Three-dimensional printing large light spot scanning path generation method

A scanning path and 3D printing technology, which is applied in the field of efficient scanning path generation with large light spots in 3D printing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

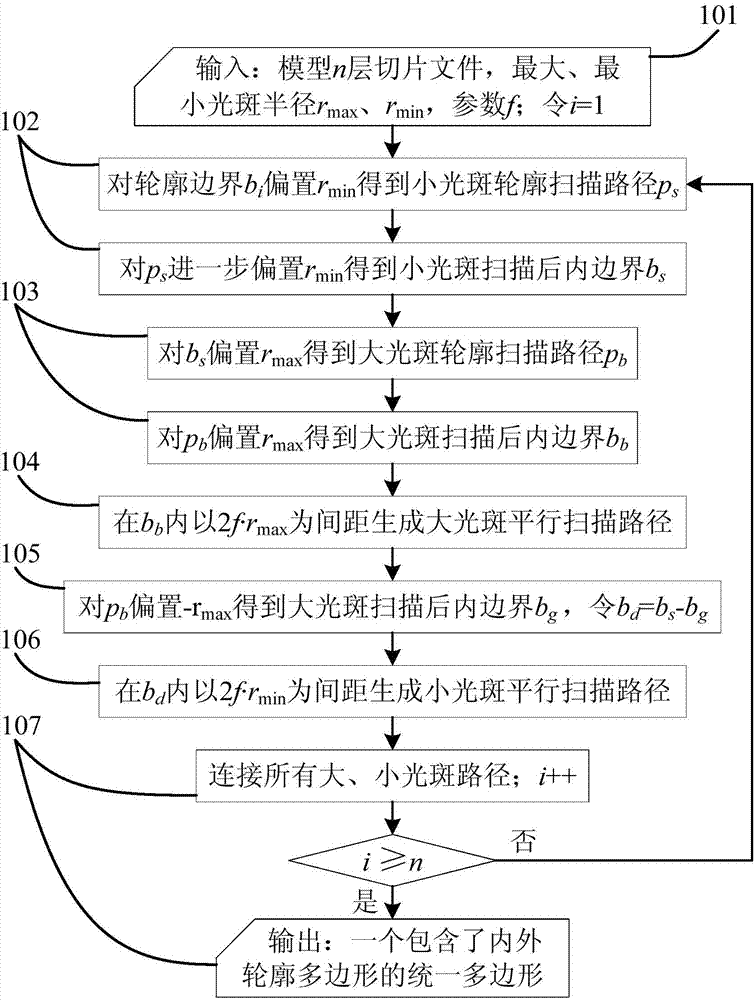

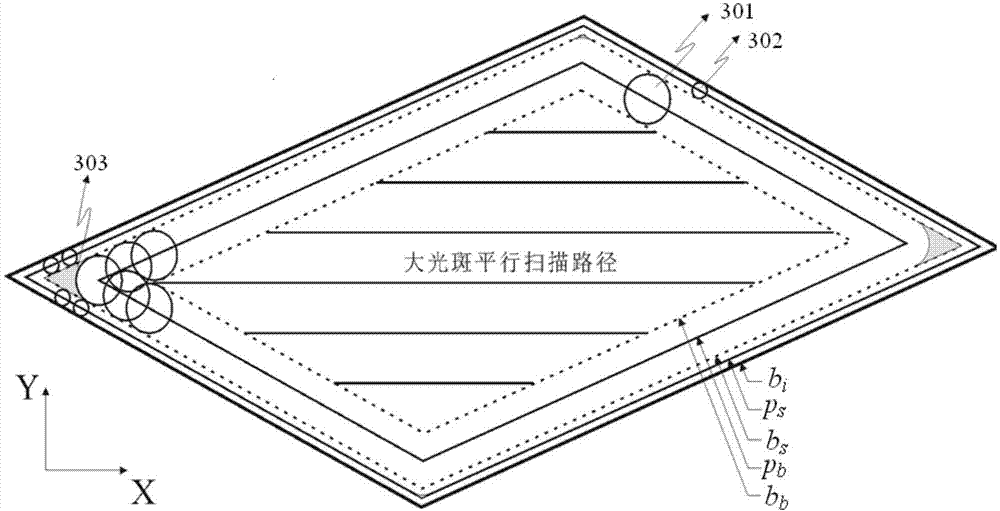

Method used

Image

Examples

Embodiment

[0067] A typical implementation example of the present invention is as follows:

[0068] 1. The part to be printed selected in this example is a puppy STL model, such as Figure 6 shown. The size of the model is about 350mm×350mm×12mm, of which 12mm is the height of the model.

[0069] 2. the puppy STL model is imported into commercial software Magics RP to generate slice files, then the slice files are imported in the test program written by the method of the present invention with C++ language.

[0070] 2. In the test program, the three-dimensional printing process is selected as photocuring, the maximum spot diameter is set to 4mm, and the minimum spot diameter is set to 0.1mm, that is, r max =2mm, r min =0.05mm; path overlap parameter f=1, that is, two adjacent paths do not overlap each other.

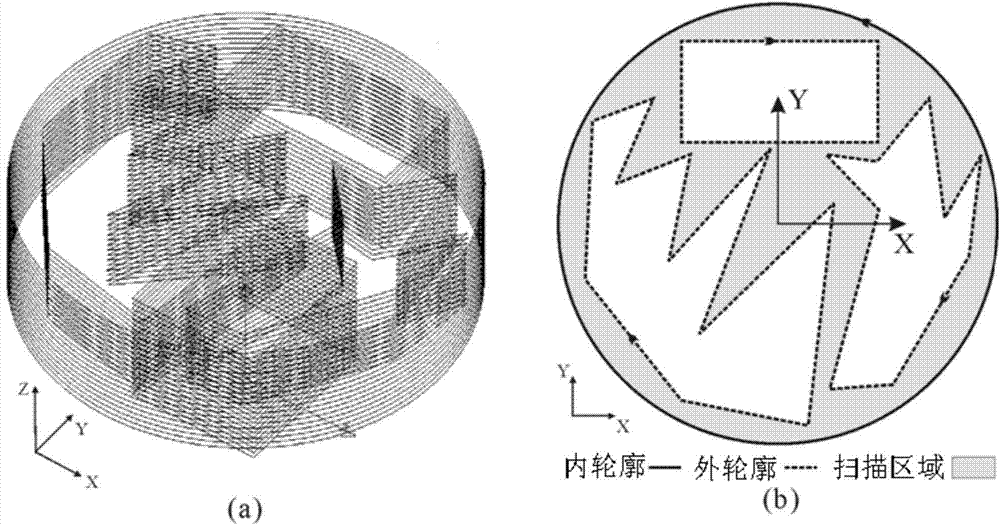

[0071] Figure 7 The scan path generated for one slice of the puppy model slice file is given. This layer slice contains a total of 9 contour curves, one of which is the oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com