Patents

Literature

1872 results about "Light curing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A curing light is a light which is designed to rapidly cure a resin. Curing lights are used primarily in the dental industry, where they are used in fillings, sealants, and adhesives for various dental procedures. Other versions of the curing light can be seen in use in manufacturing, where rapid...

Ceramic slurry preparation and 3D (three dimensional) printing light curing molding method

ActiveCN106810215ALow viscosityHigh solid contentAdditive manufacturing apparatusCeramic shaping apparatusFlexural strengthVolumetric Mass Density

The invention provides a ceramic slurry preparation and 3D (three dimensional) printing light curing molding method. 25-85vol% of ceramic powder and 15-75vol% of an optical resin premix solution are mainly involved, and the method includes: A), preparation of the optical resin premix : namely stirring a low polymer, a reactive diluent, a photoinitiator, a dispersing agent, a photosensitizer and a sensitizer according to a certain proportion under intermediate speed for 0.5-3 hours to enable the components to be mixed evenly; B), placing the premix solution and the ceramic powder in a ball mill according to certain volume for ball-milling for 5-15 hours to prepare the ceramic slurry high in solid content and low in viscosity; subjecting the ceramic slurry to curing molding layer by layer gradually on a 3D light curing molding machine to obtain a ceramic green body prior to aftertreatment of drying, degreasing, sintering and the like to obtain ceramic part. The method is high in preparation molding precision and free of molds to prepare complex structure parts, the ceramic product can reach more than 92% in density, 320-1750MPa in flexural strength and 1800-4500MPa in compression strength.

Owner:重庆摩方科技有限公司

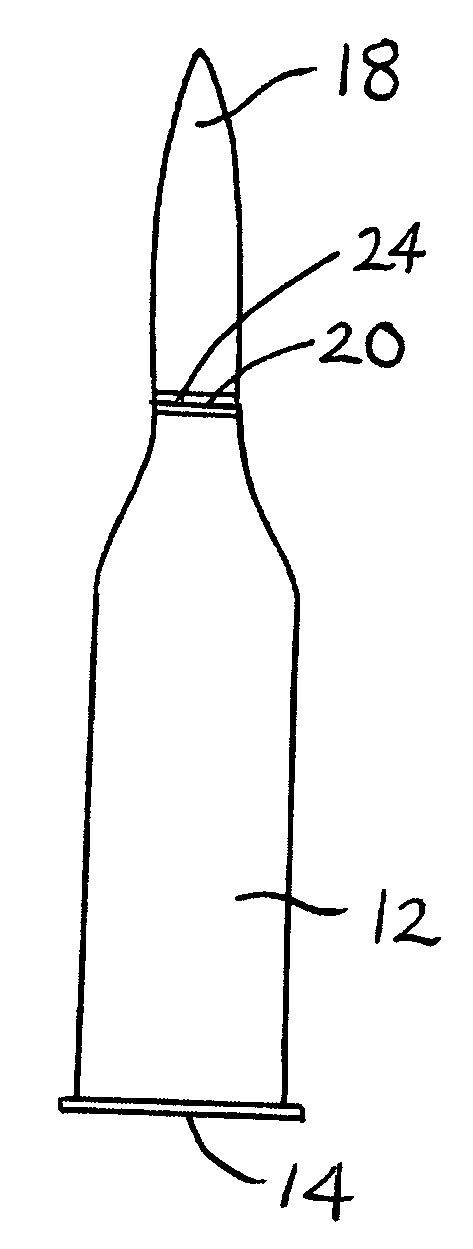

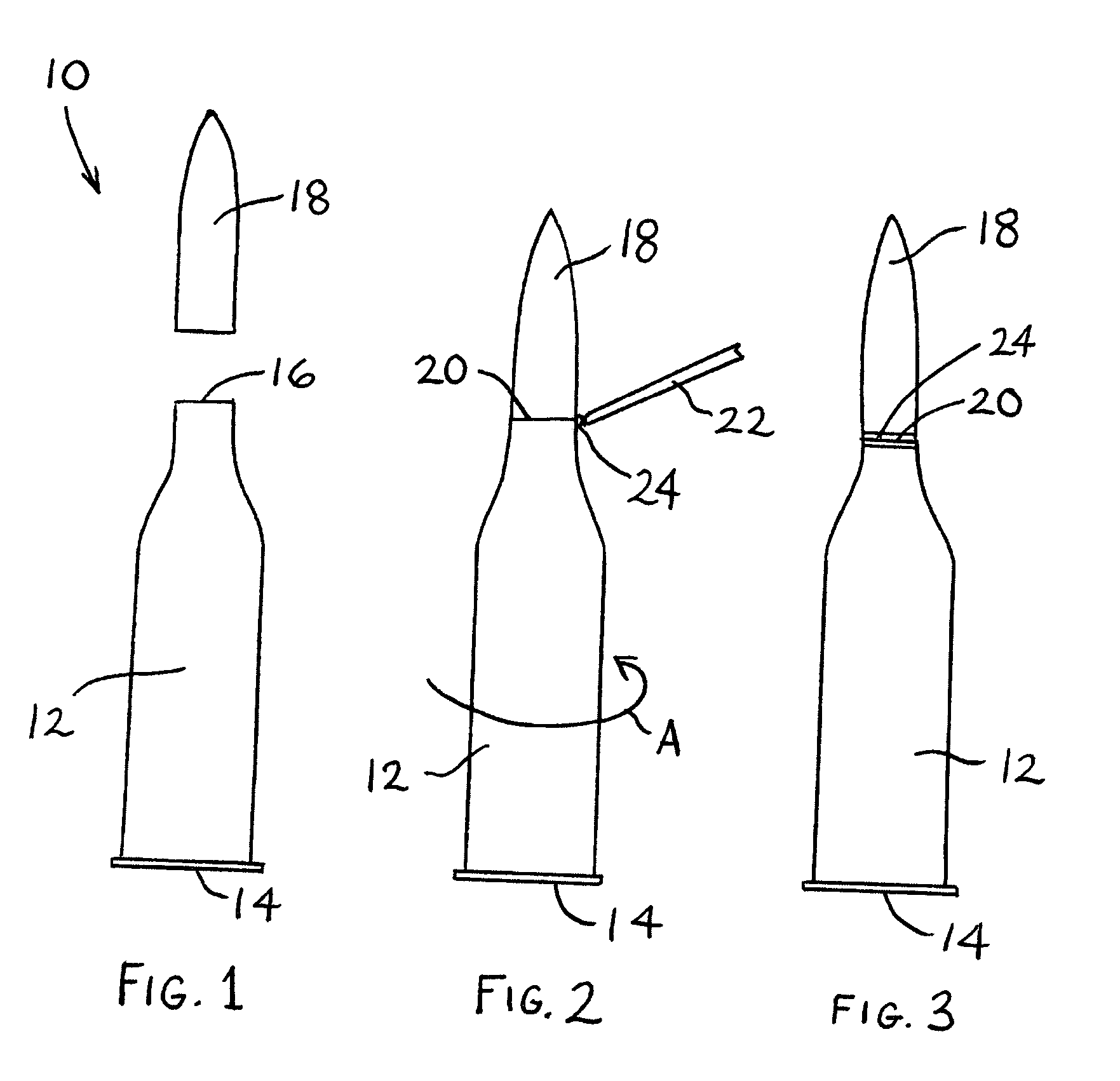

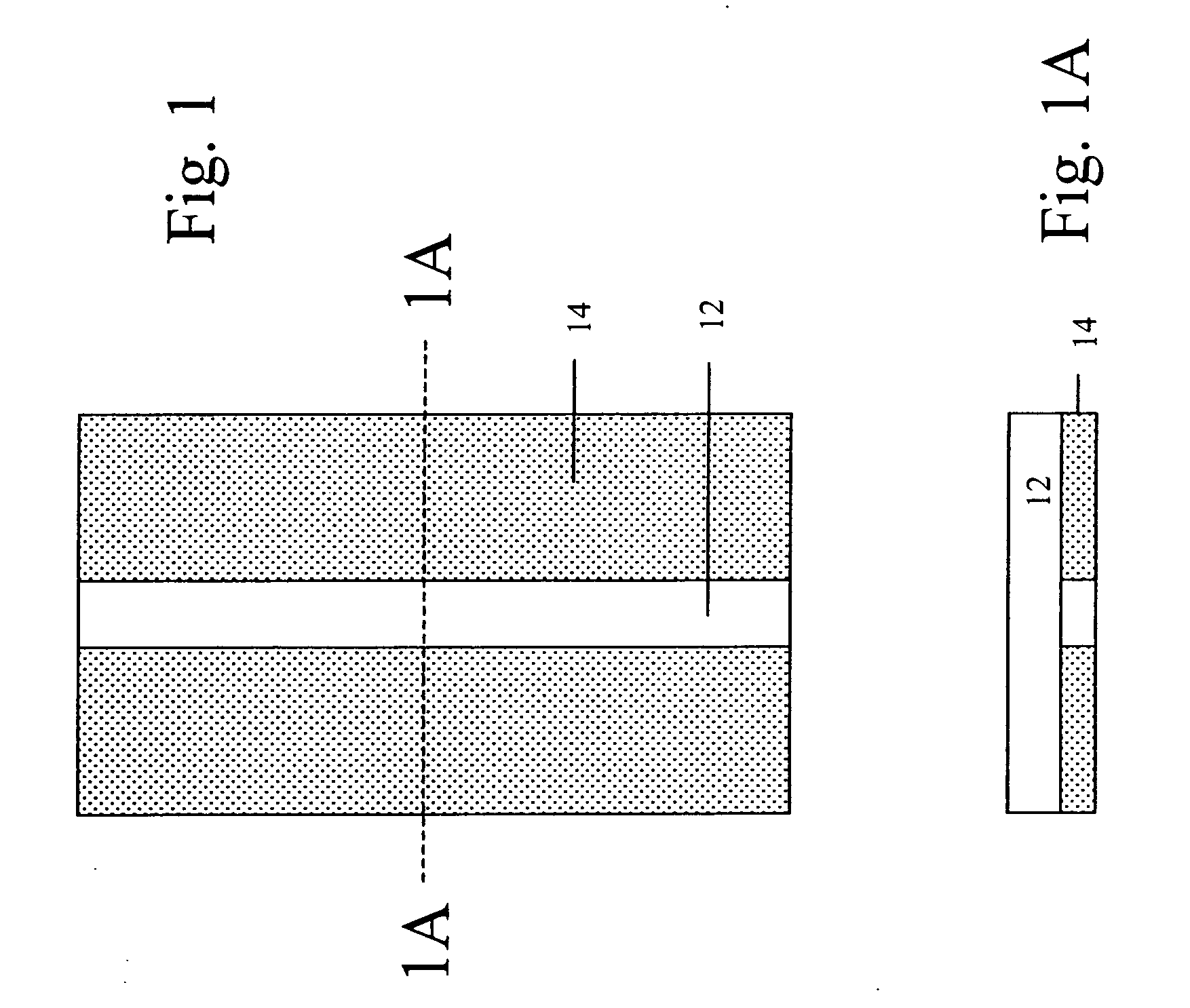

Ammunition articles comprising light-curable moisture-preventative sealant and method of manufacturing same

ActiveUS20050056183A1Ammunition projectilesAmmunition testingHigh volume manufacturingProcess engineering

A process for manufacturing an ammunition article, including: (a) providing a cartridge including a projectile disposed in a casing and presenting a joint between the projectile and the casing; (b) applying to the joint a sealingly effective amount of a light-curable sealant composition; and (c) exposing the applied sealant composition to curingly effective light. The resulting ammunition article is sealed at the projectile / casing joint against moisture incursion, and such article is amenable to high-speed, high-volume production by the method of the invention.

Owner:BEACON ADHESIVES INC

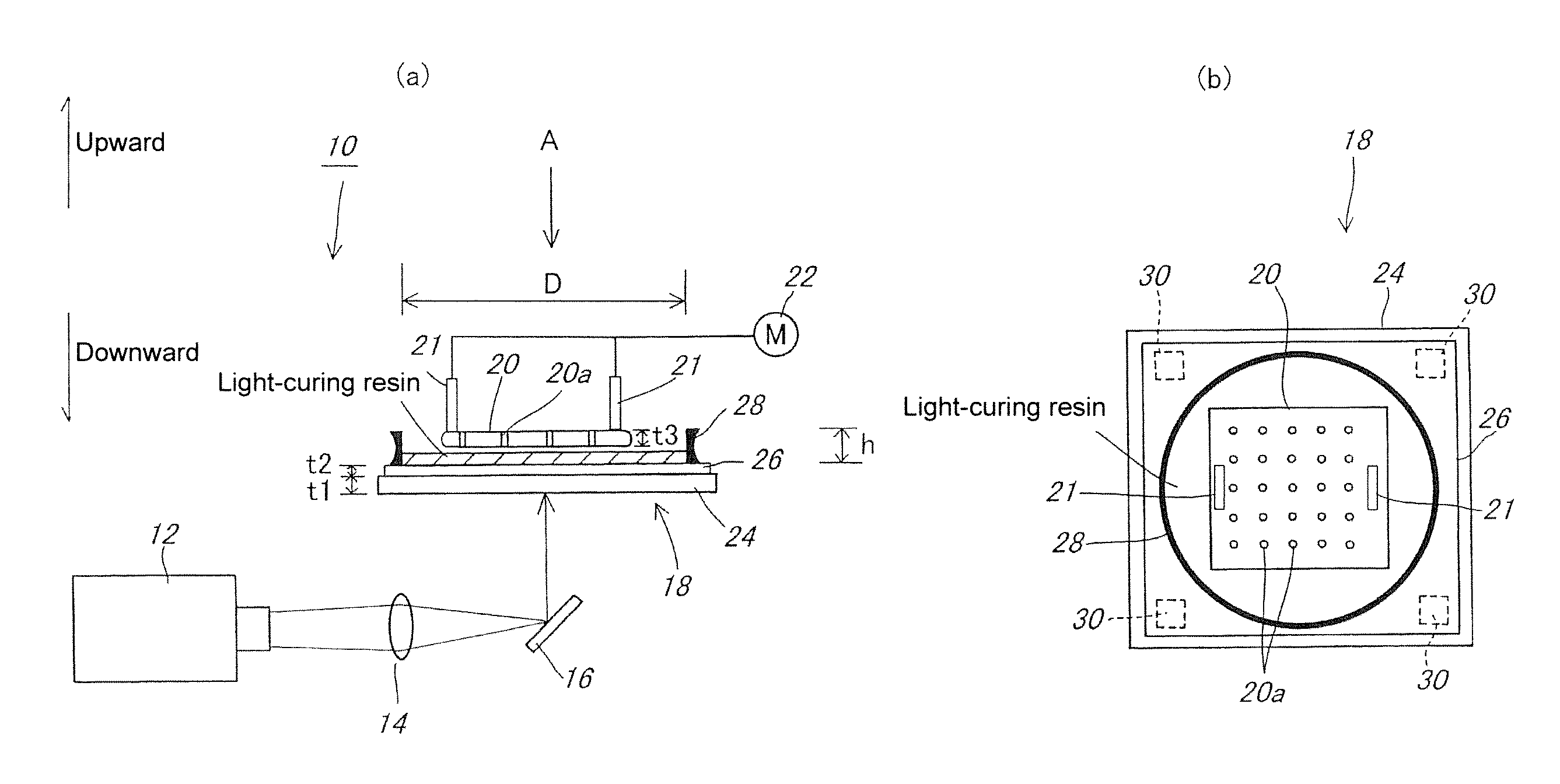

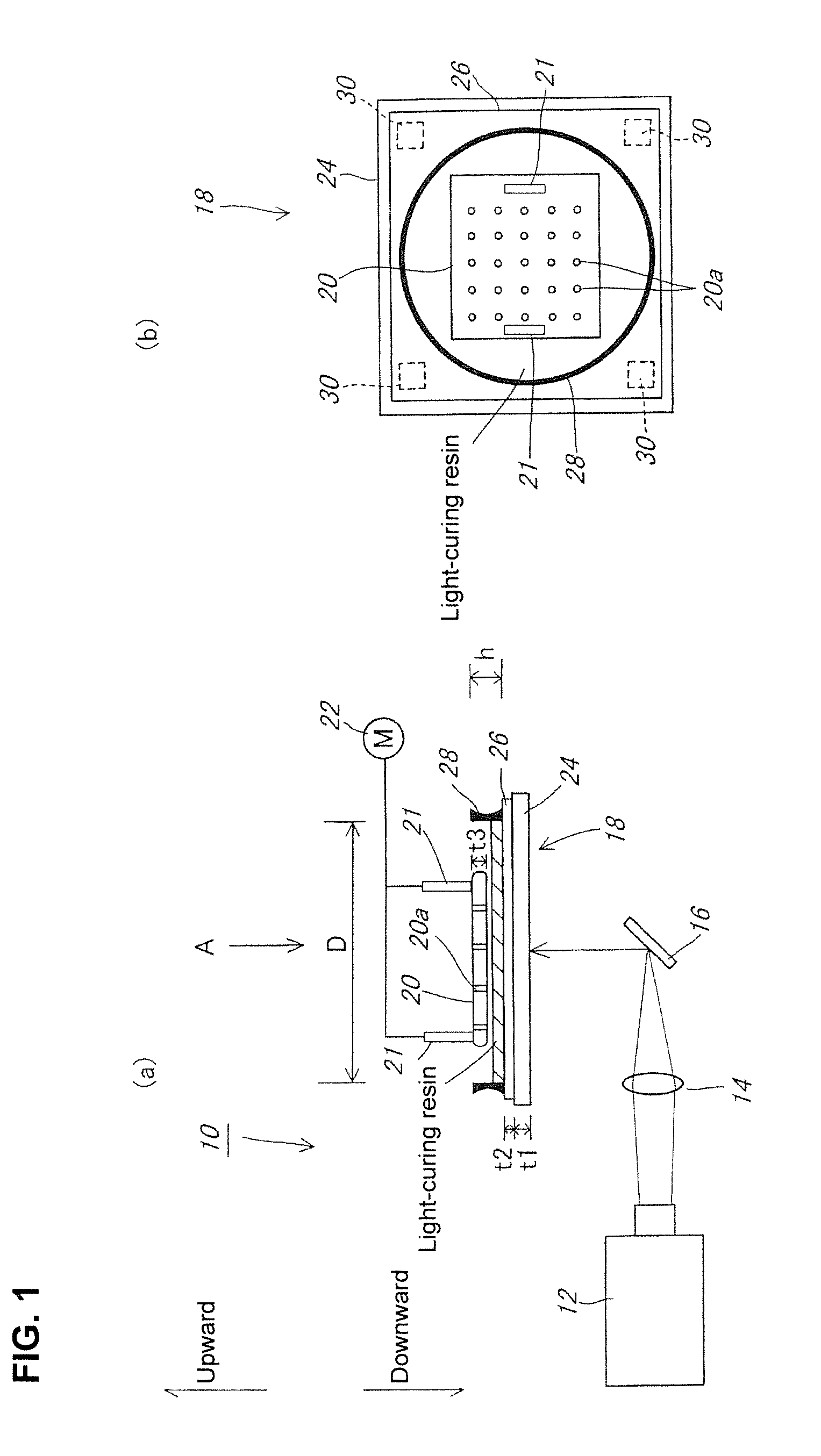

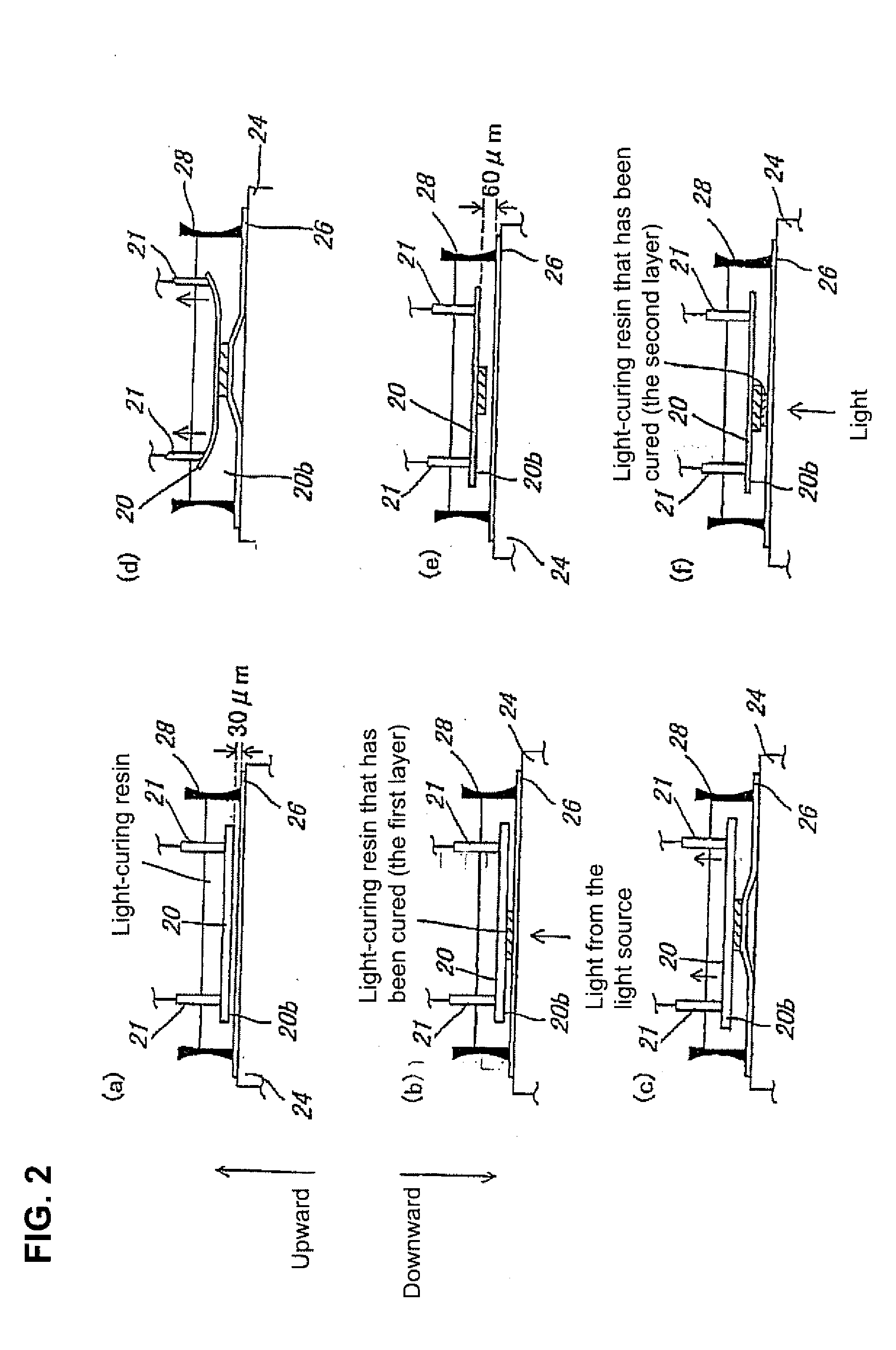

Three-dimensional molding device

InactiveUS20080174050A1Manufacturing platforms/substratesConfectioneryPolymer chemistryMaterials science

The present invention relates to a three-dimensional molding device for producing a three-dimensional molded object. The three-dimensional molding device comprises a receptacle for retaining a light-curing resin, a light source for irradiating light to cure the light- curing resin retained inside the receptacle, wherein the three-dimensional molded object is produced by curing the light-curing resin, and a flexible three-dimensional molded object holding plate, which adheres to the light-curing resin and holds the three-dimensional molded object when the resin in the receptacle is cured.

Owner:LG ELECTRONICS INC

Ceramic material for 3D light curing formation printing and preparation method of ceramic element

InactiveCN109400177AHigh ceramic contentEasy to printAdditive manufacturing apparatusOligomerAgent Combination

The invention relates to a ceramic material for 3D light curing formation printing and a preparation method of a ceramic element. The ceramic material is prepared from 30 to 70 vol percent of ceramicpowder and 30 to 70 vol percent of photosensitive resin premixed liquid, wherein the photosensitive resin premixed liquid is prepared from 37 to 50 weight percent of oligomers, 30 to 60 weight percentof reactive diluents, 0.1 to 5 weight percent of photoinitiators, 1 to 5 weight percent of dispersing agents, 0.1 to 0.6 weight percent of ultraviolet blocking agents, 0 to 0.05 weight percent of polymerization inhibitors, 1 to 4 weight percent of anti-foaming agents, 0.5 to 2.35 weight percent of anti-settling agents and 0.3 to 3 weight percent of leveling agents. In the degreasing and sinteringpost-treatment work procedures, specific parameters are used, so that a sintering element can reach good sintering density and mechanical performance. By optimizing the composition and the proportionof light curing ceramic resin, and selecting the excellent dispersing agent combination and the reasonable consumption, the ceramic powder can be better dispersed in the resin; the problems that theexisting light curing ceramic resin has poor flowability and low formation precision, and that a finally prepared ceramic product can easily generate cracks or deformation, and the like are solved.

Owner:西安点云生物科技有限公司

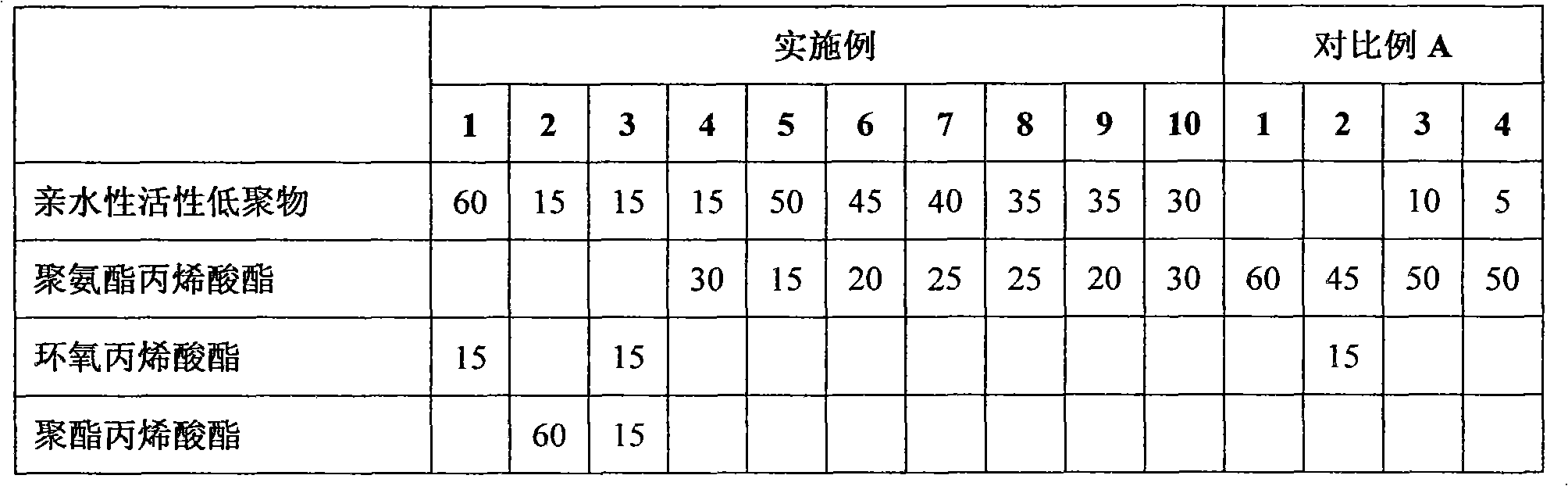

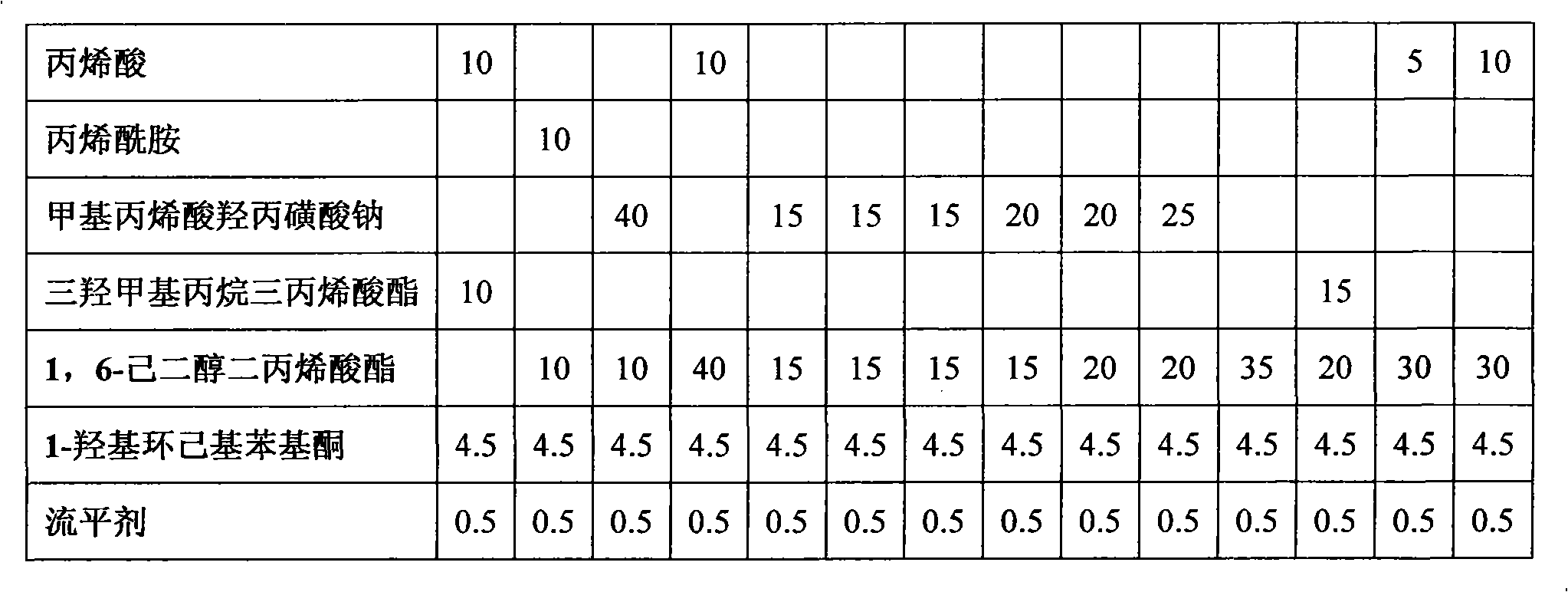

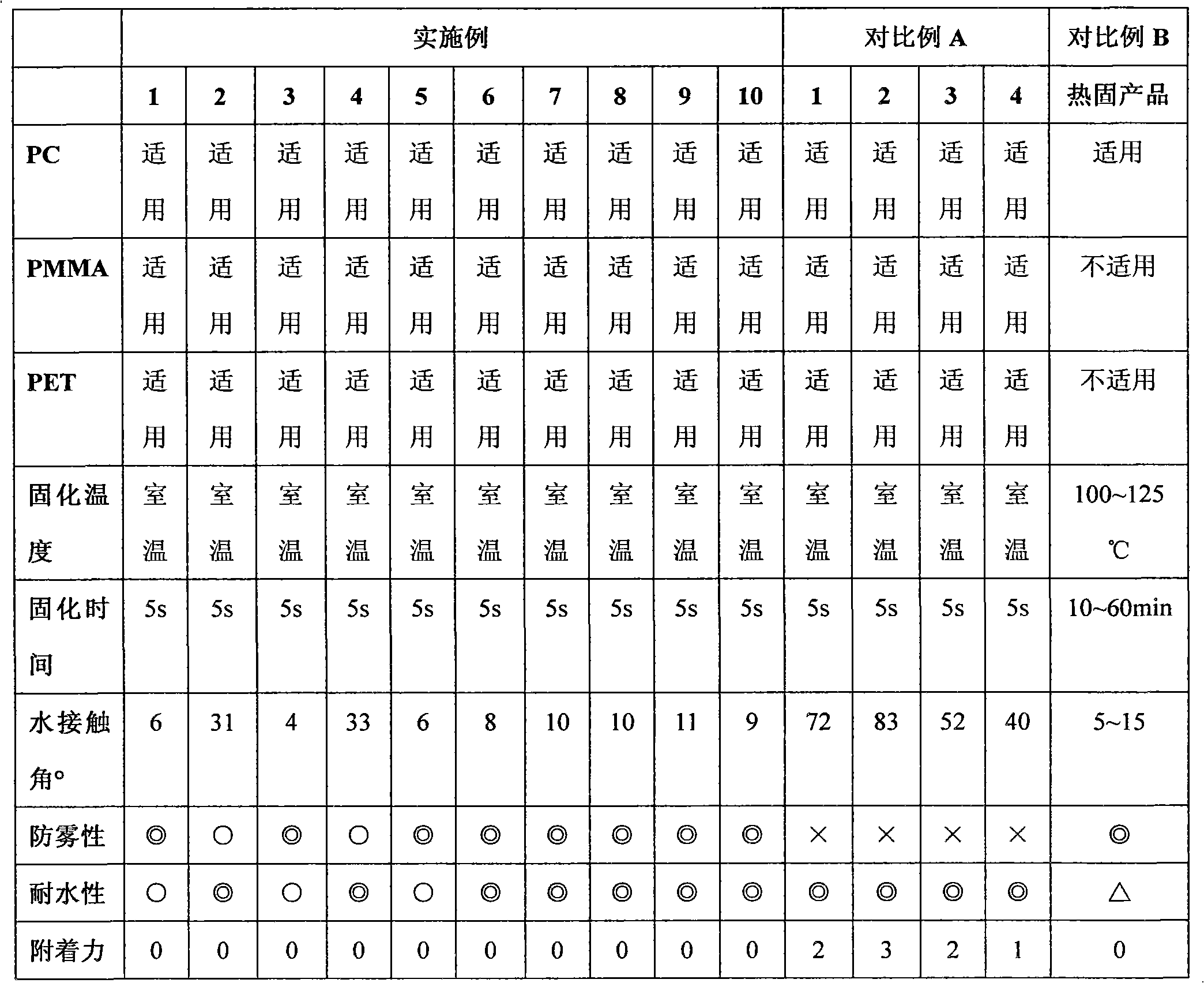

Ultraviolet light curing anti fogging coating composite and preparing method thereof

InactiveCN101602913ASimple production processIncrease productivityPolyurea/polyurethane coatingsPolyether coatingsOligomerUltraviolet lights

The invention relates to an ultraviolet light curing anti fogging coating composite with fine anti fogging effect and a preparing method thereof. The ultraviolet light curing coating composite comprises hydrophilic activated oligomer, hydrophobic light curing resin, hydrophilic polymeric monomers, hydrophobic activated diluent, photoinitiator and additive. The method comprises the following steps: accurately weighting and placing the hydrophilic activated oligomer and the hydrophobic light curing resin into a container, adding the hydrophilic polymeric monomers, the activated diluent and the additive in turn to mix for 10min, and then adding the photoinitiator, mixing for 5min to obtain the composite in the invention which is preserved in dark place. The ultraviolet light curing anti fogging coating composite provided by the invention can be coated on thermal sensitivity plastic base material such as PC, PMMA, PET and the like; the coating after the ultraviolet light curing has fine hydrophily and physical performance. The invention has fine anti fogging and fog inhibiting effect, and the coating has good adhesive force and water resistance which can ensure the durability of the anti fogging performance.

Owner:GUANGZHOU HUMAN CHEM

Graphene oxide/light cured resin composite and its preparation method and application

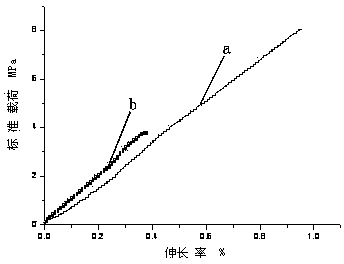

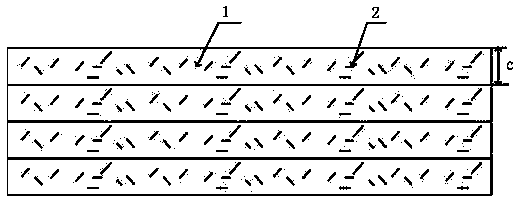

The invention provides a graphene oxide / light cured resin composite and its preparation method and application, the graphene oxide / light cured resin composite comprises two phases of graphene oxide and light cured resin, the graphene oxide is evenly dispersed in the light curing resin, the content of the graphene oxide is 0.1-1wt%, and the light cured resin comprises an oligomer, a light initiator and an active diluent. A graphene oxide nano material is dispersed in the light curing resin to obtain the graphene oxide / light cured resin nano composite, elongation at break and maximum bending strain of ordinary light cured resin is improved to a certain extent, and the impact strength of a coating film is increased by 2 times, so that a part printed by a 3D printer has better mechanical property.

Owner:QINGDAO UNIV OF SCI & TECH

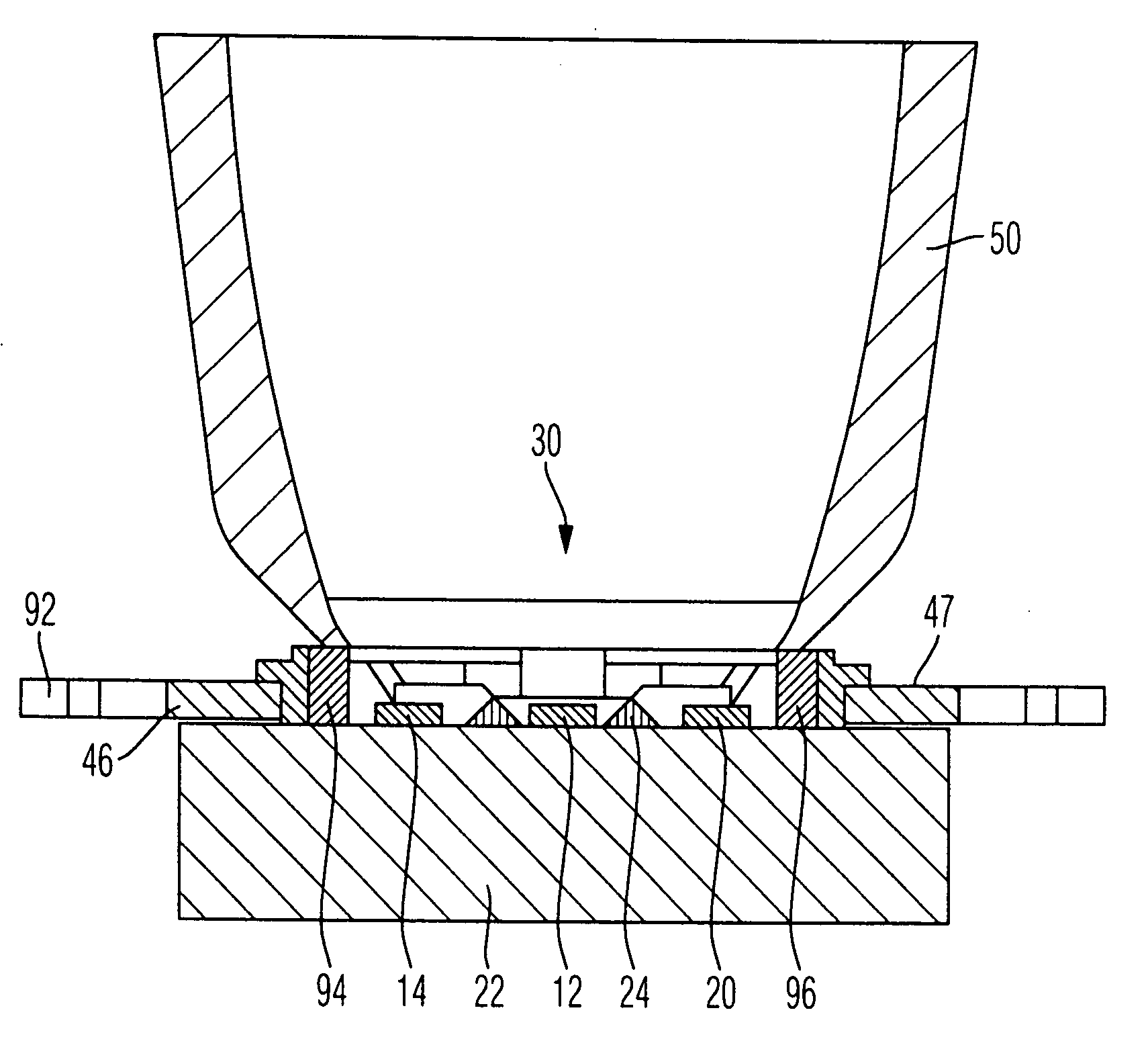

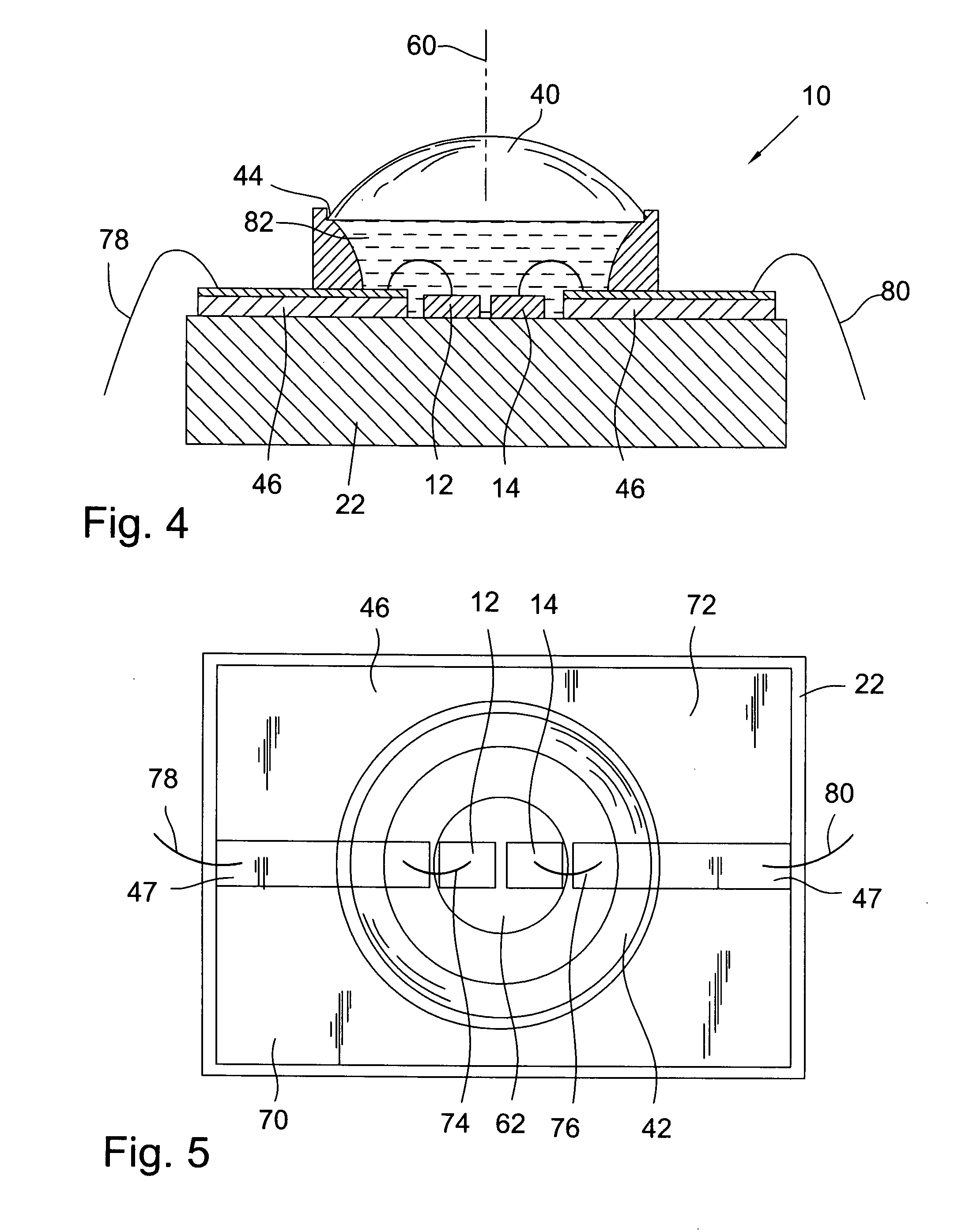

Semiconductor radiation source and light curing device

InactiveUS20070228392A1Enhanced radiationRaise the ratioDentistrySolid-state devicesEngineeringPrinted circuit board

A semiconductor radiation source has a base body on which at least two LED chips are directly mounted and are fitted to the base body using a thermally conductive connection. At least one printed circuit board is mounted on the base body and extends from the centrally arranged LED chips to the outside, in particular to the peripheral region of the base body, and projects, in particular, into free areas which extend laterally beside the chips or between the latter.

Owner:IVOCLAR VIVADENT AG

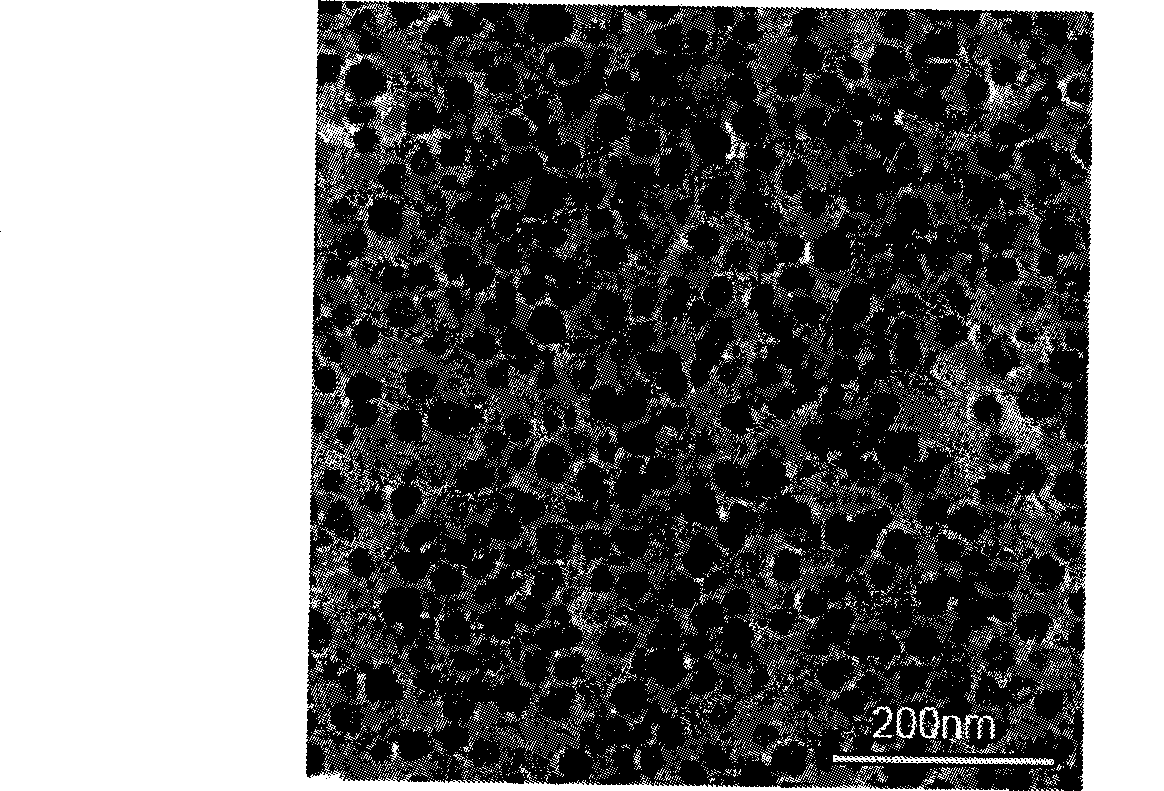

Light curing nano composite coating

The invention relates to a photo-cured nanometer composite material which consists of 0 to 64 weight percent of film forming substance, 1 to 60 weight percent of inorganic nanometer particles, 1 to 56 weight percent of active thinner, 1 to 9.3 weight percent of evocating agent, 0 to 8 weight percent of coating additive and 0 to 31 weight percent of solvent. The manufacturing method comprises the following steps: (1) the prepared photo-cured nanometer composite material is counted by 100 weight percent; according to the proportion, each composition is weighed; (2) through a sol-gel method, a mechanical dispersion method or the combination of two methods, the inorganic nanometer particles are introduced to the active thinner to obtain a mixed master material; and (3) the mixed master material, an oligomer, the evocating agent, the coating additive and the solvent are mixed and evenly stirred to prepare the photocuring nanometer composite material. The photocuring nanometer composite material has the characteristics of high content of nanometer particles, good levelling performance, high transparency, good lustrousness, high adhesive force with a polymer substrate, high rigidity, scratching resistance, ultraviolet resistance and the like.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

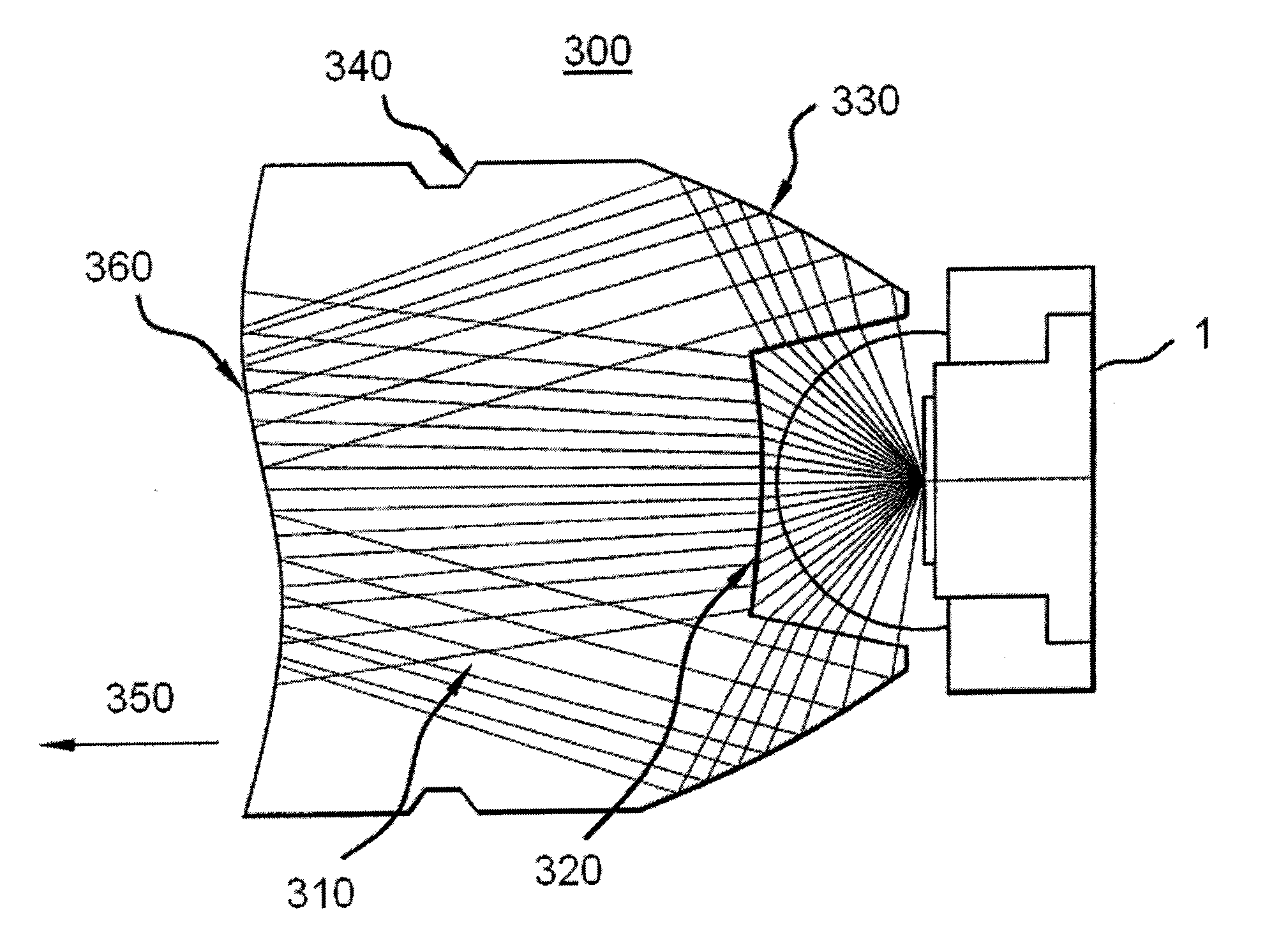

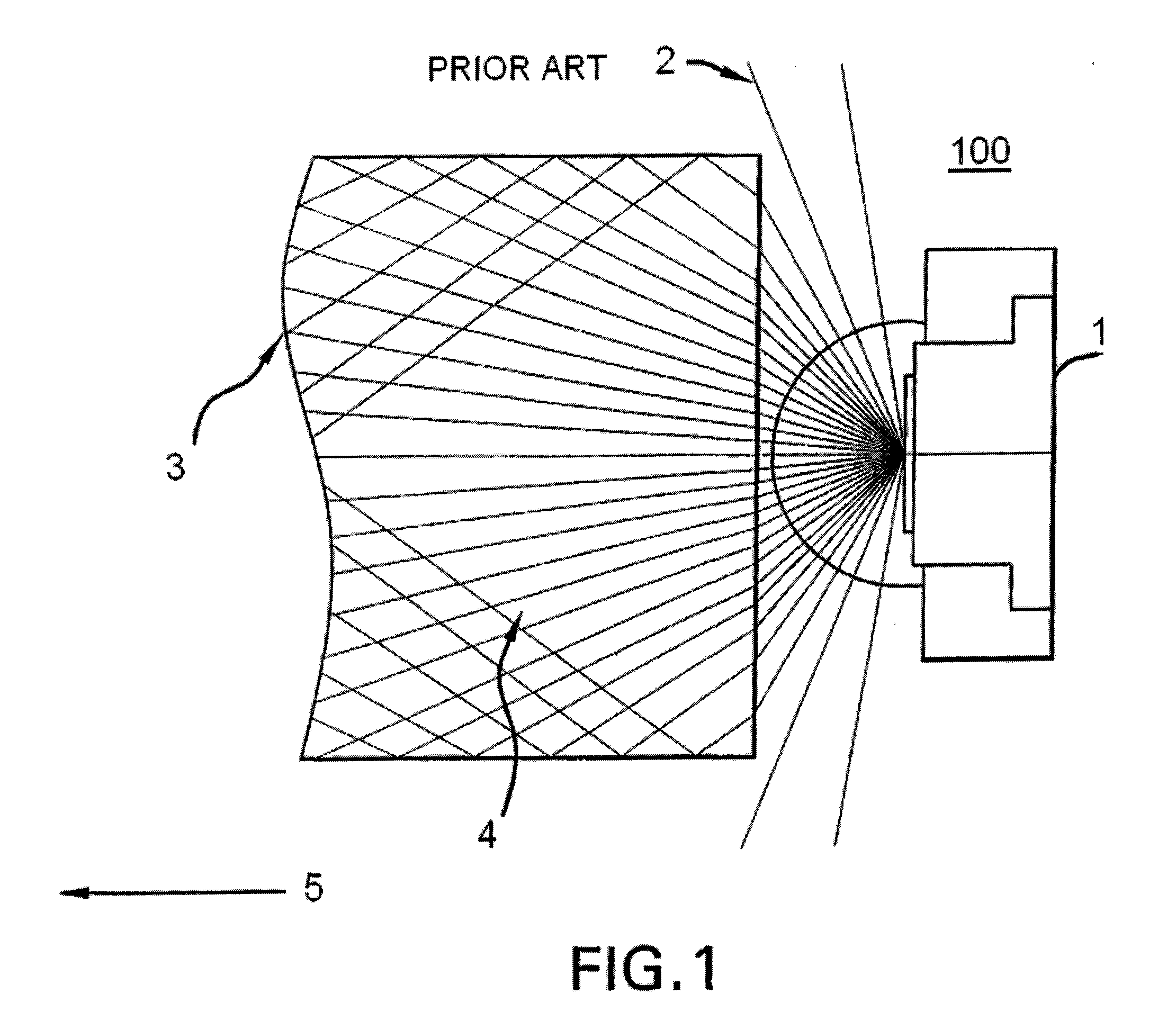

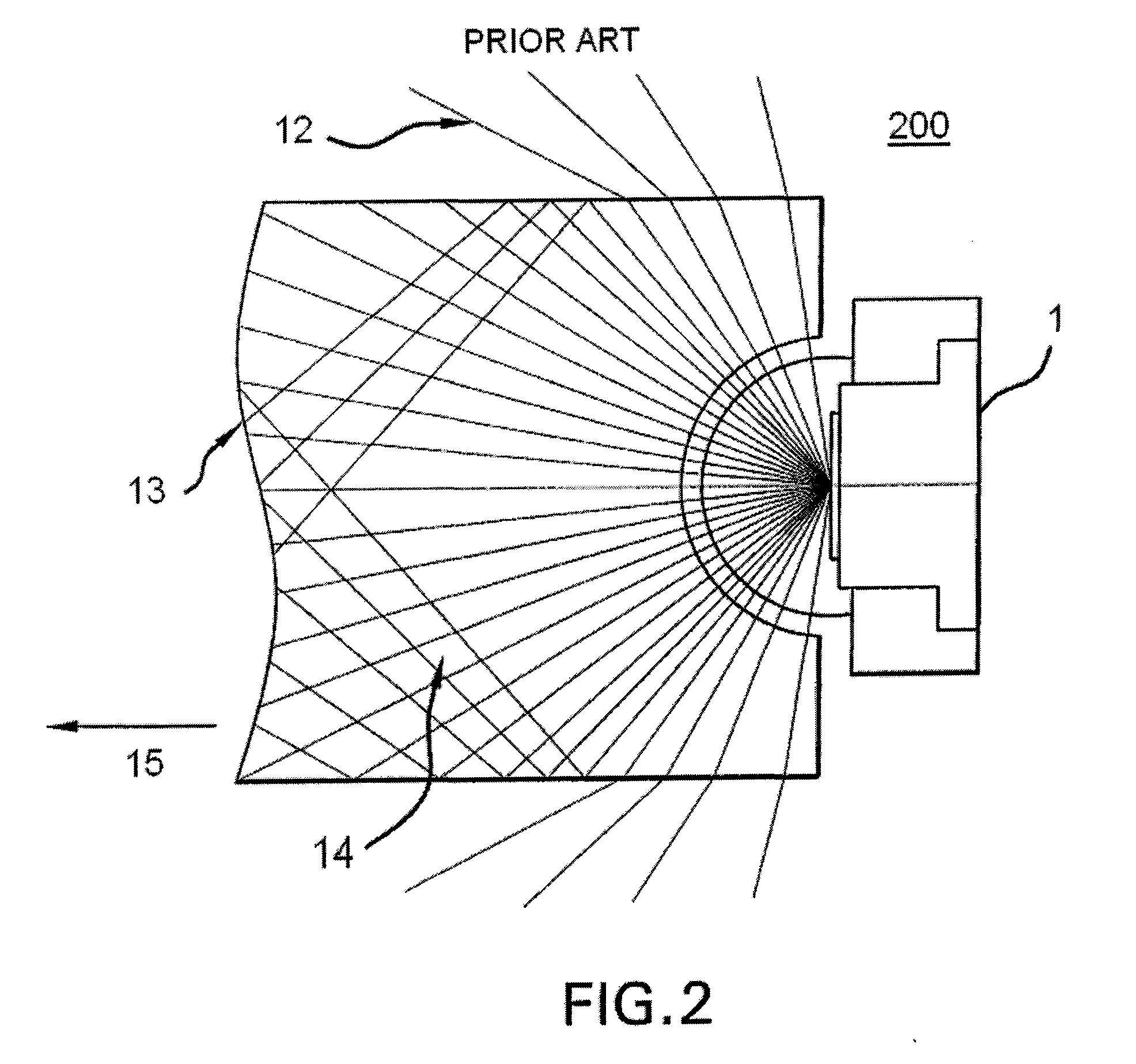

Dental illumination device with single or multiple total internal reflectors (TIR)

The present invention relates generally to a device that attaches to one or more Light Emitting Diode (LED) light source(s) to transmit and distribute light energy simultaneously across the arches of upper and lower teeth for dental tooth whitening and photo initiation of light curing resins while at the same time retaining the benefits of the light source(s) to be used for individual tooth whitening and curing.

Owner:DEN MAT HLDG

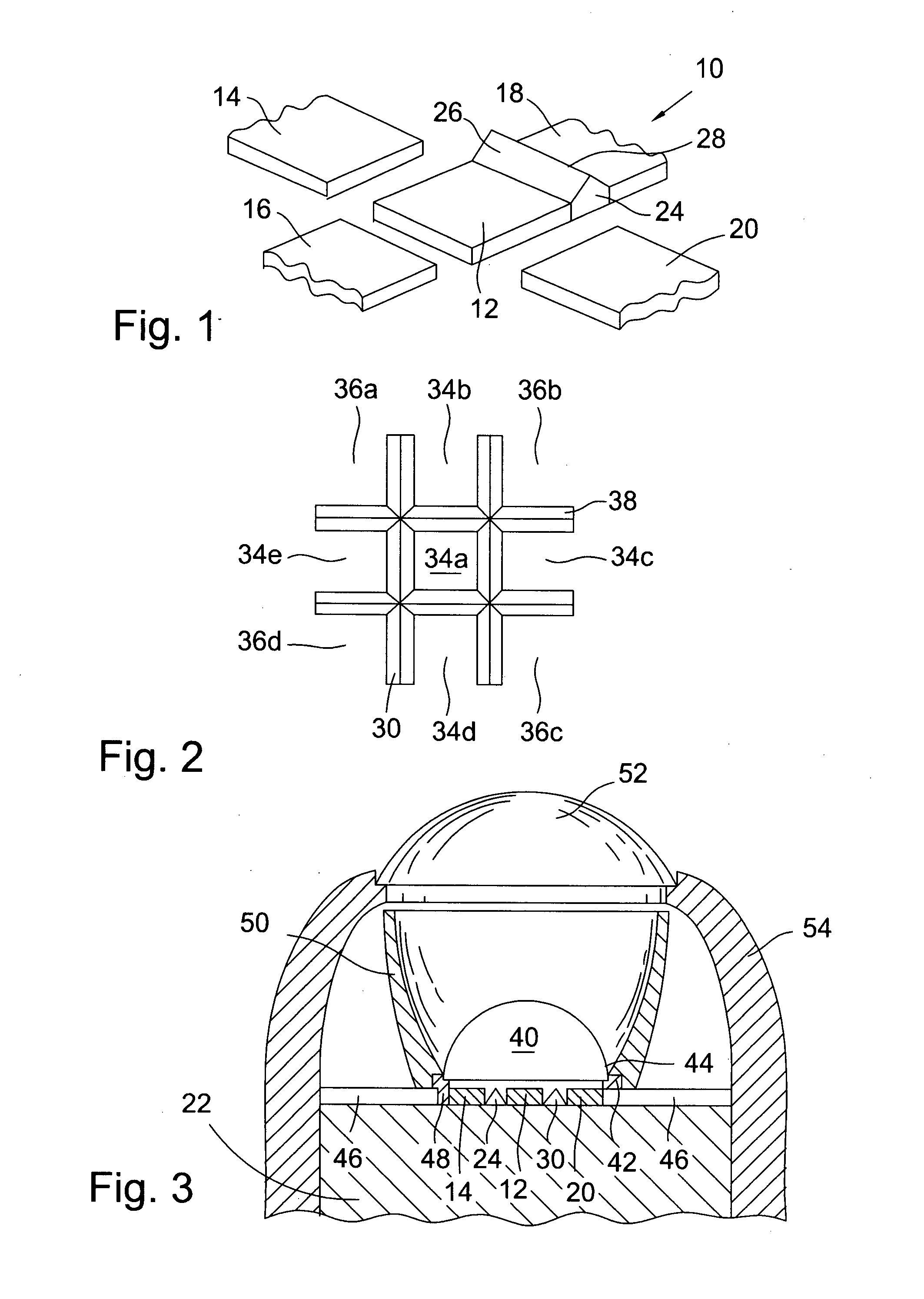

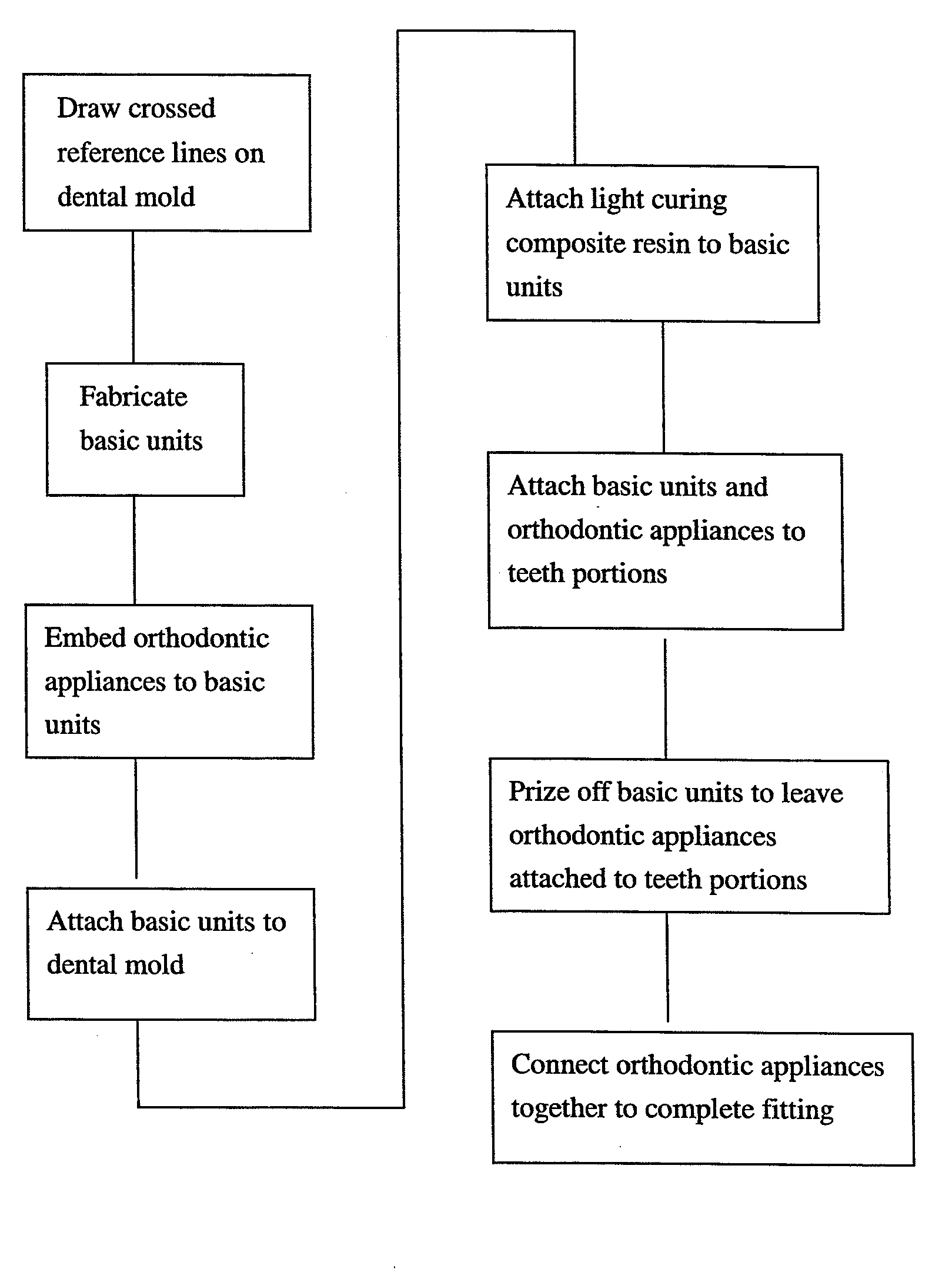

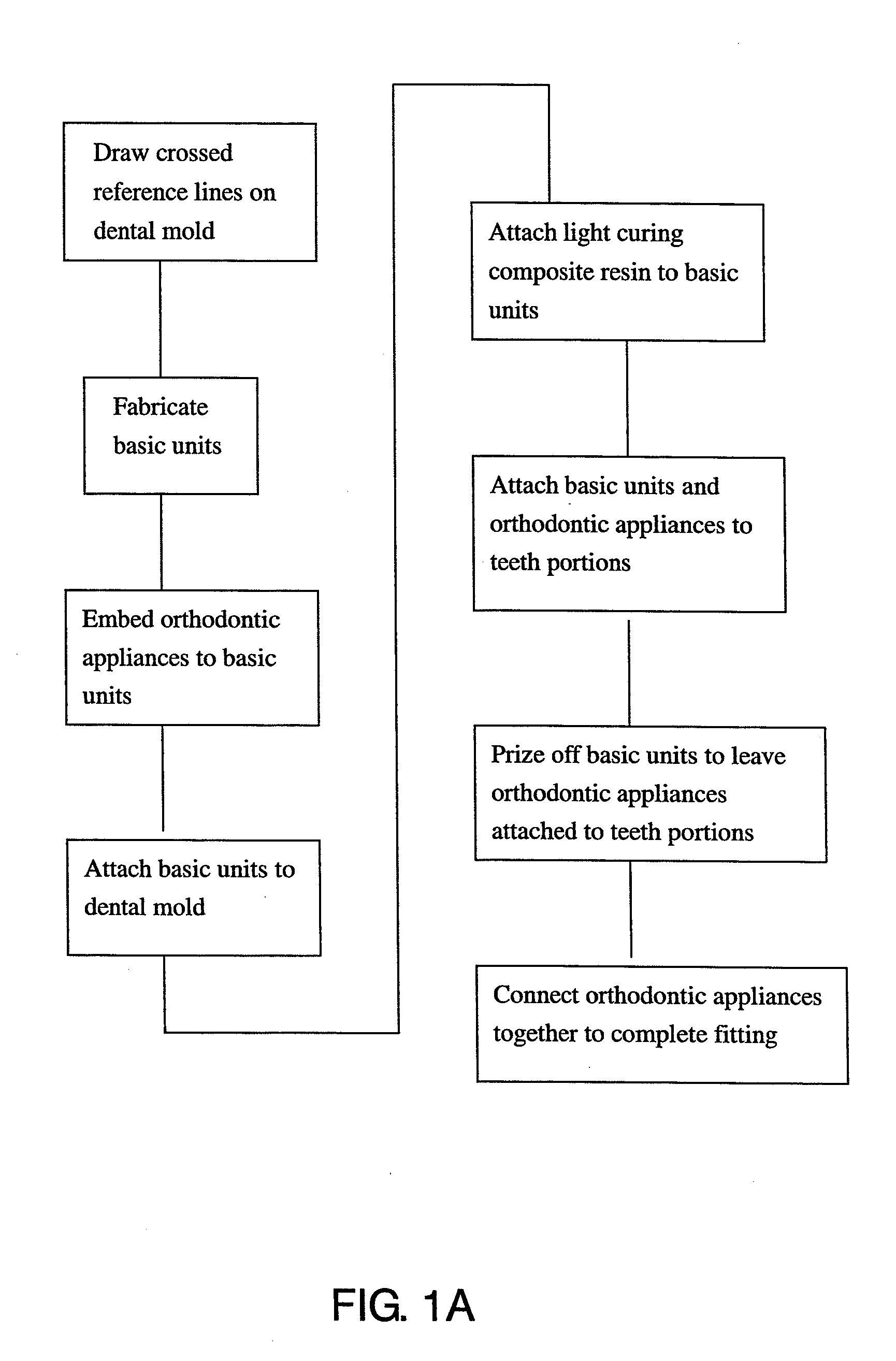

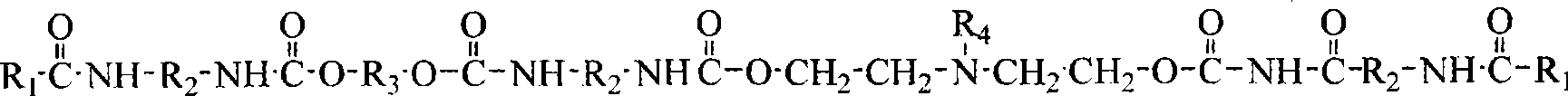

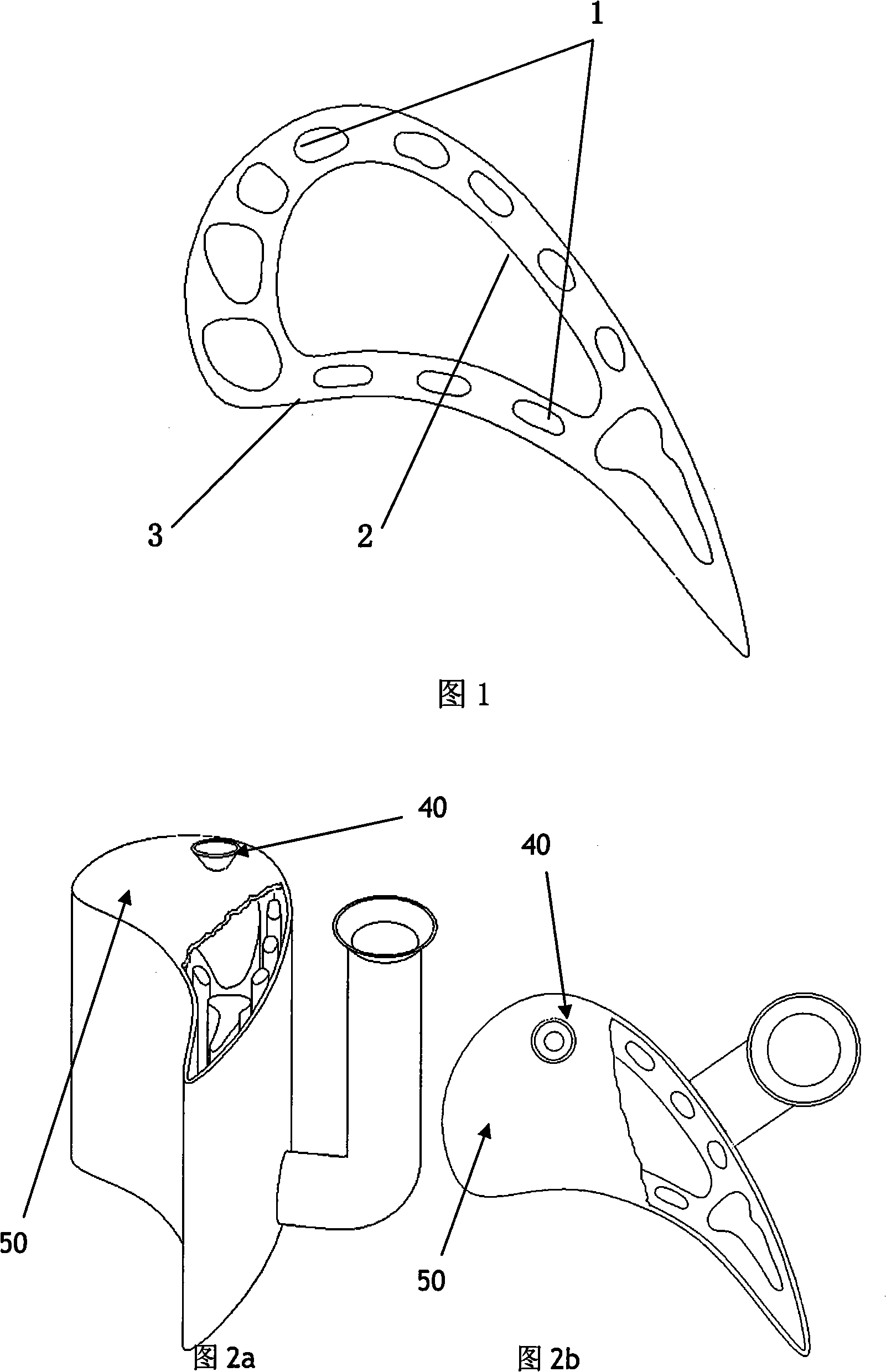

Positioning method for orthodontic appliance and structure thereof

A positioning method for orthodontic appliance and structure, mainly provided with base units molded by plastic injection. During the fabricating process, a crossed reference line is first drawn on a dental mold of the patient, after heating, the orthodontic appliance is embedded to the base unit, and a flexible member is used to bind and fixedly position the orthodontic appliance. Each of the aforementioned base units together with the orthodontic appliance is attached to the dental mold, and then light curing composite resin is attached to each of the base units. Accordingly, after applying an adhesive layer to each of the orthodontic appliances, each of the series connected base units together with the orthodontic appliances bound to the base units is directly attached to the respective teeth portion of the patient requiring straightening, thereby enabling fitting of orthodontic appliances to be more convenient and providing a more efficient fabricating process.

Owner:EZBOND DIGITAL CO LTD

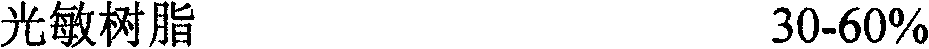

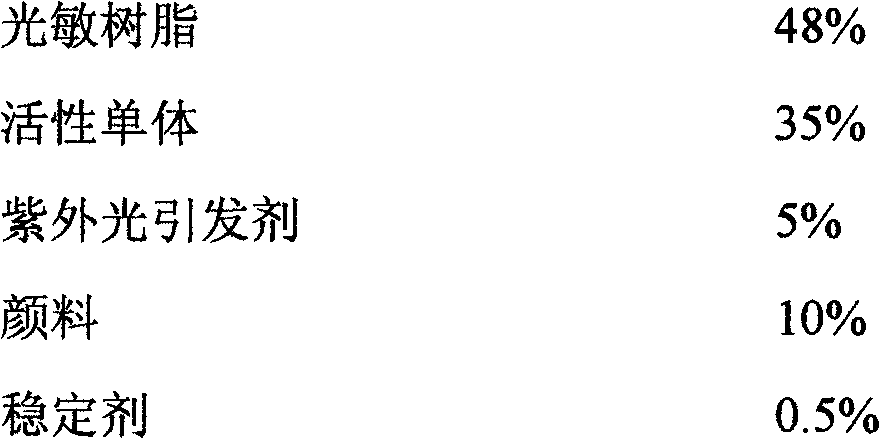

A kind of ultraviolet curing ink and preparation method thereof

The invention relates to an ultraviolet curable ink and a preparation method thereof. The ink comprises 30-60% of light sensitive resins, 15-45% of active monomers, 1-10% of ultraviolet light initiators, 10-20% of pigments and 0.5-2% of auxiliaries by mass and is an ink which is transformed from liquid state to solid state to be cured after binders in the ink are cross-linked under the irradiation of ultraviolet lights with certain wavelengths. The ultraviolet curable ink provided by the invention has the advantages of short light curing time, no need of heating, conservation in energy consumption, no volatile organic solvent VOC (Volatile Organic Compounds) in the ink, no pollution to the atmosphere, smaller effect of temperature variation on system viscosity, high solid content, suitability for multiple production methods and production requirements and excellent comprehensive properties, can be machined and used within a wider temperature range; and very good printing effects of the ultraviolet curable ink on both a hard substrate and a soft substrate can be obtained.

Owner:哈尔滨大东方新材料科技股份有限公司

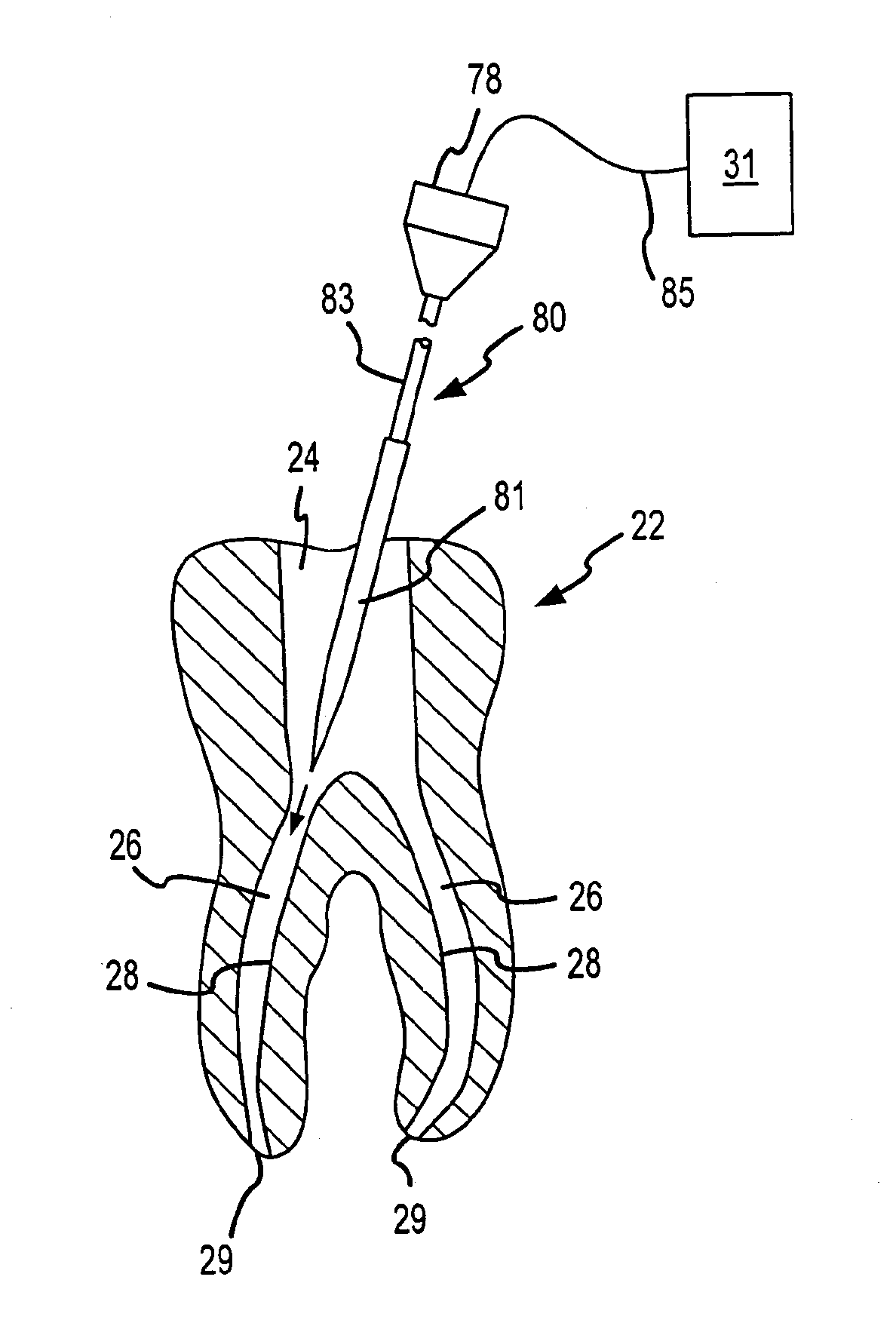

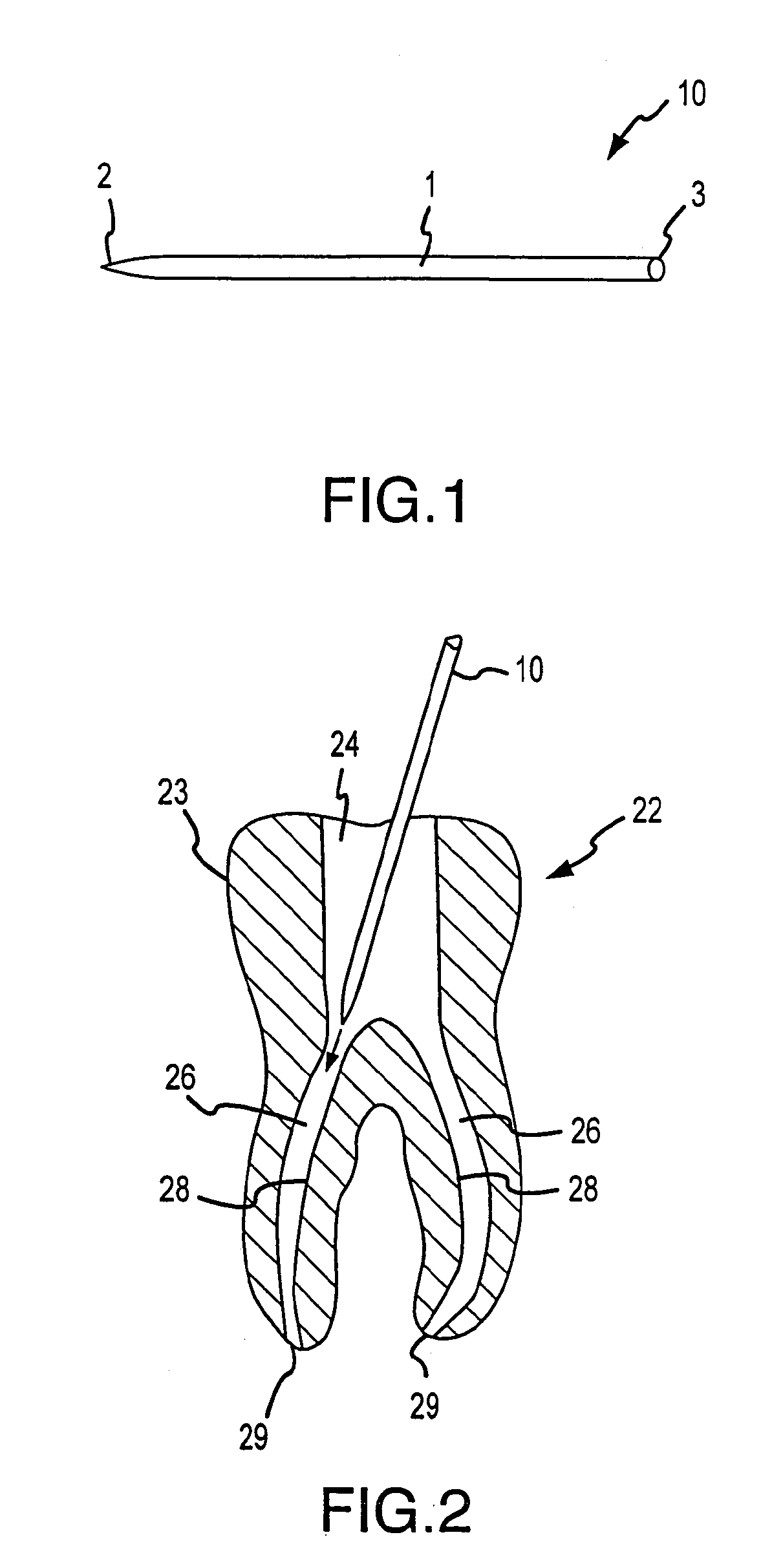

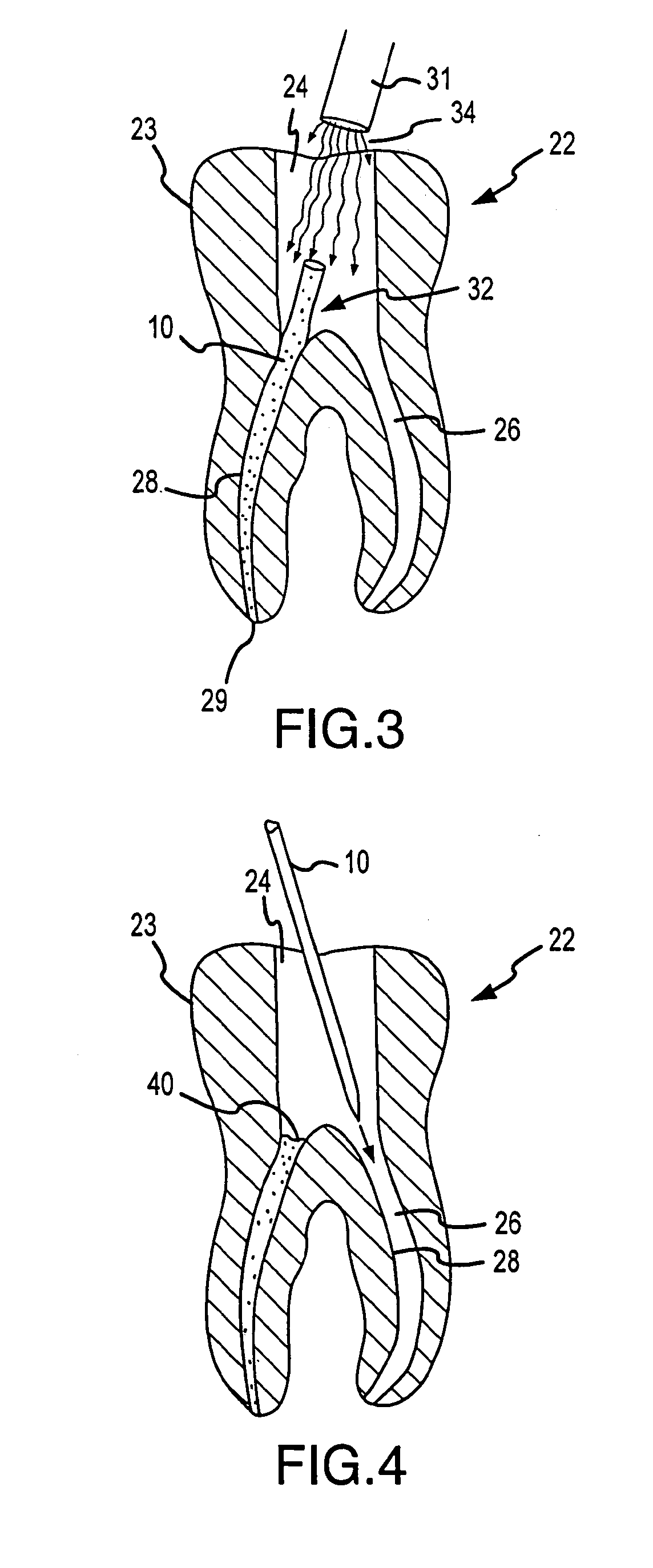

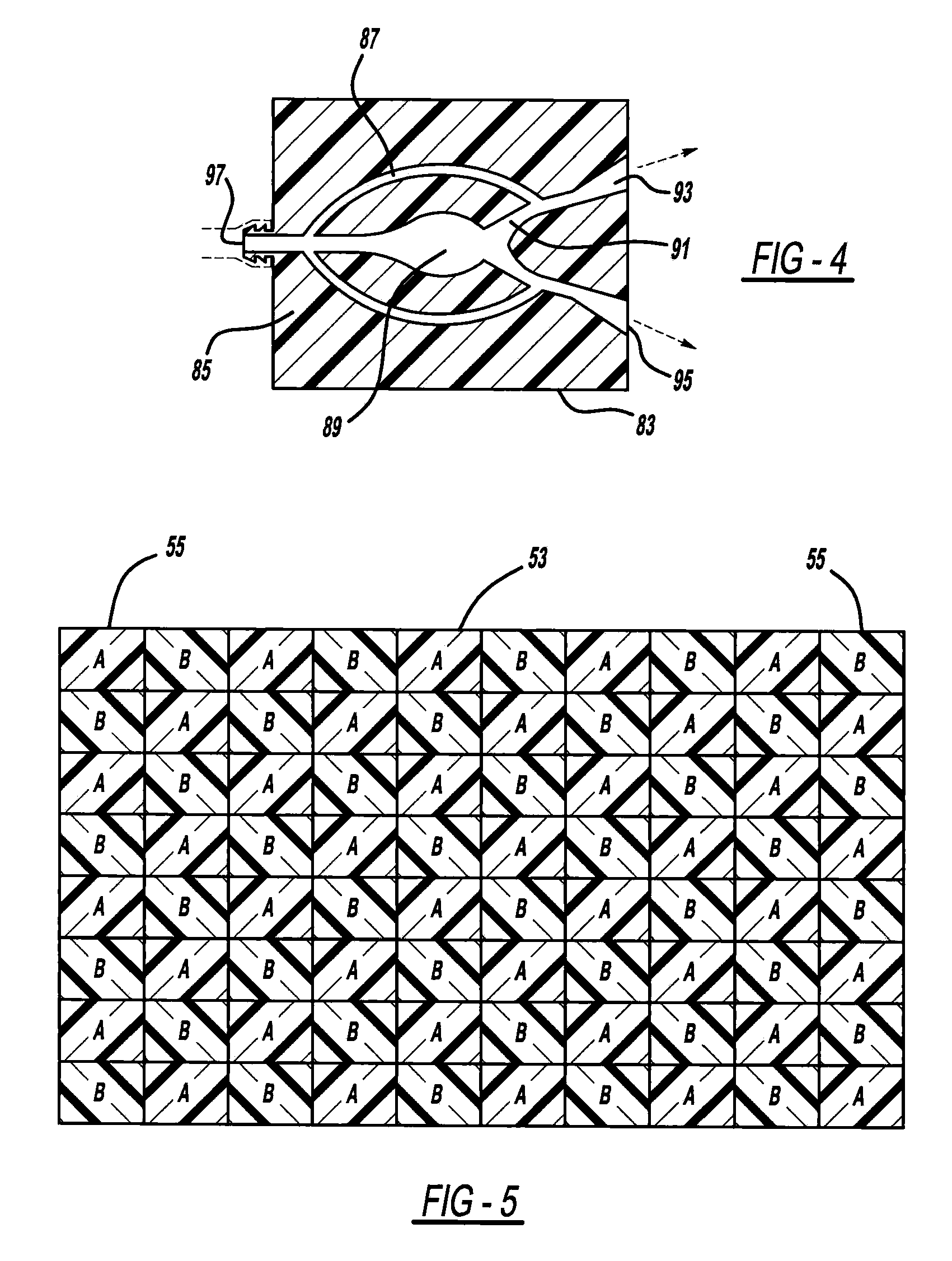

Apparatus and method for root canal obturation

The present invention is directed to root canal obturation in a tooth. In one embodiment, a plug is positioned in a root canal and bonded to the root canal by applying a light-curing adhesive to the canal and exposing the plug to a light source to bond the plug to the root canal. In another embodiment, a carrier is disclosed having an optically transmissive plug portion for insertion into the canal. In still another embodiment, the plug portion of the carrier includes an optical fiber to transmit light from a light source into the plug portion. In still yet another embodiment, a filler material is heated and injected into the root canal in a semi-liquid state and exposed to light to cure the adhesive.

Owner:CALVERT RANDALL REX

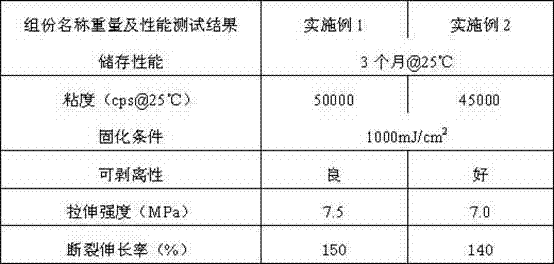

UV-cured peelable blue gel for temporary protection of touch screen and preparation method thereof

InactiveCN103031053AFast curing and film formationIncrease productivityPolyurea/polyurethane coatingsPolyether coatingsNon solventUV curing

The invention provides a UV-cured peelable blue gel for temporary protection of a touch screen and a preparation method thereof. The UV-cured peelable blue gel comprises the following components of 50-70 parts of modified acrylate resin, 20-30 parts of acrylate monomer, 1.0-5.0 parts of light curing agent, 0.1-1.0 part of thixotropic agent, 0.1-5.0 parts of auxiliary and 0.1-1.0 part of pigment; and the preparation method comprises the following steps of: accurately weighing various raw materials according to a formula ratio; firstly adding the modified acrylate resin, the acrylate monomer, the light curing agent, the auxiliary and the pigment to a reaction kettle in sequence and then stirring these materials in the reaction kettle; after these materials are uniformly stirred, adding the thixotropic agent to these materials; and uniformly dispersing an obtained mixture to discharge out a material. The UV-cured peelable blue gel provided by the invention is a non-solvent and a system containing no phthalate substance and is much safer and more environment-friendly. Through the adoption of a UV curing system, the film curing and forming speed is high and the production efficiency of the touch screen is greatly increased.

Owner:TONSAN ADHESIVES INC

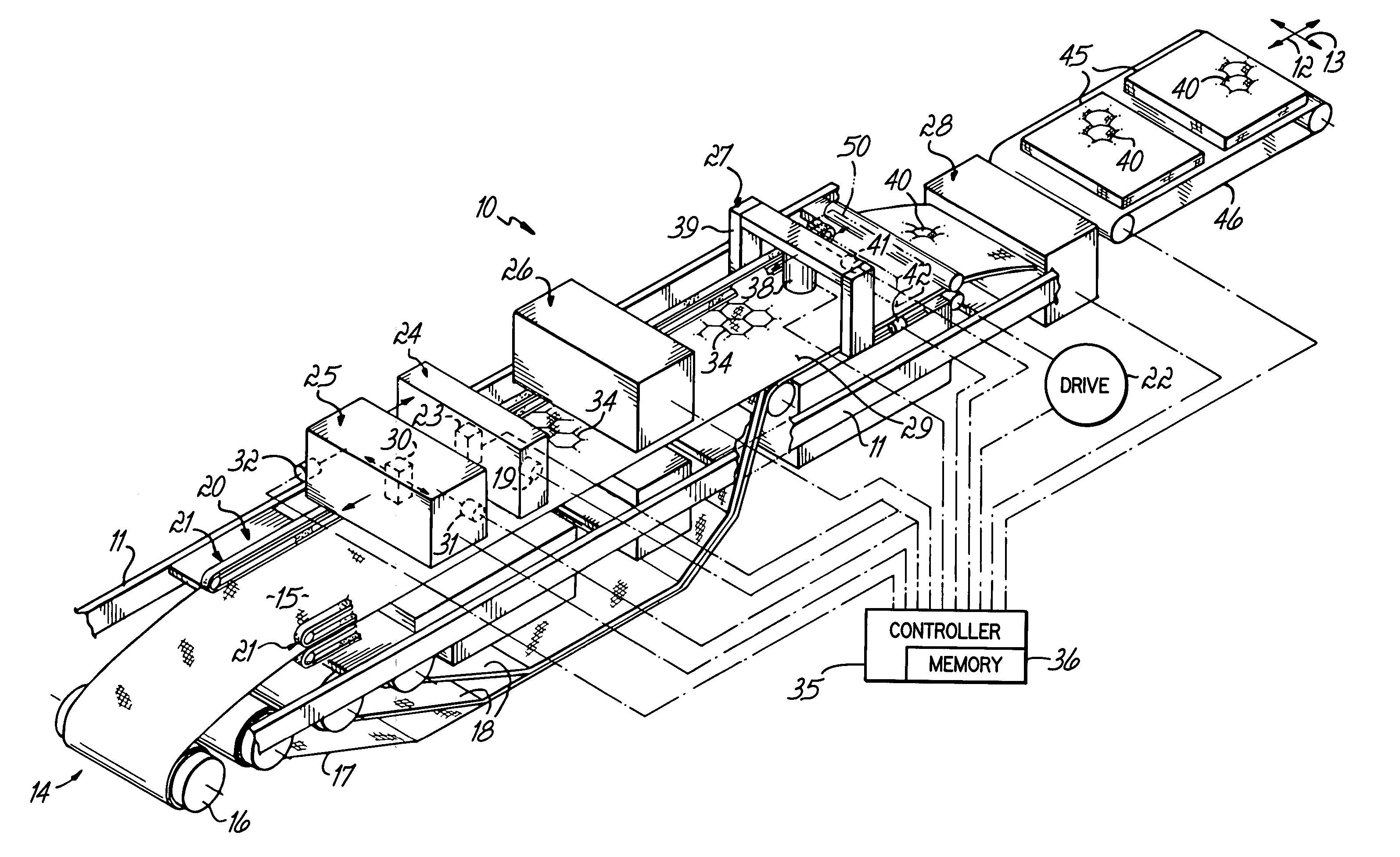

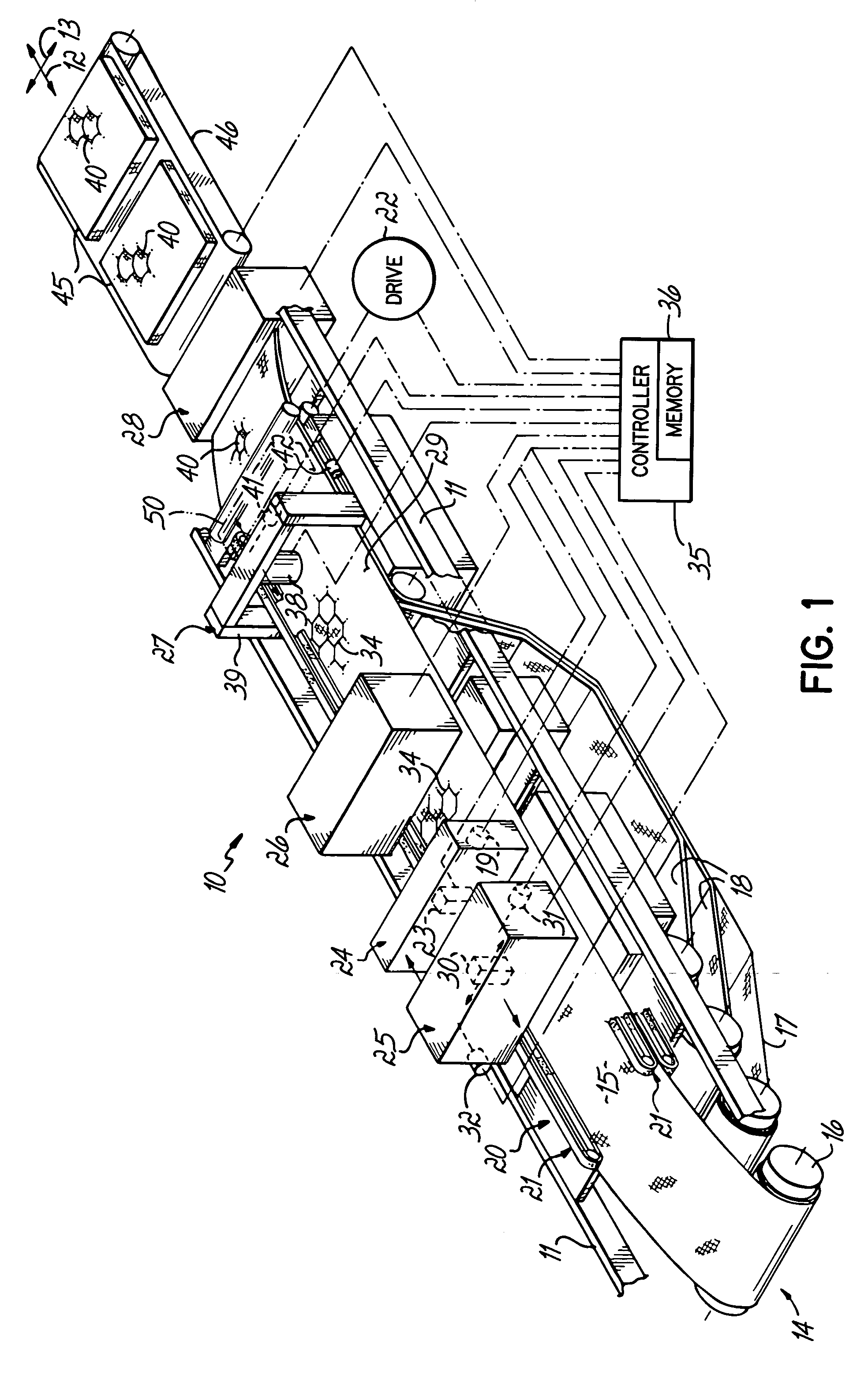

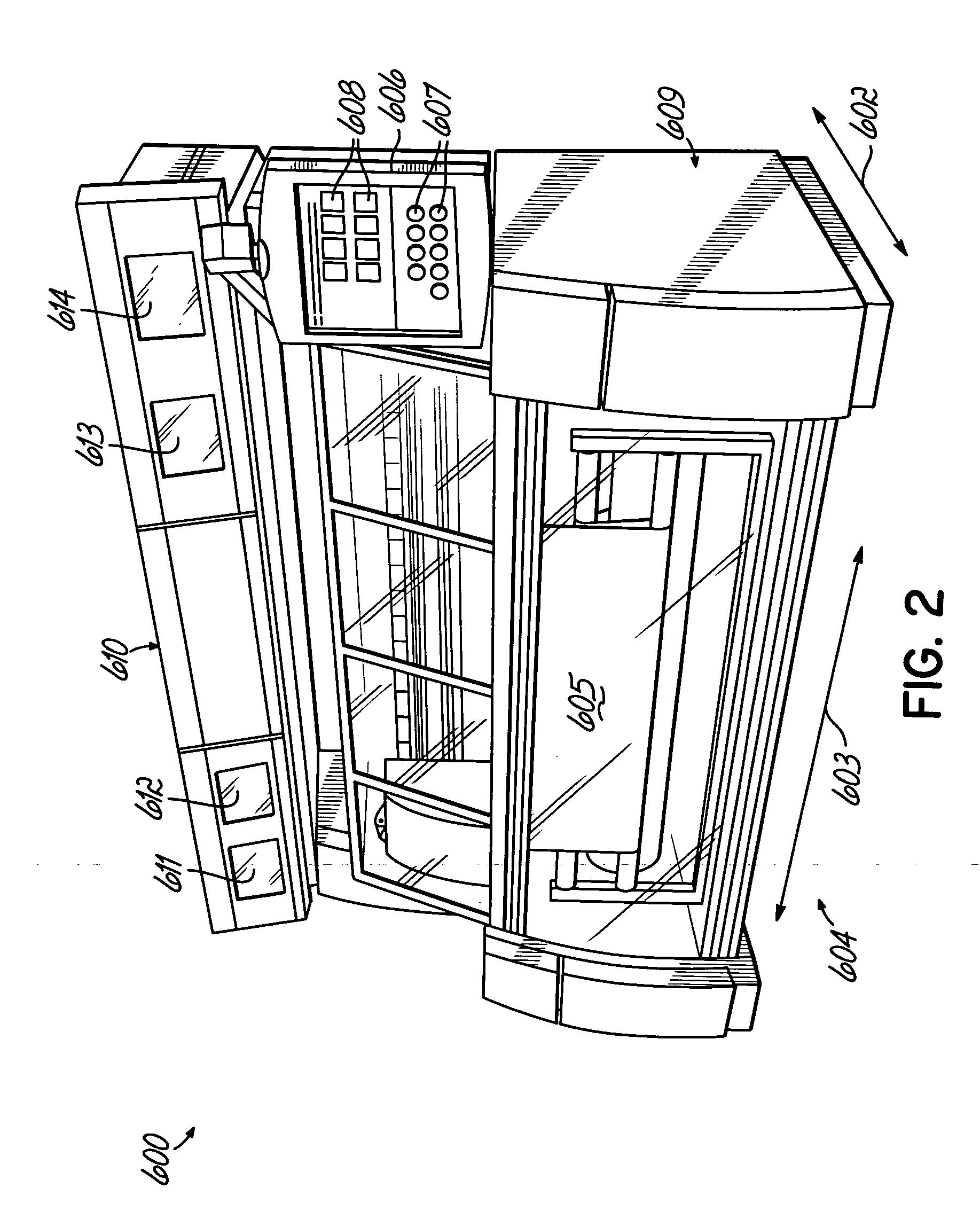

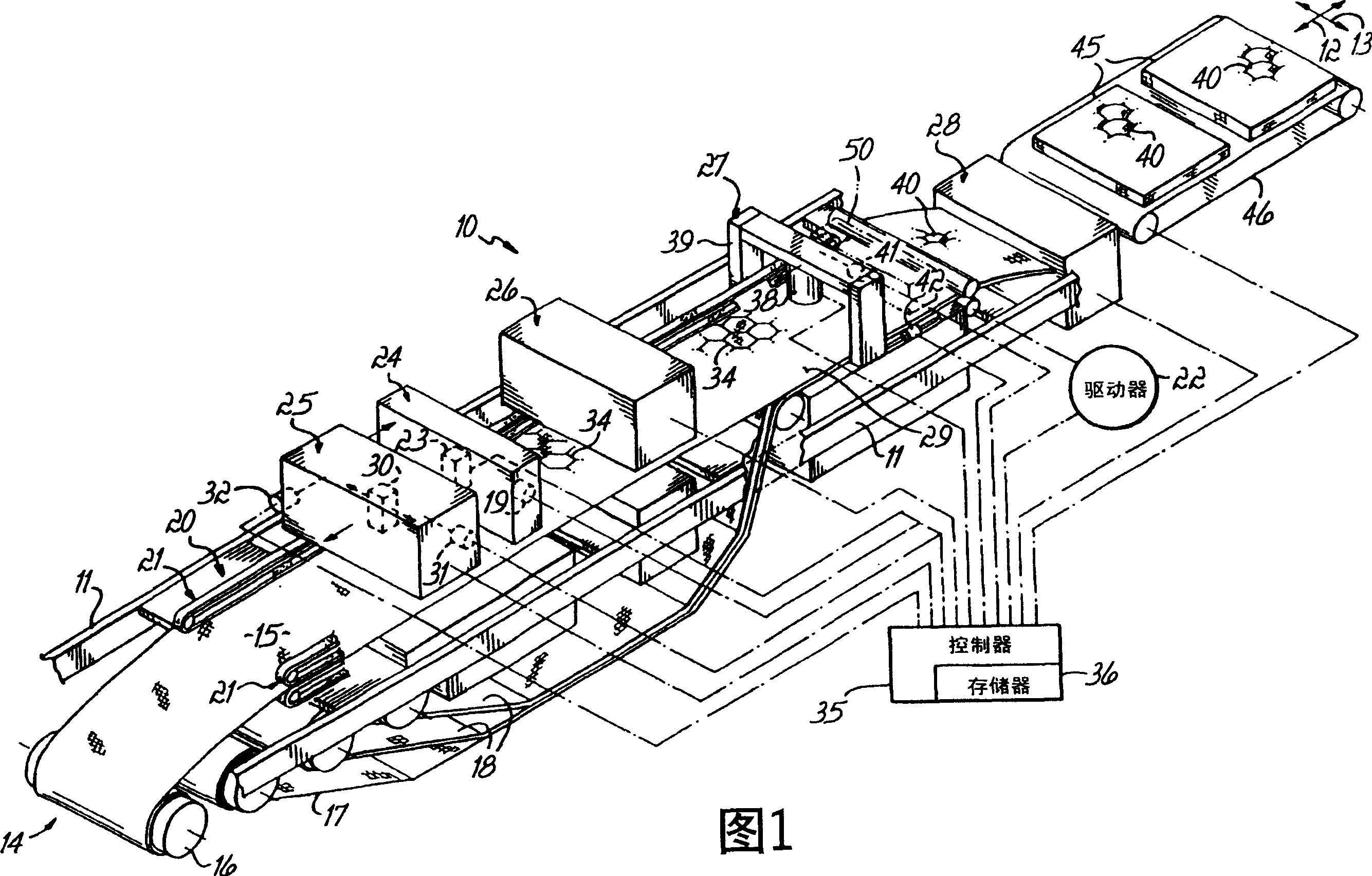

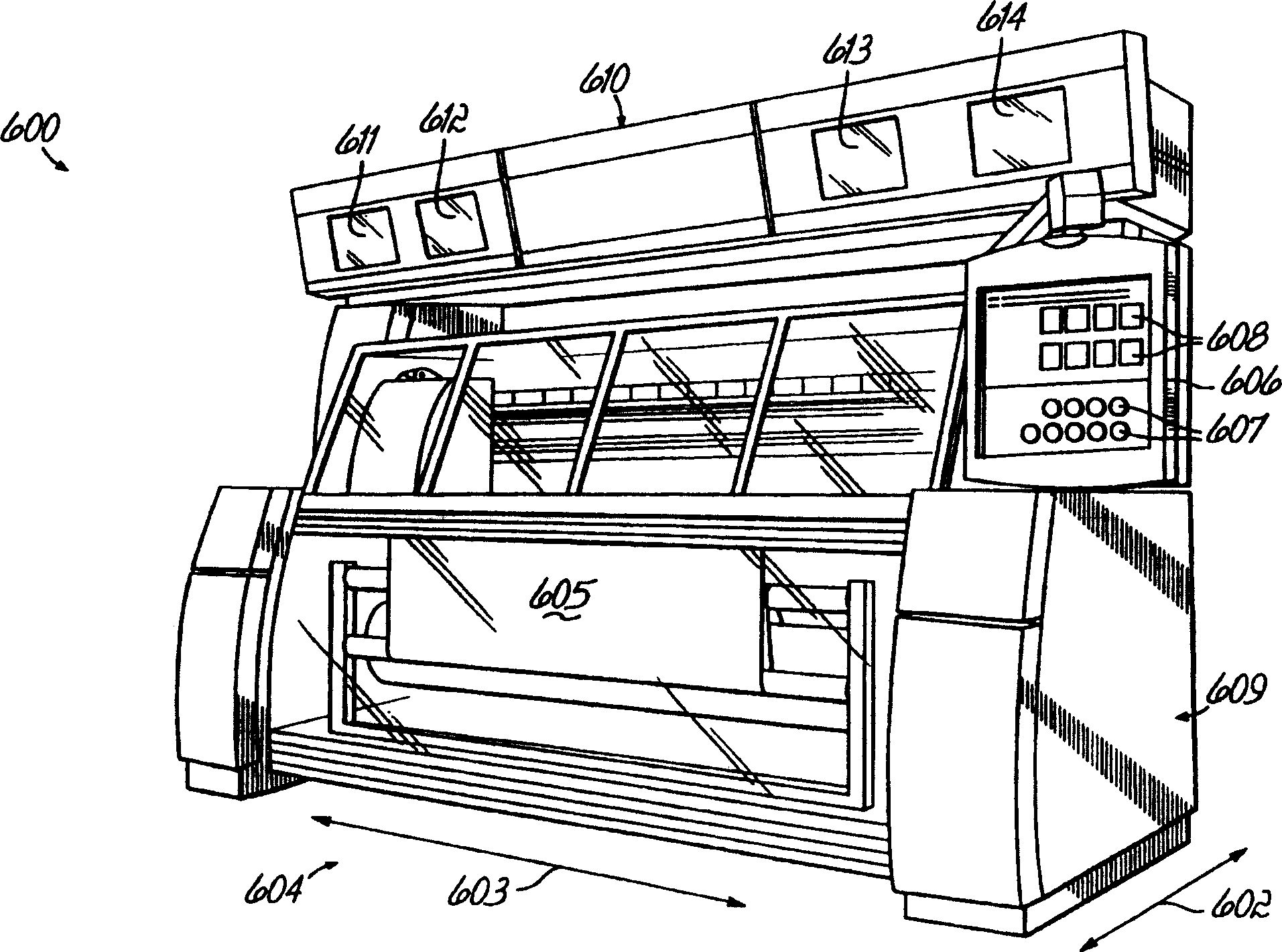

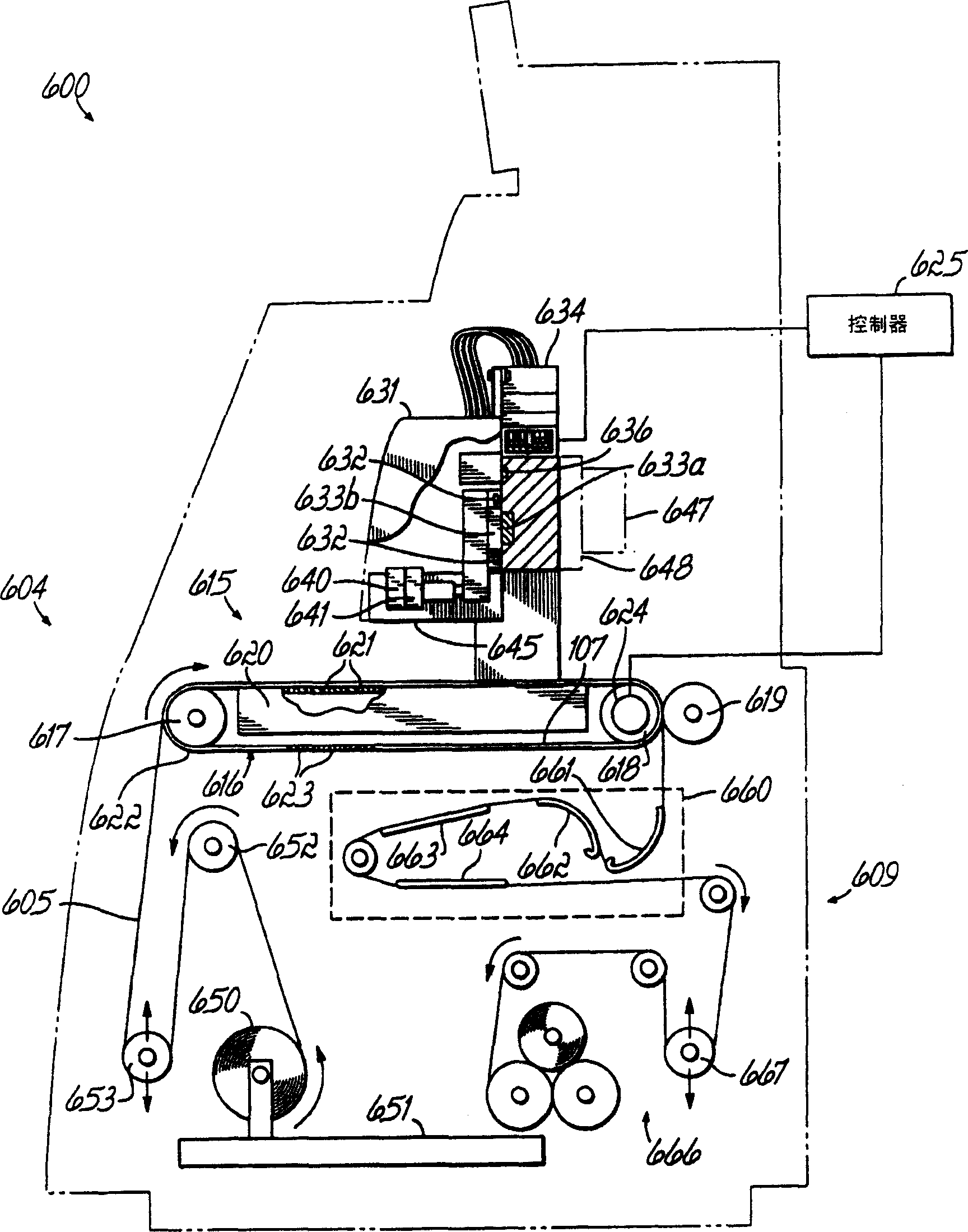

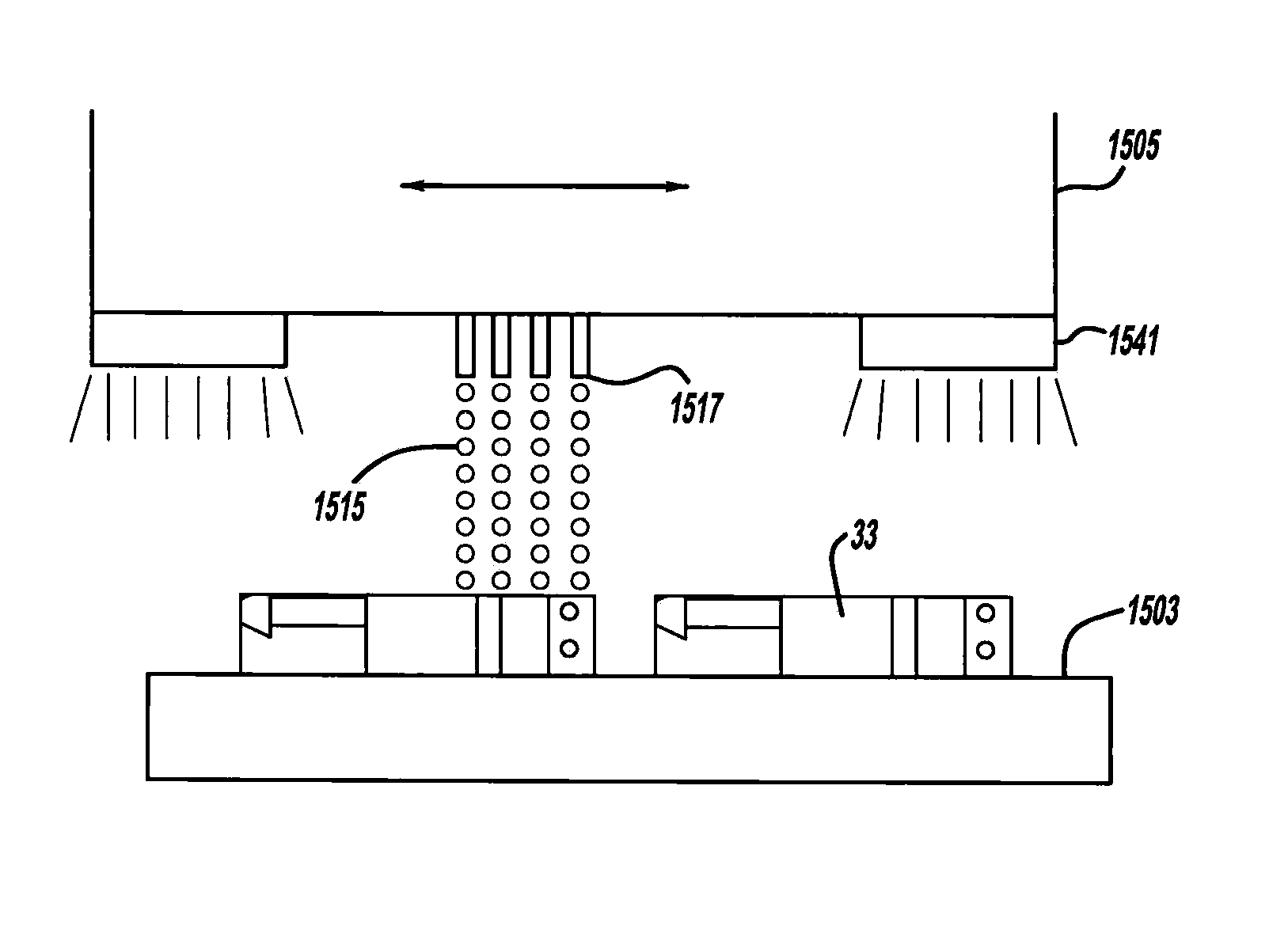

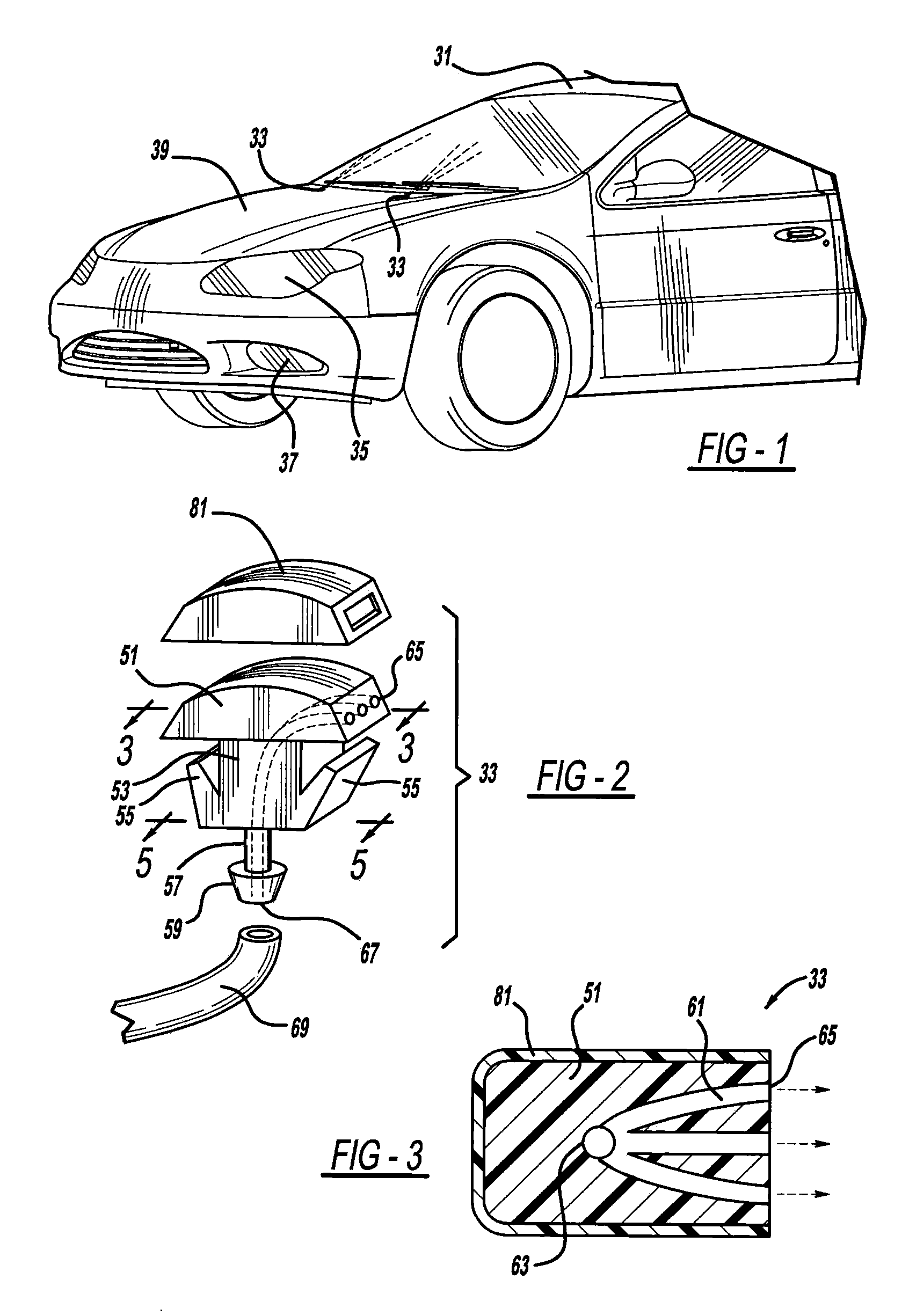

Method and apparatus for ink jet printing

InactiveUS20050174412A1Efficient curingHigh color saturation potentialDuplicating/marking methodsSpacing mechanismsPolyesterPorous substrate

Ink jet printing is provided on large area substrates such as wide width textile webs. The printheads are driven by linear servo motors (633) across a bridge (630) that extends across the substrate. The timing of the jetting of the ink is coordinated with the motion of the printheads (640,641), so that the heads can be rapidly moved and the ink can be jetted while the printheads are accelerating or decelerating as they move on the bridge. Preferably, ultraviolet (UV) light curable ink is jetted and first partially cured with UV light (645,646) and then subjected to heating to more completely reduce uncured monomers of the ink on the substrate. Preferably, the heat is applied by contacting the substrate with a heated plate (661,662). Ink jet printing is provided using ultraviolet (UV) light curable or other curable composition or stable or other printable substance. In certain embodiments the UV ink has a dye-component therein. The ink is jetted onto a substrate, the composition is cured, then heated to set the dye. Sublimation dye-based UV ink printing onto polyester is preferred. A release layer of protective material (702,704), such as a TEFLON film or sheet, covers a substrate support (705,706). A porous substrate to be printed, such as a textile material (711), is supported on or above the support. Ink is jetted onto the substrate, with some of the ink passing through pores in the substrate and landing on the protective material. UV curable ink is preferably used and is exposed by UV light from a UV light curing head, which solidifies the ink on the substrate. The UV curing light has a long enough focal length to focus on the surface of the substrate and also, where it passes through pores in the substrate, on ink on the protective material, thereby solidifying the ink on the protective material. When the substrate is removed from the support, the solidified ink on the protective material may be wiped from the protective material. The protective material may be a coating on the support over which the substrate slides or a belt that moves with the substrate. A textile substrate may be preconditioned by singeing or shaving to remove fuzz from the fabric that could clog the printheads. A printhead cleaning station is also provided.

Owner:L & P PROPERTY MANAGEMENT CO

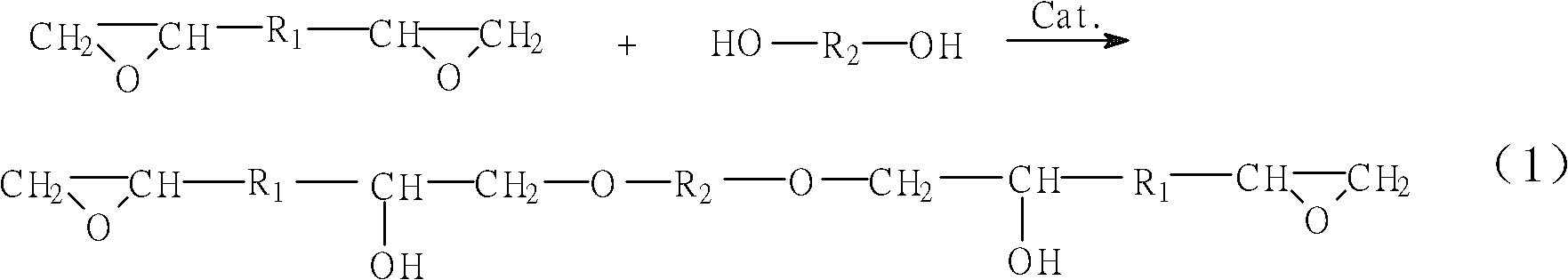

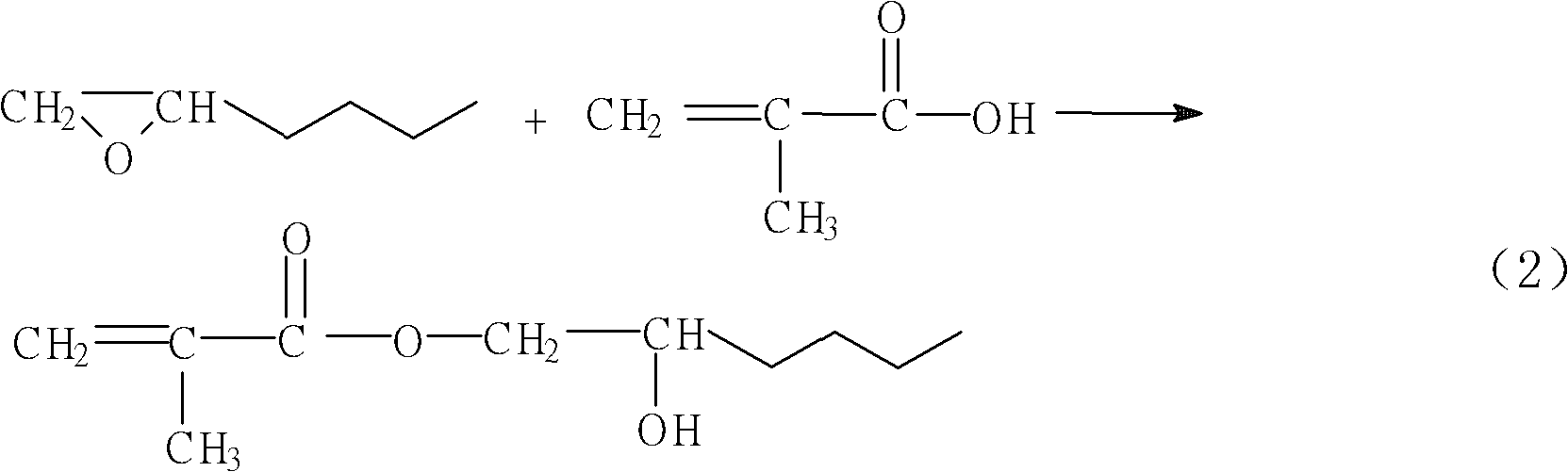

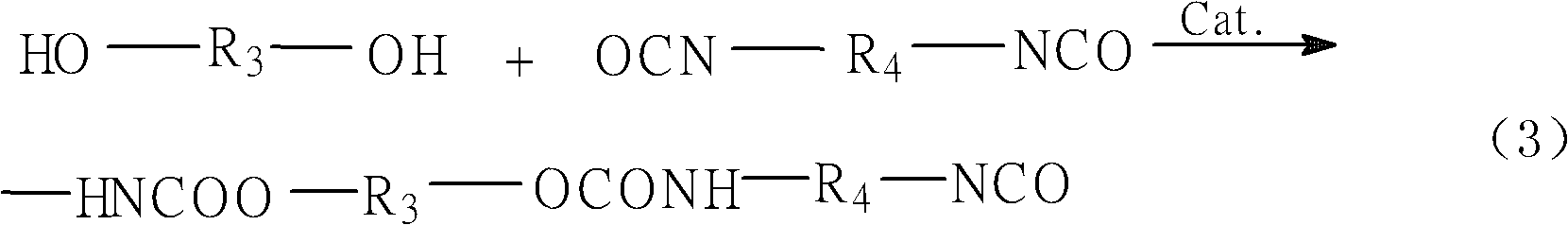

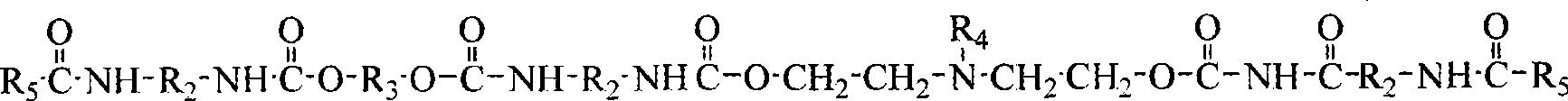

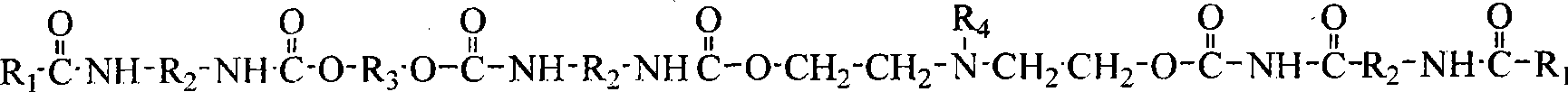

Synthesis and application of light-cured polyurethane-acrylic acid-epoxy resin adhesive

The invention relates to a novel polyurethane-acrylic acid-epoxy resin photosensitive pre-polymer, a synthesis method of the pre-polymer, a high-performance ultraviolet (UV) cured polyurethane modified acrylic acid epoxy resin adhesive prepared from the pre-polymer and application of the UV cured adhesive to bonding of a nylon membrane material and a polyurethane or modified polyurethane elastic body. A method for preparing the photosensitive pre-polymer comprises the following steps of: 1, synthesizing a lower-viscosity epoxy acrylic ester pre-polymer; 2, preparing a pre-polymer of urethane acrylate resin; and 3, mixing or reacting the two pre-polymers in a certain ratio so as to obtain the polyurethane-acrylic acid-epoxy resin photosensitive pre-polymer. A polyurethane-acrylic acid-epoxy resin UV cured adhesive is further prepared by adding a photoinitiator, a photosensitive diluent, a light curing crosslinking agent, other necessary aids and the like.

Owner:BEIHANG UNIV

Method and apparatus for ink jet printing

InactiveCN1678458AEliminate cloggingImprove reliabilityDuplicating/marking methodsSpacing mechanismsPorous substratePolyester

Ink jet printing is provided on large area substrates such as wide width textile webs. The printheads are driven by linear servo motors (633) across a bridge (630) that extends across the substrate. The timing of the jetting of the ink is coordinated with the motion of the printheads (640, 641), so that the heads can be rapidly moved and the ink can be jetted while the printheads are accelerating or decelerating as they move on the bridge. Preferably, ultraviolet (UV) light curable ink is jetted and first partially cured with UV light (645, 646) and then subjected to heating to more completely reduce uncured monomers of the ink on the substrate. Preferably, the heat is applied by contacting the substrate with a heated plate (661, 662). Ink jet printing is provided using ultraviolet (UV) light curable or other curable composition or stable or other printable substance. In certain embodiments the UV ink has a dye-component therein. The ink is jetted onto a substrate, the composition is cured, then heated to set the dye. Sublimation dye-based UV ink printing onto polyester is preferred. A release layer of protective material (702, 704) such as a TEFLON film or sheet, covers a substrate support (705, 706). A porous substrate to be printed, such as a textile material (711), is supported on or above the support. Ink is jetted onto the substrate, with some of the ink passing through pores in the substrate and landing on the protective material. UV curable ink is preferably used and is exposed by UV light from a UV light curing head, which solidifies the ink on the substrate. The UV curing light has a long enough focal length to focus on the surface of the substrate and also, where it passes through pores in the substrate, on ink on the protective material, thereby solidifying the ink on the protective material. When the substrate is removed from the support, the solidified ink on the protective material may be wiped from the protective material.

Owner:L & P PROPERTY MANAGEMENT CO

Visible light cured metal paint

The present invention relates to metal paint, and is especially visible light cured paint for the surface protection and decoration of various kinds of metal. The visible light cured paint for metal consists of prepolymer of unsaturated olefin radical 0-20 wt%, monomer of unsaturated olefin radical 20-80 wt%, light initiator 1-10 wt%, initiator assistant 0.5-30 wt%, assistant 0-10 wt%, stuffing or pigment 0-40 wt% and solvent 0-30 wt%. The visible light cured paint may be used widely in surface coating of iron and steel, aluminum, copper and other metals and alloys.

Owner:ZHUHAI DONGCHENG UV MATERIALS

Process of making a component with a passageway

A component is provided that includes at least one passageway. In another aspect, a component, such as a lamp or a vehicular washer jet, is made of layers of material, a light curable material and / or multiple built-up materials. Another aspect uses a three-dimensional printing machine to emit material from an ink jet printing head to build up a component.

Owner:A RAYMOND & CO

Ultraviolet-thermal double curing coating composition with anti-oxygen inhibition effect and preparation thereof

InactiveCN101412860AEliminate oxygen barrier effectStrong adhesionPolyurea/polyurethane coatingsOligomerChain structure

The invention relates to an ultraviolet photo-thermal double curing paint with oxygen inhibition resistant effect and a manufacturing method thereof. The double paint comprise the following compositions in weight percentage: 3.0 to 57.0 percent of ultraviolet curing oligomer, 7.0 to 40.0 percent of thermal curing polyhydroxy oligomer, 10.0 to 41.0 percent of curing agent, 15.0 to 60.0 percent of active diluted monomer, 0.5 to 9.0 percent of light evocating agent and 0.5 to 5.2 percent of additive. The double curing paint composition is prepared without needing complicated equipment and has application period as long as 7 hours; the main chain structure of the oligomer is provided with a tertiary amine group which removes the influence of oxygen inhibition effect so as to greatly accelerate the curing speed and complete the light curing process in a short period of between 5 and 15 seconds; after the ultraviolet photo-thermal double curing, a thick paint film with thickness of between 60 and 120 mu m can be prepared; and the obtained paint film has good leveling, high hardness, good impact resistance, good toughness and strong adhesive force and is suitable for coating various substrates.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

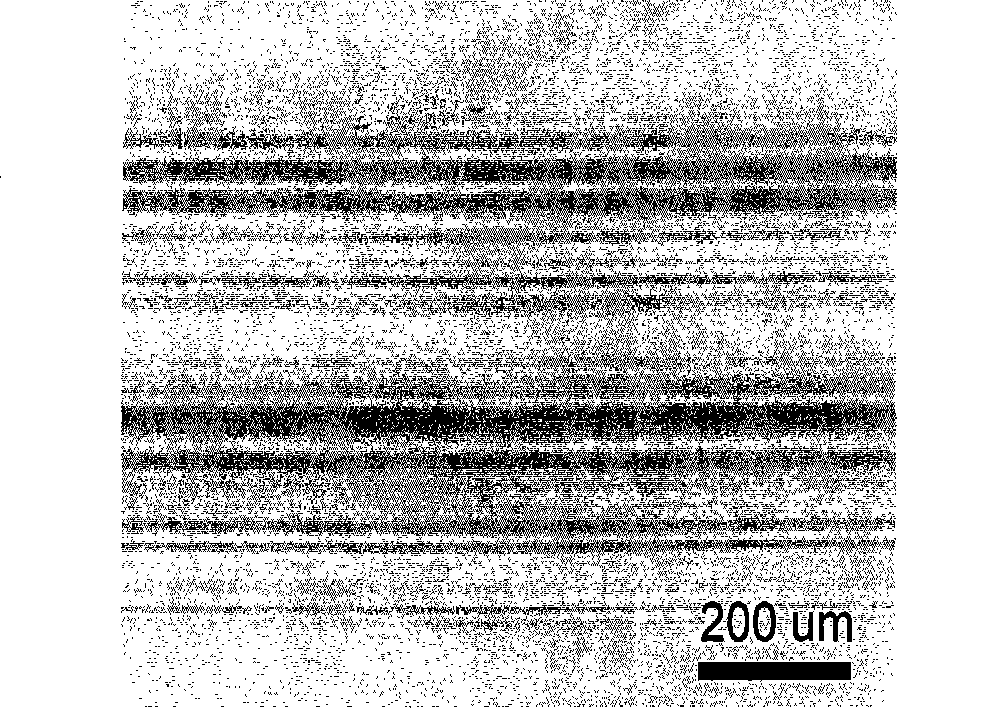

Flexographic plate CTP (computer to plate) direct printing method and equipment based on 3D rapid forming printing principle

ActiveCN103121323AEliminate complicated operation linksLow costPlate printingFoil printingComputer to plateEngineering

The invention discloses a flexographic plate CTP (computer to plate) direct printing method and equipment based on a 3D rapid forming printing principle and belongs to the technical field of printing flexographic plate manufacture. The equipment comprises a computer, a 3D rapid forming printer and one of photocuring equipment and heat drying equipment. The 3D rapid forming printer is utilized to spray a solidifiable forming material on the base surface of a flexographic plate so as to form a relieve image, the relieve image is subjected to light curing or thermocuring on-line drying so that the printing information is stabilized on the base surface of the flexographic plate, and then the printer can be used for printing; and the base of the flexographic plate is an organic polymer plate or an organic polymer-organic polymer compound plate. The method omits the middle process such as exposure and development, the plate manufacturing speed is greatly accelerated, the printing quality is improved, the printing cost is reduced, the flow is greatly shortened, the flexography environment friendliness is realized, and the application area is further expanded.

Owner:BEIJING INSTITUTE OF GRAPHIC COMMUNICATION

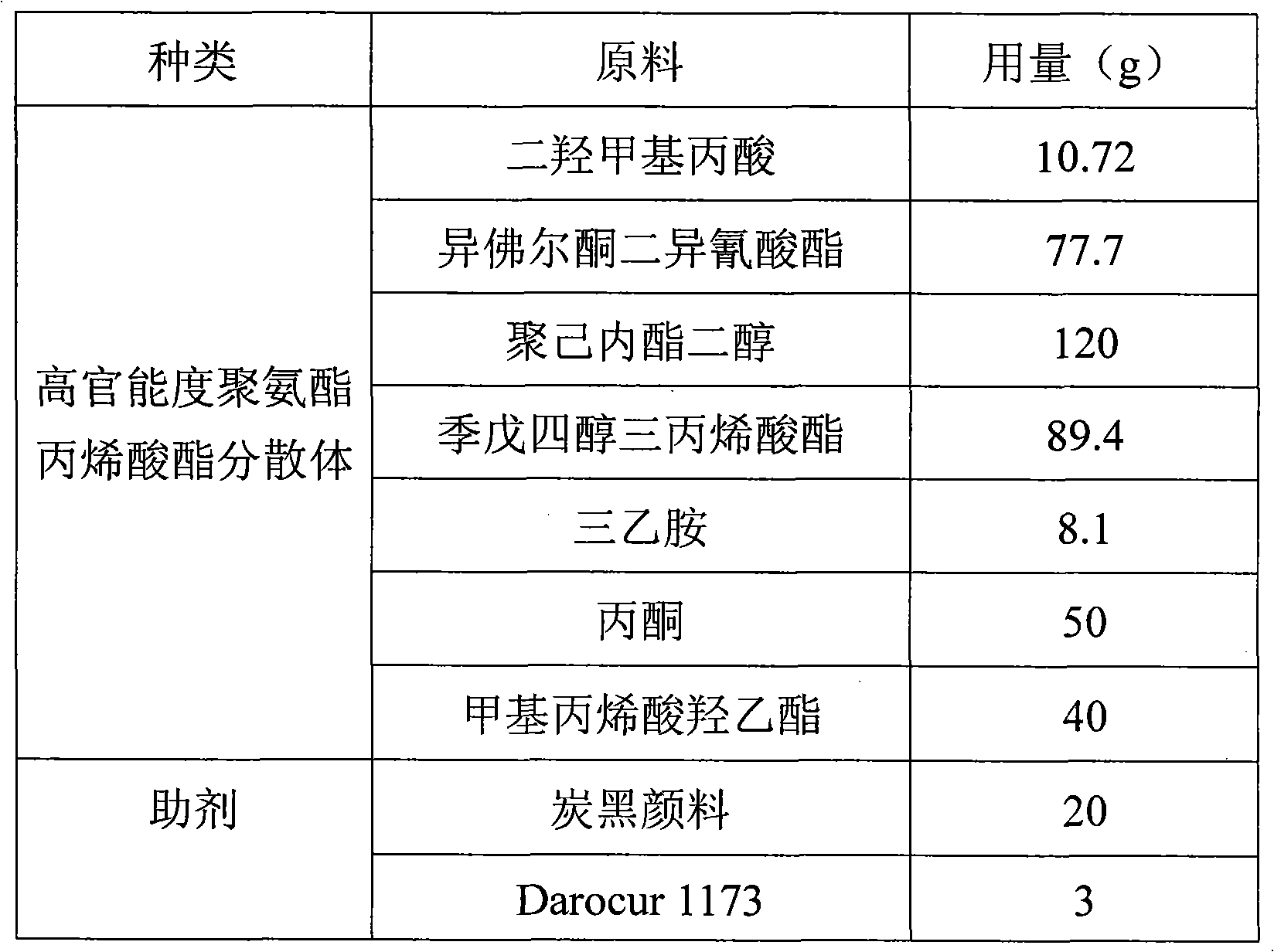

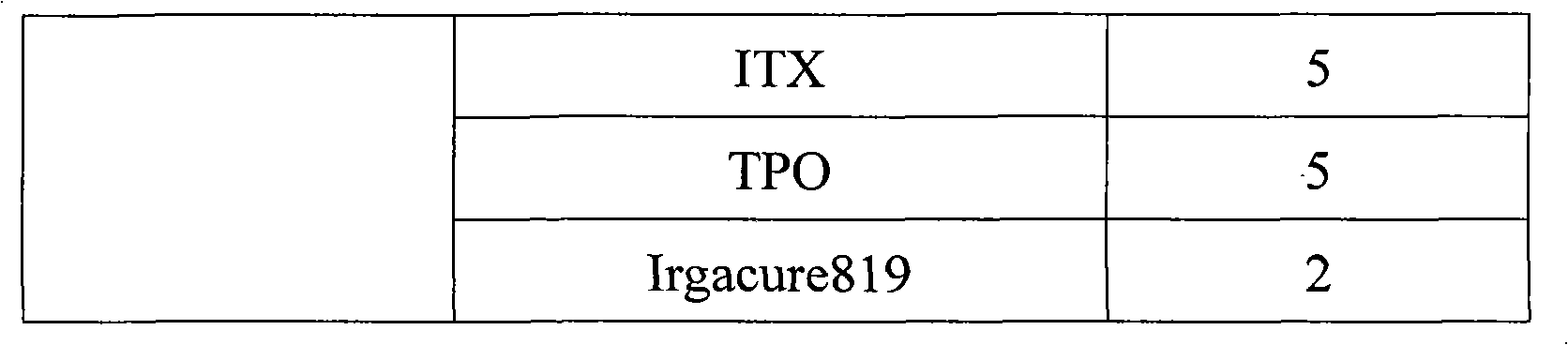

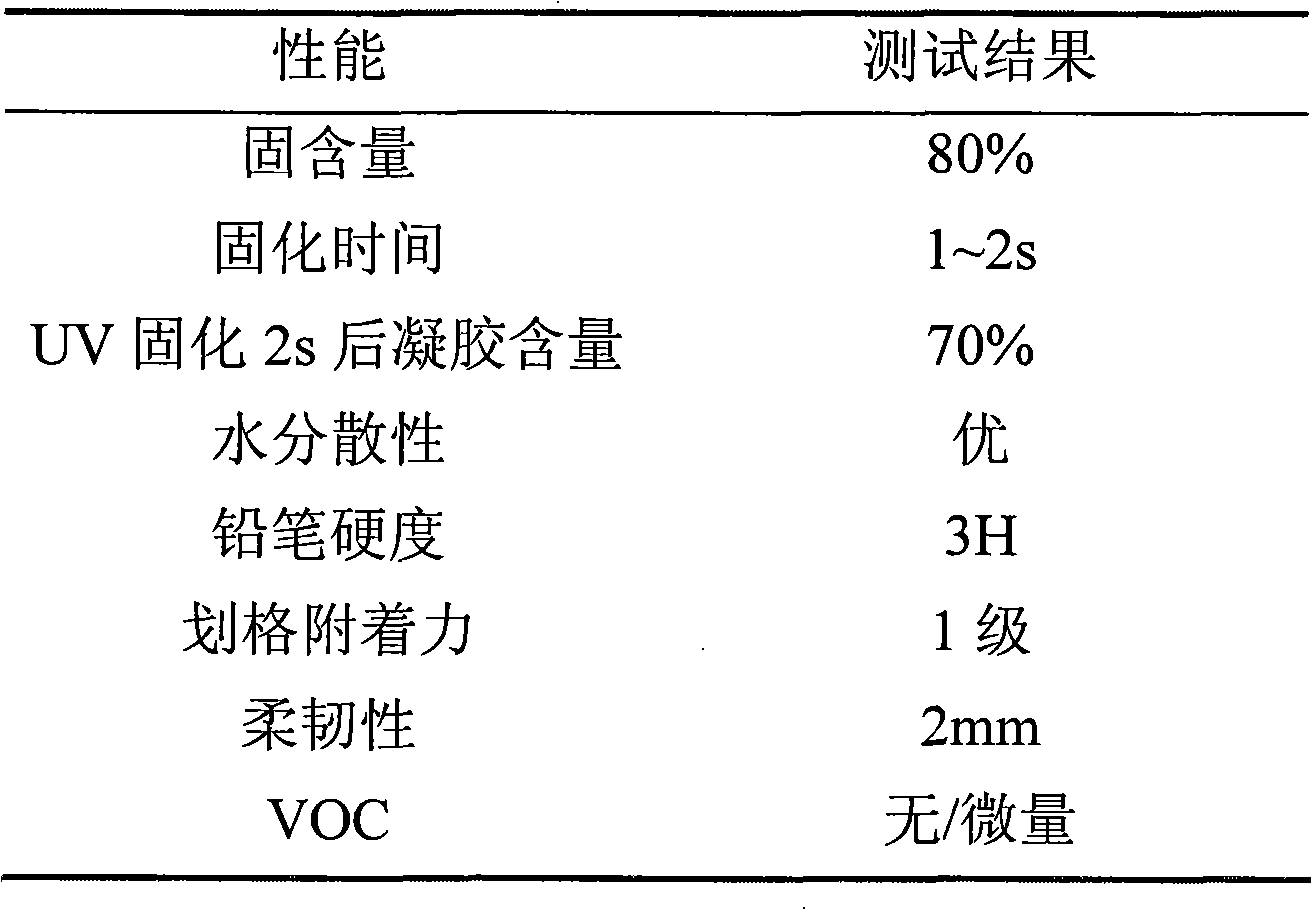

Water-based UV black ink with super-high solid content and preparation method thereof

InactiveCN101659809AEmissions are environmentally friendly and non-toxicHealthy littleInksWater basedPliability

The invention discloses water-based UV black ink with super-high solid content and a preparation method thereof. The black ink comprises the following components in percentage by weight: 20%-60% of high-functionality water-based polyurethane acrylate, 5%-8% of compound photoinitiator, 15%-35% of hydrophilic acrylate diluted body or prepolymer, 10%-25% of solvent and 5%-15% of nano-carbon black pigment. The light curing time of the water-based UV black colored paint of the invention is shorter than 5 seconds, the bottom layer can be completely cured, the comprehensive properties of adhesive force, hardness, toughness and the like are excellent, and the water-based UV black colored paint can be widely applied to the fields of ink, wood paint and the like; the solid content is as high as 80%;and the water-based UV black ink has short drying and curing time, simple construction technology and high production efficiency, can be diluted by water or ethanol or other nontoxic solvents for regulating the viscosity, is suitable for various production modes and production requirements, and is environment-friendly and nontoxic.

Owner:FOSHAN CITY SHUNDE DISTRICT DEMEI CHEM

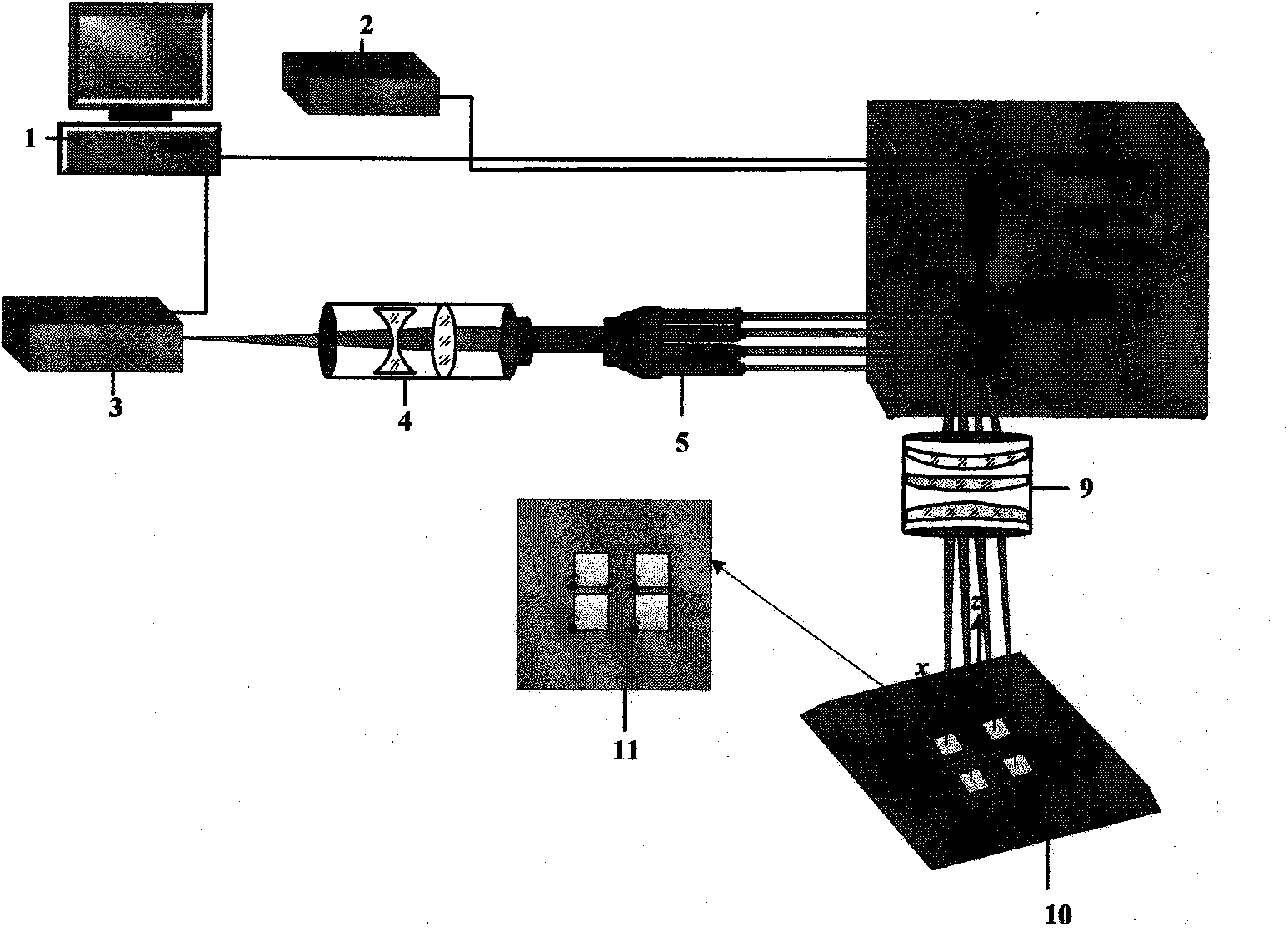

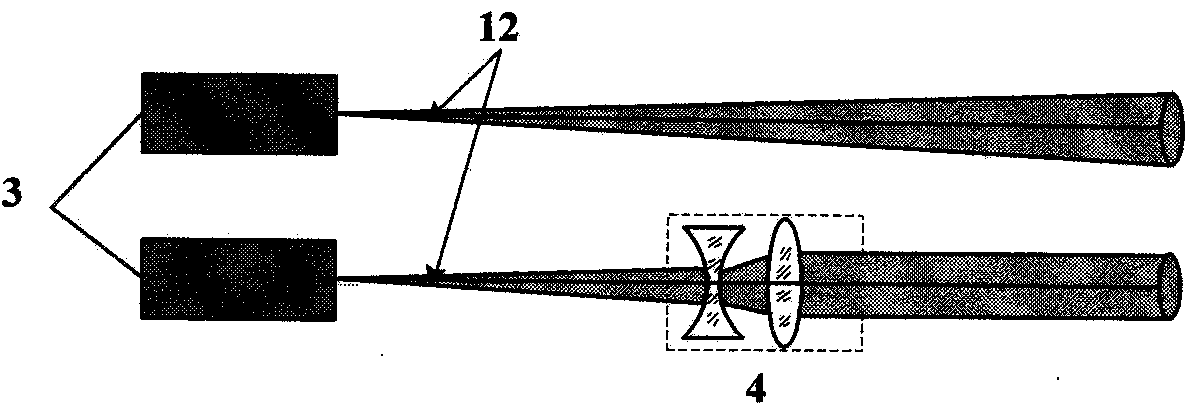

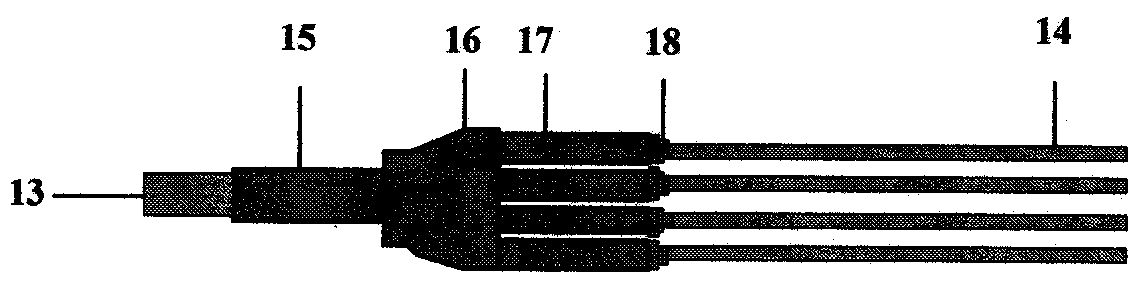

Method for improving laser scanning image light-curing quick-molding efficiency

The invention relates to a method for improving the laser scanning image light-curing quick-molding efficiency, and in particular relates to an imaging system capable of enabling liquid-state light-sensitive cured resin to be efficiently and quickly cured based on a multi-light-beam laser scanning technology. According to a specific implementation mode, light emitted by a laser light source (3) passes through a collimating lens (4), collimated laser light beams enter an optical fiber beam splitter (5), a beam of laser is split into 1*N light beam matrixes, the laser beams are reflected by scanning galvanometers (7 and 8) and are focused on a light-cured resin surface (10) by virtue of a field lens (9), a workpiece graph layer is efficiently scanned, and N workpieces can be finally, simultaneously and quickly molded. Therefore, the scanning efficiency is improved by N times correspondingly.

Owner:OCEANOGRAPHIC INSTR RES INST SHANDONG ACAD OF SCI

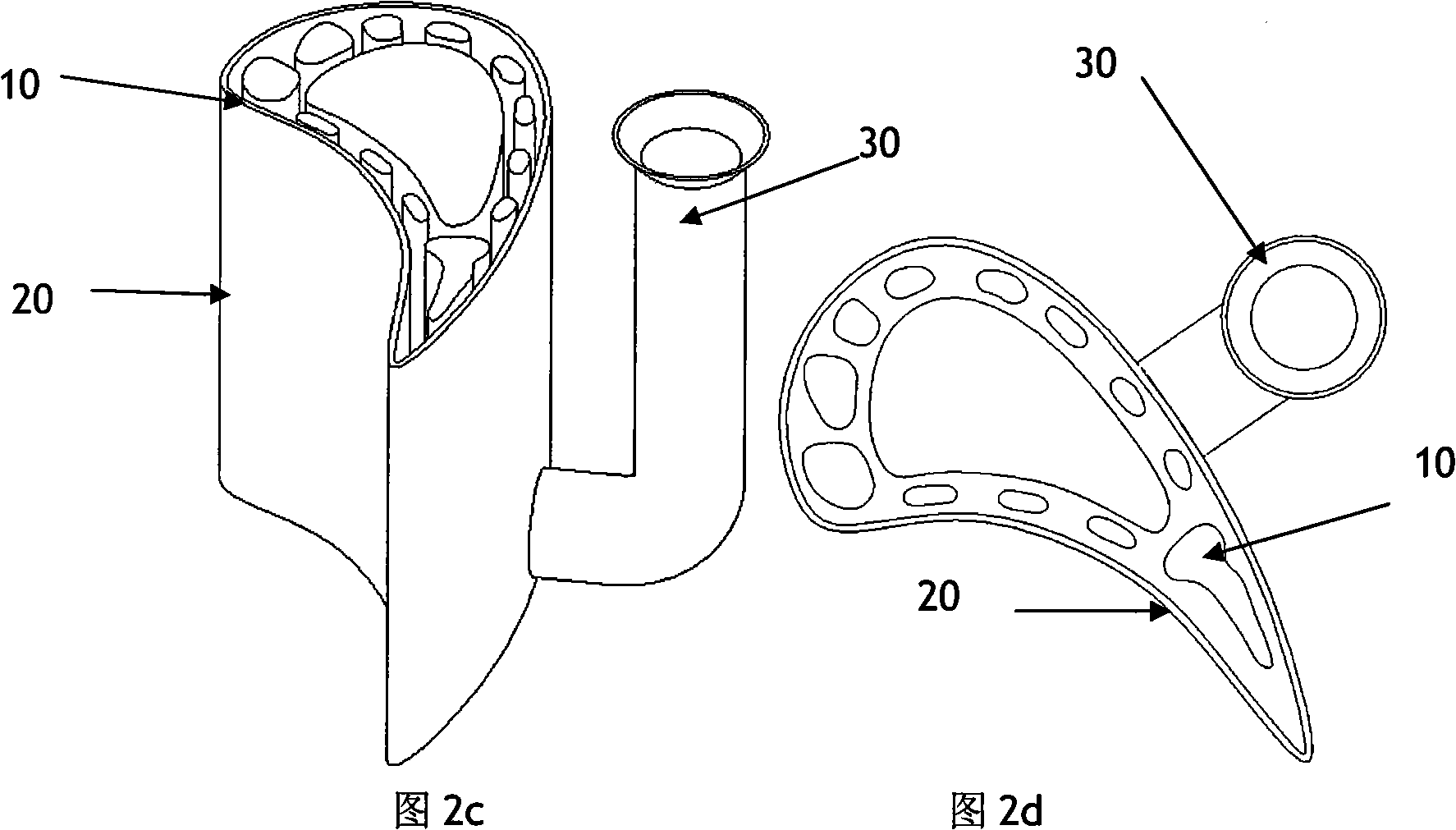

Direct light-curing fabrication method of hollow blade ceramic cast

The invention relates to a method for directly making a hollow blade ceramic mold based on a photo-curing process. The method is as follows: firstly, ceramic powder and pre-mix liquid are evenly mixed so as to make ceramic slurry; secondly, according to a hollow blade model, a hollow blade mold model containing a gating system is obtained, and the ceramic slurry is directly made into a ceramic mold biscuit on a photo-curing forming machine according to the hollow blade mold model; then, the ceramic mold biscuit is dewatered to obtain a dry ceramic mold; finally, the dry ceramic mold is placed in a high-temperature baking furnace so as to carry out degreasing and sintering, thereby making the hollow blade ceramic mold. The ceramic mold can be used in the casting of a hollow blade, and replaces a multi-layer ceramic shell and core manufacturing process adopted in the prior investment casting. The method does not need the processes of investment pattern making, slurry coating and sand spreading adopted in the prior process, and has the characteristics of simple process, short cycle, low cost and quick returns, etc.

Owner:XI AN JIAOTONG UNIV

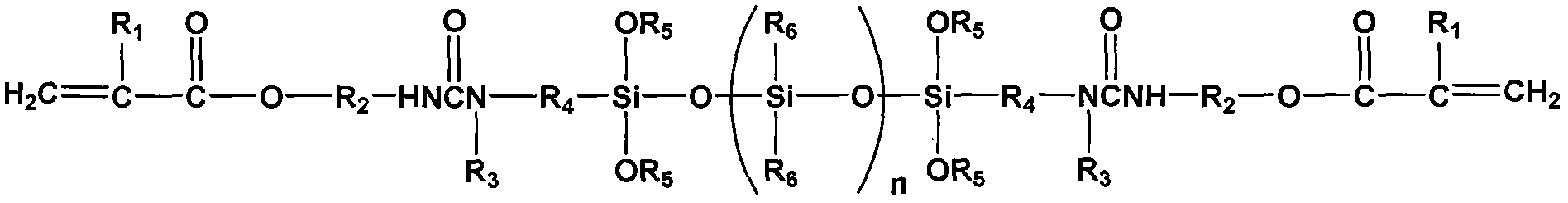

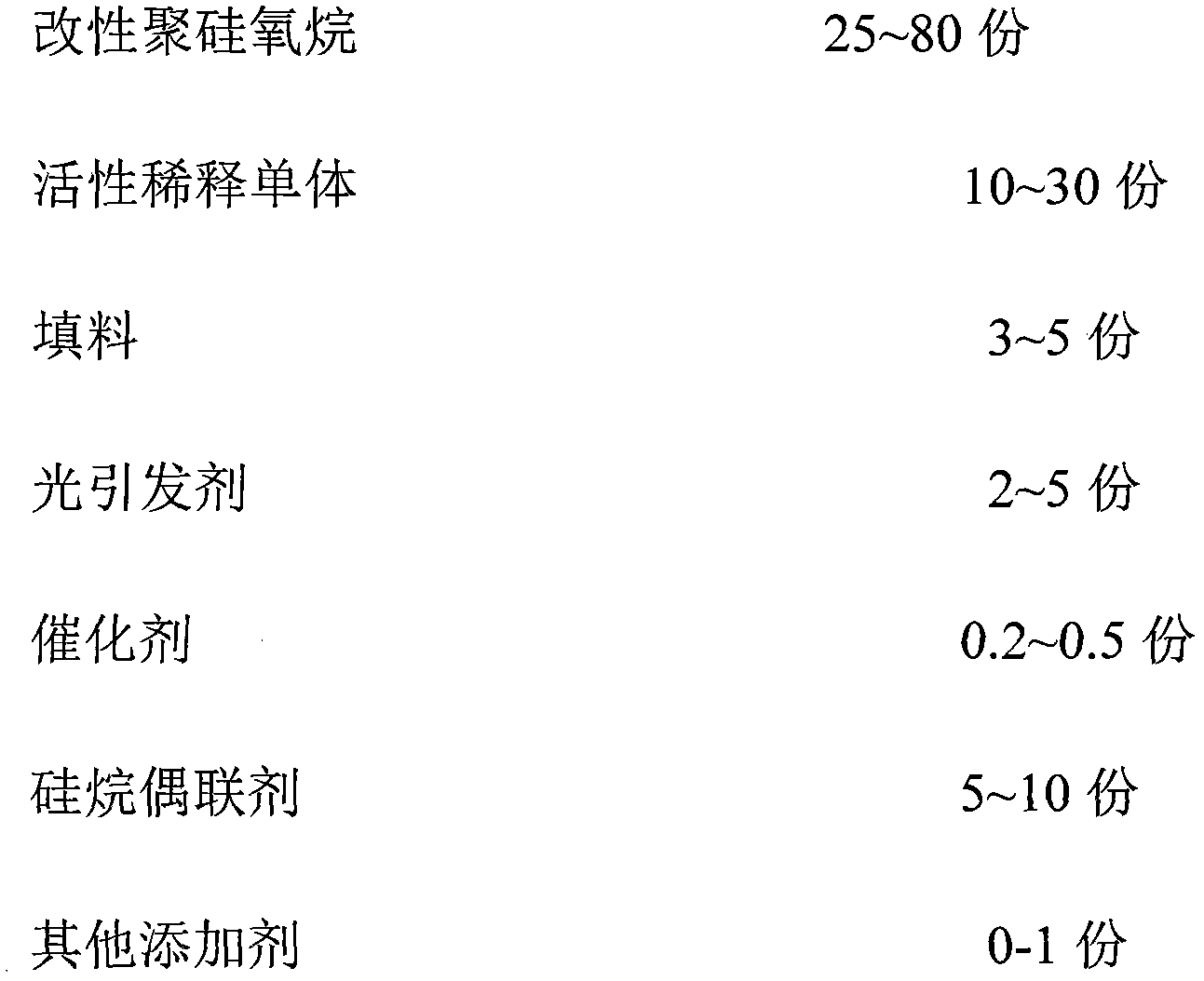

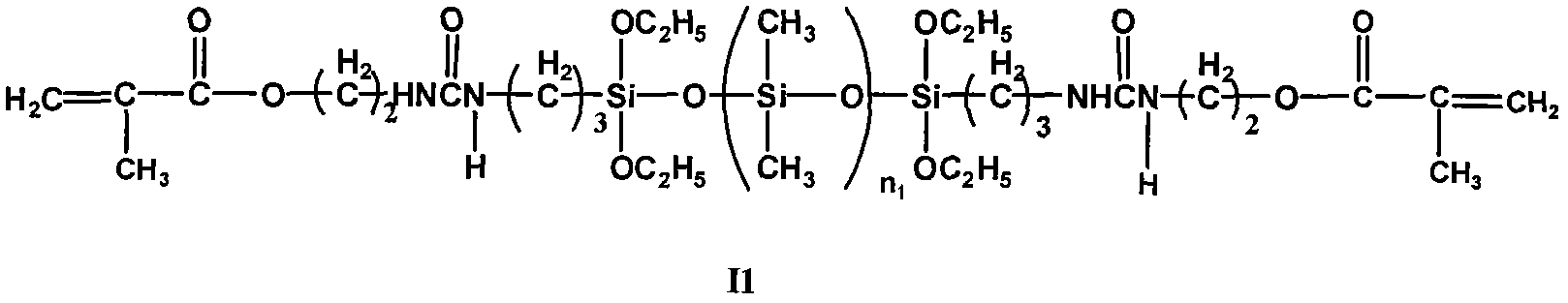

Polysiloxane with UV (Ultraviolet) and moisture double curing groups and preparation method thereof

InactiveCN103923321AThe synthesis method is simpleLow costCoatingsAdhesivesUltravioletReaction intermediate

The invention discloses polysiloxane with UV (Ultraviolet) and moisture double curing groups and a preparation method thereof. The polysiloxane is prepared by the following steps: mixing hydroxyl silicone oil with a silane coupling agent containing amido and carrying out a reaction to generate an intermediate; and then, adding an acrylic monomer containing isocyanate into the reaction intermediate and mixing and reacting to obtain the polysiloxane. The modified polysiloxane synthetic method disclosed by the invention is simple and low in cost, has the characteristics of quick curing and high efficiency, avoids the defect that the dash area or the bottom layer cannot be cured, and has the characteristics of excellent performances and photocuring technology of the organosilicon material. The modified polysiloxane can be applied to the field of binders, film coatings and encapsulating materials.

Owner:TONSAN ADHESIVES INC

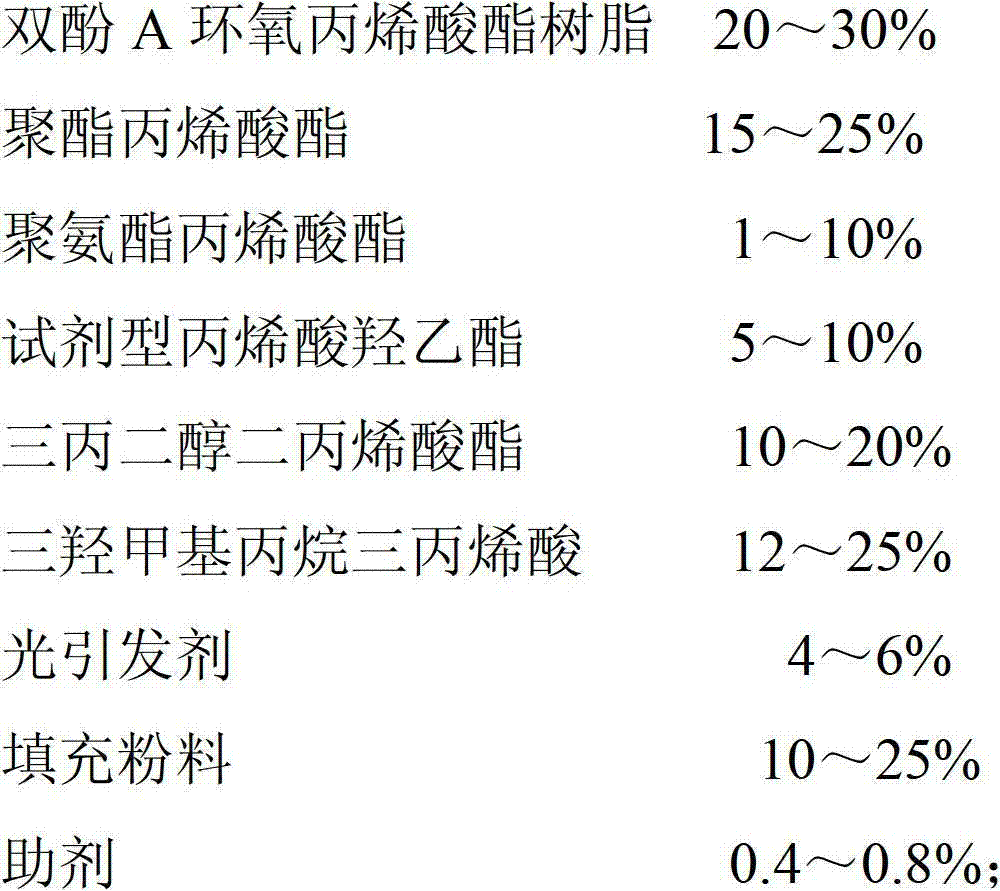

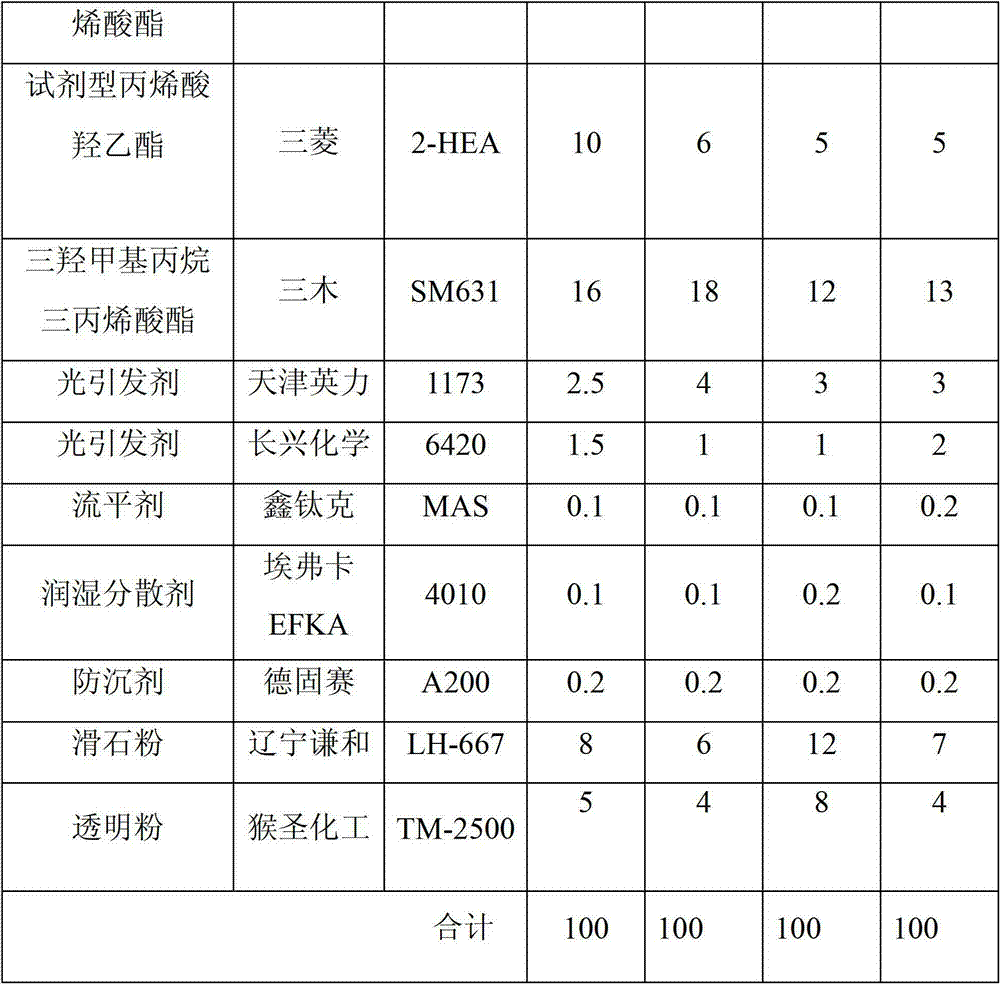

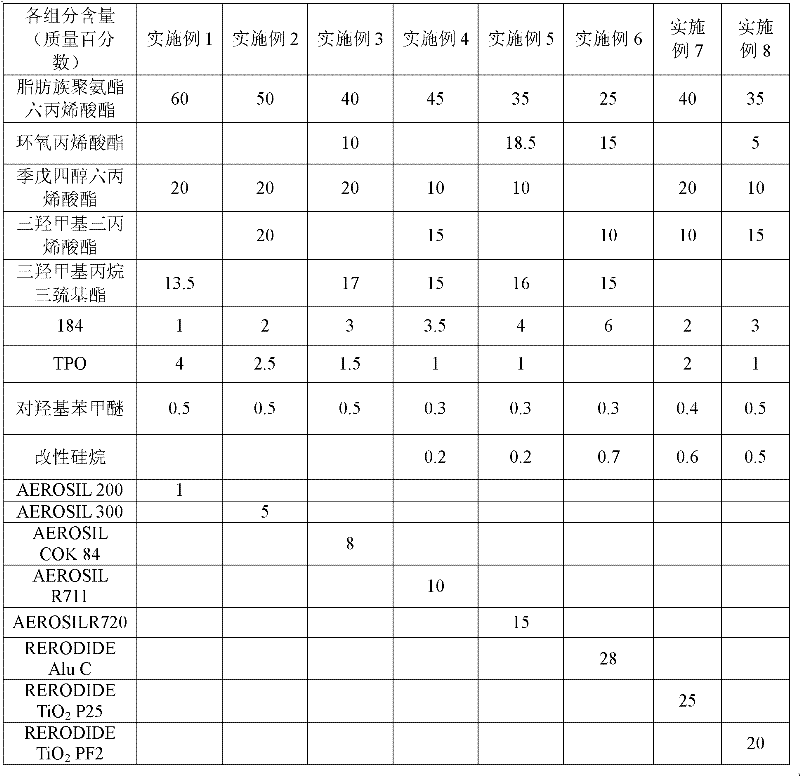

Ultraviolet light curing transparent priming paint and preparation method and use method thereof

ActiveCN102952455AReduce lossImprove product qualityPolyurea/polyurethane coatingsEpoxy resin coatingsTripropylene glycolPolyester

The invention discloses an ultraviolet light curing transparent priming paint and a preparation method and a use method thereof. The ultraviolet light curing transparent priming paint comprises the following components in percentage by weight: 20-30% of bisphenol A epoxy acrylate resin, 15-25% of polyester acrylate, 1-10% of urethane acrylate, 5-10% of reagent type hydroxyethyl acrylate, 10-20% of tripropylene glycol diacrylate, 12-25% of trimethylolpropane triacrylate, 4-6% of photoinitiator, 10-25% of filling powder and 0.4-0.8% of promotor. The ultraviolet light curing transparent priming paint is suitable for laser roller construction, has good grittiness and transparency, has the characteristics that sanding is not needed for semi-curing recoating between film layers and the like, and has thick coating performance and the performance that the surface is similar to a mirror surface, and compared with conventional roller coating, the coating weight is greatly increased, roller coating processes are saved, the priming paint is sanded by a sanding machine without large pressure and with a small number of sanded films, a workpiece has no bright spots, the fullness of a product is guaranteed, the product quality is improved, the loss of the machine is smallreduced, and the use amount of sanding belts is greatly reduced.

Owner:SHENZHEN GRANDLAND ENVIRONMENTAL COATING CO LTD

Aqueous photo-curing polyurethane resin and preparation thereof

ActiveCN101372530AAdjust dispersionAdjust water solubilityPolyureas/polyurethane adhesivesPolyurea/polyurethane coatingsPolymer scienceAdhesive

The invention relates to a method for preparing waterborne light-cured urethane resin. The waterborne light-cured urethane resin consists of polyatomic alcohol components, diisocyanate, hydroxyl (methyl) acrylic ester, a neutralizer, a catalyst, a solvent, a polymerization inhibitor and water. The target resin is prepared by one-step solution polymerization or bulk polymerization, and the preparation method is simple and easily operated. The densities of the light-curable group and hydrophilic group of the resin prepared are adjustable, and the resin has the advantages of unique hydrophilicity, superior light curing performance and high hardness of film forming matters, and has wide application prospect in the fields of coating, adhesives, ink, etc.

Owner:CHINA ACADEMY OF ENG PHYSICS FUNCTION MATERIAL RES INST

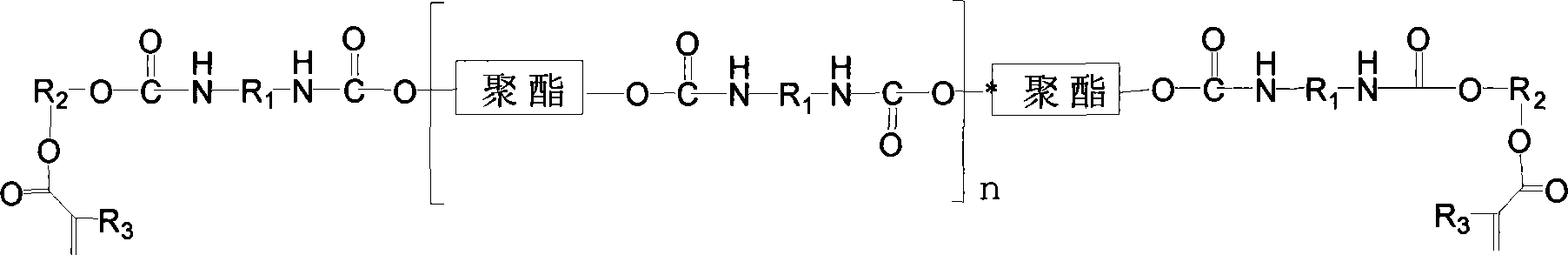

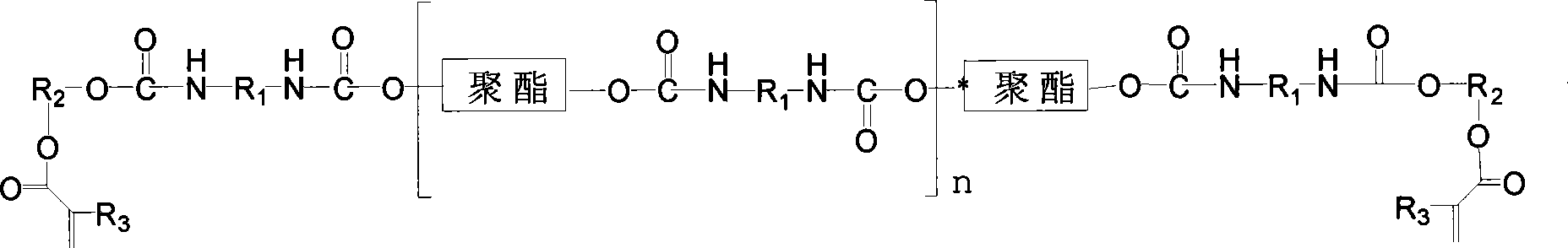

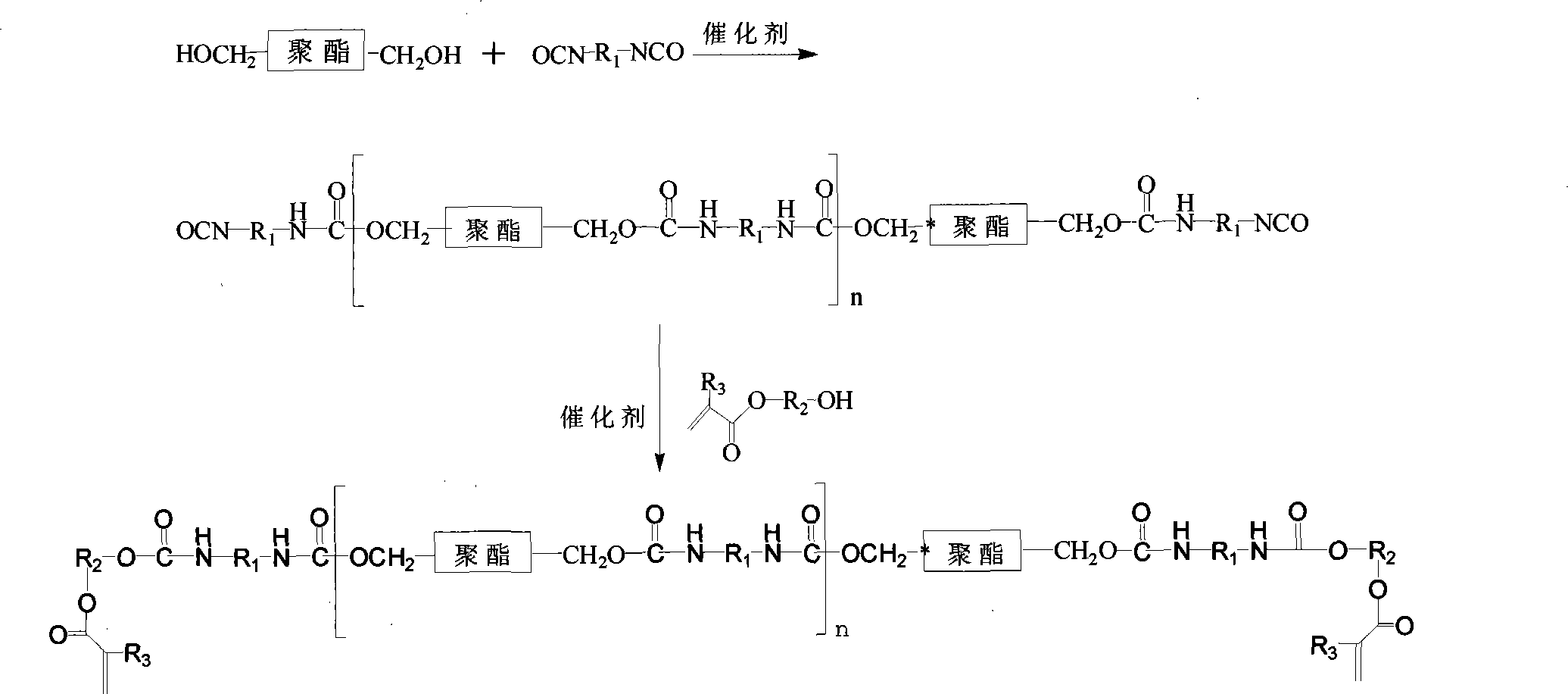

Large-molecular weight polyurethane acrylic ester and synthesizing method thereof

The invention discloses macromolecule weight urethane acrylate, which is formed by reaction on the basis of aliphatic polyester diatomic alcohol with the molecular weight of 500 to 8000, aliphatic diisocyanate and hydroxy acrylic acid monomer; wherein, polyesterglycol comprises ring-shaped resin, and the mechanical property and hydrolysis resistance property of light curing film are improved. The molecular weight of synthetic resin is 10000 to 50000 units, and acrylic ester double keys on the two ends of molecule chain enable the resin to produce high-efficiency free radical aggregation linkage under the effect of photoinitiators through the radiation of ultraviolet light. The aggregation linkage product of the finished film has good flexility and adhesive force, extremely low light curing contraction percentage, higher tensile strength and breaking elongation with hydrolysis resistance property improved. The invention can be used as the main ingredient or assistant matieral of light curing paint, light curing printing ink and light curing adhesive.

Owner:GUANGDONG BOSSIN NOVEL MATERIALS TECH CO LTD

Ultraviolet light curing material

InactiveCN102516866AIncrease profitPromote cross-linking and curingNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesDiluentUltraviolet lights

The present invention relates to an ultraviolet light curing material, which comprising the following components by weight percentage: 40-60%of light cured resin; 25-45% of light curing diluent; 2-10% of photoinitiator; 0-0.8% of ultraviolet storage stabilizer; 0.5-30%of nano filler; 0.2-1% of leveling agent. On the basis of addition of light cured resin, the light curing diluent and the photoinitiator in the ultraviolet light curing material, the nano filler is added, the ultraviolet light respectively reflects to all directions through small particles, so that the light is scattered, the utilization rate of the ultraviolet light can be increased, the crosslinking and curing speed can be accelerated, and the curing energy can be reduced.

Owner:YANTAI DARBOND TECH

Colored masking for forming transparent structures

InactiveUS20070269750A1Photomechanical exposure apparatusMicrolithography exposure apparatusPhysicsVisible spectrum

The invention relates to a process for forming a stacked transparent structure comprising providing a support, coating one side of said support with a multicolored mask, coating the other side of the support with a layer curable by visible light, and exposing the light-curable layer through the mask with visible light to cure the layer curable by light in exposed portions to form a cured pattern.

Owner:EASTMAN KODAK CO

Preparation method of novel dual-cured UV curing binder

InactiveCN104449542AAdhesive processesNon-macromolecular adhesive additivesMetallic materialsDouble bond

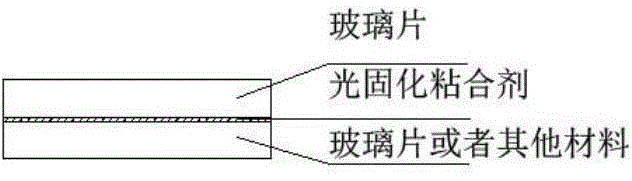

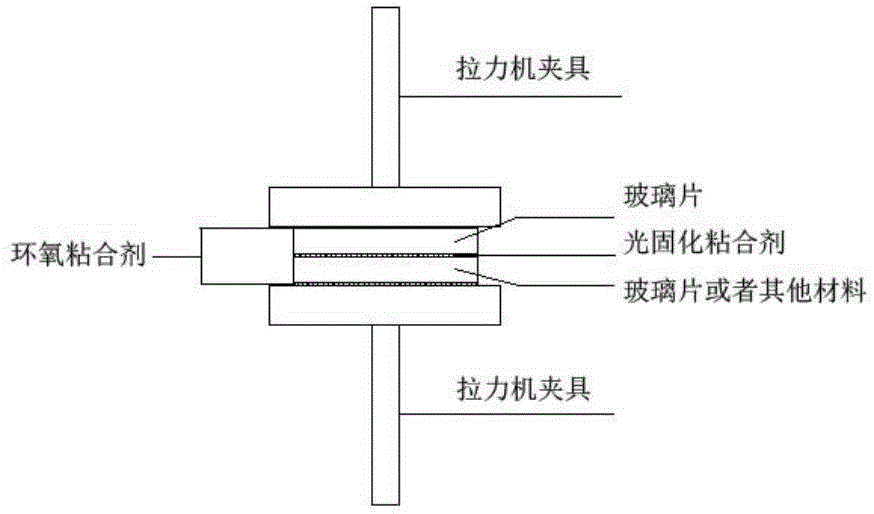

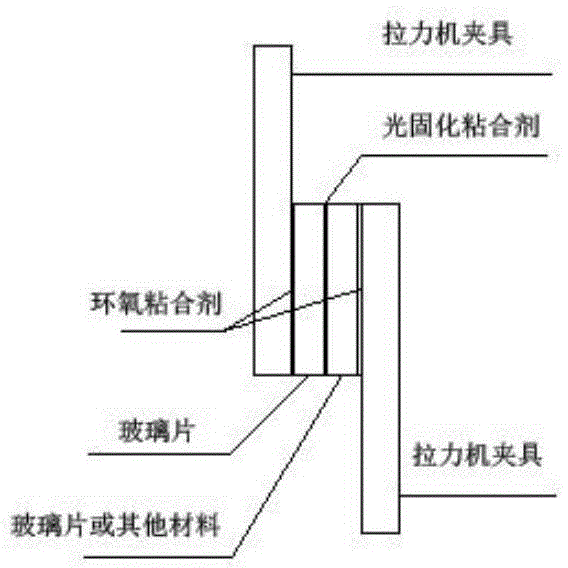

The invention relates to a preparation method of a novel dual-cured UV curing binder, and belongs to the technical field of binder industry. The novel dual-cured UV curable binder is prepared by using radical polymerizable resins such as common urethane acrylate, epoxy acrylate and unsaturated polyester as main binding materials, using a double bond-containing reactive diluent as a solvent, and using a UV initiator and a thermal initiator as a compound initiator, supplemented by other binding agents. During curing, a certain initial binding power is firstly obtained by UV curing, and higher binding power is obtained by secondary curing through heating or oxygen isolation. The preparation method provided by the invention not only has the advantages of high curing speed of the traditional light curing binders, but also has the advantages of effectively avoiding the generation of internal stress in the curing process of the traditional light curing binder, and improving the binding strength of the binder; the binder has excellent solvent resistance, high binding strength, and low cost. The binder is widely used for binding glass and glass, glass and metal materials and other transparent materials.

Owner:JIANGNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com