Patents

Literature

716 results about "Distributed Bragg reflector" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

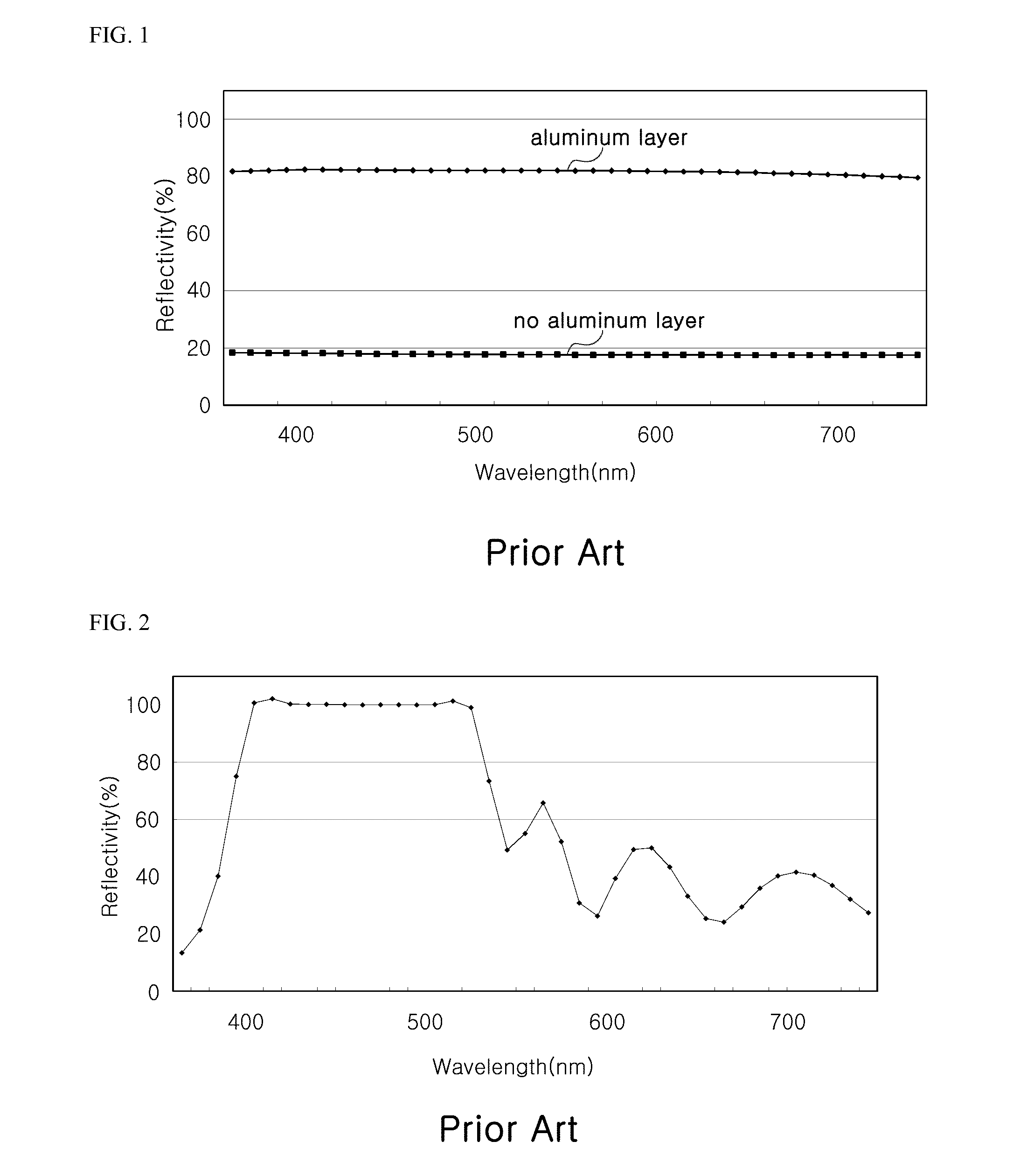

A distributed Bragg reflector (DBR) is a reflector used in waveguides, such as optical fibers. It is a structure formed from multiple layers of alternating materials with varying refractive index, or by periodic variation of some characteristic (such as height) of a dielectric waveguide, resulting in periodic variation in the effective refractive index in the guide. Each layer boundary causes a partial reflection of an optical wave. For waves whose vacuum wavelength is close to four times the optical thickness of the layers, the many reflections combine with constructive interference, and the layers act as a high-quality reflector. The range of wavelengths that are reflected is called the photonic stopband. Within this range of wavelengths, light is "forbidden" to propagate in the structure.

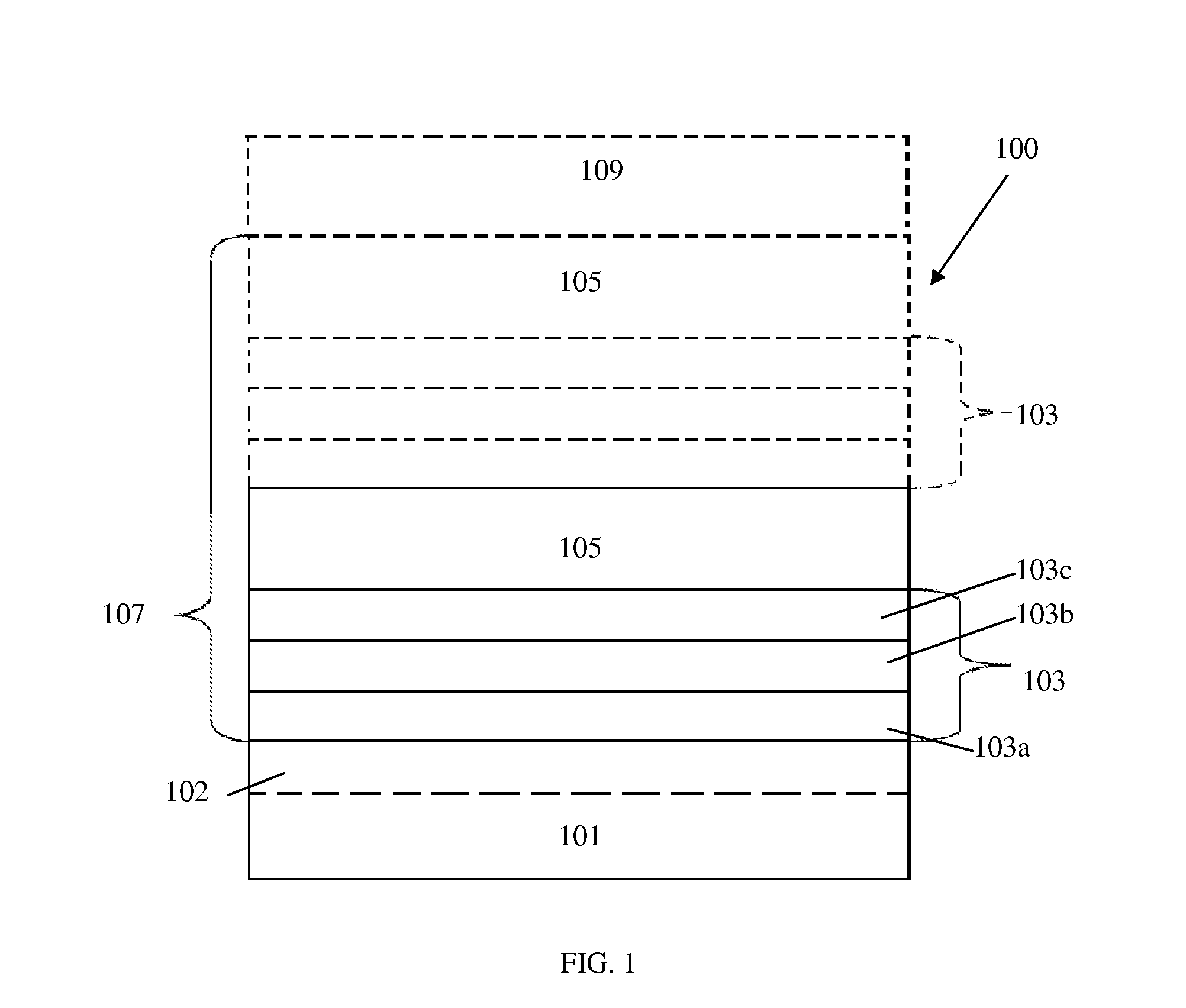

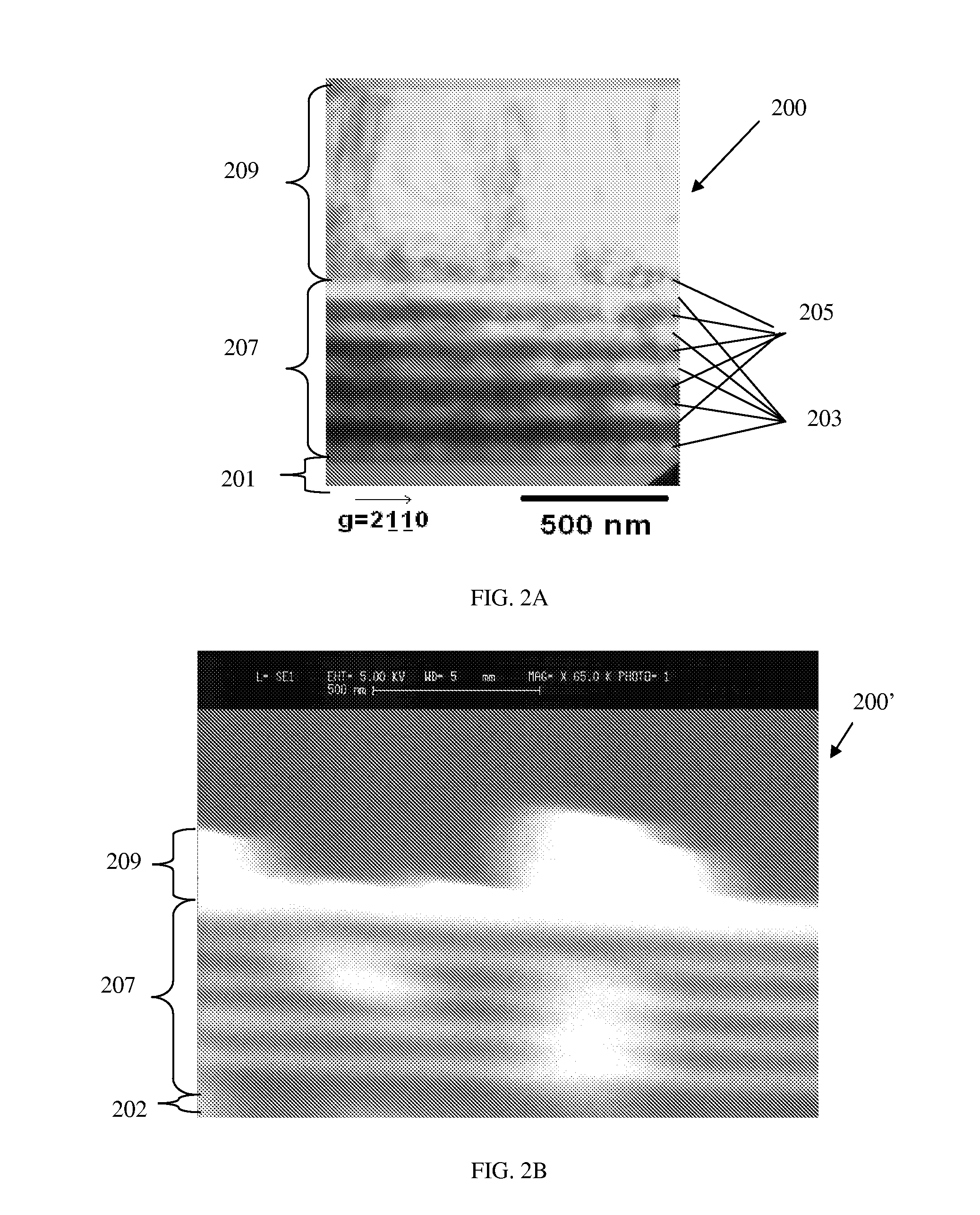

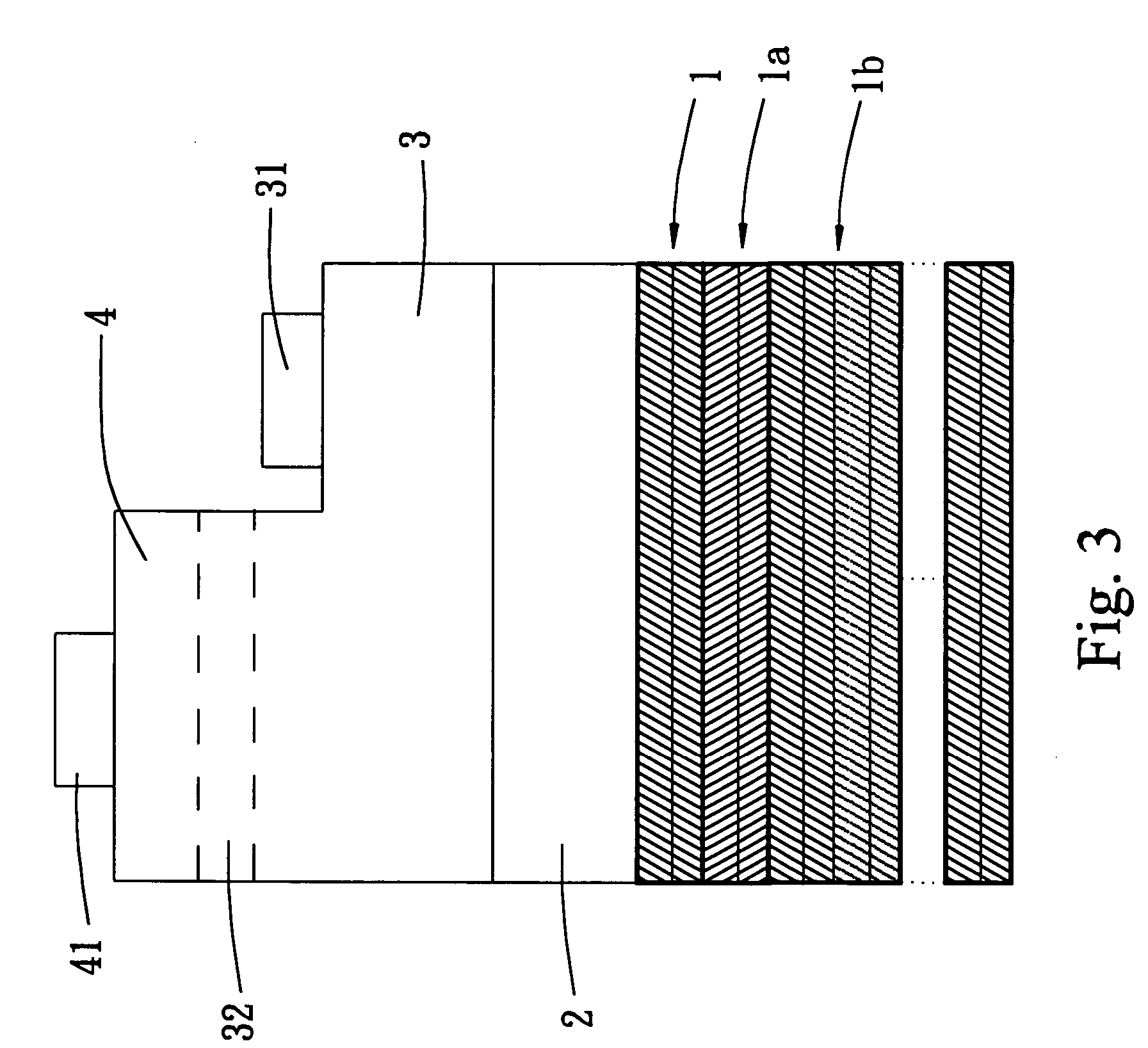

Group iii-nitride growth on silicon or silicon germanium substrates and method and devices therefor

InactiveUS20080128745A1Laser detailsSemiconductor/solid-state device manufacturingPhotovoltaic detectorsPhotodetector

A structure including a Si1-xGex substrate and a distributed Bragg reflector layer disposed directly onto the substrate. The distributed Bragg reflector layer includes a repeating pattern that includes at least one aluminum nitride layer and a second layer having the general formula AlyGa1-yN. Another aspect of the present invention is various devices including this structure. Another aspect of the present invention is directed to a method of forming such a structure comprising providing a Si1-xGex substrate and depositing a distributed Bragg reflector layer directly onto the substrate. Another aspect of the present invention is directed to a photodetector or photovoltaic cell device, including a Si1-xGex substrate device, a group III-nitride device and contacts to provide a conductive path for a current generated across at least one of the Si1-xGex substrate device and the group III-nitride device upon incident light.

Owner:NAVY U S A AS REPRESENTED BY THE SEC OF THE THE

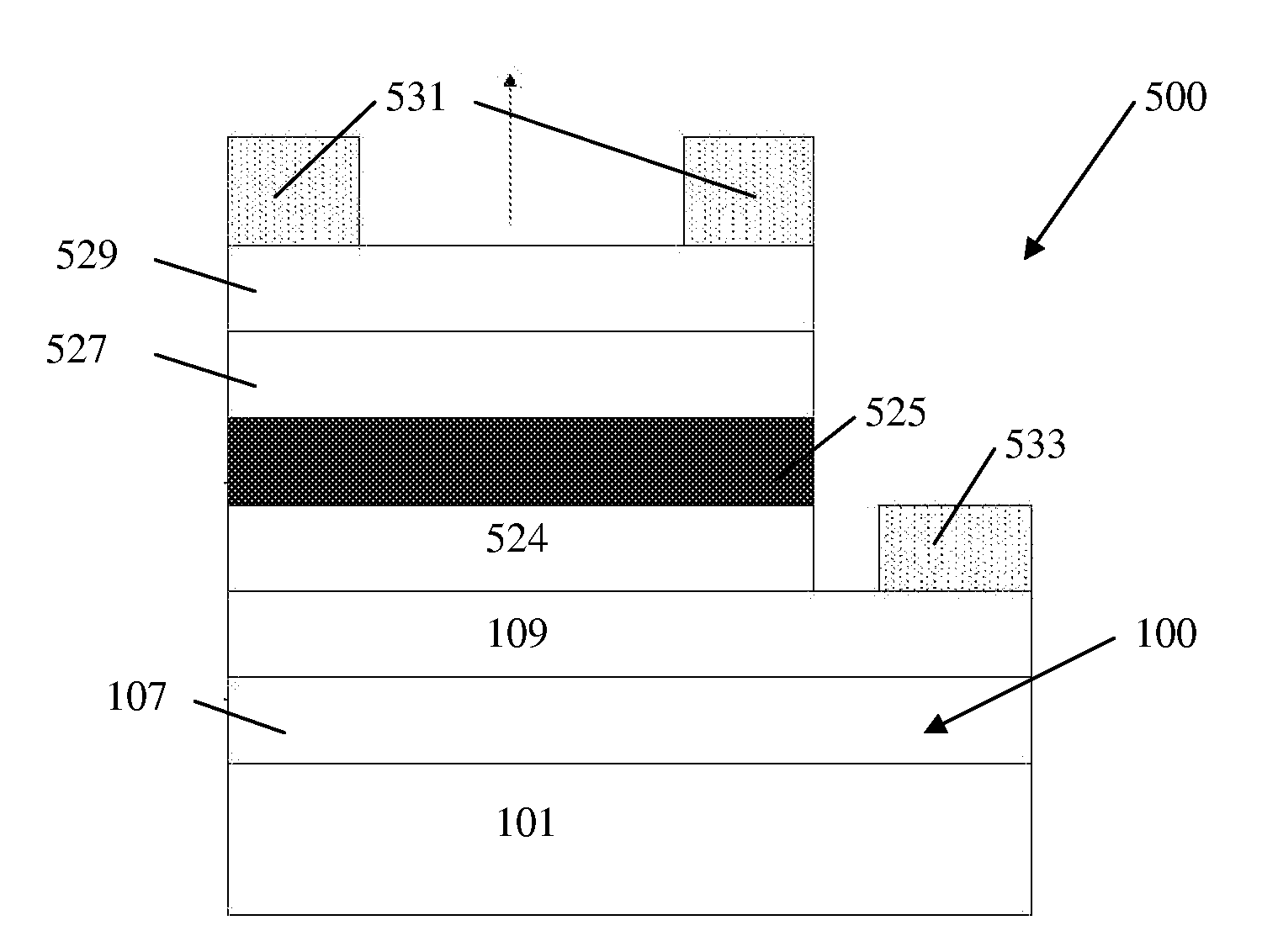

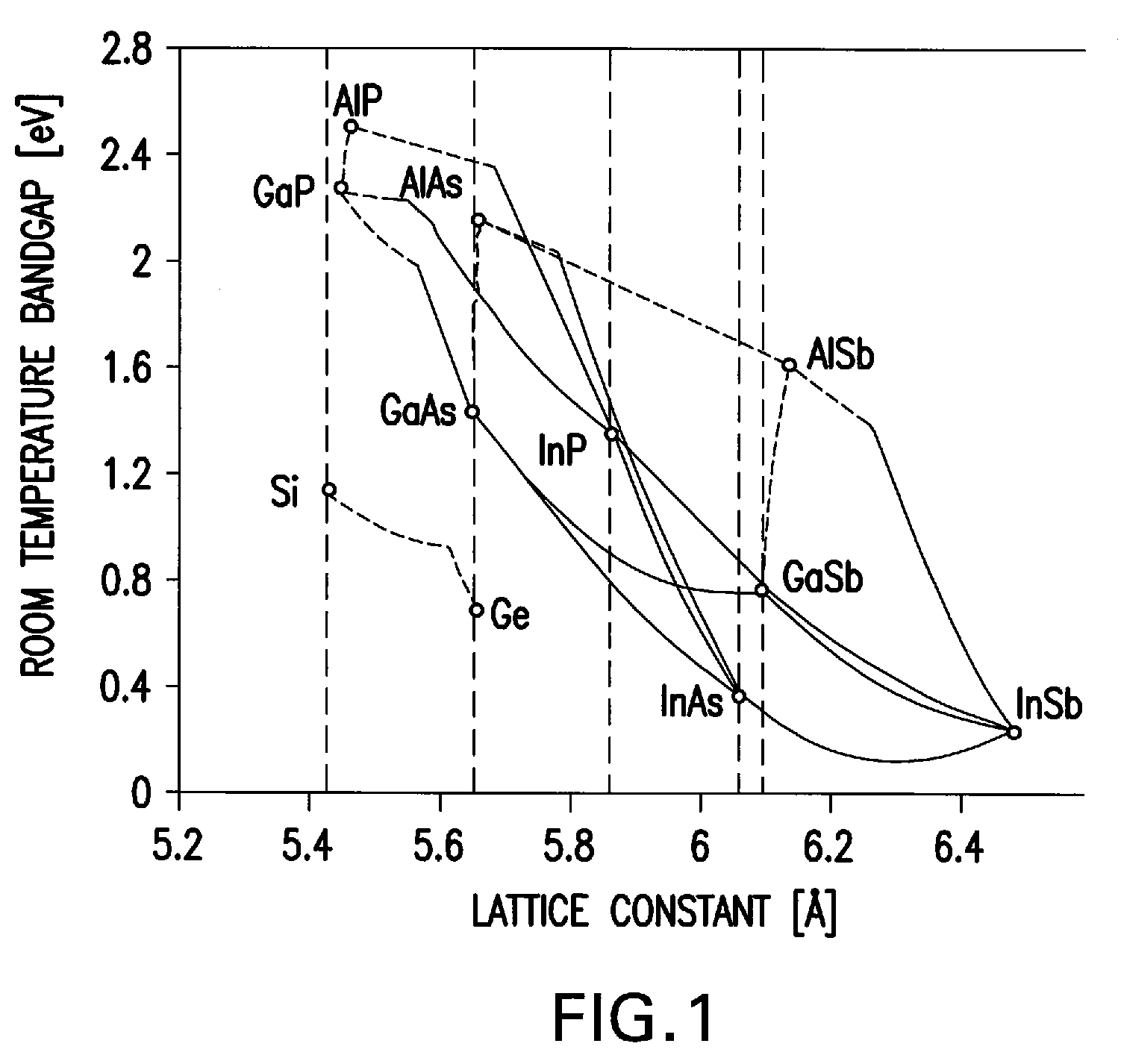

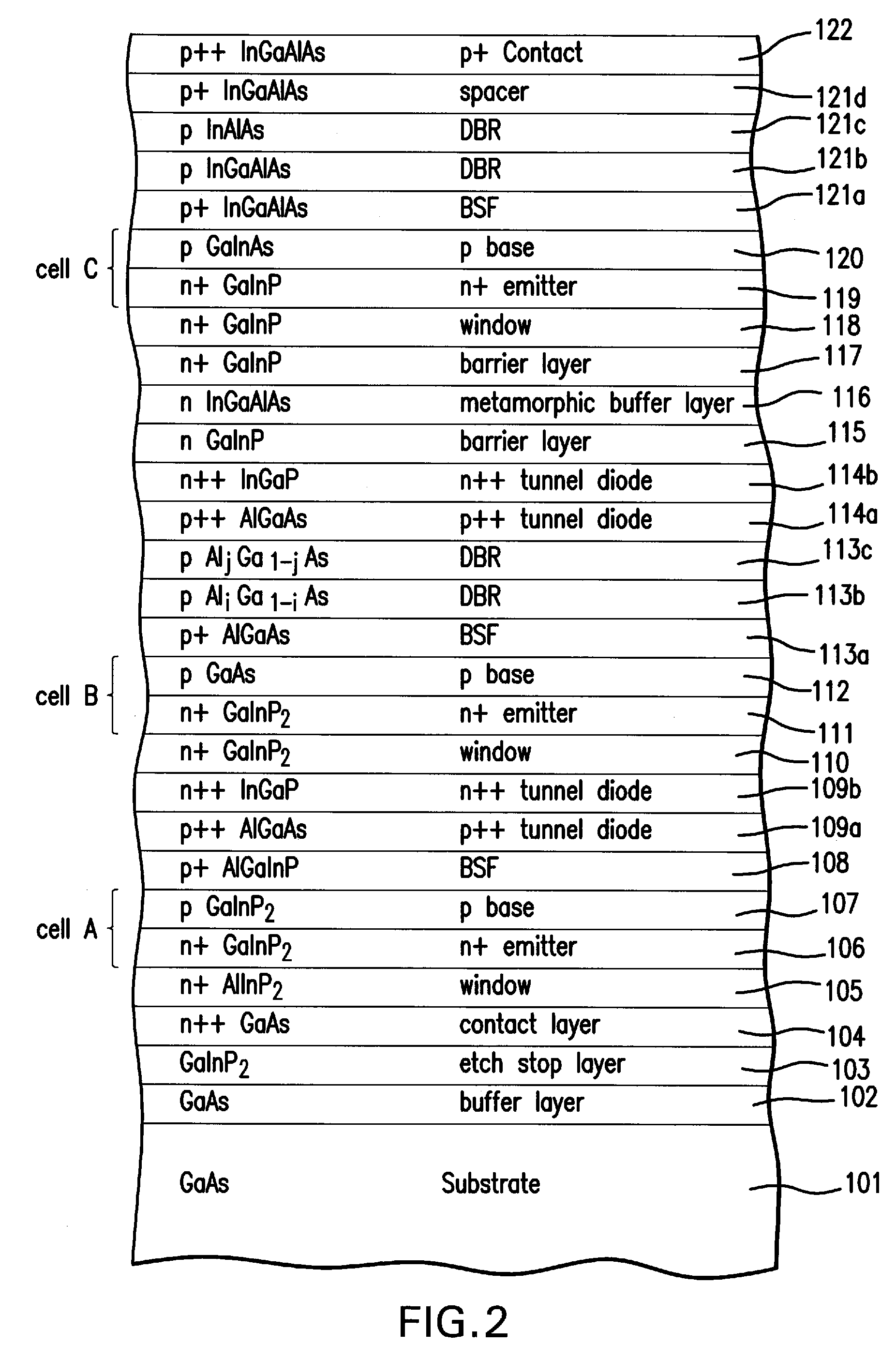

Inverted Metamorphic Multijunction Solar Cells with Distributed Bragg Reflector

InactiveUS20100147366A1Final product manufactureSemiconductor/solid-state device manufacturingLattice mismatchDistributed Bragg reflector

A multijunction solar cell including an upper first solar subcell having a first band gap; a middle second solar subcell adjacent to the first solar subcell and having a second band gap smaller than the first band gap, and having a base layer and an emitter layer, a graded interlayer adjacent to the second solar subcell; the graded interlayer having a third band gap greater than said second band gap; a third solar subcell adjacent to the interlayer, the third subcell having a fourth band gap smaller than the second band gap such that the third subcell is lattice mismatched with respect to the second subcell; and a distributed Bragg reflector (DBR) adjacent the second or third subcell.

Owner:EMCORE SOLAR POWER

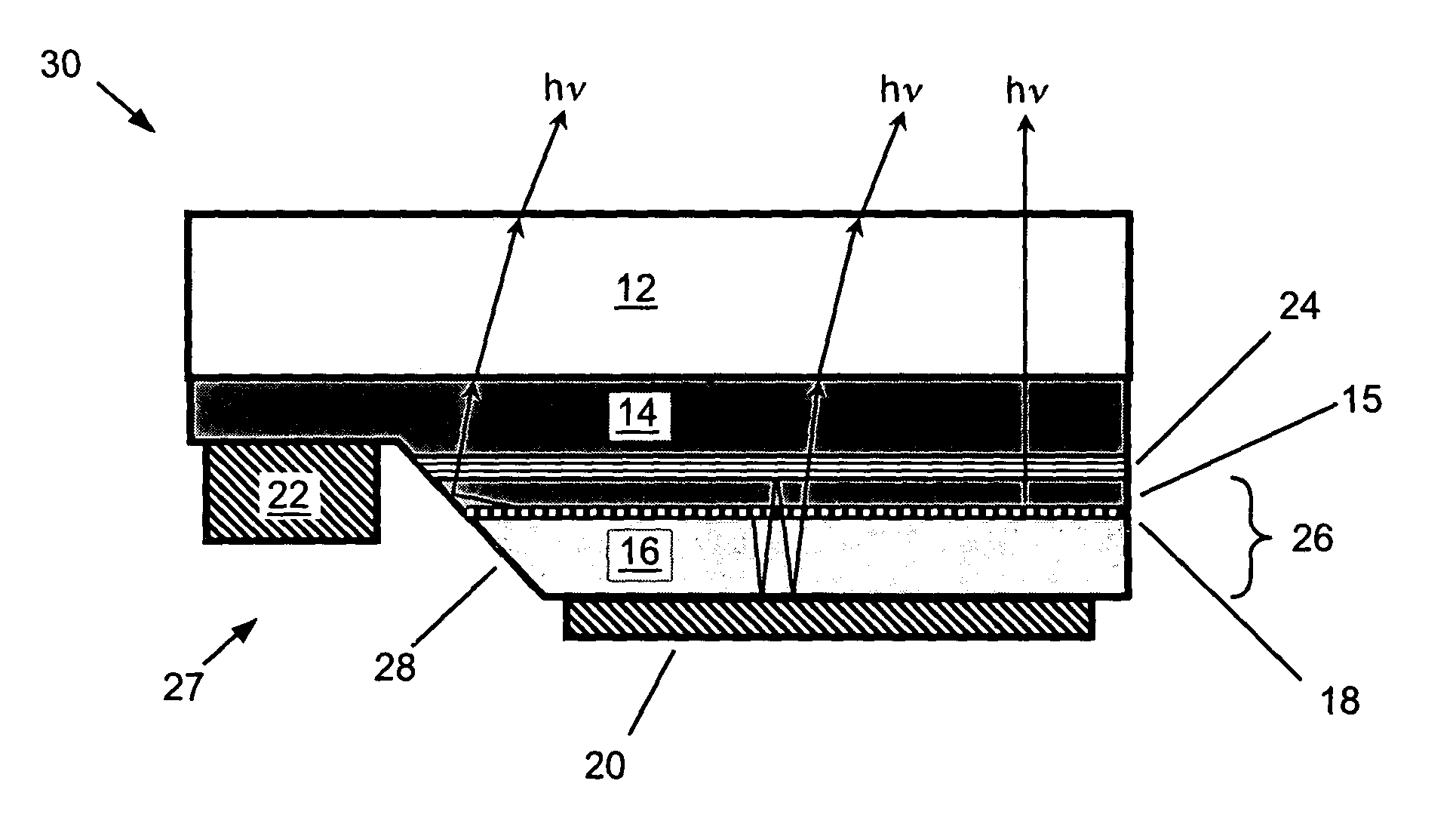

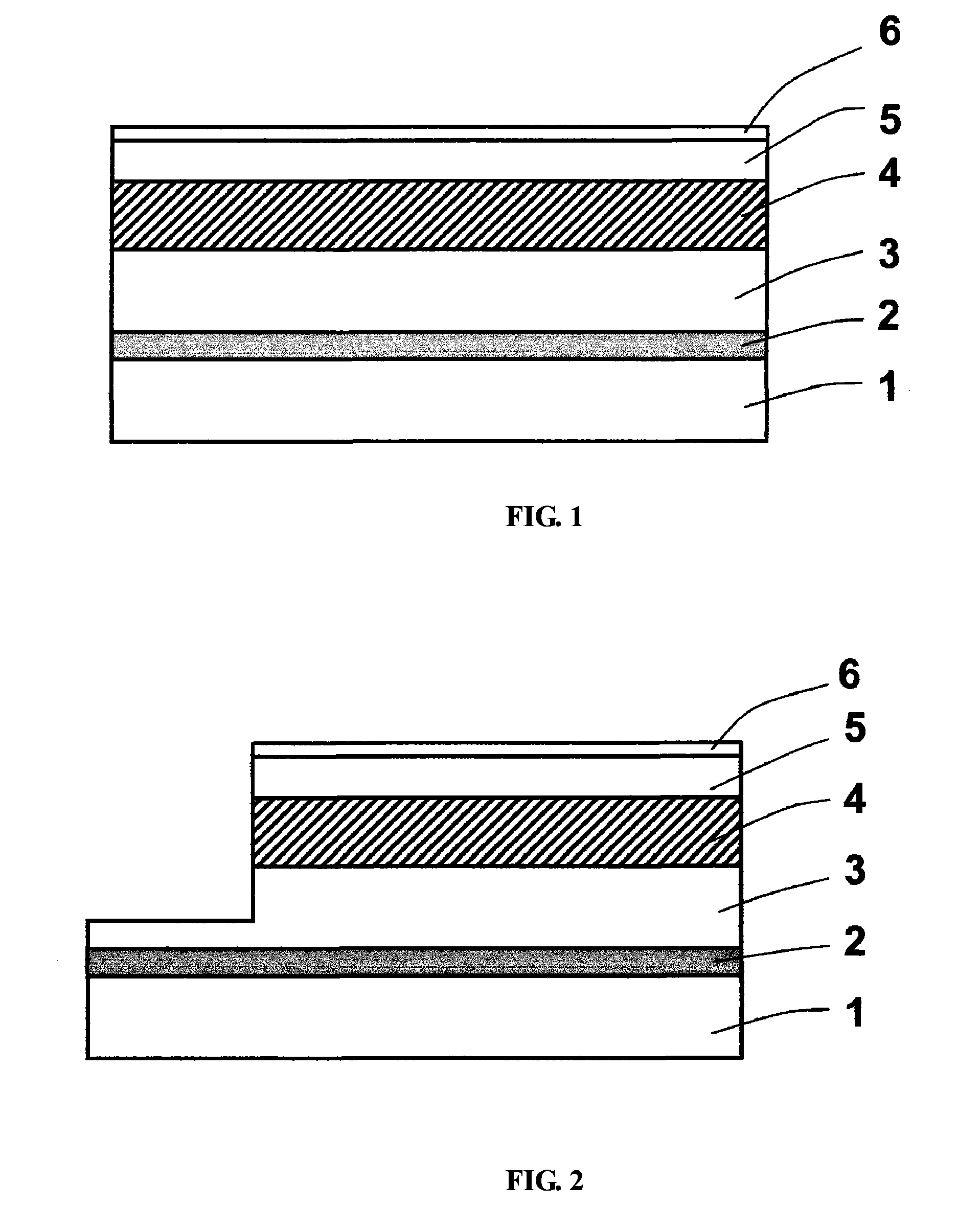

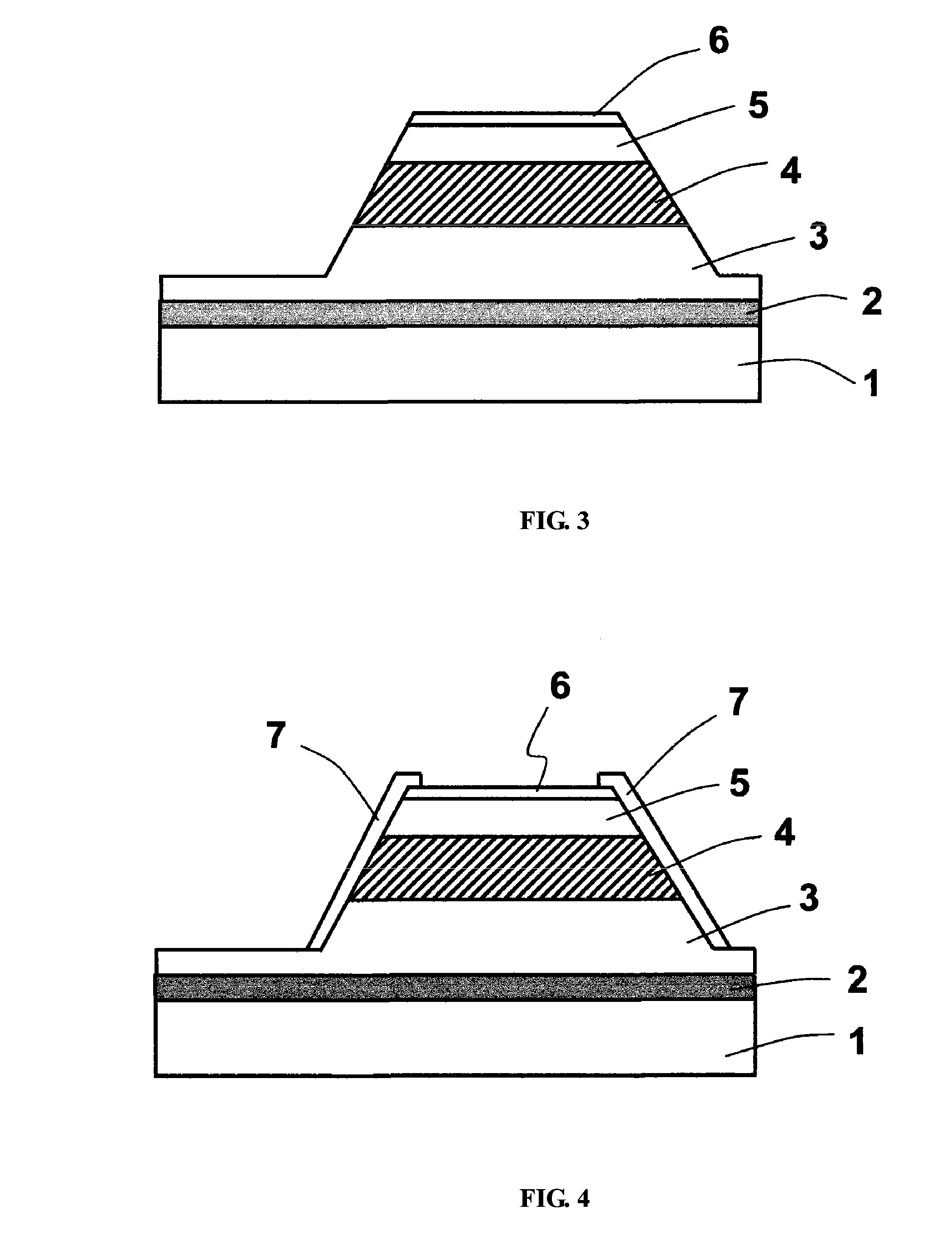

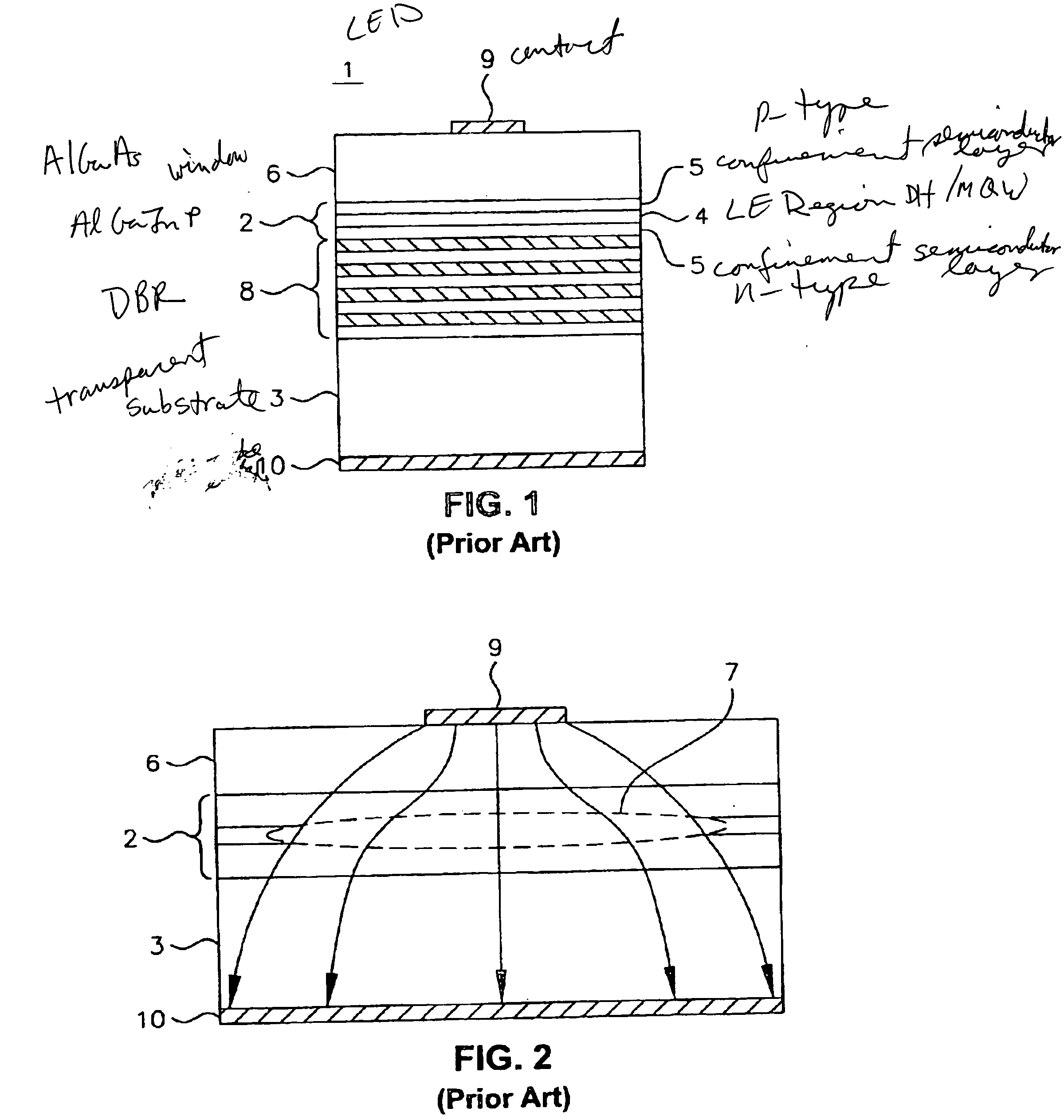

Flip-chip light emitting diode with resonant optical microcavity

InactiveUS6969874B1Improve efficiencyAccelerate emissionsSolid-state devicesSemiconductor devicesDielectric substrateGallium nitride

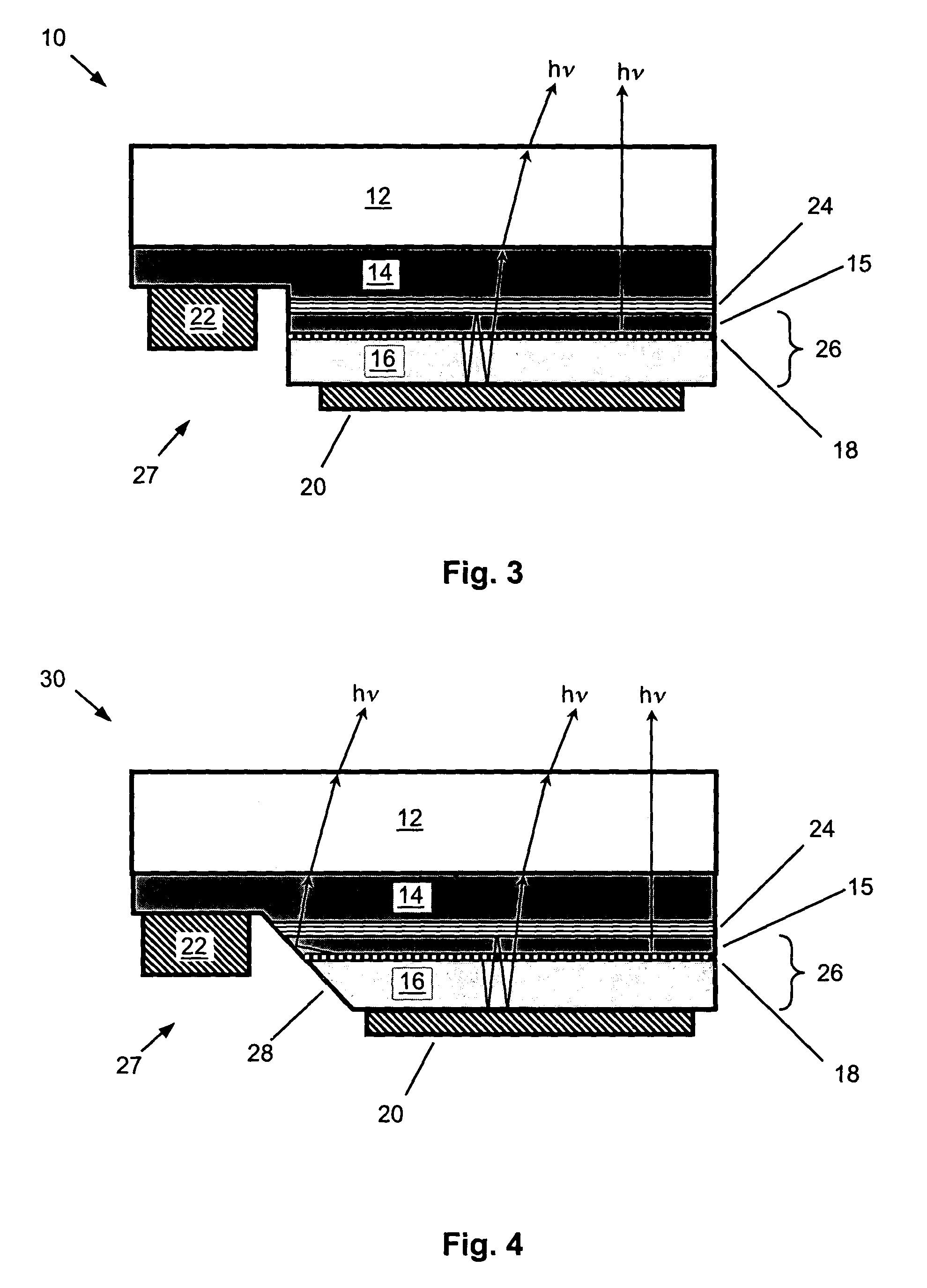

A flip-chip light emitting diode with enhanced efficiency. The device structure employs a microcavity structure in a flip-chip configuration. The microcavity enhances the light emission in vertical modes, which are readily extracted from the device. Most of the rest of the light is emitted into waveguided lateral modes. Flip-chip configuration is advantageous for light emitting diodes (LEDs) grown on dielectric substrates (e.g., gallium nitride LEDs grown on sapphire substrates) in general due to better thermal dissipation and lower series resistance. Flip-chip configuration is advantageous for microcavity LEDs in particular because (a) one of the reflectors is a high-reflectivity metal ohmic contact that is already part of the flip-chip configuration, and (b) current conduction is only required through a single distributed Bragg reflector. Some of the waveguided lateral modes can also be extracted with angled sidewalls used for the interdigitated contacts in the flip-chip configuration.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

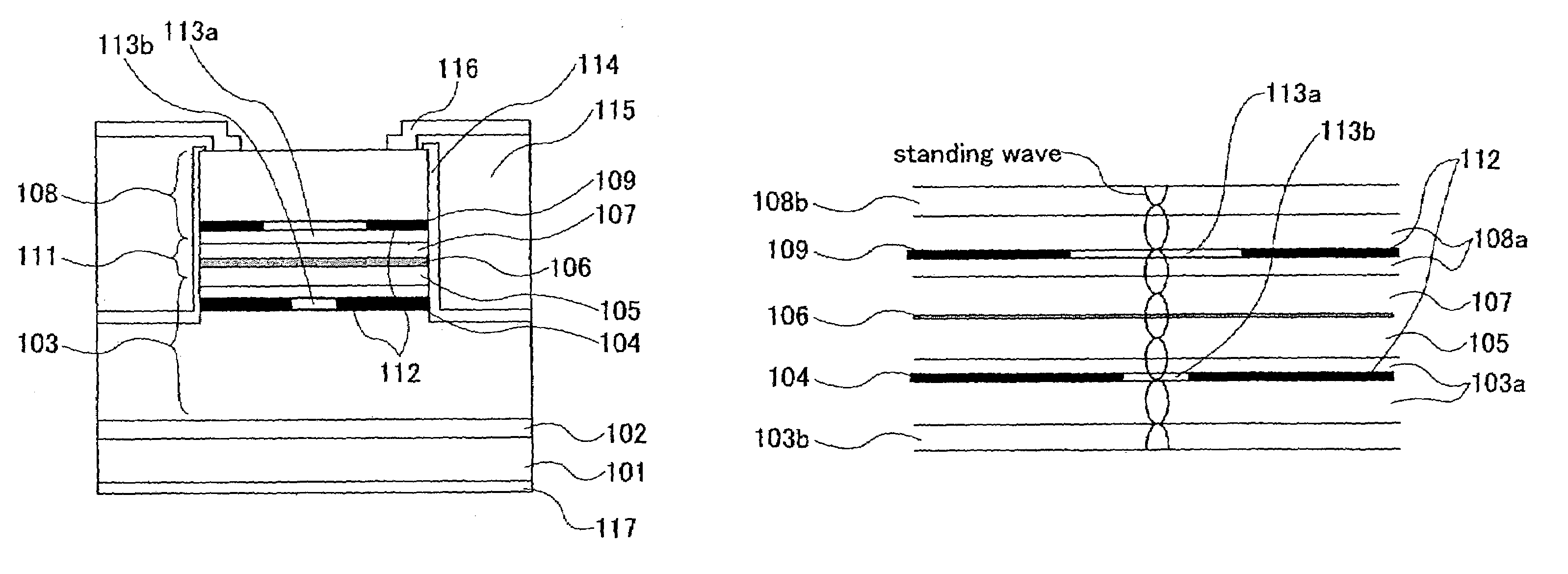

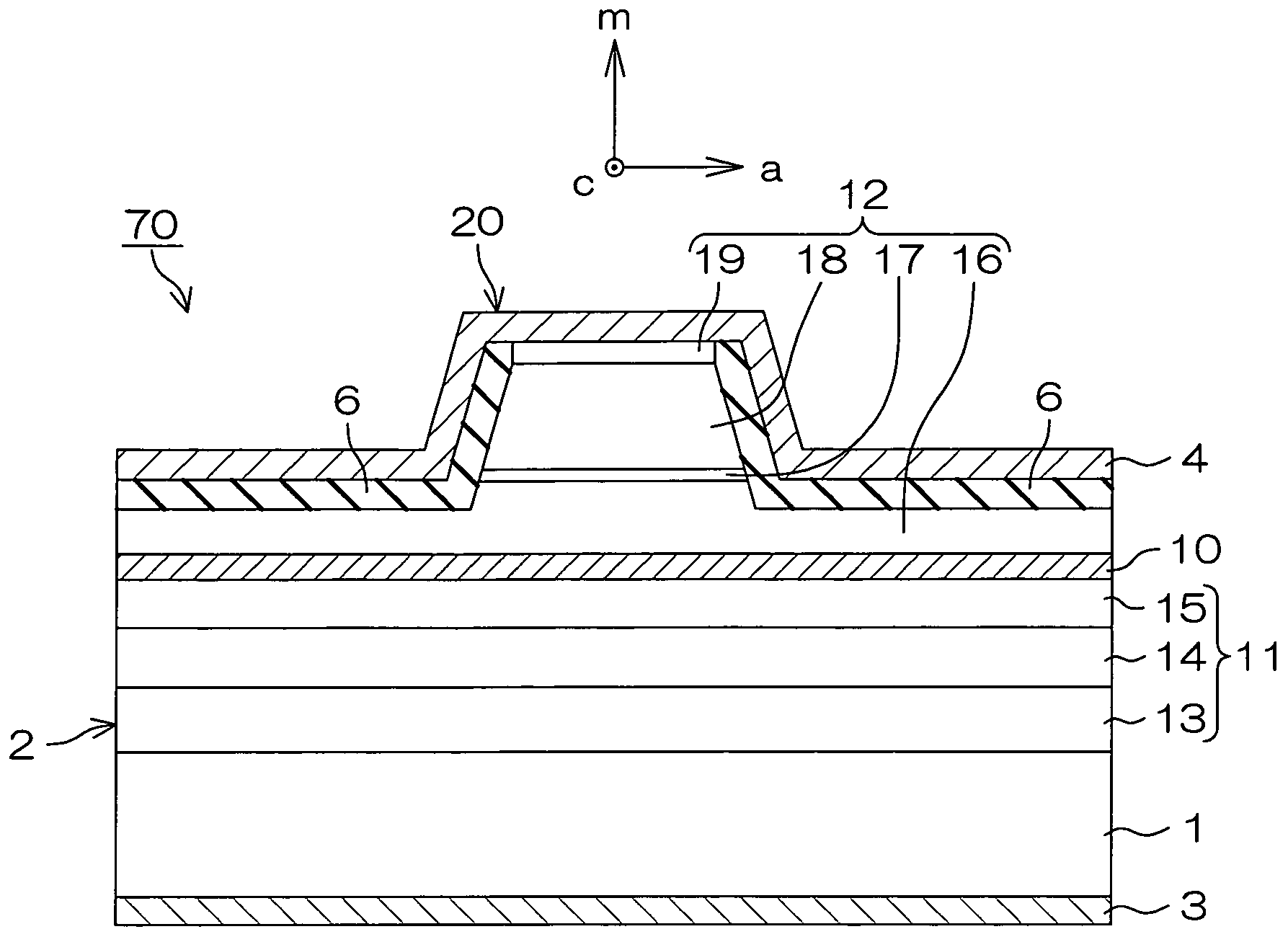

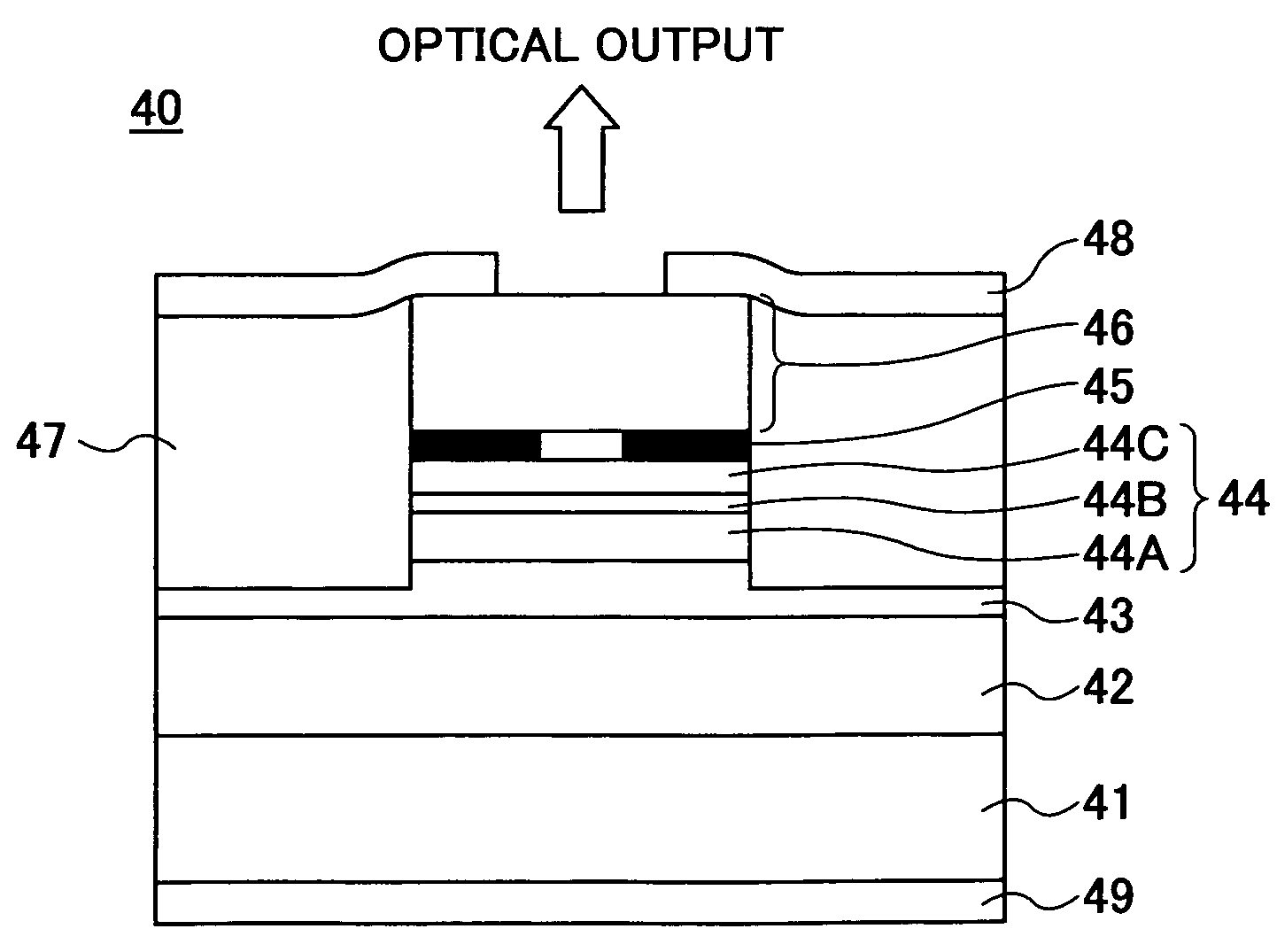

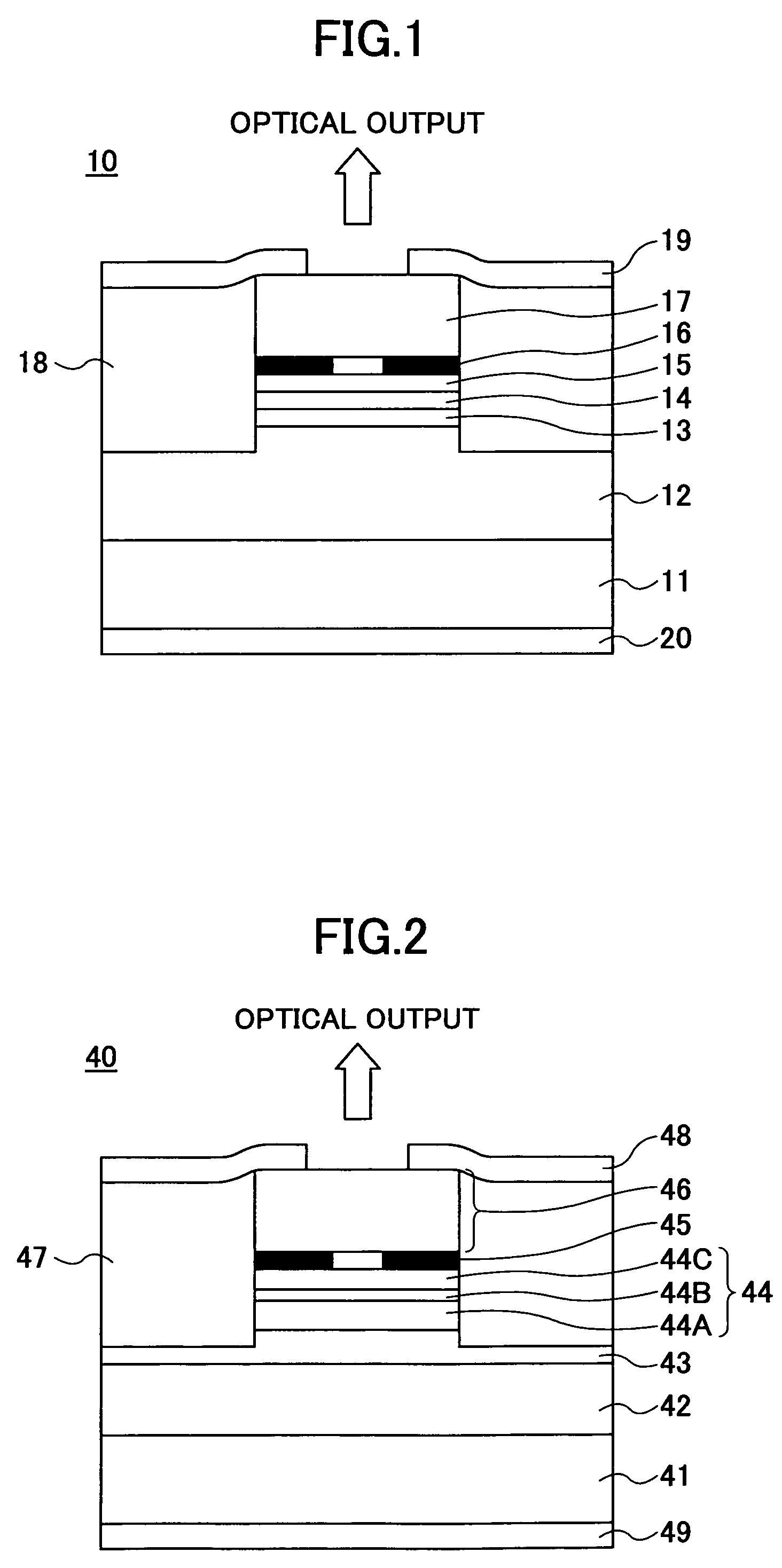

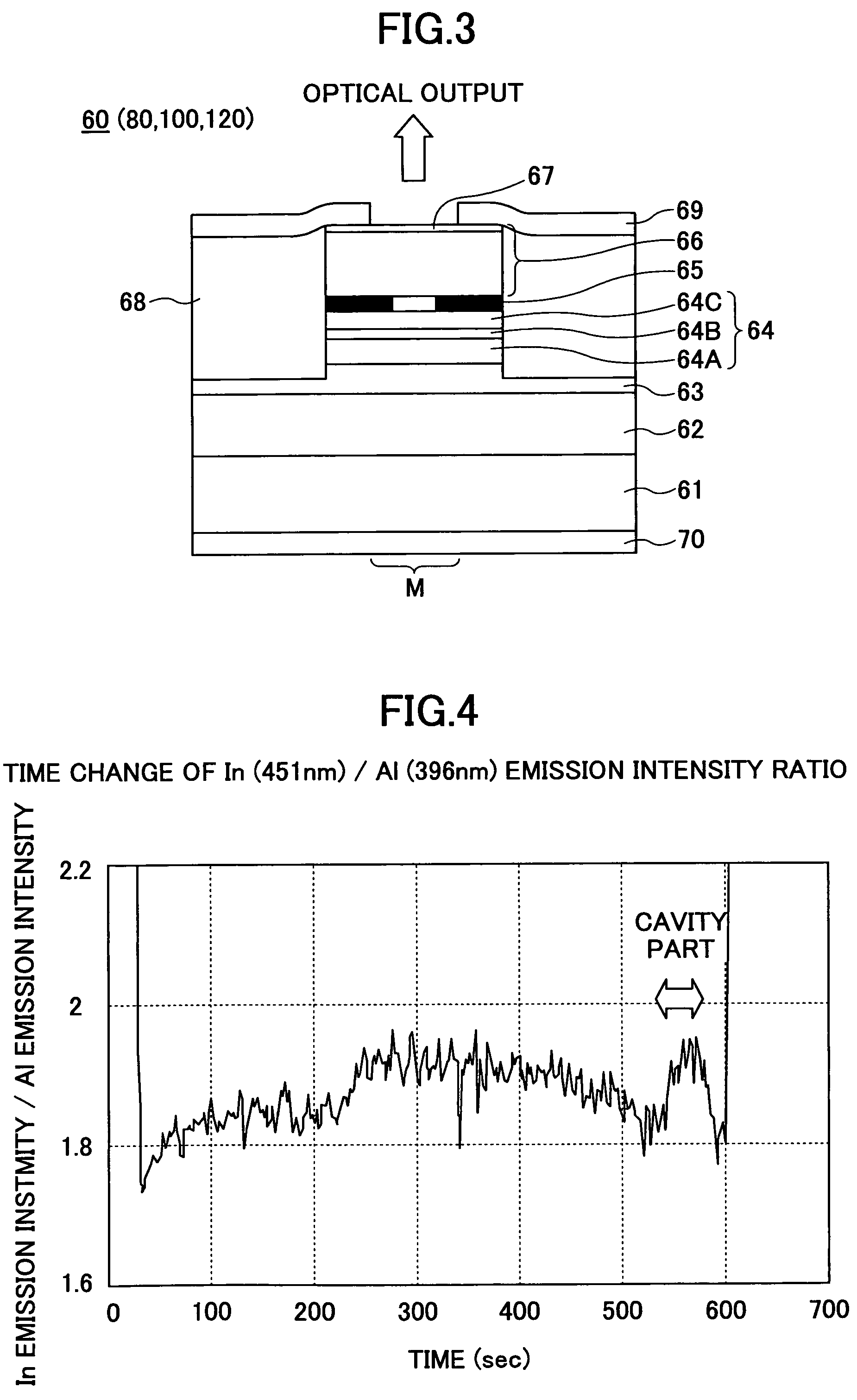

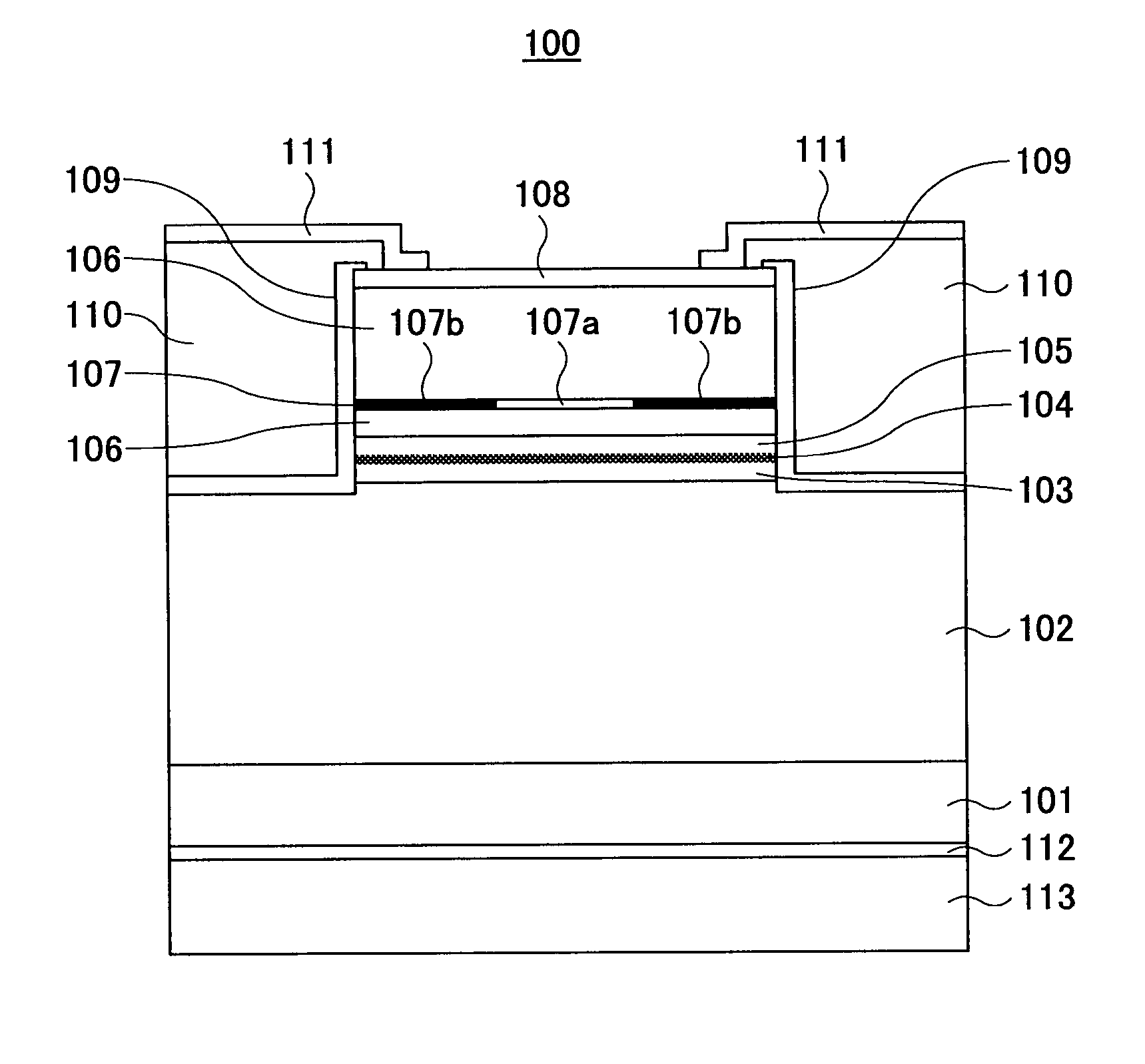

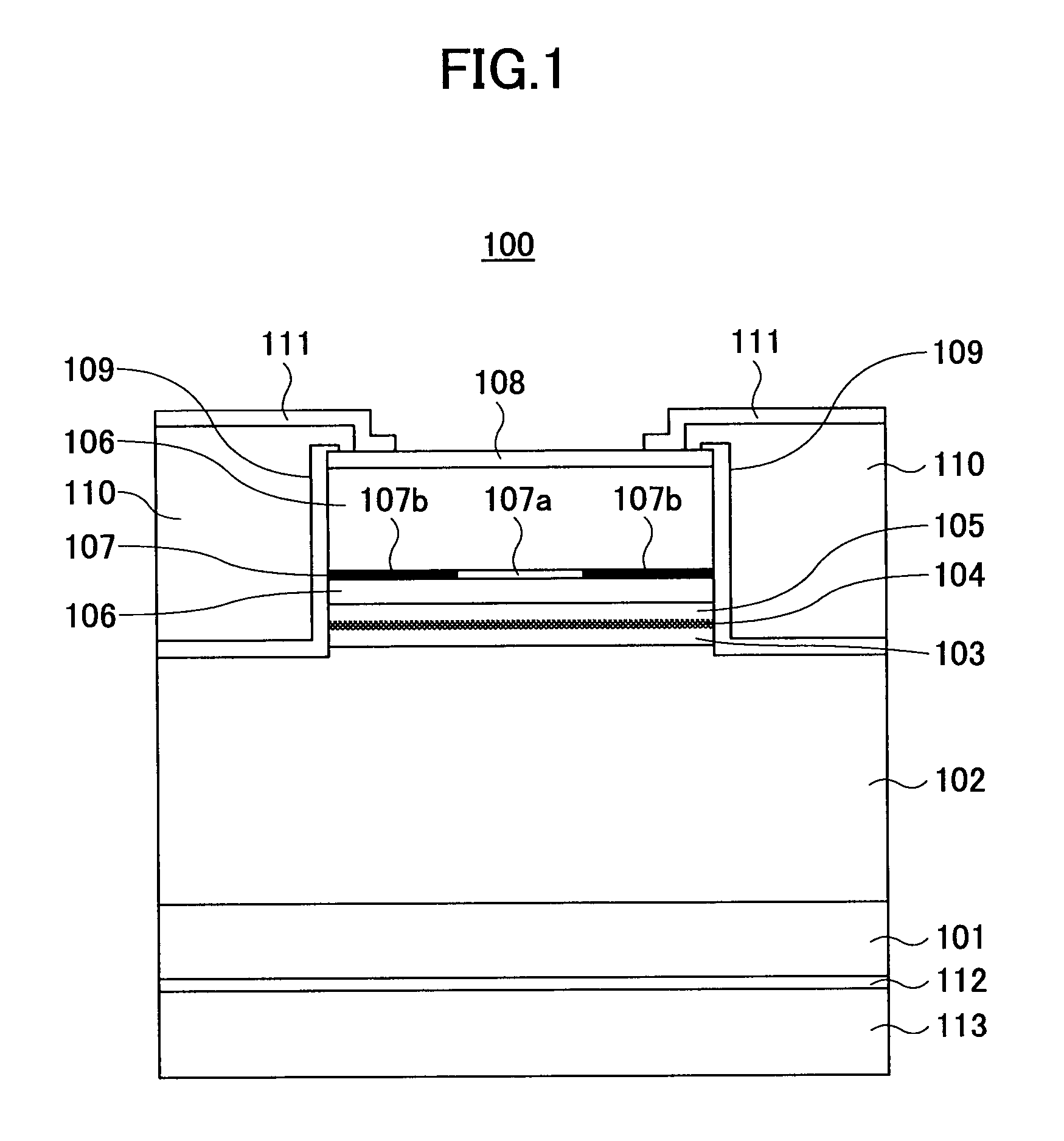

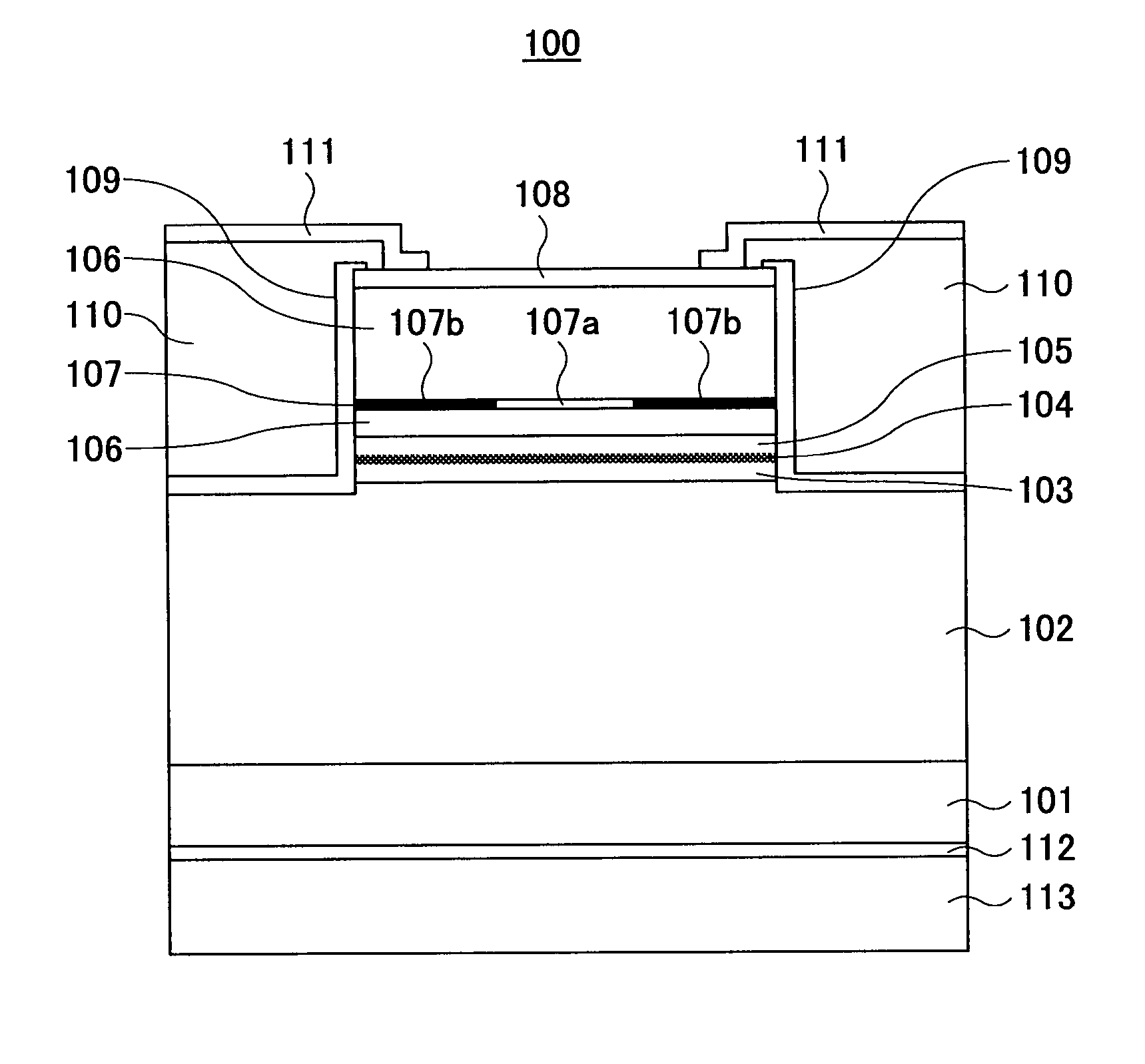

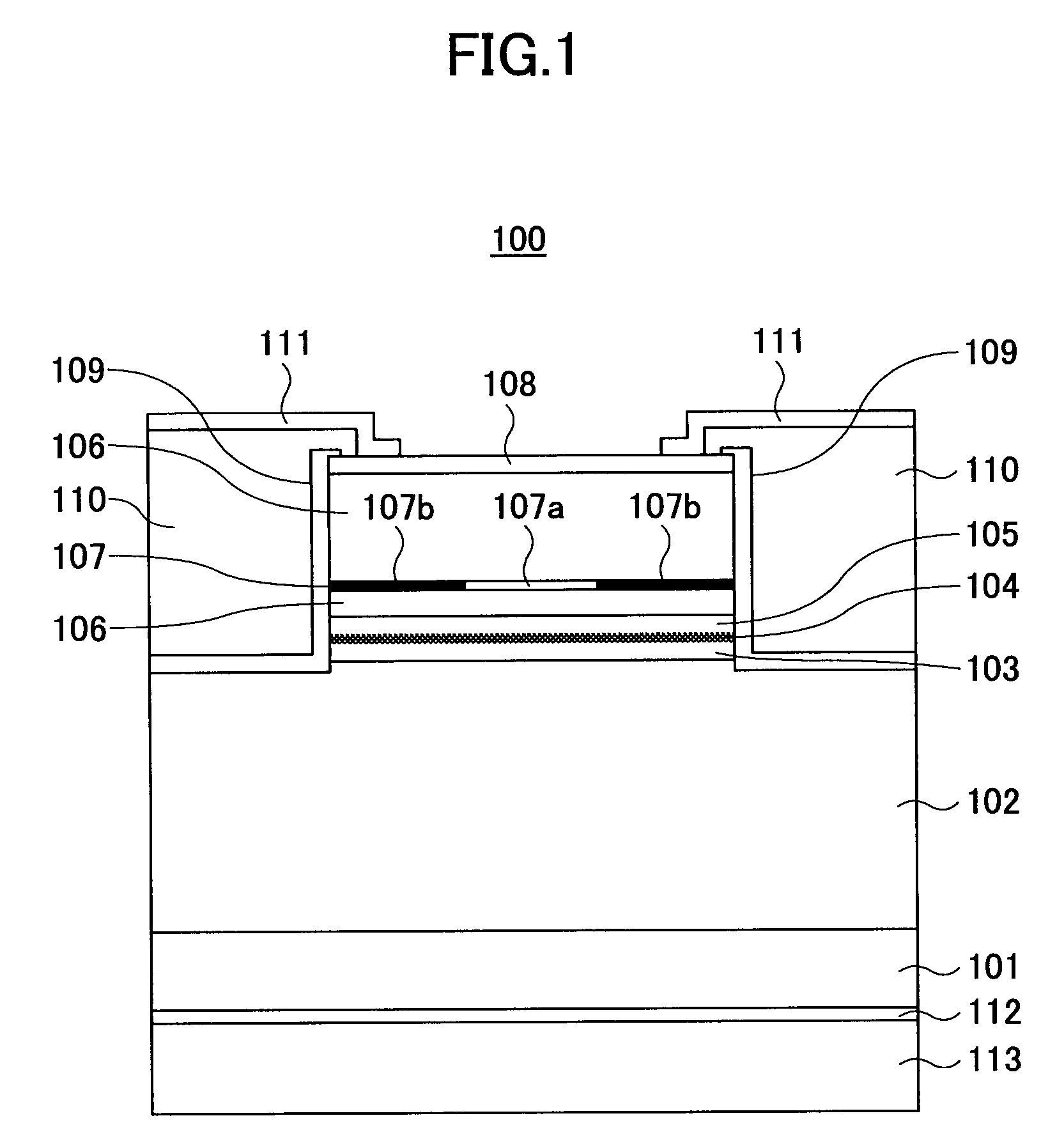

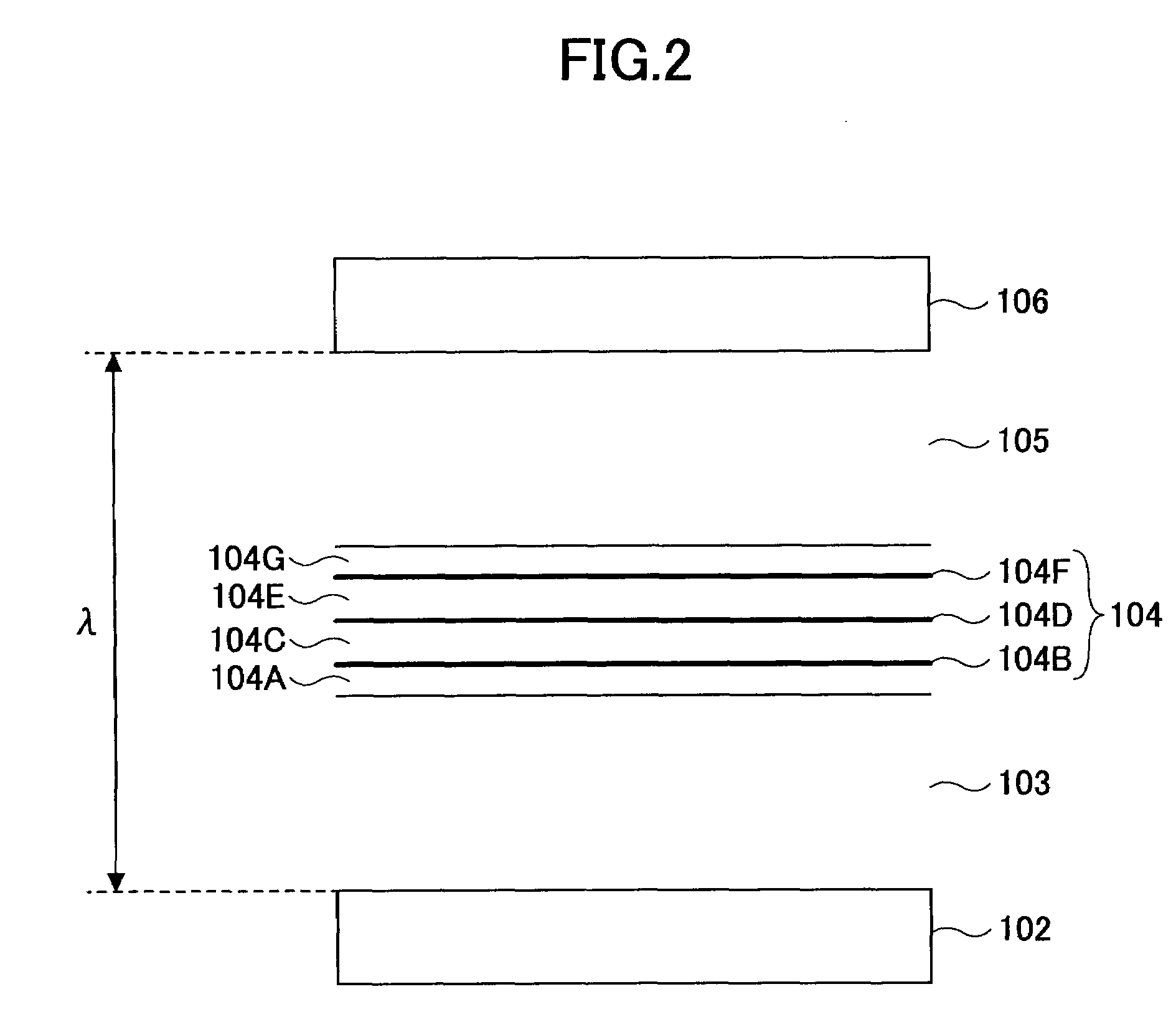

Surface-emitting laser diode having reduced device resistance and capable of performing high output operation, surface-emitting laser diode array, electrophotographic system, surface-emitting laser diode module, optical telecommunication system, optical interconnection system using the surface-emitting laser diode, and method of fabricating the surface-emitting laser diode

ActiveUS6959025B2Lower resistanceHigh-output operationOptical wave guidanceOptical resonator shape and constructionMode controlDistributed Bragg reflector

A surface-emitting laser diode device that oscillates in a direction perpendicular to the substrate is provided. This surface-emitting laser diode device includes: an active layer; a resonator structure including a first distributed Bragg reflector and a second distributed Bragg reflector that face each other and sandwich the active layer; a hole passage that extends from a first electrode to the active layer; an electron passage that extends from a second electrode to the active layer; a hole restricting structure that is located in the hole passage and defines a region for confining holes to the active layer; and an optical mode control structure that includes a non-oxide region provided in the resonator structure and an oxide region surrounding the non-oxide region, each region containing Al as a constituent element. In this surface-emitting laser diode, the area of the non-oxide region is smaller than the area of the hole restricting structure.

Owner:RICOH KK

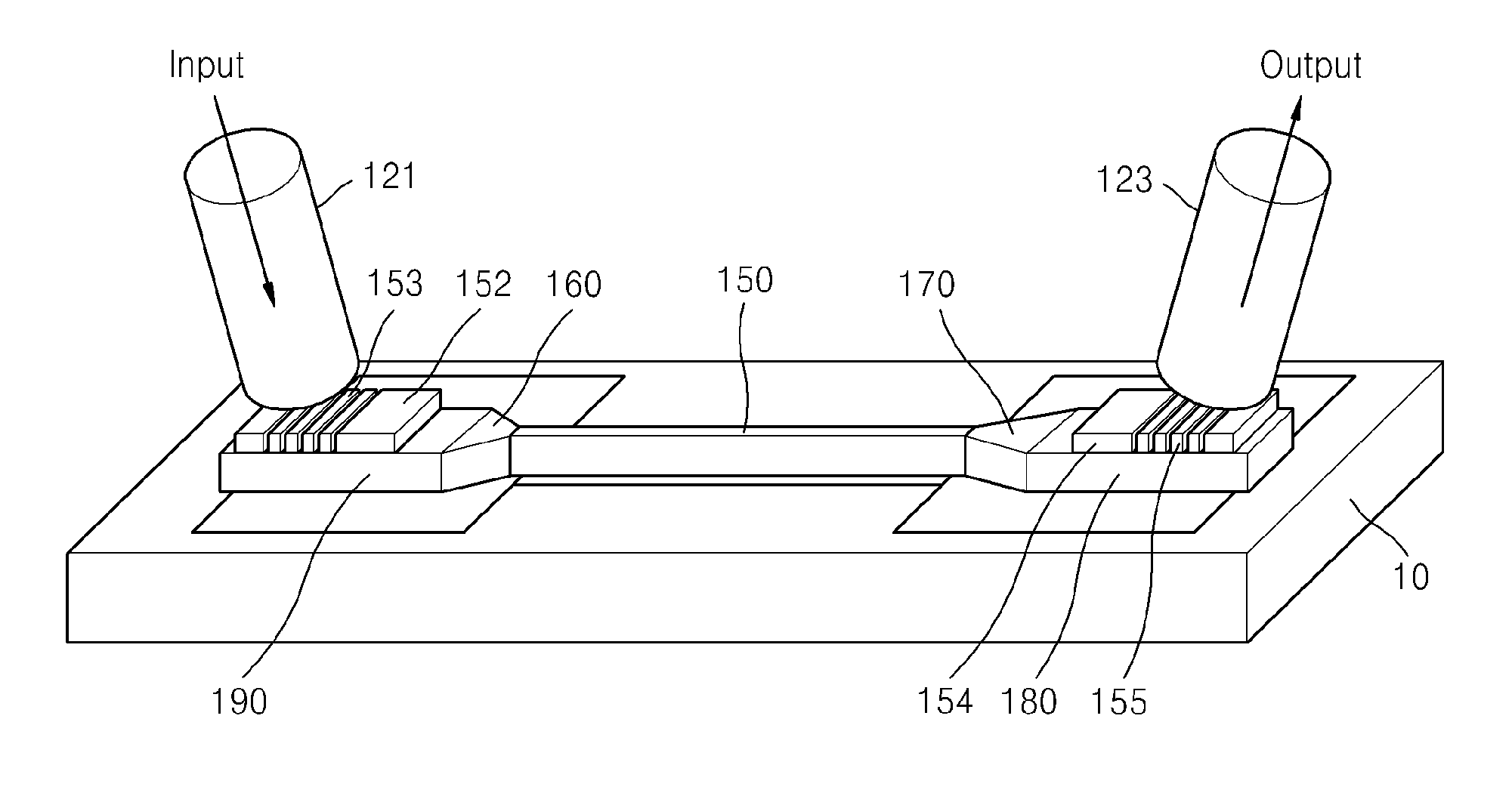

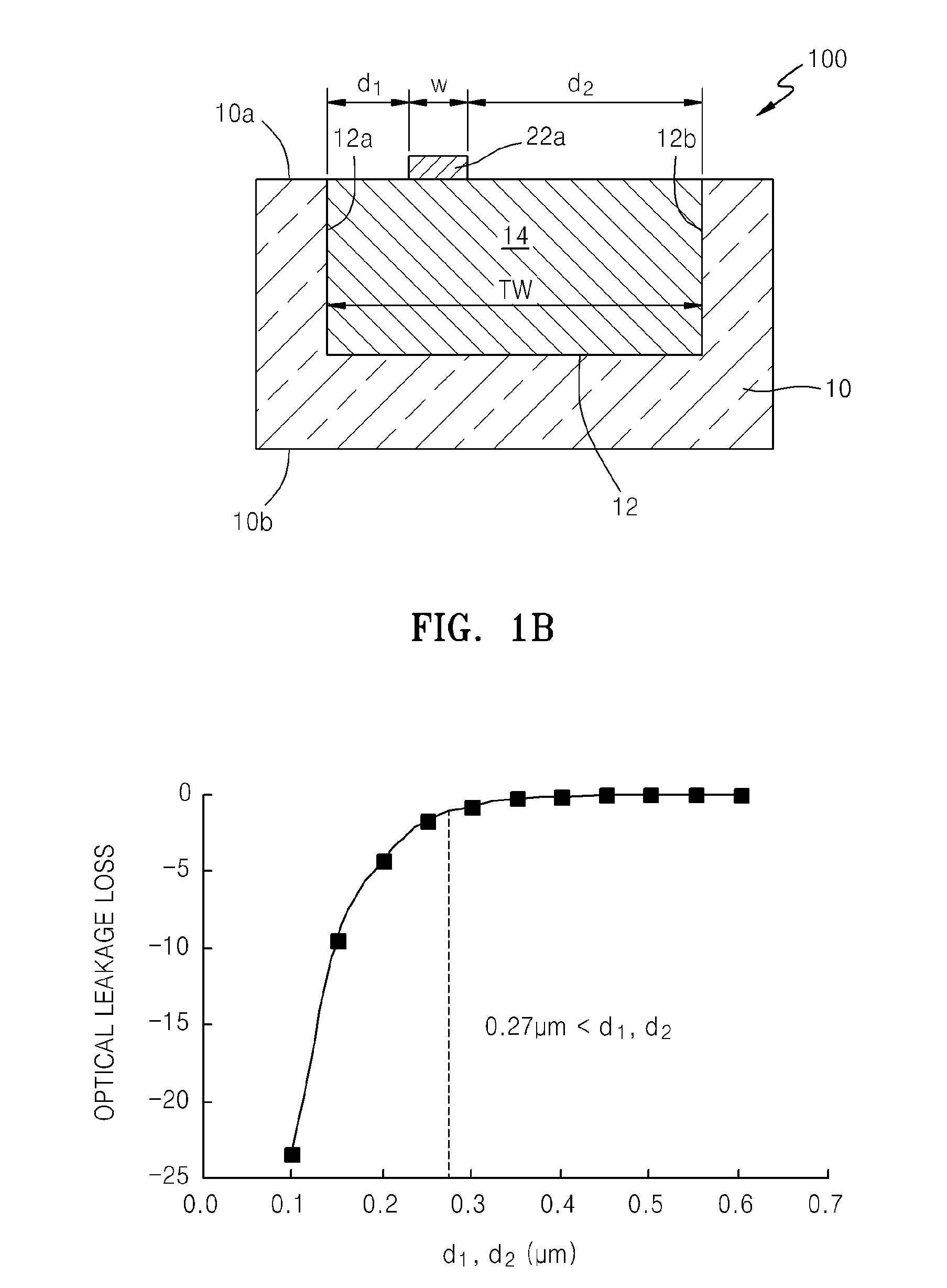

Optical waveguide and coupler apparatus and method of manufacturing the same

ActiveUS20110133063A1Cladded optical fibreSemiconductor/solid-state device manufacturingSilicon photonicsDram memory

Optical waveguide and coupler devices and methods include a trench formed in a bulk semiconductor substrate, for example, a bulk silicon substrate. A bottom cladding layer is formed in the trench, and a core region is formed on the bottom cladding layer. A reflective element, such as a distributed Bragg reflector can be formed under the coupler device and / or the waveguide device. Because the optical devices are integrated in a bulk substrate, they can be readily integrated with other devices on a chip or die in accordance with silicon photonics technology. Specifically, for example, the optical devices can be integrated in a DRAM memory circuit chip die.

Owner:SAMSUNG ELECTRONICS CO LTD

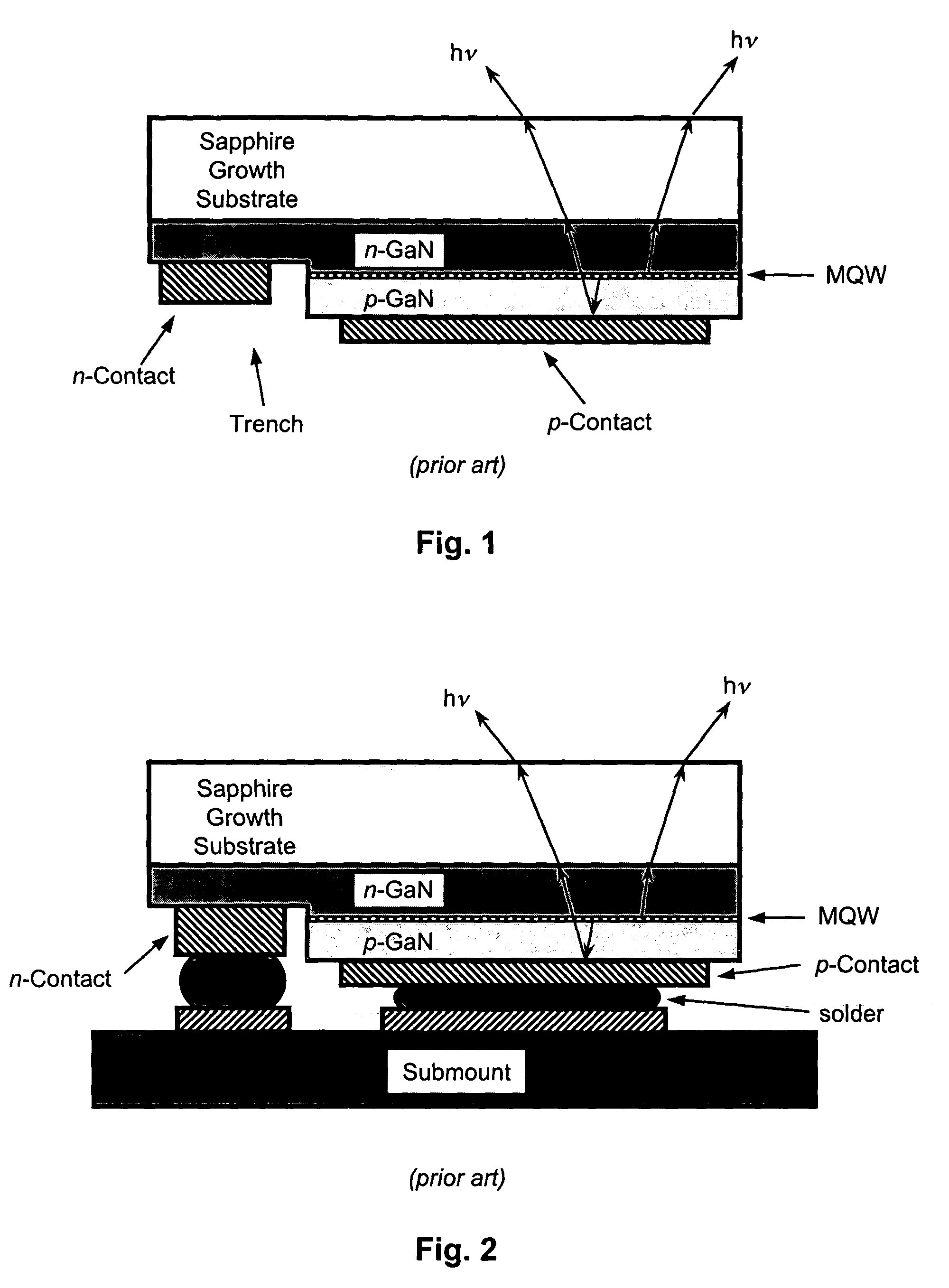

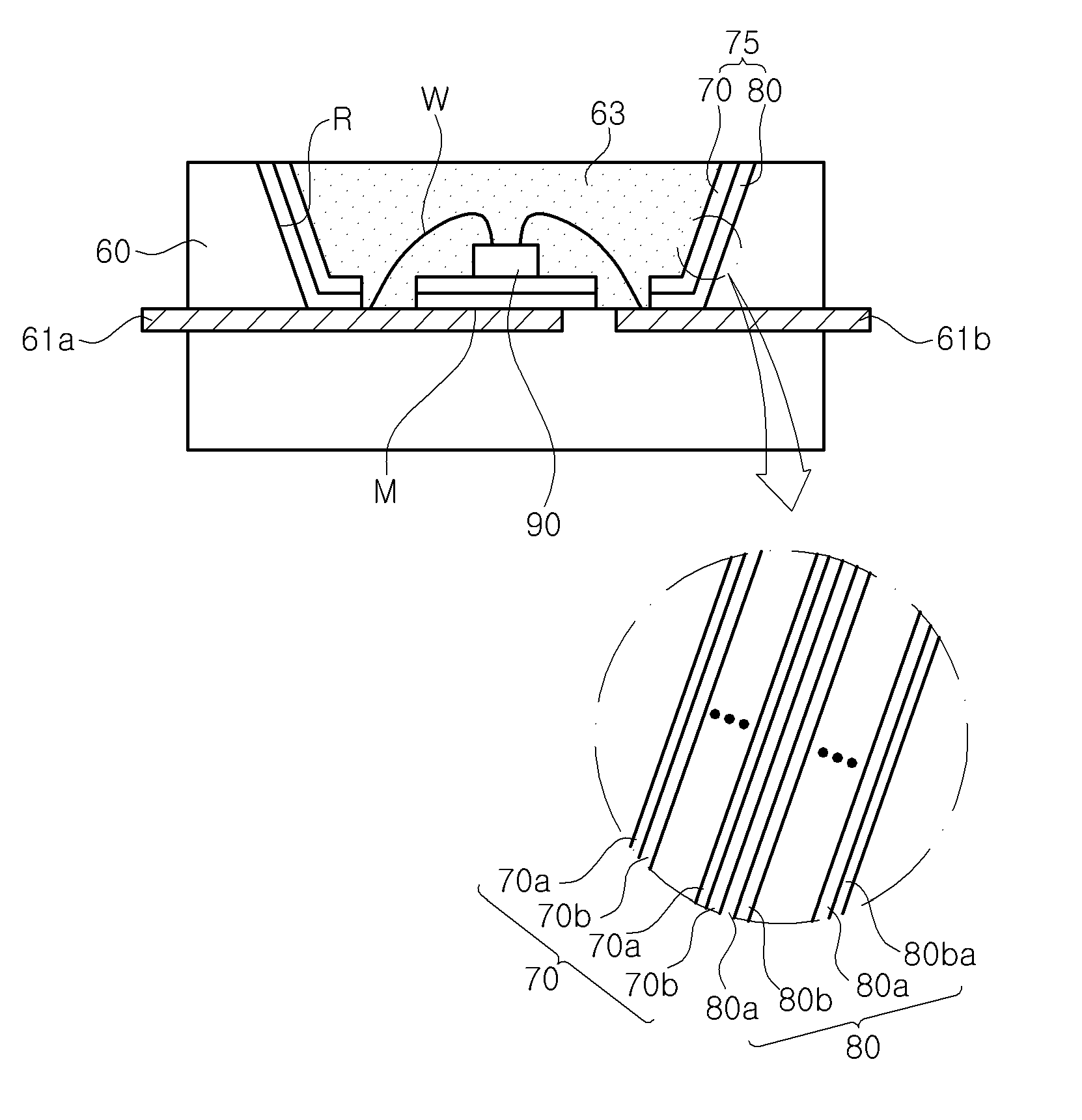

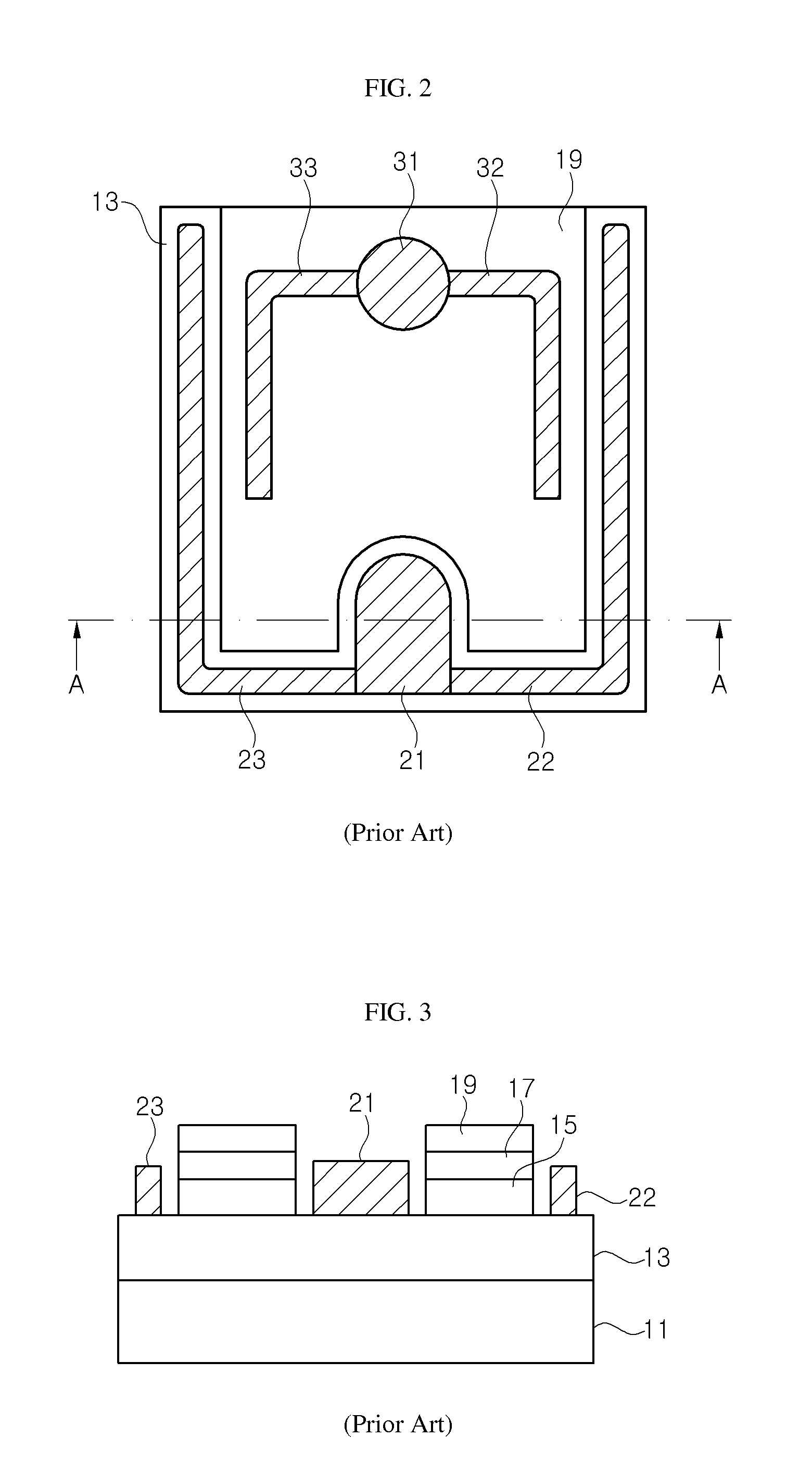

Gallium nitride-based flip-chip light-emitting diode with double reflective layers on its side and fabrication method thereof

InactiveUS20110297914A1Improve luminous efficiencyImprove reflectivitySemiconductor/solid-state device manufacturingSemiconductor devicesGallium nitrideLight-emitting diode

The present invention discloses a double-reflective-layer gallium nitride-based flip-chip light-emitting diode with both a distributed Bragg reflector and a metal reflective layer on its side and a fabrication method thereof. The light-emitting diode includes: a sapphire substrate; a buffer layer, an N-GaN layer, a multiple-quantum-well layer and a P-GaN layer stacked on the sapphire substrate in that order; a transparent conductive layer formed on the P-GaN layer; a distributed Bragg reflector formed over a side of the epitaxial layer and the transparent conductive layer; a metal reflective layer formed on the DBR; a P-type ohmic contact electrode formed on the transparent conductive layer; and an N-type ohmic contact electrode formed on the exposed N-GaN layer, wherein the P-type ohmic contact electrode and the N-type ohmic contact electrode are bonded to a heat dissipation substrate through a metal conductive layer and a ball bonder. By arranging a double reflection structure including a DBR and a metal reflective layer on the sloping side of the LED chip, the good reflectivity of the reflective layers can be fully utilized, thereby improving the light-emission efficiency of the LED.

Owner:XIAMEN SANAN OPTOELECTRONICS TECH CO LTD

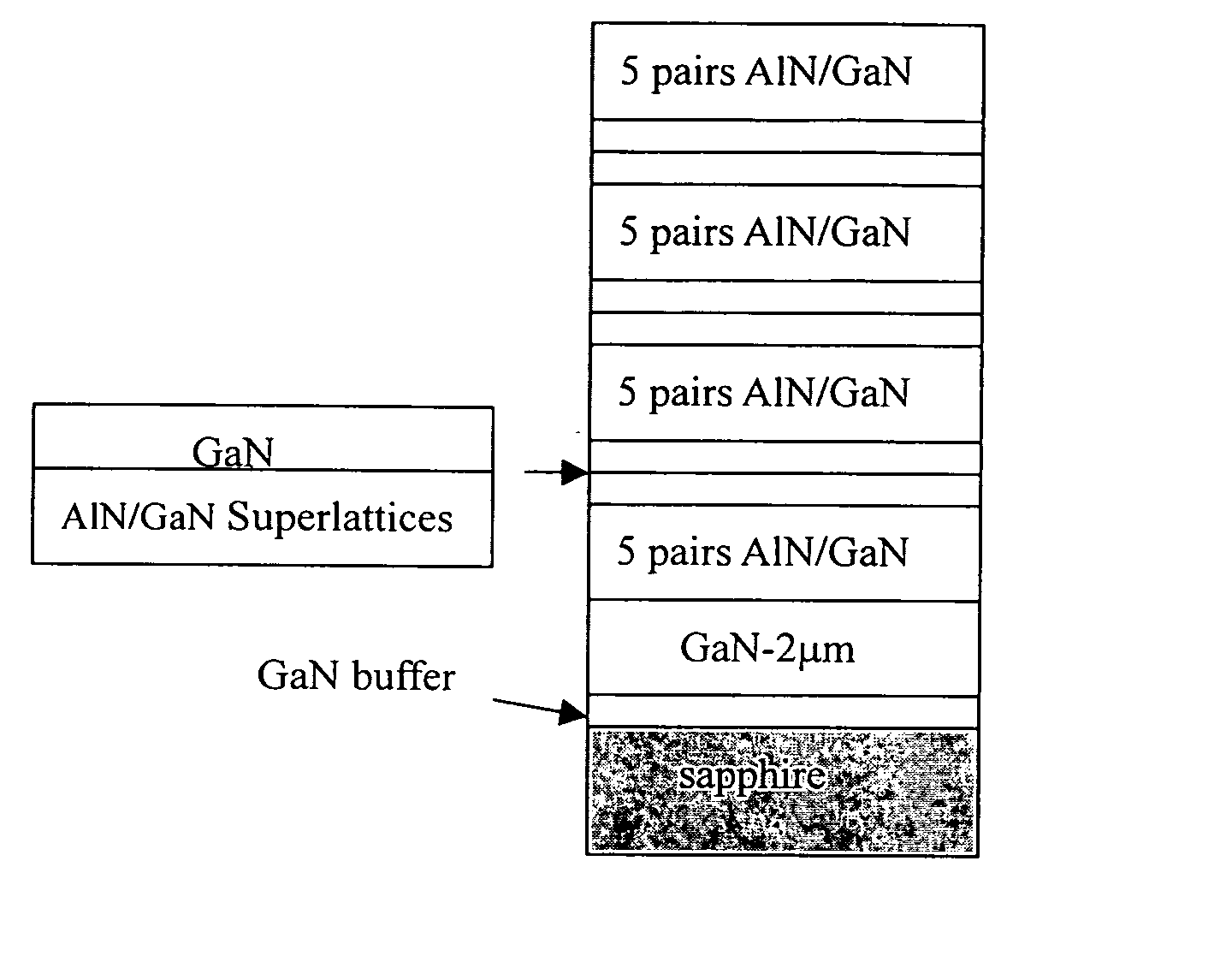

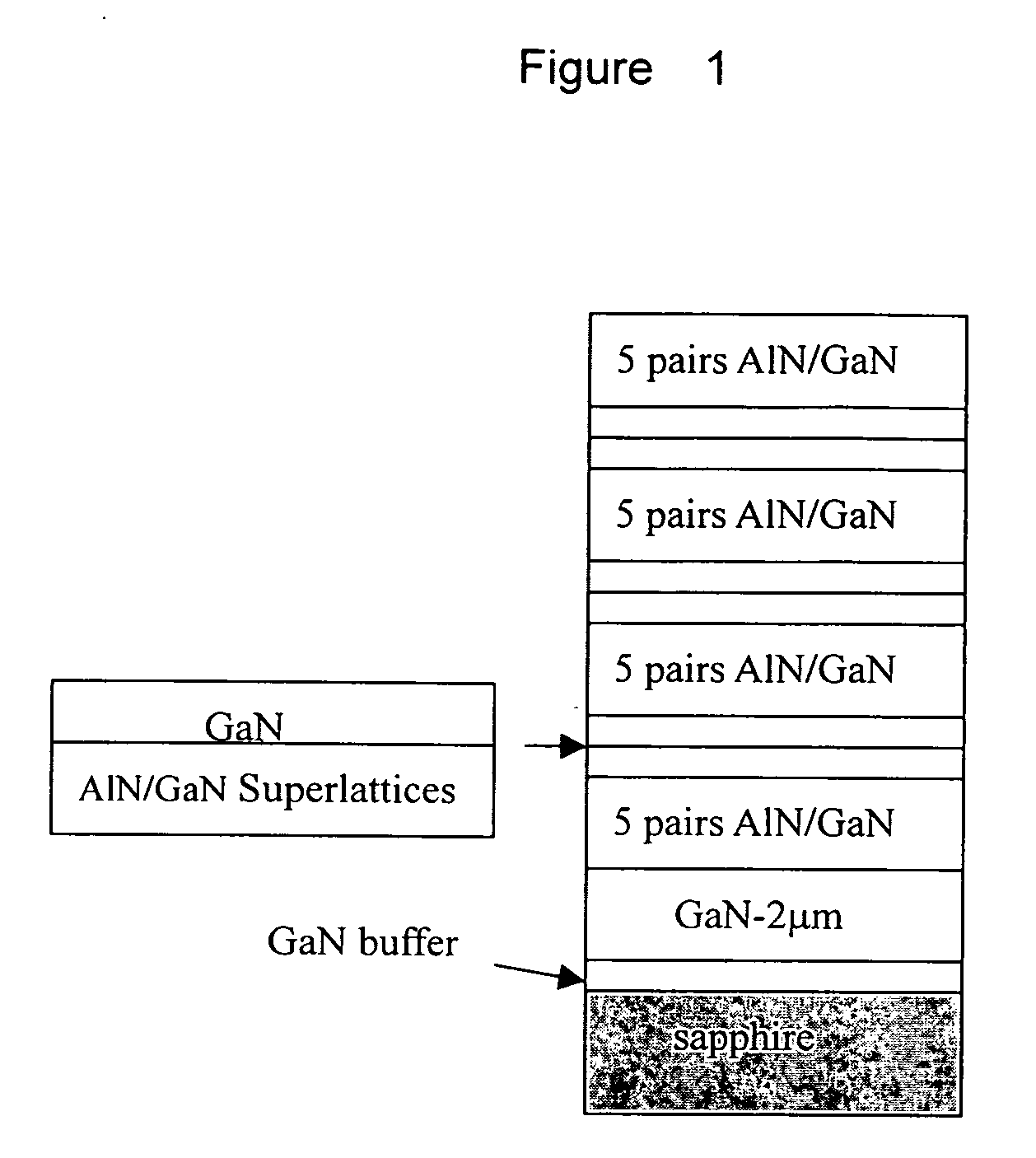

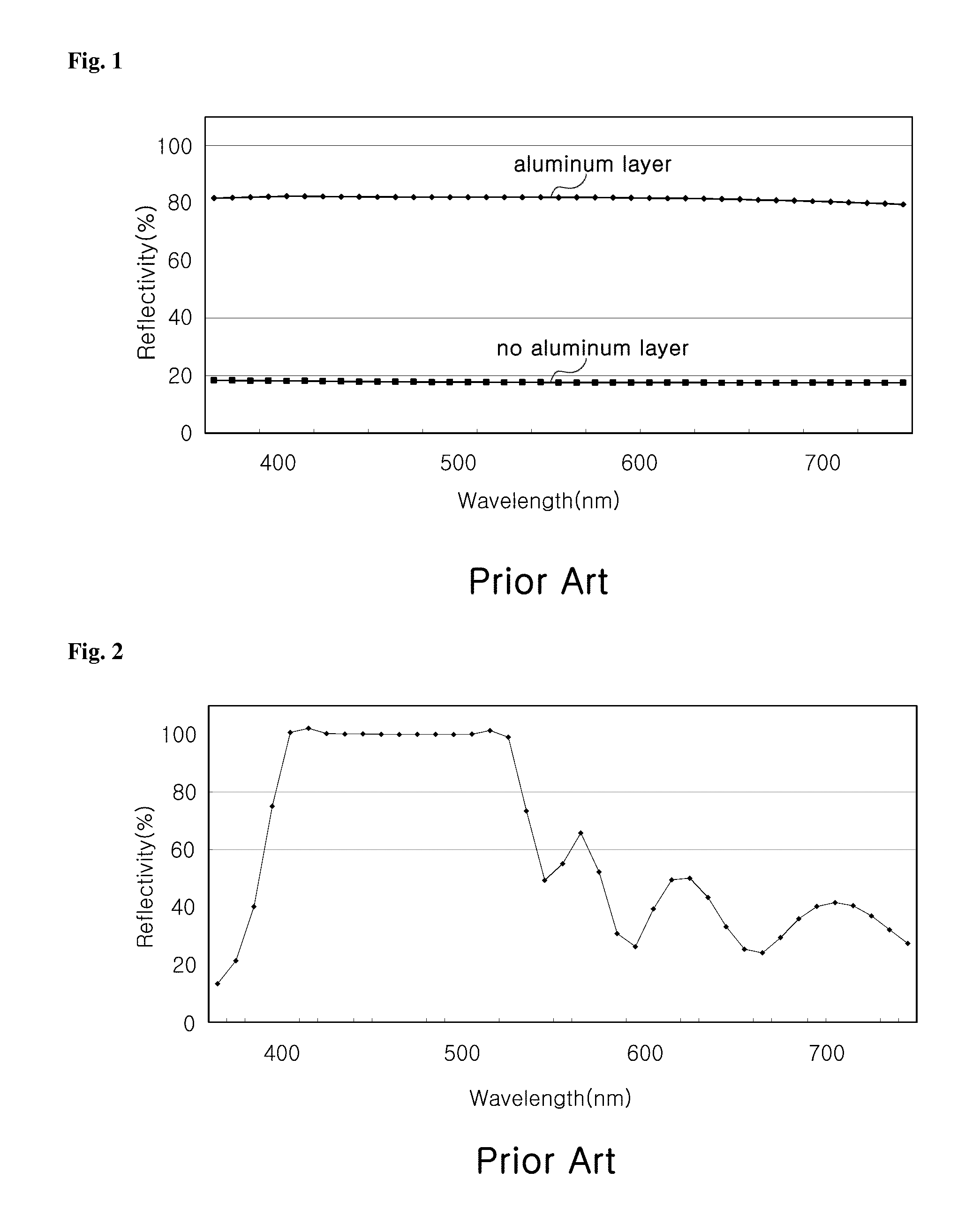

Process of producing group III nitride based reflectors

InactiveUS20070128743A1Improve reflectivityBroad stopbandLaser detailsSolid-state devicesVertical-cavity surface-emitting laserPhotovoltaic detectors

To solve the existing problems in distributed Bragg reflectors (DBR) used in the prior art, the present invention provides a fabrication method of group III nitride based distributed Bragg reflectors (DBR) for vertical cavity surface emitting lasers (VCSELs), which suppresses the generation of cracks, and a distributed Bragg reflector with high reflectivity, broad stopband, and adaptability to optical devices such as vertical cavity surface emitting lasers, micro-cavity light emitting diodes, resonance cavity light emitting diodes and photodetectors.

Owner:NAT CHIAO TUNG UNIV

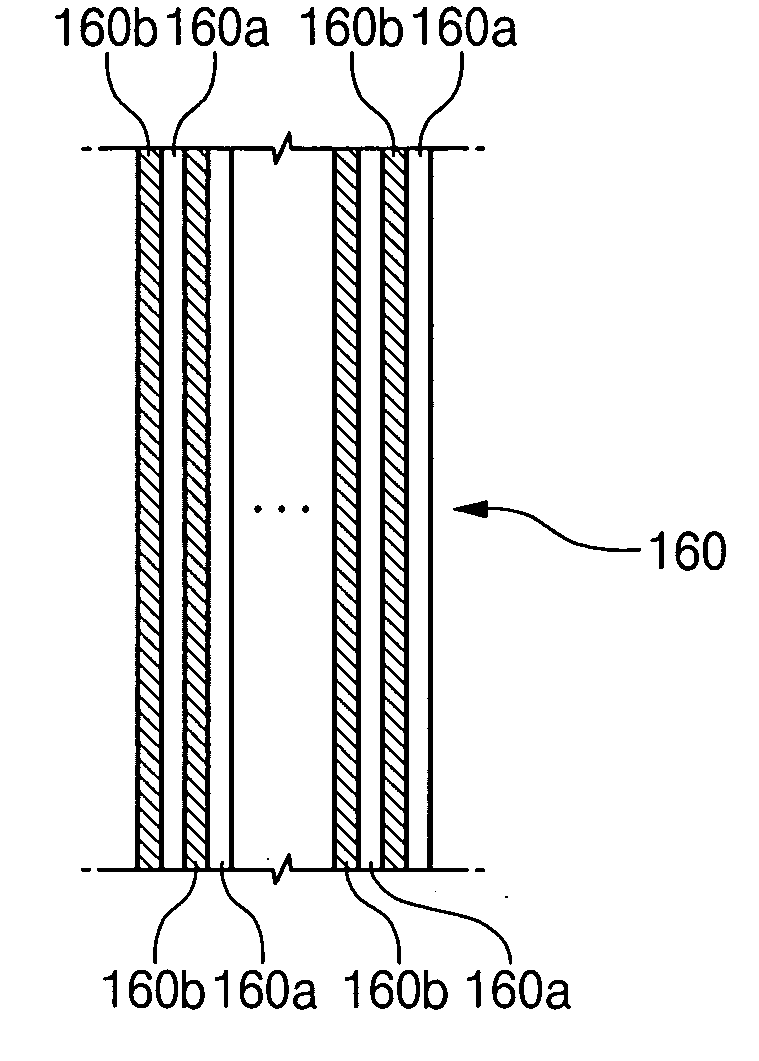

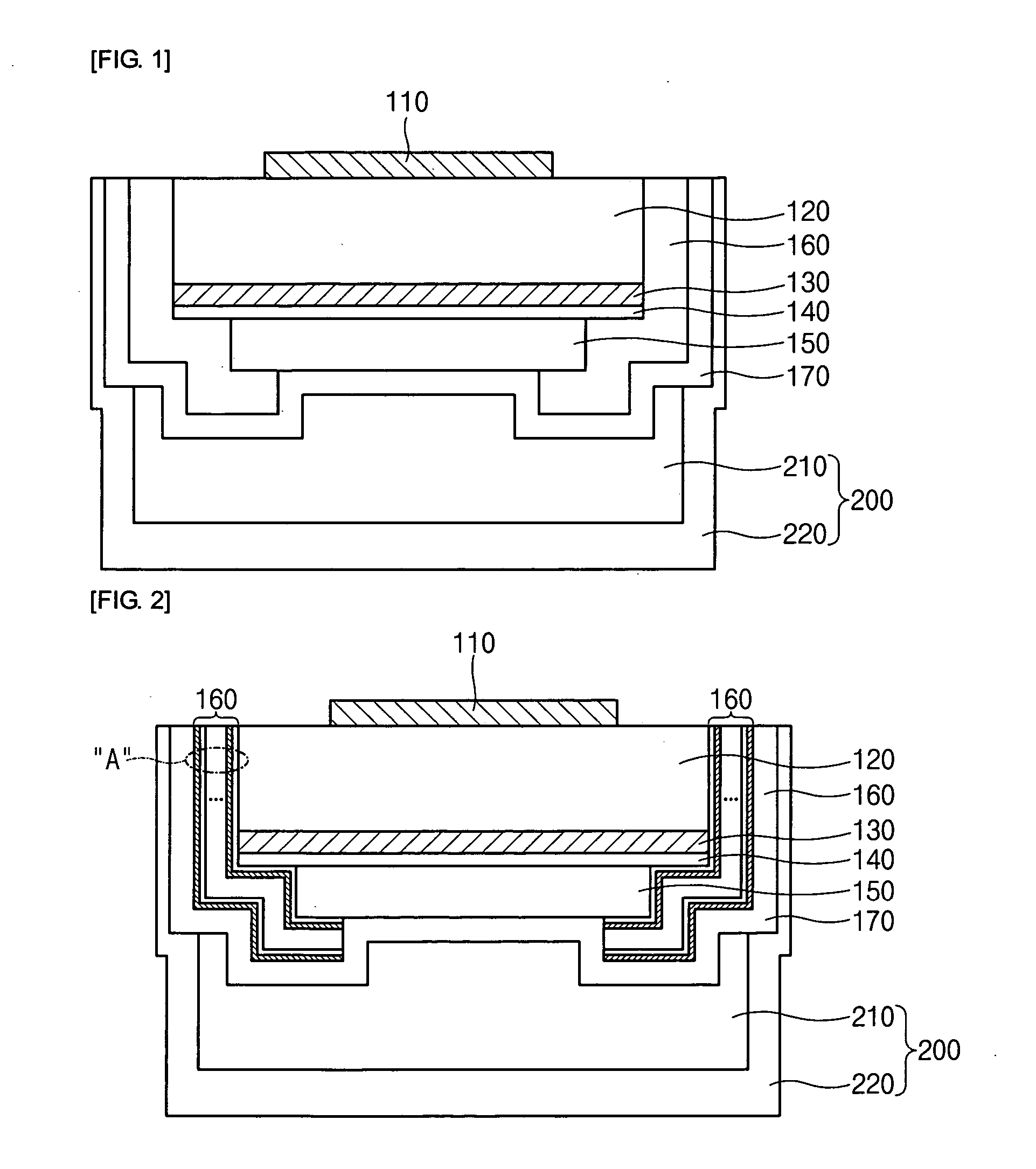

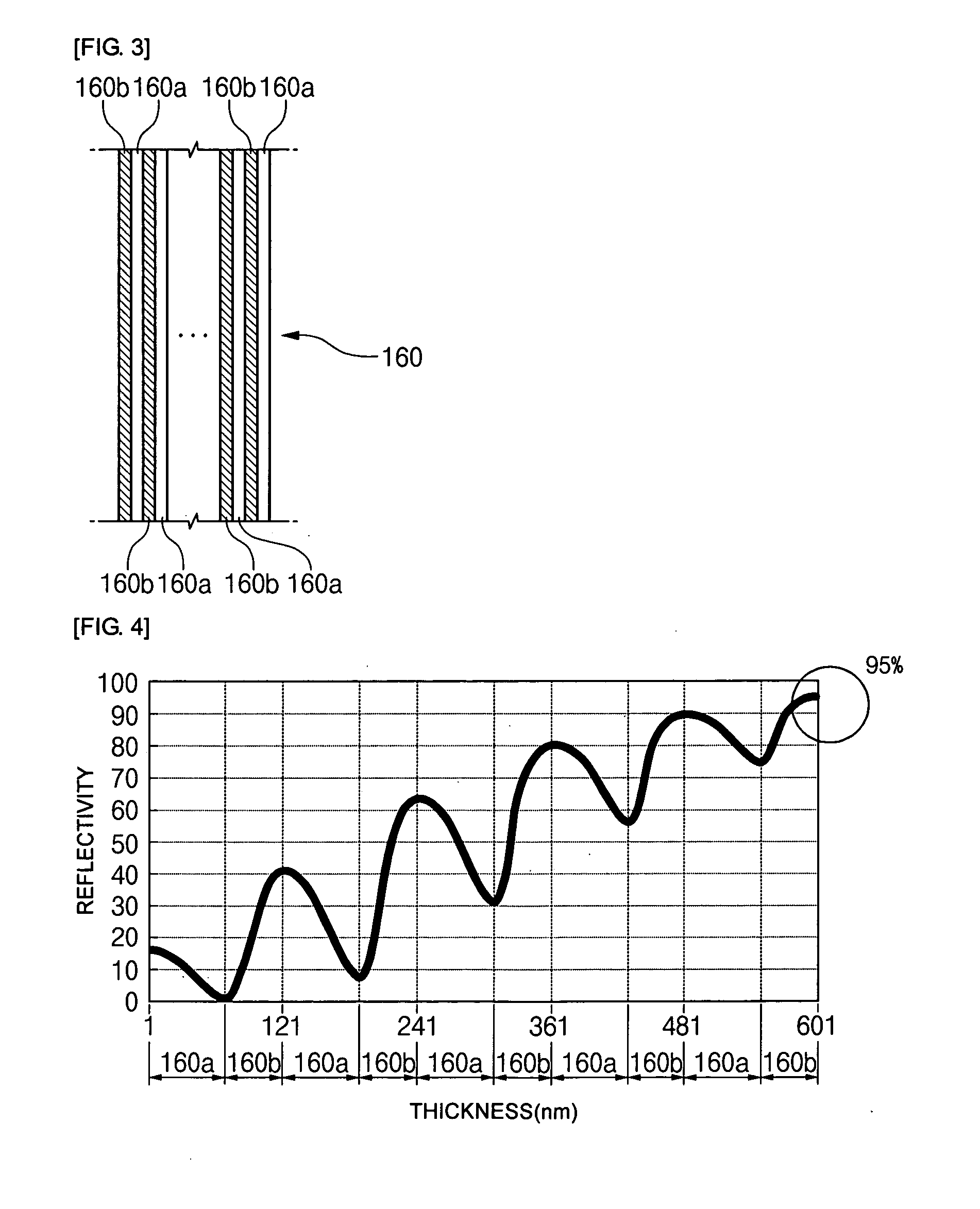

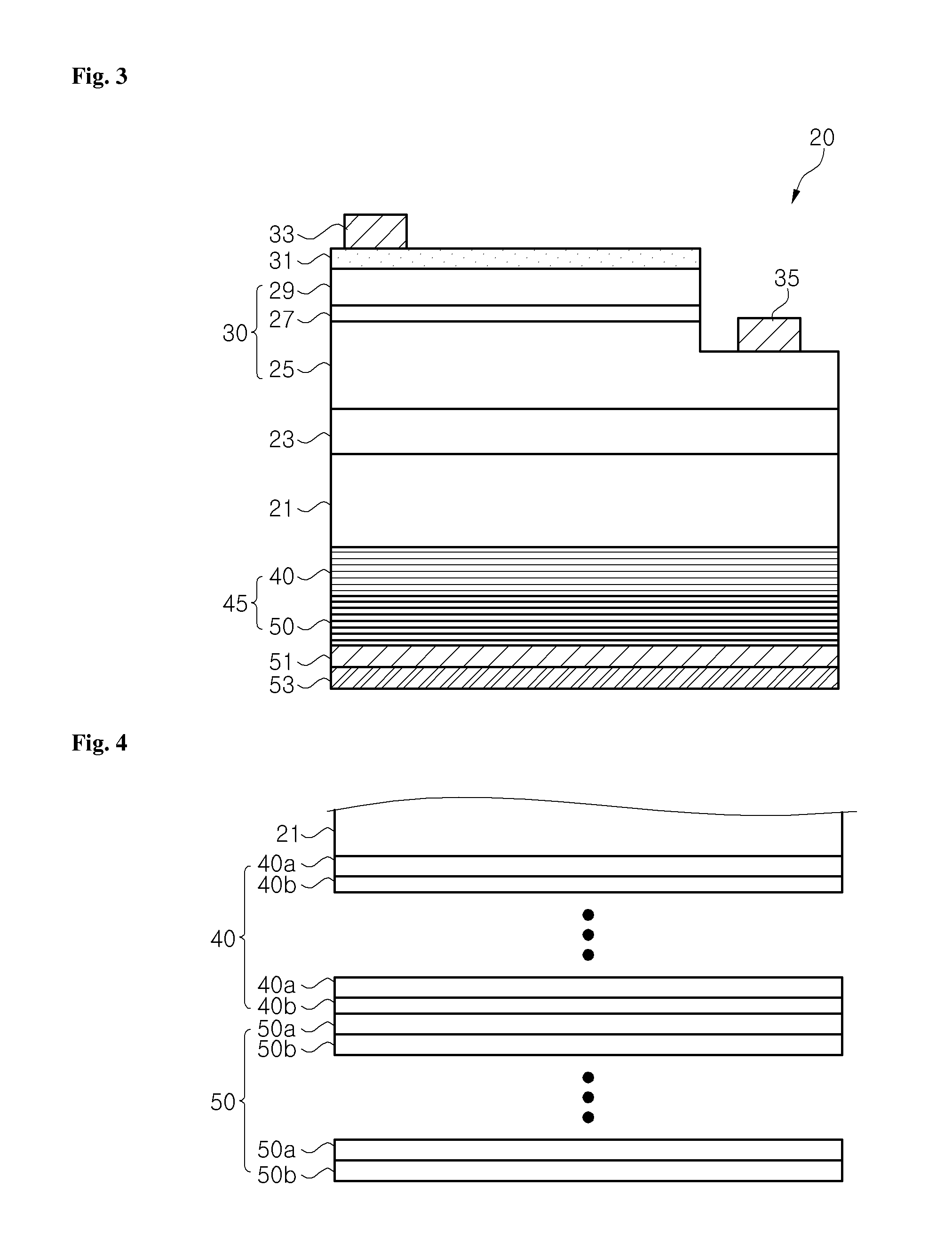

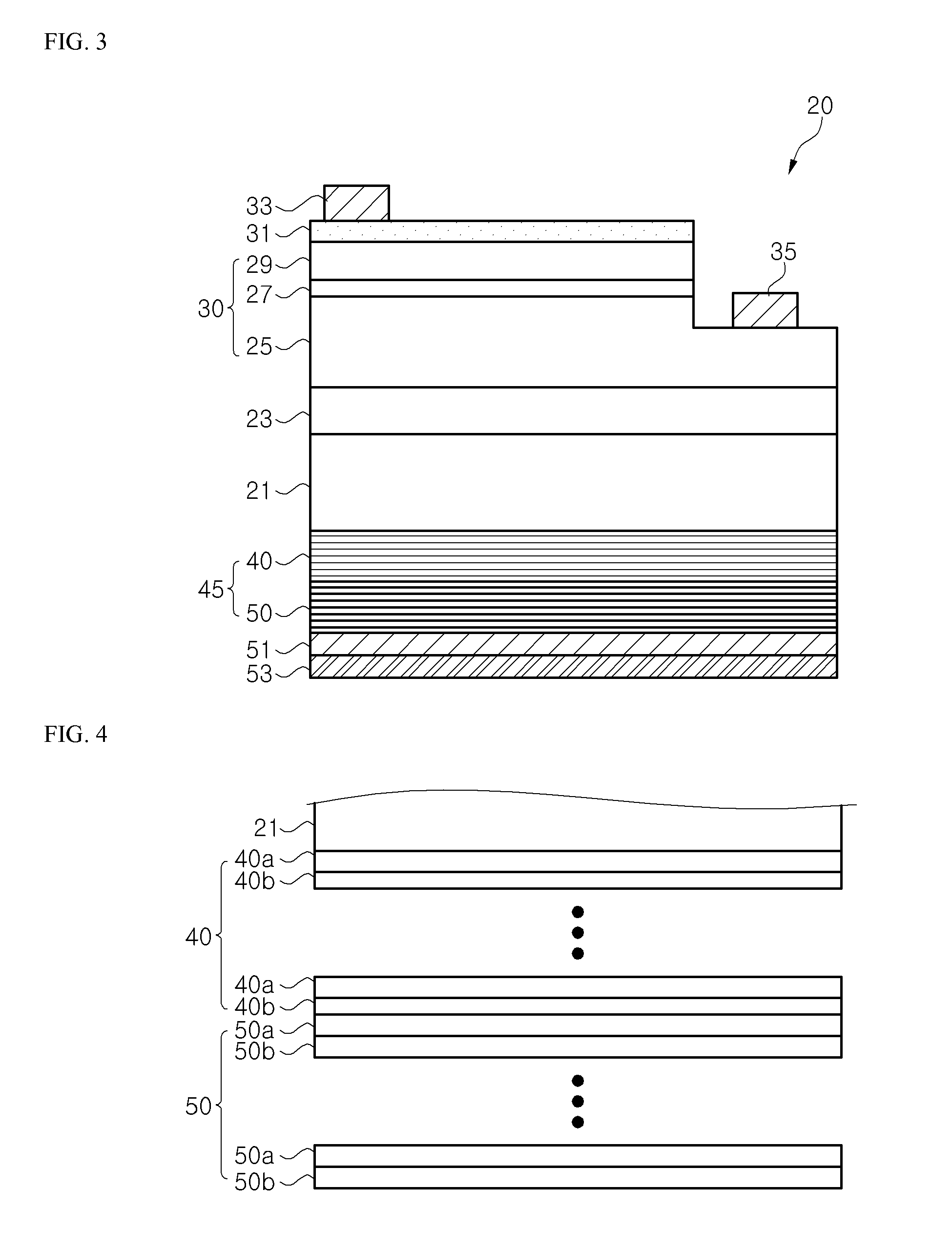

Light emitting diode having distributed bragg reflector

ActiveUS20120025244A1Light emission efficiencyAvoid light lossSolid-state devicesSemiconductor devicesDistributed Bragg reflectorActive layer

Exemplary embodiments of the present invention provide light-emitting diodes having a distributed Bragg reflector. A light-emitting diode (LED) according to an exemplary embodiment includes a light-emitting structure arranged on a first surface of a substrate, the light-emitting structure including a first conductivity-type semiconductor layer, a second conductivity-type semiconductor layer, and an active layer interposed between the first conductivity-type semiconductor layer and the second conductivity-type semiconductor layer. A first distributed Bragg reflector is arranged on a second surface of the substrate opposite to the first surface, the first distributed Bragg reflector to reflect light emitted from the light-emitting structure. The first distributed Bragg reflector has a reflectivity of at least 90% with respect to light of a first wavelength in a blue wavelength range, light of a second wavelength in a green wavelength range, and light of a third wavelength in a red wavelength range. The first distributed Bragg reflector has a laminate structure having an alternately stacked SiO2 layer and Nb2O5 layer.

Owner:SEOUL VIOSYS CO LTD

Light emitting diode

ActiveUS20090108250A1Reduce absorptionReduce light lossSemiconductor devicesDistributed Bragg reflectorActive layer

A light emitting diode (LED) has an n-type semiconductor layer, an active layer, a p-type semiconductor layer, and a transparent electrode layer. The LED includes a tunnel layer interposed between the p-type semiconductor layer and the transparent electrode layer, an opening arranged in the transparent electrode layer so that the tunnel layer is exposed, a distributed Bragg reflector (DBR) arranged in the opening, and an electrode pad arranged on the transparent electrode layer to cover the DBR in the opening.

Owner:SEOUL VIOSYS CO LTD

Vertical gallium-nitride based light emitting diode

ActiveUS20070114552A1Light extraction efficiency can be improvedImprove reflectivitySemiconductor devicesDistributed Bragg reflectorGallium nitride

A vertical GaN-based LED includes: an n-electrode; a light-emitting structure in which an n-type GaN layer, an active layer, and a p-type GaN layer are sequentially formed under the n-electrode; a p-electrode formed under the light-emitting structure; a passivation layer formed to cover the side and bottom surfaces of the light-emitting structure and expose a predetermined portion of the p-electrode, the passivation layer being formed of a distributed Bragg reflector (DBR); a plating seed layer formed under the passivation layer and the p-electrode; and a support layer formed under the plating seed layer.

Owner:SAMSUNG ELECTRONICS CO LTD

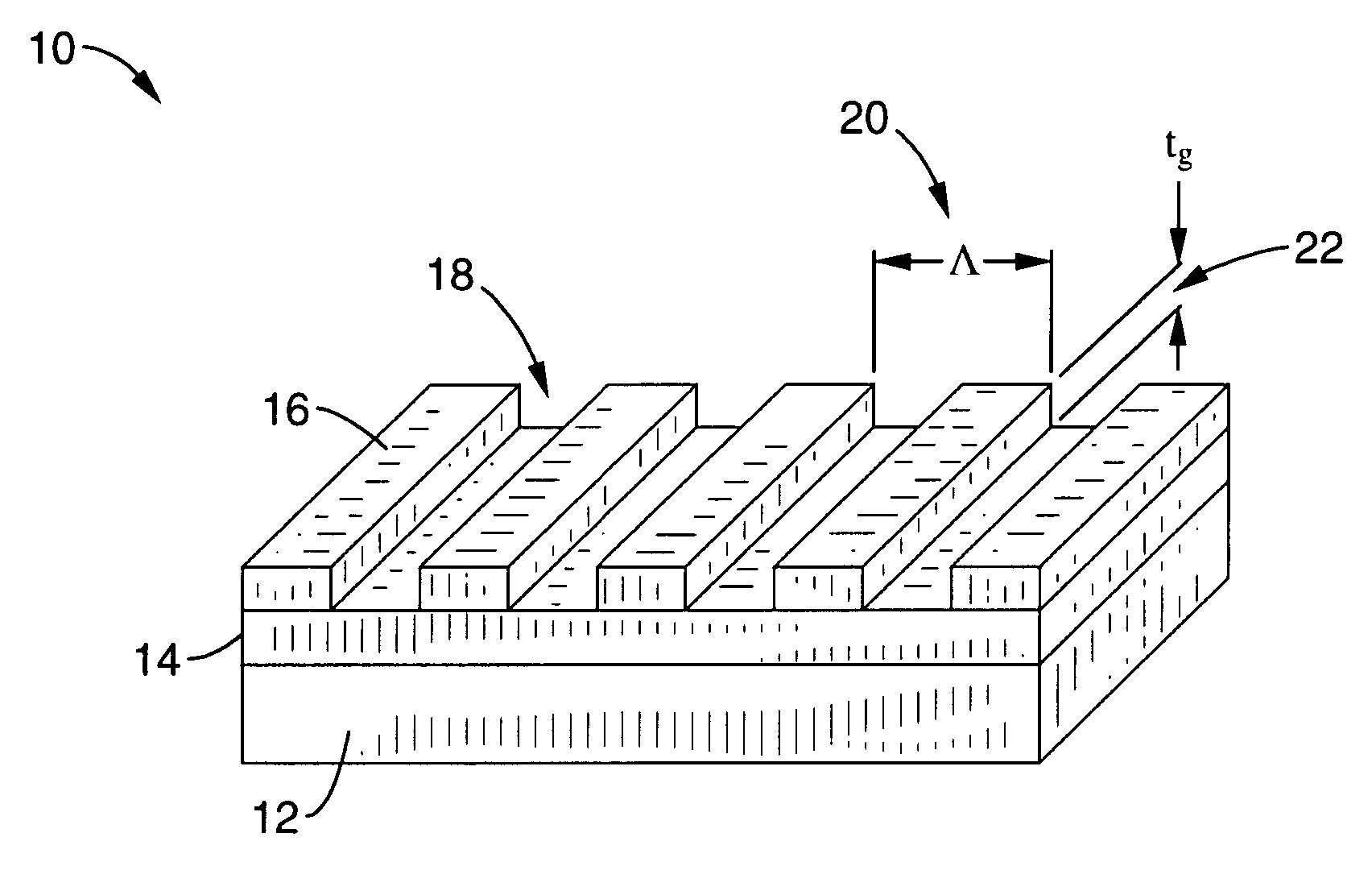

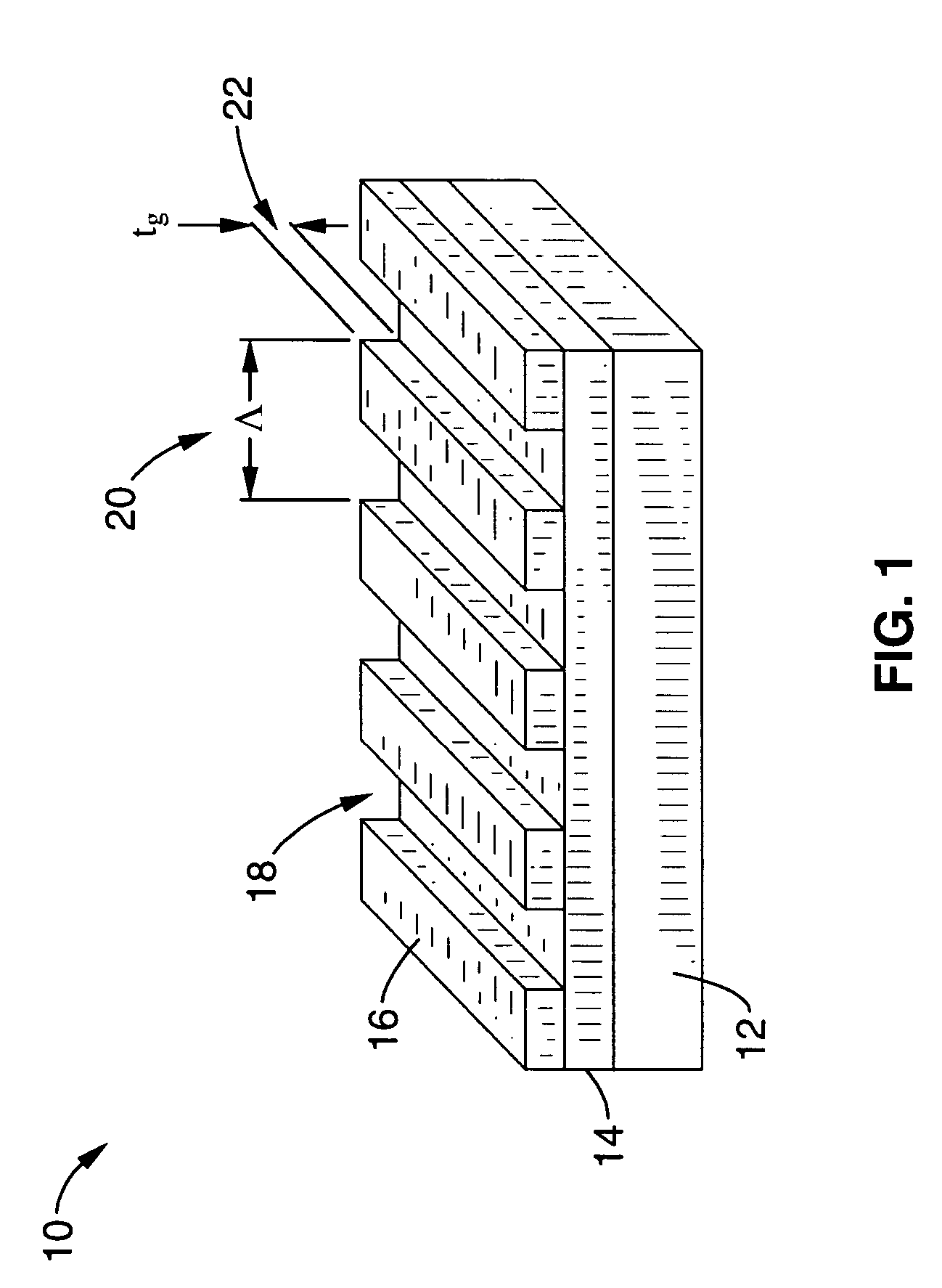

Ultra broadband mirror using subwavelength grating

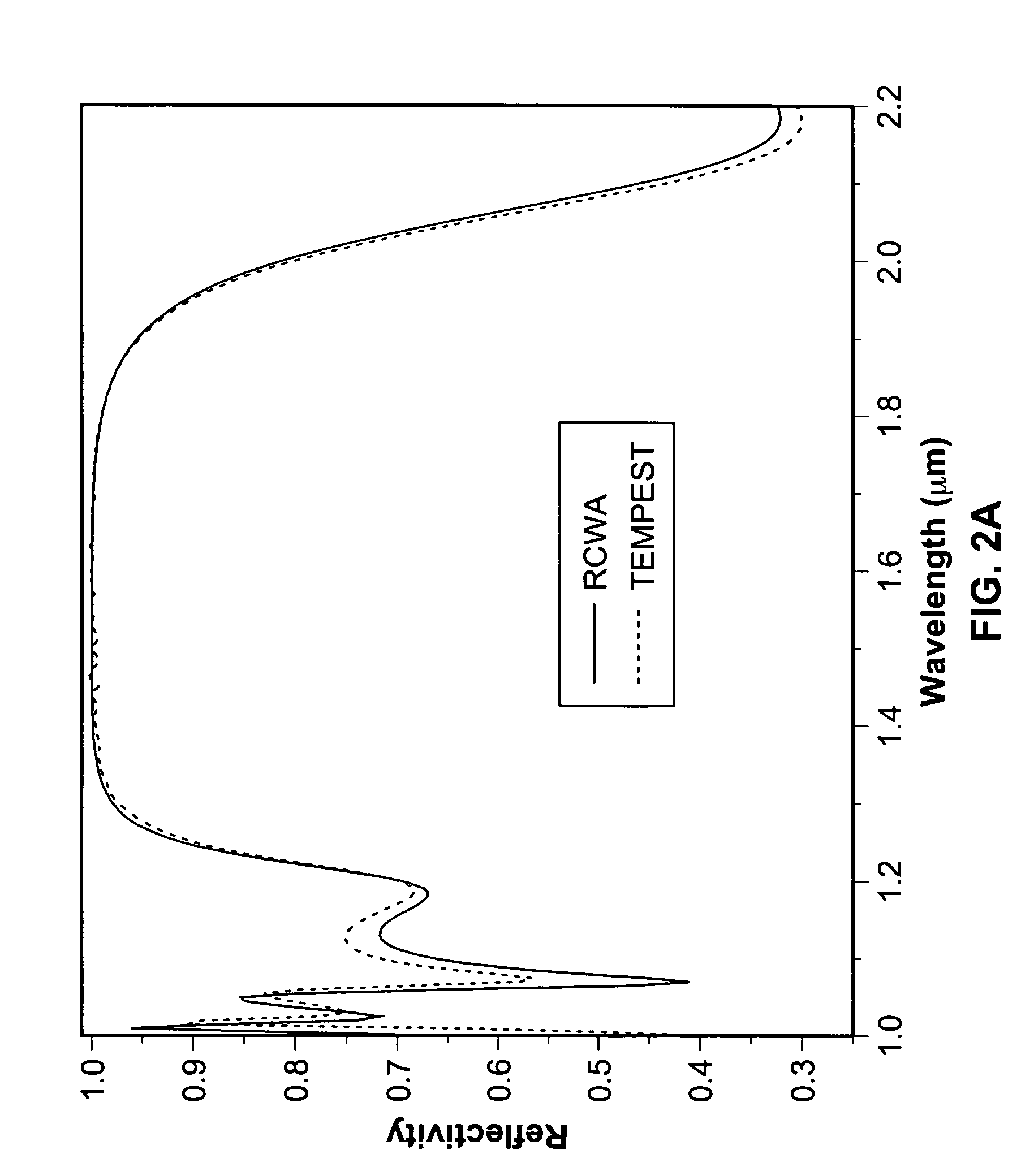

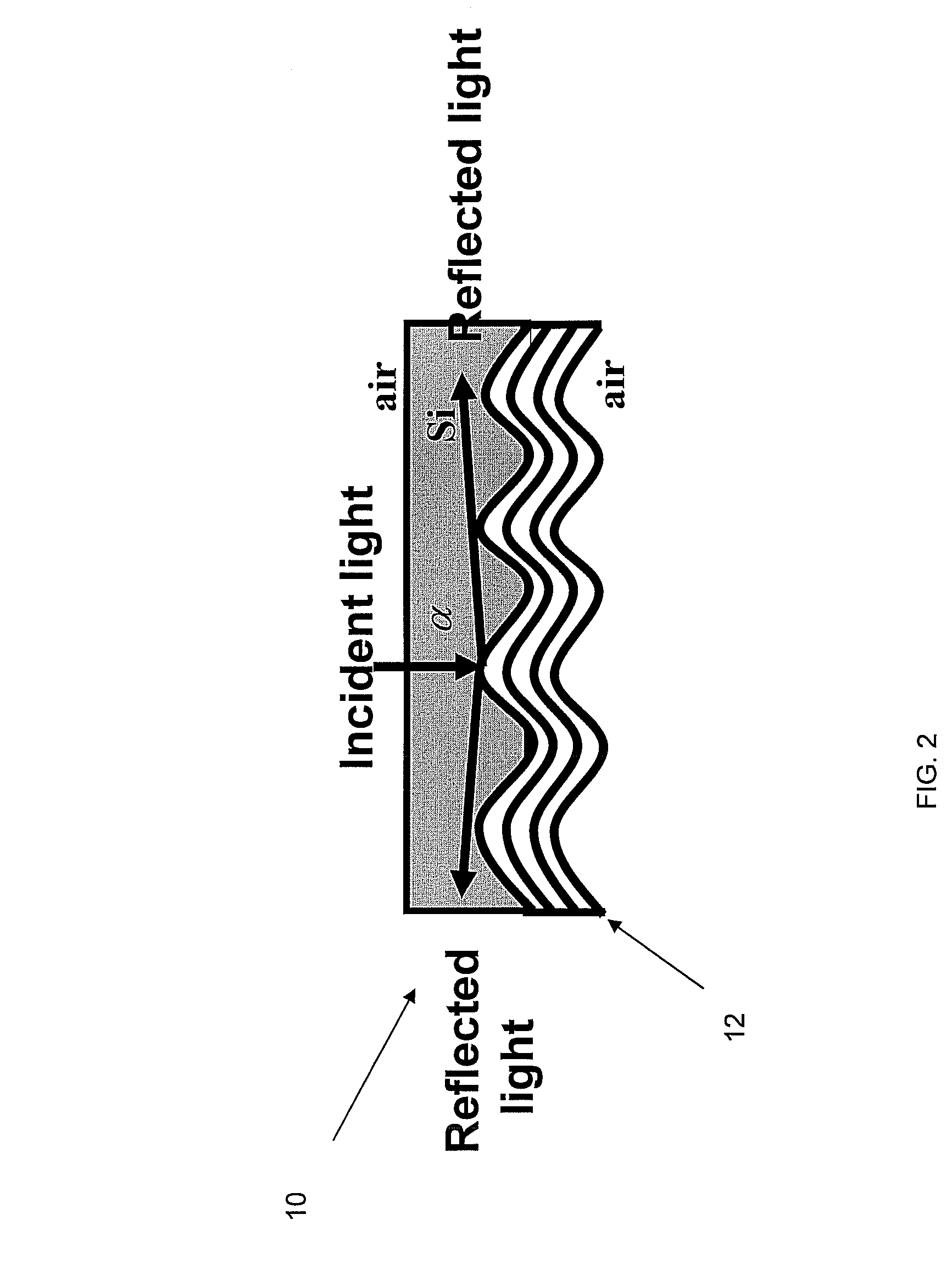

ActiveUS20070115553A1Broad reflection spectrumImprove reflectivityLaser detailsLaser optical resonator constructionGratingRefractive index

A sub-wavelength grating structure that has a very broad reflection spectrum and very high reflectivity comprising segments made of high refractive index material disposed on a layer of low refractive index material and a low refractive index material disposed above and between the segments. The index differential between the high and low index materials determines the bandwidth and modulation depth. The larger difference in refractive indices gives rise to wider reflection bands. The reflection is sensitive to parameters such as the grating period, the grating thickness, the duty cycle of the grating, the refractive index and the thickness of the low index layer underneath the grating. The design is scalable for different wavelengths, and facilitates monolithic integration of optoelectronic devices at a wide range of wavelengths from visible to far infrared. The sub-wavelength grating reflectors may be used in a variety of settings such as tunable etalon filters and as a replacement for conventional distributed Bragg reflectors.

Owner:RGT UNIV OF CALIFORNIA

Semiconductor color-tunable broadband light sources and full-color microdisplays

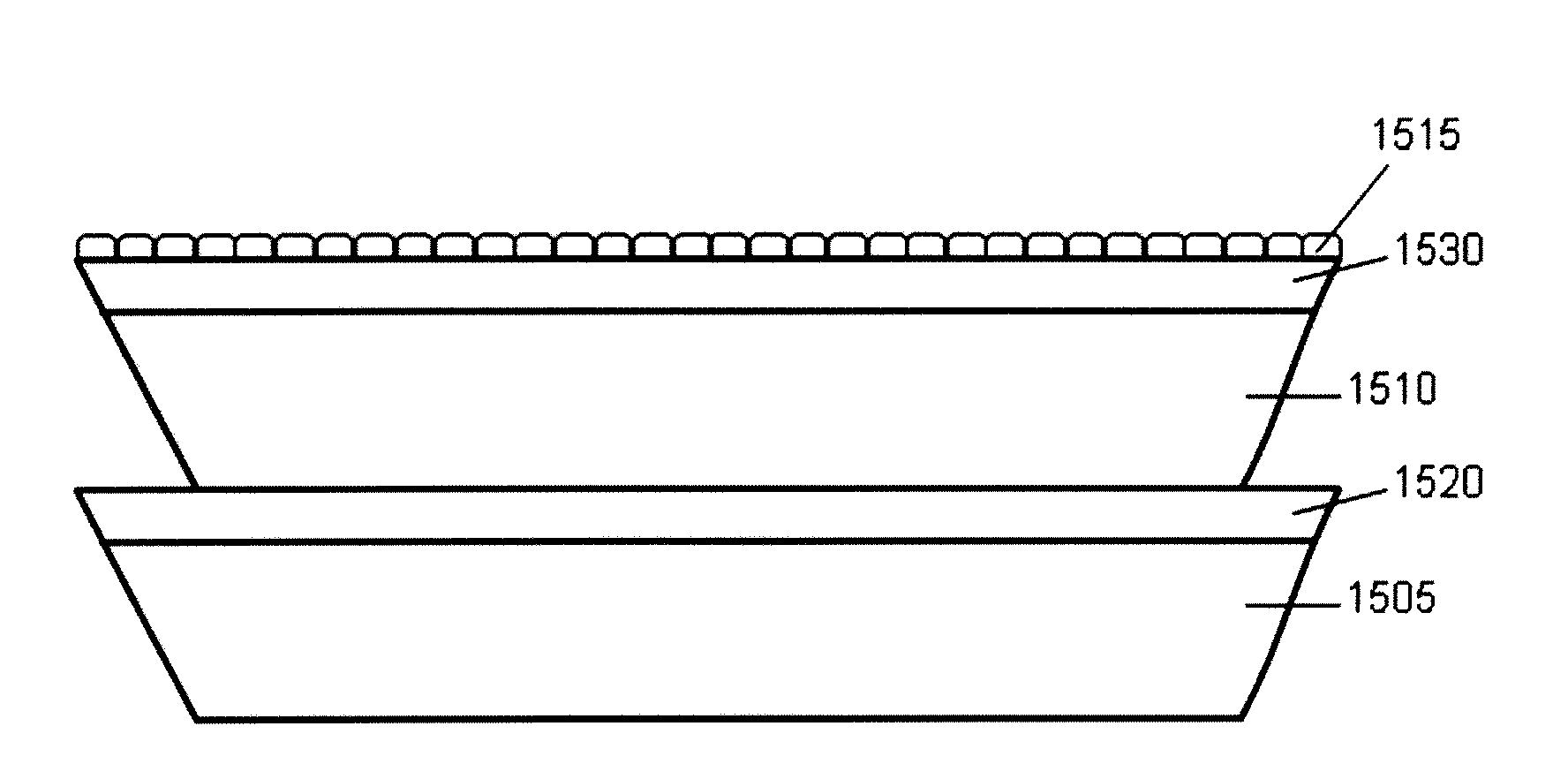

ActiveUS20100084668A1Overcomes shortcomingSolid-state devicesSemiconductor/solid-state device manufacturingDistributed Bragg reflectorDisplay device

Methods and systems are provided that may be used to utilize and manufacture a light sources apparatus. A first light emitting diode emits light having a first wavelength, and a second light emitting diode for emitting light having a second wavelength. Each of the first and second light emitting diodes may comprise angled facets to reflect incident light in a direct toward a top end of the first light emitting diode. The second light emitting diode comprising angled facets may reflect incident light in a direction toward a top end of the second light emitting diode. A first distributed Bragg reflector is disposed between the top end of the first light emitting diode and a bottom end of the second light emitting diode to allow light from the first light emitting diode to pass through and to reflect light from the second light emitting diode.

Owner:VERSITECH LTD

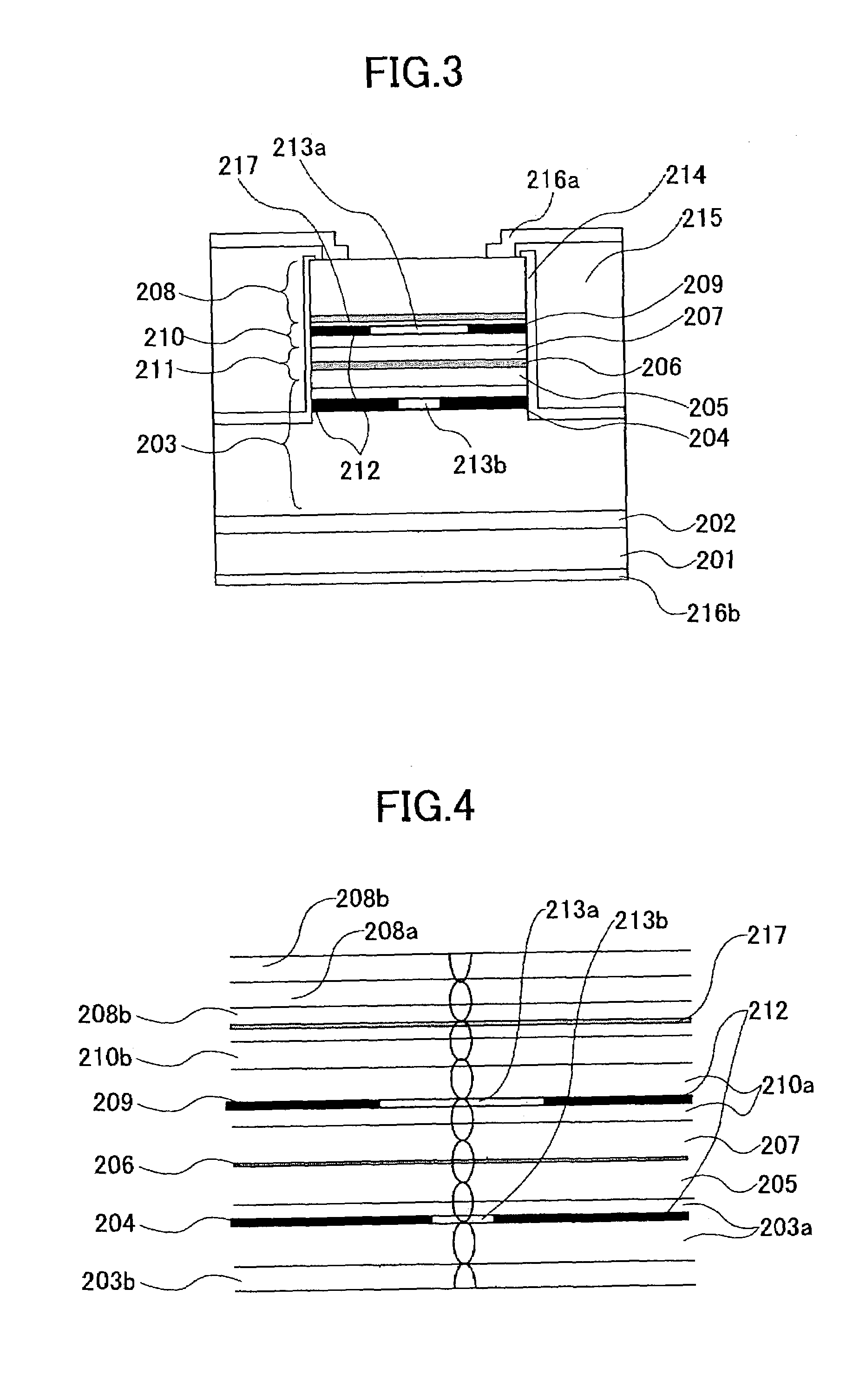

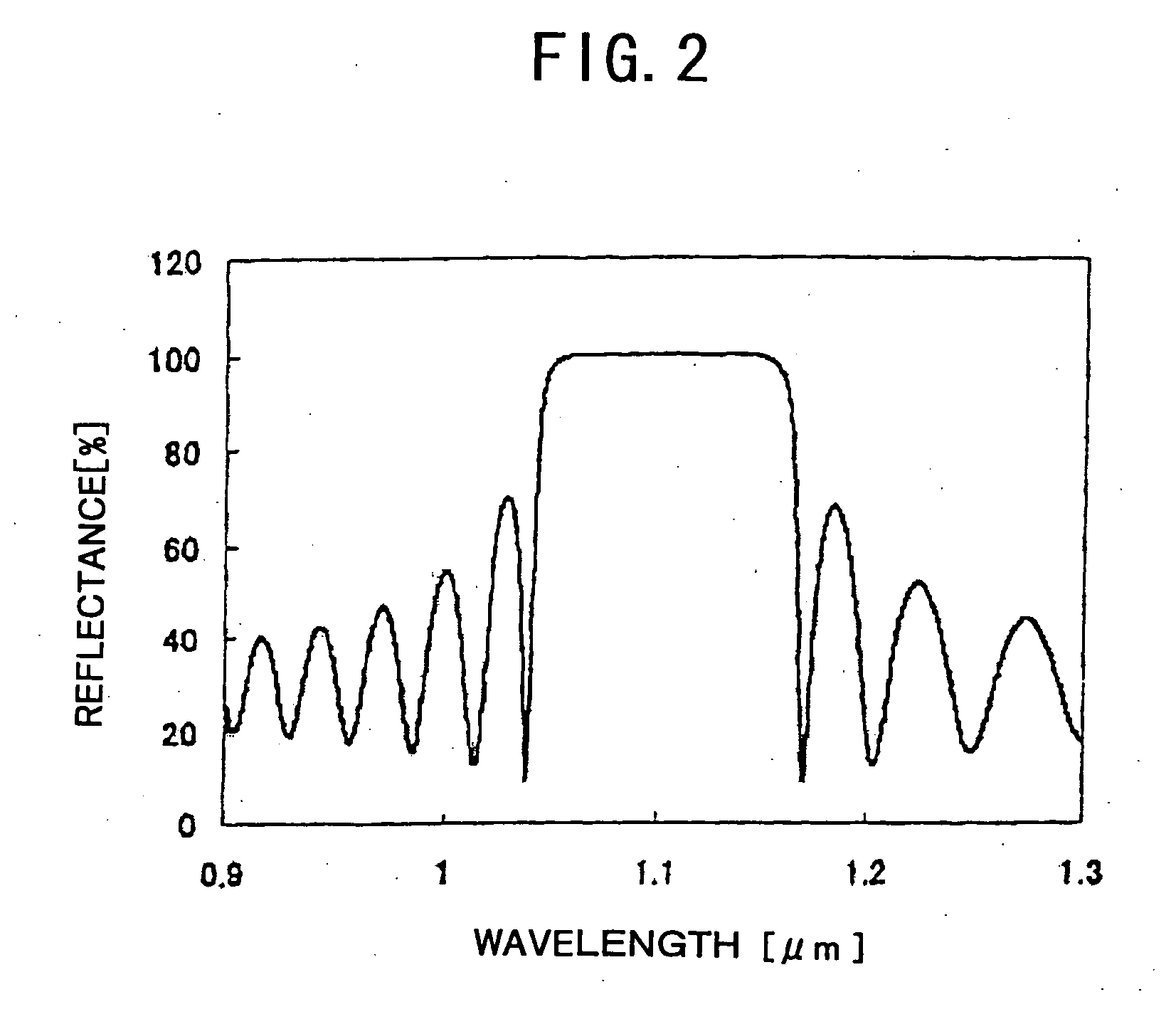

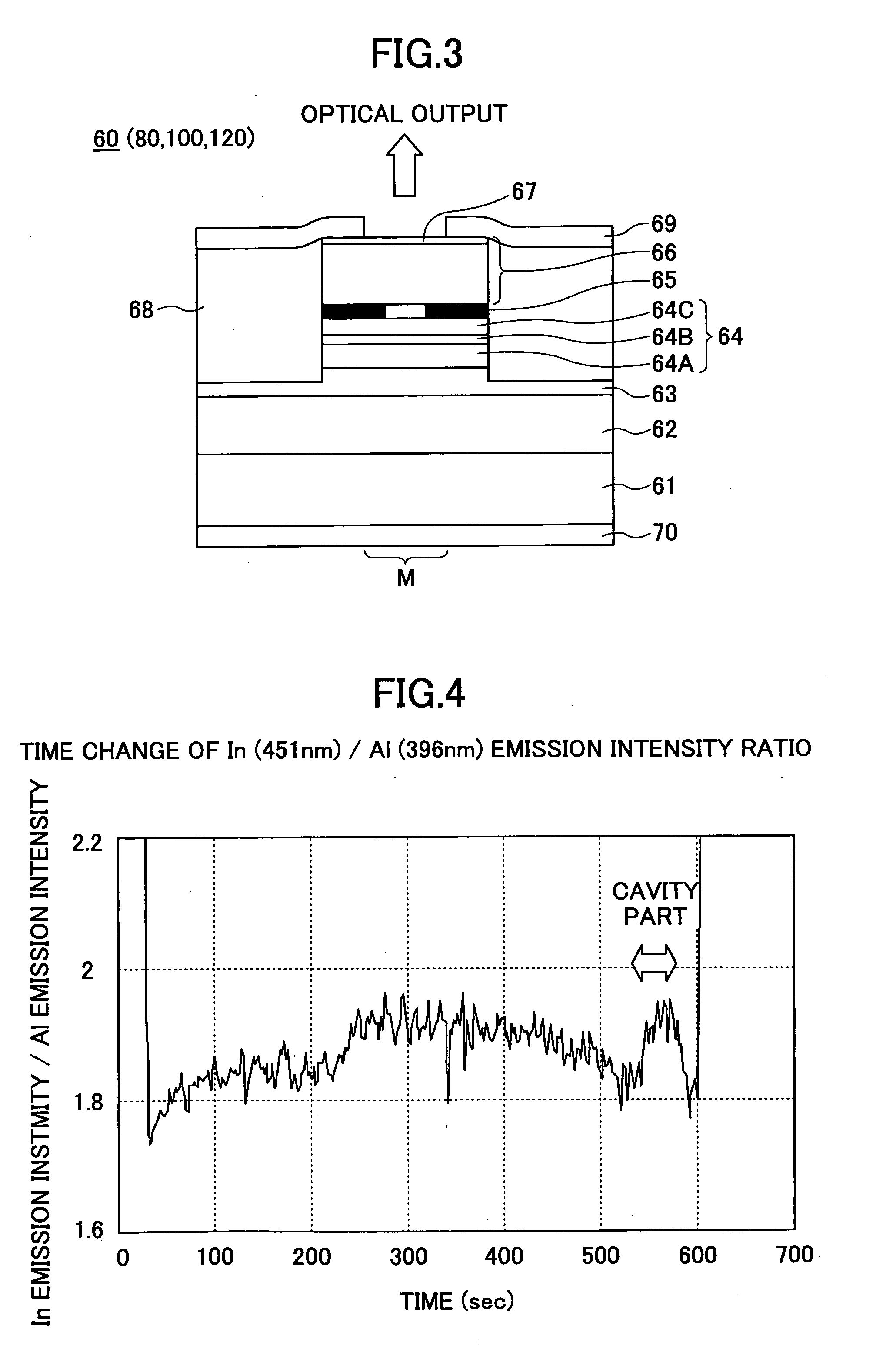

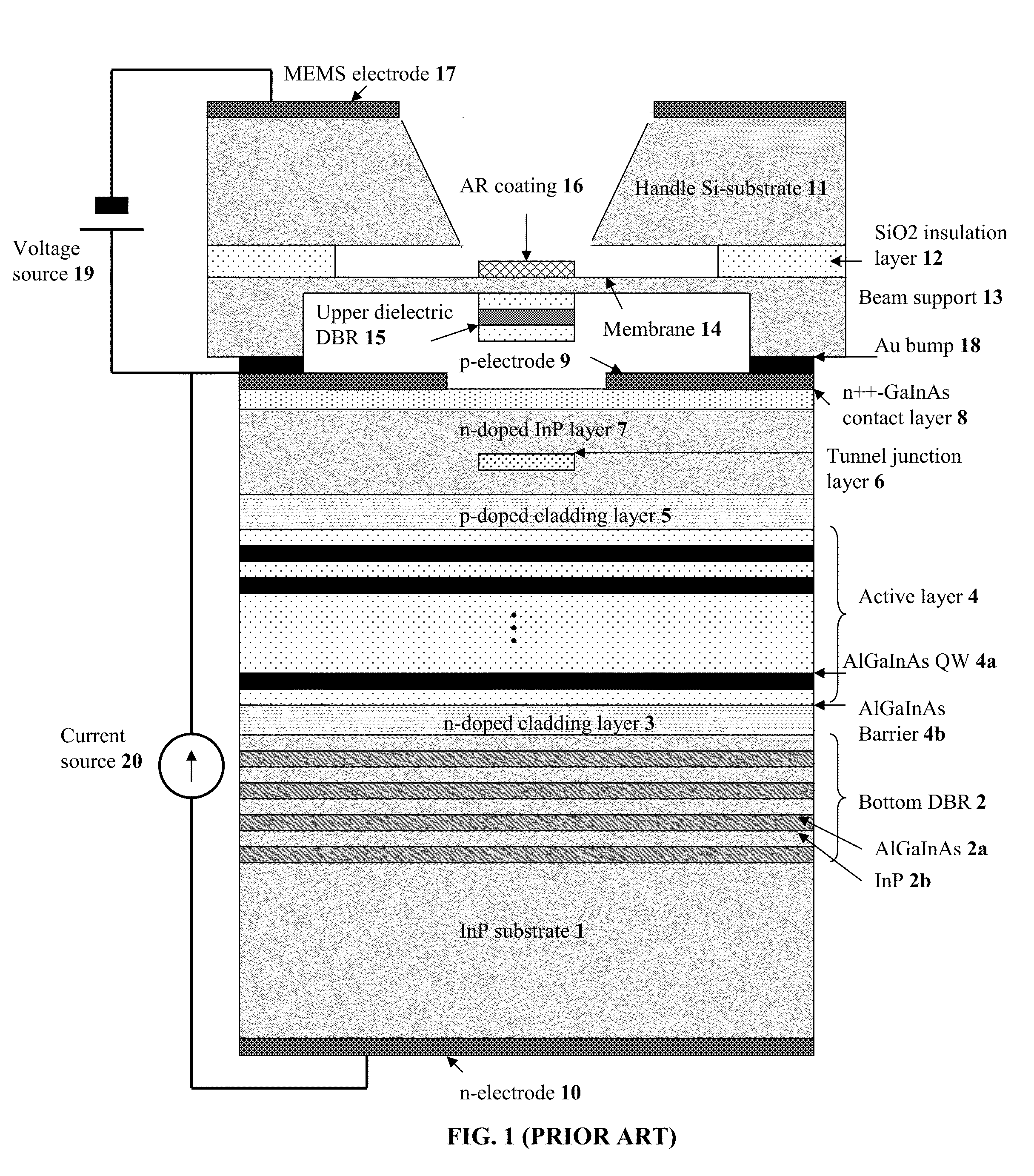

Surface-emission laser diode operable in the wavelength band of 1.1-1.7 um and optical telecommunication system using such a laser diode

InactiveUS20060093010A1Resistance minimizationImprove reflectivitySolid-state devicesOptical resonator shape and constructionDistributed Bragg reflectorRefractive index

A surface-emission laser diode includes a distributed Bragg reflector tuned to a wavelength of 1.1 μm or longer, wherein the distributed Bragg reflector includes an alternate repetition of a low-refractive index layer and a high-refractive index layer, with a heterospike buffer layer having an intermediate refractive index interposed therebetween with a thickness in the range of 5-50 nm

Owner:SEKIYA TAKURO +14

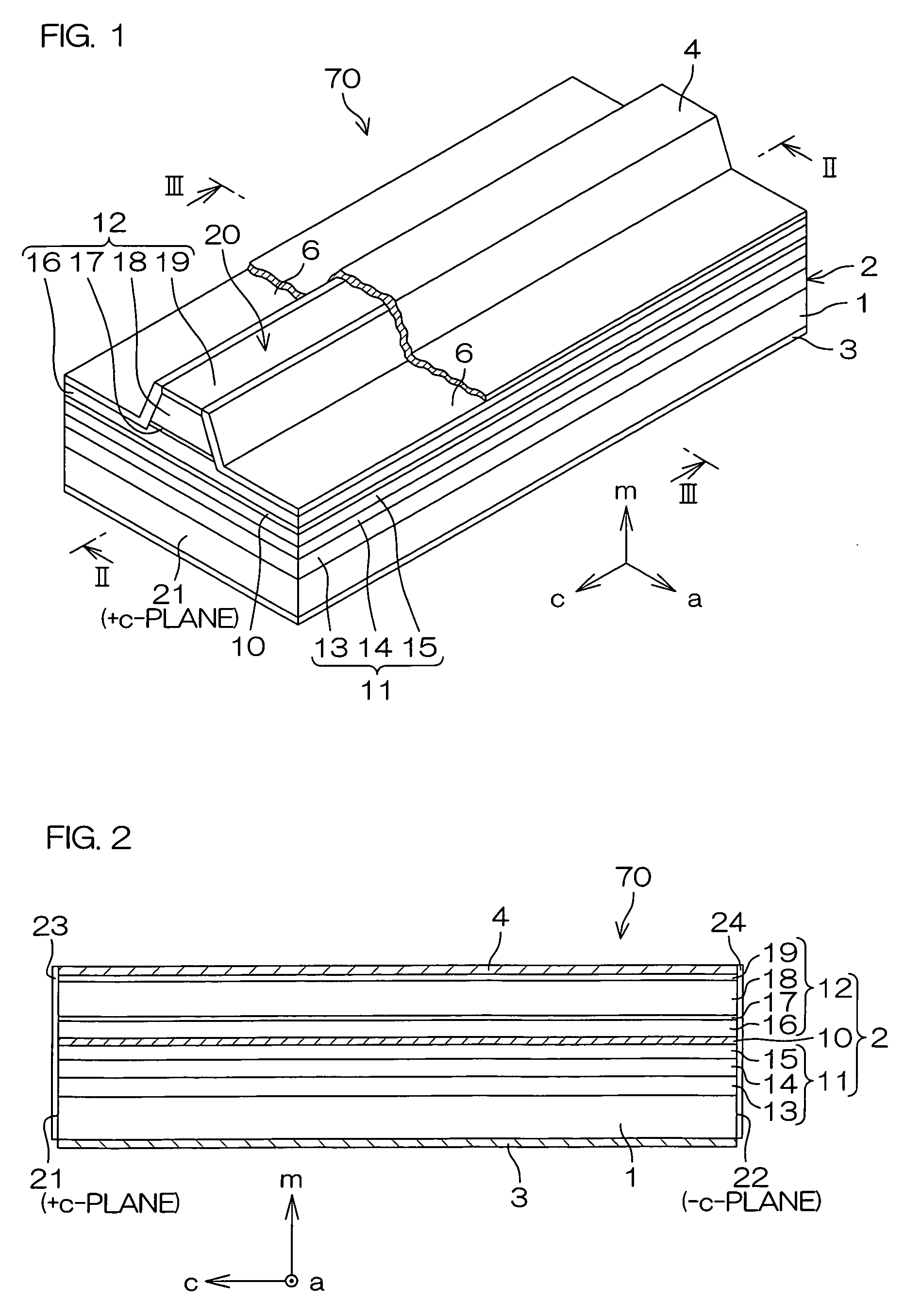

Semiconductor laser device

InactiveUS20090252191A1Polarization fieldOptical resonator shape and constructionNanoopticsDistributed Bragg reflectorLength wave

A semiconductor laser device is made of a group III nitride semiconductor having a major growth surface defined by a nonpolar plane or a semipolar plane. The semiconductor laser device includes a cavity having an active layer containing In and distributed Bragg reflectors coating both cavity end faces of the cavity respectively. In each of the distributed Bragg reflectors, a central wavelength λc of a reflectance spectrum satisfies the relation λSP−10 nm≦λc≦λSP+10 nm with respect to an emission peak wavelength λSP of spontaneous emission in the active layer.

Owner:ROHM CO LTD

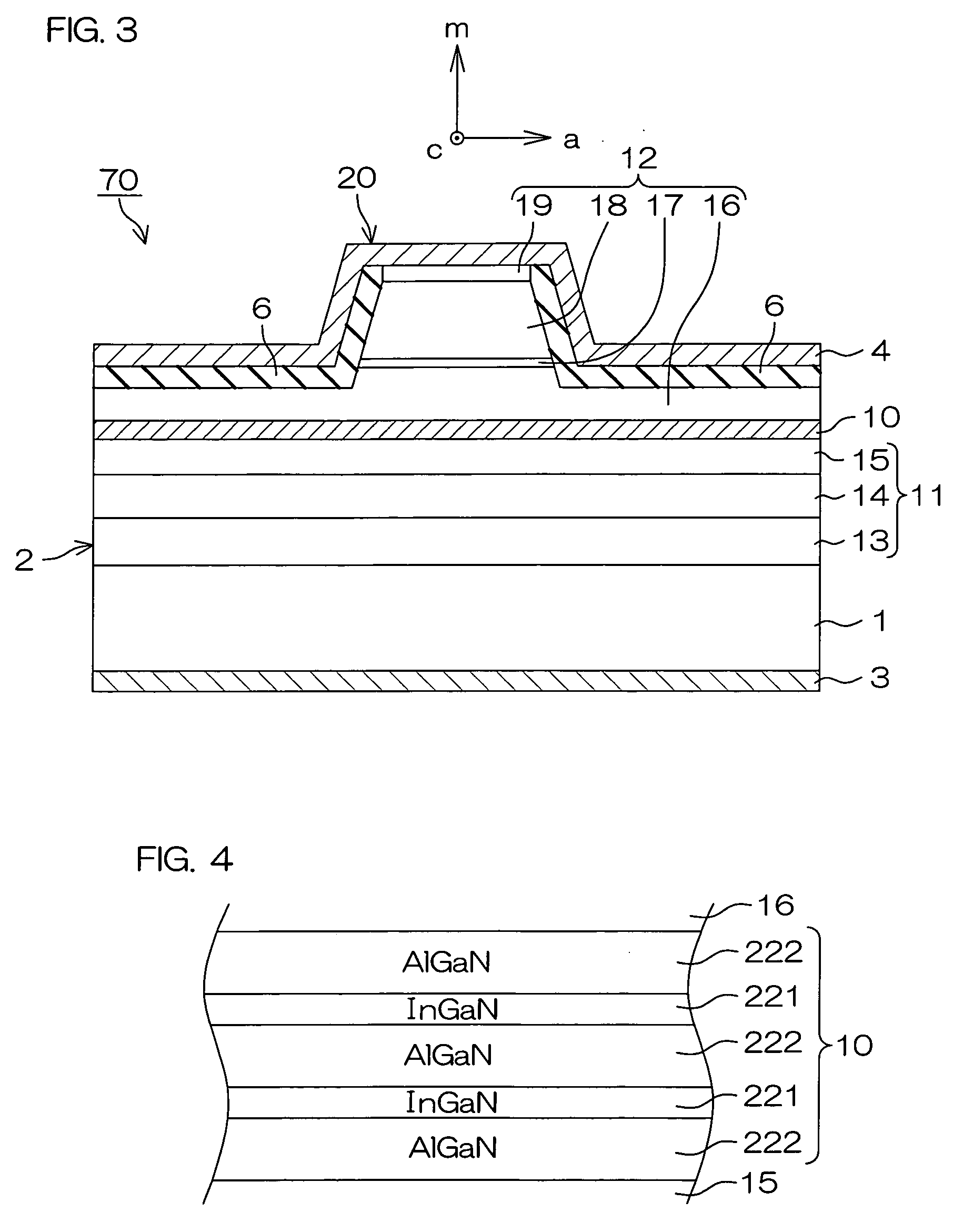

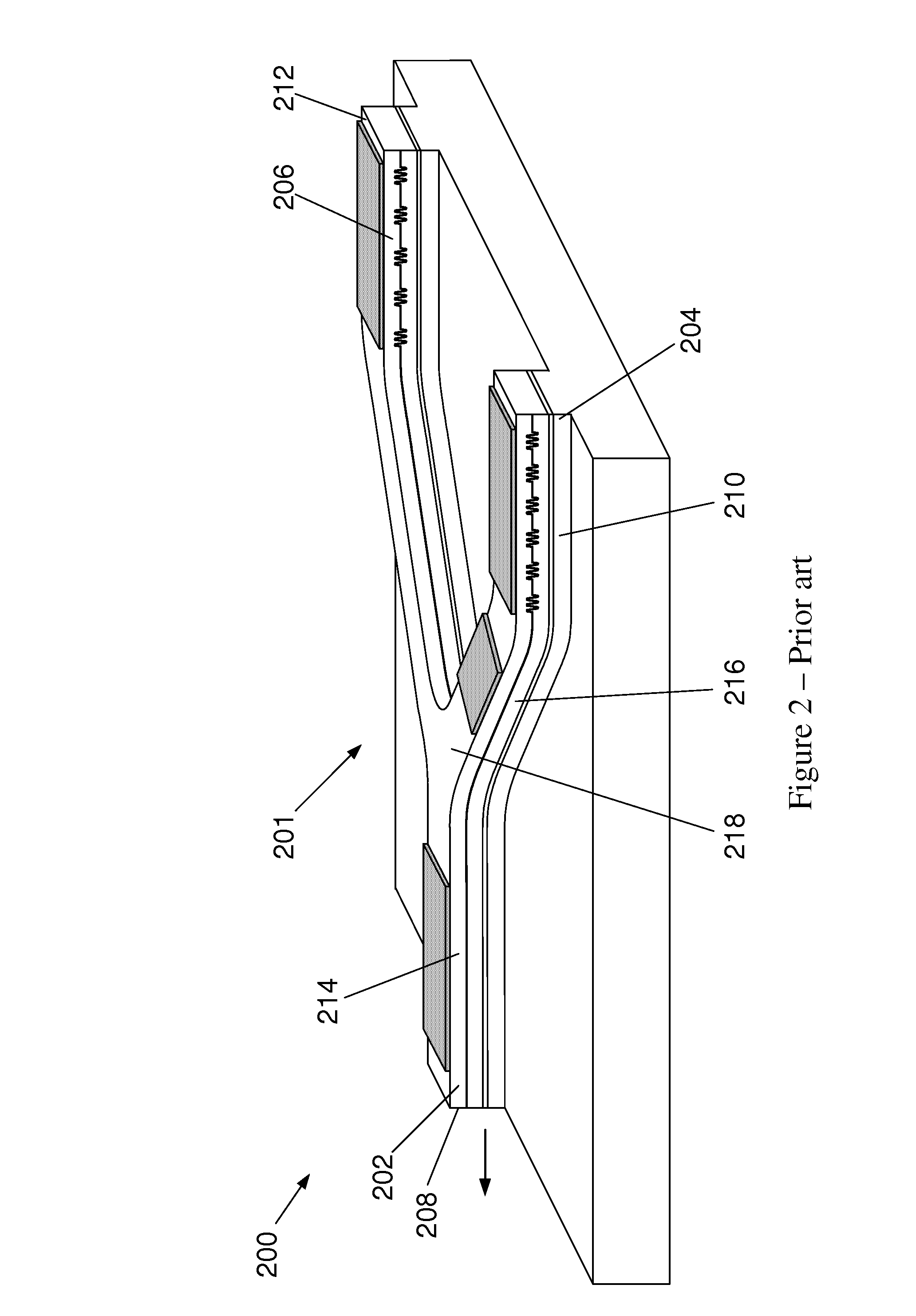

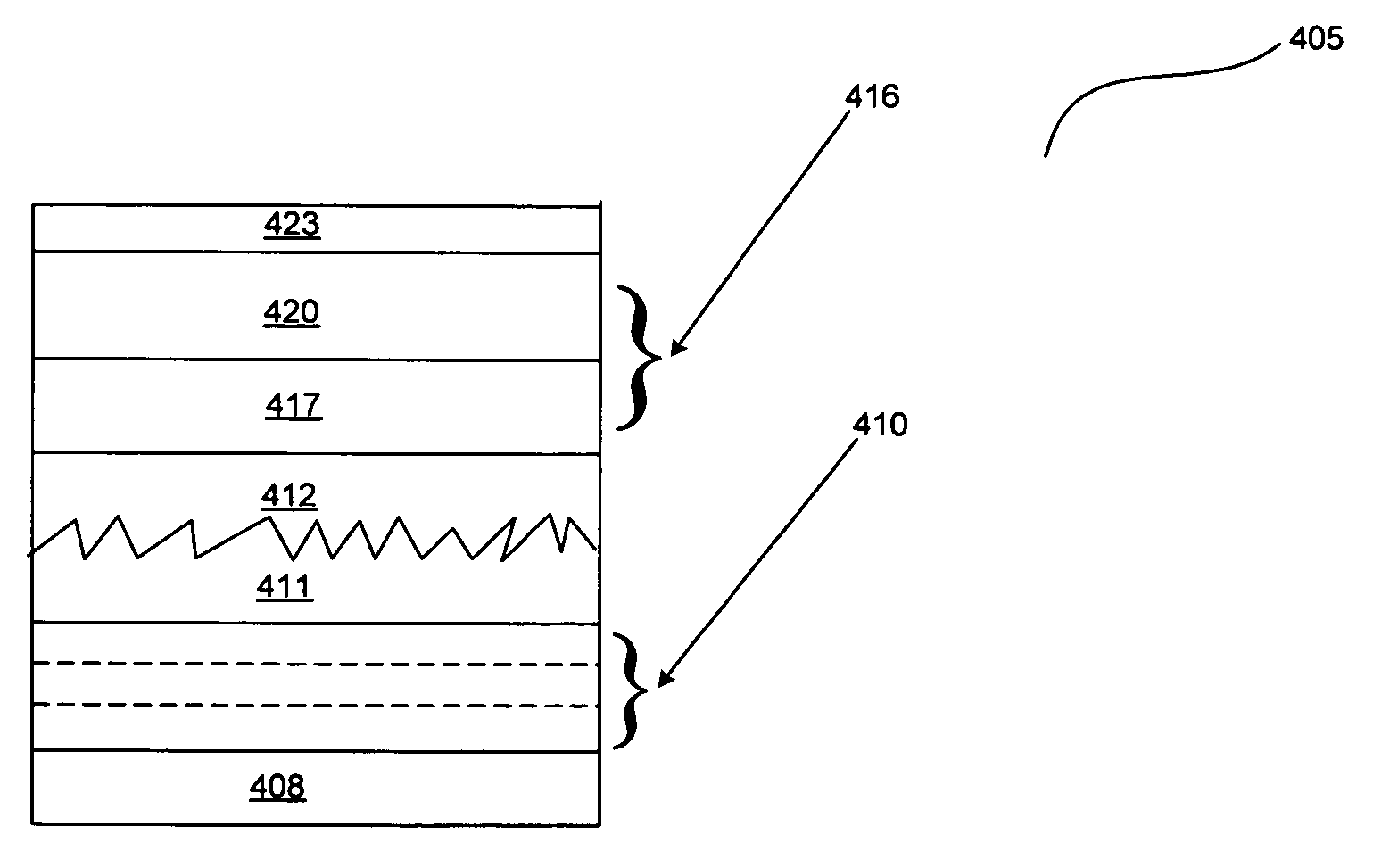

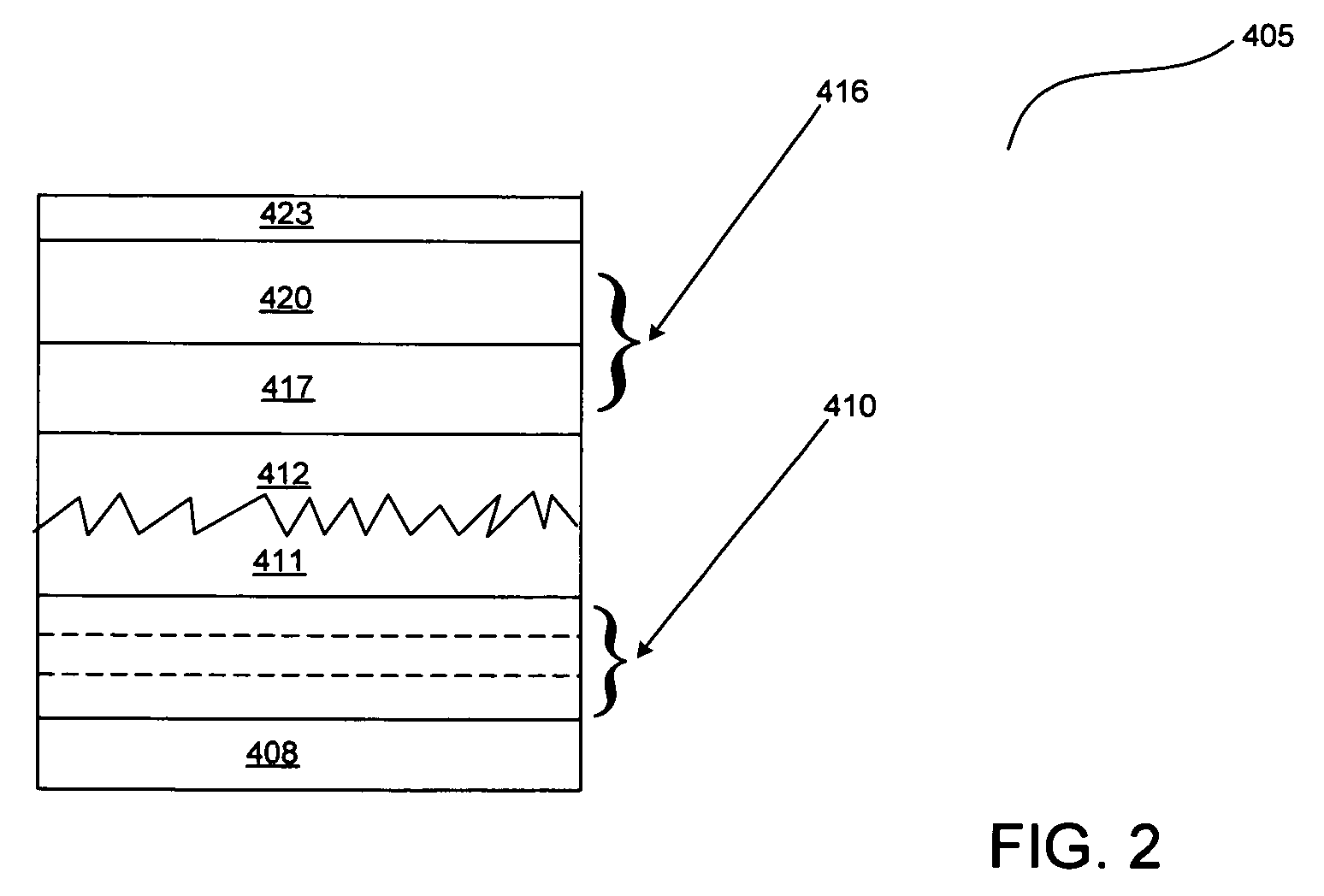

Branched waveguide multisection dbr semiconductor laser

ActiveUS20100142567A1Cavity length lowImprove reflectivityLaser optical resonator constructionOptical resonator shape and constructionGratingCoupling

The present invention concerns tunable distributed Bragg reflector (DBR) semiconductor lasers, in particular a DBR laser with a branched optical waveguide 5 within which a plurality of differently shaped lasing cavities may be formed, and a method of operation of such a laser. The laser may comprise a phase control section (418), gain section (420, 422), a sampled grating DBR (412) giving a comb-line spectrum and two tunable, chirped DBRs (414, 416) for broadband frequency training and a coupling section (410).

Owner:LUMENTUM TECH UK LTD

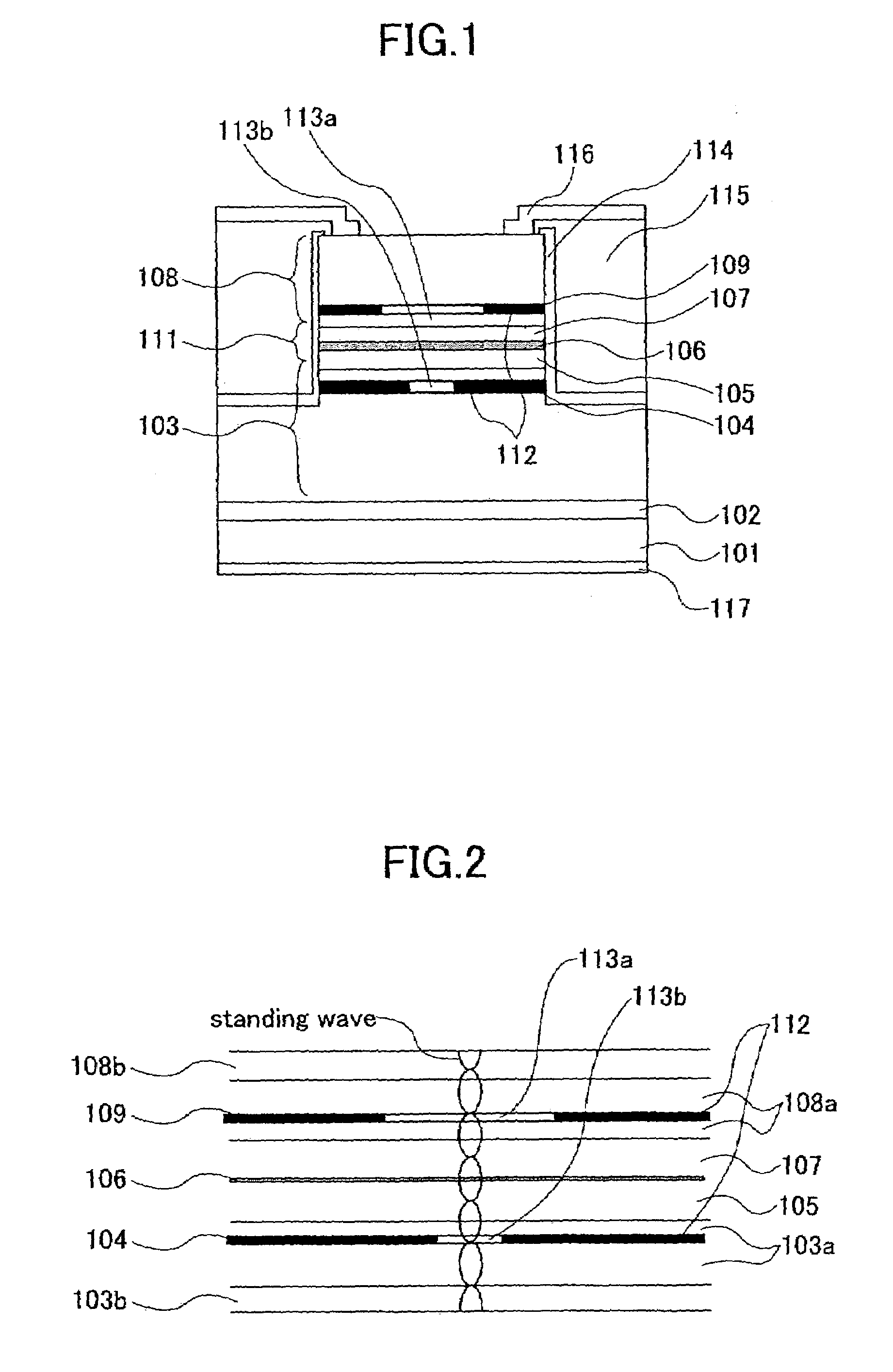

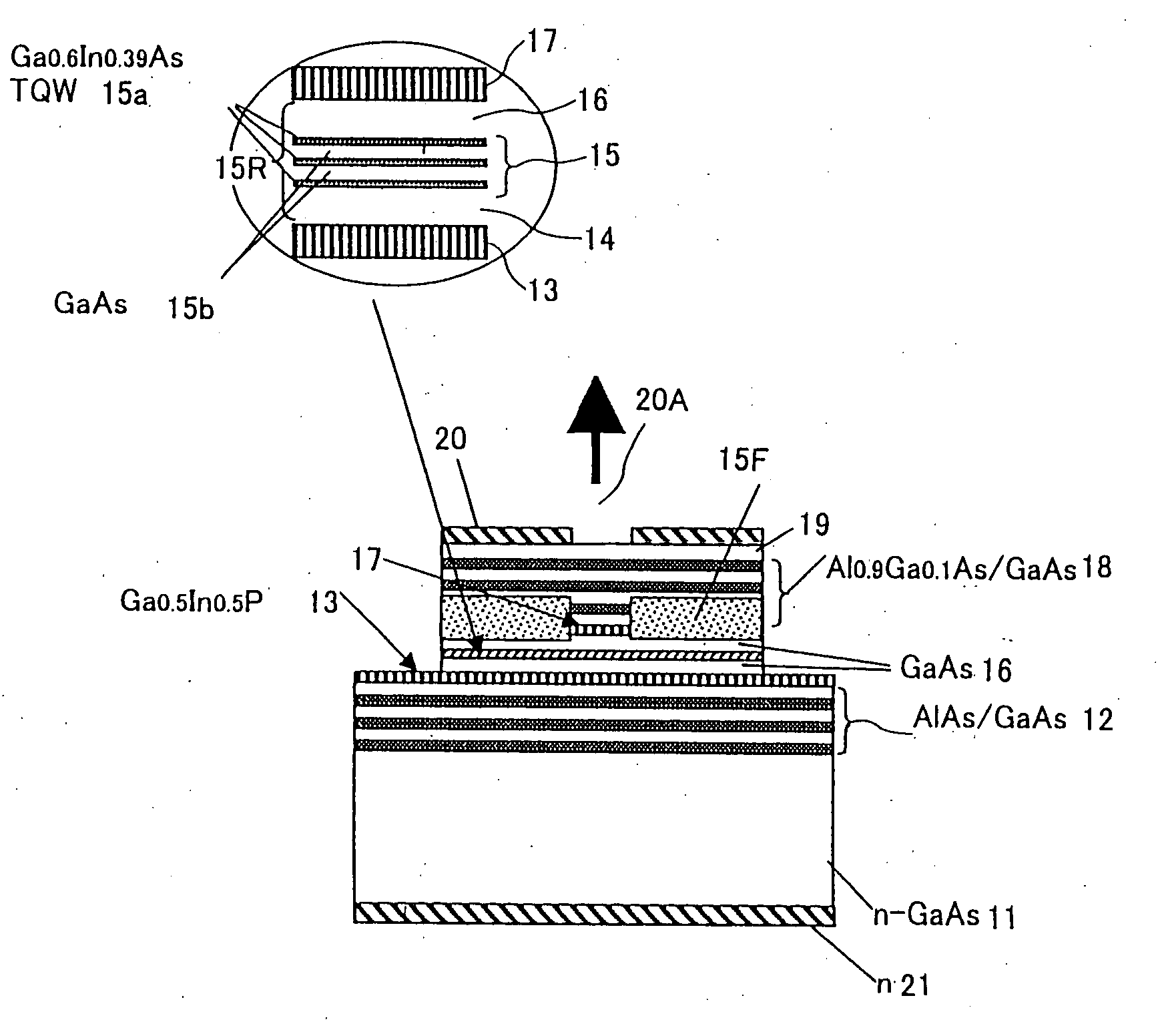

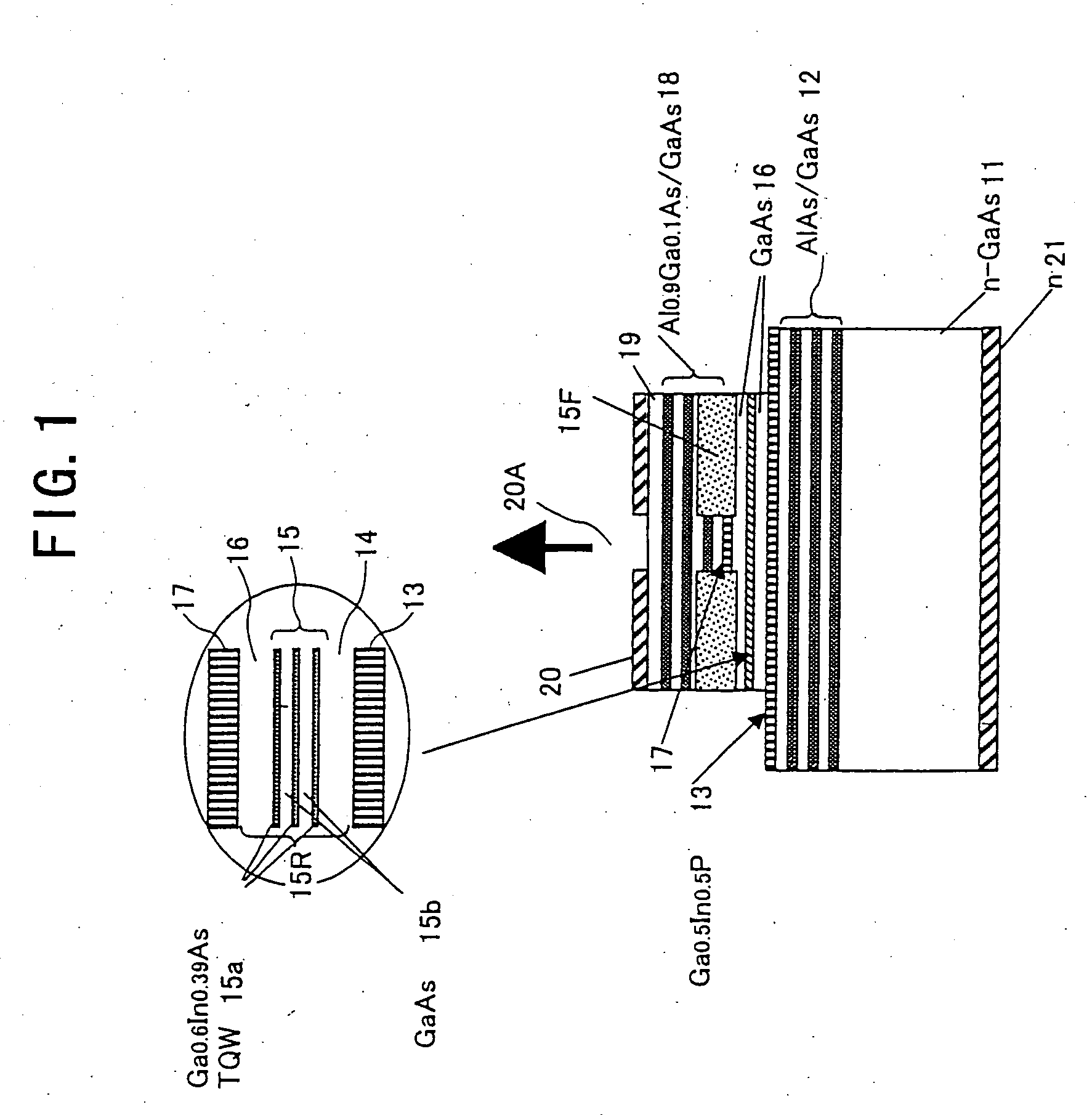

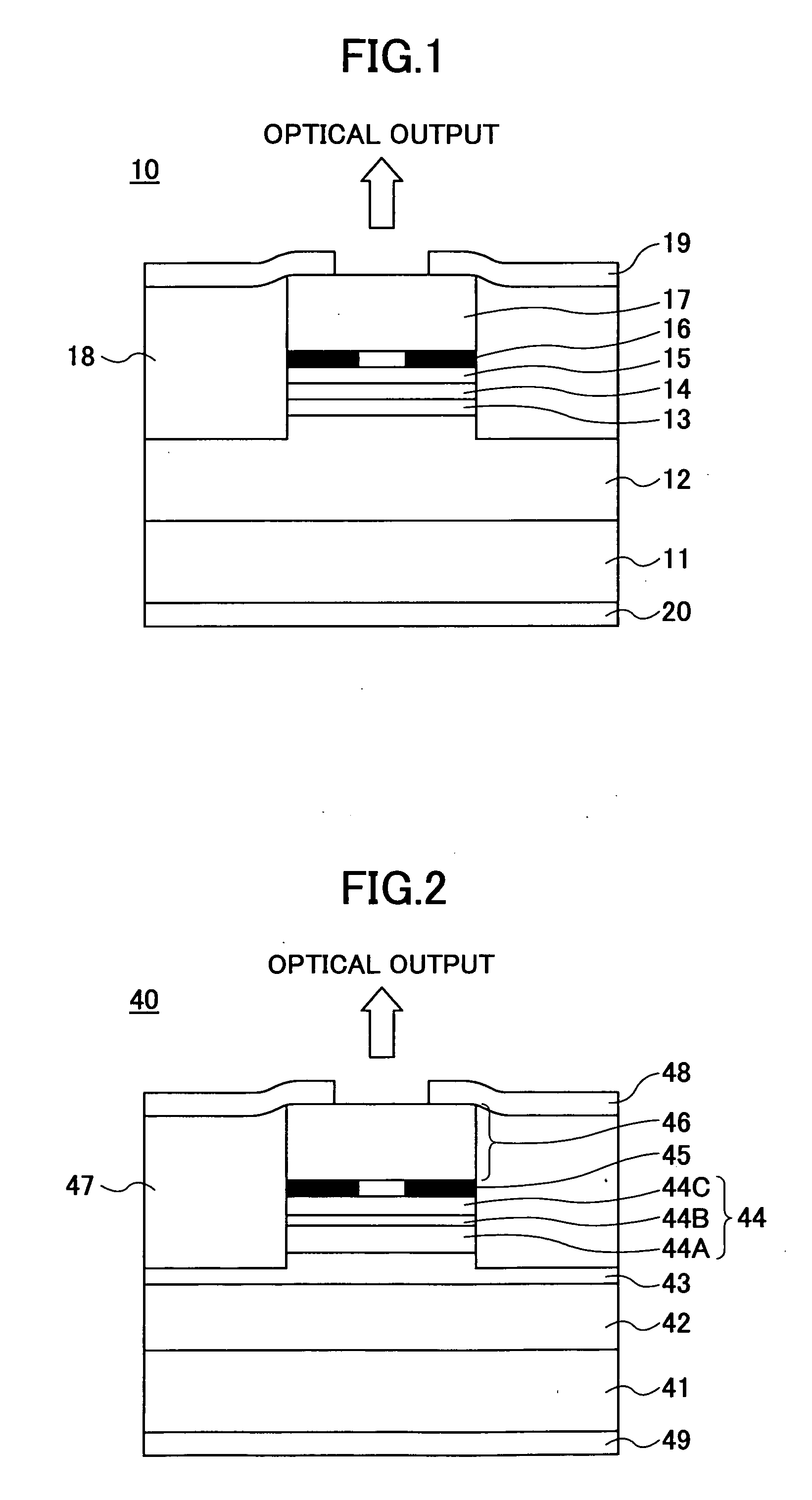

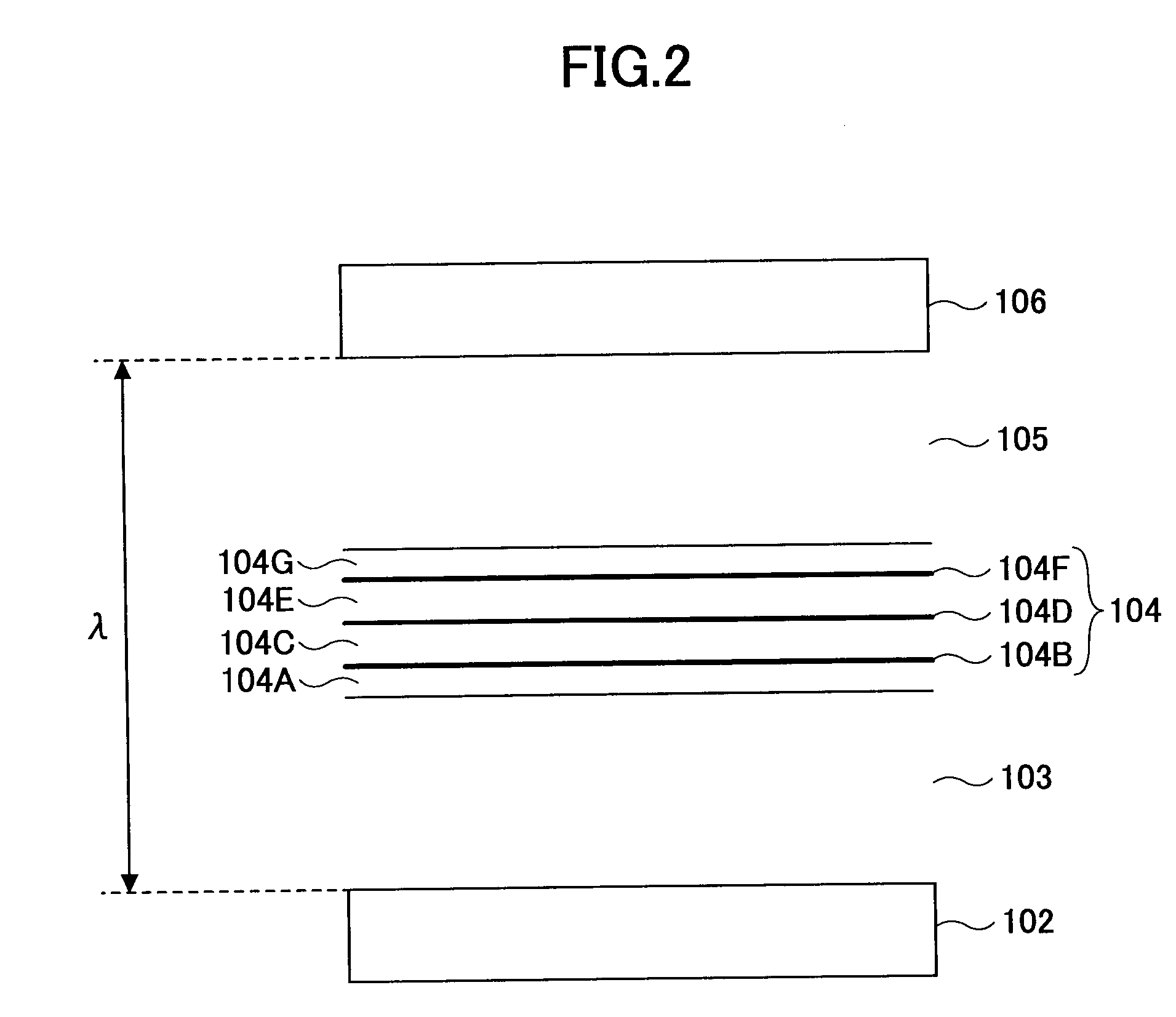

Surface-Emission Laser Diode and Fabrication Process Thereof

ActiveUS20080212636A1Large gainExcellent high-temperature characteristicOptical wave guidanceLaser detailsQuantum wellDistributed Bragg reflector

A surface-emission laser diode comprises a cavity region over a semiconductor substrate and includes an active layer containing at least one quantum well active layer producing a laser light and a barrier layer, a spacer layer is provided in the vicinity of the active layer and formed of at least one material, an upper and lower reflectors are provided at a top part and a bottom part of the cavity region, the cavity region and the upper and lower reflectors form a mesa structure over the semiconductor substrate, the upper and lower reflectors being formed of a semiconductor distributed Bragg reflector having a periodic change of refractive index and reflecting incident light by interference of optical waves, at least a part of the semiconductor distributed Bragg reflector is formed of a layer of small refractive index of AlxGa1-xAs (0<x≦1) and a layer of large refractive index of AlyGa1-yAs (0≦y<x≦1), the lower reflector is formed of a first lower reflector having a low-refractive index layer of AlAs and a second lower reflector formed on the first lower reflector, the second lower reflector has a low-refractive index layer of AlGaAs, any one layer constituting the cavity region contains In.

Owner:RICOH KK

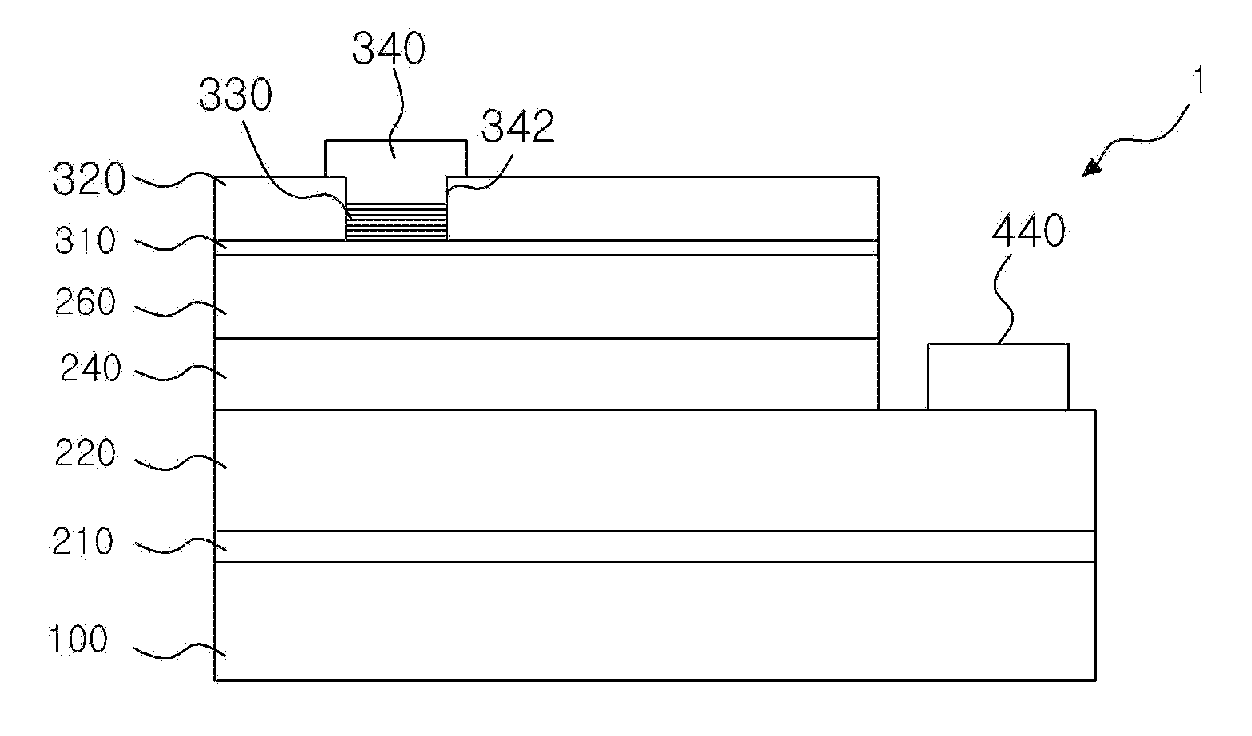

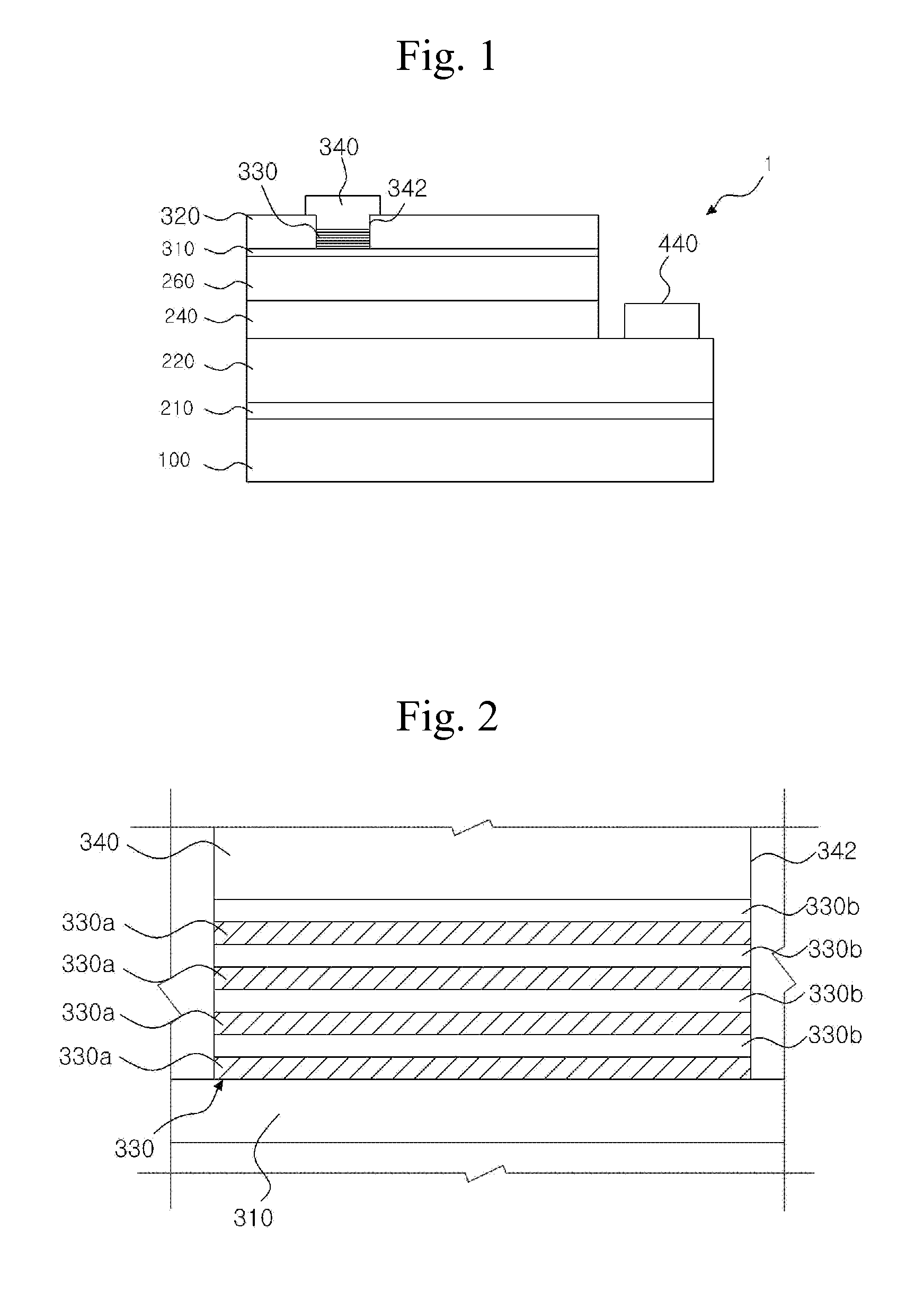

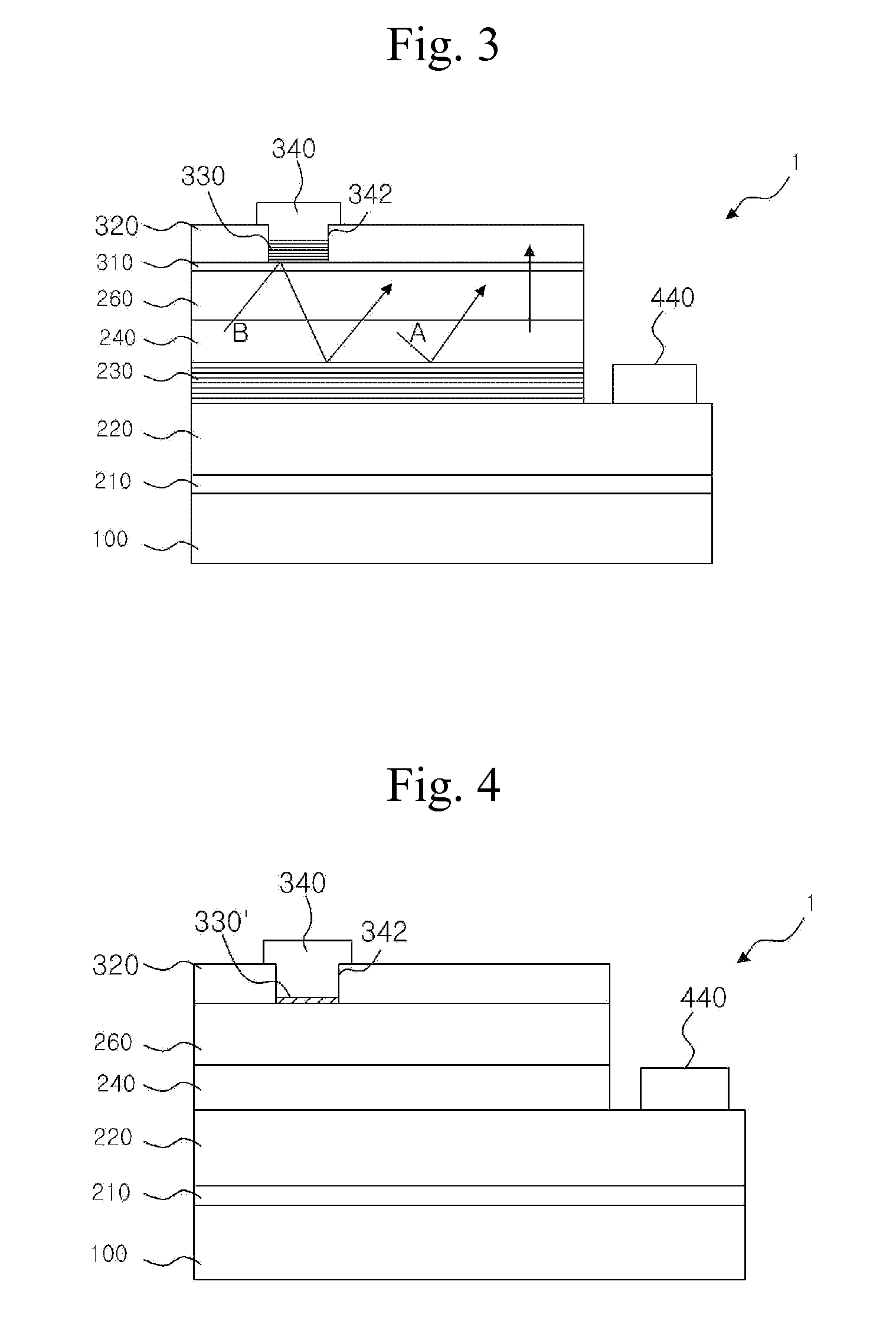

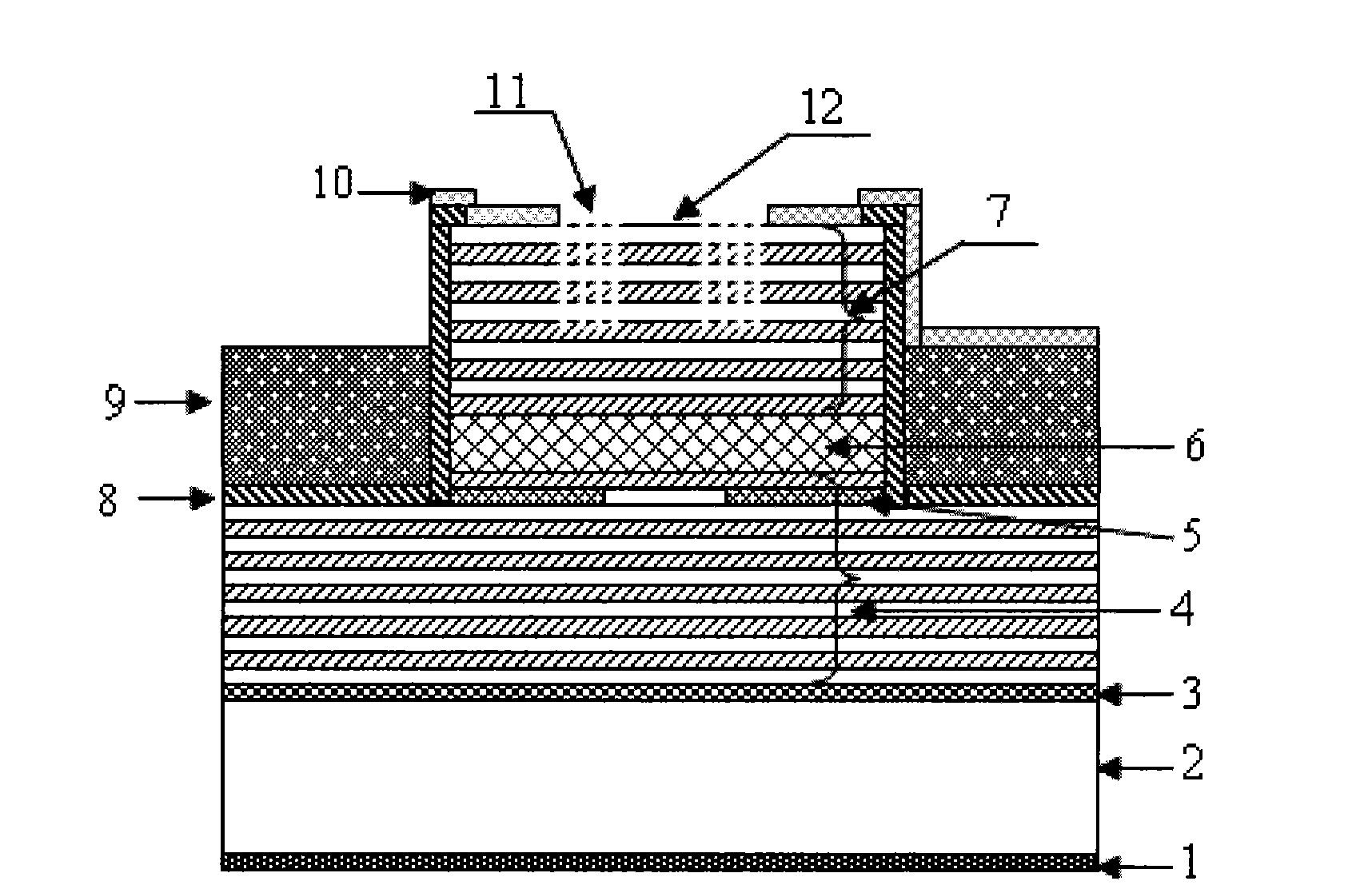

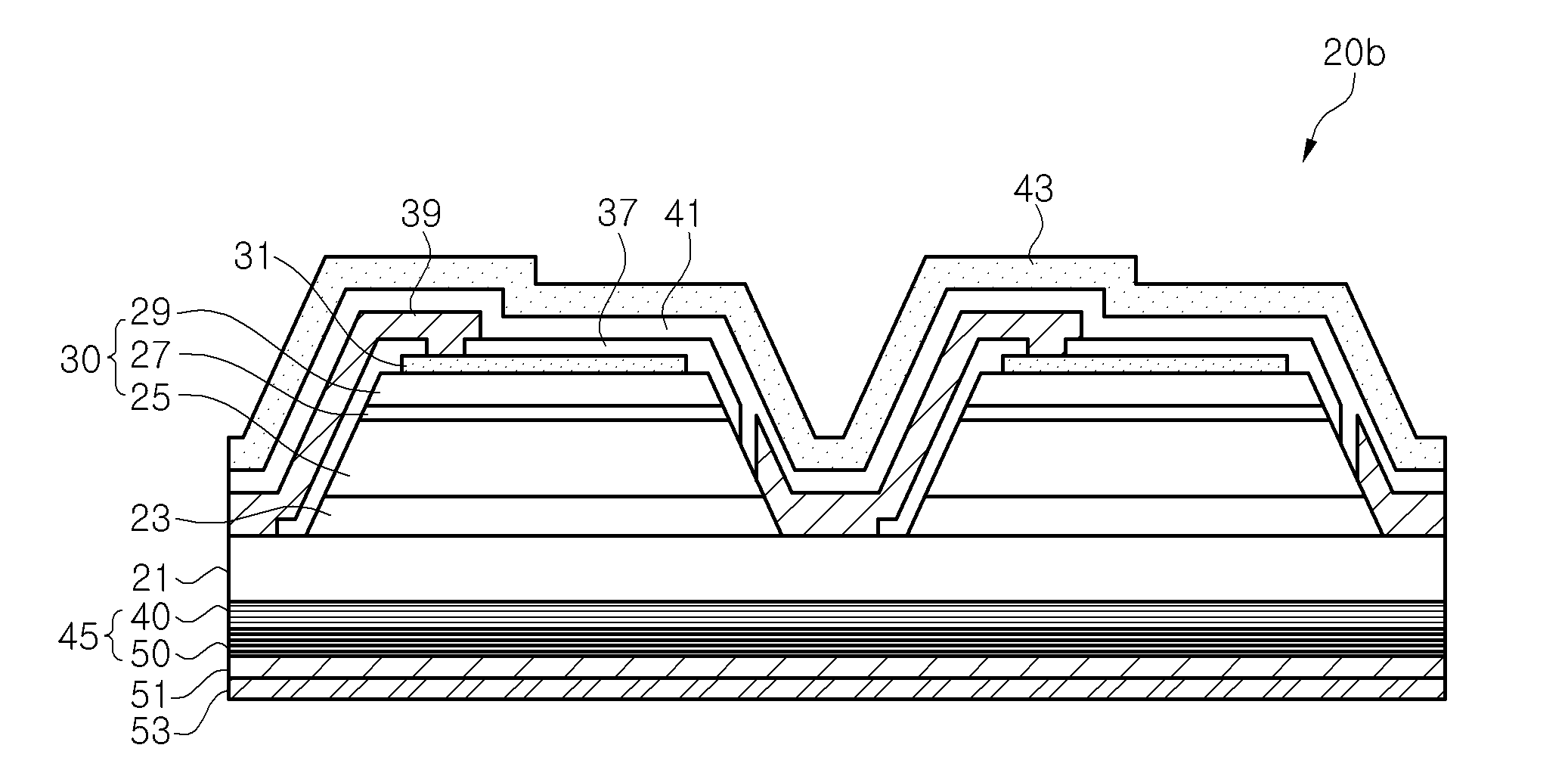

Light emitting diode chip having distributed bragg reflector, method of fabricating the same, and light emitting diode package having distributed bragg reflector

ActiveUS20110114969A1Increasing light emission efficiency of a light emitting diode packageImprove luminous efficiencySolid-state devicesSemiconductor/solid-state device manufacturingDistributed Bragg reflectorLength wave

An exemplary embodiment of the present invention discloses a light emitting diode chip including a substrate, a light emitting structure arranged on the substrate, the light emitting structure including an active layer arranged between a first conductive-type semiconductor layer and a second conductive-type semiconductor layer, and a distributed Bragg reflector to reflect light emitted from the light emitting structure. The distributed Bragg reflector has a reflectivity of at least 90% for light of a first wavelength in a blue wavelength range, light of a second wavelength in a green wavelength range, and light of a third wavelength in a red wavelength range.

Owner:SEOUL VIOSYS CO LTD

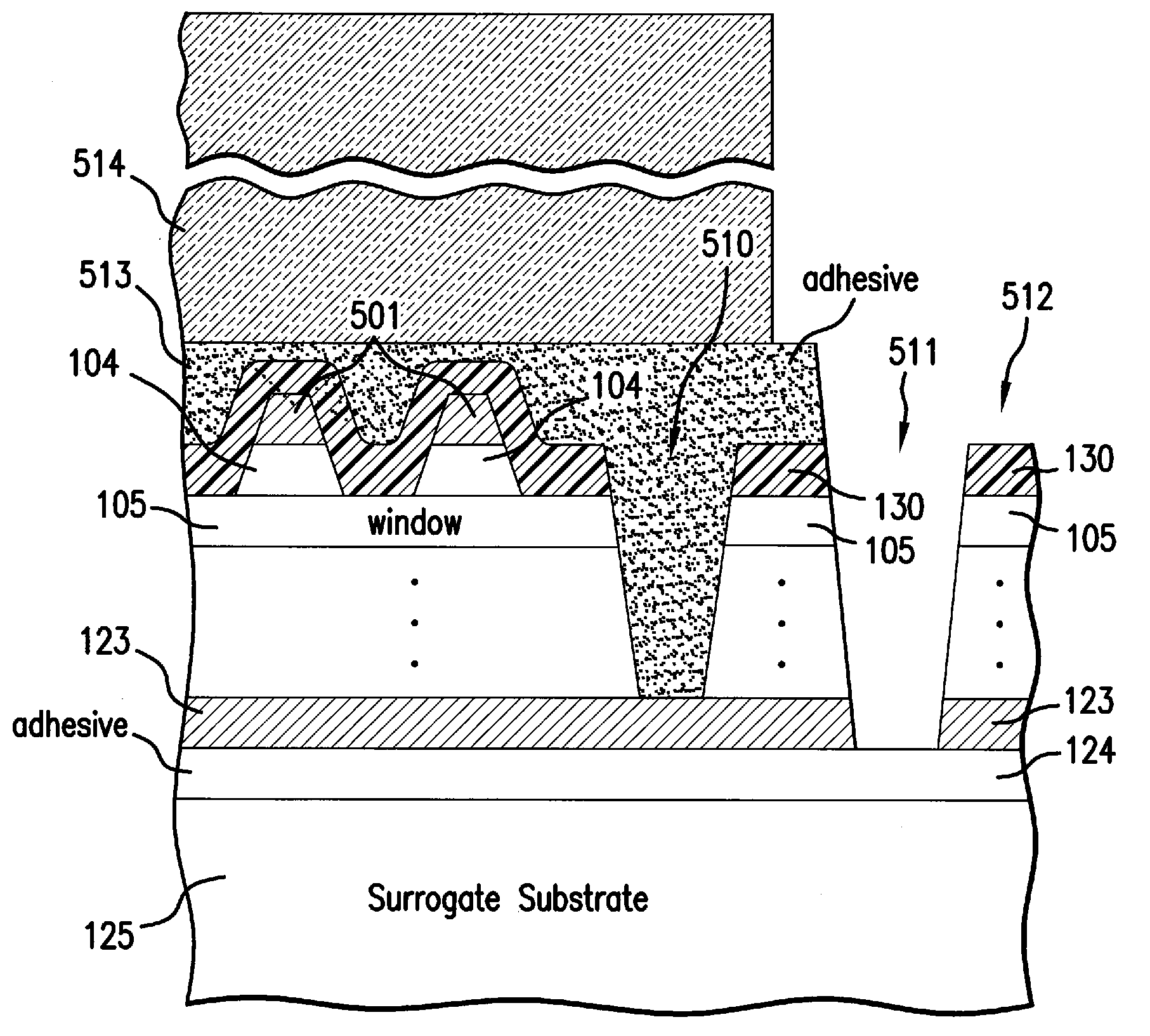

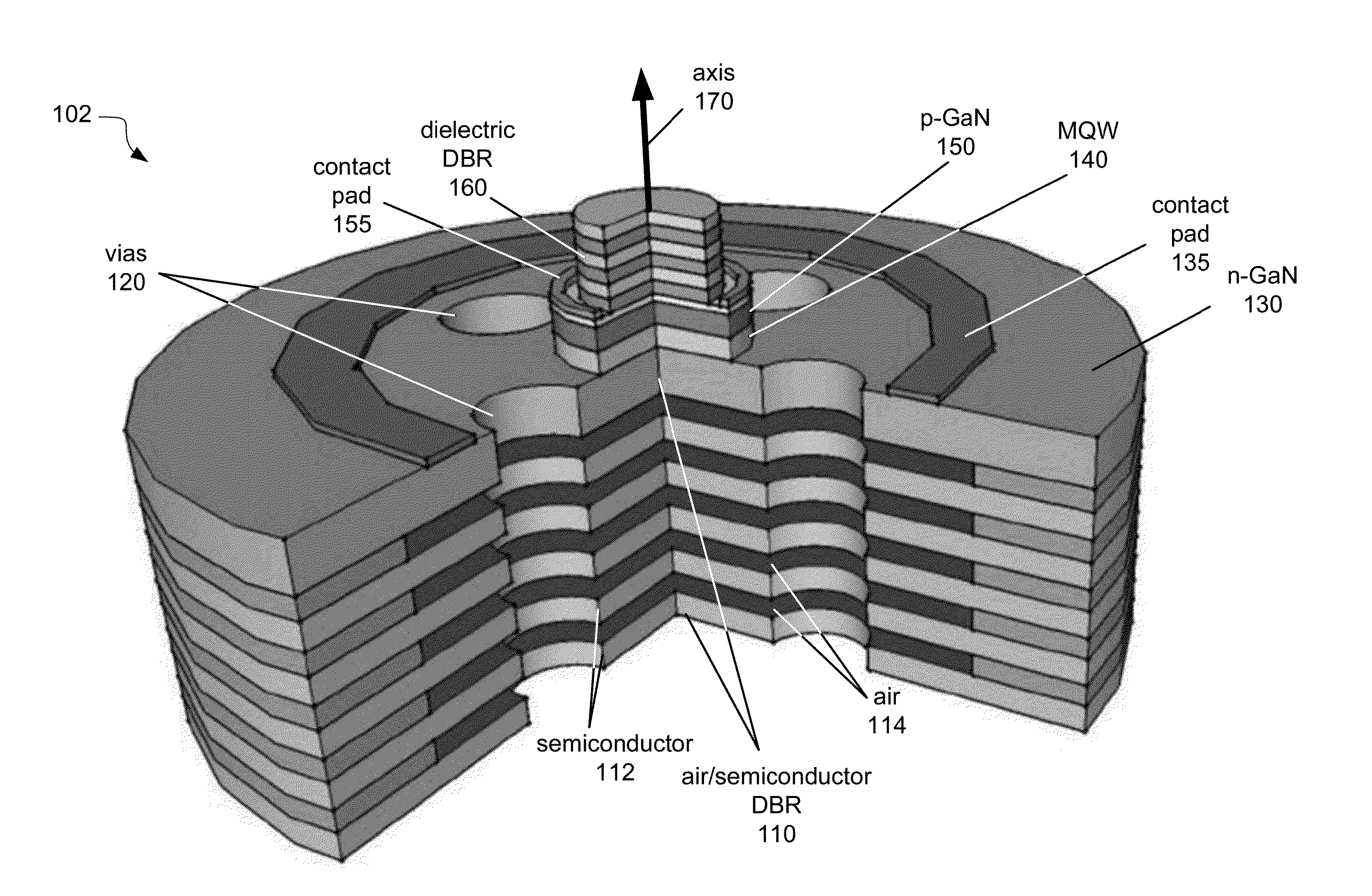

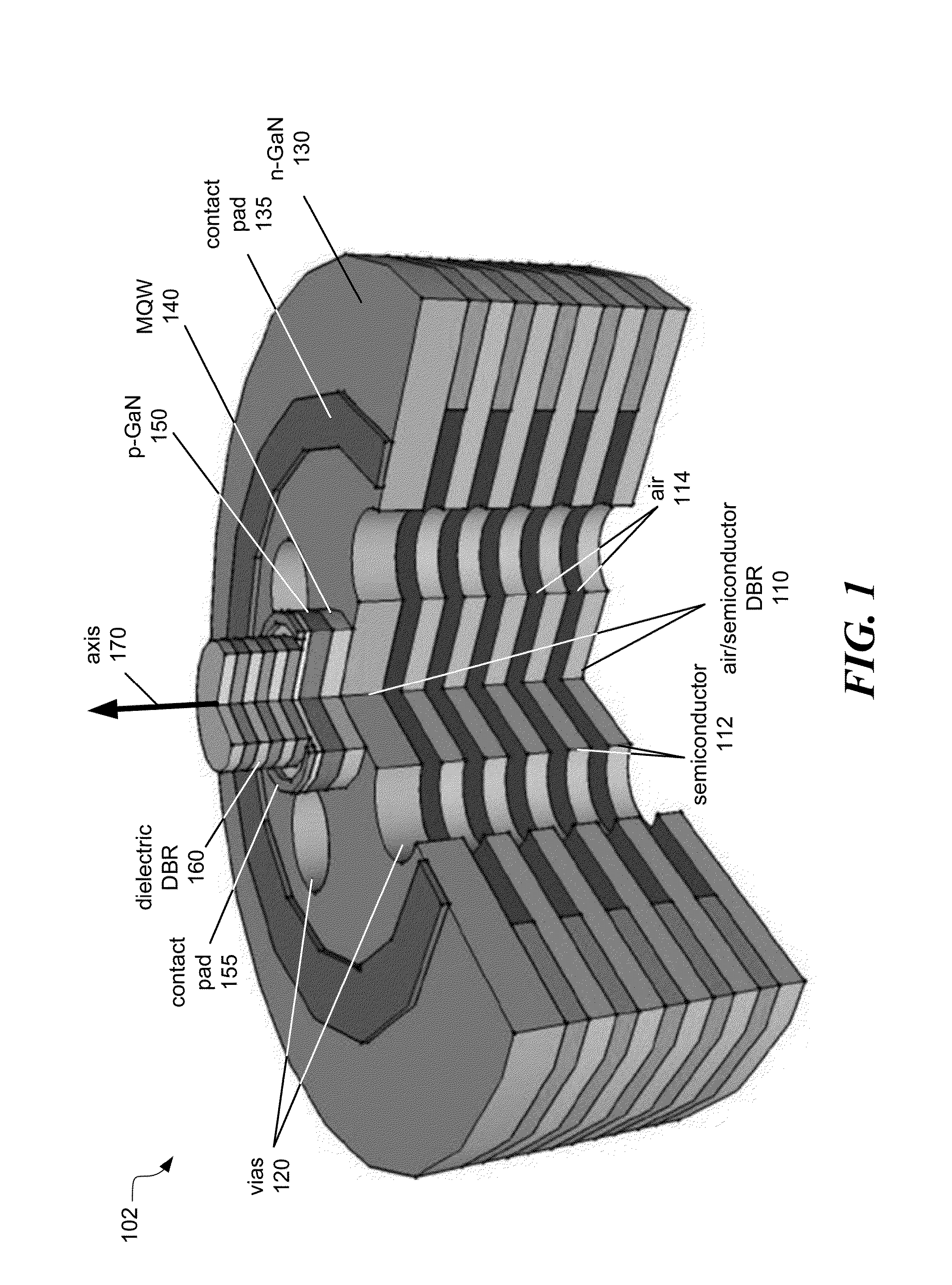

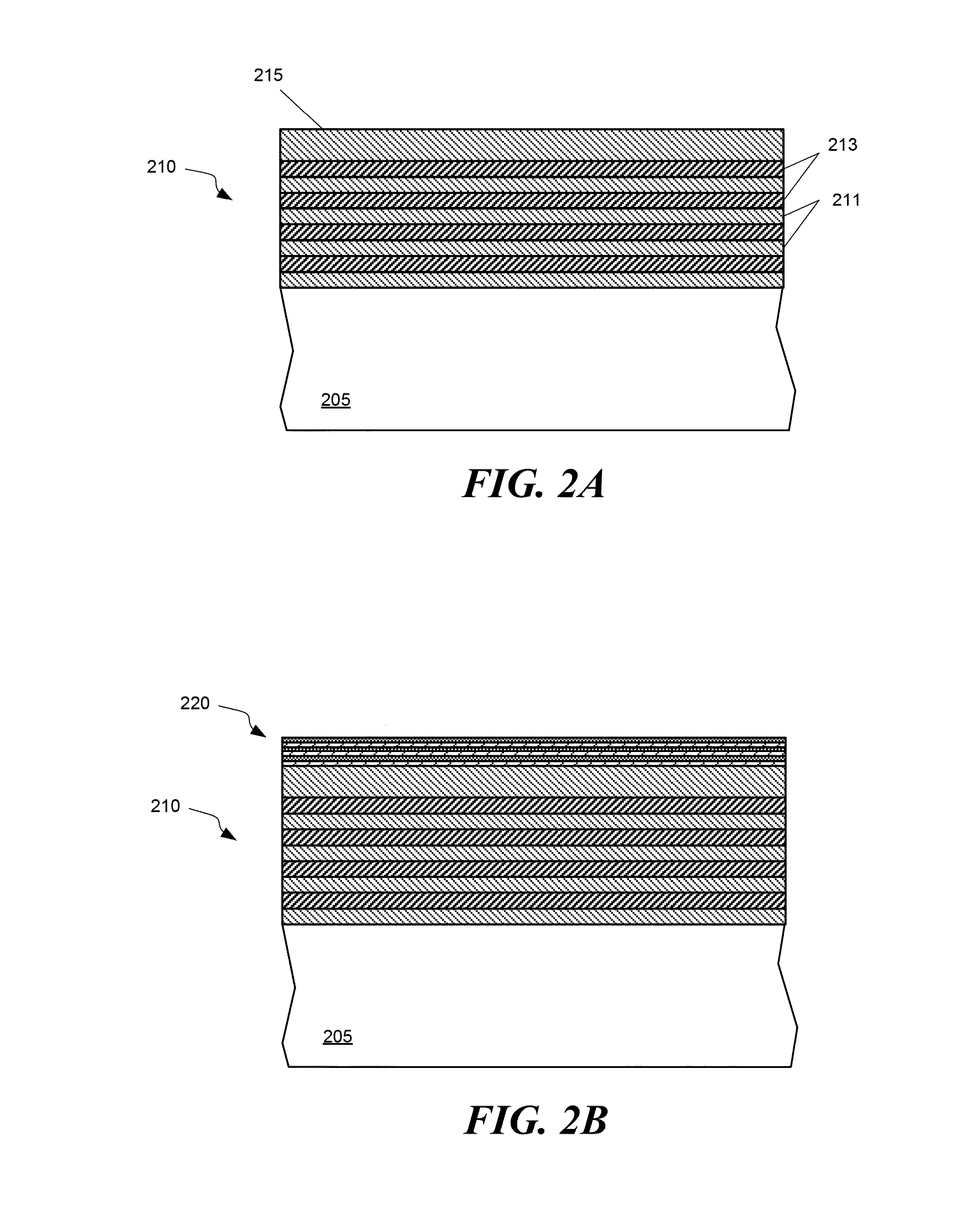

Lateral electrochemical etching of iii-nitride materials for microfabrication

ActiveUS20140003458A1High selectivityLaser detailsSolid-state devicesHigh volume manufacturingMicrofabrication

Conductivity-selective lateral etching of III-nitride materials is described. Methods and structures for making vertical cavity surface emitting lasers with distributed Bragg reflectors via electrochemical etching are described. Layer-selective, lateral electrochemical etching of multi-layer stacks is employed to form semiconductor / air DBR structures adjacent active multiple quantum well regions of the lasers. The electrochemical etching techniques are suitable for high-volume production of lasers and other III-nitride devices, such as lasers, HEMT transistors, power transistors, MEMs structures, and LEDs.

Owner:YALE UNIV

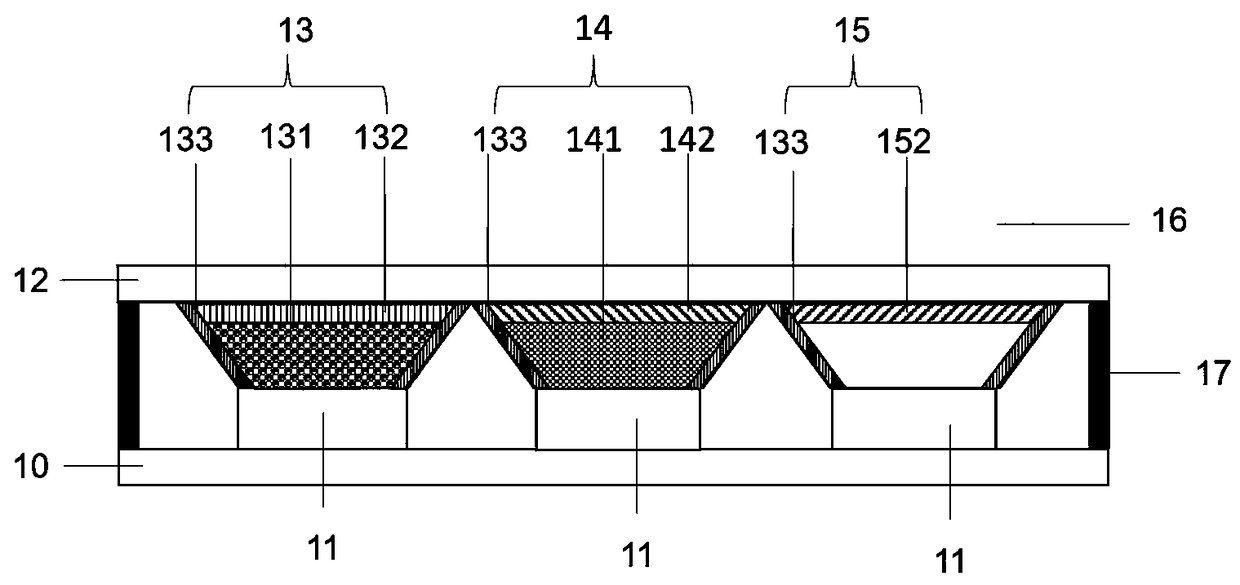

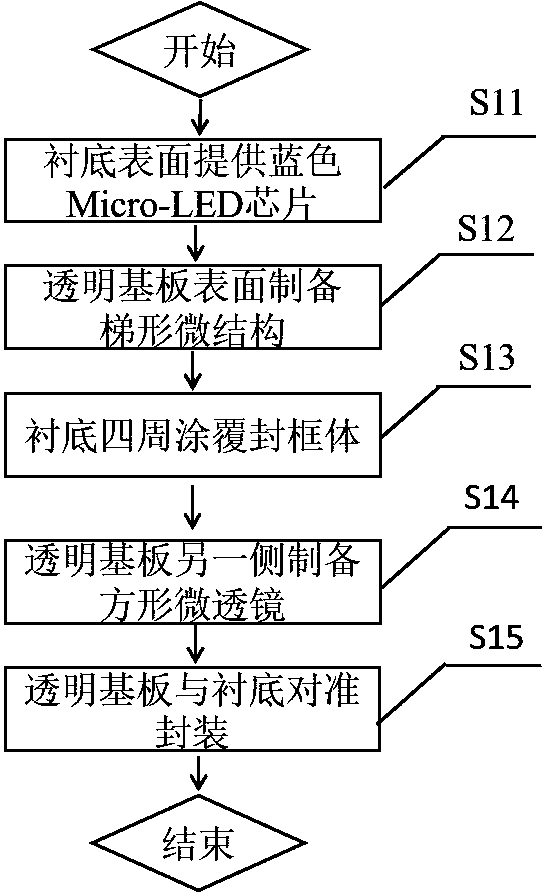

A full-color Micro-LED display structure with light efficiency extraction and pixel-free interference and a manufacturing method thereof

ActiveCN109256455ARealize full-color Micro-LED displayImprove light extraction efficiencySolid-state devicesSemiconductor devicesLED displayDistributed Bragg reflector

The invention relates to a light efficiency extraction and pixel-free full-color Micro-A LED display structure and a method for manufacture that same, includes an array of LED chips arranged on a substrate surface and arranged in an array, A microlens array arranged on the upper and lower surfaces of a transparent substrate and an inverted trapezoidal microstructure array corresponding to the microlens array, and an enclosure connecting the substrate and the transparent substrate. The inverted trapezoidal microstructure array sequentially forms an R unit for displaying red light, a G unit fordisplaying green light and a B unit for displaying blue light along the lateral direction of the LED chip. The invention utilizes a blue LED chip to excite a green quantum dot layer in a red / G unit inan R unit to be converted into red light / green light; At the same time, by using the distributed Bragg reflector in microstructure, The Micro-LED displays light efficiency, and the reflective layer and the microlens array in the microstructure can also be used to improve the light efficiency in the vertical direction and prevent the color interference of adjacent pixels, thereby realizing the light efficiency extraction and the full-color Micro- LED display.

Owner:福州市福大微纳显示科技有限公司

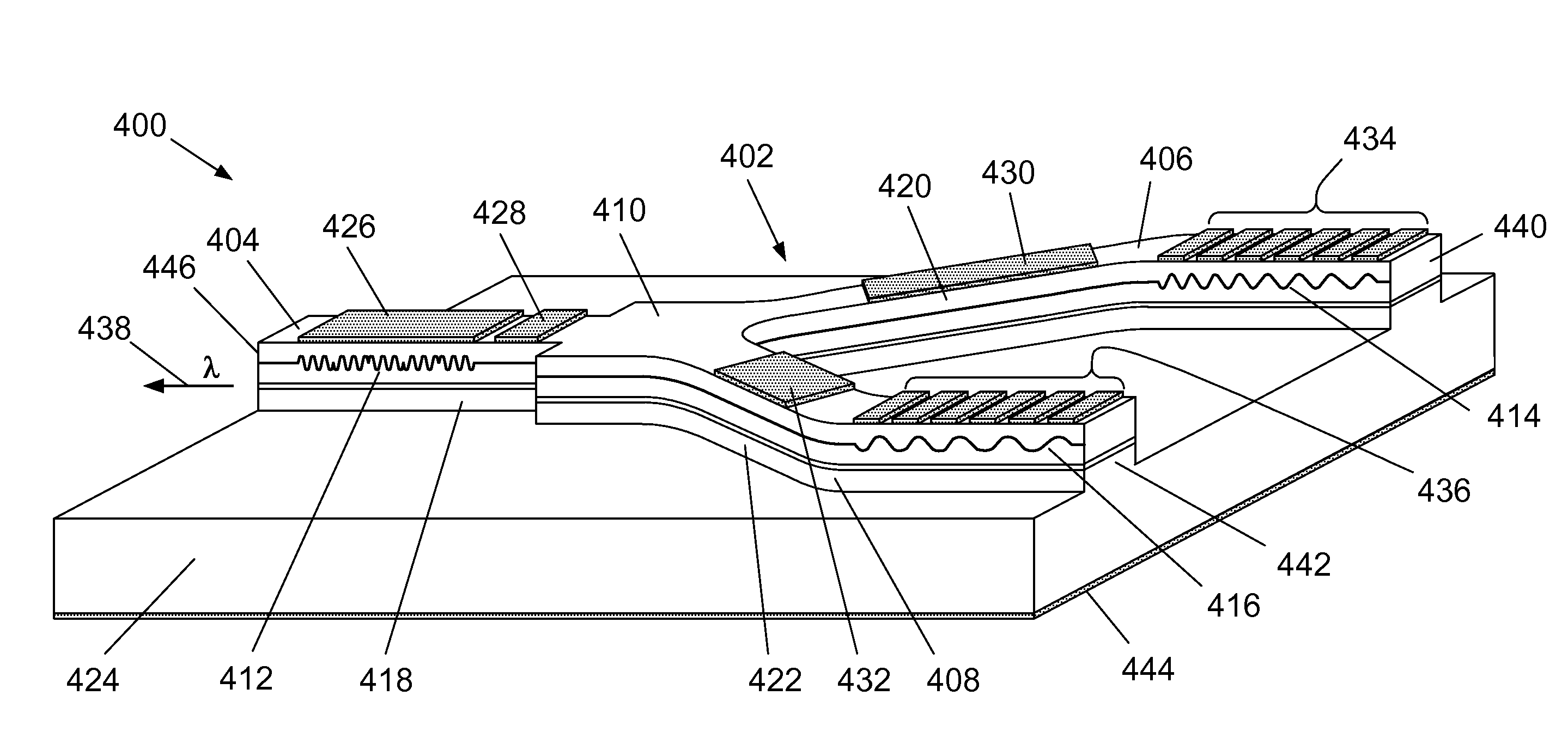

External cavity laser array system and WDM optical system including same

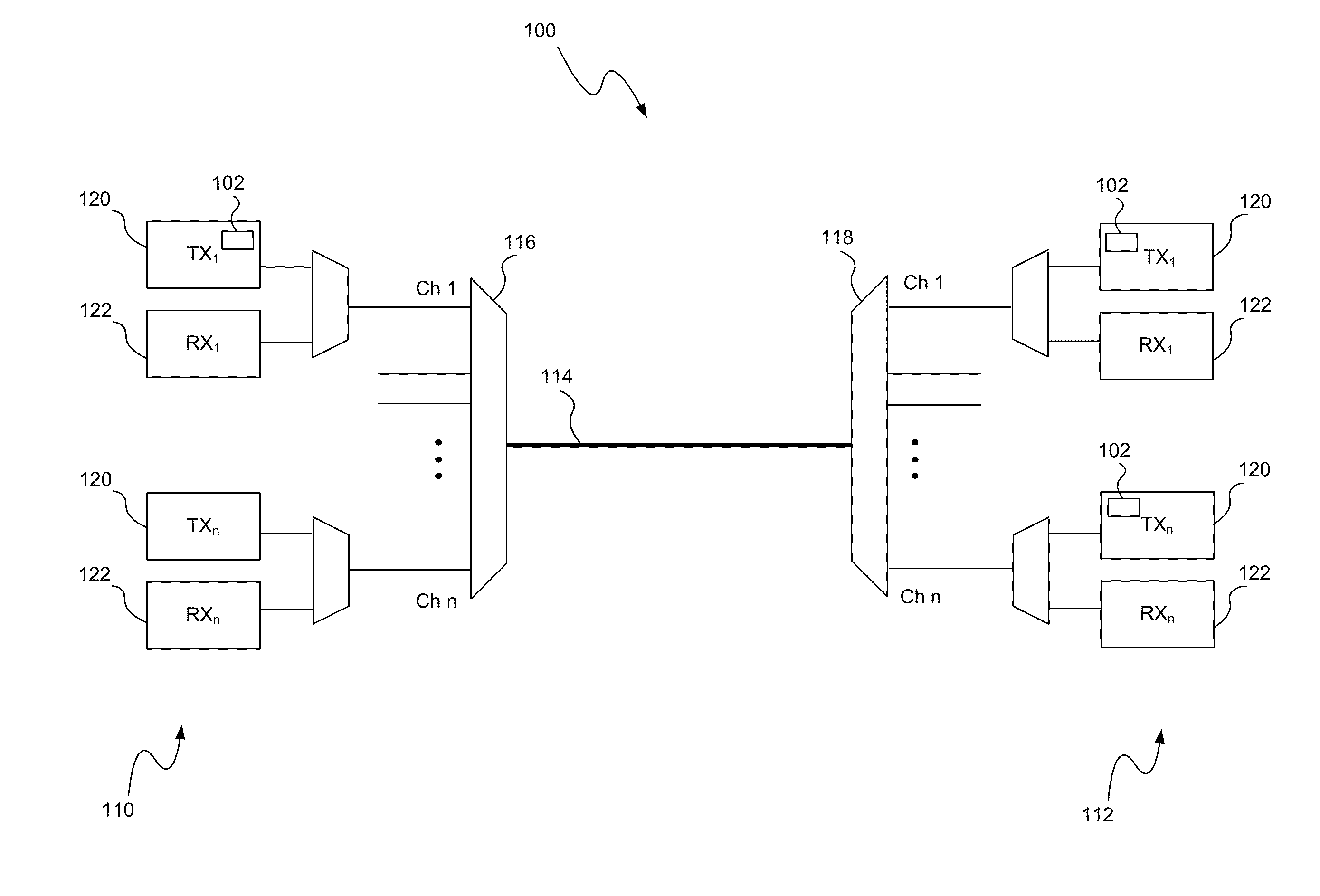

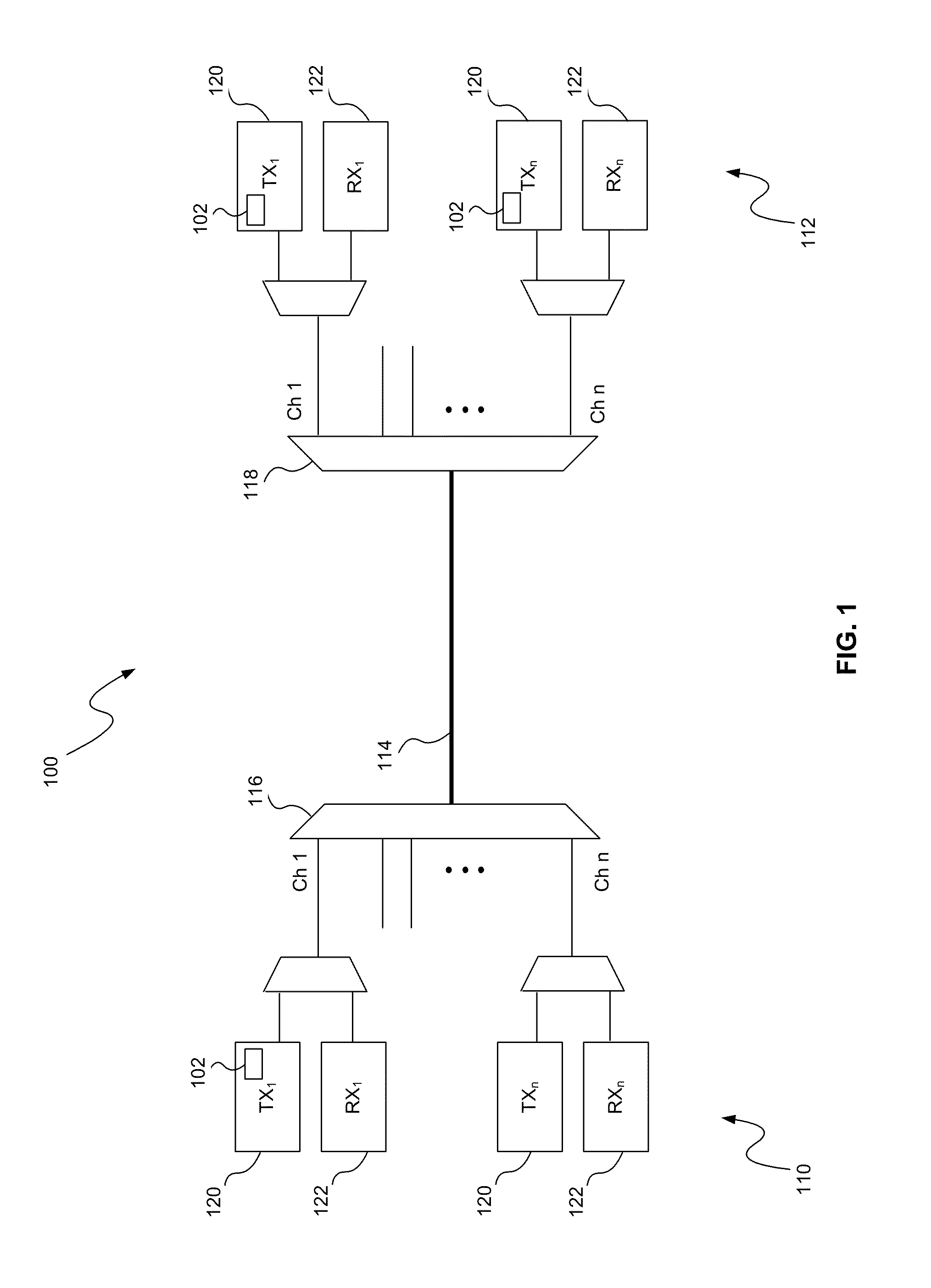

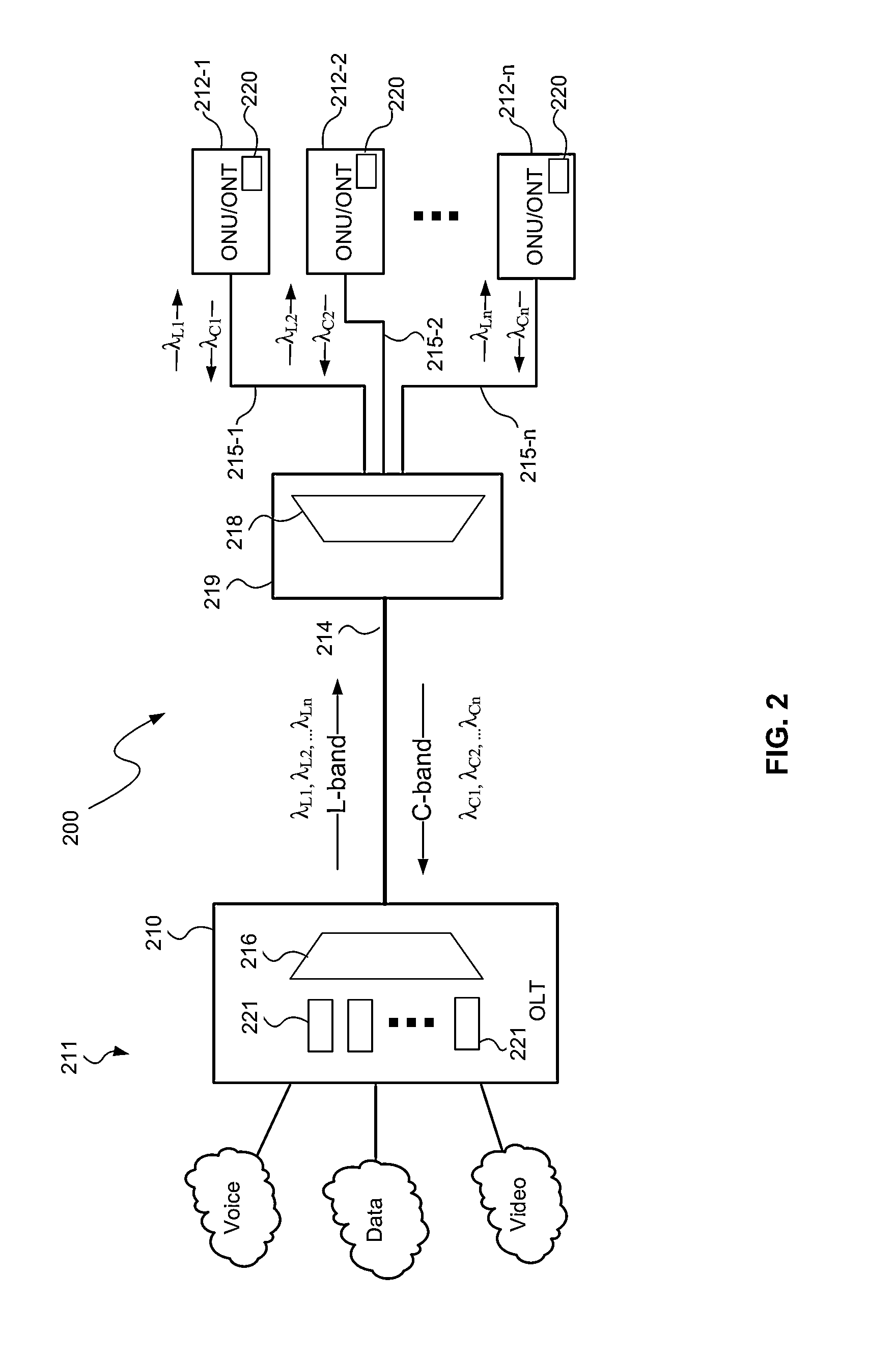

ActiveUS20130223844A1Laser detailsLaser optical resonator constructionLaser transmitterExternal cavity laser

An external cavity laser array system may be used in a WDM optical system, such as a WDM-PON, for transmitting optical signals at multiple channel wavelengths. The system generally includes a plurality of laser emitters (e.g., gain chips) optically coupled to and separated from respective exit reflectors (e.g., tunable narrow-band reflectors), thereby forming an array of external cavity lasers with extended lasing cavities. The exit reflectors may be distributed Bragg reflectors (DBRs) located in the waveguides in an arrayed waveguide grating (AWG). The laser emitters emit a range of wavelengths including multiple channel wavelengths and the DBRs reflect a subset of channel wavelengths including at least a channel wavelength associated with the laser emitter such that lasing occurs at the subset of channel wavelengths. The AWG then filters the emitted laser light at the associated channel wavelengths.

Owner:APPLIED OPTOELECTRONICS

Light emitting diode

ActiveUS20110156070A1Prevent reduction in light emittingReduce lightSemiconductor devicesInsulation layerDistributed Bragg reflector

The present invention provides a light emitting diode including a lower semiconductor layer formed on a substrate; an upper semiconductor layer disposed above the lower semiconductor layer, exposing an edge region of the lower semiconductor layer; a first electrode formed on the upper semiconductor layer; an insulation layer interposed between the first electrode and the upper semiconductor layer, to supply electric current to the lower semiconductor layer; a second electrode formed on another region of the upper semiconductor layer, to supply electric current to the upper semiconductor layer. The first electrode includes an electrode pad disposed on the upper semiconductor layer and an extension extending from the electrode pad to the exposed lower semiconductor layer. The insulation layer may have a distributed Bragg reflector structure.

Owner:SEOUL VIOSYS CO LTD

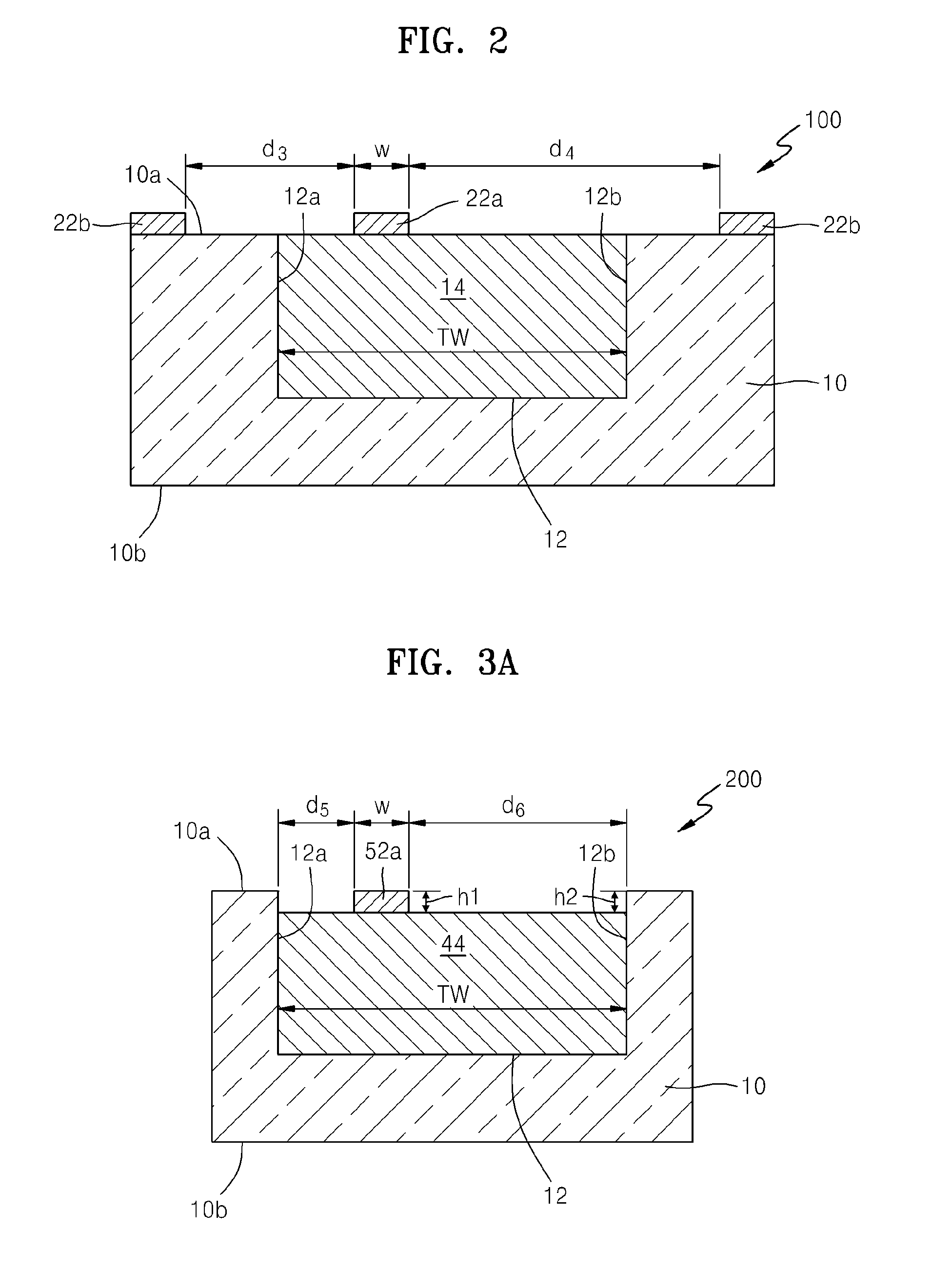

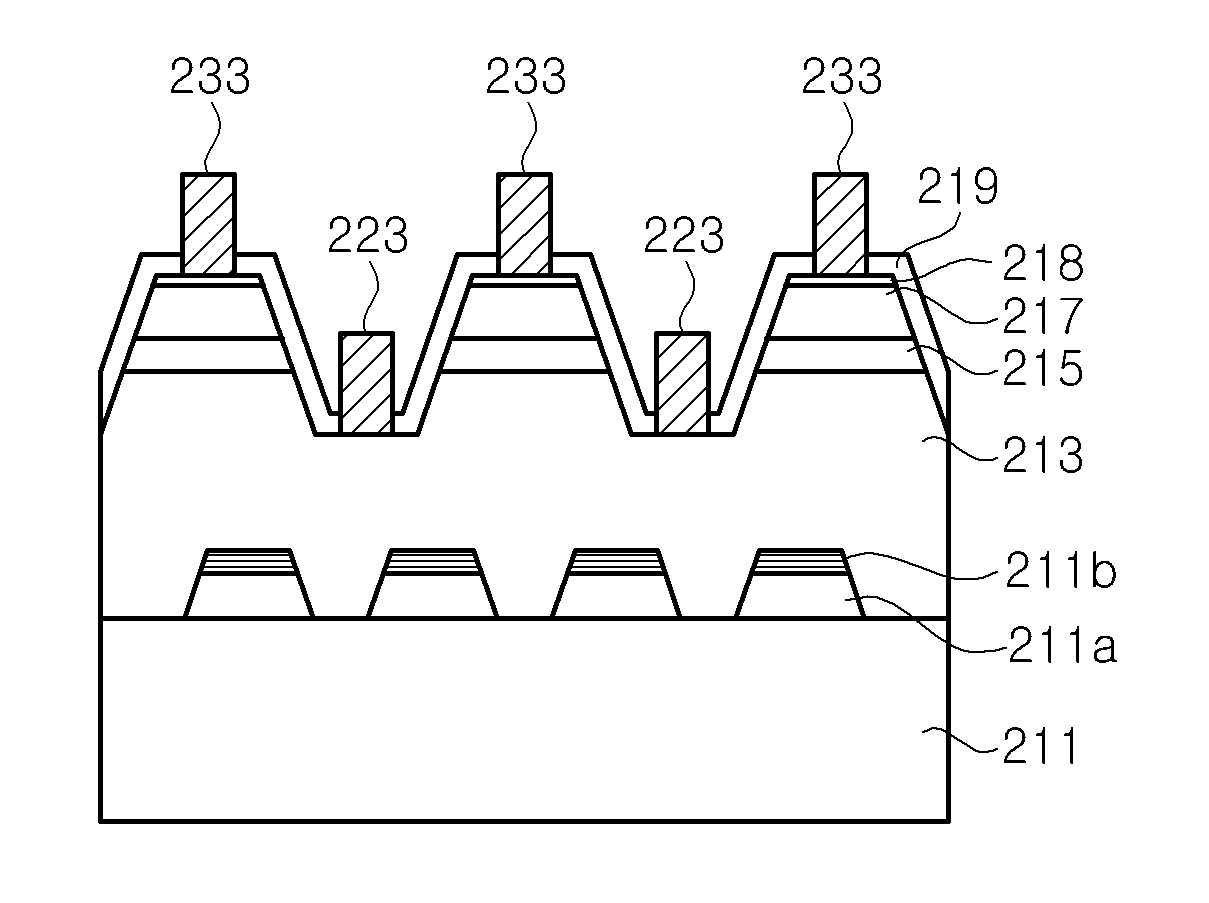

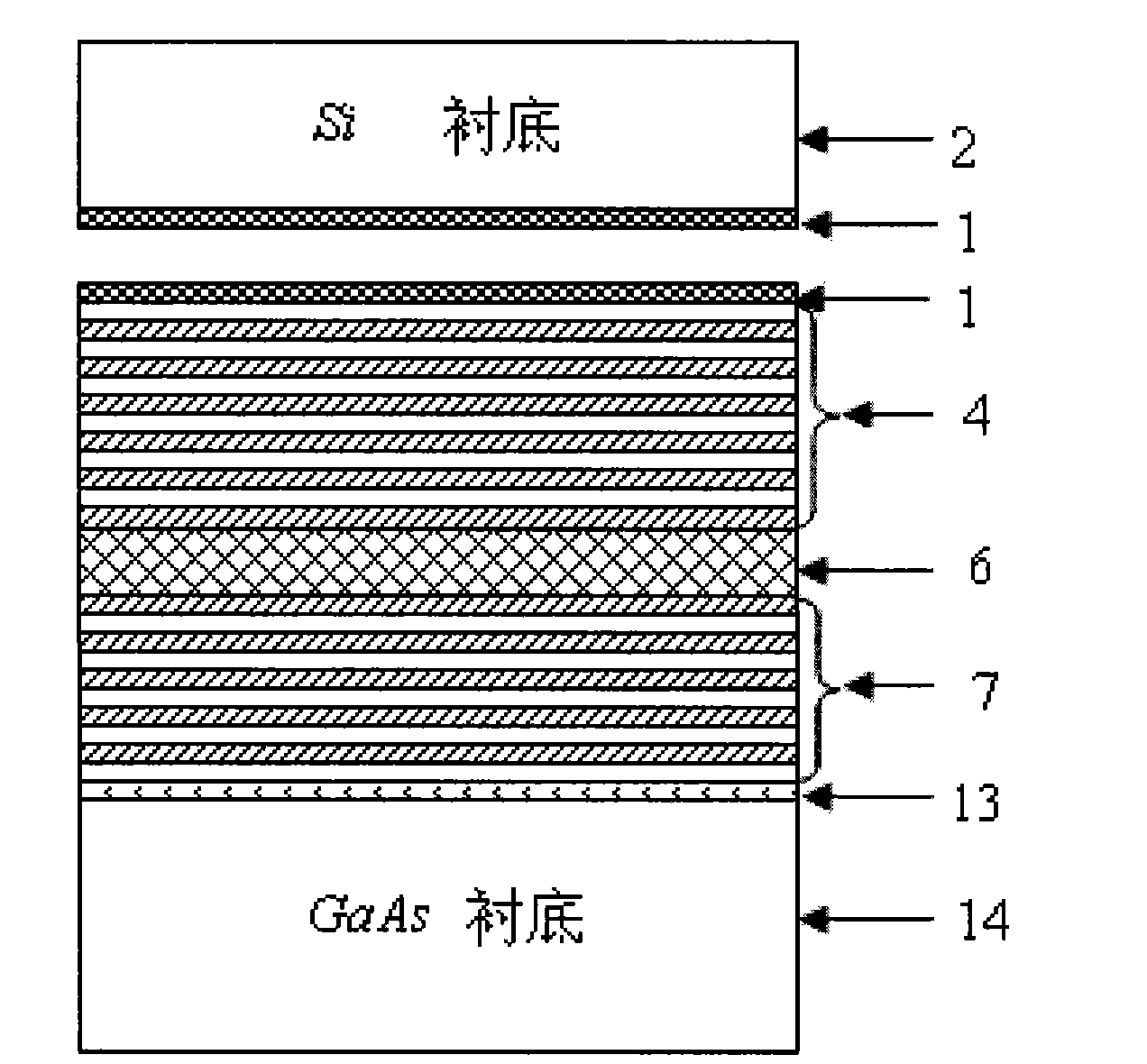

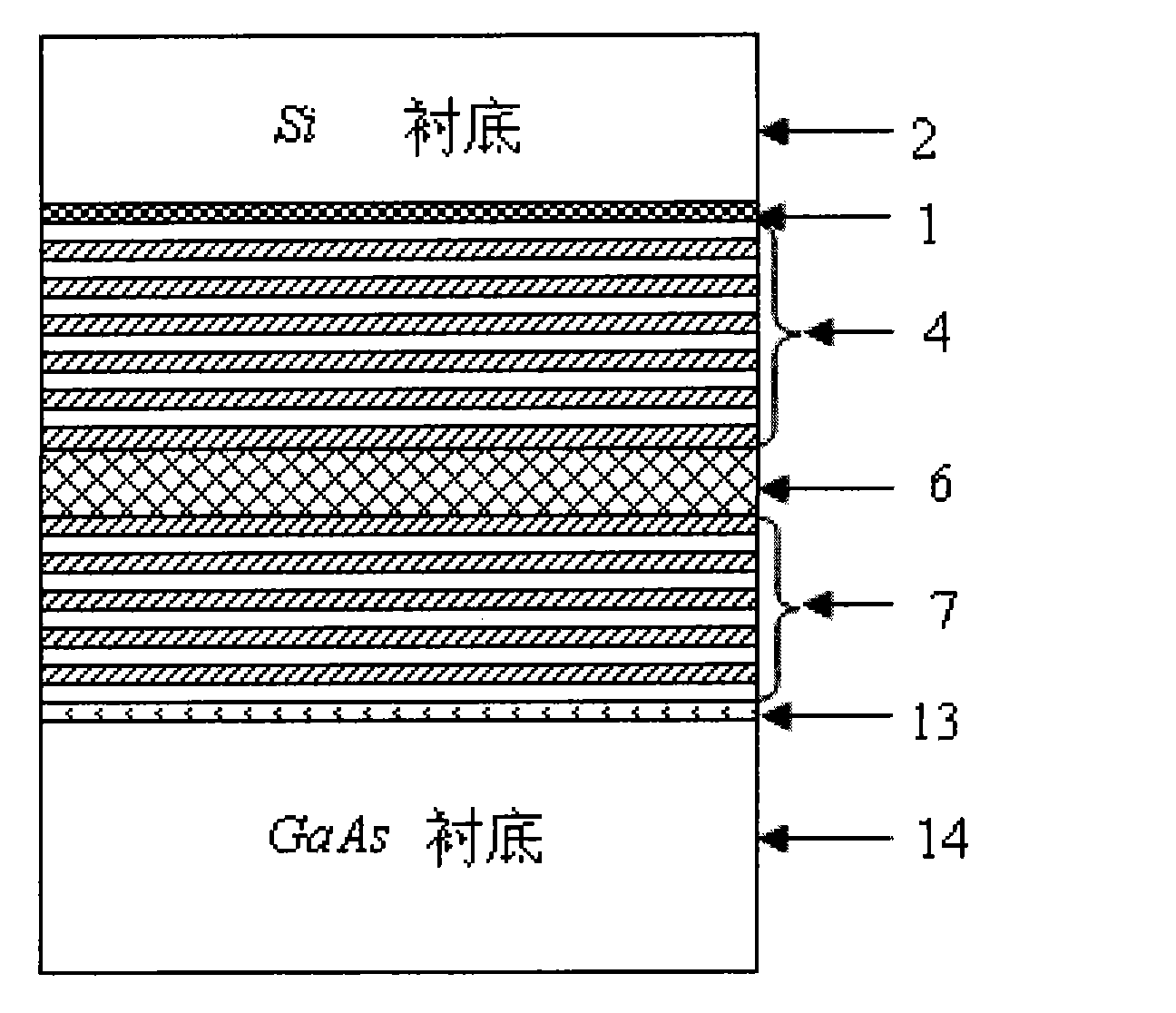

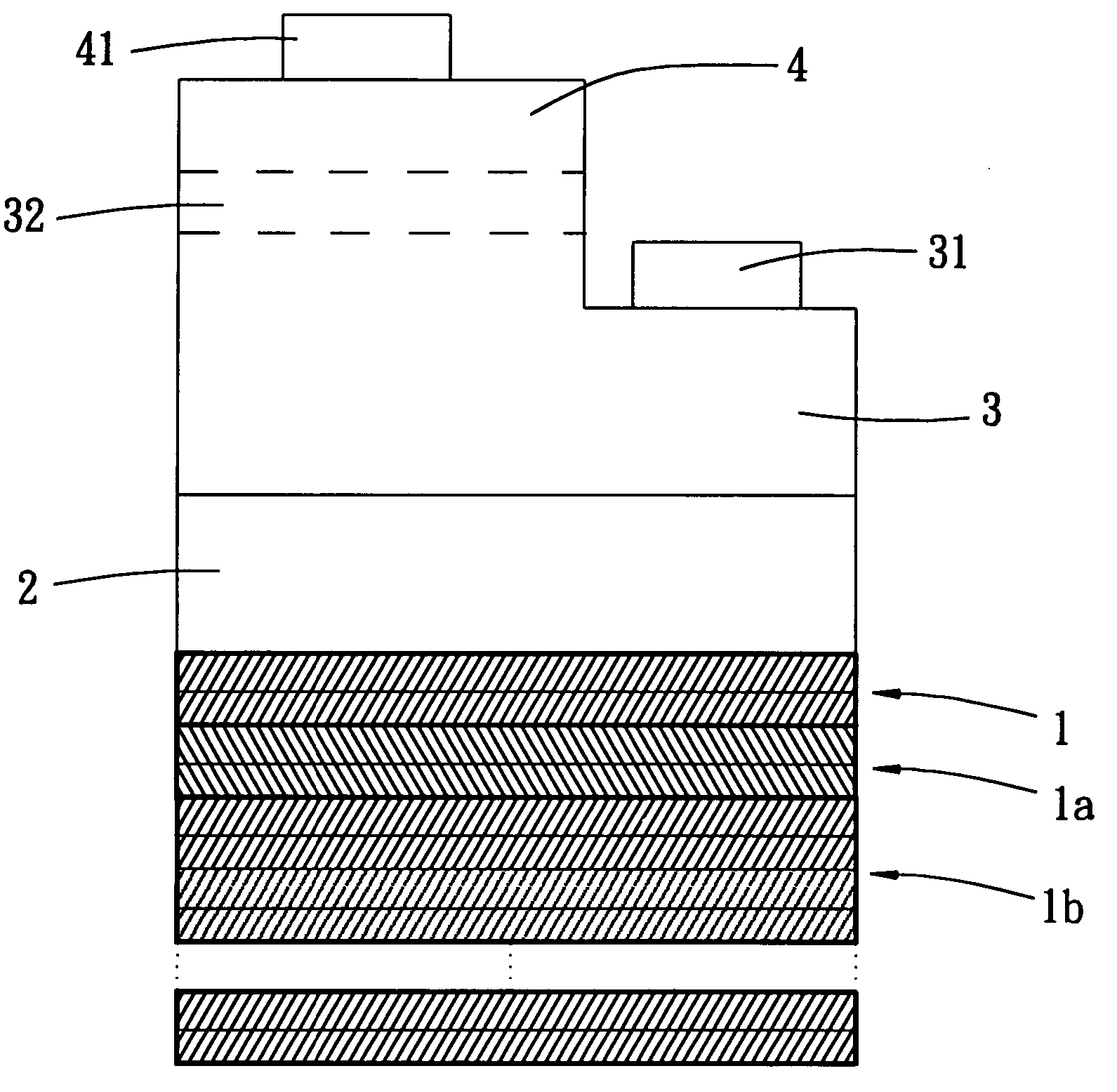

Single-mode high-power vertical cavity surface emitting laser and manufacturing method thereof

ActiveCN101667715AIncrease output powerImprove thermal propertiesLaser detailsSemiconductor lasersVertical-cavity surface-emitting laserElectron

The invention relates to a single-mode high-power vertical cavity surface emitting laser (VCSEL), which belongs to the field of semiconductor photoelectronics. The laser is characterized by comprisinga P-type electrode (1), a P-type Si substrate (2), a metal bonding layer (3), a P-type distributed Bragg reflector (DBR) (4), an oxide limiting layer (5), an active area (6), an N-type DBR (7), a SiO2 mask (8), polymide or benzocyclobutene (BCB) (9), an N electrode (10), a photonic crystal (11) and a light-exiting window (12). The introduction of the photonic crystal into the vertical cavity surface emitting laser with the structure can enlarge an oxidation aperture and improve the single-mode output power; and at the same time, the transfer of the conventional VCSEL epitaxial wafer to the Sisubstrate by adopting bonding technology and the adoption of a design of exiting light at the bottom are convenient for narrowing the distance between a VCSEL epitaxial wafer active area and the Si substrate, improving the thermal characteristics of devices and further improving the single-mode output power.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

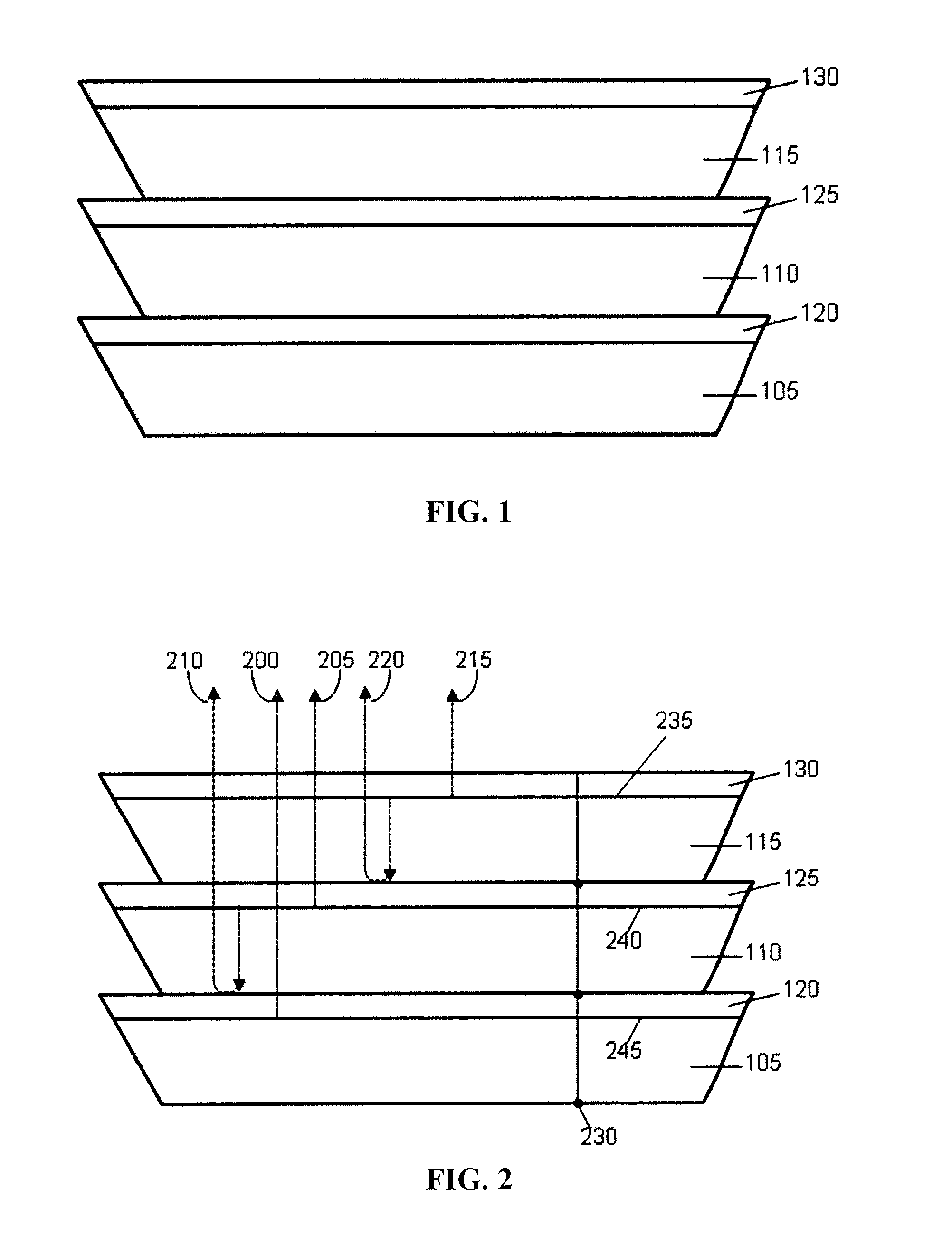

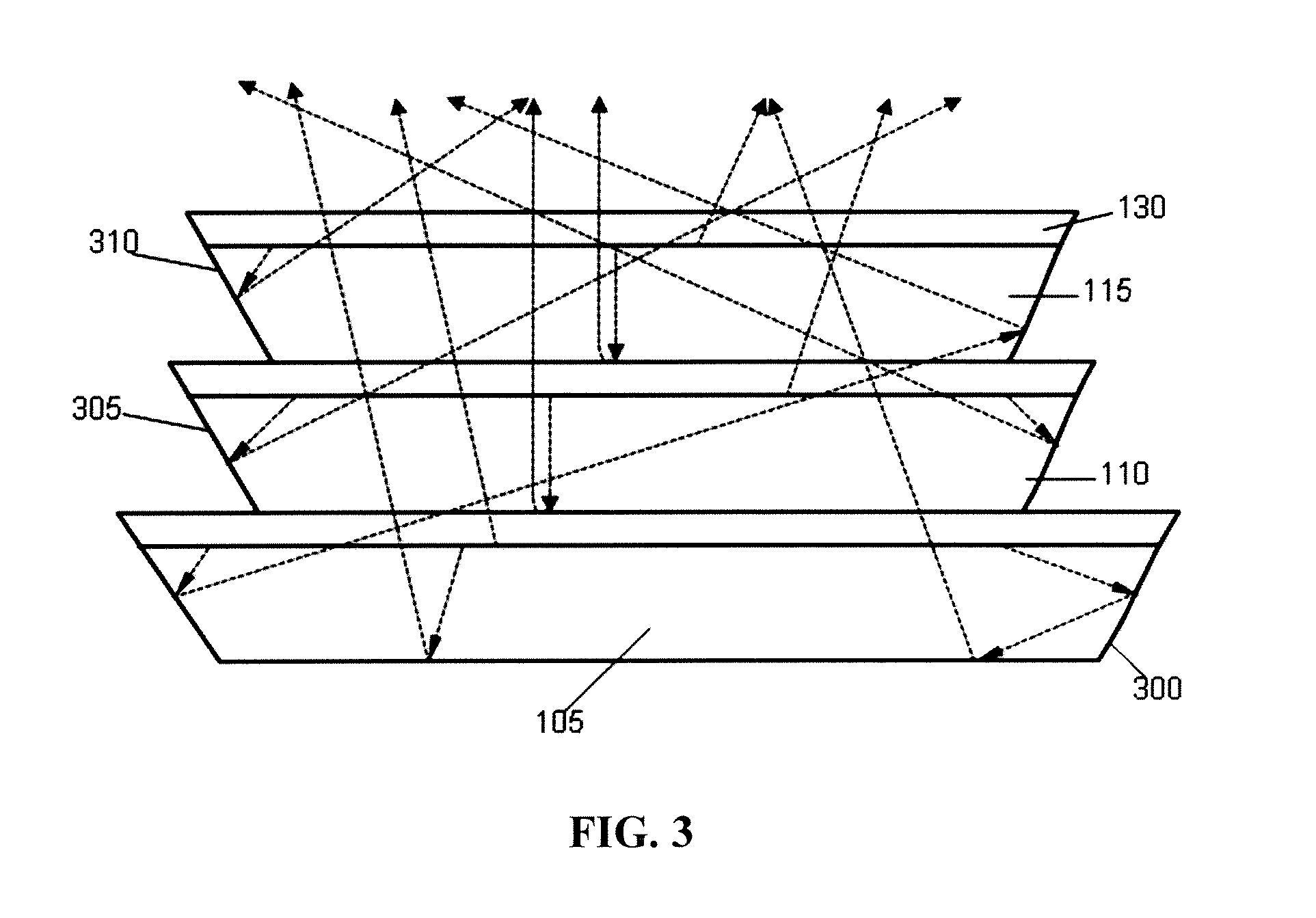

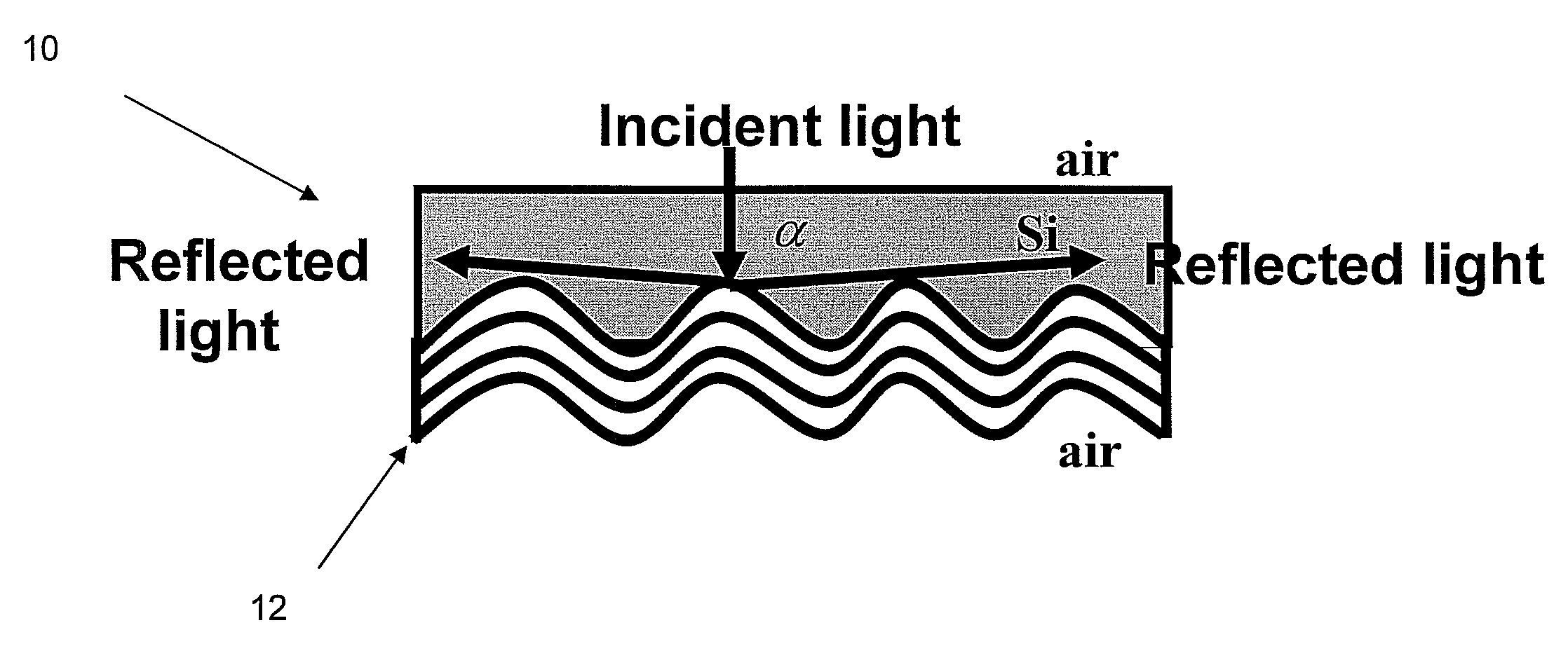

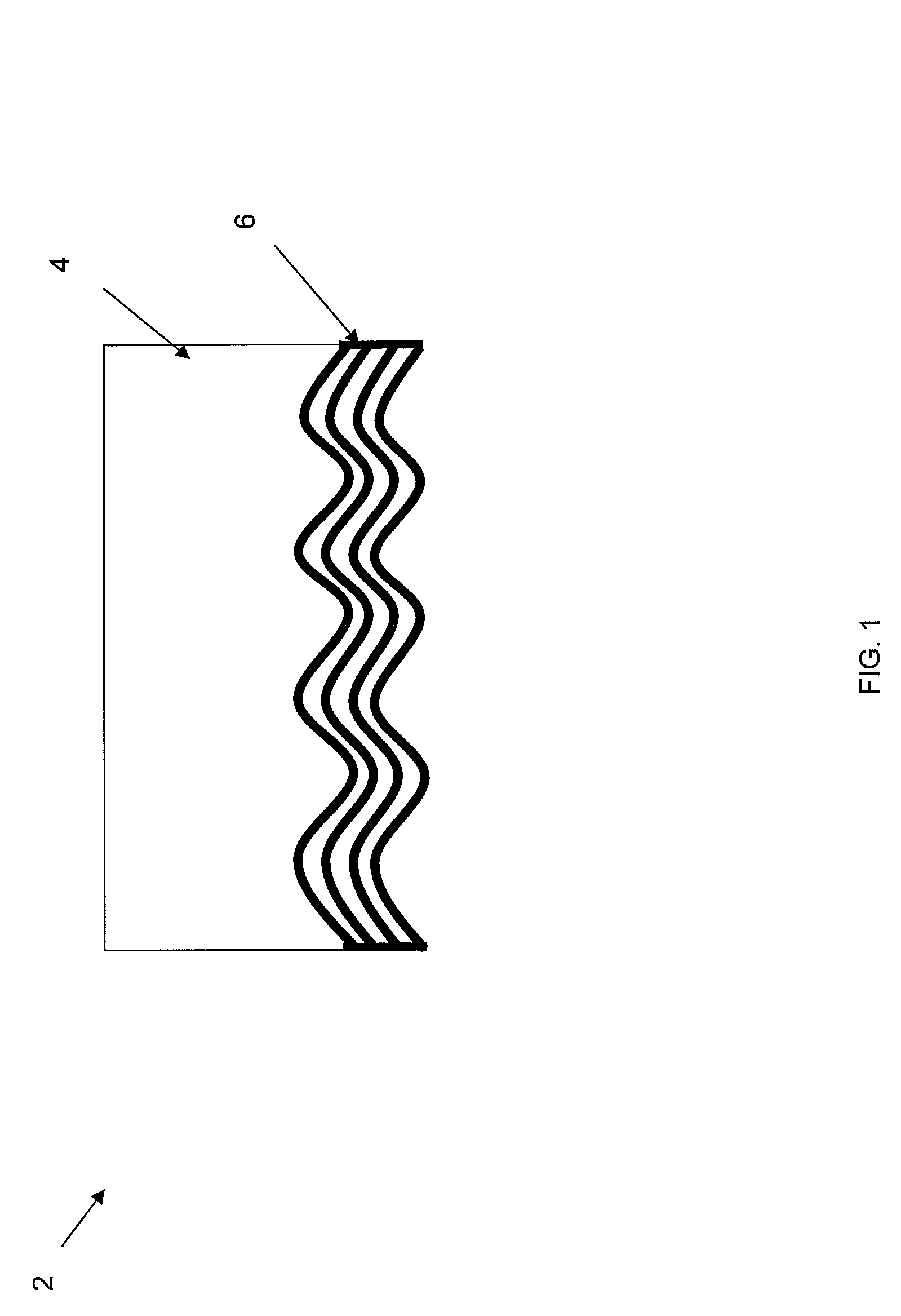

Light trapping in thin film solar cells using textured photonic crystal

A solar cell includes a photoactive region that receives light. A photonic crystal is coupled to the photoactive region, wherein the photonic crystal comprises a distributed Bragg reflector (DBR) for trapping the light.

Owner:MASSACHUSETTS INST OF TECH

Light emitting diode chip having distributed bragg reflector and method of fabricating the same

ActiveUS20110127549A1Increasing light emission efficiency of a light emitting diode packageImprove reflectivitySolid-state devicesSemiconductor/solid-state device manufacturingDistributed Bragg reflectorLength wave

Exemplary embodiments of the present invention disclose a light emitting diode chip including a substrate having a first surface and a second surface, a light emitting structure arranged on the first surface of the substrate and including an active layer arranged between a first conductive-type semiconductor layer and a second conductive-type semiconductor layer, a distributed Bragg reflector arranged on the second surface of the substrate, the distributed Bragg reflector to reflect light emitted from the light emitting structure, and a metal layer arranged on the distributed Bragg reflector, wherein the distributed Bragg reflector has a reflectivity of at least 90% for light of a first wavelength in a blue wavelength range, light of a second wavelength in a green wavelength range, and light of a third wavelength in a red wavelength range.

Owner:SEOUL VIOSYS CO LTD

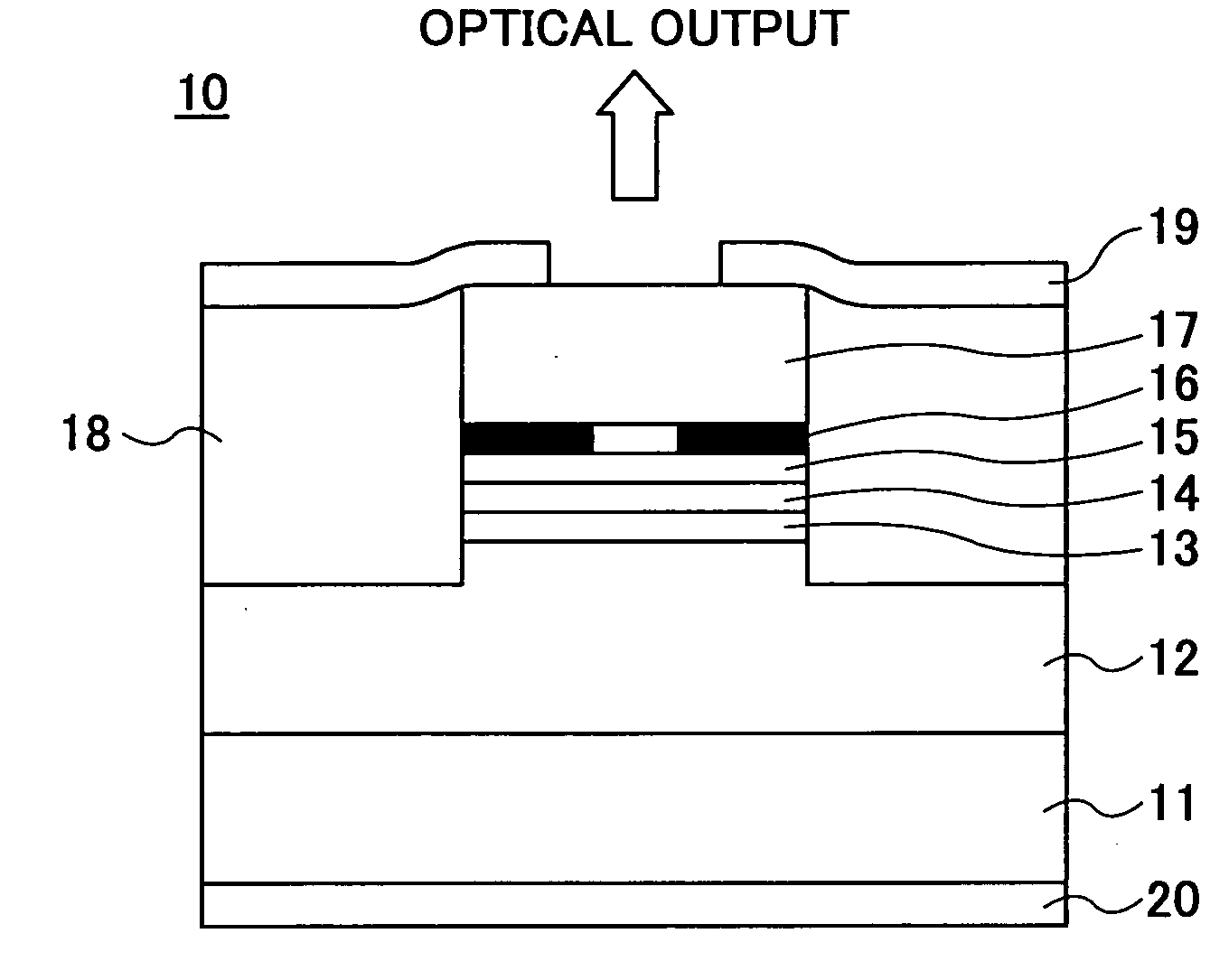

Surface-emission laser diode and fabrication process thereof

ActiveUS7684458B2Large gainLower the thresholdOptical wave guidanceLaser detailsQuantum wellDistributed Bragg reflector

A surface-emission laser diode comprises a cavity region over a semiconductor substrate and includes an active layer containing at least one quantum well active layer producing a laser light and a barrier layer, a spacer layer is provided in the vicinity of the active layer and formed of at least one material, an upper and lower reflectors are provided at a top part and a bottom part of the cavity region, the cavity region and the upper and lower reflectors form a mesa structure over the semiconductor substrate, the upper and lower reflectors being formed of a semiconductor distributed Bragg reflector having a periodic change of refractive index and reflecting incident light by interference of optical waves, at least a part of the semiconductor distributed Bragg reflector is formed of a layer of small refractive index of AlxGa1-xAs (0<x≦1) and a layer of large refractive index of AlyGa1-yAs (0≦y<x≦1), the lower reflector is formed of a first lower reflector having a low-refractive index layer of AlAs and a second lower reflector formed on the first lower reflector, the second lower reflector has a low-refractive index layer of AlGaAs, any one layer constituting the cavity region contains In.

Owner:RICOH KK

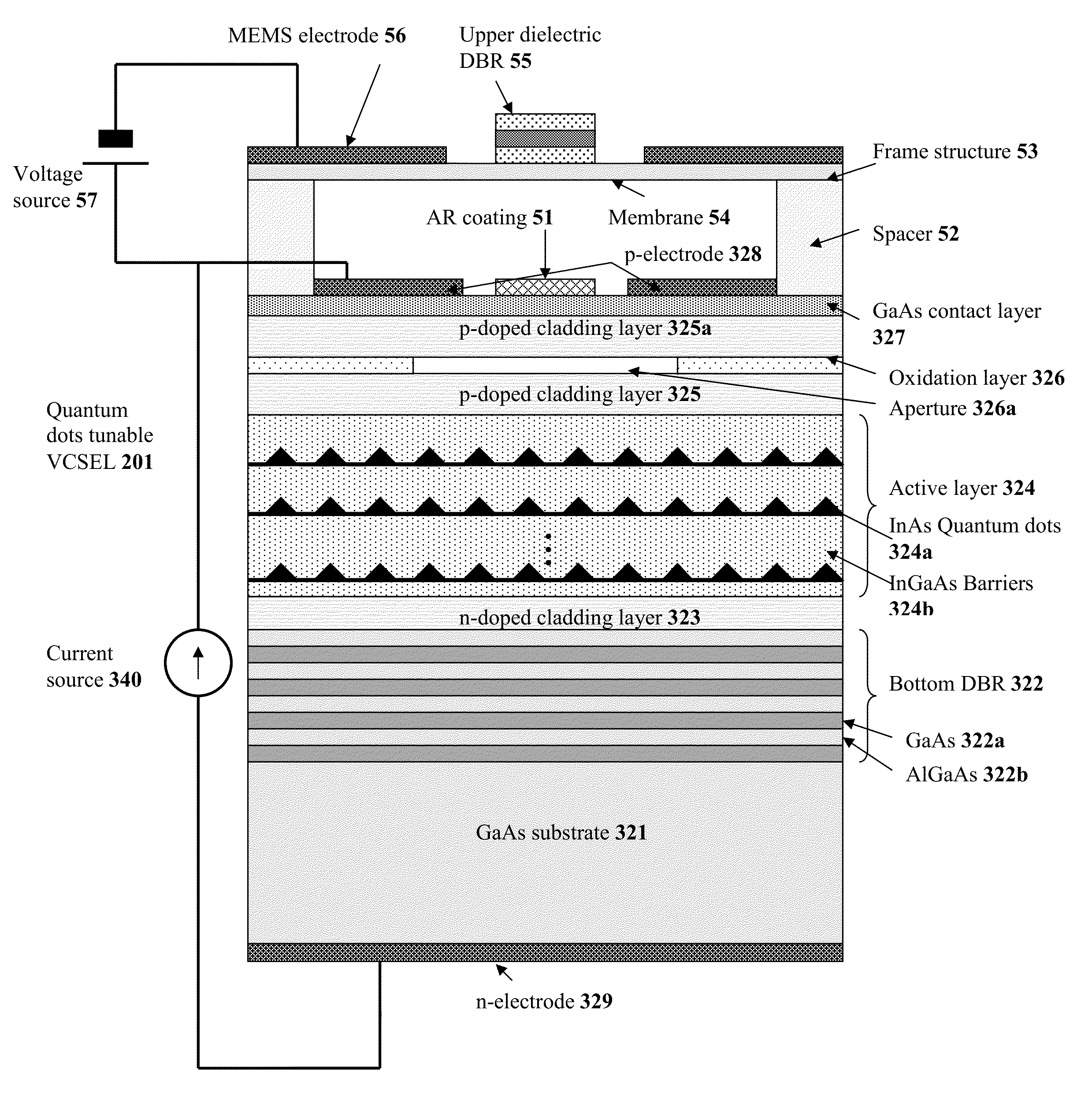

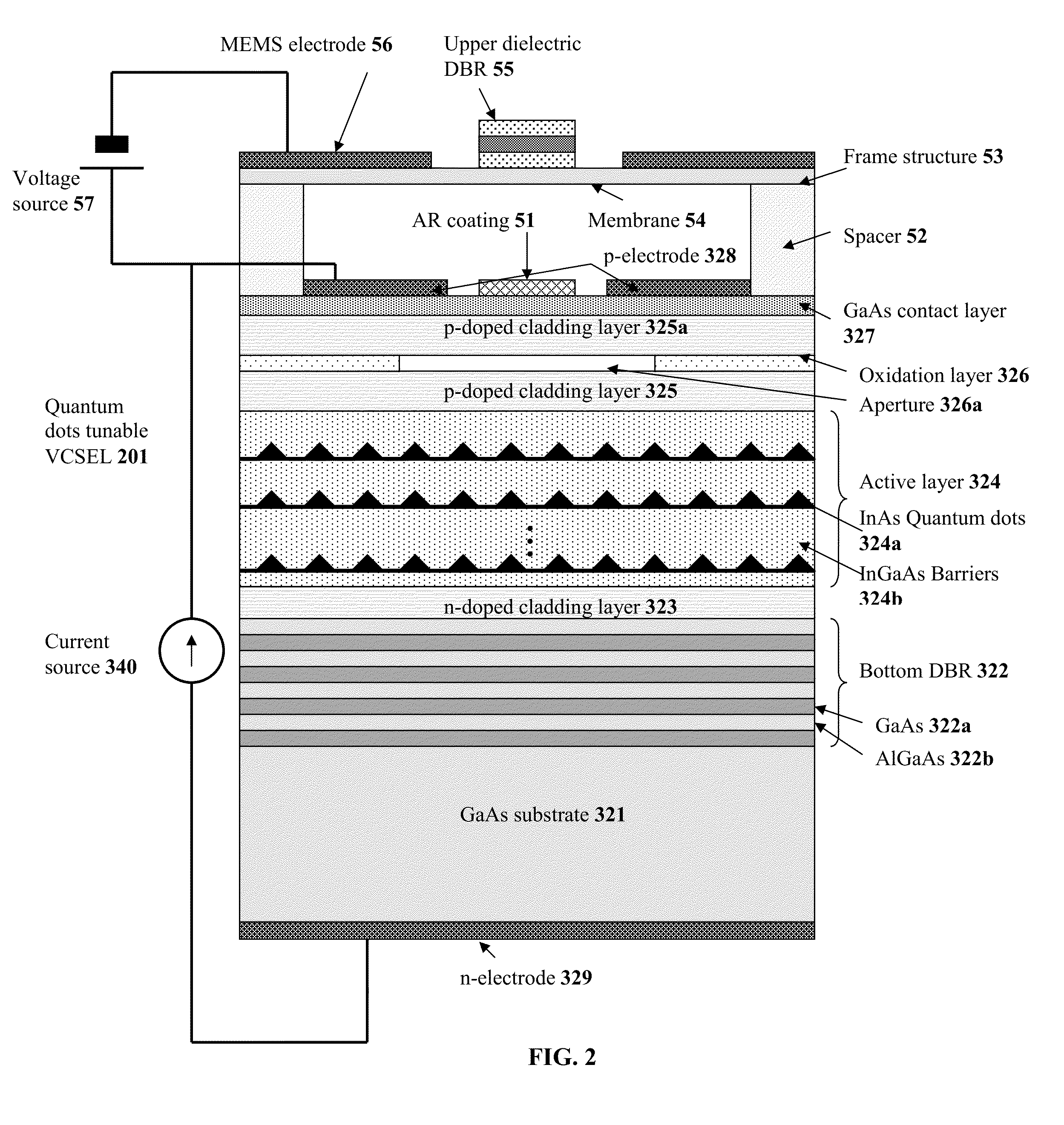

Wavelength-tunable vertical cavity surface emitting laser for swept source optical coherence tomography system

ActiveUS20150010031A1Narrow line widthWide tuning rangeLaser detailsMaterial analysis by optical meansVertical-cavity surface-emitting laserElectricity

A wavelength-tunable vertical-cavity surface-emitting laser (VCSEL) with the use of micro-electromechanical system (MEMS) technology is provided as a swept source for Optical Coherence Tomography (OCT). The wavelength-tunable VCSEL comprises a bottom mirror of the VCSEL, an active region, and a MEMS tunable upper mirror movable by electrostatic deflections. The bottom mirror comprising a GaAs based distributed Bragg reflector (DBR) stack, and the active region comprising multiple stacks of GaAs based quantum dot (QD) layers, are epitaxially grown on a GaAs substrate. The MEMS tunable upper mirror includes a membrane part supported by suspension beams, and an upper mirror comprising a dielectric DBR stack. The MEMS tunable quantum dots VCSEL can cover an operating wavelength range of more than 100 nm, preferably with a center wavelength between 250 and 1950 nm, and the sweeping rate can be from a few kHz to hundreds of kHz, and up to a few MHz.

Owner:INPHENIX

Light-emitting diode having chemical compound based reflective structure

InactiveUS20050104078A1Eliminating undesired escapeIncrease brightnessSemiconductor devicesDistributed Bragg reflectorReflective layer

A light-emitting diode (LED) includes a plurality of reflective layers stacked over each other and each comprising a distributed Bragg reflector, a substrate, an N type semiconductor formed on the substrate, a light emitting layer formed on the N type semiconductor layer and a P type semiconductor formed on the light emitting layer. The stack of the reflective layers is formed under the substrate or the stack is formed between the substrate and the N type semiconductor layer. The reflective layers receive and reflect light incident at different angles thereby alleviating escape of light from the light emitting diode and enhancing overall brightness of the light emitting diode.

Owner:ITE COMPOUND SEMICON CORP

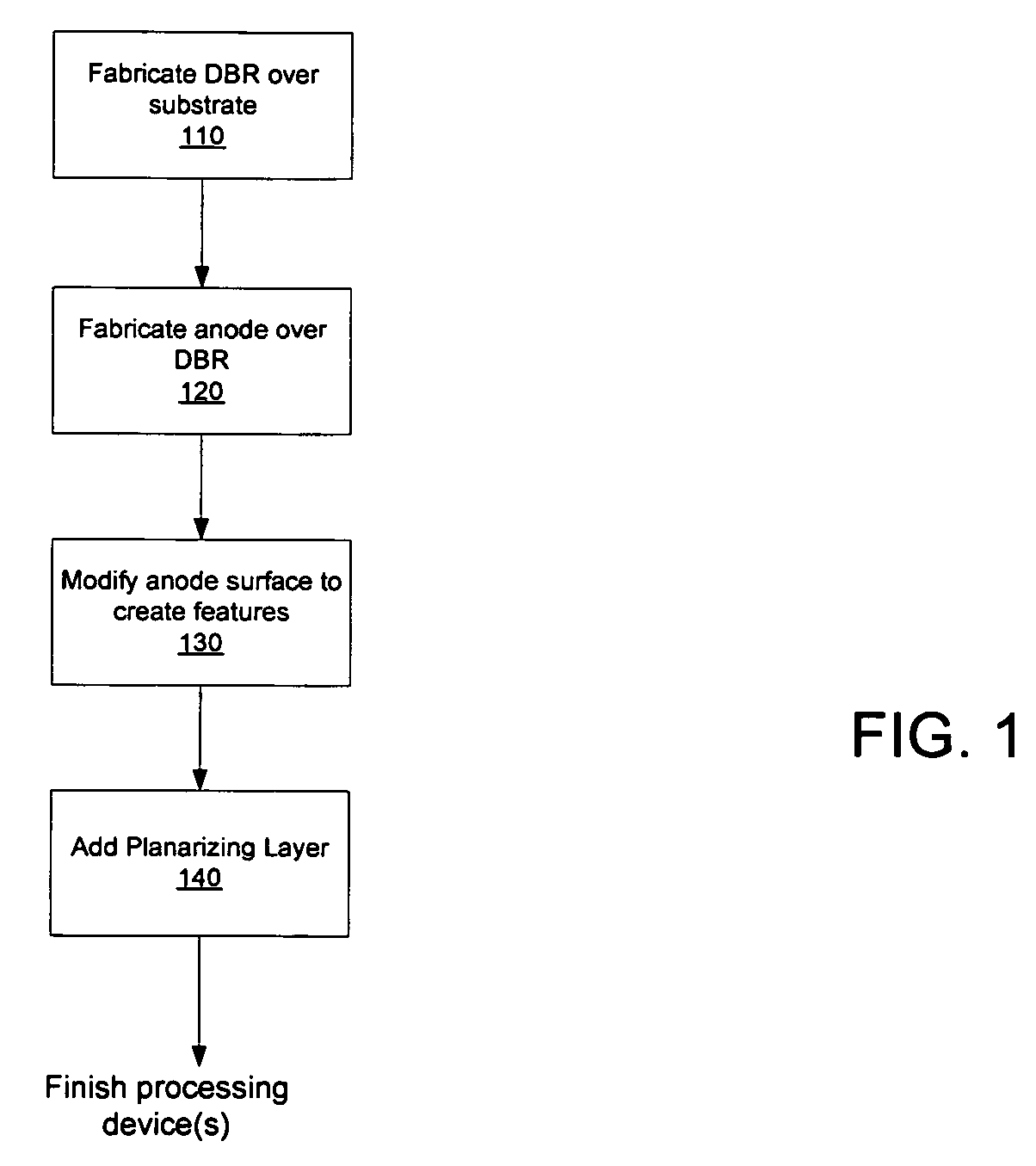

Enhancement of light extraction with cavity and surface modification

ActiveUS20060175961A1Discharge tube luminescnet screensElectroluminescent light sourcesDistributed Bragg reflectorLight-emitting diode

An organic light emitting diode (OLED) device includes an anode layer upon a DBR (Distributed Bragg Reflector) stack such that the anode layer is modified by creating lens-like features on its surface. The OLED device also includes a planarizing layer on said anode layer, said planarizing layer filling in said lens-like features, said planarizing layer providing a flat uniform surface for the deposition of other layers thereupon.

Owner:DOLYA HOLDCO 5 LTD

Surface-emitting laser device and surface-emitting laser array including same

A surface-emitting laser device is disclosed that includes a substrate connected to a heat sink; a first reflective layer formed of a semiconductor distributed Bragg reflector on the substrate; a first cavity spacer layer formed in contact with the first reflective layer; an active layer formed in contact with the first cavity spacer layer; a second cavity spacer layer formed in contact with the active layer; and a second reflective layer formed of a semiconductor distributed Bragg reflector in contact with the second cavity spacer layer. The first cavity spacer layer includes a semiconductor material having a thermal conductivity greater than the thermal conductivity of a semiconductor material forming the second cavity spacer layer.

Owner:RICOH KK

Surface-emitting laser device and surface-emitting laser array including same

A surface-emitting laser device is disclosed that includes a substrate connected to a heat sink; a first reflective layer formed of a semiconductor distributed Bragg reflector on the substrate; a first cavity spacer layer formed in contact with the first reflective layer; an active layer formed in contact with the first cavity spacer layer; a second cavity spacer layer formed in contact with the active layer; and a second reflective layer formed of a semiconductor distributed Bragg reflector in contact with the second cavity spacer layer. The first cavity spacer layer includes a semiconductor material having a thermal conductivity greater than the thermal conductivity of a semiconductor material forming the second cavity spacer layer.

Owner:RICOH KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com