Patents

Literature

252 results about "Spot scanning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

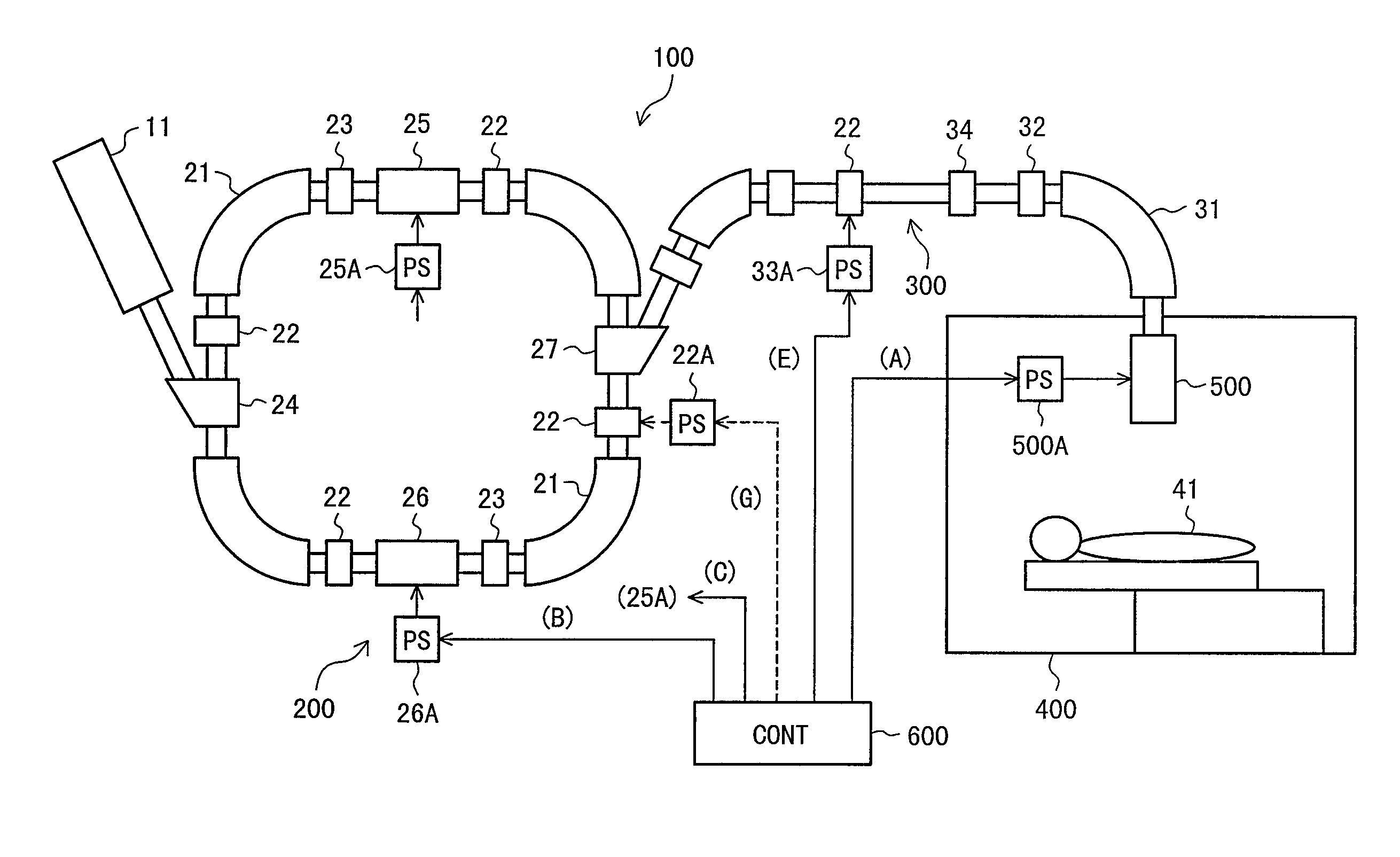

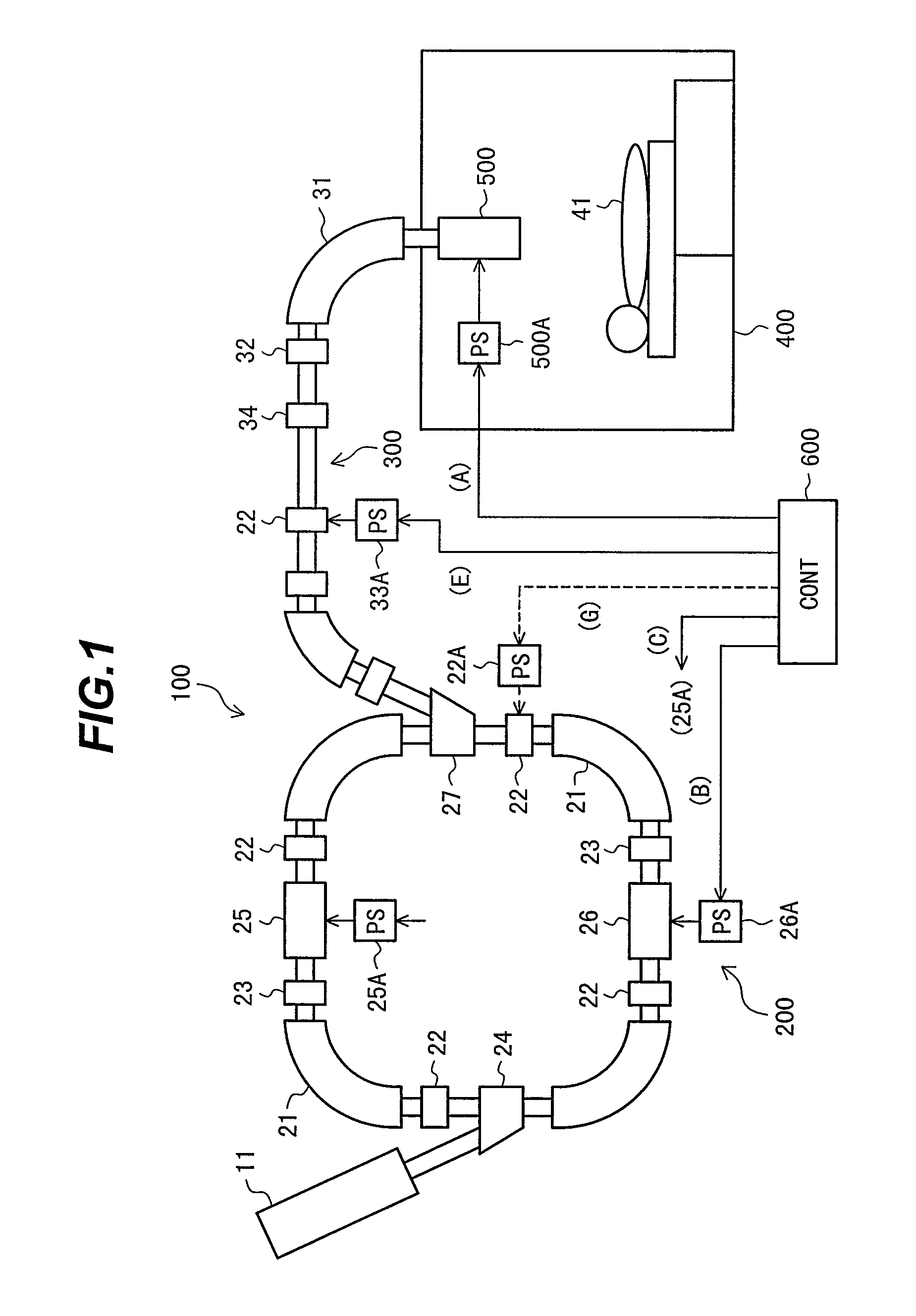

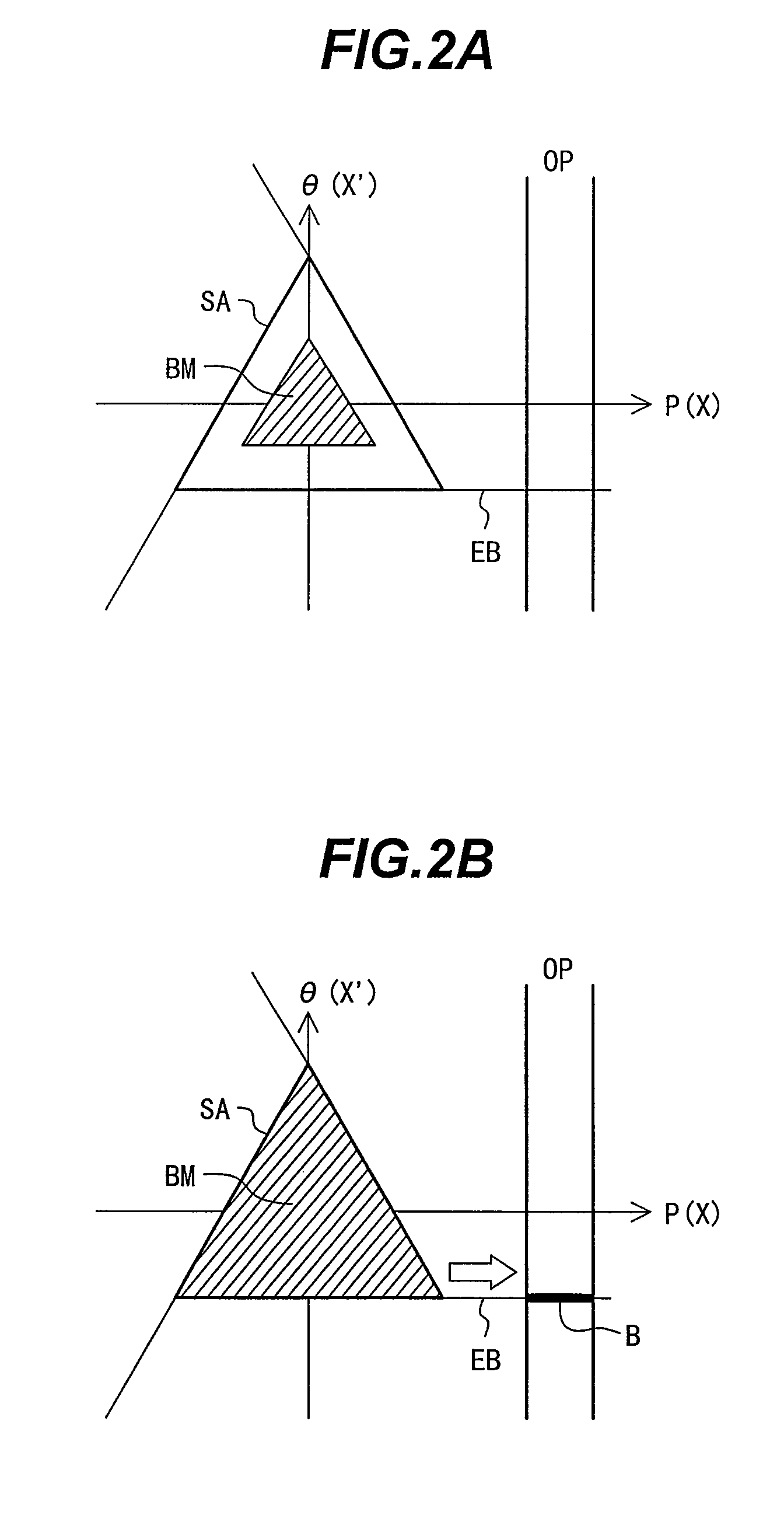

Particle beam therapy system

ActiveUS7772577B2Quality improvementLow costElectrode and associated part arrangementsMaterial analysis by optical meansTransport systemSynchrotron

A particle beam therapy system using a spot scanning method includes a synchrotron, a beam transport system, an irradiation system, and a controller. A controller is configured to turn on a radio frequency electromagnetic field to be applied to an extraction system when a charged particle beam is to be supplied to the irradiation system, and turn off the radio frequency electromagnetic field to be applied to the extraction system when the supply of the charged particle beam to the irradiation system is to be blocked by means of an electromagnet provided in the beam transport system or in the synchrotron. The controller is also adapted to turn off a radio frequency acceleration voltage to be applied to an acceleration cavity in synchronization with the turning-off of the radio frequency electromagnetic field to be applied to the extraction device.

Owner:HITACHI LTD

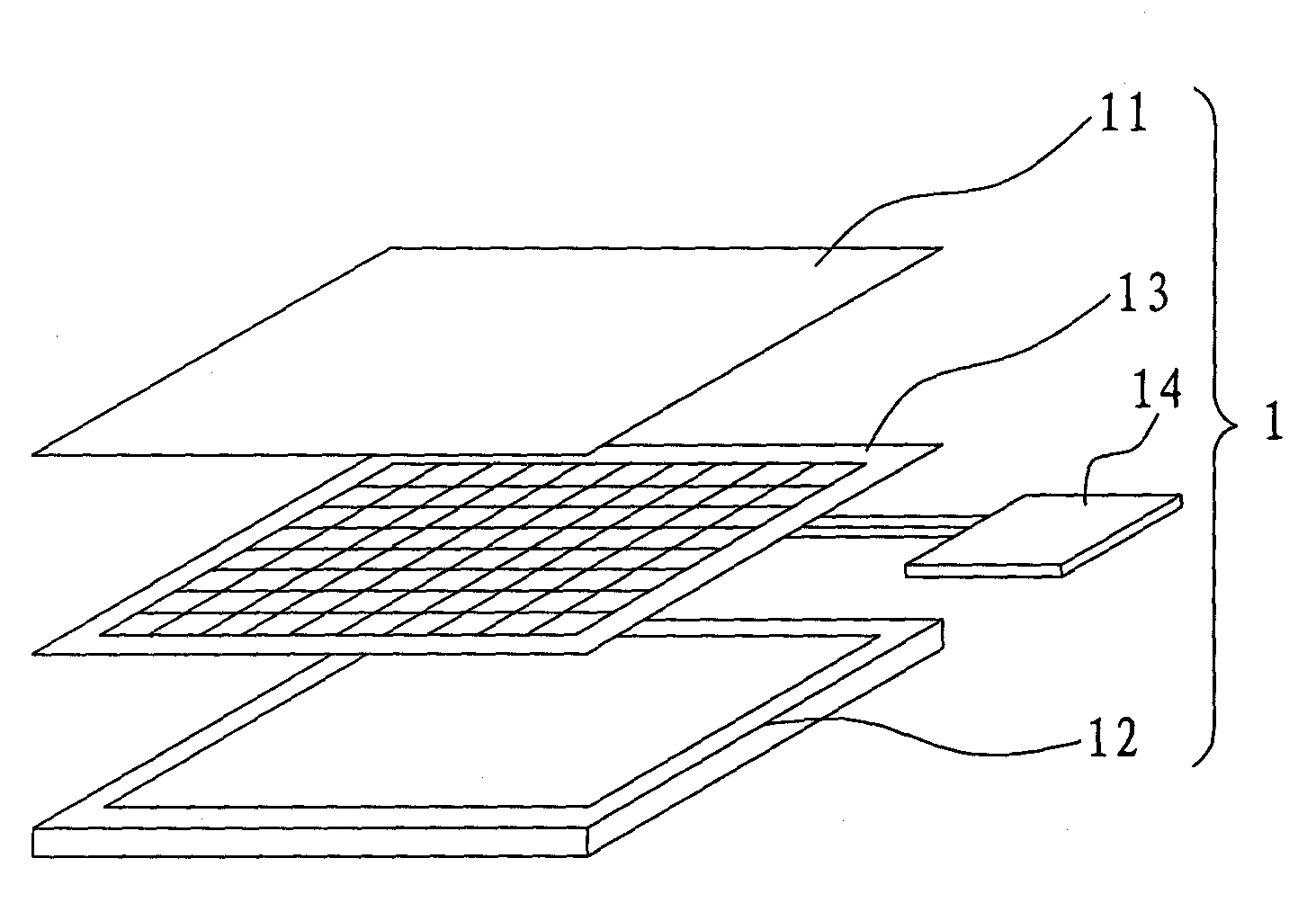

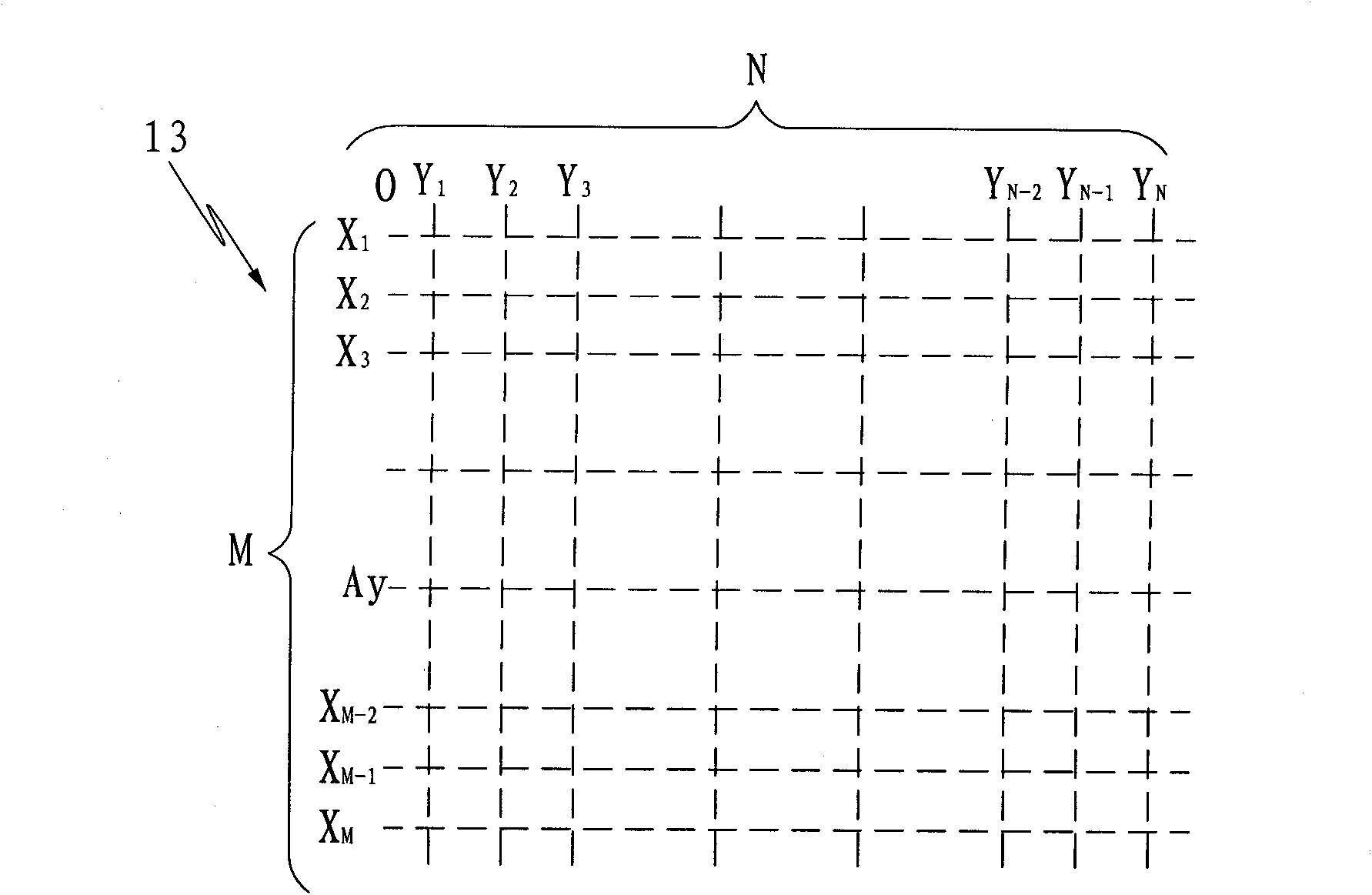

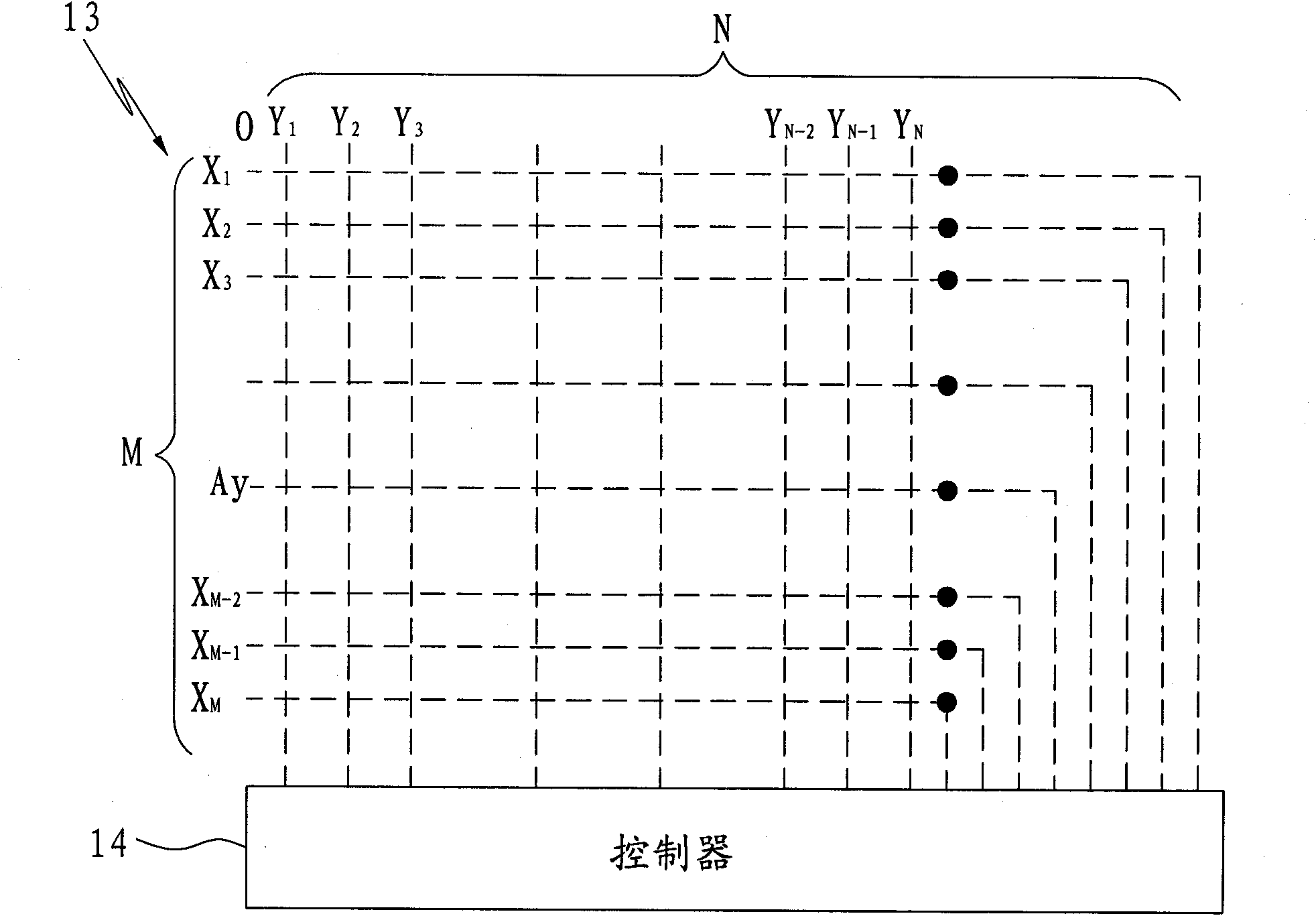

Scanning method for projected capacitive touch panels

ActiveCN101840293AReduce scan areaReduce scan timeInput/output processes for data processingTouch panelPhysics

The invention relates to a scanning method for projected capacitive touch panels, which includes the following steps that: (a) the self capacitance reference values of each first electrode and each second electrode and the mutual capacitance reference value of each intersection are set; (b) a controller scans the self capacitances of all the electrodes to obtain the current self capacitance value of each electrode, which is compared with the self capacitance reference value corresponding to the electrode to determine that the first and the second electrodes with the changed self capacitance values are touched; and (c) the controller scans the mutual capacitance of each intersection between the first and the second electrodes determined to be touched in the step b to obtain the current mutual capacitance value of each intersection, which is compared with the mutual capacitance reference value corresponding to the intersection to determine that the area where the intersection with the changed mutual capacitance value is positioned is an actually touched area. The method effectively combines self capacitance scanning with mutual capacitance scanning, the scanning frequency is high, the precision is high, and the method is particularly suitable for the multi-spot scanning of medium-sized and large-sized touch panels.

Owner:TPK TOUCH SOLUTIONS (XIAMEN) INC

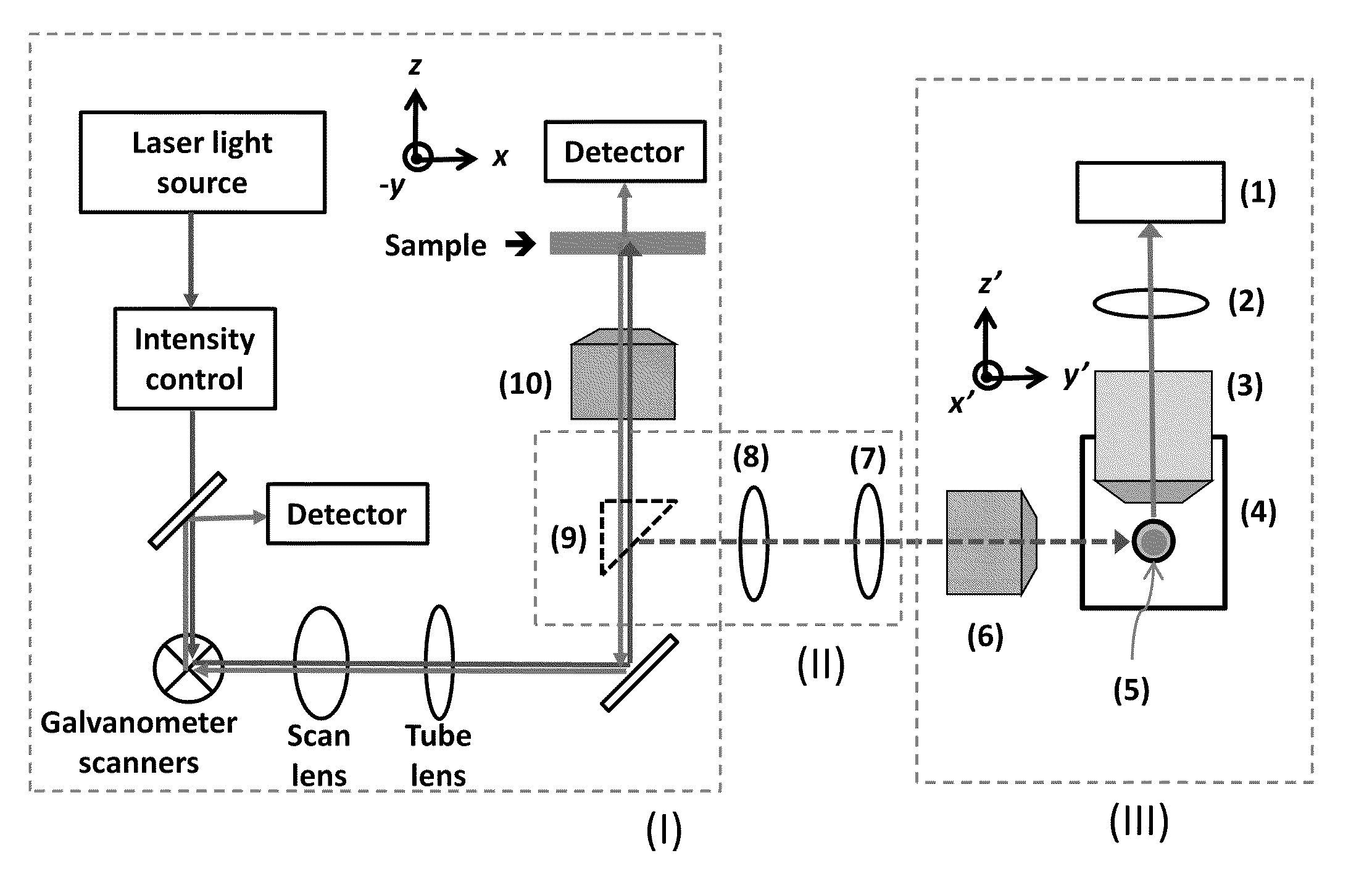

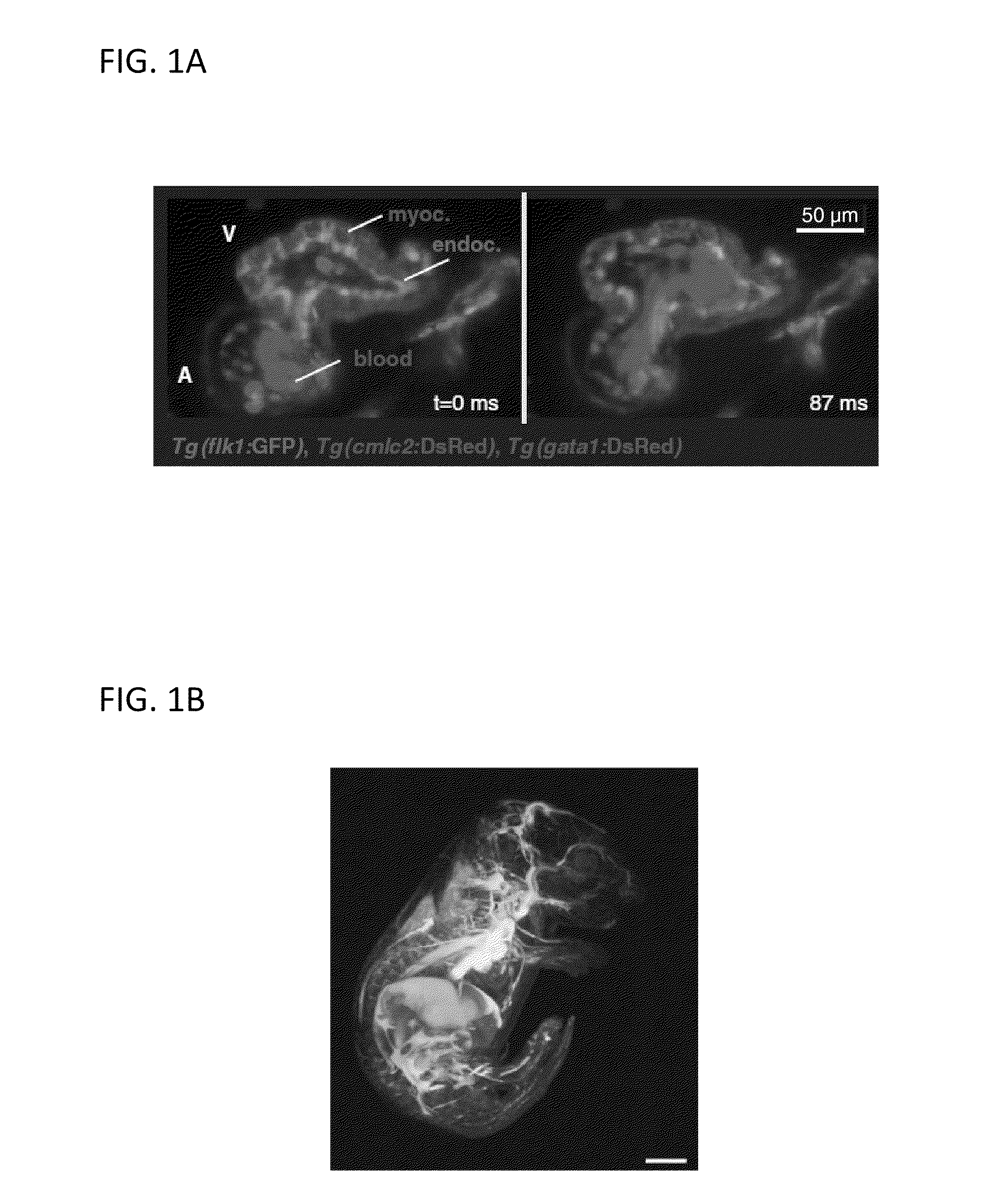

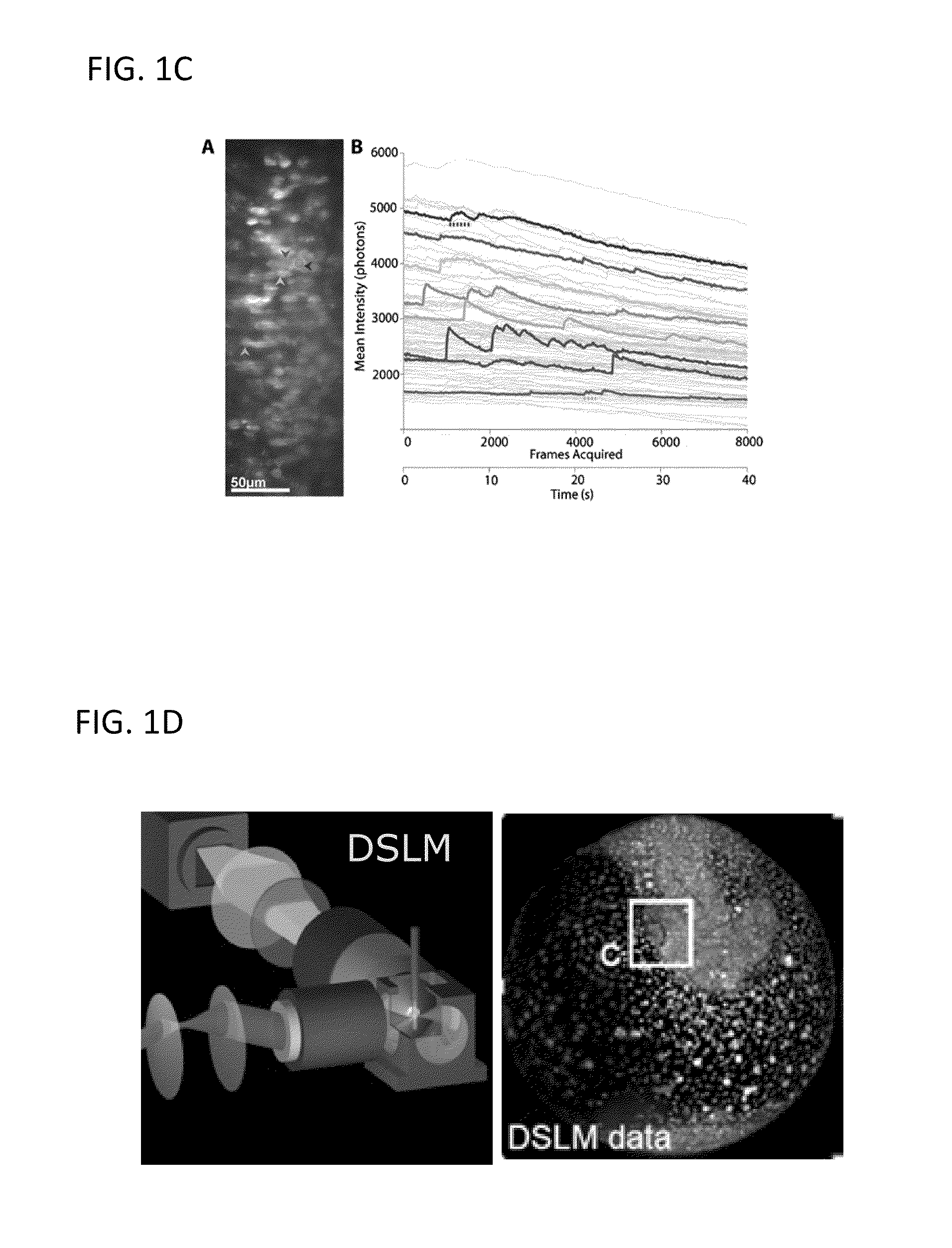

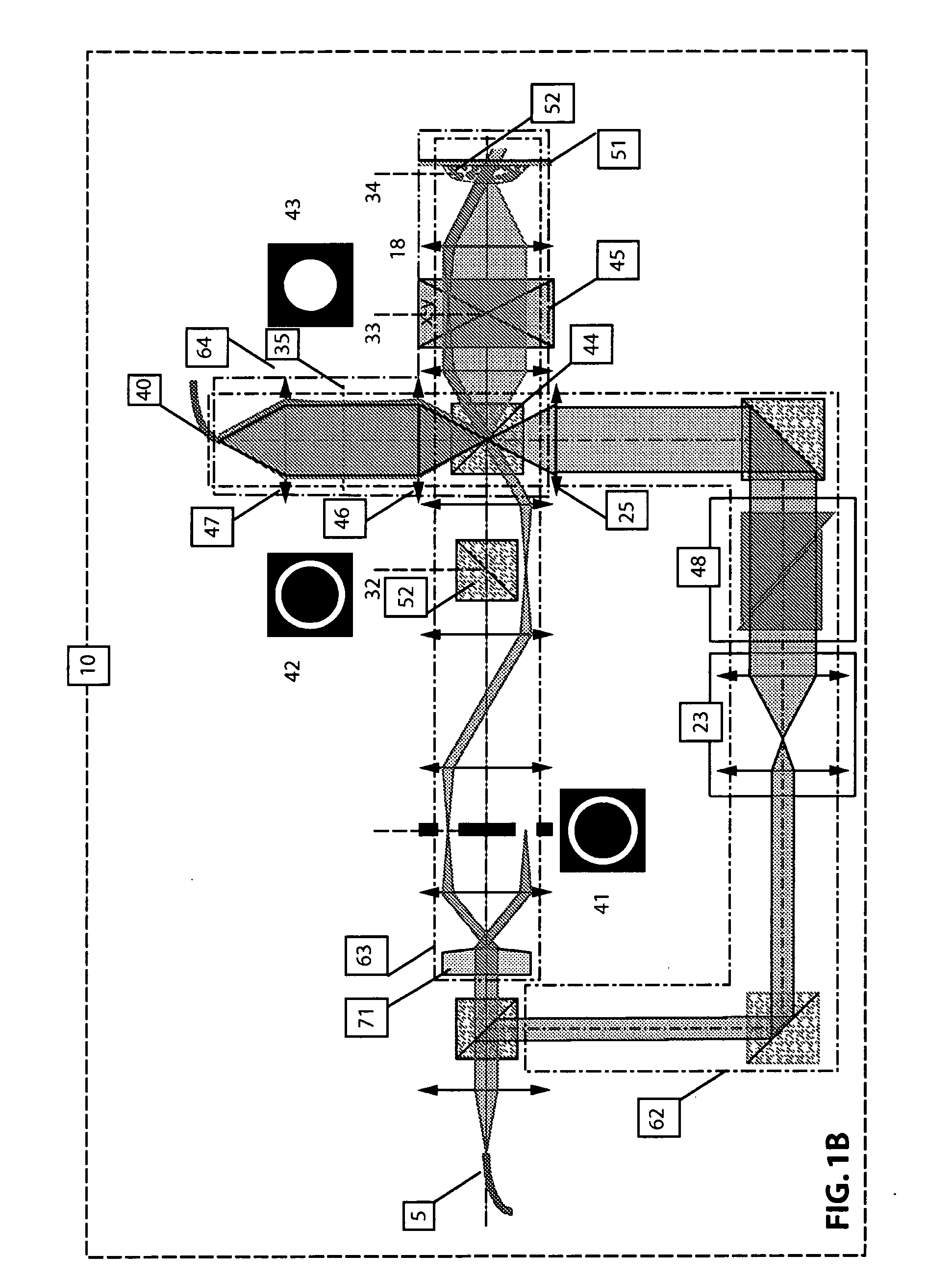

Dual-mode raster point scanning/light sheet illumination microscope

An apparatus for and method of performing light sheet microscopy (LISH) and light scanning microscopy (RAPS) in a single device are provided. The dual-mode imaging microscope allows for the use of both LISH and RAPS in a single instrument. This dual-mode device will allow researchers to have access to both types of microscopy, allowing access to the widest possible selection of samples. In addition, the device will reduce the high costs and space requirements associated with owning two different microscopes (LISH and RAPS).

Owner:CALIFORNIA INST OF TECH

Method and device for performing online aberrometrie in refractive eye correction indices

The invention relates to a method and a device for the complete correction of sight defects in the human eye. Combinations of measuring, and processing methods are described which when applied as disclosed in the invention, make it possible to fully correct sight defects in the human eye. Measuring methods are used which can precisely scan the surface of the cornea and also register other imaging defects in the light path up to the retina. Computer-aided of said measuring results determined when combined with calculation of ideally corrected ocular lenses (for example after cataract operations) or ideally corrected surfaces of the cornea opens up the possibility of manufacturing a patient-specific lens and / or achieving ideal correction of the cornea using preferably a topography-supported spot-scanning-excimer laser system.

Owner:CARL ZEISS MEDITEC AG

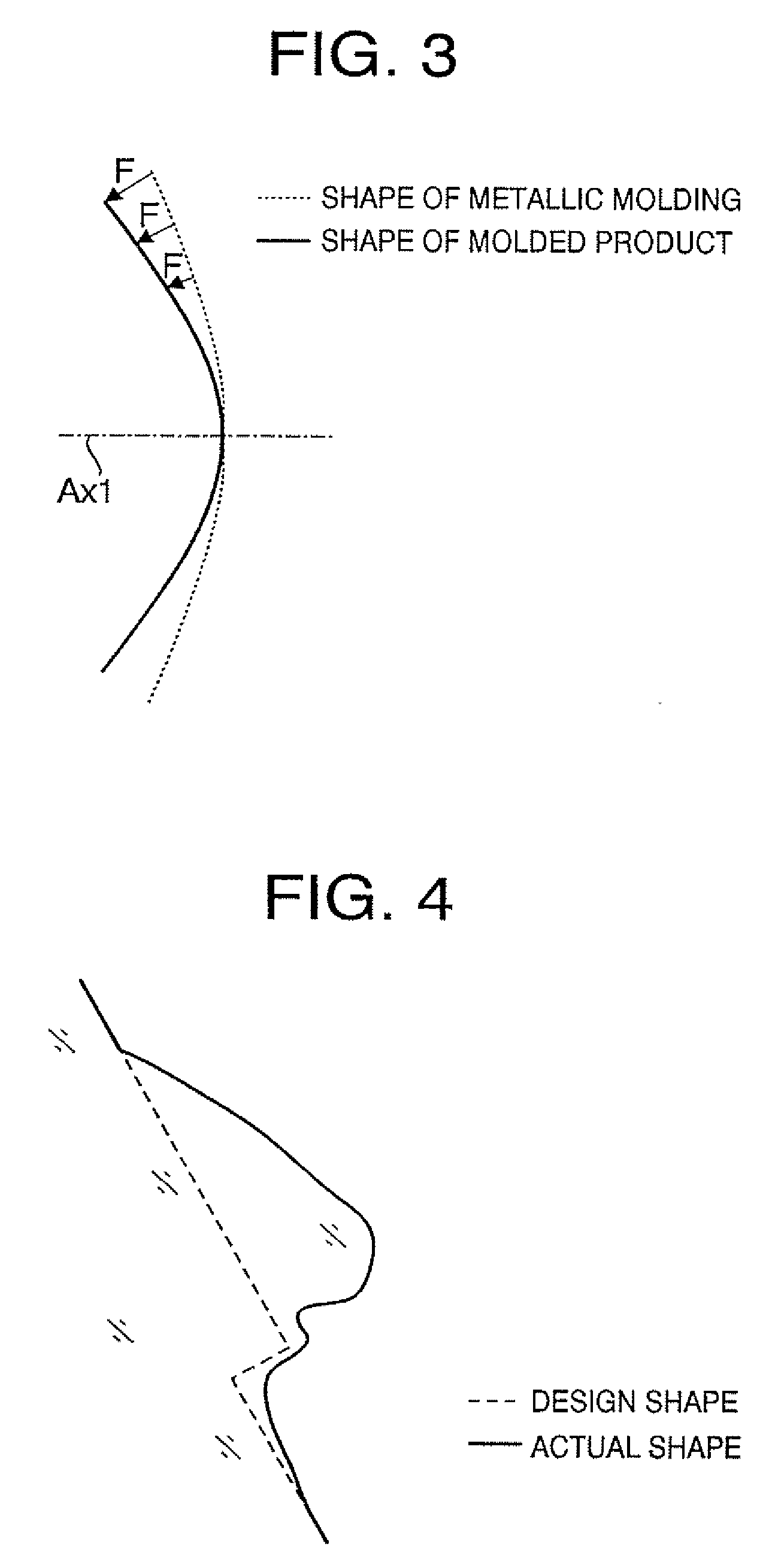

Optical scanner, optical scanning method, scanning image forming optical system, optical scanning lens and image forming apparatus

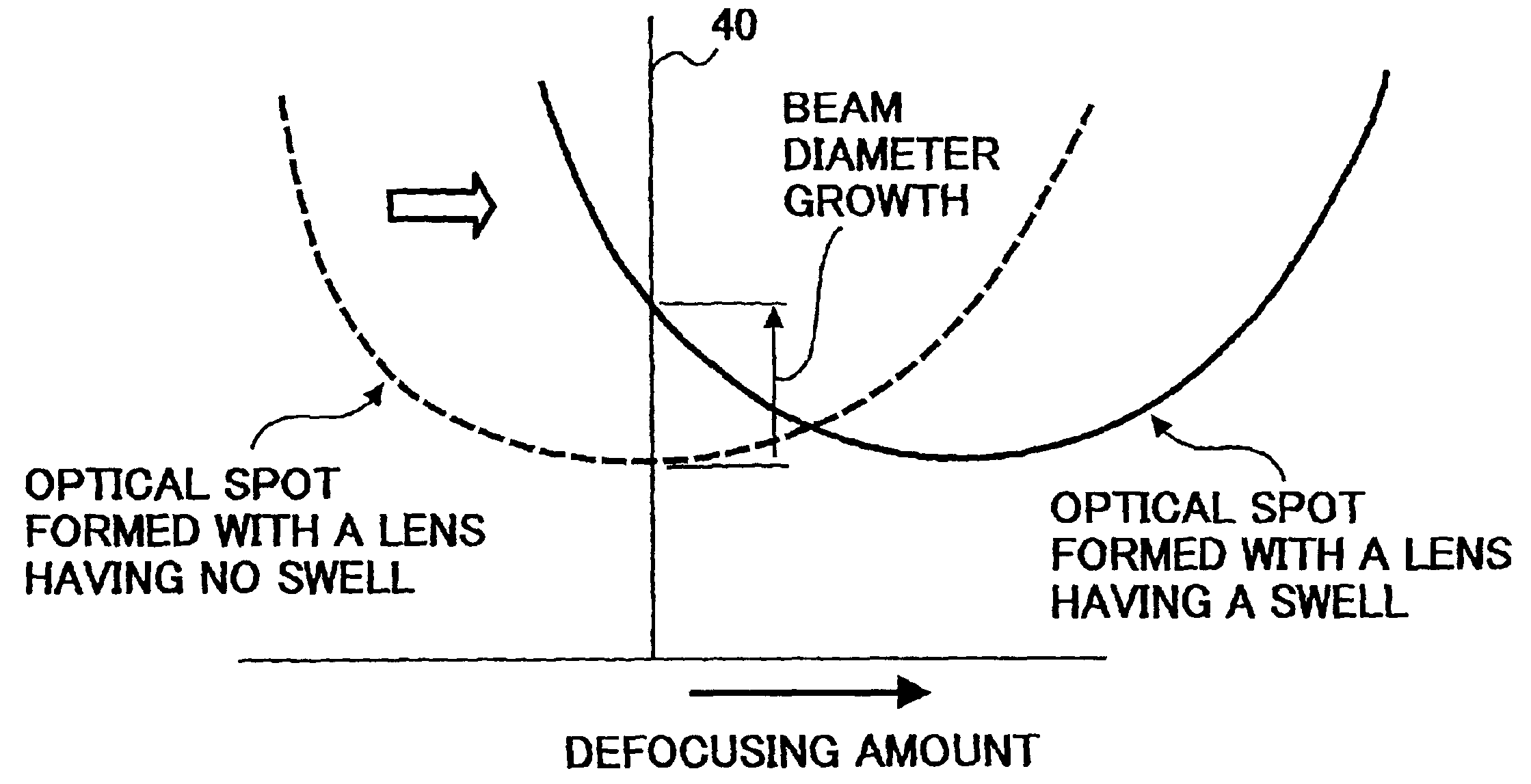

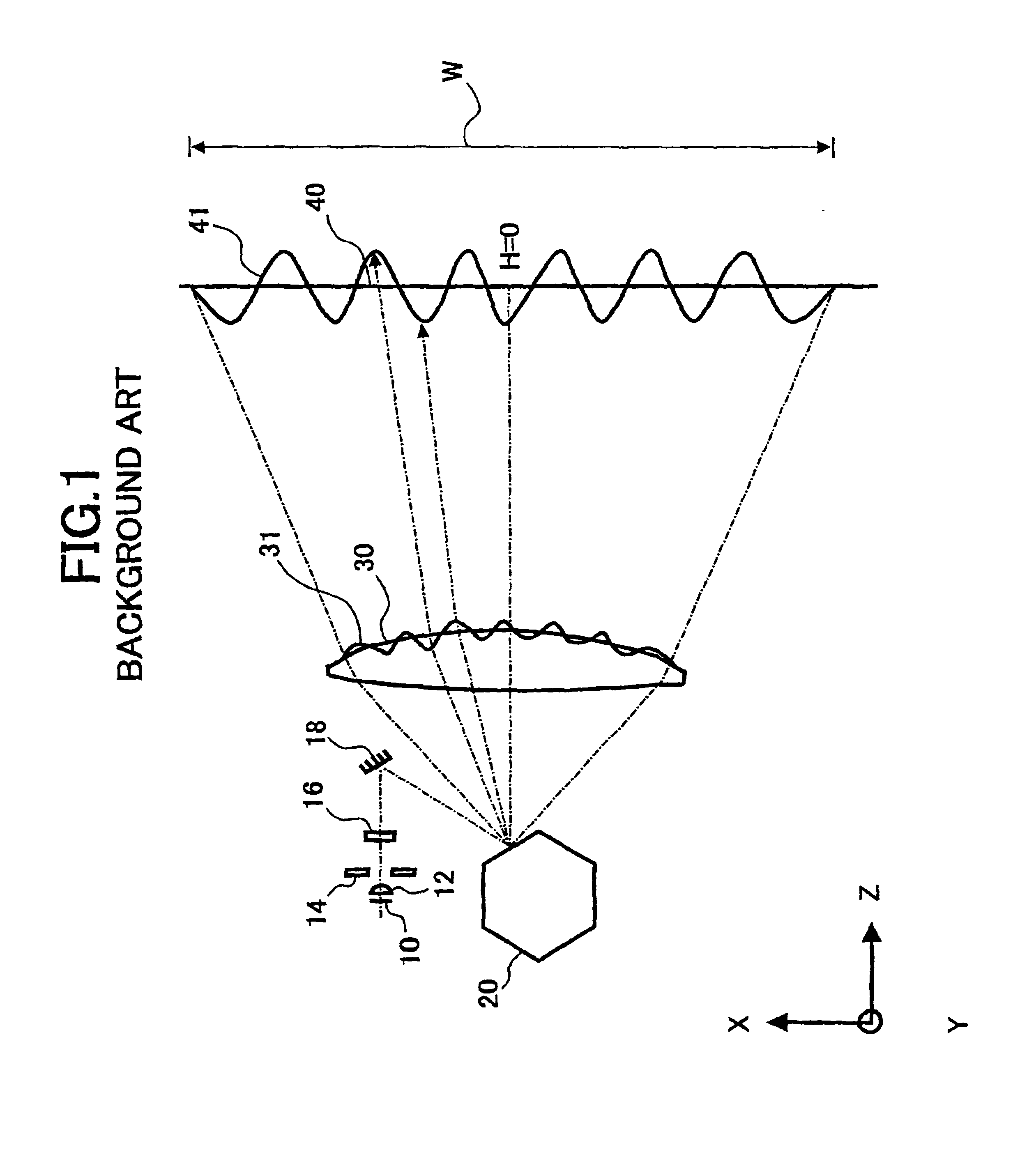

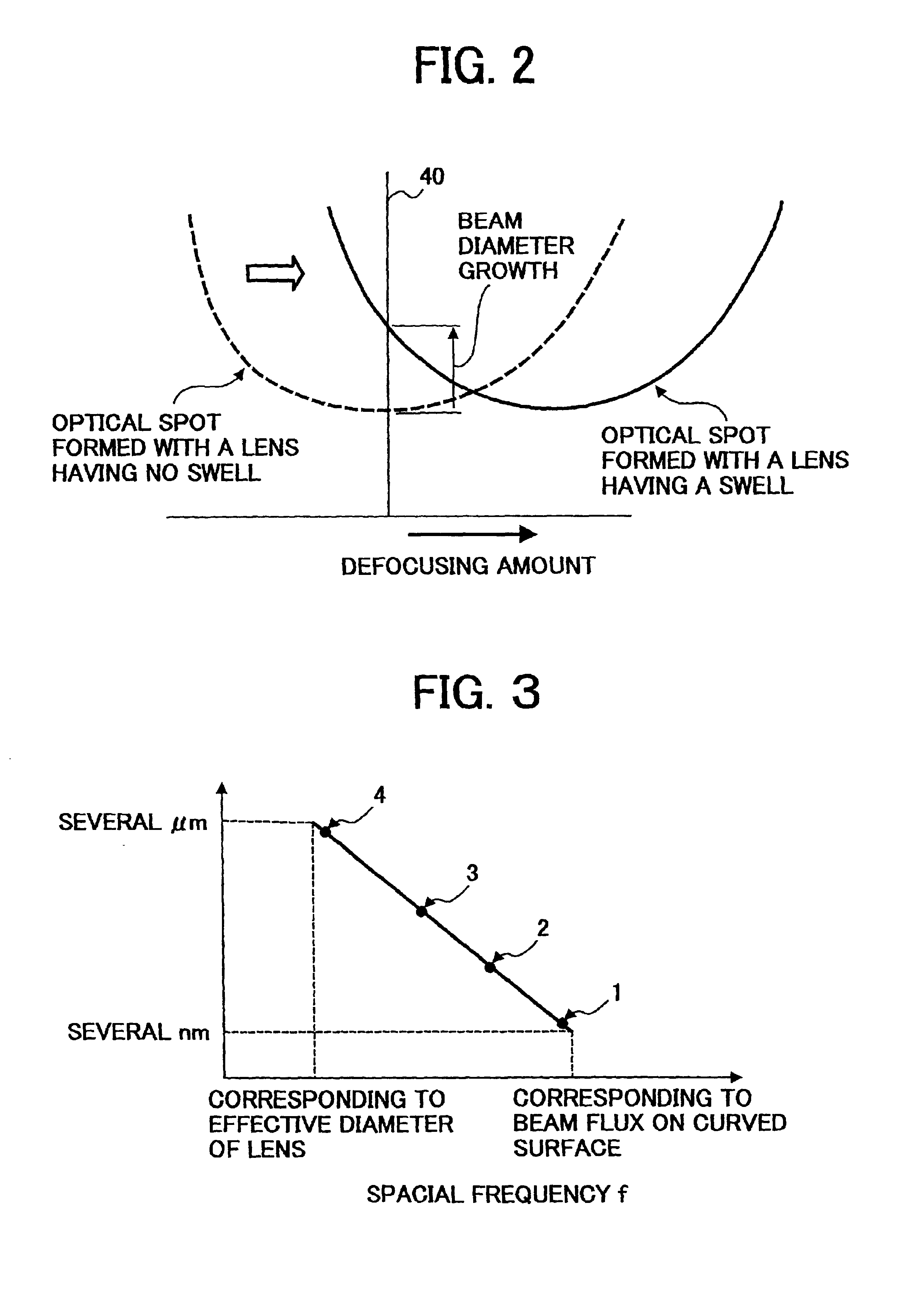

InactiveUS6999208B2Alleviate and eliminate occurrenceDigitally marking record carriersVisual presentation using printersOptical scannersLight flux

An optical scanner which performs optical scanning of a surface to be scanned by deflecting a luminous flux having a wavelength λ from a light source by means of an optical deflector, and condensing the deflected flux toward the surface to be scanned through a scanning image forming optical system, thereby forming an optical spot on the surface to be scanned. The scanning image forming optical system has at least one lens, and when the focal length fσ in the main scanning direction at a surface accuracy σi is defined as follows: fσ={2.6846 λ×√(k)×fm2 / ω2}−fm where, fm represents the focal length in the main scanning direction of the scanning image forming optical system; k represents the number of lens surfaces; ω represents the aimed spot diameter of the optical spot in the main scanning direction at an image height of 0; σI represents the surface accuracy of the i-th lens surface as counted from the optical deflector side; n represents the refractive index of material of the lens having the i-th lens surface; and 1 / l represents the spatial frequency in the main scanning direction on the lens surface; then, the surface accuracy σi, the focal length fσ, the refractive index n, and the spatial frequency 1 / L satisfy, for each lens surface, the following condition: 0<log σi<−2 log (1 / L)+log [1 / {32 fσ(n−1)}]. (1)

Owner:RICOH KK

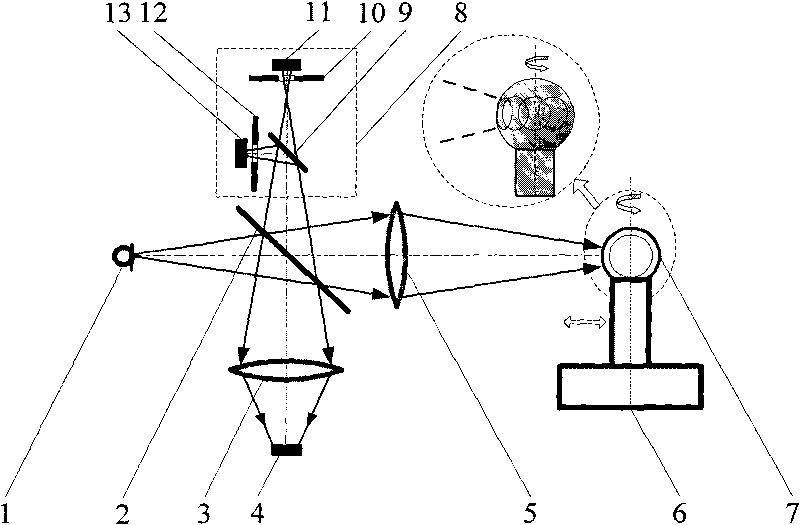

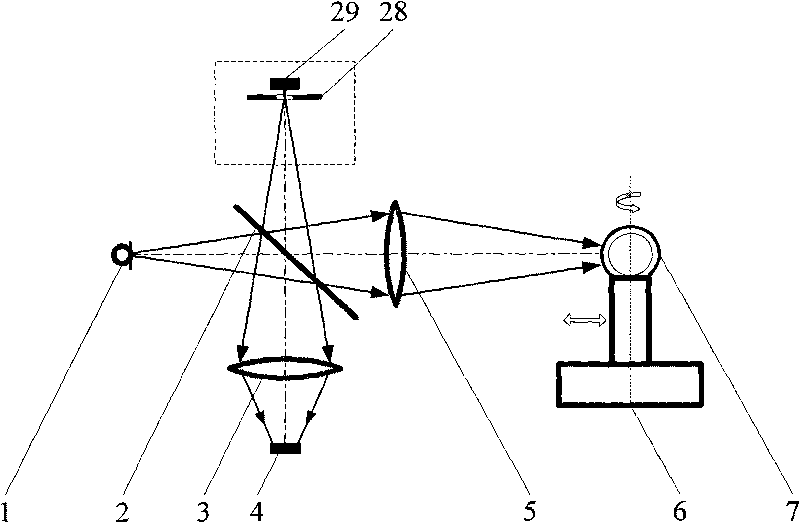

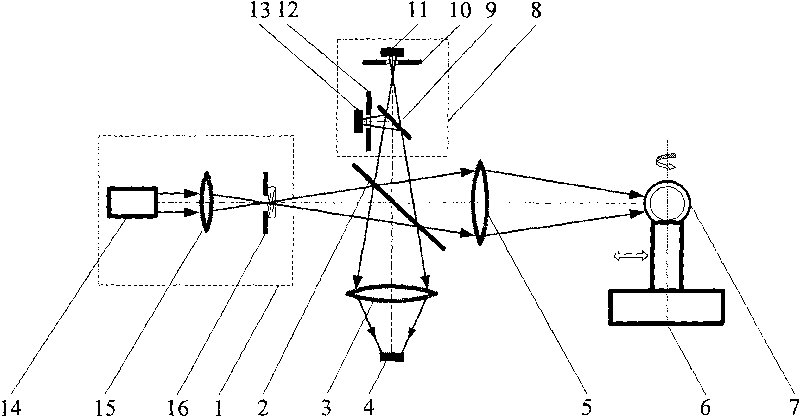

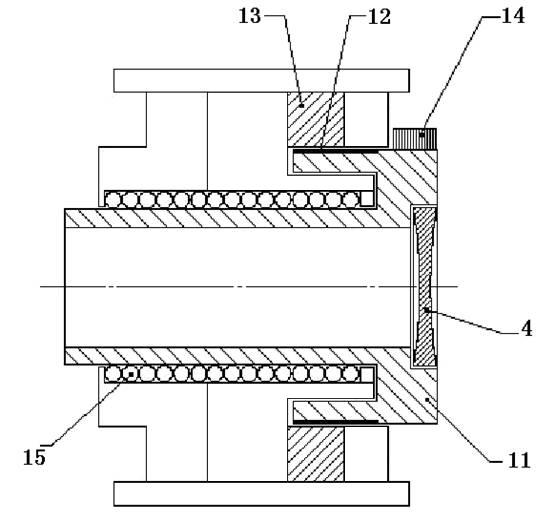

Method and device for measuring appearance and wall thickness of sphere by combining differential confocal and point-diffraction interference

The invention belongs to the field of optical precision measurement and relates to a method and a device for measuring the appearance and the wall thickness of a sphere by combining a differential confocal confocal technology and point-diffraction interference. The method realizes the high-precision rapid measurement on the appearance of the outer surface of the sphere by using the point-diffraction interference, the rotation of the measured sphere and the splice of a measuring sub-aperture; and the appearance and wall thickness of the inner surface and the outer surface of a key area of a transparent or semitransparent sphere can be scanned and measured point by point by using the differentia confocal technology. The invention organically integrates a point-diffraction interference technology and the differentia confocal technology so as to realize the synchronous measurement on the appearance and the wall thickness of the inner surface and the outer surface of the sphere, and aims to solve the difficult problems that the traditional AFM or a single confocal sensor and the other scanning methods have low measuring speed, low efficiency, easy leakage in measurement and the like during measuring the surface of the sphere. The invention has broad application prospect in the fields of testing the appearance and the wall thickness of a laser fusion pellet, the appearance and the outline of a spherical surface and the like.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

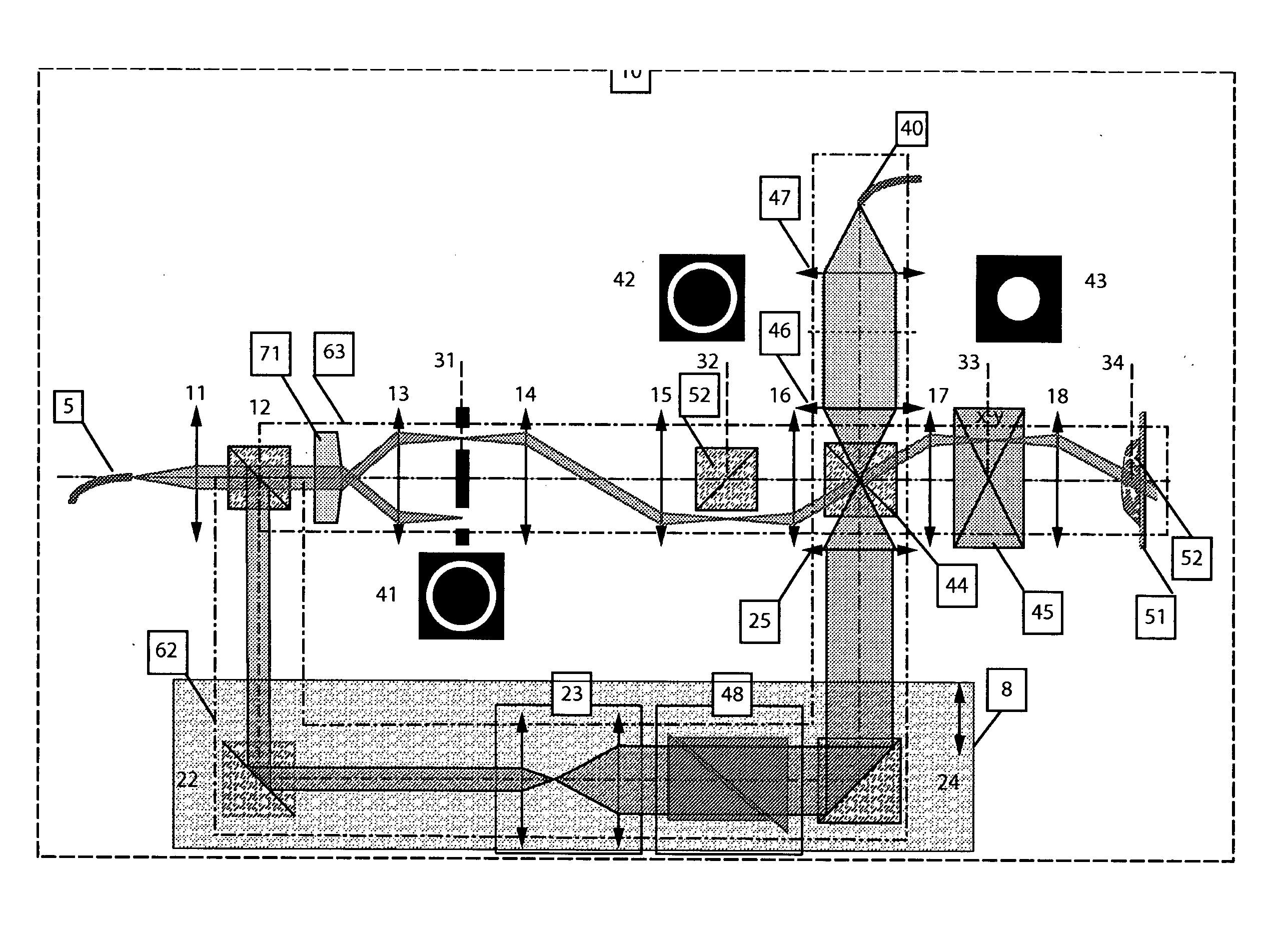

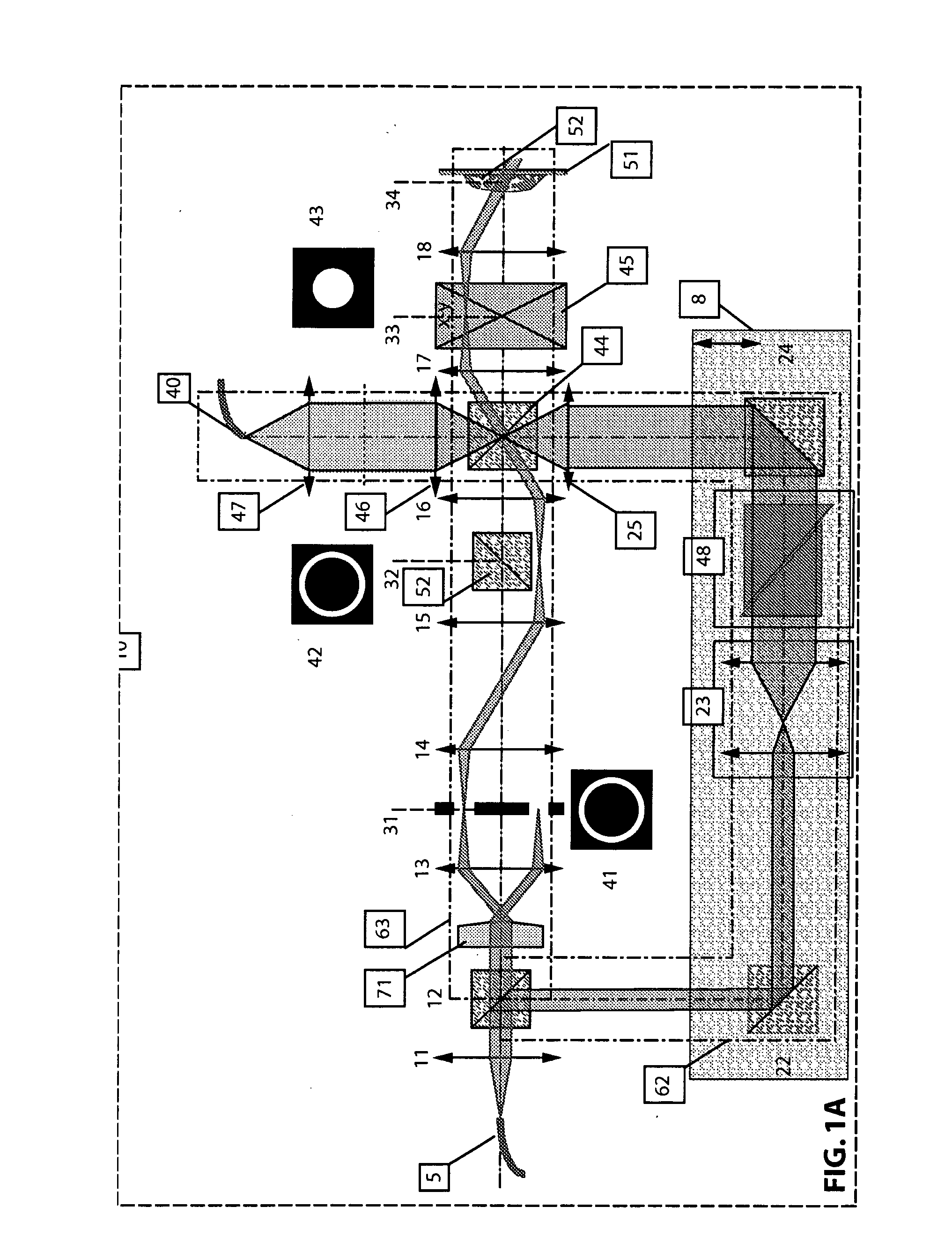

Dark field optical coherence microscopy

InactiveUS20130010283A1Improve detectionHigh frequencyInterferometersMicroscopesOptical coherence microscopySample microscopy

The invention relates to an optical coherence microscopy system for fast, phase resolved imaging by means of optical coherence microscopy with decoupled illumination and detection apertures, producing a dark-field effect with an enhanced optical contrast. The setup uses a light source with an appropriate temporal coherence, an interferometer and an array detector combined with a spectrometer. The dark-field effect is produced by optical filter means in the illumination and detection paths, positioned in conjugated planes of the sample microscope objective. These optical means comprise for example refractive or diffractive elements, amplitude or phase masks, or programmable spatial light modulators. The object is scanned via a scanning unit allowing a point scan of the object.

Owner:ECOLE POLYTECHNIQUE FEDERALE DE LAUSANNE (EPFL)

Proton accelerator complex for radio-isotopes and therapy

InactiveUS7554275B2Reduce maintenanceLarge energyMagnetic resonance acceleratorsTransit-time tubesRadio isotopesEngineering

A complex of proton accelerators, includes the following functionally interconnected components: a proton source, a cyclotron, at least one target, located either internally or externally to the cyclotron, a medium energy beam transport magnetic channel, a radiofrequency linear accelerator, a high energy beam transport channel towards an area dedicated to the irradiation of tumors with proton beams, as well as a modular system for supplying radio frequency power capable of feeding, independently two or more accelerating modules of the linac. An integrated computerized system controls the complex of accelerators so to carry out, either in alternation or simultaneously, both the production of radioisotopes—for medical, industrial and therapeutical purposes—and the therapeutical irradiation of, even deep seated tumors. The complex of accelerators produces proton beams which, applying the recently developed ‘spot scanning’ technique, are more suited for the tumor irradiation than the ones produced by cyclotrons and synchrotrons.

Owner:FOND PER ADROTERAPIA ONCOLOGICA TERA

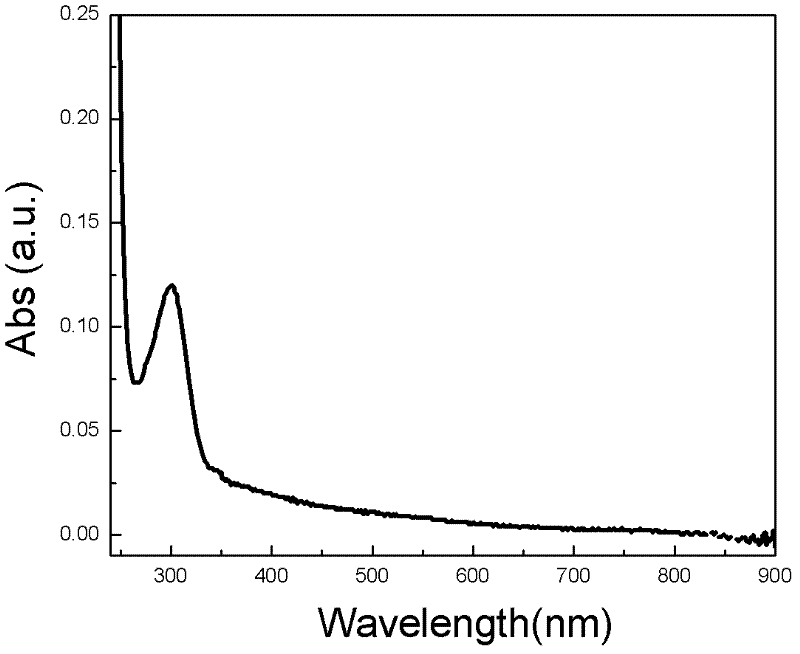

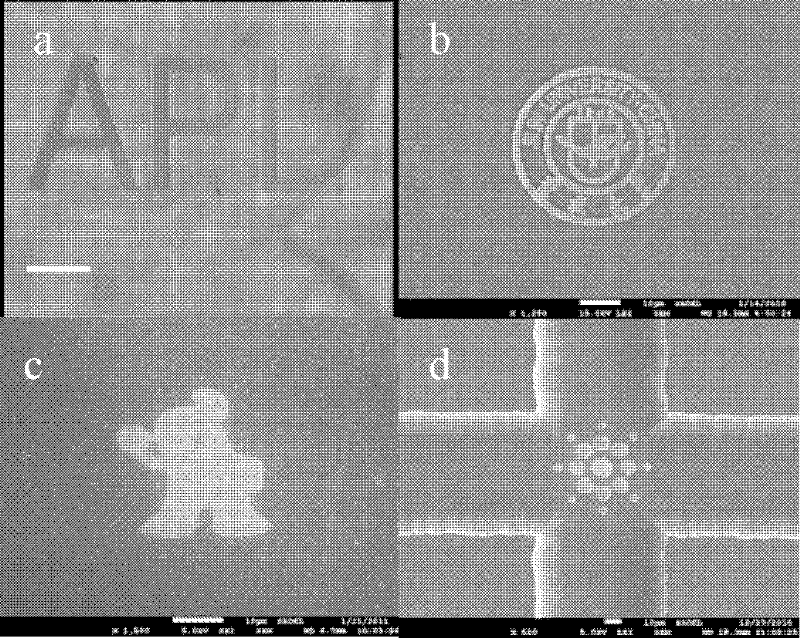

Method for preparing multistage metal micro-nanostructures inside micro fluidic chip

InactiveCN102311095ADecorative surface effectsChemical vapor deposition coatingMicro nanoSurface-enhanced Raman spectroscopy

The invention relates to a method for selectively preparing or integrating multistage silver micro-nanostructures inside various plane substrates and micro fluidic chip channels by the utilization of the femtosecond laser inducing metallic silver reduction technology. In addition, the silver multistage micro-nanostructure substrate prepared by the method is used as a reinforced substrate for surface-enhanced raman spectroscopy SERS. The method provided by the invention comprises the following steps of: preparing a silver plating solution for femtosecond laser micro-nano machining, establishing a femtosecond laser micro-nano machining system for realizing multi-point scan in the silver plating solution, placing the silver plating solution and the substrate into the femtosecond laser micro-nano machining system and preparing the multistage silver micro-nanostructures on the substrate. According to the invention, a laser beam scans in the silver plating solution along a track designed in advance by a program. The preparation method is independent of the smoothness of the substrate. In particular, the preparation of silver multistage structure SERS substrate can be accomplished on the bottom of the micro fluidic chip channels, thus realizing catalysis and surface-enhanced raman test application.

Owner:JILIN UNIV

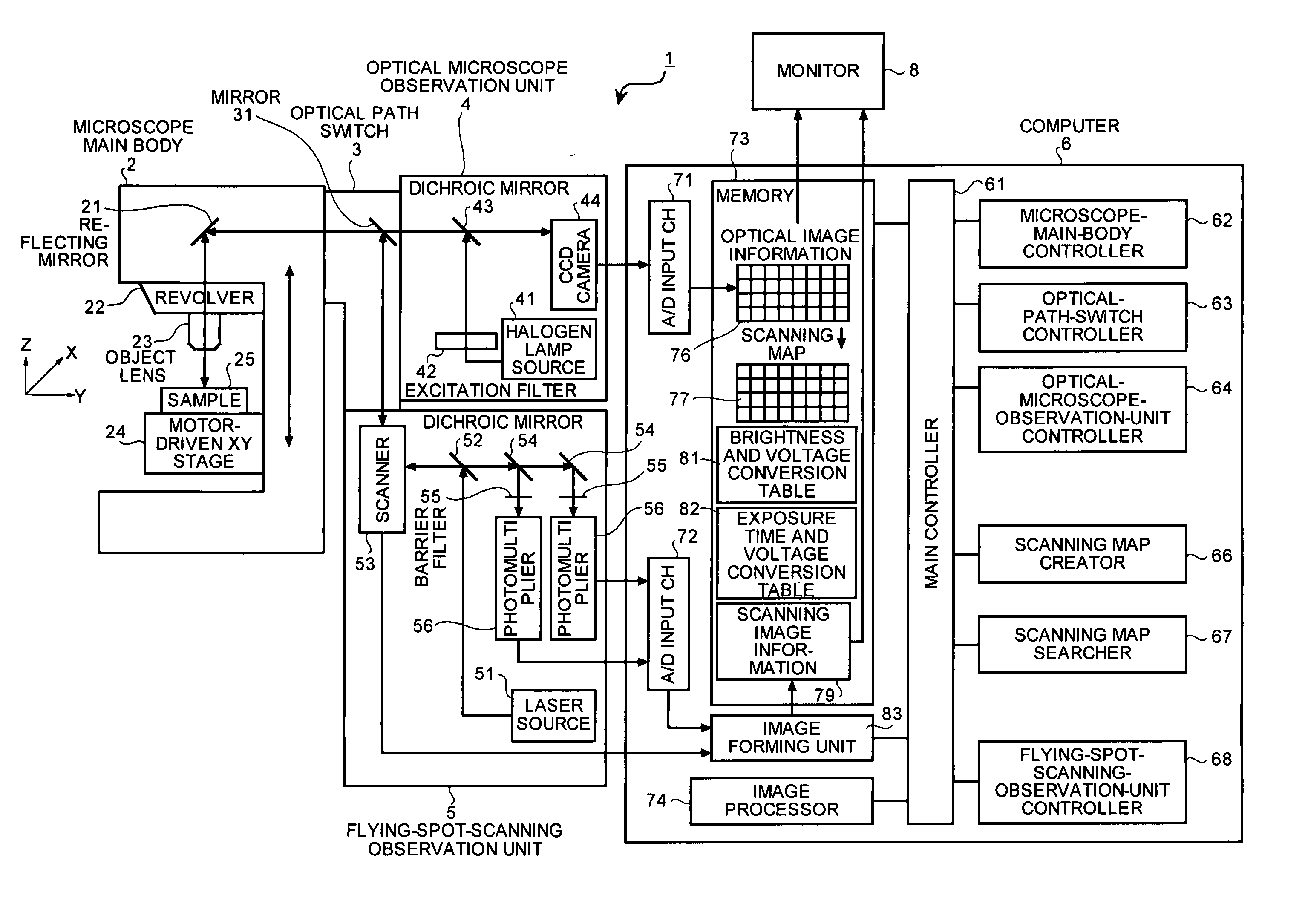

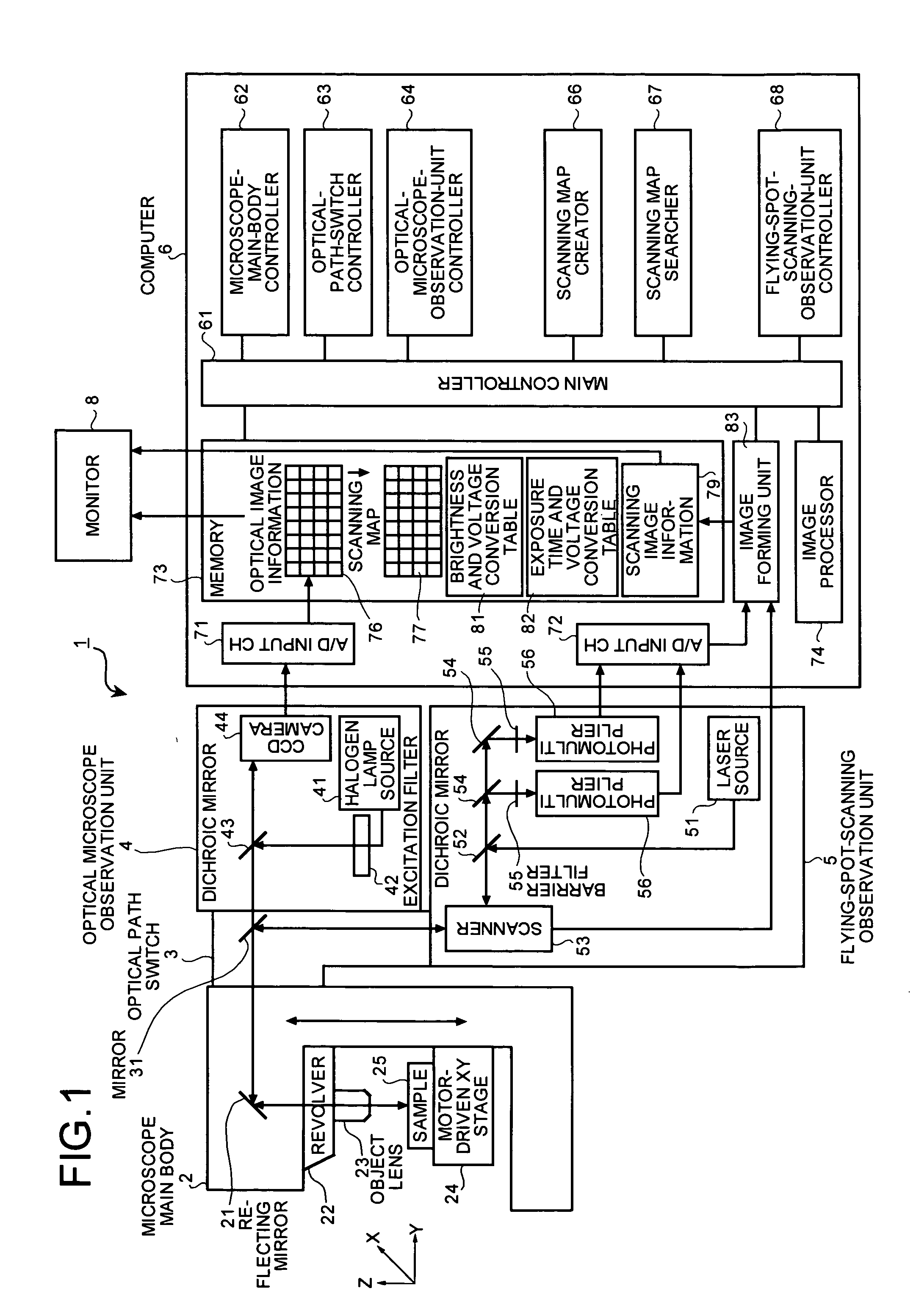

Scanning microscope system

A scanning microscope system includes an optical microscope observation unit that irradiates the sample with excitation light, and forms an optical image from fluorescence emitted from a sample. The system also includes a scanning map creator and a flying spot scanning observation unit. The scanning map creator creates a scanning map indicating a scanning region in which a substance to be scanned exists in the sample, based on brightness of pixels of the optical image. The flying spot scanning observation unit scans the scanning region of the sample with laser beam, and forms a scanning image based on fluorescence emitted from the sample.

Owner:EVIDENT CORP

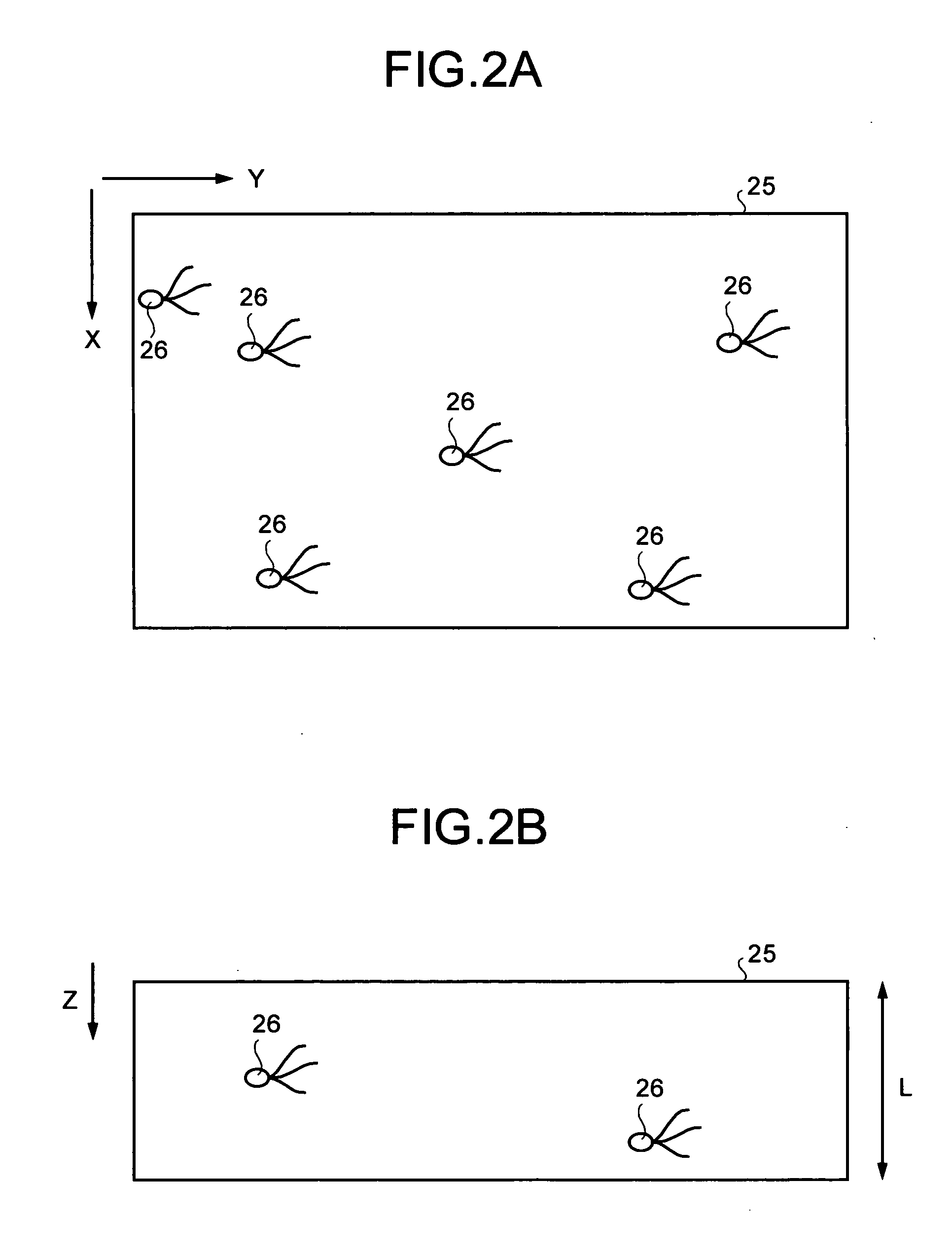

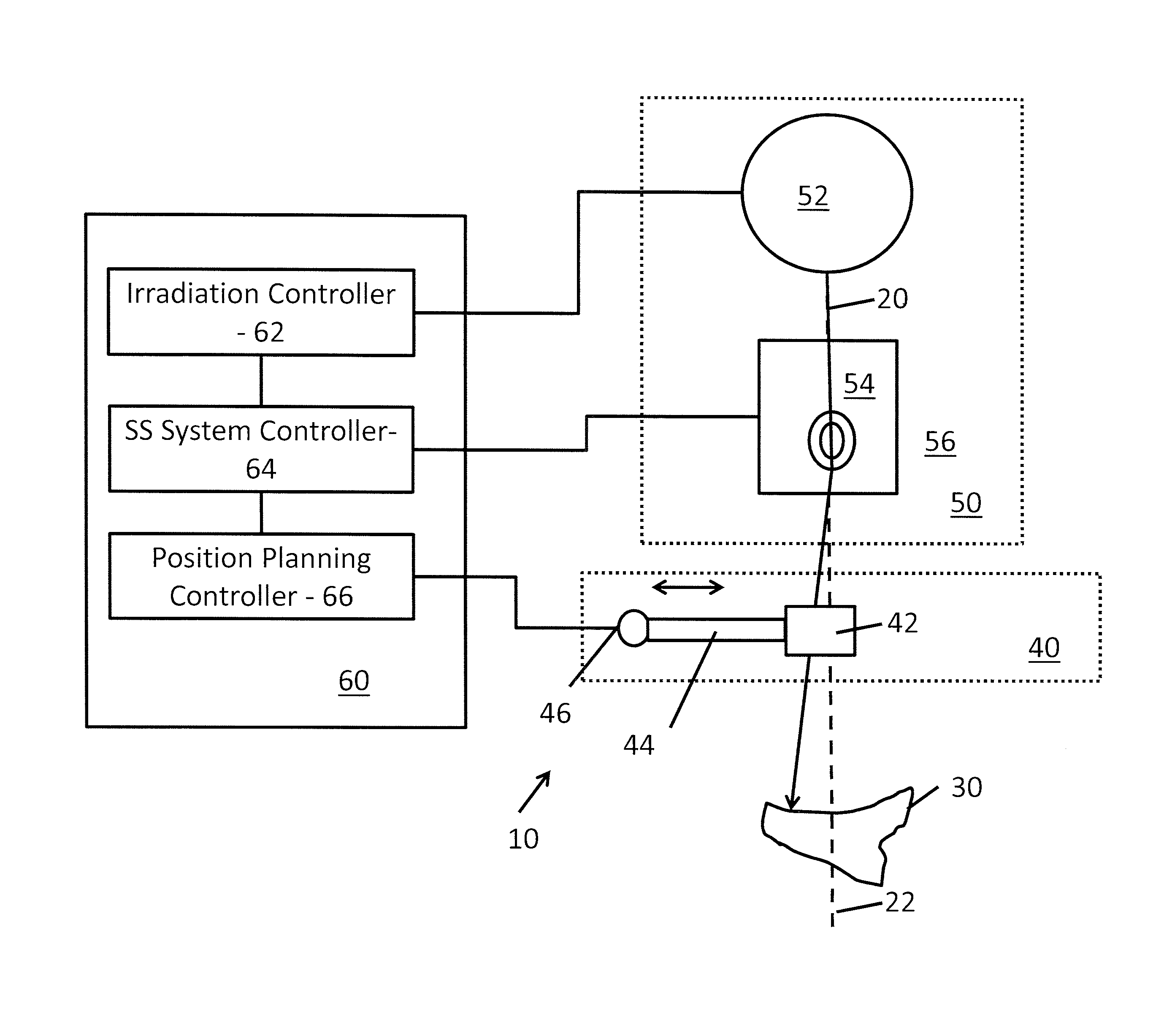

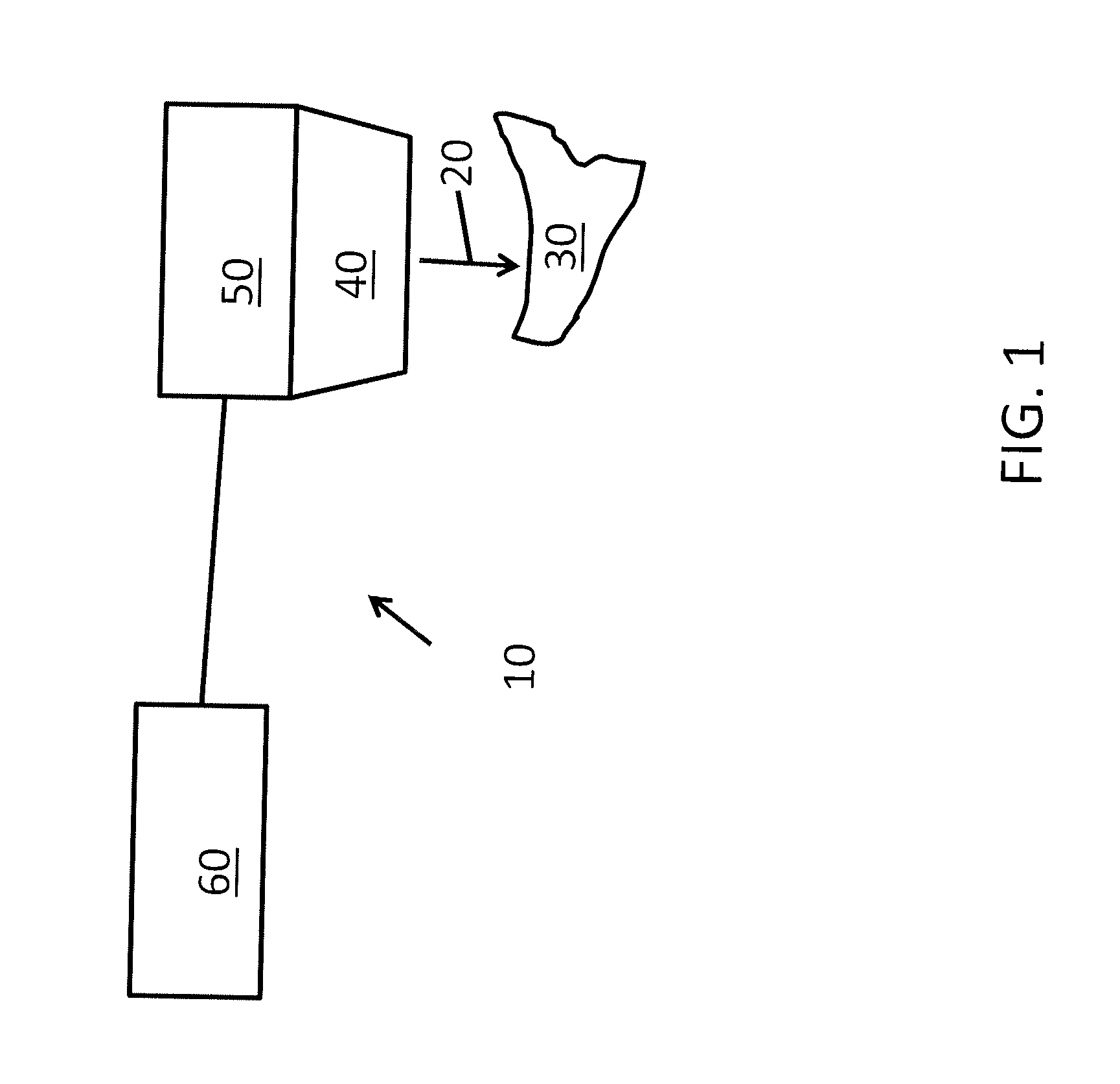

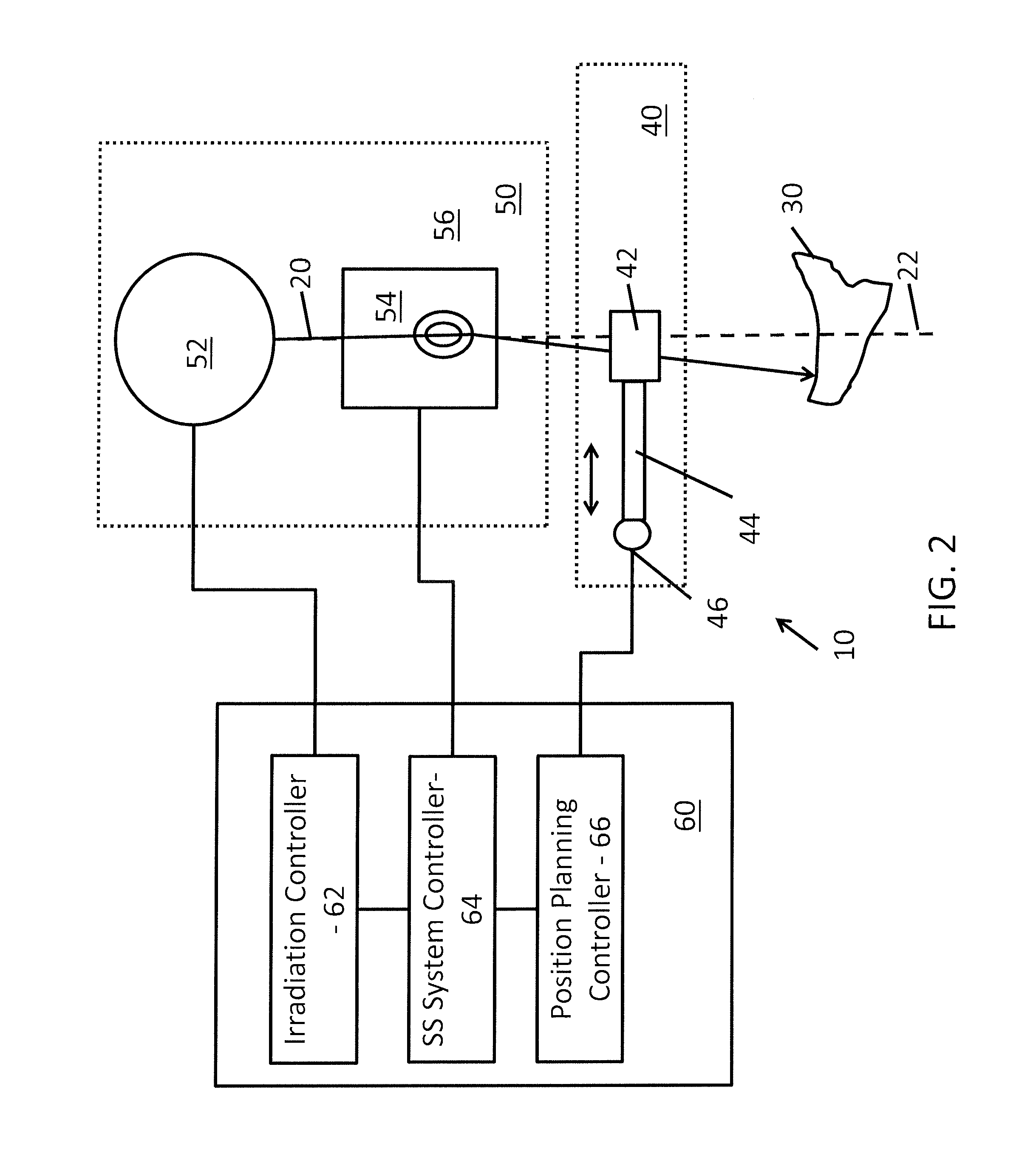

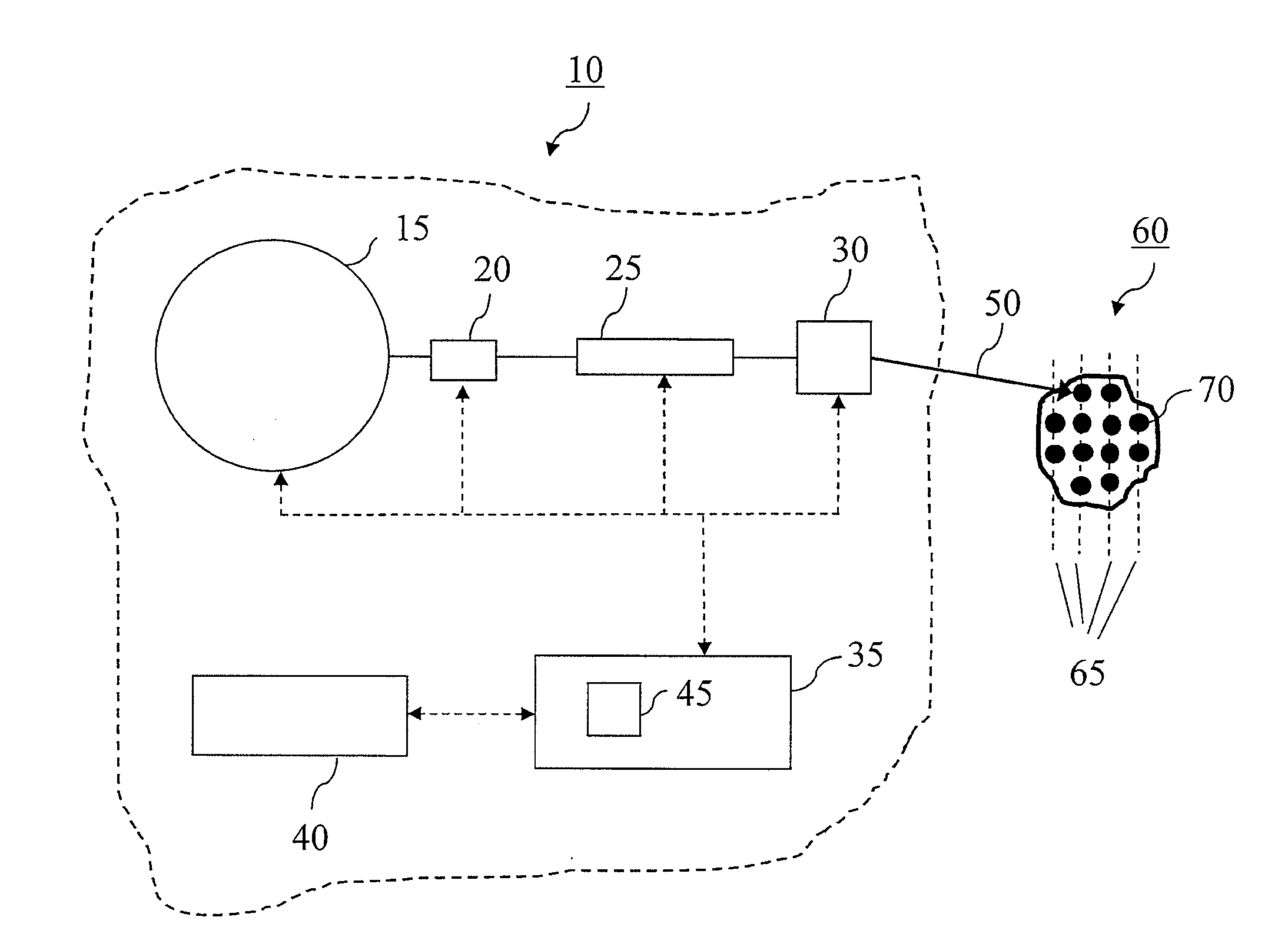

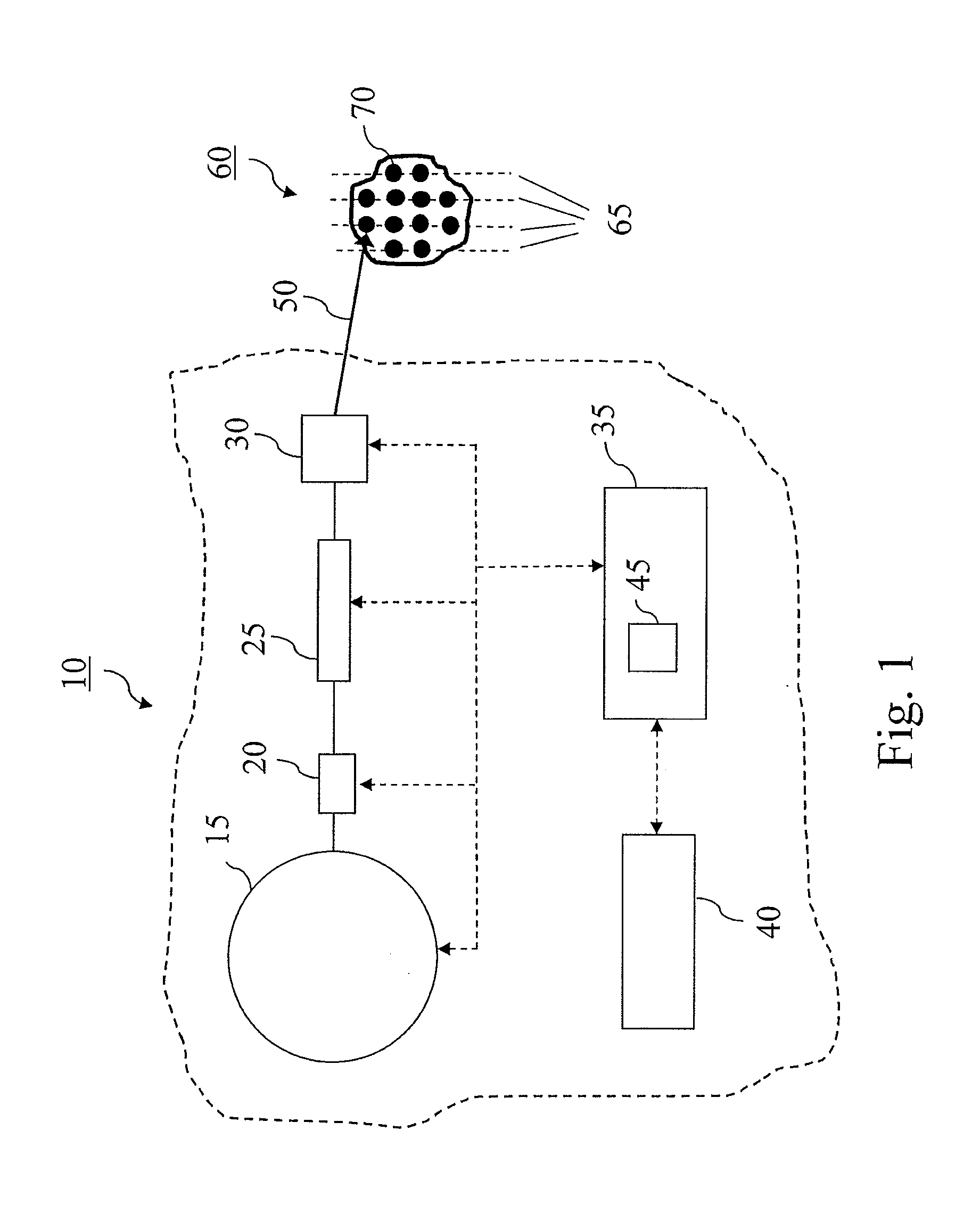

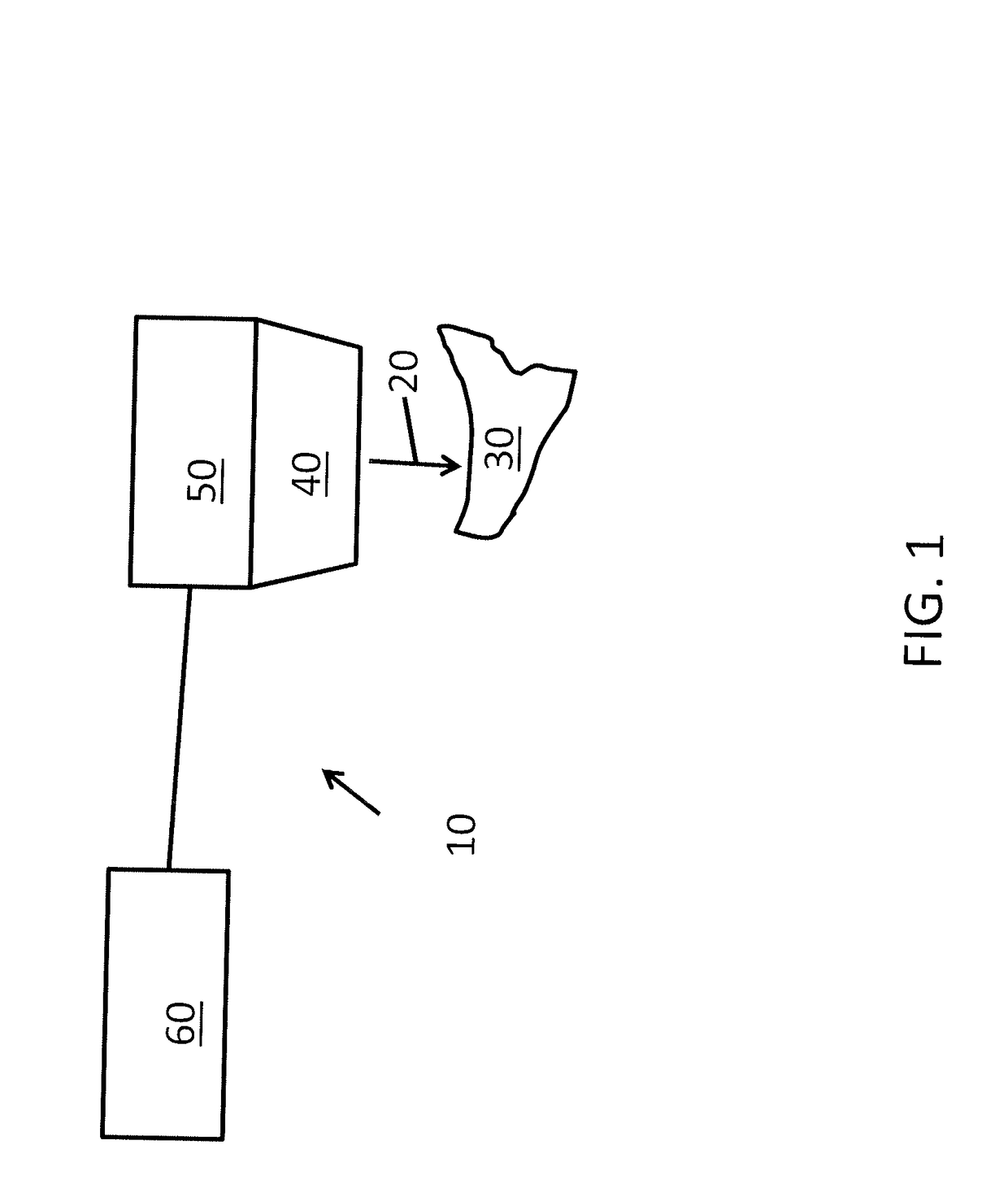

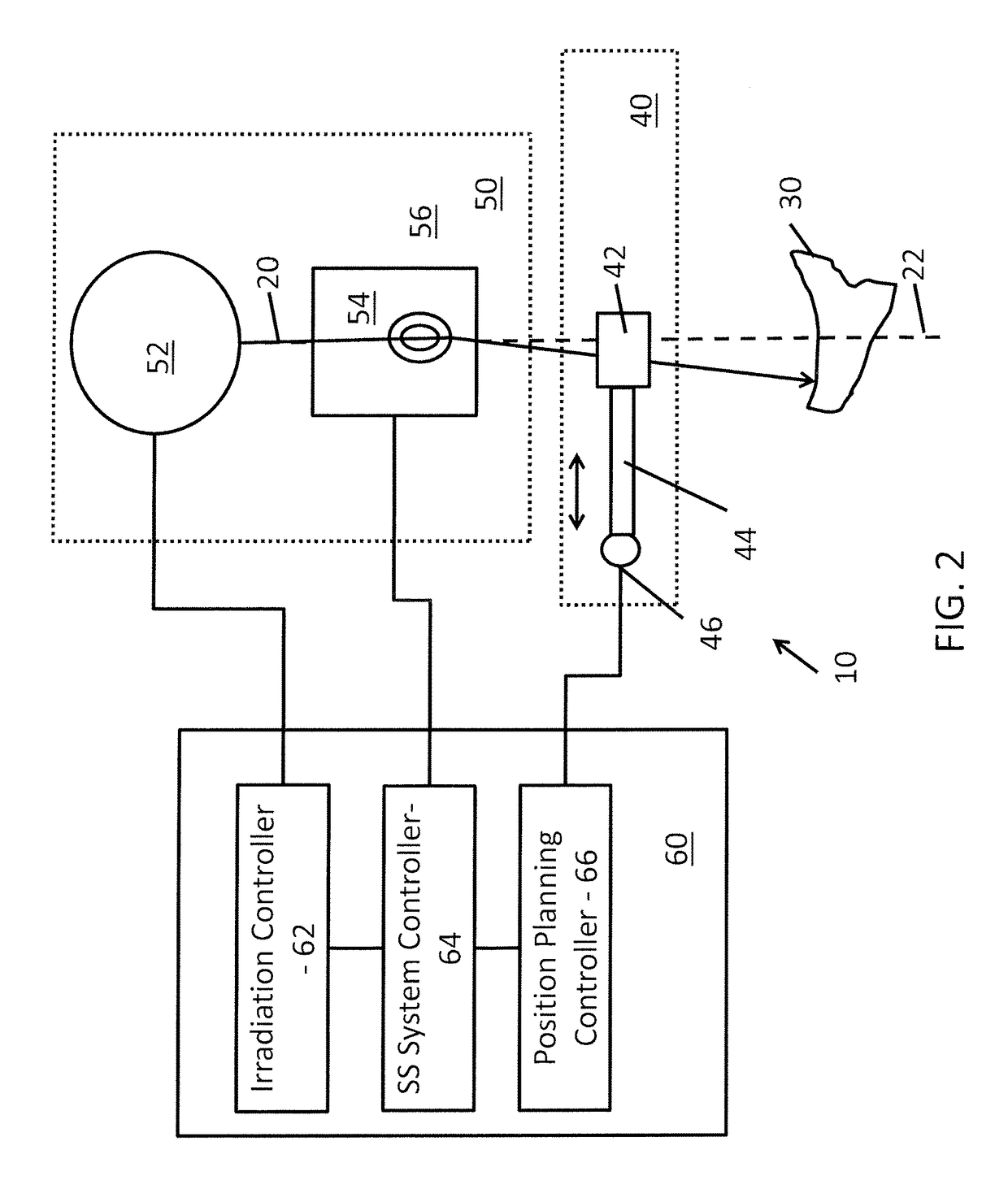

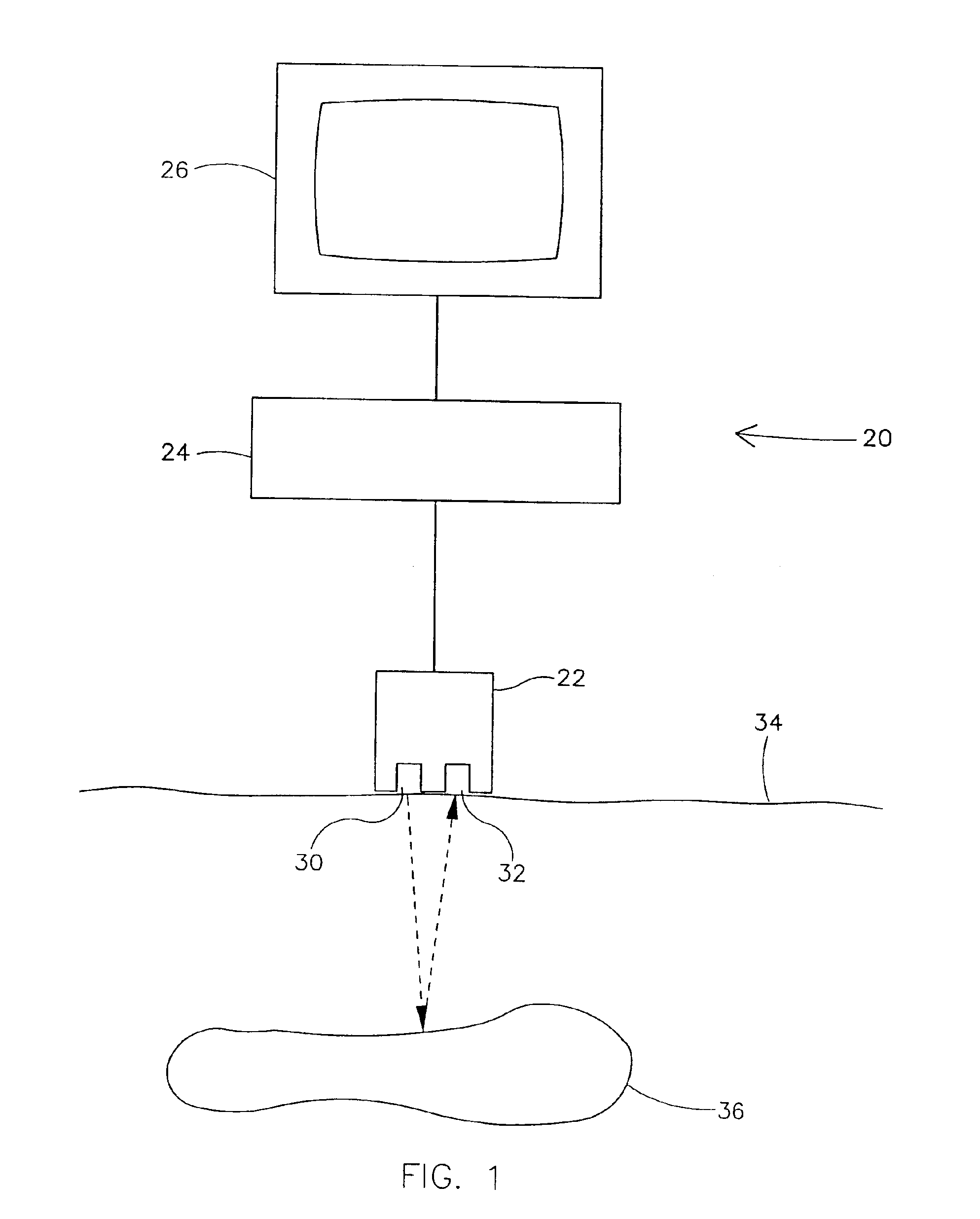

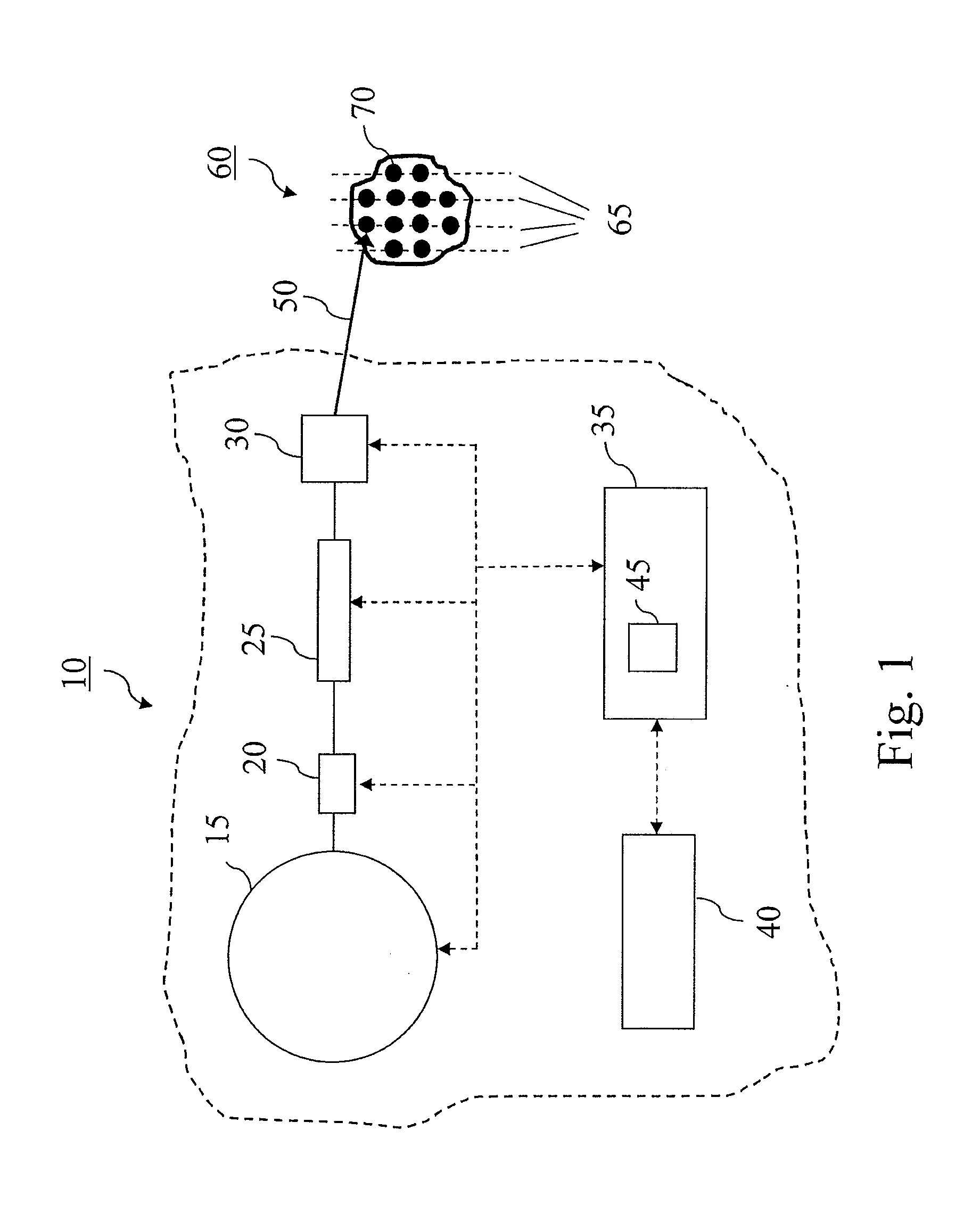

Method and system for dynamically-trimmed spot scanning for ion therapy

ActiveUS20160199667A1Reduce deliveryImproves SS ion therapyX-ray/gamma-ray/particle-irradiation therapyRadiation doseIon

A spot scanning (SS) ion therapy system configured for dynamic trimming of an ion particle pencil beam to reduce the amount of the radiation dosage outside of a target boundary.

Owner:UNIV OF IOWA RES FOUND

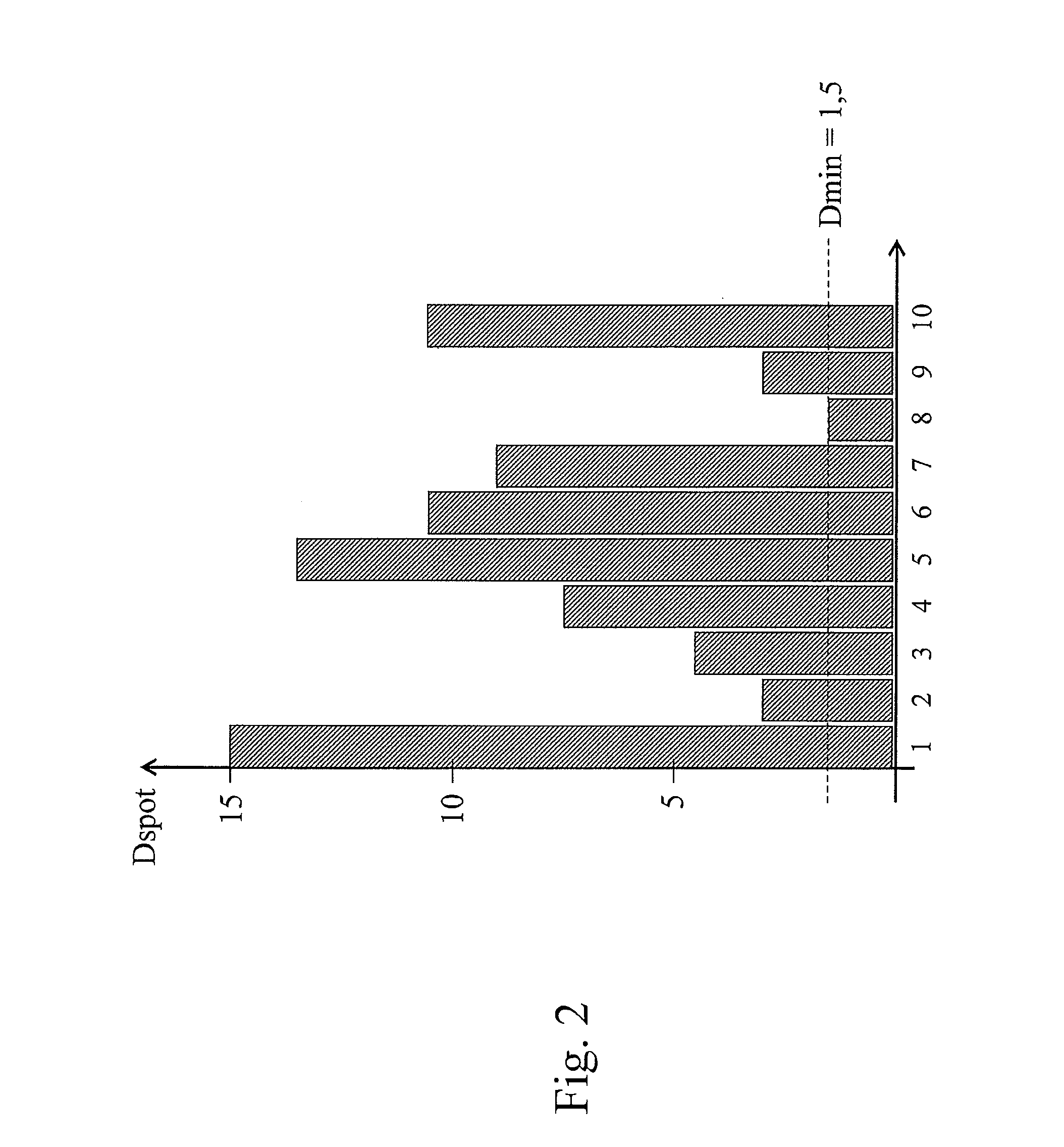

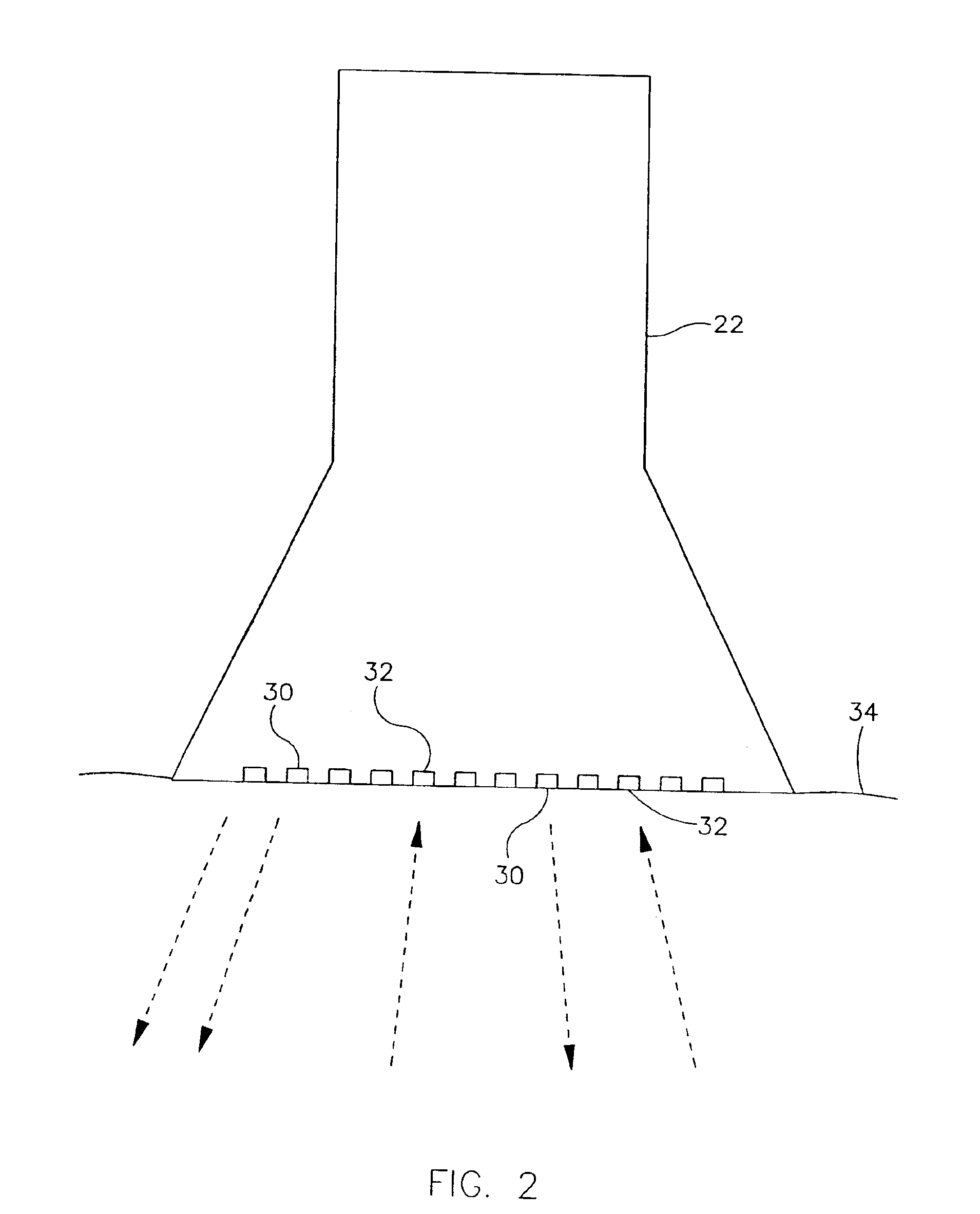

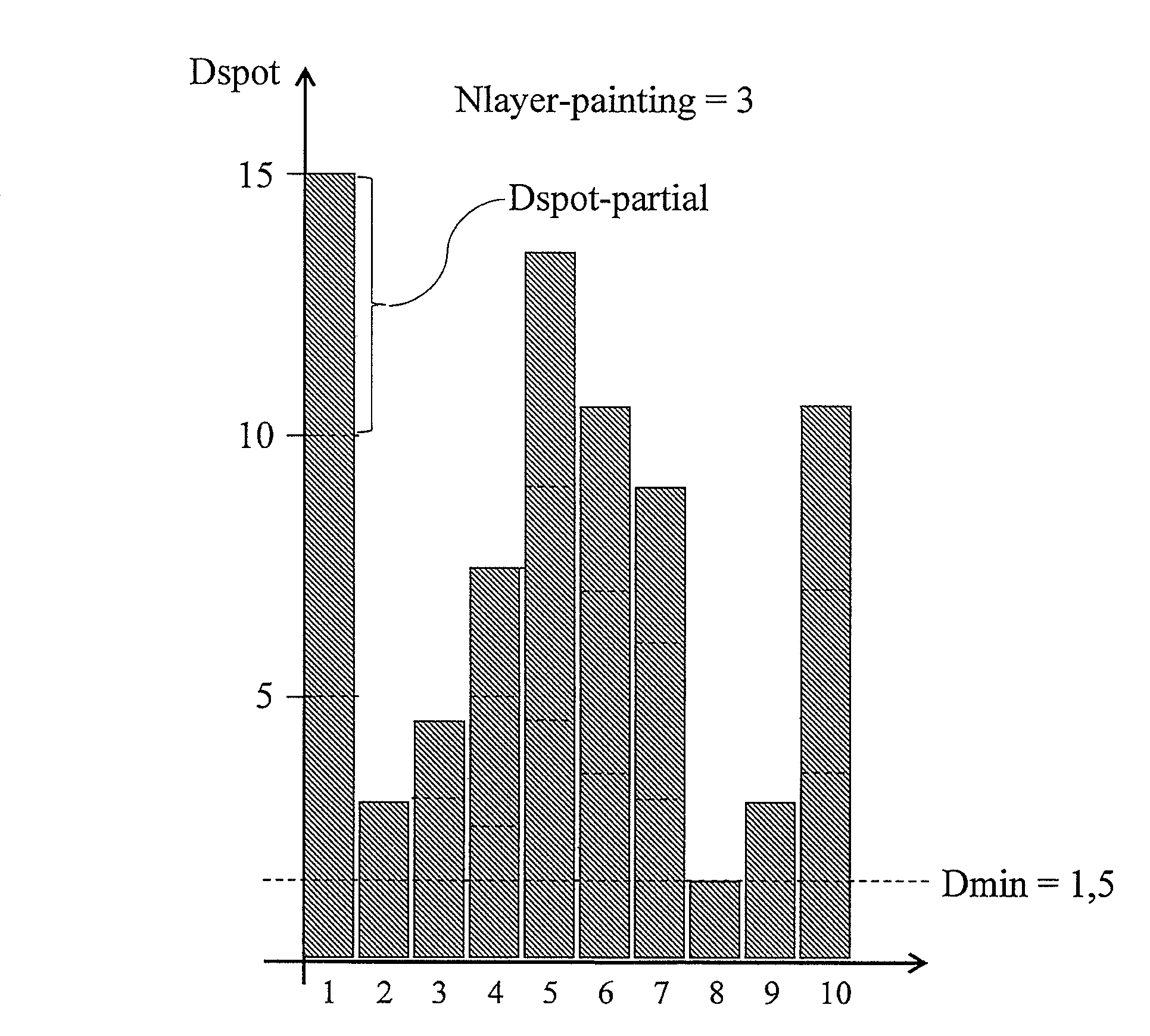

Device and method for particle beam delivery

ActiveUS20110297850A1Maximizing numberReduce impactChemical conversion by chemical reactionX-ray/gamma-ray/particle-irradiation therapyParticle beamMedicine

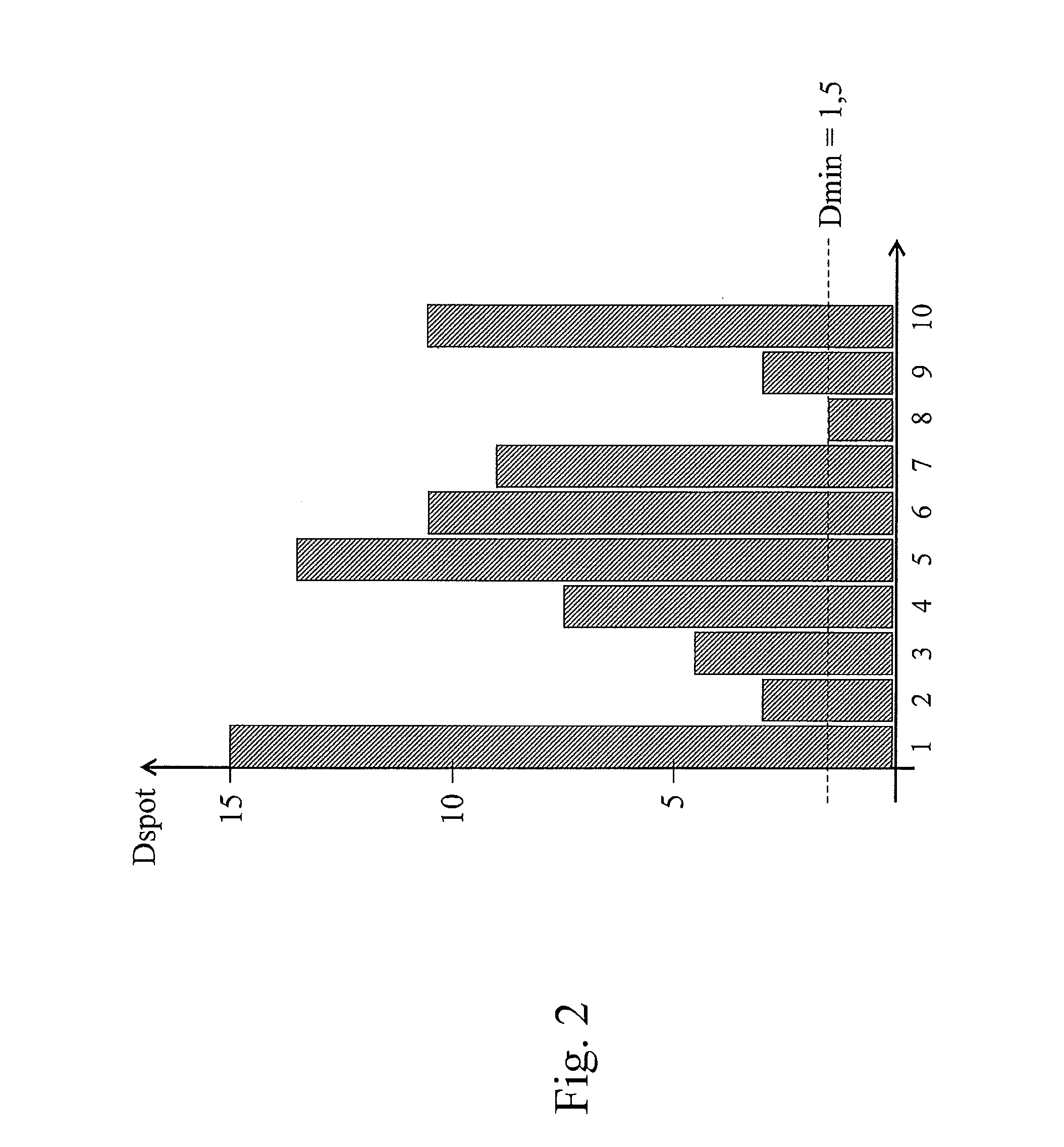

The present invention relates to a particle therapy system that comprises a spot scanning system to irradiate with a particle beam a plurality of spots in a layer of a target with prescribed spot doses for each spot of the layer. The therapy system is further adapted to perform multiple paintings of the layer and to deliver partial spot doses to selected spots of the layer during each painting time so that each spot of the layer will have received its prescribed dose after completion of the multiple paintings. The therapy system further comprises means for setting the partial spot doses and the number of times that a spot will be selected for irradiation in the course of the multiple paintings to such values that any spot of the layer will never have to be irradiated with a partial dose which would fall below a minimum dose deliverable by the system, and this whatever the number chosen for the number of layer paintings.The invention also relates to a corresponding irradiation method.

Owner:ION BEAM APPL

Method and system for dynamically-trimmed spot scanning for ion therapy

ActiveUS9776017B2Reduce deliveryImproves SS ion therapyHandling using diaphragms/collimetersX-ray/gamma-ray/particle-irradiation therapyRadiation dosePhysics

A spot scanning (SS) ion therapy system configured for dynamic trimming of an ion particle pencil beam to reduce the amount of the radiation dosage outside of a target boundary.

Owner:UNIV OF IOWA RES FOUND

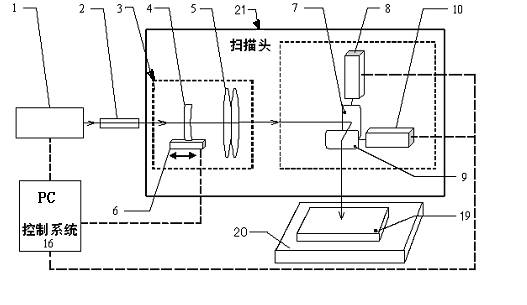

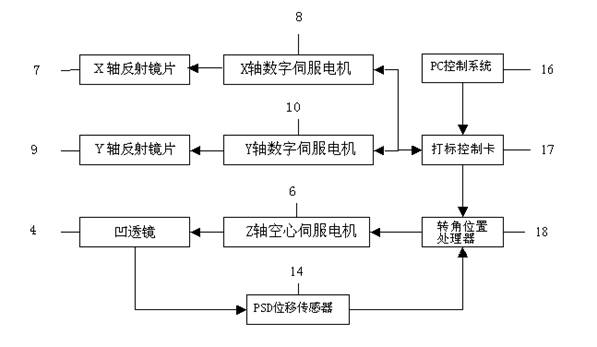

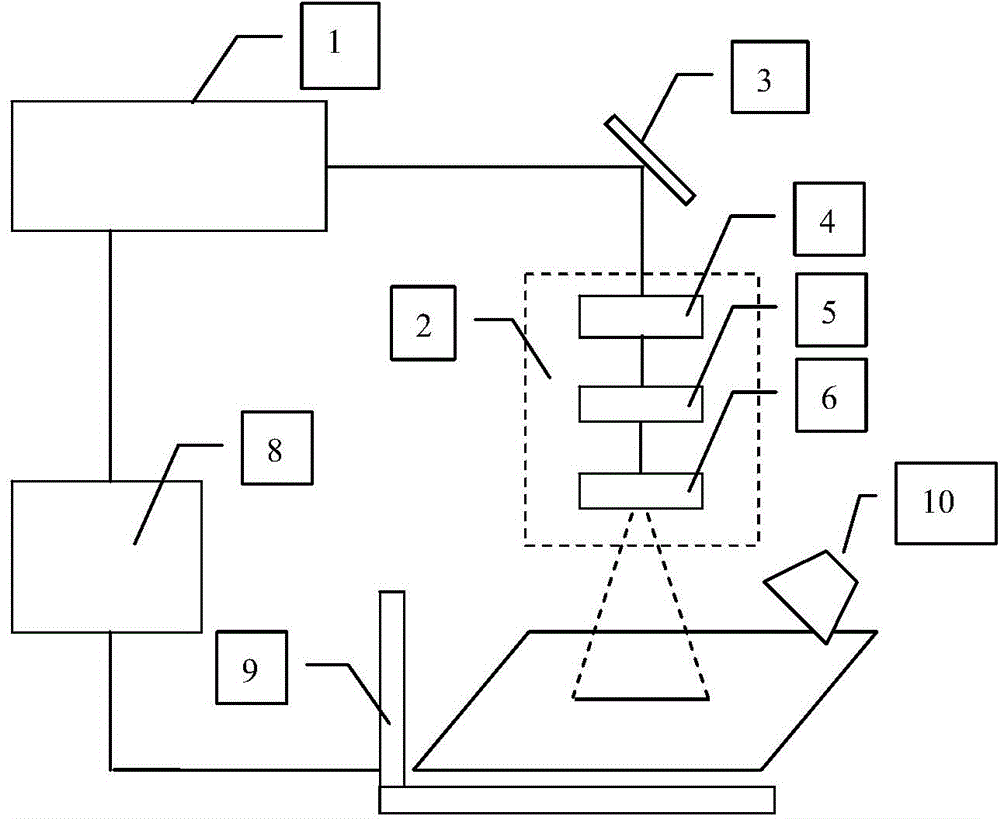

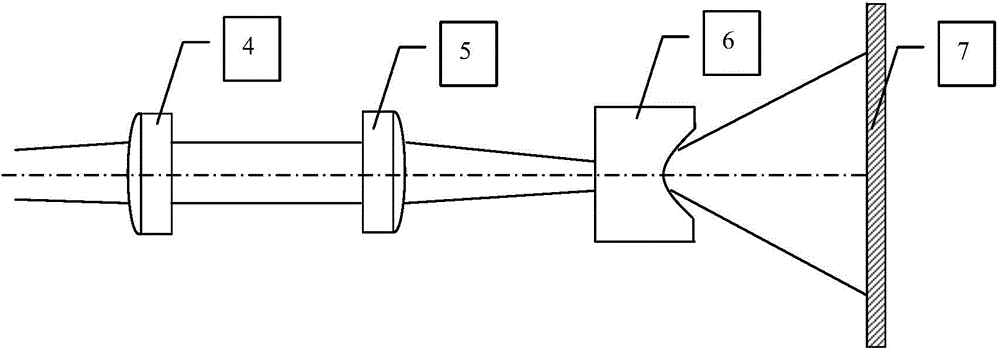

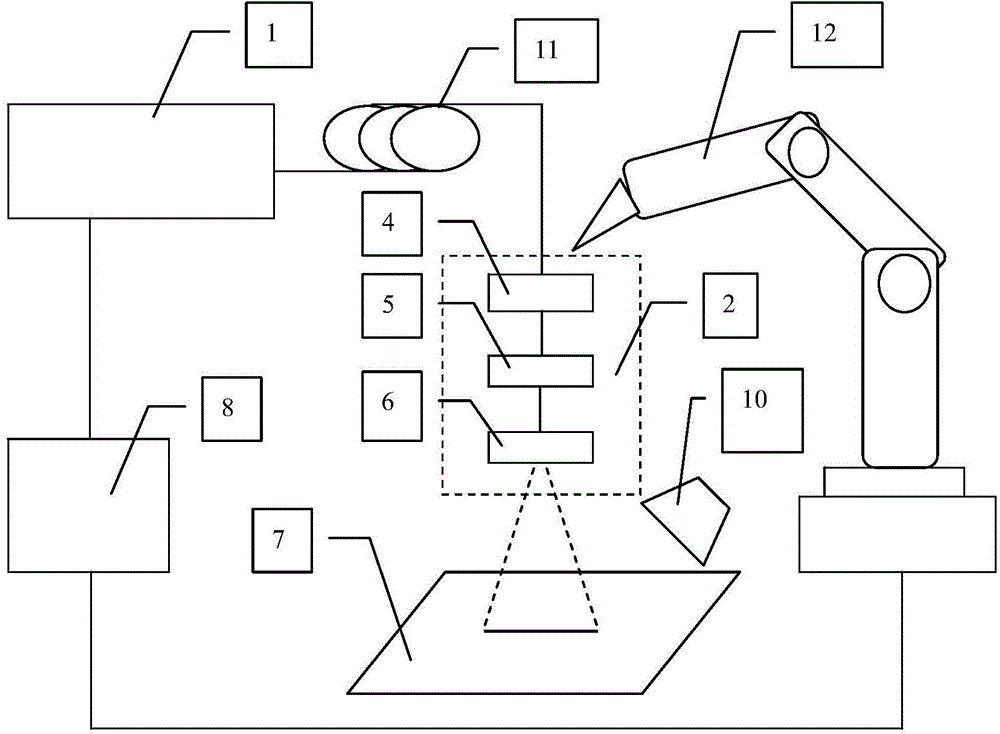

System and method for processing dynamic focusing scanning spot track of optical fiber laser or disk laser

InactiveCN101913024AQuality improvementImprove efficiencyLaser beam welding apparatusElectric machineLaser scanning

The invention discloses a system and a method for processing dynamic focusing scanning spot track of optical fiber laser or disk laser. Aiming at the defects in scanning technology of the current laser scanning welding system, an optical fiber laser or a disk laser, a PSD displacement sensor, and a dynamic focusing fast scanning head driven by a high-accuracy hollow-shaft linear motor are adopted for implementing loop closing and real-time control of a dynamic focusing module, in order to perform spot scanning processing of fast spot track on workpiece. The system and the method have the advantages of large processing scope, high quality, fast welding or spotting speed and high efficiency, in addition, accuracy and welding quality of the system are enhanced effectively, 3D welding can be realized, and extensive application value in the field of advanced manufacture is achieved.

Owner:SHANGHAI INST OF LASER TECH

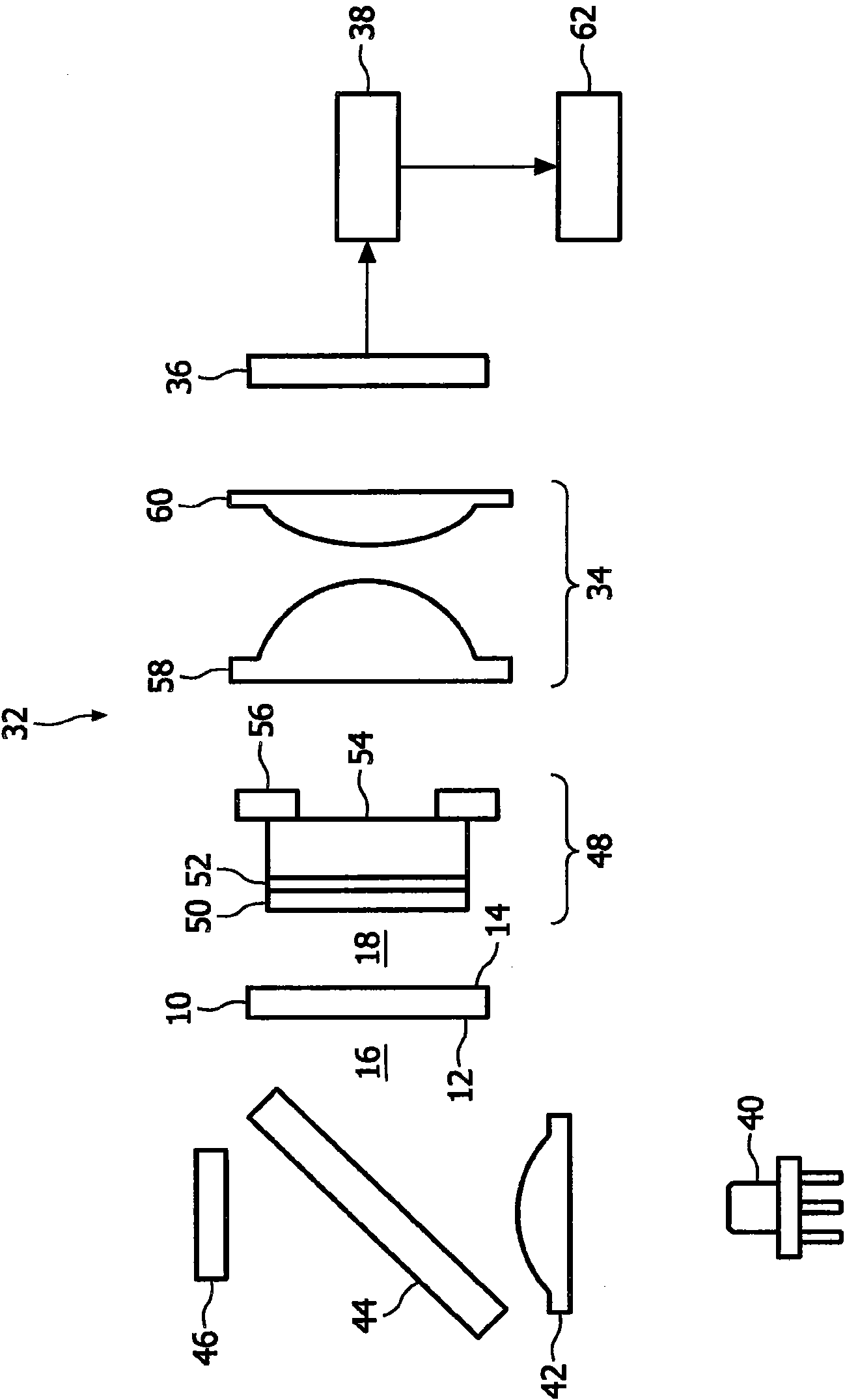

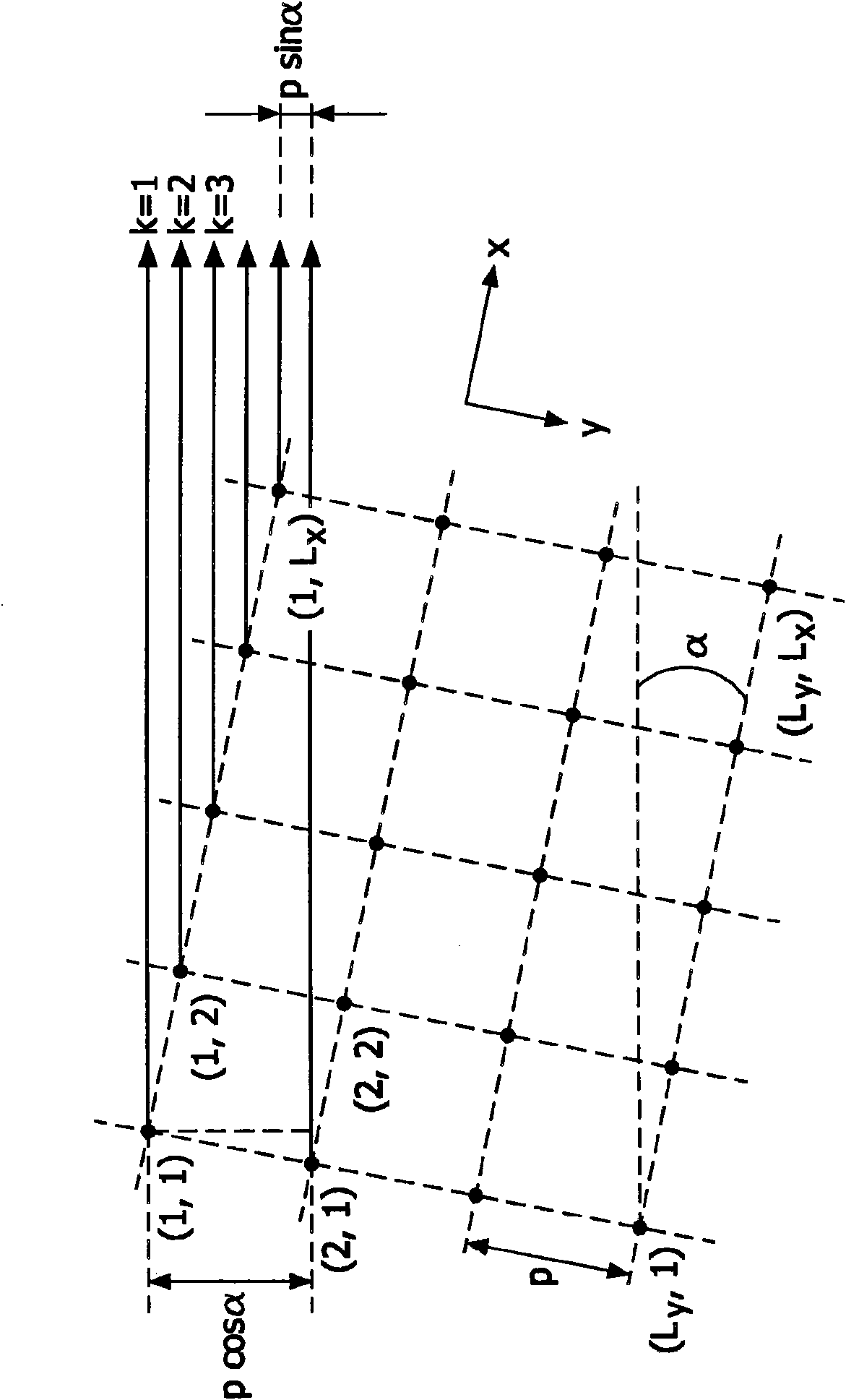

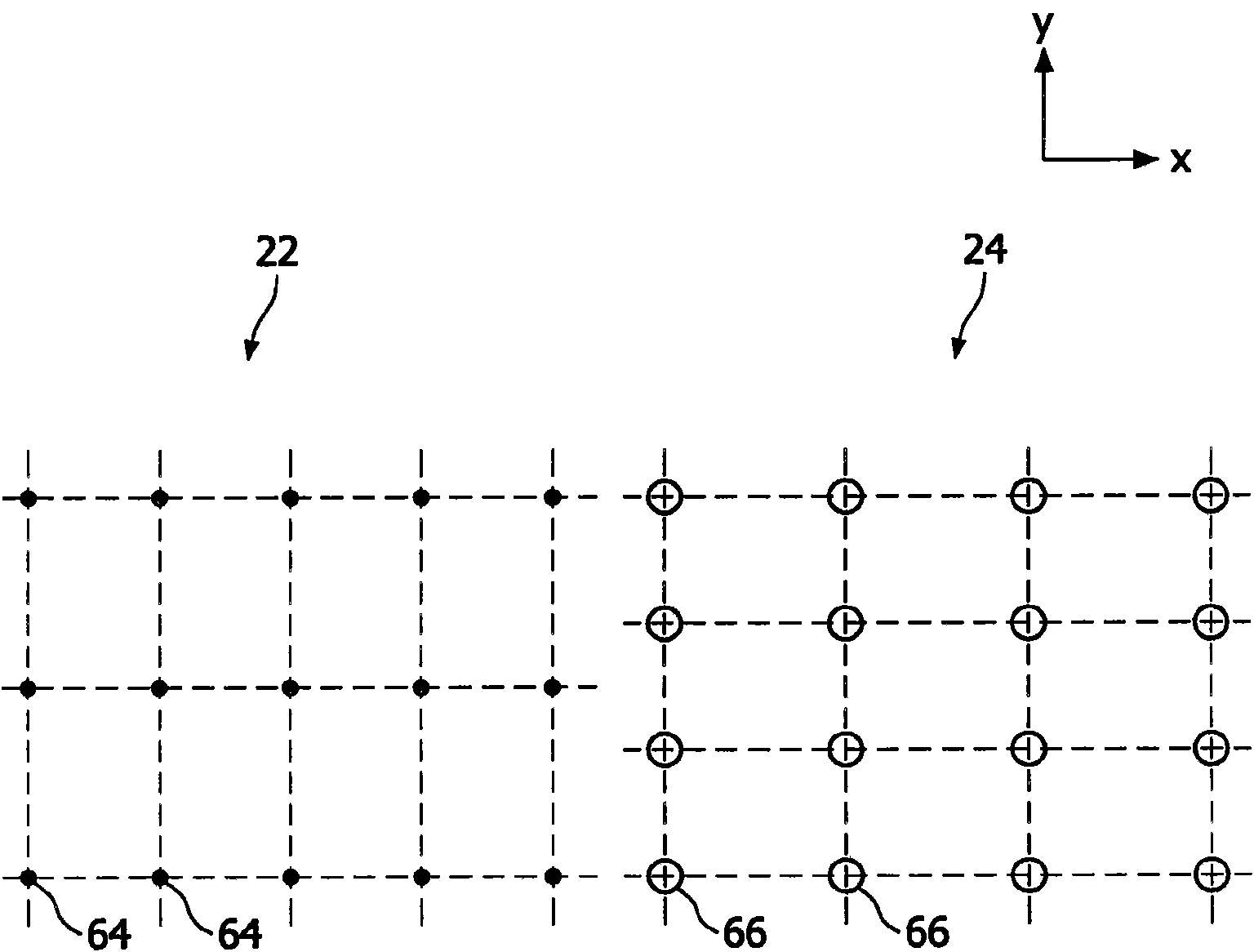

Multi-modal spot generator and multi-modal multi-spot scanning microscope

The invention relates to a spot generator (10) having: -an entrysurface (12) for receiving an incident light beam (20) and an exit surface (14) for transmitting the light beam, the entry surface defining an entryside (16) and the exit surface defining an exit side (18). According to the invention, the spot generator is designed to modulate the incident light beam to generate on the exit side a first plurality (22) and a second plurality (24) of separate light spots, each light spot belonging to the first plurality having a first angular spectrum and each light spot belonging to the second plurality having a second angular spectrum different than the first angular spectrum. Advantageously, the spot generator comprises a periodic binary phase structure. The invention further relates to a multi-spot scanning microscope and to a method of imaging a microscopic sample.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

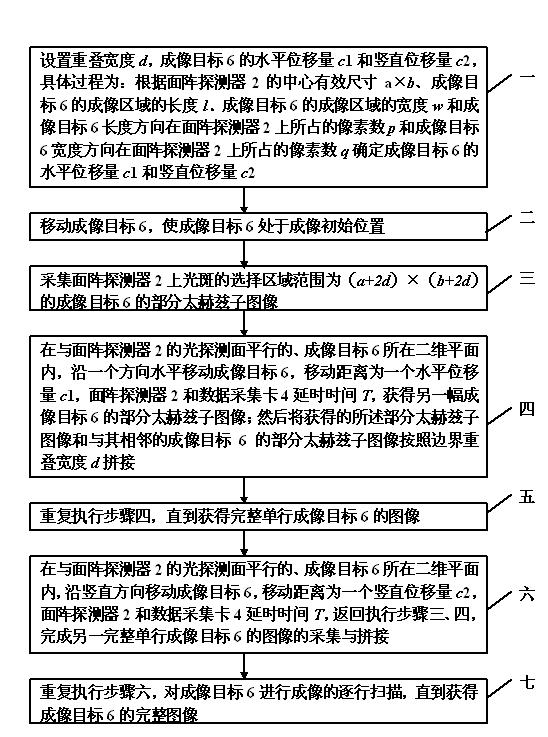

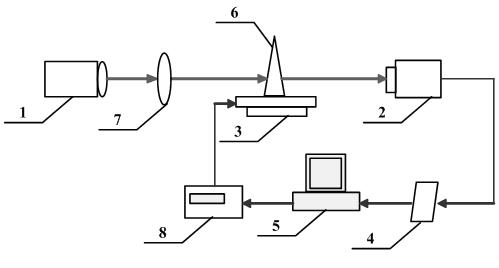

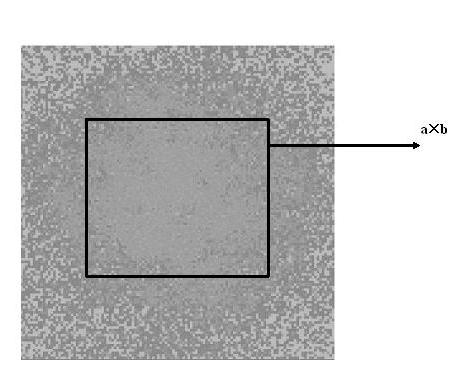

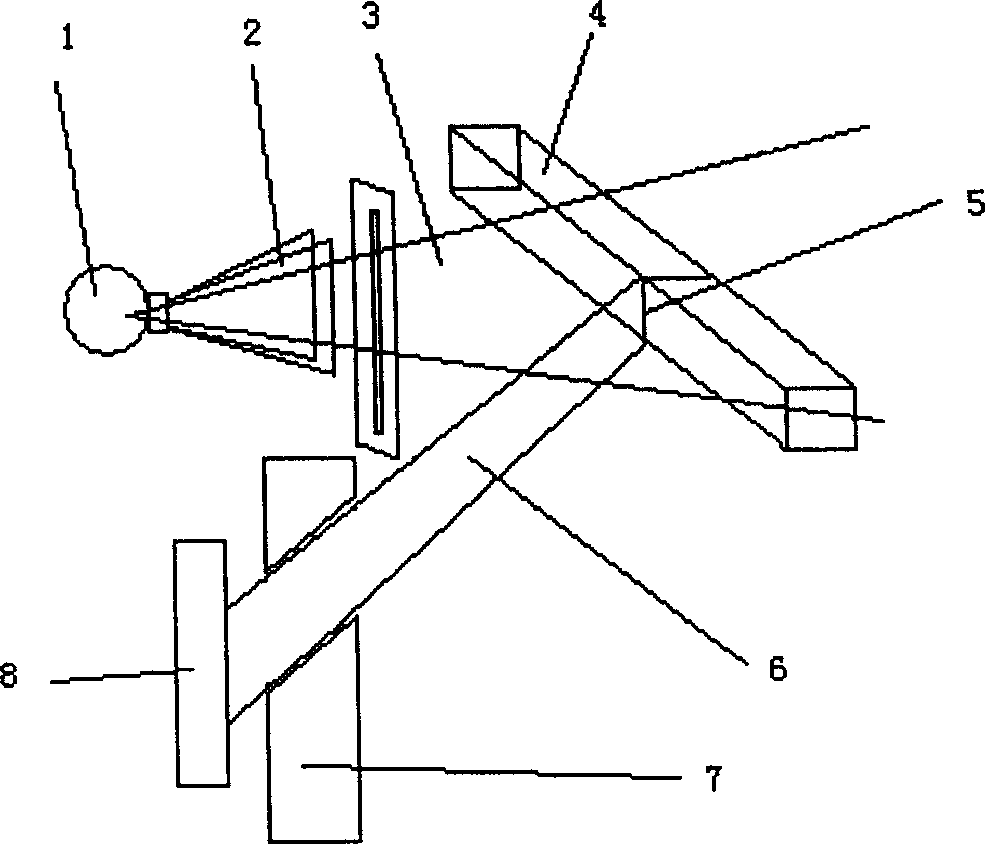

Tera-hertz two-dimensional area array scanning imaging method and imaging system for implementing same

The invention discloses a tera-hertz two-dimensional area array scanning imaging method and an imaging system for implementing the same, which relate to a tera-hertz scanning imaging method and an imaging system. The method and the system solve the problem of overlong imaging time caused by the point-by-point scanning imaging which can only process single data points in the prior art and the problem that the area array canning imaging can only image small objects in the prior art. The method comprises the following steps of: scanning and imaging a two-dimensional area array by using a tera-hertz laser, an optical system, an area array detector, a two-dimensional translation stage, a stepper motor controller, a data acquisition card and a computer; under the condition that an imaging light source is fixed, moving the a two-dimension translation stage to a proper initial position and completely scanning a target in an imaging process, wherein a certain area of the imaging object is imaged at each time, and all sub-graphs are stitched together finally. An image of the imaging target is obtained by controlling the two-dimensional translation stage and the data acquisition card and processing and storing data. The method and the system are suitable for large-size and high-speed target imaging.

Owner:HARBIN INST OF TECH

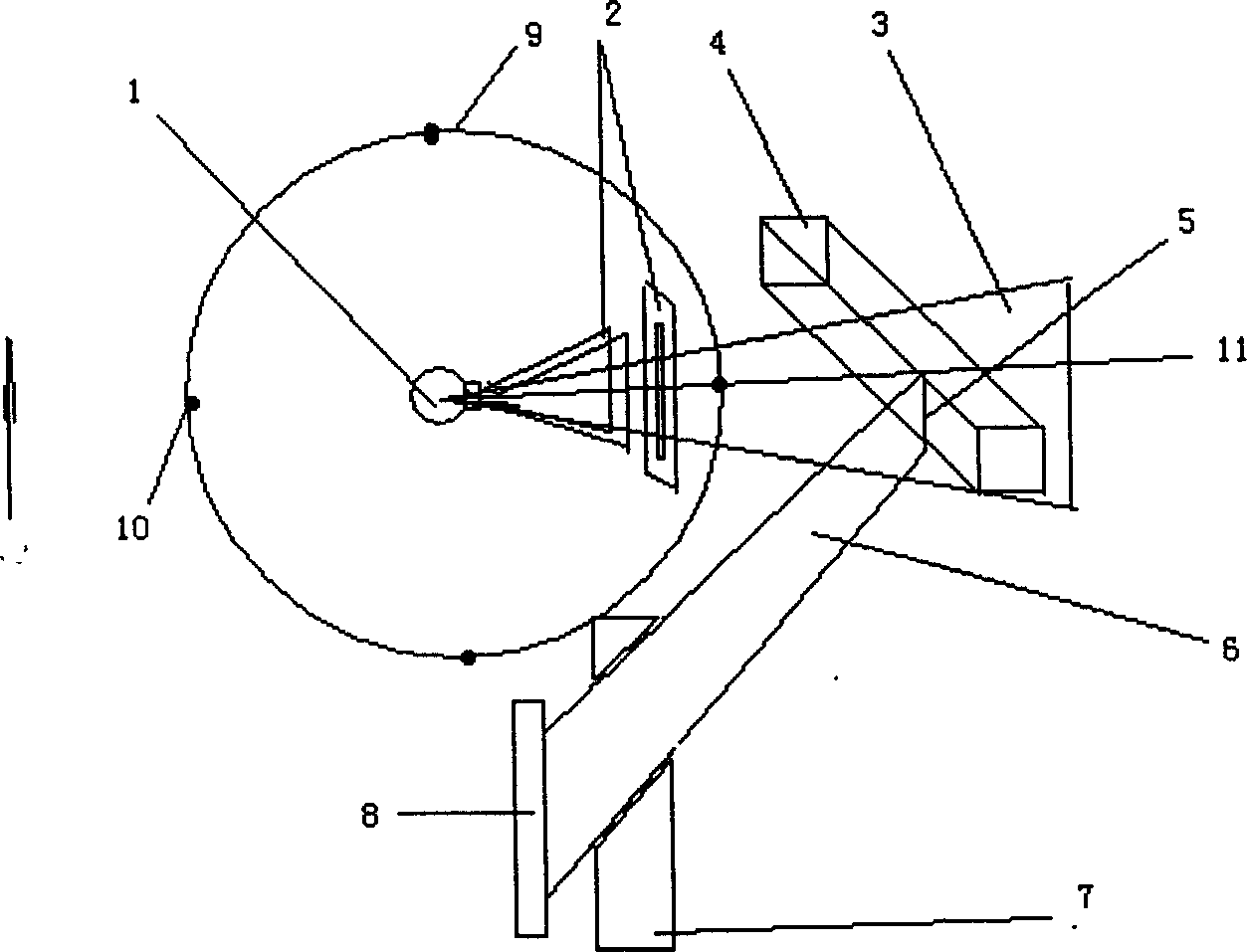

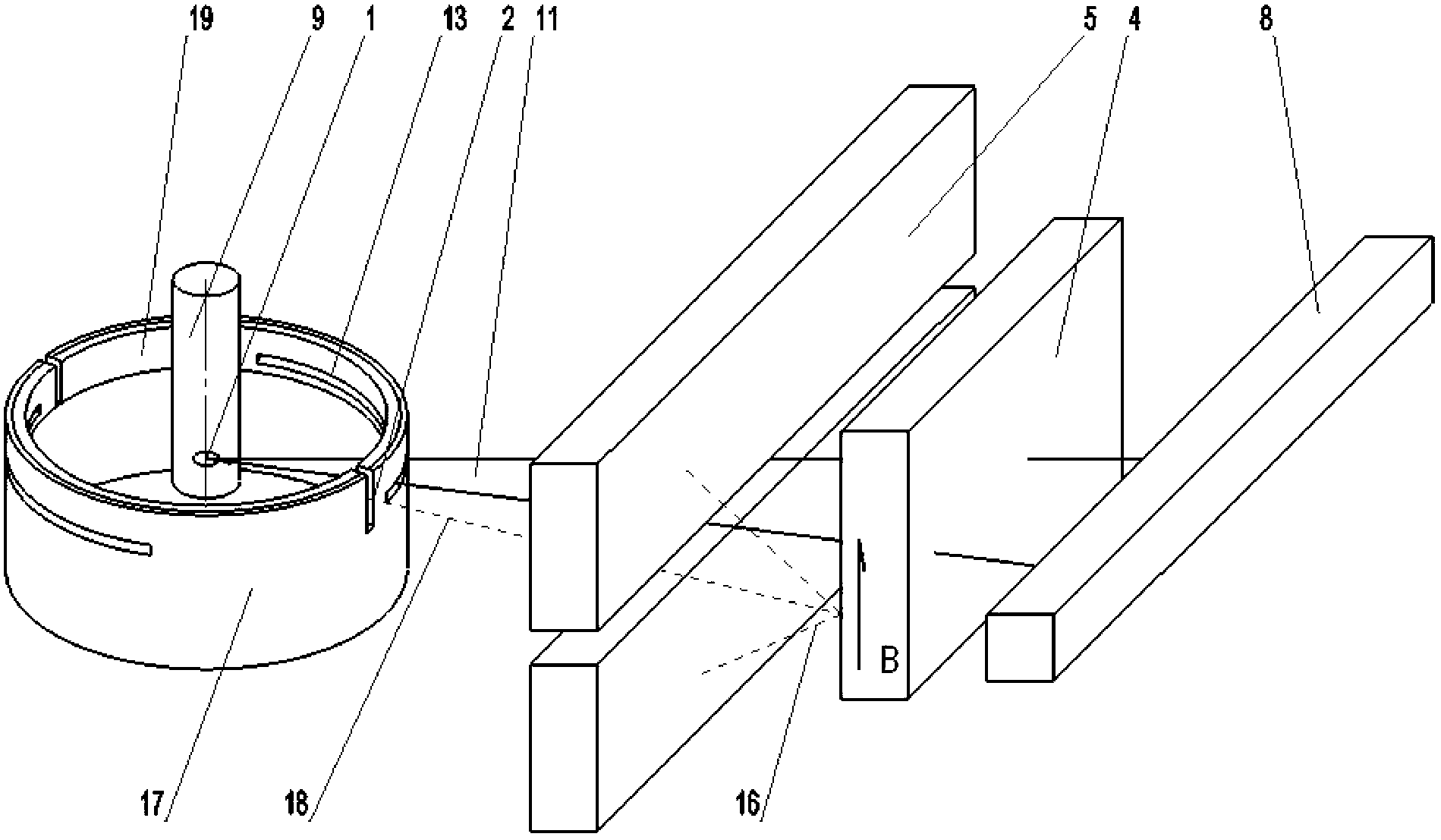

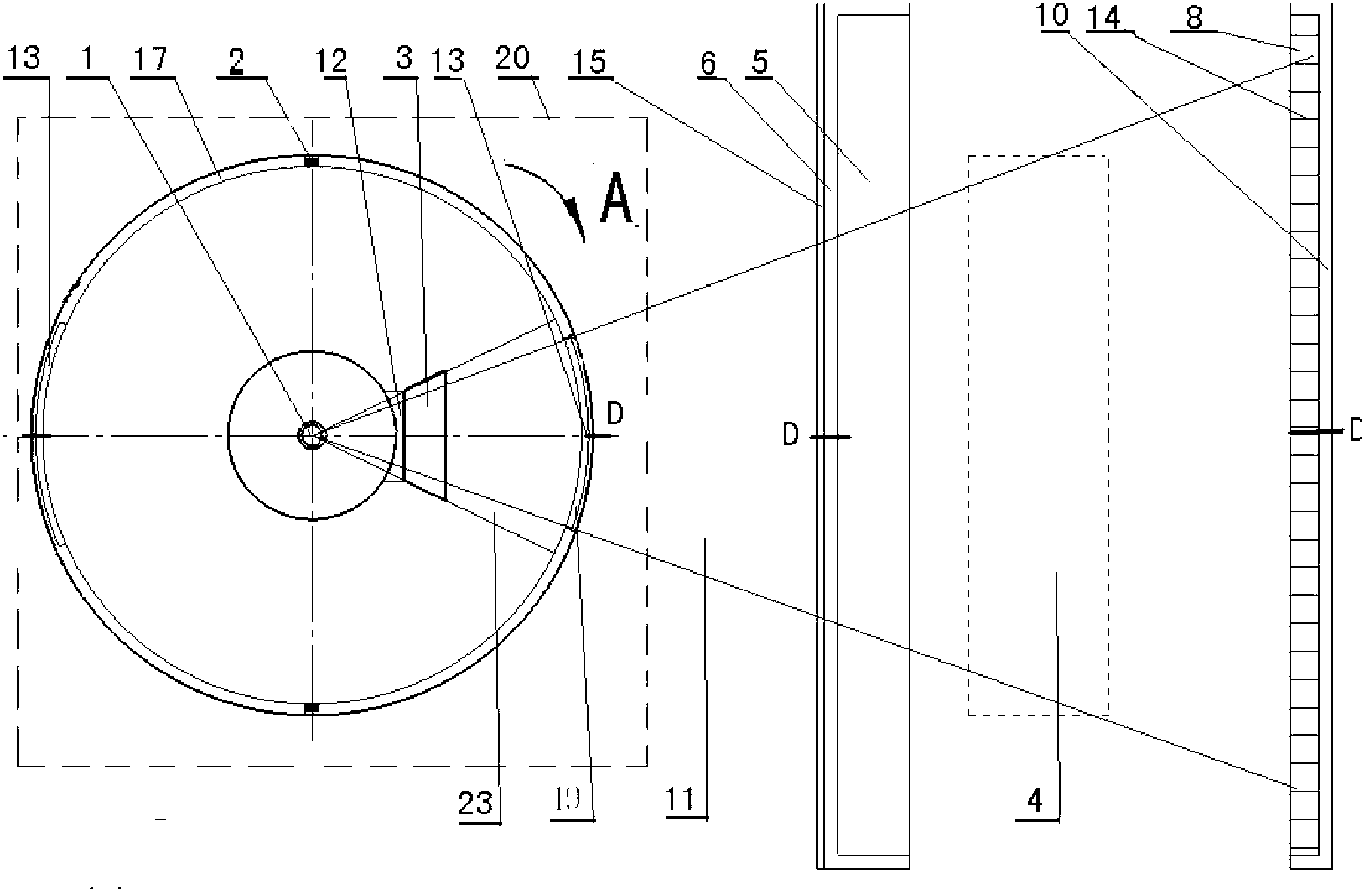

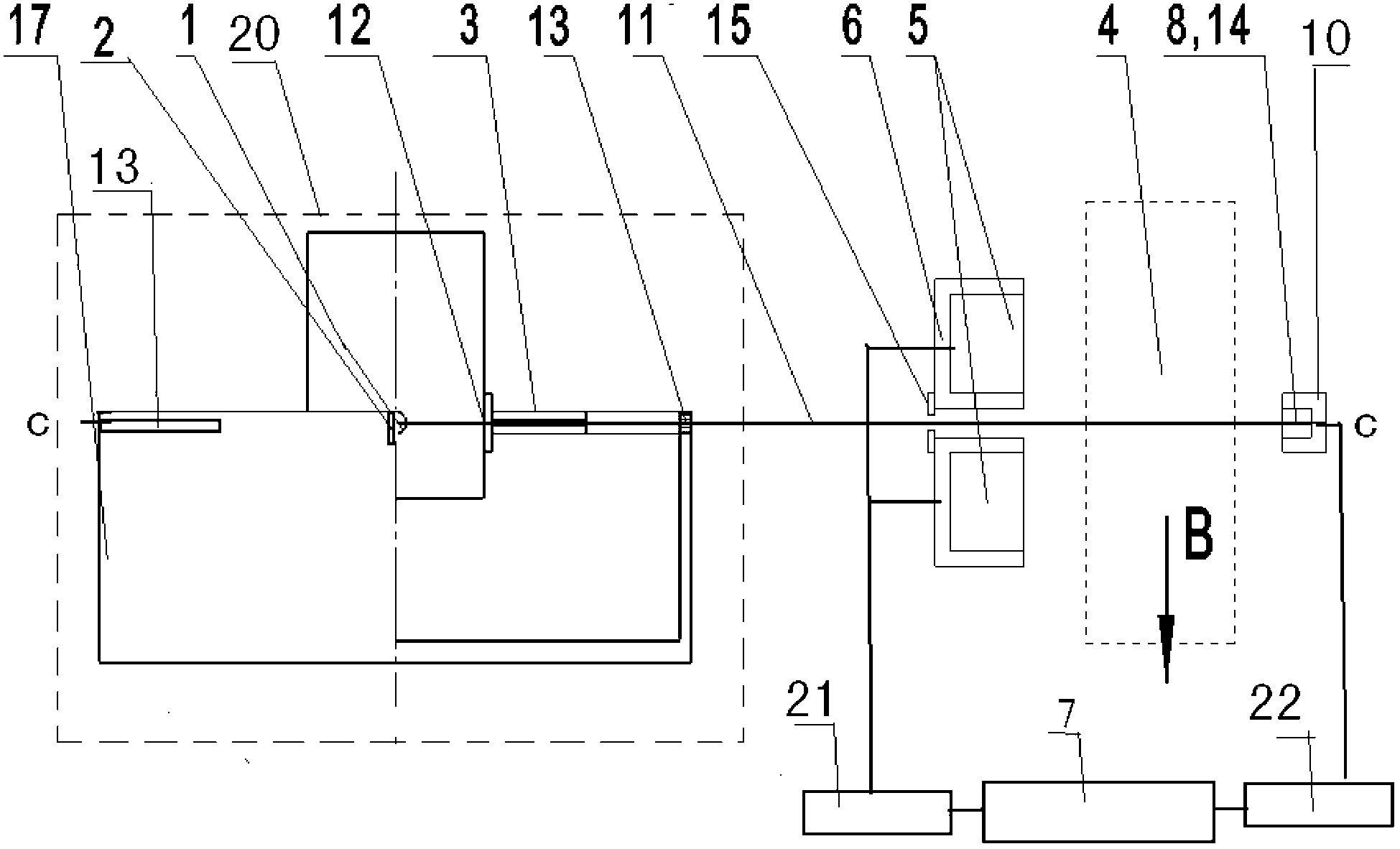

Backscattering type X-ray scanner

InactiveCN1485611AAvoid damageLarge solid angleMaterial analysis using wave/particle radiationX-rayOptoelectronics

A backscattering type flying dots radioactive ray scanning checkout apparatus, wherein a rotatable drum shape straight line flying-spot scanning arrangement is used, 1-4 circular or square holes are arranged uniformly on the same circumference of the drum, its inner side is inlaid with lead or heavy metallic shielding layer, an X-ray source and fan-shaped collimating device are all arranged in the drum, and a special detector is employed. The advantages of the installation are little scattering radiation, less damage to human body, simplified structure and easy fabrication process.

Owner:PURPLE SQUARE TECH

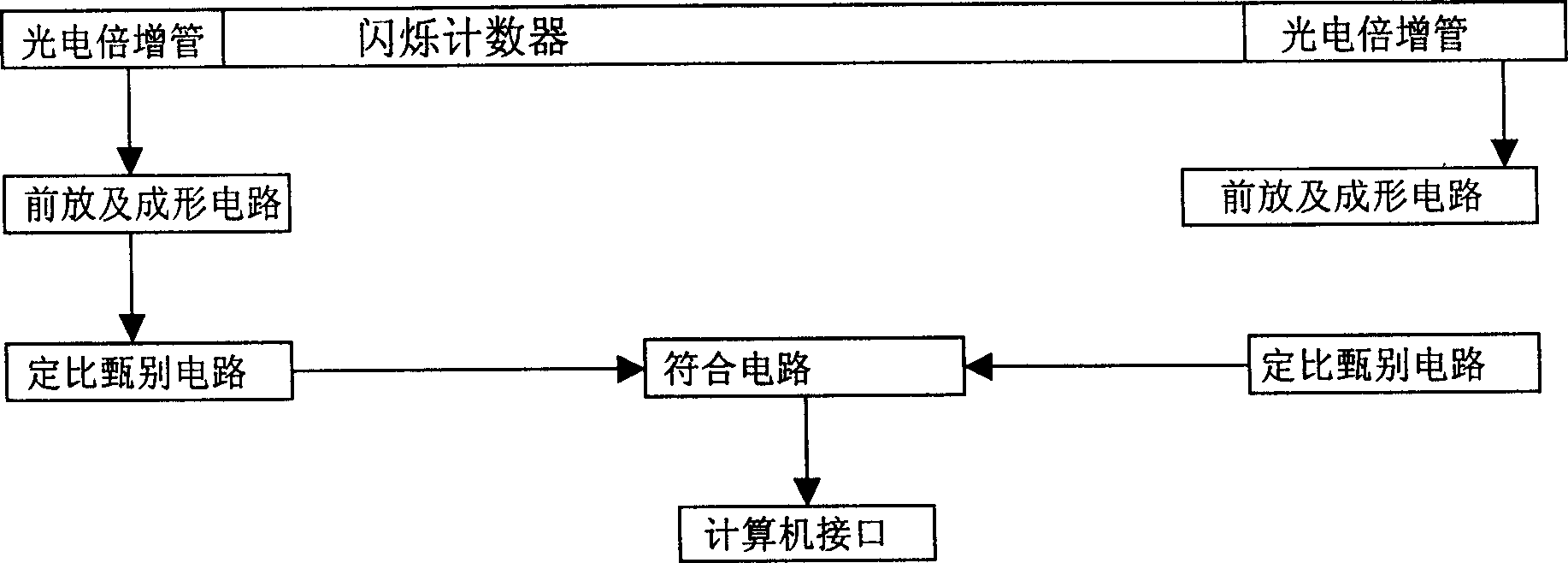

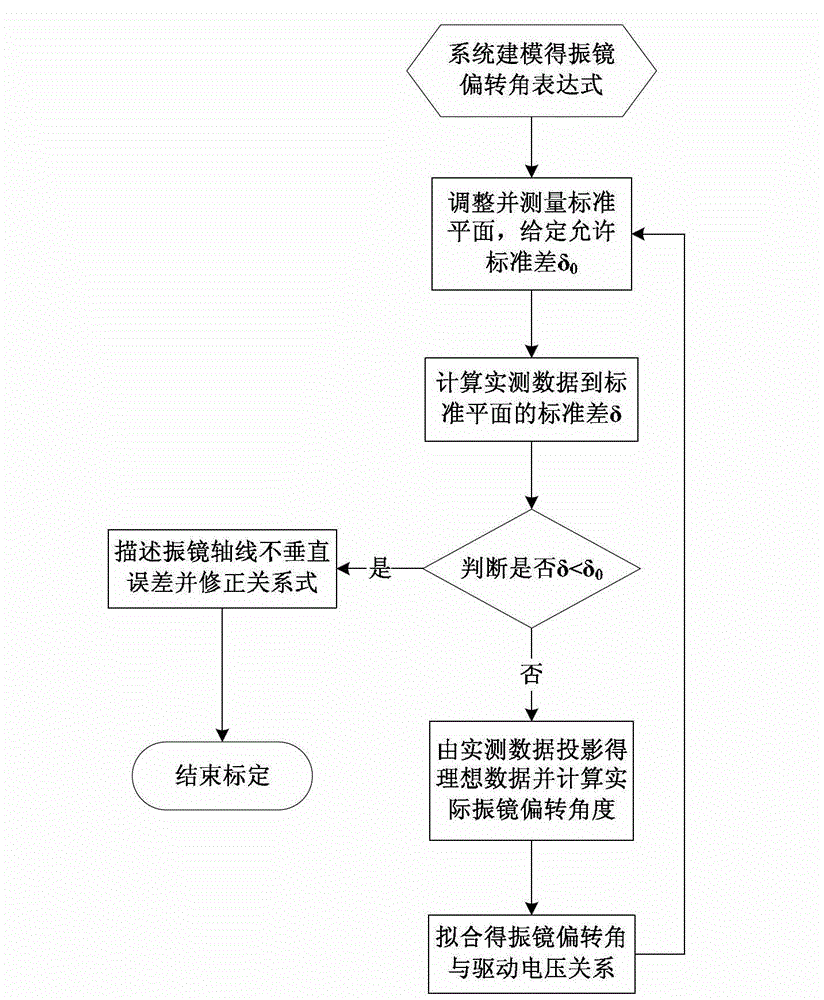

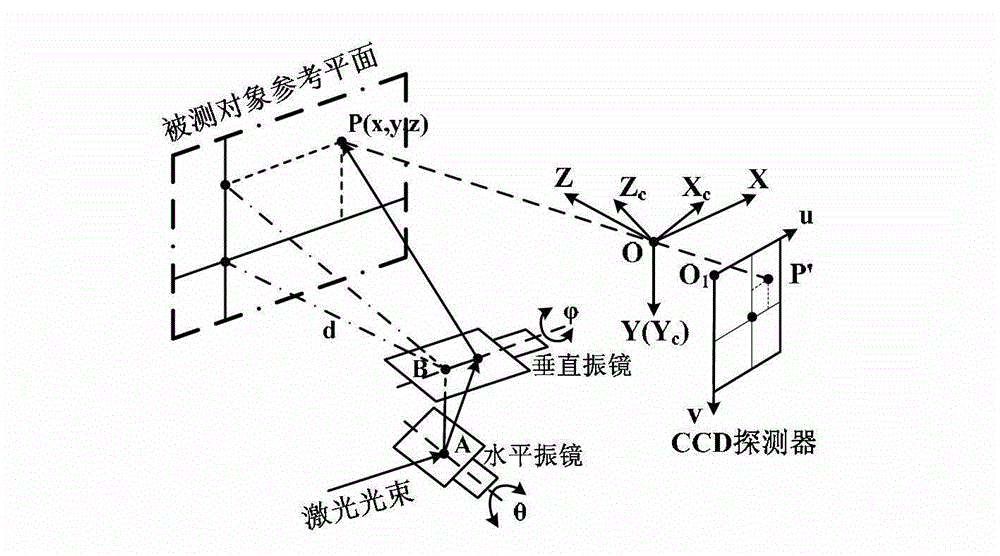

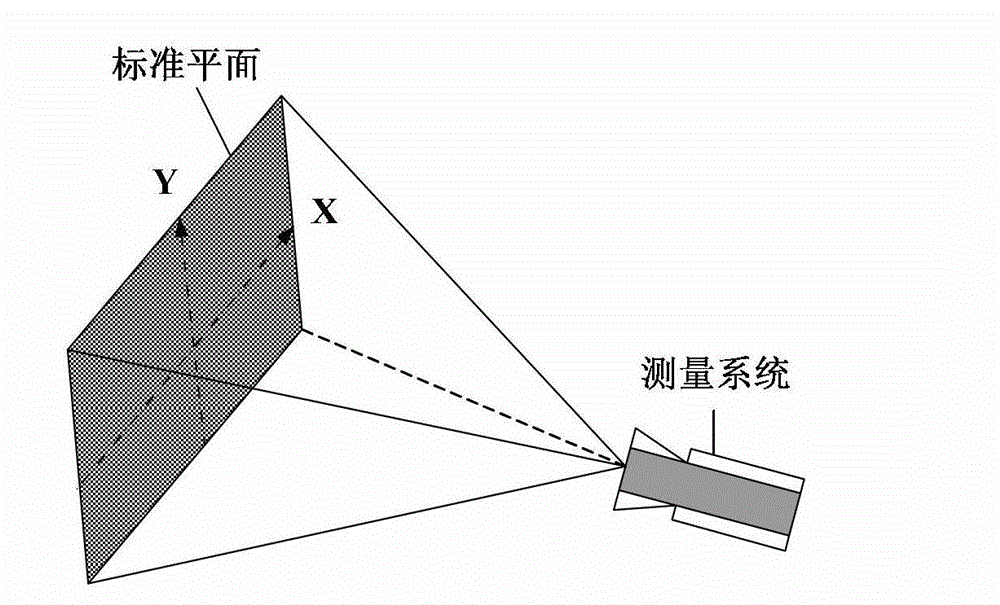

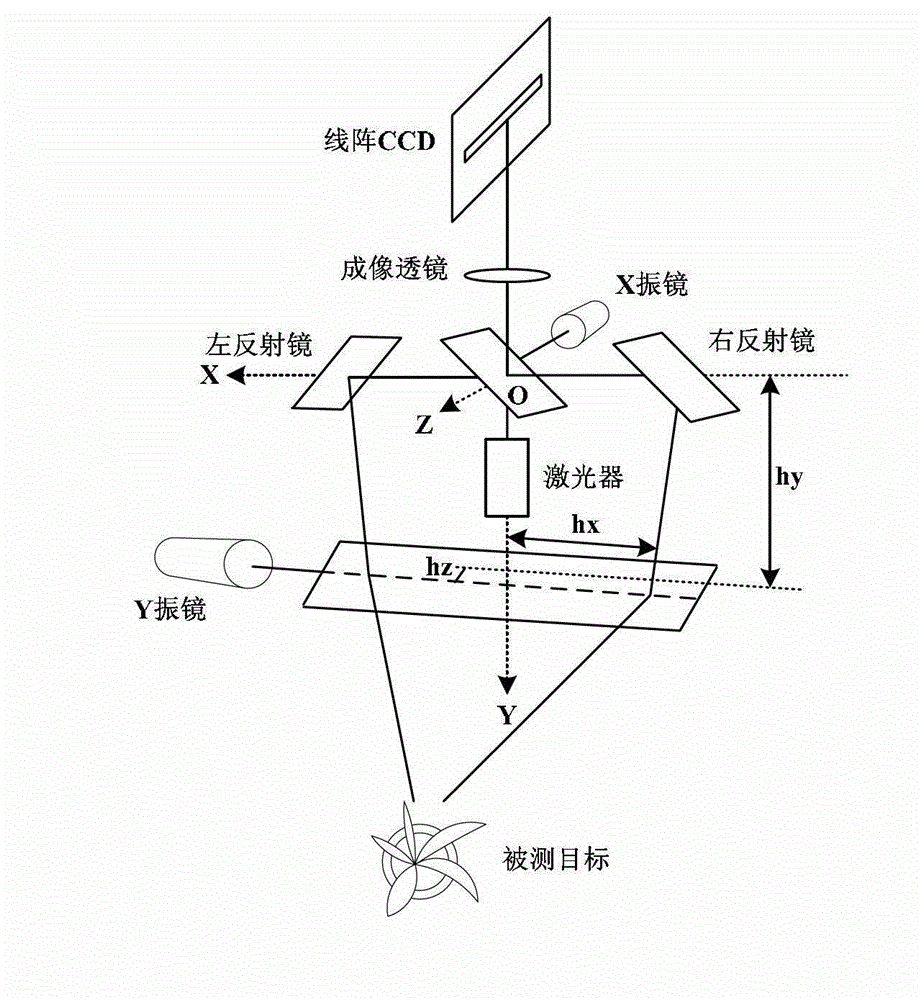

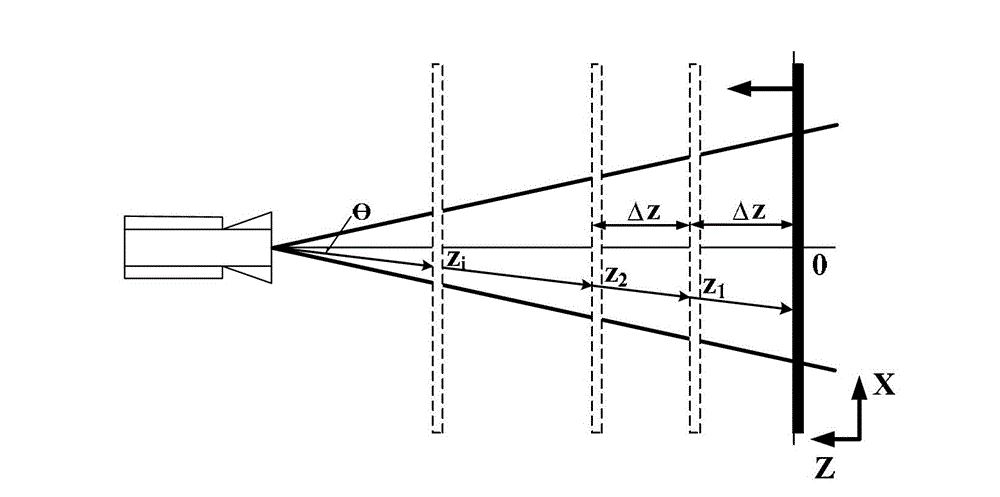

Calibration method of spot scanning galvanometer of three-dimensional measuring system

ActiveCN102941410AReduce the possibilityQuick calibrationUsing optical meansLaser beam welding apparatusLaser processingStandard plane

The invention discloses a calibration method of spot scanning a galvanometer of a three-dimensional measuring system. The calibration method comprises seven major steps as follows: firstly performing system modeling, so as to obtain a galvanometer deflection angle expression, then adjusting a standard plane to be positioned in a known position and perpendicular to a system main direction, measuring the plane, projecting measured data to the standard plane, so as to obtain ideal data, utilizing the data to calculate a galvanometer deflection angle, matching a relational expression between the galvanometer deflection angle and driving voltage, and measuring the standard plane again through the relational expression, and repeating the process till the standard deviation from the measured data to the standard plane is smaller than a set value, so as to obtain an accurate relational expression between the galvanometer deflection angle and the corresponding driving voltage, establishing the interactional relation between two galvanometers, describing the non-perpendicularity error of axes of the two galvanometers, and correcting the relational expression, so as to improve the calibration accuracy. The calibration method has higher practical value in the technical field of optical three-dimensional measurement and laser processing.

Owner:BEIHANG UNIV

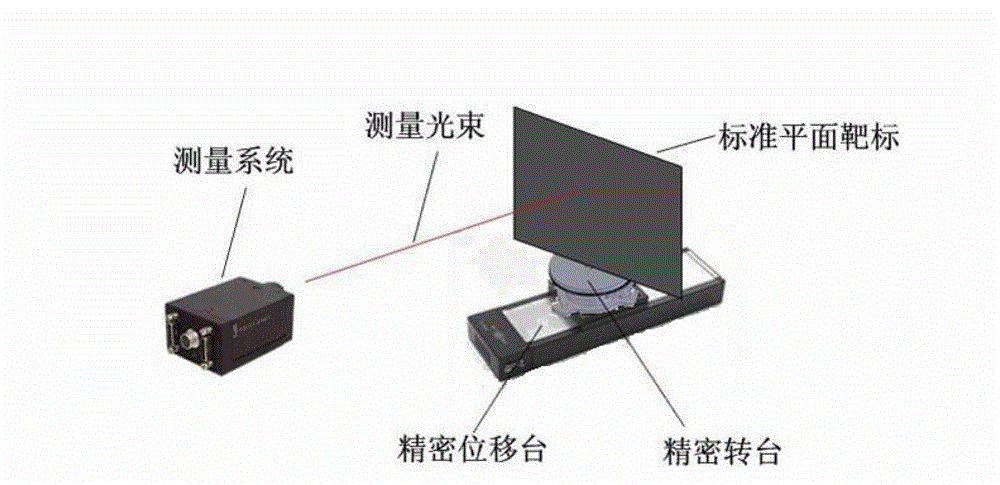

Calibration method of spot scanning three-dimensional topography measuring system

The invention discloses a calibration method of spot scanning a three-dimensional topography measuring system. The calibration method comprises three major steps as follows: firstly establishing a measuring system model and determining parameters to be calibrated, then taking a precise displacement platform, a precise rotating platform and a standard plane target as calibration devices, adjusting positions and postures of the calibration devices, so as to meet calibration requirements, driving the standard plane target to move and rotate through the precise displacement platform and the precise rotating platform, so as to obtain calibration data in all directions, and finally, solving the parameters to be calibrated through a method of maximum likelihood estimation, determining a system model, and realizing accurate calibration of the system. The calibration method has higher practical value and wide application prospect in the field of photoelectric measurement.

Owner:BEIHANG UNIV

Laser cleaning device

ActiveCN104959349AImprove cleaning efficiencyGuaranteed Power DensityCleaning processes and apparatusPoint lightLight spot

The invention provides a laser cleaning device. The device comprises a laser emitting laser beams, and a light spot generation mechanism used to perform scanning and irradiation on a to-be-cleaned workpiece. The light spot generation mechanism comprises a collimating mirror and a battery of lenses arranged in the emergent optical path of the laser beams in sequence. The battery of lenses comprises a convex cylindrical lens and a concave cylindrical lens. The convex cylindrical lens is between the collimating mirror and the concave cylindrical lens. The convex cylindrical lens and the concave cylindrical lens are arranged in an orthogonal manner. The light spot generation mechanism makes a point light source become linear beam patterns through using an optical lens system, and laser cleaning is changed to line scanning from spot scanning. On the premise of ensuring laser power density, laser cleaning efficiency is greatly improved.

Owner:苏州市星科四达激光科技有限公司

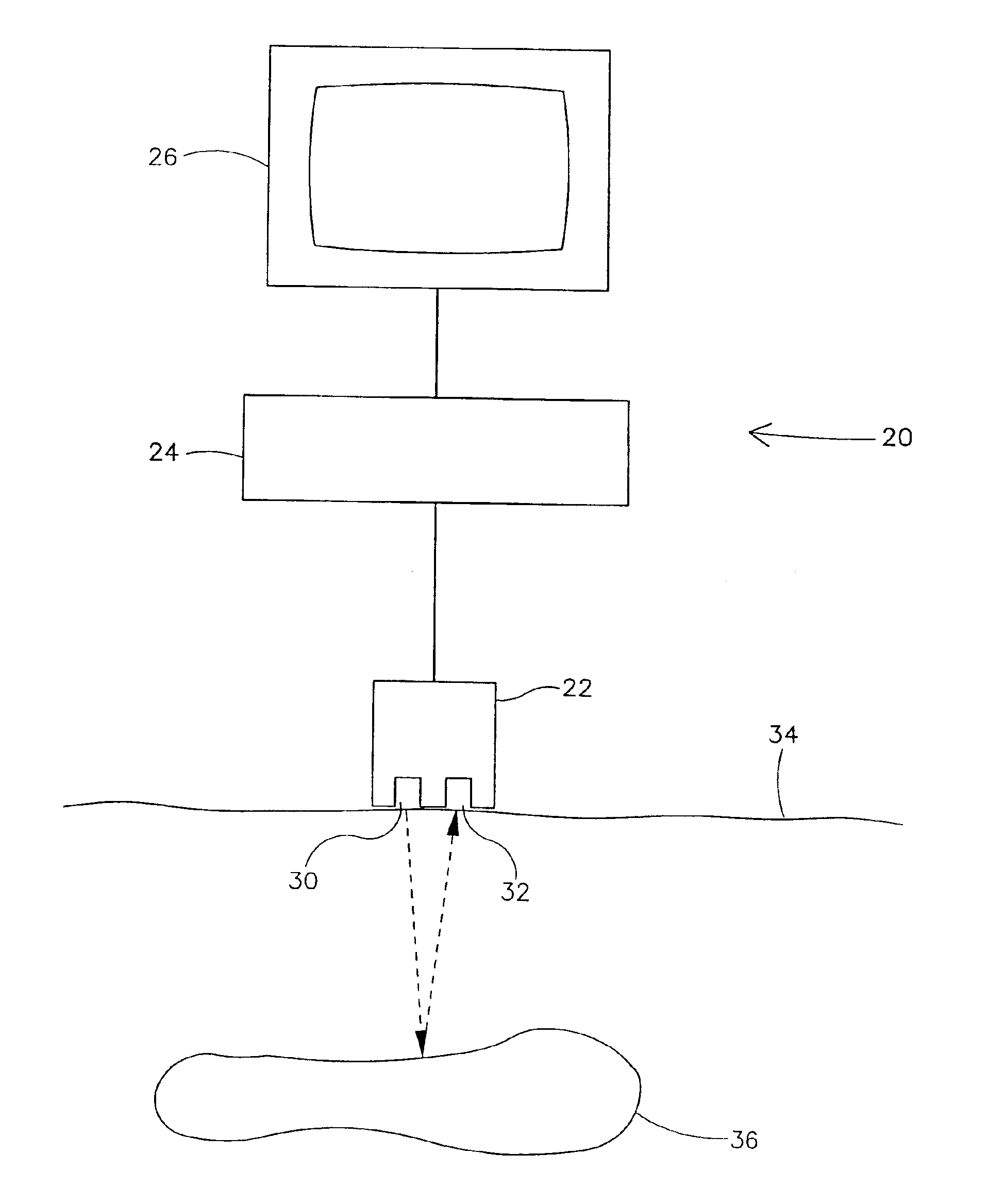

Method and apparatus for ultrasonic imaging

InactiveUS6932770B2Ultrasonic/sonic/infrasonic diagnosticsImage enhancementUltrasound imagingSonification

Owner:IMACOR INC

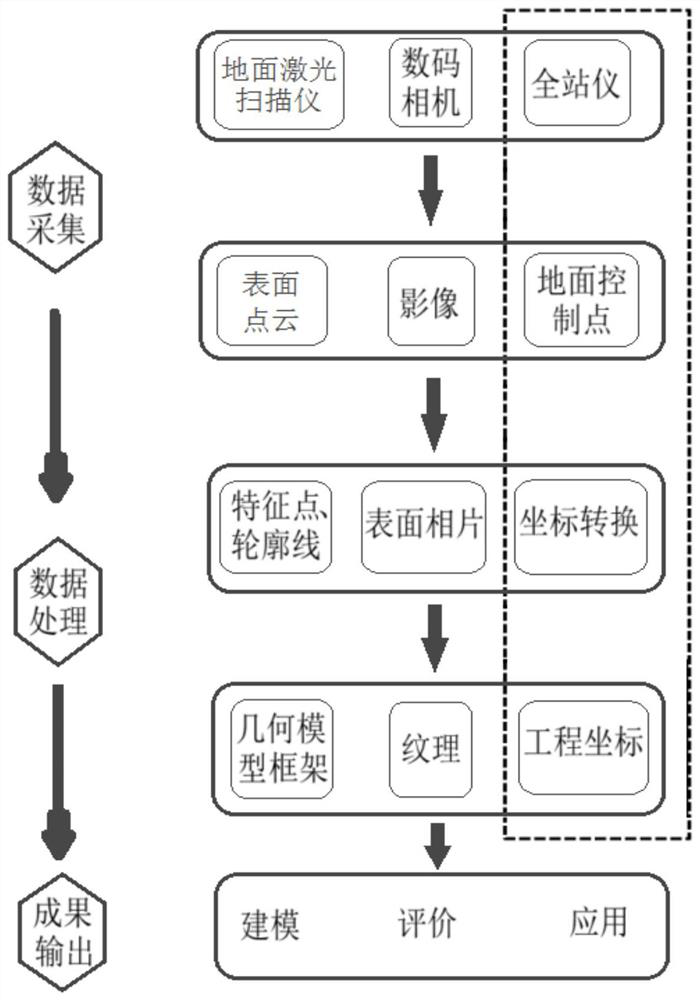

Ground feature contour extraction method based on ground laser point cloud

ActiveCN112595258AImprove measurement efficiencyHigh degree of automationUsing optical meansPoint cloudData acquisition

According to a ground feature contour extraction method based on a ground laser point cloud provided by the invention, surface-based space measurement breaking through a traditional single-point measurement mode is introduced into urban measurement application, and the urban measurement efficiency is improved. As the most important space entity of a city, the three-dimensional information of ground objects, especially buildings, is the important basic geographic information of the city and has important application value. The whole scanning process is high in data acquisition efficiency, ground control points do not need to be specially arranged, scanning measurement is slightly influenced by the external environment, and the measurement precision is high. Not only is automation degree ofbuilding space data acquisition improved, but also scanned point cloud can express real three-dimensional information and detail structure of a building in detail. Accurate contour information is acquired by means of the point cloud data, and a three-dimensional model of the building is reconstructed. The method has the advantages of high interaction performance, high intelligent degree, high expandability, high extraction speed, high contour extraction precision and the like.

Owner:湖南航天智远科技有限公司

Preparation method for metal part

ActiveCN105665706AAvoid the pitfalls of using moldsSimple processAdditive manufacturing apparatusTransportation and packagingUltraviolet lightsSlurry

The invention discloses a preparation method for a metal part. The preparation method comprises the following steps that 1, metal powder is taken, added with an organic binder under the dark condition and uniformly mixed, then an antifoaming agent is added into the metal powder and uniformly mixed, and after bubbles fade away, surface impurities are removed, so that mixed slurry is obtained; 2, the mixed slurry is put into 3 D printing forming equipment to be printed layer by layer by utilizing controllable ultraviolet light beams, through the mode of surface exposure or spot scanning and according to a three-dimensional model of the part, and hence a metal part rough blank is prepared; 3, the metal part rough blank is subjected to low-temperature degreasing treatment, so that the organic binder in the rough blank evaporates and overflows; and 4, hot isostatic pressing treatment is conducted on the metal part rough blank, and therefore the compact metal part is obtained. According to the preparation method for the metal part, the principle of light curing rapid prototyping is adopted, the shape of the part is unrestrained, the process is simplified, the manufacturing cycle is shortened, and the product compactness is good.

Owner:铂力特(江苏)增材制造有限公司

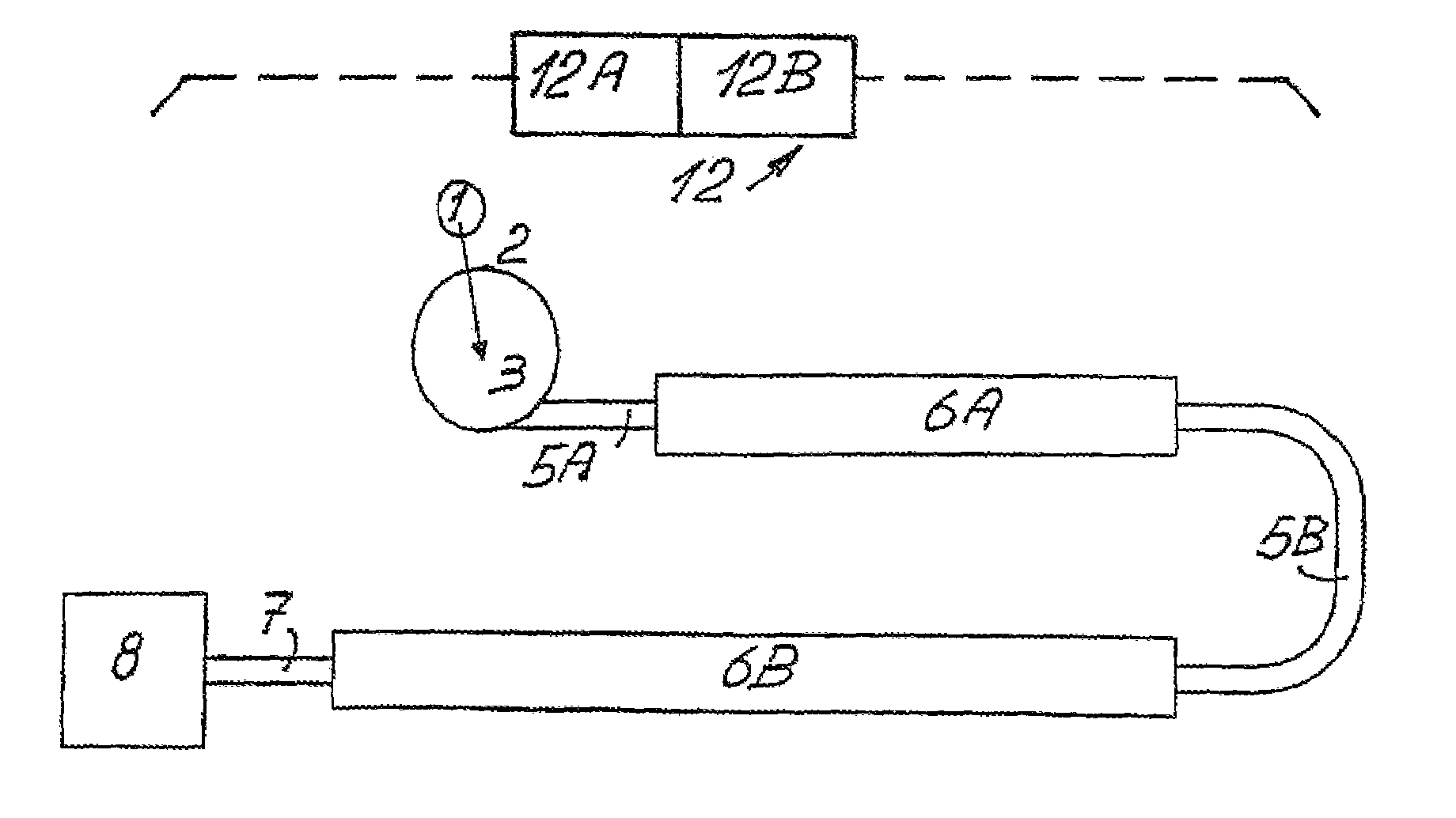

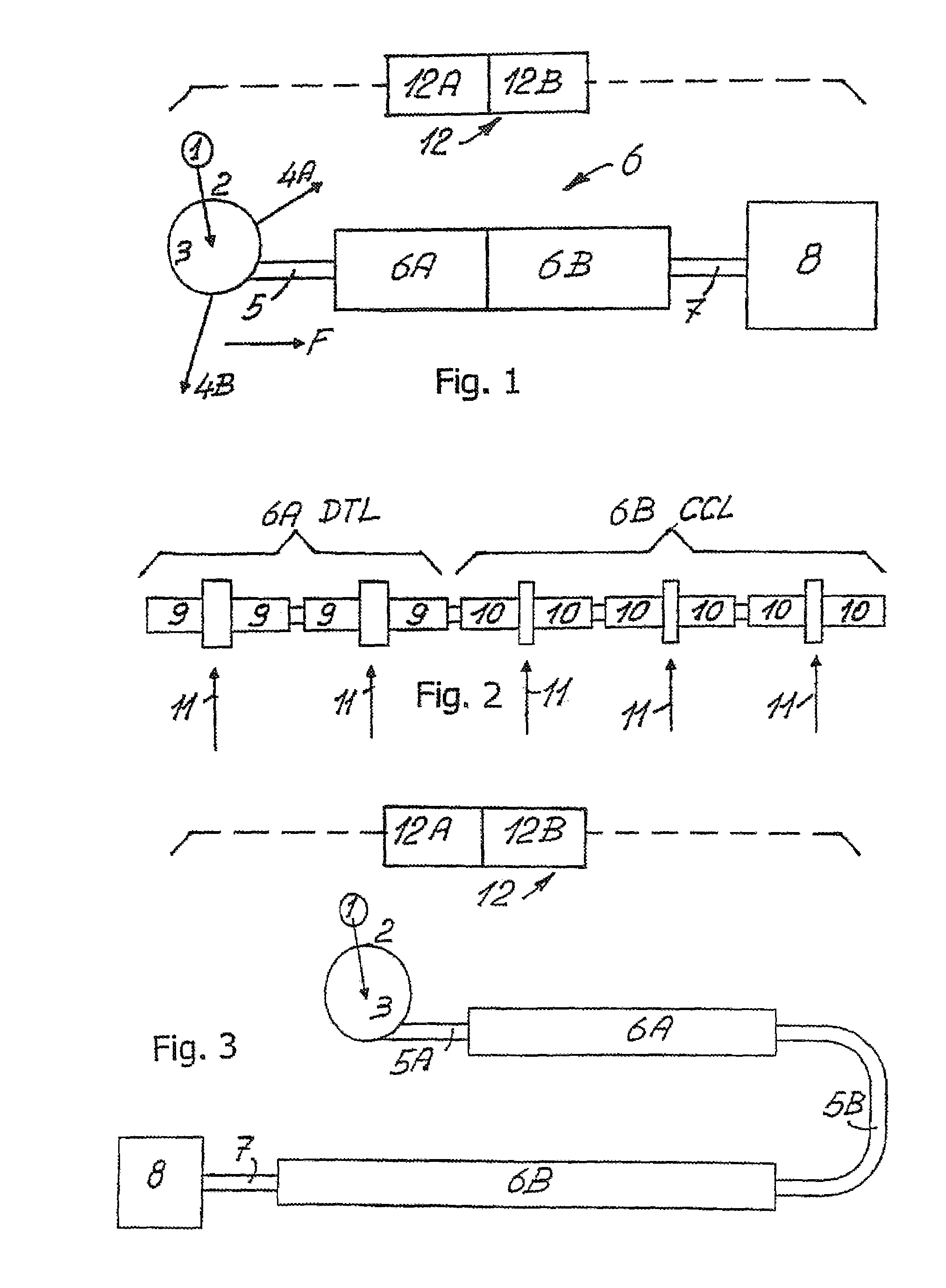

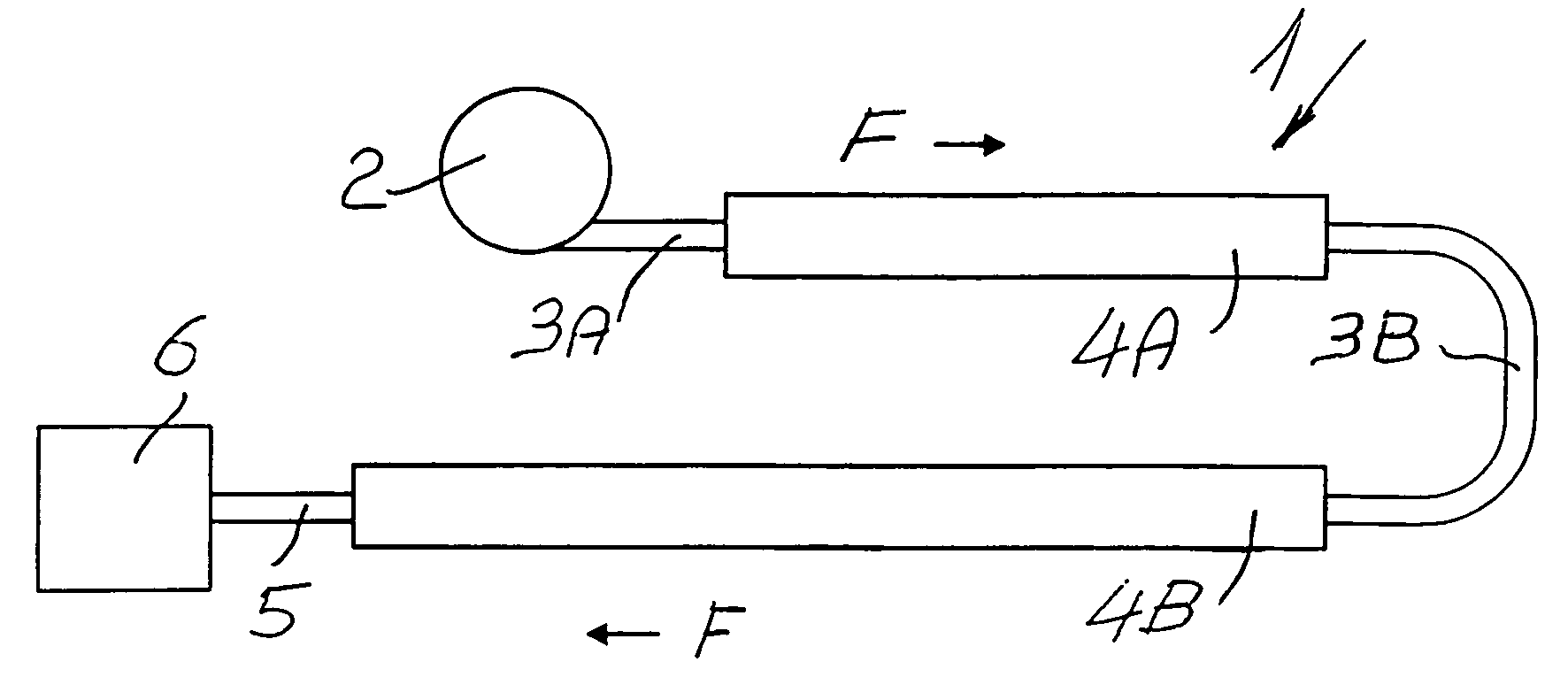

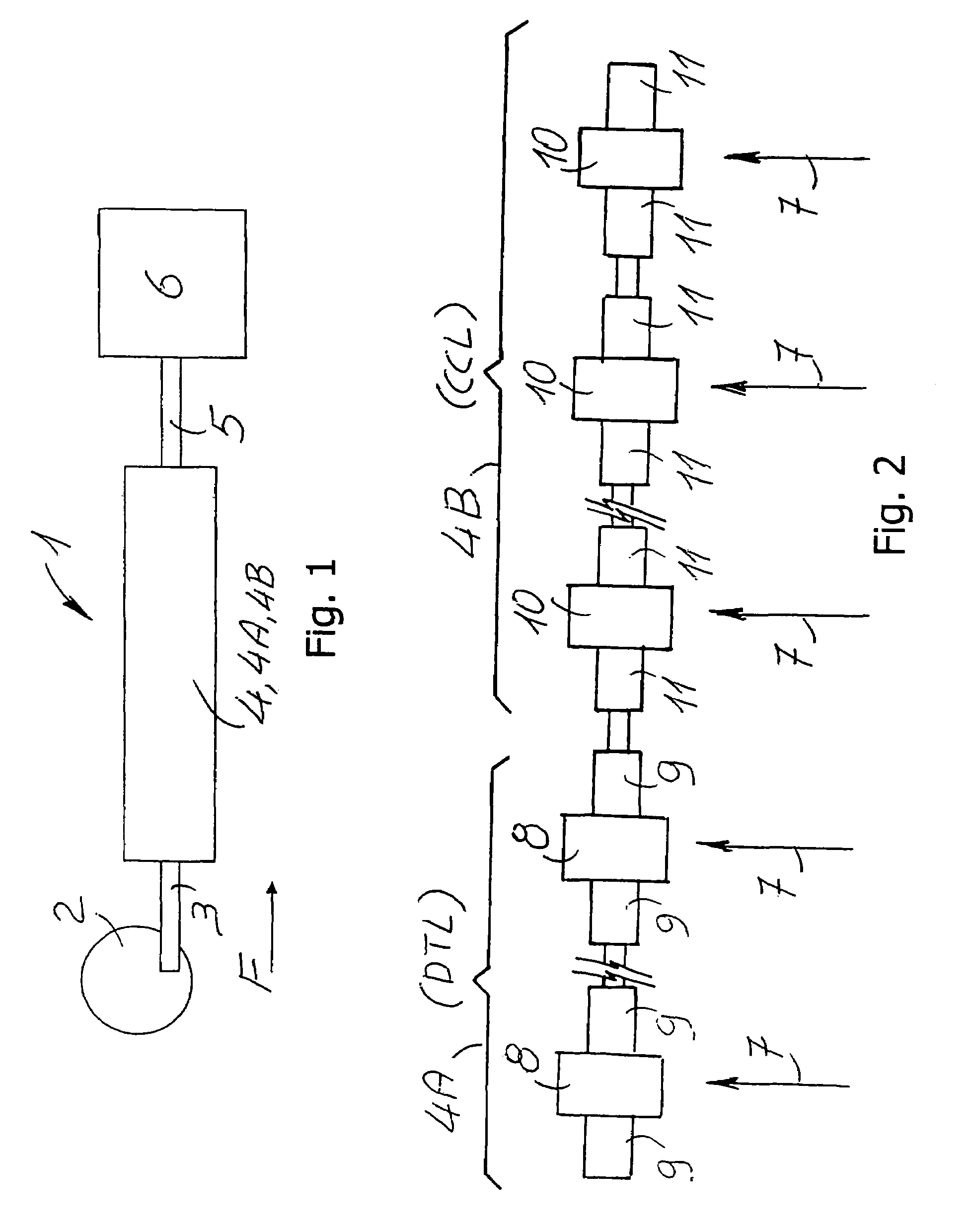

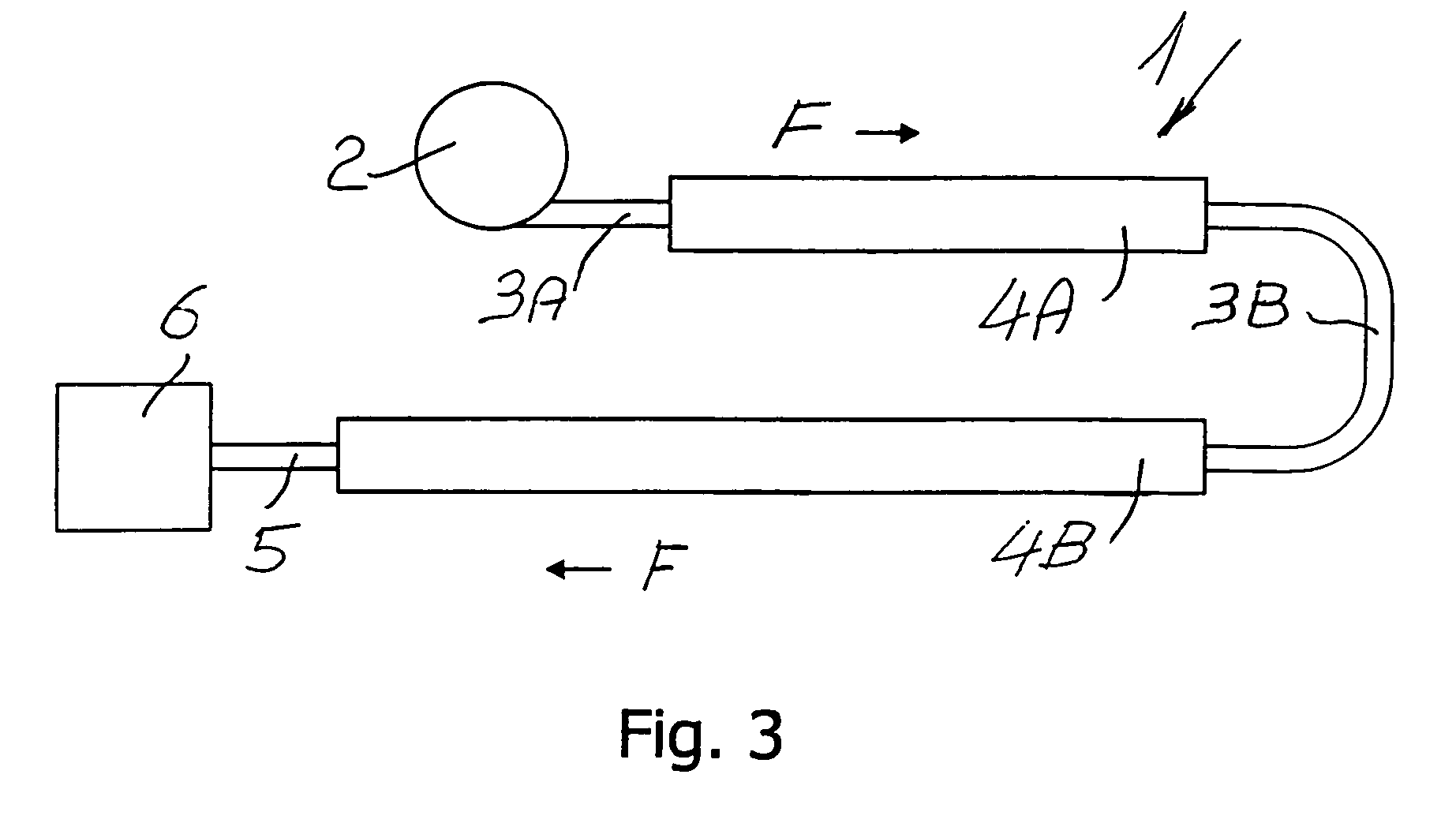

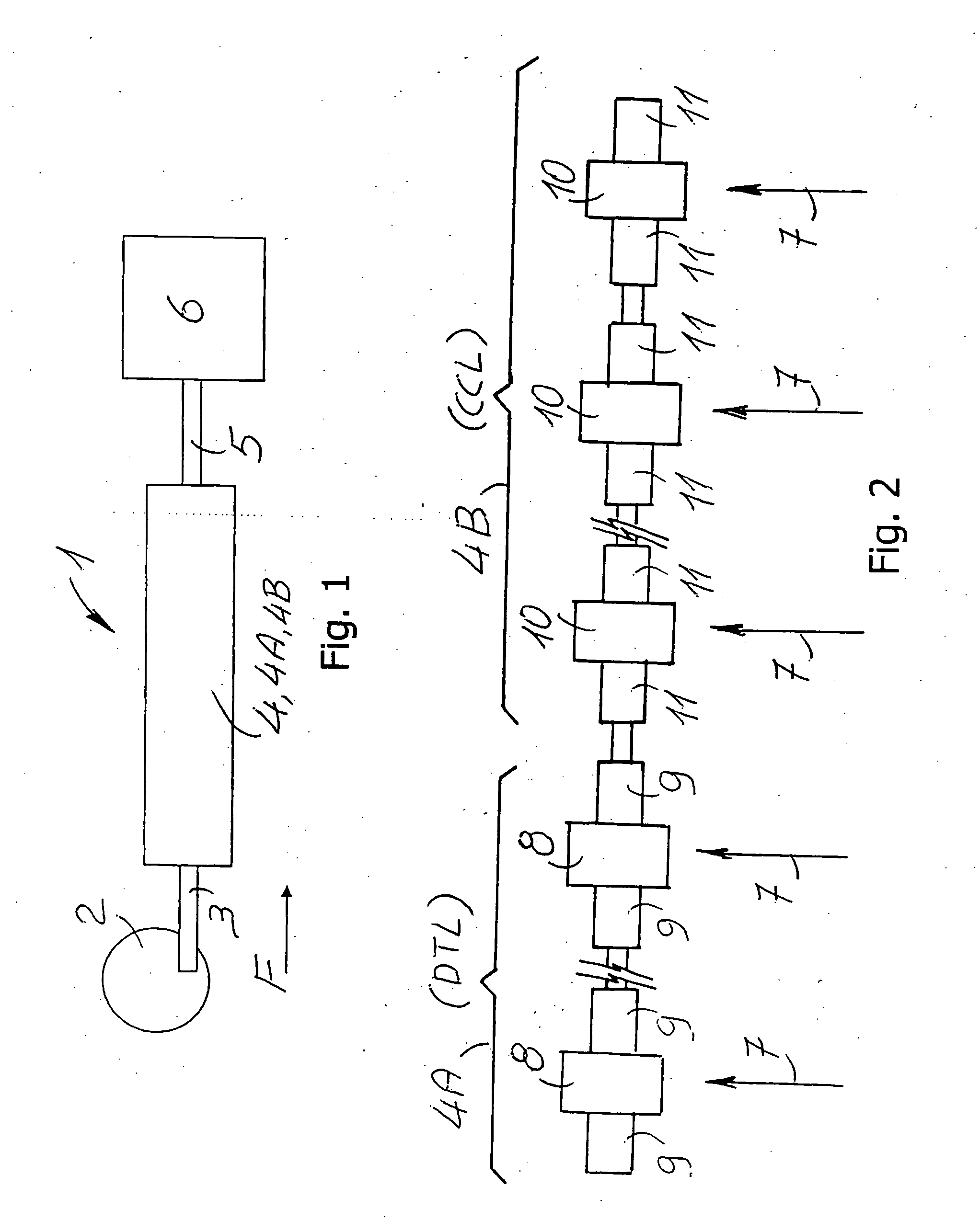

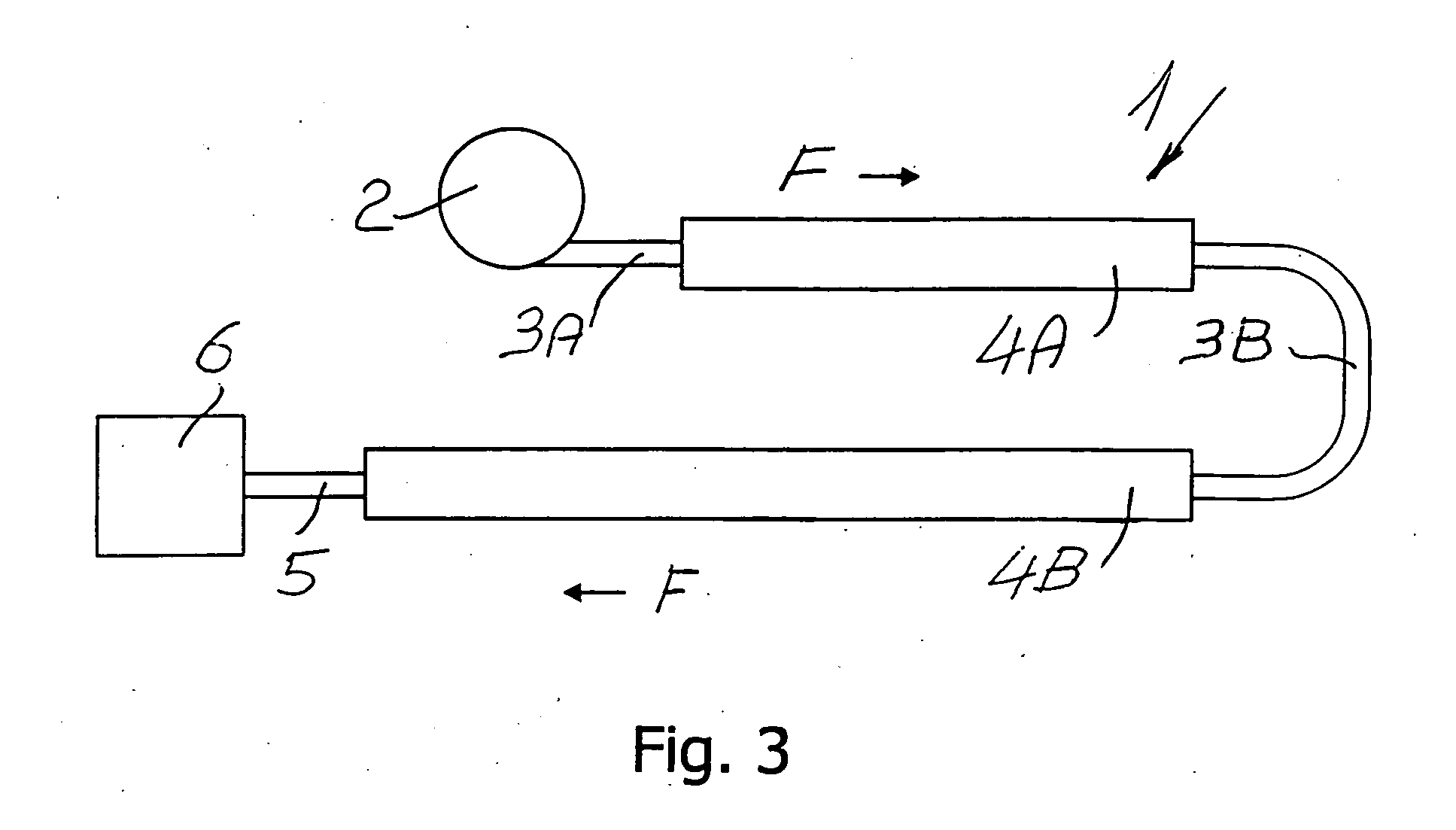

Ion acceleration system for hadrontherapy

ActiveUS7423278B2High complexityHigh errorTransit-time tubesMagnetic resonance acceleratorsTime structureHigh energy

Owner:ADVANCED ONCOTHERAPY PLC

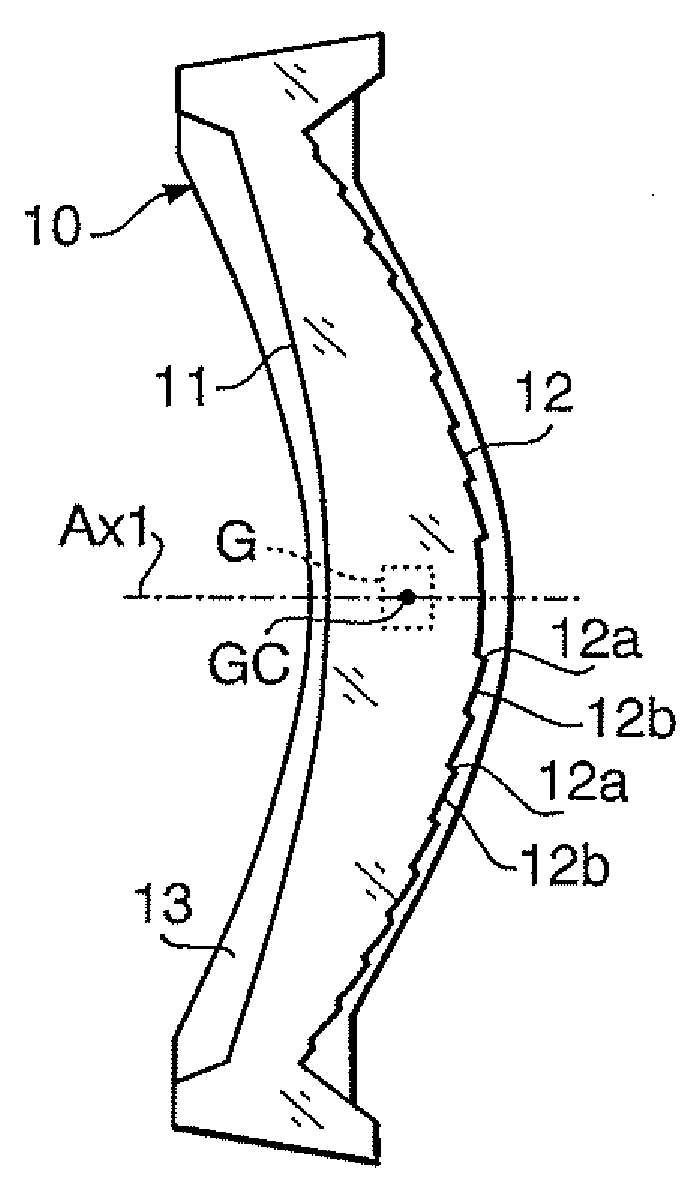

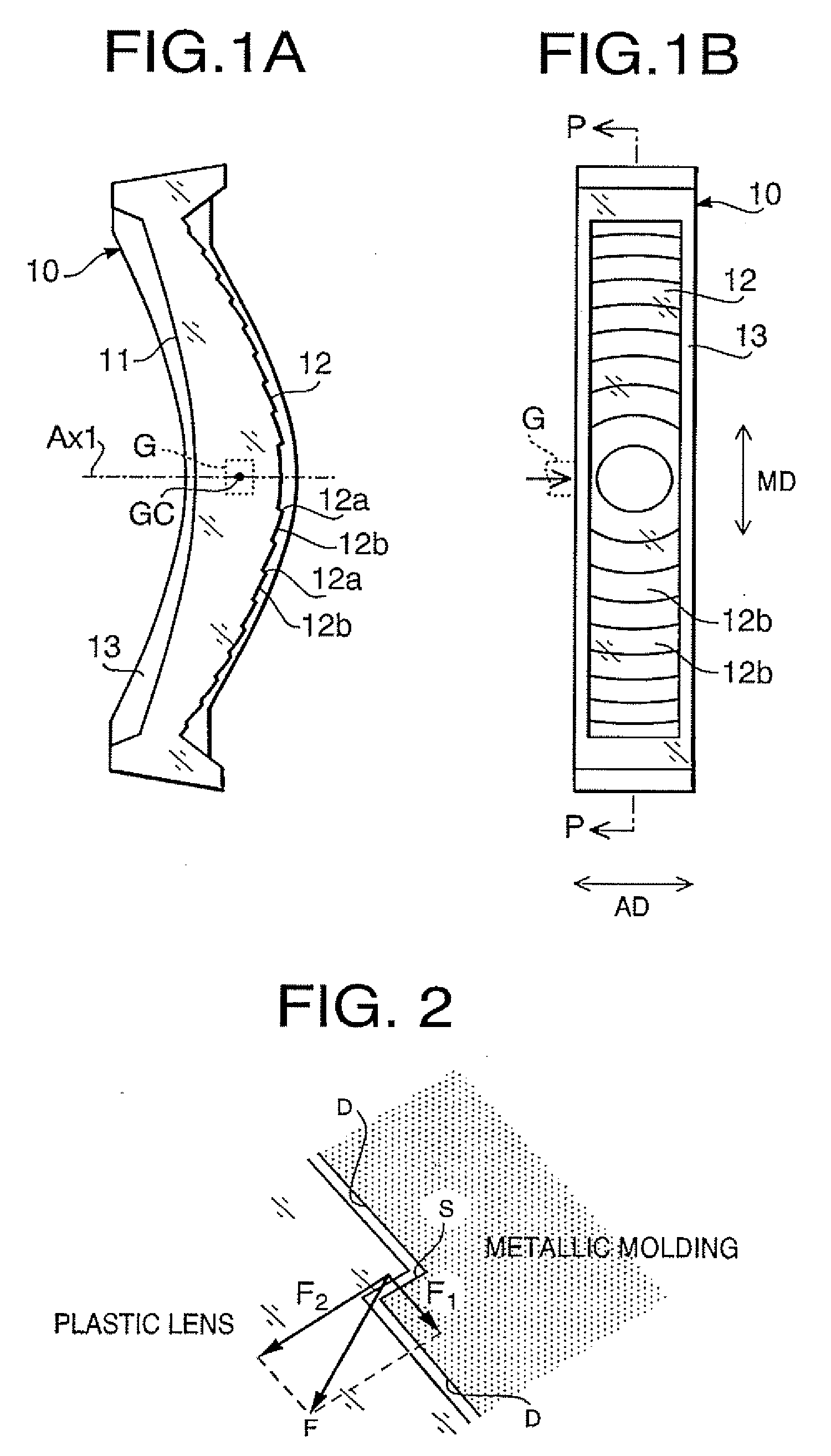

Diffractive lens and scanning lens formed with diffractive lens

InactiveUS20070002446A1Increase valueDiffractive efficiency can be retainedDiffraction gratingsLensTarget surfaceRotational axis

A scanning lens for an imaging optical system converges a beam emitted by a light source and deflected by a deflector on a target surface to form a beam spot scanning in a main scanning direction thereon. The scanning lens includes a plastic lens formed by injection molding, which has a diffractive lens structure on at least one surface thereof. The diffractive Wens structure has a plurality of annular zones arranged concentrically about a rotational axis. Each annular zone has a diffracting surface that diffracts the light beam passing therethrough. The diffractive lens structure has stepped surfaces each connecting adjoining diffracting surfaces In a plane including the rotational axis and parallel with the main scanning direction, the stepped surfaces are inclined with respect to the rotational axis so that stress working between a metallic molding for the plastic lens and each of the stepped surfaces in demolding is reduced.

Owner:HOYA CORP

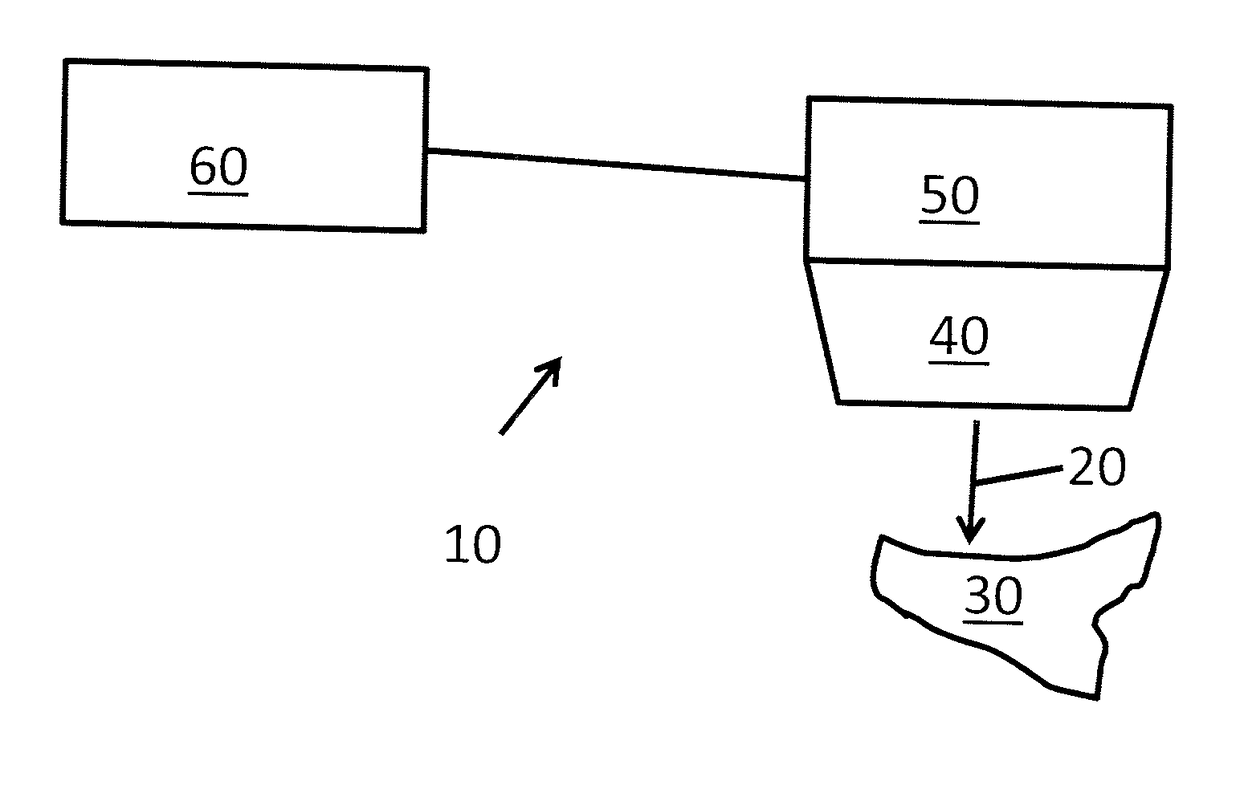

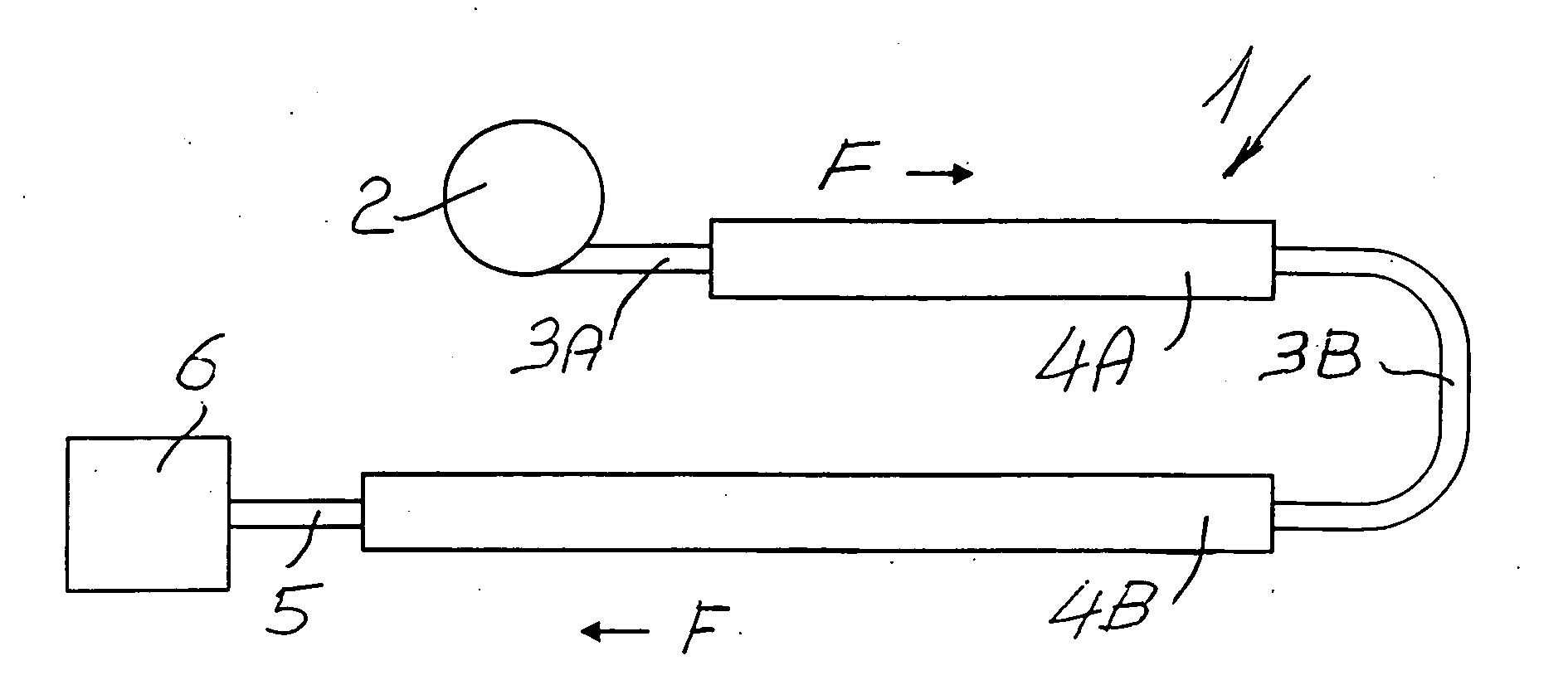

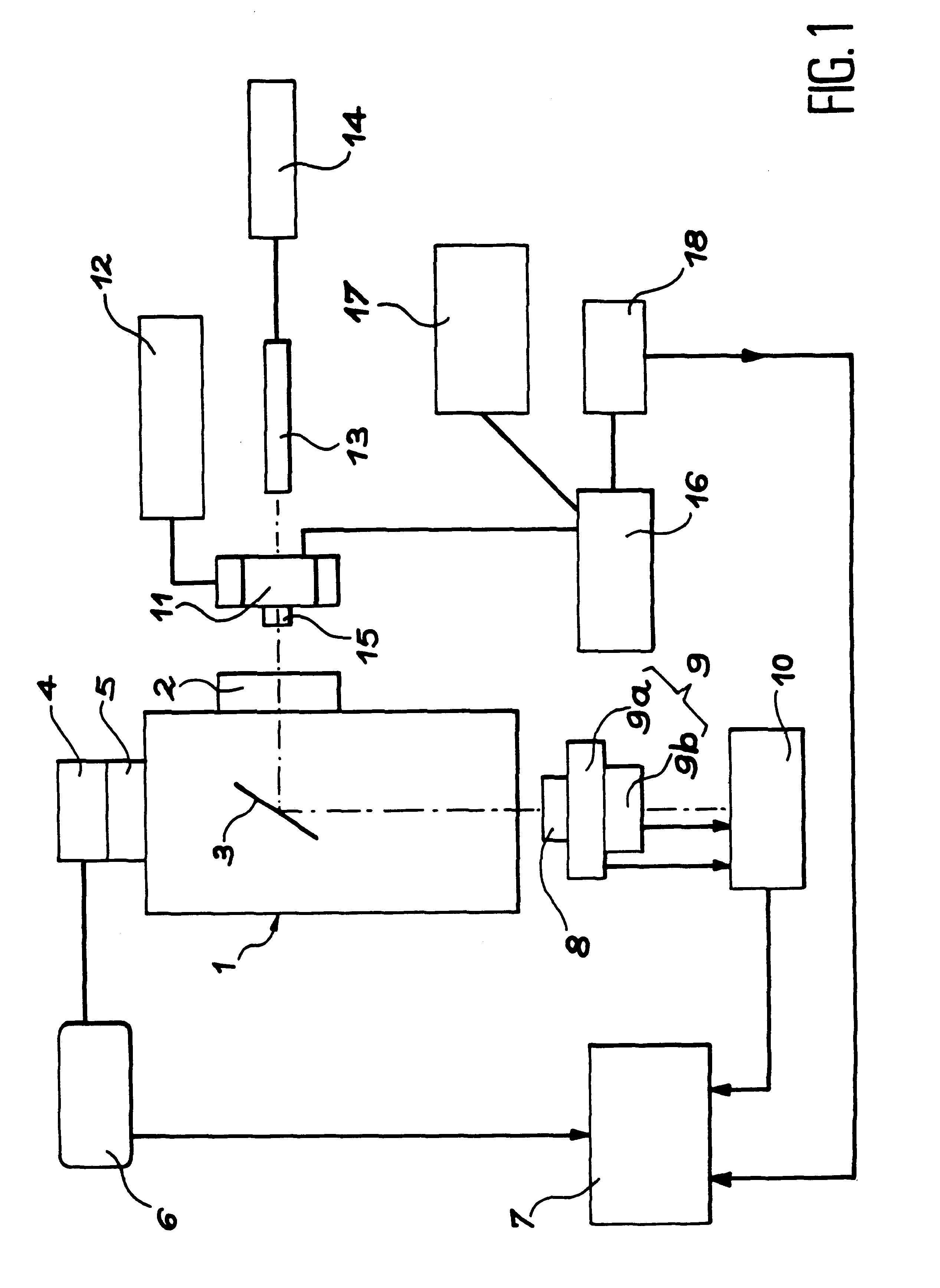

Ion acceleration system for hadrontherapy

ActiveUS20060170381A1High complexityHigh error marginTransit-time tubesMagnetic resonance acceleratorsTime structureEmissivity

A system for ion acceleration for medical purposes includes a conventional or superconducting cyclotron, a radiofrequency linear accelerator (Linac), a Medium Energy Beam Transport line (MEBT) connected, at the low energy side, to the exit of the cyclotron, and at the other side, to the entrance of the linear radiofrequency accelerator, as well as a High Energy Beam Transport line (HEBT) connected at high energy side to the radiofrequency linear accelerator exit and at the other end, to a system for the dose distribution to the patient. The high operation frequency of the Linac allows for reduced consumption and a remarkable compactness facilitating its installation in hospital structures. The use of a modular LINAC allows varying in active way the energy and the current of the therapeutic beam, having a small emittance and a time structure adapted to the dose distribution based on the technique known as the “spot scanning”.

Owner:ADVANCED ONCOTHERAPY PLC

Device and method for particle beam delivery

ActiveUS8916838B2Maximizing numberReduce impactChemical conversion by chemical reactionX-ray/gamma-ray/particle-irradiation therapyMedicineParticle beam

The present invention relates to a particle therapy system that comprises a spot scanning system to irradiate with a particle beam a plurality of spots in a layer of a target with prescribed spot doses for each spot of the layer. The therapy system is further adapted to perform multiple paintings of the layer and to deliver partial spot doses to selected spots of the layer during each painting time so that each spot of the layer will have received its prescribed dose after completion of the multiple paintings. The therapy system further comprises means for setting the partial spot doses and the number of times that a spot will be selected for irradiation in the course of the multiple paintings to such values that any spot of the layer will never have to be irradiated with a partial dose which would fall below a minimum dose deliverable by the system, and this whatever the number chosen for the number of layer paintings.The invention also relates to a corresponding irradiation method.

Owner:ION BEAM APPL

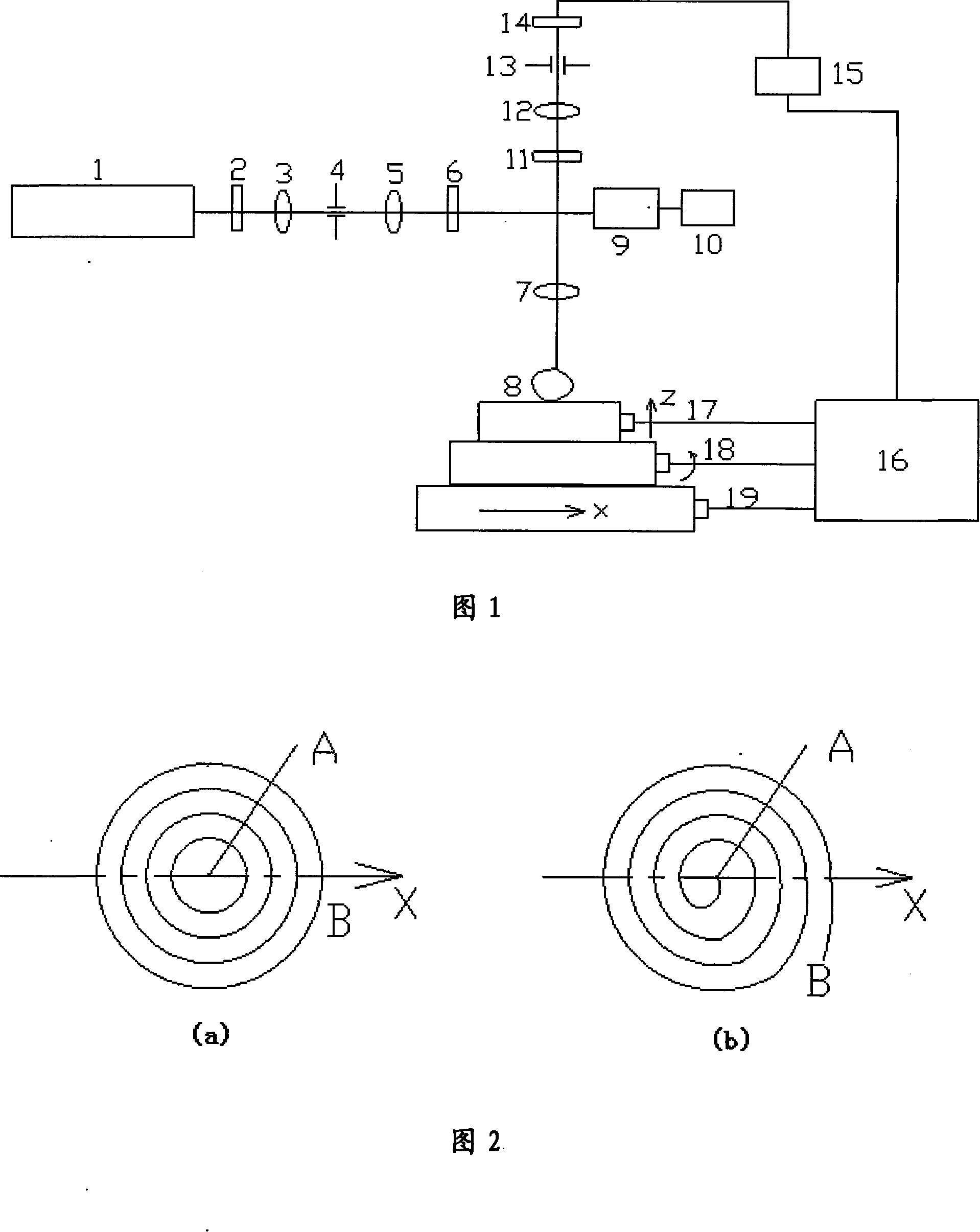

In plane scanning method and system for point scanning laser confocal microscope

The utility model discloses a scanning method and system used for scanning laser cofocal microscope, which is characterized in that: first a sample table, a computer and a scanning cofocal microscope measuring objective lens are combined to a 3D scanning system of laser cofocal scanning microscope so as to realize automatic scanning control; and then the to-be-measured sample is located on the sample table; the 3D scanning system makes the sample table rotate and move horizontally in one-dimensional direction in order until one layer of the to-be-measured sample is scanned, following the 3D scanning system resets and then scans the next layer of the to-be-measured sample until the to-be-measured sample measurement is finished. In the case of no changing light way, scanning is finished by the rotation of the sample table, thereby overcoming the defect that the prior scanning table has complicated mechanism and slow scanning speed. The utility model is mainly applied in the laser cofocal microscope for spot scanning, and can also be applied in similar spot scanning measurement system.

Owner:XI AN JIAOTONG UNIV

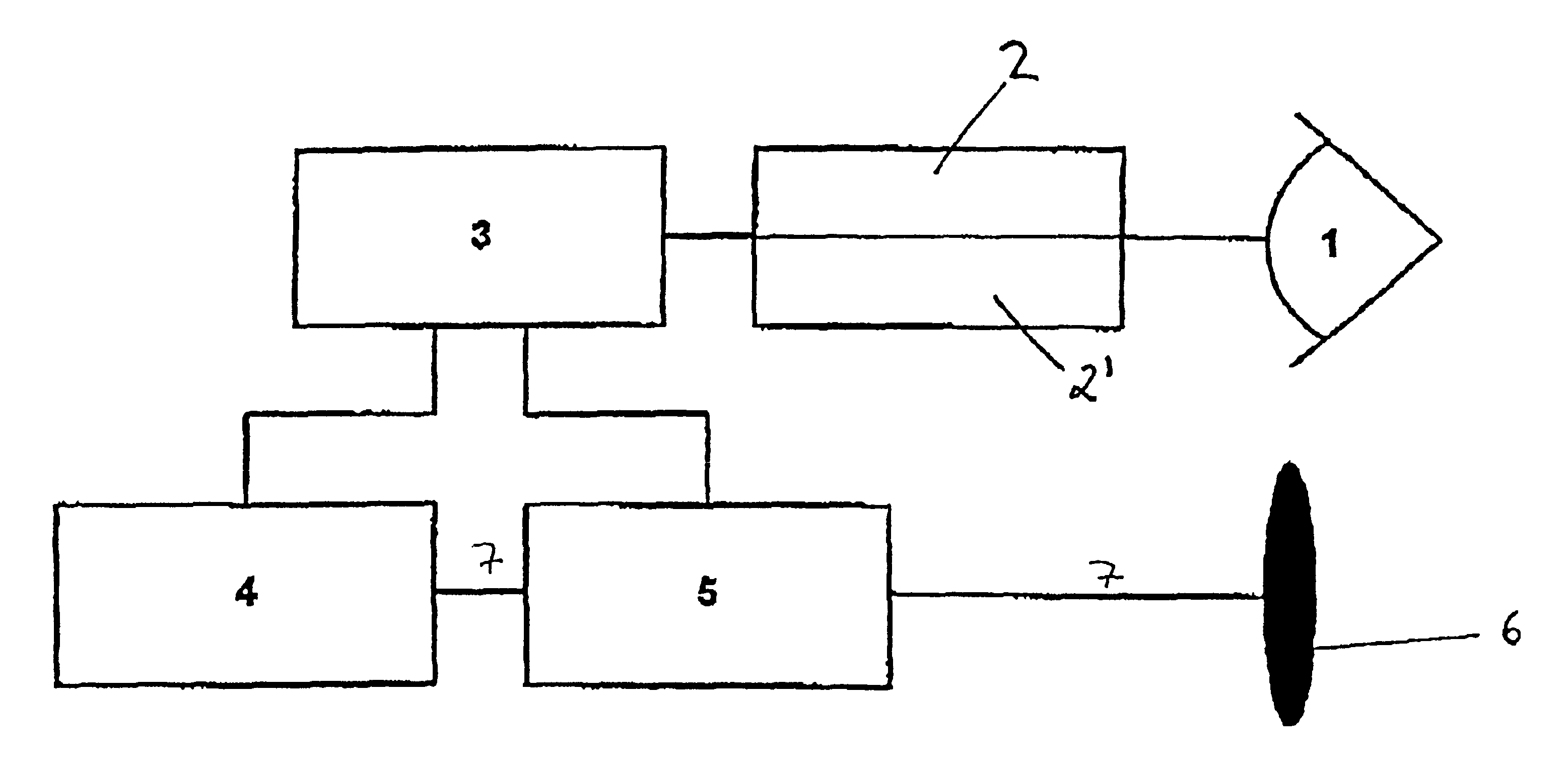

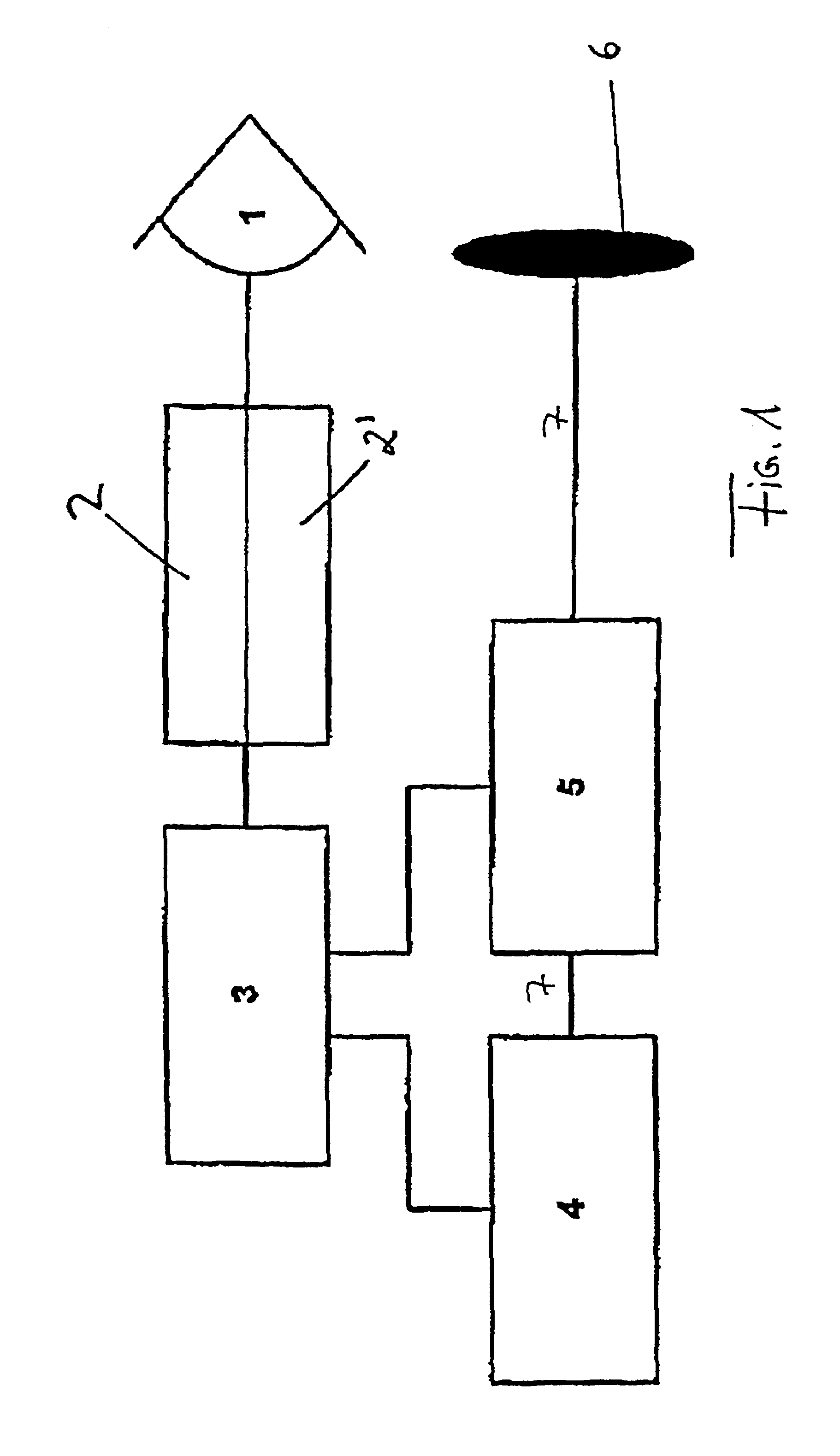

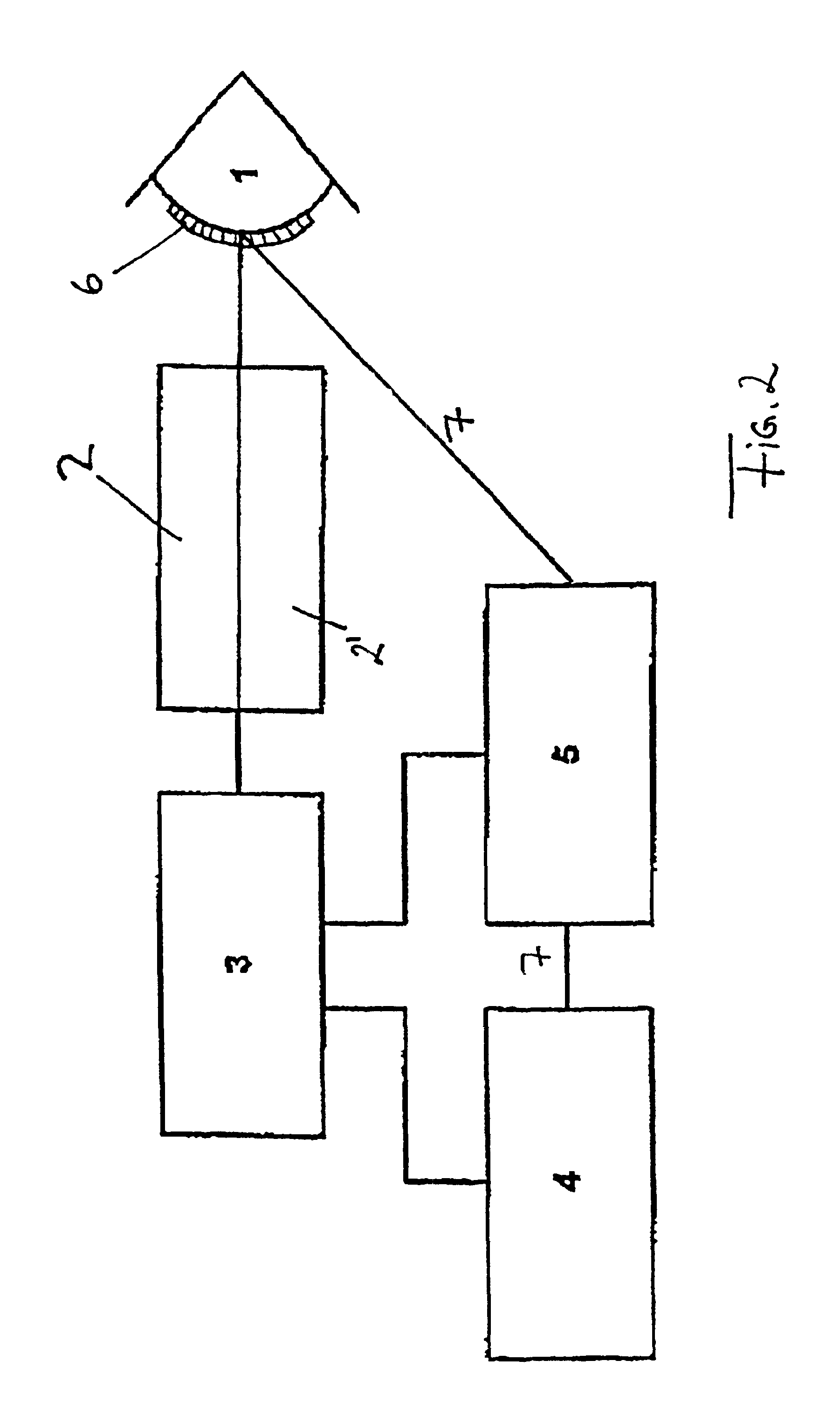

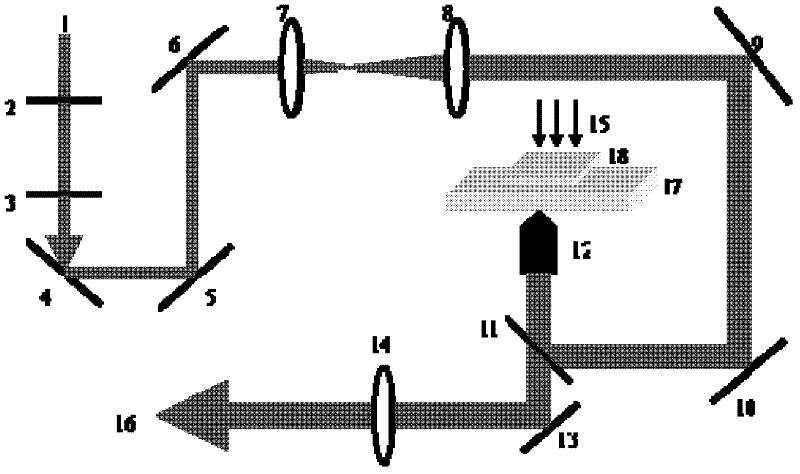

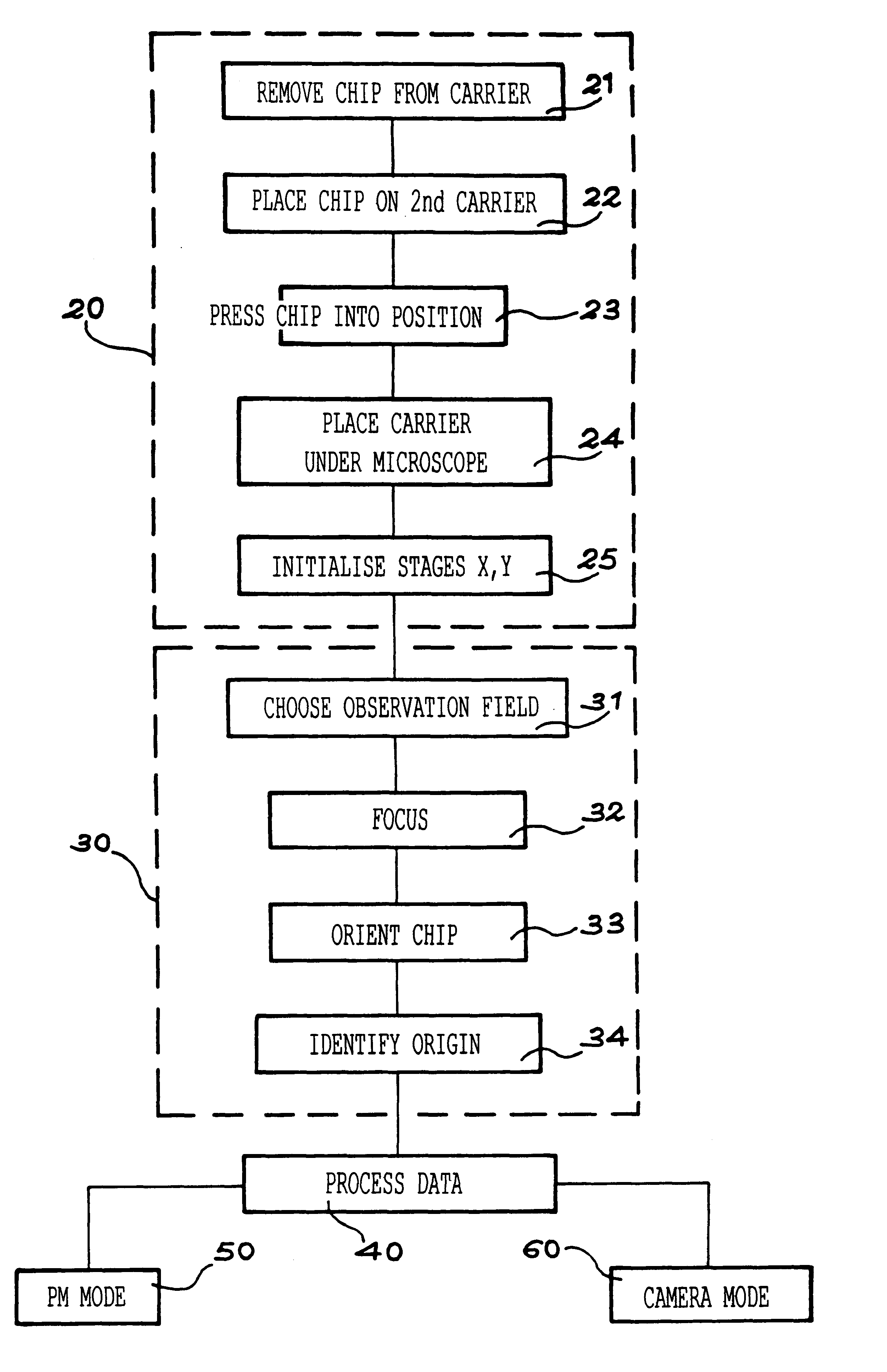

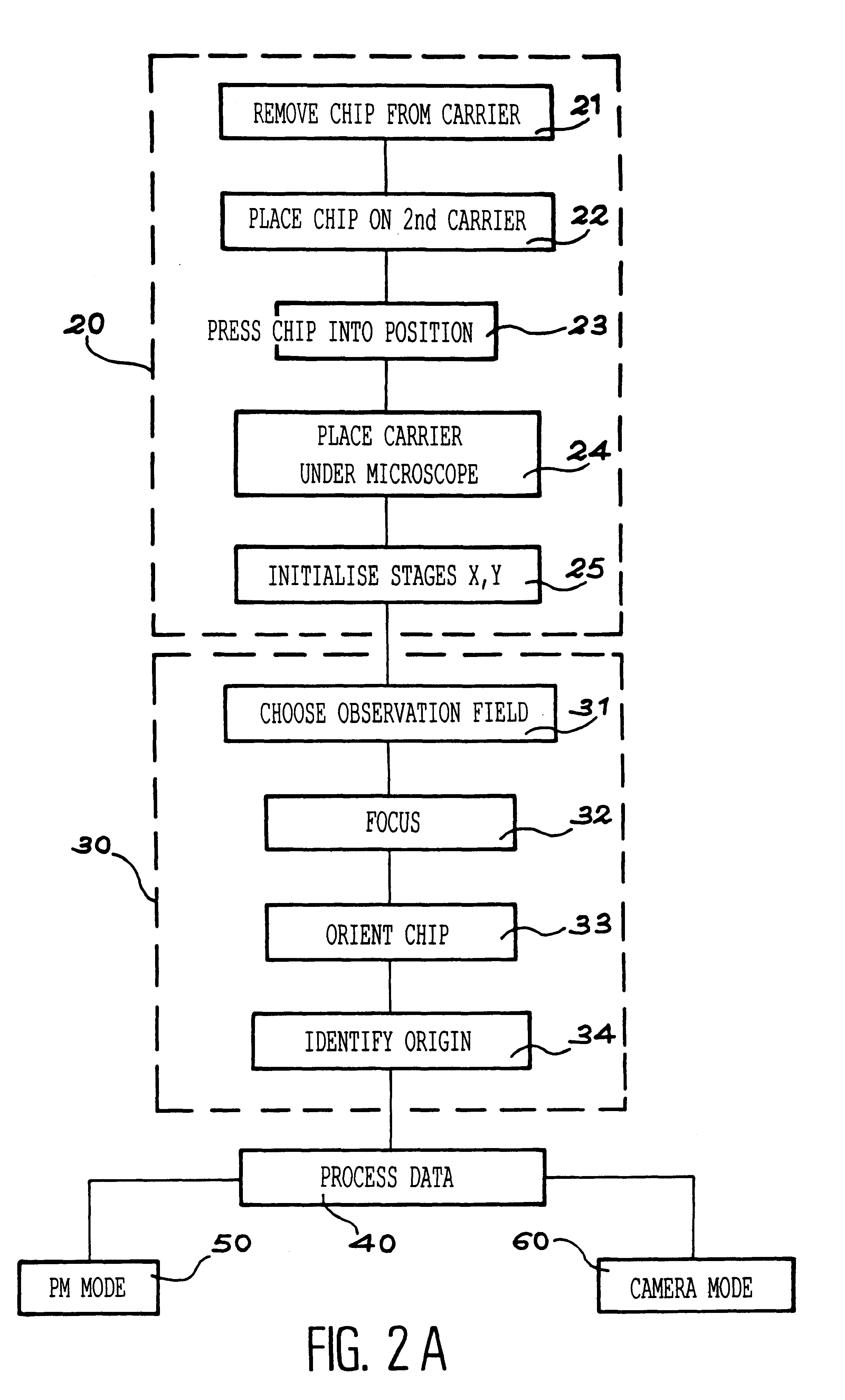

System for determining the concentration of a substance mixed with a fluorophor, its method of implementation

InactiveUS6510237B1X-ray spectral distribution measurementMaterial analysis using wave/particle radiationPhysicsFluorescence

The invention concerns a system, and its method of implementation, to determine the concentration of a substance mixed with a fluorophor and contained in one or more contacts of a matrix of contacts; it comprises:a microscope (1) associated with a magnifying objective lens (2) and with image acquisition means (4,5) to achieve a microscope image of the fluorescence of one of the contacts of the matrix or part of this contact;illumination means (11, 13) emitting a first beam to enable image acquisition in white light of said contact, and a second beam to excite the fluorophor contained in said contact;deflector means (15) for the second beam to ensure point by point scanning of the contact of the matrix;recording means (6, 7) to record the contact image; andprocessing means (6,7) of this image to quantify the fluorescence of the contact and determine the concentration of the substance.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Backscatter and transmission combined safety detector of X rays

ActiveCN102707324AResolve mutual interferenceImprove the detection rateNuclear radiation detectionNon destructiveX-ray

The invention relates to a backscatter and transmission combined safety detector of X rays, belonging to the technical field of social safety inspection and safeguard detection devices and non-destructive detection devices. The backscatter and transmission combined safety detector disclosed by the invention is mainly characterized in that a backscatter ray slit and a transmission ray bundle slit are arranged on a rotating cylinder, and the two slits respectively generate a flying-spot scanning ray bundle and a transmission ray bundle, so that the same X-ray source and the same ray bundle scanning generator can be used for simultaneously providing two kinds of ray image information of a detected object to comprehensively perform the detection and judgment and further increase the detection ratio. The backscatter and transmission combined safety detector of the X rays is characterized by simple structure, low cost and the like, and can be used for detection of bags and suitcases, scanning of the human body and safety detection on the aspects such as industry (flaw detection), military and the like.

Owner:貊梁

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com