Patents

Literature

3403 results about "Electric spark" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An electric spark is an abrupt electrical discharge that occurs when a sufficiently high electric field creates an ionized, electrically conductive channel through a normally-insulating medium, often air or other gases or gas mixtures. Michael Faraday described this phenomenon as "the beautiful flash of light attending the discharge of common electricity".

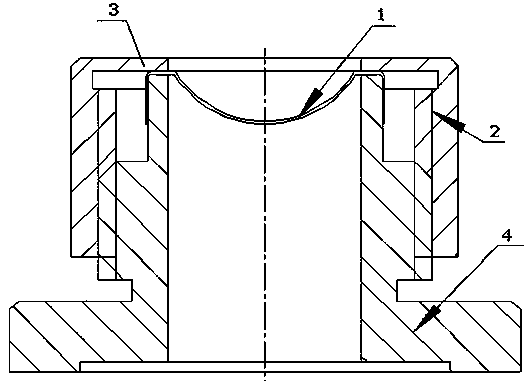

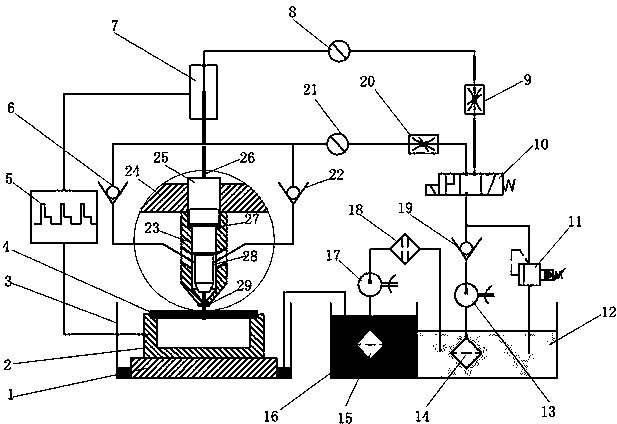

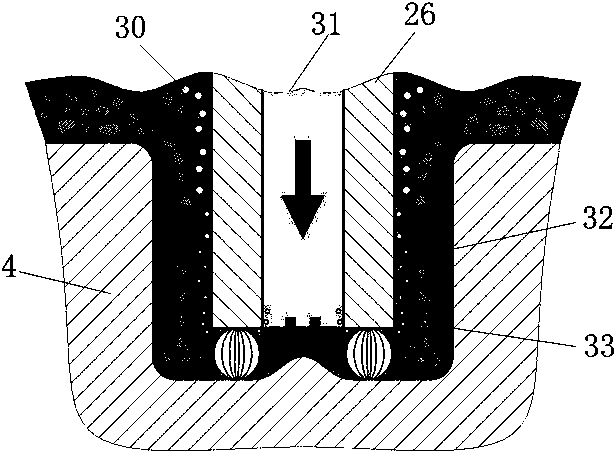

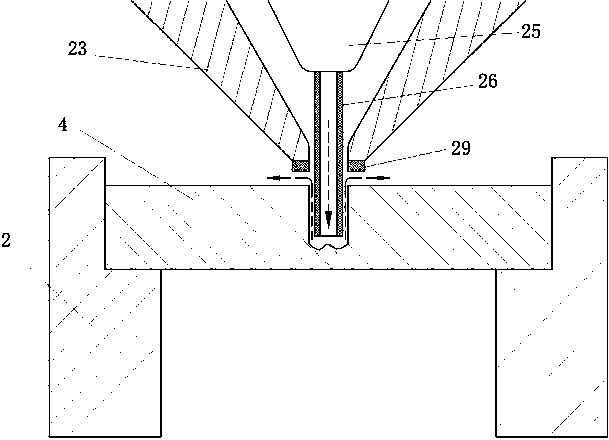

Method and apparatus for pulsed discharge forming of a dish from a planar plate

InactiveUS6591649B1Move quicklyPreclude obtainingMetal-working apparatusElectric dischargeEngineering

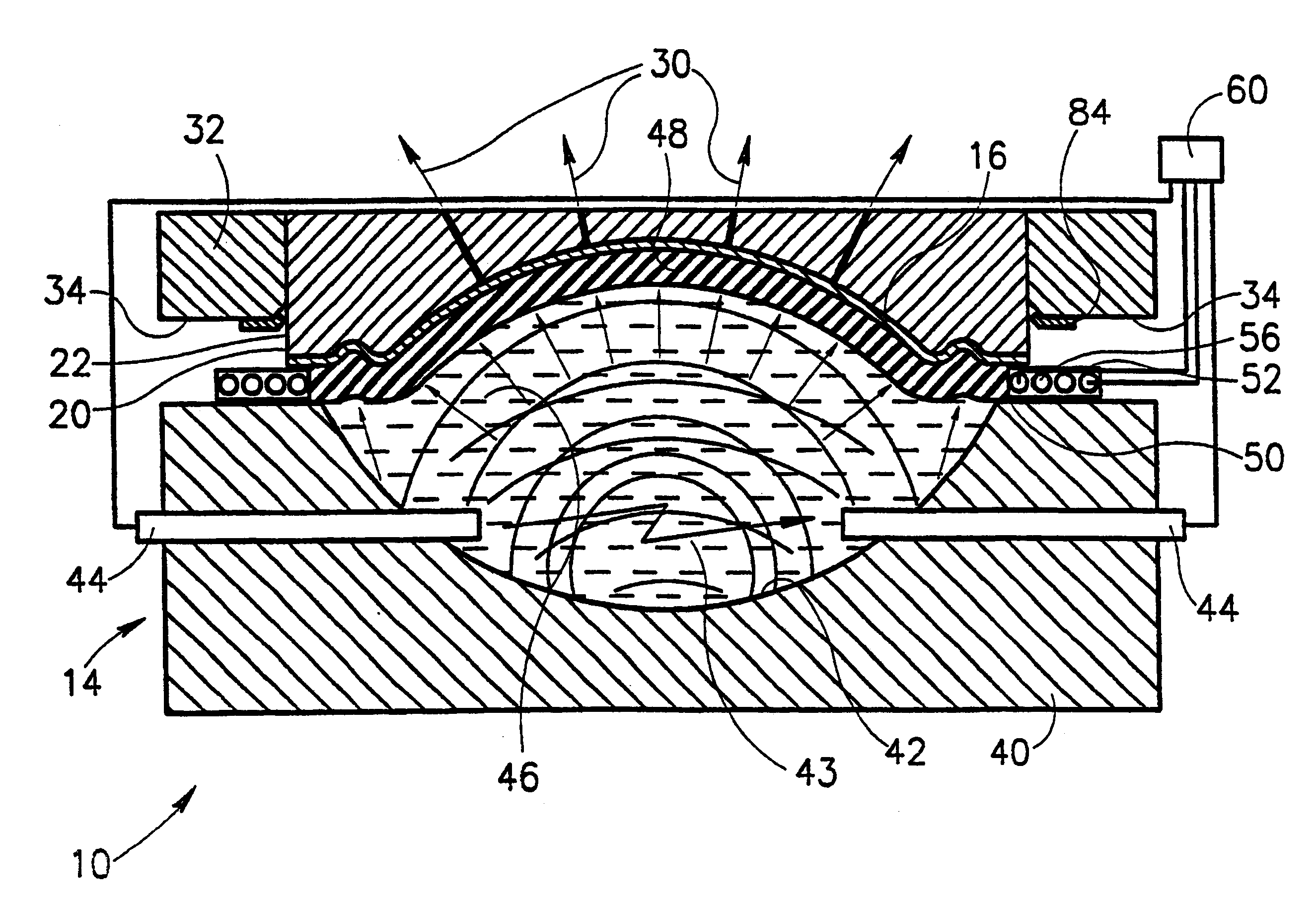

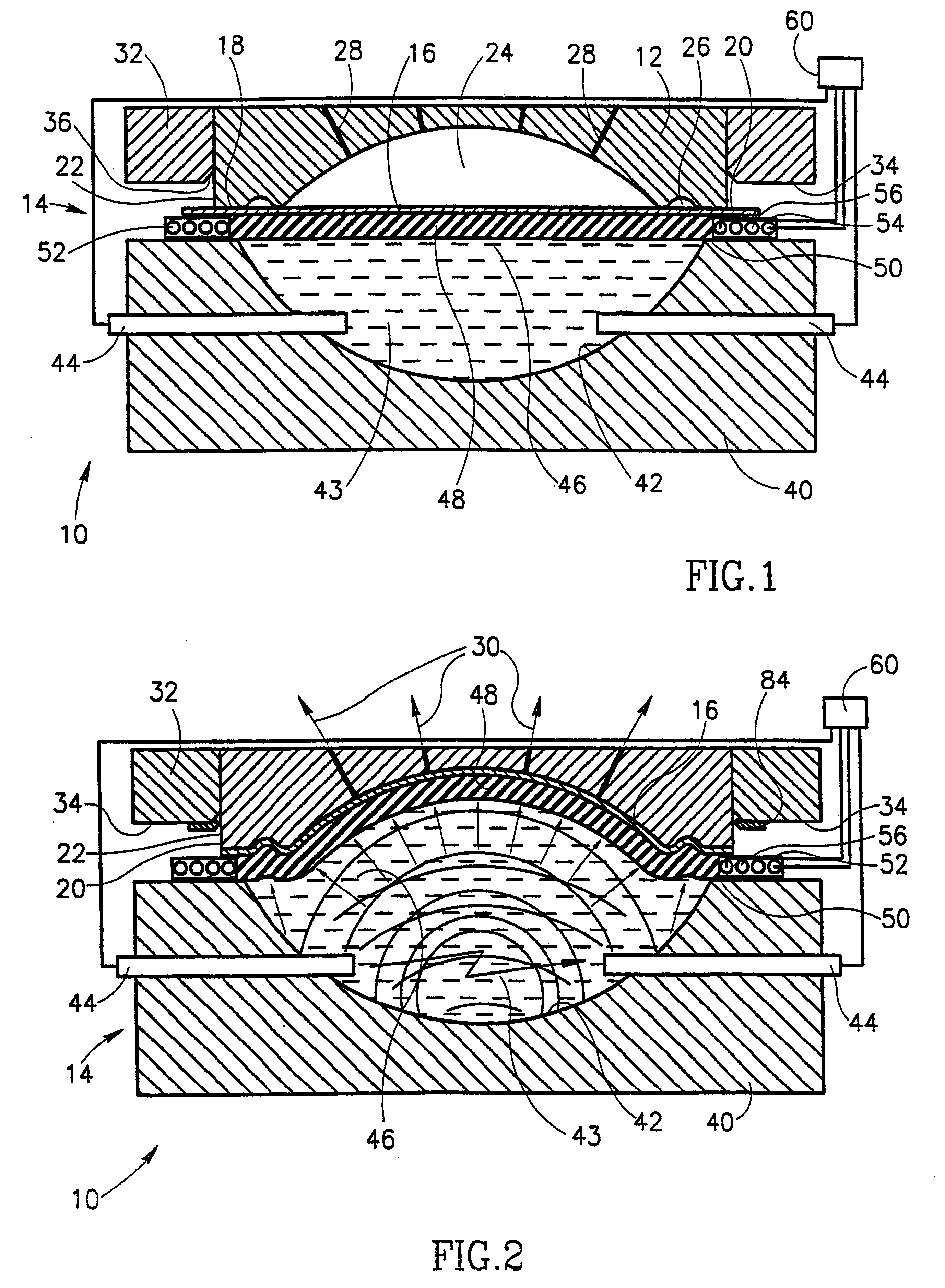

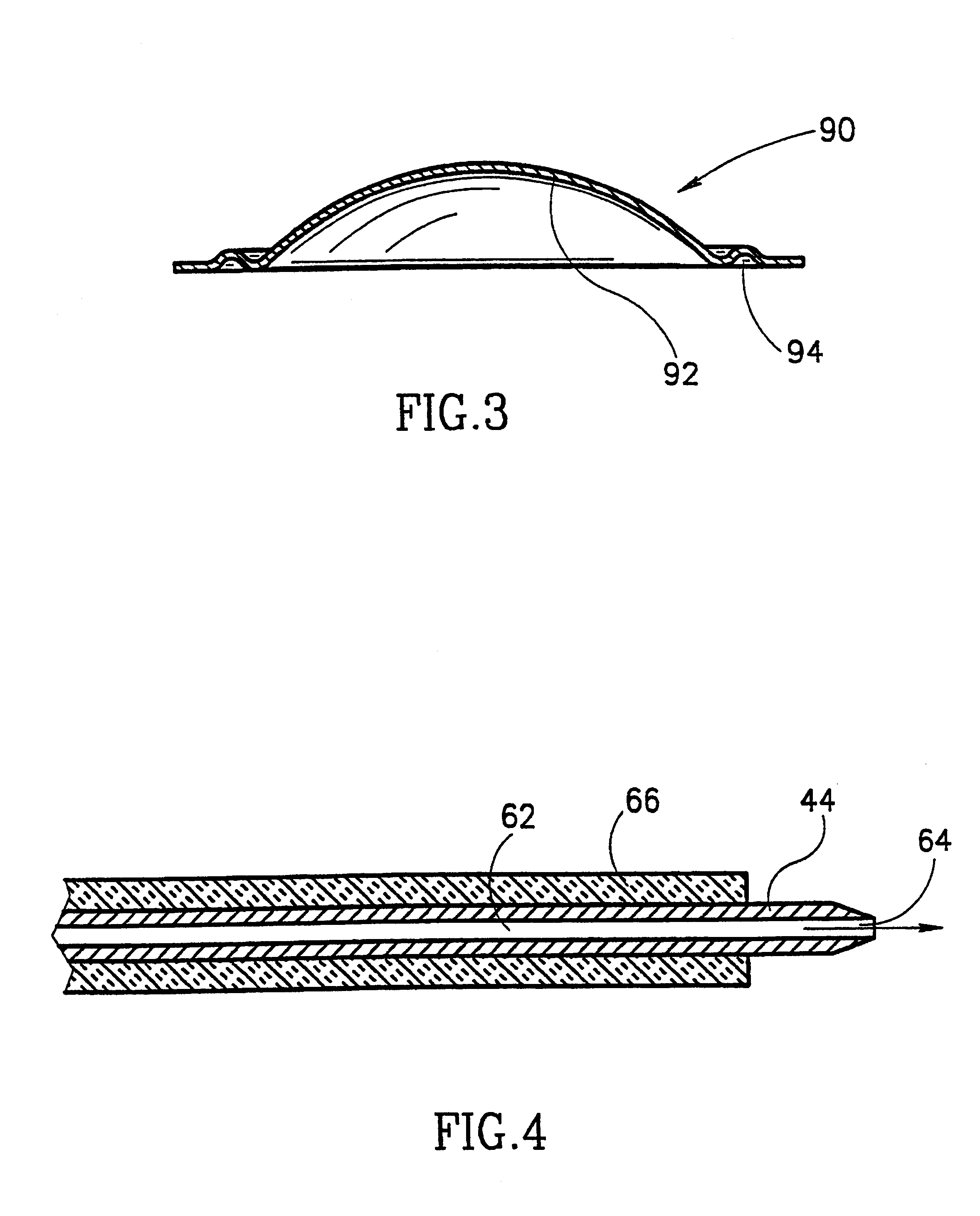

An apparatus for forming a generally planar metal plate into a dish with a three-dimensional pattern is provided. The apparatus comprises a mold having a forming surface with a contour corresponding to said three-dimensional pattern, and having edges corresponding to boundaries of the dish, which edges are defined by side walls essentially perpendicular to the forming plane; a forming device comprising a fluid basin and pairs of electric discharge members within the fluid and having an opening facing the mold to allow transmission of a pressure wave from the fluid to the metal plate; and an electric discharge circuitry for discharging a short and intense electric current through the pairs of electric discharge members generating an electric spark or breakdown within the fluid to yield formation of plasma, vapor or both.

Owner:INFINITY IP COMMERCIALIZATION ISRAEL LTD

Picosecond pulse laser cutting preparation method for grid-control traveling wave tube grid mesh

ActiveCN103531414AHigh dimensional accuracyImprove consistencyNon-emitting electrodes manufacturePicosecond laserPicosecond pulsed laser

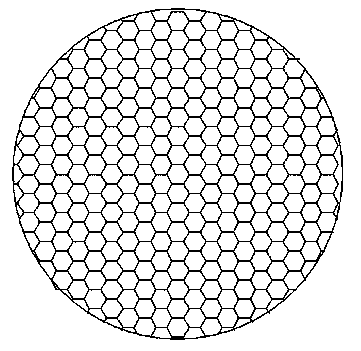

The invention discloses a picosecond pulse laser cutting preparation method for a grid-control traveling wave tube grid mesh. The method comprises the following steps of performing cleaning, hydrogen burning and annealing on a grid mesh material, then pressing the grid mesh material through a die on a punching machine to form a spherical grid mesh blank with high curvature radius precision, performing destressing hydrogen burning on the blank to eliminate stress during processing to guarantee the stability of the curvature radius of a spherical cap of a grid mesh, and finally cutting the grid mesh by adopting picosecond pulse laser of an optimized technology to prepare the grid-control traveling wave tube grid mesh with high size precision and high consistency. According to the preparation method for the grid mesh of a grid-control traveling wave tube, specific technical parameters of picosecond laser cutting are screened through a large number of experiments, the operability is high, the technical design is reasonable, and the application range is large; the prepared grid mesh is high in size precision, high in consistency, high in yield and high in reliability and has an important application value; the shortcoming of an existing electric spark grid mesh processing technology can be effectively overcome.

Owner:NANJING SANLE GROUP

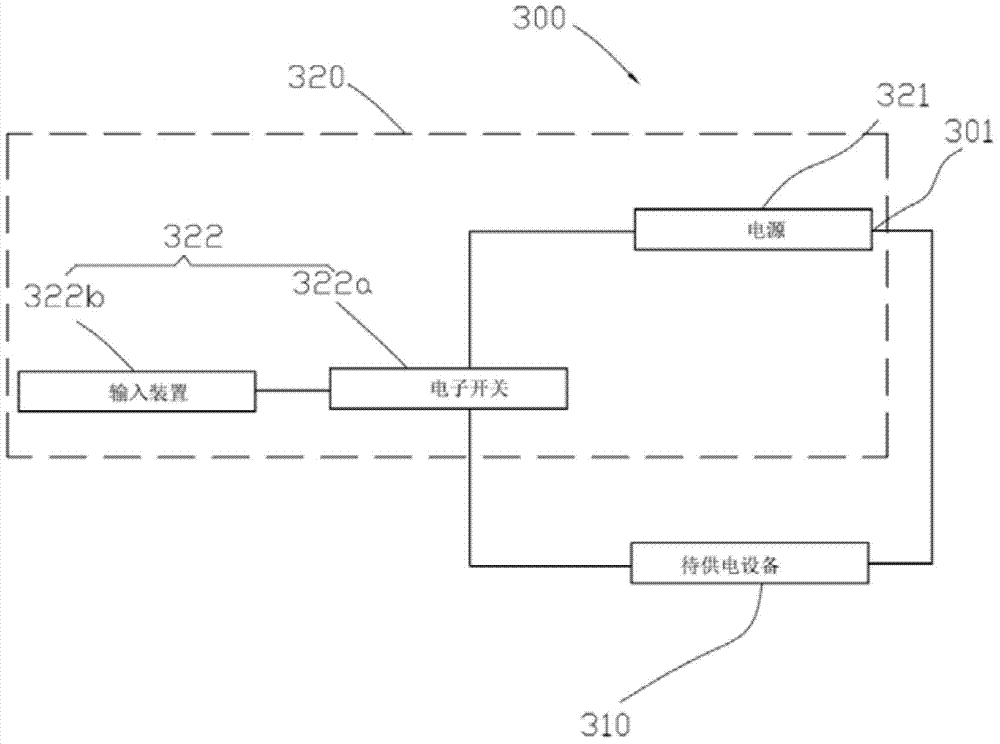

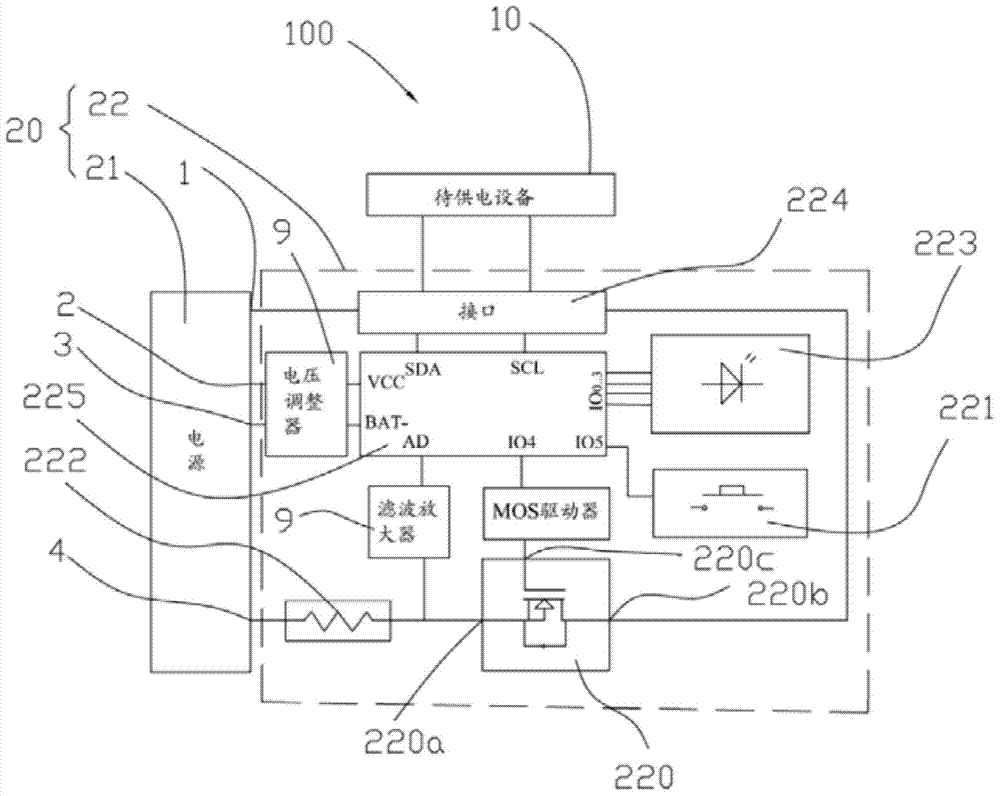

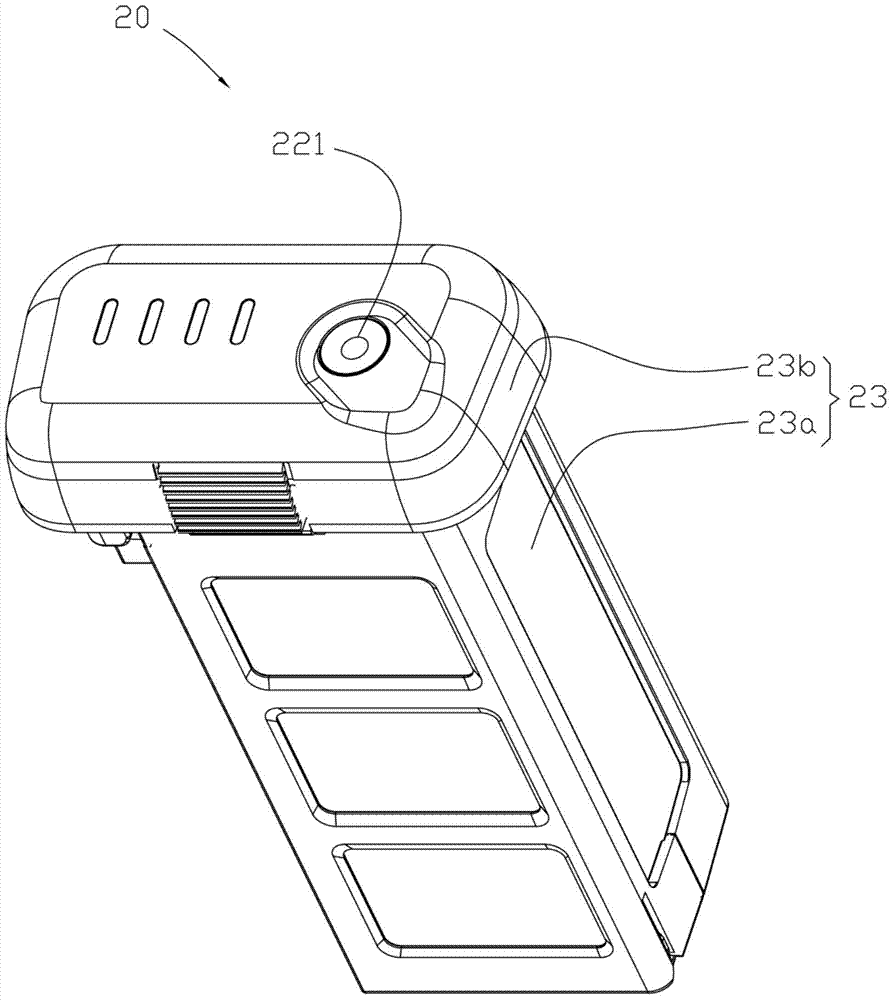

Battery, aircraft with battery and battery control method

ActiveCN103701163AEasy to useEnsure safetyCircuit monitoring/indicationEmergency protective circuit arrangementsElectricityElectrical battery

The invention discloses a battery which comprises a power supply and a power supply circuit, wherein the power supply circuit is electrically connected with the power supply and comprises an electronic switch and an input device; the electronic switch is electrically connected with an output pole of the power supply and used for controlling on and off of the power supply; and the input device is electrically connected with the electronic switch and controls an on / off state of the electronic switch. The electronic switch controls the on and off of the power supply, so that the problem of electric spark in a power-on process can be avoided, and the normal use of the battery and safety of an aircraft are ensured. Correspondingly, the invention further provides the battery, the aircraft with the battery, and a battery control method.

Owner:SZ DJI TECH CO LTD

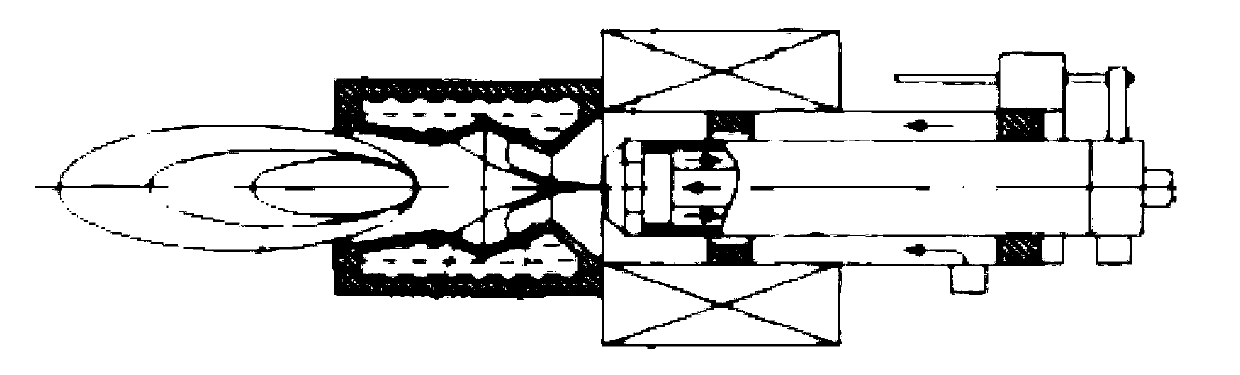

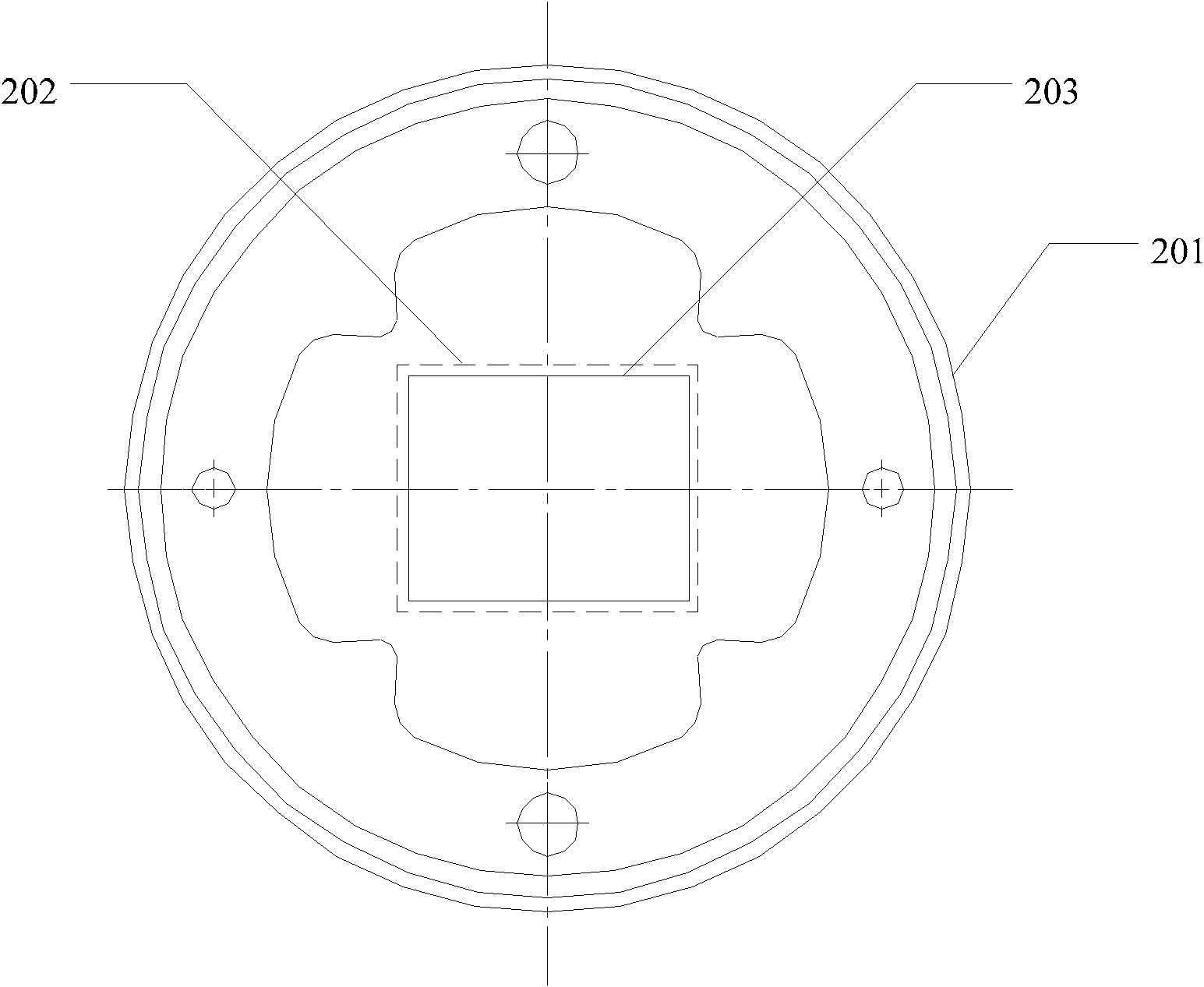

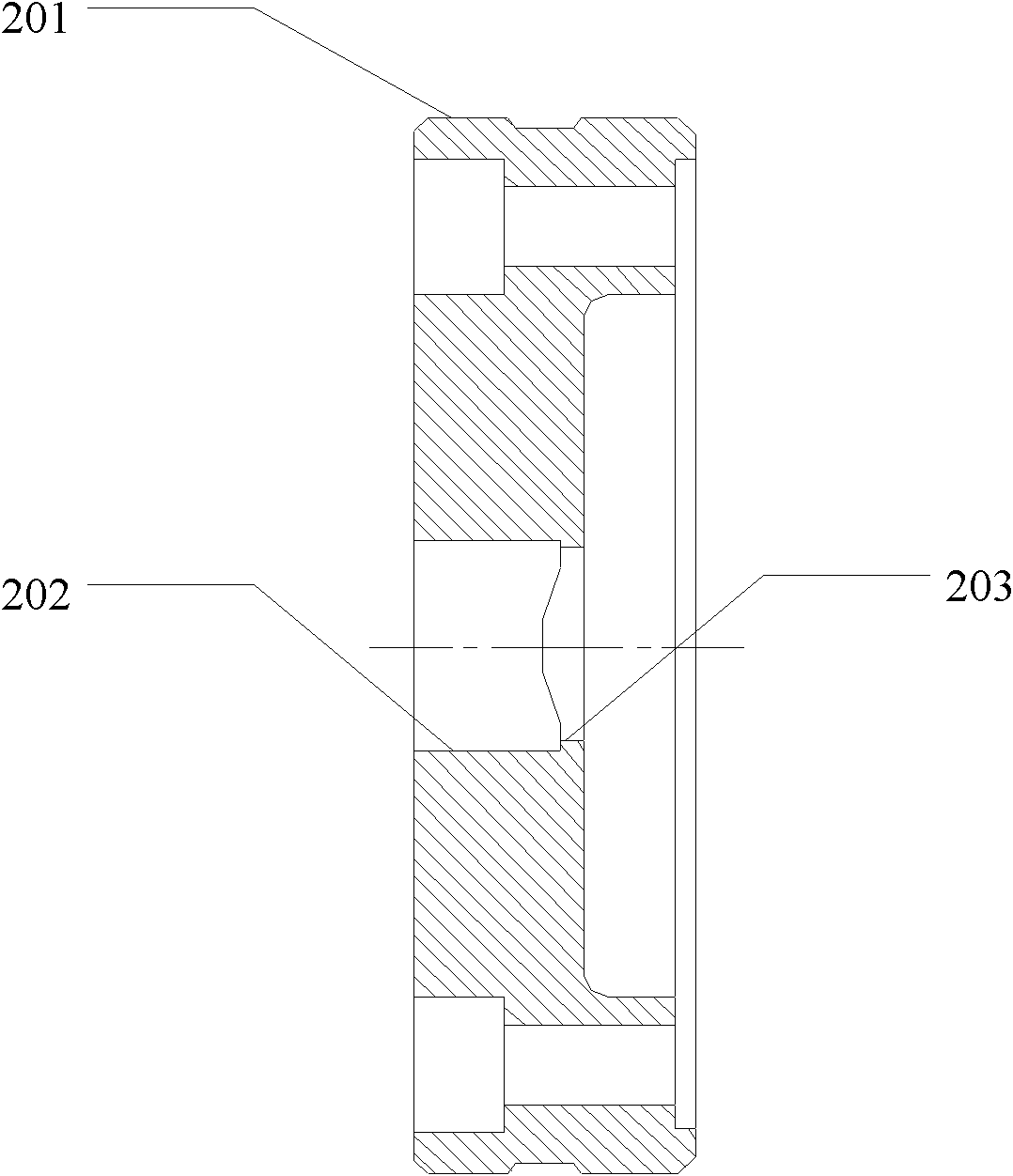

Synchronous composite processing method of micro-hole electric sparks and different electrolytic areas and special tool of synchronous composite processing method

The invention provides a synchronous composite processing method of micro-hole electric sparks and different electrolytic areas and a special tool of the synchronous composite processing method. The synchronous composite processing method includes that a tube electrode is switched to impulse voltage, and a neutral salt solution with ultra-low concentration flows into a processing area via the inner side of the tube electrode at a high speed, and then flows out of the processing area along a gap between the tube electrode and a workpiece; an end face of the tube electrode is subjected to high-speed punch processing with axial feeding of electric sparks under the ultra-low concentration of the neutral salt solution, and a hole wall processed by the electric sparks is subjected to radical electrochemical finishing and machining under the action of low-pressure voltage. By the synchronous composite processing method, processing precision is guaranteed, punching efficiency is improved, and processing requirements on various kinds of holes of an aircraft engine are met. Different from conventional electric spark processing and electrolytic processing, the synchronous composite processing method adopts the neutral salt solution with the ultra-low concentration, so that processing efficiency in electrochemical dissolution can be greatly improved and corrosion degree of equipment can be decreased.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

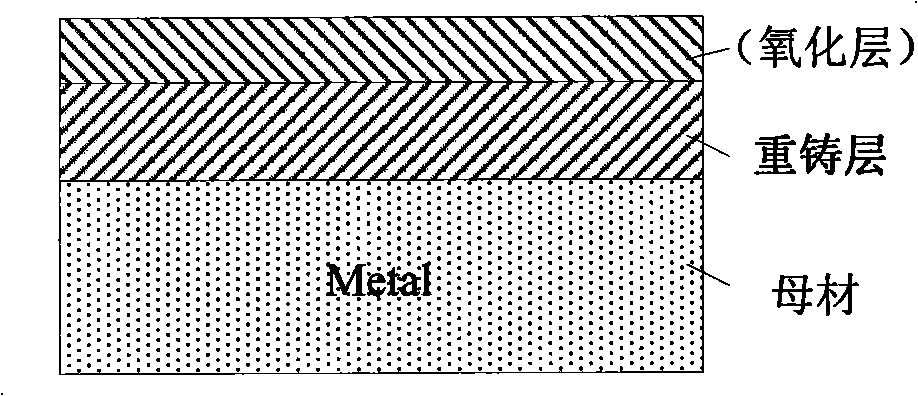

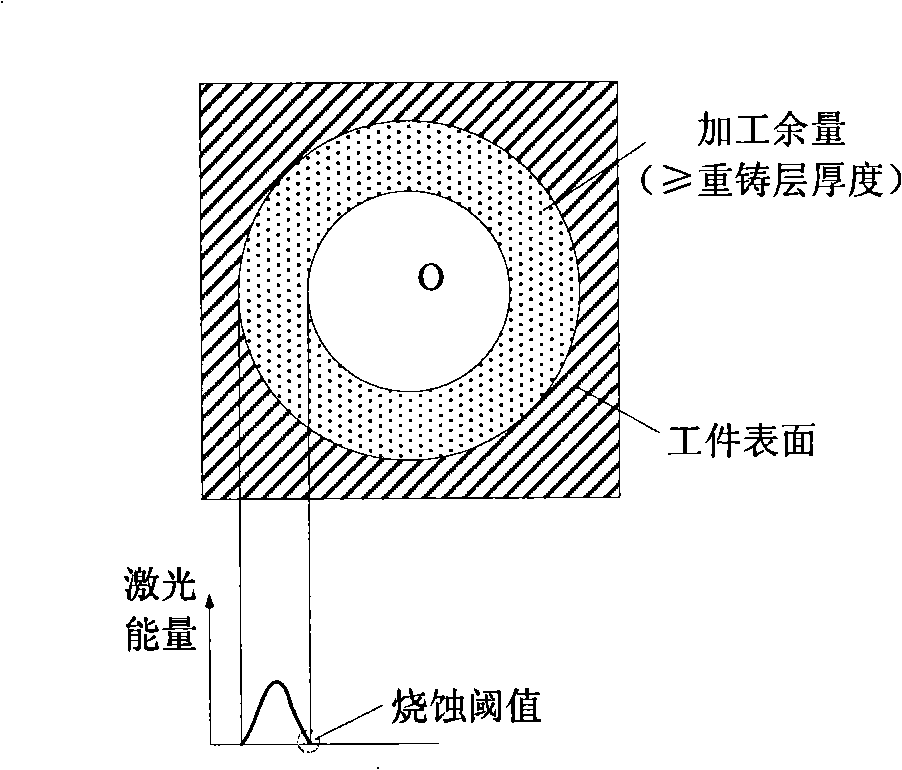

Laser compound processing and modifying method of no-recasting-layer micro deep-hole

ActiveCN101332559AEfficient solutionSolve processabilityLaser beam welding apparatusLong-focus lensHigh power lasers

The invention discloses a laser combined machining and profile modification method of a micro deep borehole without a recast layer. The method of the invention includes the following steps: first, a micro deep cooling borehole of a turbine blade is roughly machined by high power laser or electric sparks, and the like; the allowance for finish of the aperture is more than the thickness of the recast layer produced by using the machining method; and femtosecond laser is used for the secondary finish machining and profile modification of the micro deep cooling borehole; while femtosecond impulse laser is used for performing the finish machining and profile modification of the primarily machined micro deep borehole, under the precondition of guaranteeing the laser energy acting with the recast layer of a workpiece is higher than the ablation threshold of the material, a light beam is inclined for certain angle according to the spiral drilling mode; and the recast layer of the internal wall of the borehole is machined to remove erosion and profile modification by combining the method of lengthening the focal depth by a long focus lens. The concept of the combined machining method and the specific machining technology are used for solving the high-efficiency and high-precision machining problems of micro deep borehole groups of turbine blades.

Owner:XI AN JIAOTONG UNIV

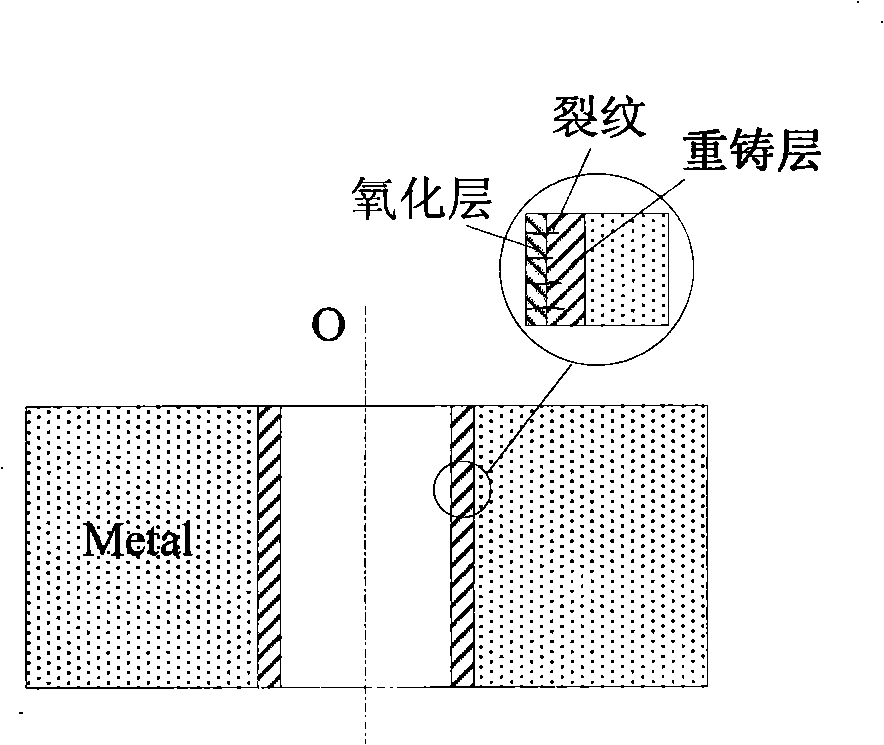

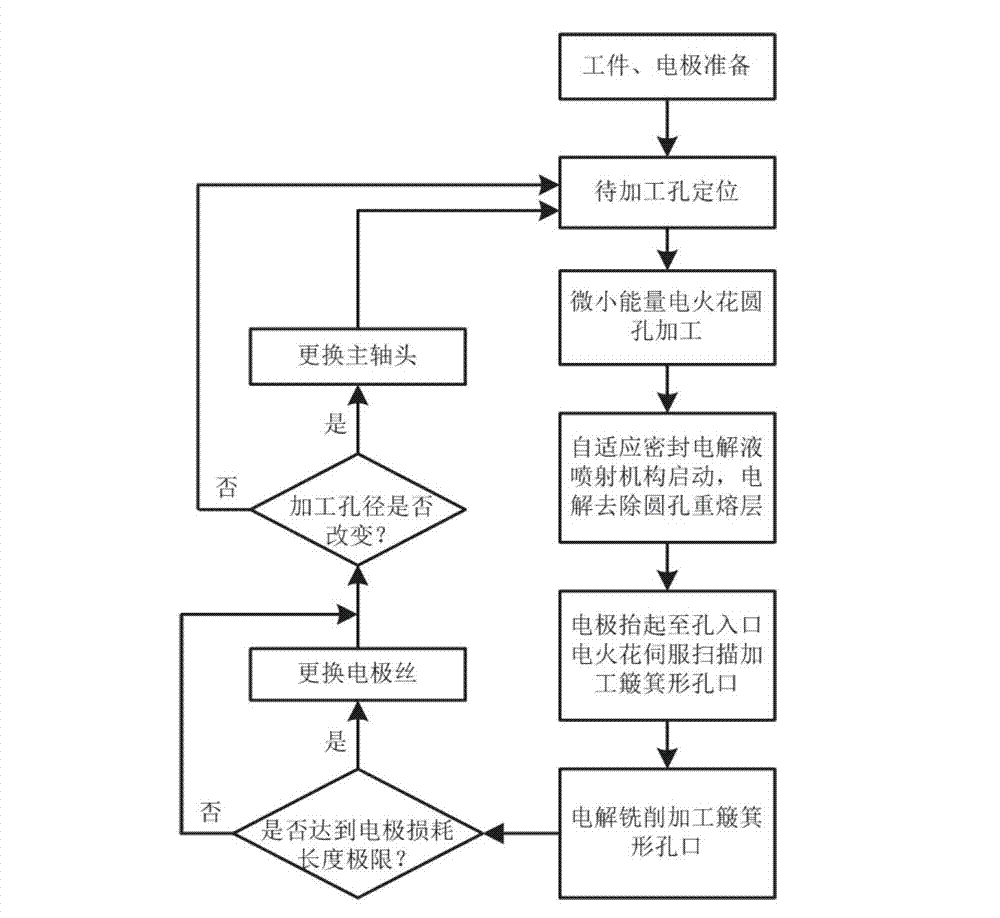

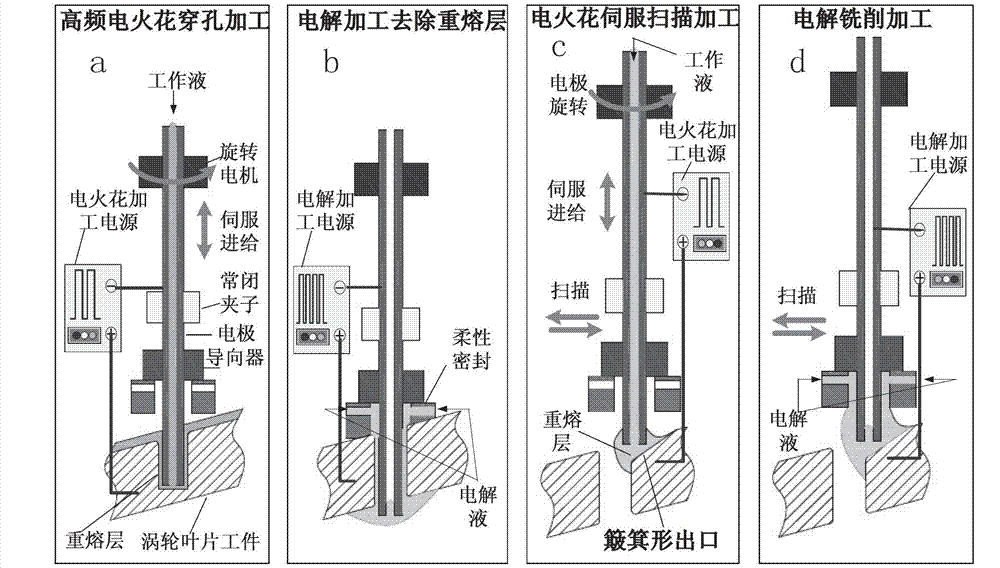

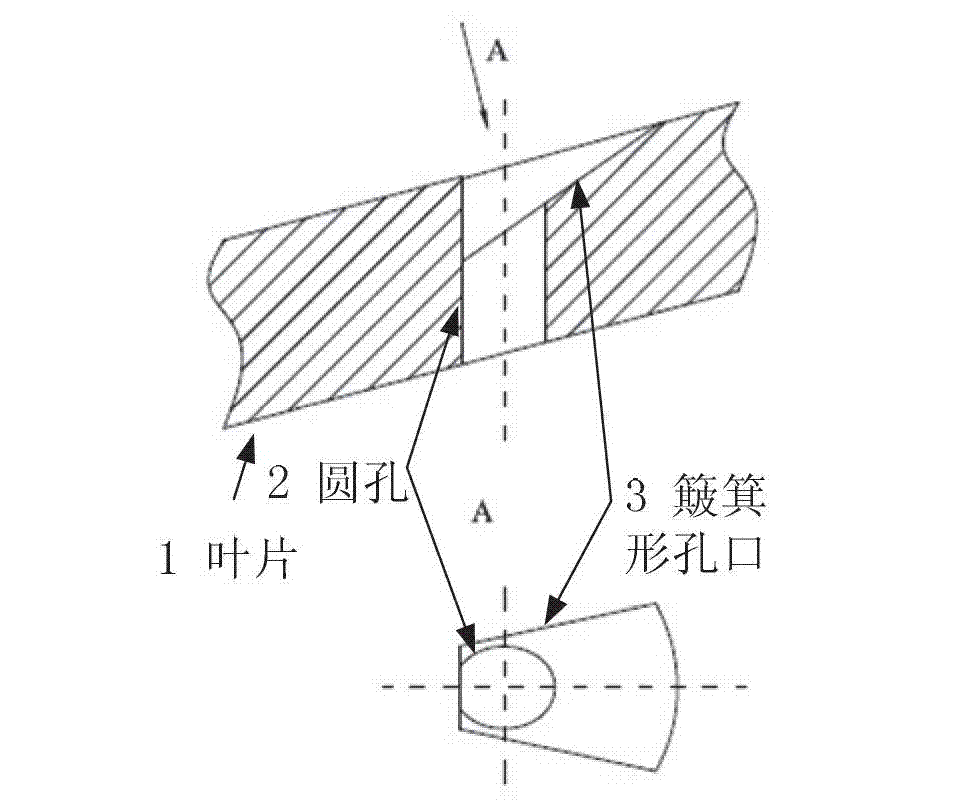

Machining method of gravity-free smelting layer air membrane hole of aviation engine turbine blade

InactiveCN102861956AReduce manufacturing difficultyShorten the manufacturing cycleAviationEngineering

The invention belongs to the technical field of small hole electric machining and particularly relates to a machining method of a gravity-free smelting layer air membrane hole of an aviation engine turbine blade. The machining method comprises four steps: firstly, machine a circular hole with a needed size a nickel-based high-temperature alloy blade on a gas turbine by utilizing washing liquid electric sparks in a hollow electrode according to a design requirement; then utilizing the same electrode to electrolyze the machined circular hole in an electrolyte environment of an outer washing solution to remove a re-smelted layer; then, raising the electrode and utilizing an electric spark servo scanning and milling and machining process to machine a dustpan-shaped hole opening of the air membrane hole; and finally, utilizing the end part of the electrode to carry out electrolytic milling machining on the dustpan-shaped hole opening to remove the re-smelted layer of the hole opening so as to improve the surface quality. According to the machining method disclosed by the invention, the problem of a residual re-smelted layer and small cracks of the air membrane hole machined by the electric sparks can be solved, a secondary clamping and positioning error is avoided and the machining efficiency is improved.

Owner:TSINGHUA UNIV

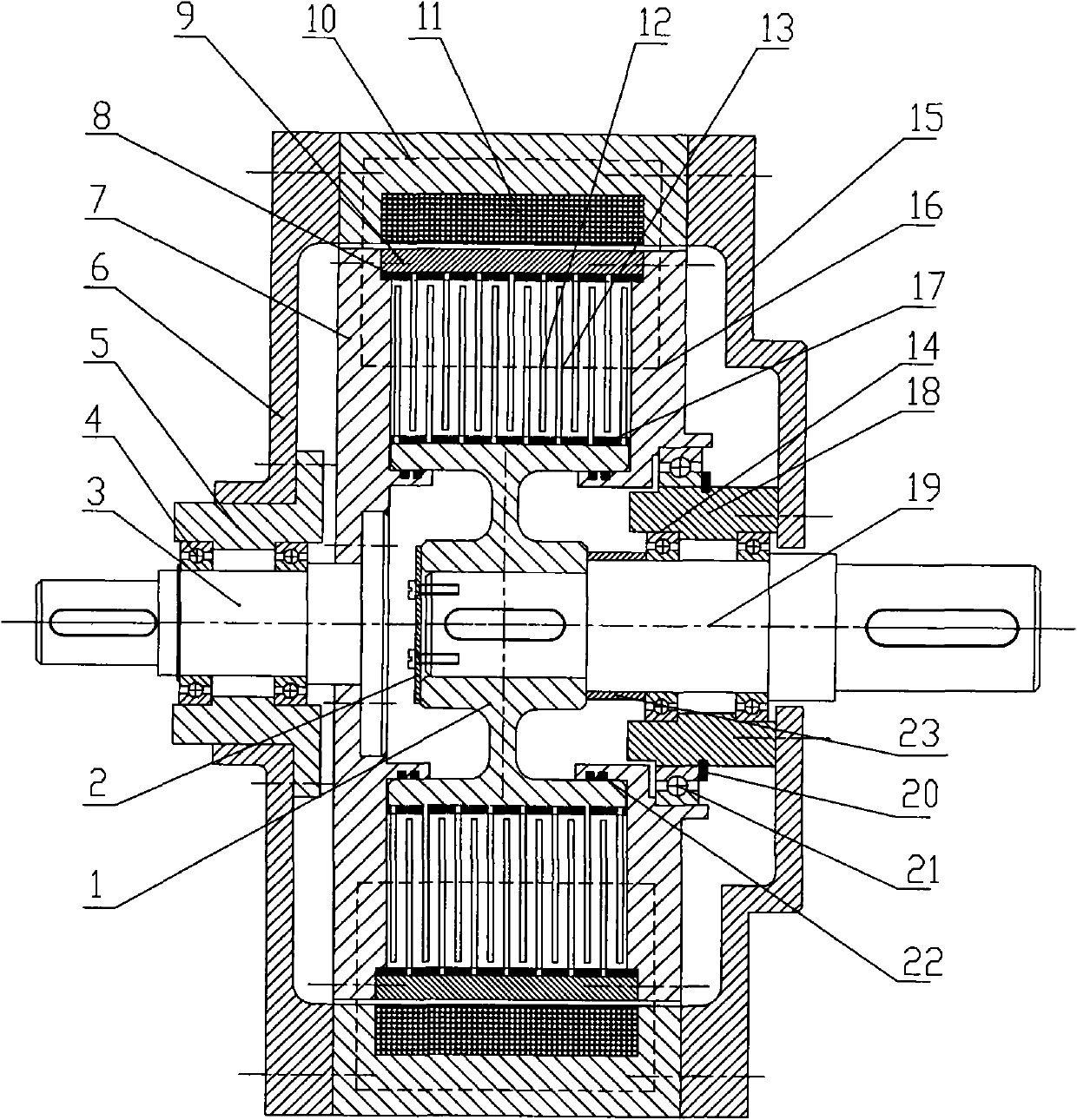

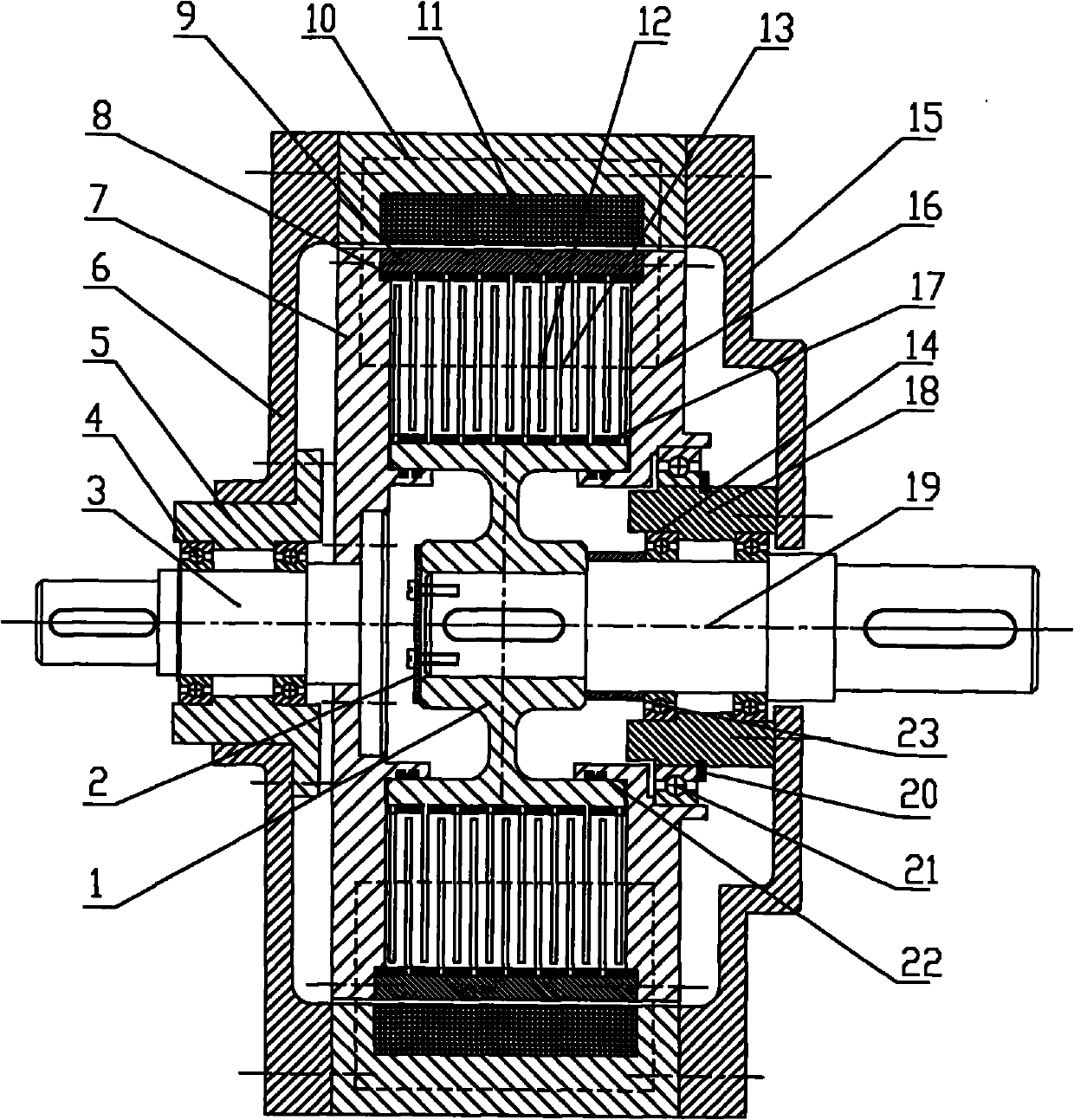

Magneto-rheological stepless speed changer

InactiveCN101793312AIncrease or decrease quantityChange speed differenceFriction gearingsDrive shaftMagneto rheological

The invention relates to a multi-disc type magneto-rheological stepless speed changer which mainly comprises a magnetic isolation hub, an input shaft, an output shaft, a driving friction plate, a driven friction plate, magnetic exciting coils and magnetic isolation rings; wherein the driving friction plate and the driven friction plate are respectively fixed on an outer magnetic isolation circular ring and the magnetic isolation hub through the magnetic isolation rings; a right magnetic conducting lateral plate is connected with the input shaft through a big magnetic isolation circular ring and a left magnetic conducting lateral plate; the output shaft is connected with the driven friction plate and the magnetic isolation hub; magneto-rheological fluid is sealed between the driving friction plate and the driven friction plate through a seal ring; the magnetic exciting coils are fixed on two bearing seats through a magnetic conducting shell, the left magnetic isolation lateral plate and the right magnetic isolation lateral plate in a motionless way, and the driving friction plate and the driving friction plate are in interleaved matching and isolated through the magnetic isolation rings. The shear yield stress of the magneto-rheological fluid can be changed by adjusting the electric current of the magnetic exciting coils, therefore, the speed difference between a driving shaft and a driven shaft is changed, and the stepless speed change is further realized. The invention has the advantages of simple structure, no electric sparks, high transmission torque and large transmission power.

Owner:CHINA UNIV OF MINING & TECH +1

Manufacturing and Use of Microperforated Substrates

ActiveUS20080047935A1Precise definitionDrop in electrical substrate resistanceElectric discharge heatingArc welding apparatusVoltage amplitudeNatural science

This invention relates to methods and devices for the production of micro-structured substrates and their application in natural sciences and technology, in particular in analysis and detection systems based on artificial and biological lipid membranes. The structure is preferably a hole or a cavity or channel and is obtained by spark perforation. Energy, preferably heat, is applied to the region to be structured so as to reduce the amplitude of voltage required and / or soften the material. The electrical parameters of the spark perforation are feedback-controlled.

Owner:ASAHI GLASS CO LTD

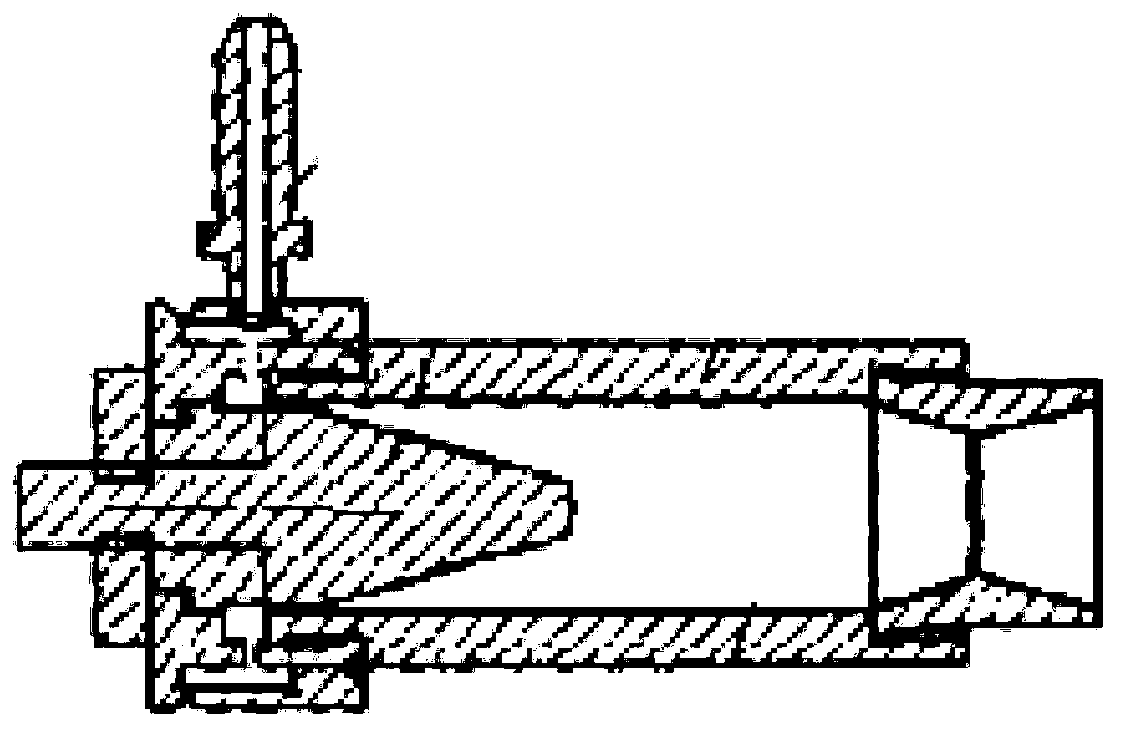

Aero-engine air rotational flow plasma igniter

InactiveCN103277231AHelps coolingGood for breakdownEngine ignitionMachines/enginesAviationCombustion chamber

Provided is an aero-engine air rotational flow plasma igniter. An insulating sleeve and a supporting sleeve are installed inside a shell, the insulating sleeve is arranged on one side of a separating plate inside the shell, the supporting sleeve is arranged inside the shell, and an air chamber is formed between the outer surface of the supporting sleeve and the inner surface of the shell. An anode sleeve is sleeved at one end, provided with the supporting sleeve, of the shell. A swirler is arranged inside the anode sleeve, and the end surface of the swirler makes contact with the end surface of the supporting sleeve. A cathode installation base is arranged inside the insulating sleeve, and the end surface of the cathode installation base makes contact with a cathode binding post in a coaxial cable. The external thread end of a cathode is fixed inside the cathode installation base and sequentially penetrates through the supporting sleeve and the swirler from top to bottom, and the arc end of the cathode extends out of the lower end surface of the swirler. The aero-engine air rotational flow plasma igniter does not change the structure and the position of an electric spark igniter originally installed in an engine combustor, penetrates through the outer duct of an engine, is installed on the outer wall of the combustor vertically, improves reliability of products, and has the advantages of being small in size, light in weight, simple in structure, and convenient to use and maintain.

Owner:AIR FORCE UNIV PLA

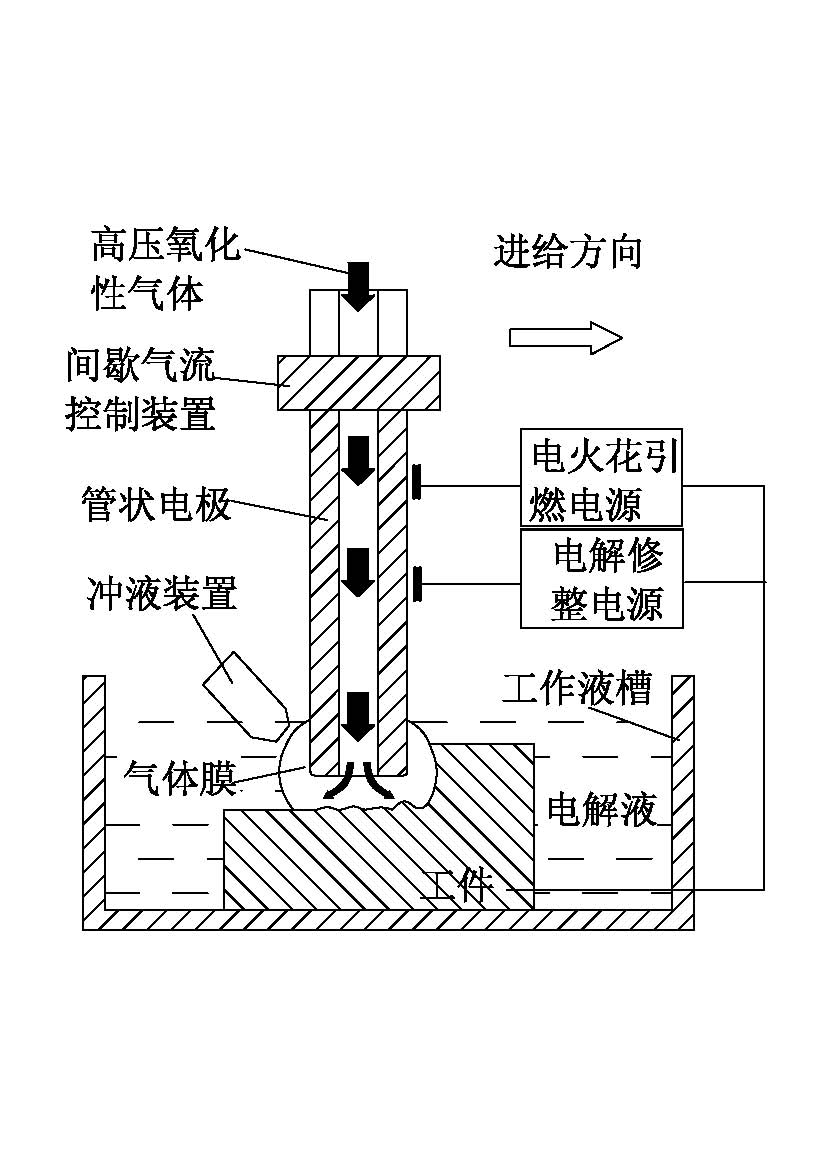

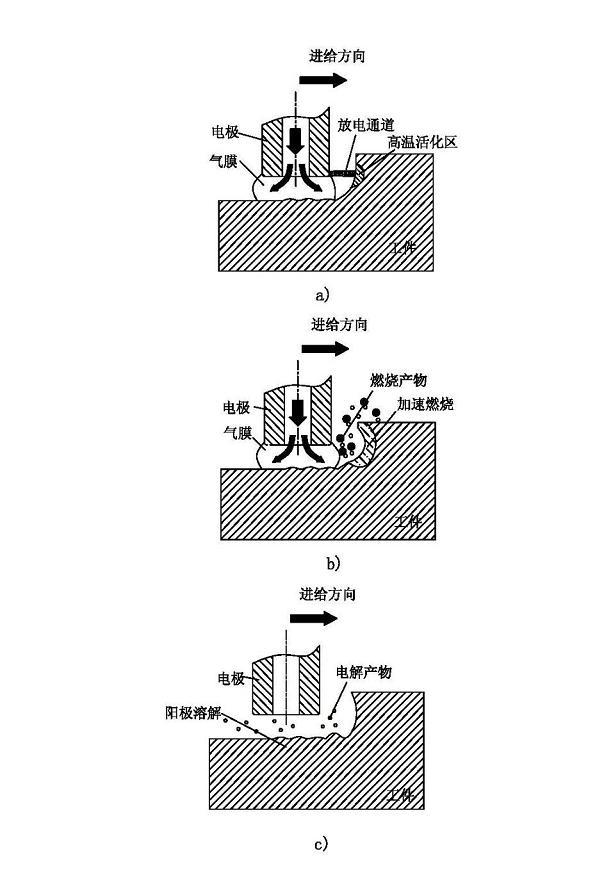

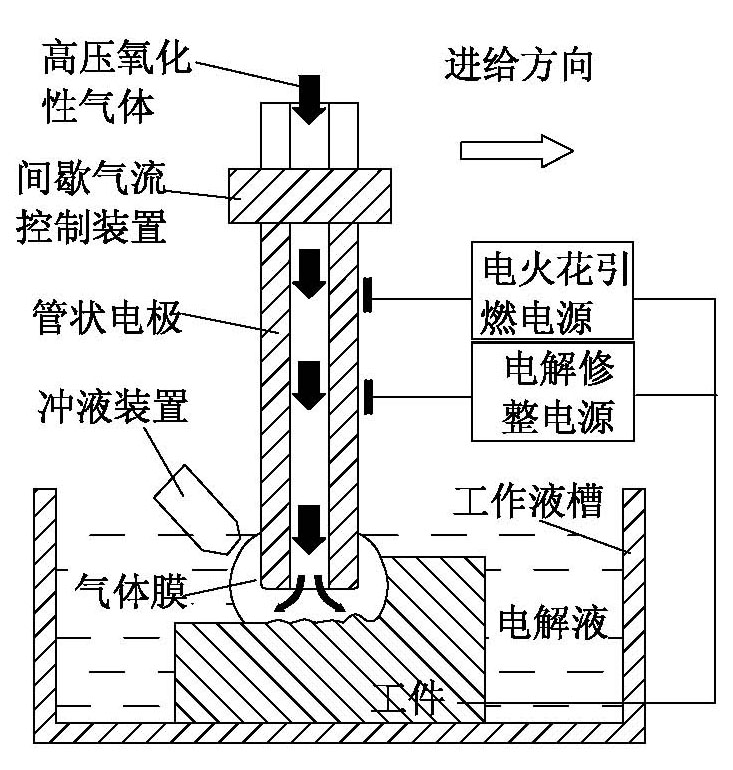

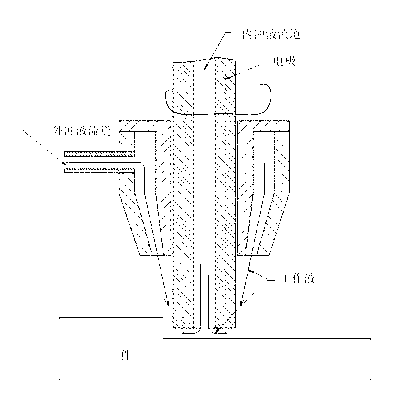

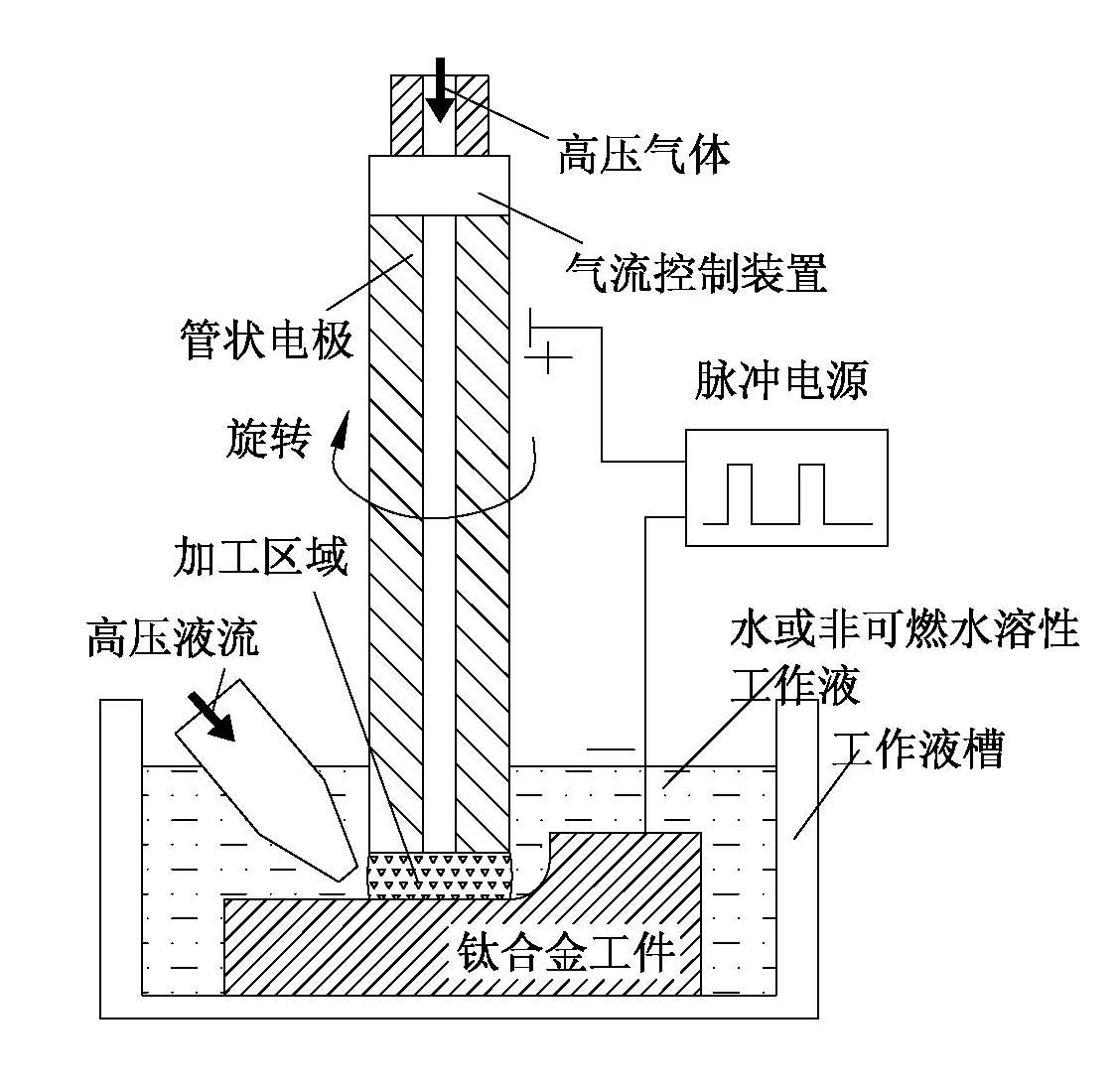

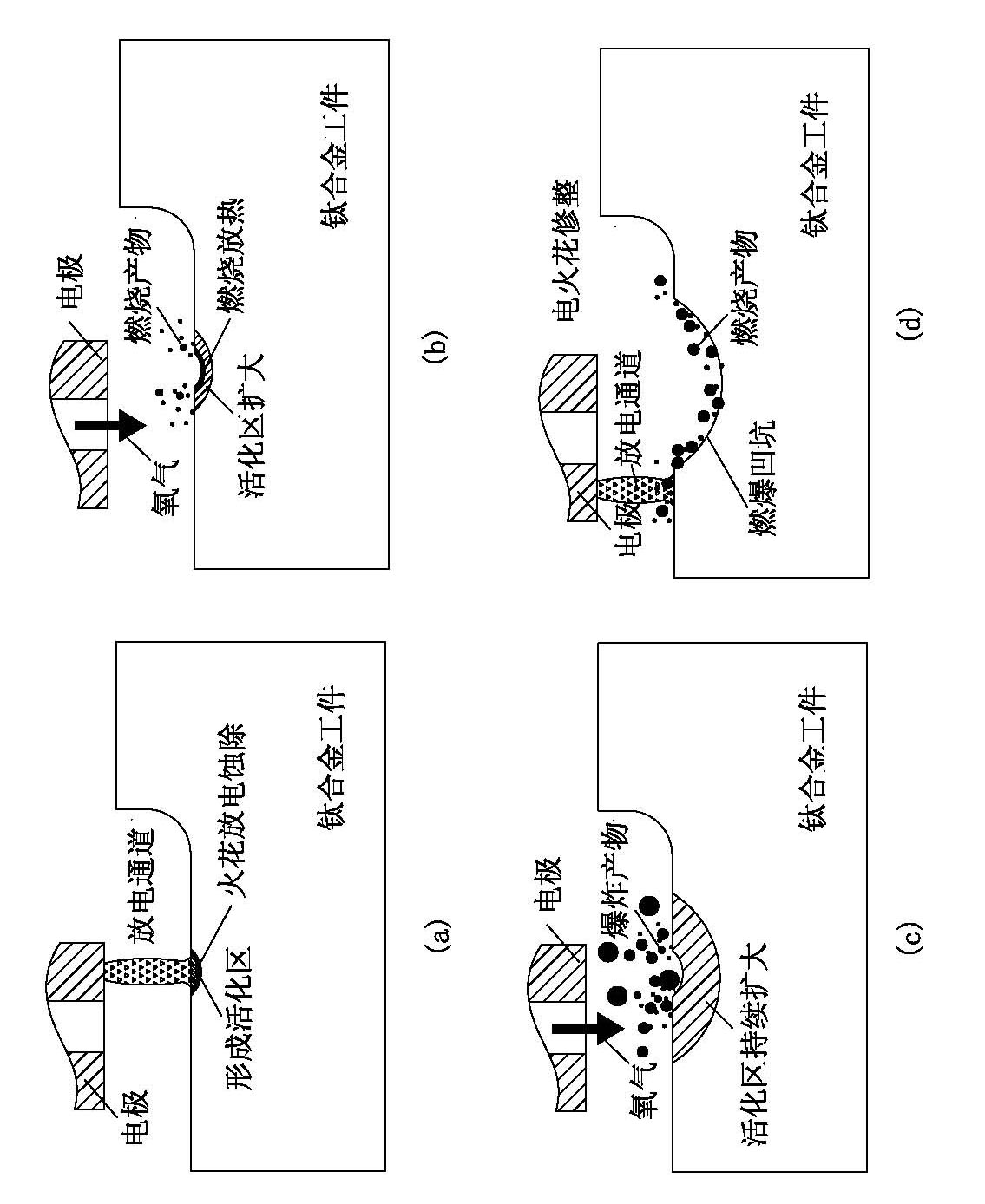

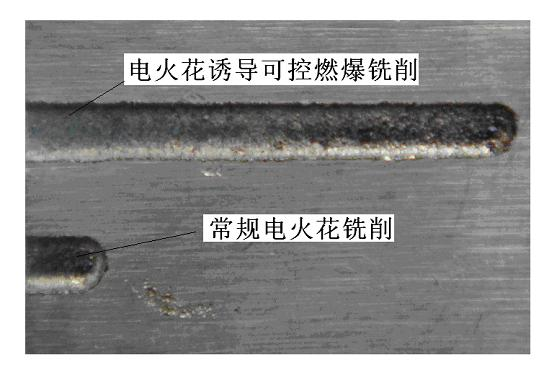

Electric spark induction controllable erosion and electrolysis compound efficient machining method

The invention discloses an electric spark induction controllable erosion and electrolysis compound efficient machining method which is characterized by comprising the steps of: with electrolyte as a working medium, immersing one end of a to-be-machined workpiece electrode and a tool electrode in the working medium, intermittently introducing air to a machining area and forming an air film between the to-be-machined workpiece electrode and the tool electrode; generating electric spark discharge between the to-be-machined workpiece electrode and the tool electrode under the action of an electric spark power supply to ensure that the to-be-machined workpiece generates an oxidation exothermic reaction with the introduced air under the action of electric spark discharge ignition and forms a burning effect so that efficient ablation is realized; in an air closed stage, carrying out electrochemical machining and surface dressing on the ablation surface under the action of an electrolysis power supply; and alternating to start an electric spark ignition pulse power supply and an electrolysis eroding power supply and moving the tool electrode until machining is finished. The invention has the advantages of high material eroding efficiency up to be several times, even tens of times of that of the conventional electric spark machining and also be higher than that of the conventional electrolysis machining under the same electrical parameters on the premise of ensuring machining quality and precision, good surface quality, precision and controllability and capability of eliminating surface residual stress.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

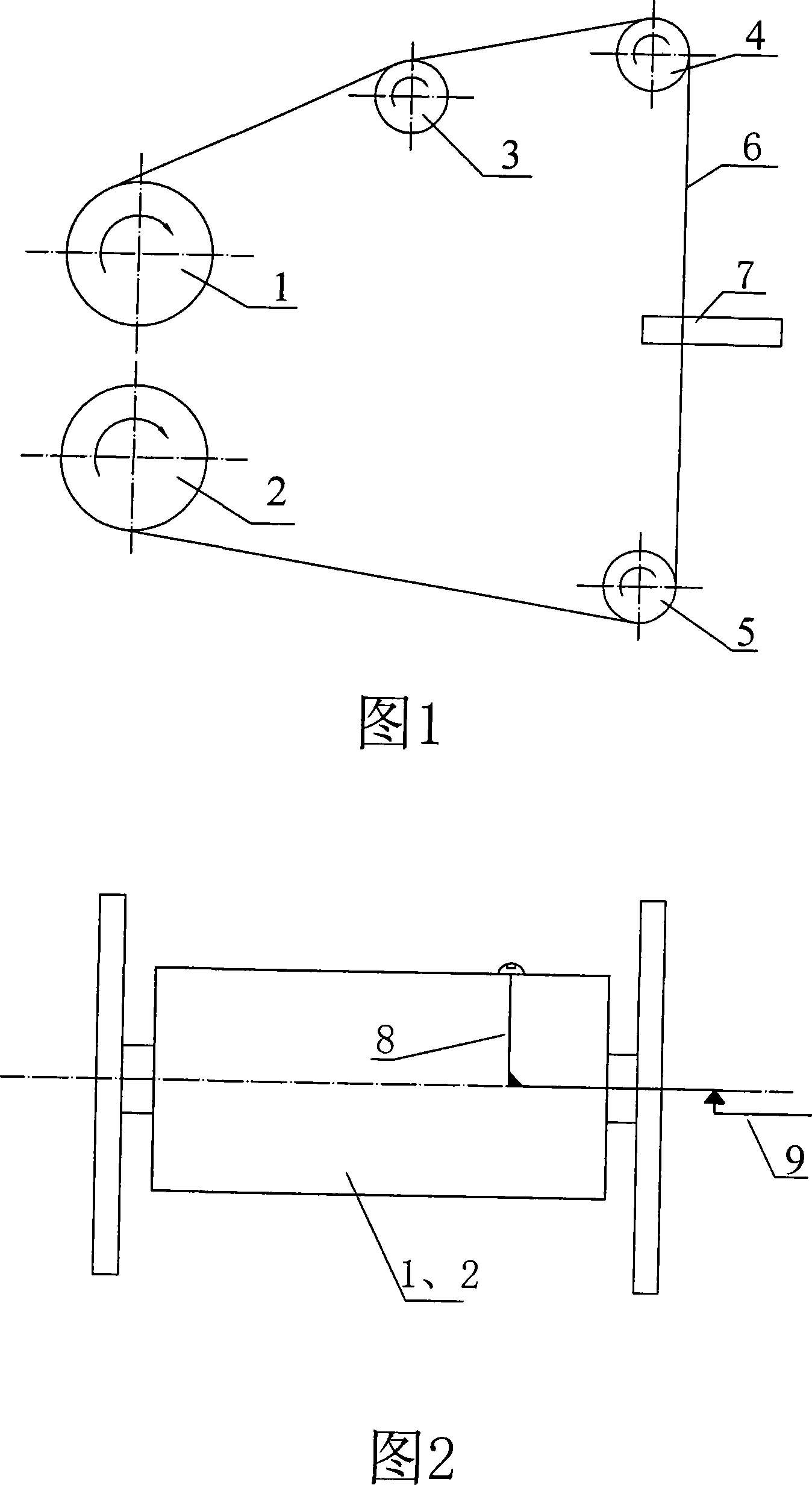

Monocrystalline silicon high-efficient composite cutting method and cutting system thereof

InactiveCN101138869AImprove cutting effectSave the texture processFine working devicesMetalElectric spark

An efficiently composite cutting method of monocrystalline silicon is characterized in that a monocrystalline silicon rod for cutting is installed and nipped at an electric spark linear cutting machine; metallic thread which is concreted with diamond grinding material is used as cutting wire to make the electric spark linear cutting; the advantages that the processing speed of the electric spark linear cutting is high and the cutting effect of the diamond grinding material at the metallic thread of the concreted grinding material is good are completely exerted; the purpose to realize the quickly and efficiently cutting towards the monocrystalline silicon rod is achieved; at the same time the surface of the cut monocrystalline silicon naturally forms a fleece-faced texture which has the effect of anti-reflection. The present invention has a series of advantages of simple method, high efficiency of processing, good quality etc.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

High-instantaneous-energy-density electric spark high-speed milling method

InactiveCN103008802AGood removal effectEfficient processingElectrical-based machining electrodesWorking fluidCombined method

The invention relates to a high-instantaneous-energy-density electric spark high-speed milling method, which belongs to the field of machining. The method comprises the following steps of: connecting a rotary rod-like electrode with an inner flushing fluid hole with a negative electrode of a power supply, connecting a to-be-machined workpiece with a positive electrode of the power supply and melting to remove the workpiece material by utilizing high-instantaneous-energy-density spark discharge between the electrodes and the workpiece in a machining process; discharging molten material out of a discharge gap by working fluid which flows at a high speed; and cooling the machined workpiece. According to the method, by utilizing high-instantaneous-energy-density spark discharge and a high-pressure forced inner flushing fluid and low-pressure outer flushing fluid combined method, the stability and the high efficiency of machining are realized, and high-efficiency machining on any conductive material, including conventional difficult-to-machine materials such as engineering ceramic with weak conductivity and high-temperature alloy, can be realized.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

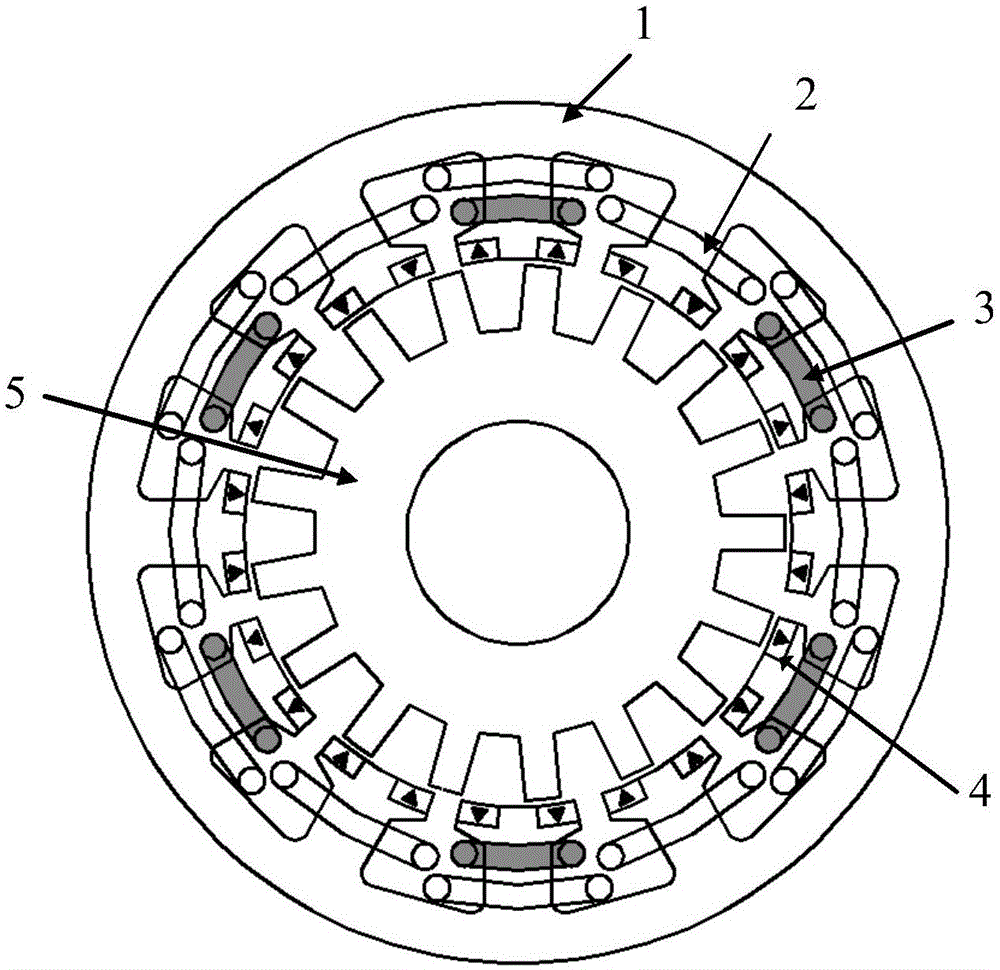

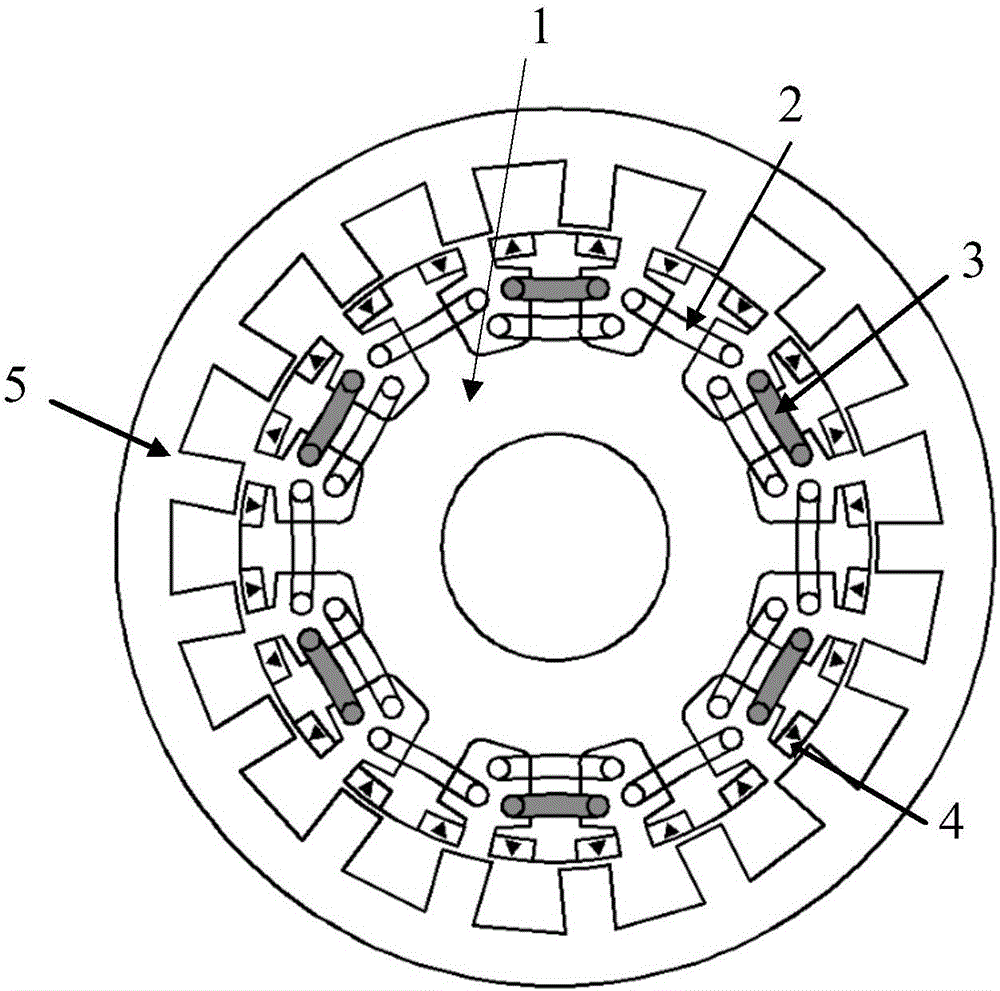

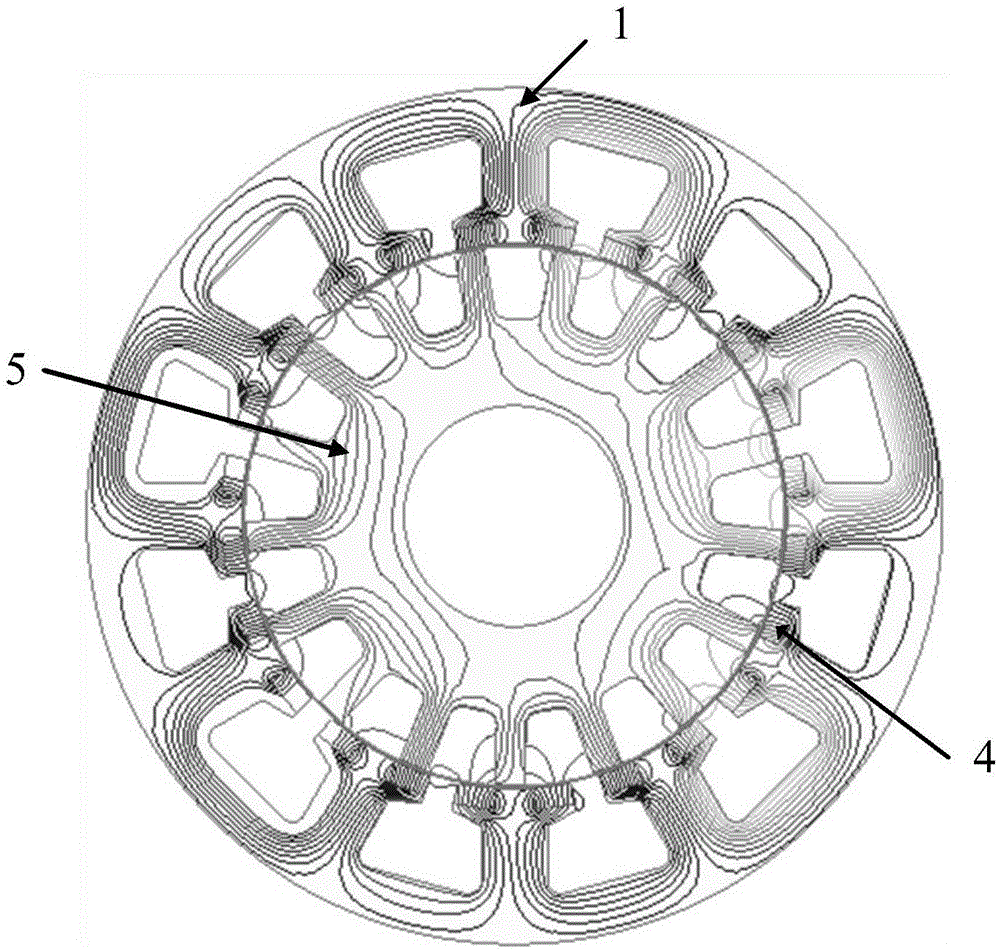

Hybrid excitation Motor

ActiveCN106385153AImprove reliabilityStrong magnetic adjustment abilitySynchronous machine detailsElectric machinesLow speedElectric machine

The present invention discloses a hybrid excitation motor. The comprises a stator and a rotor which are coaxially sleeved with each other; grooves are formed in the inner wall of the stator which sleeves the rotor or the rotor which sleeves the stator along the circumferential direction of the inner wall; grooves are formed in the outer surface of the rotor which is sleeved with the stator or the stator which is sleeved with the rotor; a direct-current excitation winding and an alternating-current armature winding are arranged in the stator grooves; each stator tooth is provided with protrusions which protrude out from the corresponding groove and are located at side surfaces of two sides of the groove; each protrusion is provided with a permanent magnet; the polarities of the two permanent magnets arranged at the two side surfaces of each stator tooth are the same; and the polarities of the permanent magnets of two adjacent teeth are opposite. When the motor of the invention operates at a low speed, current in the direct-current winding is positive, a total excitation magnetic field can be enhanced, and the overload capacity of the motor can be improved; and when the motor operates at a high speed, the current in the direct-current winding is negative, the total magnetic field can be weakened, and the flux weakening ability of the motor can be improved. The excitation motor of the invention has the advantages of low risk of irreversible demagnetization of the permanent magnets, small magnetic resistance of excitation magnetic fields, strong flux adjustment ability of the excitation windings and reliable and stable operation. According to the motor of the invention, slip rings and electric brushes are not needed, and therefore, problems such as the problem of sparks can be avoided.

Owner:HUAZHONG UNIV OF SCI & TECH

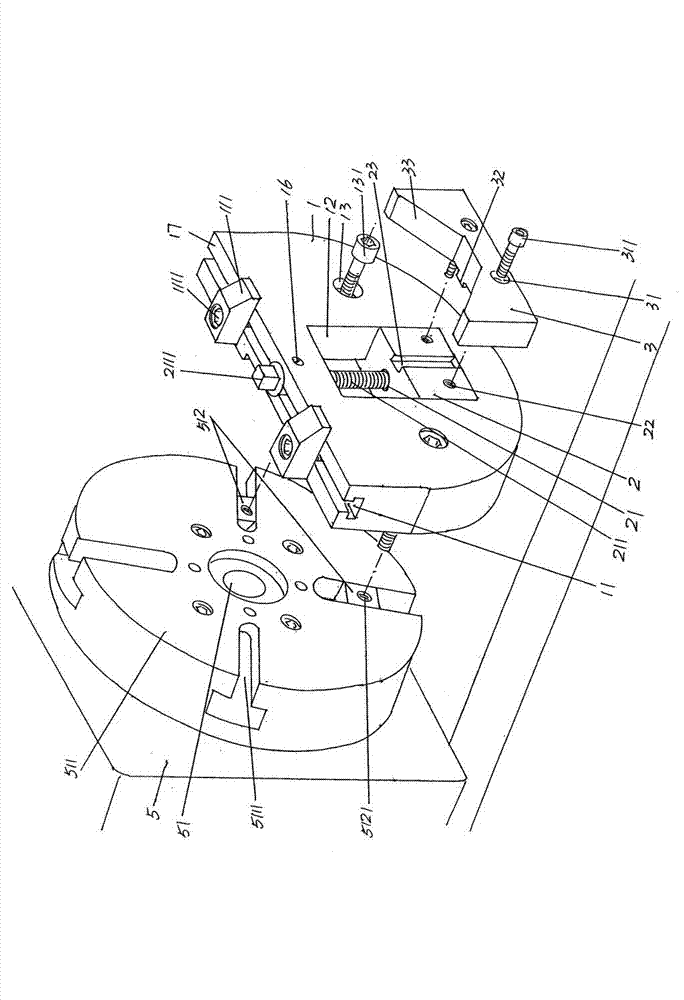

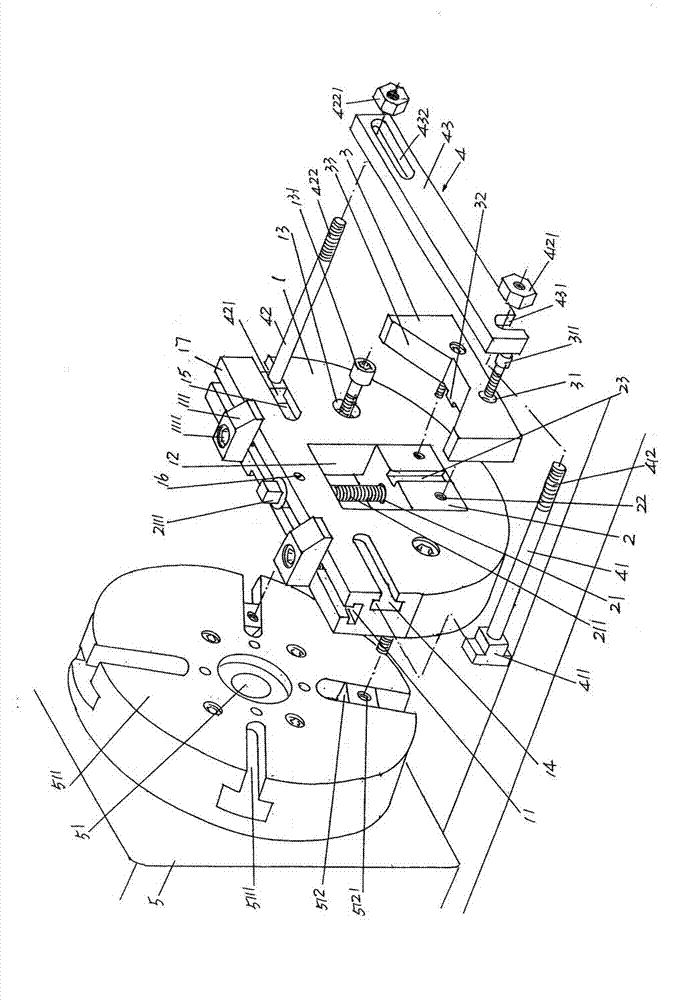

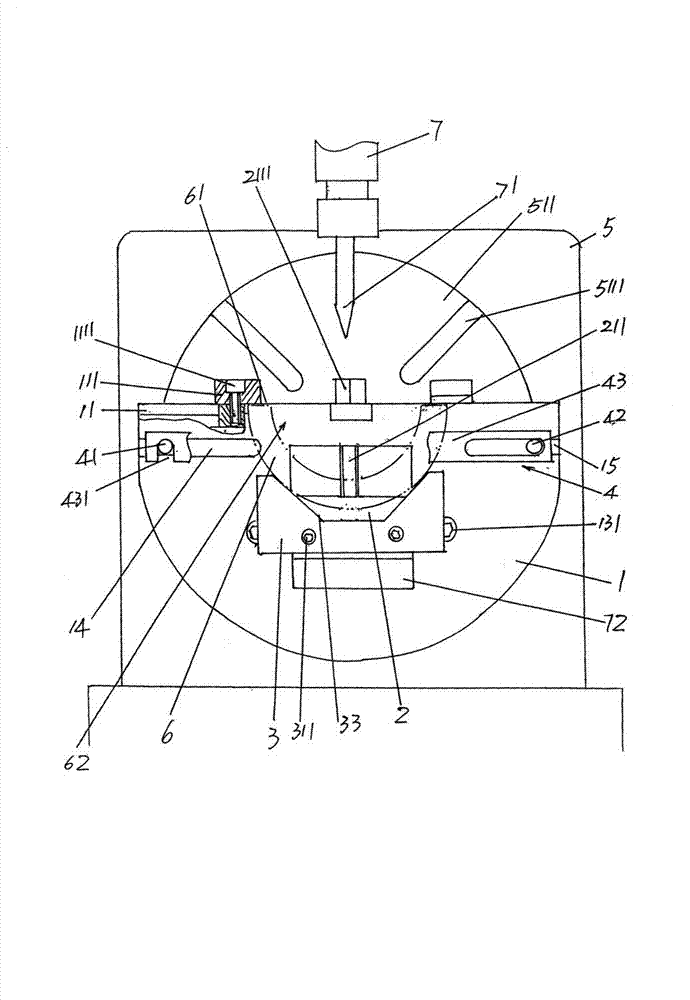

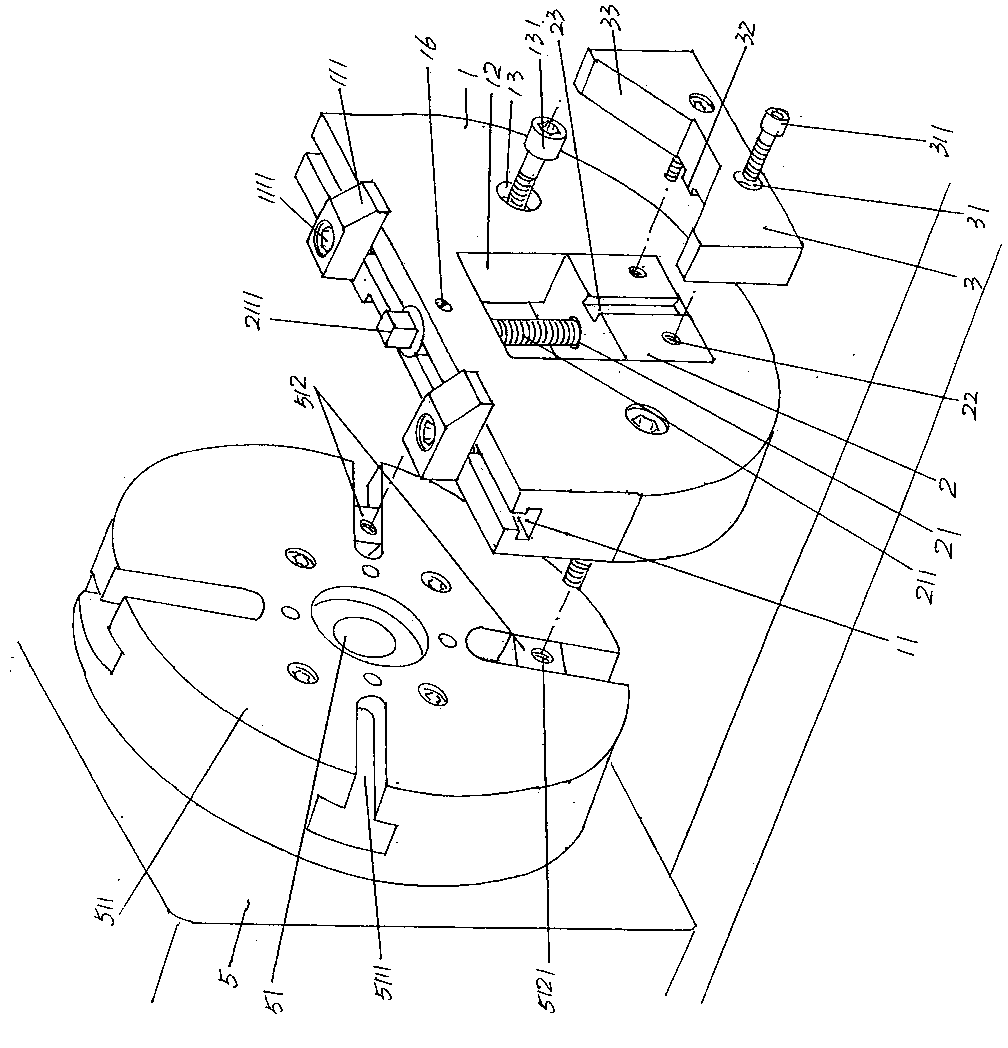

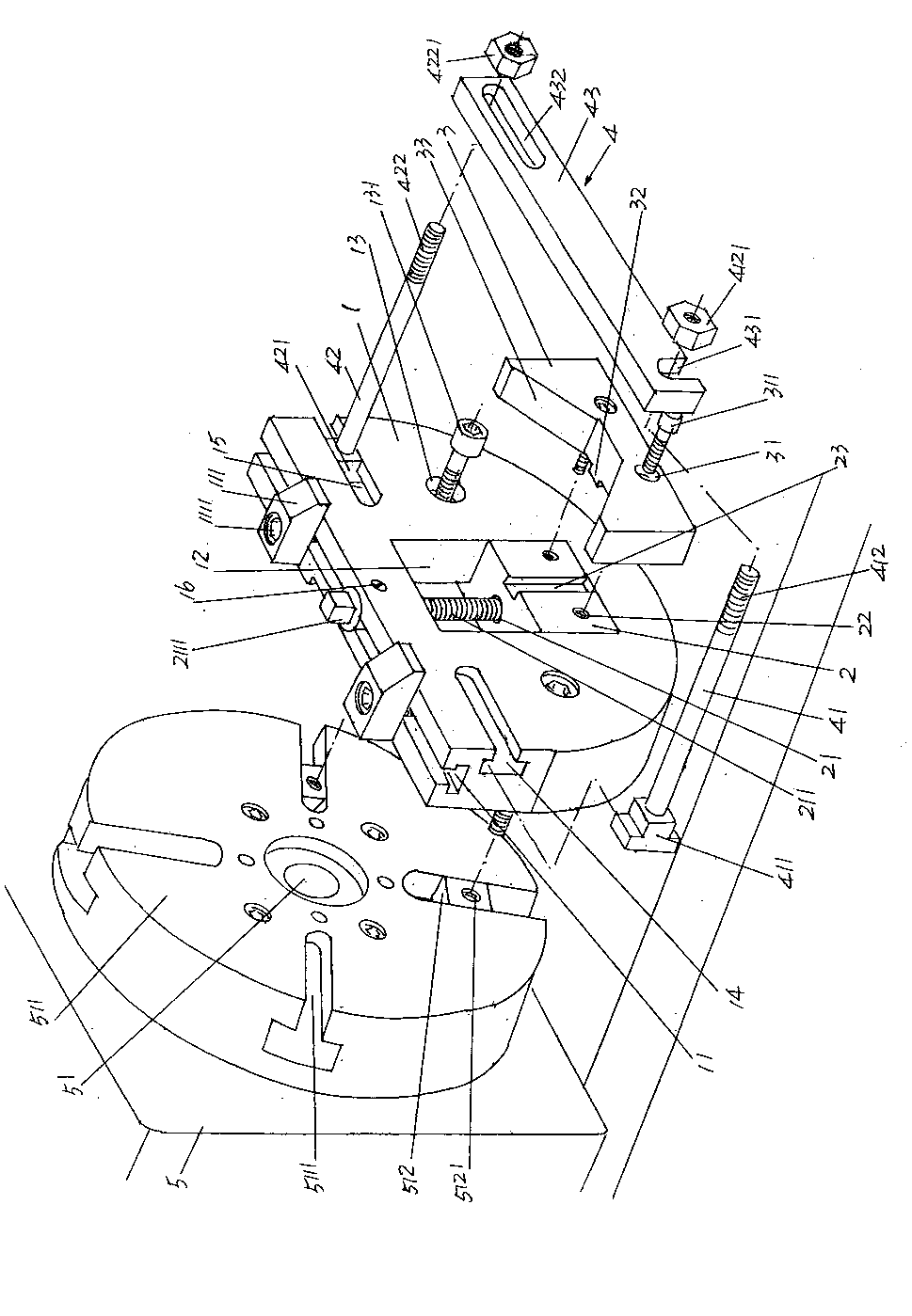

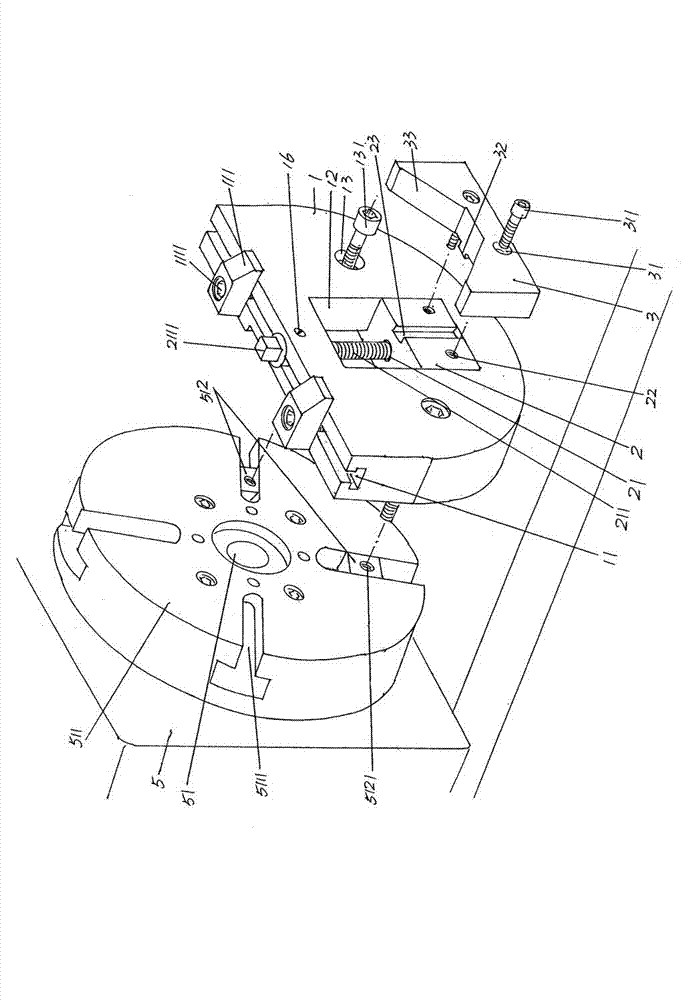

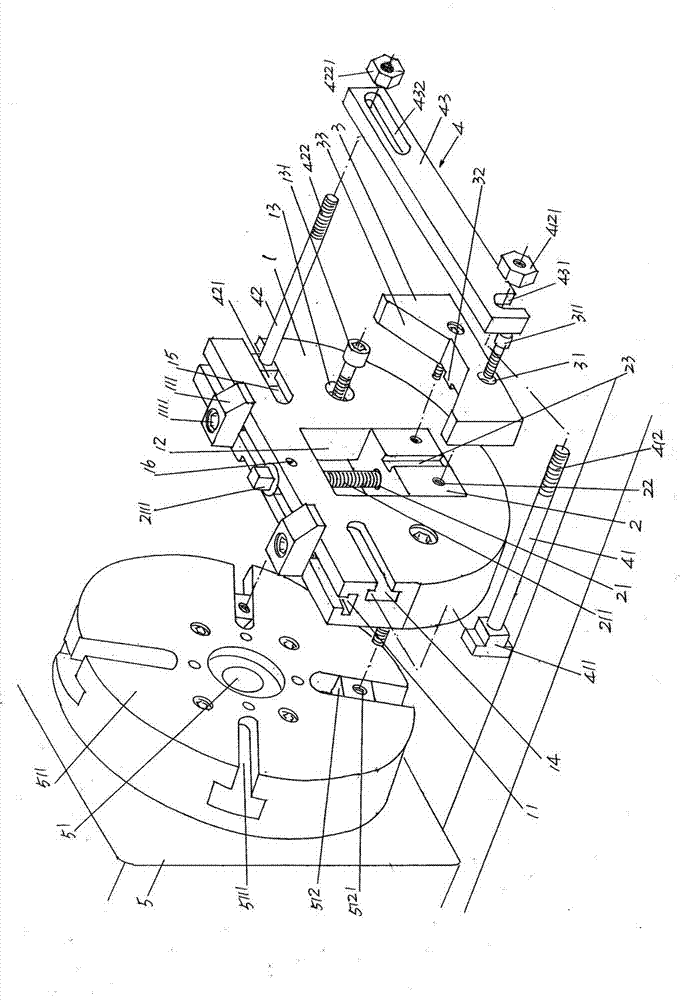

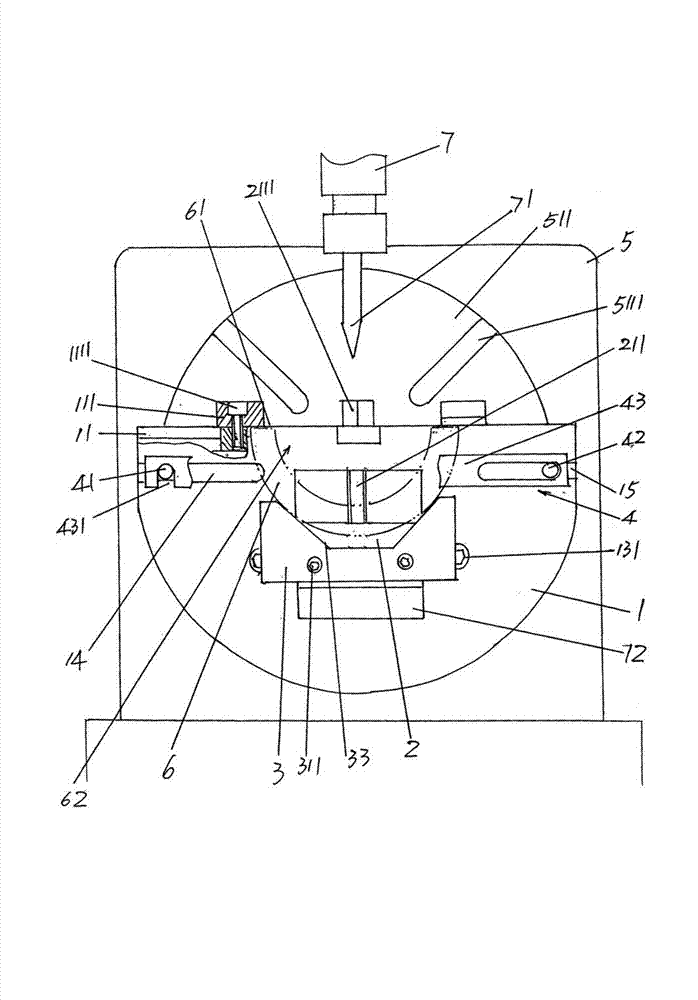

Clamping mechanism for machining glass die

ActiveCN102848245AQuality assuranceGuarantee efficiencyPositioning apparatusMetal-working holdersEngineeringCarving

The invention discloses a clamping mechanism for machining a glass die and belongs to the field of frock clamps. The clamping mechanism comprises a base, a support module fixing seat and a support module, wherein a pressure foot sliding chute is formed in a flat surface; a pressure foot is arranged in the pressure foot sliding chute; a support module fixing seat sliding cavity is formed in the base; the support module fixing seat is matched with a support module sliding cavity; a support module fixing seat nut is matched and arranged on the support module fixing seat; one end of a support module fixing seat lifting screw is connected onto the support module fixing seat nut; the other end of the support module fixing seat lifting screw is supported on the flat surface; the support module is fixedly connected with one side of the support module fixing seat; one end of the pressure foot extends out of the surface of one side of the base; a first guide sliding chute and a second guide sliding chute are formed in one side of the base; and a bottle die end surface positioning mechanism is matched and arranged on the other side of the base. The clamping mechanism has the advantages that the carving machining for an inner cavity of the glass die is realized without adopting a traditional an electric spark mode; the carving quality and efficiency are ensured; the clamping mechanism is convenient and quick in operation and is favorable in clamping adaptability; resources are saved and the interference influence on the die cavity is avoided.

Owner:CHANGSHU JIANHUA MOLD TECH

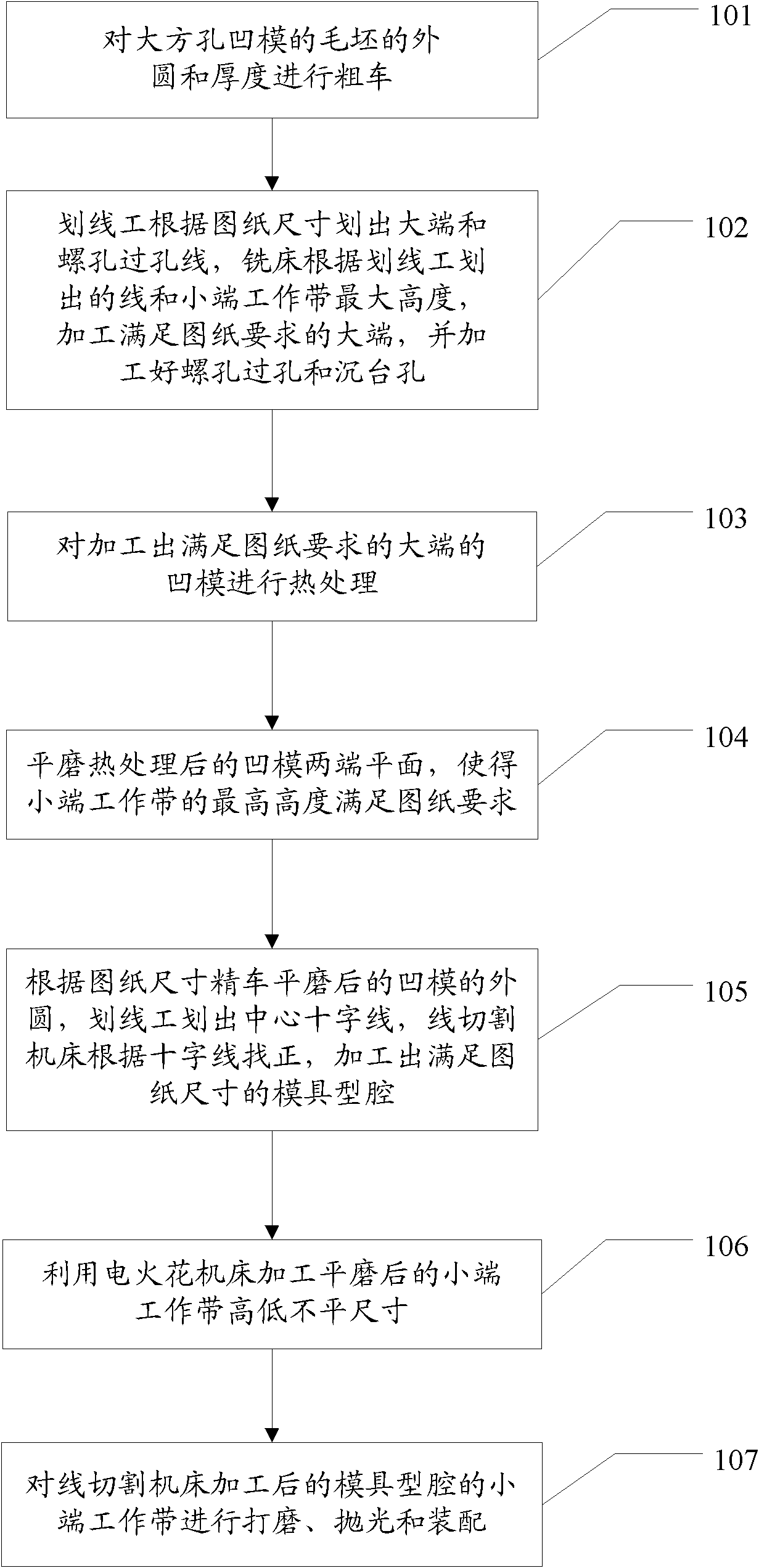

Method for processing female die with large square hole

ActiveCN102303221AHigh concentricityIncrease productivityMilling equipment detailsEngineeringMachine tool

The embodiment of the invention discloses a method for processing a female die with a large square hole. The method comprises the following steps of: roughly turning the excircle and thickness of a blank of the female die with the large square hole; processing the blank by using a milling machine, and thus obtaining a large end which meets requirements of a drawing; semi-finishing a small end by using a numerically controlled milling machine, and thus obtaining a small-end working tape which meets the requirements of the drawing; processing a screw through hole and a sunk table hole, and reserving an allowance for the size of a cavity of the small-end working tape; performing heat treatment on the female die, and flatly grinding planes at two ends of the female die to make the largest height of the small-end working tape meet the requirements of the drawing; performing finish turning on the excircle of the female die which is flatly ground; performing finish machining, and thus obtaining a mold cavity which meets the size of the drawing; processing an uneven part of the small-end working tape which is flatly ground by using an electric spark machine tool; and grinding, polishing and assembling the small-end working tape of the mold cavity which is subjected to finish machining by the numerically controlled milling machine. By adoption of the method provided by the embodiment of the invention, production efficiency can be improved, and production cost is reduced.

Owner:SOUTHWEST ALUMINUM GRP

Processing method for corroding titanium or titanium alloy by burning and exploding under electric spark induction effect

The invention relates to a processing method for corroding titanium or a titanium alloy by burning and exploding under the electric spark induction effect, which is characterized in that a gas which can generate vigorous exothermic oxidation and burning and exploding effects with a titanium or titanium alloy materal to be processed is introduced in a processing area intermittently in the conventional process for processing the titanium or titanium alloy under the electric spark induction effect so that the titanium or titanium alloy of which the surface is activated under the electric spark induction effect and the introduced gas are subjected to burning and exploding reactions and a new activated layer can be exposed, and the process is carried out repeatedly so that the surfaces of titanium or titanium alloy substrate materials can be corroded rapidly and continuously in large quantities. Compared with the conventional method for corroding the titanium or titanium alloy under the electric spark induction effect, the invention can improve the material corroding rate by dozens of times or even hundreds of times. The invention can be used for processing through the relative motion of small-scale equipment on a large-scale structural component, can solve the problems on the size, the rigidity and the like of a large-scale structural component processing machine tool and has the advantages of high efficiency, low loss, low cost, safety and no pollution.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Fixture structure for glass mould machining

ActiveCN102837213AQuality assuranceGuarantee efficiencyPositioning apparatusMetal-working holdersEngineeringMachining

The invention belongs to the field of a tool fixture and provides a fixture structure for glass mould machining. The fixture structure comprises a base seat, a pressure foot slide groove is arranged on the surface of one side of the base seat along the length direction of the surface, pressure feet are arranged on the pressure foot slide groove in a matched mode, a supporting mould block fixing seat and a supporting mould block slide cavity are arranged on the base seat, and the positions on the base seat where the supporting mould block fixing seat and the supporting mould block slide cavity are arranged correspond to the lower portion of the center position of the length direction of the pressure foot slide groove; the supporting mould block fixing seat is matched with the supporting mould block slide cavity, a supporting mould block fixing seat nut is arranged on the supporting mould block fixing seat in matched mode, the supporting mould block fixing seat nut is connected with one end of a lifting screw rod of the supporting mould block fixing seat, and the other end of the lifting screw rod of the supporting mould block fixing seat is arranged on the pressure foot slide groove in a supporting mode; a supporting mould block is fixed with one side of the supporting mould block fixing seat, one end of each pressure feet stretches out the surface of one side of the base seat, wherein the end and the surface both face towards the supporting mould block. The fixture structure for the glass mould machining has the advantages that the fixture structure breaks away from a traditional electric spark mode that flower engraving machining is used for a cavity of the glass mould, the flower engraving quality and efficiency are ensured, and the operation is convenient and fast.

Owner:CHANGSHU JIANHUA MOLD TECH

Work fixture for glass mould machining

ActiveCN102848246AGood clamping adaptabilityQuality assurancePositioning apparatusMetal-working holdersEngineeringBottle

The invention discloses a work fixture for glass mould machining, belonging to the technical field of the work fixture. The work fixture comprises a base, a support mould block fixed seat and a support mould block, wherein the surface of one side of the base is provided with a pressure pin sliding chute; a pressure pin is arranged on the pressure pin sliding chute in a matching manner; the base is provided with a support mould block fixed seat sliding cavity; the support mould block fixed seat is matched with the support mould block sliding cavity and provided with a support mould block fixed seat nut in a matching manner; the support mould block fixed seat nut is connected with one end of a support mould block fixed seat lifting screw rod; the other end of the support mould block fixed seat lifting screw rod is supported on the pressure pin sliding chute; the support mould block is fixed with one side of the support mould block fixed seat; one end of the pressure pin stretches out of the surface of one side of the base; one side of the base is provided with a first guide sliding chute and a second guide sliding chute; and the other side of the base is provided with a bottle mould end face locating mechanism in a matching manner. The work fixture for glass mould machining disclosed by the invention has the advantages that the conventional electric sparking method for carving the inner cavity of a glass mould is gotten rid of, the carving quality and efficiency are ensured, the operation is convenient and rapid, the work fixture has good clamping adaptability, and resources are saved.

Owner:CHANGSHU JIANHUA MOLD TECH

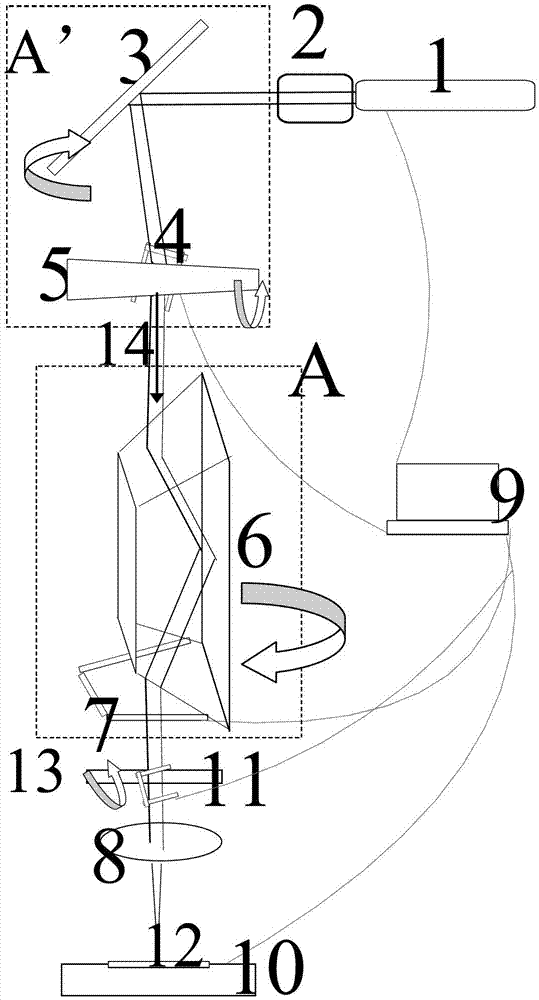

System and method for processing micro conical bore by rotation of laser beam

InactiveCN102950385AControllable taperHigh precisionLaser beam welding apparatusLaser processingOptical axis

The invention discloses a system and a method for processing a micro conical bore by rotation of a laser beam. The system comprises a laser generating unit, a laser deflection unit, a laser rotating unit, a taper control unit and a laser processing unit; the laser generating unit is used for generating a beam of short-pulse laser and sending the short-pulse laser to the incident end of the laser deflection unit; the laser deflection unit is used for sending the short-pulse laser to the incident end of the laser rotating unit by the exit end of the laser deflection unit after carrying out deflection on the short-pulse laser; the laser rotating unit is used for rotating the laser beam and transmitting the laser beam to the incident end of the taper control unit by the exit end of the laser rotating unit; and the taper control unit is used for correcting a horizontal distance between the laser beam and an optical axis and then transmitting the laser beam to a processed workpiece on the laser processing unit by the exit end of the taper control unit. The invention can overcome the technical defects of conventional processing means of processing a fine round hole in a mechanical and electric spark manner and the like and completely avoids the defects of a great number of burrs, difficulty in control on the accuracy, poor reliability and the like of a current fine conical bore.

Owner:CHINA KEHAN LASER FUJIAN

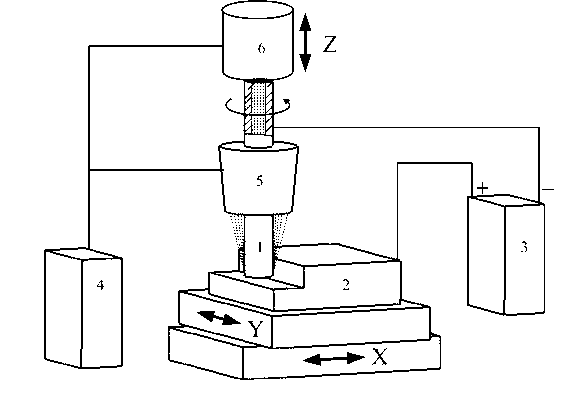

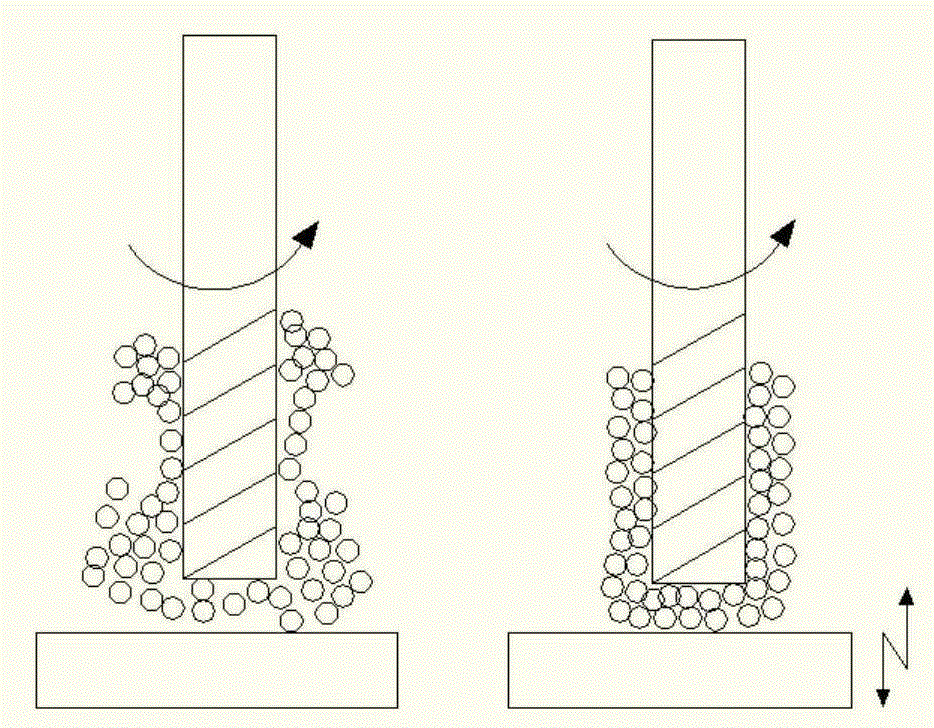

Efficient micro-machining method and device for non-conductive crisp and hard material

InactiveCN105215487AEasy to updateAccelerated exclusionStone-like material working toolsElectrolysisAuxiliary electrode

The invention belongs to the field of combined micro-machining and discloses an efficient micro-machining method and device for a non-conductive crisp and hard material. According to the machining method, ultrasonic vibration, electrolyzing, electric sparks, high-speed drill milling and other machining methods are organically combined to complete machining of non-conductive microstructures. In other words, a workpiece, a tool electrode and an auxiliary electrode are immersed into an electrolyte; the auxiliary electrode and the tool electrode are subjected to an electrolytic reaction; hydrogen evolution happens to the surface of the tool electrode connected with a negative electrode, and an insulation air film is formed; generation and homogenizing of the air film on the surface of the tool electrode are facilitated under the cavatition effect of ultrasonic vibration; and during machining, the tool electrode and the electrolyte on the surface of the workpiece generate spark discharge to puncture the air bubble film, and therefore a high-temperature erosion non-conductive workpiece material is generated. The machining device comprises a machine tool bed, an electrolysis-electrical discharge machining unit, an ultrasonic vibration worktable and a feeding worktable. Due to high-speed rotation of the spiral tool electrode and ultrasonic vibration of the workpiece, a clearance flow field can update the electrolyte efficiently. The efficient micro-machining method and device have the beneficial effects that efficiency and precision are high, and cost is low, and the efficient micro-machining method and device are very suitable for micro-machining of the non-conductive hard and crisp materials.

Owner:SHANDONG UNIV

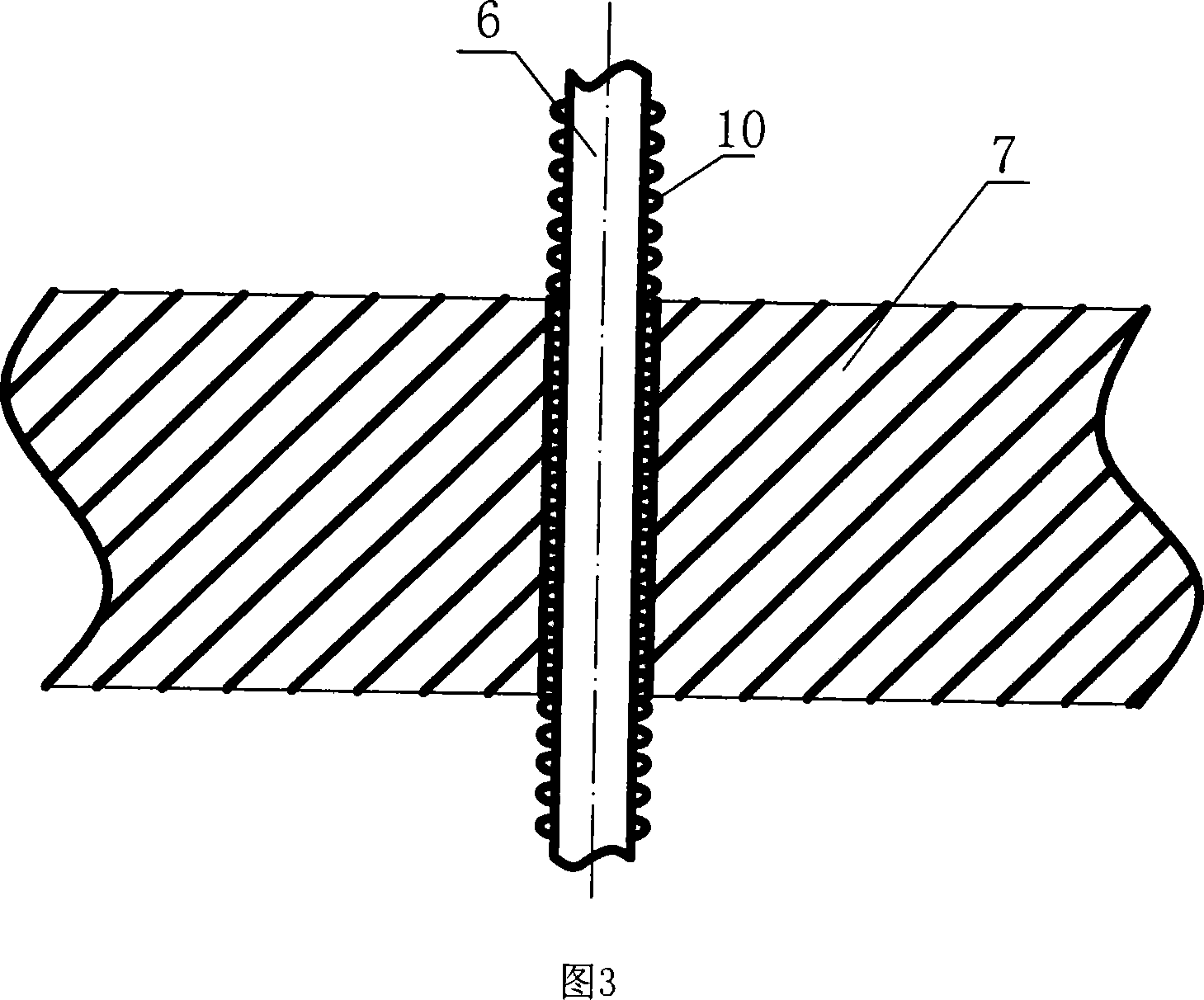

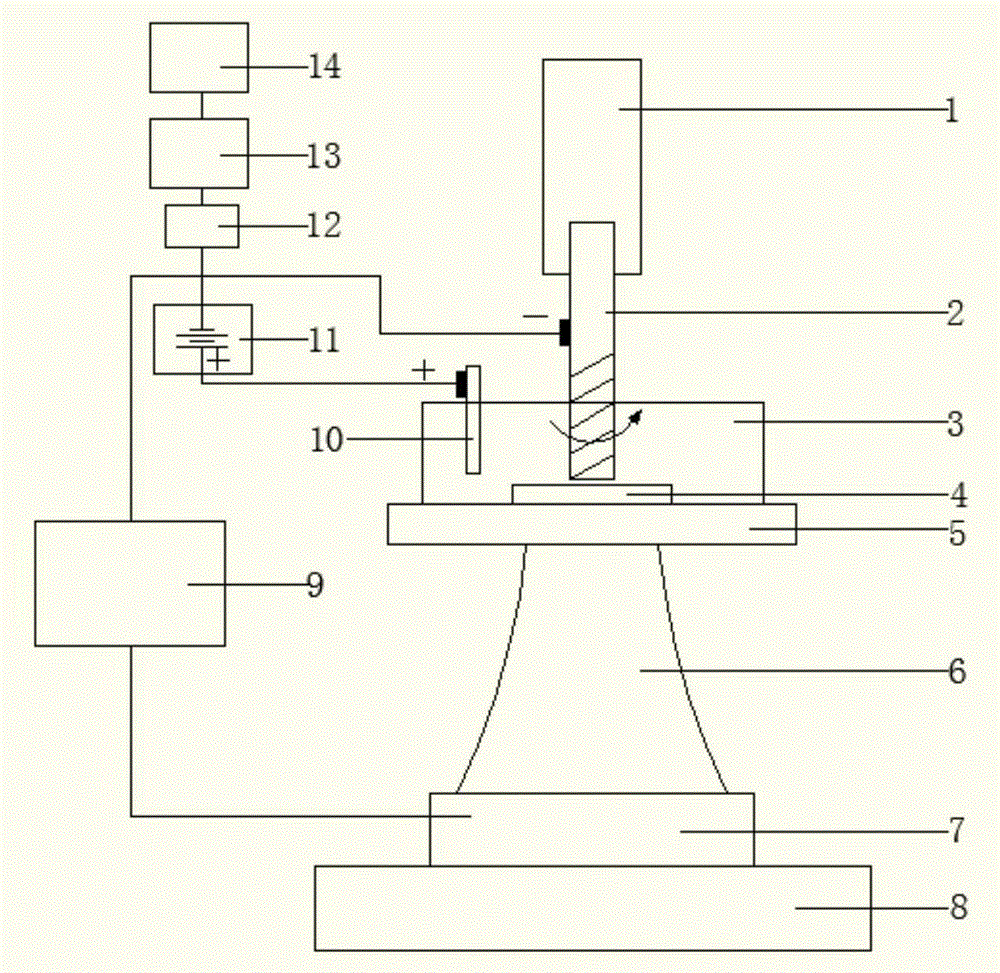

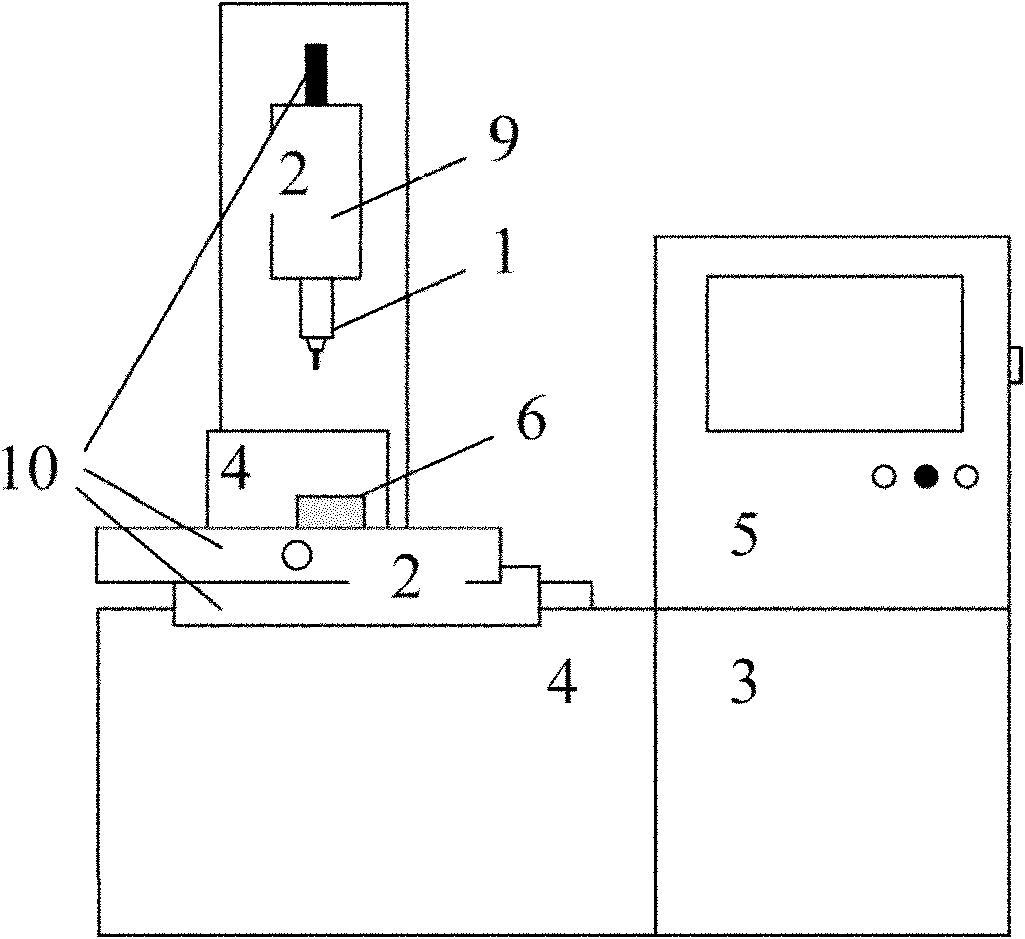

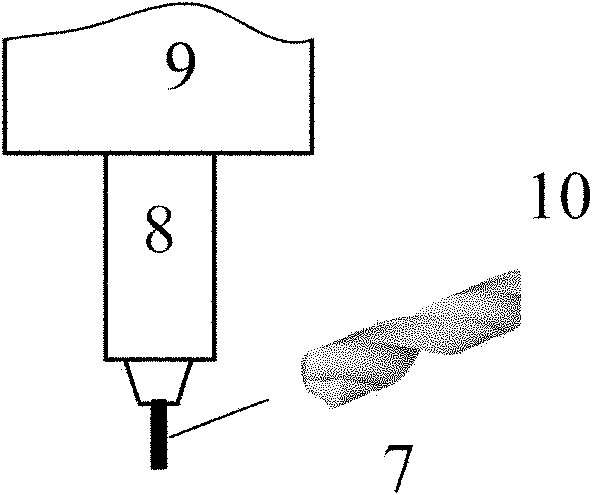

Electrolytic electric spark cutting composite micromachining device and method

InactiveCN101972874AHigh removal rateHigh hardnessOther manufacturing equipments/toolsElectrolysisControl system

The invention relates to electrolytic electric spark cutting composite micromachining device and method in the technical field of mechanical manufacture. The electrolytic electric spark cutting composite micromachining device comprises a cutter system, a mechanical movement system, a power supply system, a working solution system and a control system. On the basis of the traditional non-conducting material electrolytic electric spark machining technology, the invention introduces cutting machining by utilizing physical contact characteristics of a machining electrode and a non-conducting workpiece to be machined so that the cutting machining becomes new electrolytic electric spark cutting composite micromachining. The composite machining method overcomes the defects of machining efficiency, machining precision, and the like of the traditional electrolytic electric spark machining method and improves the machinability of difficult machining materials, such as glass, ceramics, and the like.

Owner:SHANGHAI JIAO TONG UNIV

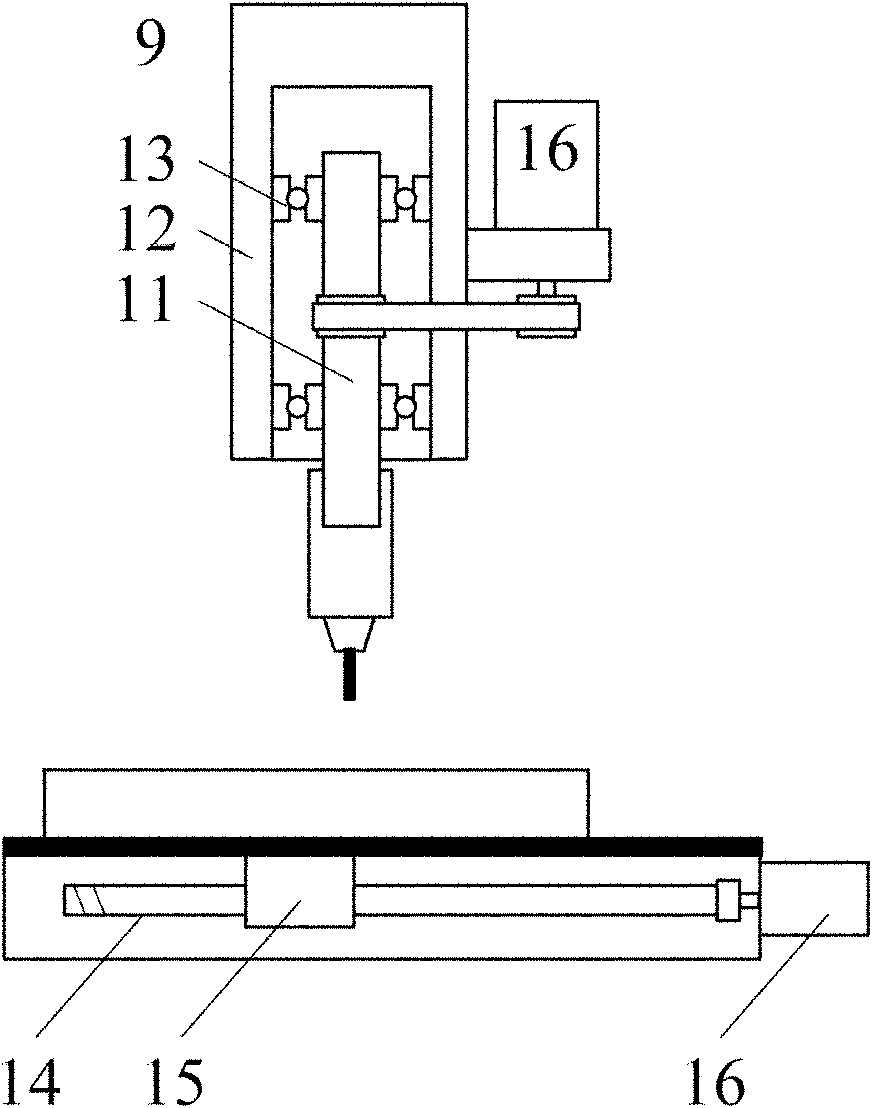

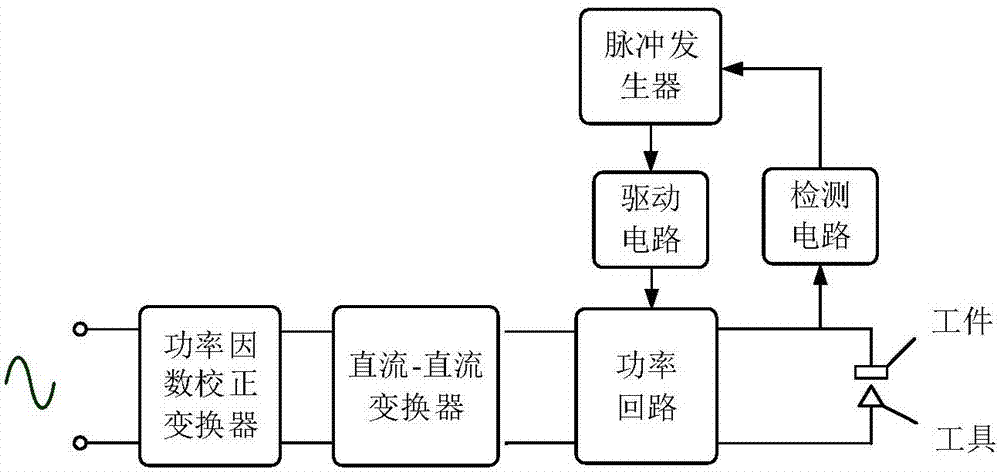

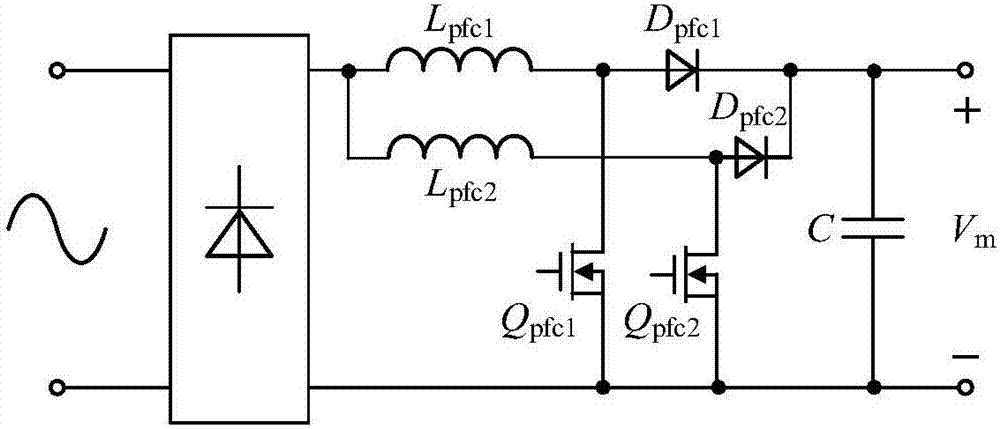

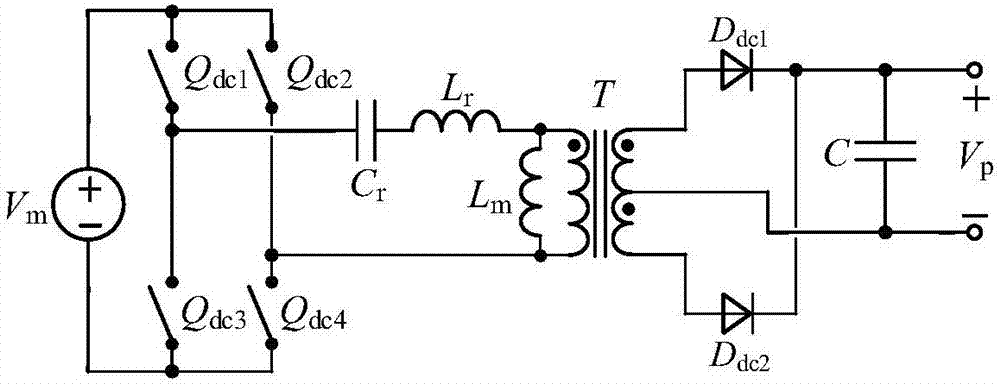

Micro electrical discharge pulse power source and segmental control method based on micro electrical discharge pulse power source

ActiveCN107276405ASimple topologyReduce volumeDc-dc conversionElectric circuitsDriver circuitDc dc converter

The invention discloses a micro electrical discharge pulse power source. The micro electrical discharge pulse power source comprises a power factor correction converter, a DC-DC converter, a power loop, a driving circuit, a pulse generator and a detection circuit, wherein the power loop comprises 6 switch tubes Qp, Q1, Q2, Q3, Q4 and Qoff and one inductor Llimit, the four switch tubes Q1-Q4 are connected in a bridge structure, the switch tube Qp is connected with an output side of the DC-DC converter and an input side of a full-bridge converter, after the switch tube Qoff is in parallel connection with a gap, one end of the switch tube Qoff is connected with a center point of a bridge arm through the inductor Llimit, and the other end is directly connected with a center point of another bridge arm. The invention further comprises a segmental control method based on the micro electrical discharge pulse power source. The micro electrical discharge pulse power source is advantaged in that only one power loop is comprised, the structure is simple, the volume is small, switching of voltage control and current control is carried out in a set of power loop through the corresponding segmental control method, voltage control and current control are mutually independent, and fast switching and precise and stable control can be realized.

Owner:NANJING UNIV OF SCI & TECH

Blisk manufacturing method based on 3D (three-dimensional) printing and electric spark finishing

ActiveCN104690517AWide range of processingHigh precisionAdditive manufacturing apparatusIncreasing energy efficiencyNumerical controlEngineering

The invention discloses a blisk manufacturing method based on 3D (three-dimensional) printing and electric spark finishing. The blisk manufacturing method includes: 1) manufacturing a wheel hub of a blisk, washing the wheel hub of the blisk prior to positioning and fixing the wheel hub on a numerical control table; 2) generating a slicing file; 3) manufacturing a blisk blank on the numerical control table by 3D printing according to the slicing file; 4) subjecting the blisk blank to hot isostatic pressing; 5) measuring a practical three-dimensional model of the blisk blank; 6) acquiring the accuracy error and deformation amount between the practical three-dimensional model of the blisk blank and a target three-dimensional model of the blisk; 7) determining spark machining allowance according to the accuracy error and the deformation amount; 8) subjecting the blisk bland to spark machining according to the spark machining allowance so as to obtain a blisk sample; 9) removing a fused layer on the surface of the blisk sample and grinding the blisk sample to obtain the blisk. The blisk manufacturing method based on 3D printing and electric spark finishing has the advantages of capability of blisk manufacturing, material saving and high machining precision.

Owner:XI AN JIAOTONG UNIV

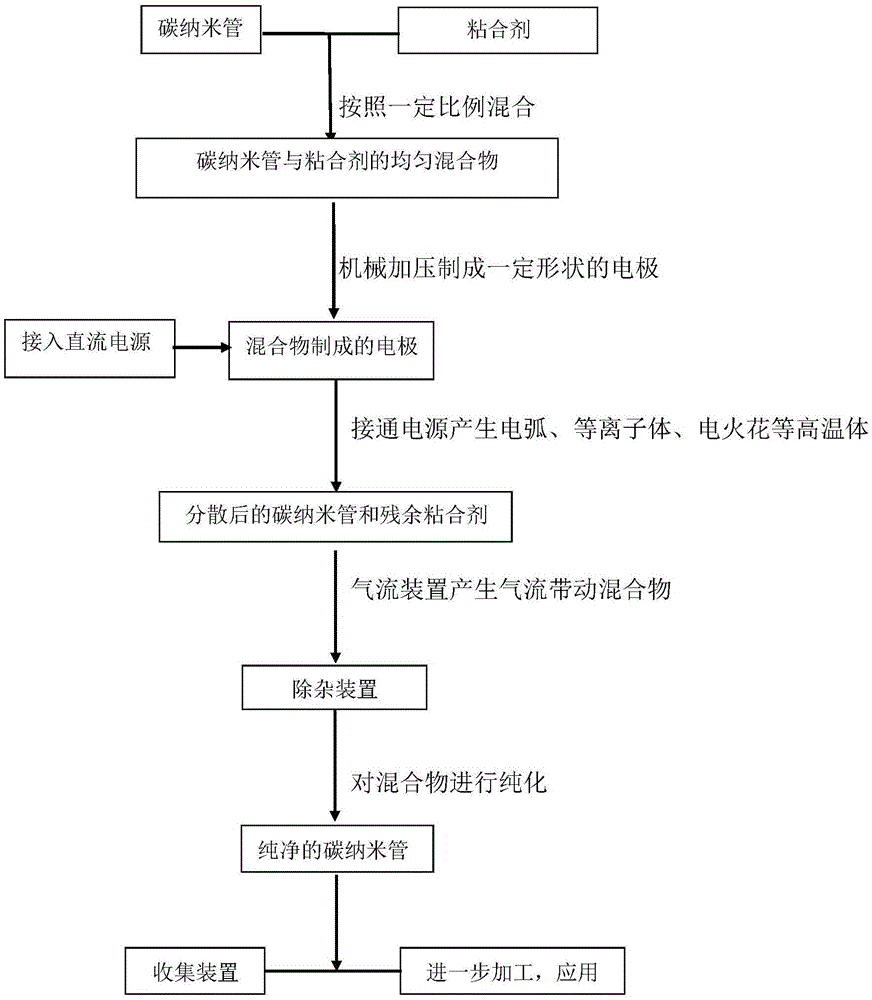

Dispersion method for carbon nanotubes

ActiveCN105536585AGood dispersionRealize large-scale preparationTransportation and packagingMixing methodsCarbon nanotubePhase change

The invention discloses a dispersion method for carbon nanotubes, belonging to the field of new materials. The method comprises the following steps: (1) mixing the carbon nanotubes with a binder; (2) pressing the obtained mixture so as to prepare an electrode; (3) connecting the electrode with a negative electrode of a direct-current power supply, and using materials like metal as a positive electrode of the power supply; (4) keeping a certain distance between the positive electrode and the negative electrode of the power supply; and (5) turning on the power supply so as to generate electro-induced heat sources like electric arcs, plasmas and electric sparks with a certain strength between the two electrodes of an electric circuit, and subjecting the binder absorbed by the carbon nanotubes to phase change under the action of high temperature so as to effectively disperse the carbon nanotubes. The invention has the following beneficial effects: the dispersion method for the carbon nanotubes provided by the invention has obvious dispersion effect and is easy to realize large-scale preparation.

Owner:QINGDAO UNIV OF SCI & TECH

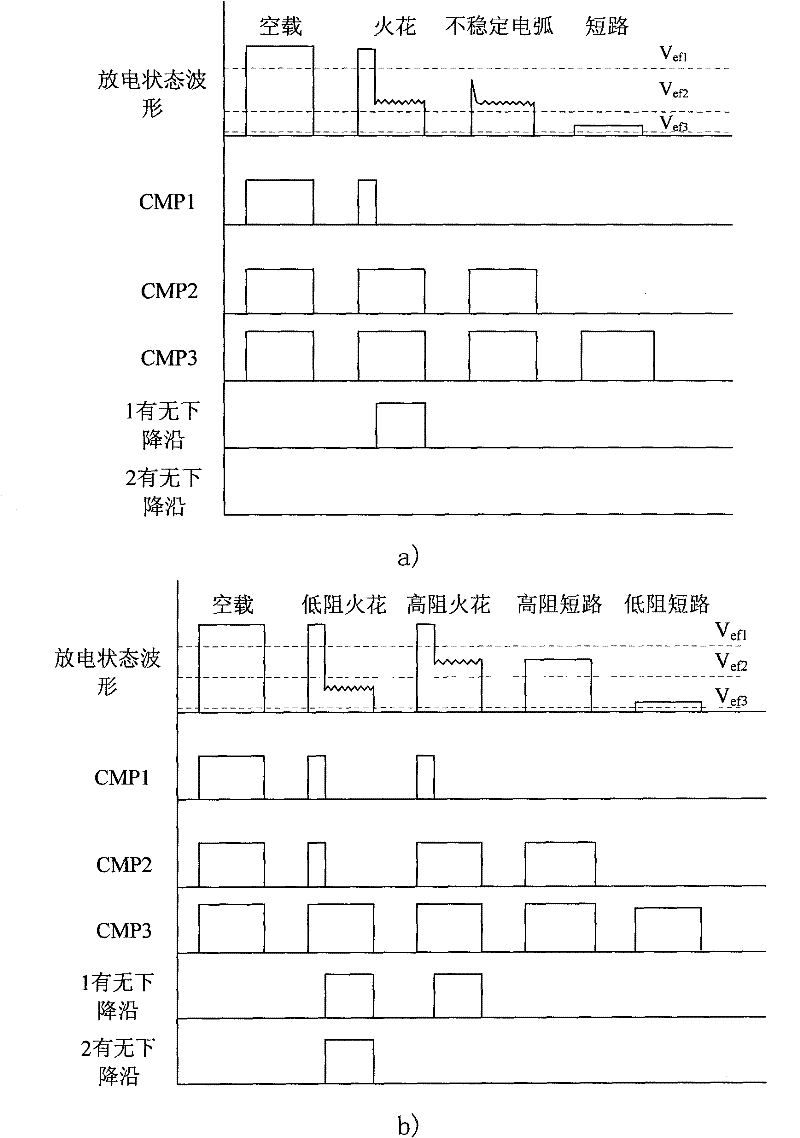

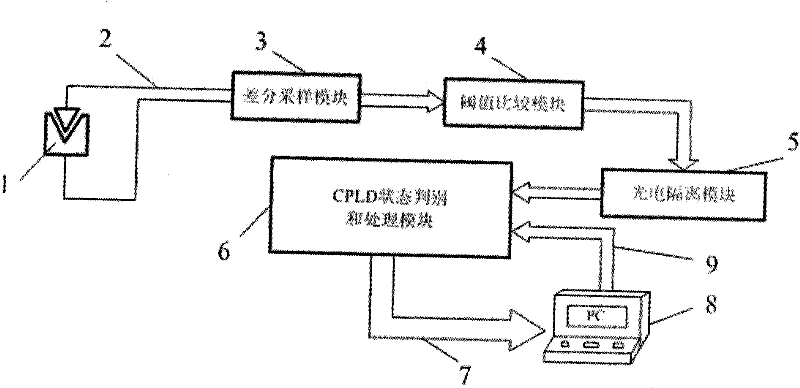

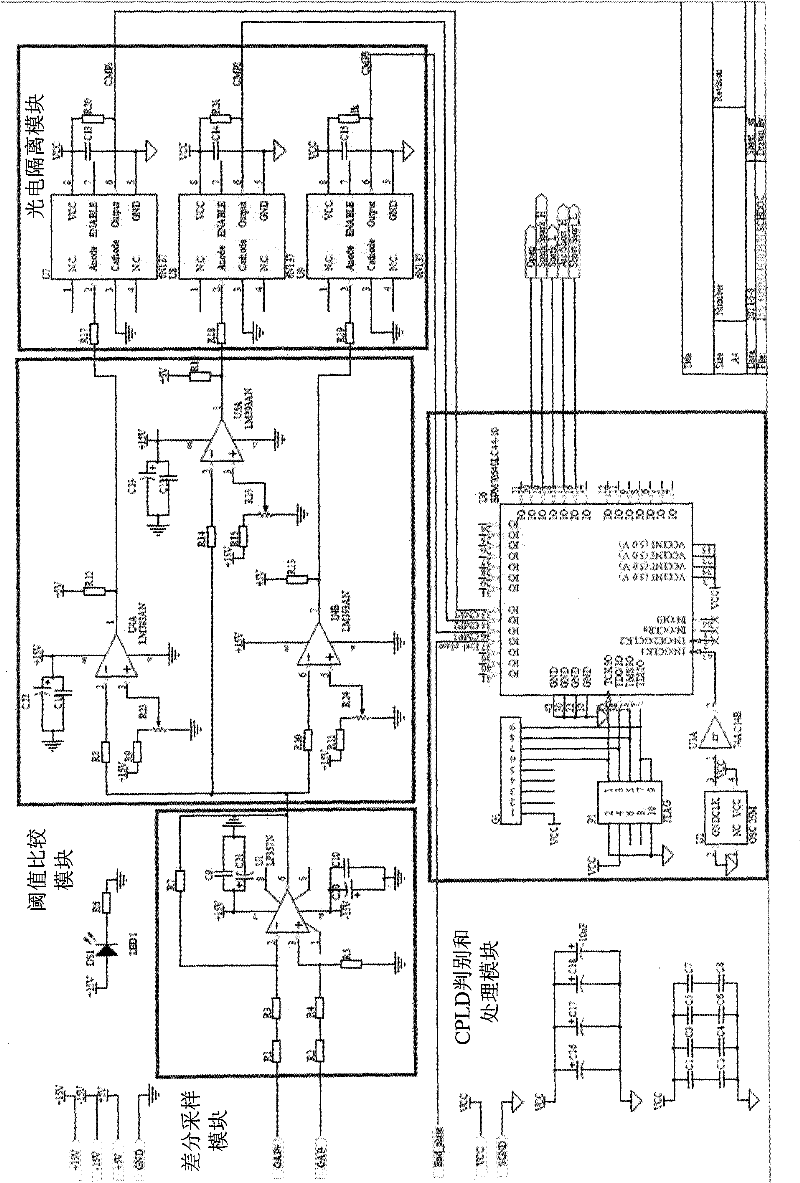

Device and method for detecting discharge state in electric spark linear cutting work gap

InactiveCN102248235AImprove flexibilityAccurate discriminationComplex programmable logic deviceOpto electronic

The invention relates to a device and a method for detecting the discharge state in an electric spark linear cutting work gap, and belongs to the technical field of electric spark machining. A differential sampling module of the device is connected with the two poles of an electric spark machine tool through a signal transmission cable; a signal output end of the differential sampling module is connected with a signal input end of a threshold value comparison module; a signal output end of the threshold value comparison module is connected with a signal input end of a photoelectric isolation module; a first signal input end of a complex programmable logic device (CPLD) state distinguishing and processing module is connected with a signal output end of the photoelectric isolation module; and a signal output end of the upper computer is connected with a second signal input end of the CPLD state distinguishing and processing module through a CPLD program downloading cable. The threshold value comparison module compares sampled gap voltage signals with set three threshold values through an integration comparator, and sends the comparison result to the photoelectric isolation module. The device and the method can be used for detecting the pulse discharge state of the gap in the electric spark linear cutting machine tool.

Owner:HARBIN INST OF TECH

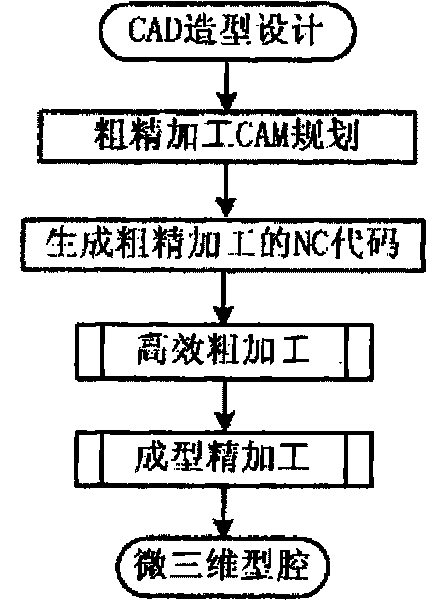

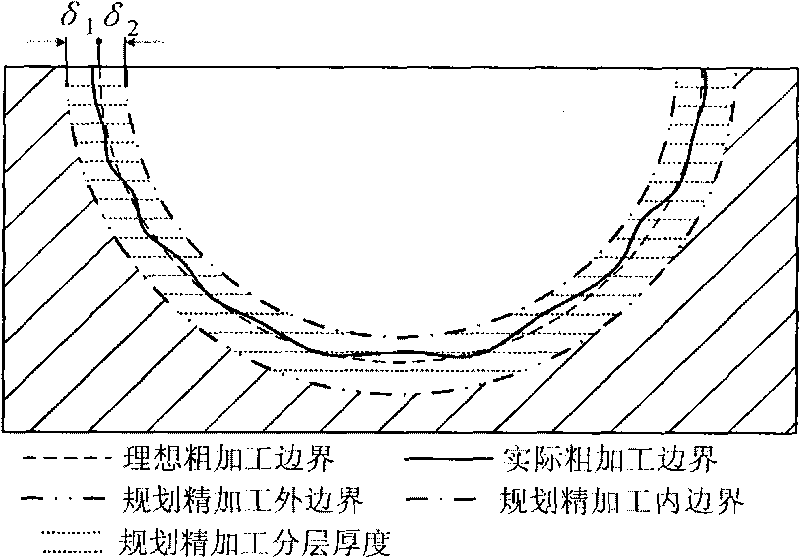

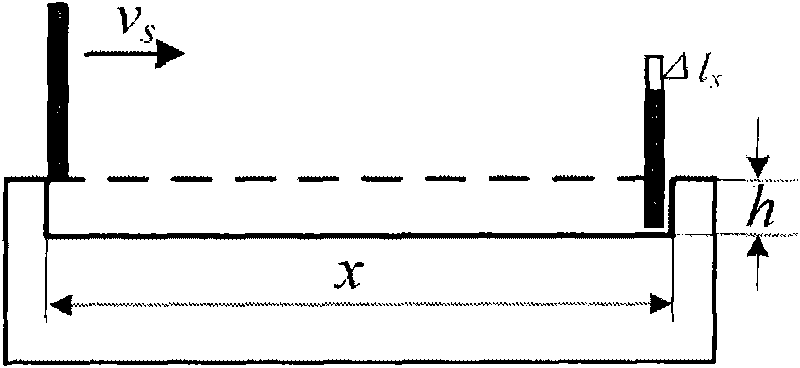

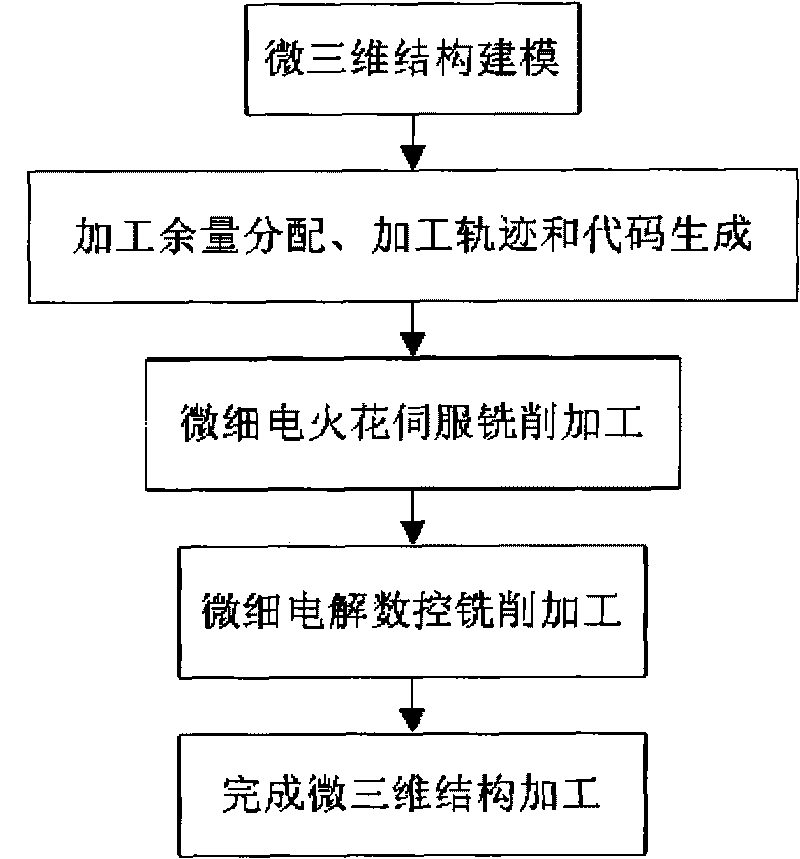

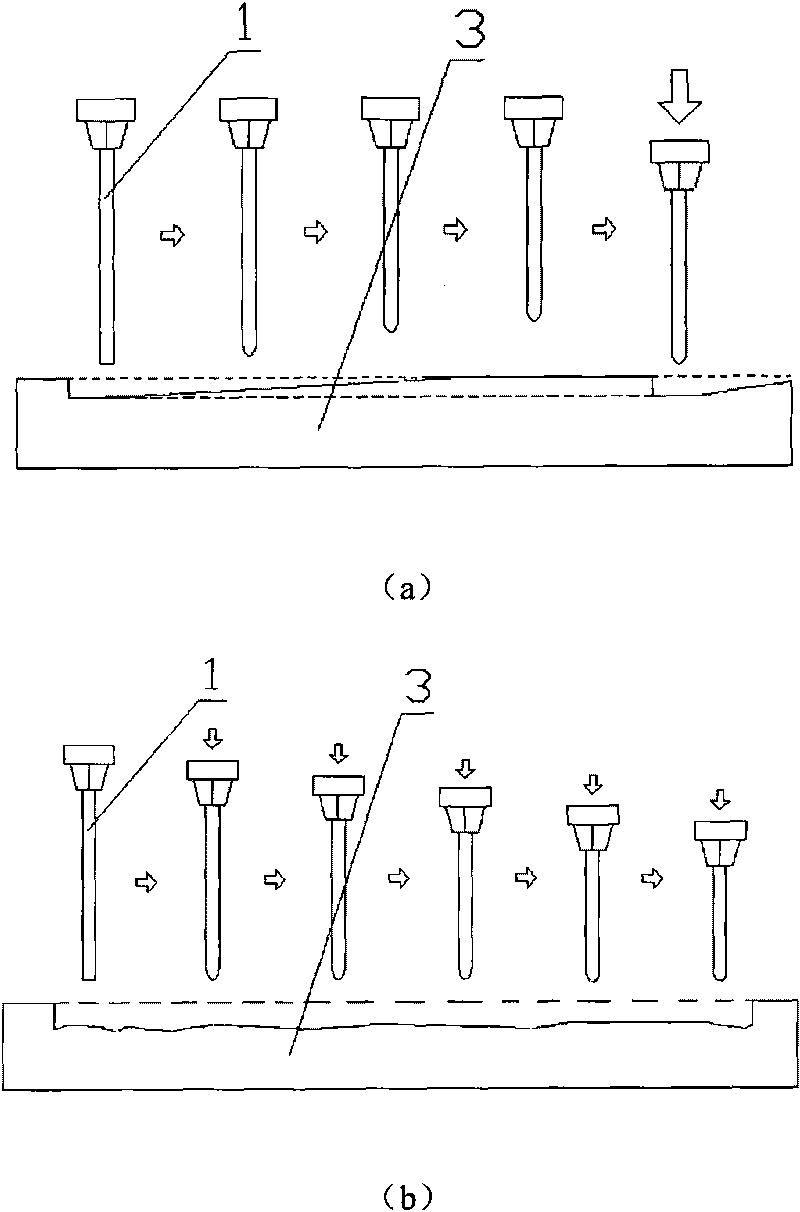

Three-dimensional fine electric spark servo scanning rough and finish machining combined process

A three-dimensional fine electric spark servo scanning rough and finish machining combined process belongs to the technical field of special micro machining. The process which is adaptive to machining of micro three-dimensional cavities with millimeter-sized and utilizes a servo control discharge clearance to realize real-time on-line compensation of axial consumption of an electrode includes removing a large quantity of cavity materials rapidly when in rough machining, applying a maximum method of servo feed depth of an tool electrode of each scanning point to avoid and reduce lack of machining and over-cutting machining and guarantee consistency of processed depths of different layers when in finish machining, further, feeding back processed depth of each layer by combing with tool electrode low-voltage electric contact in a closed loop form, then applying a variable velocity servo scanning method to compensate depth error, and finally completing molding process with high surface precision and high size precision by adopting low discharge energy and thin dividing thickness. The combined process resolves the problem of precision limitation of processed depth of three-dimensional servo scanning, eliminates contradiction between high precision and high efficiency, and can be applied to high-precision and high-efficiency machining of micro three-dimensional cavities made of metal alloy and conductive silica-based materials.

Owner:TSINGHUA UNIV

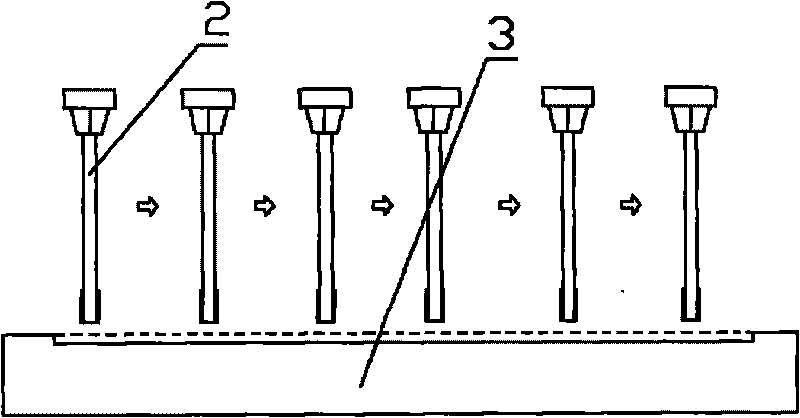

Electric spark and electrolysis combined milling machining method of micro three-dimensional structure

InactiveCN101693313AConsecutive completionFinish quicklyMachining working mediaElectrolysisMetal alloy

An electric spark and electrolysis combined milling machining method of a micro three-dimensional structure belongs to the technical field of micromachining, and is characterized in that a plurality of metal alloy material and complicated cavities and surfaces can be machined through adopting simple electrodes to operate the combined machining of micro electric spark milling and micro electrolysis milling by means of the layered milling principles. The combined machining method has two steps of fast finishing the most of machining through adopting the machining method of the micro electric spark closed-loop gap servo scanning and milling, then carrying out the residual machining through adopting the machining method of the micro electrolysis layered open-loop digital control scanning and milling, thereby finally finishing the shaping of a micro three-dimensional structure, wherein a machining electrode whose side wall is insulated is used in the electrolysis milling for improving the machining localization and machining precision. The method fully utilizes the advantages that the micro electric spark servo scanning and milling has fast machining speed, and the micro electrolysis digital control milling can not abrade the machining electrode, and has excellent surface machining quality.

Owner:TSINGHUA UNIV

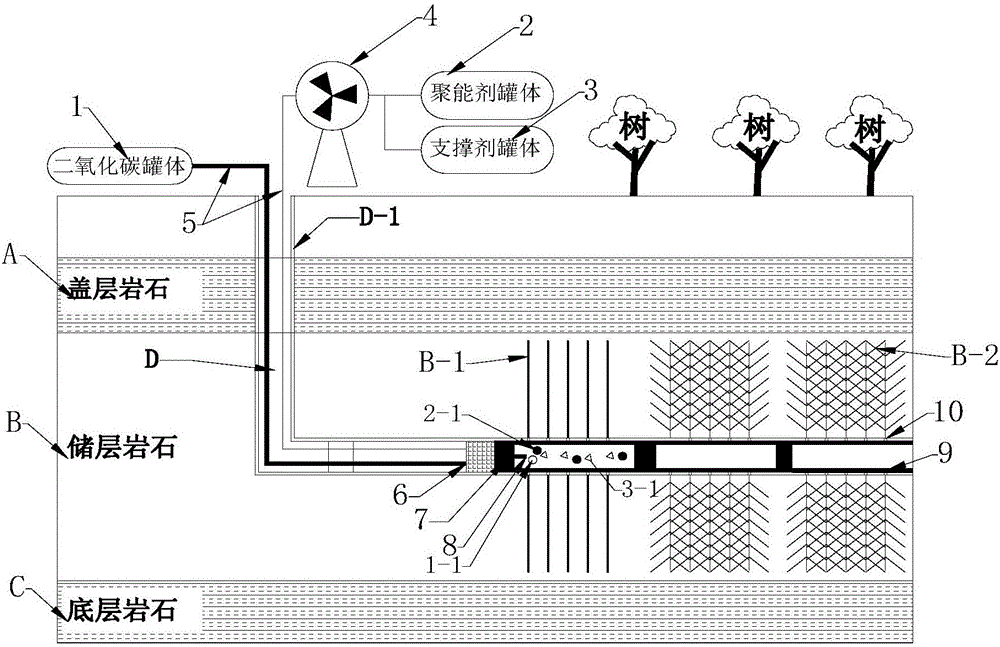

Carbon dioxide stamping phase change detonation fracturing system and method

The invention discloses a carbon dioxide stamping phase change detonation fracturing system and a method thereof, and relates to the field of development and utilization of unconventional oil and gas resources in underground deep-buried reservoirs. The system is characterized in that a supporting and protecting casing pipe (D-1) is arranged at a vertical section of a drilled well (D); a directed casing pipe (9) is arranged at a horizontal section of the drilled well (D); a mixture generator (6), a packer (7), an electric spark ignition device (8) and a jet hole (10) are arranged in the directed casing pipe (9) from left to right in sequence; an energy concentrator tank body (2) and a supporting agent tank body (3) are respectively connected with a boosting pump (4) through pipelines; and a carbon dioxide tank body (1) and the boosting pump (4) are respectively connected with the mixture generator (6) through injection pipelines (5). The carbon dioxide stamping phase change detonation fracturing system can fully use high-energy impact waves generated by detonation of carbon dioxide and an energy concentrator to enable rocks in the reservoirs to generate fractures, and the high-energy impact waves can be adjusted according to a fracturing demand; and reaction raw materials adopted by the system are pollution-free to the environment.

Owner:胡少斌

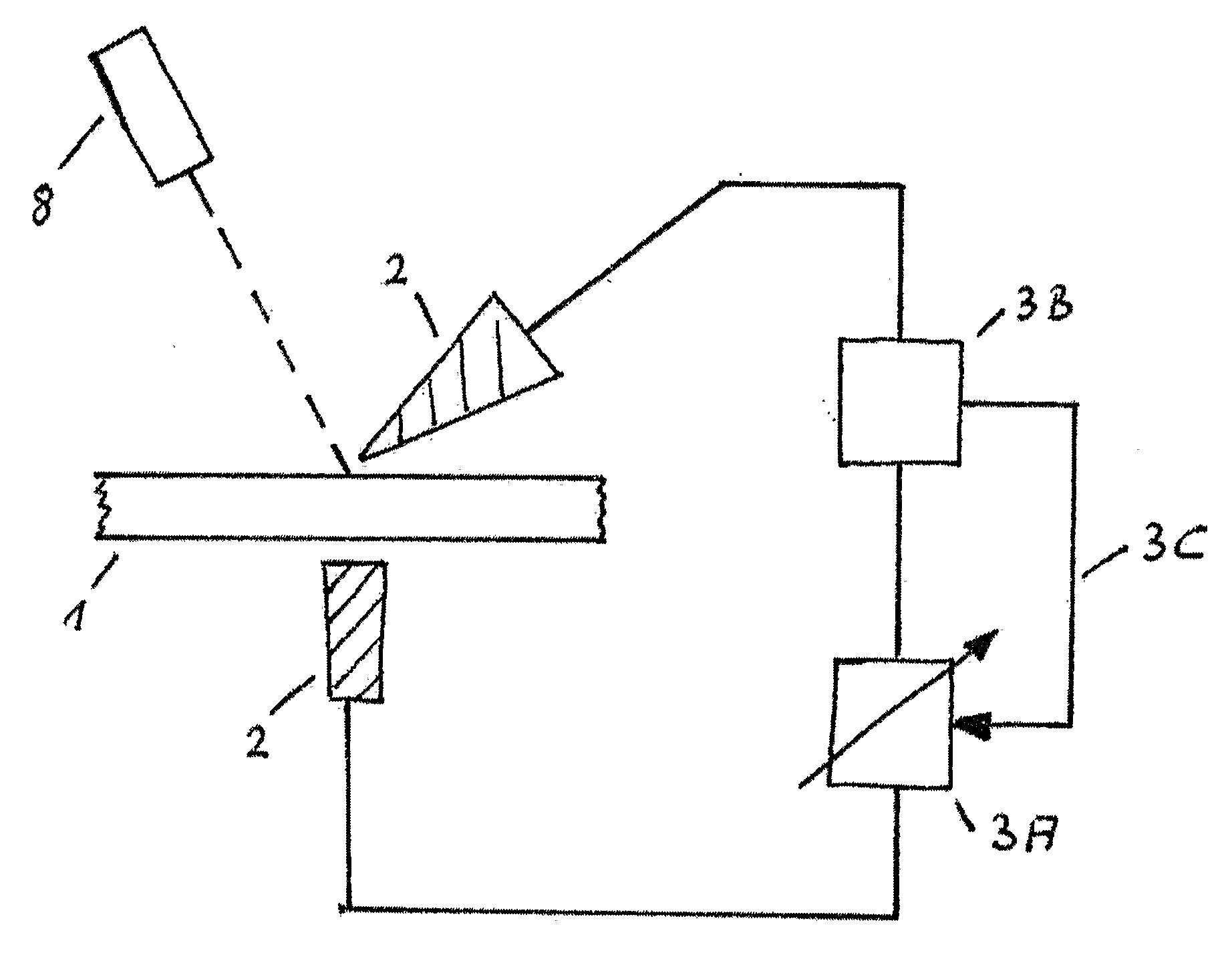

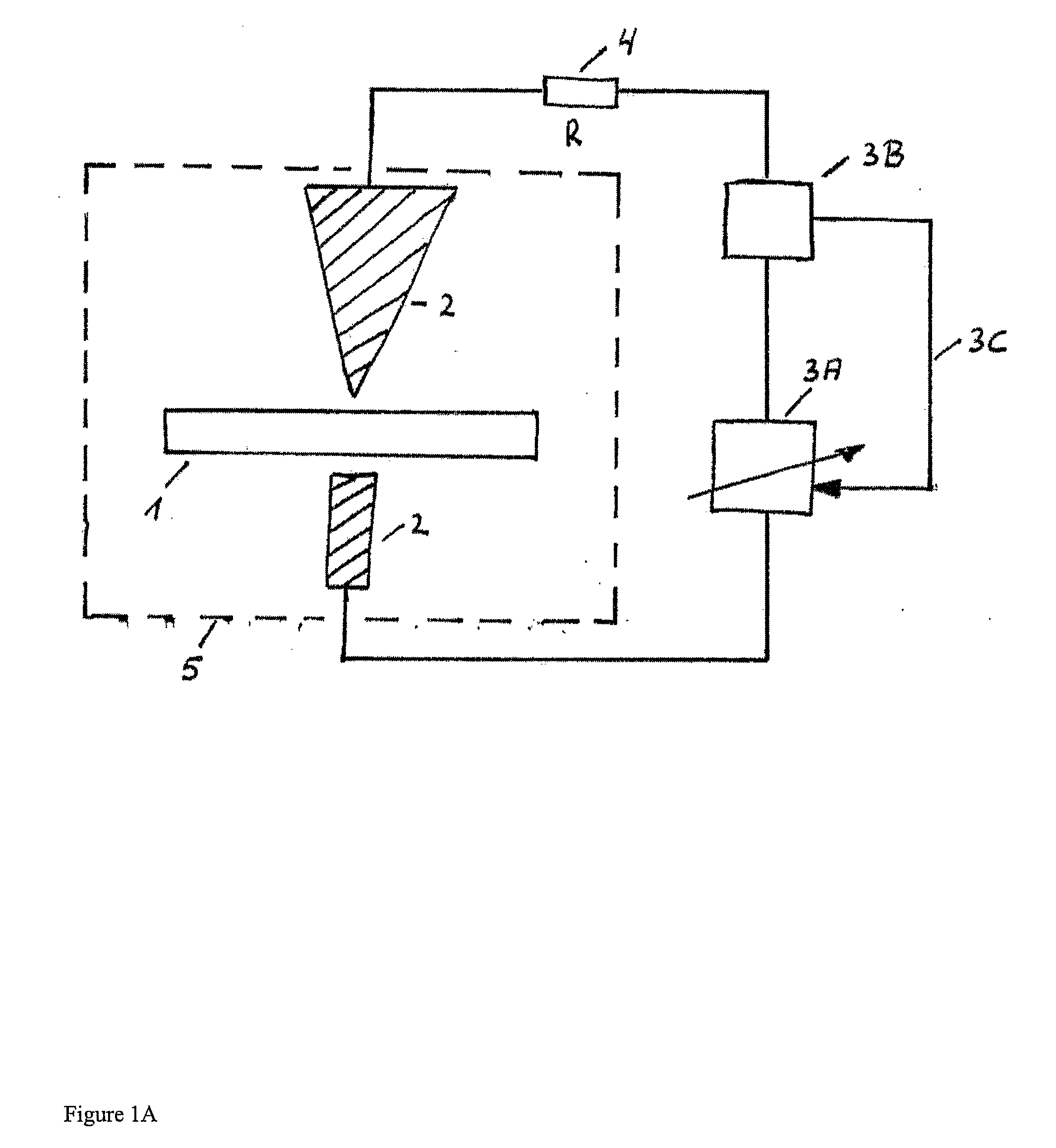

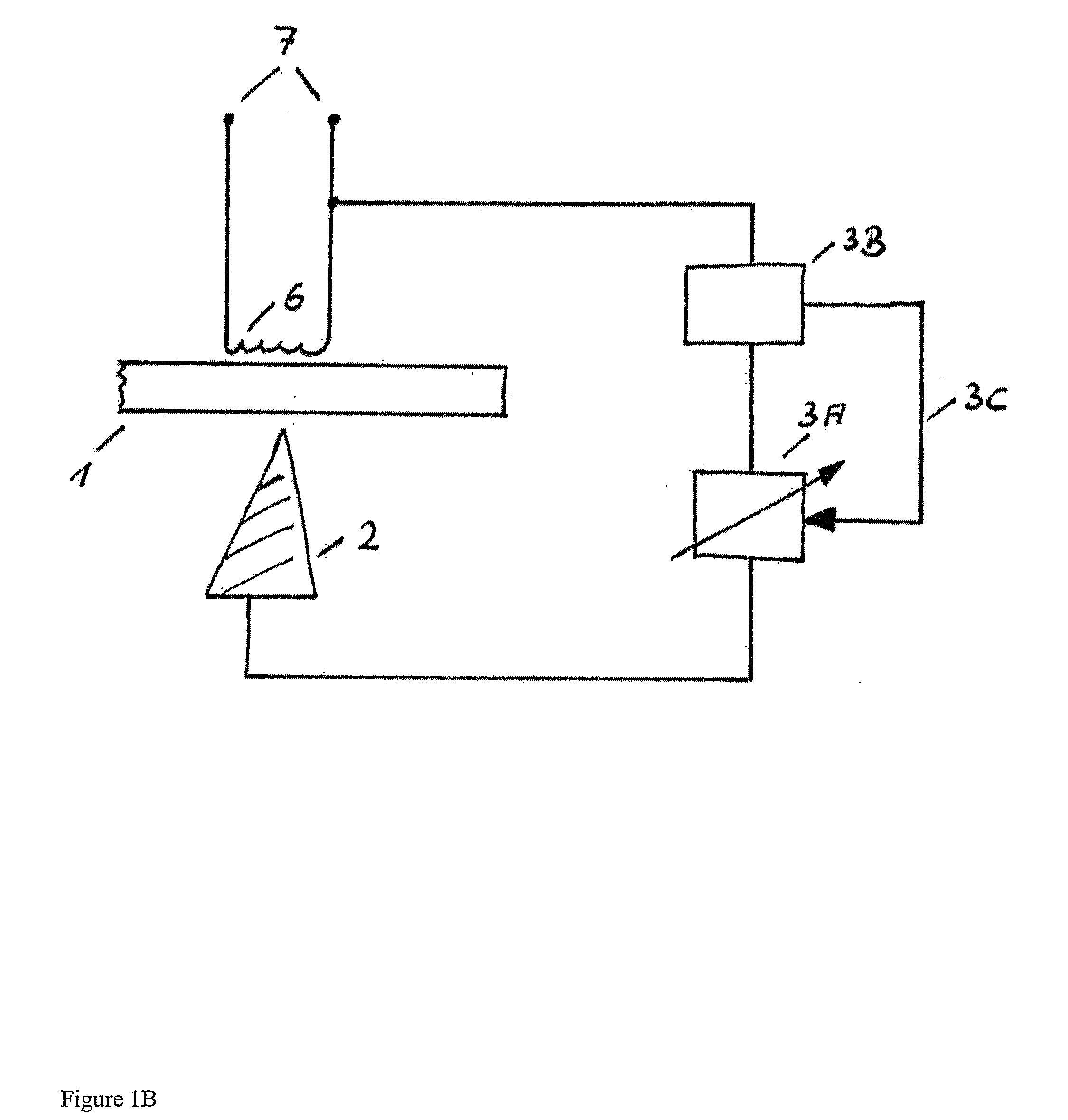

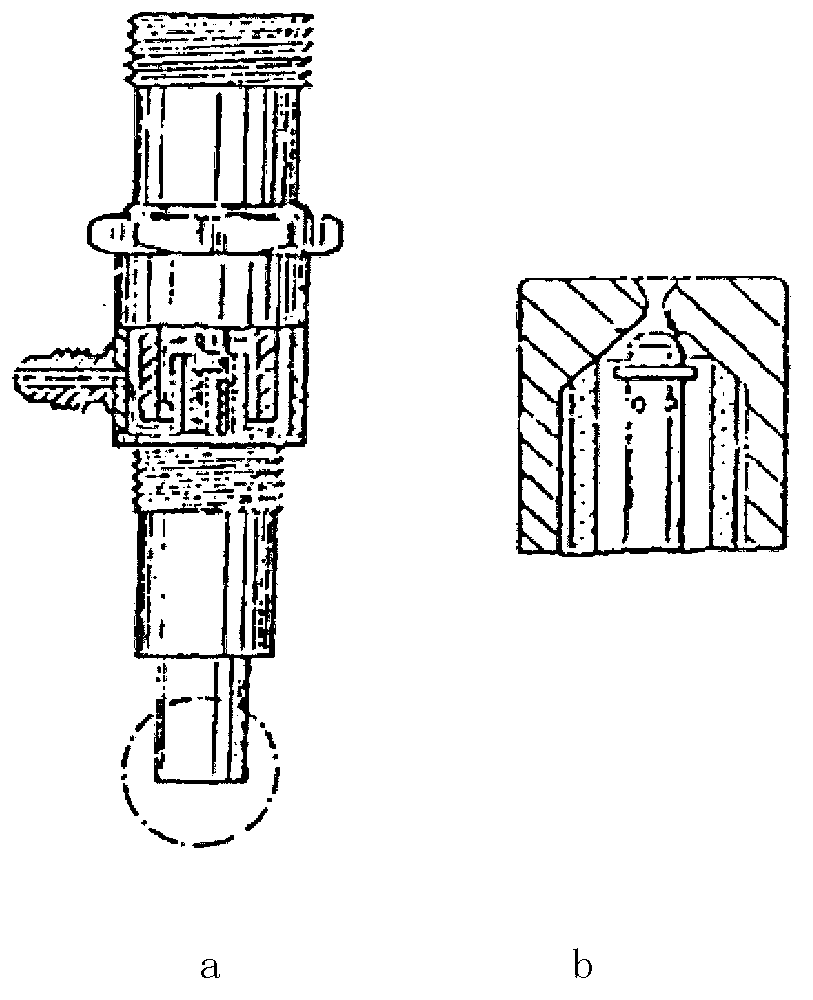

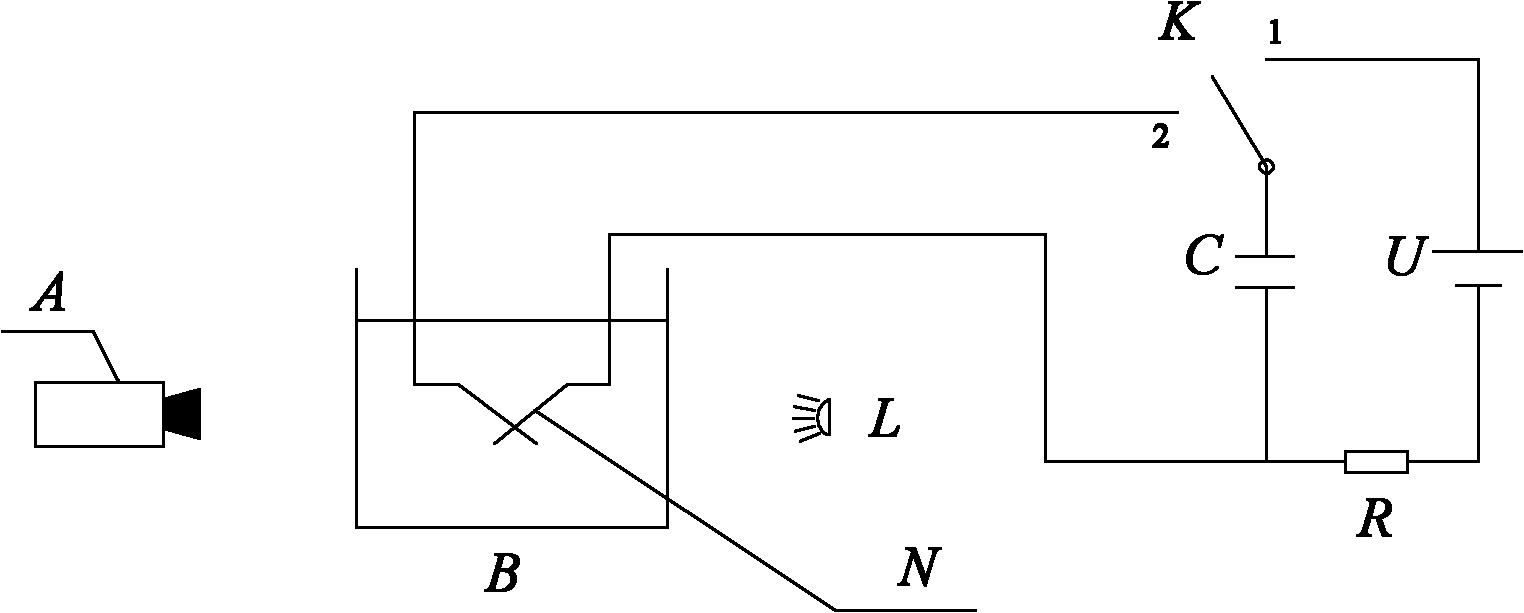

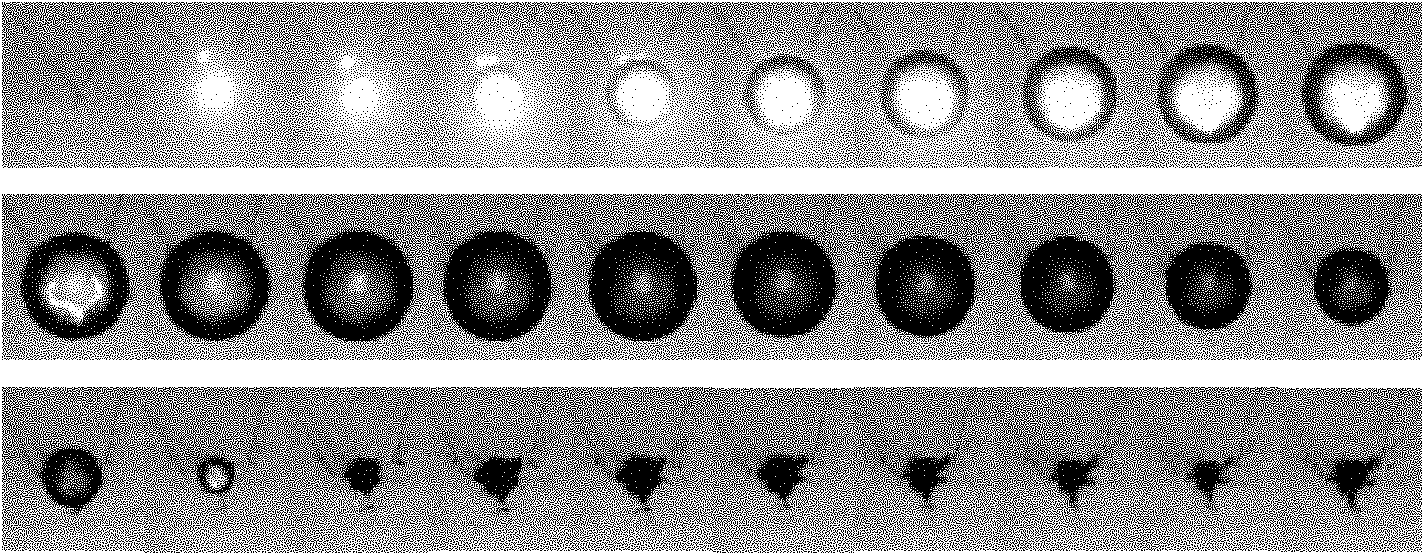

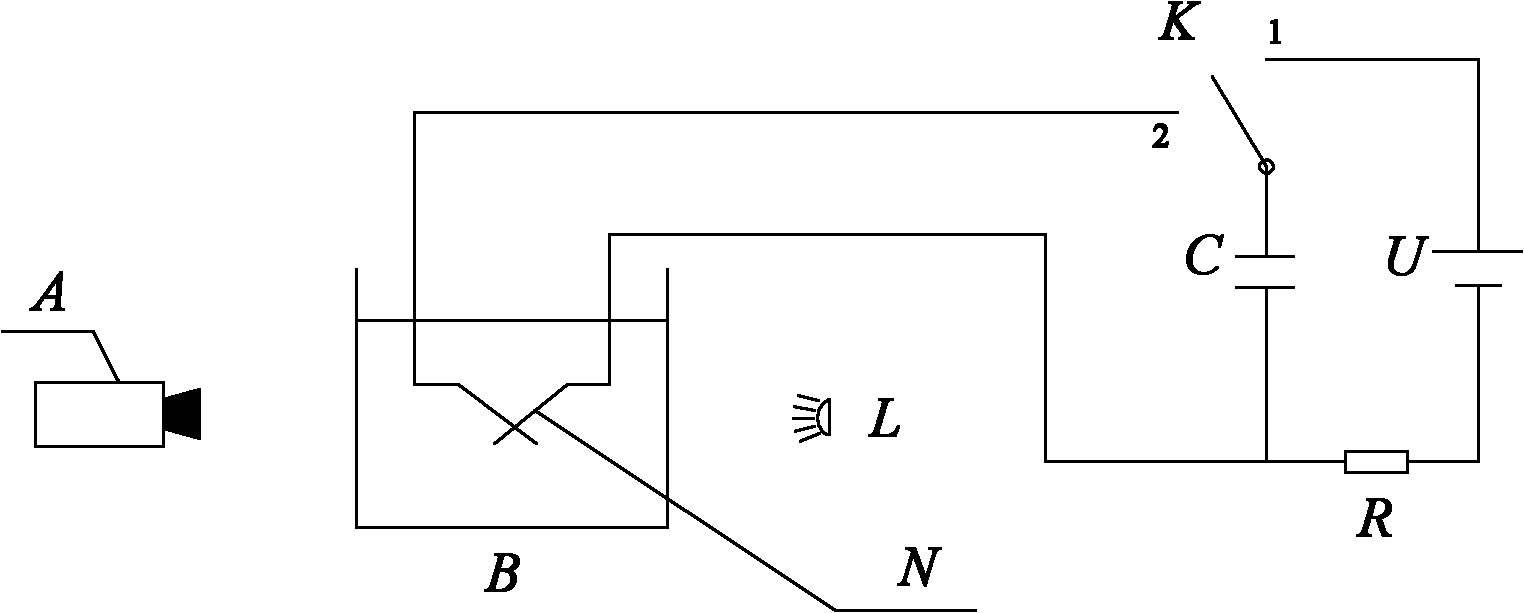

Experimental device and experimental method for generation of bubbles of electric spark in water

InactiveCN102141523AShort blast timeExplosion reflected violentlySpark gapsInvestigating moving fluids/granular solidsCapacitanceUnderwater explosion

The invention provides an experimental device and an experimental method for generation of bubbles of an electric spark in water. Two copper wires are fixed on two metal electrodes respectively; the two metal electrodes and a capacitor (C) are connected in parallel to two ends of a resistor (R) and two ends of a power supply (U); the experimental device also comprises a single-pole double-throw switch (K); the single-pole double-throw switch (K) is connected with one end of the power supply, one end of each copper wire and one end of the capacitor respectively; the two metal electrodes are placed in a transparent water tank; a high-speed camera and a light source are arranged on two sides of the water tank; the high-speed camera and the light source are in the same horizontal plane; and degassed water is filled in the water tank. The experimental device serves as a generation device of the bubbles in a mode of electric spark lighting, and the copper wires are melted by great energy which is released by electrode discharging so as to gasify surrounding fluids to form the bubbles. By the invention, real underwater explosion can be simulated simply relatively; the experimental method becomes powerful experiment means which replaces the real explosion; and an effective experimental way is provided for research of a bubble theory.

Owner:HARBIN ENG UNIV

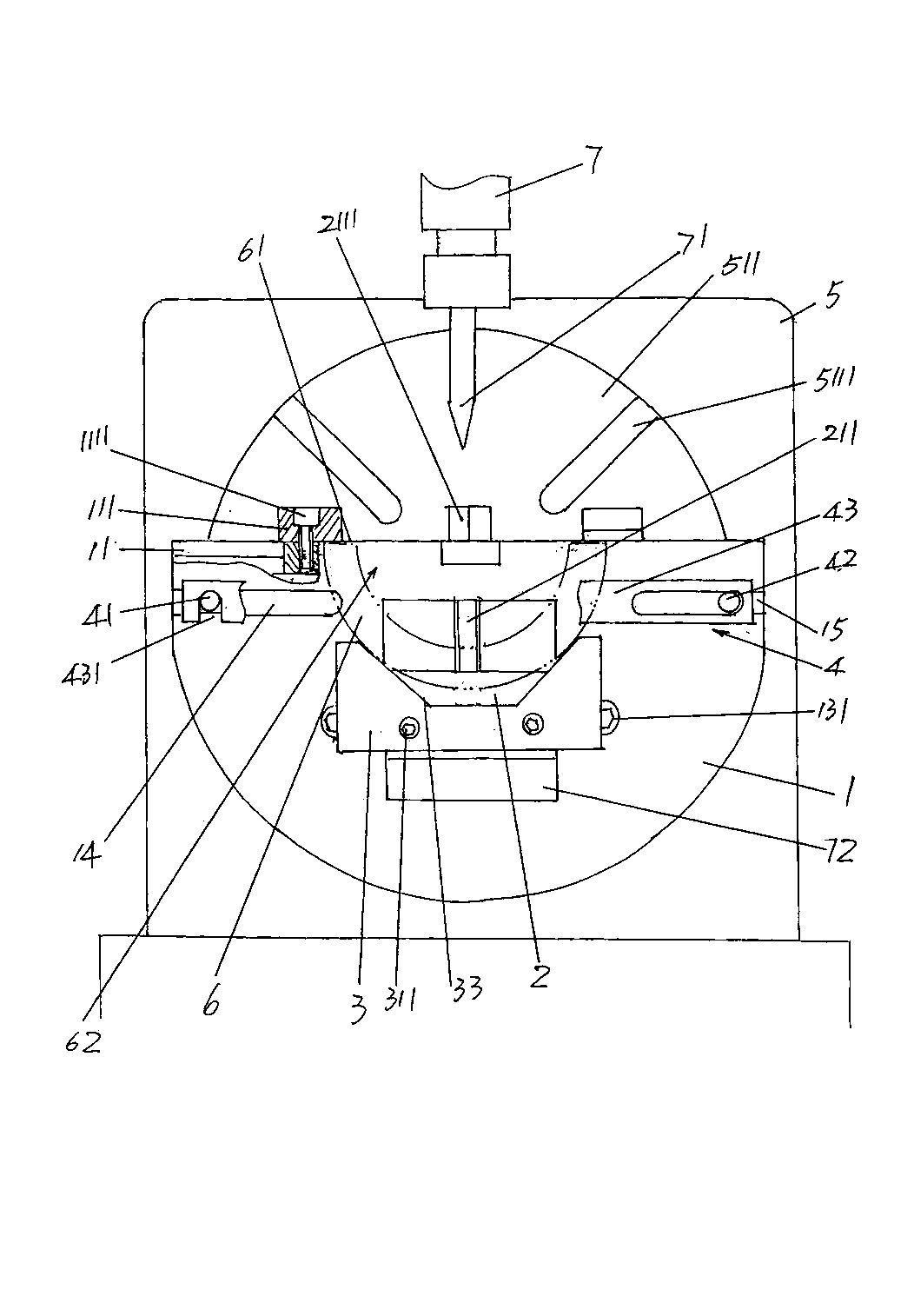

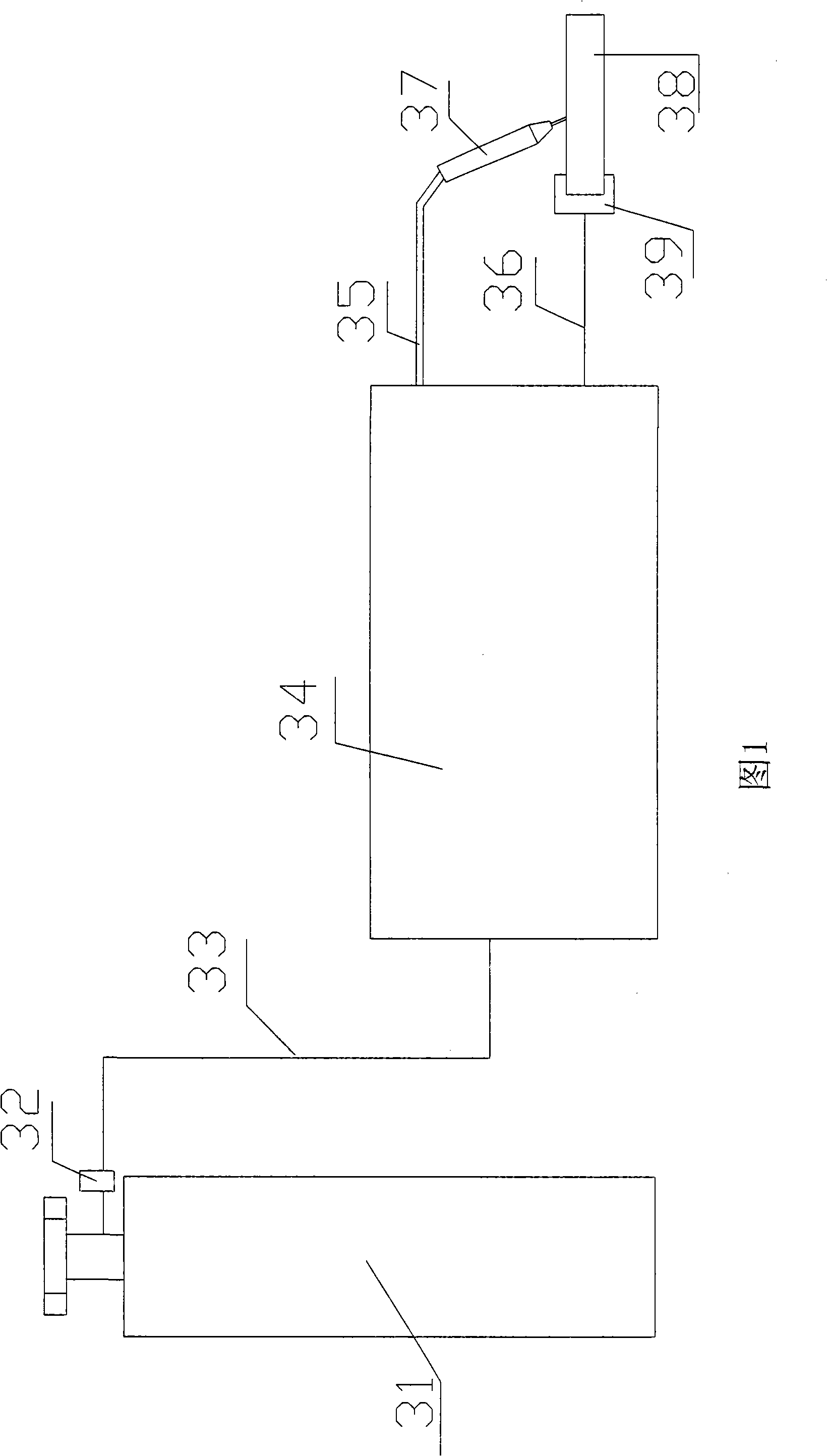

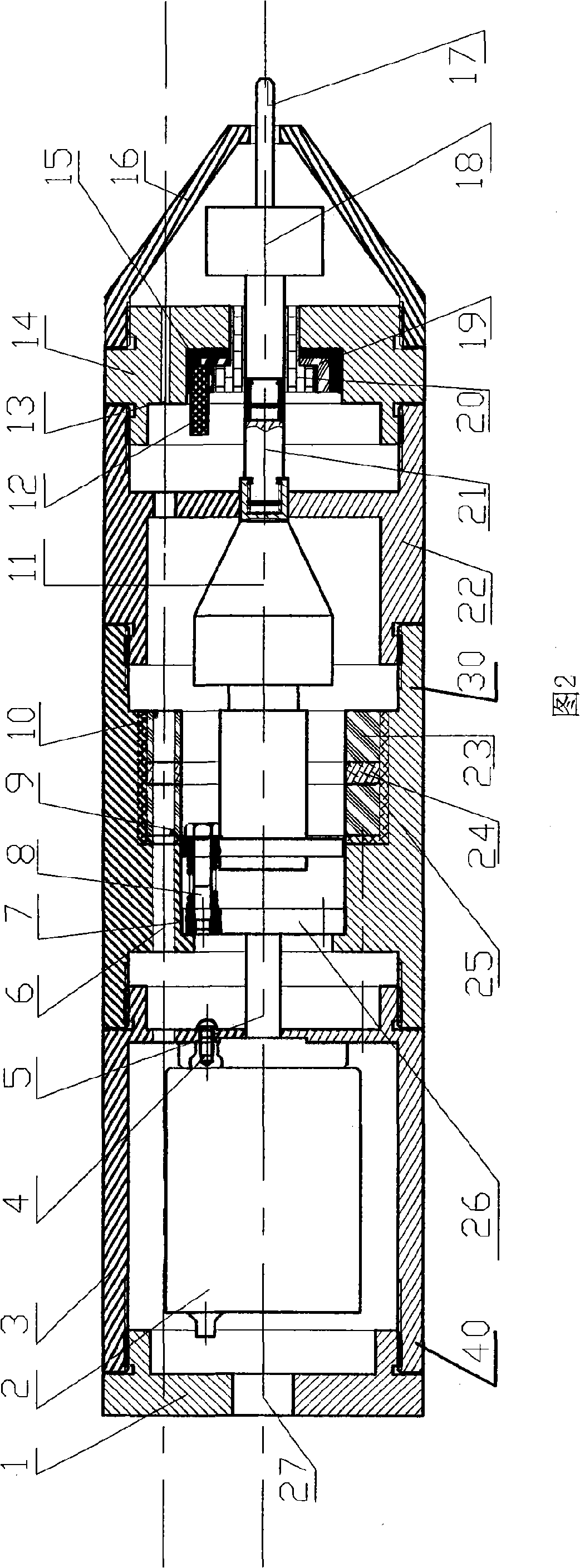

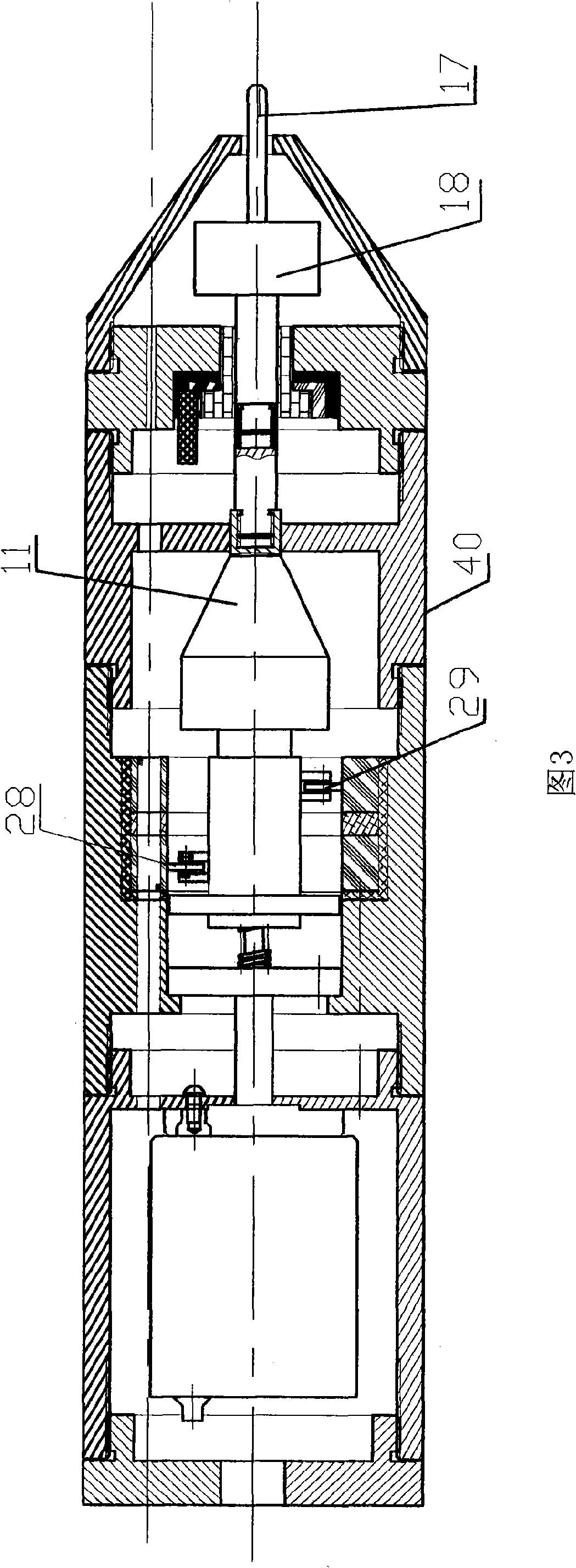

Integrated device of ultrasound auxiliary electric spark deposition and repair and ultrasound polish and method thereof

InactiveCN101284341AQuality improvementReduce repair costsArc welding apparatusUltrasonic vibrationEngineering

The invention relates to a device integrating ultrasound assisted electrospark deposition repair and ultrasonic polishing and a method thereof. The device comprises a gas feeding device, a power source and a control box (34), a connection (35), an electrode assembly (37) and a workpiece clamp head (39). By using the combination of the electrospark deposition technique and the ultrasonic mechanical vibration rubbing effect, the repair of the surface defect of a mould can be realized, and the surface of the mould can be mechanically polished by using the ultrasonic vibration energy after the repair is completed. In the invention, the electrospark deposition technique and the ultrasonic polishing technology are comprehensively utilized, so that the repair cost is low while repair precision is high. The combination processing can not only repair the invalid surface material of the mould with high efficiency, but also suit the occasions when major repair equipment is not available. The method for integrating ultrasound assisted electrospark deposition repair and ultrasonic polishing has the advantages of simple operation, convenience and practicality.

Owner:GUANGDONG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com