Patents

Literature

182 results about "Nano machining" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

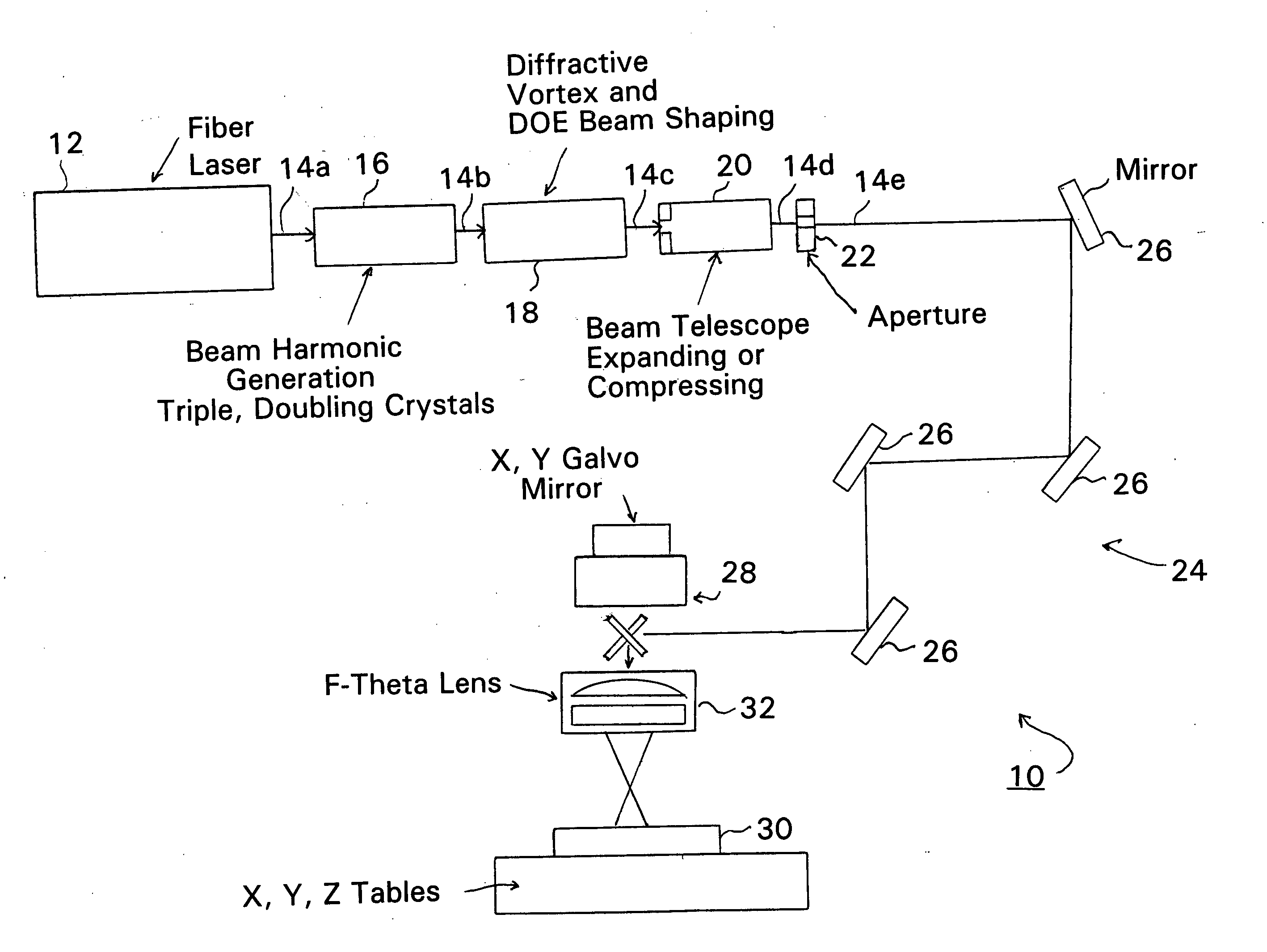

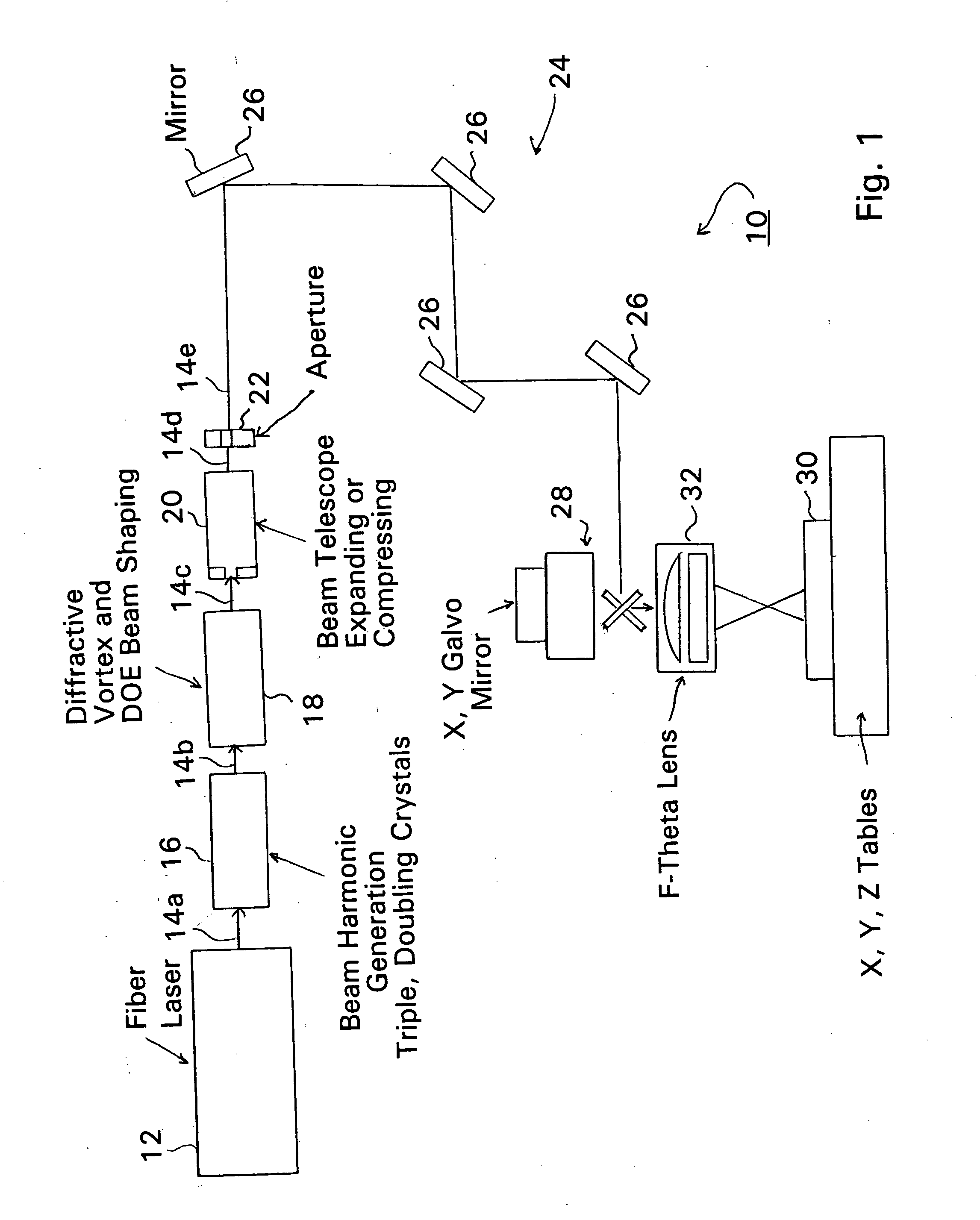

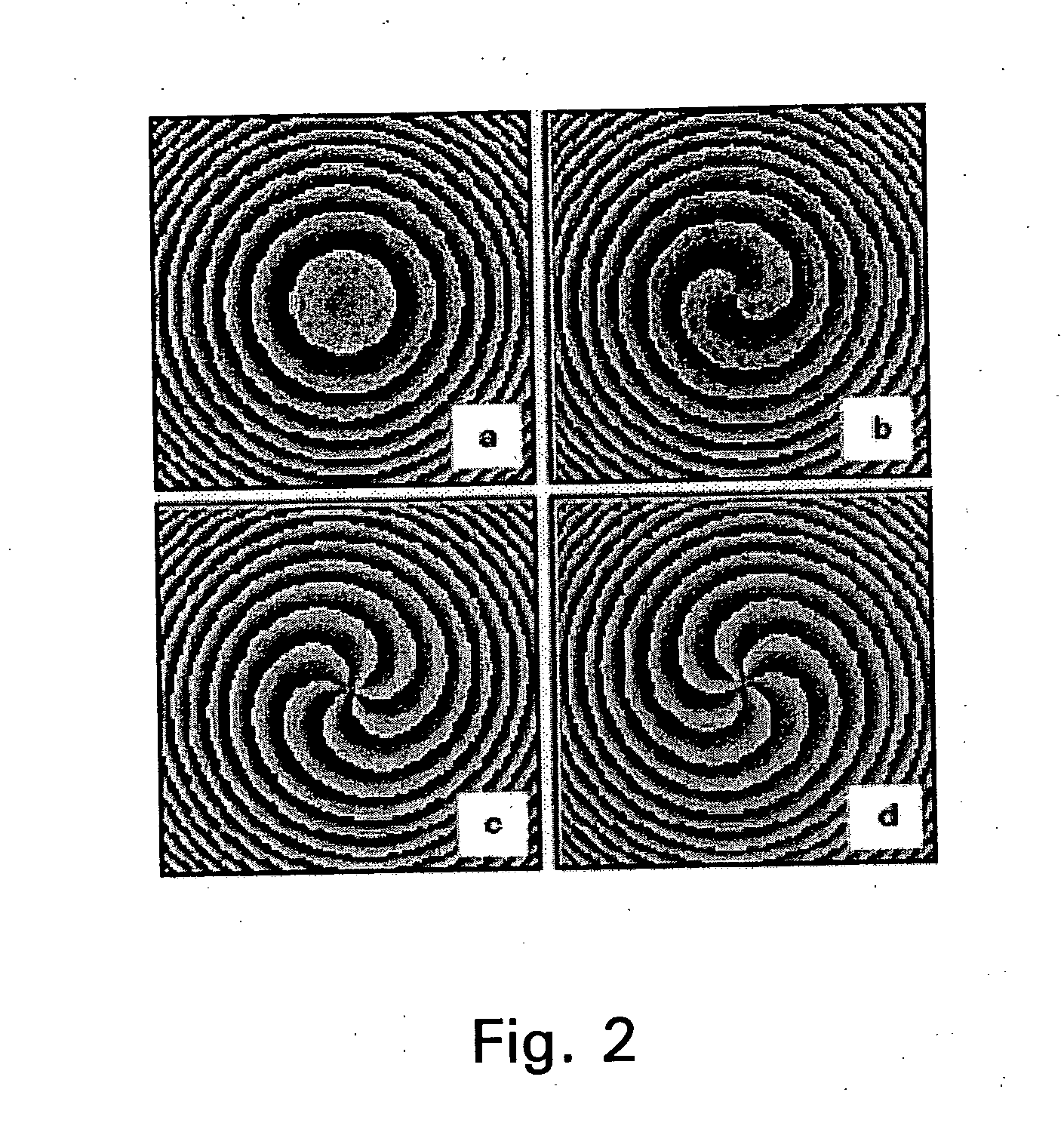

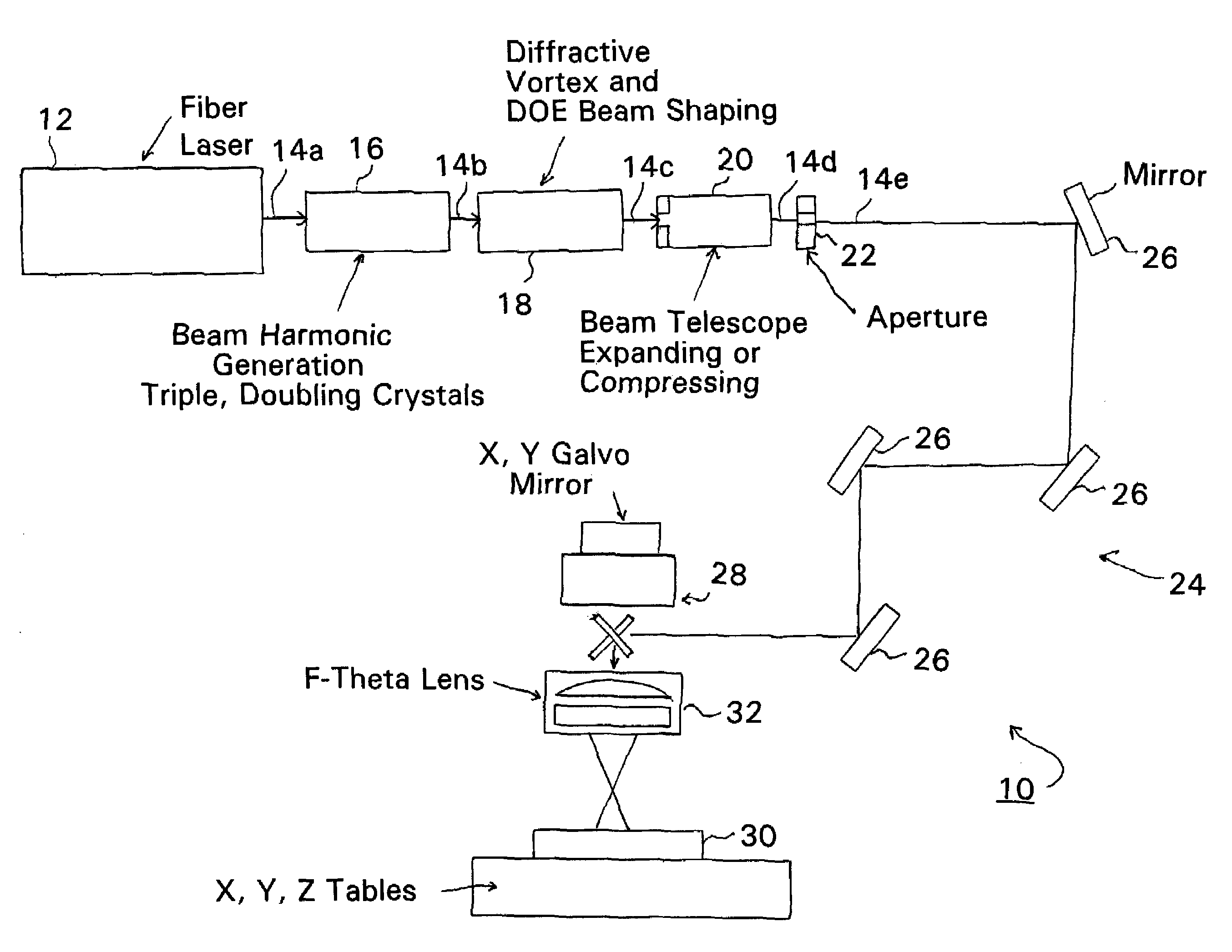

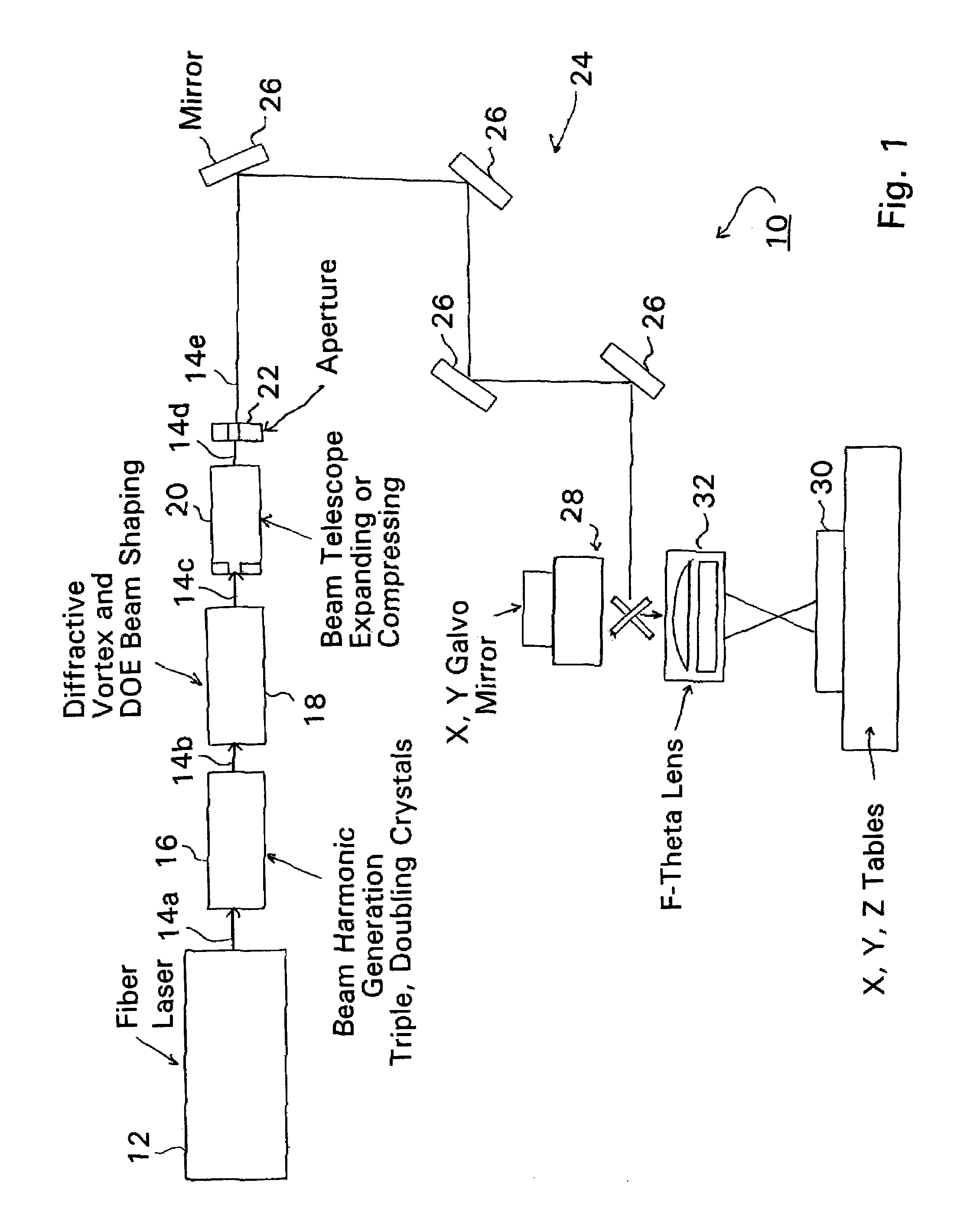

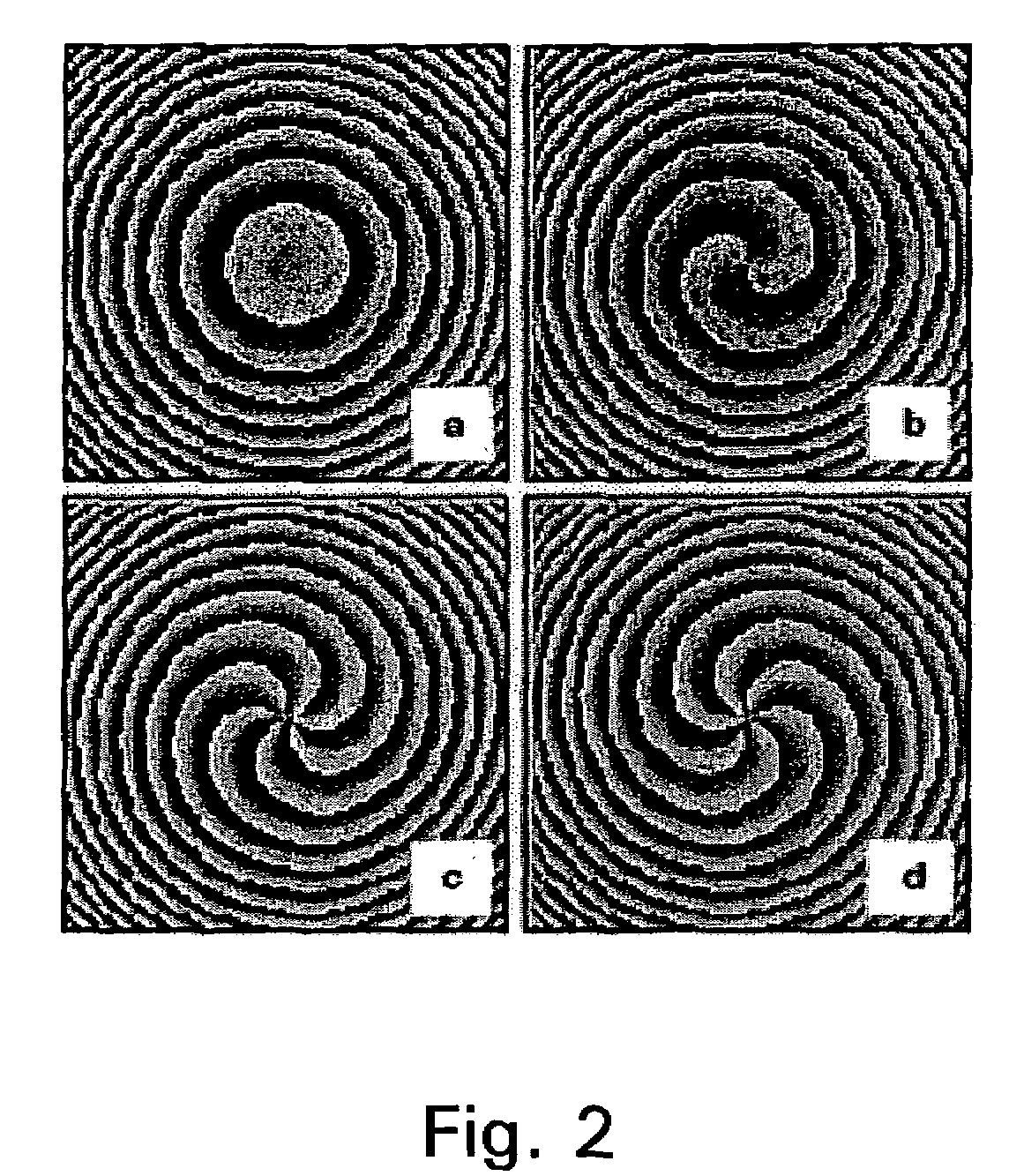

Fiber laser based production of laser drilled microvias for multi-layer drilling, dicing, trimming or milling applications

InactiveUS20060065640A1Additive manufacturing apparatusLaser using scattering effectsNano machiningOptoelectronics

Fiber lasers and methods for constructing and using fiber lasers for micro- / nano-machining with output beams including stacked pulses and combinations of continuous wave, pseudo-continuous wave and pulse sequence components.

Owner:HITACHI SEIKO LTD

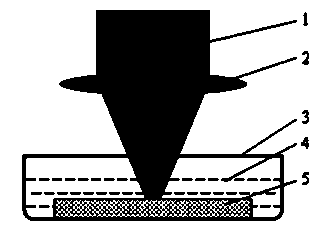

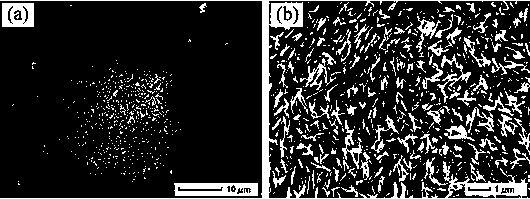

Method for preparing multistage metal micro-nanostructures inside micro fluidic chip

InactiveCN102311095ADecorative surface effectsChemical vapor deposition coatingMicro nanoSurface-enhanced Raman spectroscopy

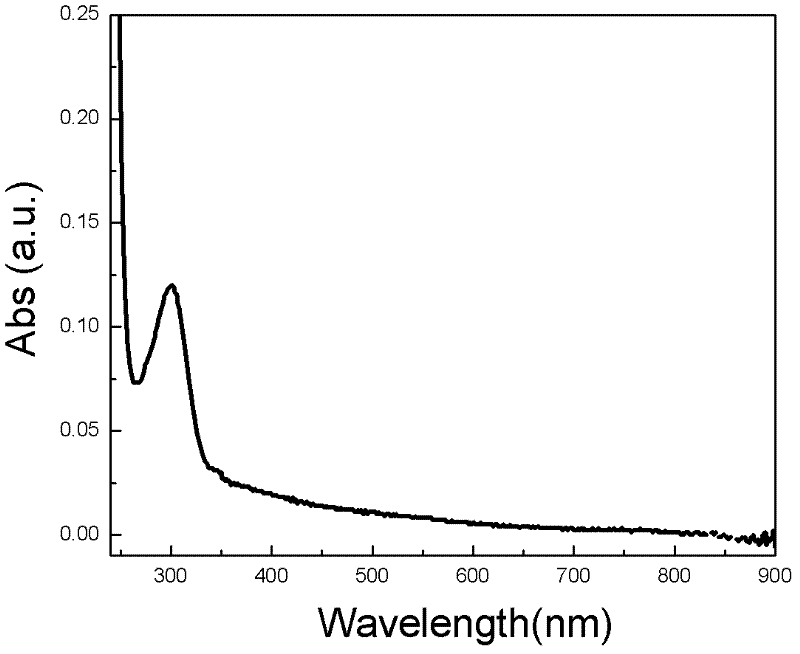

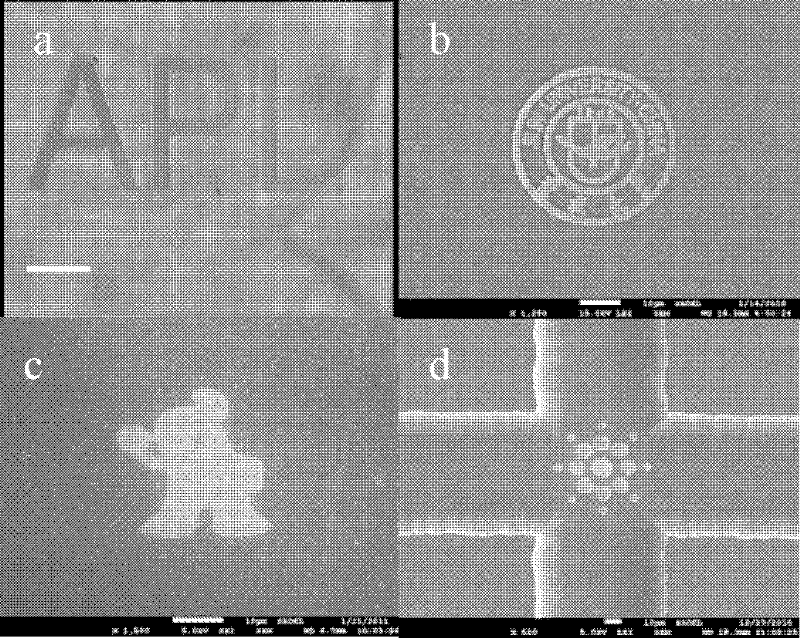

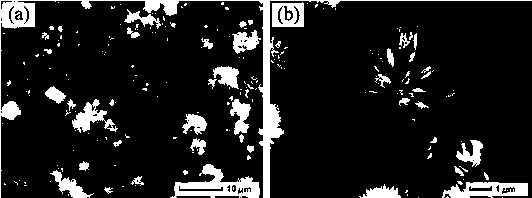

The invention relates to a method for selectively preparing or integrating multistage silver micro-nanostructures inside various plane substrates and micro fluidic chip channels by the utilization of the femtosecond laser inducing metallic silver reduction technology. In addition, the silver multistage micro-nanostructure substrate prepared by the method is used as a reinforced substrate for surface-enhanced raman spectroscopy SERS. The method provided by the invention comprises the following steps of: preparing a silver plating solution for femtosecond laser micro-nano machining, establishing a femtosecond laser micro-nano machining system for realizing multi-point scan in the silver plating solution, placing the silver plating solution and the substrate into the femtosecond laser micro-nano machining system and preparing the multistage silver micro-nanostructures on the substrate. According to the invention, a laser beam scans in the silver plating solution along a track designed in advance by a program. The preparation method is independent of the smoothness of the substrate. In particular, the preparation of silver multistage structure SERS substrate can be accomplished on the bottom of the micro fluidic chip channels, thus realizing catalysis and surface-enhanced raman test application.

Owner:JILIN UNIV

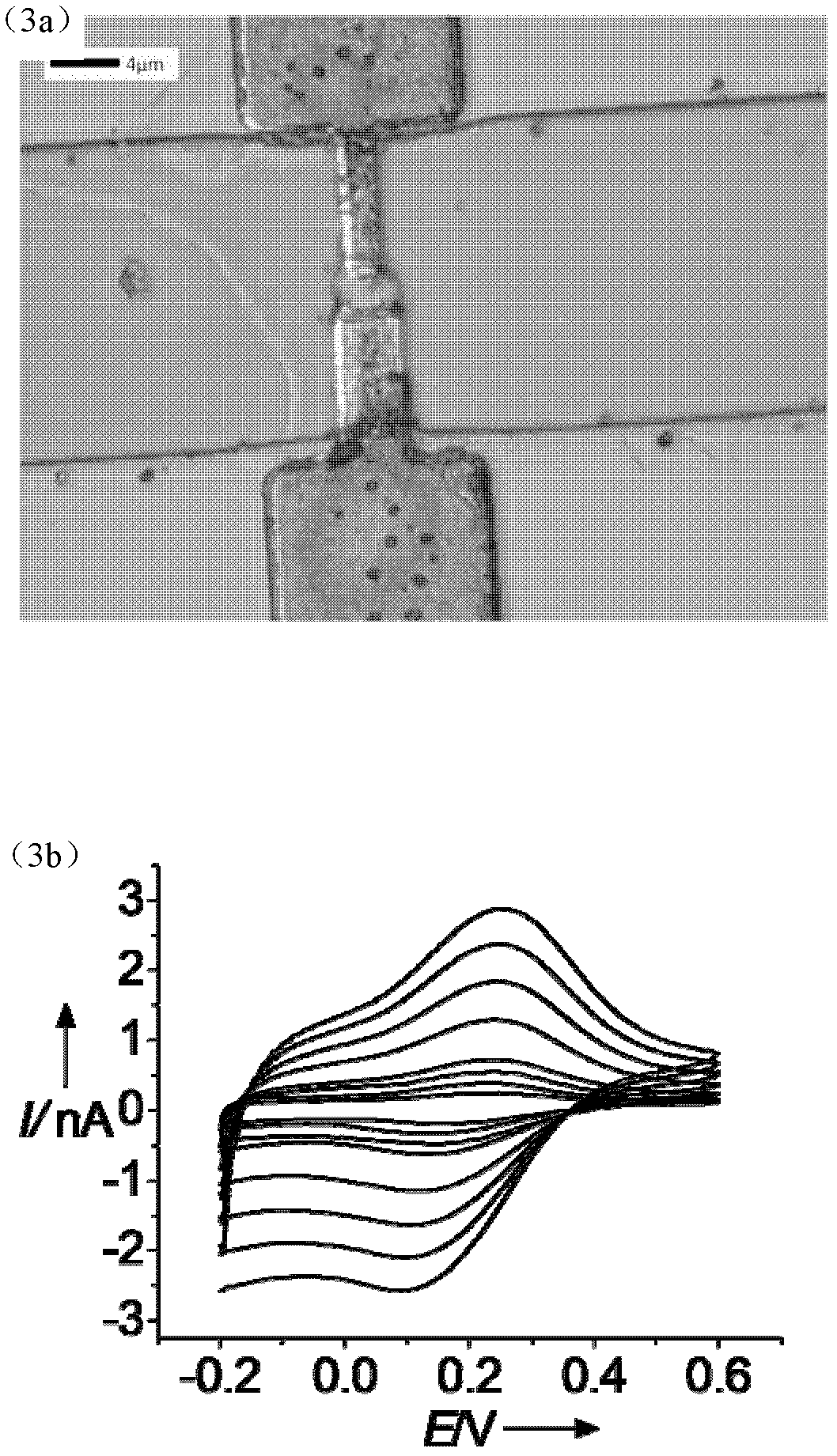

Micro-nano machining method based on electrochemical micro-nano system for functional material and device thereof

InactiveCN102887478AEfficient processingDecorative surface effectsChemical vapor deposition coatingAll solid stateInformation processing

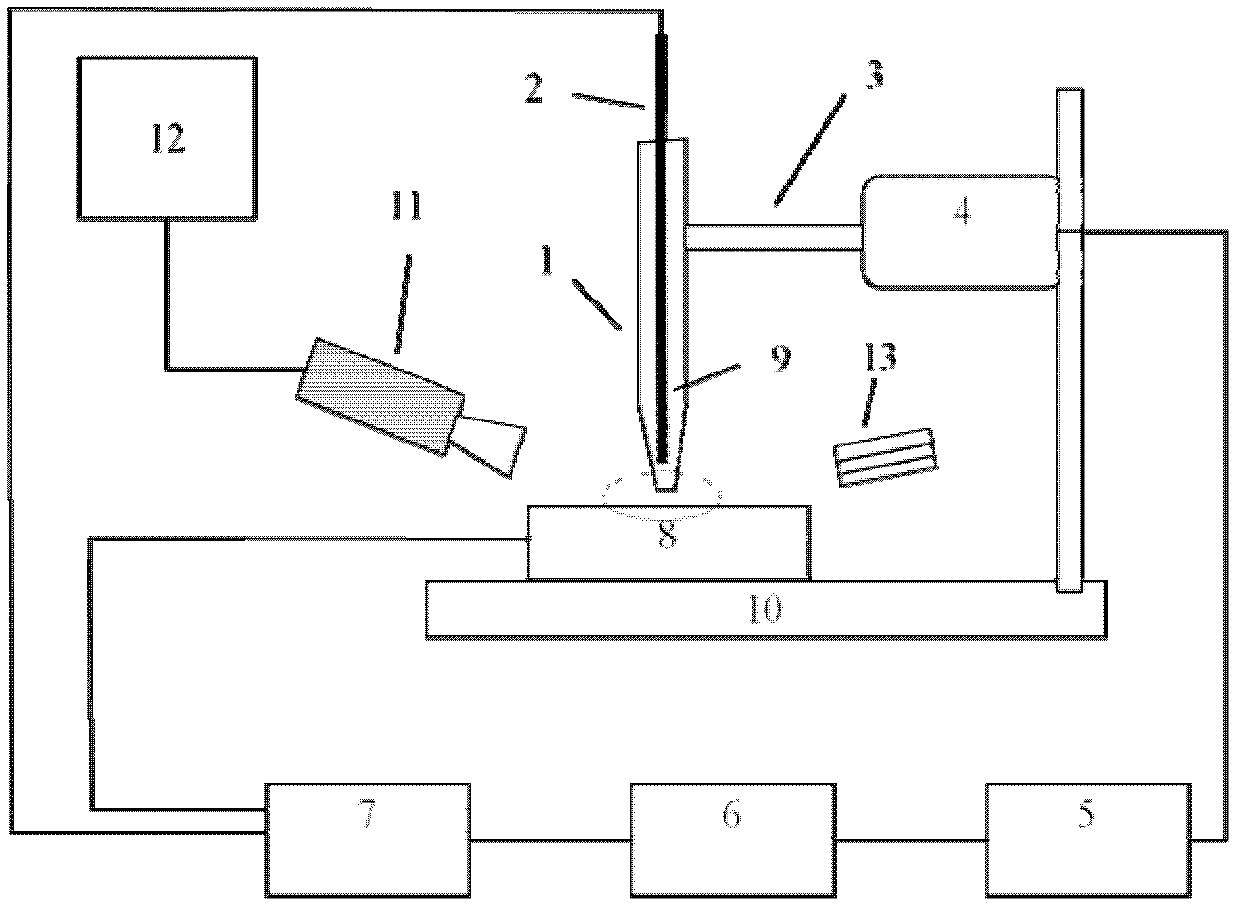

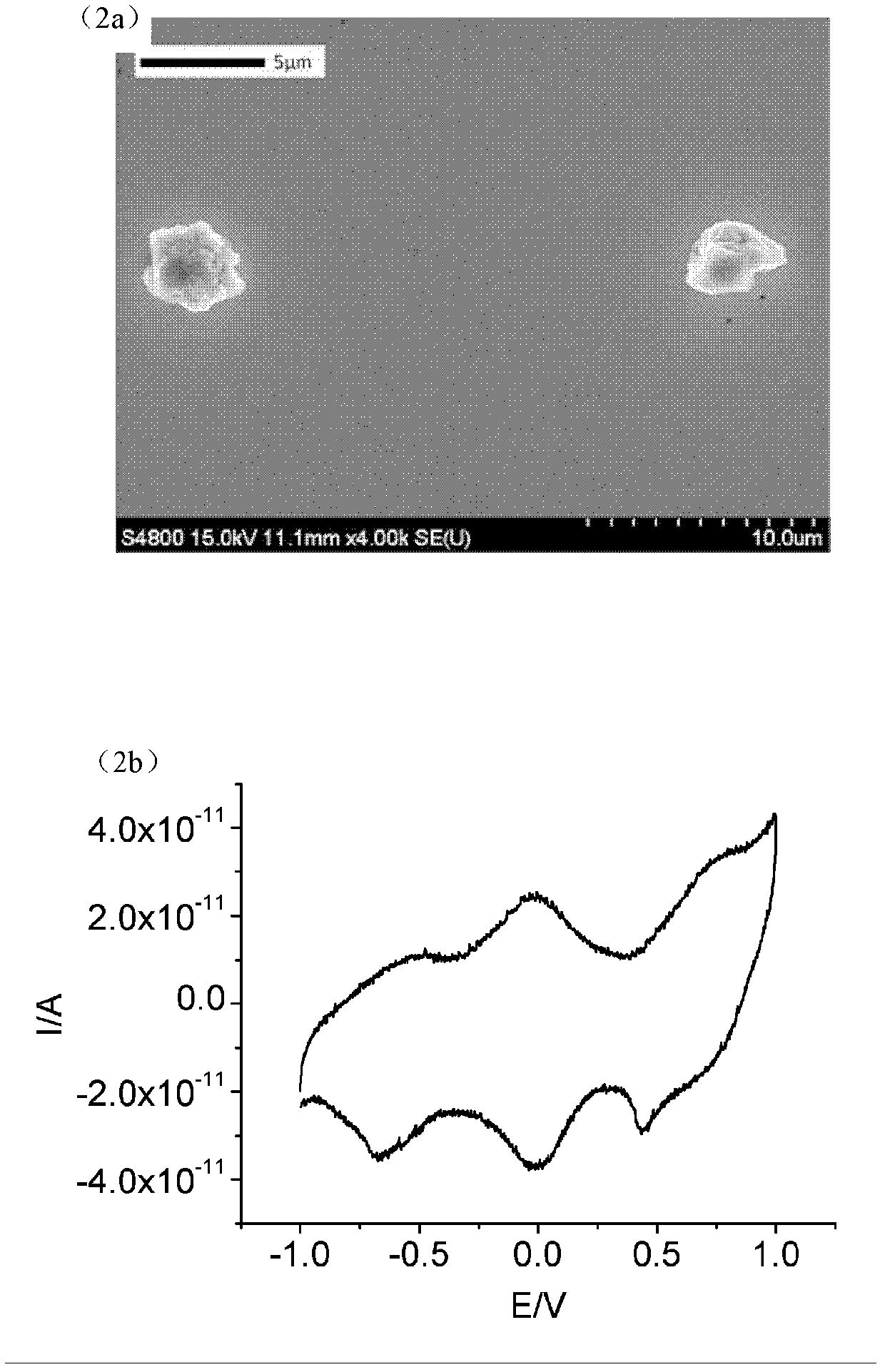

The invention provides a micro-nano machining method based on an electrochemical micro-nano system for a functional material and a device thereof. According to the method and the device, a functional material of a micro-nano scale can be synthesized in situ on a specific substrate or a micro-nano chip for constructing an all-solid-state micro-nano device. The method comprises the following steps of: constructing an electrochemical reactor of a micro-nano scale to limit a physical-chemical process for synthesizing the functional material in a space of a micro-nano scale; and regulating and controlling a micro-area physical-chemical environment on a conducting substrate or a chip to be processed to synthesize the functional material of the micro-nano scale in situ on the conducting substrate or the micro-nano chip. The device comprises an electrochemical reactor of a micro-nano scale, an electrochemical workstation, a three-dimensional inching system of micro-nano accuracy, a video monitor and an information processing computer.

Owner:XIAMEN UNIV

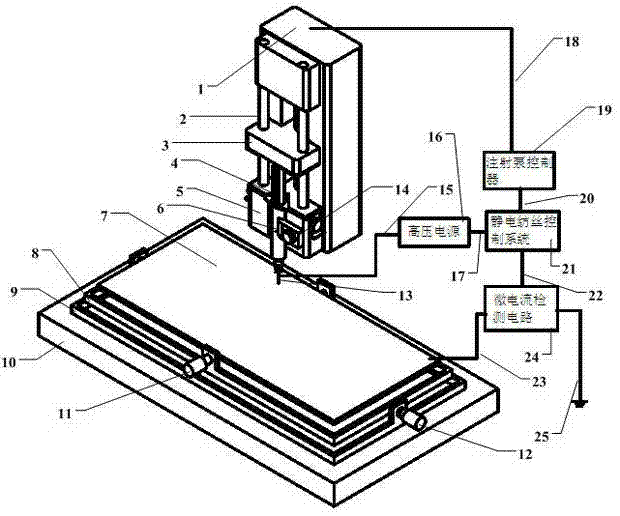

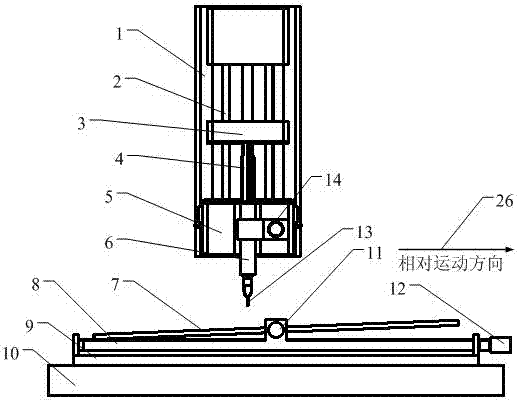

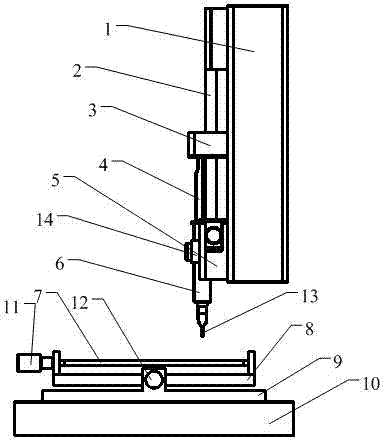

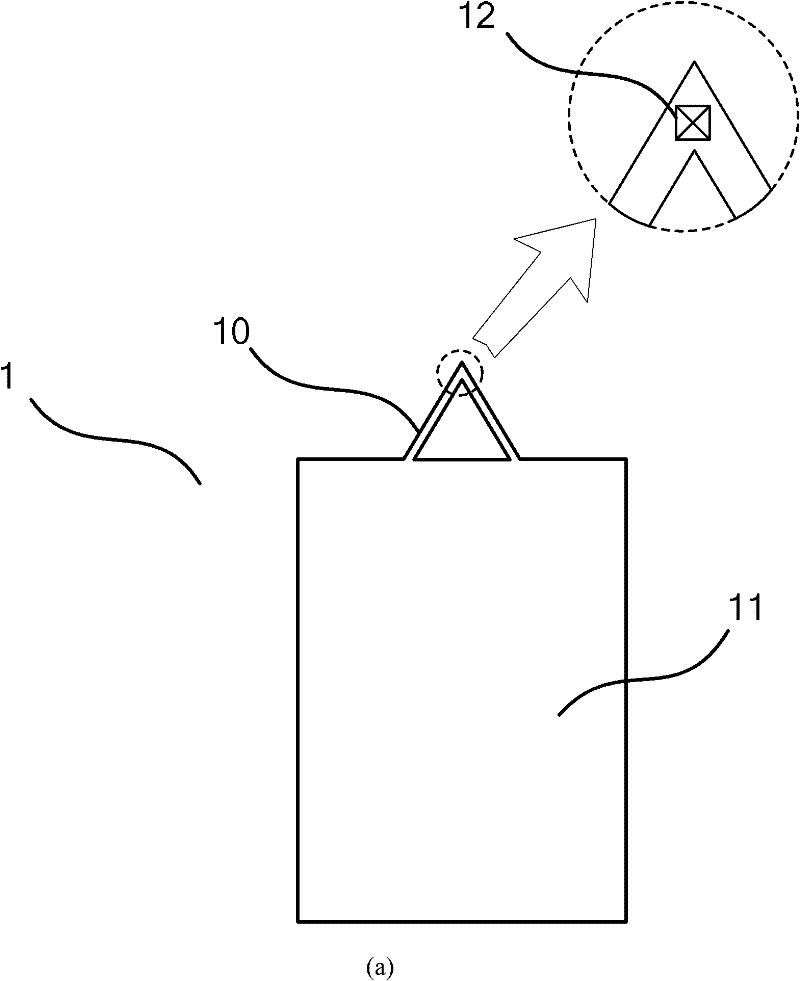

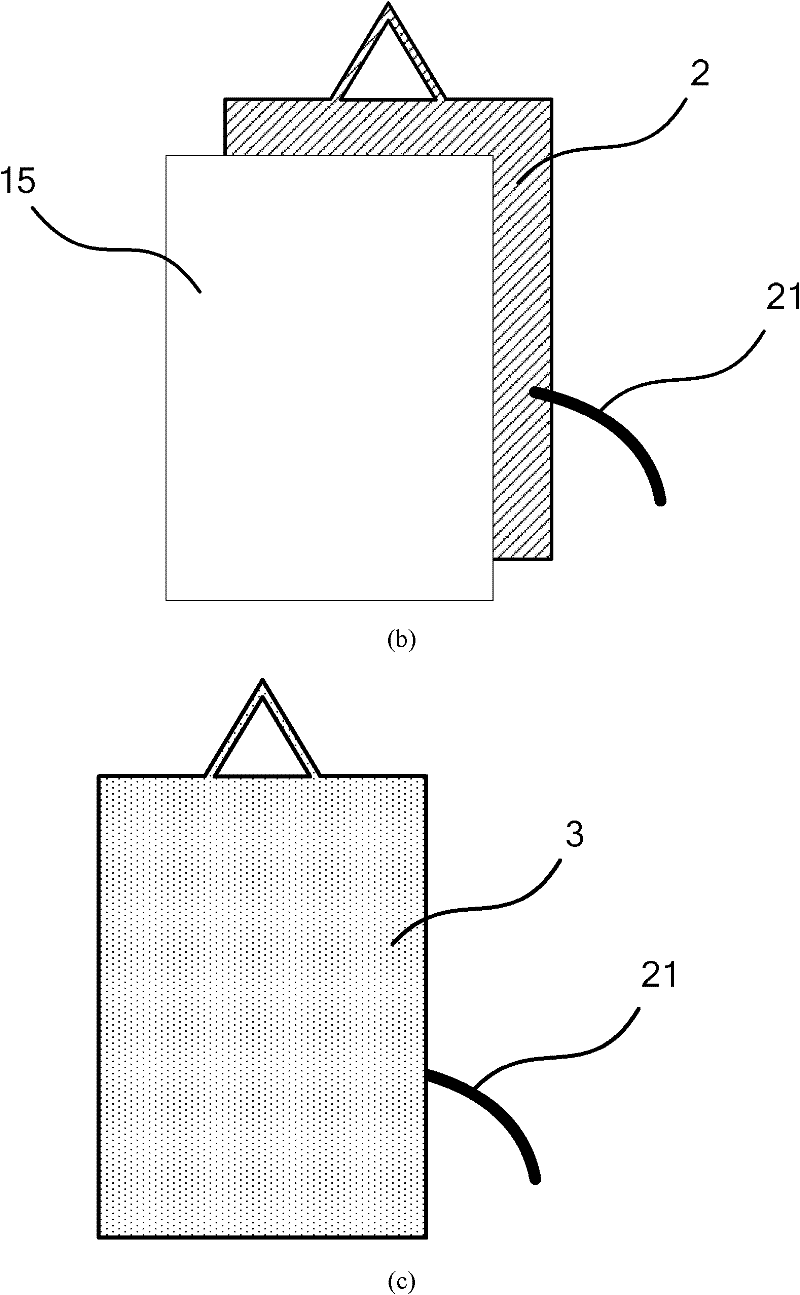

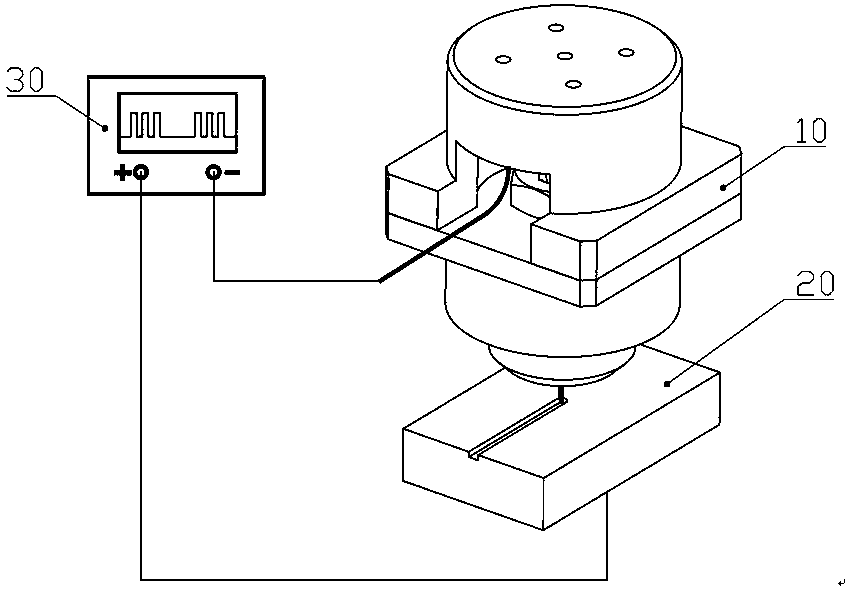

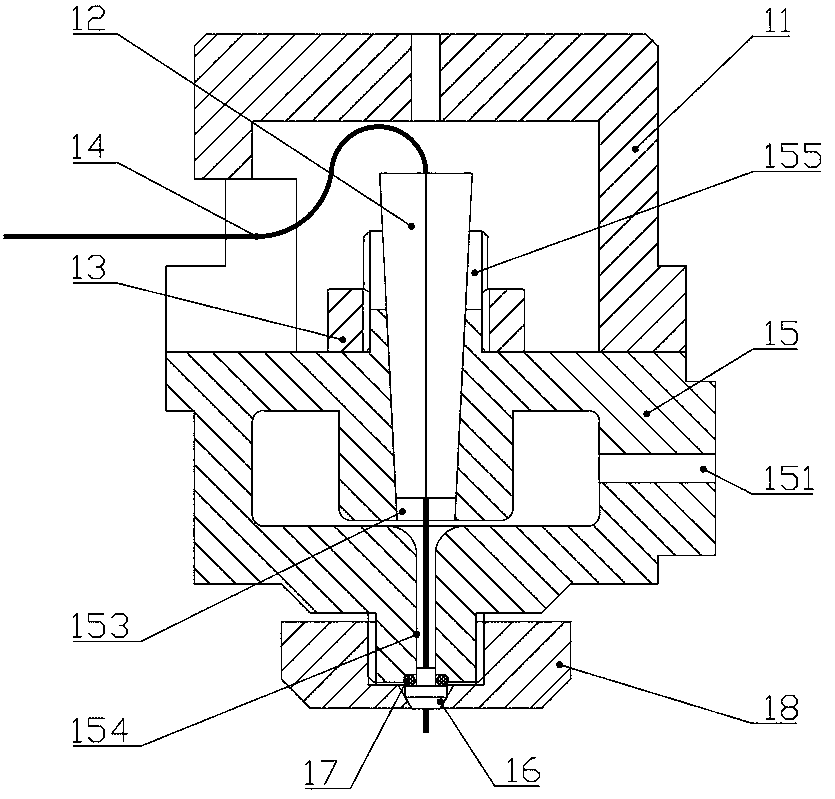

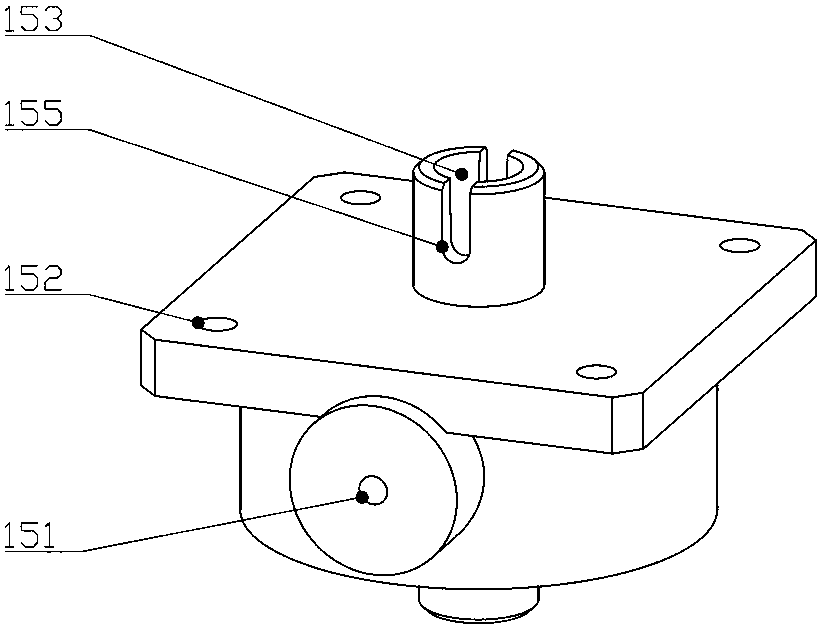

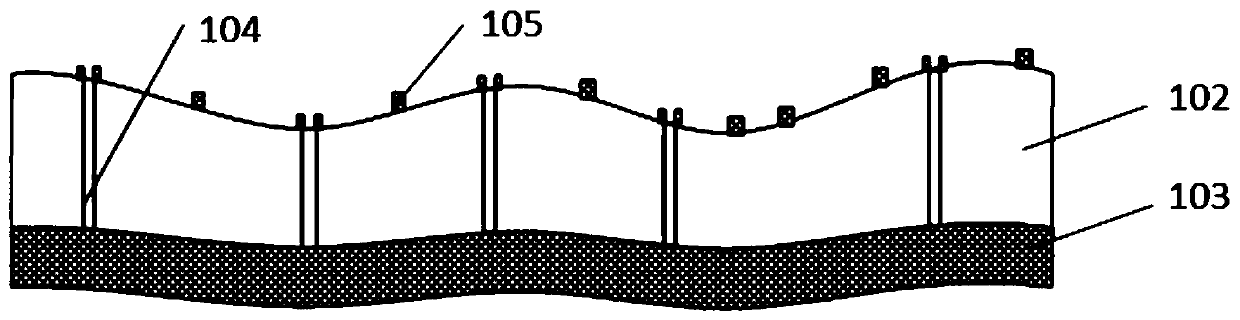

Electrospinning jet flow fast stabilization control device for micro-nano machining and control method thereof

ActiveCN103898618AOvercome the problem of lagging response of spinning input voltageOvercoming the problem of input voltage response lagFilament/thread formingJet flowStabilization control

The invention relates to an electrospinning jet flow fast stabilization control device for micro-nano machining and a control method of the electrospinning jet flow fast stabilization control device. The control device comprises a precise injection pump (1), an X-Y-Z-axis movement platform (10), a fixed support (9) of a platform rotating around a Y axis, the platform (8) rotating around the Y axis, a platform (7) rotating around an X axis, an electrospinning collector, a micro-current detection circuit (24) and a high-voltage direct-current power supply (16). According to the control device and the control method, jet flow starting and stopping are precisely controlled, and production quality is guaranteed. The problems that in the existing near-field electrospinning process, initial jet flow is instable and hard to control, and when the jet flow enters in a stable state cannot be predicated are solved. The electrospinning jet flow fast stabilization control device for micro-nano machining and the control method of the electrospinning jet flow fast stabilization control device are convenient to implement and practical.

Owner:GUANGDONG RATIONAL PRECISION INSTR

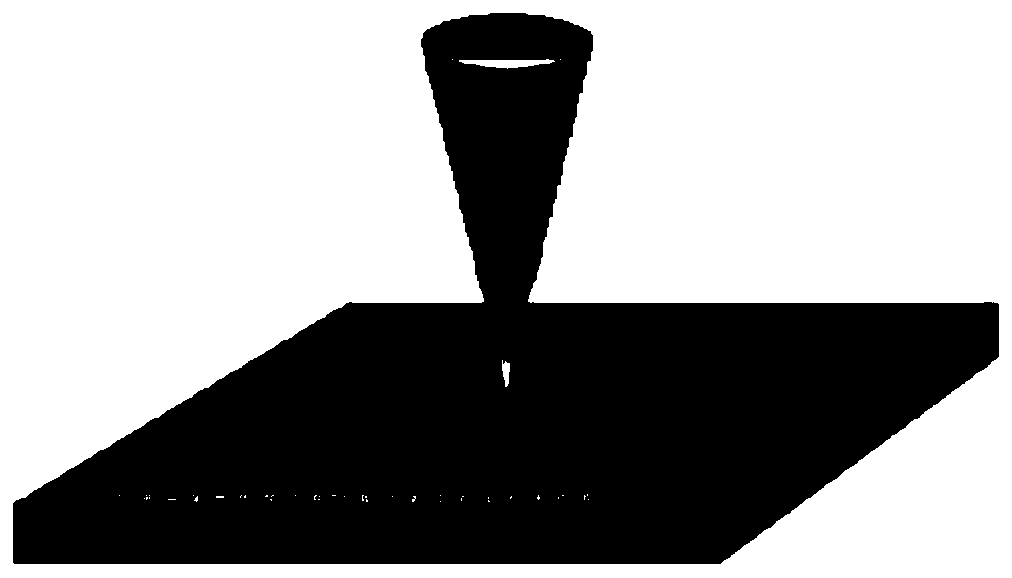

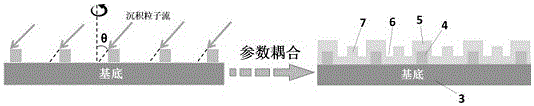

Plasma nano-structure assisted femtosecond laser nano-manufacturing method and system

InactiveCN109848565AEnhanced near-field damage effectWide range of machinable materialsLaser beam welding apparatusOptical diffractionNano structuring

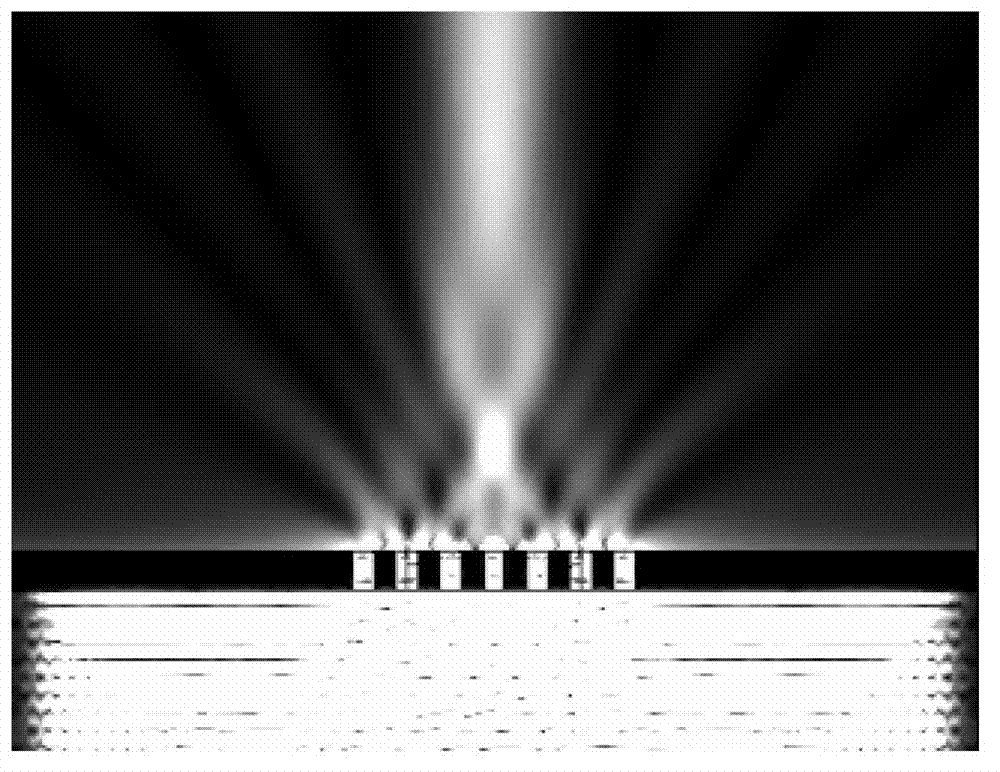

The invention provides a plasma nano-structure assisted femtosecond laser nano-manufacturing method and system and belongs to the field of laser micronano-structure processing. Through the plasma nano-structure assisted femtosecond laser nano-manufacturing method and system, the problems that the optical diffraction limit is hard to break through during conventional laser precision machining, a hard and brittle material is hard to machine, the requirements for the machining environment are high, the cost is high and machining is hard to implement in the air environment are solved. According tothe method, through LSPR enhancement of a plasma nano-structure is motivated through femtosecond laser to generate a space height localized patterning optical near field beyond the optical diffraction limit on the surface of the material to be machined, and the material is subjected to area arrayed and patterned ultrahigh resolution nano-machining. Through the method, the limitation of the optical diffraction limit of a traditional machining method can broken through, and wide-range and high-precision parallel machining is realized. The method has the characteristics that the range of the machining material is wide, free special machining is realized, the cost is low, and the method is simple and easy to implement.

Owner:XI AN JIAOTONG UNIV

Method for preparing miniature thermocouple probe of scanning thermal microscopy

InactiveCN102175894AEase of manufacture and simplicitySimplify processing stepsScanning probe microscopyAtomic force microscopyNano machining

The invention discloses a method for preparing a miniature thermocouple probe of a scanning thermal microscopy, which belongs to the technical fields of nano machining, nanoscale performance measurement and electronic science. The method for preparing the miniature thermocouple probe of the scanning thermal microscopy comprises the following steps of: a) manufacturing a first metal layer on the front of a cantilever pinpoint of an atomic force microscopy; b) manufacturing an insulating layer on the first metal layer; c) removing the insulating layer in a set area on the tip of the pinpoint; and d) manufacturing a second metal layer on the insulating layer, wherein the second metal layer is in contact with the first metal layer in the set area, and is made from a material different from that of the first metal layer. The method can be used for the technical fields of nano machining, nanoscale performance measurement and the like.

Owner:PEKING UNIV

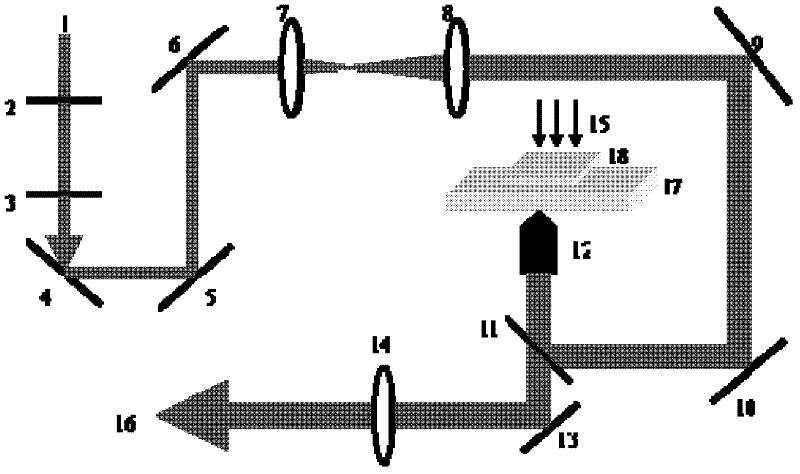

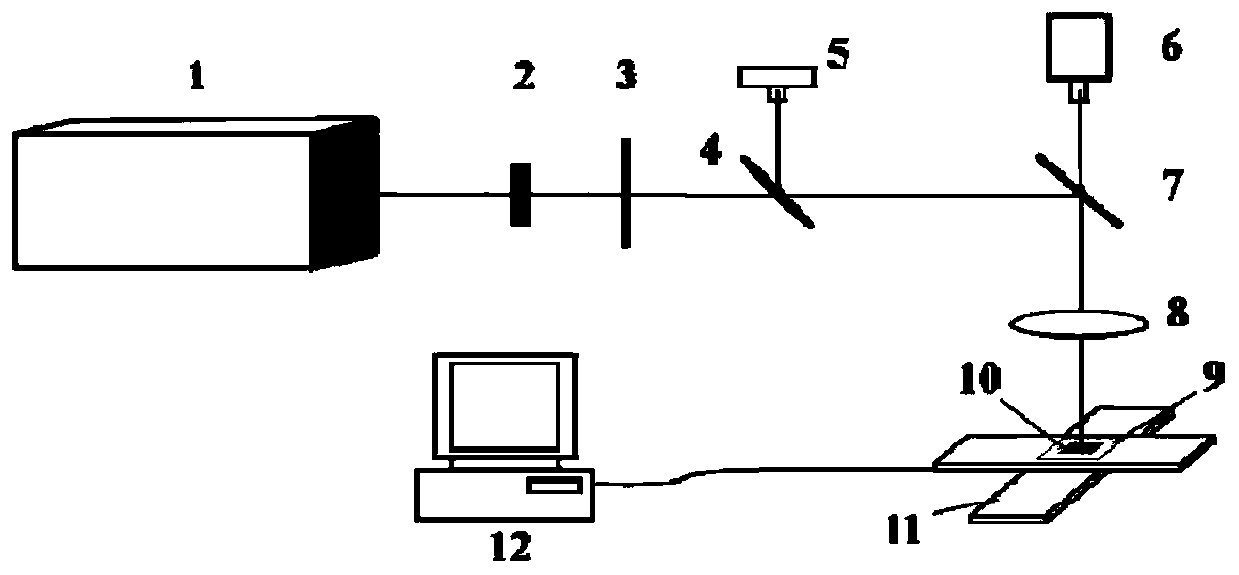

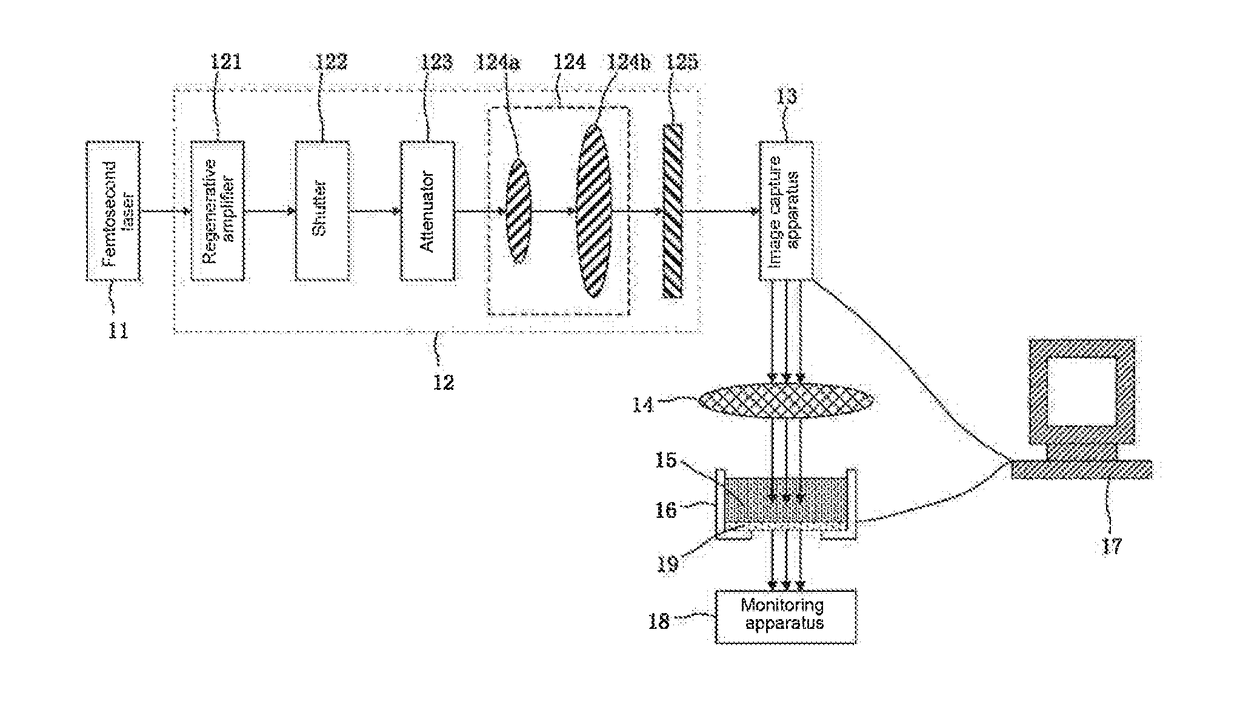

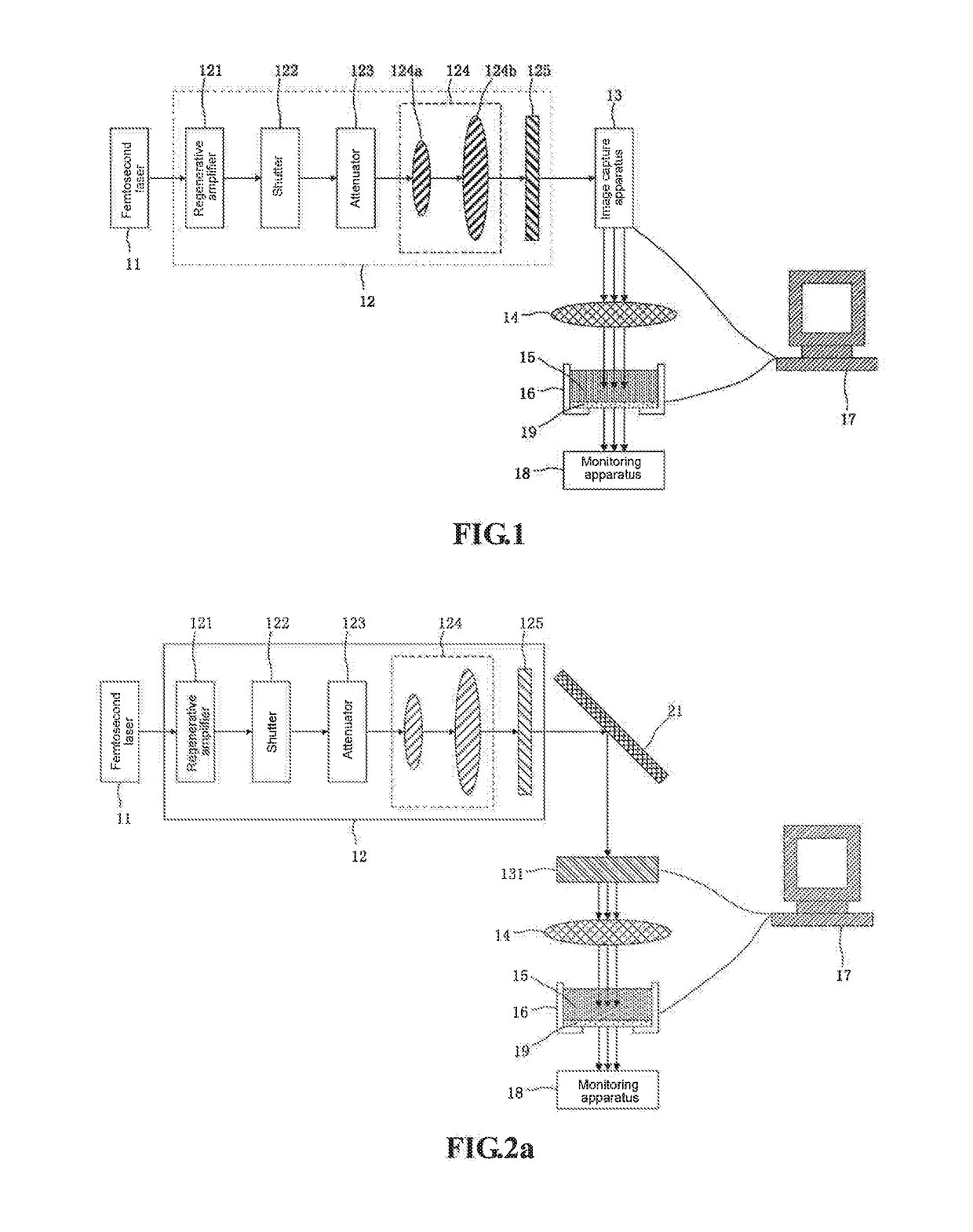

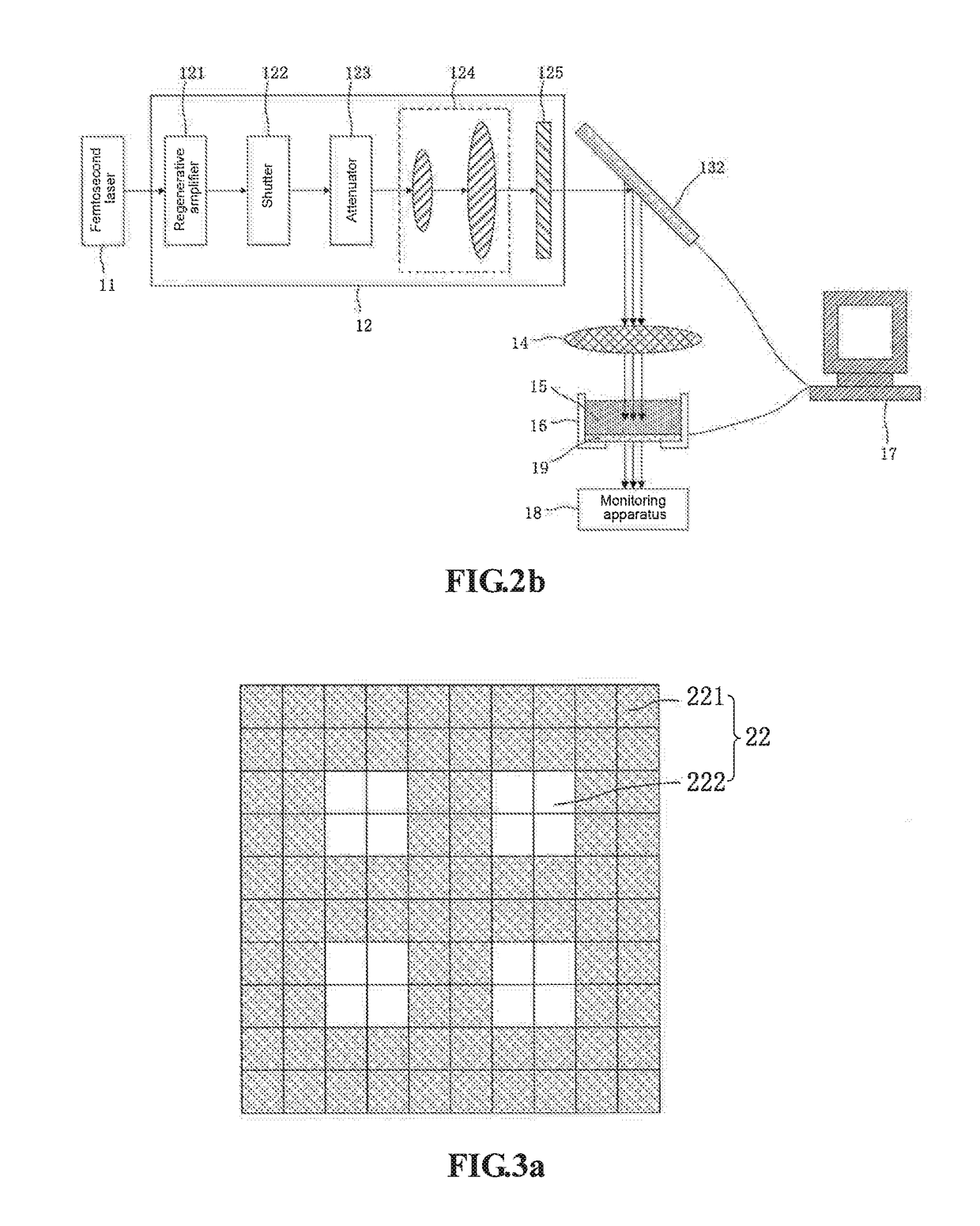

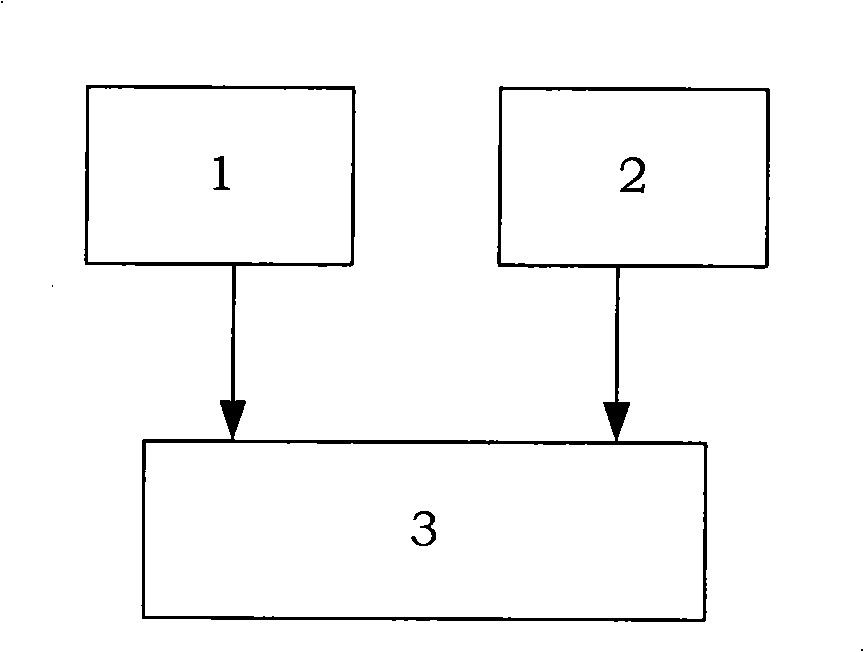

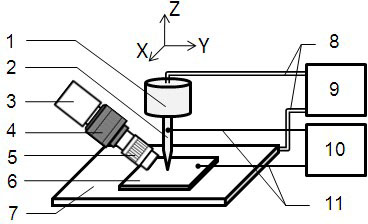

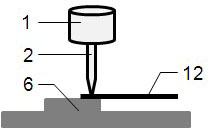

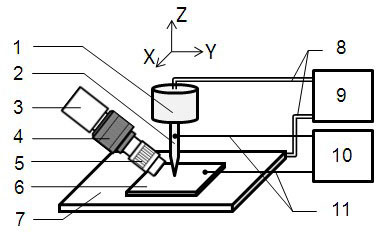

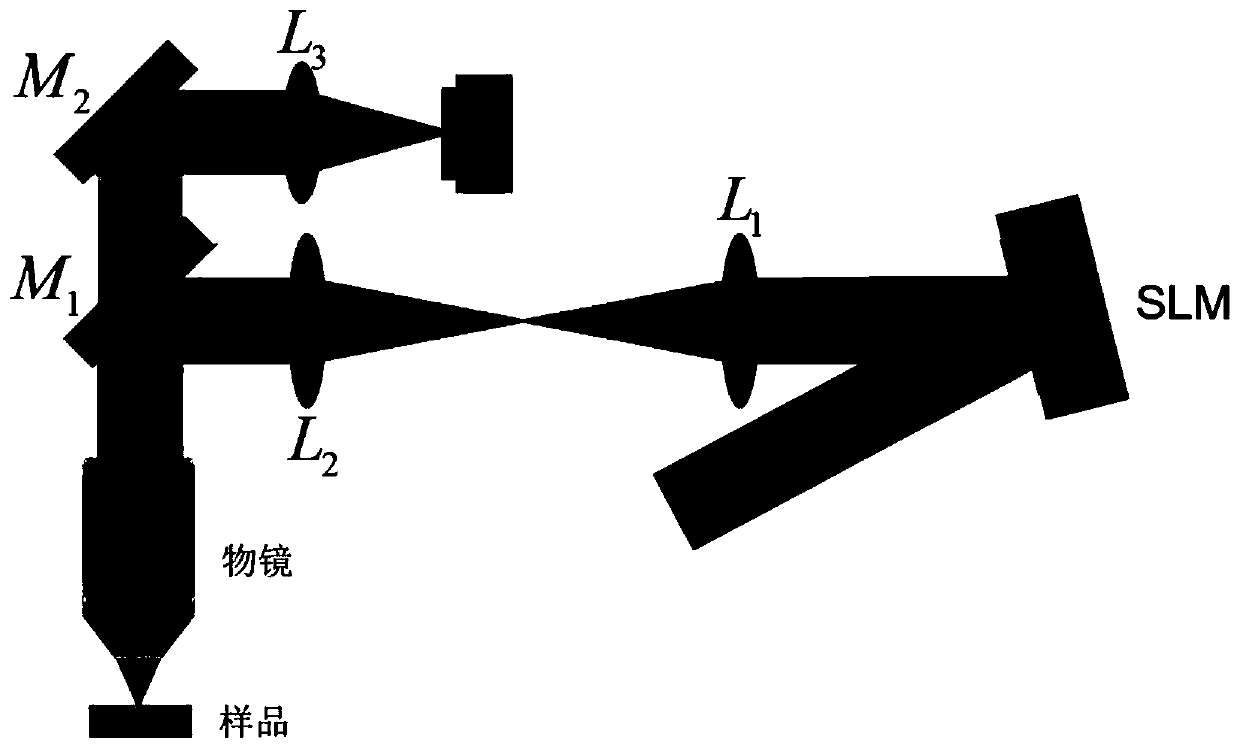

System and method for micro-nano machining by femtosecond laster two-photon polymerization

ActiveUS20170212424A1Improve efficiencySpeed up the flowPhotomechanical exposure apparatusMicrolithography exposure apparatusMicro nanoLight beam

Disclosed are a system and method for micro-nano machining by femtosecond laser two-photon polymerization. The system includes: a femtosecond laser, an external light path modulation unit, an image capture apparatus, a focusing lens, a displacement platform, a computer and a monitoring apparatus, where the image capture apparatus is configured to capture cross-section graphs of a three-dimensional micro-nano device layer by layer, so that modulated femtosecond lasers form parallel beams arranged according to all layers of the cross-section graphs.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

Electron beam-ion beam micro-nanometer process composite system

InactiveCN101301994AClear imagingStable structureNanostructure manufactureElectric discharge tubesImaging qualityScanning electron microscope

The invention discloses an electron beam-ion beam micro and nano machining combination system, wherein the electron beam and the ion beam can be operated simultaneously, and the electron in SEM can be integrated with the positively charged ion to effectively decrease influence on observation and analysis caused by charge accumulation on the surface of sample. The electron beam-ion beam micro and nano machining combination system of the invention comprises a flange, a scan electron microscope, a focused ion beam device, a computer which is a part of the scan electron microscope, wherein the flange is arranged on the bevel of a reaction chamber of the scan electron microscope, and the ion gun of the focused ion beam is arranged in the through hole of the flange. By adopting electron beam and ion beam symmetric device, the design scheme has advantages of stabilized, simple and aesthetic structure, convenient and accurate alignment, defined image and high stabilization of sample stage etc., being beneficial to improvement of the imaging quality of the electron beam.

Owner:BEIHANG UNIV

Fiber laser based production of laser drilled microvias for multi-layer drilling, dicing, trimming of milling applications

InactiveUS7602822B2Additive manufacturing apparatusLaser using scattering effectsLight beamOptoelectronics

Fiber lasers and methods for constructing and using fiber lasers for micro- / nano-machining with output beams including stacked pulses and combinations of continuous wave, pseudo-continuous wave and pulse sequence components.

Owner:HITACHI SEIKO LTD

Composite jet flow micro-nano machining method and device

InactiveCN109482991AQuality improvementHigh precisionElectrochemical machining apparatusElectrical-based auxillary apparatusMicro structureMicro nano

The invention discloses a composite jet flow micro-nano machining method and device. The upper end of an electrode wire is fixed, the lower end of the electrode wire penetrates through a nozzle to form an overhanging end, an electrolyte is added into a nano polishing particle, when the electrolyte is sprayed out through a nozzle at the high speed, the electrolyte is subject to jet flow, the electrode wire overhanging end is straightened, the electrode wire is subjected to radial position restraint, the upper end of the electrode wire is connected with a negative electrode of a narrow pulse wide group pulse electrolysis power source, a workpiece anode is connected with a positive electrode of the narrow pulse wide group pulse electrolysis power source, the electrolysis effect is generated between the electrode wire overhanging end and the machining surface of the workpiece anode, the nano polishing particle is driven by the electrolyte to carry out polishing on the machining surface ofthe workpiece anode, and composite machining of the workpiece anode machining surface is achieved until the needed micro structure characteristics are obtained. The machining method and device can effectively improve the locality of micro electrolytic machining, the stray corrosion phenomenon can be effectively restrained, the medium transfer process can be improved, and high-precision, high-surface-quality and high depth and width ratio micro structure characteristic efficient machining is achieved.

Owner:INST OF MACHINERY MFG TECH CHINA ACAD OF ENG PHYSICS

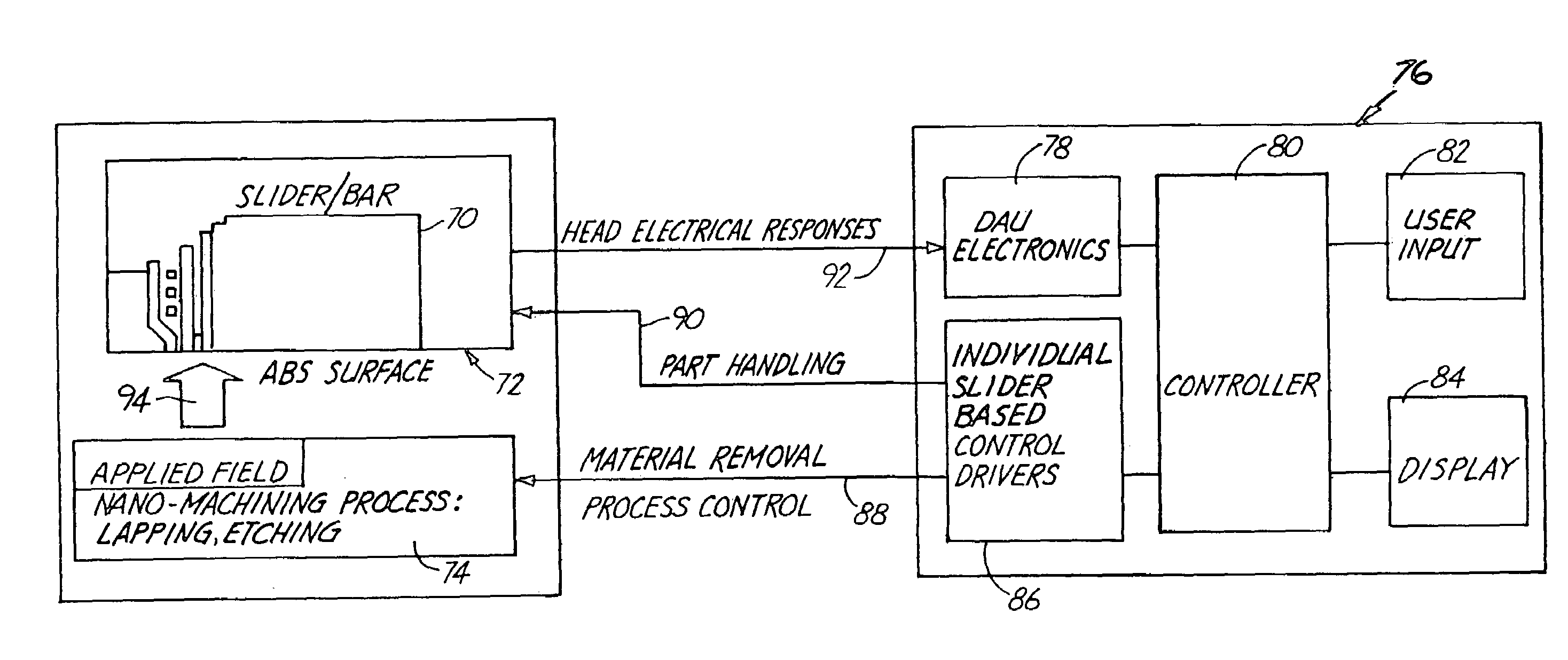

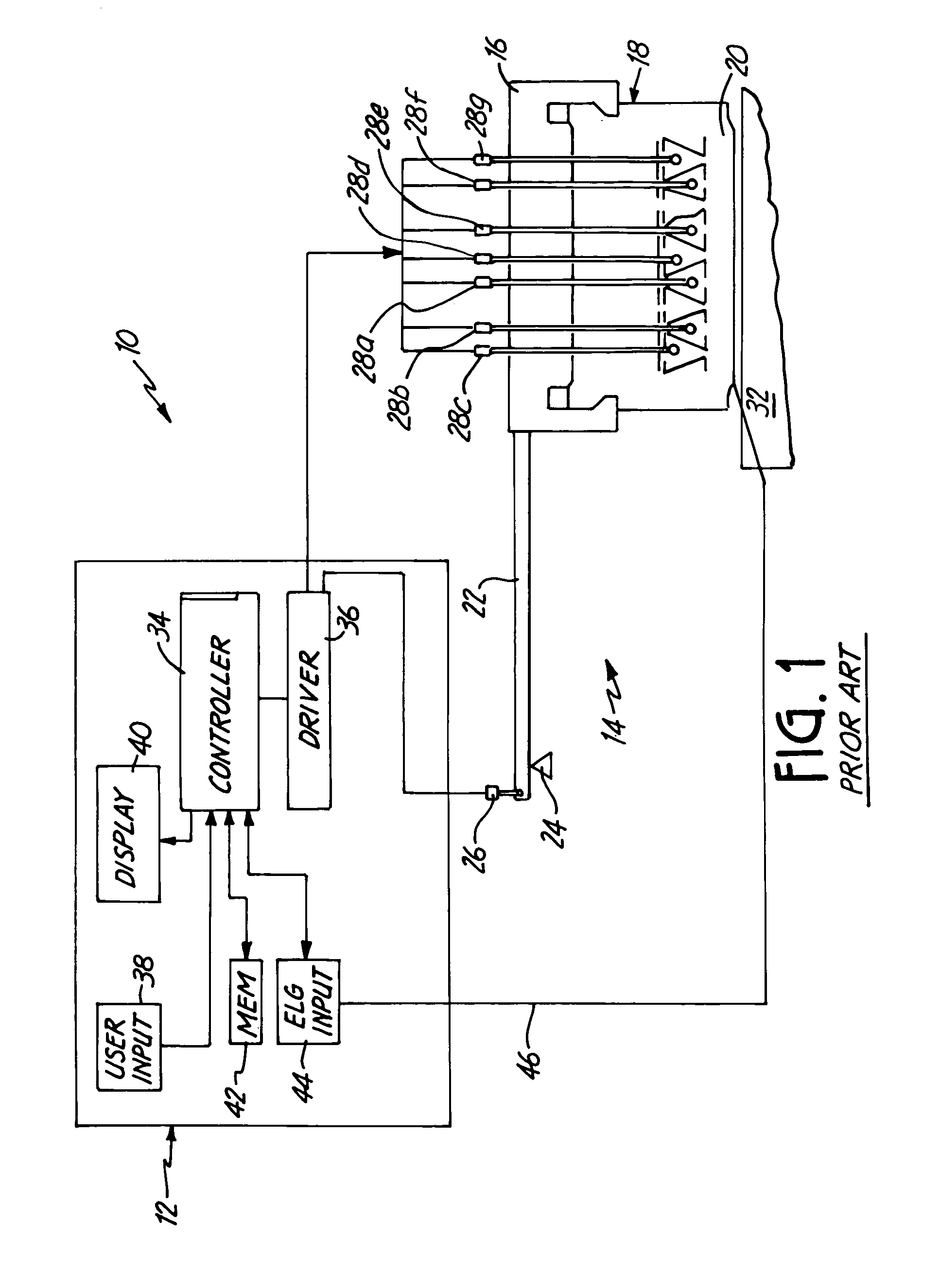

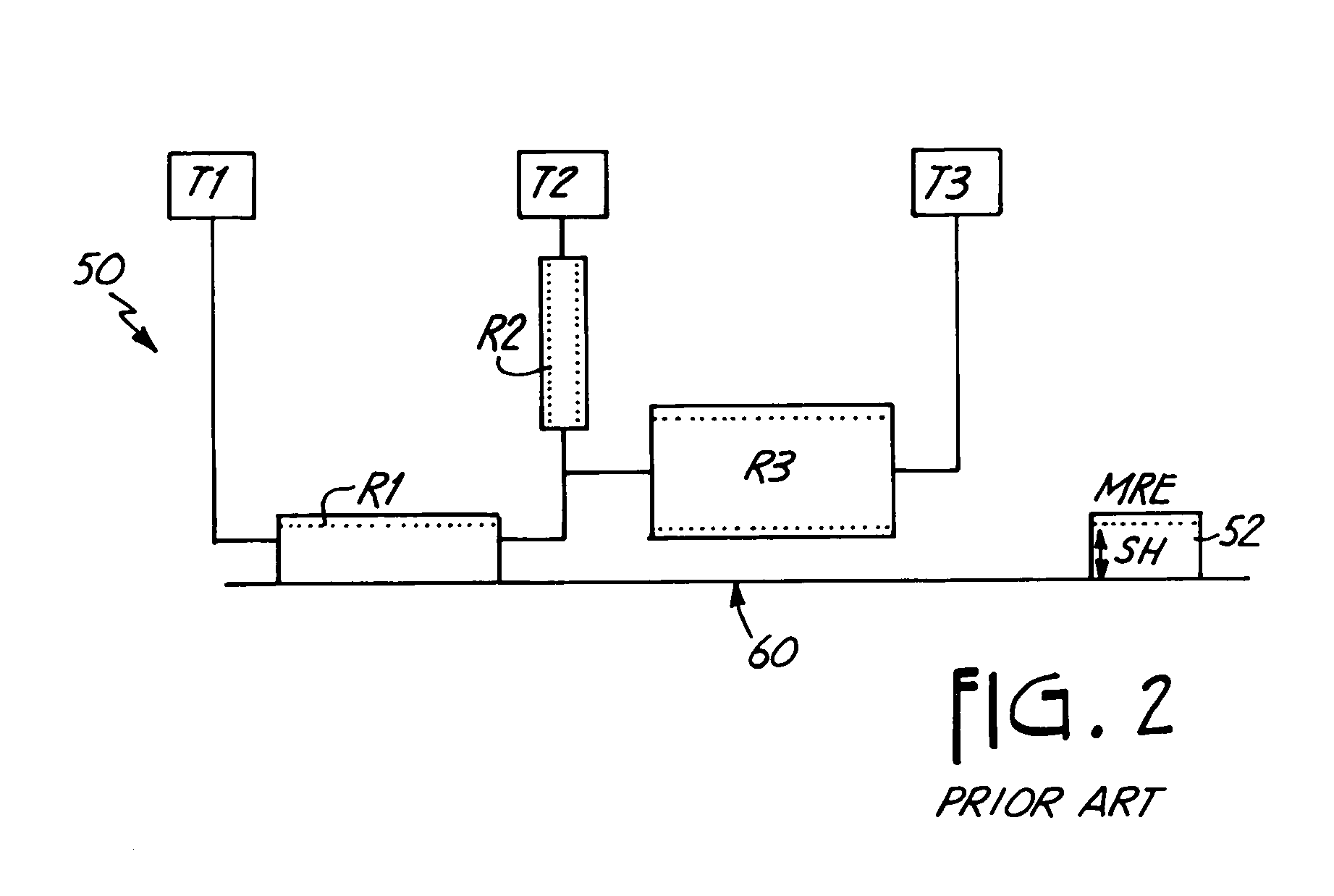

Head performance based nano-machining process control for stripe forming of advanced sliders

InactiveUS7147539B1Electrical transducersLapping machinesElectrical resistance and conductancePower flow

The present invention is a method of using direct head electrical response signals for feedback process control. When lapping the air bearing surface of a bar of sliders, a magnetic field is applied to the air bearing surface and a bias current is applied to the reader elements. A head electrical response, such as amplitude or resistance change, is measured and is used to control the lapping device. Using a fixture which allows individual slider machining, a controller can be used to monitor the head response signal for each slider on the bar and individually control each slider on the bar so that material removal over each slider proceeds until a predetermined target stripe height is reached.

Owner:SEAGATE TECH LLC

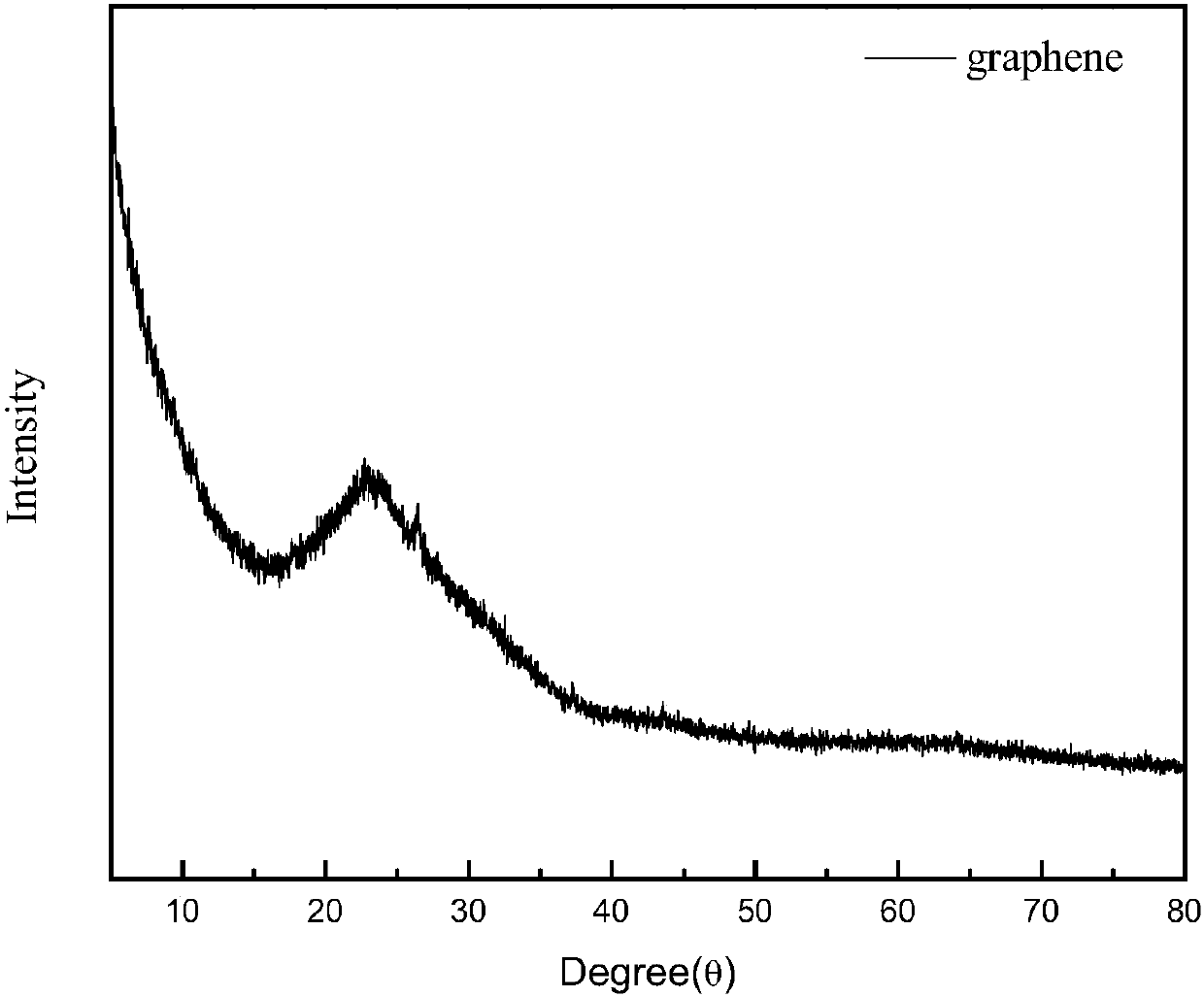

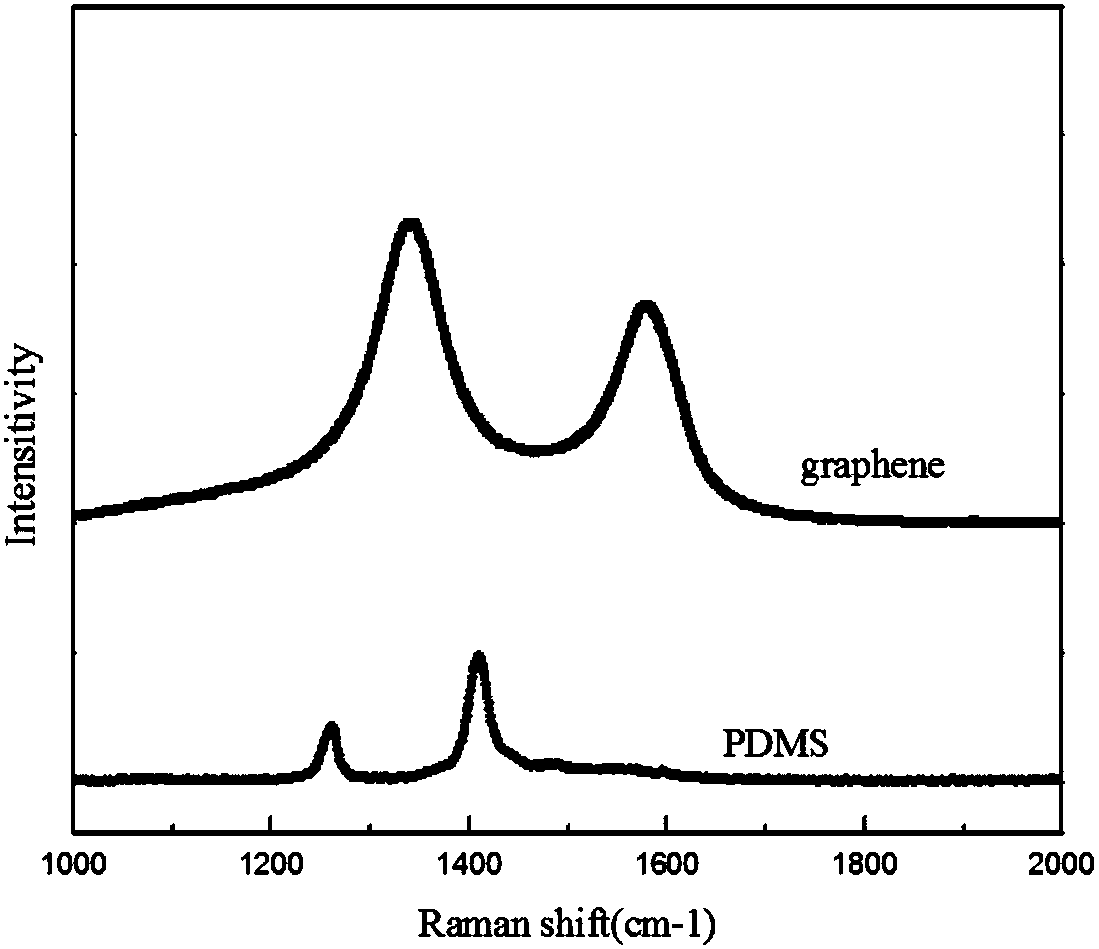

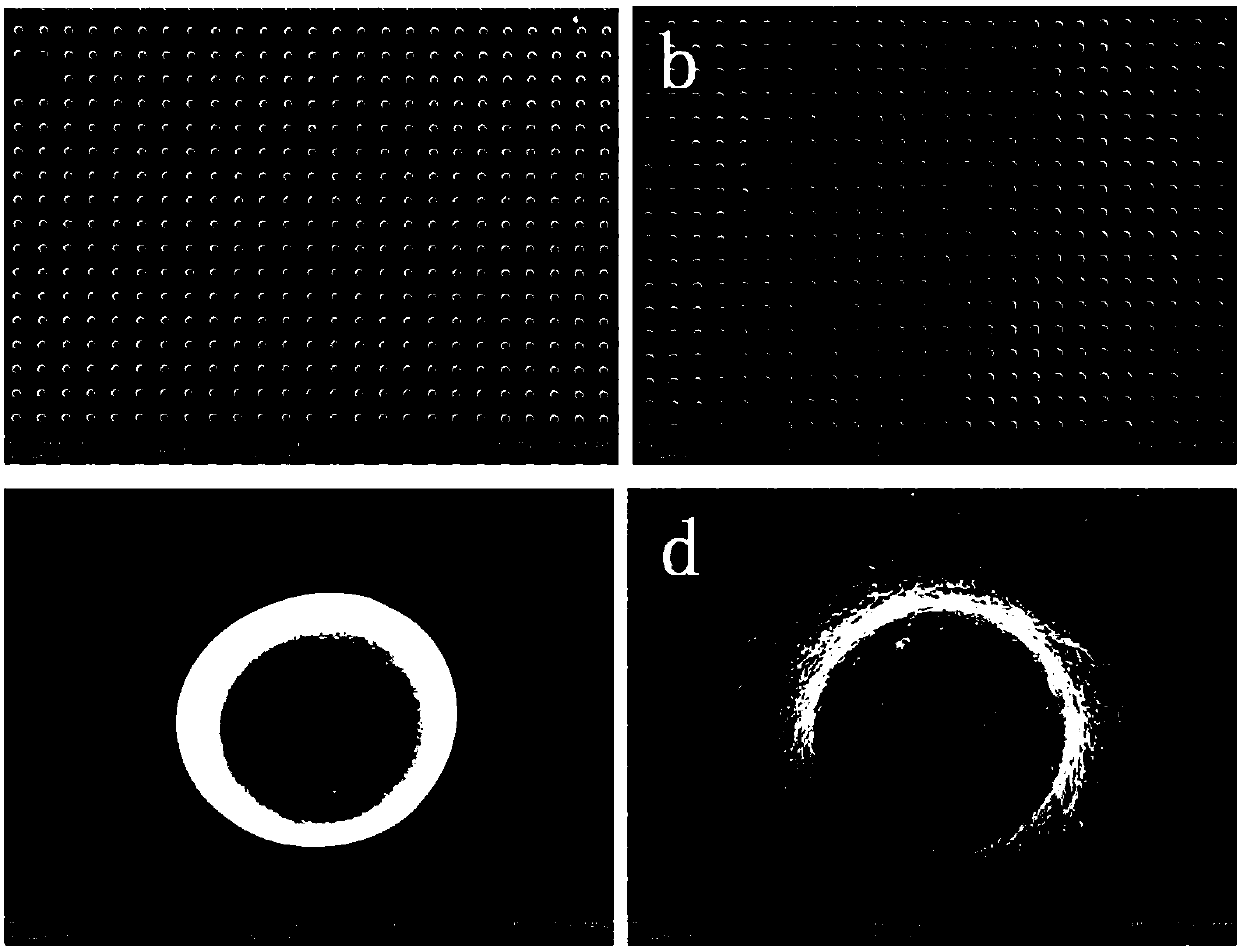

Preparation method of flexible thin film based on graphene micro column array

The invention discloses a preparation method of a flexible thin film based on a graphene micro column array and belongs to the field of micro-nano machining. The preparation method comprises the following steps: washing a micro array silicon template and then pouring PDMS (Polydimethylsiloxane) after the micro array silicon template is subjected to hydrophobic treatment; curing and stripping to obtain PDMS with a micro array structure, carrying out plasma oxygen etching and soaking with a diallyldimethylammonium chloride solution, dispensing a graphene aqueous solution, drying, and then enabling the graphene to be uniformly spread on the surface and the side face of the micro column array; and finally, obtaining the flexible micro column array thin film. The preparation method has the advantages of simplicity and feasibility, controllable process parameters, low cost and high repeatability.

Owner:TONGXIANG BEITE TECH CO LTD

Three-dimensional asymmetric miniature resonant cavity polymer single-mode laser

ActiveCN104868352AAchieve the desired effectOptical resonator shape and constructionPhotomechanical exposure apparatusMicro nanoNon symmetric

The invention discloses a three-dimensional asymmetric miniature resonant cavity polymer single-mode laser, and belongs to the field of dye miniature resonant cavity lasers. A femtosecond laser micro-nano machining system is employed at first for the machining of SU-8 photoresist materials doped with dye Rhodamin B, thereby forming a polymer miniature resonant cavity laser. The shape of the miniature resonant cavity employs a no-pillar structure to be directly integrated on a substrate, and a double-layer stacked three-dimensional structure is designed, wherein the double-layer stacked three-dimensional structure is specifically a three-dimensional geometrical asymmetric structure where a spiral ring in a smaller size is internally tangent to a circular ring. The laser manufactured through the above method achieves the emission of laser with a single-longitudinal-mode wavelength under the room temperature, and the emitted laser is better in direction selectivity in a port direction of the spiral ring, thereby facilitating the further coupling and integration of a miniature optical element and the application in the field of light interconnection.

Owner:JILIN UNIV

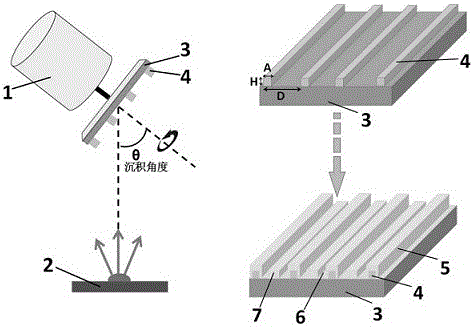

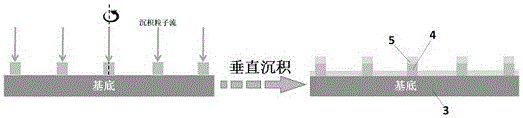

Large-area nanometer slot array and manufacturing method therefor

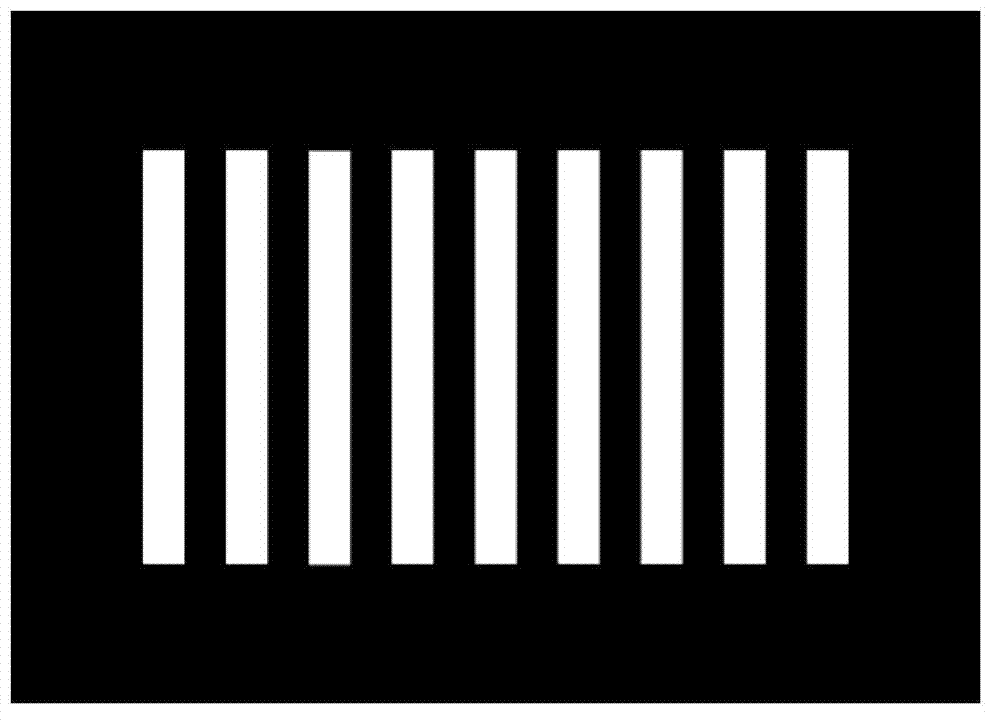

InactiveCN106773540ASuitable for commercializationWide applicabilityPhotomechanical exposure apparatusMicrolithography exposure apparatusGratingNano machining

The invention discloses a manufacturing method for a large-area nanometer slot array, and relates to the field of micro-nano machining. By combination of an angle deposition shadow effect and substrate rotation, and by regulating a rotary speed of the substrate, a nanometer mask structure, a deposition angle and a deposition speed parameter to be matched mutually, the novel and large-area nanometer slot array is manufactured. In addition, based on the technology disclosed by the invention and by taking a raster as a deposition mask substrate, a large-area periodical nanometer slot array structure is already manufactured.

Owner:SICHUAN UNIV

Pulse laser-induced preparation method of zinc oxide nano-structure

InactiveCN103641155ANo pollution in the processSecurity NoneMaterial nanotechnologyZinc oxides/hydroxidesMicro nanoPhysical chemistry

The invention relates to the technical field of micro-nano material preparation and laser micro-nano machining, and in particular relates to a pulse laser-induced preparation method of a zinc oxide nano-structure. The zinc oxide nano-structures in different morphologies are prepared by using ultra-short pulse laser to radiate the surface of the zinc-based material in hydrogen peroxide, the method is suitable for a zinc plate or zinc-plated materials adopting different substrates.

Owner:JIANGSU UNIV

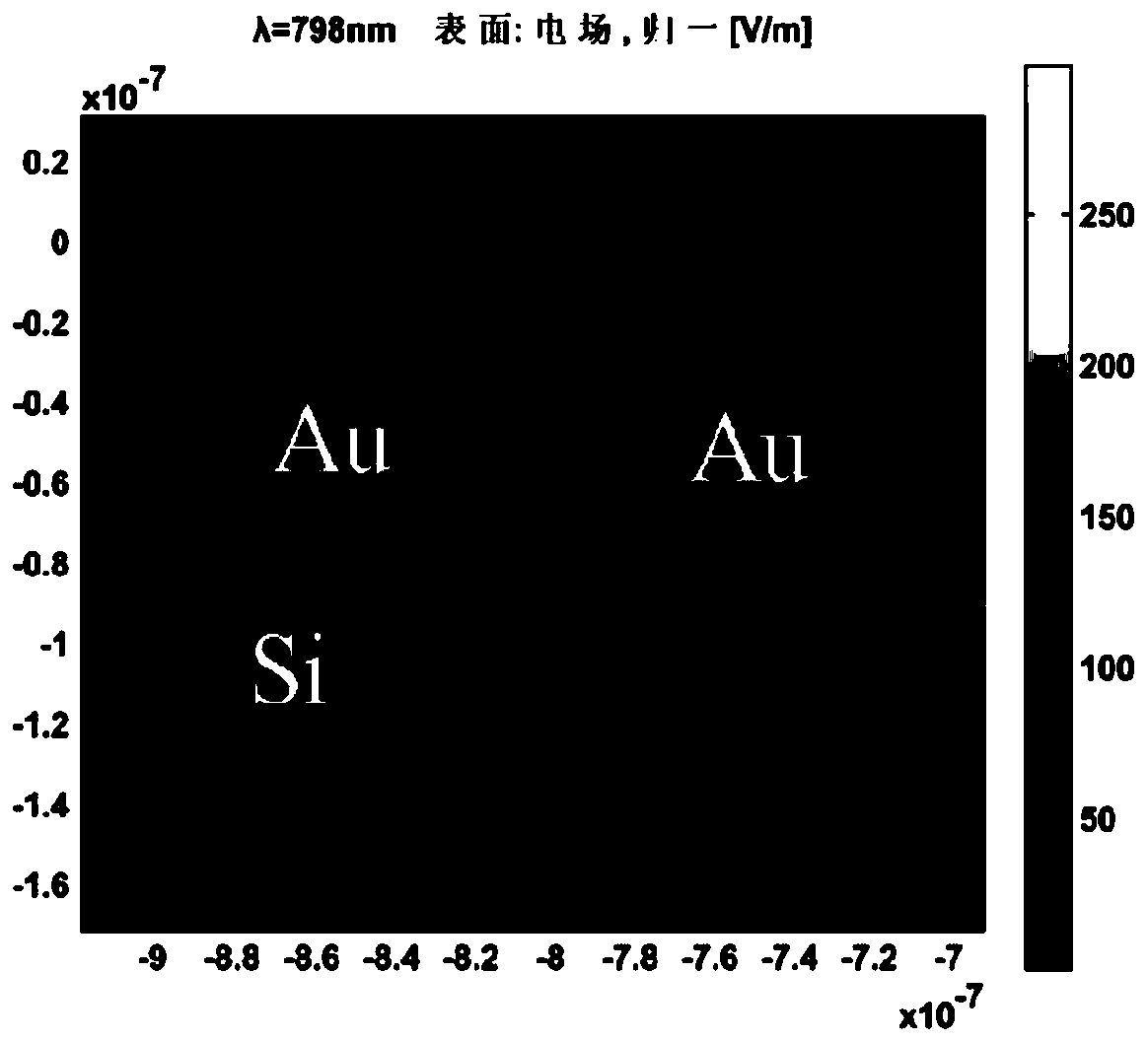

Method for preparing nano-gap metal focusing lens

ActiveCN102862950AExtended Delay Modulation MeansSimple structureDecorative surface effectsChemical vapor deposition coatingIon beamNano machining

The invention provides a method for preparing a nano-gap metal focusing lens, which comprises the following steps of: firstly, determining the incident wavelength, selecting an appropriate light-passing base material, evaporating a layer of metal film on a base, and enabling incident light to be vertical to the surface of the metal film; machining slit or circular gap arrays which are equal in width in the metal film by using a nano machining technology; and focusing light at a preset focus position, calculating phase delay distribution of slits or circular gaps arranged at different positions by a light wave when the light is focused at the focus position, and through focusing ion beams, guiding a medium with a special deposition thickness to meet the phase delay requirements of slits or circular gaps arranged at different positions by the light wave, so that the metal focusing lens realizes the focusing of incident light at the preset focus position. According to the invention, the deposition thickness of mediums in slits or circular gaps of the metal focusing lens is changed according to a preset focus position so as to realize near-field or far-field light focusing, the method can be applied to the integration of light path systems conveniently, and therefore, the method has a broad application prospect.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

Nanoscale resistance spot welding device and nanoscale resistance spot welding method

InactiveCN102581460AEasy to operateLow costNanostructure manufactureResistance welding apparatusMicro nanoElectrical resistance and conductance

The invention belongs to the field of welding and material nano-machining, and particularly relates to a nanoscale resistance spot welding device and a nanoscale resistance spot welding method. The device comprises a high-power optical microscope, a scanning probe microscope, a welding control power supply and a welding connecting line, wherein the high-power optical microscope is used for primarily positioning a position to be welded of a machined workpiece and observing a welding process in real time, and the welding control power supply is used for supplying power needed in welding. The scanning probe microscope is used for accurately positioning and welding the position to be welded of the machined workpiece and comprises a conductive scanning probe, a control and feedback connecting line and a control and feedback module, wherein the scanning probe is capable of working in an accurately positioning mode and in a welding mode, and is respectively connected with the control and feedback module and the welding control power supply. The device and the method can be used for realizing nanoscale resistance spot welding, and have important significance for design and manufacture of novel micro-nano devices.

Owner:杭州轻巧科技有限公司

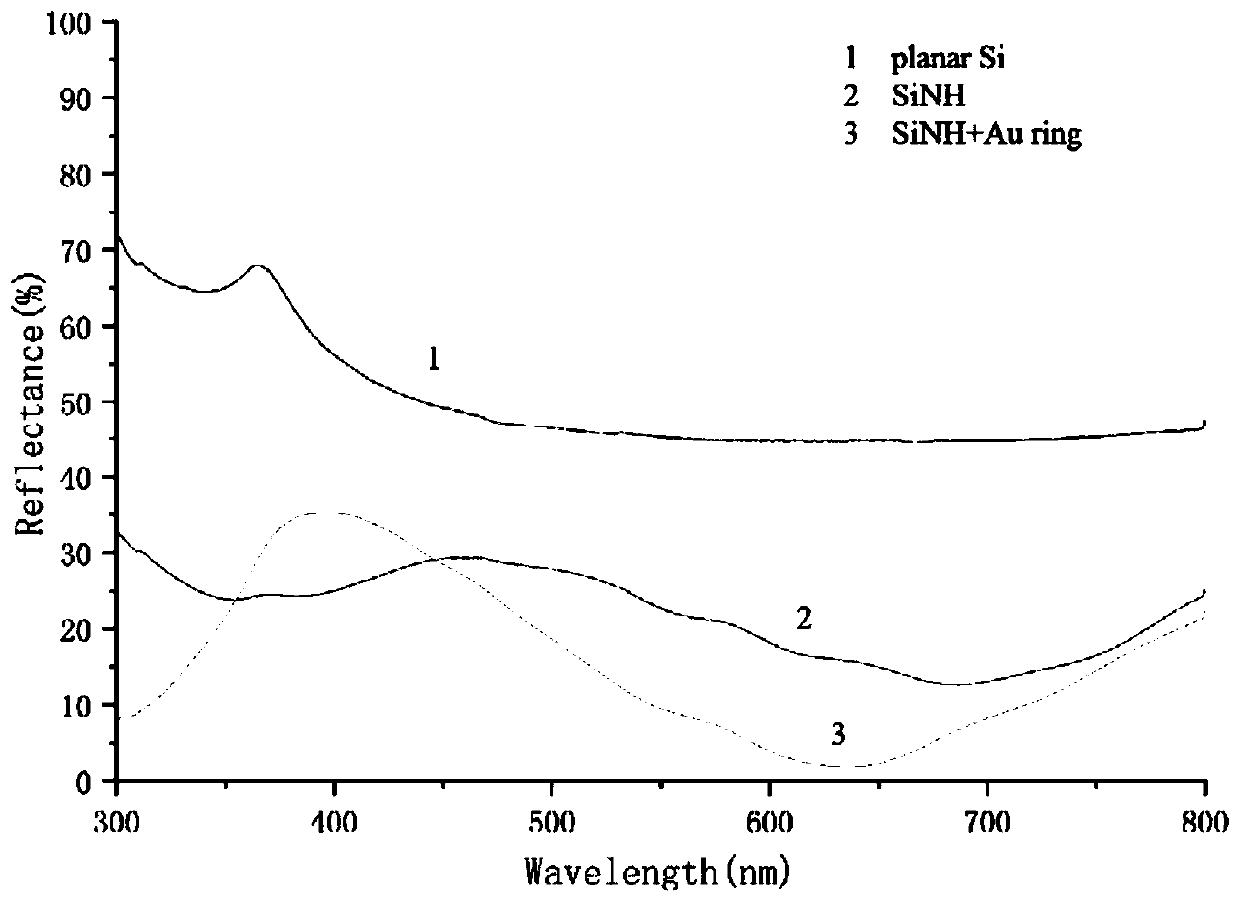

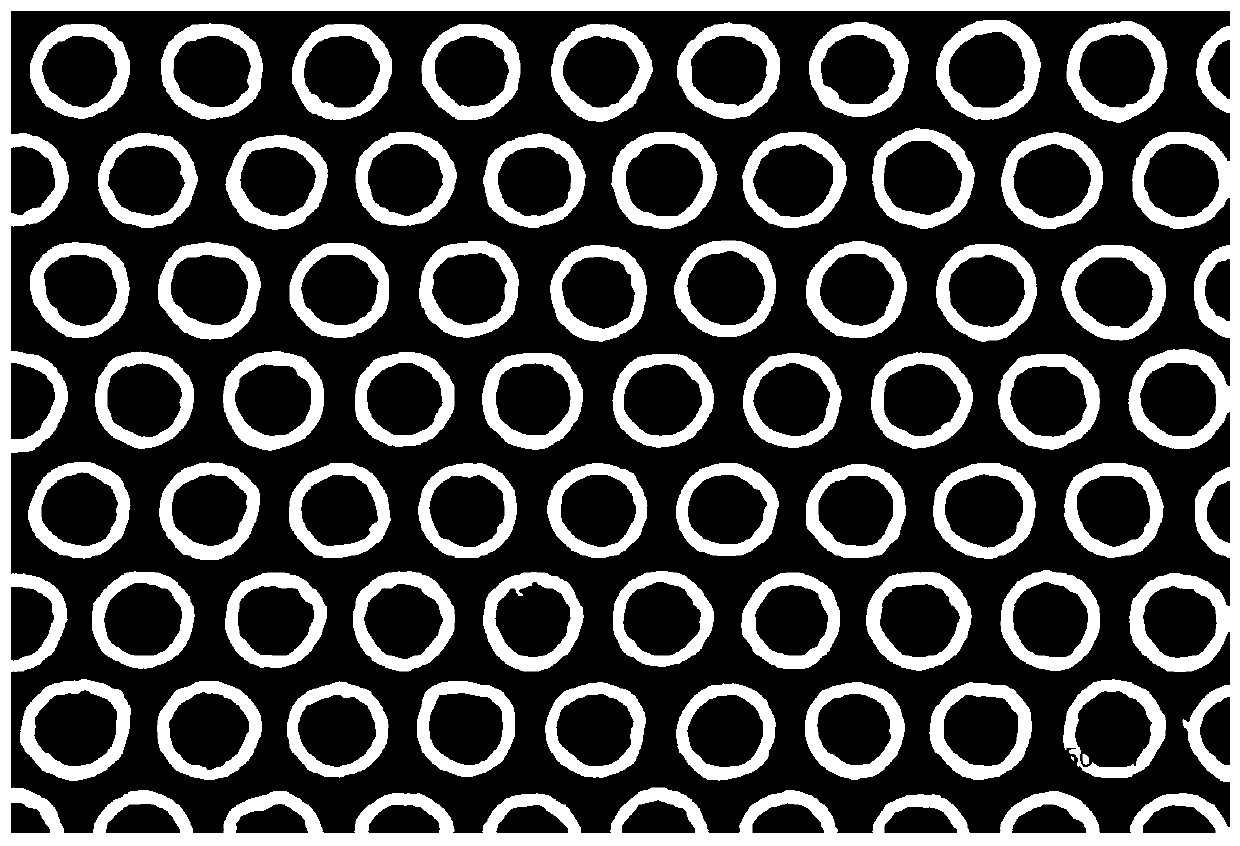

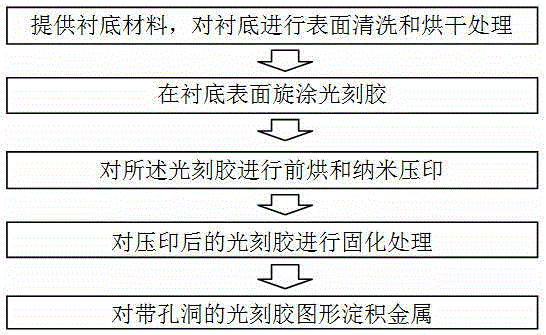

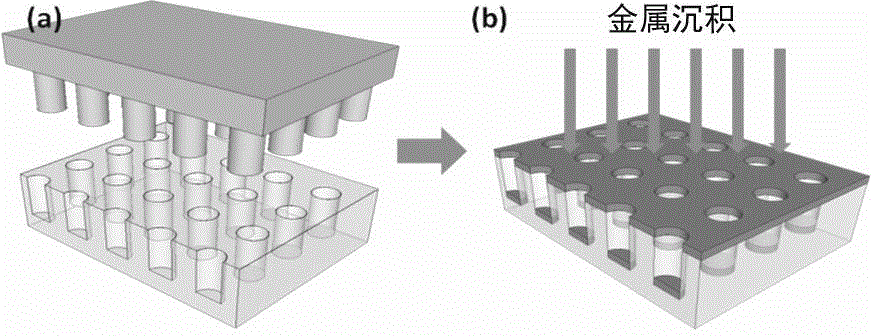

Preparation method of a nanopore array structure with an embedded metal ring

ActiveCN109795979AChange heightChange the thickness of the ring wallDecorative surface effectsChemical vapor deposition coatingMicro nanoTrapping

The invention belongs to the technical field of micro-nano machining, and particularly relates to a preparation method of a nanopore array structure with an embedded metal ring. The preparation methodcomprises the following steps: spin-coating a high-molecular layer and an ultraviolet curing adhesive layer on the surface of a substrate in sequence; imprinting by ultraviolet light, carrying out etching, evaporation and lift-off to obtain a substrate with a metal layer with a nanopore array structure, then etching the substrate to obtain a substrate with the nanopore array structure, plating metal on the surface, the hole bottom and the hole side wall of the substrate, and etching the metal layer on the surface and the hole bottom plane of the substrate to obtain the nanopore array structure embedded with the metal ring. The preparation method comprises the following steps of controlling a template structure; The structure, size and distribution of the metal ring are adjusted through etching and coating process parameters, so that the local surface plasmon effect generated by the metal nano-ring array is regulated and controlled, the local surface plasmon effect and the light trapping effect brought by the substrate with the nanopore array structure are synergistic, and the light conversion efficiency can be further improved in the fields of photoelectric devices, photocatalysisand the like.

Owner:NANJING UNIV

A method for obtaining full-color-spectrum structural color through preparing metal holes having a chassis by utilizing nano-imprint lithography

Owner:FUDAN UNIV

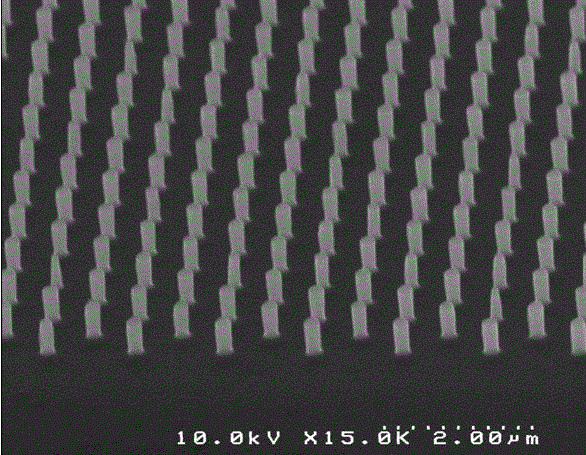

Method for preparing bionic micro-nano structure of butterfly wing

InactiveCN104934303AControl Spin Coating ThicknessPrecise control cycleDecorative surface effectsSemiconductor/solid-state device manufacturingNano structuringEngineering

The invention belongs to the technical field of micro-nano machining, and specifically to a method for preparing a bionic micro-nano structure of a butterfly wing. The method of the invention comprises the steps as follows: firstly using a spin-coating method to alternately spin a plurality of layers of photoresist with different sensitivities in turn on a silicon substrate; then using electron beam lithography to expose the photoresist; then using two developing liquids to alternatively develop the exposed sample; finally preparing hierarchical periodic or quasi-periodic bionic micro-nano structure with excellent characteristic, such as morpho bionic micro-nano structure, and so on. By combining with technologies of the plurality of layers of the photoresist and electron beam lithography, the preparation process of the invention does not need a biological template and could control the spin-coating thickness of every layer of the photoresist to achieve accuracy control of longitudinal dendritic cycle and duty ratio. The method of the invention is simple in preparation technology and could obtain the bionic micro-nano structures of the butterfly phosphorus wing with different structure parameters.

Owner:FUDAN UNIV

Sub- and micro- Newton level force measuring system

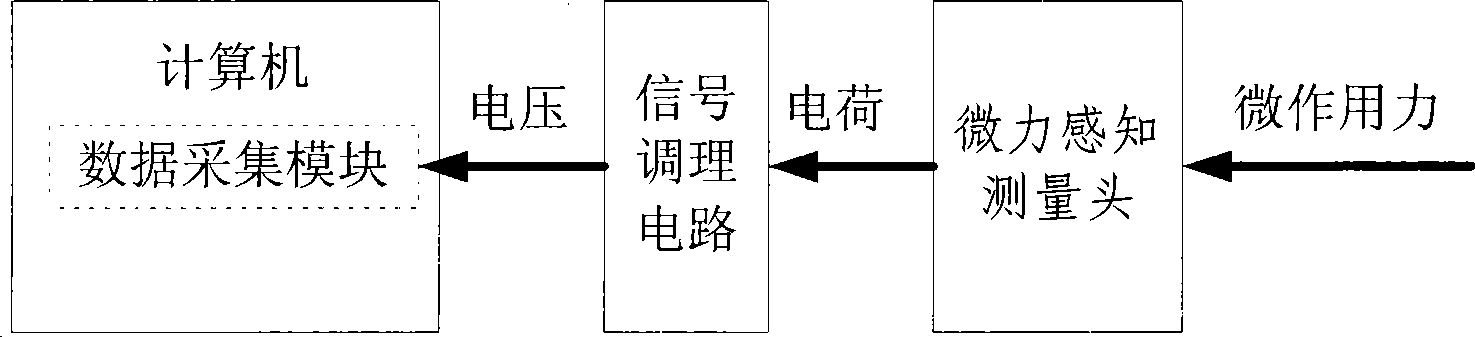

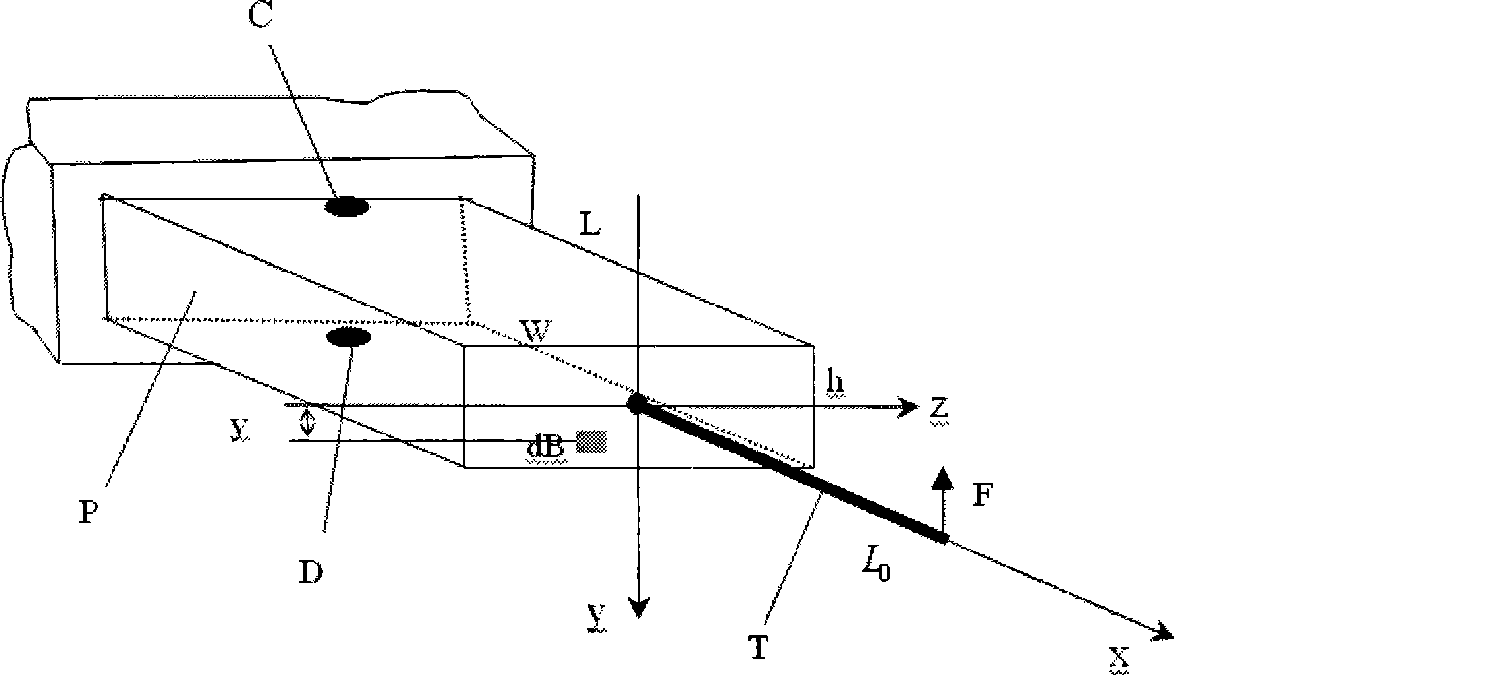

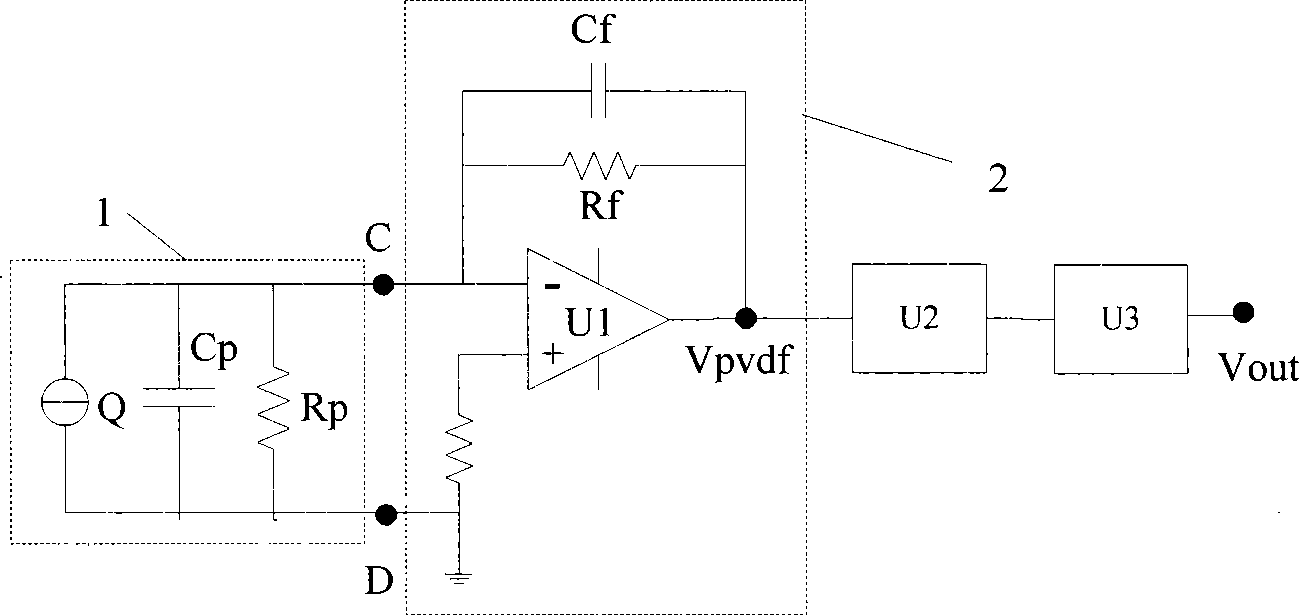

InactiveCN101373156ASimple structureSmall rangeTelevision system detailsImpedence networksSignal conditioning circuitsData acquisition

The invention relates to a technology for measuring micro Newton force based on a PVDF piezoelectric material, particularly a system for measuring submicro Newton force which comprises a micro force perception measuring head, a signal disposal circuit and a data acquisition module, wherein the micro force perception measuring head receives micro force from a probe, converts a force signal to electric charge and then sends the electric charge to the signal disposal circuit; the signal disposal circuit converts the electric charge into a sizable and detectable pressure signal and sends the pressure signal to the data acquisition module; the data acquisition module conducts A / D convert of the received pressure signal and converts a pressure value into a micro force value by using the relationship between the calibrated micro force and the output pressure of the signal disposal circuit. The technology solves the problem of measuring submicro Newton contact force during the micro assembling process, and is mainly used in the technical fields of micro / nano machining, assembling, etc.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

Method for preparing hollowed structure on surface of transparent material and in transparent material

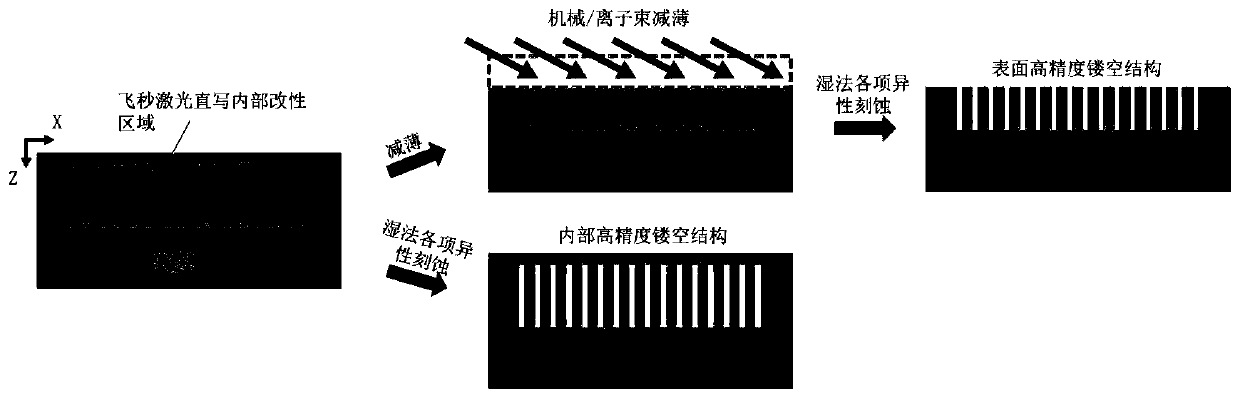

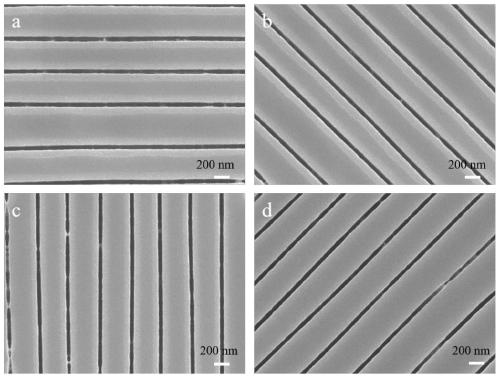

ActiveCN111185678AAbility to realize three-dimensional processingAchieve machining accuracyCleaning using liquidsLaser beam welding apparatusEtchingFemto second laser

The invention discloses a method for preparing a hollowed structure on the surface of a transparent material and in the transparent material, and belongs to the technical field of femtosecond laser micro-nano machining. According to the method, the polarization and machining power is precisely controlled, a modified area with the precision of hundreds of nano is directly written in the transparentmaterial in a femtosecond laser direct writing manner, then the surface of the transparent is thinned to the machining area position (surface machining) in a mechanical / ion beam thinning manner, finally the material is etched through a wet etching process, and preparation of the hollowed structure with high precision, any patterned structure and the precision of hundreds of nano is achieved. According to the method, efficient high-precision machining of multiple common transparent materials can be achieved in a vacuum environment, and the problems that in the prior art, the requirement for the environment is high, and the machining efficiency is low are solved.

Owner:JILIN UNIV

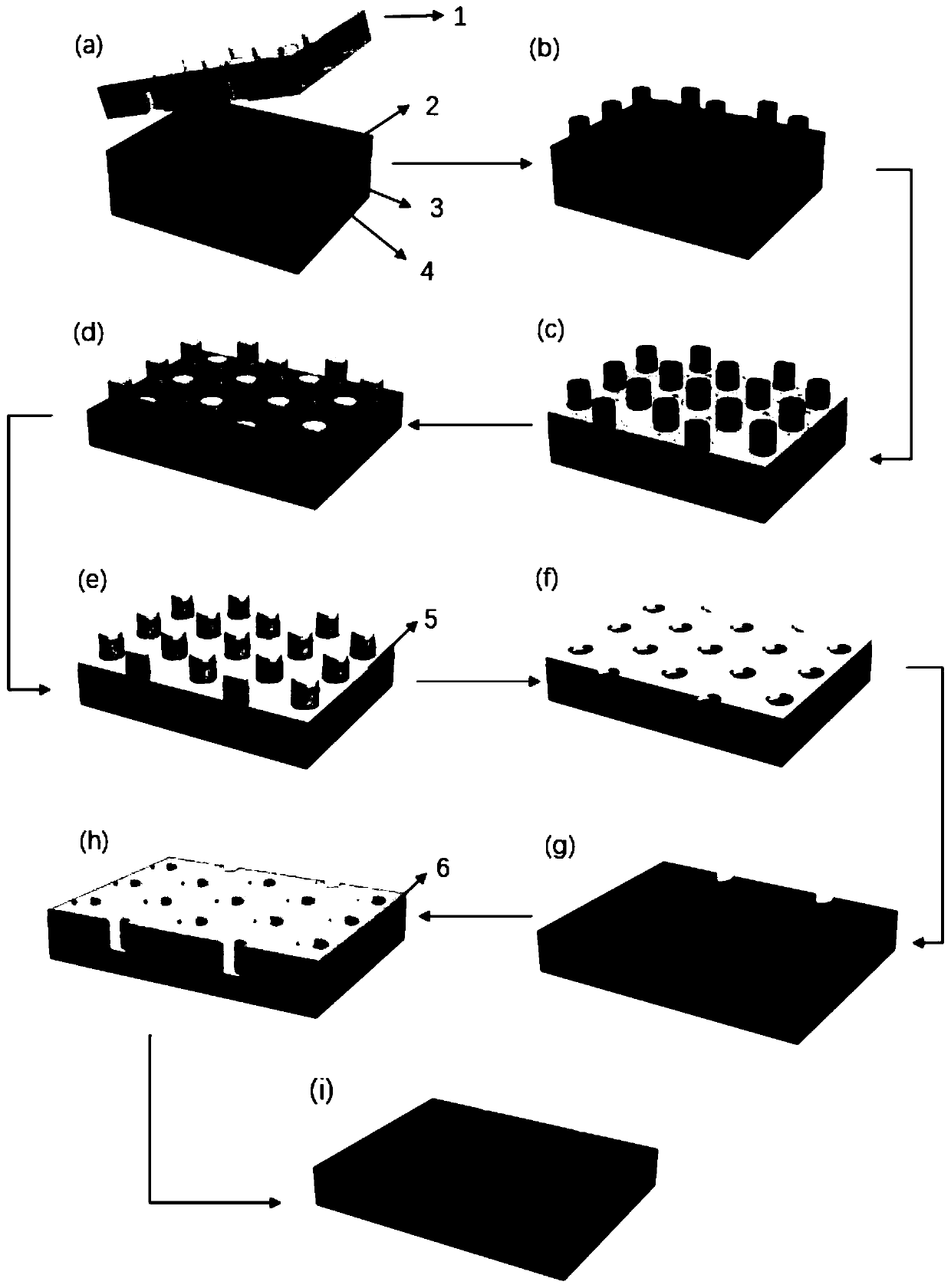

Vertical interconnection substrate based on laser nanoprocessing technology and manufacturing method thereof

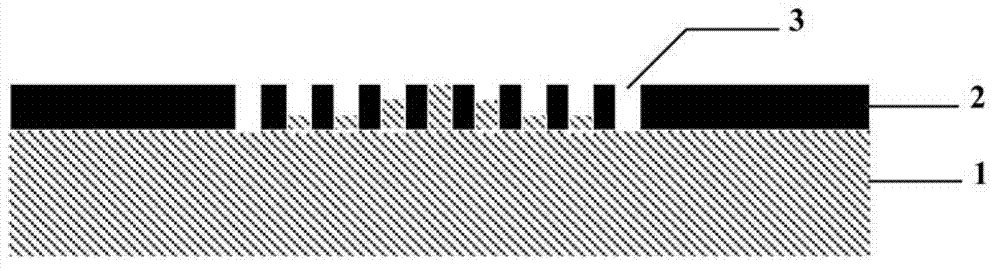

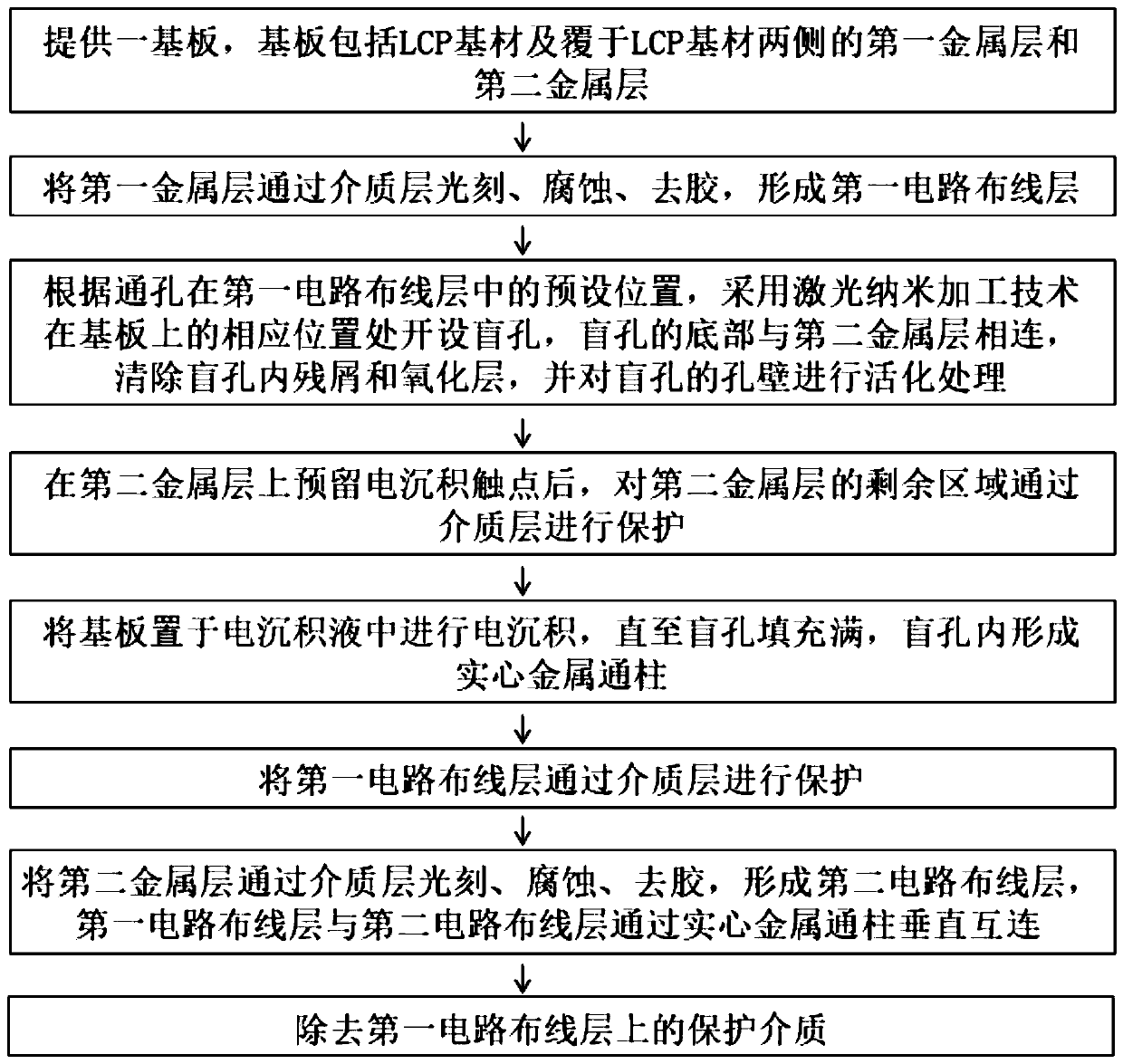

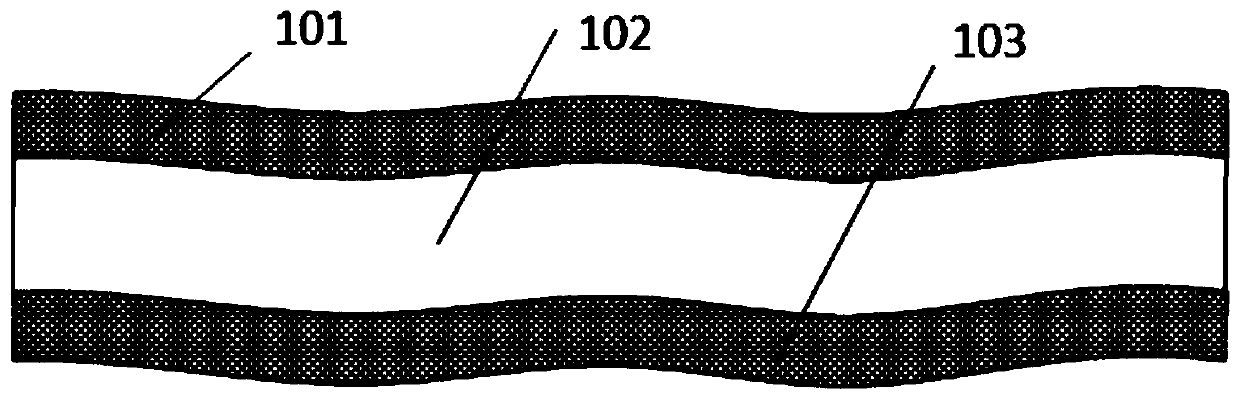

ActiveCN111163582AHigh precisionHigh densityConductive pattern formationElectrical connection printed elementsCapacitanceHemt circuits

The invention discloses a vertical interconnection substrate manufacturing method based on a laser nanometer processing technology. The method comprises the following steps of photoetching, corrodingand degumming a dielectric layer to form a first circuit wiring layer at one side of the substrate, then, forming a blind hole at the corresponding position of the substrate by adopting a laser nano machining technology, putting the substrate into an electro-deposition solution for electro-deposition, filling the blind hole, and finally photoetching, corroding and degumming the dielectric layer toform a second circuit wiring layer at the other side of the substrate. The manufacturing method is concise in process flow, and the laser nano-machining technology is high in precision. Cavities do not exist in the through holes, the interconnection is reliable, and the density and reliability of the three-dimensional packaging of a LCP flexible substrate are improved. Meanwhile, the vertical interconnection between LCP double-sided circuit wiring layers is achieved through the metallized through holes, the interconnection distance can be effectively shortened, the signal delay is reduced, the parasitic inductance and capacitance are reduced, and the high-frequency characteristic is improved, and therefore the system integration performance is improved.

Owner:SHANGHAI SPACEFLIGHT ELECTRONICS & COMM EQUIP RES INST

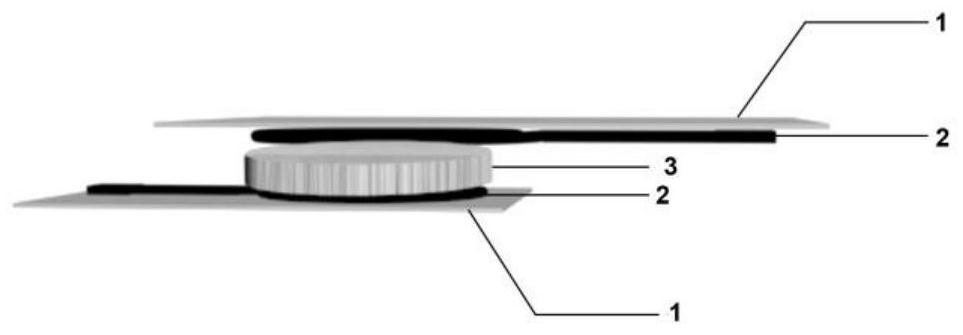

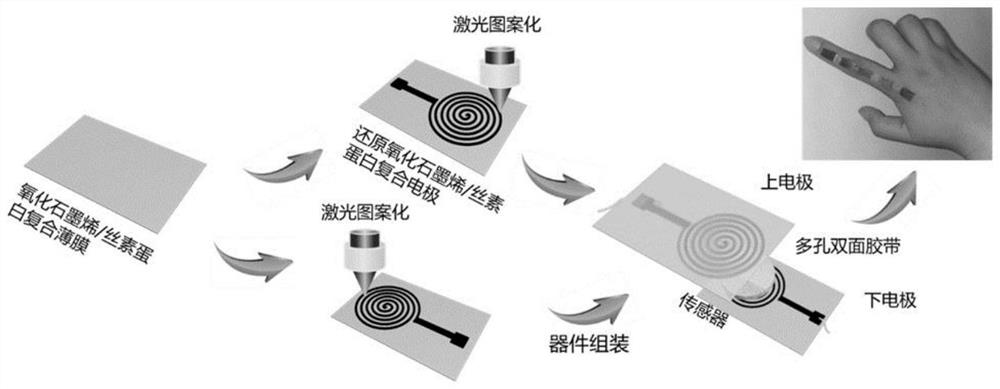

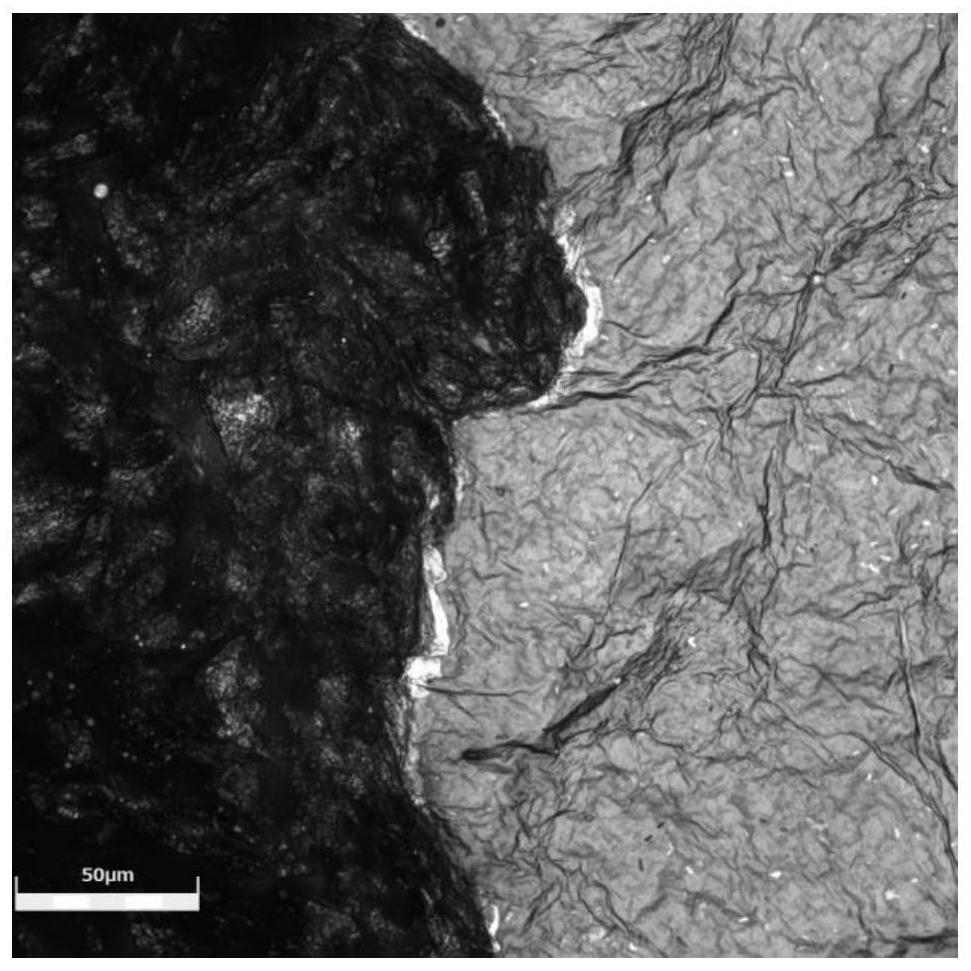

Flexible pressure sensor with complementary spiral structure, preparation method and application thereof

ActiveCN113670484AQuick restoreRestore fineForce measurementFluid pressure measurement using capacitance variationCapacitanceComposite film

The invention discloses a flexible pressure sensor with a complementary spiral structure, a preparation method and application thereof, and belongs to the technical field of laser micro-nano machining. Laser is utilized to process the surface of a graphene oxide / silk fibroin composite film, and the photothermal effect of the laser can remove oxygen-containing functional groups in the graphene oxide, so that the graphene oxide is reduced and a spiral structure electrode is formed at the same time; after a porous adhesive tape is clamped between the pair of electrodes with the complementary spiral structures, the high-performance flexible pressure sensor with the complementary spiral structures is obtained, dual-mode detection of finger bending and finger approaching can be achieved, the porous structure of the adhesive tape is beneficial to large change of capacitance when the sensor is bent, and accurate detection of finger bending can be realized. And meanwhile, the spiral structure of the electrode increases the area of the edge region of the electrode, so that more electric fields can be expanded from the electrode plate region to the outer space, and sensitive detection of finger approach is realized.

Owner:吉林大学重庆研究院

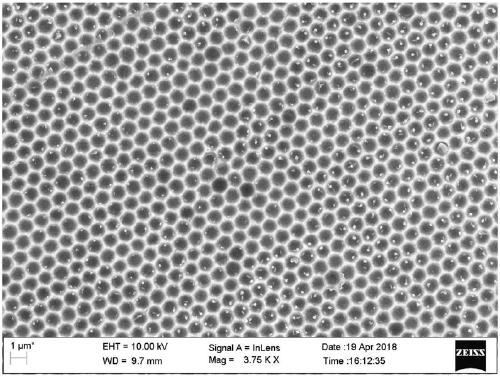

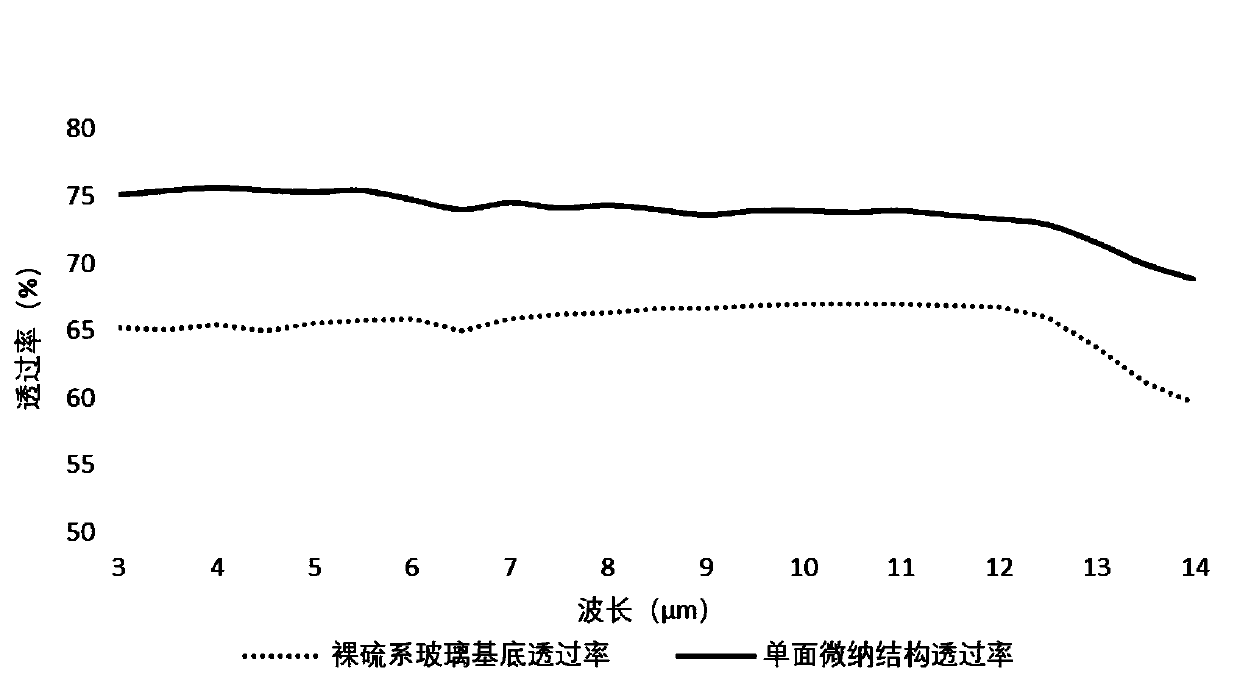

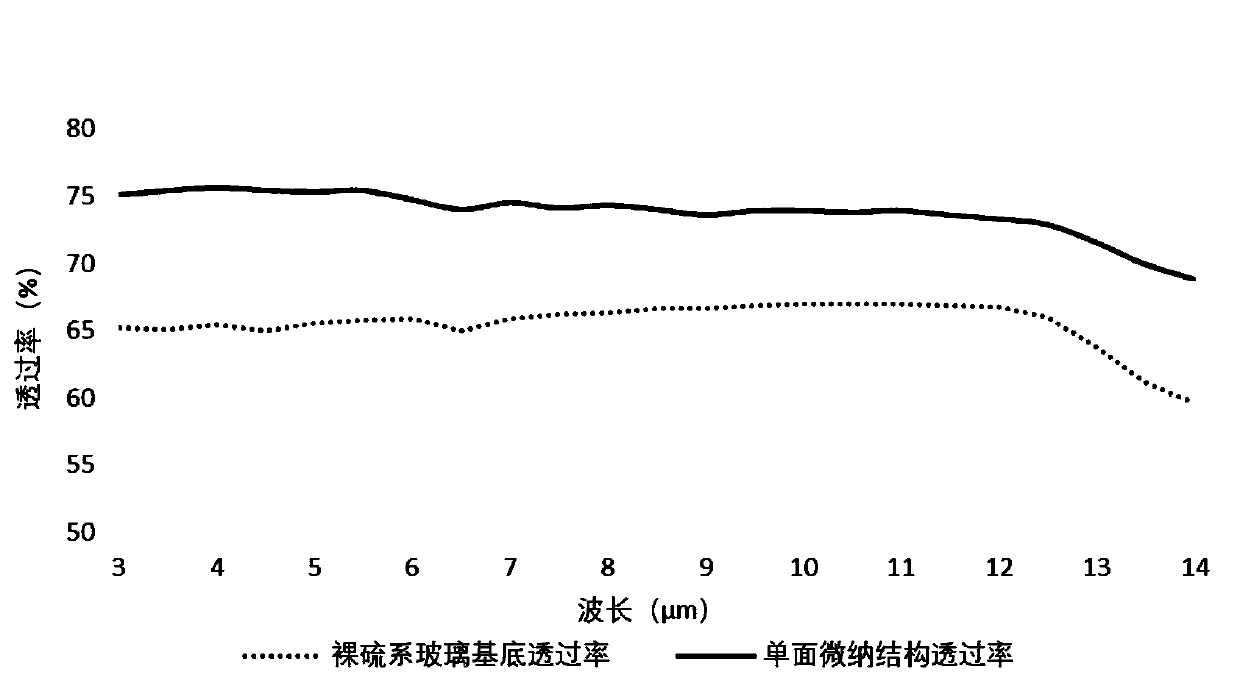

Method for improving infrared band transmittance by processing micro-nano structure on surface of chalcogenide glass

ActiveCN111175857AAvoid introducingGood anti-reflection effectOptical elementsNano structuringChemical reaction

The invention relates to a method for improving infrared band transmittance by processing a micro-nano structure on a surface of chalcogenide glass, and belongs to the technical field of infrared optical glass processing and application. According to the method, the micro-nano structure with a proper refractive index is directly manufactured on the surface of the chalcogenide glass, introduction of a new film material is avoided, and problems that a multi-layer film material is limited and quality of a film layer is poor in a traditional infrared antireflection film plating process are solved;reactive ion etching adopted in the method is mainly based on a chemical reaction of a gas and the chalcogenide glass, does not generate any effect on a part covered by a polymer coating, avoids generation of a stress, is performed at a normal temperature and in a vacuum state, and does not generate gasification and leakage of toxic components; and according to the method, micro-nano structure pattern impressing of a non-planar surface can be achieved, a category of large-area micro-nano machining optical elements is expanded, and efficient antireflection of the chalcogenide glass in all infrared wave bands can be achieved by changing a target graphic structure and technological parameters.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +1

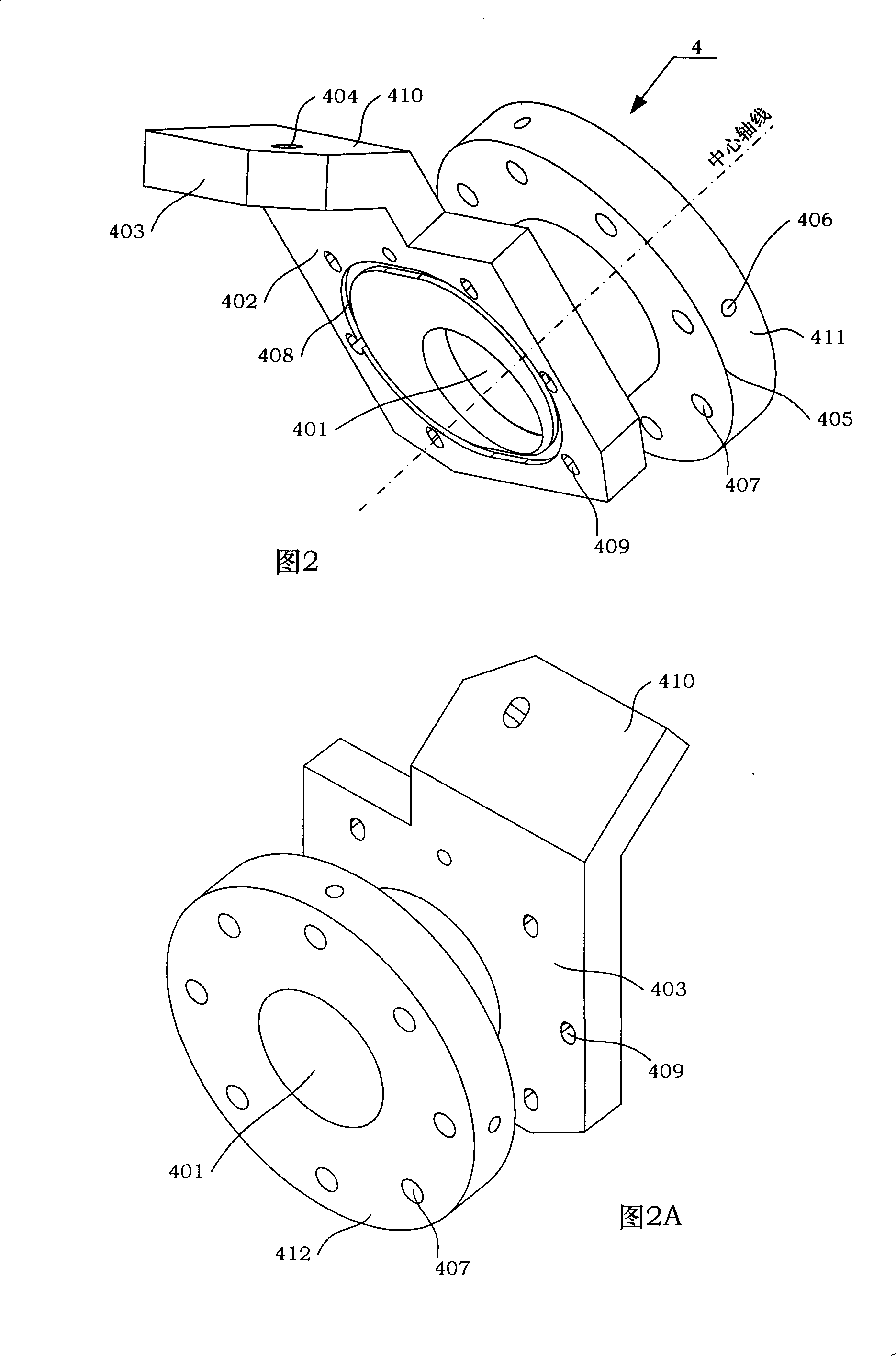

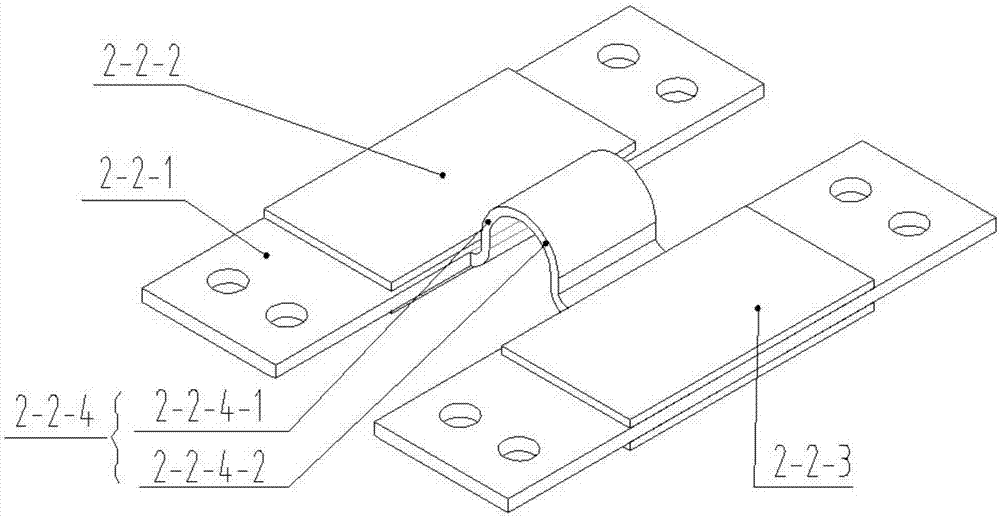

A double-butterfly-shaped stator piezoelectric linear actuator

PendingCN107124119ACompact structureIncrease the itineraryPiezoelectric/electrostriction/magnetostriction machinesAviationDrive by wire

The invention discloses a double-butterfly-shaped stator piezoelectric linear actuator belonging to the field of precision driving technology. The double-butterfly-shaped stator piezoelectric linear actuator comprises a butterfly-shaped stator 1 (1), a butterfly-shaped stator 2 (2), a mover (3) and a pedestal (4), wherein the butterfly-shaped stator 1 (1) and the butterfly-shaped stator 2 (2) are placed on both sides of the mover (3) in mirror symmetry and are in elastic contact with the mover (3) and fixedly mounted on the pedestal (4). The butterfly-shaped stator 1 (1) and the butterfly-shaped stator 2 (2) have the same structure. A sinusoidal drive electric signal for lagging behind the butterfly-shaped stator 1 (1) for half a cycle is applied to the butterfly-shaped stator 2 (2). The butterfly-shaped stator 1 (1) and the butterfly-shaped stator 2 (2) alternately step to drive the mover (3) to move to effectively overcome backing of the mover (3). The double-butterfly-shaped stator piezoelectric linear actuator of the invention has advantages of a simple and compact structure, a large stroke, high precision, a large load and being capable of effectively inhibiting backspacing and being applied to the fields such as micro-nano machining, space flight and aviation and precision optics.

Owner:JILIN UNIV

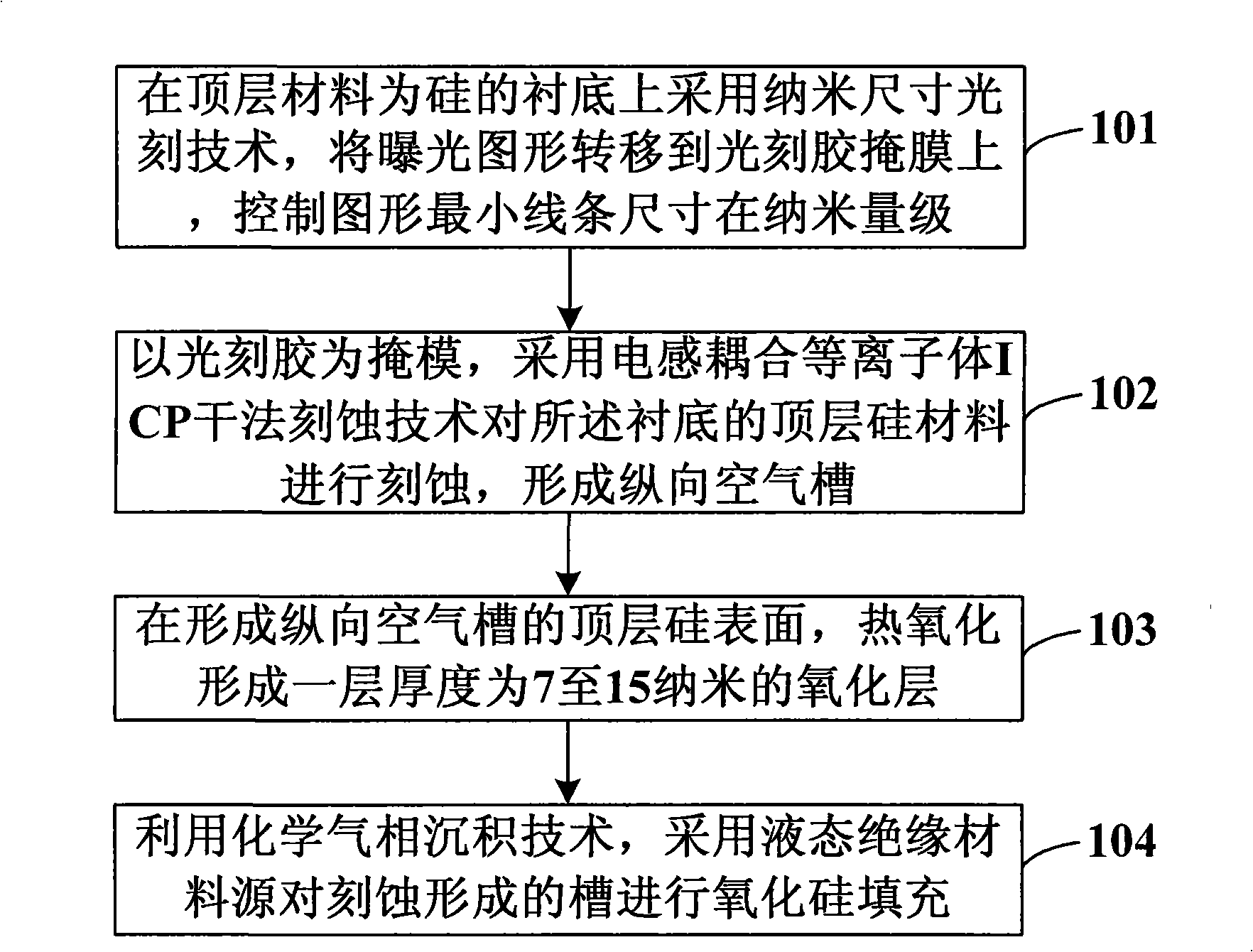

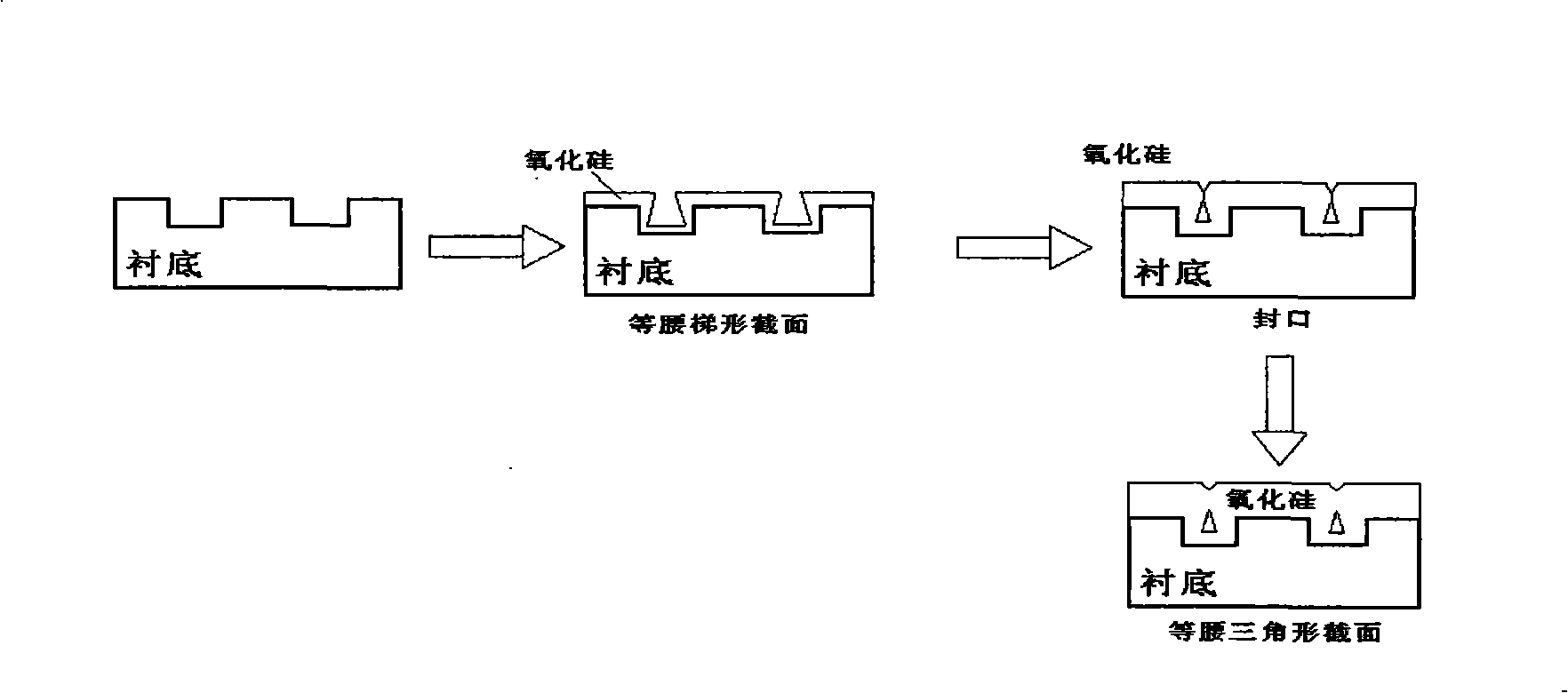

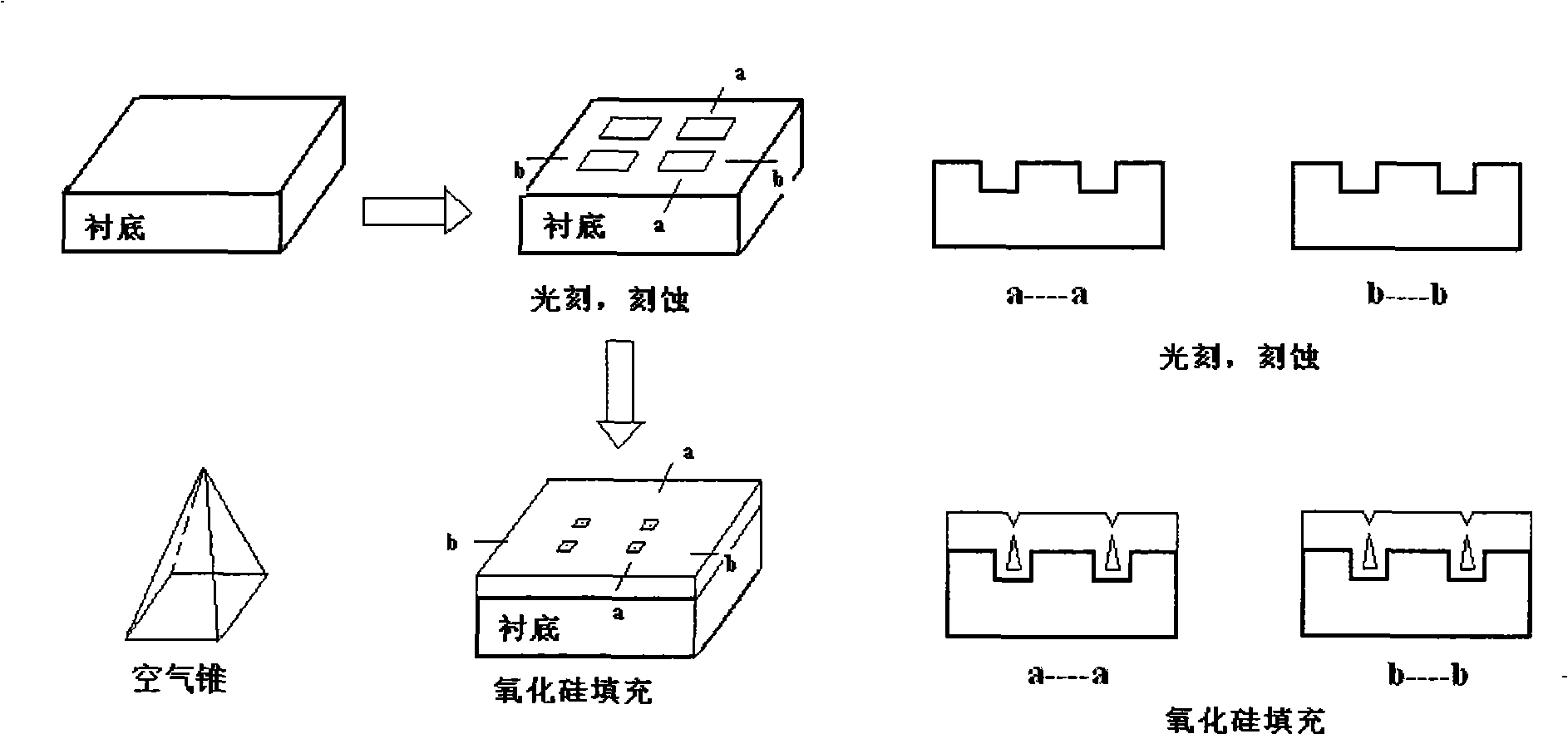

Method for making nanometer dimension triangle air pocket

InactiveCN101325171AManufacturing process compatiblePrecise control of deposition thicknessNanostructure manufactureSemiconductor/solid-state device manufacturingLiquid stateSilicon oxide

The invention discloses a manufacturing method of a nanometer triangular air slot, belonging to the technology field of micro / nano processing techniques. The method comprises the steps of: (1) on a substrate with a silicon top layer, transferring an exposure pattern on a photoresist mask by using nanometer photoetching technique and controlling the minimal line of the pattern at a nanometer scale; (2) etching the top layer silicon of the substrate with the photoresist as a mask by using inductively coupled plasma (ICP) dry etching technique to form a longitudinal air slot; (3) forming an oxidizing layer of thickness 7-15 nanometers on the surface of the top layer silicon forming the longitudinal air slot by thermal oxidization; and (4) filling the etched slot with silicon oxide adopting a liquid state insulating material by using chemical vapor deposition technique. The inventive method can manufacture the nanometer triangular air slot.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

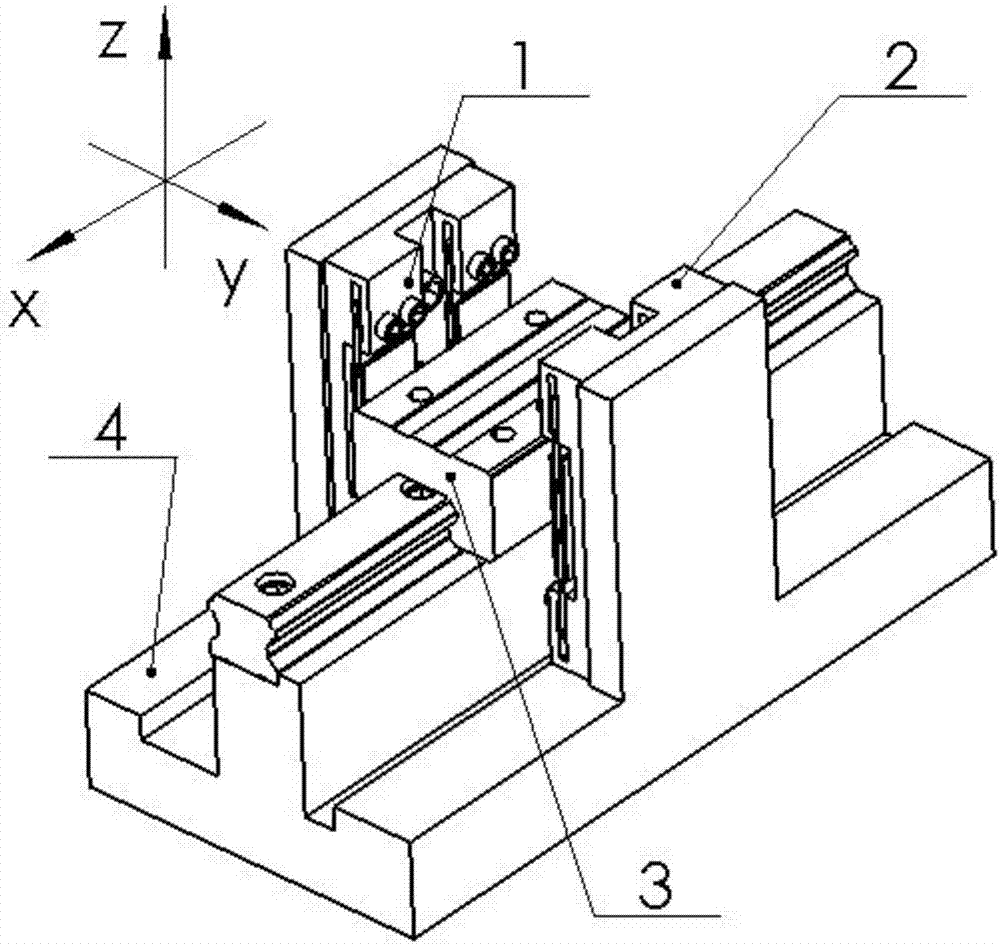

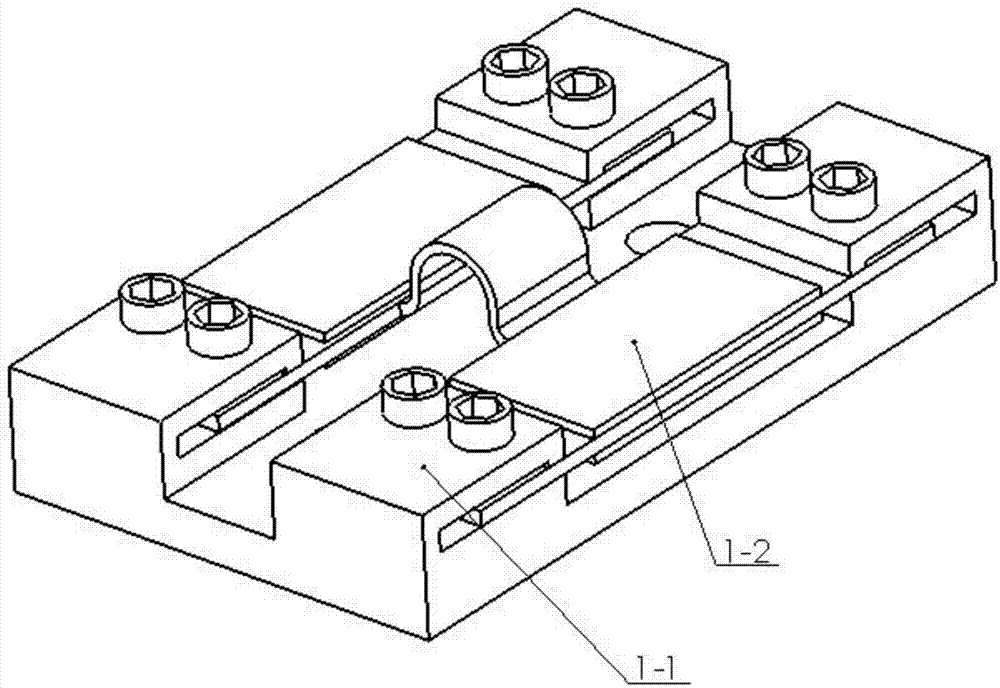

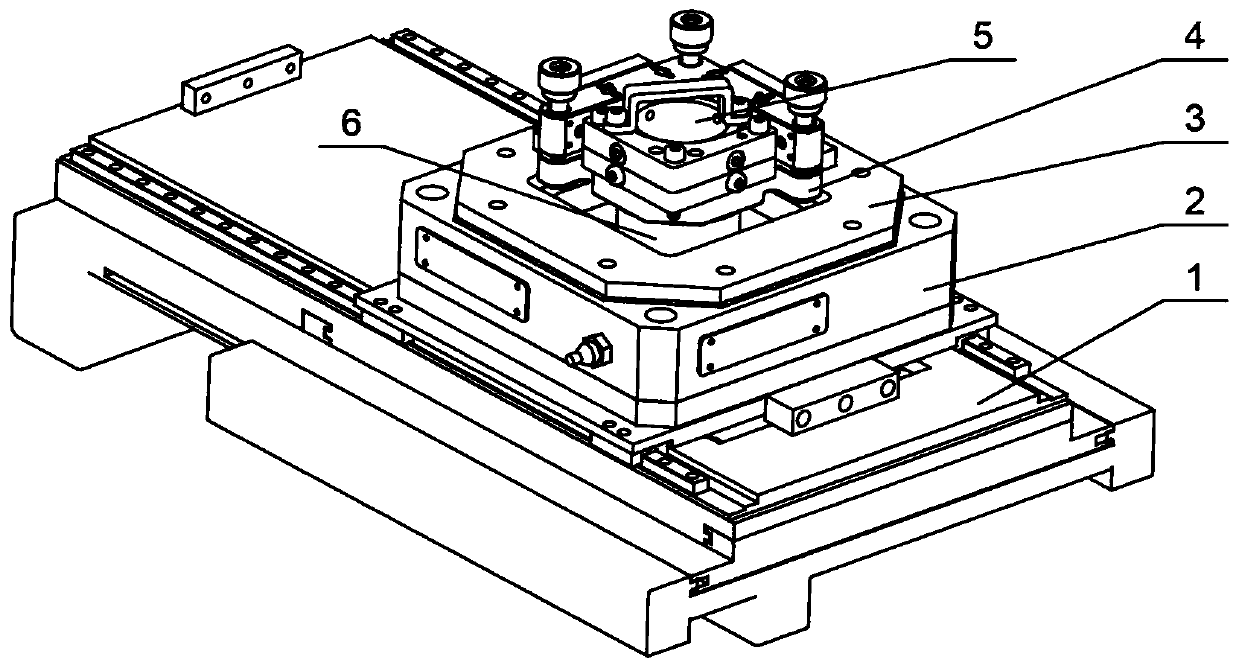

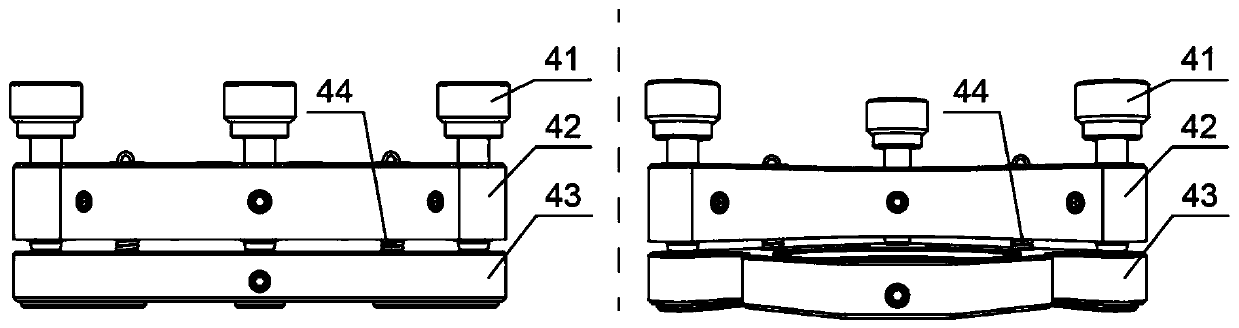

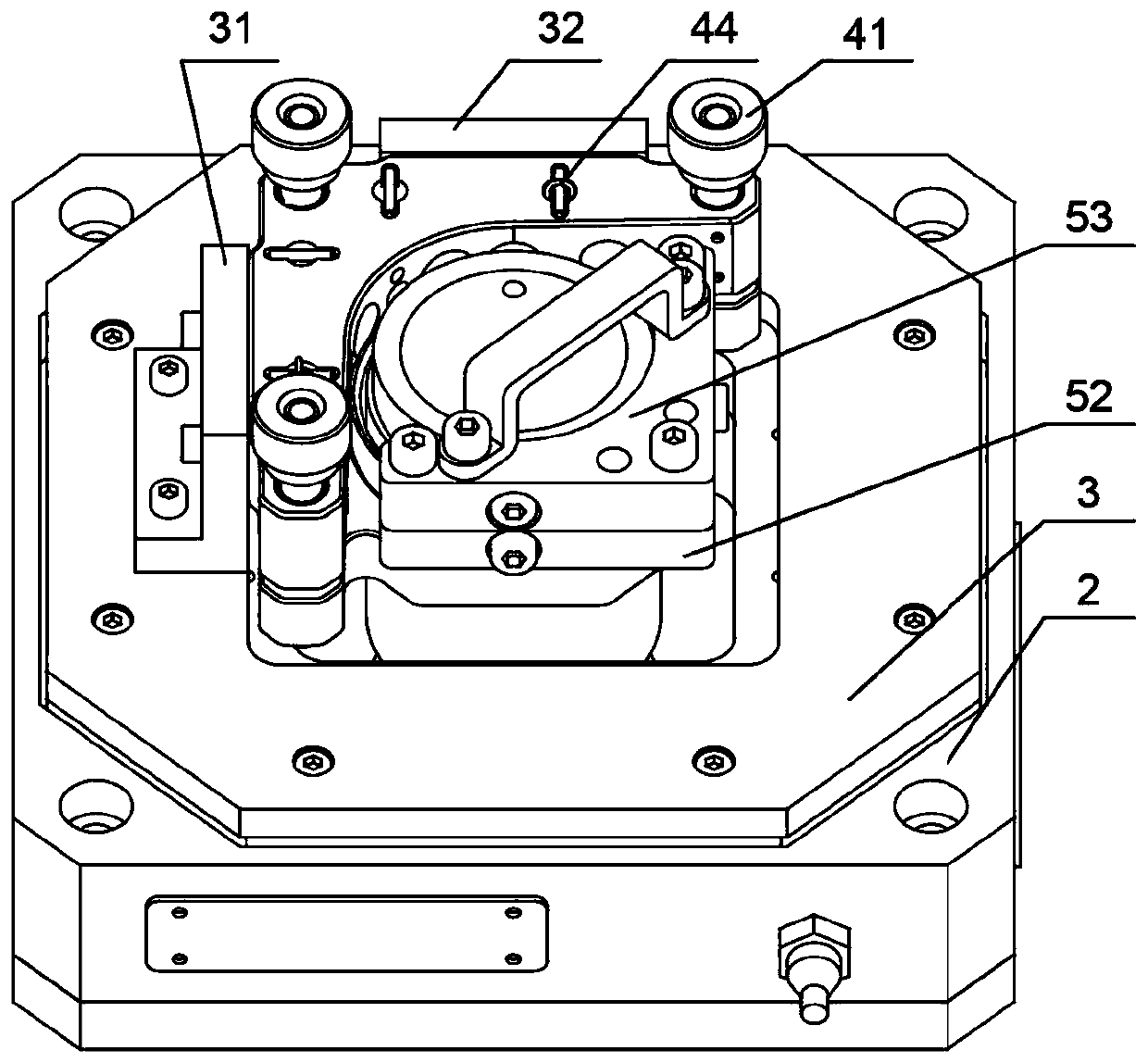

Sample precise jig for cross-scale two-photon polymerization machining and leveling method

ActiveCN111421228AFlexible settingsGuaranteed molding accuracyLaser beam welding apparatusEngineeringNano machining

The invention belongs to the field of micro-nano machining, and particularly relates to a sample precise jig for cross-scale two-photon polymerization machining and a leveling method. The jig comprises an X-axis and Y-axis moving platform, a Z-axis displacement table and a base plate which are fixedly connected, and a fine-adjusting assembly, a transition assembly and a carrying table which are arranged on the base plate. One end of the transition assembly is fixed to the fine-adjusting assembly, and the other end of the transition assembly is fixed to the carrying table. The X-axis and Y-axismoving platform is used for driving the Z-axis displacement table and the base plate to move in the X-axis direction and the Y-axis direction. The Z-axis displacement table is used for driving the base plate to drive the fine-adjusting assembly, the transition assembly and the carrying table to move in the Z-axis direction. The fine-adjusting assembly is used for driving the transition assembly to drive the carrying table to adjust the levelness and flatness. By means of the sample precise jig, the real-time three-dimensional leveling precision of a cross-scale two-photon polymerization machining system is controlled within 100 nanometers, the accurate focusing of the two-photon polymerization machining system during machining and the forming precision of a machined product are effectively ensured, and the machining scale is expanded from the micro-nano scale to the millimeter-centimeter scale.

Owner:HUAZHONG UNIV OF SCI & TECH

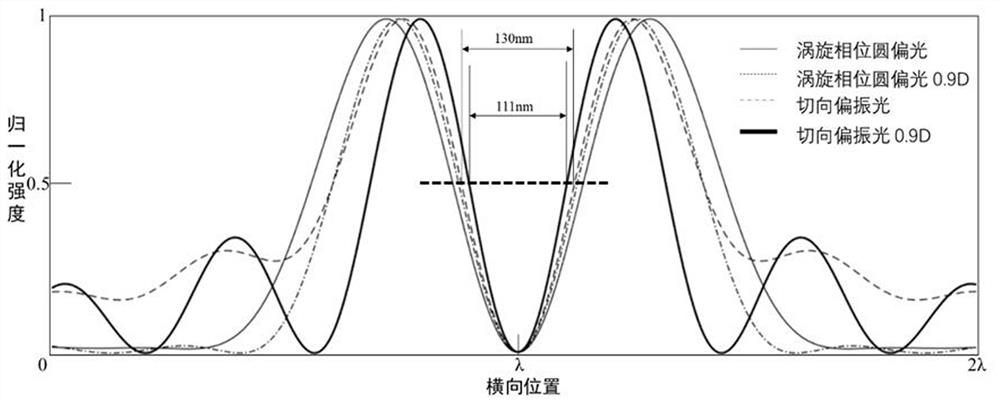

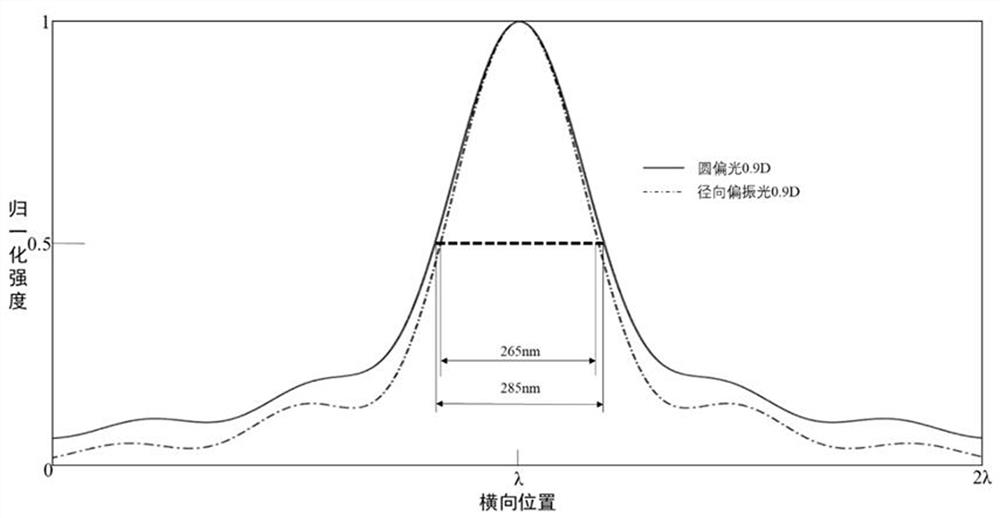

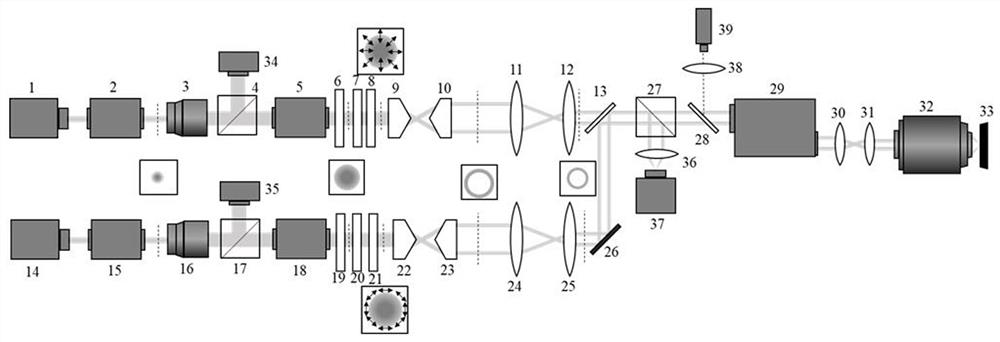

Super-resolution laser printing device based on columnar vector polarized light

ActiveCN112286014ASmall Hollow Half Height Full WidthRetain energyPhotomechanical exposure apparatusMicrolithography exposure apparatusLight spotPolarizer

The invention discloses a super-resolution laser printing device based on columnar vector polarized light, and belongs to the field of super-resolution laser micro-nano machining. A light beam outputby a direct-writing laser is collimated into a parallel light beam by a collimator after being subjected to intensity modulation by an acoustic optical modulator, and then the light beam is convertedinto tangential polarized light through a polarizer, a 1 / 2 wave plate and a vortex half-wave plate; a light beam output by a suppression laser is collimated into a parallel light beam by the collimator after being subjected to intensity modulation by the acoustic optical modulator, and then the parallel light beam is converted into radial polarized light through the polarizer, the 1 / 2 wave plate and the vortex half-wave plate; the two columnar vector polarized lights are respectively shaped into annular parallel light beams through two conical lenses in sequence; then the two beams of light are combined into one path of light which is focused by a high numerical aperture objective lens; the annular radial polarized light is focused into a solid light spot, and the annular tangential polarized light is focused into a hollow dark spot; the full widths at half maximum of the two light spots are smaller than that of the light spots formed by circularly polarized light under the same focusing condition, so that higher printing resolution can be obtained.

Owner:ZHEJIANG LAB

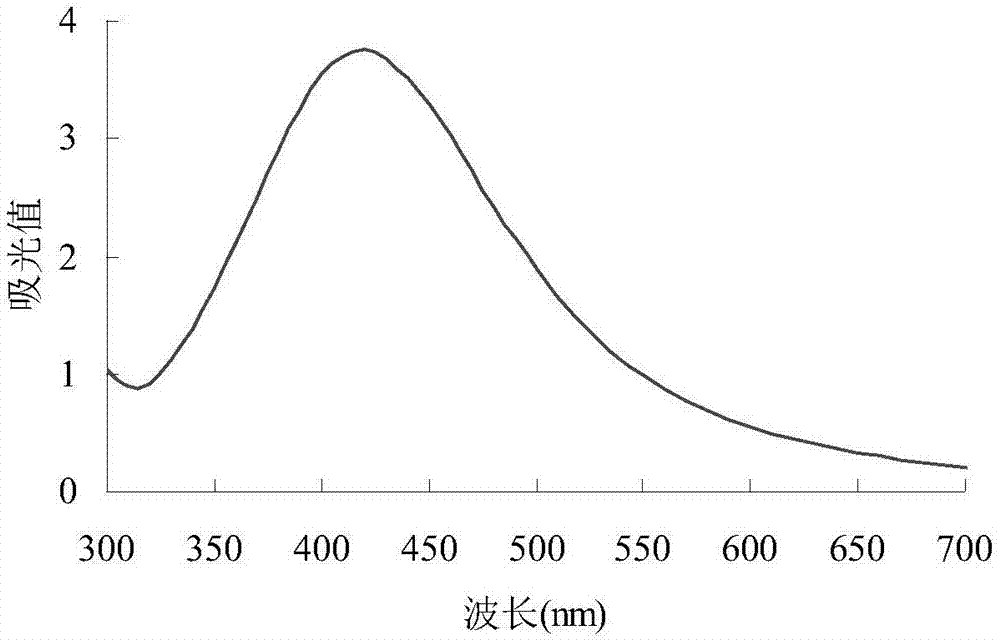

Environment-friendly fast nano silver sol preparation method implemented through abalone viscus degradation products

ActiveCN107498067AImprove dispersion stabilityHigh biosecurityMaterial nanotechnologyTransportation and packagingMicrowaveNano machining

The invention provides an environment-friendly fast nano silver sol preparation method implemented through abalone viscus degradation products, and belongs to the technical field of nano-machining. The preparation method of nano silver sol comprises the steps that the abalone viscus degradation products and silver nitrate are mixed and dissolved in a water-phase system, and the nano silver sol which is even in dispersion and good in stability is prepared through microwave heating, hot bath, oil bath or ultraviolet radiation. The preparation method is simple, safe and fast, and a green, environment-friendly and fast method is provided for preparation of the nano silver sol. Abalone viscera belong to by-products of the abalone processing industry and are reproducible biological resources. A new method is provided for synthesis of the nano silver sol, and meanwhile, high-value application of the abalone viscera is achieved.

Owner:XIAMEN MEDICAL COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com