Patents

Literature

309 results about "Nose cone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

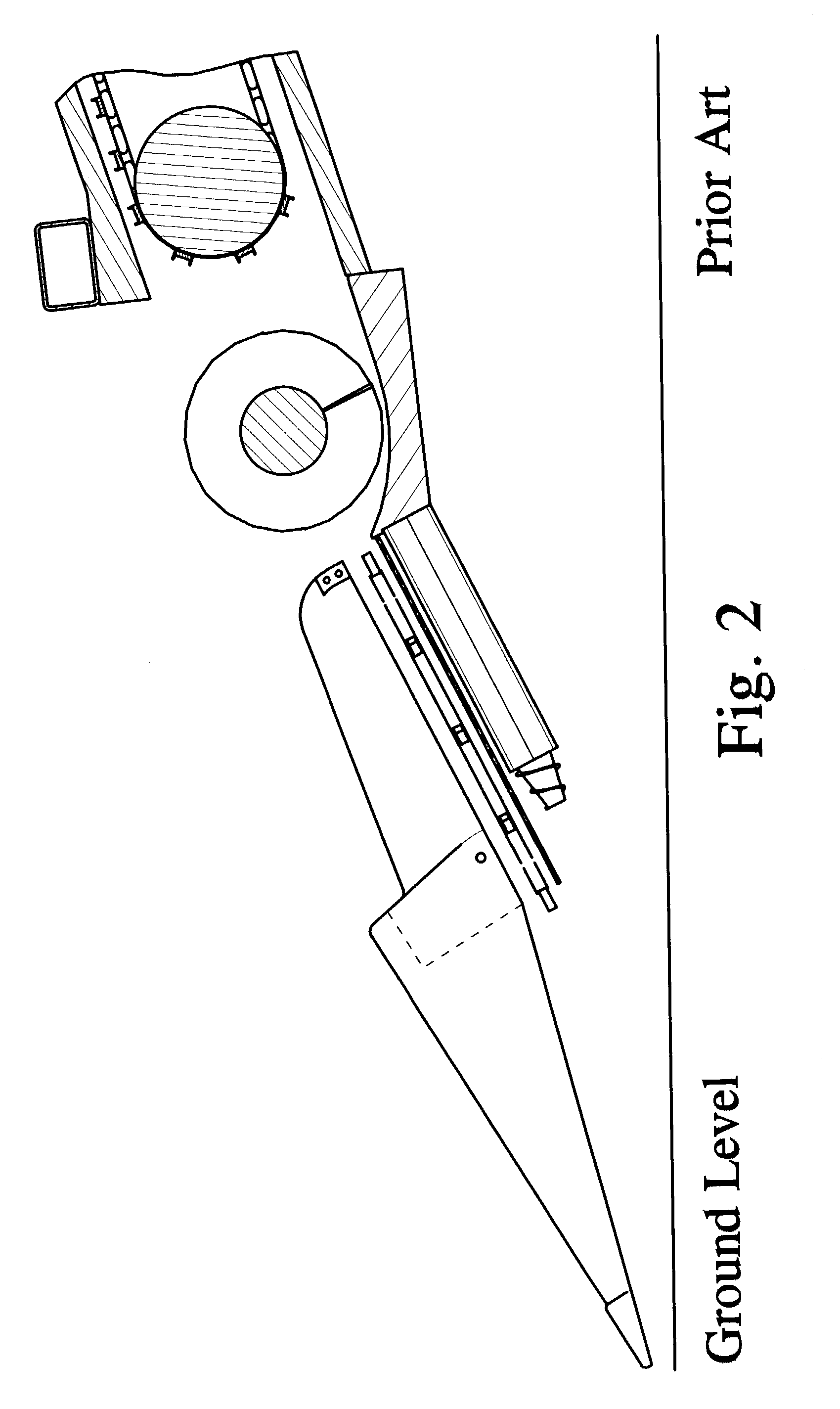

A nose cone is the forwardmost section of a rocket, guided missile or aircraft. The cone is shaped to minimize aerodynamic drag. Nose cones are also designed for travel in and under water and in high-speed land vehicles.

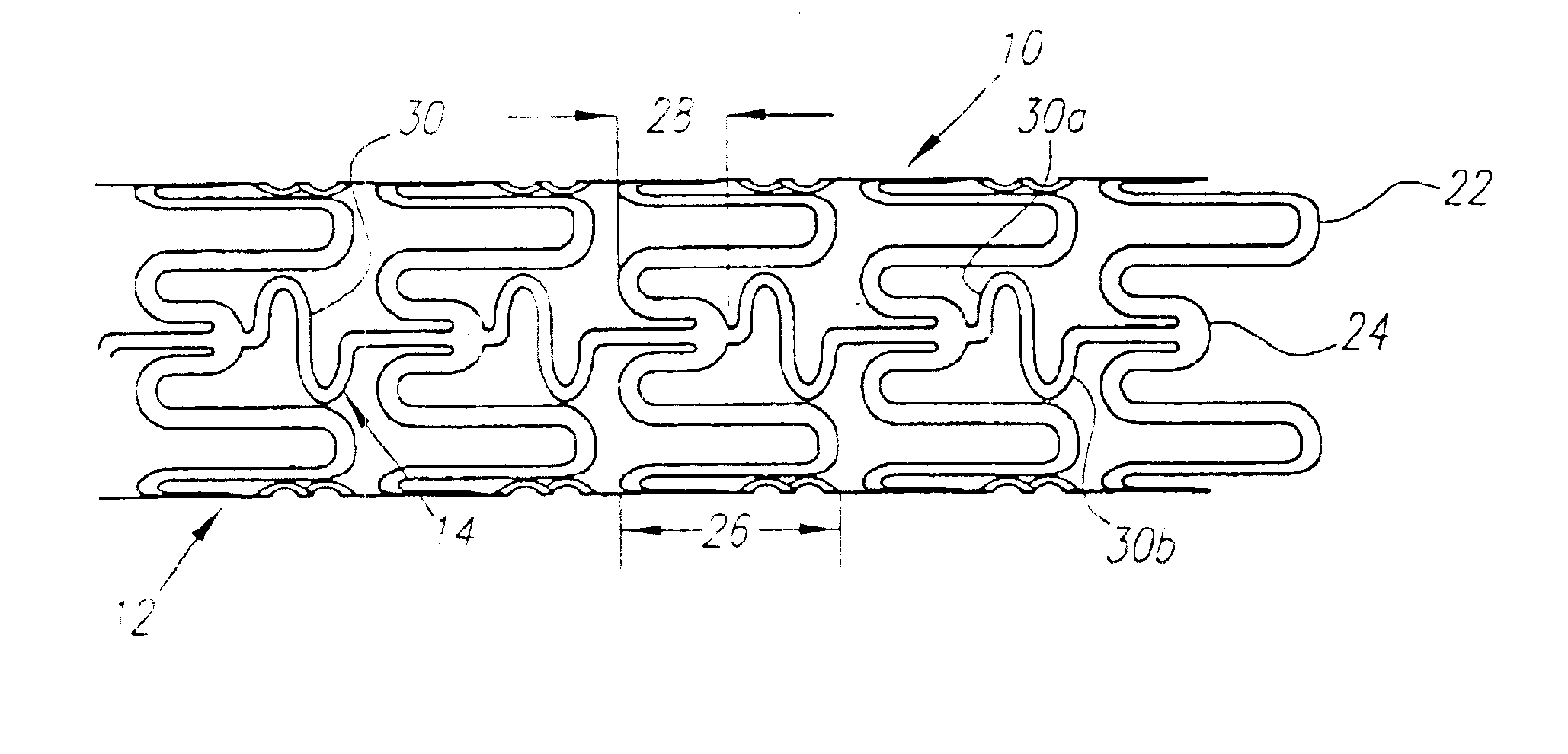

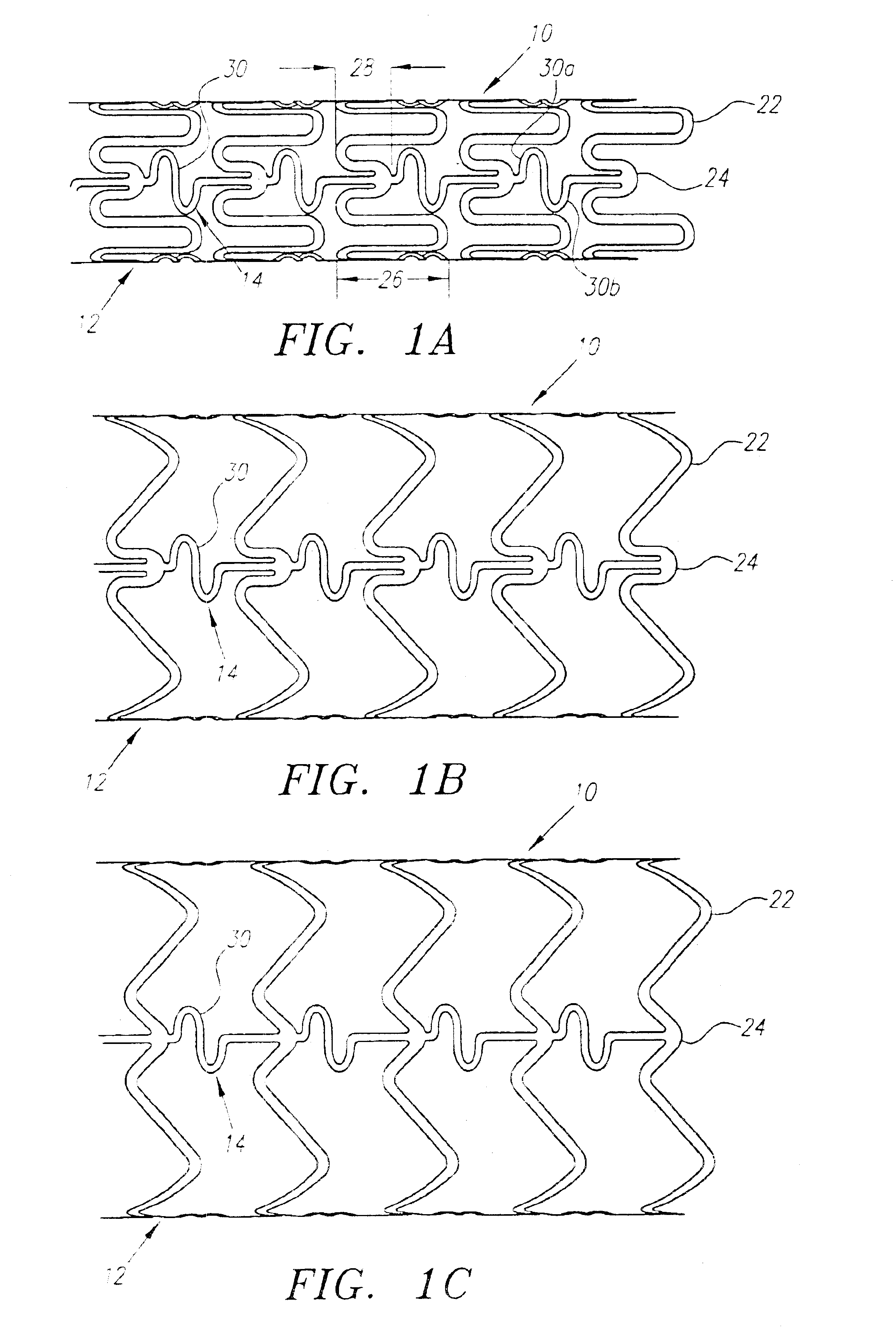

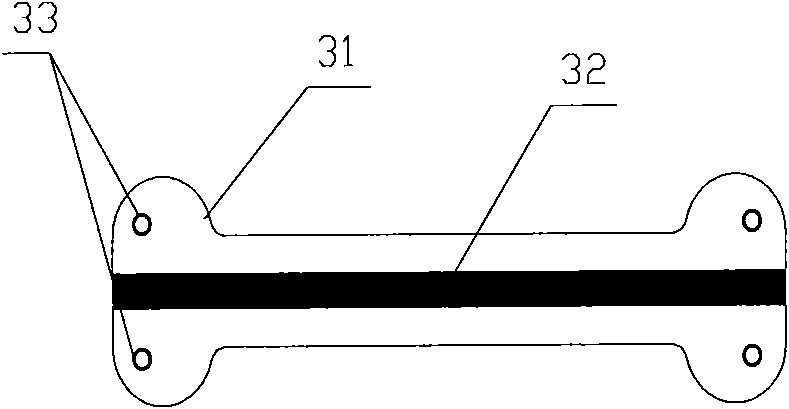

Deformable scaffolding multicellular stent

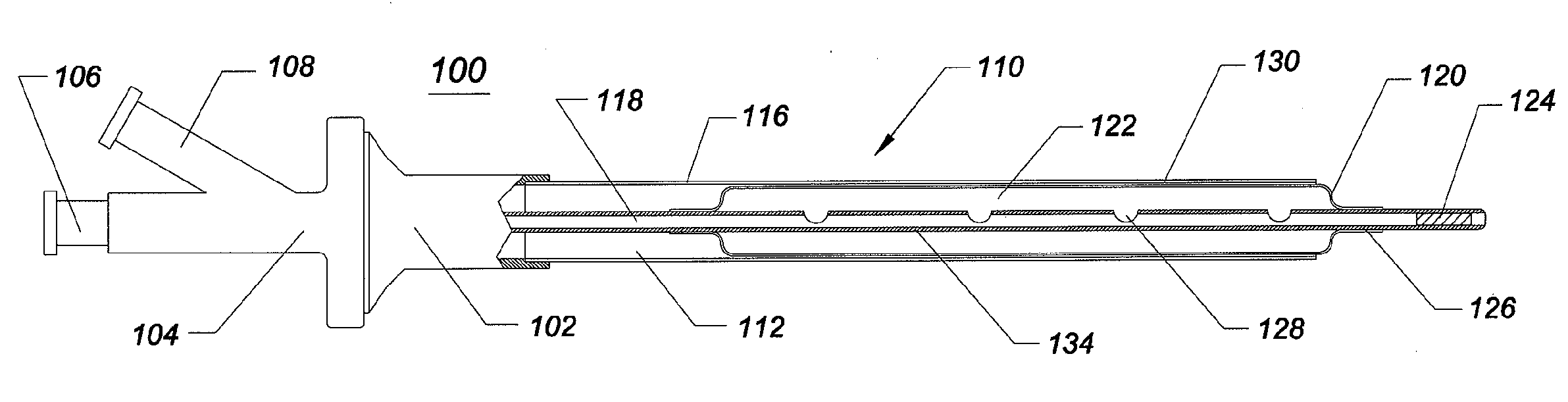

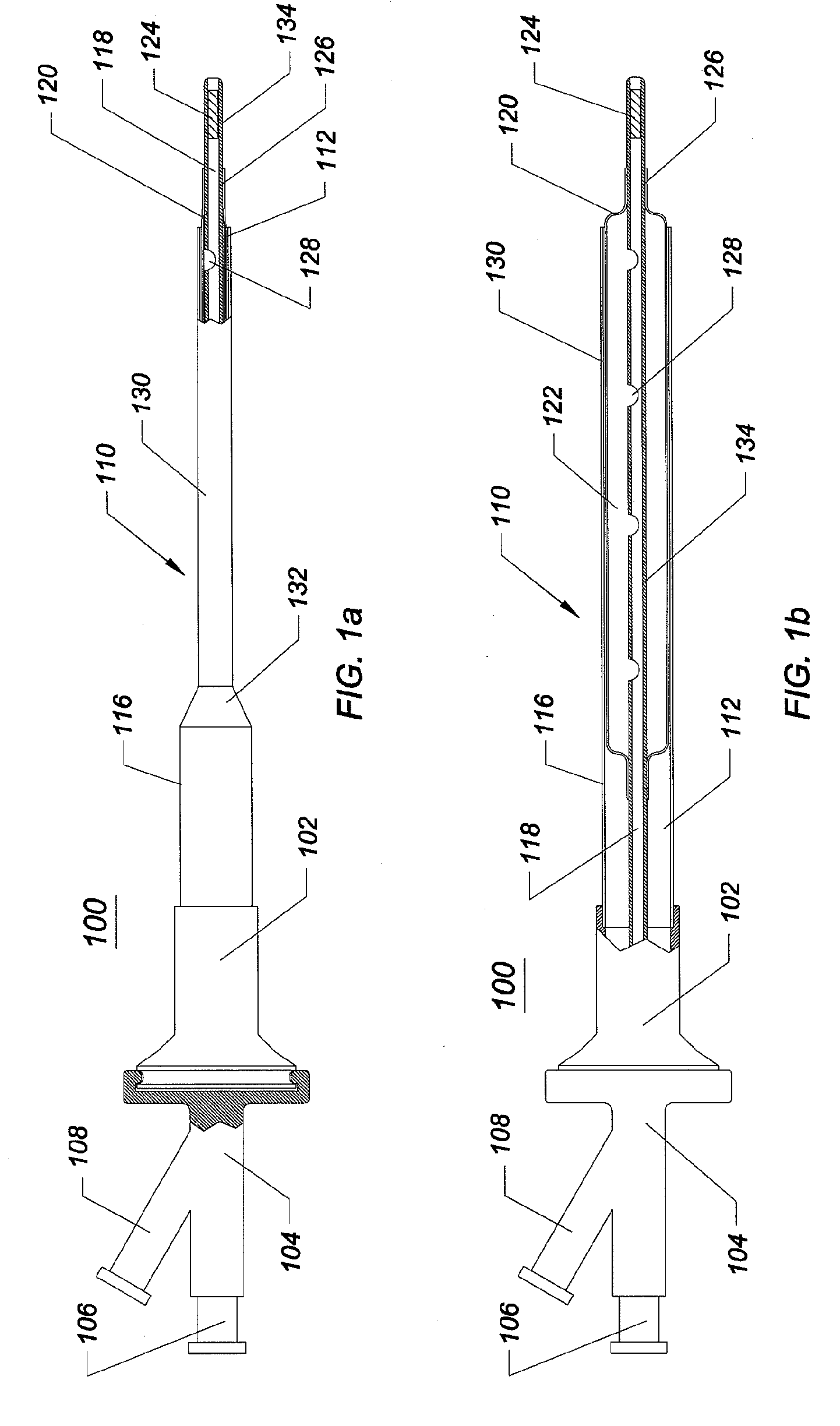

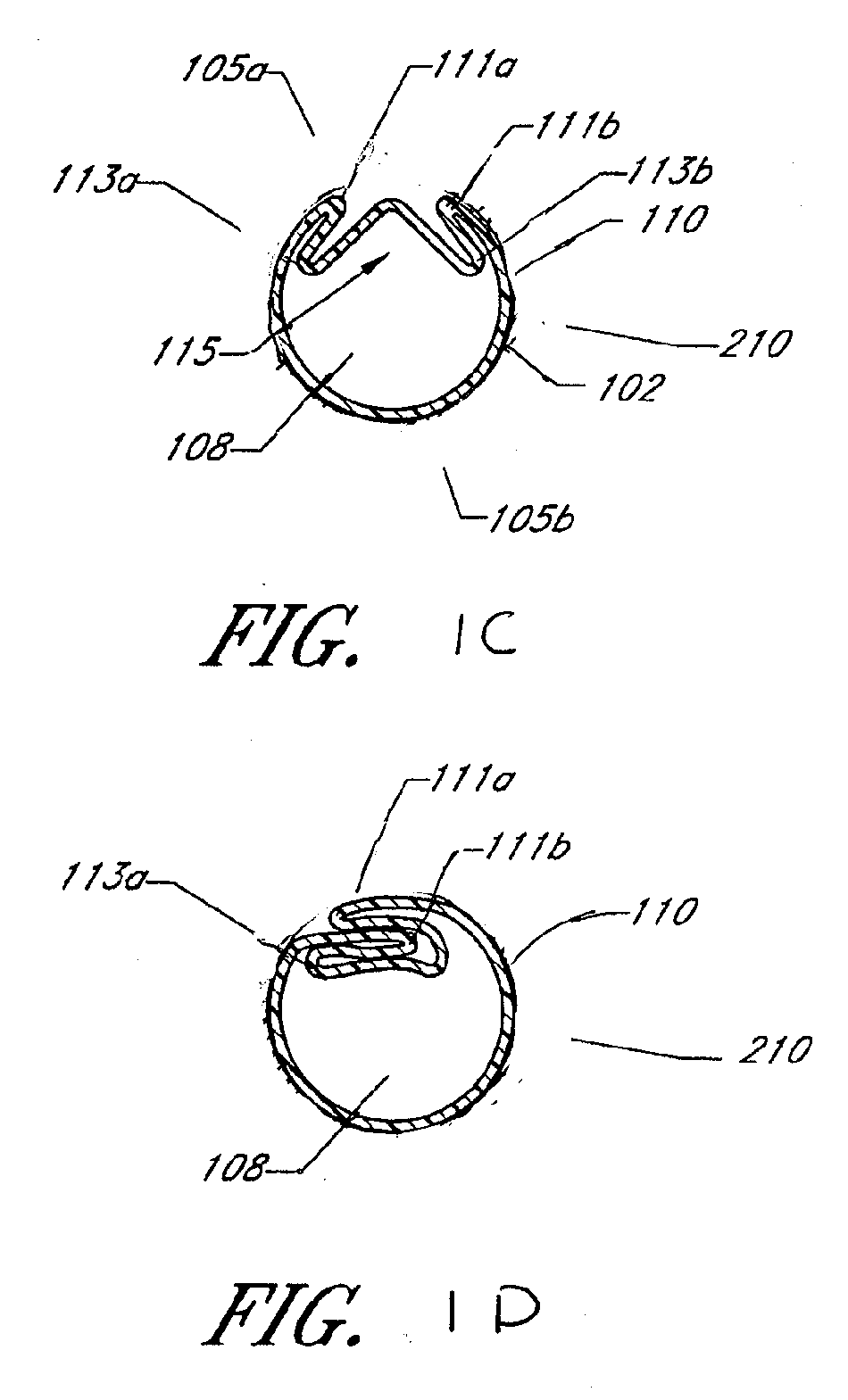

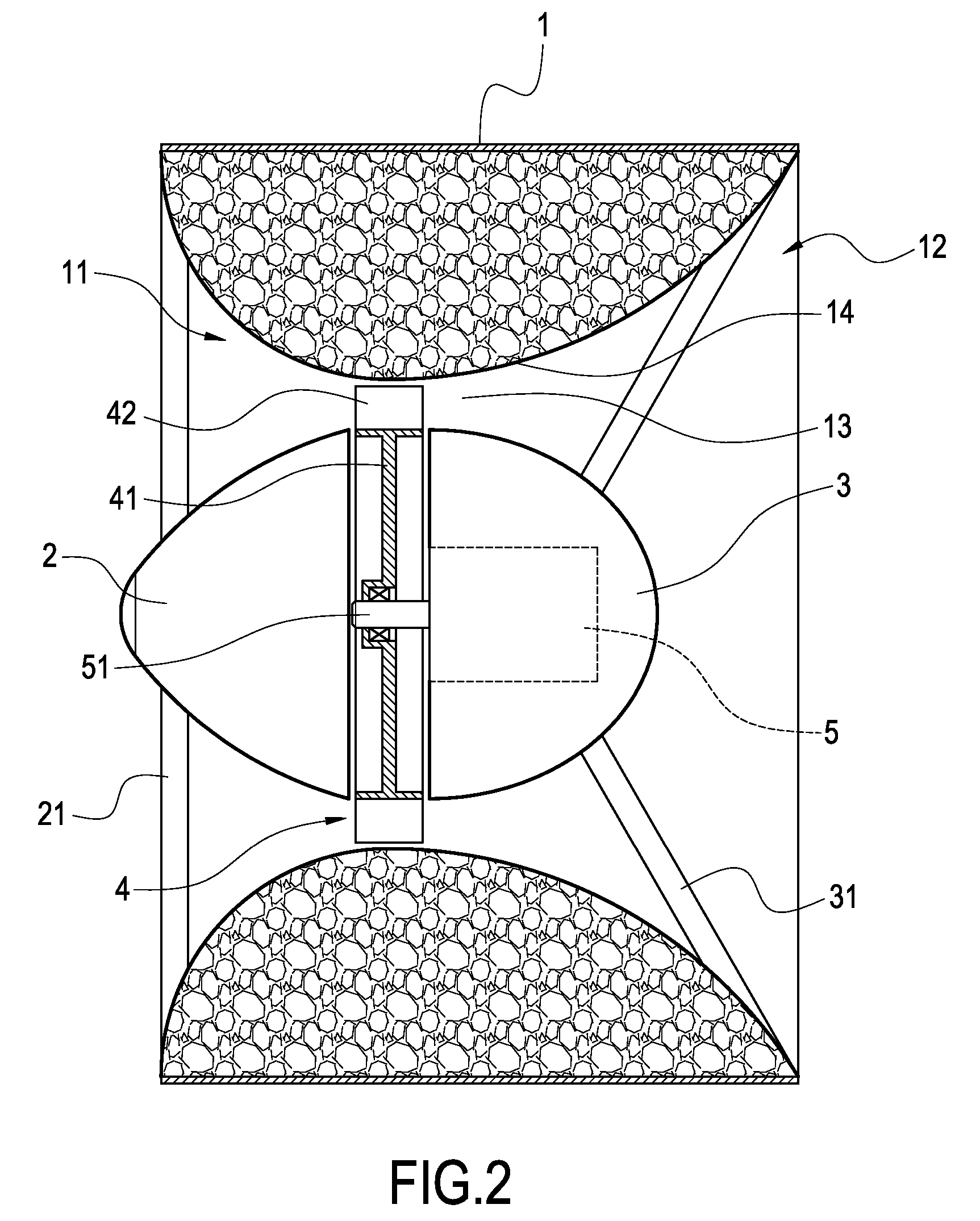

A plastically deformable stent for implantation within a body passage includes a plurality of cylindrical segments, and a plurality of connectors extending between adjacent segments. Each segment has an alternating pattern of curvilinear elements extending about its circumference, including first and second sets of curvilinear elements having different resistances to expansion, and preferably defining “U” shapes with alternating lengths that are connected to one another to define a substantially sinusoidal pattern. The connectors define a sinusoidal shape adapted to extend and compress axially substantially evenly when the adjacent segments are subjected to bending. The stent may be delivered on a device including an elongate member with a nose cone, an expandable member, and a proximal shoulder thereon, and an outer sheath for slidably receiving the elongate member therein. The outer sheath and / or nose cone may have perfusion holes for allowing continued perfusion of fluid during stent delivery. The device may be used in a method for implanting a stent within a curved region of a body passage, particularly for creating and / or maintaining a channel connecting a vein to an adjacent artery, preferably in the coronary system.

Owner:MEDTRONIC VASCULAR INC

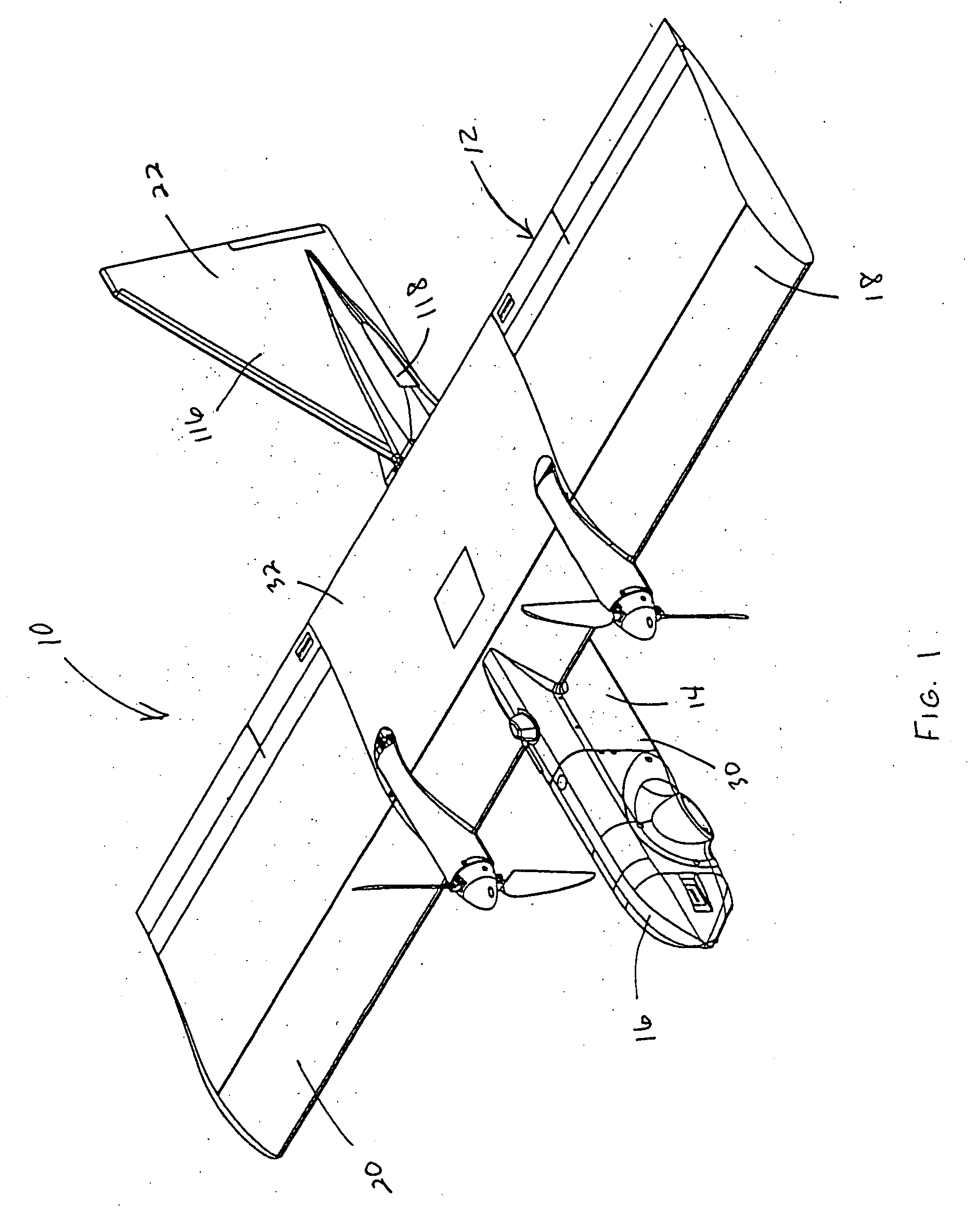

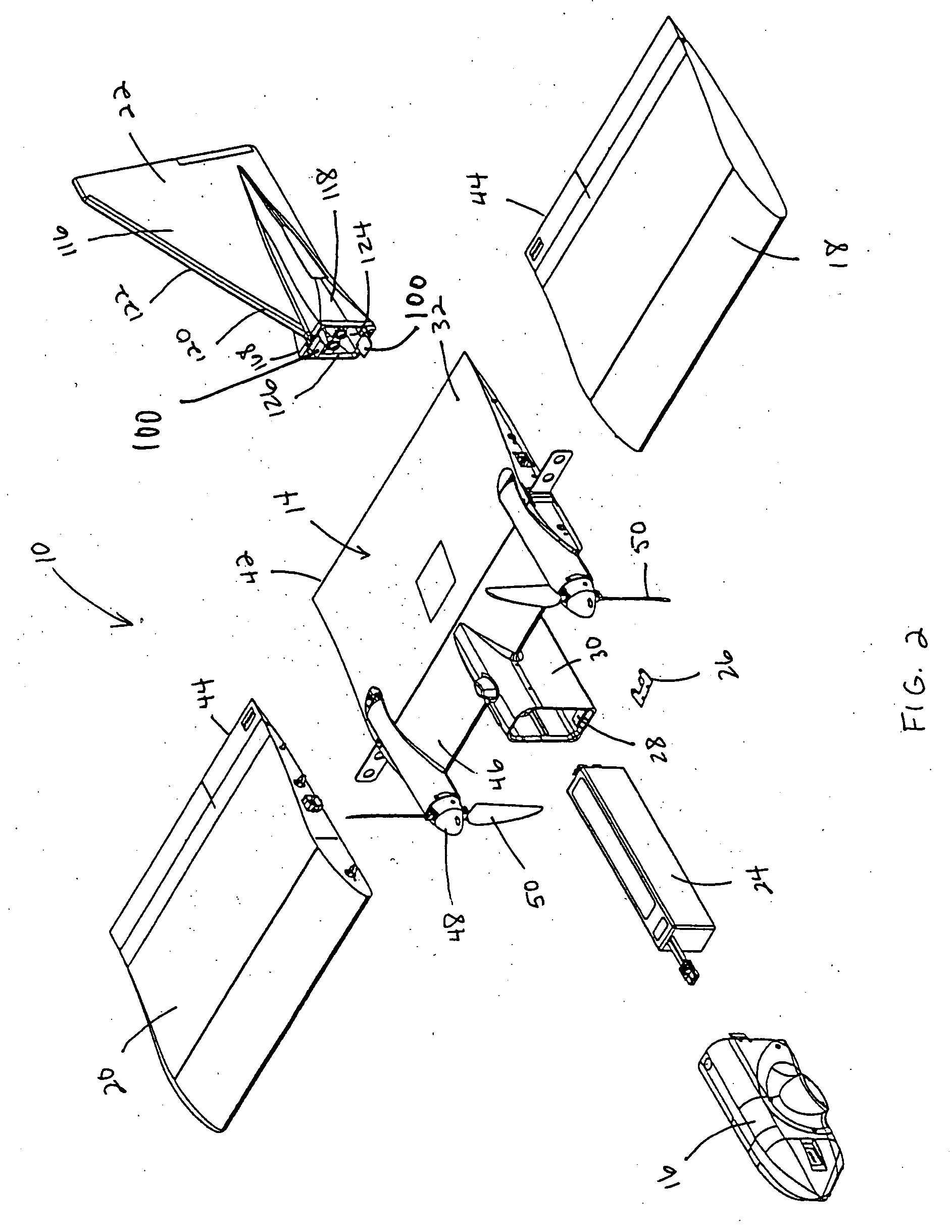

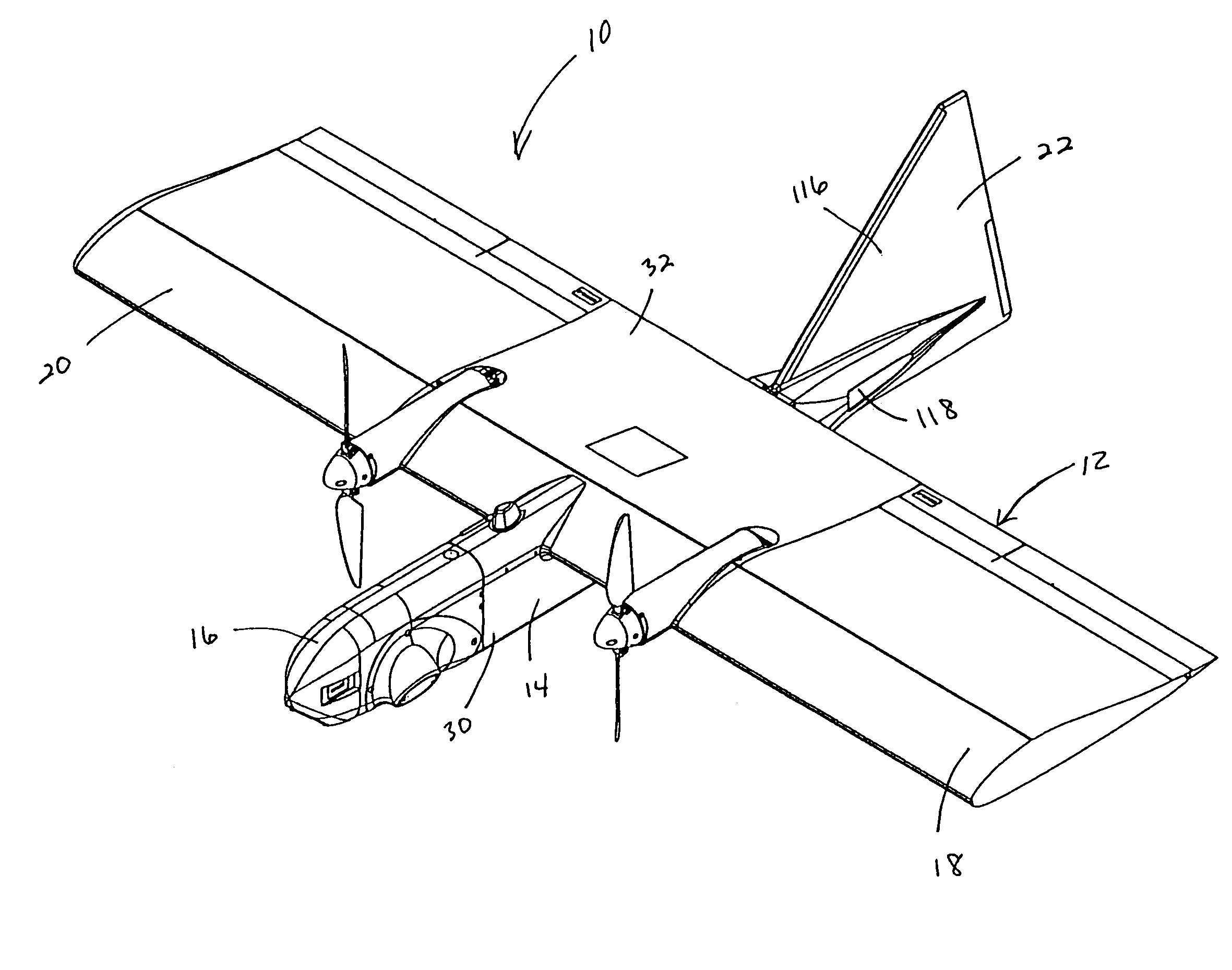

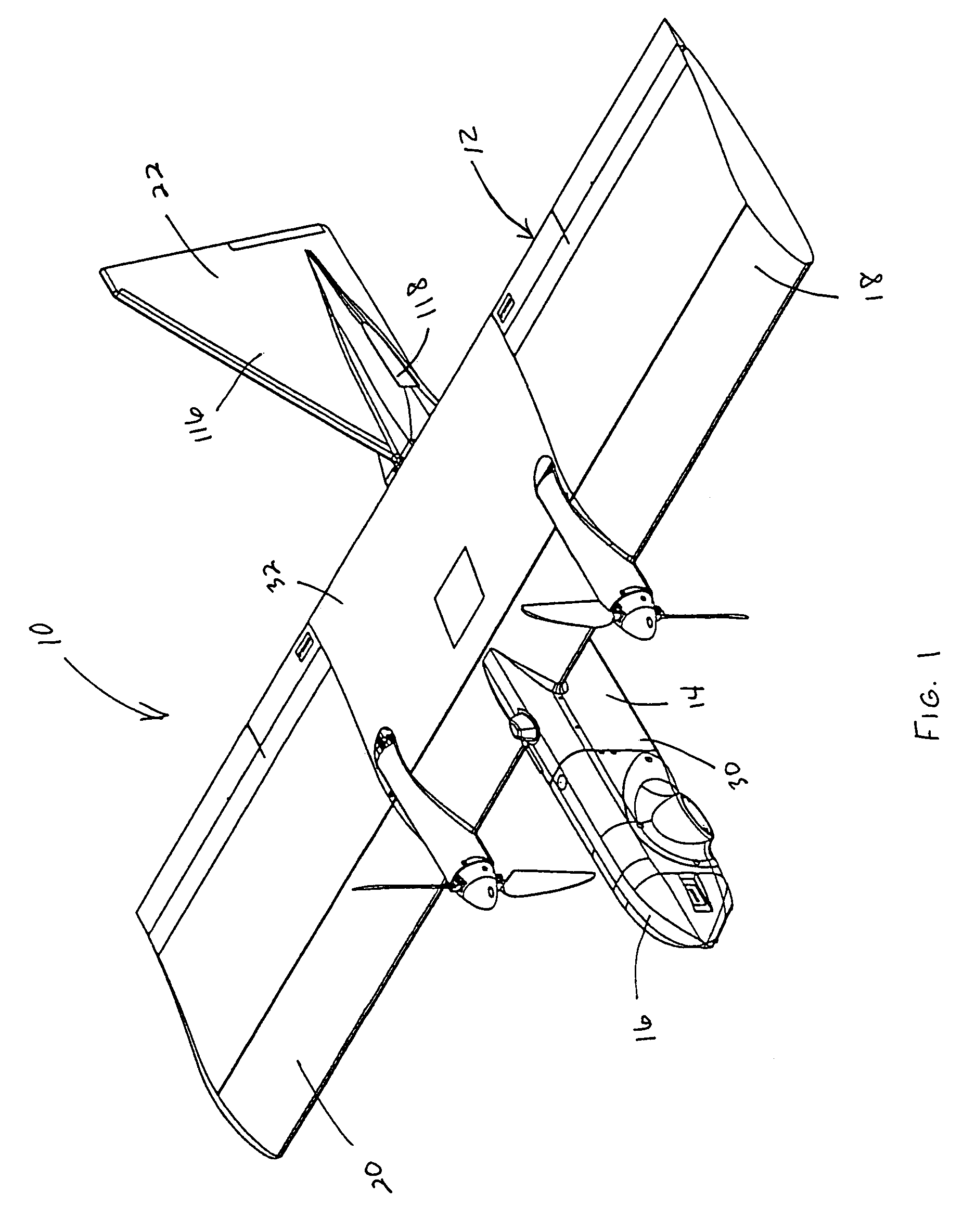

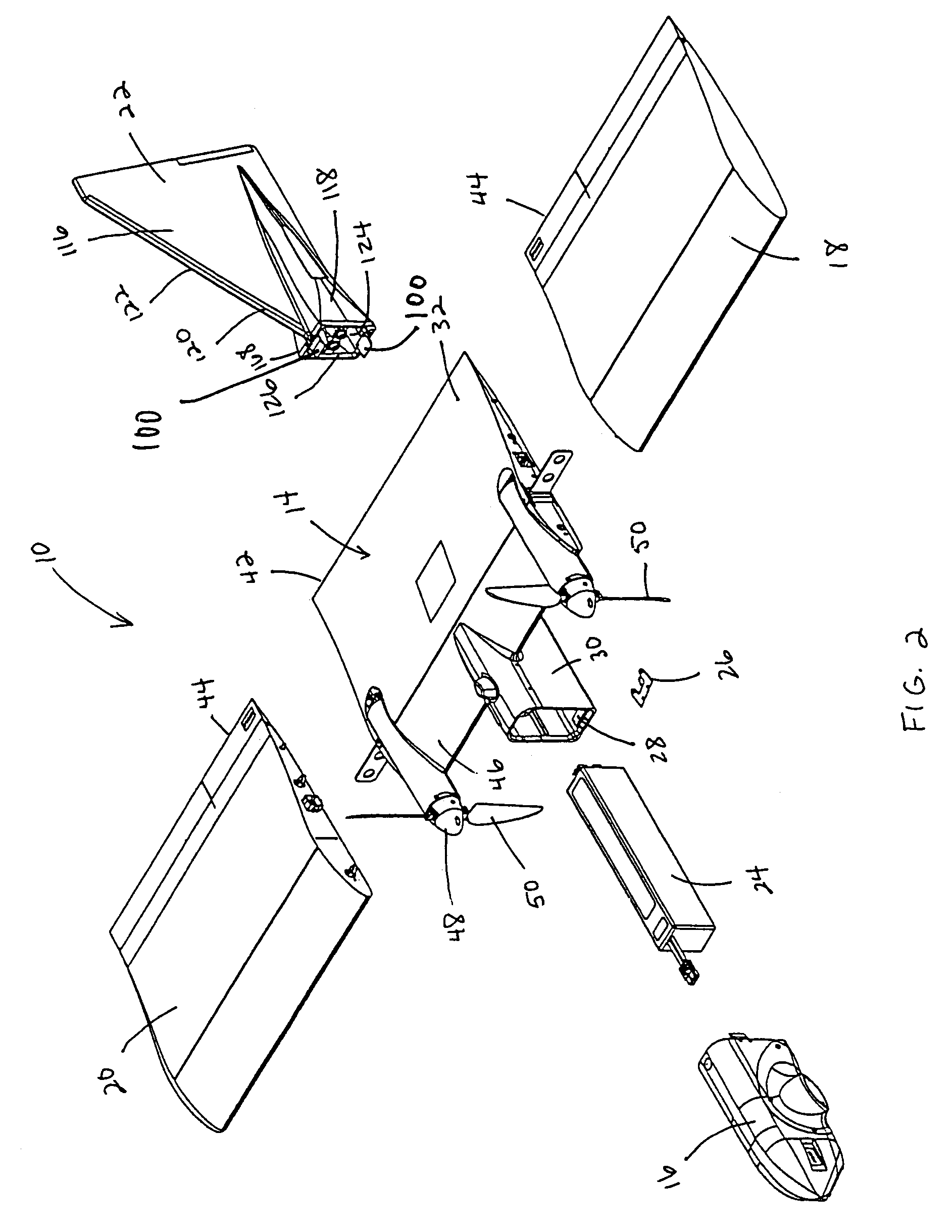

Autonomous, back-packable computer-controlled breakaway unmanned aerial vehicle (UAV)

InactiveUS20060091258A1Quick assemblyOvercome problemsUnmanned aerial vehiclesLuggageUncrewed vehicleNose cone

A modular unmanned aerial vehicle (UAV) having a fuselage, a nose cone, a left wing piece, a right wing piece, and a tail section. The tail section and nose cone each join to the fuselage through mating bulkhead structures that provide quick connection capability while being readily separated so as to enable the UAV to break apart at these connection points and thereby absorb or dissipate impact upon landing. The UAV is capable of rapid assembly in the field for two-man launch and data retrieval, as well as quick disassembly into these five component parts for transport and storage in a highly compact transport case that can be carried as a backpack.

Owner:L 3 COMM CORP

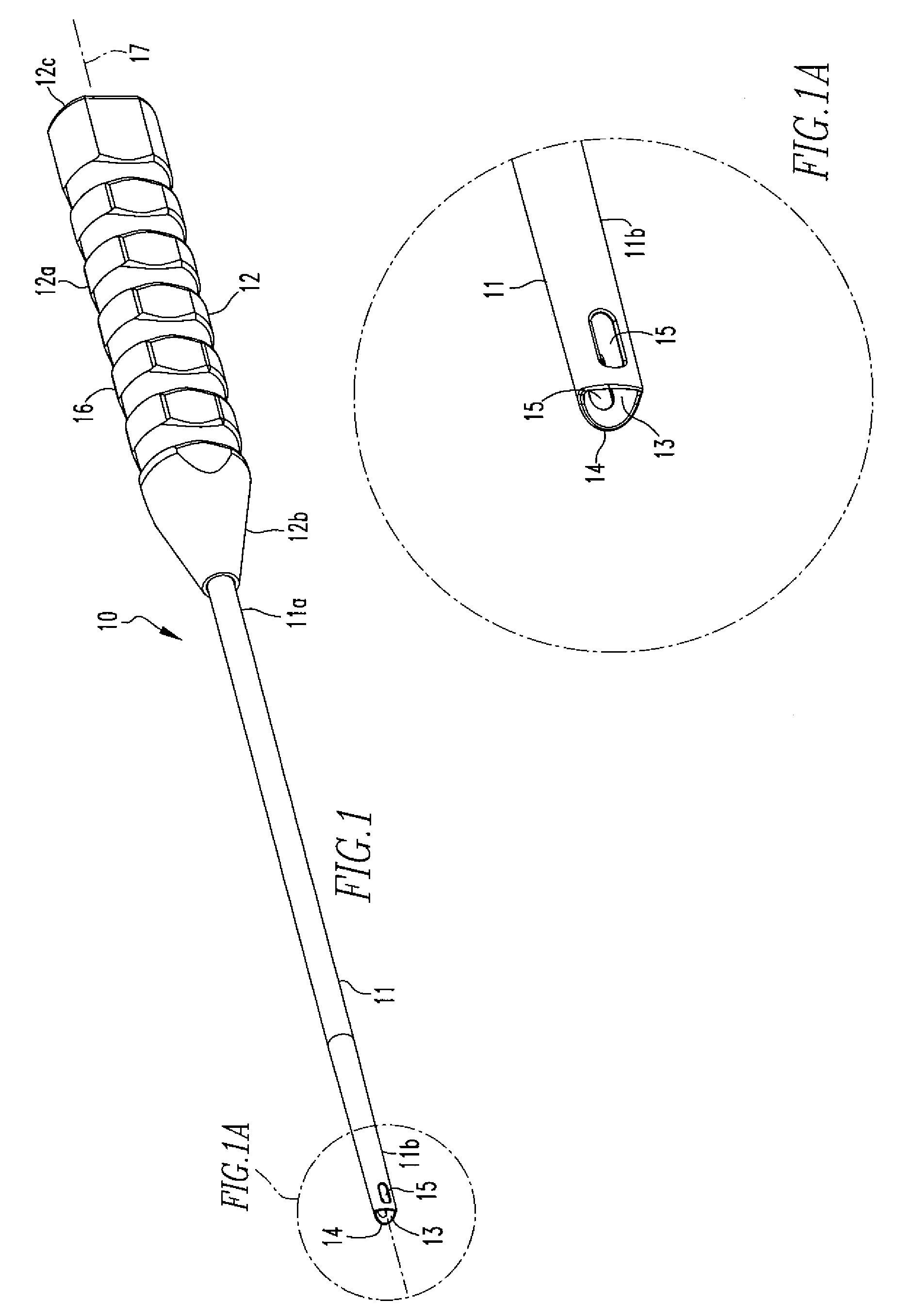

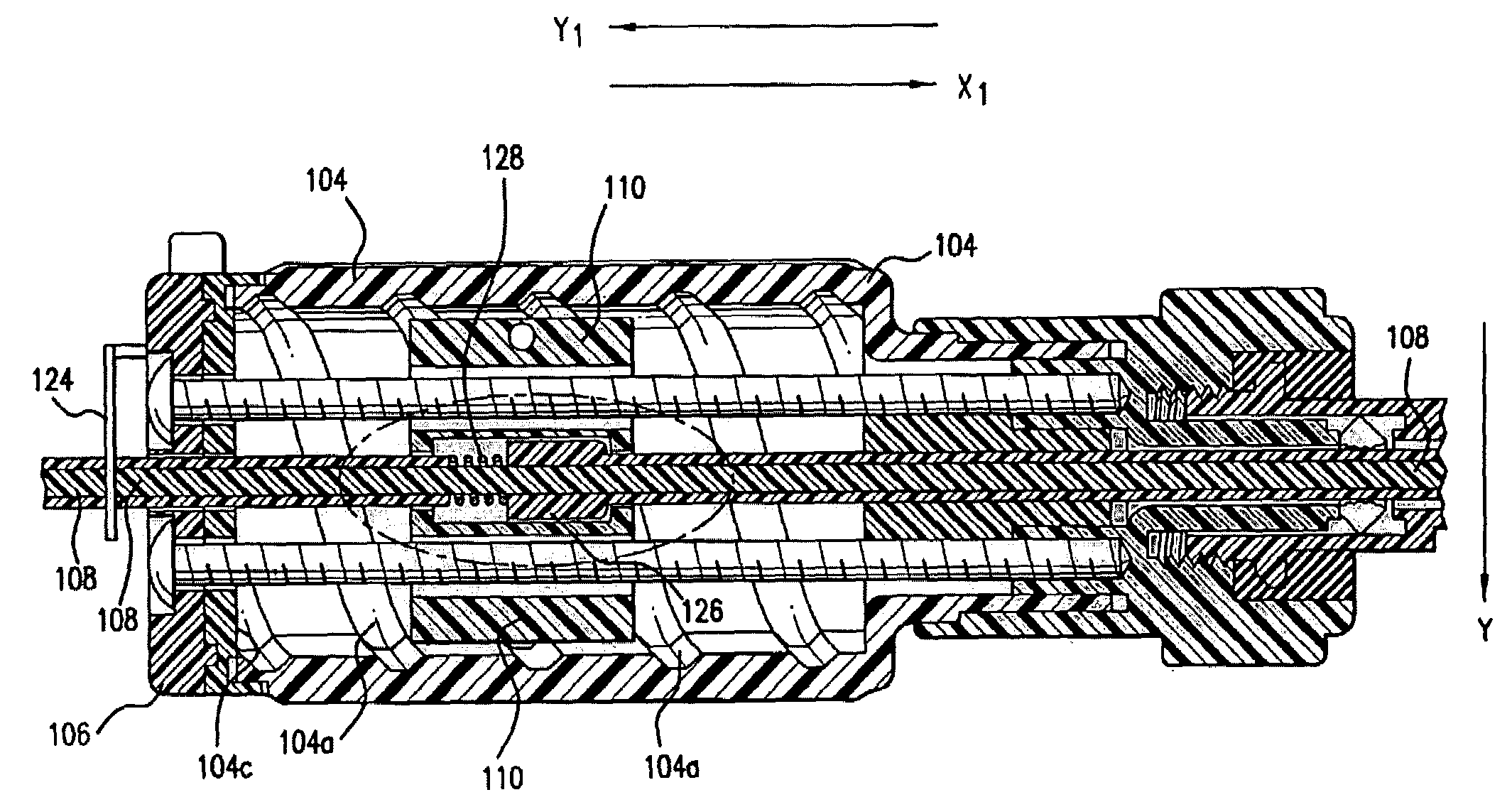

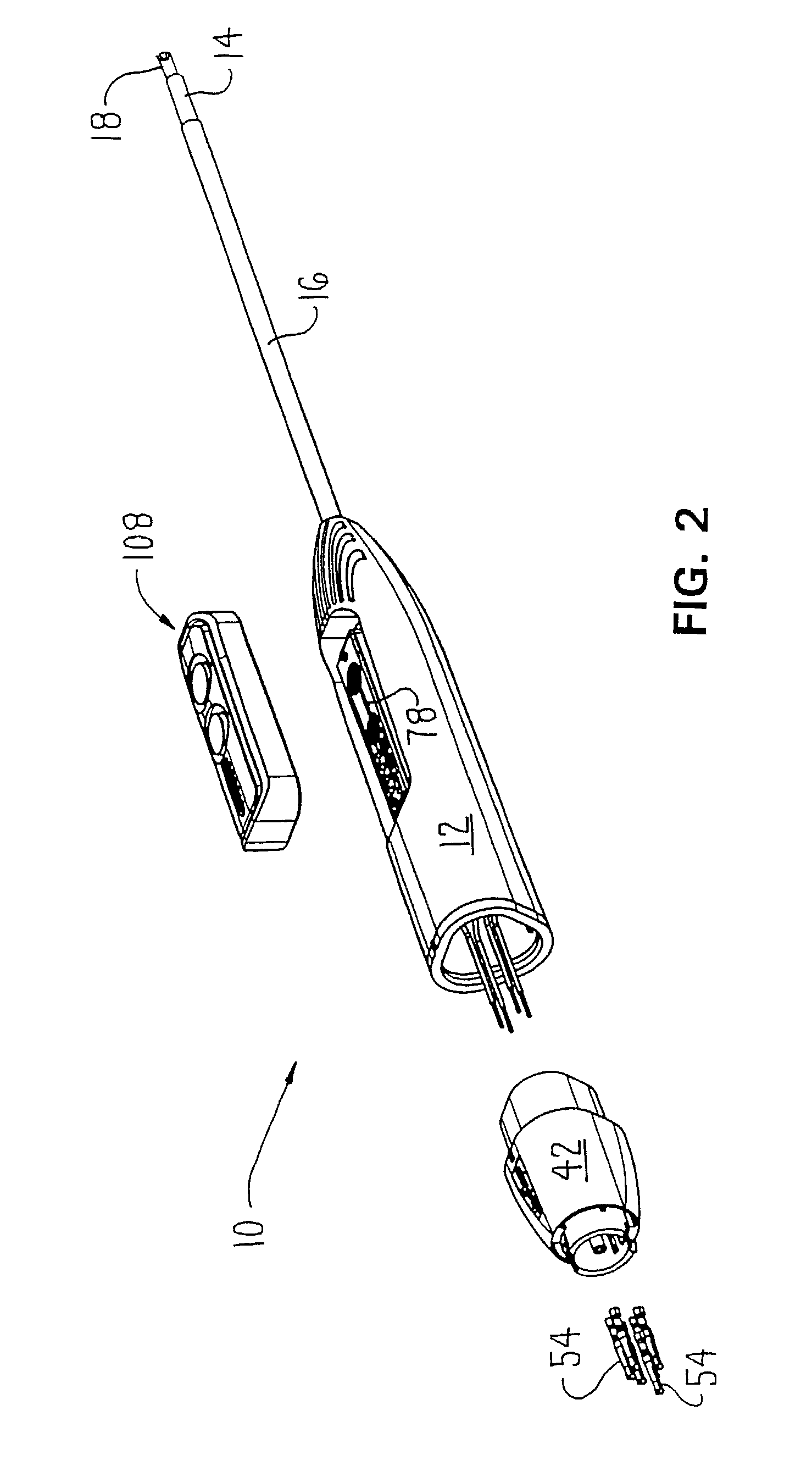

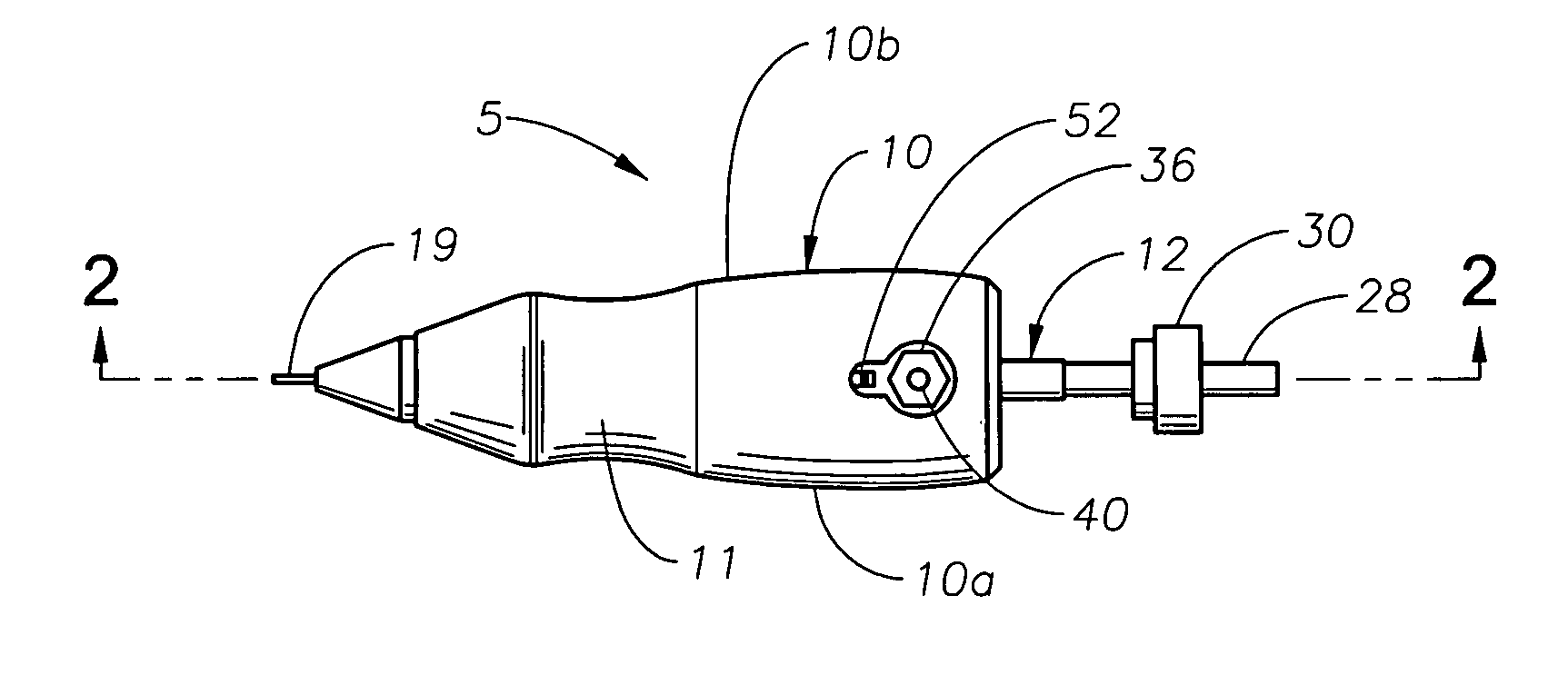

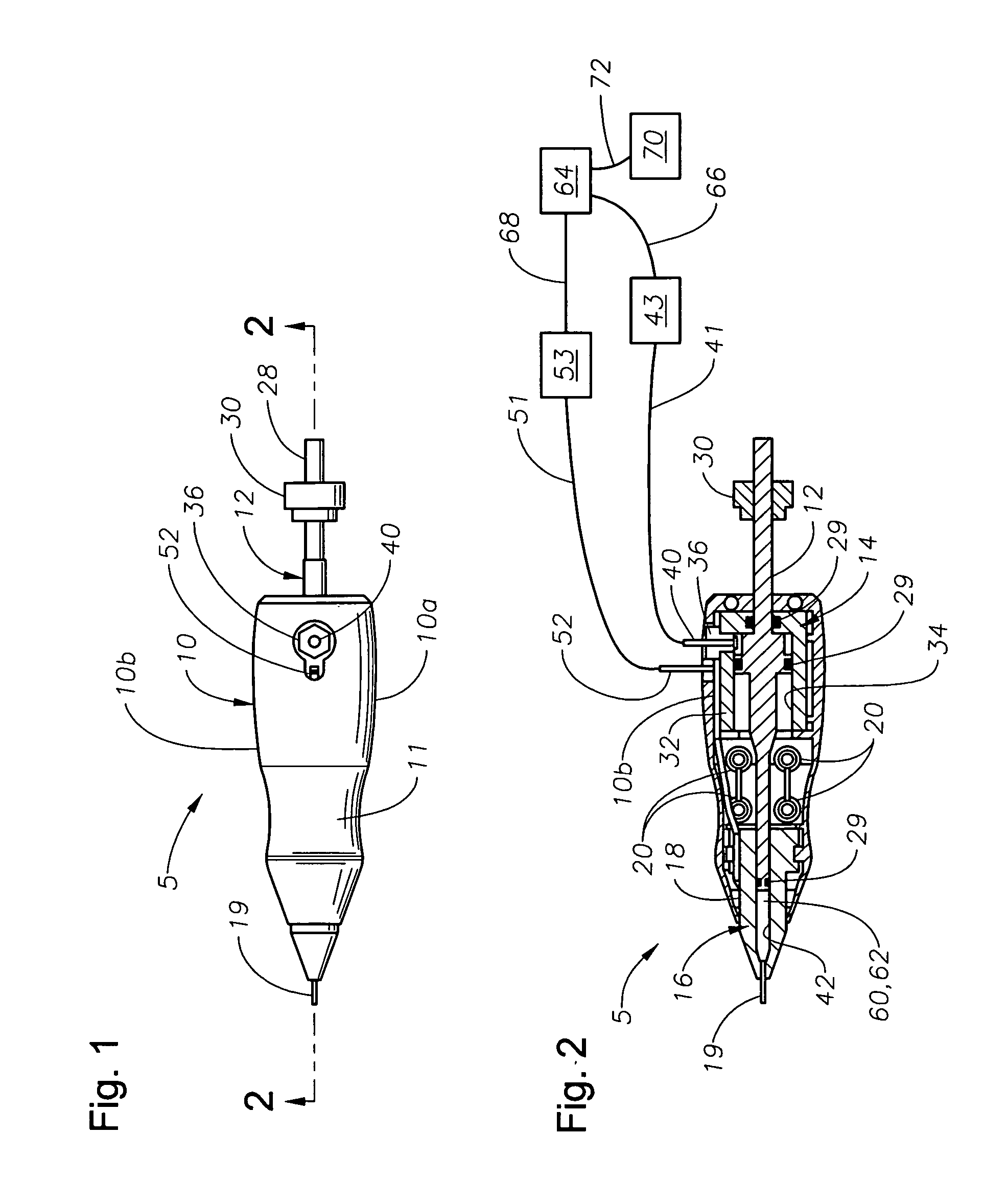

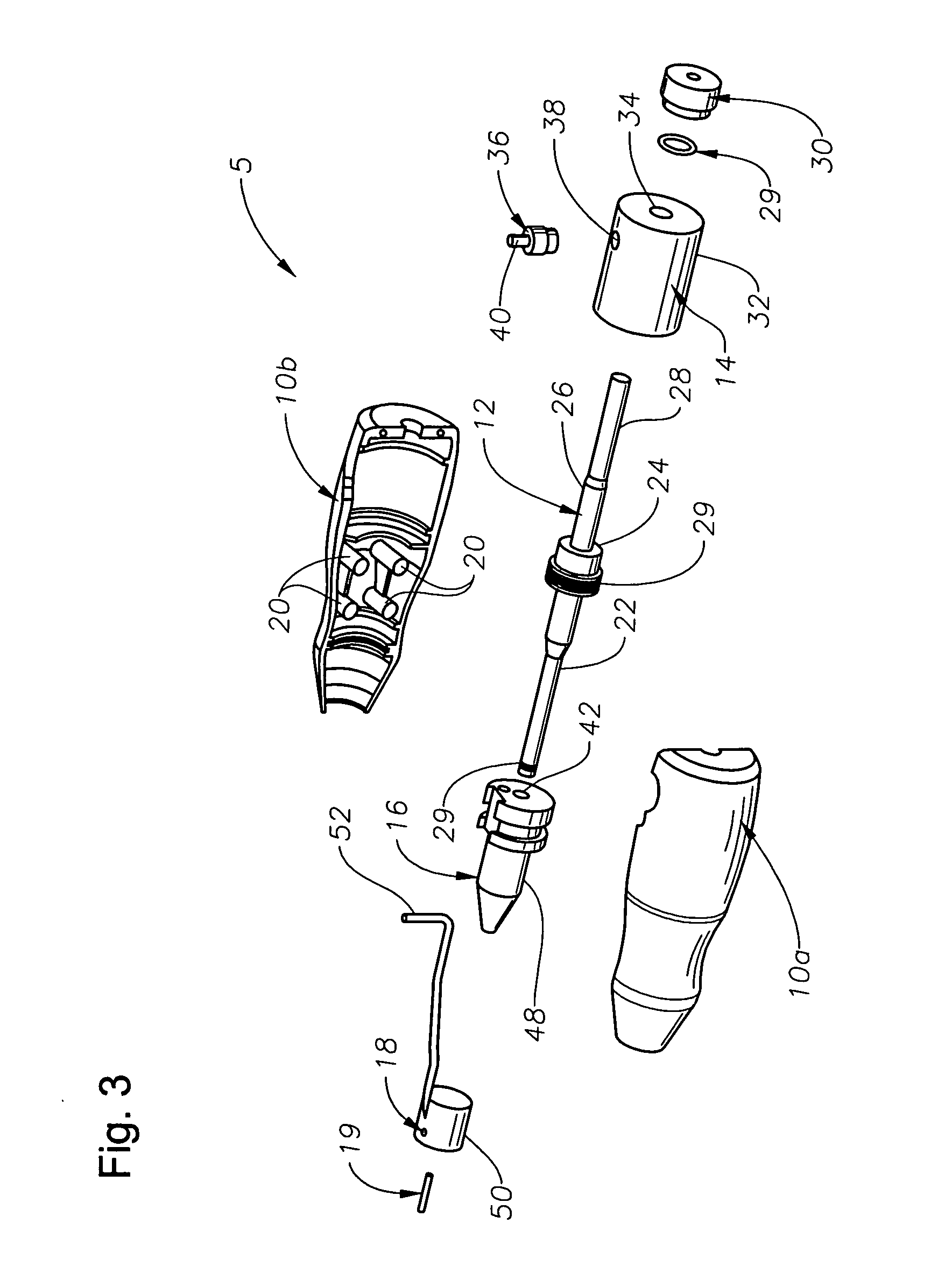

Handpiece system for multiple phacoemulsification techniques

InactiveUS6852092B2Prevent crashMinimizing the visual field of a physicianElectrotherapyEye surgeryNosePhacoemulsification

A handpiece system for multiple phacoemulsification procedures is provided which includes a housing having a distal end adapted for sealably and releasably engaging a plurality of nose cones and a sonic generator disposed within the housing. A horn having a body connected to the sonic generator and a needle is provided for radiating sonic energy into an eye for fragmenting eye tissue. A plurality of nose cones are provided which are adapted for being sealably and releasably engaged with the housing and provide structure enabling varied phacoemulsification procedures.

Owner:JOHNSON & JOHNSON SURGICAL VISION INC

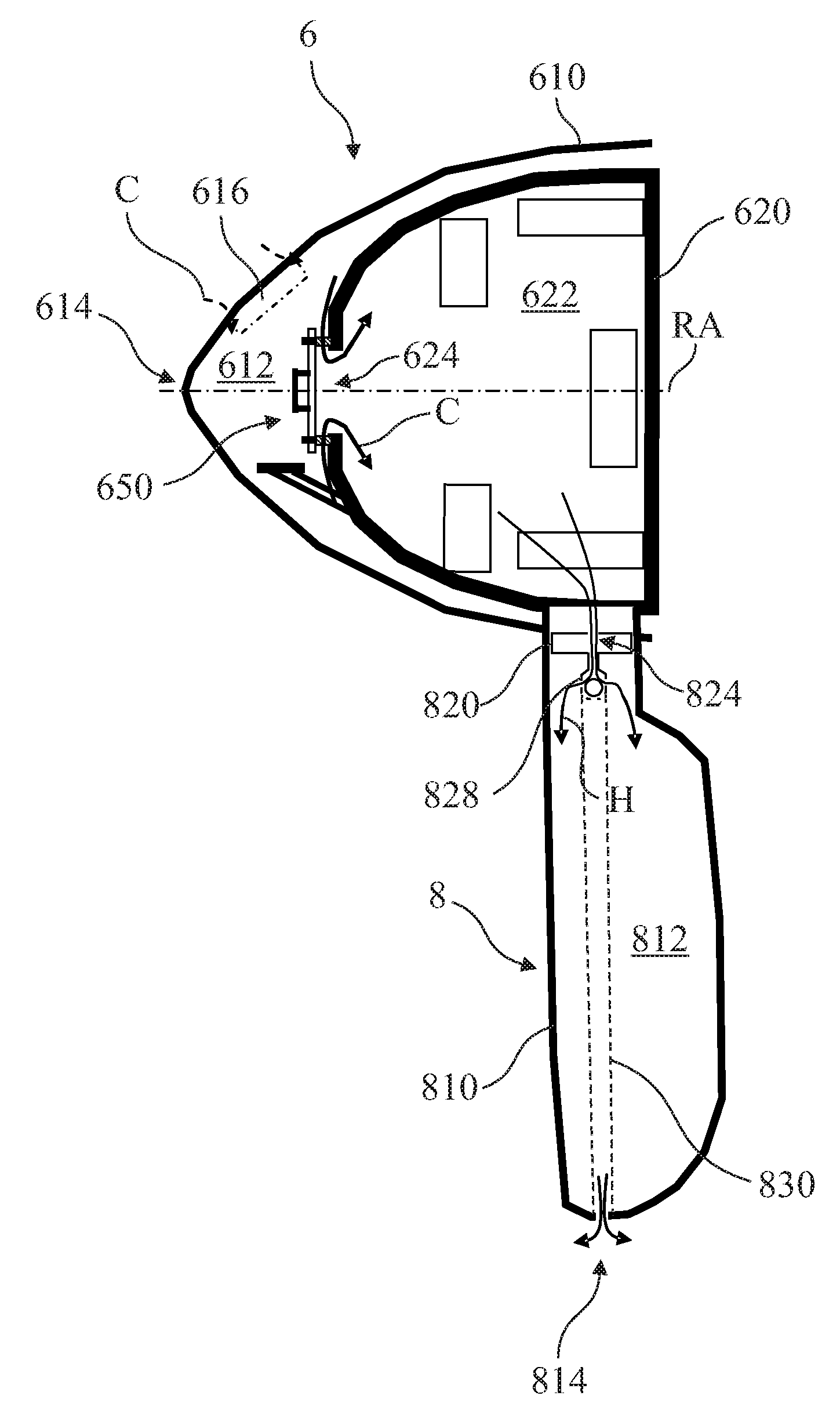

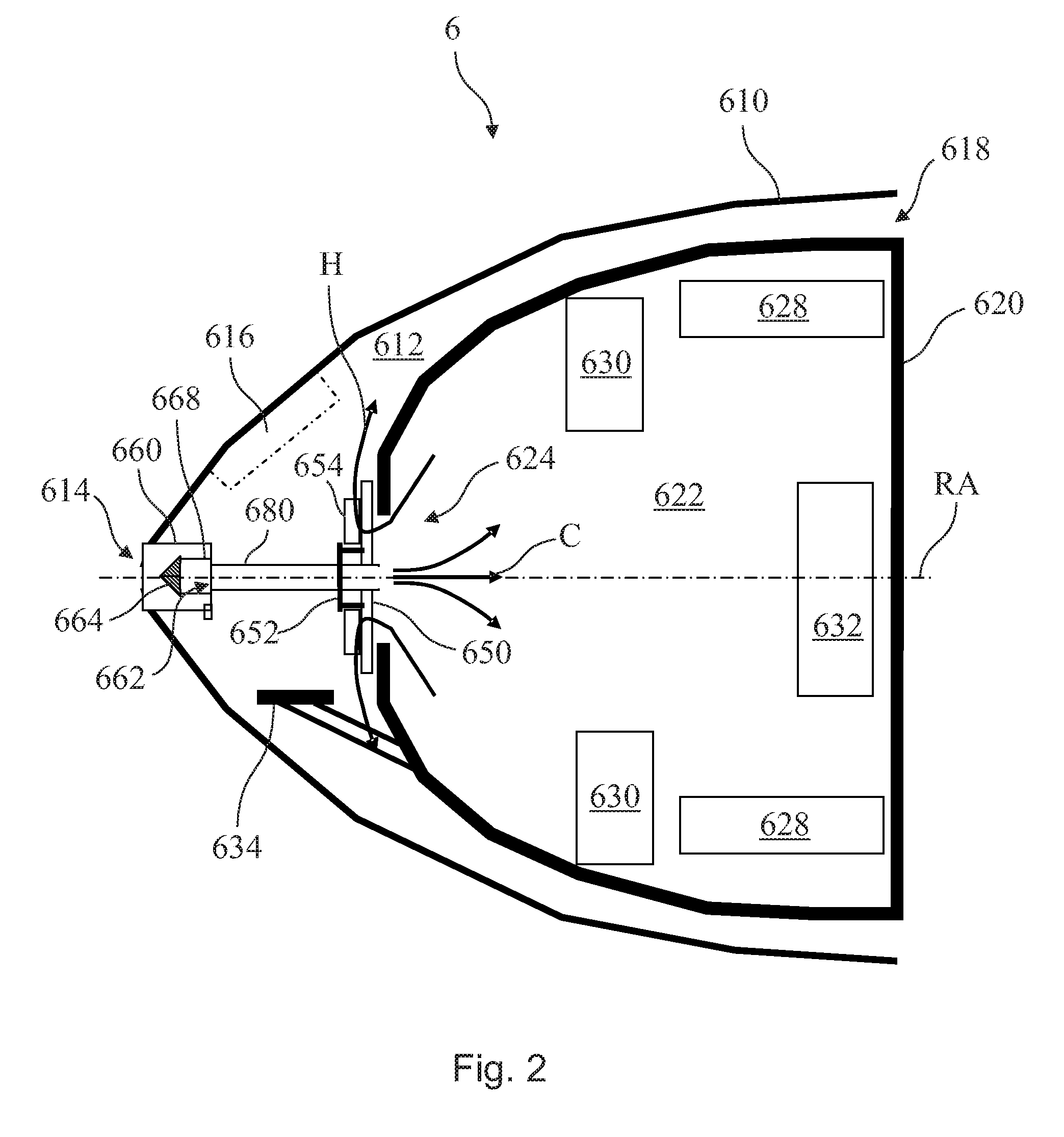

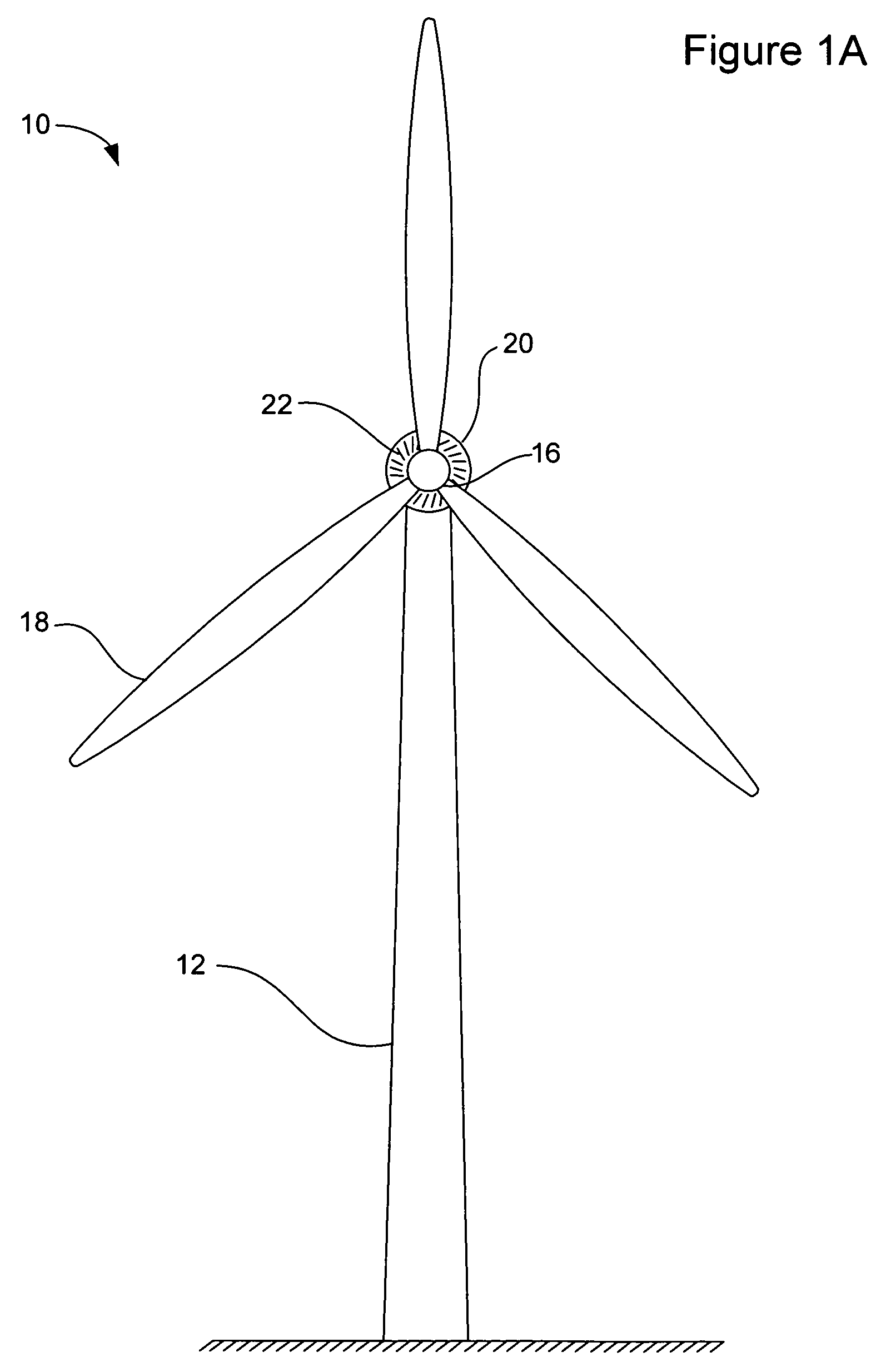

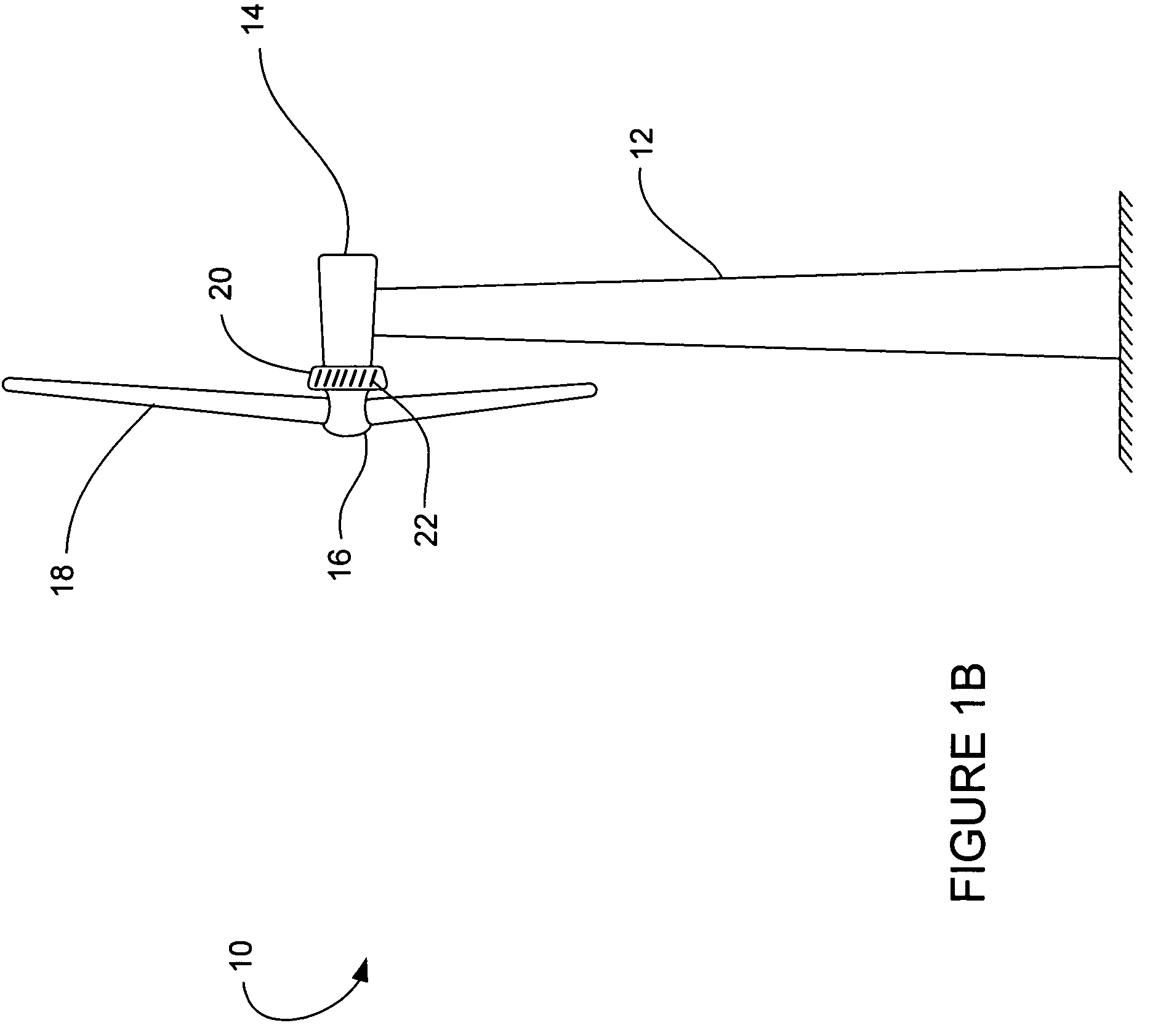

Ventilation arrangement

A ventilation arrangement for a wind turbine includes an air inlet opening located in a nose cone of said wind turbine, a manhole cover for covering a manhole of a rotor hub of said wind turbine, the manhole cover providing a vent opening for venting hot air from an internal space of said rotor hub, and a flexible piping establishing fluid communication between the internal space of the rotor hub and the air inlet opening.

Owner:GENERAL ELECTRIC CO

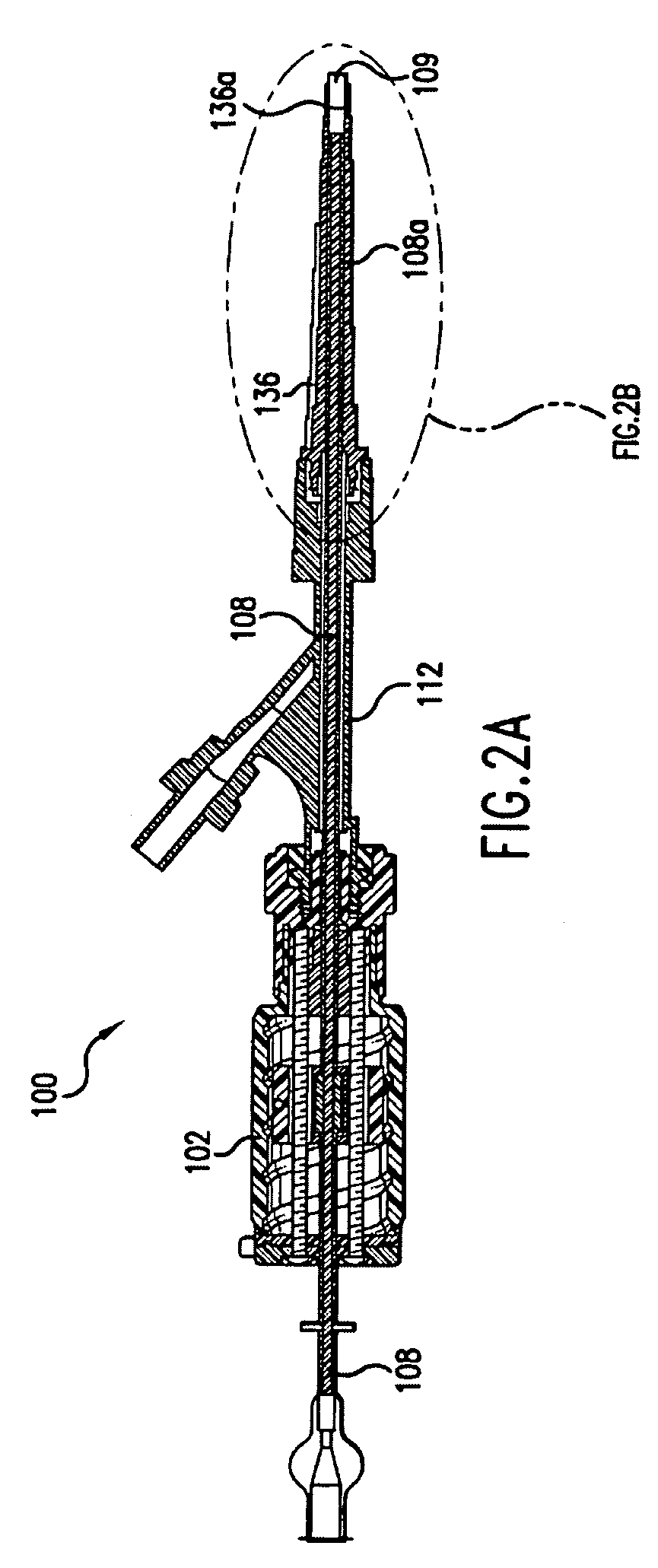

Anchor Delivery System

The present disclosure relates to an anchor delivery system. The system includes a guide and an anchor delivery tool disposed within the guide. The tool includes a shaft and a handle coupled to a proximal portion of the shaft. The handle includes a hub and a nose cone coupled to the hub. In an embodiment, the tool further includes a knob coupled to the hub and located between the handle and the nose cone. In an embodiment, the system further includes an anchor, such as a suture anchor, coupled to a distal portion of the shaft. An anchor delivery tool and a method of repairing soft tissue are also disclosed.

Owner:SMITH & NEPHEW INC +1

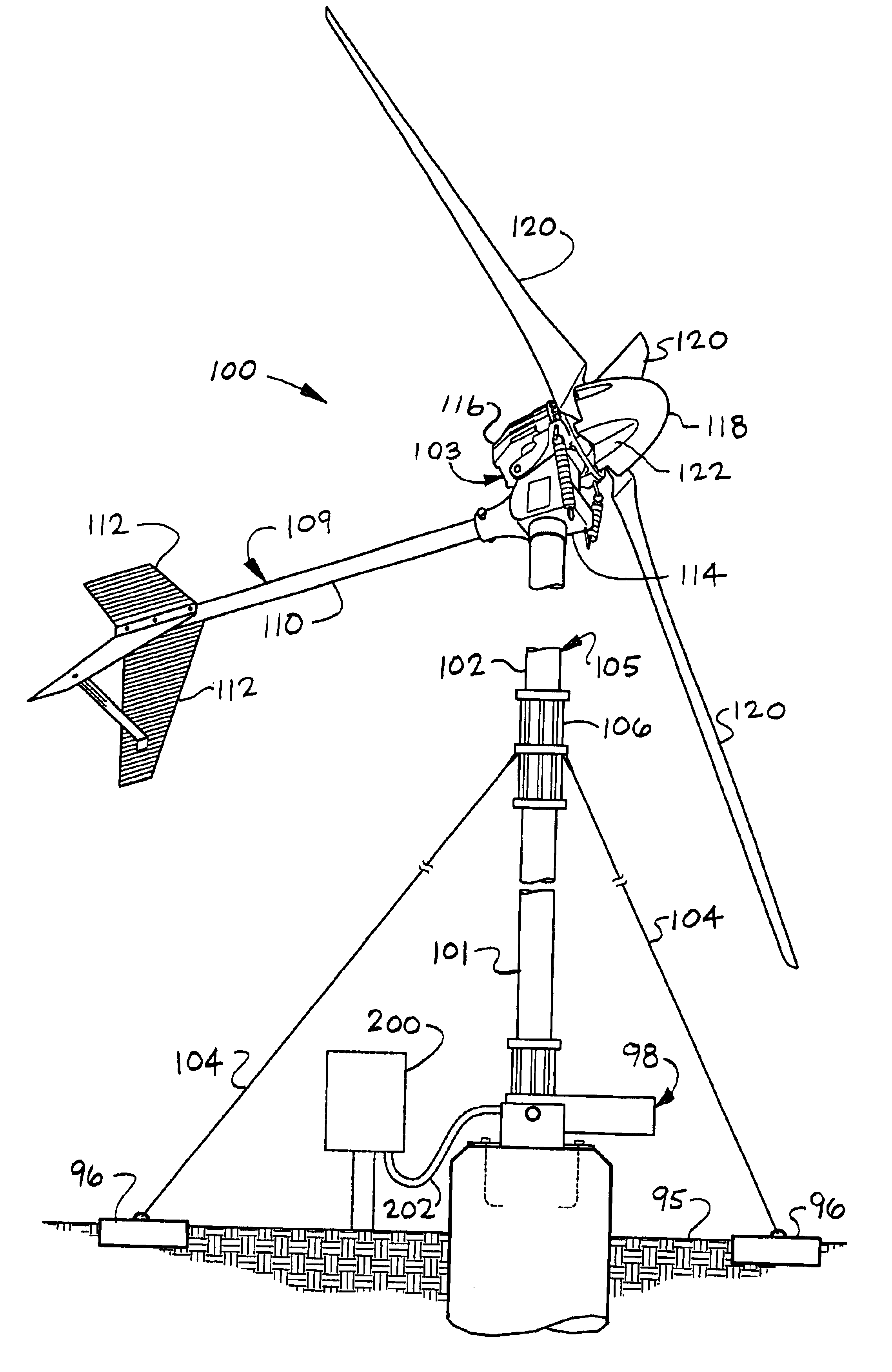

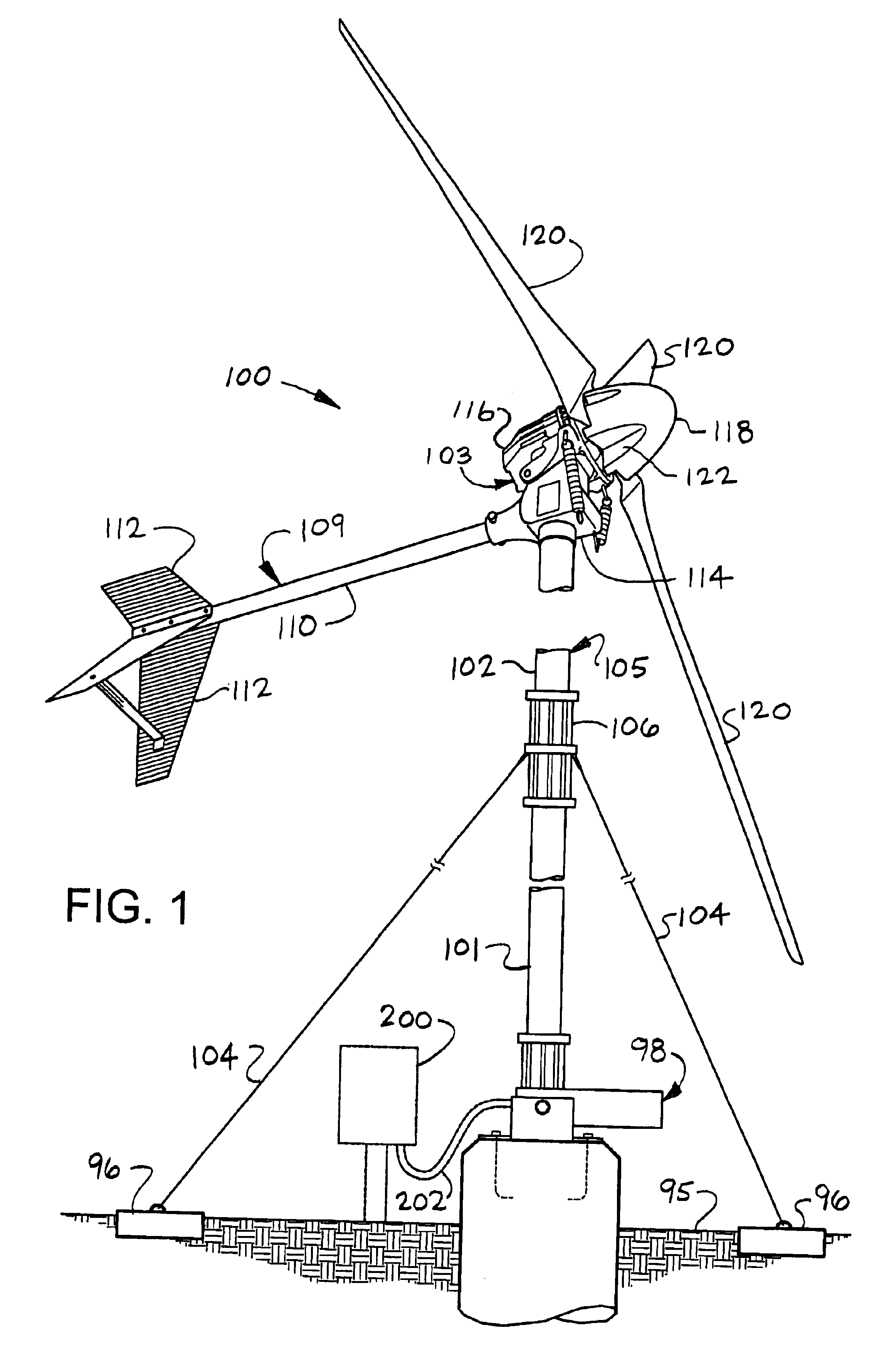

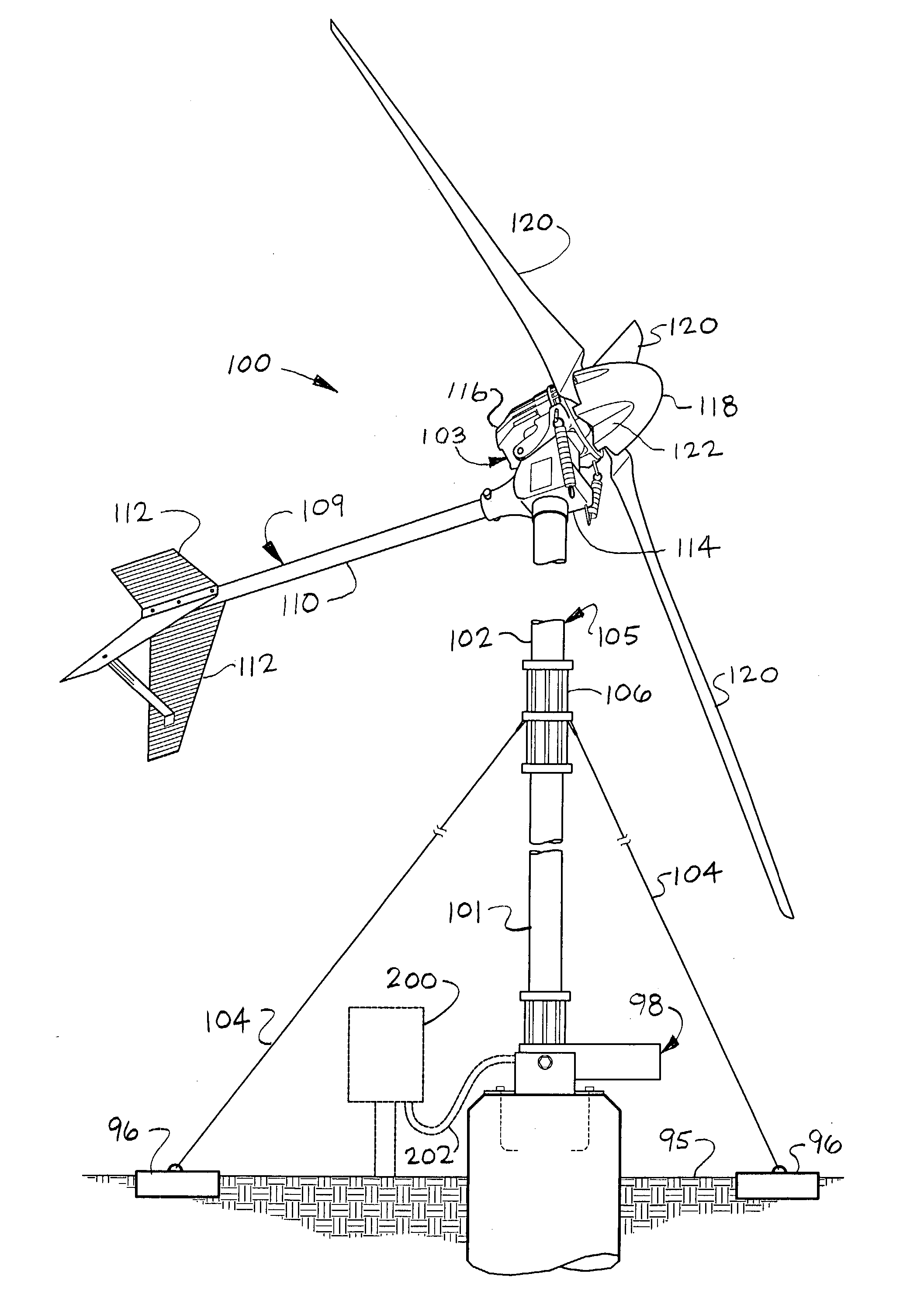

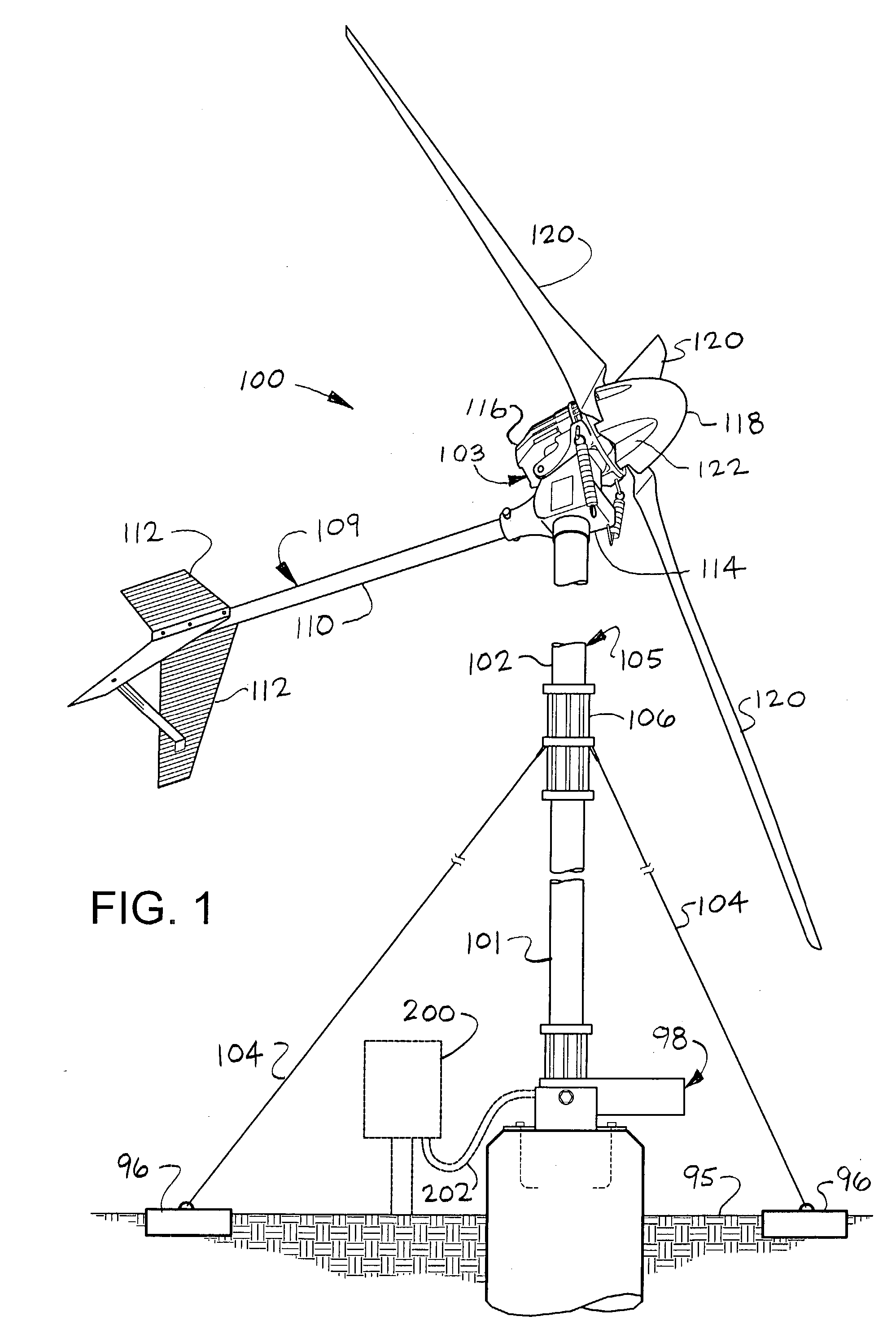

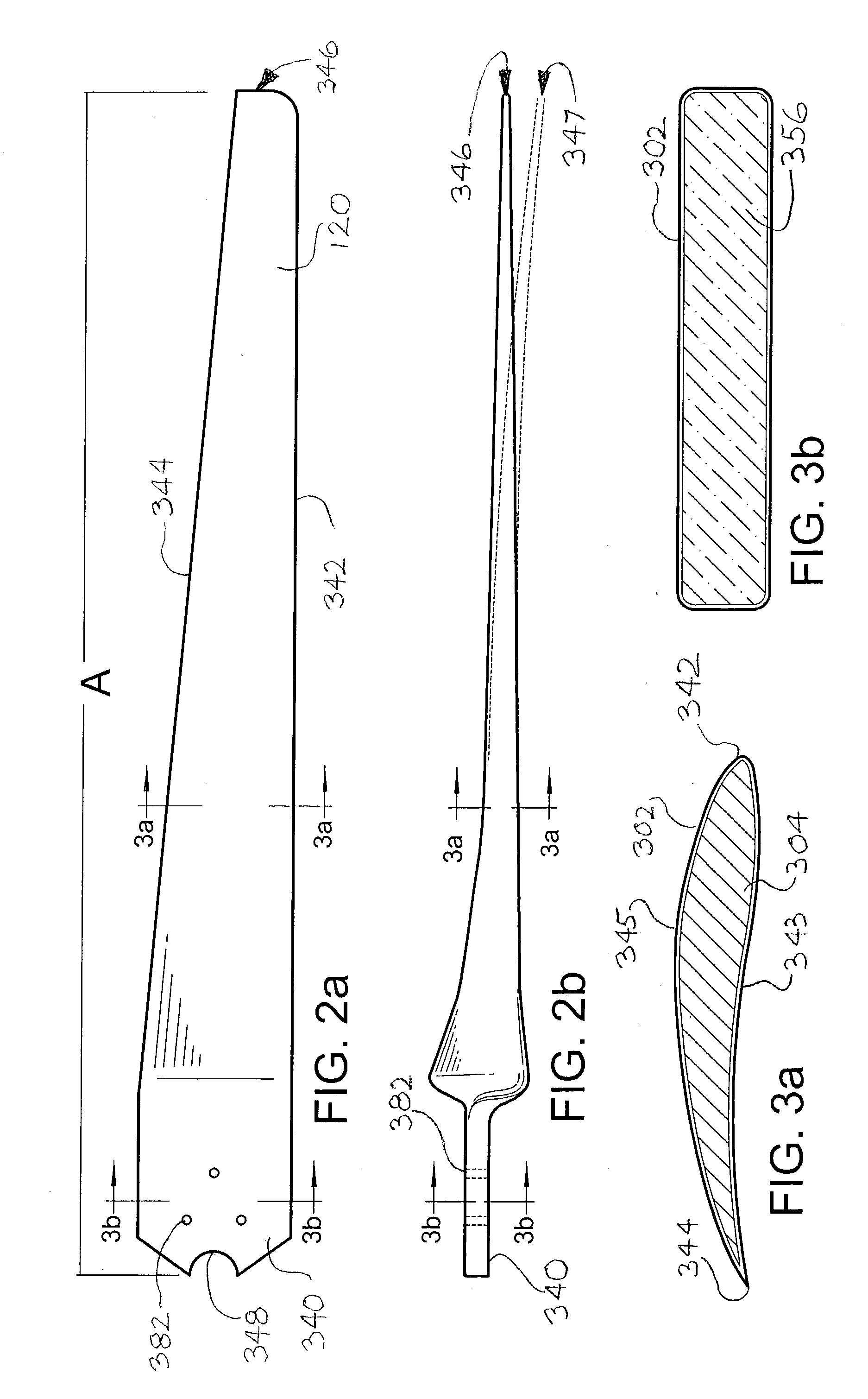

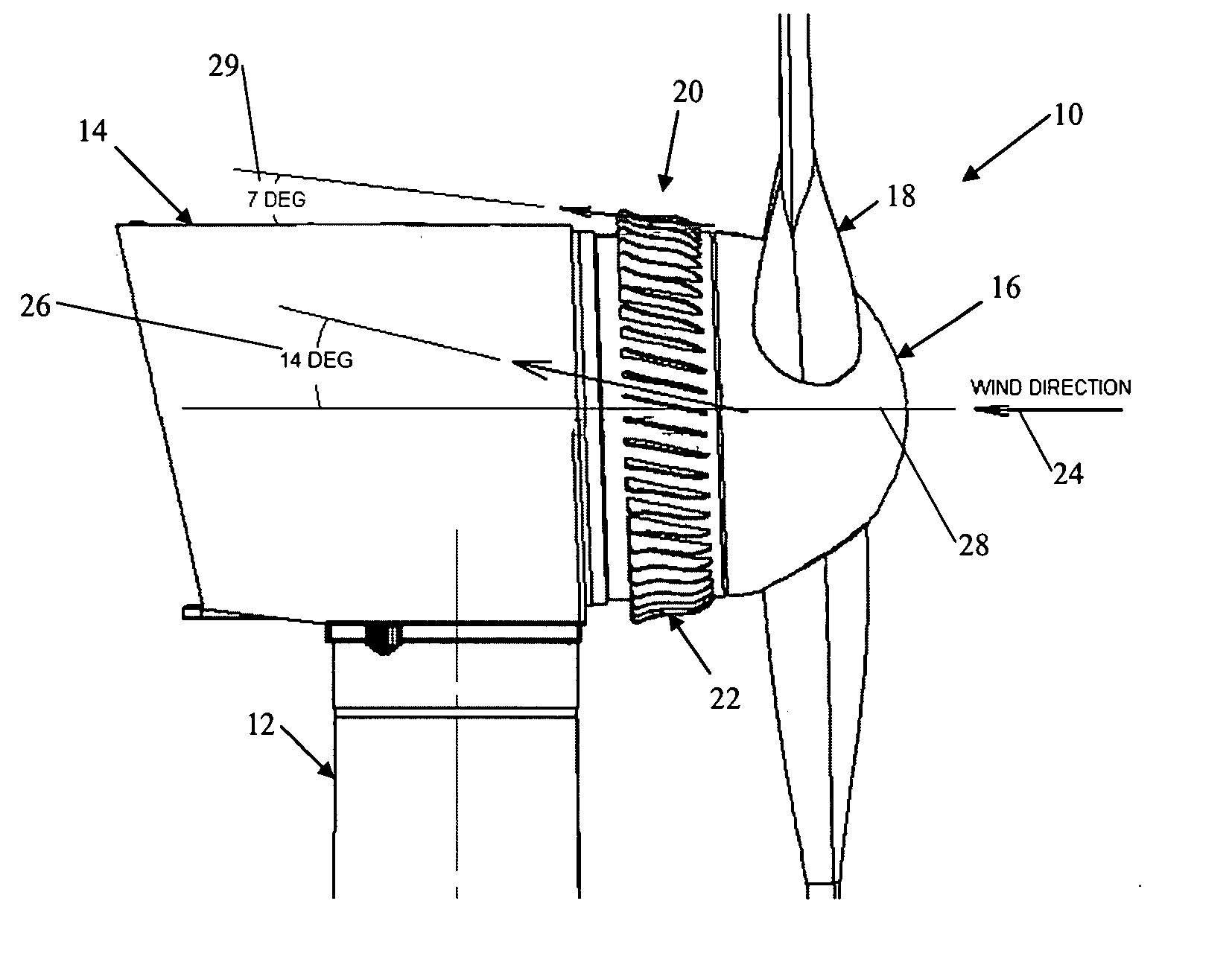

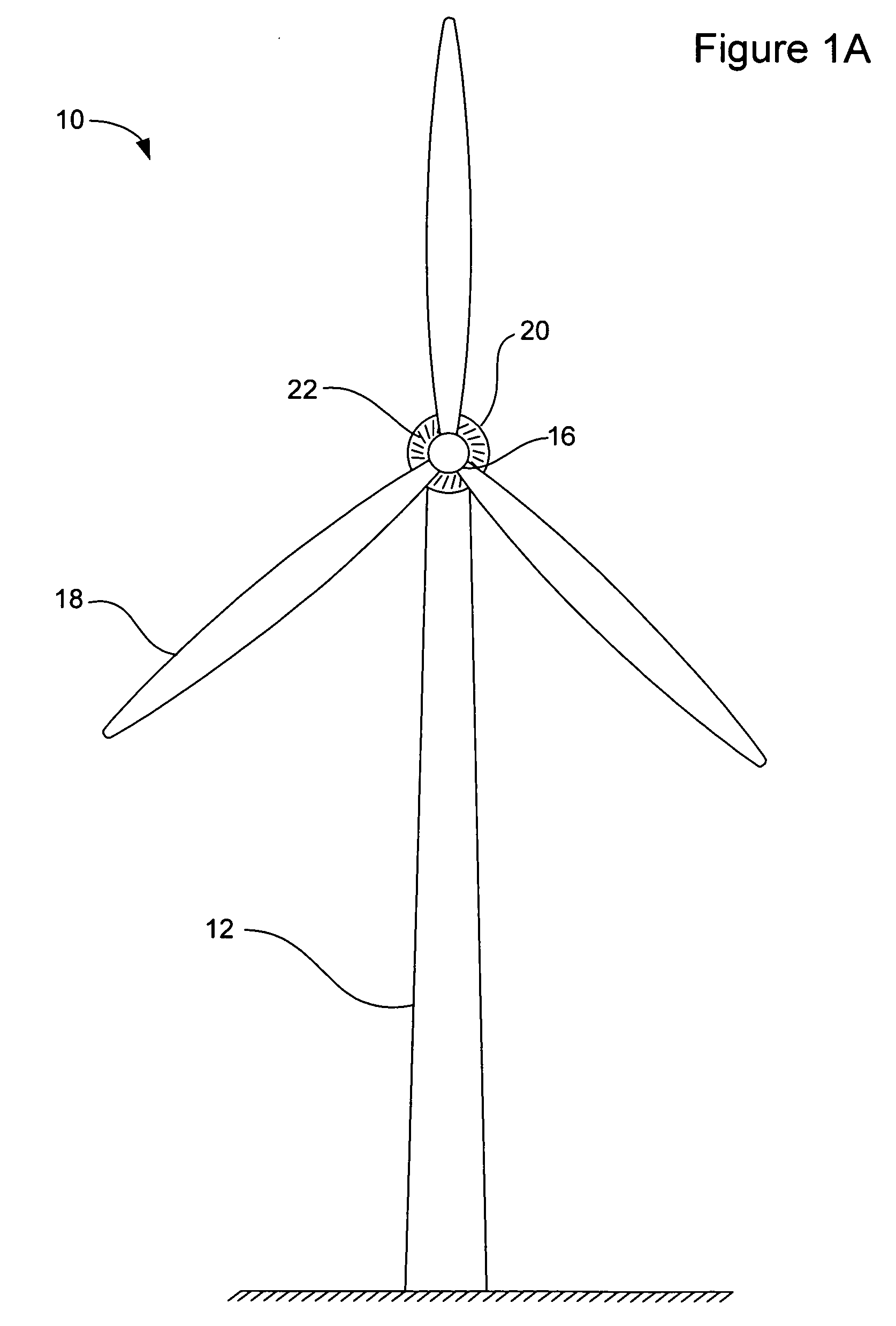

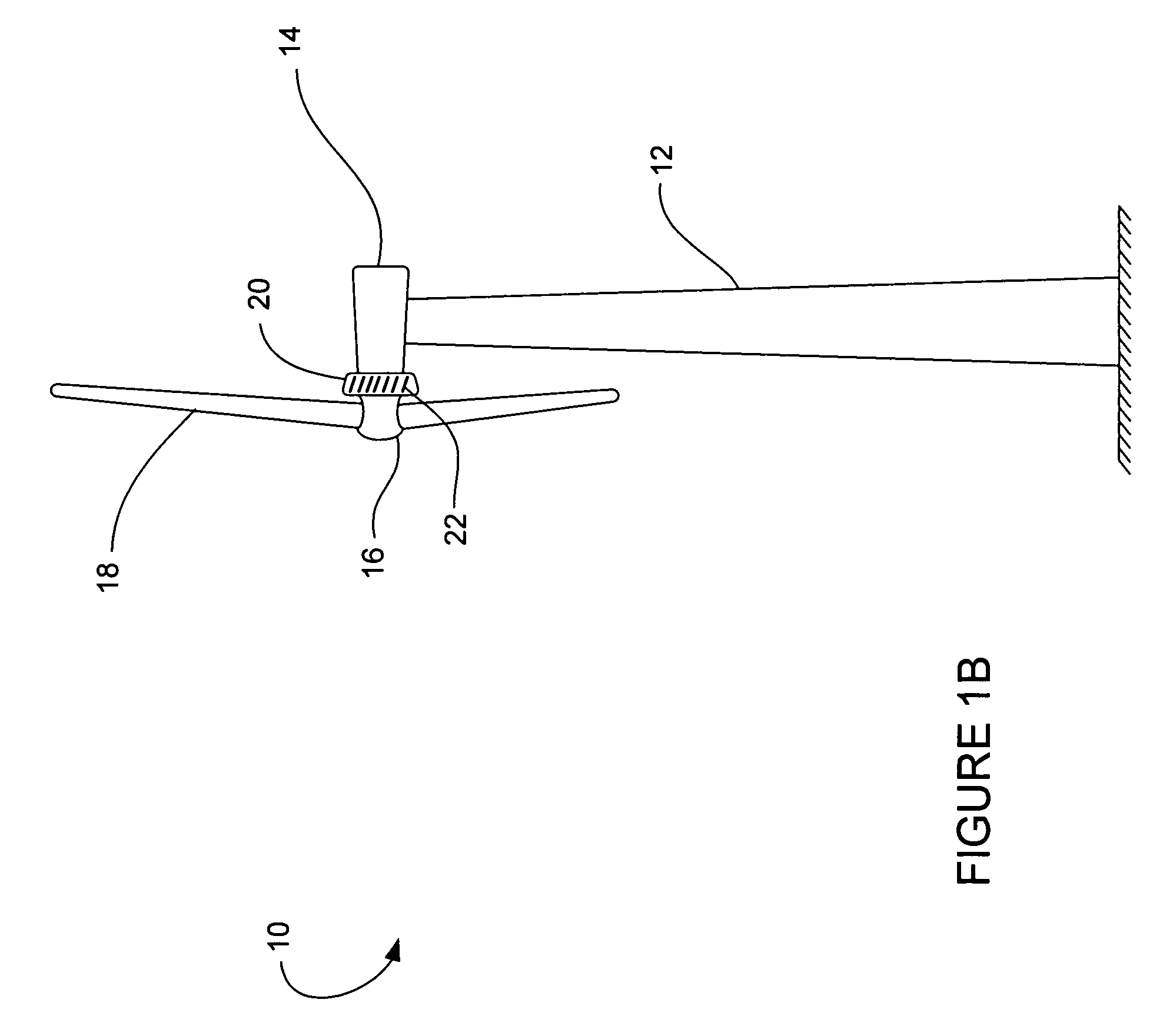

Wind power system

InactiveUS6800956B2Low costImprove efficiencyFinal product manufactureWind motor combinationsWind drivenFiber

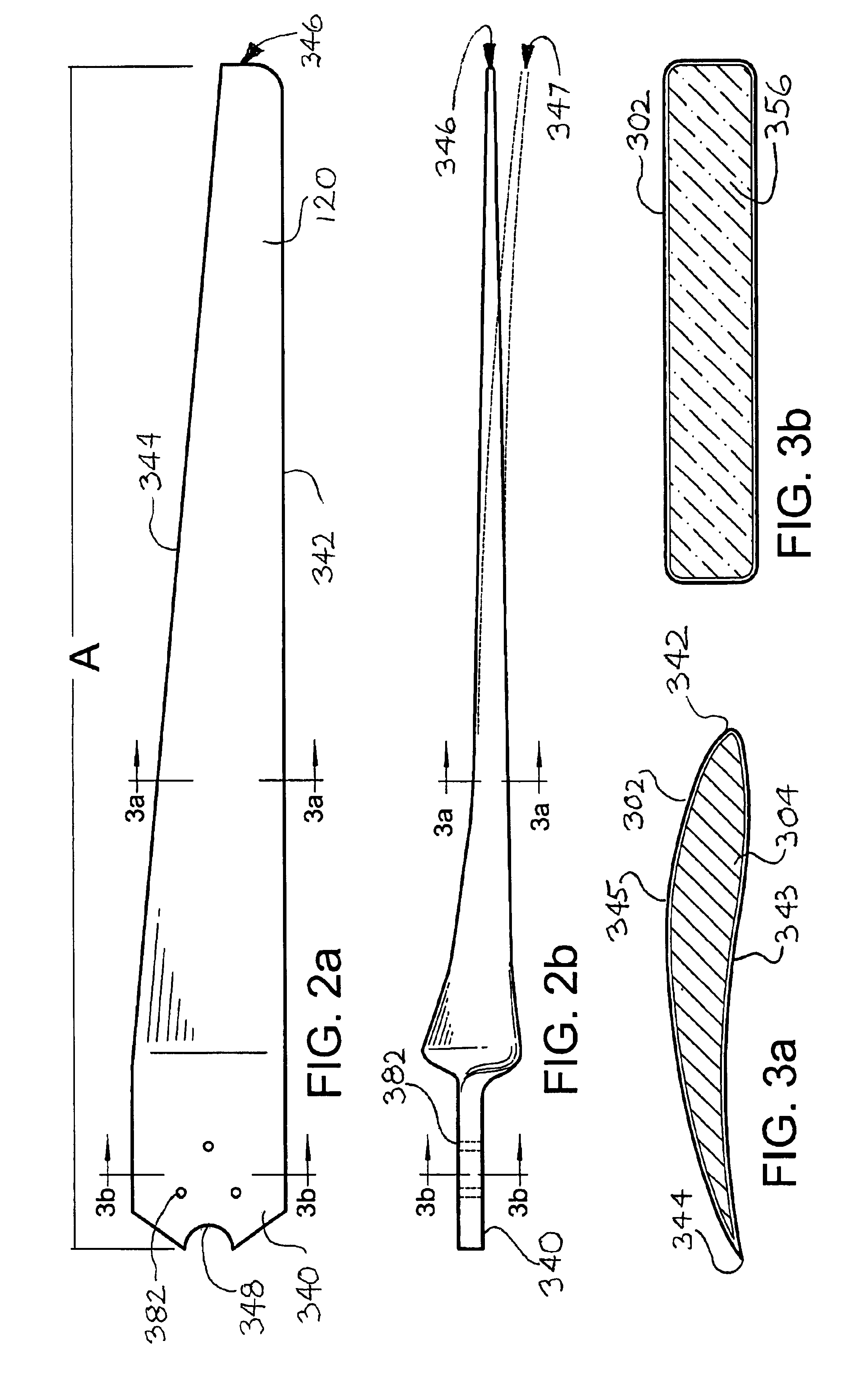

A system for the generation of electrical power using an improved 600-watt to 900-watt wind turbine system. The system comprises a wind driven generator utilizing an array of uni-directional carbon fiber turbine blades, an air-ducting nose cone, and a supporting tower structure. Additionally, a method of blade fabrication utilizing expanding foam, to achieve improved blade edge strength, is disclosed. The support tower utilizes a compressive coupler that permits standard fence pipe to be joined without welding or drilling.

Owner:BARTLETT LEXINGTON

Expandable medical access sheath

An expandable medical sheath is configured to be introduced into a body in a first, low cross-sectional area configuration, and expanded to a second, enlarged cross-sectional configuration. The sheath is maintained in the first, low cross-sectional configuration by structures or elements within the sheath wall that maintain a collapsed shape. Upon expansion with a dilator, the sheath maintains a second, enlarged cross-sectional configuration by elements or structures within the sheath tubing wall that resist re-collapse. The sheath includes a nose cone or tapered fairing to deflect tissue from entering the collapsed distal end of the sheath during introduction. The fairing collapses following expansion and subsequent deflation of the dilator, thus allowing the tapered fairing to be withdrawn proximally through the central lumen of the sheath. In one application, the sheath is utilized to provide access for a diagnostic or therapeutic procedure such as percutaneous nephrostomy or urinary bladder access.

Owner:ONSET MEDICAL CORP

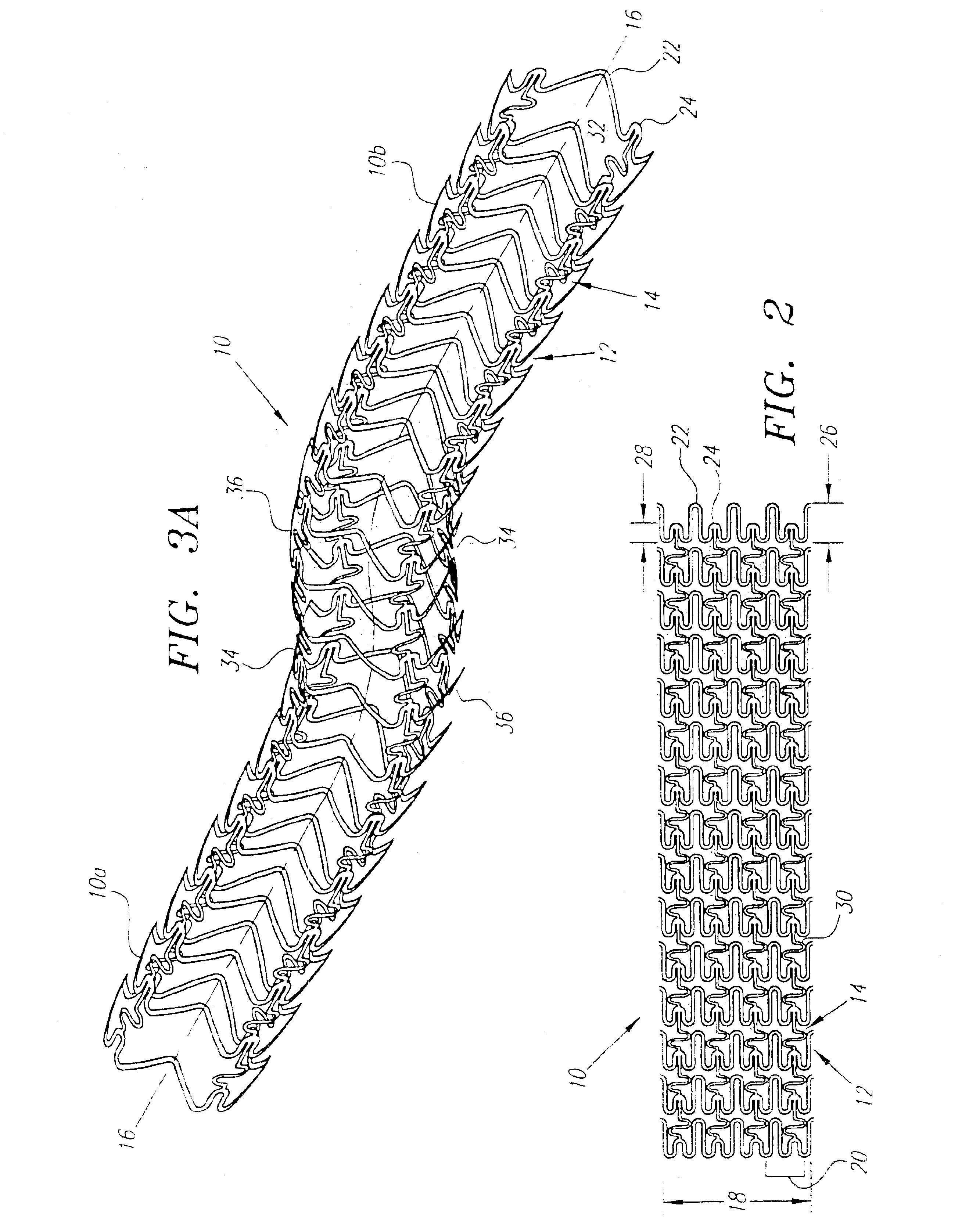

Autonomous, back-packable computer-controlled breakaway unmanned aerial vehicle (UAV)

InactiveUS7237750B2Quick assemblyOvercome problemsUnmanned aerial vehiclesLuggageData retrievalModularity

A modular unmanned aerial vehicle (UAV) having a fuselage, a nose cone, a left wing piece, a right wing piece, and a tail section. The tail section and nose cone each join to the fuselage through mating bulkhead structures that provide quick connection capability while being readily separated so as to enable the UAV to break apart at these connection points and thereby absorb or dissipate impact upon landing. The UAV is capable of rapid assembly in the field for two-man launch and data retrieval, as well as quick disassembly into these five component parts for transport and storage in a highly compact transport case that can be carried as a backpack.

Owner:L 3 COMM CORP

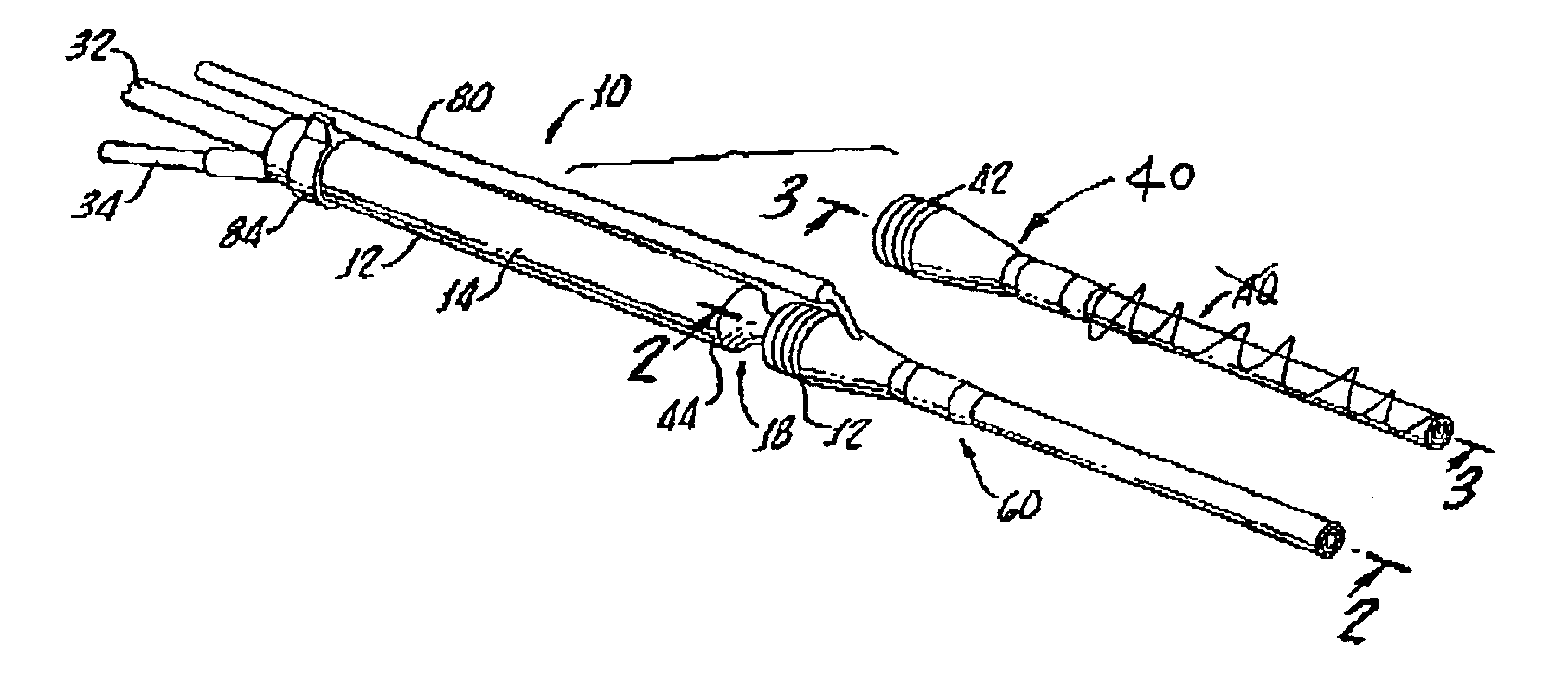

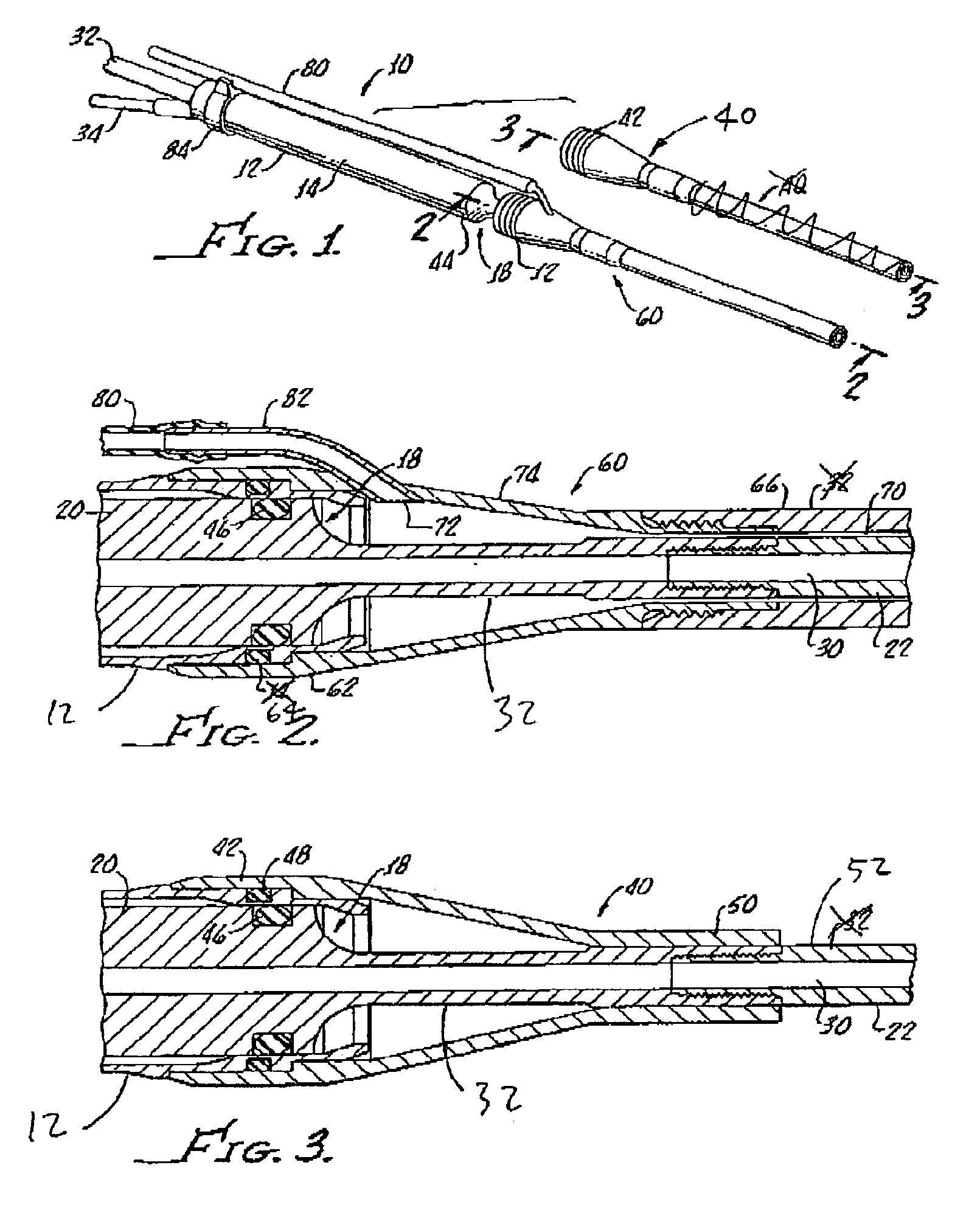

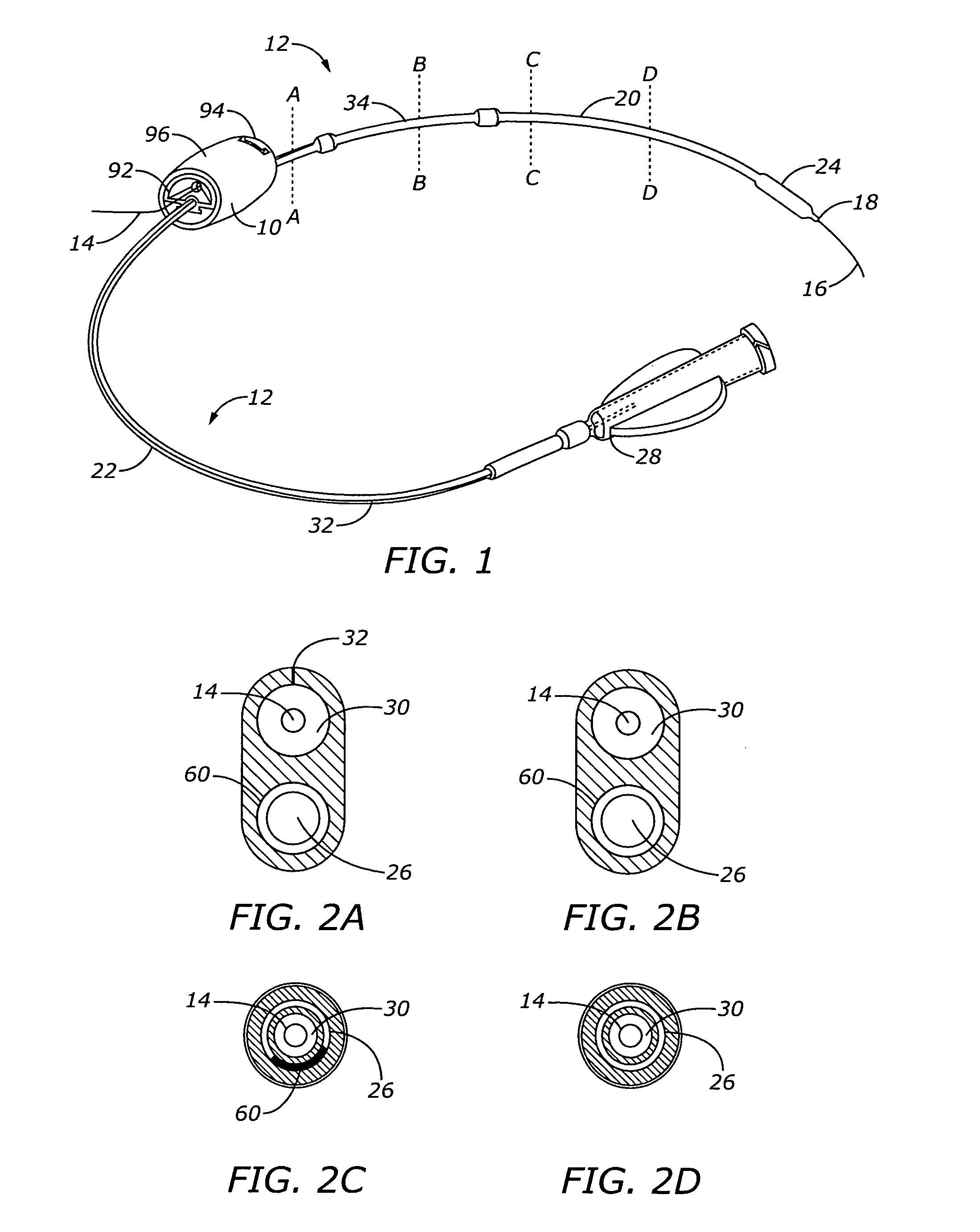

Multi-exchange catheter guide member with improved seal

A catheter and a guidewire exchange system includes a catheter and a guide member. The catheter includes a lumen extending through the shaft and sized to receive the guidewire, and a longitudinal guideway enabling transverse access from the shaft exterior surface to the lumen. The guide member includes a housing, a catheter passageway extending through the housing and adapted to slidably receive the catheter, a guidewire passageway extending from one end of the housing into the catheter passageway and including a tube adapted to merge the guidewire transversely through the guideway and into the first lumen, a rigid nose cone attached to the housing and having an aperture extending therethrough that is continuous with the catheter passageway and adapted to slidably receive the catheter, and a first gasket positioned in line with the catheter passageway and tightenable to impede catheter movement through the catheter passageway.

Owner:MEDTRONIC VASCULAR INC

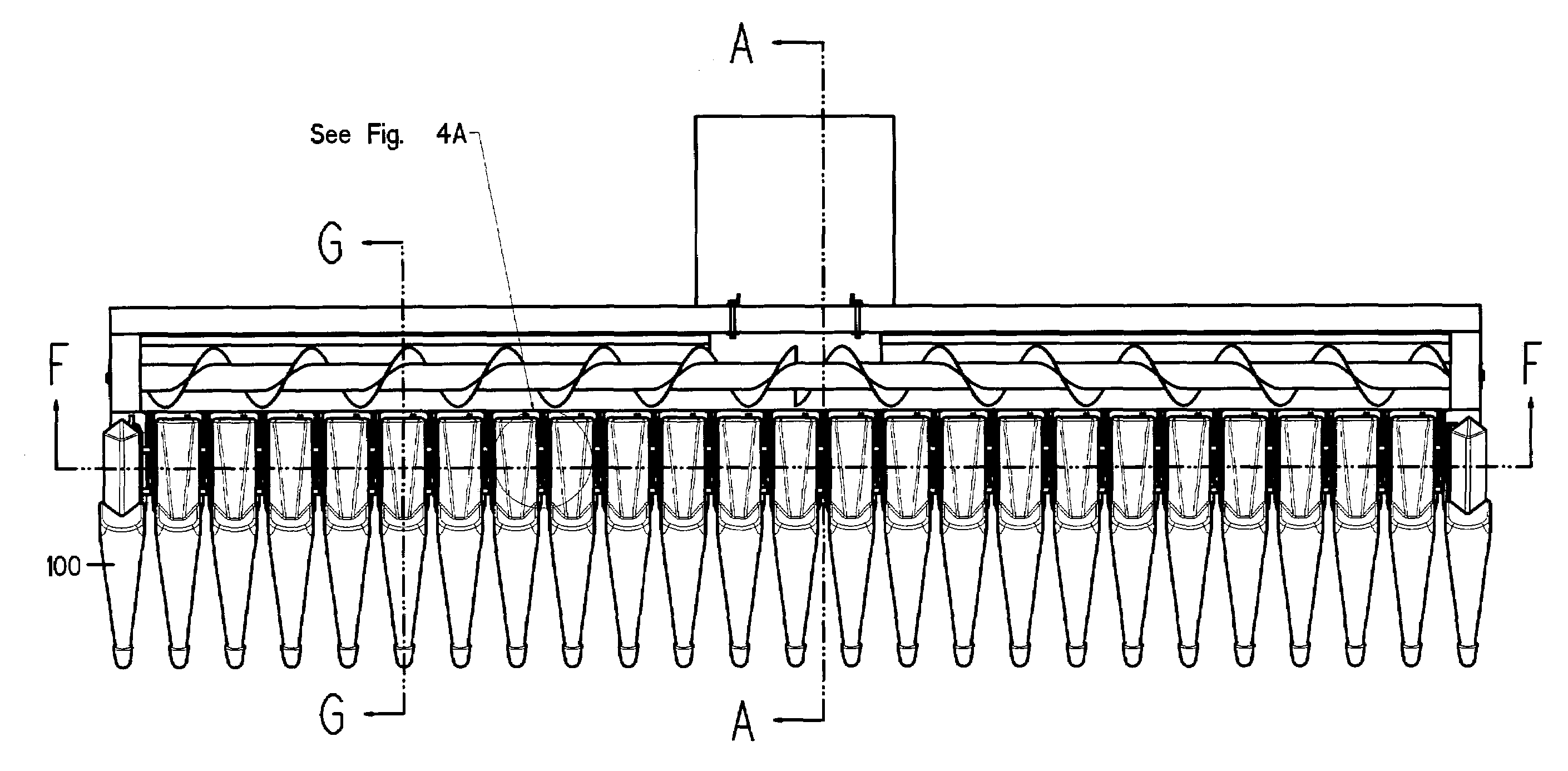

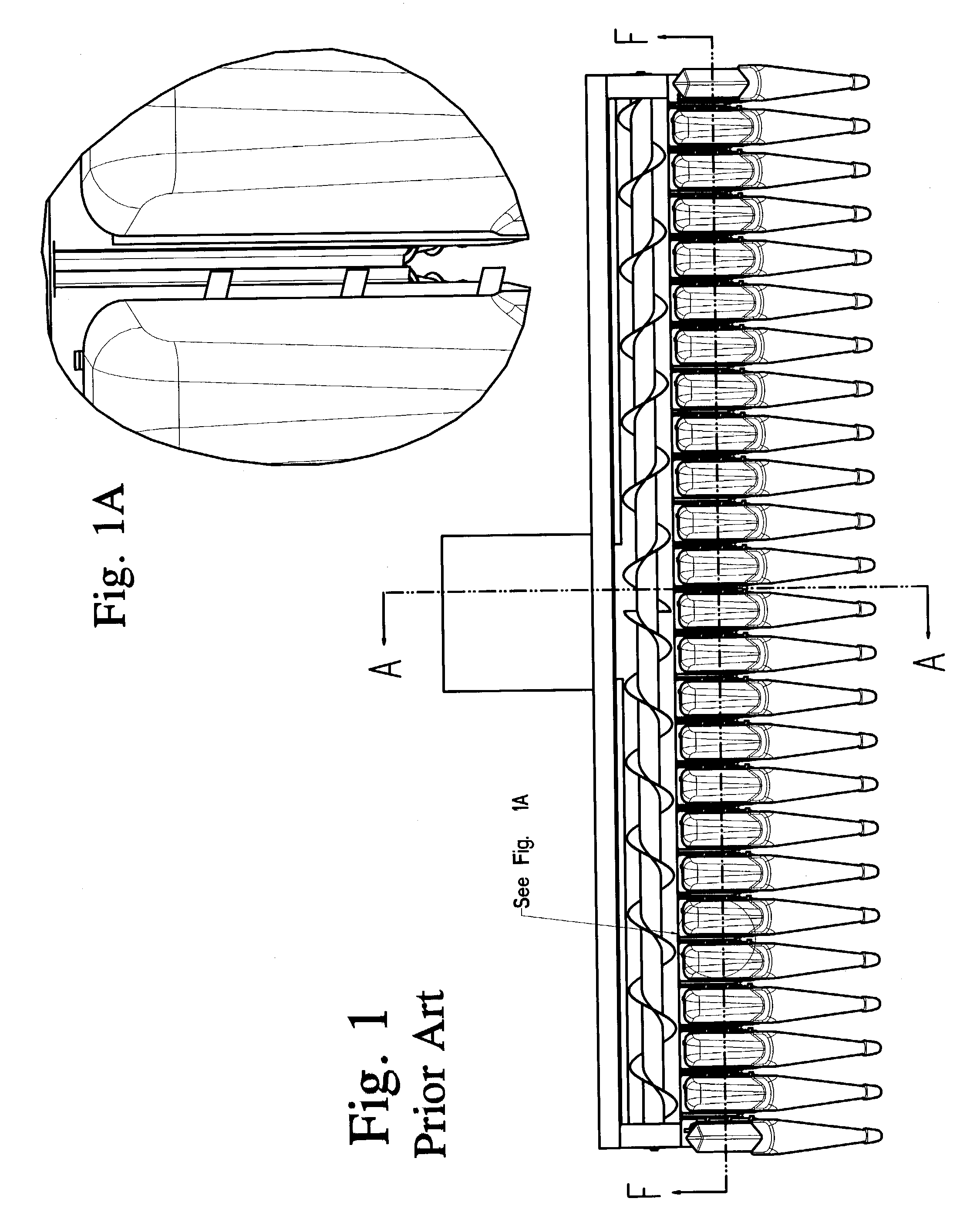

Corn head row unit

This row unit utilizes an improved multi-zone, multi-functional stalk roll, which contains a novel revolving entry window to improve entry and increase engagement of the fluted portion of the stalk roll flutes with the corn stalk. The stalk rolls described are multi-sectional and contain multi-length variable flutes. The number of flutes described for each zone may vary as well as whether the flutes are meshing or non-meshing and angled or non-angled. The stalk rolls described allow a constant speed drive shaft to create lower and / or higher effective circumferential contact speeds within each zone of the stalk roll. The invention provides that the rotating transport vanes located on the helical nose cone at the entry area to the stalk roll flutes lock the corn stalk into a revolving entry window. This novel row unit contains a multi-zone, multi-functional stripper plate that ensures minimal ear wedging and maximum discharge of material other than ears. This row unit utilizes a novel gathering / conveying chain(s), which reduces the number of and increases the angle and size of the paddles. This row unit design optimizes operation between the components imparting force to the corn plant and ears. The invention has a smooth uninterrupted improved flow of corn stalk material through the ear separation chamber and is the first row unit designed to be environmentally friendly by ensuring that the majority of the corn plant remains connected to its original root system which prevents it from rapidly decomposing, blowing or washing away. The row unit cover is spatially designed for improved flow in down, damp and tough harvesting conditions.

Owner:CALMER MARION

Header assembly

A header assembly includes an outer housing holding a center contact and a dielectric body. The outer housing has a rear shell and an outer contact extending forward from the rear shell. The outer contact has a catch extending therefrom positioned forward of the rear shell. The header assembly includes a nose cone coupled to the outer contact. The nose cone surrounds the outer contact. The nose cone has one or more keying ribs along an exterior thereof. The nose cone has a latch engaging the catch to secure the nose cone to the outer housing in one of at least two distinct rotational orientations.

Owner:TE CONNECTIVITY CORP

Catheter deployment device

Owner:ABBOTT LAB INC

Wind power system

InactiveUS20030141721A1Reduce sound levelEasy to installFinal product manufactureMachines/enginesFiberWind driven

A system for the generation of electrical power using an improved 600-watt to 900-watt wind turbine system. The system comprises a wind driven generator utilizing an array of uni-directional carbon fiber turbine blades, an air-ducting nose cone, and a supporting tower structure. Additionally, a method of blade fabrication utilizing expanding foam, to achieve improved blade edge strength, is disclosed. The support tower utilizes a compressive coupler that permits standard fence pipe to be joined without welding or drilling.

Owner:BARTLETT LEXINGTON

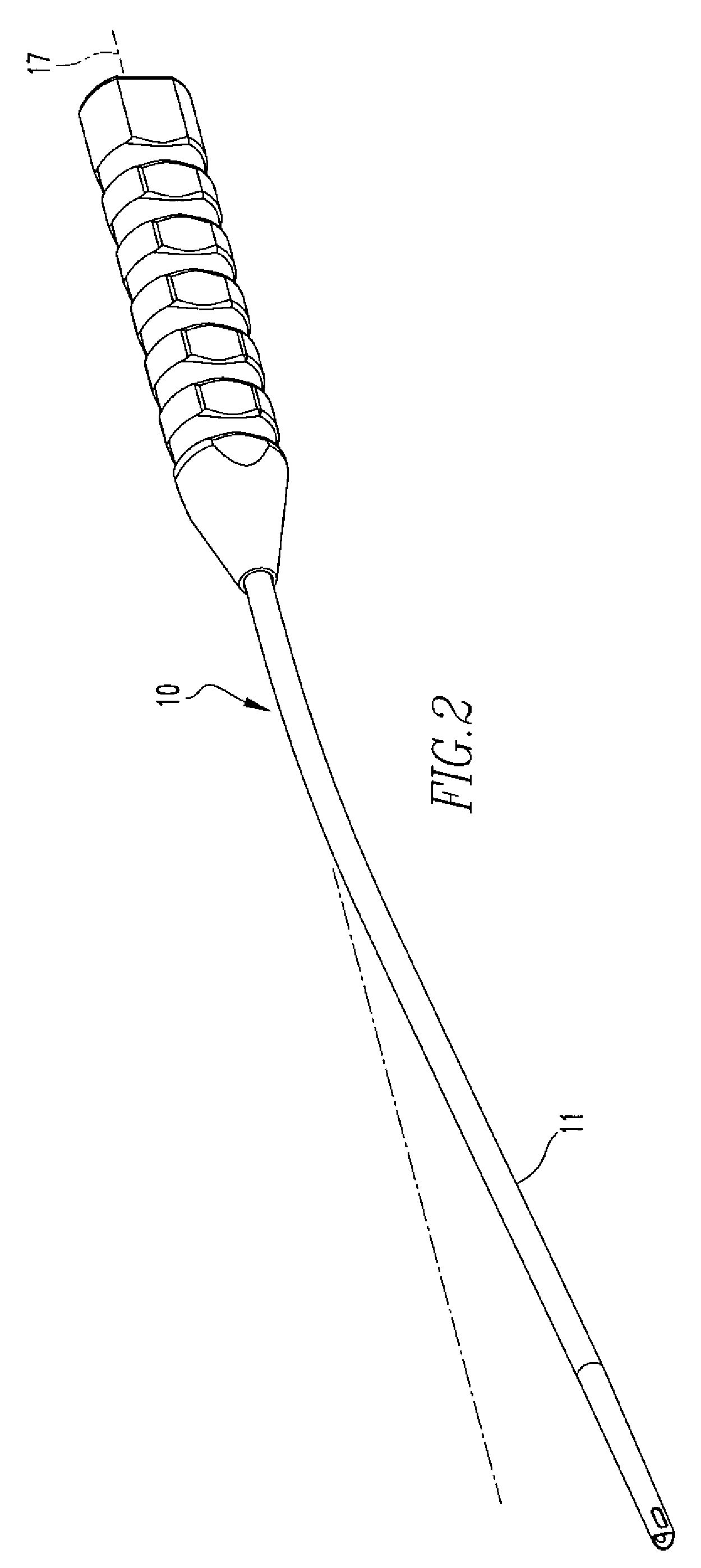

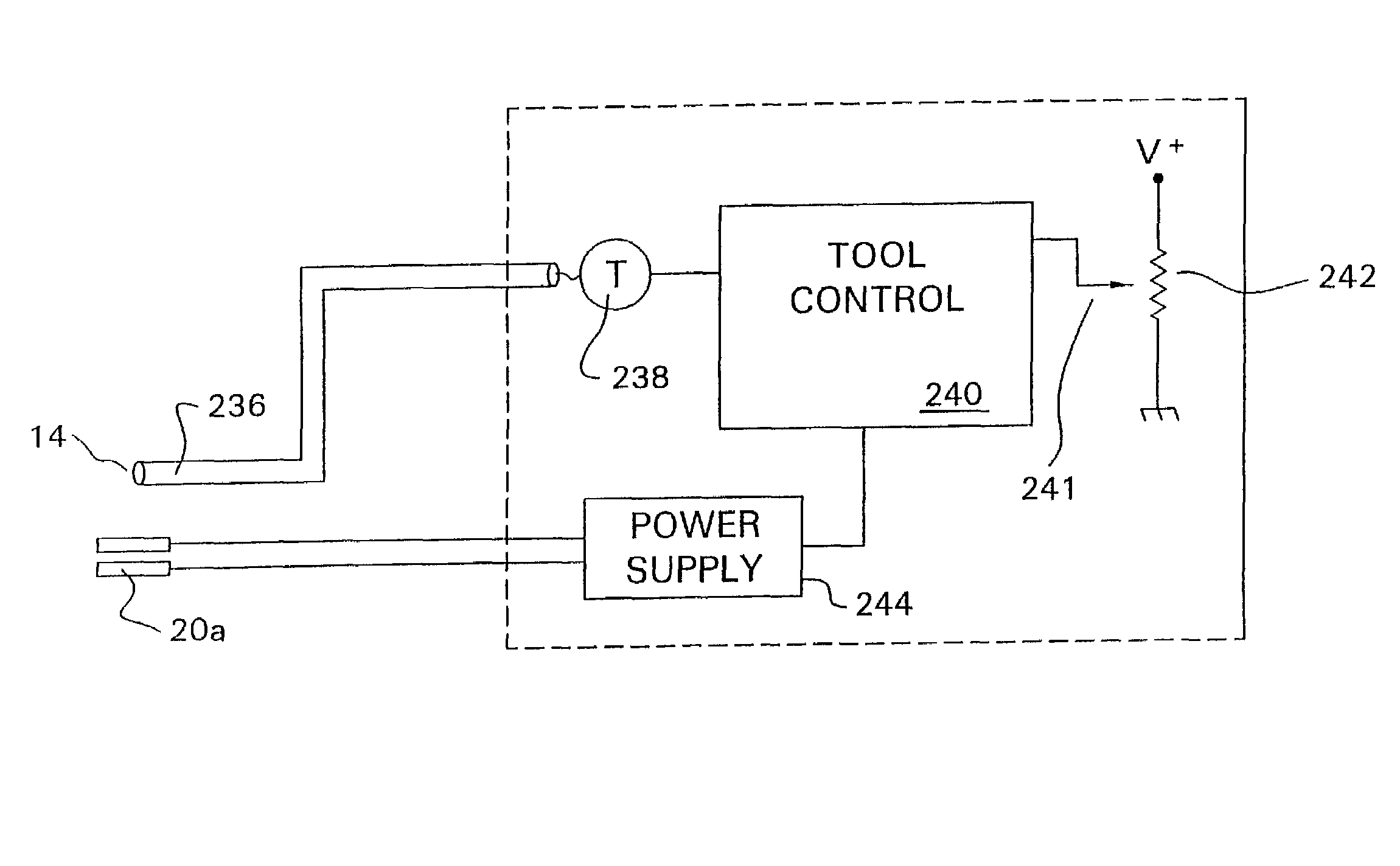

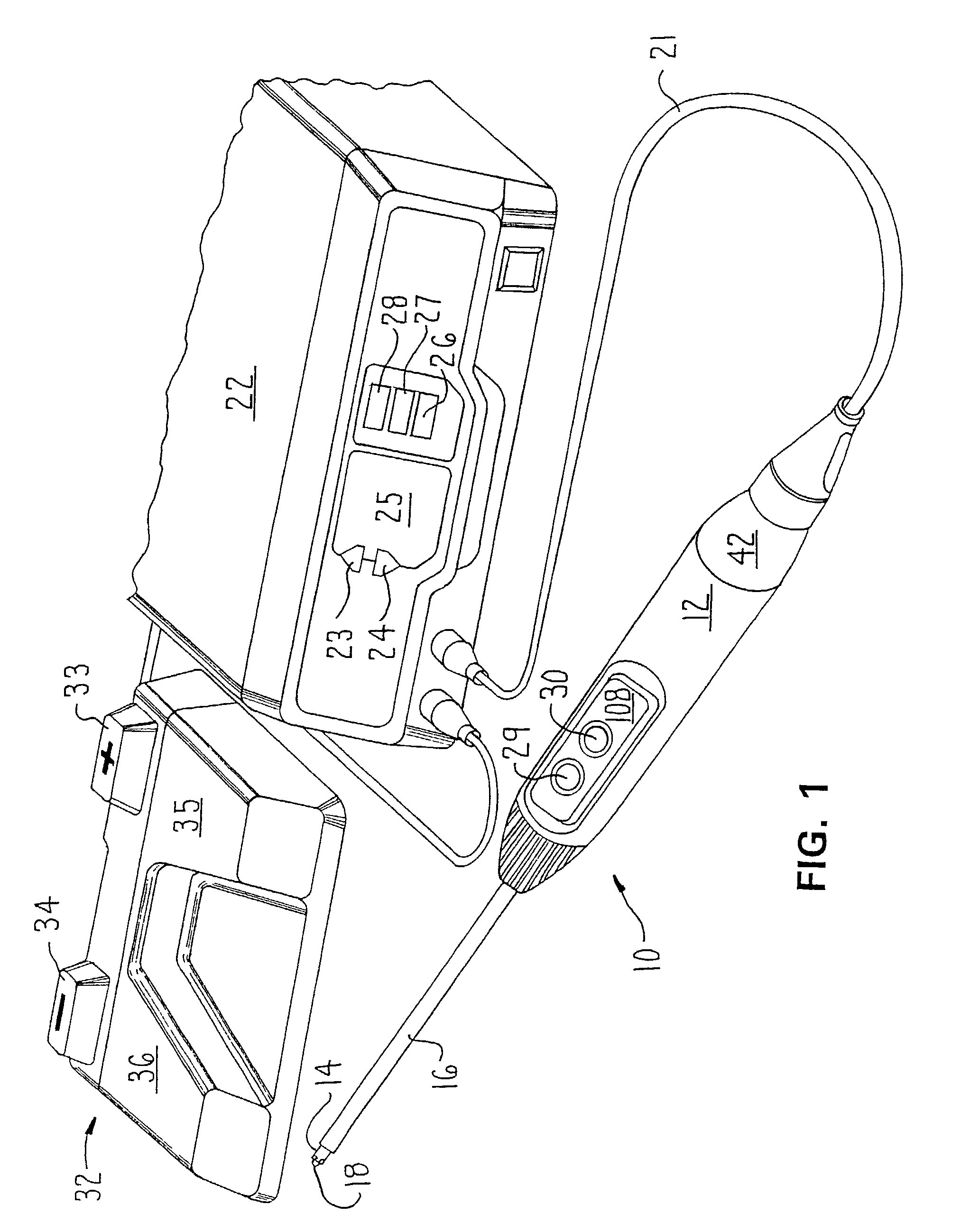

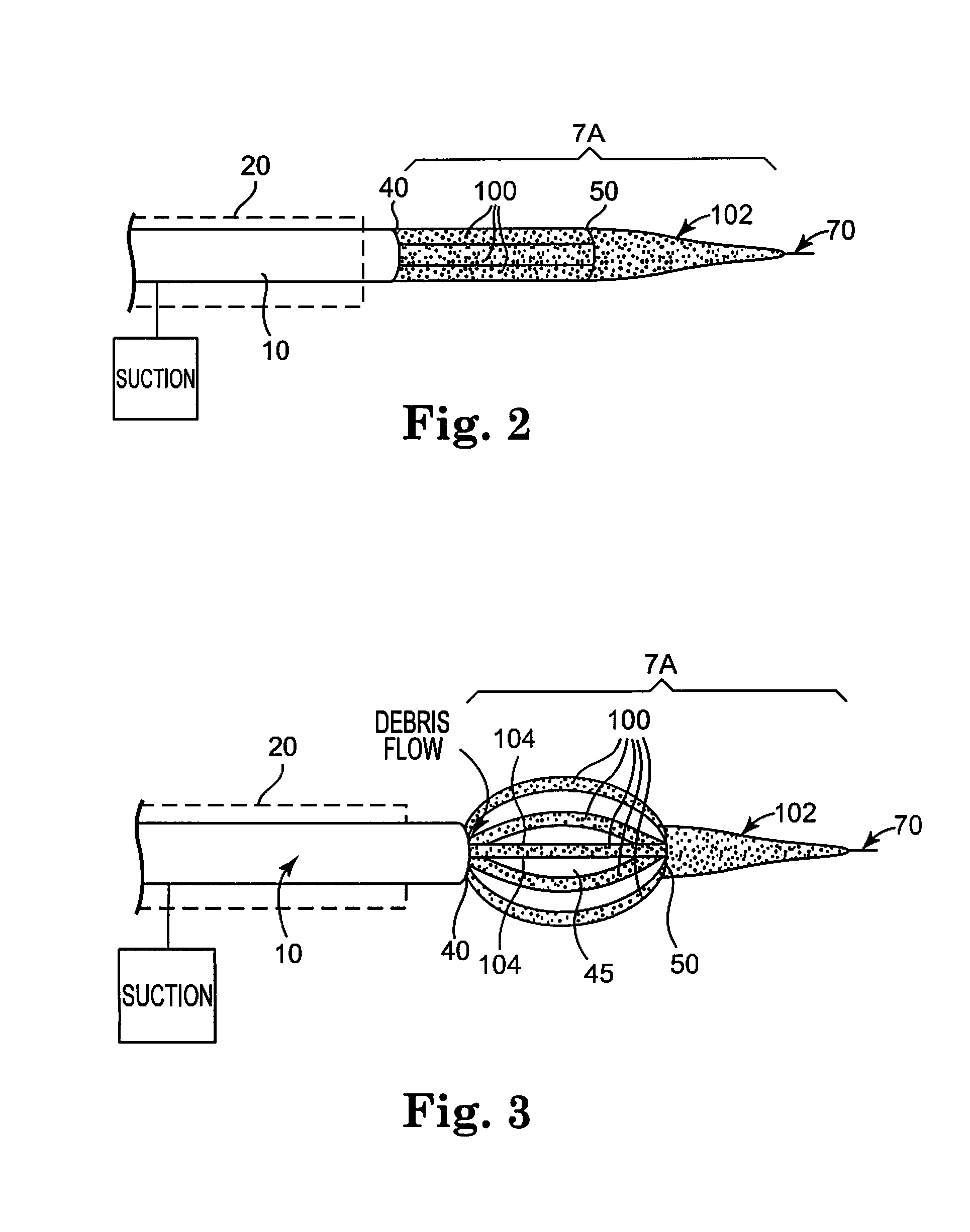

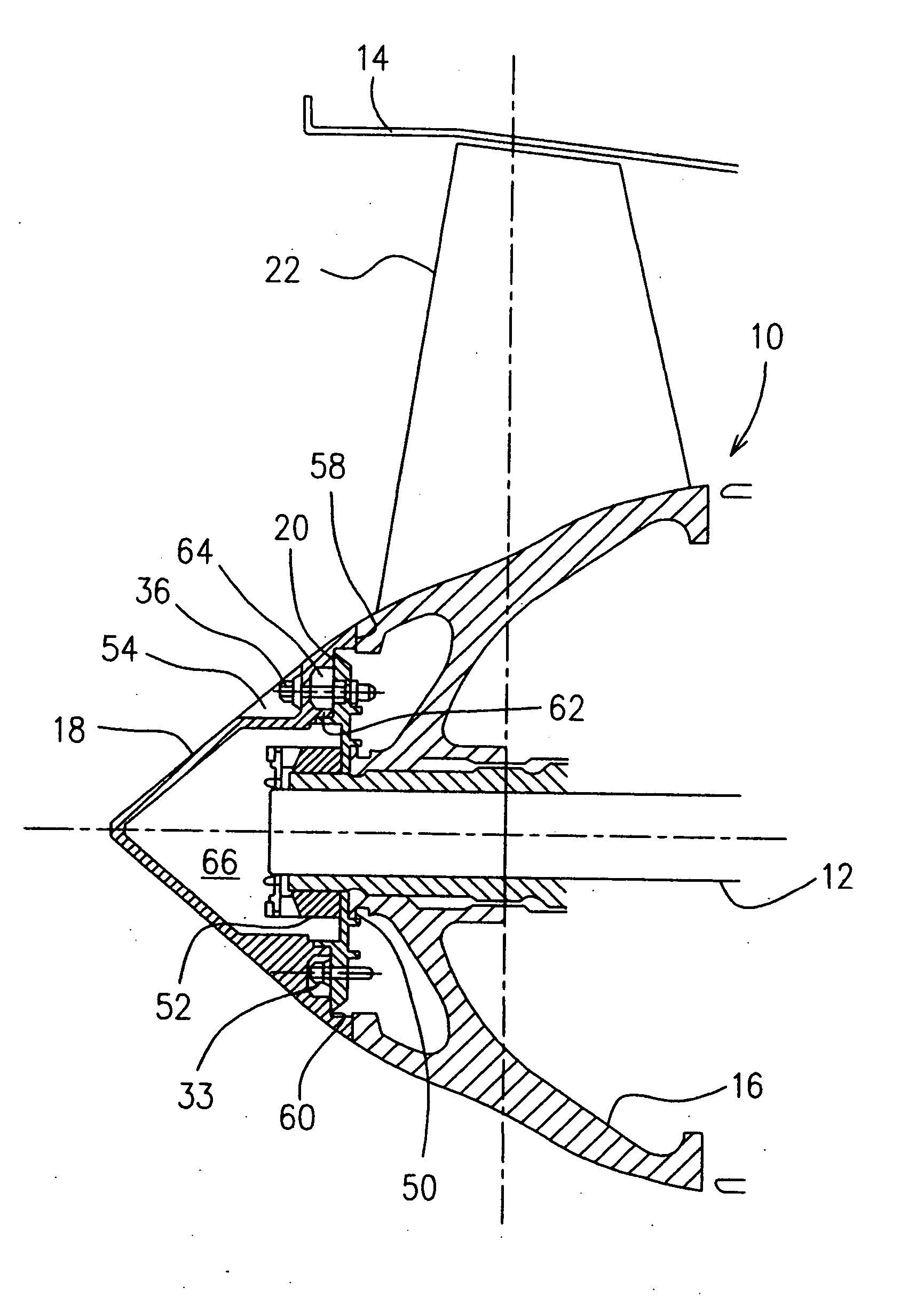

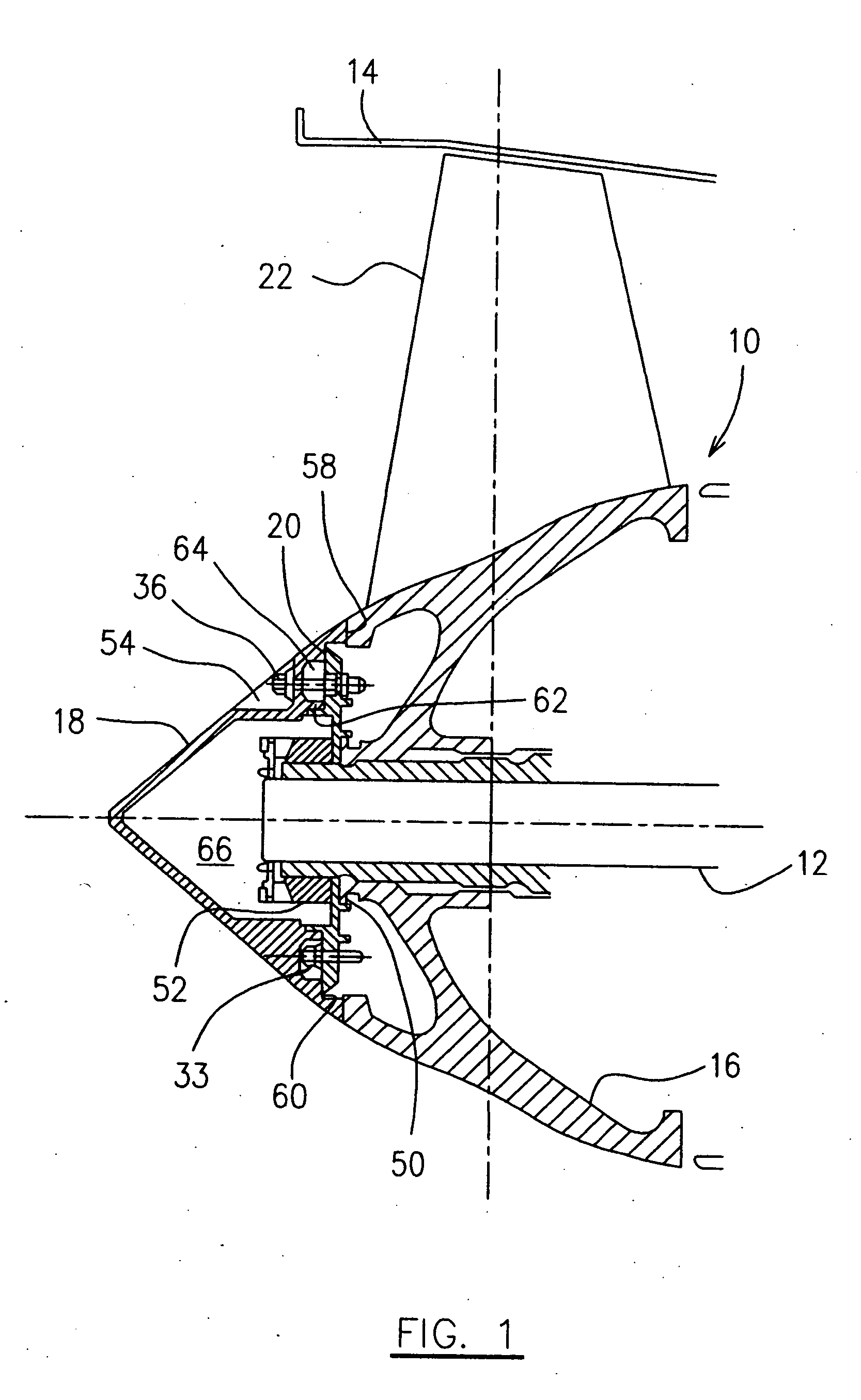

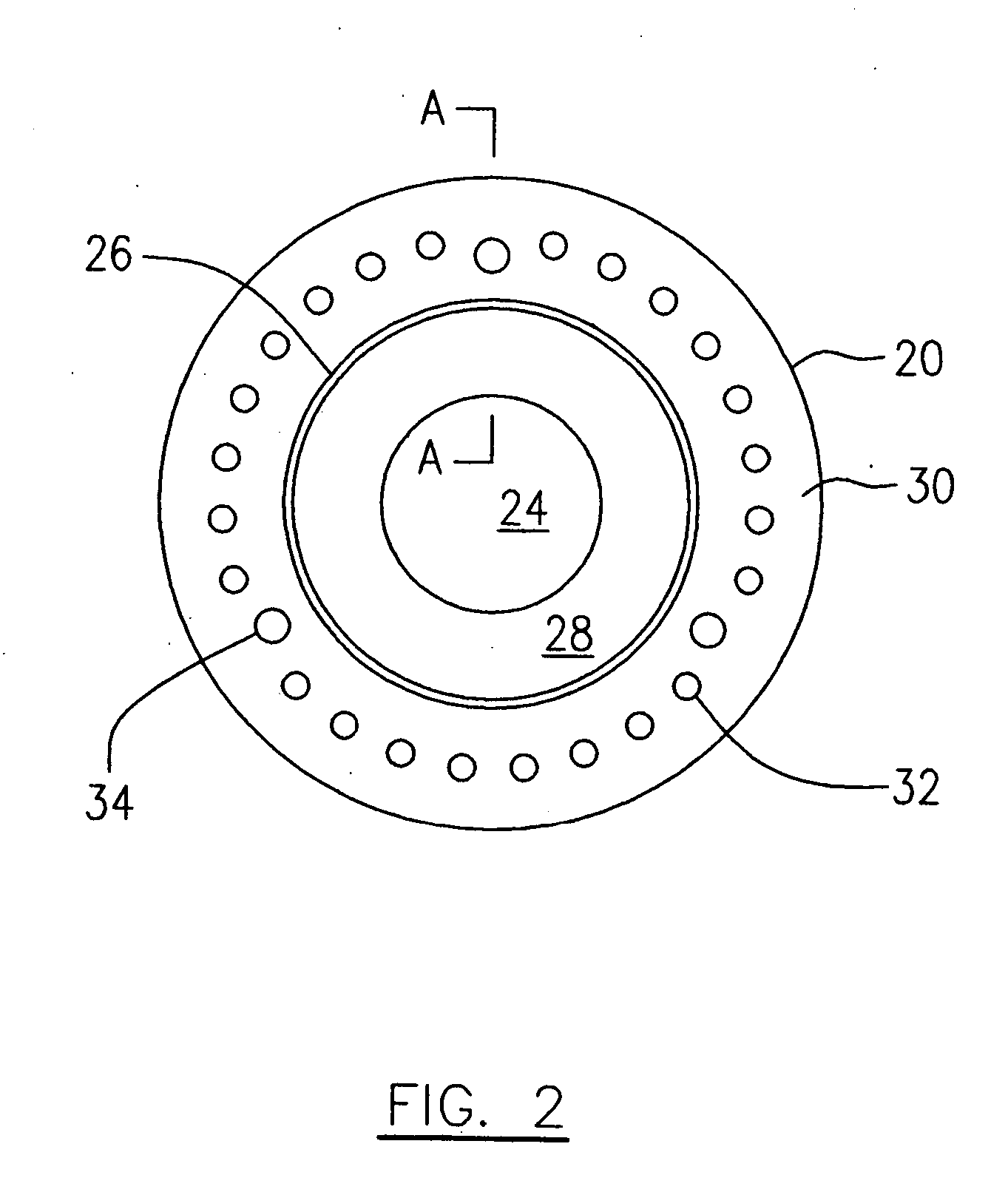

System and method for regulating an amount of thermal energy generated by an electrosurgical tool

InactiveUS7306592B2Easy to moveSurgical instruments for heatingSurgical instruments for aspiration of substancesThermal energyContact pad

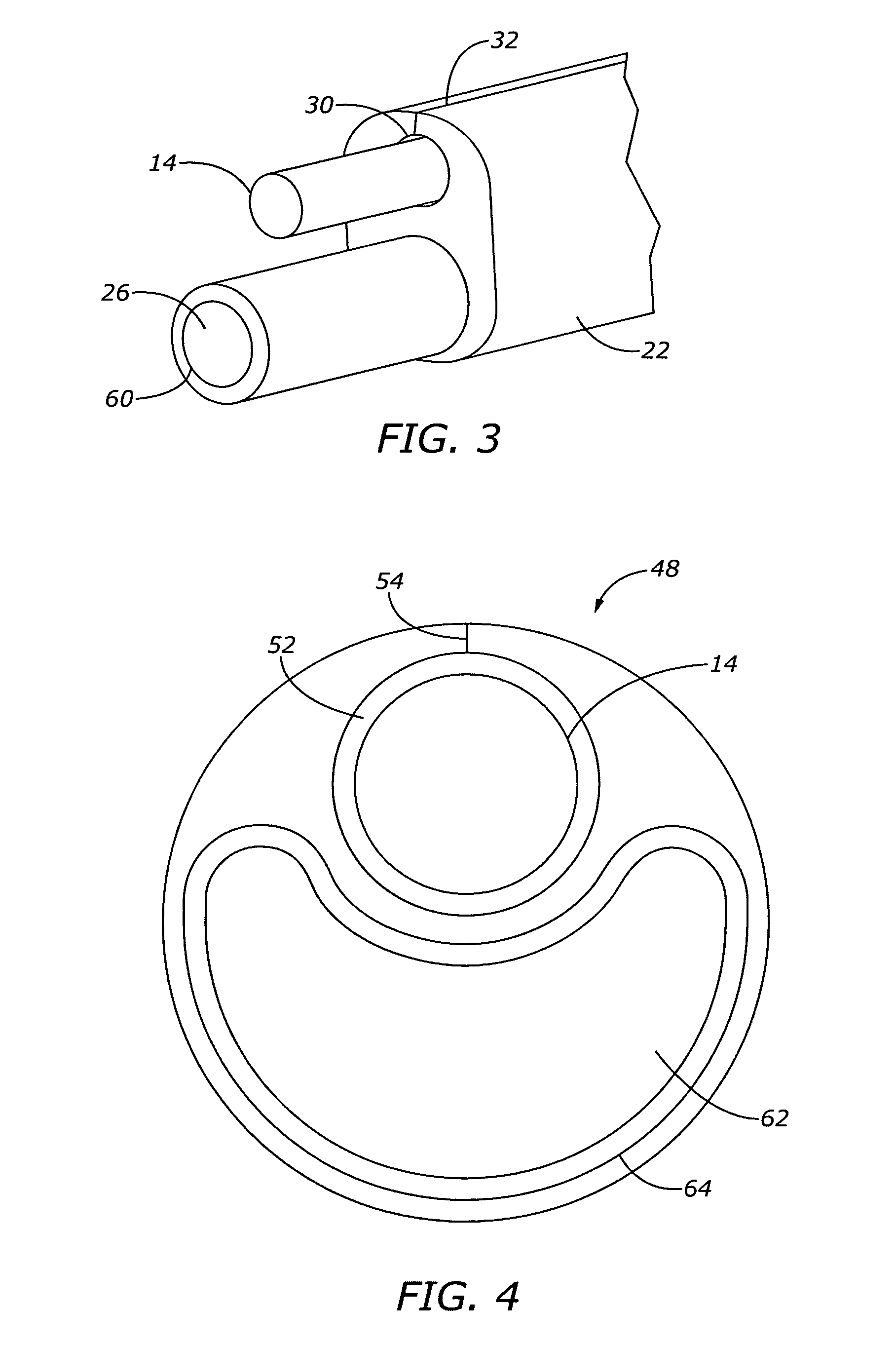

An bipolar electrosurgical tool (10) for cauterizing or ablating tissue. The tool has a nose cone (12) which serves as a handle. A conductive shaft (14) extends from the nose cone. A tip assembly (18) with an active electrode (20) is mounted to the shaft. A circuit board (78) is mounted in the nose cone. Conductive traces that forming contact pads (96, 102) are formed on the circuit board. A web (108) formed from a single piece of elastomeric material is seated over the opening in which the printed circuit board is mounted to seal the opening shut. Integrally formed with the web are buttons (116, 118) that are in registration over the contact pads. The buttons can be depressed downwardly towards the contact pads. When a button is so depressed, a conductive landing pad (120) integral with the button closes the connection between the traces that form the contact pad. Thus, the tool of this invention is provided with switches. The circuit board also has two conductive traces (92, 104a) that run in parallel. If there is a leak into the nose cone, a connection is established across these traces and shorts out a resistor (105). The shorting out of this resistor provides a control console (22) with an indication that there is a leak. The electrode is formed from a single piece of tantalum. The electrode has a head formed with a hole (172) trough which fluid flows. The electrode is seated in a sleeve (136b) provided with a through bore (177) in registration with the electrode hole.

Owner:STRYKER CORP

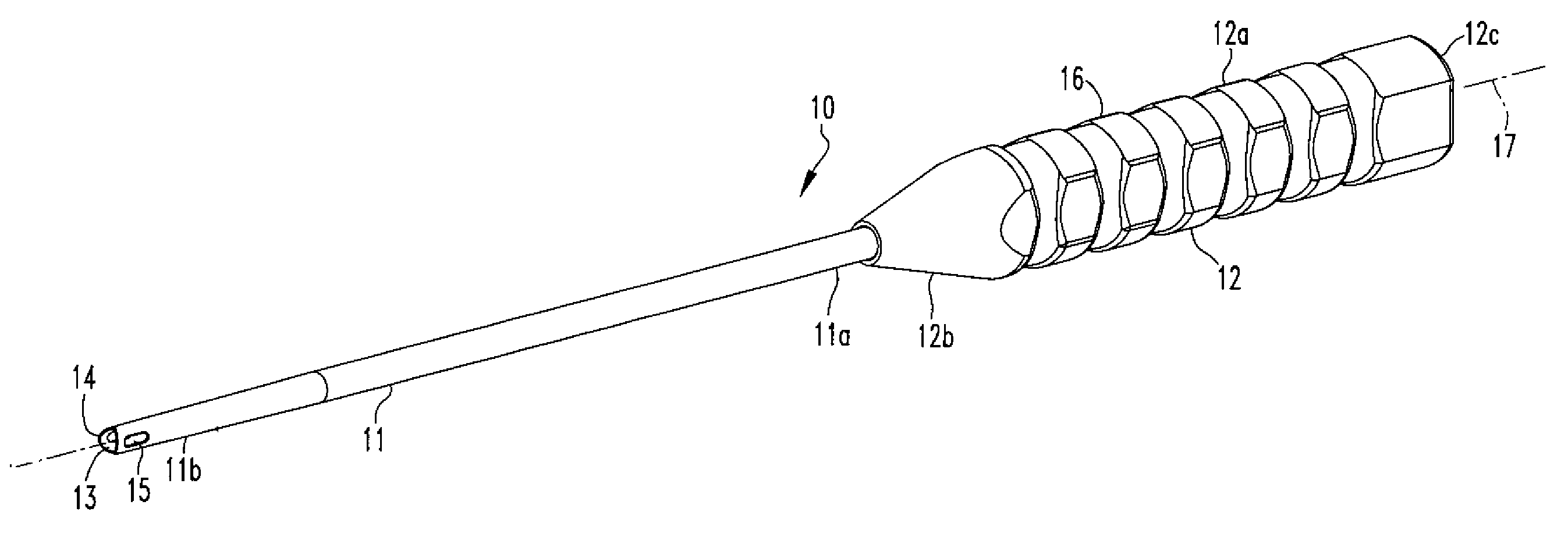

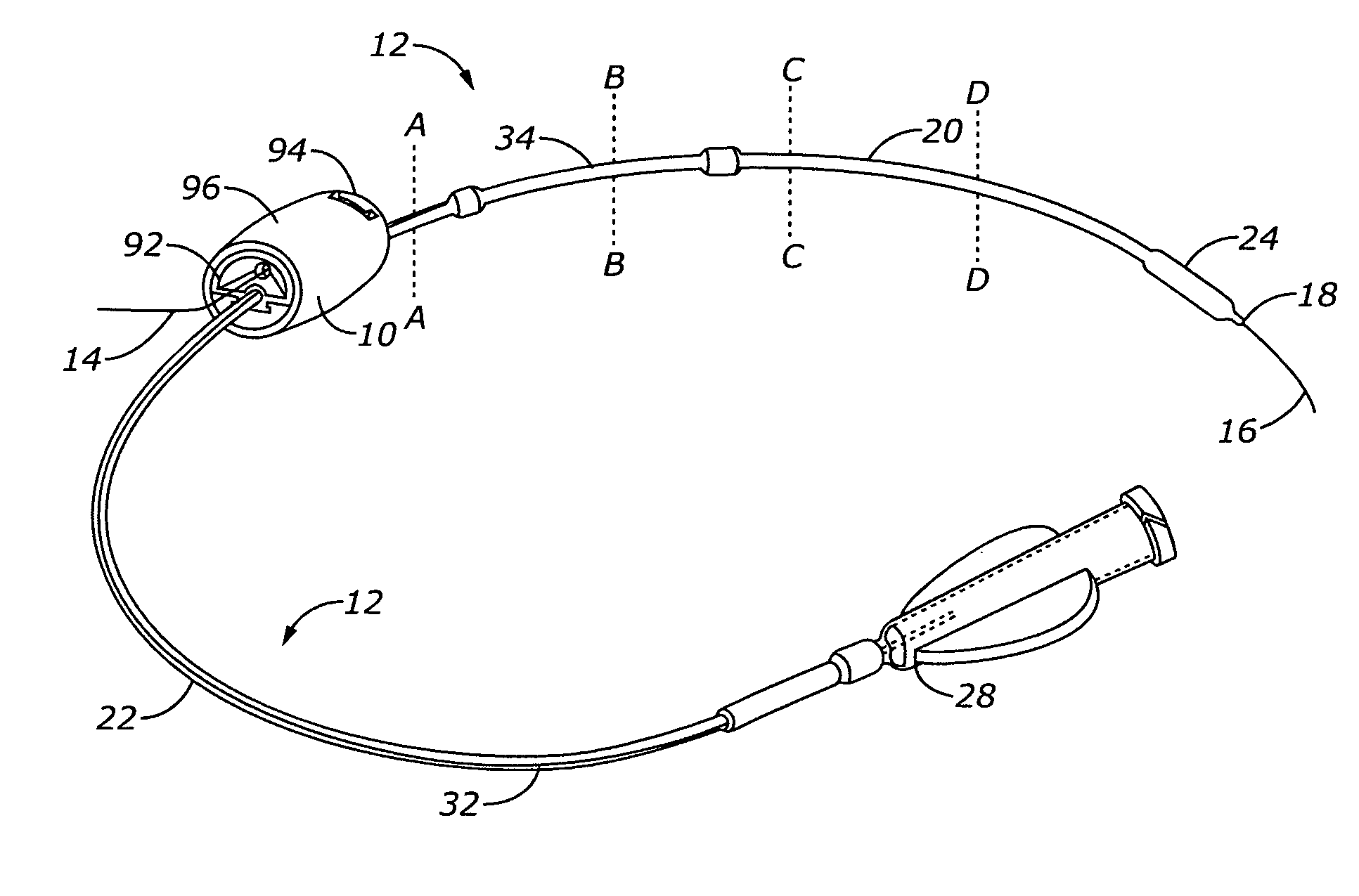

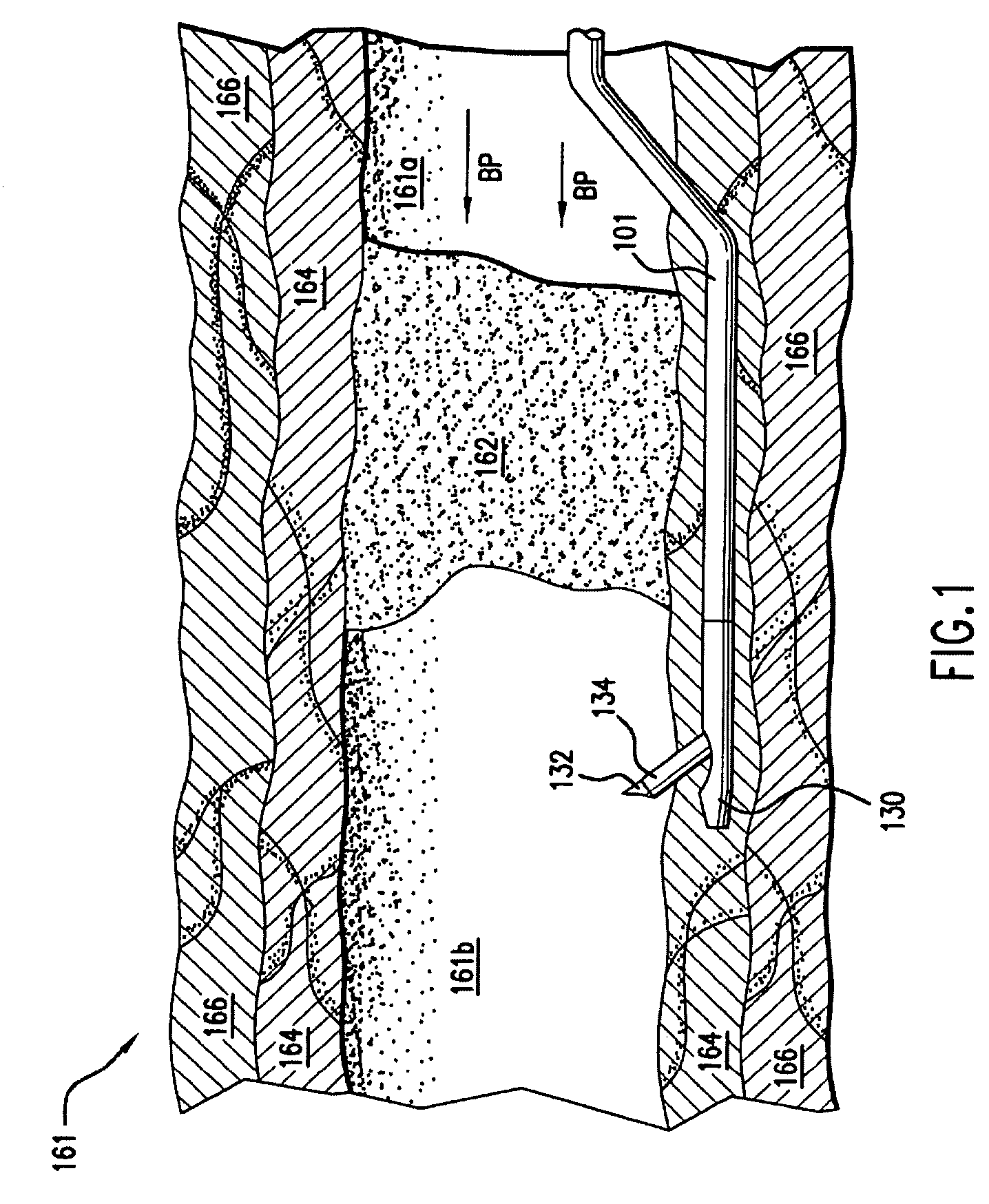

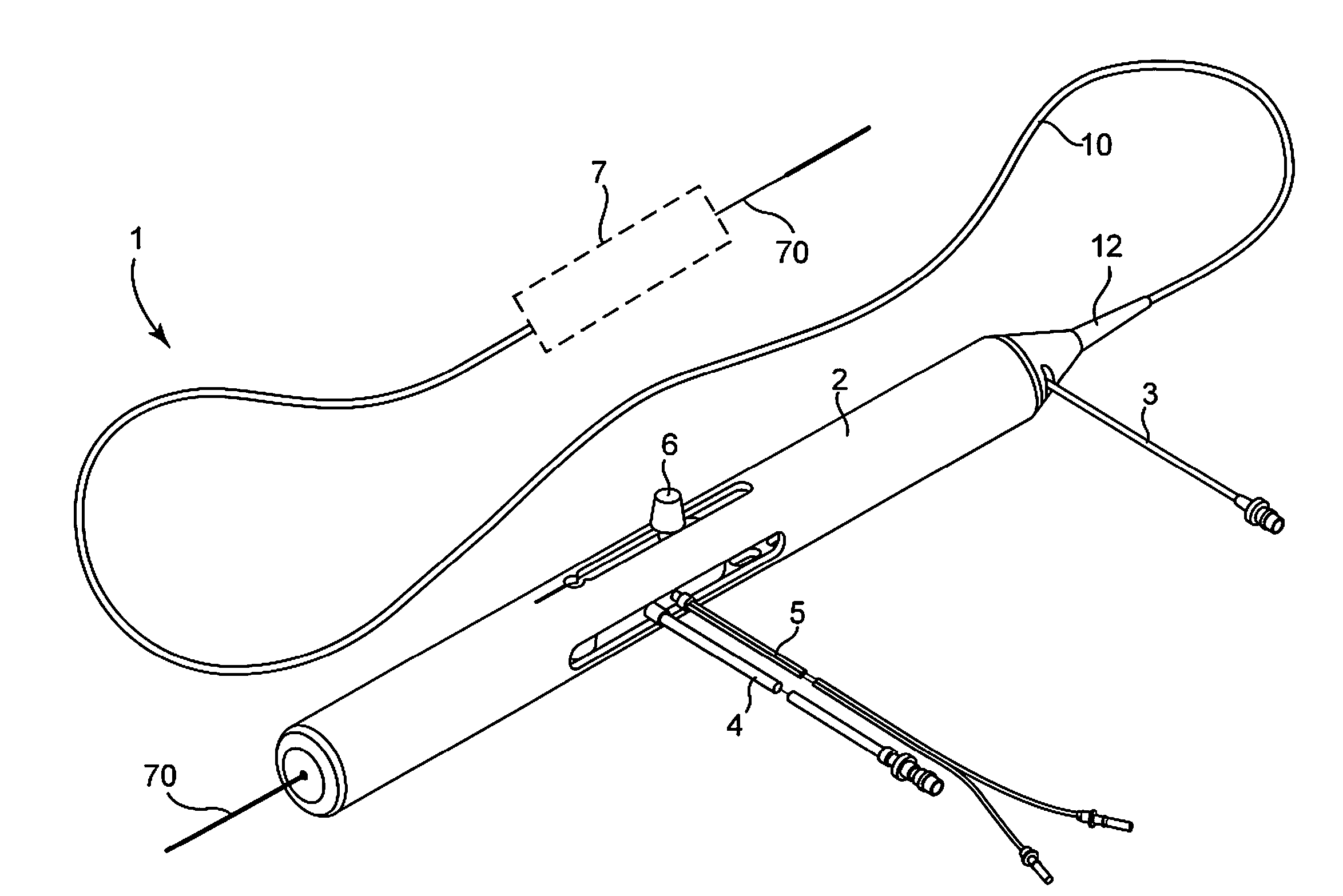

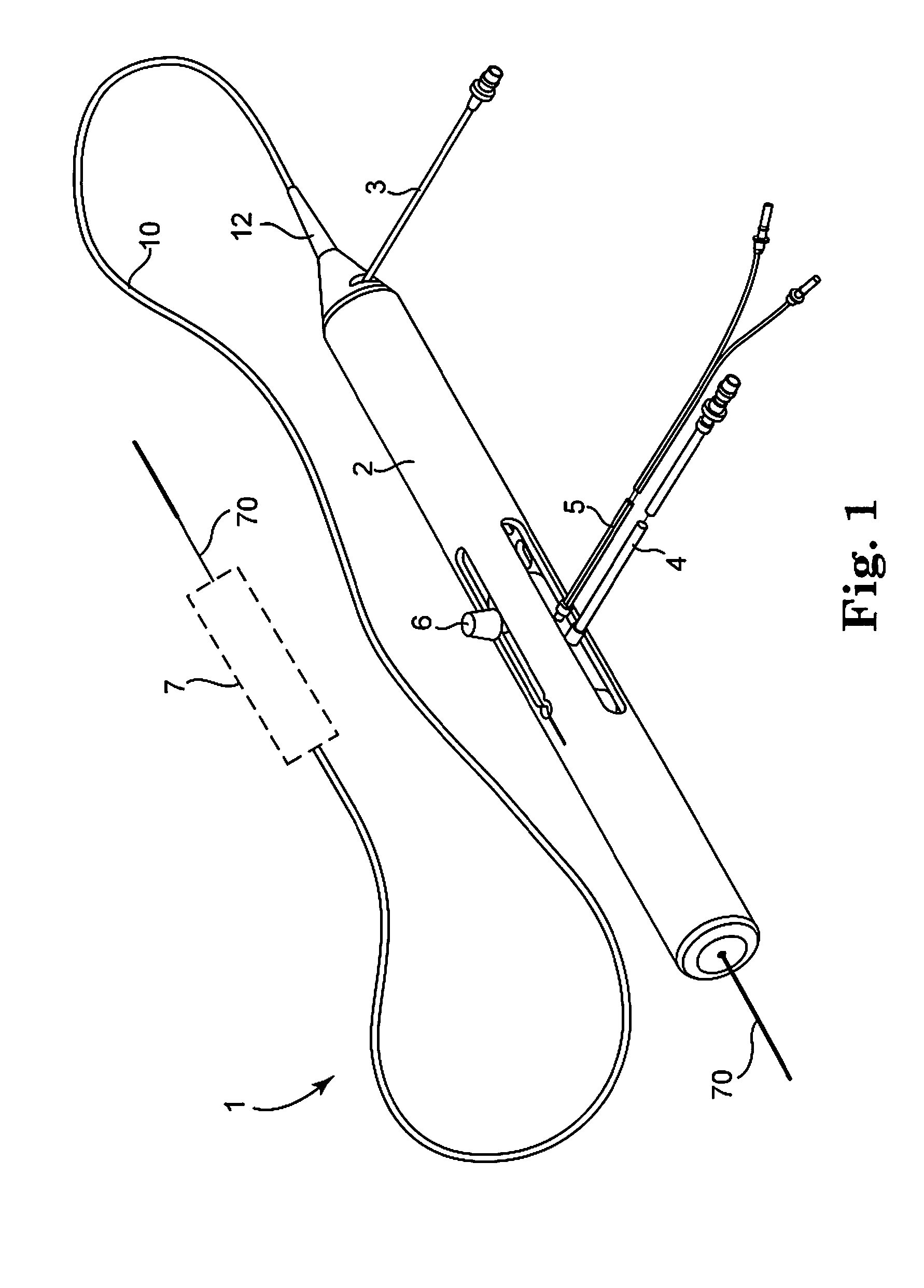

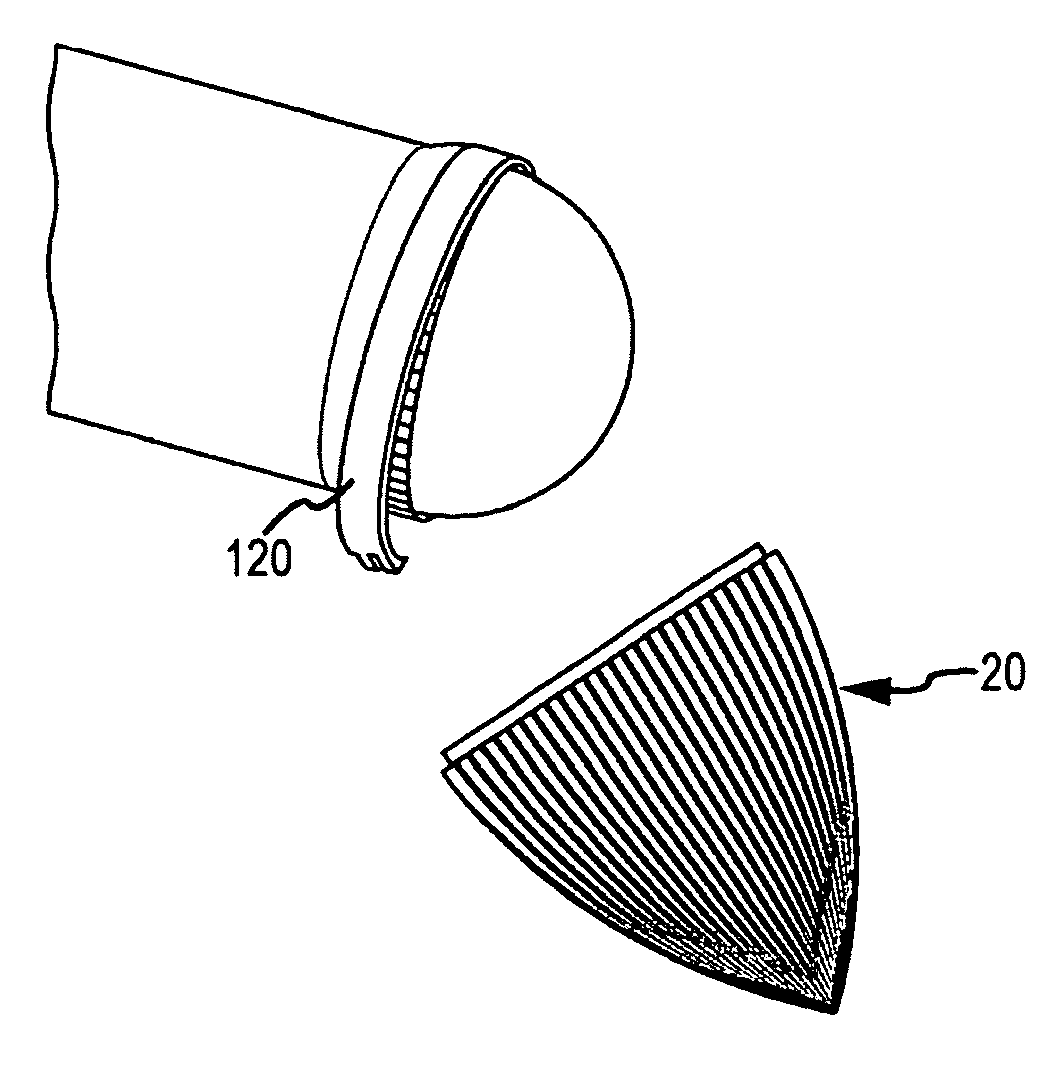

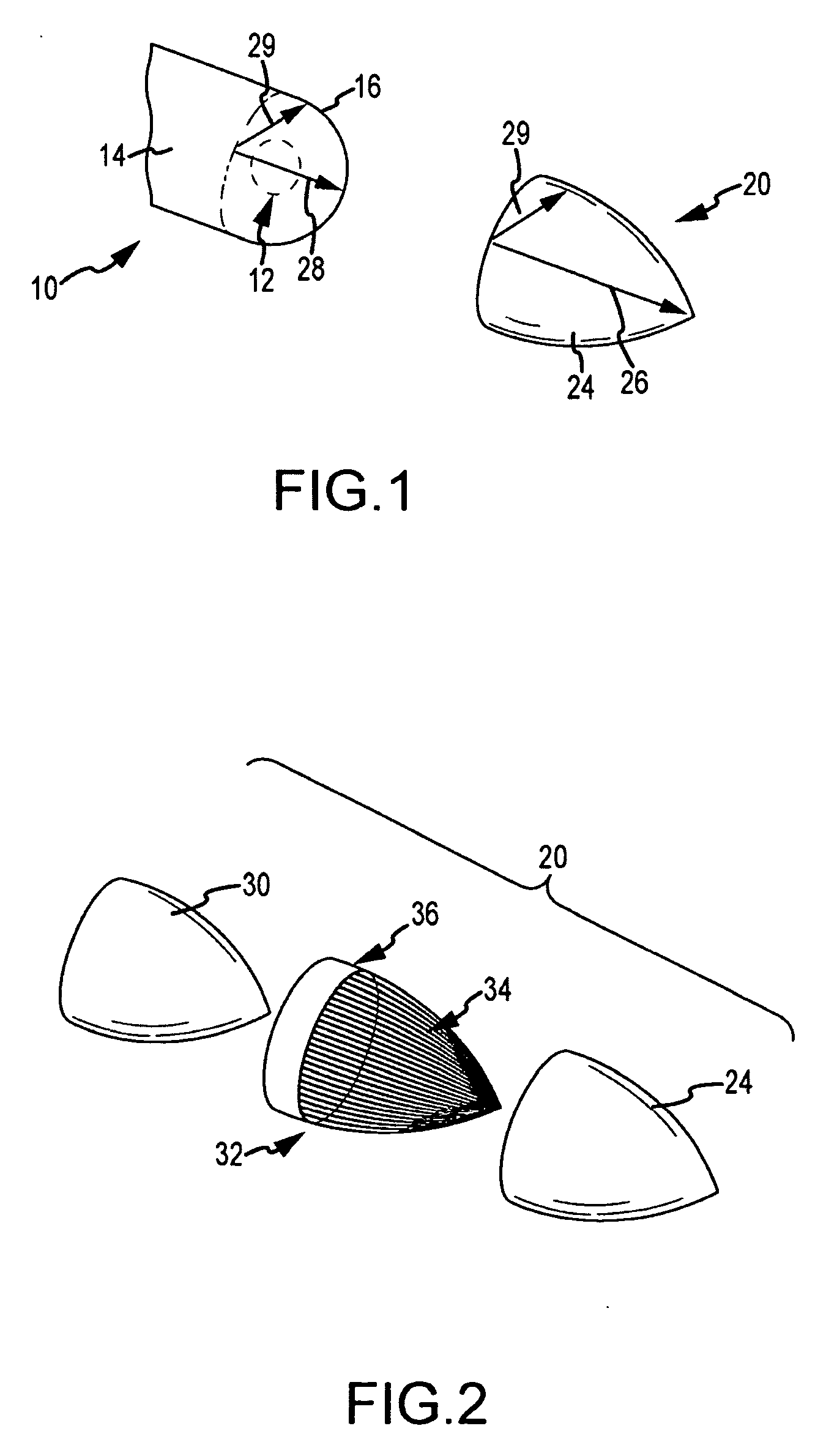

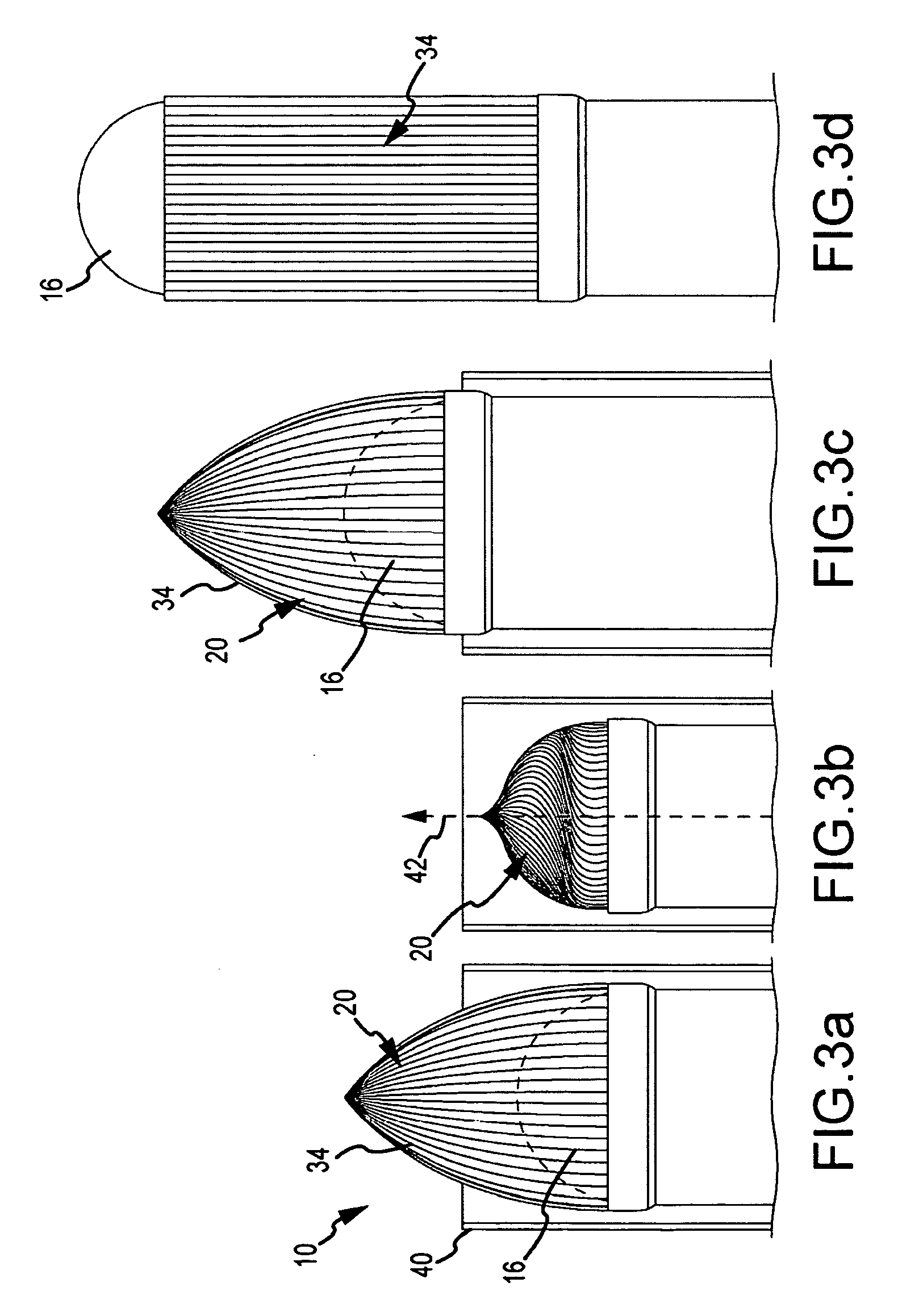

Abrasive nose cone with expandable cutting and sanding region for rotational atherectomy device

An rotational atherectomy apparatus for abrading tissue, comprising: a flexible, elongated, rotatable drive shaft having a proximal end and a distal end opposite the proximal end; a nose cone operatively attached proximate the distal end of the drive shaft comprising a distal tapered section and a plurality of elongate, flexible members adjacent to the distal tapered section of the drive shaft, each member in the plurality being fixed at both a proximal end and a distal end opposite the proximal end; a proximal mount rotatable with the drive shaft and fixedly connected to the proximal ends of all the flexible members in the plurality; and a distal mount axially separated from the proximal mount and fixedly connected to the distal ends of all the flexible members in the plurality. When the axial separation of the proximal and distal mounts is reduced by pulling the distal tapered section proximally, each member in the plurality bows outward from the drive shaft and expands radially in an at least partially elliptical profile.

Owner:CARDIOVASCULAR SYST INC

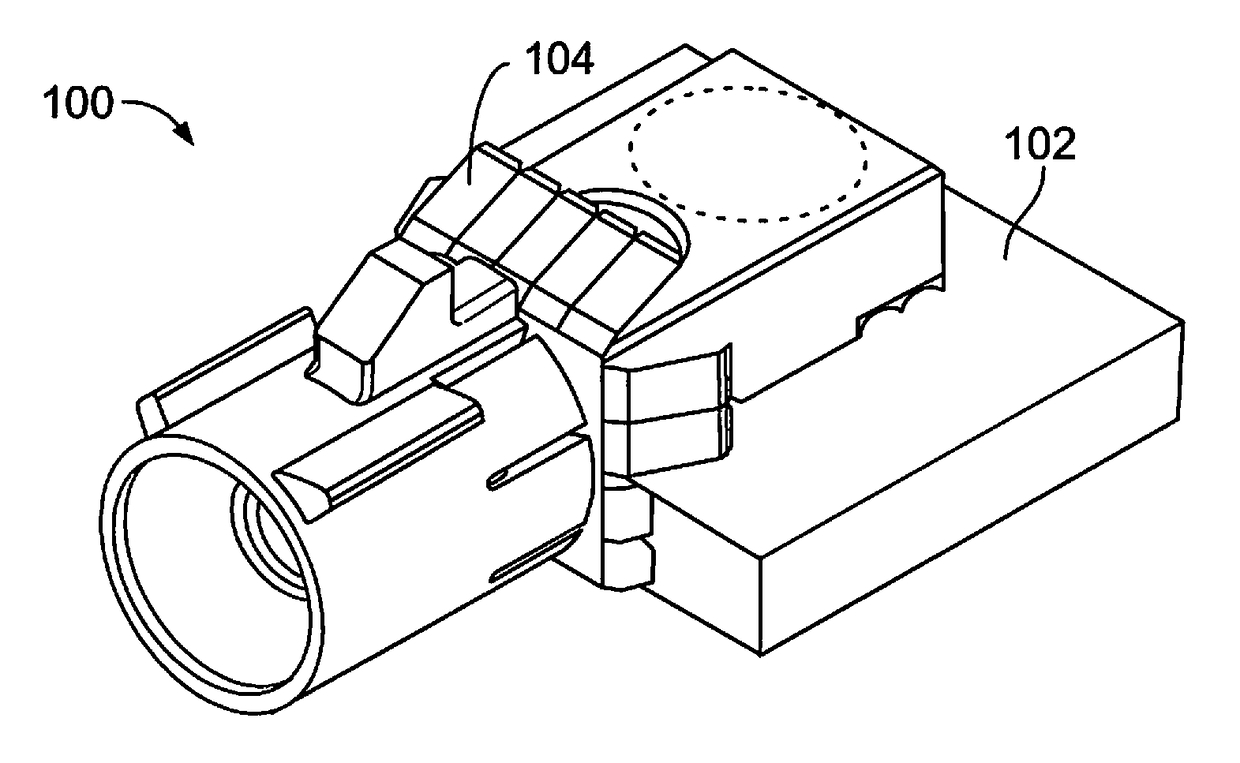

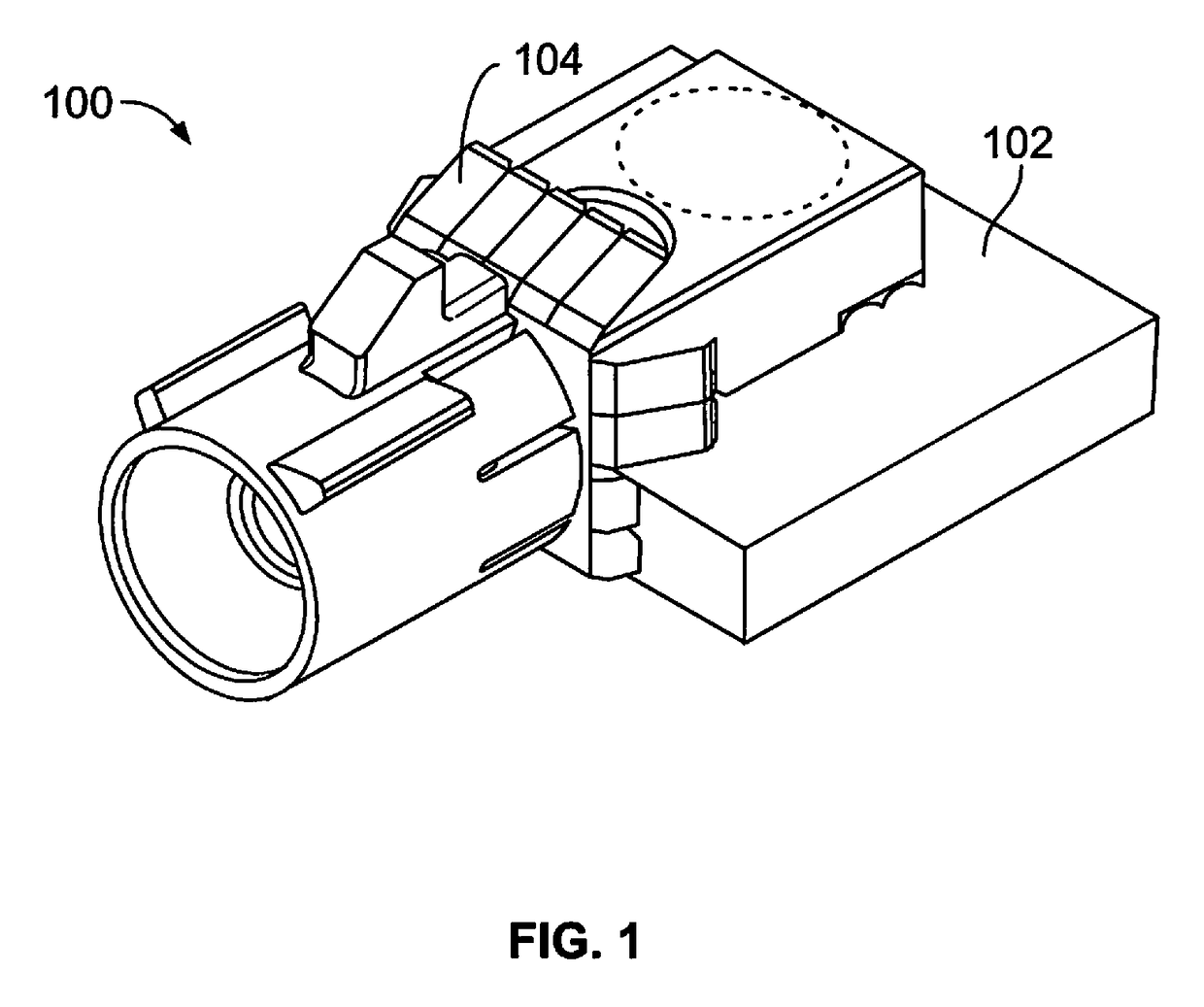

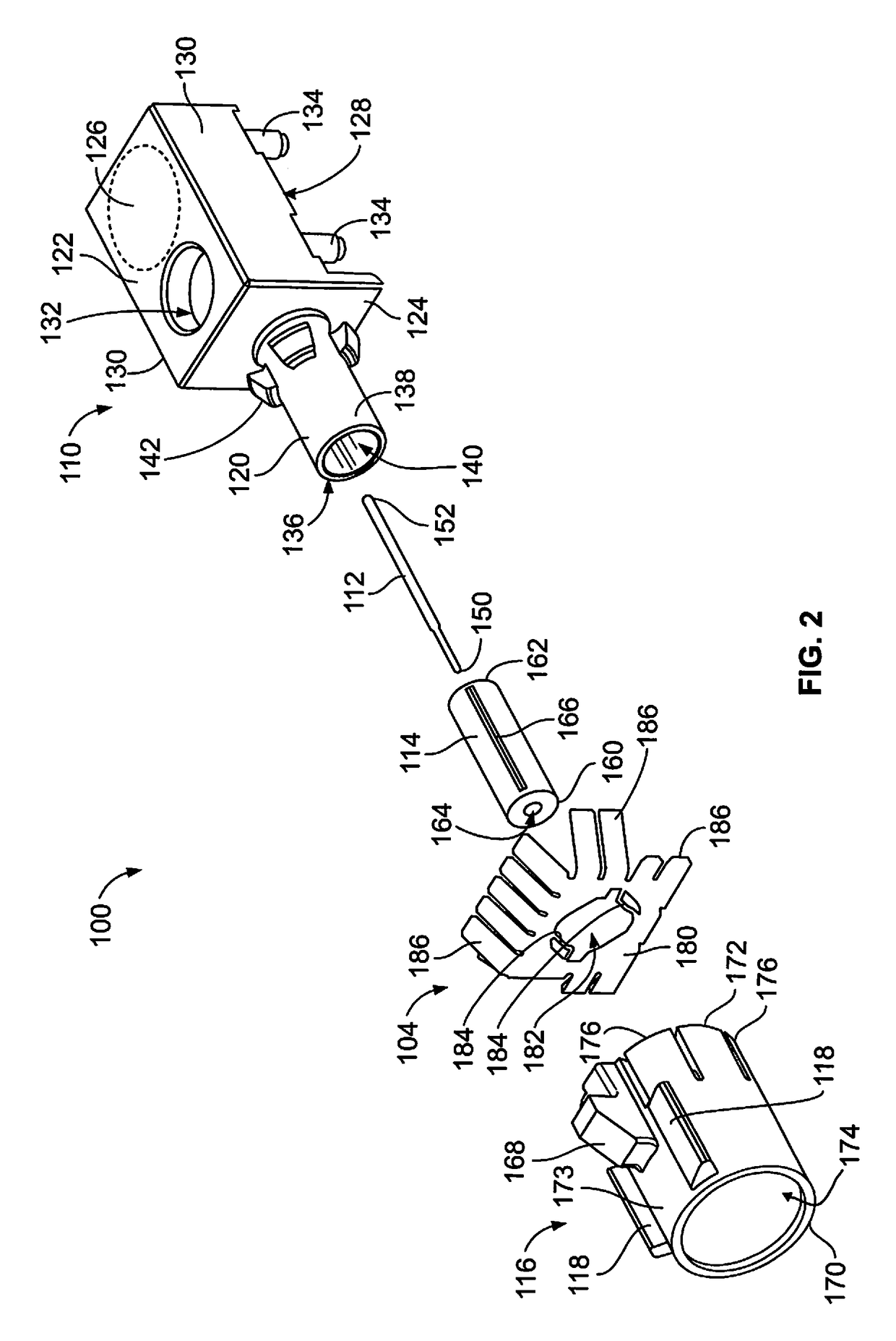

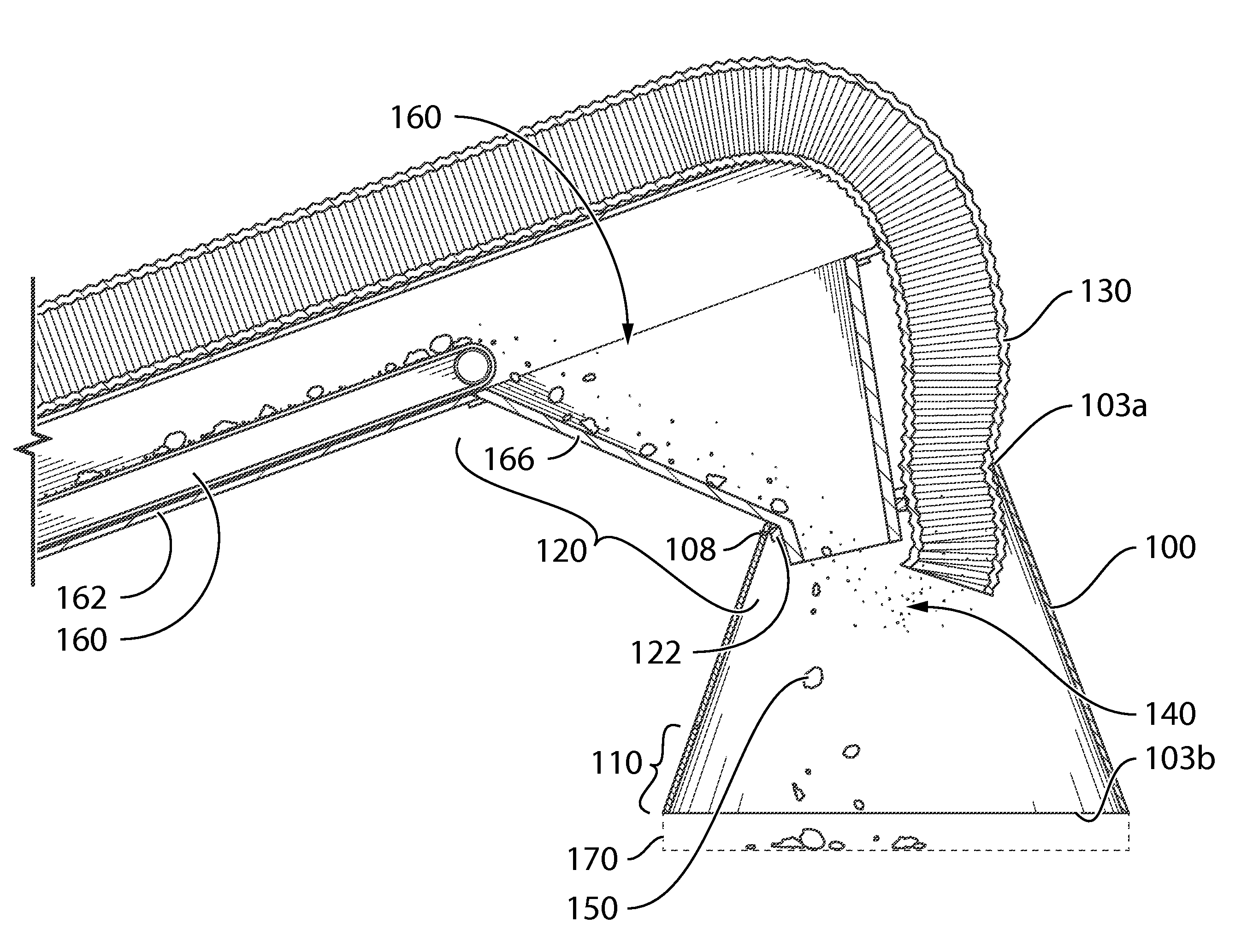

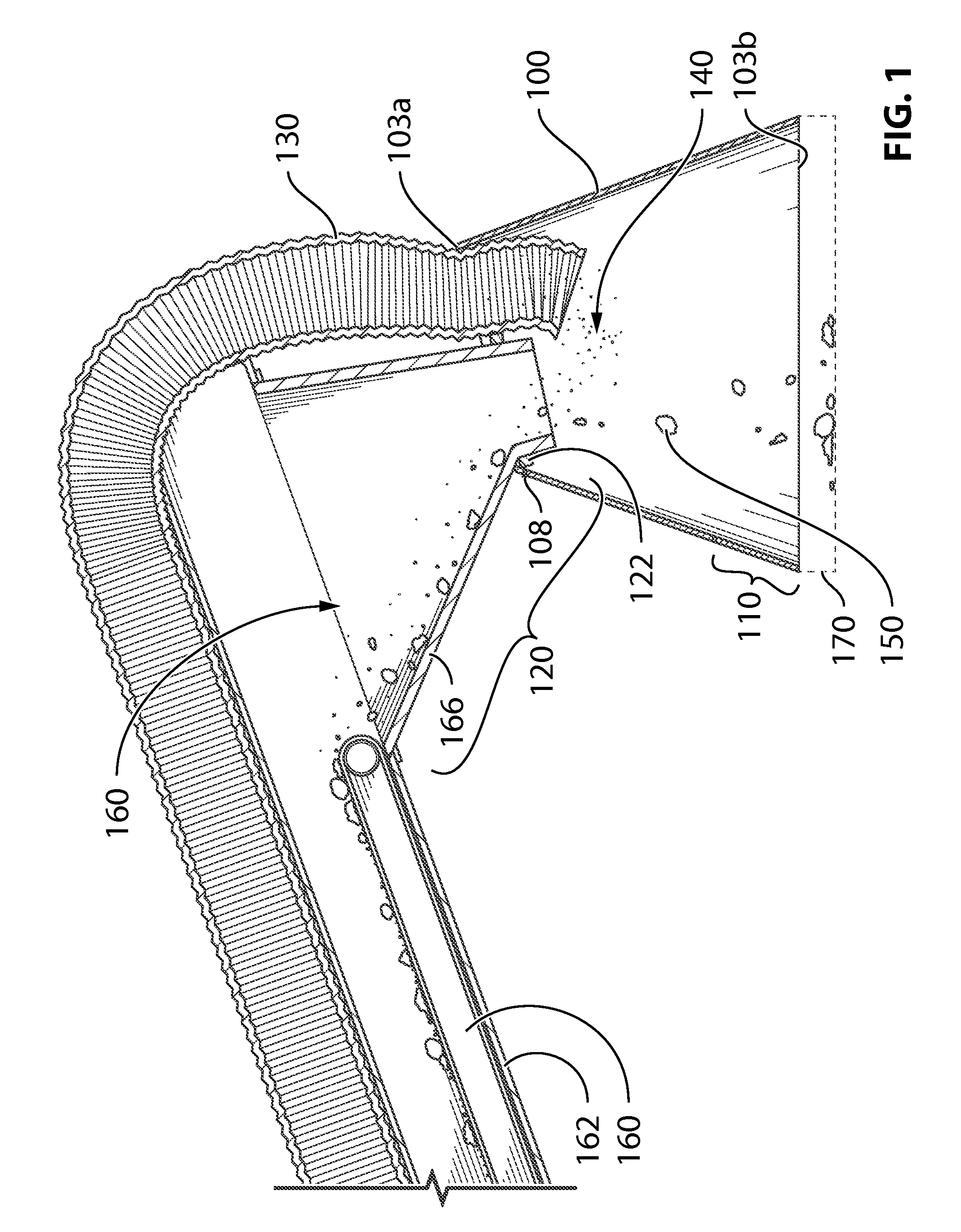

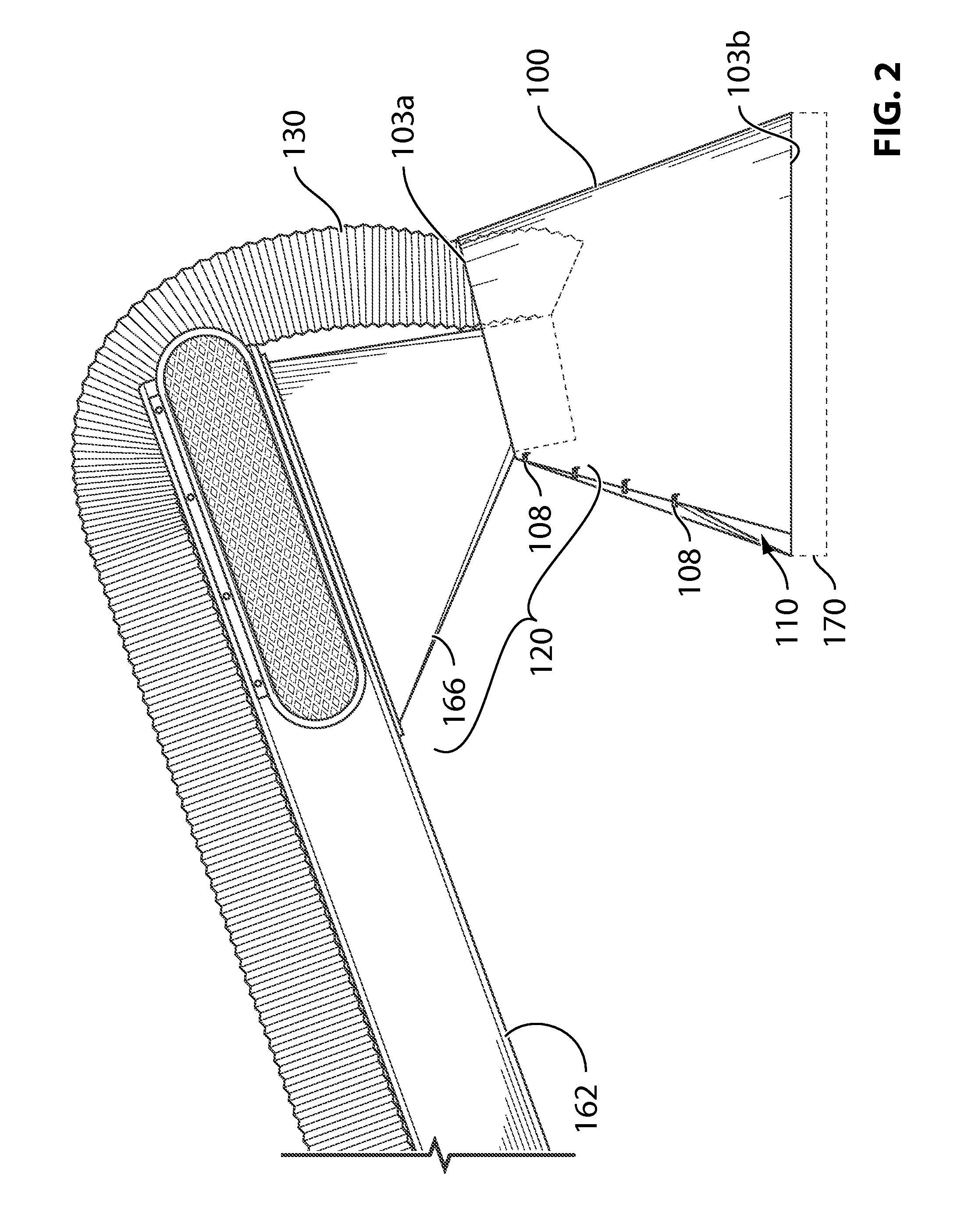

Nose cone for dust control

Preferred nose cones 100 associatable with a tail spout 120 of a sand handler and a vacuum hose 130 of a vacuum system are described herein. A method for containing respirable and / or inhalable particles 140 created in an industrial process is also disclosed herein.

Owner:ASSOC RES - EDC

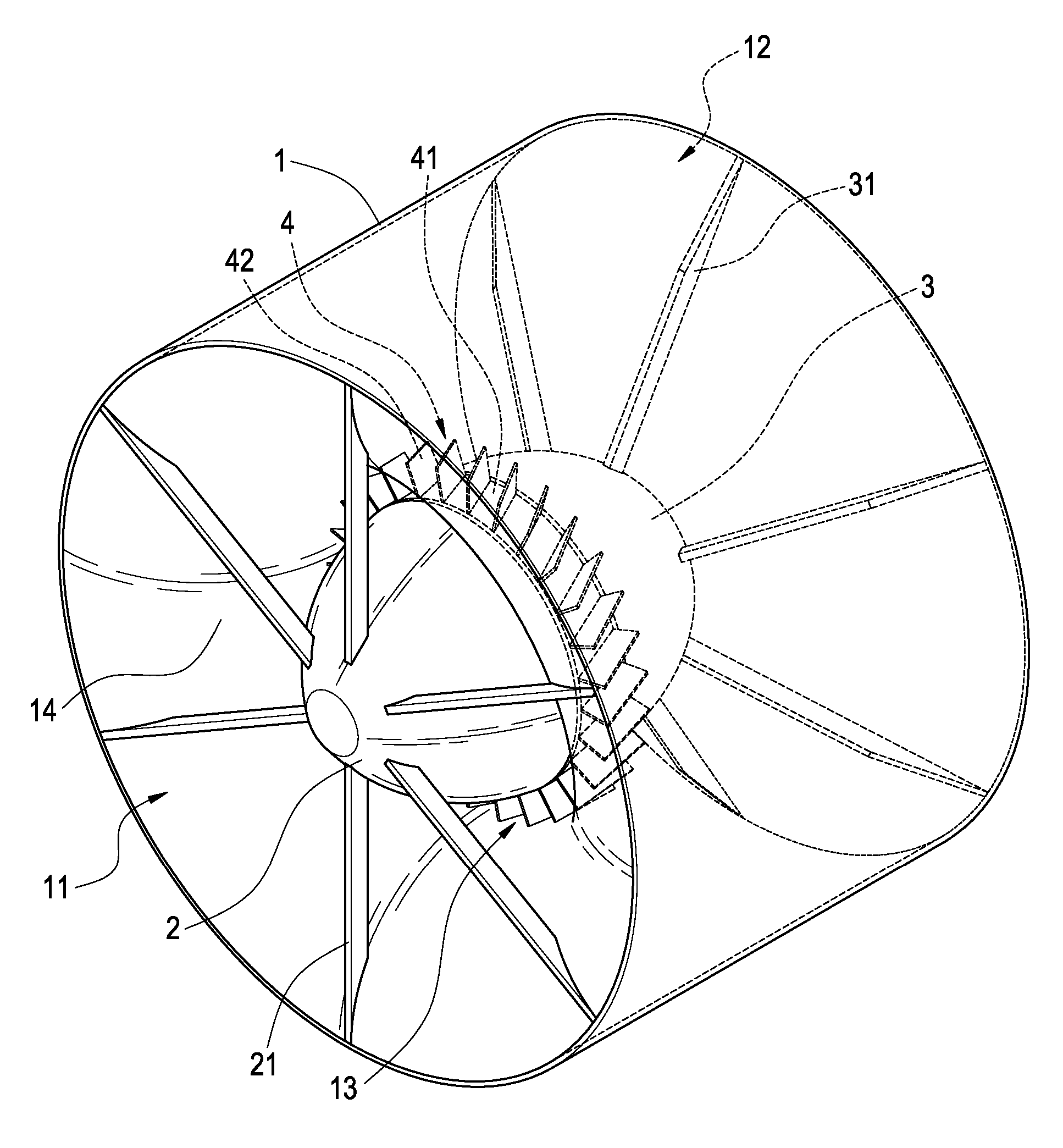

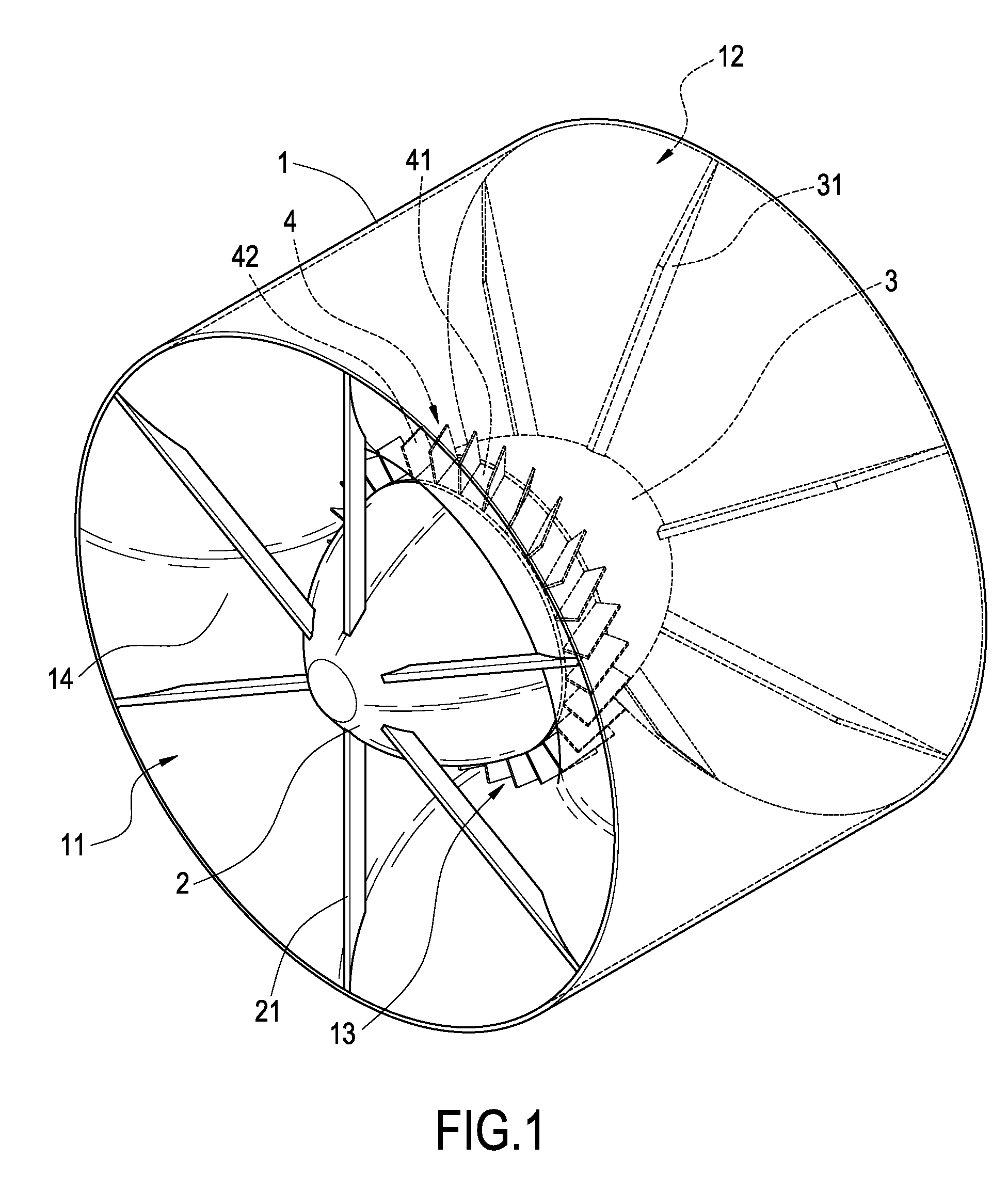

Passively cooled direct drive wind turbine

ActiveUS20060113804A1Improve heat transfer performanceIncrease air velocityEngine fuctionsMachines/enginesTurbineWind force

A wind turbine is provided that passively cools an electrical generator. The wind turbine includes a plurality of fins arranged peripherally around a generator house. Each of the fins being oriented at an angle greater than zero degrees to allow parallel flow of air over the fin. The fin is further tapered to allow a constant portion of the fin to extend beyond the air stream boundary layer. Turbulence initiators on the nose cone further enhance heat transfer at the fins.

Owner:WEG ELECTRIC CORP +1

Wind Power Generator

InactiveUS20070013196A1Efficient windward areaGreat driving forceWind motor combinationsMachines/enginesElectricityWind force

A wind power generator includes a cover, a front nose cone, a rear nose cone and a vane unit. The cover has a curved air-guiding portion. The front nose cone and the rear nose cone have a plurality of supporting pillars fixedly connected to the front portion and rear portion of the inner wall of the cover, respectively. The vane unit is provided between the front nose cone and the rear nose cone. After the wind enters the passage formed between the curved surface of the front nose cone and the front portion of the curved air-guiding portion of the cover, the wind speed is accelerated due to the narrowing of the flowing path, thereby to generate a larger kinetic energy to cause the rotation of the vane unit. In this way, the generator within the rear nose cone obtains a greater capacity of generating electricity. Further, the generator can be still activated even under a lower wind speed.

Owner:CHEN SHIH H

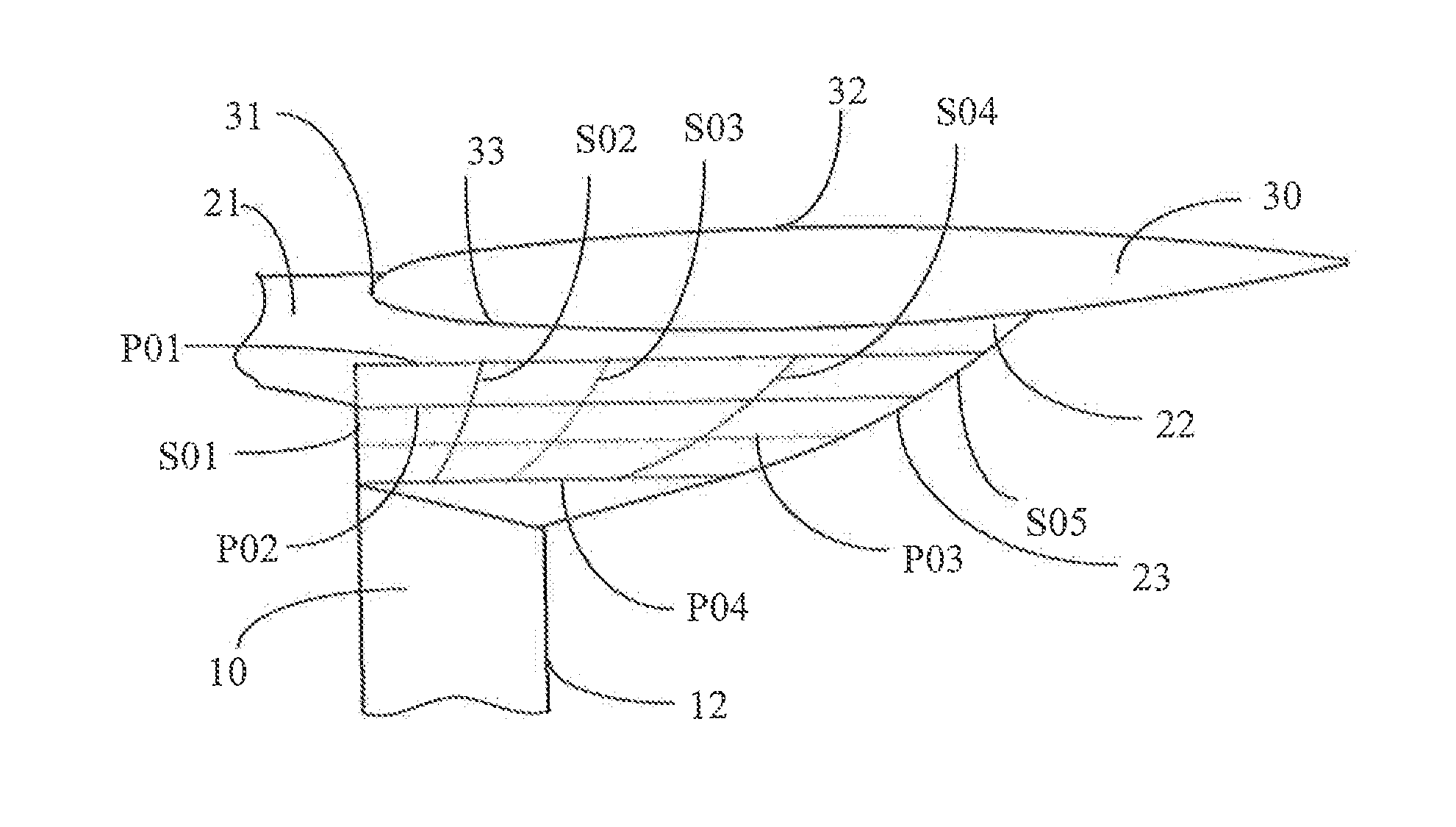

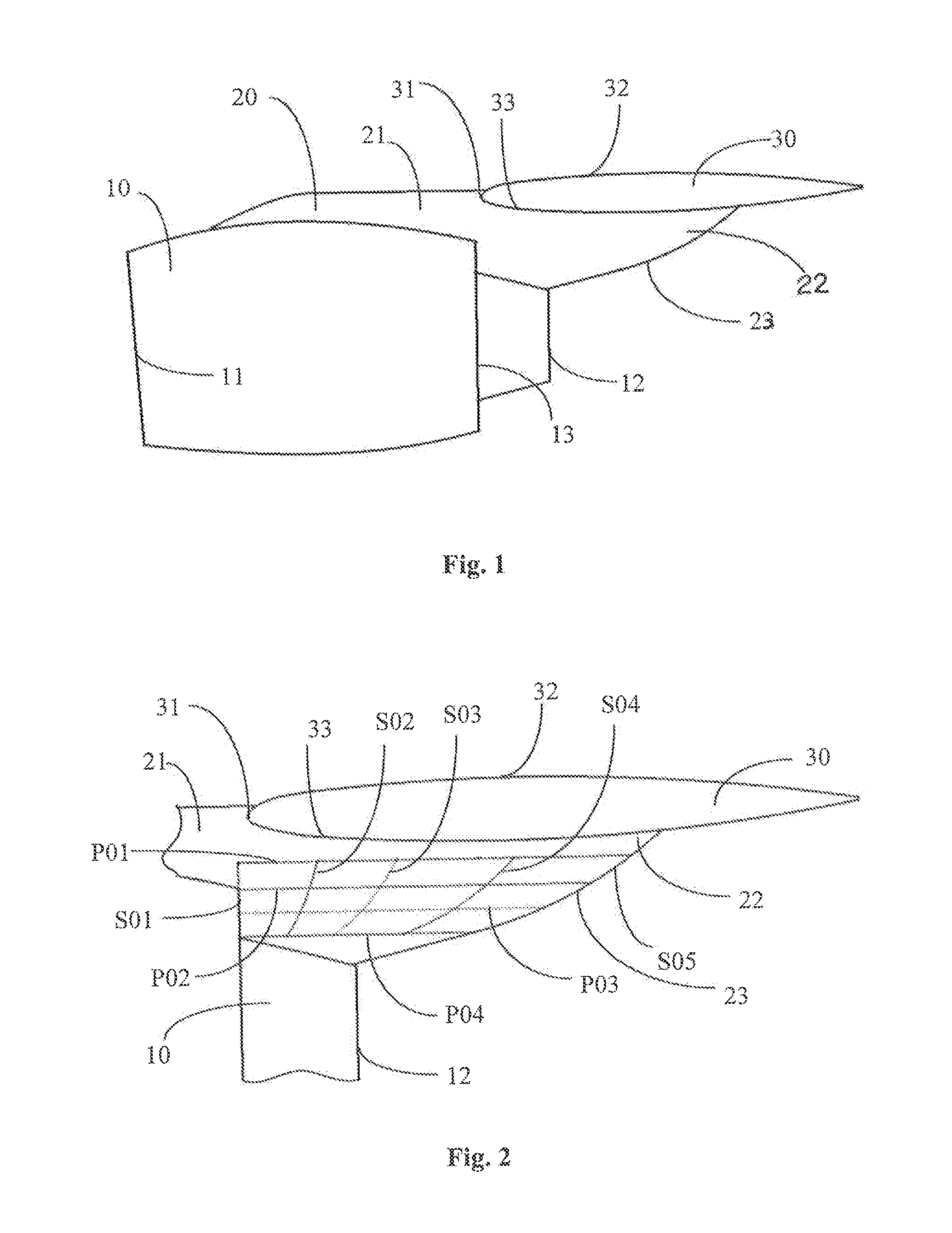

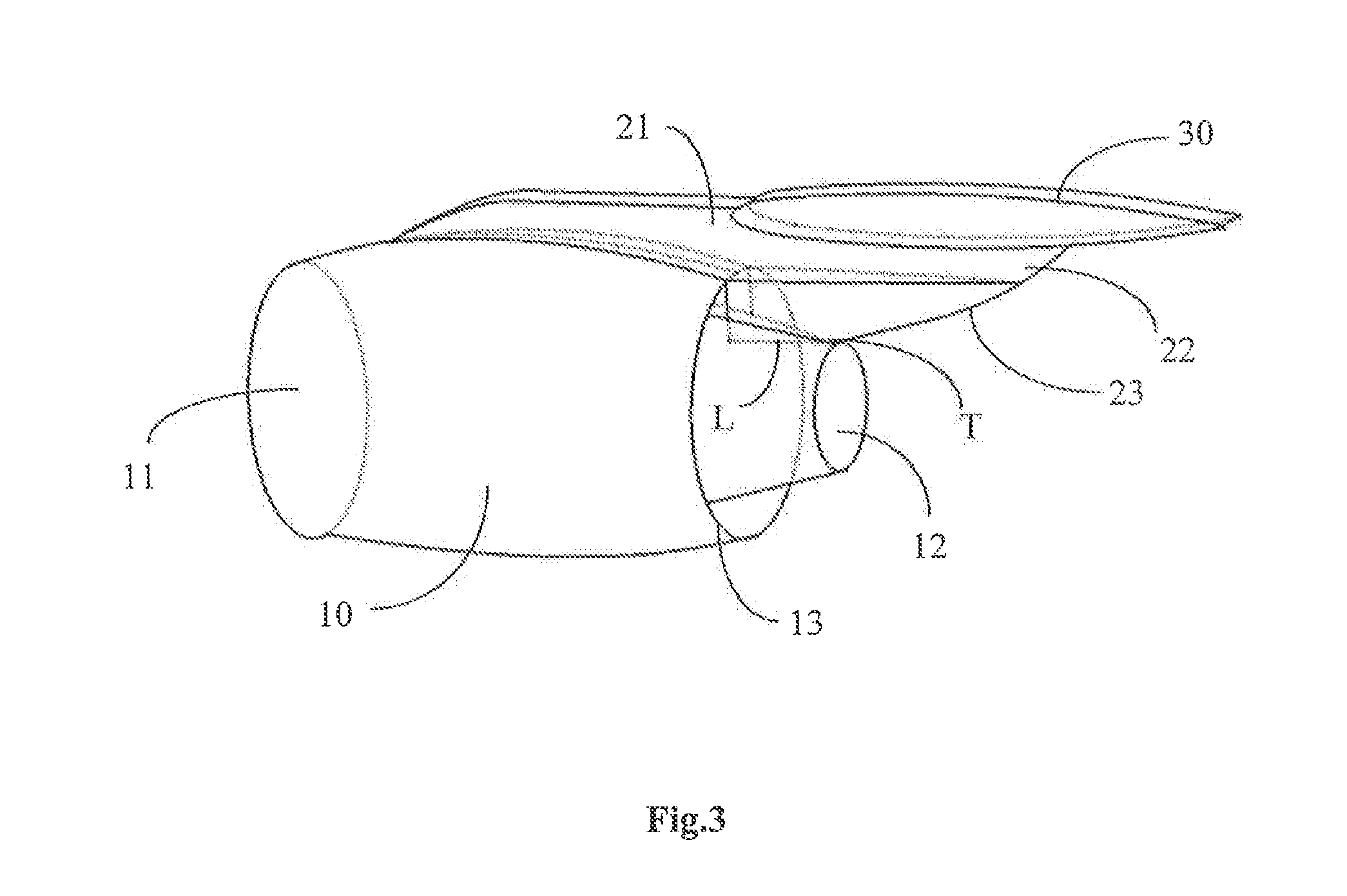

Nose cone structure for pylon of aircraft with wing-hung layout

InactiveUS20160272335A1Improve performanceReduce resistancePower plant arrangements/mountingAircraft power plant componentsLeading edgeNacelle

An aircraft with a wing-hung layout has a nose cone structure for a pylon. A front nose cone is located in front of a wing leading edge, and a rear nose cone is located behind the wing leading edge. At least a part of the rear nose cone is modeled and shaped by cross section control lines and has at least one group of horizontal position control lines and at least one group of longitudinal position control lines. The rear nose cone of the pylon is shaped by horizontal position control lines. By controlling the rear nose cone curvature of the pylon the passageway area of the space between the pylon / wing / engine nacelle is optimized without deflection of the rear portion of the pylon.

Owner:COMAC +1

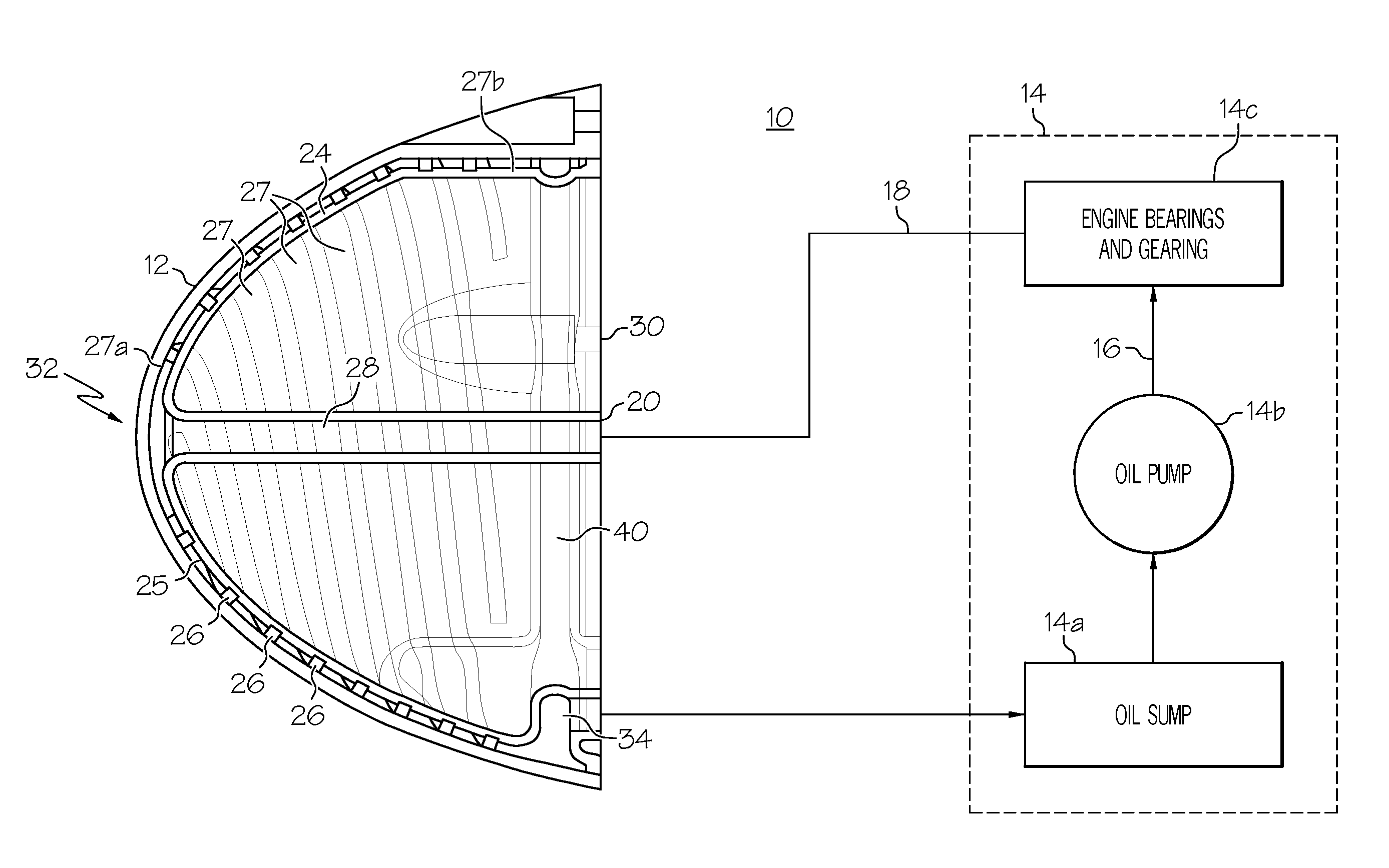

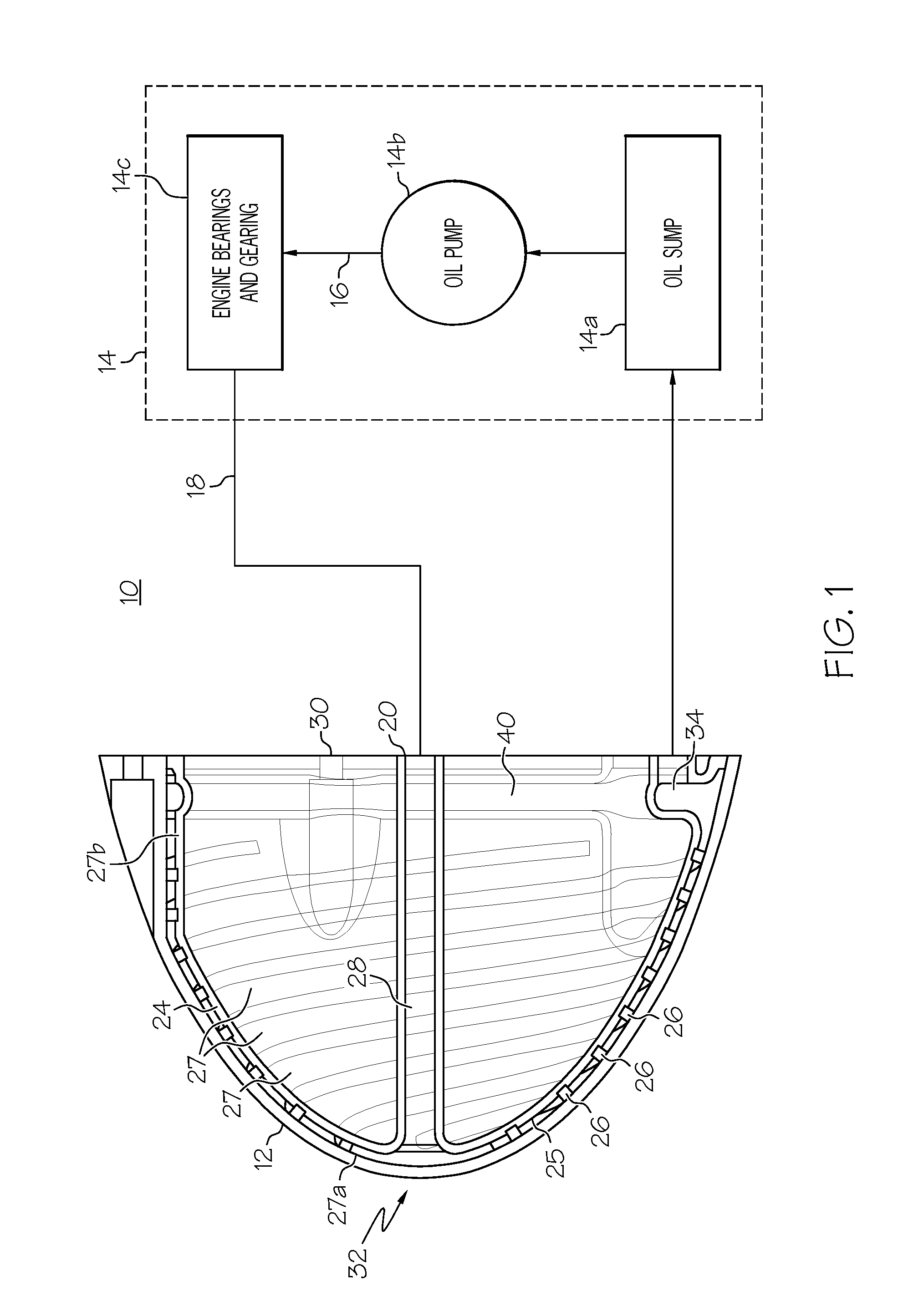

Heated engine nose cone using spiral channels

A nose cone of a turbomachine, such as an aircraft engine, is heated to prevent ice formation. The nose cone is configured as a conical shell positioned concentrically over an inner shell with a space therebetween. Spiral spacers in the space provide distributed passages through which heated lubricating oil flows. A system for separating entrained air from the lubricating oil as part of this mechanism is disclosed.

Owner:HONEYWELL INT INC

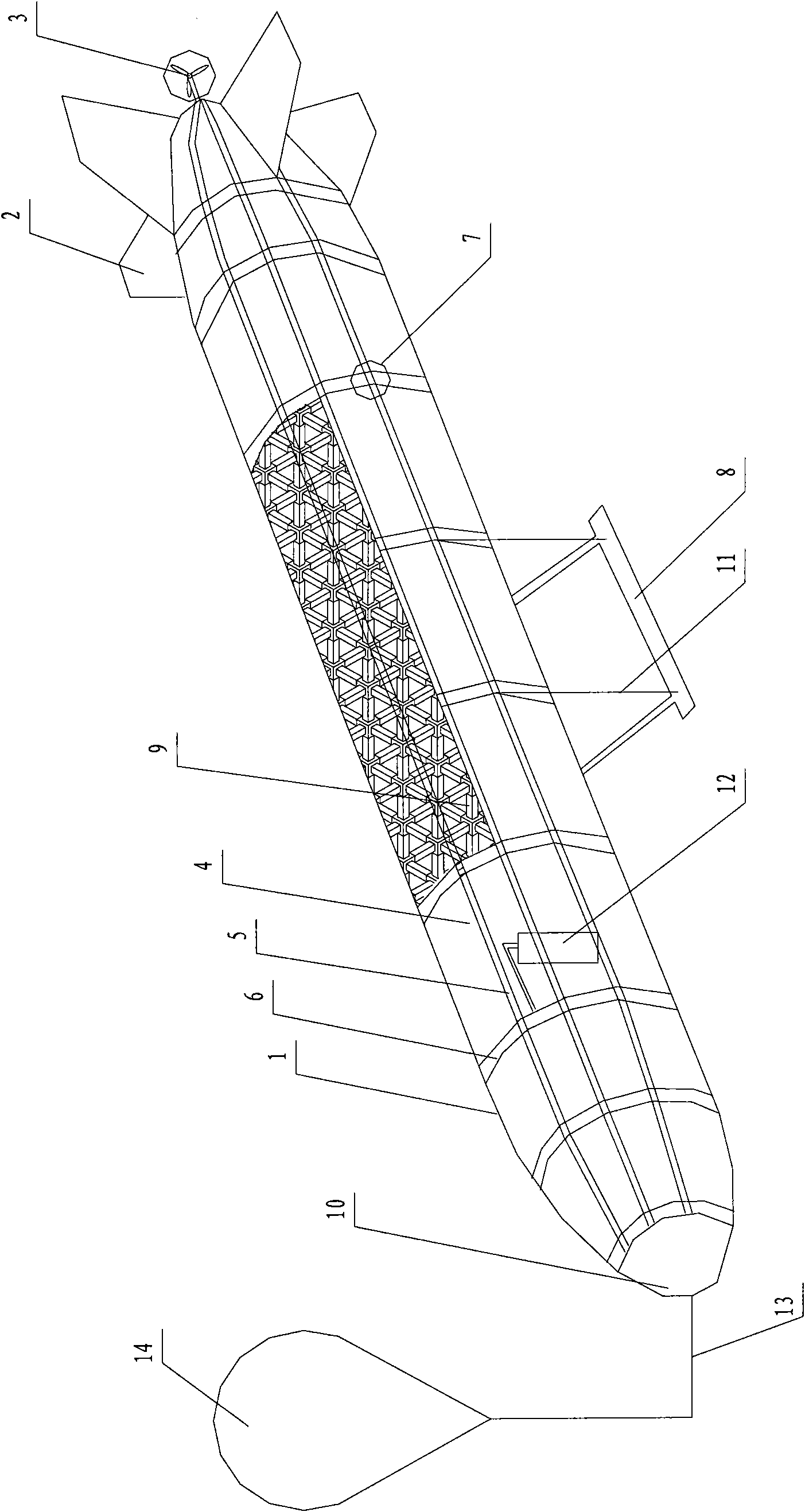

Airship with inflating skeleton expanding in air

The invention discloses an airship with an inflating skeleton expanding in air, which comprises an airship body 1, a tail wing 2, a tail thruster 3, a connecting element 7, a payload bay 8, a solar cell panel 9, a nose cone 10, a first auxiliary rope 11, an automatic inflating device 12, a second auxiliary rope 13 and two high-altitude balloons 14. The airship is characterized in that a dimensional element of the airship body 1 is skin 4, a longitudinal element is a rigid skeleton 5, and an annular element is an inflating skeleton 6; the inflating skeleton 6 is connected with the rigid skeleton 5 by the connecting element; and the skin 4 is fixedly connected on the outer surface of a grid formed by the rigid skeleton 5 and the inflating skeleton 6. The invention overcomes the defect that a soft bag in a folding state and a connecting part of a pod and other rigid structures are easily torn by strong wind and vortex in the lifting process.

Owner:HARBIN INST OF TECH

Collapsible shape memory alloy (SMA) nose cones for air vehicles, method of manufacture and use

ActiveUS20090314890A1Reduce resistanceReduce air resistanceAmmunition projectilesDirection controllersStored energyAerodynamic drag

A nose cone formed from a shape memory alloy (SMA) having a recoverable strain of at least 2% collapses about the dome for storage, deploys at launch to protect the sensor dome and reduce drag during atmospheric flight and is shed to allow sensing for terminal maneuvers. The SMA is shape-set at elevated temperatures in its Austenite phase with a memorized shape having a radius of curvature greater than that of the sensor dome to reduce aerodynamic drag. The temperature is reduced and the SMA collapsed to conform to the curvature of the sensor dome within the recoverable strain for storage. A first mechanism is configured to return the collapsed SMA to its memorized shape at launch or prior to going supersonic. In one embodiment, the SMA is stored below its Martensite finish temperature in a temperature-induced Martensite phase in which case the mechanism heats the SMA above the Austenite finish temperature to return the material to its memorized shape. In another embodiment, the SMA is stored above its Austenite finish temperature in which case collapsing the SMA places the material in a strain-induced Martensite phase. The mechanism holds the collapsed SMA in place and the releases the stored energy allowing the SMA to return to the memorized shape.

Owner:RAYTHEON CO

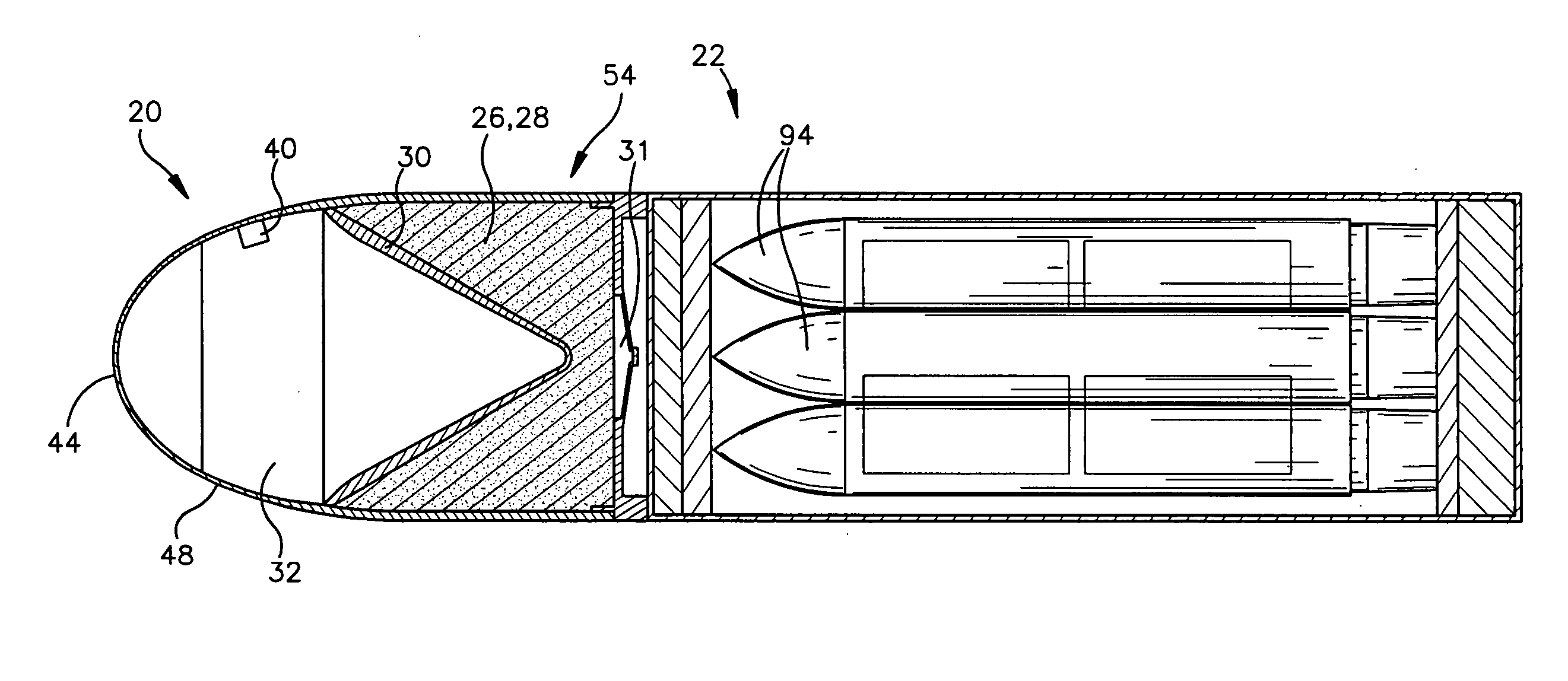

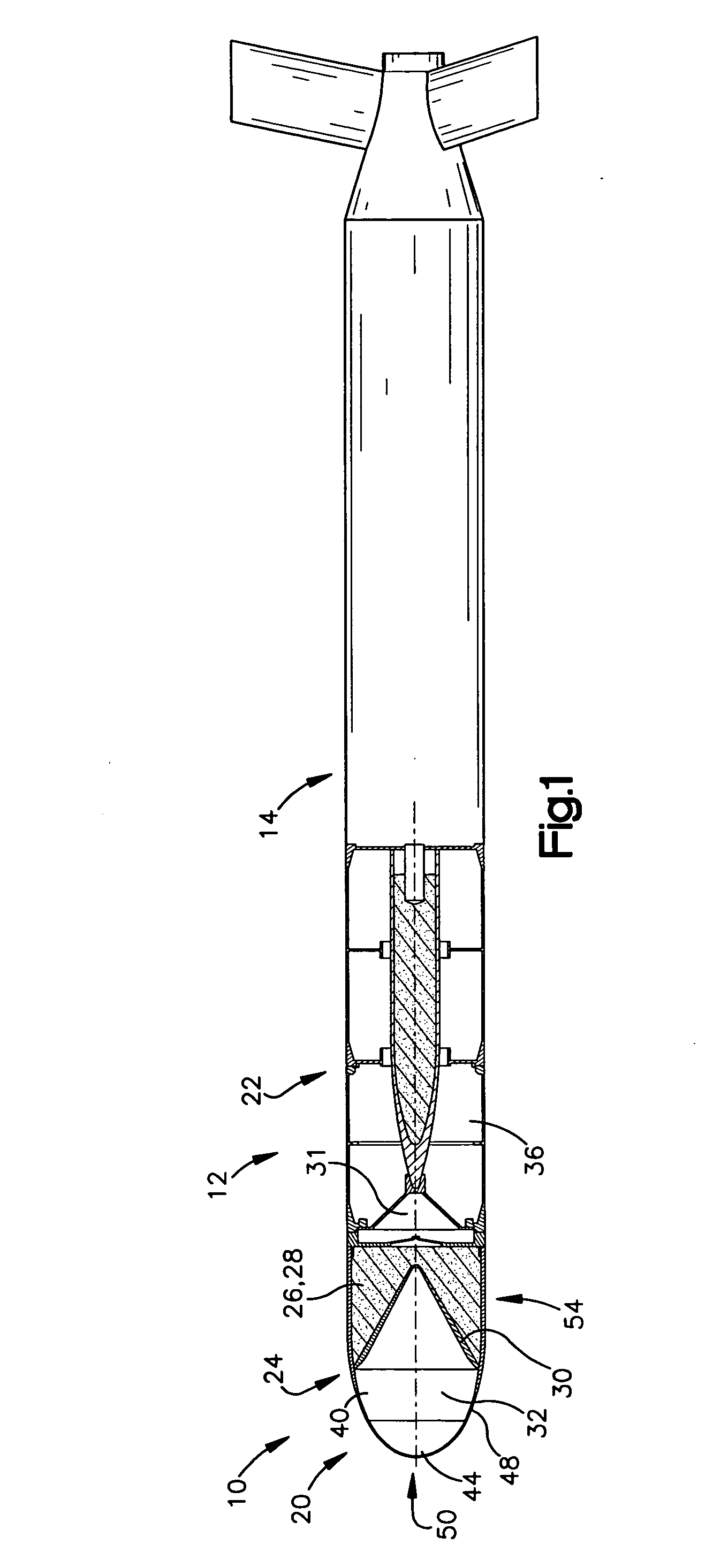

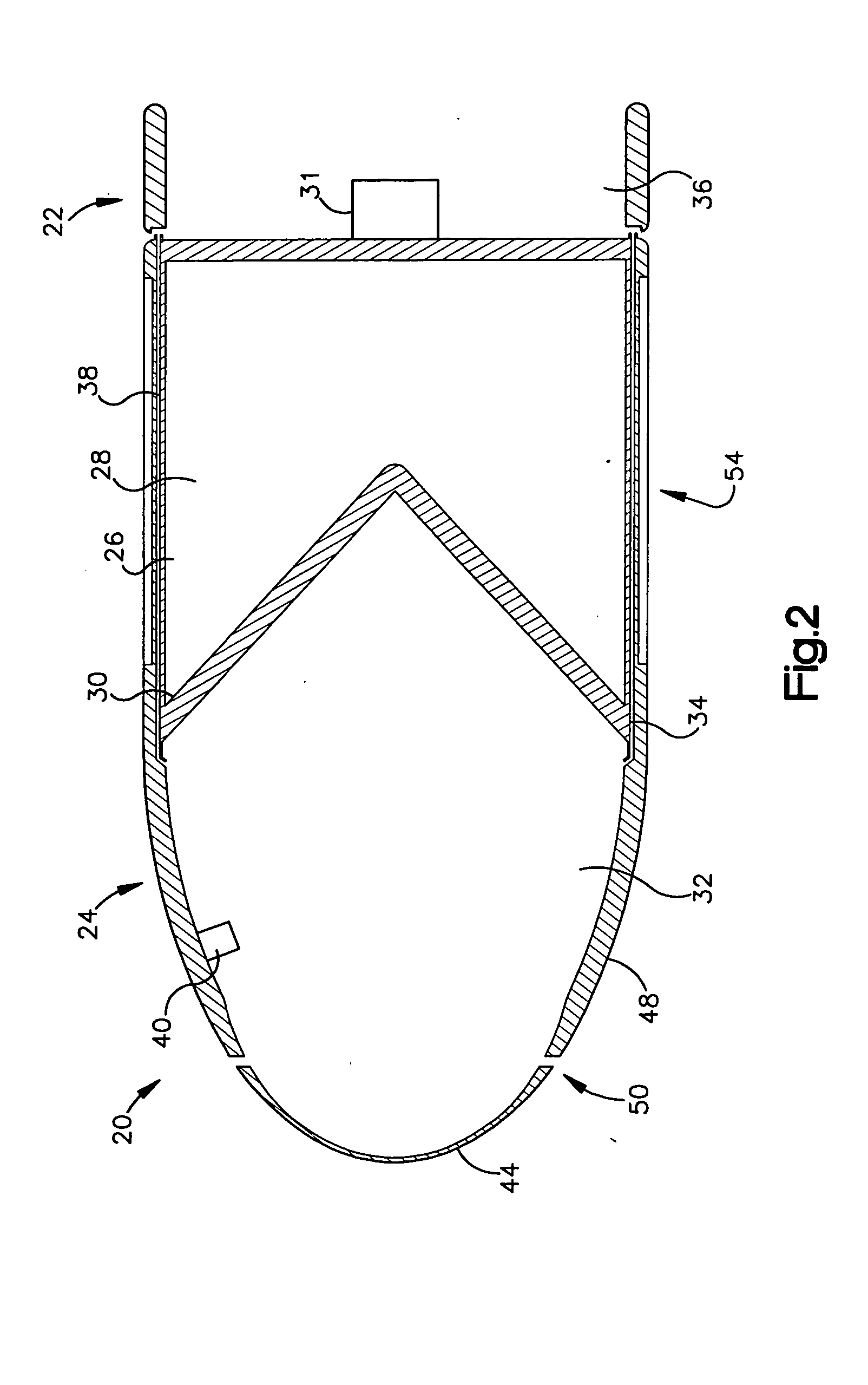

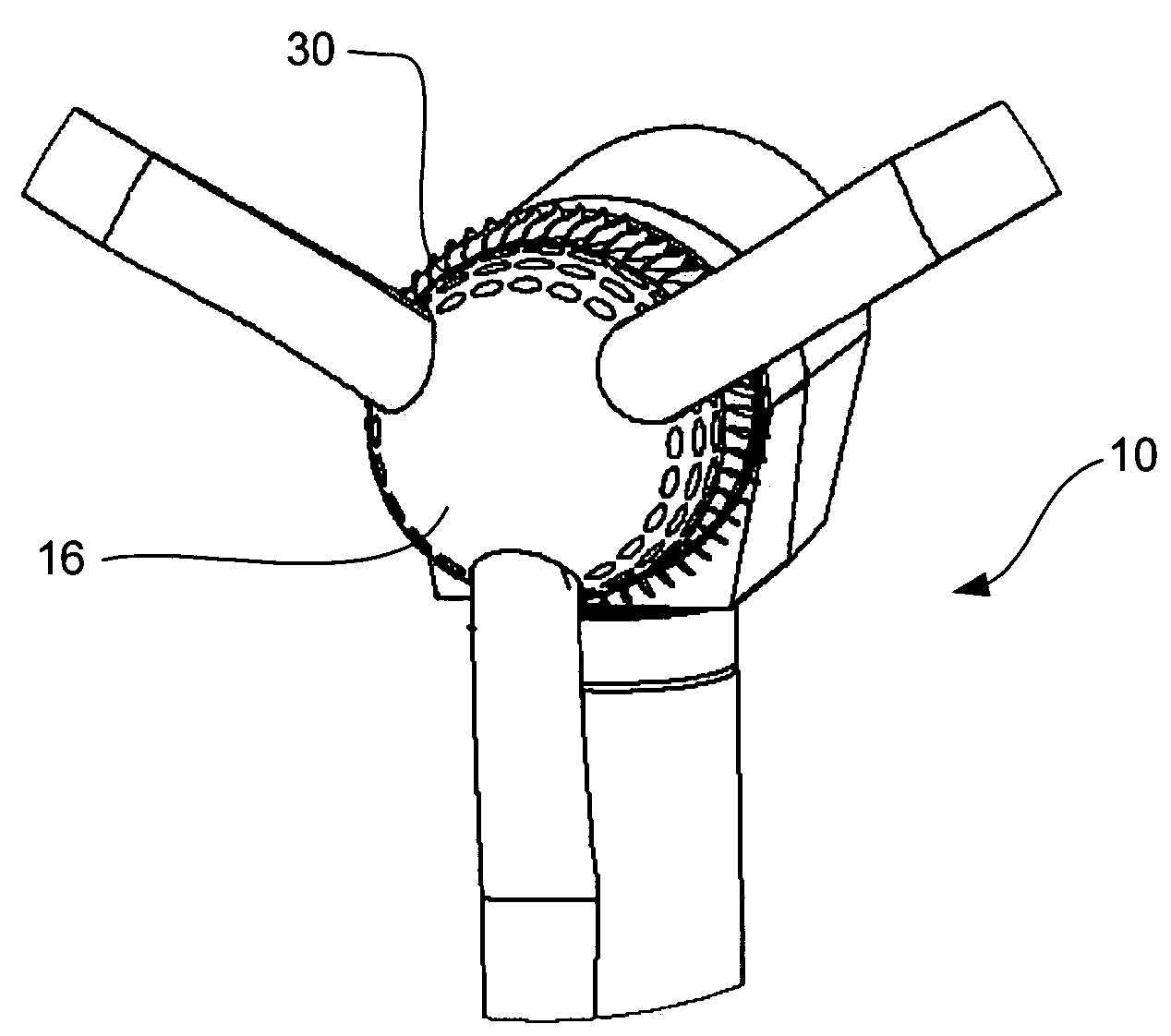

Multi-mission payload system

A missile, such as a cruise missile, has a nose payload portion having a frangible nose cover and a relatively hard target penetration nose cone. The nose cone may have a liquid fuel tank within, and a chemical energy explosive charge, such as a shaped charge, aft of the liquid fuel tank. The target penetration nose cone enables perforation of certain types of targets prior to detonation of the chemical energy explosive and the liquid fuel. The frangible nose cover is configured to be easily perforated or otherwise removed by the explosive force of the chemical energy explosive charge when the missile system is utilized for the attack of hard targets. The nose payload portion may have a fragmentation case, with one or more features designed to enhance fragmentation during detonation of the explosive and / or the liquid fuel.

Owner:RAYTHEON CO

Passively cooled direct drive wind turbine

ActiveUS7345376B2Improve heat transfer performanceIncrease air velocityEngine fuctionsMachines/enginesTurbineWind force

A wind turbine is provided that passively cools an electrical generator. The wind turbine includes a plurality of fins arranged peripherally around a generator house. Each of the fins being oriented at an angle greater than zero degrees to allow parallel flow of air over the fin. The fin is further tapered to allow a constant portion of the fin to extend beyond the air stream boundary layer. Turbulence initiators on the nose cone further enhance heat transfer at the fins.

Owner:WEG ELECTRIC CORP +1

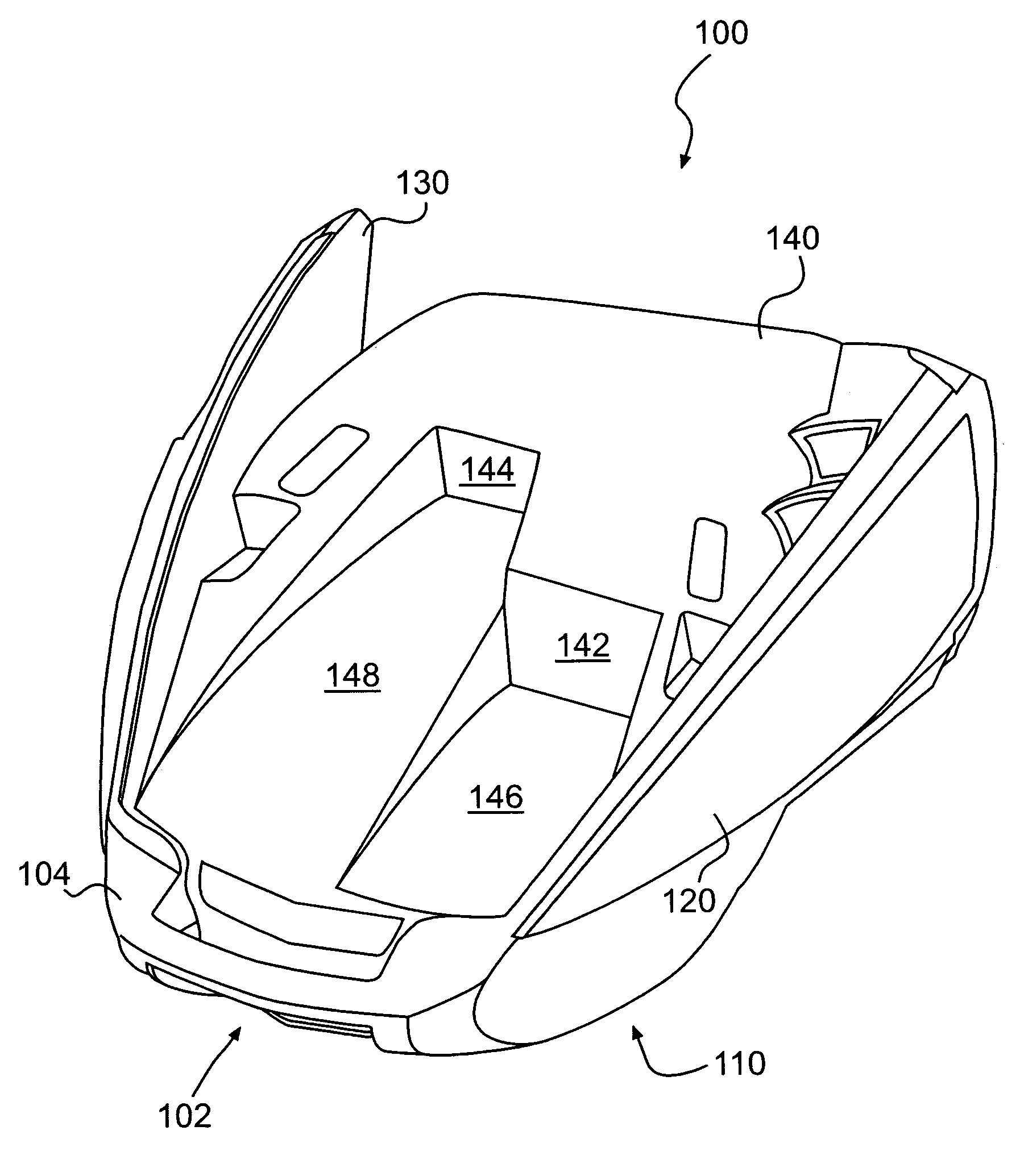

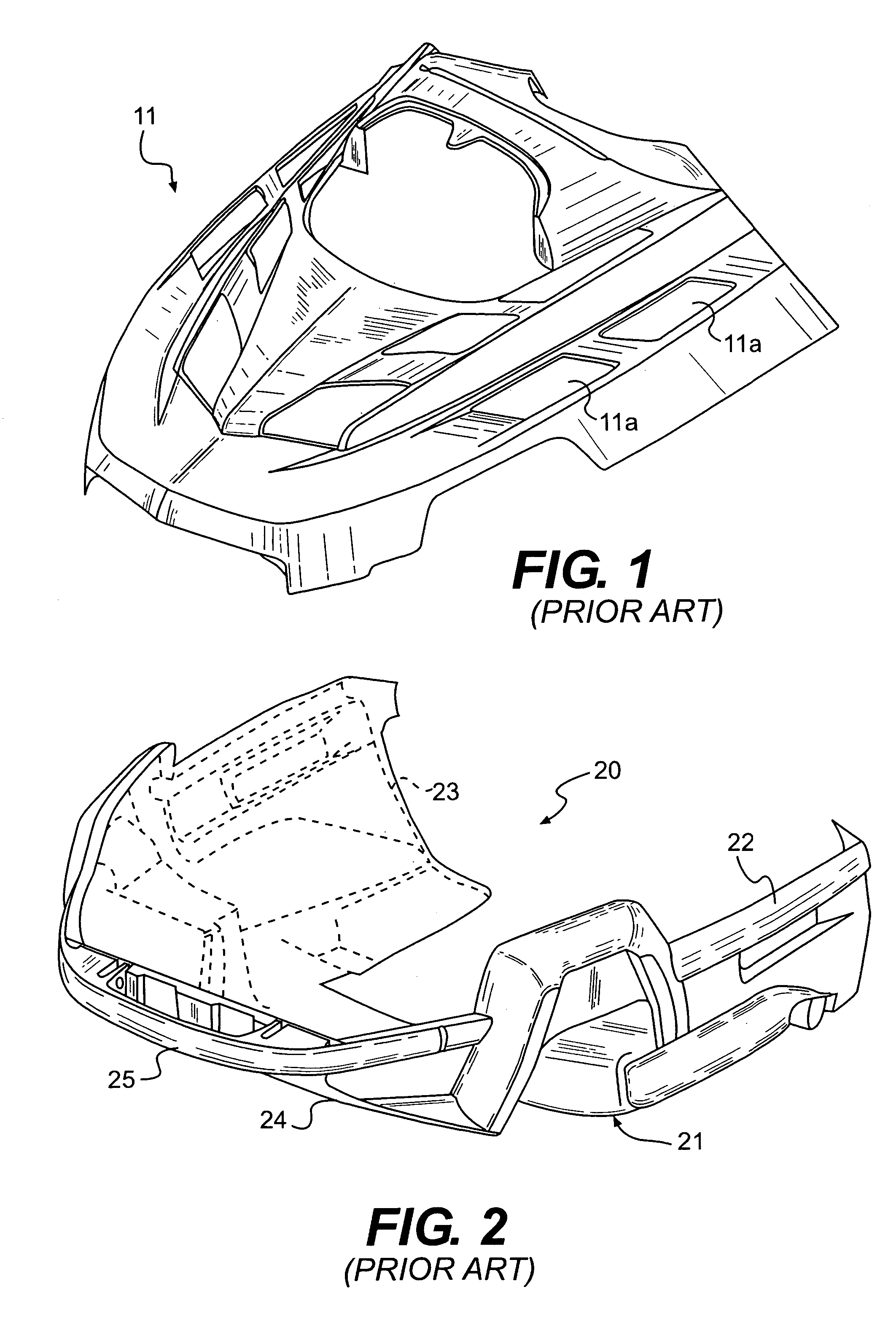

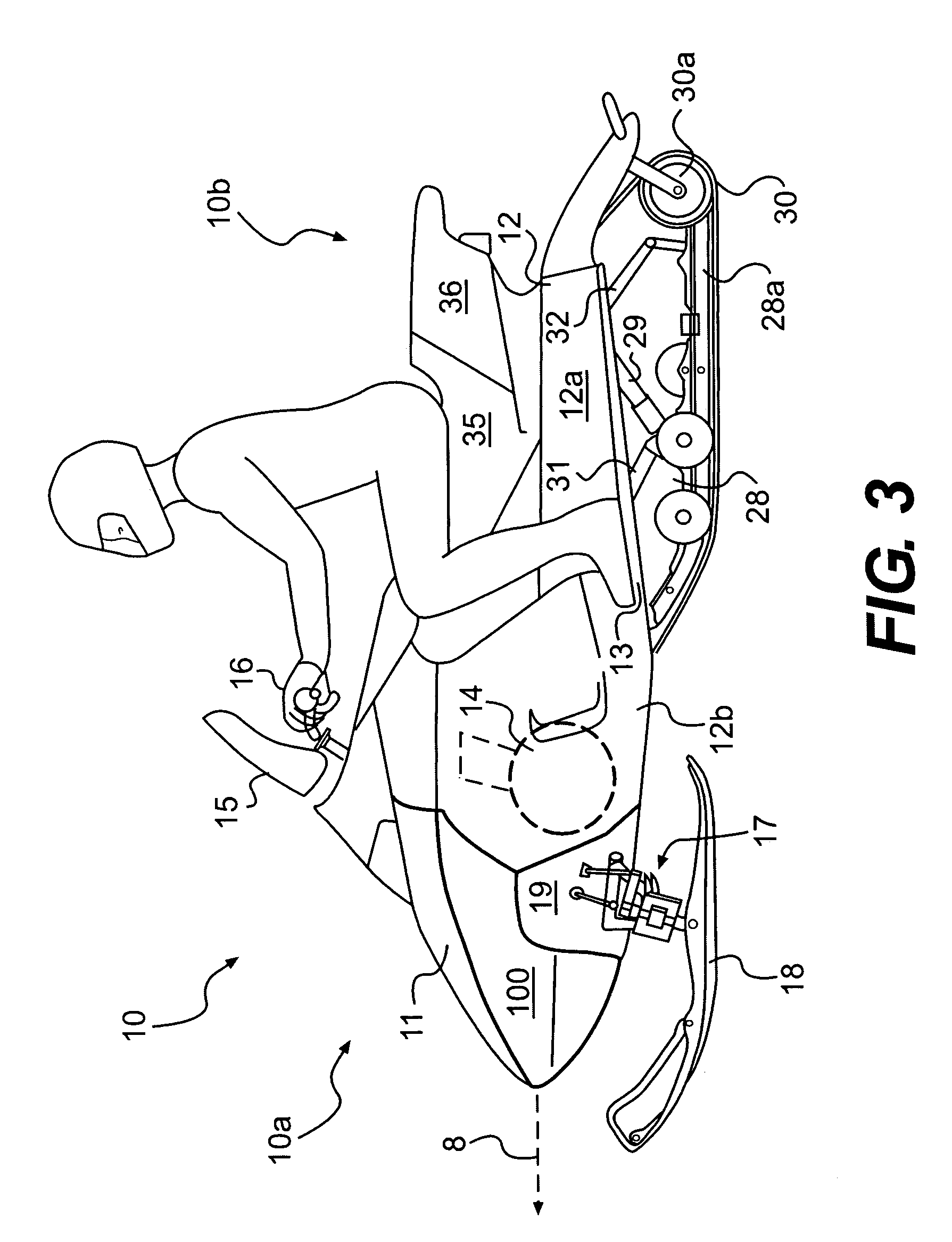

Nose cone for a snowmobile

A snowmobile includes a nose cone having an underbelly, first and second side walls and a top cover together defining a substantially conical enclosure for enclosing a forward end of the snowmobile. The top cover includes a pair of air inlets for admitting air into the engine compartment as well as air guides connected to the inlets for directing the air to desired regions of the engine compartment for improving engine performance. The top cover also includes grilles for filtering out snow and other debris. Furthermore, the air guides are designed to suppress engine noise.

Owner:BRP FINLAND

Apparatus and method of balancing a shaft

ActiveUS20050231052A1Reduce manufacturing costsInertia force compensationPropellersEngineeringBalance shaft

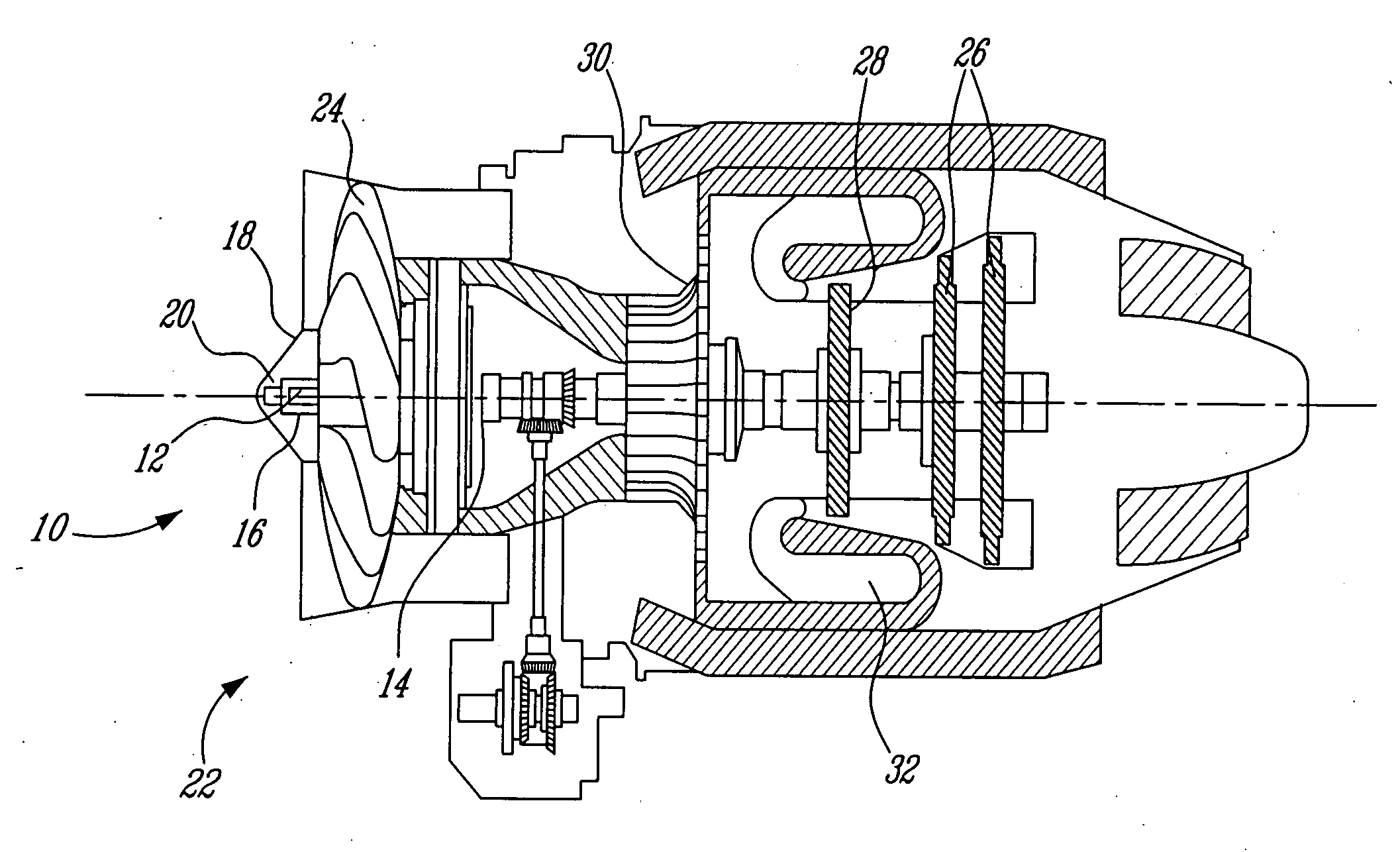

An apparatus for balancing a shaft of an aircraft engine preferably includes a plate and the use of standard fasteners. The plate provides mounting for nose cone, and the balancing apparatus may be accessed from the front of the assembled engine.

Owner:PRATT & WHITNEY CANADA CORP

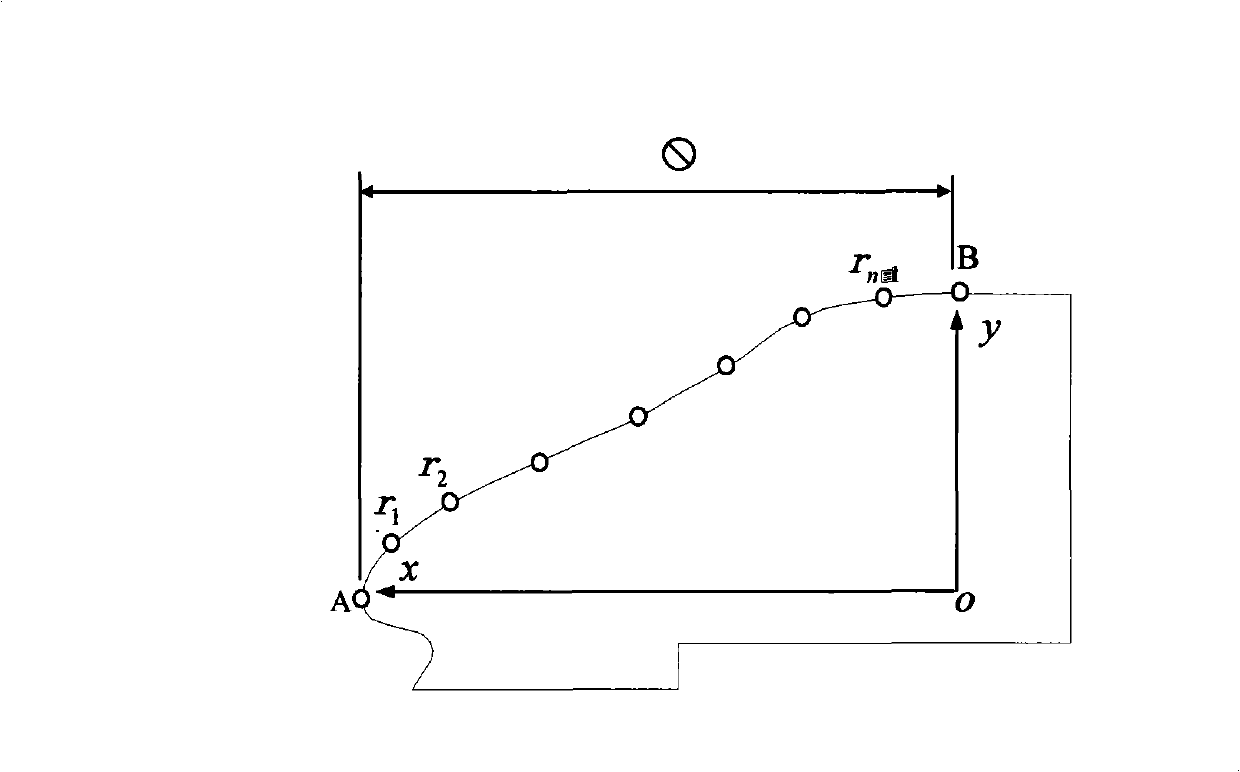

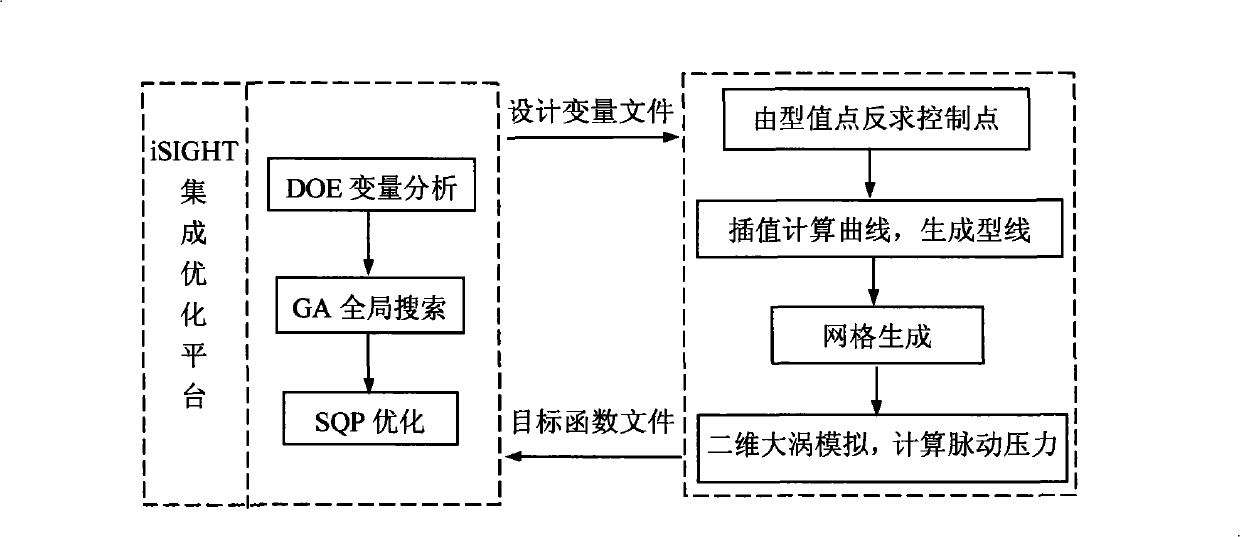

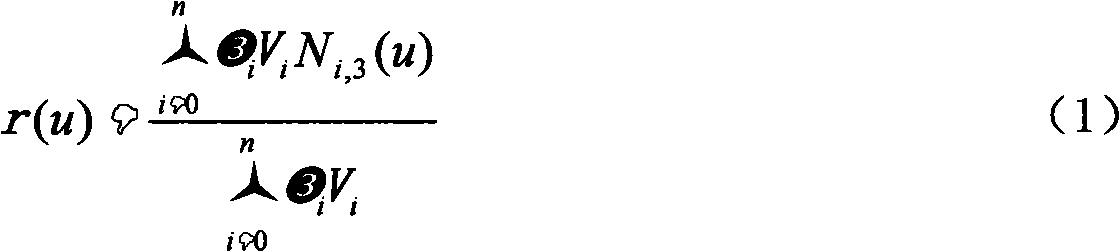

Method for optimizing low pneumatic noise of high-speed train head section longitudinal symmetry plane line

ActiveCN101354729AAccelerated aerodynamic noise controlAerodynamic Noise Control ScienceSpecial data processing applications3D modellingNoise controlRailway passenger car

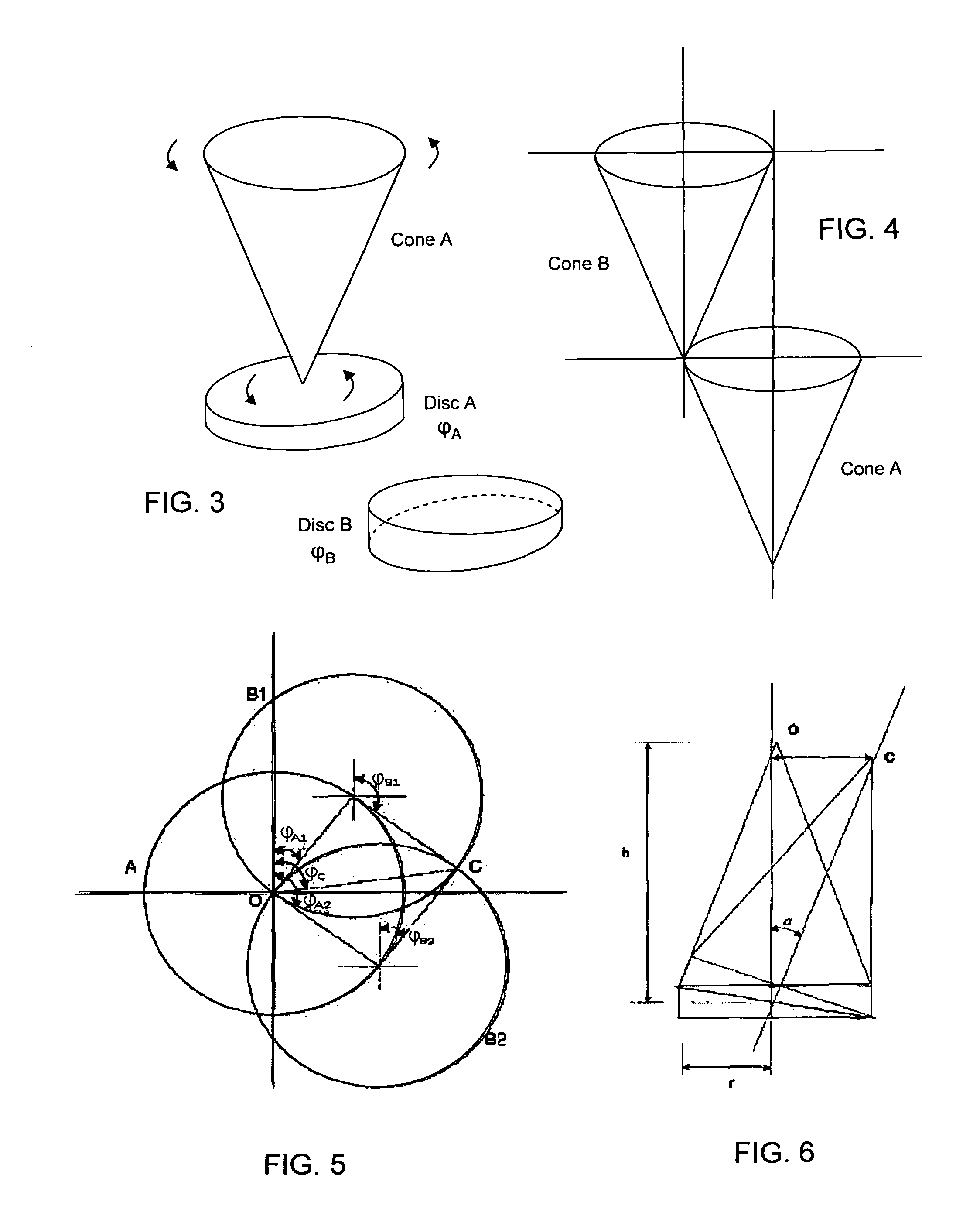

The invention relates to a method for optimizing low aerodynamic noise of molded lines of longitudinal symmetrical surface for the head part of a high-speed train. The molded lines of the longitudinal symmetrical surface for the head part of the high-speed train are basic molded lines for determining the running trend of the whole appearance, wherein the part of the molded line between nose cone points A and transition points B from the train head to the train body is the key part in the molded line design. The invention is the optimized design of the part. The method performs the parameterized model and CFD value calculation on the molded lines of longitudinal symmetrical surface for the head part of a high-speed train by utilizing the NURBS curves, combines the optimized arithmetic to link the change in the aerodynamic performance of the molded line and the adjustment of the geometrical shape, and adjusts the molded lines repeatedly through a flow field computation program and an optimized program, thereby accurately determining the optimal position of the value point of the molded lines of the longitudinal symmetrical surface so that the aerodynamic noise of the head part of the train is reduced to the minimum, lowering the design and the manufacture costs of the aerodynamic noise control of the high-speed train, accelerating the production process of the high-speed train, and making the noise control of the train more scientific.

Owner:CRRC QINGDAO SIFANG CO LTD

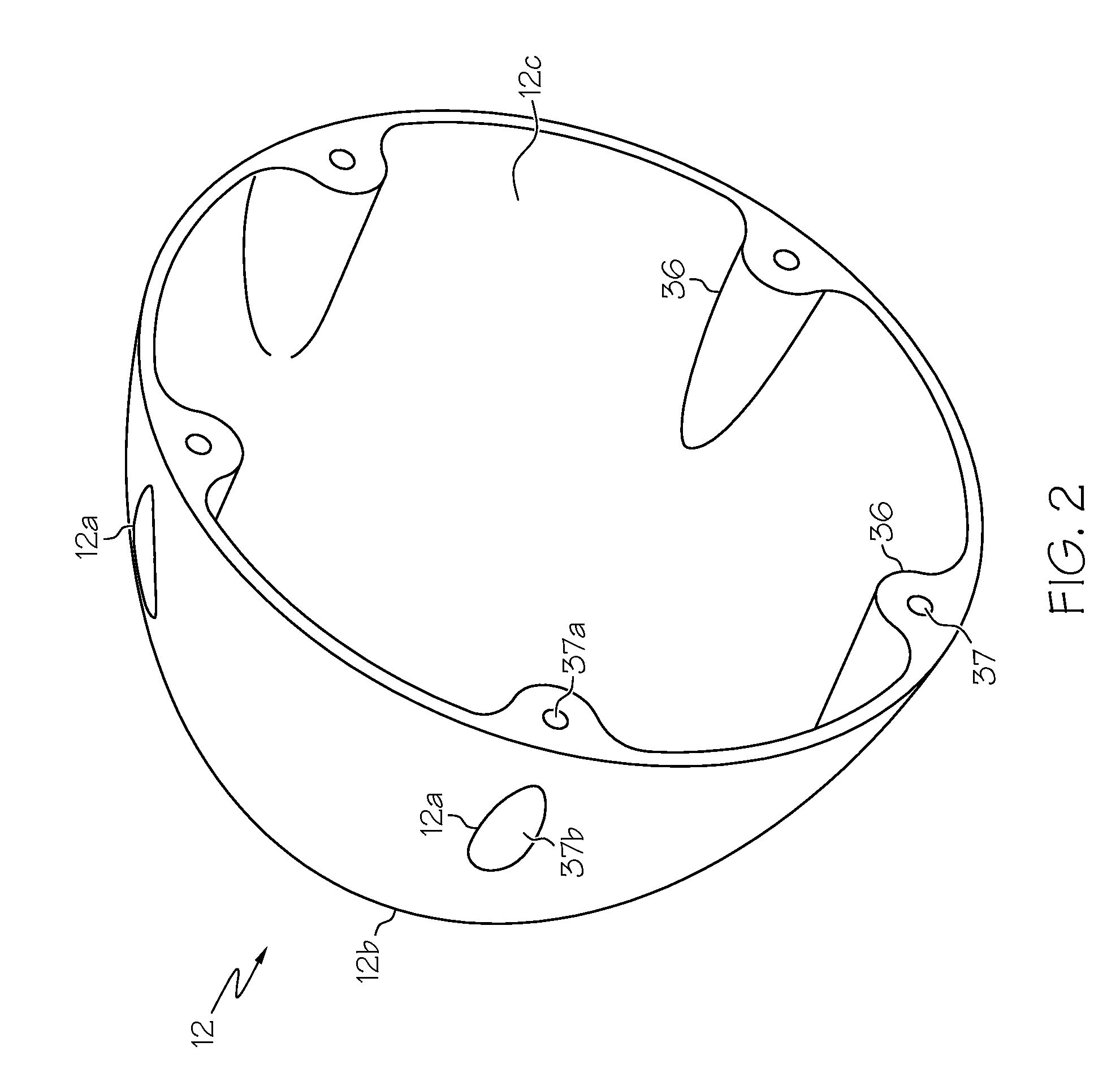

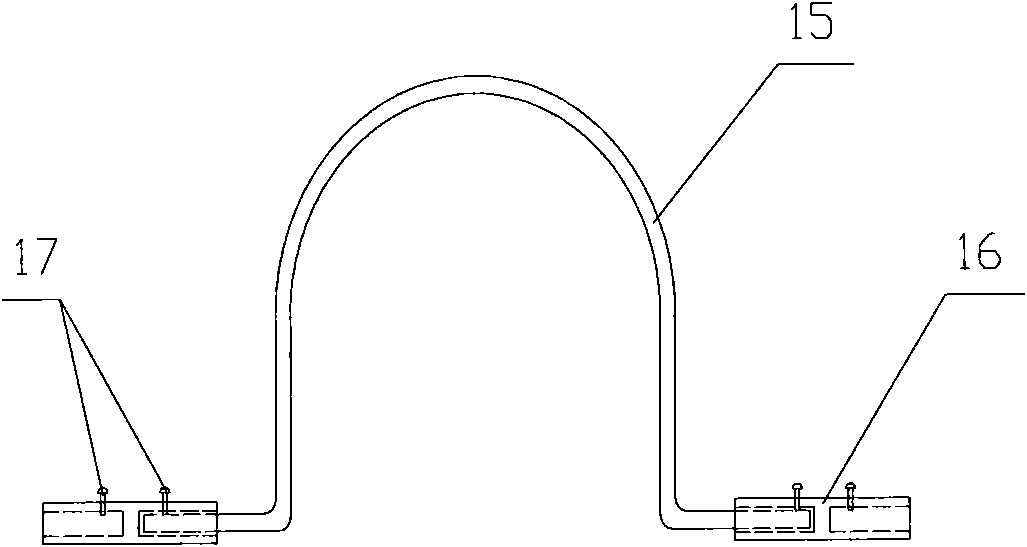

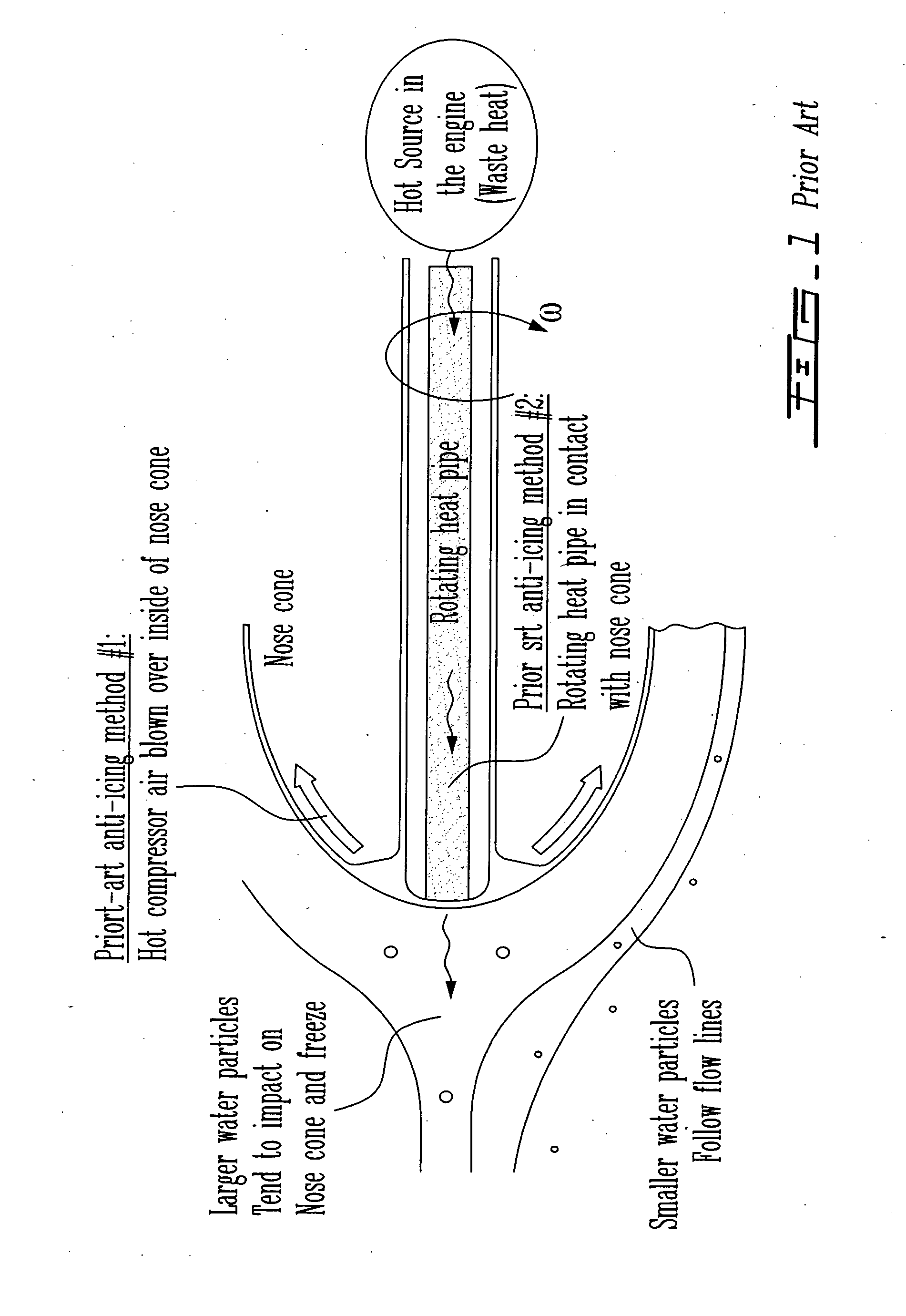

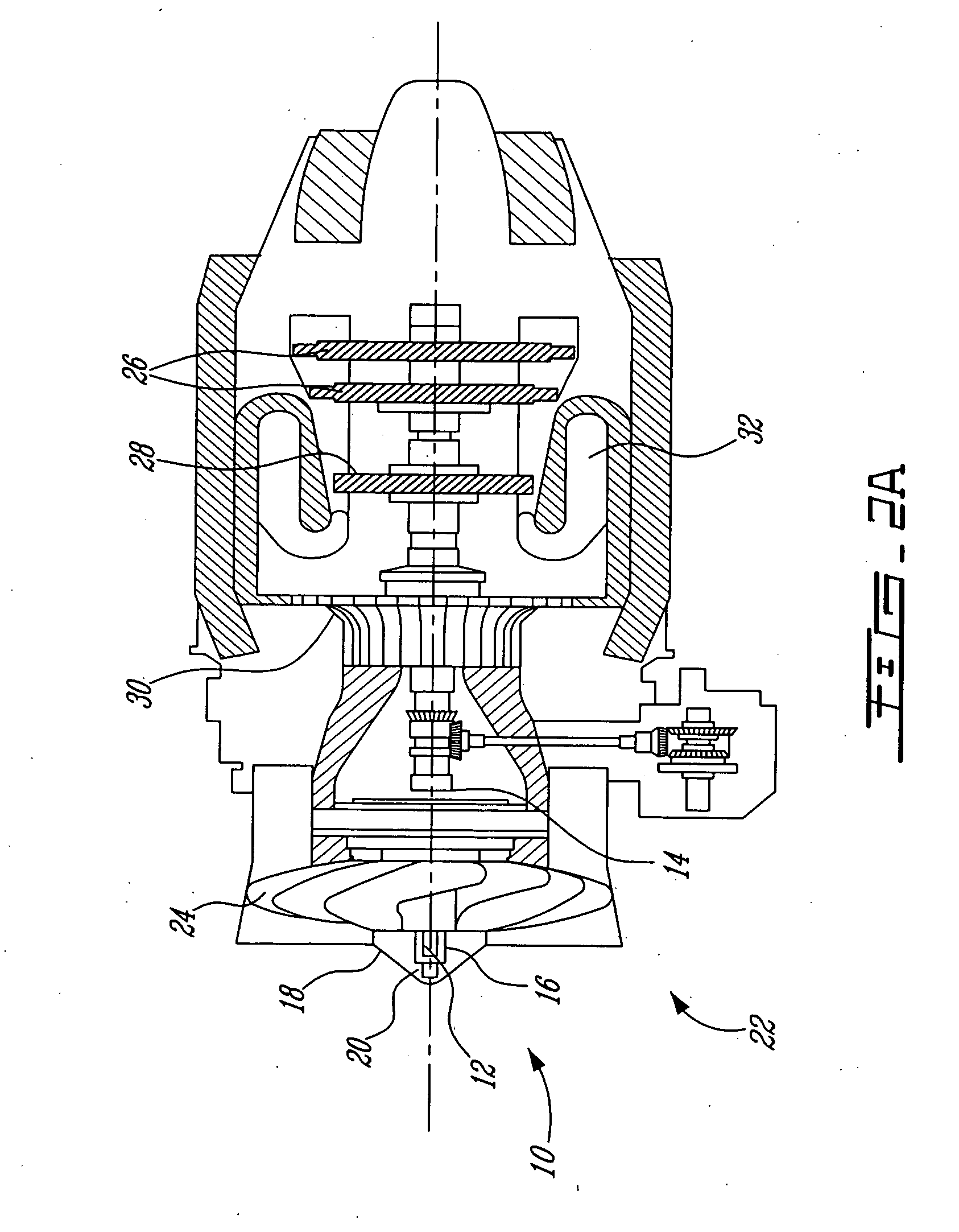

Anti-icing apparatus and method for aero-engine nose cone

An aero-engine nose cone anti-icing system (10) using a rotating heat pipe (12) is provided to replace the current method of blowing hot compressor bleed air over the nose cone surface. Heat is transferred from a hot source (36) within the engine (22) to the nose cone (18) through a rotating heat pipe (12) along the central shaft (16). A condenser (20) and evaporator (14) are provided which are adapted to the heat transfer requirements and space constraints in the engine (22).

Owner:PRATT & WHITNEY CANADA CORP

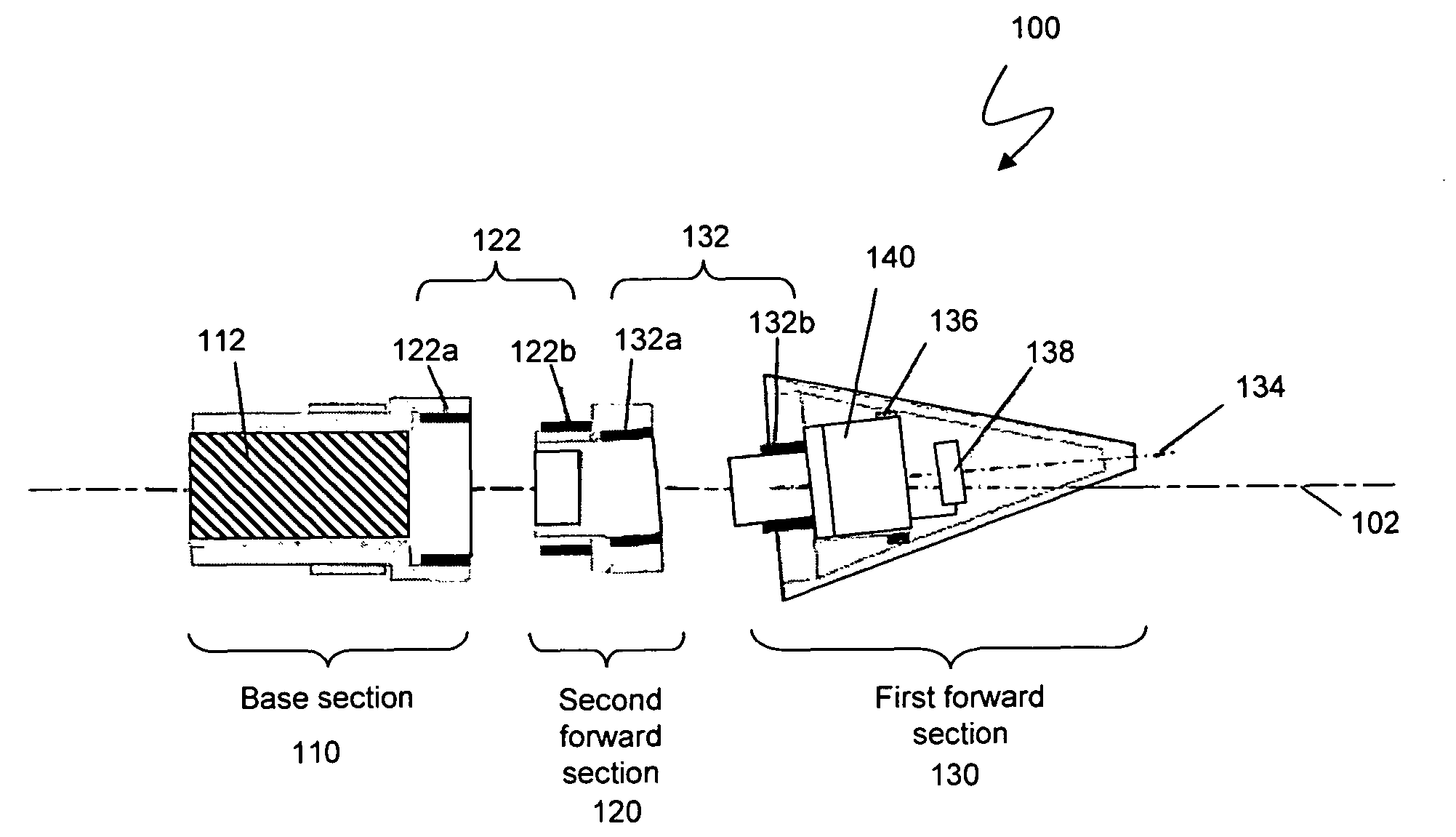

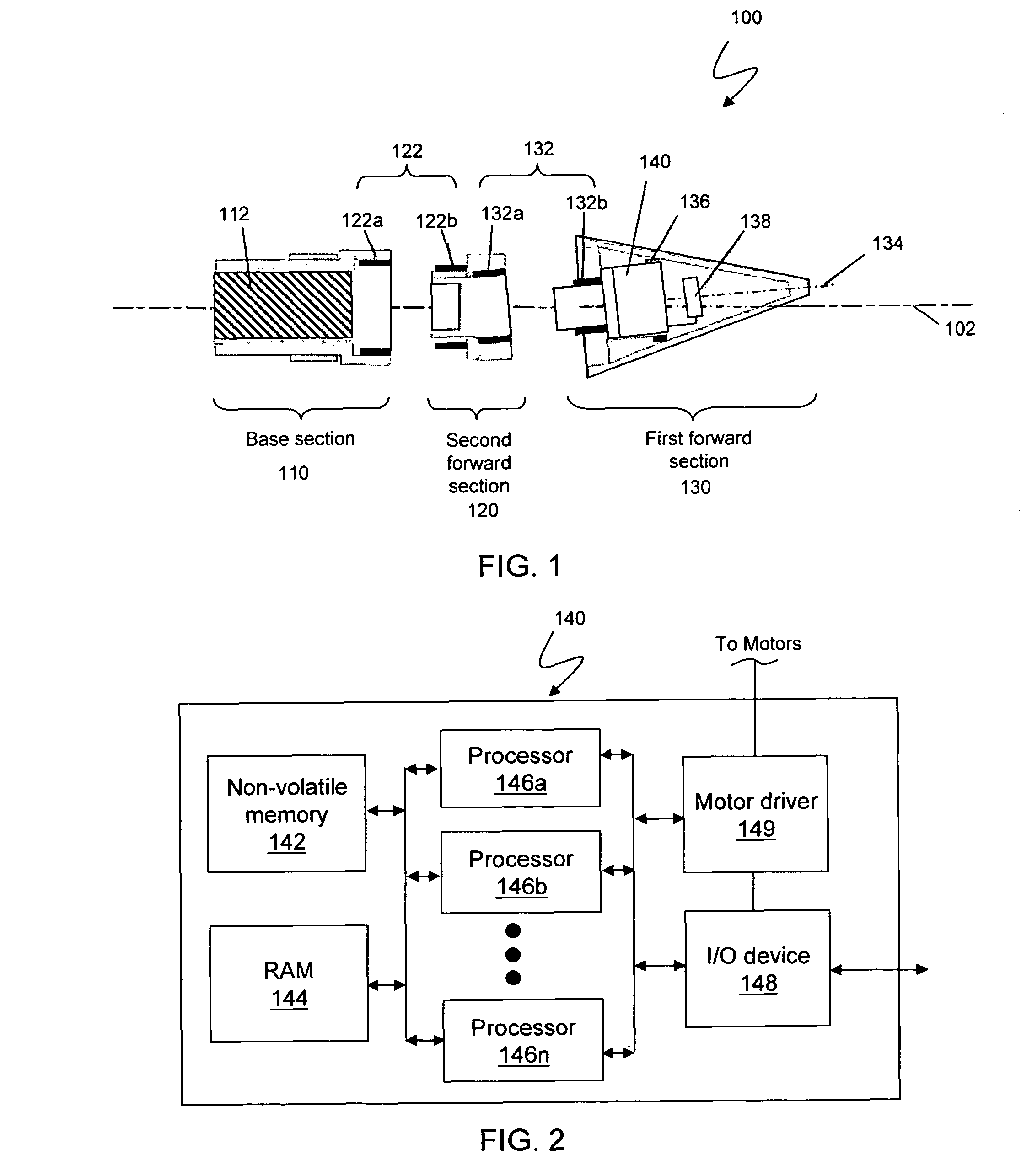

Spin stabilized projectile trajectory control

A Reconfigurable Nose Control System (RNCS) is designed to adjust the flight path of spin-stabilized artillery projectiles. The RNCS uses the surface of a projectile nose cone as a trim tab. The nose cone may be despun by the action of aerodynamic surfaces, to zero spin relative to earth fixed coordinates using local air flow, and deflected by a simple rotary motion of a Divert Motor about the longitudinal axis of the projectile. A forward section of the nose cone having an ogive is mounted at an angle to the longitudinal axis of the projectile, forming an axial offset of an axis of the forward section with respect to the longitudinal axis of the projectile. Another section of the nose cone includes another motor, the Roll Generator Motor, that is rotationally decoupled from the forward section and rotates the deflected forward section so that its axis may be pointed in any direction within its range of motion. Accordingly, deflection and direction of the forward section may be modulated by combined action of the motors during flight of the projectile.

Owner:SIMMONDS PRECISION PRODS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com