Patents

Literature

10442results about How to "Improve surface quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flat float glass

InactiveUS6846760B2High degreeLess sensitiveGlass furnace apparatusGlass rolling apparatusArsenic oxideTransmittance

This invention relates to a flat float glass that can be prestressed or transformed into a glass ceramic with high quartz mixed crystals or keatite mixed crystals. To eliminate undesirable surface defects during floating and to achieve superior characteristics of the glass or of he glass ceramic, in particular with regard to a low coefficient of thermal expansion and high light transmittance, the glass has a concentration of less than 300 ppb Pt, less than 30 ppb Rh, less than 1.5 wt. % ZnO and less than 1 wt. % SnO2, and is refined during melting without the use of the conventional fining agents arsenic oxide and / or antimony oxide.

Owner:SCHOTT AG

Selective deposition of silicon-containing films

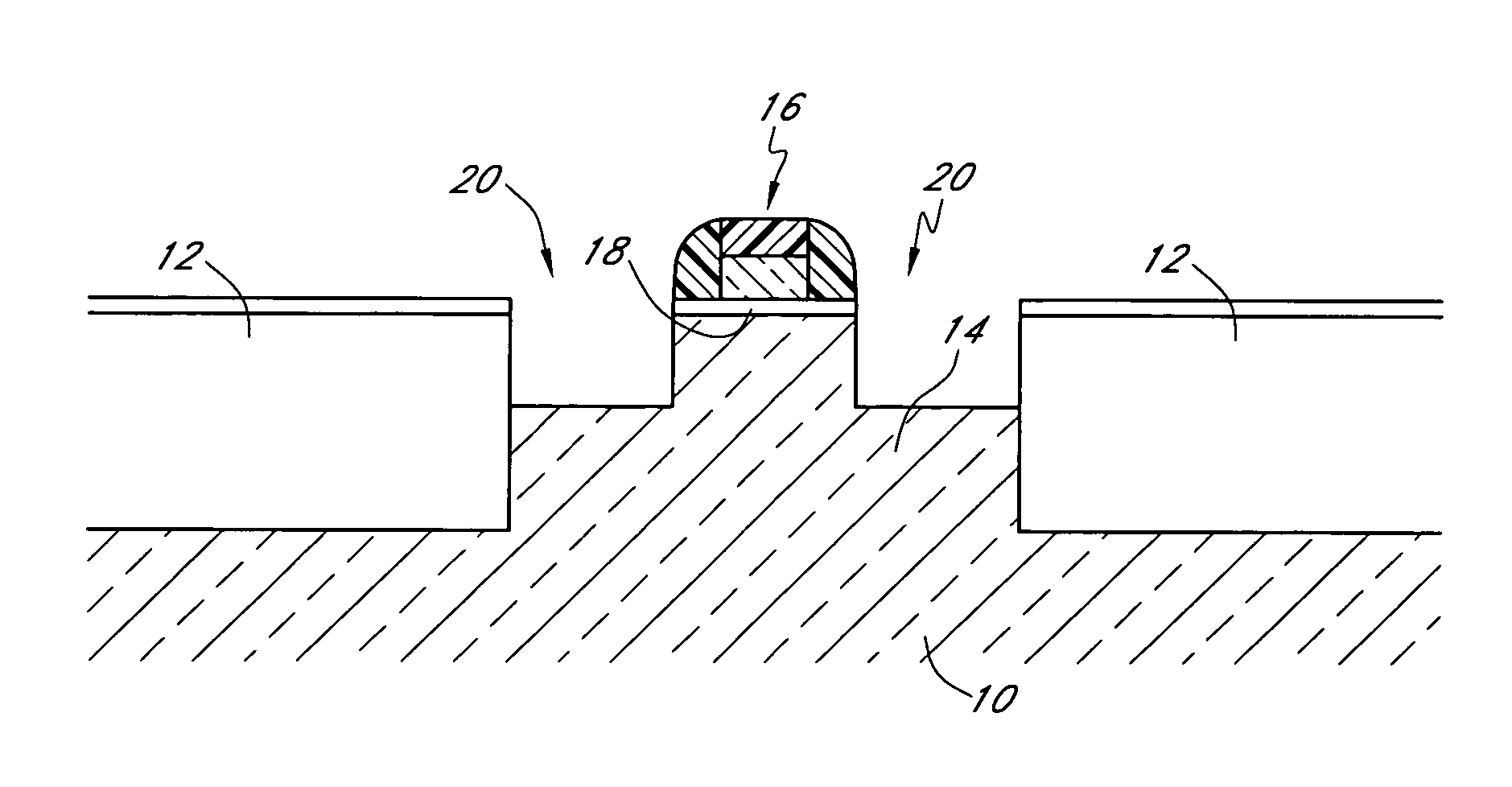

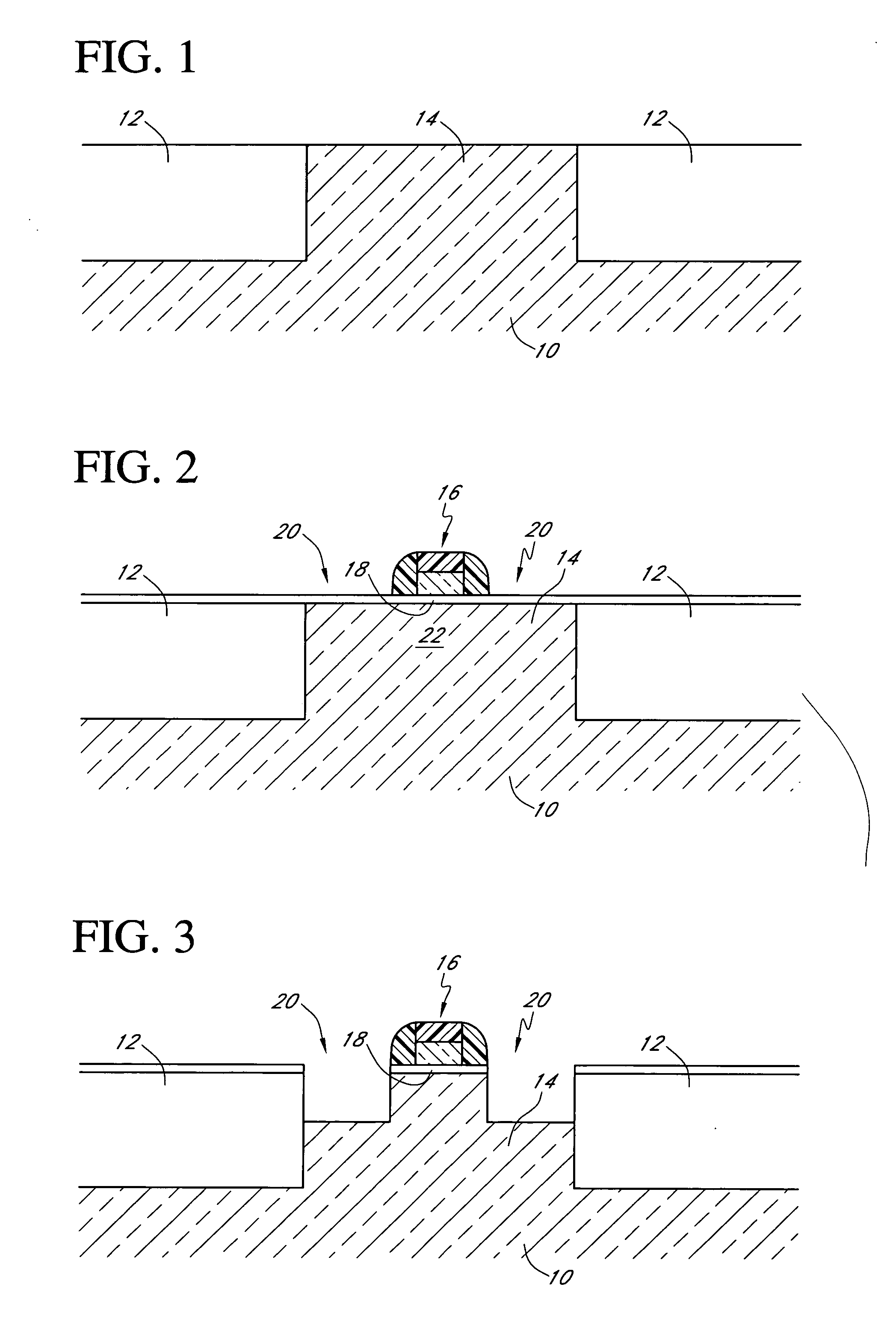

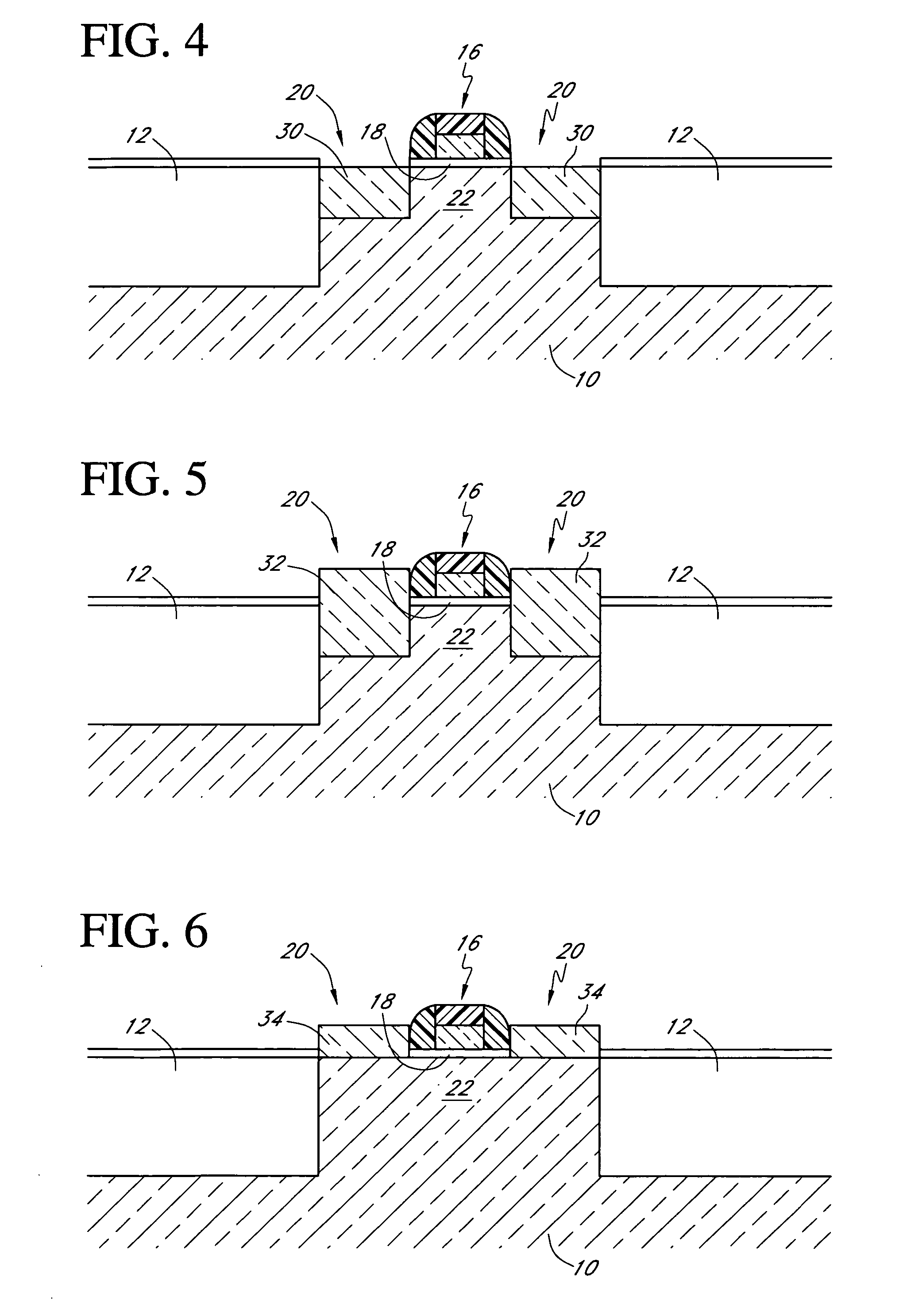

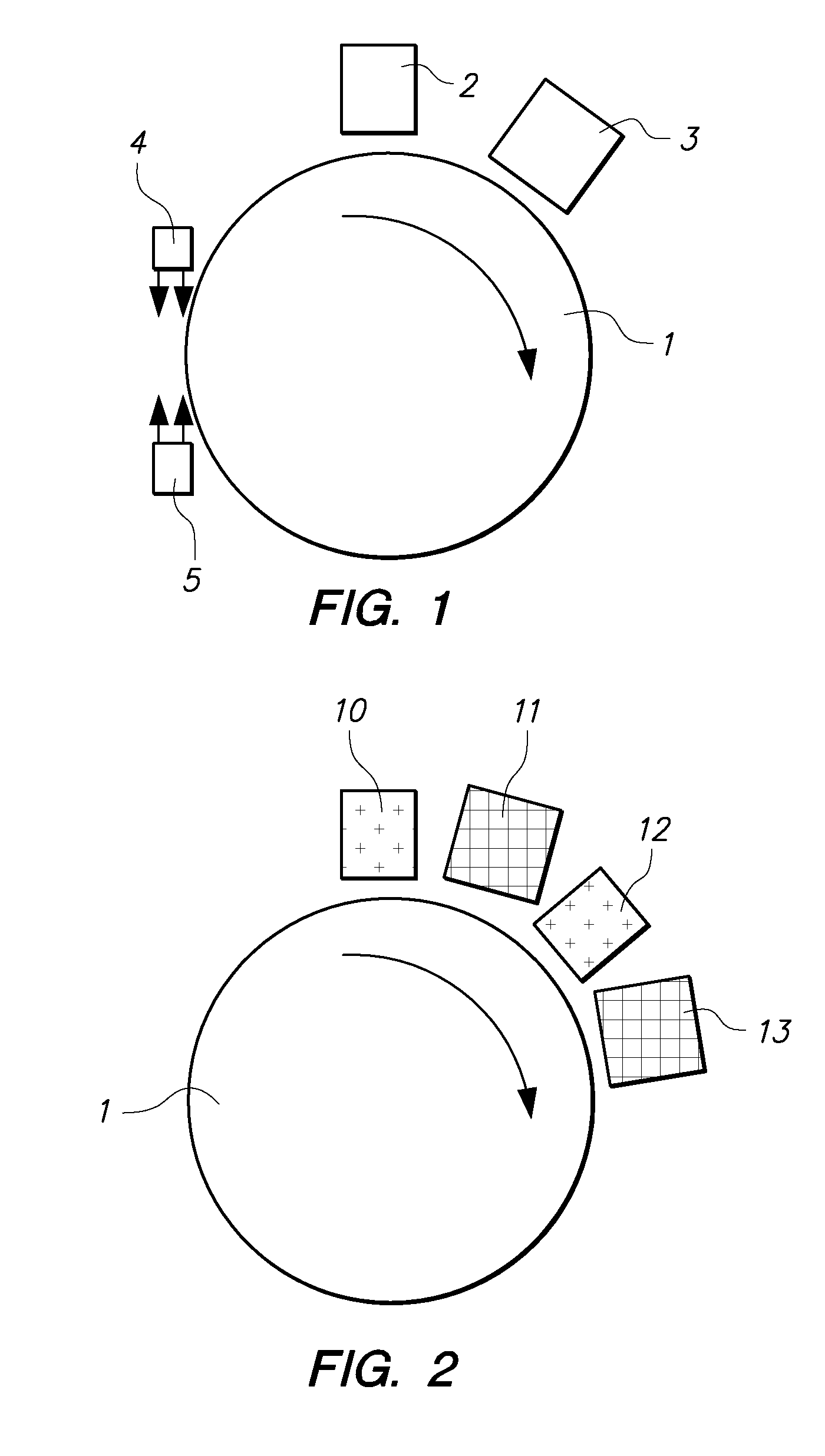

ActiveUS20060234504A1Quality improvementImprove surface qualityPolycrystalline material growthSemiconductor/solid-state device manufacturingHalogenGas phase

Chemical vapor deposition methods use trisilane and a halogen-containing etchant source (such as chlorine) to selectively deposit Si-containing films over selected regions of mixed substrates. Dopant sources may be intermixed with the trisilane and the etchant source to selectively deposit doped Si-containing films. The selective deposition methods are useful in a variety of applications, such as semiconductor manufacturing.

Owner:ASM IP HLDG BV

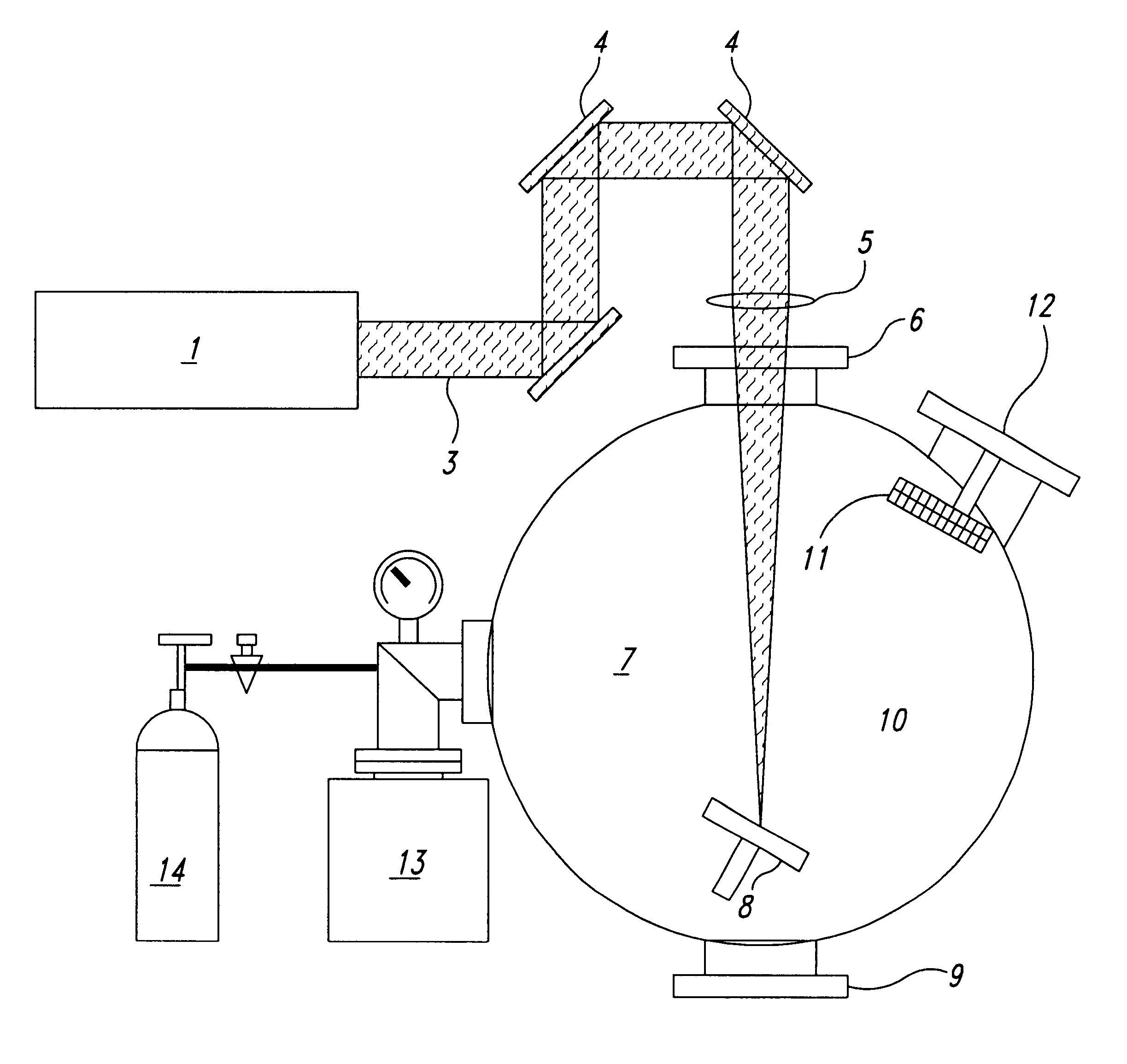

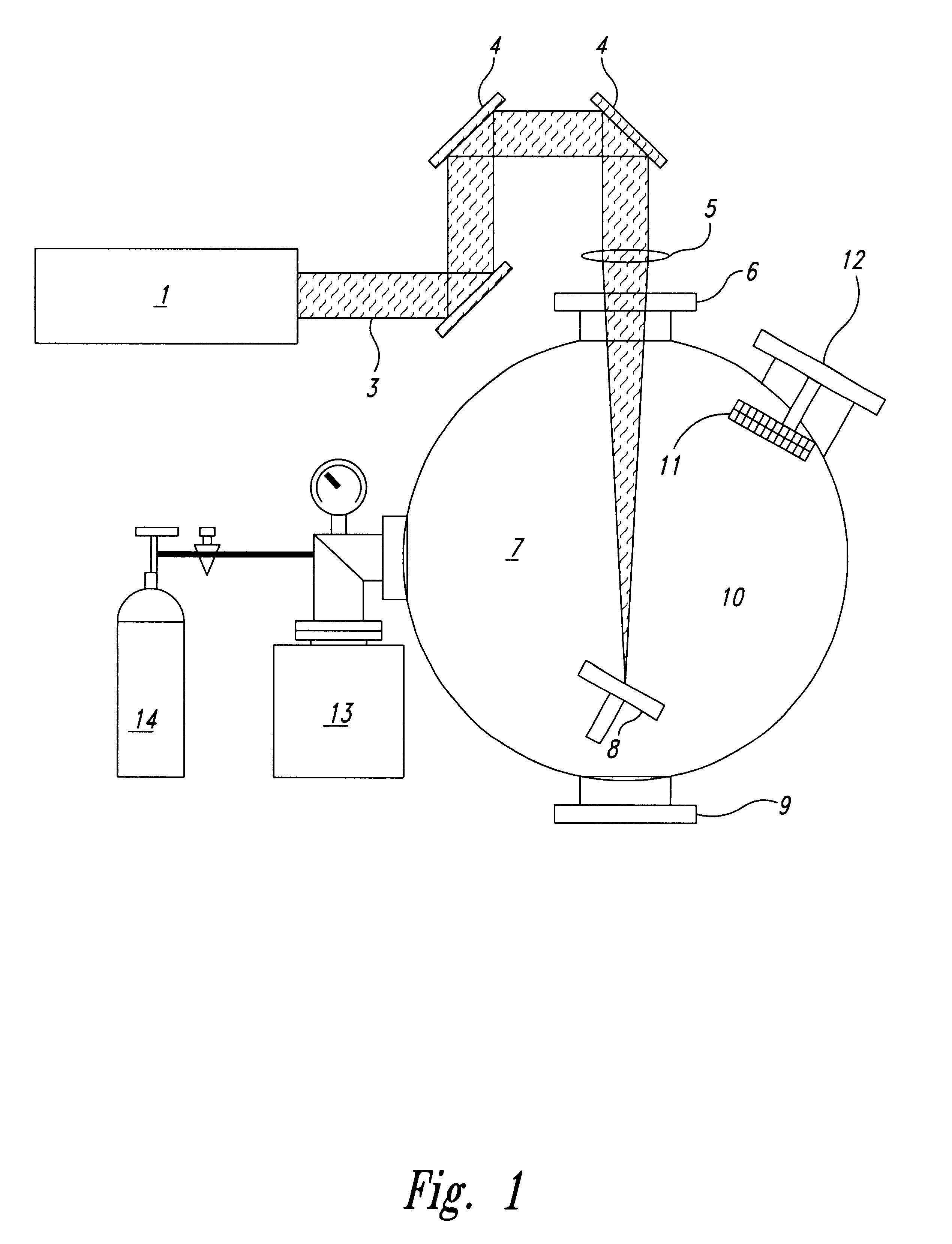

Method of deposition of thin films of amorphous and crystalline microstructures based on ultrafast pulsed laser deposition

InactiveUS6312768B1Improve surface qualityImprove efficiencyMaterial nanotechnologyElectric discharge heatingMacroscopic scaleCarbon nanotube

Powerful nanosecond-range lasers using low repetition rate pulsed laser deposition produce numerous macroscopic size particles and droplets, which embed in thin film coatings. This problem has been addressed by lowering the pulse energy, keeping the laser intensity optional for evaporation, so that significant numbers of the macroscopic particles and droplets are no longer present in the evaporated plume. The result is deposition of evaporated plume on a substrate to form thin film of very high surface quality. Preferably, the laser pulses have a repetition rate to produce a continuous flow of evaporated material at the substrate. Pulse-range is typically picosecond and femtosecond and repetition rate kilohertz to hundreds of megahertz. The process may be carried out in the presence of a buffer gas, which may be inert or reactive, and the increased vapour density and therefore the collision frequency between evaporated atoms leads to the formation of nanostructured materials of increasing interest, because of their peculiar structural, electronic and mechanical properties. One of these is carbon nanotubes, which is a new form of carbon belonging to the fullerene (C60) family. Carbon nanotubes are seamless, single or multishell co-axial cylindrical tubules with or without dome caps at the extremities. Typically diameters range from 1 nm to 50 nm with a length >1 mum. The electronic structure may be either metallic or semiconducting without any change in the chemical bonding or adding of dopant. In addition, the materials have application to a wide range of established thin film applications.

Owner:AUSTRALIEN NAT UNIV

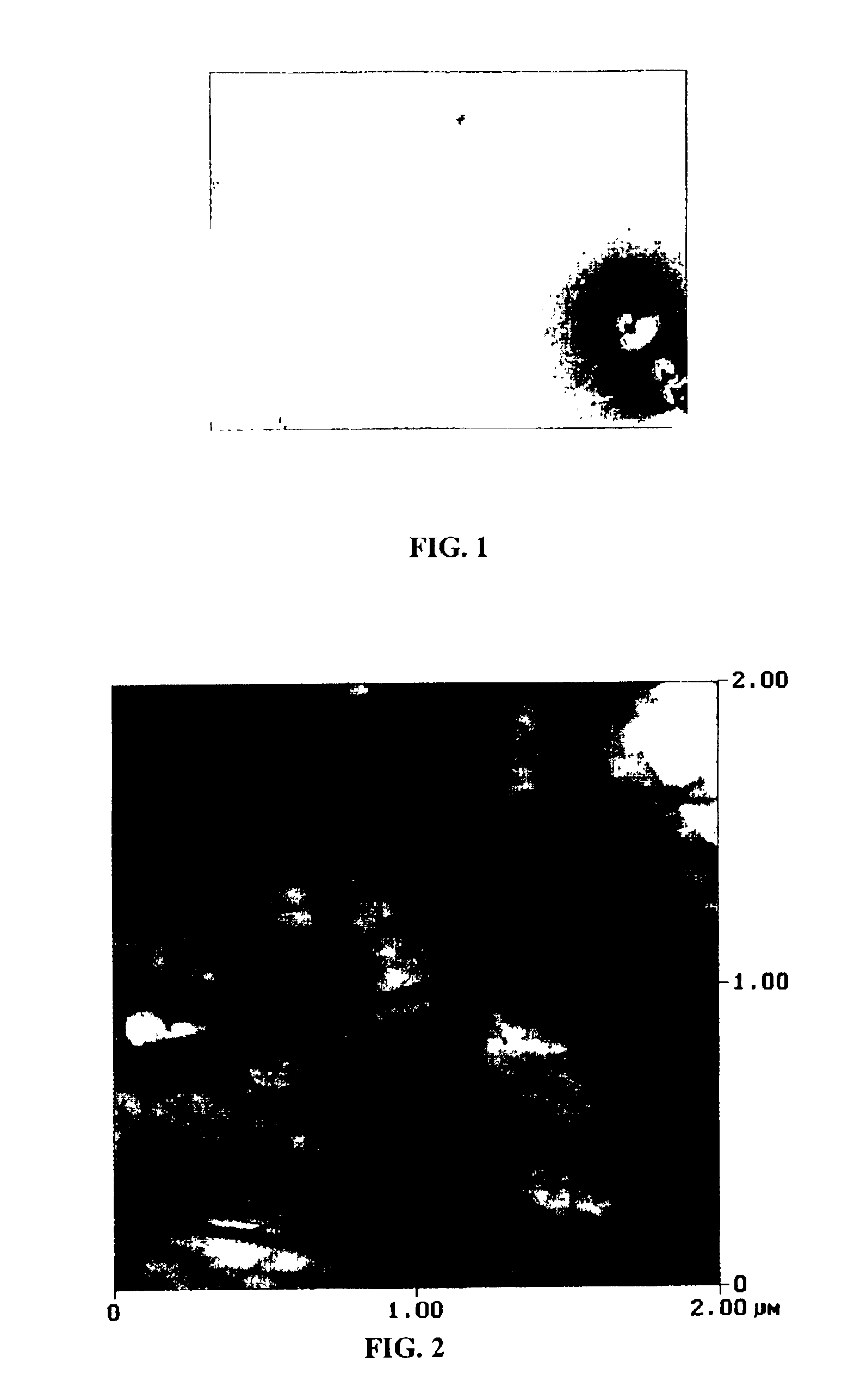

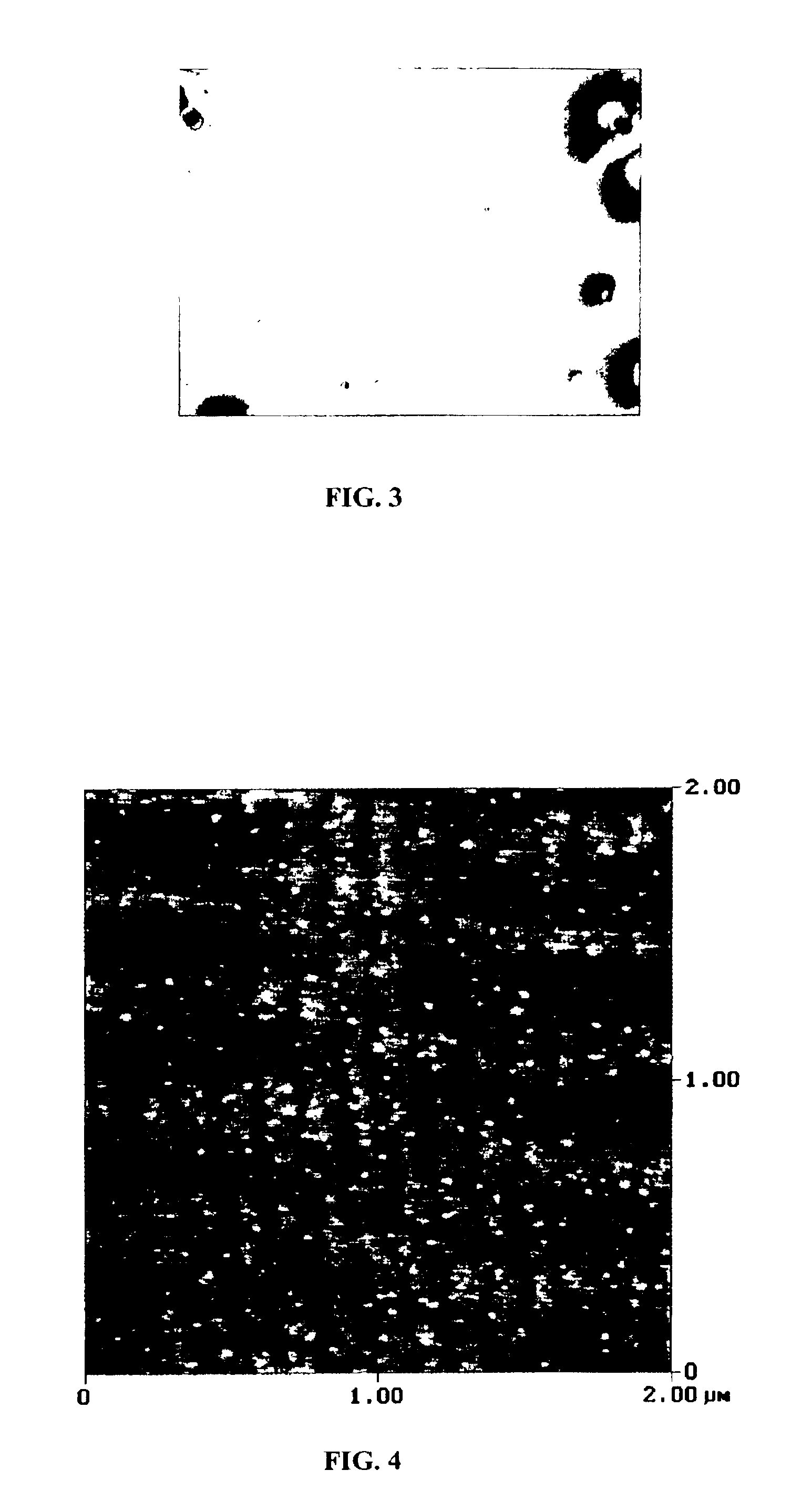

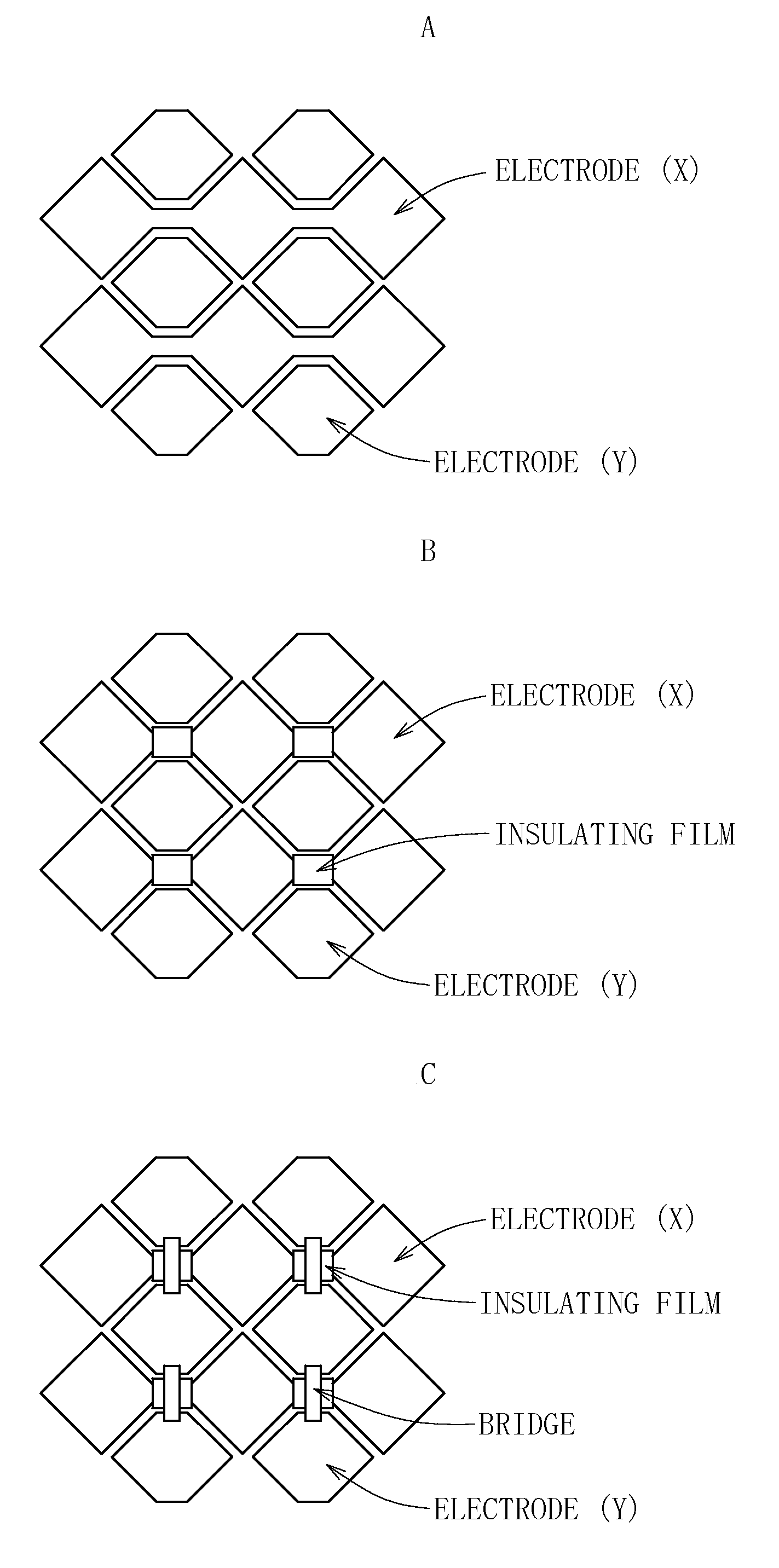

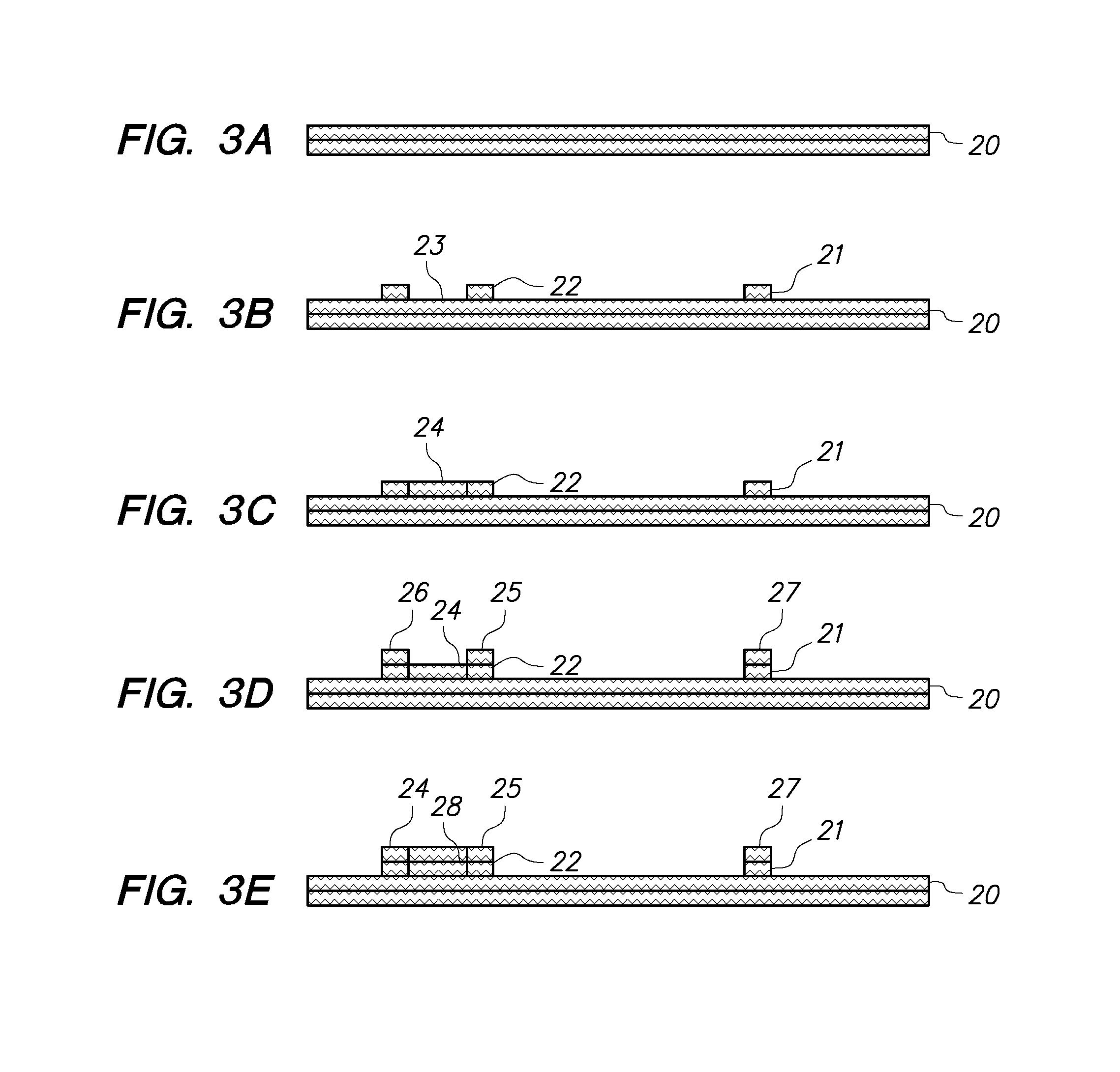

High surface quality GaN wafer and method of fabricating same

InactiveUS6951695B2Improve surface qualityPolycrystalline material growthAfter-treatment detailsSurface roughnessHigh surface

AlxGayInzN, wherein 0≦x≦1, 0≦y≦1, 0≦z≦1, and x+y+z=1, characterized by a root mean square surface roughness of less than 1 nm in a 10×10 μm2 area. The AlxGayInzN may be in the form of a wafer, which is chemically mechanically polished (CMP) using a CMP slurry comprising abrasive particles, such as silica or alumina, and an acid or a base. High quality AlxGayInzN wafers can be fabricated by steps including lapping, mechanical polishing, and reducing internal stress of said wafer by thermal annealing or chemical etching for further enhancement of its surface quality. CMP processing may be usefully employed to highlight crystal defects of an AlxGayInzN wafer.

Owner:WOLFSPEED INC

Flat float glass

InactiveUS20020023463A1High degreeLess sensitiveGlass furnace apparatusGlass rolling apparatusArsenic oxideThermal expansion

This invention relates to a flat float glass that can be prestressed or transformed into a glass ceramic with high quartz mixed crystals or keatite mixed crystals. To eliminate undesirable surface defects during floating and to achieve superior characteristics of the glass or of he glass ceramic, in particular with regard to a low coefficient of thermal expansion and high light transmittance, the glass has a concentration of less than 300 ppb Pt, less than 30 ppb Rh, less than 1.5 wt. % ZnO and less than 1 wt. % SnO2, and is refined during melting without the use of the conventional fining agents arsenic oxide and / or antimony oxide.

Owner:SCHOTT AG

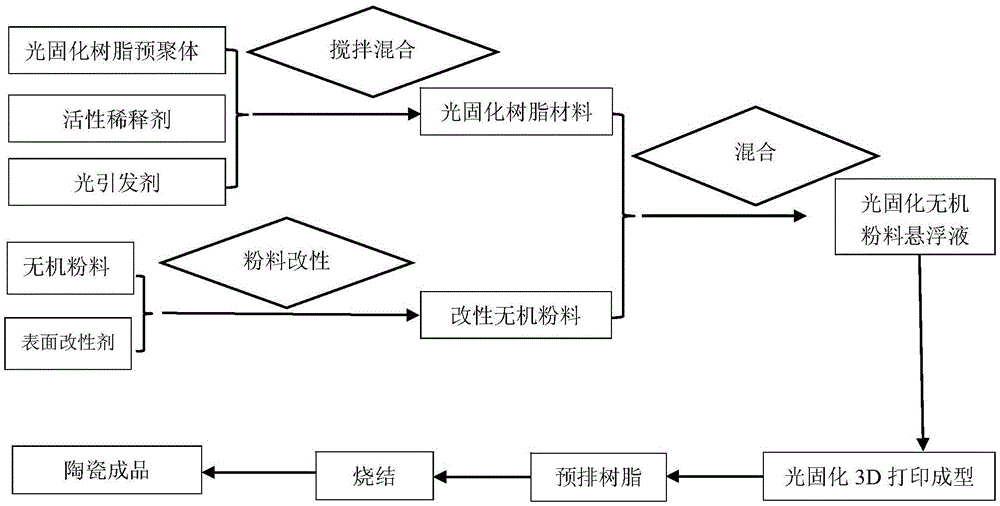

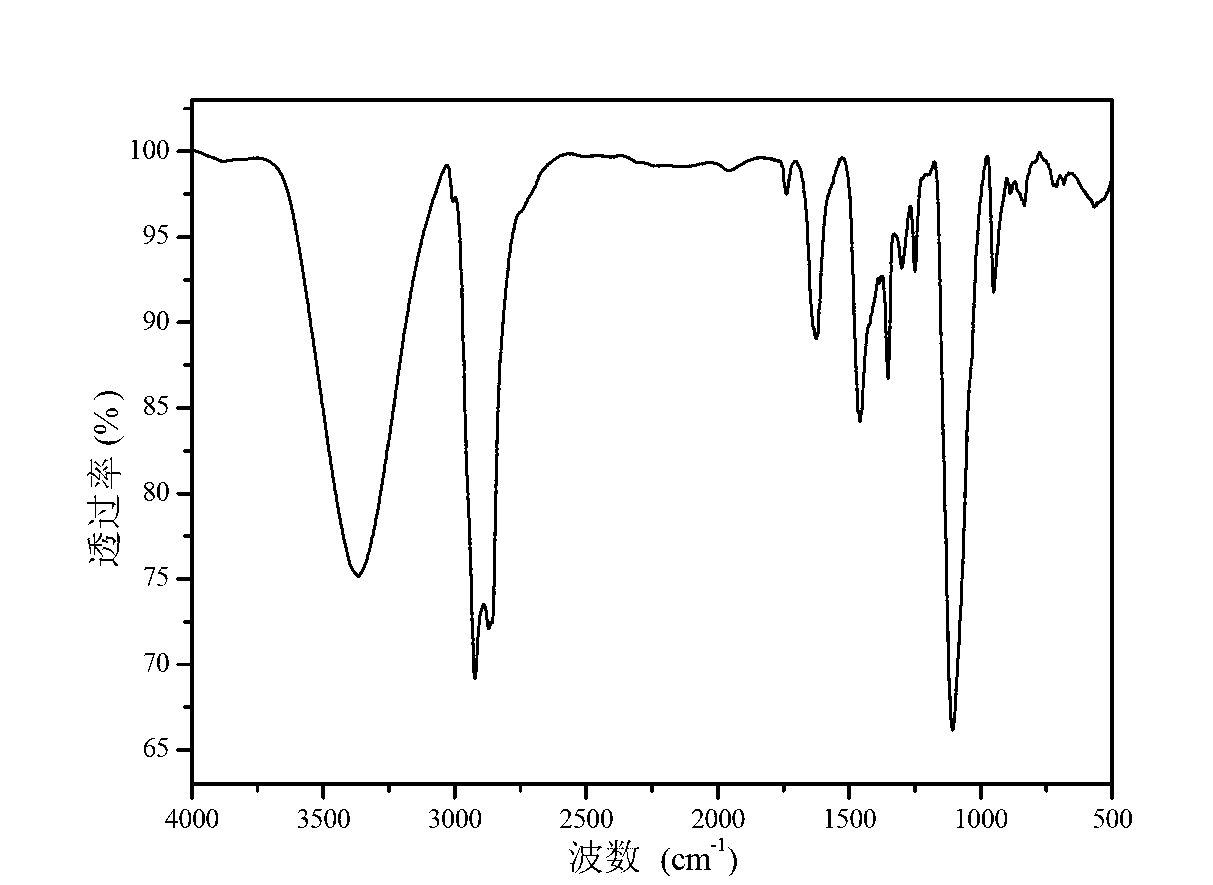

Ceramic material for 3D (three-dimensional) light curing forming printing and preparation method thereof

The invention provides a ceramic material for 3D (three-dimensional) light curing forming printing. The ceramic material is prepared from the following ingredients in percentage by weight: 25 to 85 weight percent of light curing resin and 15 to 75 weight percent of modified inorganic powder. The invention also further provides a preparation method and a use method of the ceramic material for 3D light curing forming printing. The ceramic material for 3D light curing forming printing provided by the invention is applicable to the preparation of a ceramic product by 3D light curing forming technologies such as the light curing laser fast forming and digital-based light processing projection curing forming. The defect of the current condition that the light curing forming technology in the prior art is not used for producing the ceramic product is overcome; the dimension precision of the obtained ceramic product is high; the 3D printing forming of various ceramic elements in complicated shapes can be realized; the ceramic material can be applied to aviation and aerospace industry, the medical field and the industrial field.

Owner:SHANGHAI UNION TECH

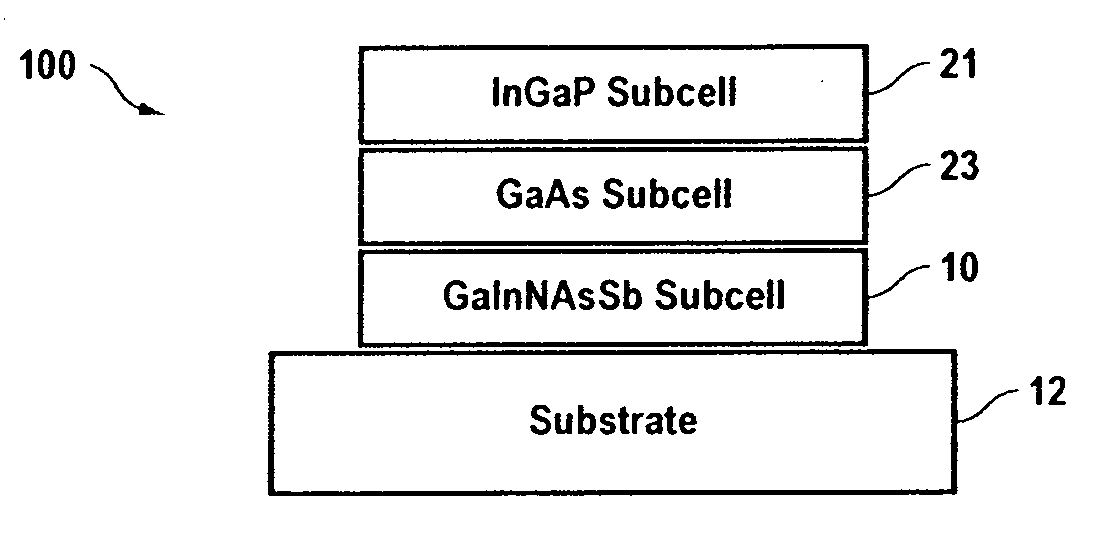

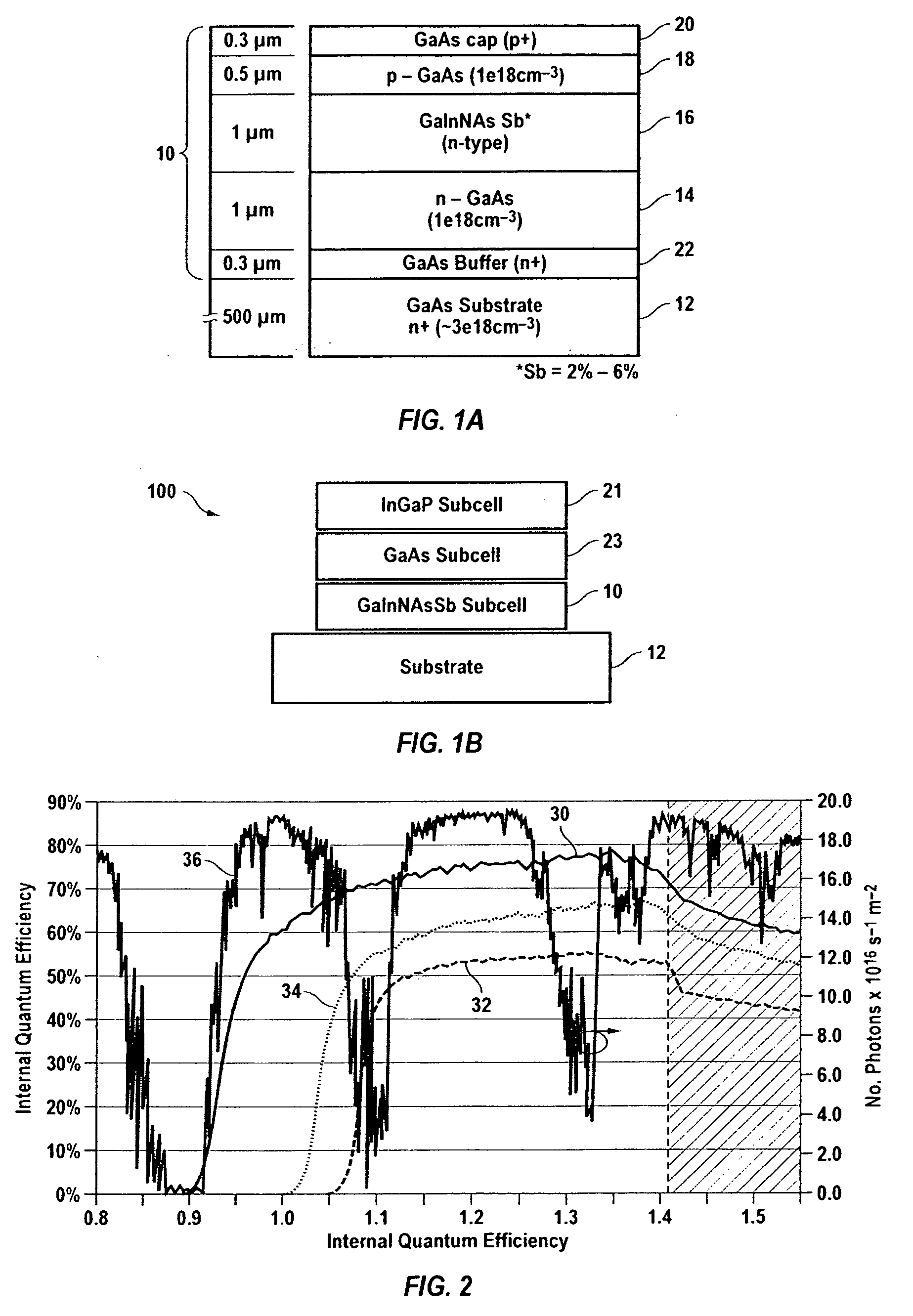

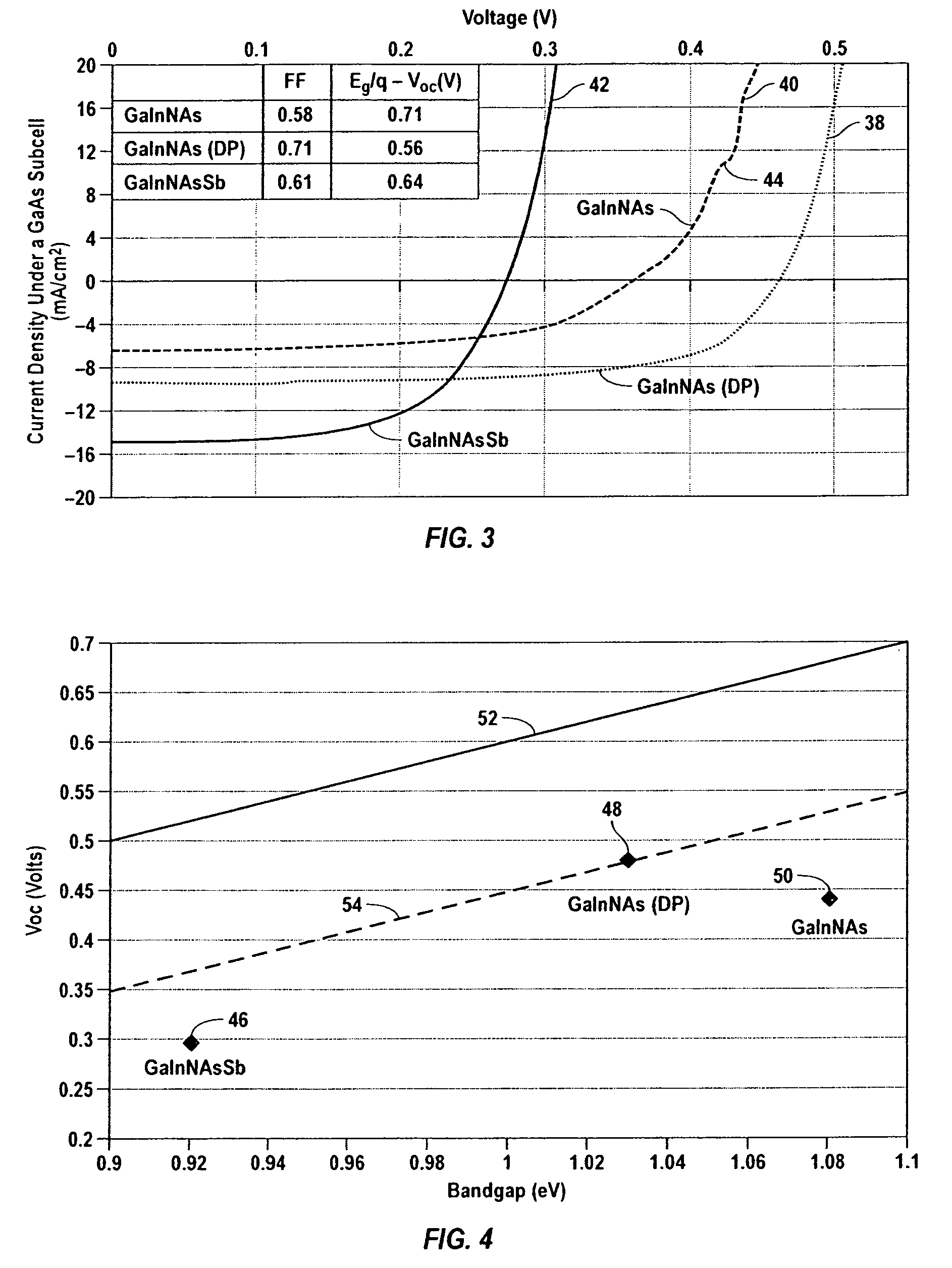

GaInNAsSb solar cells grown by molecular beam epitaxy

InactiveUS20090014061A1Improve featuresPromote efficient solar energy conversionFinal product manufacturePhotovoltaic energy generationIndiumSemiconductor alloys

A high efficiency triple-junction solar cell and method of manufacture therefor is provided wherein junctions are formed between different types of III-V semiconductor alloy materials, one alloy of which contains a combination of an effective amount of antimony (Sb) with gallium (Ga), indium (In), nitrogen (N, the nitride component) and arsenic (As) to form the dilute nitride semiconductor layer GaInNAsSb which has particularly favorable characteristics in a solar cell. In particular, the bandgap and lattice matching promote efficient solar energy conversion.

Owner:CACTUS MATERIALS INC +1

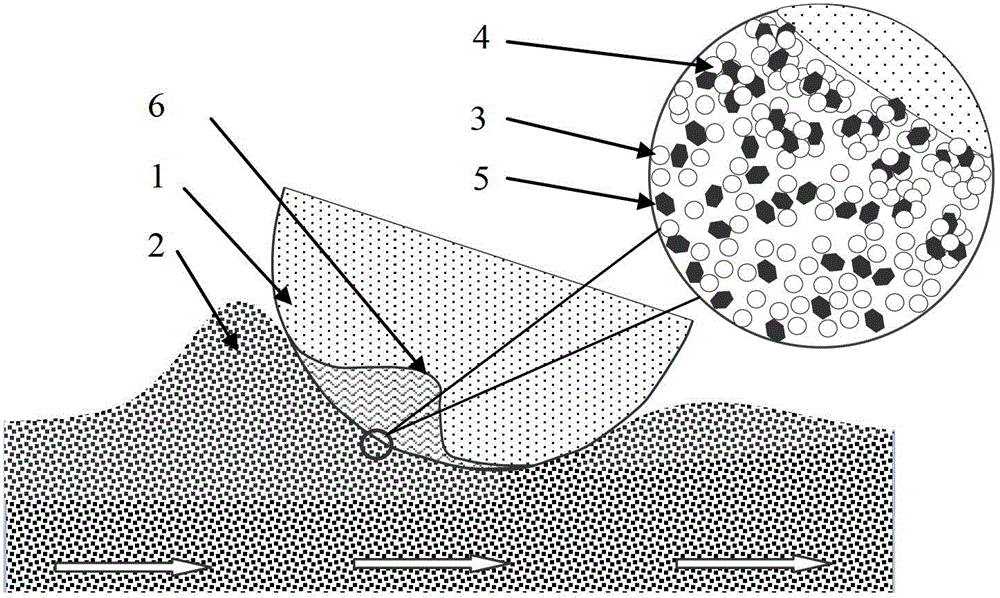

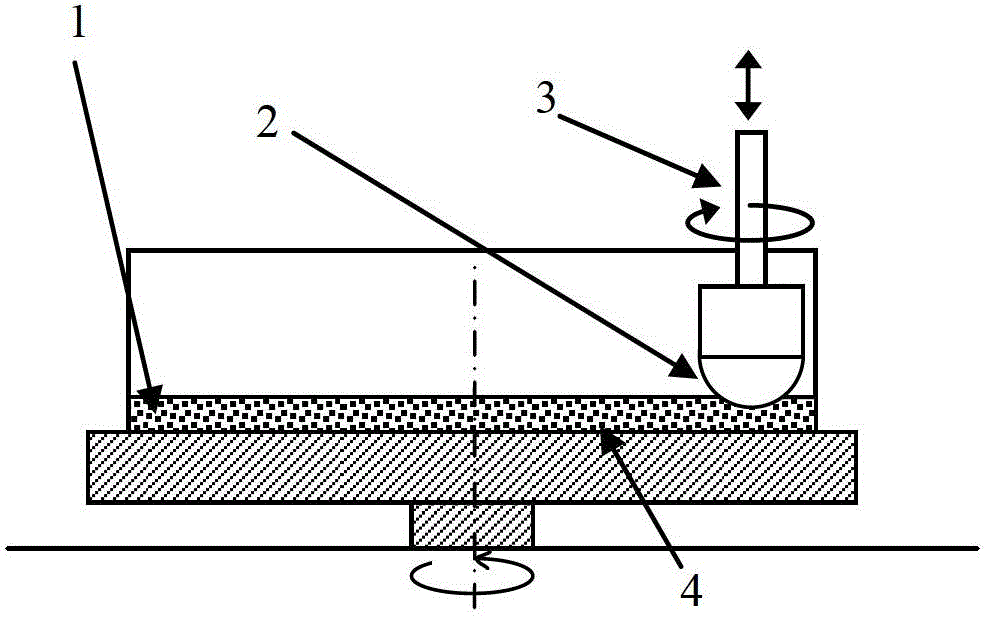

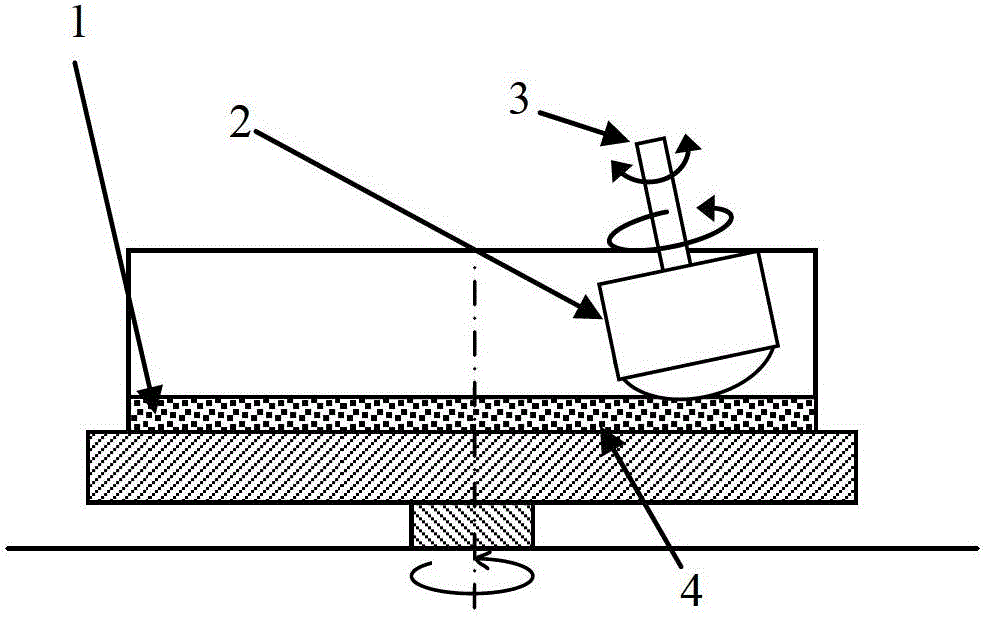

Ultra-precise curved surface finishing method based on non-Newtonian fluid shear thickening effect

ActiveCN102717325AImprove gripAvoid damagePolishing machinesOther chemical processesSocial benefitsSurface finish

The invention discloses an ultra-precise curved surface finishing method based on non-Newtonian fluid shear thickening effect. The method includes: adding abrasive particles or micropowder into non-Newtonian fluid with shear thickening effect to prepare non-Newtonian fluid polishing solution, wherein the non-Newtonian fluid accounts for 50%-90% of the mass of the polishing solution, the abrasive particles or the micropowder account for 10%-50% of the mass of the polishing solution, and the particle size of the abrasive particles or the micropowder ranges from 0.05 micrometer to 50 micrometers. Relative motion is generated between a workpiece and the polishing solution during polishing, shear thickening is generated at a contact portion of the polishing solution and the workpiece under shearing action, viscosity of the polishing solution in the contact area is increased to enhance holding force to the abrasive particles or the micropowder, and removal of workpiece surface materials is achieved under the micro cutting or chemical mechanical action of the adding abrasive particles or micropowder with polishing effect in the polishing solution on the workpiece, so that polishing of the workpiece surface is achieved. The ultra-precise curved surface finishing method based on the non-Newtonian fluid shear thickening effect can achieve efficient and high-quality polishing to various curved surfaces, in particular to complex curved surfaces and has great economic and social benefits.

Owner:ZHEJIANG UNIV OF TECH

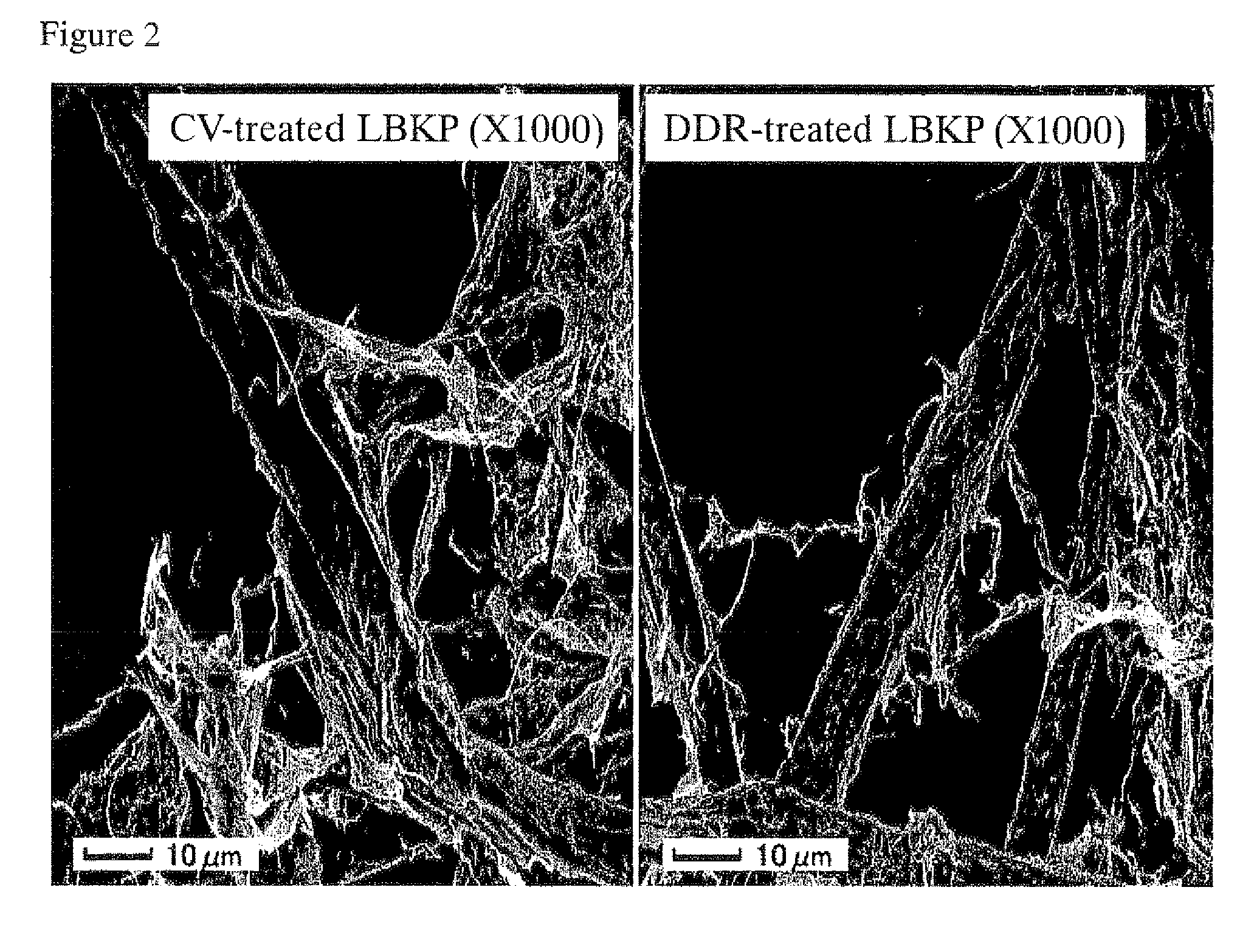

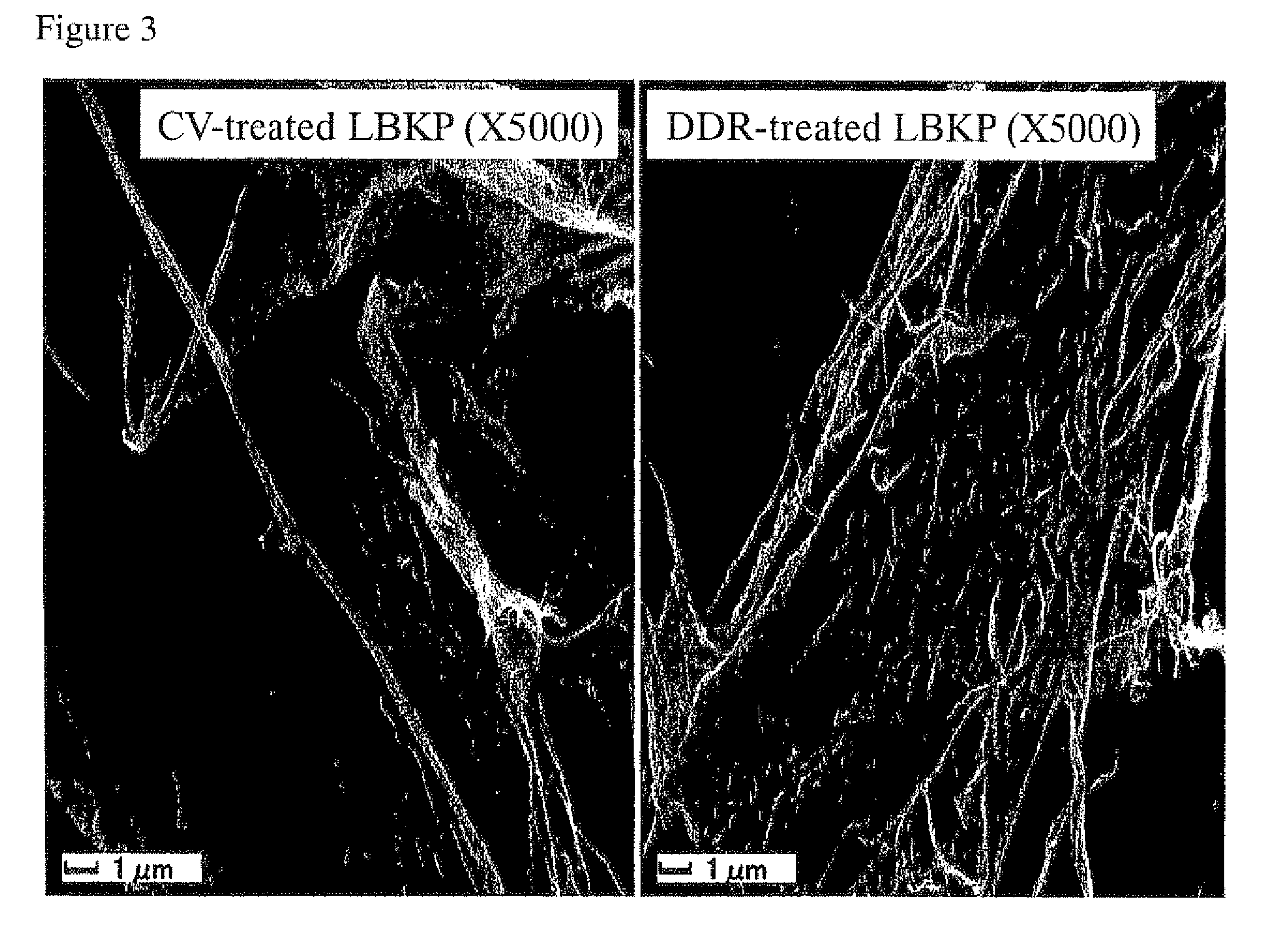

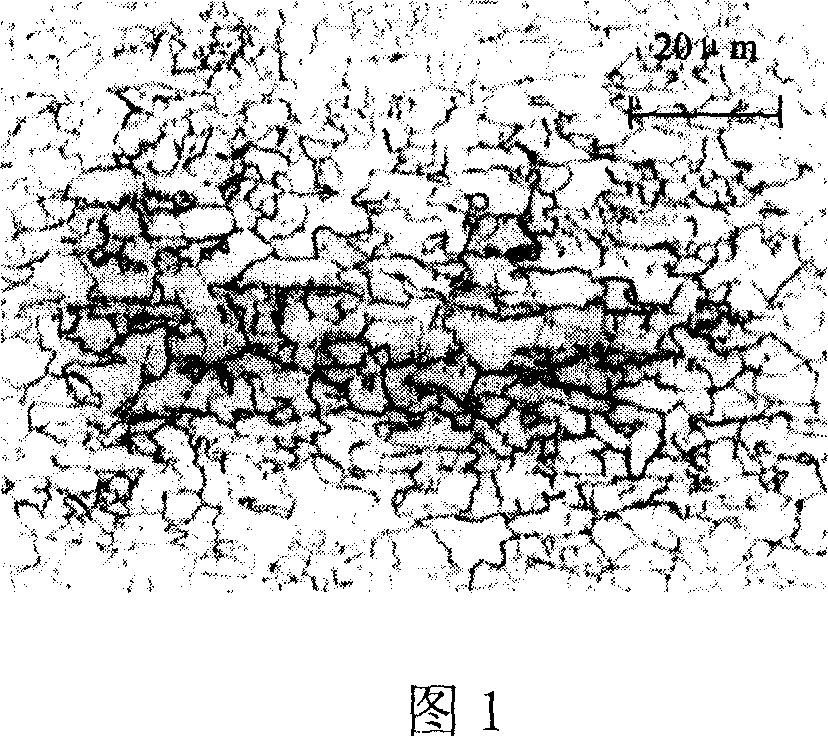

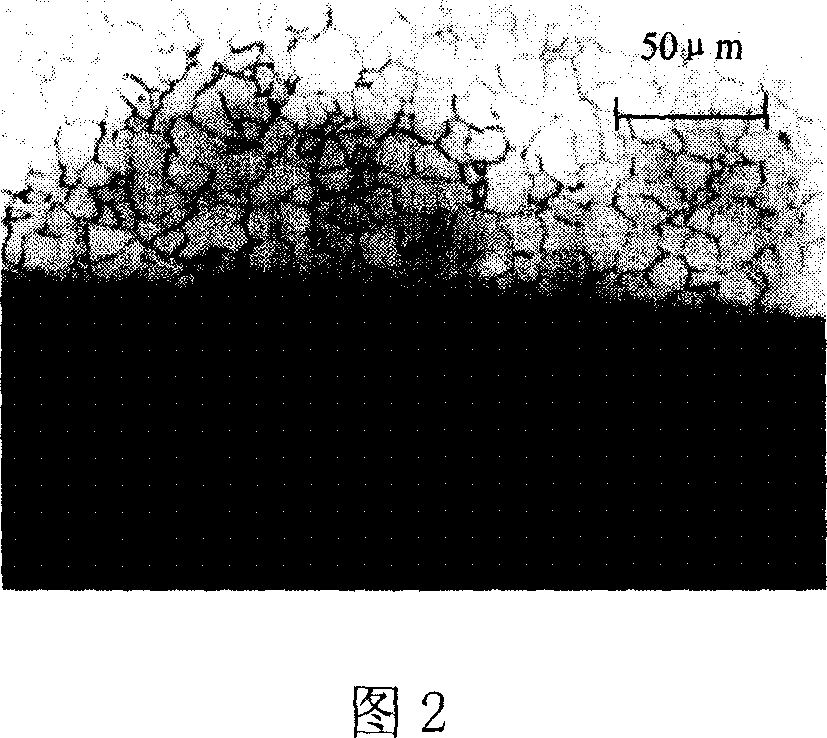

Cellulose-based fibrous materials

InactiveUS8012312B2Low densityImprove surface qualityCellulosic pulp after-treatmentCalendersFiberPolymer science

The present invention aims to provide cellulose-based fibrous materials for obtaining papers and sheets having low density, high surface quality, good size stability despite of high strength, and high opacity. Cellulose-based fibrous materials having external fibrils consisting of an assembly of scale-like microfibrils exhibit a higher fiber stiffness, a lower water retention value and a higher specific surface area as compared with fibrous materials having filamentous external fibrils at the same freeness. Papers and sheets having low density, high surface quality, good size stability and high opacity can be obtained by using such fibrous materials.

Owner:NIPPON PAPER IND CO LTD

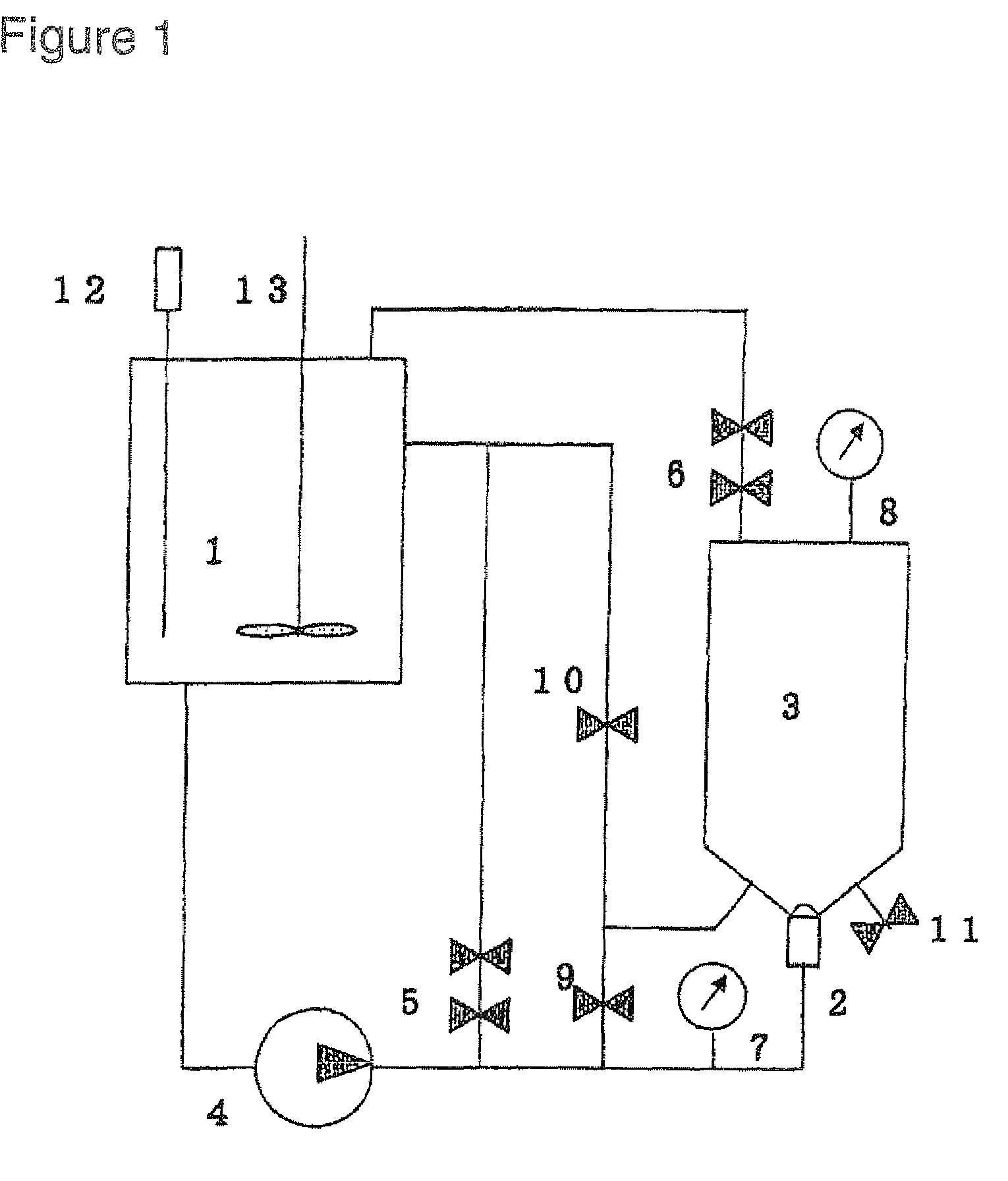

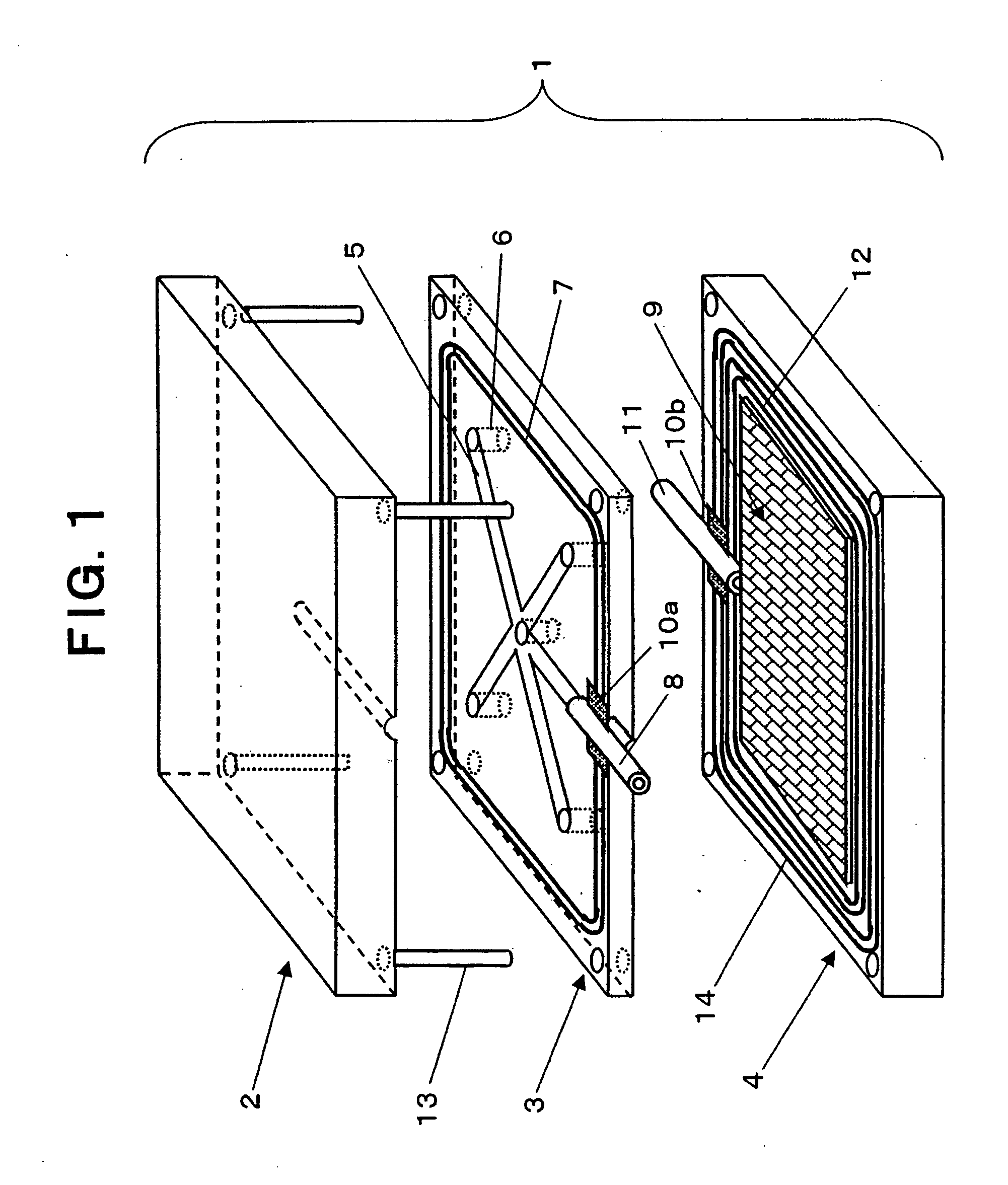

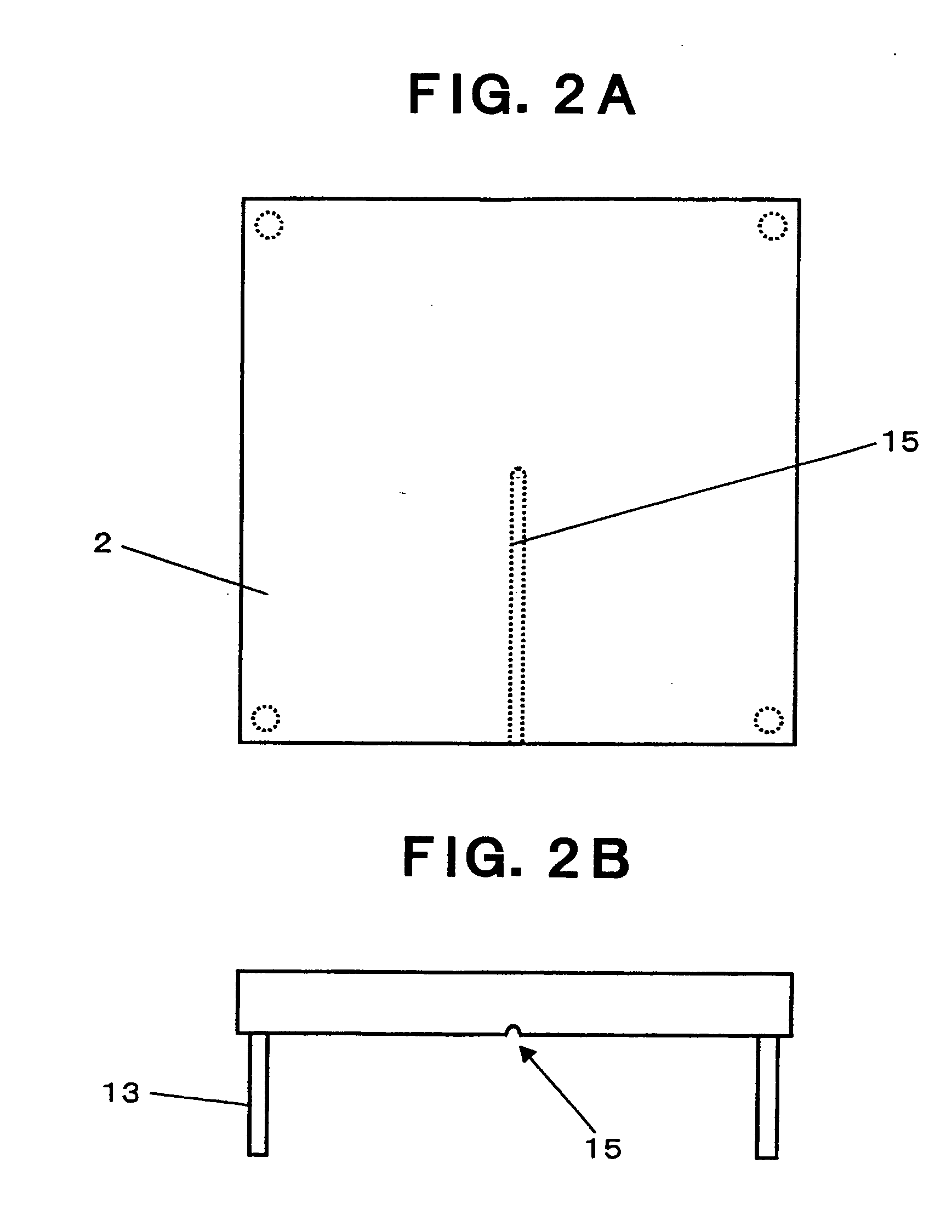

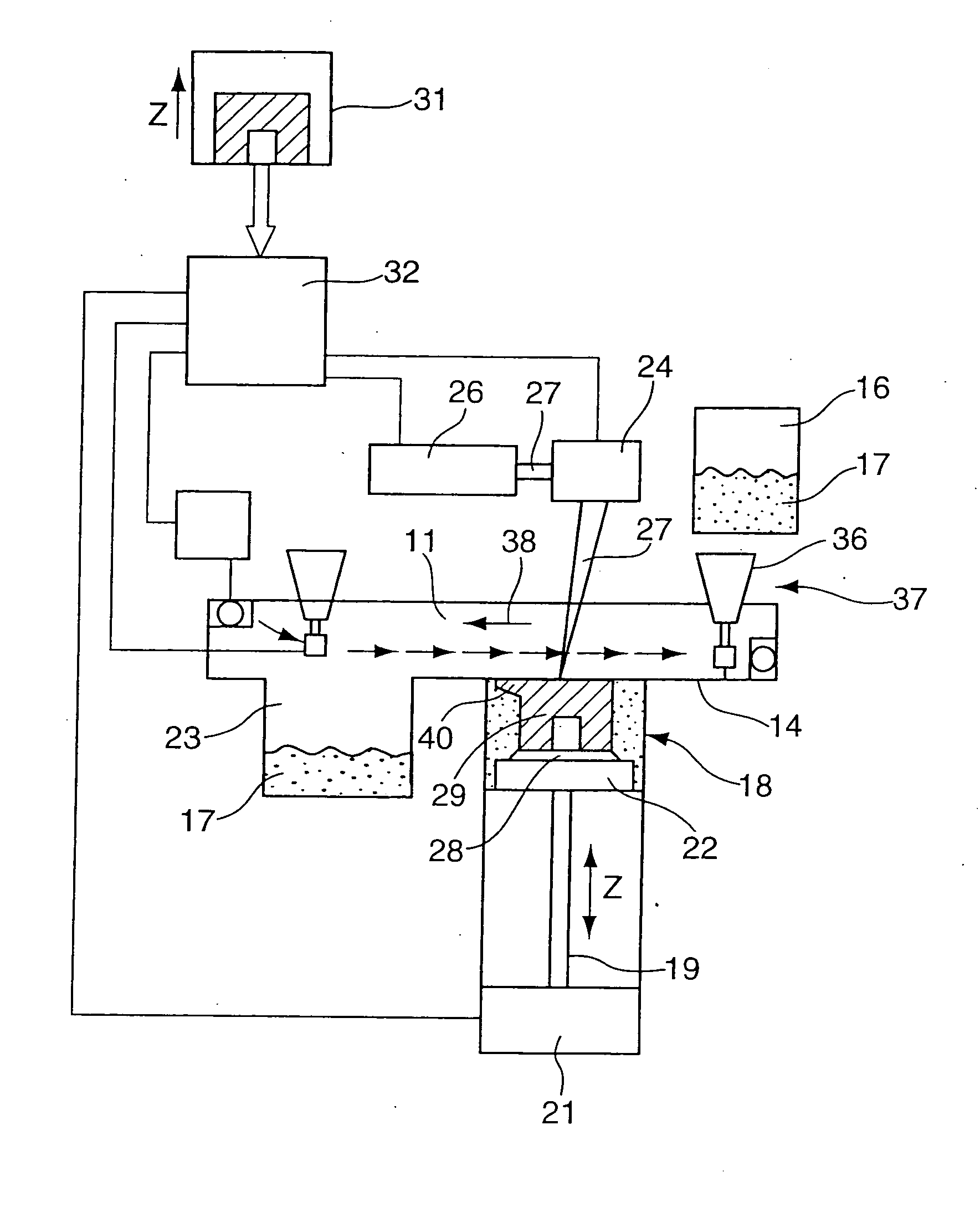

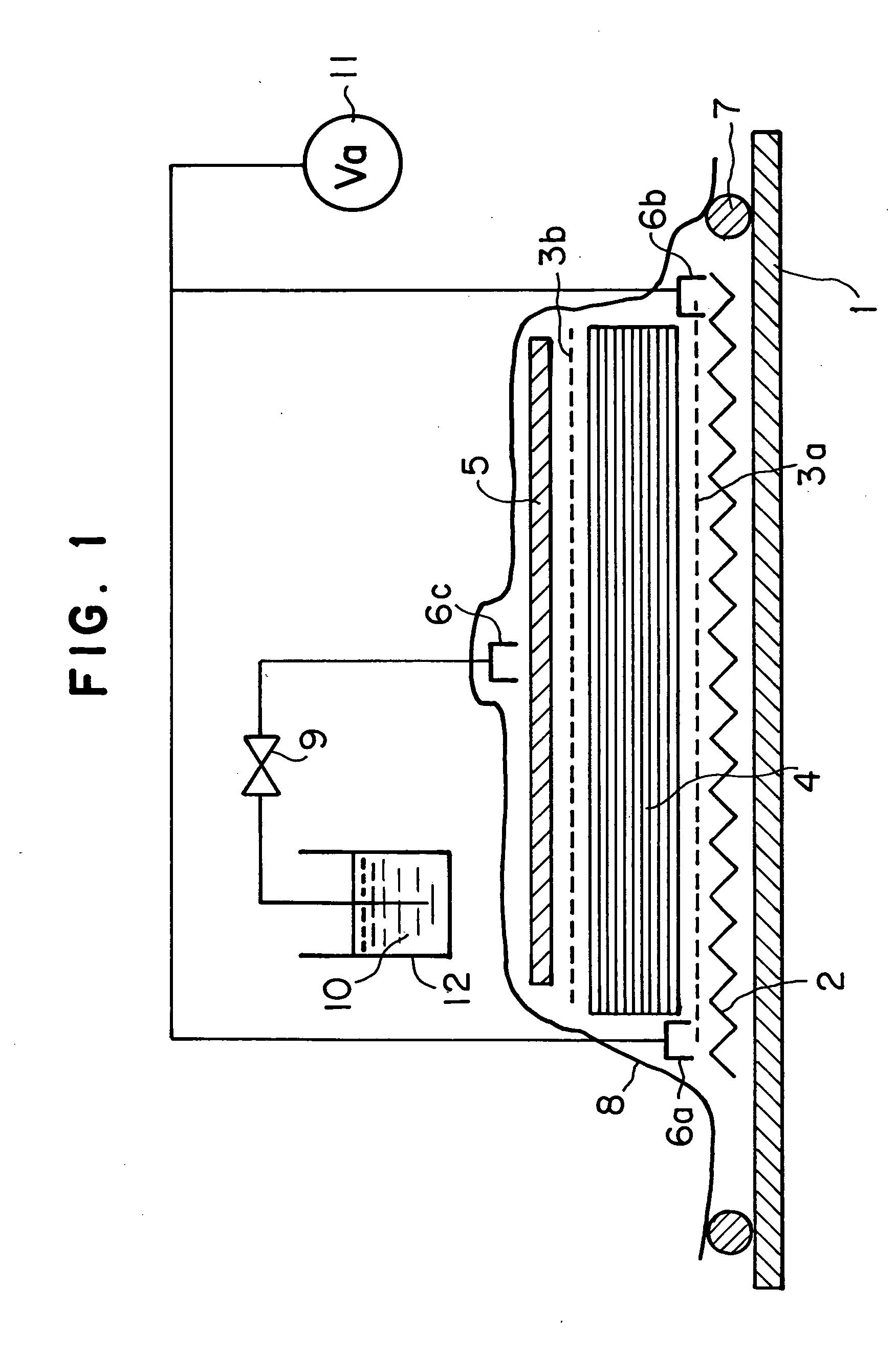

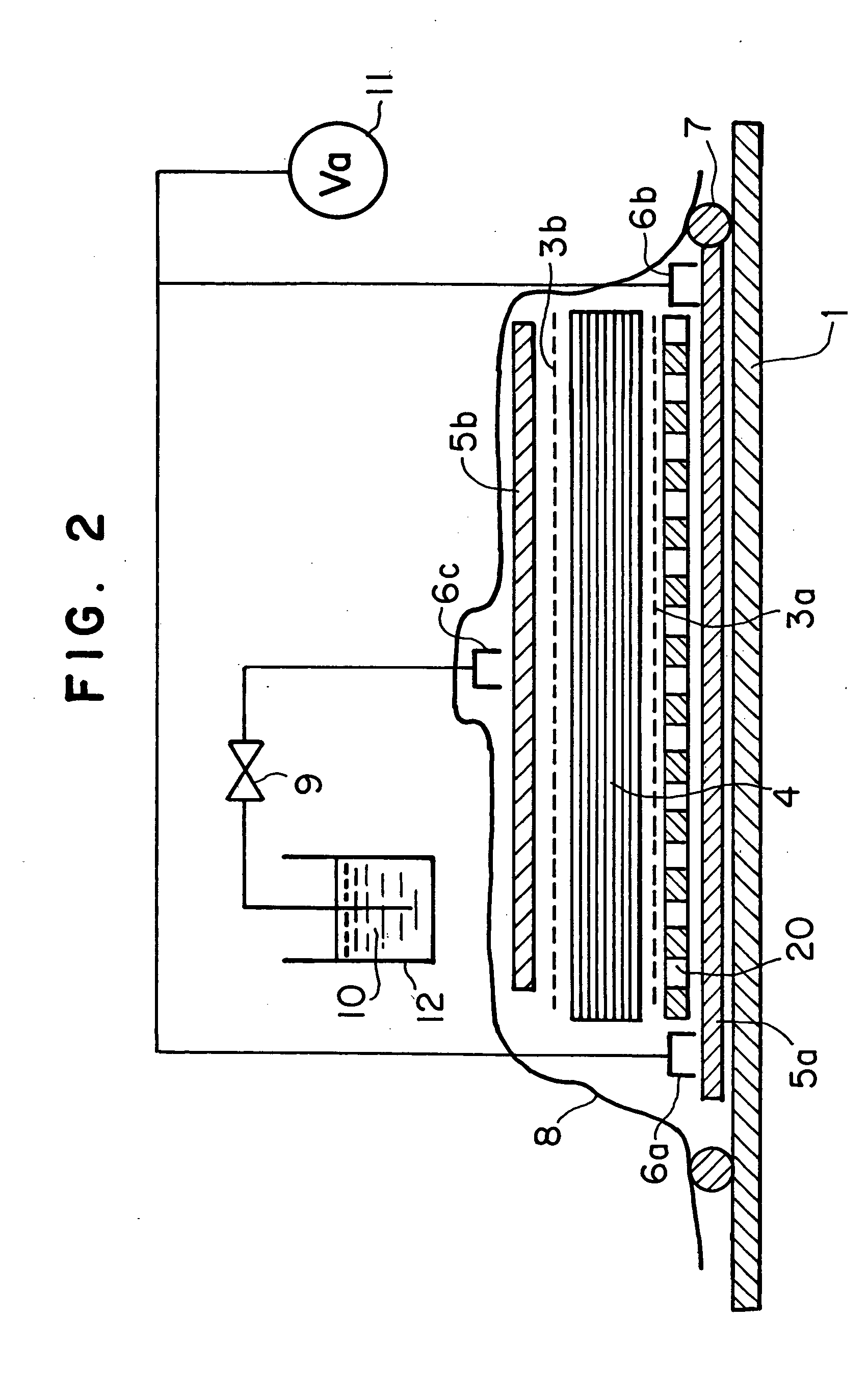

Rtm molding method and device

InactiveUS20070182071A1Shorten molding timeReduce the amount of solutionConfectioneryWood working apparatusFiber

An RTM molding method comprising disposing a reinforcing fiber substrate in a cavity of a mold consisting of a plurality of dies, clamping the mold, and thereafter injecting resin to complete molding, characterized in that divided areas with respect to the surface direction of the reinforcing fiber substrate are assumed, each divided area is one in which injected resin expands over the entire surface in the area and can be substantially uniformly impregnated in the thickness direction of the substrate, and resin introducing paths are formed for respective assumed divided areas for introducing the injected resin into the respective divided areas; and an RTM molding device. When a relatively large molded product is to be molded, a molding step from resin injection to impregnating / curing can be implemented at high speed without generating a non-resin-flowing area, thereby enabling a high-quality molded product to be produced free from voids, etc., with a molding time shortened and production speed and volume increased.

Owner:TORAY IND INC

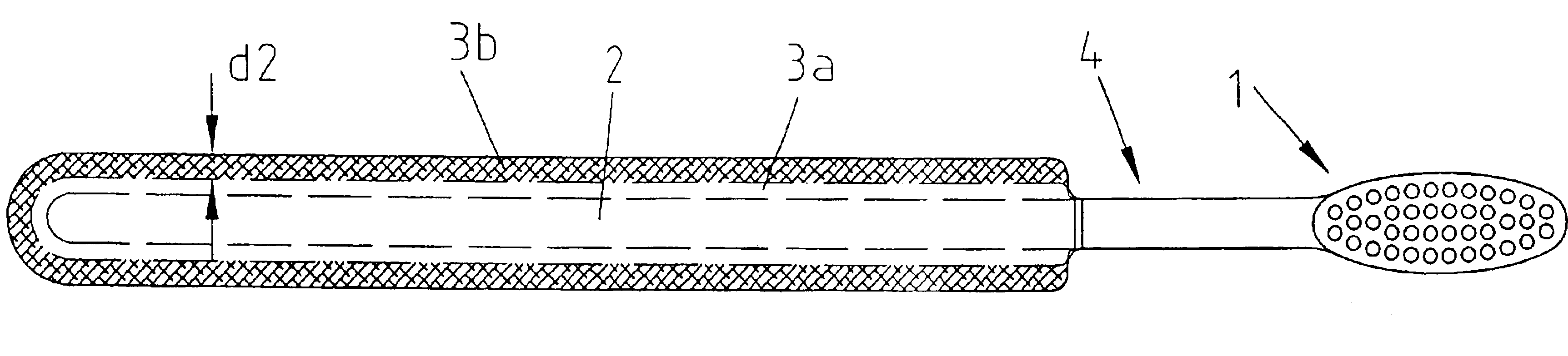

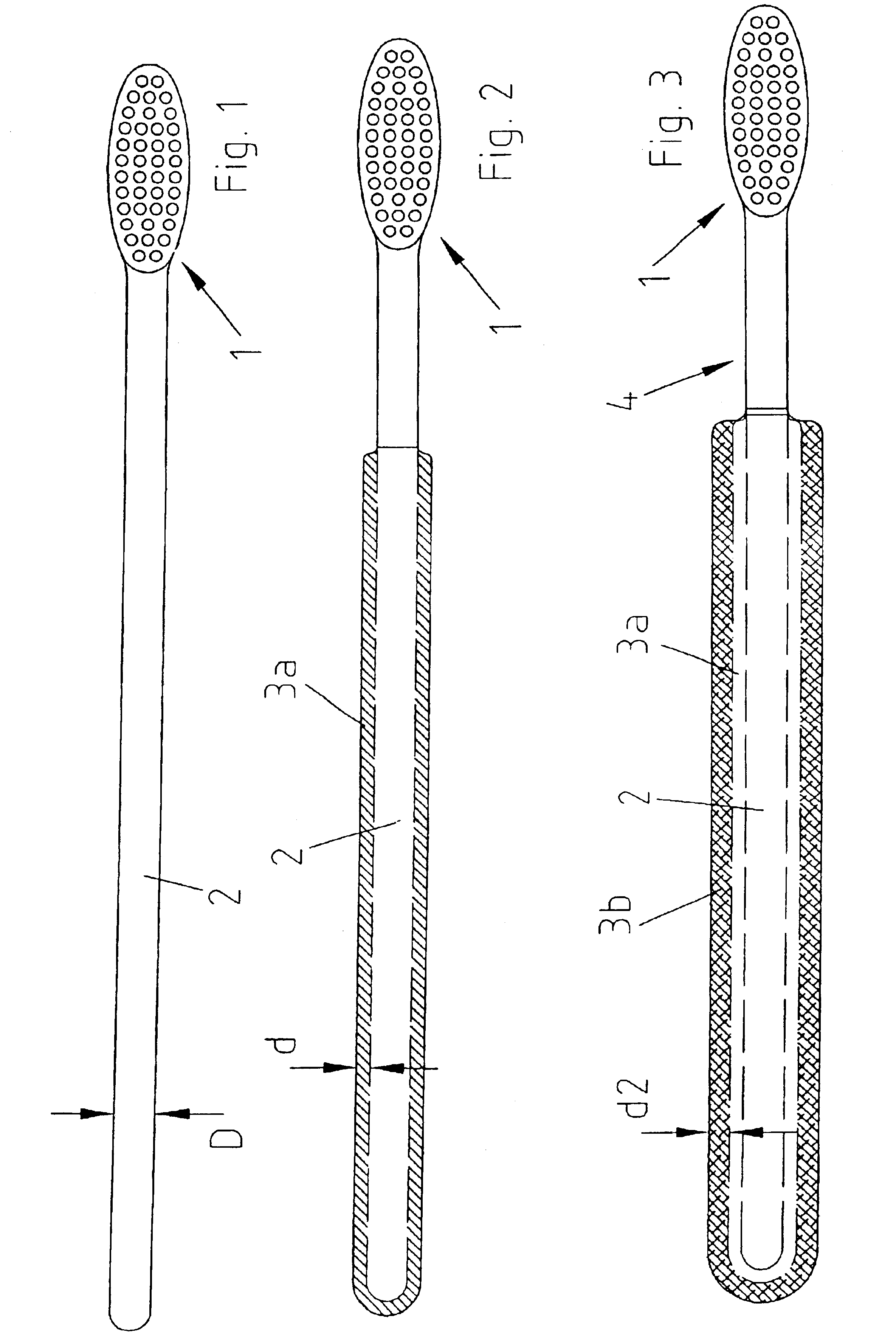

Method of producing thick-walled brushes, in particular toothbrushes

InactiveUS6919038B2High productivityGood surface qualityCarpet cleanersMouldsProduction rateEngineering

The present invention relates to a method of producing thick-walled brushes, in particular toothbrushes, with a grip piece and a brush head supporting bristle filaments. In order to increase the productivity, the method mentioned at the start is further developed by the present invention in that a core produced in a first injection molding cycle is coated with a plastic component in at least one subsequent injection molding cycle so as to form a multi-layered grip piece.

Owner:M C SCHIFFER

High surface quality GaN wafer and method of fabricating same

InactiveUS20060029832A1Improve surface qualityPolycrystalline material growthAfter-treatment detailsSurface roughnessCompound (substance)

Owner:XU XUEPING +1

Tempered glass and method for producing same

InactiveUS20140170380A1Efficiently provideImprove surface qualityRecord information storageMagnetic recordingMetallurgyCompression stress

A tempered glass of the present invention is a tempered glass having a compression stress layer in a surface thereof, the tempered glass comprising, as a glass composition in terms of mol %, 45 to 75% of SiO2, 3 to 15% of Al2O3, 0 to 12% of Li2O, 0.3 to 20% of Na2O, 0 to 10% of K2O, and 1 to 15% of MgO+CaO, and having a molar ratio (Al2O3+Na2O+P2O5) / SiO2 of 0.1 to 1, a molar ratio (B2O3+Na2O) / SiO2 of 0.1 to 1, a molar ratio P2O5 / SiO2 of 0 to 1, a molar ratio Al2O3 / SiO2 of 0.01 to 1, and a molar ratio Na2O / Al2O3 of 0.1 to 5, characterized in that the surface or an end surface of the tempered glass is etched after tempering treatment.

Owner:NIPPON ELECTRIC GLASS CO LTD

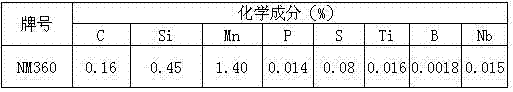

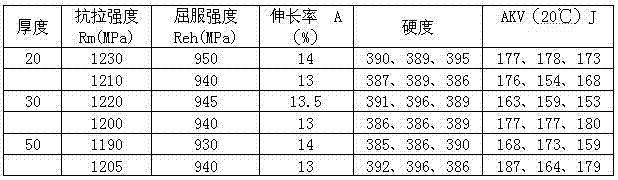

Method for producing wear-resisting steel plate

The invention relates to a method for producing a wear-resisting steel plate. Steel comprises the following chemical ingredients in percentage by mass: 0.15 to 0.20 percent of C, 0.4 to 0.7 percent of Si, 0.7 to 1.50 percent of Mn, less than or equal to 0.020 percent of P, less than or equal to 0.010 percent of S, 0.020 to 0.10 percent of Ti, 0.0005 to 0.0020 percent of B, 0.010 to 0.020 percent of Nb and the balance of Fe and inevitable impurities. A production process for the steel comprises the following steps of: desulfurizing by molten iron, smelting by a converter, refining, casting continuously, rolling and performing quenching-carbon partition (Q-P) treatment. In the ingredients of the wear-resisting steel, a C-Si-Mn-Nb-Ti ingredient system and the Nb and Ti micro alloy treatment are adopted, the hardenability of the steel is improved by adding B, an appropriate heat treatment process is adopted to ensure that the steel plate has high plasticity and toughness, and the impact energy of the steel plate is improved by over one time; and the heat treatment is performed by a Q-P process, lath martensite and lath retained austenite (between 5 and 10 percent) are formed and 50 to100 nanometers of carbide complex tissue is precipitated, so that the tissue is fine and uniform, and the tenacity of the steel plate is high.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

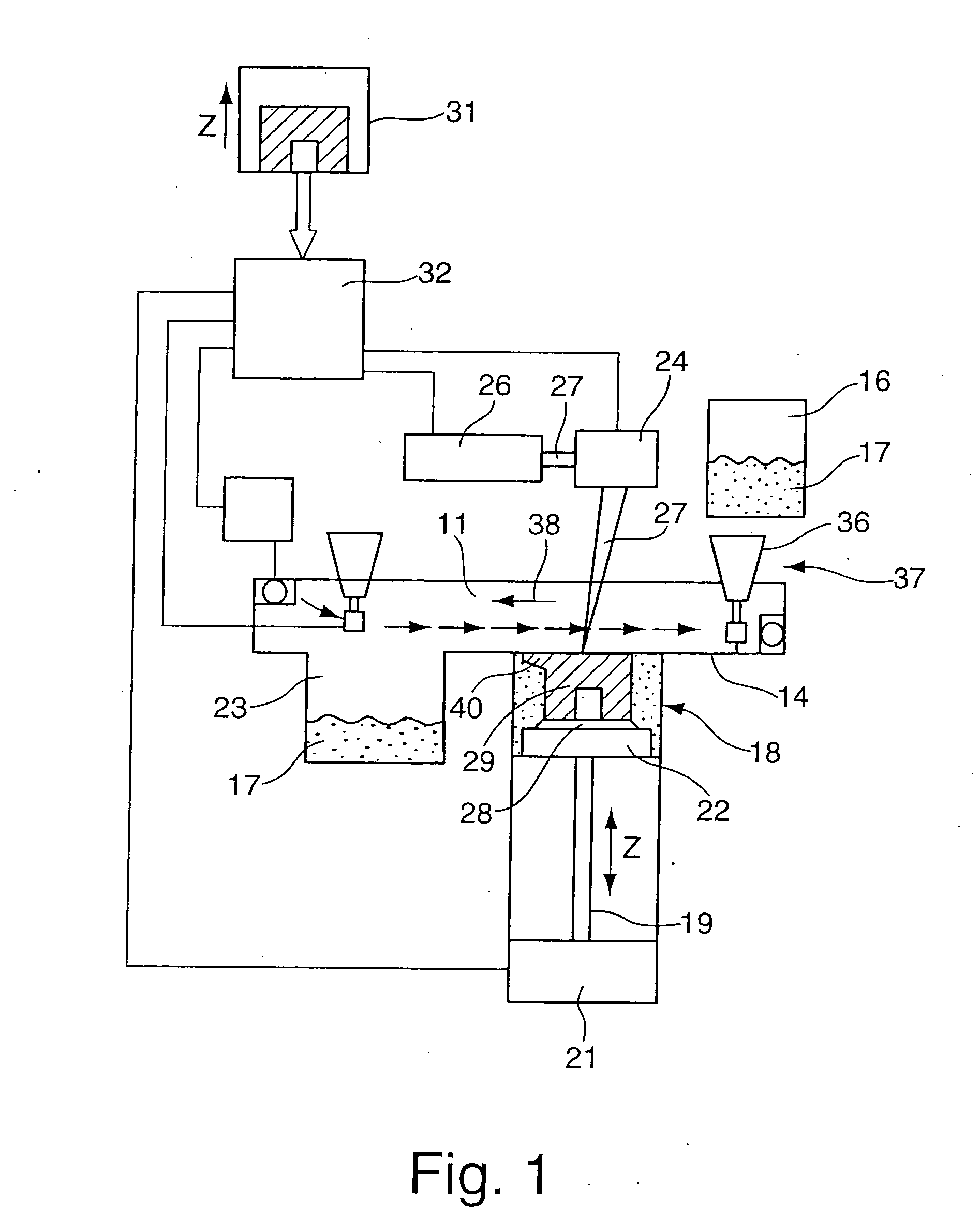

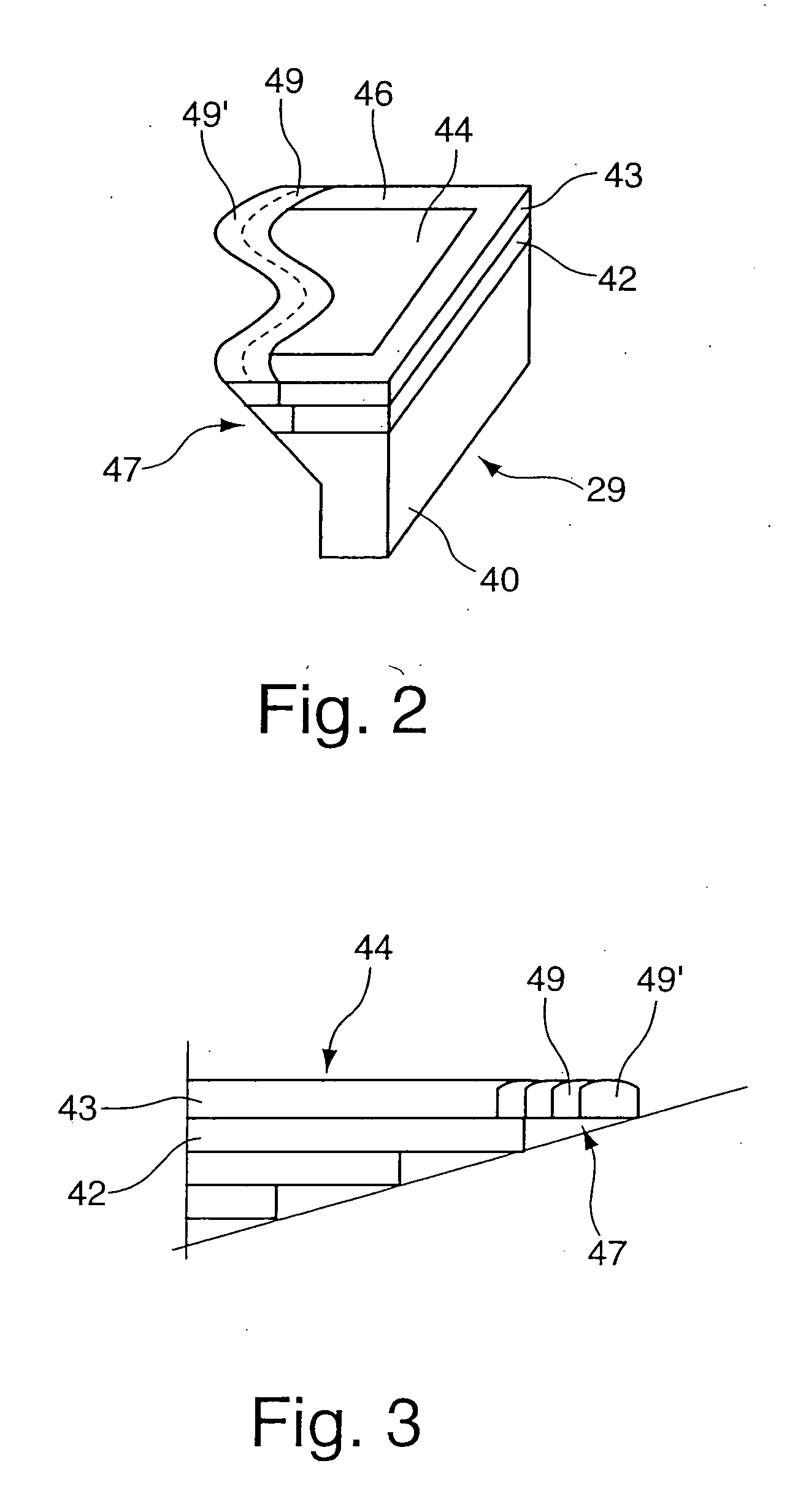

Method for the manufacture of a three-dimensional molding

InactiveUS20070035069A1Improve surface qualityHigh strengthAdditive manufacturing apparatusIncreasing energy efficiencyMaterials scienceRadiation

The invention relates to a method for the manufacture of a three-dimensional molding (29), wherein the molding (29) is generated from a solidifiable powder material by consecutively solidifying individual layers through the effect of radiation (27), while generating a new layer by exposing traces that are arranged adjacent to each other to radiation, wherein, in order to form an overhang region (47), a contour trace (49) is formed on a coherently solidified region and on a powder material (17) that has not solidified yet, the contour trace (49) is adjusted to an outer contour at least in the region of transition from the solidified region to the powder material (17) that has not solidified yet, and the at least one further contour trace (49′) adjusted to the outer contour is formed of non-solidified material (17) while comprising a high overlapping degree in relation to the previously formed contour trace (49).

Owner:TRUMPF WERKZEUGMASCHINEN GMBH & CO KG

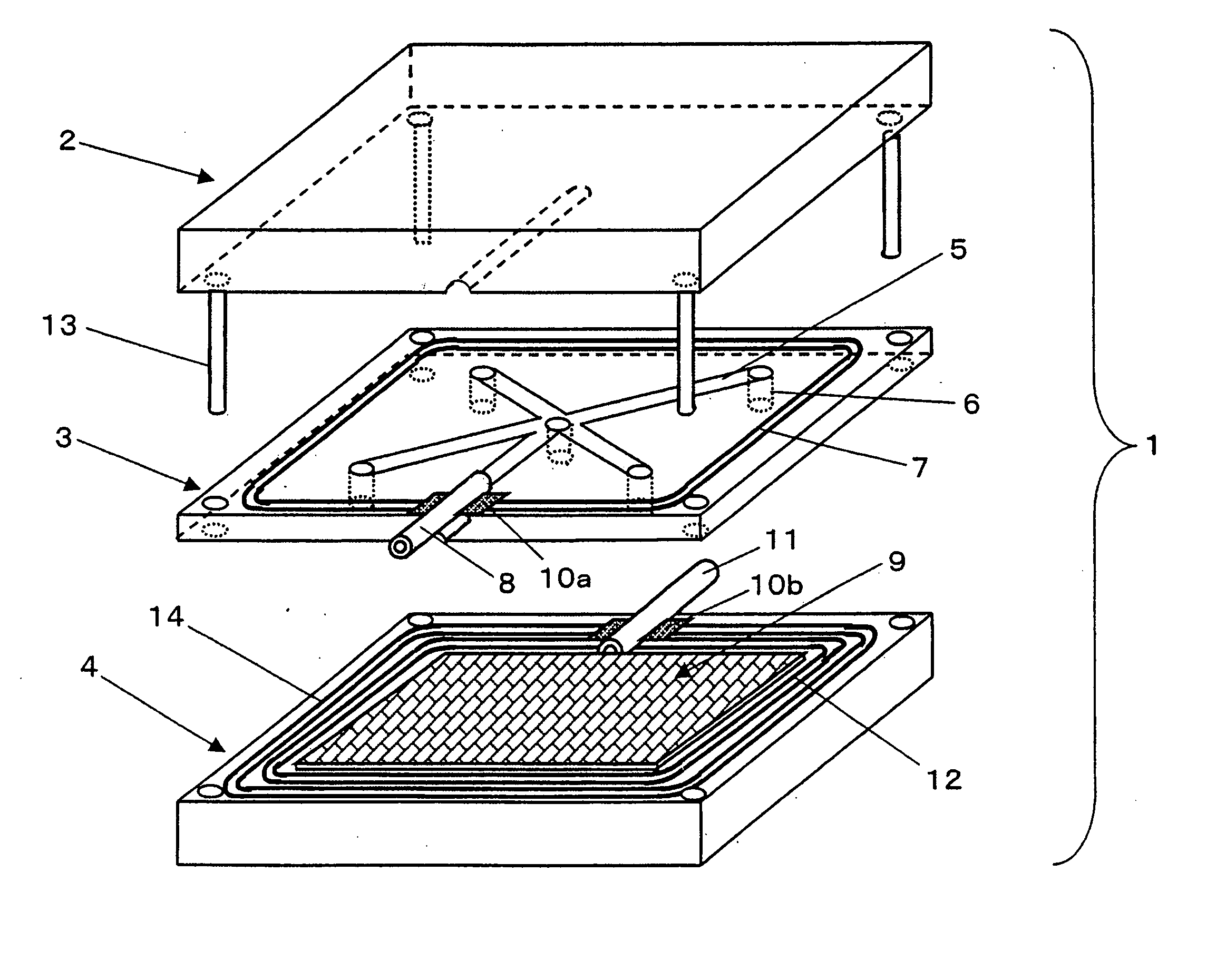

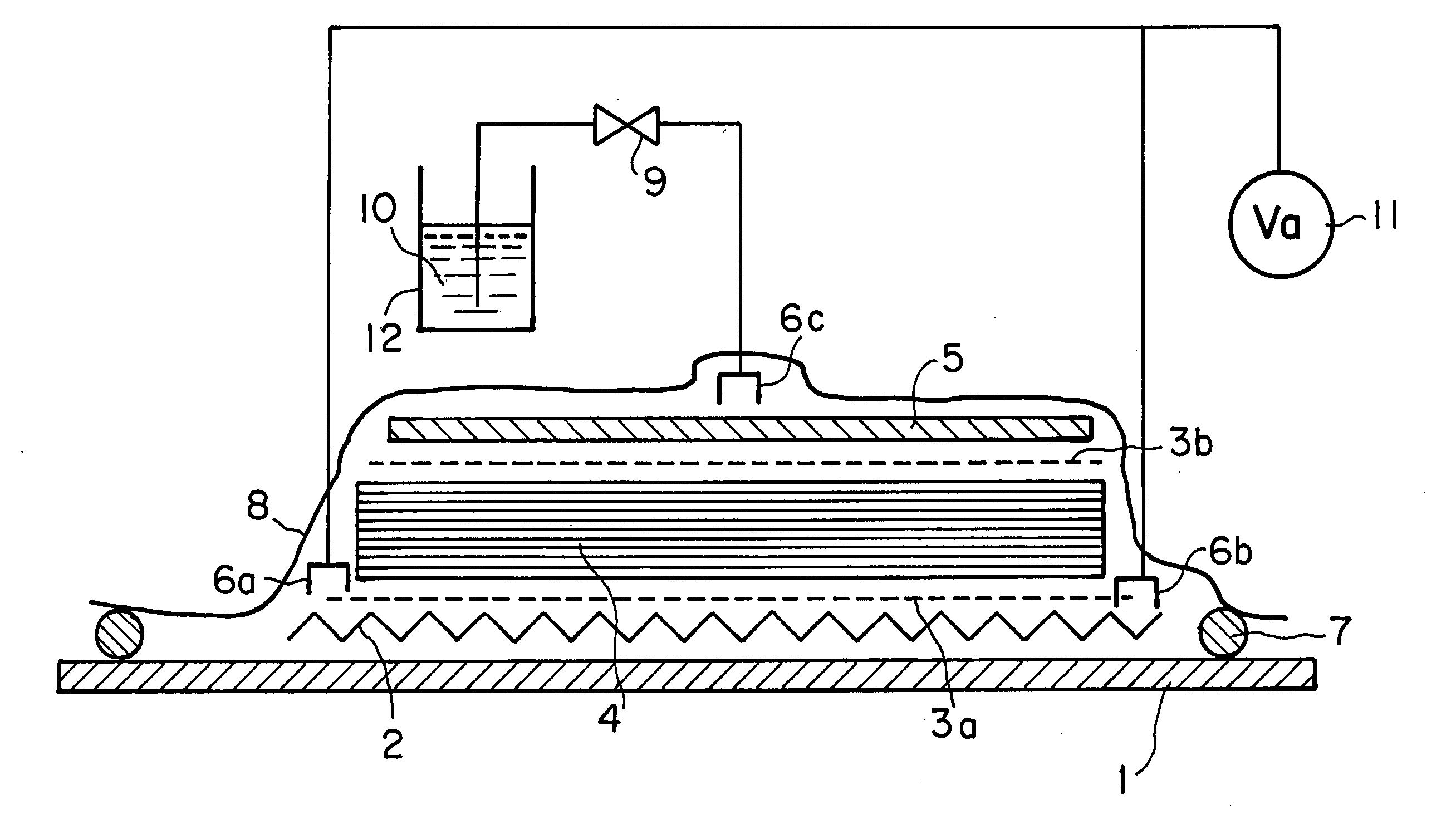

Method of rtm molding

ActiveUS20060125155A1Excellent impregnationImprove surface qualityLaminationLamination apparatusFiber

A method of RTM molding wherein a reinforcing fiber substrate is placed in a mold, each of a first and a second resin distribution media exhibiting a resin flow resistance lower than the resistance of the reinforcing fiber substrate is placed on each surface of the reinforcing fiber substrate, and the inside of the mold is evacuated and a resin is injected into the mold to thereby impregnate the reinforcing fiber substrate with the resin injected, characterized in that the first resin distribution medium exhibits a resin flow resistance lower than that of the second resin distribution medium, and the evacuation is carried out through the second resin distribution medium while the resin is injected through the first resin distribution medium. The method can be advantageously employed for producing, in particular, FRP structure which is thick and excellent in designability, lightweight property and / or strength.

Owner:TORAY IND INC +1

Steel plate for hot-rolled double-side enamel and method for producing same

InactiveCN1966753AIncrease productivityUniform compositionTemperature control deviceSheet steelChemical composition

The invention provides a kind of hot-rolled double-sided enamel-used nickelclad, the chemical components of which is: C 0.02%-0.06%, Si <=0.50%, Mn 0.15%-0.40, P <=0.15%, S <=0.006%, N<=0.003%, Ti 0.08%-0.20%, Als 0.005%-0.055%, Ti / C 2.2-5,unavoidable impurities and Fe as balance. The architecture of the nickelclad is ferrite with grain diameter = 2 mum-20 mum under hot rolling conditions, and TiC particles (diameter < 20nm is uniformly distinguished in the architecture. V 0.015%-0.060% and / or Cr 0.05%-0.20% can also be added. The production method of the clad is: producing unburnt earthenware with continuous cast method, heating to 1180-1260DEG C, descaling with high-handed water, rough rolling, finish rolling for 5-7 passes at 1100-960 DEG C and finally at 920DEG C-840DEG C, continuously cooling to 450- 630DEG C at a speed of >=30DEG C / S in 0-7S, and coiling. The nickelclad has the advantages of good performance and high strength, and can meet the requirement of large scaled engineering fembers.

Owner:ANGANG STEEL CO LTD

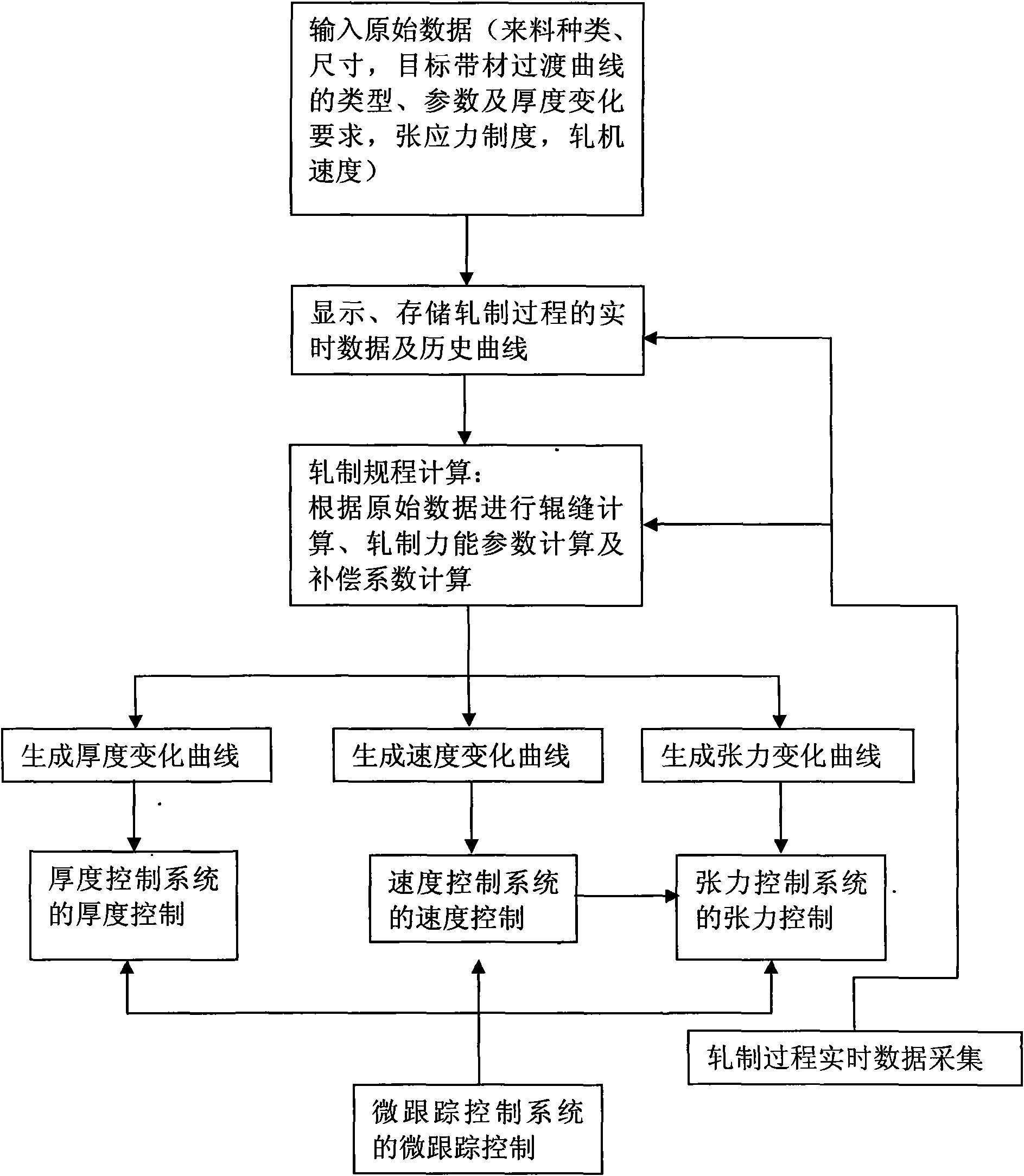

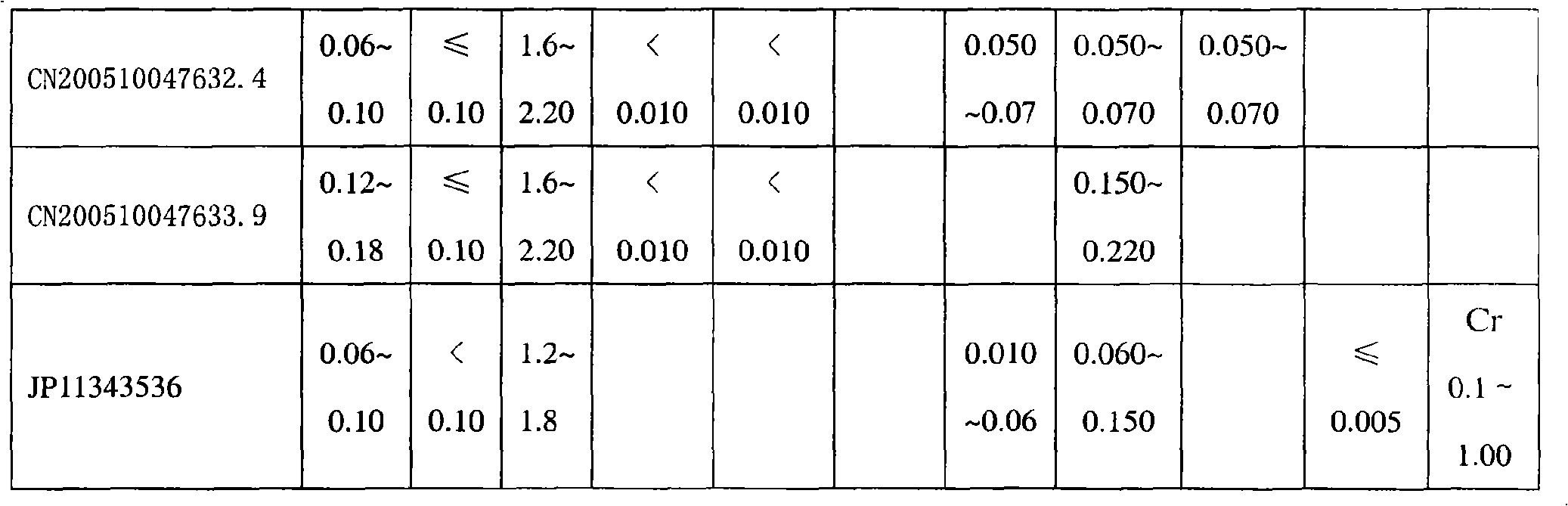

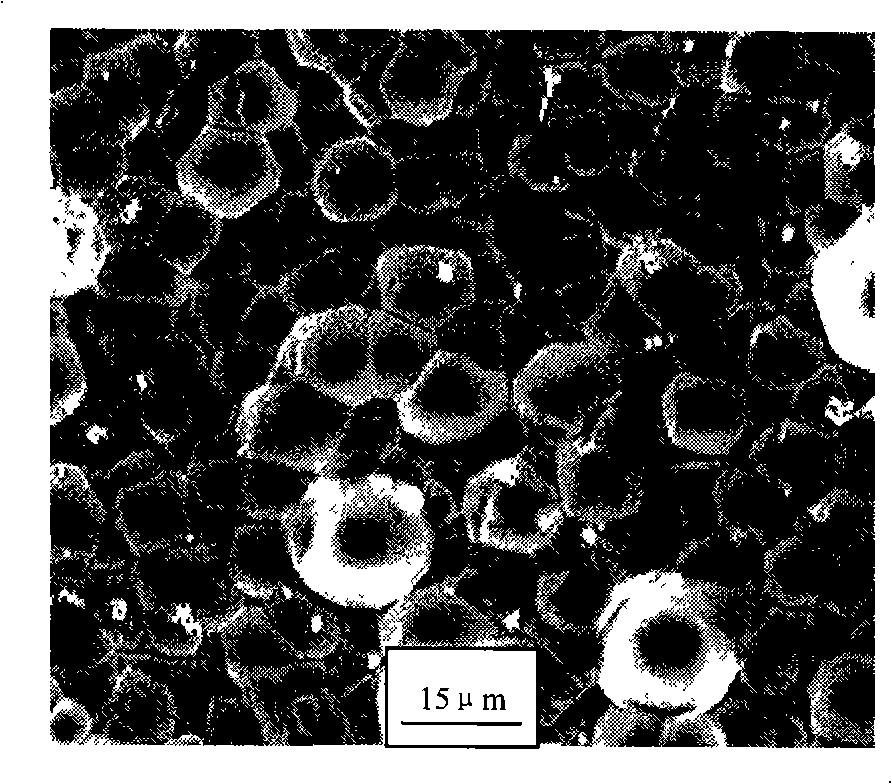

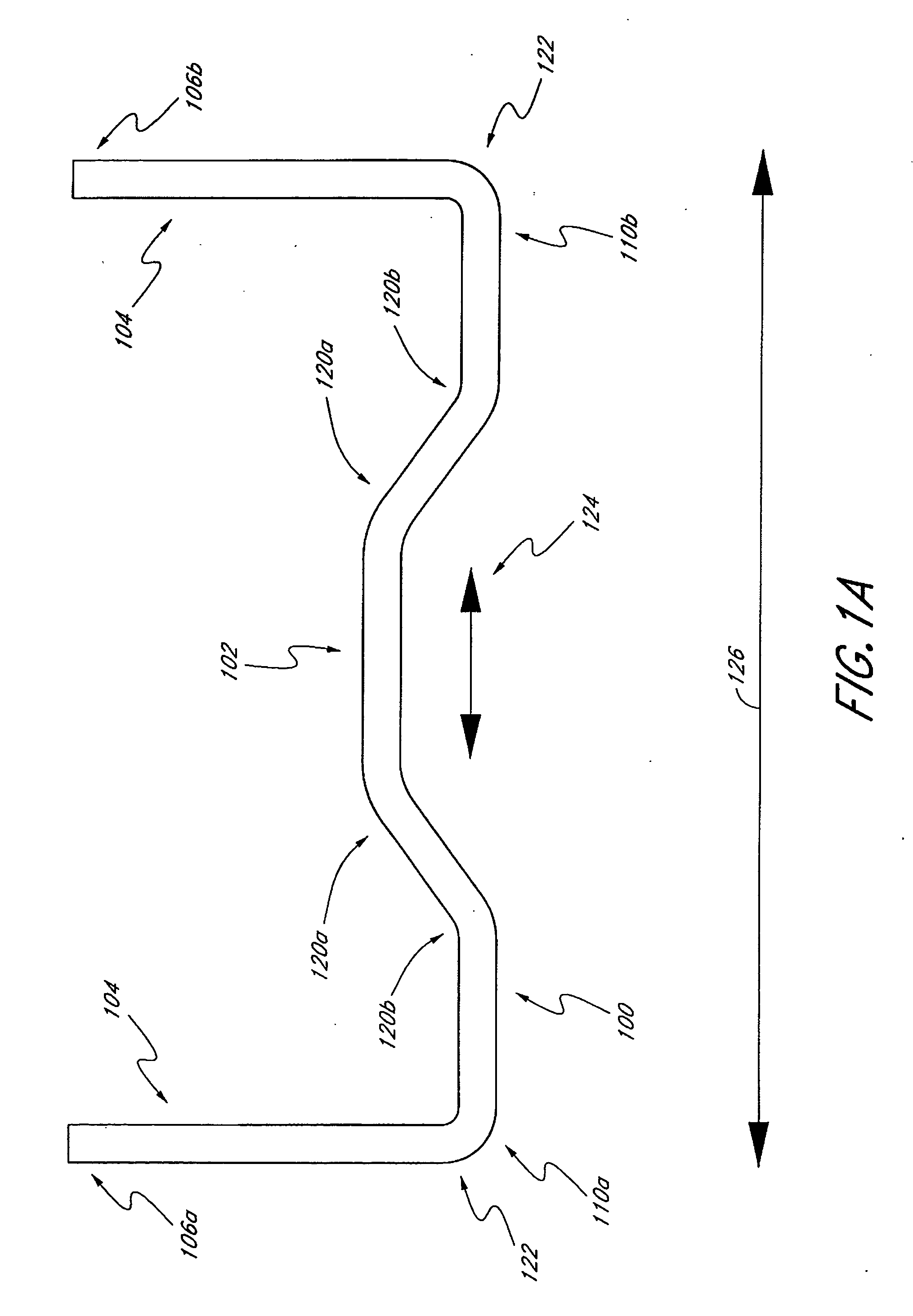

Periodic longitudinal variable-thickness strip and longitudinal variable-thickness plate and preparation method thereof

ActiveCN101607264AReduce welding processReduce manufacturing costProgramme control in sequence/logic controllersMetal rolling arrangementsComputer control systemVariable thickness

The invention belongs to the rolling technical field. The thickness of a periodic longitudinal variable-thickness strip changes periodically, the periodic longitudinal variable-thickness strip has more than two kinds of thicknesses regions and transition regions within a change period, and is formed by rolling. The control procedure of the periodic longitudinal variable-thickness strip comprises the following steps: inputting original data; displaying and storing real-time data and a history curve; computing the rolling procedure; generating a change curve; tracking the position of a rolling piece; and controlling the thickness, the speed and the tension. A device comprises a rolling mill, a reeling machine and a thickness measurer which are arranged at two sides of the rolling mill, and a length measuring roll arranged between the reeling machine and the rolling mill, wherein a reel diameter measurer is arranged on the reeling machine; a rolling force sensor and a hydraulic cylinder are arranged on the rolling machine; a pulse coder and a tension meter are respectively arranged on and below the length measuring roll; and the thickness measurer and the like are connected with a computer control system. A longitudinal variable-thickness plate has two or more kinds of different thickness regions, transition regions are arranged among the thickness regions, and the plate is formed by the strip through the steps of annealing, unreeling by an unreeler, leveling by a leveler, and cutting by a cutting machine.

Owner:SHENYANG DONGBAO HAIXING METAL MATERIAL TECH

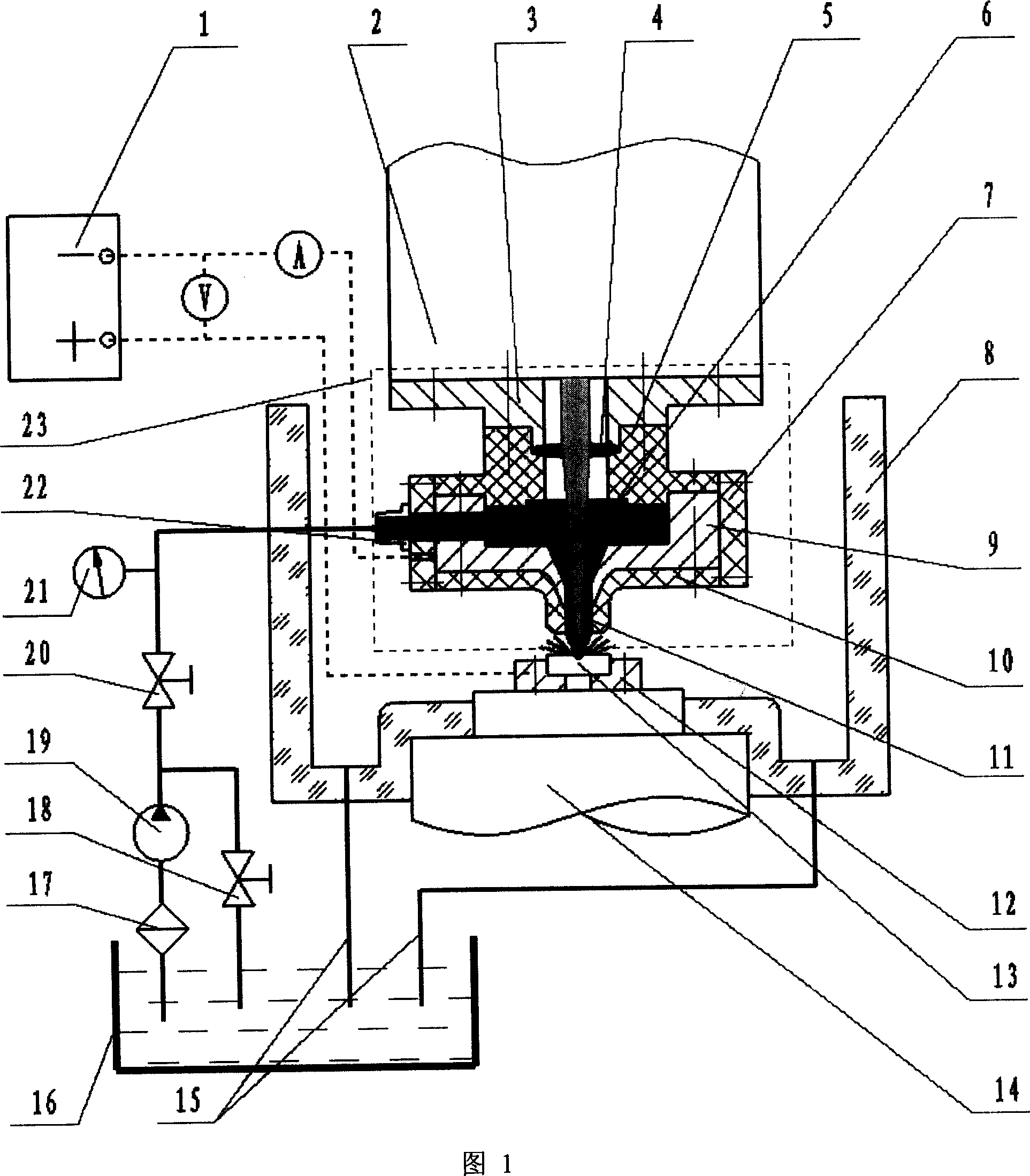

Spraying liquid bunch electrolysis-laser composite processing method and apparatus thereof

InactiveCN1919514ASolve processing problemsEfficient removalLaser beam welding apparatusElectrolysisLaser processing

The invention discloses a spraying liquid beam electrolytic-laser compound manufacturing method and device, which comprises the following steps: utilizing layer generating device to produce laser beam on the working piece, manufacturing hole, seam and groove, generating high-speed spraying liquid removing material with the same shaft of laser beam through spraying liquid beam device. The device contains layer, working piece assembling chuck, power and spraying liquid beam device, wherein the spraying liquid beam device concludes assembling seat of spraying device, insulating switching seat, cathode, focal lens, protective lens, insulating sleeve and sprayer.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

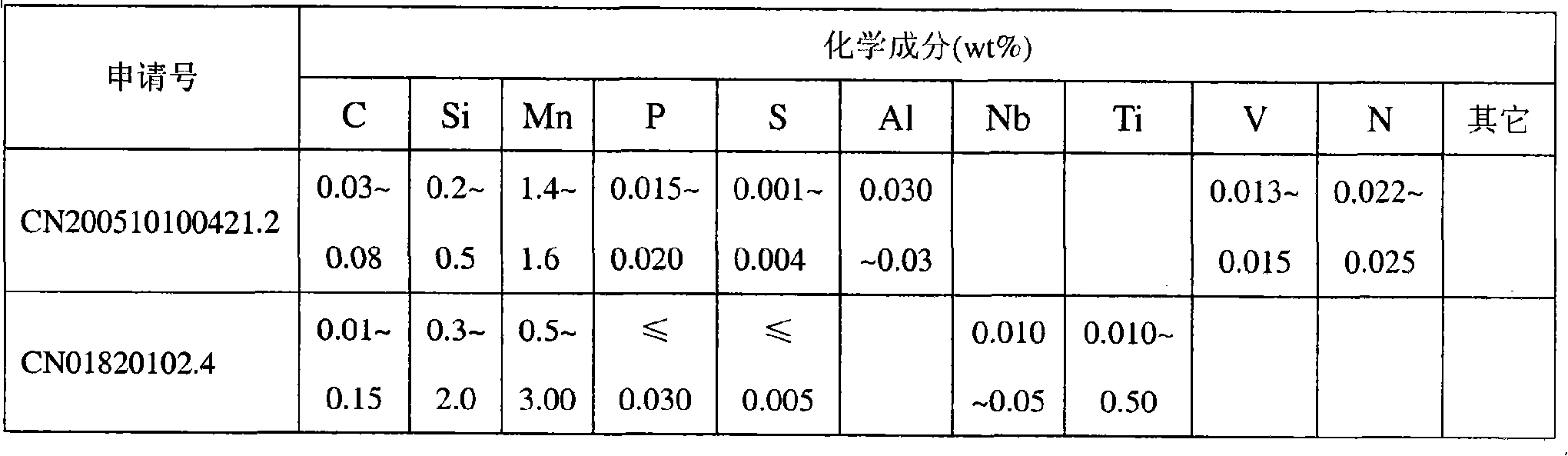

High-strength hot rolling automotive frame steel plate and manufacturing method thereof

InactiveCN101565794AEasy to produceLose weightTemperature control deviceMetal rolling arrangementsChemical compositionSheet steel

The invention provides a high-strength hot rolling automotive frame steel plate which comprises the following chemical components according to the weight percent: 0.05 to 0.10 of C, less than or equal to 0.10 of Si, 1.1 to 1.85 of Mn, less than or equal to 0.025 of P, less than or equal to 0.0030 of S, 0.015 to 0.060 of Al, less than or equal to 0.0060 of N, 0.015 to 0.050 of Nb, 0.015 to 0.150 of Ti, less than or equal to 0.0050 of Ca and the balance of Fe and inevitable impurities. The invention also provides a manufacturing method of a steel plate, comprising rolling control and cold control processes. By adopting the chemical components and reasonable production process, the yield strength of the hot rolling automotive frame steel plate can reach the grade of 550-700Mpa; and the hot rolling automotive frame steel plate has excellent cold forming performance and higher fatigue strength and is suitable for manufacturing longitudinal beams and cross beams of an automotive frame and other members.

Owner:BAOSHAN IRON & STEEL CO LTD

Producing a flexographic printing plate

InactiveUS20090197013A1High qualityImprove surface qualityPretreated surfacesSpecial surfacesFlexographyInkjet printing

A method of producing a flexographic printing plate, comprises:a) inkjet printing a layer of flexographic material in a predetermined pattern onto a substrate;b) partially curing at least part of the printed layer of flexographic material so as to immobilize it on the substrate; andc) repeating steps (a) and (b) so as to print and partially cure one or more further layers of flexographic material in the predetermined pattern on the previous layer(s),characterized by additionally curing one or more lower printed layers before or while printing one or more upper layers so as to reduce spreading of the lower printed layer(s).

Owner:FFEI LTD

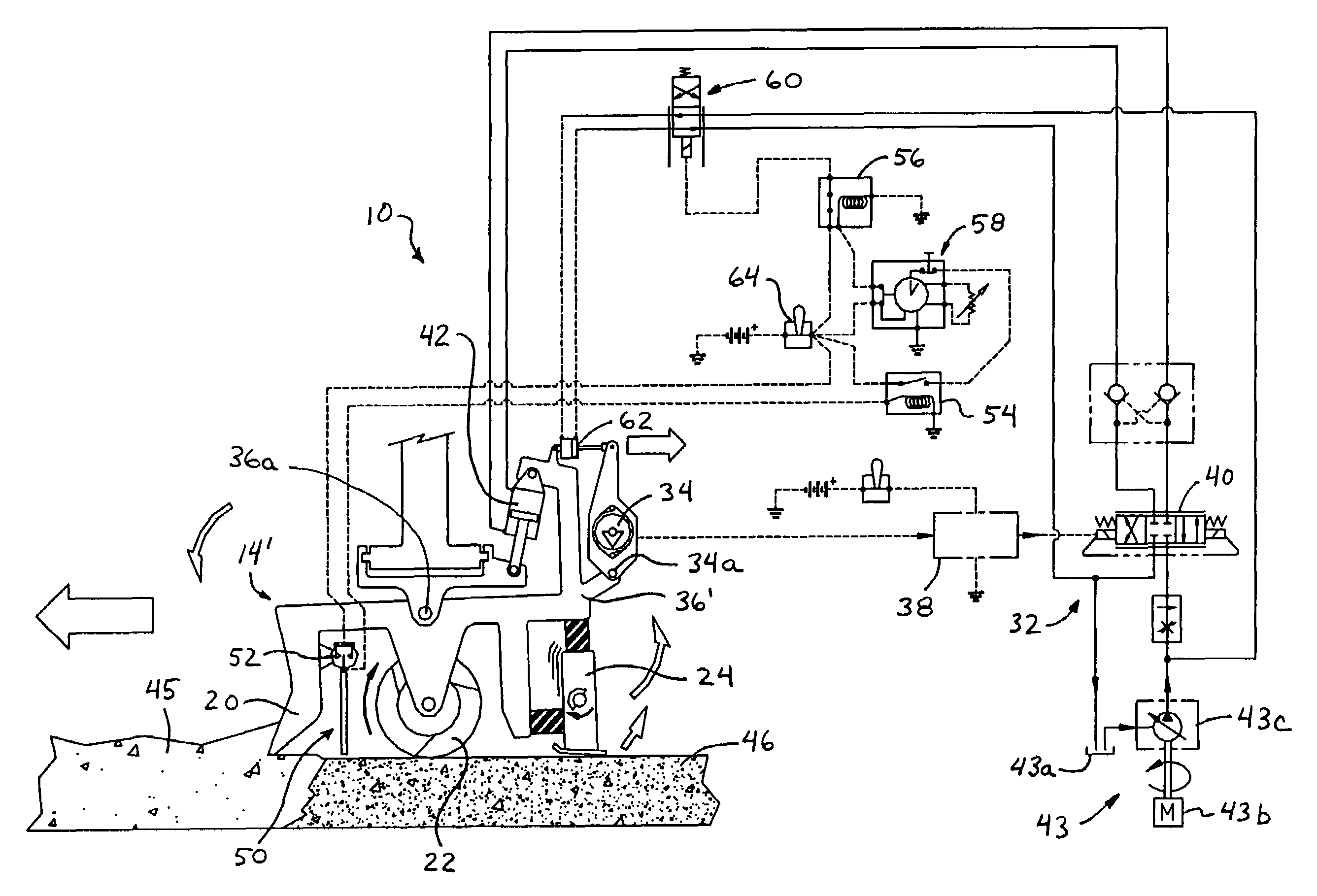

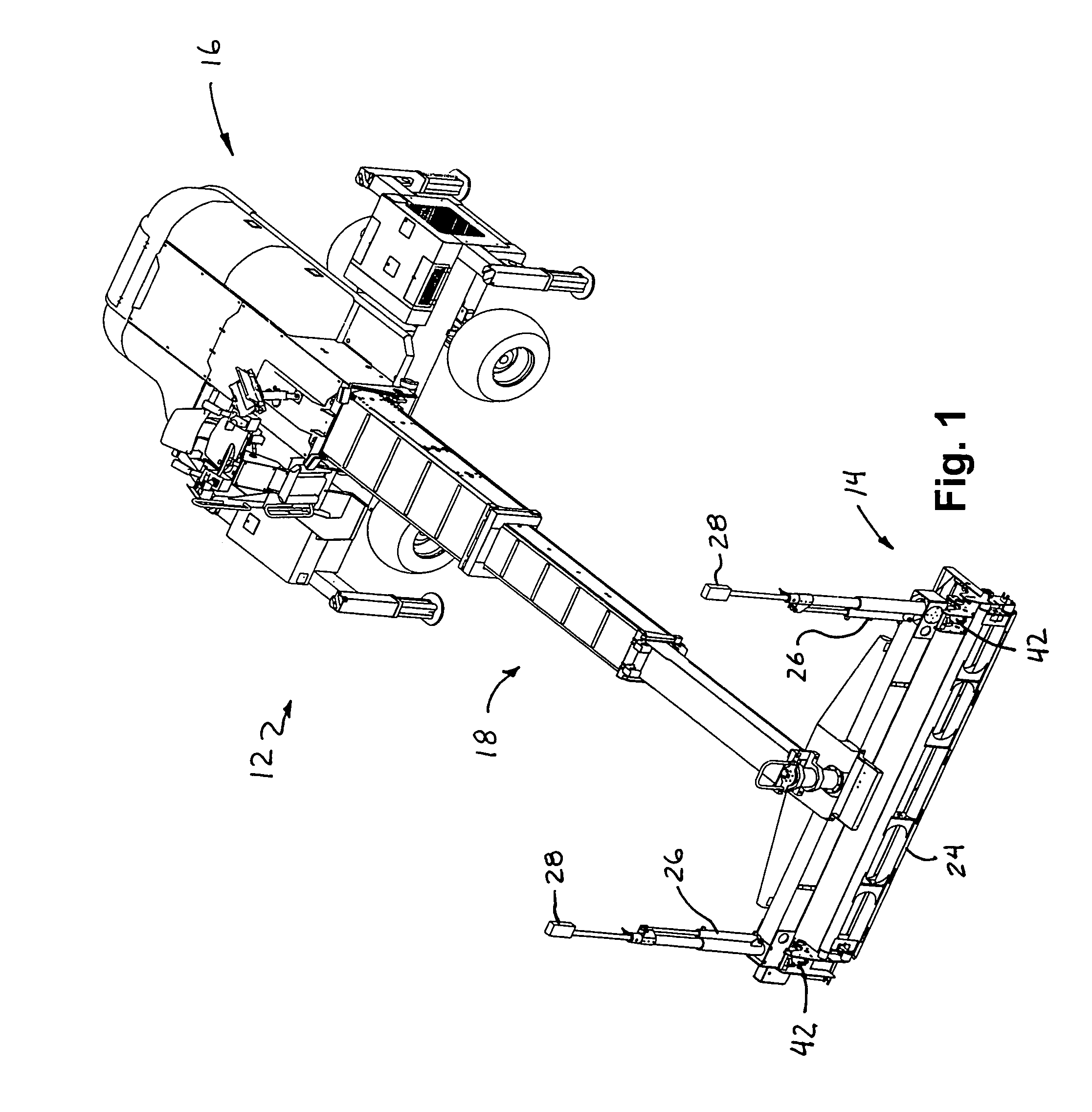

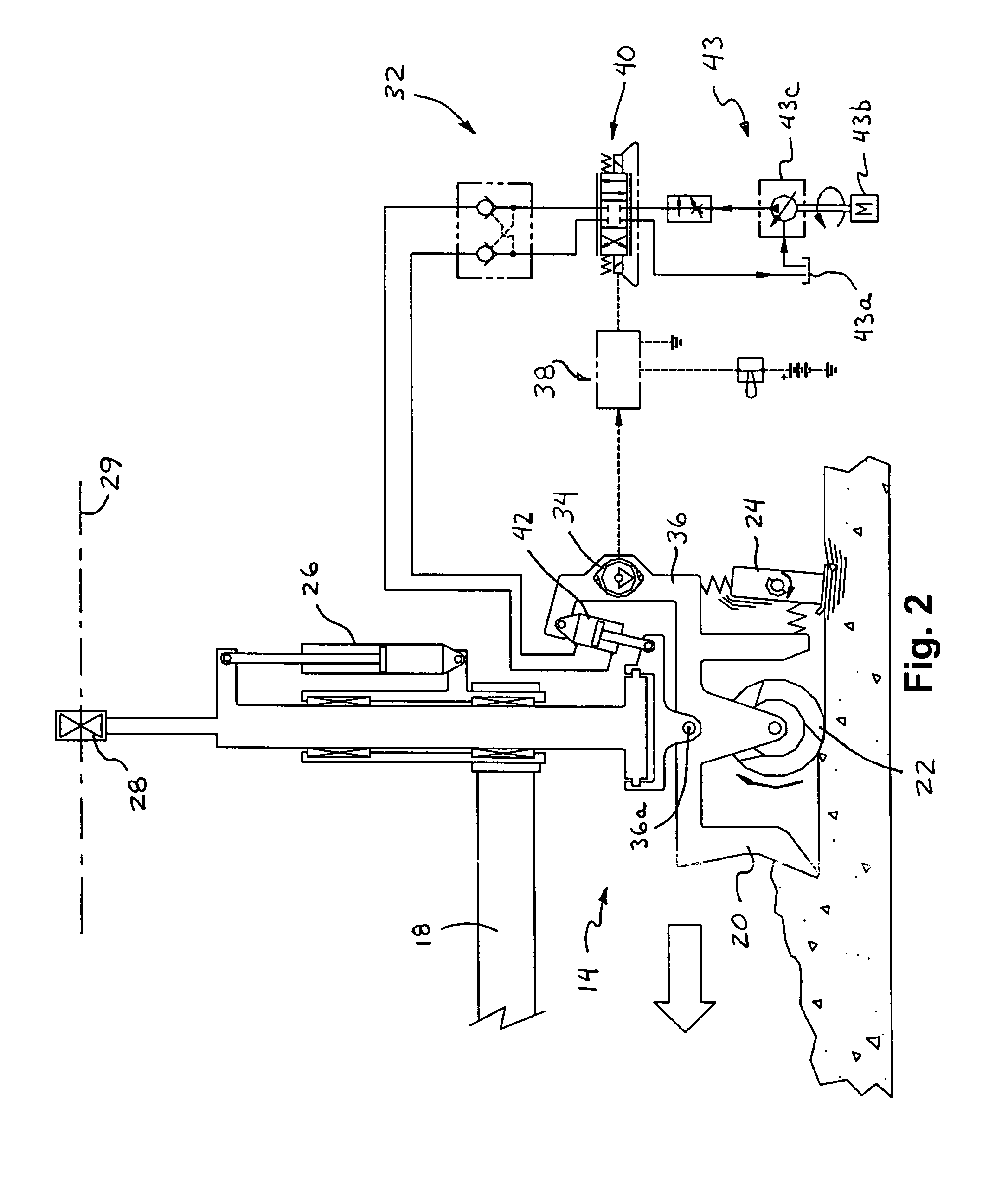

Apparatus and method for improving the control of a concrete screed head assembly

ActiveUS7044681B2Easy to controlImprove surface qualityRoads maintainenceBuilding material handlingScreedControl system

A soft landing control system for a screeding device is operable to automatically lower a vibrating member of a screed head assembly into engagement with a concrete surface at a time and place where the vibrating member is not positioned over an overlap area of already screeded concrete. The vibrating member is automatically lowered onto newly placed concrete at or near the junction or cold-joint between the already screeded concrete and the area of newly placed concrete, so as to avoid depressions in the already placed concrete. Optionally, the soft landing control system may include a timing device and may lower the vibrating member after a period of time following an activating event. Optionally, the control system may detect when the vibrating device is positioned at or near the newly placed concrete and may lower the vibrating member in response to such detection.

Owner:SOMERO ENTERPRISES INC

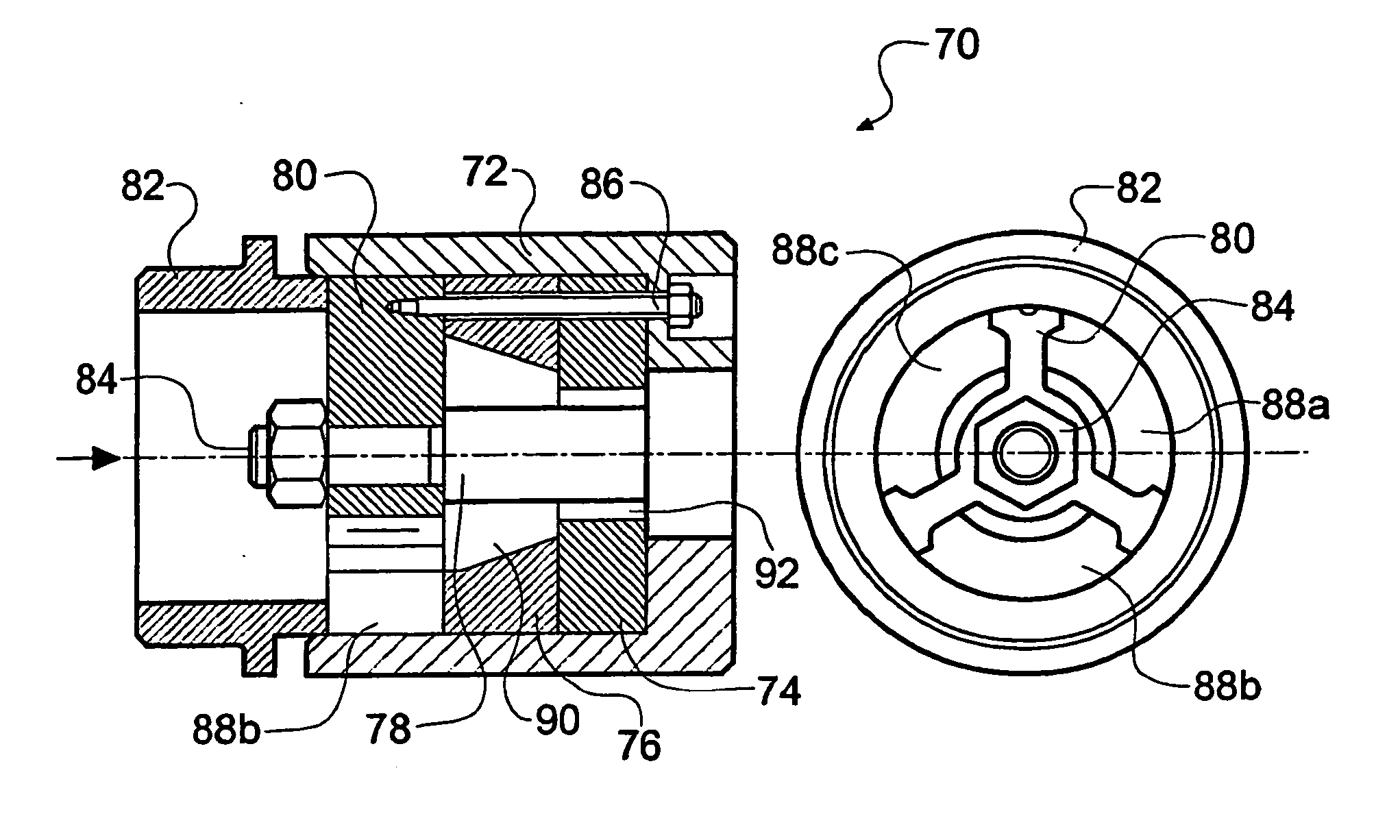

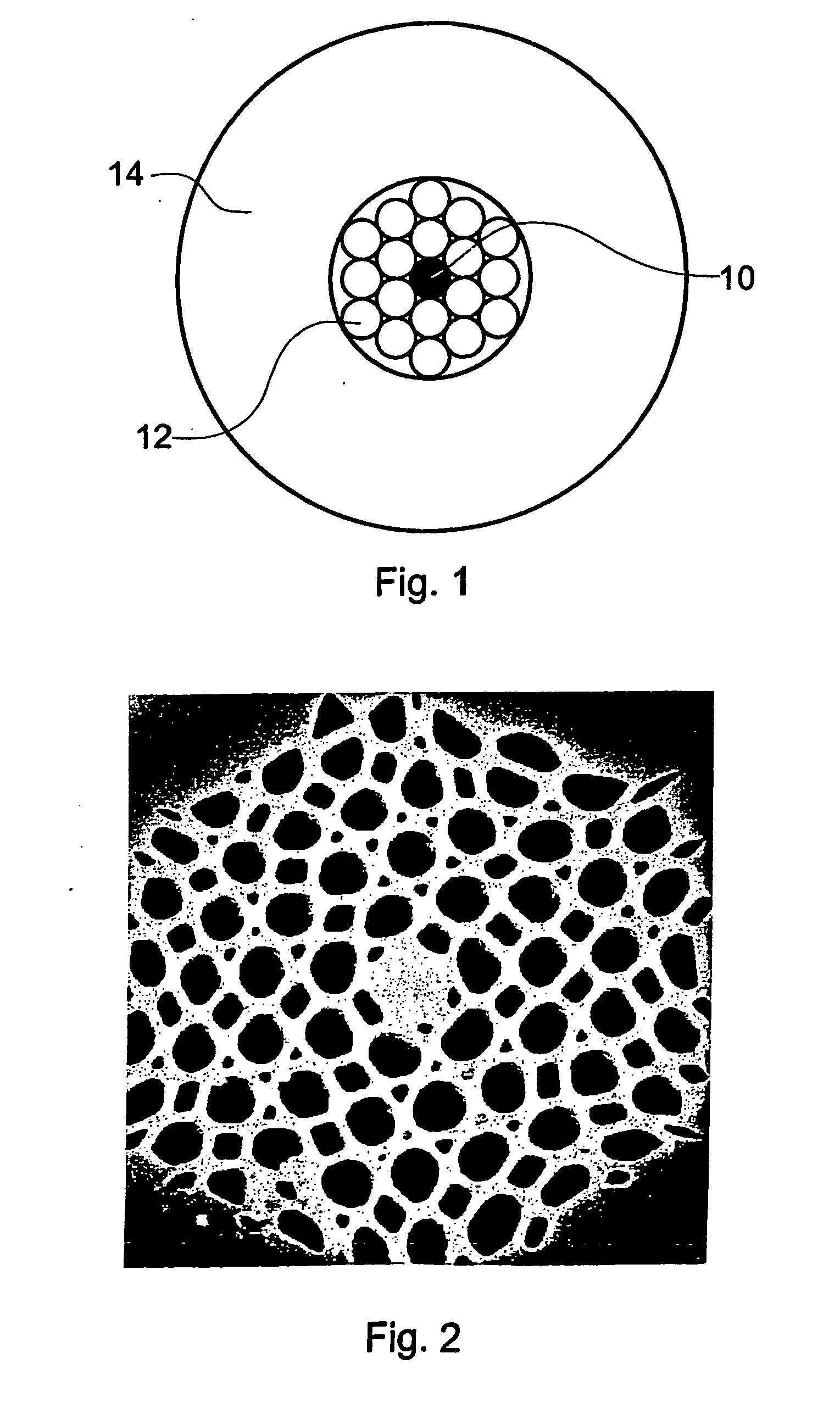

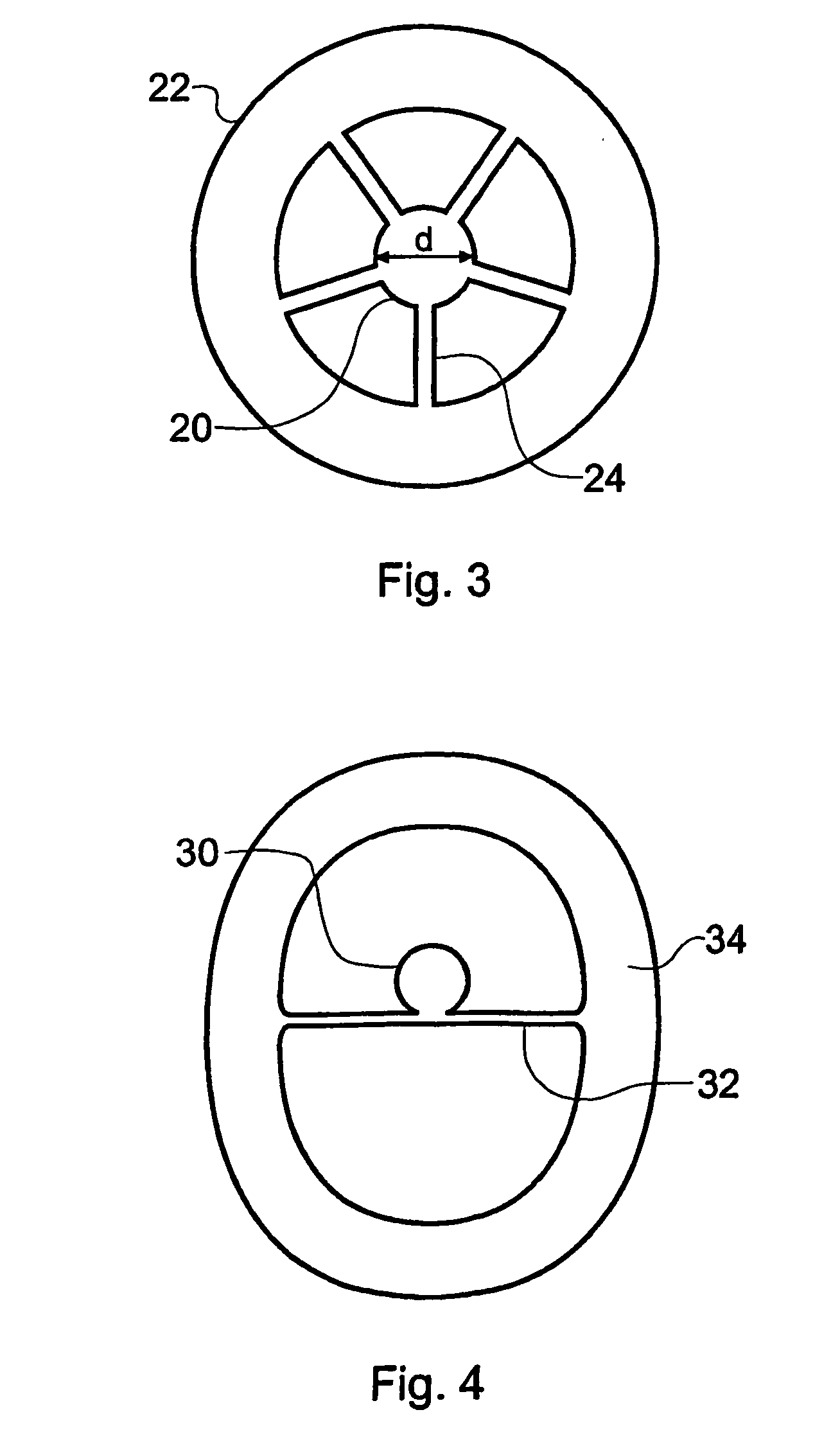

Fabrication of microstructured optical fibre

InactiveUS20060104582A1Smooth materialImprove optical qualityLaser using scattering effectsCladded optical fibreAudio power amplifierExtinction

Microstructured optical fibre is fabricated using extrusion. The main design of optical fibre has a core suspended in an outer wall by a plurality of struts. A specially designed extruder die is used which comprises a central feed channel, flow diversion channels arranged to divert material radially outwards into a welding chamber formed within the die, a core forming conduit arranged to receive material by direct onward passage from the central feed channel, and a nozzle having an outer part in flow communication with the welding chamber and an inner part in flow communication with the core forming conduit, to respectively define an outer wall and core of the preform. With this design a relatively thick outer wall can be combined with thin struts (to ensure extinction of the optical mode field) and a core of any desired diameter or other thickness dimension in the case of non-circular cores. As well as glass, the extrusion process is suitable for use with polymers. The microstructured optical fibre is considered to have many potential device applications, in particular for non-linear devices, lasers and amplifiers.

Owner:UNIV OF SOUTHAMPTON

Grinding fluid for processing LED (light-emitting diode) substrate and preparation method thereof

InactiveCN102337084AReduce surface roughnessReduce surface scratchesPolishing compositions with abrasivesSemiconductor devicesSolventSilicon dioxide

The invention relates to a grinding fluid for processing an LED (light-emitting diode) substrate. The grinding fluid comprises a solvent, an additive and a grinding agent, wherein the grinding agent consists of diamond micropowder and non-diamond nano polishing material; the purity of the diamond micropowder is more than 99%, and the particle size of the diamond micropowder is W0.5-W20; and the non-diamond nano polishing material is any one or a mixture of any of alumina, silicon dioxide, cerium oxide and chromic oxide, the particle size of the non-diamond nano polishing material is 10-100nm, and the purity of the non-diamond nano polishing material is more than 99%. According to the invention, micron diamond is used as a grinding material while the non-diamond nano polishing material is also compositely added, thereby ensuring the grinding rate and well guaranteeing the processing quality of the surface of a workpiece.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD +1

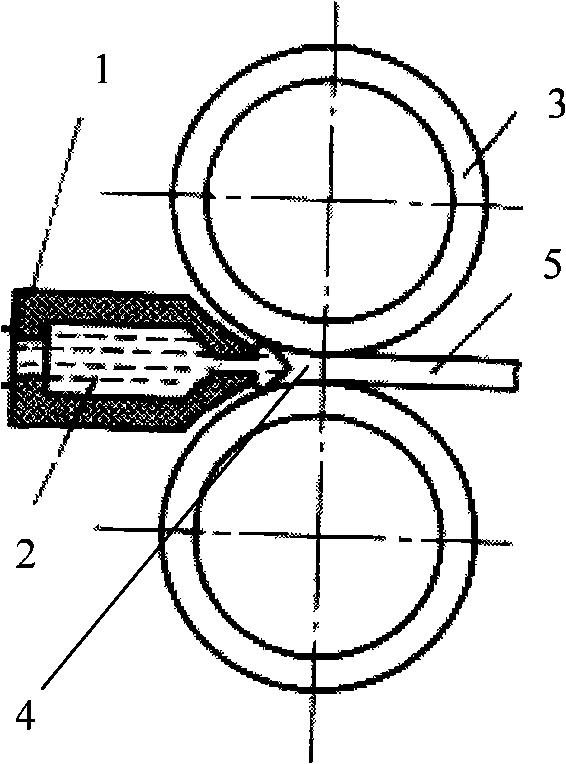

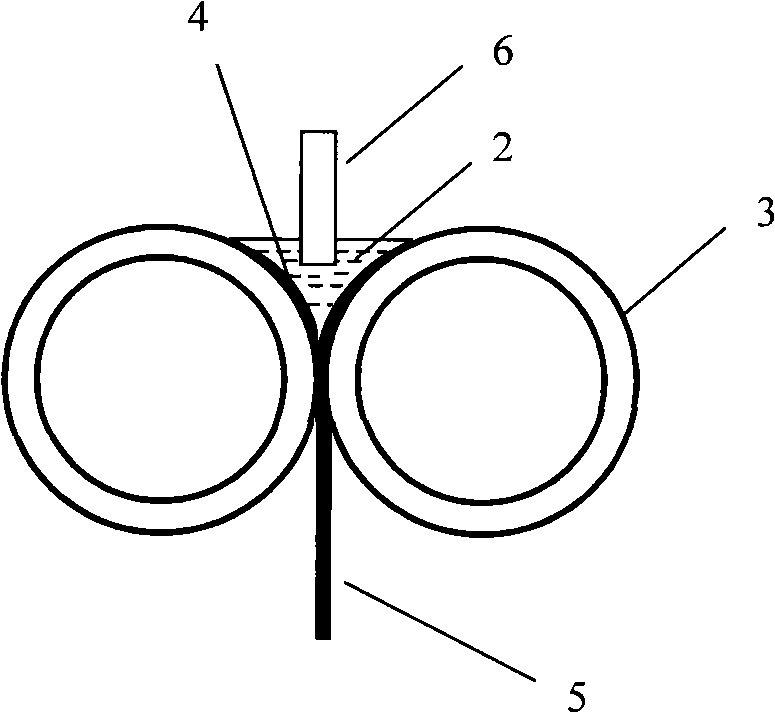

Continuous casting technique for aluminum alloy thin belt blank

InactiveCN101269406AImprove organizationComprehensive mechanical properties of high thin stripIngotMaterials science

The invention discloses a continuous casting process of an aluminum thin billet, which is characterized in that the following steps are included: aluminum alloy ingots are preheated and are melted in a melting furnace in the role of a flux; before casting, a side closure system is preheated to 400-450 DEG C, when the temperature of a melting body ranges from 650 DEG C to 680 DEG C, the aluminum alloy ingots are arranged into a tundish for 15 to 30 minutes in the role of the flux, then through a flux distributing device, the aluminum alloy ingots flow into an equant vertical twin-roll thin strip billet continuous caster, with a left forging seam gap being 0 mm and maintaining the height of a melting pool between 90 mm and 340 mm, the casting is carried out in a sinking way; when in casting, the casting speed of the casting machine ranges from 20 to 120m / min, the thin strip blank is sent into a pinch roll after leaving a casting roller, and the forged aluminum alloy thin strip has a thickness between 1.0 mm and 3.5 mm. The continuous casting process can directly make aluminum alloy thin strip blank from the liquid aluminum alloy, the forged thin strip blank has good quality on the surface, and the internal organizational structure is uniform, thereby being conducive to succeeding rolling processes. The continuous casting process for an aluminum thin blank has short process and low cost.

Owner:CHONGQING UNIV

Method for manufacturing pure titanium seamless tubes

ActiveCN101708511ASimple processImprove efficiencyMetal rolling arrangementsRoll speed control devicePunchingTitanium

The invention relates to a method for manufacturing pure titanium seamless tubes. The method is characterized by comprising the following steps of: preparing tube blank bars; machining the tube blank bars; diagonally rolling and punching holes: heating blank to 700 to 980 DEG C, punching holes once or twice by utilizing a two-roll diagonally rolling mill group, wherein molybdenum mandrels or water-cooled mandrels are utilized, the inclined angle of punching roll is 8 degrees, the number of revolutions of the roll is 40 to 90 basic speed to 195 r / min; preparing the pierced billet after punching hole, wherein the specifications of the pierced billet are that the outside diameter is phi 72 to phi 125mm,the wall thickness is 5 to 20mm, and the length is; carrying out cold rolling; and carrying out heat treatment on finished product, detecting performance and entering warehouse. The invention has the characteristics of high production efficiency, low production cost, high material yield, short production period, low device investment, better product quality, and the like. The produced pure titanium seamless tubes have good quality, the mechanical properties accord with state requirements, and the pure titanium seamless tubes can meet the need for large-scale industrial production.

Owner:PANGANG GROUP SICHUAN CHANGCHENG SPECIAL STEEL

Cold-rolled sheet rolling emulsified oil containing modified nano copper and preparation method thereof

The invention relates to a cold-rolled sheet rolling emulsified oil containing a modified nano copper and preparation method thereof, which belong to the field of organic chemistry. The emulsified oil comprises the following components, in percentage by weight: 54-80% of a base oil, 15-32% of an oiliness agent, 0.1-1% of a modified nano copper particle, 2-4% of an extreme pressure agent, 0.5-2% of an anti-rusting agent, 2-6% of an emulsifier, 0.4-1% of an anti-oxidant, 0.03-0.1% of an anti-foaming agent, and 0.2-0.6% of an anti-mildew agent. The cold-rolled sheet rolling emulsified oil containing the modified nano copper is diluted with water into a 2-6 wt% emulsion, and the emulsion is directly used in the cold rolling process of the strip steel and has very good lubrication, cleaning property of the rolling mill and annealing cleaning property, after annealing, the steel plate not subjected to degreasing has a clean surface without pollutants, so as to satisfy rolling production requirement under high pressure at high speed.

Owner:NORTHEASTERN UNIV

Micro-alloying steel for oil gas transport seamless pipeline and its preparation method

InactiveCN101186994AElimination of abnormal tissueImprove toughnessTemperature control deviceForeign matterChemical composition

The invention discloses micro-alloying seamless pipeline steel and process for preparation. According to weight percentage, the range of the chemical components of the invention includes that C holds 0.08% to 0.20%, Si is equal to or less than 0.04%, Mn takes 0.60% to 1. 50%, S is equal to or less than 0.015%, P is equal to or less than 0.025%, Al is equal to or less than 0.04%, Ti is equal to or less than 0.04%, H is equal to or less than 2.5*10-4%, O is equal to or less than 25*10-4%, the rest is Fe and unavoidable foreign matters. The process for preparation comprises technique steps, including smelting, refining, continuous casting, hot rolling and slow cooling. Round steel with the size of phi 70 to 150 millimeters can be produced by the process for preparation. The seamless pipeline steel of the invention has perfect anti-sulphide stress corrosion (SSC resistance) capability and anti-HIC property. The pipeline steel which can substitute for welding pipe can be utilized in the filed of oil pipeline and the like, and the invention increases the reliability of material and adaptability of variety, in particular being adaptable for the low submarine temperature and corrosion-resistant environment and for manufacture of thick-walled tubes.

Owner:LAIWU IRON & STEEL GRP

Method of sheet billet continuously casting and rolling to produce thin strip steel coil

ActiveCN101108394AShort production processSave construction investmentMetal rolling arrangementsProduction lineStrip mill

A method of using thin plate adobe continuous casting and rolling to producing thin band steel coil is provided, which belongs to rolling metal at once after continuous casting, in particular relating to thin standard band steel production method. The invention is characterized in that: a conticaster, a swing shear, a roller-hearth type heating furnace, a scale breaker, a vertical miller, 7 mill groups, laminar flow cooling device and reeling machine are connected to a CSP produce line, the produce line adopts reasonable temperature system, rolling equipment, rolling way and combining with cooling after rolling, the molten steel after continuous casting is a casting adobe of 50 to 70mm thick and 900 to 1300 wide, after cutting, heating, scale breaking, proceed continuous rolling to form a thin band of 1.2 to 1.5mm thick and 900 to 1300 wide, then after cooling to reel steel coil. The production flow is short, the equipment is few, the investment is less and the running expense is low; The technics and equipment is reasonable and high efficient, double locomotive and double flow casting, heating by two furnaces, seven rolling machines roll continuously, the production is smooth and saves energy with high production efficiency; the product performance is even and stable, the board shape is regular with high accuracy and good surface quality.

Owner:MAANSHAN IRON & STEEL CO LTD

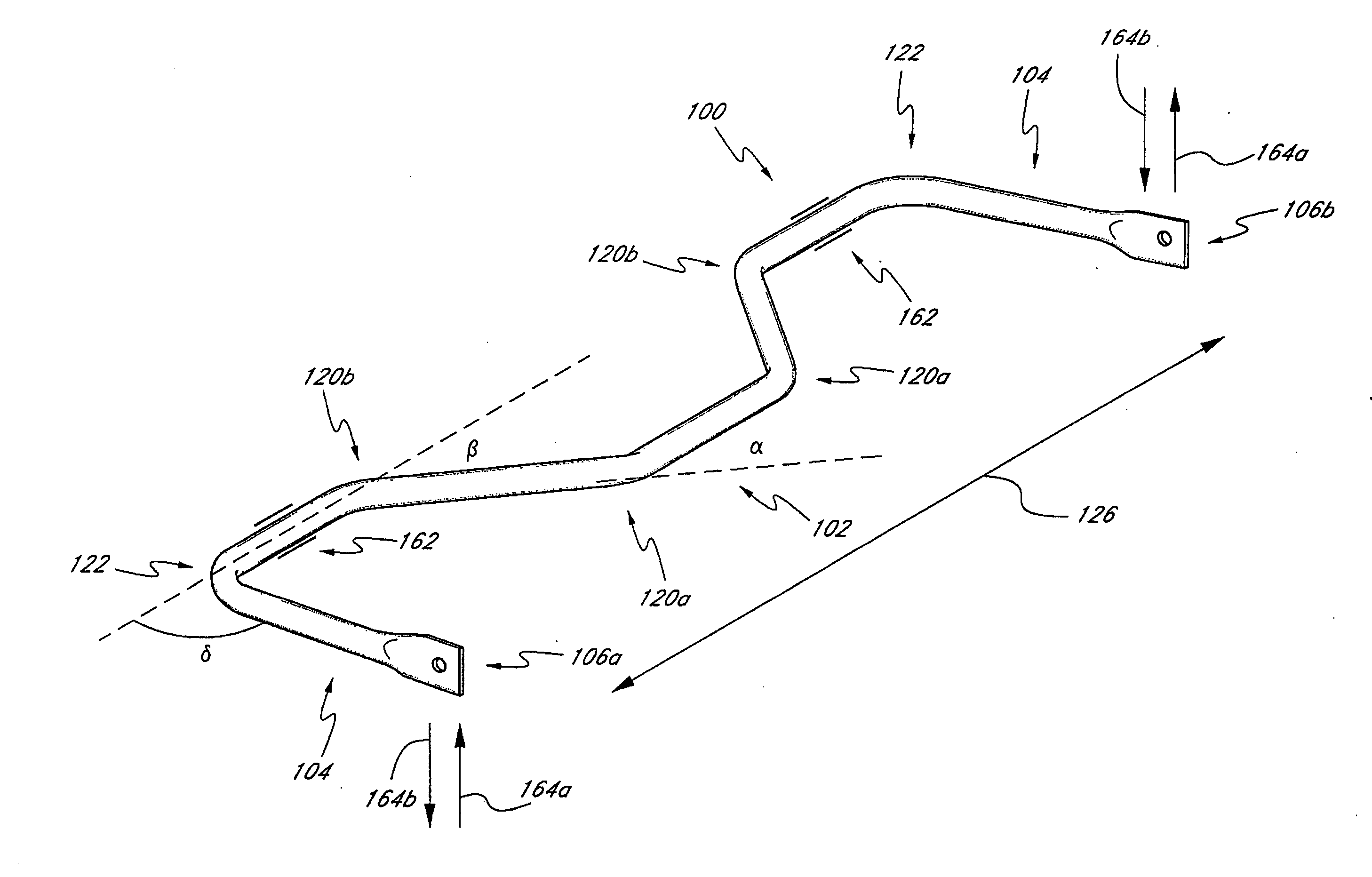

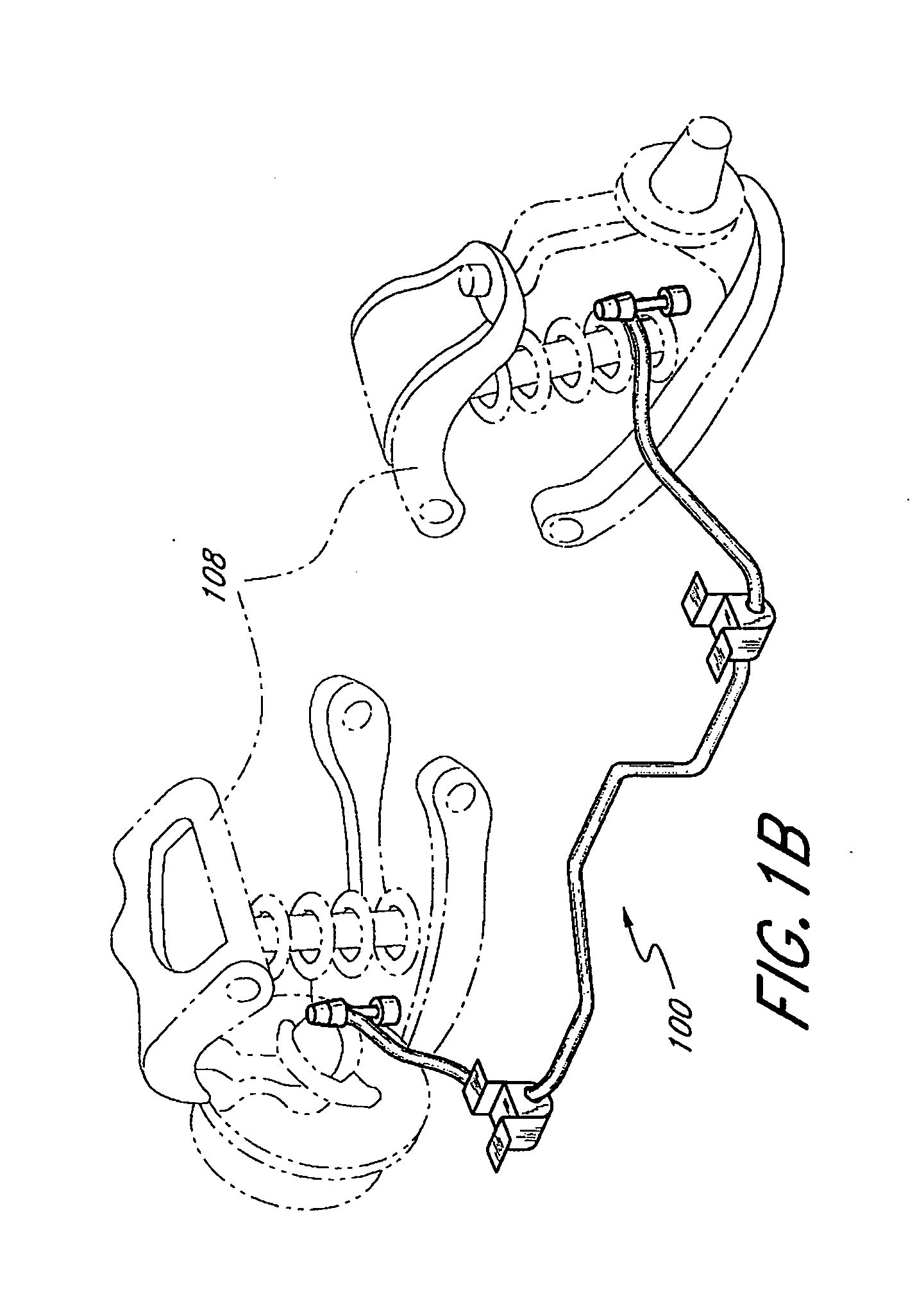

Methods of producing high-strength metal tubular bars possessing improved cold formability

ActiveUS20070216126A1Maintain mechanical propertiesOvercome problemsTorsion springsInduction heatingAlloyHigh intensity

A method for producing a tubular bar, more particularly a stabilizer bar, is provided. The method comprises providing a tubular bar of desired size having an outer and inner surface, heating the bar to an elevated temperature, quenching the bar by application of a cooling fluid to the surfaces of the bar, and forming the tube to a desired shape without annealing. The method further provides for the composition of a high-strength, high formability carbon steel alloy to be used in conjunction with the method. Advantageously, the bar is formable without thermal processing subsequent to quenching. In this fashion, metal tubular bars, such as stabilizer bars, may be formed at reduced cost.

Owner:TENARIS CONNECTIONS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com