Patents

Literature

296 results about "Structure pattern" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pattern is an underlying structure that organizes surfaces or structures in a consistent, regular manner. Pattern can be described as a repeating unit of shape or form, but it can also be thought of as the "skeleton" that organizes the parts of a composition.

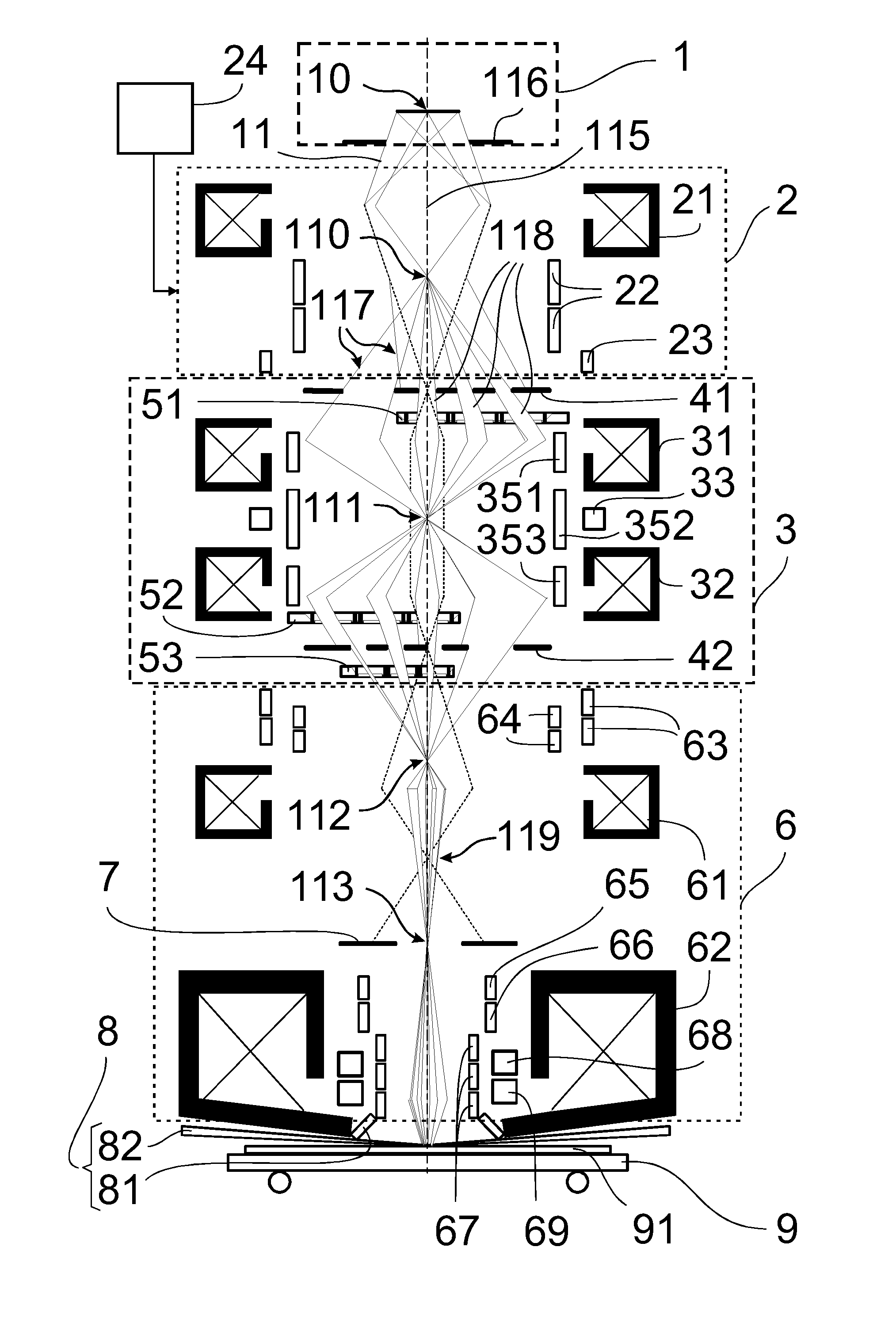

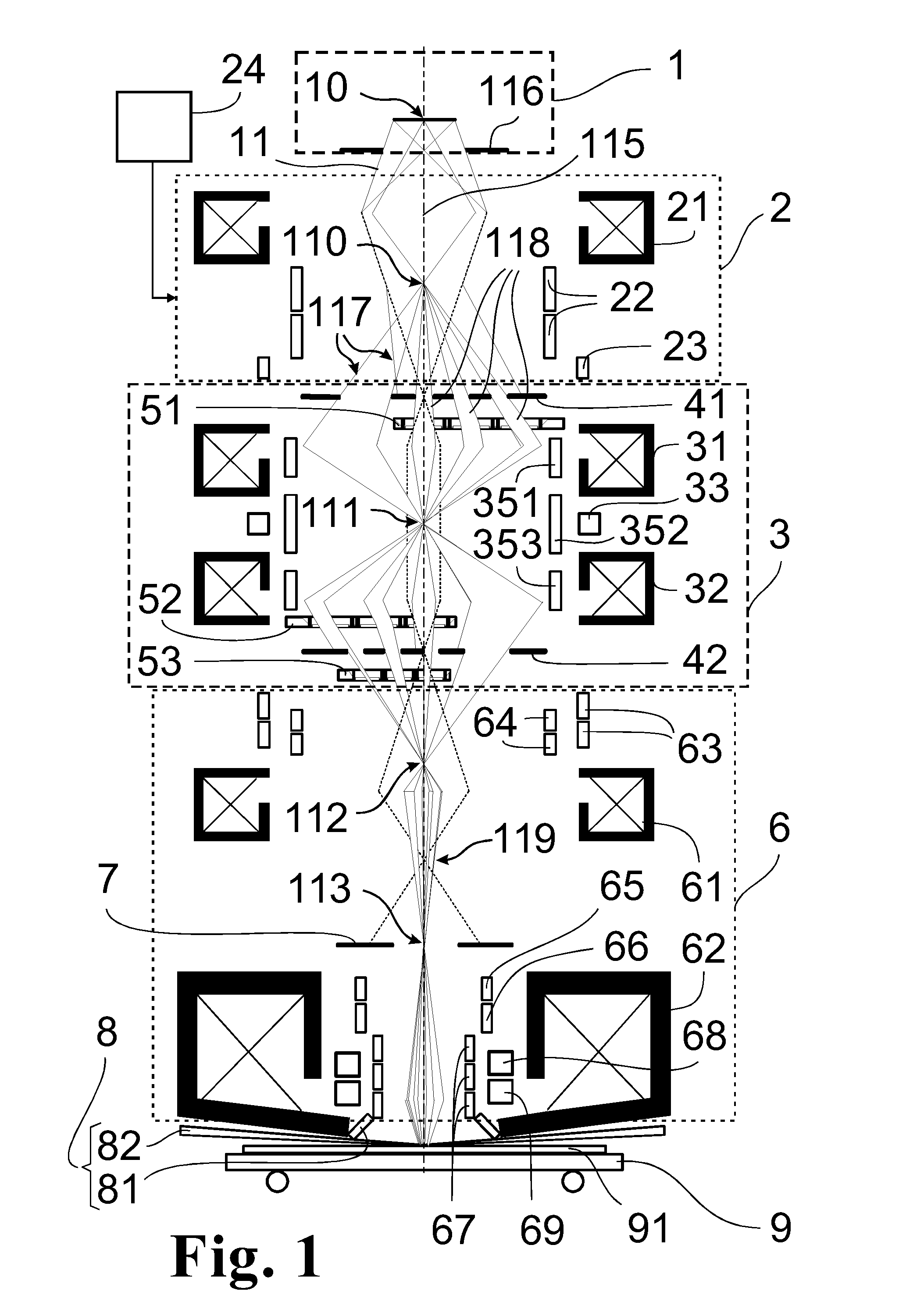

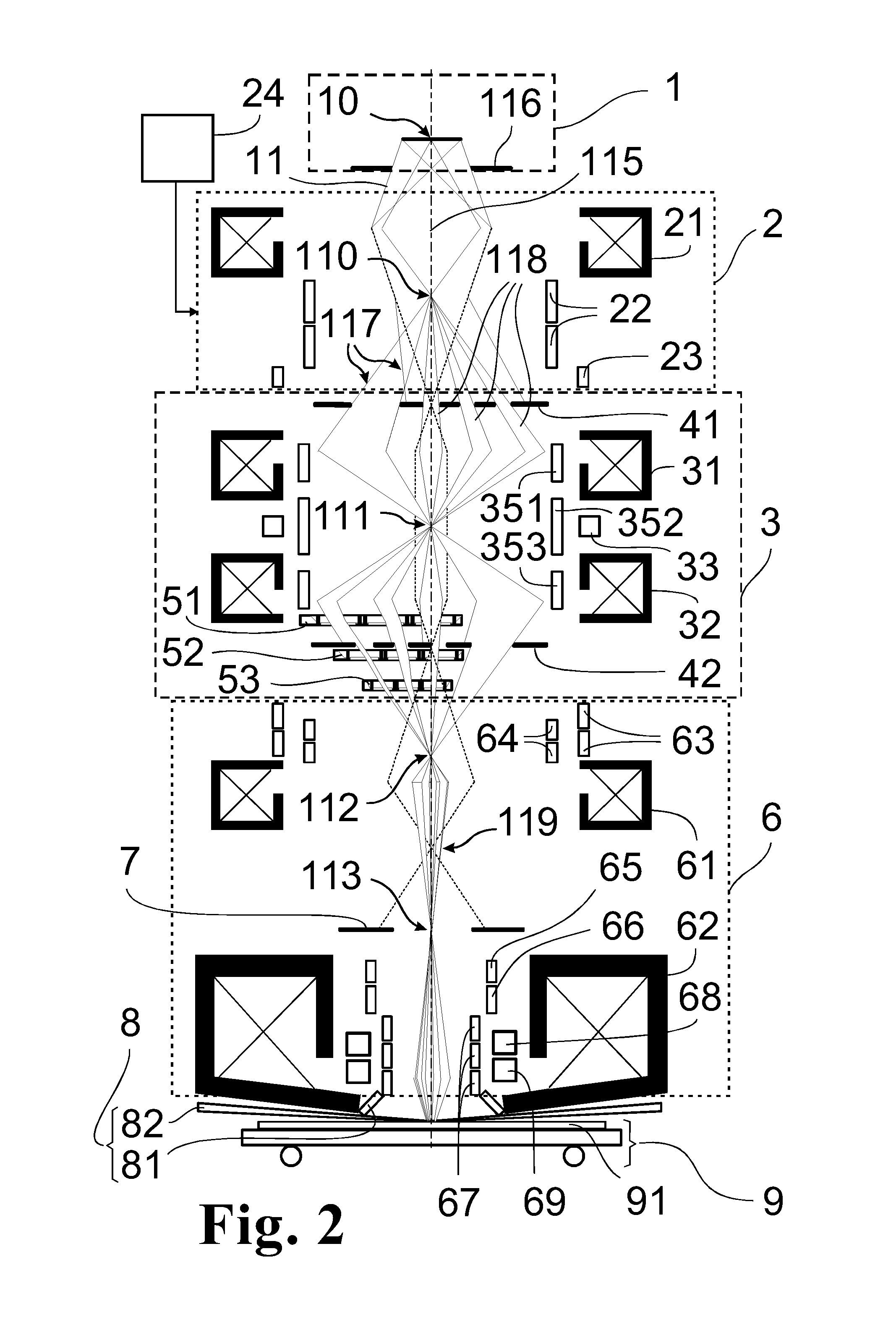

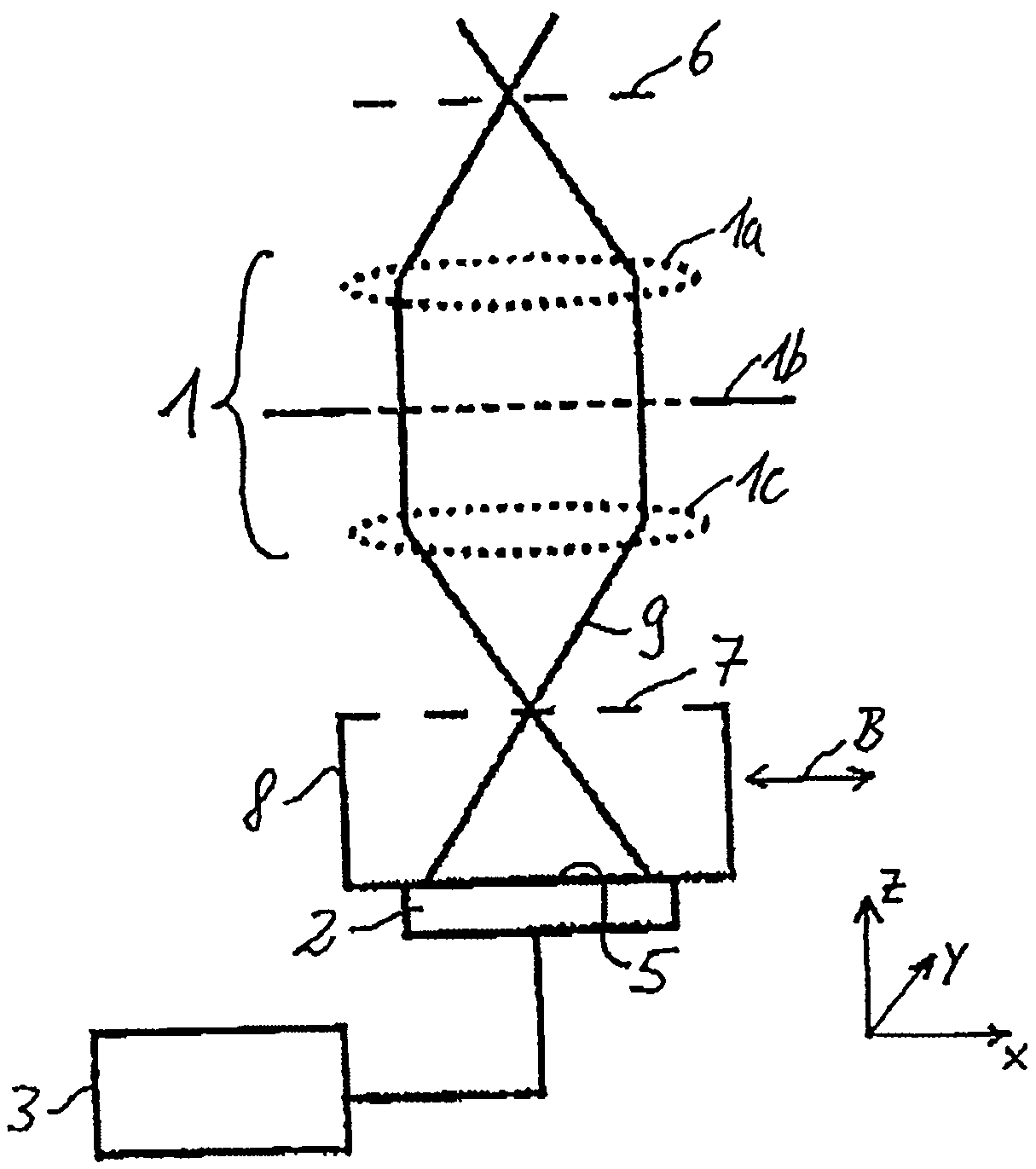

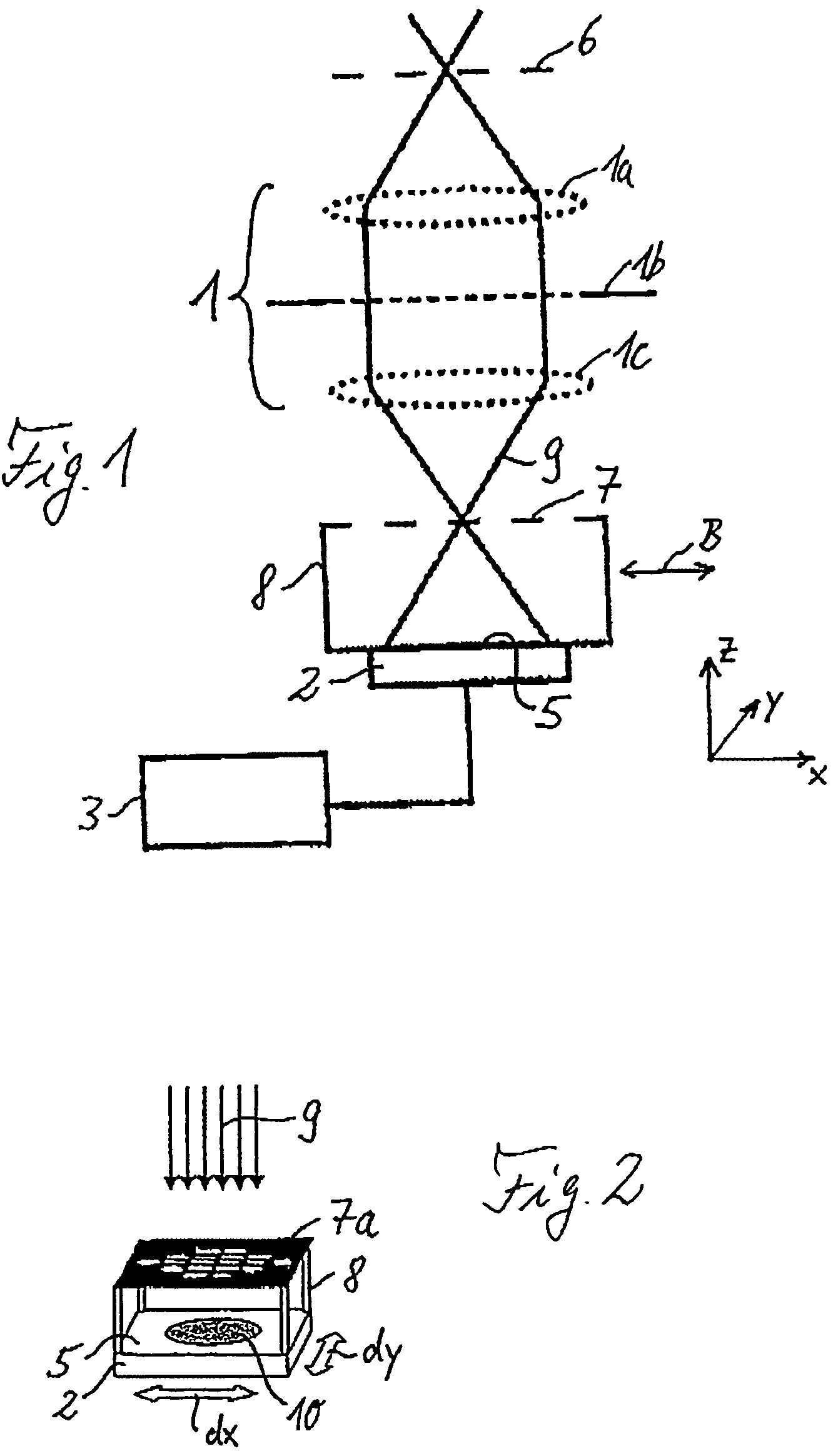

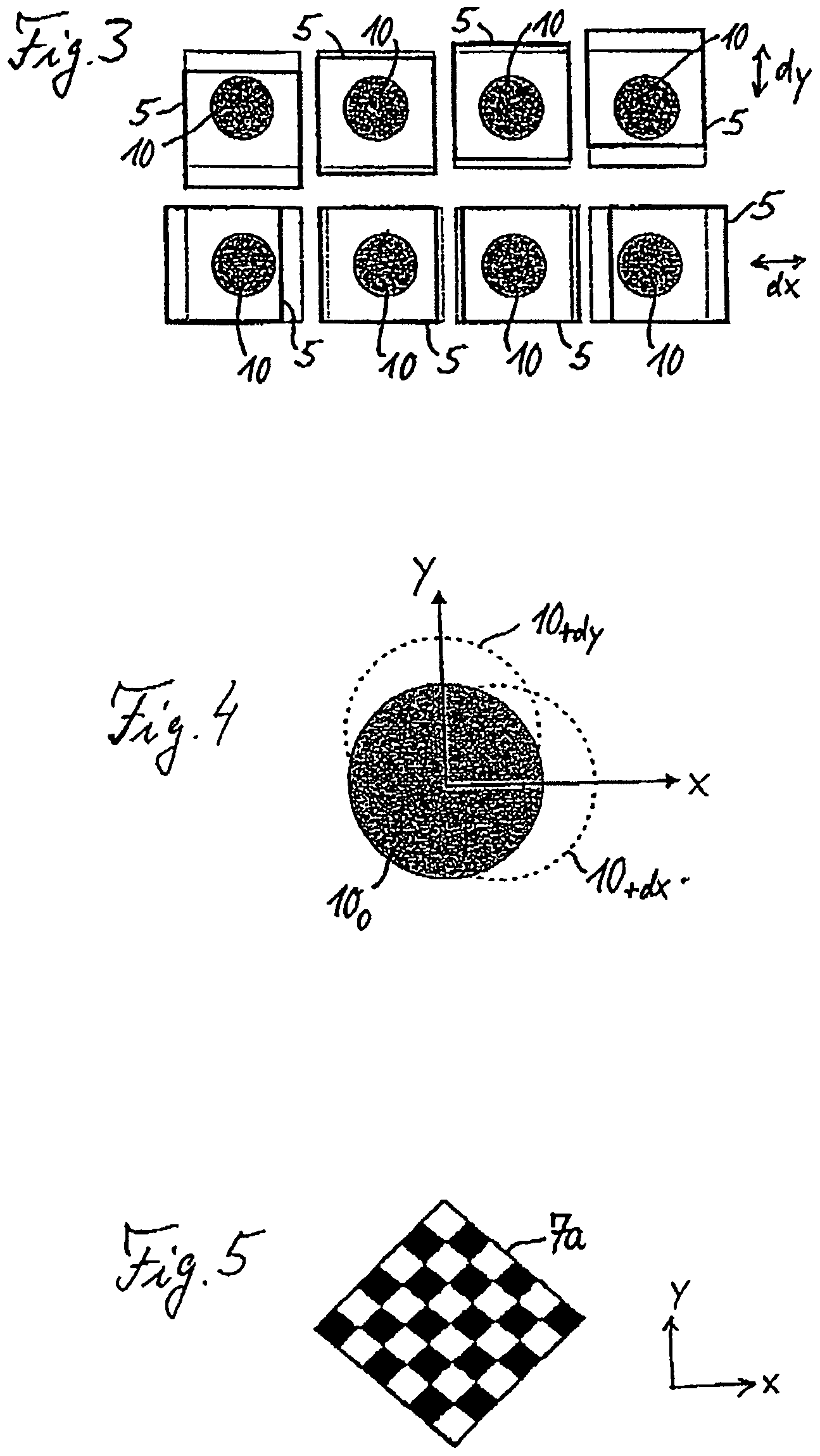

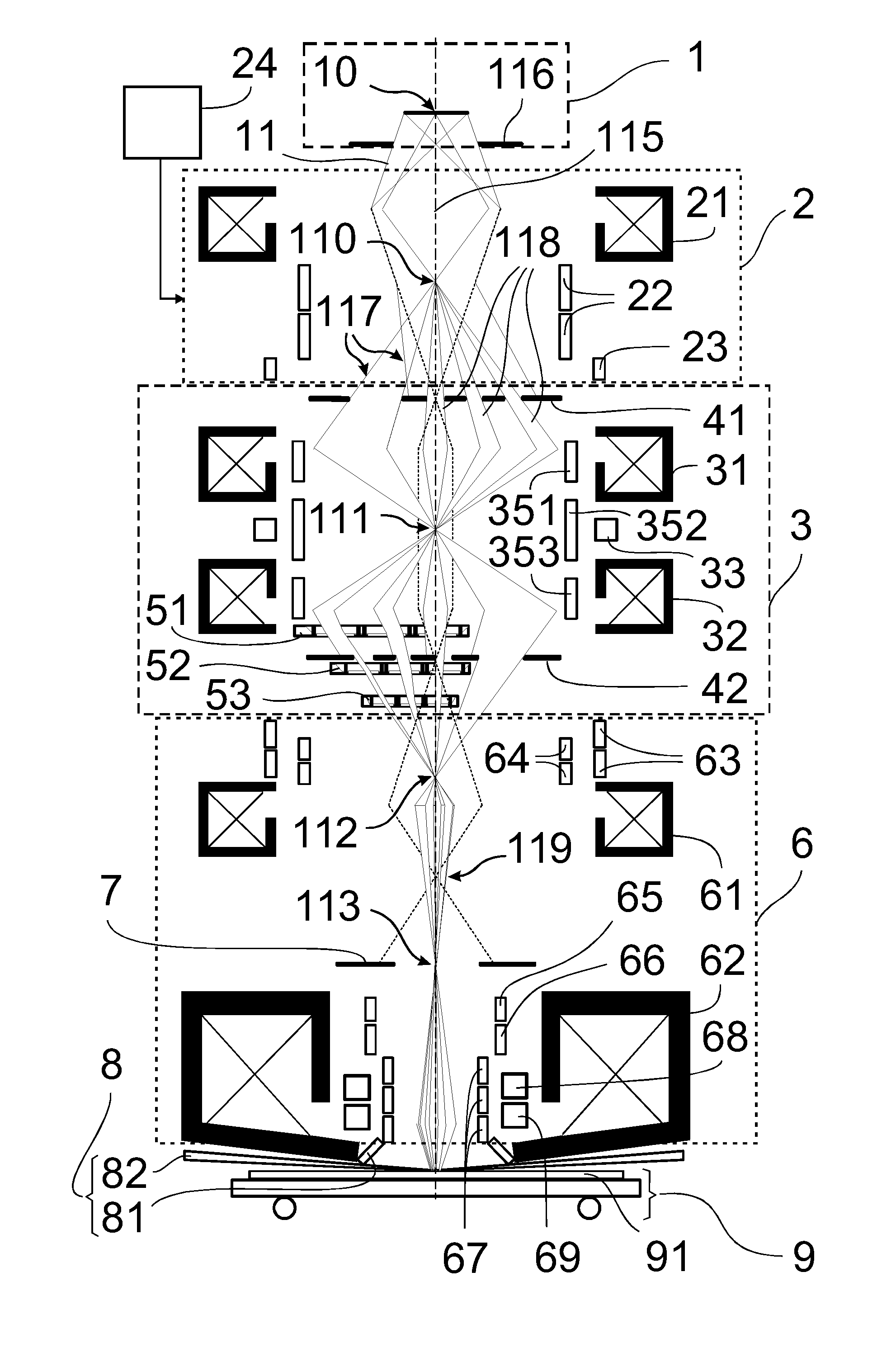

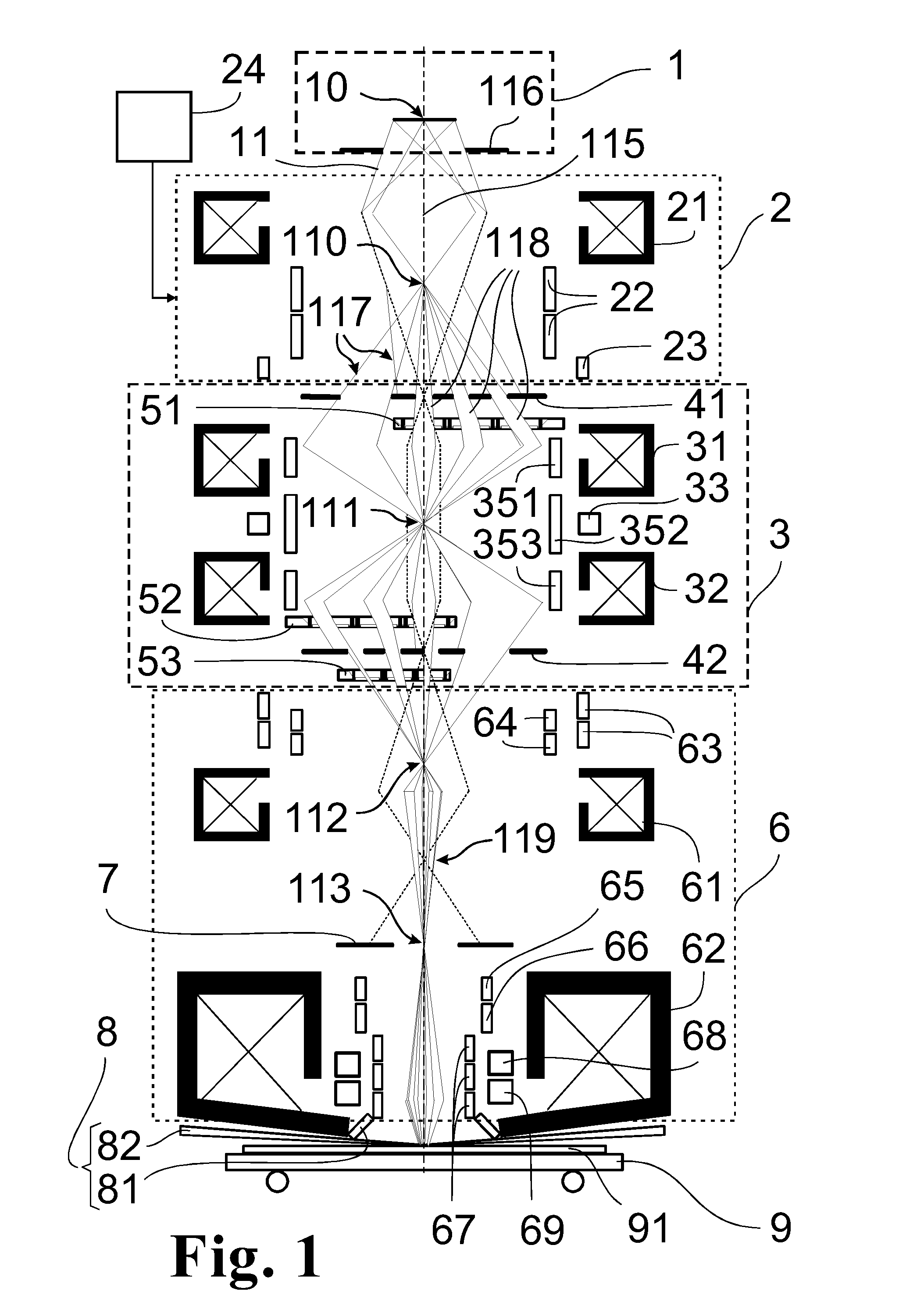

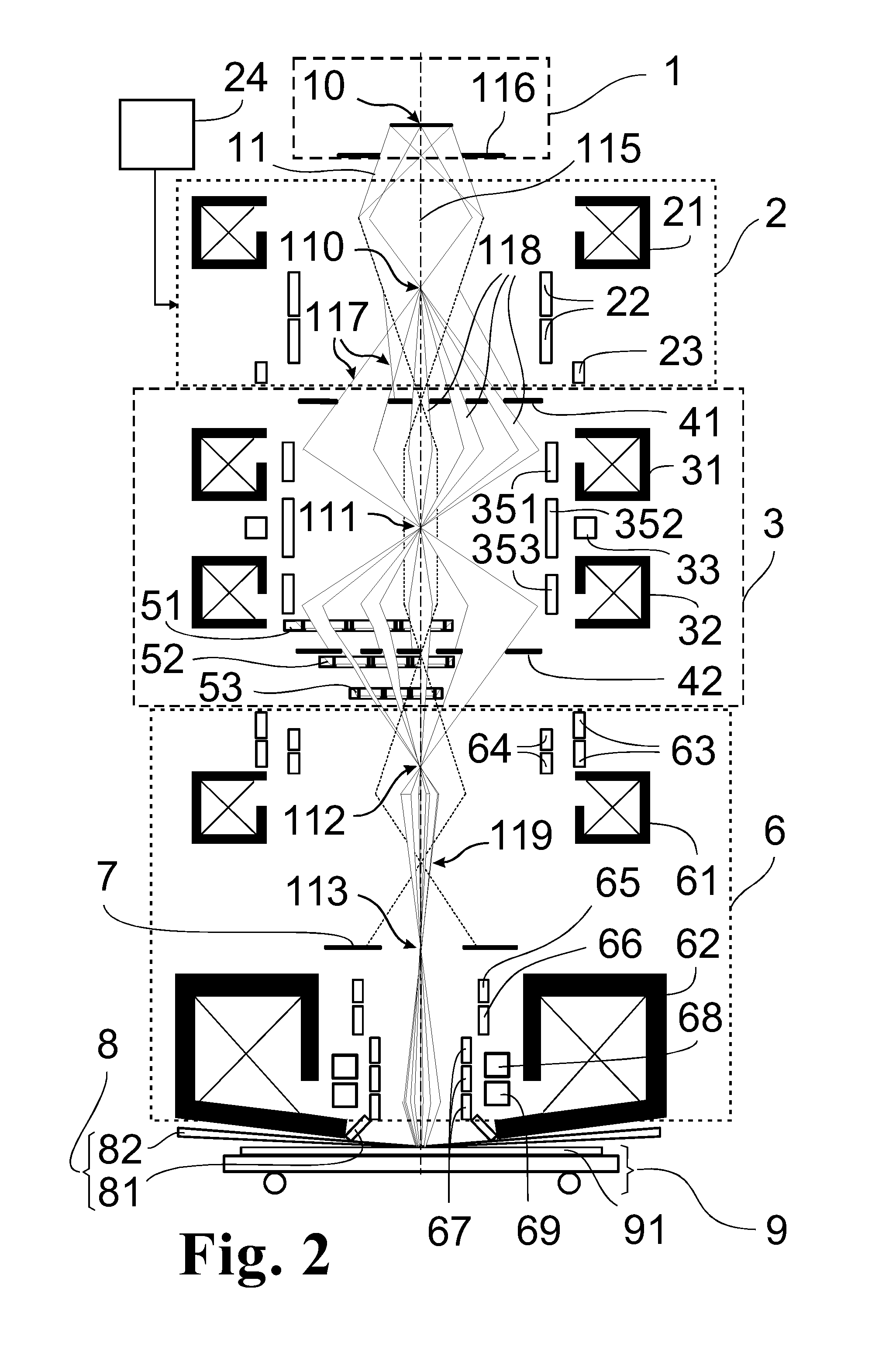

Arrangement for the Illumination of a Substrate with a Plurality of Individually Shaped Particle Beams for High-Resolution Lithography of Structure Patterns

ActiveUS20100148087A1High substrate throughputIncrease structural flexibilityThermometer detailsStability-of-path spectrometersParticle beamLight beam

The invention is directed to an arrangement for the illumination of a substrate with a plurality of individually shaped, controllable particle beams, particularly for electron beam lithography in the semiconductor industry. It is the object of the invention to find a novel possibility for illuminating a substrate (91) with a plurality of individually shaped, controllable particle beamlets (118) which permits a high-resolution structuring of substrates with a high substrate throughput without limiting the flexibility of the applicable structure patterns or limiting the high substrate throughput due to a required flexibility. According to the invention, this object is met in that a first aperture diaphragm array and a second aperture diaphragm array are constructed as multiple-format diaphragm arrays (41, 42) for generating particle beamlets (118) with different beam cross sections, and at least three multibeam deflector arrays (51, 52, 53) for individual deflection of the particle beamlets (118) are associated with the first multiple-format diaphragm array (41) and with the second multiple-format diaphragm array (42), wherein at least one multibeam deflector array (51) is arranged between the first multiple-format diaphragm array (41) and the second multiple-format diaphragm array (42) in order to generate different cross sections of the particle beamlets (118), at least a second multibeam deflector array (52) is arranged in the vicinity of the second multiple-format diaphragm array (42) in order to blank or deflect individual particle beamlets (118) into individual crossovers, and at least a third multibeam deflector array (53) is arranged downstream of the second multiple-format diaphragm array (42) at a distance of 10-20% of the distance to the next crossover (112) in order to generate different positions of the particle beamlets (118) on the substrate (91).

Owner:VISTEC ELECTRON BEAM

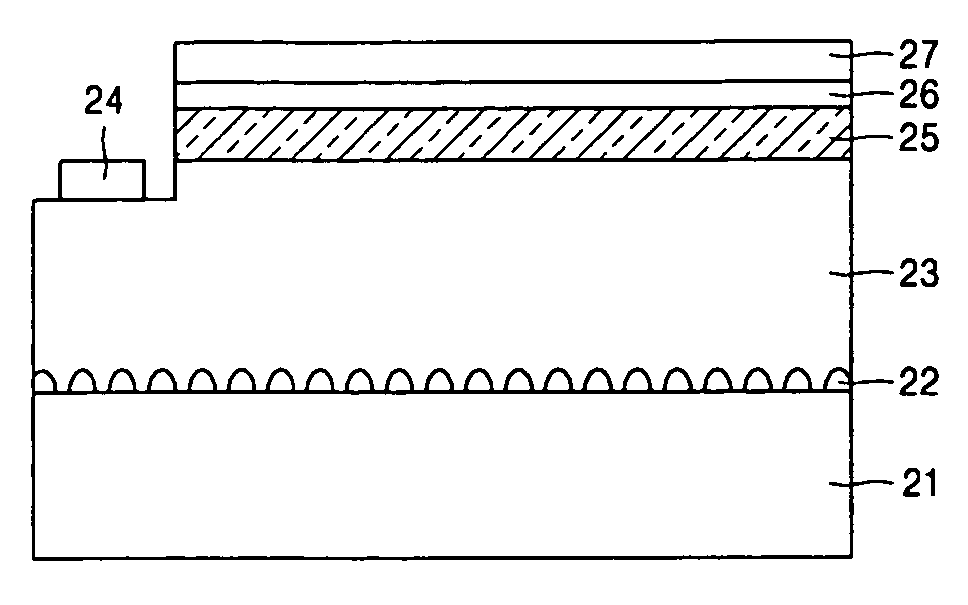

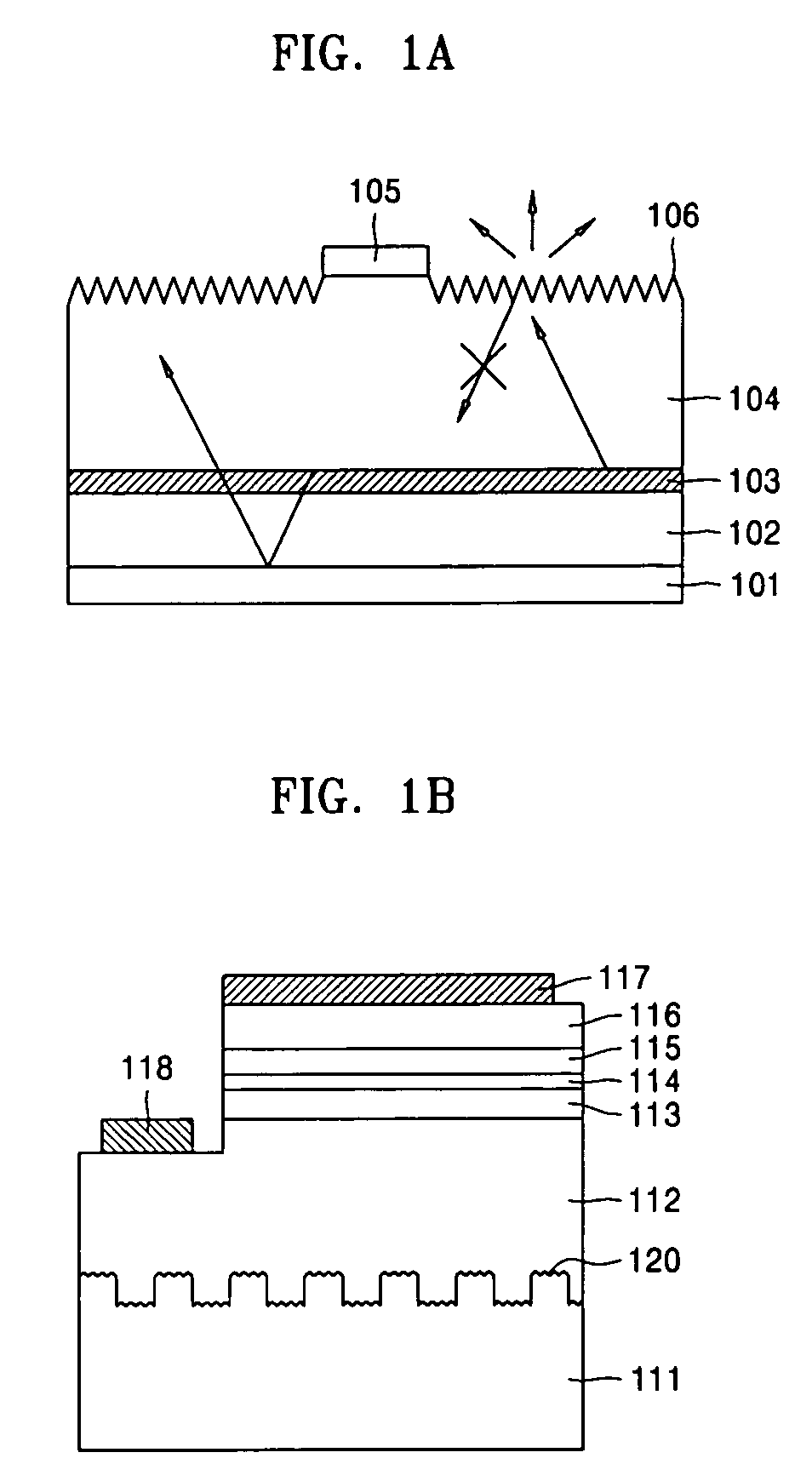

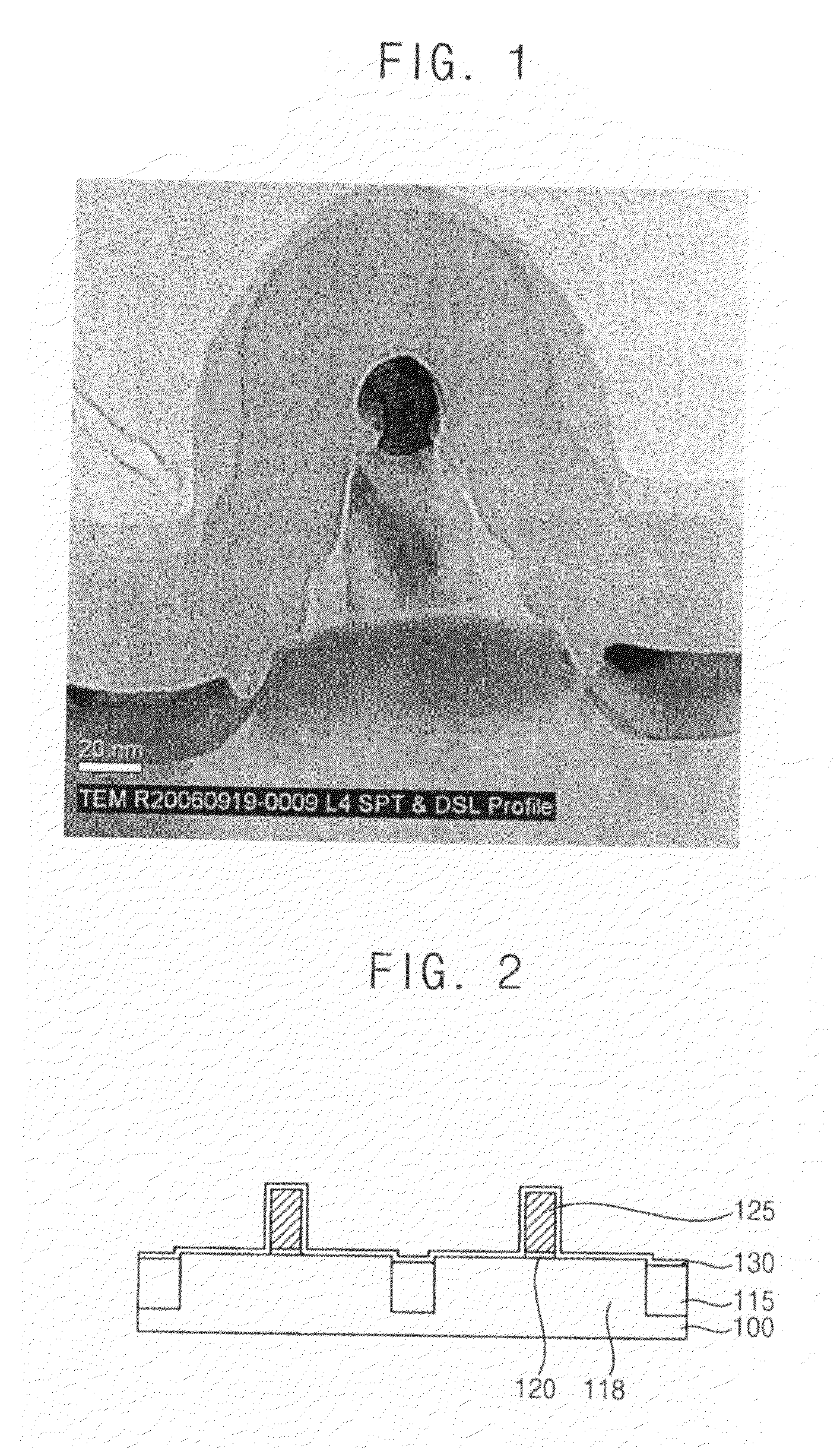

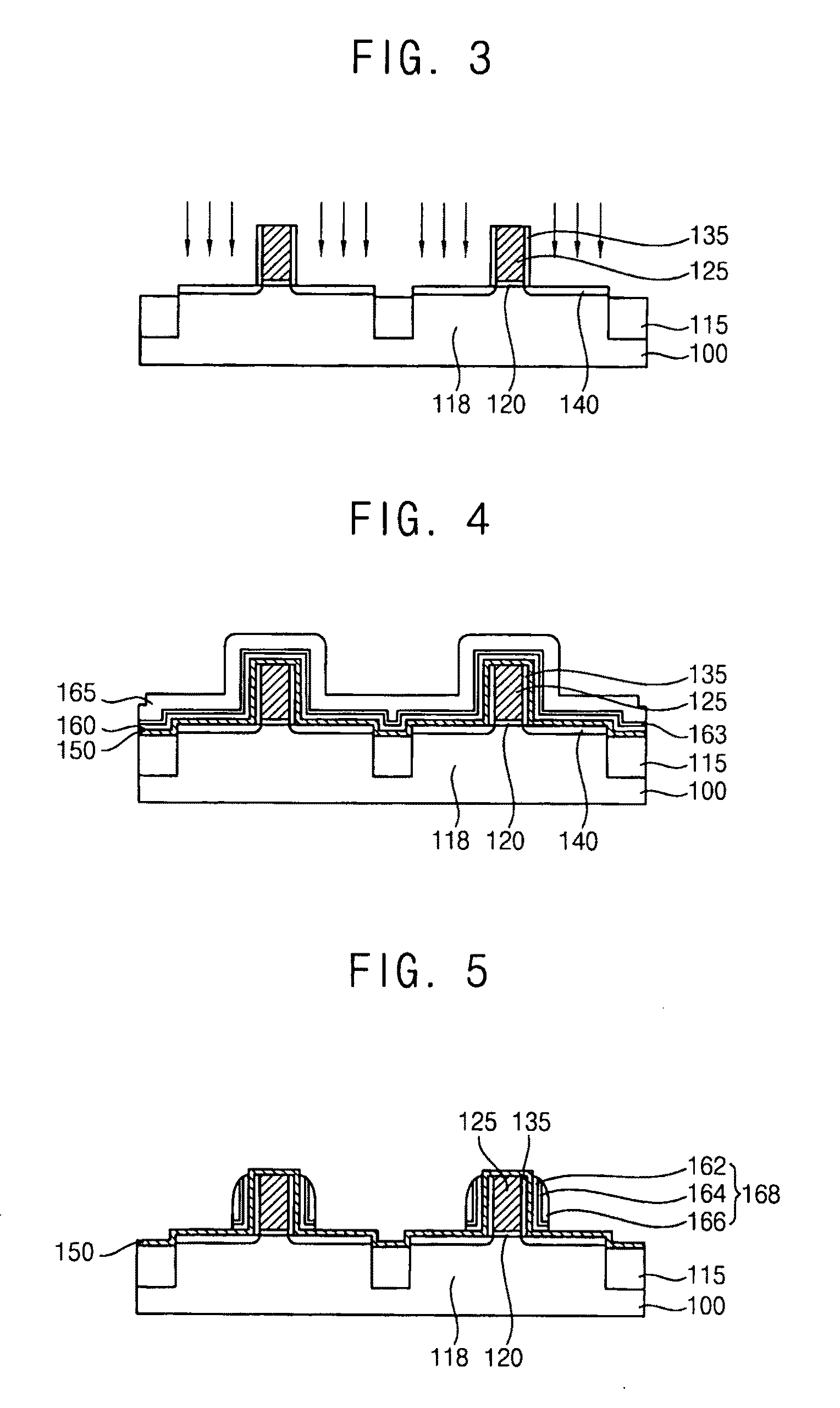

Semiconductor light emitting diode having high efficiency and method of manufacturing the same

ActiveUS20060118803A1Inhibition formationLight extraction efficiency can be improvedSemiconductor/solid-state device manufacturingSemiconductor devicesElectrical conductorActive layer

Provided is a semiconductor light emitting diode having a textured structure formed on a substrate. In a method of manufacturing the semiconductor light emitting diode, a metal layer is formed on the substrate, and a metal oxide layer having holes is formed by anodizing the metal layer. The metal oxide layer itself can be used as a textured structure pattern, or the textured structure pattern can be formed by forming holes in the substrate or a material layer under the metal oxide layer corresponding to the holes of the metal oxide layer. The manufacture of the semiconductor light emitting diode is completed by sequentially forming a first semiconductor layer, an active layer, and a second semiconductor layer on the textured structure pattern.

Owner:SAMSUNG ELECTRONICS CO LTD

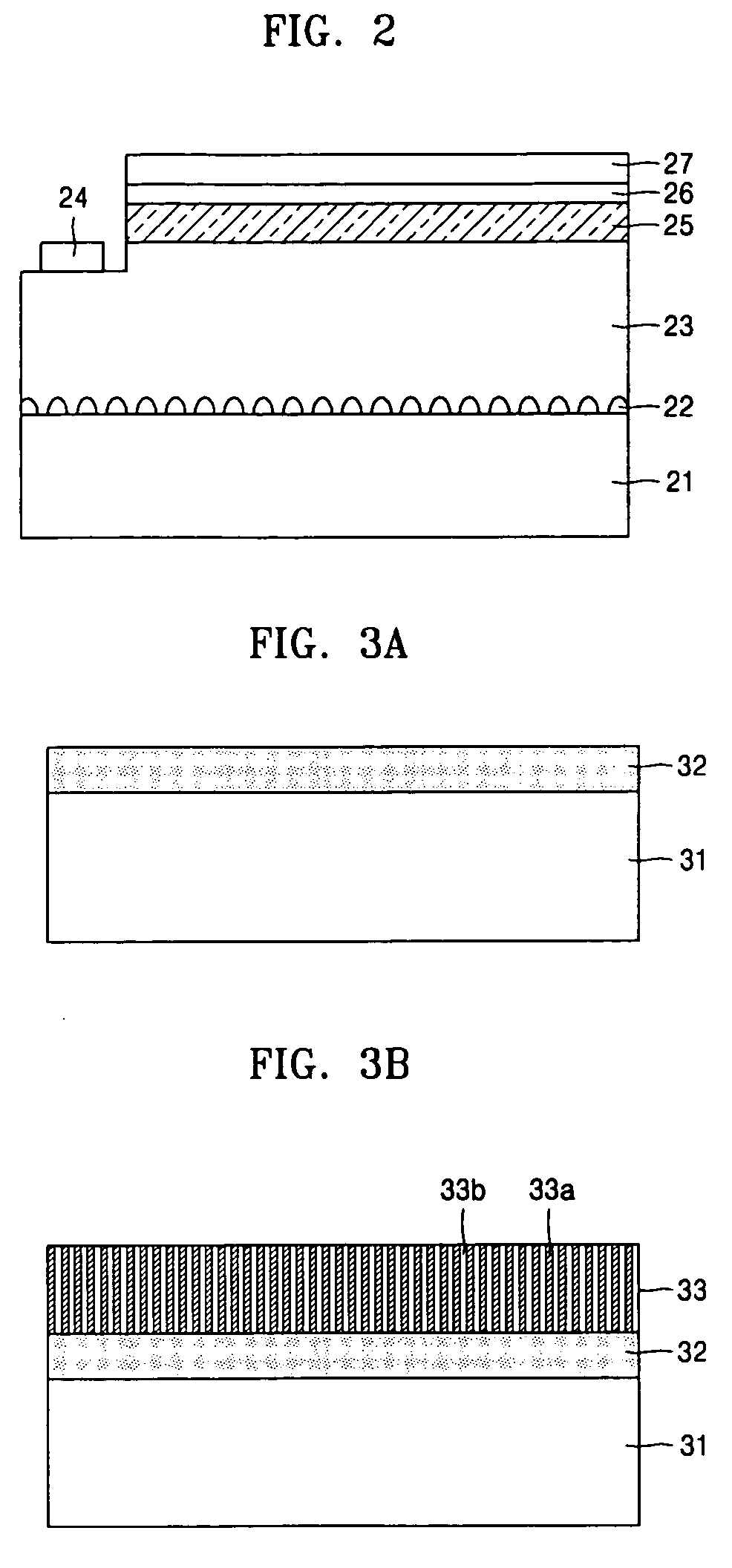

Patterned fibrous structures

InactiveUS20050247416A1Non-fibrous pulp additionNatural cellulose pulp/paperFiberBiomedical engineering

Owner:THE PROCTER & GAMBLE COMPANY

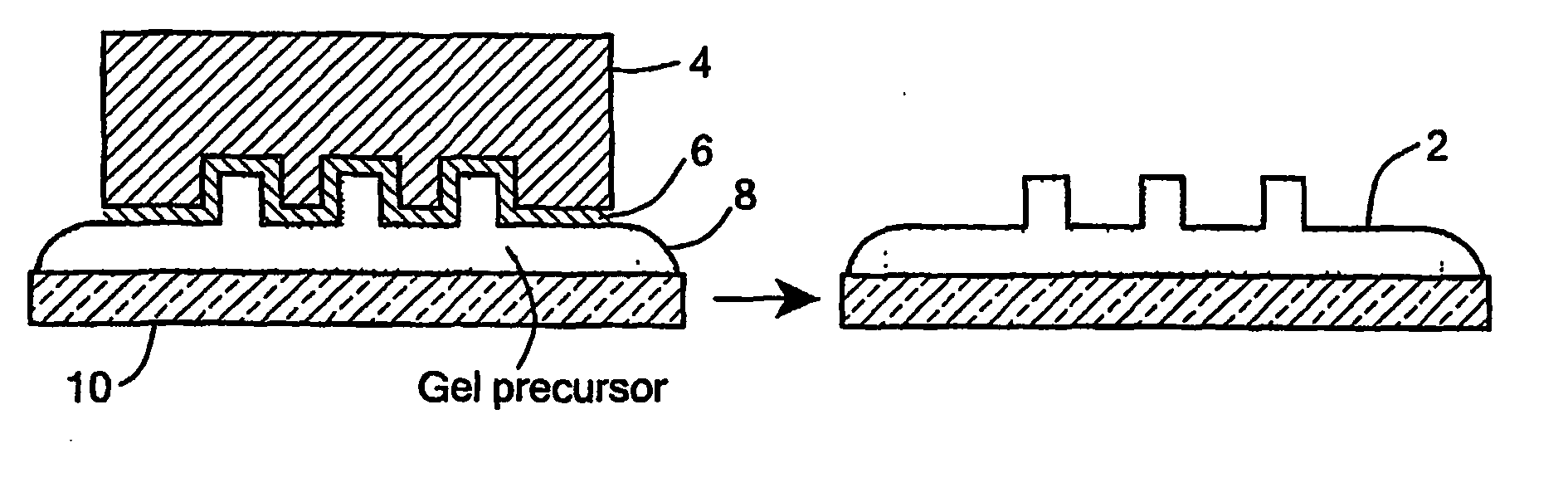

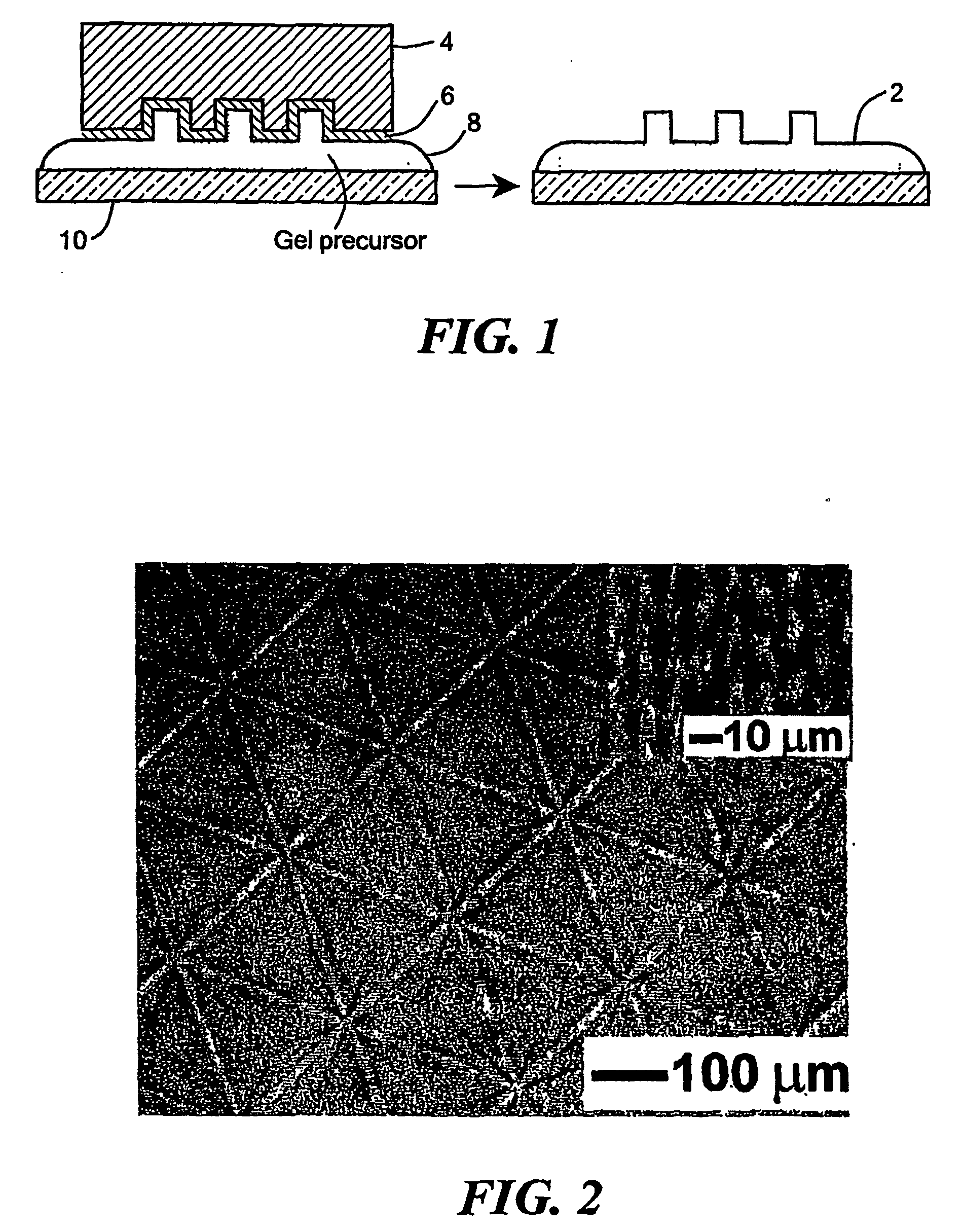

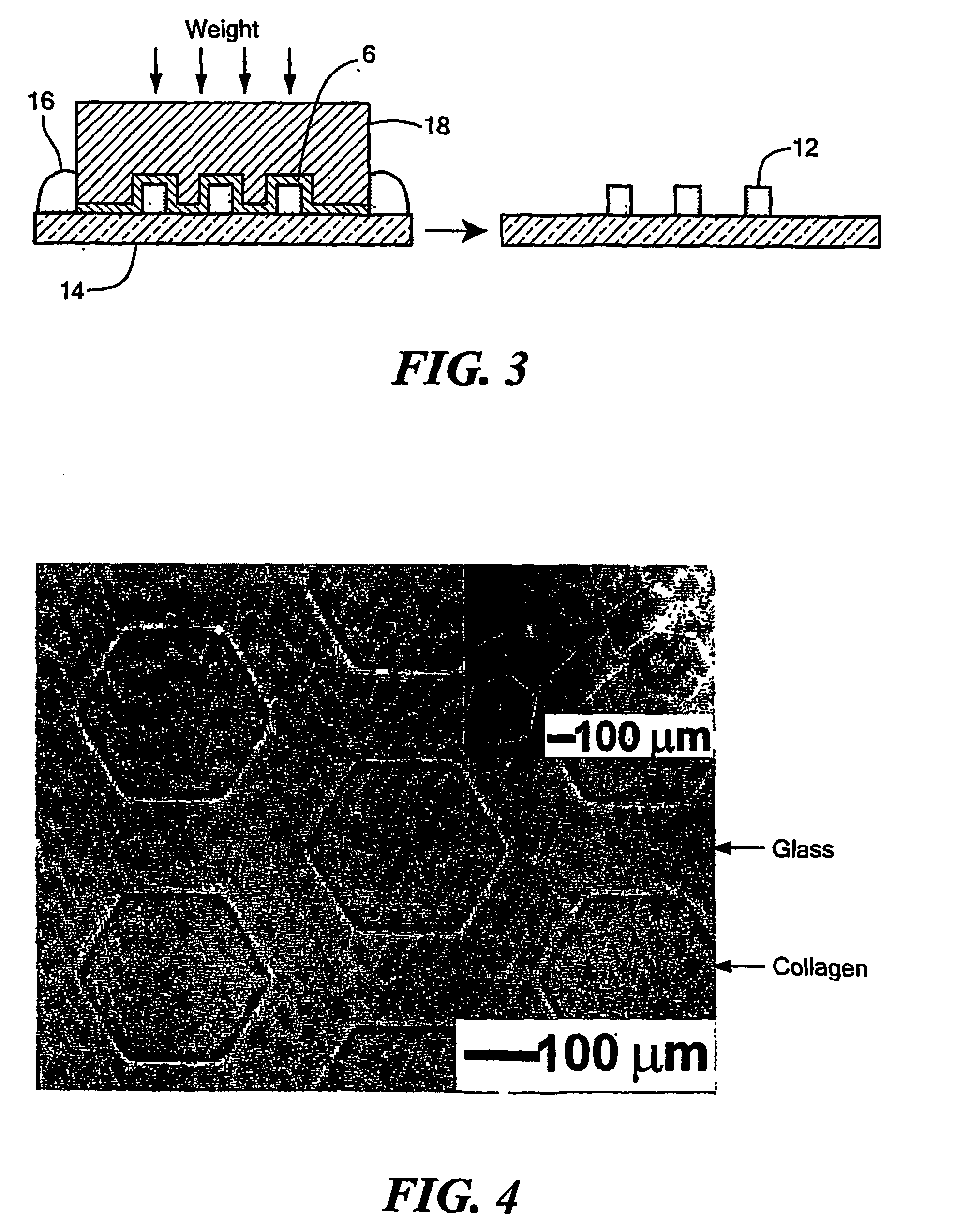

Three-dimensional gels that have microscale features

InactiveUS20070110962A1Eliminate nonspecific bindingMaterial nanotechnologyMicrobiological testing/measurementEngineeringBiomedical engineering

The present invention provides three-dimensional hydrogel structures patterned by a treated micropattern mold. The treated mold is capable of transferring the inverse of its micropattern to a hydrogel by contact during formation or polymerization of the structure from a precursor. The treated micropattern mold surface allows the mold to be separated from the hydrogel without collapsing the structure or irreparably damaging its micropattern. The transferred micropattern may yield individual features and / or interconnected channels in the hydrogel. The invention also provides a hydrogel network fabricated by interfacing at least two hydrogels in which one or more of the hydrogels may be a micropatterned structure. Micropatterned hydrogel structures can also be specifically aligned to interconnect their patterns. Structures or networks of the invention comprise hydrogels that can adhere together by chemically bonding and / or mechanically entangling.

Owner:TIEN JOE +2

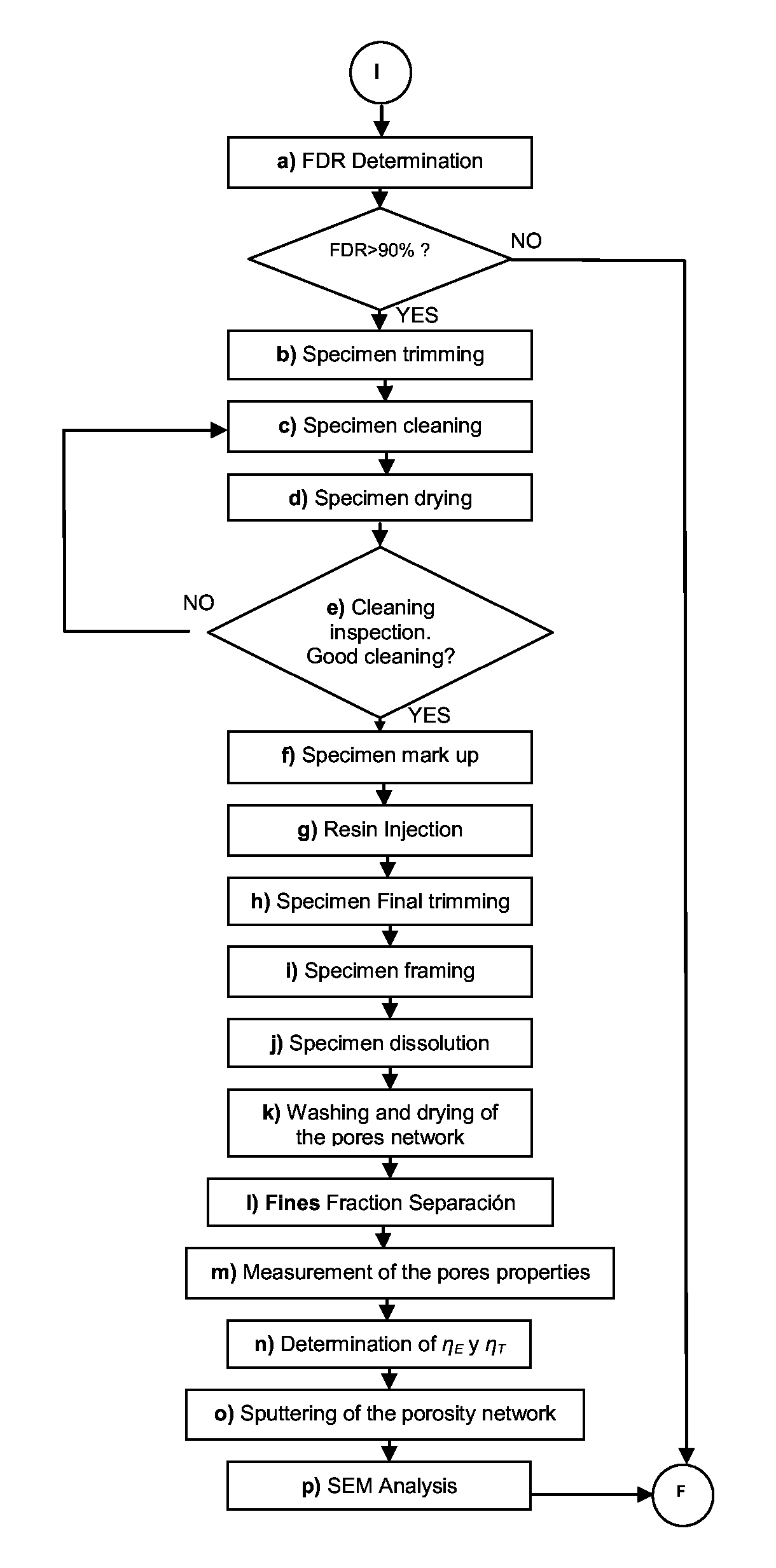

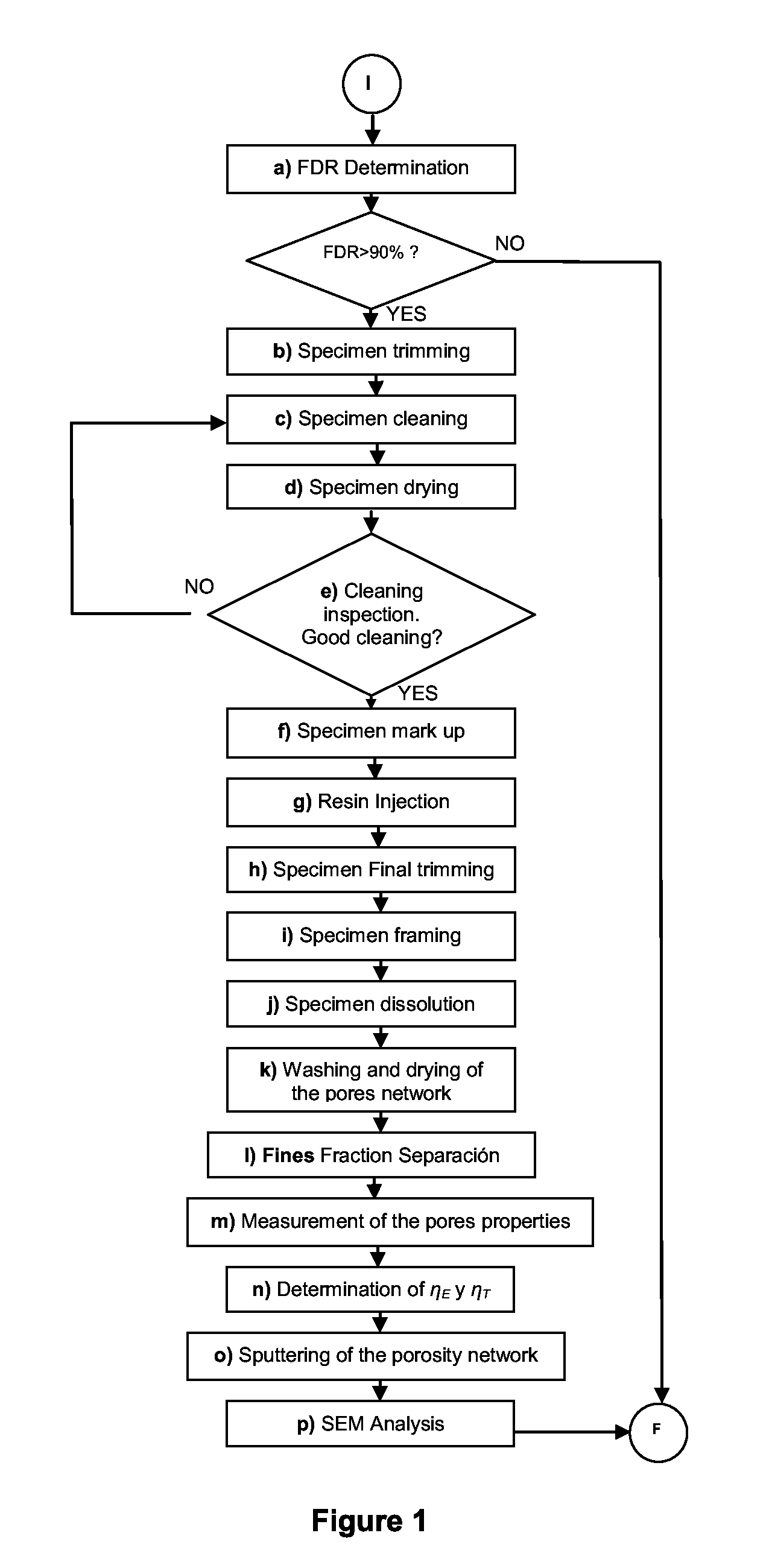

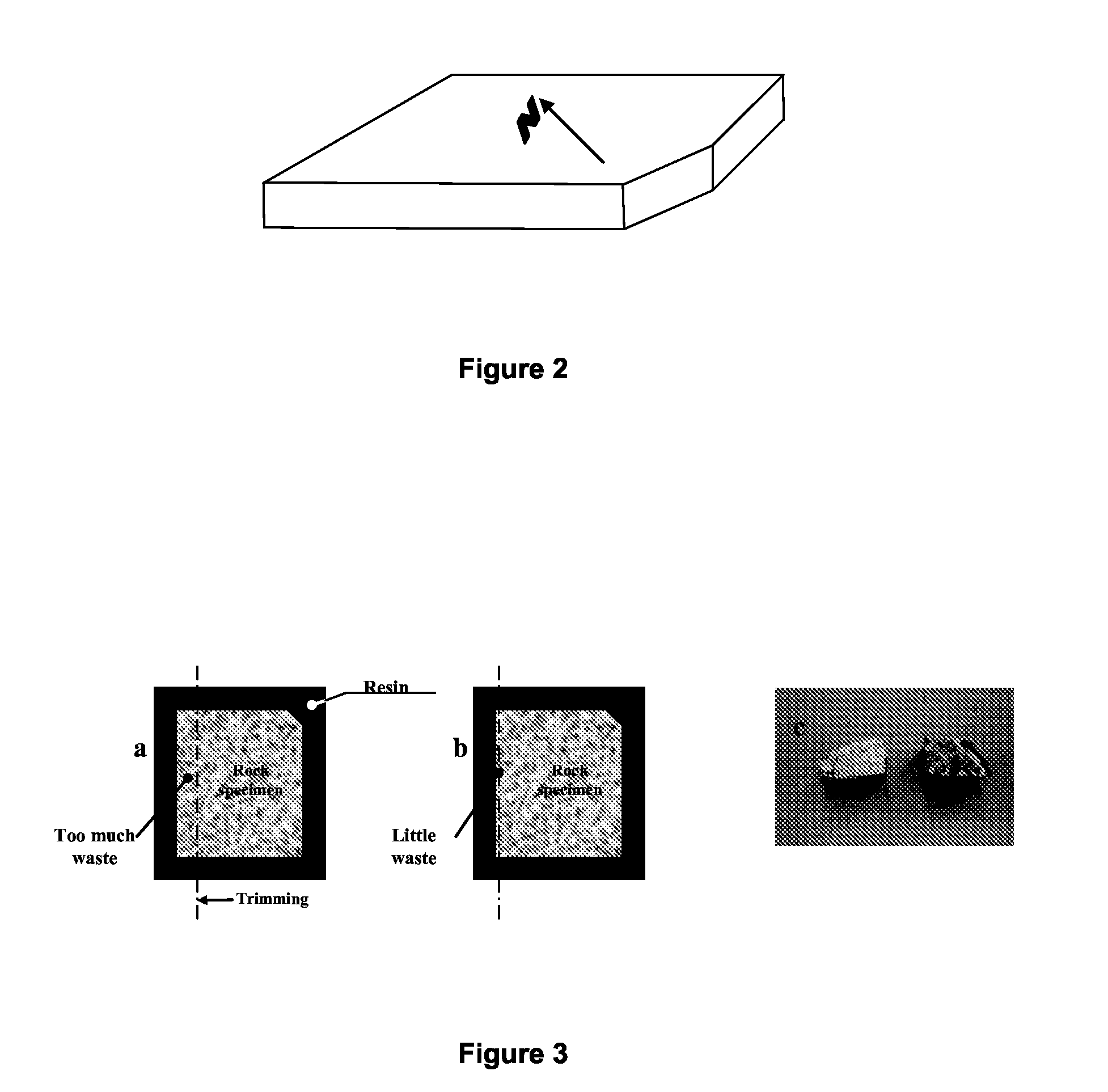

Procedure for the determination of effective and total porosity of carbonated sedimentary rocks, and morphology characterization of their micro and nanopores

InactiveUS20120197526A1Reliable applicationMeasure quickly and accuratelyElectric/magnetic detectionSpecial data processing applicationsThroatStructure of the Earth

The present invention is concerned with a procedure to quantitatively determine both, total and effective porosity of carbonated sedimentary rocks, and is based on the elaboration of molds of the rock pores-structure and on the determination of the volumetric and gravimetric properties of the rock and its mold.Determination of the effective porosity is achieved by using an original formula, developed by the authors of the present invention.Additionally, the structure of micro and nanopores in the rock is characterized by scanning electron microscopy (SEM), to identify relevant properties for permeability analyses such as: dimensions, shapes, type of connections, pore-structure patterns and pore throats. These and other parameters are used as indicators of the reservoir production and storage capacity.

Owner:INST MEXICANO DEL GASOLINEEO

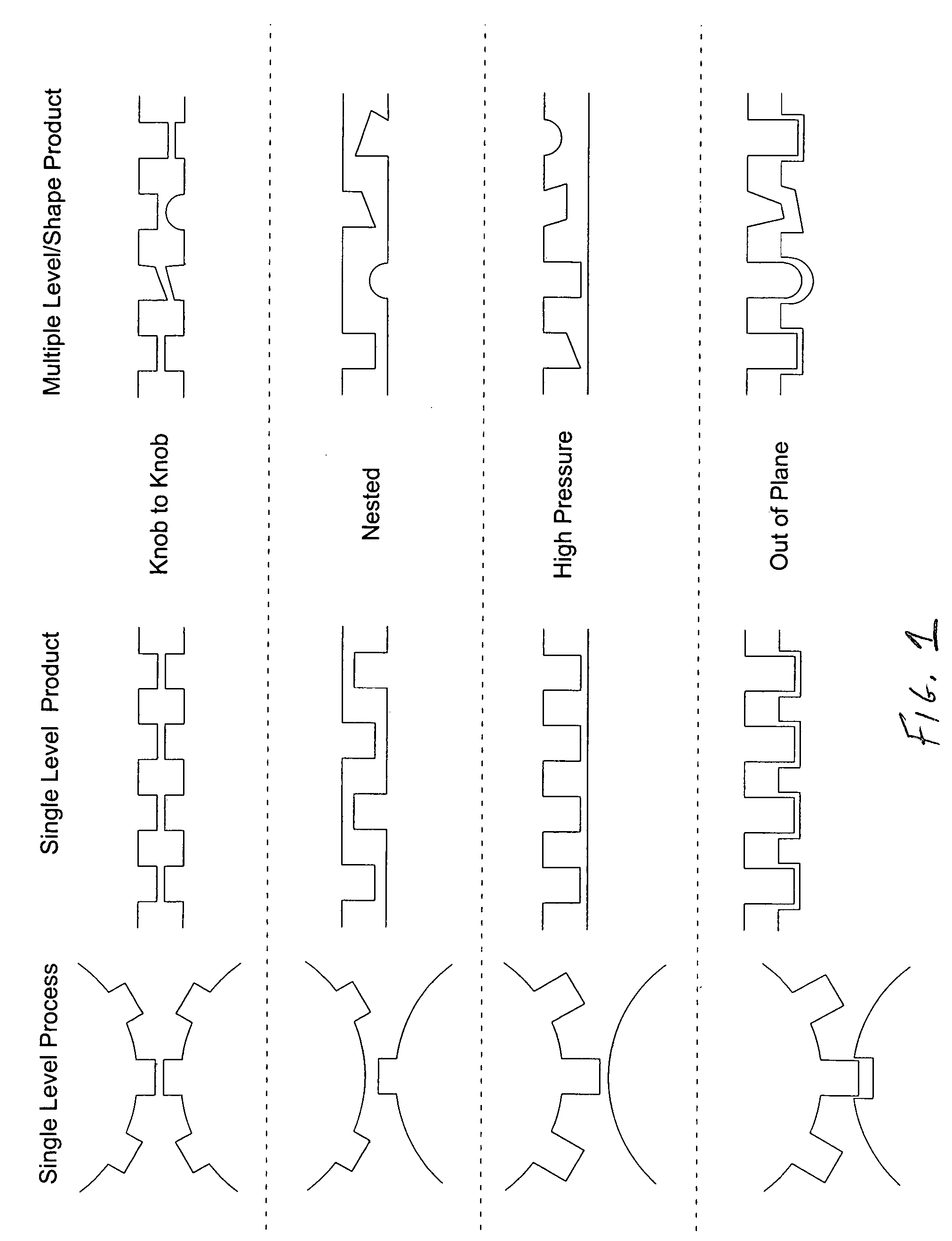

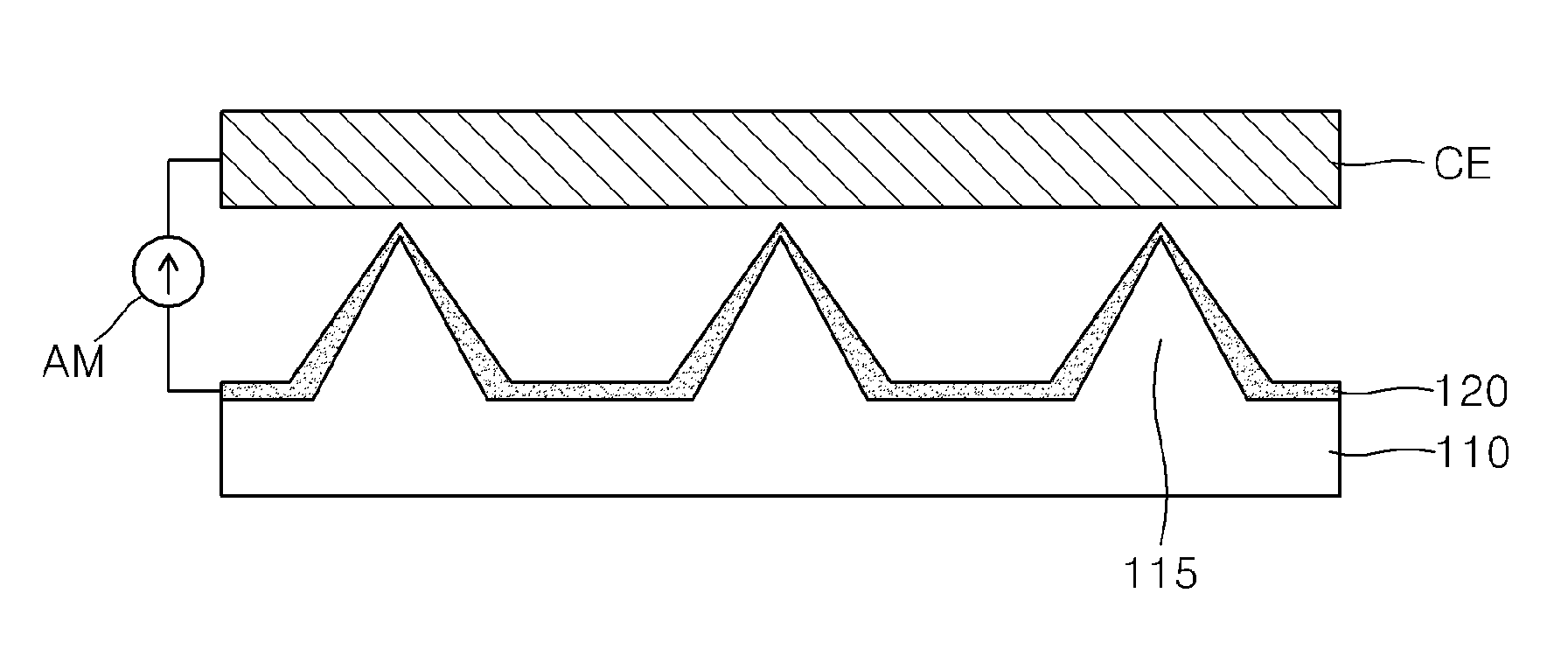

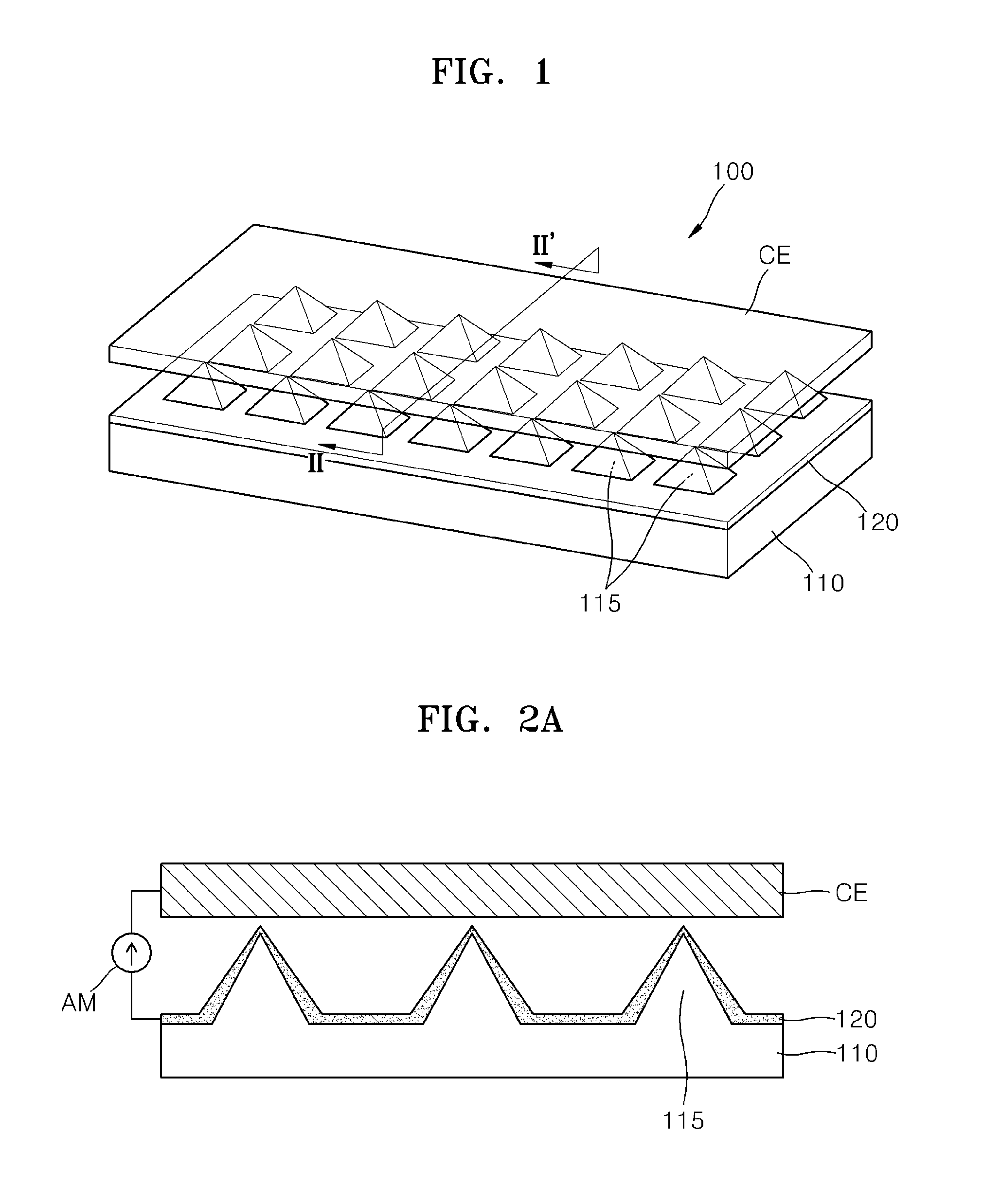

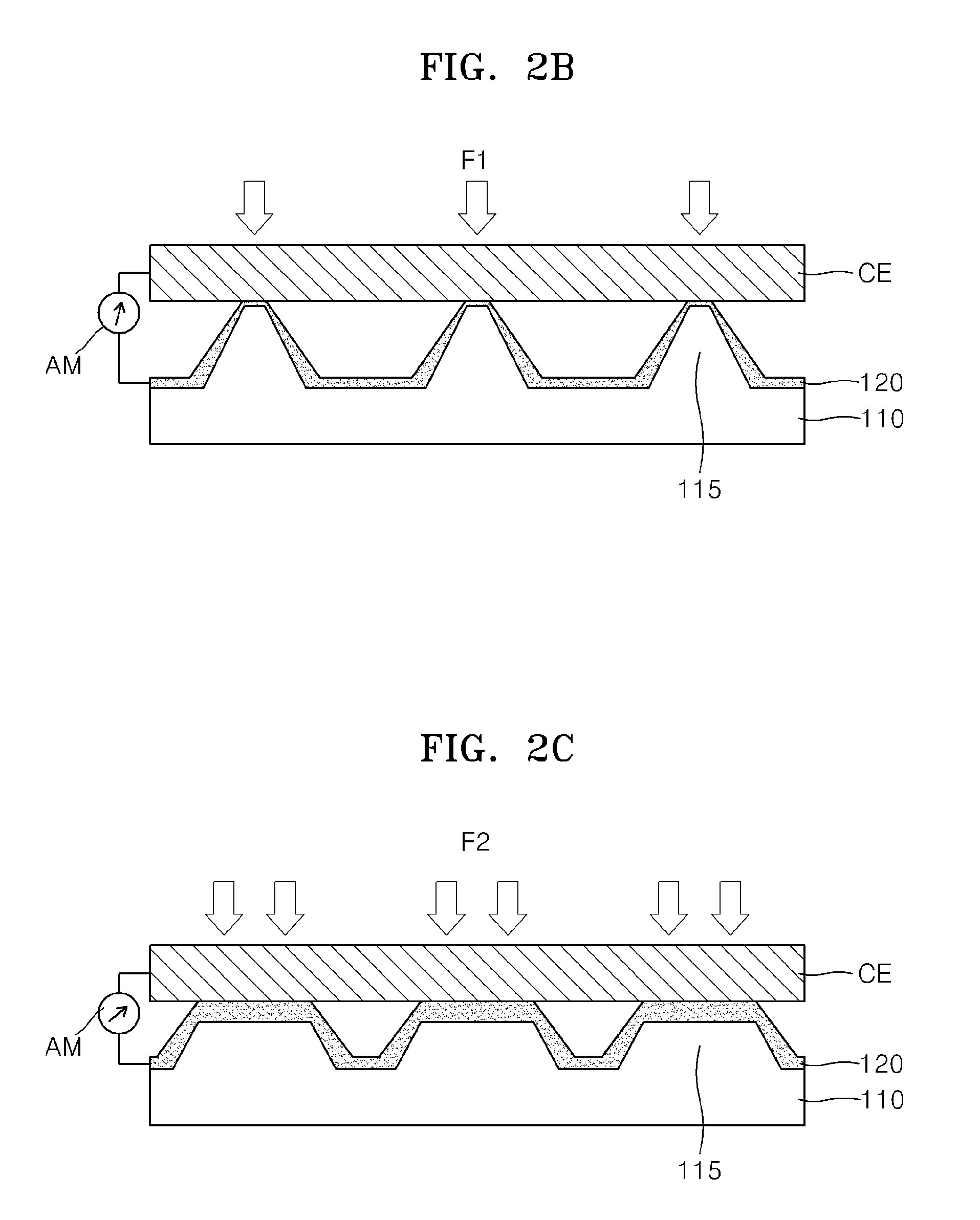

Resistive pressure sensor including piezo-resistive electrode

ActiveUS20150059486A1High sensitivityFluid pressure measurement using ohmic-resistance variationForce measurement using piezo-resistive materialsElastomerForce sensor

Provided is a pressure sensor including an elastic thin film including a first surface and a second surface that face each other, the elastic thin film including an elastomer material, a plurality of protruding deformable structures patterned on the first surface; a piezoresistive electrode formed along surfaces of the plurality of protruding deformable structures; and a counter electrode disposed to face the piezoresistive electrode.

Owner:SAMSUNG ELECTRONICS CO LTD

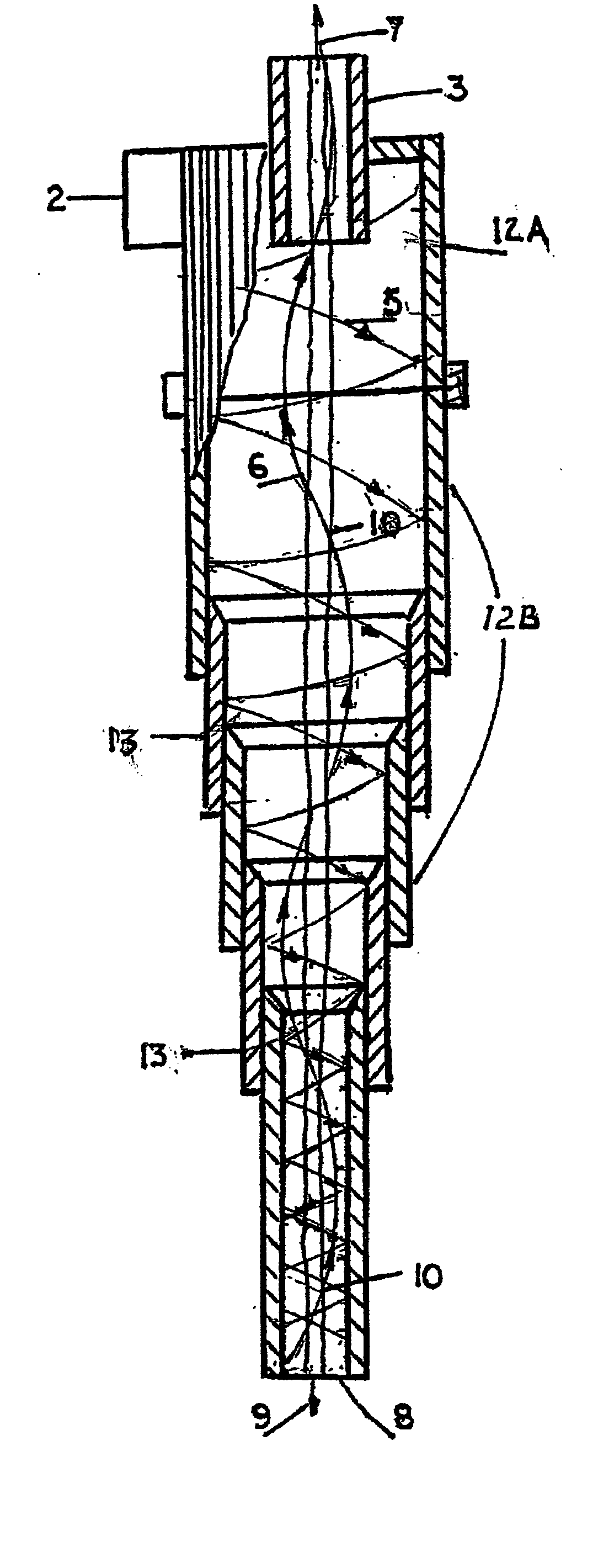

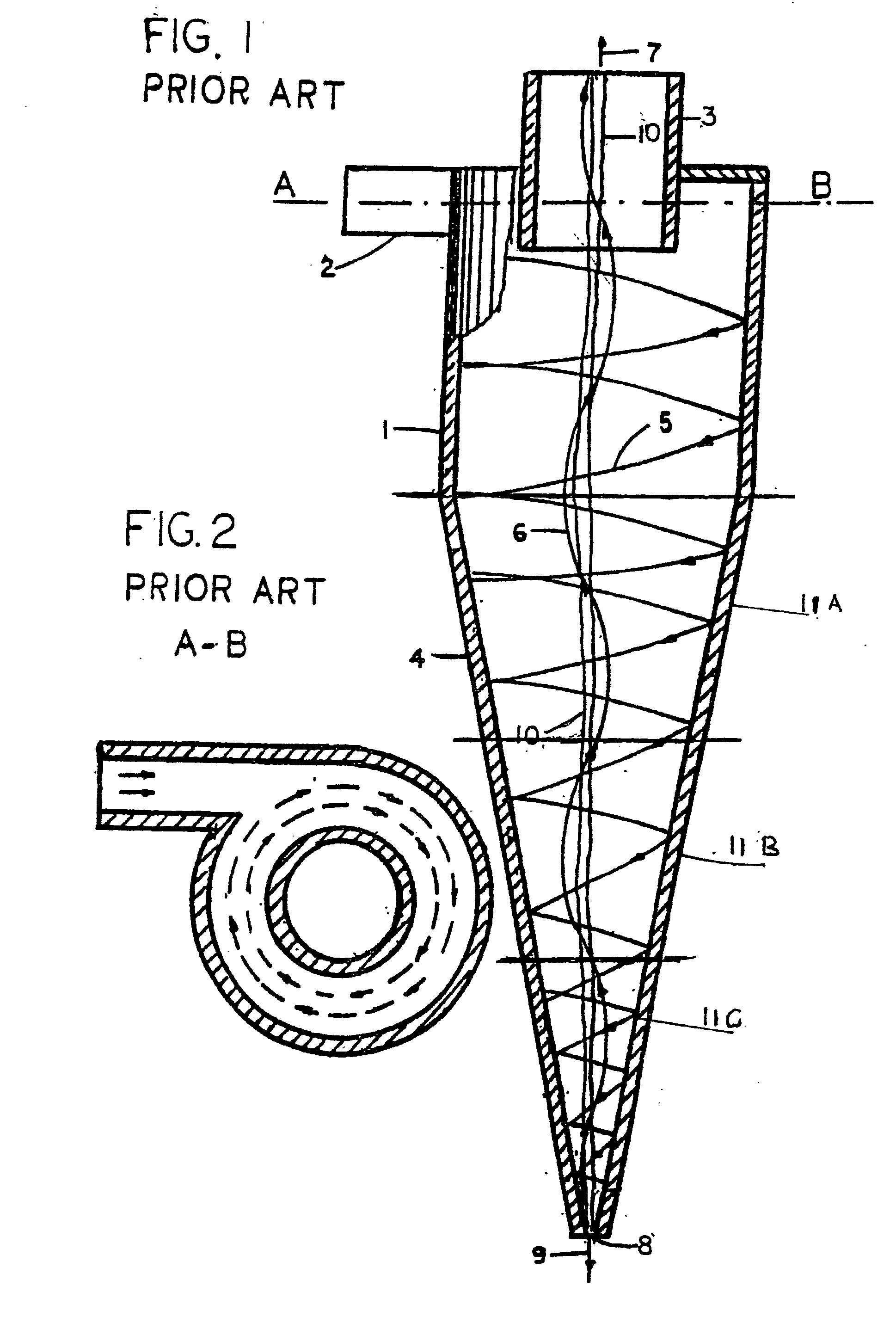

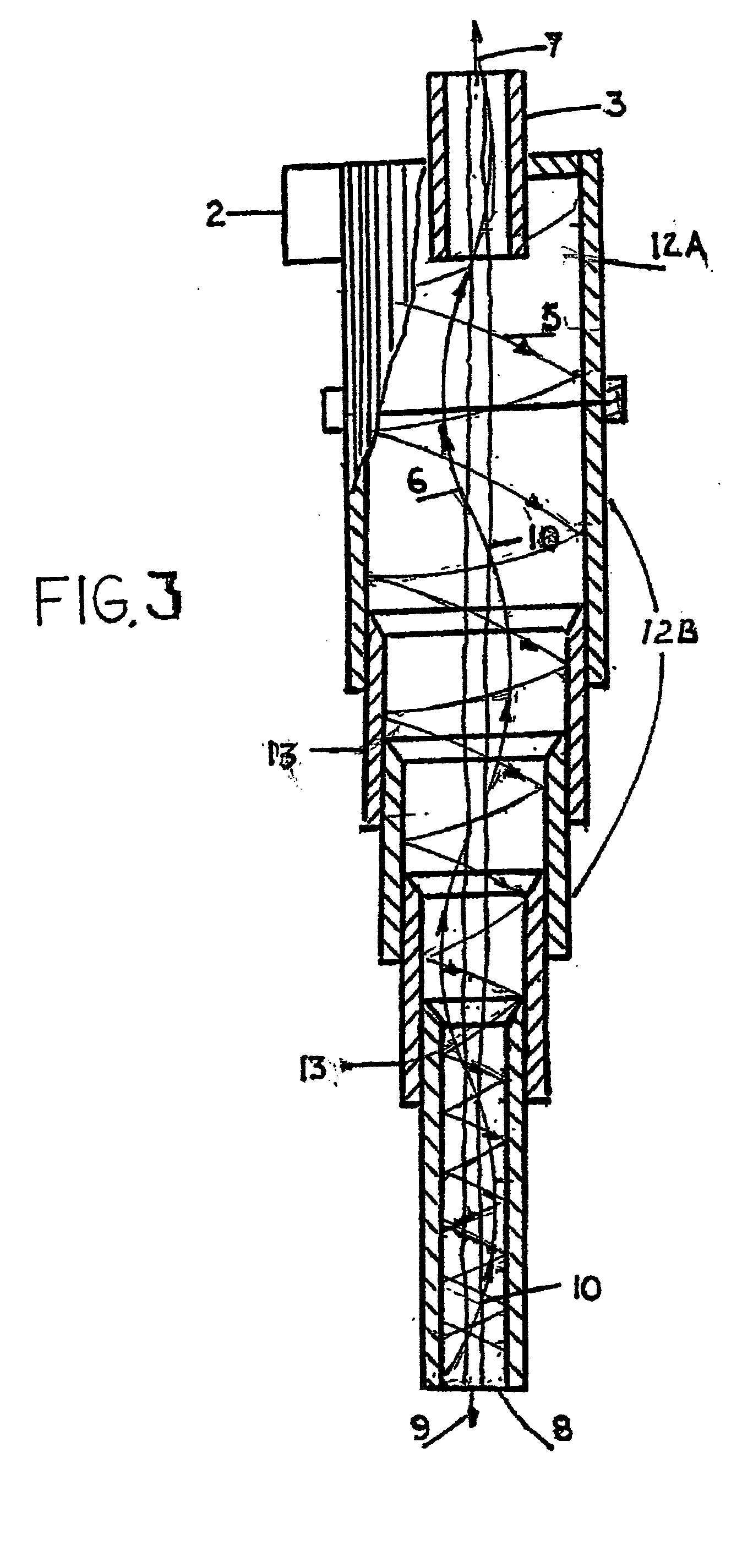

Cylindrical telescopic structure cyclone apparatus

InactiveUS20050155916A1Separation efficiency is lowHigh energy consumptionSievingReversed direction vortexCycloneEngineering

The cylindrical-telescopic cyclone apparatus structure pattern is the base for multi-compartment cylindrical-telescopic separation chamber cyclone as well as for one compartment conical separation chamber cyclone for both to be a most economic solution.

Owner:TUSZKO WLODZIMIERZ J +1

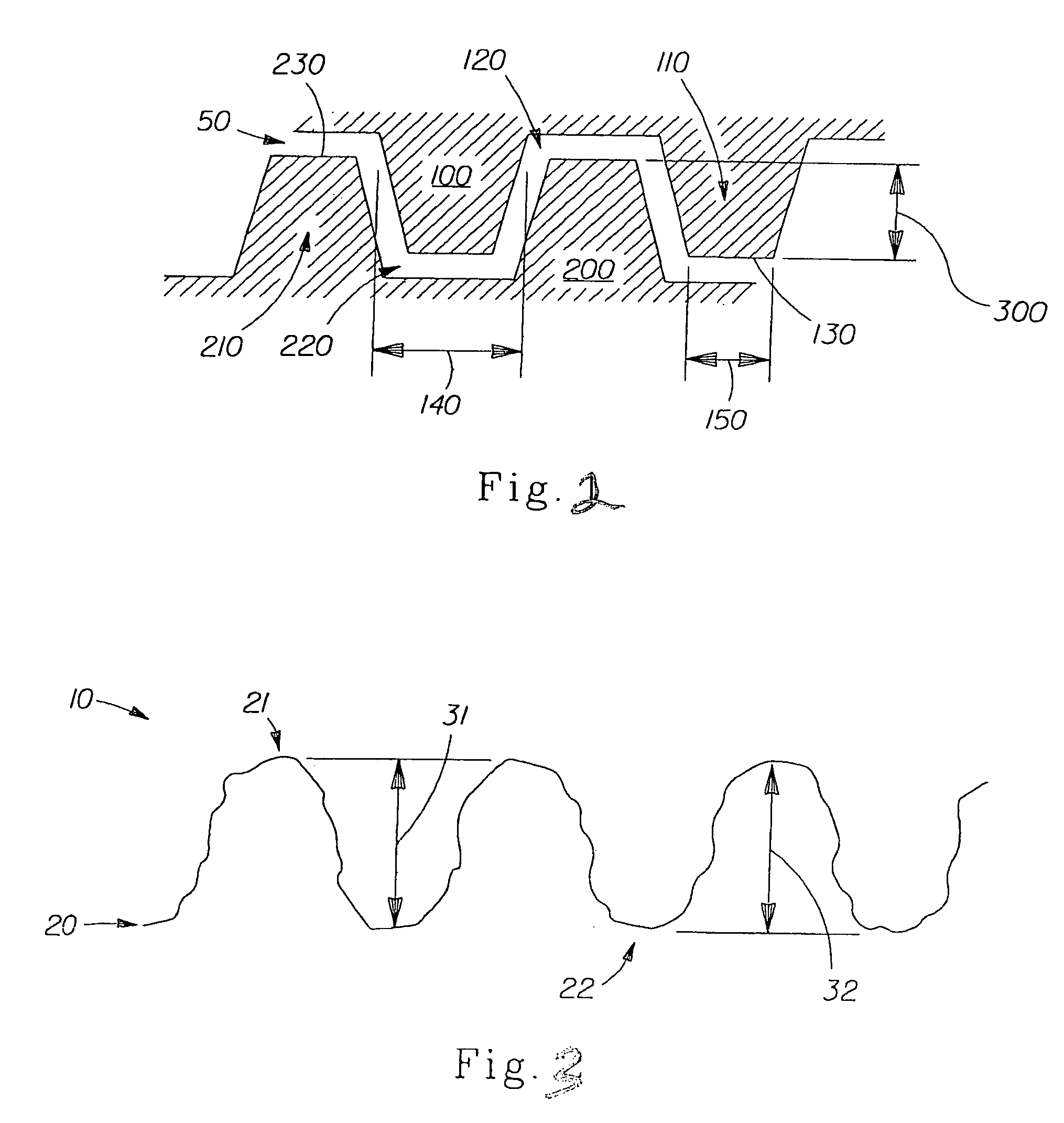

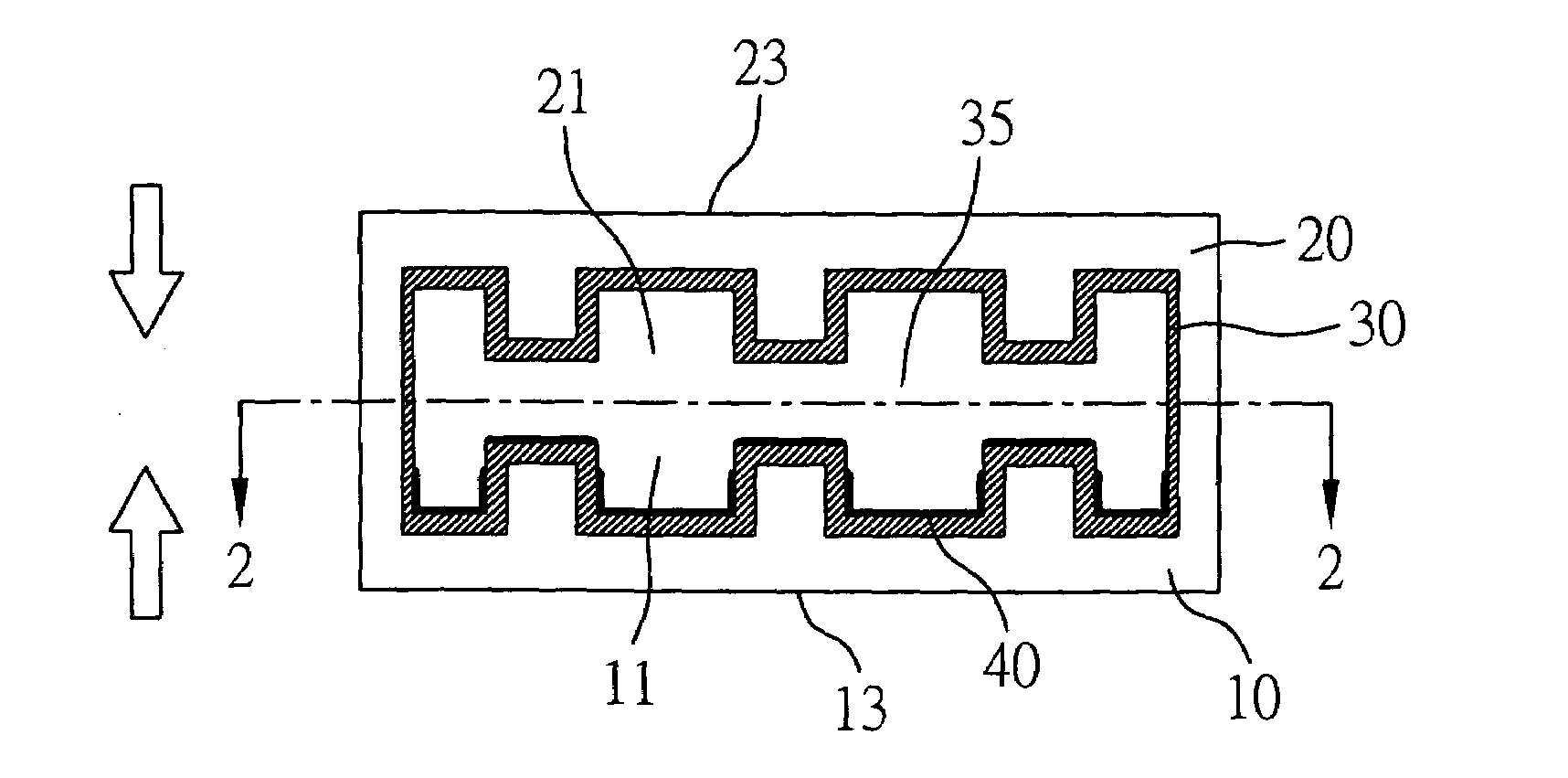

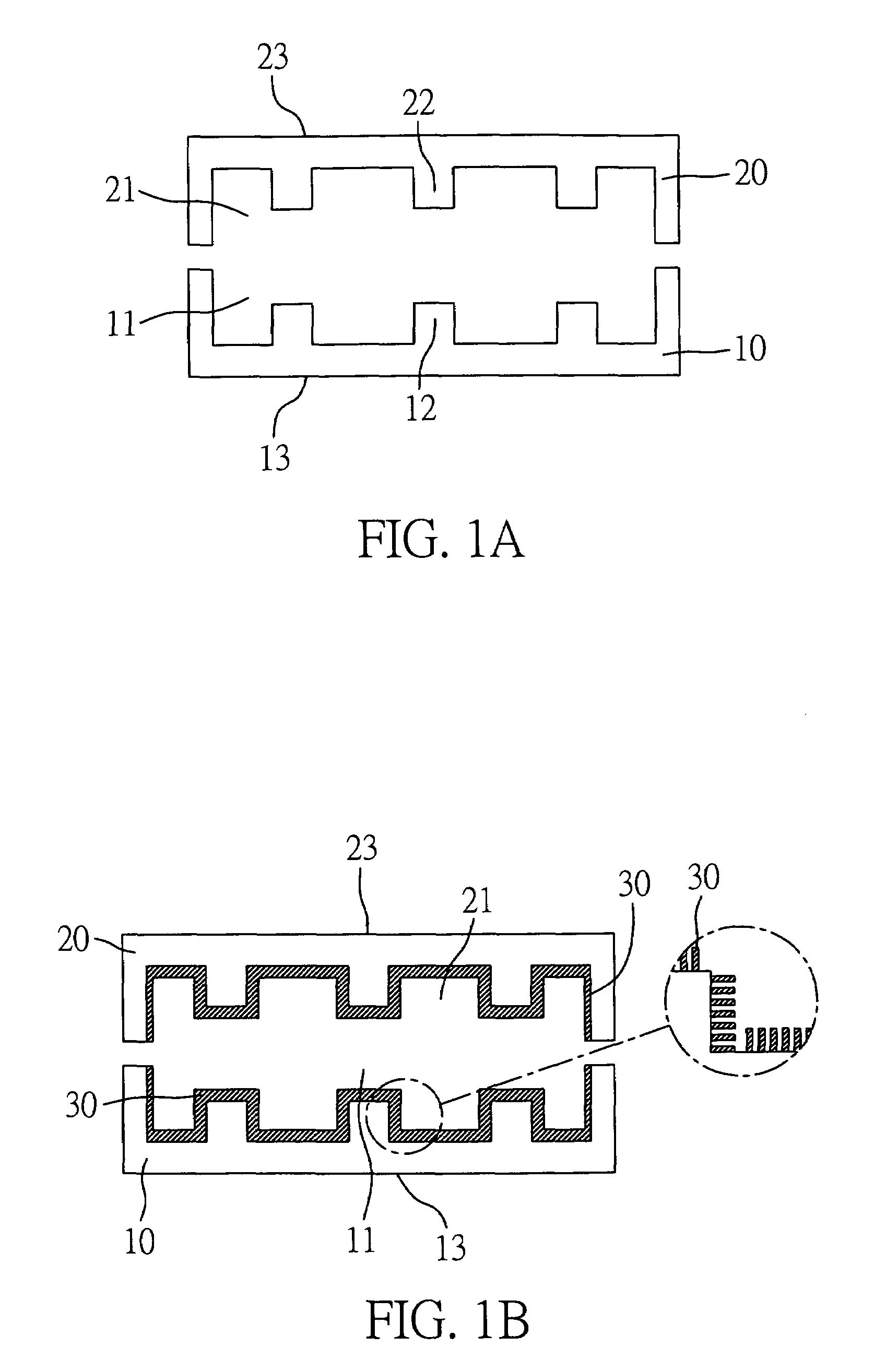

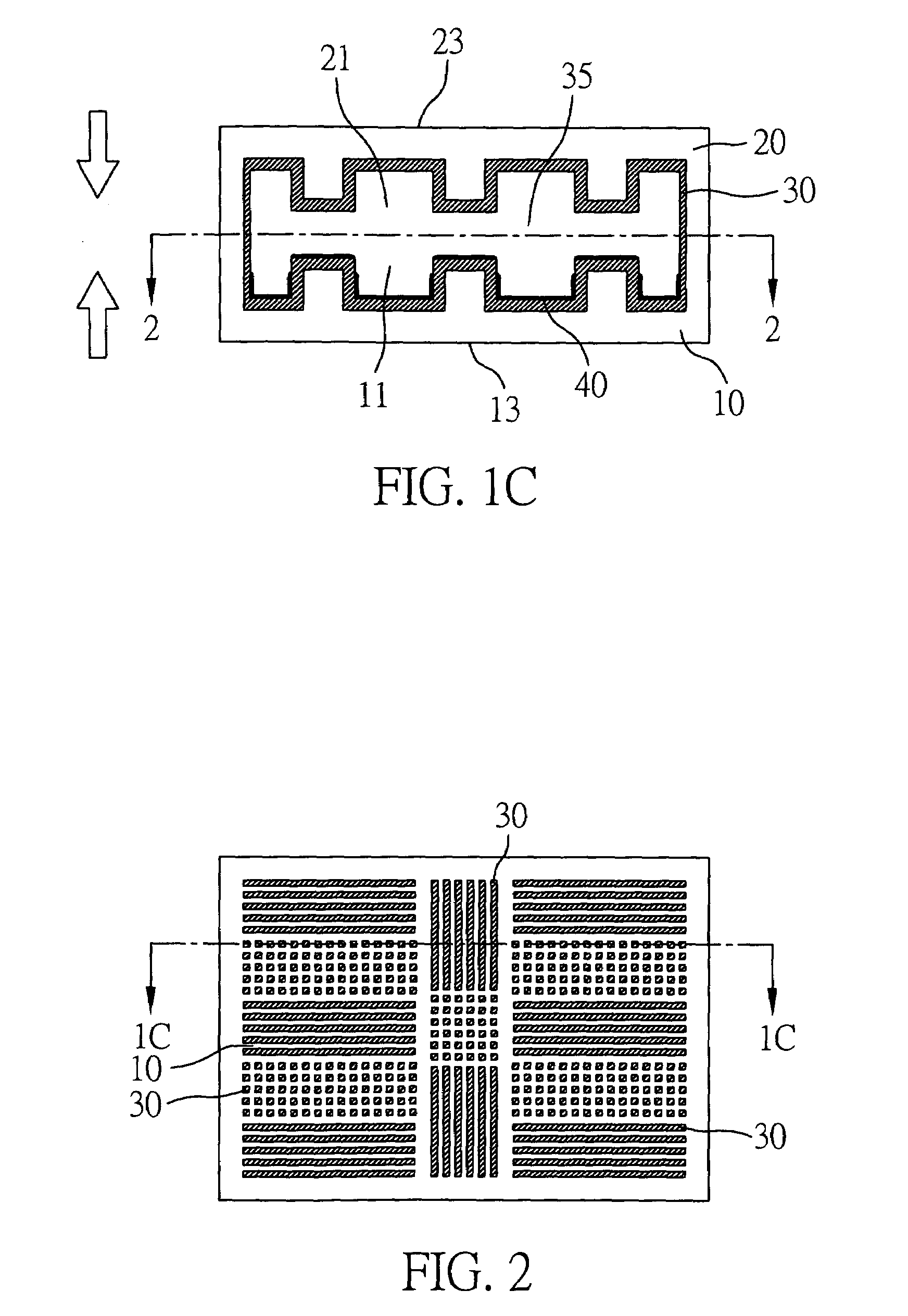

Heat dissipating apparatus having micro-structure layer and method of fabricating the same

InactiveUS7237337B2Improve cooling efficiencySimple methodSemiconductor/solid-state device detailsSolid-state devicesMicro structureWorking fluid

The present invention relates to a heat dissipating apparatus having micro-structure layer and method for fabricating the same. The method provides two highly heat conductive members having structure patterns. A highly heat conductive material is coated on the structured patterns by means of injection molding for forming a micro-structure layer. The two highly heat conductive members are assembled to form a heat dissipating apparatus having micro-structure layer. The heat dissipating apparatus comprises a main body composed of the highly heat conductive members. The main body forms an accommodating cavity, and inner surfaces of the accommodating cavity form the micro-structure layer. A working fluid is filled into the accommodating cavity for transferring heat from a heat absorbing surface to a heat dissipating surface.

Owner:IND TECH RES INST

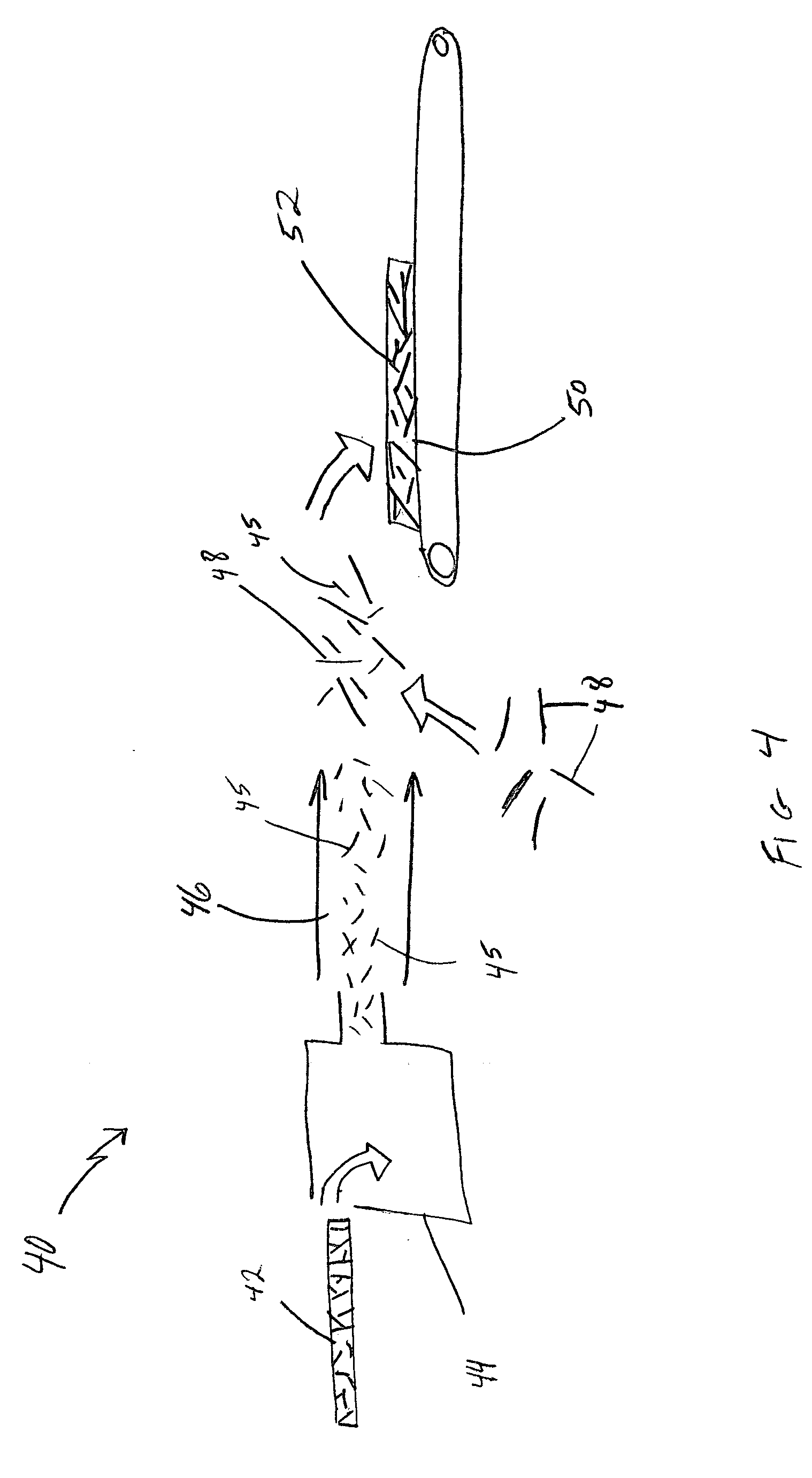

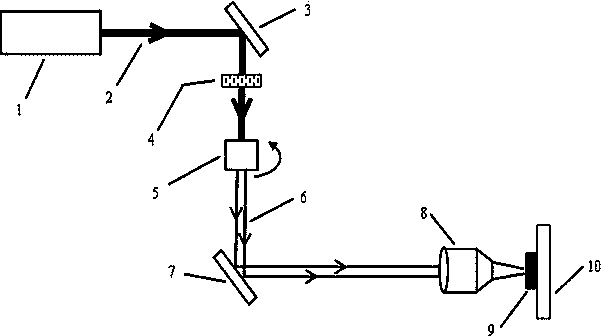

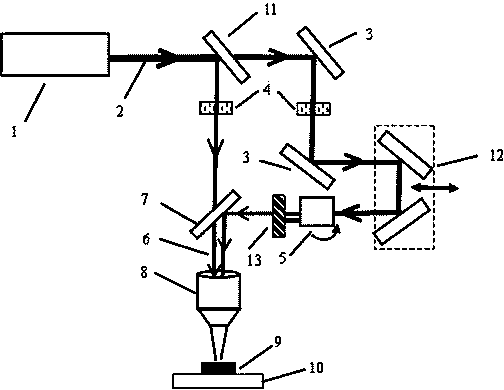

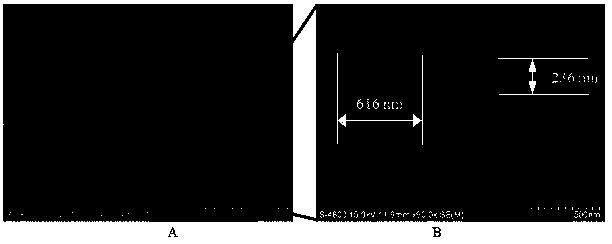

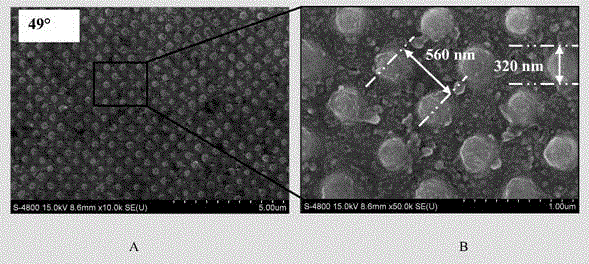

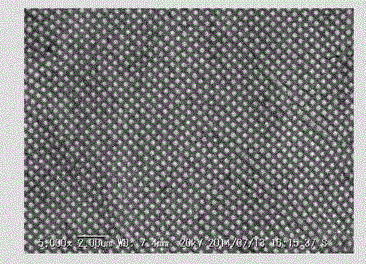

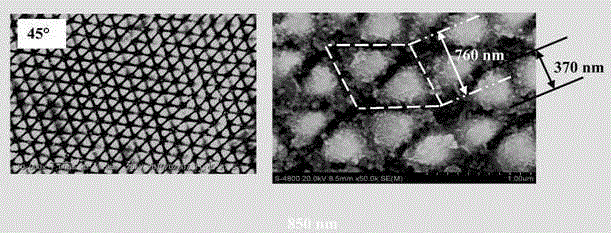

Method for preparing two-dimensional periodic metal particle array structure through dual-wavelength femtosecond lasers

InactiveCN103862171AThe technical method is simpleEasy to operateLaser beam welding apparatusMicro nanoTime delays

The invention provides a method for preparing a two-dimensional periodic metal particle array structure through dual-wavelength femtosecond lasers. The method and an implementation device for preparing the two-dimensional periodic particle array structure on the surface of metal by focusing two-color femtosecond laser pulses are provided. The method and the implementation device are characterized in that the metal particle structure is distributed in the two-dimensional direction in a periodic submicron dimension mode; two-color femtosecond lasers with different characteristic parameters are collinearly focused and irradiated on a sample after common channel or branch channel time delay through a nonlinear frequency doubling technology, and formed two-dimensional periodic structure patterns can be effectively adjusted and controlled by changing the azimuth angle of frequency doubling crystals and the power ratio of the two-color lasers. The method has the advantages that through the combinational design of different wavelengths and the polarization property of the femtosecond lasers, the submicron dimension two-dimensional periodic metal particle array structure can be conveniently and quickly prepared. The novel method for preparing the structure through the two-color femtosecond lasers has potential and important application value in the field of material micro-nano processing.

Owner:NANKAI UNIV

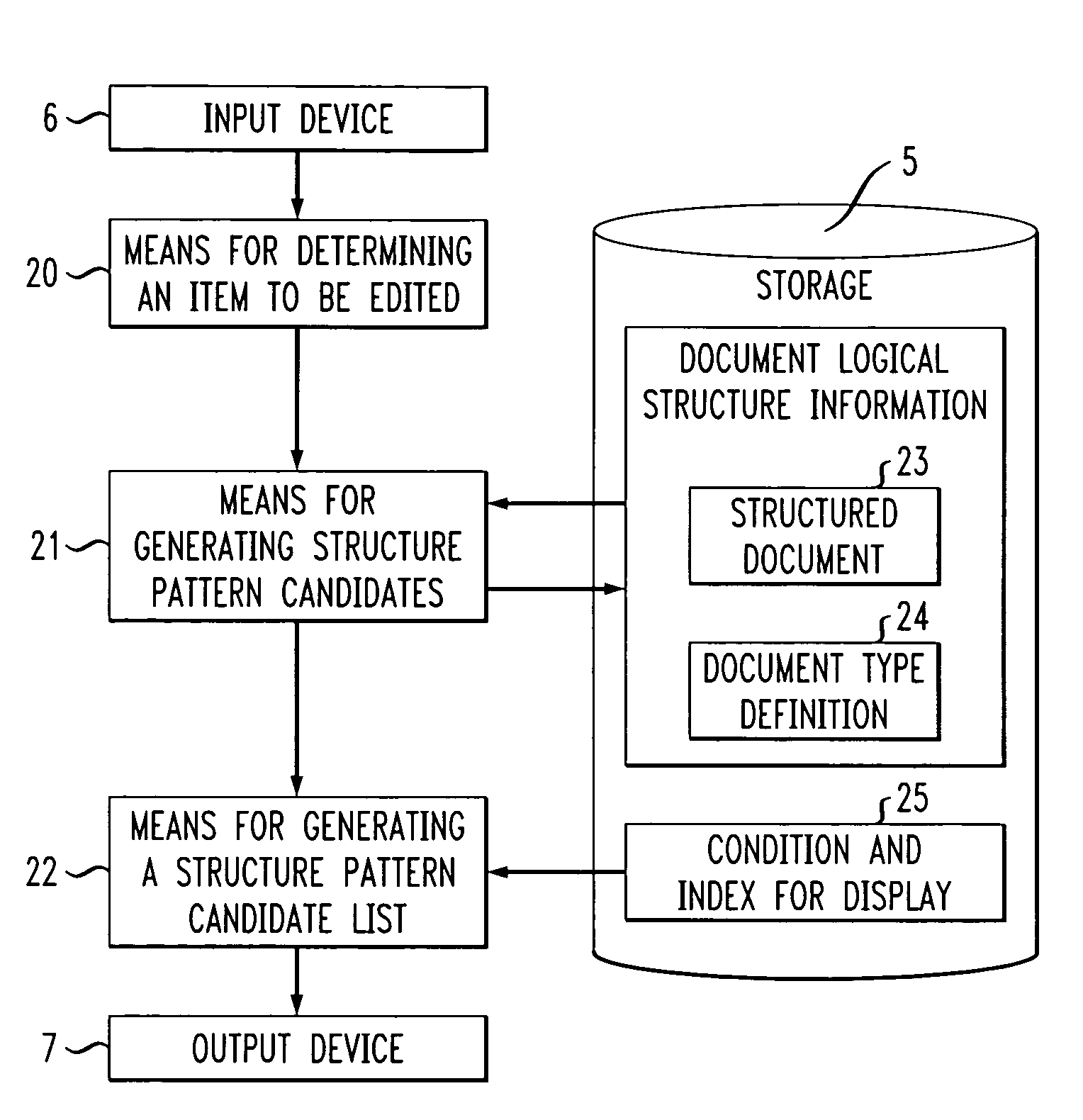

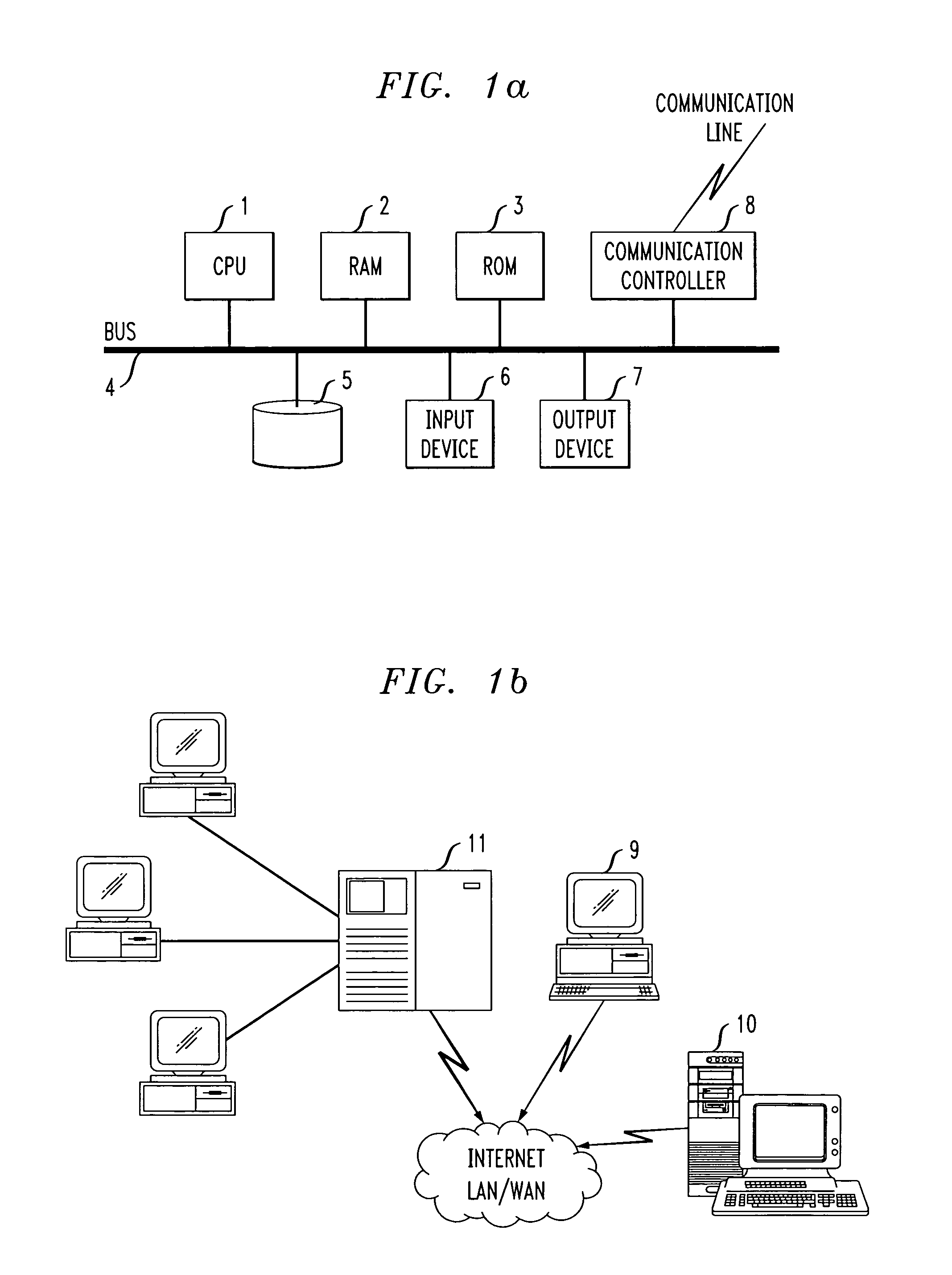

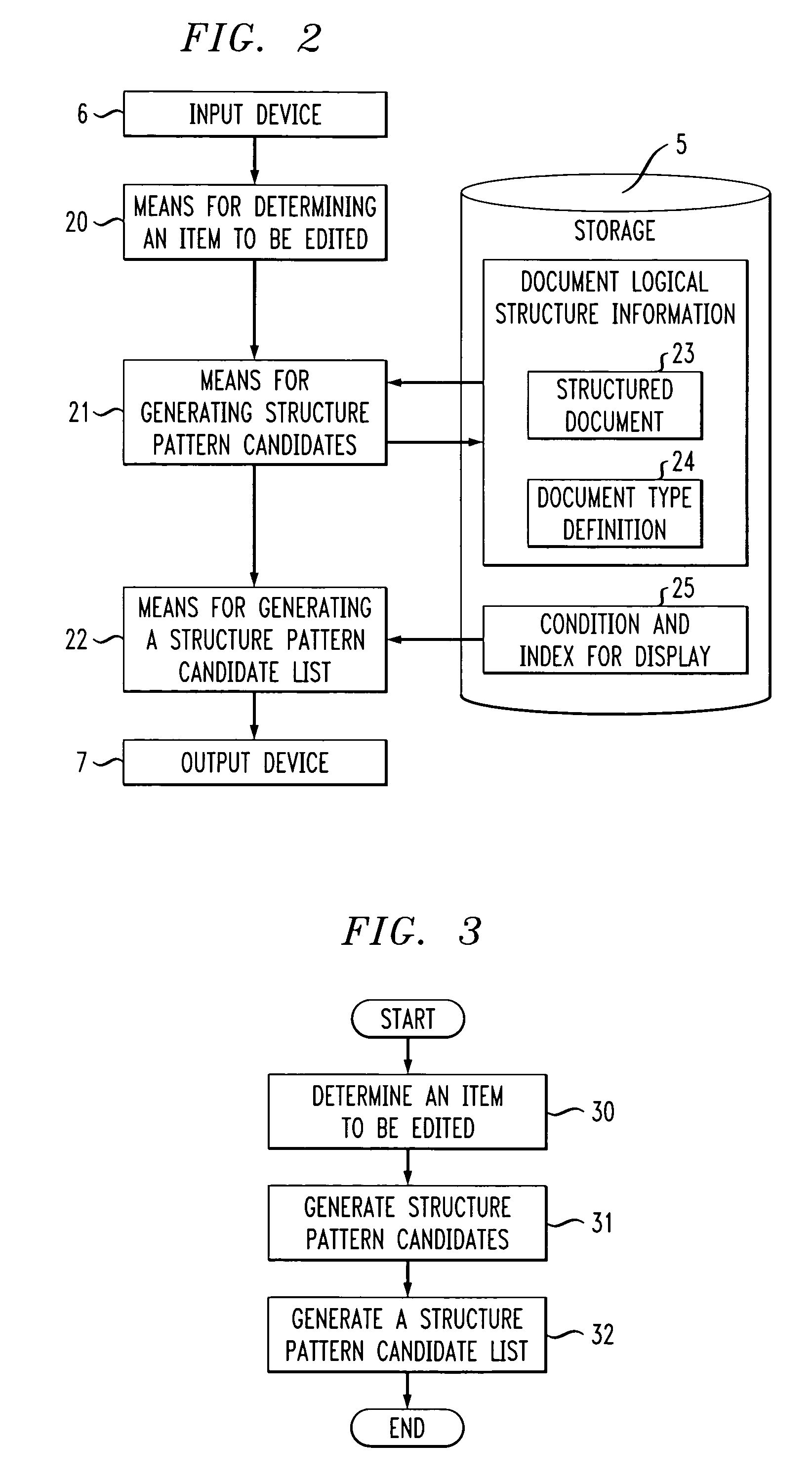

Method, system and program for generating structure pattern candidates

InactiveUS7197510B2Avoiding trouble of inputAvoid mistakesData processing applicationsDigital data information retrievalSelection criterionComputer science

A structure pattern candidate generating system is disclosed for automatically generating many kinds of complicated structure pattern candidates and facilitating selection of a structure pattern suitable for the purpose. When the system is provided with a structure pattern pointing to an element or an element set in a document logical structure of a structured document, that has been specified by a user, a method for determining an item to be edited determines an item to be edited among the items composing the structure pattern. A method for generating structure pattern candidates replaces the item to be edited with items in different expressions based on the document logical structure information about the structured document to generate structure pattern candidates. A method for generating a structure pattern candidate list arranges the generated structure pattern candidates based on a condition and index for display for giving selection criteria to the user to generate a structure pattern candidate list. If the system is provided with an item desired to be edited, that has been specified by the user for the structure pattern, the method for determining an item to be edited determines the item desired to be edited as the item to be edited.

Owner:IBM CORP

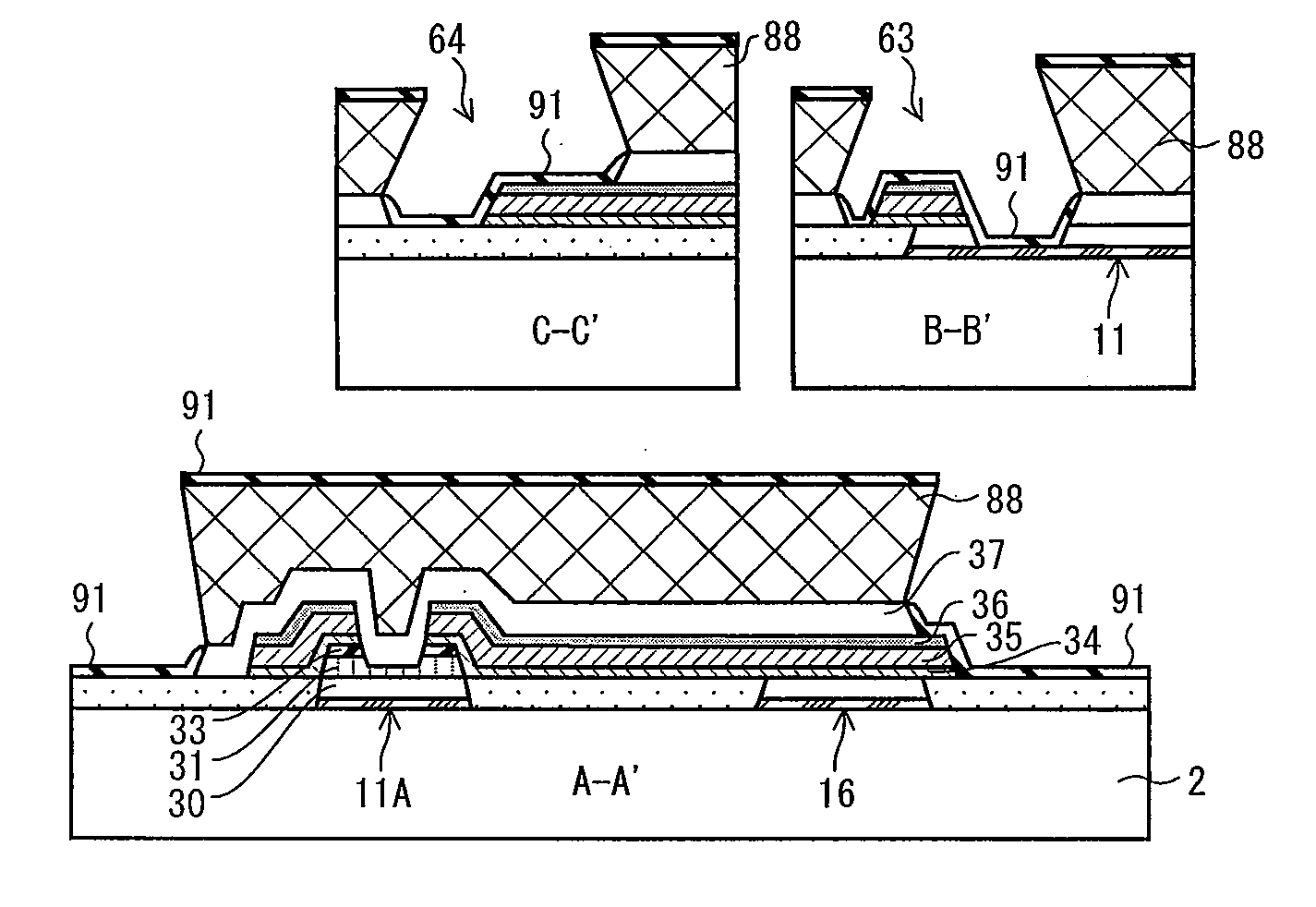

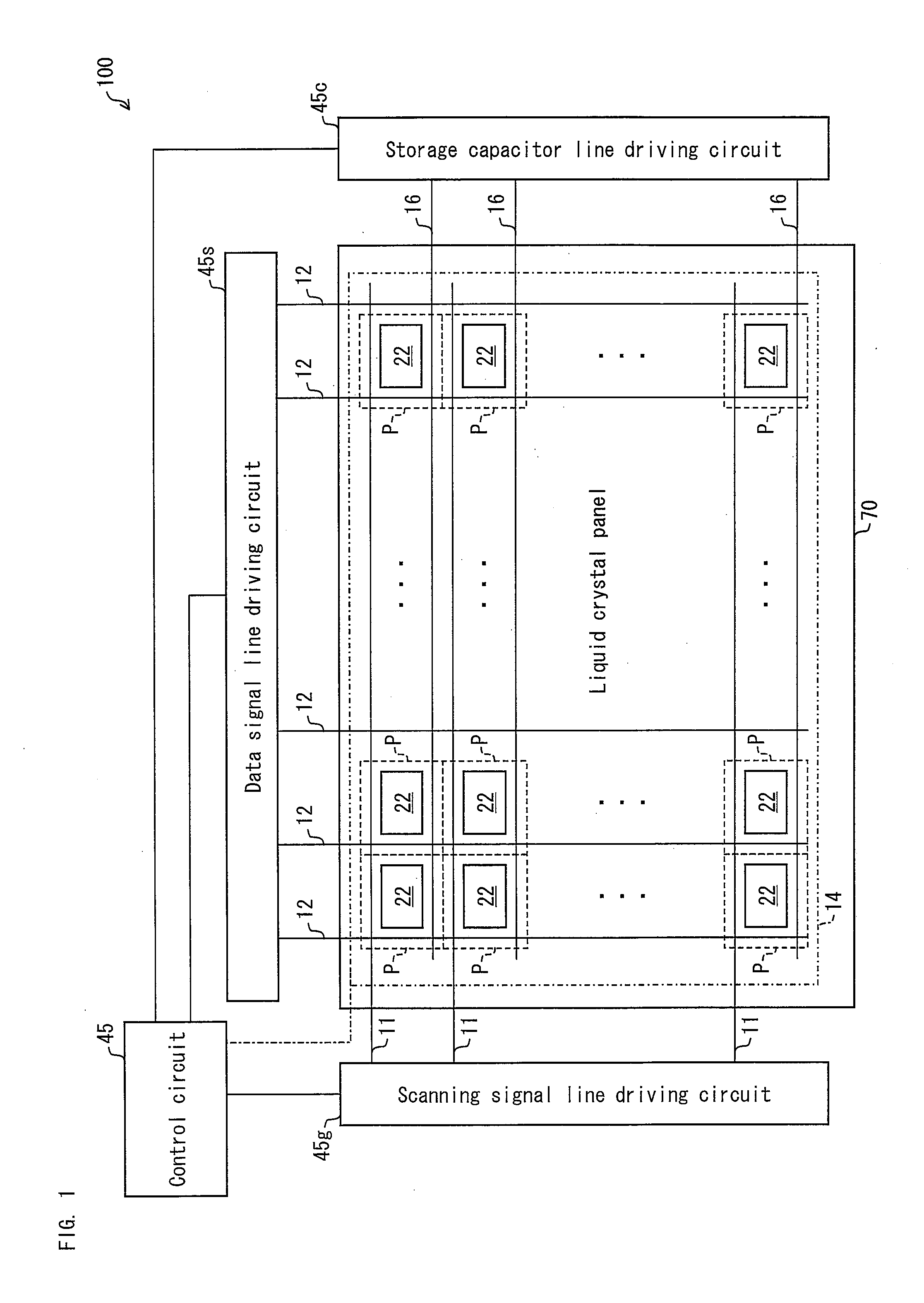

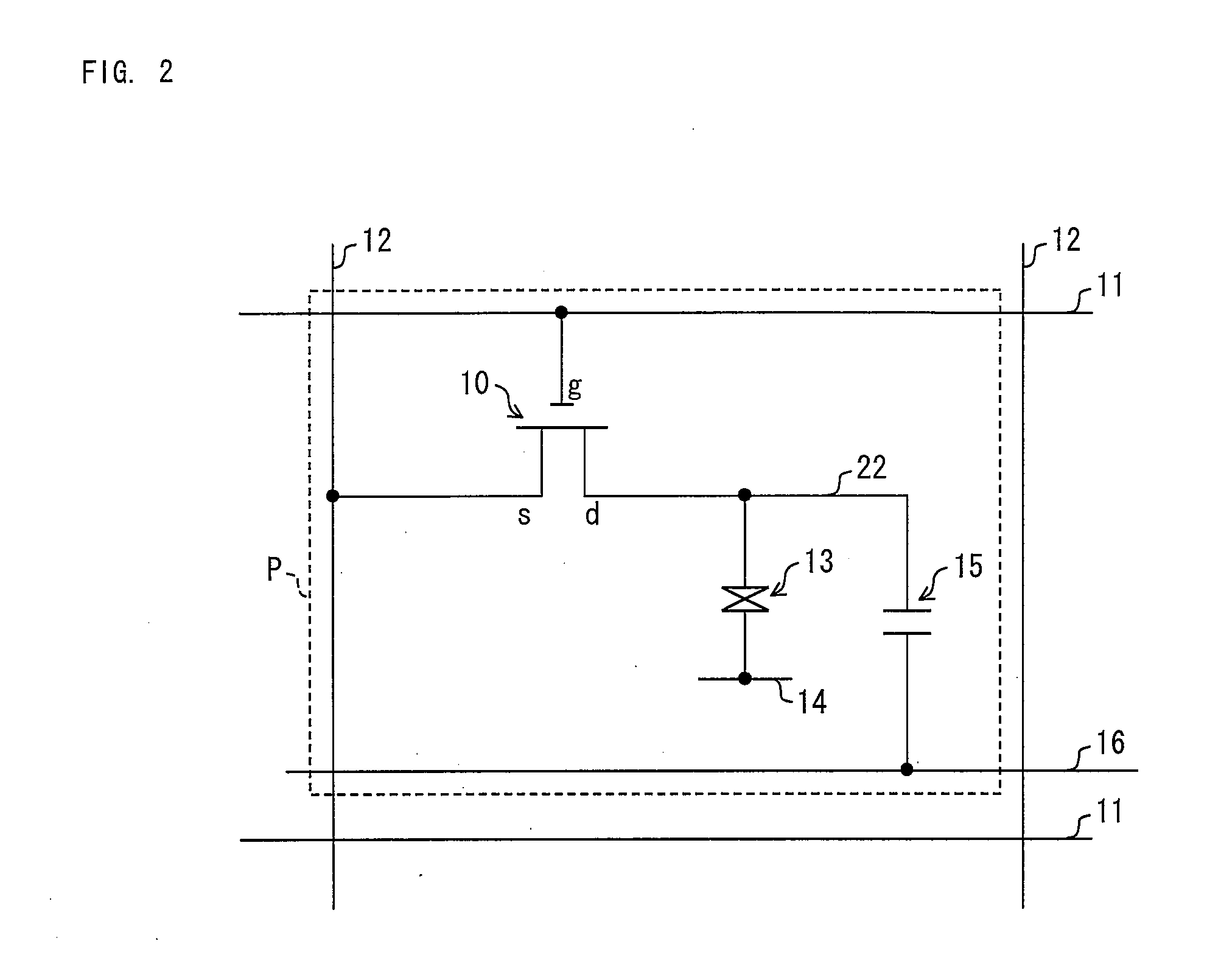

Active matrix substrate manufacturing method and liquid crystal display device manufacturing method

InactiveUS20110250713A1Reduce in quantityLow costSolid-state devicesSemiconductor/solid-state device manufacturingLiquid-crystal displayActive matrix

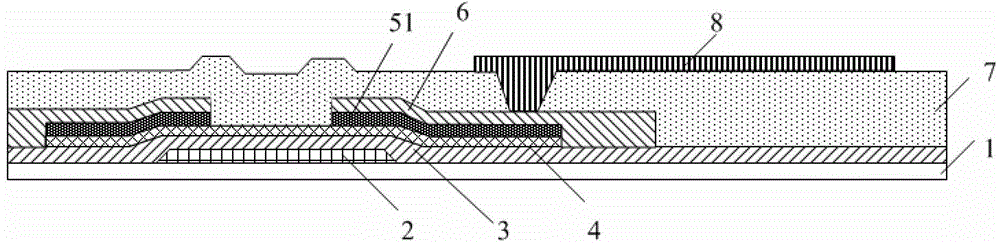

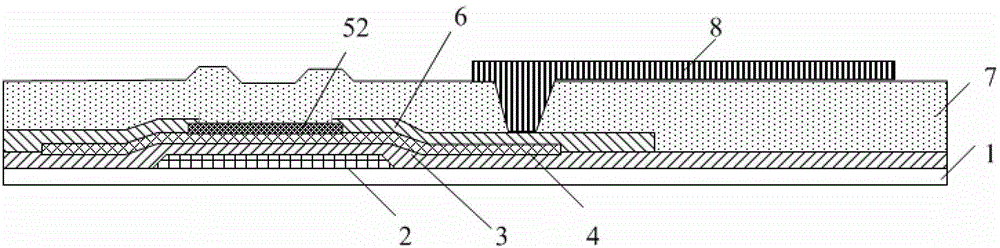

Provided is an active matrix substrate manufacturing method, including the steps of: selectively forming a laminated structure pattern, by forming the laminated structure on a glass substrate (2), by forming a first photosensitive resin pattern (PR) on the laminated structure, and by selectively forming the laminated structure pattern using the first photosensitive resin pattern (PR), the laminated structure including a metal layer (a scanning signal line (11) material), a gate insulative layer (30), and a semiconductor layer (31, 33) (transistor material); fluorinating a surface of the first photosensitive resin pattern (PR) by dry-etching with fluorine gas; applying a coating-type transparent insulative resin (60) onto the glass substrate (2) to fill a space in the laminated structure pattern; and removing the fluorinated first photosensitive resin pattern (PR). This enables to form, in an active matrix substrate manufacturing process, a scanning signal line and a semiconductor layer with a single mask process.

Owner:SHARP KK

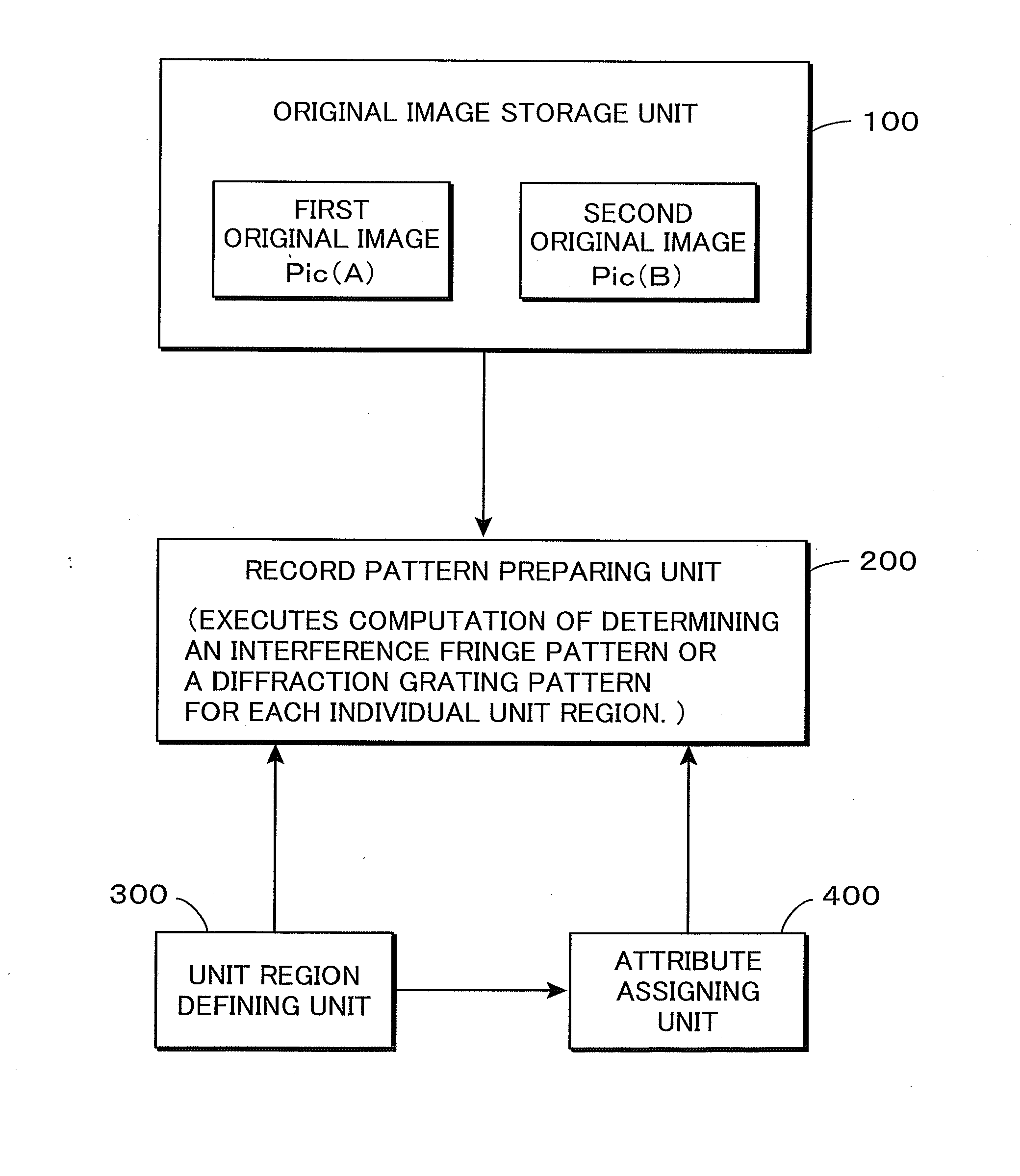

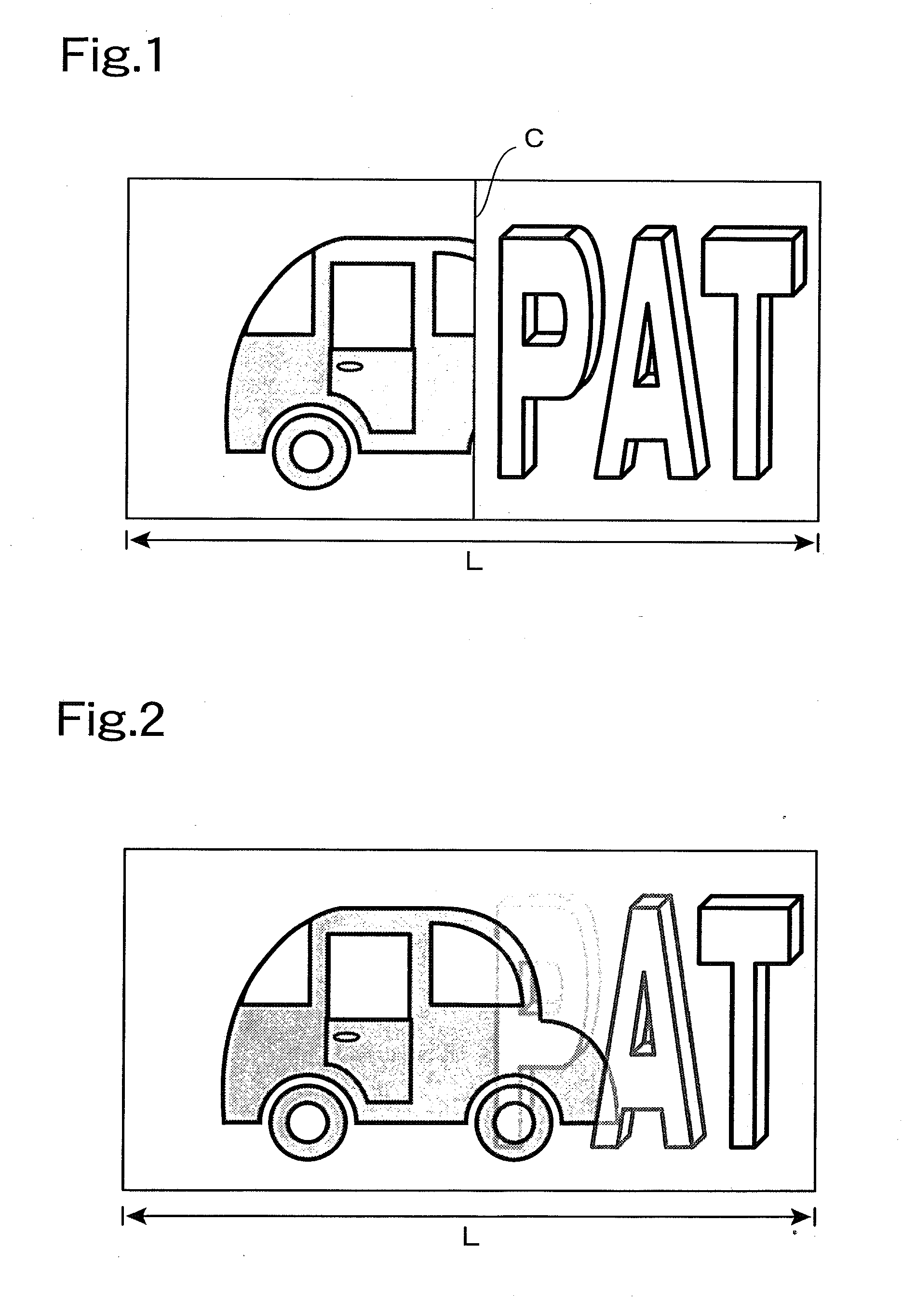

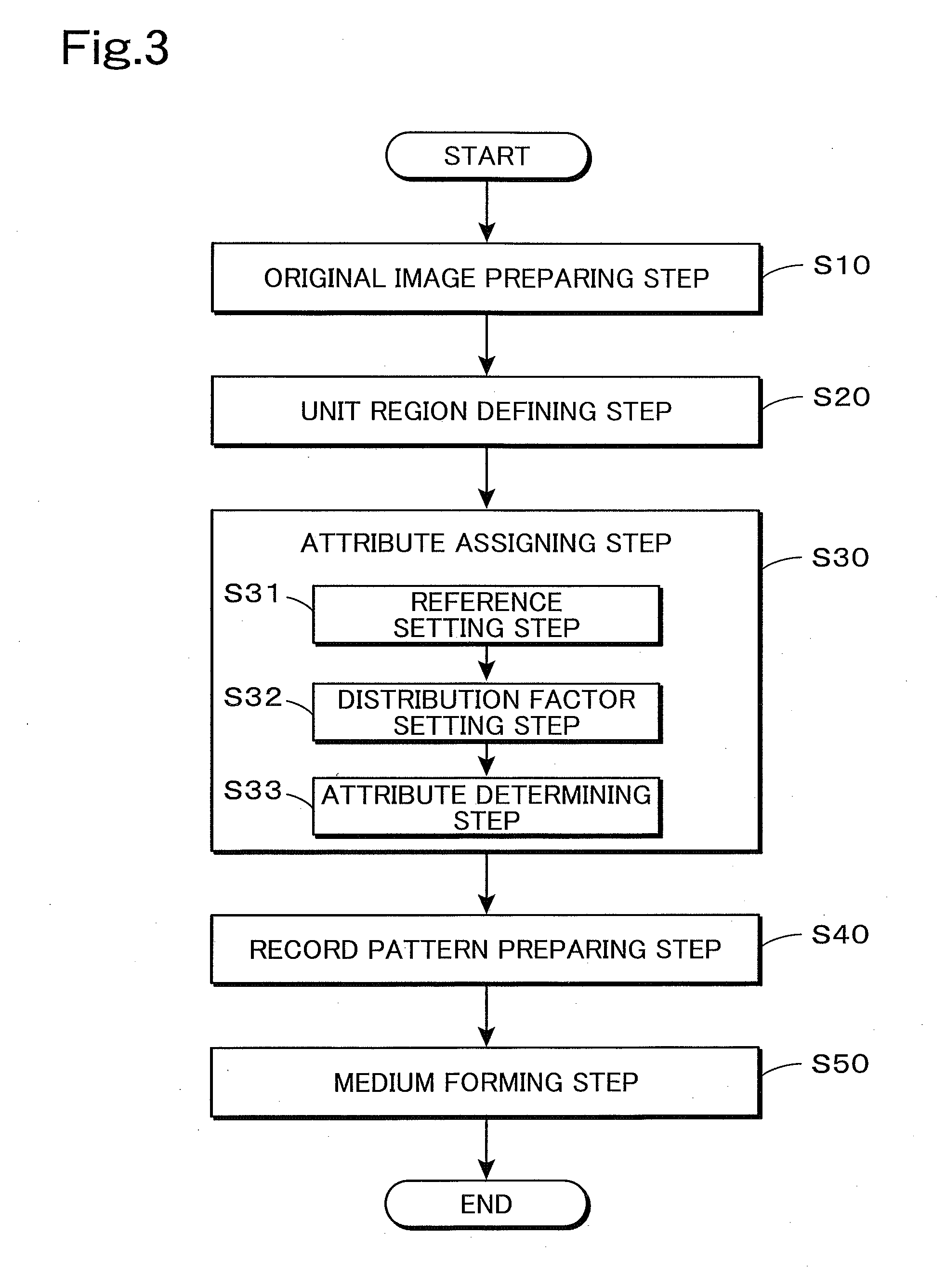

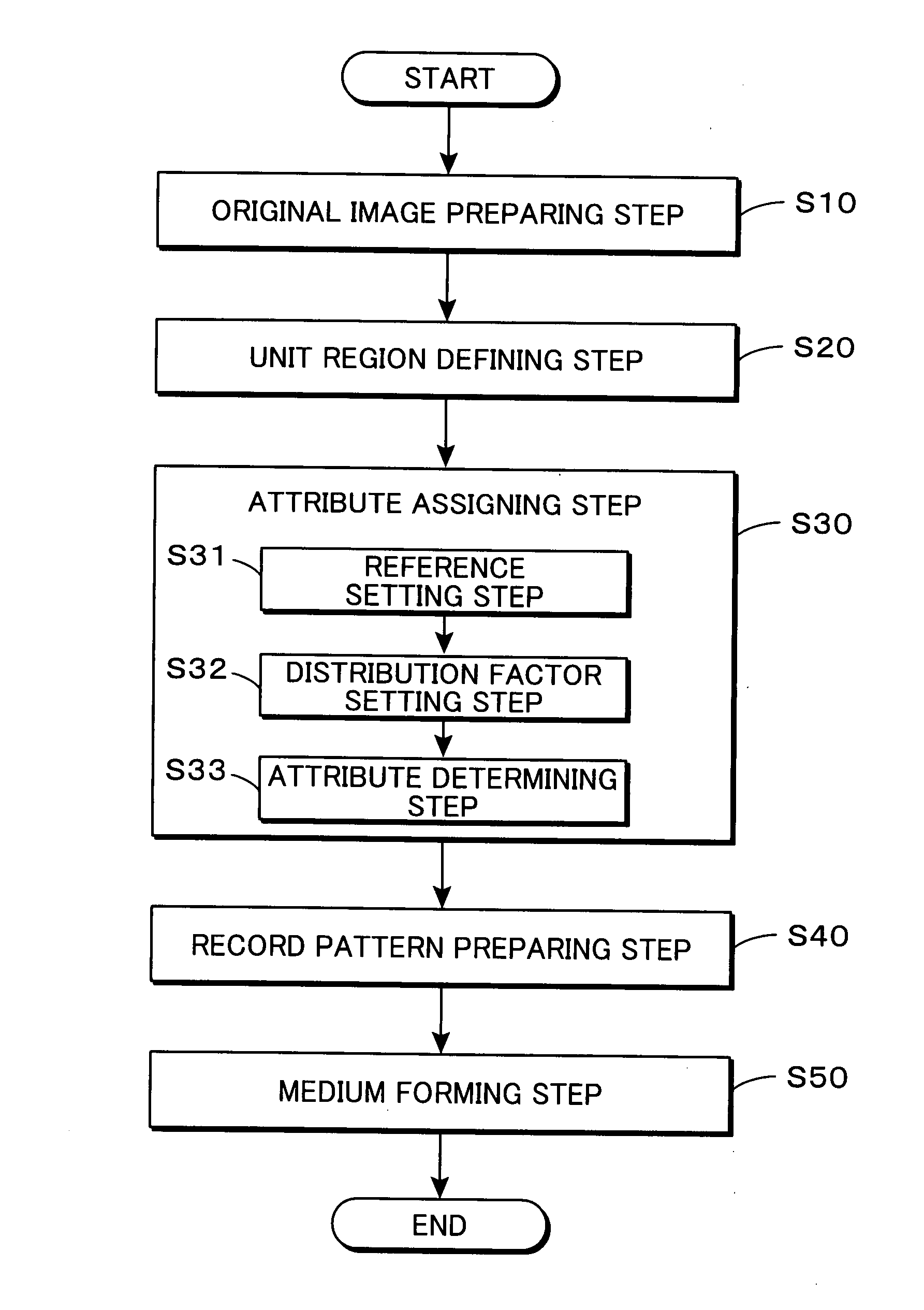

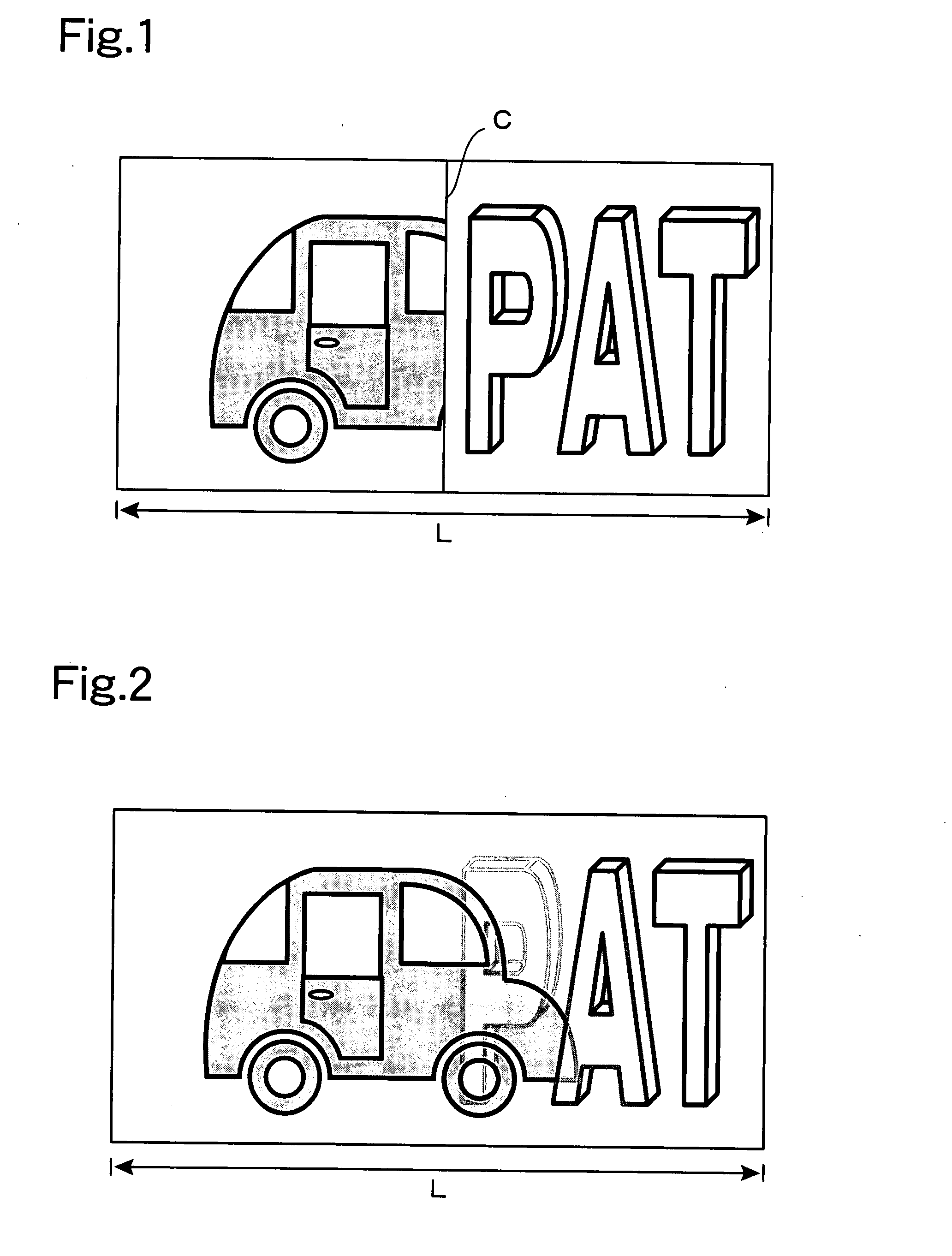

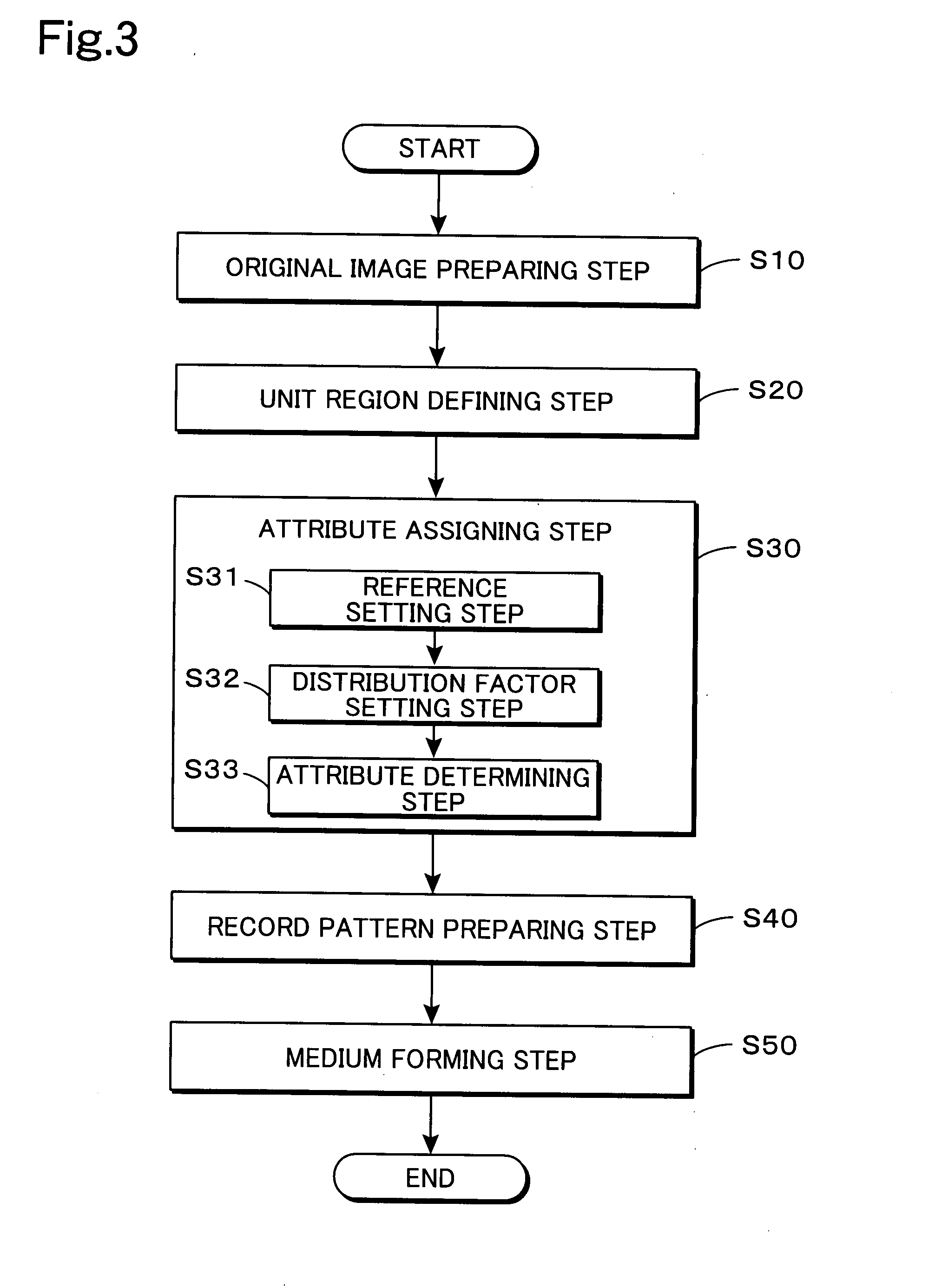

Method for preparing a hologram recording medium

ActiveUS20110267664A1Good blendingHolographic object characteristicsInformation cardsComputer scienceRecording media

Two original images to be recorded are prepared as data (S10). A plurality of unit regions, each having an adequate area to record interference fringes of visible light, are defined and positioned on a hologram recording surface (S20). A gradation pattern, with which appearance probabilities of two record attributes gradually change in space, is overlapped onto the recording surface, and to each unit region, one of either record attributes is assigned according to the appearance probabilities of the respective record attributes at each individual position (S30). In each unit region, to which the first record attribute is assigned, the first original image is recorded as an interference fringe pattern, a diffraction grating pattern, or a scattering structure pattern, and in each unit region, to which the second record attribute is assigned, the second original image is recorded as an interference fringe pattern, a diffraction grating pattern, or a scattering structure pattern (S40), and a record pattern is formed on a physical medium (S50).

Owner:DAI NIPPON PRINTING CO LTD

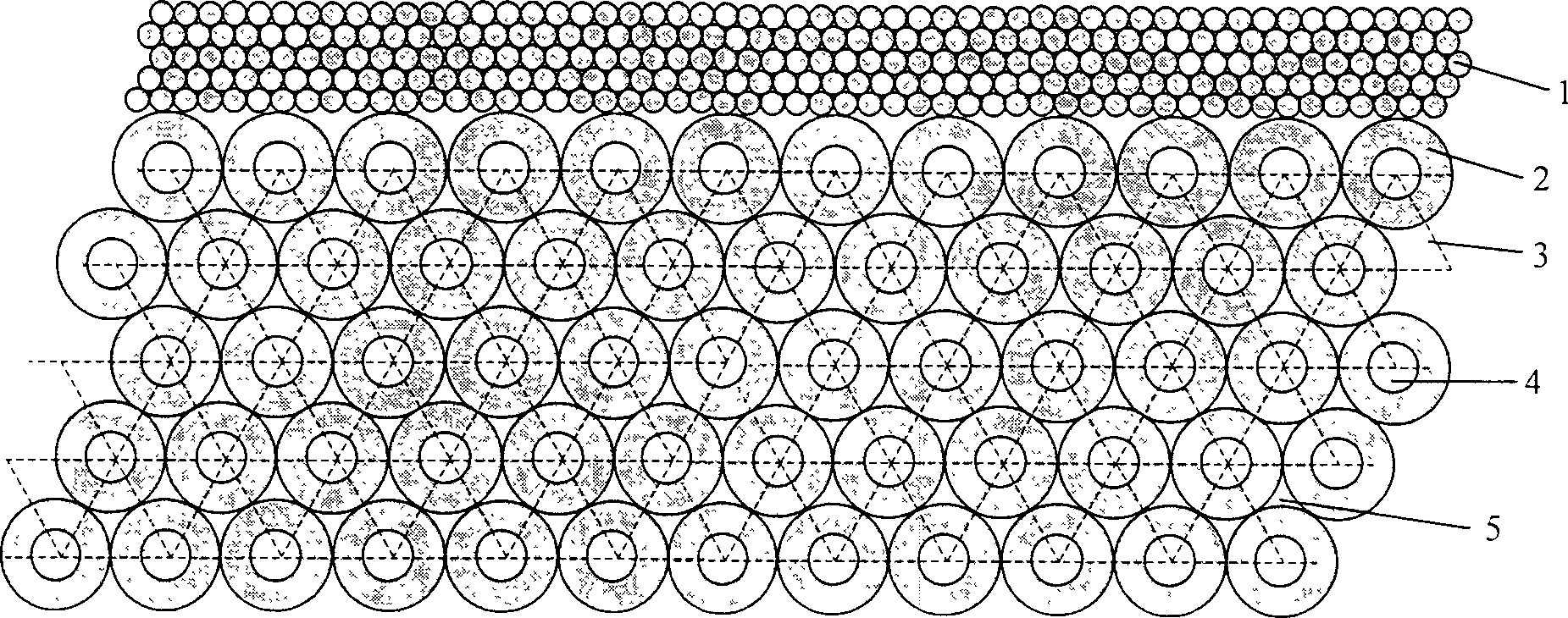

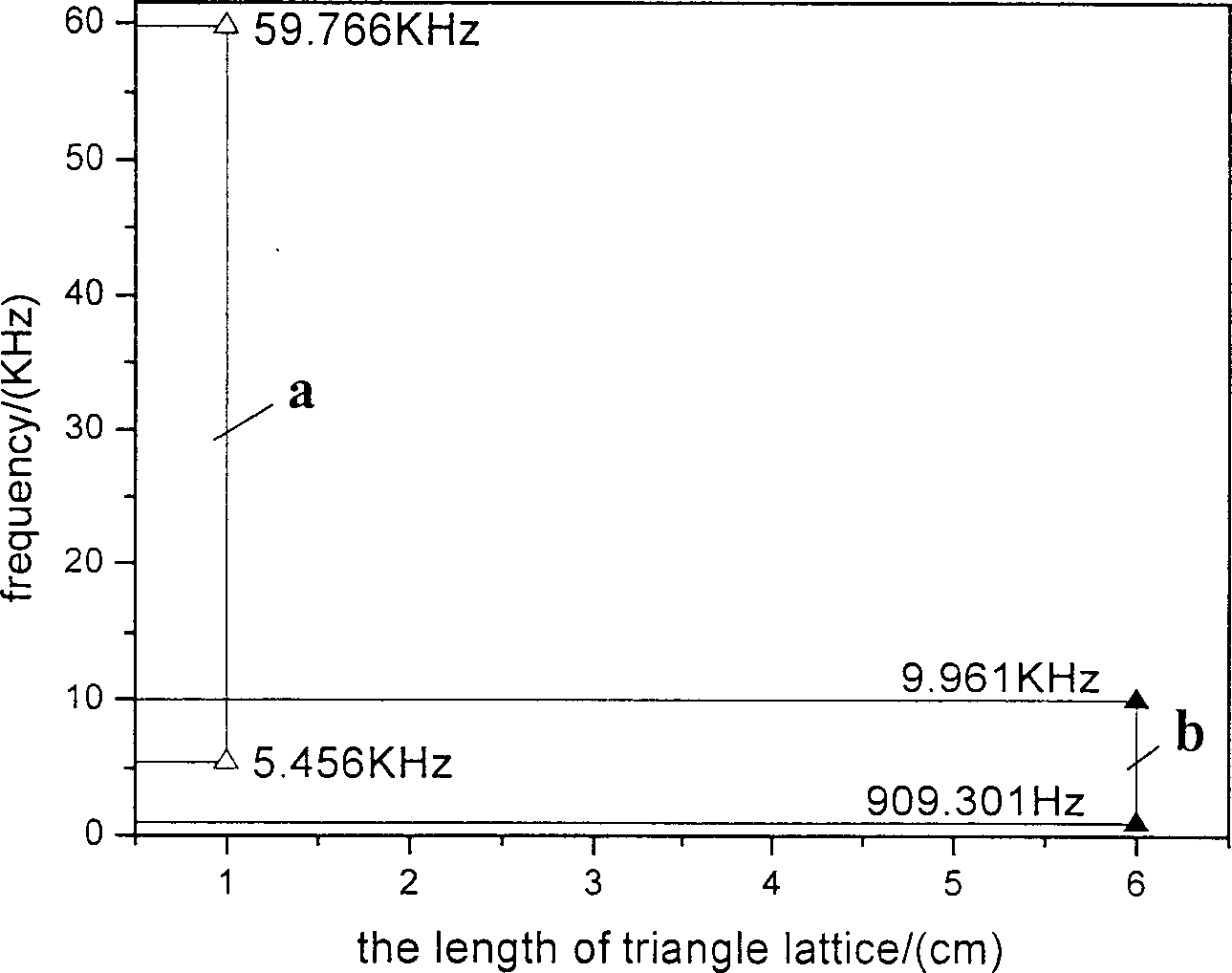

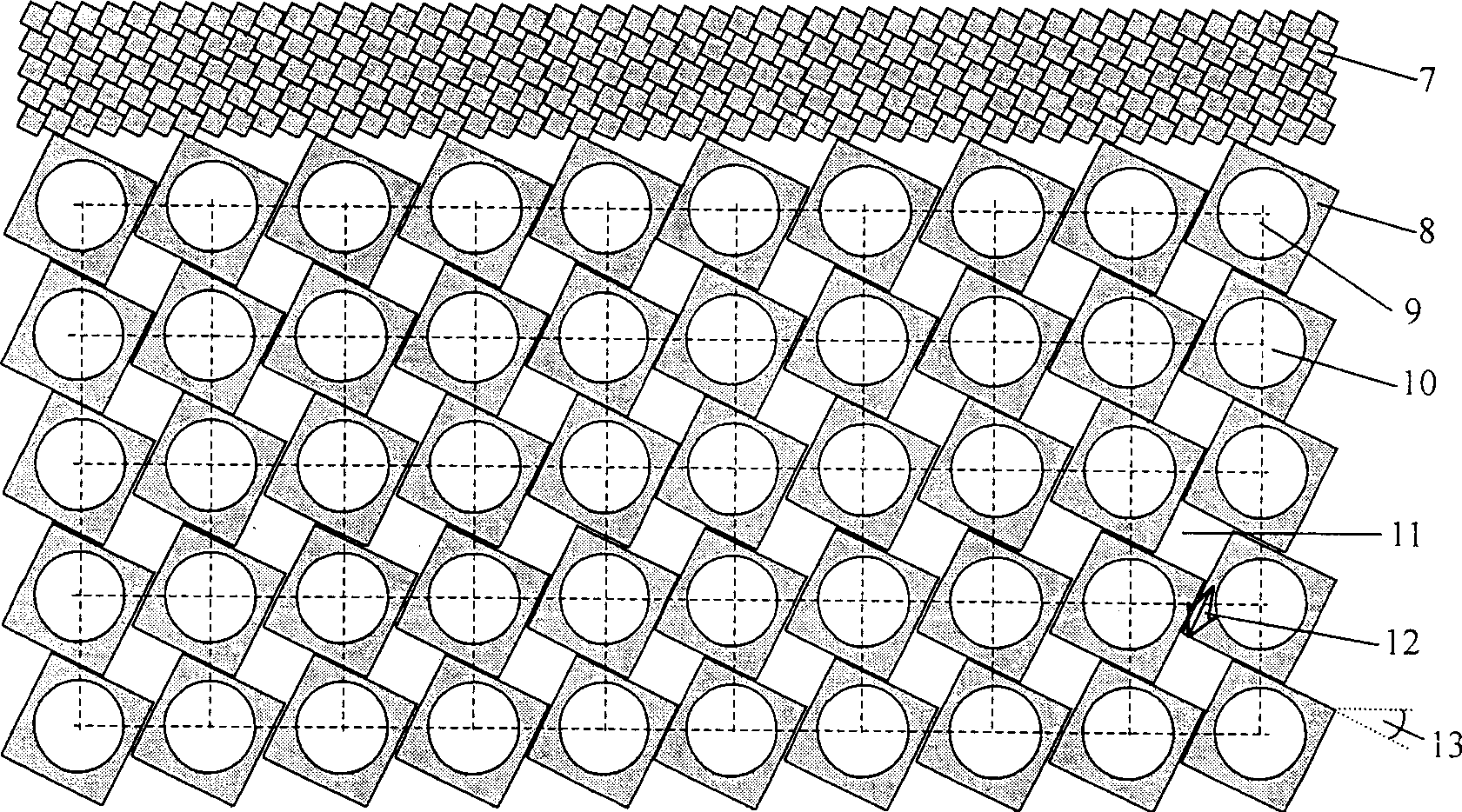

Acoustic construction of 2D phonon crystal

InactiveCN1797541AImprove sound insulationSimple preparation processSound producing devicesCrystal structureAcoustic wave

The invention discloses a 2D phonon crystal sound insulation structure, composed of parallel rigid cylinders arranged in 2D lattice periodical structure in the air; for effectively insulating sound wave, each structural mode at least needs five layers of cylinders; for broadening the frequency range of sound wave band gap, cascading and combining several structures with different lattice constants together. And it has good sound insulating effect, simple making process and strong designability, suitable for wall materials insulating medium- and high- frequency range sound waves or making sound insulation.

Owner:GUANGDONG UNIV OF TECH

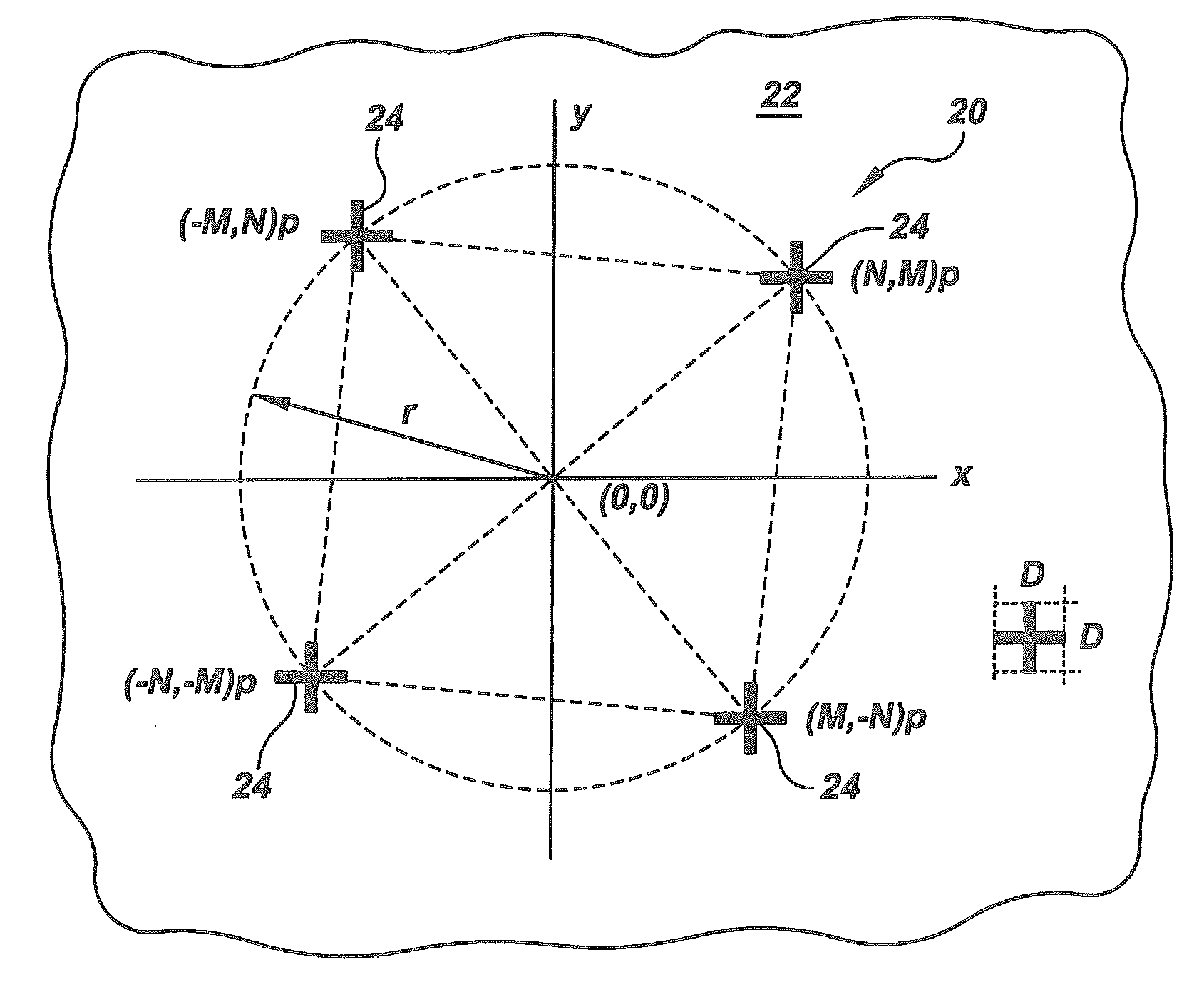

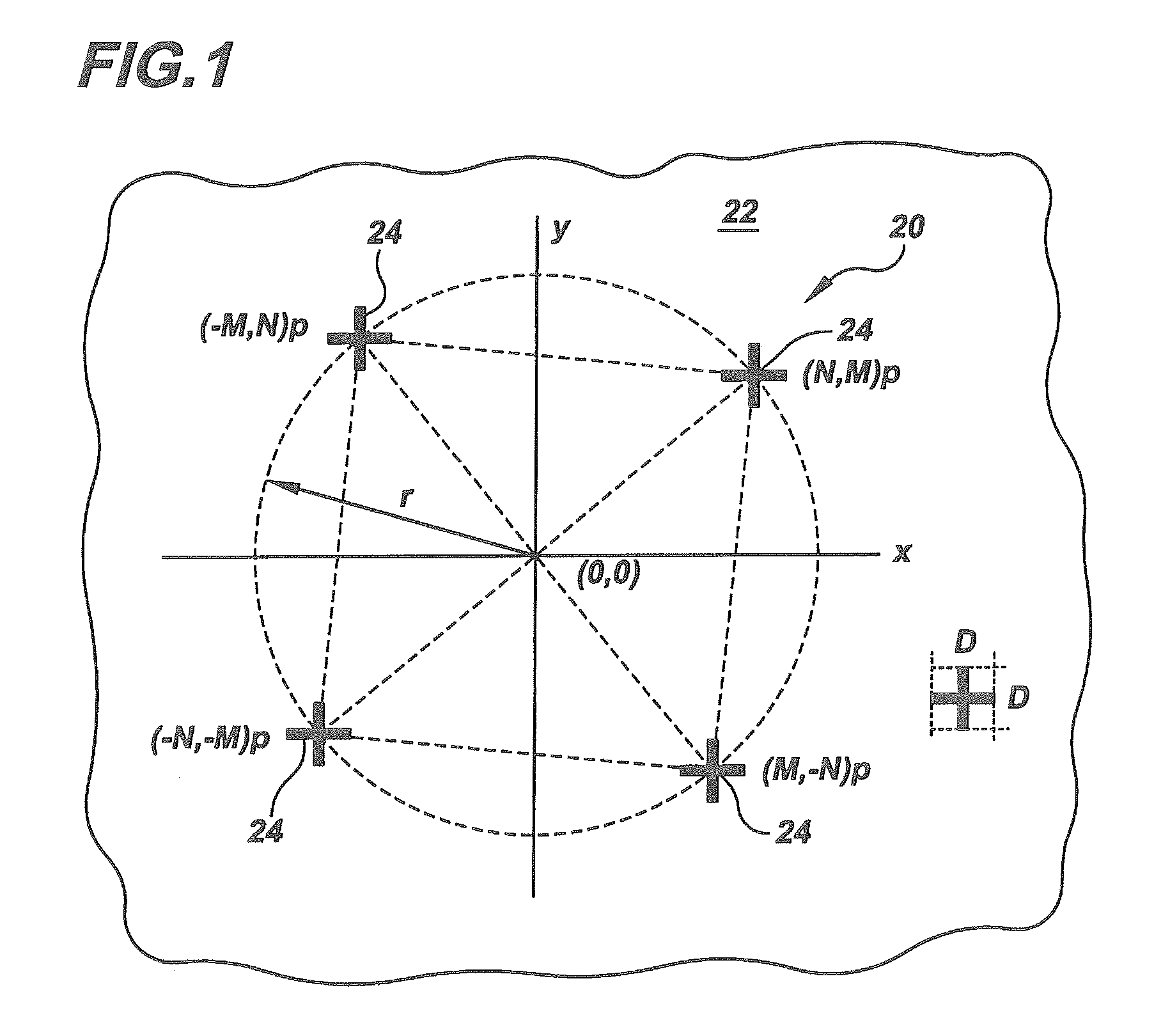

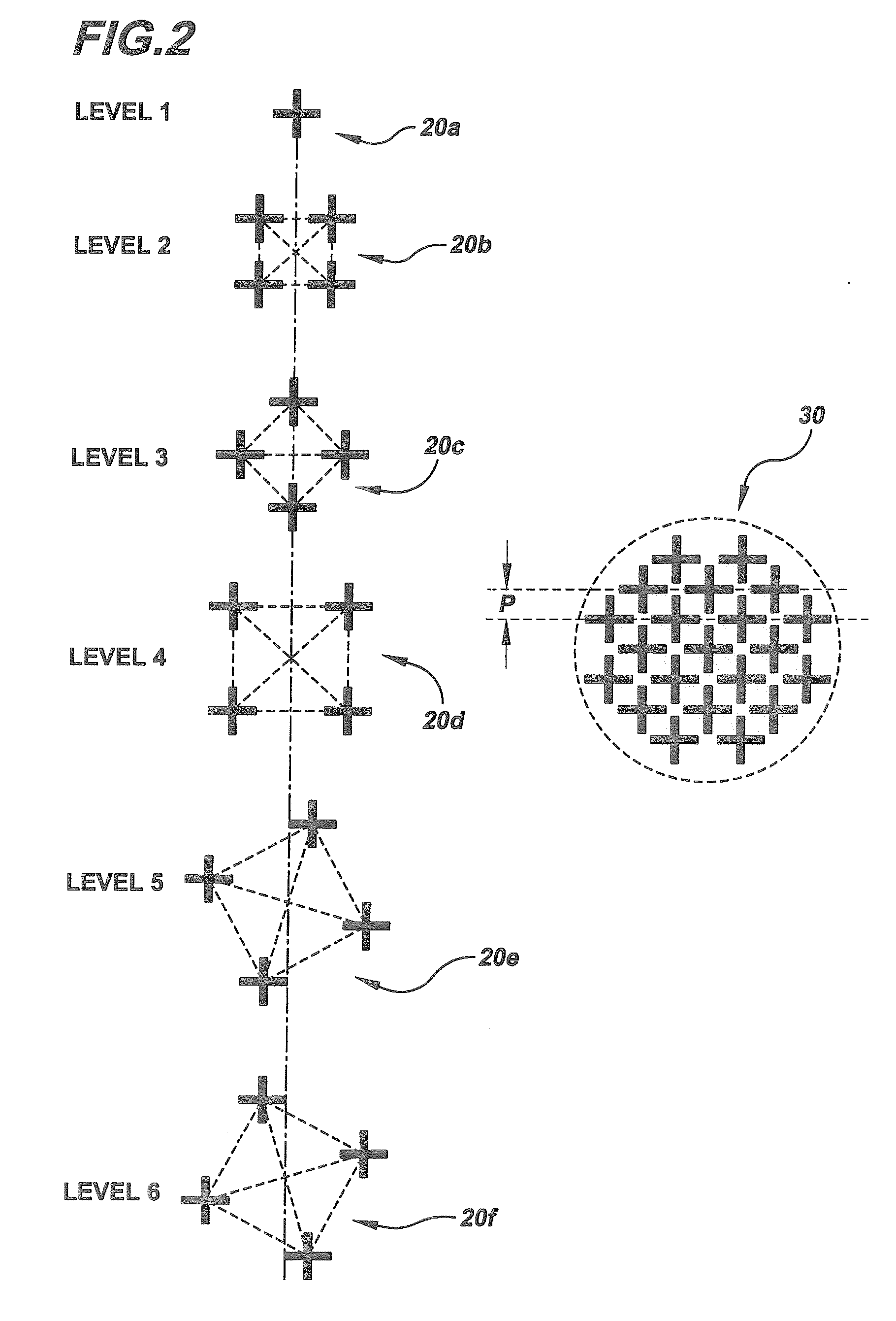

Target and method for mask-to-wafer cd, pattern placement and overlay measurement and control

InactiveUS20100190096A1Photomechanical apparatusSemiconductor/solid-state device manufacturingCritical dimensionComputer science

A method for mask-to-wafer correlation among multiple masking levels of a semiconductor manufacturing process. The method includes creating compact targets containing structure patterns suitable for pattern placement, critical dimension and overlay measurement at a set of common locations on two or more patterning layers, and creating at least two masks containing functional circuit structure patterns and the compact targets at locations between functional circuit structure patterns. The method then includes measuring the targets, determining overlay variation between the masks, exposing and creating with one mask a first lithographic processing layer on a wafer, and exposing and creating with another mask a second lithographic processing layer on the wafer, over the first layer. The method further includes measuring the targets on the wafer at one or more of the layers, and correlating the mask and wafer measurements to distinguish mask and lithography induced components of critical dimension and overlay variation.

Owner:GLOBALFOUNDRIES INC

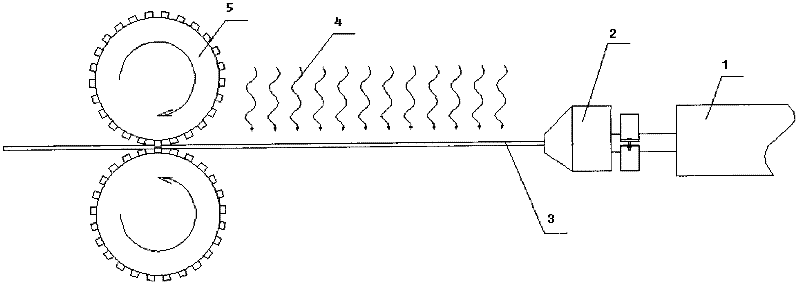

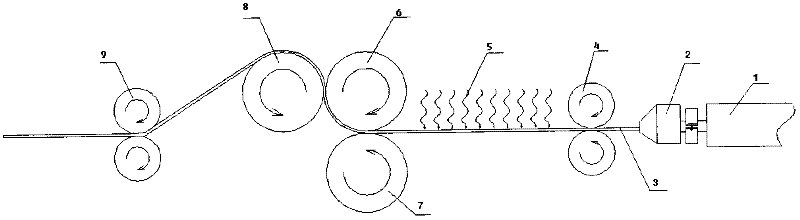

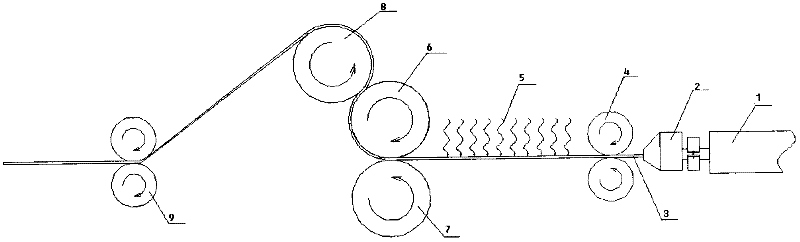

Method for polymer extruding and micro embossing shaping

Polymer micro embossing is a shaping method for forming micro-nano-structured patterns on polymer substrate materials by hot embossing. Polymer micro embossing method is widely applied in the manufacturing of various polymer micro-nano structures. The experiment apparatus mainly comprises: a polymer substrate extruder, a substrate pressing and thickness adjusting apparatus, a temperature controlling apparatus, an embossing apparatus, a pressure controlling apparatus, a pressure maintaining cooling apparatus, and a pulling apparatus. The pressing and thickness adjusting apparatus is used for flattening the extruded polymer; the temperature controlling apparatus is used for ensuring the surface temperature of the polymer substrate requiring flattening; the embossing apparatus is provided with embossing molds with micro embossing structures, wherein the micro embossing structures are transferred with applied pressures; the pressure controlling apparatus is used for adjusting the pressures applied to the polymer substrate; and the pressure maintaining cooling apparatus is used for cooling and shaping the micro structures. With the shaping method, a large amount of time and energy required by heating and cooling can be saved, the embossing equipment can be greatly simplified, the production efficiency is high, the operation is simple, and the cost is low.

Owner:BEIJING UNIV OF CHEM TECH

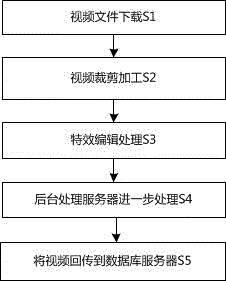

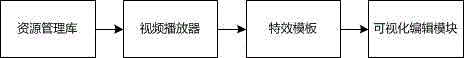

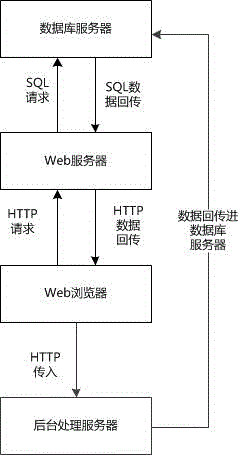

Html5-based multitrack video editing method and system

InactiveCN106210451AReduce configuration requirementsEasy to useTelevision system detailsColor television detailsHTML5Video player

The invention discloses an html5-based multitrack video editing method and system. The method comprises the following steps that: a user edits materials in a resource management library or stores edited video files, and extracts video raw materials or edited and archived video materials from the resource management library; and a special effect function is added through a special effect template, and meanwhile a B / S (Browser / Server) network structure mode is utilized, so that a program producer can edit the video files with a browser through a network, and play videos synchronously in real time. Through adoption of the html5-based multitrack video editing method and system, certain necessary video editing functions are combined with an Html5 technology. The system comprises the resource management library, the special effect template, a video player and a visual editing module, is suitable for rapid editing and low-configuration computers, and has the characteristics of portability and high efficiency in use, and cross-platform and cross-browser characteristics.

Owner:CHENGDU SOBEY DIGITAL TECH CO LTD

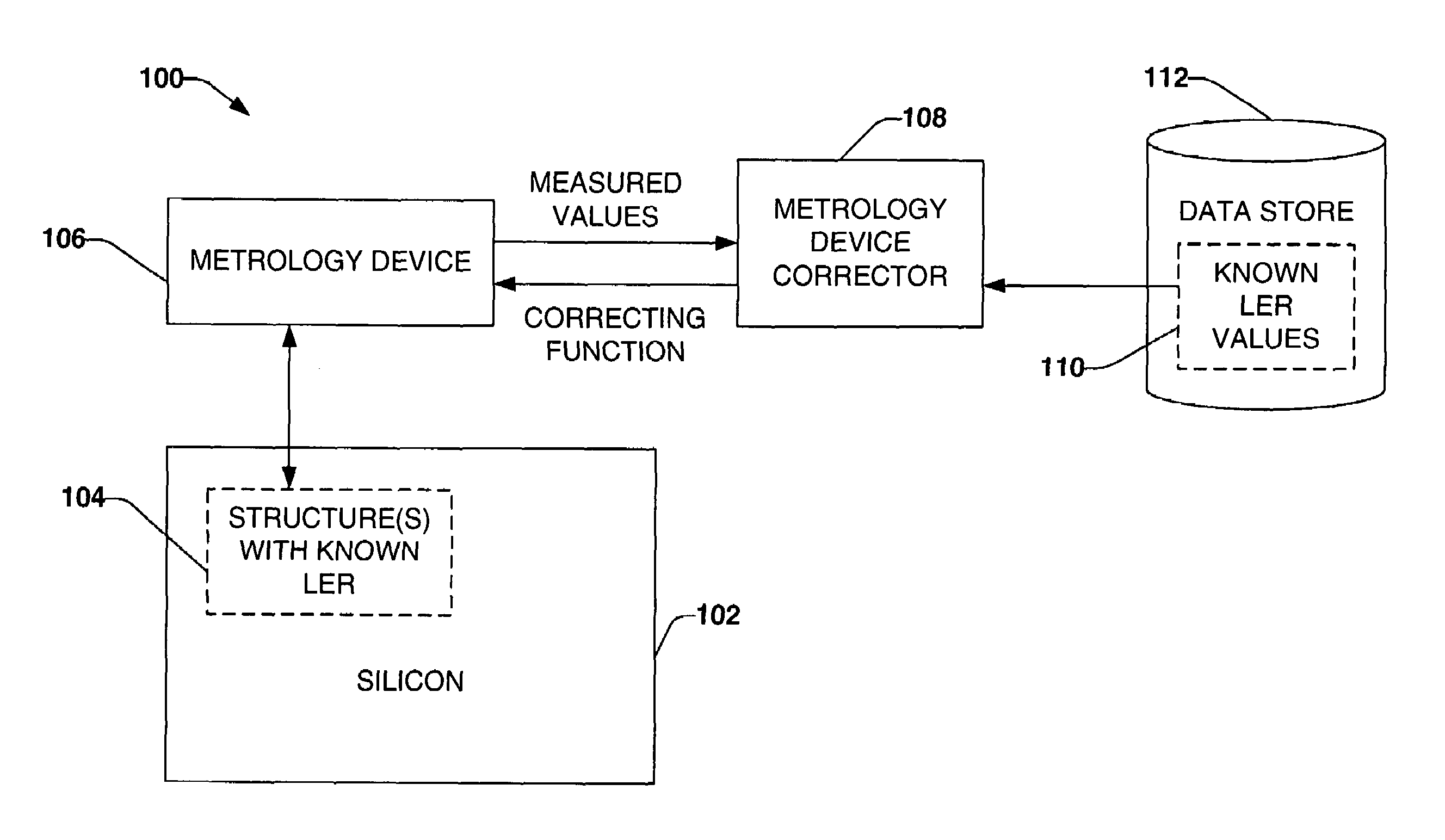

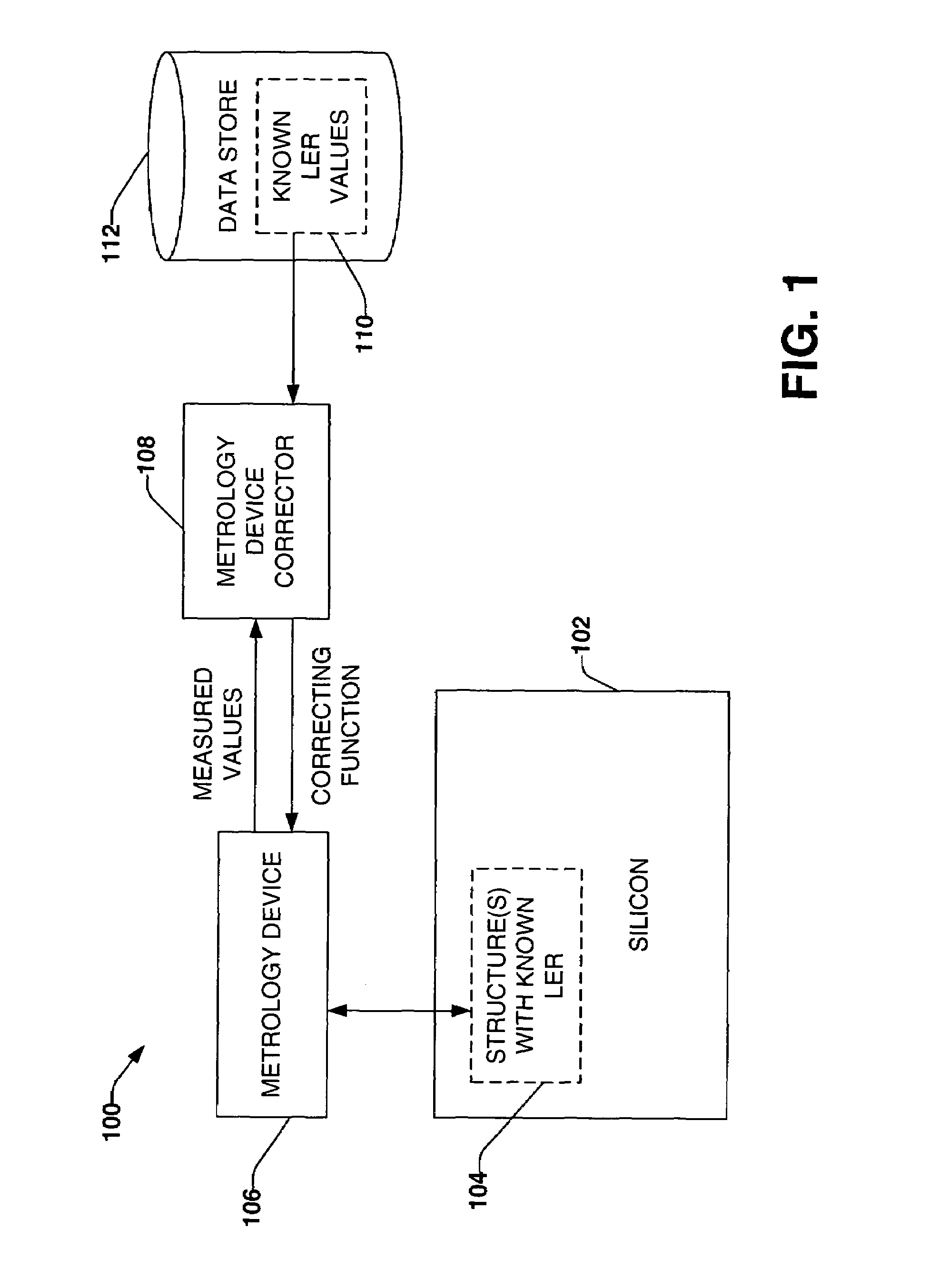

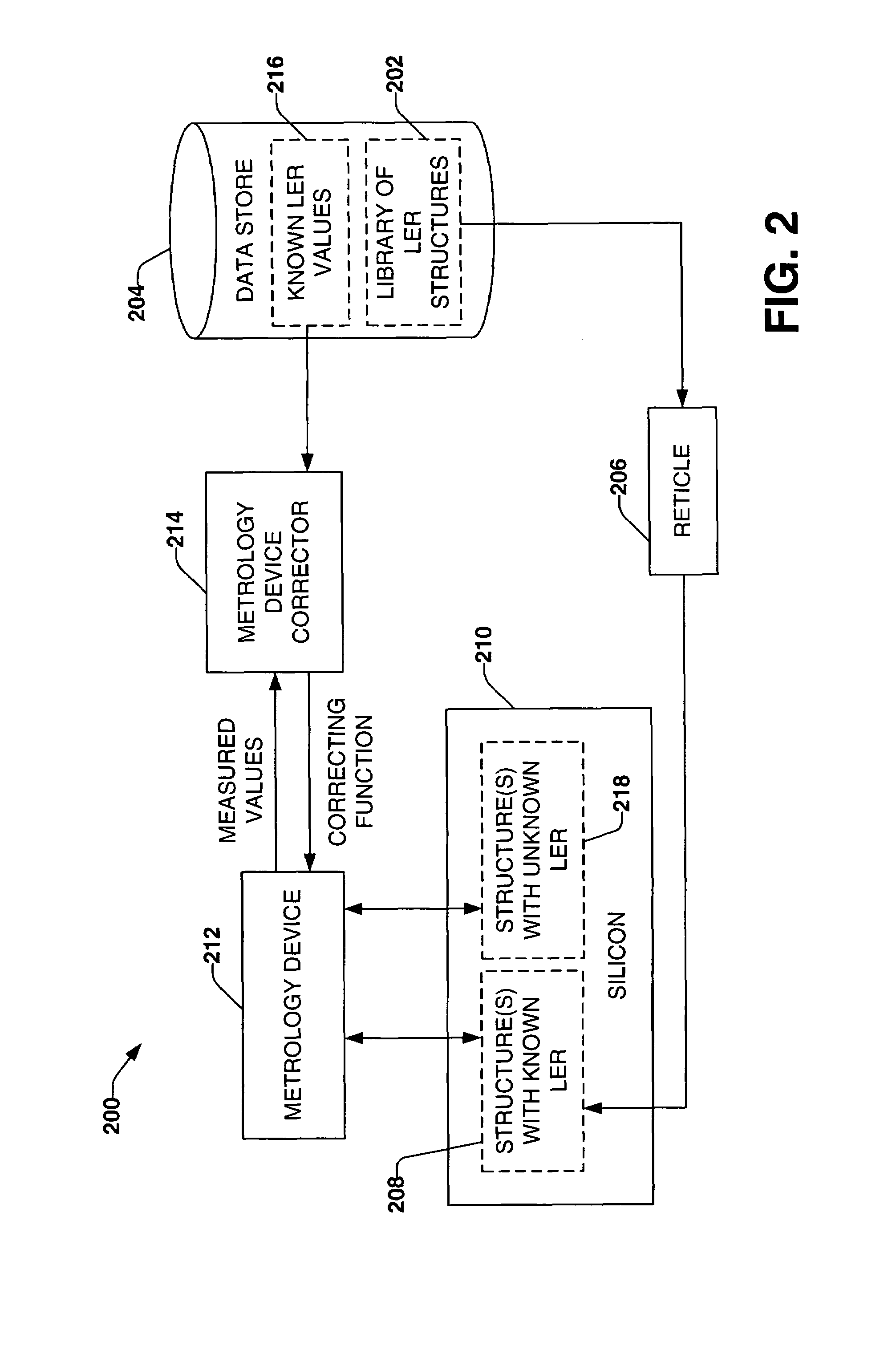

Extraction of tool independent line-edge-roughness (LER) measurements using in-line programmed LER and reliability structures

InactiveUS7310155B1Easy accessEffectively de-convolveScattering properties measurementsUsing optical meansMetrologyEngineering

A system that facilitates extraction of line edge roughness measurements that are independent of proprietorship of a metrology device comprises a structure patterned onto silicon with known line edge roughness values associated therewith. A metrology device obtains line edge roughness measurements from the structure, and a correcting component generates an inverse function based upon a comparison between the known line edge roughness values and the measured line edge roughness values. The metrology device can thereafter measure line edge roughness upon a second structure patterned on the silicon, and the inverse function can be applied to such measured line edge roughness values to enable obtainment of line edge roughness measurements that are independent of proprietorship of the metrology device.

Owner:ADVANCED MICRO DEVICES INC

High-temperature-tolerance frequency selection wave-transmitting structure and preparation method thereof

ActiveCN106630979AImprove mechanical propertiesImprove electrical performanceLaser beam welding apparatusFiberElectrical conductor

The invention discloses a high-temperature-tolerance frequency selection wave-transmitting structure. The high-temperature-tolerance frequency selection wave-transmitting structure successively comprises a wave-transmitting layer, a modification bonding layer and a frequency selection layer from inside to outside, wherein the wave-transmitting layer is made of a continuous fiber reinforced ceramic-based wave-transmitting composite material; the modification bonding layer is made of a low-dielectric-constant material; the frequency selection layer is a noble metal physical plating layer or a noble metal glass conductor coating with periodic structure patterns. The high-temperature-tolerance frequency selection wave-transmitting structure can tolerate high temperature of 700 DEG C or more, and has excellent high temperature tolerance. The invention also provides a production method of the high-temperature-tolerance frequency selection wave-transmitting structure; the modification bonding layer is produced by using a plasma spraying process; the thermal damage to the substrate can be avoided, so that the substrate has high strength retention rate; the size accuracy of the frequency selection layer produced by a laser processing process can be higher than 20 microns; the frequency selection layer has high size accuracy.

Owner:NAT UNIV OF DEFENSE TECH +1

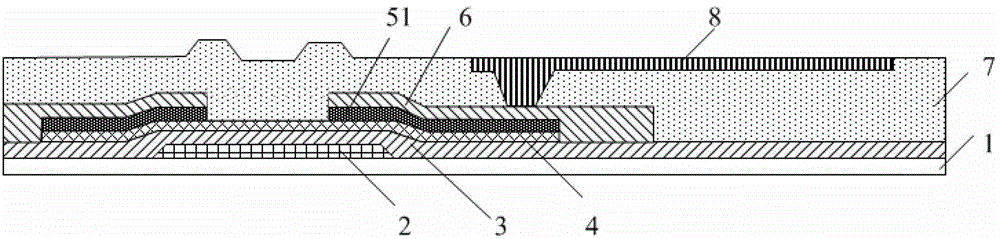

Thin film transistor array substrate, preparing method and display device

ActiveCN103151305AReduce usageIncrease profitSolid-state devicesSemiconductor/solid-state device manufacturingInsulation layerDisplay device

The invention relates to a preparing method of a thin film transistor array substrate, a thin film transistor array substrate and a display device, and belongs to the displaying technical field. The preparing method comprises the following steps of: forming a gate electrode layer, a gate insulation layer, an active layer, a source and drain electrode layer, a passivation layer and a pixel electroed layer on the substrate, wherein the passivation layer forms a structure pattern comprising through holes through a composition technology, the pixel electrode layer is formed in the structure pattern region by a dripping mode, and the source and drain electrode layer is connected with the pixel electrode layer through the through holes. By the preparing method, the steps for forming the pixel electrode layer by the composition technology are reduced, the usage amount of a mask plate is reduced, the use ratio of the pixel electrode forming material is improved, and the production cost is reduced.

Owner:BOE TECH GRP CO LTD

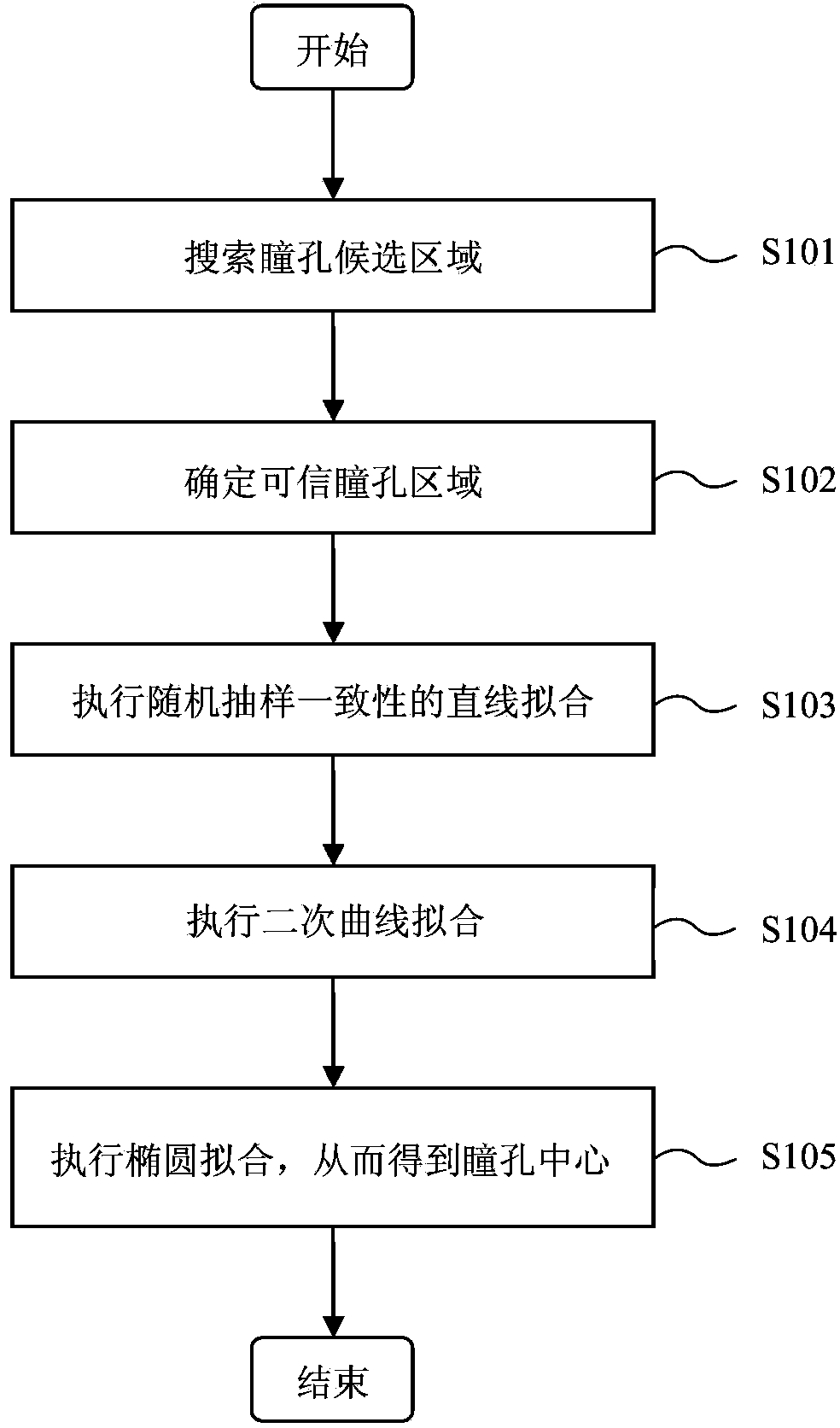

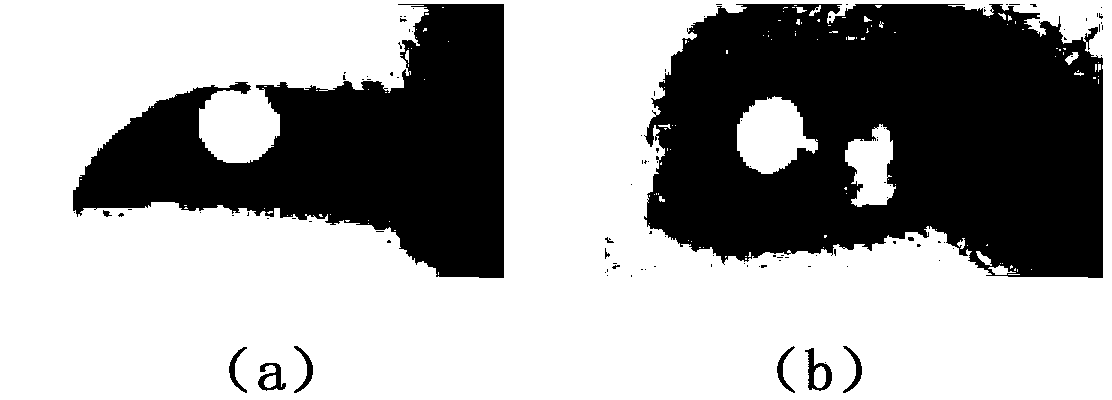

Pupil detection method and device

InactiveCN104182720AEliminate distractionsHigh precisionCharacter and pattern recognitionCurve fittingPupil

Disclosed are a pupil detection method and device. The pupil detection method includes the following steps: searching for areas of a black-white-black structural mode in a shot bright pupil image line by line and pixel by pixel and using the areas as pupil candidate areas and recording edge points and a midpoint of each line of white line of the pupil candidate areas; according to the circularity and average grey degree of each pupil candidate area, determining a trustable pupil area; executing random sample consensus linear fitting on midpoints of the white lines of the determined trustable pupil area so that reliable midpoints of the white lines of the trustable pupil area and edge points corresponding to the reliable midpoints are obtained; executing second curve fitting on the edge points corresponding to the reliable midpoints so that reliable edge points of the trustable pupil area are obtained; and carrying out elliptic fitting on the reliable edge points of the trustable pupil area so that a pupil center is obtained.

Owner:BEIJING SAMSUNG TELECOM R&D CENT +1

Method for preparing a hologram recording medium

InactiveUS20070216978A1Good blendingHolographic object characteristicsInformation cardsComputer scienceRecording media

Two original images to be recorded are prepared as data (S10). A plurality of unit regions, each having an adequate area to record interference fringes of visible light, are defined and positioned on a hologram recording surface (S20). A gradation pattern, with which appearance probabilities of two record attributes gradually change in space, is overlapped onto the recording surface, and to each unit region, one of either record attributes is assigned according to the appearance probabilities of the respective record attributes at each individual position (S30). In each unit region, to which the first record attribute is assigned, the first original image is recorded as an interference fringe pattern, a diffraction grating pattern, or a scattering structure pattern, and in each unit region, to which the second record attribute is assigned, the second original image is recorded as an interference fringe pattern, a diffraction grating pattern, or a scattering structure pattern (S40), and a record pattern is formed on a physical medium (S50).

Owner:DAI NIPPON PRINTING CO LTD

Device and method for wavefront measurement of an optical imaging system by means of phase-shifting interferometry

InactiveUS7417745B2High measurement accuracyOptical measurementsPhotomechanical apparatusGratingWavefront

Owner:CARL ZEISS SMT GMBH

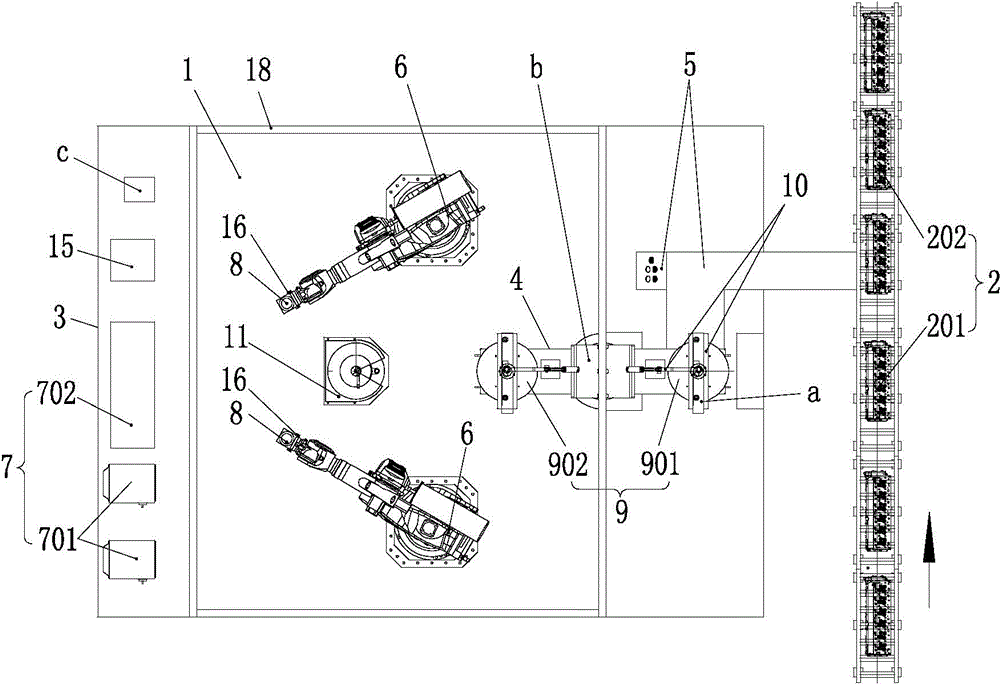

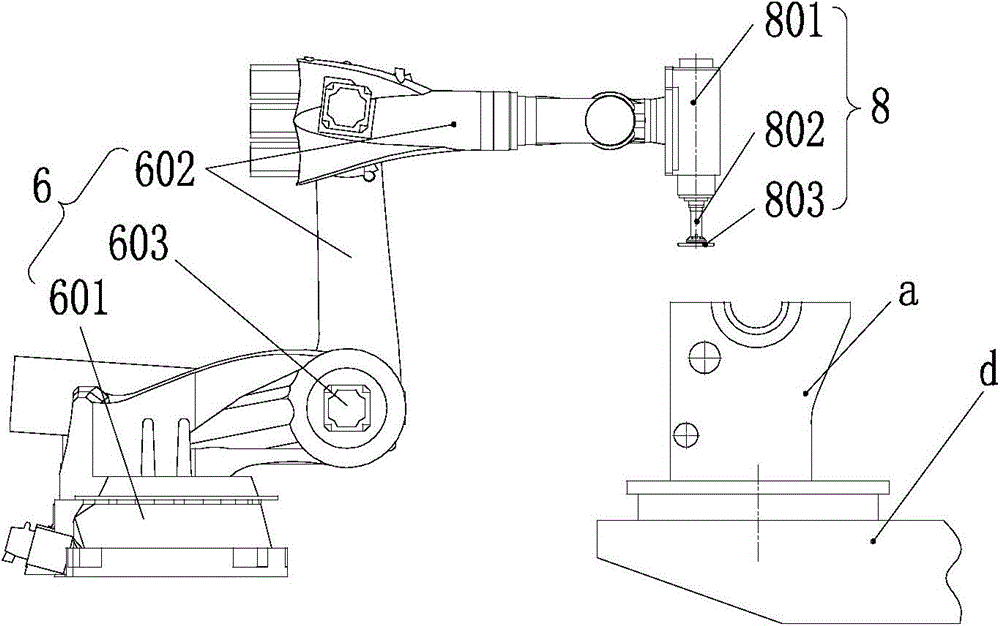

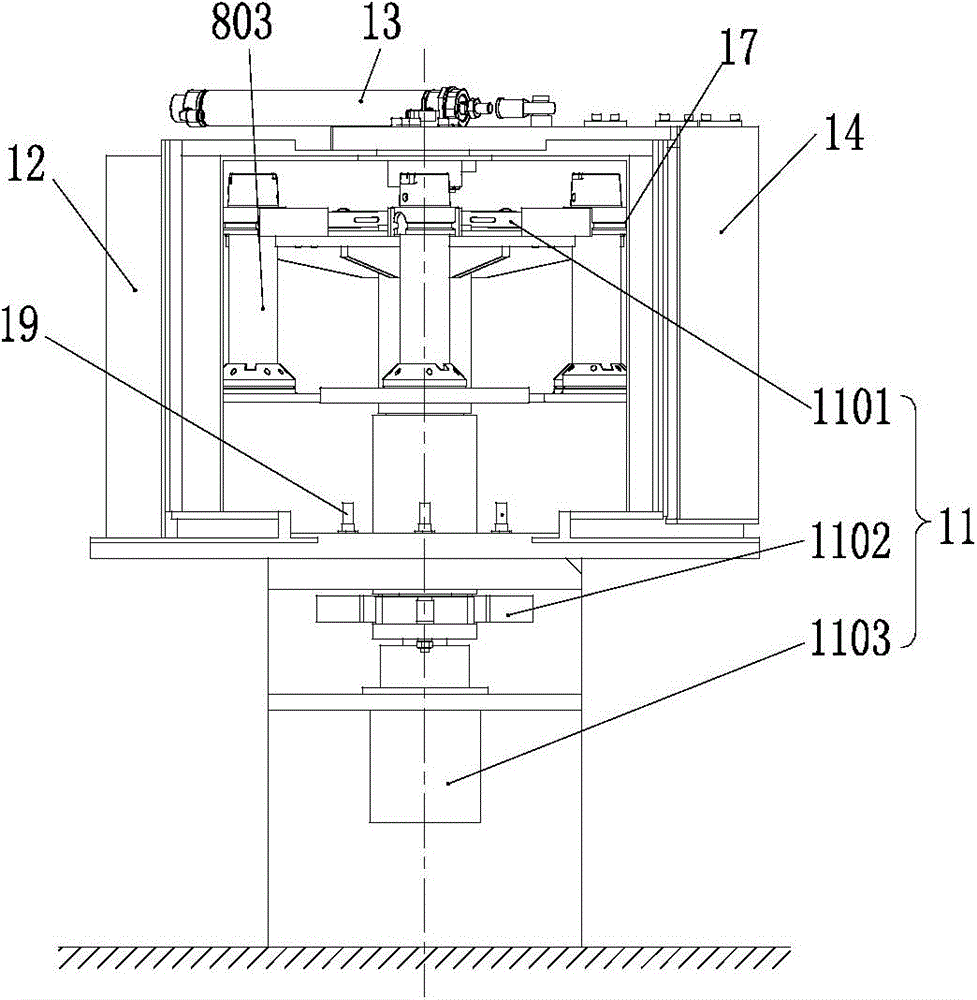

Working station for finishing iron casting and iron casting finishing method

Owner:CHANGSHA CTR ROBOTICS

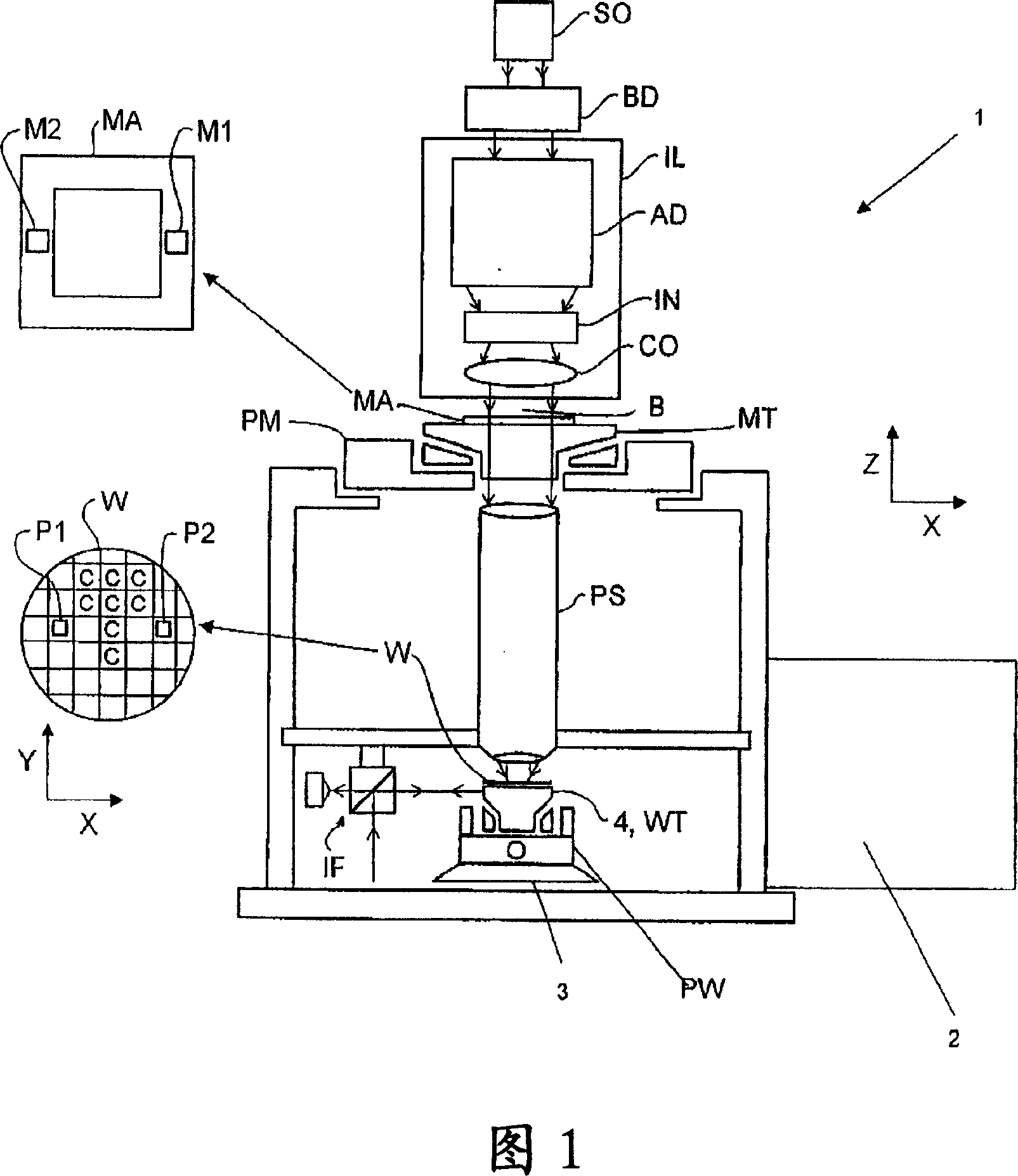

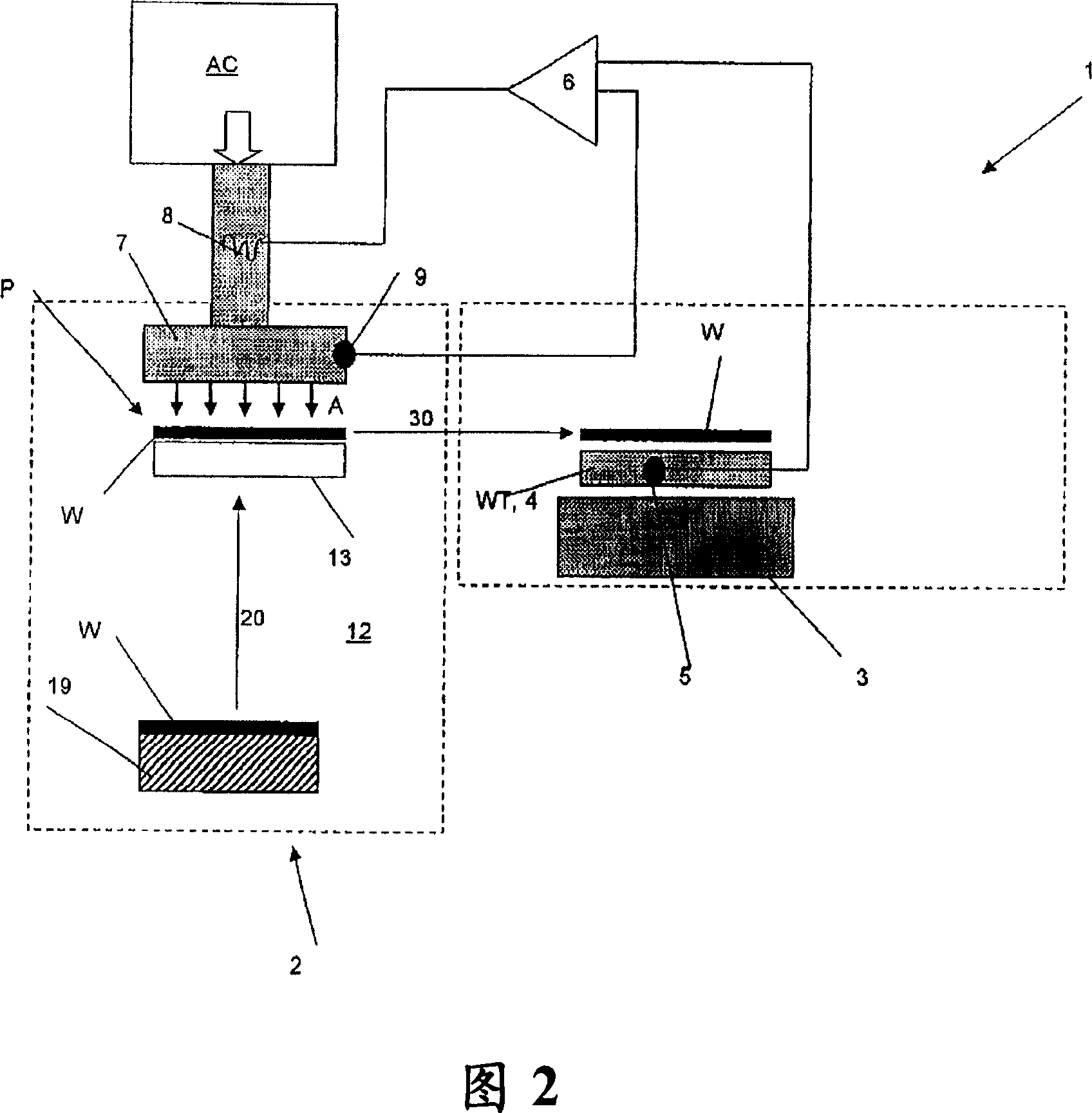

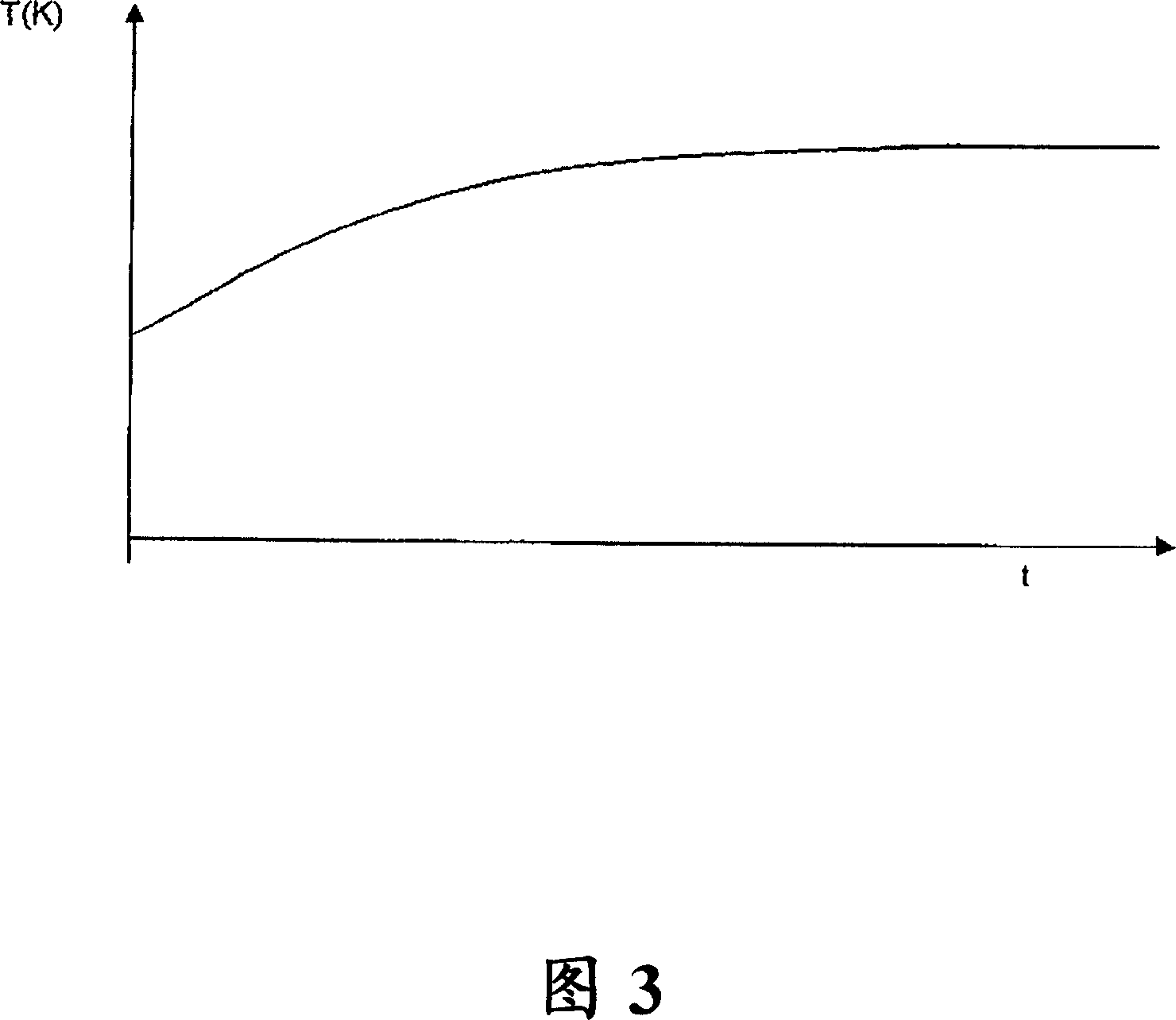

Lithographic apparatus, device manufacturing method and device manufactured thereby

ActiveCN1940729ASemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusEngineeringPhotolithography

A lithographic apparatus configured to transfer a pattern from a patterning structure to a substrate is disclosed, comprising a substrate holder configured to hold a substrate and a substrate configured to transfer the substrate to the substrate holder. A substrate temperature regulator that adjusts the temperature of the substrate to substantially match the temperature of the substrate holder before, during, or both. Further provided is a lithographic apparatus configured to transfer a pattern from a patterned structure onto a substrate, comprising a first patterning structure holding device configured to hold the patterned structure; A pattern forming structure temperature adjusting device for adjusting the temperature of the pattern forming structure before being transferred to the pattern forming structure holding device, wherein the pattern forming structure temperature adjusting device is provided with a second pattern forming structure holding device; and at least one for applying the first and the second A system in which two patterning structure fixtures are thermally conditioned to approximately the same temperature.

Owner:ASML NETHERLANDS BV +1

Method for preparing two-dimensional metallic photonic crystal structure in large area through femtosecond laser direct writing

InactiveCN105108342AAvoid complicated proceduresThe technical method is simpleLaser beam welding apparatusBirefringent crystalTime delays

Owner:NANKAI UNIV

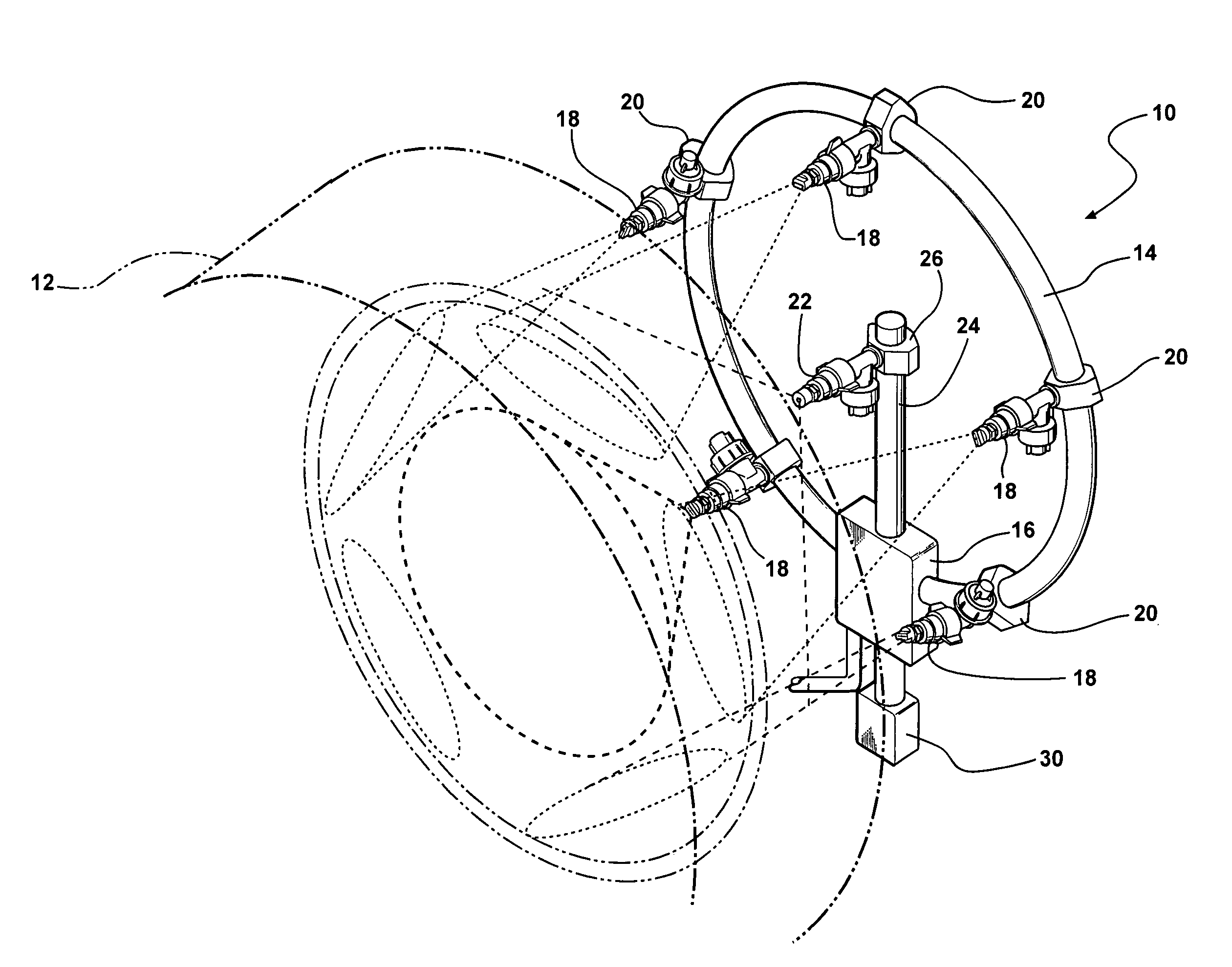

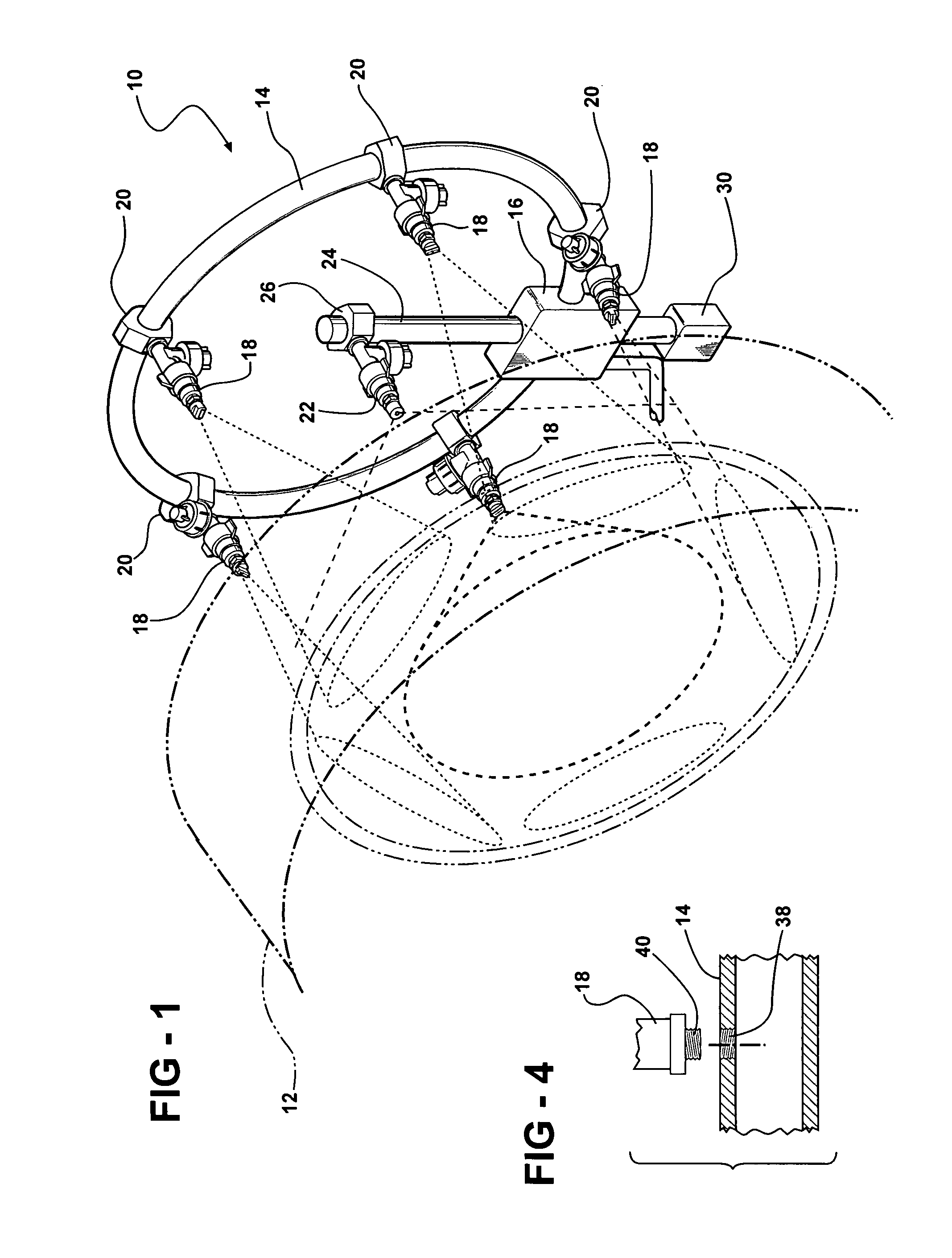

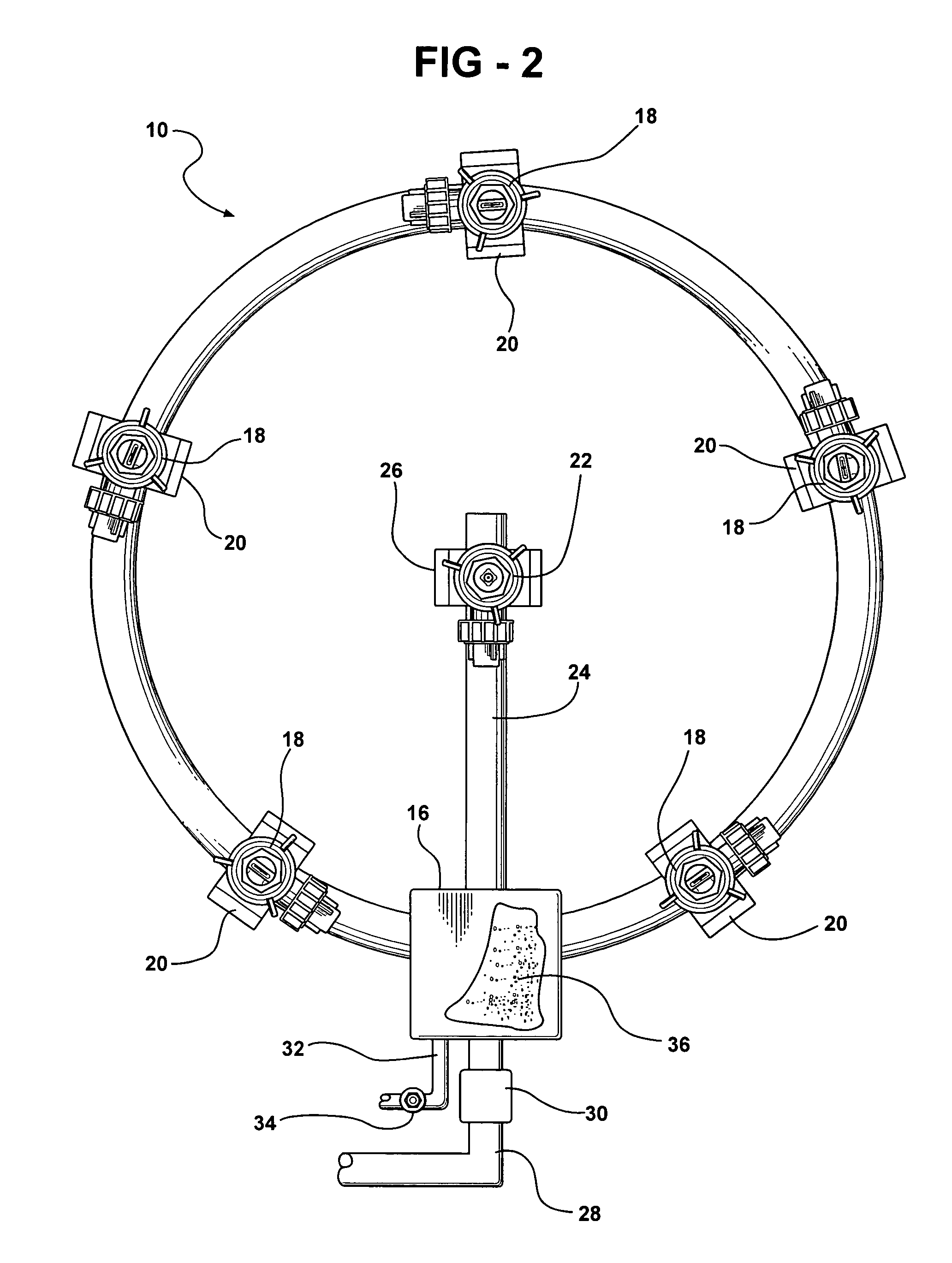

Spray-type automotive wheel washer

InactiveUS7243665B1Raise the possibilityElectrostatic cleaningVehicle cleaning apparatusHigh pressureShadow effect

An automotive wheel washer comprising a circular conduit having a diameter of approximately 12 to 20 inches and further provided with a plurality of circumferentially spaced nozzles which direct cleaning fluid and chemicals laterally of the wheel washer and toward the adjacent wheel in an inwardly converging fashion. An additional 360° center nozzle produces an outwardly diverging spray pattern which, in combination with the plurality of spaced outer nozzles, is effective to cause direct application of cleaning chemicals to all surfaces of a wheel and reduce the shadowing effect caused by intricate wheel structure patterns. Foaming is created by a porous material in a foaming chamber serving as a common inlet to all nozzles and further having a high pressure air inlet. The circular conduit may be made of plastic or stainless steel or any of a number of essentially equivalent materials.

Owner:BELANGER

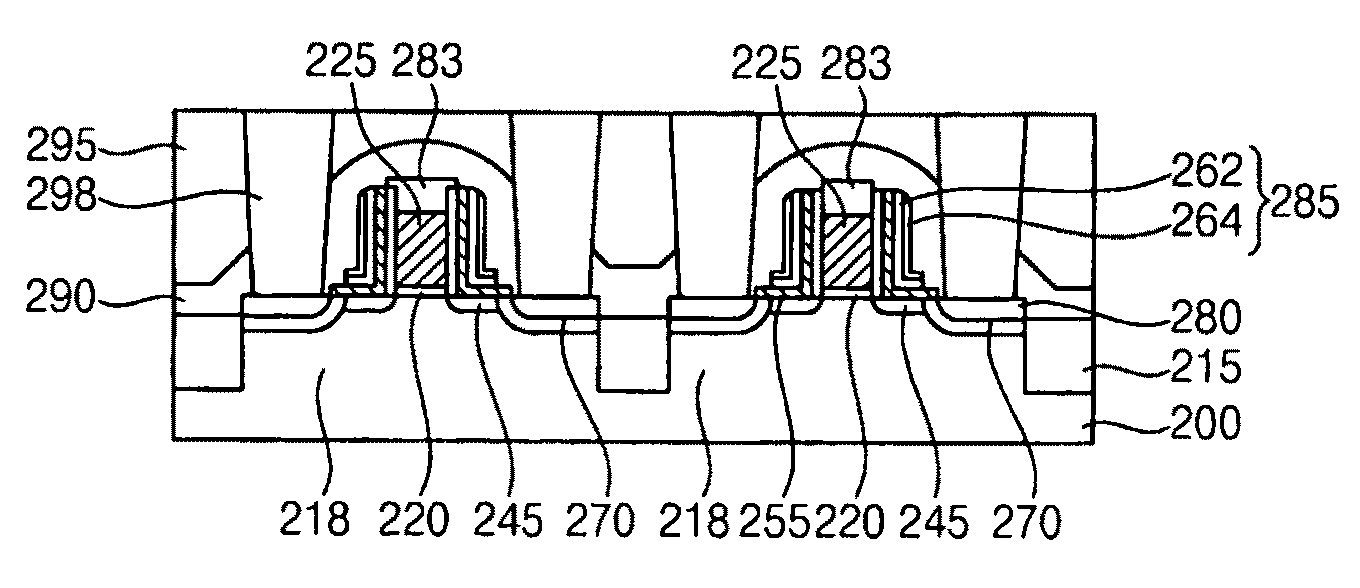

Methods of manufcturing a semiconductor device

ActiveUS20090227082A1Excellent electrical propertiesStress concentrationSemiconductor/solid-state device manufacturingSemiconductor devicesDevice materialSemiconductor

Isolation regions are formed on a substrate to define an active region. A gate electrode is formed on the active region. A spacer structure is formed on a sidewall of the gate electrode. A gate silicide layer is formed on the gate electrode and a source / drain silicide layer is formed on the active region adjacent to the gate electrode. An upper portion of the gate silicide layer and a portion of the spacer structure are simultaneously removed to form a spacer structure pattern and a gate silicide layer pattern. A stress layer is formed to cover the gate electrode and spacer structure pattern.

Owner:SAMSUNG ELECTRONICS CO LTD

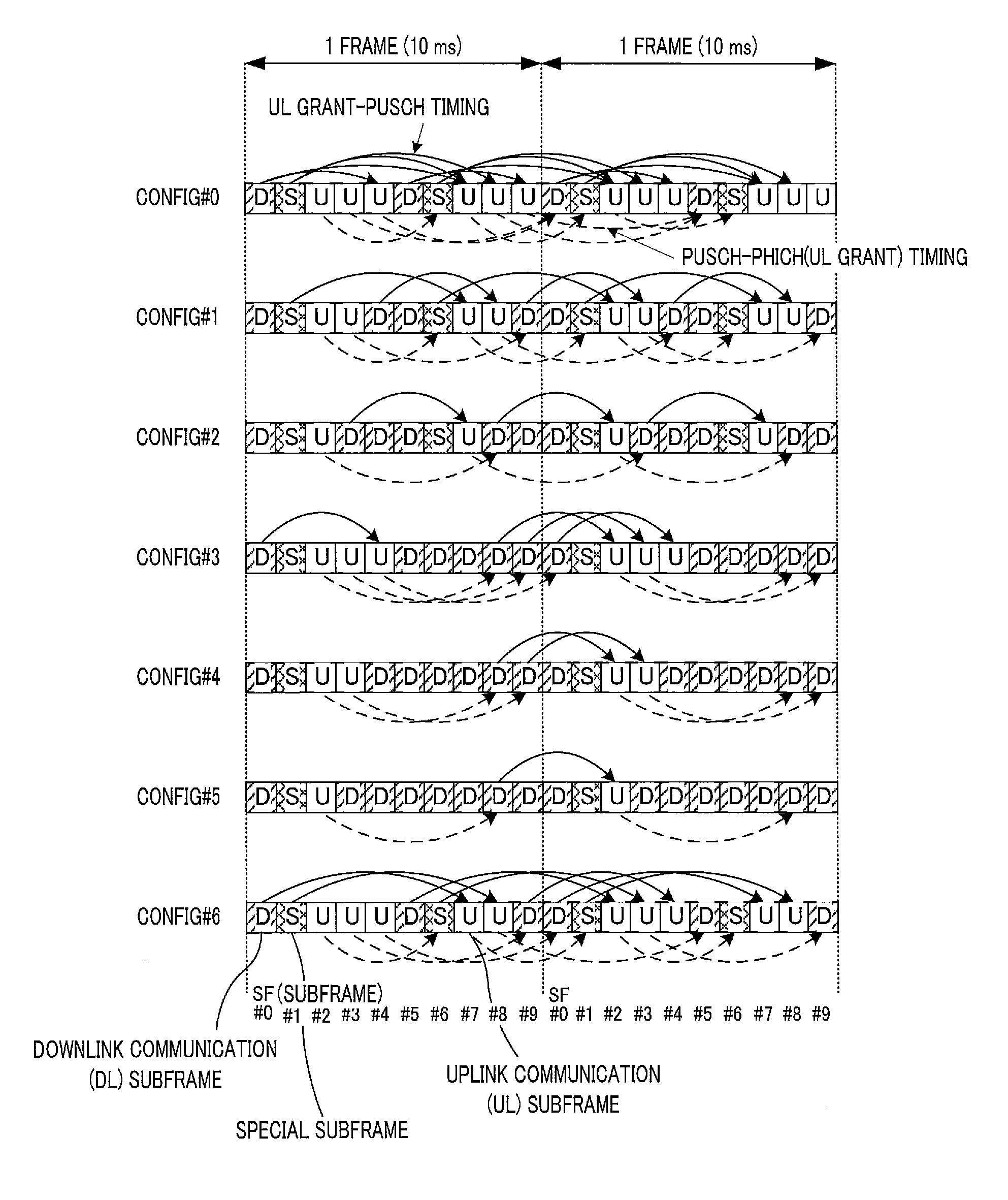

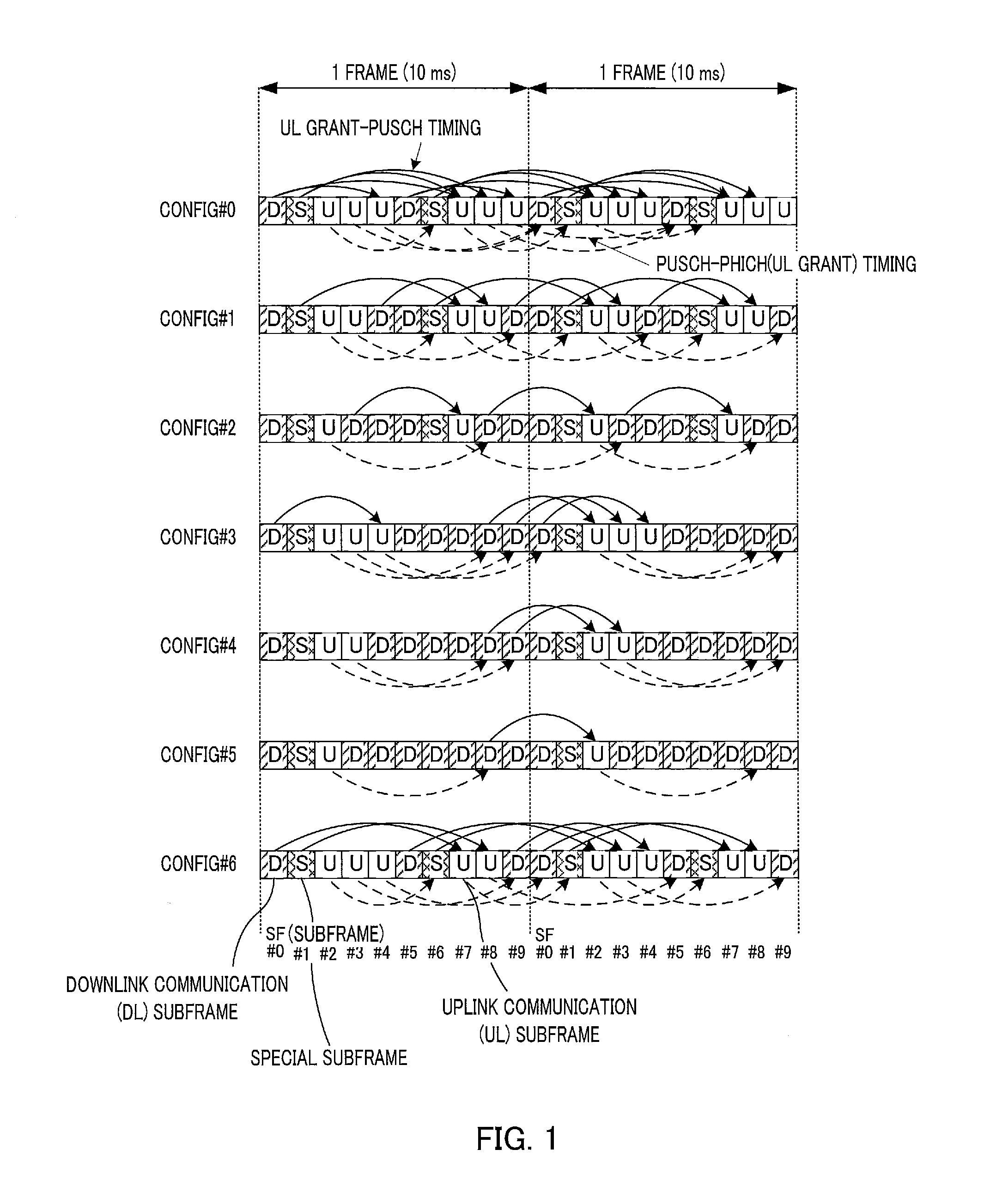

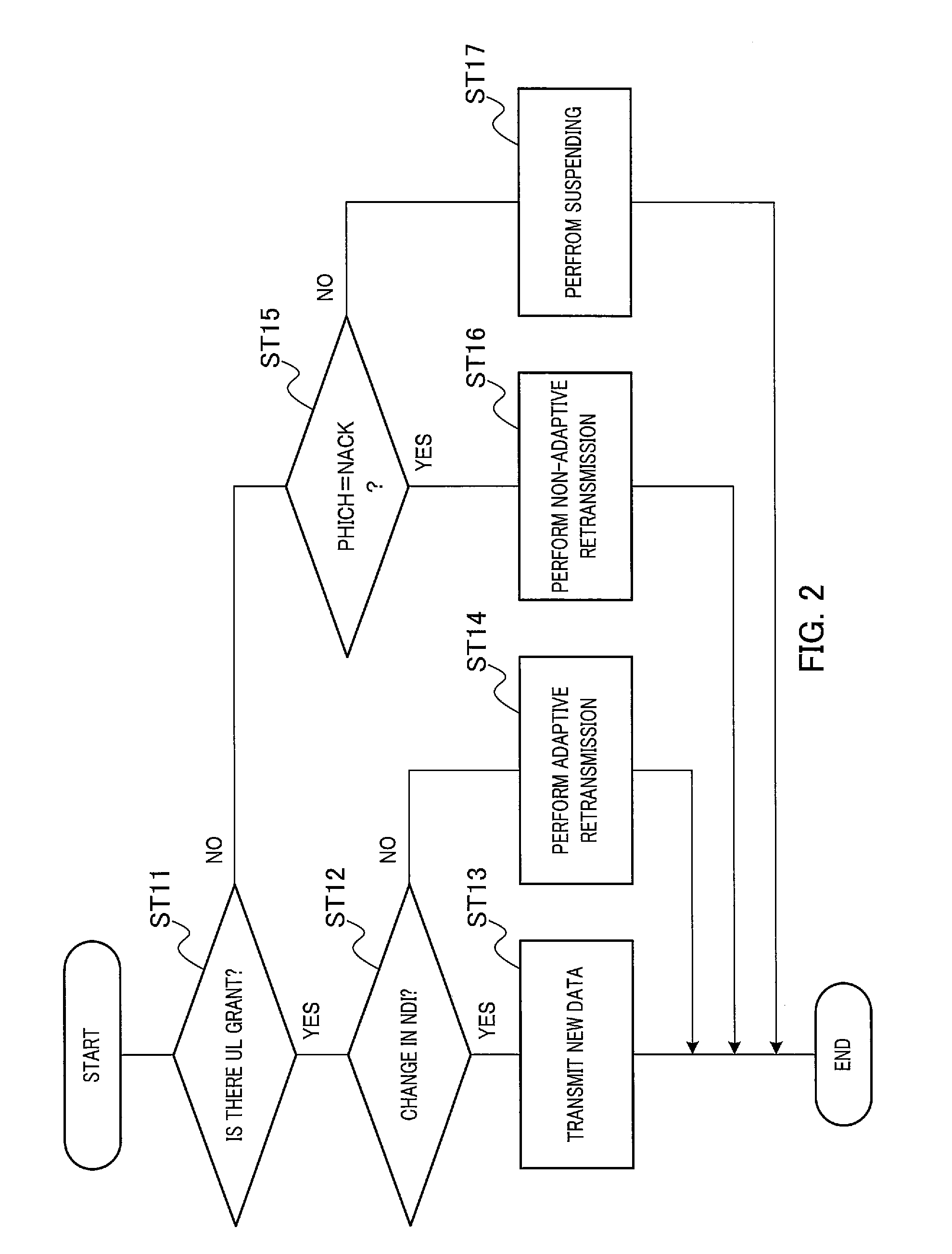

Terminal apparatus, base station apparatus, reception method and transmission method

ActiveUS20150289261A1Suppress constraintError preventionMulti-frequency code systemsTerminal equipmentStructure of Management Information

Provided is a terminal apparatus that, when two terminals having mutually different subframe structure patterns are coexistent, can suppress DCI scheduling constraints of those terminals in a base station. In a terminal (200), a signal separation unit (203) separates, from a received signal, both a response signal assigned to a first resource determined on the basis of a number of resources associated with the first subframes in which the signal was received and downstream control information assigned to a second resource. It should be noted that at a timing when both a first structure pattern that has been set in the terminal (200) and a second structure pattern that has been set in another terminal that cannot change the setting of the structure pattern are the first subframes, the signal separation unit (203) uses a number of resources associated with the first subframes of the second structure pattern.

Owner:SUN PATENT TRUST

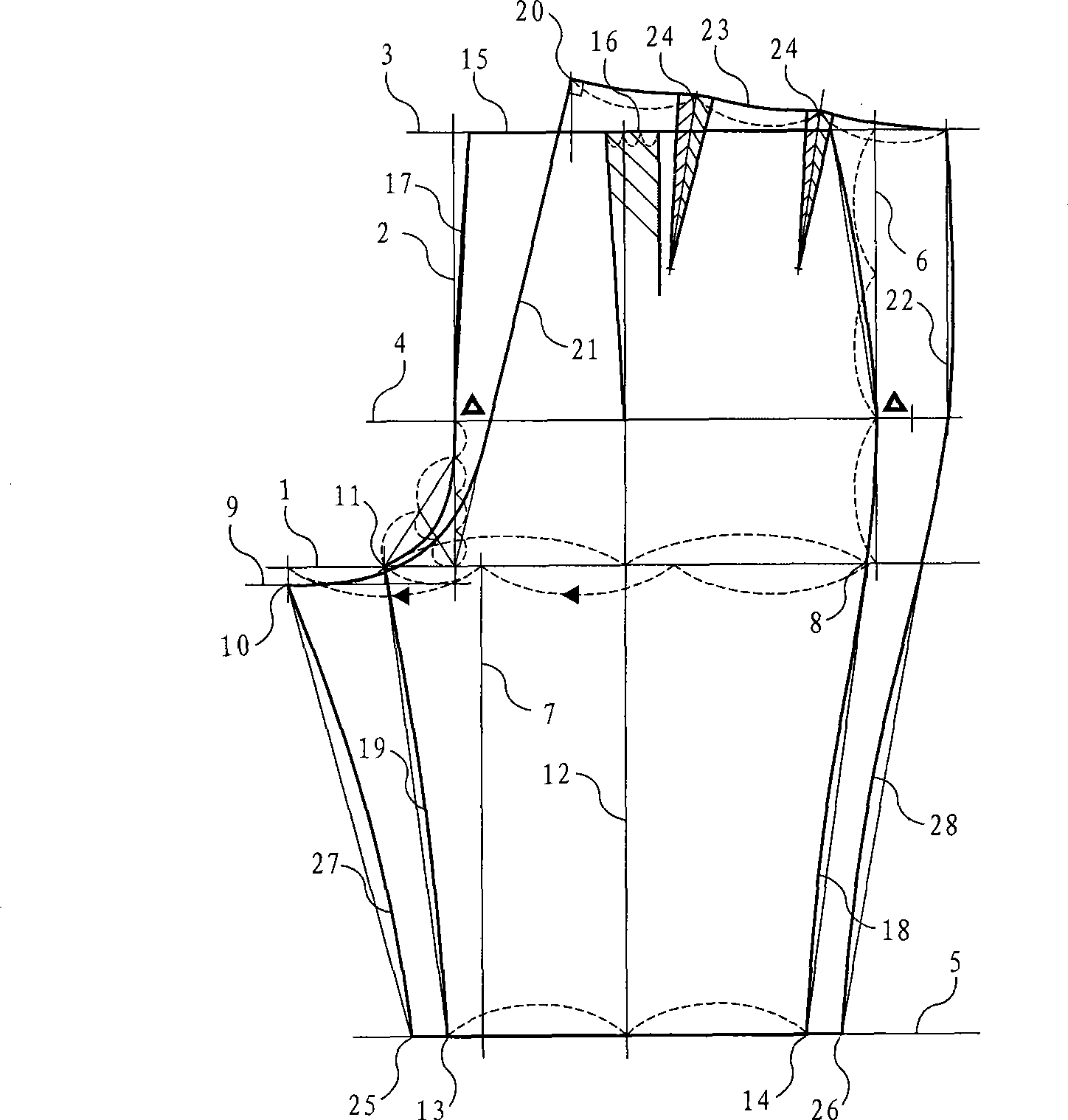

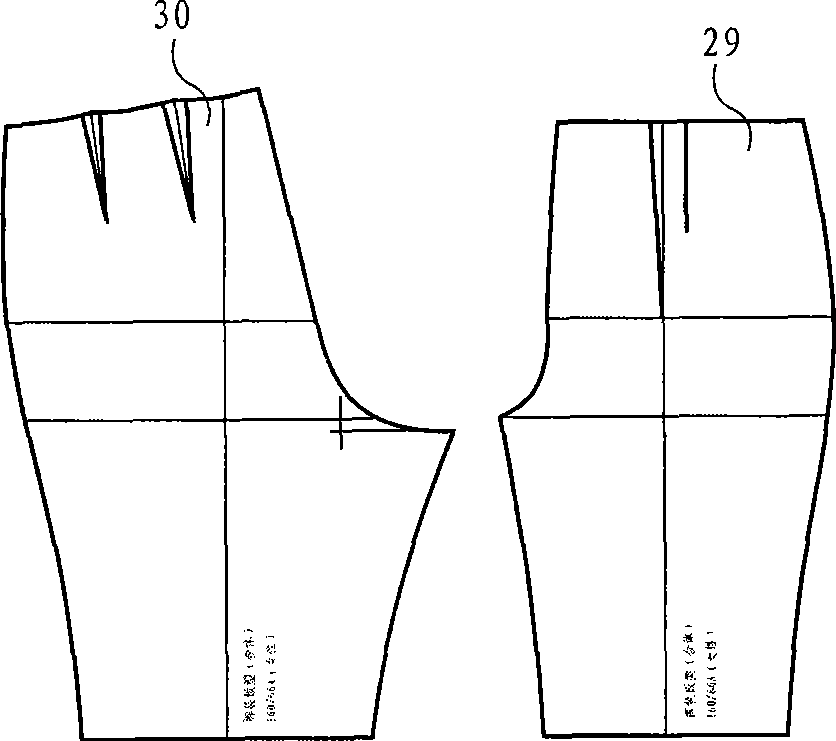

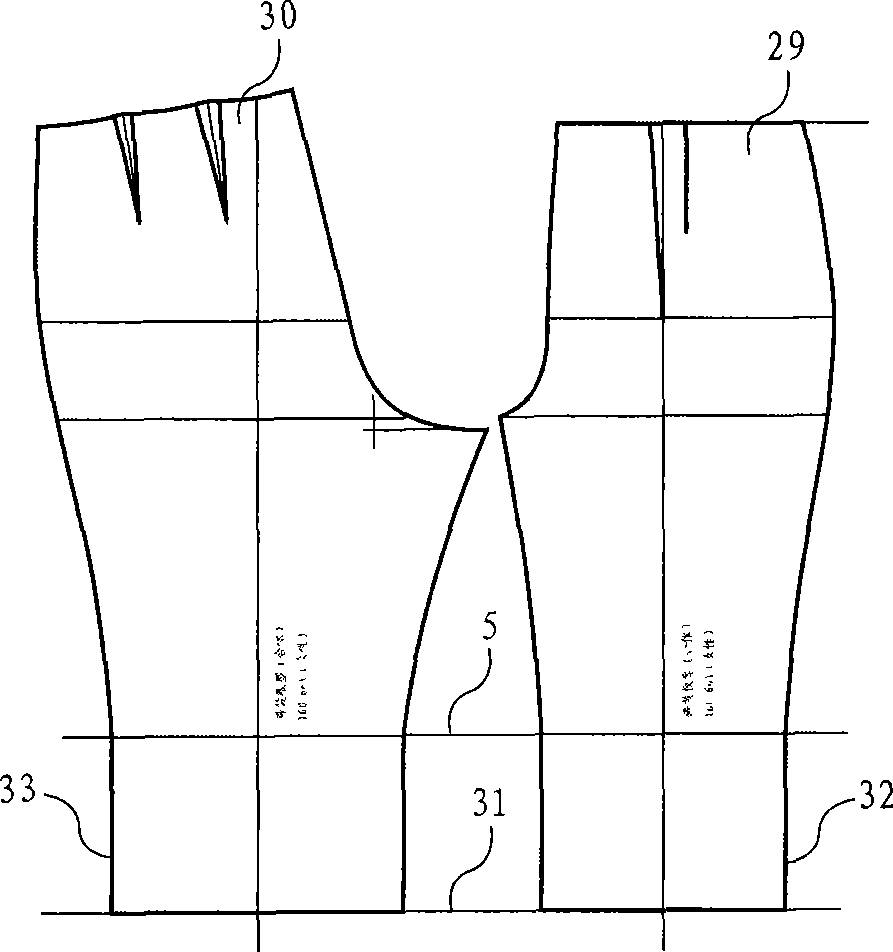

Trouser suit pattern as well as structure design skill and technique for trouser suit

The invention provides a method for designing the pant suit pattern and the pant suit modeling structure. Based on studying the human body structure and pant suit structure, and pant suit modeling structural characteristics and rules, the method for designing the pant suit pattern and the pant suit structure is obtained through a large number of experiments and practical applications. The method has the advantages of simpleness, easy learning, intuition, easy understanding and strong maneuverability, gives full play to advantages of convenient understanding and operation of the equant graphics, and overcomes the defects that the prior pant suit structure pattern has complicated formula calculation, multiple sizes, uncertainty, hard memory and small design changing space. The method can also better reflect the relation between the human body and the pant suit structure and has flexible and accurate modeling structural changes. The designed pant suit modeling has steady and unique style pattern, and the design efficiency is greatly improved. The method not only deepens the theoretical study of the pant suit structure, but also further expands the thought and the method of the pant suit structural design, has good practicability and economic value potential, and has the practical significance of promoting the raiment culture development and improving the production efficiency of the clothing industry.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

Arrangement for the illumination of a substrate with a plurality of individually shaped particle beams for high-resolution lithography of structure patterns

ActiveUS8148702B2Reduced flexibilitySacrificing aThermometer detailsStability-of-path spectrometersLithographic artistParticle beam

The invention is directed to an arrangement for the illumination of a substrate with a plurality of individually shaped, controllable particle beams, particularly for electron beam lithography in the semiconductor industry. It is the object of the invention to find a novel possibility for illuminating a substrate with a plurality of individually shaped, controllable particle beamlets which permits a high-resolution structuring of substrates with a high substrate throughput without limiting the flexibility of the applicable structure patterns or limiting the high substrate throughput due to a required flexibility.

Owner:VISTEC ELECTRON BEAM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com