Ultrasonic-vibration micro electric discharge machining workbench

A technology of ultrasonic vibration and electric discharge, applied in the field of micro electric discharge machining, can solve the problems of difficult chip removal in micro holes or special-shaped holes, unsuitable for micro electric discharge machining, and difficult discharge of electric erosion products, so as to facilitate transfer and promote discharge , the effect of increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

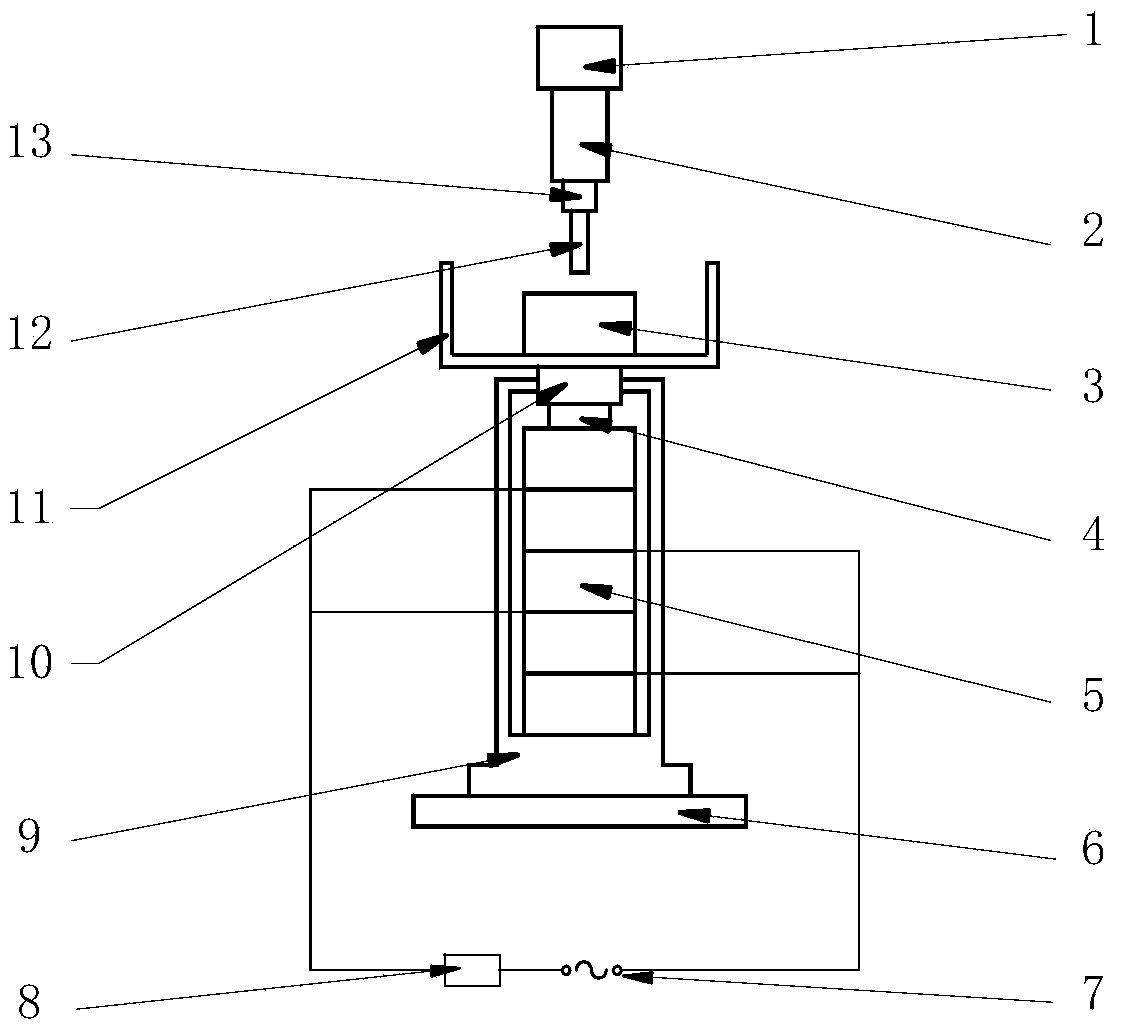

[0015] Such as figure 1 As shown, the present invention is an ultrasonic vibration micro-EDM workbench based on a micro-EDM machine tool, including a preload spring 4, a piezoelectric ceramic 5, a machine tool base 6, a power supply 7, an adjustable resistor 8, a piezoelectric Actuator housing 9, push rod 10, working fluid tank 11. When the mass of the processed workpiece 3 is small, the dynamic follow-up effect is better. The ultrasonic vibration micro-EDM workbench can adopt high-frequency ultrasonic vibration, and the frequency range is 38KHz-42KHZ. The processed workpiece is fixed in the working fluid tank 5 by bolts. And immersed in the working fluid, the processing effect is better. The number of laminated piezoelectric ceramics 5 is three. The piezoelectric actuator housing 9 plays the role of protecting the piezoelectric ceramic 5 and is made of corrosion-resistant stainless steel. The specific size is determined according to the size of the piezoelectric ceramic 5 a...

Embodiment 2

[0021] Such as figure 1 As shown, when performing rough machining, the number of laminated piezoelectric ceramics 5 is five, so as to obtain greater machining efficiency. Others are the same as embodiment one.

Embodiment 3

[0023] Such as figure 1 As shown, when the workpiece 3 is small in size, it is difficult to fix it mechanically. The workpiece 3 is glued and fixed in the working fluid tank 5 and immersed in the working fluid. After processing, the workpiece is dissolved by an organic solvent to remove it. Others are the same as embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com