Patents

Literature

1088results about How to "Improve scanning efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

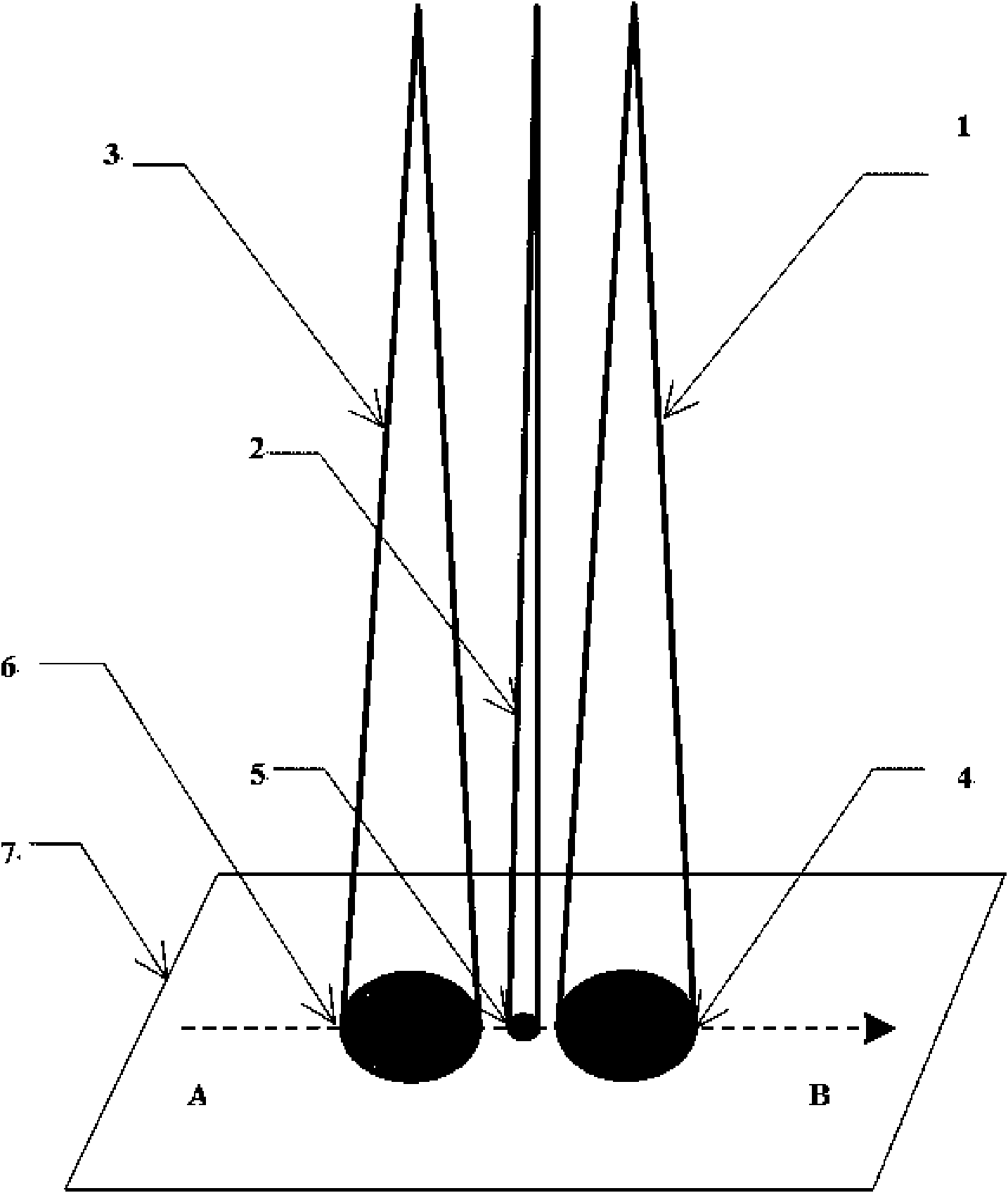

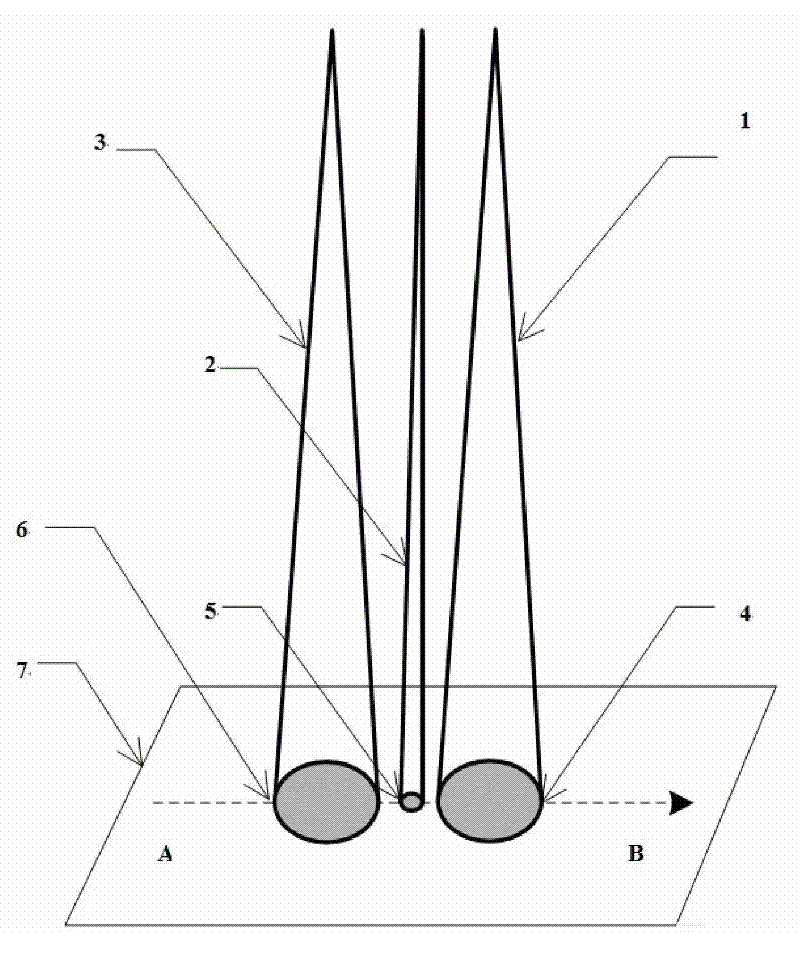

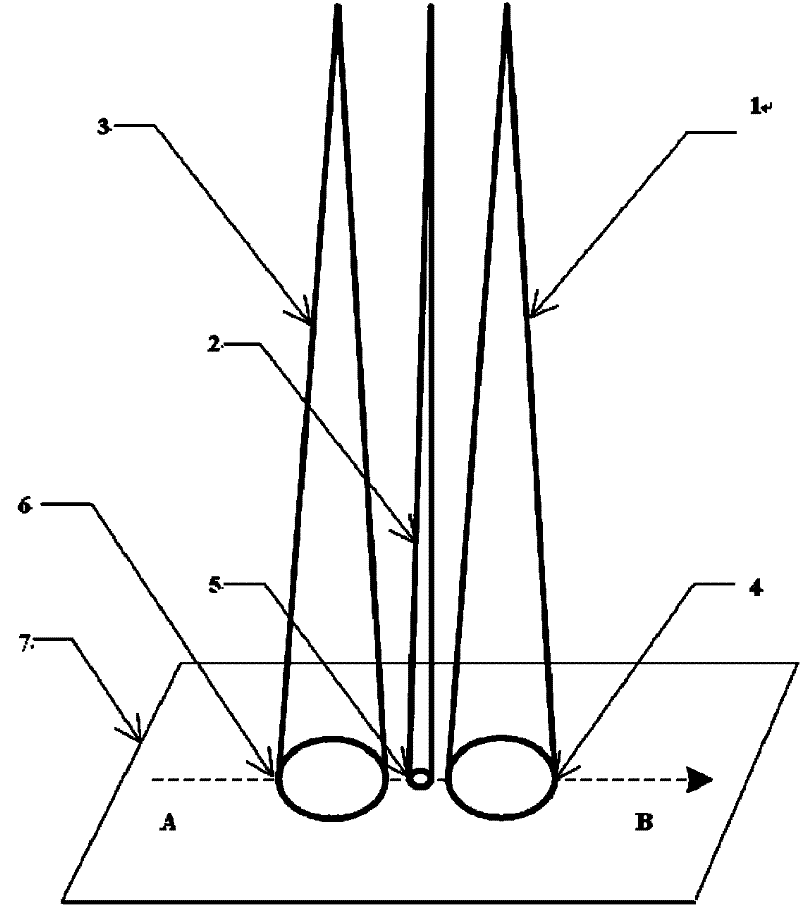

Fast forming method of fusion of metal powder of three beams of laser compound scanning

The invention discloses a fast manufacturing method of three-beam laser compound scanning. The method comprises the following steps of: firstly utilizing long-wavelength laser (CO2 laser) for preheating the metal powder, then utilizing short-wavelength laser (YAG or optical fiber laser) for fusing the metal powder and finally utilizing long-wavelength laser (CO2 laser) to carry out heat treatment to the frozen metal. The fast manufacturing method uses the three beams of laser to carry out compound scanning, namely uses long-wavelength laser to preheat, short-wavelength laser to fuse and then long-wavelength laser to carry out heat treatment, can realize the compound process of preheating, fusion and heat treatment of the metal powder. The three beams of laser compound scanning mode can reduce internal stress of the metal part, avoid warping and cracking, improve organization and improve performance.

Owner:HUAZHONG UNIV OF SCI & TECH

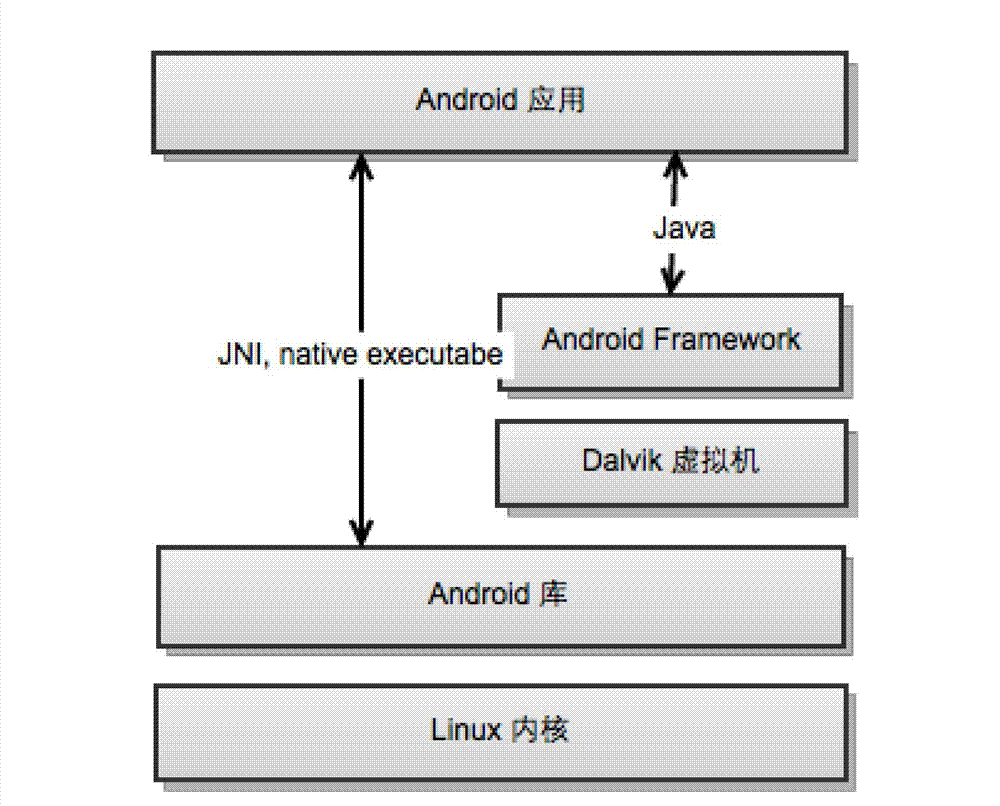

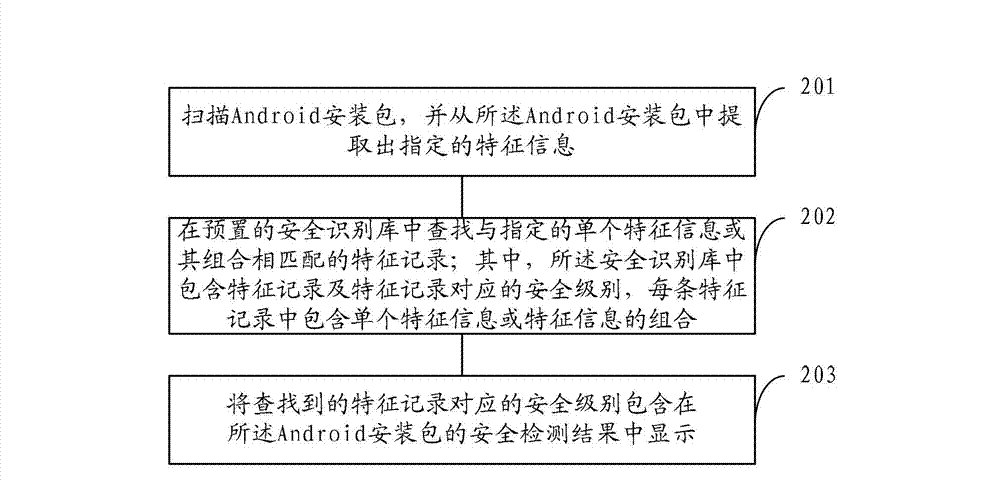

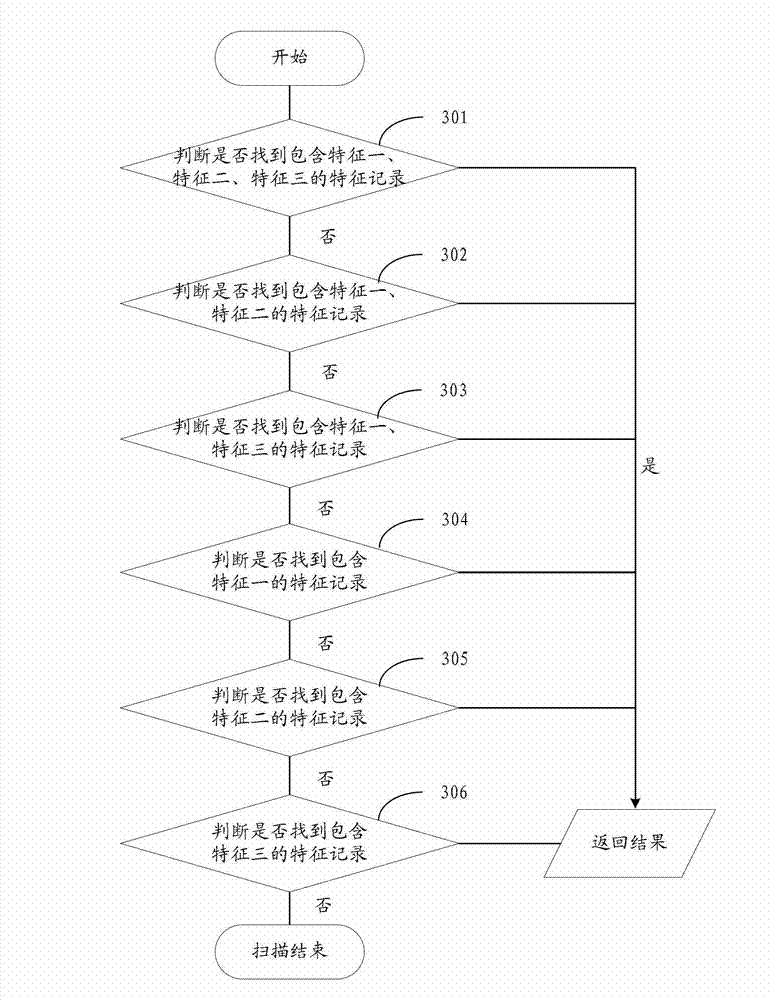

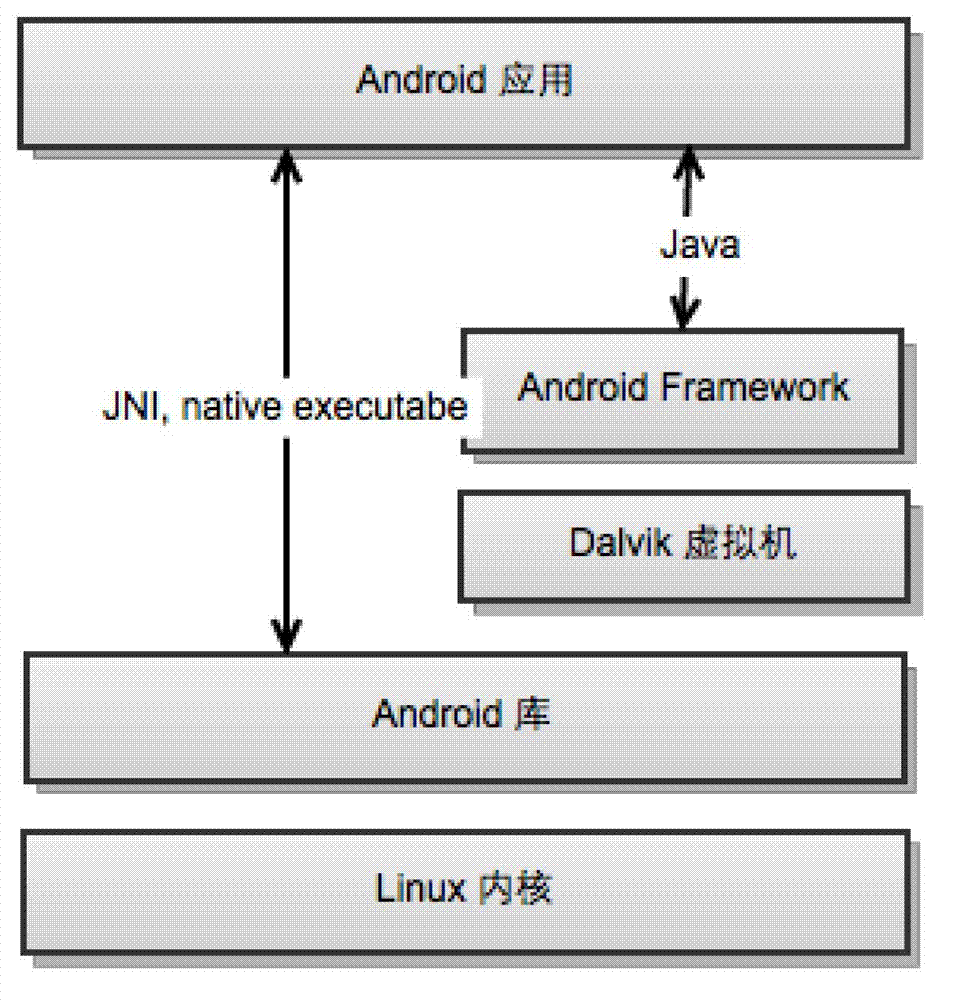

Security detection method and system of Android application program

ActiveCN102779257ACause harmImprove scanning efficiencyComputer security arrangementsSoftware engineeringApplication software

The invention provides a security detection method and system of an Android application program, aiming to solve the problems of an antivirus method of the existing Android platform that the scanning speed is slow and the false positive ratio is high. The method comprises the following steps of: scanning an Android installation package and extracting appointed characteristic information from the Android installation package; finding characteristic records which are matched with the appointed single characteristic information or a combination thereof from a pre-arranged security identification base, wherein the security identification base comprises the characteristic records and security grades corresponding to the characteristic records, and each characteristic record comprises single characteristic information or the combination of the characteristic information; and respectively displaying the security grade corresponding to the found characteristic records in a security detection result of the Android installation package. The security detection method and system of the Android application program disclosed by the invention have the advantages of fast scanning speed and high searching and killing accuracy.

Owner:360 TECH GRP CO LTD

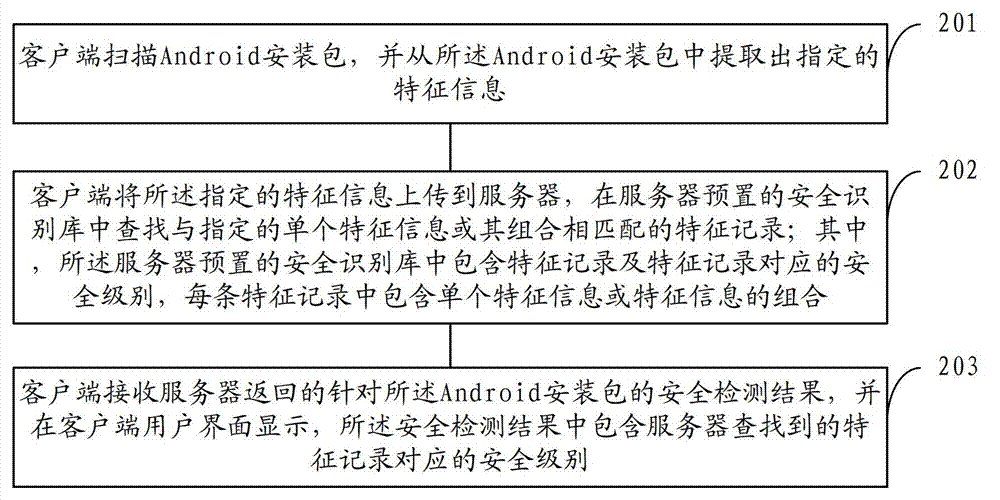

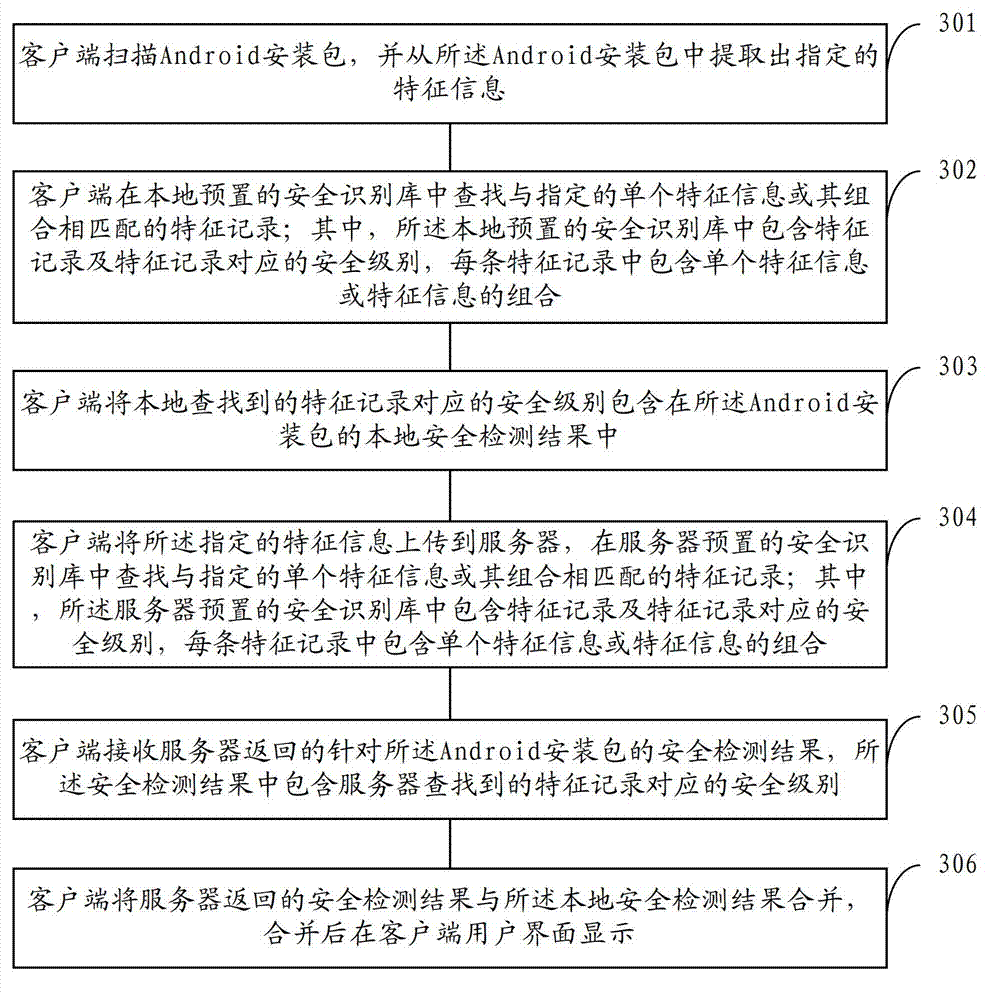

Security detection method and system of Android application program

ActiveCN102831338ACause harmImprove scanning efficiencyComputer security arrangementsSpecial data processing applicationsSecurity levelFalse alarm

The invention provides a security detection method and system of an Android application program, solving the problems of low scanning speed and high false alarm rate of the traditional virus killing method of an Android platform. The security detection method comprises the steps of: scanning an Android installation package, extracting appointed characteristic information from the Android installation package; uploading the appointed characteristic information to a server, searching a characteristic record matched with appointed single characteristic information or combination from a security identification base preset in the server; and receiving a security detection result returned by the server aiming at the Android installation package, and displaying on a client end user interface, wherein the security detection result includes a security level corresponding to the characteristic record searched by the server. The client end detection is combined with the server detection, thus the security detection method is high in scanning speed and high in killing accuracy rate.

Owner:360 TECH GRP CO LTD

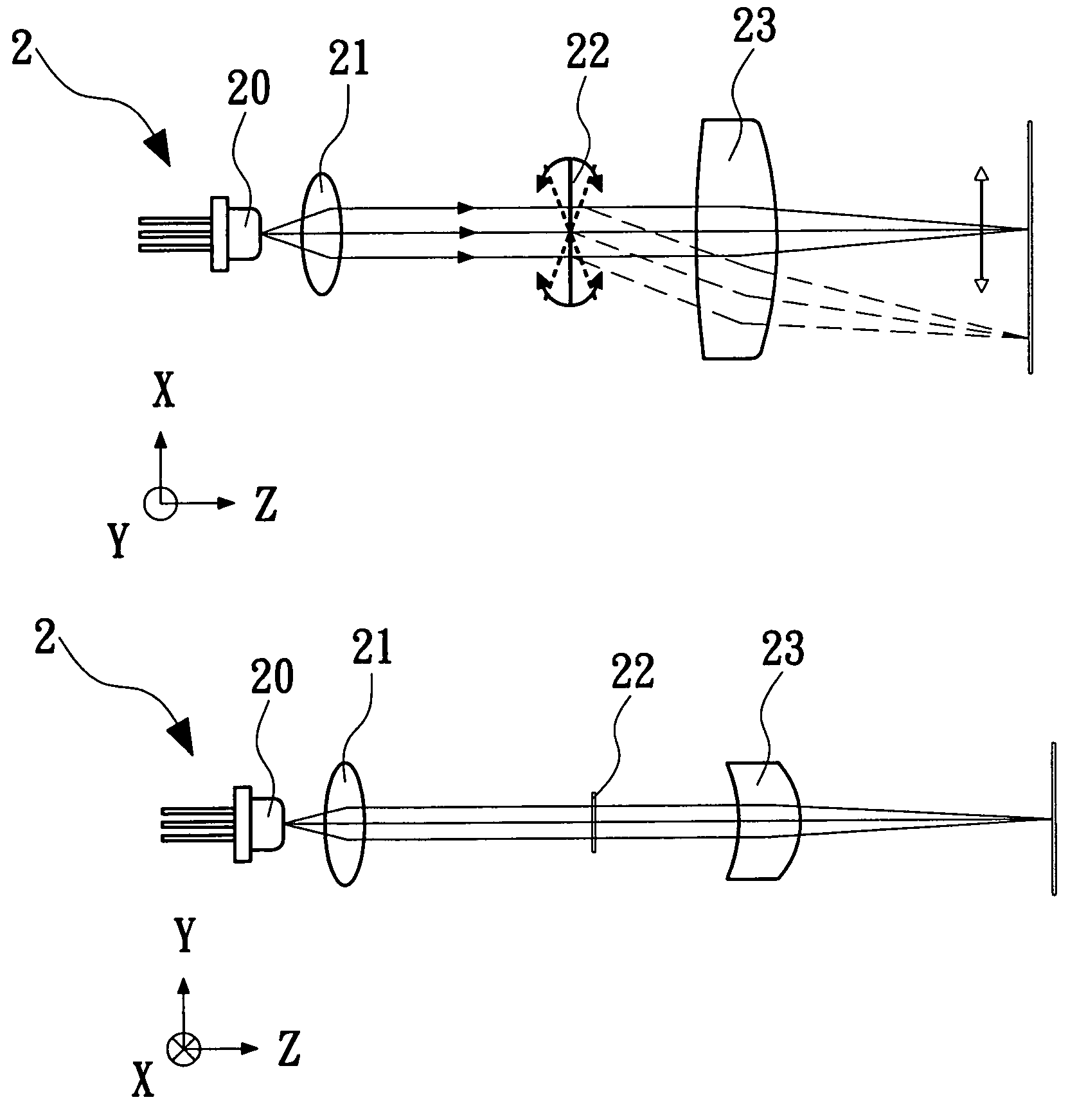

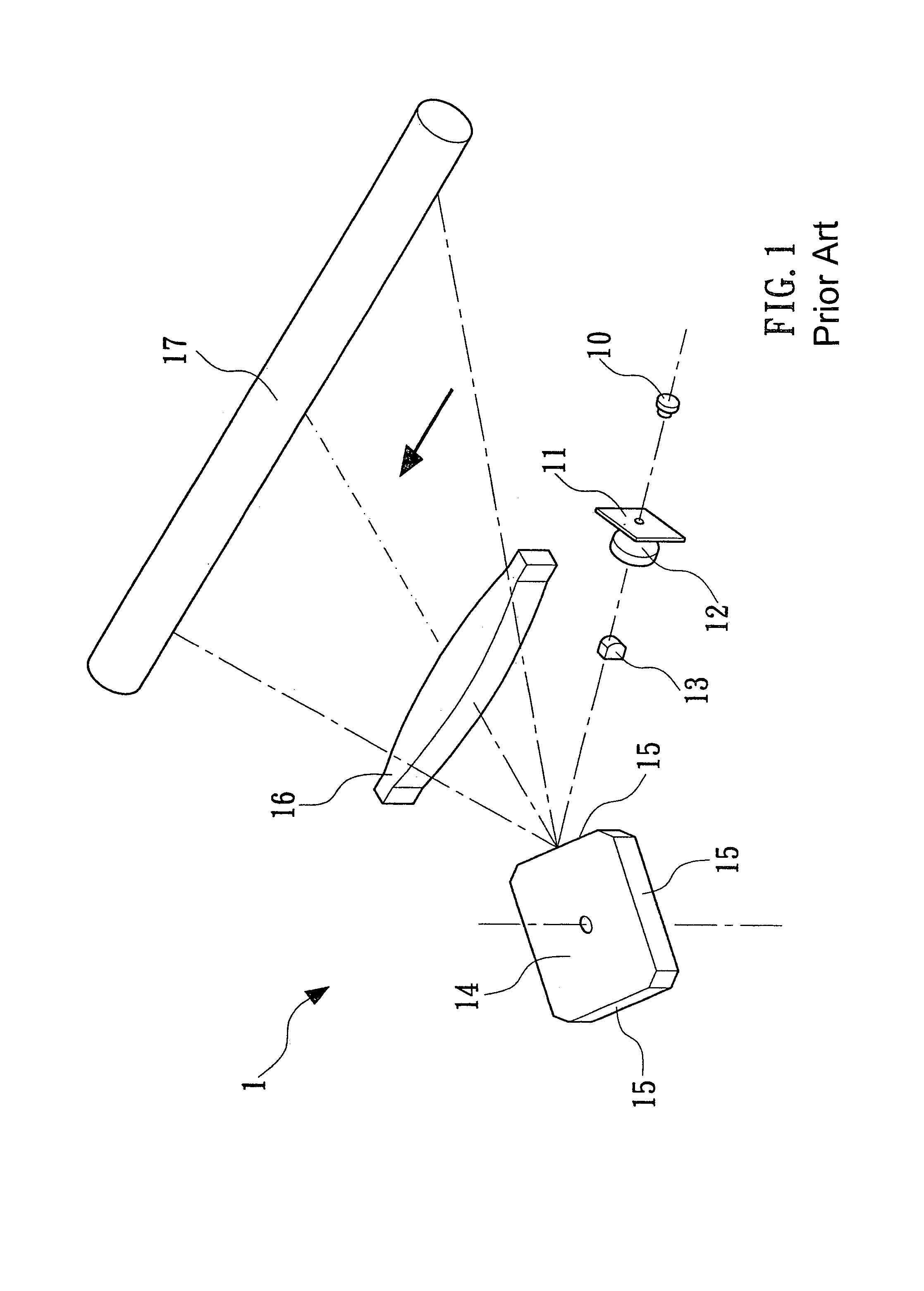

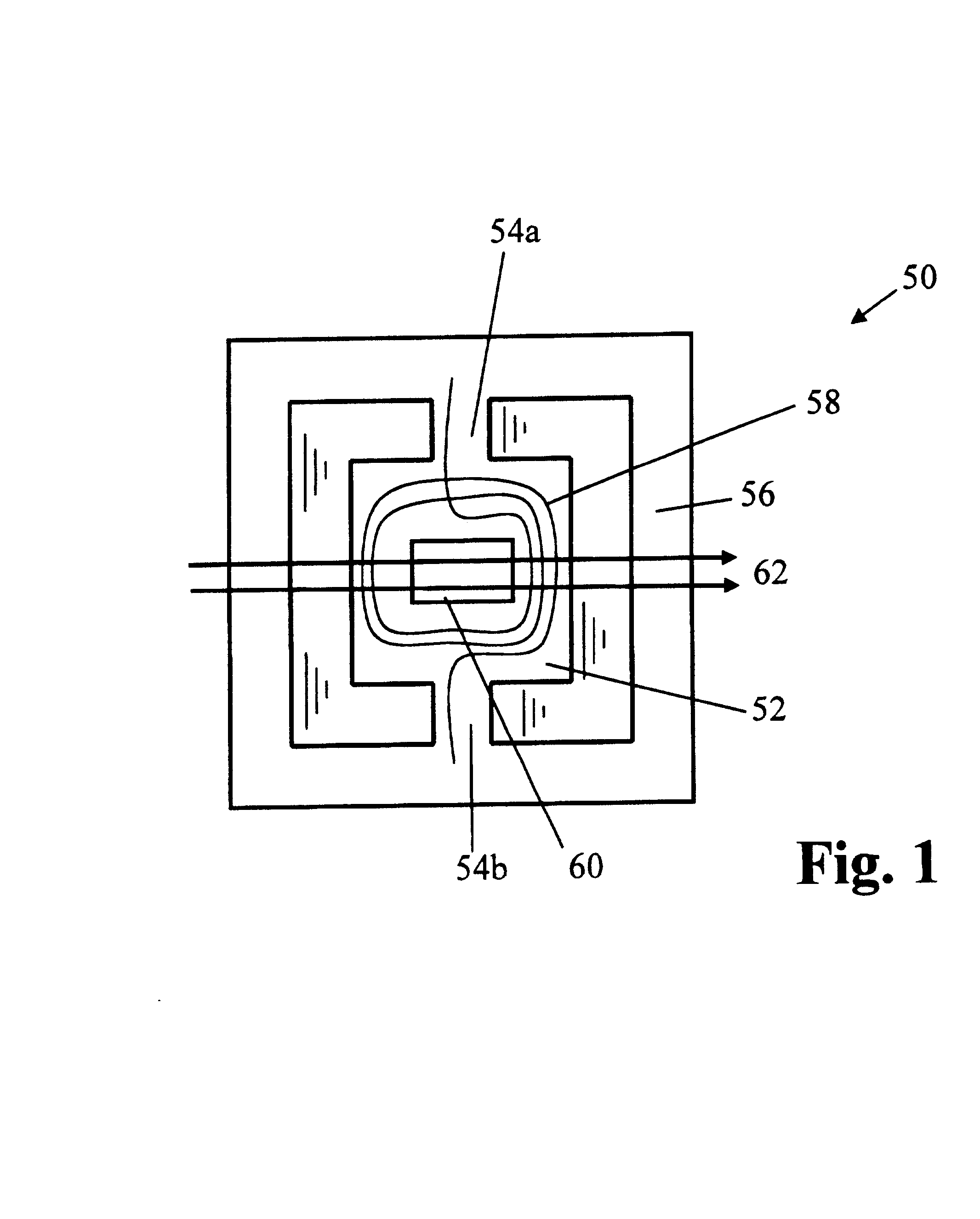

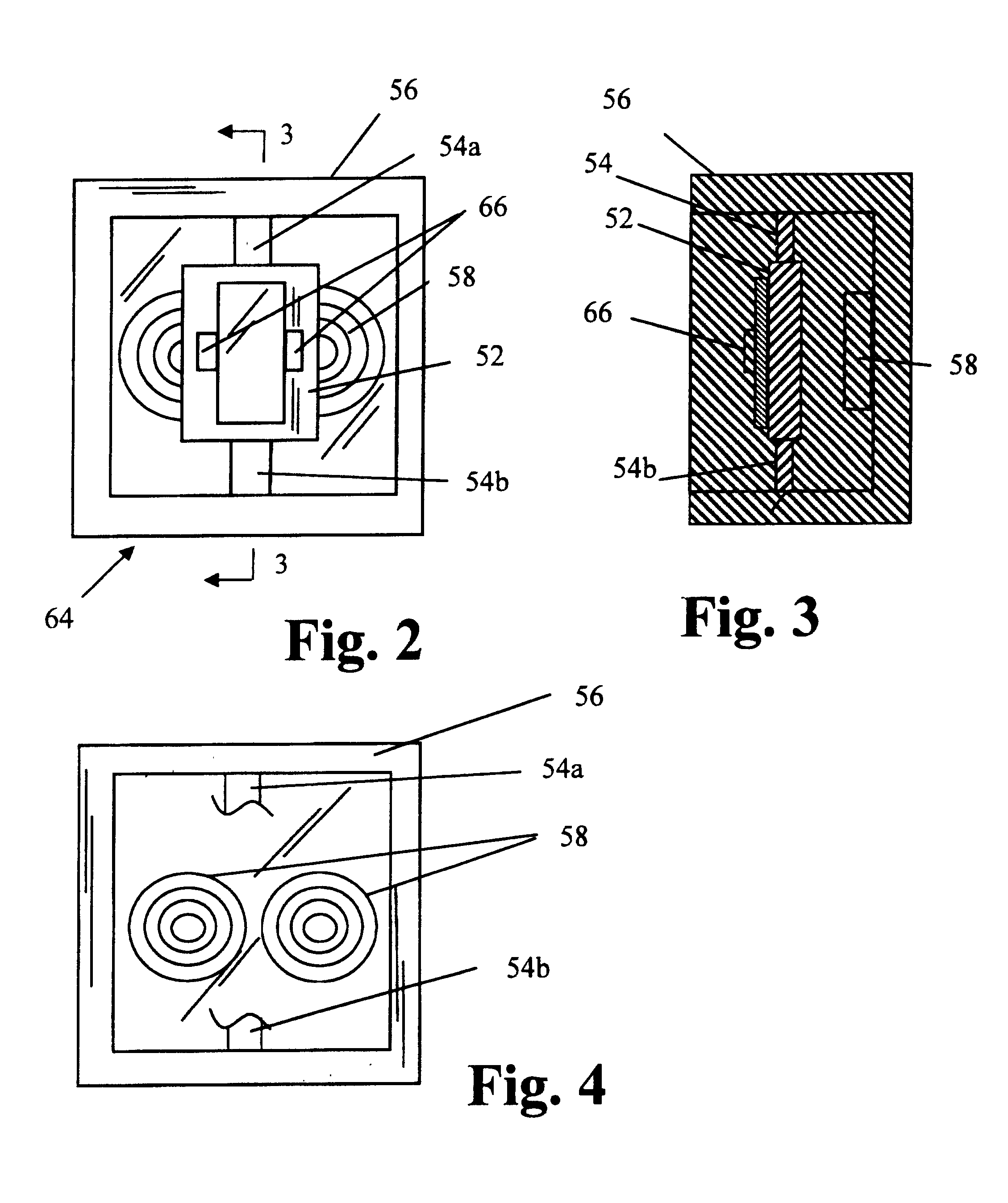

Laser scanning unit

InactiveUS7190499B2Reduce in quantityIncrease scan frequencyMountingsPrintingLaser scanningOptoelectronics

A laser scanning unit mainly includes a semiconductor laser, a collimator, a micro electronic mechanic system (MEMS) oscillatory mirror, and an fθ lens or an f sin θ lens. The MEMS oscillatory mirror is disposed between the collimator and the fθ lens to replace a conventional rotary polygonal mirror for controlling a direction in which laser beams are projected from the oscillatory mirror to the fθ lens. With the MEMS oscillatory mirror, the cylindrical lens may be omitted from the laser scanning unit and noises produced by the polygonal mirror rotating at high speed may be avoided. Moreover, the MEMS oscillatory mirror allows bi-directional scanning to therefore enable increased scanning frequency, simplified structure, and improved scanning efficiency.

Owner:E PIN OPTICAL IND

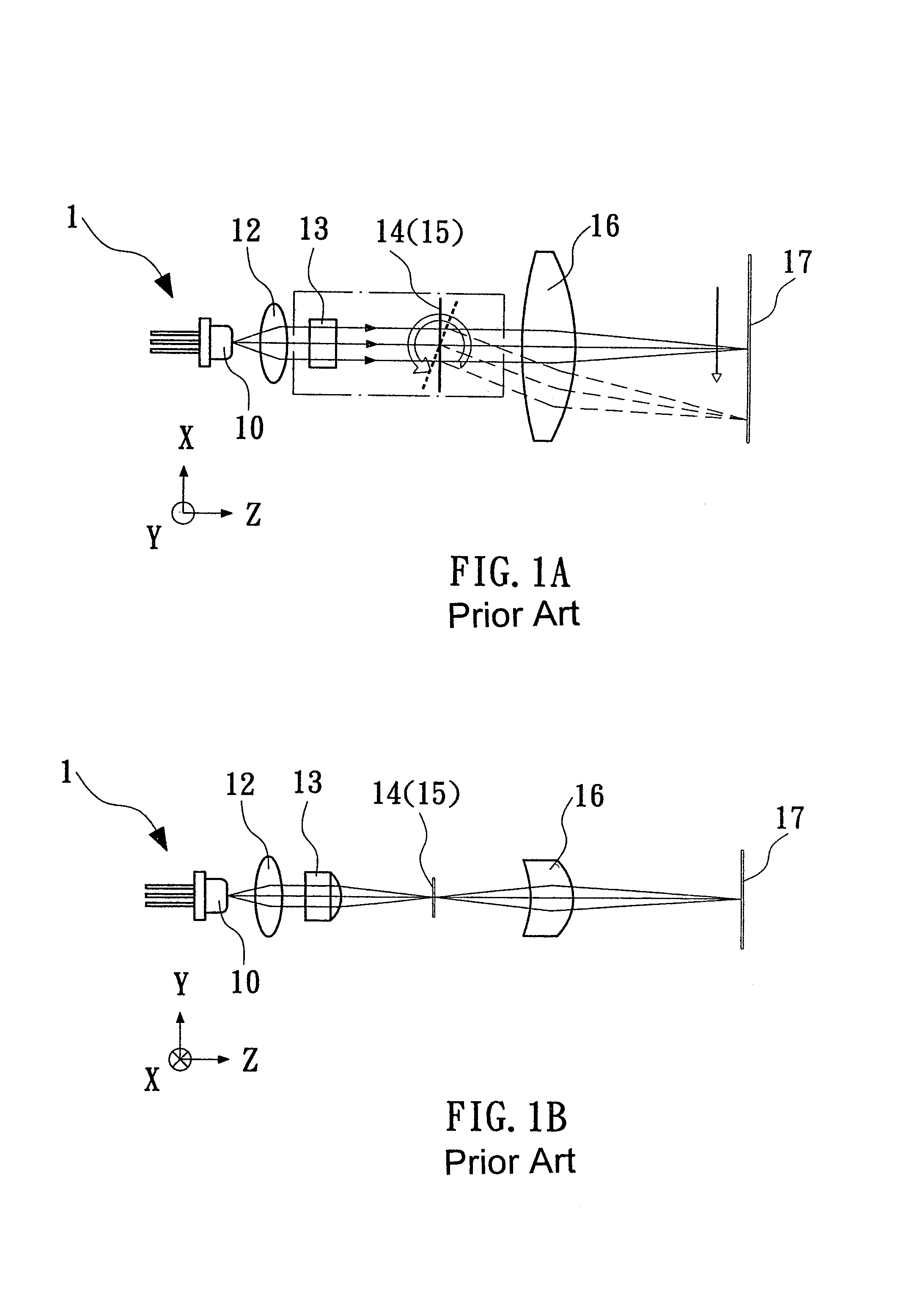

Detecting overlapping images in an automatic image segmentation device with the presence of severe bleeding

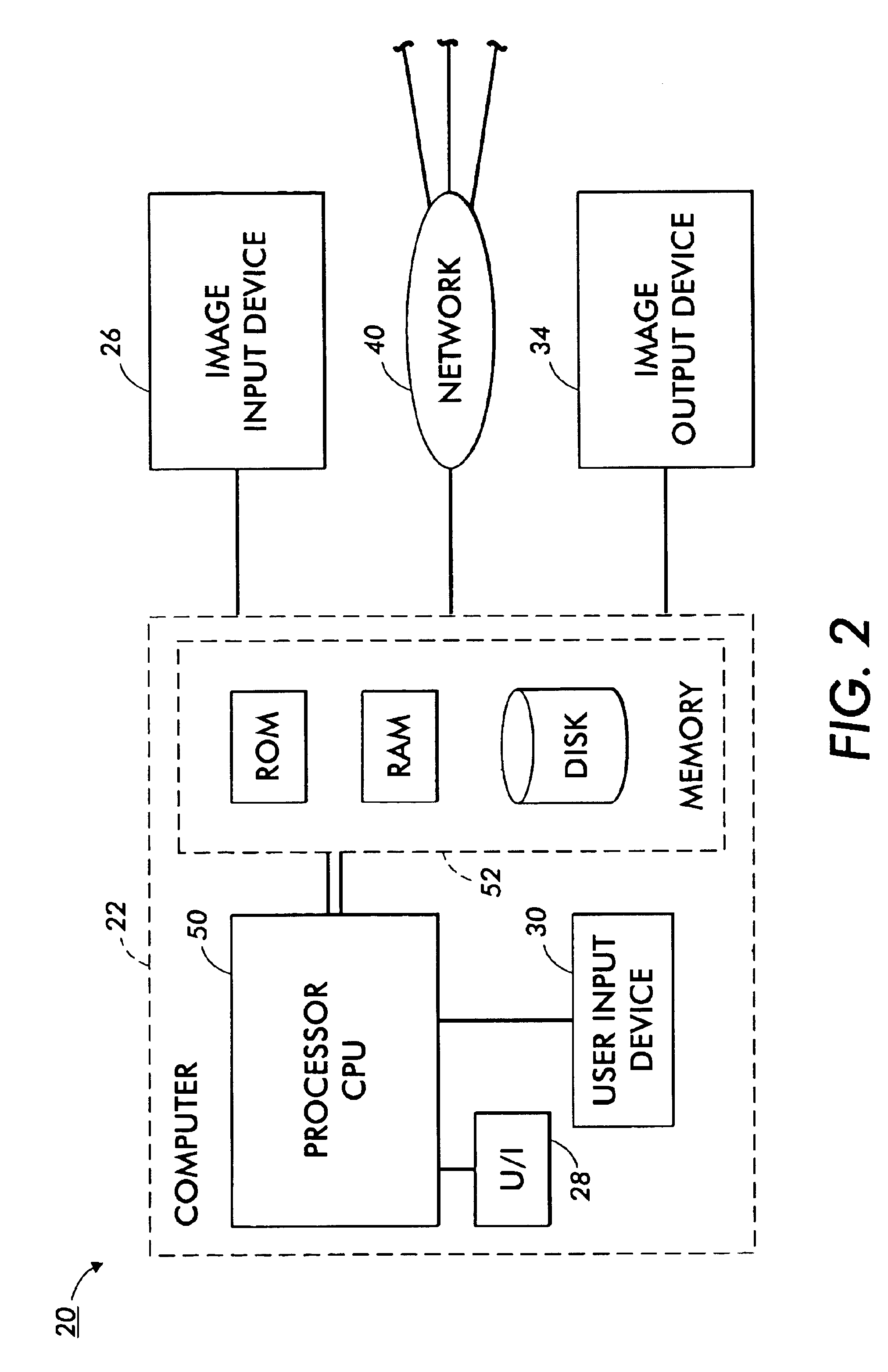

InactiveUS6839466B2Improve scanning efficiencyImage enhancementImage analysisImage segmentationComputer vision

A method for processing multiple digital images using an imaging input device so as to reduce bleeding of edges of the multiple digital images by determining the boundaries of each of the digital images, including detecting a boundary of a first image; detecting a boundary of a second image; determining an overlap between the detected boundaries of the first image and second images; calculating the overlap between the first and second images and modeling a third image from the calculated overlap of the first and second images wherein the third image contains at least said first and second images and represents a depiction of said first and second images without an overlap between said first and second images.

Owner:XEROX CORP

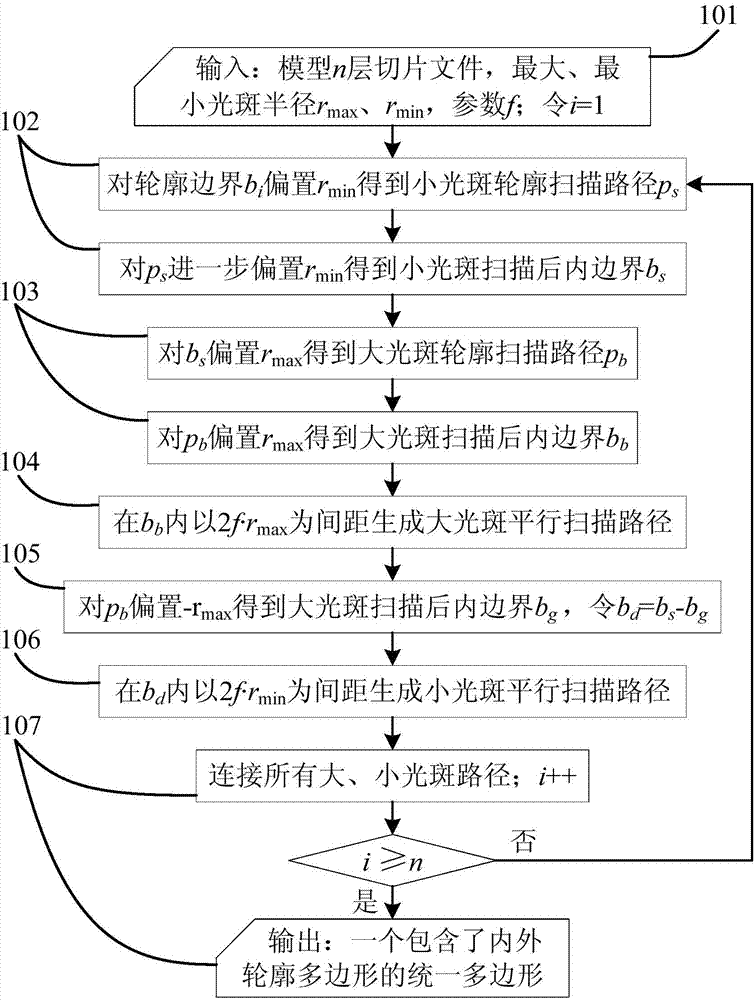

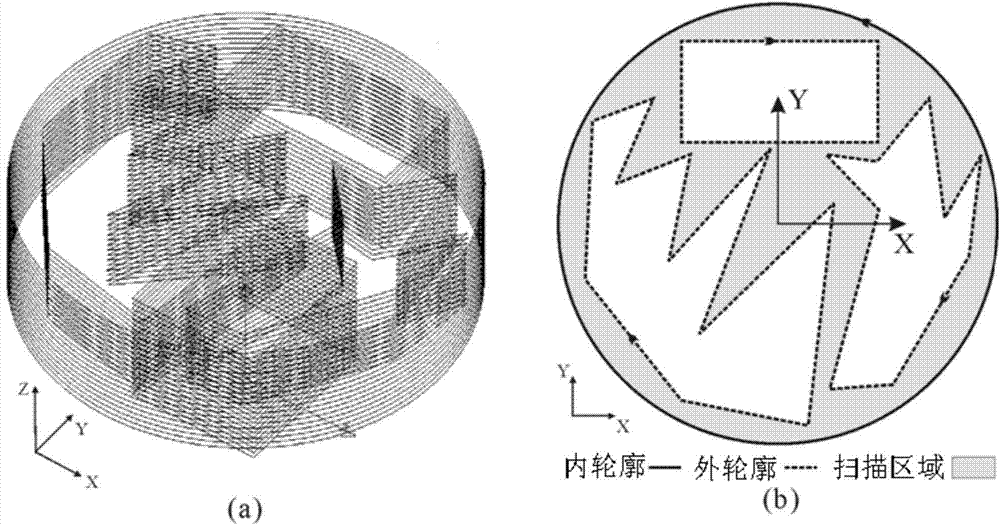

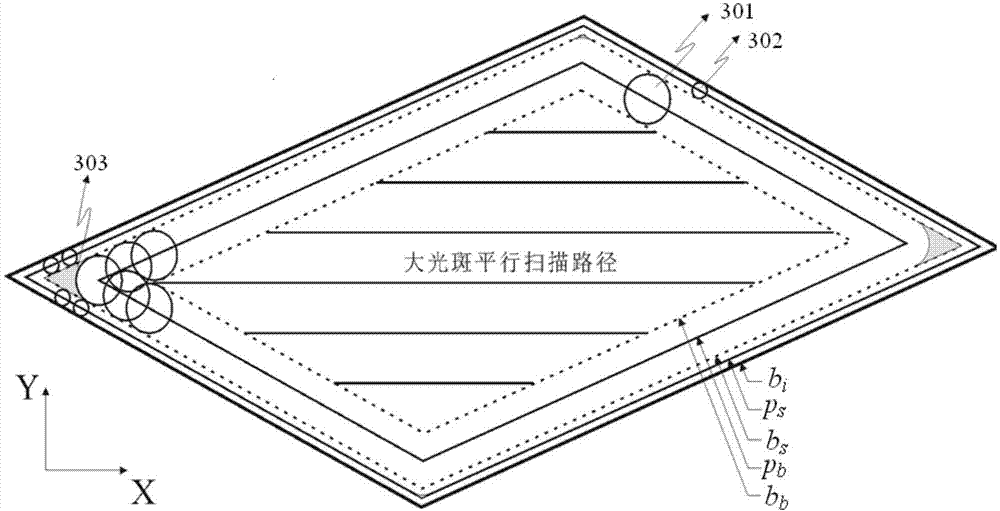

Three-dimensional printing large light spot scanning path generation method

ActiveCN103894608AImprove scanning efficiencyGuaranteed contour printing accuracyLight spotPath generation

The invention discloses a three-dimensional printing large light spot scanning path generation method which comprises the steps of inputting a model slice file, the maximum light spot radius rmax, the minimum light spot radius rmin and a path overlapping parameter f; performing offset on a contour boundary bi of the current layer of the slice for the rmin to generate a small light spot contour scanning path ps, and performing offset on the ps for the rmin to obtain an internal boundary bs of small light spots subjected to scanning; performing offset on the bs for the rmax to obtain a large light spot contour scanning path pb, and performing offset on the pb for the rmax to obtain an internal boundary bb of large light spots subjected to scanning; performing offset on the pb for -rmax to obtain an internal boundary bg of the large light spots subjected to scanning, and performing Boolean subtraction on bs and bg; generating a small light pot parallel scanning path in an unscanned region; connecting all the large light pot scanning paths and all the small light pot scanning paths until printing is completed and the scanning paths are output. By means of the three-dimensional printing large light spot scanning path generation method, the small light spot scanning and the large light spot scanning are combined, the unscanned region is filled with the small light spots to achieve elimination, and part forming accuracy and efficiency are increased.

Owner:ZHEJIANG UNIV

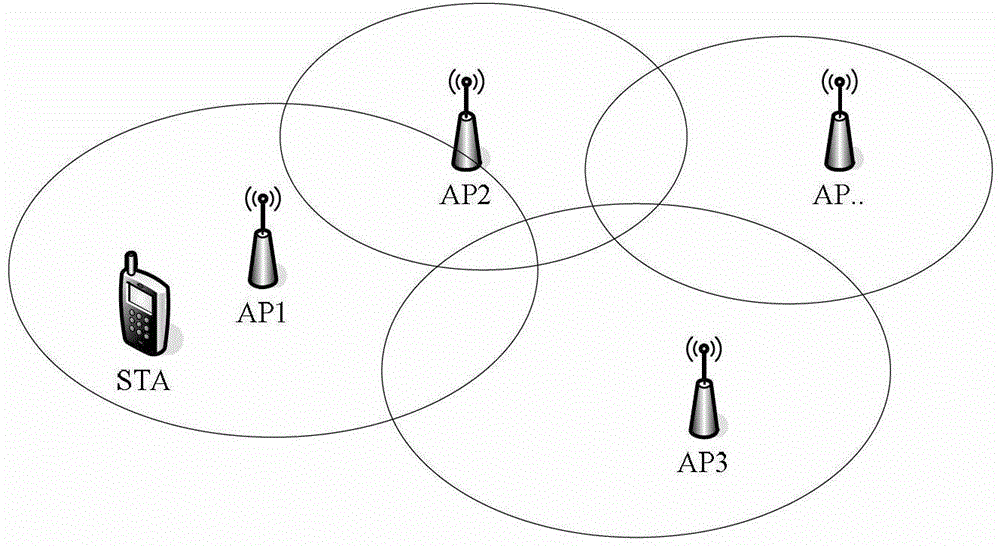

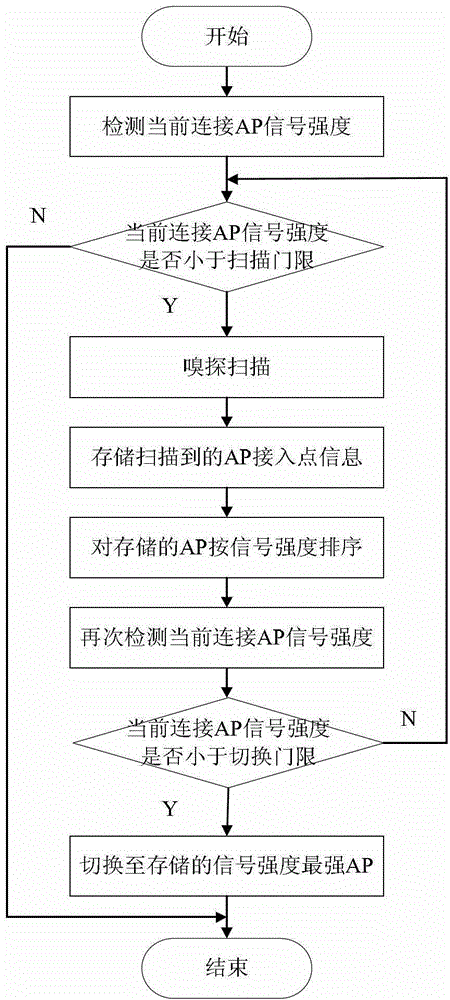

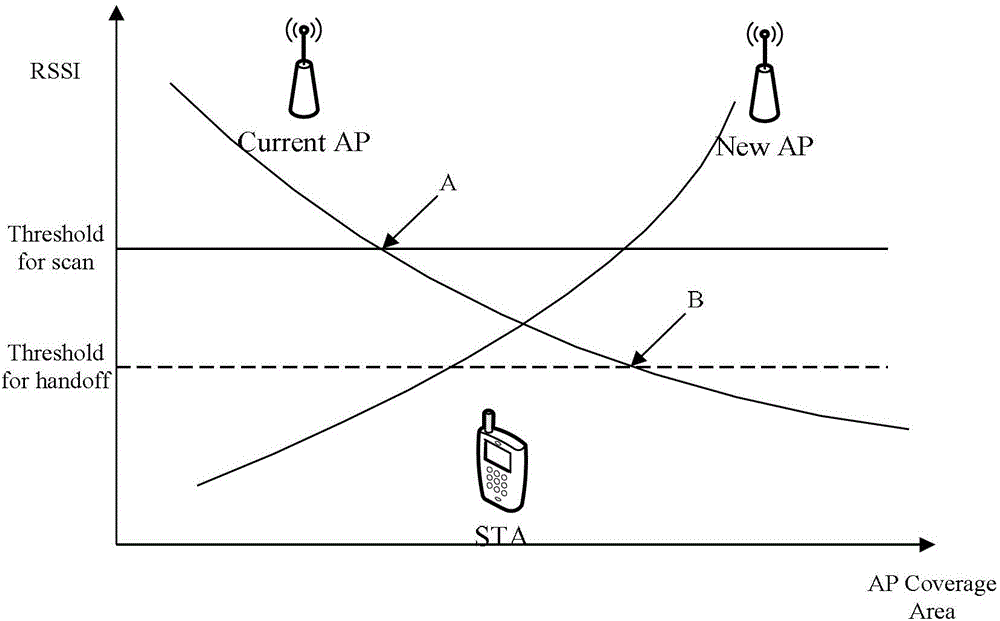

AP (application process) switching method used in WiFi (wireless fidelity) communication

InactiveCN102917424AQuick switchImprove scanning efficiencyNetwork topologiesTelecommunicationsWifi network

The invention discloses an AP (application process) switching method used in WiFi (wireless fidelity) communication, and provides a WiFi access point switching method for dynamically adjusting threshold values in real time. The AP switching method is characterized in that after a mobile terminal detects received signal intensity of a currently connected AP, the signal intensity is compared to a scanning threshold value, scanning is started if the signal intensity is lower than the scanning threshold value, and scanned adjacent AP information is dynamically stored; the mobile terminal continues detecting received signal intensity of the currently connected AP, the signal intensity is compared to a switching threshold value, AP switching is realized if the signal intensity is lower than the switching threshold value, and a switching object is an AP access point with the highest stored signal intensity; and the scanning threshold value and the switching threshold value are adjusted simultaneously. By the AP switching method, the mobile terminal can be quickly switched to the optimal AP when moving within a coverage area of a WiFi network, and satisfactory access service and communication effect are obtained.

Owner:SHAANXI UNIV OF SCI & TECH

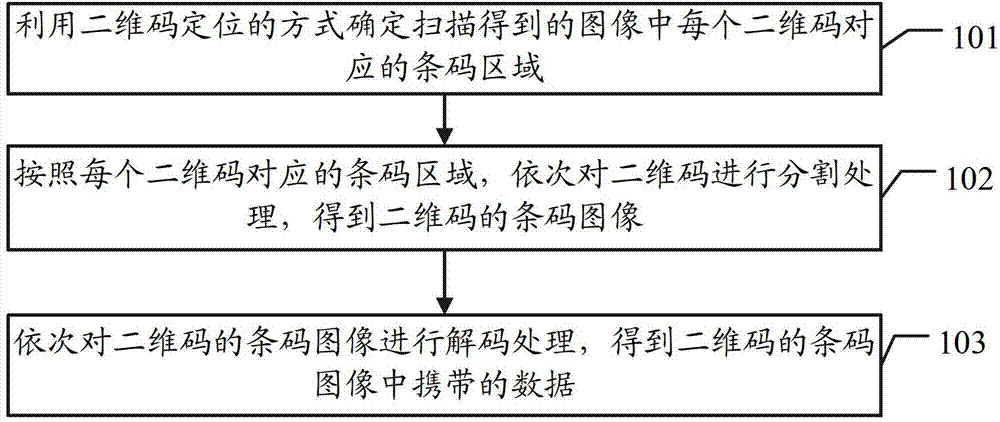

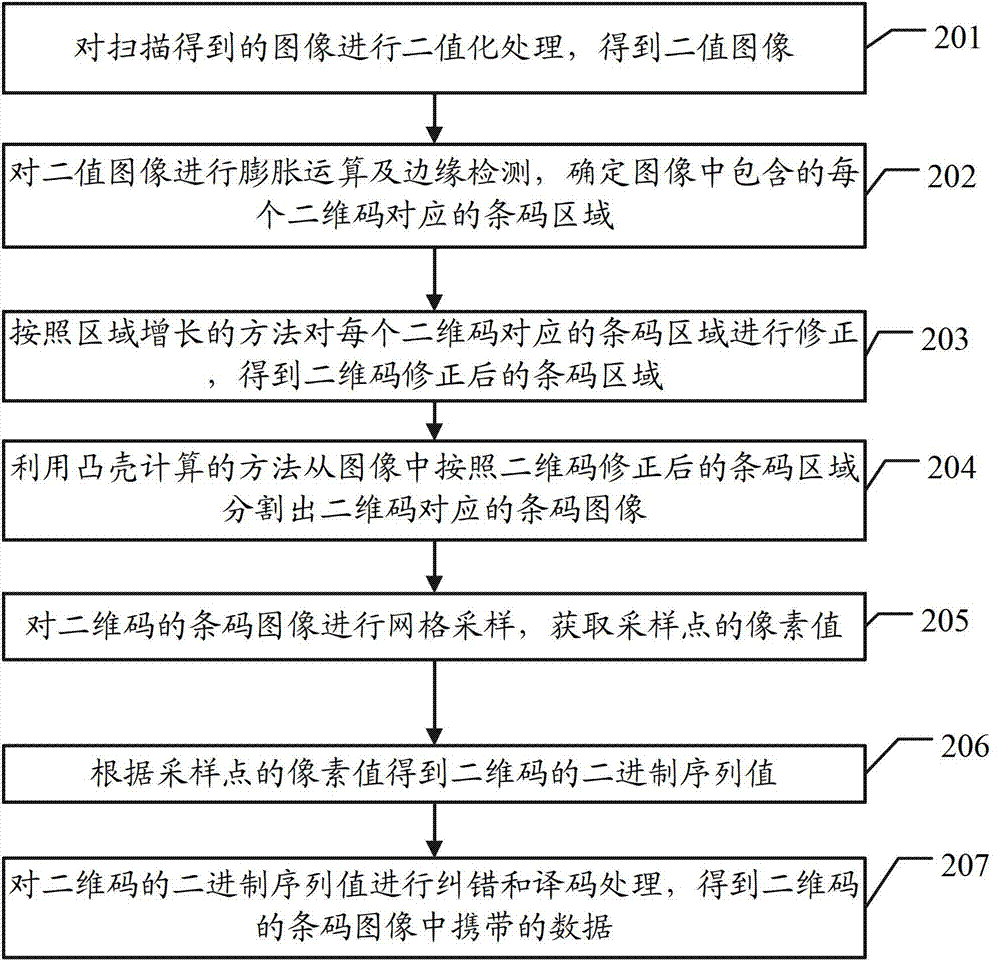

Batch scanning method of two-dimensional codes, and scanning equipment

ActiveCN102880850ABatch scanning is easy to operateSave operating timeCharacter and pattern recognitionRecord carriers used with machinesAlgorithmBarcode

The embodiment of the invention discloses a batch scanning method of two-dimensional codes, and scanning equipment, which are used for batch scanning of two-dimensional codes. The method comprises the steps as follows: determining a barcode area corresponding to each two-dimensional code in an image obtained through scanning in a two-dimensional code locating way; segmenting the two-dimensional codes in sequence according to the barcode area corresponding to each two-dimensional codes to obtain a barcode image of each two-dimensional code; and decoding the barcode images of the two-dimensional codes in sequence to obtain data carried in the barcode images of the two-dimensional codes. According to the batch scanning method of two-dimensional codes and the scanning equipment disclosed by the invention, the batch scanning operation of the two-dimensional codes is simplified, the operation time is saved, and the scanning efficiency is improved.

Owner:TENCENT TECH (SHENZHEN) CO LTD

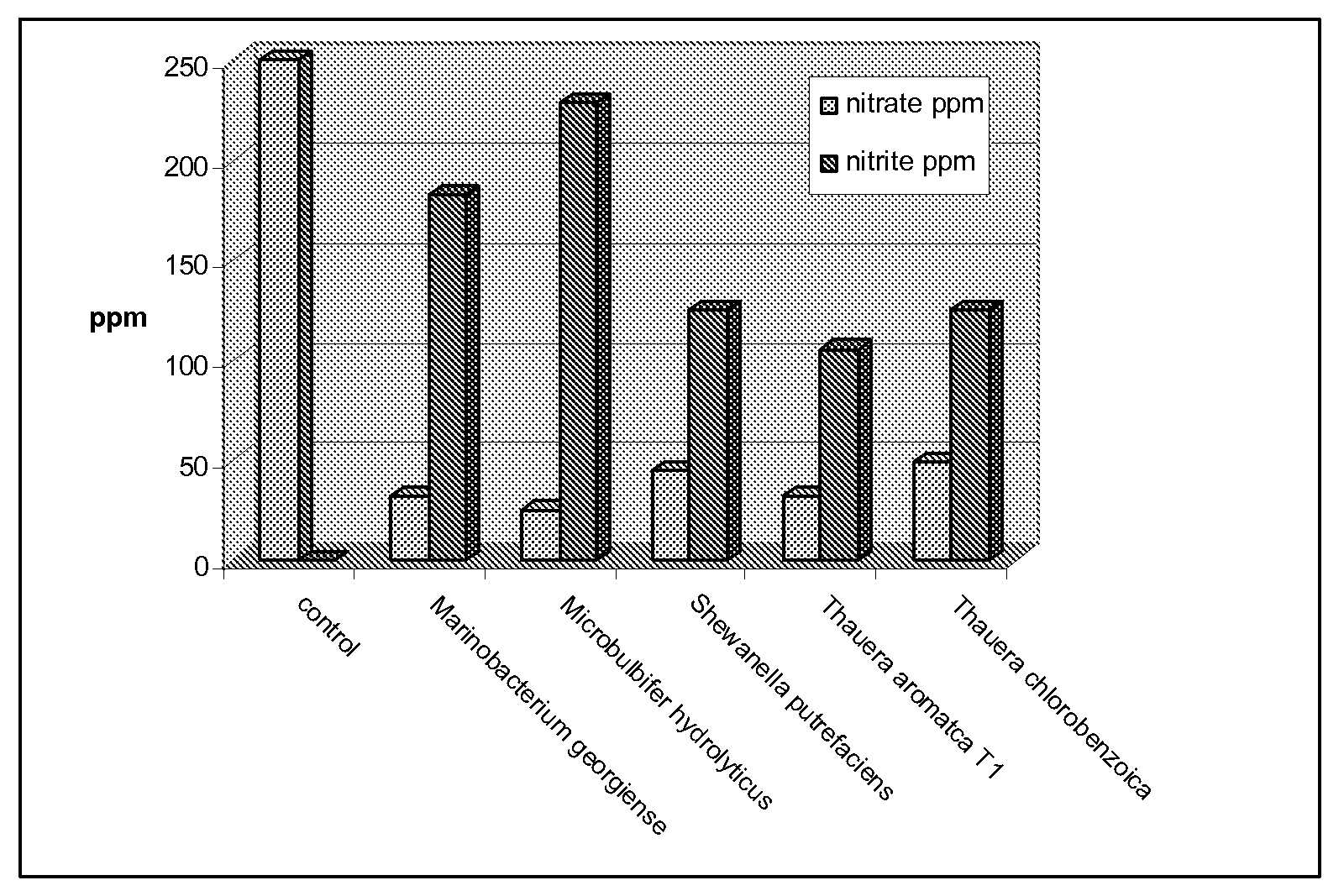

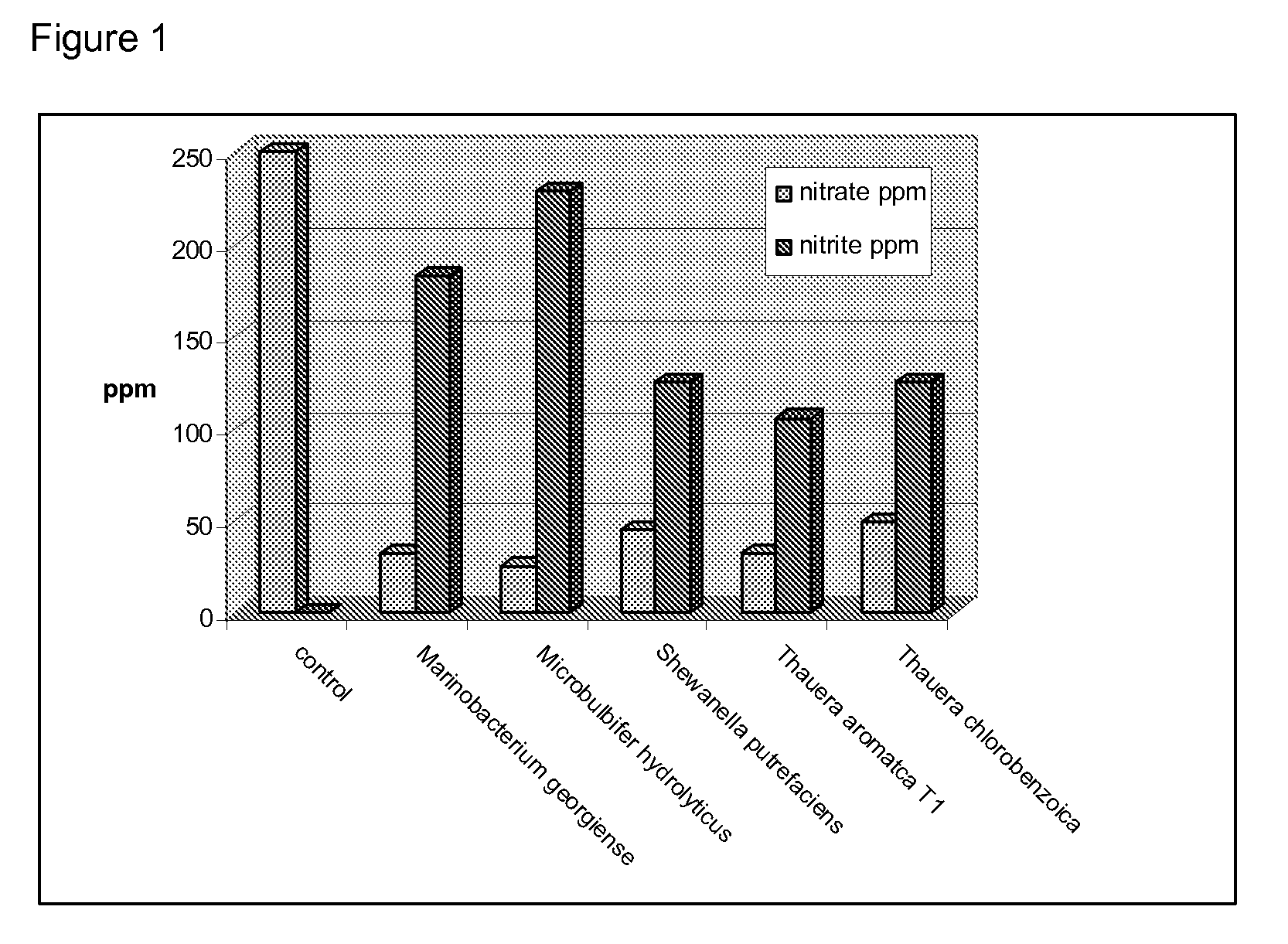

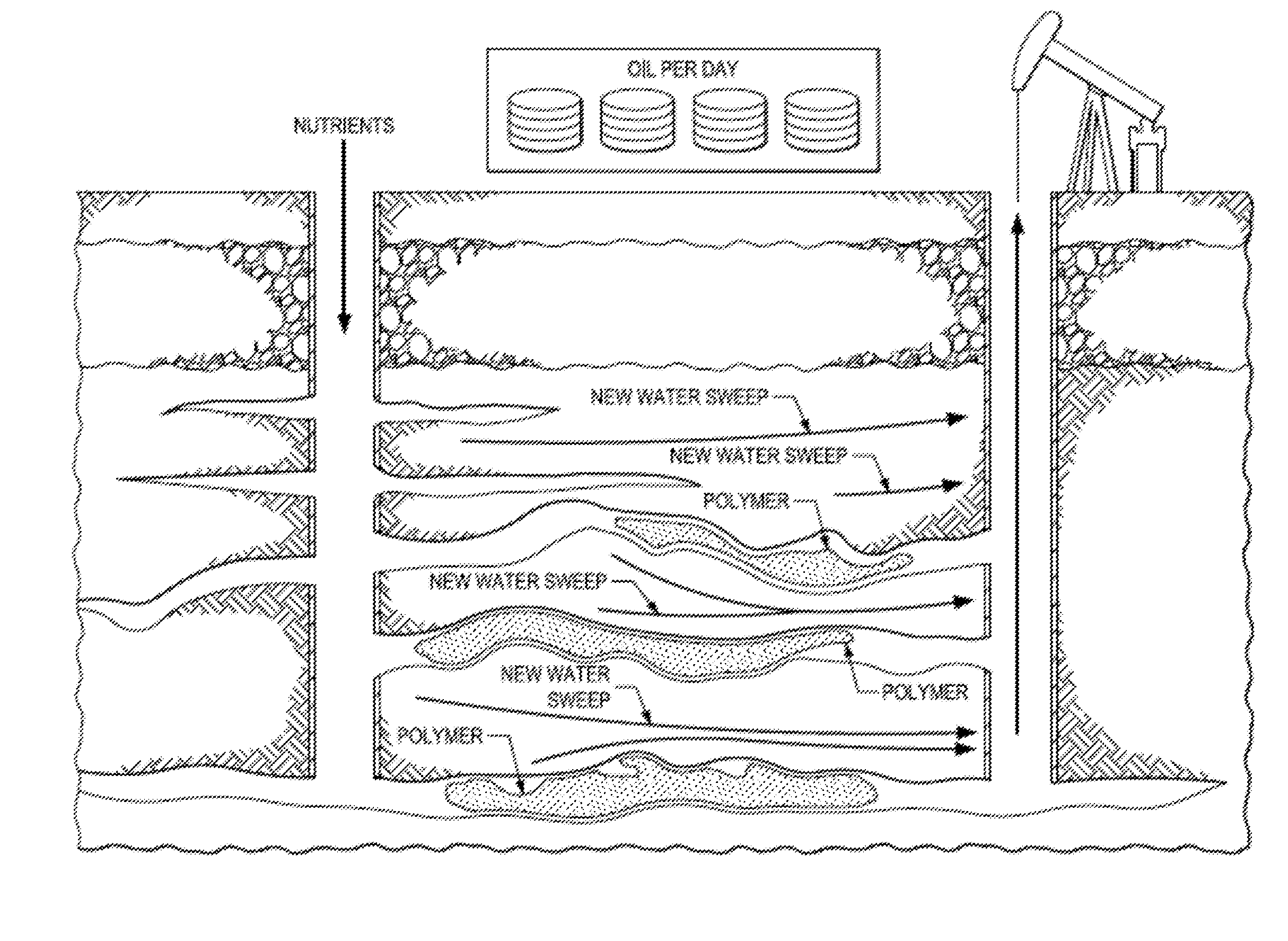

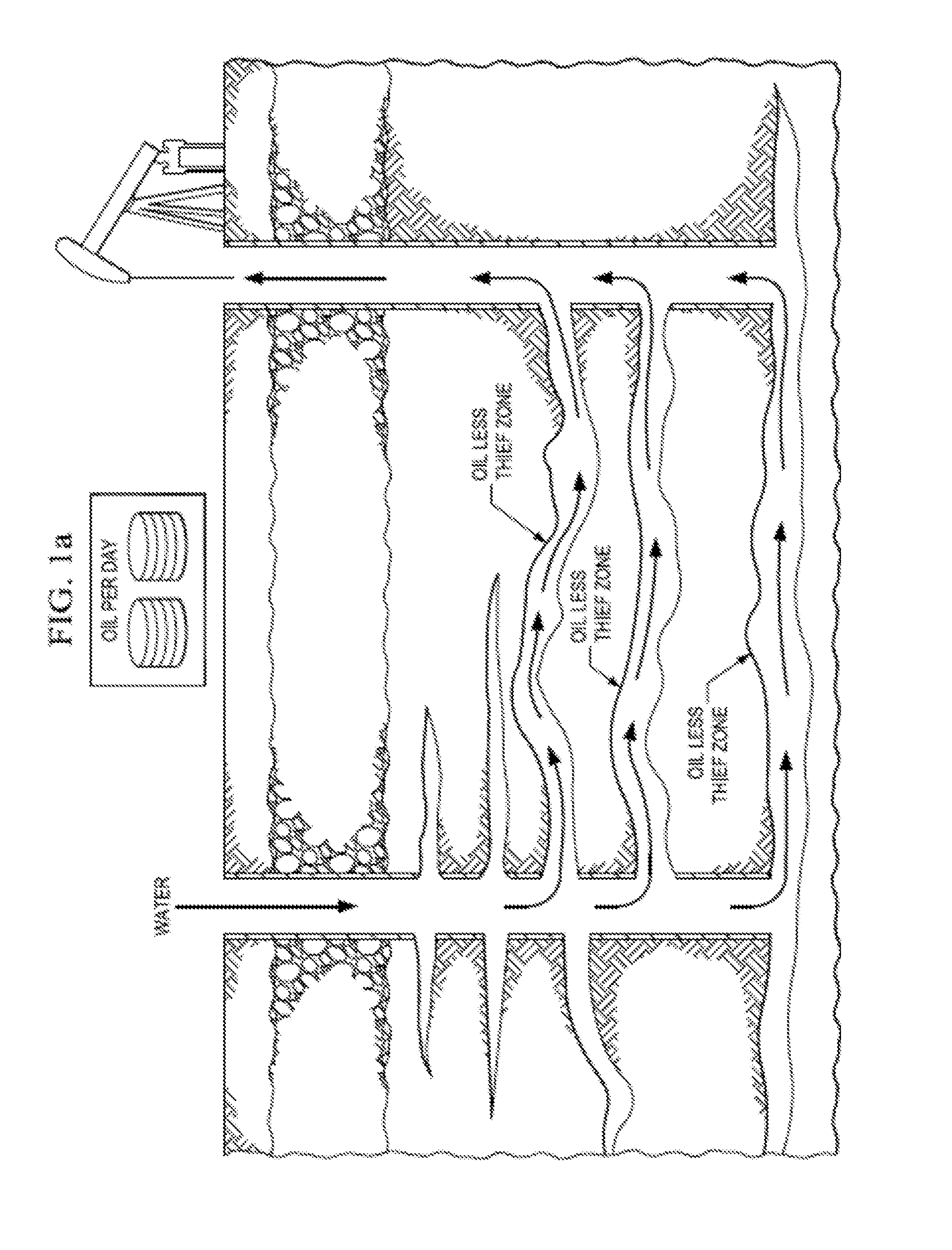

Method for identification of novel anaerobic denitrifying bacteria utilizing petroleum components as sole carbon source

InactiveUS20100044031A1Enhanced overall recoveryImprove liquiditySurveyBacteriaMicroorganismPhylogenetic identification

A method for the phylogenetic identification of indigenous anaerobic denitrifying bacterial species in an oil well is described. The method avoids the process of enrichment of microbial samples.

Owner:EI DU PONT DE NEMOURS & CO

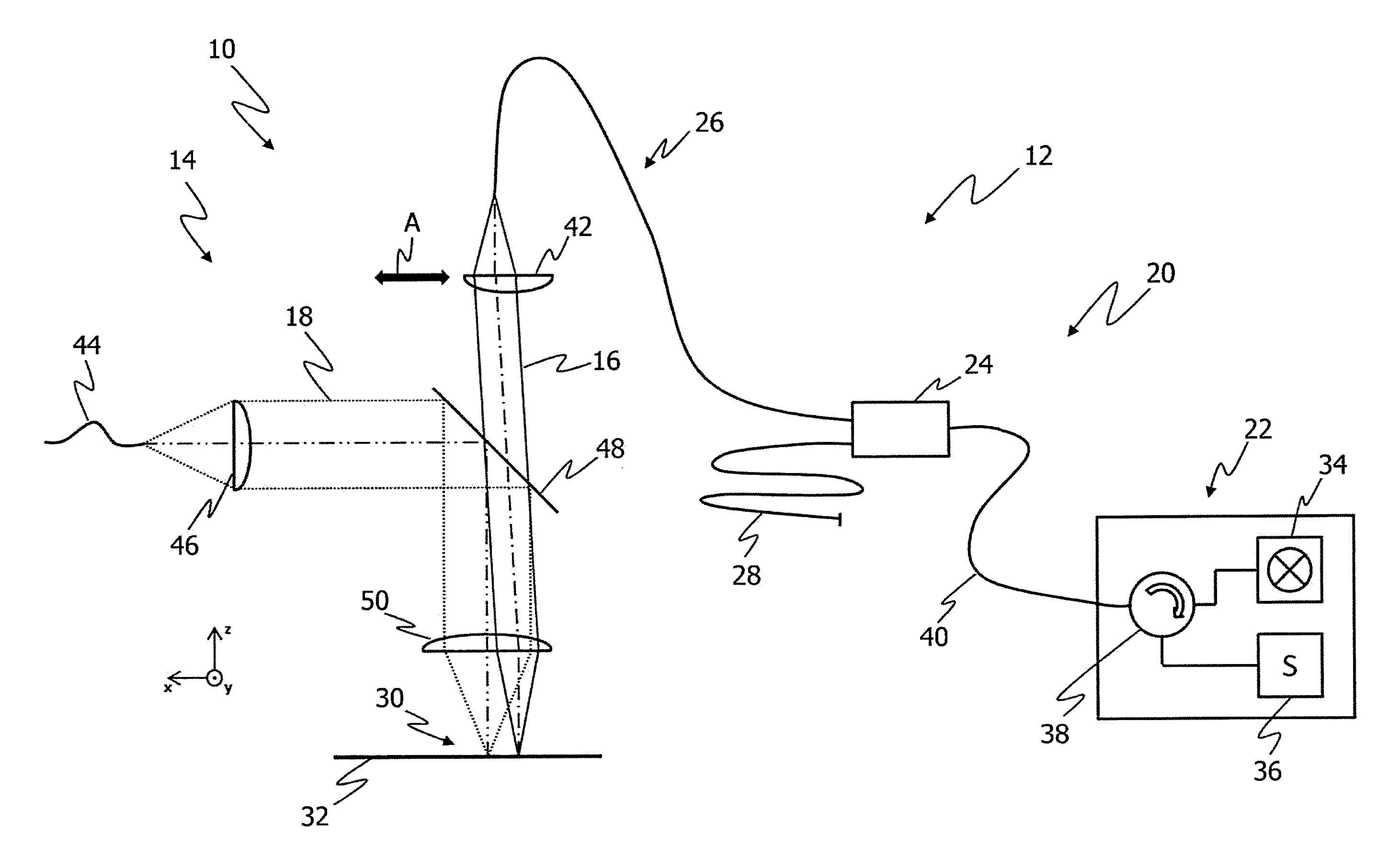

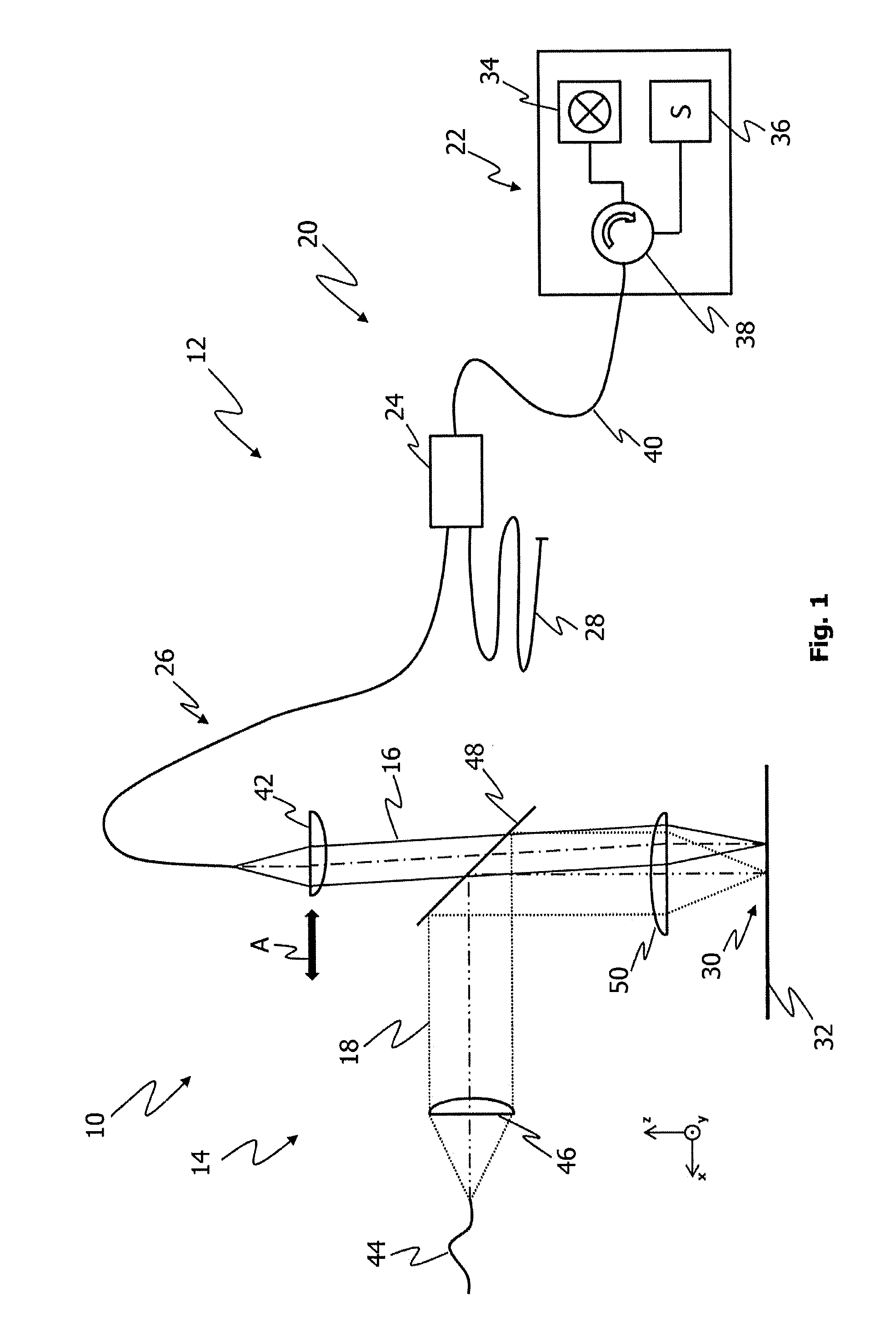

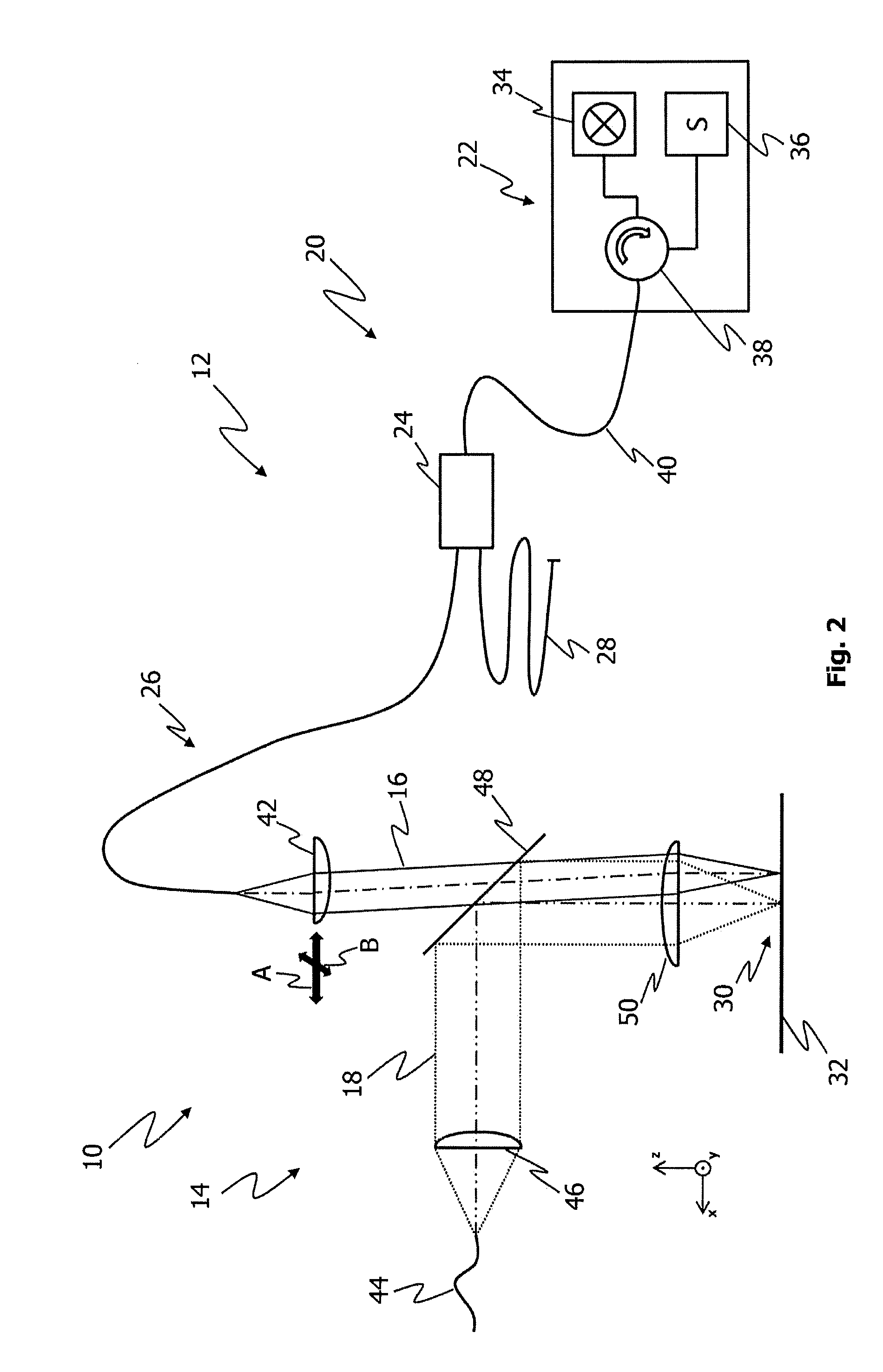

Measurement device for a laser processing system and a method for performing position measurements by means of a measurement beam on a workpiece

ActiveUS20160356595A1Efficient executionImprove scanning efficiencyInterferometersUsing optical meansMeasurement deviceLaser processing

The invention relates to a measurement device for a laser processing system, for carrying out position measurements by means of a measurement beam on a workpiece, which is intended for processing by means of a high energy processing beam, which can be moved relative to the workpiece along a predetermined main processing path. The measurement device can be coupled to a processing device and includes an optical coherence tomograph. The measurement device is equipped to shift the measurement beam on the workpiece in the direction of the main processing path in at least one first measurement position and one second measurement position in order to scan measurement positions transversely to the direction of the main processing path in the measurement positions.

Owner:LESSMULLER LASERTECHN

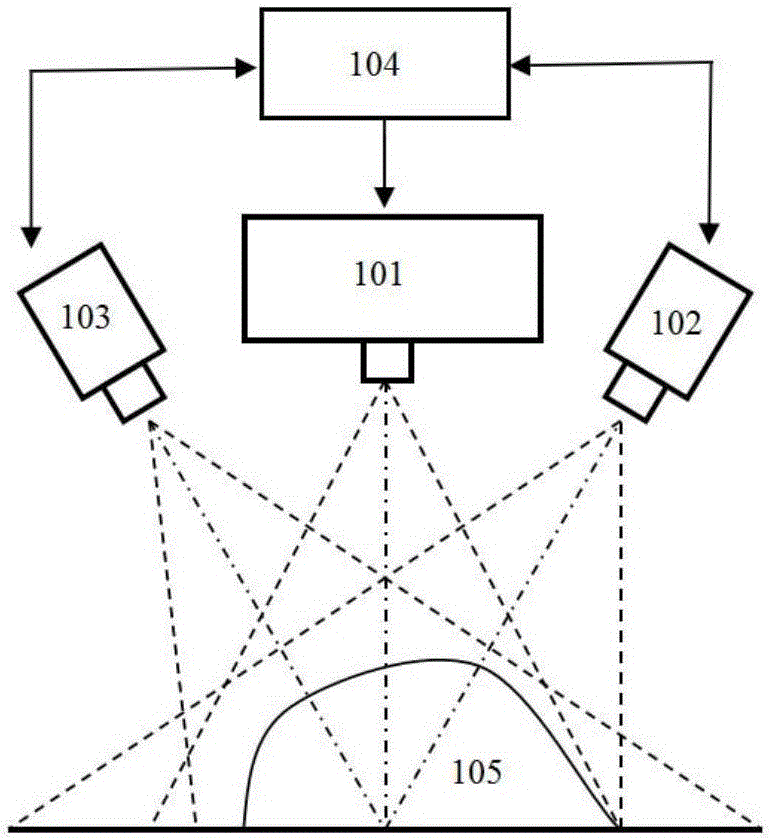

Three-dimensional scanning system and scanning method thereof

ActiveCN106802138AImprove scanning efficiencyHigh precisionImage enhancementImage analysisPoint cloudBack projection

The invention relates to a three-dimensional scanning system, which is used for obtaining three-dimensional stripe point cloud data of a detected object. The system comprises: a light source, which successively and alternately projects multiple speckle patterns and stripe patterns on the detected object; a left camera and a right camera, which synchronously collect left and right speckle images and left and right stripe images of the detected object; a speckle data and sign point data reconstruction module, which obtains speckle three-dimensional data and sign point three-dimensional data on the basis of the speckle images; a stripe matching module, which conducts back projection onto the left and right stripe images according to the speckle three-dimensional data and the sign point three-dimensional data, and guides matching for stripes of the left and right stripe images; and a three-dimensional reconstruction module, which reconstructs the corresponding matched stripes of the left and right stripe images into three-dimensional stripe point cloud data. The invention also provides a scanning method of the three-dimensional scanning system.

Owner:SHINING 3D TECH CO LTD

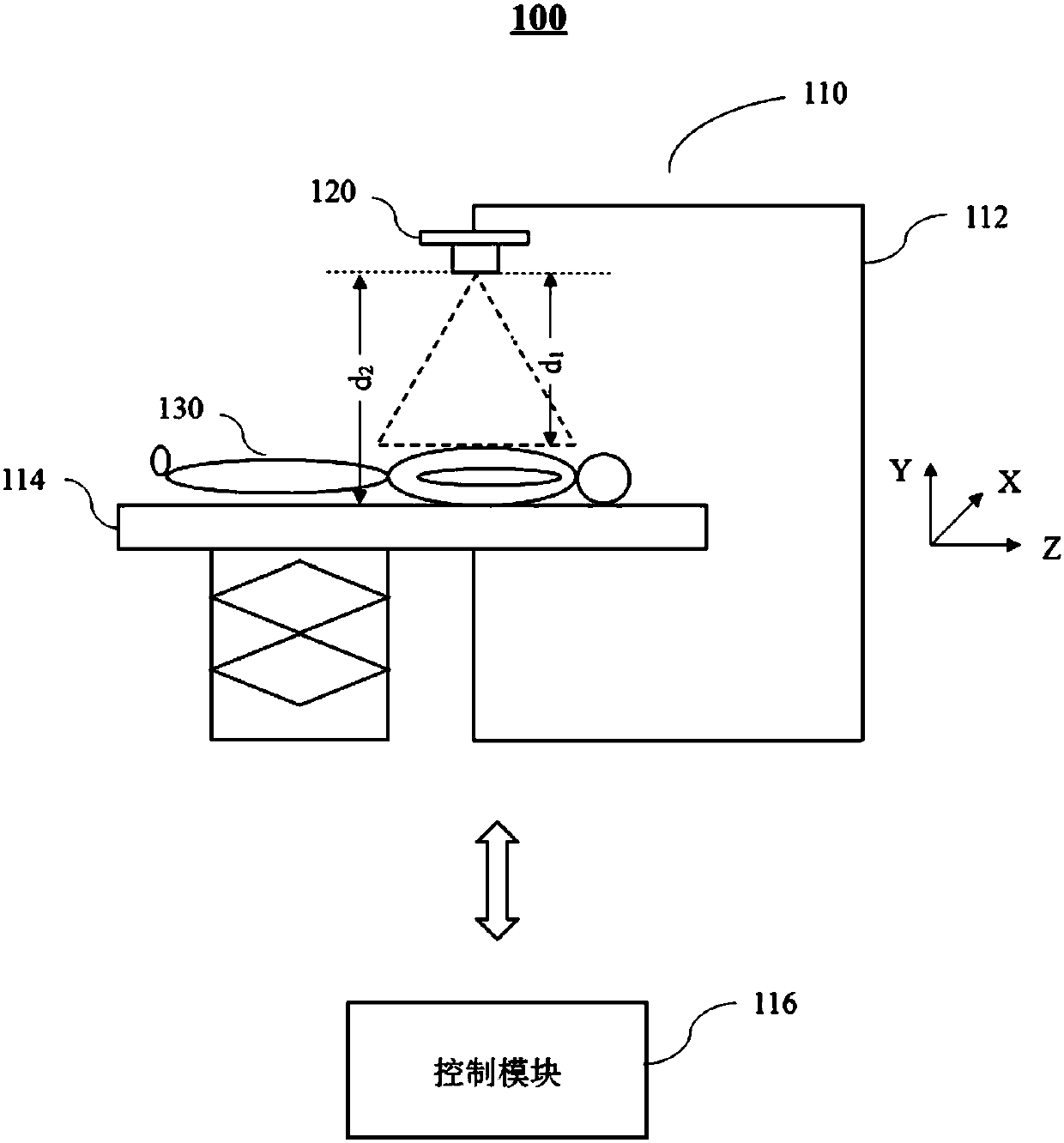

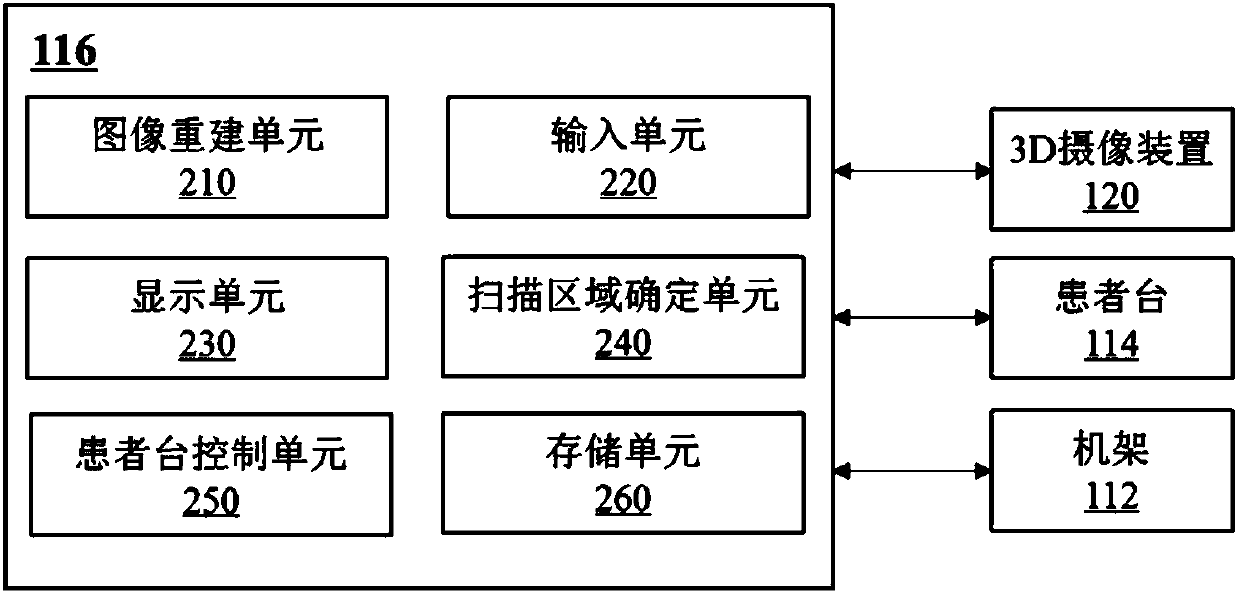

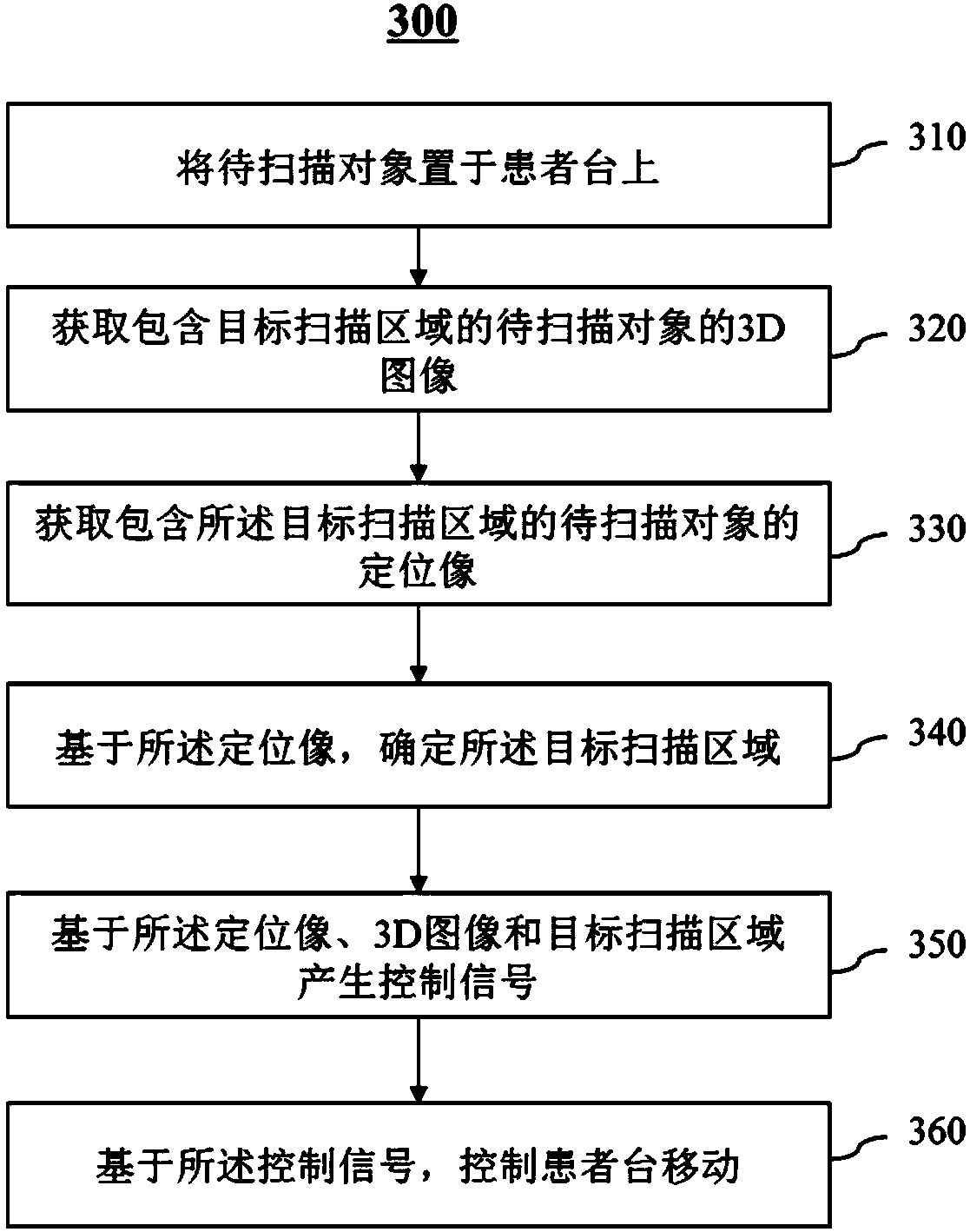

Positioning method and system for imaging scanning

ActiveCN107789001AImprove scanning efficiencyImprove accuracyRadiation diagnostic image/data processingRadiation diagnostic device control3d image3d camera

The invention discloses a positioning method and system for imaging scanning. The method includes the steps of putting a to-be-scanned object on a patient table; obtaining a 3D image including a target scanning area of the to-be-scanned object through a 3D camera shooting device, wherein the 3D image includes depth information of the to-be-scanned object; obtaining a positioning image including the target scanning area of the to-be-scanned object through a scanning device; determining the target scanning area based on the positioning image; moving the patient table in at least one direction based on the positioning image, the 3D image and the target scanning area. By means of the positioning system, a user does not need to position a patient manually before scanning, positioning can be directly and automatically conducted after scanning of a positioning piece is completed, scanning efficiency is improved, and the positioning accuracy can be improved by means of a 3D field depth camerashooting technology.

Owner:SHANGHAI UNITED IMAGING HEALTHCARE

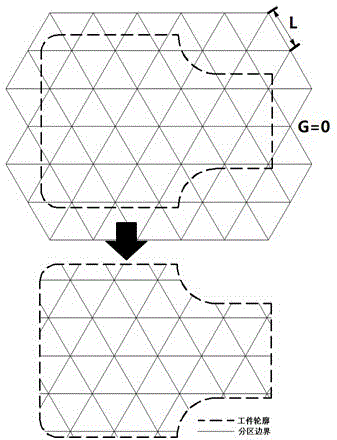

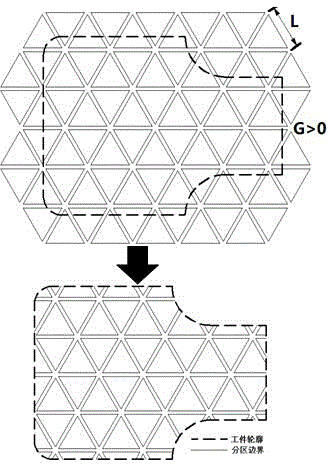

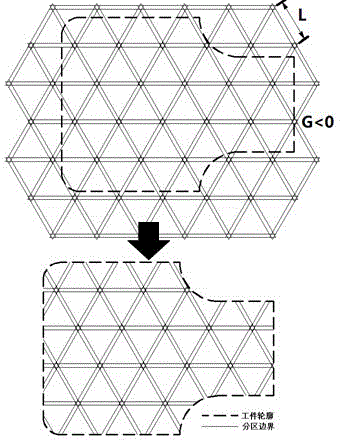

Laser scanning method for laser melting in selected area

ActiveCN104550950AGuaranteed compactnessGuaranteed accuracyIncreasing energy efficiencyGraphicsLaser scanning

The invention discloses a laser scanning method for laser melting in a selected area. The laser scanning method comprises the following steps: dividing a workpiece area into a plurality of latticed regular triangles with side length being 1mm-10mm and a plurality of irregular figures at borders according to the cross section information of a workpiece, taking a gap G between the adjacent figures from -1mm to 1mm; scanning the irregular figures at the borders as the zoning regular triangles and adopting an equidistant scanning line for successively finishing the zoning figure scanning; according to the zoning direction, adopting the equidistant scanning line for successively finishing the gap scanning; scanning along a practical outline of the workpiece or the outline deviating within 1mm inward or outward to the practical outline of the workpiece according to the requirement, or repeatedly scanning along a plurality of outlines deviating from the practical outline of the workpiece within 1mm, thereby finishing the cross section canning for the workpiece. According to the scanning method provided by the invention, the scattering effect of residual stress in the workpiece during a laser scanning process is improved, the laser scanning direction during the scanning process does not need to be repeatedly changed, the scanning efficiency is high, the technique control is simple, and the compactness and the precision of the workpiece are ensured.

Owner:HUNAN FARSOON HIGH TECH CO LTD

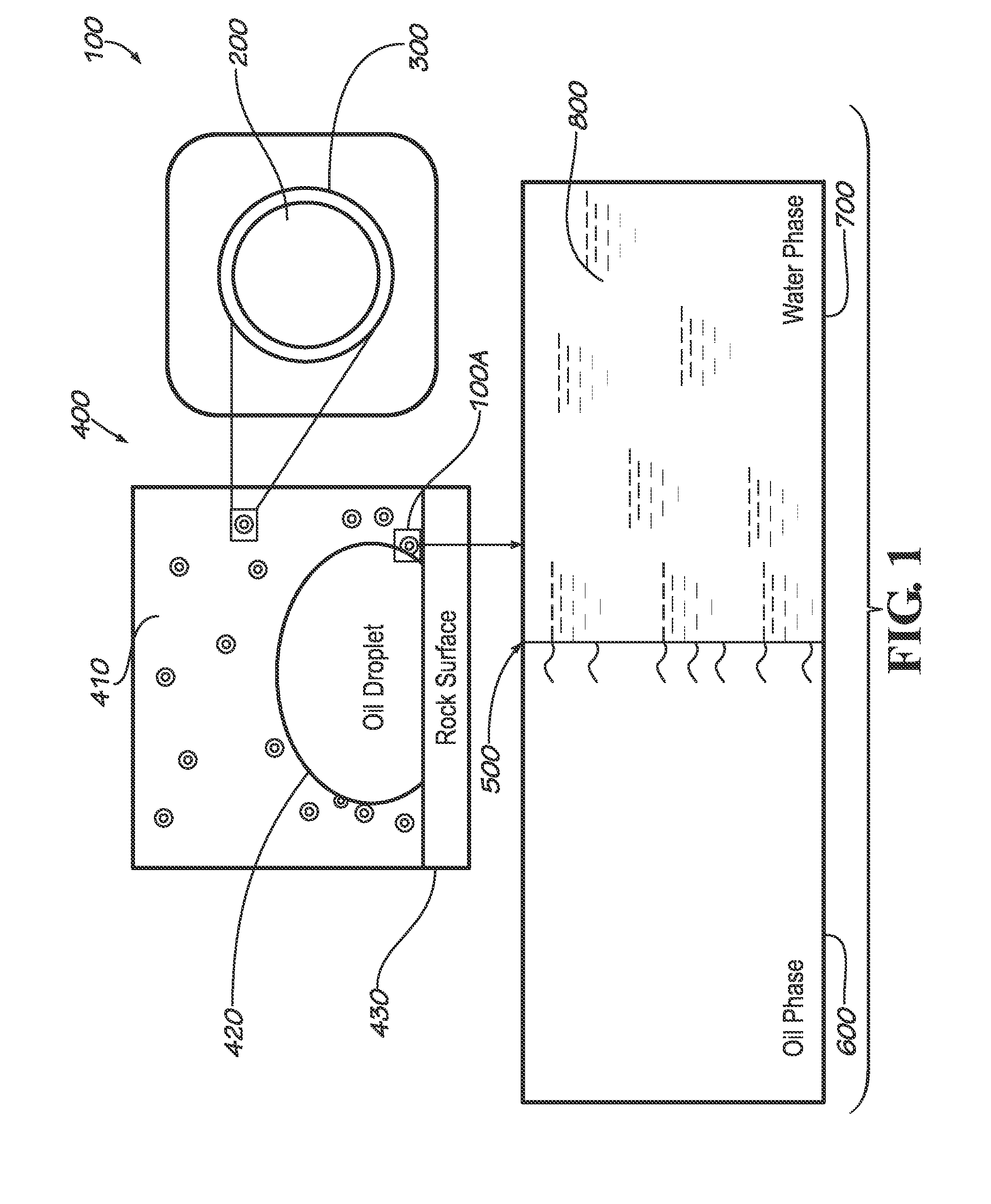

Method of improving waterflood performance using barrier fractures and inflow control devices

ActiveUS20110042083A1Reduce inflowImprove scanning efficiencySurveyFluid removalSweep efficiencyTransverse fracture

The present invention is directed to a method of hydrocarbon production from a hydrocarbon reservoir. The method includes providing a substantially horizontal wellbore having at least one productive interval within a hydrocarbon reservoir and forming at least one non-conductive transverse fracture in the reservoir along the substantially horizontal wellbore. An injection well is also provided. A fluid is injected into the reservoir through the injection well to displace hydrocarbons within the reservoir toward a production portion of the substantially horizontal wellbore. Hydrocarbons are drained from the reservoir into at least one production interval of the substantially horizontal wellbore. Fluid production from the at least one production interval into the substantially horizontal wellbore flows through an inflow control device that can restrict the fluid flow. A non-conductive transverse fracture can form a barrier within the reservoir to divert injected fluids to increase sweep efficiency and reduce the influx of injected fluids into the production interval.

Owner:HALLIBURTON ENERGY SERVICES INC

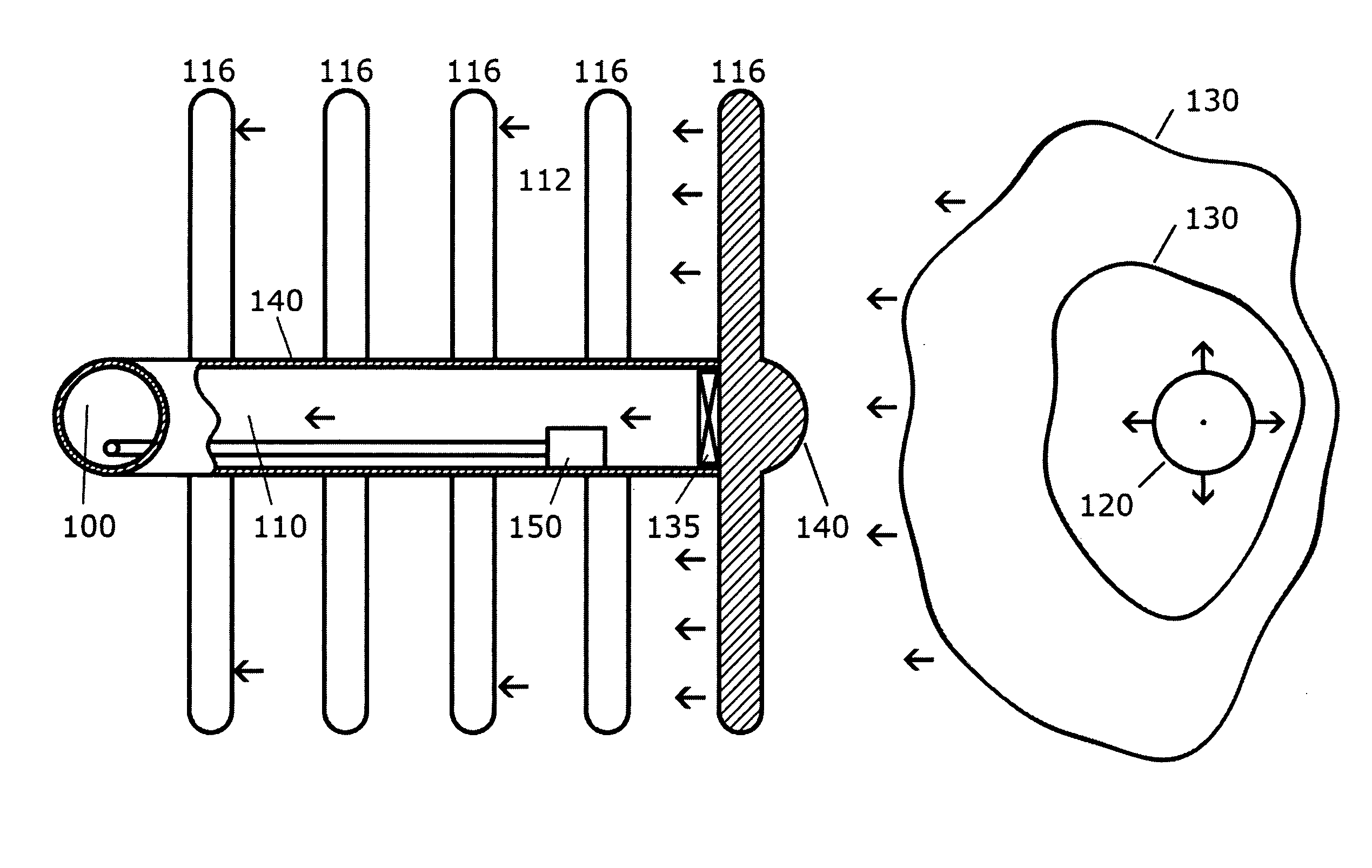

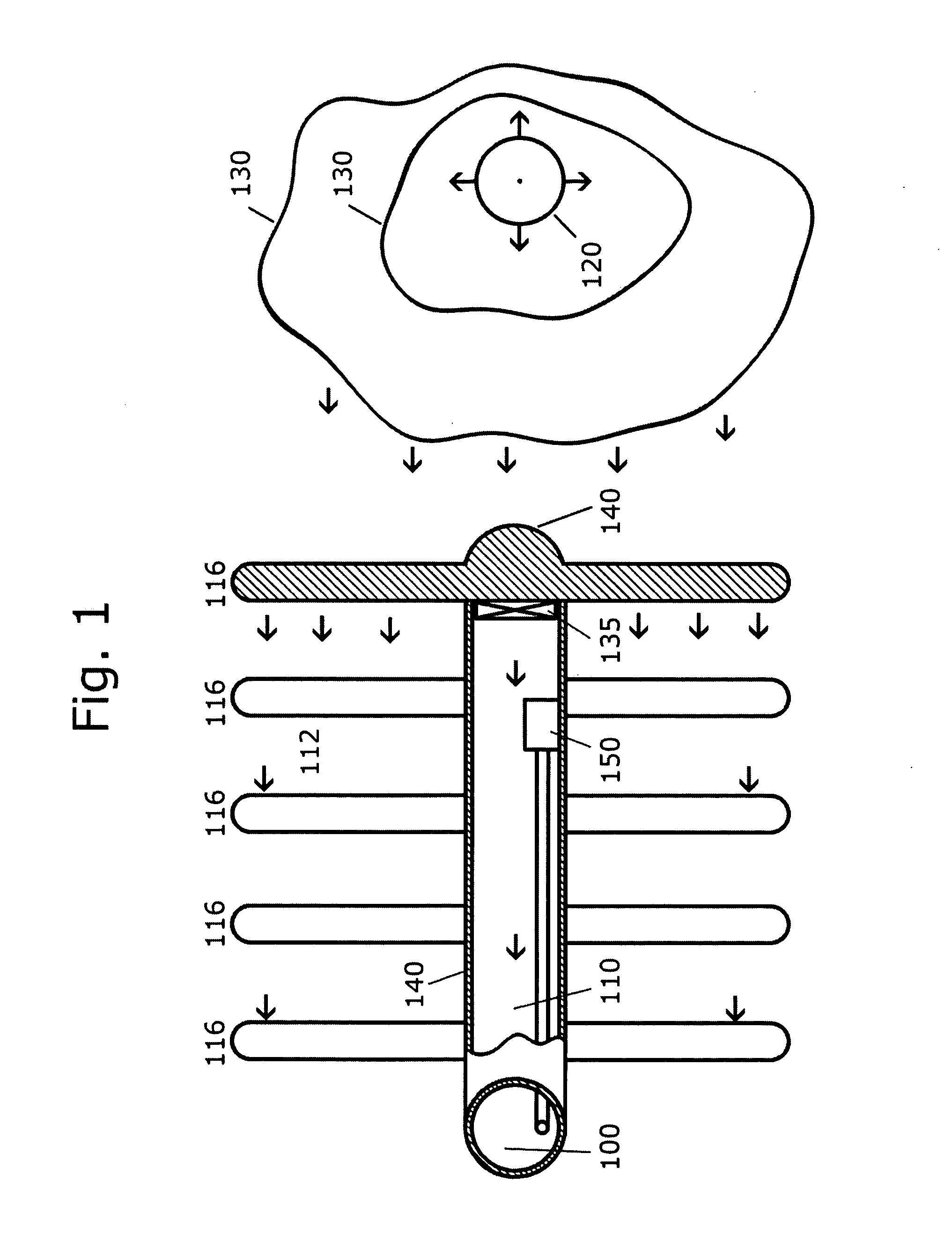

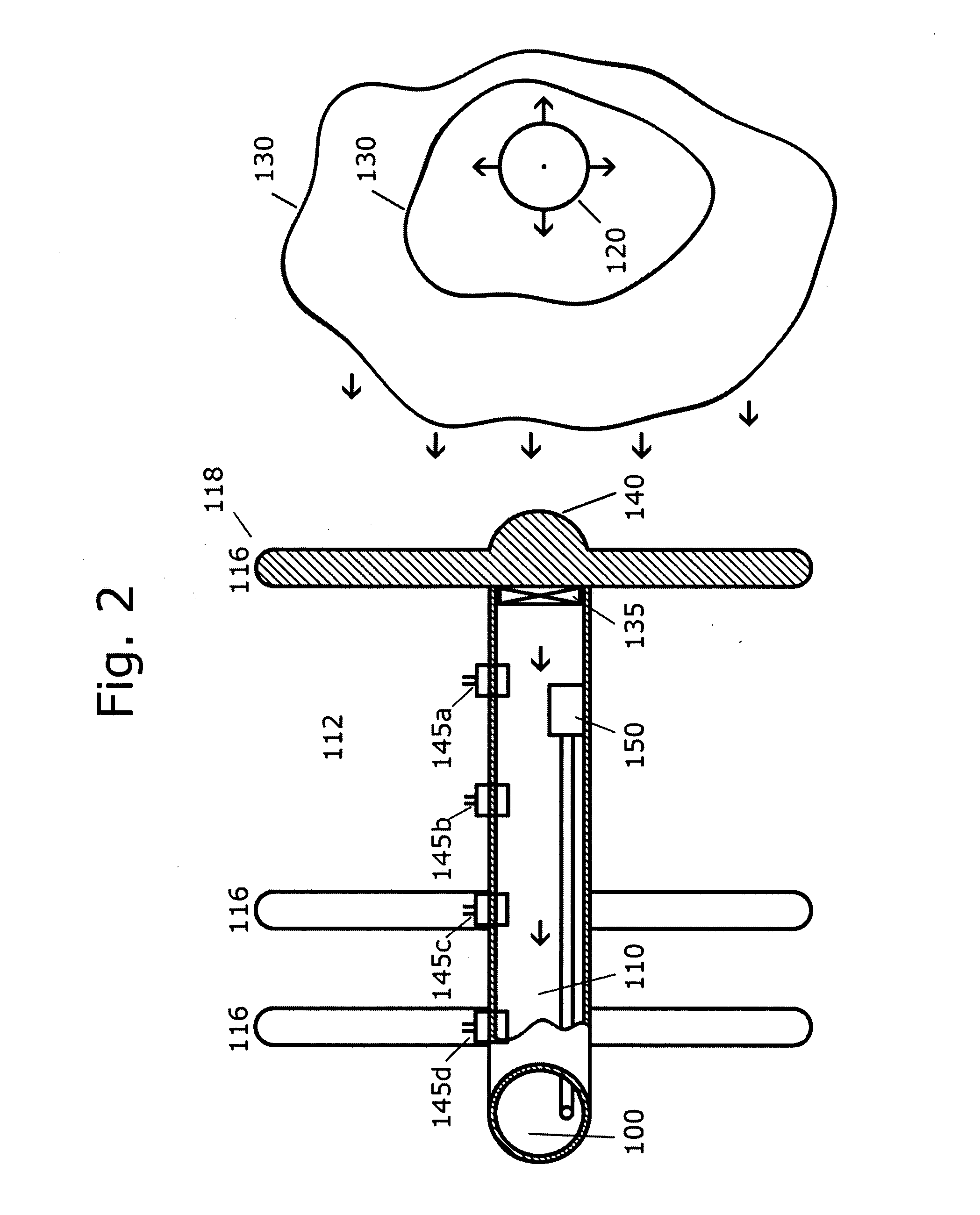

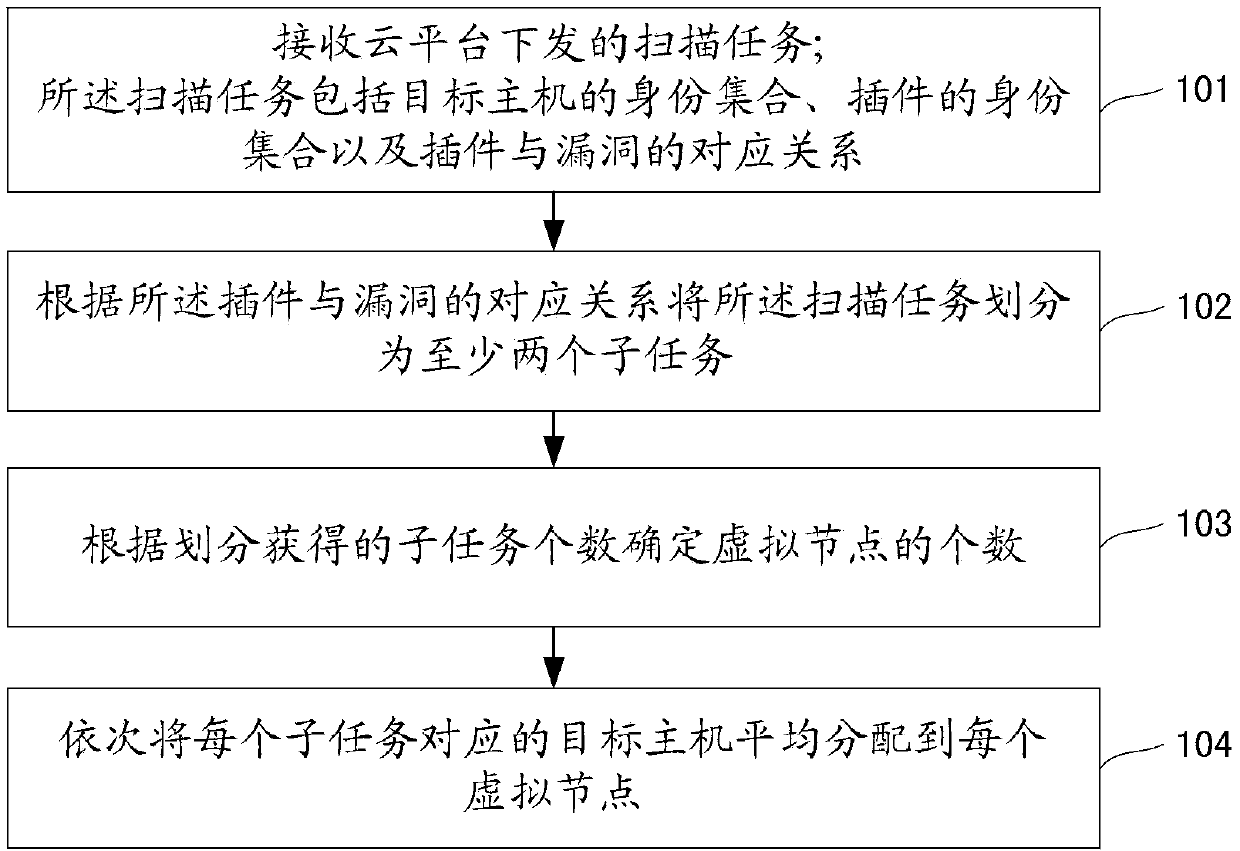

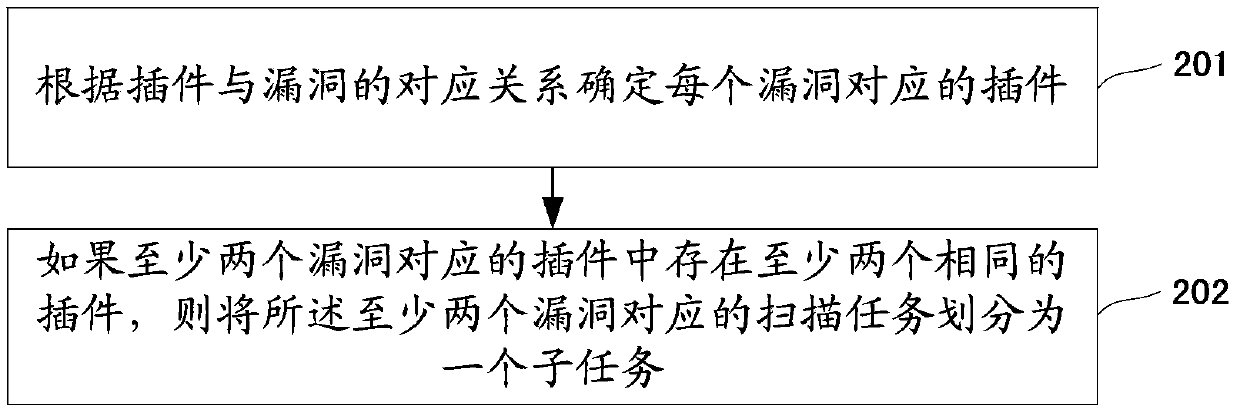

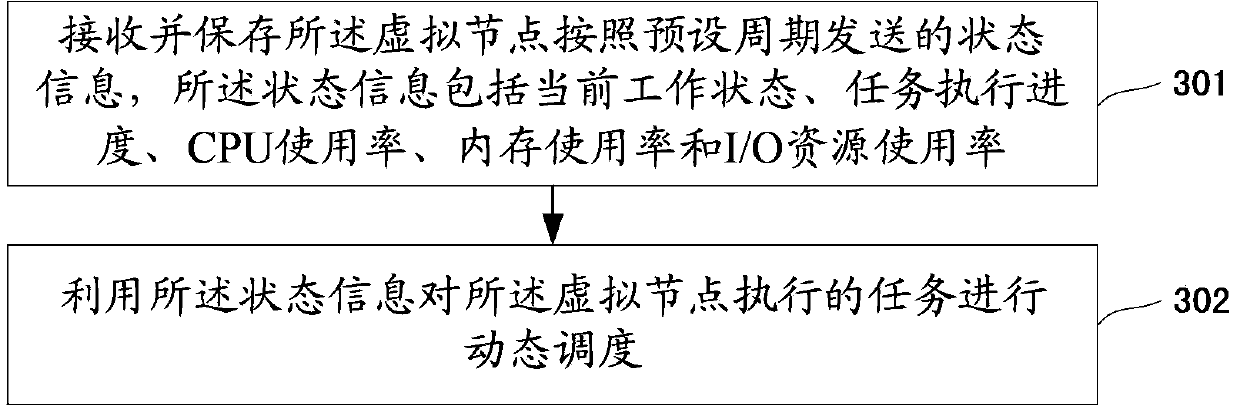

Method and device for assigning large-scale vulnerability scanning task

ActiveCN103870334AImprove scanning efficiencyImprove rationalityResource allocationTransmissionNODALOperating system

The invention discloses a method and a device for assigning a large-scale vulnerability scanning task. The method comprises the following steps: receiving a scanning task issued by a cloud platform, wherein the scanning task comprises the identity set of target hosts, the identity set of a plug-in and a corresponding relation of the plug-in and vulnerability; partitioning the scanning task into at least two sub-tasks according to the corresponding relation of the plug-in and vulnerability; determining the number of virtual nodes according to the number of partitioned sub-tasks; assigning target hosts corresponding to each sub-task to each virtual node on average in sequence. By adopting the technical scheme of the invention, the scanning task assigning rationality and the vulnerability scanning efficiency are increased.

Owner:CHINA MOBILE COMM GRP CO LTD

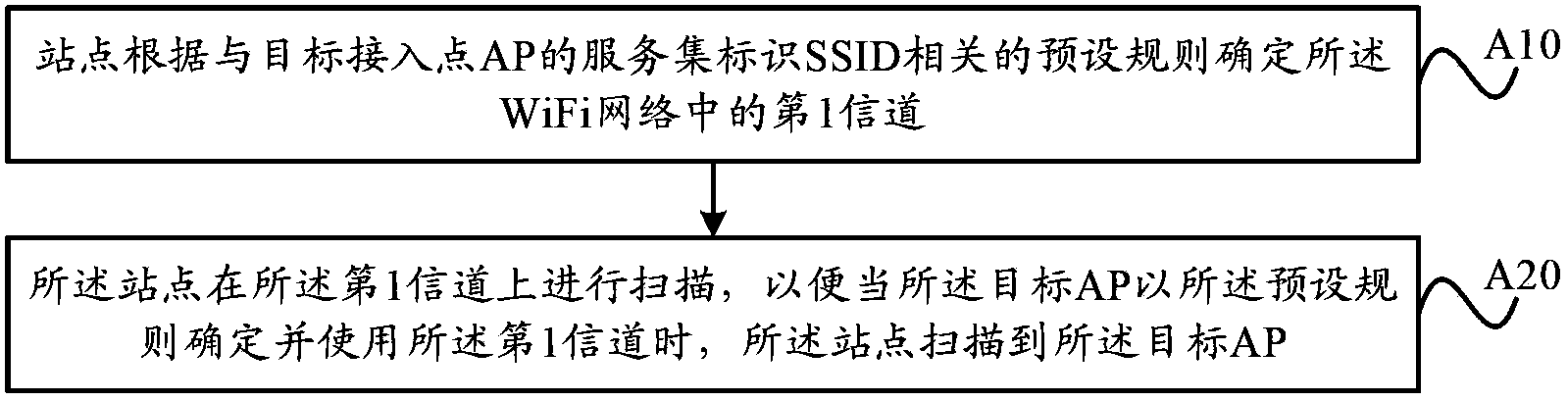

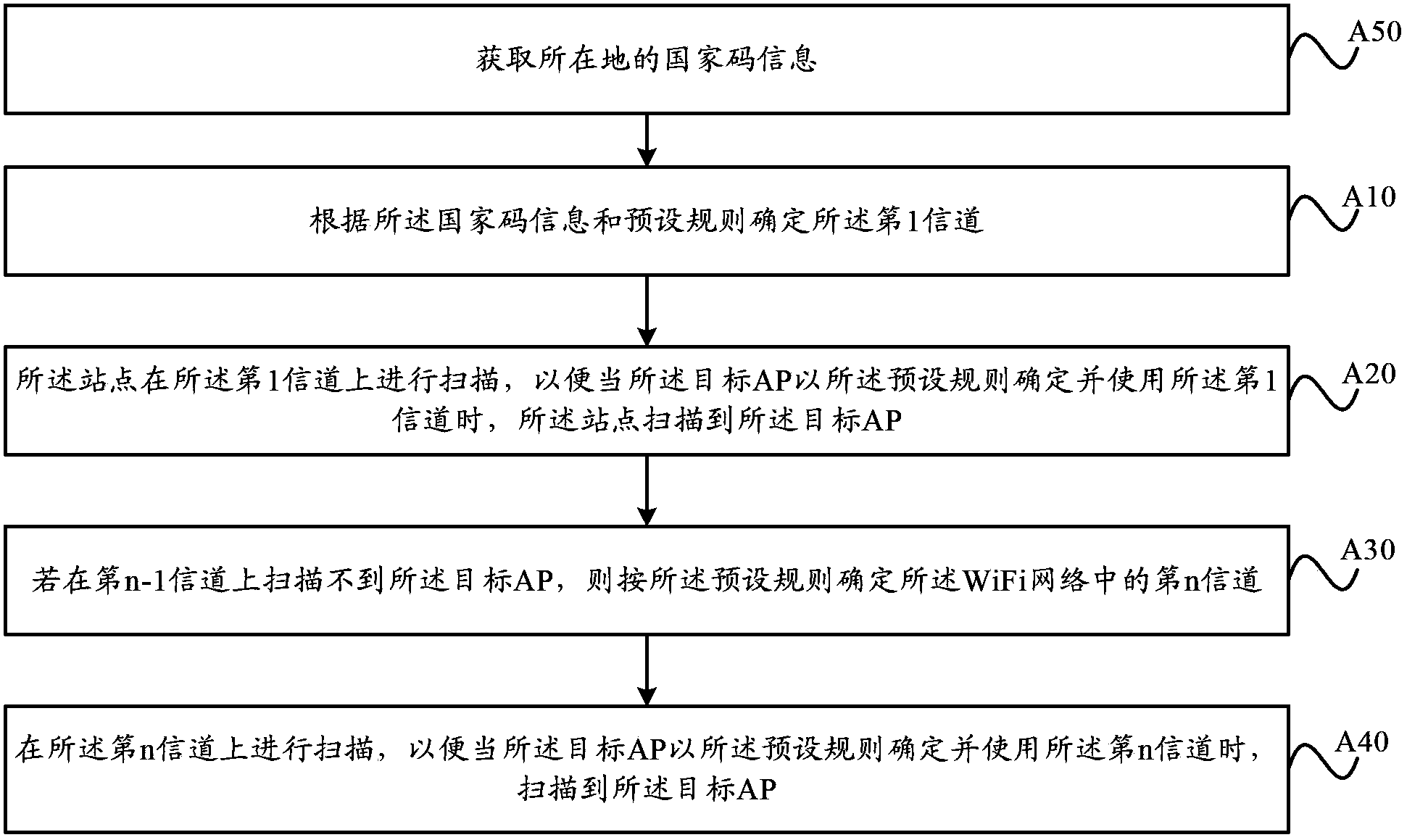

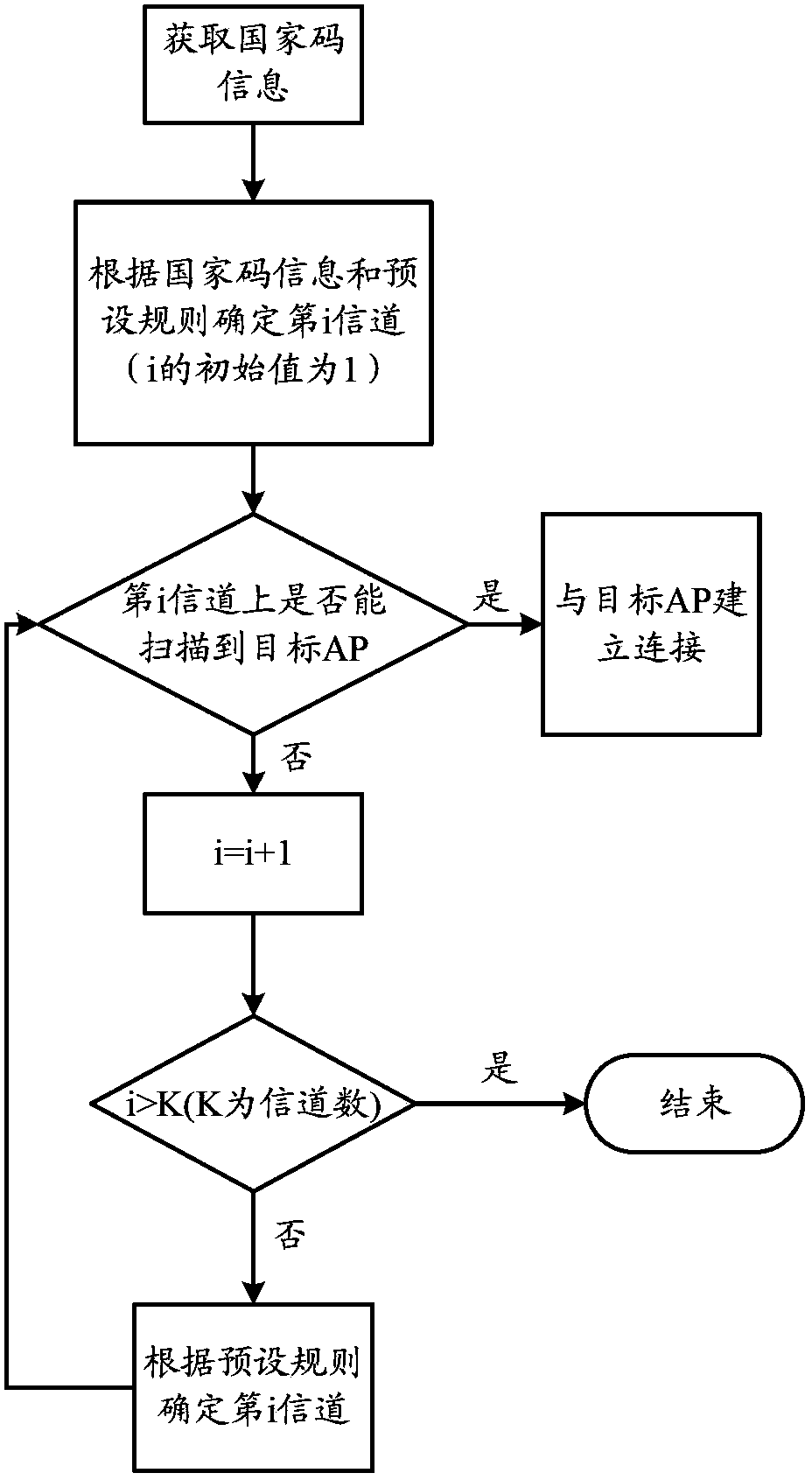

Scanning access point in wireless fidelity network, channel selecting method, equipment and system

ActiveCN103533604ATargetedImprove scanning efficiencyAssess restrictionWifi networkReal-time computing

An embodiment of the invention provides a scanning access point in a wireless fidelity network, a channel selecting method, a set of equipment and a system thereof. The channel selecting method comprises the following steps: determining a first channel in the WiFi network by a site according to a preset role related with a service set identification SSID of a target access point AP; and scanning by the site on the first channel so as to scann the target AP when the target AP exists and the first channel is determined and used according to the preset role. According to the scanning access point in the wireless fidelity network, the channel selecting method, the equipment and the system, because the STA determines the first channel according to the preset role, the target AP selects the channel according to the preset role, when the target AP use the first channel, the STA can scan the target AP in the first-time channel scanning, and the scanning process has pertinency, thereby greatly improving the scanning efficiency.

Owner:HUAWEI DEVICE CO LTD

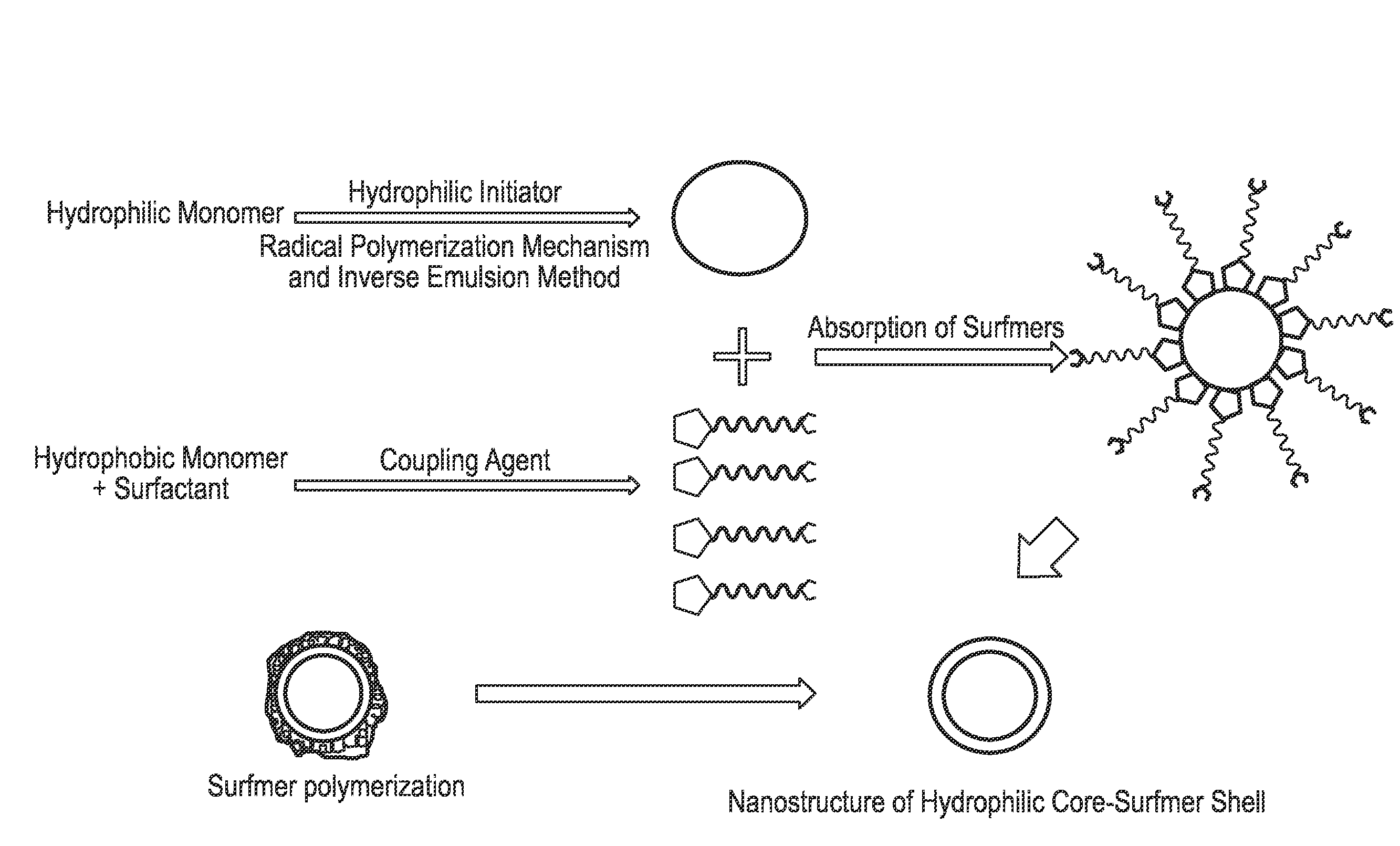

Delayed gelling agents

ActiveUS20140209305A1High viscosityPrevent premature gellingFluid removalFlushingPolyelectrolyteMedicine

The disclosure is directed to polyelectrolyte complex nanoparticles that can be used to deliver agents deep into hydrocarbon reservoirs. Methods of making and using said polyelectrolyte complex nanoparticles are also provided.

Owner:CONOCOPHILLIPS CO +2

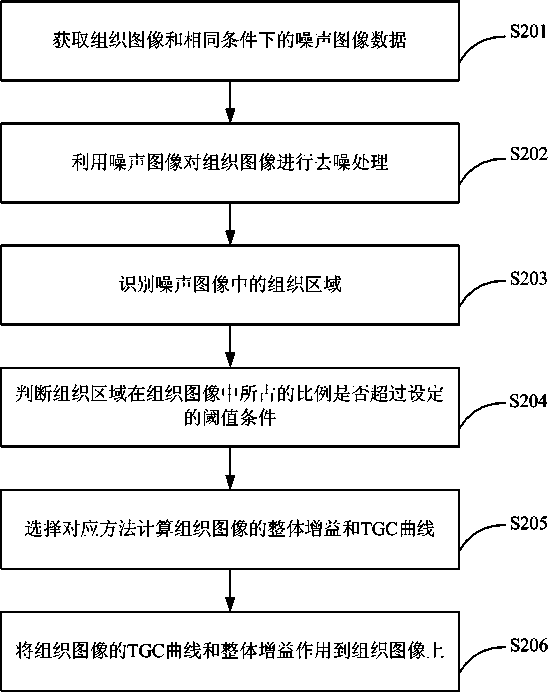

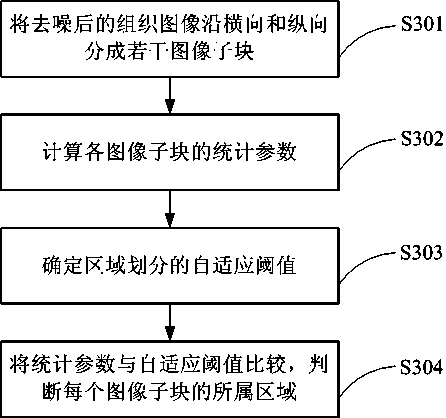

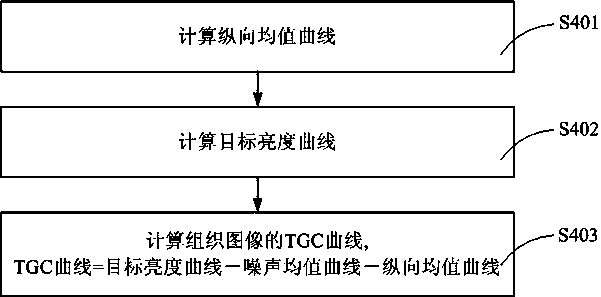

Gain optimization method for ultrasound images and ultrasound imaging gain automatic optimization device

ActiveCN103845077AMeet the requirements of uniform brightnessGuaranteed Lossless DisplayImage enhancementImage analysisUltrasonic imagingRadiology

The invention discloses a gain optimization method for ultrasound images. The gain optimization method comprises the following steps: acquiring a tissue image and data of a noise image under the same condition; performing de-noising processing on the tissue image by utilizing the noise image; identifying a tissue area in the tissue image; judging whether the proportion of the tissue area in the tissue image exceeds a set threshold condition or not; calculating the master gain and a TGC (time gain compensation) curve of the tissue image by selecting a corresponding method; enabling the TGC curve and the master gain to act on the tissue image. The gain optimization method for the ultrasound images provided by the invention is also suitable for various types of ultrasound images under conventional B-mode imaging and coherent contrast imaging, and not only is capable of guaranteeing the lossless display of information in the image but also meets the requirement that the optimized images are uniform and consistent in brightness. The invention also provides an ultrasound coherent contrast imaging gain optimization method and an ultrasound imaging automatic optimization device; compared with the prior art, the ultrasound coherent contrast imaging gain optimization method and the ultrasound imaging automatic optimization device are capable of enabling the different individual contrastographic images after subjected to gain optimization to be basically consistent in brightness, and therefore, the scanning efficiency of a doctor is greatly improved.

Owner:SHENZHEN MINDRAY BIO MEDICAL ELECTRONICS CO LTD +1

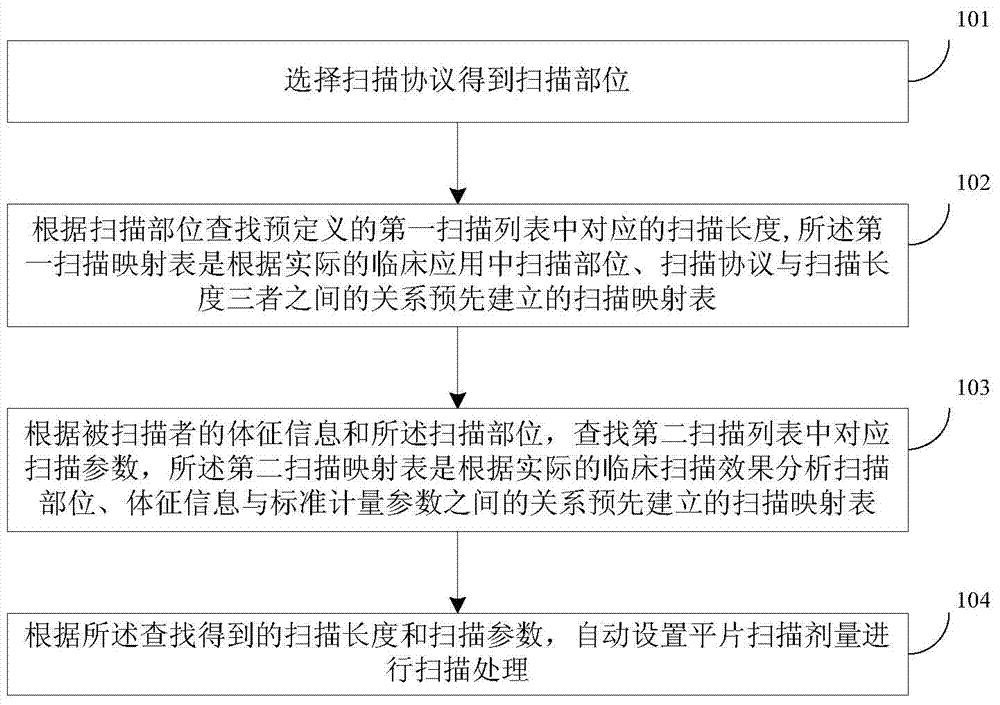

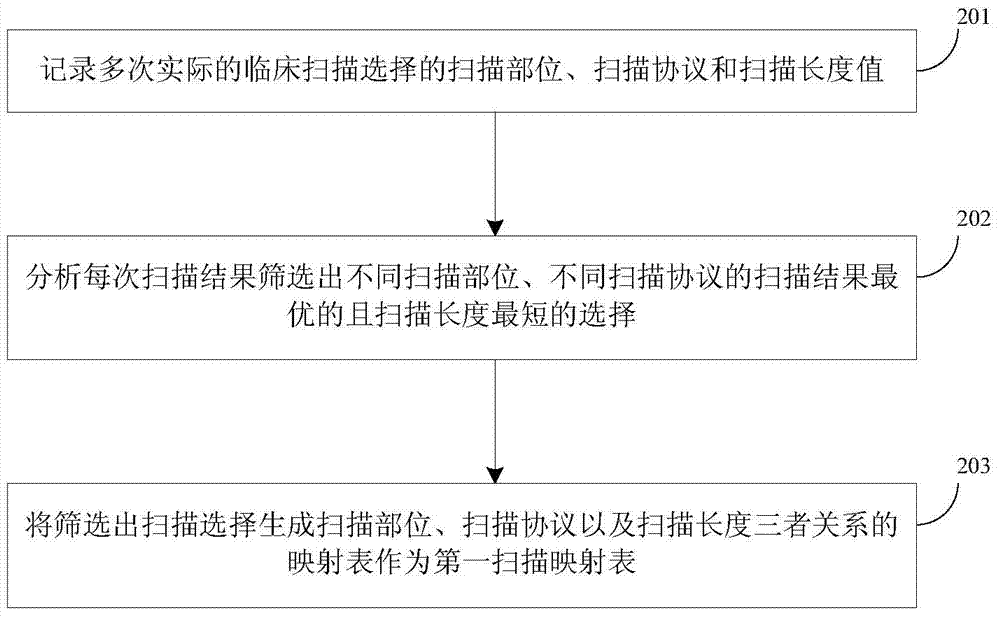

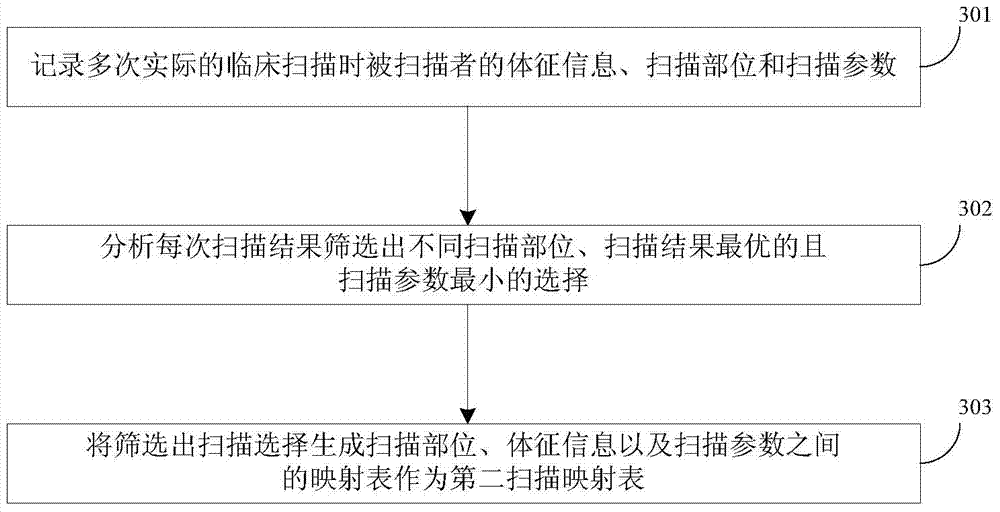

Plain film scanning method and device

ActiveCN103494613AImprove scanning efficiencyReduce harmRadiation diagnostics testing/calibrationMagnetic measurementsPlain filmComputer science

The embodiment of the invention discloses a plain film scanning method and device. The plain film scanning method comprises the steps that a scanning agreement is selected and a scanned part is obtained; a scanning length corresponding to a first predefined scanning list is searched for according to the scanned part; scanning parameters corresponding to a second scanning list are searched for according to the physical sign information of a person to be scanned and the scanned part; the plain film scanning dose is set automatically according to the searched scanning length and the scanning parameters, and then scanning is carried out. According to the plain film scanning method and device, the plain film scanning dose and scanning range which are matched with the person to be scanned can be determined automatically according to the physical sign information of different persons to be scanned, plain film scanning efficiency is improved, the scanning dose is saved, and injury, caused by scanning, to a patient is reduced.

Owner:NEUSOFT MEDICAL SYST CO LTD

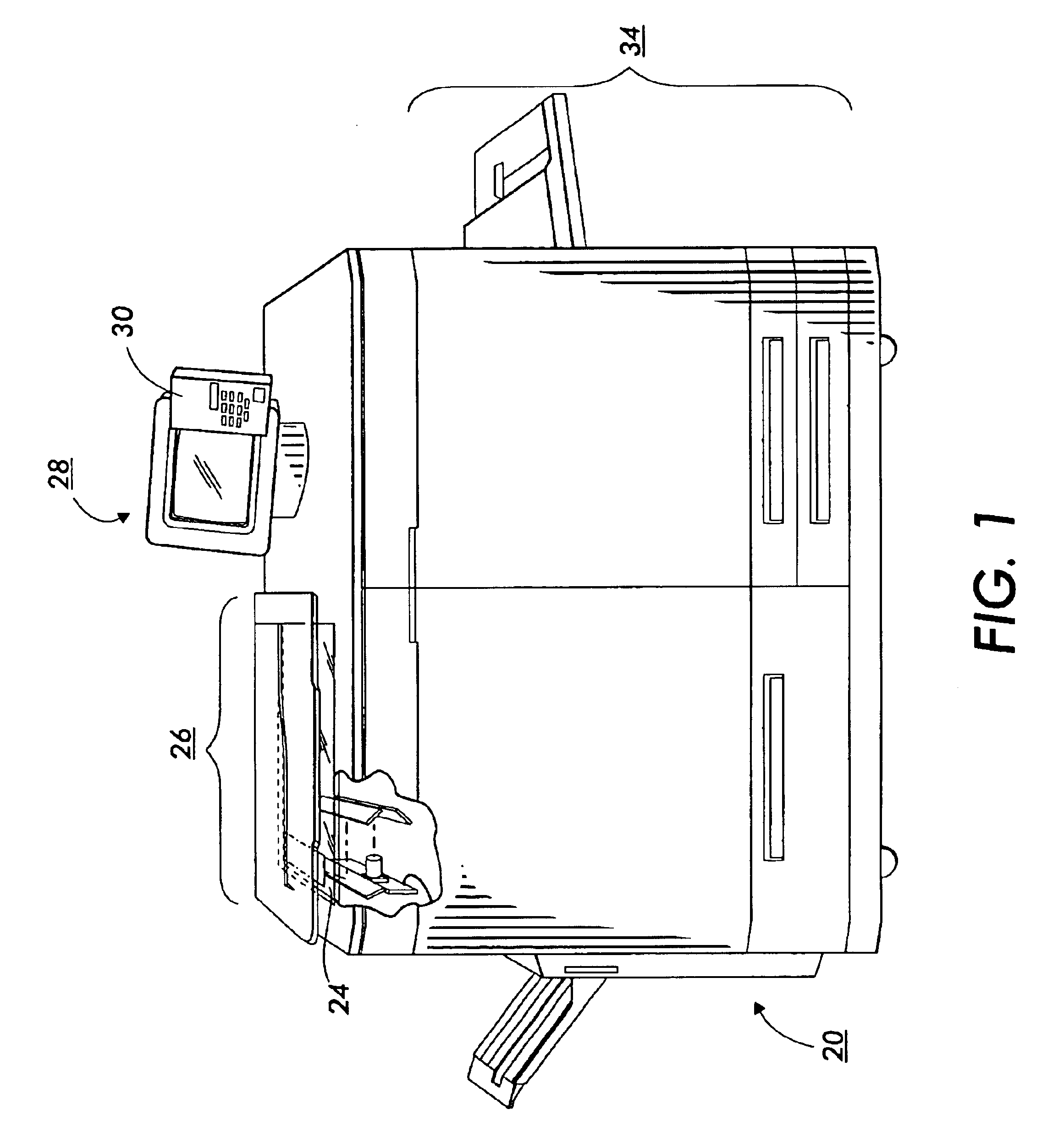

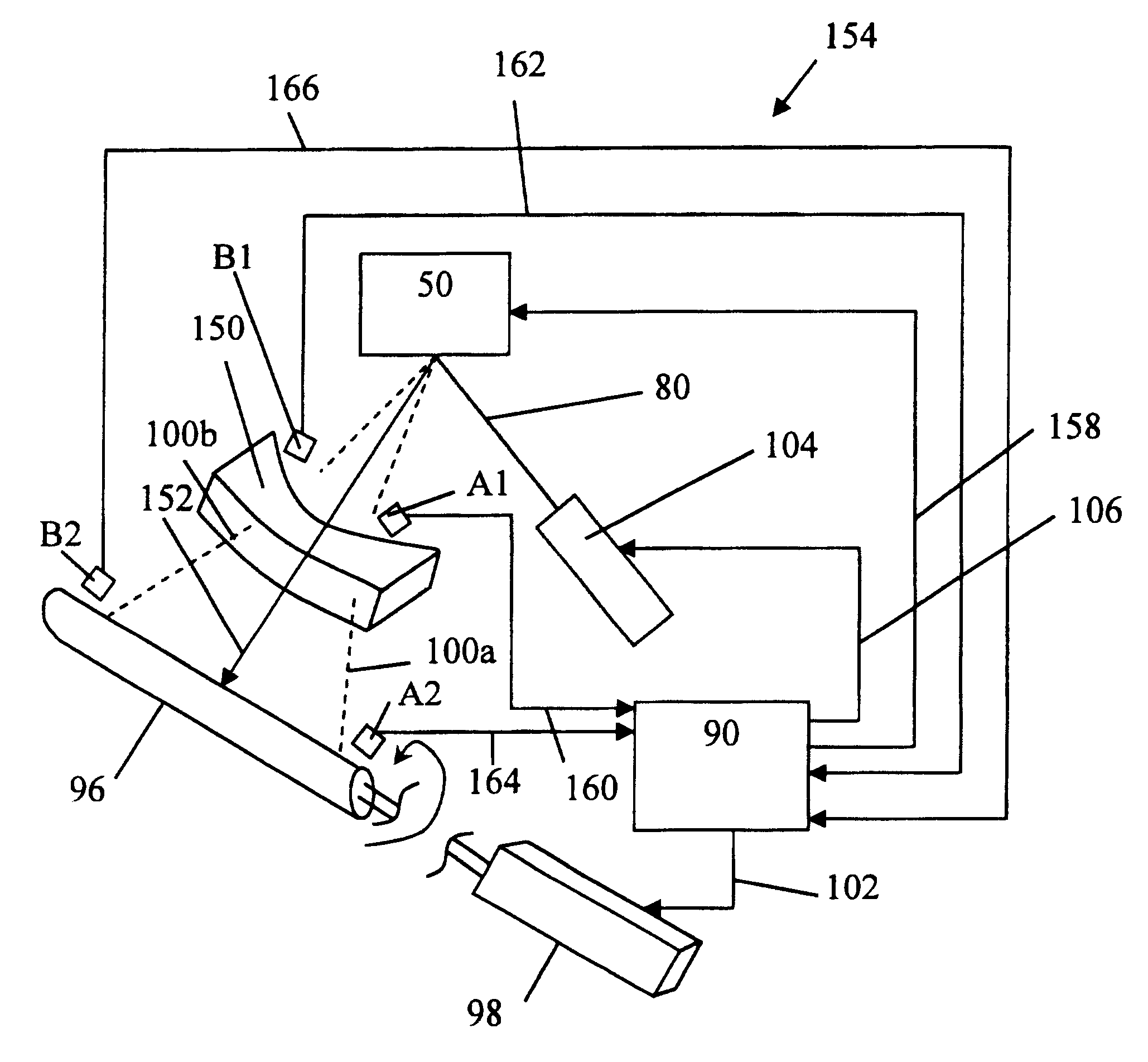

Bi-directional galvonometric scanning and imaging

InactiveUS6870560B2Improve scanning efficiencyReduce operating frequencyInking apparatusOther printing apparatusLight beamData transmission

In bi-directional imaging, such as bi-directional printing, a galvanometric oscillator scans a light beam through a scan path across an imaging window. A controller enables transmission of video data to a modulator when the light beam is positioned for imaging on the imaging window. Video data is transmitted to the modulator when the light beam is traveling in a forward direction or a reverse direction across the imaging window, whereby a modulated light beam is capable of producing an image when traveling in the forward or reverse directions.

Owner:LEXMARK INT INC

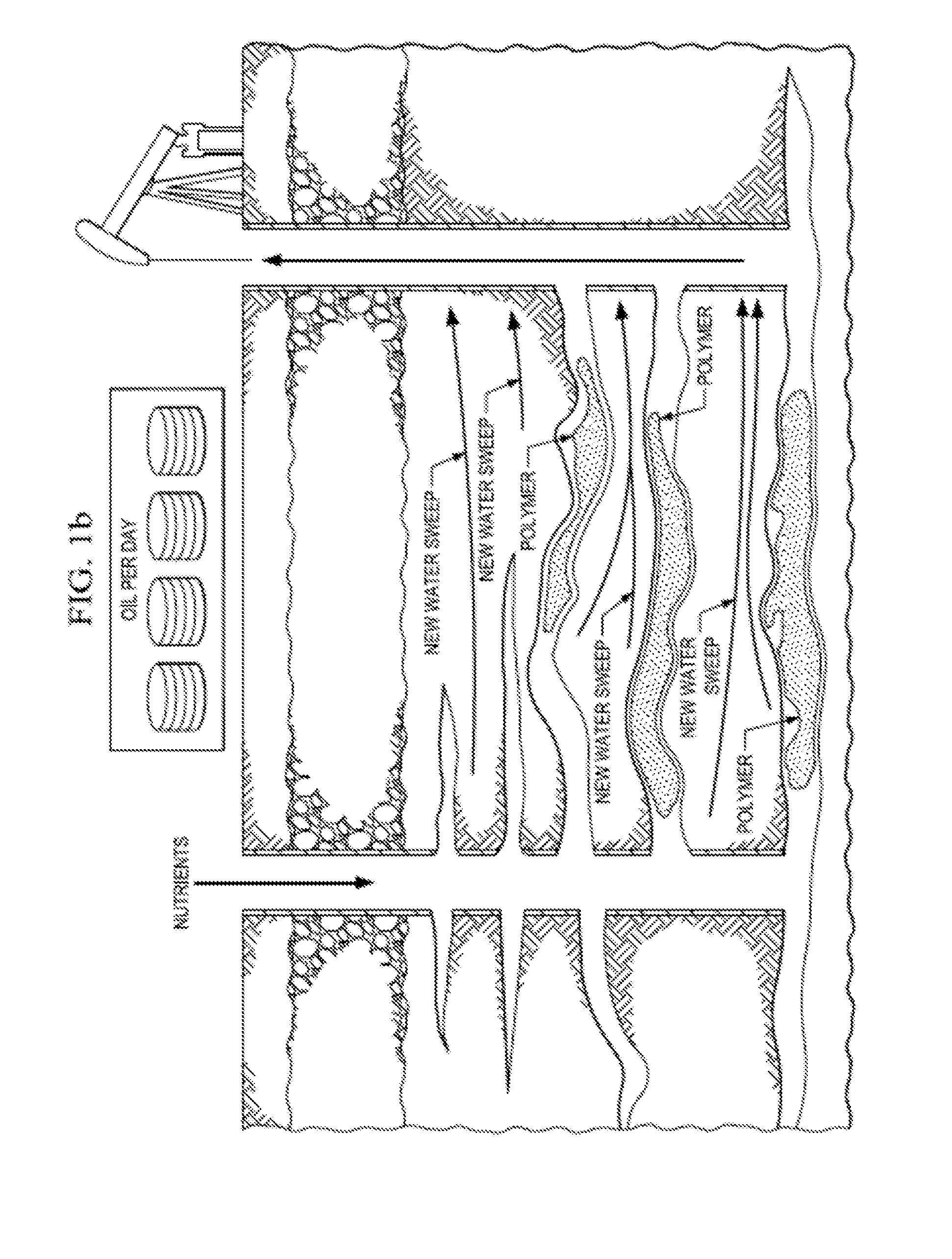

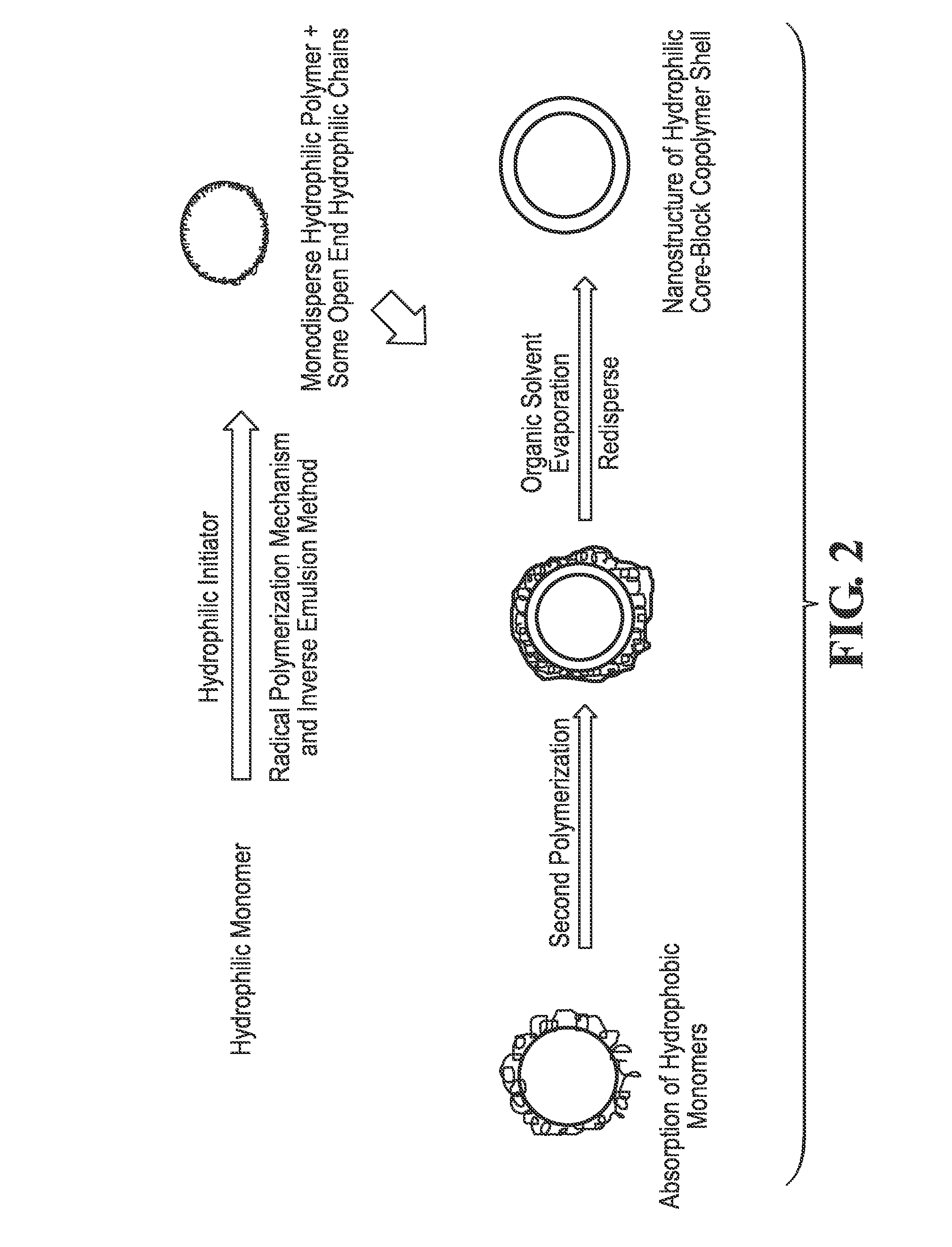

Smart polymer flooding process

ActiveUS20150148269A1Improve efficiencyReduce the amount requiredFlushingDrilling compositionHydrophilic polymersSmart polymer

Owner:TAMSILIAN YOUSEF +1

Fast forming method of fusion of metal powder of three beams of laser compound scanning

ActiveCN101607311BSlow down drastic changesUniform temperature fieldIncreasing energy efficiencyLength waveMetal powder

Owner:HUAZHONG UNIV OF SCI & TECH

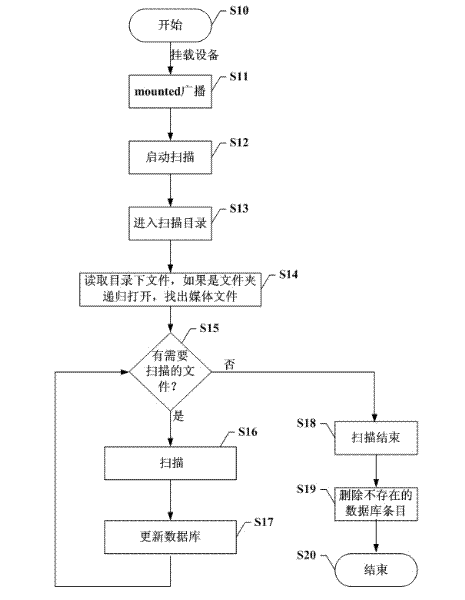

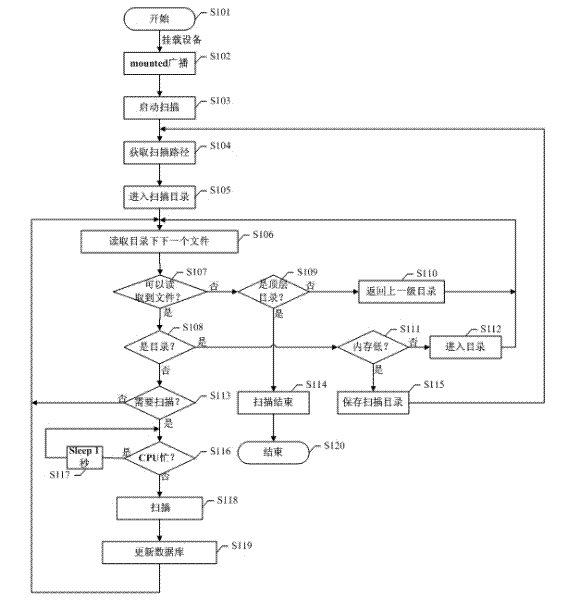

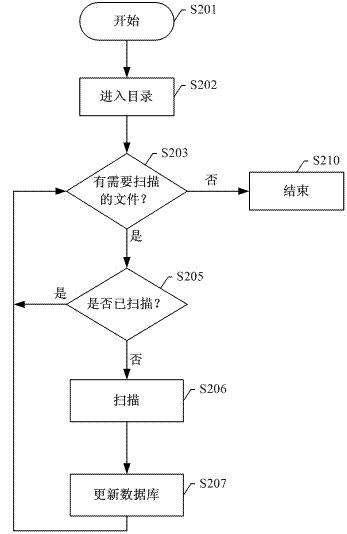

Android system-based file scanning method and device

ActiveCN102411628AReduce waiting timeScan stableSpecial data processing applicationsOperating systemWaiting time

The invention discloses an android system-based file scanning method and device. The method comprises the steps of background scanning of a first stage, adopted when a storage device is mounted, and foreground scanning in a second stage, triggered when entering a local application, wherein in the background scanning step, when file scanning is executed, current CPU condition is read, if a CPU is busy, first preset time is waited and then scanning is carried out, when a catalog is accessed, the current memory condition is read, if a memory is low, the current scanning catalog is recorded, and all recursion catalogs are exited, all memories are released, and the catalogs are re-accessed for scanning; and in the foreground scanning of the second stage, when a file catalog corresponding to a database is accessed, the bottom scanning is called for scanning all files to be scanned, which are not scanned in the background scanning step under the catalog and the scanned files are updated in the database. According to the invention, scanning efficiency is increased and waiting time of a user is greatly saved.

Owner:TCL CORPORATION

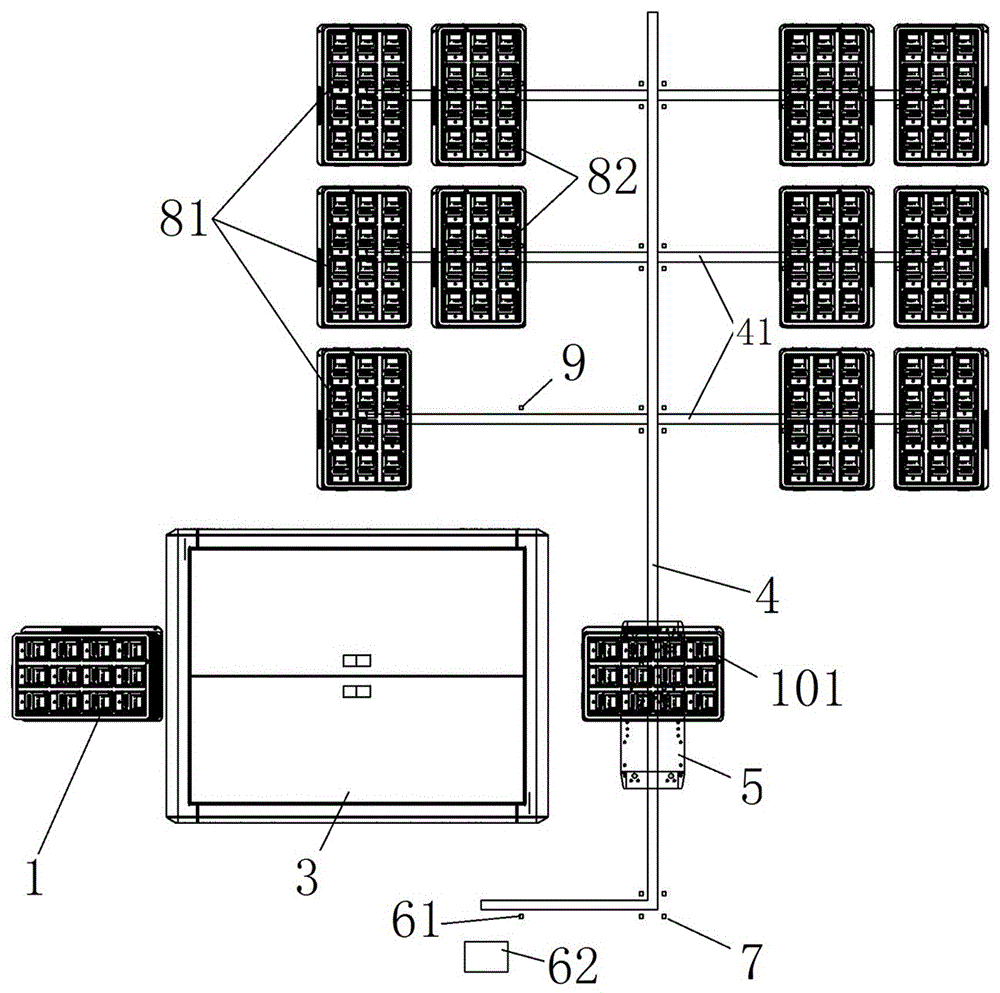

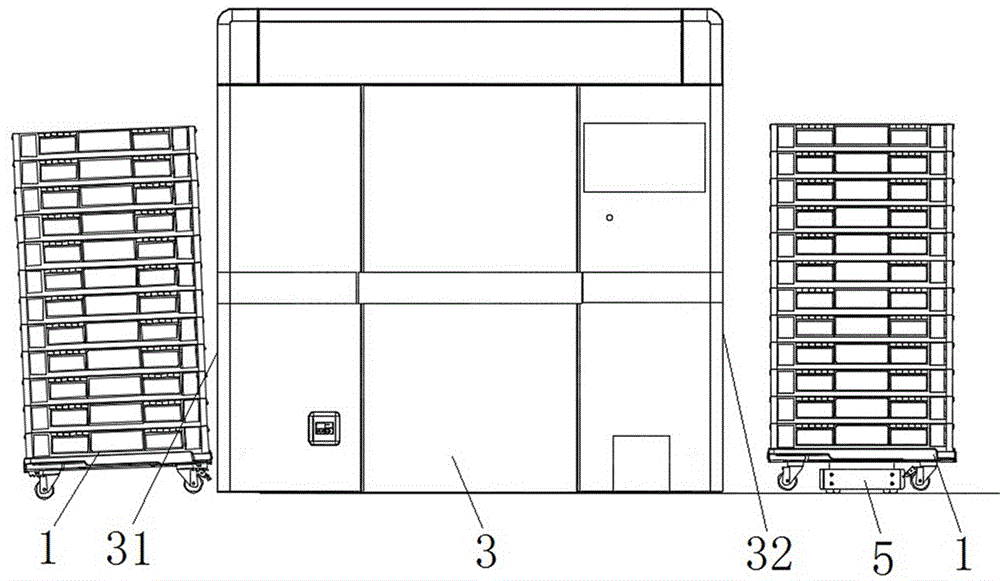

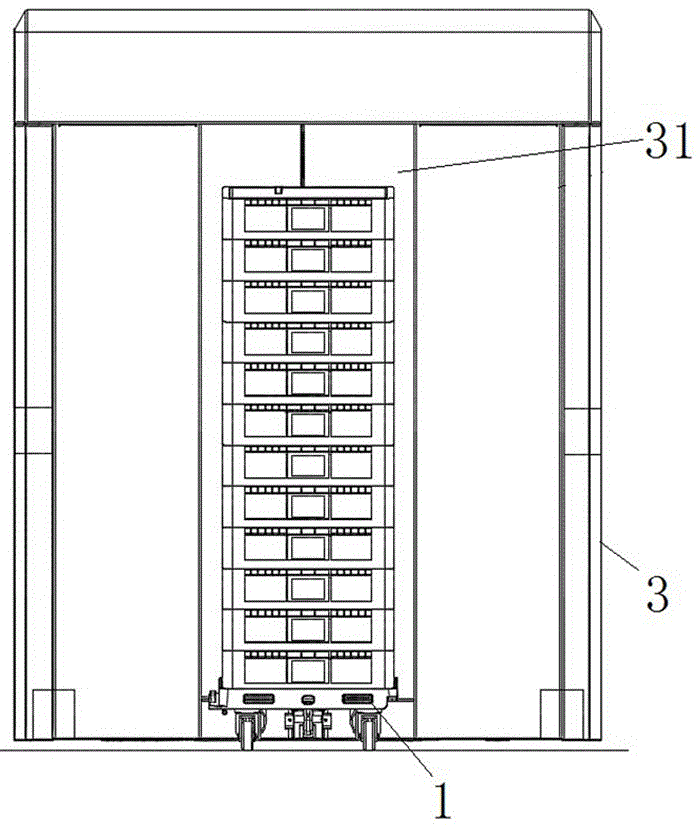

Warehousing system based on AGV delivering and loading small handcart and warehousing and warehouse-out method

ActiveCN106743014AConvenient automatic dockingConvenient logistics and warehousing processStorage devicesLogistics managementEngineering

The invention relates to a warehouse system based on an AGV delivering and loading small handcart and a warehousing and warehouse-out method. The loading small handcart is a tool outside a warehouse and for delivering goods and a carrier inside the warehouse and for loading the goods, and the goods can be scanned on the loading small handcart and do not need to be scanned gradually by manual work; and when the goods are out of the warehouse, the loading small handcart is directly delivered to an entrance of the warehouse through an AGV trolley to be wholly scanned, when the goods of the loading small handcart are completely unloaded, the loading small handcart is placed at a gate of the warehouse so as to be used when the goods are stored, and thus a good in-out warehouse cycle is formed. Compared with tradition manual goods storing and taking or other warehousing systems or methods in the prior art, the storing steps can be reduced, and the automated degree is high, so that the whole logistical warehousing process is neat, efficient and convenient; when goods allocation of the warehouse is changed, only a navigation magnetic stripe and a RFID positioning piece need to be planned and arranged again, and due to the fact that the navigation magnetic stripe and the RFID positioning piece are adhered to the ground, no damage is caused to the ground; and the warehouse is very convenient to use for other purposes.

Owner:YUNNAN ZHUOPEI TECH

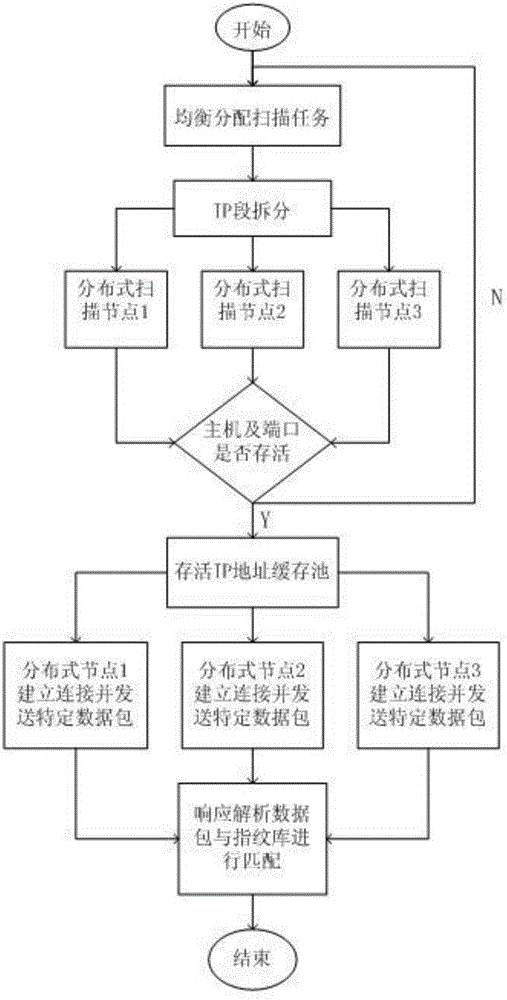

Method for quickly identifying networked industrial control device

The invention discloses a method for quickly identifying a networked industrial control device. The method is characterized by comprising a pre-scanning stage and an industrial control device identification stage, wherein the pre-scanning stage comprises: uniformly allocating scanning tasks by using a distributed scanning mechanism, splitting a specified IP address segment, judging whether an IP host and a port survive by using a TCP stateless detector, and storing IP addresses of the survival IP host and the survival port in an IP buffer pool identified by the device, and the industrial control device identification stage comprises: obtaining the survival IP host and the port from the IP buffer pool, establishing a complete TCP connection, sending a specific industrial control protocol identification data packet of the port, waiting for the response of a server, returning a data packet by the networked industrial control device, analyzing the data packet, and matching the data packet with a fingerprint library of the industrial control device. According to the method disclosed by the invention, the distributed scanning technology is imported, segmented scanning is carried out by fully using scanning nodes, the resources of a computer are saved, the scanning efficiency is greatly improved, and meanwhile the survivability of the IP host and the industrial control port are clarified before the industrial control device is identified, thereby shortening the response delay time caused by the non-survival of the port.

Owner:CHINA ELECTRONICS TECH CYBER SECURITY CO LTD

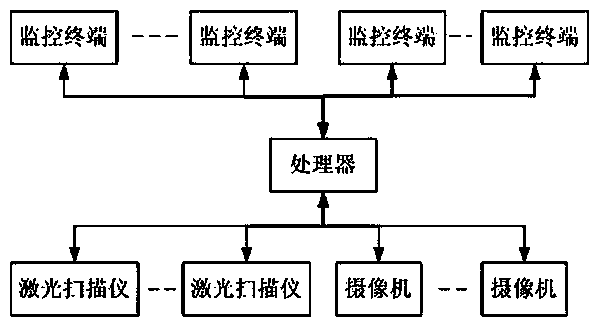

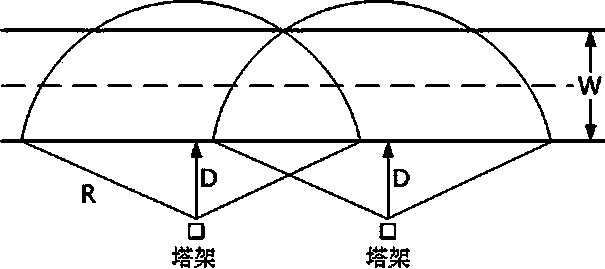

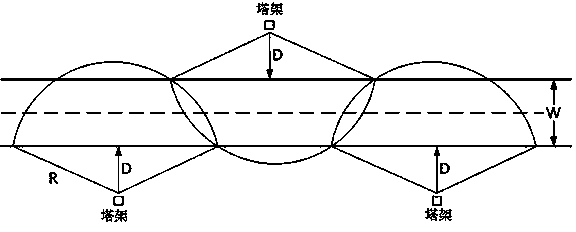

Runway pavement monitoring device and method based on point cloud detection

ActiveCN103675939AEnsure the safety of take-off and landingAccurate and effective processingOptical detectionPoint cloudLaser scanning

The invention relates to the technical fields of foreign body invasion monitoring and laser scanning, in particular to a runway pavement monitoring device and method based on point cloud detection. According to the technical problem to be solved that a foreign body invades an airfield runway, so that taking off and landing of a flight are threatened, the three-dimensional laser scanning technique is mainly applied in combination with a video / image recognition device, the runway pavement monitoring device arranged outside the runway in an erected mode and the method are designed for monitoring the invading foreign body appearing on the airfield runway. Meanwhile, the device and the method can also be used for accurately measuring and timely feeding back the pavement flatness of the runway. The runway pavement monitoring device based on the point cloud detection comprises the structural design among at least one laser scanning device, at least one video camera, a processor and the like. The runway pavement monitoring device and method based on the point cloud detection are applied to the field of airfield runway plane invading body monitoring.

Owner:THE SECOND RES INST OF CIVIL AVIATION ADMINISTRATION OF CHINA

Method for recovering crude oil from a subterranean formation

InactiveUS20090023618A1Easy extractionReduce adsorptionOrganic detergent compounding agentsAnionic surface-active compoundsPhysical chemistryOrganic phosphorus

Owner:RHODIA OPERATIONS SAS

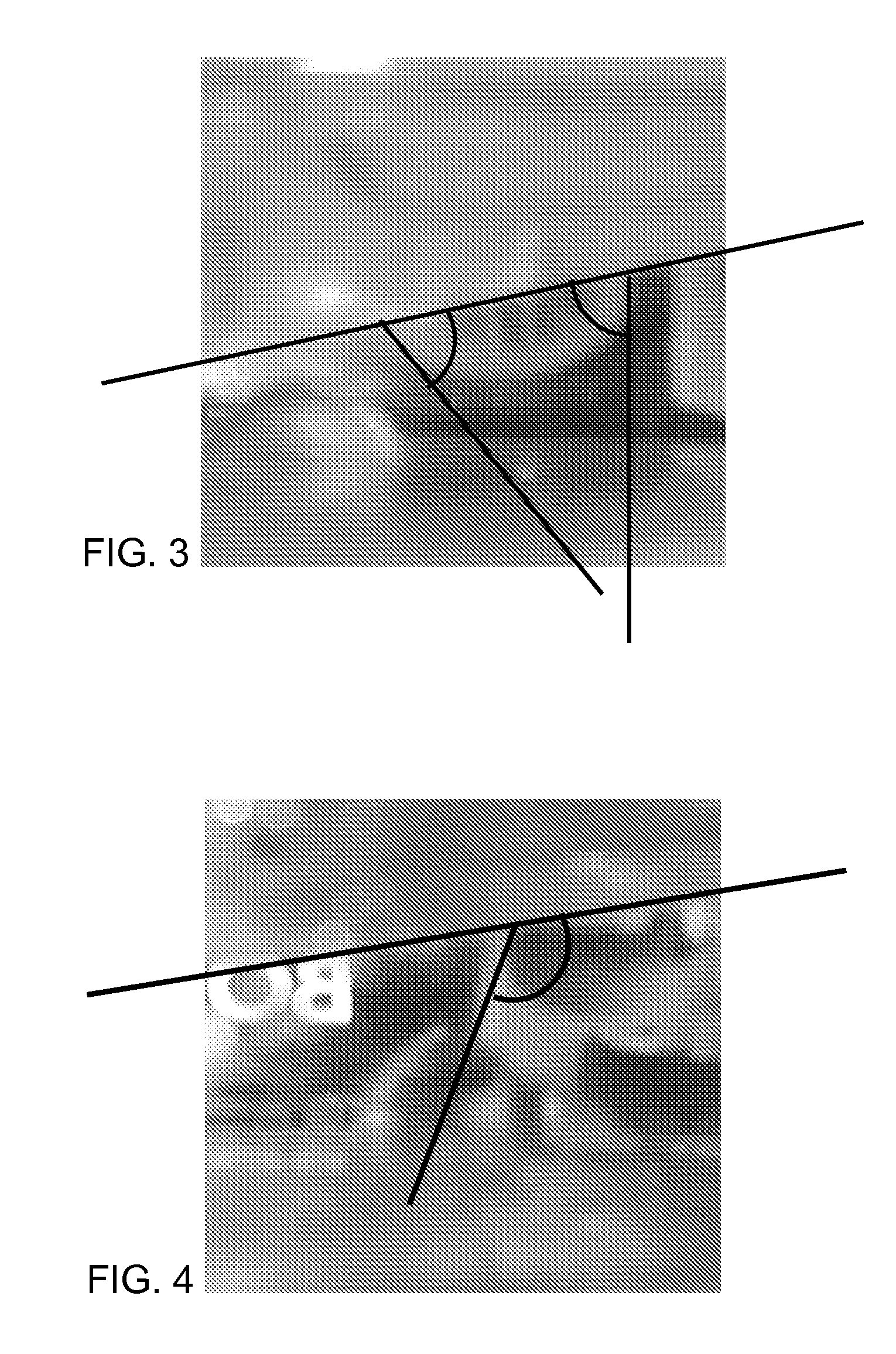

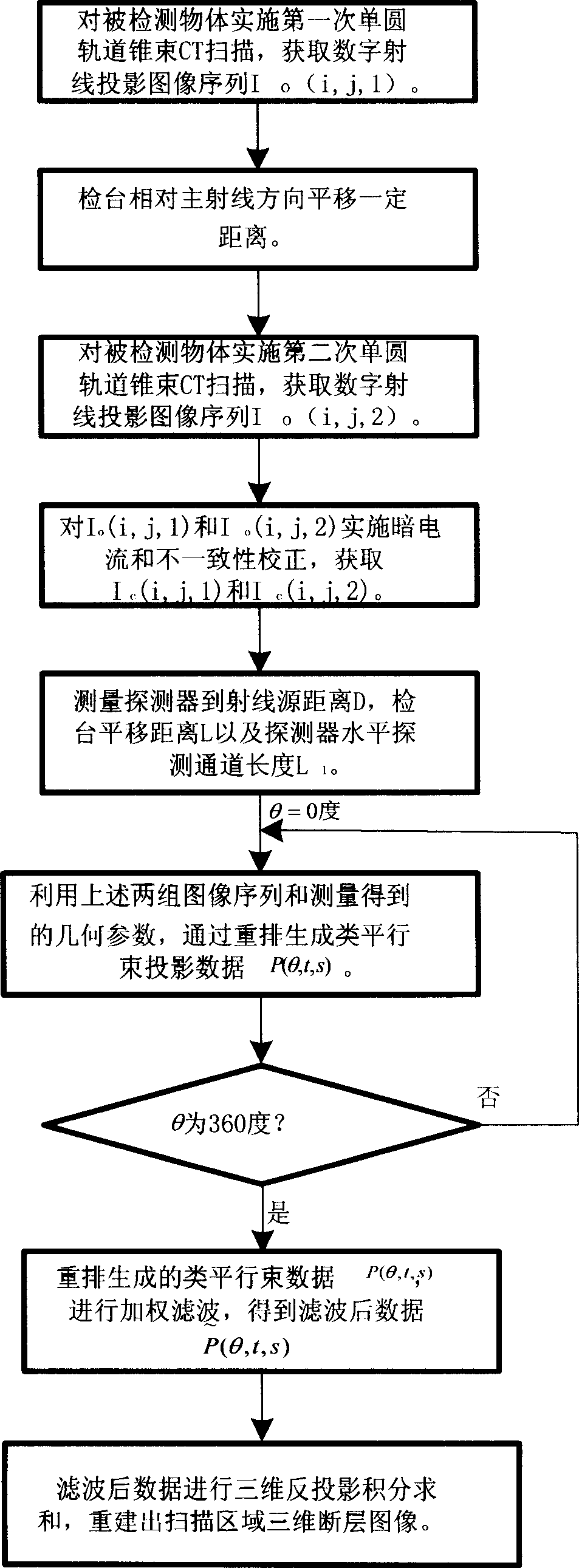

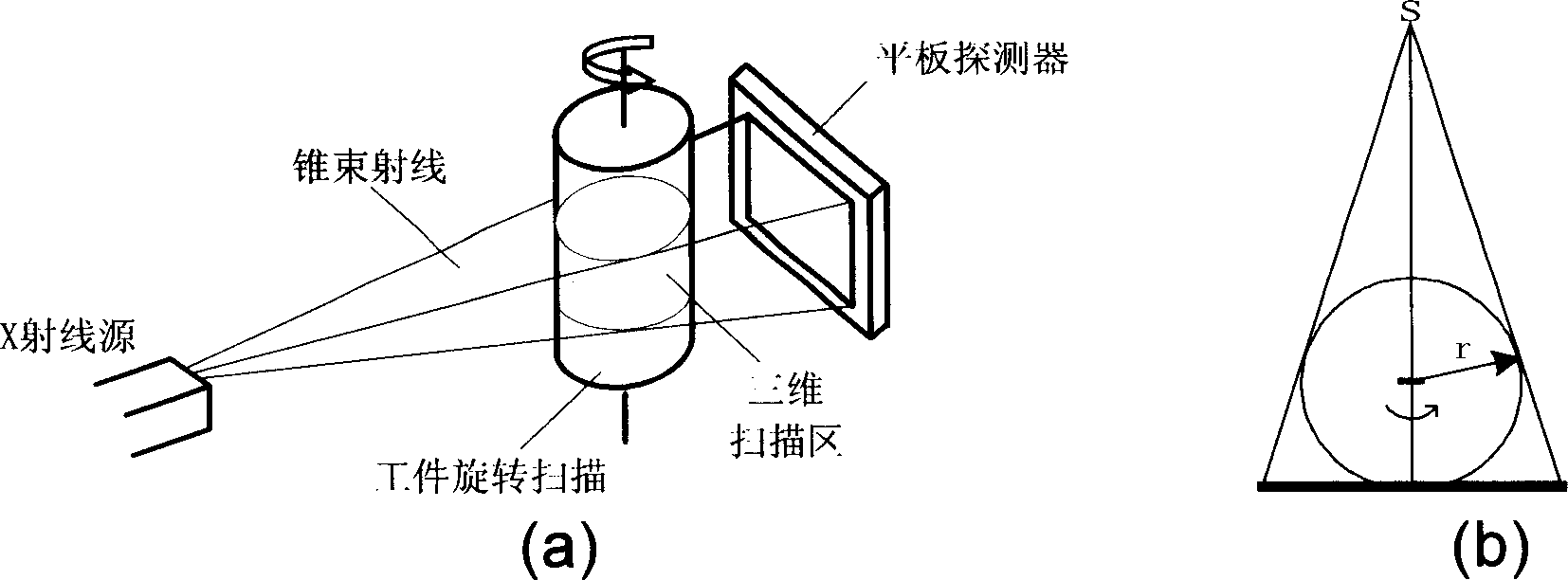

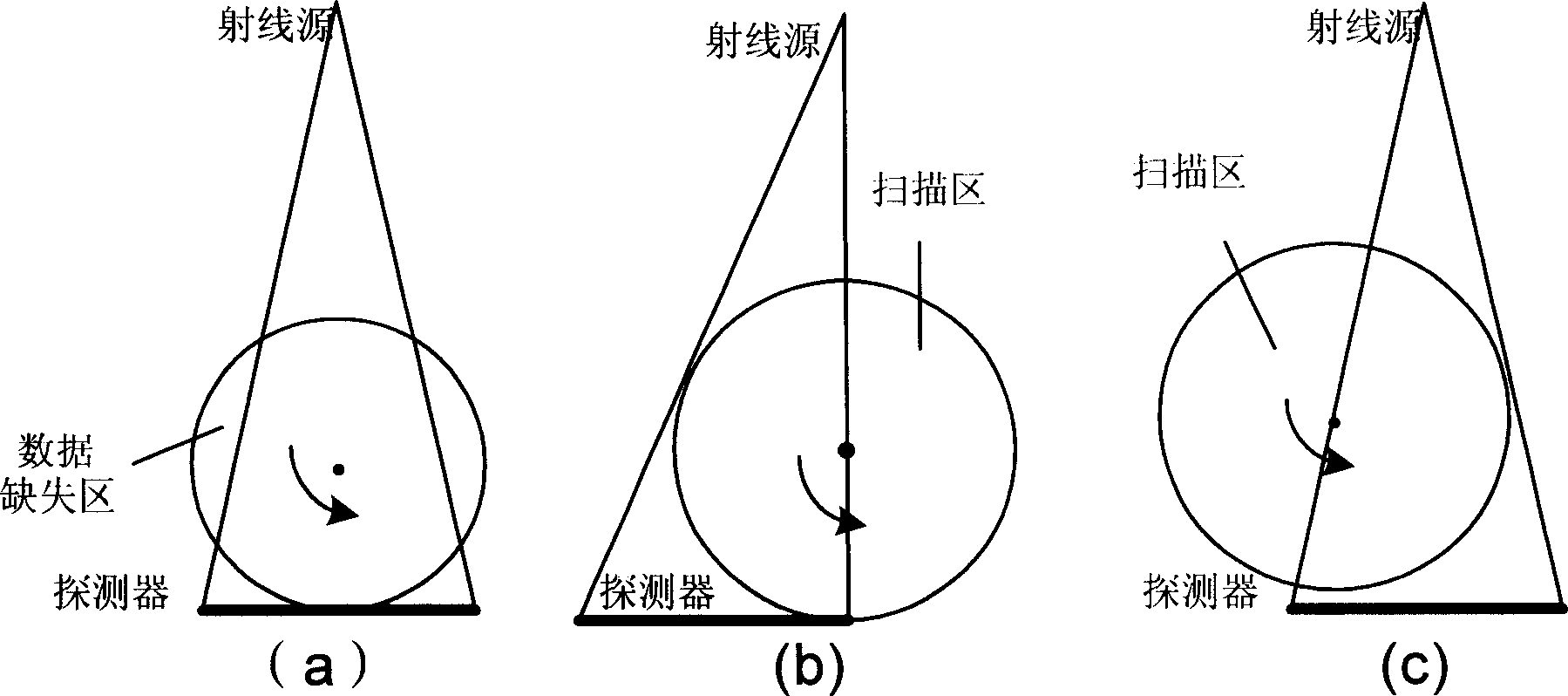

Wide view-field three-D CT imaging method

InactiveCN1865954AScan structure is simpleCompatibleComputerised tomographsTomographyDigital RayVisual field loss

The 3D CT imaging method for large view field comprises: (1) taking first single-circular orbit cone-beam CT scanning to obtain the first digital ray projection image sequence; (2) removing the platform vertical the main ray with some distance to take the second CT scanning and obtain the second image sequence; (3) correcting former two images for dark current and inconsistency; (4) recording distance from ray source to detector, former moved distance and detector level channel number; (5) with the projection rearrangement algorithm in this invention, rearranging former two images into self-contained quasi-parallel image sequence; (6) with the quasi-parallel ray reconstructing algorithm in this invention, reconstructing the 3D CT image. This invention can enlarge the view area more than 3 times with high efficiency.

Owner:BEIHANG UNIV

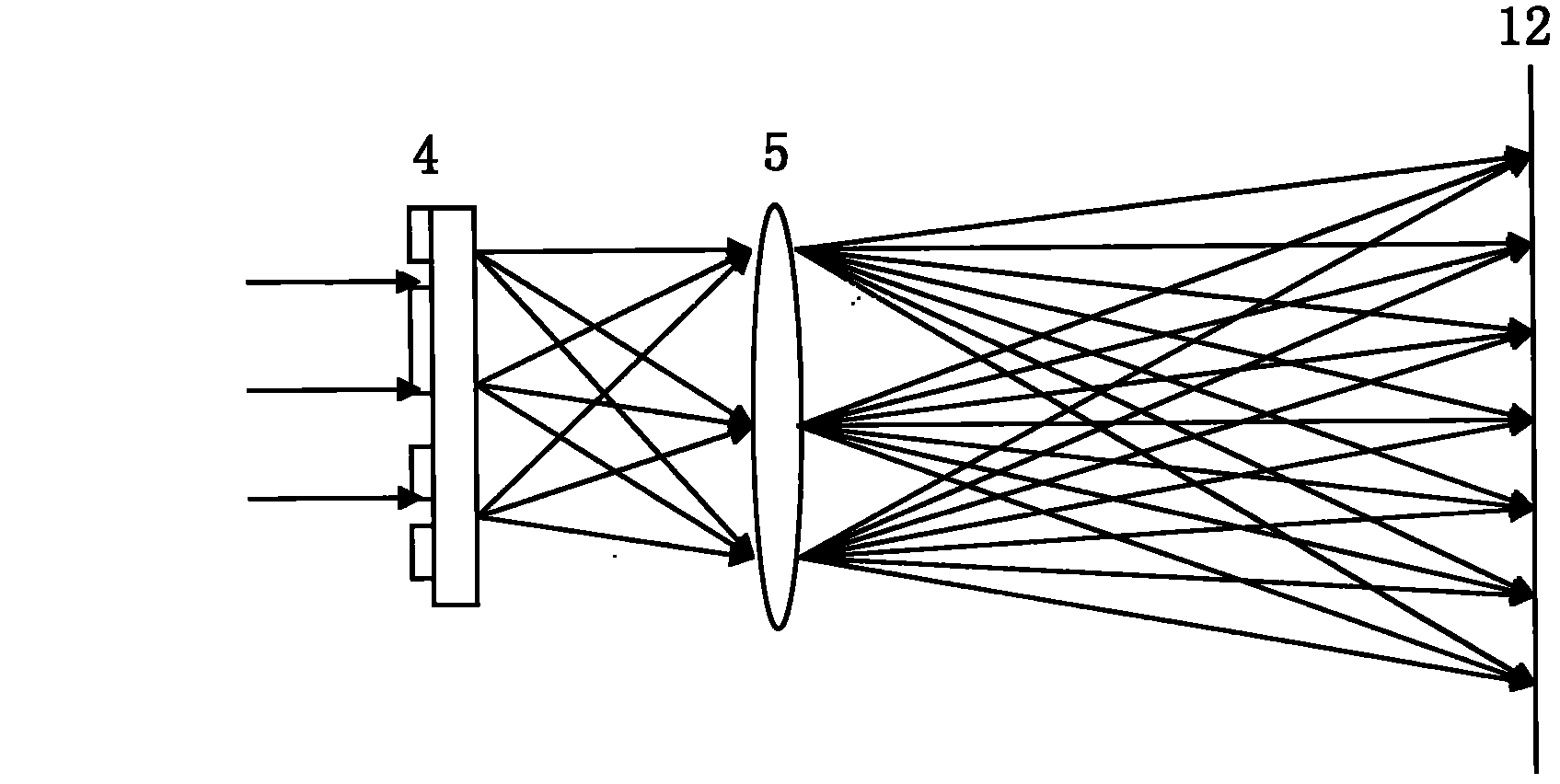

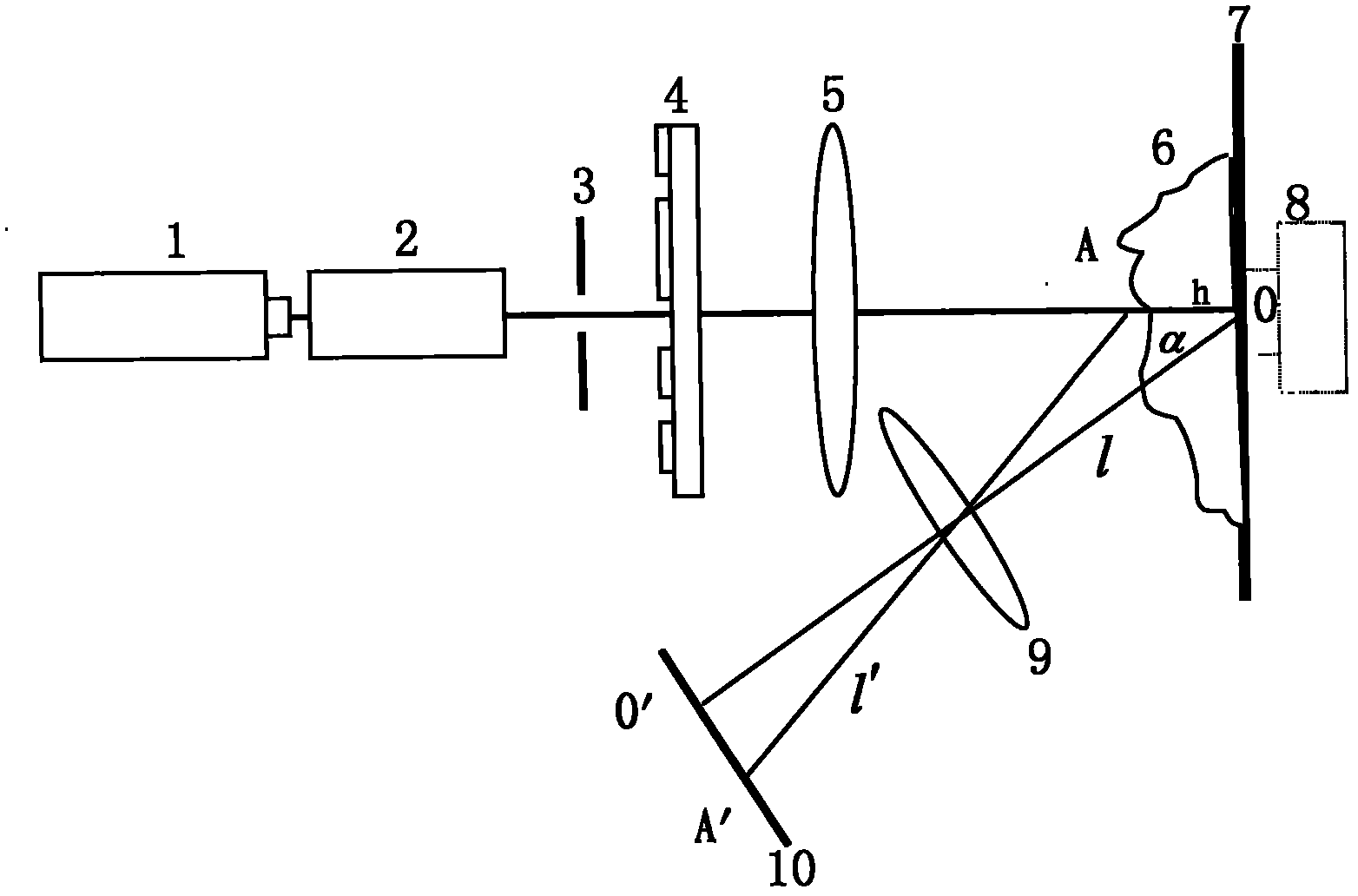

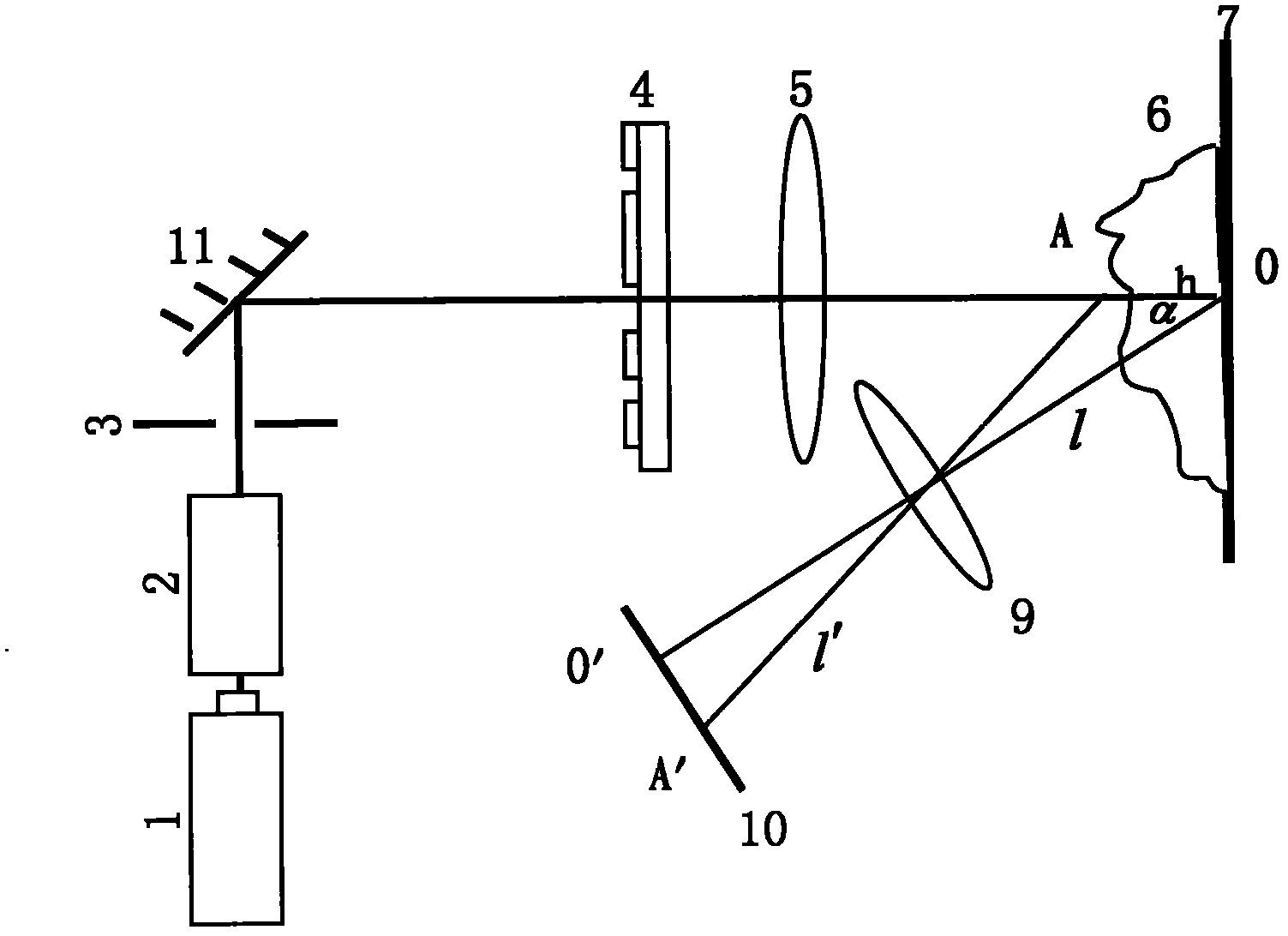

Three-dimensional surface topography measurement device based on one-dimensional Dammann grating

InactiveCN102155925ANo rotation errorReduced Uniformity RequirementsUsing optical meansMeasurement deviceGrating

The invention discloses a three-dimensional surface topography measurement device based on one-dimensional Dammann grating. A one-dimensional Dammann grating is inserted between a collimated laser source and a measured object, and the measured object and a reference surface are placed on a Fourier transform plane of a collimating lens. A charge coupled device (CCD) receives structured light reflected by the object, and the imaging relative distance of reflecting points of the reference surface and the actual object surface on a CCD target surface is used for determining the relative distance between the reflecting point of the object surface and the reflecting point of the reference surface. The Dammann grating is used for equally dividing the light intensity of the light source into multiple parts so as to acquire high spatial resolution at the same time of realizing multi-point scanning. Moreover, because the relative distance of diffraction spots of each level of the Dammann grating is strictly fixed, the rotating error of a vibrating mirror during single-point scanning is furthest reduced. The device has high measurement precision and spatial resolution, greatly improves the scanning efficiency, and has important practical significance.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

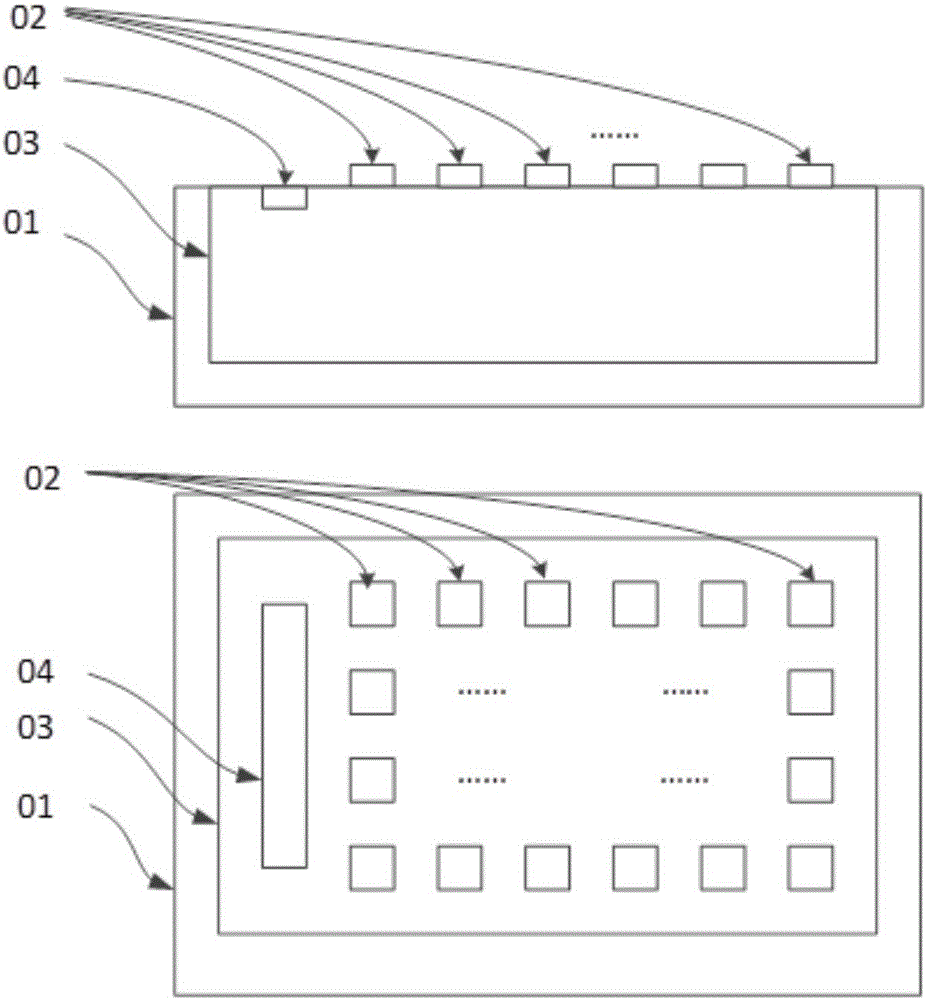

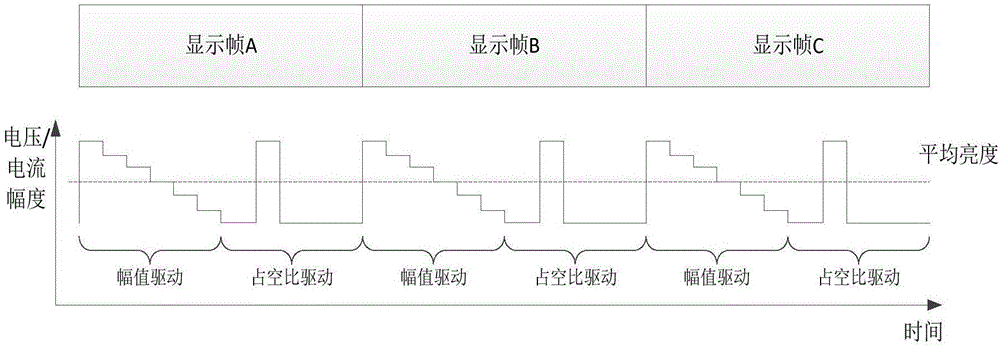

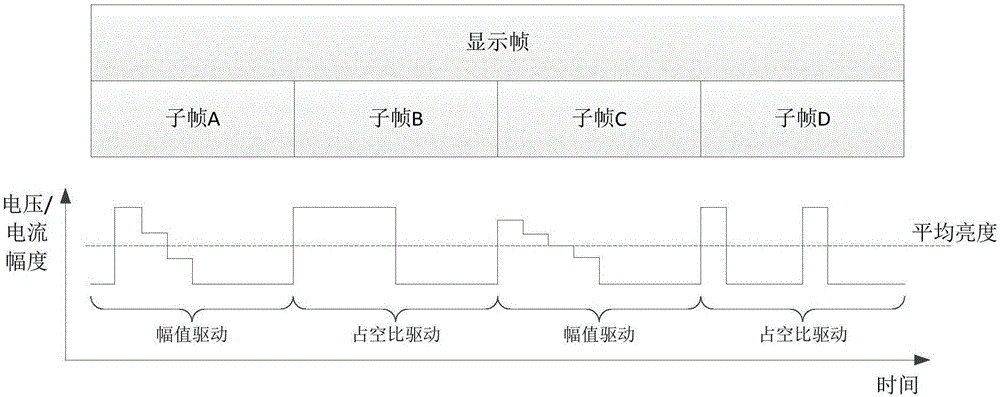

Silicon-based display adopting digital-analog hybrid drive

ActiveCN106652963AReduced precision requirementsImprove conversion accuracyStatic indicating devicesVoltage amplitudeDigital analog converter

The invention discloses a silicon-based display adopting digital-analog hybrid drive. Pixels are driven to emit light through the method of combining the simulation amplitude modulation drive strategy and a digital pulse width modulation drive strategy, wherein the luminance of the pixels is determined by output current or voltage amplitude of the pixels in the subframe and the duty ratio of time of the output current or voltage of the pixels in the subframe, the frame of image is divided into a plurality of different digital subframes and simulation subframes, the digital drive strategy is adopted for the digital subframes, the time proportionable drive mode or luminance proportionable drive mode is adopted, the simulation drive strategy is adopted for the simulation subframes, many digital-analog converters with few digits are adopted, input data is converted into amplitude quantity of voltage or current, so that the pixels emit light, and the simulation subframes and the digital subframes are combined to generate the final display frame. The requirements of the simulation amplitude modulation drive strategy for the digital-analog converter and the requirements of the pixel circuit for the precision of analog quantity are reduced, and the conversion speed of the digital-analog converter and the contrast of the pixel luminance are improved.

Owner:南京昀光科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com