Patents

Literature

402 results about "Plasma spray process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multilayer thermal barrier coating and preparation method thereof

InactiveCN102127738ANo layer peeling phenomenon occursImprove hot corrosion resistanceMolten spray coatingVacuum evaporation coatingPorosityElectron beam physical vapor deposition

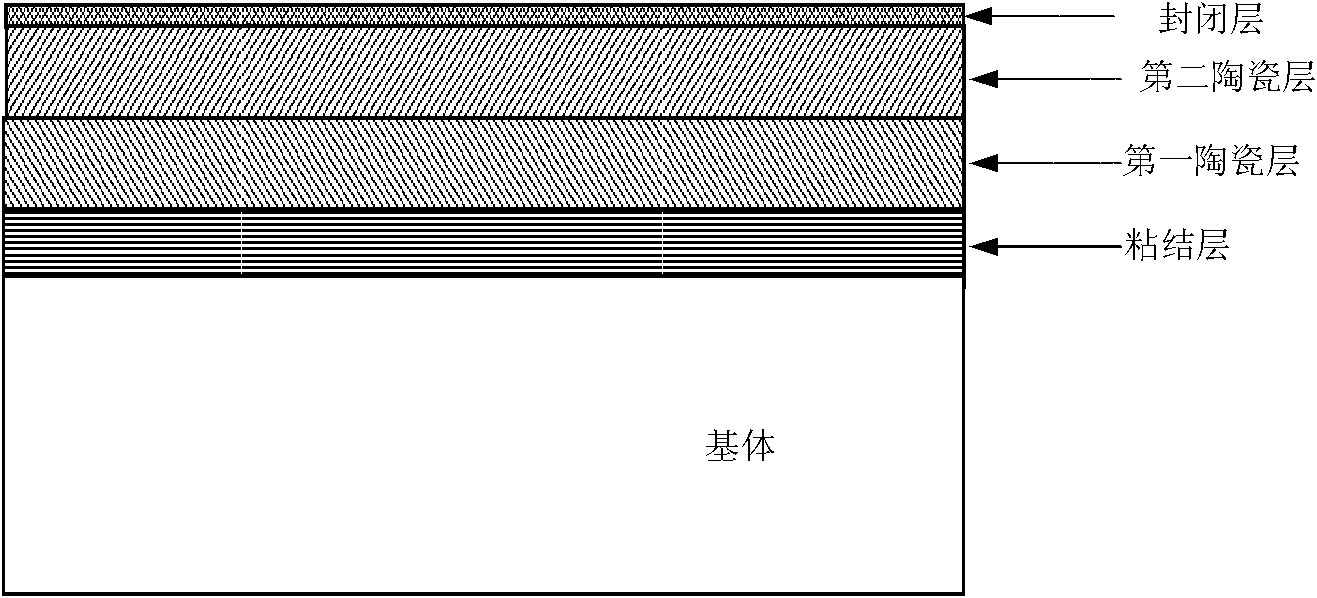

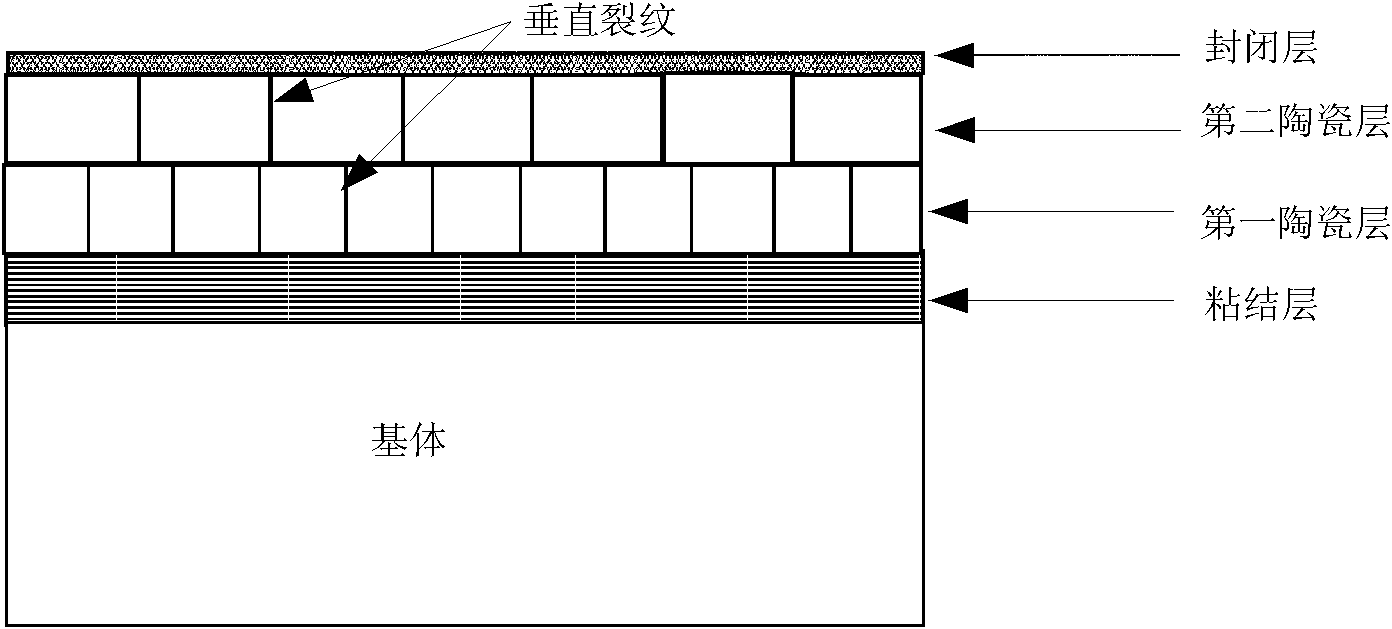

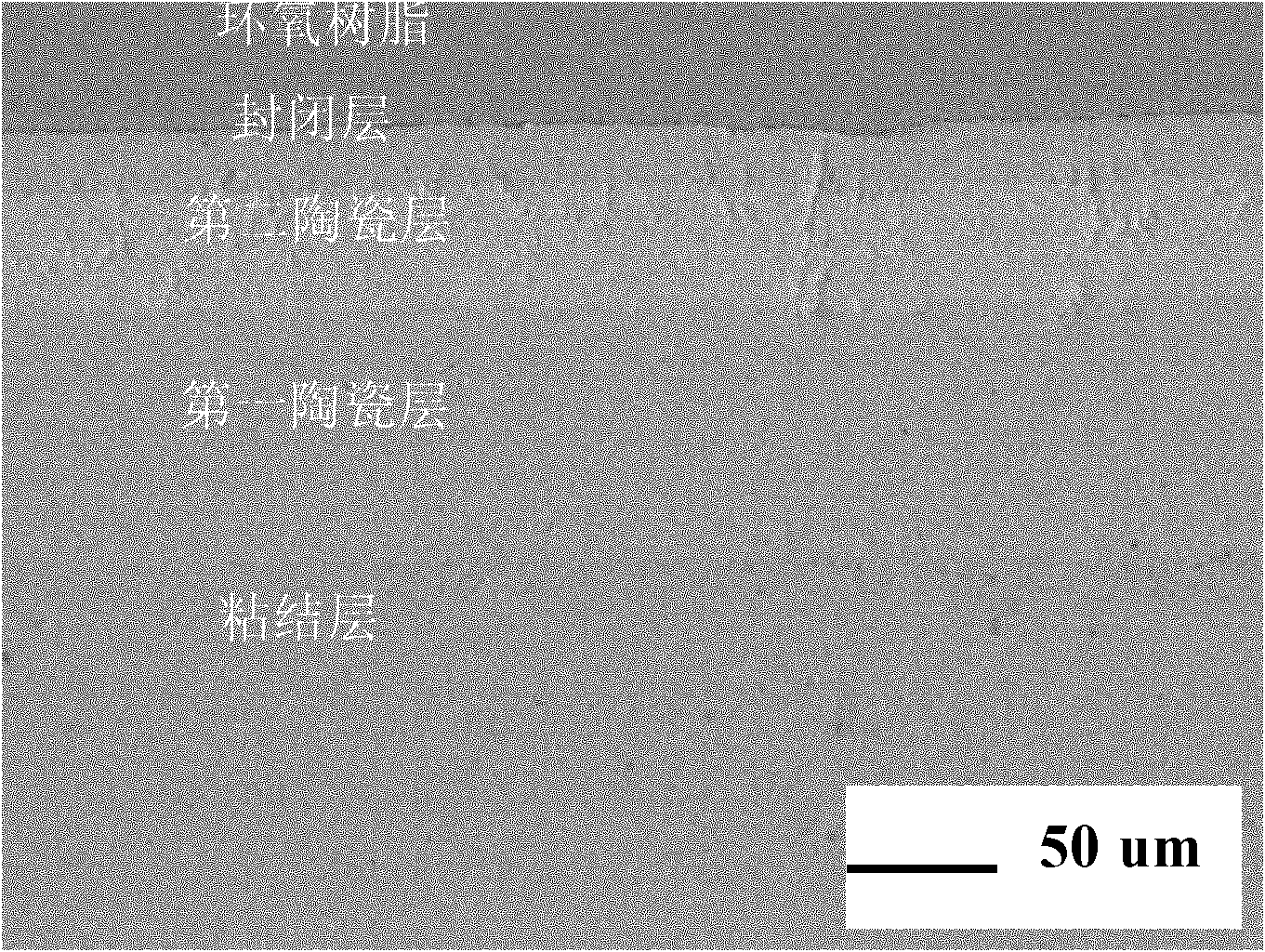

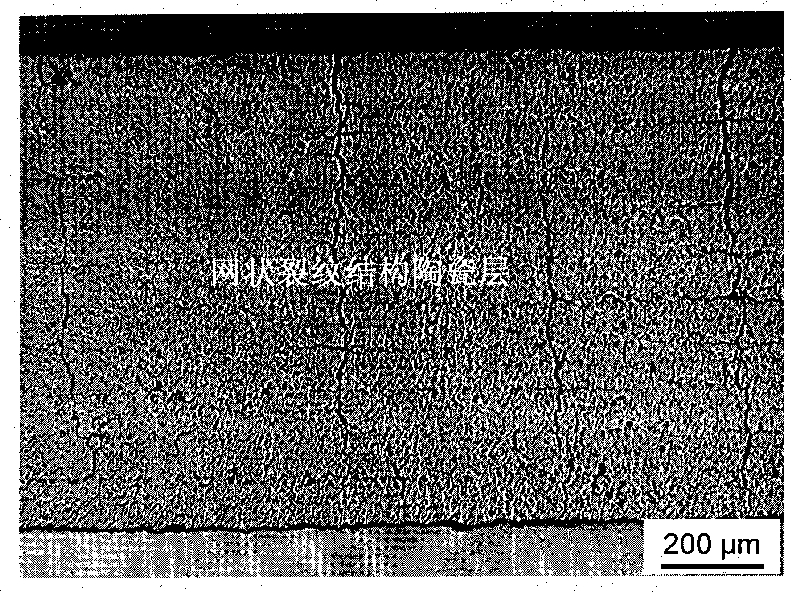

The invention provides a multilayer thermal barrier coating and a preparation method thereof. The multilayer thermal barrier coating sequentially comprises an adhesion layer, a first ceramic layer, a second ceramic layer and a closing layer from bottom to top, wherein the closing layer has the thickness of 10-30 micros and the porosity of 2-8 percent and is made from the Al2O3. The thermal barrier coating can be prepared by adopting an electron beam physical gas-phase deposition technology or a plasma spraying method. The multilayer thermal barrier coating provided by the invention can avoid the stripping of the ceramic layers in a thermal circulating process, the thermal erosion resistance of the thermal barrier coating is greatly improved than the dual ceramic layers; and vertical crackles are introduced in the ceramic layer through improving a conventional plasma spraying process so that the thermal shock life of the thermal barrier coating is greatly prolonged.

Owner:BEIHANG UNIV

Multielement rare earth oxide doped zirconia thermal barrier coating with craze crack structure and preparing method thereof

InactiveCN101723667AGood phase stability at high temperatureLow temperature for long-term useMolten spray coatingEfficient propulsion technologiesThermal insulationRare earth

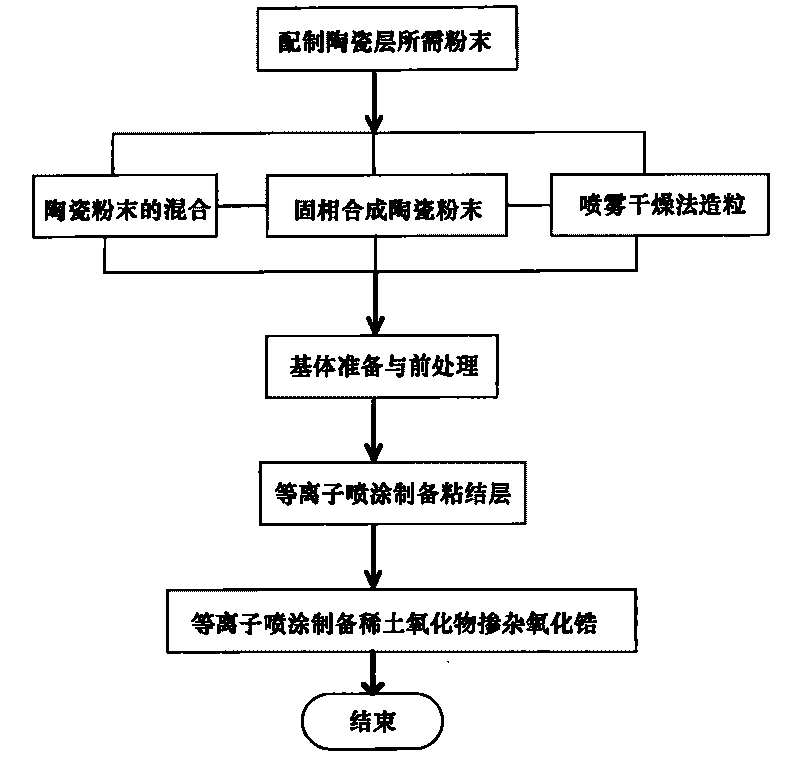

The invention discloses a method for preparing a rare earth oxide doped zirconia thermal barrier coating with a craze crack structure, which solves the problems of low thermal shock resistance property, difficult further thermal conductivity reduction and the like of the thermal coating prepared by conventional plasma spraying. Under the condition of the plasma spraying technology, the preheating temperature of a base body, the moving speed of a plasma spraying gun and a powder delivery rate are adjusted, then a rare earth oxide doped zirconia thermal barrier coating (BH-TBCO1) with a craze crack structure and stable thermodynamics is prepared. The rare earth oxide doped zirconia thermal barrier coating with a craze crack structure has good high-temperature phase stability at the temperature below 1300 DEG C; the thermal insulation property of the thermal barrier coating is further enhanced, and the thermal insulation temperature achieves more than 150 DEG C and is enhanced by more than 50% when compared with the coating prepared by the conventional plasma spraying; the thermal shock life of the coating exceeds 4000 cycles and is enhanced by more than 1 time when compared with the coating prepared by the conventional plasma spraying.

Owner:BEIHANG UNIV

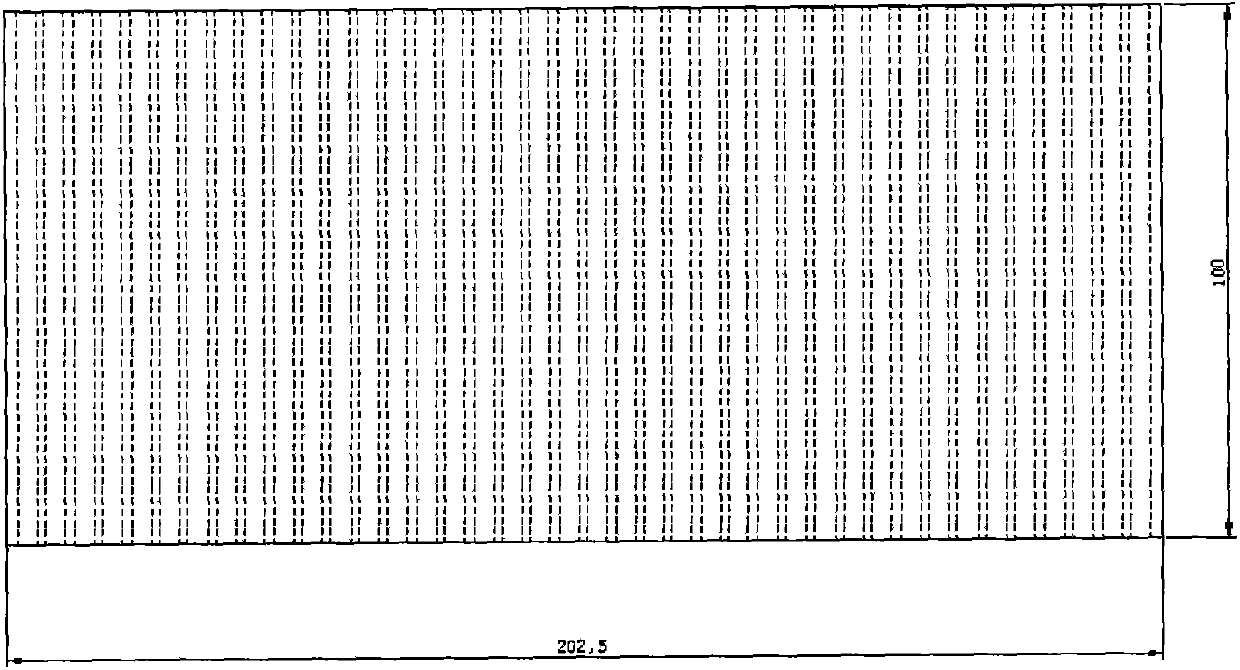

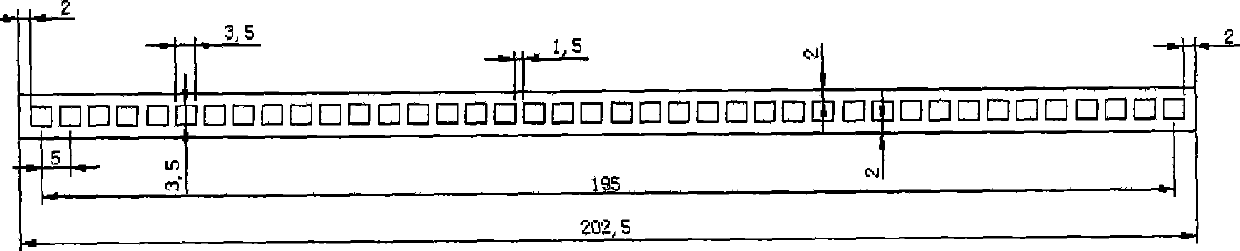

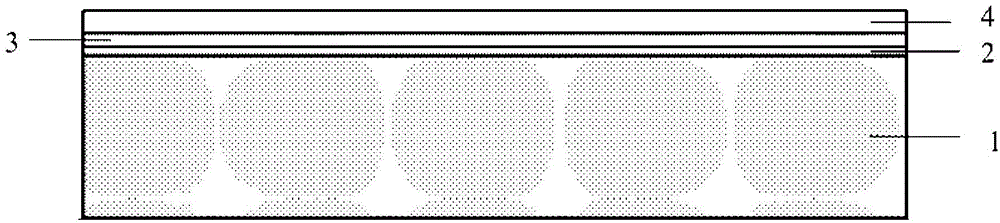

Preparation method of hollow flat plate structure type ceramic filter membrane element

ActiveCN103623711ALower sintering temperatureSmall filter resistanceSemi-permeable membranesAluminium hydroxideChemical separation

The invention provides a preparation method of a hollow flat plate structure type ceramic filter membrane element. The method comprises the following steps: (1) preparing a hollow structure type ceramic membrane supporting body by using an extrusion molding method, namely sintering aluminum hydroxide obtained by calcination at 600 DEG C as a main raw material to prepare the ceramic membrane supporting body; (2) preparing the ceramic filter membrane by using a plasma spray method. When the ceramic membrane supporting body is prepared, the selected and used raw material is calcined aluminum hydroxide, so that the sintering temperature of the ceramic membrane supporting body can be greatly reduced, and the sufficient strength of the supporting body can be guaranteed; when the ceramic filter membrane layer is prepared, the thickness of the filter membrane can be excellently controlled by using the plasma spray process, and the filter resistance is reduced; the membrane layer has the uniform pore size distribution and the high separation accuracy; the membrane layer is closely combined with the supporting body. The ceramic filter membrane is prepared by using plasma spraying without sintering, so that the process is simple, the production cost of the ceramic filter membrane can be effectively reduced, the production efficiency is improved, and the process can be widely applied to the fields of sewage treatment and filtration, solid-liquid chemical separation, and the like.

Owner:雅安沃克林环保科技有限公司

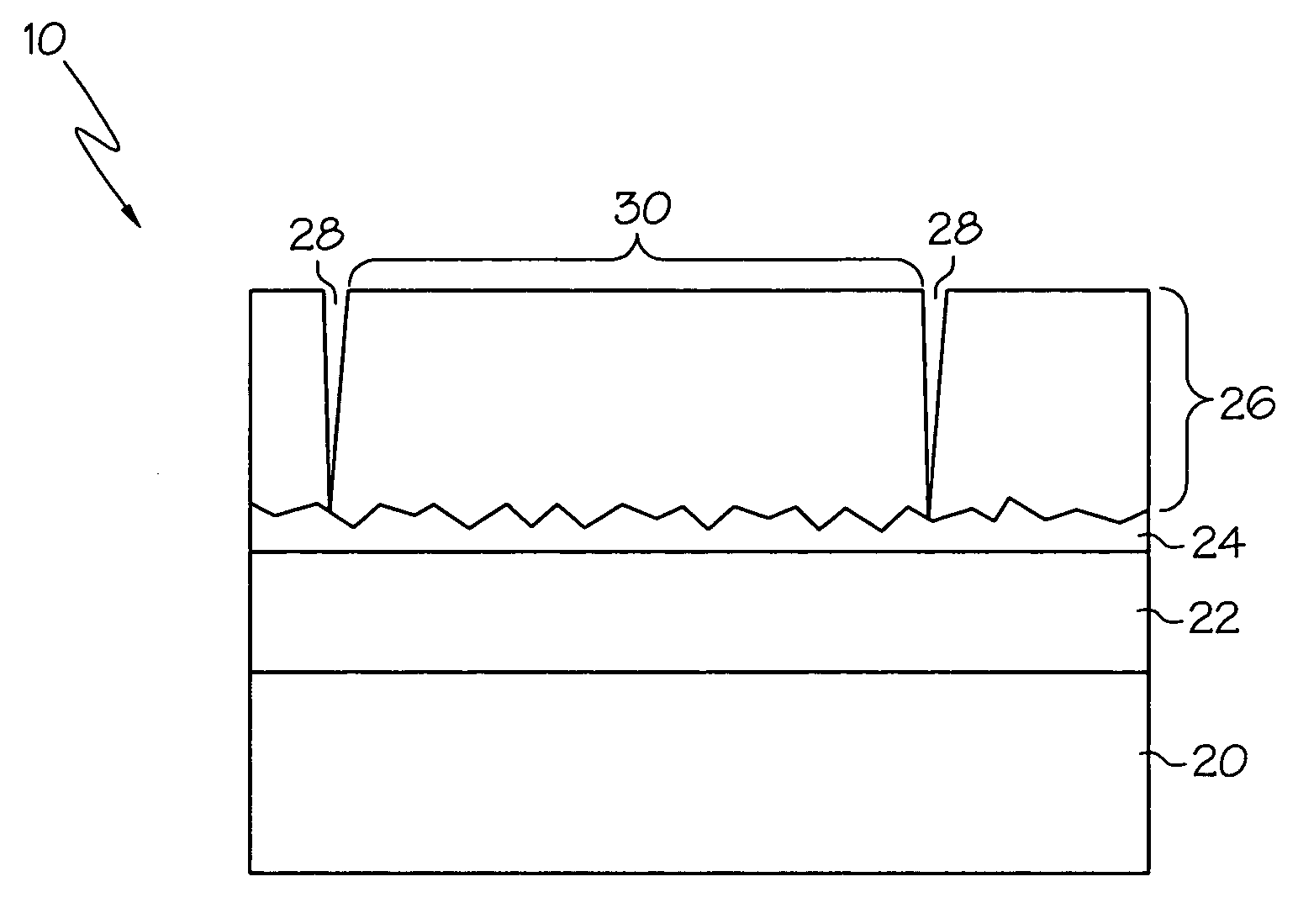

Protective coating for oxide ceramic based composites

InactiveUS20060024528A1Improve accommodationGlass/slag layered productsNatural mineral layered productsOxide ceramicPorosity

A layered structure includes a substrate comprising a layer of an oxide / oxide ceramic based composite material, a first oxide layer disposed directly on the substrate and formed from a material that has no greater than about 10% porosity and is substantially impermeable by water vapor, and a second oxide layer disposed directly on the first oxide layer and having a greater porosity than the first oxide layer. Either or both the first and second oxide layers of the coating system may be deposited using a plasma spraying process, a slurry deposition process which is followed by a sintering step, or an EB-PVD process.

Owner:HONEYWELL INT INC

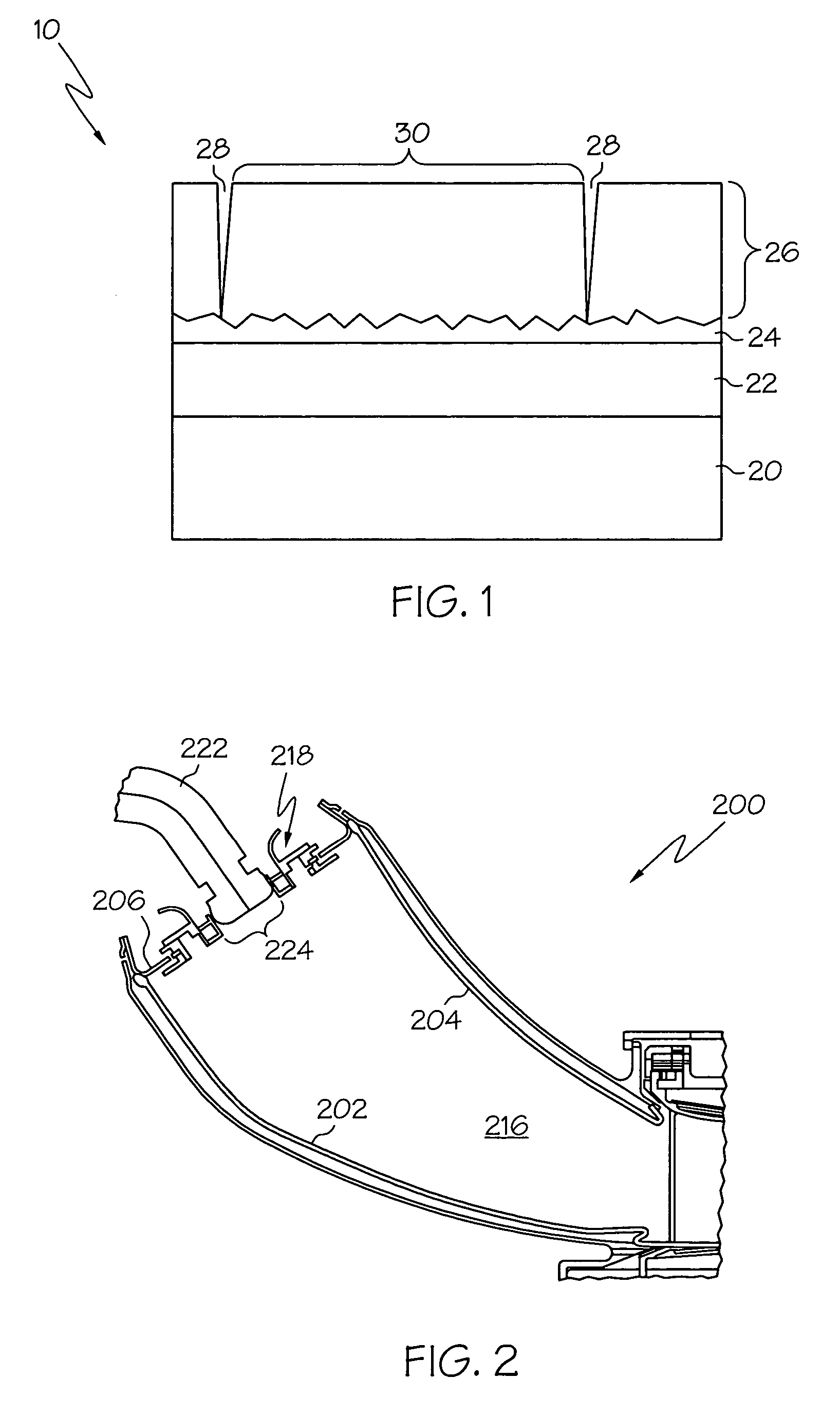

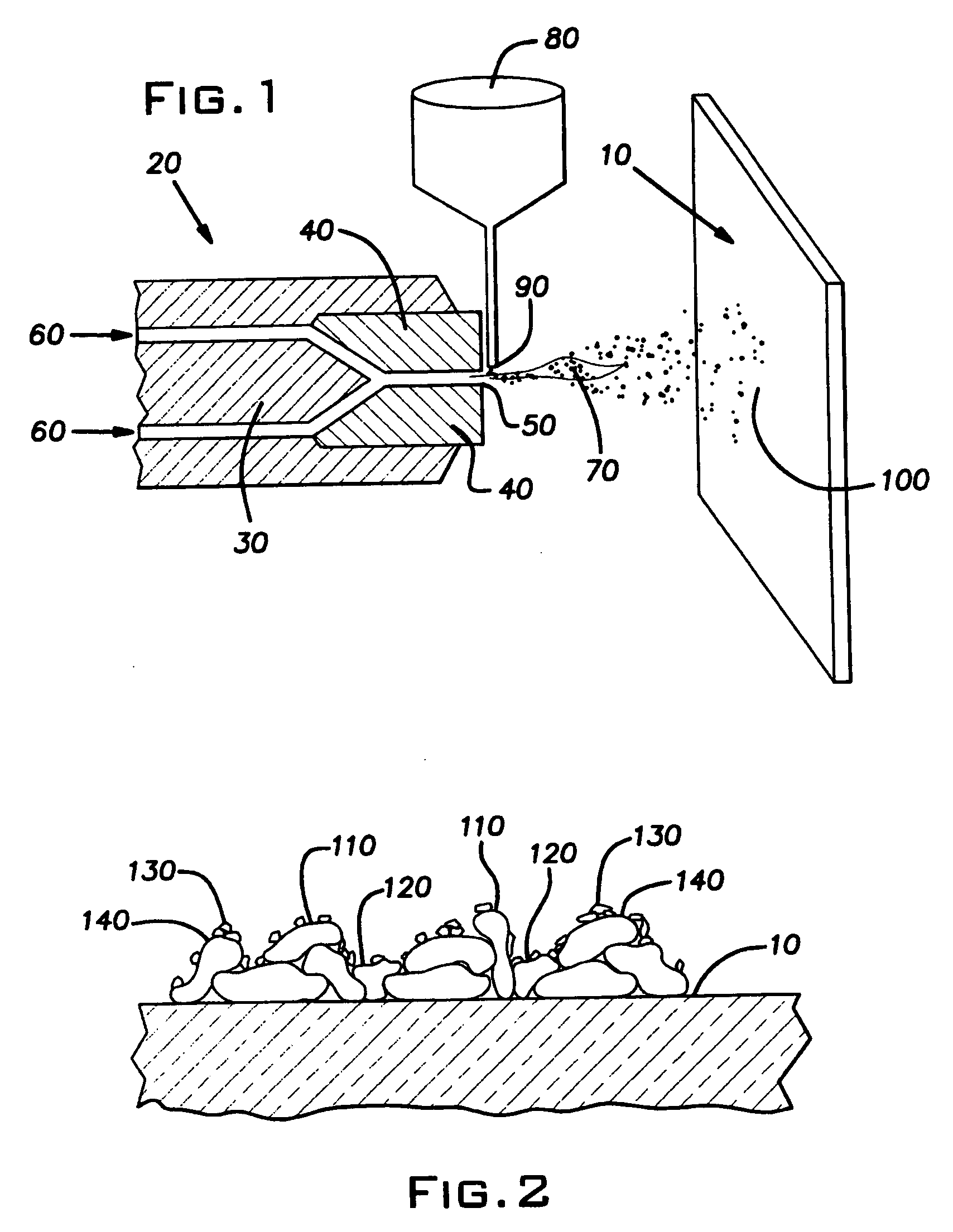

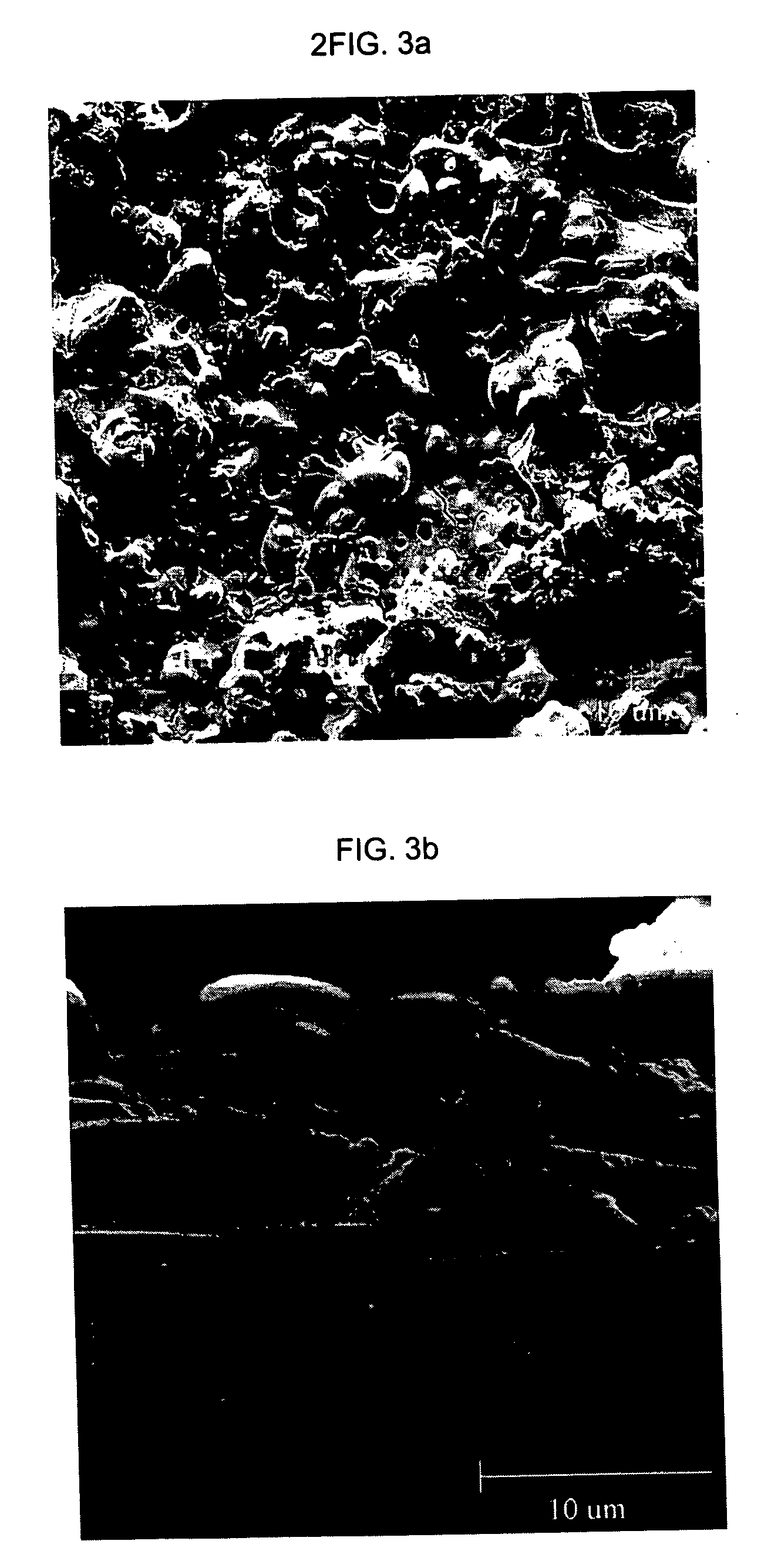

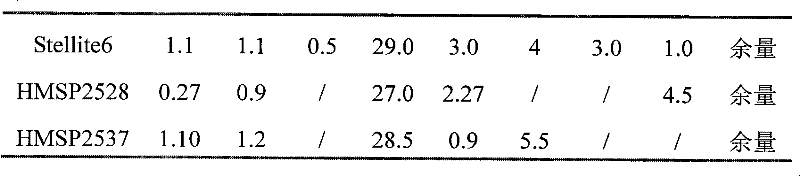

Process for structuring self-cleaning glass surfaces

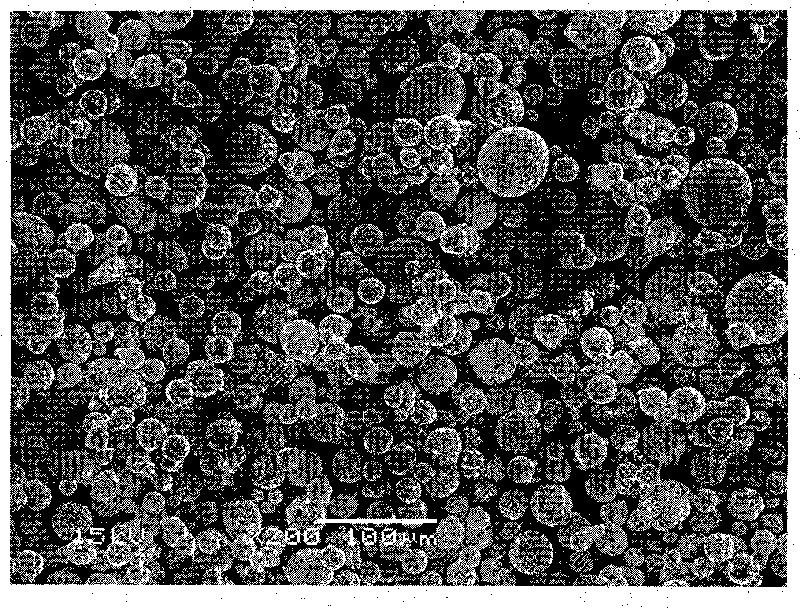

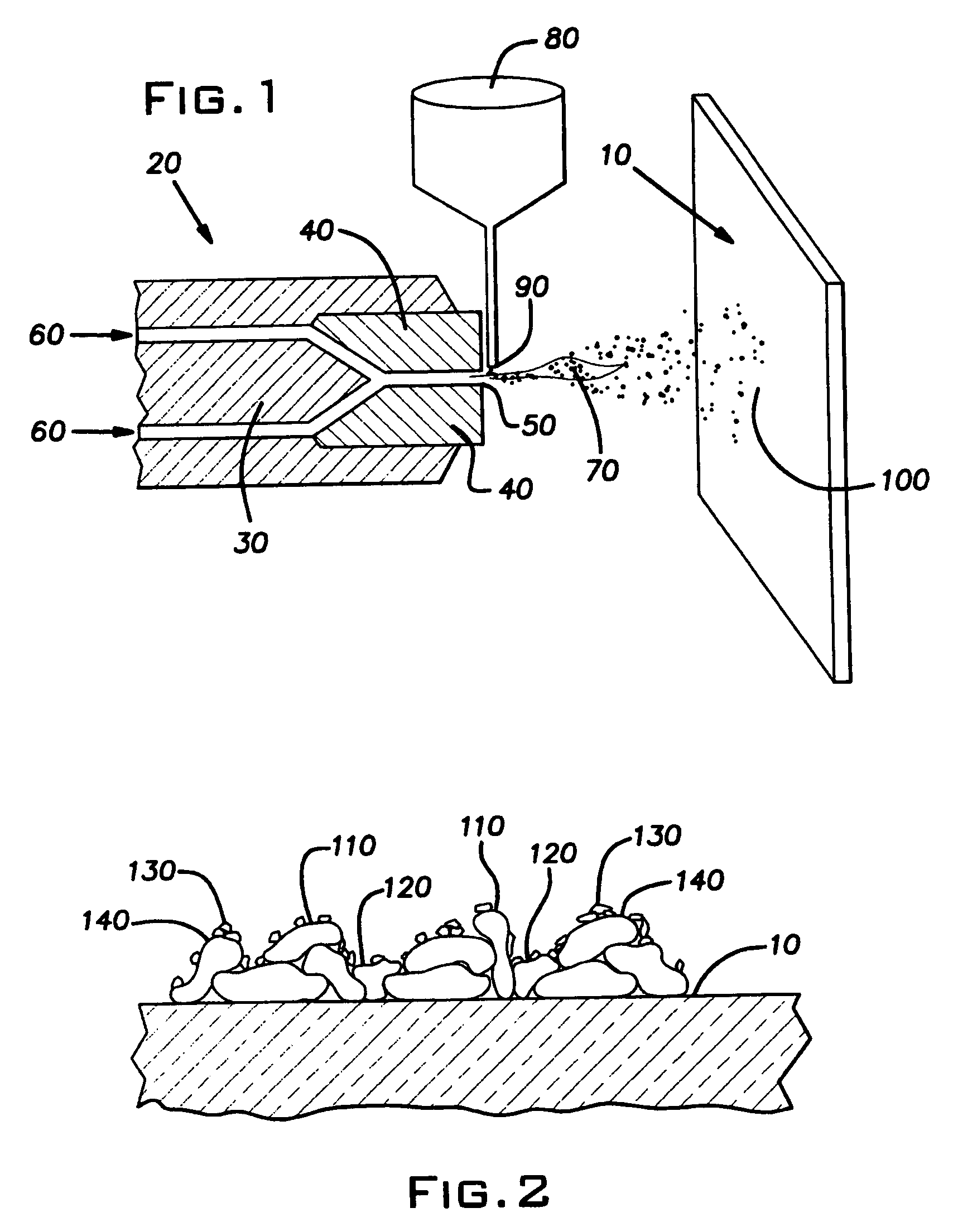

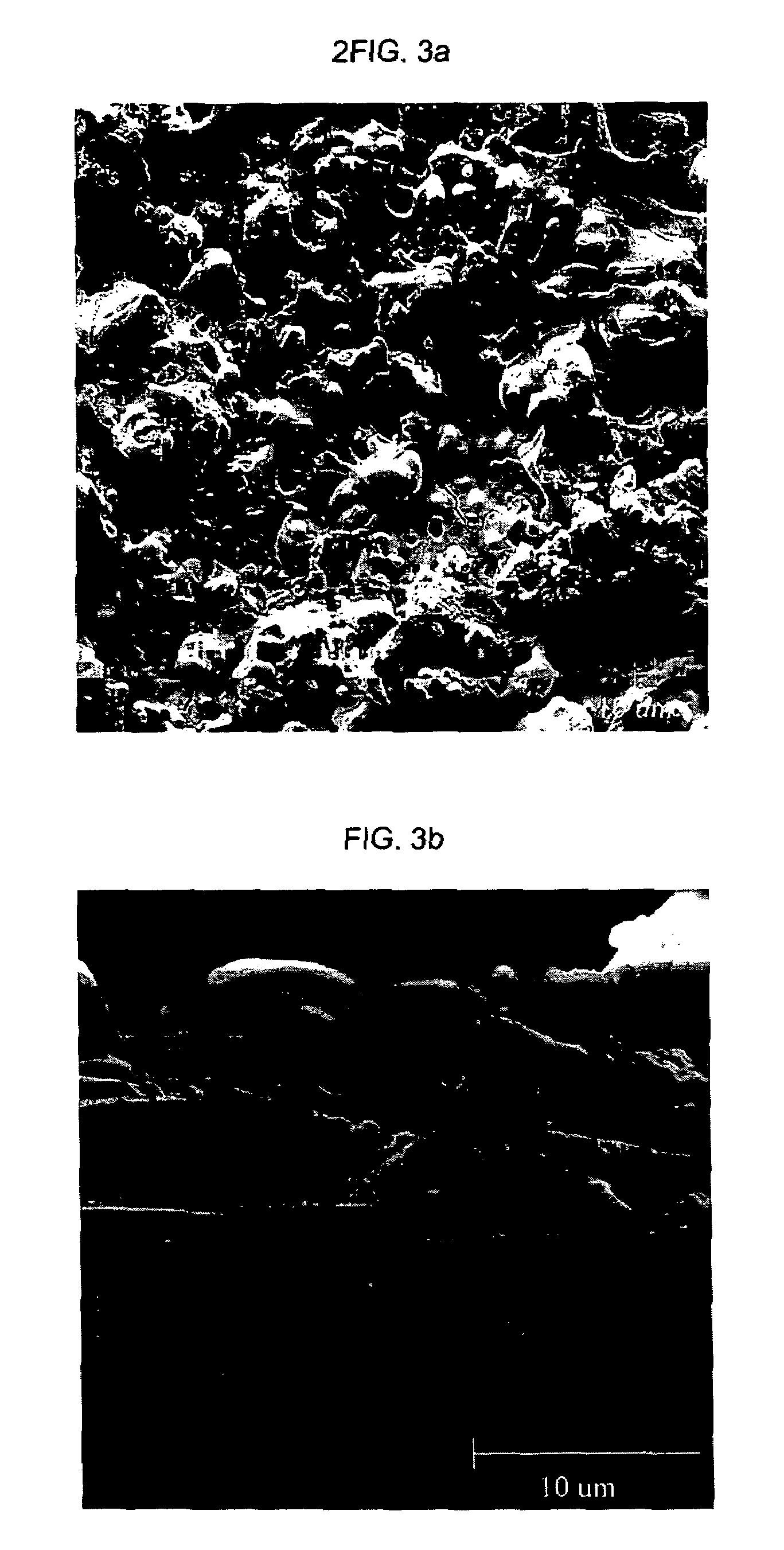

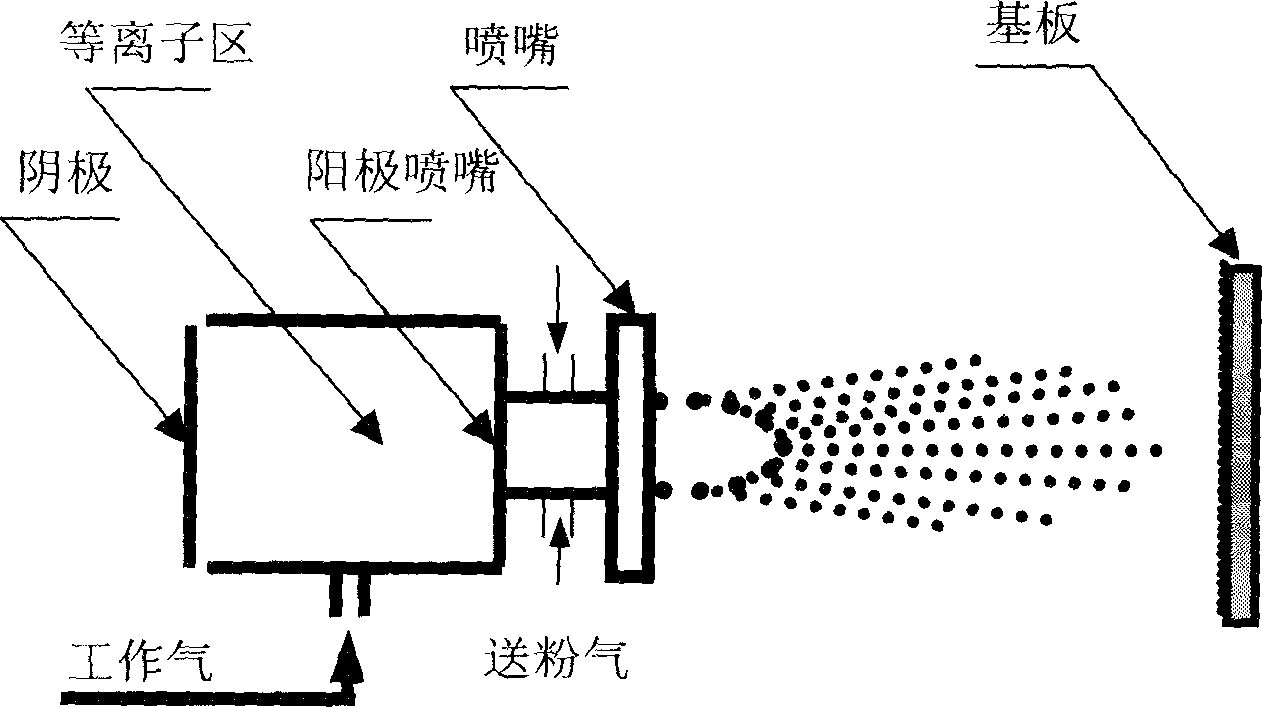

A plasma spray process for structuring self-cleaning glass surfaces and self-cleaning glass surfaces formed according to the process. Molten or heat softened particles of inorganic material are plasma spray deposited onto the surface of a substrate to create a micro-rough surface. If desired, a hydrophobic top coating layer can optionally be applied to the micro-rough surface. The micro-structured surface formed according to the invention is durable and self-cleaning.

Owner:FERRO CORP

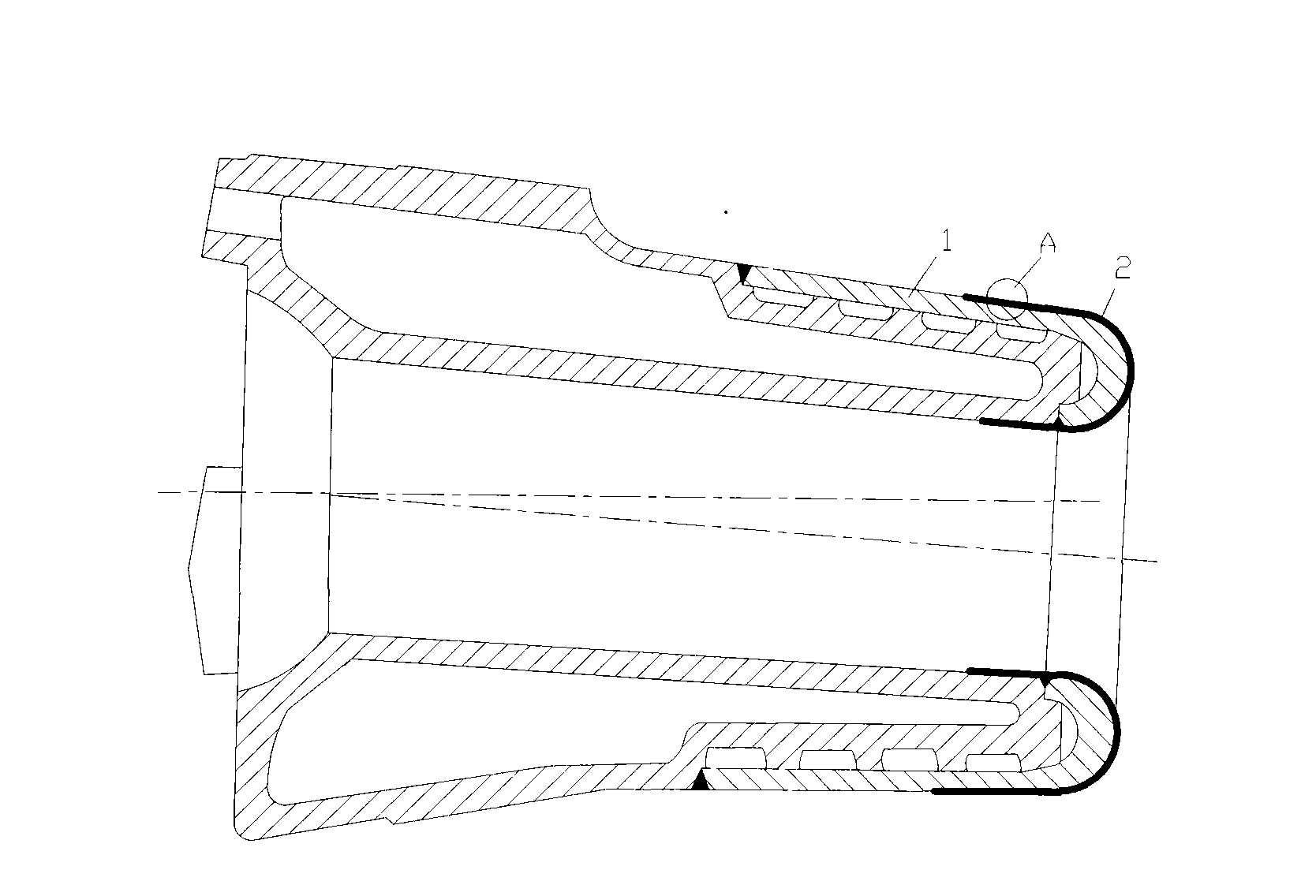

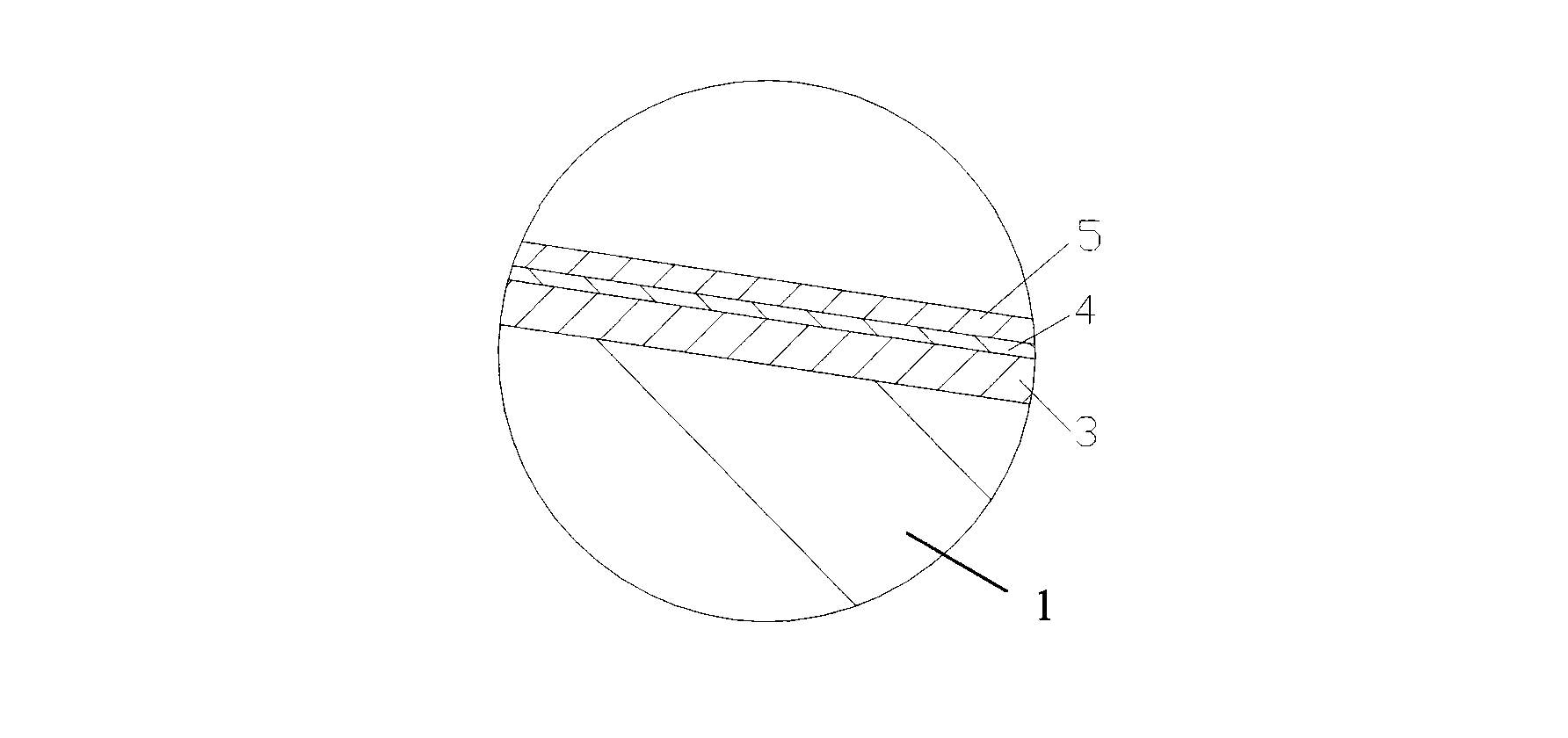

Tuyeres of blast furnace surface recombination coating and method for preparing the same

ActiveCN101492749AImprove thermal shock resistanceReasonable distribution of temperature fieldMolten spray coatingArc welding apparatusAlloyThermal shock

Owner:BAOSHAN IRON & STEEL CO LTD +1

Preparation method of nanometer zirconia heat barrier coating

InactiveCN101660115AImprove applicabilityGood dispersionMolten spray coatingEfficient propulsion technologiesRare earthShock resistance

The invention relates to a preparation method of a nanometer zirconia heat barrier coating which is mixed with rare-earth oxide and used for liquid-phase plasma spraying. The method comprises that precursor sol is used as a spraying raw material, atomized into fine liquid drops under atomized gas pressure, sent into plasma flame flow and sprayed and deposited on a matrix to obtain the nanometer zirconia heat barrier coating. The precursor sol is hydroxid precursor sol. According to weight proportion, the raw material includes 63 to 73 percent of ZrOCl2.8H2O and 27 to 37 percent of crystalline-state stabilizer oxide which is rare earth oxide. The invention can overcome the problems of poor sol distribution, poor sol flowing performance, chlorid ion erosion, poor sol granule atomizing effect, uneven granule sizes, and the like in the the traditional liquid-phase plasma spraying process. In the invention, a composite coating is prepared, and has the advantages of high depositing efficiency, low cost, wide spraying material, strong adaptability of the liquid-phase precursor, low heat conductivity, good heat and shock resistance, and the like.

Owner:WUHAN UNIV OF TECH

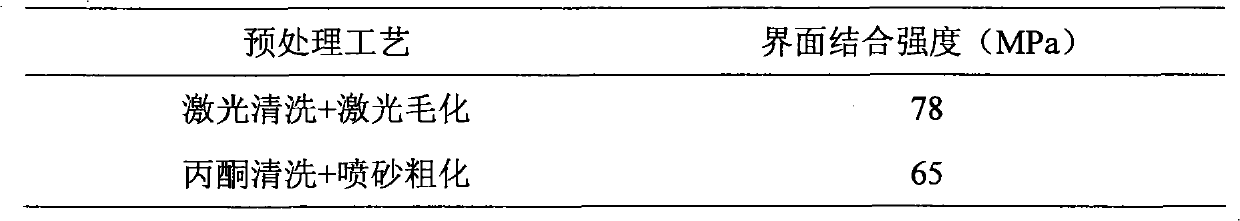

Method for preparing thermal barrier coating by laser compound plasma spraying

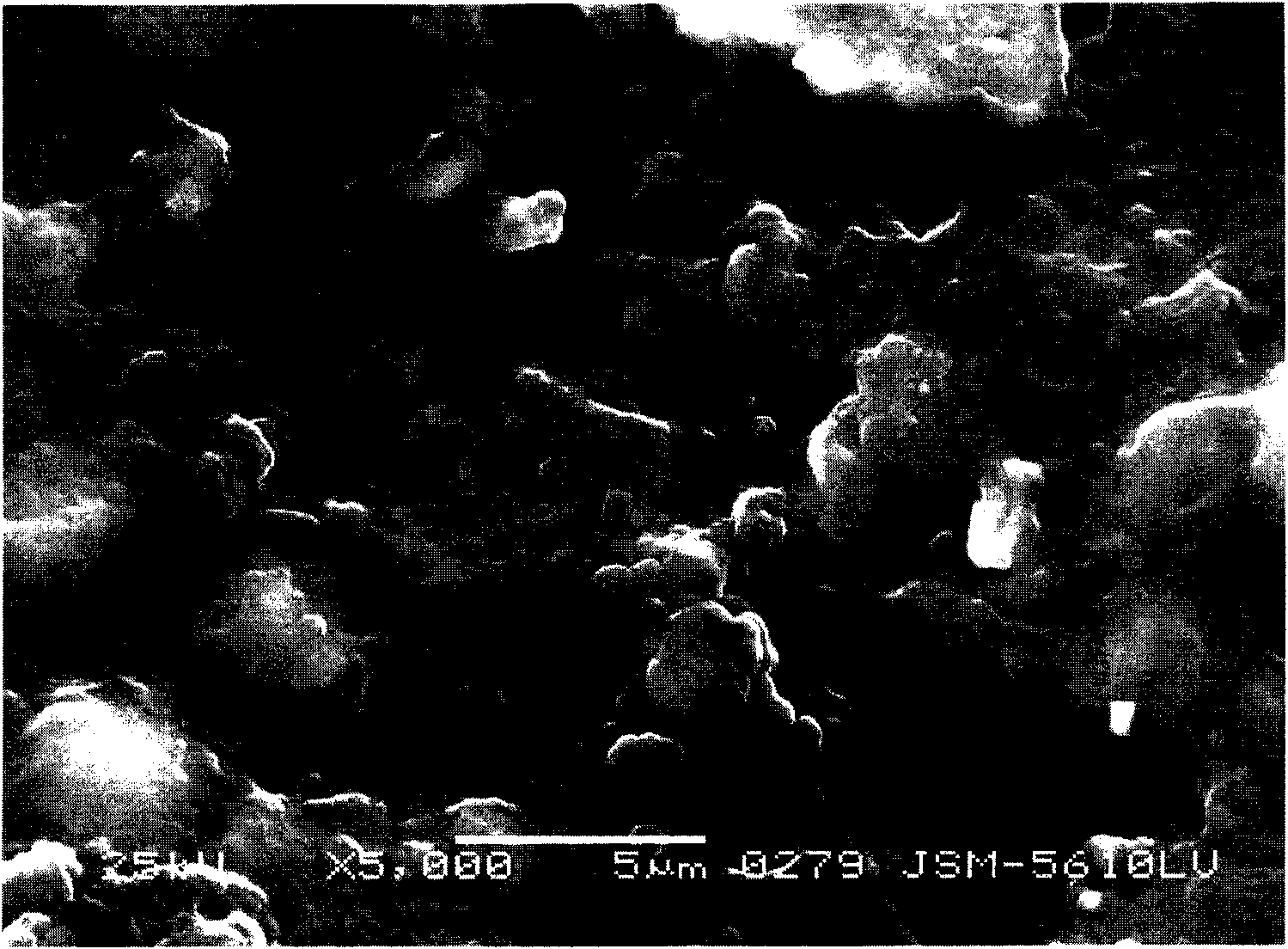

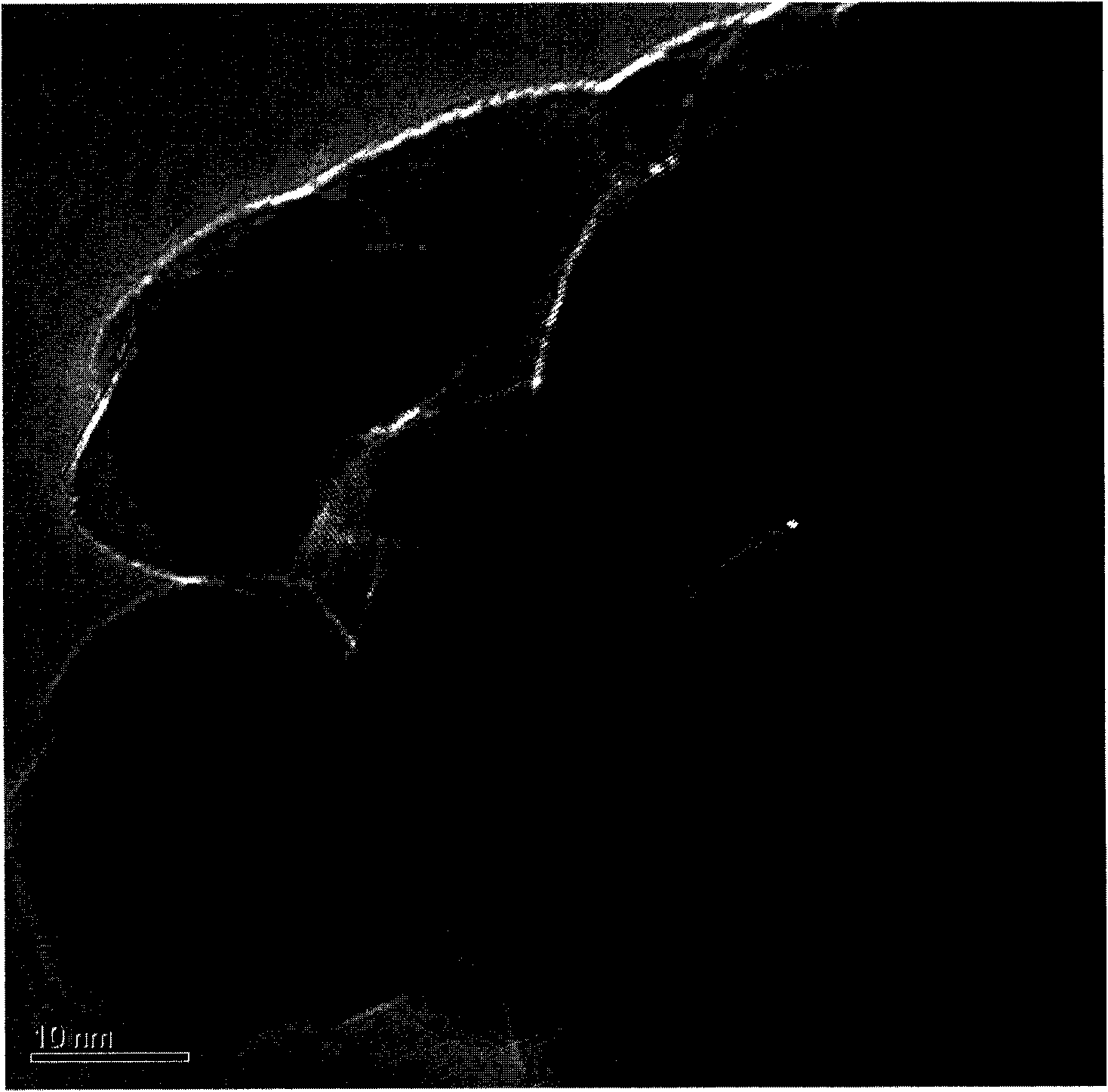

InactiveCN101768714AImprove thermal shock resistanceImprove mechanical propertiesMolten spray coatingEfficient propulsion technologiesAdhesivePlasma sprayed

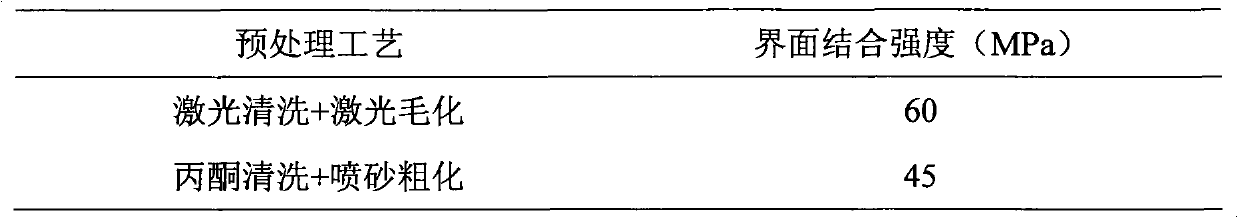

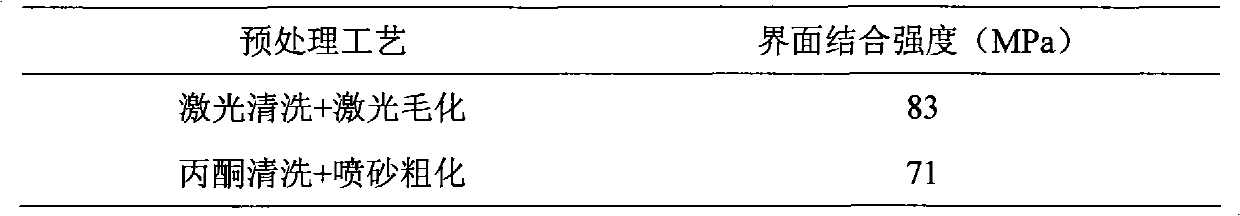

The invention discloses a method for preparing a thermal barrier coating by laser compound plasma spraying, which relates to the field of surface coatings. The method comprises the following steps: 1) cutting a material to be treated into required size by adopting line cutting; 2) polishing the surface of the cut material by using abrasive paper; 3) cleaning the surface of the polished material by adopting pulse laser; 4) performing laser texturing treatment on the surface of the cleaned material to roughen the surface of the material; and 5) filling spraying material powder into a powder feeder, fixing the roughened material on a turntable, and preparing the thermal barrier coating by plasma spraying; or first preparing a middle adhesive layer, then repeating the cleaning and texturing processes in the steps 3) and 4), and preparing the thermal barrier coating by the plasma spraying process. The interface of the thermal barrier coating prepared by the method is firmly combined, and the thermal shock resistance and mechanical property of the thermal barrier coating are remarkably improved. The method has simple processes, is suitable for large-scale mass production, and can prepare the high-performance thermal barrier coating with firm interface combination.

Owner:JIANGSU UNIV

A kind of metal surface modification method

InactiveCN102268626AWide range of applicationsSave resourcesMolten spray coatingCoated surfaceState of art

The invention relates to a metal surface modification method. The invention first obtains a textured surface with a certain surface roughness value on the surface of a material by an electron beam texturing method, forms uniform tiny pits, and increases the bonding strength of the interface; then uses plasma The spraying process uses Co-based alloy or Ni-based alloy powder as the material to form a coating; finally, laser remelting technology is used to remelt the coating surface to improve the surface structure of the coating and improve the surface performance. Compared with the existing technology, this process can realize high temperature resistance, corrosion resistance, oxidation resistance, and fatigue resistance, and has high bonding strength, and the coating structure is uniform and compact, thereby greatly broadening the application range.

Owner:SHANGHAI UNIV OF ENG SCI

Process for structuring self-cleaning glass surfaces

Owner:FERRO CORP

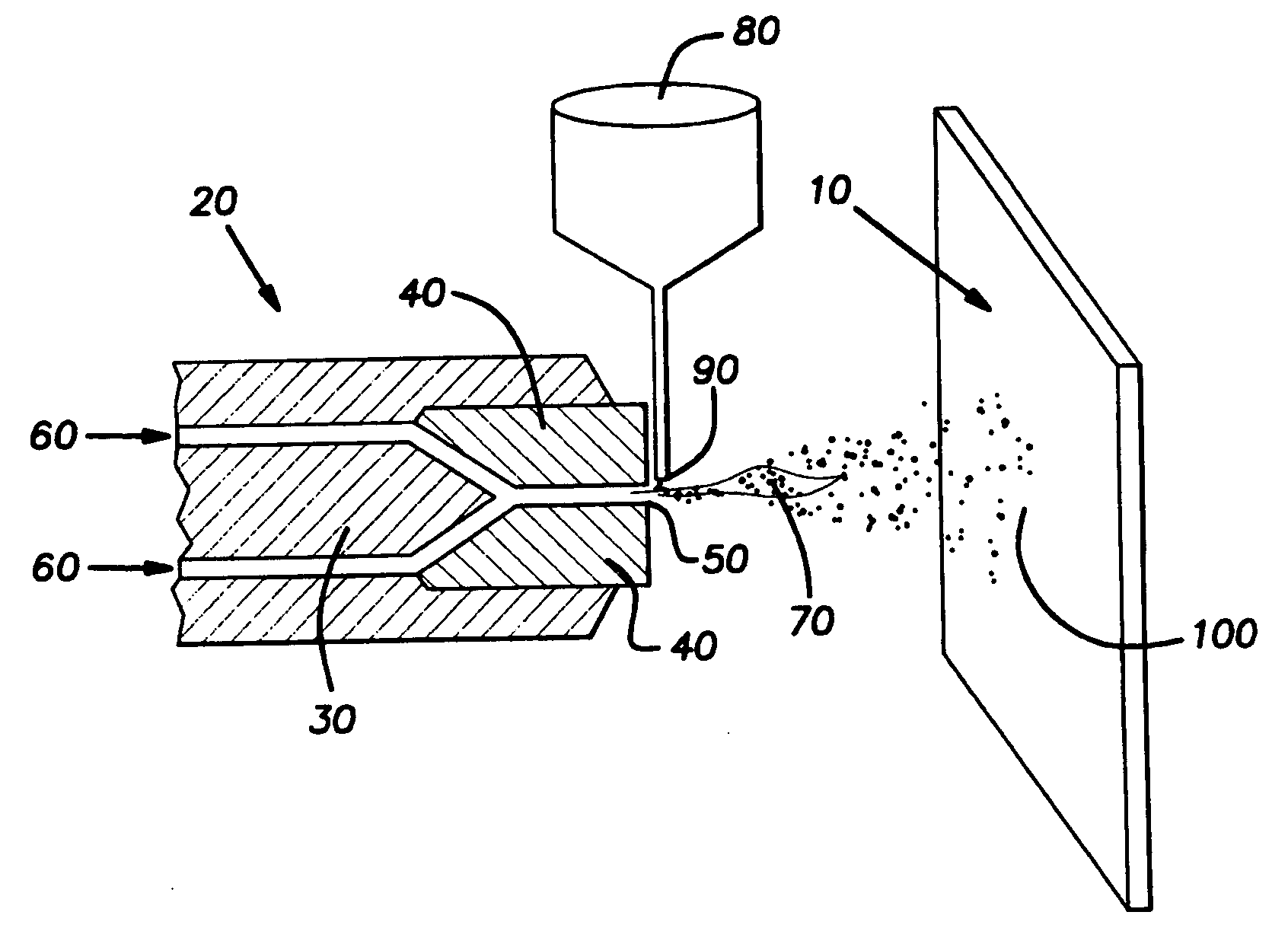

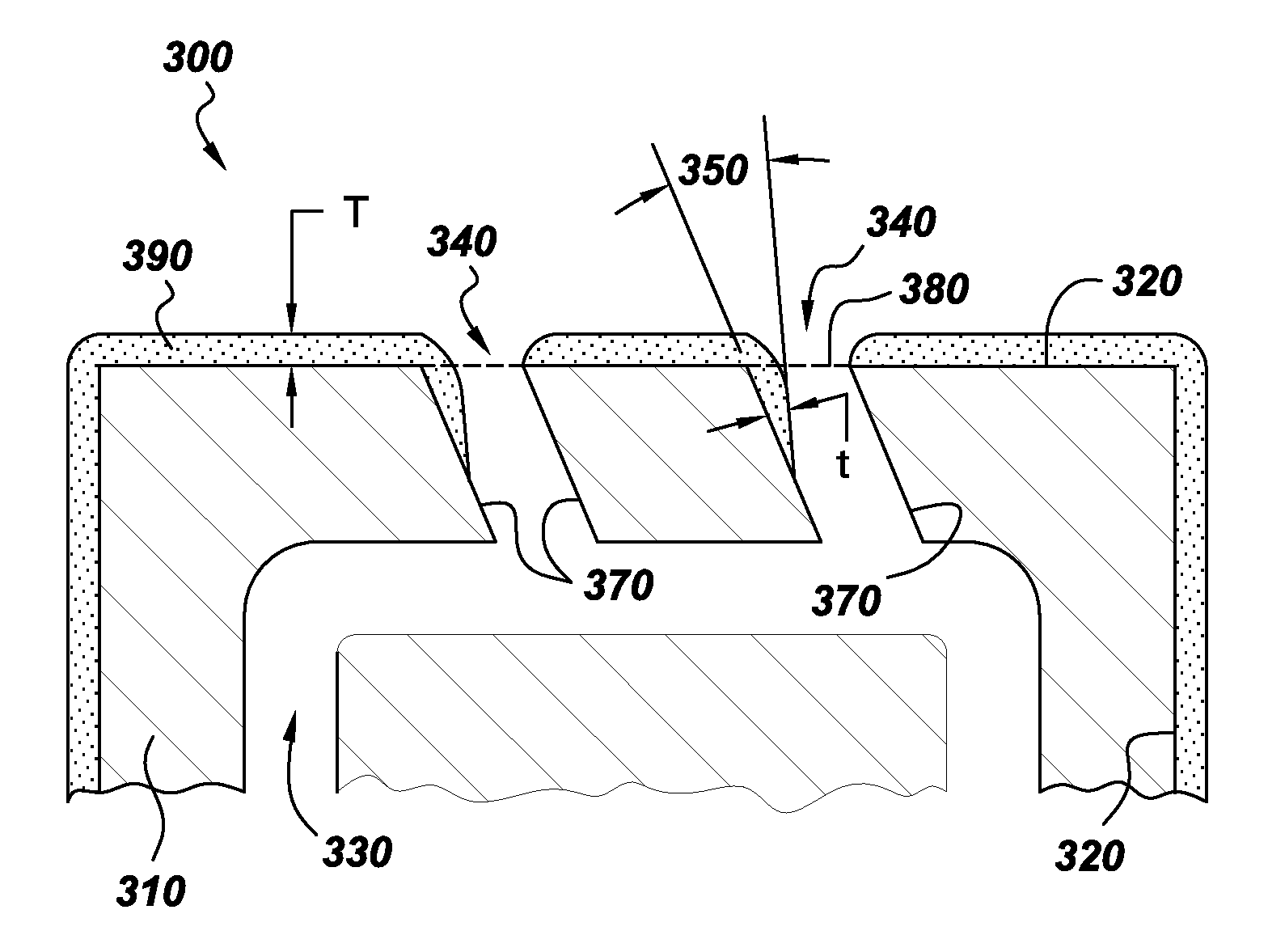

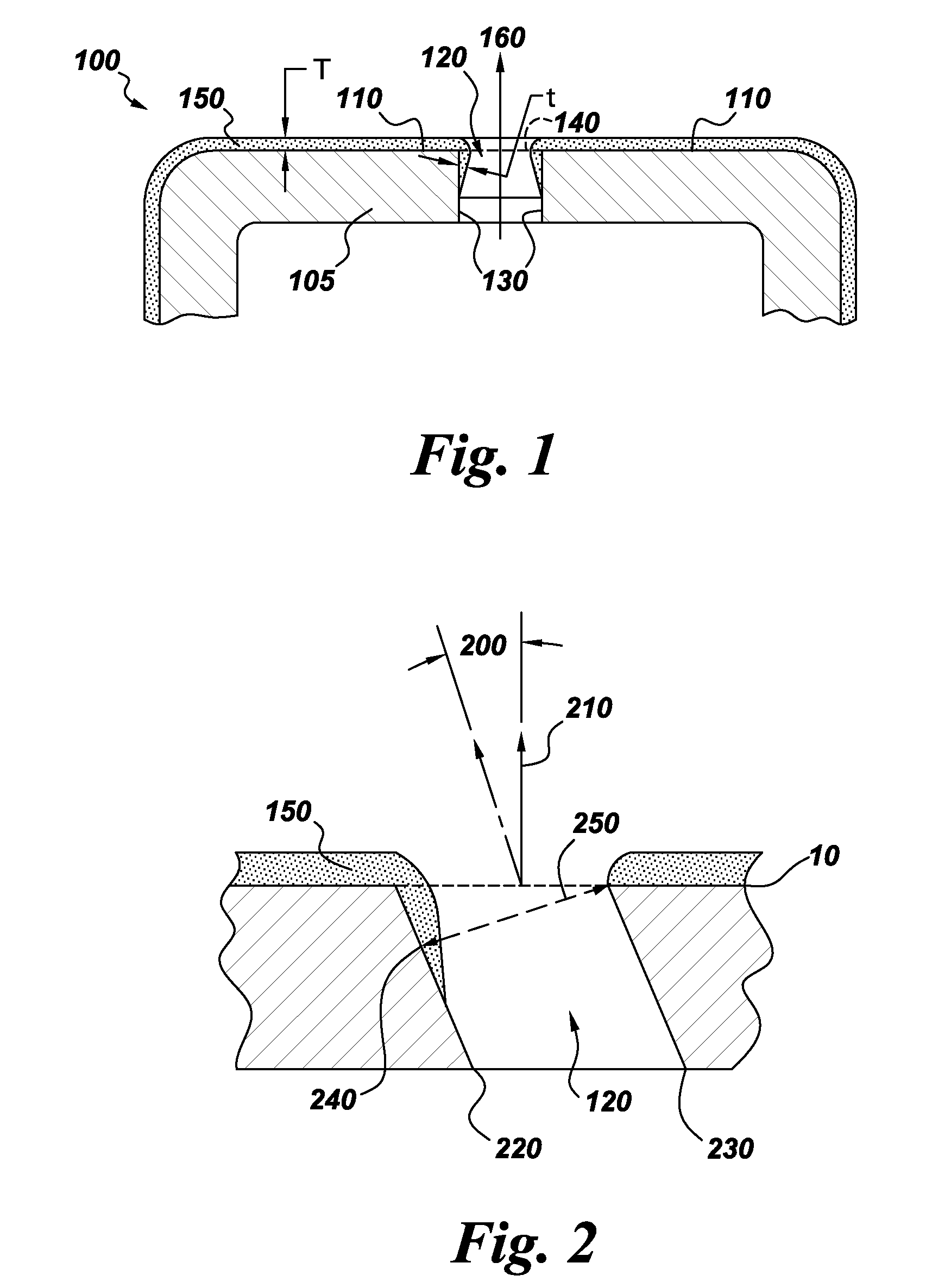

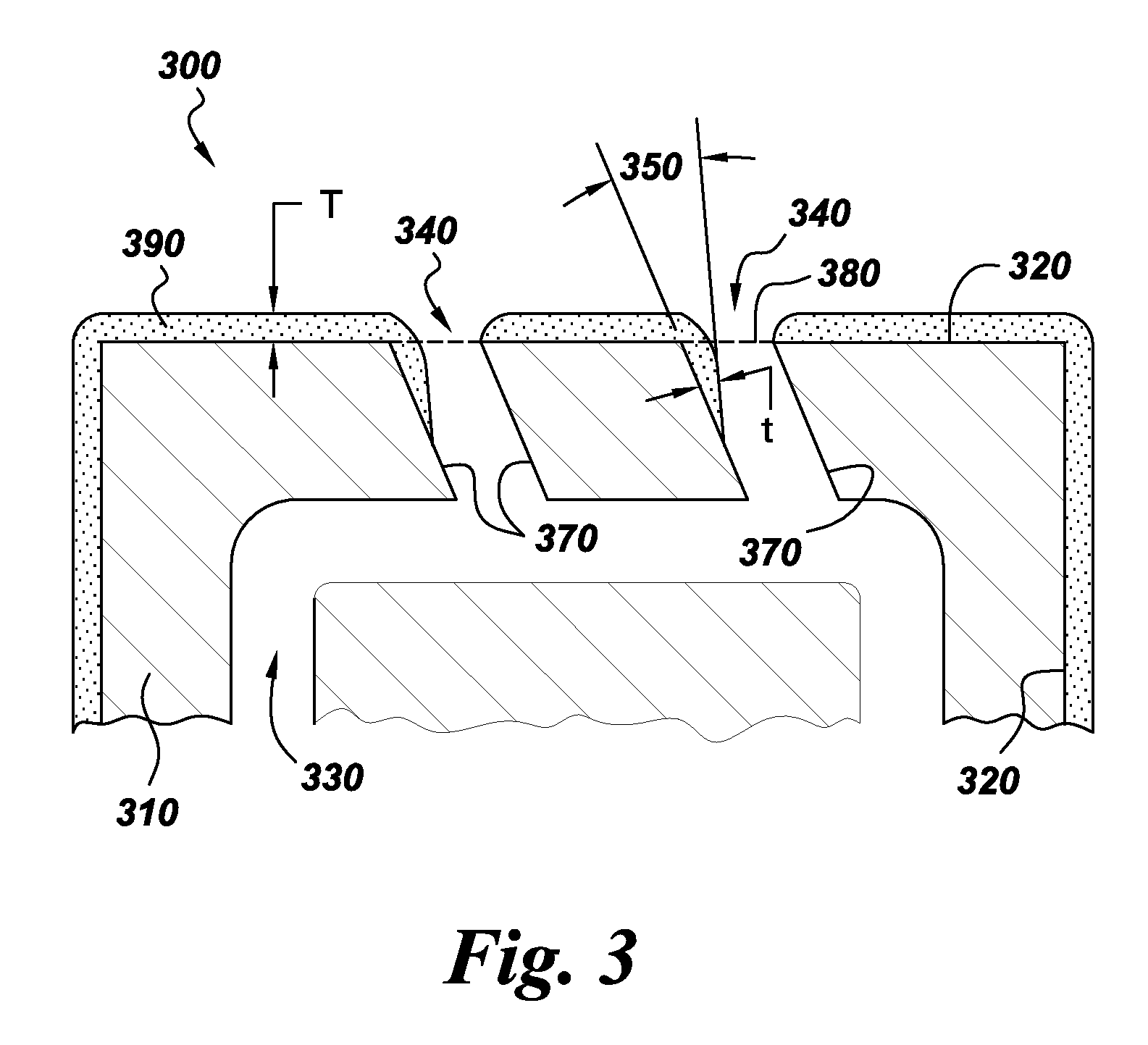

Articles for high temperature service and methods for their manufacture

Articles coated via a plasma spray process, and methods for making such articles, are presented. For example, one embodiment is an article comprising a substrate comprising a top surface and a channel disposed in the substrate. The channel is defined by an internal channel surface disposed beneath the top surface and having a terminal end at an orifice at the top surface. A coating is disposed on the top surface and on at least a portion of the internal channel surface. A coating thickness at any point on the internal channel surface is less than a nominal coating thickness on the top surface, and the coating comprises a plurality of at least partially melted and solidified particles.

Owner:GENERAL ELECTRIC CO

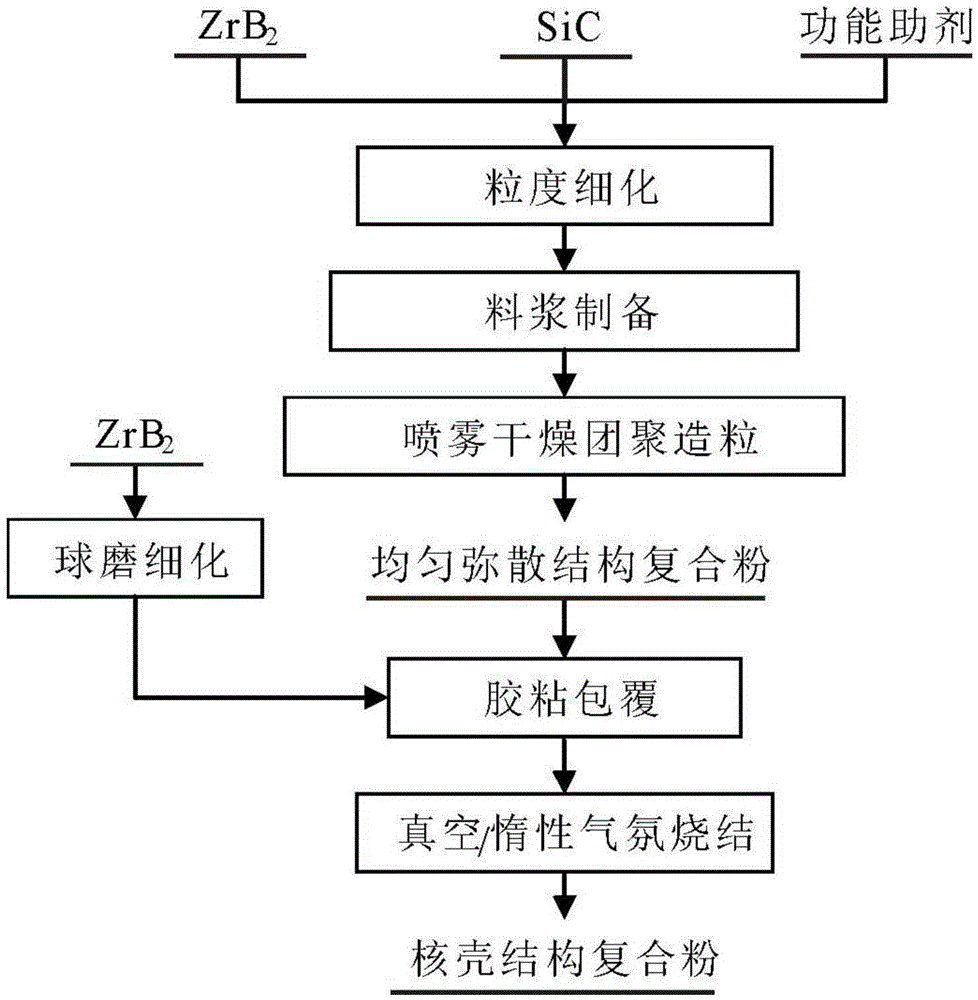

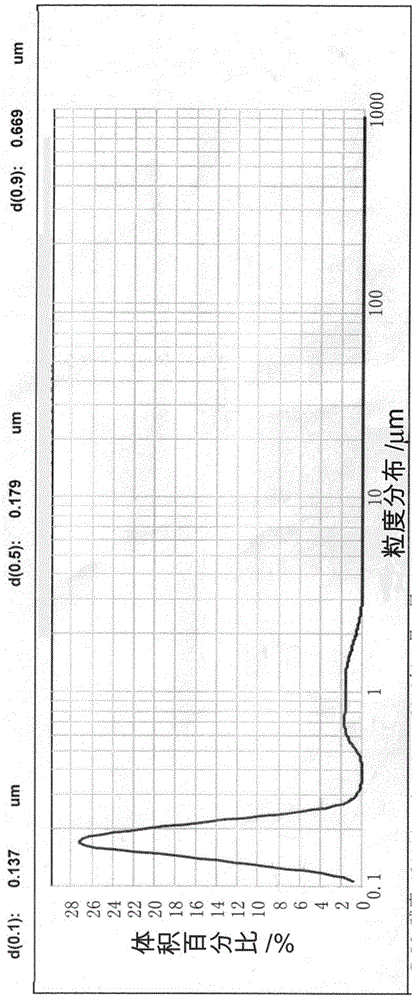

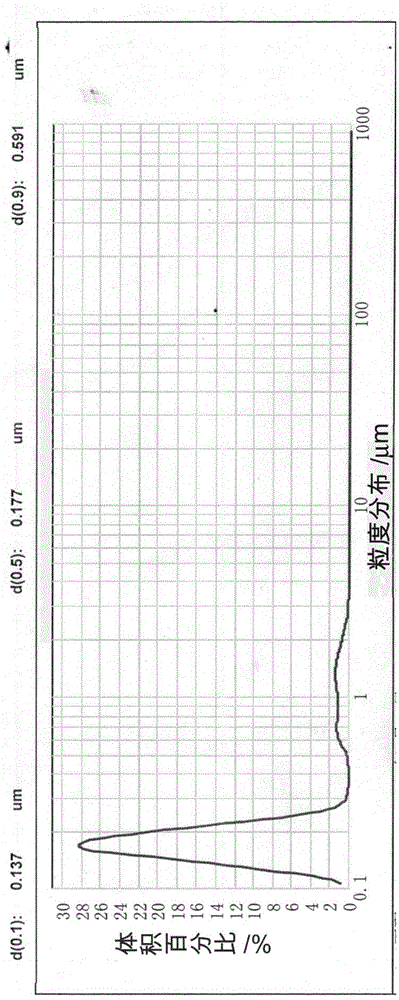

Core-shell-structure ZrB2-SiC/Si composite powder and preparation method thereof

ActiveCN104557050AAvoid decomposition and burningAchieve consistencyCoatingsDecompositionPlasma sprayed

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY +1

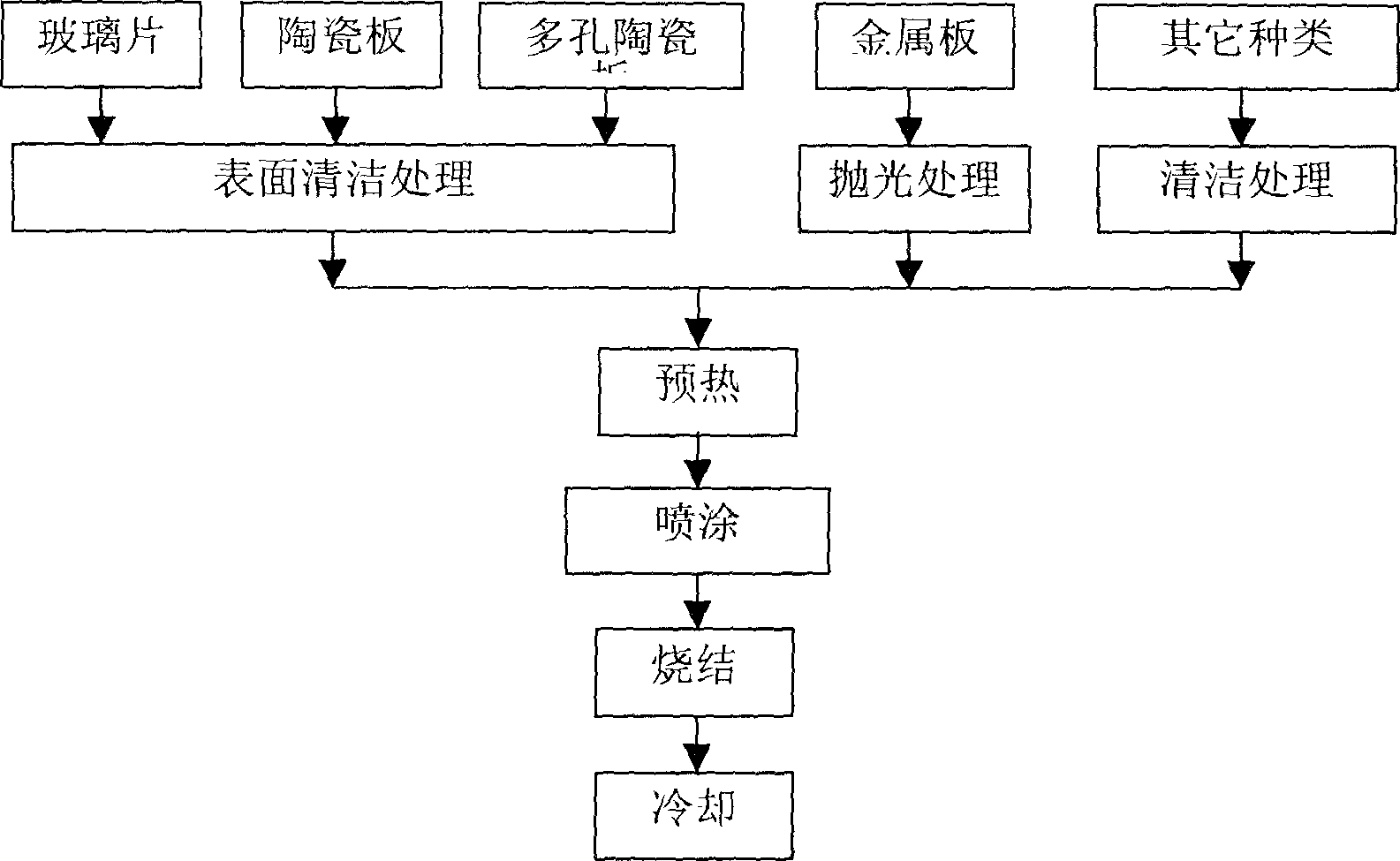

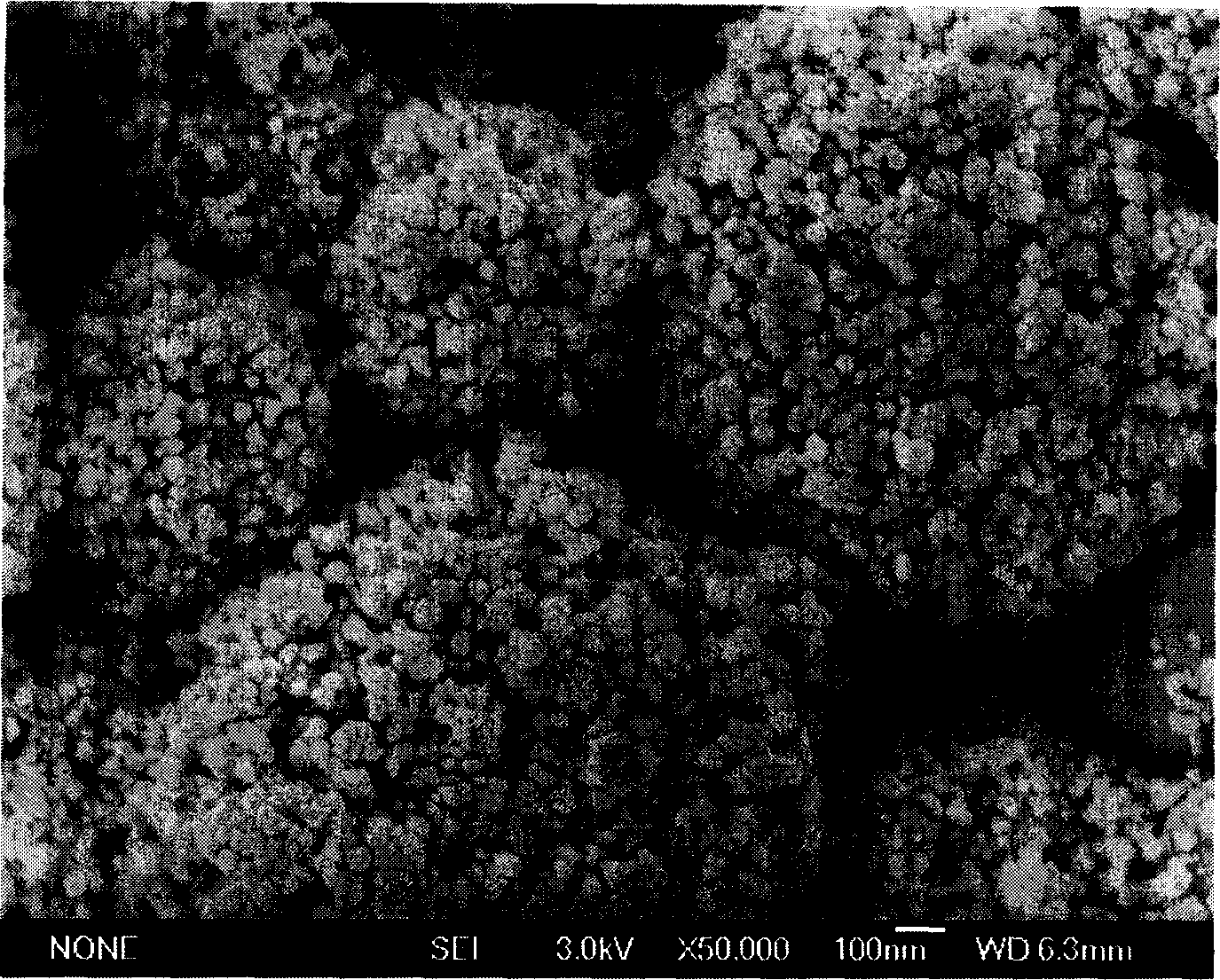

Method for forming nano TiO2 light catalystic active agenbt coating on substrate

InactiveCN1491753AImprove photocatalytic activityThe method is simpleLiquid surface applicatorsMolten spray coatingHydrogenNitrogen

The present invention belongs to the field of coating technology, and is especially plasma spray process of forming nano TiO2 photocatalytic activator coating on substrate. The process includes utilizing the mixed gas of nitrogen or argon and hydrogen as work gas and nitrogen as powder feeding gas; cleaning the substrate, preheating at 200-600 deg.c, spraying nano TiO2 powder onto the surface of the substrate in a plasma spraying equipment to form nano TiO2 film; and sintering at 500-600 deg.c to cure the nano TiO2 film completely and obtain the nano TiO2 photocatalytic activator coating. The coating is firm, stable and high in photocatalytic activity. The present invention may be used widely in the carrying of photocatalyst and heat spraying of nano powder.

Owner:INST OF CHEM CHINESE ACAD OF SCI

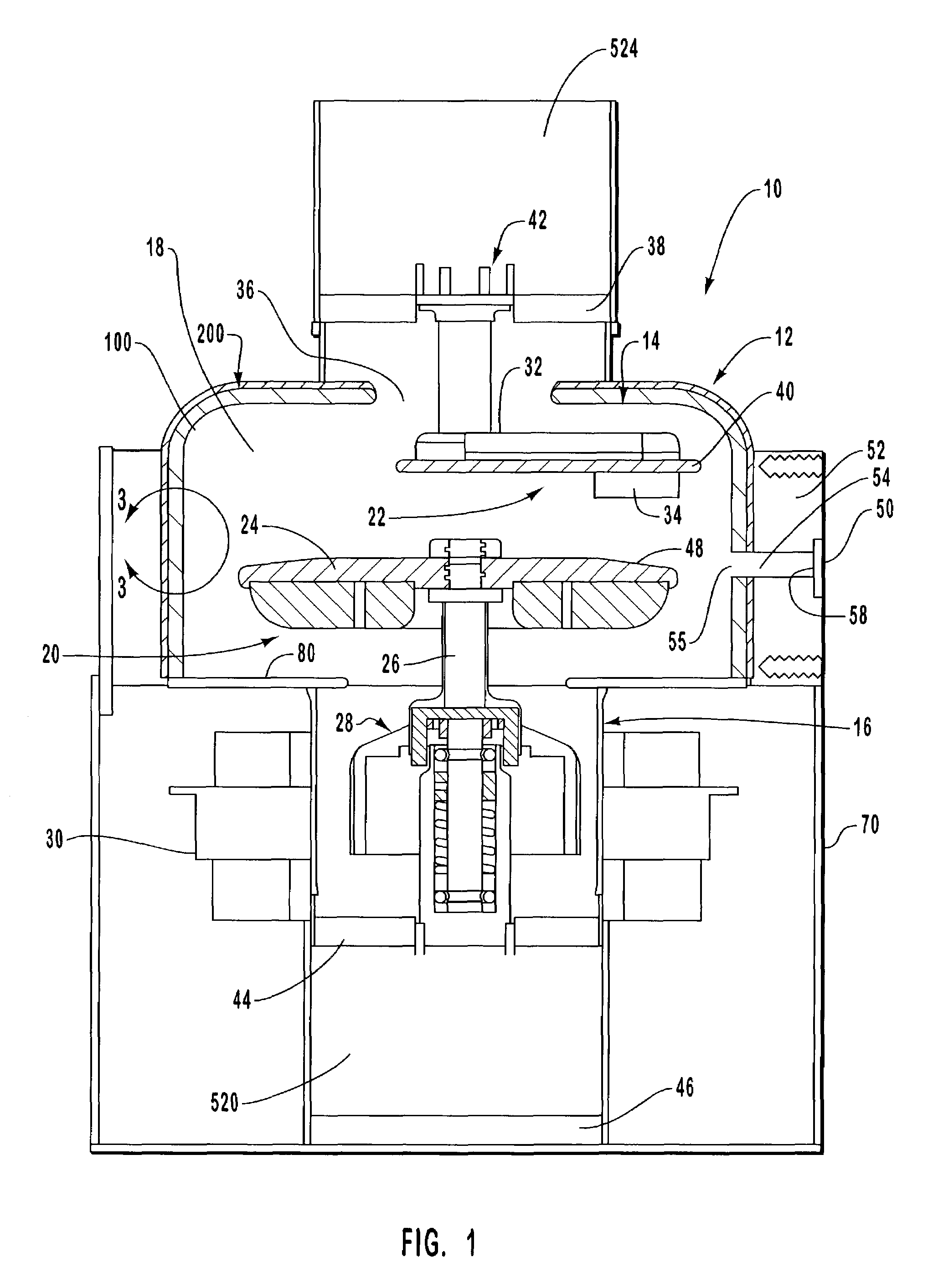

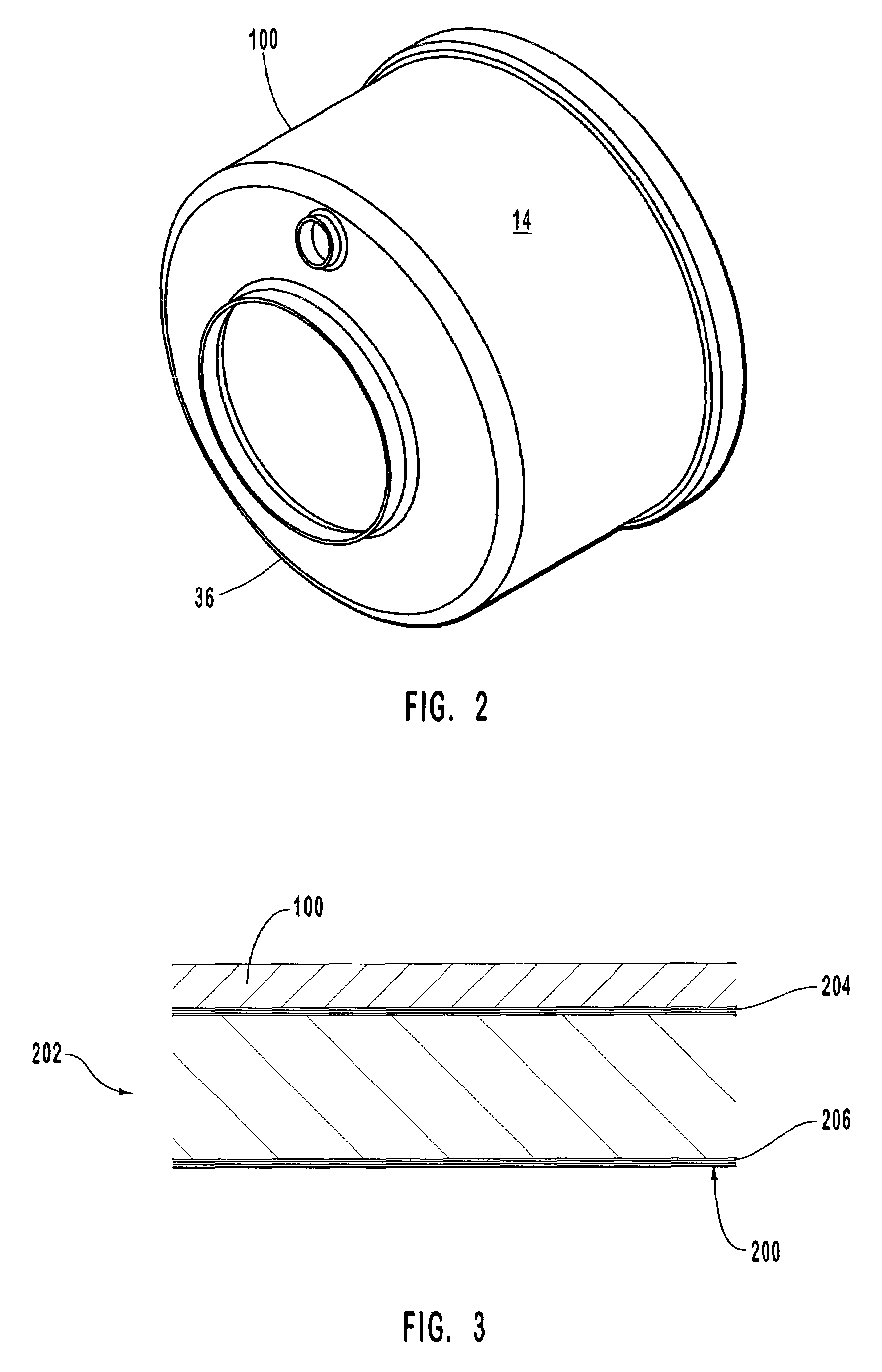

X-Ray tube and method of manufacture

InactiveUS7079624B1Reduce component countReduce weightX-ray tube electrodesConductive materialHydrogenPlasma sprayed

The present invention is directed to an air-cooled radiographic apparatus, and its method of manufacture, that utilizes a single integral housing for providing an evacuated envelope for an anode and cathode assembly. The integral housing is preferably formed from a substrate material that has a radiation shielding layer comprising a powder metal that is deposited with a plasma spray process. The powder metal includes, for example, tungsten and iron, so that the radiation shield layer provides sufficient radiation blocking and heat transfer characteristics such that an additional external housing is not required. In one alternative embodiment, the integral housing is composed of a solidified, integrated mixture of metallic powders that function together as both the integral housing wall and the radiation shielding. In another alternative embodiment, chromium is intermixed into the mixture of metallic powders to form a thermally emissive surface upon firing the housing in a wet hydrogen environment.

Owner:VAREX IMAGING CORP

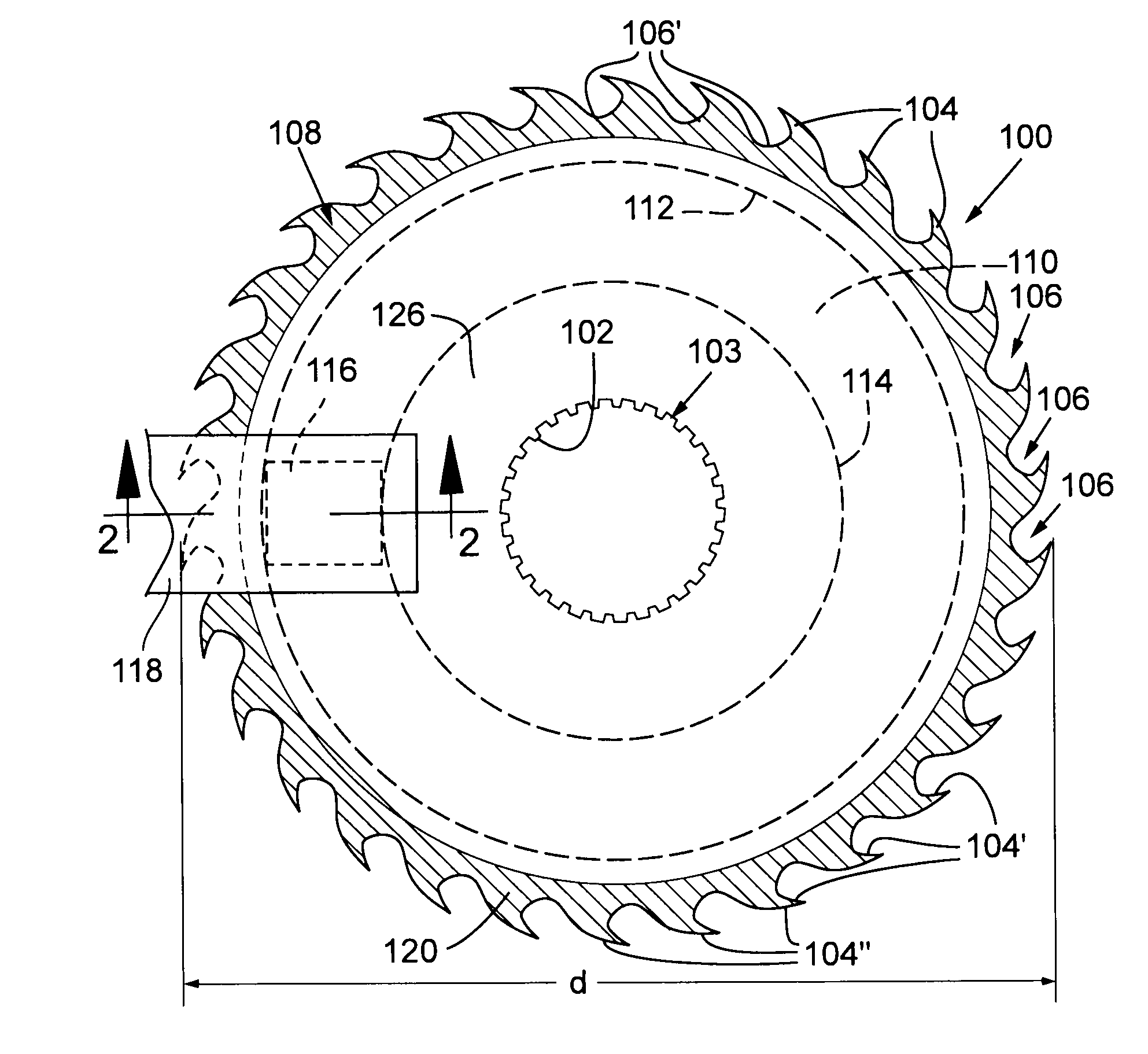

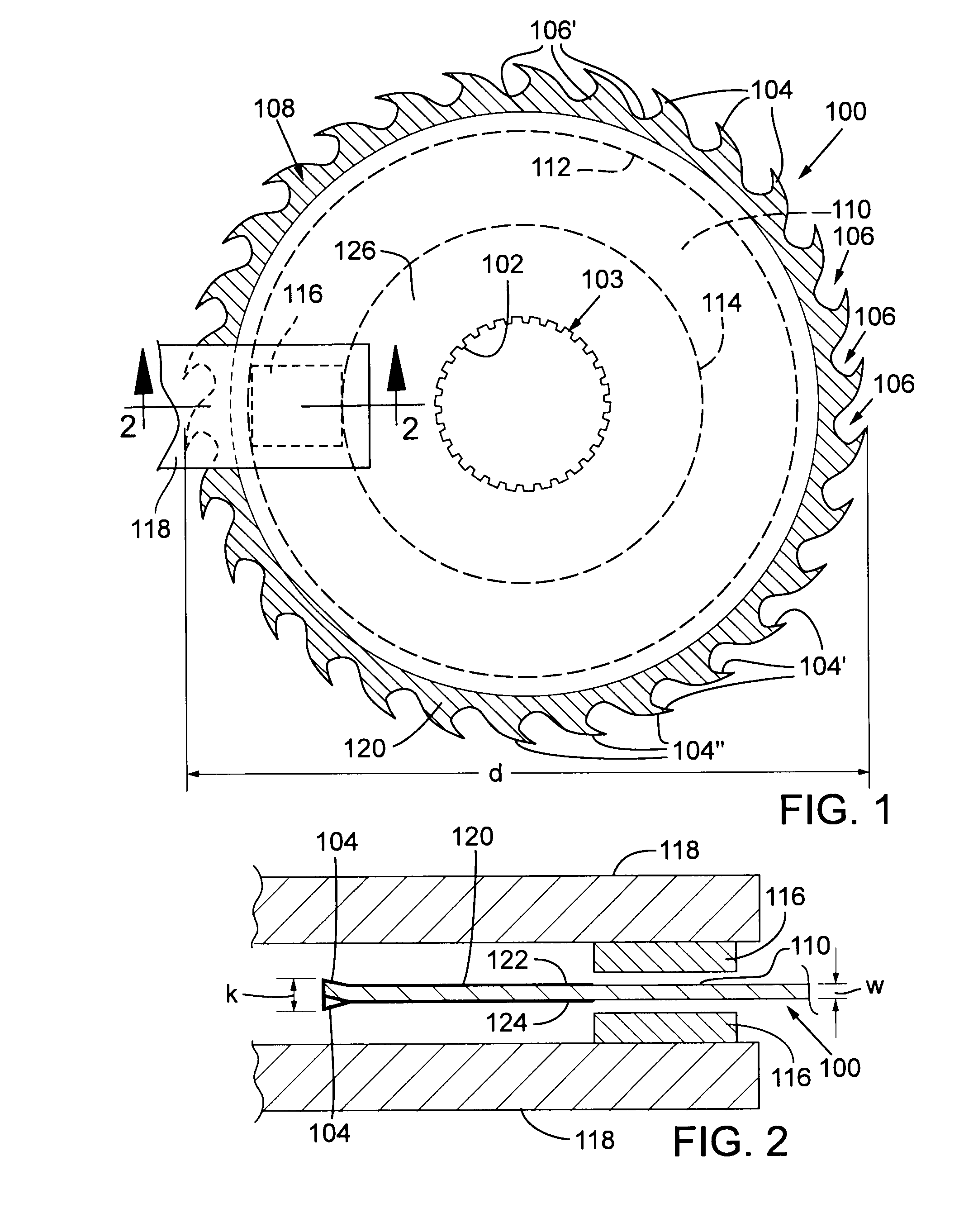

Circular saw blade with thermal barrier coating

InactiveUS20100122620A1Increase temperatureMetal sawing devicesMolten spray coatingCeramic coatingCircular saw

A circular saw blade includes a ceramic coating applied to opposing major surfaces in an outer margin of the circular saw blade where cutting teeth of the saw blade are arranged in spaced-apart relation and separated by blade tooth gullets. The ceramic coating inhibits abrupt increases in temperature of the outer margin during cutting operation to thereby inhibit the cutting teeth from deviating laterally. Methods of making saw blades include applying a ceramic coating to the outer margin using a plasma spray process or another coating process.

Owner:SIMONDS INT L L C

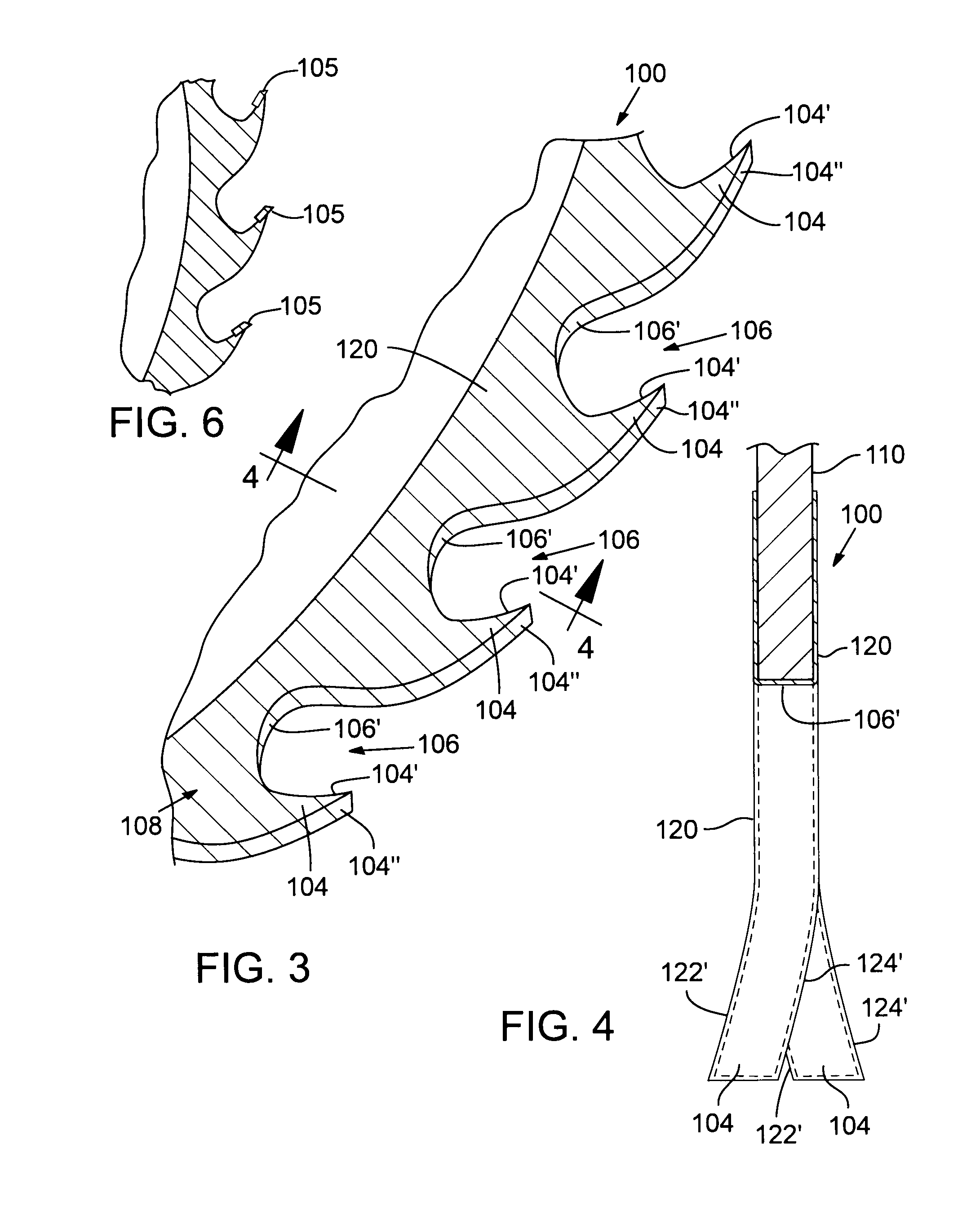

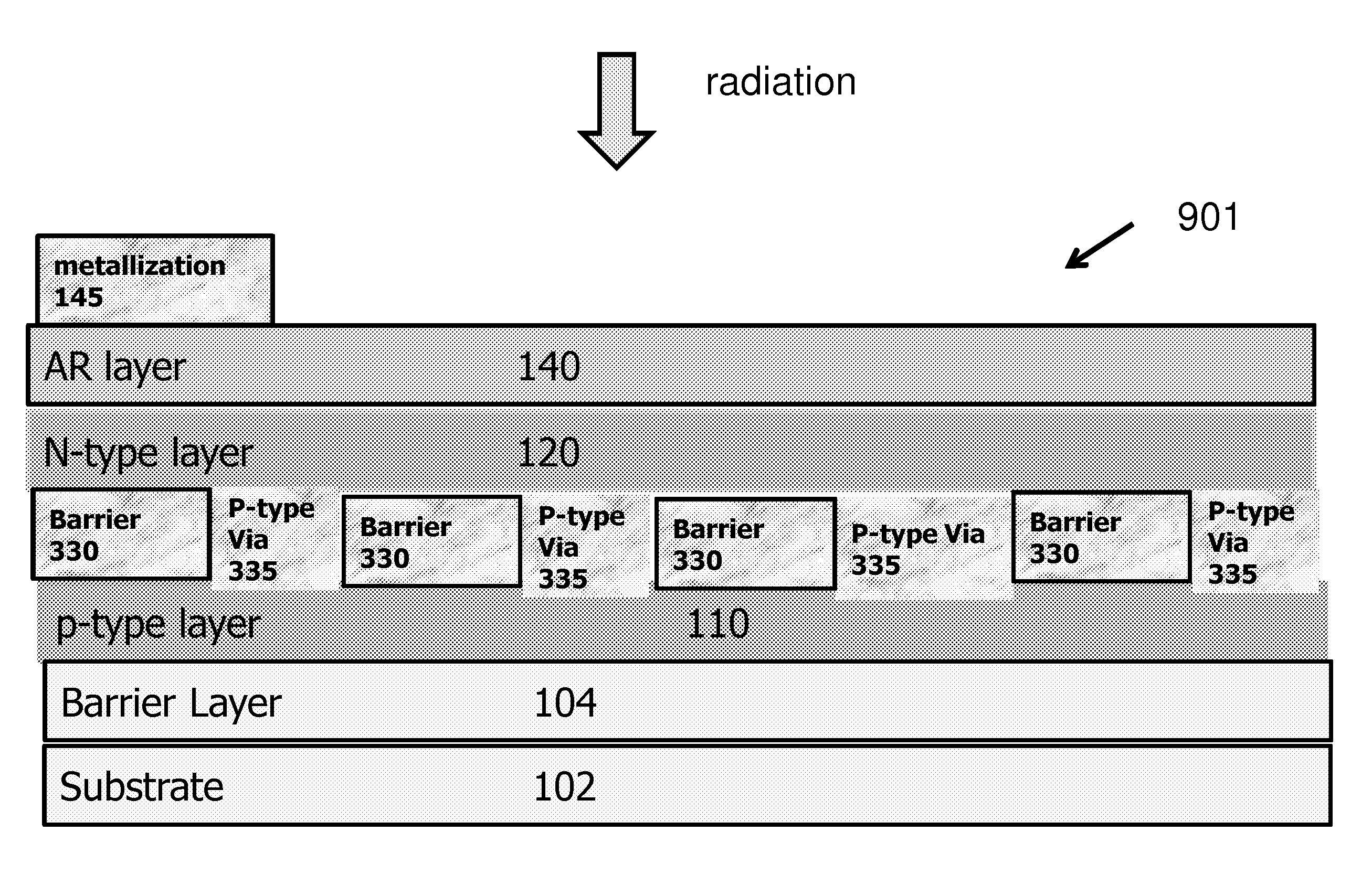

Photovoltaic Cell on Substrate

InactiveUS20110041903A1Low efficiencyEfficient collectionFinal product manufactureSolid-state devicesDistributed Bragg reflectorSemiconductor

A photovoltaic device on a non-semiconductor substrate is disclosed. The device comprises two semiconductor layers forming an active region; at least one of the semiconductor layers is formed by a high-purity plasma spray process; optional layers include one or more barrier layers, a cap layer, a conductive and / or metallization layer, an anti-reflection layer, and distributed Bragg reflector. The device may comprise multiple active regions.

Owner:INTEGRATED PHOTOVOLTAICS

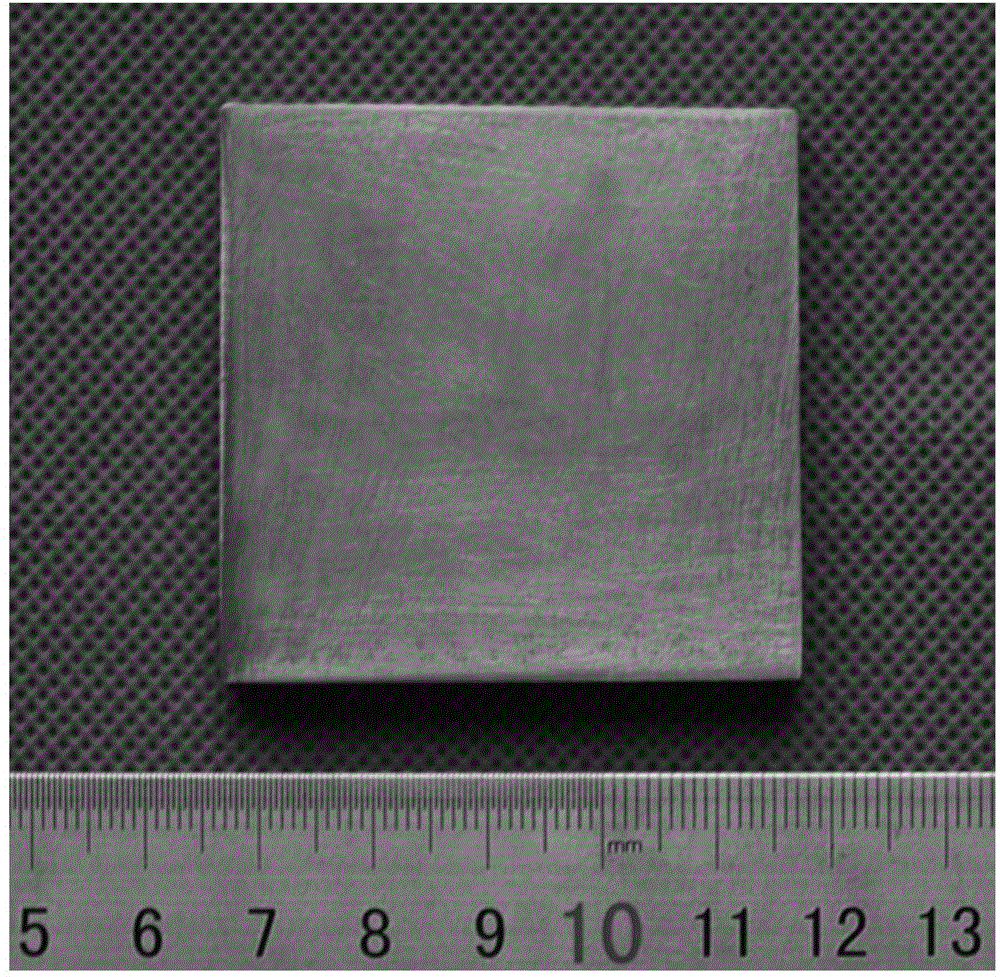

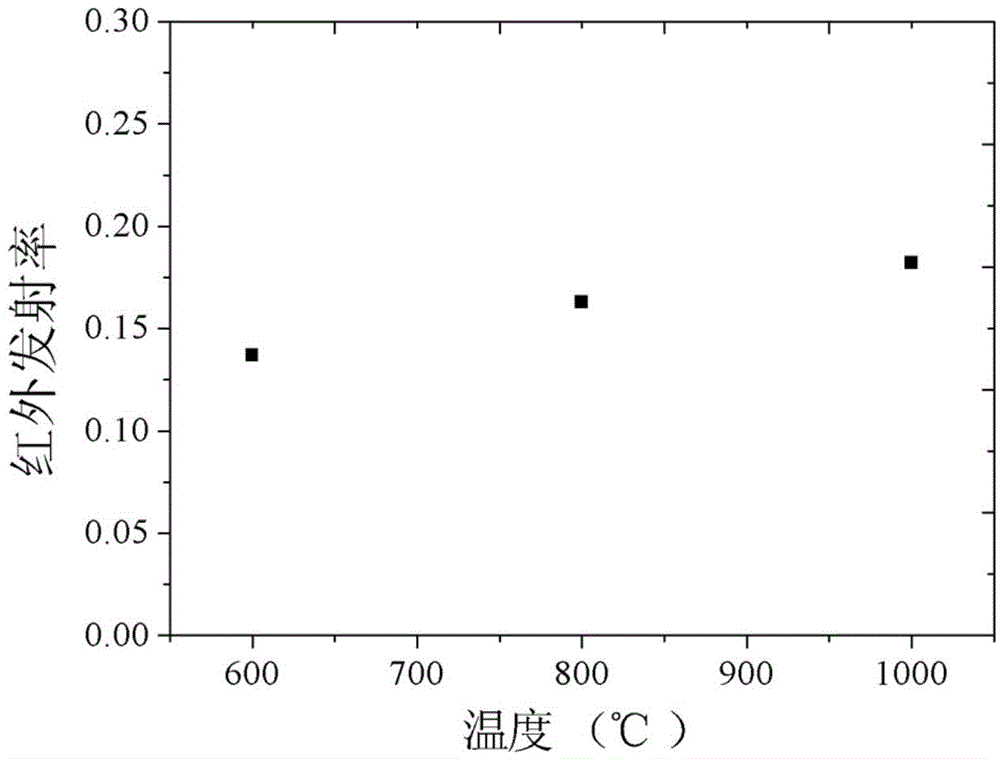

High-temperature-resistant high-bonding-strength low infrared emissivity composite coating, metal alloy material with coating and preparation method of metal alloy material

ActiveCN104818482AHigh bonding strengthMitigate Thermal MismatchMolten spray coatingSuperimposed coating processEmissivityMetal alloy

The invention discloses a high-temperature-resistant high-bonding-strength low infrared emissivity composite coating which sequentially comprises a NiCrAlY plasma spraying layer, a ZrO2 plasma spraying layer and ZrO2-Al2O3-SiO2 system containing AgPd alloy glass coating from inside to outside. The surface roughness of a metal alloy material coated with the coating is lower than 2.0 micrometers, the bonding strength of the metal alloy material exceeds 10MPa, the tolerable temperature of the coating is higher than 1000 DEG C, and the average infrared emissivity of the coating in a specified band is less than 0.3. A preparation method of the metal alloy material includes the steps: firstly, performing sand blasting for a base; secondly, sequentially spraying the NiCrAlY layer and the ZrO2 layer on the base by a plasma spraying process; finally, uniformly brushing or printing coatings on the ZrO2 layer, and drying and sintering the coatings to obtain the finished metal alloy material. The metal alloy material can be used in a high-temperature environment, infrared radiation of a high-temperature component is effectively reduced, and the metal alloy material is stable in performance and low in cost.

Owner:NAT UNIV OF DEFENSE TECH

High-temperature oxidation resistant coating on niobium alloy surface and preparation method of high-temperature oxidation resistant coating

InactiveCN104561882AHigh strengthImprove toughnessMolten spray coatingHigh energyOxidation resistant

The invention belongs to the field of thermal spraying, and relates to a high-temperature oxidation resistant coating on a niobium alloy surface and a preparation method of the high-temperature oxidation resistant coating. The coating is in a dual-layer structure with a bottom coating Mo1-xWx(Si1-y-zAlyBz)2 and a surface coating Mo1-xWx(Si1-y-zAlyBz)2-(10-20)%wt HfSi2, and prepared on a niobium alloy matrix surface by a high-energy plasma spraying process, wherein a bottom coating powder material Mo1-xWx(Si1-y-zAlyBz)2 is prepared by a self-propagating process, and the spherical particles meeting the requirements of the spraying process are obtained by applying a plasma spheroidizing process; surface coating powder materials Mo1-xWx(Si1-y-zAlyBz)2 and HfSi2 are mixed evenly in a mechanical mixing manner. The coating has excellent high-temperature oxidation resistance at 1500-1800 DEG C, and can be applied to high-temperature protection of niobium alloy parts.

Owner:CHINA IRON & STEEL RES INST GRP +1

Method for preparing high-temperature wear-resistant coating on continuous casting crystallizer copper alloy plate surface

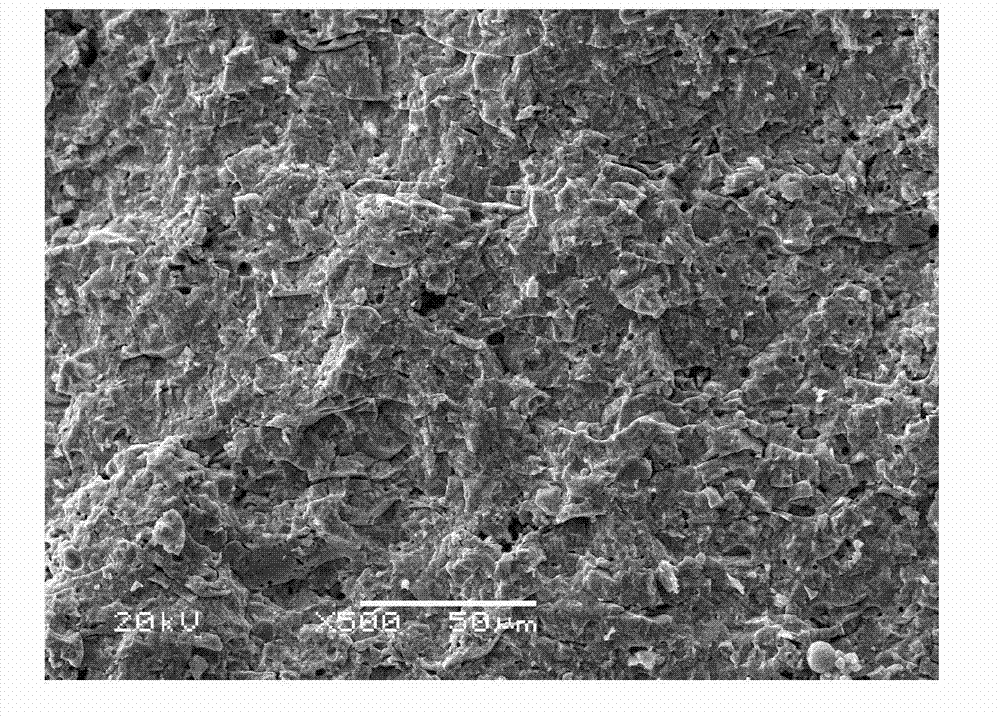

InactiveCN102851632AHigh bonding strengthImprove deposition efficiencyMolten spray coatingWear resistantThermal shock

The invention discloses a method for preparing a high-temperature wear-resistant coating on a continuous casting crystallizer copper alloy plate surface, which comprises the following step: spraying metal ceramic powder on a pretreated copper alloy plate surface by a plasma spraying process to form a metal ceramic coating of which the thickness is 0.5mm, wherein the metal ceramic powder is Cr3C2-NiCr powder of which the particle size is 325-500 meshes; the Cr3C2-NiCr powder comprises 70-80 wt% of Cr3C2 and the balance of NiCr alloy powder; and the Ni / Cr mass ratio in the NiCr alloy powder is 80:20. The coating prepared by the method disclosed by the invention has the advantages of high bonding strength, favorable thermal shock resistance and long thermal-fatigue life, can satisfy the working requirements for crystallizer copper alloy plates, and obviously prolongs the service life of the crystallizer copper alloy plate.

Owner:JIANGSU UNIV OF SCI & TECH

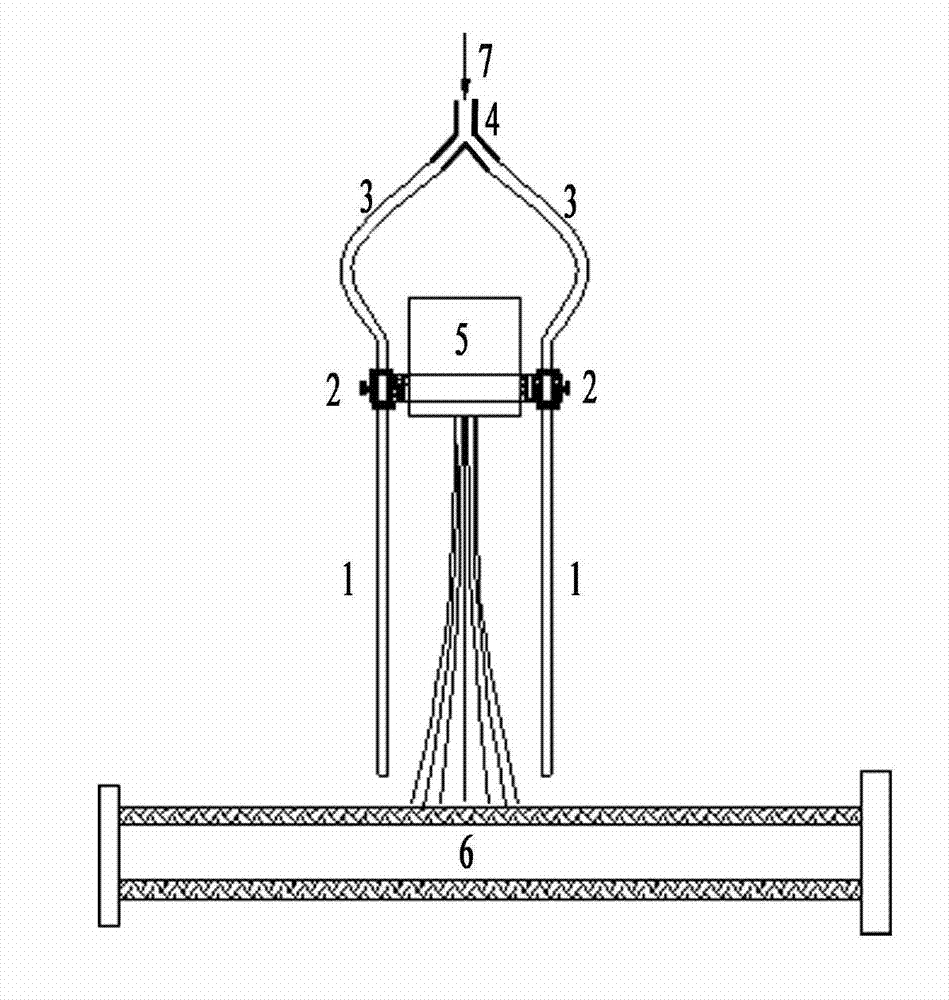

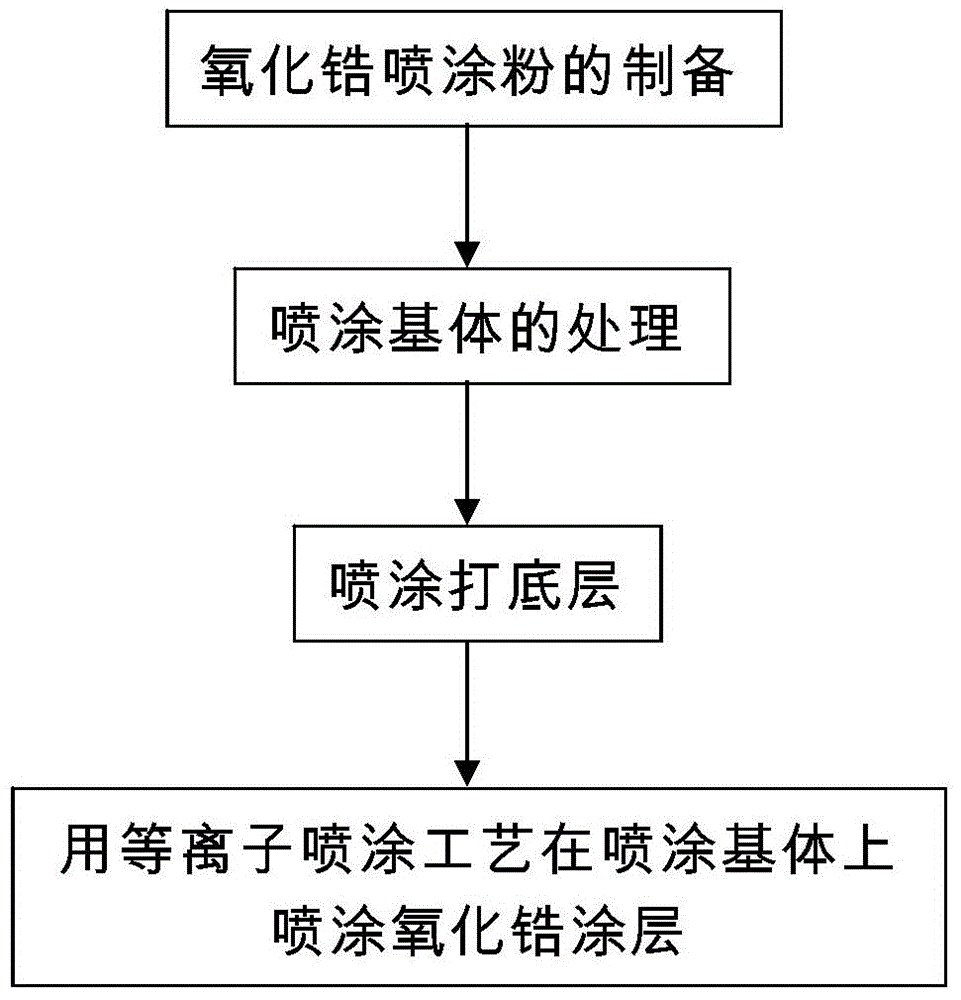

Rotary niobium oxide target material and preparation method thereof

ActiveCN103045995ACompact structureUniform compositionMolten spray coatingVacuum evaporation coatingVolumetric Mass DensityNiobium oxide

The invention relates to a rotary niobium oxide target material and a preparation method thereof. The preparation method comprises the following steps: preparing a niobium oxide spraying powder, treating a spraying matrix, spraying a priming coat and spraying the niobium oxide spraying powder on a matrix tube by using a plasma spraying process. The rotary niobium oxide target material prepared by the preparation method provided by the invention has the advantages of compact structure, uniform components, no crack and no limitation on spraying length and diameter; the thickness of the rotary niobium oxide target material can reach 12 mm, the density of the rotary niobium oxide target material is 4.6-5.2 g / cm<3>, and the component of the target is Nb2O4.3-4.9. The preparation method provided by the invention has the advantages of simple and convenient production process and lower cost.

Owner:宁夏中色新材料有限公司

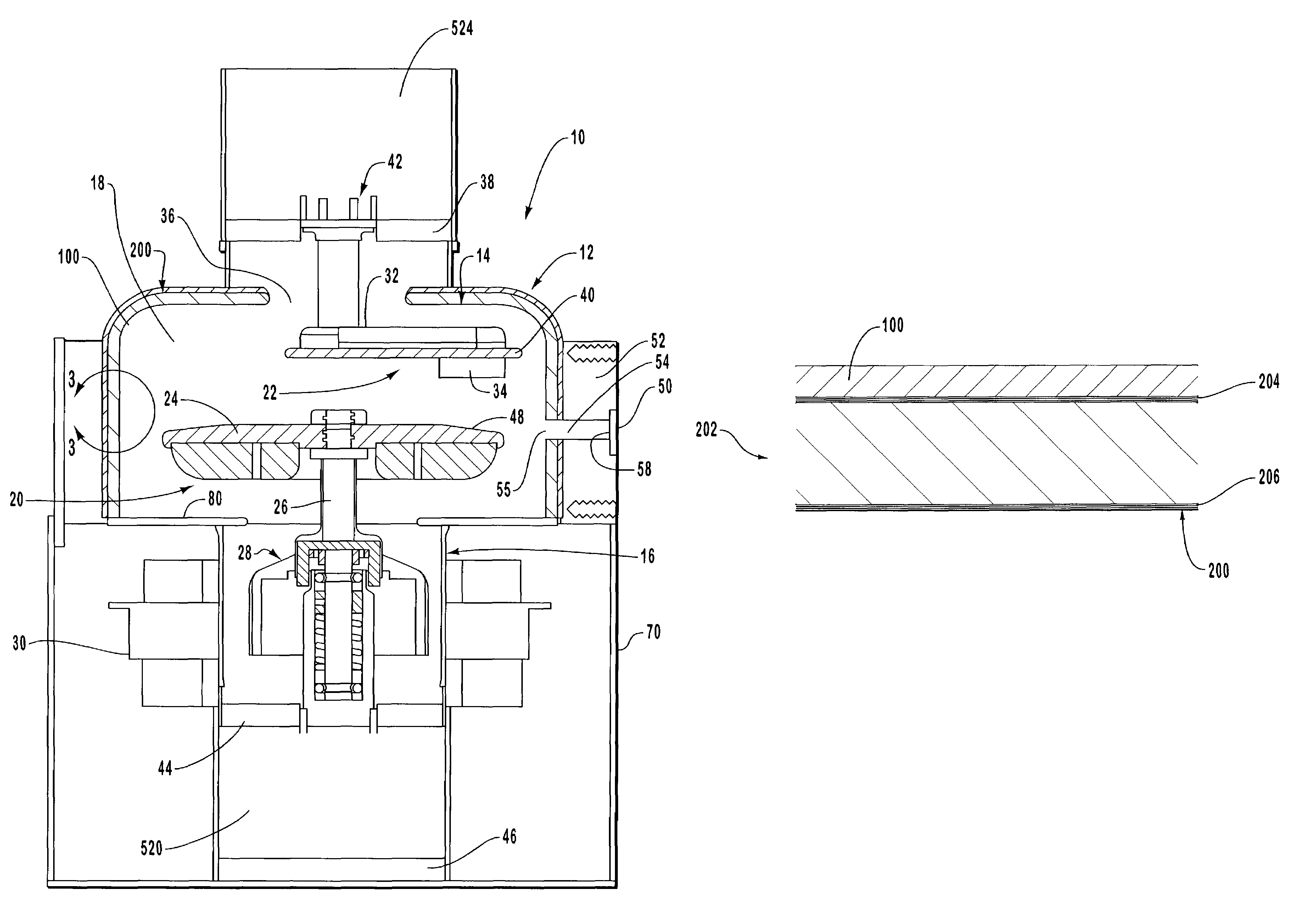

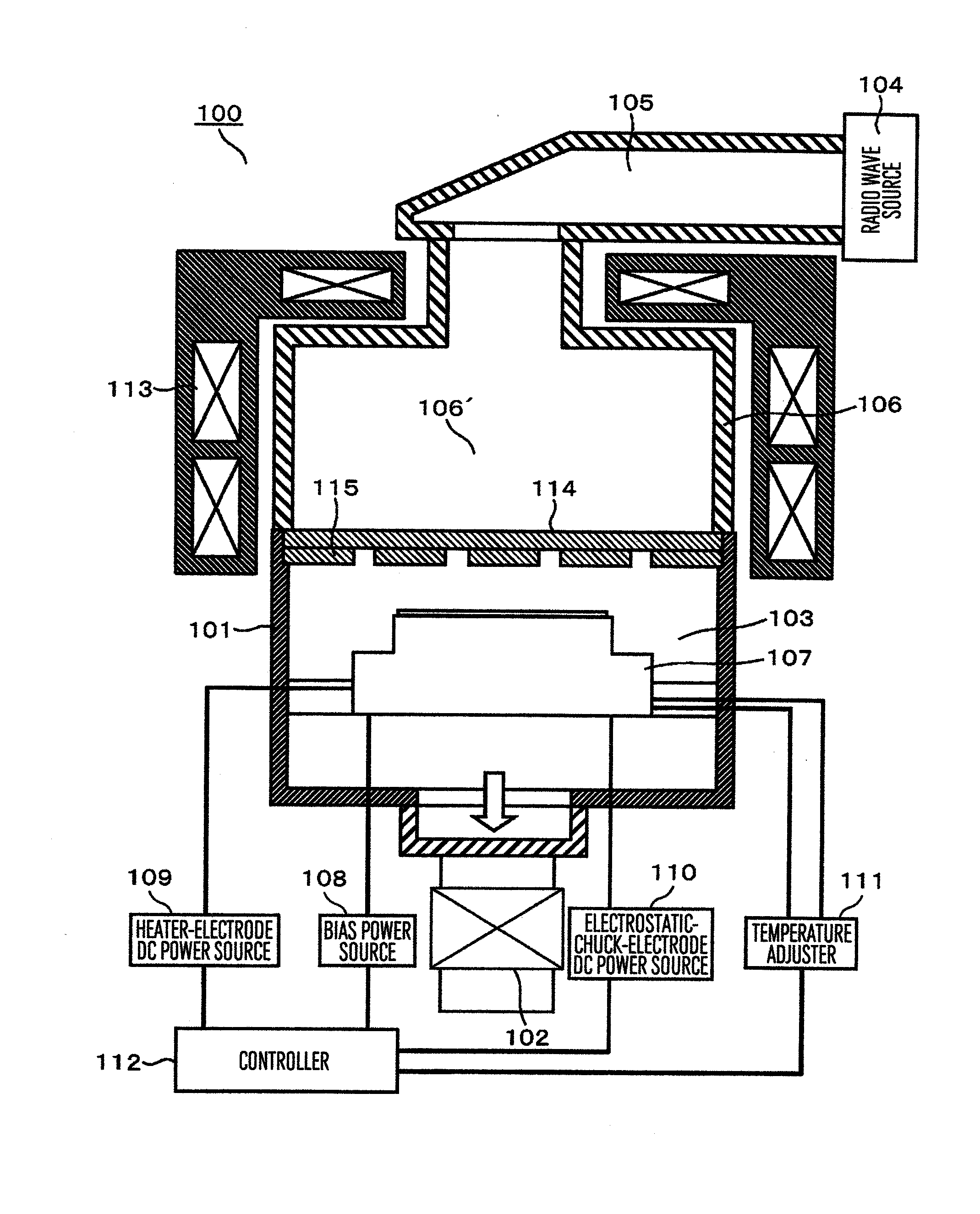

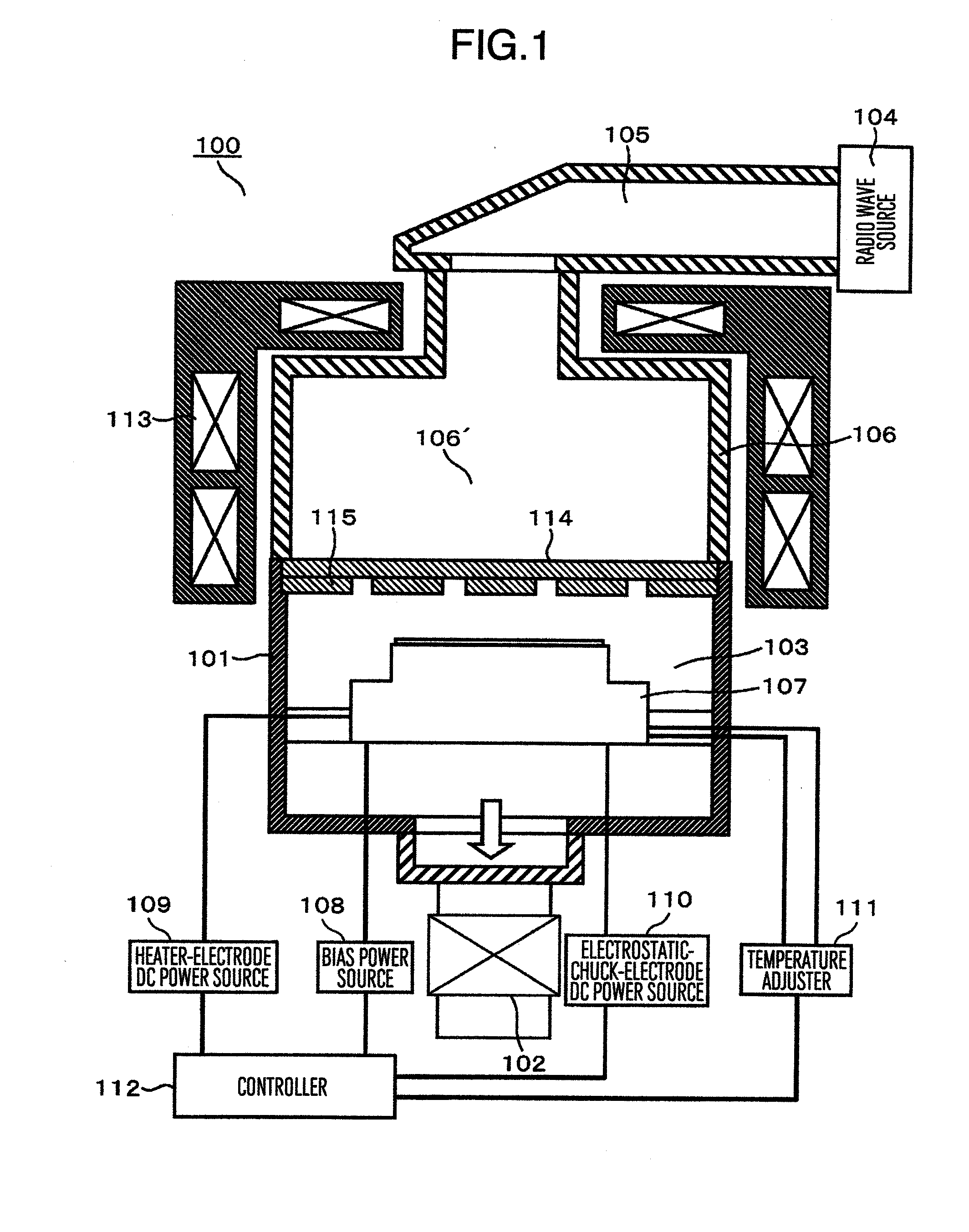

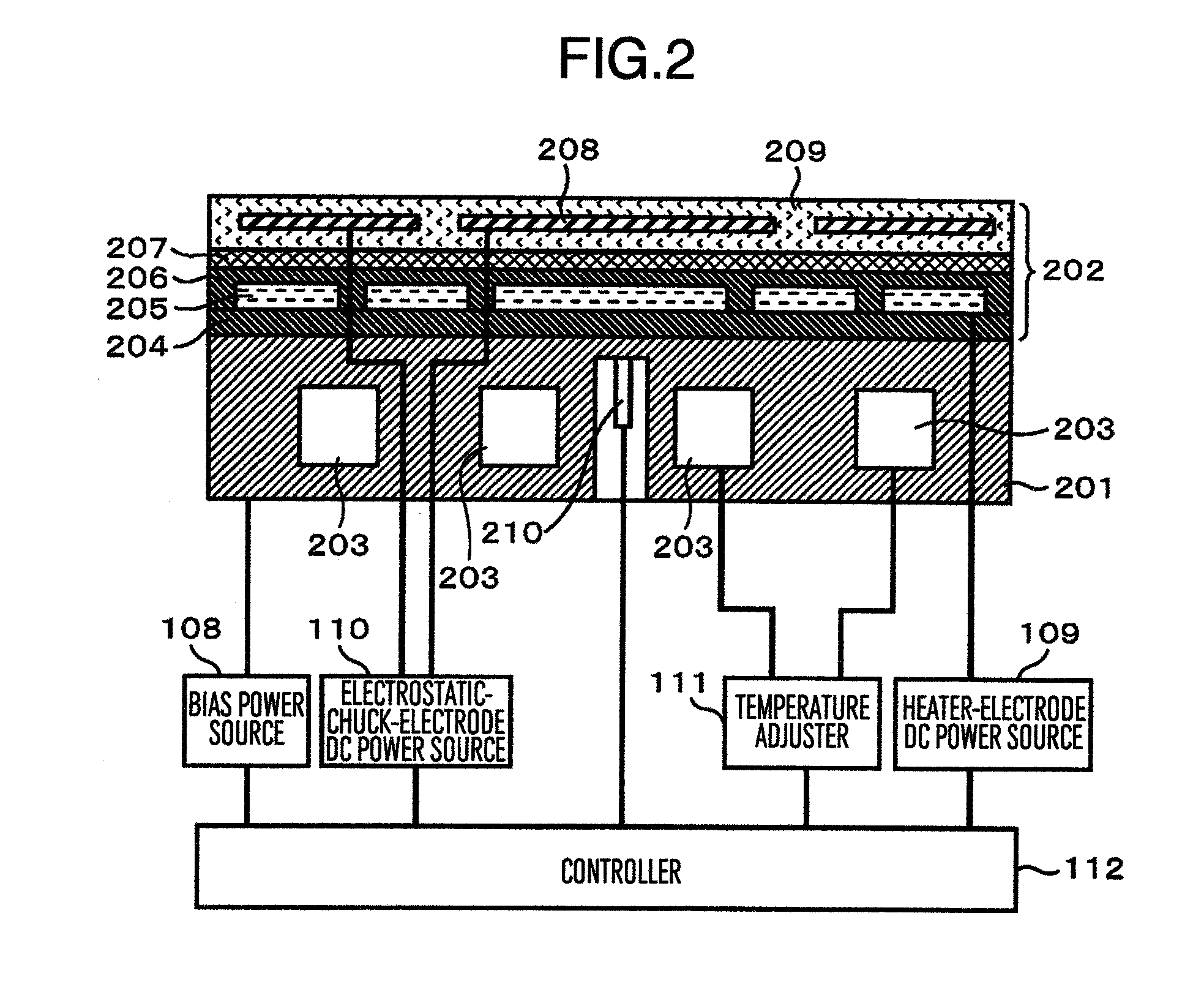

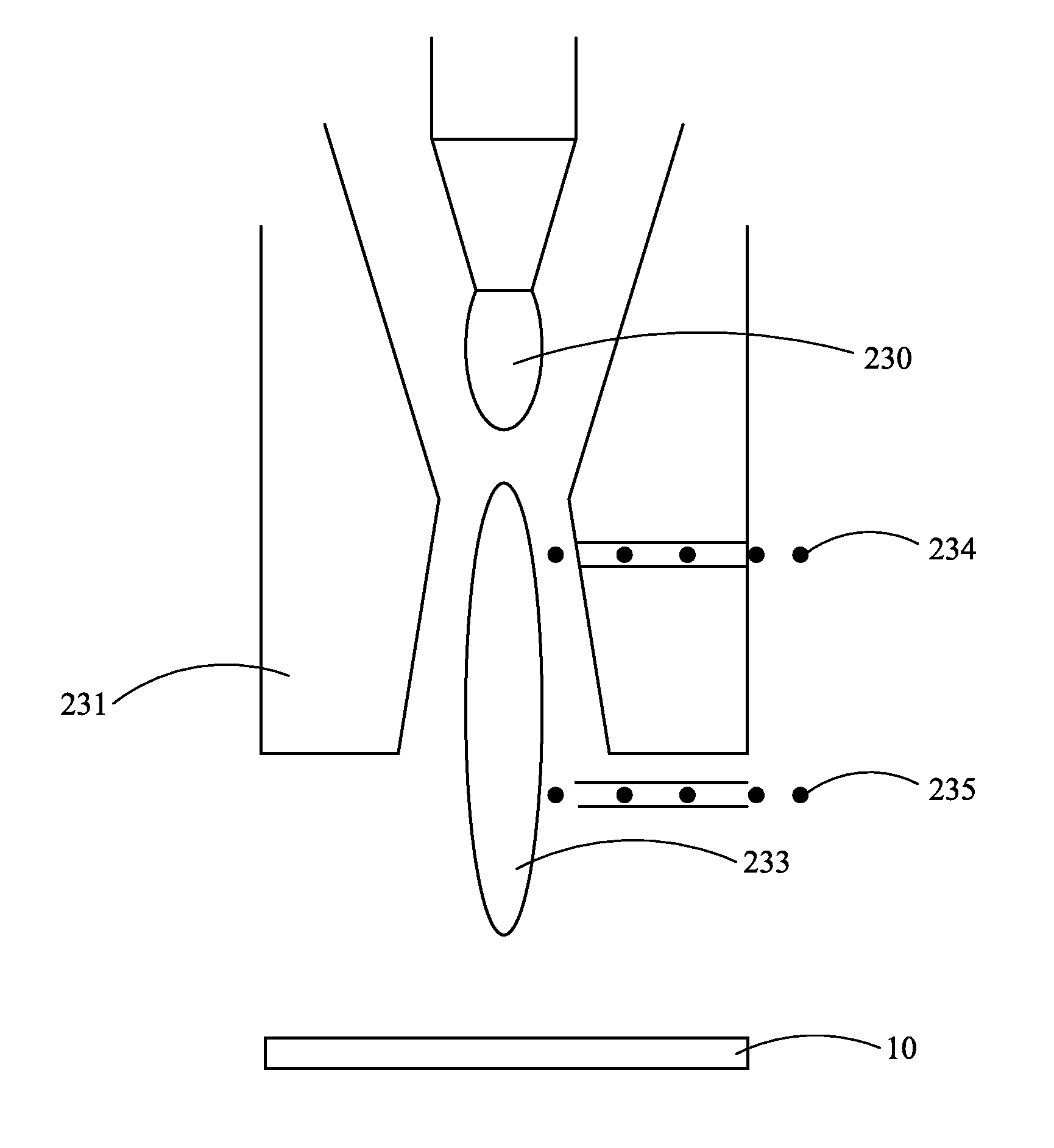

Plasma processing apparatus and sample stage

ActiveUS20110297082A1High precisionIncreasing the thicknessLiquid surface applicatorsMolten spray coatingDielectricMetallurgy

A plasma processing apparatus includes a metallic basic material arranged in a sample stage, a dielectric film of dielectric material disposed on an upper surface of the basic material, the dielectric film being formed through a plasma spray process; a film-shaped heater disposed in the dielectric film, the heater being formed through a plasma spray process; an adhesive layer arranged on the dielectric film; a sintered ceramic plate having a thickness ranging from about 0.2 mm to about 0.4 mm, the sintered ceramic plate being adhered onto the dielectric film by the adhesive layer; a sensor disposed in the basic material for sensing a temperature; and a controller for receiving an output from the sensor and adjusting quantity of heat generated by the heater.

Owner:HITACHI HIGH-TECH CORP

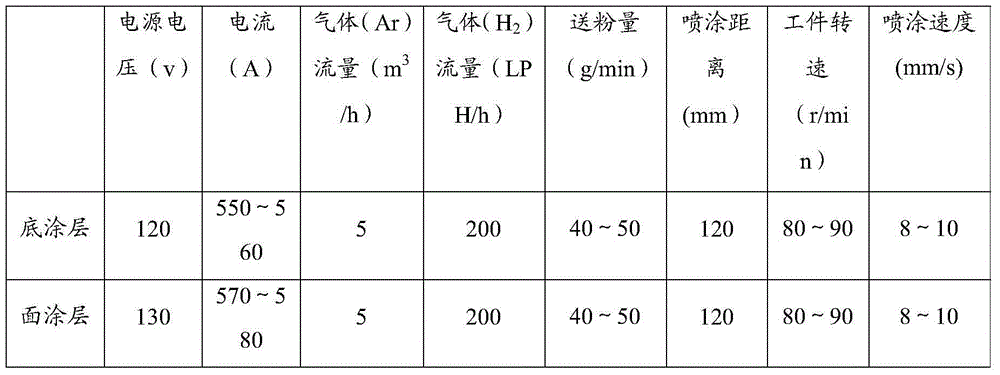

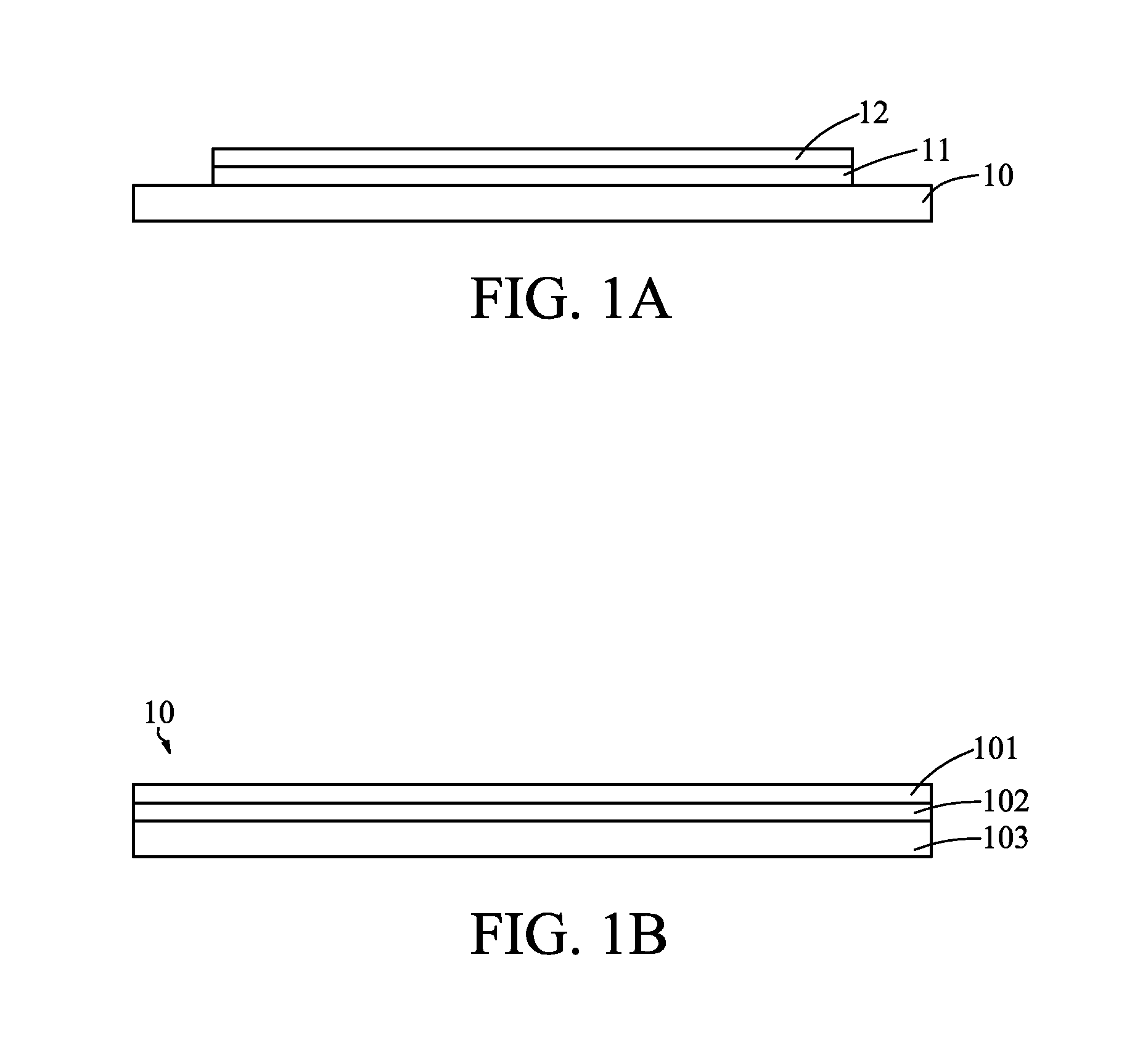

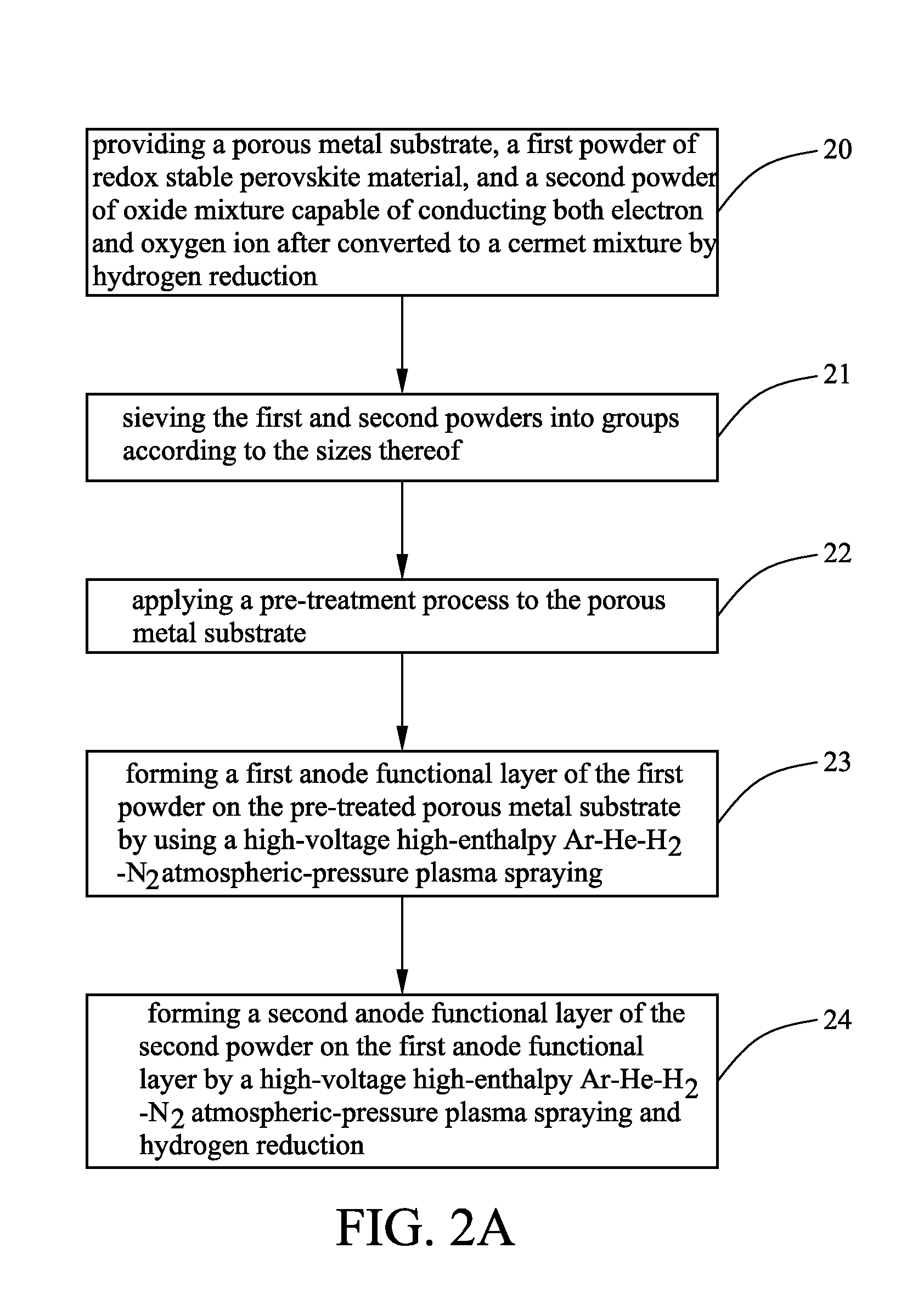

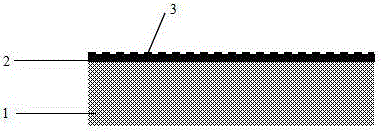

Anode on a pretreated substrate for improving redox-stability of solid oxide fuel cell and the fabrication method therof

ActiveUS20120021332A1Improve redox abilityDrag minimizationLiquid surface applicatorsMolten spray coatingOptoelectronicsHigh pressure

The disclosure provides a double-layer anode structure on a pretreated porous metal substrate and a method for fabricating the same, for improving the redox stability and decreasing the anode polarization resistance of a SOFC. The anode structure comprises: a porous metal substrate of high gas permeability; a first porous anode functional layer, formed on the porous metal substrate by a high-voltage high-enthalpy Ar—He—H2—N2 atmospheric-pressure plasma spraying process; and a second porous anode functional layer, formed on the first porous anode functional layer by a high-voltage high-enthalpy Ar—He—H2—N2 atmospheric-pressure plasma spraying and hydrogen reduction. The first porous anode functional layer is composed a redox stable perovskite, the second porous anode functional layer is composed of a nanostructured cermet. The first porous anode functional layer is also used to prevent the second porous anode functional layer from being diffused by the composition elements of the porous metal substrate.

Owner:INST NUCLEAR ENERGY RES ROCAEC

High-temperature-tolerance frequency selection wave-transmitting structure and preparation method thereof

ActiveCN106630979AImprove mechanical propertiesImprove electrical performanceLaser beam welding apparatusFiberElectrical conductor

The invention discloses a high-temperature-tolerance frequency selection wave-transmitting structure. The high-temperature-tolerance frequency selection wave-transmitting structure successively comprises a wave-transmitting layer, a modification bonding layer and a frequency selection layer from inside to outside, wherein the wave-transmitting layer is made of a continuous fiber reinforced ceramic-based wave-transmitting composite material; the modification bonding layer is made of a low-dielectric-constant material; the frequency selection layer is a noble metal physical plating layer or a noble metal glass conductor coating with periodic structure patterns. The high-temperature-tolerance frequency selection wave-transmitting structure can tolerate high temperature of 700 DEG C or more, and has excellent high temperature tolerance. The invention also provides a production method of the high-temperature-tolerance frequency selection wave-transmitting structure; the modification bonding layer is produced by using a plasma spraying process; the thermal damage to the substrate can be avoided, so that the substrate has high strength retention rate; the size accuracy of the frequency selection layer produced by a laser processing process can be higher than 20 microns; the frequency selection layer has high size accuracy.

Owner:NAT UNIV OF DEFENSE TECH +1

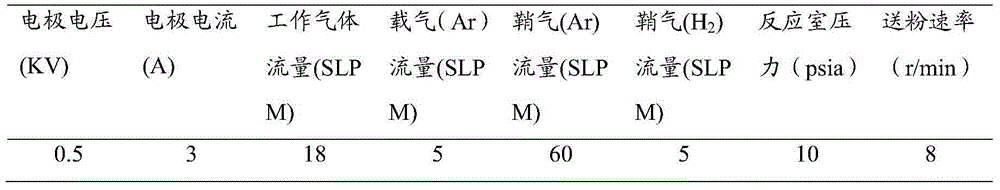

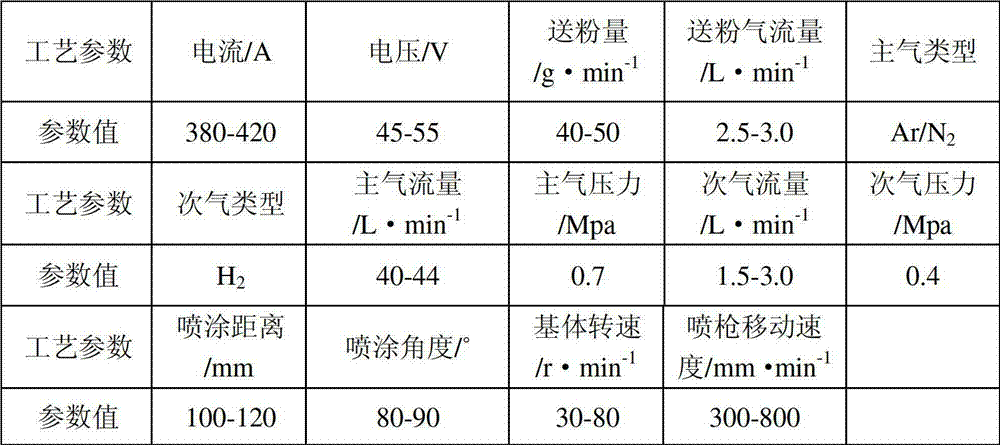

Preparation method of aluminum alloy wear-resistant coating

InactiveCN103103469AImprove bindingHigh bonding strengthMolten spray coatingWear resistantSand blasting

The invention relates to a preparation method of an aluminum alloy wear-resistant coating. The preparation method comprises the following steps of: carrying out sand blasting roughening treatment on the surface of an aluminum alloy matrix; spraying a metal alloy coating on the surface of the aluminum alloy matrix by using a plasma spraying system; subsequently spraying ceramic powder on the metal alloy coating by using the plasma spraying system so as to obtain the aluminum alloy wear-resistant coating, wherein the parameters of the plasma spraying process are as follows: the spraying distance is 80-100mm, the powder feeding rate is 60-65g / min, the argon flow is 30-40L / min, the hydrogen flow is 7-9L / min, the current is 55A and the voltage is 60-65V. The metal alloy coating is a Ni-Al alloy coating. The granularity of the Ni-Al alloy powder is 50-100mu m. The preparation method has the beneficial effects that the aluminum alloy wear-resistant coating with good binding strength is prepared by using a plasma spraying process, and due to the introduction of a Ni-Al transit layer, the aluminum alloy can be well bonded with the coating.

Owner:龙口市丛林铝材有限公司

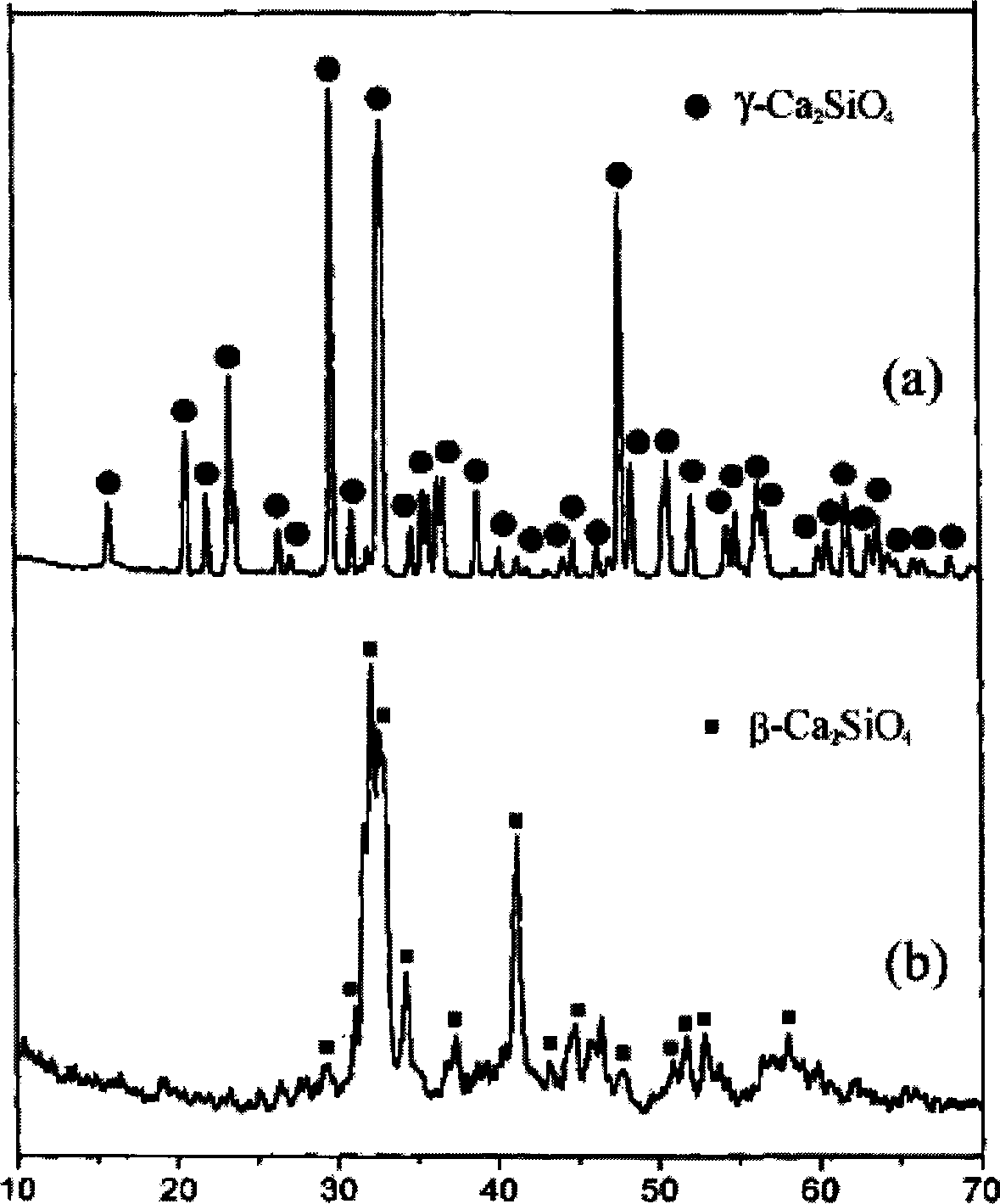

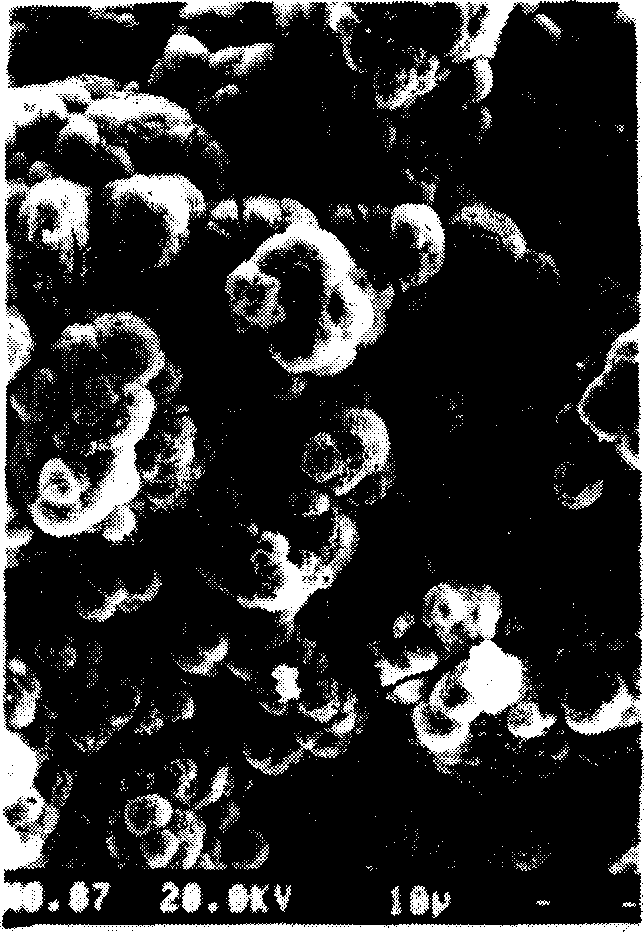

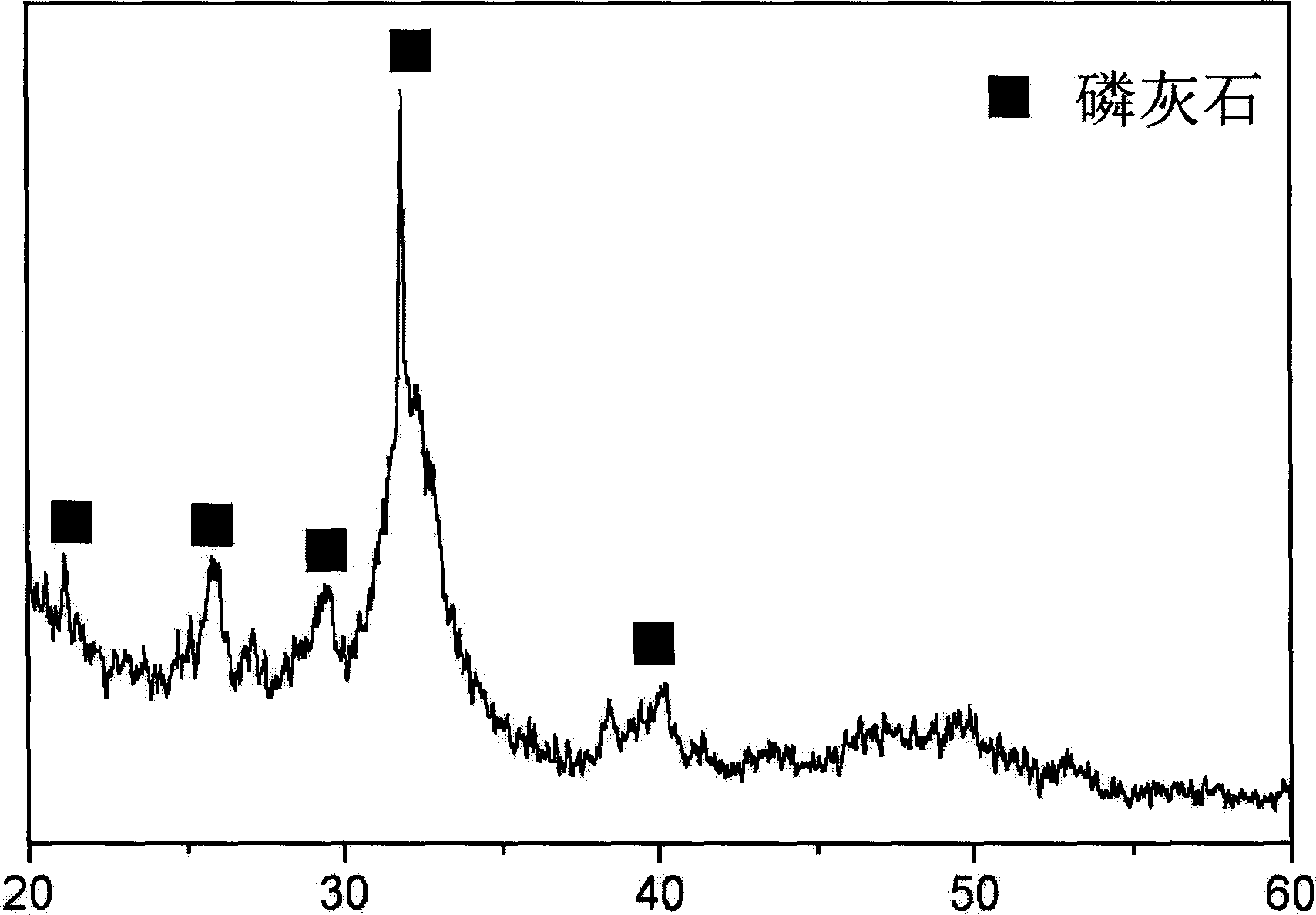

Dicalcium silicate coating layer-titanium alloy loading bone replacement material and its preparation method

The present invention relates to a bone substituted material. Said bone substitute material is dicalcium silicate coating layer deposited on the surface of titanium alloy of Ti-6Al-4V, said coating layer is formed from beta-Ca2SiO4 and glass phase, and its thickness if 50-400 micrometers. Its preparation method incldues the following steps: firstly, synthesizing gamma-Ca2SiO4, then using atmospheric plasma spraying process to deposit the dicalcium silicate coating layer on the titanium alloy base body, and the combination strength of said coating layer and base body is greater than 34-40 MPa.The tests show that the bone apatite can be formed on the surface of dicalcium silicate, and cell can quickly grow and proliferate on the beta-Ca2SiO4 coating layer surface, so that said substitute material possesses good biological activity and compatibility.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

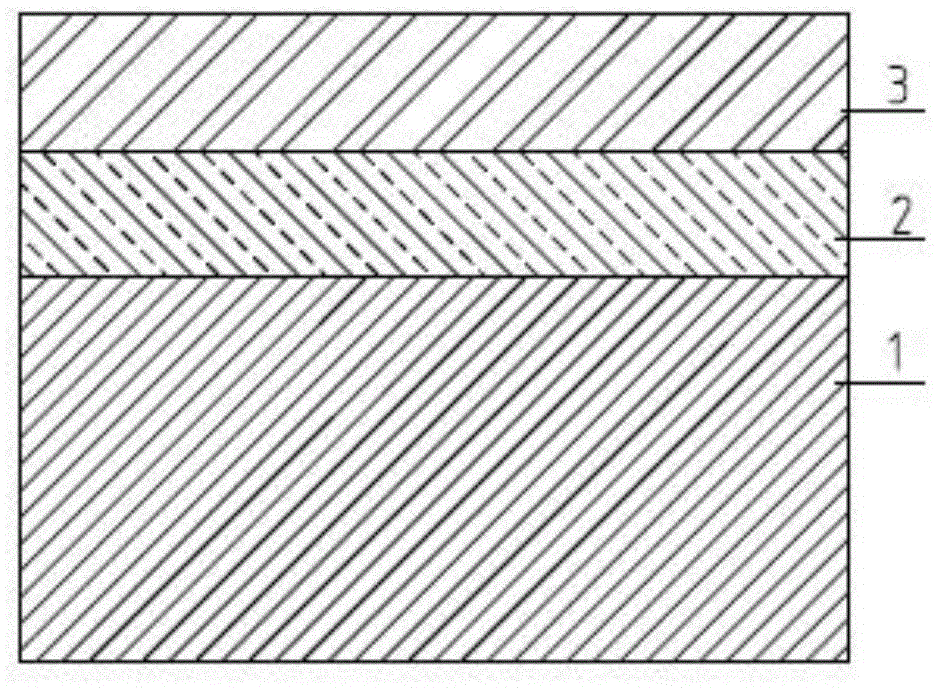

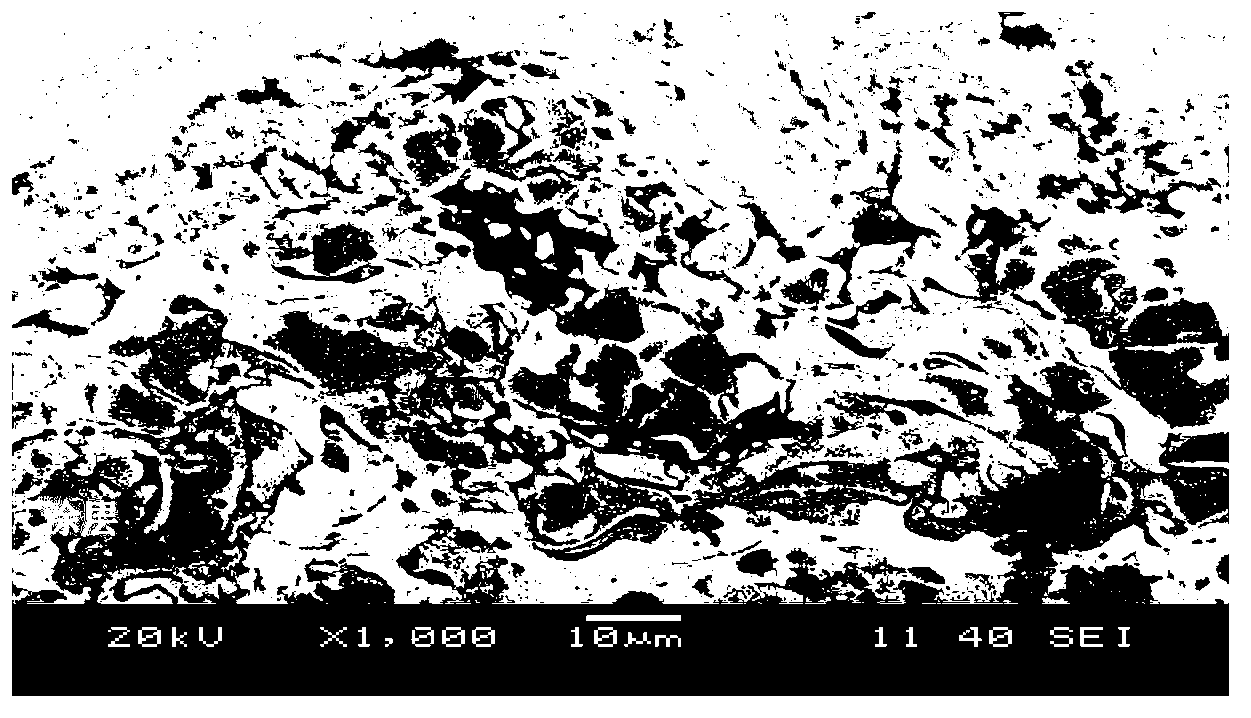

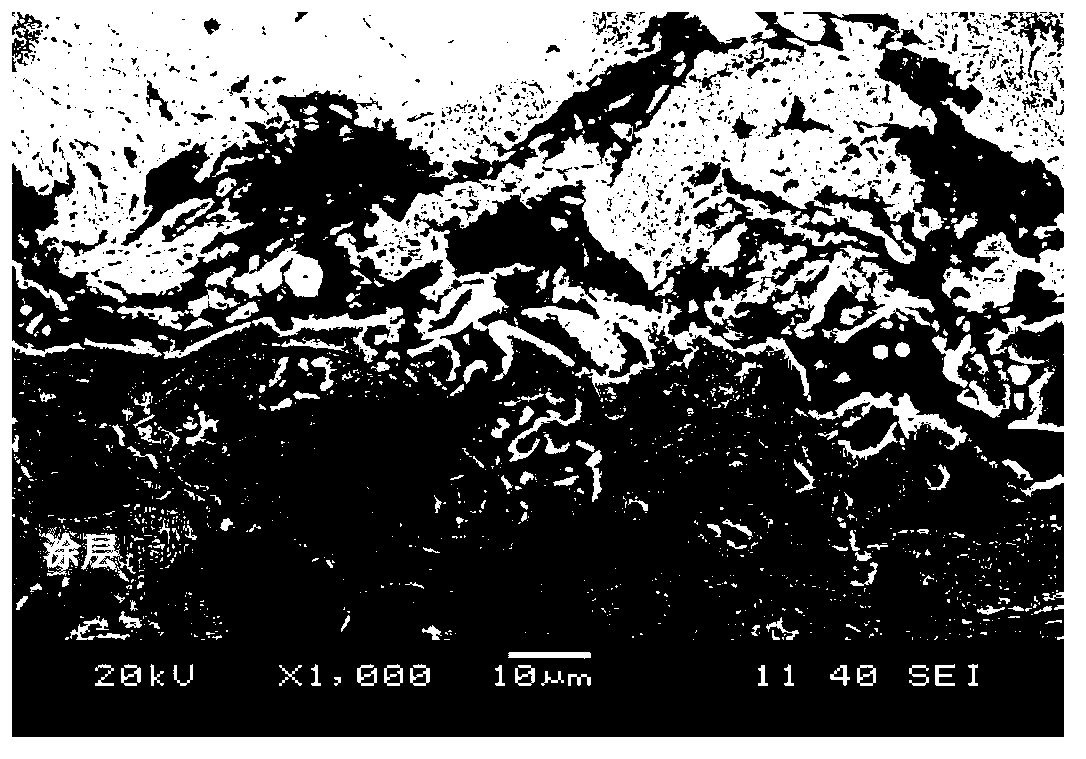

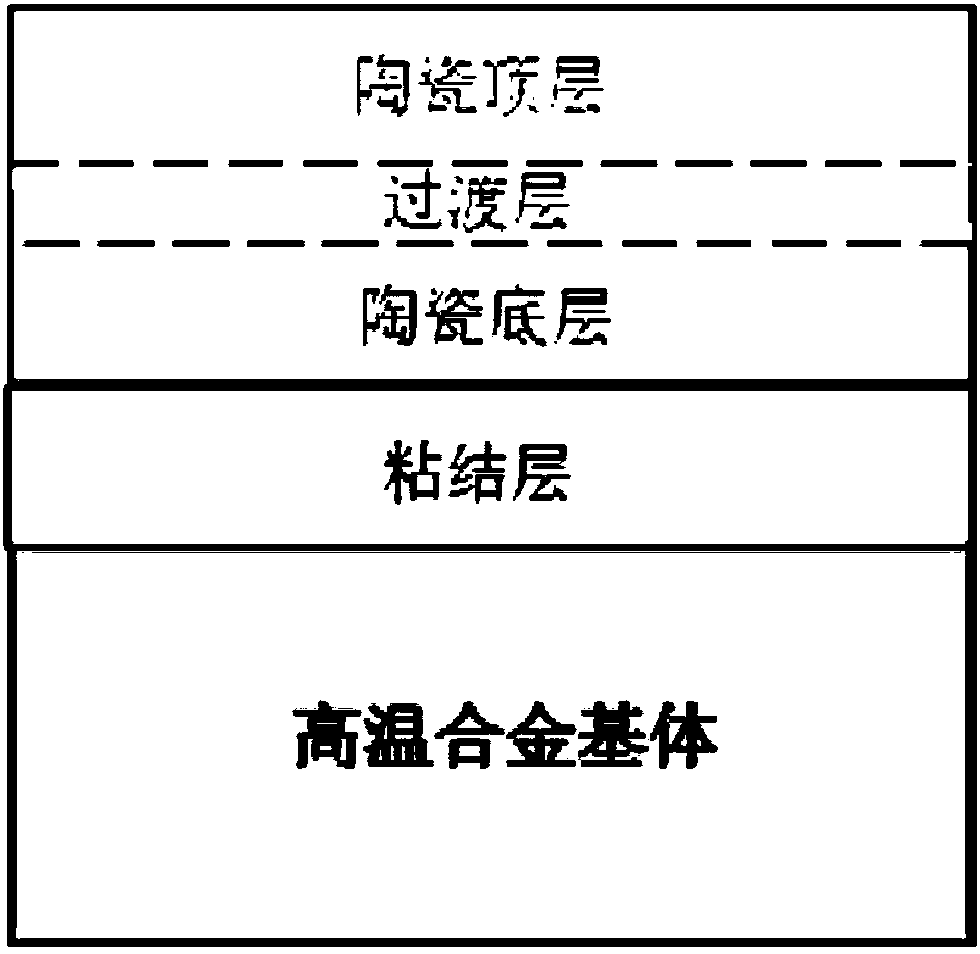

Gradient thermal barrier coating with continuous change of compositions at interface of double ceramic layers and preparation method of coating

ActiveCN108468011AImproved thermal shock lifeImprove the interface binding forceMolten spray coatingSurface layerThermal barrier coating

The invention discloses a gradient thermal barrier coating with continuous change of compositions at an interface of double ceramic layers and a preparation method of the coating. The gradient thermalbarrier coating has a substrate, a bonding layer, the ceramic underlayer, a transition layer and the ceramic surface layer which are disposed from bottom to top in sequence, wherein the compositionson the transition layer between the ceramic underlayer and the ceramic facing layer are continuously changed. The thermal barrier coating can be prepared by a plasma spraying process, and typical preparation processes include atmospheric plasma spraying, ultra-low pressure plasma physical multiphase deposition and the like. The obtained thermal barrier coating no longer has the problem of crackingand spalling at the interface of the double ceramic layers during thermal cycle, so that the thermal shock resistance life of the thermal barrier coating is greatly prolonged.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD +1

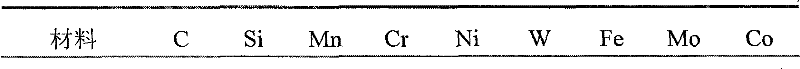

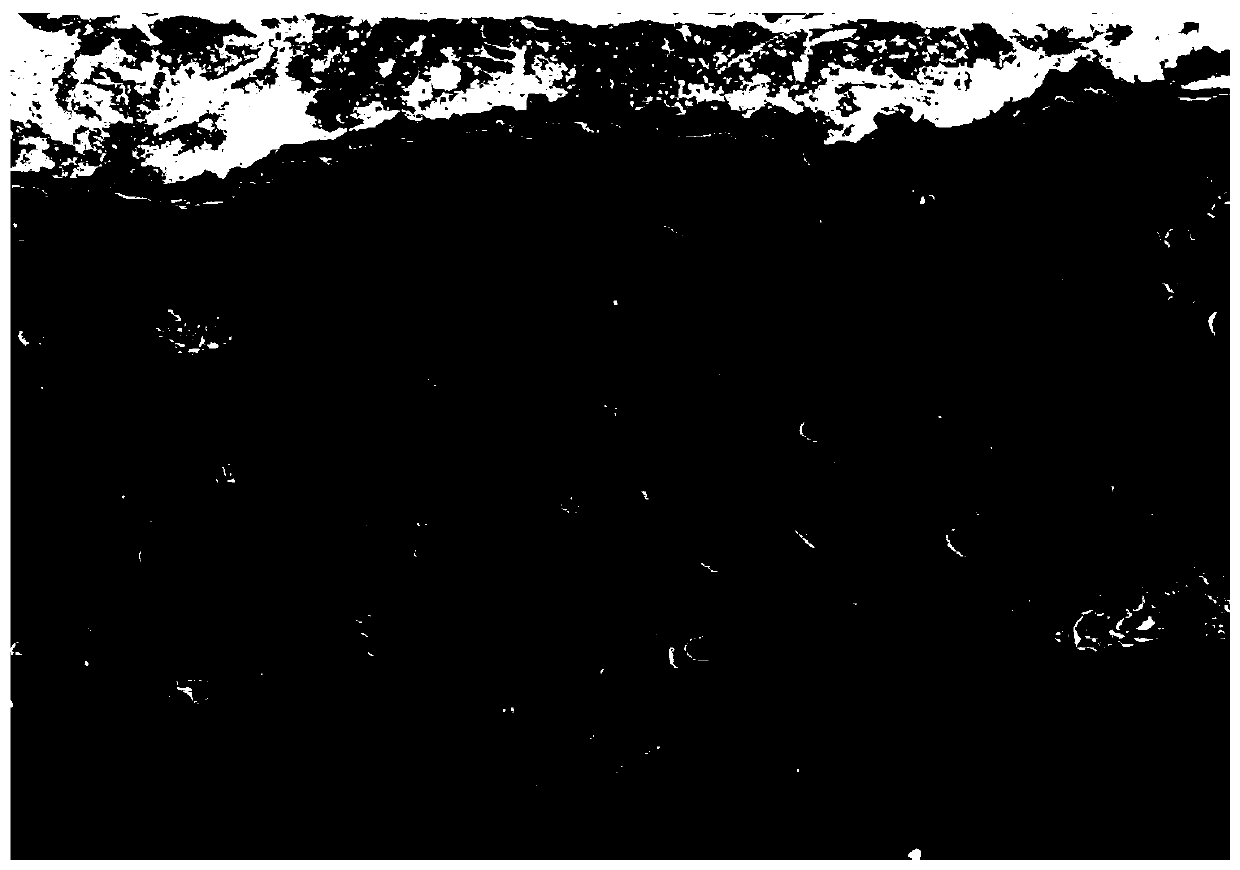

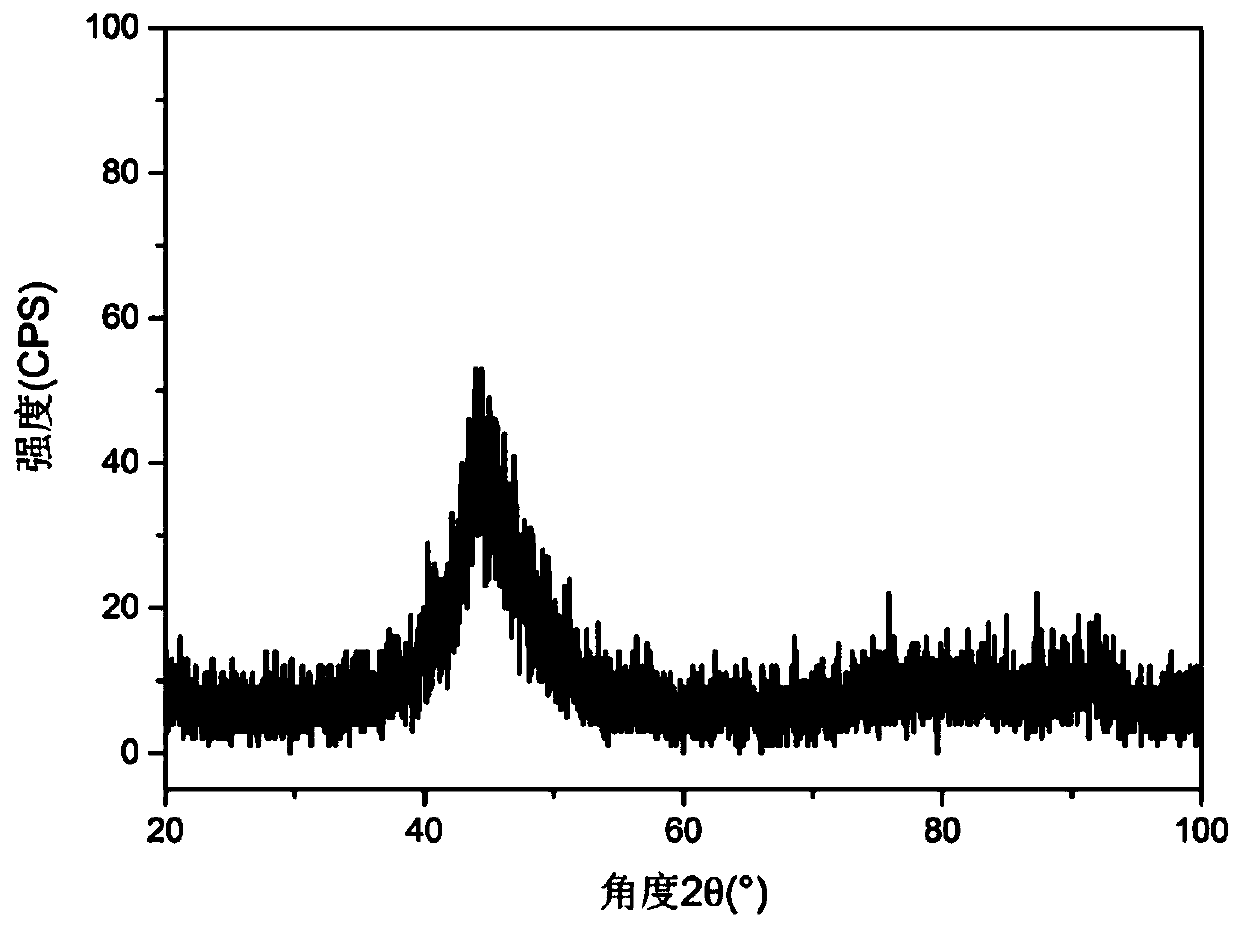

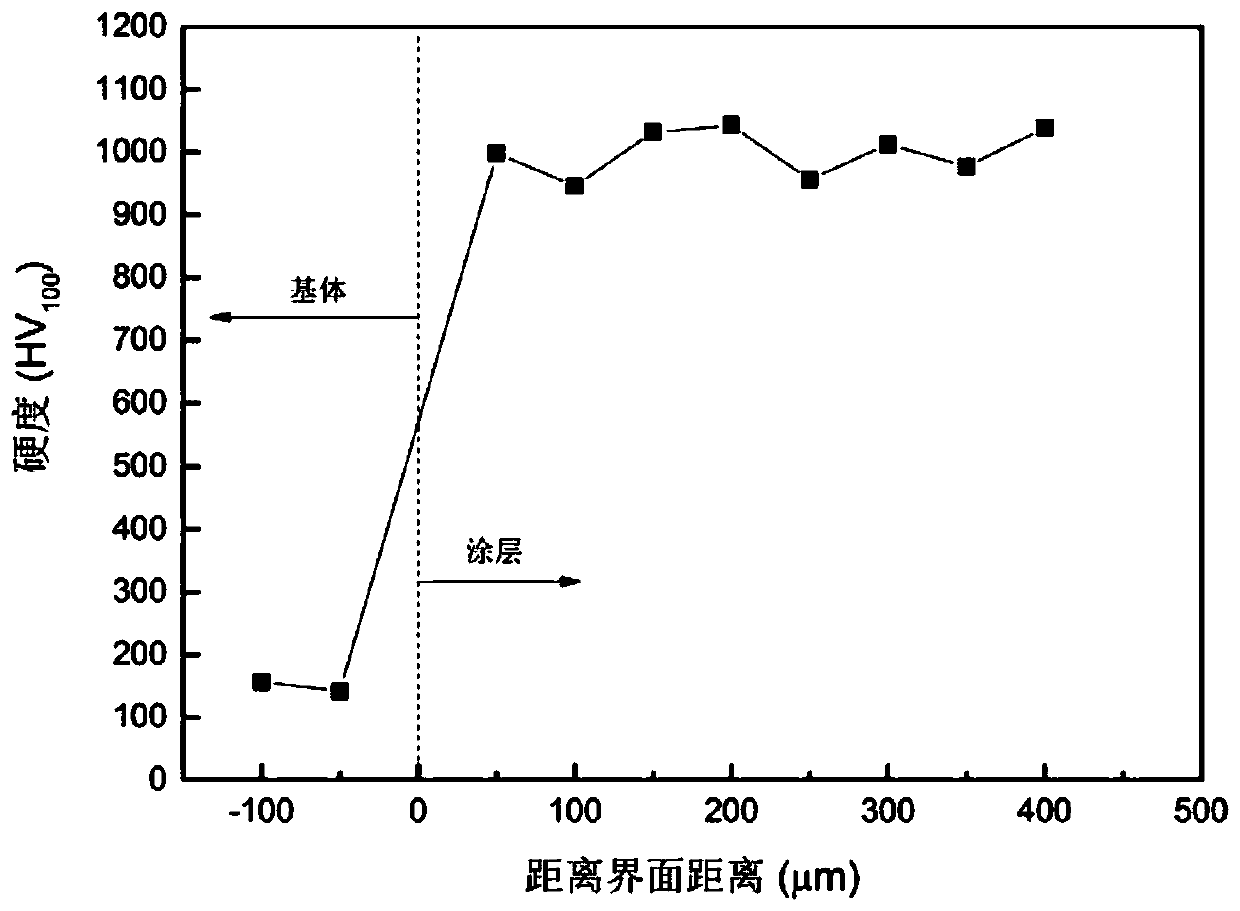

Plasma spraying high-temperature-erosion-resistant high-entropy amorphous powder and coating thereof, coating preparation method and application

InactiveCN110699629AImprove high temperature resistanceAccelerated corrosionMolten spray coatingSteam turbine bladePetrochemical

The invention discloses plasma spraying high-temperature-erosion-resistant high-entropy amorphous powder and a coating thereof, a coating preparation method and application. The high-entropy amorphouspowder is prepared through a vacuum induction gas atomization method. The powder comprises, by atomic percent, 20% of Fe, 20% of Co, 20% of Ni, 20% of Cr, 10% -16% of B and 4% -10% of Si; the particle size of the powder obtained after screening is 300-400 meshes. The preparation method of the high-entropy amorphous coating comprises the steps that (a) a workpiece is pretreated; (B) a high-entropyamorphous powder material is prepared; and (c) the high-entropy amorphous coating is prepared through a plasma spraying technology. The amorphous content of the high-entropy amorphous coating is morethan or equal to 98%, the porosity is smaller than 1%, the bonding strength is more than 50MPa, the Vickers hardness is more than 900Hv, and the excellent high-temperature-erosion-resistant performance is achieved. The plasma spraying high-temperature-erosion-resistant high-entropy amorphous powder can be widely applied to high-temperature-erosion-resistant and corrosion-resistant protection of key components such as power plant boilers, petrochemical engineering pipelines and smoke turbine blades, and the service life of mechanical engineering equipment can be remarkably prolonged.

Owner:HOHAI UNIV +1

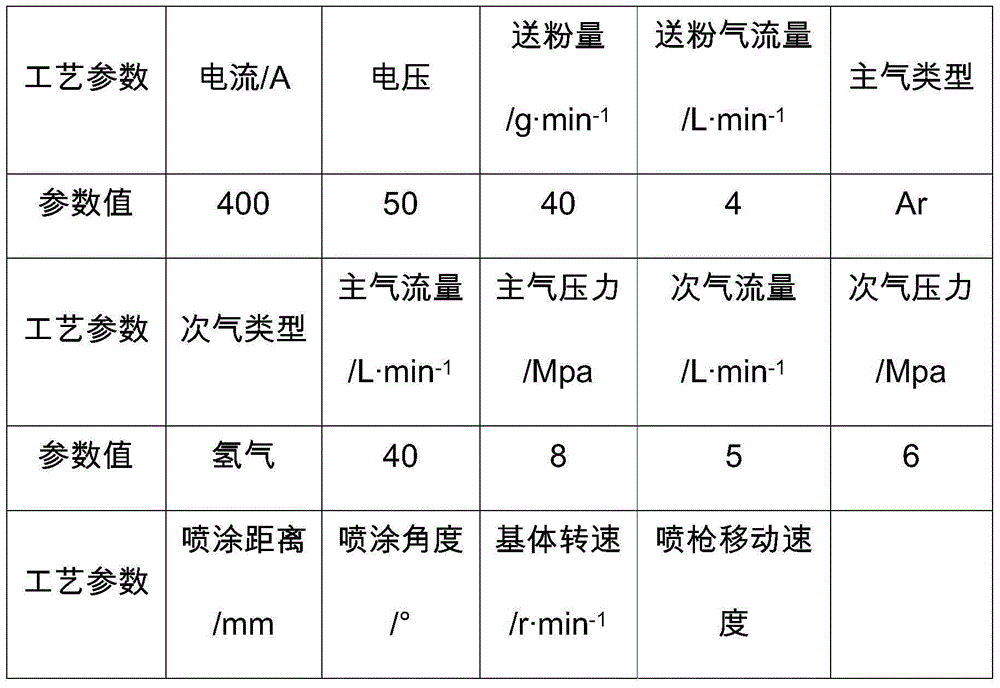

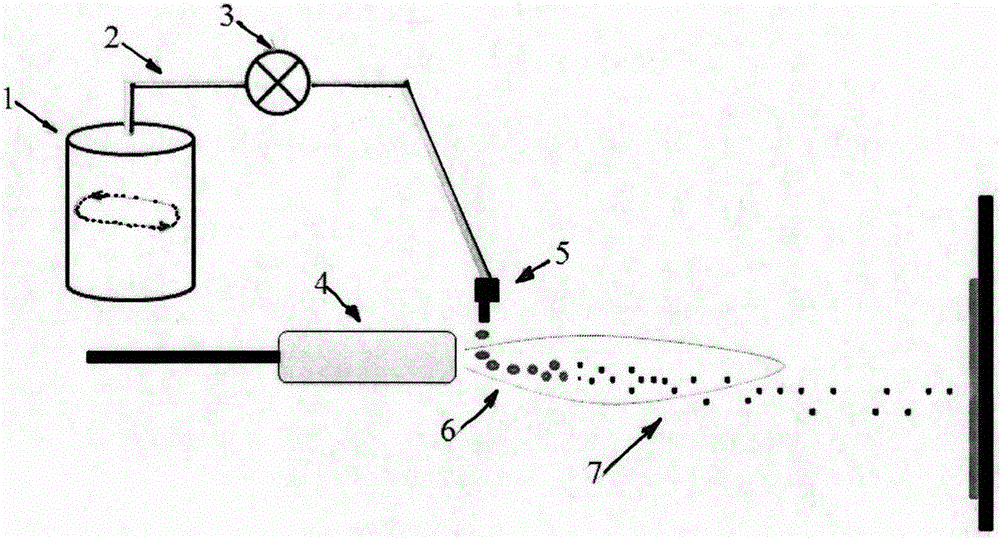

Conductive zirconia revolving target and preparation method thereof

ActiveCN104451582ACompact structureSimple production processVacuum evaporation coatingSputtering coatingPlasma spray processNanotechnology

The invention provides a conductive zirconia revolving target. The conductive zirconia revolving target is composed of ZrOx and has a density of 5.18-5.8 g / cm3, wherein X is larger than or equal to 1.2 and smaller than or equal to 1.8. The invention also provides a preparation method of the conductive zirconia revolving target. The method comprises preparing zirconia spraying powder; processing a spray substrate; spraying a priming coat; spraying a zirconia coating onto the spray substrate through a plasma spraying process. The conductive zirconia revolving target is compact in structure, uniform in composition, high in electrical conductivity, crackless and free from restriction to spray length and diameter can reach a thickness of 13 mm and a density of 5.18-5.8 g / cm3. The preparation method of the conductive zirconia revolving target is simple and convenient in production process and relatively low in cost.

Owner:江苏拓创新材料科技有限公司

Fiber reinforced high temperature thermal barrier composite ceramic thick coating material as well as preparation and application thereof

InactiveCN101518968AGood heat insulationIncreasing the thicknessLaminationLamination apparatusAtmospheric layerComposite ceramic

The invention relates to a fiber reinforced high temperature thermal barrier composite ceramic thick coating material. The fiber reinforced high temperature thermal barrier composite ceramic thick coating material has the following structure: spray coating layers having the 'concrete' action and reinforced layers which are arranged between the spray coating layers and have the 'steel bar' action are arranged in turn on the surface of a metallic matrix workpiece of a spray coating and cementing bottom layer; the spray coating layers at least have 3 layers and are prepared from a powdery composite coating material with double effects of high temperature thermal barrier and ablative heat protection by a plasma spraying process; and the reinforced layers are formed by high temperature fibers which wrap the spray coating layers in a paralleled or staggered mode for one or two times, and the use temperature of high temperature fibers is more than or equal to 700 DEG C. The material is prepared by the following steps: preparation of a matrix, spray coating, wrapping and the like. The material can be coated on the surfaces of various aircrafts moving at a high speed in the atmospheric layer through the plasma spraying process so as to have the actions of the high temperature thermal barrier and the ablative composite protective layer. The material can improve the upper limit of the working temperature of a metallic matrix in a high temperature environment and simultaneously prolong the service time of the metallic matrix in a high temperature extreme environment. The material has high practicability and is suitable for the industrialized production.

Owner:WUHAN UNIV OF TECH

Preparation method for hydroxylapatite coating

InactiveCN105648390AHigh crystallinityReduce residual stressMolten spray coatingPeristaltic pumpApatite

The invention relates to a preparation method for a hydroxylapatite coating. A liquid material which is a calcium salt solution precursor or hydroxylapatite suspension liquid serves as the feedstock. Plasma spraying or hypersonic flame spraying or common flame spraying thermal spraying flame flow serves as the heating means to heat liquid drops. The liquid material is injected into the flame flow through a pressure pump or a peristaltic pump, and after entering the flame flow, the liquid drops are subjected to all or a part of the processes of decomposition, evaporation, nucleation, growth, melting and acceleration and are deposited on a metallic matrix to form the coating. According to the preparation method for the hydroxylapatite coating, the defects that a hydroxylapatite coating in the plasma spraying process is prone to being decomposed, low in crystallinity, large in residual stress and the like are overcome; the flame flow is surrounded by water vapor which beneficially improves the crystallinity of the hydroxylapatite, accordingly, compared with a conventional coating method, reducing of the residual stress in the coating is facilitated through liquid material spraying, and the crystallinity of the hydroxylapatite coating is very high.

Owner:YANGZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com