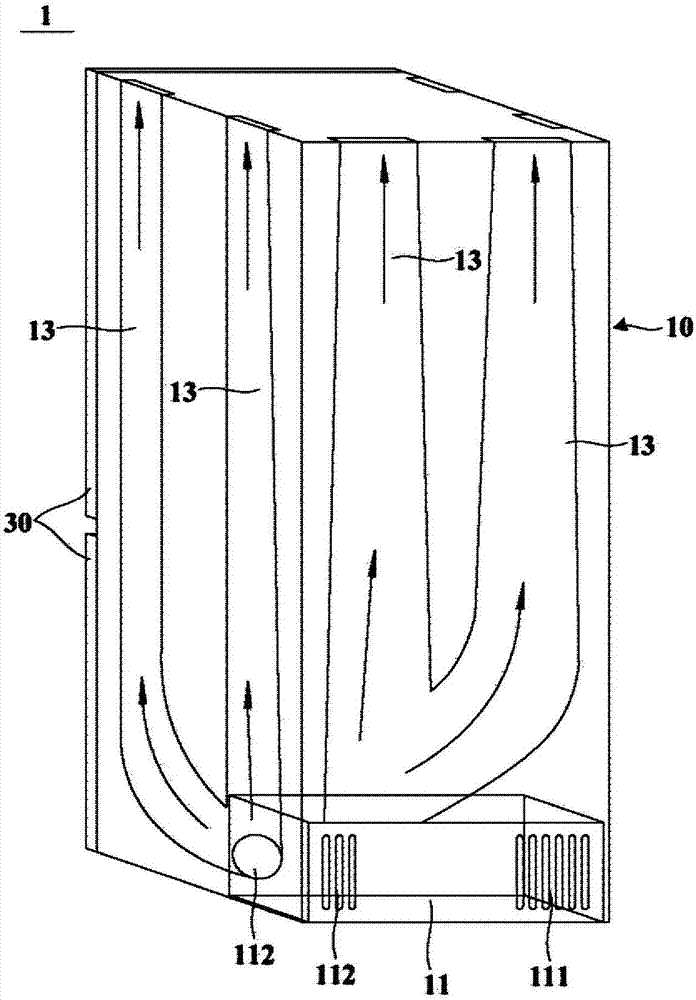

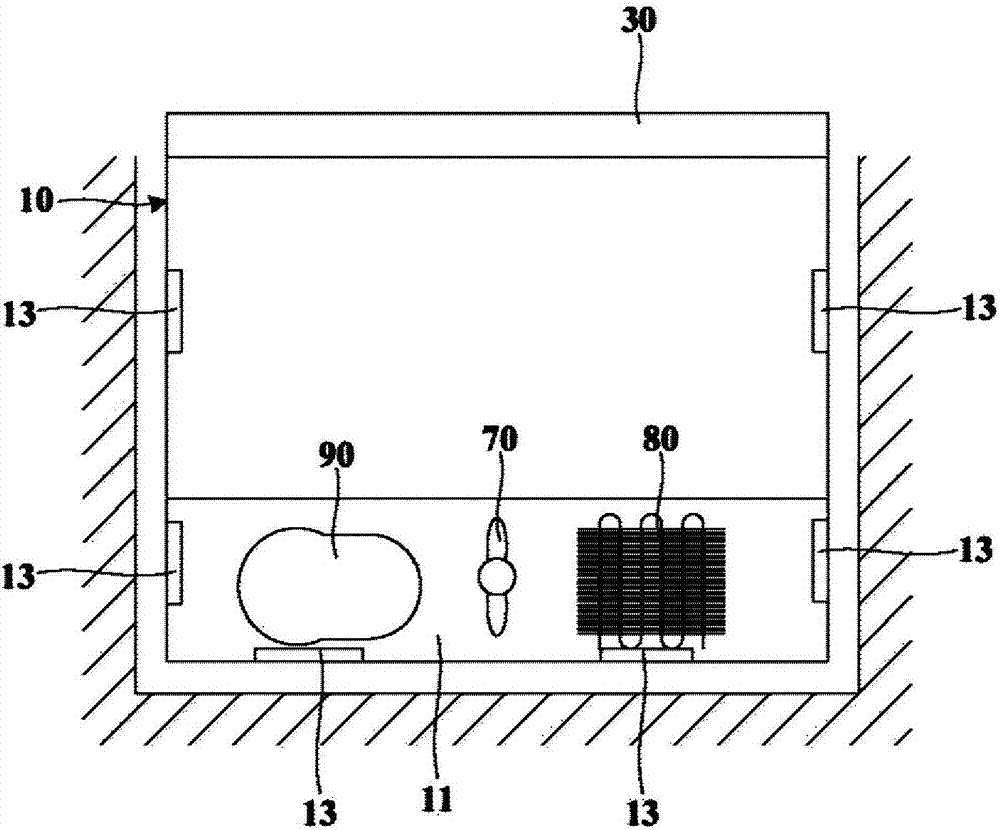

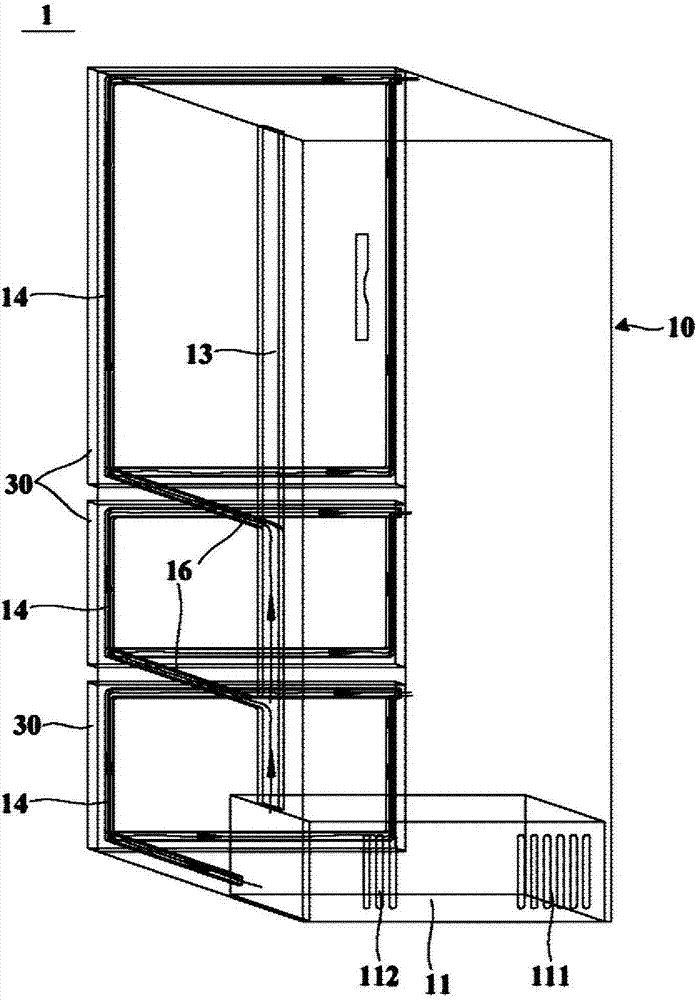

Cold storage and refrigeration device

InactiveCN107461986AImprove cooling effectSpeed up dischargeLighting and heating apparatusDomestic refrigeratorsEngineeringRefrigerant

The invention relates to a cold storage and refrigeration device. The device comprises a box body, a machine room is arranged on the lower portion of the rear side of the box body, a compressor used for compressing refrigerants and a condenser used for carrying out heat exchange with air are contained in the machine room, the machine room is provided with an air inlet and an air outlet which are used for allowing the air flow to circulate between the air inlet / the air outlet and the exterior environment, at least one first box body exhaust channel is formed in a side plate of the box body, each first box body exhaust channel is directly or indirectly communicated with the air outlet of the machine room or an air outlet area adjacent to the air outlet, and therefore at least part of hot airflow generated in the machine room is guided into the first box body exhaust channels; heat in the part of hot airflow can be sufficiently used for improving the temperature of the side plate of the box body; heat in the machine room can be sufficiently used, condensation generated by the side plate of the box body can be effectively prevented, and meanwhile, the device is simple in structure and easy to obtain.

Owner:QINGDAO HAIER REFRIGERATOR CO LTD +1

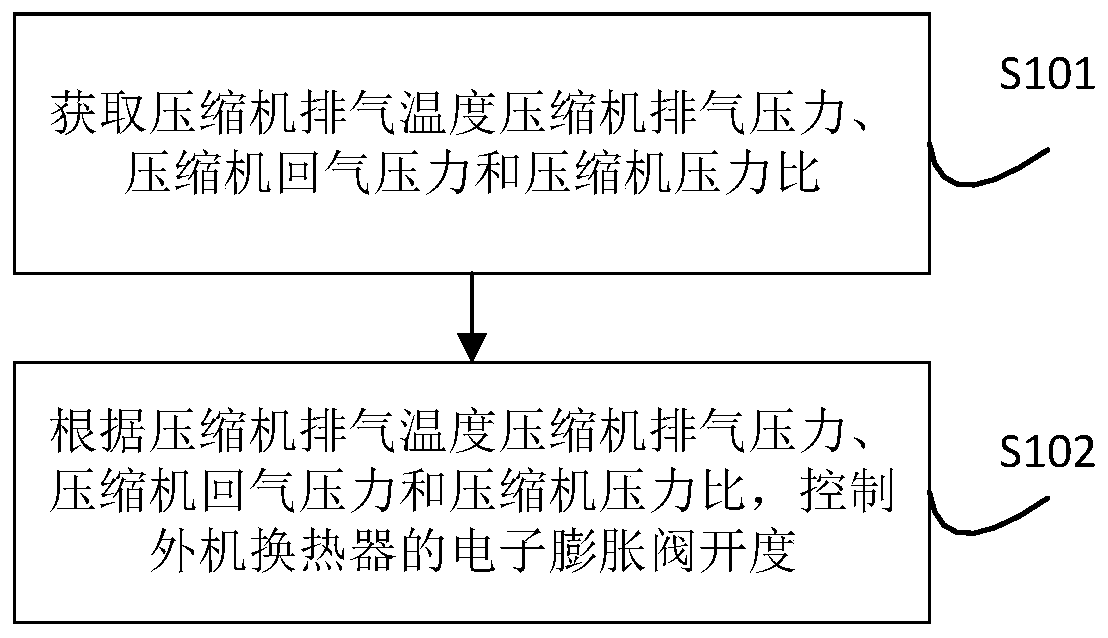

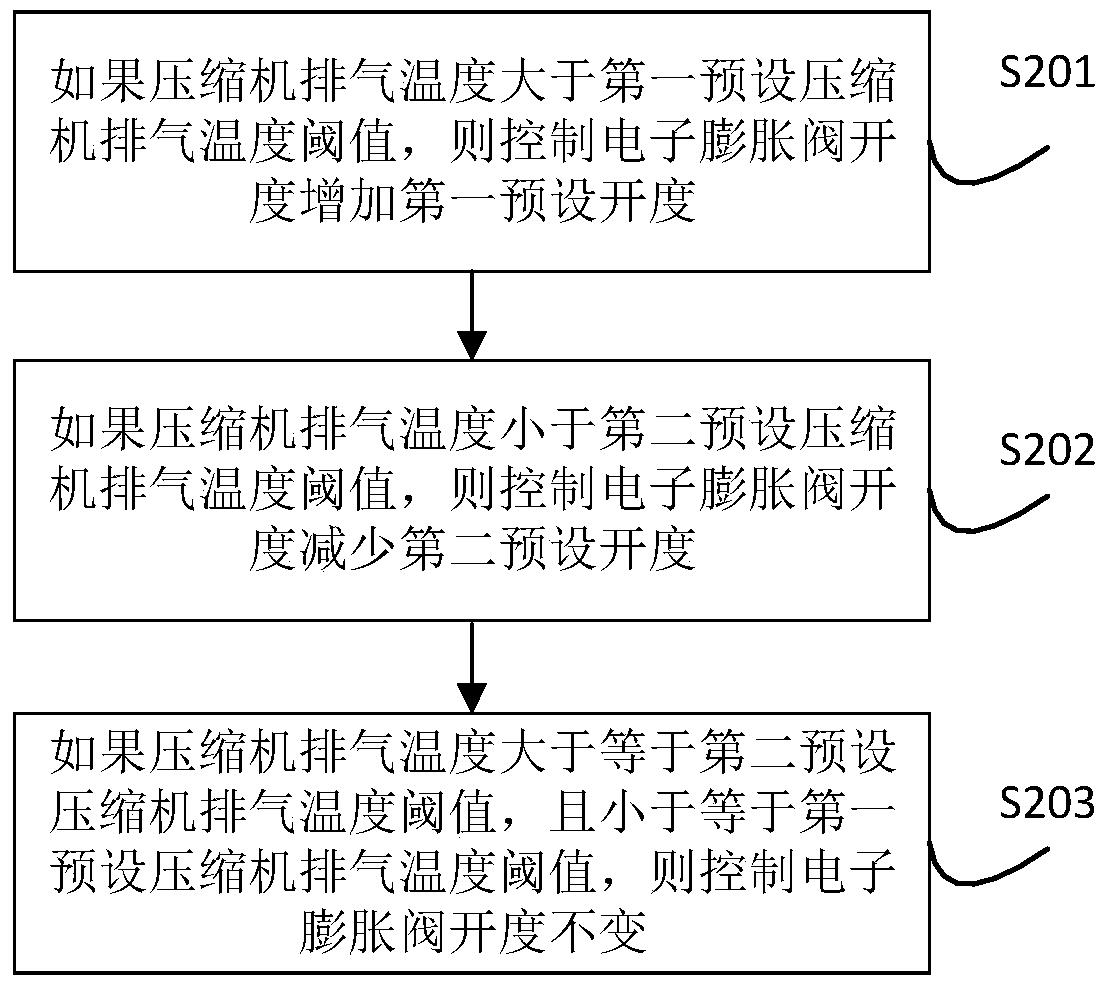

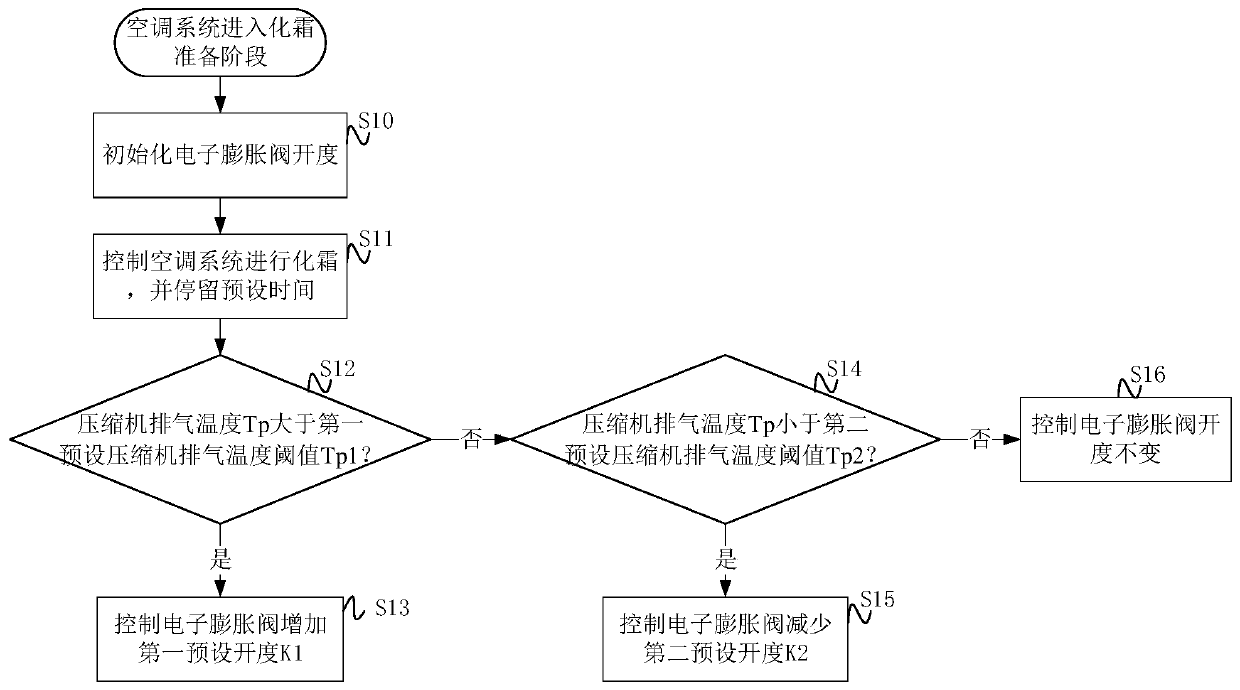

Method and device for controlling electronic expansion valve of external unit heat exchanger

InactiveCN109798626ASpeed up dischargeImprove reliabilityMechanical apparatusSpace heating and ventilation safety systemsEngineeringAir conditioning

The invention provides a method and device for controlling an electronic expansion valve of an external unit heat exchanger. The method comprises the steps that the discharge temperature of a compressor, the discharge pressure of the compressor, the air return pressure of the compressor and the pressure ratio of the compressor are obtained; and the opening degree of the electronic expansion valveof the external unit heat exchanger is controlled according to the discharge temperature of a compressor, the discharge pressure of the compressor, the air return pressure of the compressor and the pressure ratio of the compressor. During a defrosting stage, the discharge speed of a refrigerant in a low pressure tank is accelerated, the liquid return of the compressor is avoided, and the reliability of an air conditioning system is improved.

Owner:GD MIDEA HEATING & VENTILATING EQUIP CO LTD +1

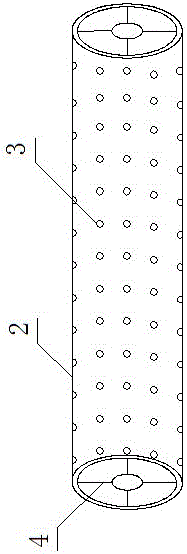

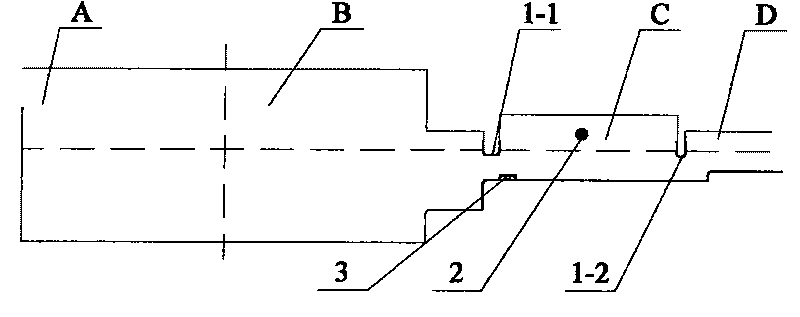

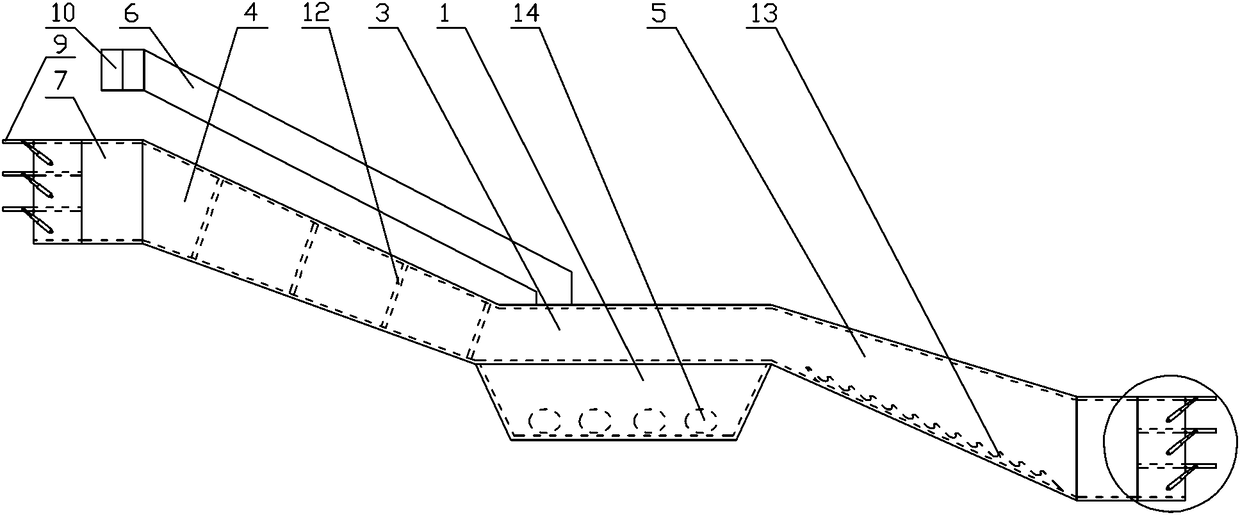

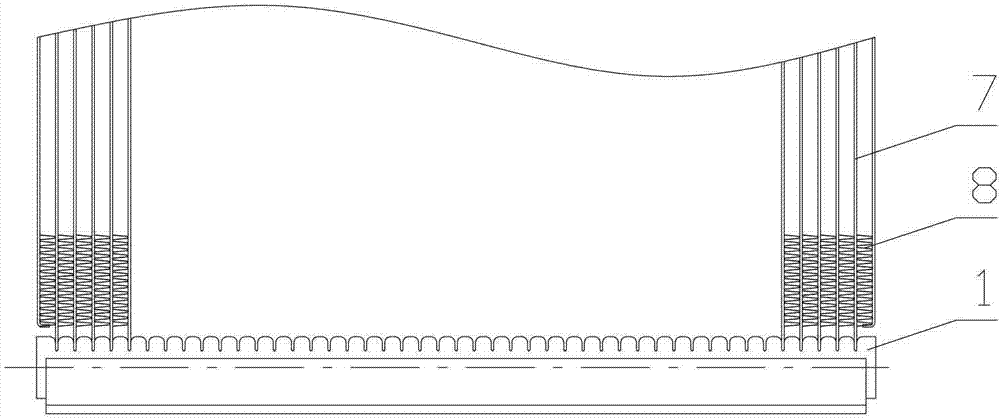

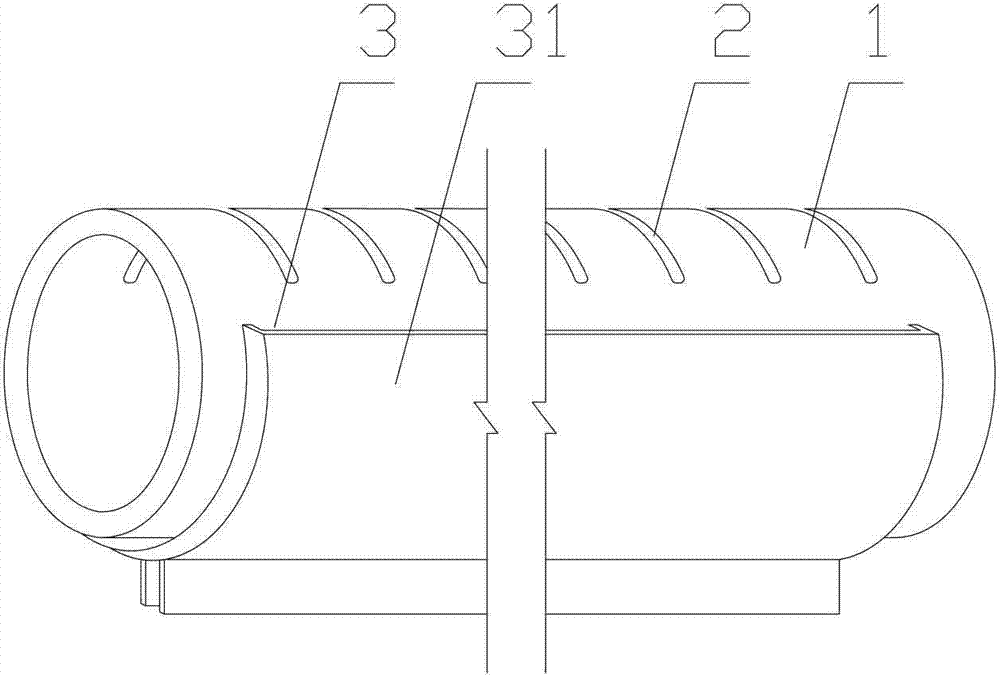

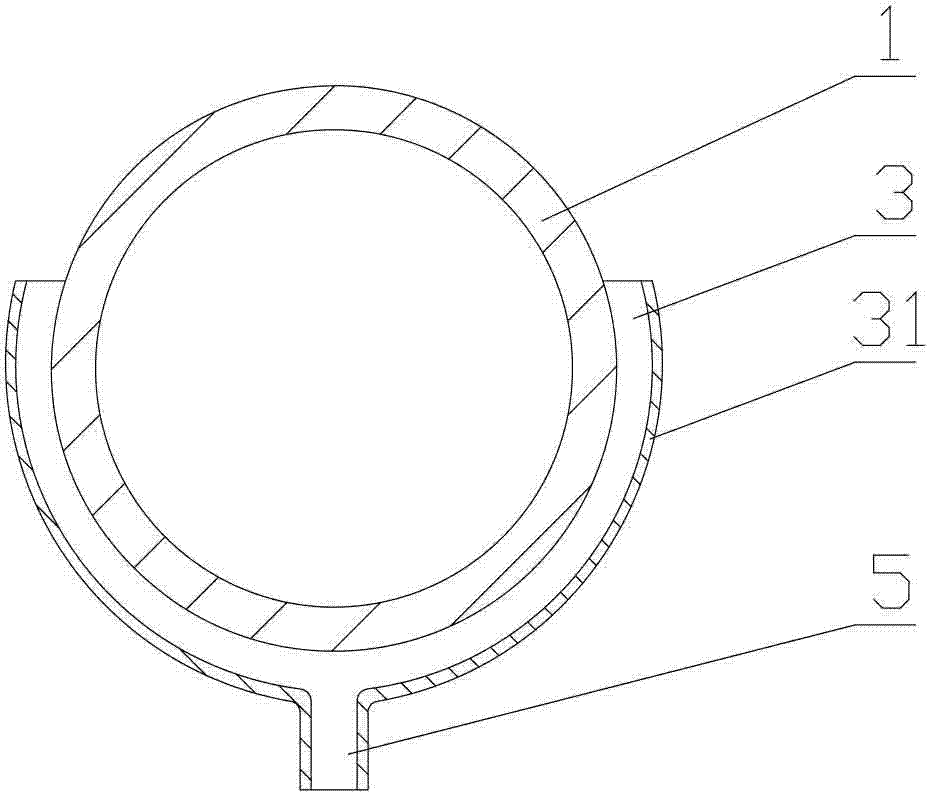

Convection-accelerating ventilating and cooling anchor pipe and construction method

ActiveCN105672313ASpeed up dischargeEnhanced convective heat transfer rateExcavationsBulkheads/pilesFiberPermafrost

The invention discloses a convection-accelerating ventilating and cooling anchor pipe and a construction method and belongs to the field of slope supporting in cold areas. The convection-accelerating ventilating and cooling anchor pipe and the construction method are suitable for permafrost slopes. The ventilating and cooling anchor pipe comprises an anchor pipe body, a convection pipe, a fiber bag, a connector, an exhaust pipe and a freezing system. The freezing system is composed of a water pump, a water tank, a guide pipe and saline water. The anchor pipe body penetrates a positioning frame and is embedded in the convection pipe. The rear end of the anchor pipe body is connected with the connector. The fiber bag is fixed between two check rings of the connector from the outer side through a clamp. Slurry is frozen and expanded to be anchored to a stable stratum. An anchoring tool is used for anchoring the anchor pipe body to a gasket, and a convection switch penetrates the anchor pipe body and is installed at the end of the convection pipe. One end of the exhaust pipe is provided with an exhaust switch, and the other end of the exhaust pipe is connected with the anchor pipe body through a clamp. The exhaust switch controls closing and opening of the exhaust pipe, and the convection switch controls closing and opening of the convection pipe.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Grinding device capable of performing bilateral rotation

InactiveCN101898163APrevent movementAccess assistanceGrain treatmentsMechanical engineeringPulverizer

The invention relates to a grinding device capable of performing bilateral rotation. The grinding device mainly has the following beneficial characteristics and effects: 1) a material-fixing rack is arranged on one end of a cutter wheel A where material to be grinded enters, thus preventing that the material which is not grinded or completely grinded rotates with the cutter wheel A to move and ensuring the material to be grinded enters the cutter groove of the cutter wheel A; 2) two cutter wheels are designed to have cutter grooves with two different inclination directions, thus pressure can be applied to the material to be grinded between the material-fixing rack and a screen to perform solid cyclic grinding and the grindability of each cutter groove can be effectively utilized; 3) the screen is arranged on one end of a cutter wheel B where the grinded material is discharged, the screening speed and discharging speed of the grinded material passing through screen holes are increased owning to the pressure, the grinded material not passing through screen holes can perform cyclic grinding along with the cutter grooves; and 4) by adopting the parts of the grinding device, the grinding space of the grinding cutting tool can be reduced and the devices such as the additional vibrating screen and swinging screen can be eliminated, thus the volume of the grinding machine can be reduced and the residual quantity of the grinded material can be lowered.

Owner:叶德坚

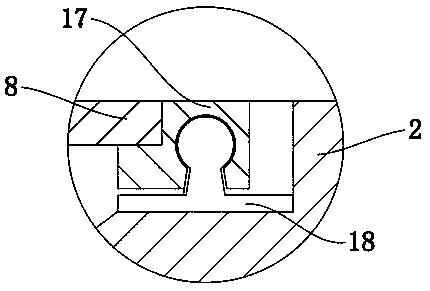

Scraping plate for filter and matched filter plate

InactiveCN106362472ASpeed up dischargeSpeed up the effluxMoving filtering element filtersAgricultural engineeringMatched filter

The invention discloses a scraping device for a filter and a matched filter plate. The scraping device comprises a scraping plate and a mounting bracket, wherein the scraping plate is an arc-shaped structure of which a scraping surface is protruded outwards; the scraping plate is installed on the mounting bracket through a radian adjusting device and an angle adjusting device, and is arranged above the filter plate in an inclined manner. The scraping device is simple in structure and high in filter efficiency, and the arc and mounting angle of the scraping device can be adjusted according to the blanking speed of a solution needing to be filtered and the content of particles in the solution.

Owner:CHANGNING HUAJUN RENEWABLE RESOURCES

Method for optimizing down fired reforming furnaces

ActiveUS20150239736A1Reduce deflectionIncreasing burner discharge velocityHydrogenHydrocarbon from carbon oxidesCombustorMomentum

A method of optimizing steam methane reforming in a multiple cell, down-fired furnace. The method includes the steps of introducing hydrocarbons and steam to a plurality of catalyst filled process tubes, combusting gases through a plurality of center cell down-fired burners at a burner discharge velocity of V m / s, and a mass flow rate of 1 kg / s, combusting gases through outer cell down-fired burners at a burner discharge velocity of 1.5V-2V m / s and a mass flow rate of 0.5-0.65 kg / s, and finally discharging combustion products from the outer cell down-fired burners and the center cell down-fired burners at a substantially uniform momentum.

Owner:HONEYWELL INT INC

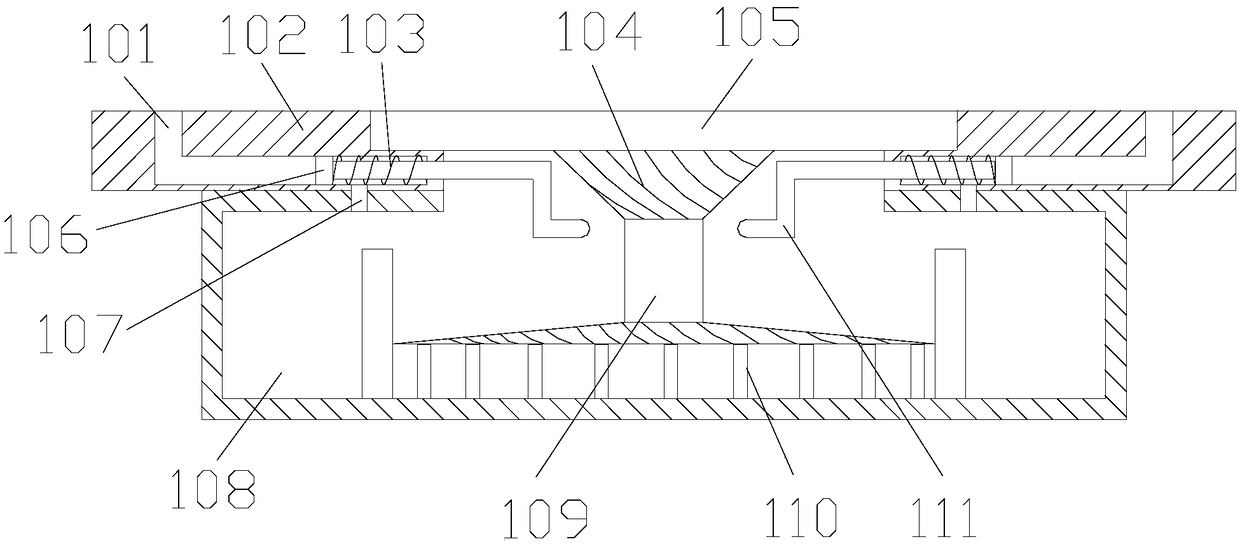

Method for improving clarifying effect of molten glass in floating production and kiln device

InactiveCN101717178ASpeed up dischargeExtend the life cycleGlass furnace apparatusGeneration rateKiln

The invention relates to a method for improving a clarifying effect of molten glass in floating production and a kiln device, which solve the technical problems of improving the clarifying effect of molten glass in floating production and further reducing the generation rate of bubbles so as to produce a high-quality glass base plate. The method is realized in a molten glass clarifying kiln; after a glass material is melted in the clarifying kiln and processed by a clarifying area and a cooling adjustment area, the molten glass is output; a clarification forcing area is additionally arranged between the clarifying area and the cooling adjustment area of the clarifying kiln, and the length and the detention time of a clarifying process of the molten glass are increased to match for carrying out clarification forcing processing on the molten glass; the kiln device is provided with two U-shaped walls, and the two U-shaped walls form a sealed clarification forcing area by a top wall, a bottom wall and a side wall of a kiln body. The invention obviously improves the clarifying effect and the qualified rate of products and can efficiently carry out defoaming clarification on the molten glass and obviously reduce the influence of the clarifying bubbles on the quality of the glass base plate.

Owner:TUNGHSU GRP

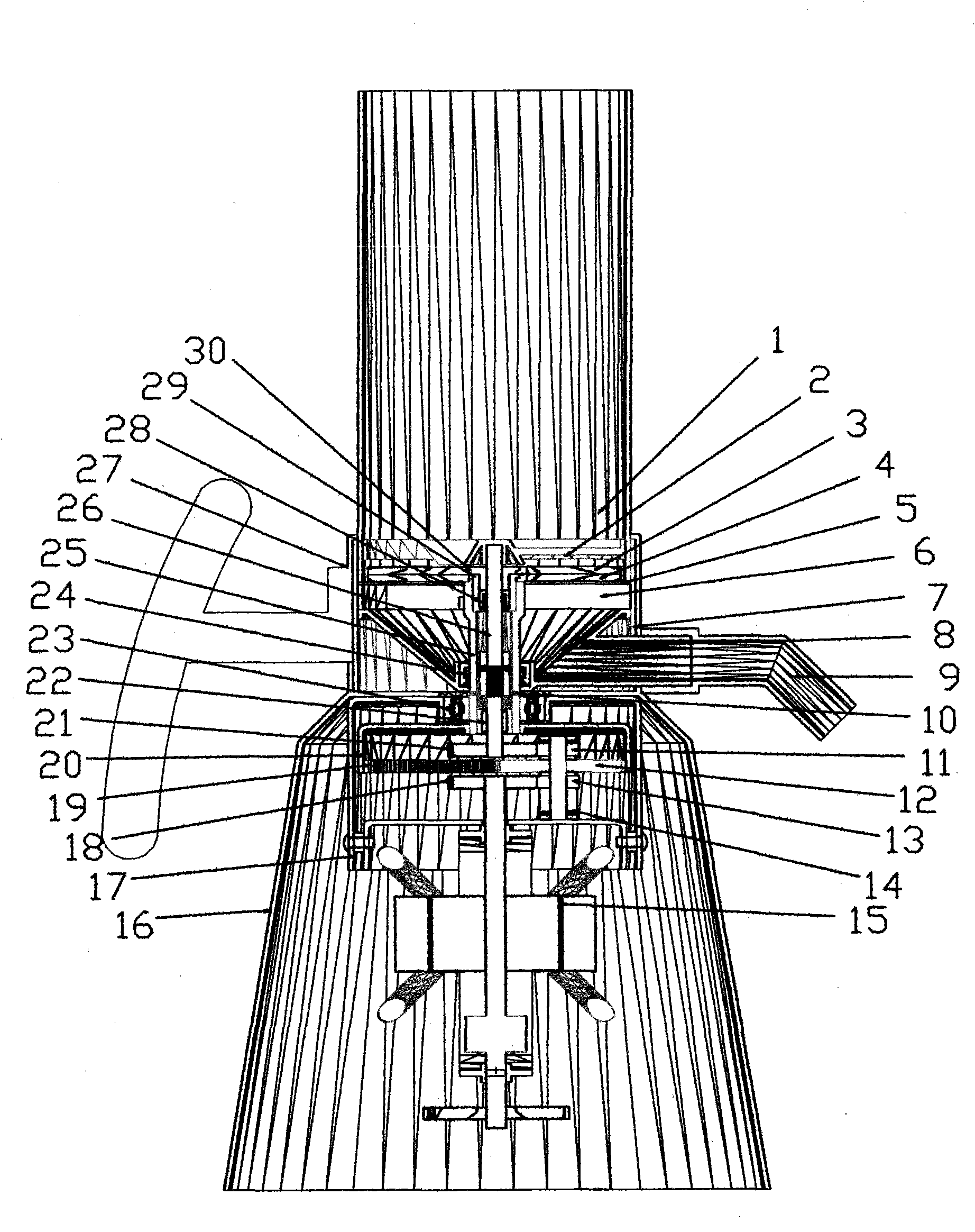

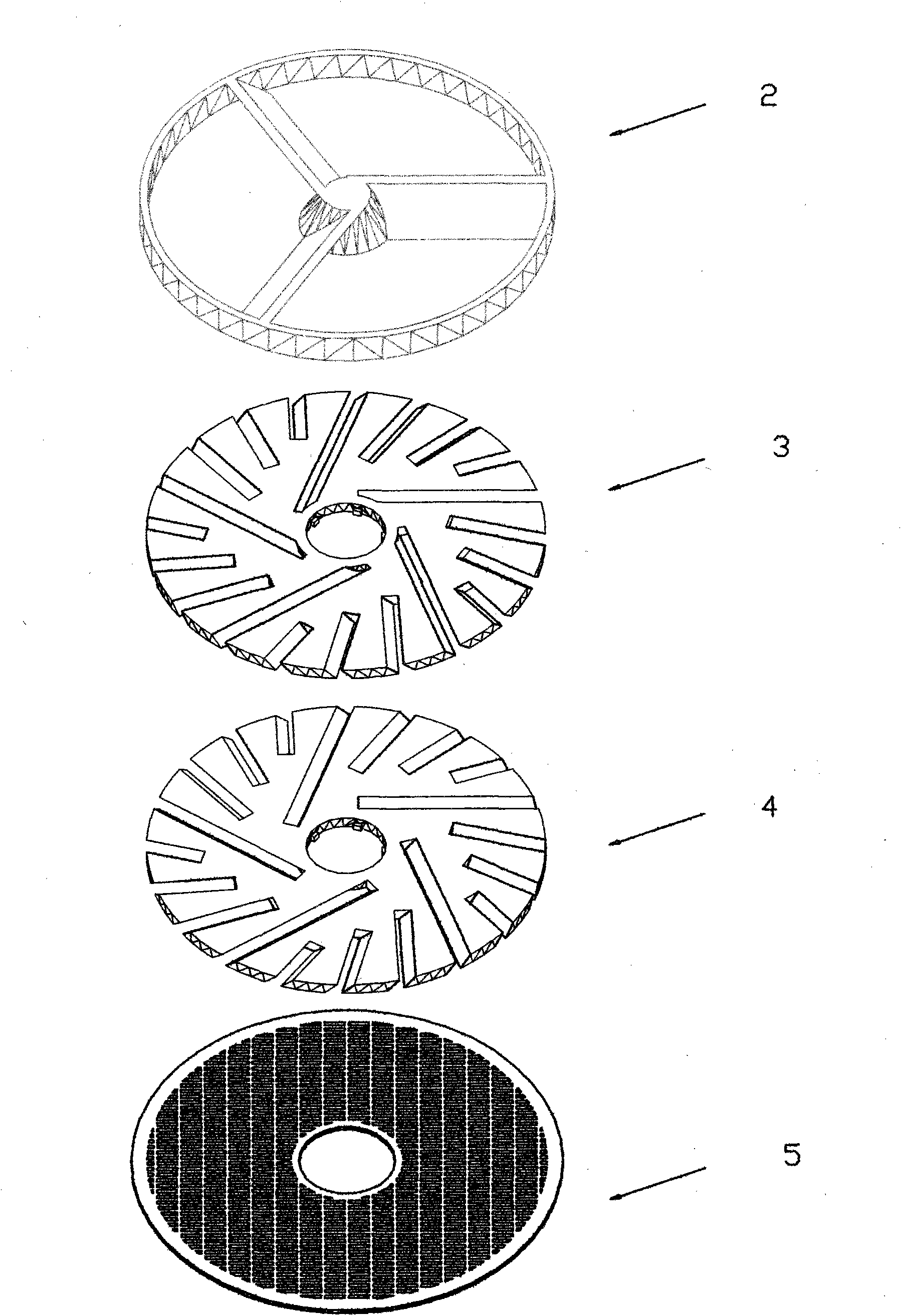

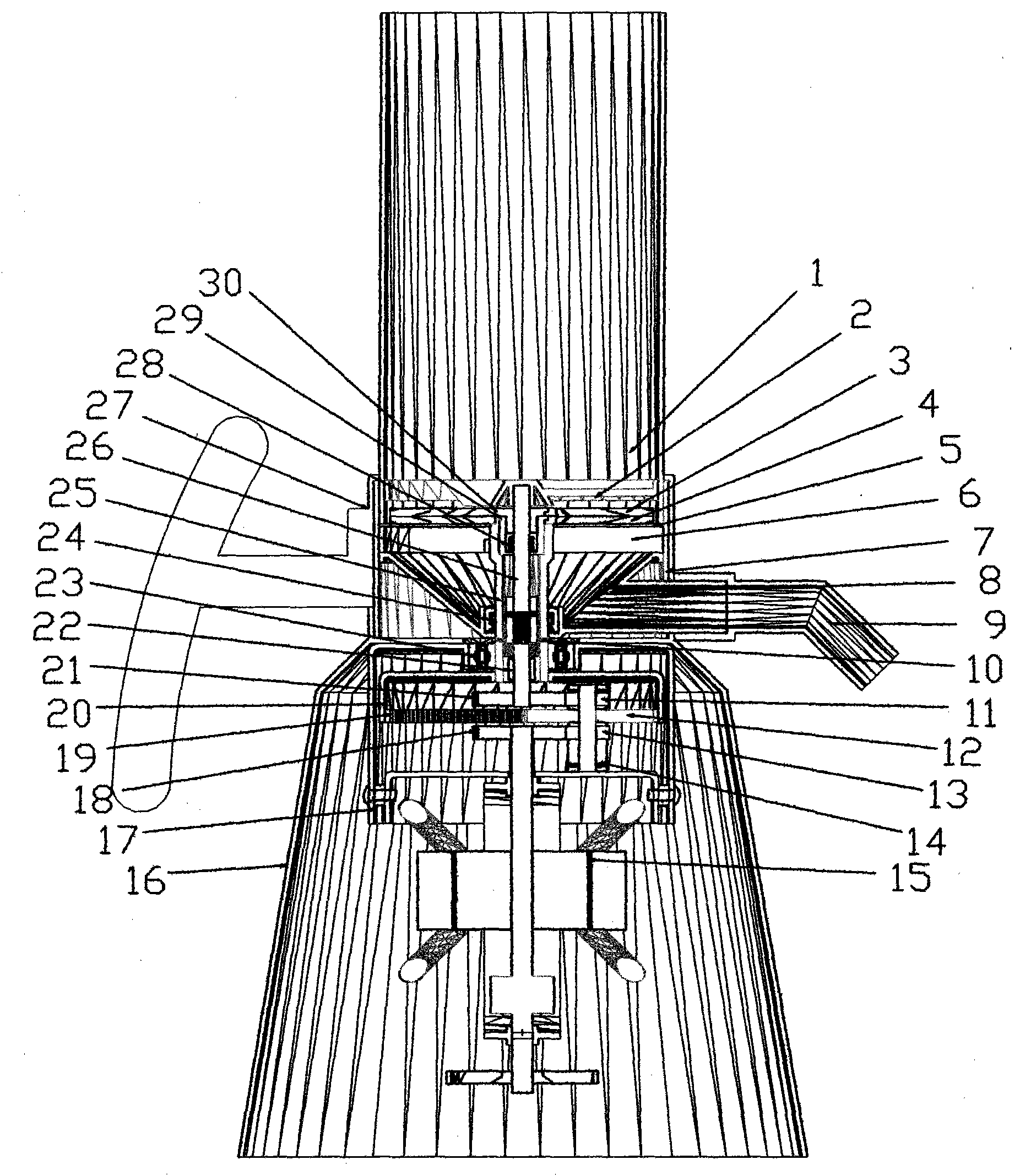

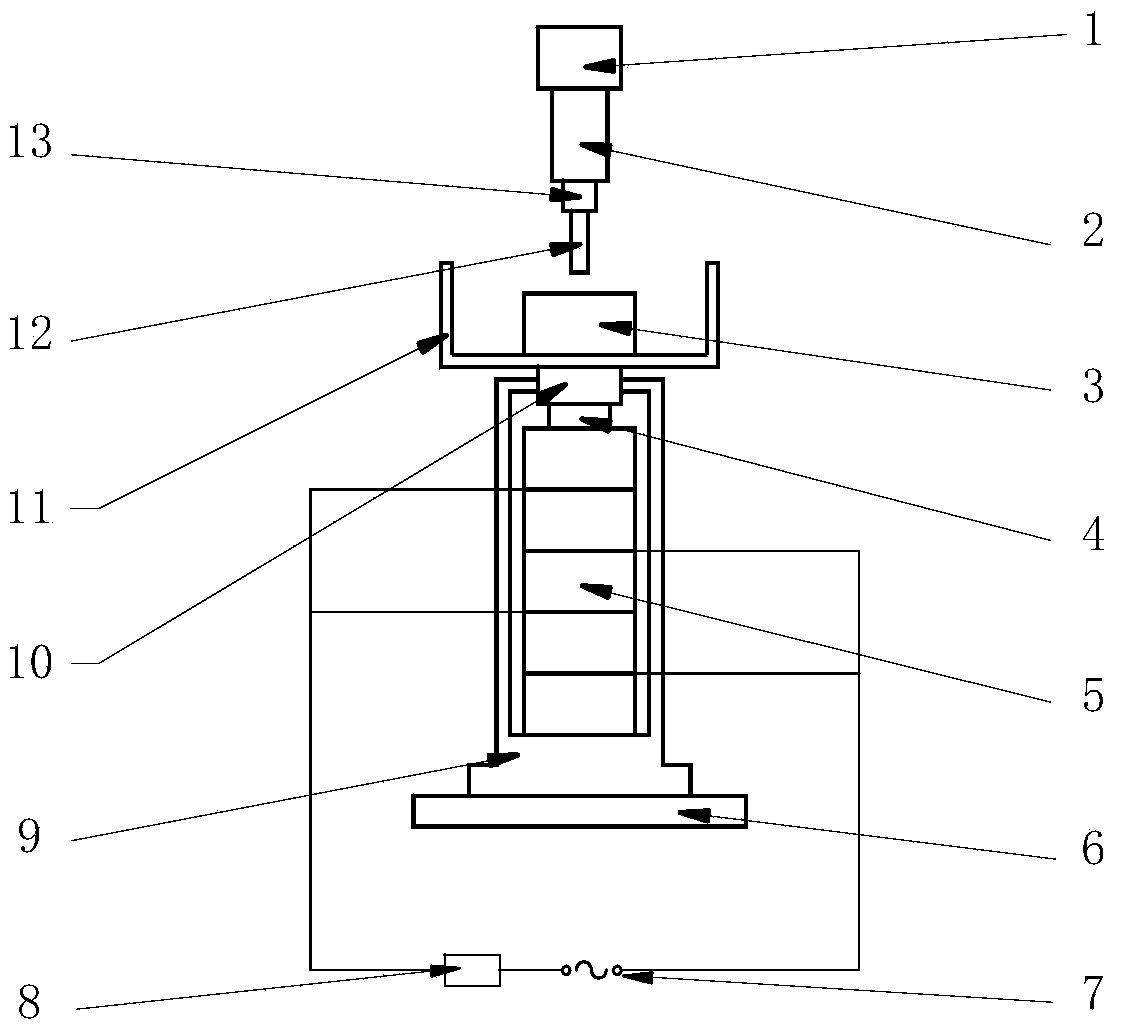

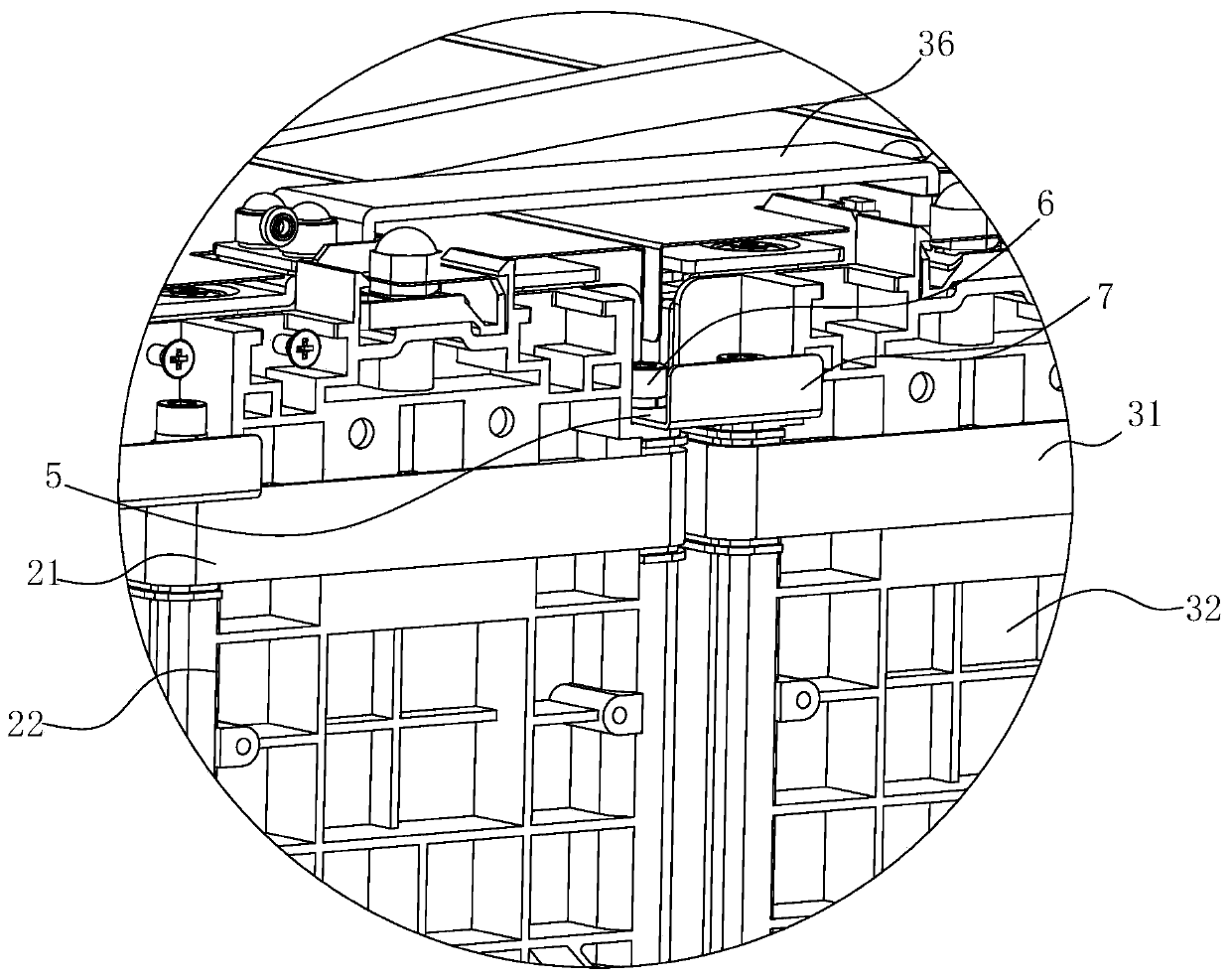

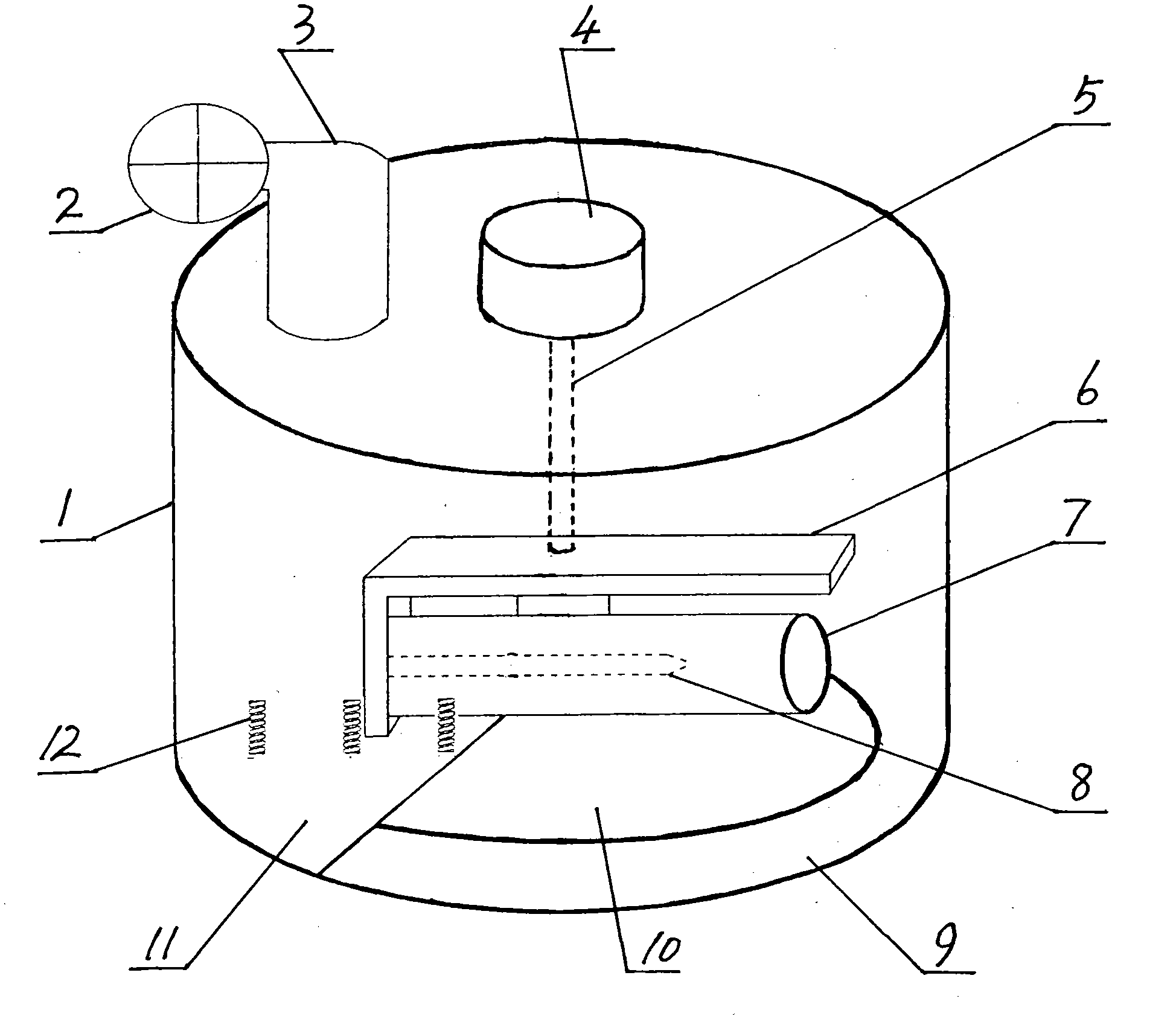

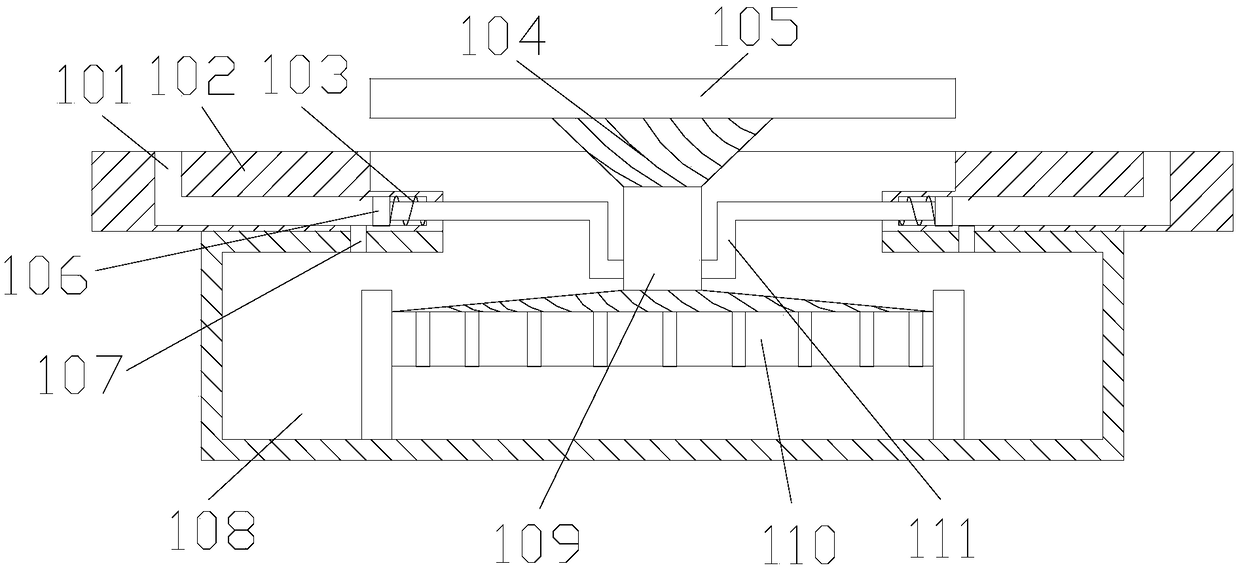

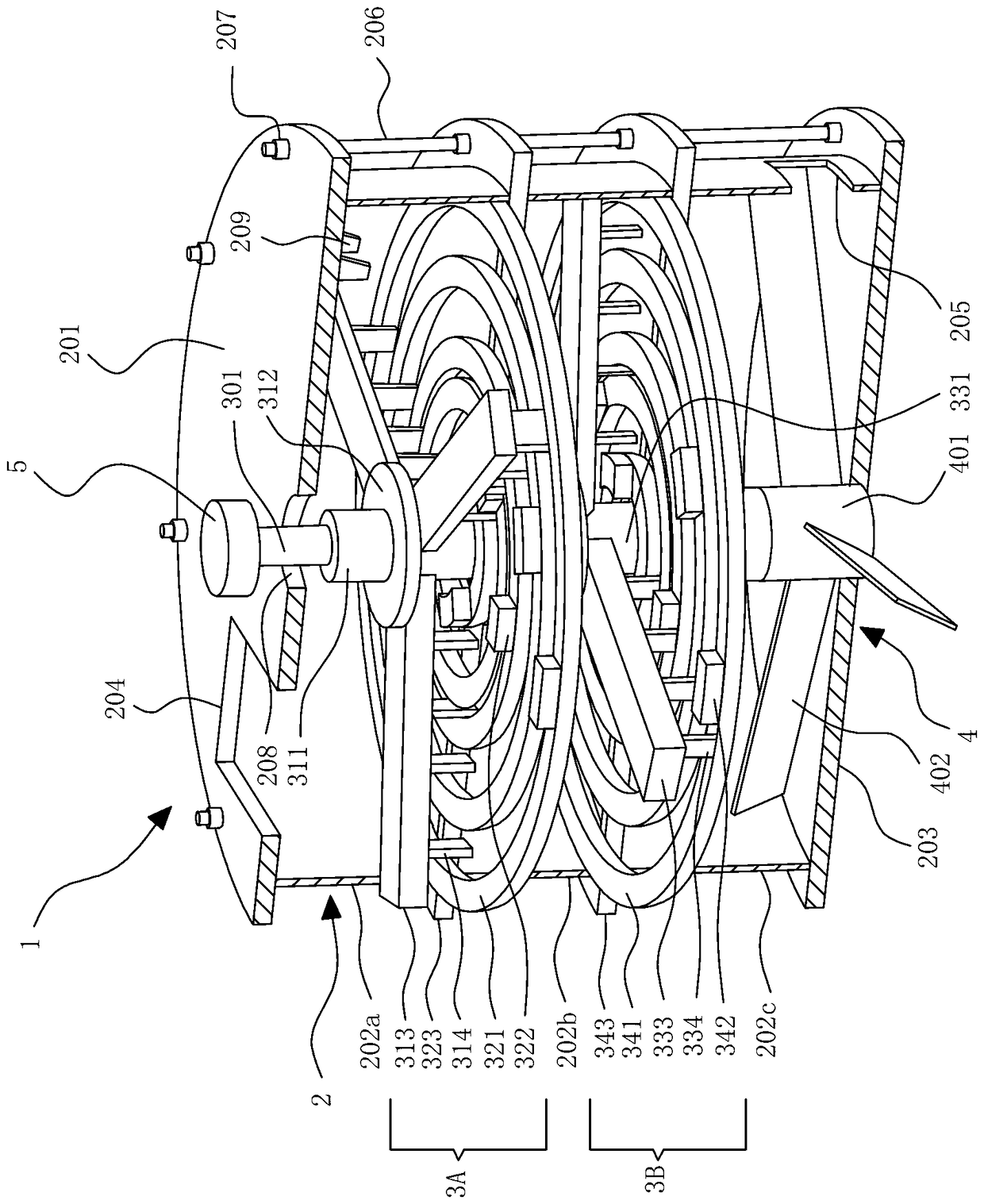

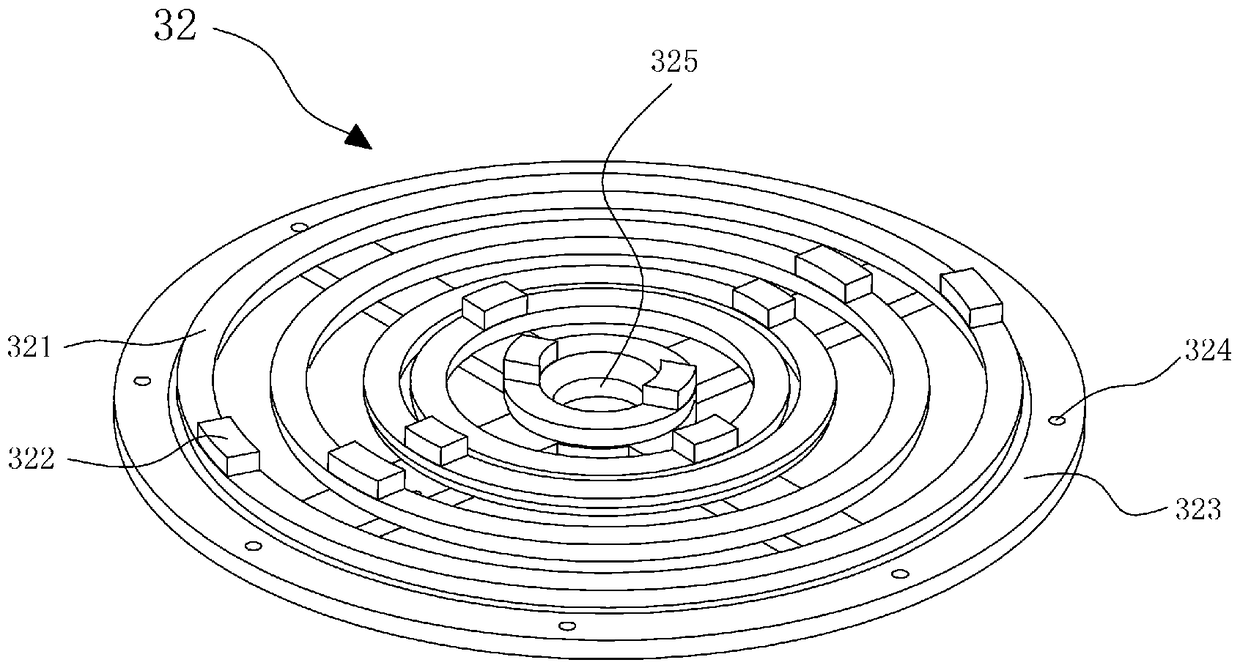

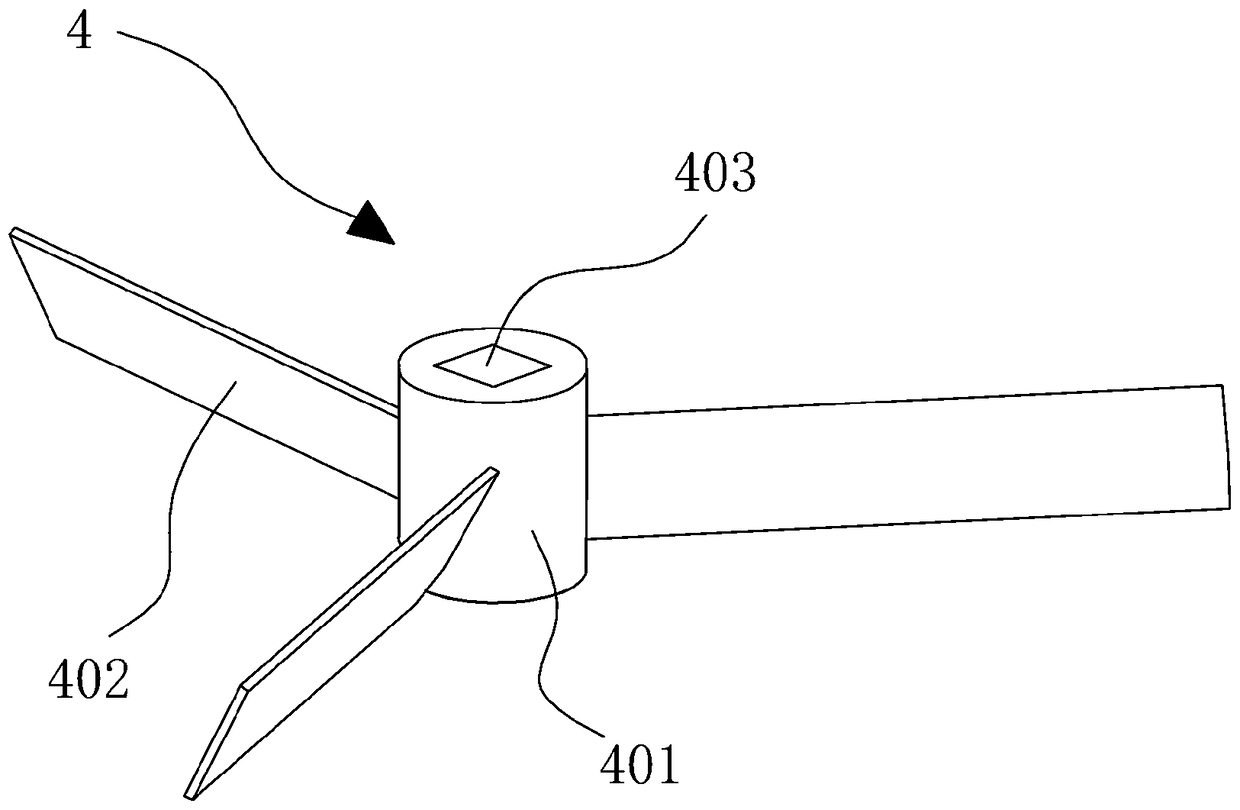

Ultrasonic-vibration micro electric discharge machining workbench

The invention relates to an ultrasonic-vibration micro electric discharge machining workbench which comprises a machine tool base 6, a power source 7, an adjusting resistor 8 and a working liquid tank 11. The ultrasonic-vibration micro electric discharge machining workbench is characterized by further comprising a pre-tightening spring 4, piezoelectric ceramic 5, a piezoelectric actuator shell 9 and a pushing rod 10; an overlying and combining form is adopted to parallelly connecting the piezoelectric ceramic 5 mutually in a circuit; the piezoelectric ceramic 5 serving as a micro-vibration exciting component converts electric energy into mechanical vibration energy; under the action of voltage, by utilizing the inverse piezoelectric effect of the piezoelectric ceramic, the piezoelectric ceramic drives the working surface to extend or shorten. During electric discharge machining, by utilizing ultrasonic vibration of a workpiece, the circulating state of working liquid is effectively improved, discharging of an electric corrosion product is promoted, stability of the machining process is improved, the phenomena like shorting-out and arcing can be automatically eliminated, and the ultrasonic-vibration micro electric discharge machining workbench is especially suitable for micro deep hole and deep groove machining.

Owner:SHANDONG UNIV

Household wastewater filtering device with cleaning function

InactiveCN108553985AIncrease outflow speedSpeed up dischargeMoving filtering element filtersWastewaterDrive motor

The invention discloses a household wastewater filtering device with a cleaning function in the technical field of environment protection. The household wastewater filtering device comprises a filtering box, wherein a screen net is arranged at an inner cavity of the filtering box; the height of the right side of the screen net is greater than the height of the left side; a sliding groove is formedin a connecting position of the right side of the screen net and the filtering box; the bottom of an inner cavity of the sliding groove is provided with a support spring; the top of the support spring is connected with the bottom of the screen net; a driving motor is arranged at each of the outer walls of the front end and the back end of the right side of the filtering box; the output end of theinner side of each driving motor extends into an inner cavity of the filtering box and is connected with an eccentric wheel; a connecting bottom is attached to the top of the eccentric wheel; the topof a top cover is provided with a wastewater inlet; the eccentric wheel is driven by the motor to rotate in the device, so that the right side of the screen net vertically moves in a repeated way, the screen net vibrates, the impurity flowing-out speed is accelerated, and the device blockage is prevented; meanwhile, the screen net is in inclined arrangement, so that the impurity discharging-out speed is further accelerated, and the work efficiency is improved.

Owner:丁永才

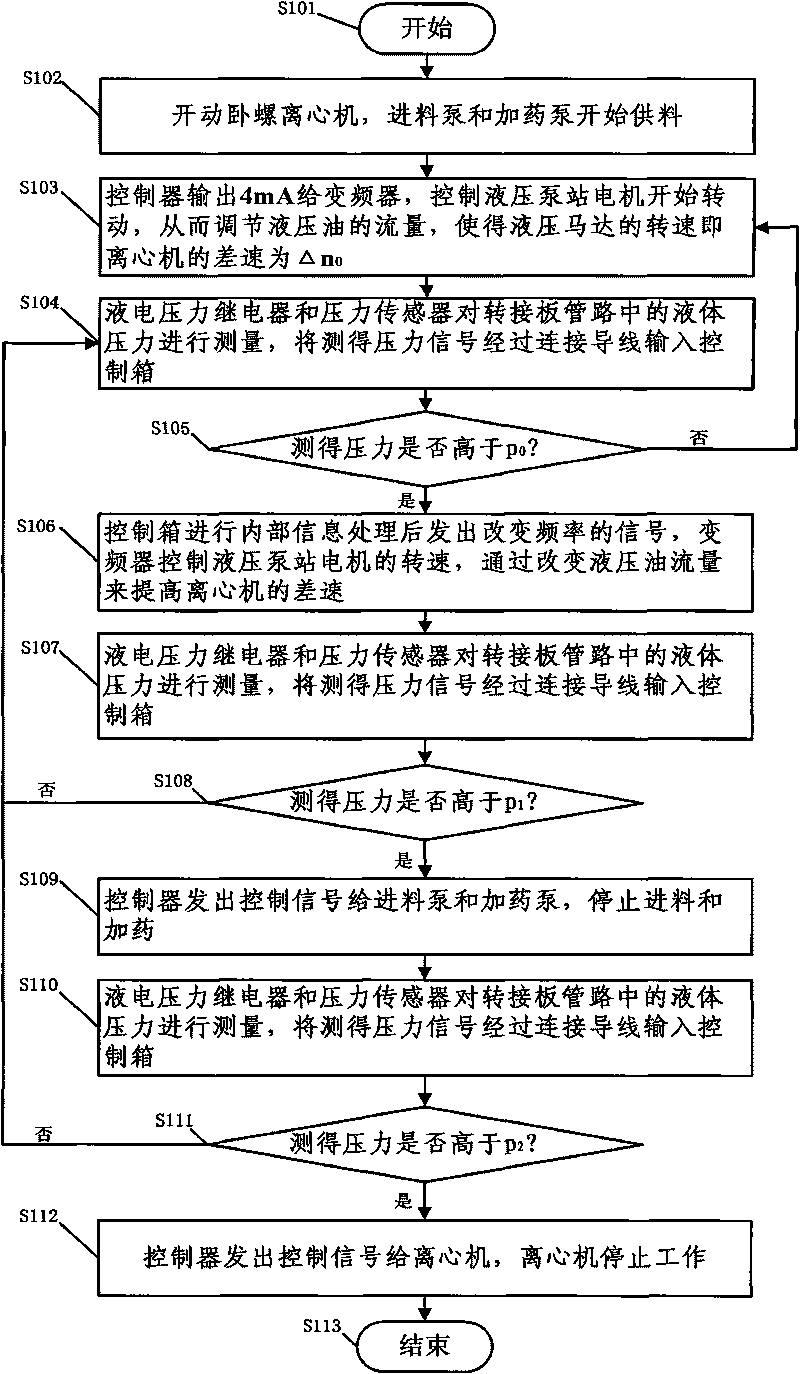

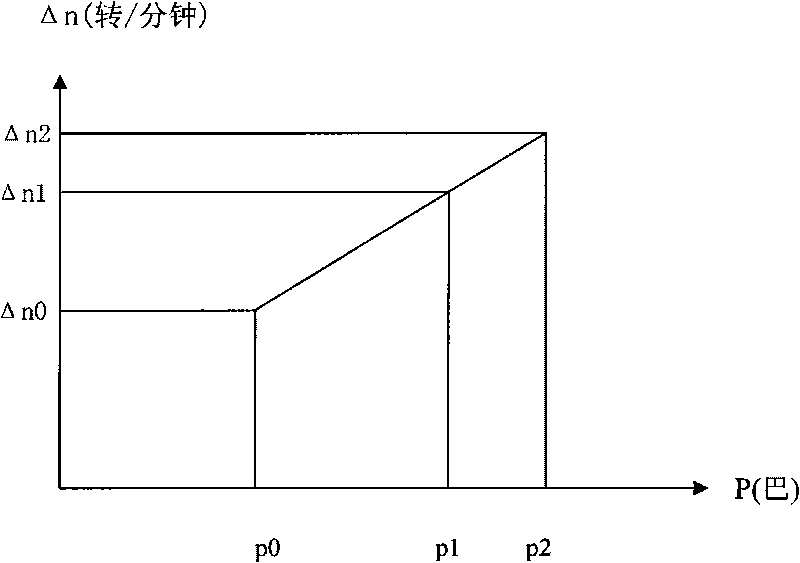

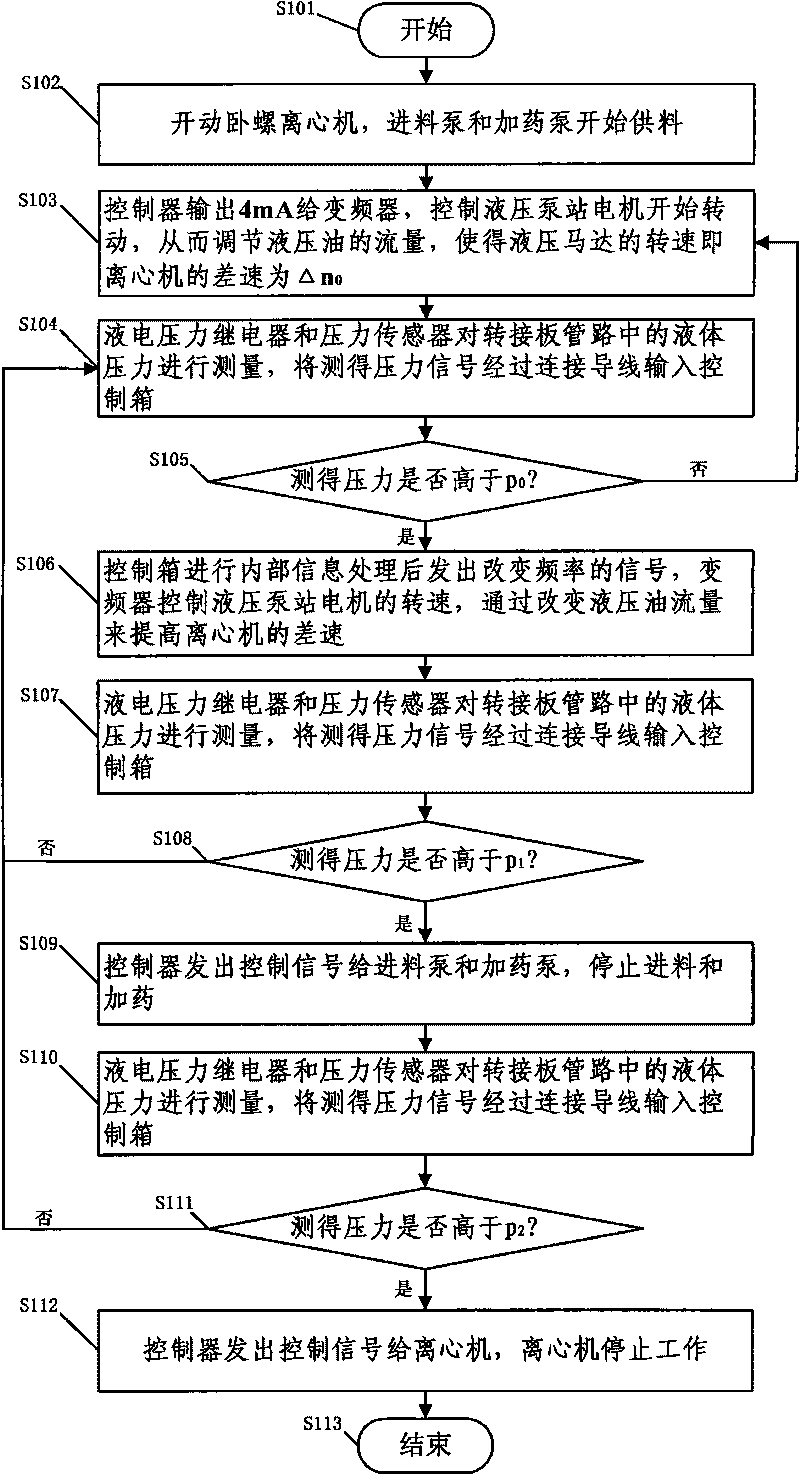

Method for electrically controlling hydraulic differential of centrifuge

The invention relates to a method for electrically controlling the hydraulic differential of a centrifuge, in particular to a method for electrically controlling the hydraulic differential of a horizontal decanter centrifuge for sludge dewatering. The method realizes the electrical control of the hydraulic differential by using a programmable intelligent instrument as a controller, wherein three pressure values p0, p1 and p2 are set on the controller; when the pressure is less than p0, the differential of the centrifuge remains delta n0 unchanged; when the pressure is greater than p0, the differential is increased along with the increment of the pressure; when the pressure is greater than p1, a feed pump and a dosing pump are stopped; and when the pressure is greater than p2, the centrifuge is stopped. Through the method, a liquid pressure changing signal in a pipeline of an adapter plate can be fed back to the controller in time; according to the change of the pressure, the flow of a hydraulic system can be adjusted proportionally in real time; the structure is simple and the usage is convenient; and at the same time, the production cost of the hydraulic differential controller of the horizontal decanter centrifuge is greatly reduced, which is one third of the price of the similar foreign products.

Owner:SHANGHAI CENTRIFUGE INST

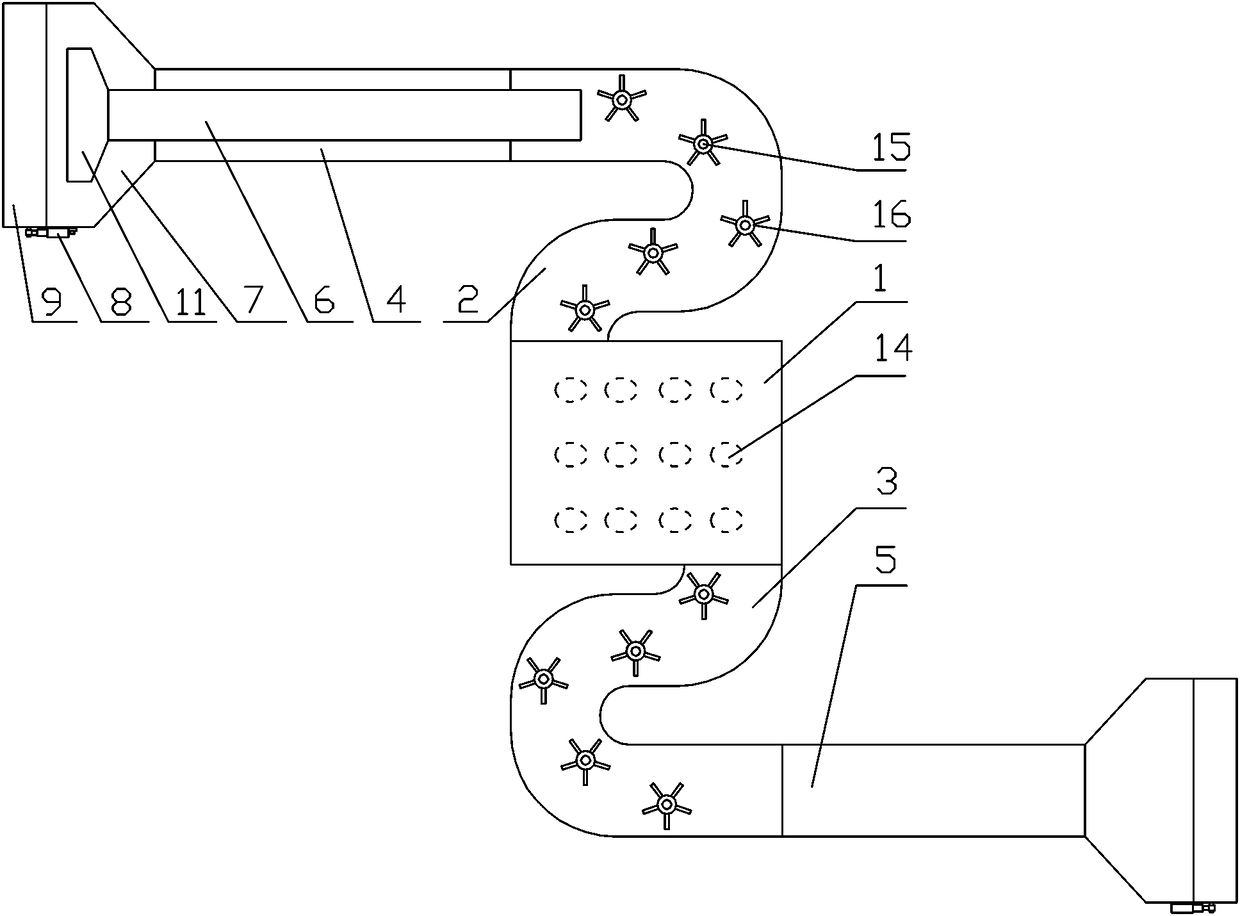

Artificial nature type slope fishway and fish entering method

ActiveCN108118667AEasy data collectionConvenient real-time image acquisitionBarrages/weirsClimate change adaptationRed mulletWater flow

The invention discloses an artificial nature type slope fishway and a fish entering method. An upper bent channel and a lower bent channel are arranged on and connected with the two sides of a restingpool respectively, an upper inclined channel is connected with the end of the upper bent channel, a lower inclined channel is connected with the end of the lower bent channel, the end of the upper inclined channel and the end of the lower inclined channel are each provided with a multi-layer fish inlet, a multi-stage oil cylinder is installed on one side of each multi-layer fish inlet, the multi-stage oil cylinders are all matched with an inlet baffle, a multi-edge plate frame is detachably connected with the lower inclined channel, the upper bent channel and the lower bent channel are each internally and detachably connected with a water blocking wheel. By means of the artificial nature type slope fishway, the water flow speed can be effectively reduced, places can be provided for allowing migration fishes to temporarily have a rest, fish migration is facilitated, the normal operation of an ecological system is ensured, a flooding function is fused, and the slope fishway is worthy ofapplication and popularization.

Owner:CHINA THREE GORGES UNIV

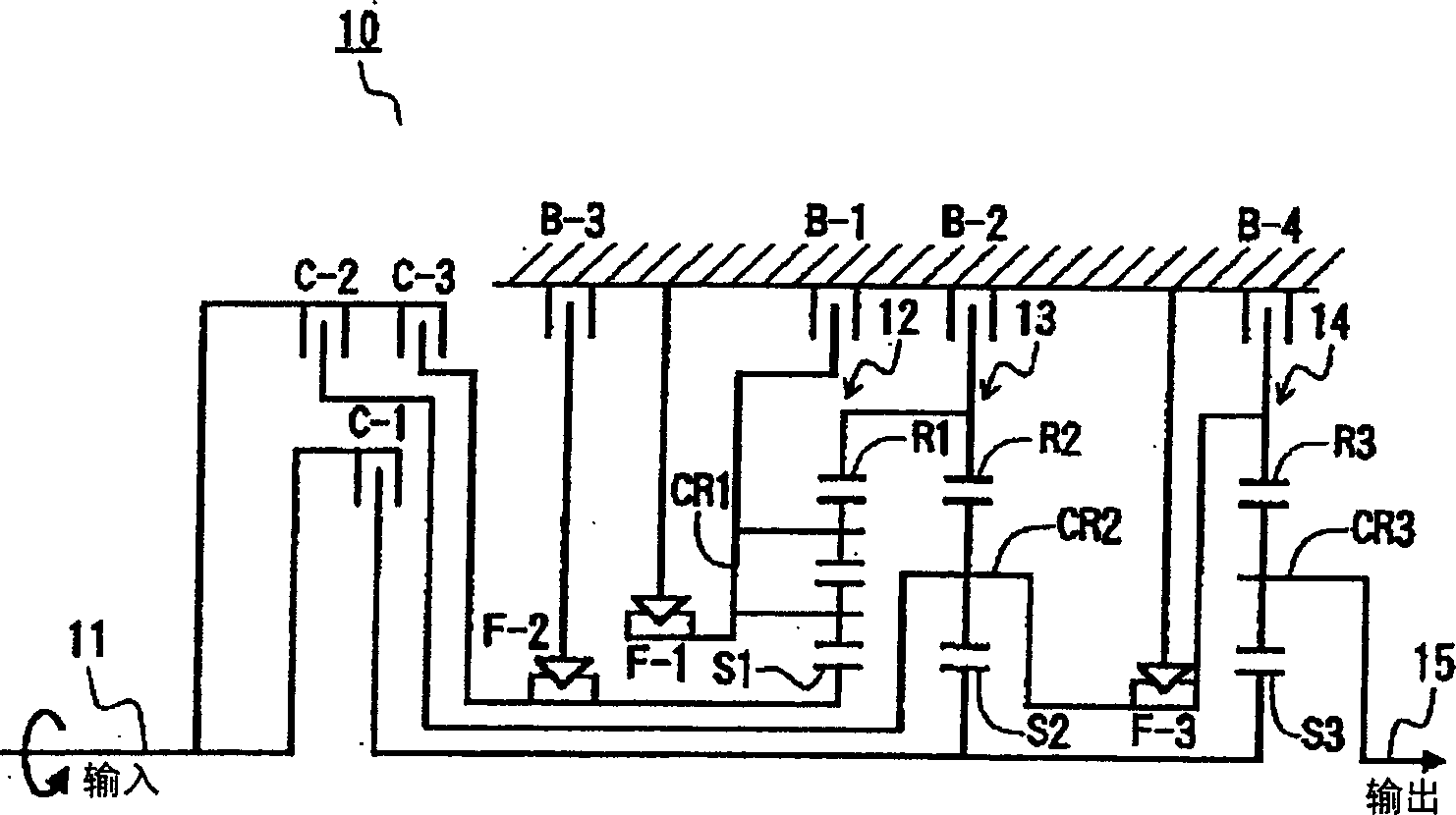

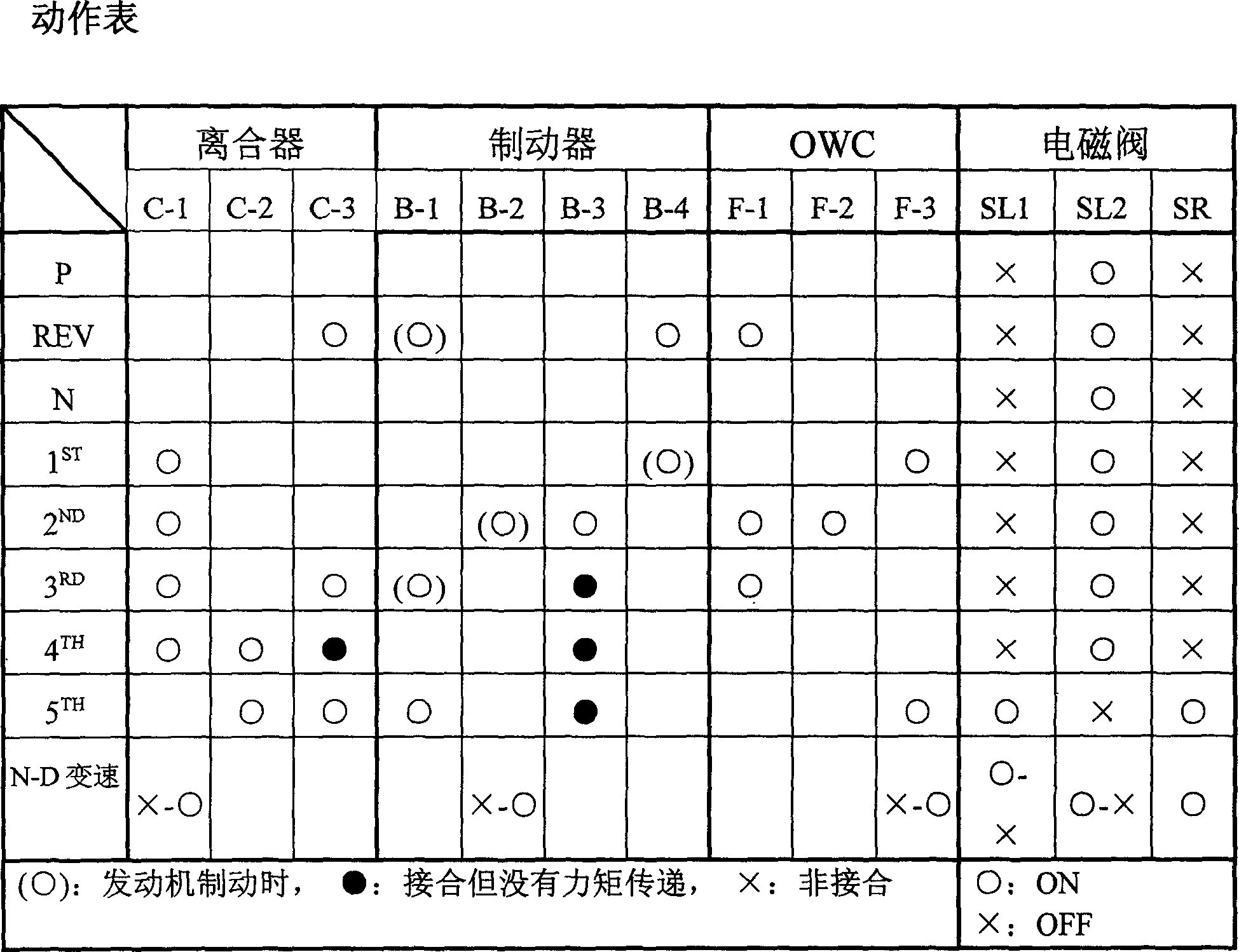

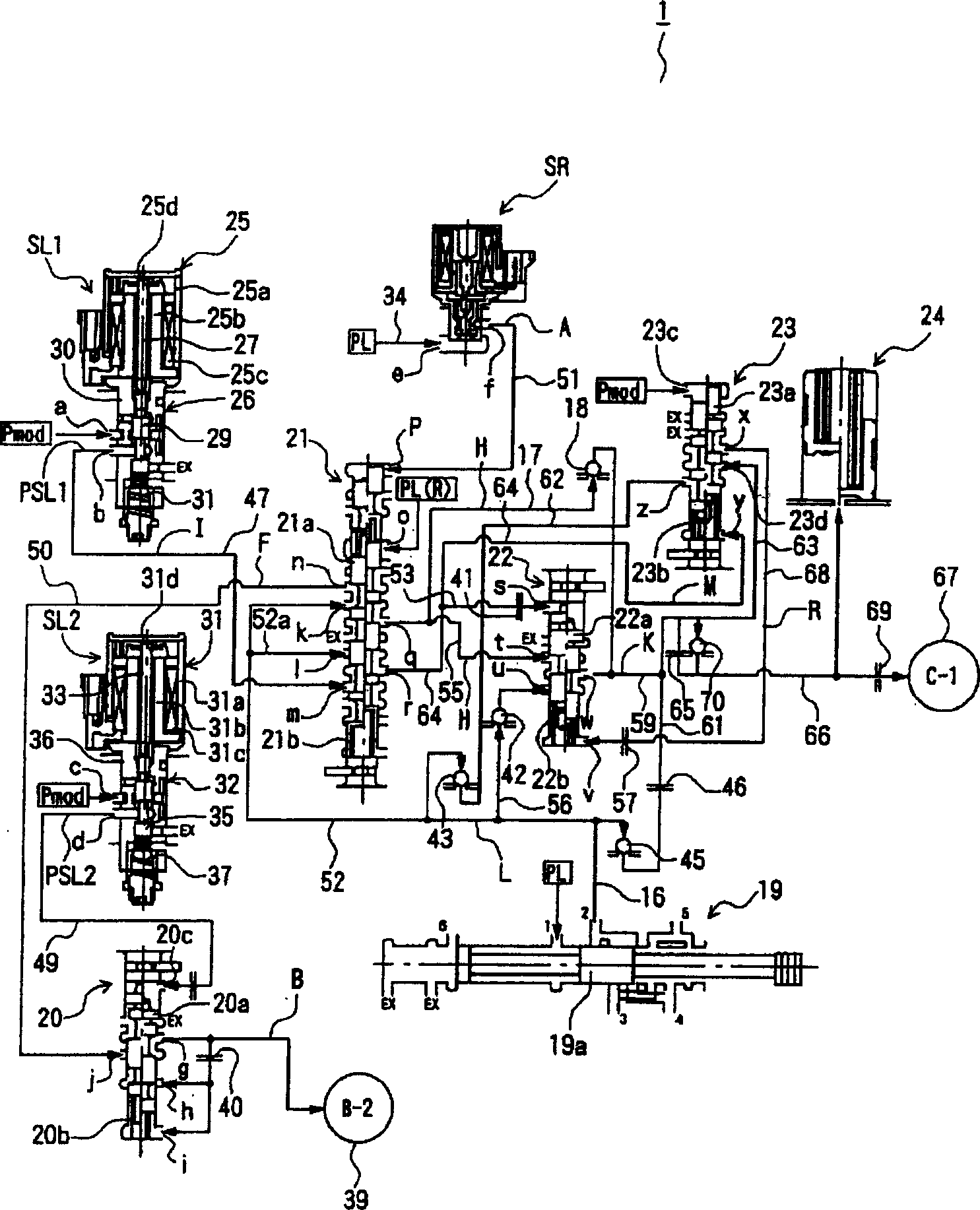

Oil-pressure control device of automatic speed variator

InactiveCN1470784APrevent bad situationsEfficient dischargeGearing controlAutomatic transmissionControl valves

The invention provides an oil pressure control device for an automatic speed-changer (1), wherein, when a clutch (C-1) is released, a bonder pressure (K), which is supplied by an oil type servo-motor (67) used for the clutch (C-1), can bypass a control valve (22) and be exhausted through an circuitous oil circuit (61, 62, and 63). Moreover, the exhaust is forbidden to use the ball check valve (42), which can safely prevent the oil from being exhausted through the path between a manual valve (19) and an input port (u). Therefore, the oil pressure control device has the advantage of avoiding that the valve, especially the middle part, of the control valve be stuck.

Owner:AISIN AW CO LTD +1

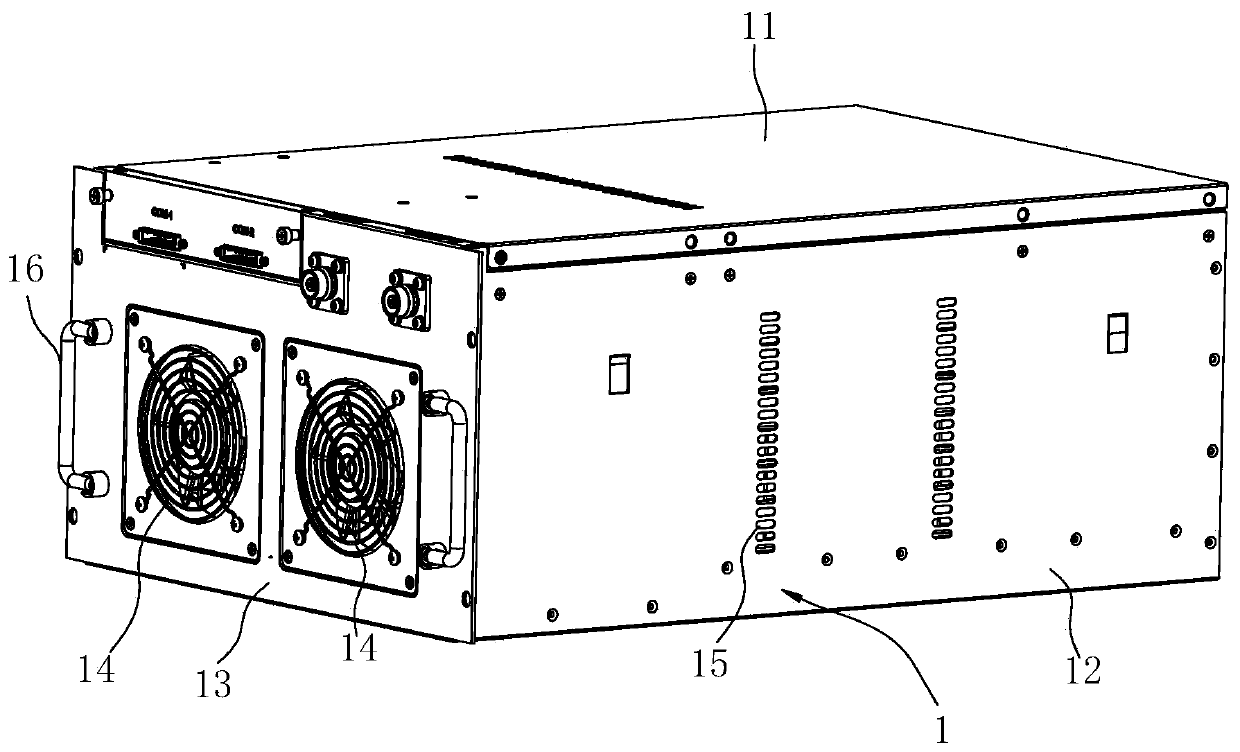

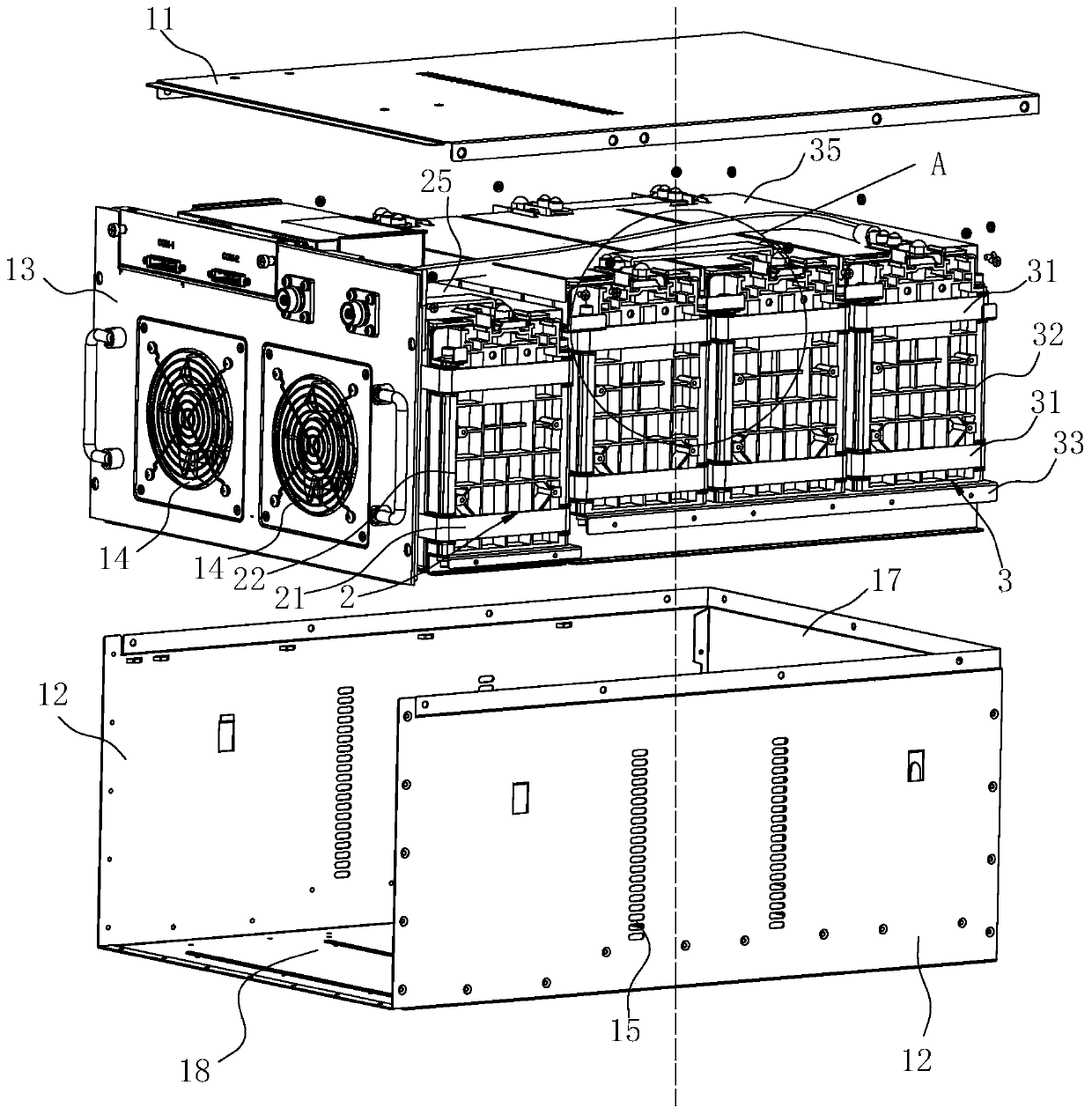

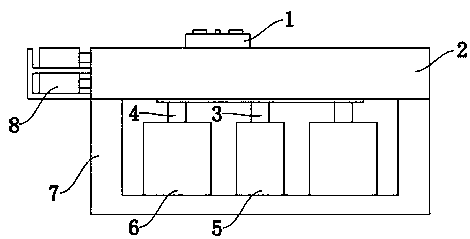

Battery box

ActiveCN110265749AReduce the temperatureSpeed up dischargeSecondary cellsCell component detailsEngineeringTemperature difference

The invention discloses a battery box, which comprises a box body, an exhaust fan and two battery units arranged inside the box body. The two battery units are a first battery unit and a second battery unit respectively. The exhaust fan is arranged at the front end of the box body, and is located between the first battery unit and the side wall of the box body. The box body is provided with an exhaust outlet at a position corresponding to the exhaust fan. There is a first ventilation duct between the two battery units and the top of the box body. A cushion frame is arranged between the second battery unit and the bottom of the box body. There is a second ventilation duct between the cushion frame and the bottom of the box body. A third ventilation duct is formed in a spaced manner between the first battery unit and the second battery unit, and the third ventilation duct is communicated with the first ventilation duct and the second ventilation duct. At least one air inlet is arranged in the side wall of the box body, and the at least one air inlet is communicated with one end of the second ventilation duct away from the first battery unit. The temperature difference inside the battery box can be reduced, the temperature consistency inside the battery box can be improved, and the battery box has good heat dissipation performance.

Owner:HUBEI JINQUAN NEW MATERIALS CO LTD

Crushing device with two-way rotation

The invention relates to a material fixing frame. The material fixing frame is characterized in that an included angle is formed by the side surface (the side surface in the leaking hole according to the forward direction of the rotating direction of a cutter wheel A) in a leaking hole and the side surface close to the cutter wheel A, and the included angle can be selected between 0 degree and less than 90 degrees; and the included angle can be more beneficial to leading crushed materials to slide into a cutting groove of the cutting wheel A, preventing uncrushed materials or materials without being crushed completely from moving along the rotation of the cutter wheel A, assisting the crushed materials to enter the cutter groove of the cutter wheel A, playing a role in fixing the crushed materials and leading the cutter wheel A to carry out solid crushing on the crushed materials.

Owner:叶德坚

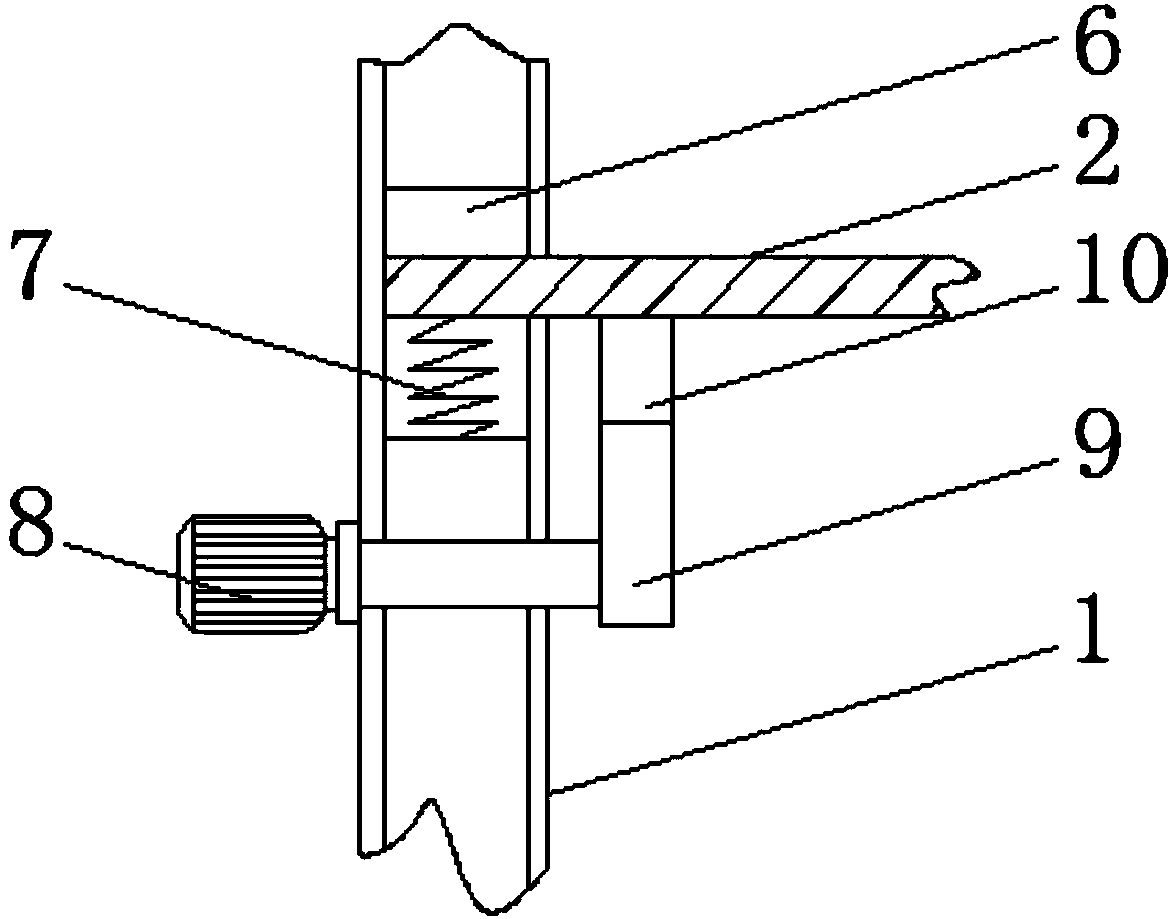

Cutting base of cutting machine tool and using method of cutting base

InactiveCN108723794ASpeed up dischargeDoes not affect machiningLarge fixed membersPositioning apparatusFiltrationHelical blade

The invention discloses a cutting base of a cutting machine tool and a using method of the cutting base. The base comprises a base body; the base body is installed on a support; the base body is provided with a groove, then the groove is internally and movably provided with a working table for clamping a workpiece; the groove is internally and rotatably connected with a rotating shaft and a screwrod; the rotating shaft and the screw rod are separately and fixedly connected with an output end of a stepping motor; a first helical blade is welded and fixed on the rotating shaft; the screw rod isconnected with a lug plate by means of threads; the lug plate is welded and fixed at the bottom of the working table. According to the cutting base of the cutting machine tool, debris and cutting fluid can be separated from each other by means of filtration of a filter screen, and are stored in different areas; the debris drives the rotating shaft to rotate under the action of the stepping motor;the first helical blade and a second helical blade can be used for respectively pushing the debris in the groove into through holes formed at the two sides, so that the discharge speed of the debrisis accelerated, and the debris can be cleaned during the processing without affecting the cutting process.

Owner:张阳康

Header pipe and heat exchanger

ActiveCN102889819AEasy dischargeSpeed up dischargeEvaporators/condensersHeat exchanger casingsWater flowEngineering

The invention discloses a header pipe which comprises a pipe main body; the upper part of the pipe main body is provided with a flat pipe groove; the outer side of the lower part of the pipe main body is provided with a capillary groove wall; a clearance between the inner wall surface of the capillary groove wall and the outer wall surface of the pipe main body forms a capillary groove; the lower end of the capillary groove is provided with a water outlet communicated with the capillary groove; two ends of the wall of the capillary groove are provided with end parts which are matched with the outer wall surface of the pipe main body; condensed water flows down from the upper part of the heat exchanger, and the capillary groove can generate the capillary phenomenon when the condensed water flows through the outer wall of the pipe main body and is in contact with the capillary groove; under the effect of the capillary phenomenon, the condensed water is exhausted out through the water outlet rapidly, and the header pipe with the structure accelerates the exhaust speed of the condensation water; and the improvement of the exhaust speed of the condensation water can effectively prevent problems caused if the condensed water is not exhausted in time. The invention also discloses a heat exchanger comprising the header pipe.

Owner:SANHUA HANGZHOU MICRO CHANNEL HEAT EXCHANGER

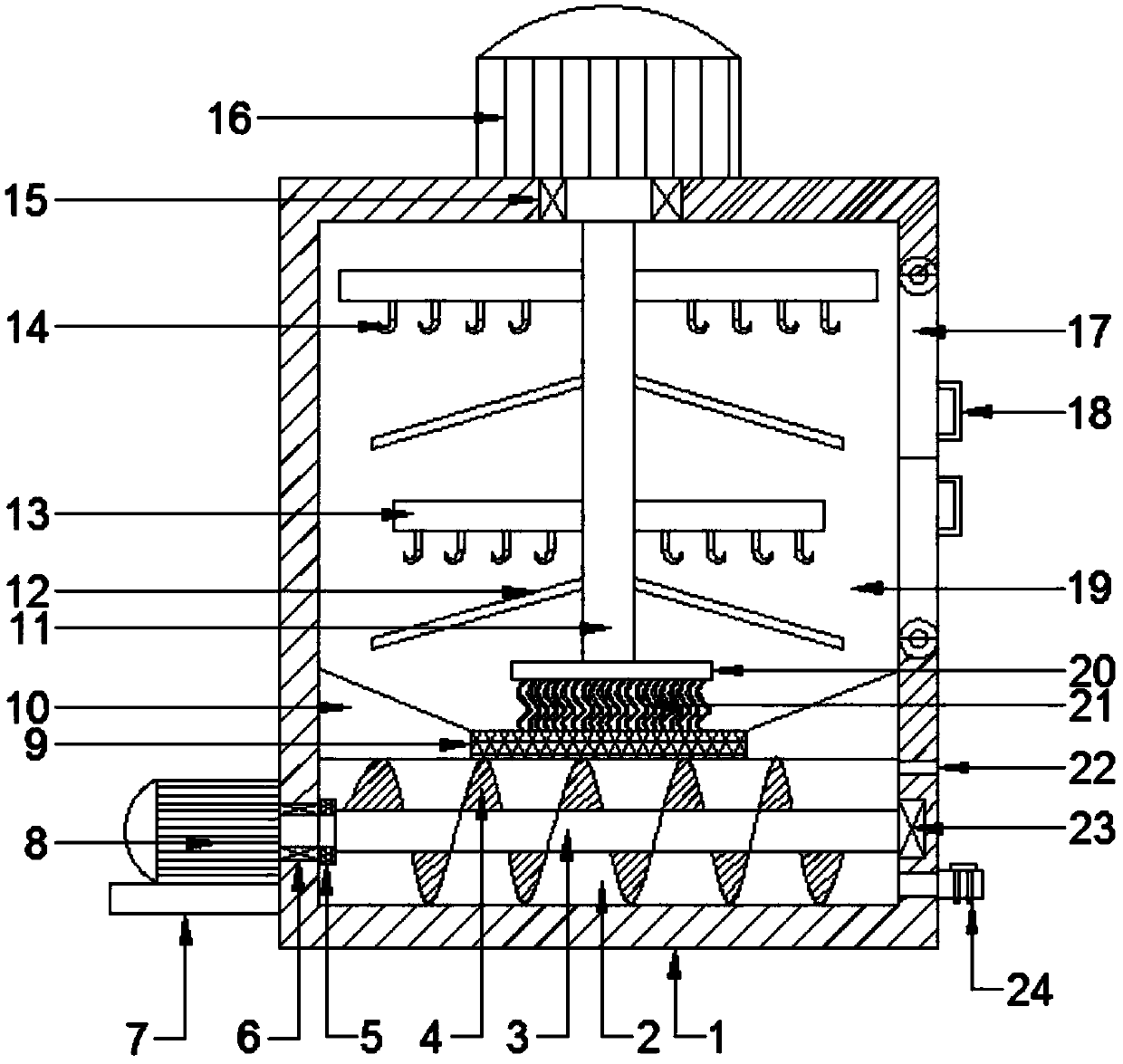

Industrial waste gas dedusting, purifying and waste heat utilizing device

ActiveCN105126512AAvoid harmEasy to collectHuman health protectionCombination devicesElectricityCombustion

The invention discloses an industrial waste gas dedusting, purifying and waste heat utilizing device. The device comprises a deduster body; the bottom end in one side of the deduster body is provided with a flue gas inlet, the top end of the deduster body is provided with a gas outlet; a blowing and sucking chamber, a dust settling chamber, and a dust storage cavity are arranged in the deduster body from top to bottom; and a filtering layer and an electric dedusting layer are arranged in the dust settling chamber. The industrial waste gas generated by combustion is introduced into the deduster body through the flue gas inlet, then the waste gas goes through the filtering layer and the electric dedusting layer in the dust settling chamber to remove the dusts, and the separated dusts are collected and stored in the dust storage cavity. The environment is protected, and the damage to the human body is avoided. At the same time, an air outlet pipeline and a cold water tank are arranged on the gas outlet; the air outlet pipeline is coiled and tightly attached on the external wall of the cold water tank, thus the waste heat of industrial waste gas can be utilized to heat the cold water in the cold water tank, the waste heat is utilized, the energy is saved, and the environment is protected.

Owner:广州绿寰环保科技有限公司

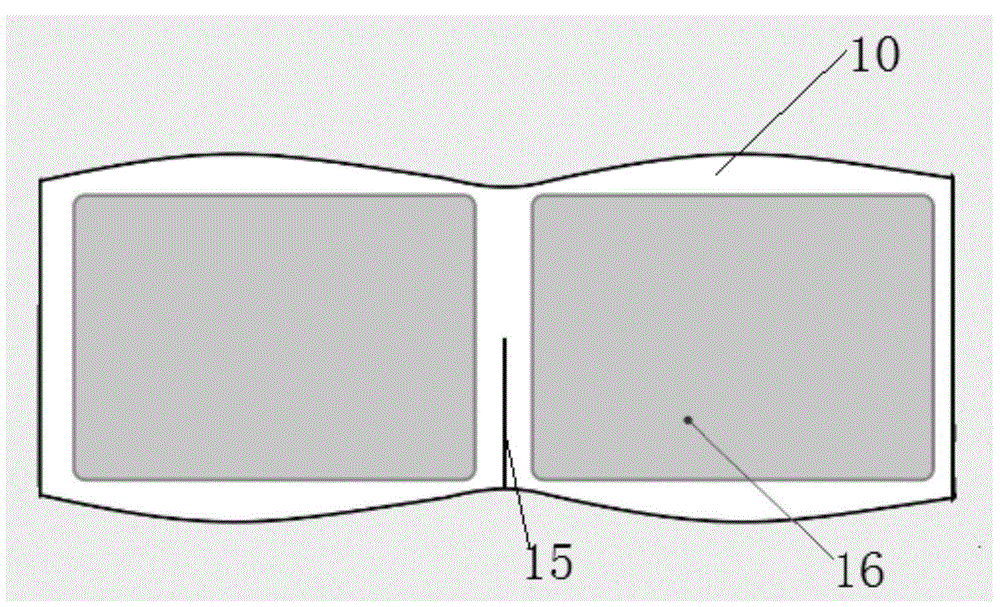

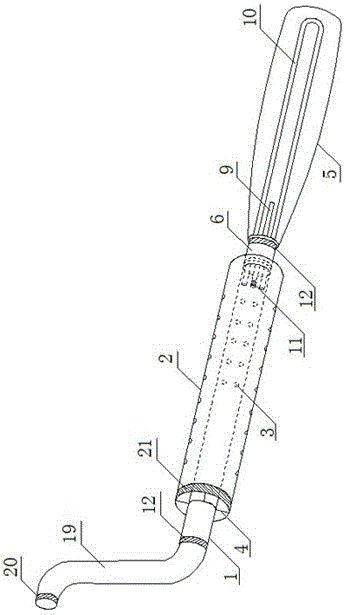

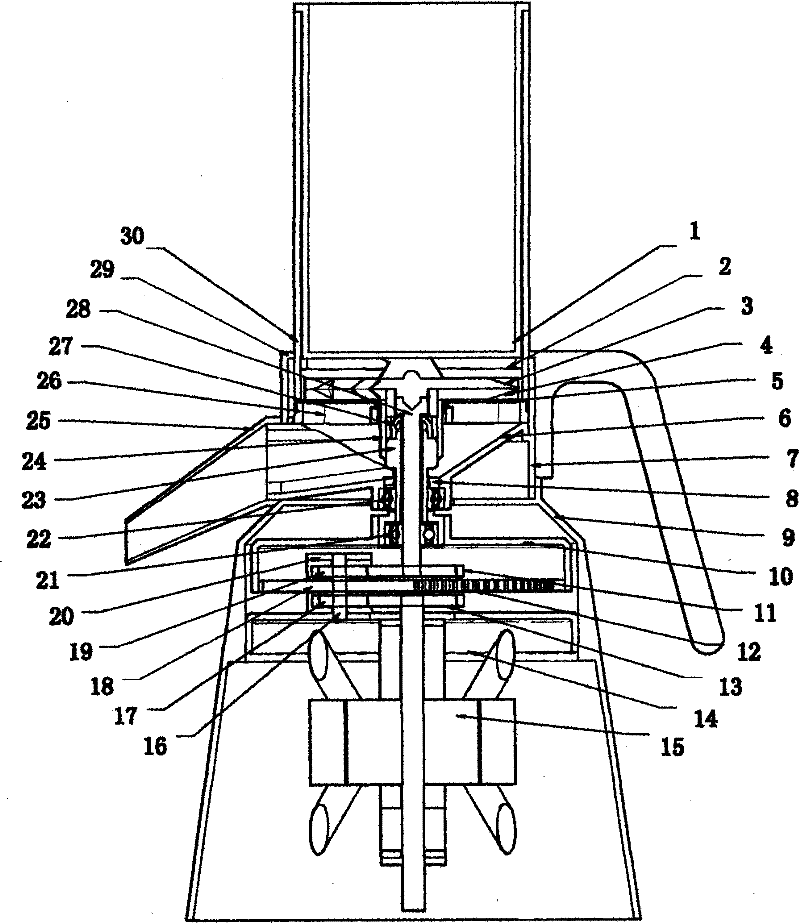

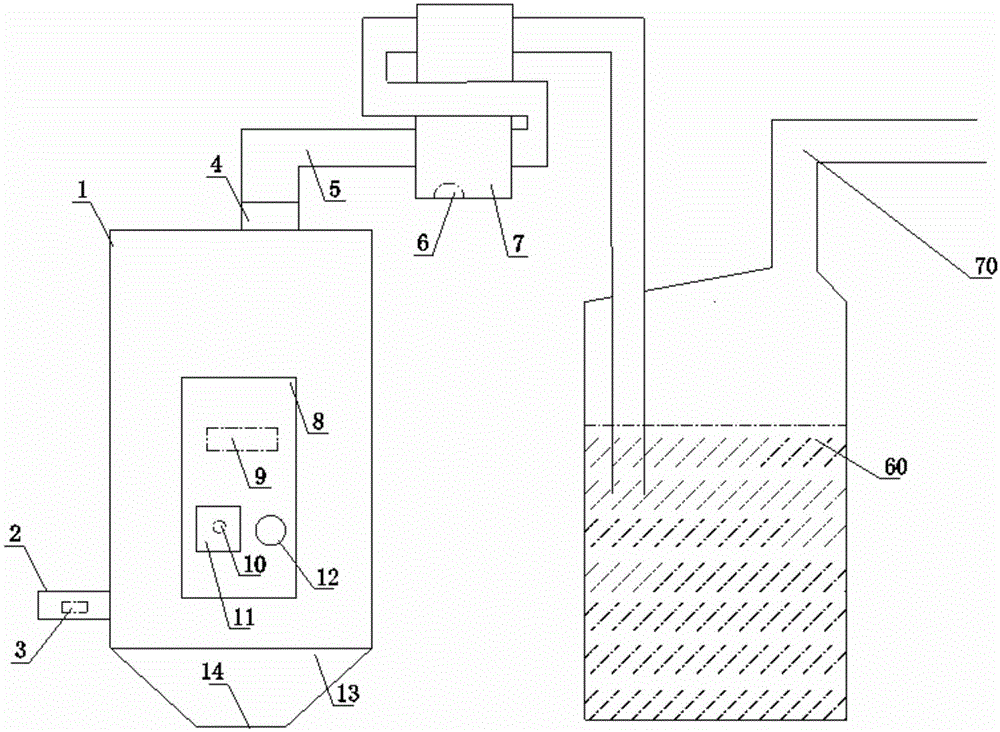

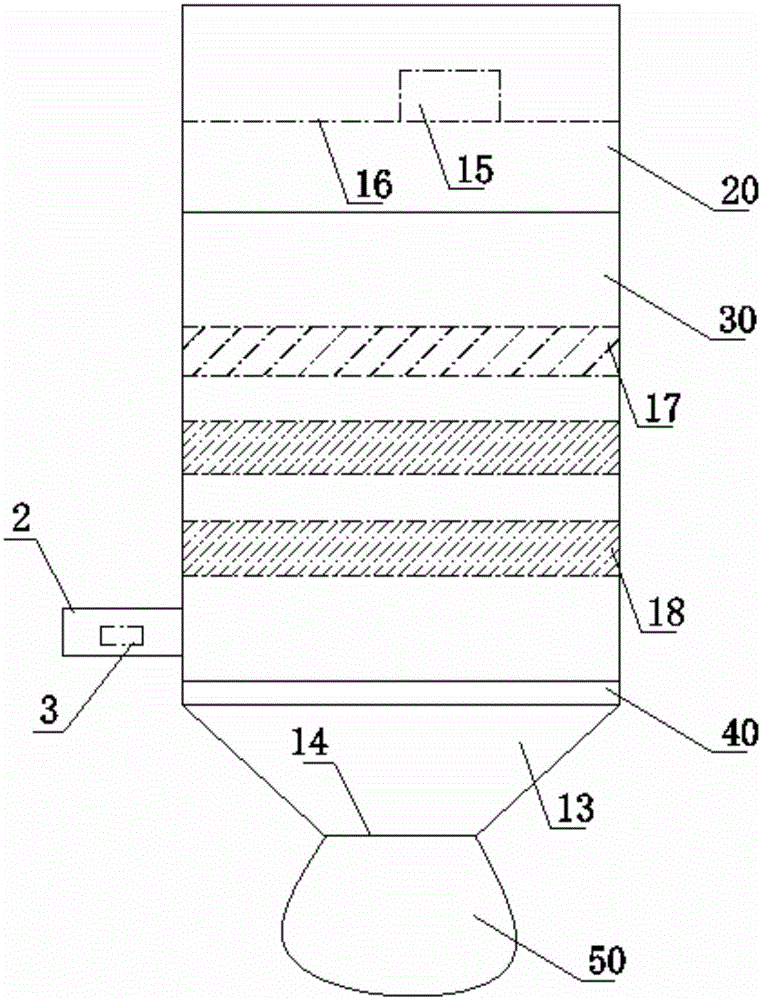

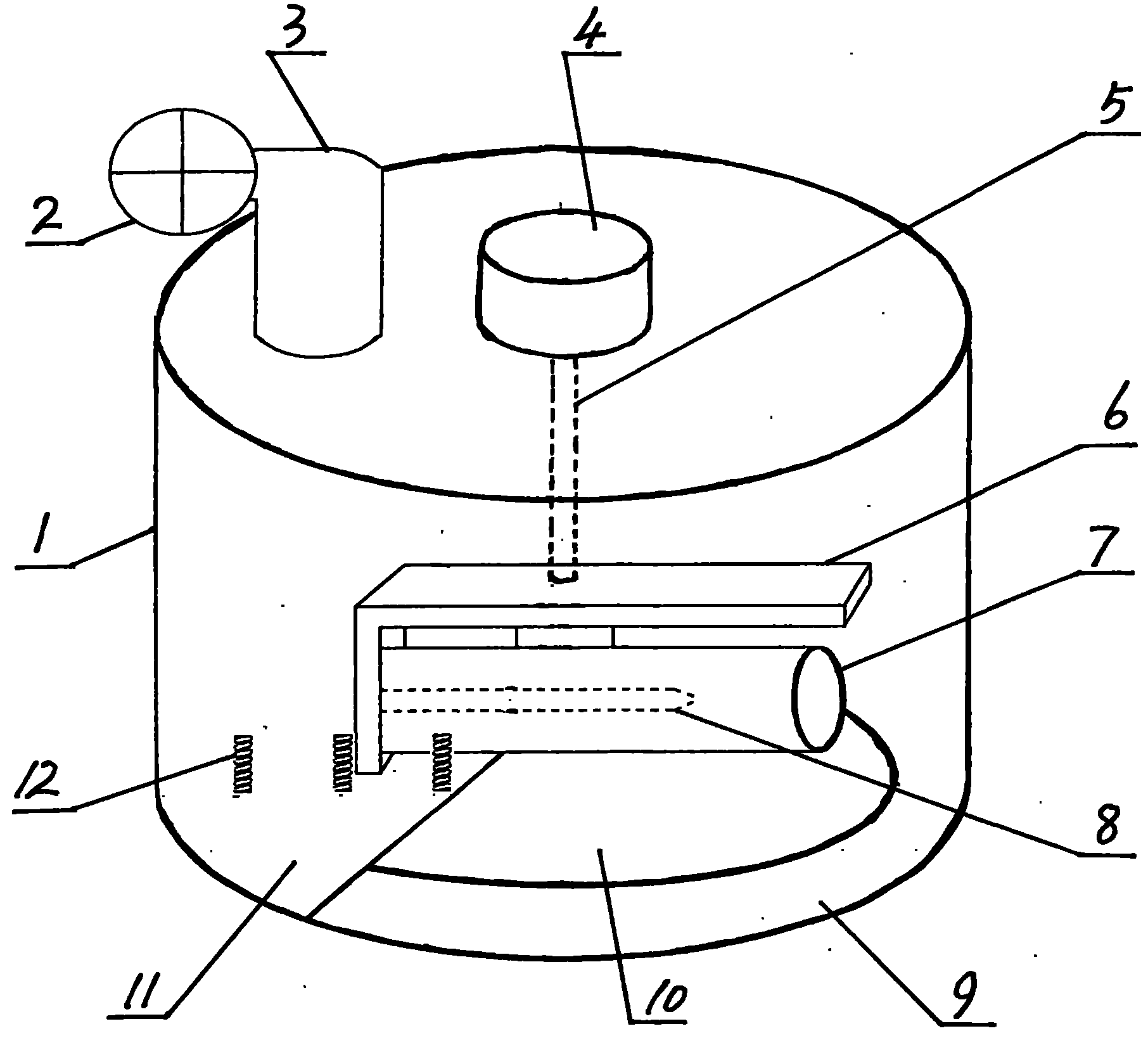

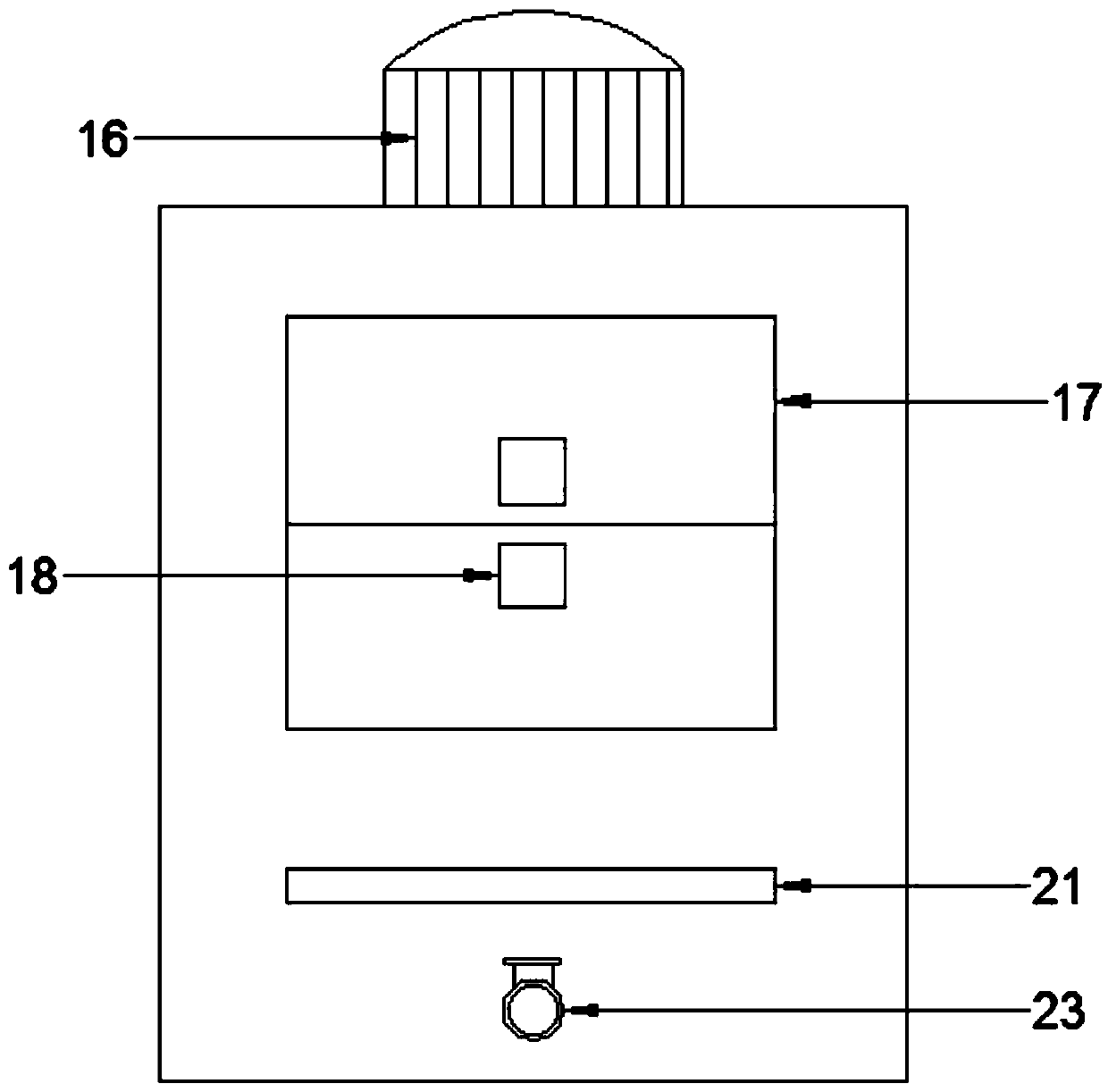

Program-controlled moxibustion device

InactiveCN102525803ASpeed up dischargeTo achieve the adjustment effectDevices for heating/cooling reflex pointsMotor driveElectric machine

The invention relates to a program-controlled moxibustion device which comprises a cylindrical housing (1), wherein a smoke exhaust port and a smoke exhaust pipe (3) are arranged at the top of the housing, a stepping motor (4) that is controlled by a motion control chip is arranged at the top of the housing, the output end of the stepping motor is connected with a moxa stick holder (6) through a connecting rotary shaft (5), an ejector (8) is arranged transversely on the moxa stick holder, a bed (9) is arranged at the bottom of the housing (1), a semi-circular heat radiation window (10) is formed on a half part of the bed, an ash removal chamber (11) is formed at the other half part of the bed, and a plurality of ash scrapping springs (12) are vertically arranged inside the ash removal chamber and distributed from the outside to the center of the bed (9). The program-controlled moxibustion device has a simple structure, is convenient to operate, adopts the rotating structure which rotates around the stepping motor driving shaft as center to greatly simplify the driving process of the stepping motor, has the effects of removing smoke and ash and controlling temperature during moxibustion, and is applied to health thermal moxibustion in related acupoints and surrounding sensitive regions of users to achieve the effect of health care.

Owner:龙琼珍

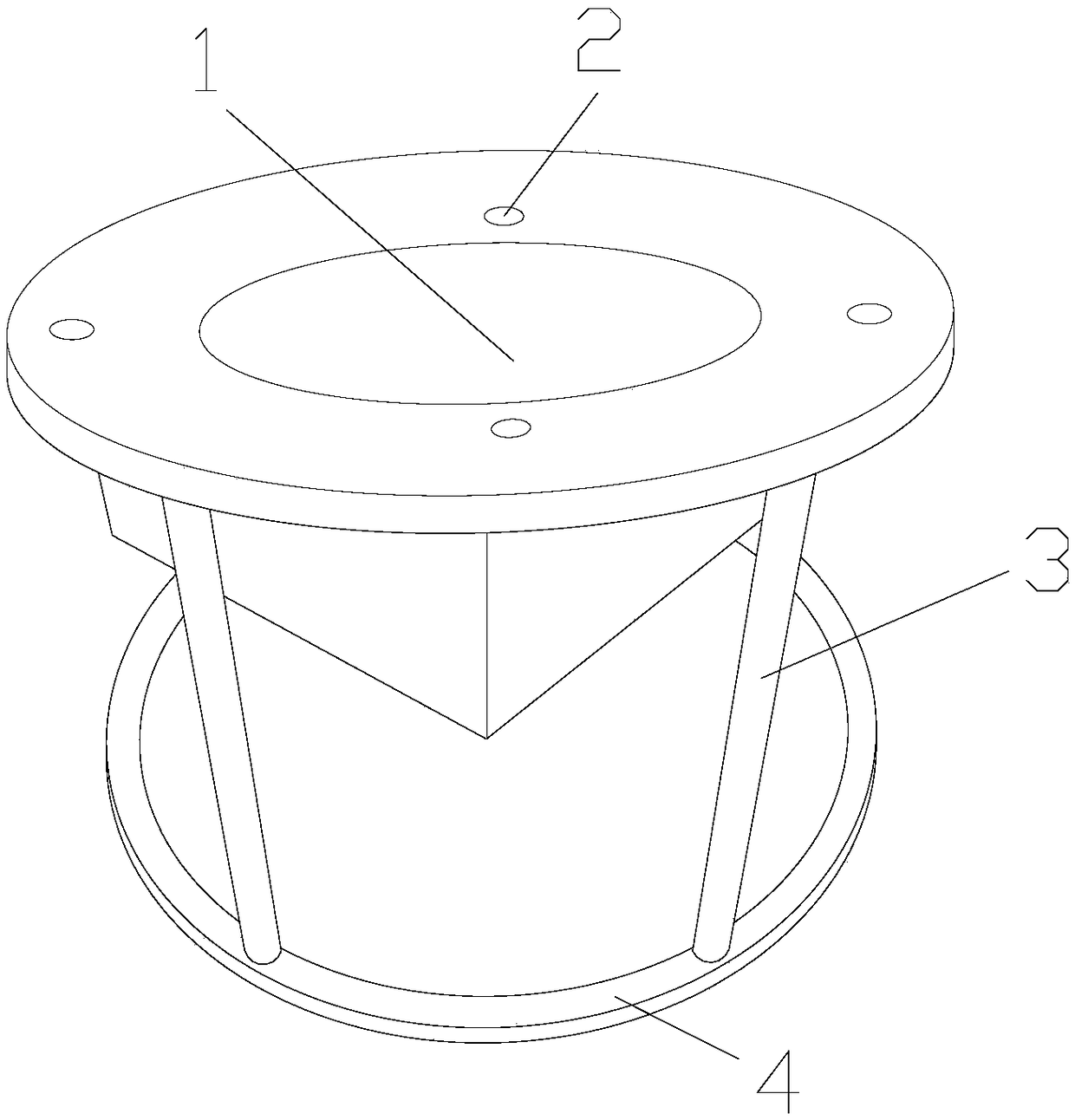

Flood flow-increasing drainage concrete manhole cover

ActiveCN109138131ASpeed up dischargeImprove flood control abilitySewerage structuresWater level riseEngineering

The invention discloses a flood flow-increasing drainage concrete manhole cover, the structure includes: a flood aid and drainage device, a water inlet, a support bar and a fixing frame, wherein the flood aid and drainage device comprises a flushing hole, a manhole cover main body, a compression spring, a deflector, a supporting float, a micro force piston, water collection holes, a buoyancy drainage tanks, a push rod, a buoyancy deflector and a clamping block. A slight force piston is nested in that flushing hole, the inner surface of the well cover main body is in contact with the outer surface of the supporting floating plate. The beneficial effects are: in case of heavy rain or sustained rainfall in the city, under the action of the flushing hole and the water collecting hole, when theinternal water level rises, the supporting floating plate floats upward, so that people do not step into the well by mistake, and under the action of the diversion platform, the water generates eddycurrent state, finally forms siphon effect, improves the drainage speed, avoids the flood caused by heavy rain in the city, and causes the phenomenon of slow drainage after the water accumulates in the city.

Owner:HANGZHOU ZHUILIE TECH

Livestock bloodletting device with pushing device

InactiveCN107927119AAvoid cloggingSpeed up dischargeBlood collection/stirring apparatusPoultry processing support devicesPropellerBlood vessel walls

The invention discloses a poultry bleeding device with a pushing device, which comprises a bleeding box, and the bleeding box is provided with a collection chamber and a bleeding chamber, the collection chamber is located at the bottom of the bleeding box, and the bleeding chamber is located in the collection chamber Above, a diversion slope is provided between the leach chamber and the collection chamber, and a filter screen is provided at the bottom of the diversion slope. A push motor is provided on the left wall of the leach box, and a push propeller is fixed on the push rod. The collection chamber The bottom of the right side wall is provided with an outlet vessel, the top of the right side wall of the collection chamber is provided with an observation port, the center of the top of the leach tank is equipped with a leach motor, the motor shaft of the leach motor is vertically fixed to the rotating rod, and the rotating rod is The suspension frame and the baffle are fixed, the bottom surface of the suspension frame is fixed with a hook, the bottom end of the rotating rod is fixed with a cleaning turntable and a cleaning brush, and a push door is rotated and fixed on the right side wall of the bleeding chamber; the present invention can realize centrifugal acceleration bleeding , Prevent poultry from leach blood pollution, prevent filter clogging and grind and push blood to discharge multiple functions.

Owner:ZHENGZHOU TIANSHUN ELECTRONICS TECH CO LTD

Sludge crusher and method of crushing sludge with the same

The invention relates to a sludge crusher for crushing sludge blocks. The sludge crusher comprises: a shell, which is formed by an upper cover, a cylinder wall and a base plate; at least one crushingcomponent arranged in the shell; a cylinder wall segment corresponding to each of the at least one crushing component; a power input device; and a plurality of screw rods and nuts. The at least one crushing component is arranged in series along the vertical direction, specifically the rotating shafts of adjacent crushing components are connected to each other through upper and lower connecting parts so as to rotate together. The invention also relates to a method of crushing sludge with the sludge crusher.

Owner:广州正晟科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com