Patents

Literature

331results about How to "Optimize geometry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

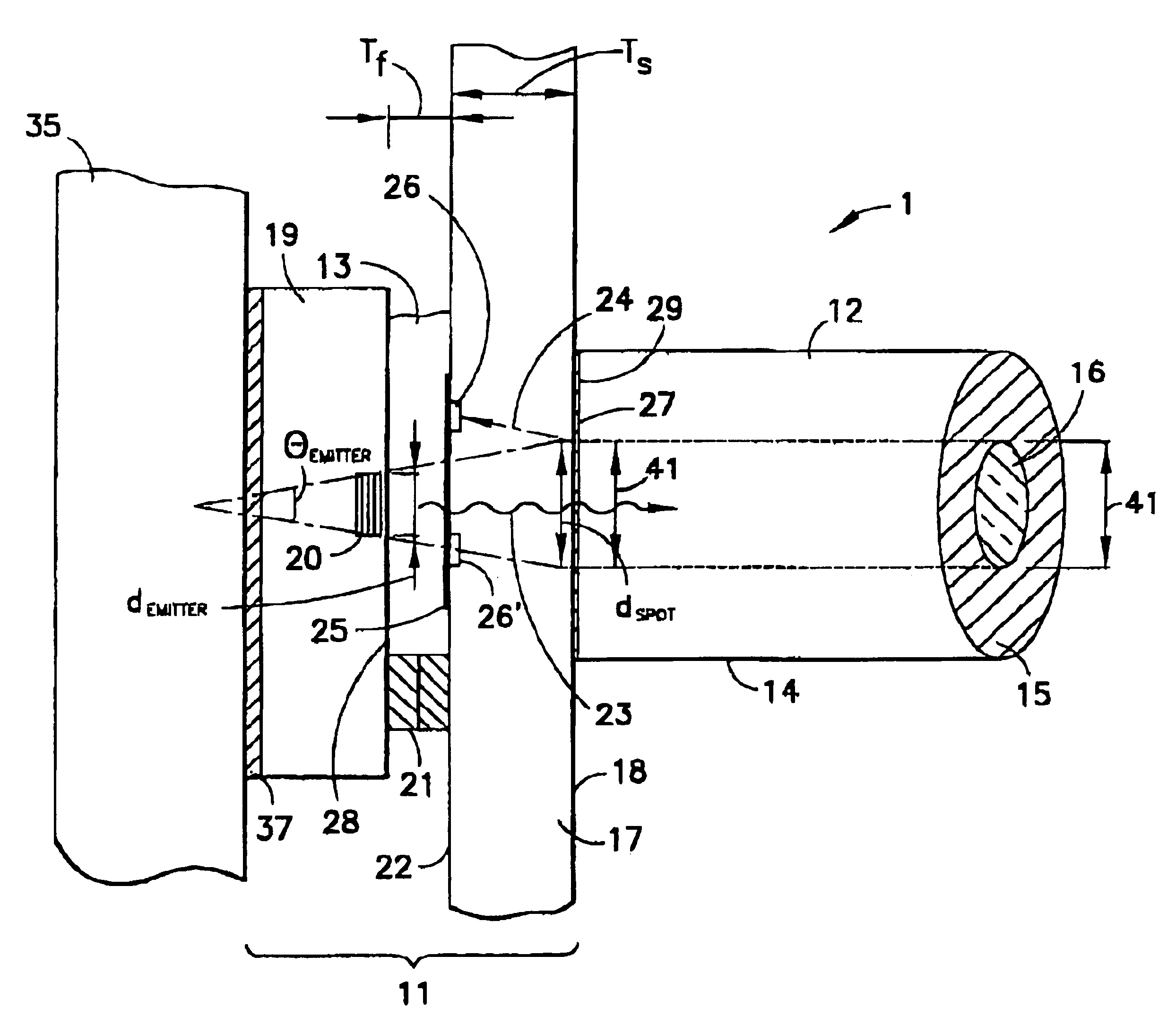

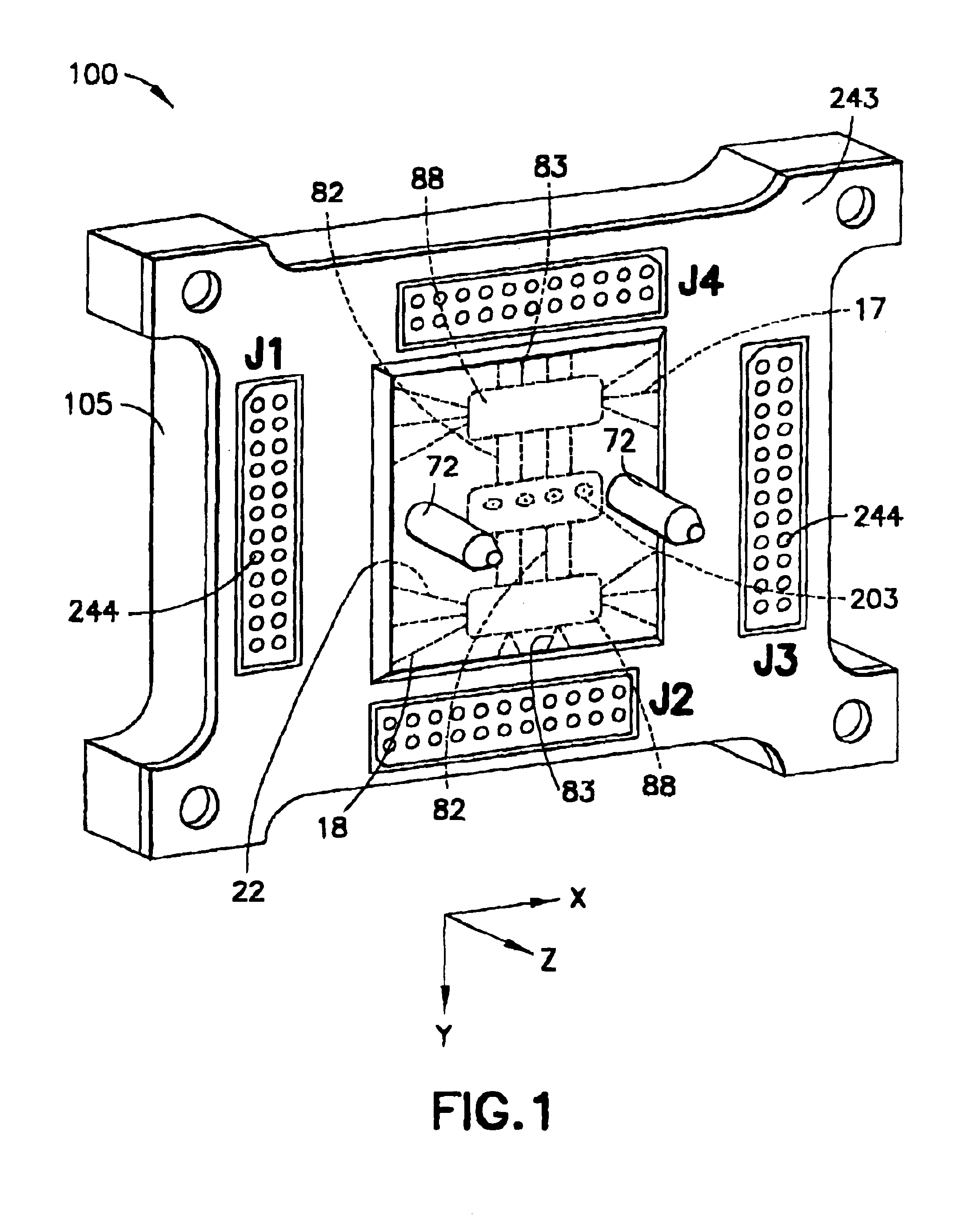

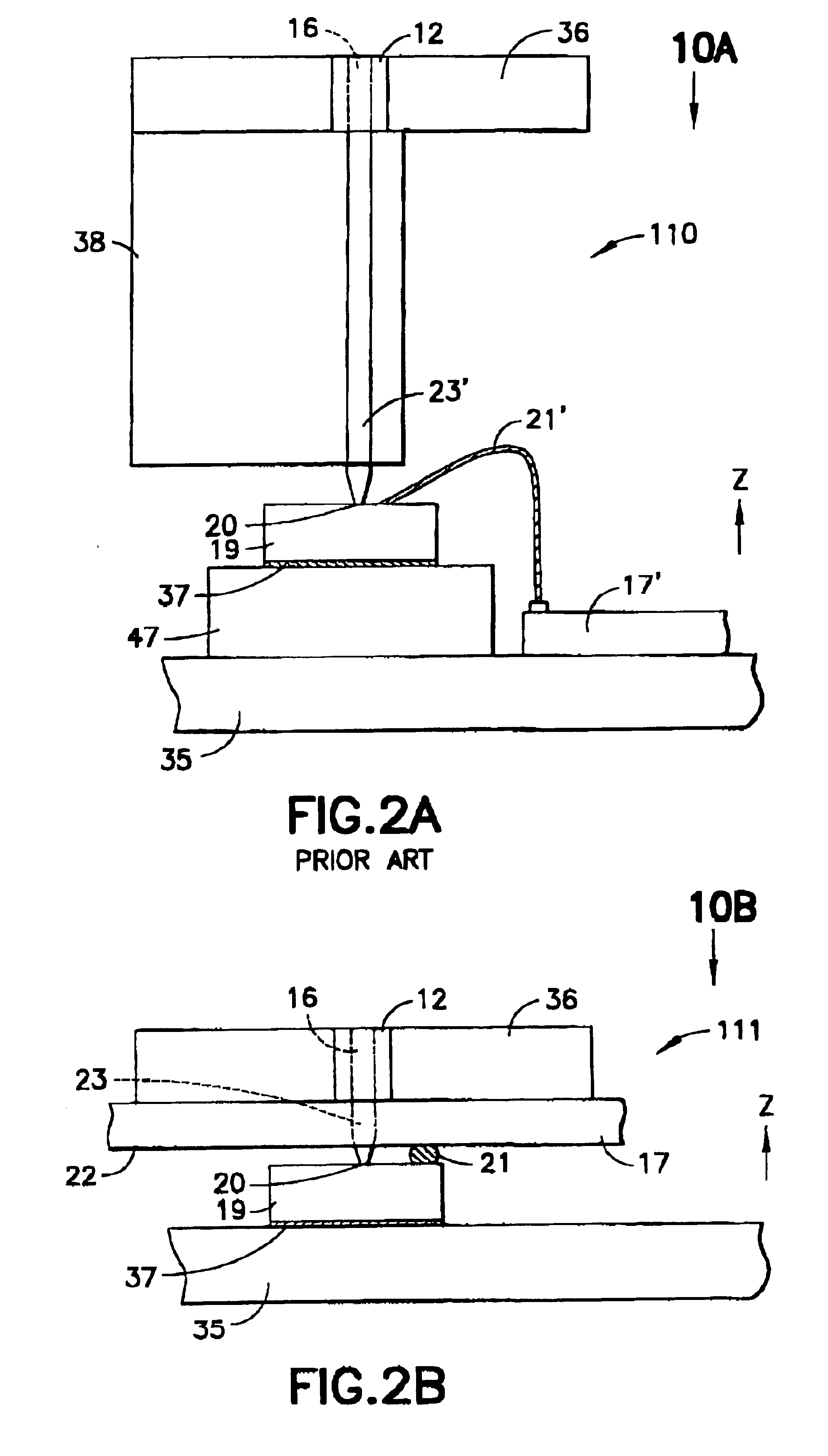

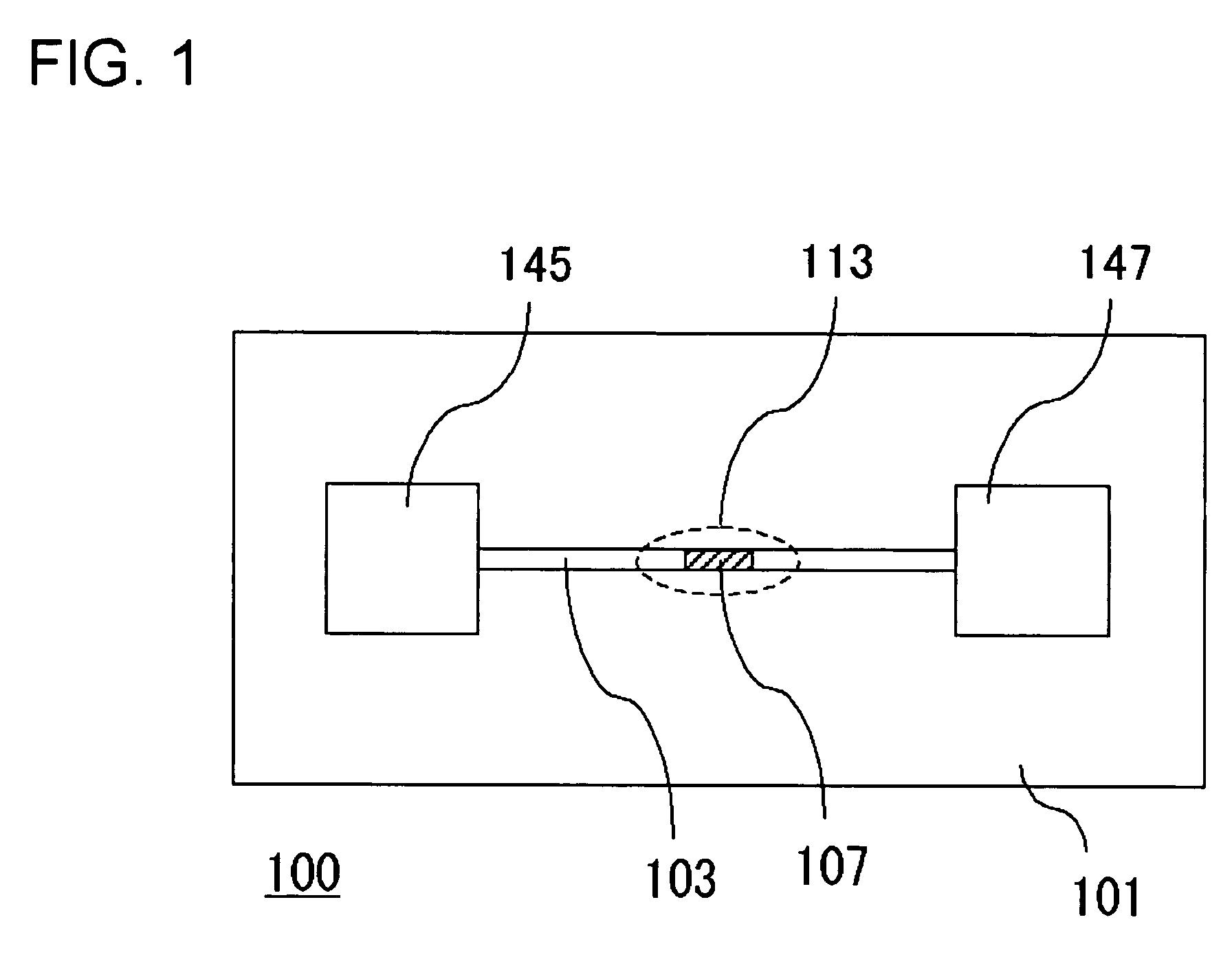

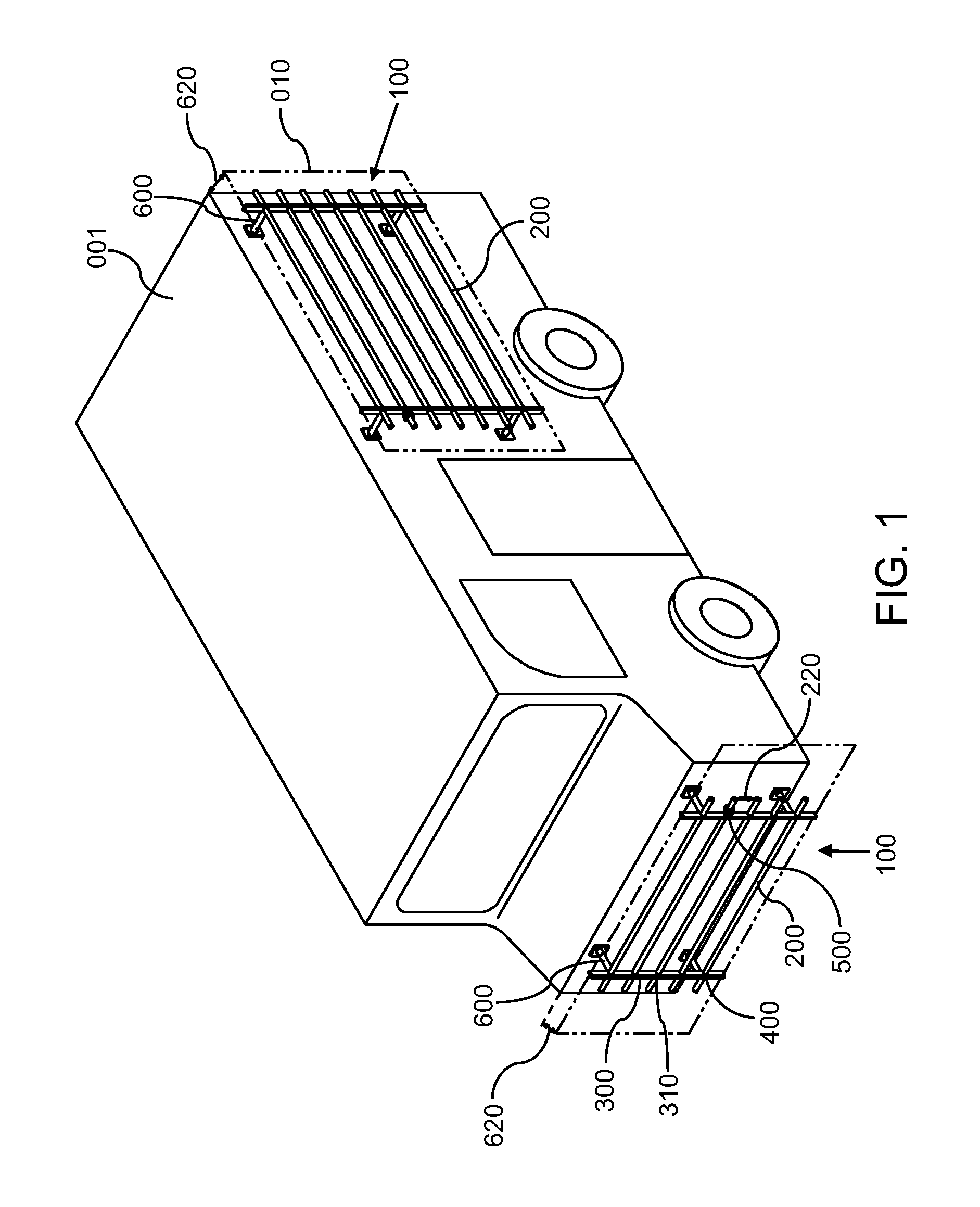

Small-scale optoelectronic package

InactiveUS6910812B2Easy to manufactureSacrifice speedSemiconductor/solid-state device detailsSolid-state devicesFiberElectricity

An integrated circuit / optoelectronic packaging system (100) which comprises OE and IC components packaged to provide electrical input / output, thermal management, an optical window, and precise passive or mechanical alignment to external optical receivers or transmitters. A transparent insulating substrate having electrical circuitry in a thin silicon layer formed on its top side is positioned between the optical fiber and the optoelectronic device such that an optical path is described between the optoelectronic device and the optical fiber core through the transparent insulating substrate. The optoelectronic devices are mounted on the transparent insulating substrate in a precise positional relationship to guide holes in the substrate. The optical fibers are fixed in an optical fiber connector and are held in a precise positional relationship to guide holes in the connector. Alignment is accomplished with complementary guide pins that pass through guide holes in the fiber optic connector and in the transparent substrate.

Owner:PSEMI CORP

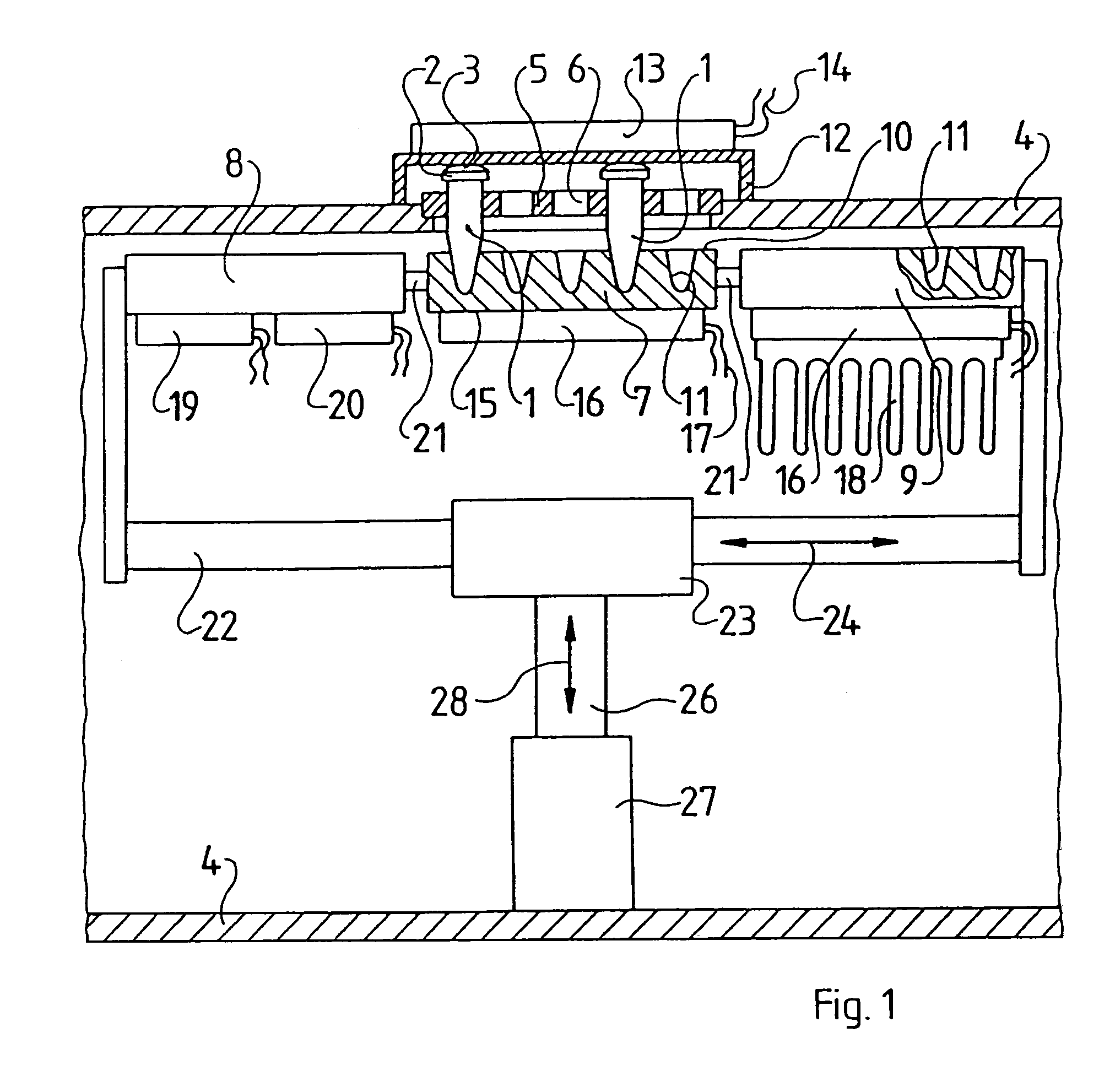

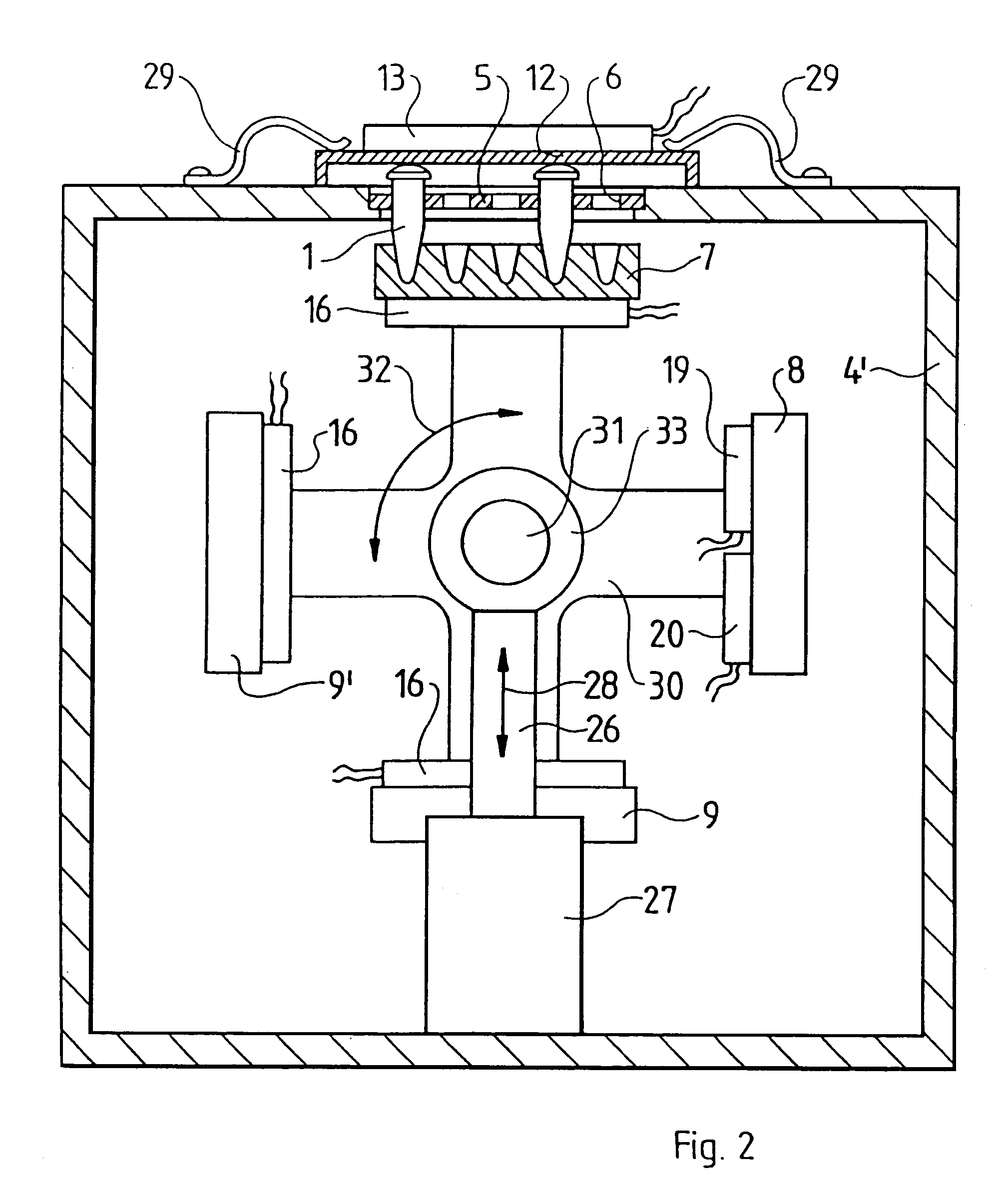

Chemical vapor deposition reactor

InactiveUS8778079B2Improve the deposition effectOptimize geometrySemiconductor/solid-state device manufacturingLiquid transferring devicesGas phaseProcess engineering

Owner:VALENCE PROCESS EQUIP

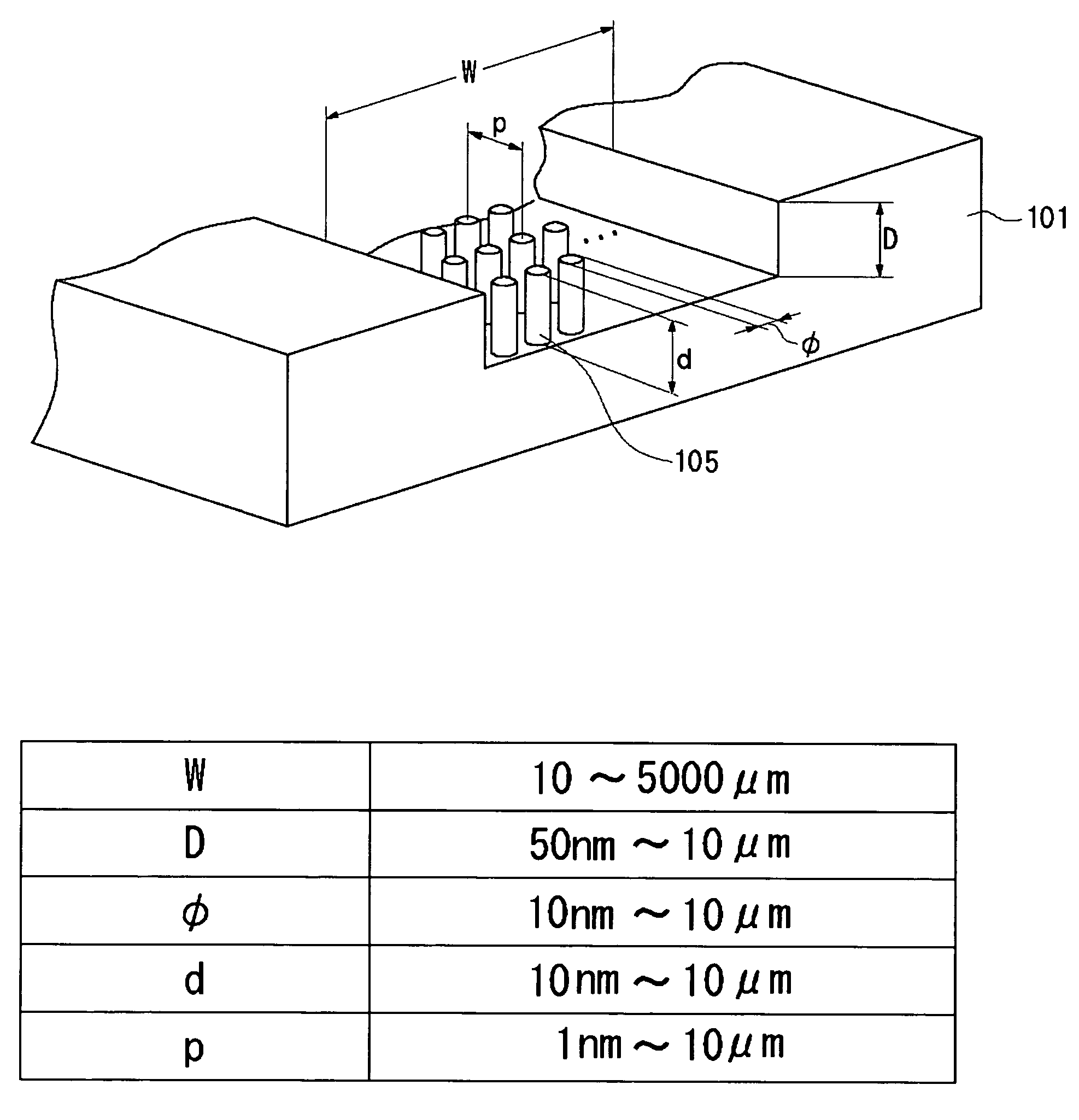

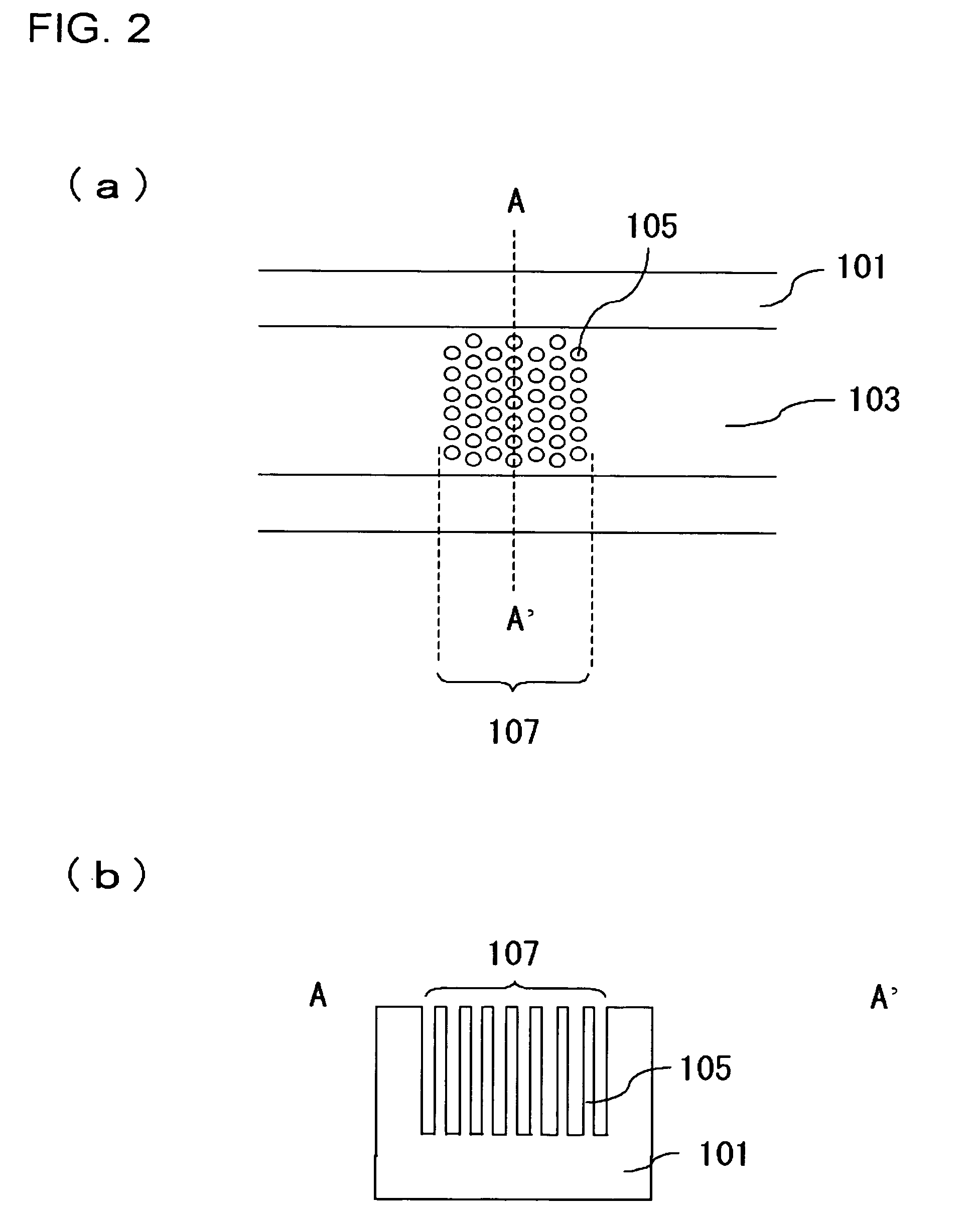

Separation apparatus and separation method

InactiveUS20060000772A1Improve efficiencyHigh activityIon-exchange process apparatusSemi-permeable membranesBuffer solutionAnalytical chemistry

A channel (103) is formed in a substrate (101), and a portion of the channel (103) is provided with a separating portion (107). A number of pillars are formed in the separating portion (107), and an adsorptive substance layer having an adsorptive substance, which exhibits a specific interaction for a specific substance, immobilized on the surface thereof, is formed. Once a sample is introduced into the channel (103), the specific substance is adsorbed on the adsorptive substance layer to be separated from other components. After washing the inside of the channel (103) with a buffer solution, the specific substance is desorbed from the adsorptive substance layer by flowing a eluting solution through the channel (103) and the specific substance is recovered.

Owner:NEC CORP

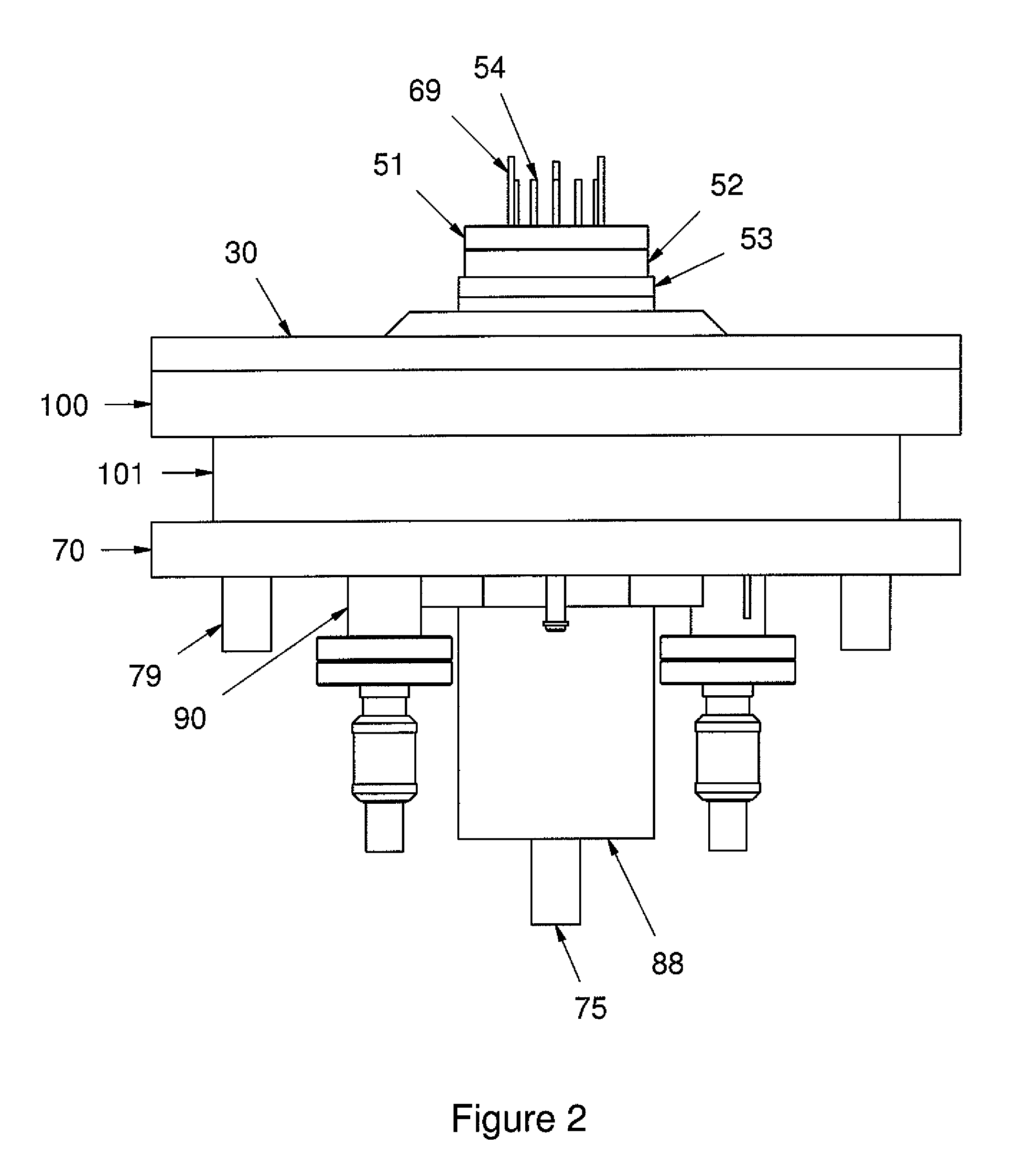

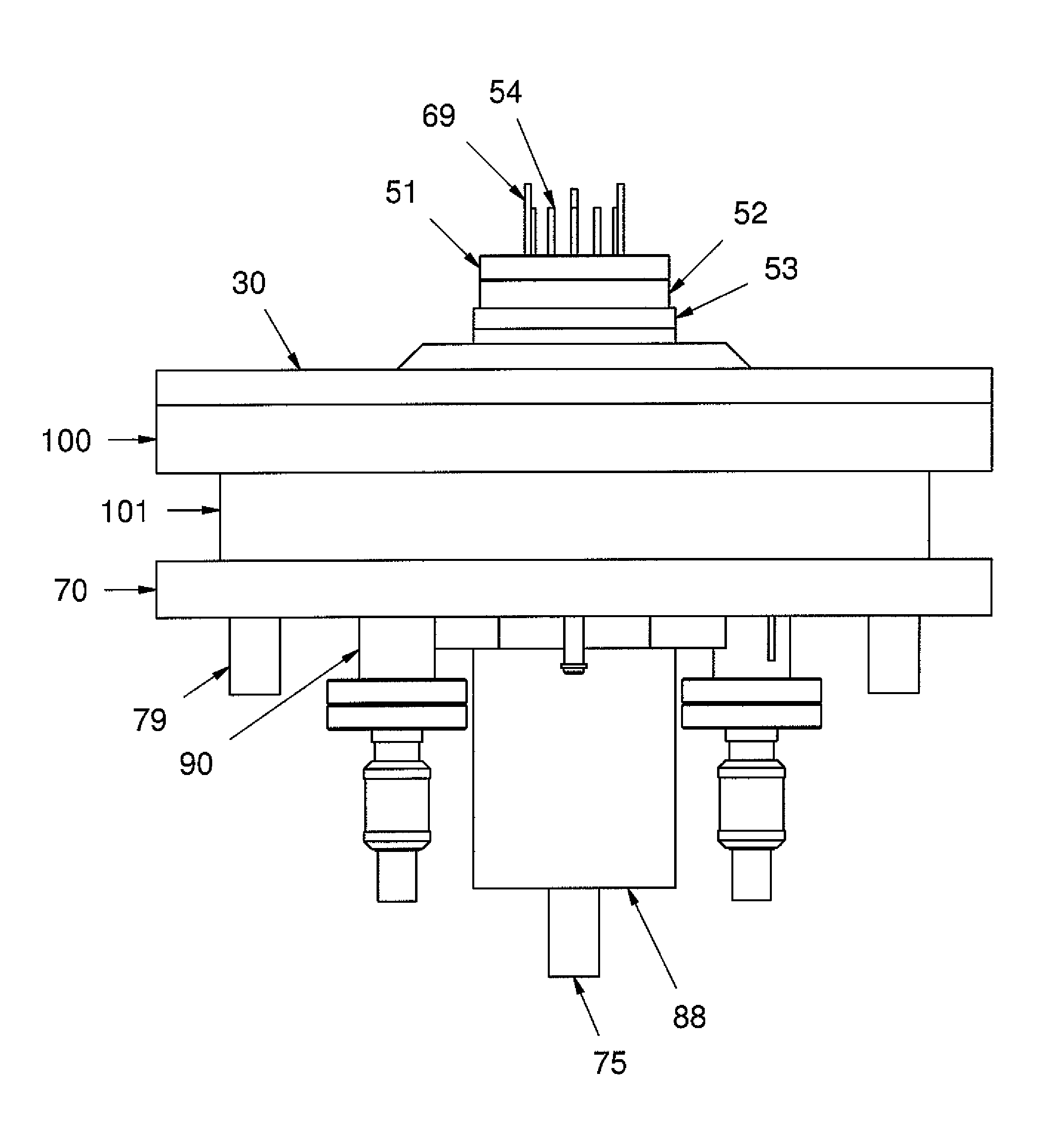

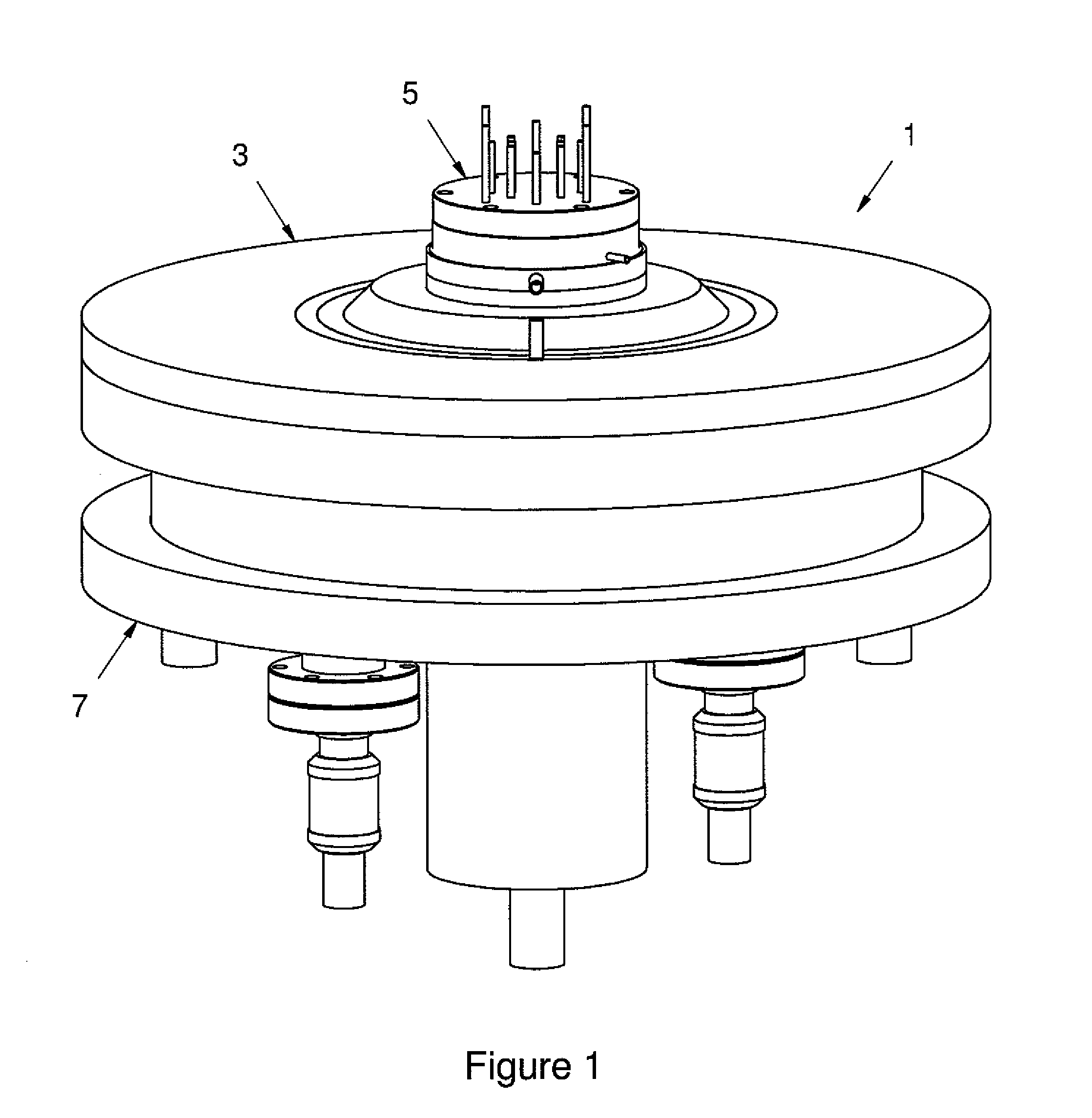

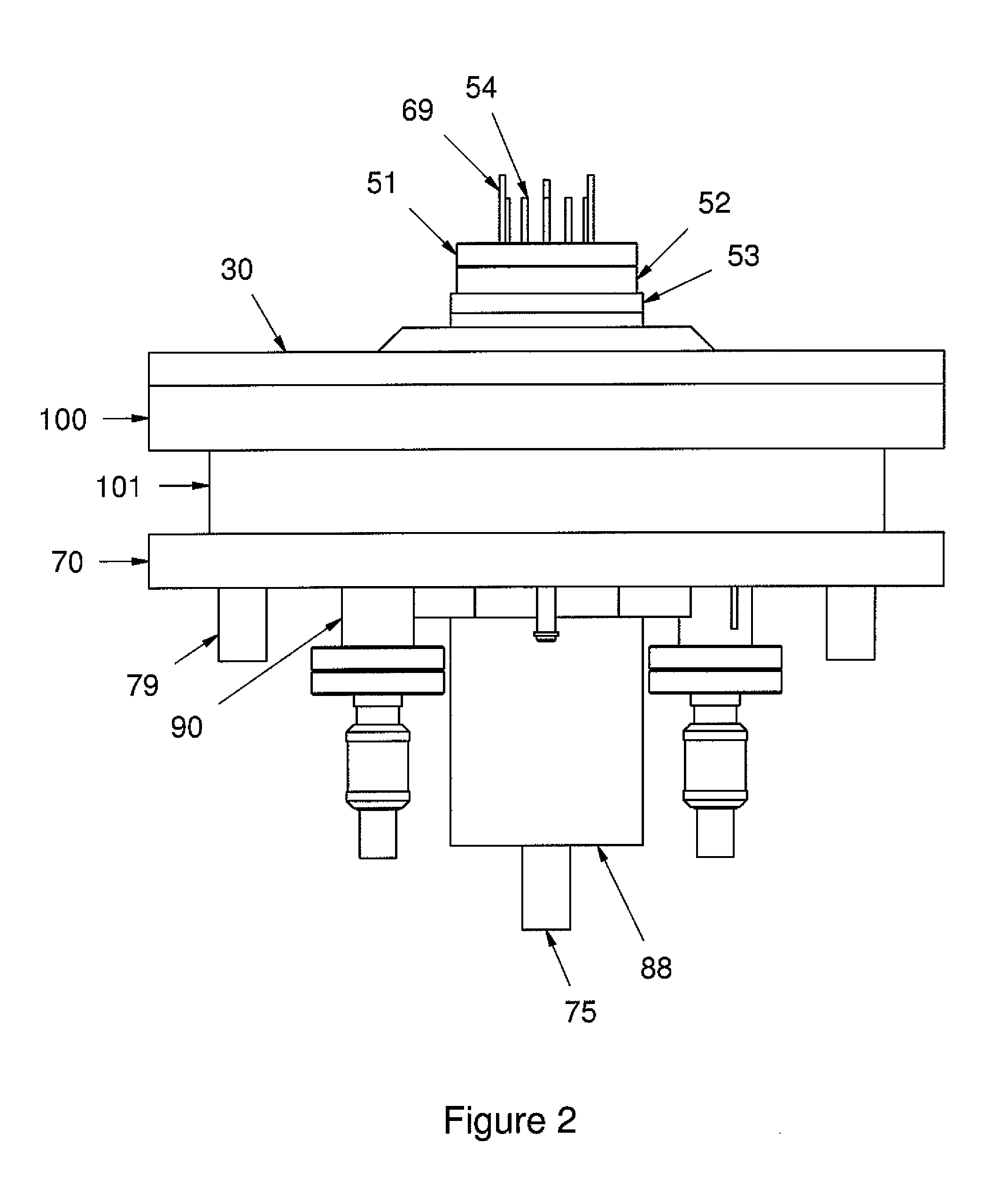

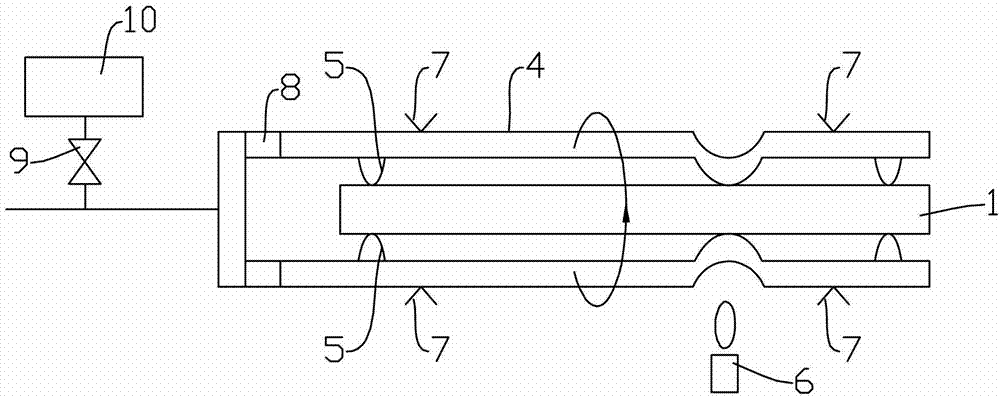

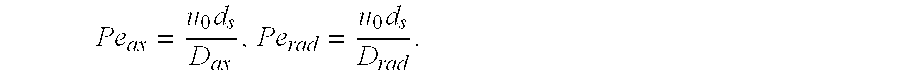

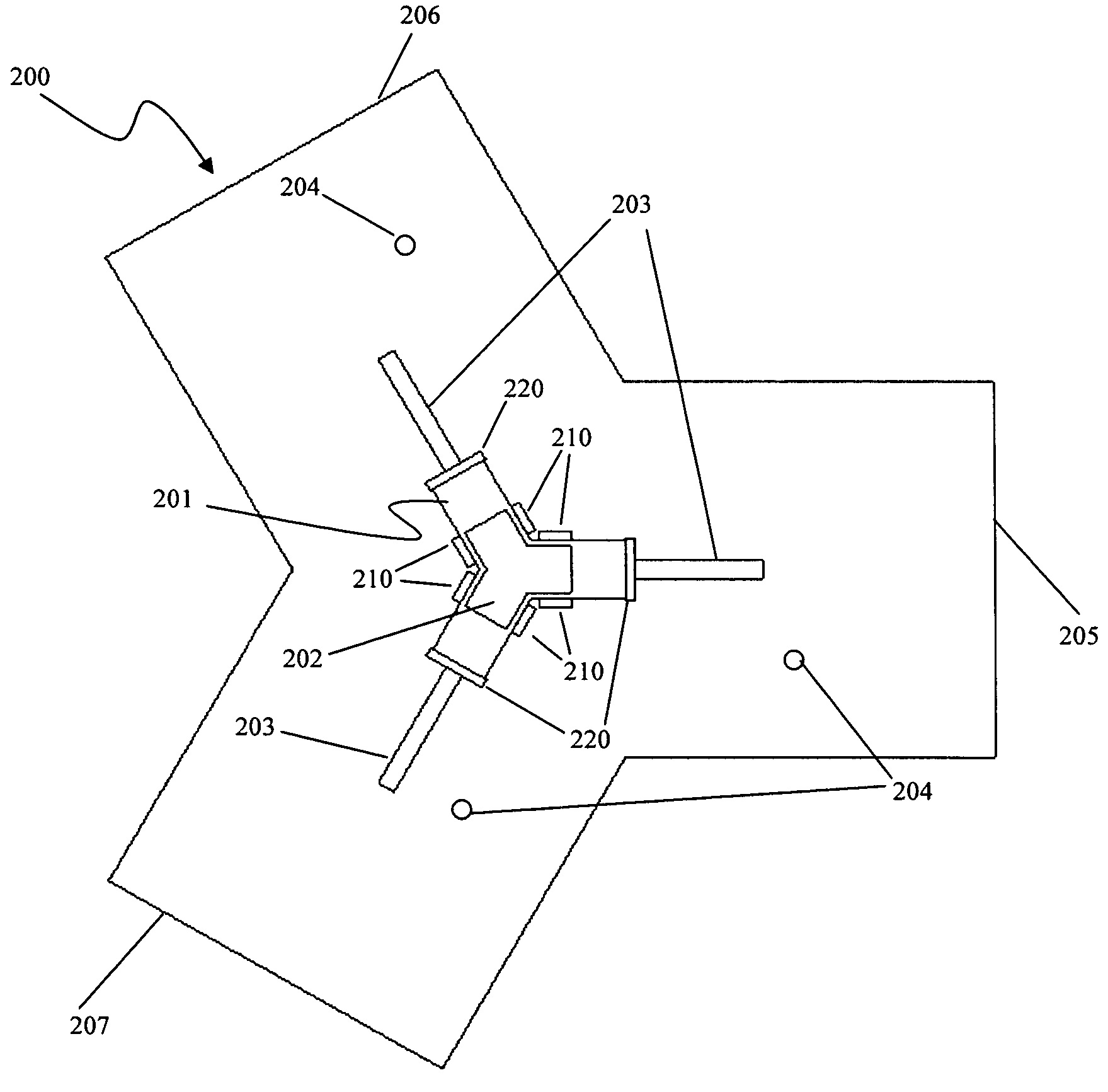

Chemical vapor deposition reactor

InactiveUS20120111271A1Improve the deposition effectOptimize geometrySemiconductor/solid-state device manufacturingLiquid transferring devicesGas phaseProcess engineering

A CVD reactor, such as a MOCVD reactor conducting metalorganic chemical vapor deposition of epitaxial layers, is provided. The CVD or MOCVD reactor generally comprises a flow flange assembly, adjustable proportional flow injector assembly, a chamber assembly, and a multi-segment center rotation shaft. The reactor provides a novel geometry to specific components that function to reduce the gas usage while also improving the performance of the deposition.

Owner:VALENCE PROCESS EQUIP

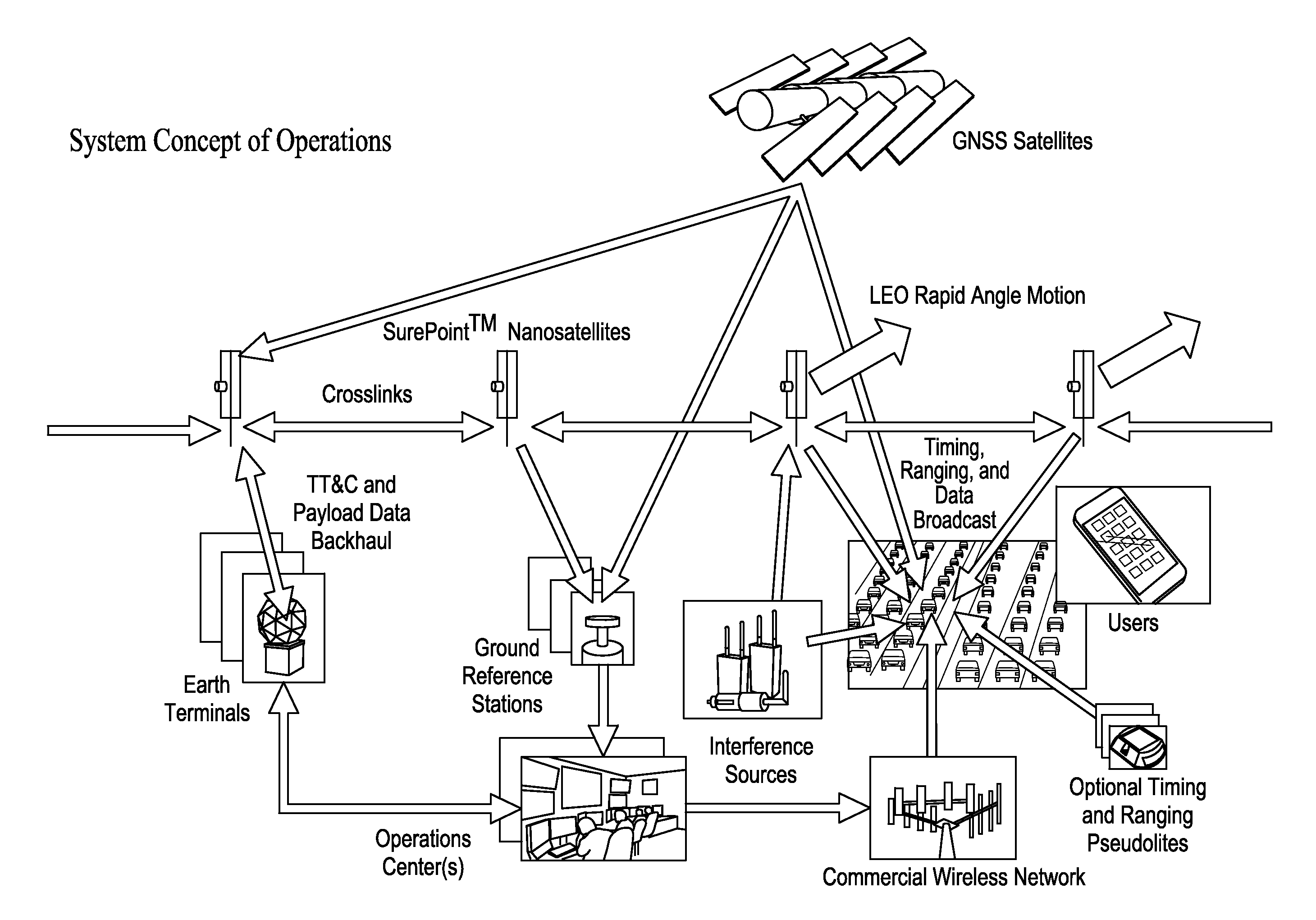

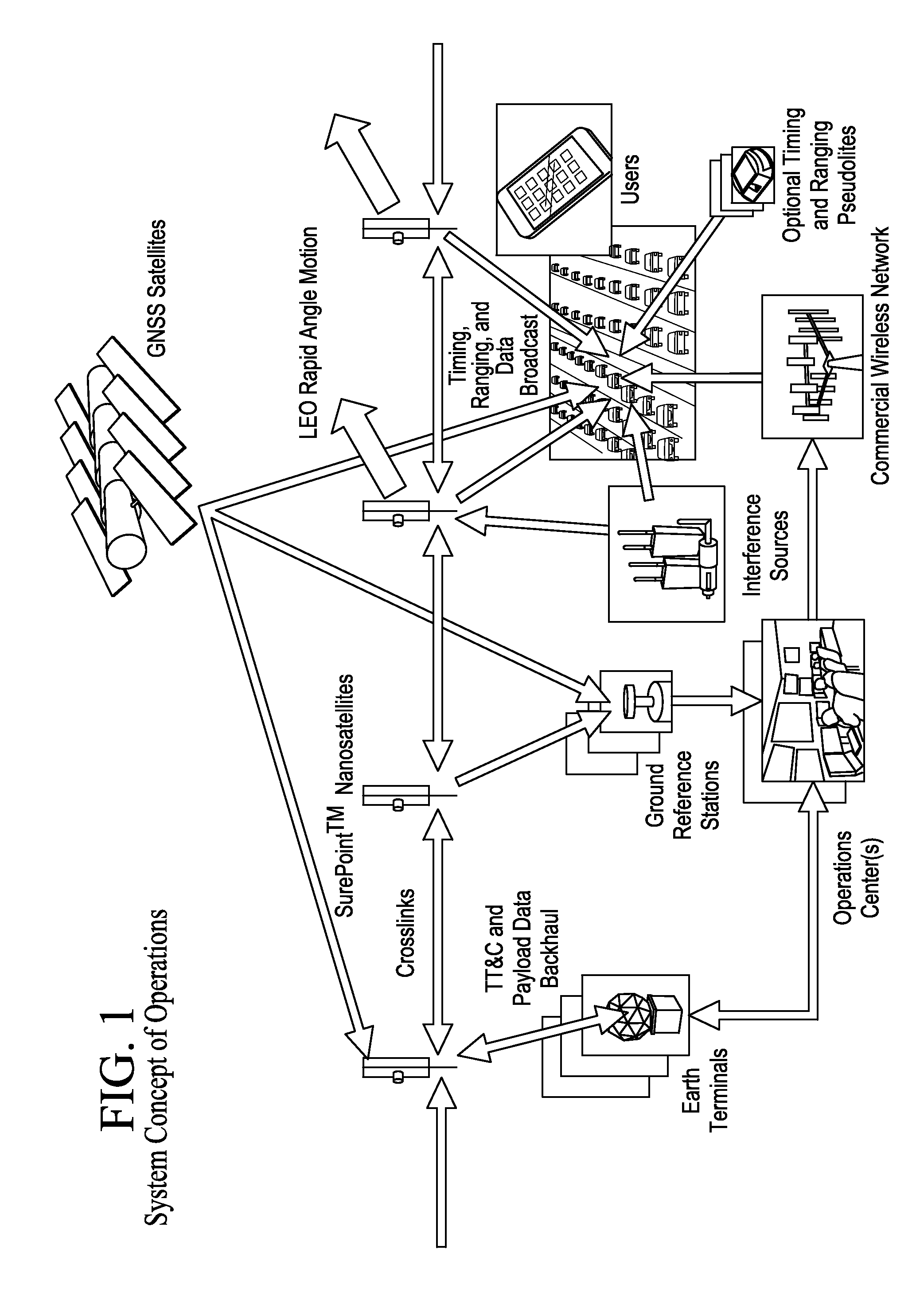

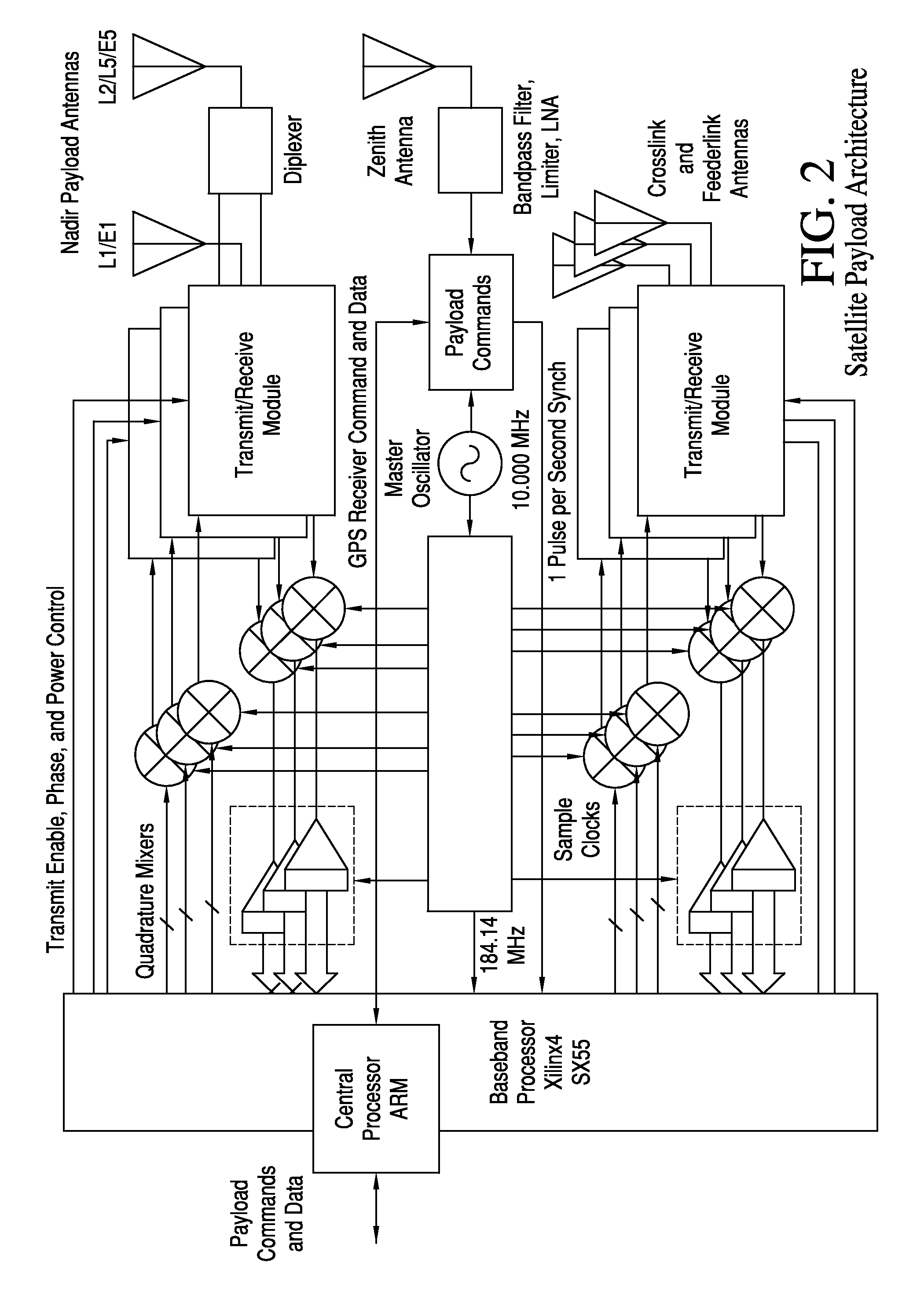

Performance and Cost Global Navigation Satellite System Architecture

ActiveUS20160011318A1Improve performanceCost effectiveSatellite radio beaconingAviationFrequency spectrum

Significant, cost-effective improvement is introduced for Position, Navigation, and Timing (PNT) on a global basis, particularly enhancing the performance of Global Navigation Satellite Systems (GNSS), an example of which is the Global Positioning System (GPS). The solution significantly improves performance metrics including the accuracy, integrity, time to acquire, interference rejection, and spoofing protection. A constellation of small satellites employing a low-cost architecture combined with improved signal processing yields an affordable enabler for spectrum-efficient transportation mobility. As air traffic management modernization transitions to a greater dependence on satellite positioning, the solution provides aviation users new protections from both intentional and unintentional interference to navigation and surveillance. And in response to an era in which intelligent transportation is under development for automobiles, reliable where-in-lane positioning enables new applications in connected and autonomous vehicles. New military capability increases PNT availability.

Owner:PNT HLDG INC

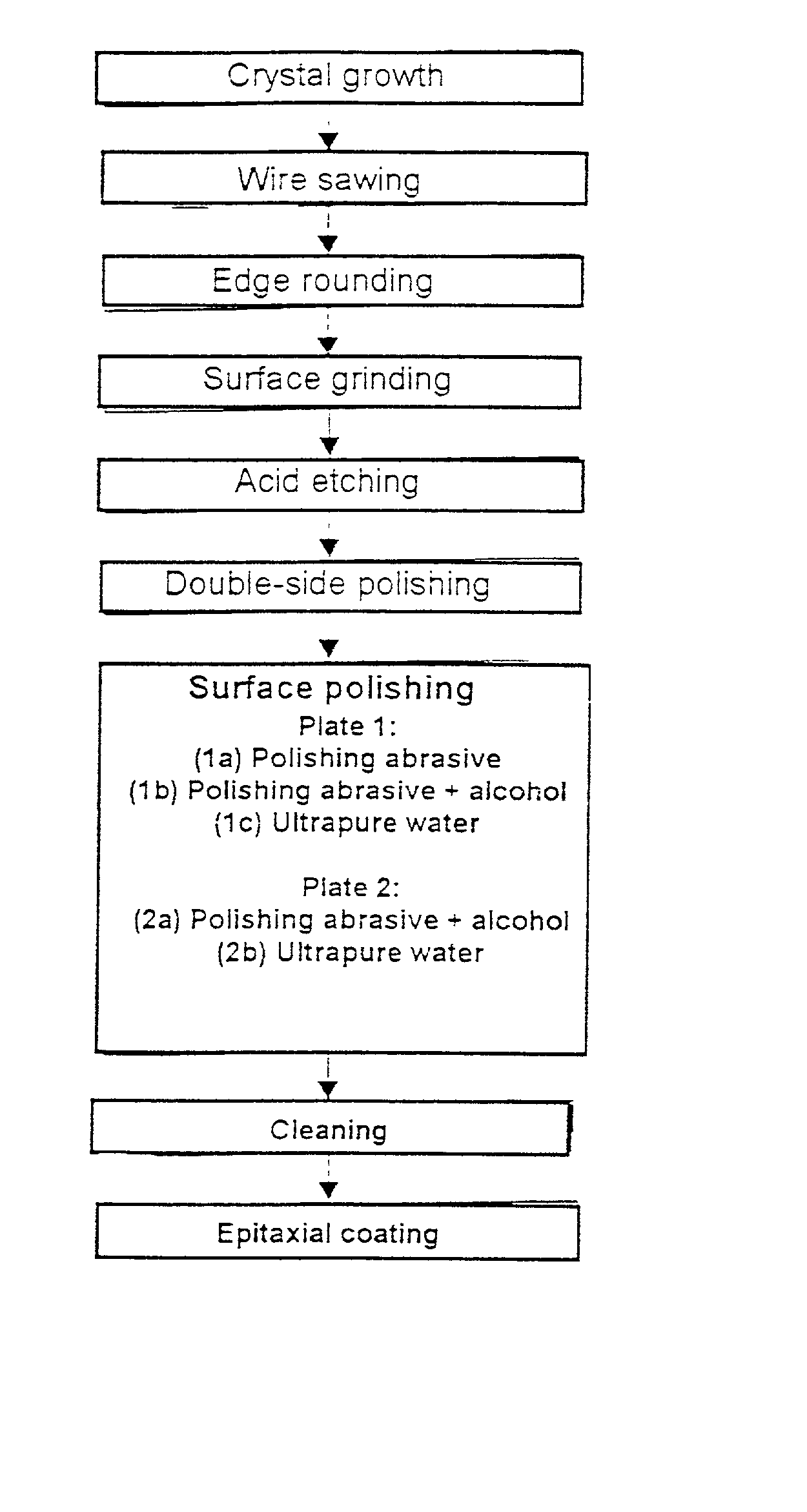

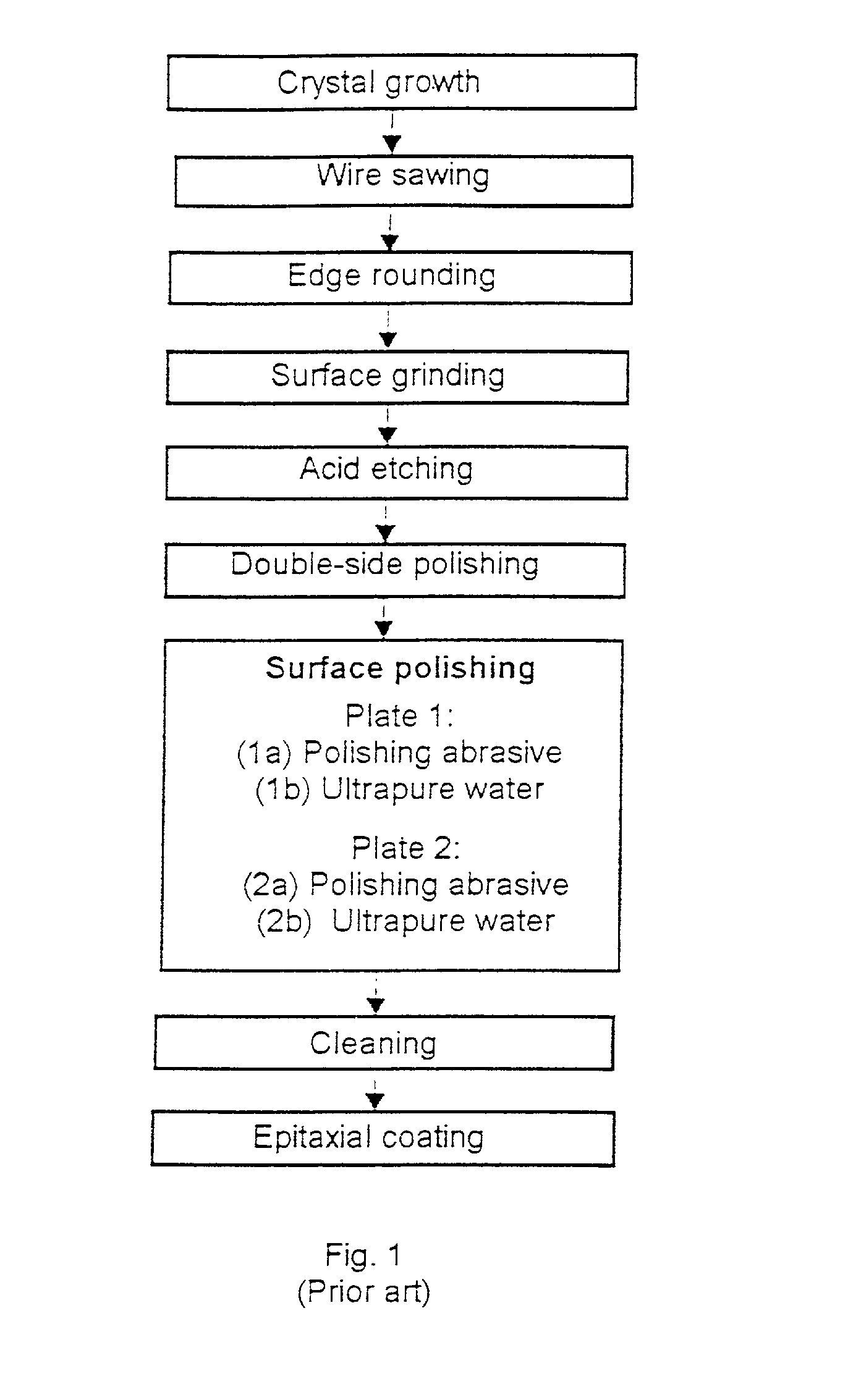

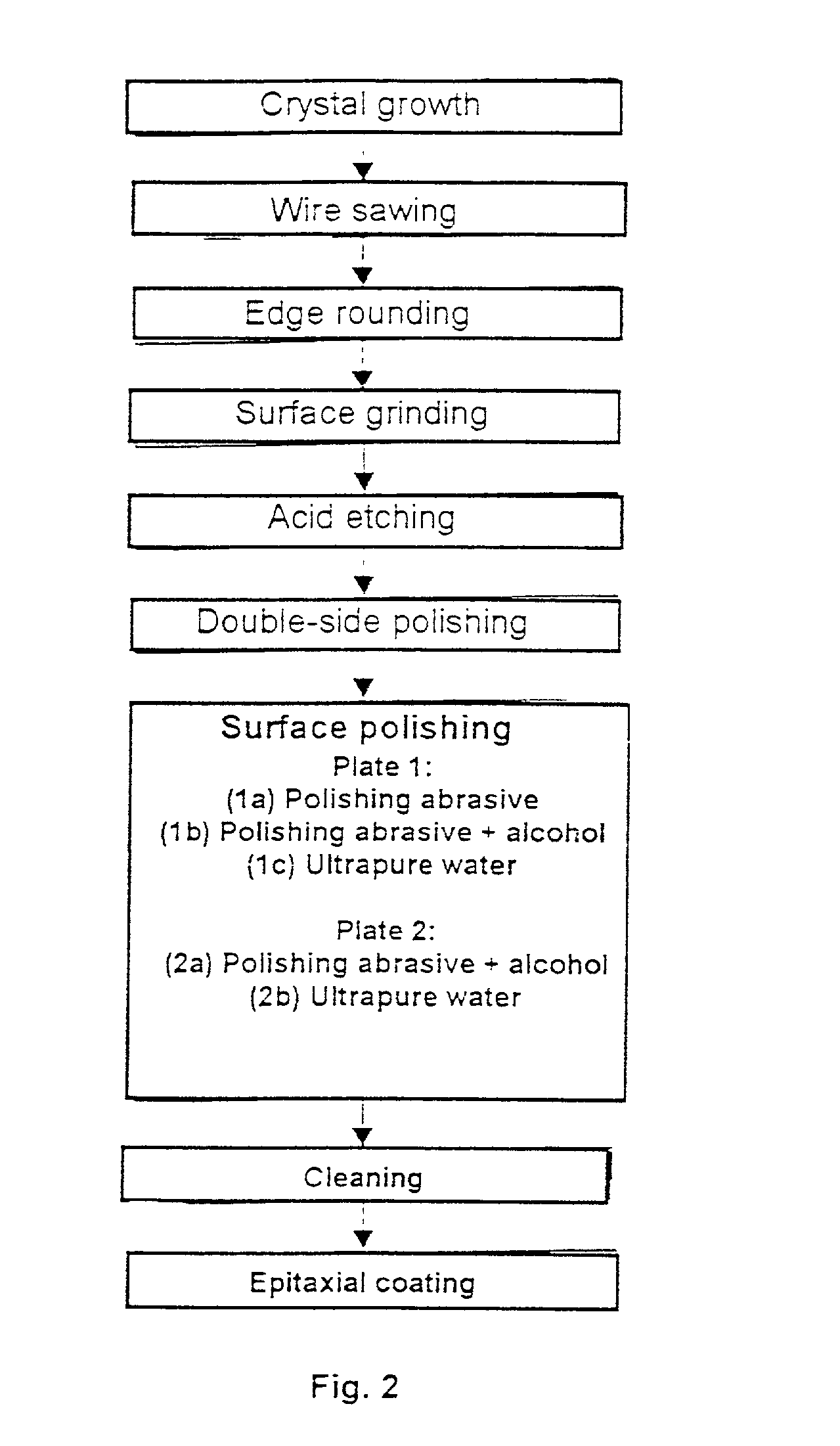

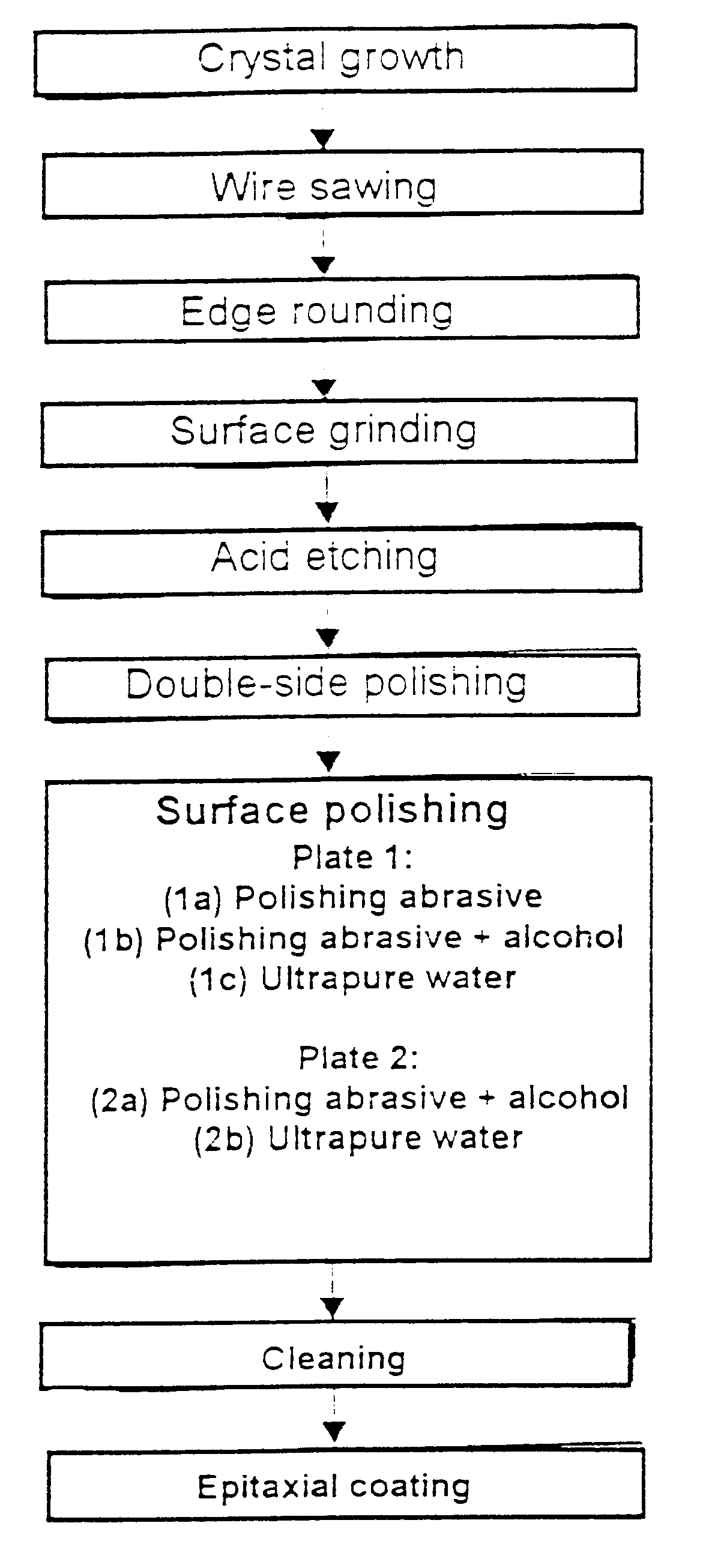

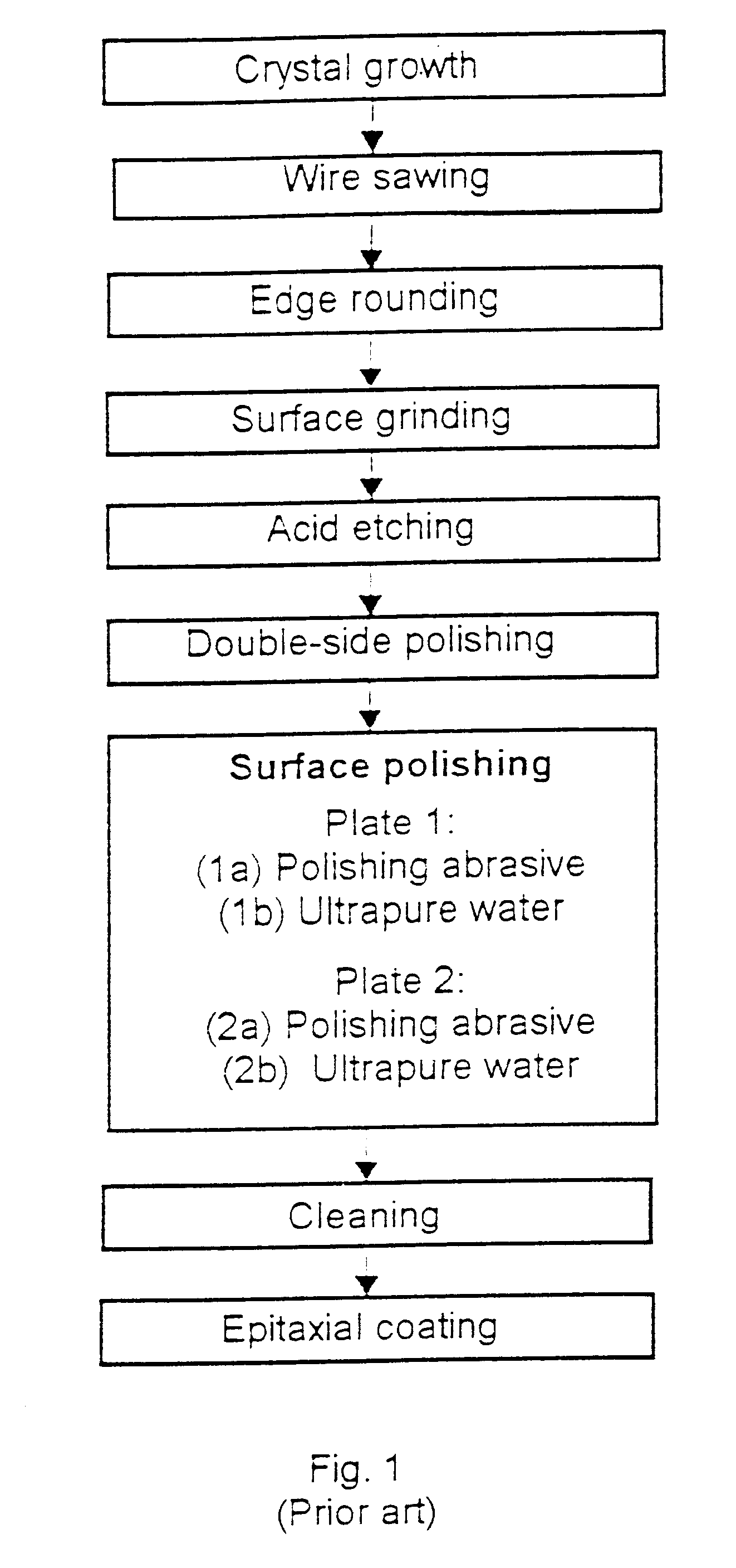

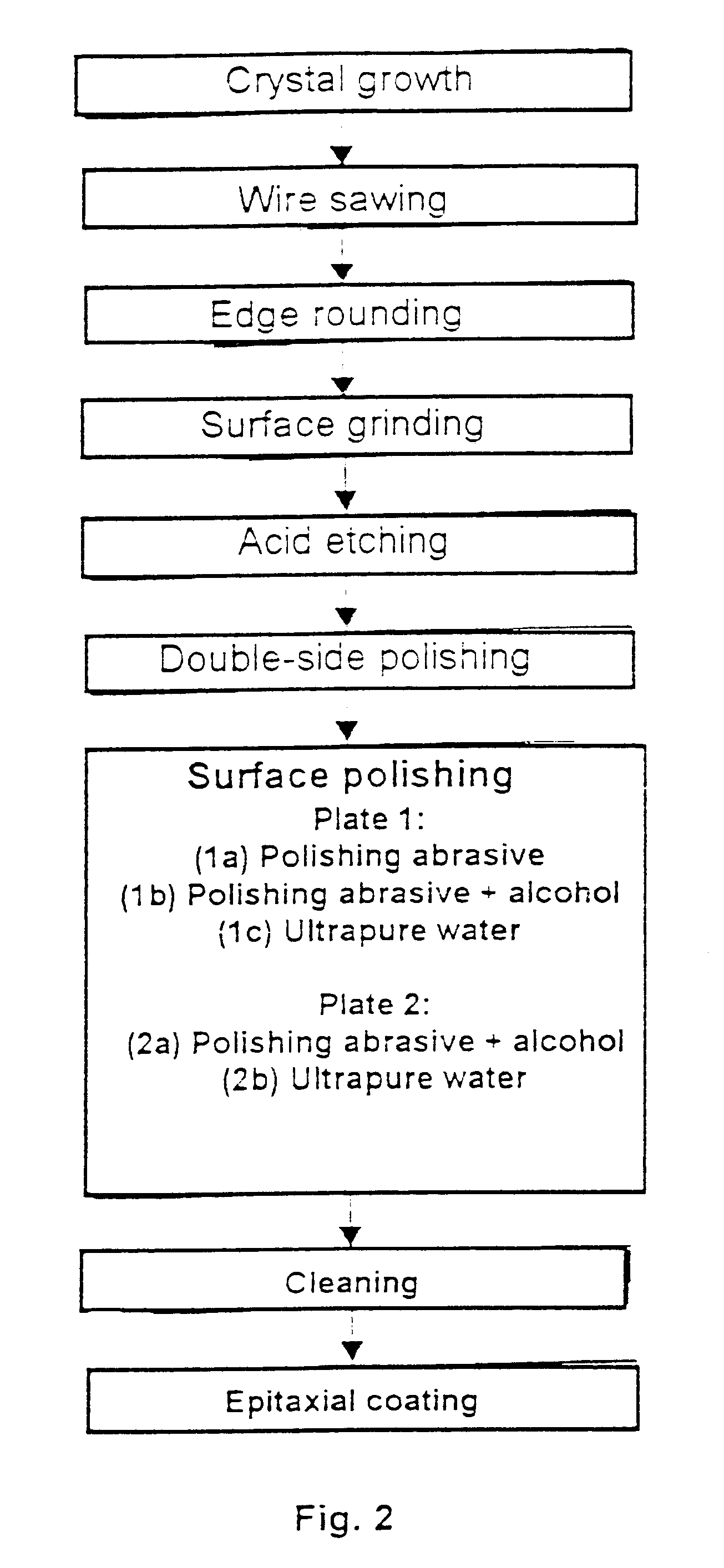

Process for the surface polishing of silicon wafers

InactiveUS20020077039A1High yieldLow costPigmenting treatmentPolishing machinesUltrapure waterAlcohol

A process for the surface polishing of a silicon wafer, includes the successive polishing of the silicon wafer on at least two different polishing plates covered with polishing cloth, with a continuous supply of alkaline polishing abrasive with SiO2 constituents, an amount of silicon removed during the polishing on a first polishing plate being significantly higher than on a second polishing plate, with the overall amount of silicon removed not exceeding 1.5 mum. A polishing abrasive (1a), then a mixture of a polishing abrasive (1b) and at least one alcohol, and finally ultrapure water (1c) are added to the first polishing plate, and a mixture of a polishing abrasive (2a) and at least one alcohol and then ultrapure water (2b) are added to the second plate.

Owner:SILTRONIC AG

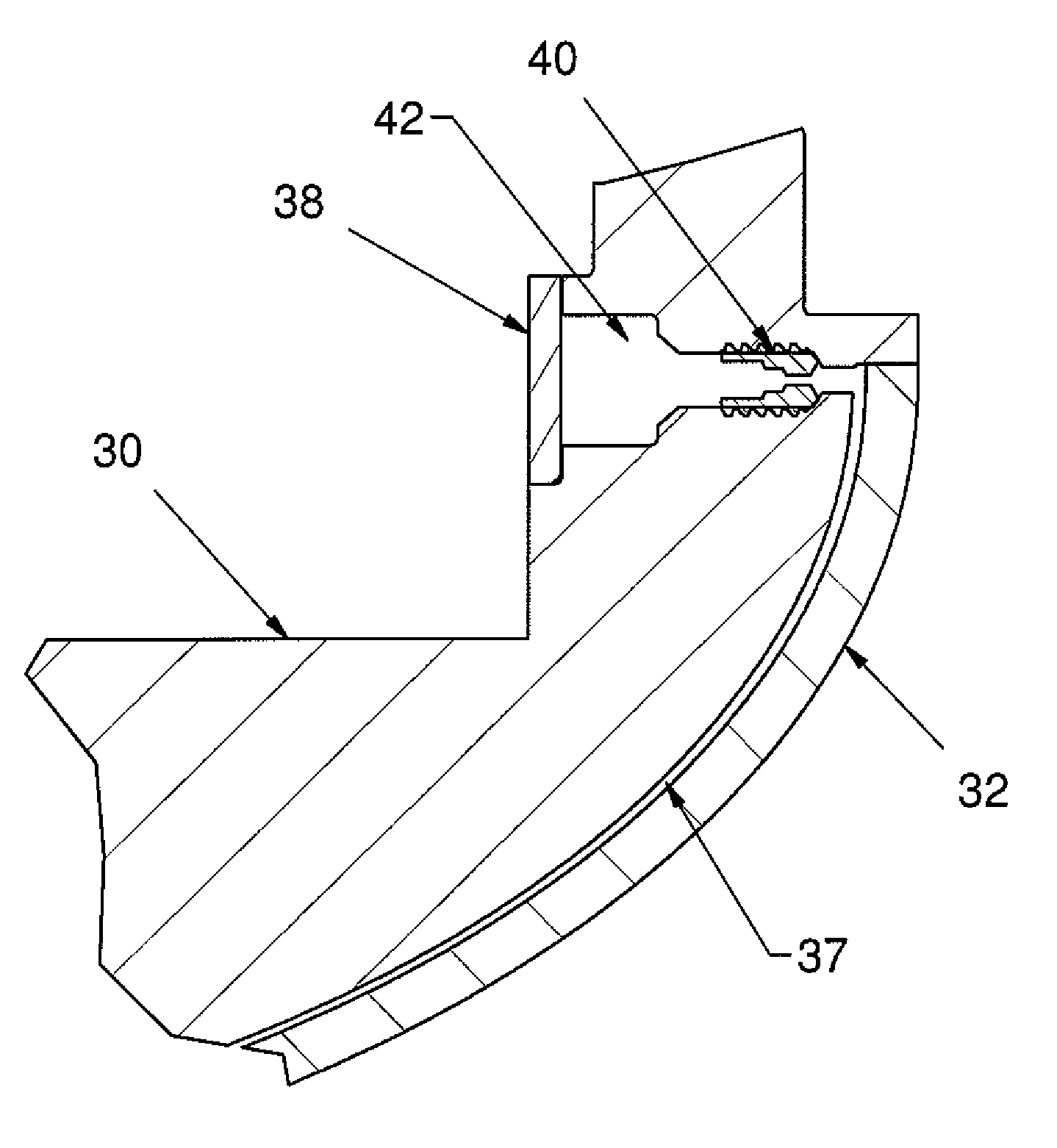

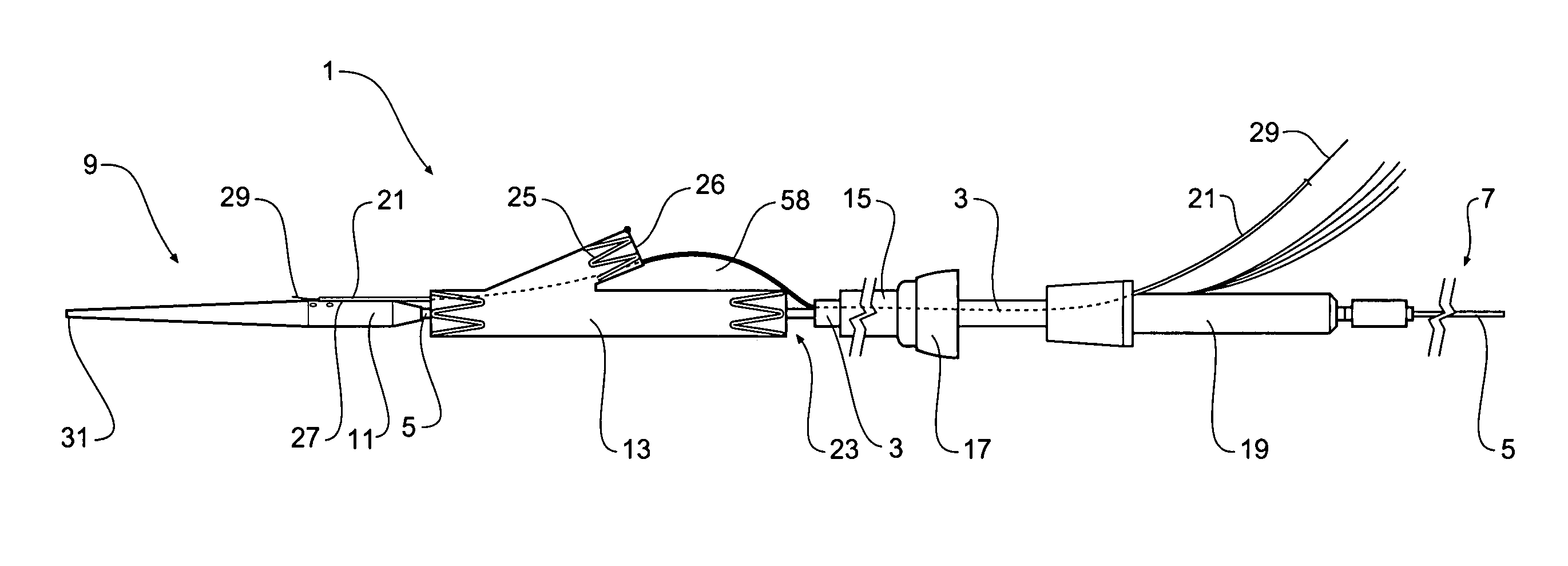

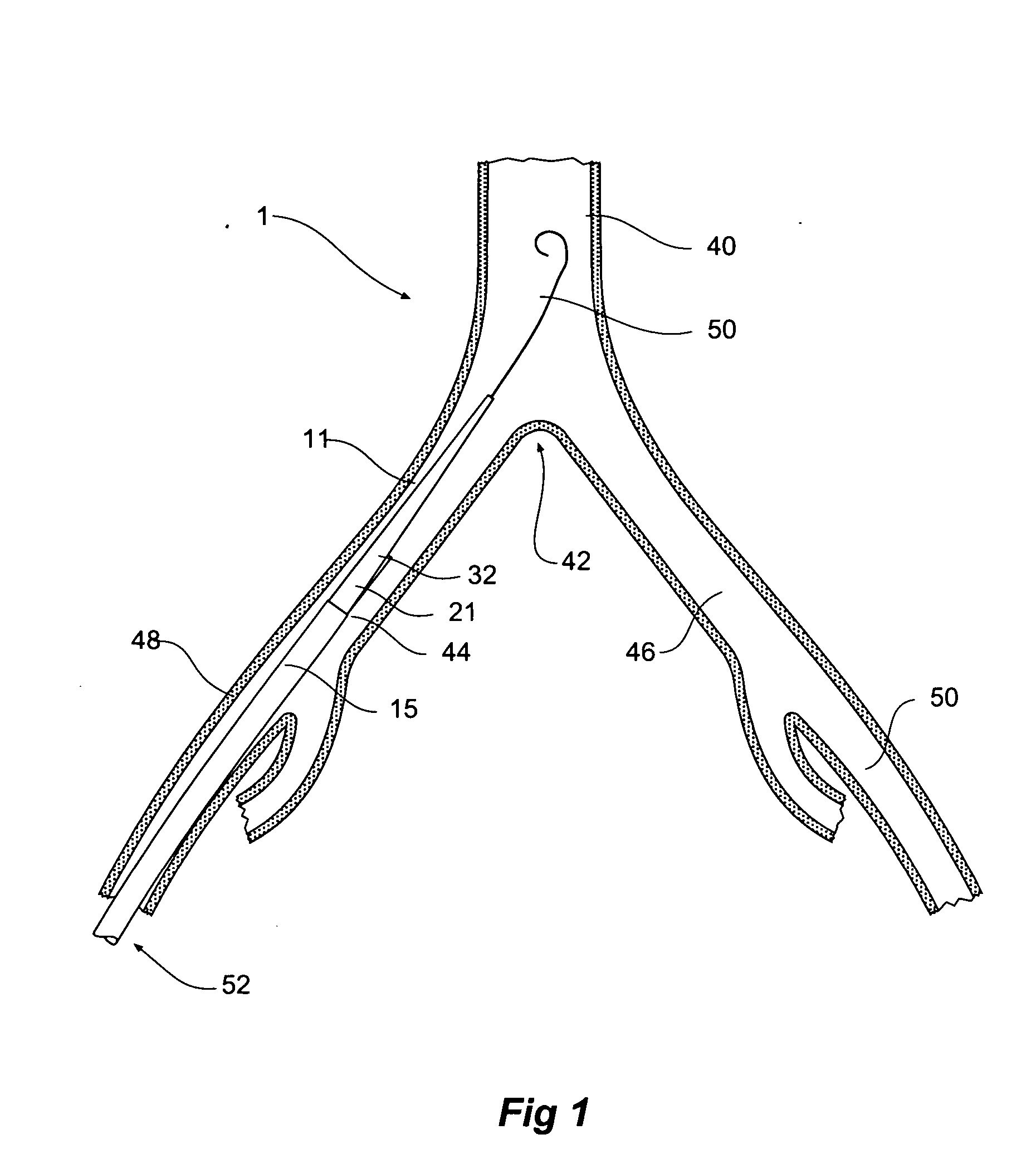

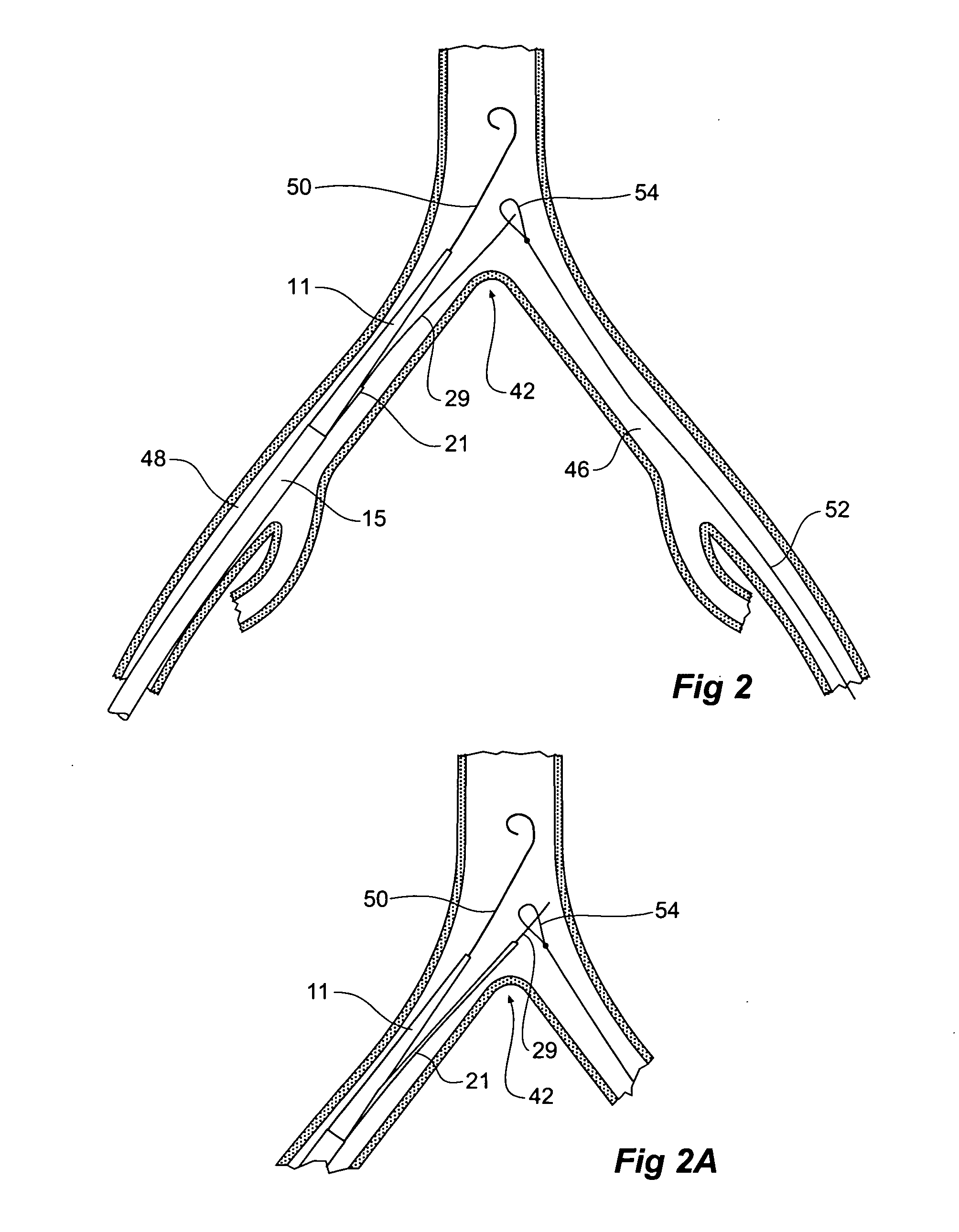

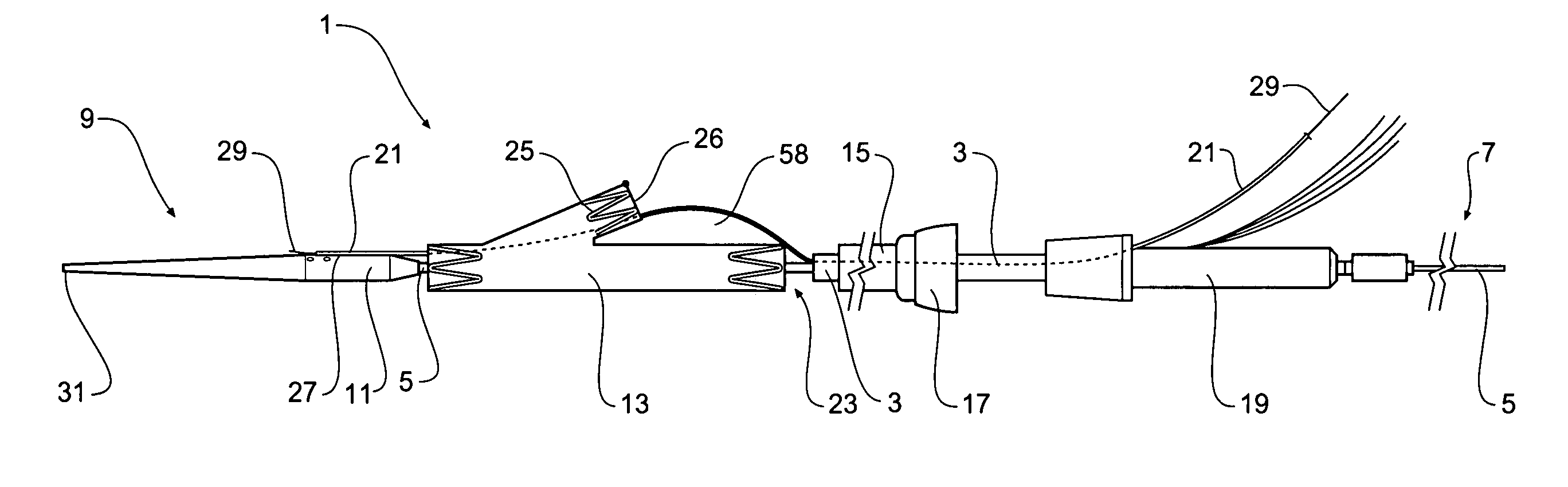

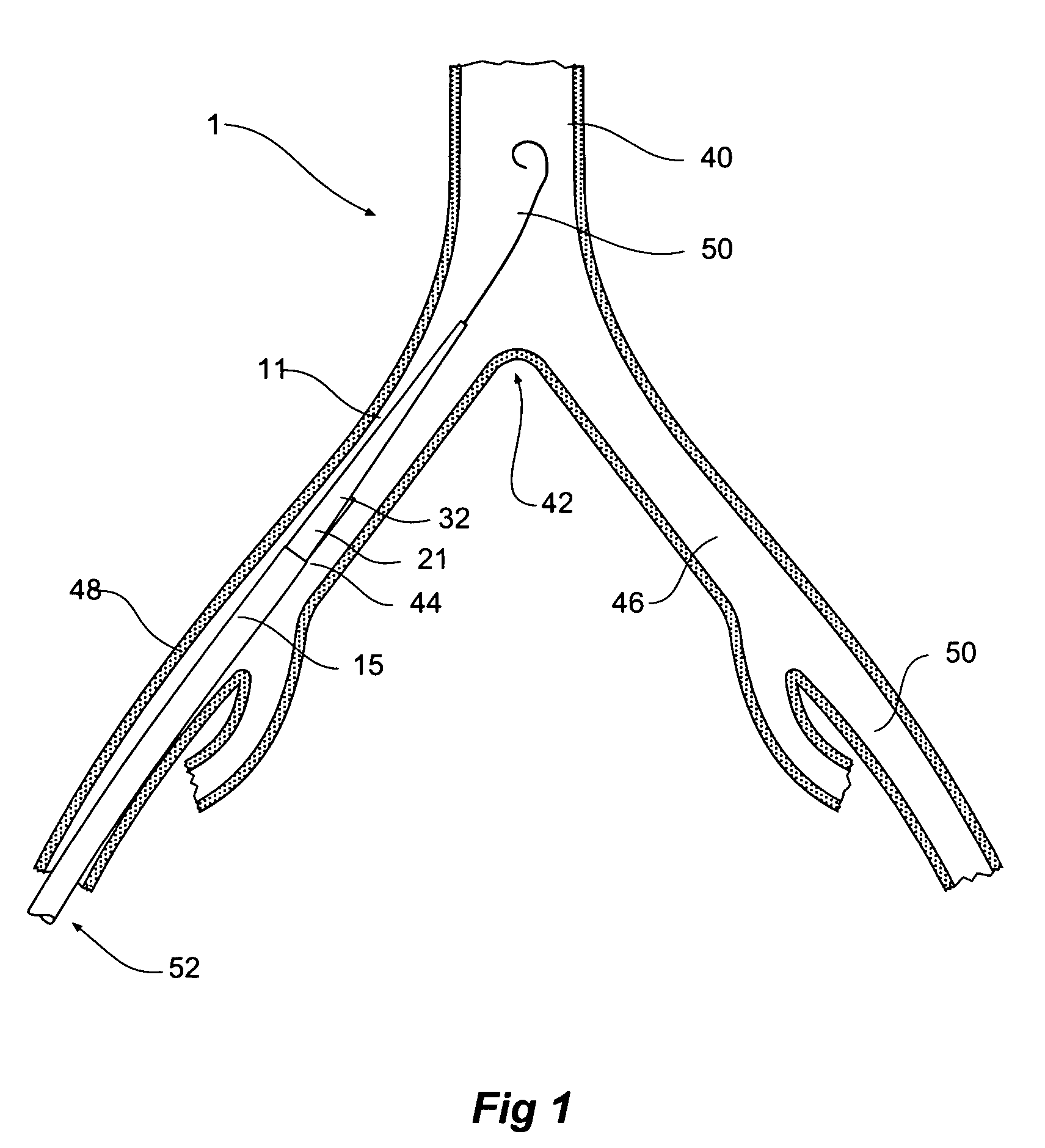

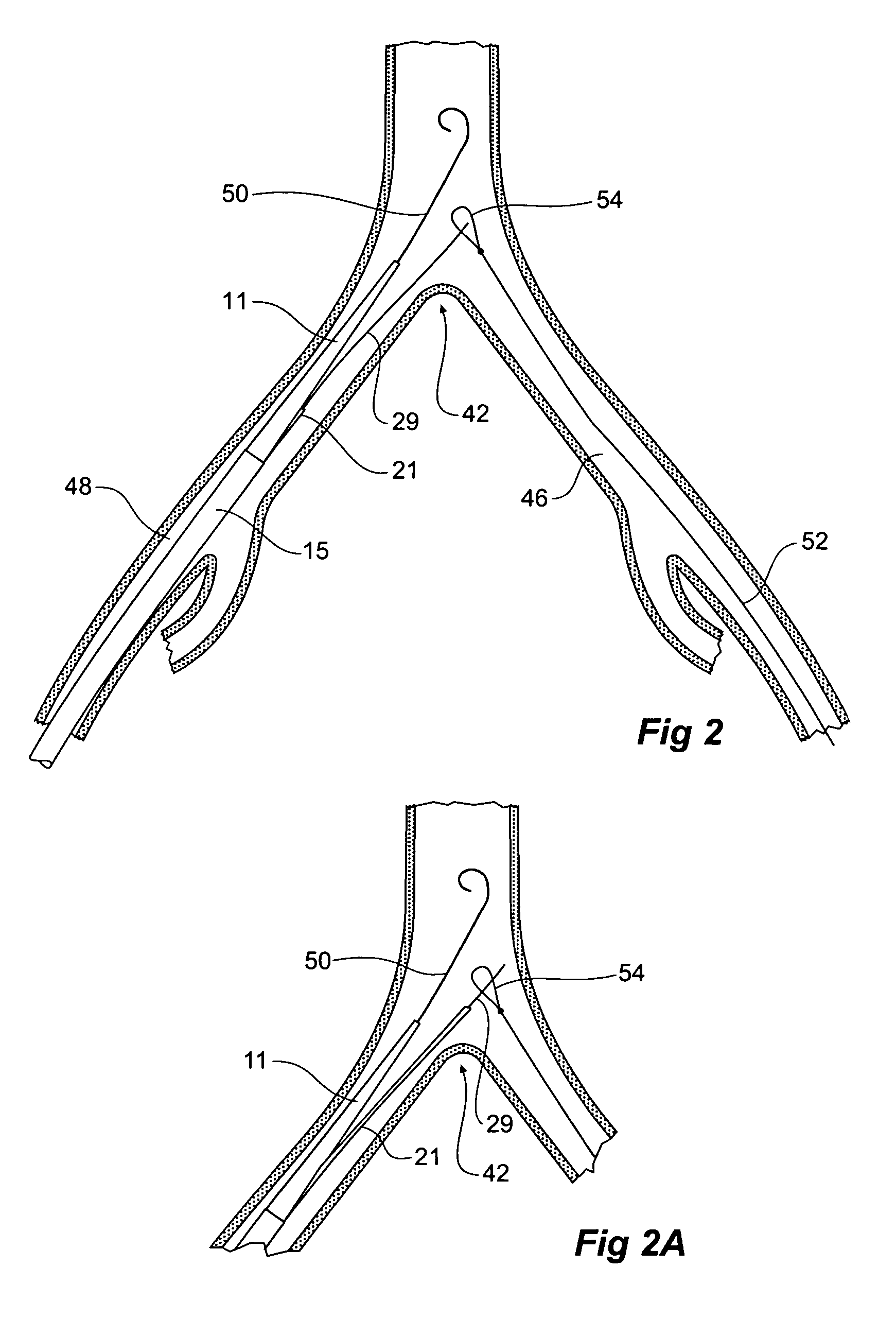

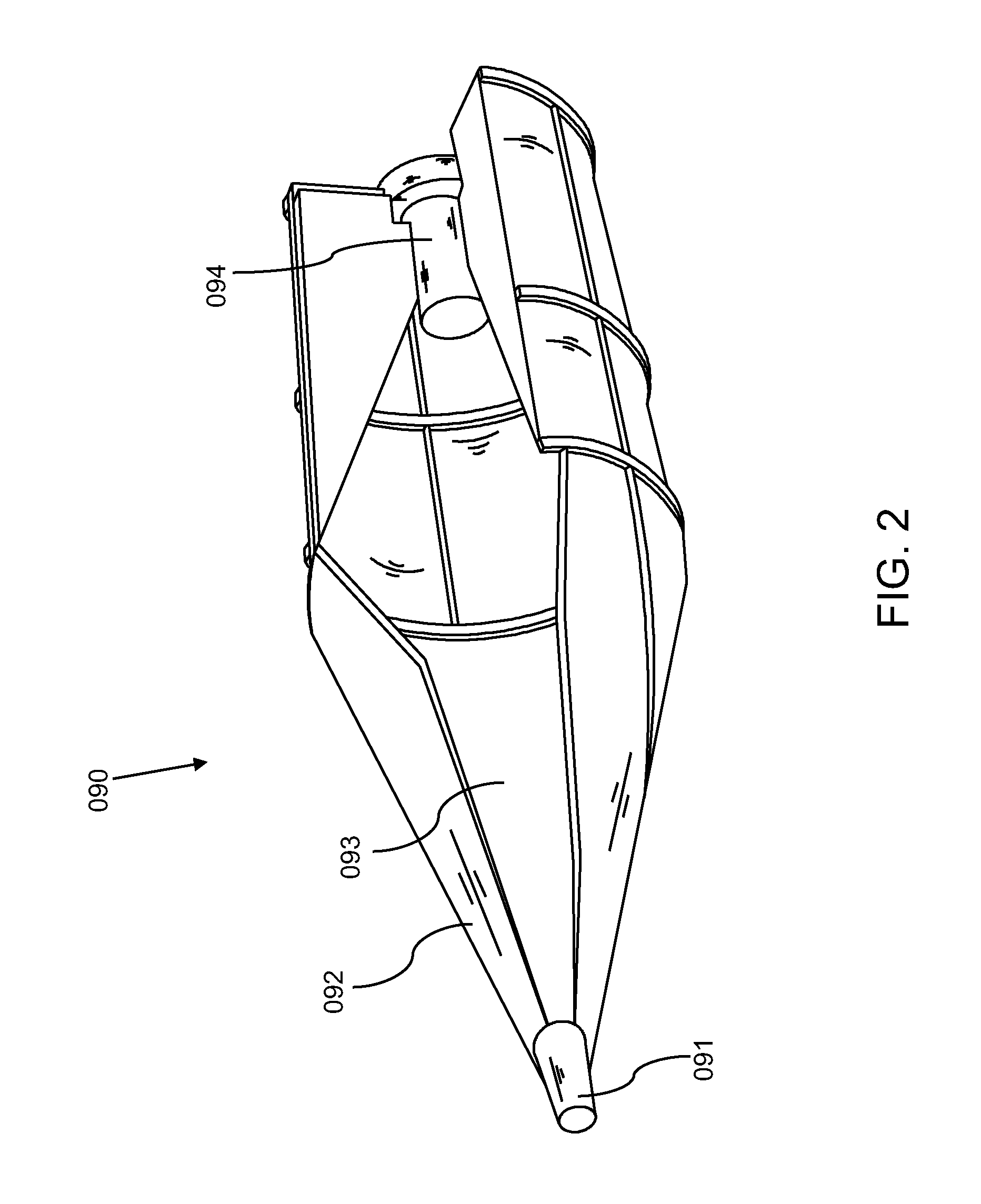

Introducer for an iliac side branch device

An introduction arrangement for a fenestrated or branched stent graft ( 13 ) intended for deployment into the lumen of a vessel having a blind vessel extending from it. The introducer ( 1 ) has a distal end intended to remain outside a patient in use and a proximal end with a nose cone dilator ( 11 ) and an arrangement to retain the branched stent graft distally of the nose cone dilator. A sheath ( 15 ) on the introducer extends over the branched stent graft to the nose cone dilator. An indwelling catheter ( 22 ) extends from the distal end of the introducer and enters the fenestration or side arm and through to the nose cone dilator, the indwelling catheter has a guide wire ( 29 ) extending through it. The guide wire can be extended beyond the nose cone dilator in use before the sheath is withdrawn from the branched stent graft so that it can be snared from the contra-lateral artery.

Owner:COOK MEDICAL TECH LLC +1

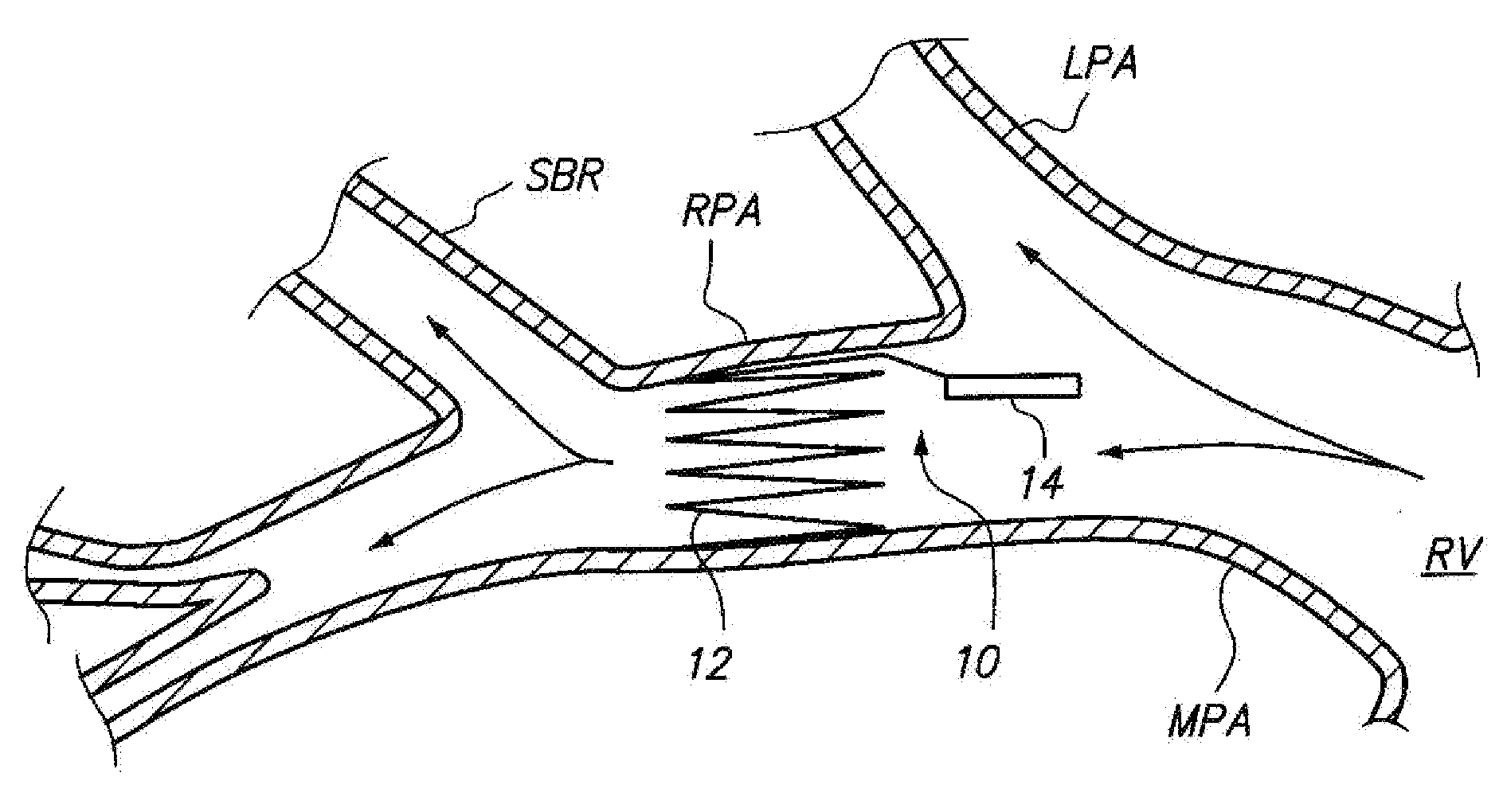

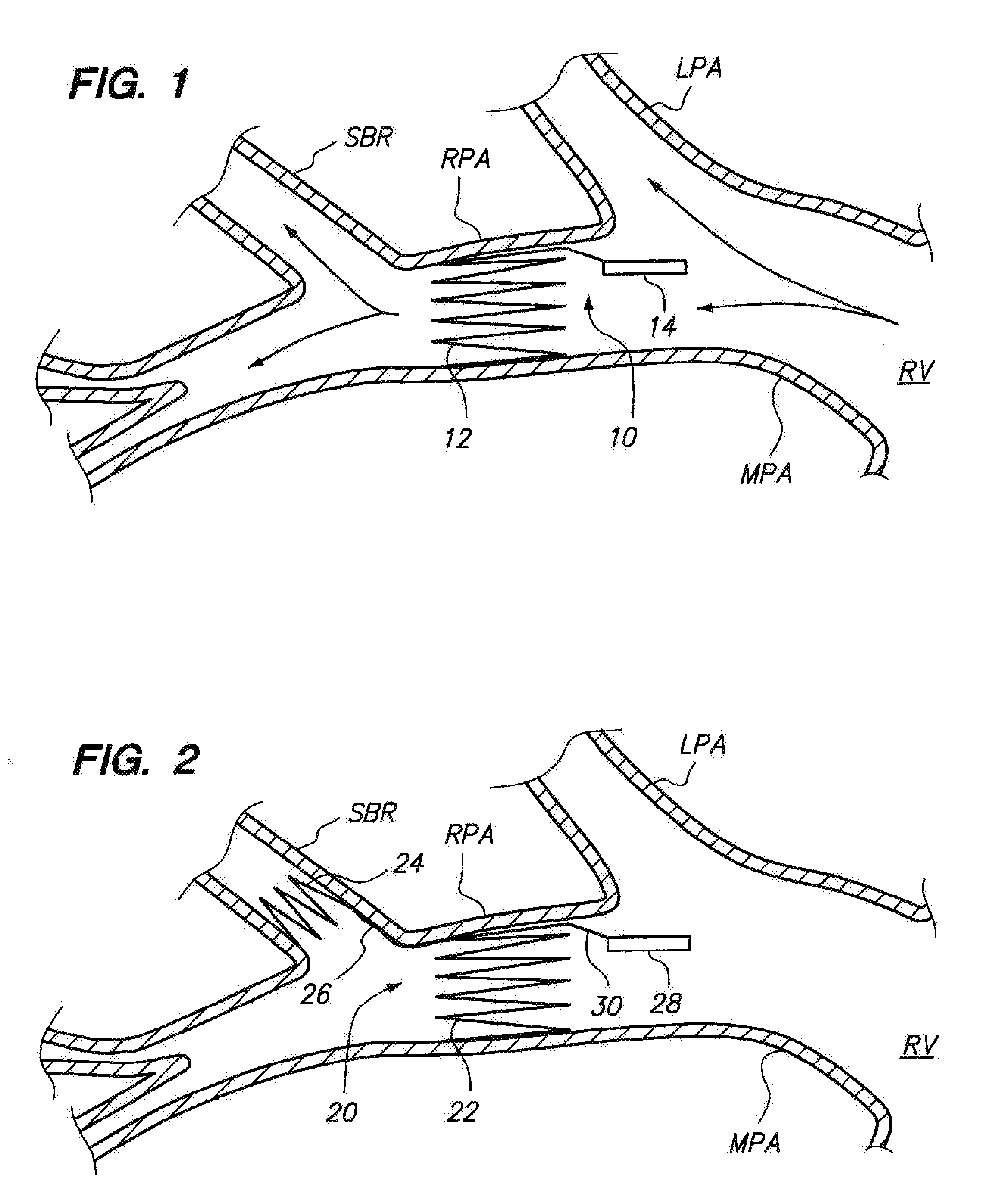

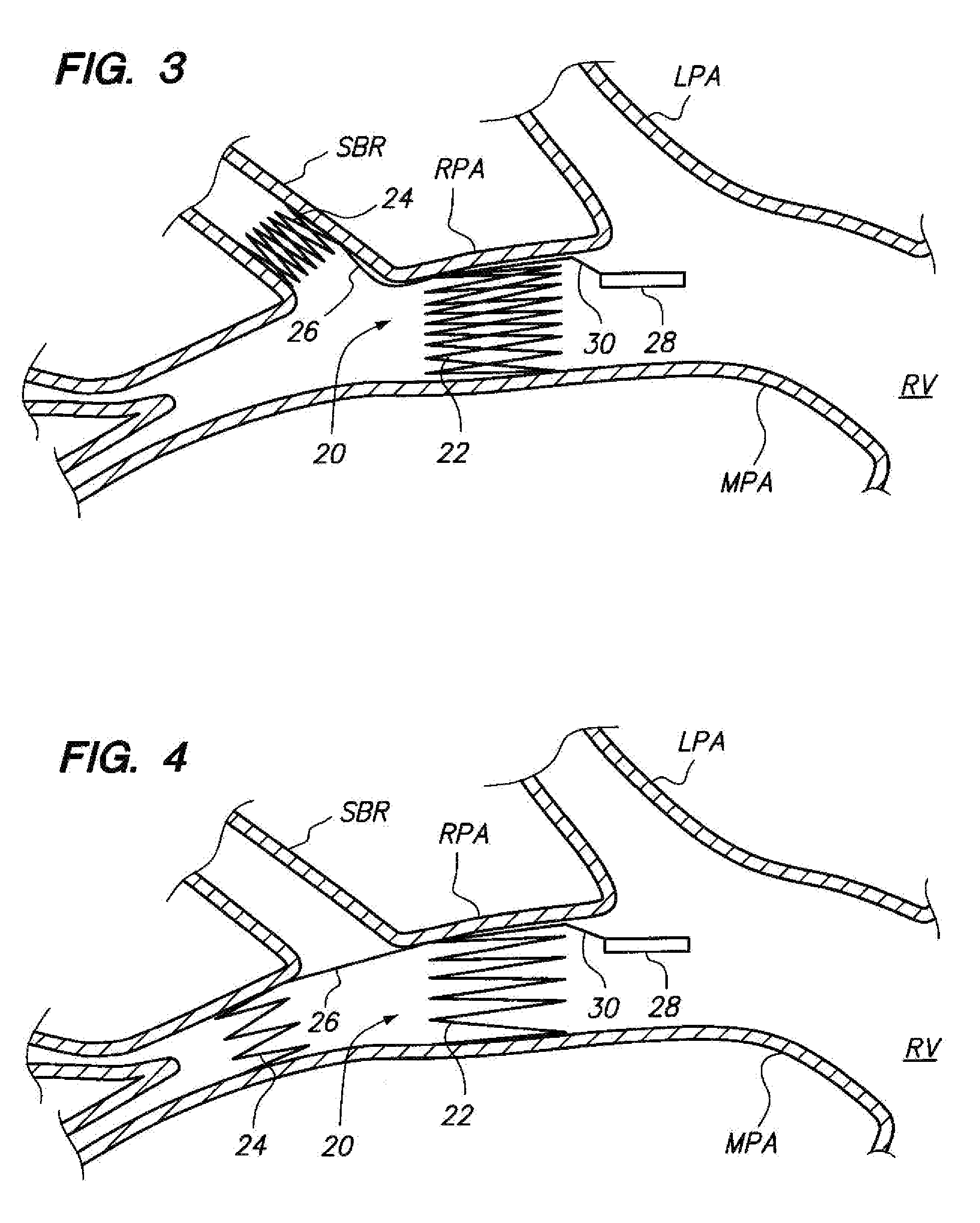

Devices For Fixing A Sensor In A Lumen

Sensing devices and methods of implanting sensing devices within an anatomical vessel network of a patient are provided. In one method, a fixation element (e.g., a stent or coil) of the sensing device is expanded into firm contact with a wall of a main anatomical vessel (e.g., a right pulmonary artery), and a stabilization element of the sensing device is placed into contact with a wall of an anatomical vessel branch of the main anatomical vessel. In another method, a first fixation element of the sensing device is expanded into firm contact with the wall of the main anatomical vessel (e.g., a right pulmonary artery) at a longitudinal location proximal to the anatomical vessel branch, and a second fixation element of the sensing device is expanded into firm contact with the wall of the main anatomical vessel at a longitudinal location distal to the anatomical vessel branch.

Owner:REMON MEDICAL TECH

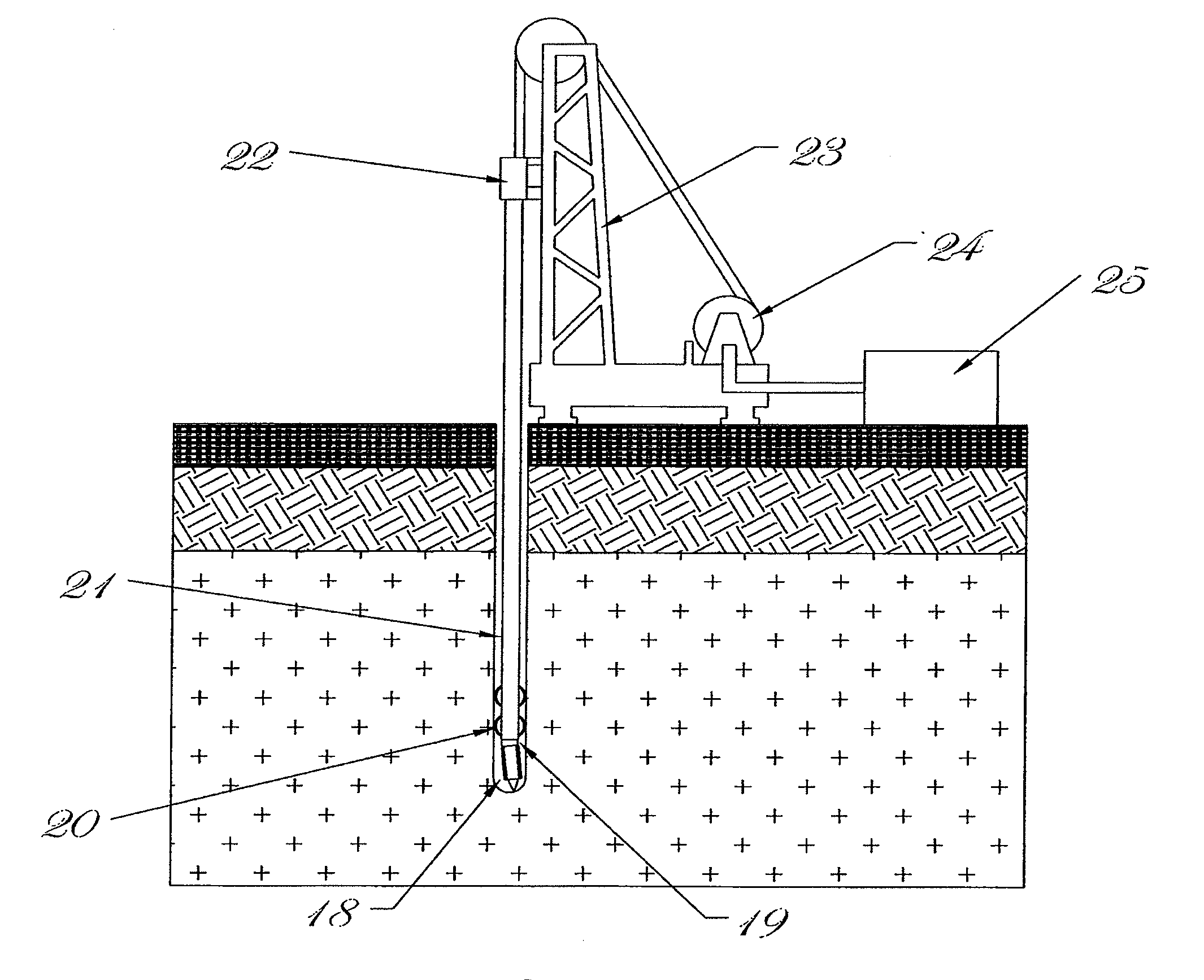

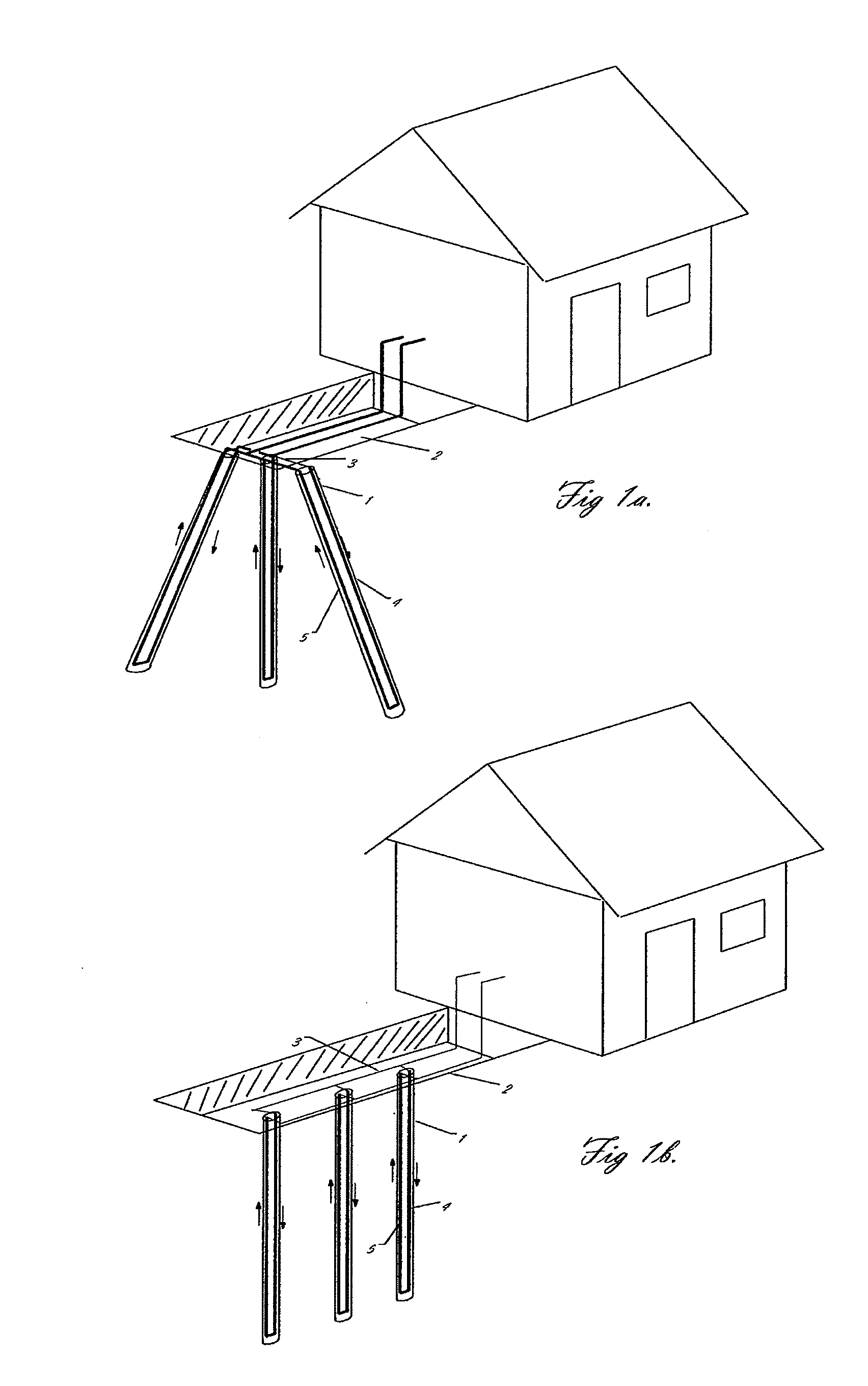

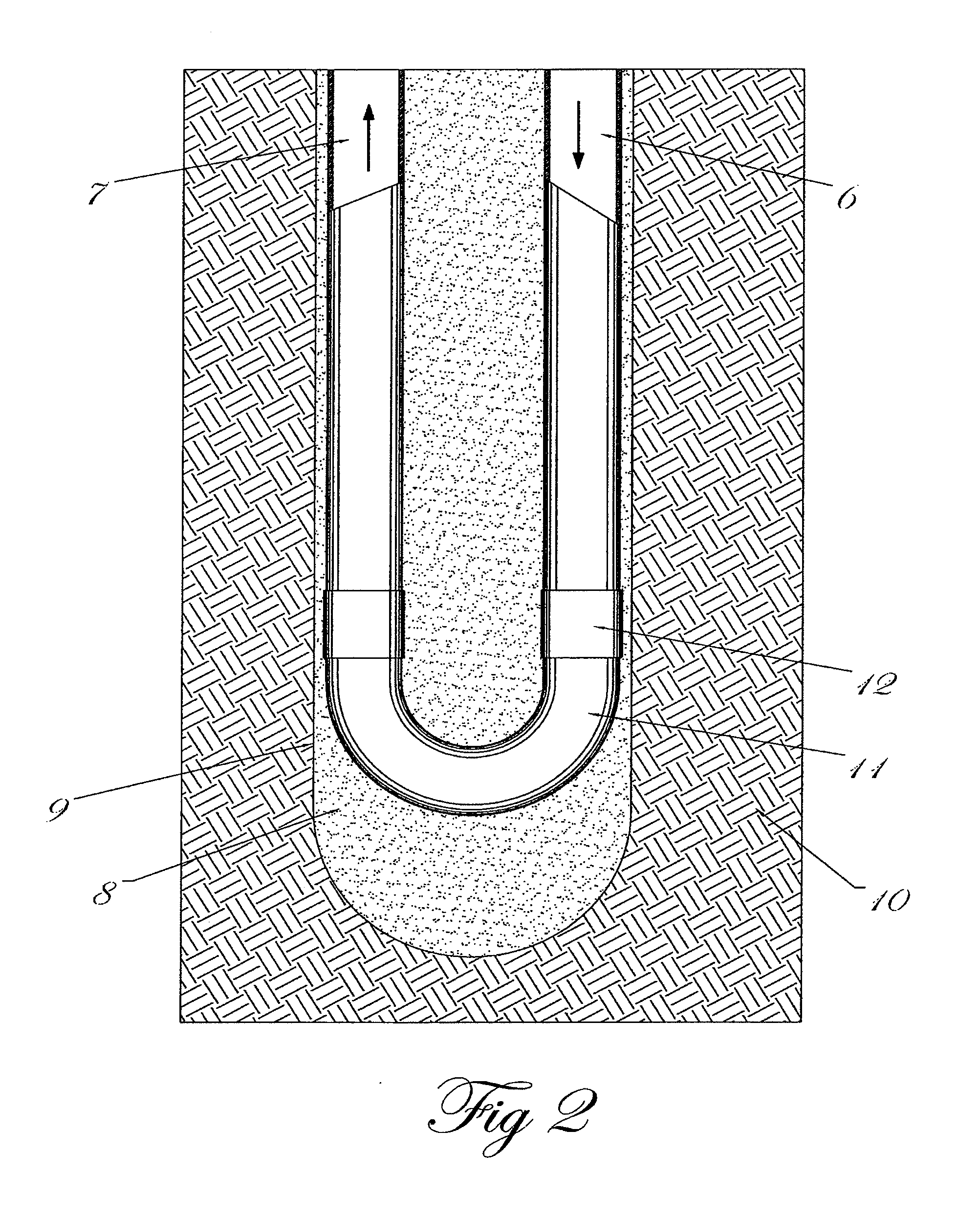

Method and System for Forming a Non-Circular Borehole

InactiveUS20100032207A1Easy to installEasy to operateCollector components/accessoriesLighting and heating apparatusEngineeringDissolution

System and methods for creating shaped, non-circular boreholes in rocks especially for use with geothermal heat pump applications and for increasing wellbore support in applications such as horizontal oil and gas drilling are described. The systems and methods when applied to geothermal heat pumps create an elliptical shaped hole that is optimized for placing heat transfer tubes with a minimum of grout used. The significantly reduced cross-sectional area of the elliptical borehole also increases the overall drilling rate in rock and especially in hard rocks. In horizontal hard-rock drilling, creation of a horizontal non-circular borehole or modification of a circular borehole to a non-circular geometry is used to stabilize the borehole prior to casing insertion, and may also allow the use of lower mud pressures improving drilling rates. The system uses a non-contacting drilling system which in one embodiment uses a supersonic flame jet drilling system with a movable nozzle that swings between pivot points. In a second embodiment the elliptical shaped hole is created by an abrasive fluid or particle bearing-fluid or air jet drill that moves between pivot points. In another embodiment a non-contacting drill can use dual parallel nutating nozzles that create a pair of overlapping circular holes. The non-circular shaped hole is created by either the high temperature flame or water-particle jet or chemically active fluid jet as it removes rock material by erosion, dissolution and or thermal spalling. Modifications of circular boreholes to a generally elliptical shape can also be done using milling or jetting techniques.

Owner:POTTER JARED MICHAEL +3

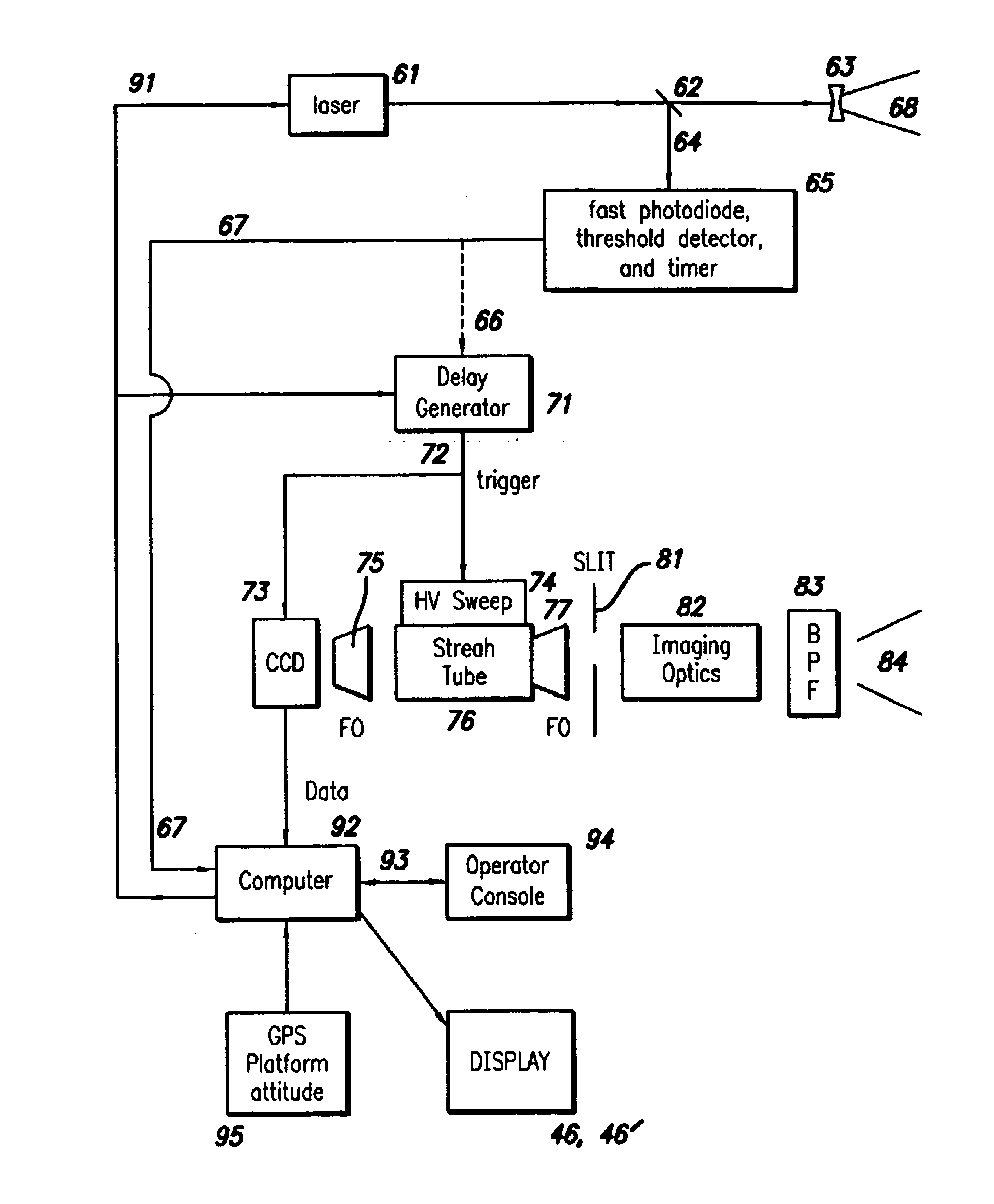

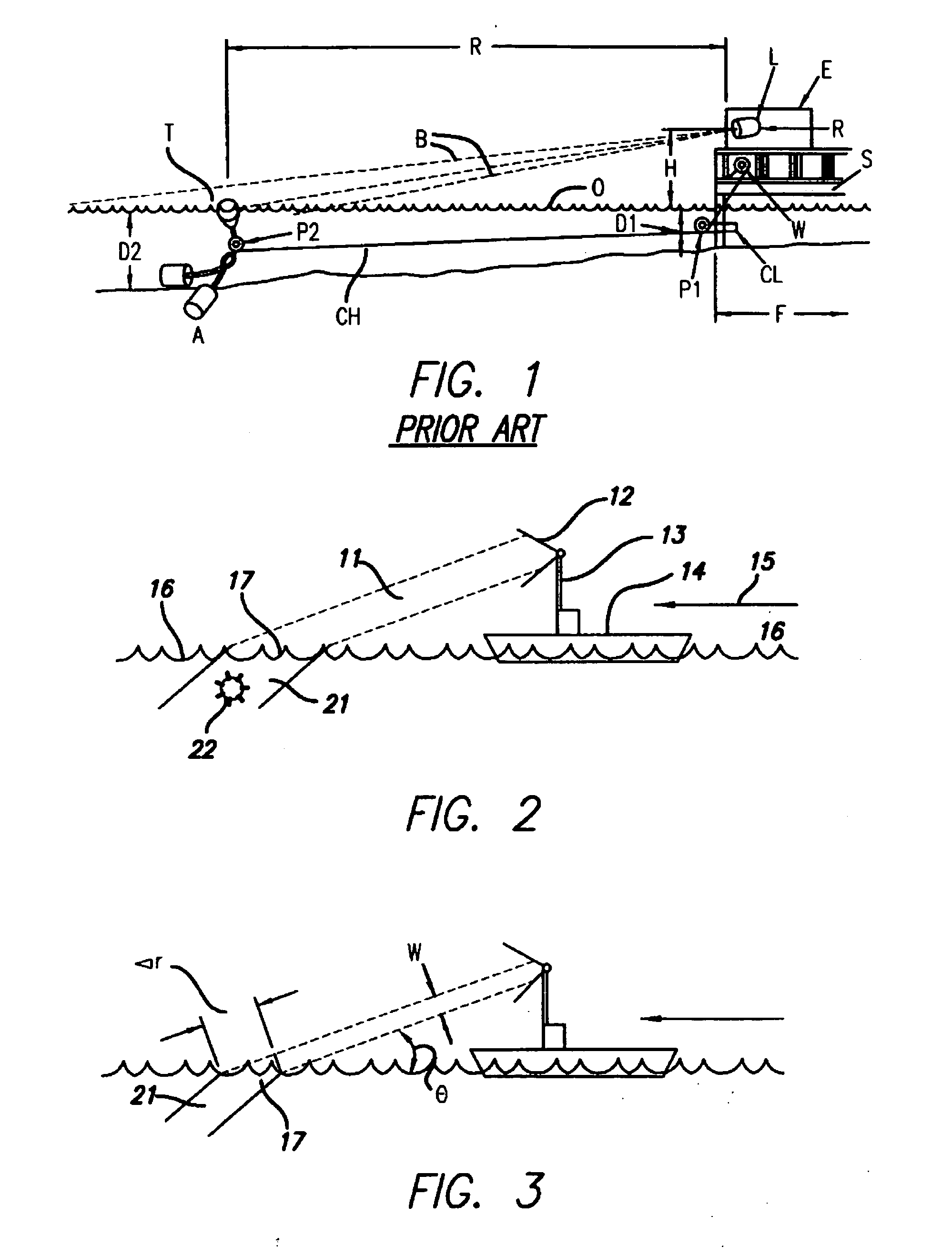

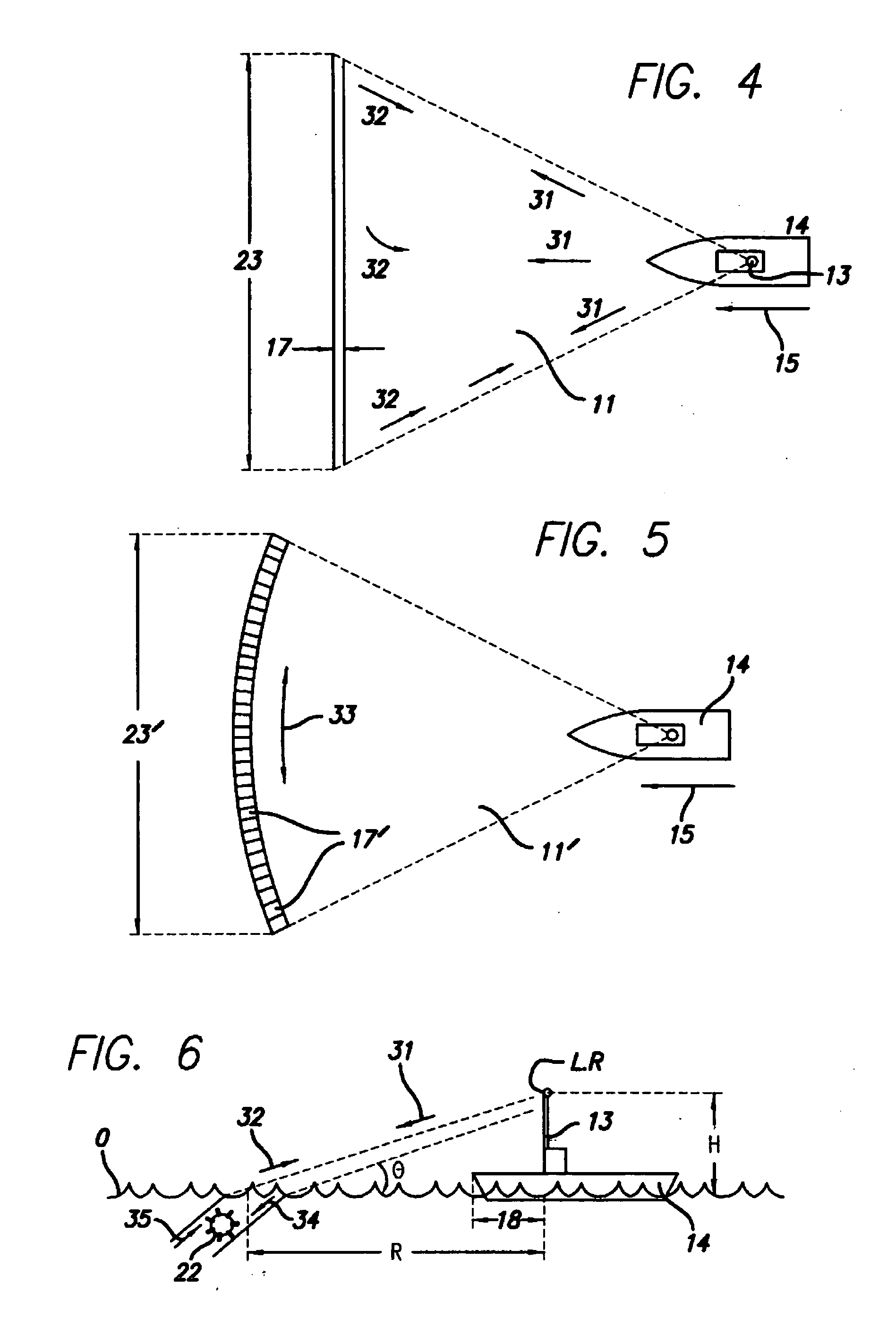

Lidar with streak-tube imaging, including hazard detection in marine applications; related optics

InactiveUS20070035624A1Full coverageOptimize geometryColor television detailsClosed circuit television systemsRadar3d image

The system and method relate to detection of objects that are submerged, or partially submerged (e. g. floating), relative to a water surface. One aspect of the invention emits LIDAR fan-beam pulses and analyzes return-pulse portions to determine water-surface orientations and derive submerged-object images corrected for refractive distortion. Another defines simulated images of submerged objects as seen through waves in a water surface, prepares an algorithm for applying a three-dimensional image of the water surface in refractive correction of LIDAR imaging through waves—and also models application of the algorithm to the images, and finally specifies the LIDAR-system optics. Yet another emits nearly horizontal pulses to illuminate small exposed objects at tens of kilometers, detects reflected portions and images successive such portions with a streak-tube subsystem. Still others make special provisions for airborne objects.

Owner:ARETE ASSOCIATES INC

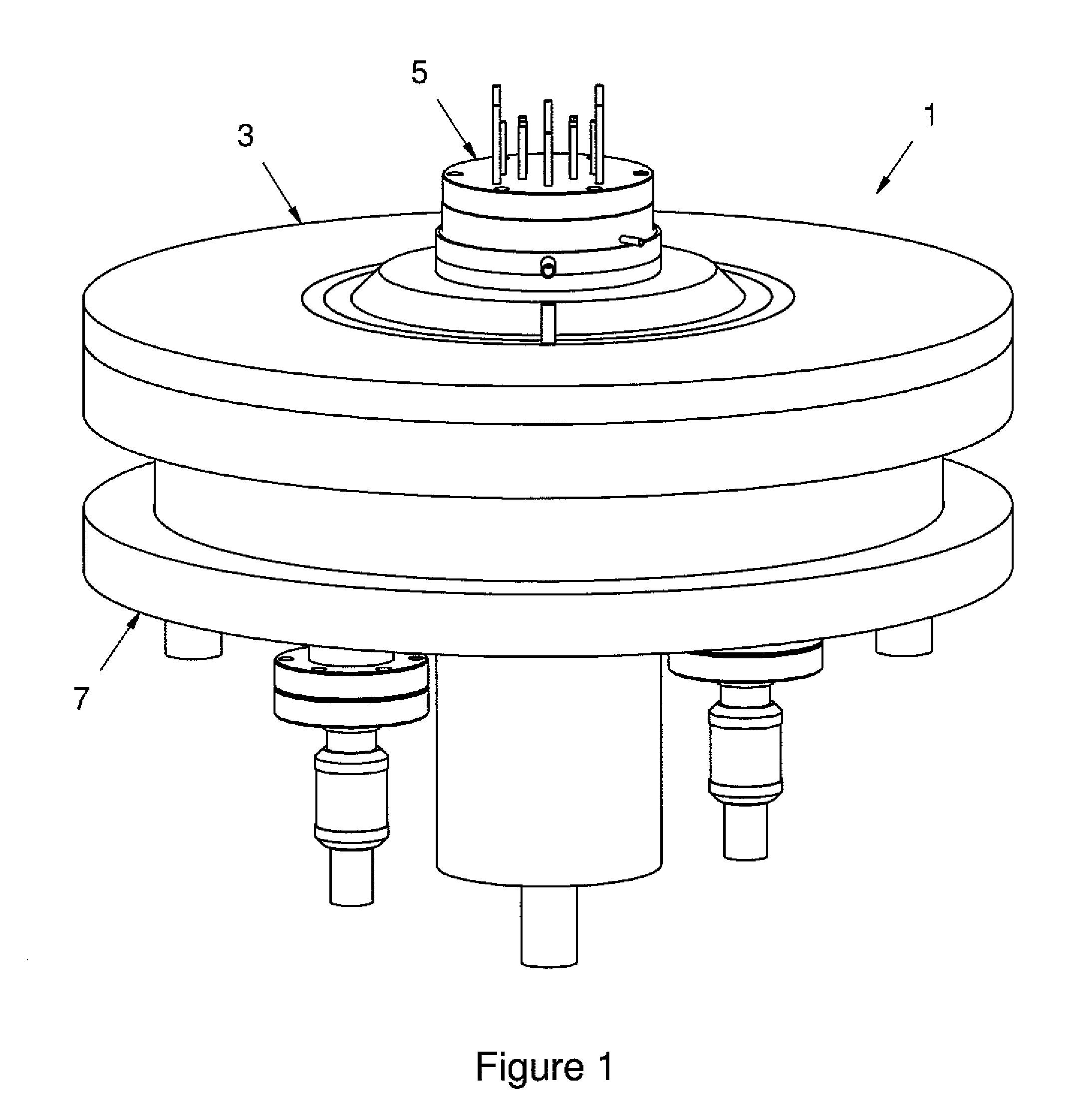

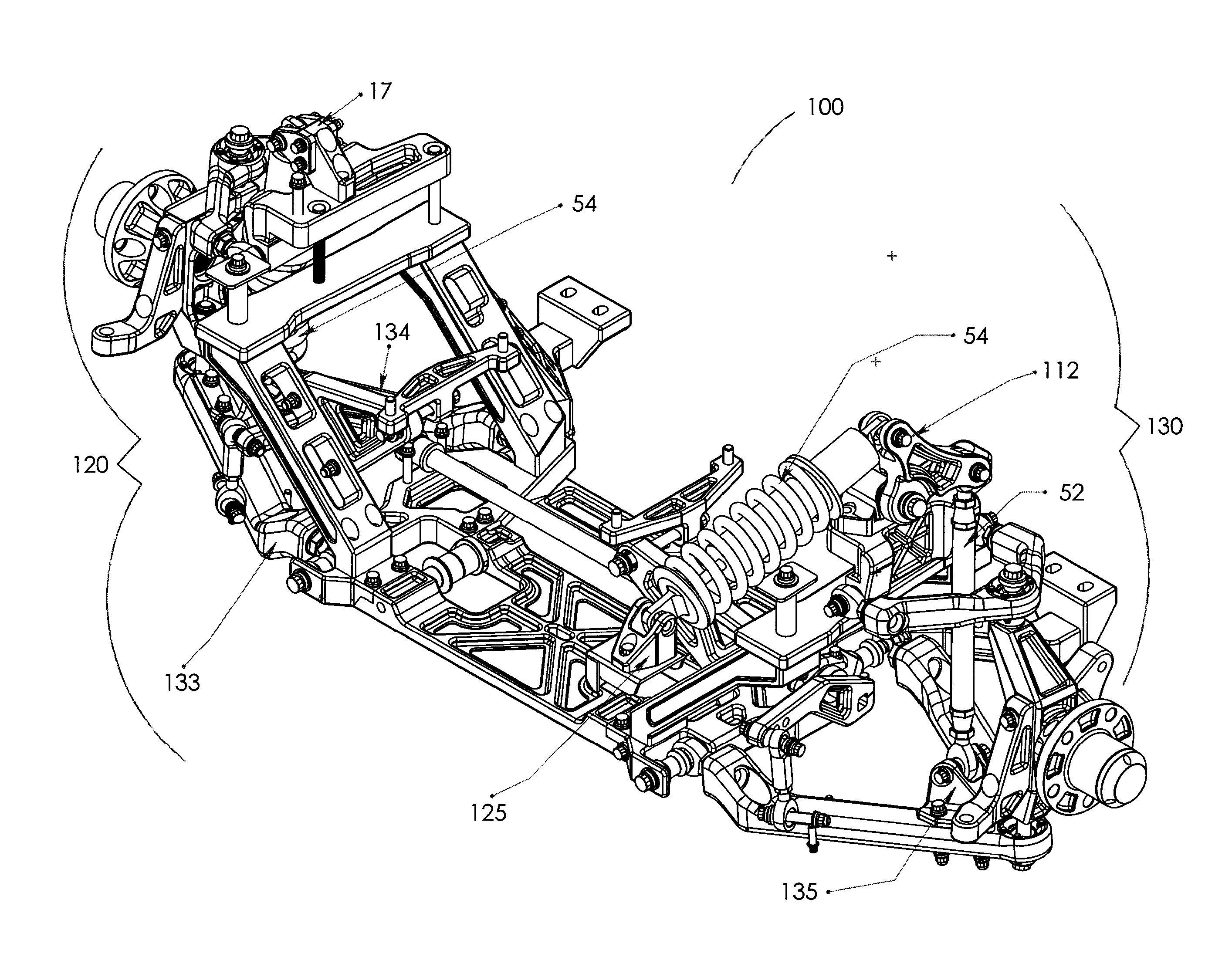

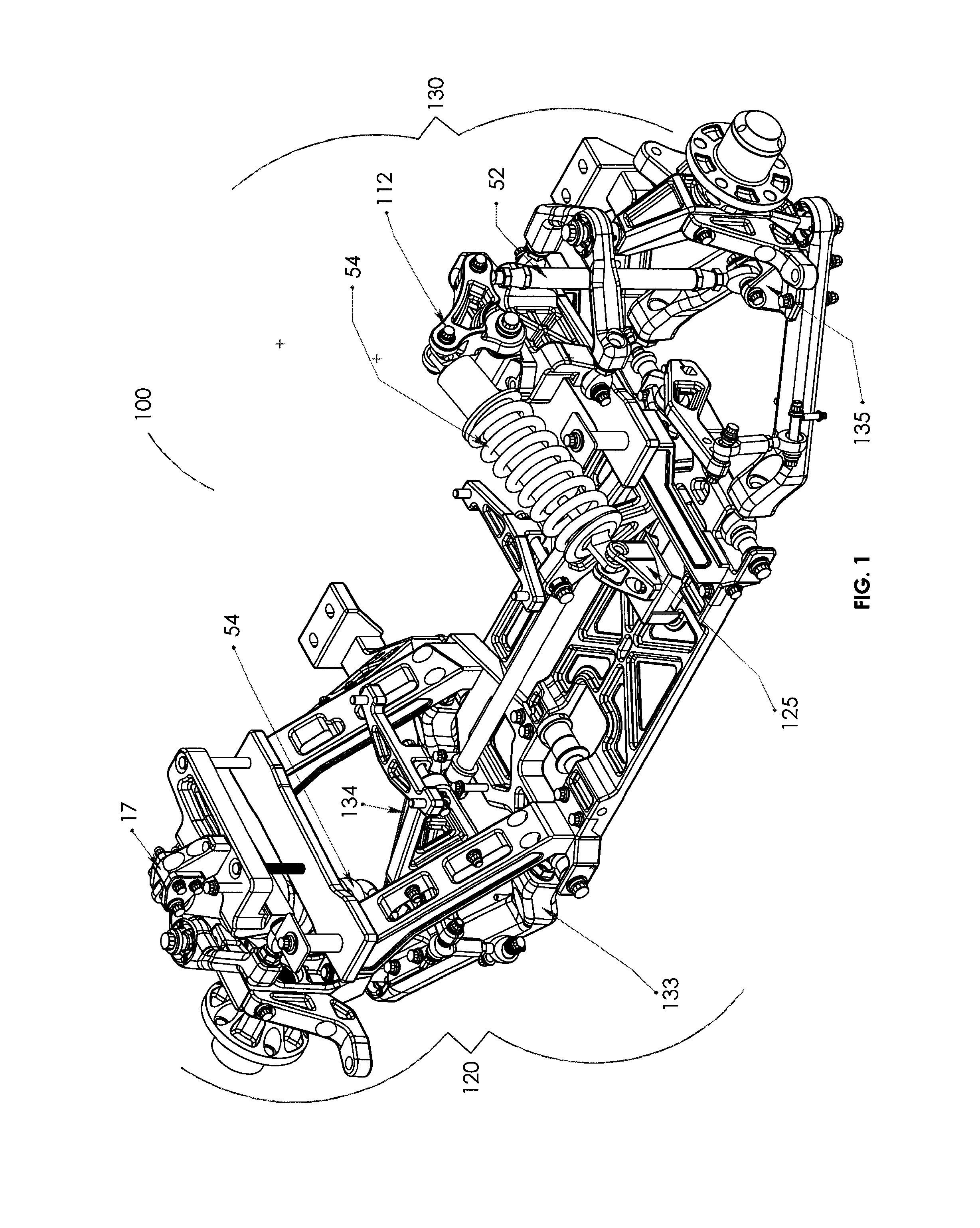

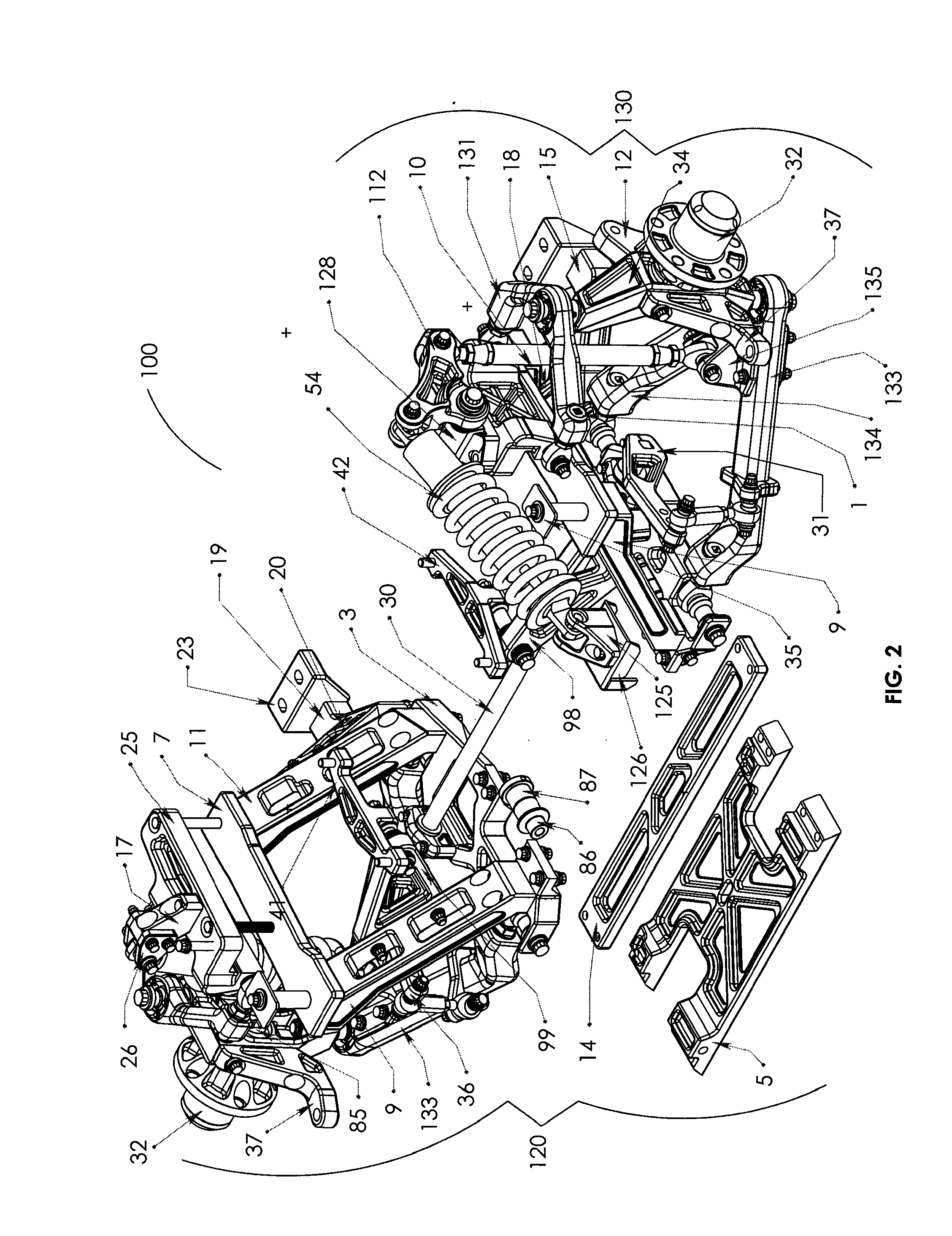

Modular suspension system

InactiveUS20090230650A1Improve performanceReduce maintenanceSpringsResilient suspensionsModularityTruck

A modular suspension system for automobiles and trucks. The present invention relates to a suspension system which is both modular in design and specifically manufactured for high performance wheeled vehicles. This system has multiple modular parts which enable the system to function in various makes and models of vehicles. The modular aspects of this system also enable the cradle to be removable so that the engine and transmission of the vehicle can be easily reached. The modular aspects also allow this system to be set-up with a traditional shock configuration or with a rocker set-up shock system.

Owner:JME ENTERPRISES

Prosthetic knee joint having at least one diamond articulation surface

InactiveUS20050203630A1Less disruptiveImprove overall utilizationAnkle jointsBone implantArticular surfacesKnee Joint

Prosthetic joints, components for prosthetic joints, superhard bearing and articulation surfaces, diamond bearing and articulation surfaces, substrate surface topographical features, materials for making joints, bearing and articulation surfaces, and methods for manufacturing and finishing the same, and related information are disclosed, including prosthetic knee joint having at least one diamond articulation surface.

Owner:POPE BILL J +4

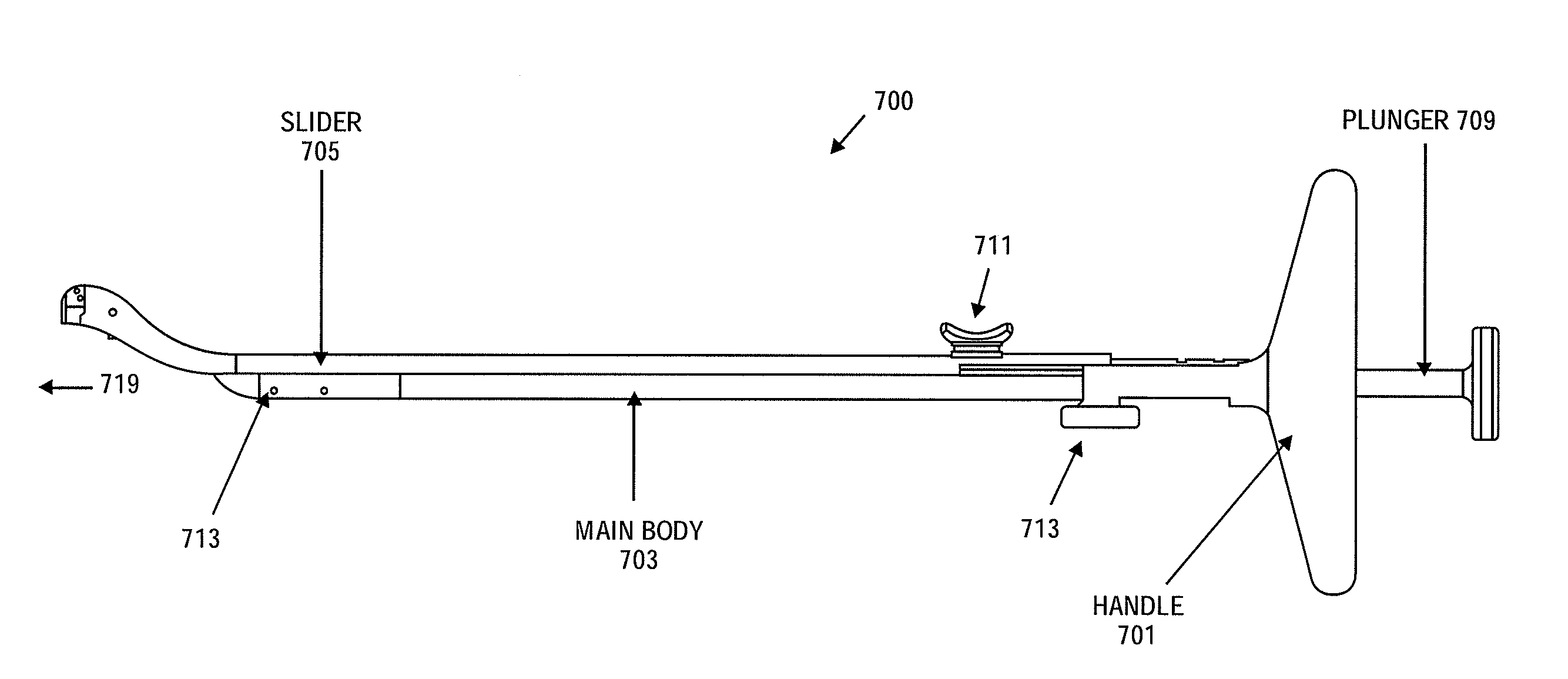

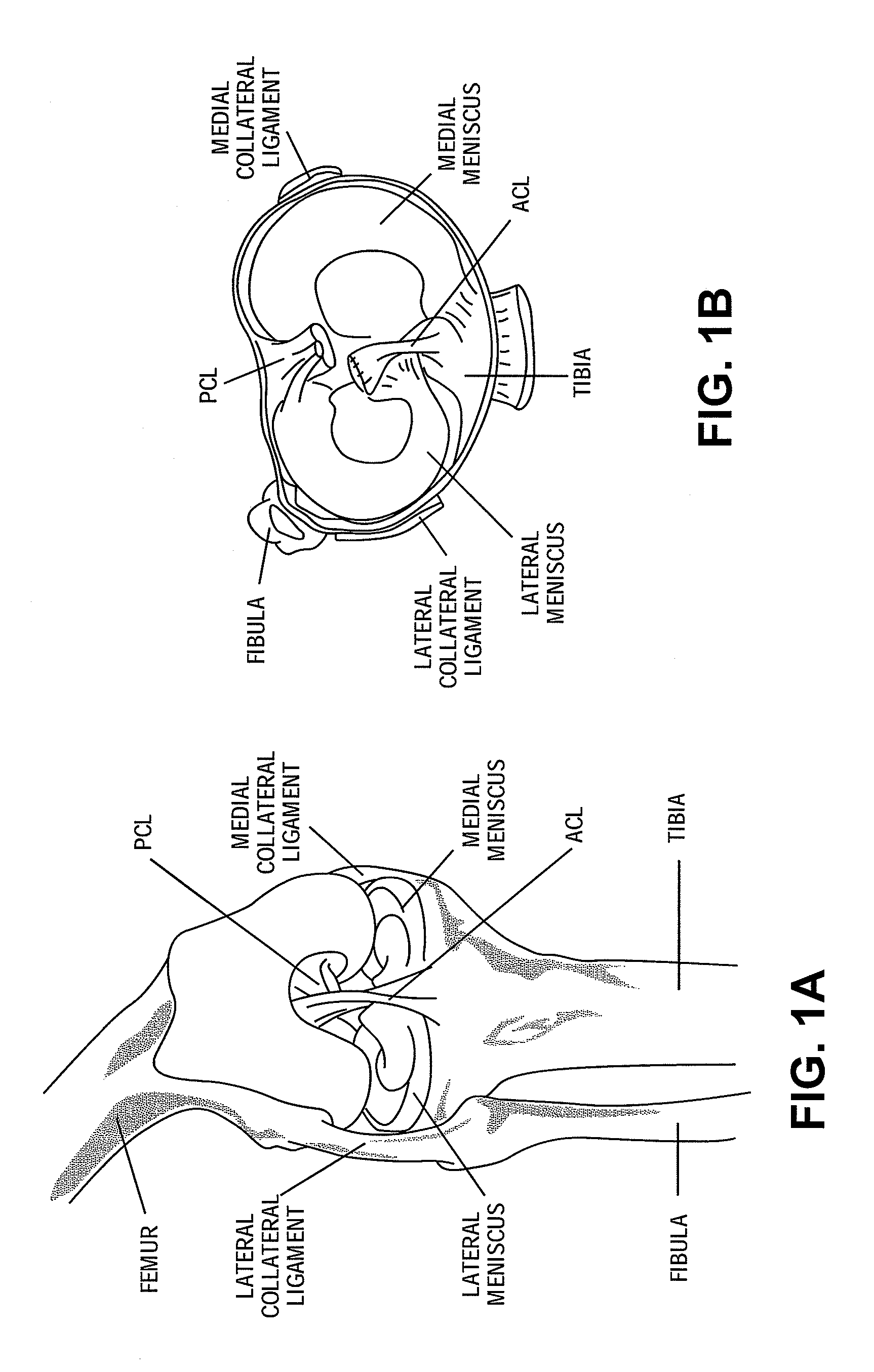

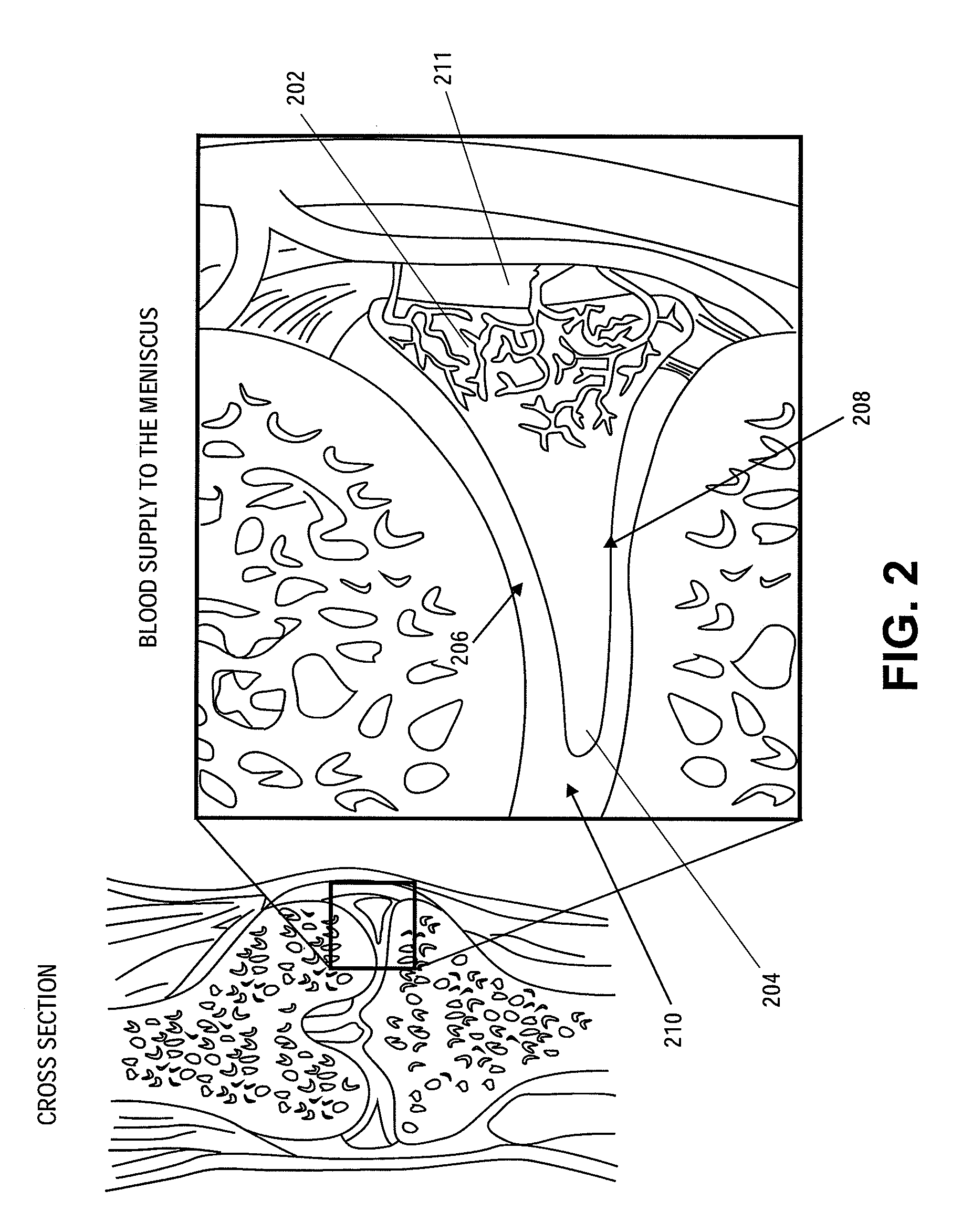

Meniscus repair

ActiveUS20120283750A1Minimize heightSpace minimizationSuture equipmentsSurgical needlesTibiaMeniscal tissue

Methods for repairing a meniscus, and particularly a torn meniscus. A method of repairing a meniscus may include using a suture passer to pass a suturing element from the region between the superior surface of the meniscus and the femoral condyle, through the meniscus tissue, into the region between the inferior surface of the meniscus and the tibial plateau, across the inferior surface of the meniscus, and back to the superior surface of the meniscus, without deeply penetrating the posterior capsular region of the knee. Equivalently, the suture element may be passed from the inferior surface of the meniscus to the superior surface and back to the inferior surface.

Owner:CETERIX ORTHOPAEDICS

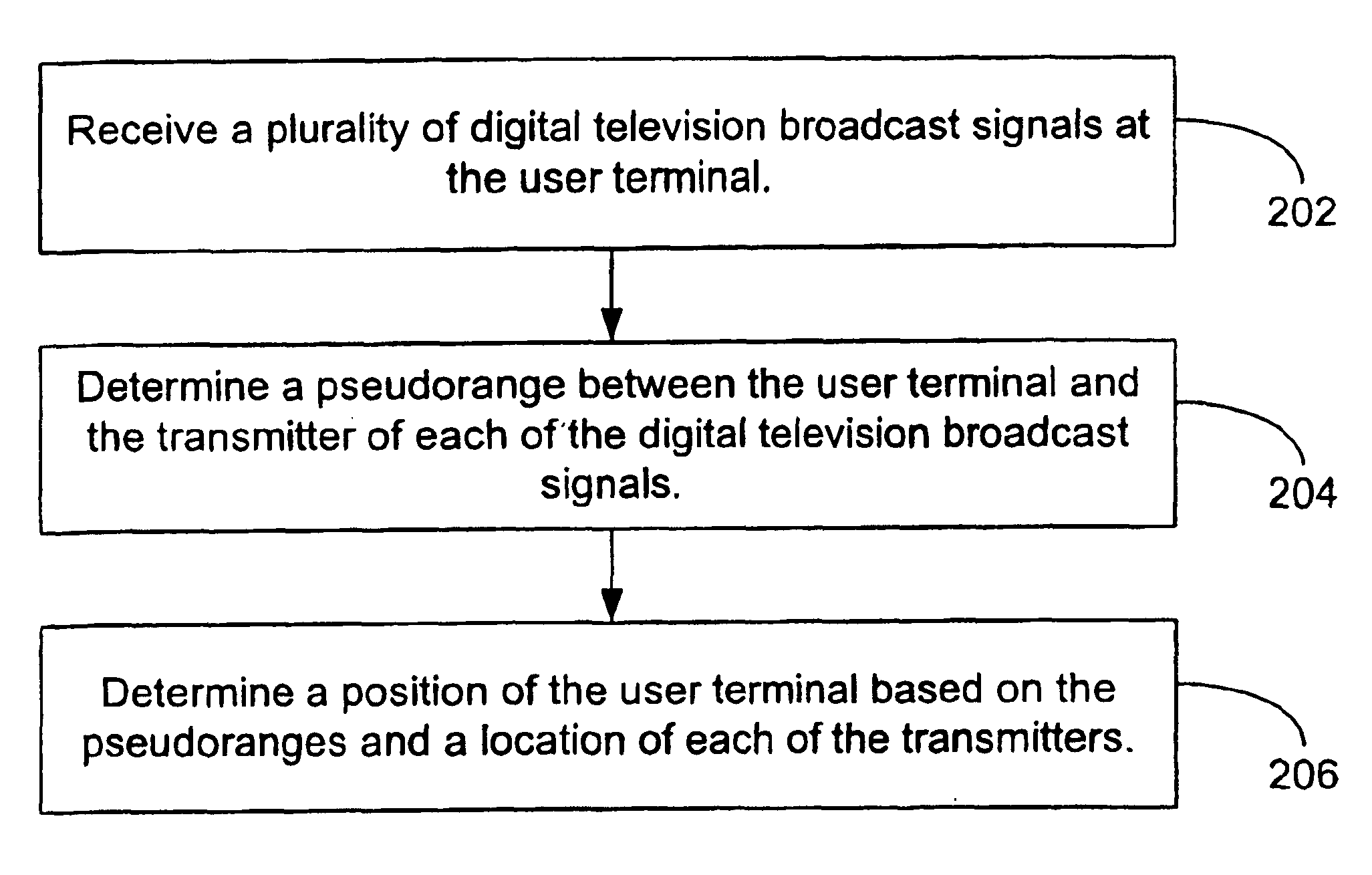

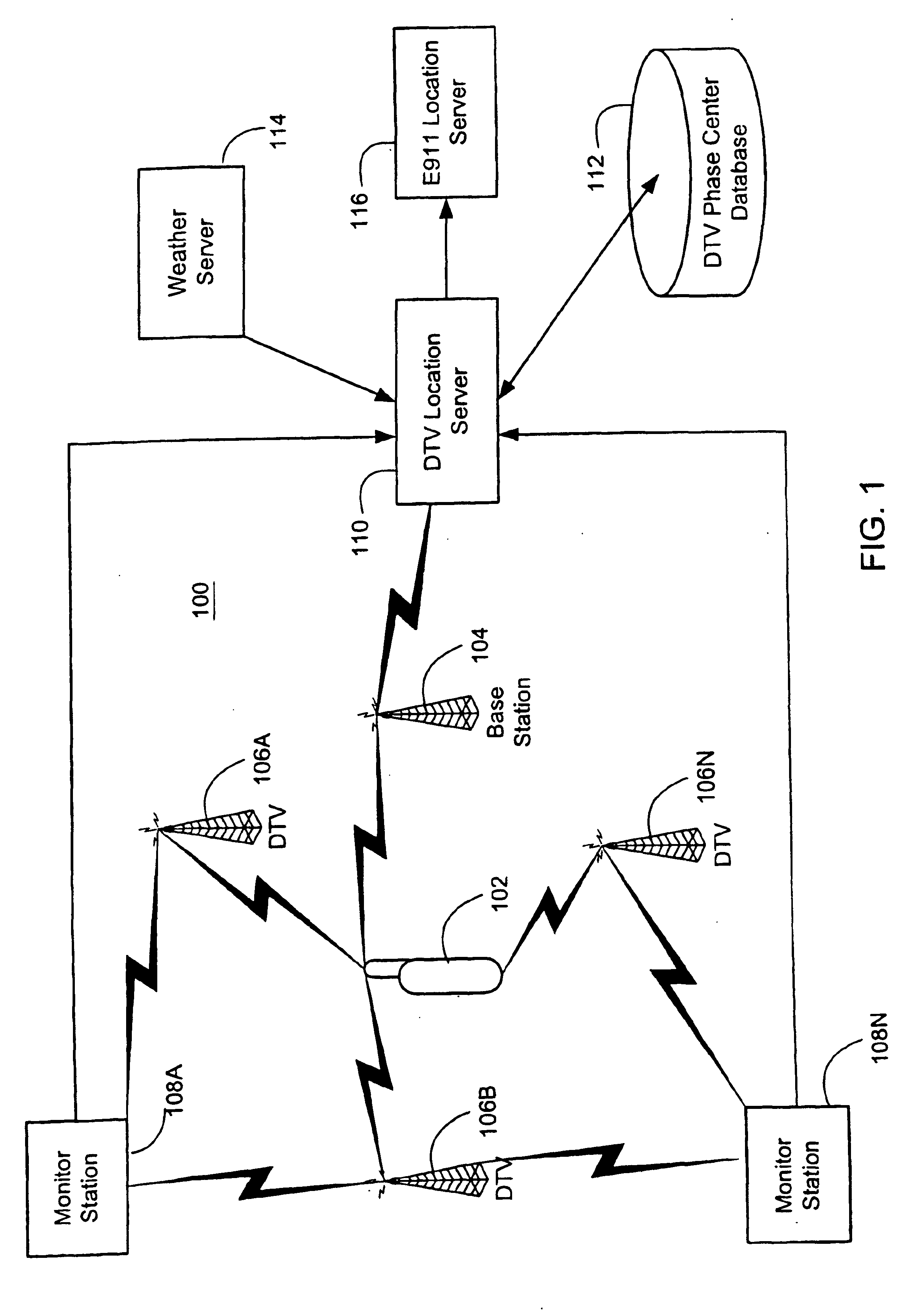

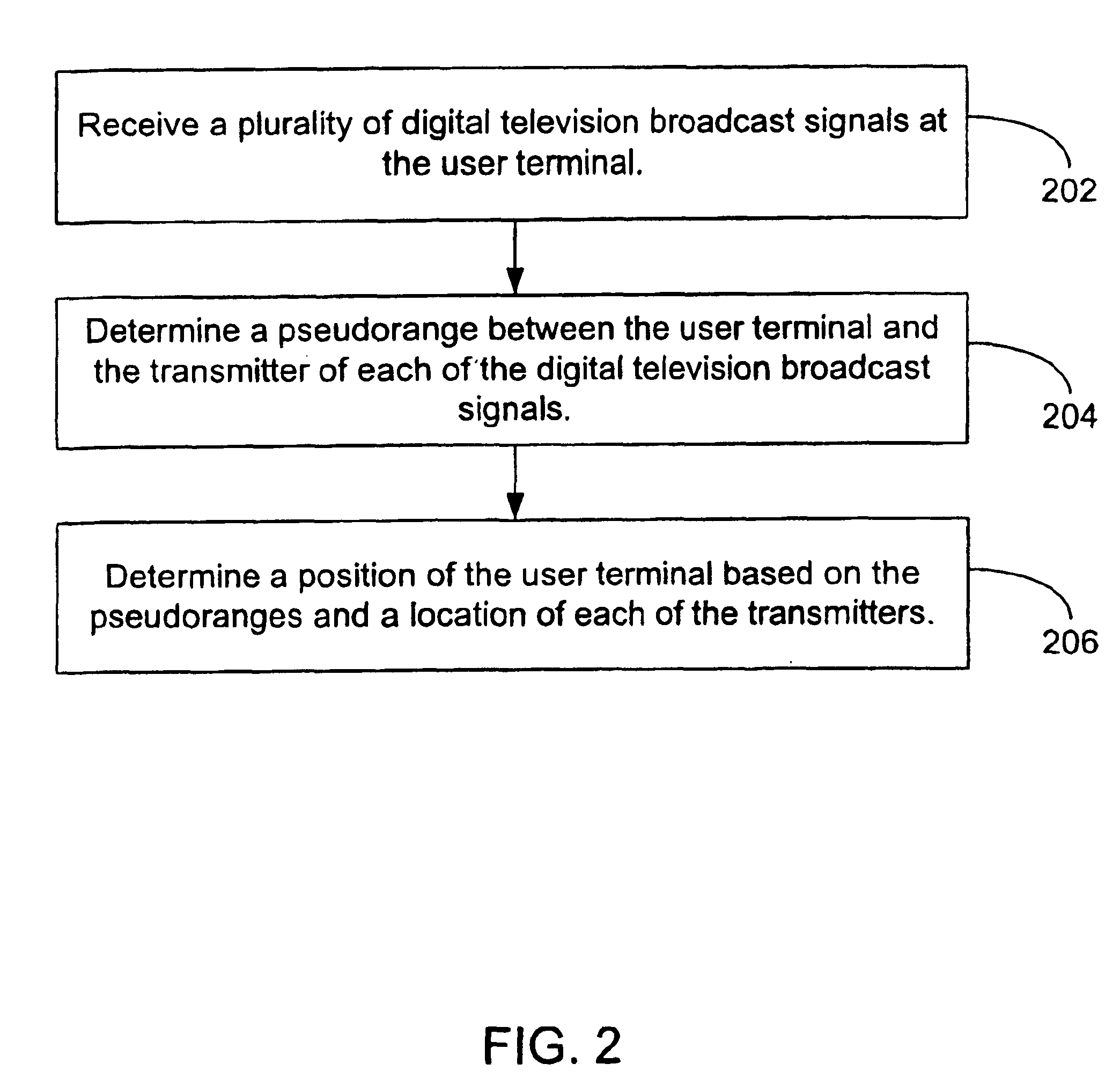

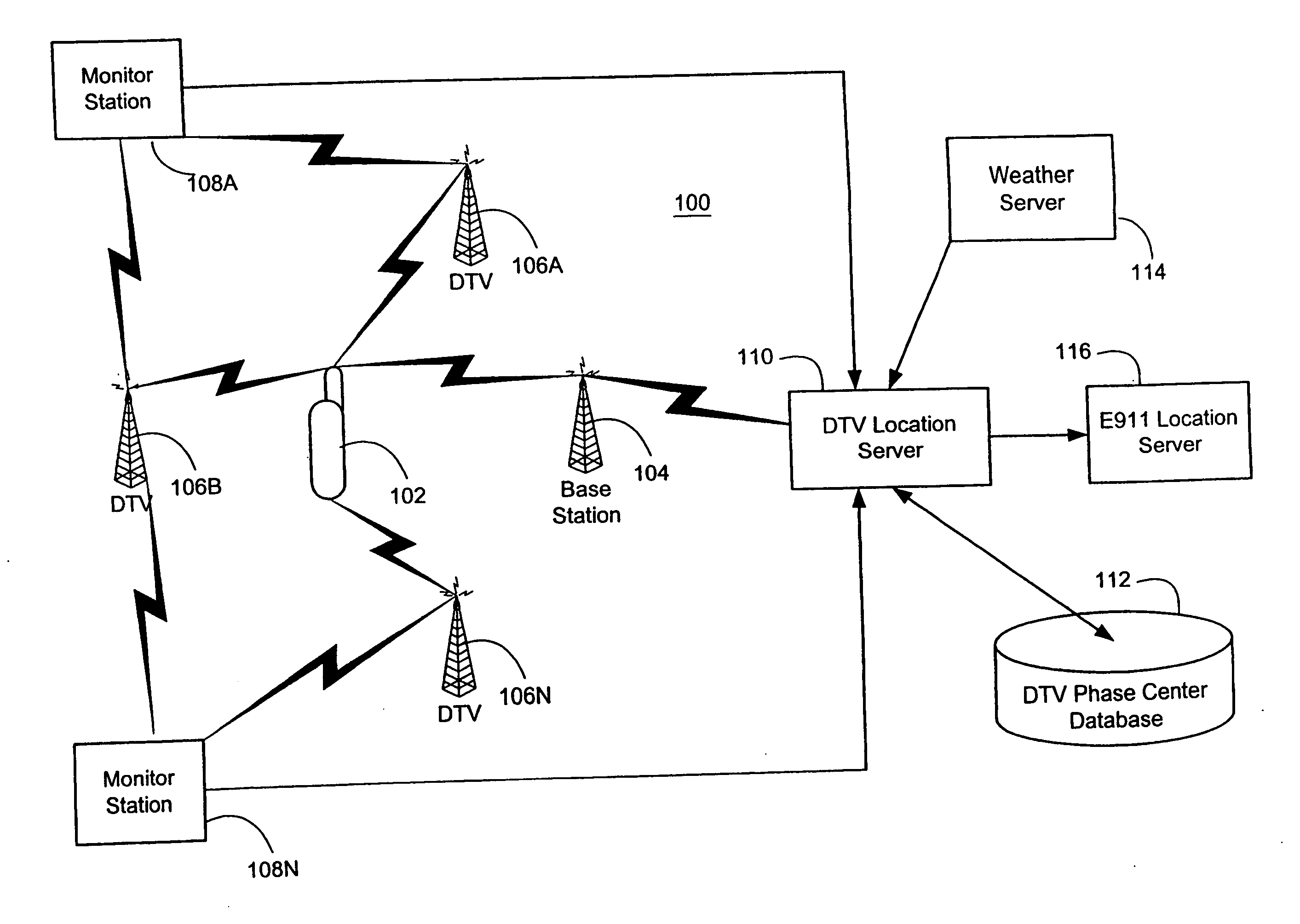

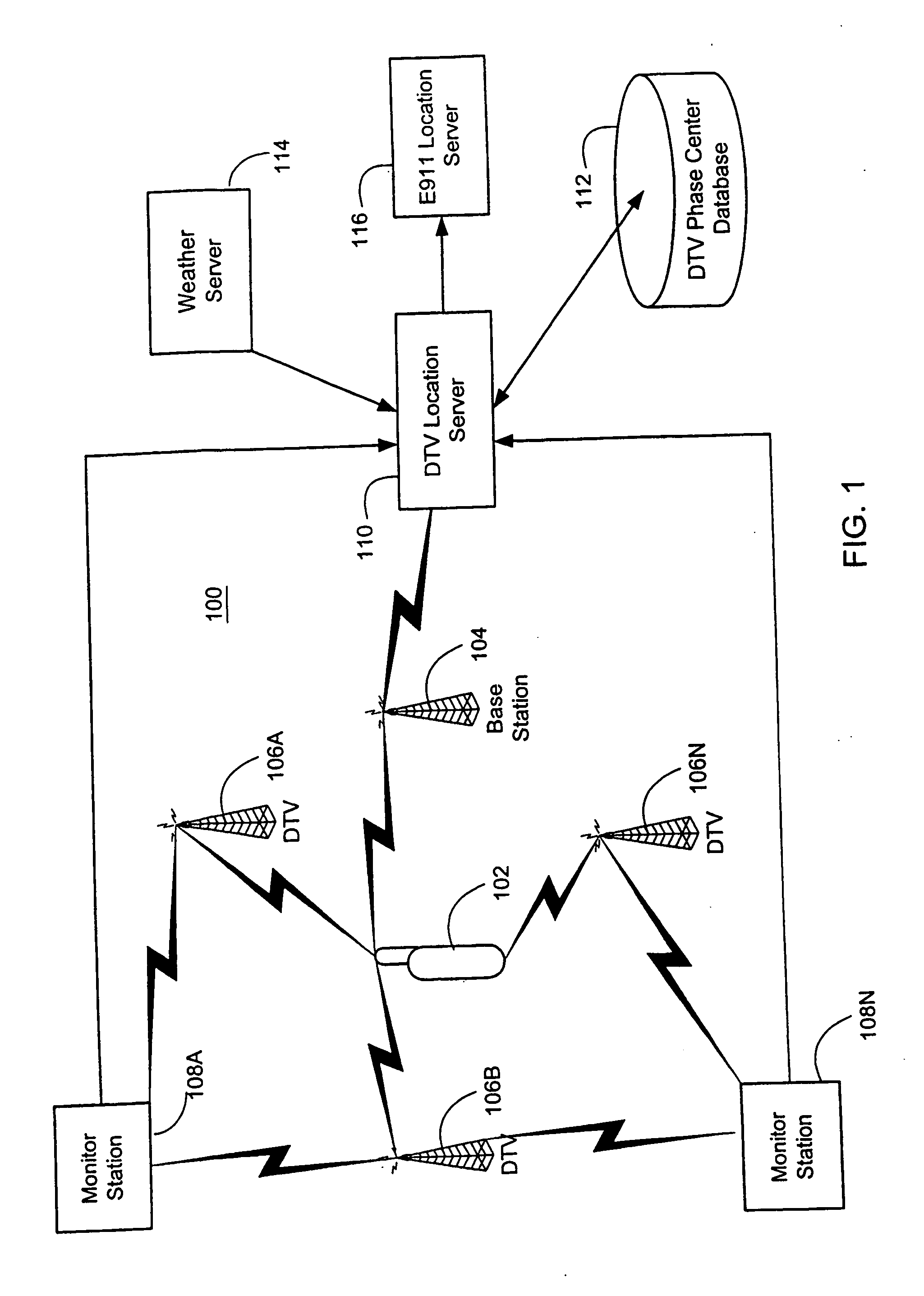

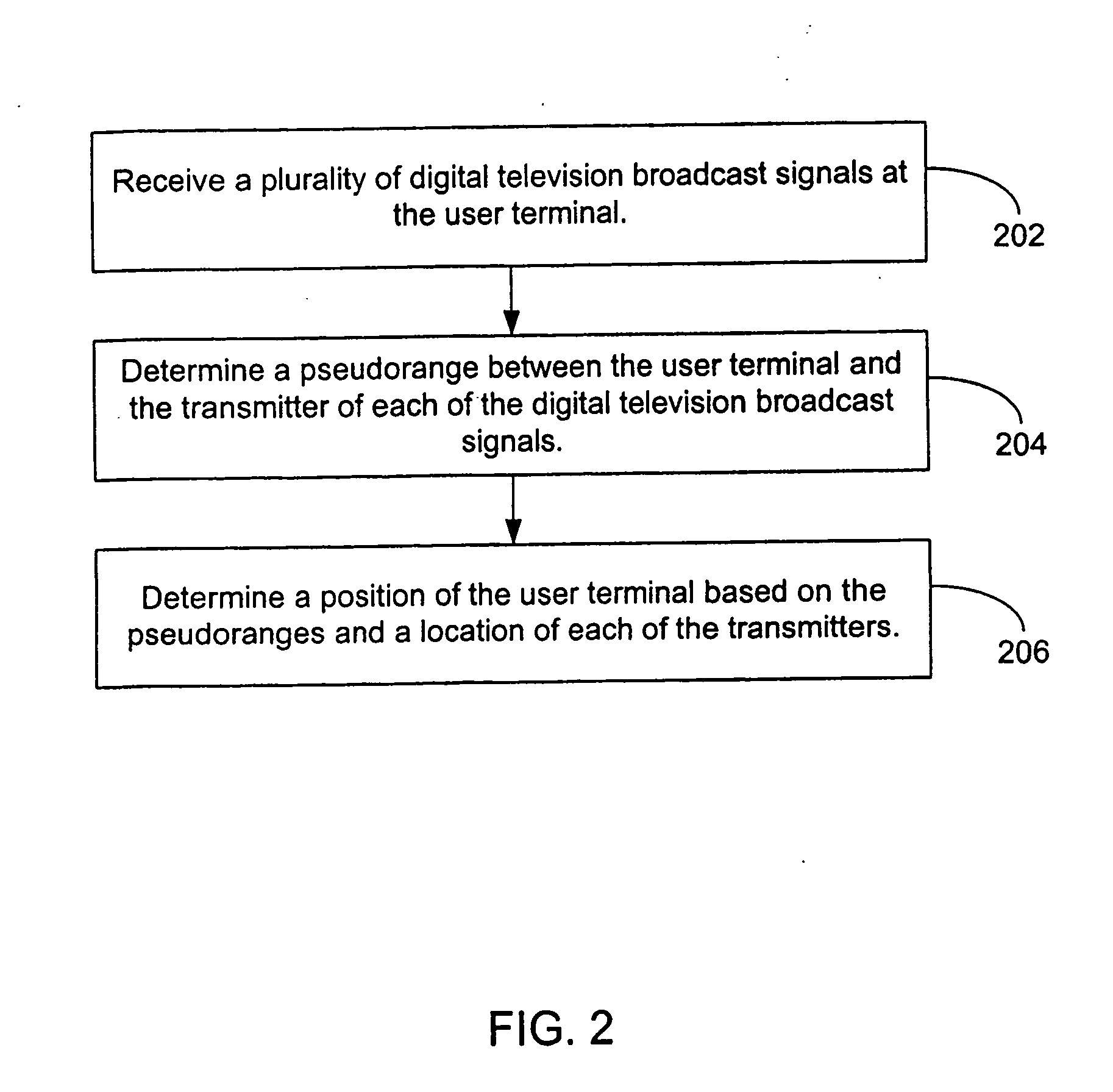

Position location using broadcast digital television signals

InactiveUS6861984B2Optimize geometryMinimize impactPulse modulation television signal transmissionIndoor gamesComputer terminalDigital television

A computer program product, apparatus, and method for determining the position of a user terminal. It includes receiving at the user terminal a plurality of digital television (DTV) broadcast signals from a plurality of DTV transmitters, determining a pseudo-range between the user terminal and each DTV transmitter based on the DTV broadcast signals, and determining a position of the user terminal based on the pseudo-ranges and a location of each of the DTV transmitters.

Owner:TRUE POSITION INC

Use of shaped bodies having catalytic properties as reactor internals

InactiveUS8119554B2Easy to useLower overall pressure dropAdditive manufacturing apparatusInorganic chemistryChemical reactionActive component

Shaped bodies having catalytic properties which can be obtained by a process comprising the steps:a) production of a shaped body by means of a powder-based rapid prototyping process,b) if appropriate, a heat treatment of the shaped body,c) if appropriate, application of at least one catalytically active component to the shaped body,d) if appropriate, a further heat treatment,where steps b), c) and / or d) can be carried out a number of times,are used as reactor internals in heterogeneously catalyzed chemical reactions.

Owner:BASF SE

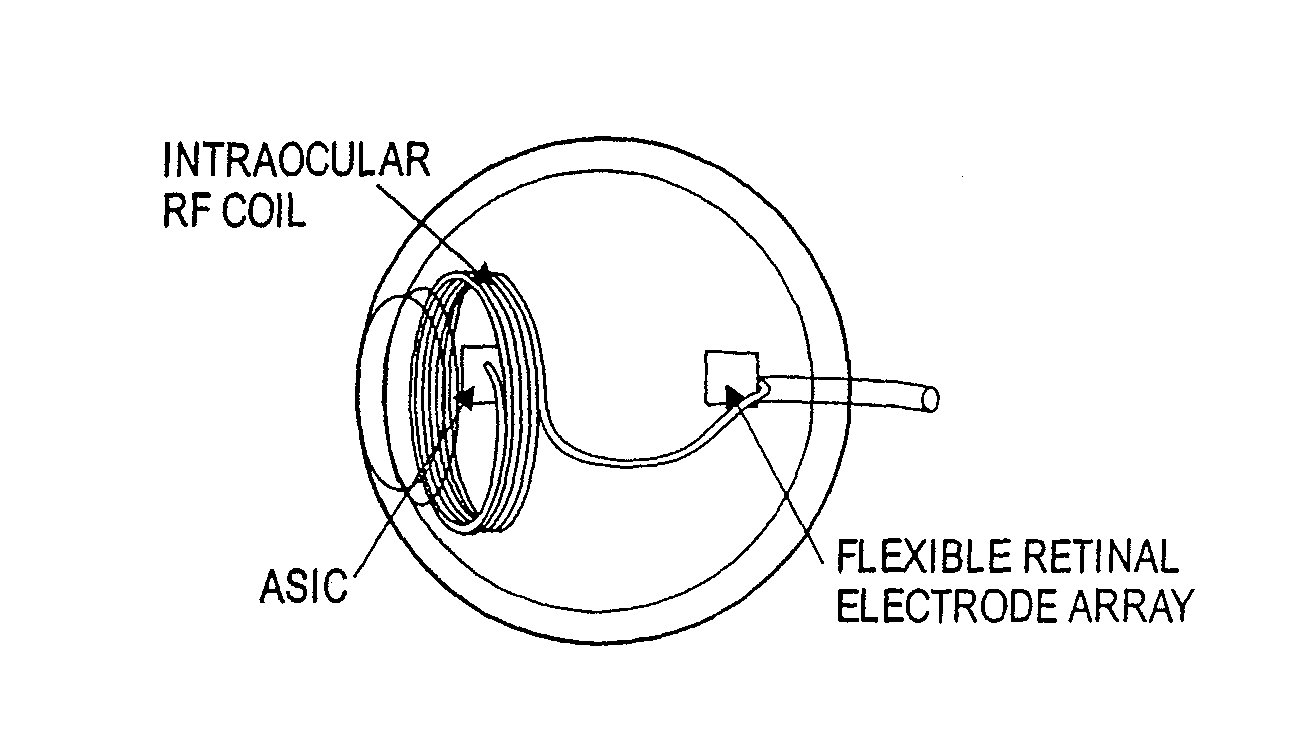

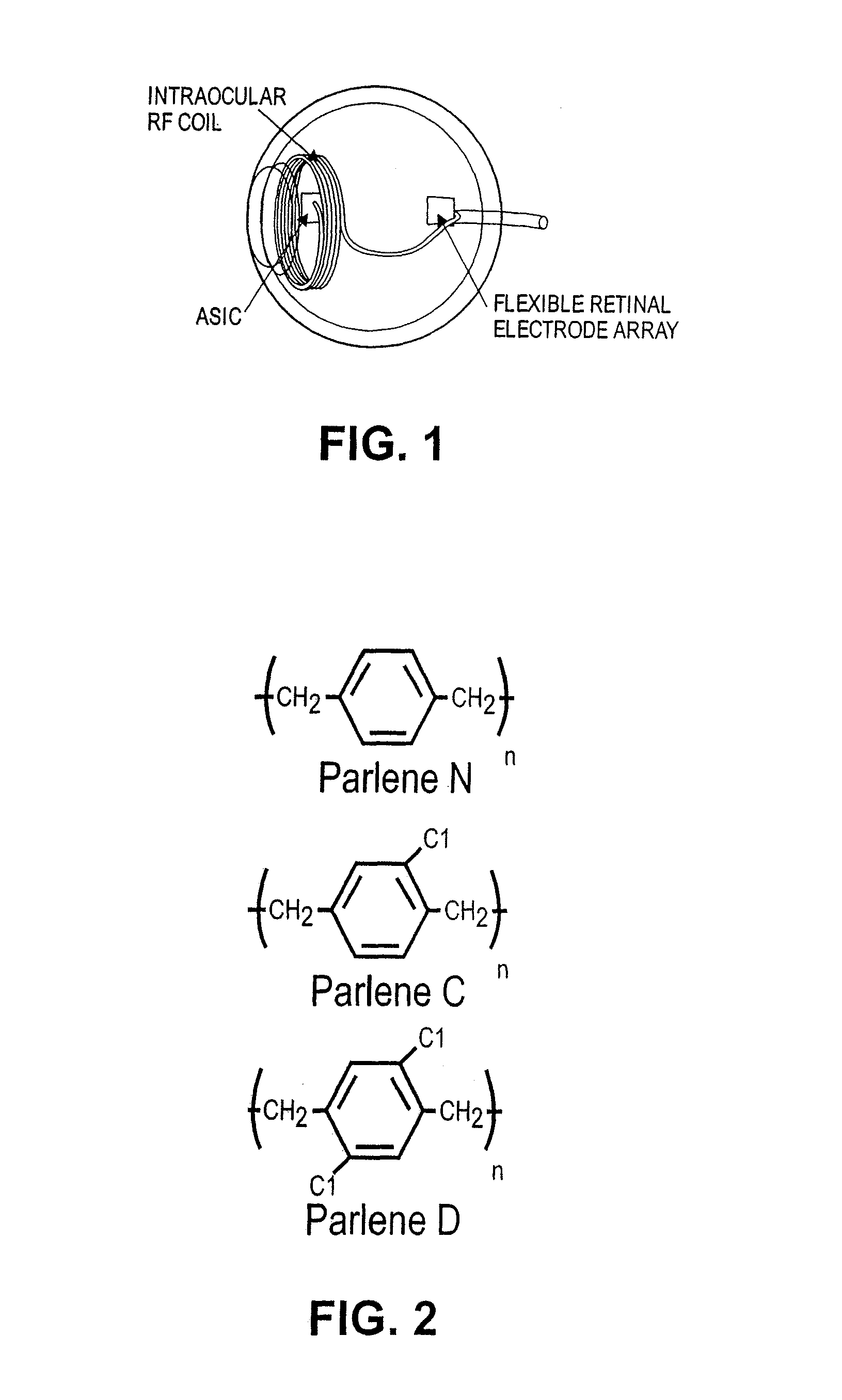

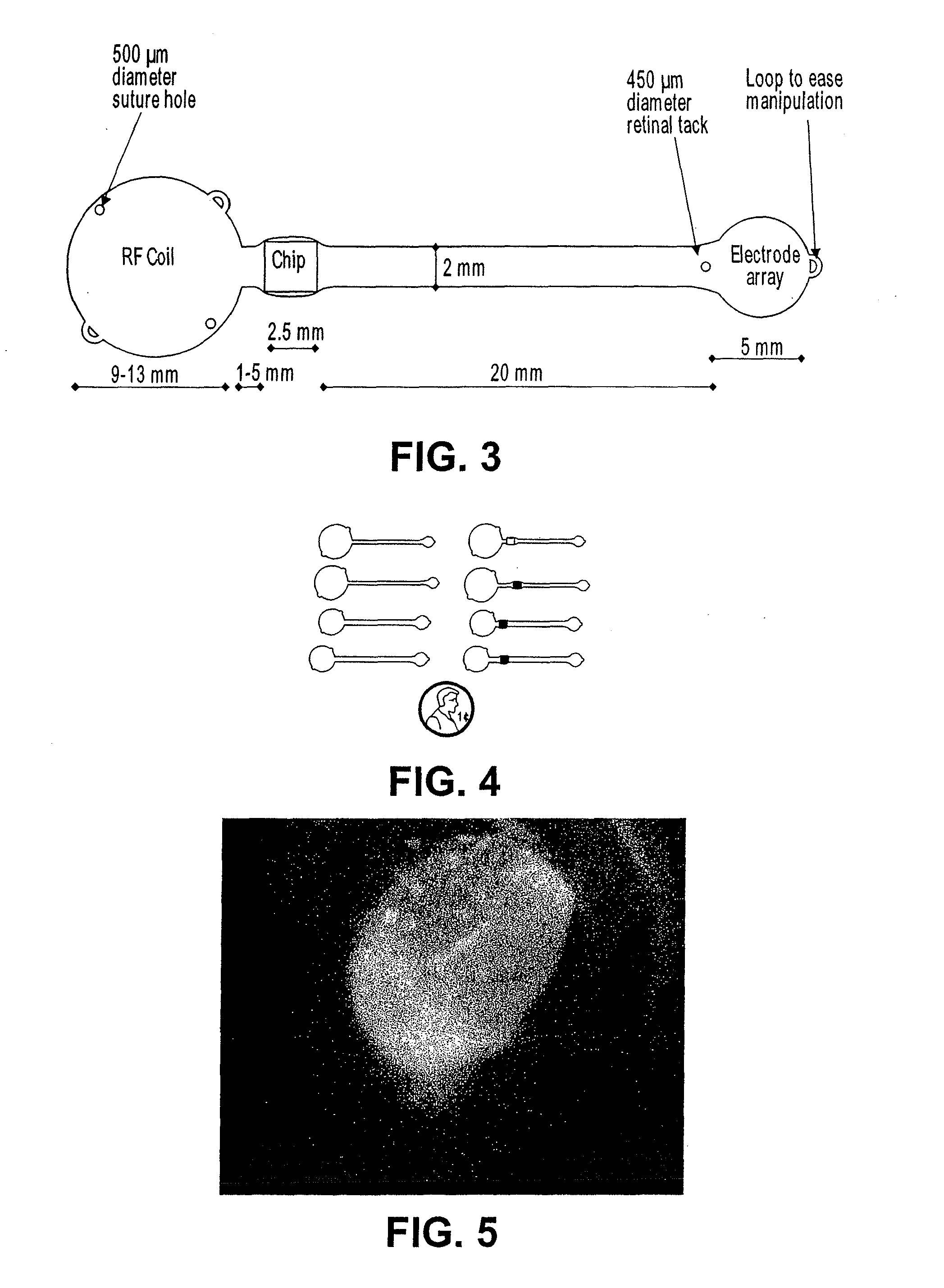

Method of fabricating an integrated intraocular retinal prosthesis device

ActiveUS7774931B2Function increaseDecrease traction and pullingPrinted circuit assemblingLine/current collector detailsProsthesisData management

Intraocular retinal prosthesis devices and methods for fabricating the same. A prosthesis device includes a cable region that connects an electrode array region with a power and data management region. The electrode array region includes one or more arrays of exposed electrodes, and the power and data management region includes various power and control elements. The power and data management elements, in one aspect, include an RF coil or coils and circuit arrangements and / or chips configured to provide drive signals to the electrodes via a cable and receive power and signals from the RF coil or coils. Each region includes elements fabricated on or in a single polymer layer during the same fabrication process.

Owner:UNIV OF SOUTHERN CALIFORNIA +1

Introducer for an iliac side branch device

An introduction arrangement for a fenestrated or branched stent graft (13) intended for deployment into the lumen of a vessel having a blind vessel extending from it. The introducer (1) has a distal end intended to remain outside a patient in use and a proximal end with a nose cone dilator (11) and an arrangement to retain the branched stent graft distally of the nose cone dilator. A sheath (15) on the introducer extends over the branched stent graft to the nose cone dilator. An indwelling catheter (22) extends from the distal end of the introducer and enters the fenestration or side arm and through to the nose cone dilator, the indwelling catheter has a guide wire (29) extending through it. The guide wire can be extended beyond the nose cone dilator in use before the sheath is withdrawn from the branched stent graft so that it can be snared from the contra-lateral artery.

Owner:COOK MEDICAL TECH LLC +1

Process for the surface polishing of silicon wafers

A process for the surface polishing of a silicon wafer, includes the successive polishing of the silicon wafer on at least two different polishing plates covered with polishing cloth, with a continuous supply of alkaline polishing abrasive with SiO2 constituents, an amount of silicon removed during the polishing on a first polishing plate being significantly higher than on a second polishing plate, with the overall amount of silicon removed not exceeding 1.5 mum. A polishing abrasive (1a), then a mixture of a polishing abrasive (1b) and at least one alcohol, and finally ultrapure water (1c) are added to the first polishing plate, and a mixture of a polishing abrasive (2a) and at least one alcohol and then ultrapure water (2b) are added to the second plate.

Owner:SILTRONIC AG

Position location using broadcast digital television signals

InactiveUS20050066373A1Optimize geometryMinimize impactPulse modulation television signal transmissionIndoor gamesDigital televisionTransmitter

A computer program product, apparatus, and method for determining the position of a user terminal. It includes receiving at the user terminal a plurality of digital television (DTV) broadcast signals from a plurality of DTV transmitters, determining a pseudo-range between the user terminal and each DTV transmitter based on the DTV broadcast signals, and determining a position of the user terminal based on the pseudo-ranges and a location of each of the DTV transmitters.

Owner:ROSUM CORP

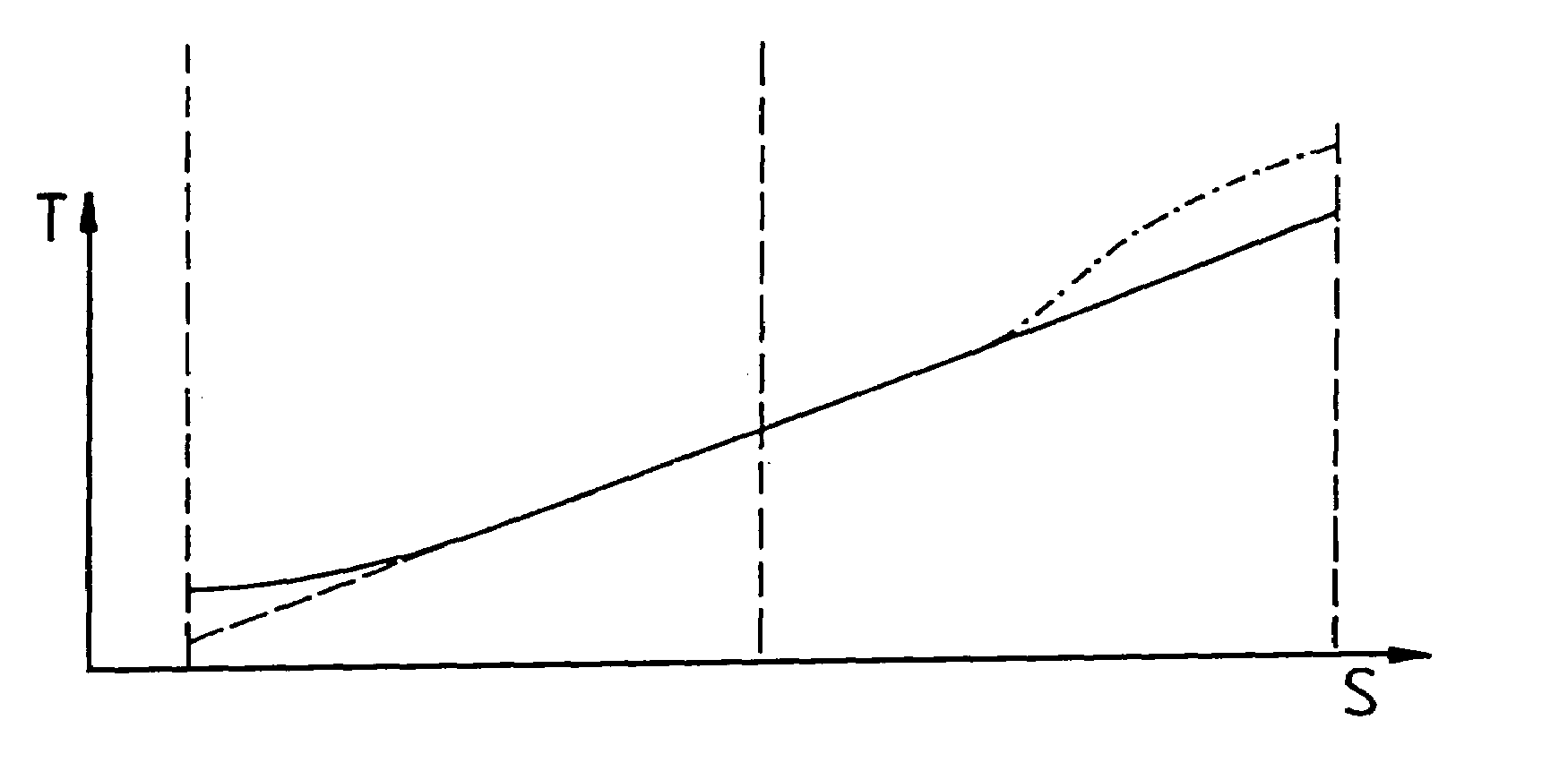

Thermostated block with heat-regulating devices

InactiveUS7074367B2Gradient is shallowHigh gradientBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringThermal conditioning

Owner:EPPENDORF AG

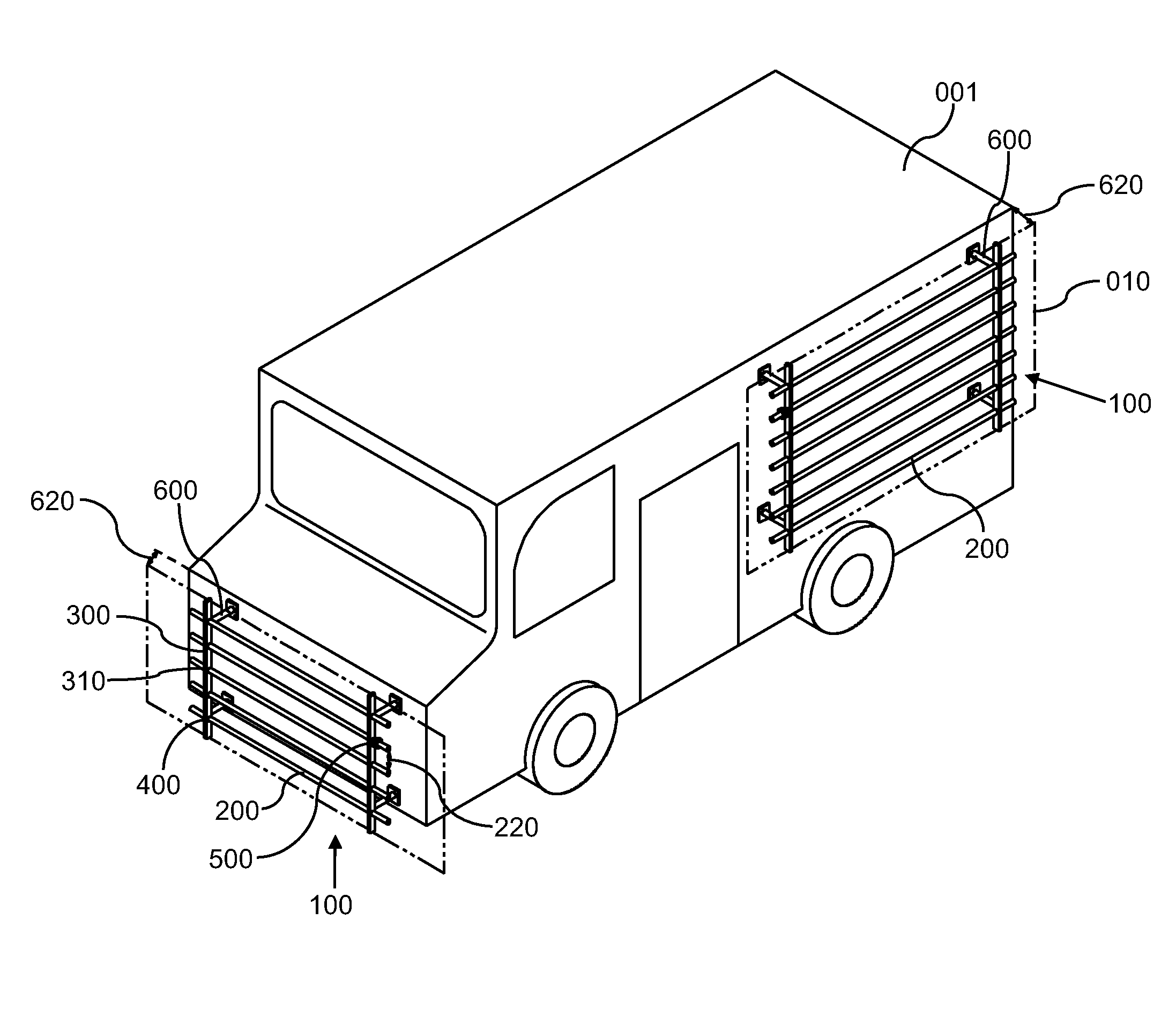

Bar armor system for protecting against rocket-propelled grenades

InactiveUS20110232472A1Optimize geometryInhibition of translationArmourArmoured vehiclesVertical barShaped charge

A bar armor system is provided for reducing damage caused by RPGs launched towards a vehicle. The bar armor system includes at least one bar array, comprised of lateral bars and vertical bars, wherein the lateral bars are set in predetermined positions so as to reduce the possibility of shaped charges being directed towards the target vehicle. Tubular shaft retainers are provided to be positioned in annular openings in the vertical bars. The lateral bars can be of a round or hexagonal cross-section, and when hexagonal lateral bars are employed, the flat surfaces of the cross-section are positioned horizontally by the tubular shaft retainers so as to minimize the area presented to an oncoming RPG, particularly when the RPG strikes at a non-normal incidence. Push washers can be employed at the outside surfaces of the vertical bars so as to hold them in position. A mounting system is provided that is capable of positioning the bar armor system at close distances to the vehicle so that the overall size and weight of the vehicle is not unduly increased by the bar armor system. The mounts can include rotary latches to provide easy installation and removal. The system can also be of an electrically-conductive unified composition so that efficient electrostatic coating techniques can be used to cover the system. The system can also be provided in the form of kits for ready installation and for more economical repair.

Owner:GENERAL ATOMICS

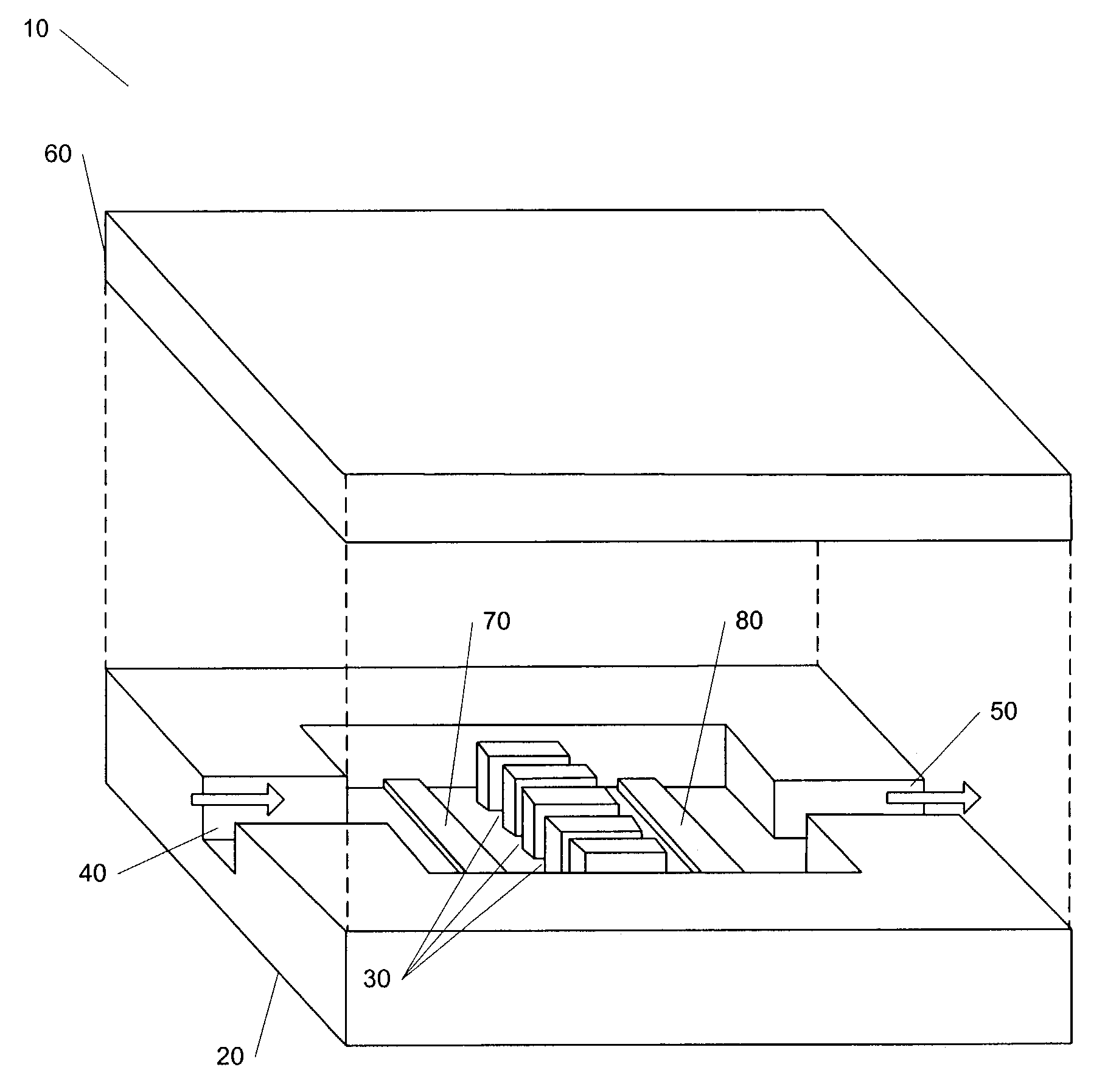

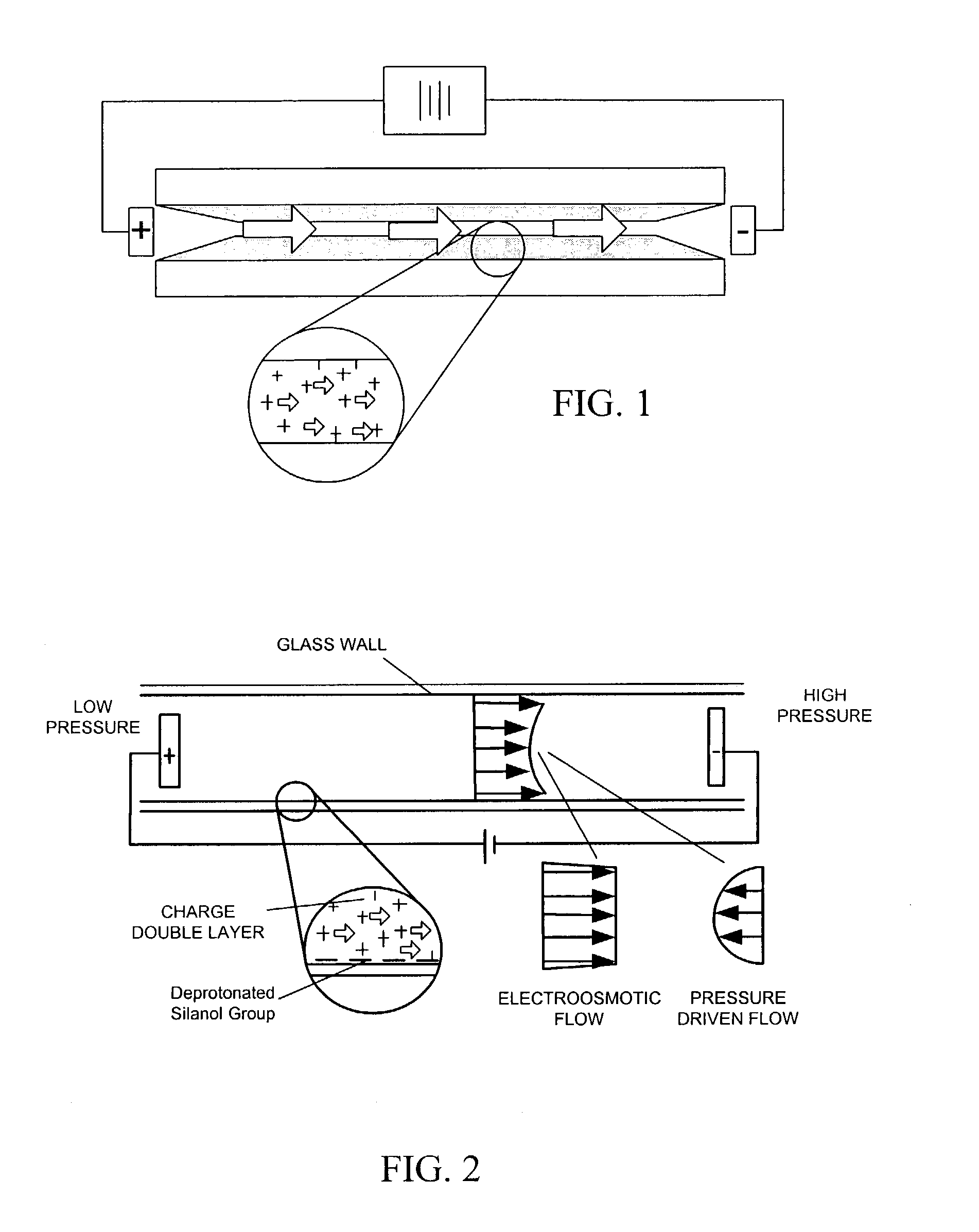

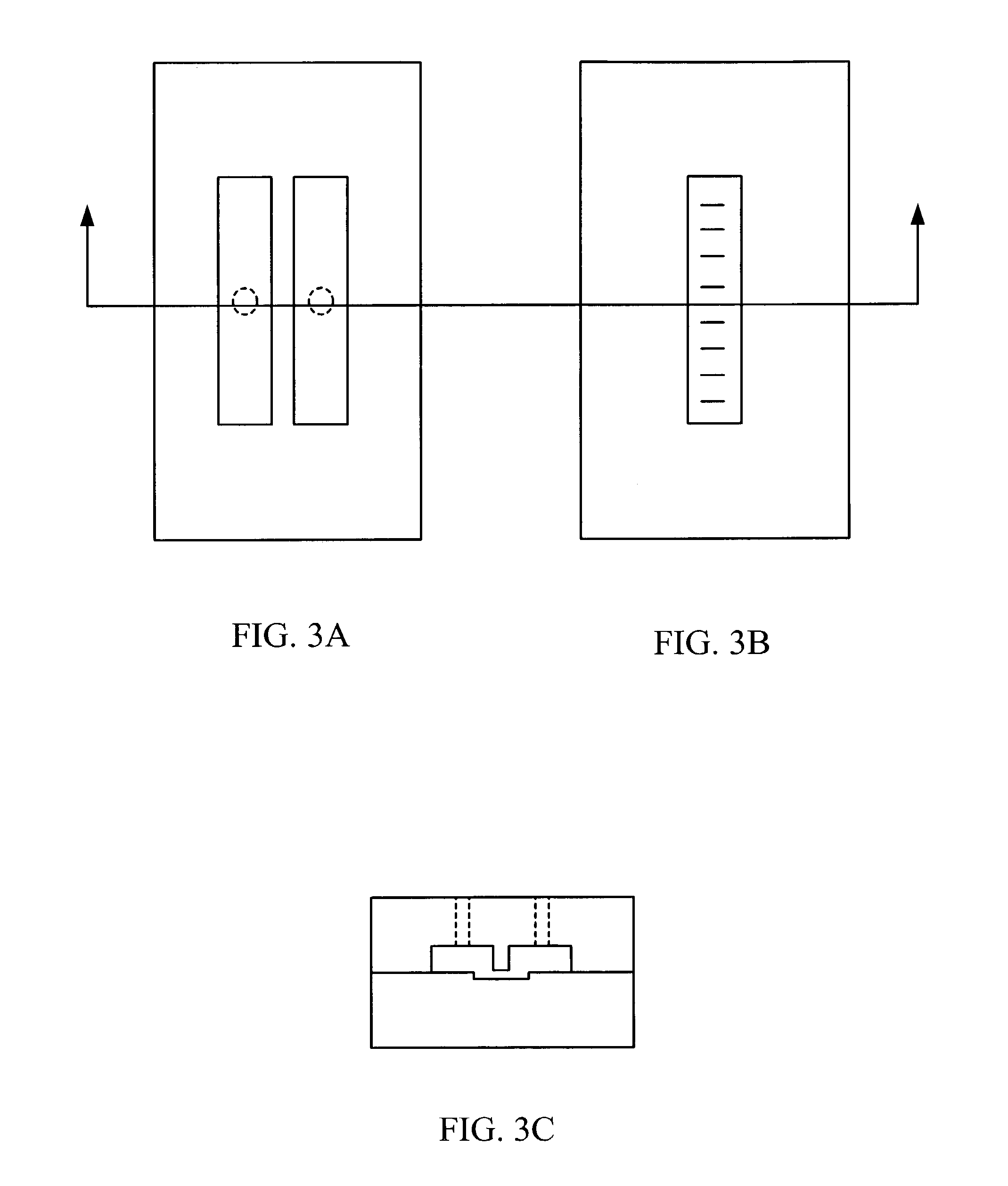

Electroosmotic micropump with planar features

InactiveUS7316543B2Improve micropump performanceOptimize geometrySludge treatmentPump componentsMicropumpEngineering

An electroosmotic micropump having a plurality of thin, closely-spaced, approximately planar, transversel aligned partitions formed in or on a substrate, among which electroosmotic flow (EOF) is generated. Electrodes are located within enclosed inlet and outlet manifolds on either side of the partition array. Inlet and outlet ports enable fluid to be pumped into and through the micropump and through an external friction load or head. Insulating layer coatings on the formed substrate limit substrate leakage current during pumping operation.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

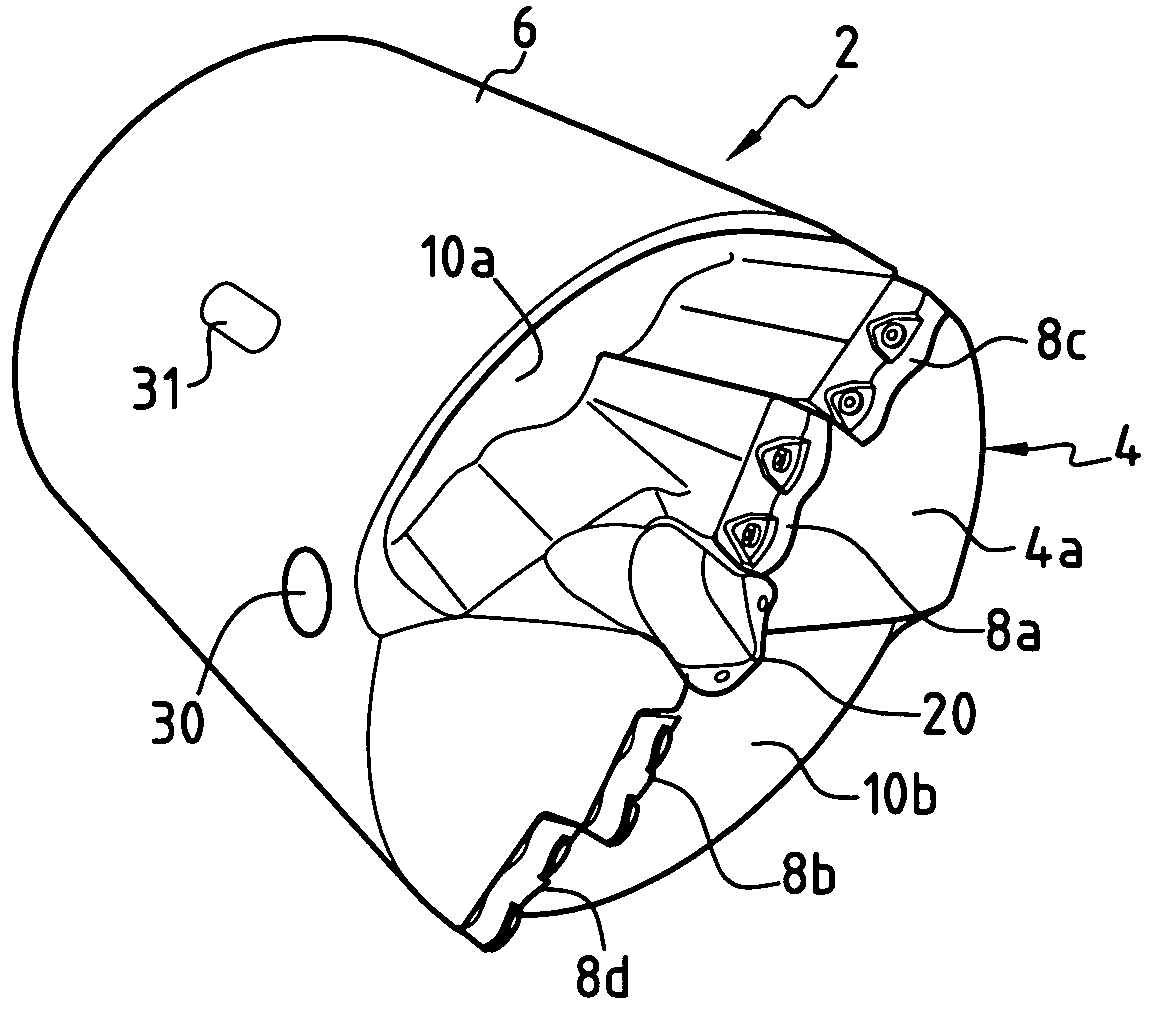

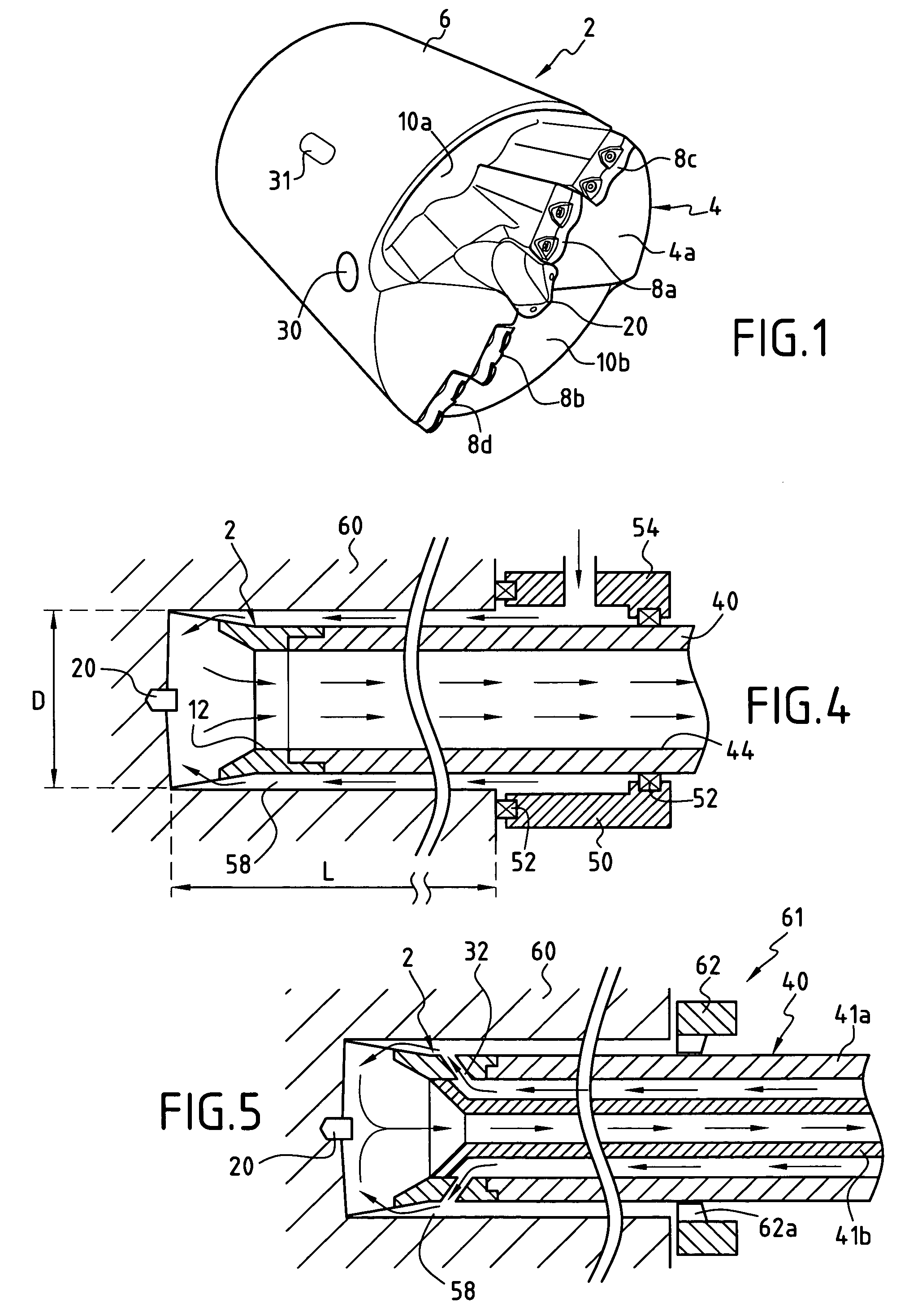

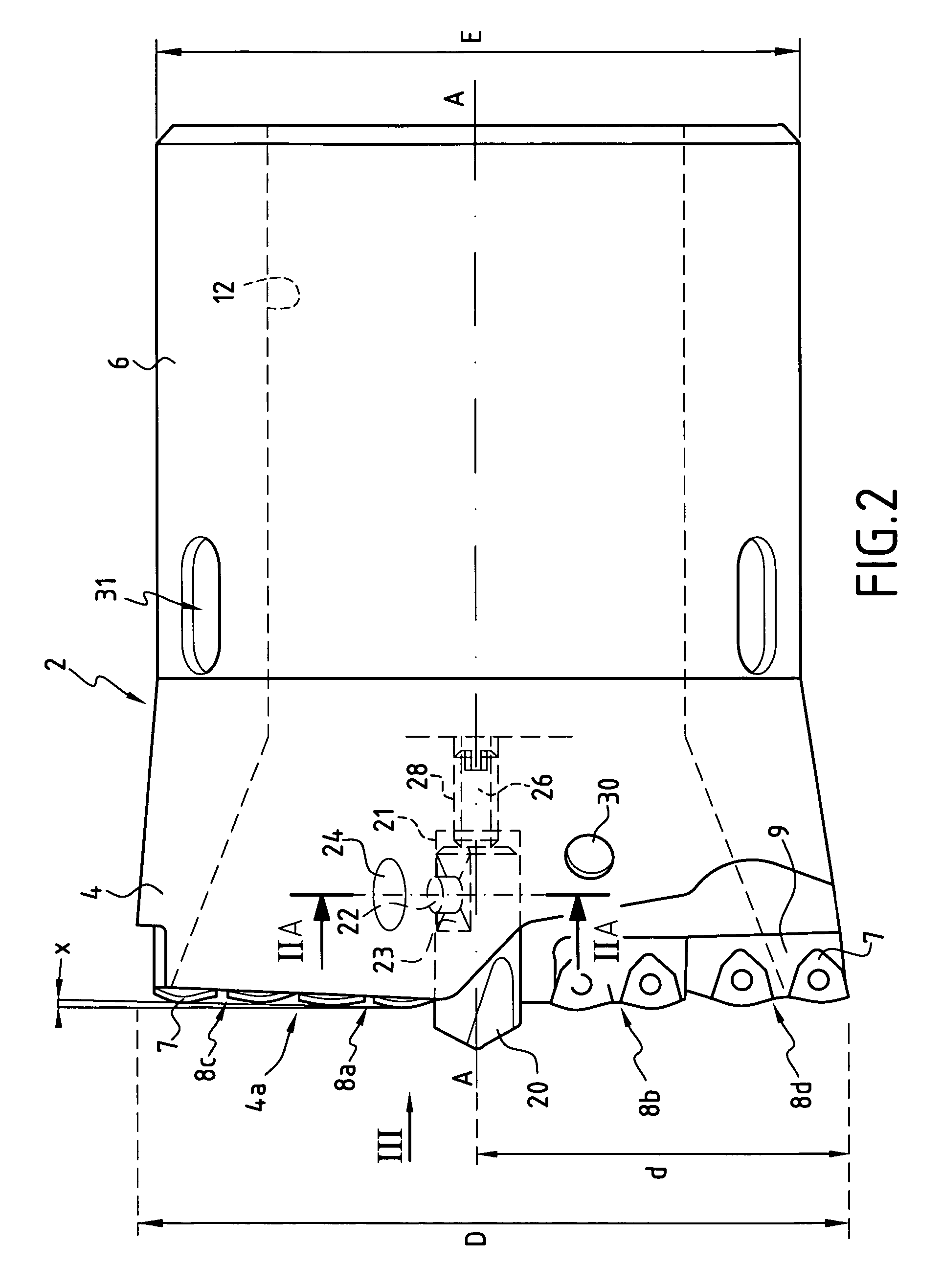

Deep hole boring head and deep hole boring method for boring a production piece

A deep hole boring head is provided which is capable of rotating about a central axis, a body whose front part has at least one cutting edge followed by a recess which leads to a duct inside the body, this duct allowing the chips formed during the boring to be cleared away rearwards, and includes at a front end thereof and at a center portion thereof a pilot drill bit capable of guiding the head during boring. Use for the boring of a production piece is made of titanium, the ratio L / D between the depth L of the hole bored and the diameter D of the latter being greater than or equal to 10, and the diameter D being greater than or equal to 65 mm.

Owner:SAFRAN LANDING SYSTEMS

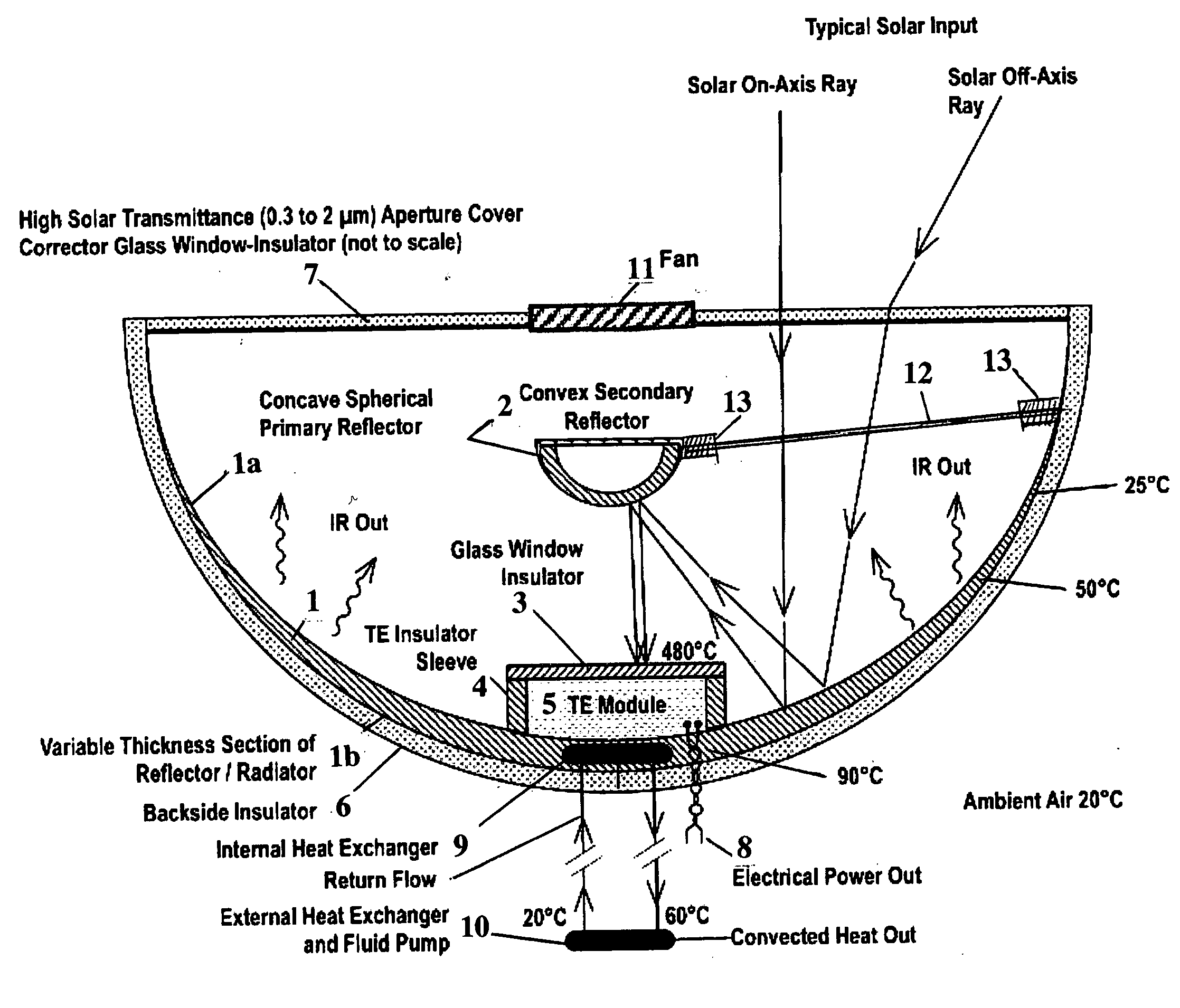

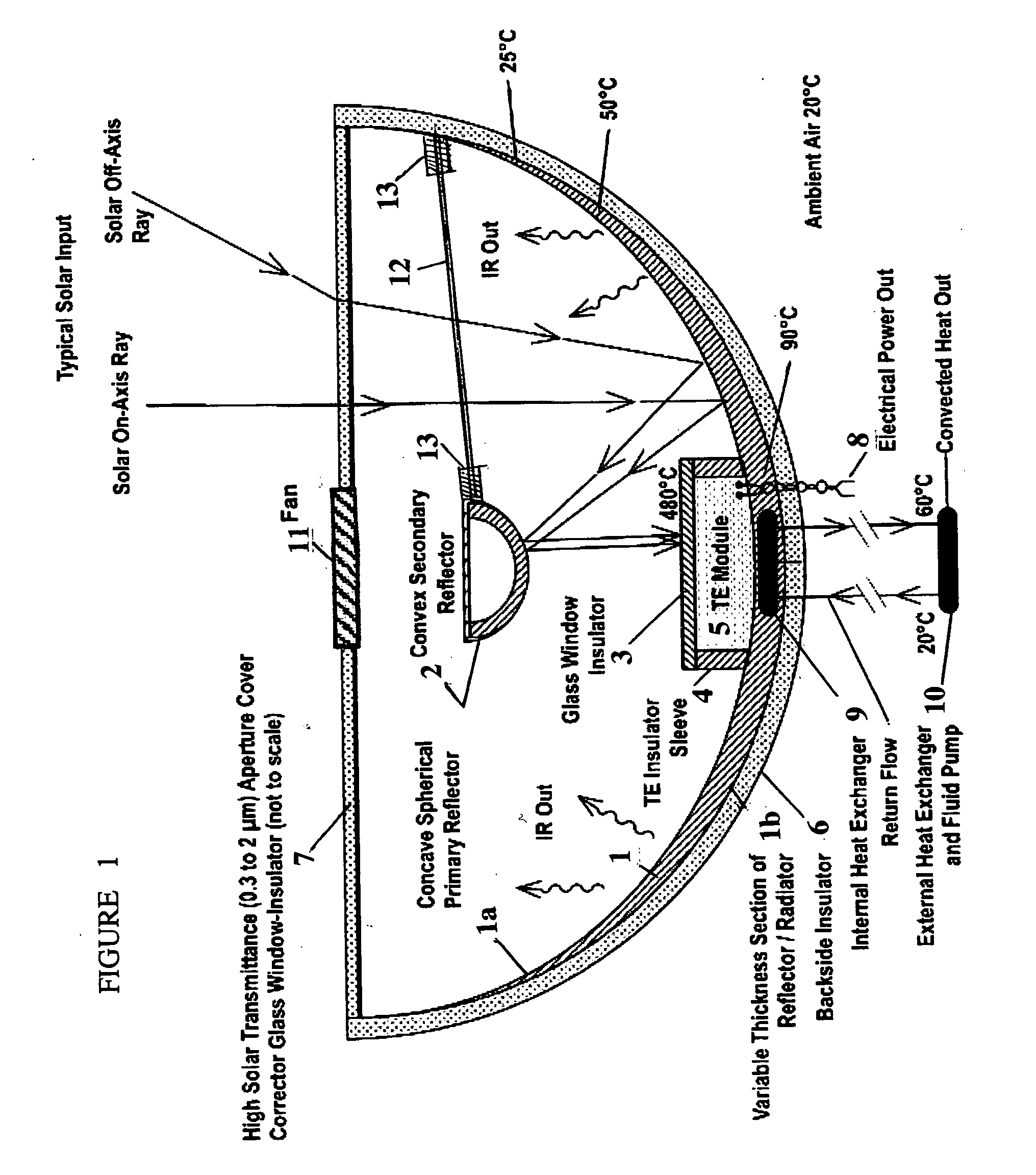

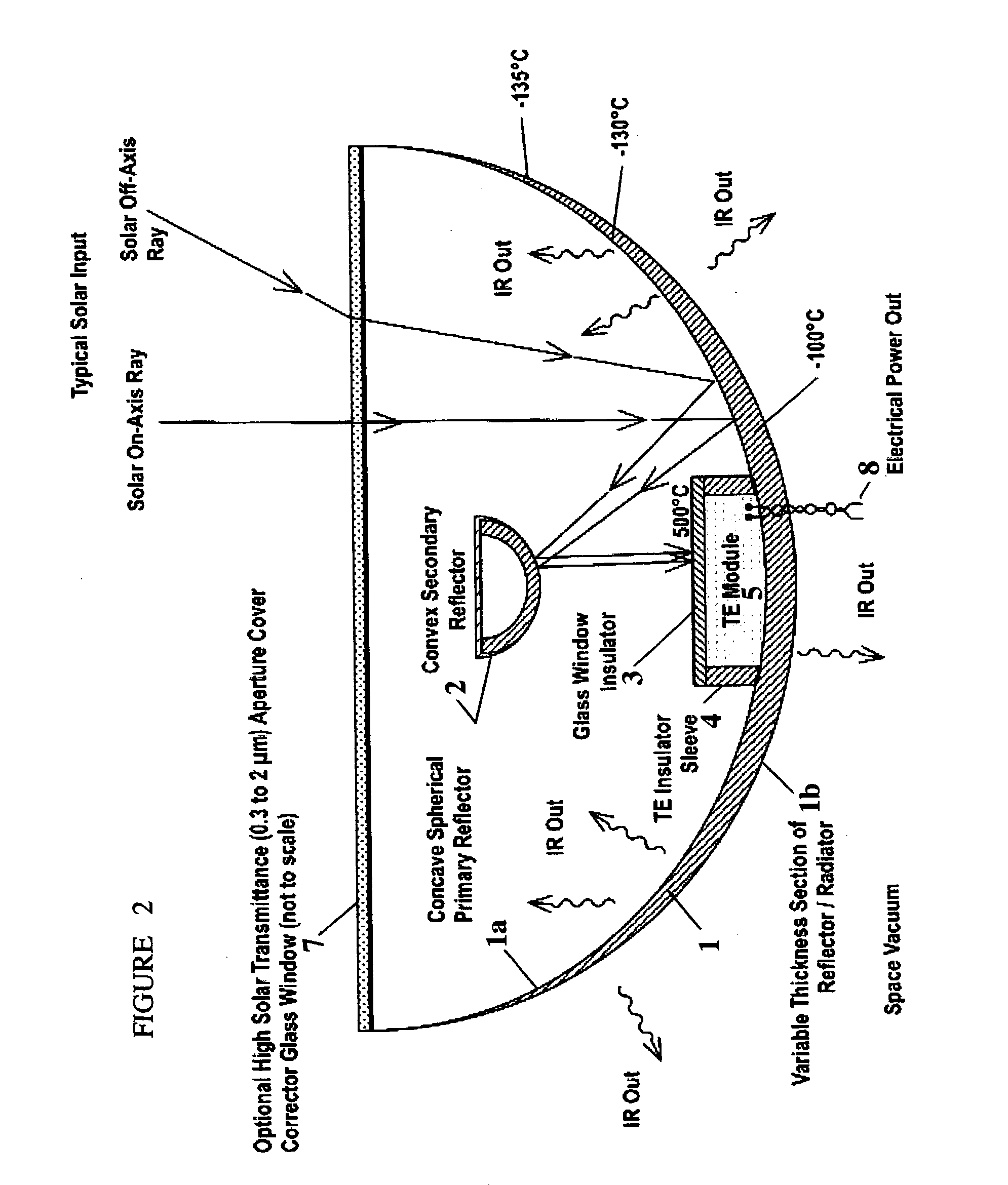

Concentrated solar thermoelectric power system and numerical design model

ActiveUS20110073149A1High solar energy-to-electricity conversion efficiencyComponents are compactSolar heating energySolar heat simulation/predictionSystem configurationEngineering

The invention, the Concentrated Solar Thermoelectric Power System, herein abbreviated as C-STEPS, is a thermo-optical system configuration for the purpose of achieving a high solar energy-to-electricity conversion efficiency based on thermoelectric (TE) devices that use the Seebeck effect. It does so by implementing a system for concentrated solar energy using a design that combines a dual-function reflector / radiator component with an active or passive heat convection mechanism to ensure that TE module operation is maintained in a safe elevated temperature range with respect to the ambient temperature. Unsafe module temperatures are avoided by automatically adjusting the TE module hot side temperature directly or indirectly by regulating the TE cold side temperature using a variety of passive or active mechanisms, including the reflector / radiator component, phase change material, or convection / conduction mechanisms. A Numerical Design Model is used to optimize the configuration geometry and performance in various terrestrial and space applications and it is a central feature of the invention.

Owner:LADNER DANIEL RAY

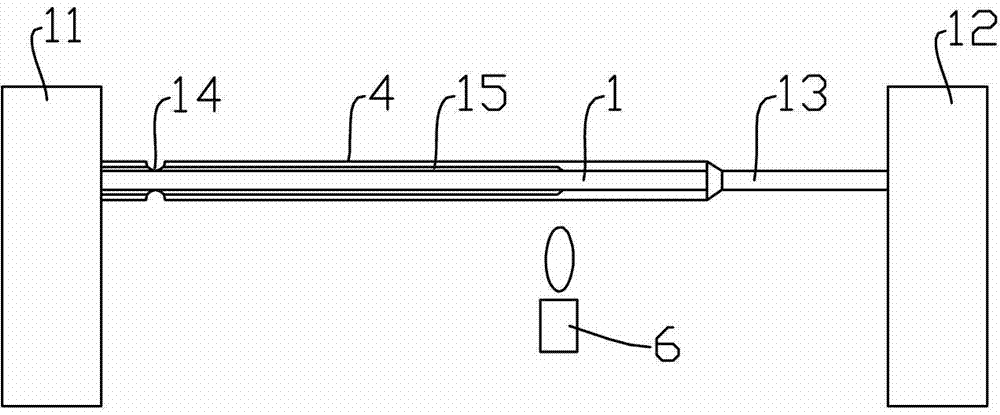

Method for manufacturing external coating layer of optical fiber preform rod through sleeve method

ActiveCN103086598AEasy to collapseAvoid wastingGlass making apparatusGlass productionManufacturing technologyOptical fiber fabrication

The invention discloses a method for manufacturing an external coating layer of an optical fiber preform rod through a sleeve method, belongs to an optical fiber manufacturing technology and aims to overcome the defects of sleeve waste and the like in the manufacturing of an external coating layer of an optical fiber preform rod through a sleeve method in the prior art. In the invention, a core rod is welded onto an auxiliary glass rod, an external diameter enlarged part is arranged at the welding position, and the whole core rod is concentrically inserted into a sleeve, thus forming an annular space between the external surface of the core rod and the internal surface of the sleeve; the circumference of the sleeve is provided with at least three recess parts for fixing the core rod; a blowtorch is used to heat the external diameter enlarged part which seals the sleeve and the core rod, and negative pressure is applied to the annular space; and the blowtorch is moved to heat the sleeve and the core rod, so that the sleeve can collapse onto the core rod to form a solid optical fiber preform rod. According to the invention, the sleeve utilization rate is high; the existing improved chemical vapor deposition equipment can be fully utilized, no additional equipment investment is required, the production cost can be lowered, and the production time can be saved; and the optical fiber preform rod manufactured by the method has favorable physical dimension.

Owner:FUTONG GROUP CO LTD +1

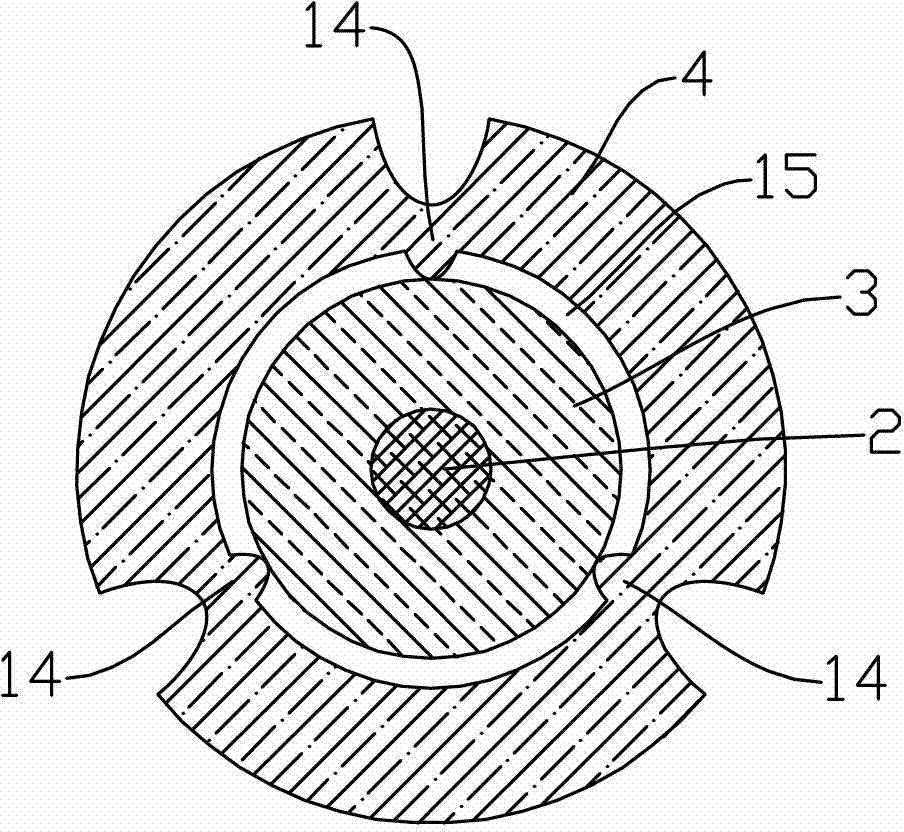

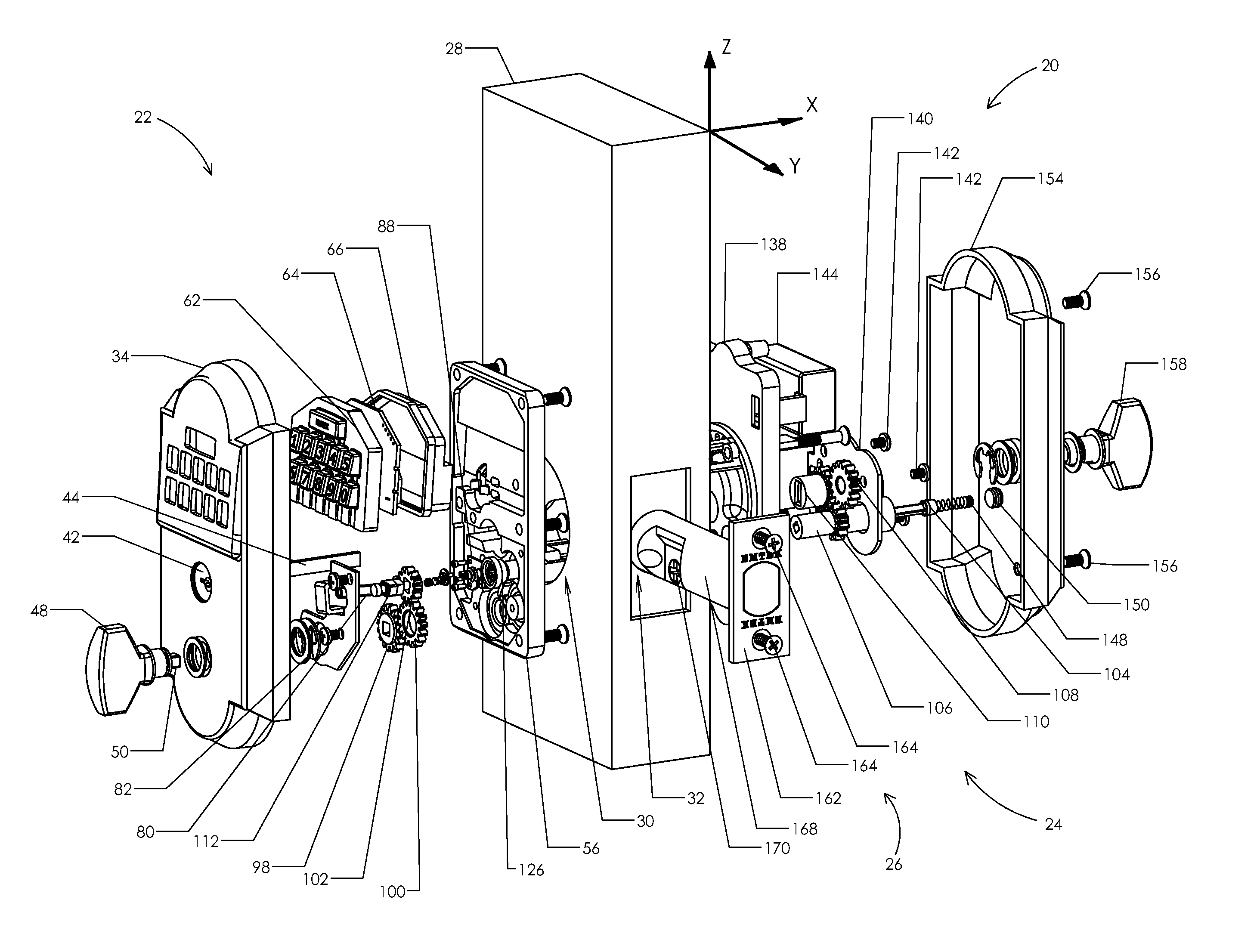

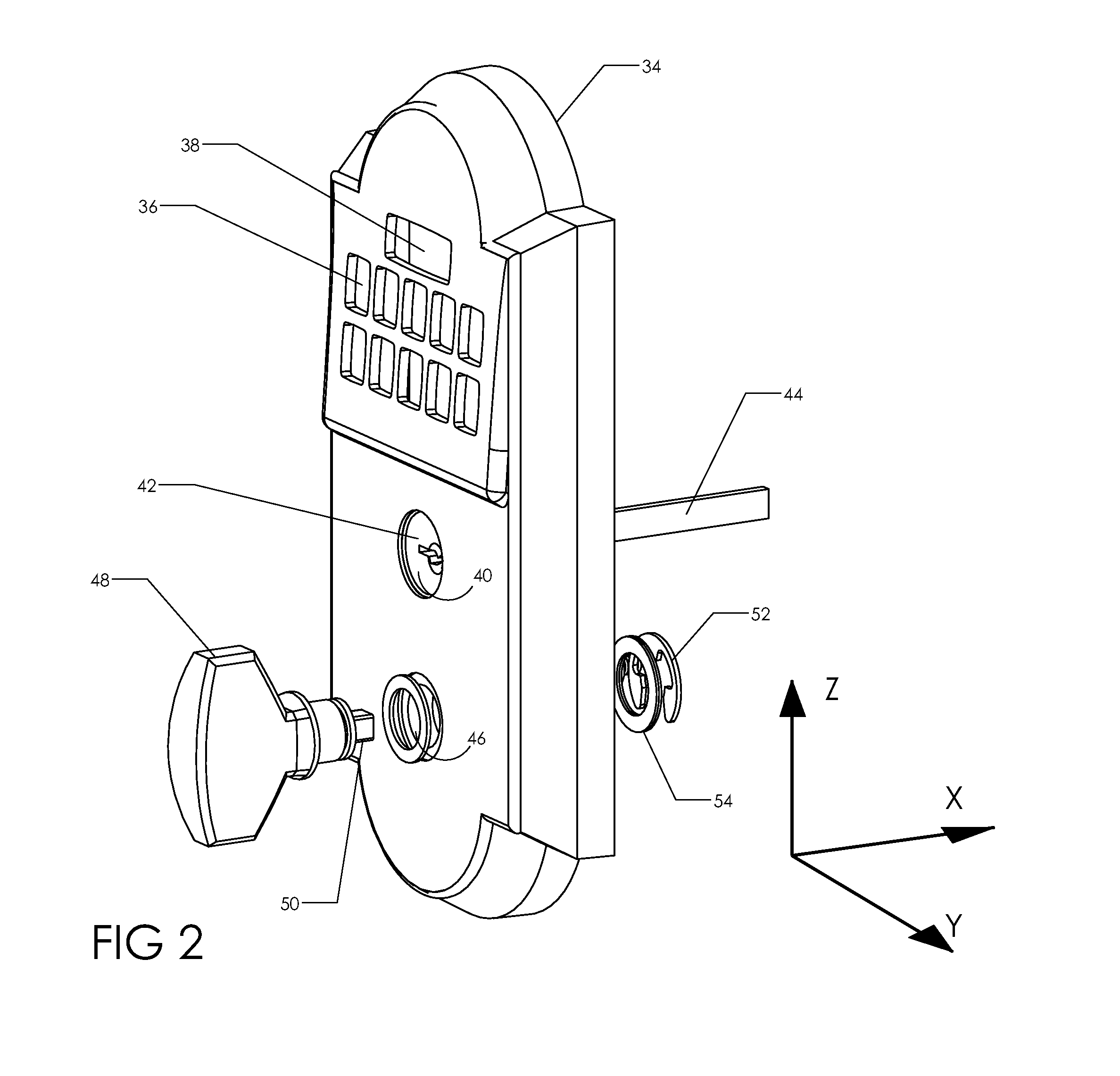

Keypad lockset

ActiveUS20120055213A1Low profileAbility to useNon-mechanical controlsConstruction fastening devicesElectrical FailureEngineering

A keypad lockset adapted for deadbolt as well as lever locks, and having as a first embodiment an exterior gear train, an interior gear train, and an electronically controlled clutch for coupling the gear trains when engaged and for uncoupling the gear trains when the clutch is disengaged, so that when the clutch is engaged rotation of an external thumb turn will permit the door latch to be withdrawn and thus to permit opening of the door, and a mechanical override mechanism that can be operated in case of electrical failure, and in which clutch mechanism and the override mechanism both operate through the single, standard 2 and ⅛ inch door preparation hole, or alternatively as a second embodiment, a keypad lockset in which two four-bar mechanical linkages are used in place of gears as means to actuate the clutch, and alternatively to provide for a pass-through override function.

Owner:ASSA ABLOY RESIDENTIAL GRP INC

Use of shaped bodies having catalytic properties as reactor internals

InactiveUS20100222209A1Easy to useLower overall pressure dropAdditive manufacturing apparatusInorganic chemistryChemical reactionActive component

The invention relates to moulded bodies having catalytic properties, obtained due to a method that comprises the following said steps: a) a moulded body is produced by means of a powder-based rapid-prototyping-method, b) said moulded body is optionally heat-treated, c) at least one catalytically active component is optionally applied to the moulded body, d) said moulded body is optionally subjected to another heat-treatment. The steps b, c) and / or d) can be performed several times. Said moulded bodies are used as reactor fittings in heterogeneously catalyzed chemical reactions.

Owner:BASF AG

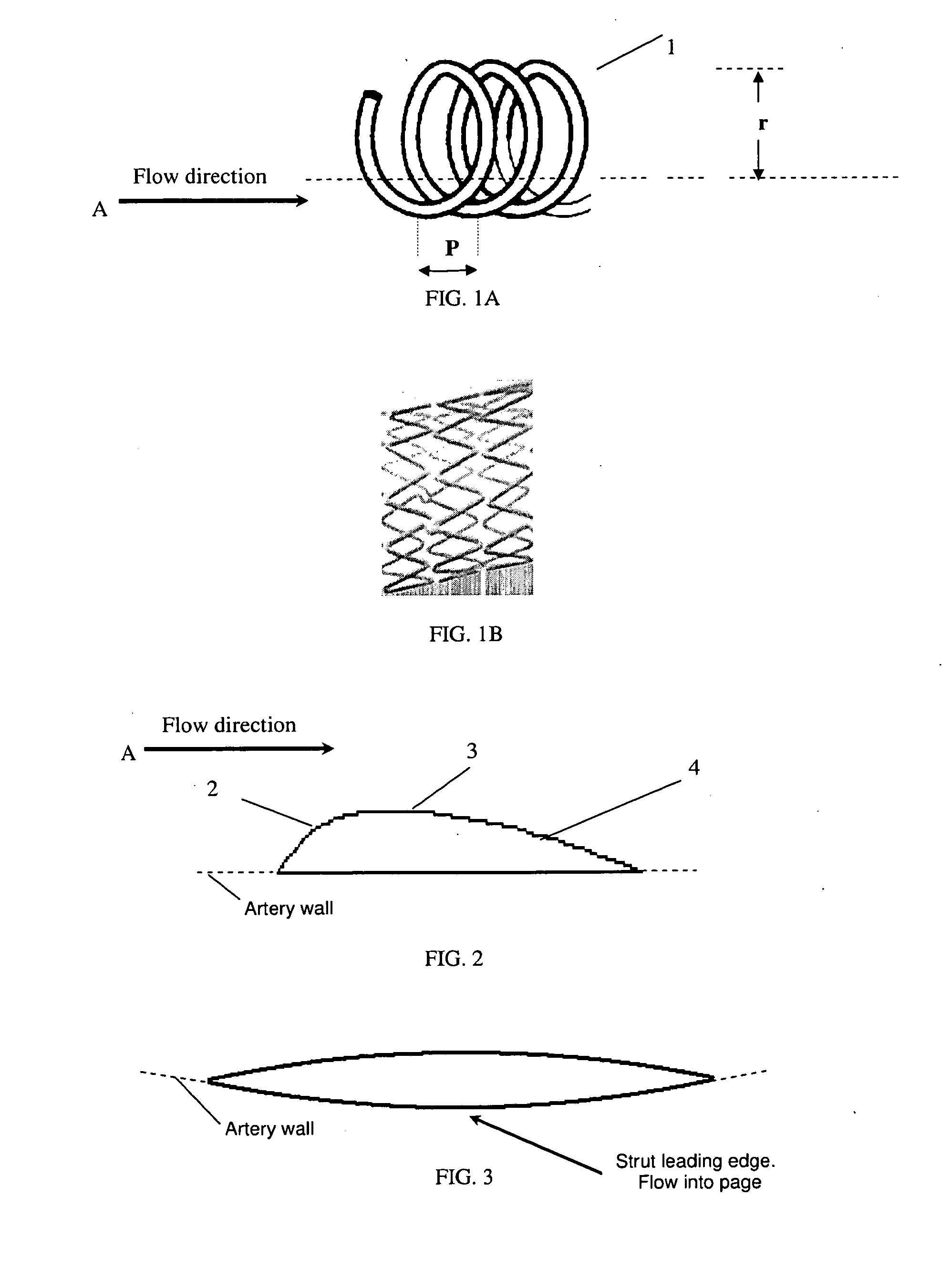

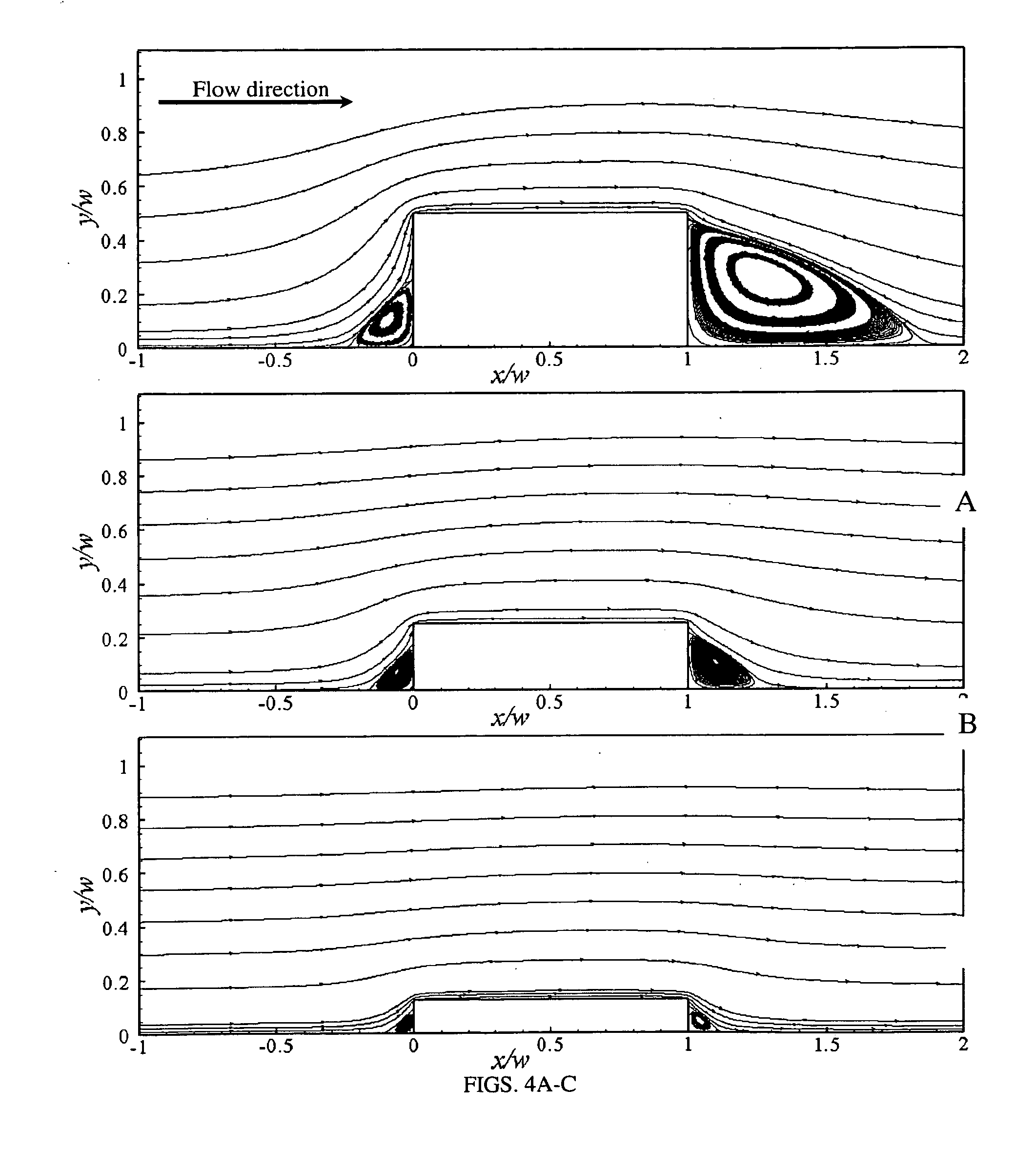

Vascular stent design

InactiveUS20110276123A1Minimize and eliminate local flow disturbanceEnhanced inhibitory effectStentsBlood vesselsRestenosisThrombus

This invention is directed to the design of radially expandable vascular stents to optimize hemodynamic flow characteristics that are favorable for the inhibition of stent-associated thrombosis, inflammation, and restenosis (neointimal formation) and that will reduce the risk of adverse events post-deployment.

Owner:THE TRUSTEES OF THE UNIV OF PENNSYLVANIA

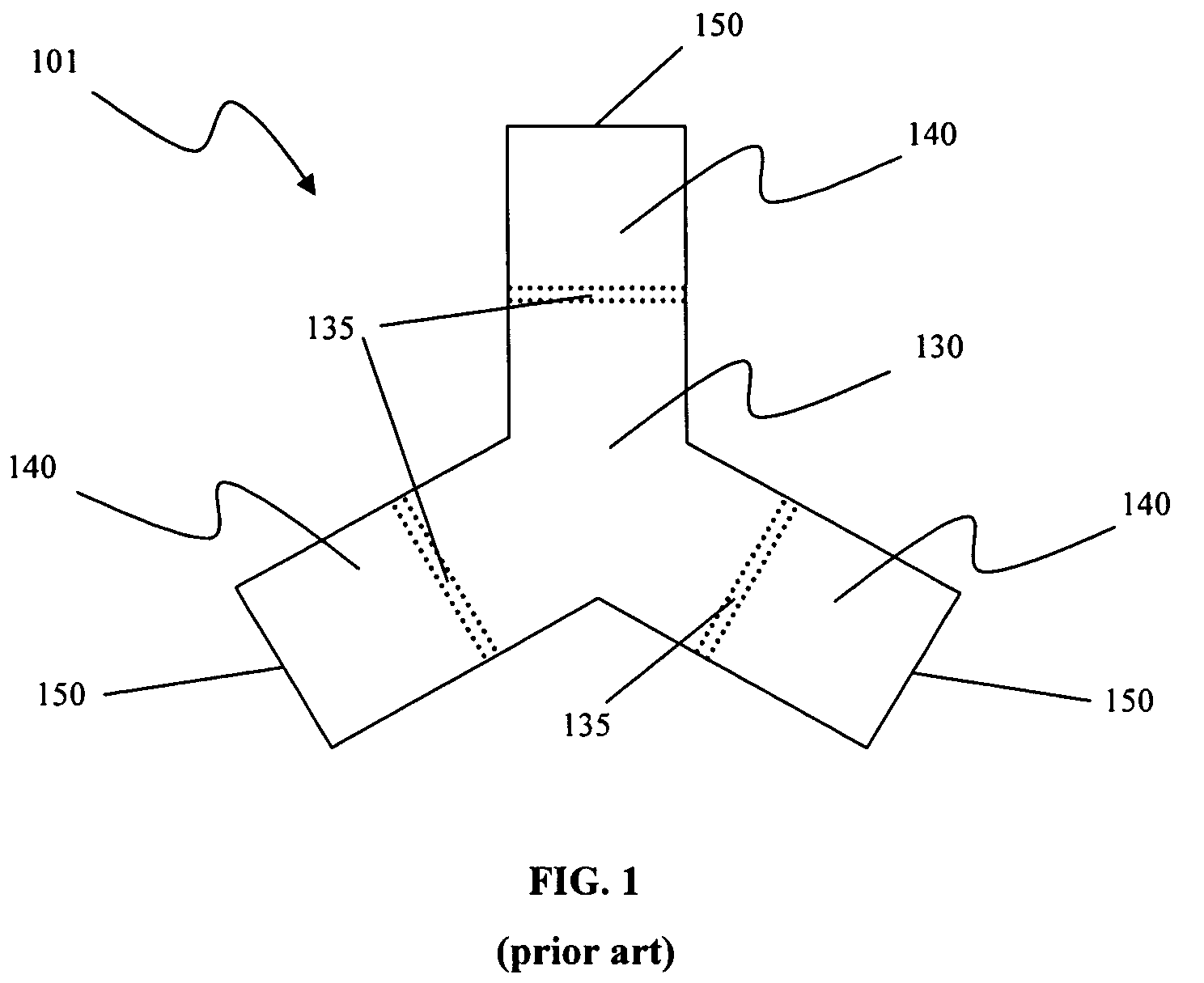

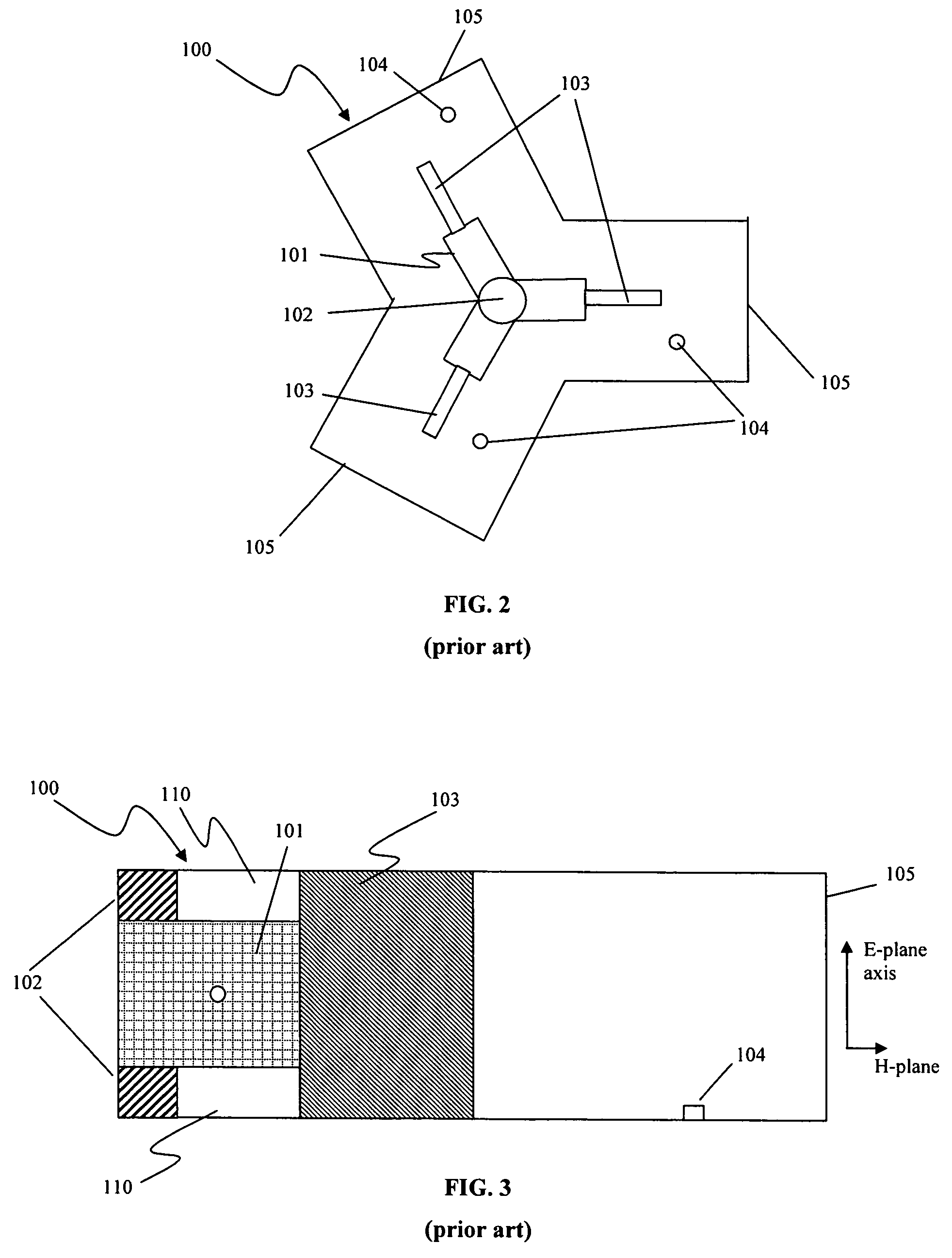

Ferrite waveguide circulator with thermally-conductive dielectric attachments

ActiveUS7683731B2Reduce temperature riseImprove thermal conductivityWaveguide type devicesElectricityPath length

The present invention improves the geometry of ferrite circulators in order to increase the average power handling by decreasing the temperature rise in the ferrite and associated adhesive bonds. Embodiments of the present invention utilize dielectric attachments on the sides of the ferrite element, which maximizes the area of contact and minimizes the path length from the ferrite element out to the thermally conductive attachments.

Owner:EMS TECHNOLOGIES

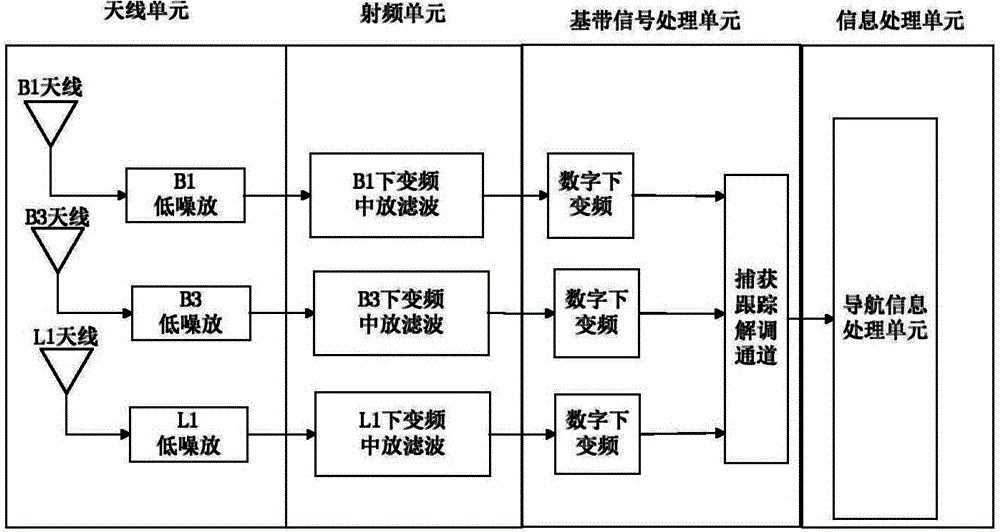

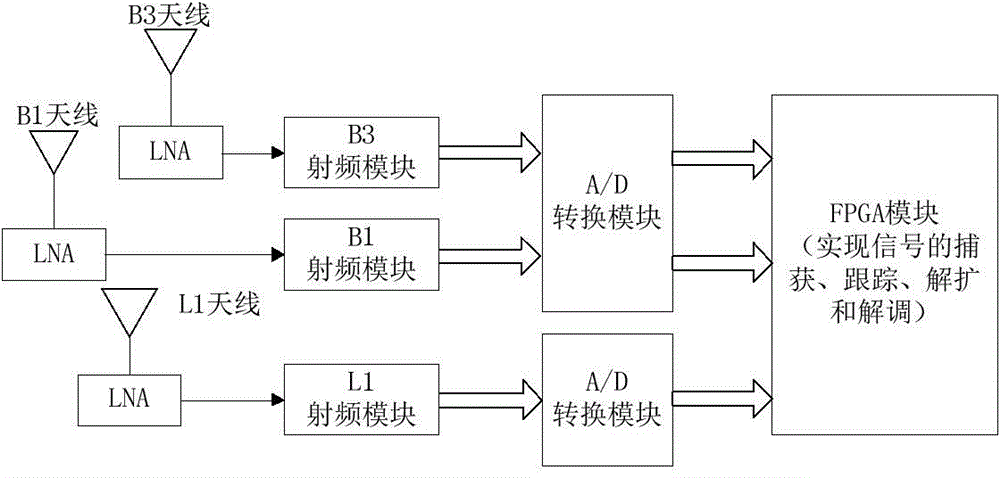

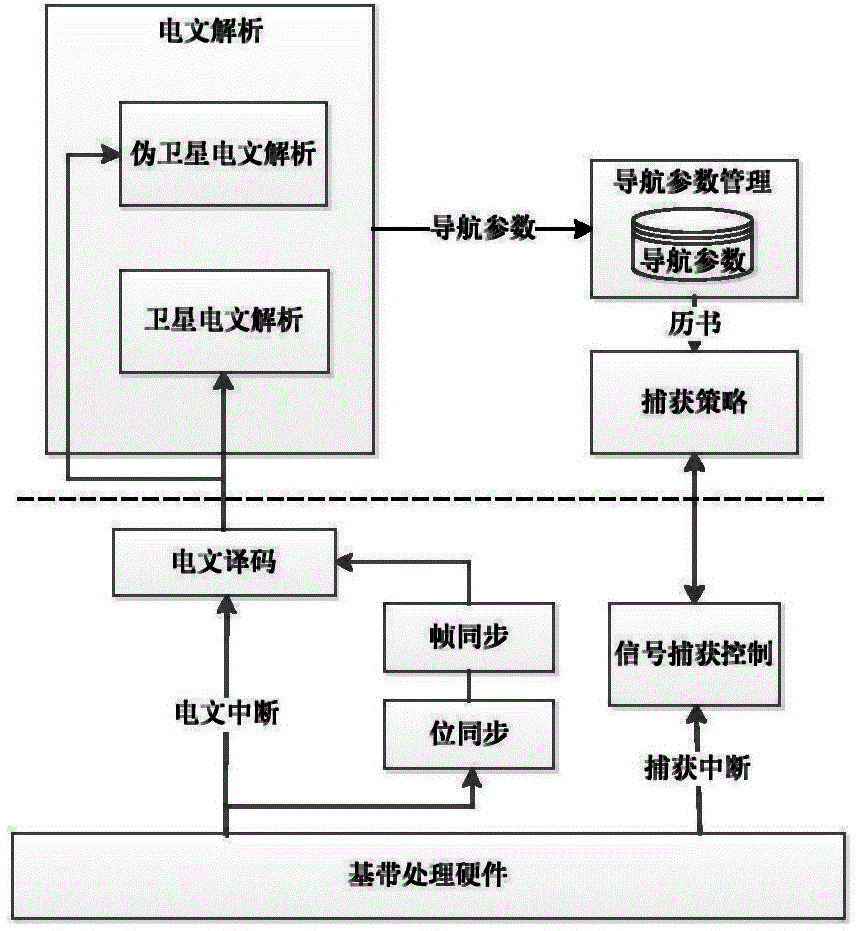

Beidou terminal signal receiving and processing device and method

ActiveCN104991264ASolve the problem of near-far effectAchieve captureSatellite radio beaconingInformation processingIntegrated antenna

The invention belongs to the field of radio navigation location technology and especially relates to a Beidou terminal signal receiving and processing device and method. The device includes an antenna unit, a radio frequency unit, a baseband signal processing unit, an information processing unit, a power unit and a display control unit connected successively. The method includes capturing fake satellites and satellites respectively by adopting a storage-based baseband capturing method; receiving fake satellite signals and real satellite signals for fake satellite and satellite information decoding; performing updating operation on extracted navigation parameters; extracting carrier phase, code phase and Doppler observation information and performing calculation on location, speed measurement and time service. According to the invention, by the design of an integrated antenna receiving the satellite signals and the fake satellite signals and a radio frequency front end and with the adoption of an algorithm realizing seamless positioning depending on independent positioning and compatible positioning for solving a problem of near-far effect of the two kinds of signals, constellation geometric structure is improved and user positioning precision is improved.

Owner:交信北斗(海南)科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com