Patents

Literature

1676results about How to "Reduce light loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

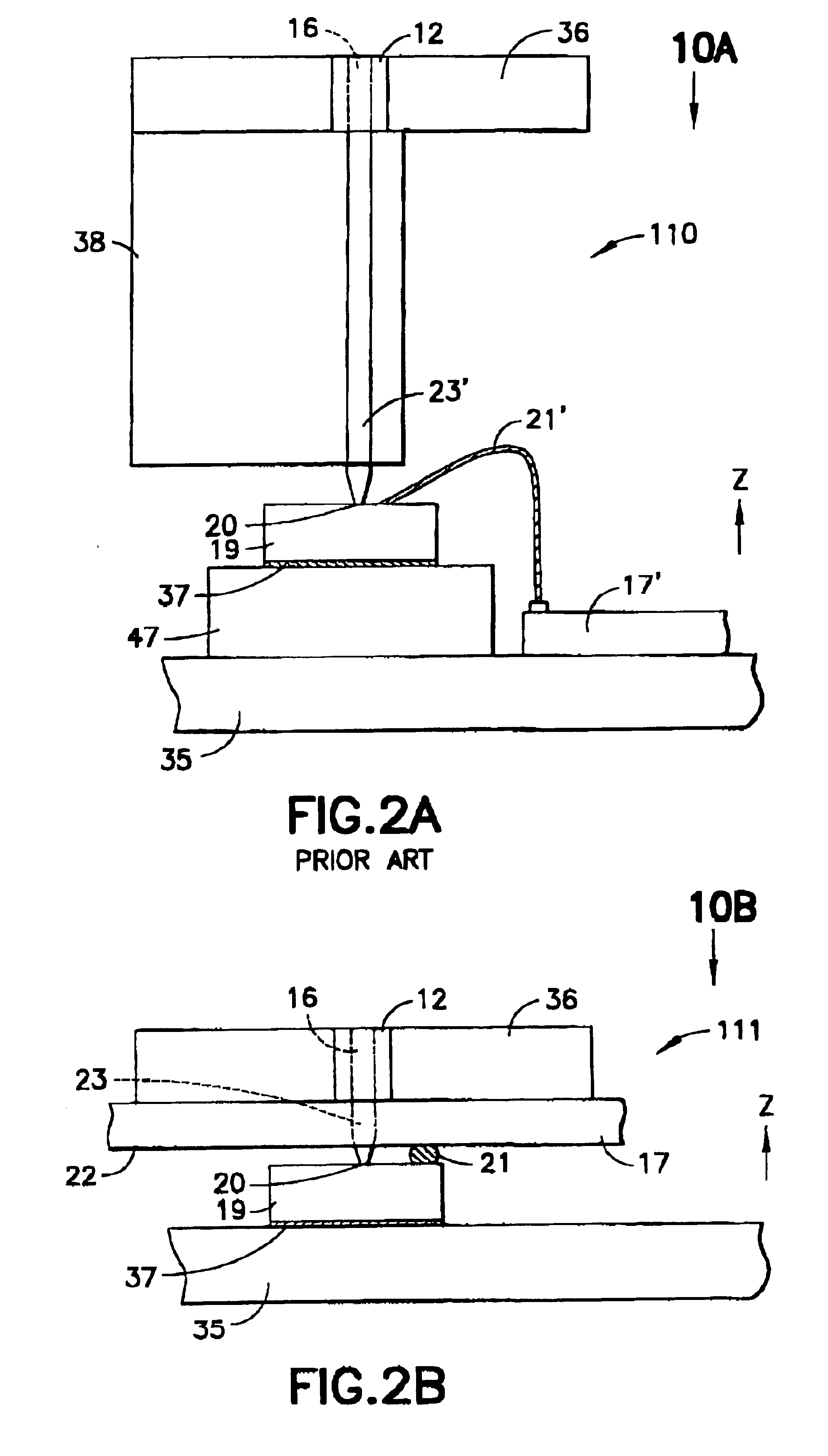

LED retrofit lamp

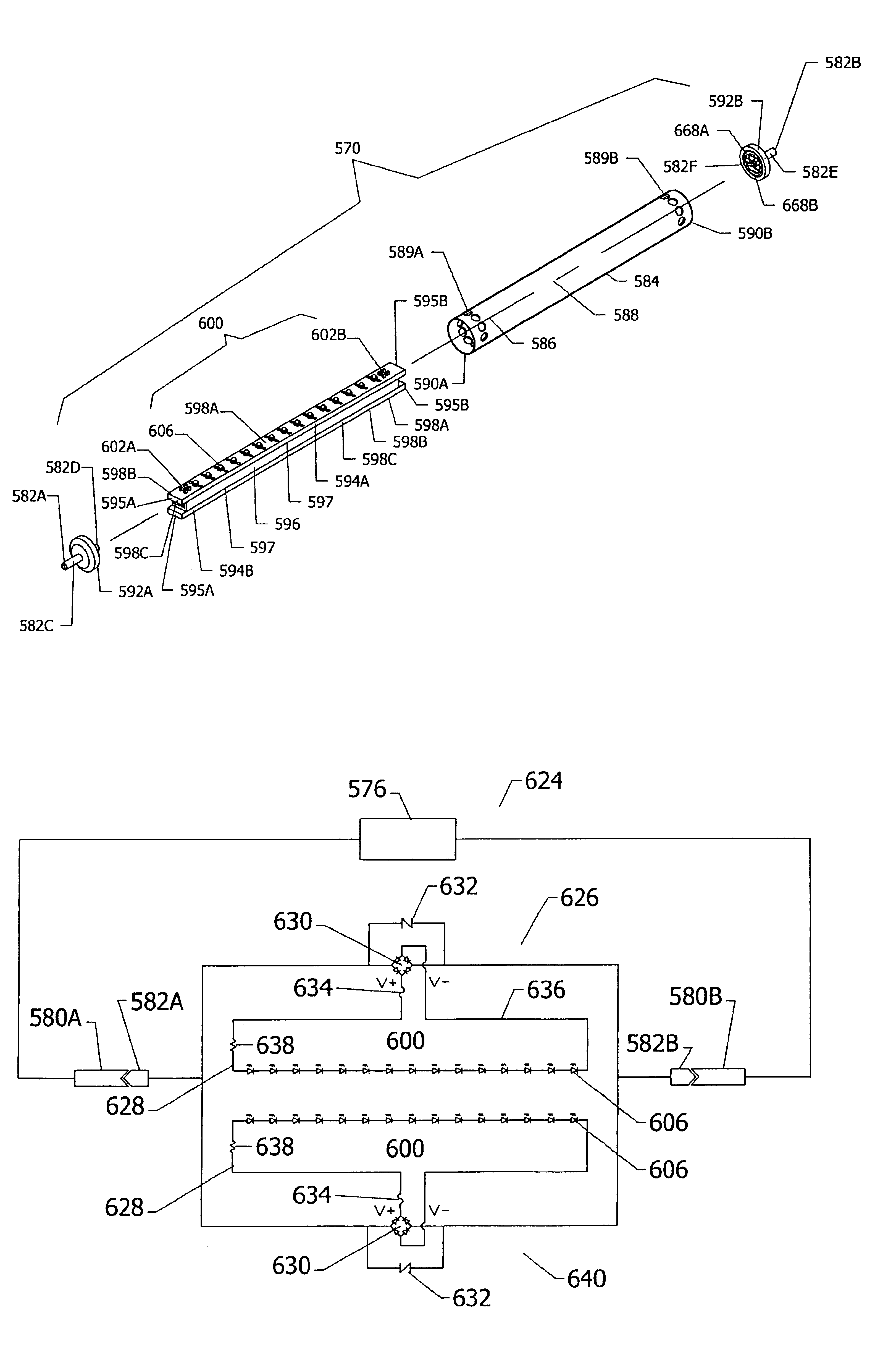

InactiveUS6853151B2Reduce materialReduce power consumptionPoint-like light sourceElongate light sourcesElectrical connectionLED lamp

An LED lamp for mounting to an existing fluorescent lamp fixture having a ballast assembly including ballast opposed electrical contacts, comprising a tubular wall generally circular in cross-section and having tubular wall ends with one or more LEDs positioned within the tubular wall between the tubular wall ends. An electrical circuit provides electrical power from the ballast assembly to the LED(s). The electrical circuit includes at least one metal substrate circuit board and means for electrically connecting the electrical circuit with the ballast assembly. The electrical circuit includes an LED electrical circuit including opposed electrical contacts. Each metal substrate circuit board supports and holds the one or more LEDs and the LED electrical circuit. Each metal substrate circuit board is positioned within the tubular wall between the tubular wall ends. At least one electrical string is positioned within the tubular wall and generally extends between the tubular wall ends. One or more LEDs are in electrical connection with at least one electrical string and are positioned to emit light through the tubular wall. Means for suppressing ballast voltage is included. The metal substrate circuit board includes opposed means for connecting the metal substrate circuit board to the tubular wall ends, which include means for mounting the means for connecting, and the one or more metal substrate circuit boards.

Owner:SIGNIFY HLDG BV

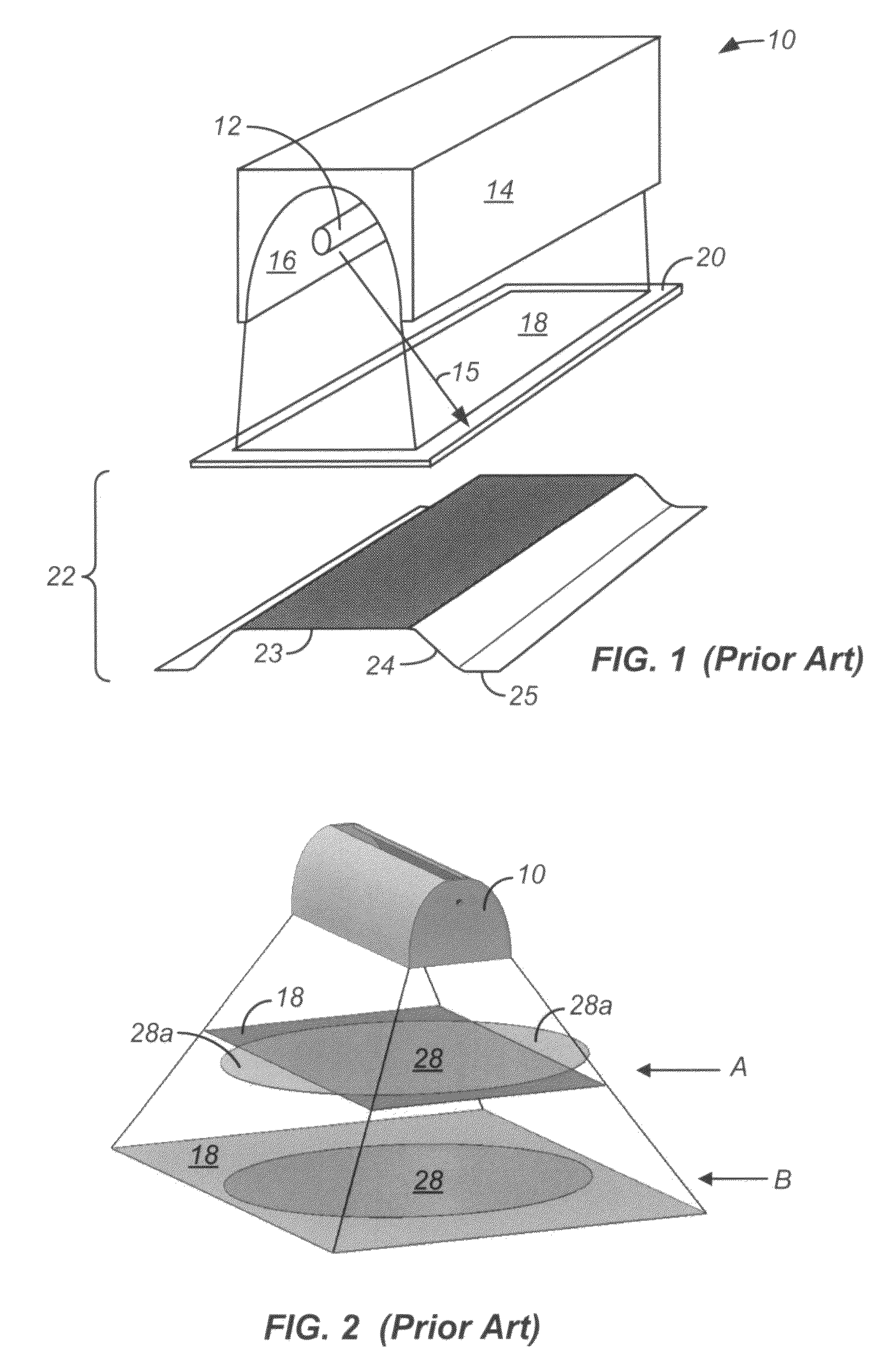

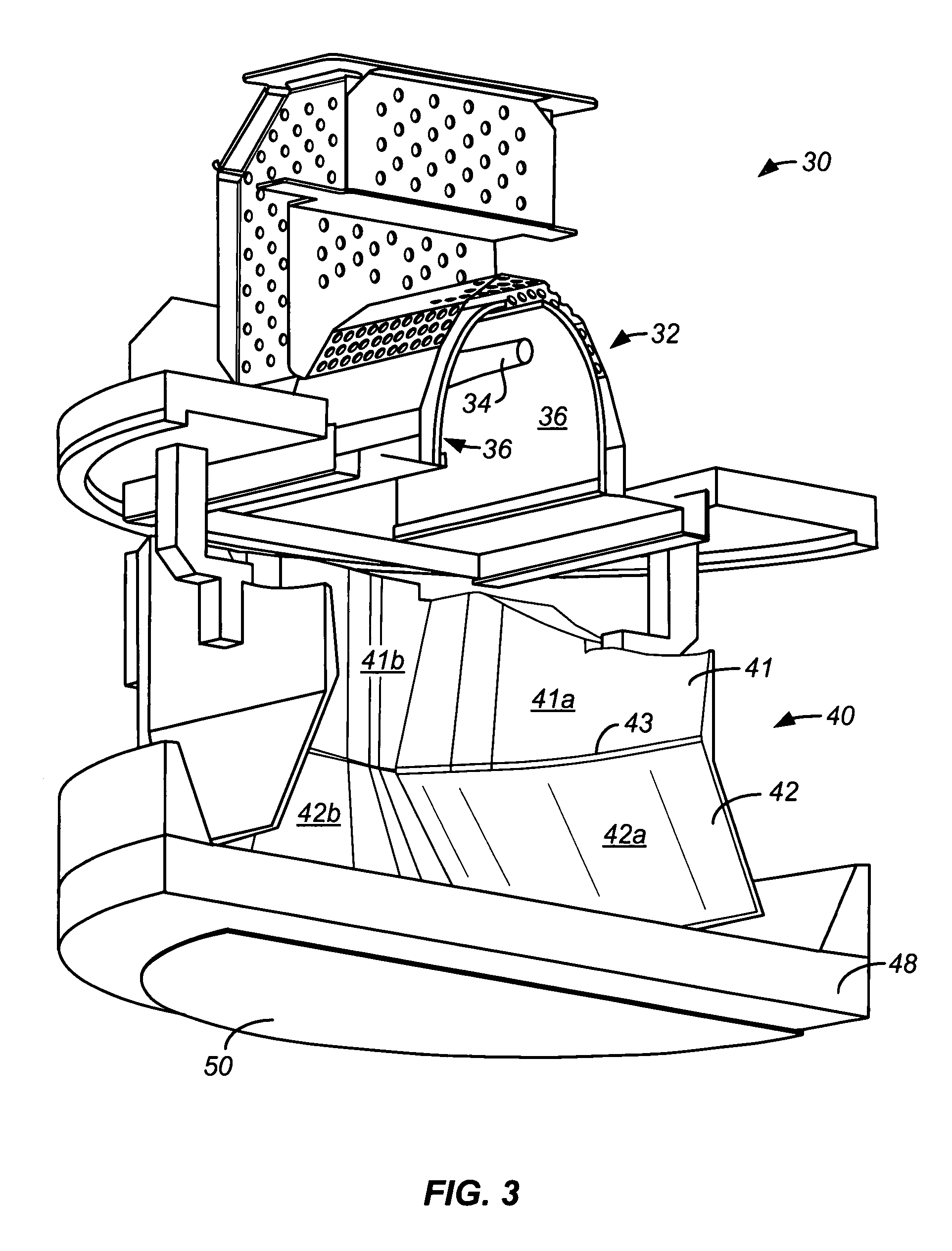

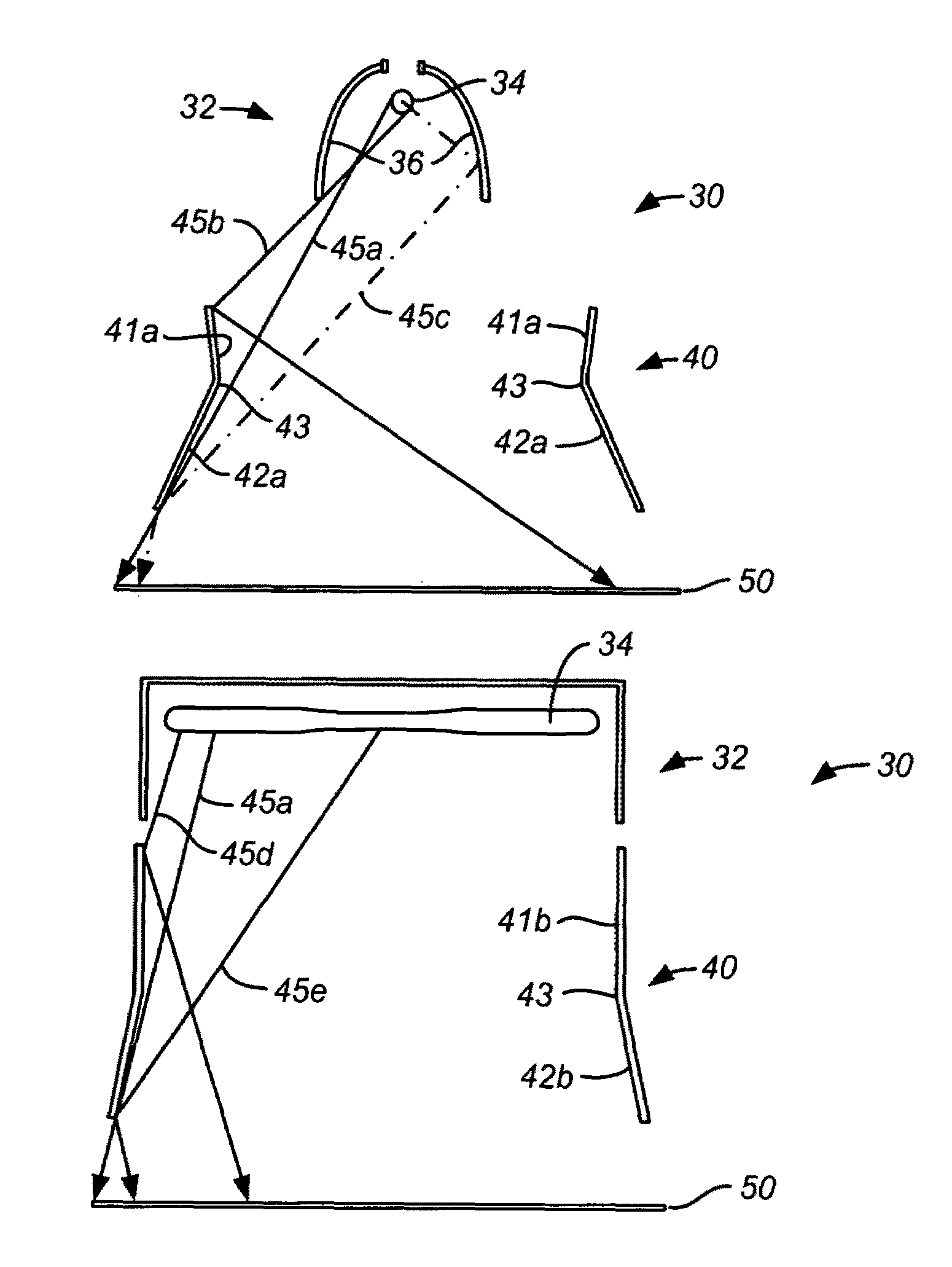

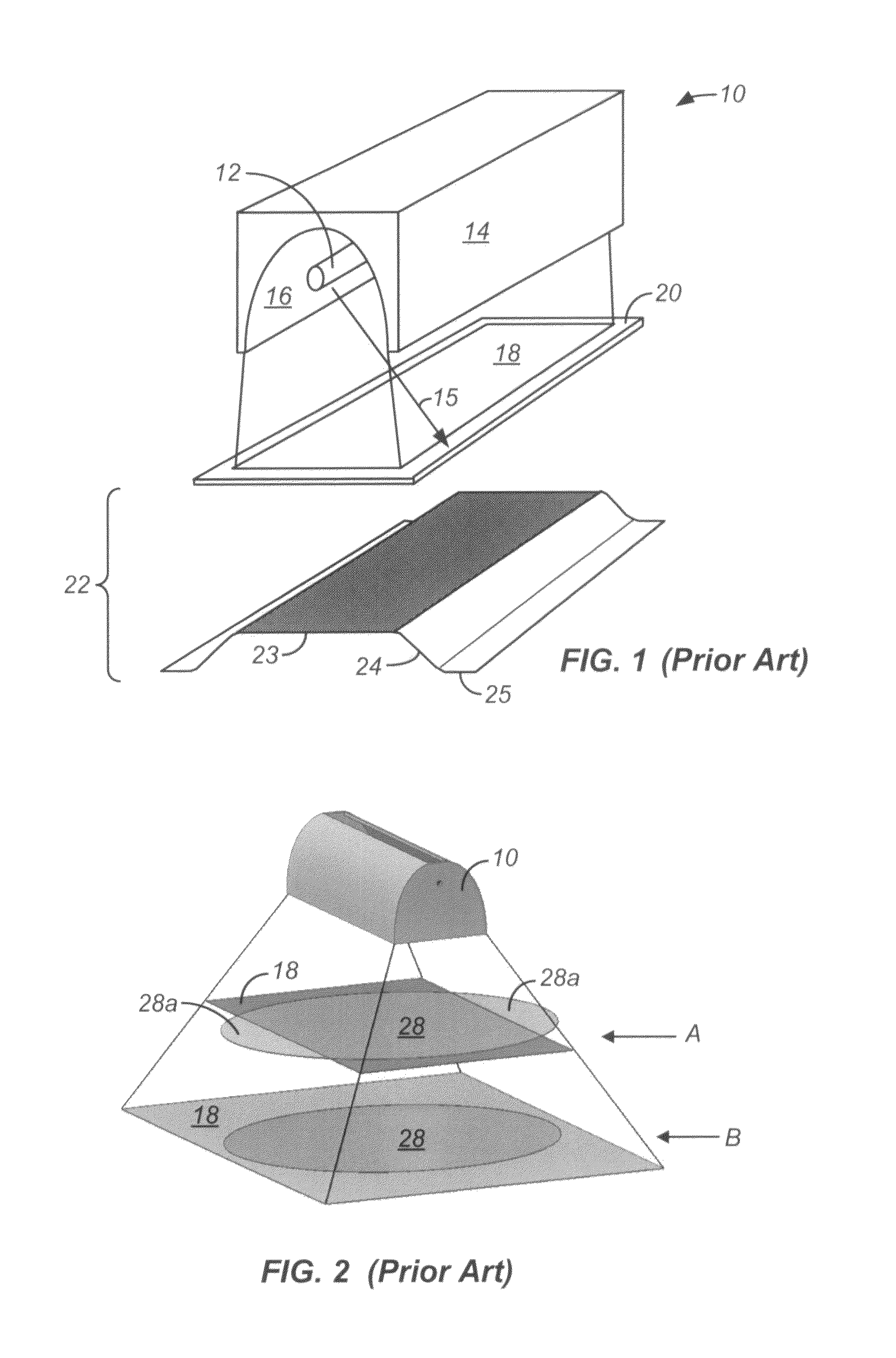

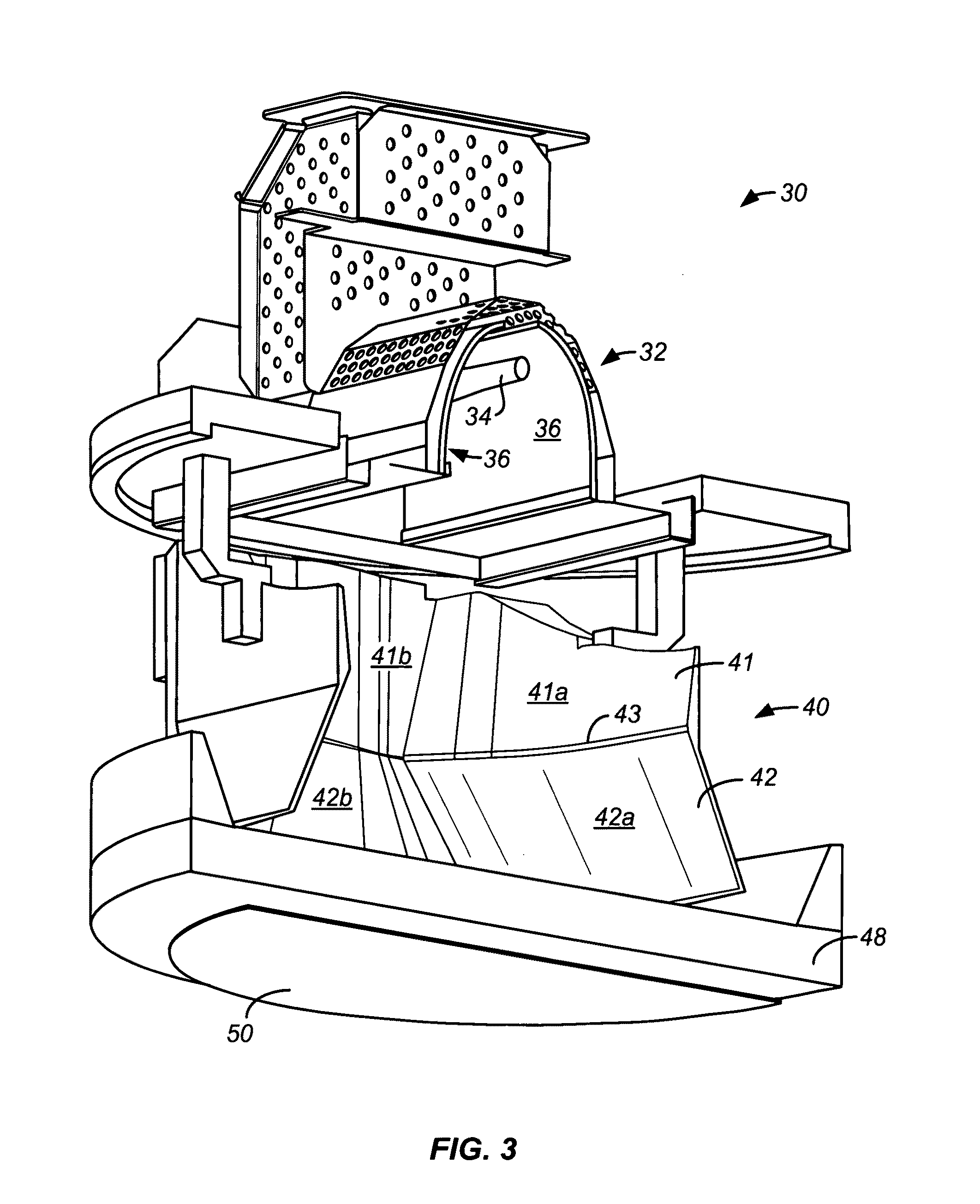

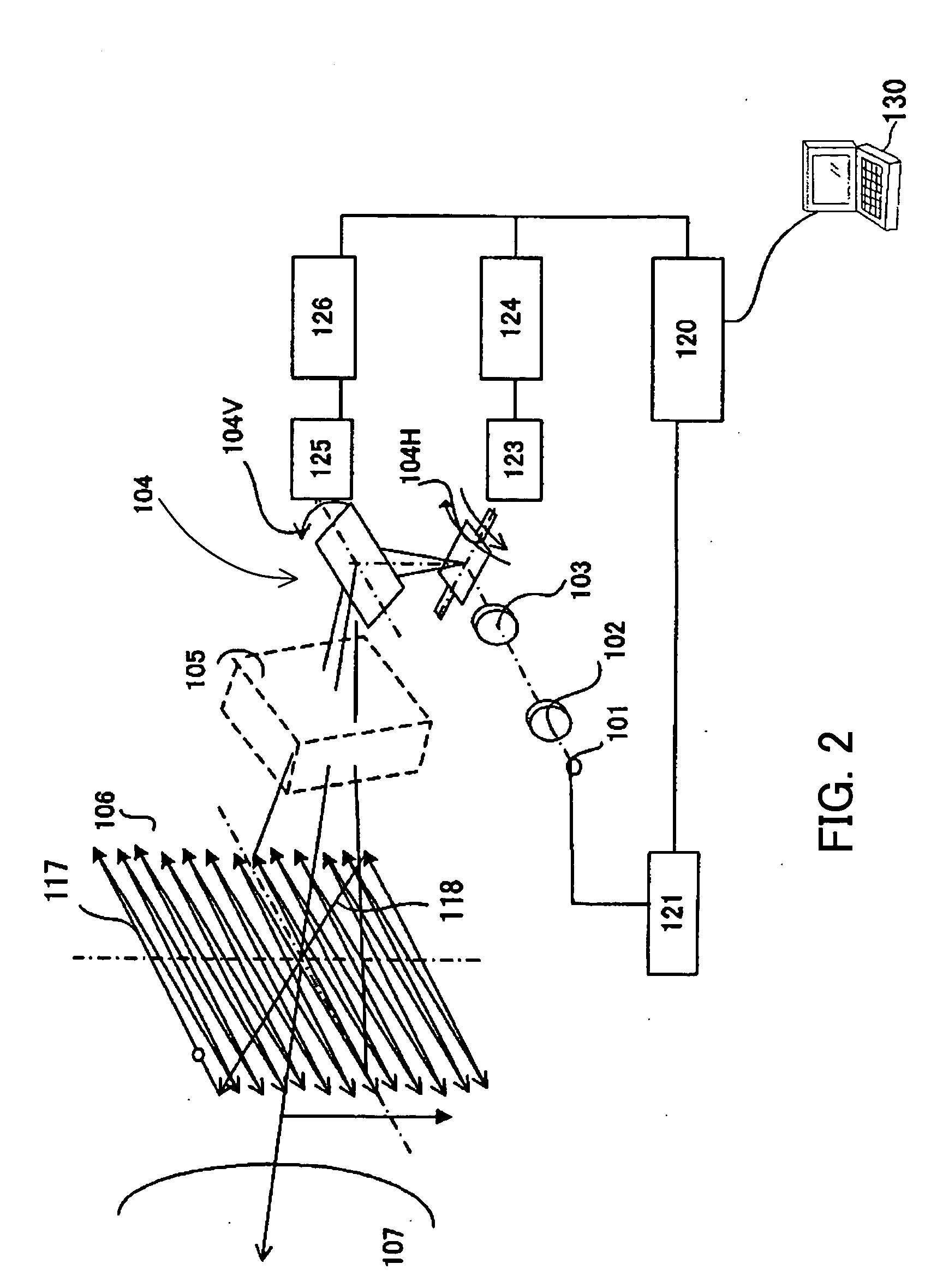

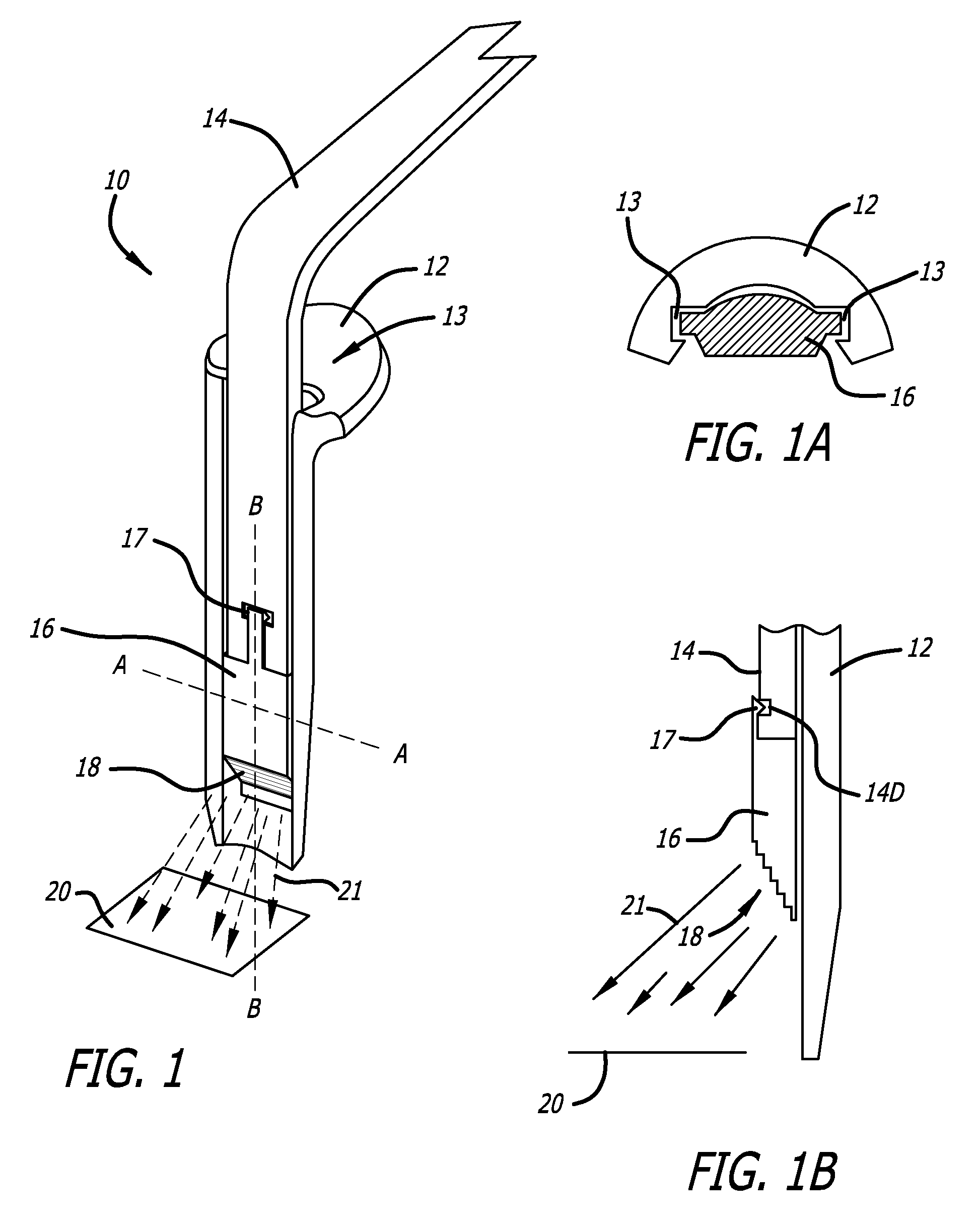

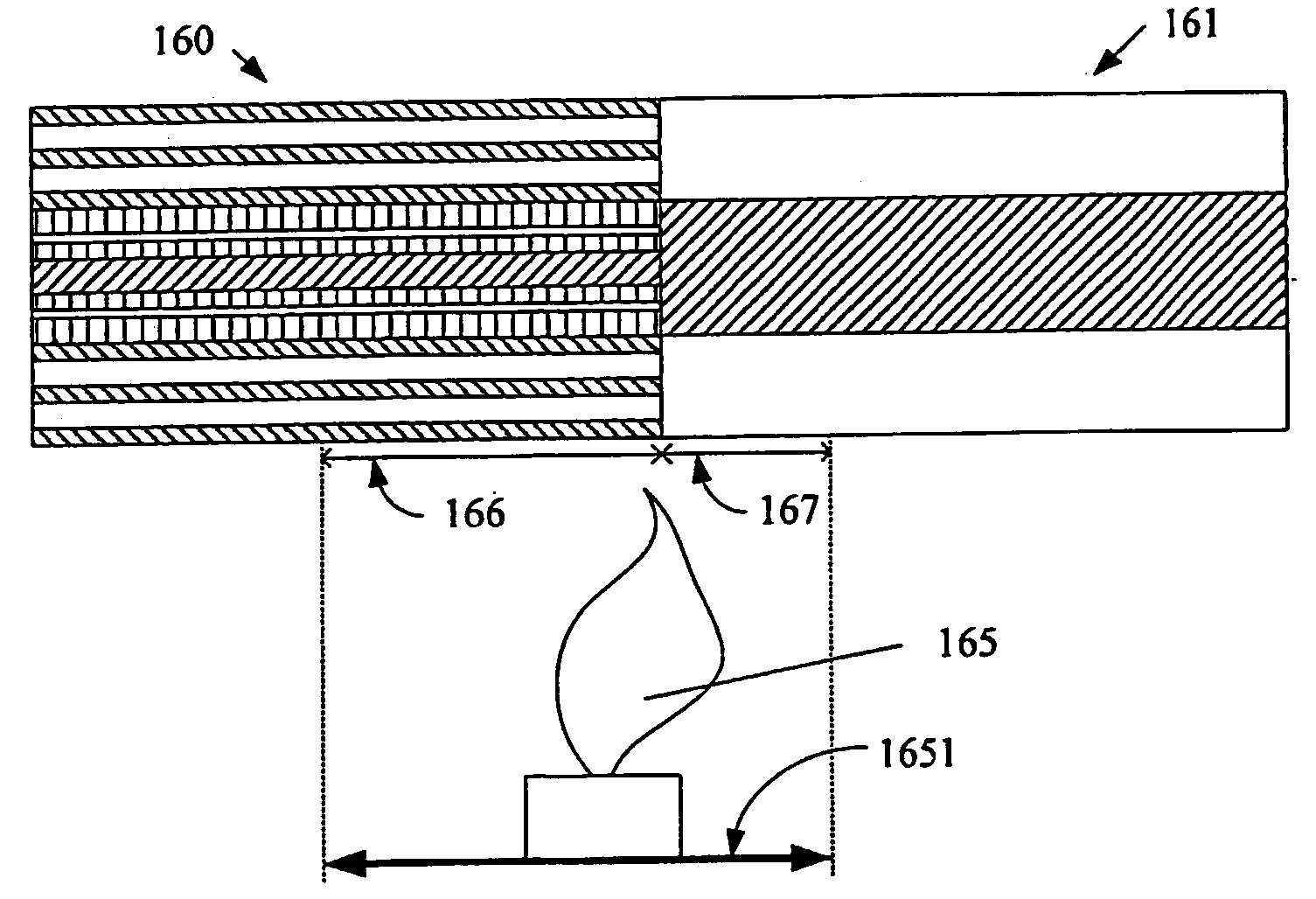

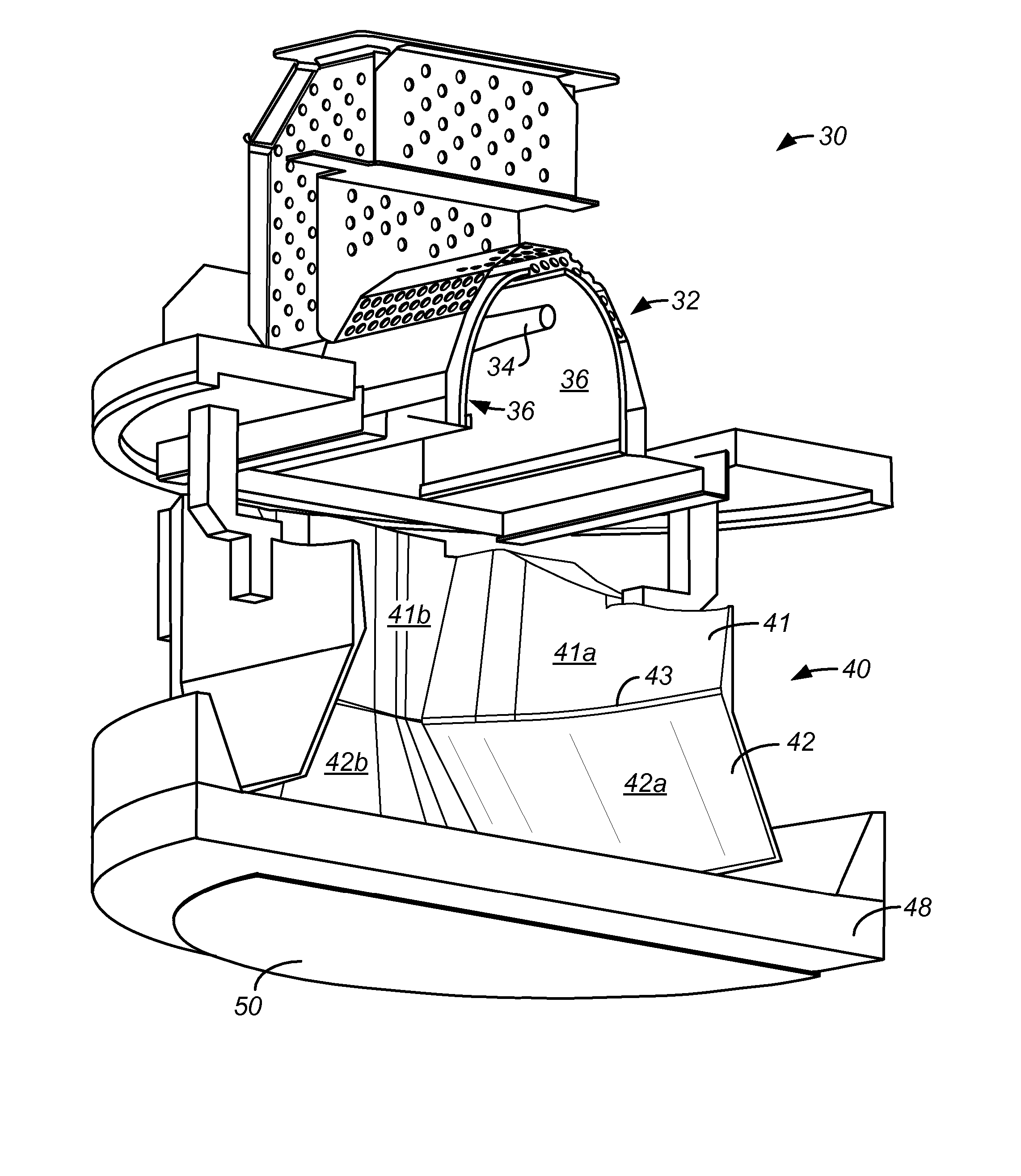

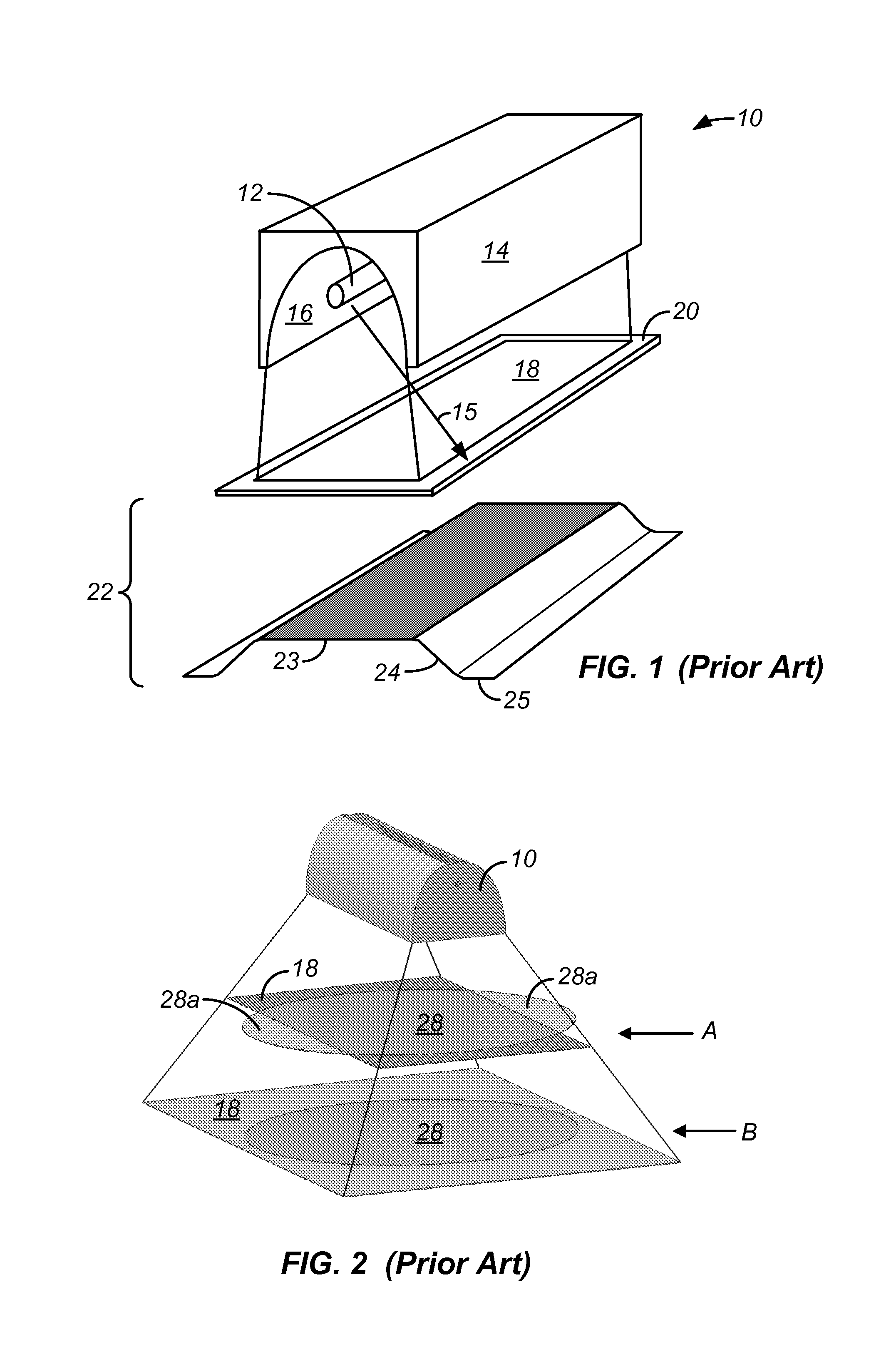

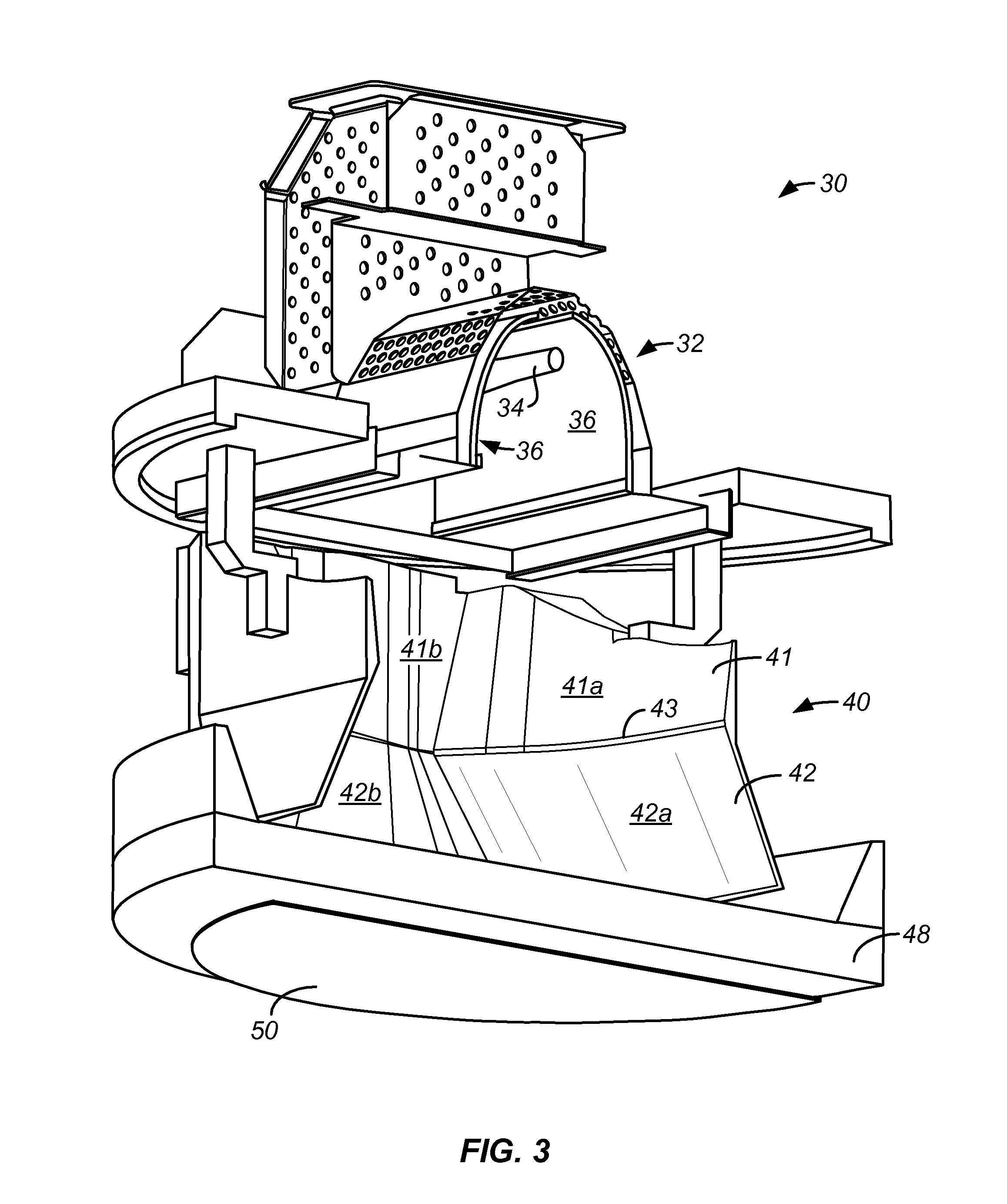

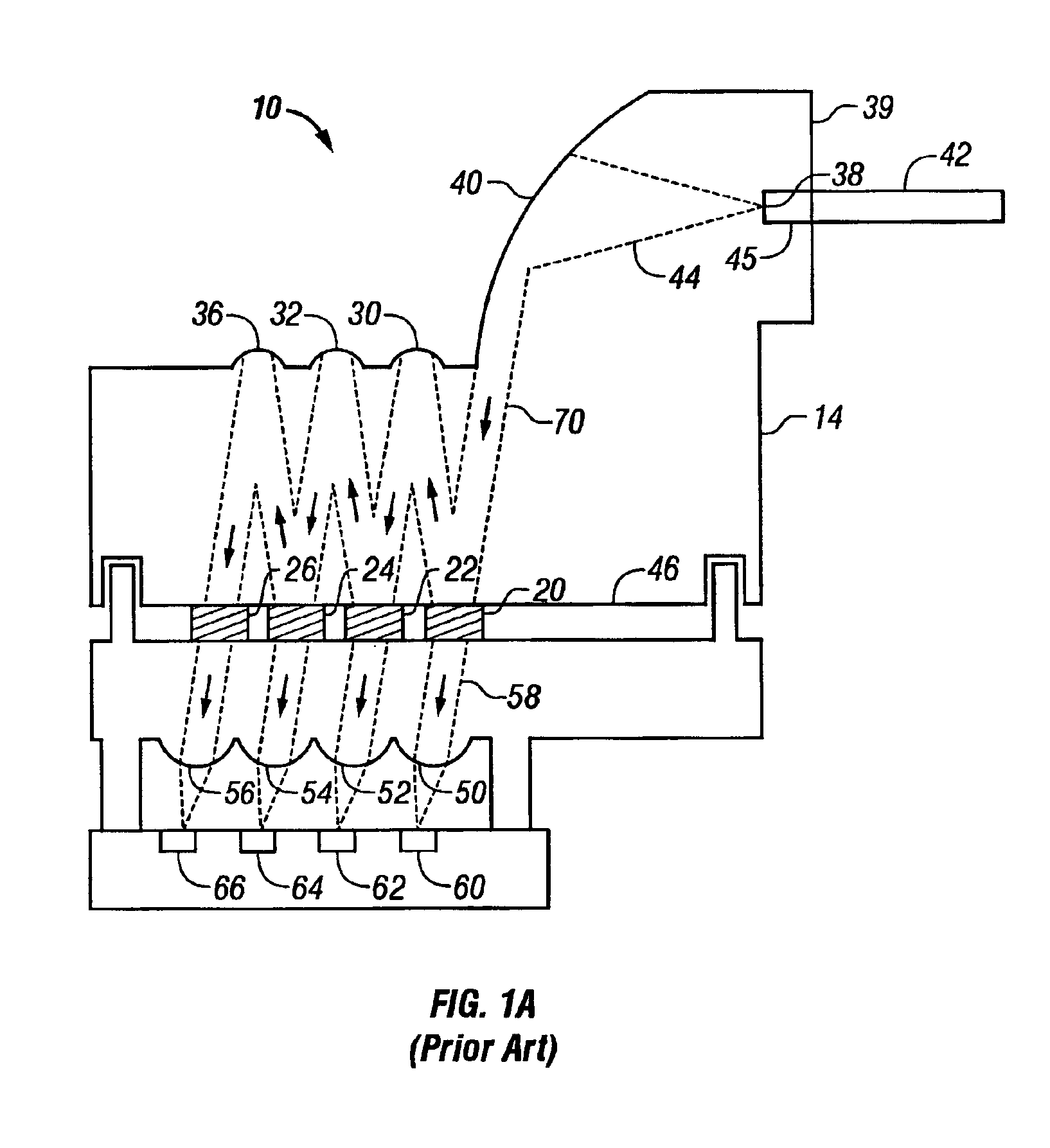

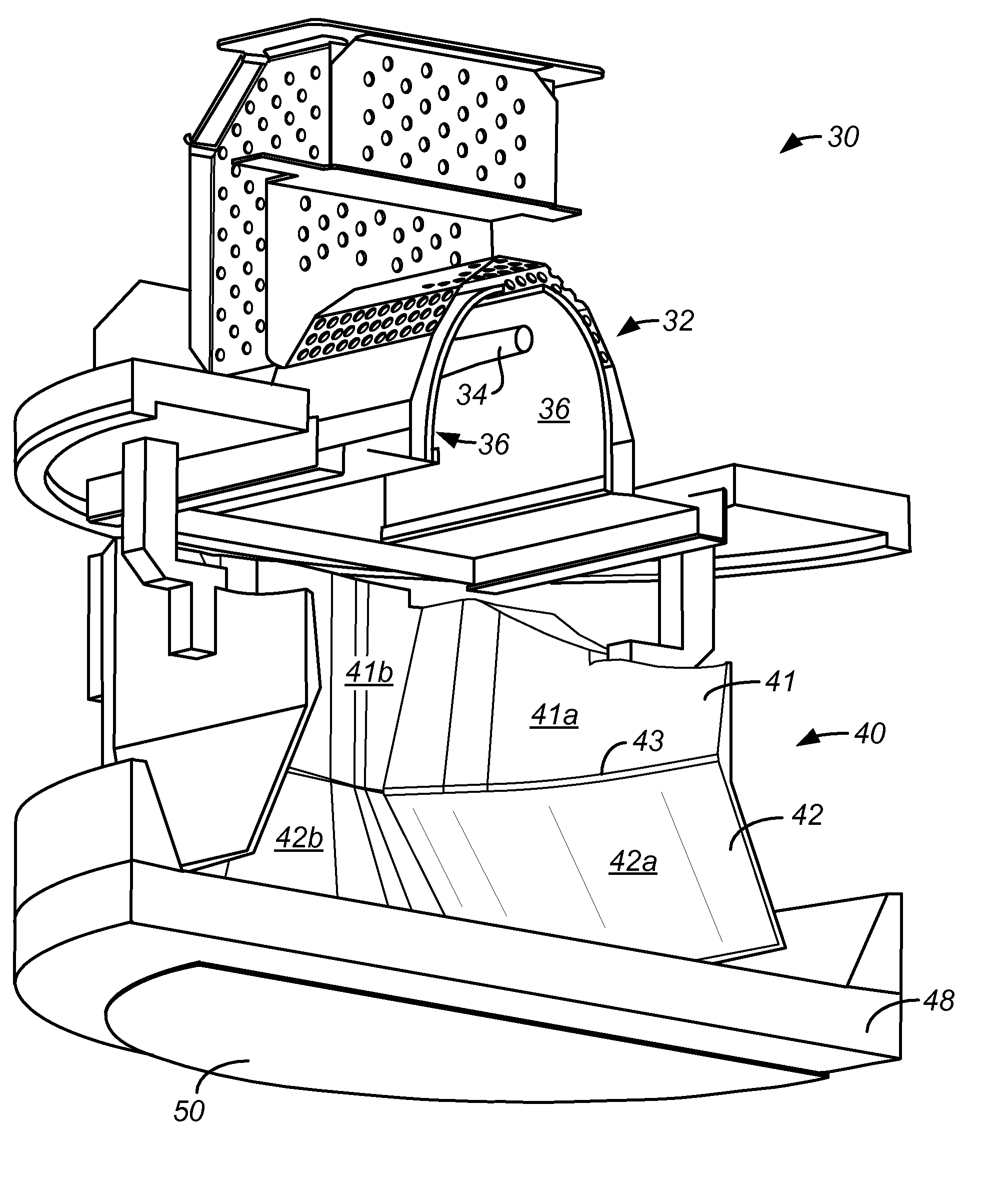

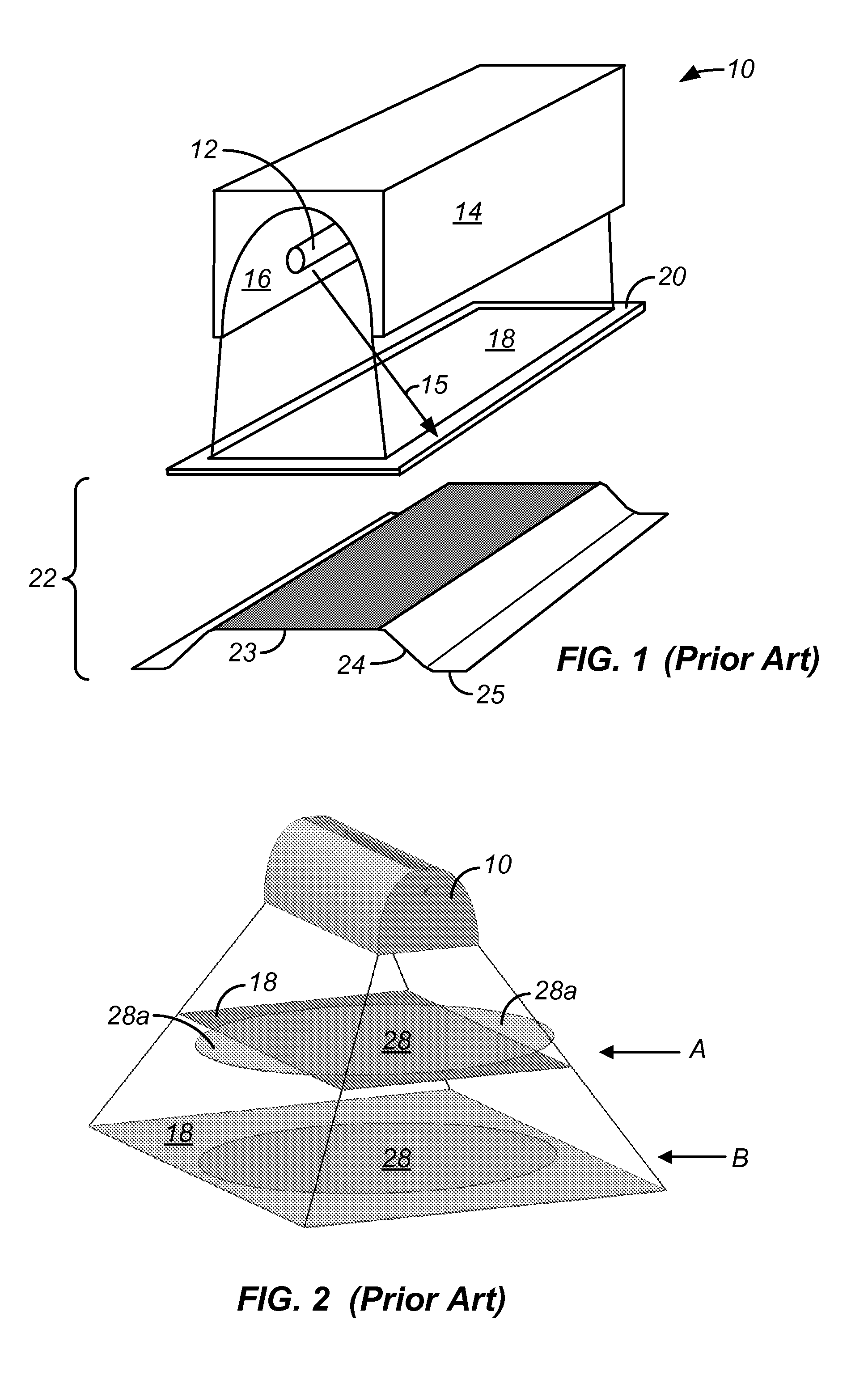

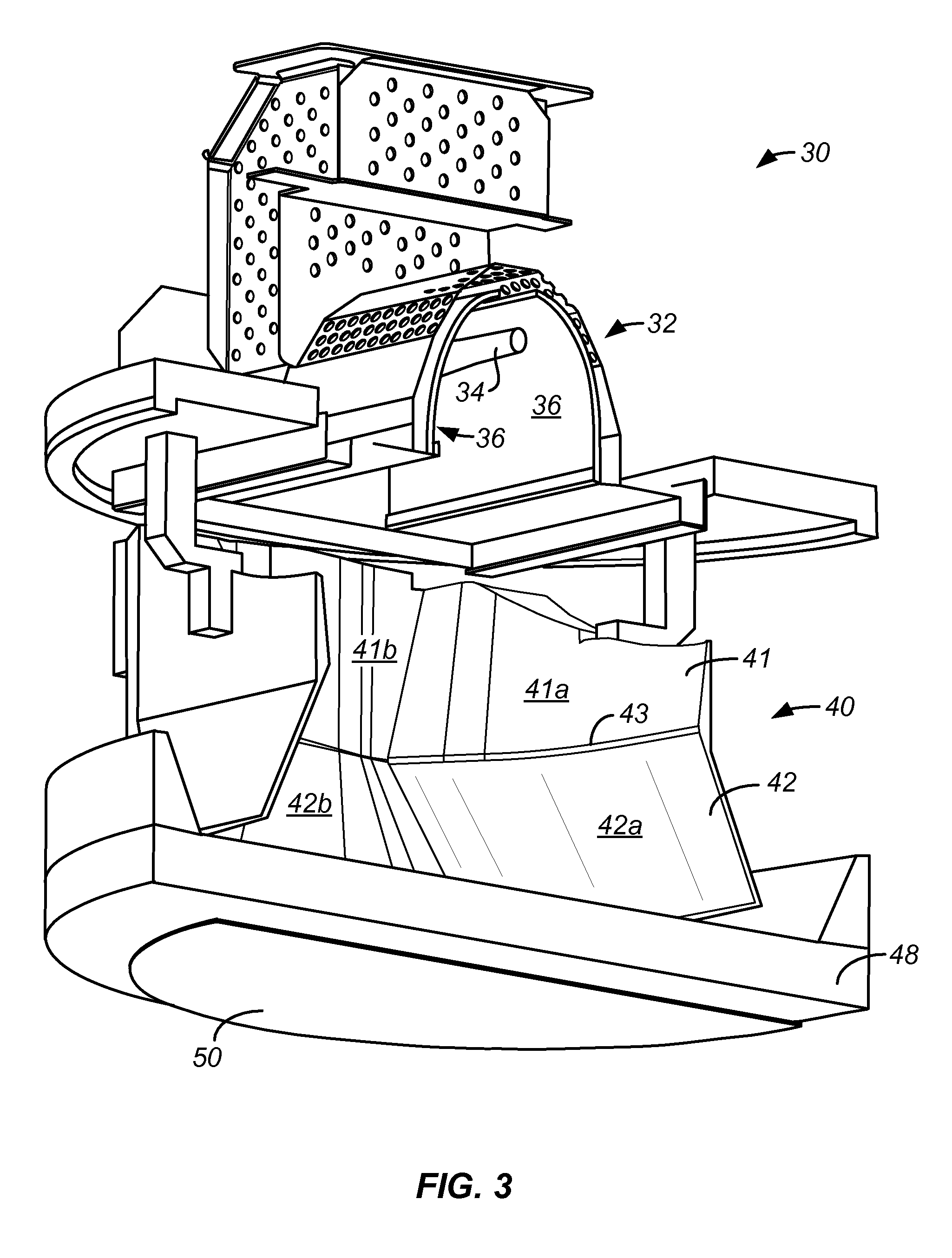

Apparatus and method for treating a substrate with UV radiation using primary and secondary reflectors

ActiveUS7566891B2Reduce light lossRadiation pyrometryPretreated surfacesProcess regionUltraviolet radiation

Embodiments of the invention relate generally to an ultraviolet (UV) cure chamber for curing a dielectric material disposed on a substrate and to methods of curing dielectric materials using UV radiation. A substrate processing tool according to one embodiment comprises a body defining a substrate processing region; a substrate support adapted to support a substrate within the substrate processing region; an ultraviolet radiation lamp spaced apart from the substrate support, the lamp configured to transmit ultraviolet radiation to a substrate positioned on the substrate support; and a motor operatively coupled to rotate at least one of the ultraviolet radiation lamp or substrate support at least 180 degrees relative to each other. The substrate processing tool may further comprise one or more reflectors adapted to generate a flood pattern of ultraviolet radiation over the substrate that has complementary high and low intensity areas which combine to generate a substantially uniform irradiance pattern if rotated. Other embodiments are also disclosed.

Owner:APPLIED MATERIALS INC

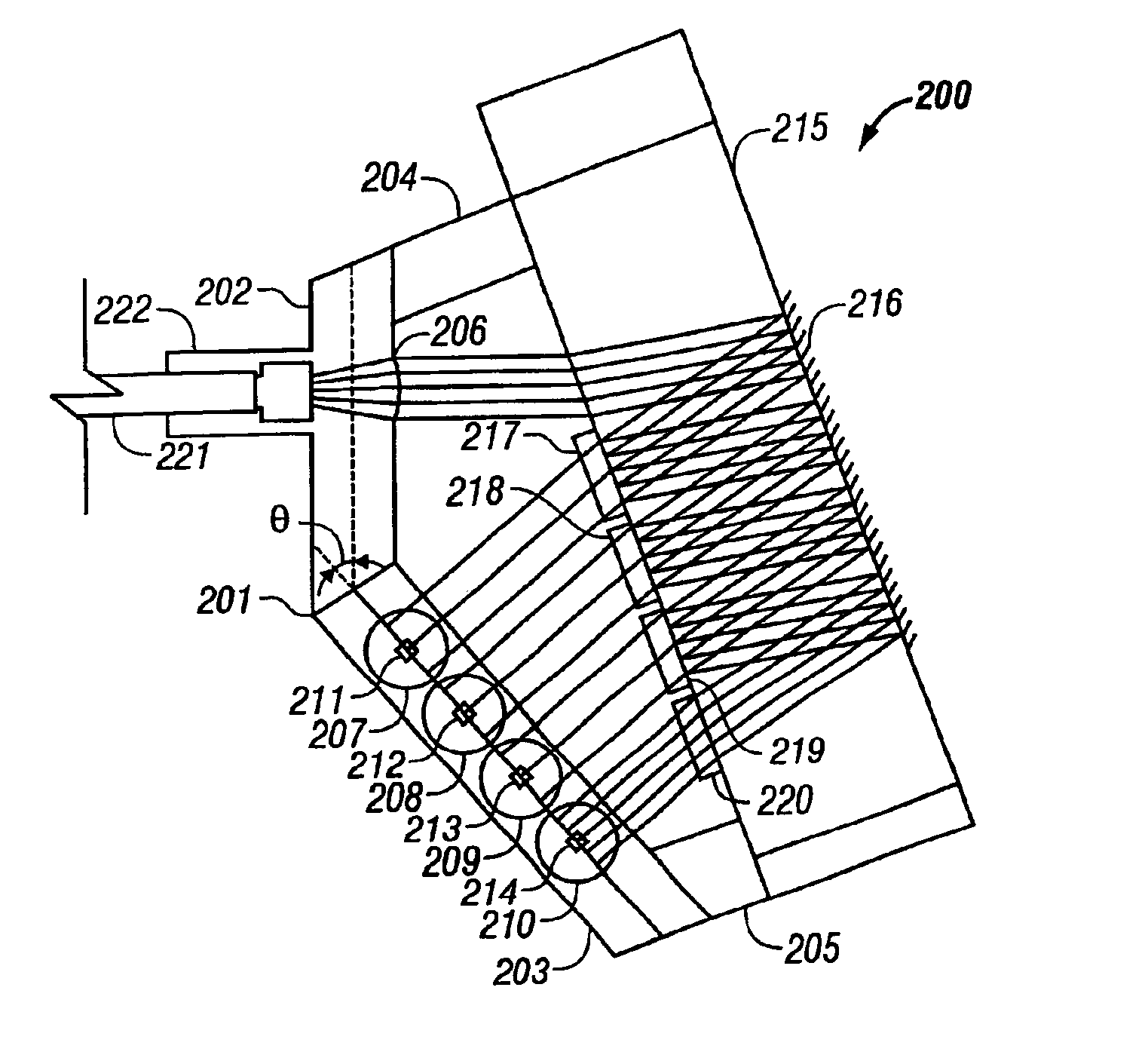

Apparatus and method for exposing a substrate to UV radiation using asymmetric reflectors

ActiveUS7692171B2Reduce light lossNanoinformaticsSemiconductor/solid-state device manufacturingProcess regionUltraviolet radiation

Embodiments of the invention relate generally to an ultraviolet (UV) cure chamber for curing a dielectric material disposed on a substrate and to methods of curing dielectric materials using UV radiation. A substrate processing tool according to one embodiment comprises a body defining a substrate processing region; a substrate support adapted to support a substrate within the substrate processing region; an ultraviolet radiation lamp spaced apart from the substrate support, the lamp configured to transmit ultraviolet radiation to a substrate positioned on the substrate support; and a motor operatively coupled to rotate at least one of the ultraviolet radiation lamp or substrate support at least 180 degrees relative to each other. The substrate processing tool may further comprise one or more reflectors adapted to generate a flood pattern of ultraviolet radiation over the substrate that has complementary high and low intensity areas which combine to generate a substantially uniform irradiance pattern if rotated. Other embodiments are also disclosed.

Owner:APPLIED MATERIALS INC

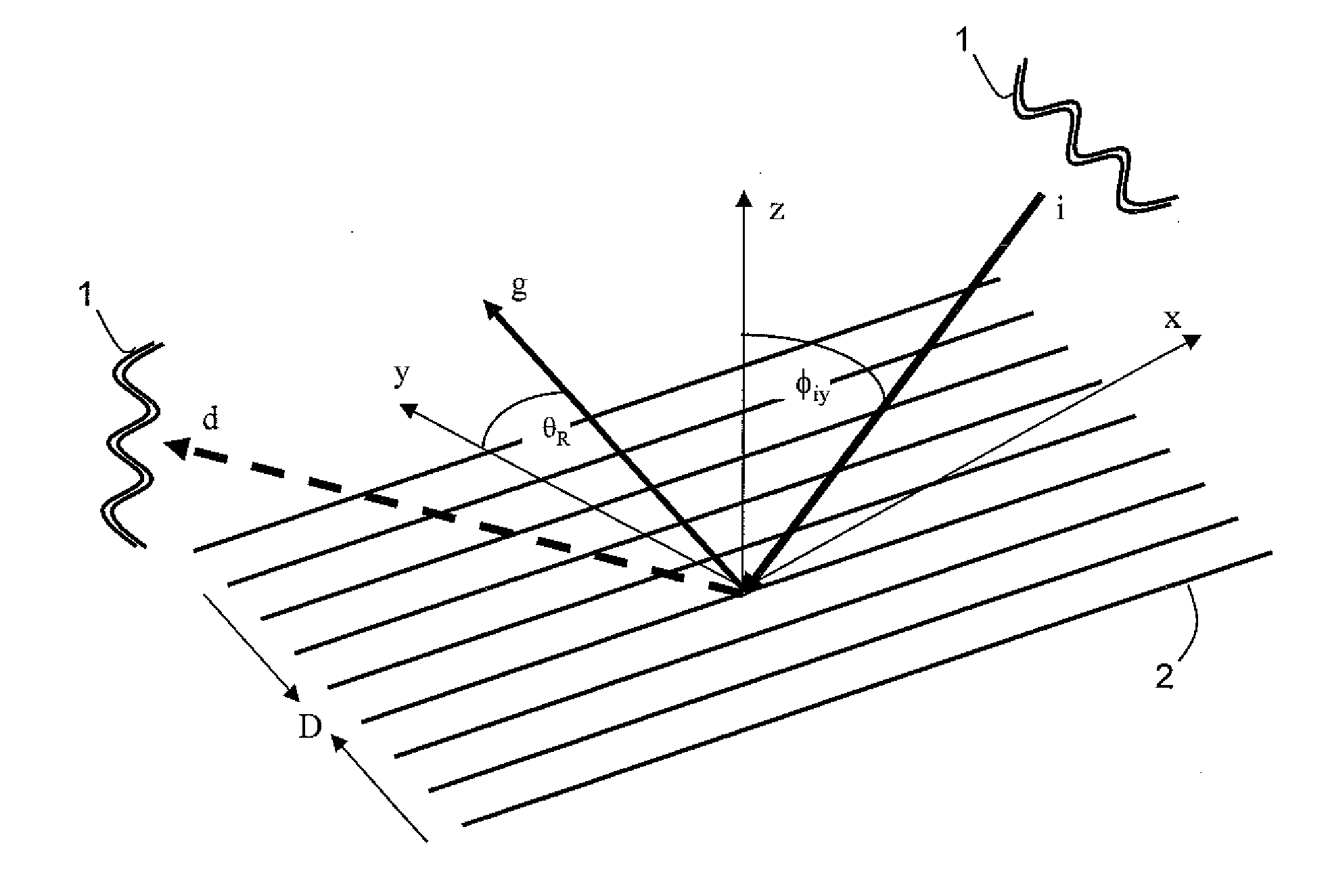

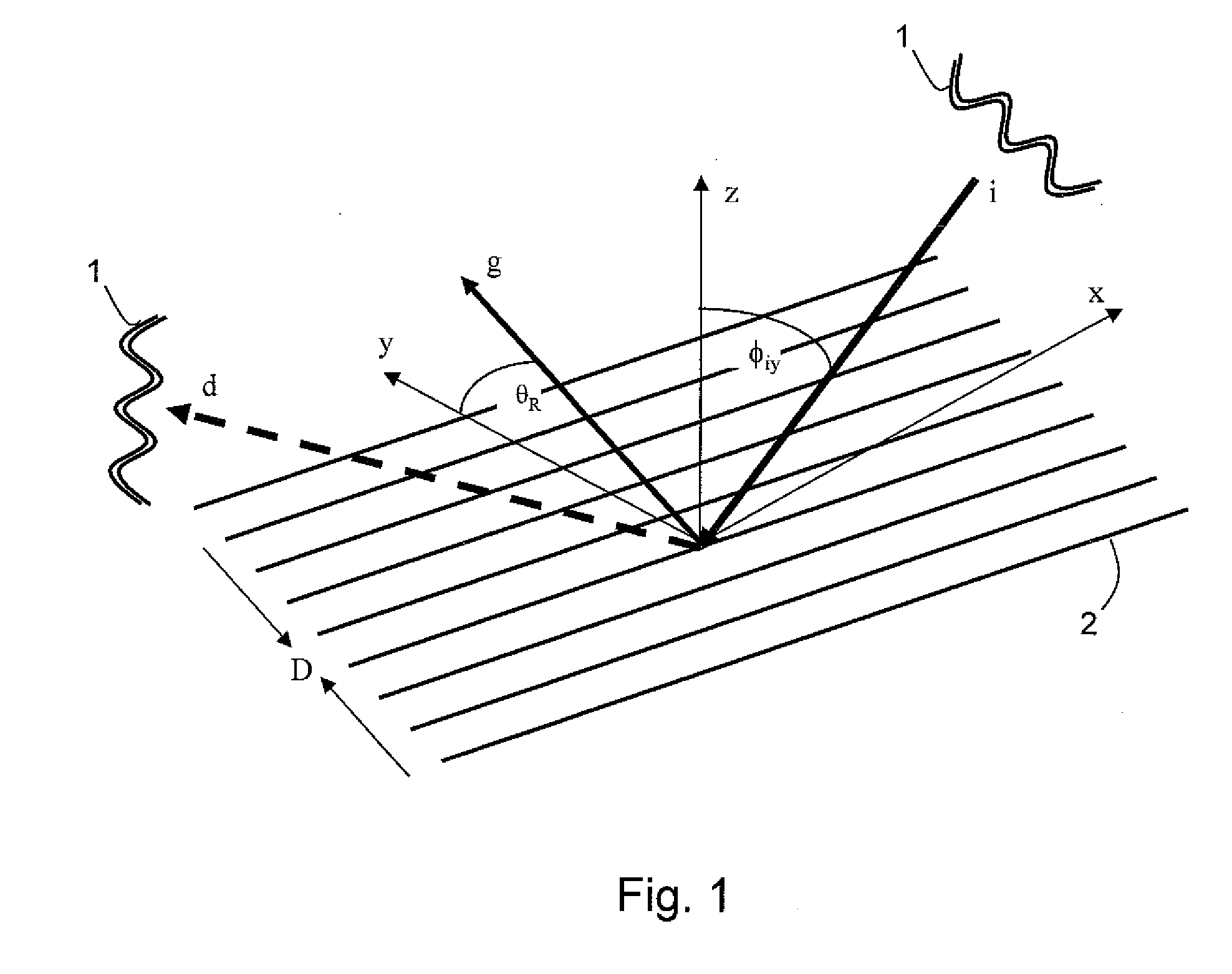

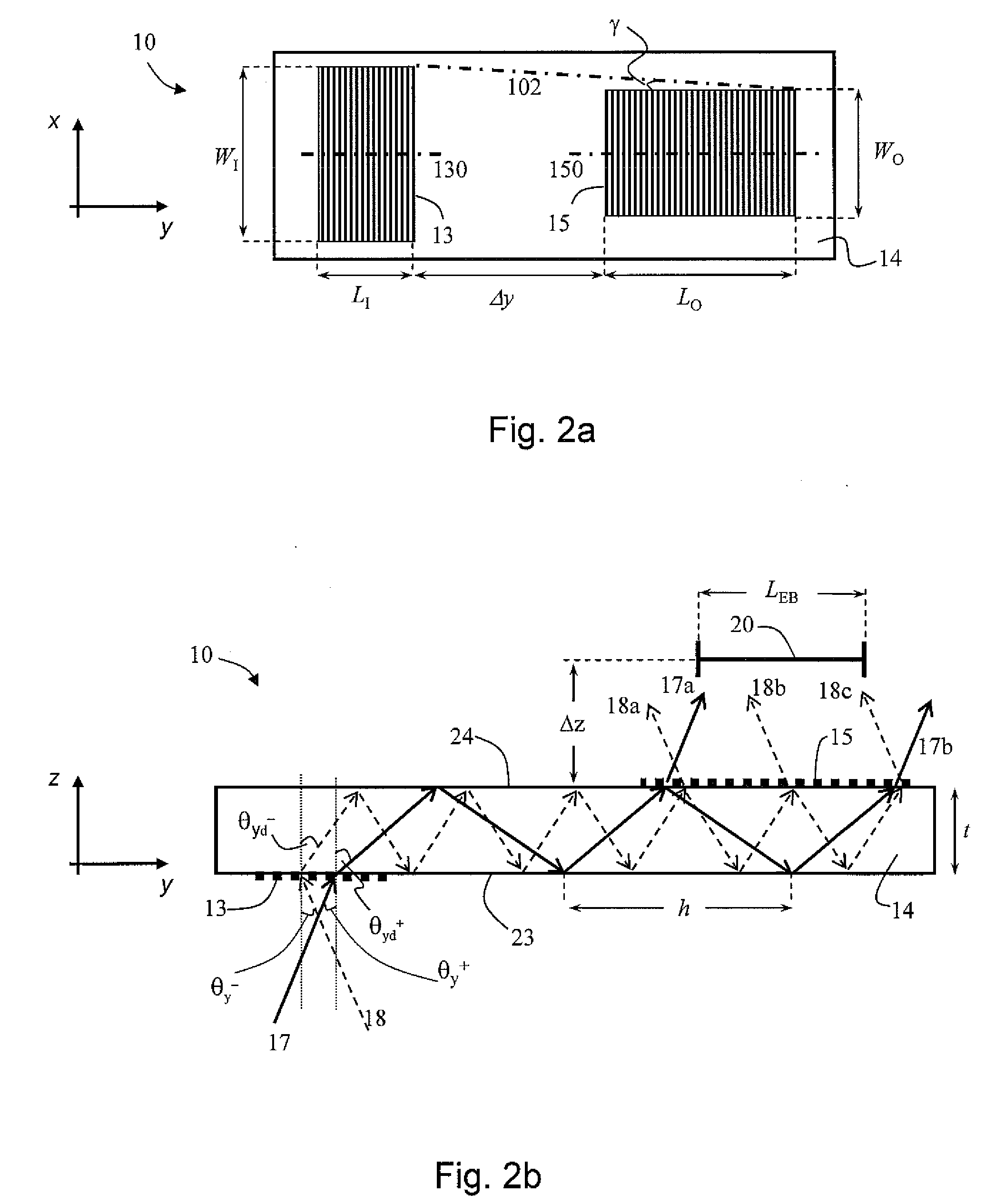

Diffractive optical relay device with improved color uniformity

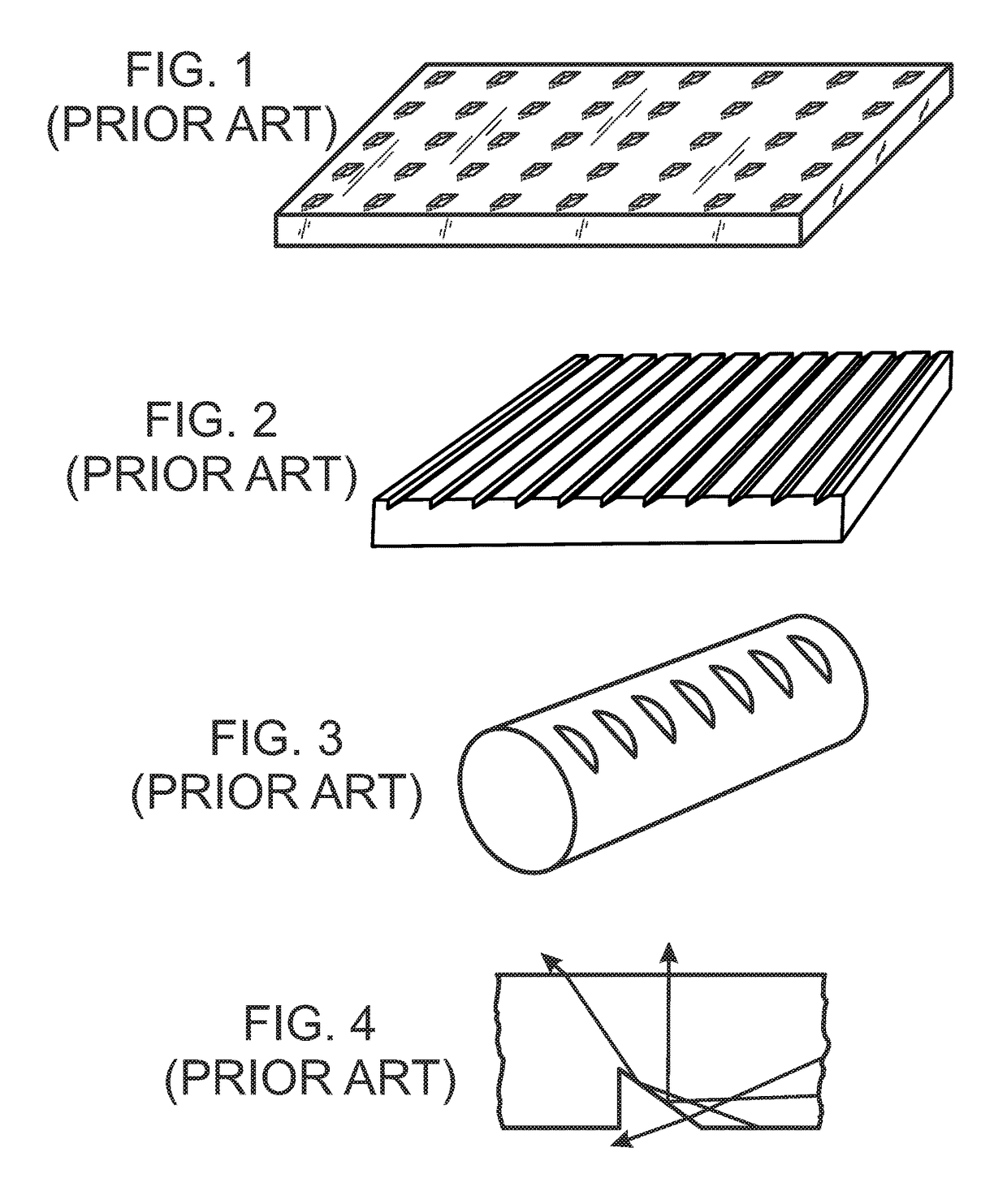

InactiveUS20100177388A1Reduce overall chromatic aberrationImprove performanceDiffraction gratingsOptical light guidesLight beamDiffraction optics

An optical relay comprises a light-transmissive substrate having a plurality of diffractive optical elements, where at least one diffractive optical element is characterized by nonuniform diffraction efficiency. The substrate and diffractive optical elements are designed and constructed to relay at least a portion of a light beam emanating from an object to at least one predetermined eye-box in a manner such that for each point of the object, there is a set of parallel outgoing light rays originating from the point and arriving to the eye-box. The color difference between any two parallel light rays of the set is less than 50 ΔE* units.

Owner:MIRAGE INNOVATIONS

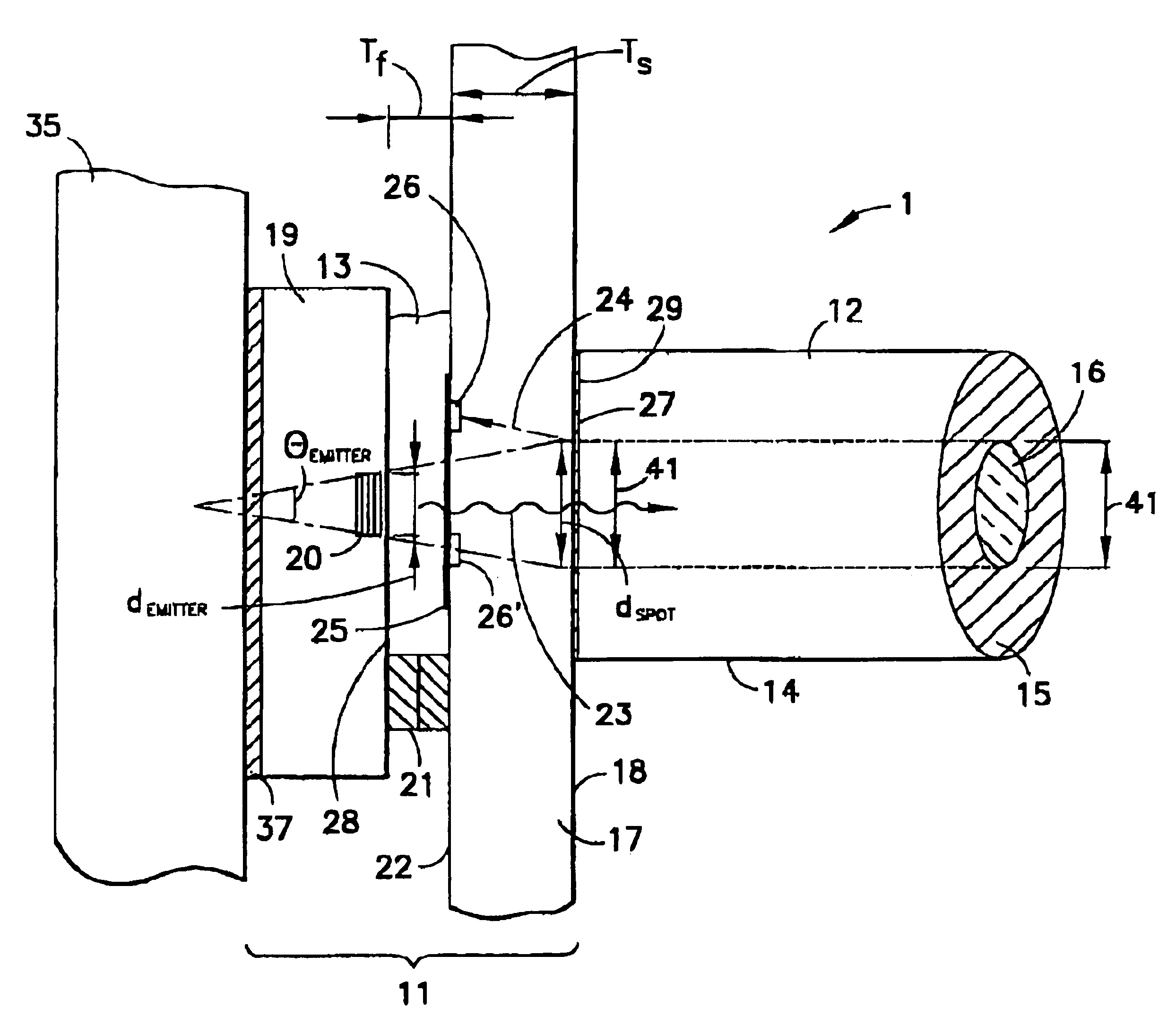

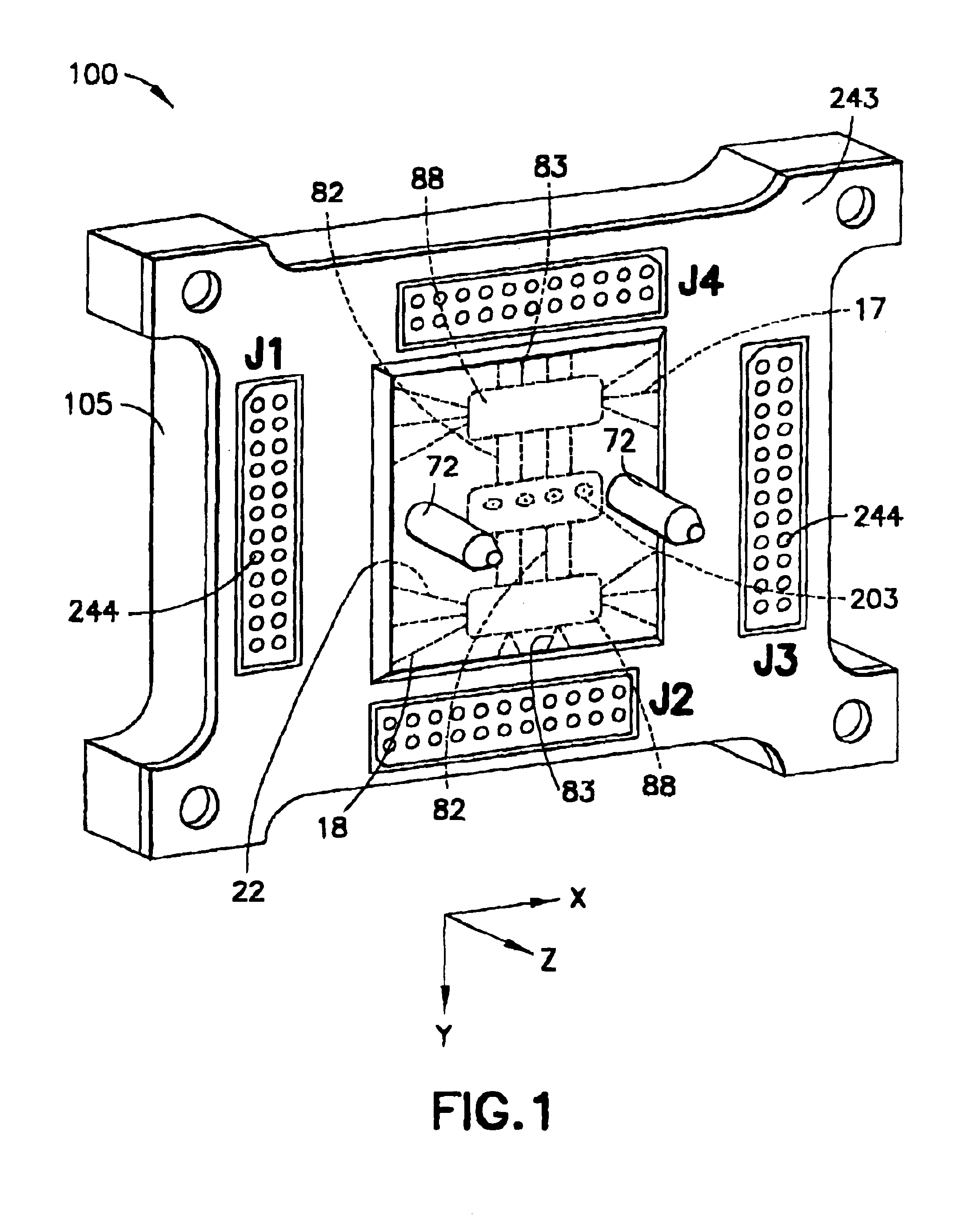

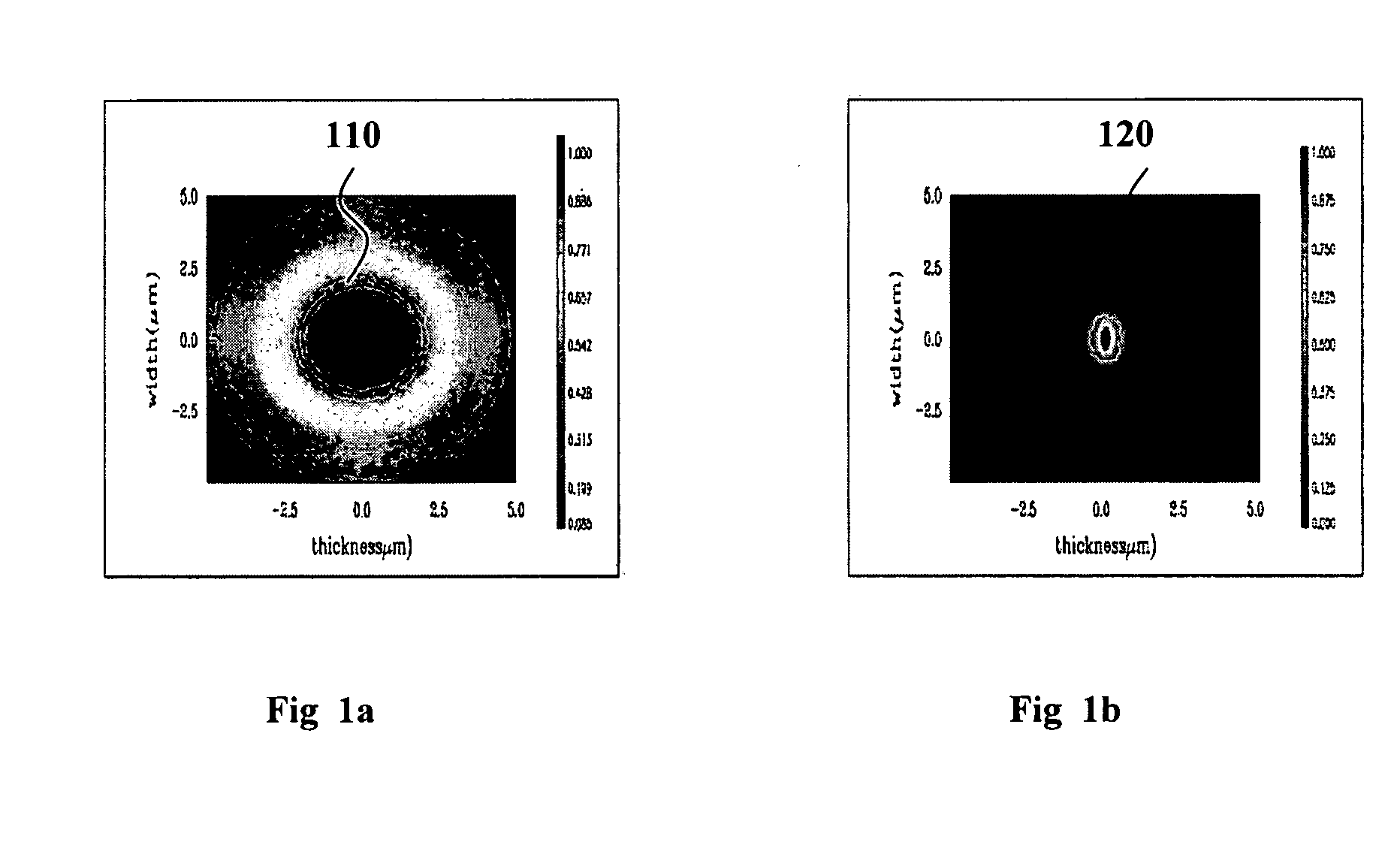

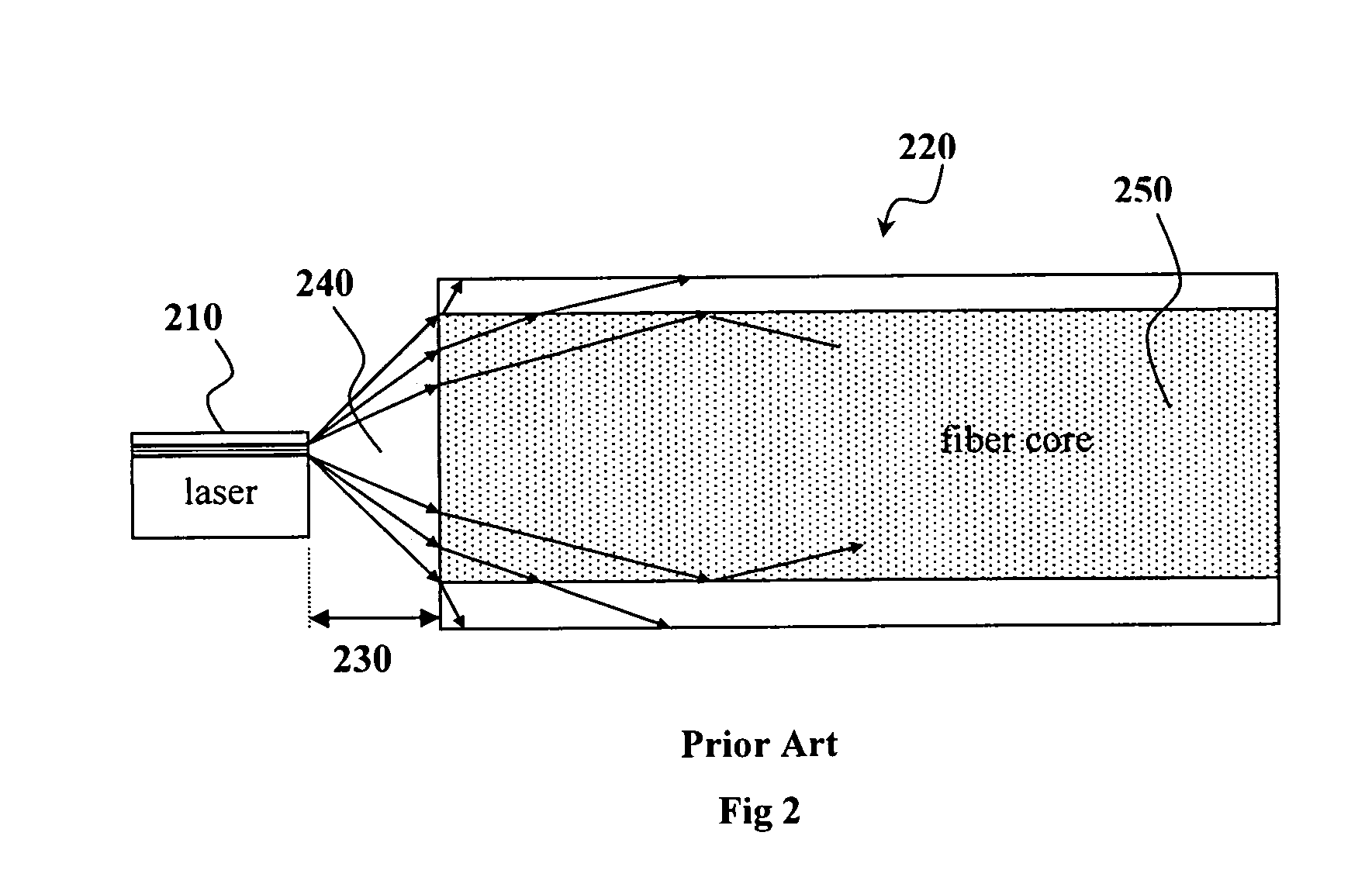

Small-scale optoelectronic package

InactiveUS6910812B2Easy to manufactureSacrifice speedSemiconductor/solid-state device detailsSolid-state devicesFiberElectricity

An integrated circuit / optoelectronic packaging system (100) which comprises OE and IC components packaged to provide electrical input / output, thermal management, an optical window, and precise passive or mechanical alignment to external optical receivers or transmitters. A transparent insulating substrate having electrical circuitry in a thin silicon layer formed on its top side is positioned between the optical fiber and the optoelectronic device such that an optical path is described between the optoelectronic device and the optical fiber core through the transparent insulating substrate. The optoelectronic devices are mounted on the transparent insulating substrate in a precise positional relationship to guide holes in the substrate. The optical fibers are fixed in an optical fiber connector and are held in a precise positional relationship to guide holes in the connector. Alignment is accomplished with complementary guide pins that pass through guide holes in the fiber optic connector and in the transparent substrate.

Owner:PSEMI CORP

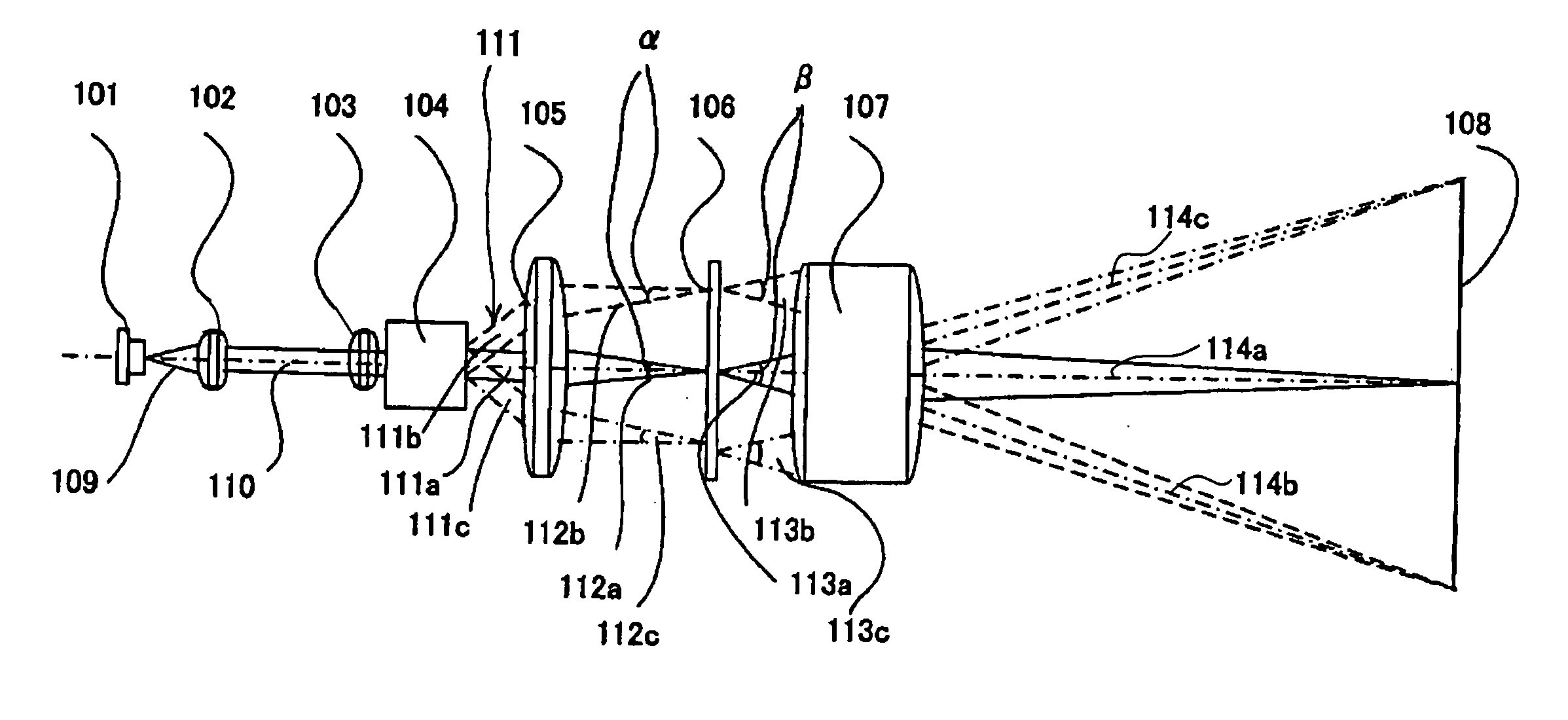

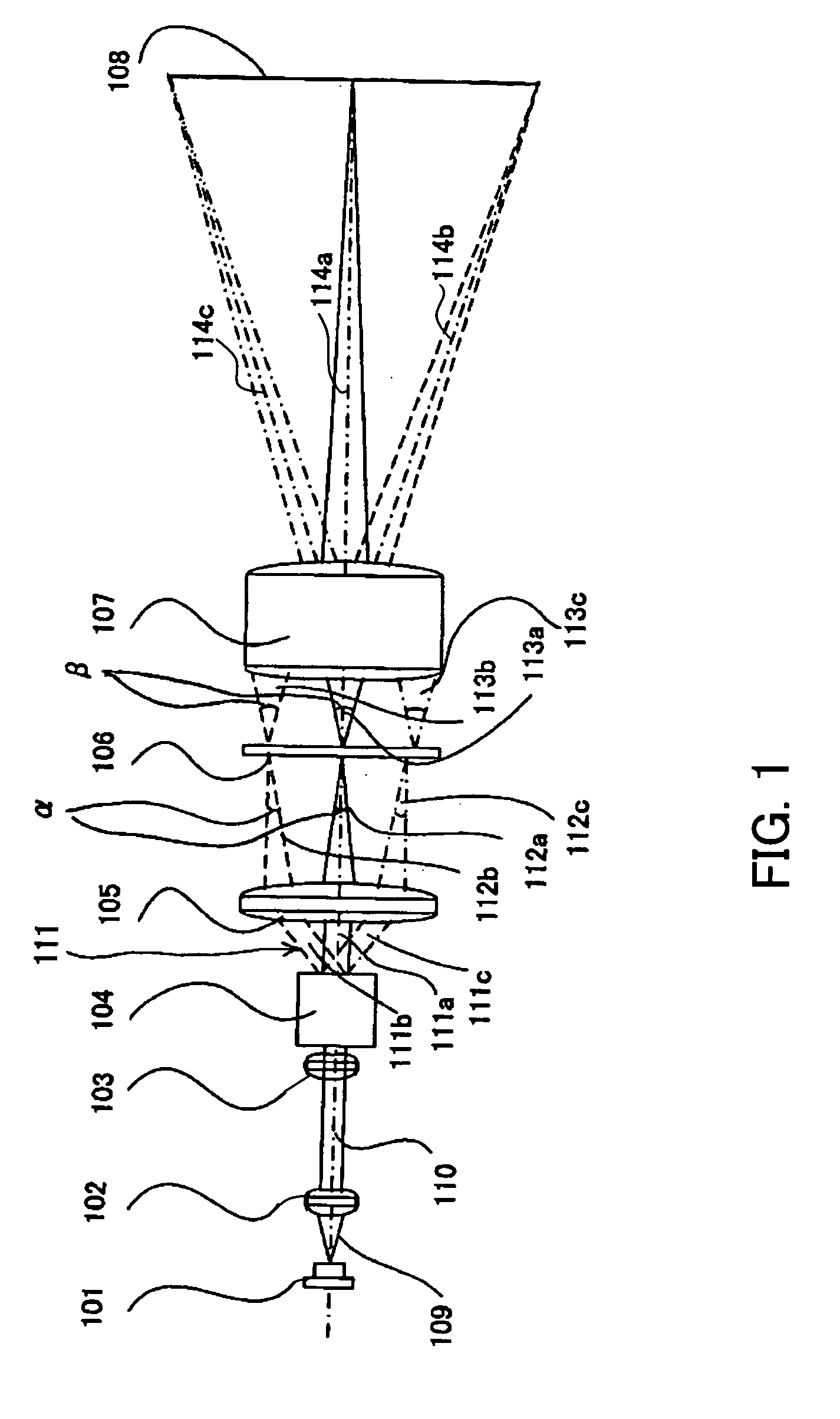

Displaying optical system and image projection apparatus

InactiveUS20060033009A1Reduce light lossReduce speckle noiseTelevision system scanning detailsProjectorsIntermediate imageDivergence angle

A displaying optical system is disclosed, which is capable of reducing a speckle noise. The displaying optical system comprises a light source emitting coherent light, a scanning device scanning the light, a first optical system causing the light from the scanning device to form an intermediate image, a second optical system causing the light from the intermediate image to form an image on a real display surface, and an optical element arranged between the first and second optical systems. The optical element widens the divergence angle of the light emerged from the optical element toward the second optical system more than the incident angle of the light on the optical element from the first optical system.

Owner:CANON KK

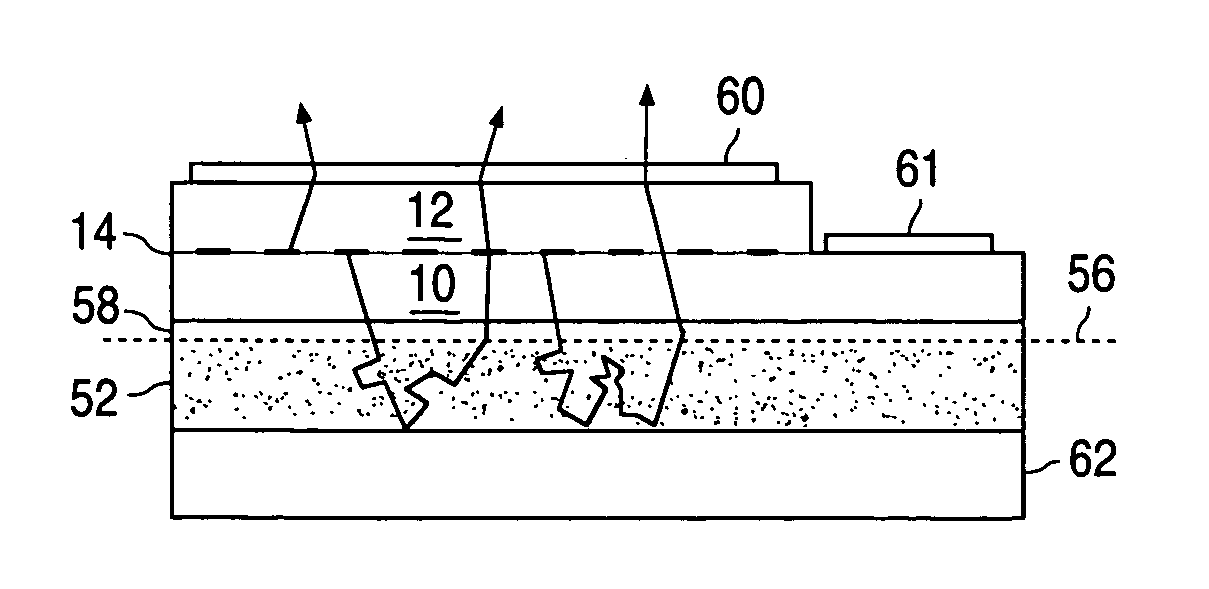

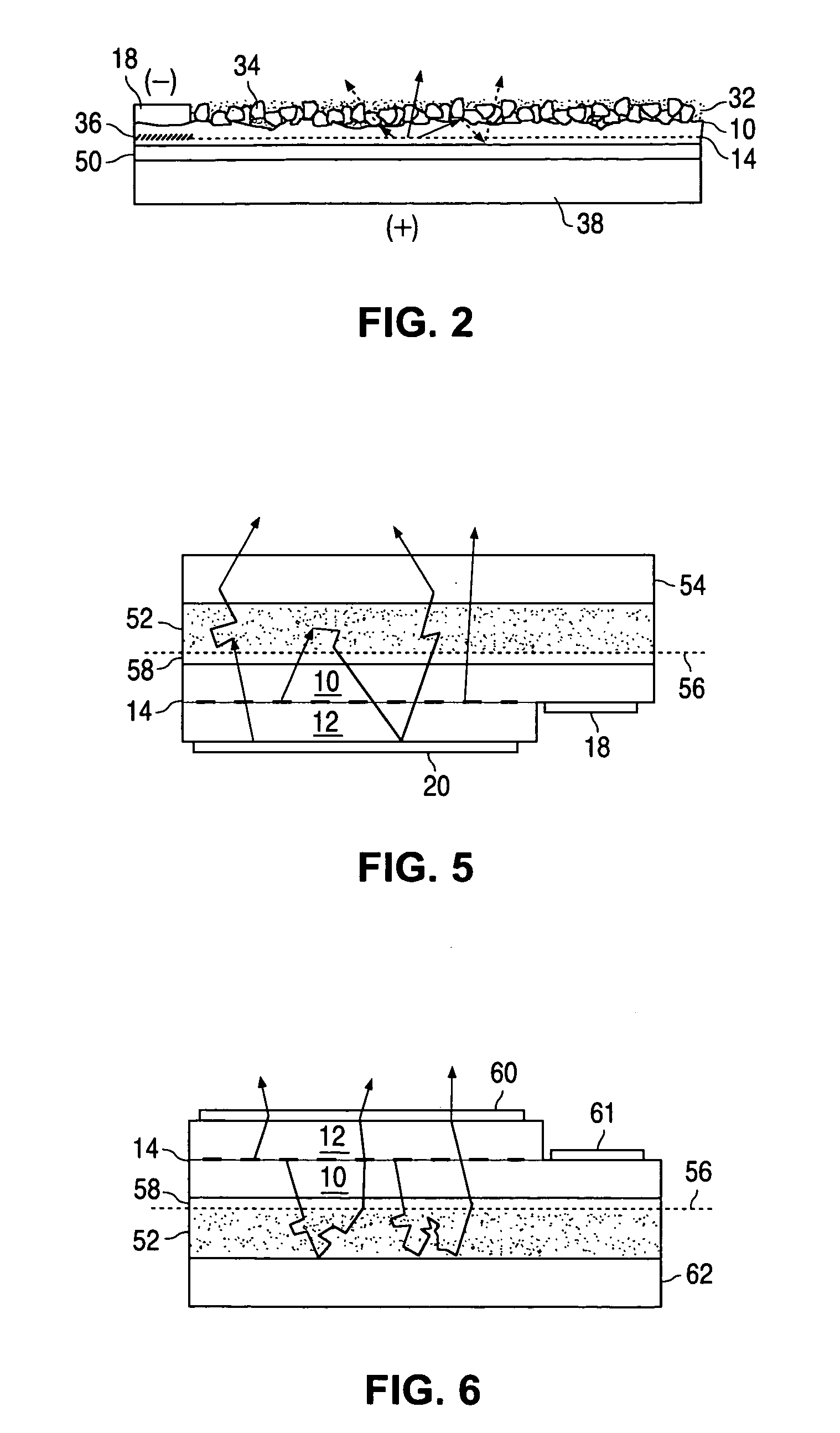

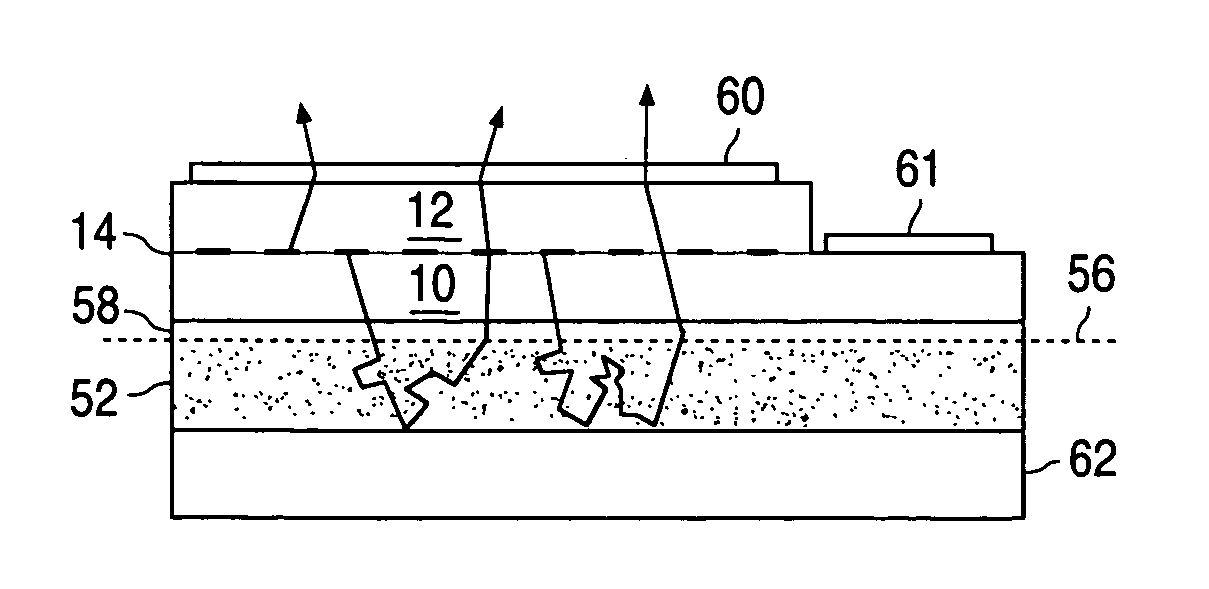

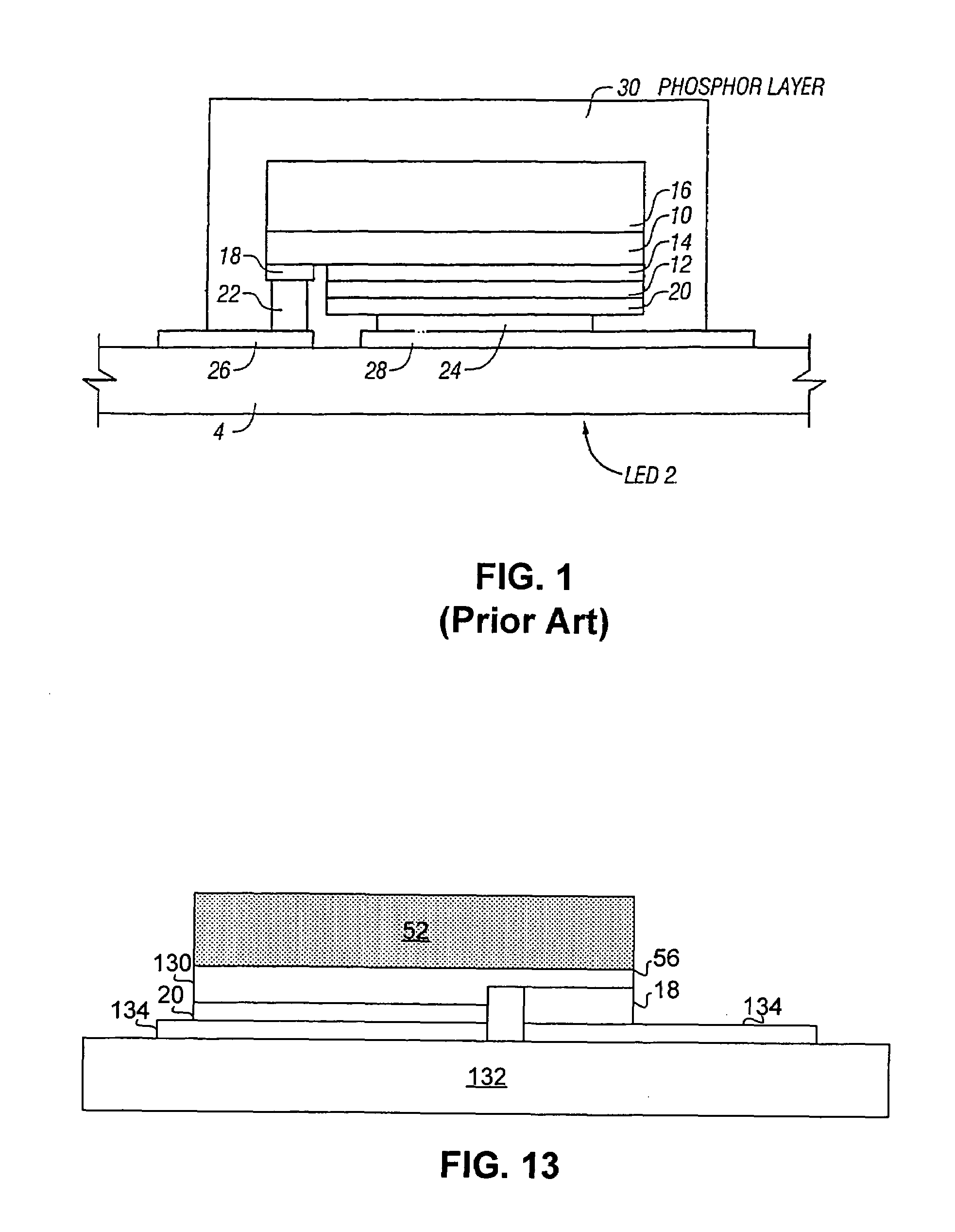

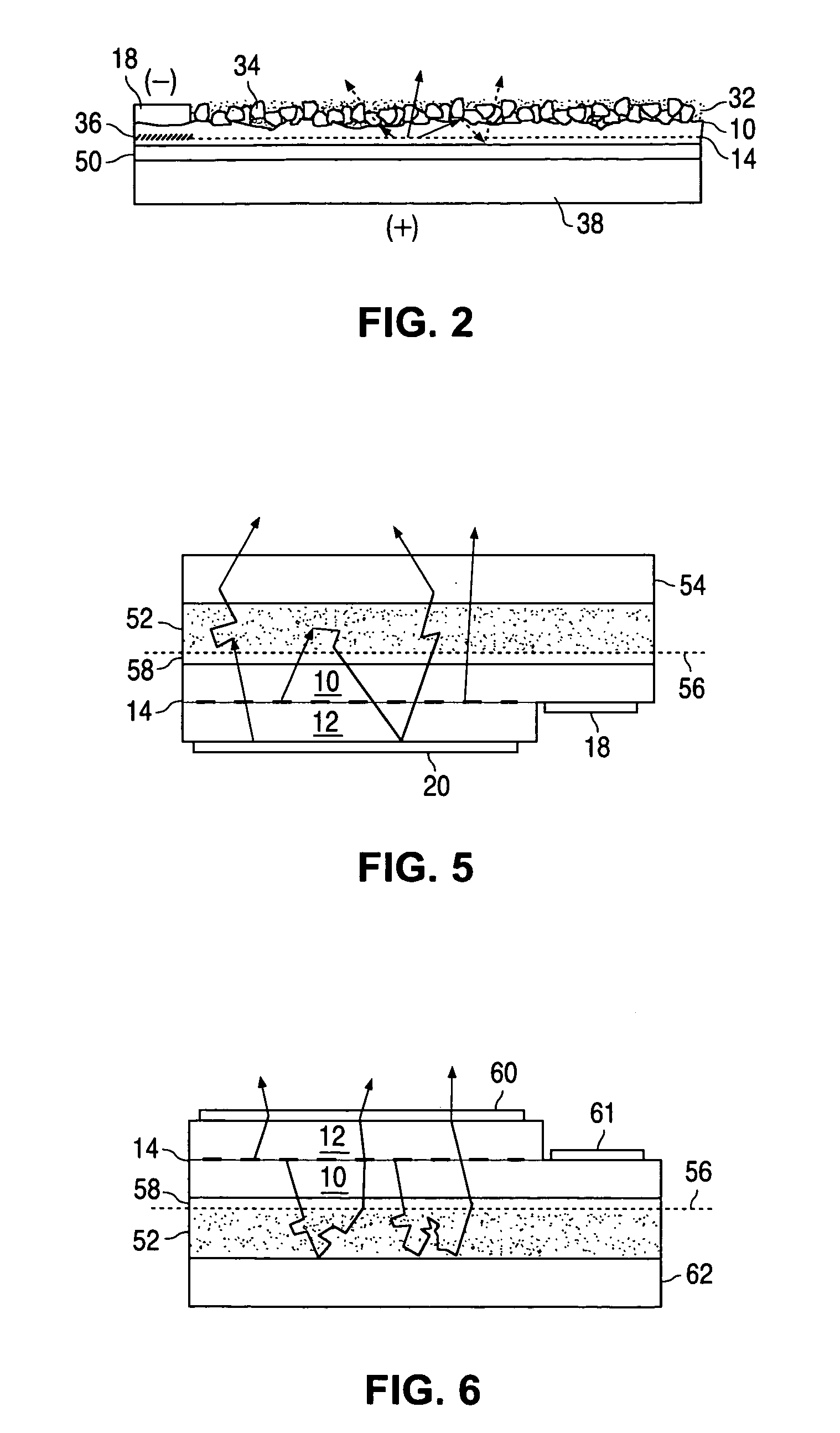

Wavelength-converted semiconductor light emitting device

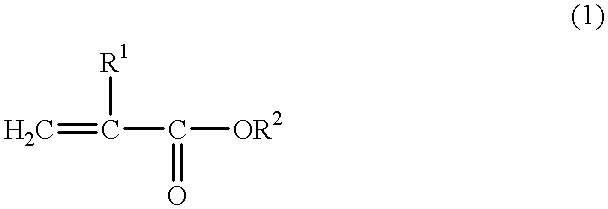

ActiveUS20060202105A1Effective lightingStrong water absorptionMaterial nanotechnologySolid-state devicesPhosphorSemiconductor structure

A material such as a phosphor is optically coupled to a semiconductor structure including a light emitting region disposed between an n-type region and a p-type region, in order to efficiently extract light from the light emitting region into the phosphor. The phosphor may be phosphor grains in direct contact with a surface of the semiconductor structure, or a ceramic phosphor bonded to the semiconductor structure, or to a thin nucleation structure on which the semiconductor structure may be grown. The phosphor is preferably highly absorbent and highly efficient. When the semiconductor structure emits light into such a highly efficient, highly absorbent phosphor, the phosphor may efficiently extract light from the structure, reducing the optical losses present in prior art devices.

Owner:LUMILEDS

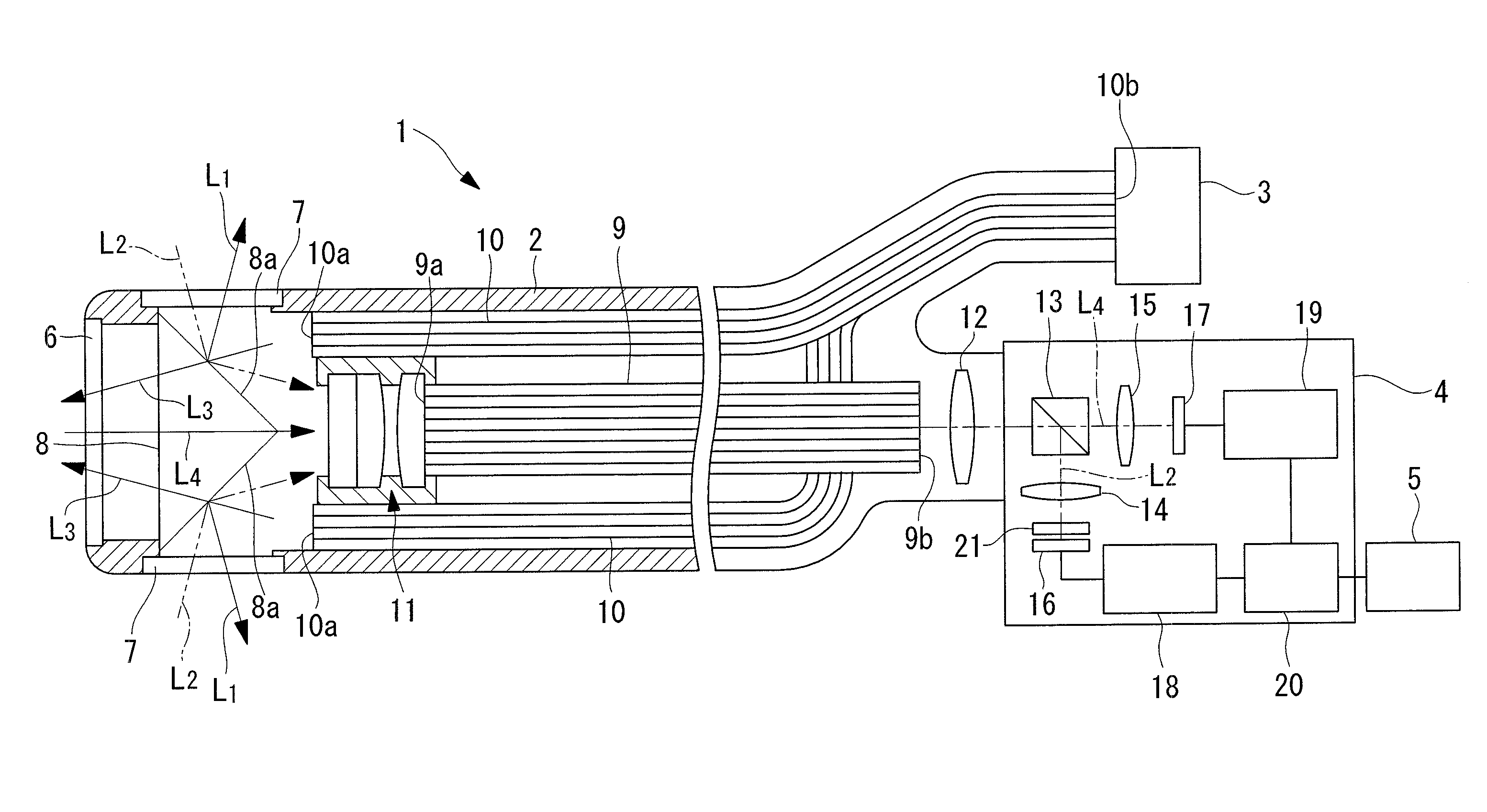

Endoscope apparatus

ActiveUS20100053312A1Reduce the overall diameterSimple structureSurgeryEndoscopesLength waveTransmitted light

The distal end of an inserted portion, having a simple structure, is reduced in diameter, loss of light incident from a body cavity is reduced, and light from two different directions is observed simultaneously and in a separated fashion. Provided is an endoscope apparatus (1) including an inserted portion (2) to be inserted inside a body cavity; a first dichroic mirror (8), disposed in a distal end portion of the inserted portion (2), that transmits light (L4) in a first wavelength band, which is incident from a longitudinal axial direction and that deflects light (L2) in a second wavelength band, which is incident from a radial direction, in the longitudinal axial direction, thereby multiplexing it with the light (L4) in the first wavelength band; a second dichroic mirror (13) that splits the light (L2, L4) multiplexed by the first dichroic mirror (8) into each wavelength band; and two image-acquisition units (16, 17) that respectively acquire the light (L2, L4) in the first and second wavelength bands split by the second dichroic mirror (13).

Owner:OLYMPUS CORP

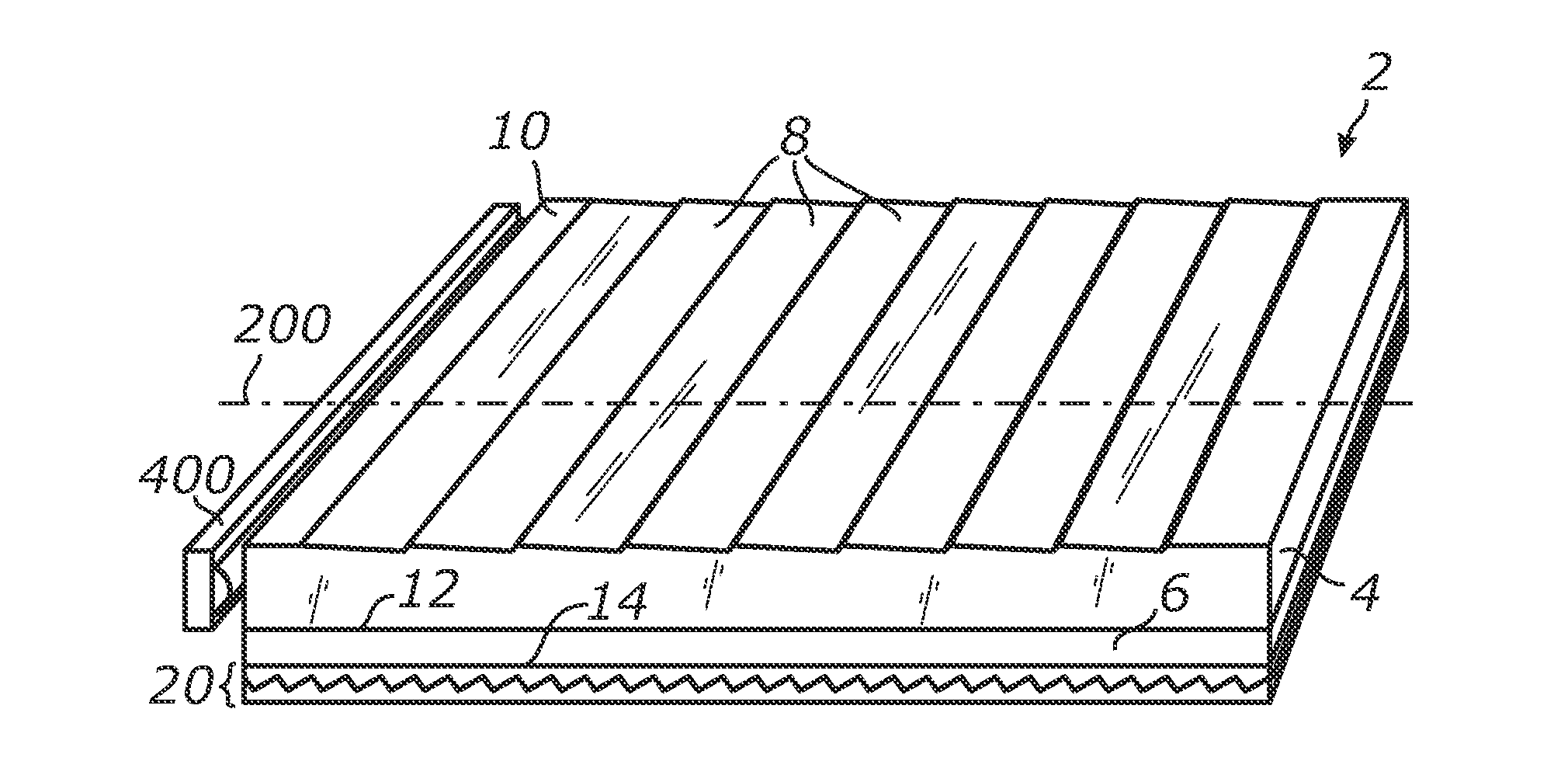

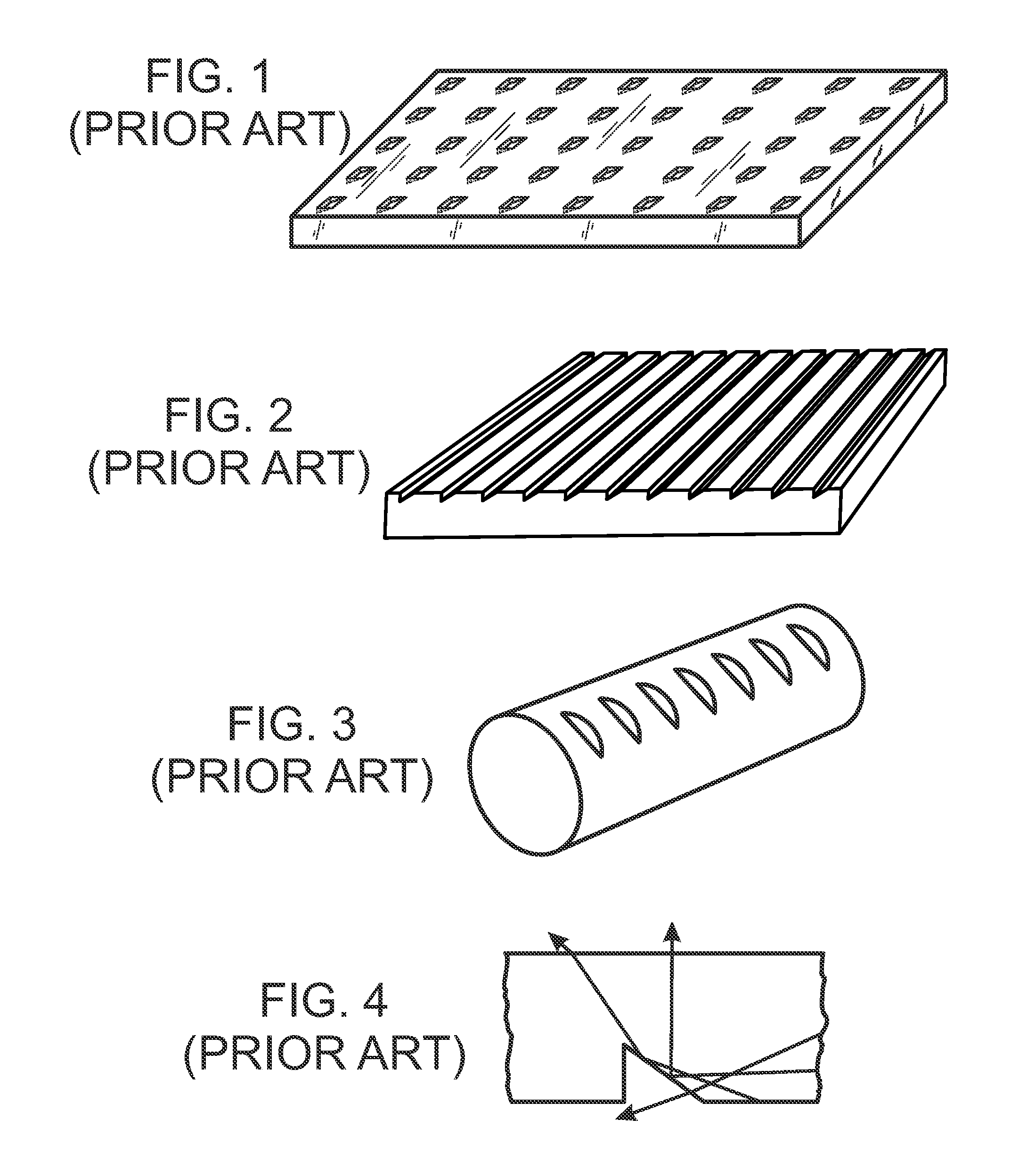

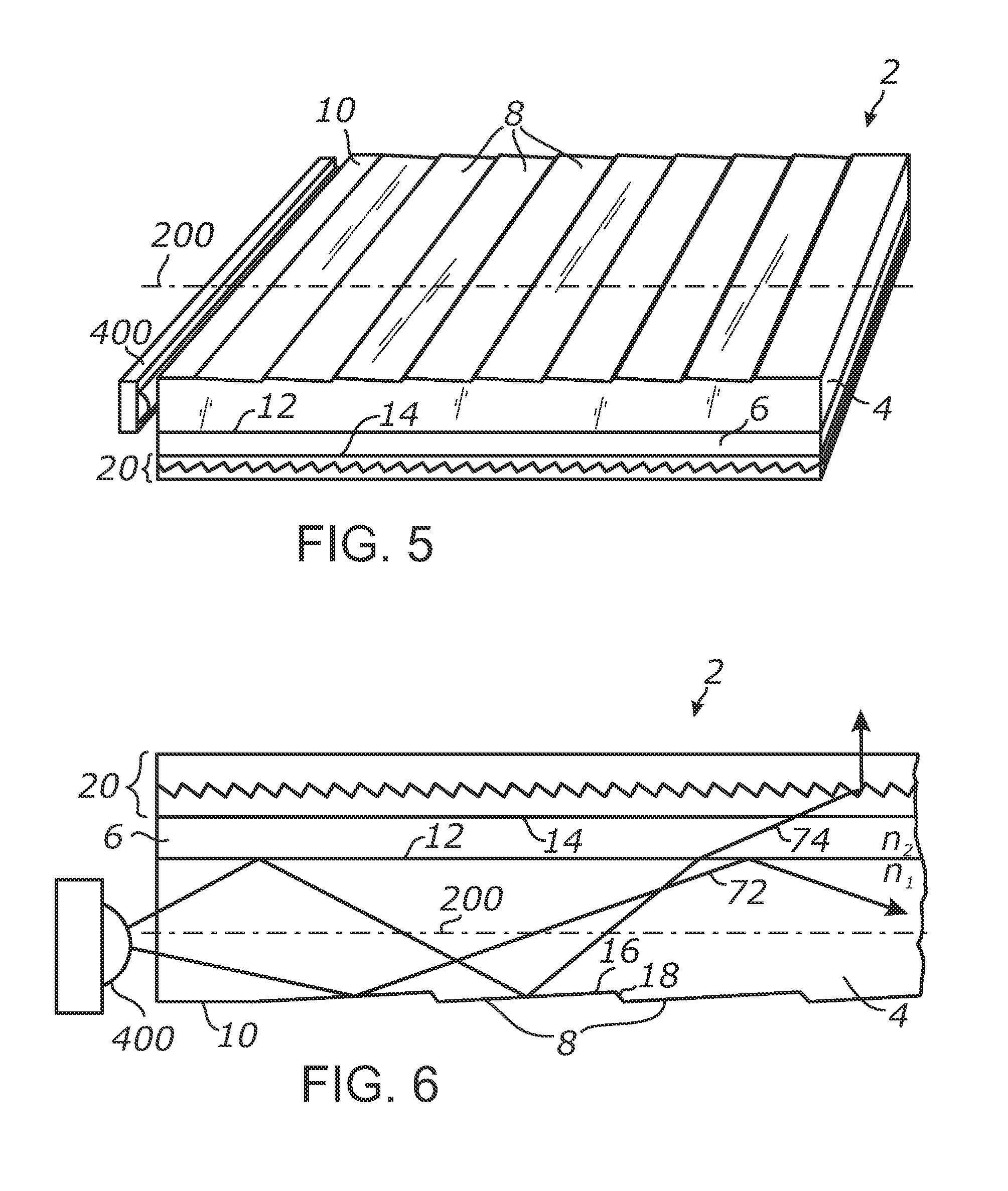

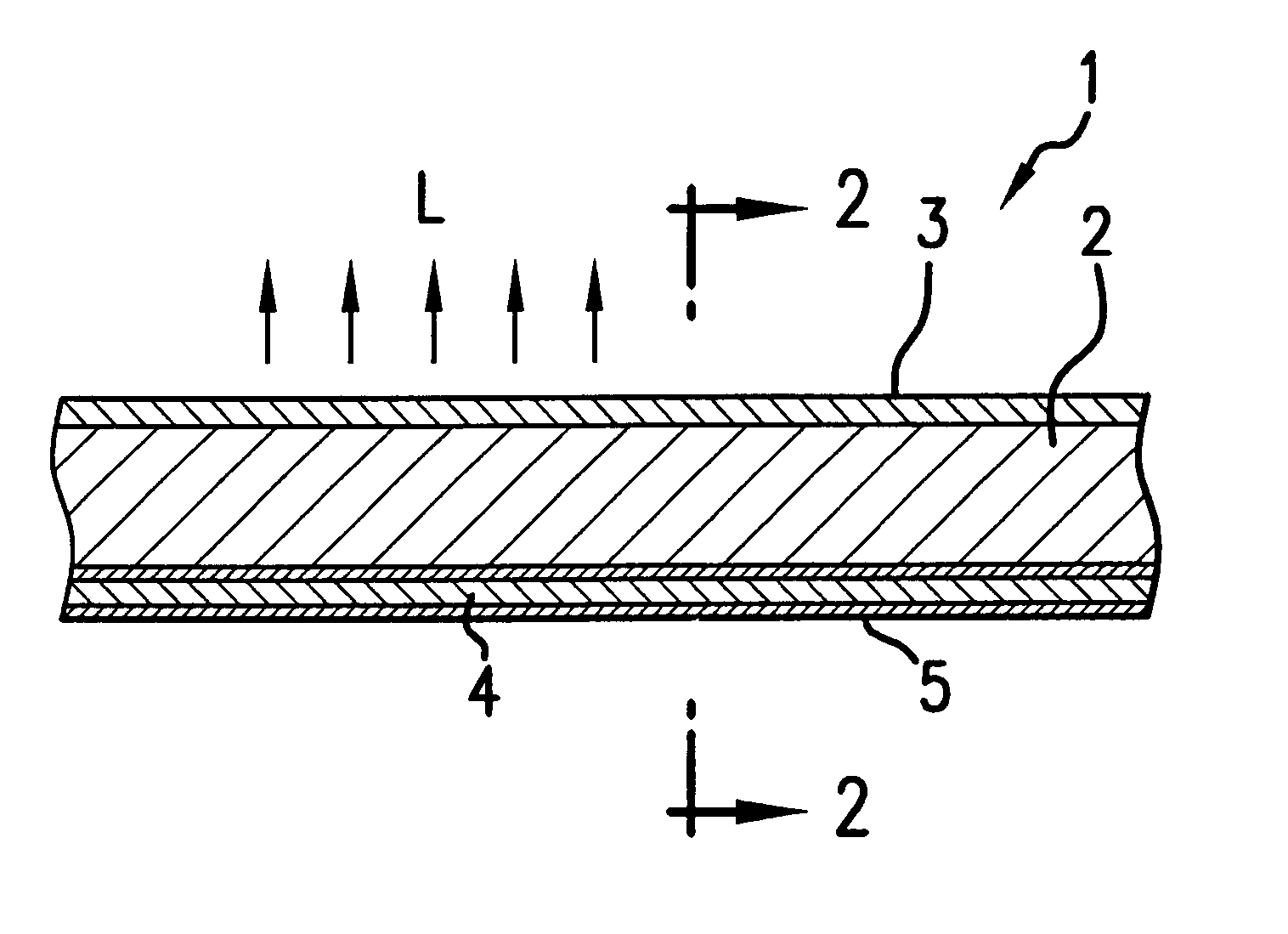

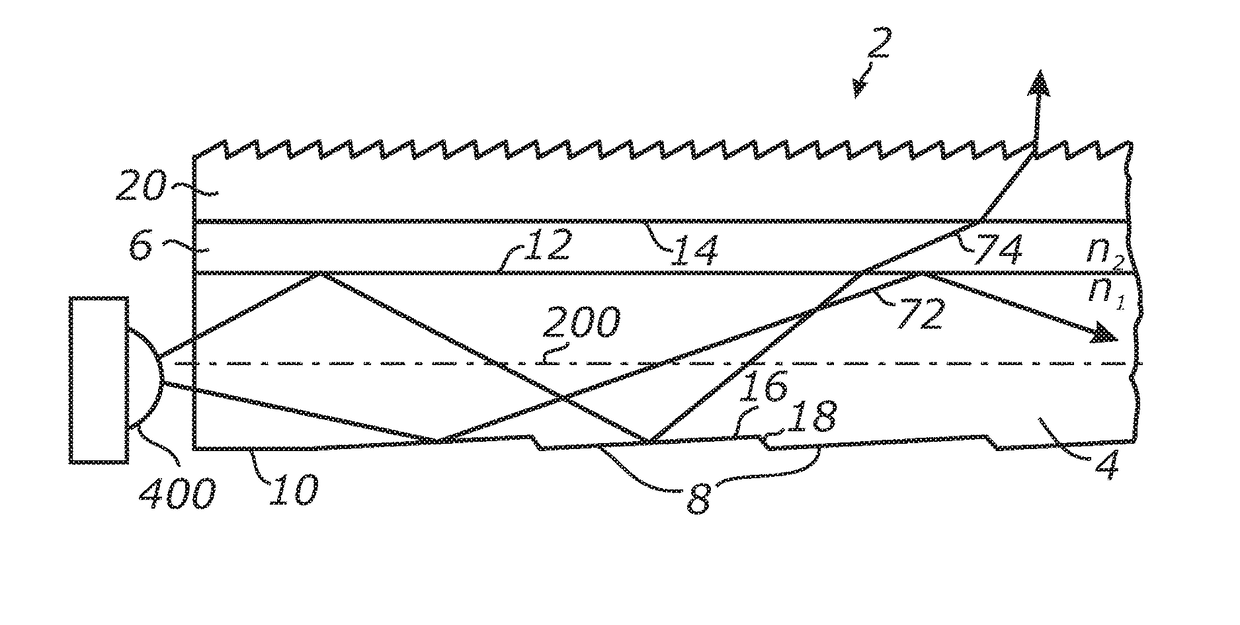

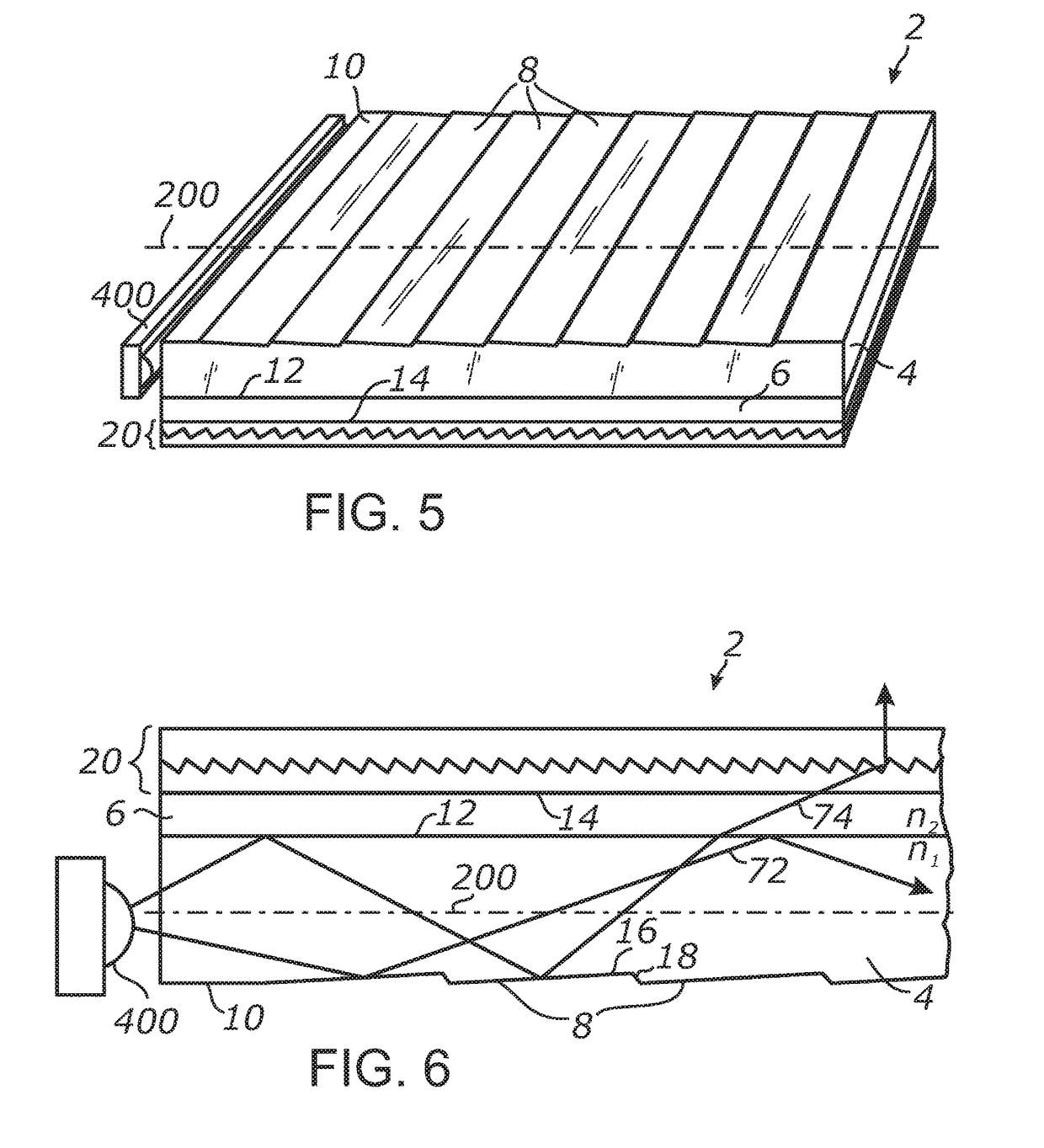

Waveguide illumination system

InactiveUS20140140091A1Reduce light lossMinimizes lightMechanical apparatusElectric lightingForward scatterTotal internal reflection

An illumination system employing a waveguide. Light received from an edge or an end of a waveguide is propagated in response to transmission and total internal reflection. Light deflecting elements distributed along the propagation path of light continuously change the out-of-plane propagation angle of light rays and cause decoupling of portions of the propagated light from the core of the waveguide at different distances from the light input edge or end. Light escapes from the waveguide into an intermediate layer at low out-of-plane angles and is further redirected by light extraction features out of the system. In one embodiment, the illumination system is configured to emit collimated light. In one embodiment, the illumination system includes shallow surface relief features. In one embodiment, the light deflecting elements include forward-scattering particles distributed throughout the volume of the waveguide. Additional collimating and non-collimating illumination units and methods are also disclosed.

Owner:VASYLYEV SERGIY VICTOROVICH

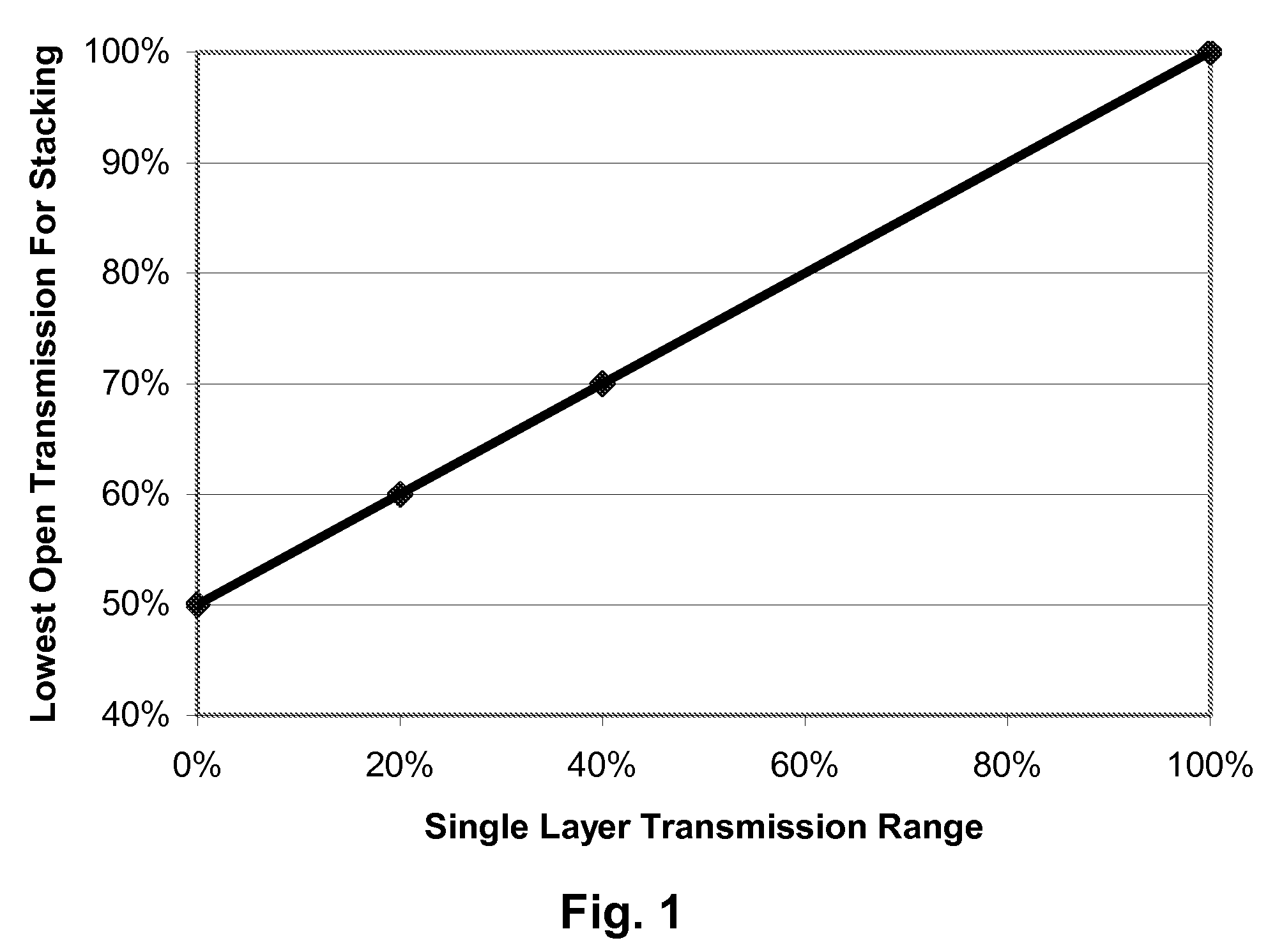

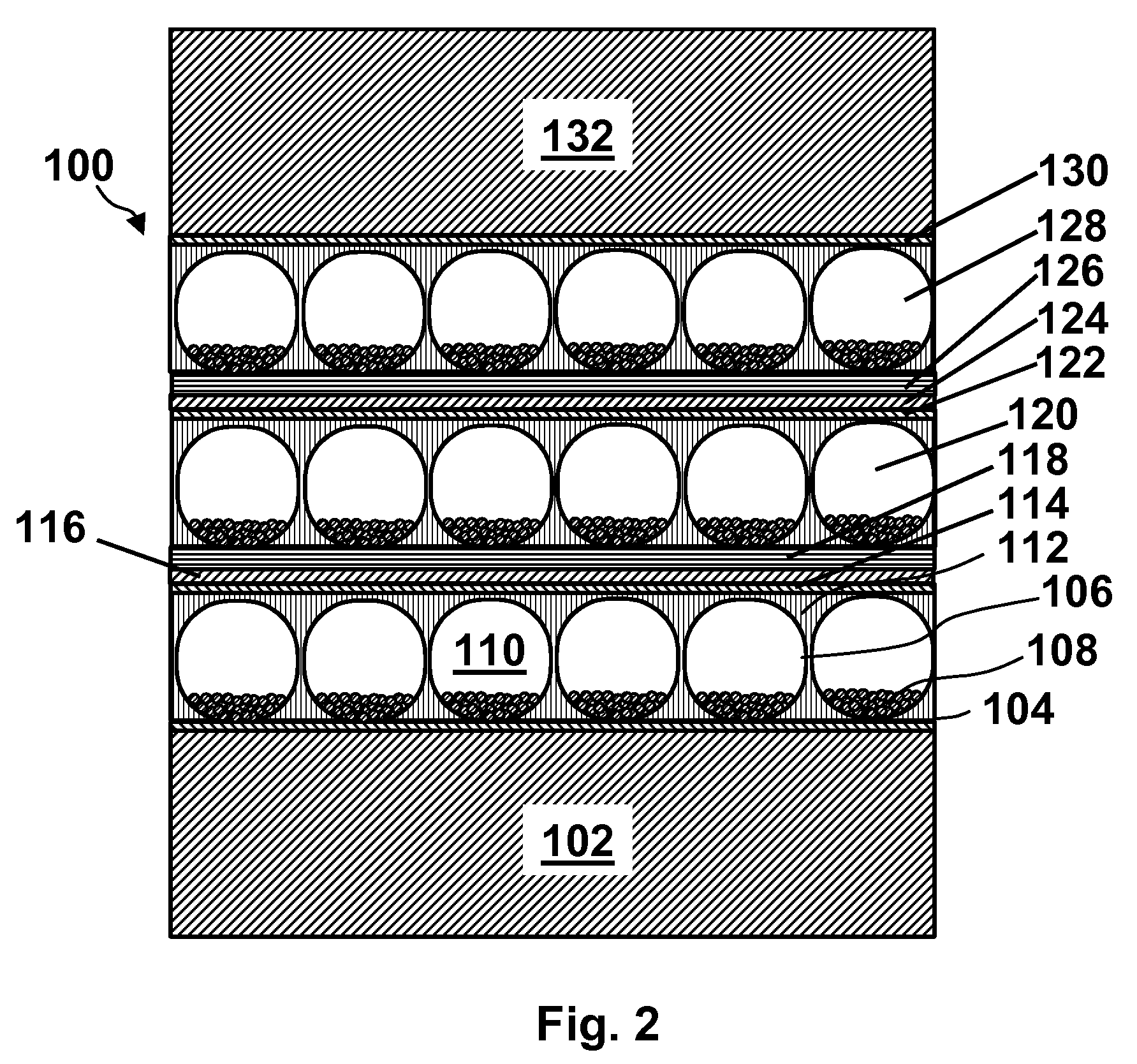

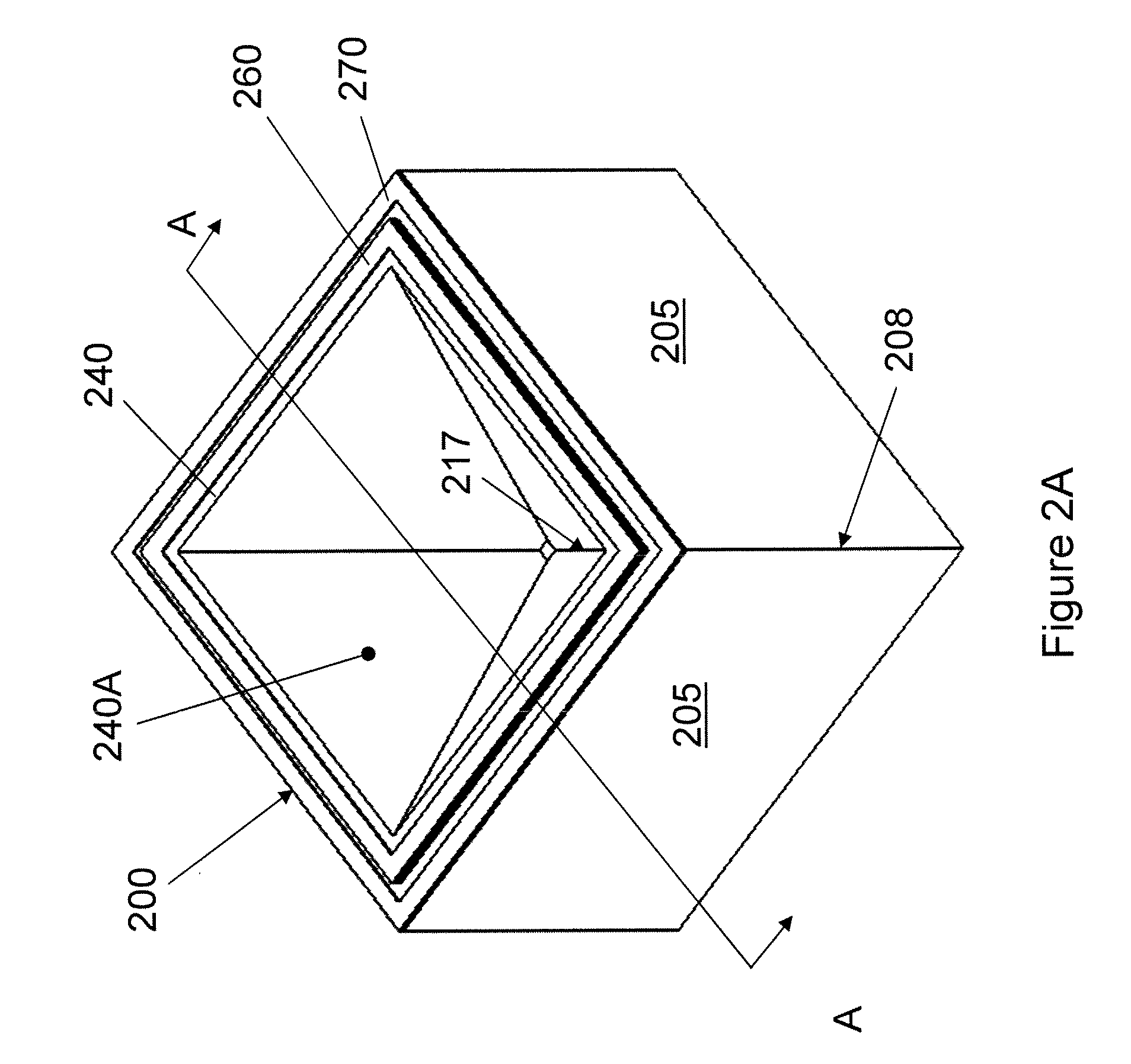

Multi-layer light modulator

ActiveUS7492497B2Reduce light lossRecording apparatusStatic indicating devicesOptic layerHigh transmission

A light modulator comprises a plurality of discrete variable transmission electro-optic layers arranged so that light will pass successively through the plurality of layers; the light modulator has a higher transmission range than any of the individual electro-optic layers separately.

Owner:E INK CORPORATION

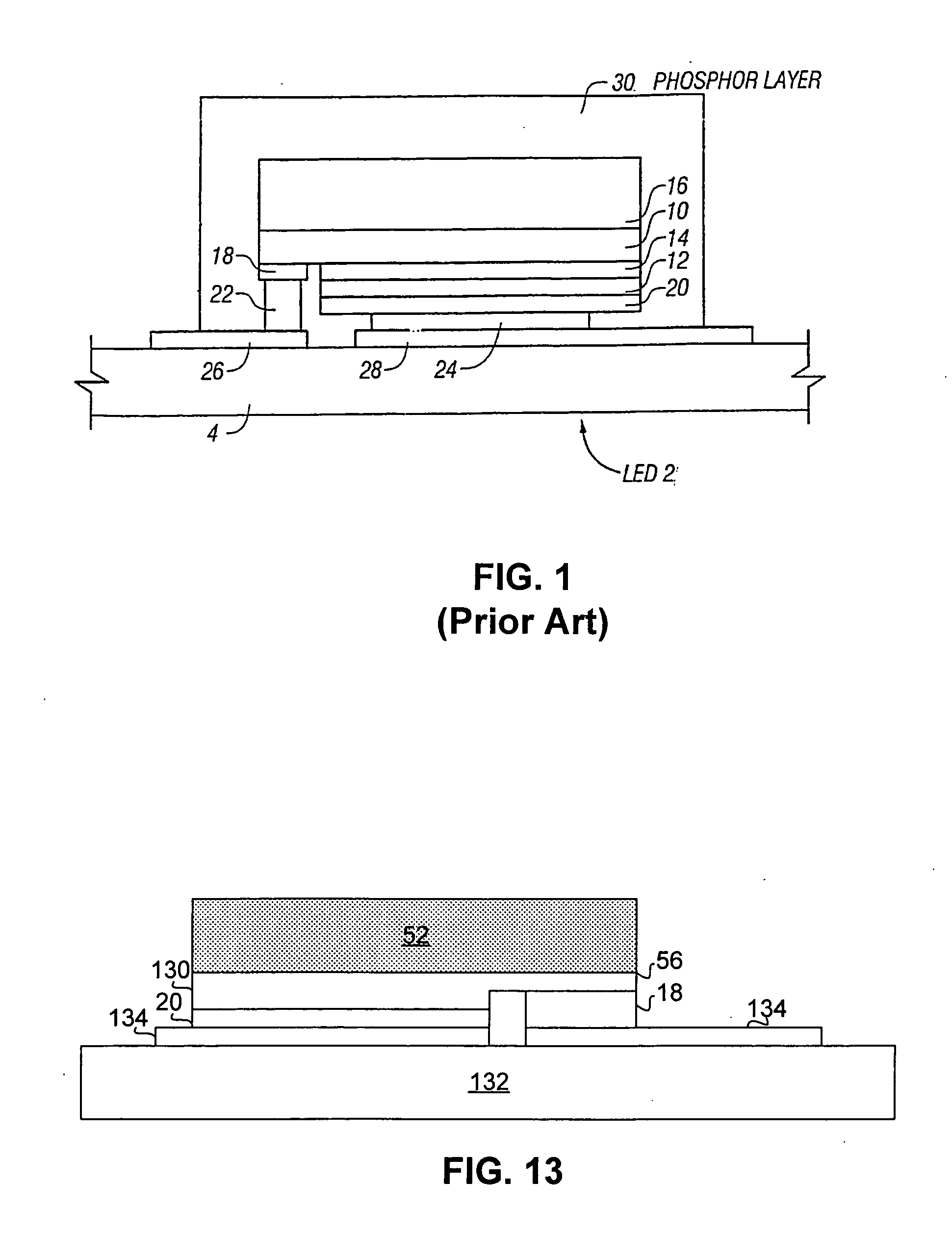

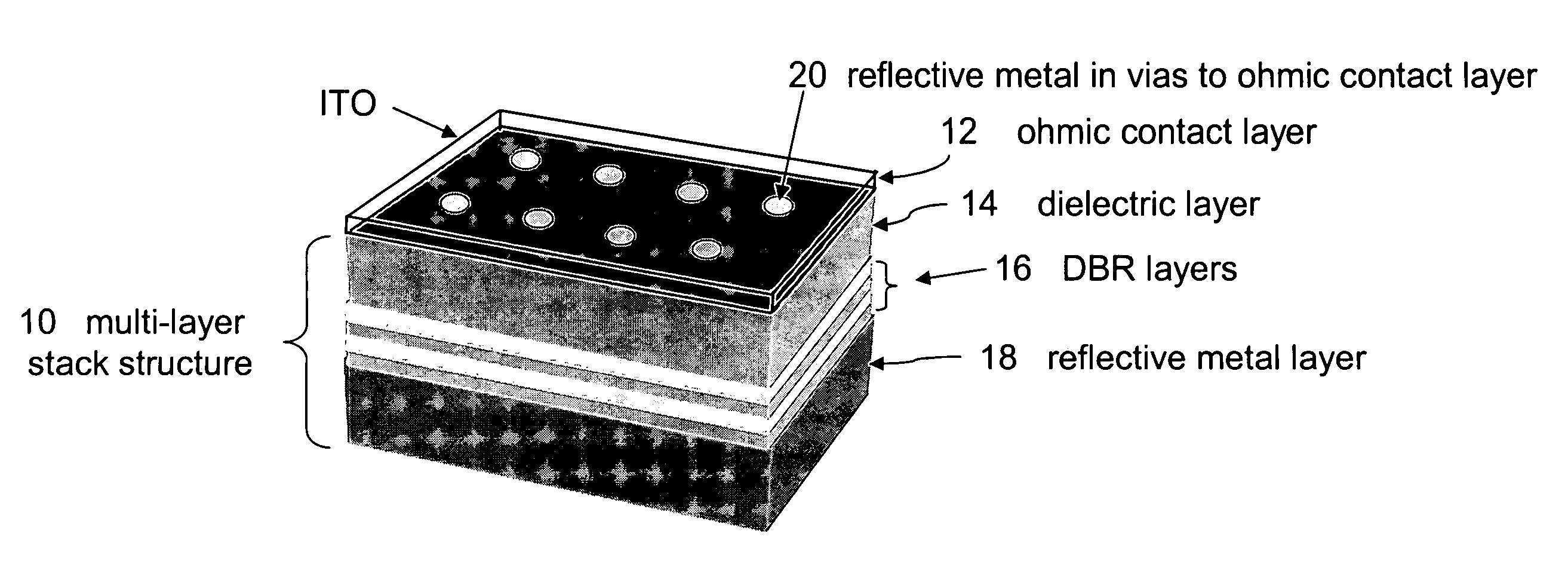

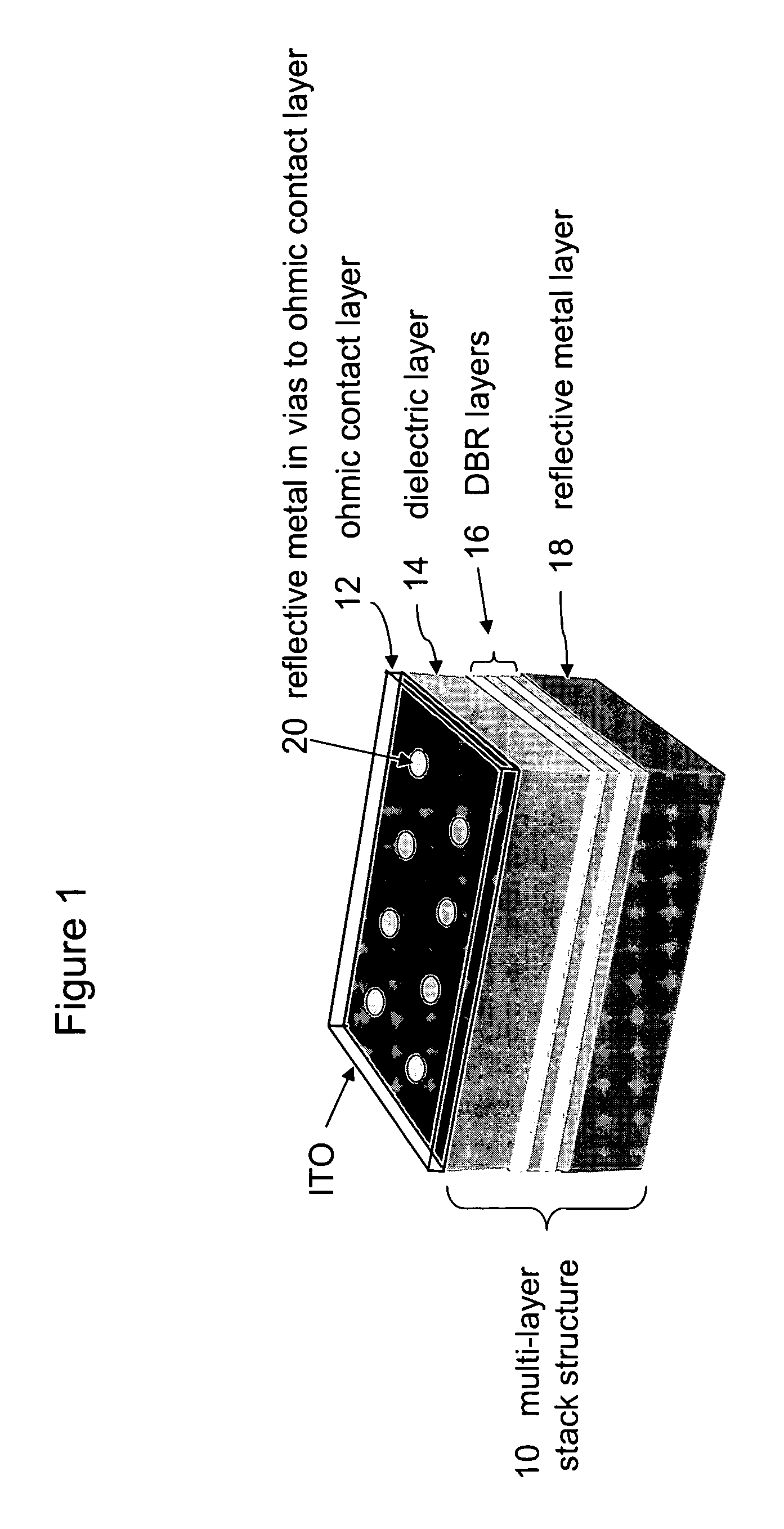

Highly reflective mounting arrangement for LEDs

InactiveUS7622746B1Improves overall device light emissionLow possible additional manufacturing costSemiconductor devicesElectrical resistance and conductanceSemiconductor materials

A semiconductor device emitting light about a predetermined wavelength comprising a structure comprising a plurality of layers, sometimes referred to as a stack, providing low resistance, high reflectivity and ohmic contacts to at least one semiconductor material.

Owner:KK TOSHIBA

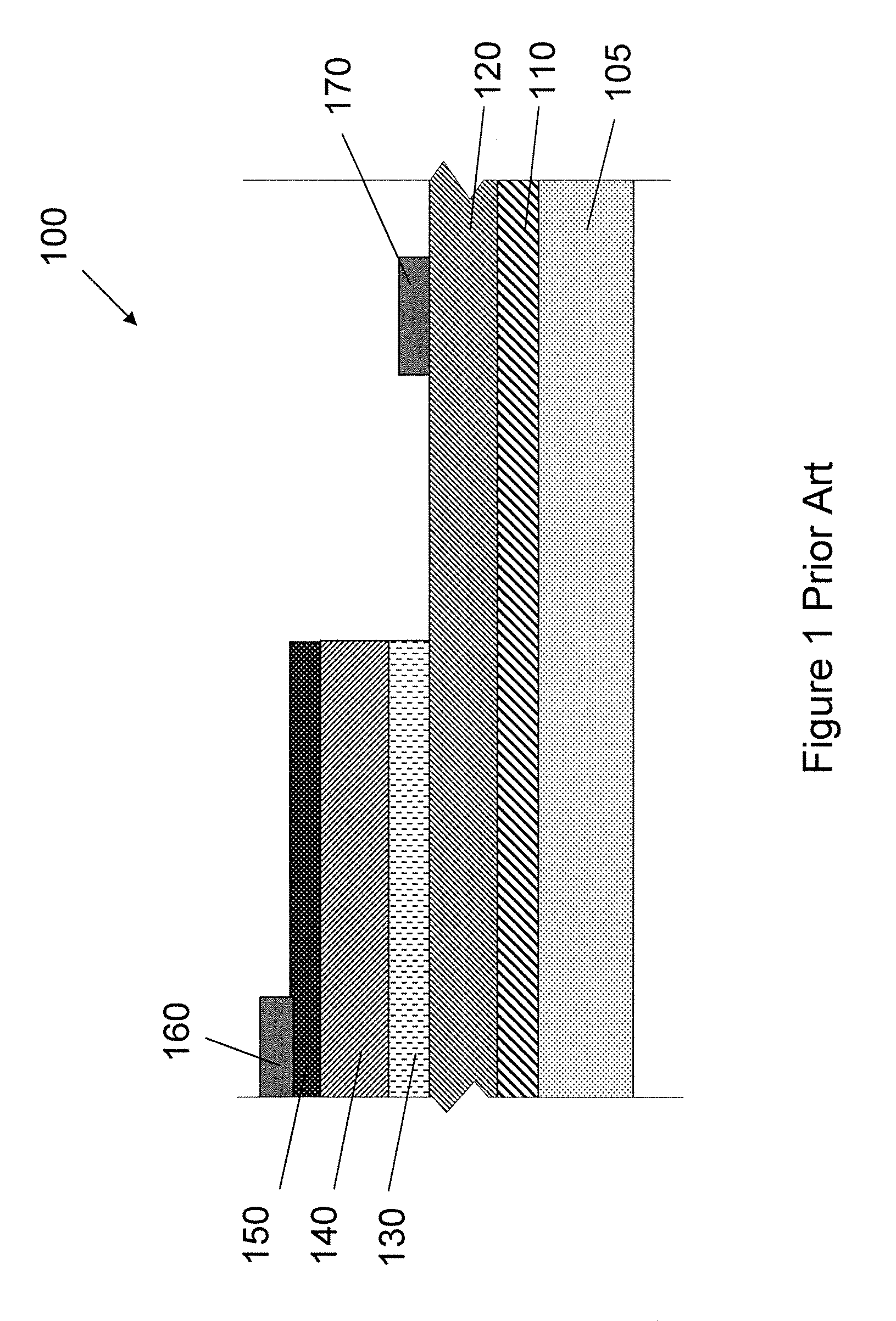

Vertical LED with conductive vias

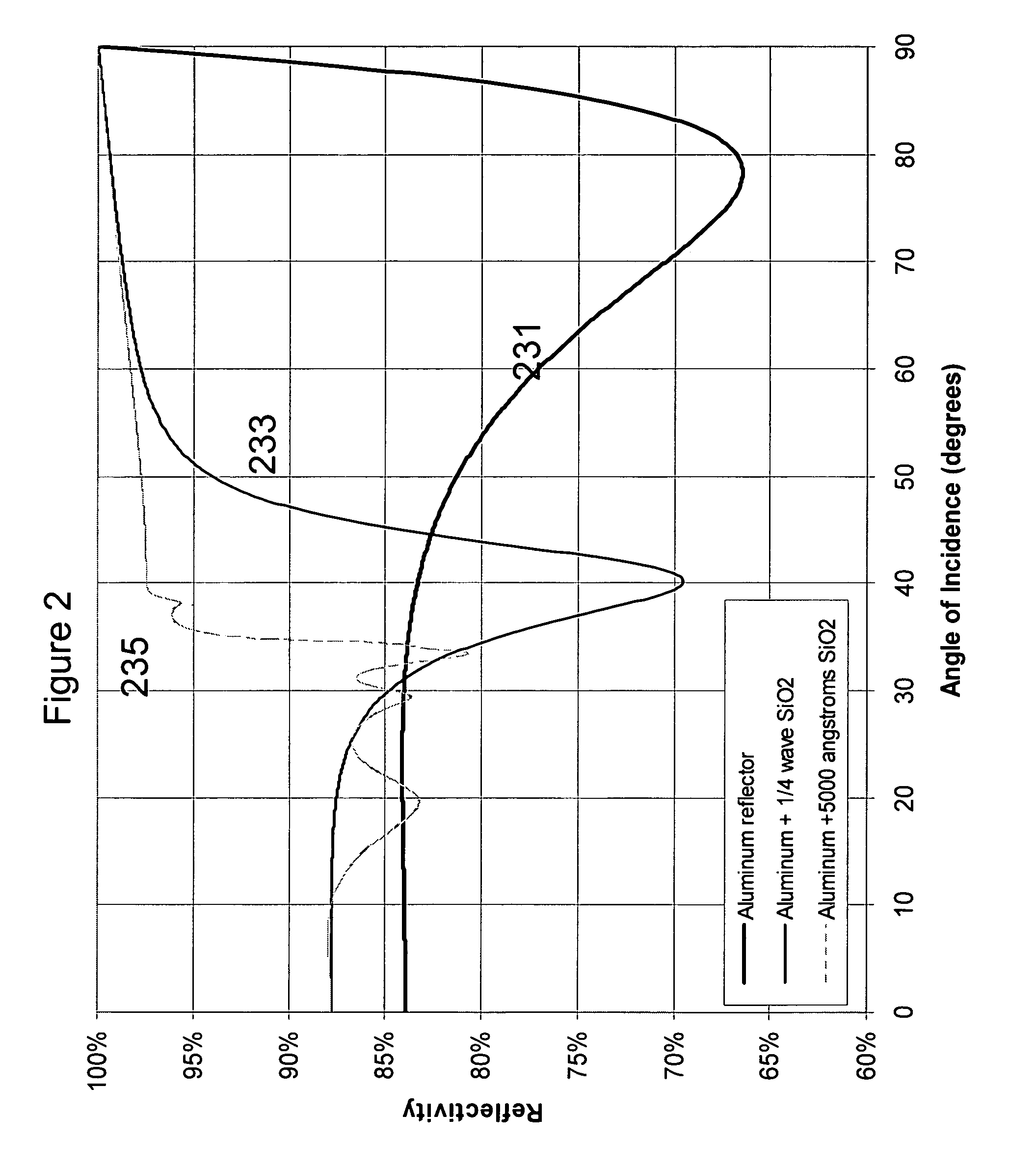

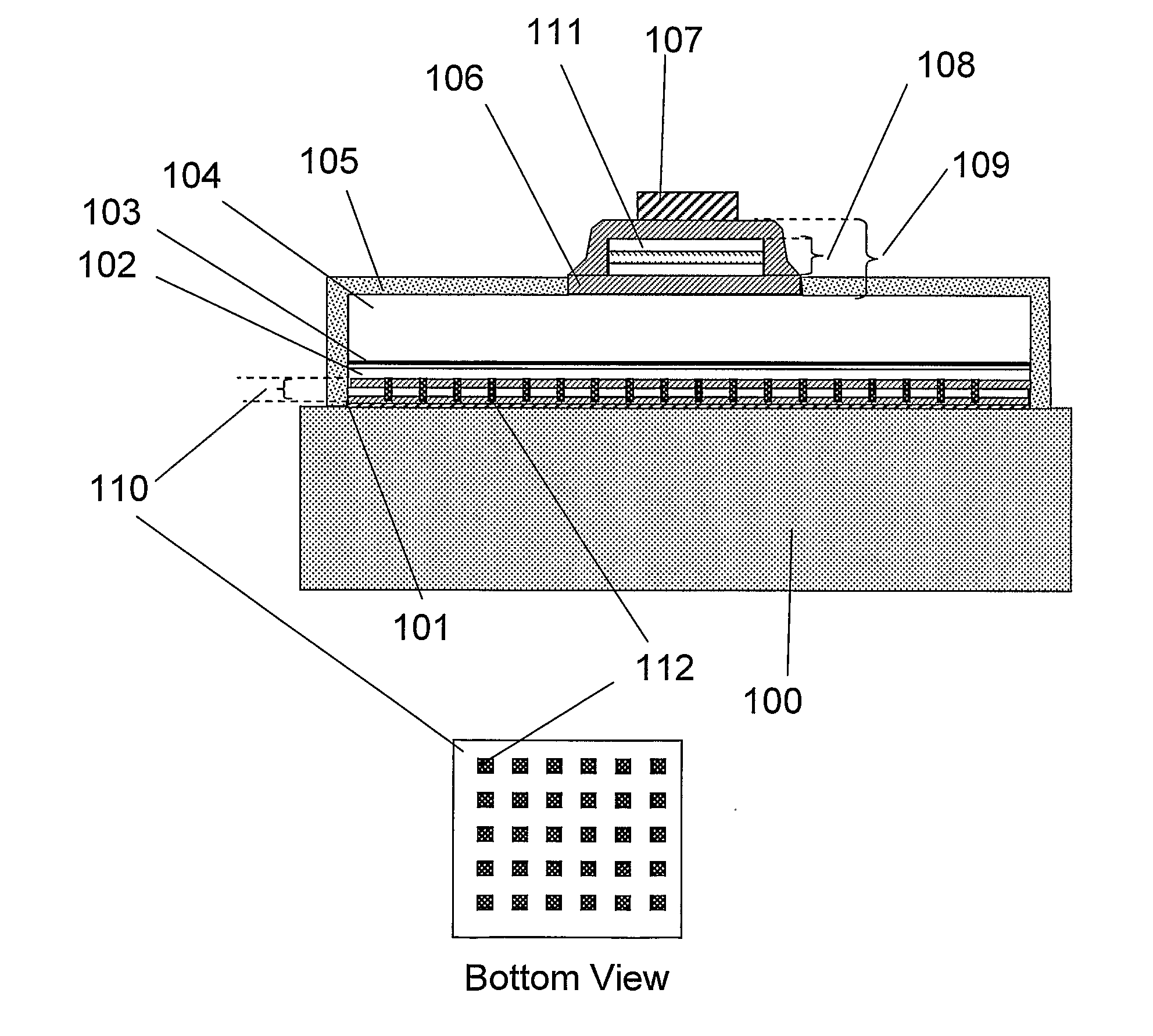

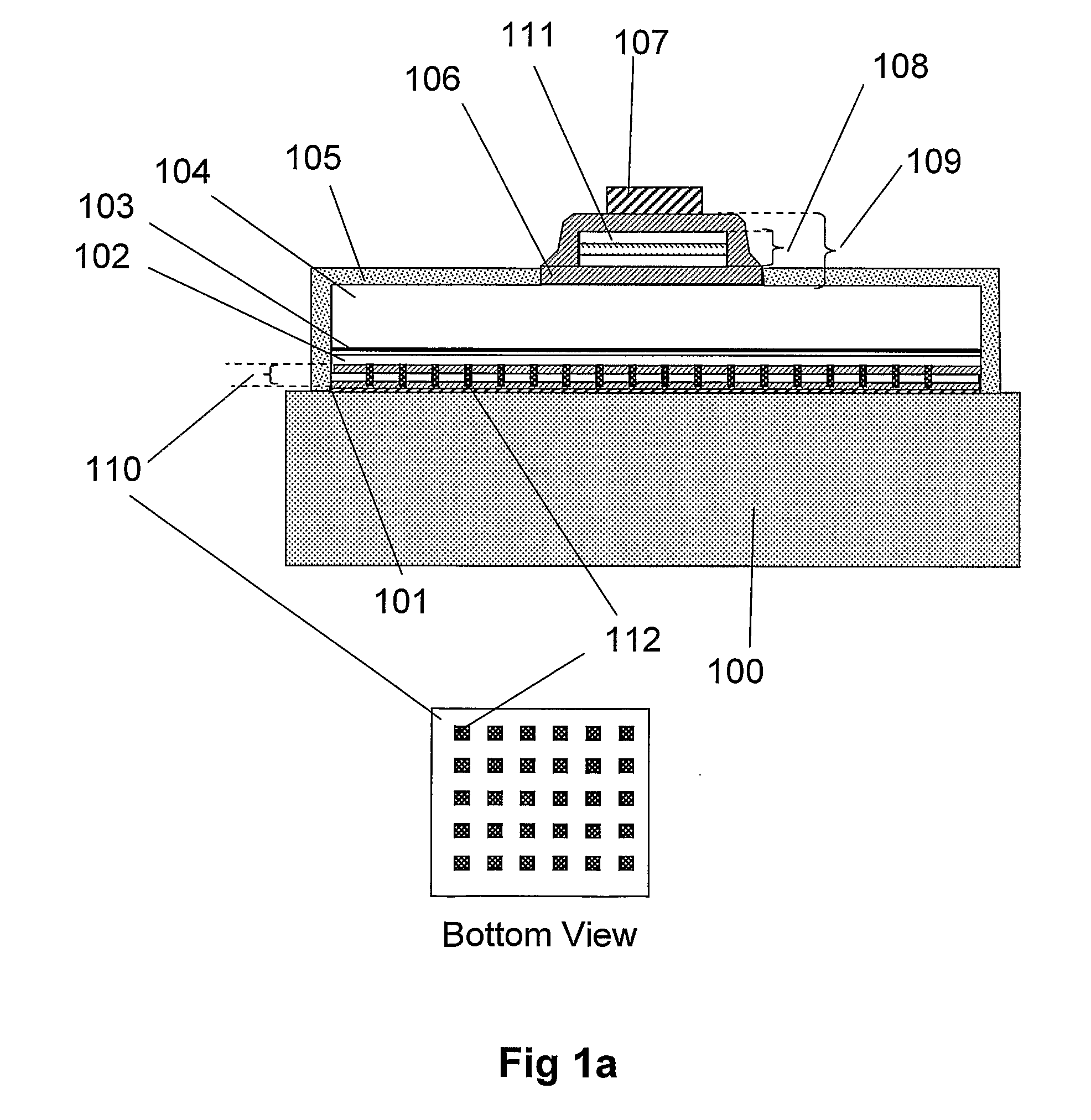

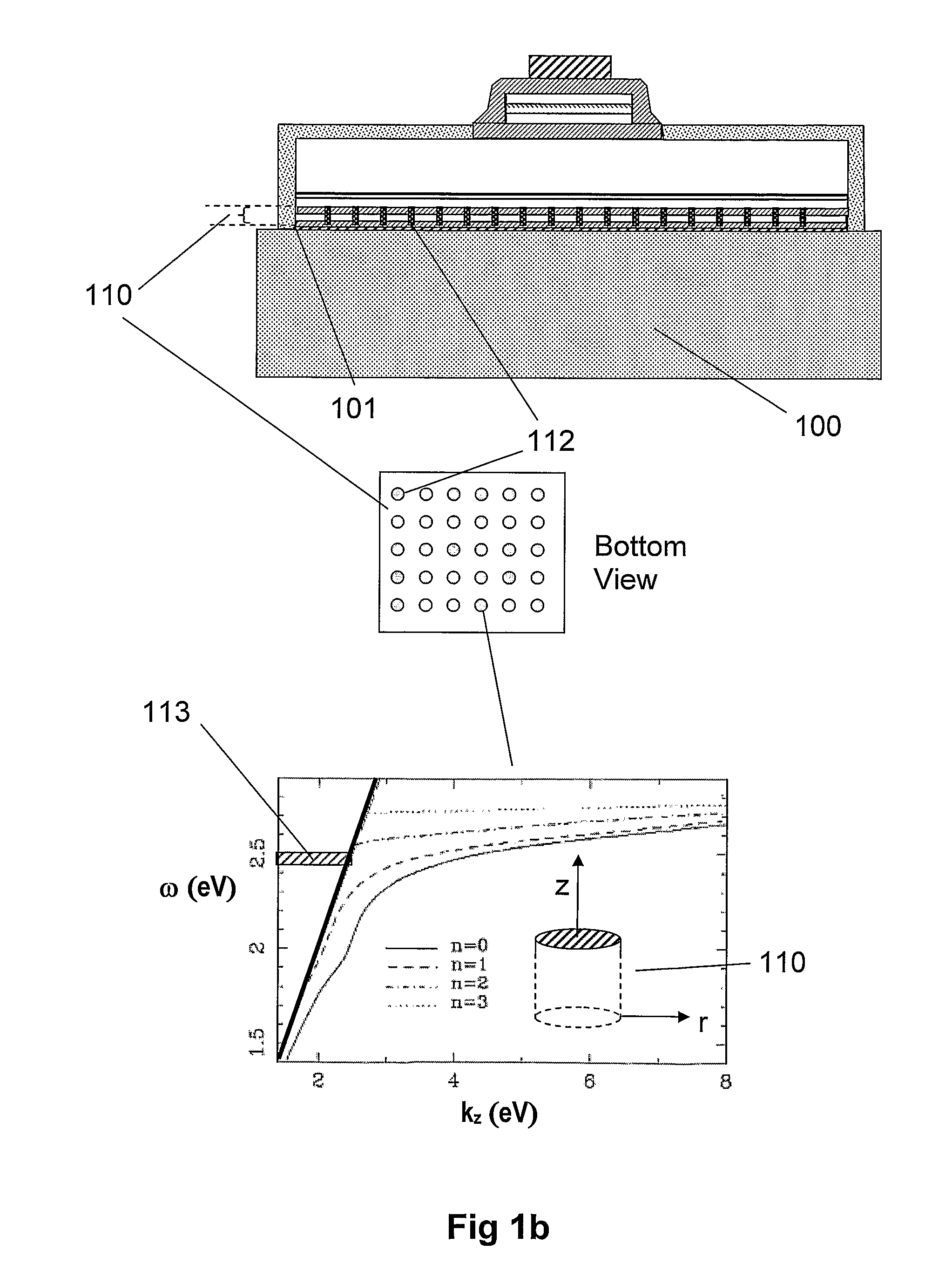

ActiveUS20100213485A1Maximizing light extractionLight extraction efficiency can be improvedSolid-state devicesSemiconductor/solid-state device manufacturingSurface plasmonHigh reflectivity

A light emitting device comprises a novel low-loss array of conductive vias embedded in a dielectric multilayer stack, to act as an electrically-conductive, low-loss, high-reflectivity reflector layer (CVMR). In one example the CVMR stack is employed between a reflective metal bottom contact and a p-GaN semiconductor flip chip layer. The CVMR stack comprises at least (3) layers with at least (2) differing dielectric constants. The conductive vias are arranged such that localised and propagating surface plasmons associated with the structure reside within the electromagnetic stopband of the CVMR stack, which in turn inhibits trapped LED modes coupling into these plasmonic modes, thereby increasing the overall reflectivity of the CVM R. This technique improves optical light extraction and provides a vertical conduction path for optimal current spreading in a semiconductor light emitting device. A light emitting module and method of manufacture are also described.

Owner:LUMILEDS HLDG BV

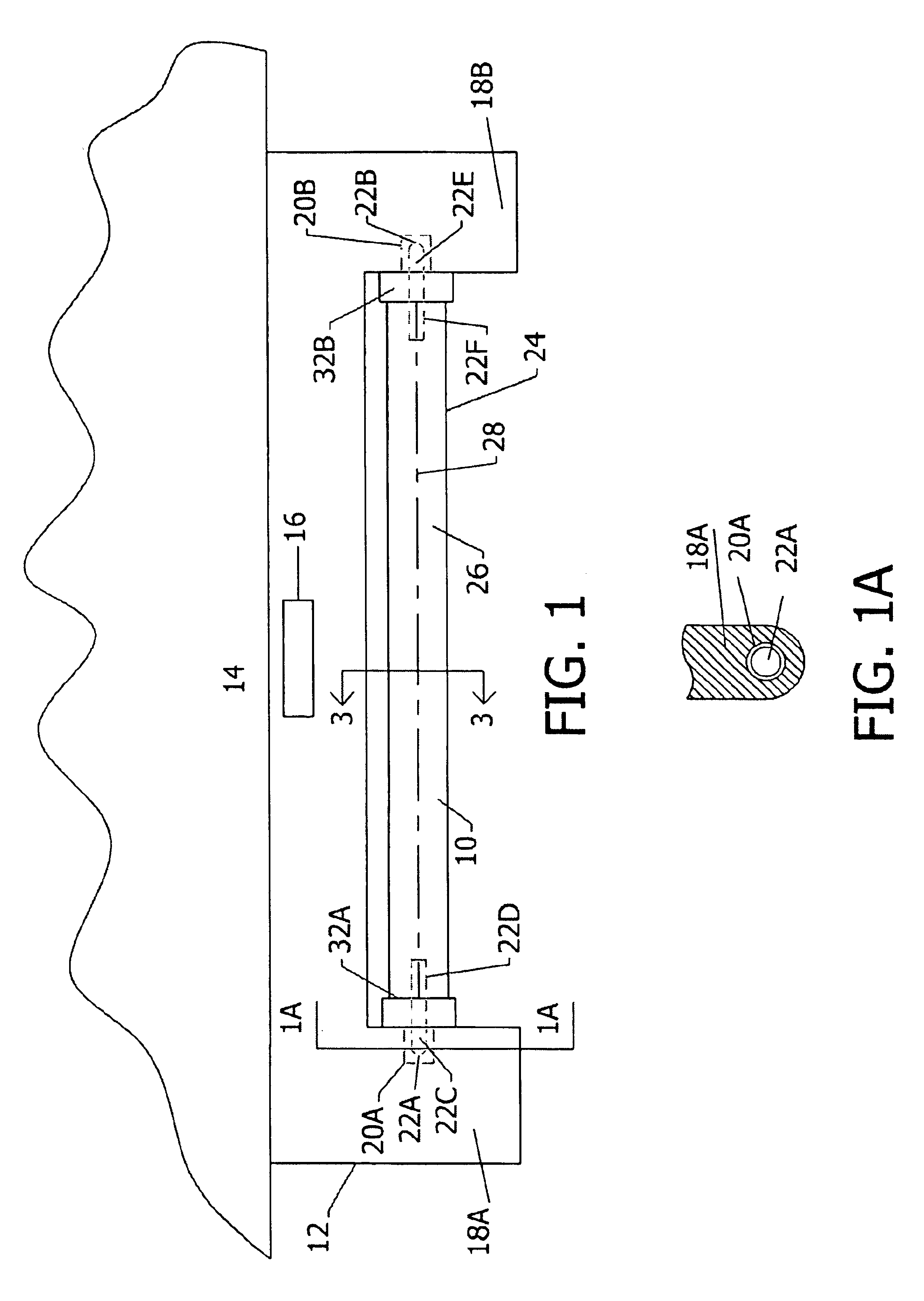

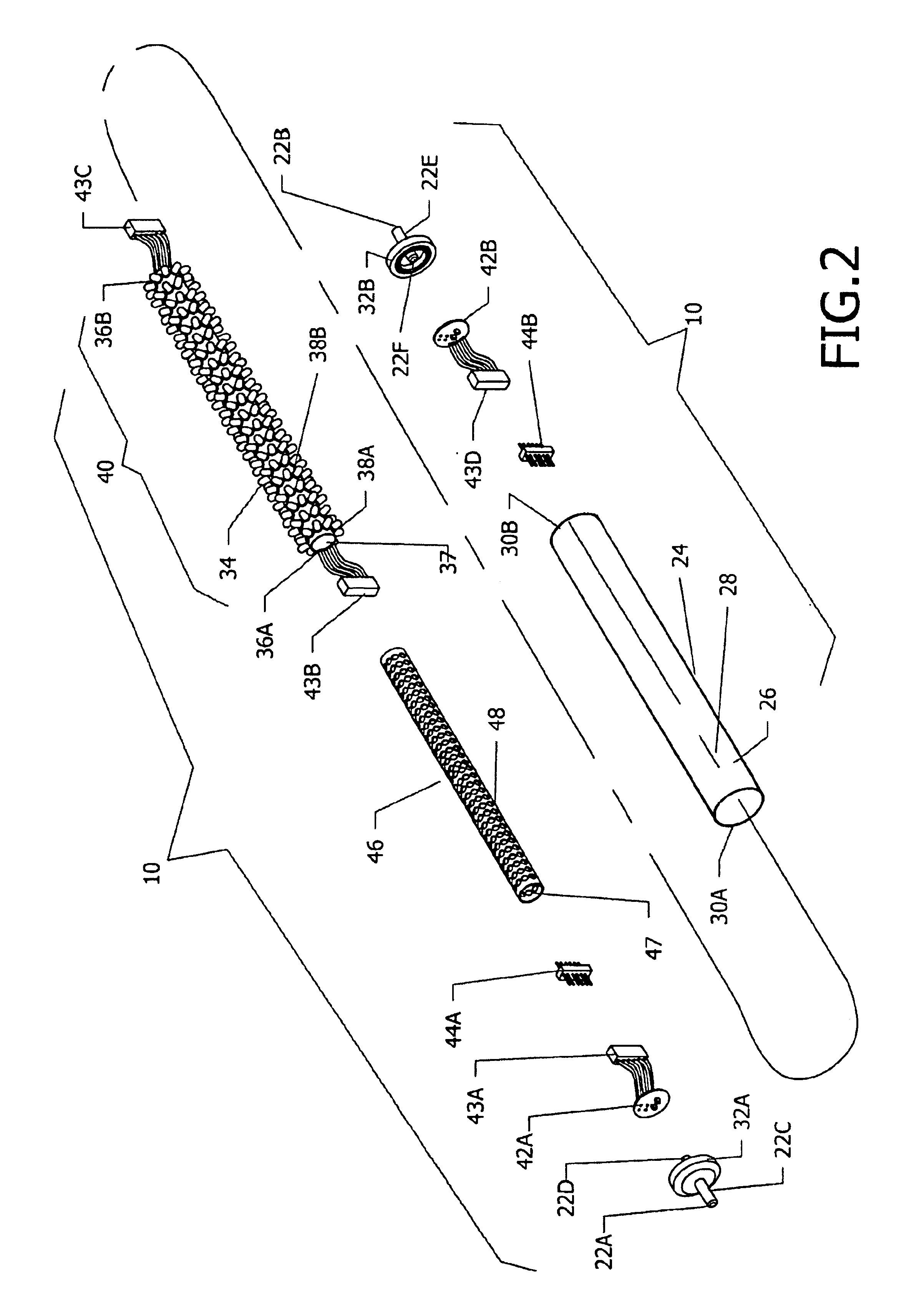

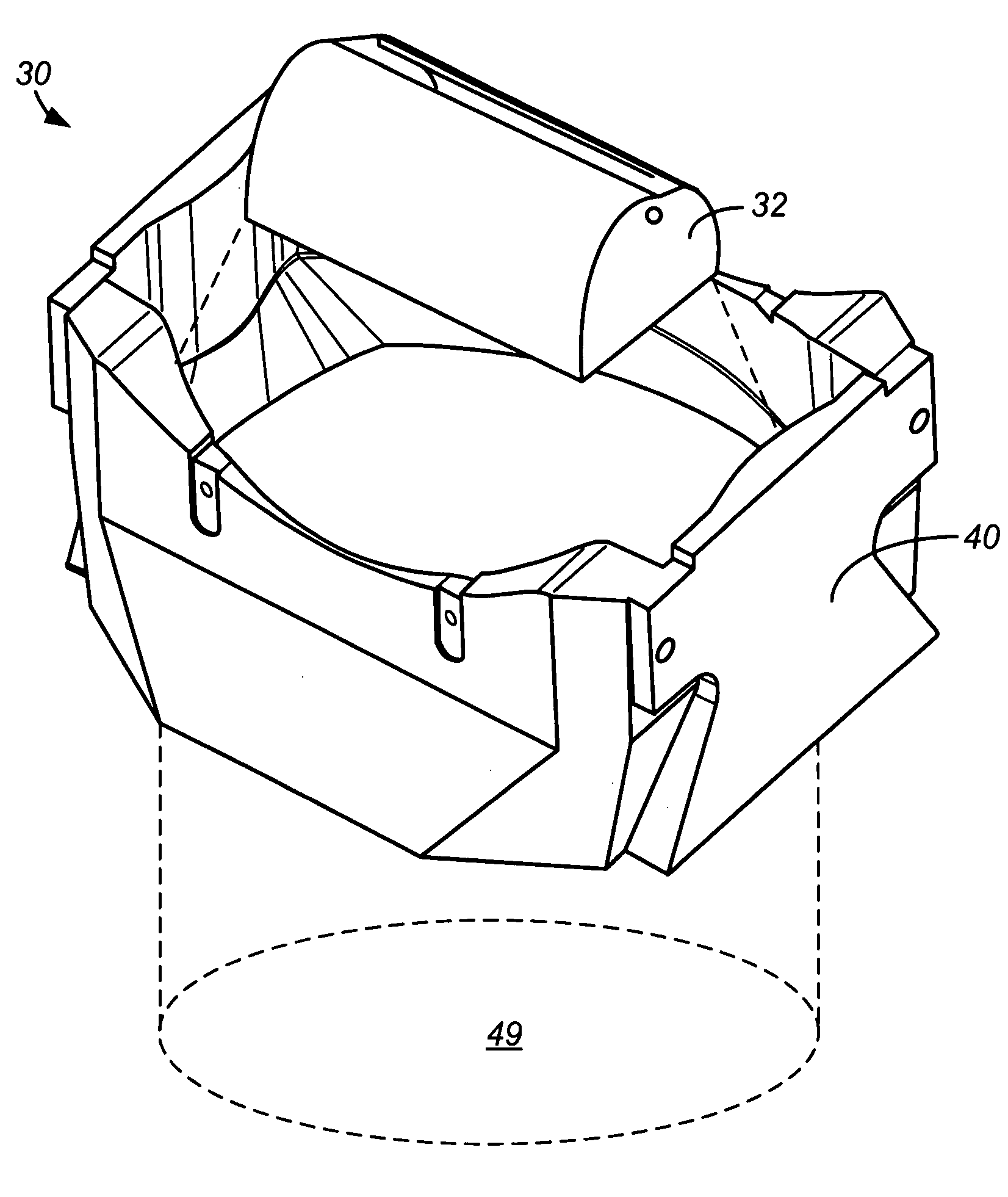

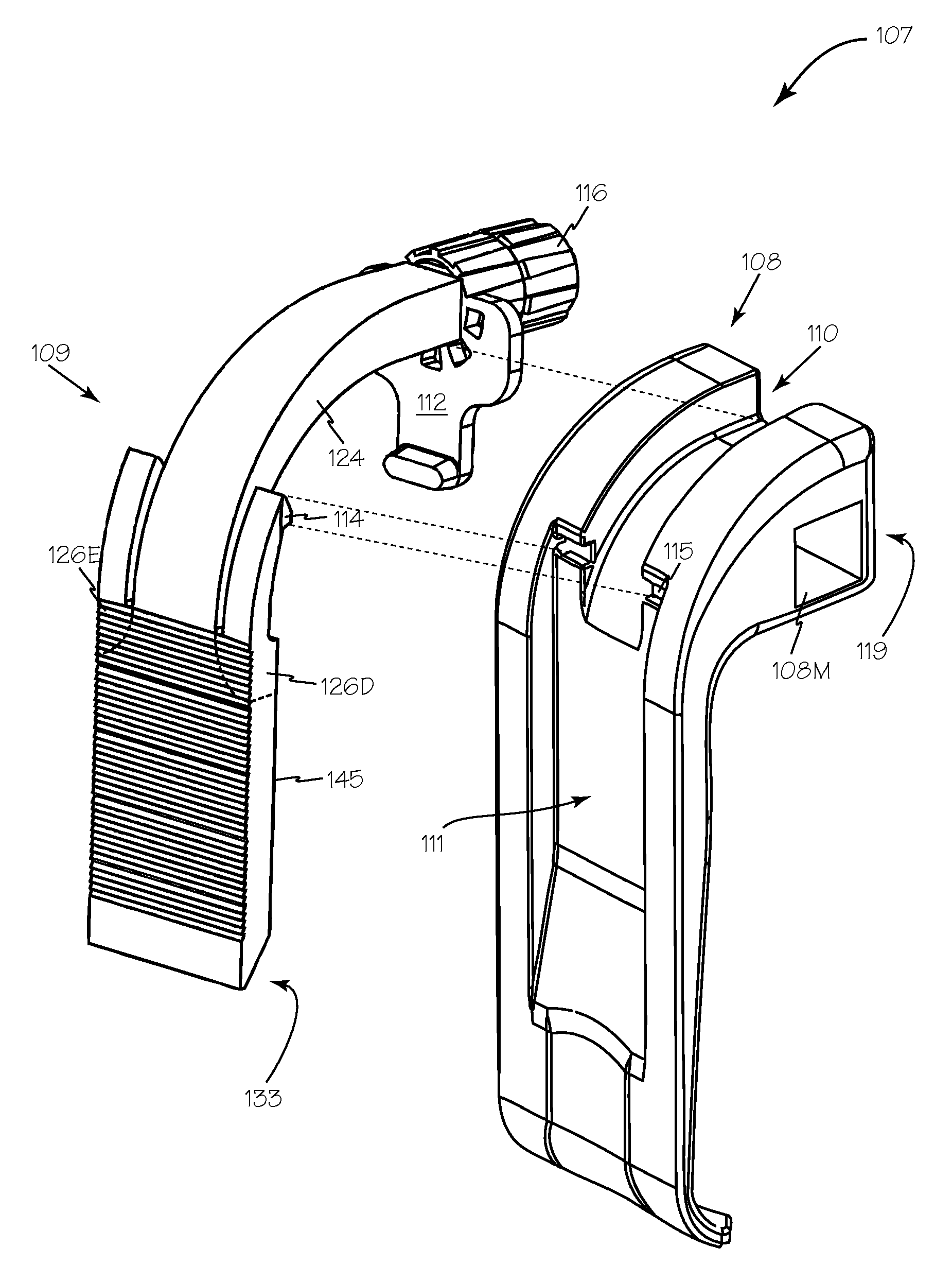

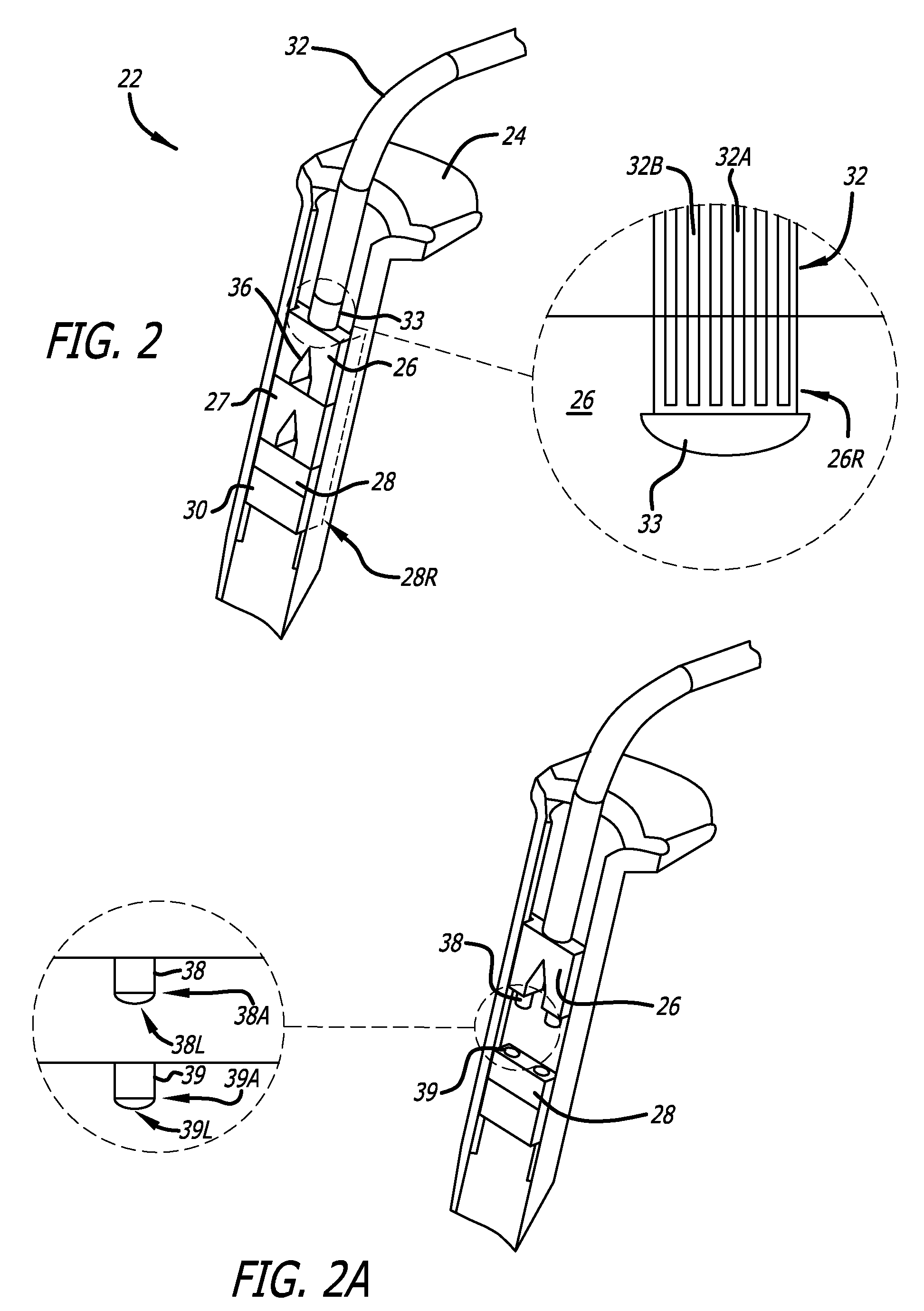

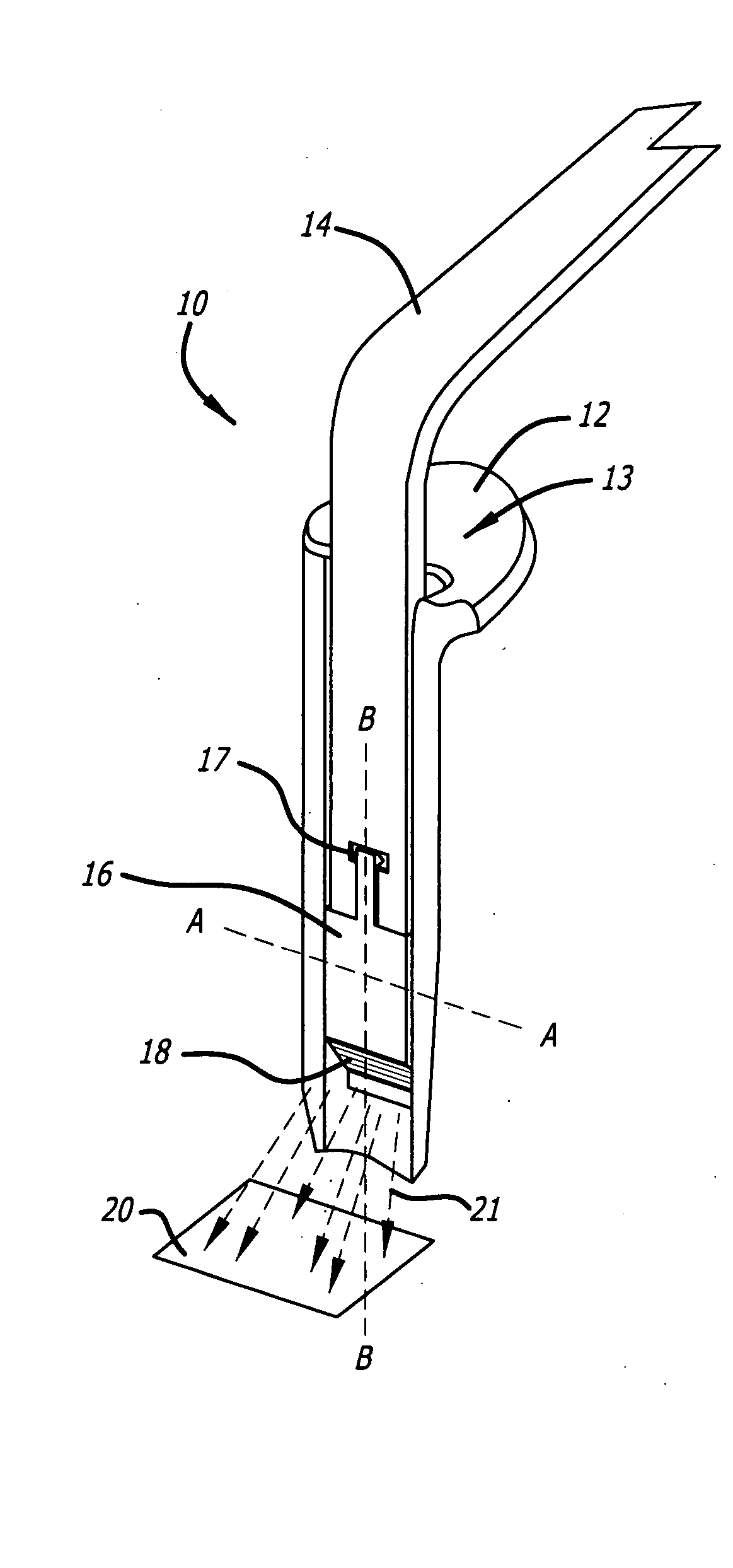

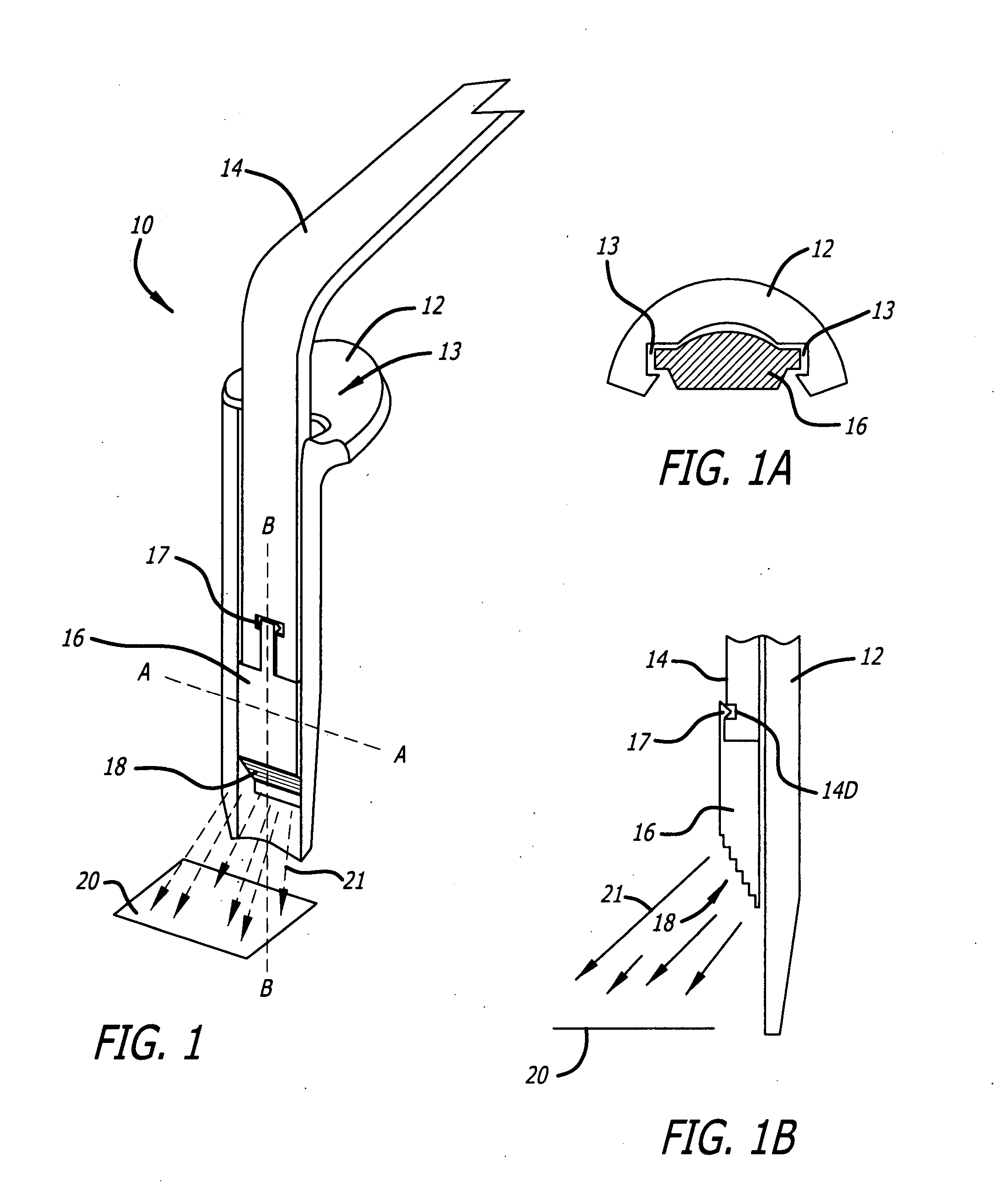

Blade insert illuminator

ActiveUS8088066B2Maximize light transferReduce light lossEndoscopesSurgical field illuminationPlastic materialsEngineering

An air gap retractor illumination system includes any suitable retractor such as a McCulloch with a channel in the blade to accommodate an air gap illuminator. The illuminator is preferably made from a suitable light conducting plastic material such as acrylic or polycarbonate or silicone. The illuminator has active portions in which light passes and inactive or dead zones in which light does not pass as a result of the configuration and orientation of the input, output and surfaces of the illuminator. The illuminator is formed to have an air gap surrounding any active portion of the illuminator extending from the light input to the light output portion. The dead zones may include elements to allow the illuminator to securely engage the retractor. The light output portion of the illuminator contains from two to eight output zones, each zone having specially designed output optical structures that control and direct light to escape the illuminator to shine onto a predetermined area of interest or to form one or more predetermined shapes or footprints.

Owner:INVUITY

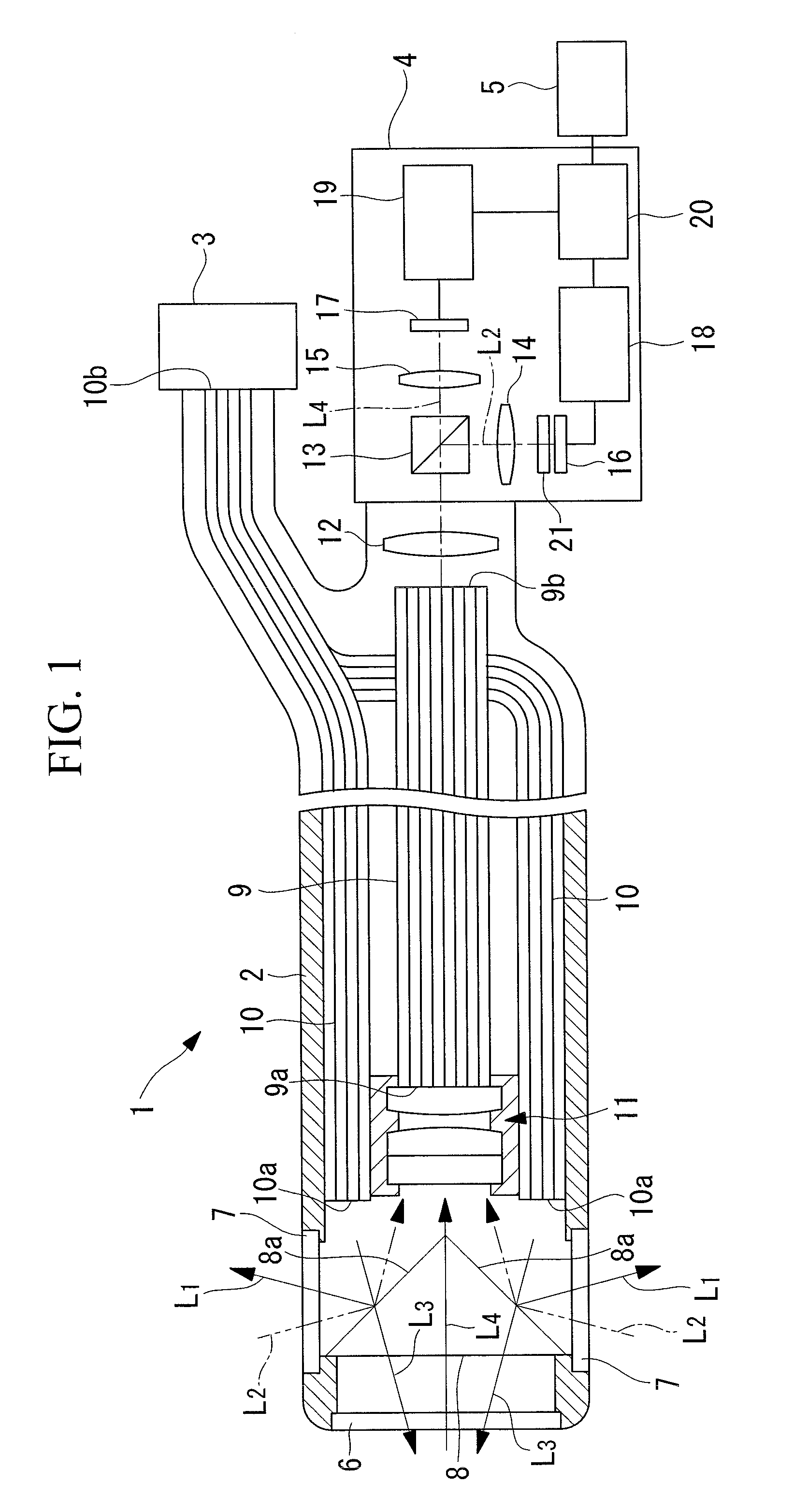

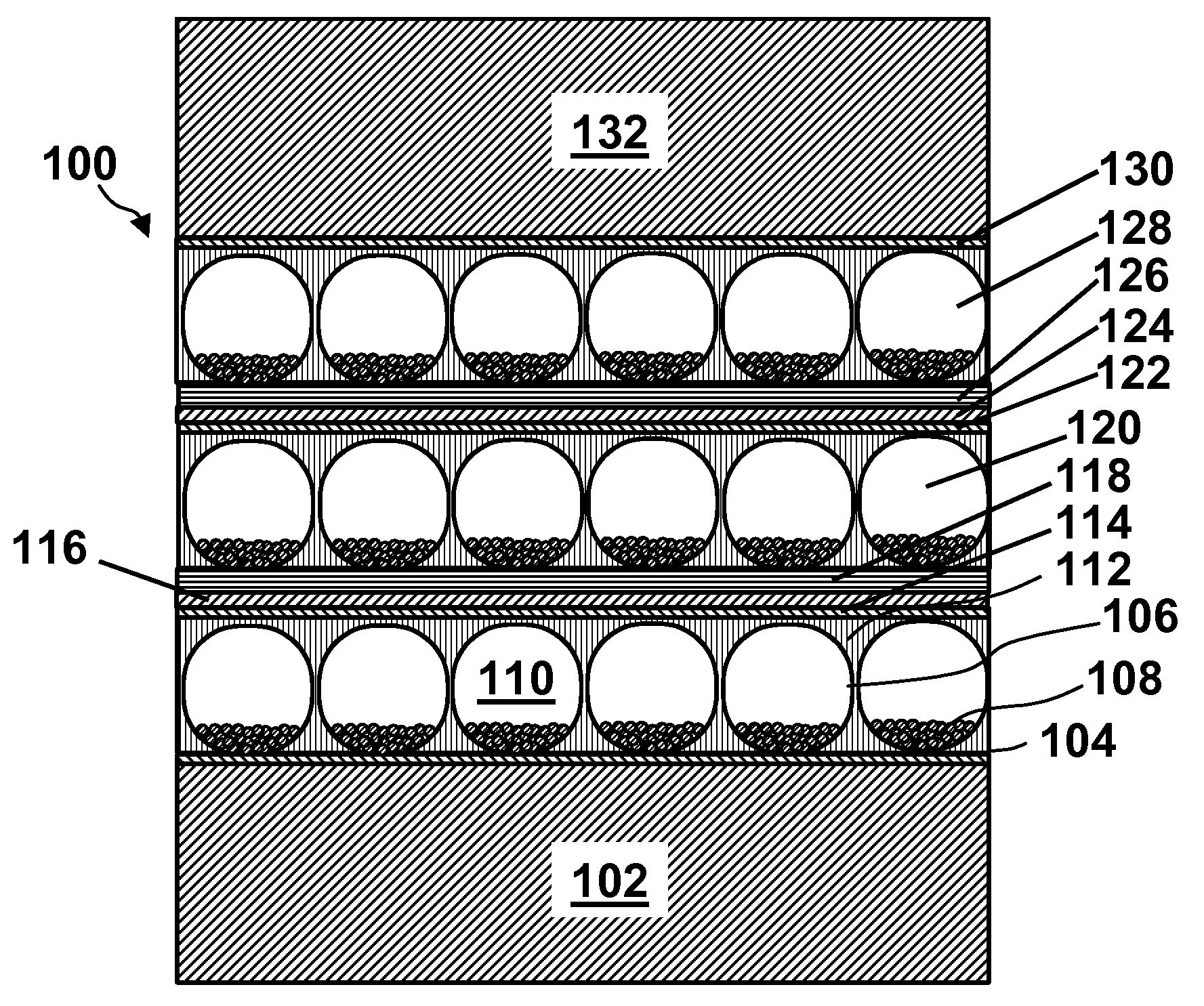

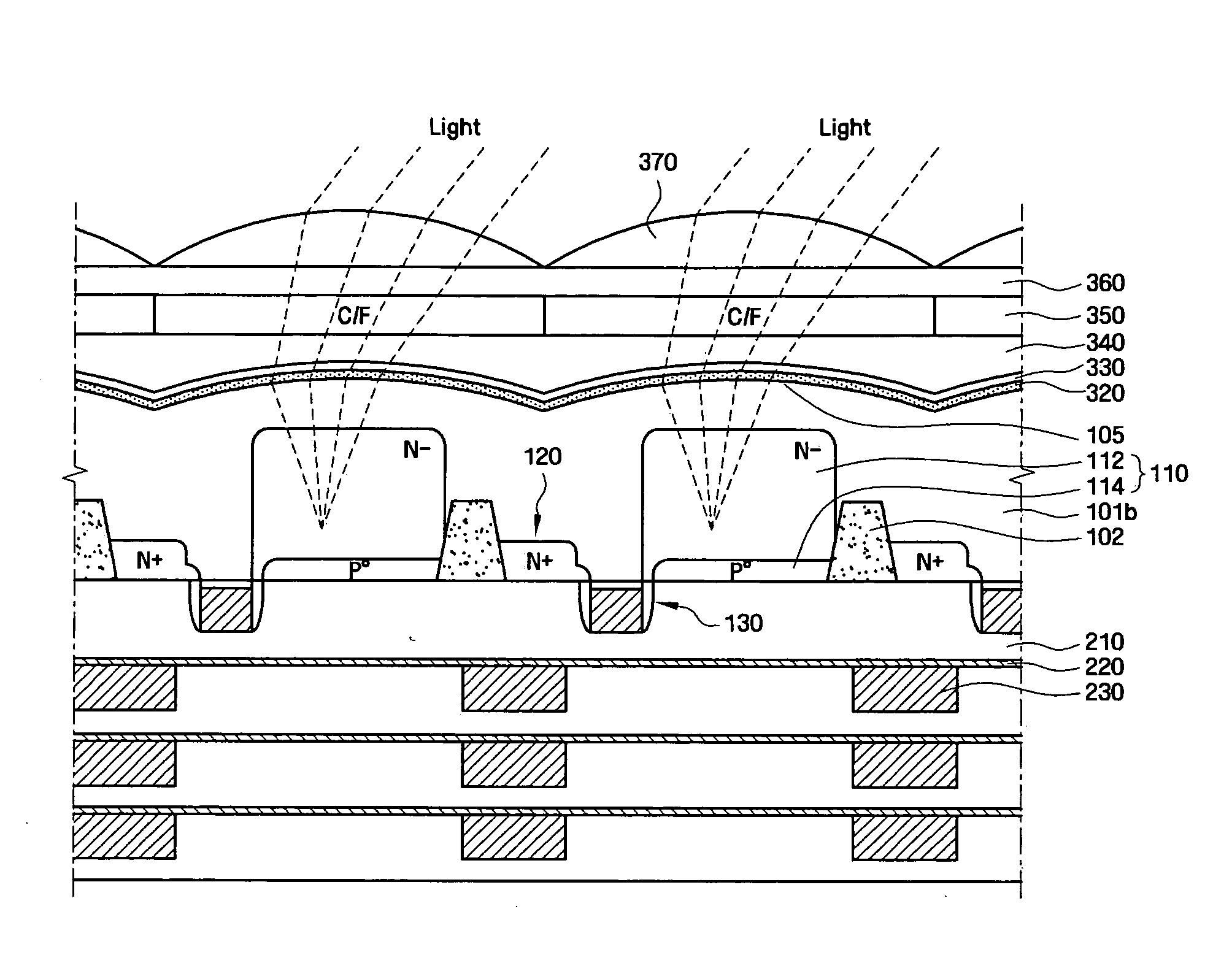

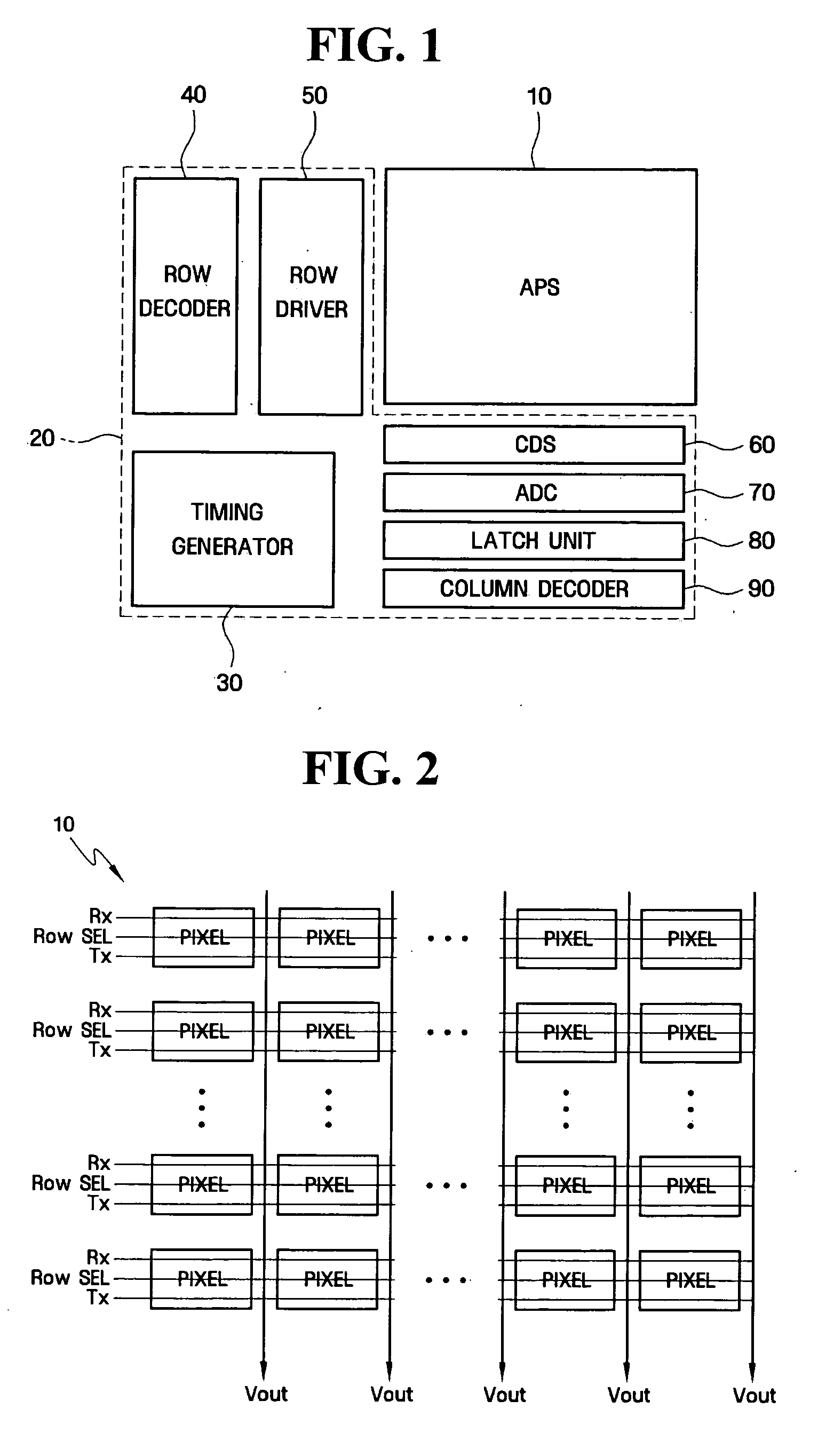

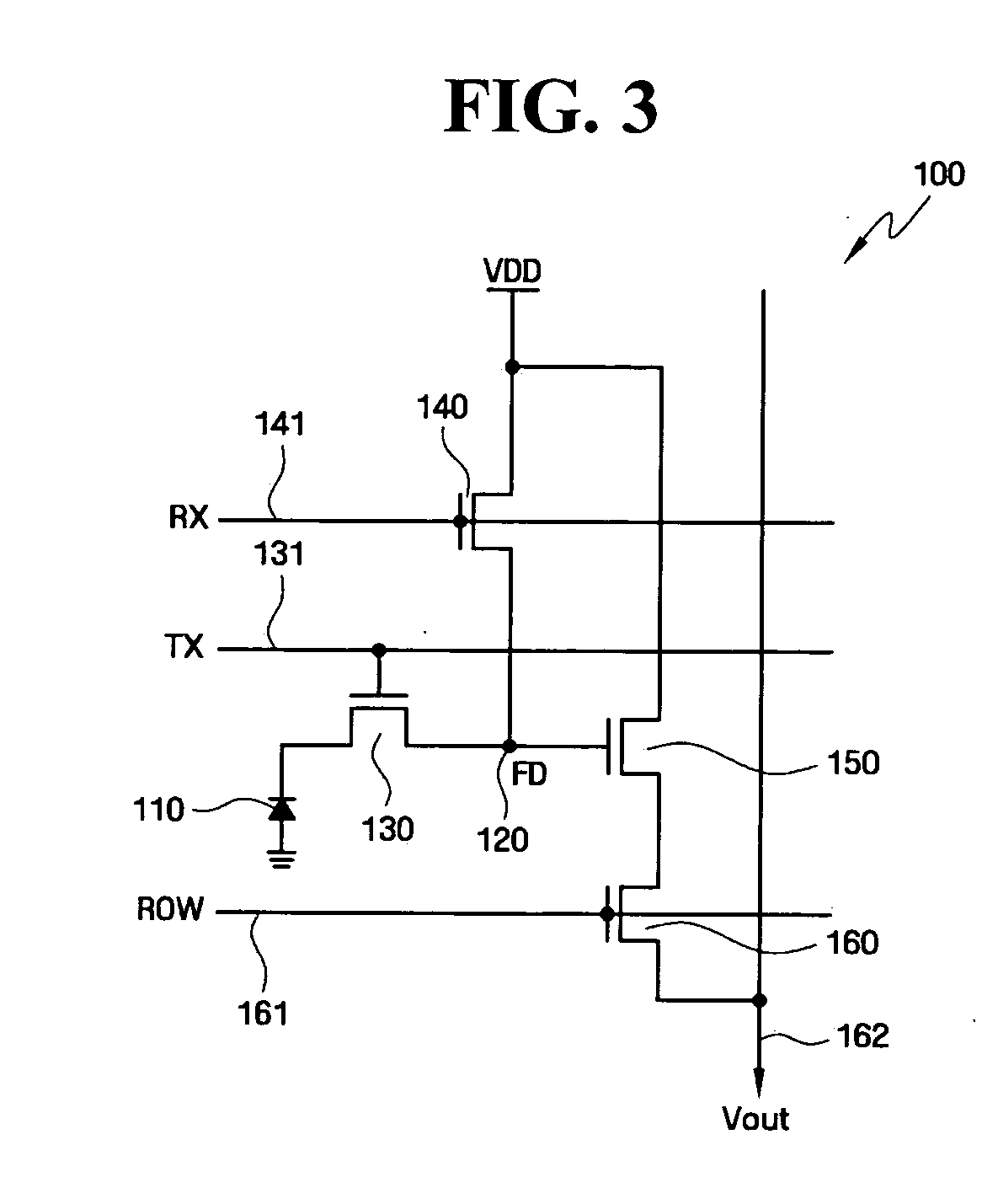

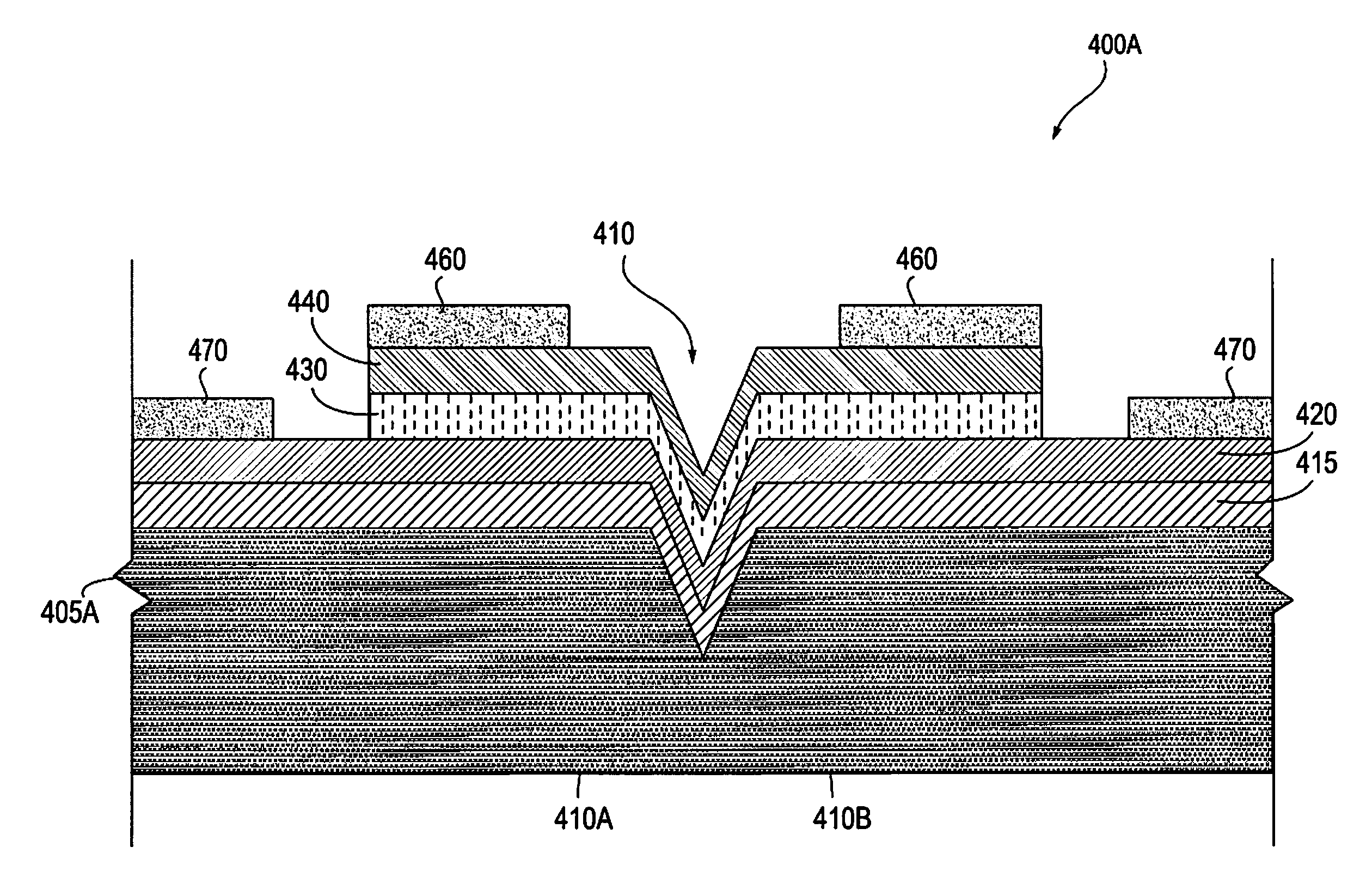

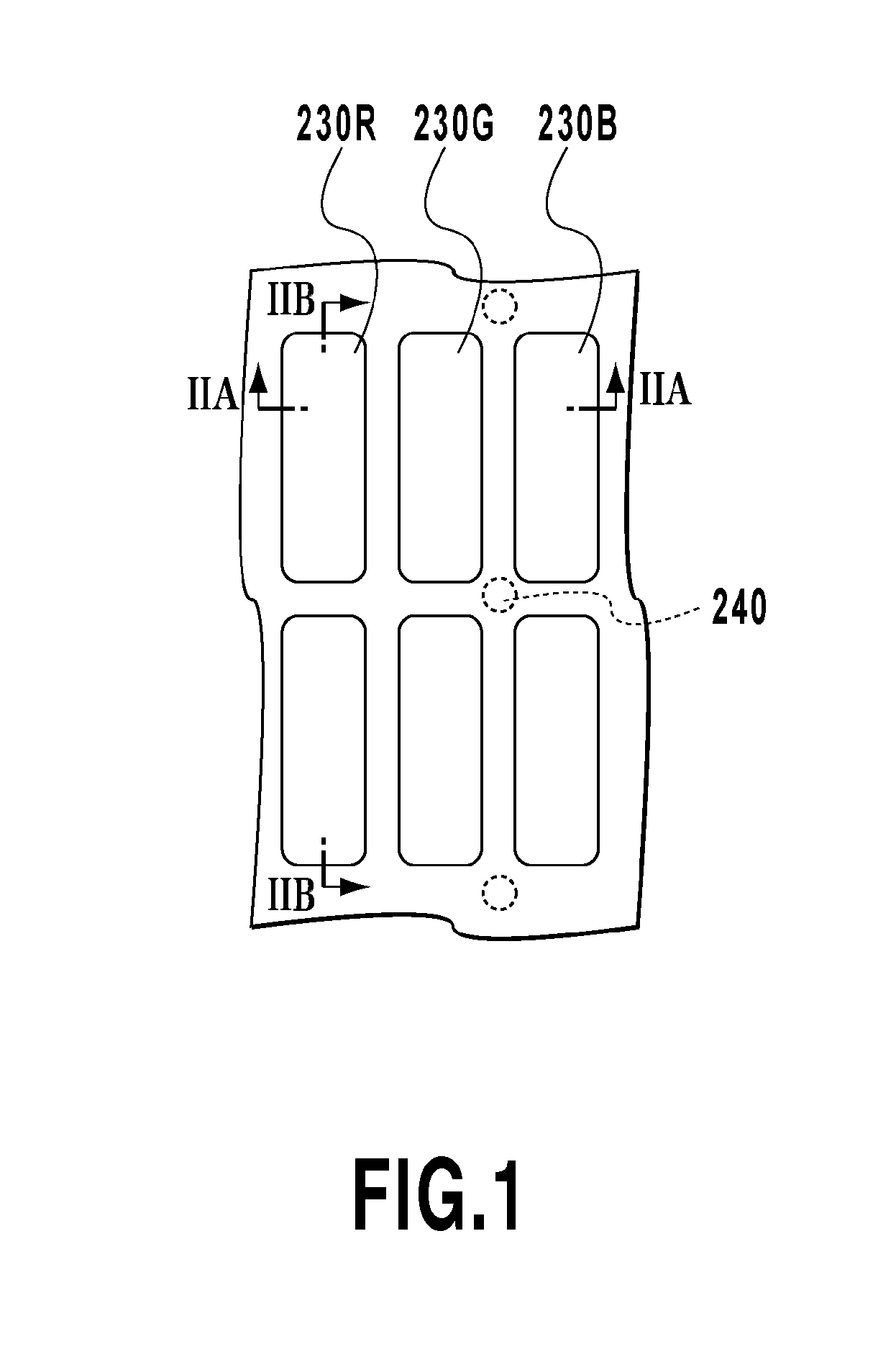

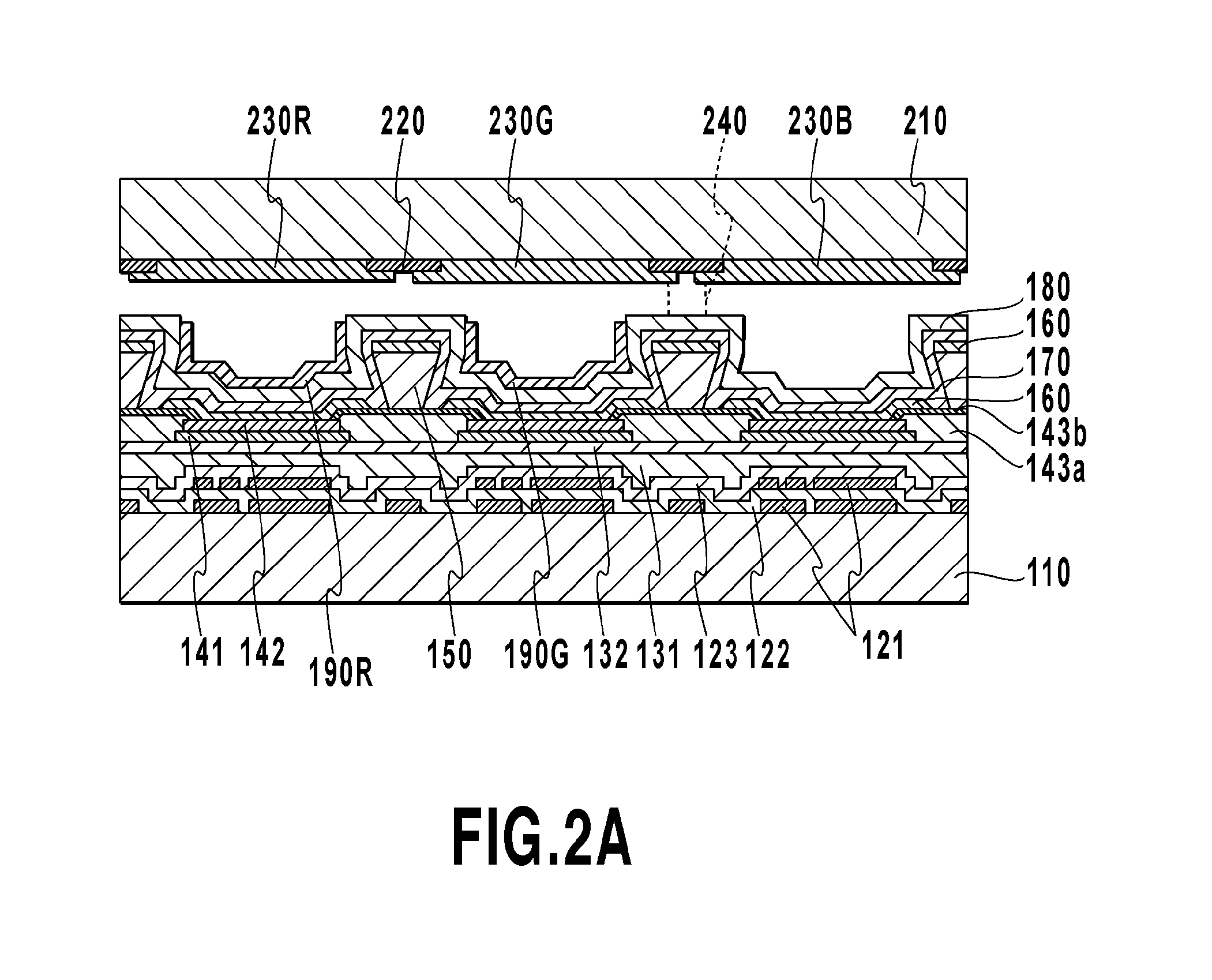

Unit pixels, image sensor containing unit pixels, and method of fabricating unit pixels

ActiveUS20090090937A1Increase photosensitivityReduce light lossSolid-state devicesSemiconductor/solid-state device manufacturingTransducerSemiconductor

Example embodiments provide a unit pixel, an image sensor containing unit pixels, and a method of fabricating unit pixels. The unit pixel may include a semiconductor substrate, photoelectric transducers formed within the semiconductor substrate, multi-layered wiring layers formed on a frontside of the semiconductor substrate, inner lenses formed on a backside of the semiconductor substrate corresponding to the photoelectric transducers, and microlenses formed above the inner lenses.

Owner:SAMSUNG ELECTRONICS CO LTD

Light emitting device

InactiveUS20090032799A1High luminous intensityLarge luminous surfaceSemiconductor/solid-state device manufacturingSemiconductor devicesLight emitting deviceLight emission

A light emitting device includes a substrate having a first surface and a second surface not parallel to the first surface, and a light emission layer disposed over the second surface to emit light. The light emission layer has a light emission surface which is not parallel to the first surface.

Owner:SIPHOTON

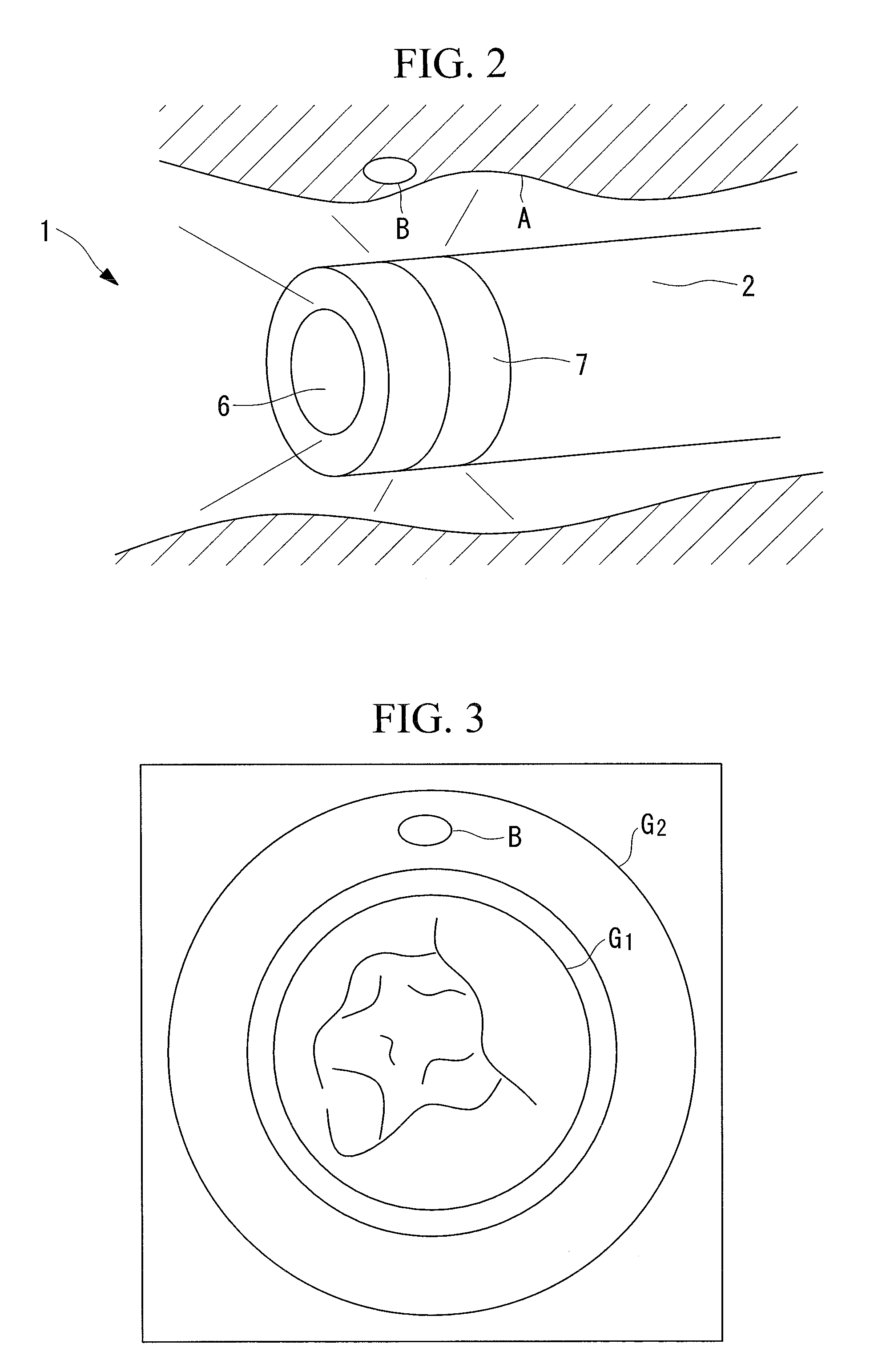

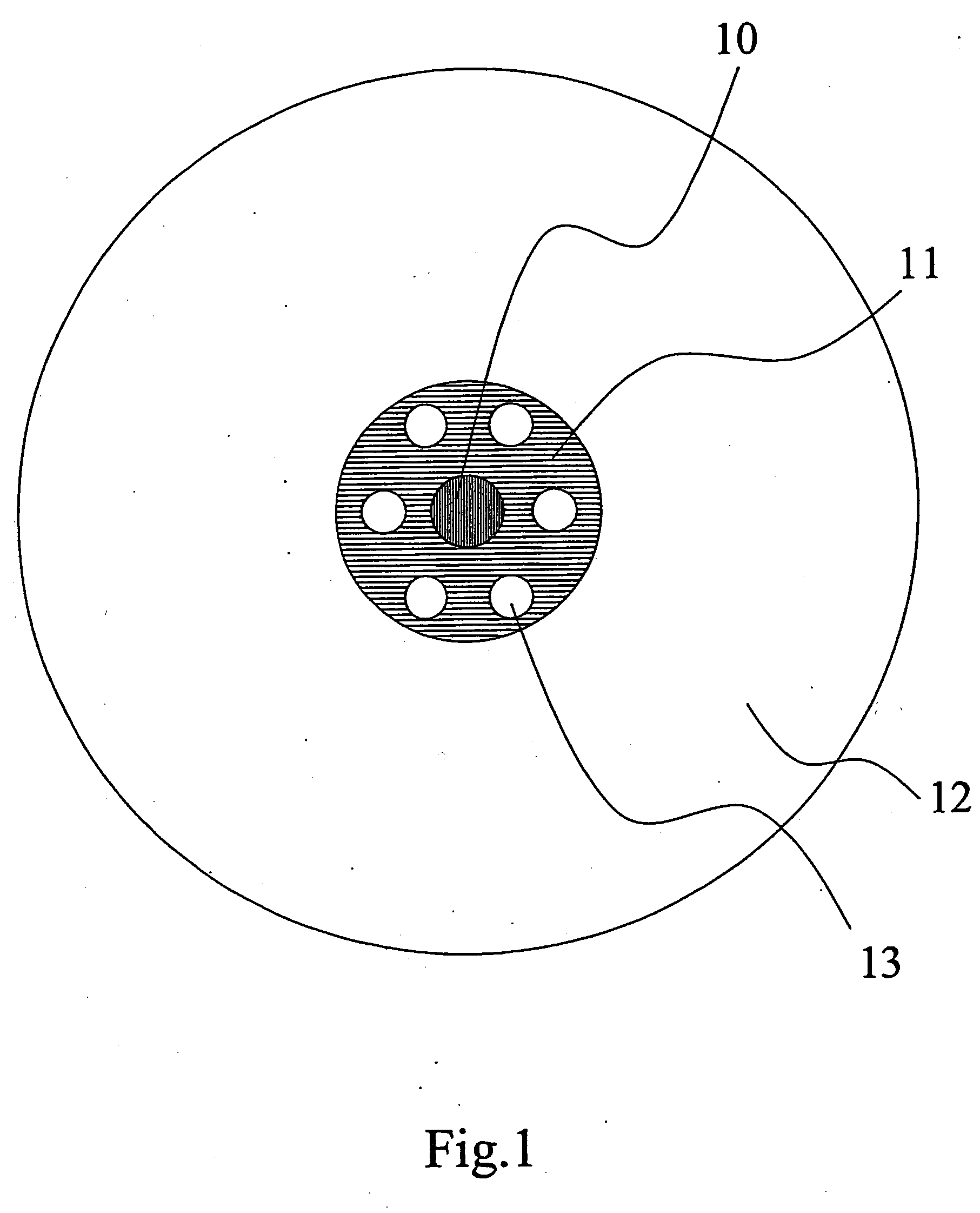

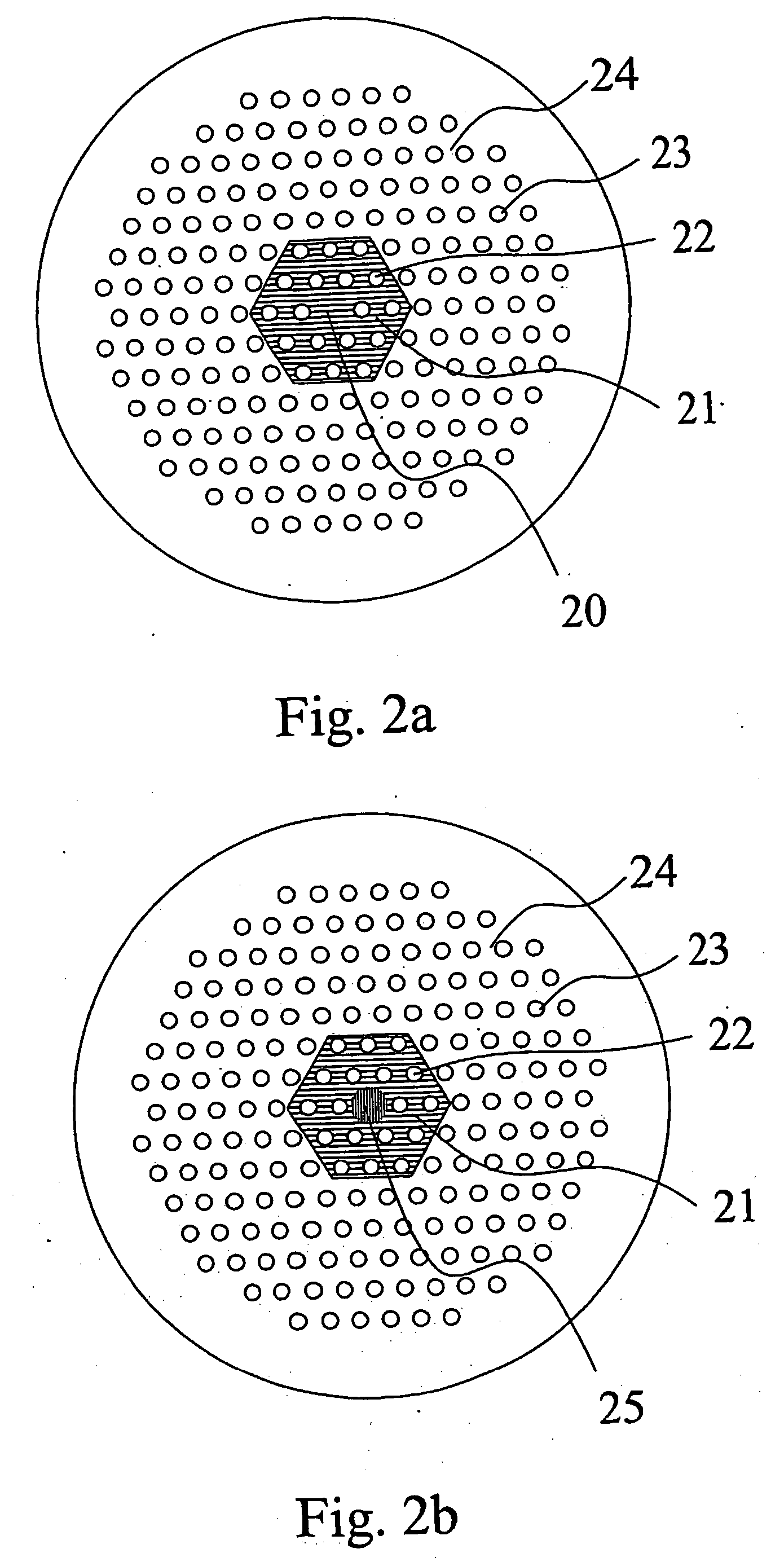

Splicing and connectorization of photonic crystal fibres

InactiveUS20060067632A1Reduce lossReduce couplingCladded optical fibreCoupling light guidesPhotonic crystalCoupling

A method of coupling a spliceable optical fibre for transmission of light in its longitudinal direction to an optical component, the method comprising (A) providing the spliceable optical fibre, said spliceable optical fibre comprising: (a) a core region (10, 20, 25, 30, 110); and (b) a microstructured cladding region, said cladding region surrounding said core region and comprising: (b1) an inner cladding region with inner cladding features (13, 22, 112) arranged in an inner cladding background material (11, 21, 111) with a refractive index n1, said inner cladding features comprising thermally collapsible holes or voids, and (b2) an outer cladding region with an outer cladding background material (12, 24, 114) with a refractive index n2; said spliceable optical fibre having at least one end; (B) collapsing said thermally collapsible holes or voids by heating said least one end of said spliceable optical fibre; and (C) coupling said collapsed spliceable optical fibre end to the optical component. A spliceable optical fibre; a preform for producing a spliceable optical fibre; a method of producing a spliceable optical fibre comprising drawing of the preform; a heat-treated spliceable optical fibre; an article comprising a spliceable optical fibre is further disclosed.

Owner:CRYSTAL FIBRE AS

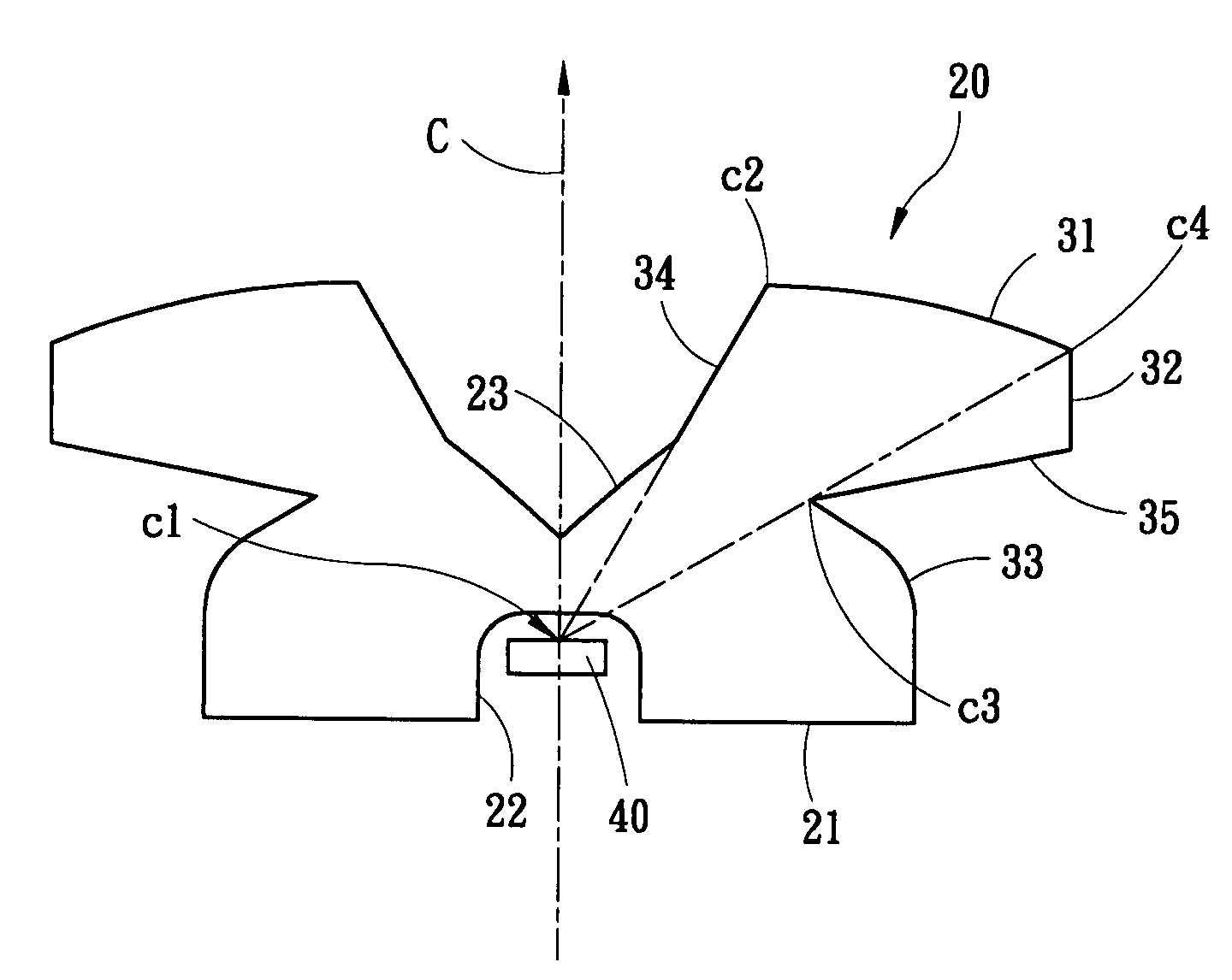

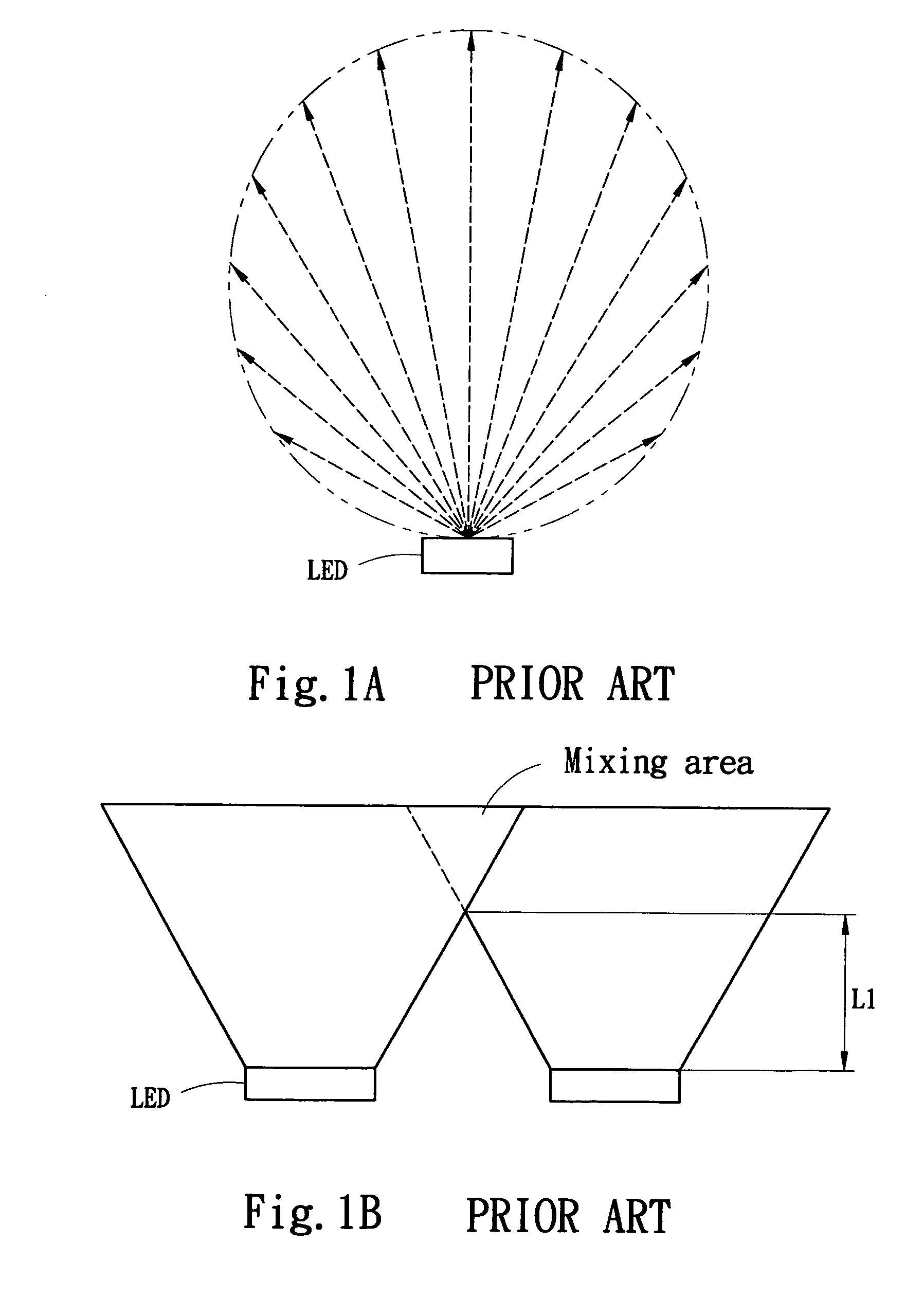

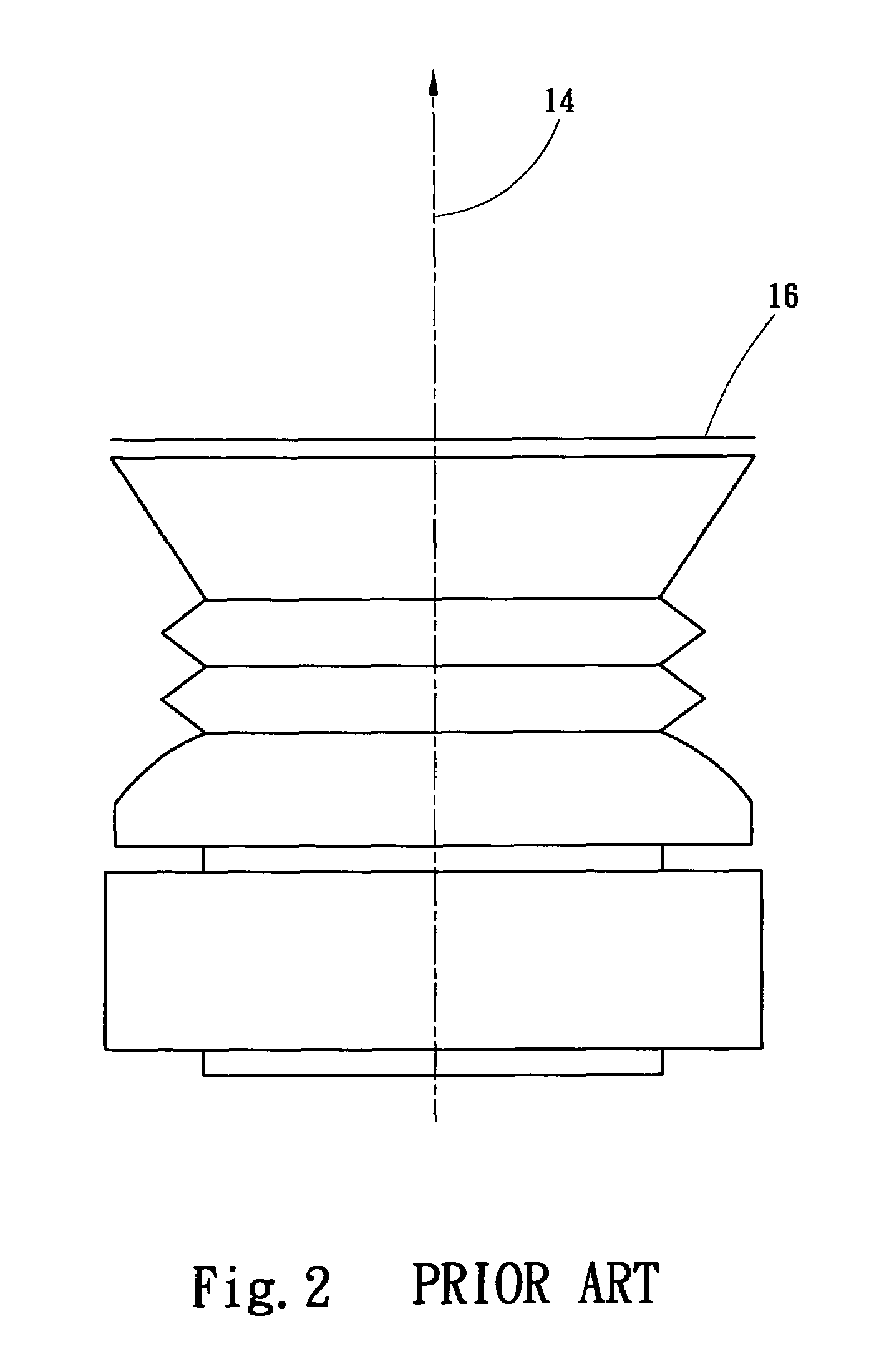

Side emitting LED and lens

InactiveUS7254309B1Improper reflectionImproper refractionPoint-like light sourceCondensersCamera lensOptoelectronics

A lens of a side emitting LED includes a bottom surface, an incident surface, a reflective surface, a first refractive surface, a second refractive surface and a third refractive surface. An light emitted by a LED enters the lens through the incident surface. A portion of the light is reflected by the reflective surface in an internal total reflection manner to the second refractive surface and emits out of the lens along a first optical path. The other portion of light directly emits out of the lens through the first refractive surface and the third refractive surface. A transitive surface is located between the first refractive surface and the reflective surface. Such a design allows the light entered the lens through the incident surface not cross with the transitive surface. Hence an improper reflection or refraction can be prevented.

Owner:CORETRONIC

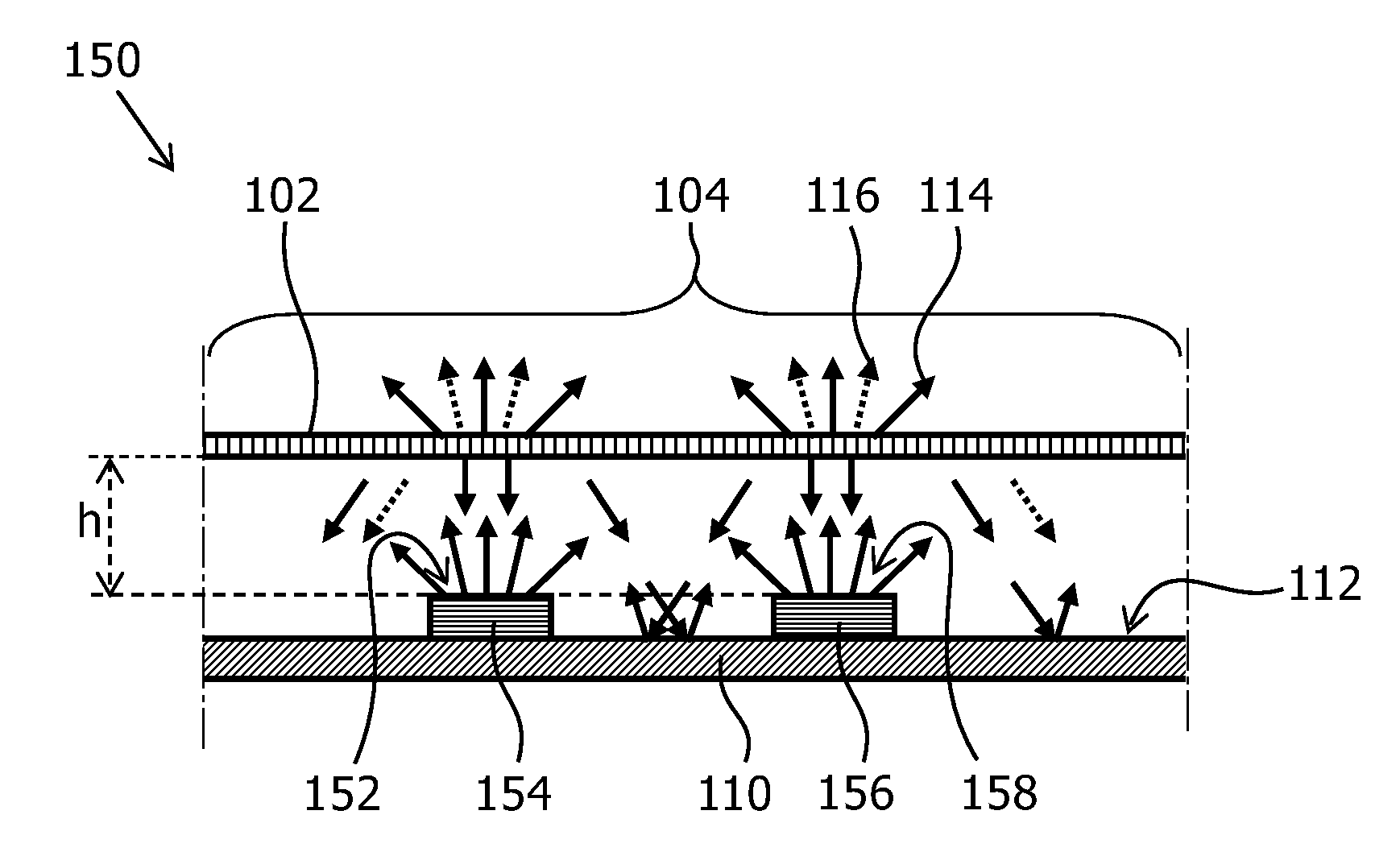

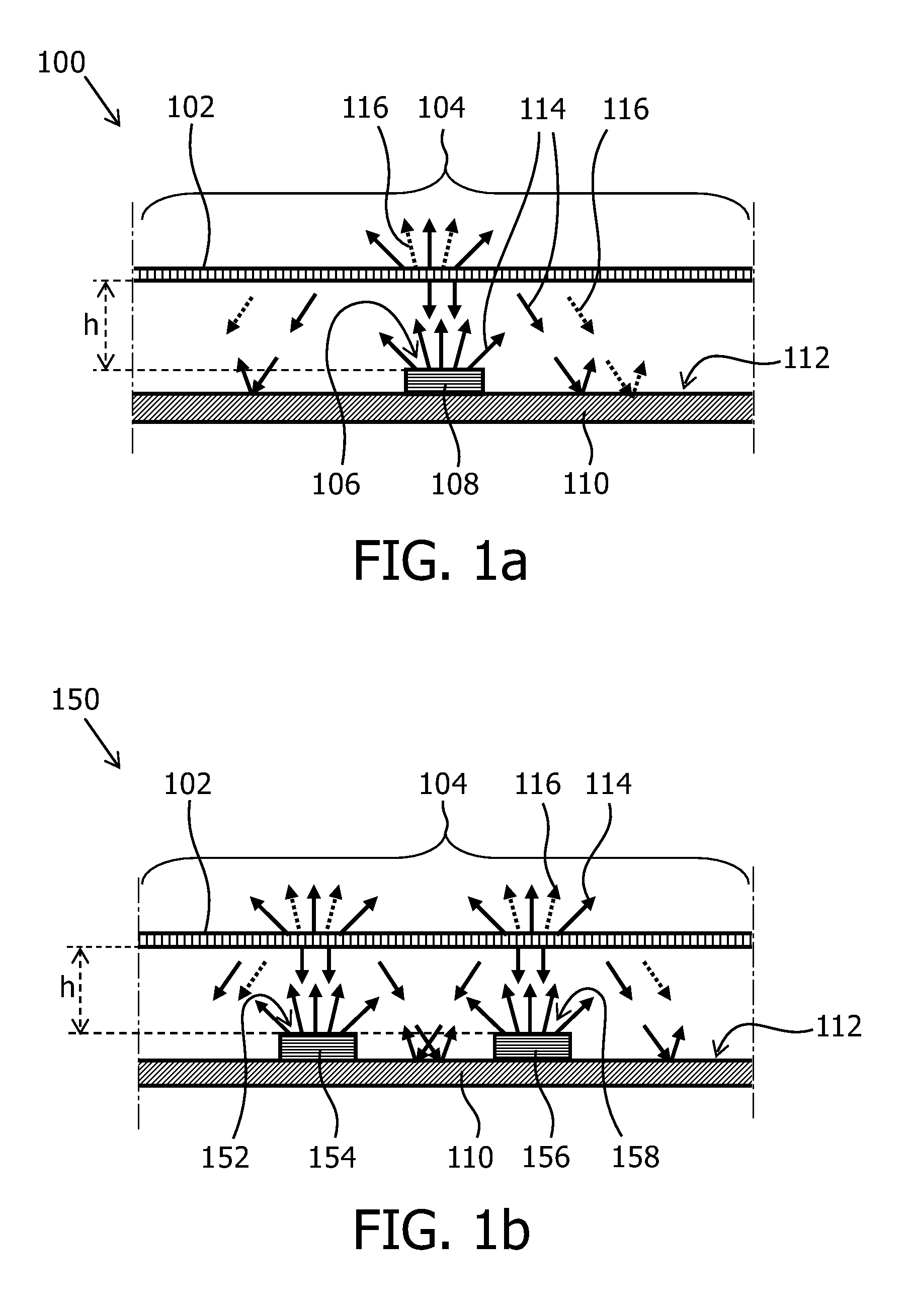

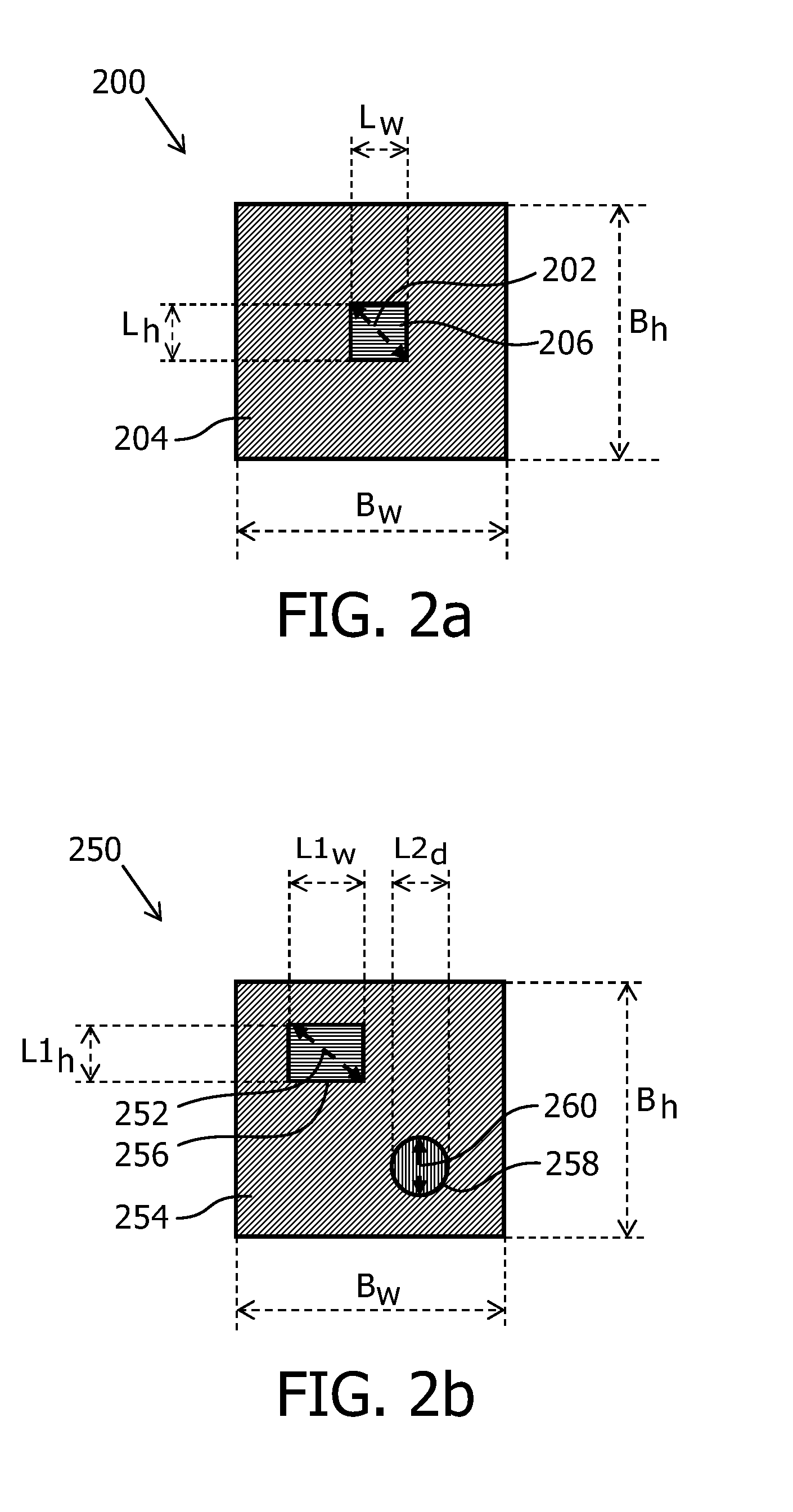

Light emitting module, a lamp, a luminaire and a display device

ActiveUS20130334559A1Cost reductionLess lightSolid-state devicesSemiconductor devicesReflection coefficientSolid-state

A light emitting module 150 emits light through a light exit window 104 and comprises a base 110, a solid state light emitter 154, 156 and a partially diffusive reflective layer 102. The base 110 has a light reflective surface 112 which faces towards the light exit window 104. The light reflective surface 112 has a base reflection coefficient Rbase which i defined by a ratio between the amount of light that is reflected by the light reflective surface and the amount of light that impinges on the light reflective surface. The solid state light emitter 154, 156 emits light of a first color range 114, comprises a top surface 152, 158 and has a solid state light emitter reflection coefficient R_SSL which is defined by a ratio between the amount of light that is reflected by the solid state emitter 154, 156 and the amount of light that impinges on the top surface 152, 158 of the solid state light emitter 154, 156. The light exit window 104 comprises at least a part of the partially diffusive reflective layer 102. A solid state light emitter area ratio ρSSL is defined as the ratio between the area of the top surface of the at least one solid state light emitter and the area of the light reflective surface of the base. A relatively efficient light emitting module is obtained if Rbase>R_SSL+c*(1−R_SSL) and the factor c is 0.2≦c≦1 for 0<ρSSL<0.1, 0.3≦c≦1 for 0.1≦ρSSL≦0.25, and 0.4≦c≦1 for ρSSL>0.25.

Owner:LUMILEDS

Apparatus and method for exposing a substrate to a rotating irradiance pattern of UV radiation

ActiveUS20070286963A1Reduce light lossPretreated surfacesSemiconductor/solid-state device manufacturingPhysicsProcess region

Embodiments of the invention relate generally to an ultraviolet (UV) cure chamber for curing a dielectric material disposed on a substrate and to methods of curing dielectric materials using UV radiation. A substrate processing tool according to one embodiment comprises a body defining a substrate processing region; a substrate support adapted to support a substrate within the substrate processing region; an ultraviolet radiation lamp spaced apart from the substrate support, the lamp configured to transmit ultraviolet radiation to a substrate positioned on the substrate support; and a motor operatively coupled to rotate at least one of the ultraviolet radiation lamp or substrate support at least 180 degrees relative to each other. The substrate processing tool may further comprise one or more reflectors adapted to generate a flood pattern of ultraviolet radiation over the substrate that has complementary high and low intensity areas which combine to generate a substantially uniform irradiance pattern if rotated. Other embodiments are also disclosed.

Owner:APPLIED MATERIALS INC

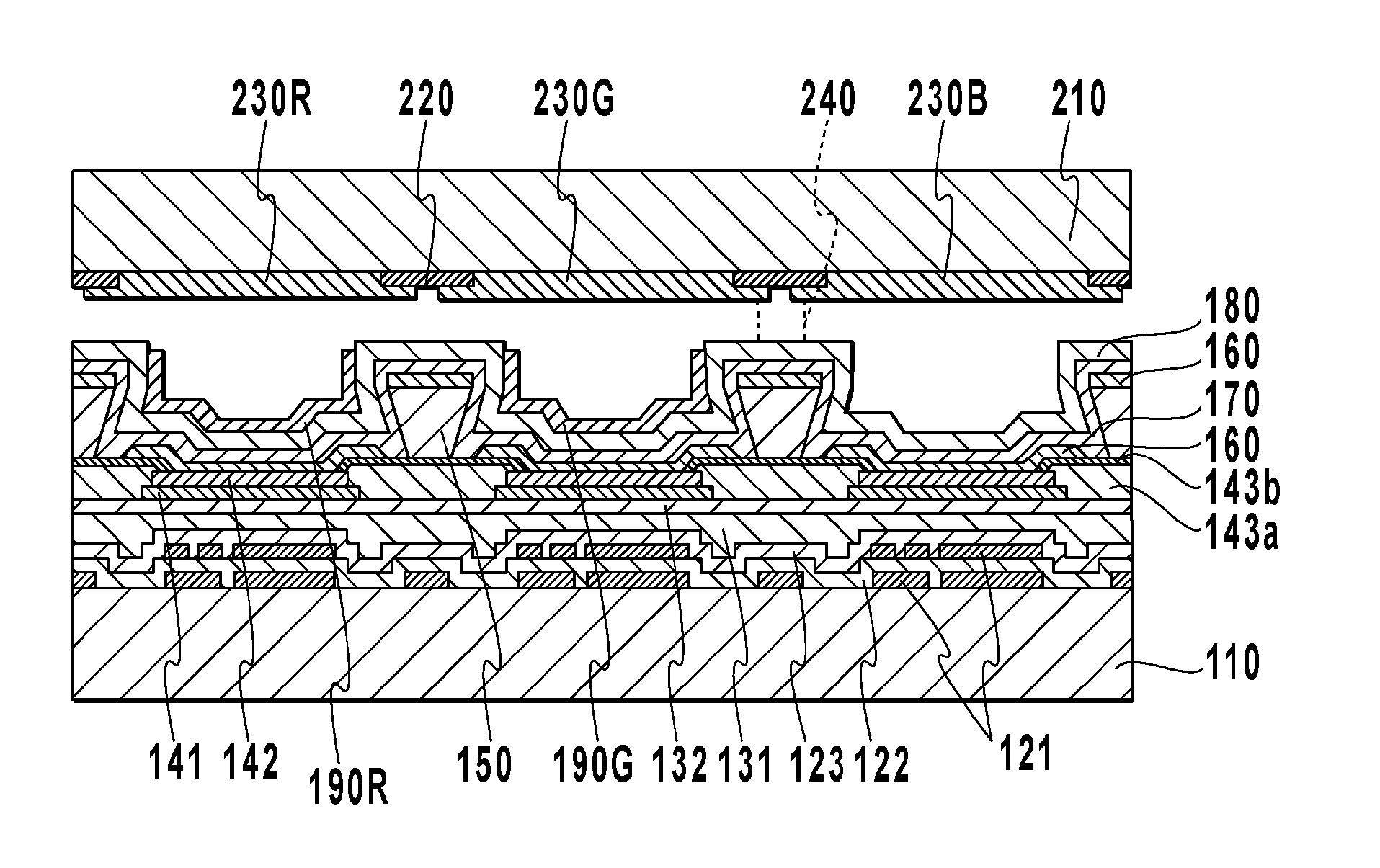

Organic el display

InactiveUS20120228603A1Improve color conversion efficiencyReduce reflection lossSolid-state devicesSemiconductor/solid-state device manufacturingOptoelectronicsElectrode

An object of the present invention is to provide an organic EL display that has a reduced optical loss and high efficiency, and can be manufactured by an inexpensive method. The organic EL display of the present invention is formed by bonding an organic EL element substrate including a substrate, reflective electrode, organic EL layer, separation wall, barrier layer, transparent electrode, and color conversion layer; and a sealing substrate together, wherein: the reflective electrode includes a plurality of partial electrodes; the organic EL layer is formed on the reflective electrode and includes a plurality of parts separated by the separation wall; the transparent electrode is formed on the organic EL layer; the barrier layer covers the separation wall and the transparent electrode, and has a recessed part in a location corresponding to the reflective electrode; and the color conversion layer is formed in the recessed part.

Owner:UNIFIED INNOVATIVE TECH

Light transmission tubes

InactiveUS6278827B1Increase brightnessImprove directivityMechanical apparatusOptical fibre with multilayer core/claddingBand shapeRefractive index

A light transmission tube includes a tubular clad and a core section having a higher refractive index than that of the tubular clad. A belt-like reflecting layer is formed between the tubular clad and the core section, extending in the longitudinal direction of the tubular clad, in a manner such that a light passing through the core section is reflected and scatterred by the reflecting layer and then emitted from an outer surface area of the tubular clad, which outer surface area is located opposite to one side of the tubular clad where the reflecting layer has been formed. Further, the reflecting layer may be so formed that a light is allowed to be emitted in a plurality of directions. Moreover, the belt-like reflecting layer may be formed into a spiral configuration. The width of the belt-like reflecting layer may be changed in the longitudinal direction of the light transmission tube. The tubular clad is allowed to have a non-circular cross section. The clad formation material may contain an ultraviolet light shielding material or an ultraviolet light absorbing material.

Owner:BRIDGESTONE CORP

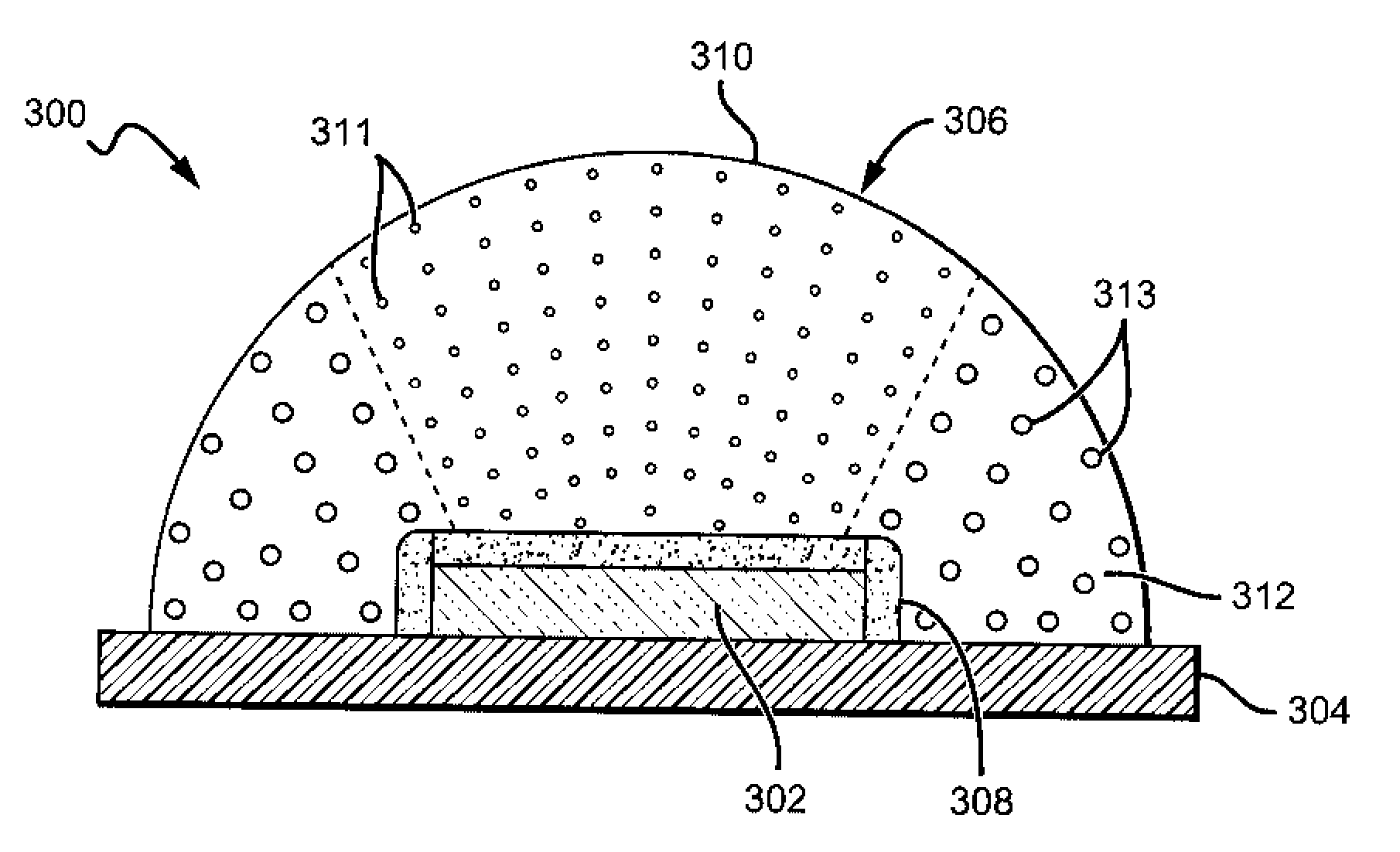

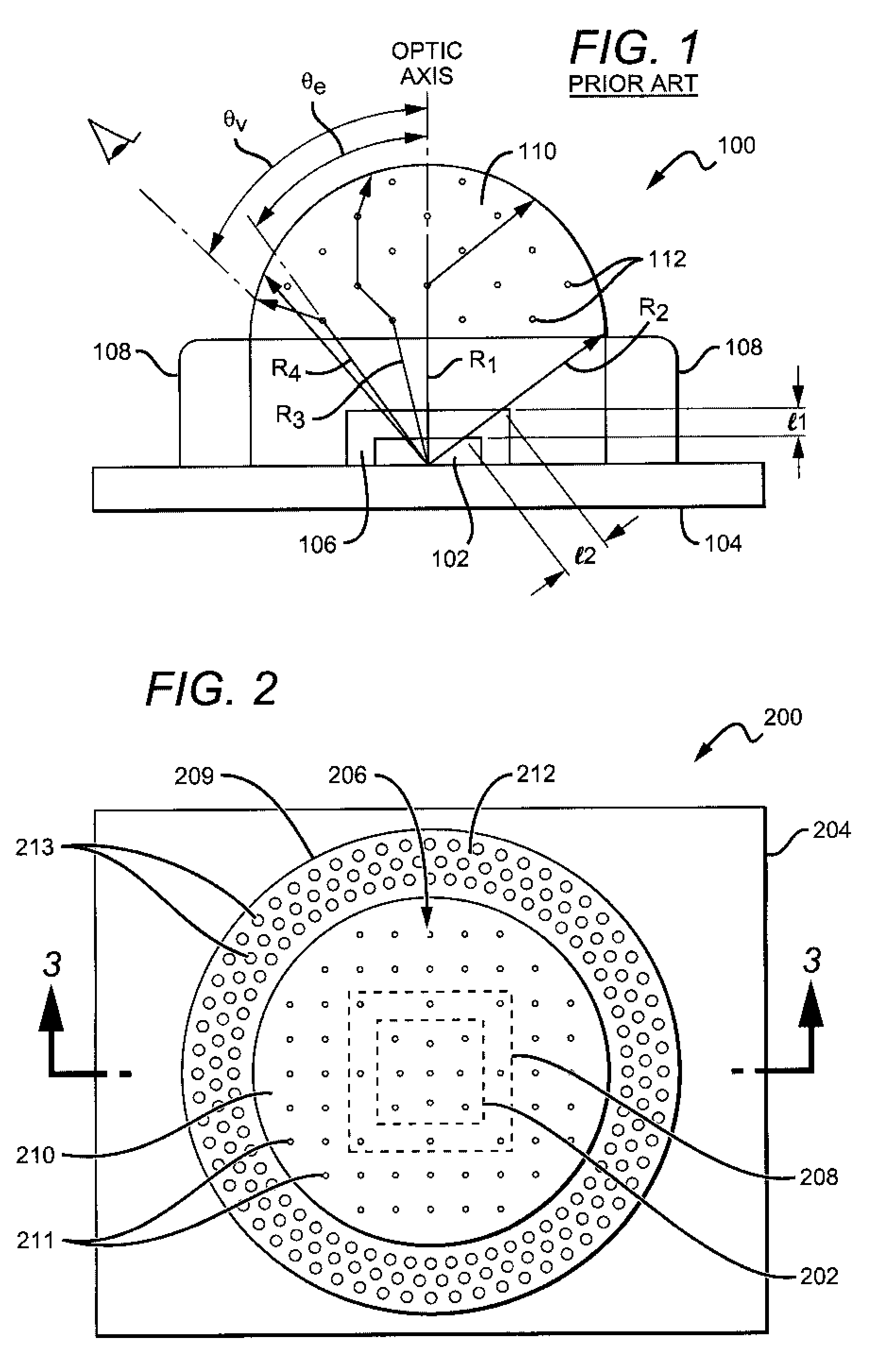

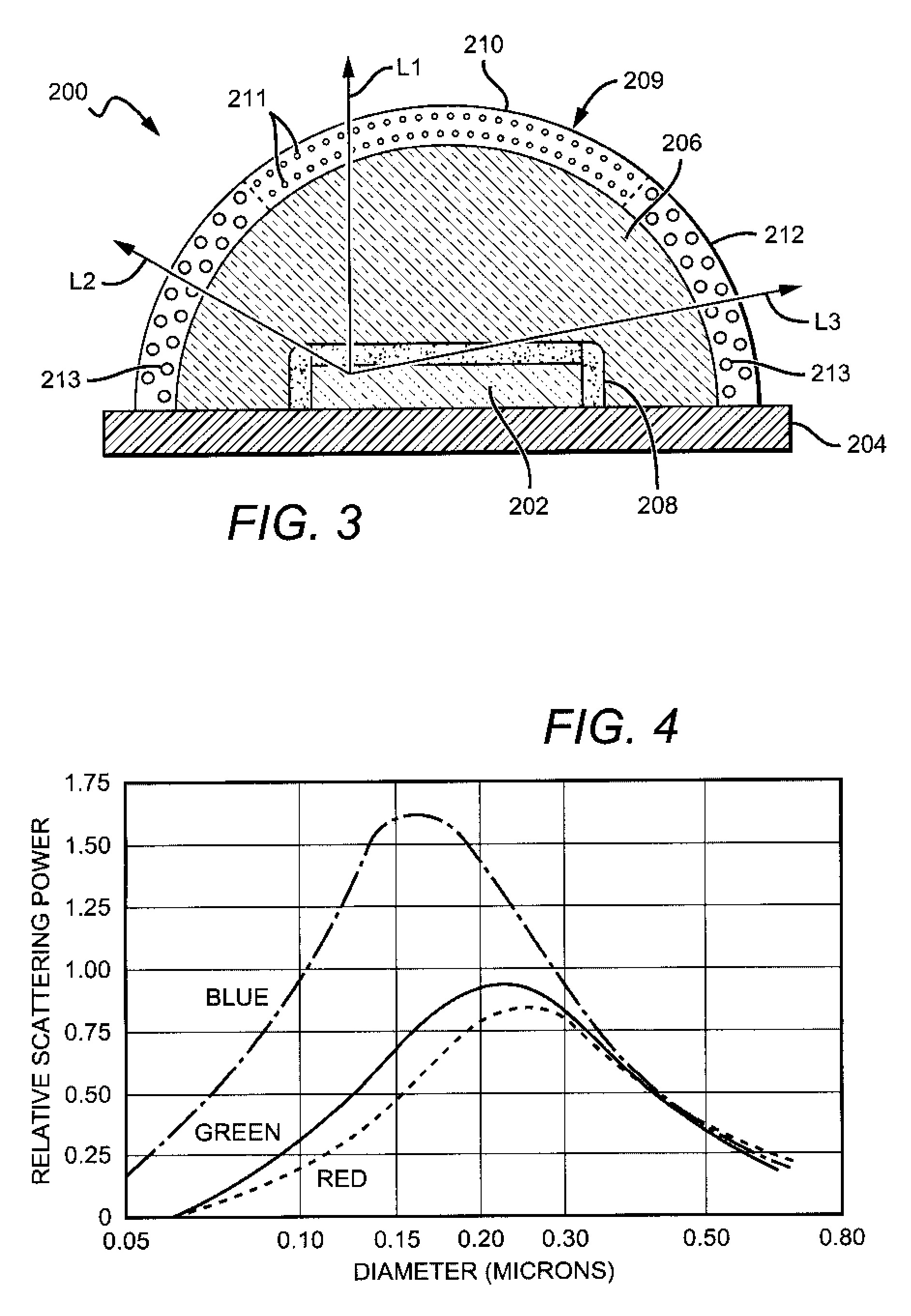

LED packages with scattering particle regions

ActiveUS20110001151A1Improve uniformityEmission efficiency lossSolid-state devicesSemiconductor devicesLength waveEmission efficiency

An LED package comprises at least one LED that emits LED light in an LED emission profile. The LED package includes regions of scattering particles with the different regions scattering light primarily at a target wavelength or primarily within a target wavelength range. The location of the regions and scattering properties are based at least partially on the LED emission profile. The regions scatter their target wavelength of LED light to improve the uniformity of the LED emission profile so that the LED package emits a more uniform profile compared to the LED emission profile. By targeting particular wavelengths for scattering, the emission efficiency losses are reduced.

Owner:CREELED INC

Planar lightwave circuits with air filled trenches

InactiveUS20090087137A1Easy to integrateReduce light lossMaterial analysis by optical meansNanoopticsPhotovoltaic detectorsPhotodetector

An air filled trench is formed underneath the waveguide to reduce propagation loss, which in turn allowing the waveguide to be in the close proximity of on-chip devices, such as a photodetector. The air filled trench is formed from the back side of the substrate; hence it would not disturb the integration and the formation of components on the front side of the substrate. In another embodiment, for silicon-on-insulator (SOI) based device, with an air filled trench and a metal electrode, a back gate is formed. In yet another embodiment, air filled trench also reduces the substrate loss of RF passive components and passive antenna operating in Giga Hertz range. Air filled trenches can be used for both photonic and electronic circuits in a planar lightwave circuit. Finally, another embodiment is for the trench to effectively guide gases and fluids to pass through the detection area.

Owner:DOAN MY THE

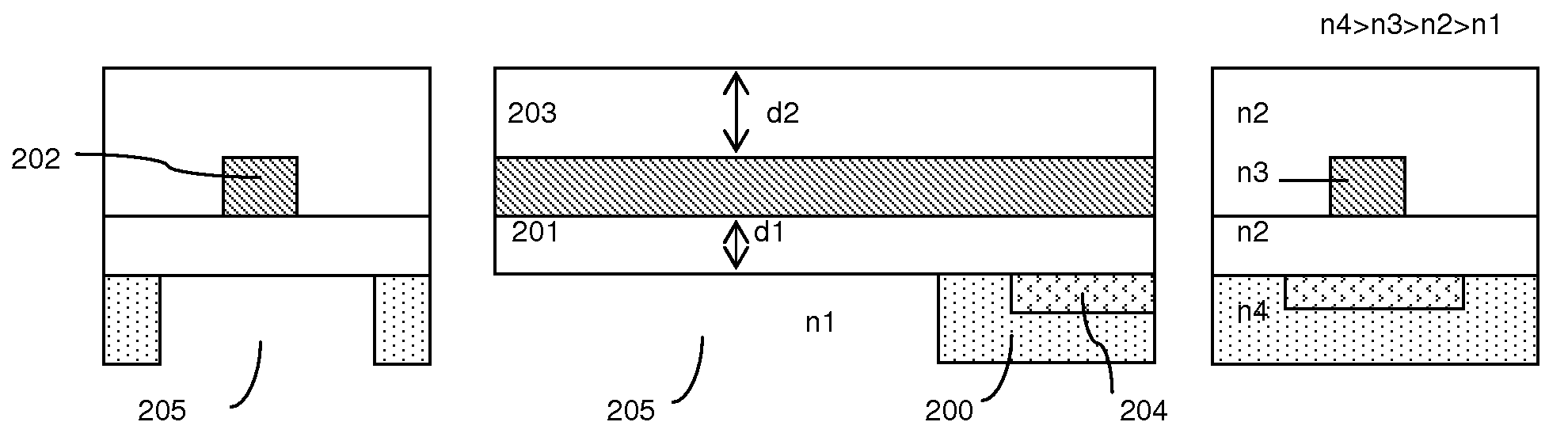

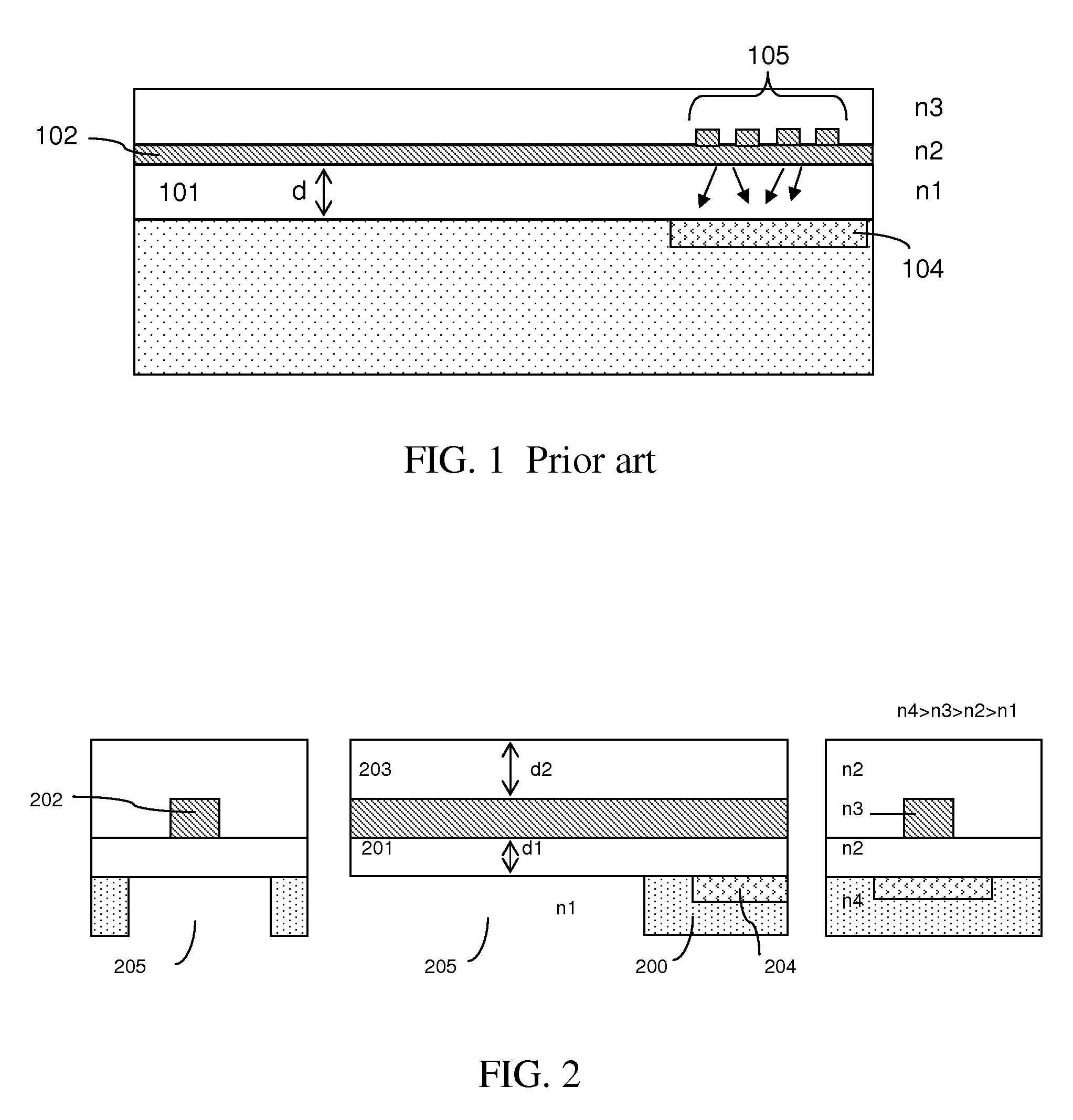

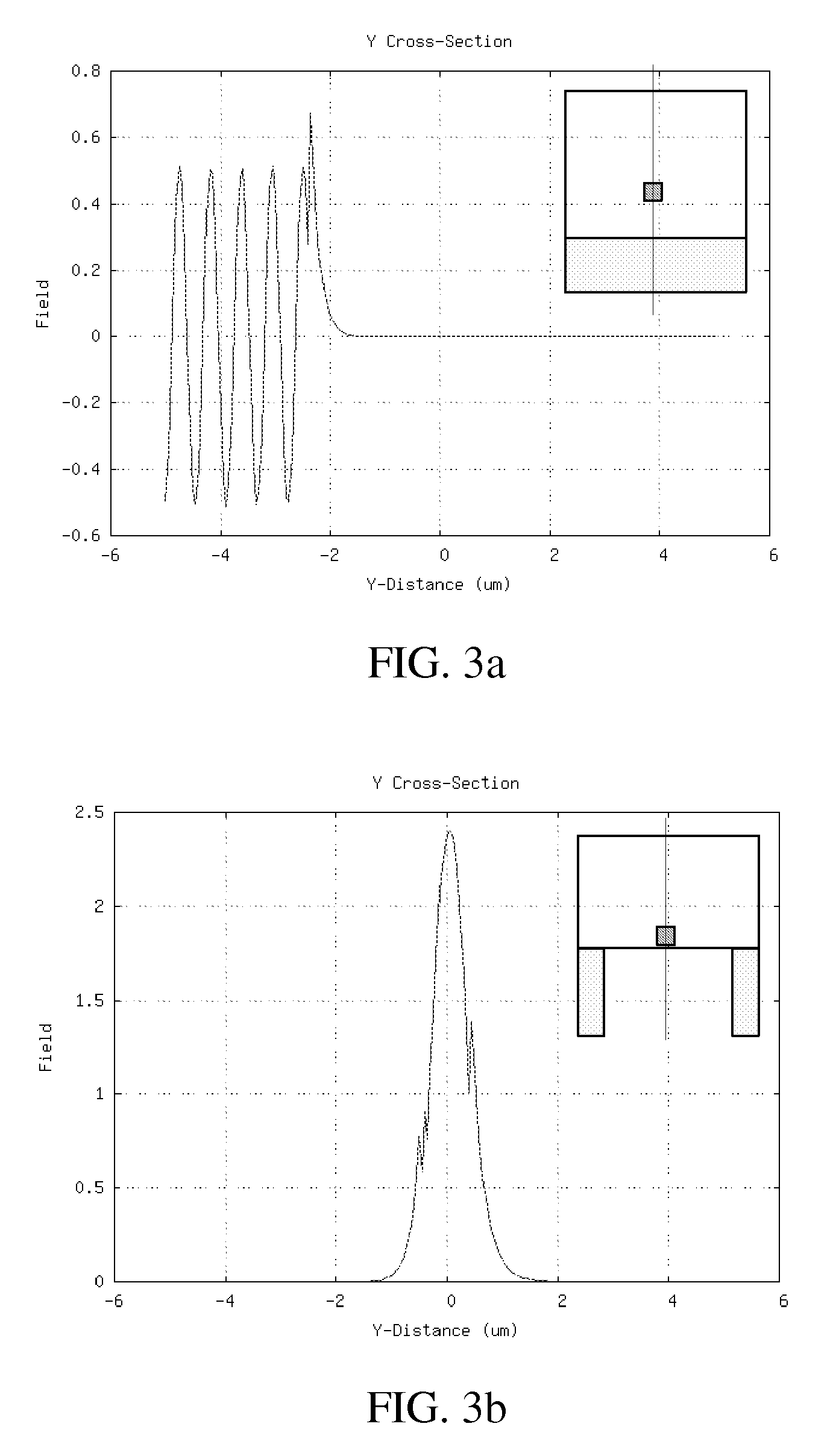

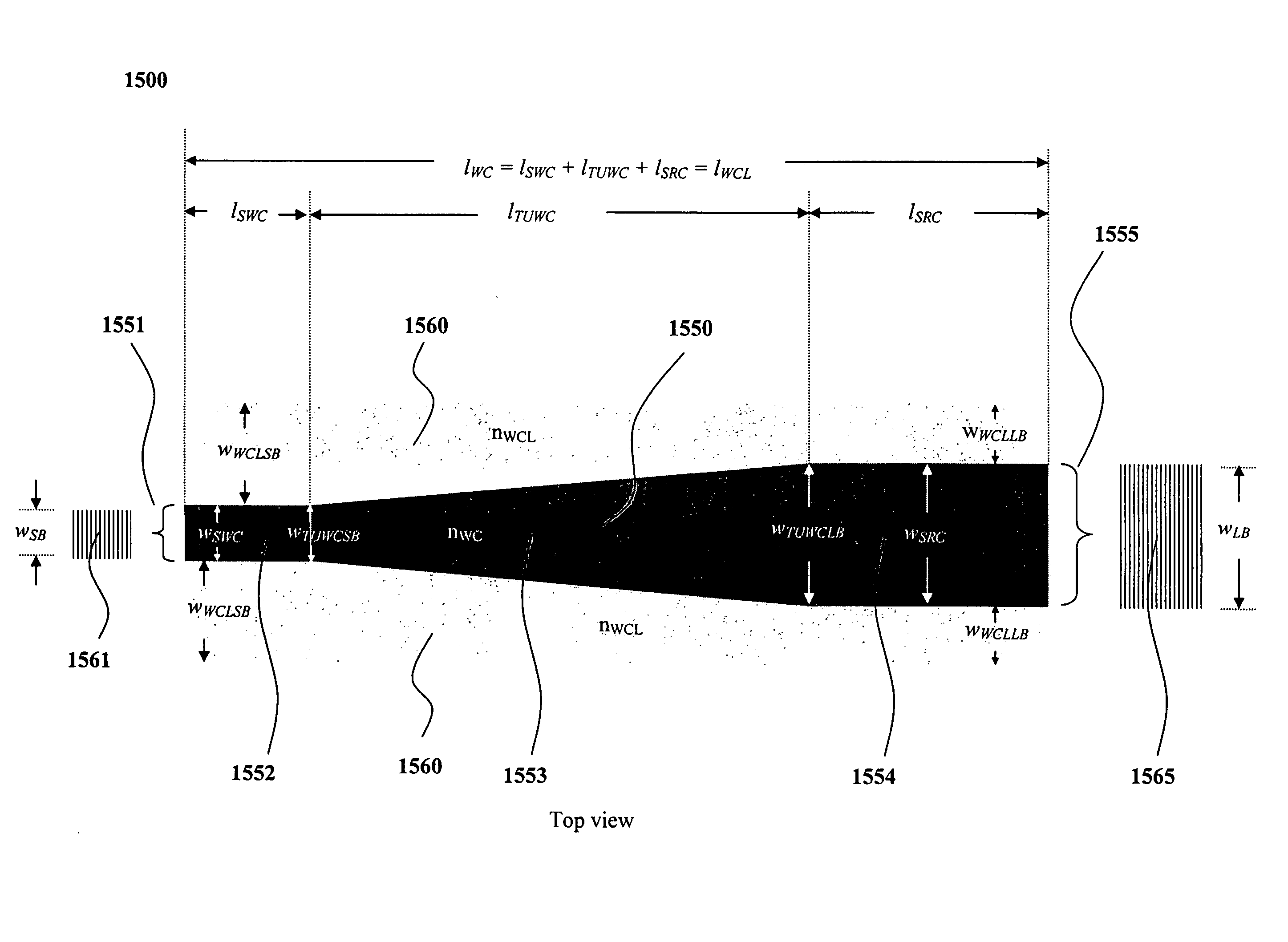

Integrated planar composite coupling structures for bi-directional light beam transformation between a small mode size waveguide and a large mode size waveguide

InactiveUS7218809B2Reduce manufacturing costReduce sensitivityCoupling light guidesOptical waveguide light guideFiberRefractive index contrast

Composite optical waveguide structures or mode transformers and their methods of fabrication and integration are disclosed, wherein the structures or mode transformers are capable of bi-directional light beam transformation between a small mode size waveguide and a large mode size waveguide. One aspect of the present invention is directed to an optical mode transformer comprising a waveguide core having a high refractive index contrast between the waveguide core and the cladding, the optical mode transformer being configured such that the waveguide core has a taper wherein a thickness of the waveguide core tapers down to a critical thickness value, the critical thickness value being defined as a thickness value below which a significant portion of the energy of a light beam penetrates into the cladding layers surrounding the taper structure thereby enlarging the small mode size. This primary tapered core structure may be present in either a vertical or horizontal direction and may be combined with further up taper or down taper structures in the directions transverse to the primary taper direction. Another aspect of the present invention is directed to a non-cylindrical graduated refractive index (GRID) lens structure. The non-cylindrical GRIN structure has a graded refractive index having a maximum value at its core and a minimum value at its outer edges. The grading of the refractive index is provided in a either the vertical or horizontal directions and may have either a fixed refractive index or a graded refractive index in the transverse directions. Yet another aspect of the present invention is directed to composite optical mode transformers that are combinations of the taper waveguide structures and the non-cylindrical graduated refractive index structures. Yet another aspect of the present invention is the further integration of the mode transformers with V-grooves for multiple input / output fibers and alignment platform for multiple input / output photonic chips or devices.

Owner:HO SENG TIONG

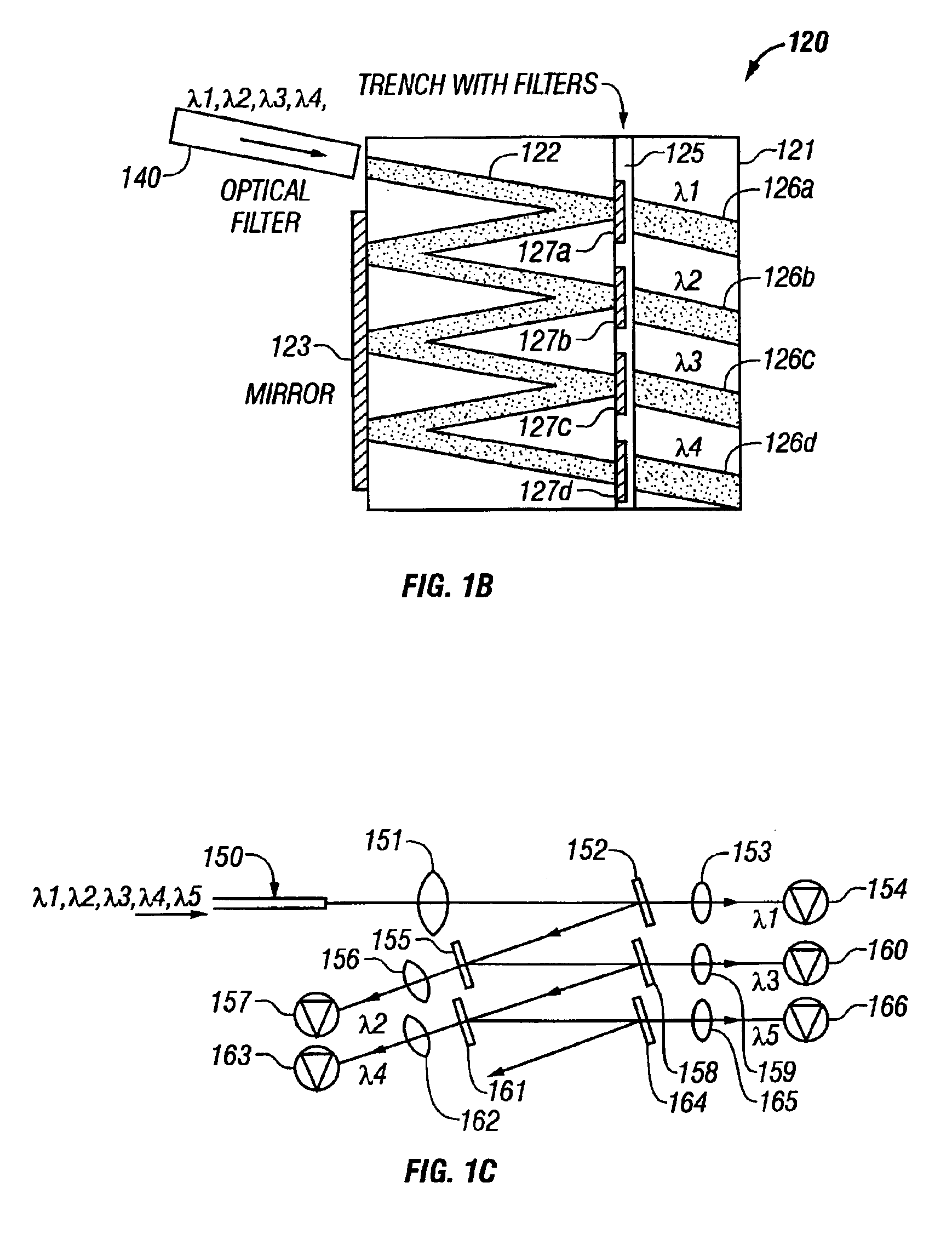

Filter based multiplexer/demultiplexer component

InactiveUS6870976B2Easy to assembleRequires little time in alignmentWavelength-division multiplex systemsOptical articlesCamera lensOptical axis

A multiplexer / demultiplexer optical system component that is passively aligned upon assembly is disclosed. The optical system includes a lens block and a mirror-filter block. In some embodiments, optical filters are positioned and epoxyed to the mirror-filter block using a positioning tool. In some embodiments, optical filters are positioned and epoxyed on a support structure which has been etched to receive the optical filters. The mirror-filter block is a block having flat surfaces, one of which is a flat reflecting surface. The lens block is formed by injection molding and includes a barrel for holding and positioning an optical fiber, placement for a collimating lens, and placements for focusing lenses such that, when assembled, light incident on each of the focusing lenses propagates along the optical axis of the focusing lens. In some embodiments, the collimating lens and the focusing lenses are integrally formed with the lens block. In some embodiments, one or more of the collimating lens or focusing lenses are formed separately and inserted into holders integrally formed with the lens block to receive the lens. In some embodiments, the lens block includes a reflecting surfaces that directs light onto the focusing lenses. Assembly and alignment of the multiplexer / demultiplexer involves positioning a flat surface of the mirror-filter block against a receiving surface of the lens block with the filters between them and epoxying the components in place.

Owner:LUMENTUM FIBER OPTICS INC

Wavelength-converted semiconductor light emitting device

ActiveUS7341878B2Effective lightingStrong water absorptionMaterial nanotechnologySolid-state devicesSemiconductor structurePhosphor

A material such as a phosphor is optically coupled to a semiconductor structure including a light emitting region disposed between an n-type region and a p-type region, in order to efficiently extract light from the light emitting region into the phosphor. The phosphor may be phosphor grains in direct contact with a surface of the semiconductor structure, or a ceramic phosphor bonded to the semiconductor structure, or to a thin nucleation structure on which the semiconductor structure may be grown. The phosphor is preferably highly absorbent and highly efficient. When the semiconductor structure emits light into such a highly efficient, highly absorbent phosphor, the phosphor may efficiently extract light from the structure, reducing the optical losses present in prior art devices.

Owner:LUMILEDS

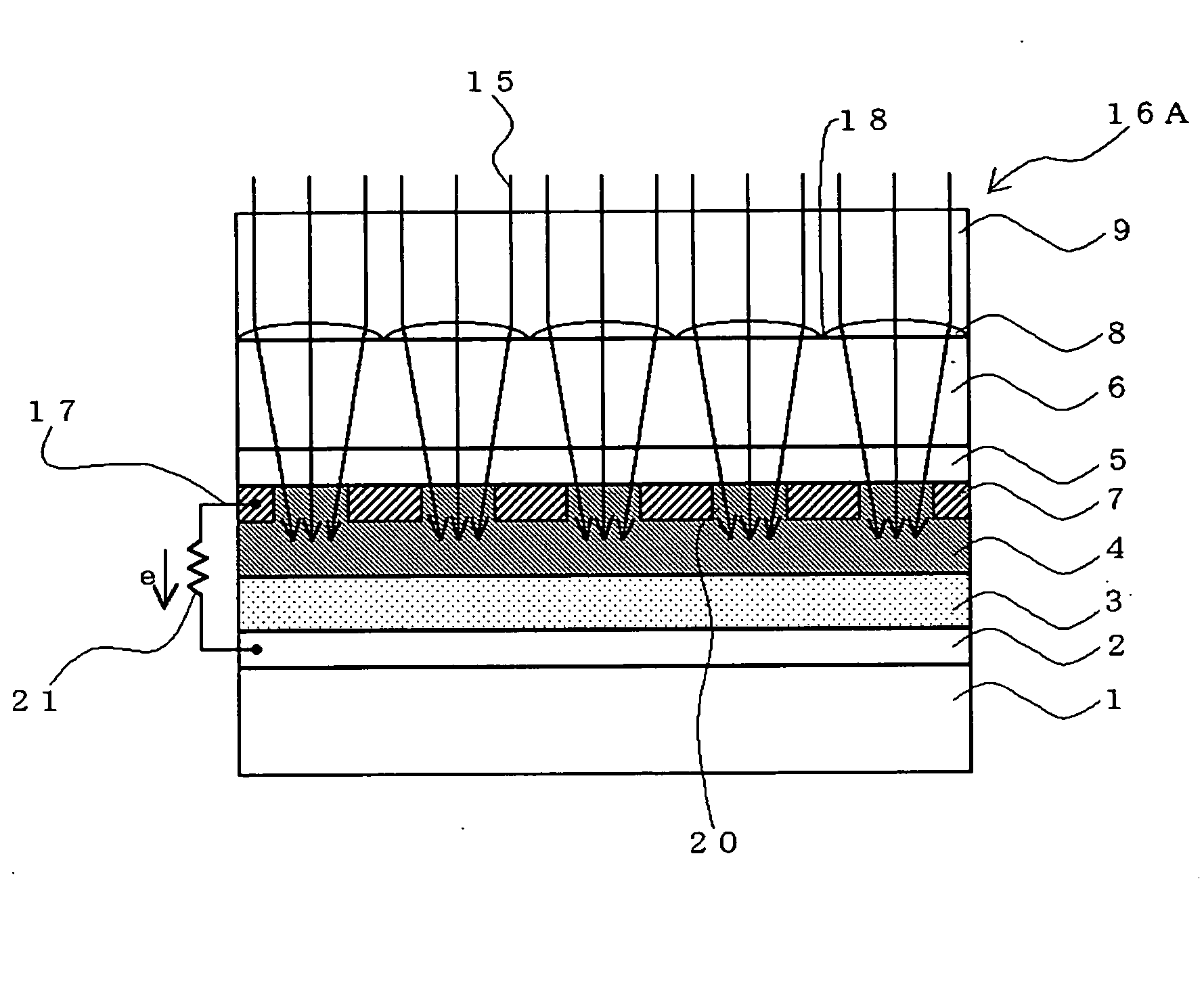

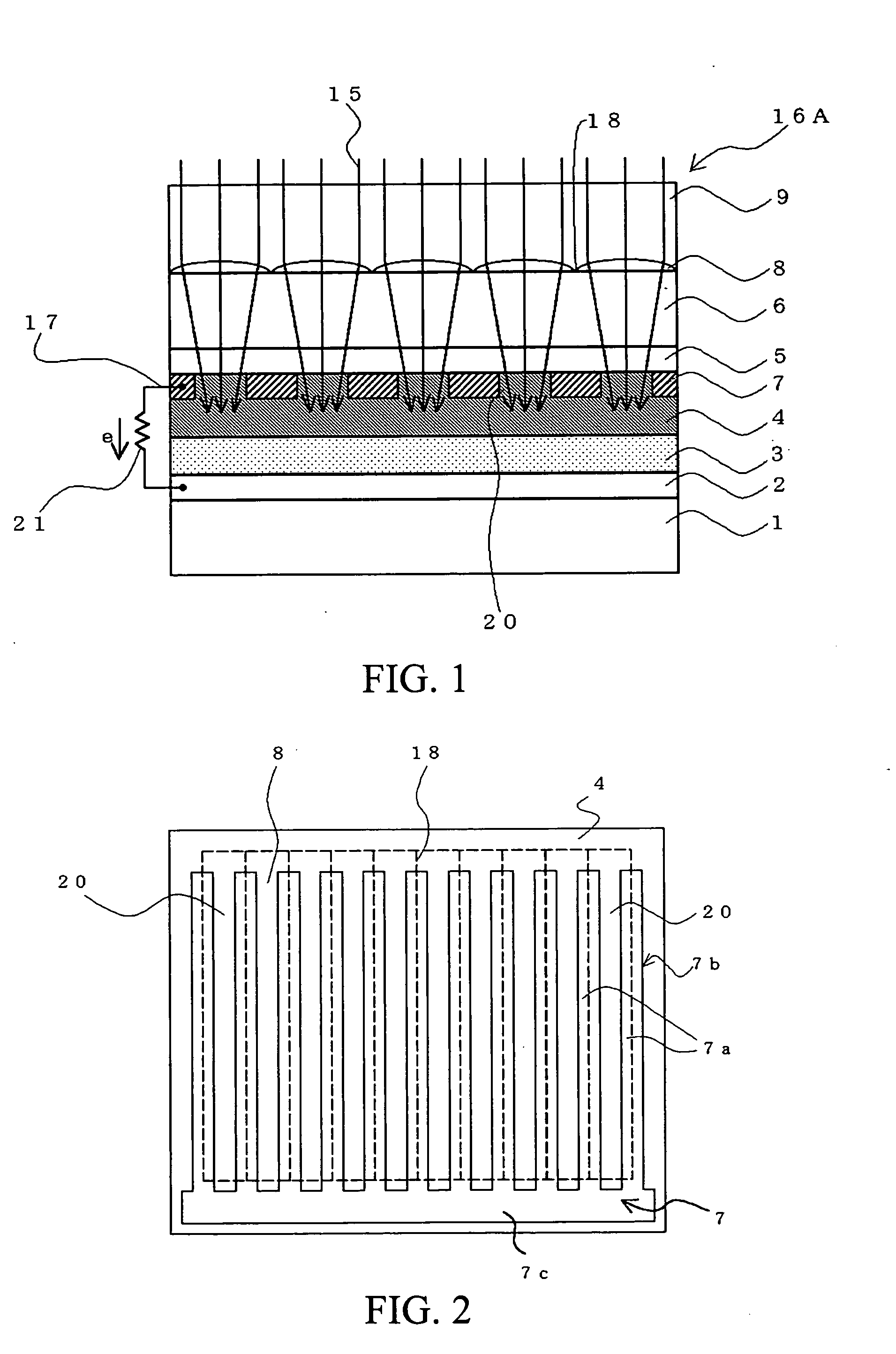

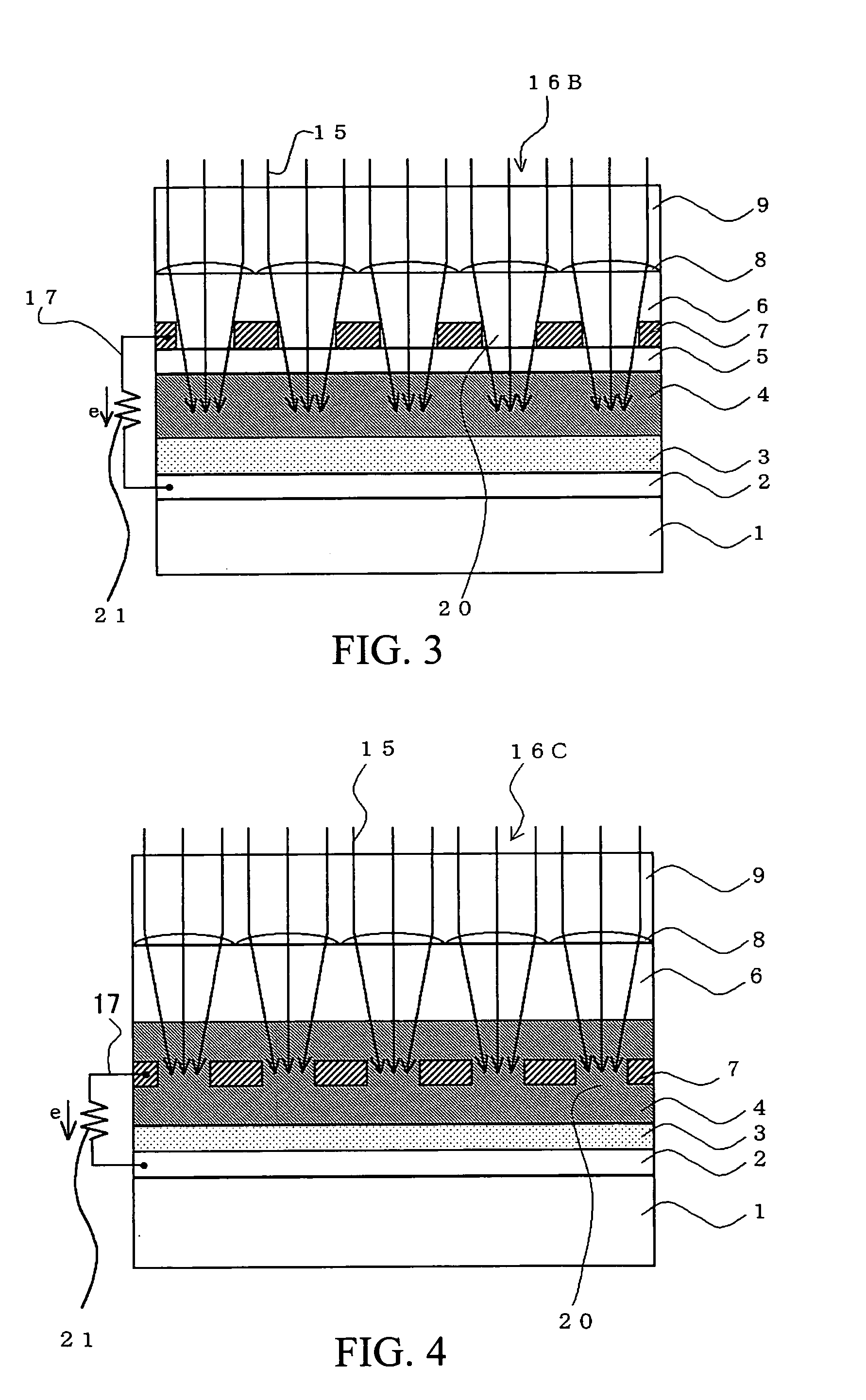

Photoelectric conversion device

InactiveUS20050166957A1Conductor loss is reducedImprove mobilityLight-sensitive devicesPV power plantsLight energyTransducer

A photoelectric transducer having a relatively simple structure and capable of reducing the loss of light energy of incident light and conductor loss due to electrical resistance. A photoelectric transducer 16A includes a conductive layer 2; a electrolytic layer 3 that is in contact with the conductive layer 2; a charge separating layer 4; a transparent conductive layer 5 and a metal lines 7, which are in contact with the charge separating layer 4; and convex lenses 8 converging incident light 15 on openings 20 provided between the metal lines 7, the incident light 15 being converged on the charge separating layer 4 by the convex lenses 8. Electrons generated by photoelectric conversion move to the exterior through an external circuit 17 having a low resistivity.

Owner:SONY CORP

Blade insert illuminator

A blade insert illumination system includes one or more illumination elements composed of a transparent or semi-transparent polymer that is preferably biocompatible and sterilizable. The illumination elements operate as a waveguide and may incorporate optical components such as, for example, facets, lenses, gratings, prisms and or diffusers to operate as precision optics for customized delivery of the light energy. The illumination elements may be modular, allowing components to be mixed and matched for different sizes of blade retractors, or may be a single integrated unit.

Owner:INVUITY

Apparatus and method for exposing a substrate to UV radiation while monitoring deterioration of the UV source and reflectors

ActiveUS20070228289A1Reduce light lossDrying solid materials with heatLighting heating/cooling arrangementsPhysicsLower intensity

Embodiments of the invention relate generally to an ultraviolet (UV) cure chamber for curing a dielectric material disposed on a substrate and to methods of curing dielectric materials using UV radiation. A substrate processing tool according to one embodiment comprises a body defining a substrate processing region; a substrate support adapted to support a substrate within the substrate processing region; an ultraviolet radiation lamp spaced apart from the substrate support, the lamp configured to transmit ultraviolet radiation to a substrate positioned on the substrate support; and a motor operatively coupled to rotate at least one of the ultraviolet radiation lamp or substrate support at least 180 degrees relative to each other. The substrate processing tool may further comprise one or more reflectors adapted to generate a flood pattern of ultraviolet radiation over the substrate that has complementary high and low intensity areas which combine to generate a substantially uniform irradiance pattern if rotated. Other embodiments are also disclosed.

Owner:APPLIED MATERIALS INC

Waveguide illumination system

ActiveUS20170212295A1Reduce light lossMinimizes lightMechanical apparatusElectric lightingForward scatterTotal internal reflection

An illumination system employing a waveguide that receives and propagates light in response to transmission and total internal reflection. Light deflecting elements distributed along the propagation path incrementally change the out-of-plane angles of light rays and cause decoupling of portions of light from the waveguide at different distances from the light input edge or end. Light may escape from the waveguide into an intermediate layer at low out-of-plane angles and can be further redirected by light extraction features out of the system. In one embodiment, the illumination system is configured to emit collimated light. In one embodiment, the illumination system includes shallow surface relief features. In one embodiment, the light deflecting elements include forward-scattering particles distributed throughout the volume of the waveguide.

Owner:S V V TECH INNOVATIONS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com