High-temperature-tolerance frequency selection wave-transmitting structure and preparation method thereof

A technology of frequency selection and wave-transmitting structure, applied in manufacturing tools, welding equipment, laser welding equipment, etc., can solve the problems of poor thermal shock resistance, poor high temperature oxidation resistance, and high brittleness of porous silicon nitride ceramic materials. Achieve excellent high temperature oxidation resistance, good high temperature resistance, and avoid brittleness problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

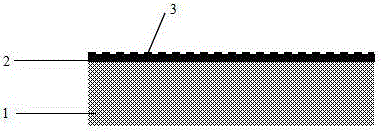

[0043] A high temperature resistant frequency selective wave transparent structure of the present invention, such as figure 1 As shown, the frequency-selective wave-transparent structure includes a wave-transparent layer 1, a modified adhesive layer 2, and a frequency-selective layer 3 from the inside to the outside. The wave-transparent layer 1 is a quartz fiber-reinforced quartz composite material, and the modified adhesive layer The junction layer 2 is a quartz glass coating, the frequency selective layer 3 is a silver-palladium glass conductor coating with a periodic structure pattern, the thickness of the bonding layer 2 is 0.1 mm, and the thickness of the silver-palladium glass conductor coating is is 30 μm.

[0044] The method for preparing the high-temperature-resistant frequency-selective wave-transparent structure of this embodiment includes the following steps:

[0045] (1) Determine that the material of the wave-transmitting layer is quartz fiber reinforced quartz...

Embodiment 2

[0056] A high temperature resistant frequency selective wave transparent structure of the present invention, such as figure 1 As shown, the frequency-selective wave-transparent structure includes a wave-transparent layer 1, a modified adhesive layer 2, and a frequency-selective layer 3 from the inside to the outside. The wave-transparent layer 1 is a quartz fiber-reinforced quartz composite material, and the modified adhesive layer The junction layer 2 is a mullite coating, the frequency selective layer 3 is a gold plating layer with a periodic structure pattern, the thickness of the bonding layer 2 is 0.1 mm, and the thickness of the gold plating layer is 2 μm.

[0057] The method for preparing the high-temperature-resistant frequency-selective wave-transparent structure of this embodiment includes the following steps:

[0058] (1) Determine that the material of the wave-transmitting layer is quartz fiber reinforced quartz composite material, and use the quartz fiber reinforc...

Embodiment 3

[0064] A high temperature resistant frequency selective wave transparent structure of the present invention, such as figure 1 As shown, the frequency selective wave-transparent structure includes a wave-transparent layer 1, a modified bonding layer 2, and a frequency-selective layer 3 from the inside to the outside, and the wave-transparent layer 1 is an aluminosilicate fiber-reinforced silica composite material, The modified bonding layer 2 is a mullite coating, the frequency selective layer 3 is a silver-palladium glass conductor coating with a periodic structure pattern, the thickness of the bonding layer 2 is 0.1mm, and the silver-palladium glass The thickness of the conductive coating was 30 μm.

[0065] The method for preparing the high-temperature-resistant frequency-selective wave-transparent structure of this embodiment includes the following steps:

[0066] (1) Determine that the material of the wave-transmitting layer is aluminosilicate fiber-reinforced silica comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com