Electrolytic electric spark cutting composite micromachining device and method

A micro-machining and EDM technology, applied in the direction of manufacturing tools and other manufacturing equipment/tools, etc., can solve the problems of small machining depth-to-diameter ratio, overcutting phenomenon and thermal influence, low material removal rate, etc., and achieves high machining accuracy, The method is simple and practical, and the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

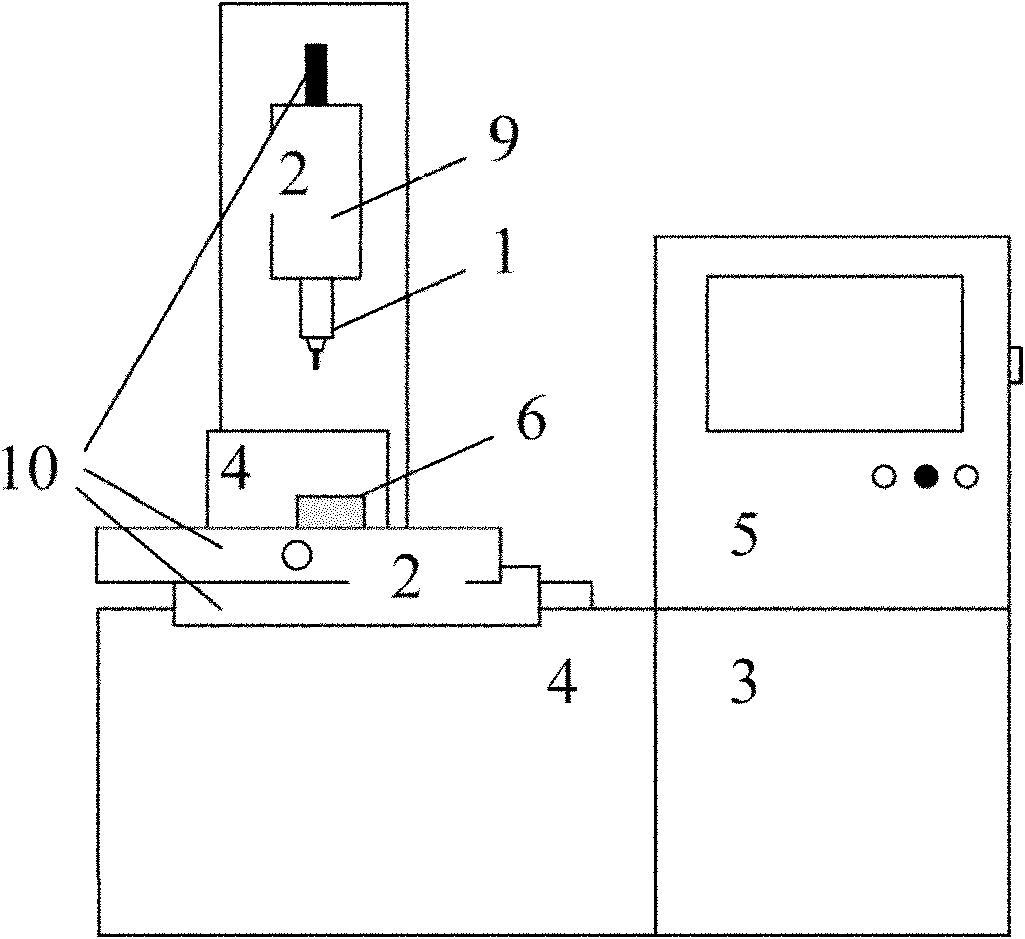

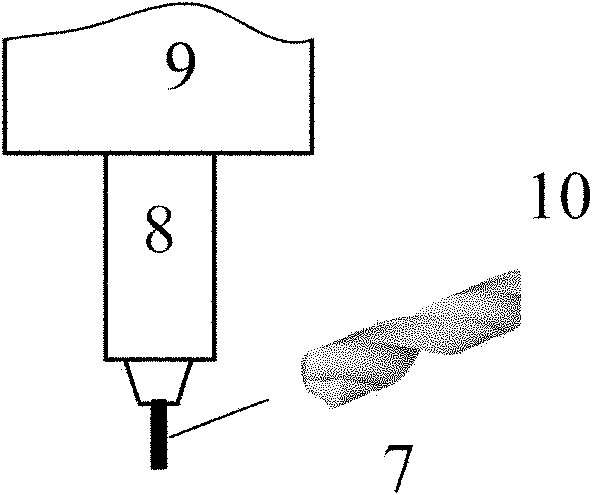

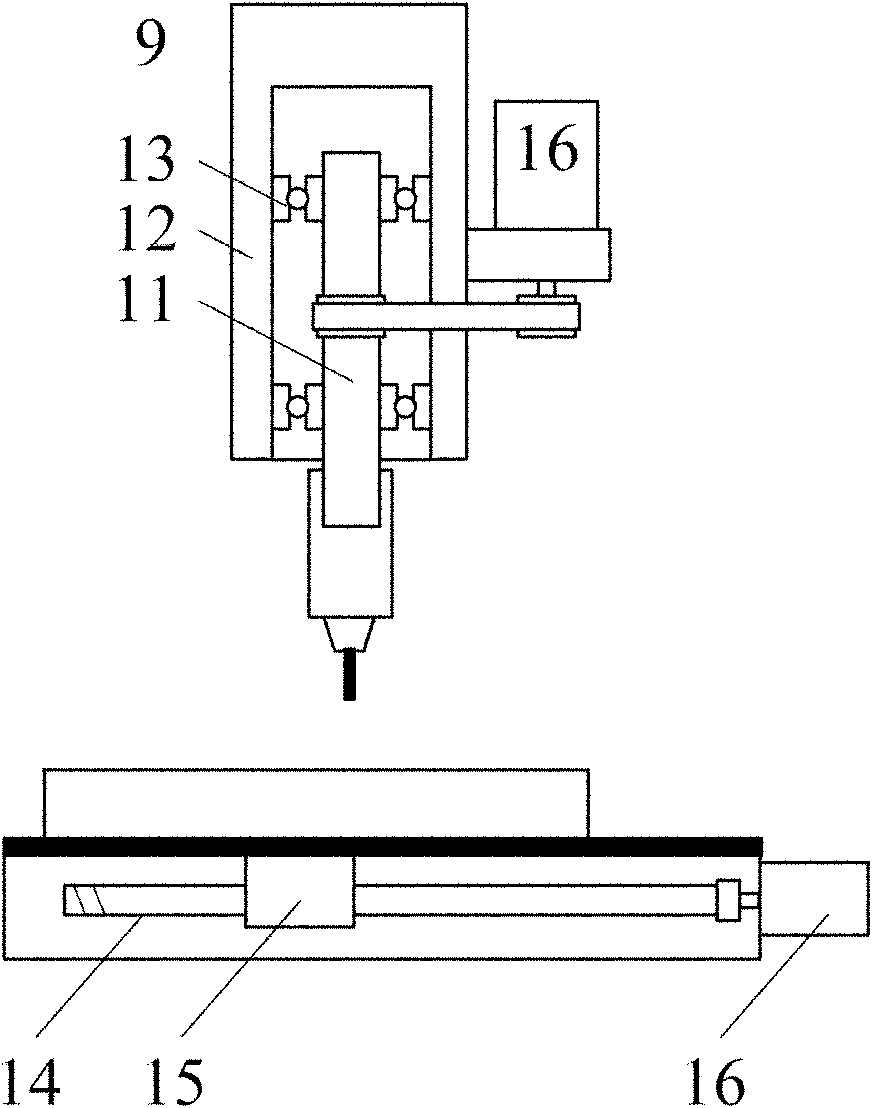

[0028] like figure 1 As shown, this embodiment includes: a tool system 1, a mechanical motion system 2, a power supply system 3, a working fluid system 4 and a control system 5, wherein: the tool system 1 is installed on the rotating spindle 9 of the mechanical motion system 2, and the mechanical motion system The three linear moving axes 10 of 2 drive the rotation of the tool and the relative movement between the tool and the workpiece 6 to be processed. The control system 5 is connected with the mechanical motion system 2 and outputs work instructions, and drives the mechanical motion system 2 to complete the mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com