Patents

Literature

1158 results about "Balance shaft" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Balance shafts are used in piston engines to reduce vibration by cancelling out unbalanced dynamic forces. The balance shafts have eccentric weights and rotate in opposite direction to each other, which generates a net vertical force.

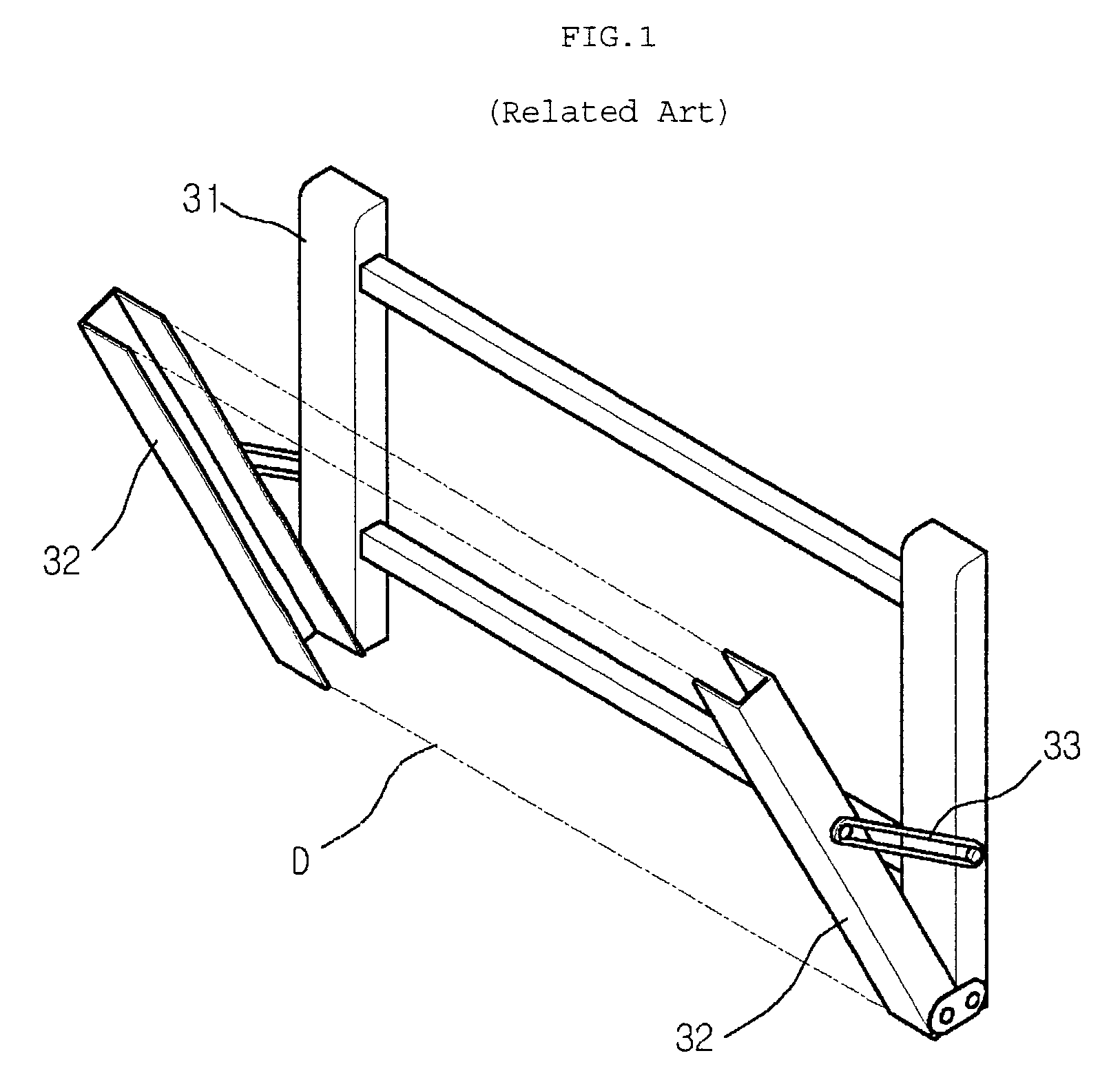

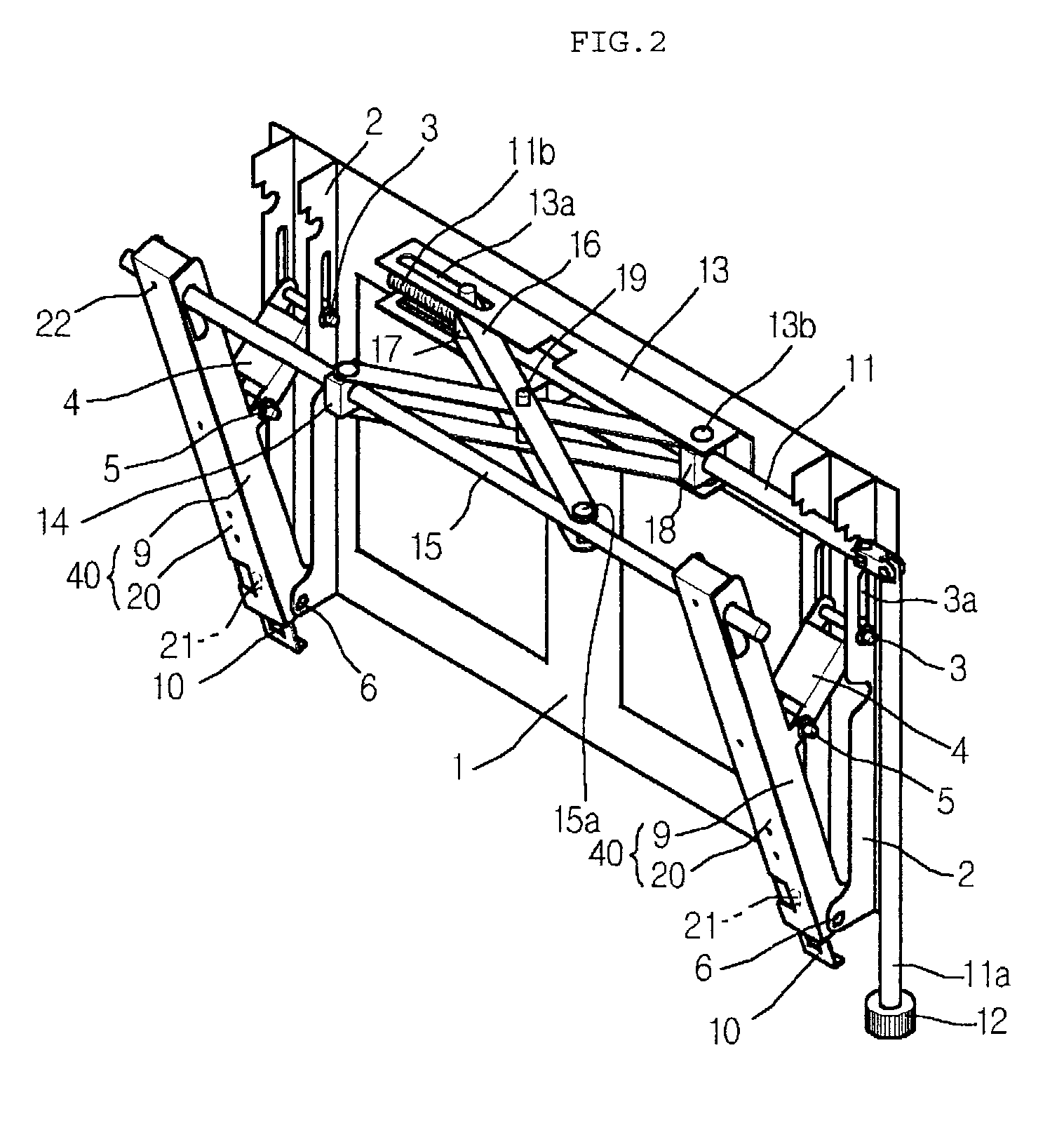

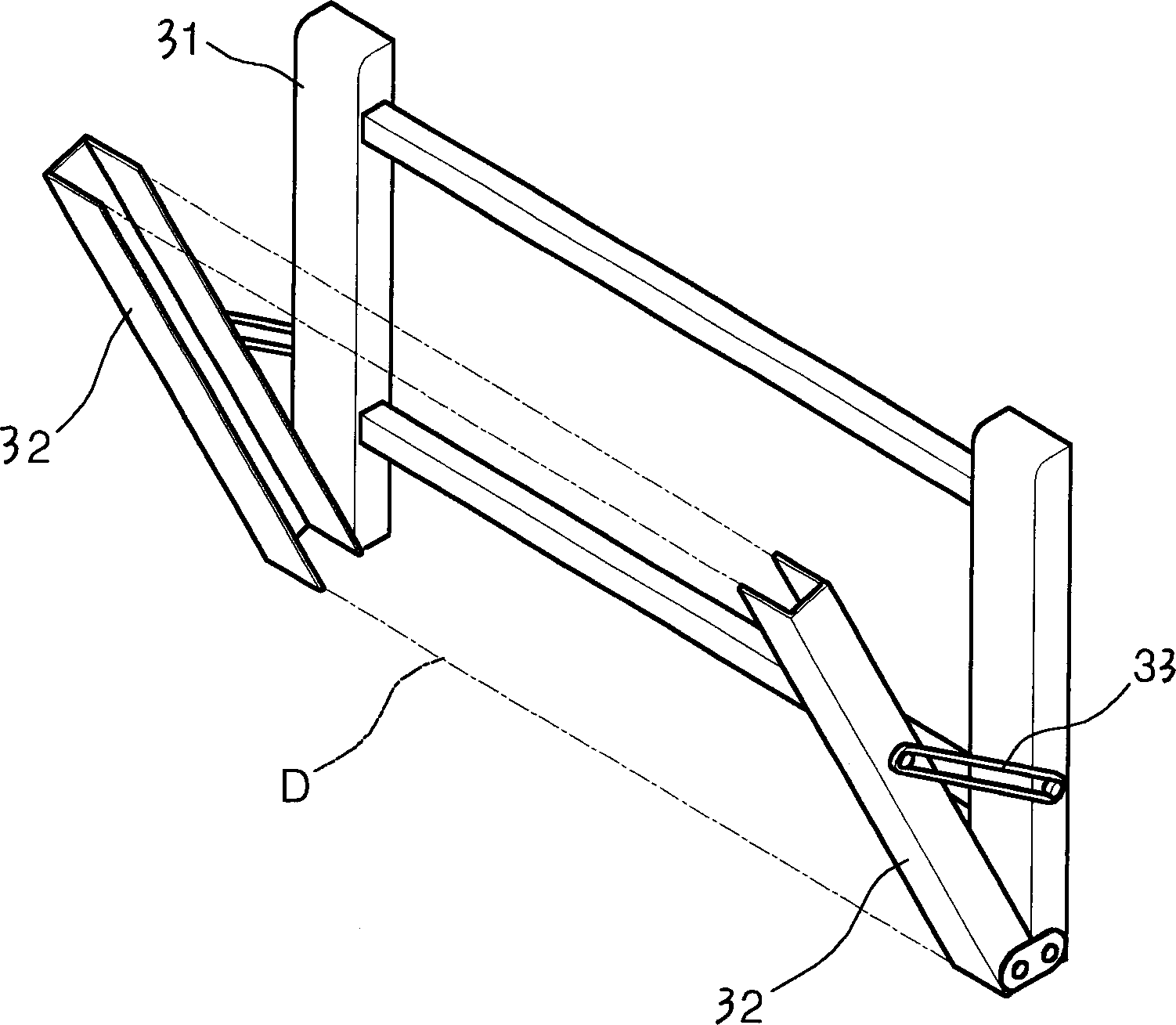

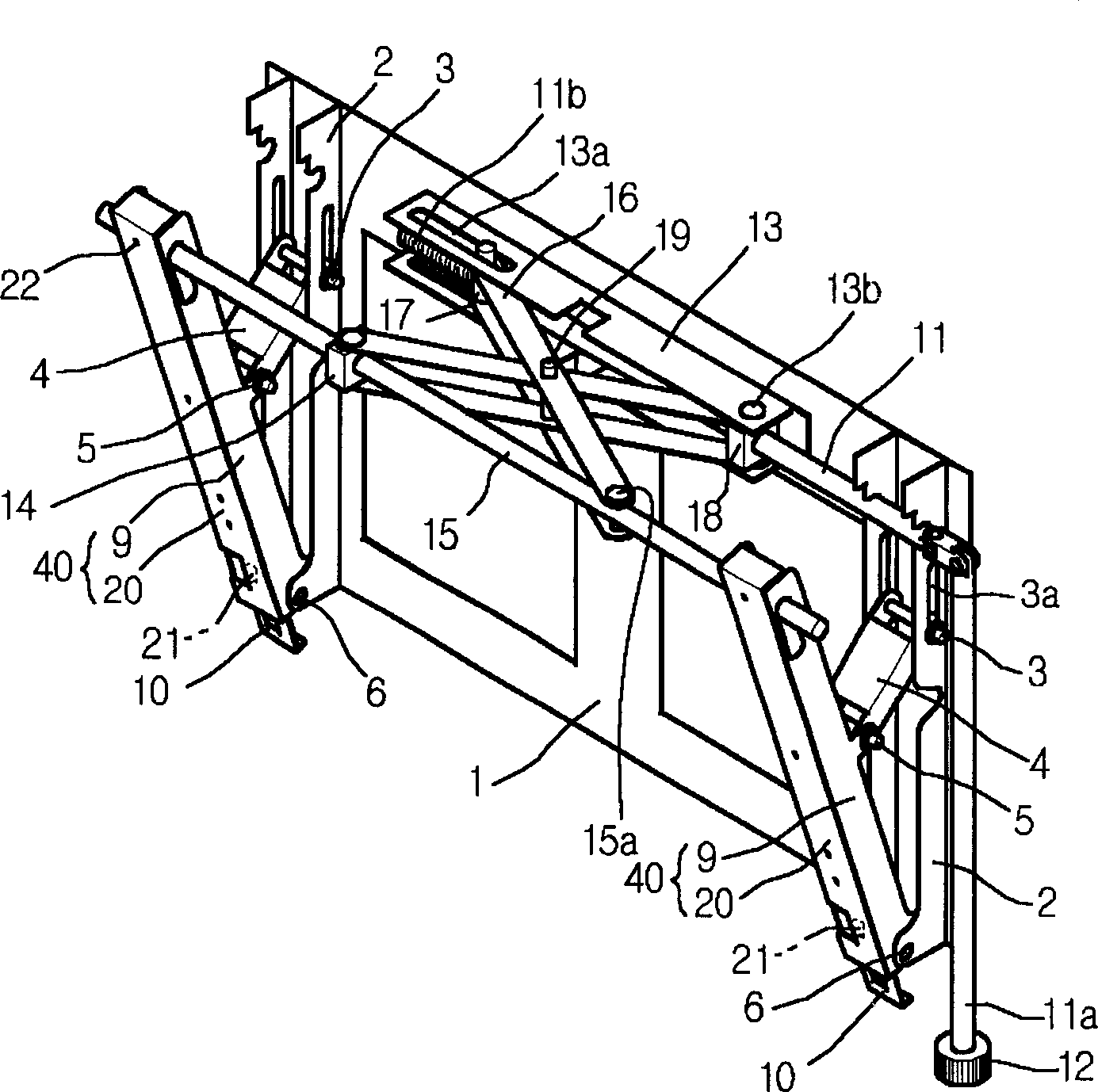

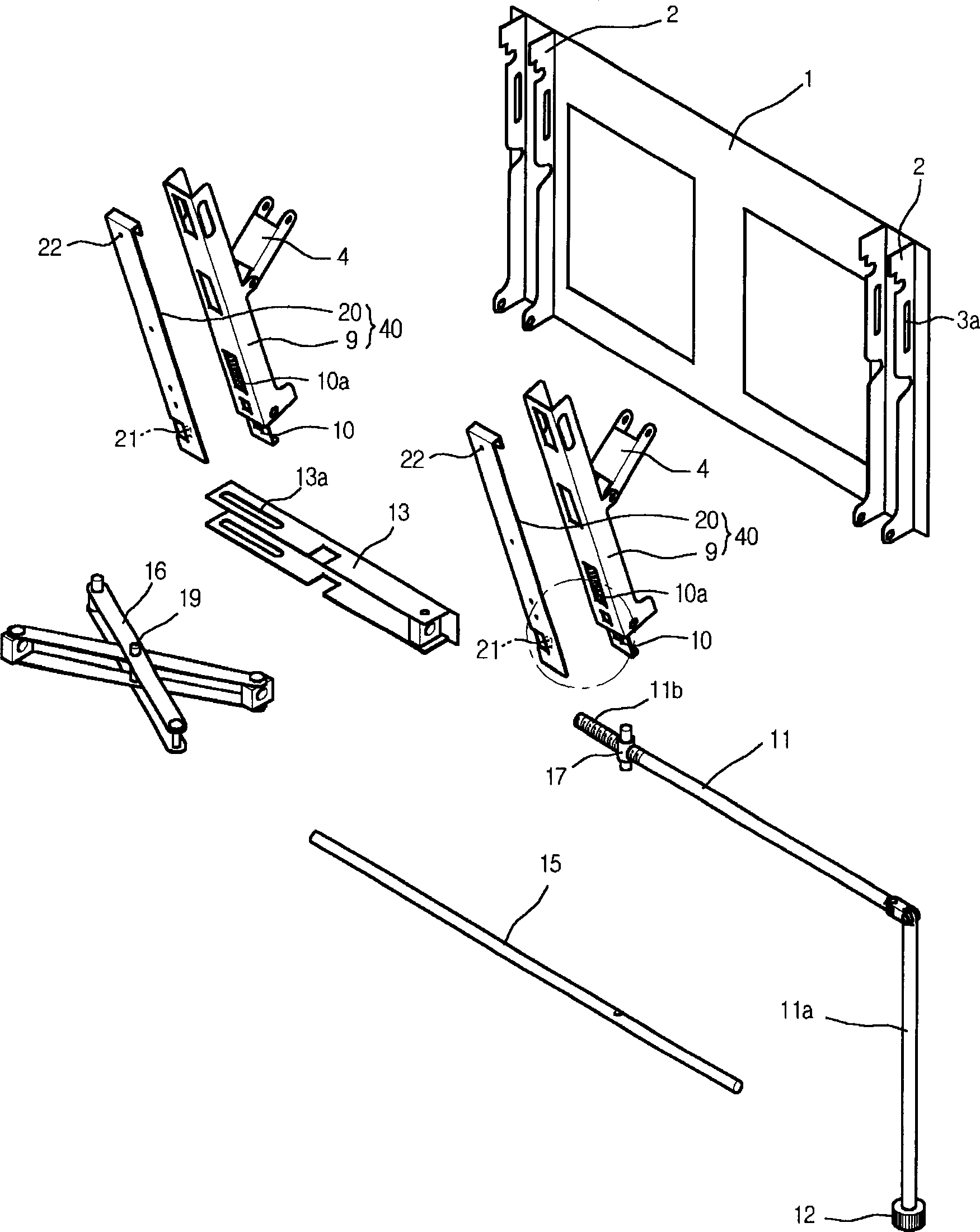

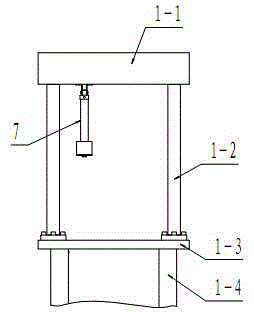

Apparatus for adjusting an angle of a display means and a connection bracket thereof

InactiveUS7063295B2Easy to controlGood adhesionTelevision system detailsDigital data processing detailsDisplay deviceBalance shaft

An apparatus for adjusting an angle of a display which easily controls the view angle of the display so as to comply with a user s wishes, and a connection bracket of the apparatus are provided. A series of guide brackets and connection brackets couple the display to a fixing bracket fixed to a wall or support. A flap-fixing bracket is attached to the fixing bracket, and a flap, comprising two crossed flap members coupling a balance shaft and an angle adjustable shaft allow a viewing angle to be adjusted through the spreading and the folding of the flap. The connection bracket includes a product bracket attached to a holding-down bracket. The product bracket attaches on one surface to the display, and at its ends to the holding doxvn bracket. The holding-down bracket is easily attached to and separated from the product bracket. Thus the angle of the display is easily adjusted, using limited force, so as to comply with a user's wishes.

Owner:LG ELECTRONICS INC

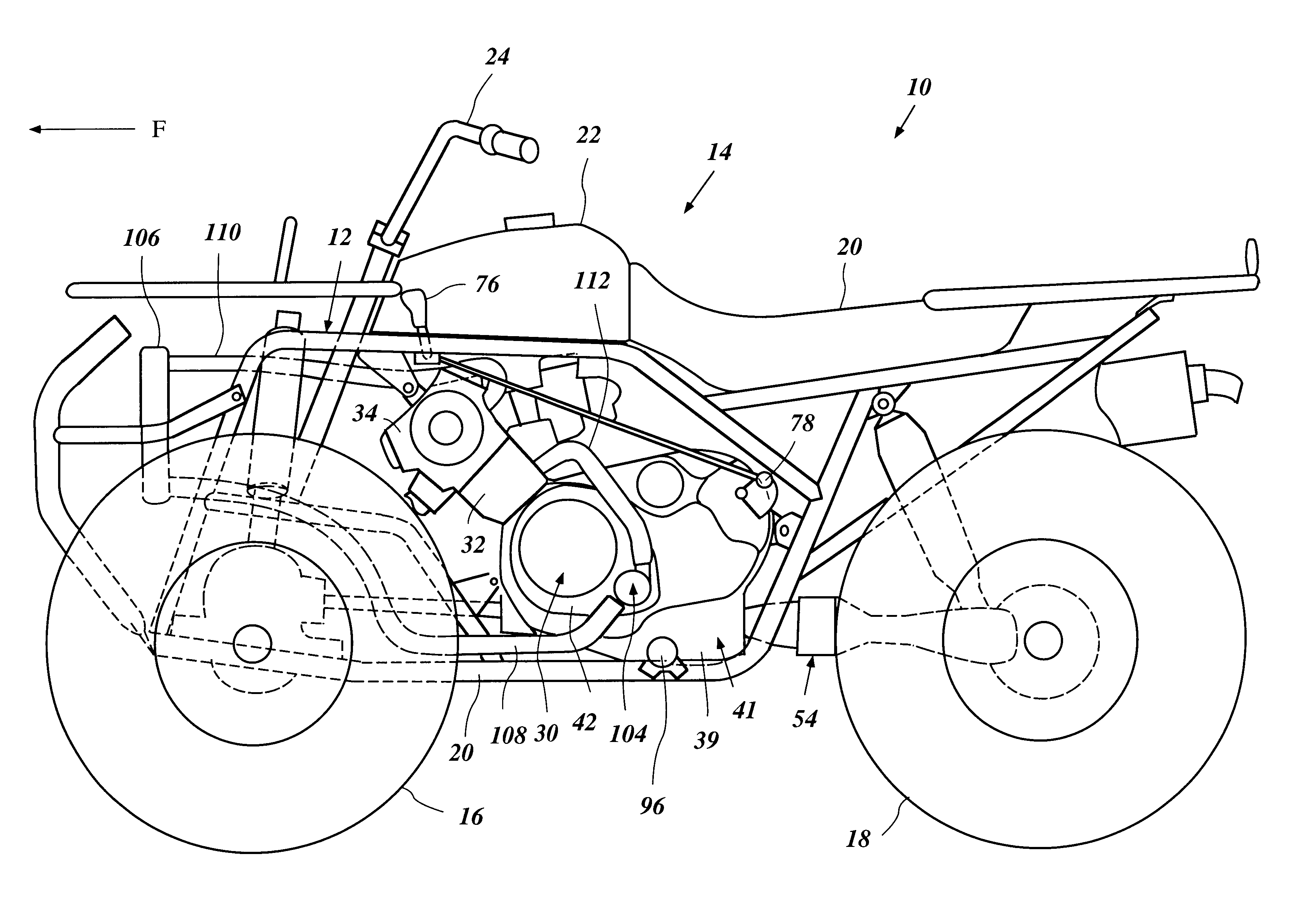

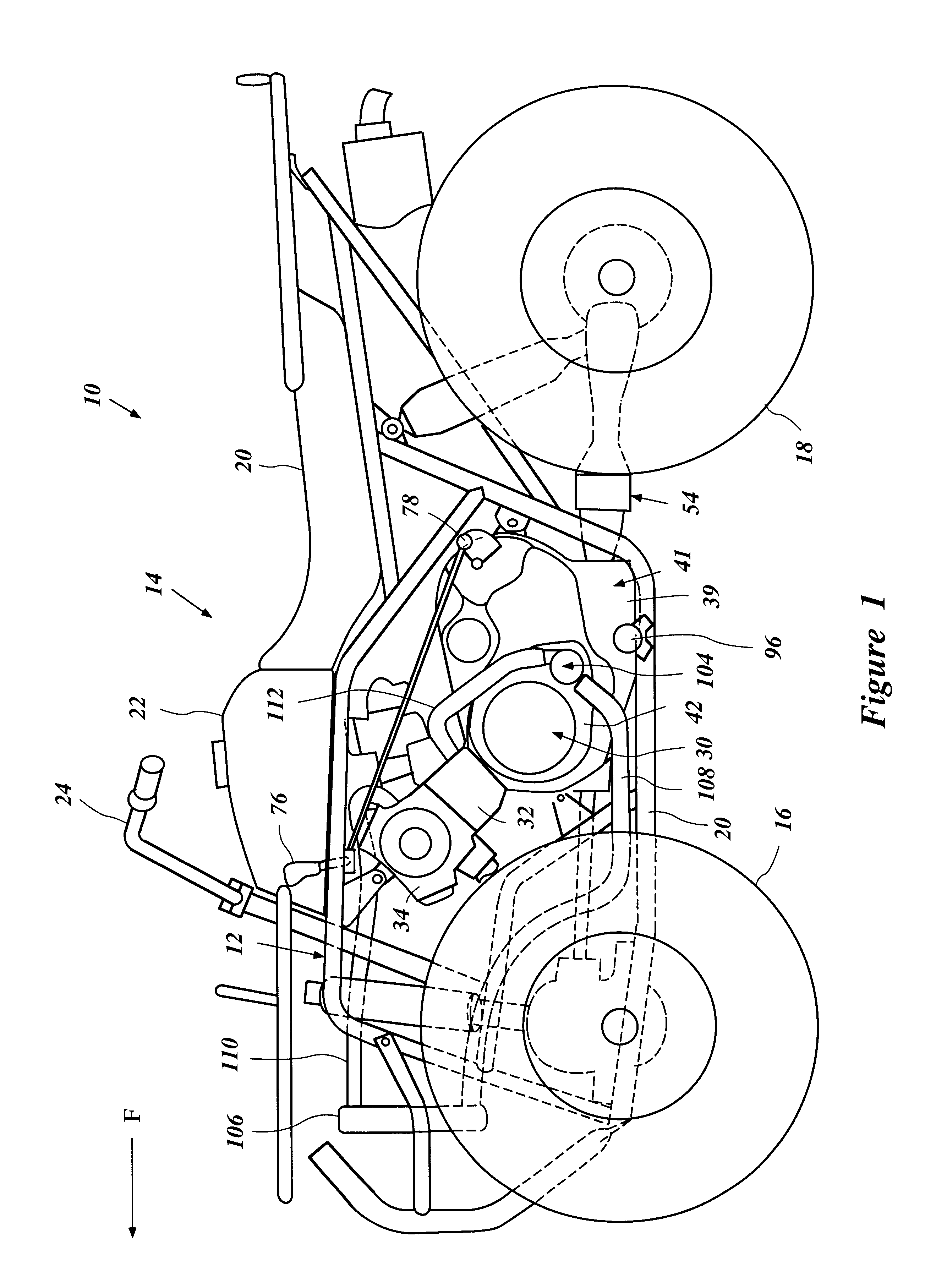

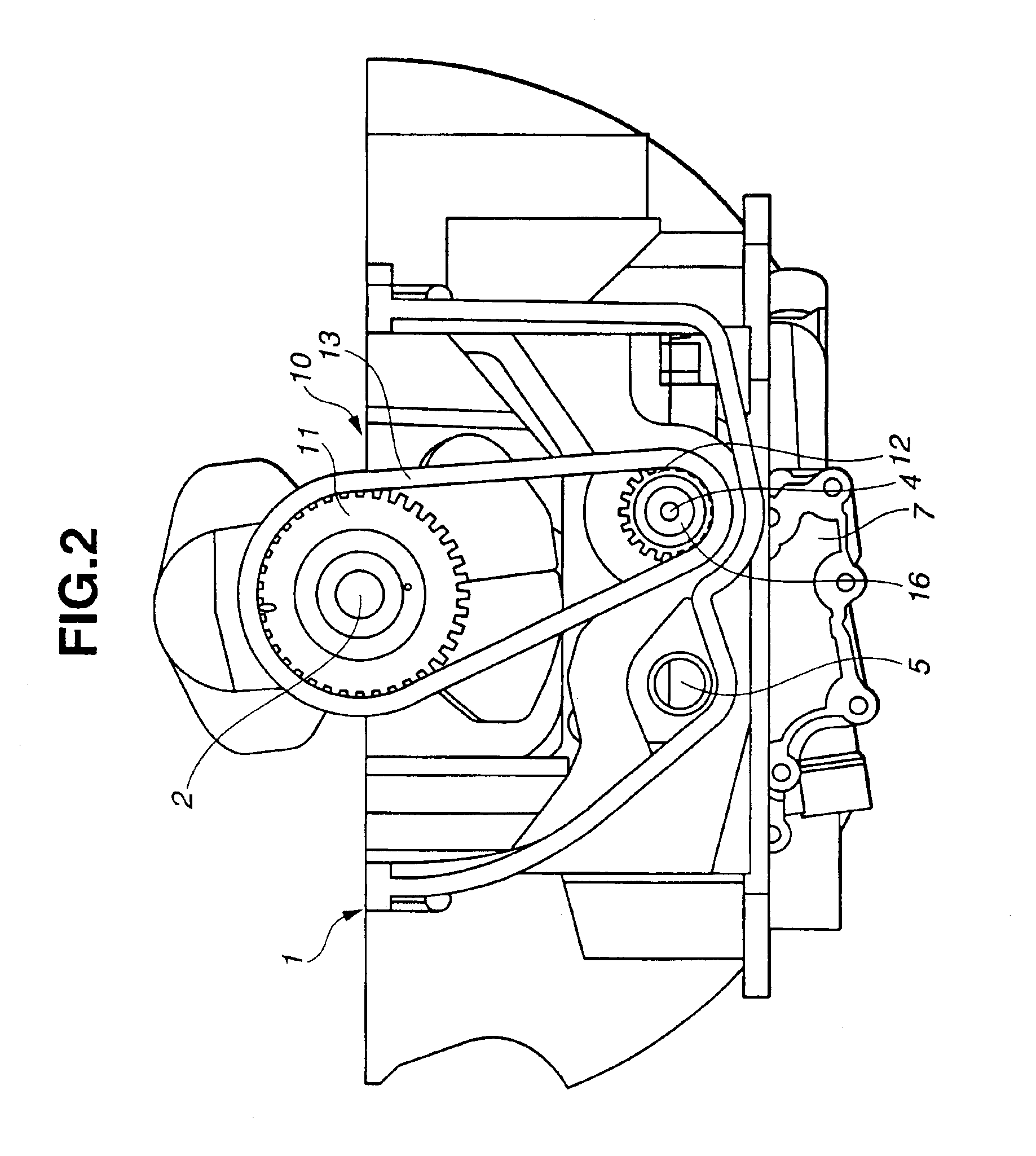

Cooling arrangement for all terrain vehicle

An all terrain vehicle has a cooling pump that is driven off a balancer shaft. The balancer shaft, in turn, is driven off a crankshaft. The cooling pump is preferably recessed inside of an outer surface of a crankcase cover member. Additionally, a lubricant pump is also driven off the balancer shaft and arranged inwardly from the cooling pump. The cooling pump is arranged to one side of the all terrain vehicle while a variable speed transmission is arranged to the other side of the all terrain vehicle.

Owner:YAMAHA MOTOR CO LTD

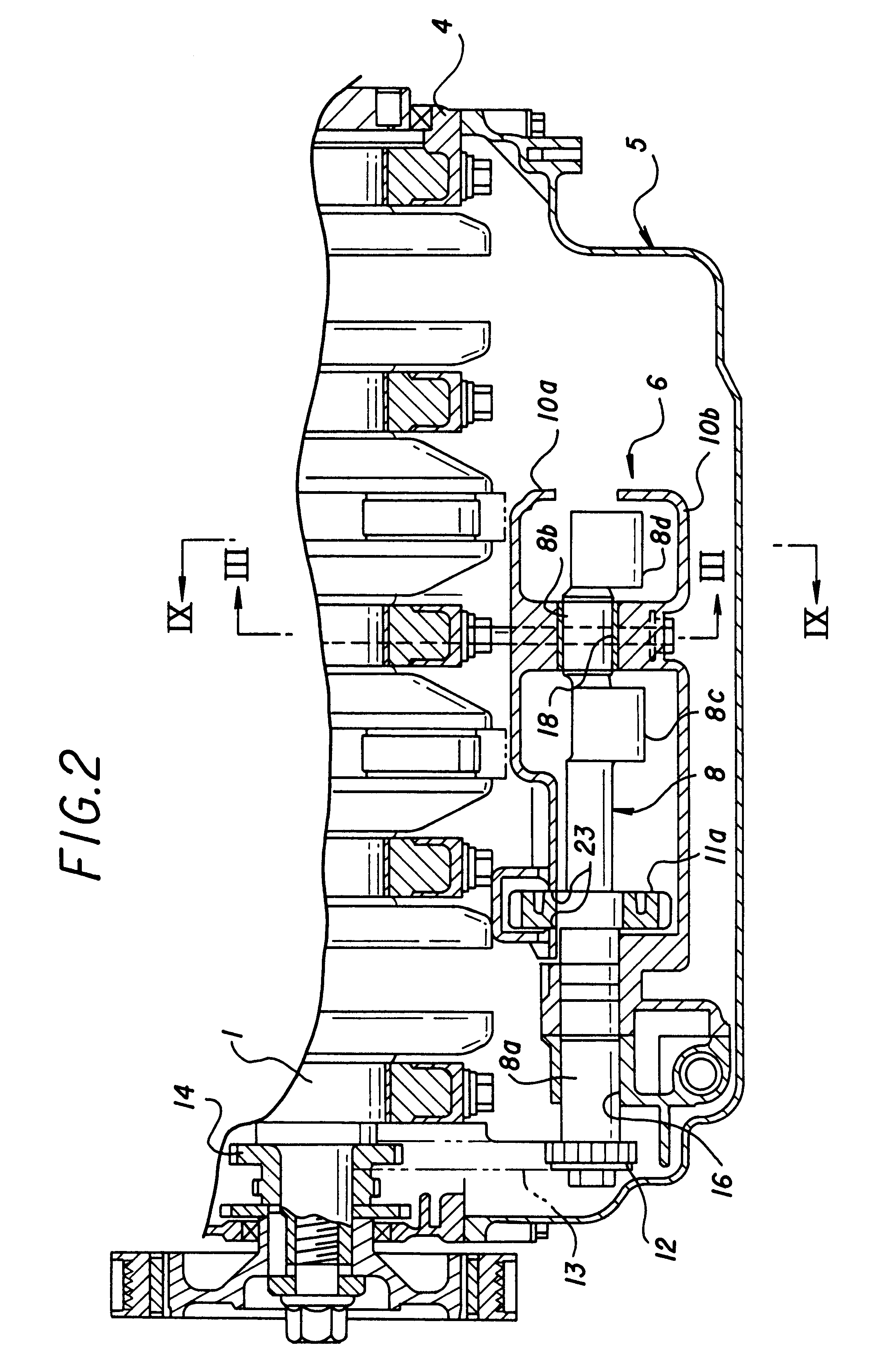

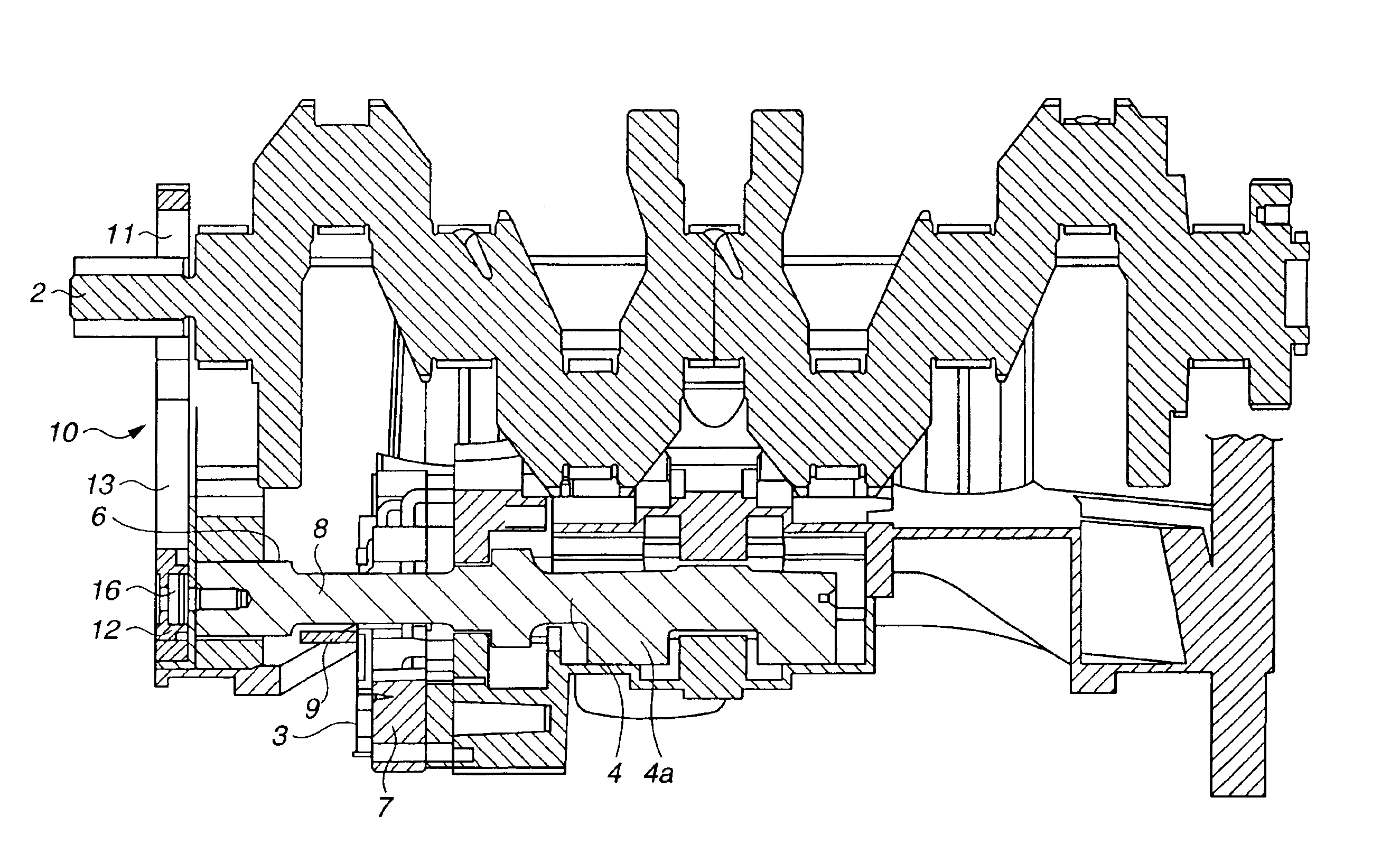

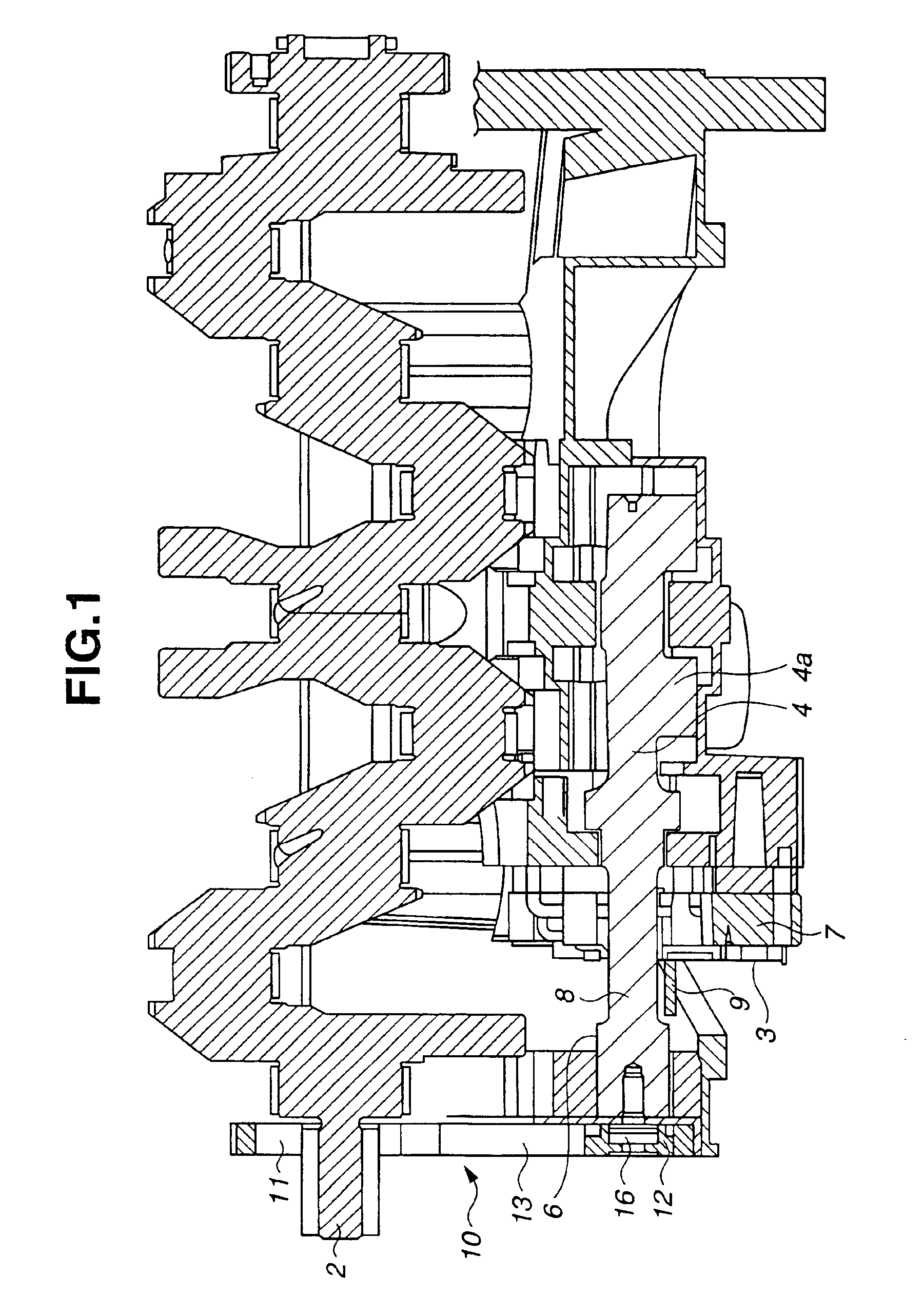

Engine balance shafts supporting structure

A casing accommodating therein a pair of balance shafts below the cylinder block comprises an upper casing and a lower casing that can vertically be split, and an oil pump body is molded integrally with one of the upper and lower casings. In addition, one end of each of the two casings is inserted into the oil pump body for support therein, and the two balance shafts are each supported on a bearing provided between the two casings in such a manner as to be split into two halves at an intermediate portion or the other end thereof. With this construction, the oil pump body can be molded together with the casing, thereby making it possible to reduce the number of components used and man hours for assembling. In addition, since the bearings can be split into two halves, when compared with other portions of the balance shafts, the journal portion can be thinned, thereby making it possible not only to reduce the sliding friction but also to make the casing smaller in size and lighter in weight. More over, the degree of freedom of designing balance shafts can also be improved. With the balance shaft supporting structure for an engine the durability of a balancer, as well as the degree of freedom of designing the same are improvided without making the engine larger in size and increasing the number of components used.

Owner:HONDA MOTOR CO LTD

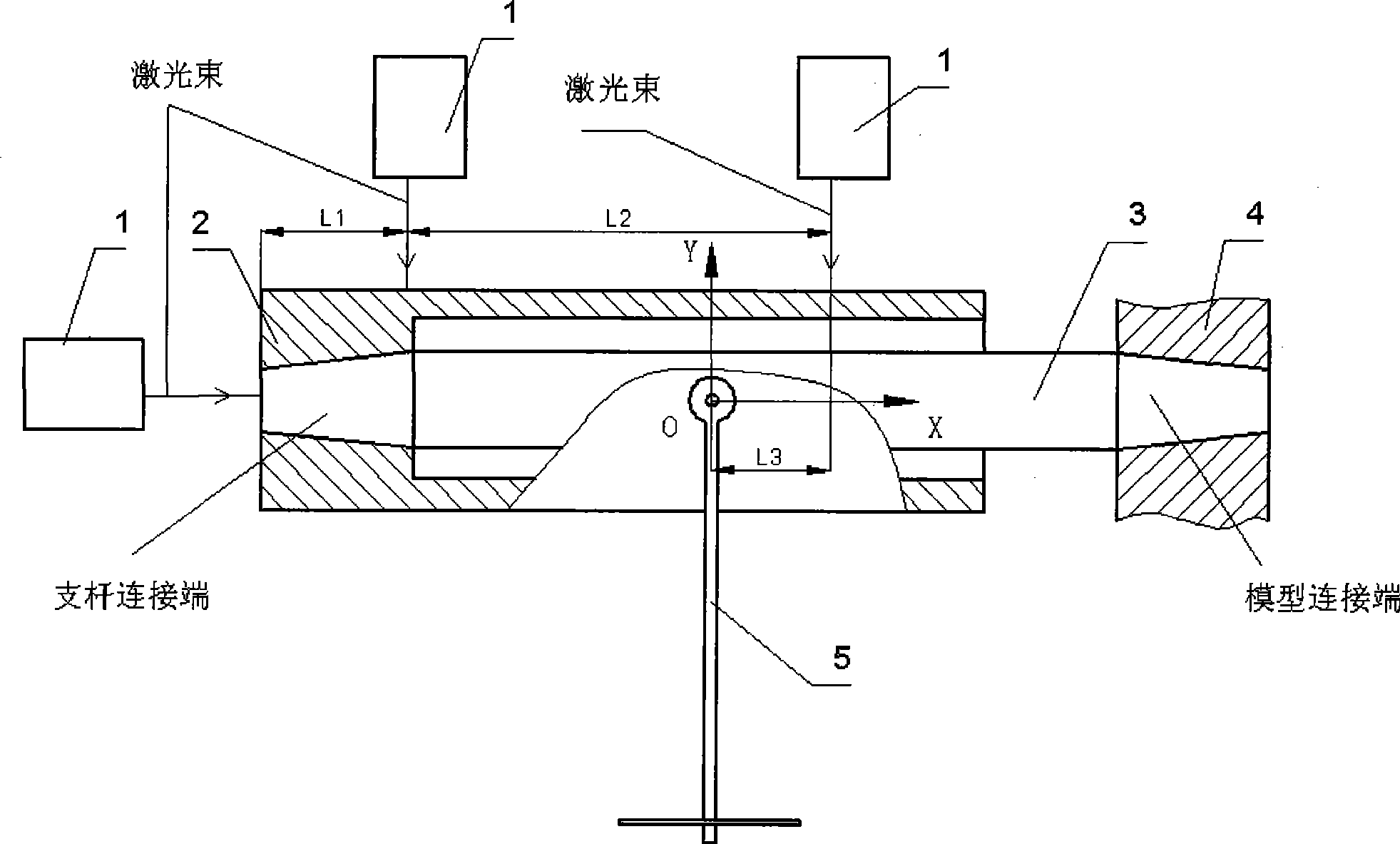

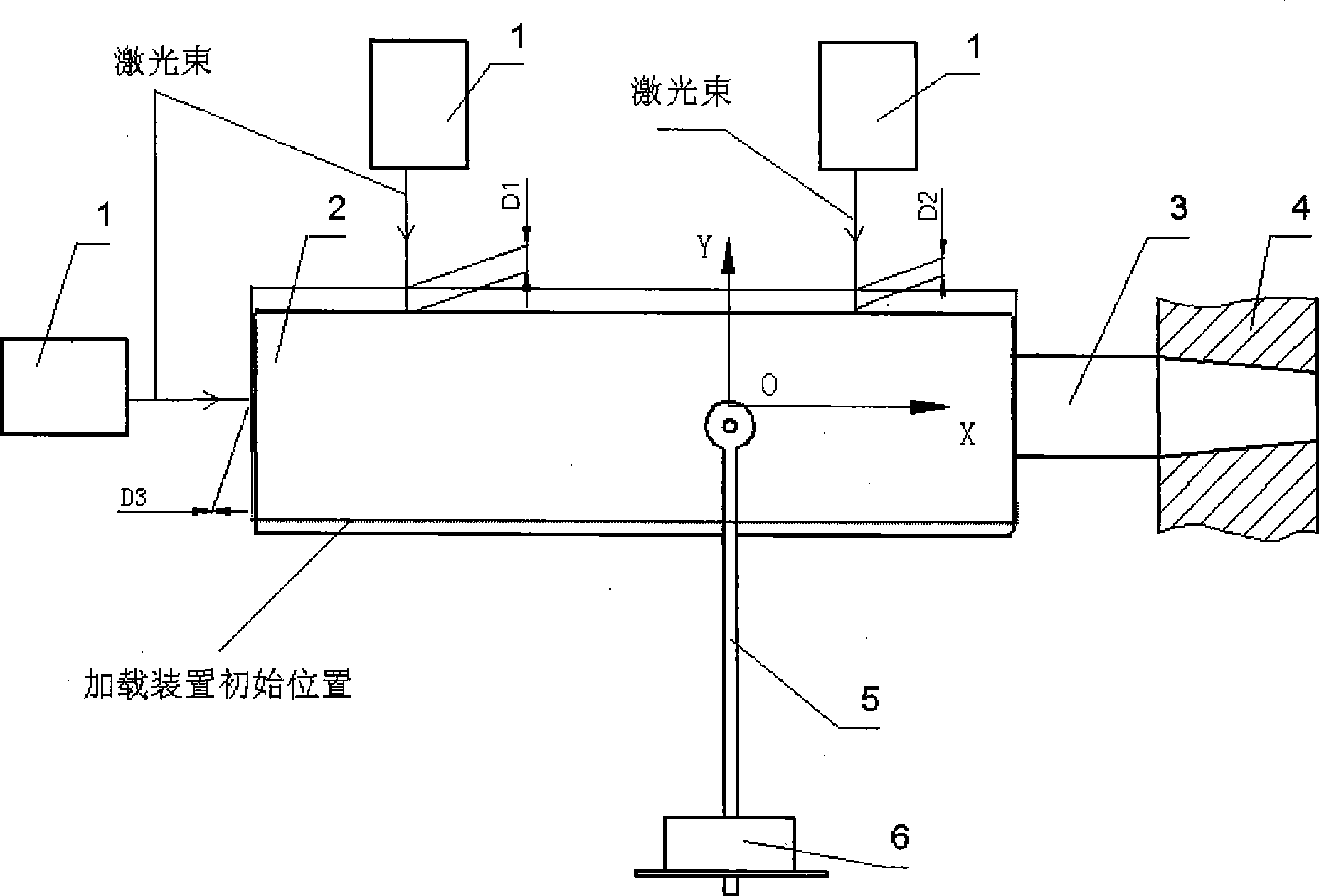

Support reaction type wind-tunnel balance shafting static calibration method

ActiveCN101419118ASimplify static calibration deviceSimple calculationAerodynamic testingGaussian eliminationEngineering

The invention relates to a method for statically calibrating a body axial system of a bearing reaction wind tunnel balance, wherein a loading device is arranged on a connecting end of a supporting rod of the wind tunnel balance, and the displacement of the loading device of the wind tunnel balance is measured through a laser displacement sensor which is arranged on a rigid support; after the wind tunnel balance is loaded, the reading of the laser displacement sensor is acquired, and the displacement of the loading device of the wind tunnel balance and the displacement of various loading points are calculated; the load exerted is subjected to translation and synthesized on an origin of a coordinate system of a body axle, and the bearing reaction generated on the wind tunnel balance by a base on the origin of the coordinate system of the body axle is solved and taken as the load of the body axial system of the wind tunnel balance; and a static calibration formula of the wind tunnel balances is solved through the least square method and the Gaussian elimination method by combination of the increment of outputted voltage signals before and after loading of all the wind tunnel balances and the loads of body axial systems. The static calibration method can simplify a static calibration device of the wind tunnel balance, not only does not need to use a complex offset-type or single-vector motion mechanism but also does not need to be limited by the performance of a reference balance, and is simple to calculate due to fixed position of the body axial system of the wind tunnel balance compared with the displacement method of a measuring and loading device.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

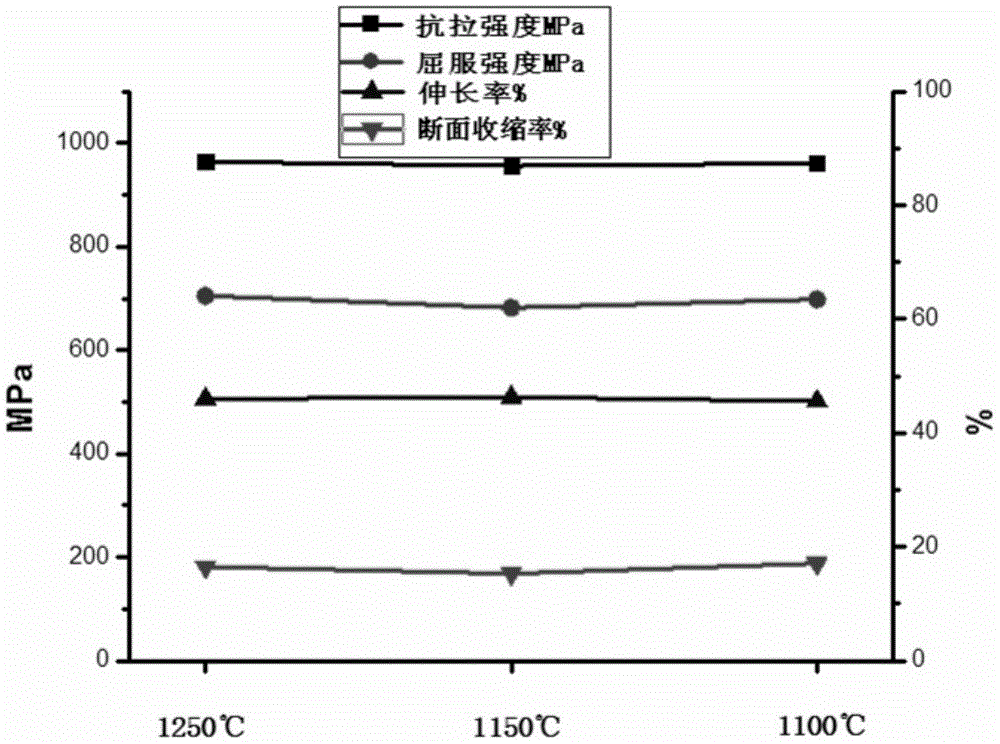

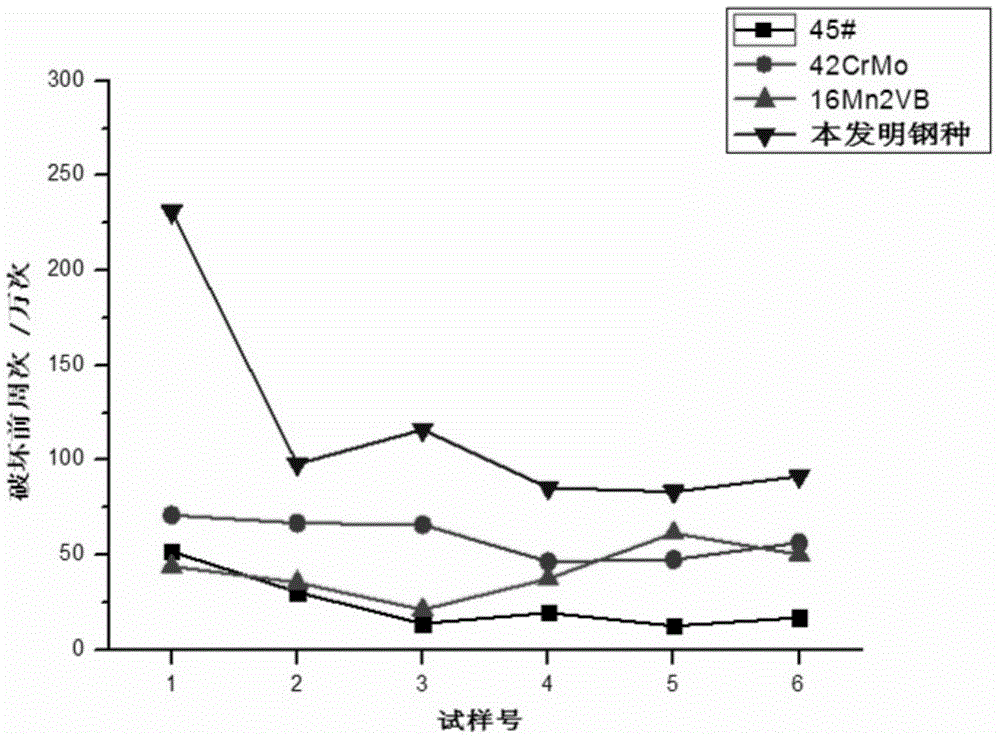

Non-quenched and tempered steel for heavy truck balance shaft and manufacturing method thereof

The invention discloses a non-quenched and tempered steel for a heavy truck balance shaft. The non-quenched and tempered steel is prepared from the following components in percentage by mass: C, Si, Mn, P, S, Cr, V, Ni, Cu, Mo, Ti, Alt, N, O, H, Sn, Sb, As, Pb and Fe. The invention also provides a preparation method of the non-quenched and tempered steel for the heavy truck balance shaft; the non-quenched and tempered steel is produced by virtue of smelting and refining, and reasonable heating, rolling control and cold control processes, and is excellent in properties: the tensile strength of the steel is 960-1000MPa, the yield strength of the steel is 700-750MPa, the elongation percentage of the yield is greater than or equal to 15%, the percentage reduction of area of the steel is greater than or equal to 40% and the longitudinal impact of the steel at the normal temperature of 20 DEG C is greater than or equal to 50J; in addition, the steel has an excellent toughness match, and is excellent in processability, high in forging technical adaptability and steady in performance.

Owner:NANJING IRON & STEEL CO LTD

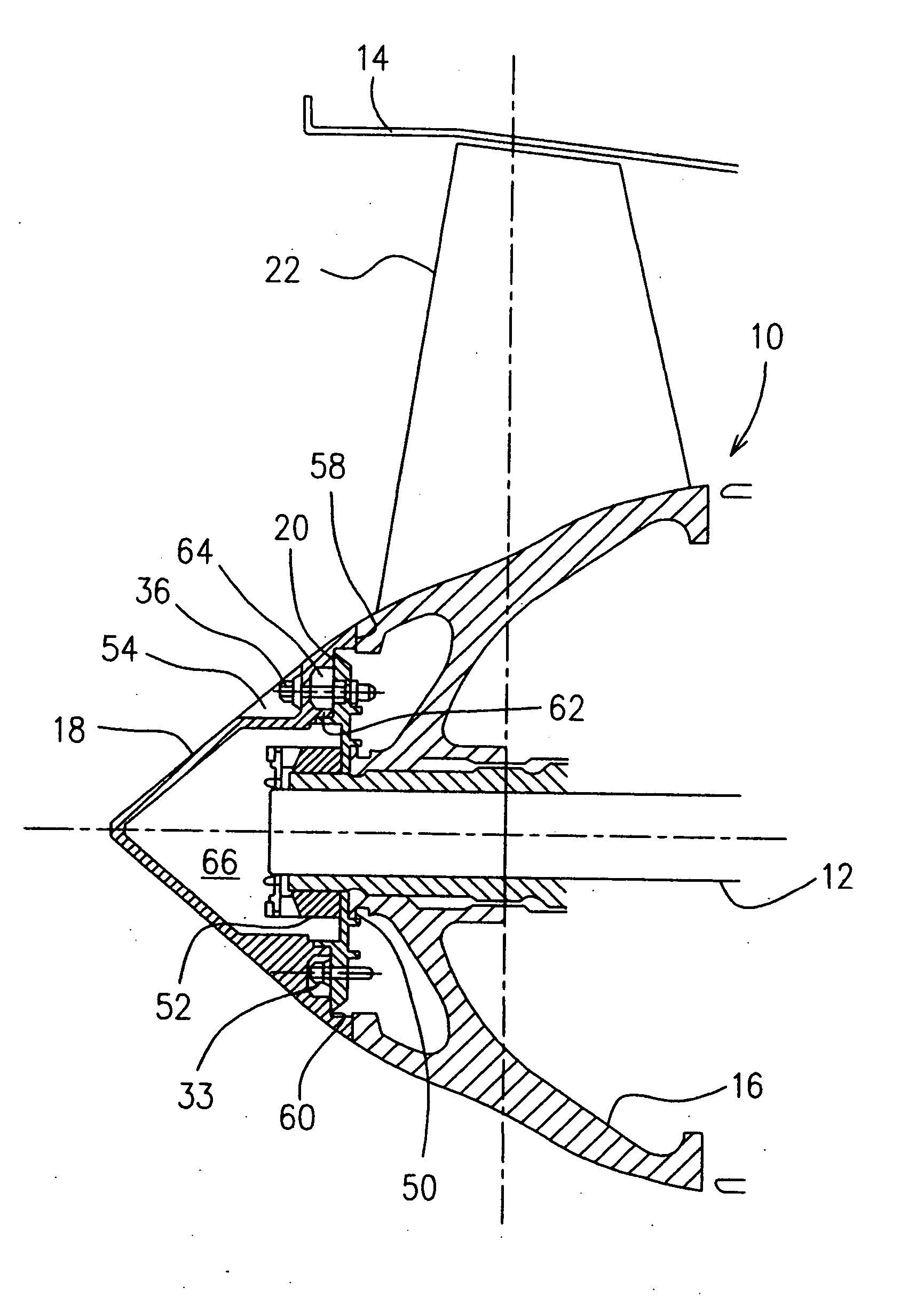

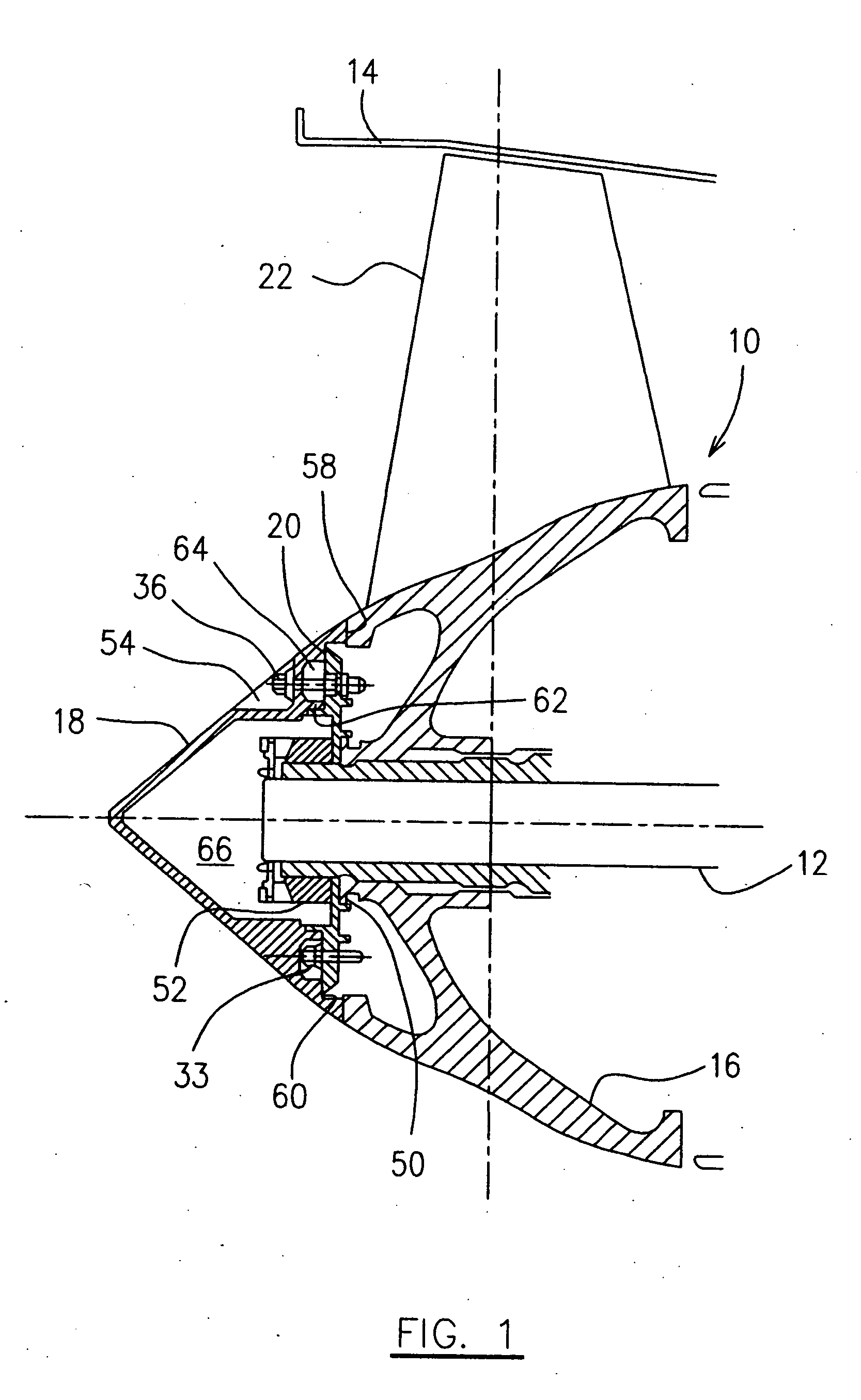

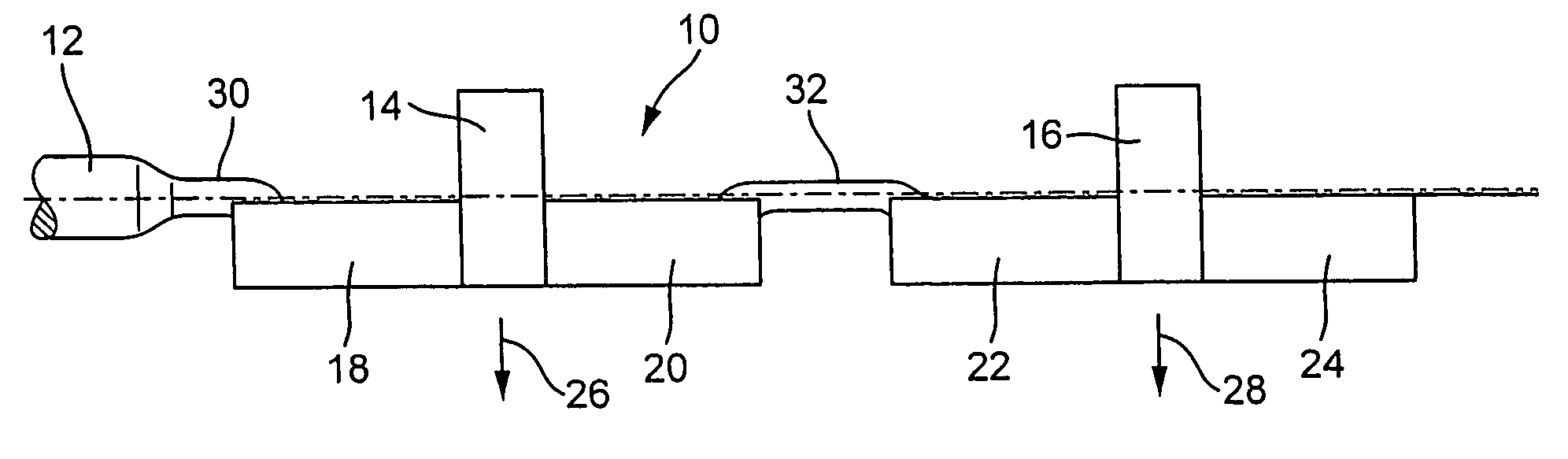

Apparatus and method of balancing a shaft

ActiveUS20050231052A1Reduce manufacturing costsInertia force compensationPropellersEngineeringBalance shaft

An apparatus for balancing a shaft of an aircraft engine preferably includes a plate and the use of standard fasteners. The plate provides mounting for nose cone, and the balancing apparatus may be accessed from the front of the assembled engine.

Owner:PRATT & WHITNEY CANADA CORP

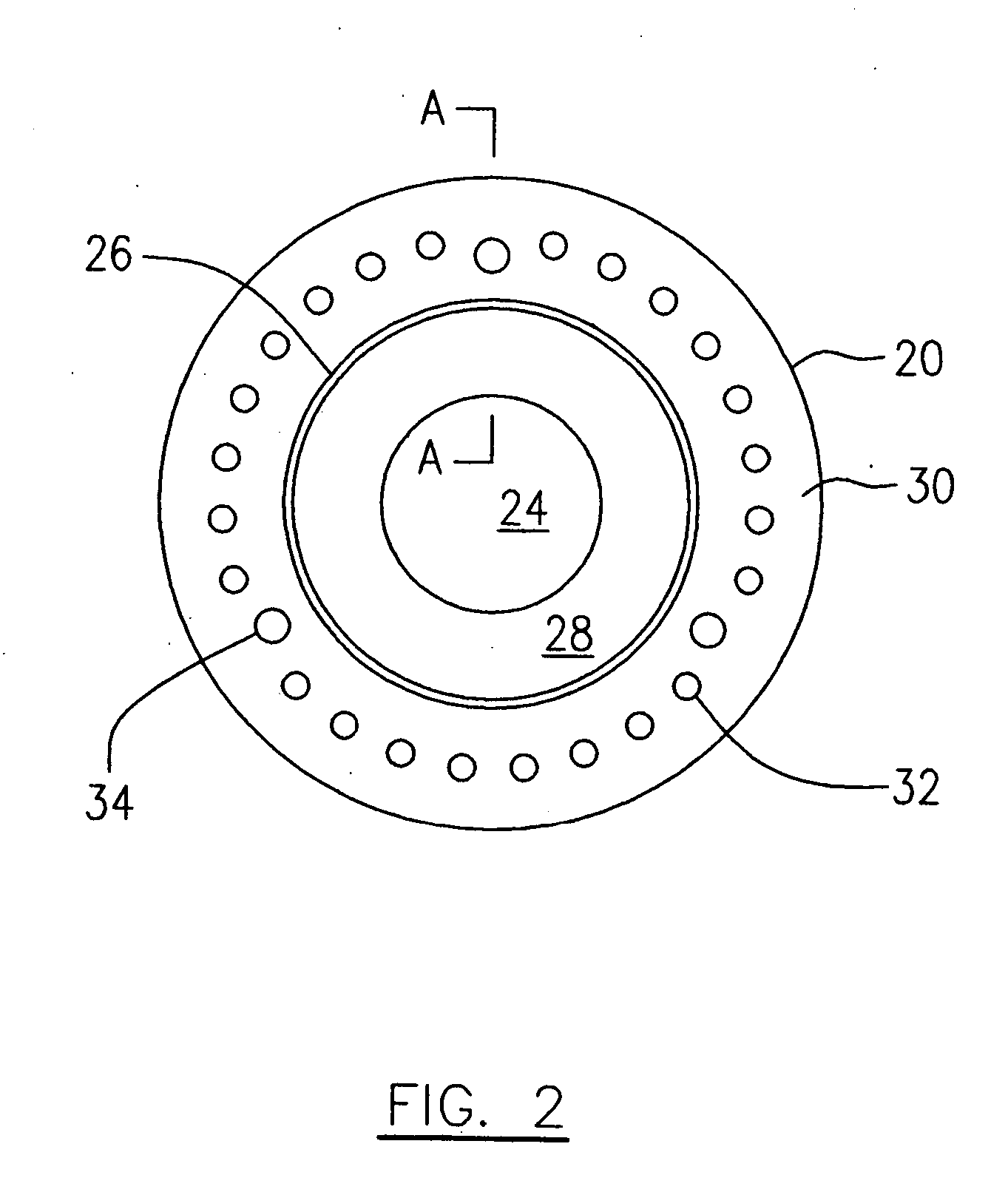

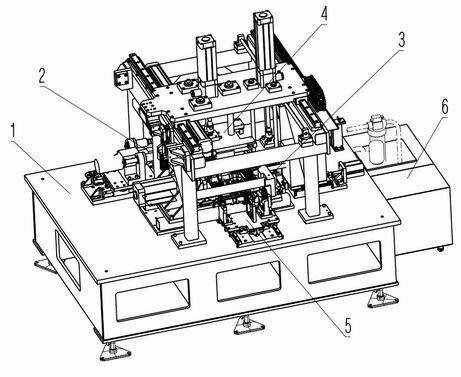

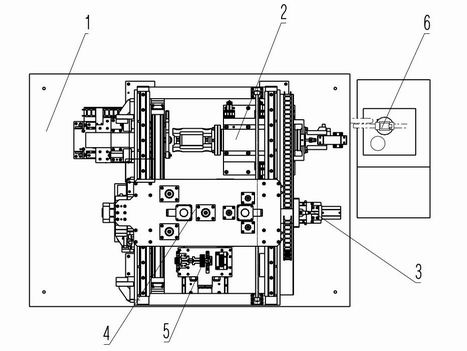

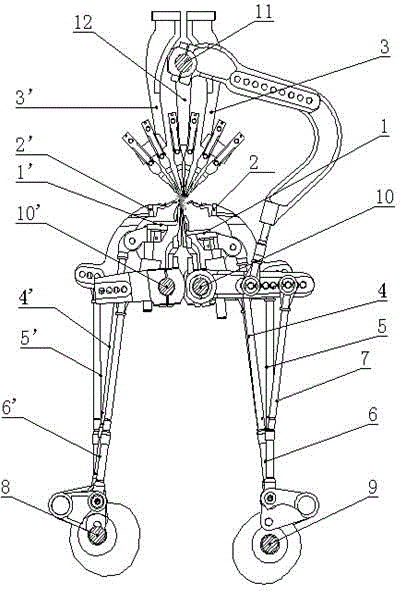

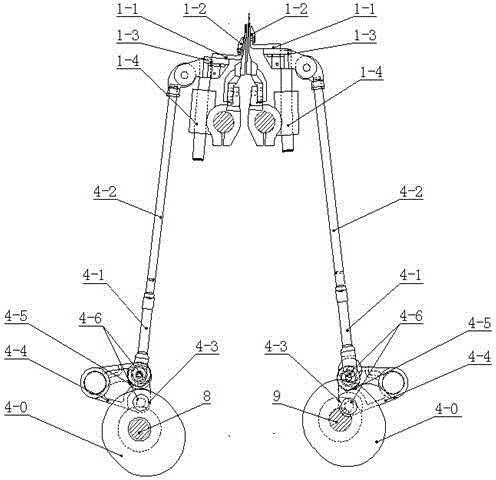

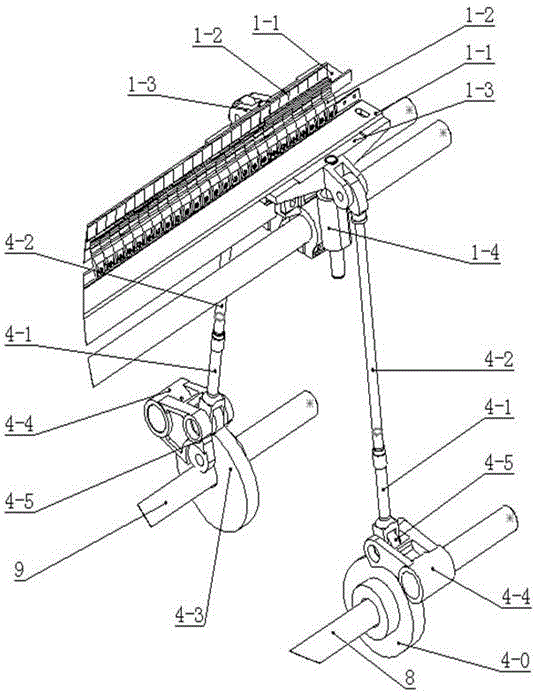

Automatic hot-pressing assembly device of balancing shaft and helical gear

InactiveCN102029501AImprove reliabilityWill not polluteMetal working apparatusBalancing machineGear wheel

The invention discloses an automatic hot-pressing assembly device of a balancing shaft and a helical gear, comprising a dynamic balancing machine (2), a gear hot-pressing machine (3), a manipulator (4) and a feeding and blanking station (5), wherein the manipulator (4) clamps a balancing shaft to be assembled and a helical gear to be assembled on the feeding and blanking station (5) and respectively sends the balancing shaft to be assembled and the helical gear to be assembled to the dynamic balancing machine (2) and the gear hot-pressing machine (3), the dynamic balancing machine (2) measures the dynamic unbalance quantity of the balancing shaft and carries out direction alignment on the balancing shaft, the helical gear is heated in the gear hot-pressing machine (3), and the balancing shaft subjected to dynamic unbalance measurement and direction alignment is sent into the gear hot-pressing machine (3) through the manipulator (4) and is in hot-pressing assembly with the heated helical gear. The device has sufficient static, dynamic and heat stable rigidity and accuracy; the whole system has good dynamic performance; and an execution element which is selected for a detection measurement and display system has the advantages of high accuracy, good reliability, strong anti-interference ability, high response speed and stable continuous processing performance.

Owner:HUAZHONG UNIV OF SCI & TECH

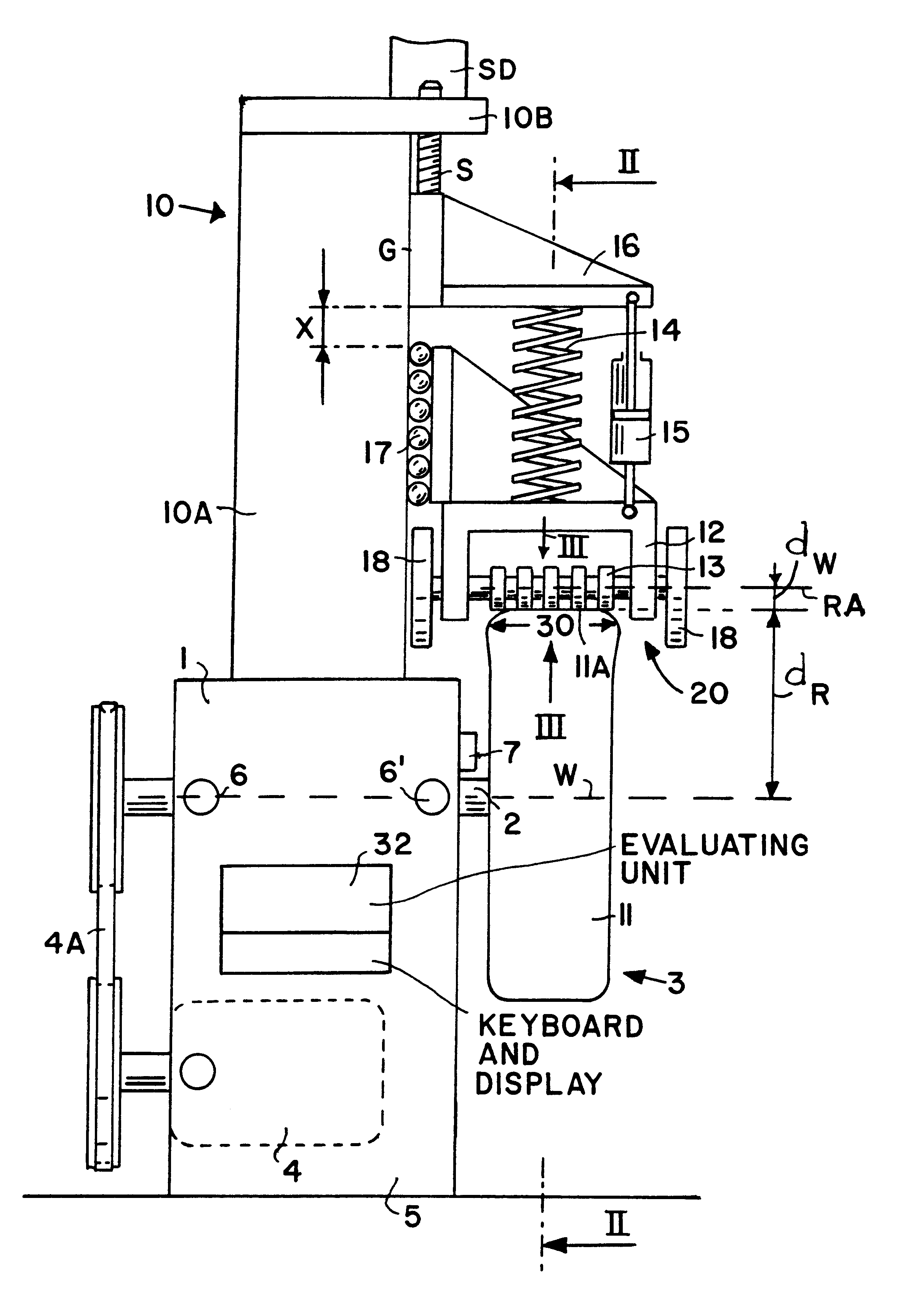

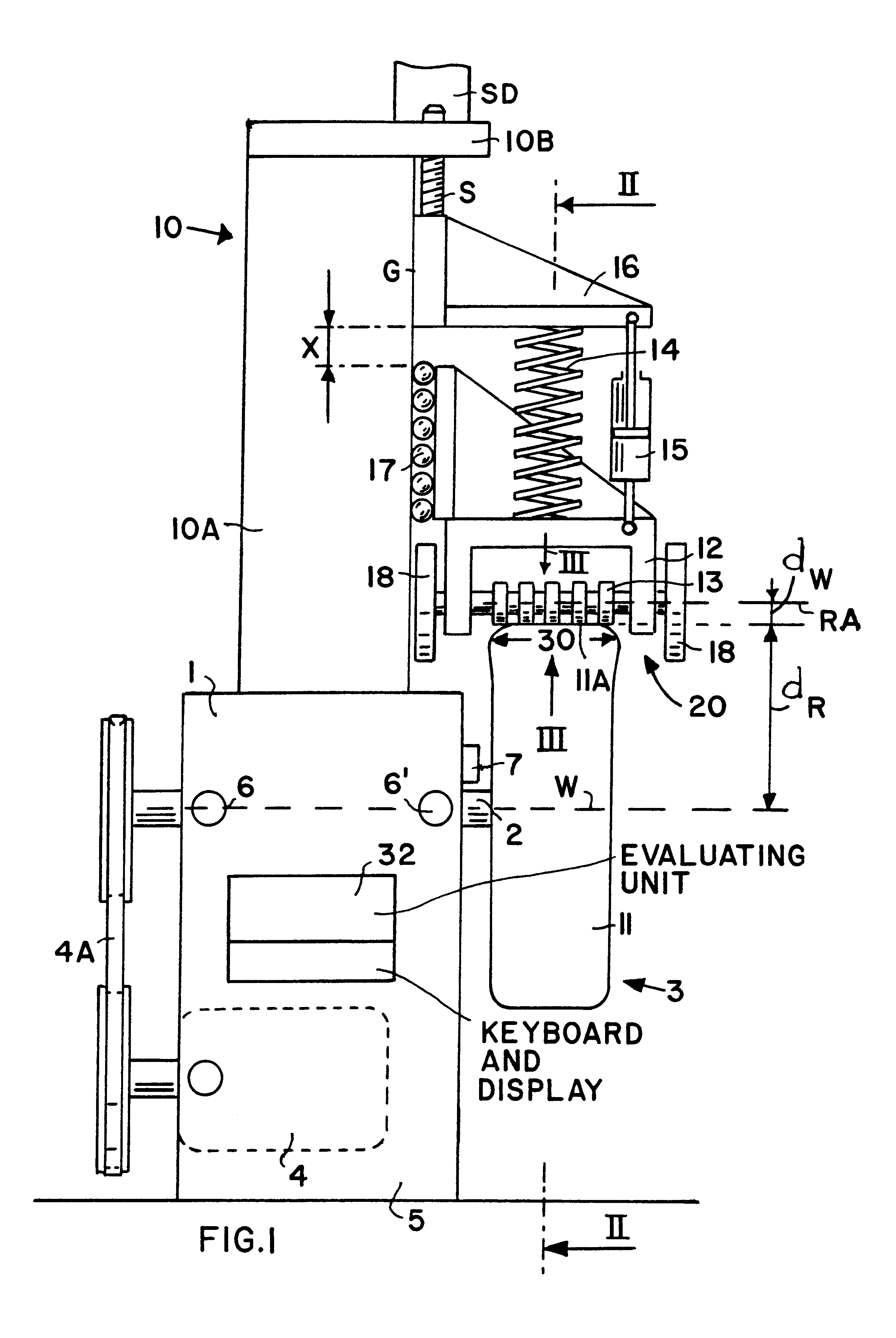

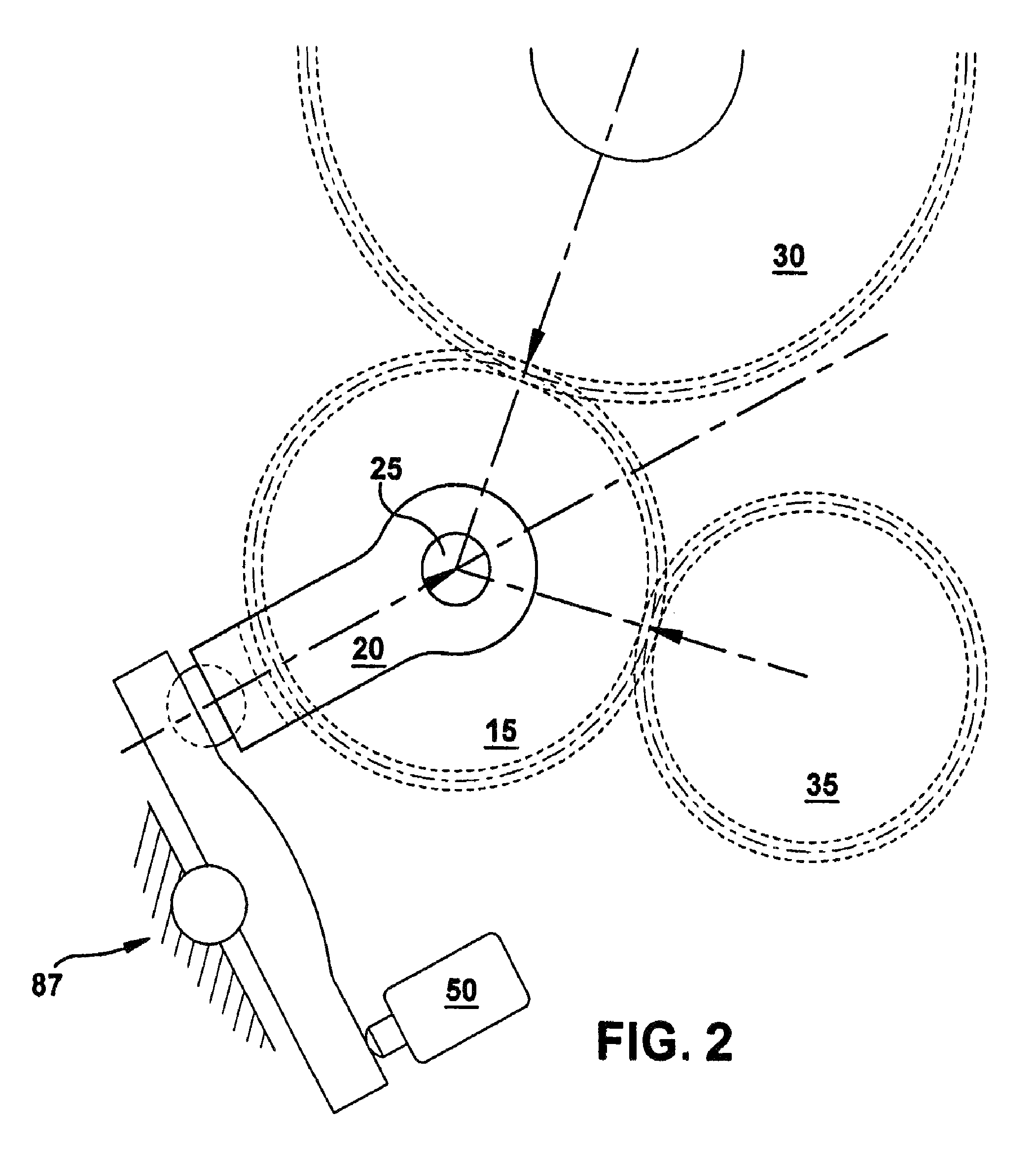

Method and apparatus for reducing vibrations transmitted to a vehicle from a wheel unit

InactiveUS6360593B1High simulationSimpler to precisely determineStatic/dynamic balance measurementUsing mechanical meansBrakeDynamic balance

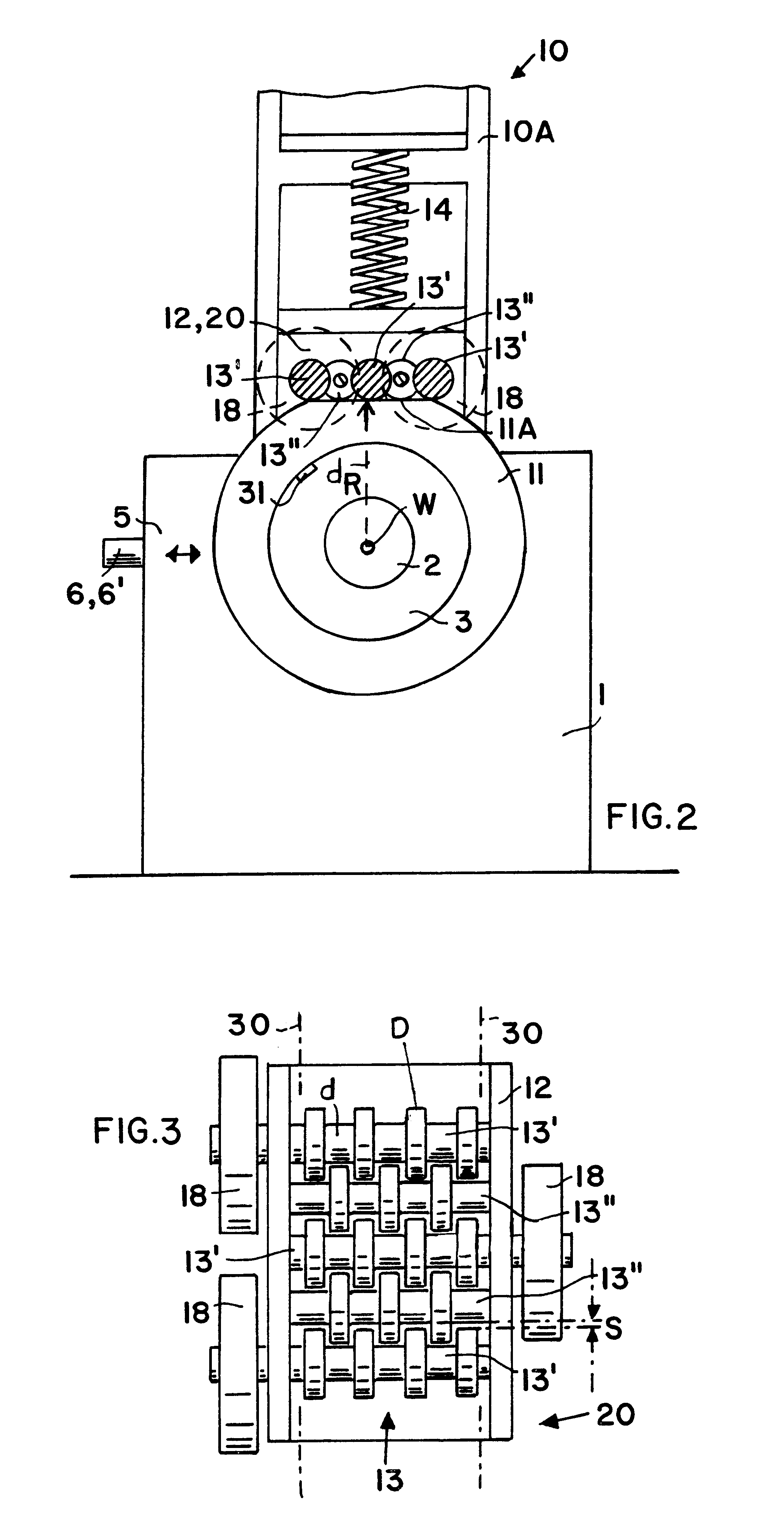

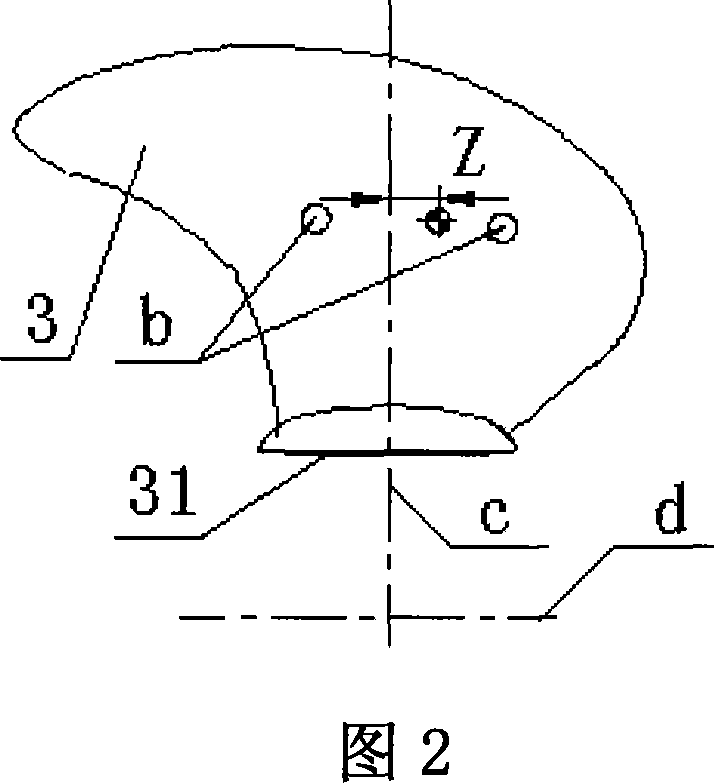

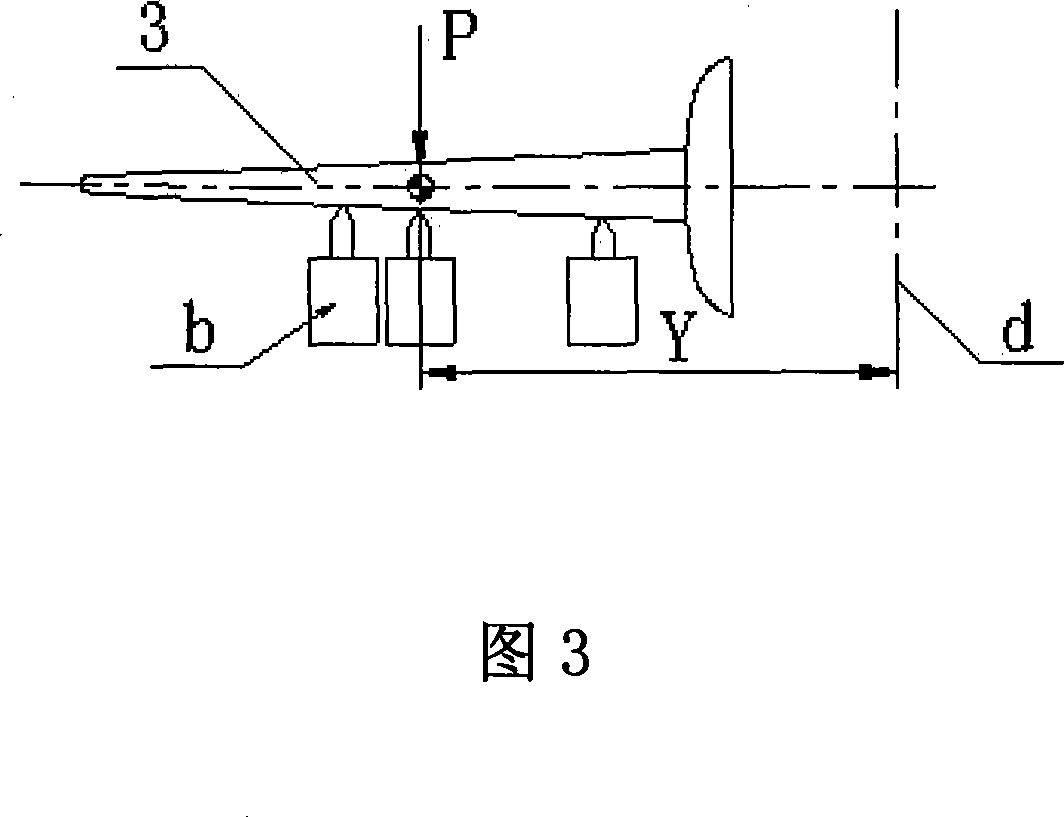

Vibrations generated by the wheel units of a vehicle are reduced by a low pulsating operation that optimally simulates actual vehicle operating conditions. For this purpose the mass moment of inertia of the wheel unit and of rotating components such as the hub and the brake disc are taken into account. The wheel unit is rotatably mounted on a balancing spindle (2) in a measuring apparatus to determine the mass and angular location of balancing weights (31). The vibrations are measured at a speed that corresponds to a typical travel speed of a vehicle. A loading mechanism including a roller shoe (20) applies a force to the tire tread surface through a spring damping (14, 15) to optimally simulate the conditions of a roadway. The roller shoe (20) has rollers (13) with sections of larger and smaller diameters so that neighboring rollers intermesh. The combined masses of the rollers, as reduced to the roller radius dw, corresponds to the rotational mass of the vehicle wheel as reduced to the tread radius (dR). It is also possible to disengage the contact force from the tread surface for dynamically balancing the wheel unit under load-free conditions. Thus, wheel-balancing steps under loaded and load free conditions can be done on one machine.

Owner:SCHENCK ROTEC GMBH

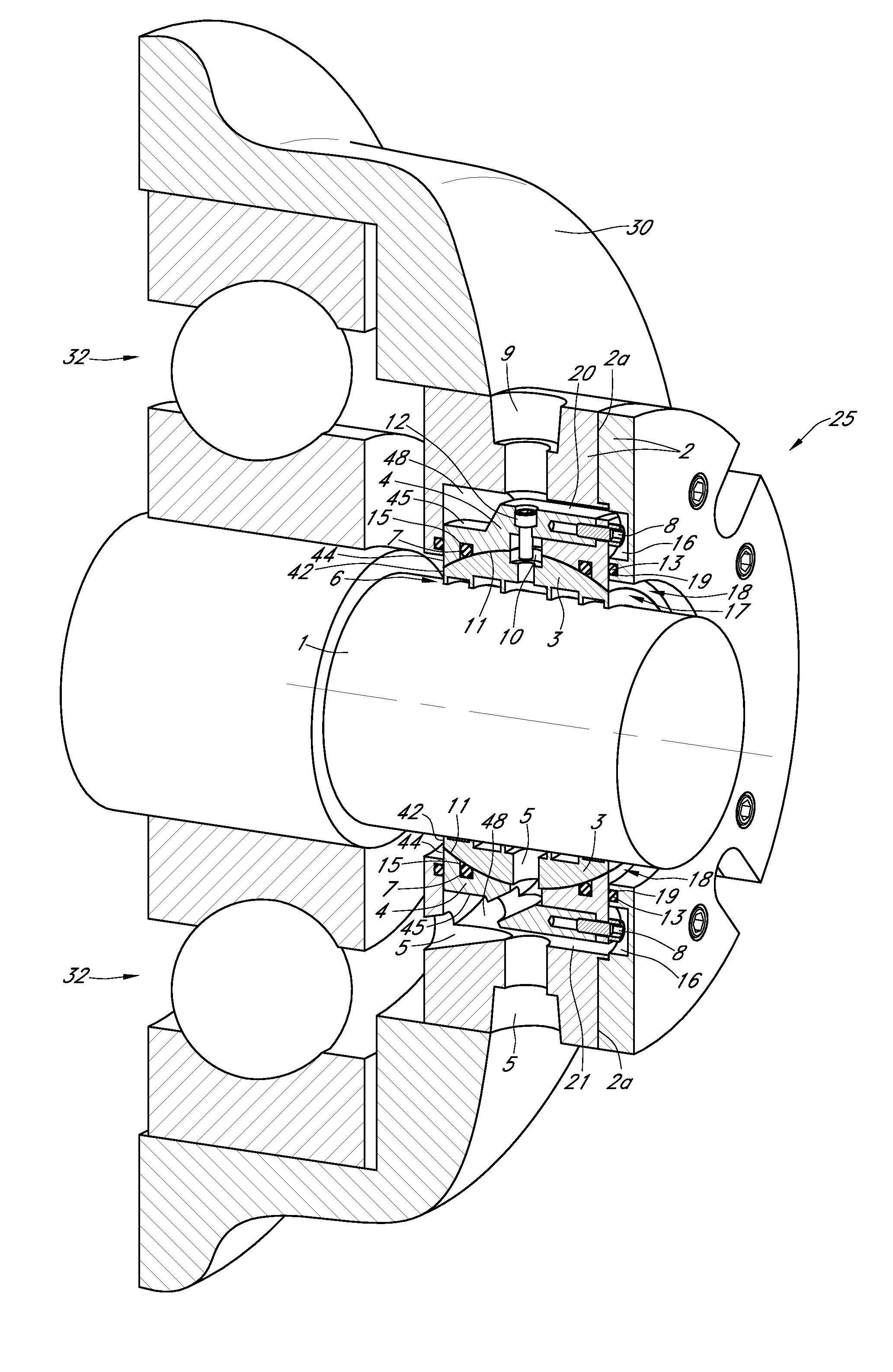

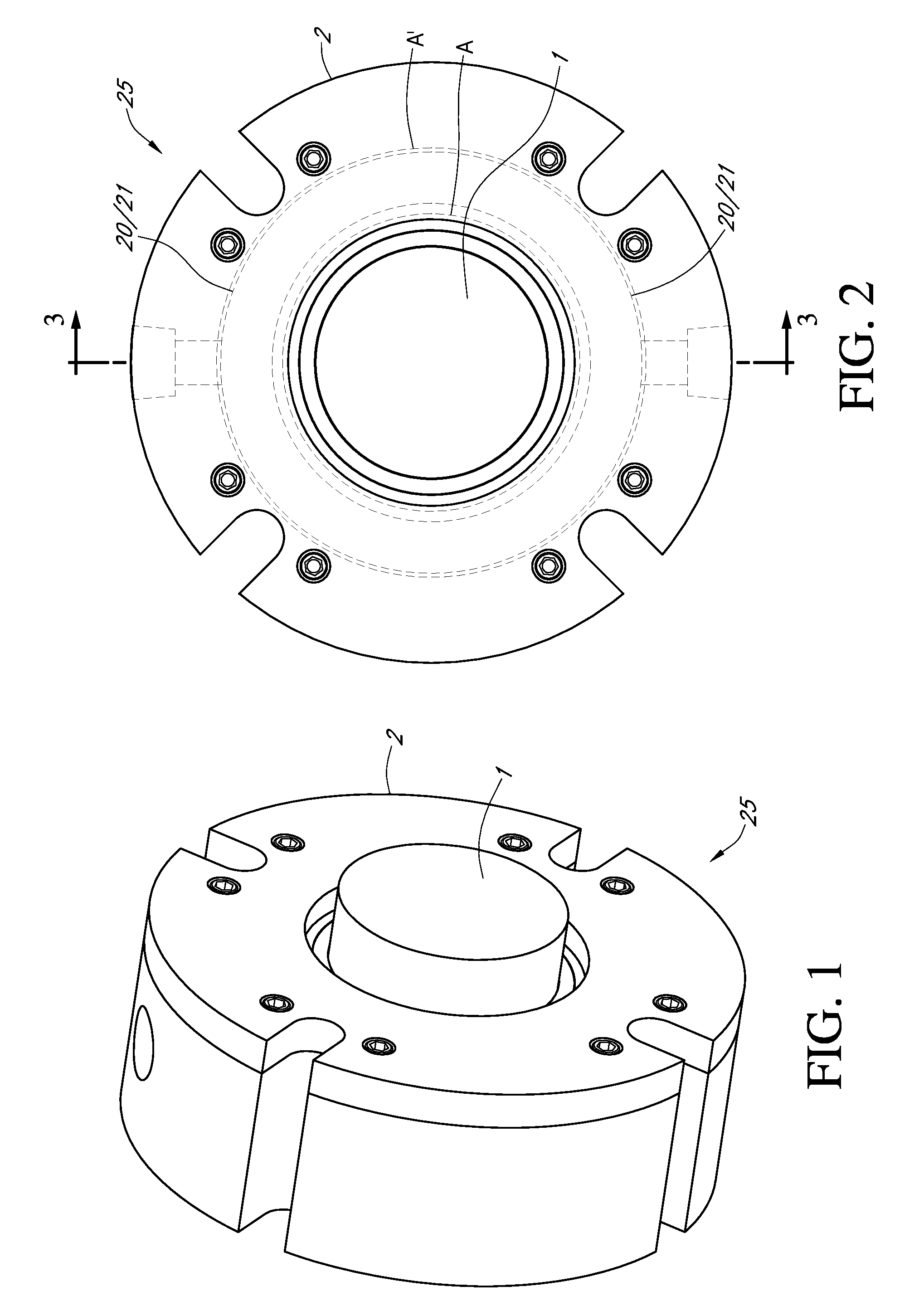

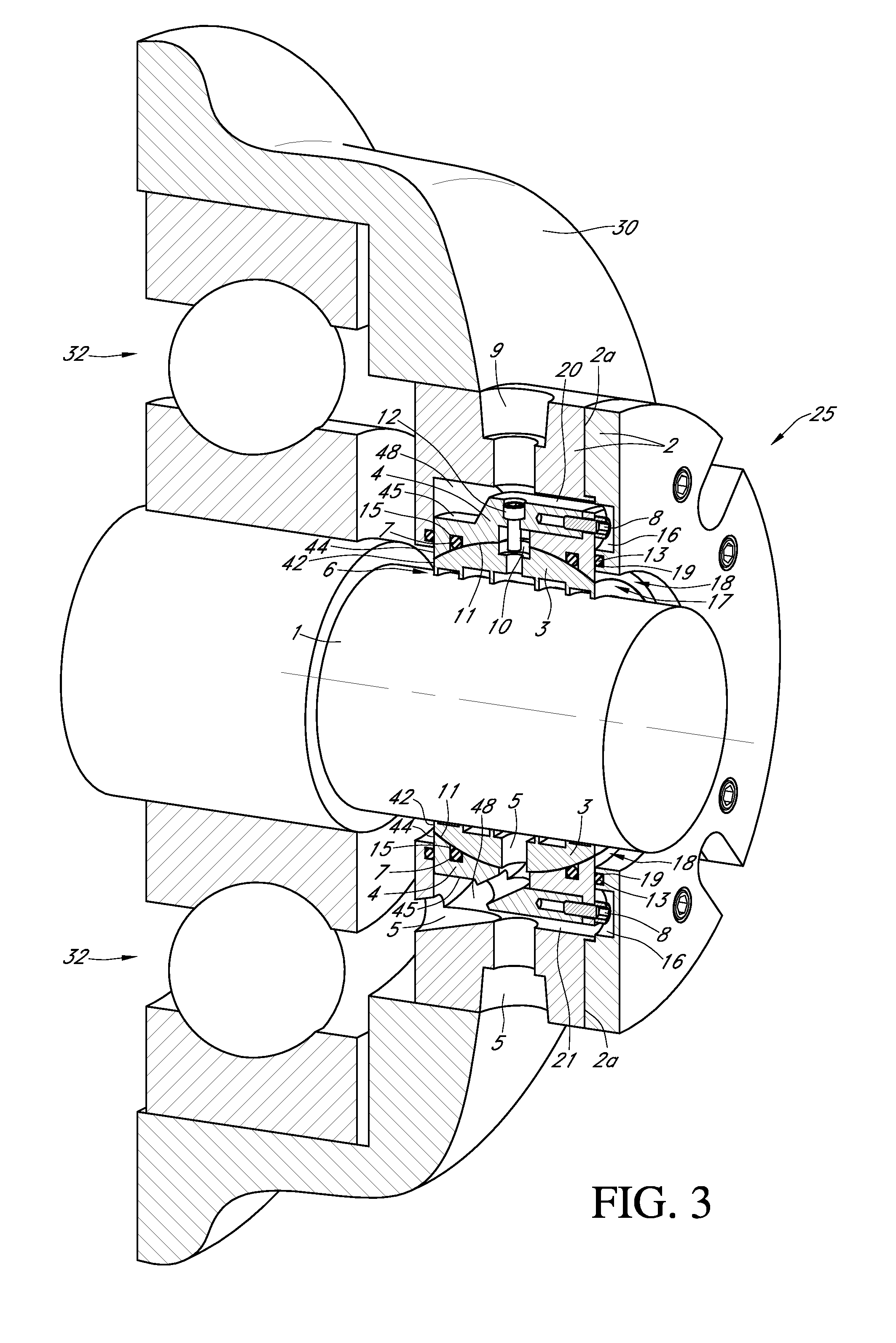

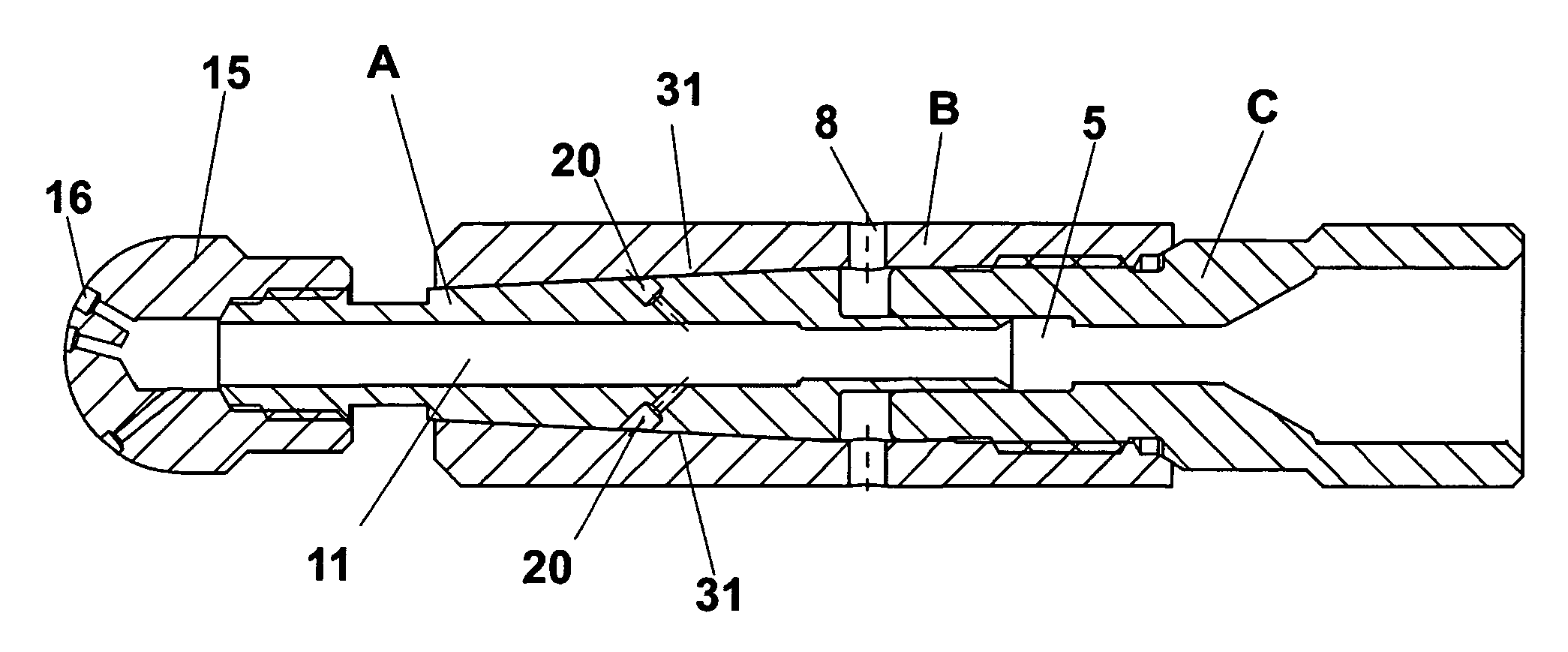

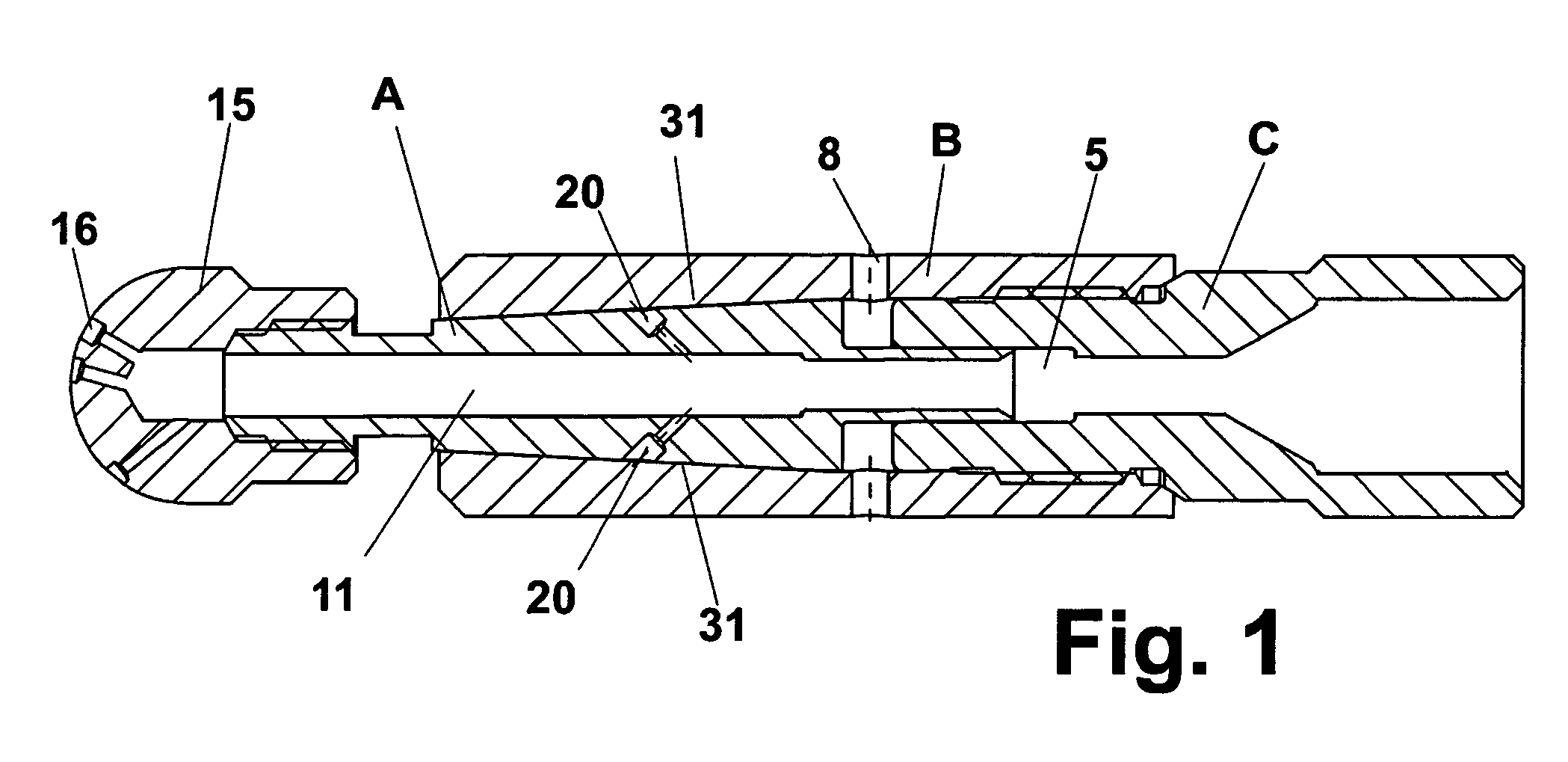

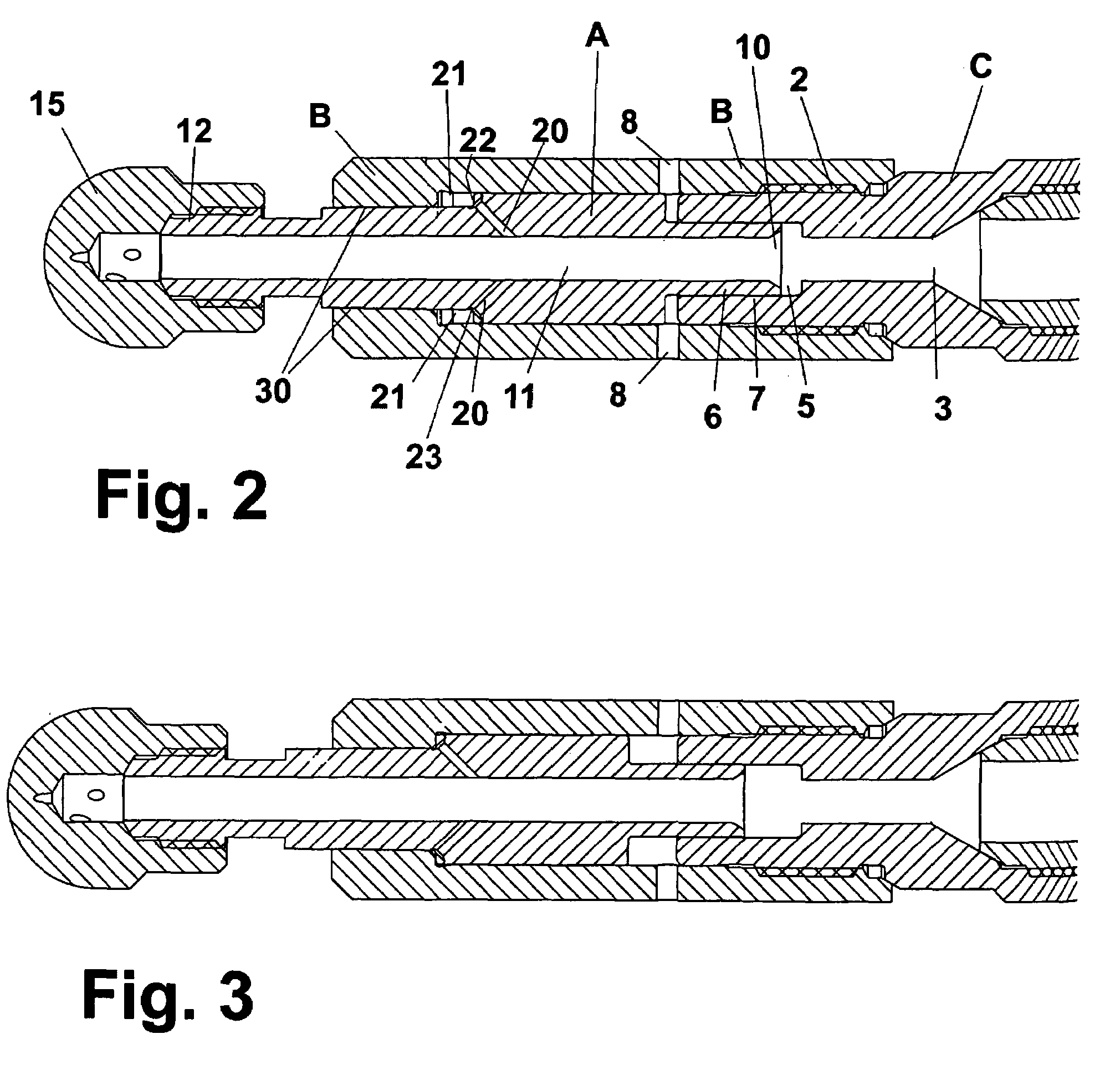

Pressure balanced shaft seal assembly

InactiveUS7726661B2Improve performanceFunction increaseEngine sealsRolling contact bearingsAxial pressureEngineering

A pressure balanced shaft seal assembly that allows a seal to dynamically respond to angular or radial misalignment of a shaft is disclosed. The pressure balanced shaft seal assembly includes a fixed stator, a floating stator, and a labyrinth seal. In one embodiment, the floating stator and labyrinth seal are mounted within an annular groove formed in the fixed stator such that the floating stator and labyrinth seal may move a predetermined amount in the radial direction with respect to the fixed stator. A spherical interface between the labyrinth seal and floating stator may allow the labyrinth seal to pivot with respect to the floating stator during angular misalignment of a shaft around which the pressure balanced shaft seal assembly is mounted. A pressure balancing annular channel formed in the floating stator allows pressurized seal fluid to balance the axial pressure exerted on the floating stator by the process fluid.

Owner:INPRO INC

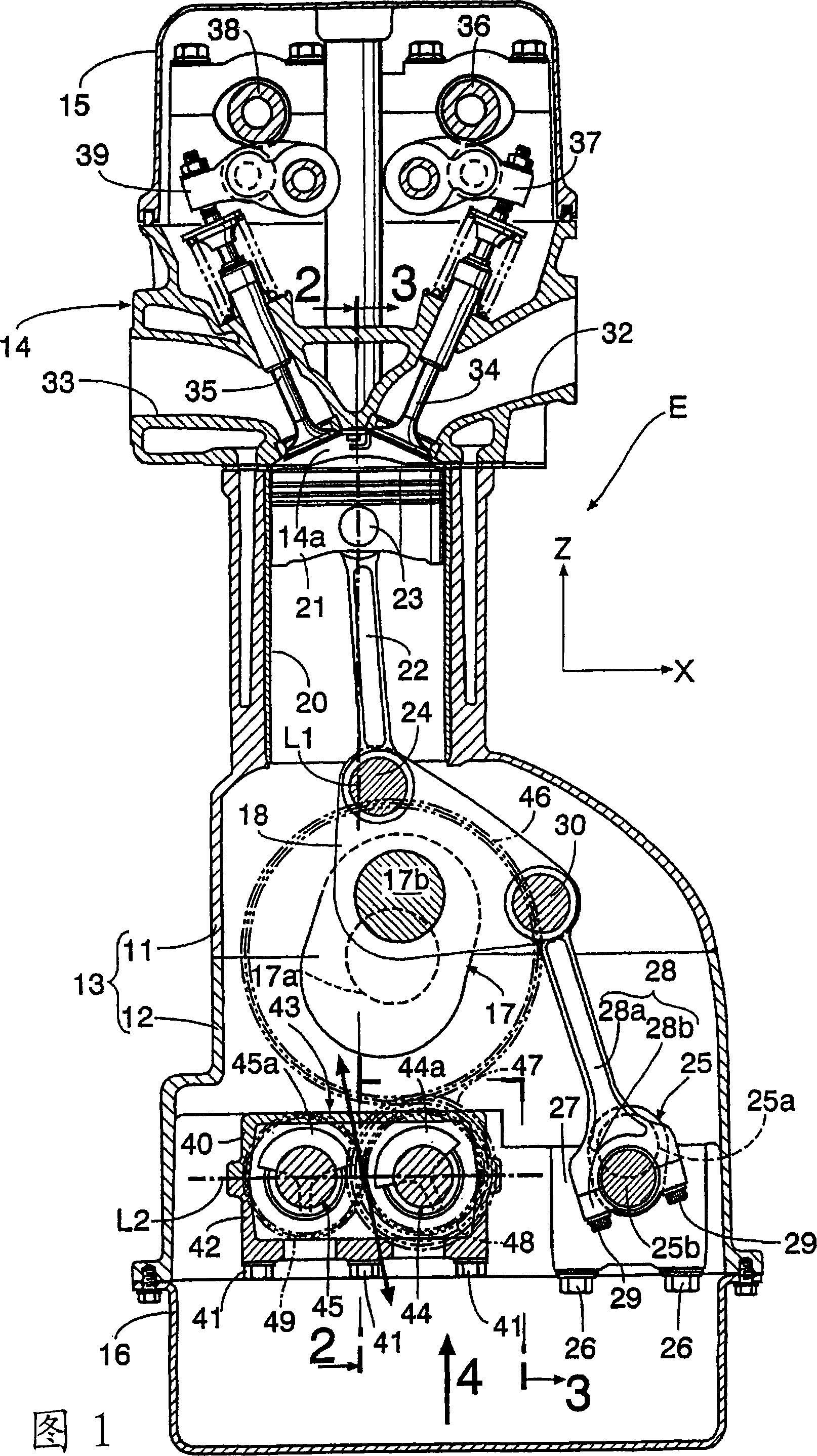

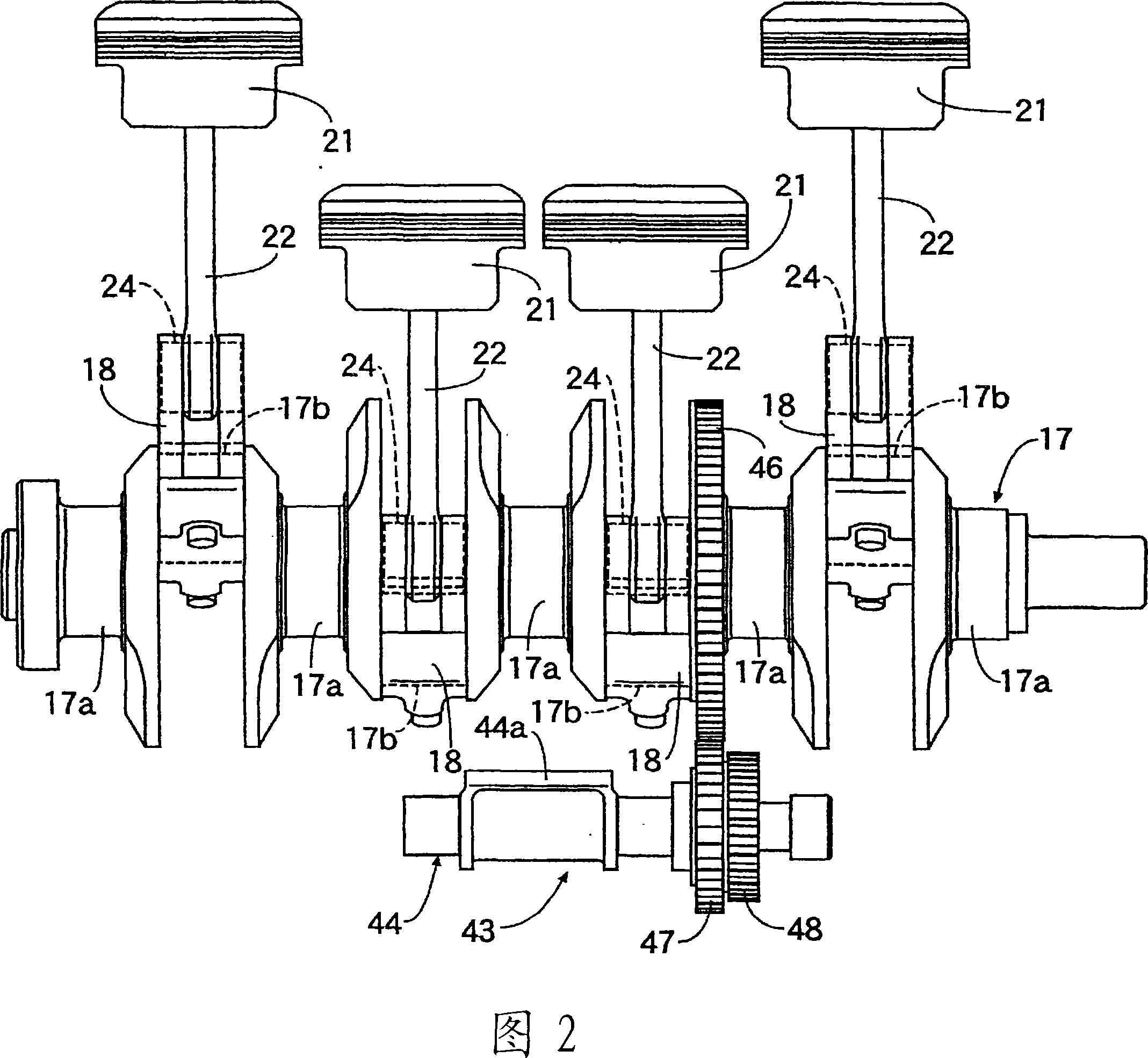

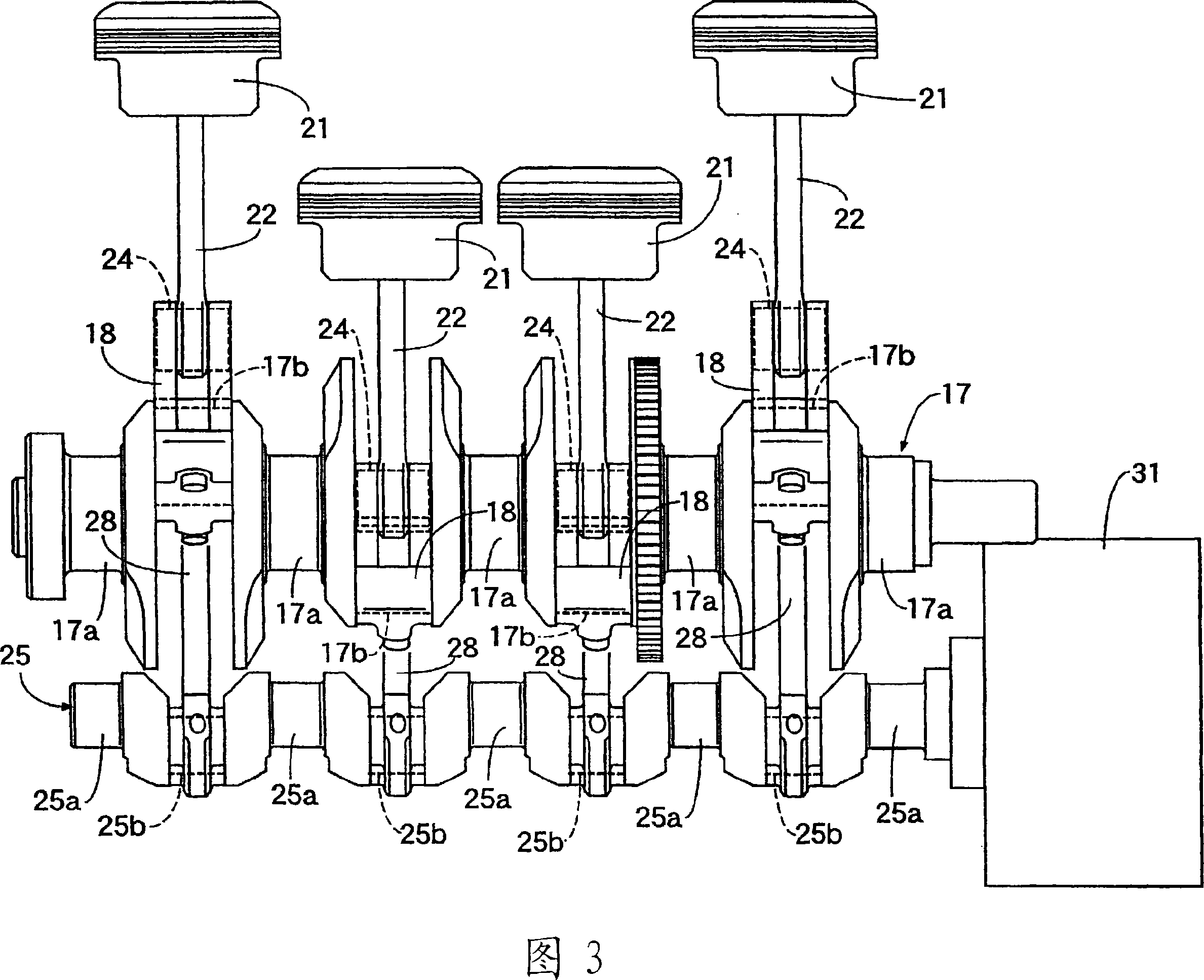

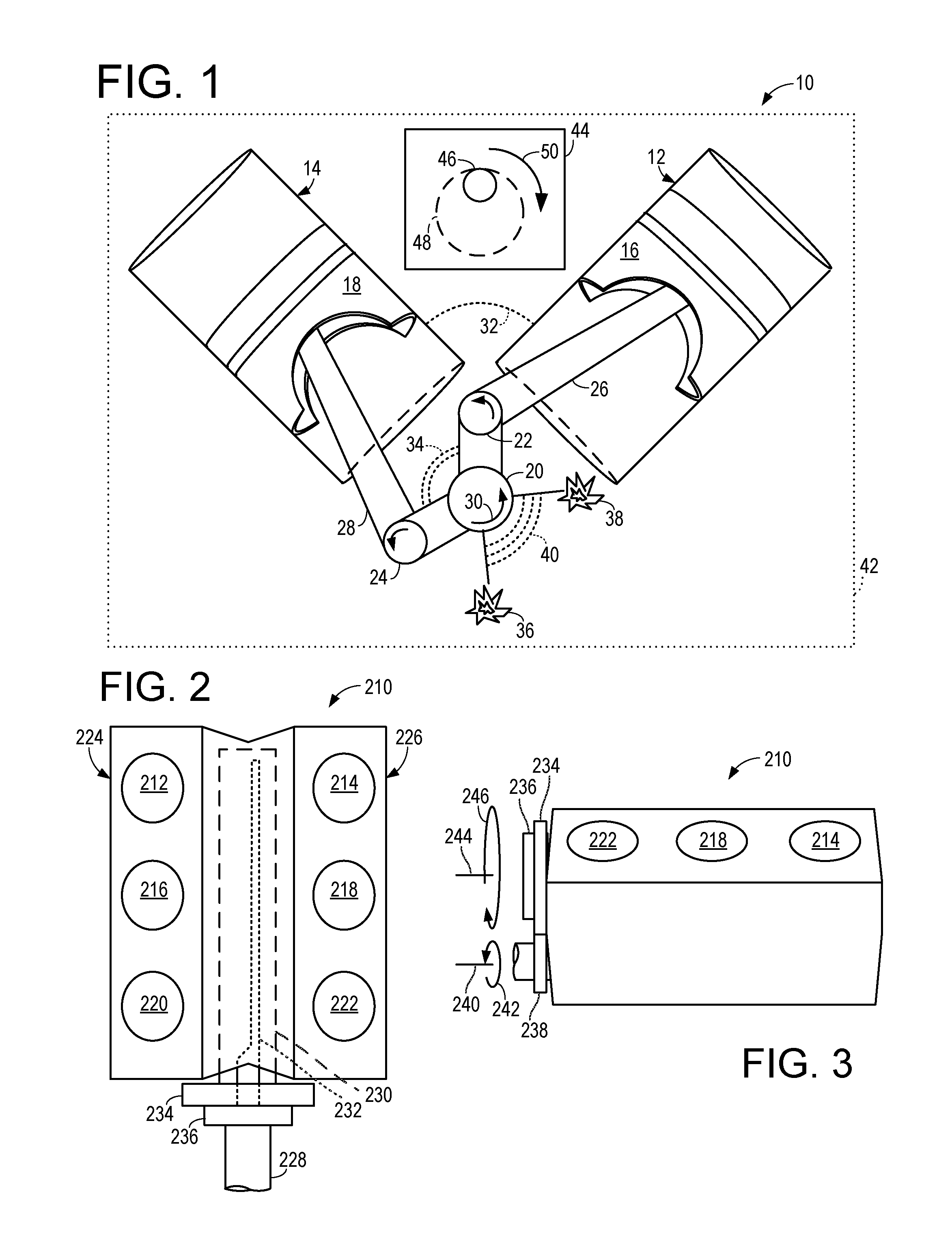

Device for removing engine vibration and engine whose stroke characteriscts are variable

InactiveCN101052822AEliminate vibrationInertia force compensationMachines/enginesEngineeringBalance shaft

A device for removing engine vibration, capable of effectively removing secondary vibration cause by reciprocation of a piston (21) of a multilink-type variable compression ratio engine (E). The secondary vibration can be removed even if the direction of the secondary vibration is inclined relative to the cylinder axis (L1), and the removal is made by inclining the direction (see the arrow direction) of vibration exciting force, produced by a secondary balancer device (43), so that it matches the direction of the secondary vibration. The secondary balancer device (43) is constructed by having balancer weights (44a, 45a) respectively supported by a pair of balancer shafts (44, 45) rotating in the directions opposite from each other. Displacing the phases of the balancer weights (44a, 45b) enables the direction of the produced vibration exciting force to be inclined so that it matches the direction of the secondary vibration of the engine (E).

Owner:HONDA MOTOR CO LTD

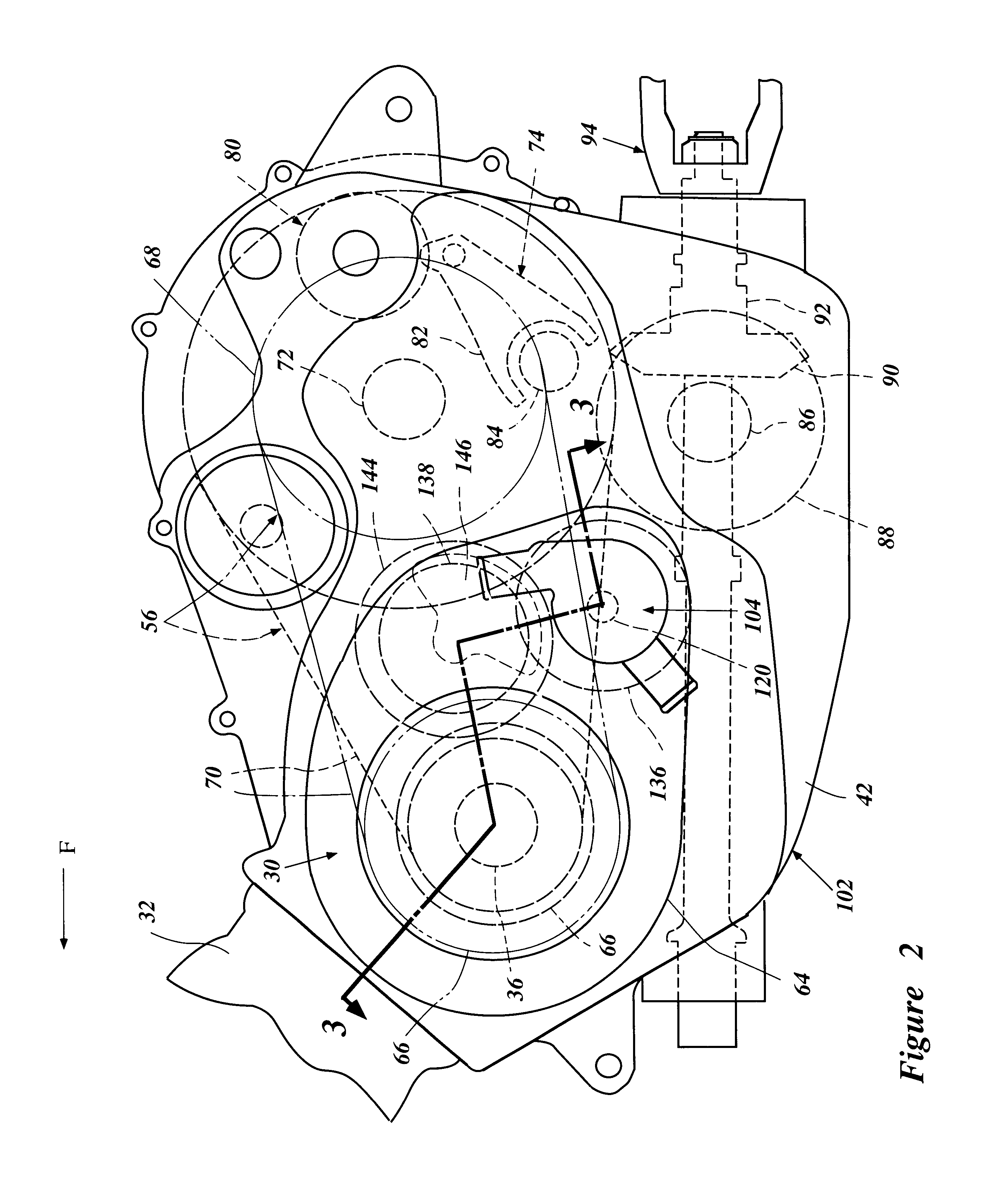

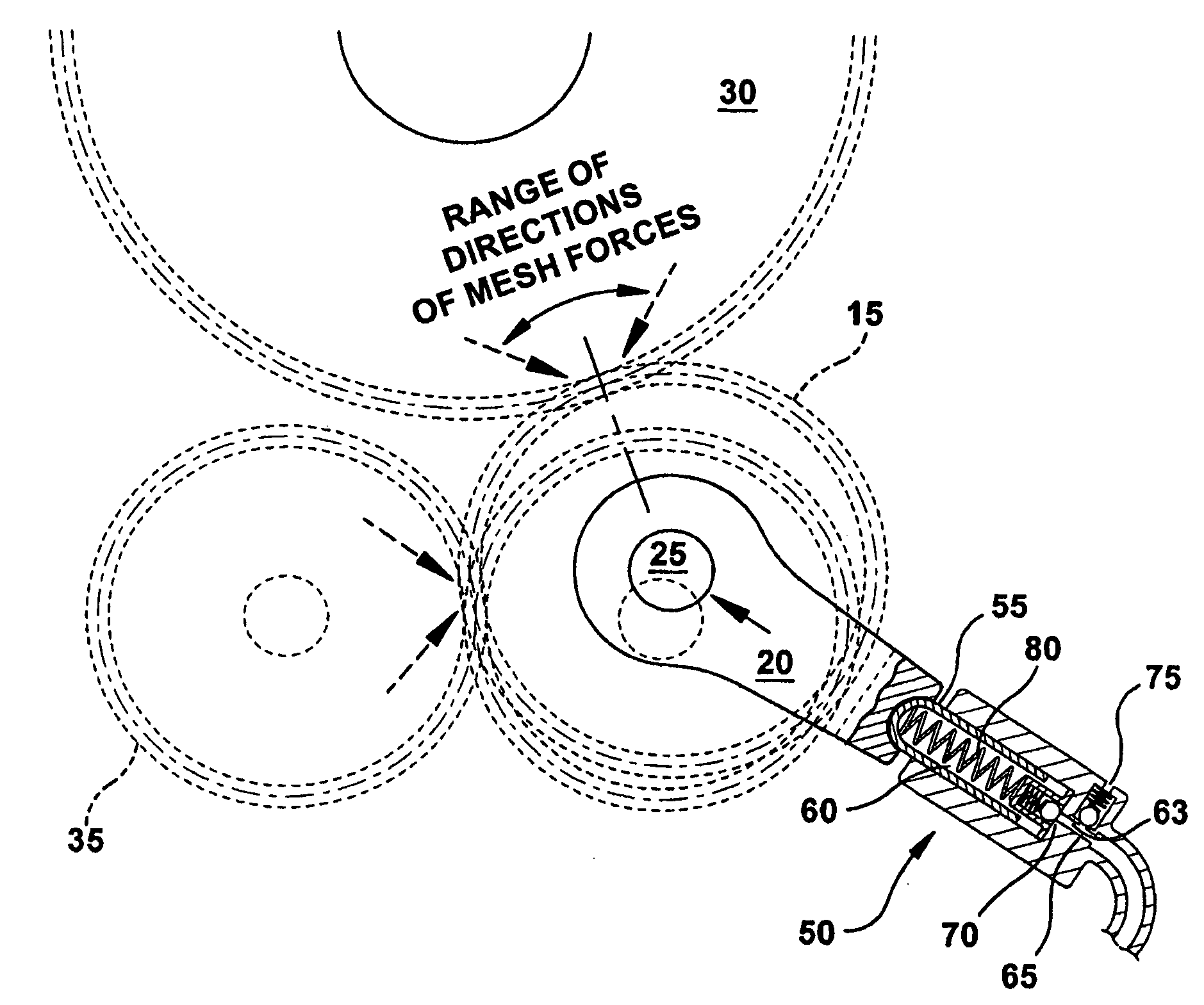

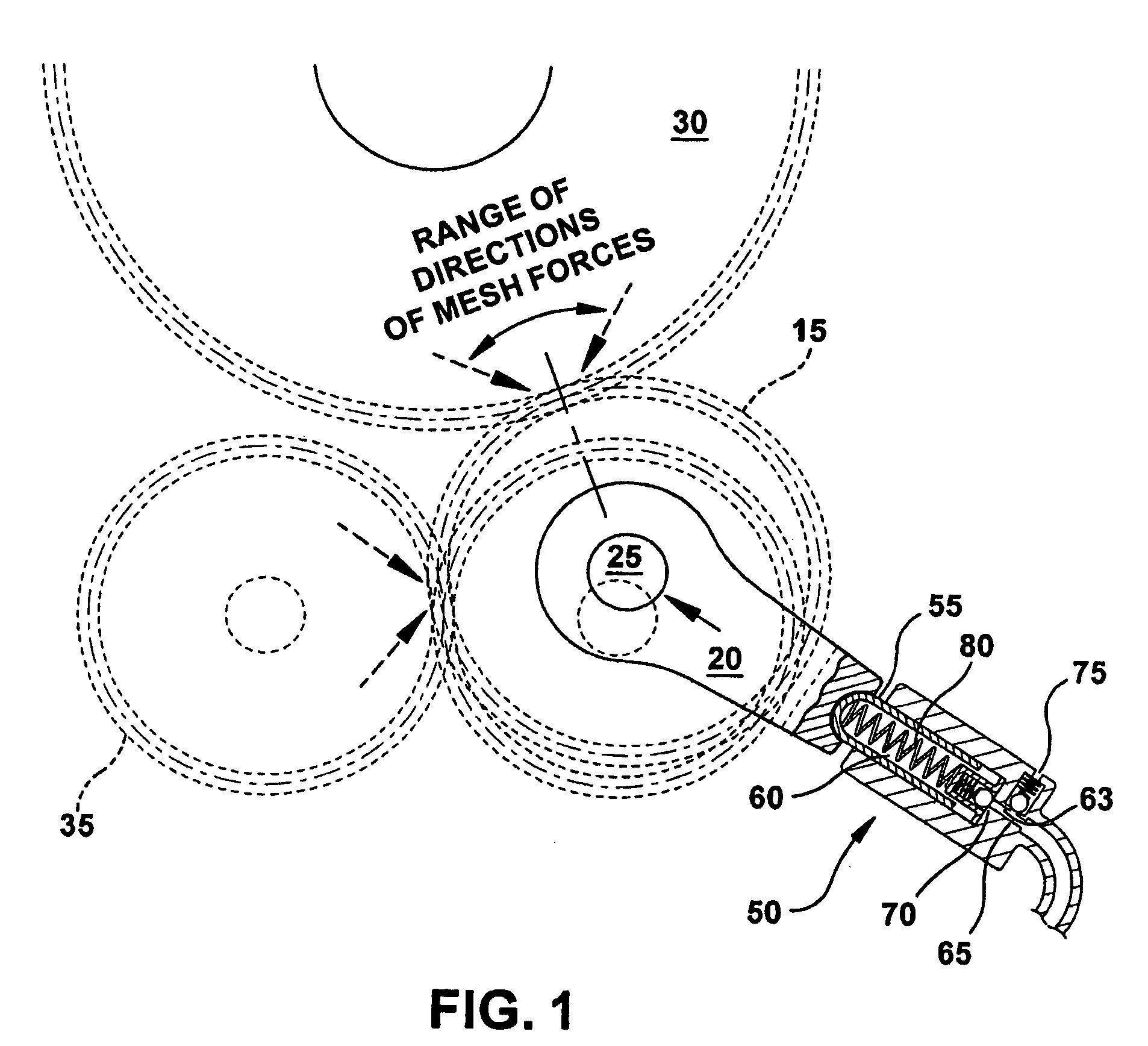

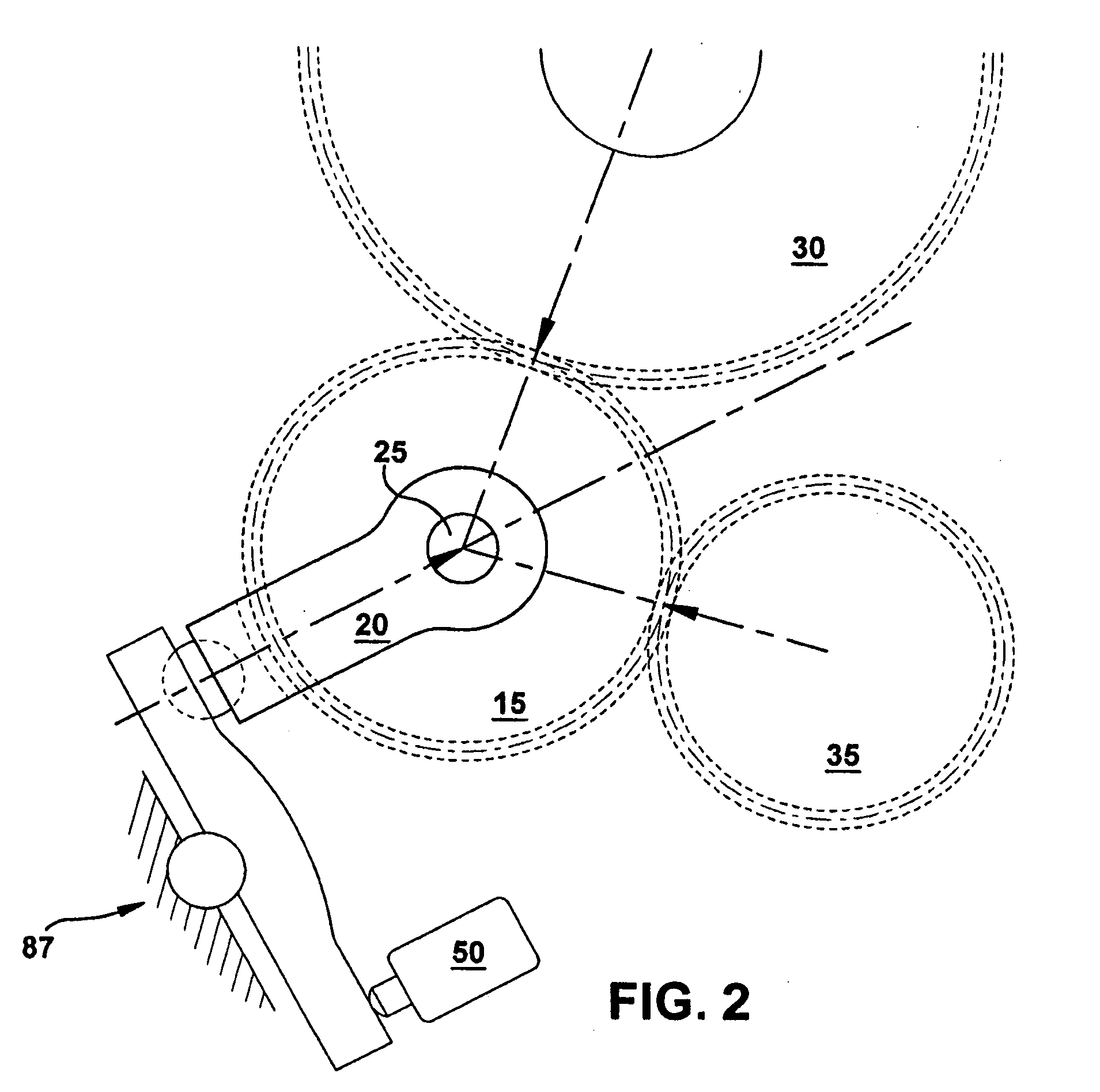

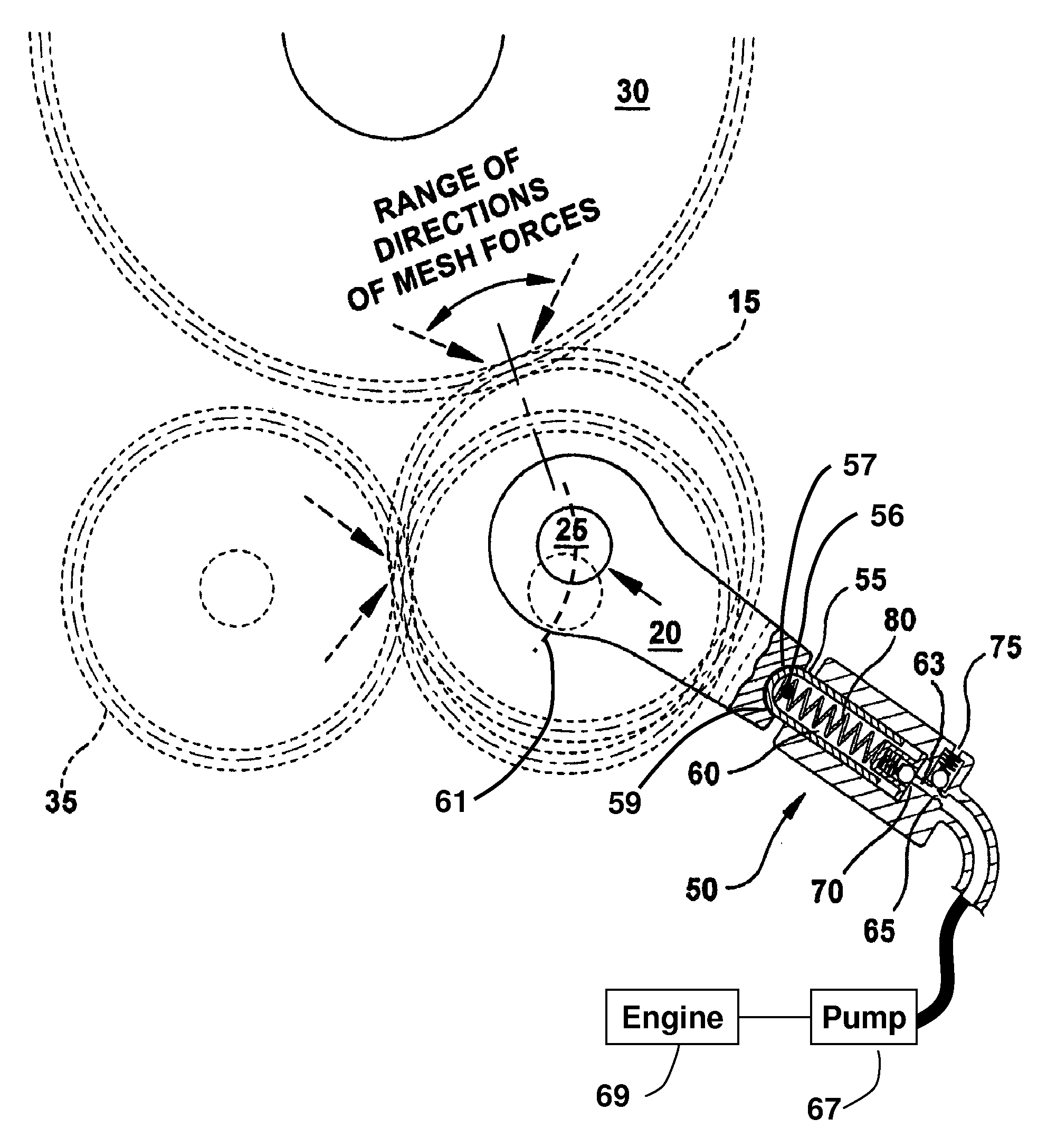

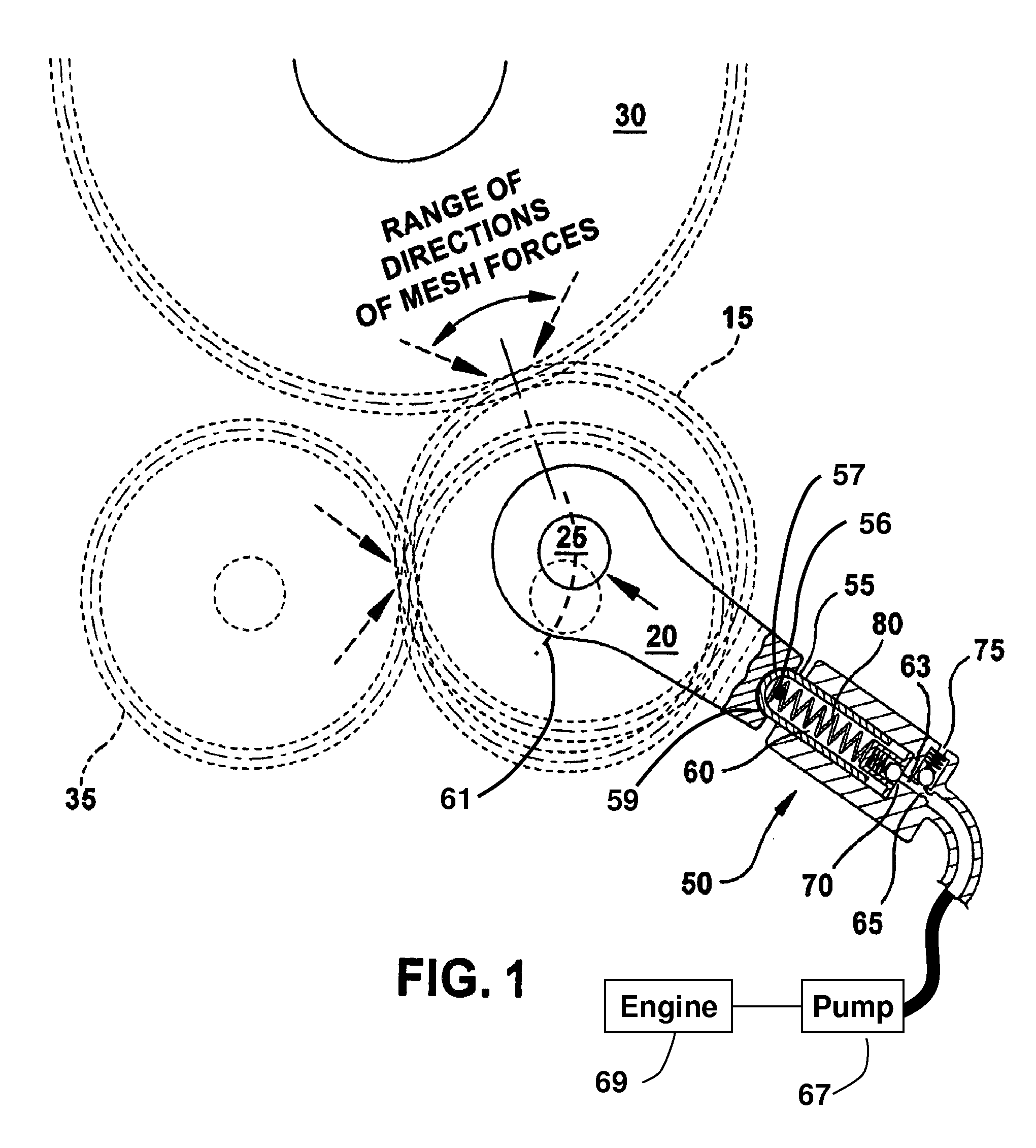

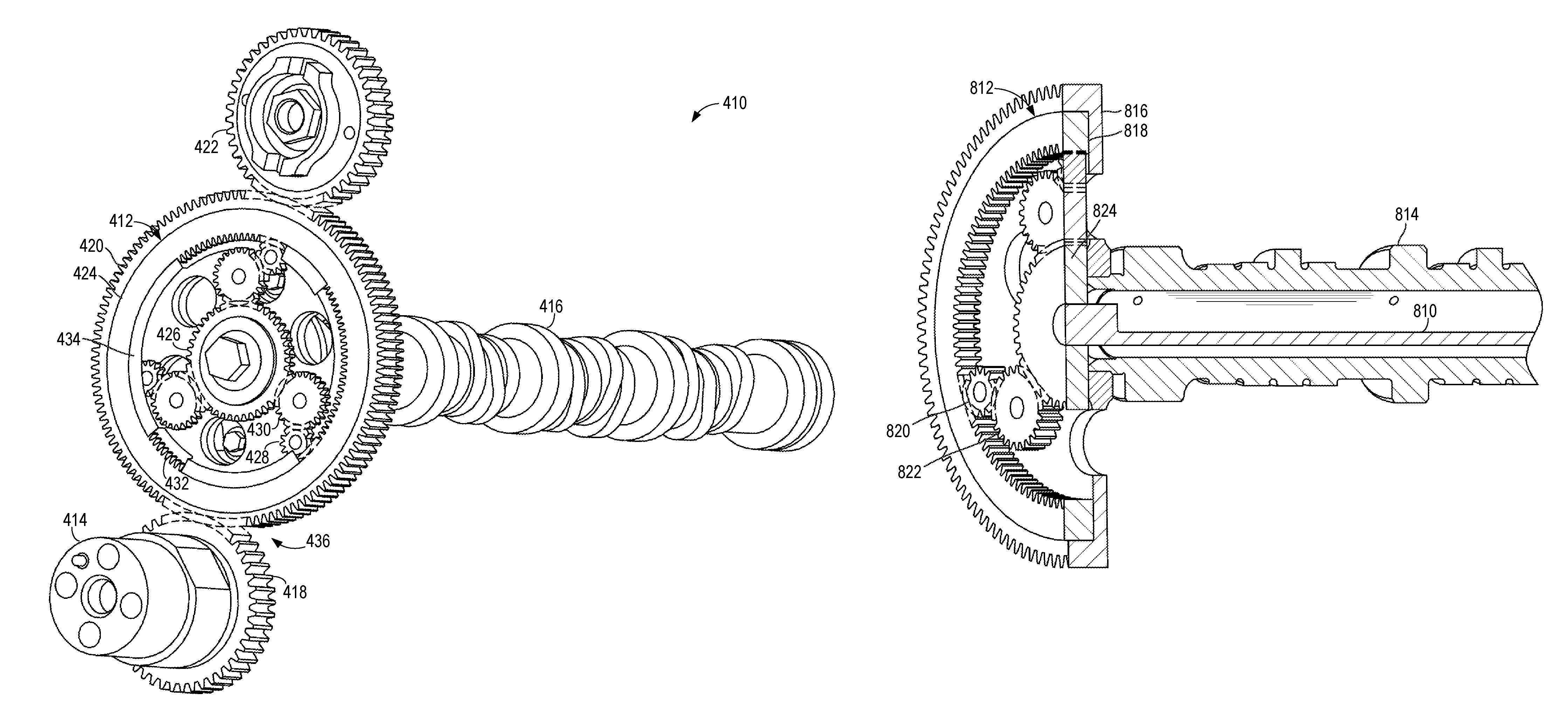

Gear-driven balance shaft apparatus with backlash control

Owner:METALDYNE BSM

Gear-driven balance shaft apparatus with backlash control

Owner:METALDYNE BSM

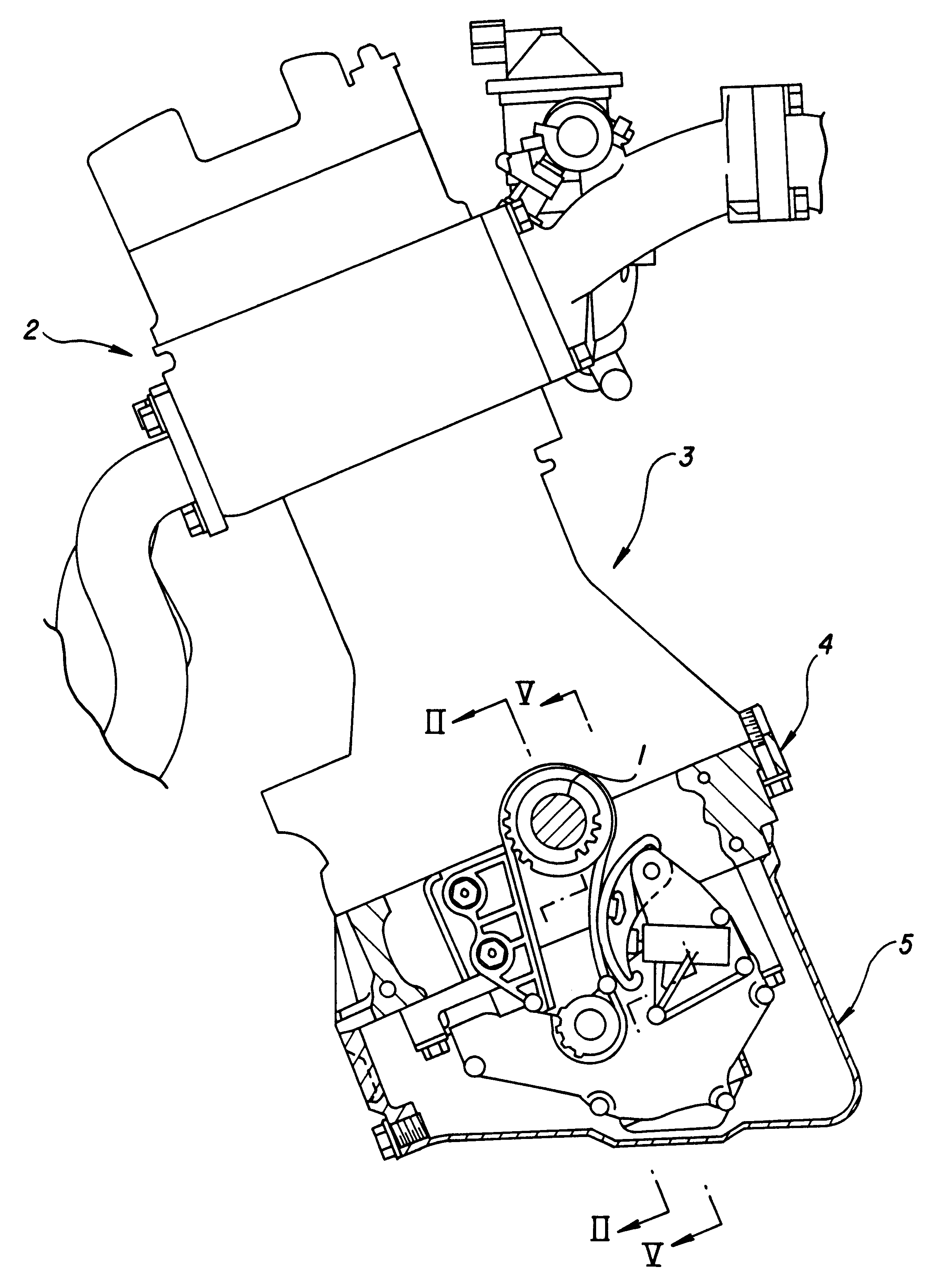

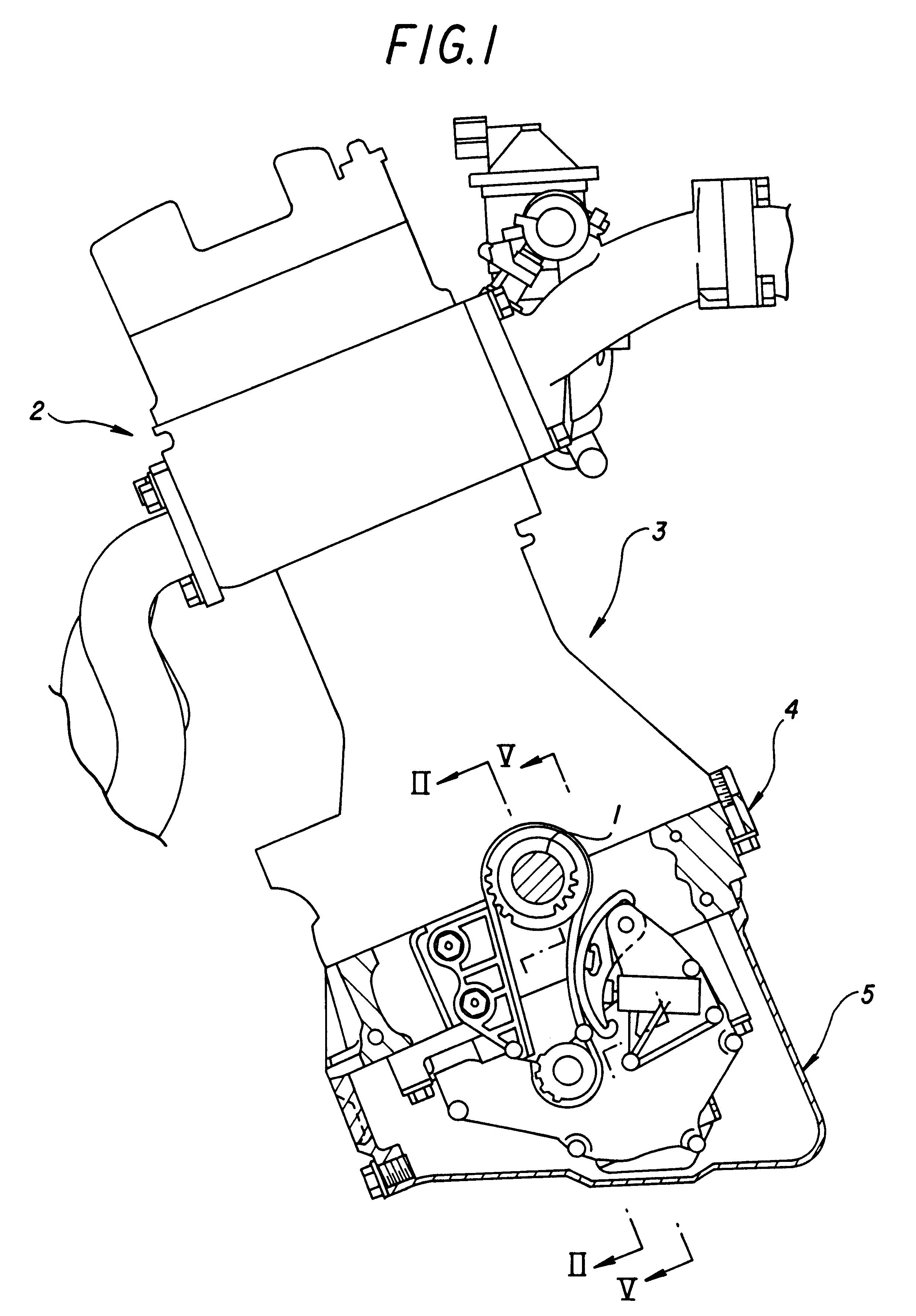

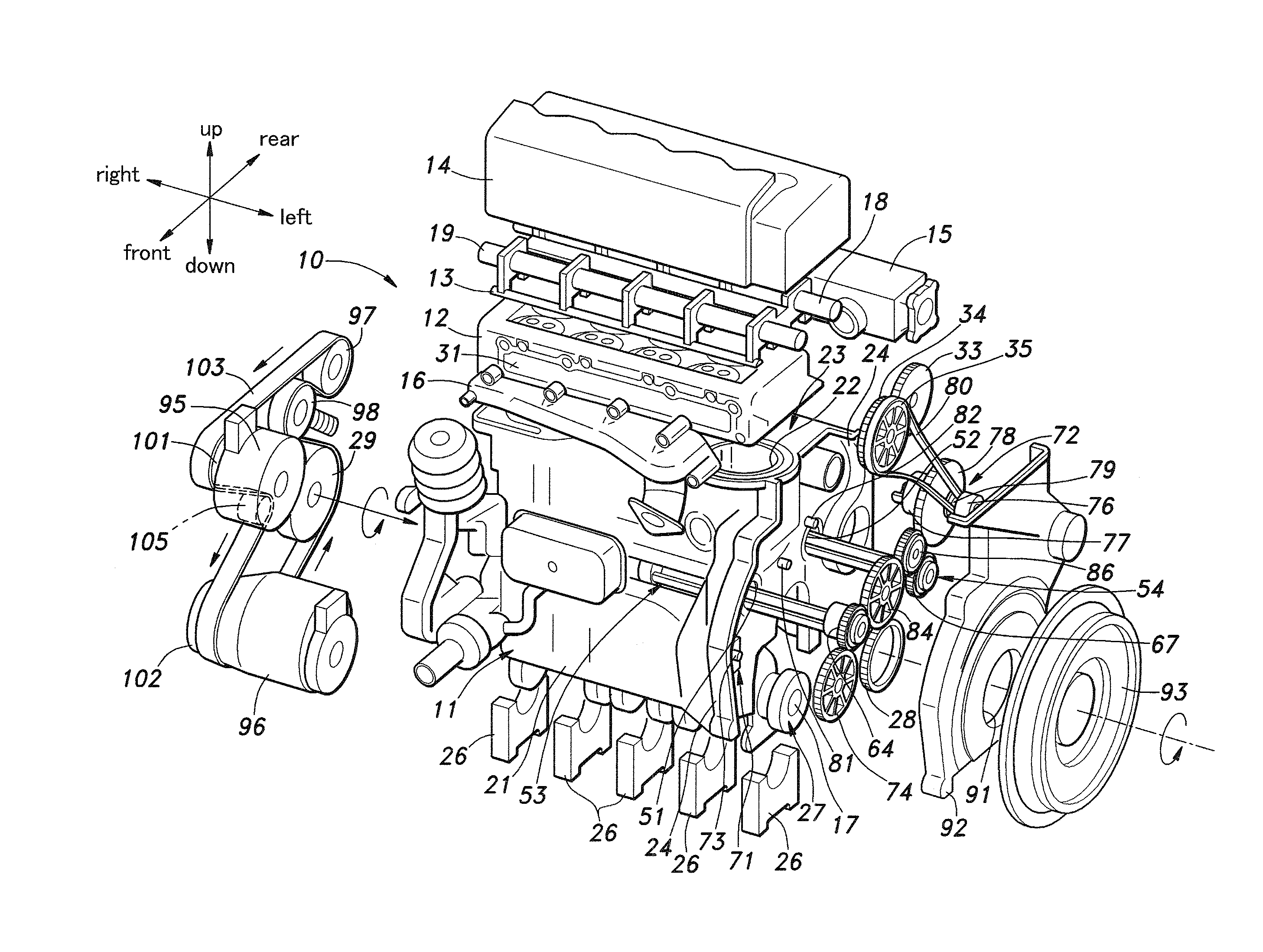

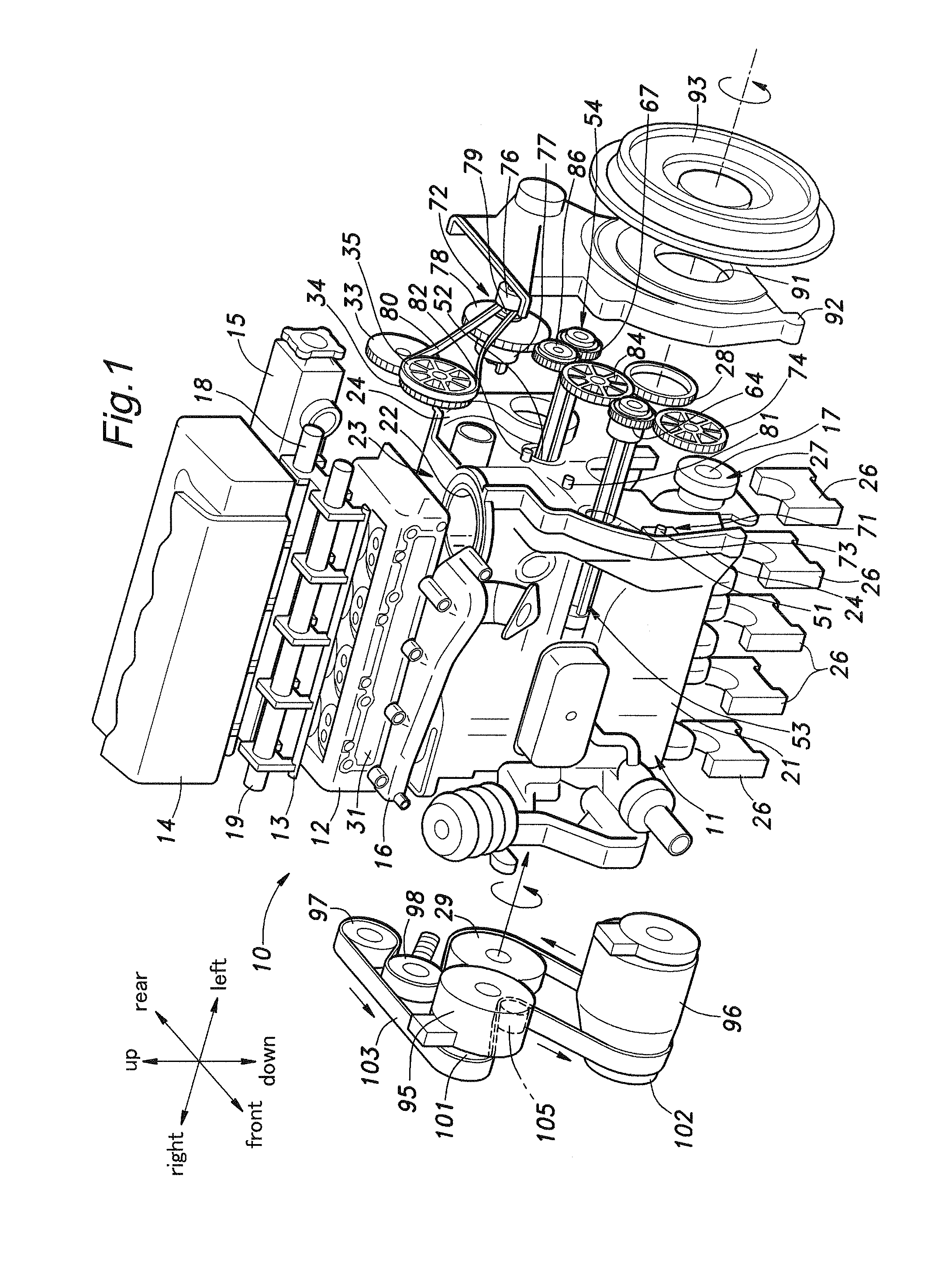

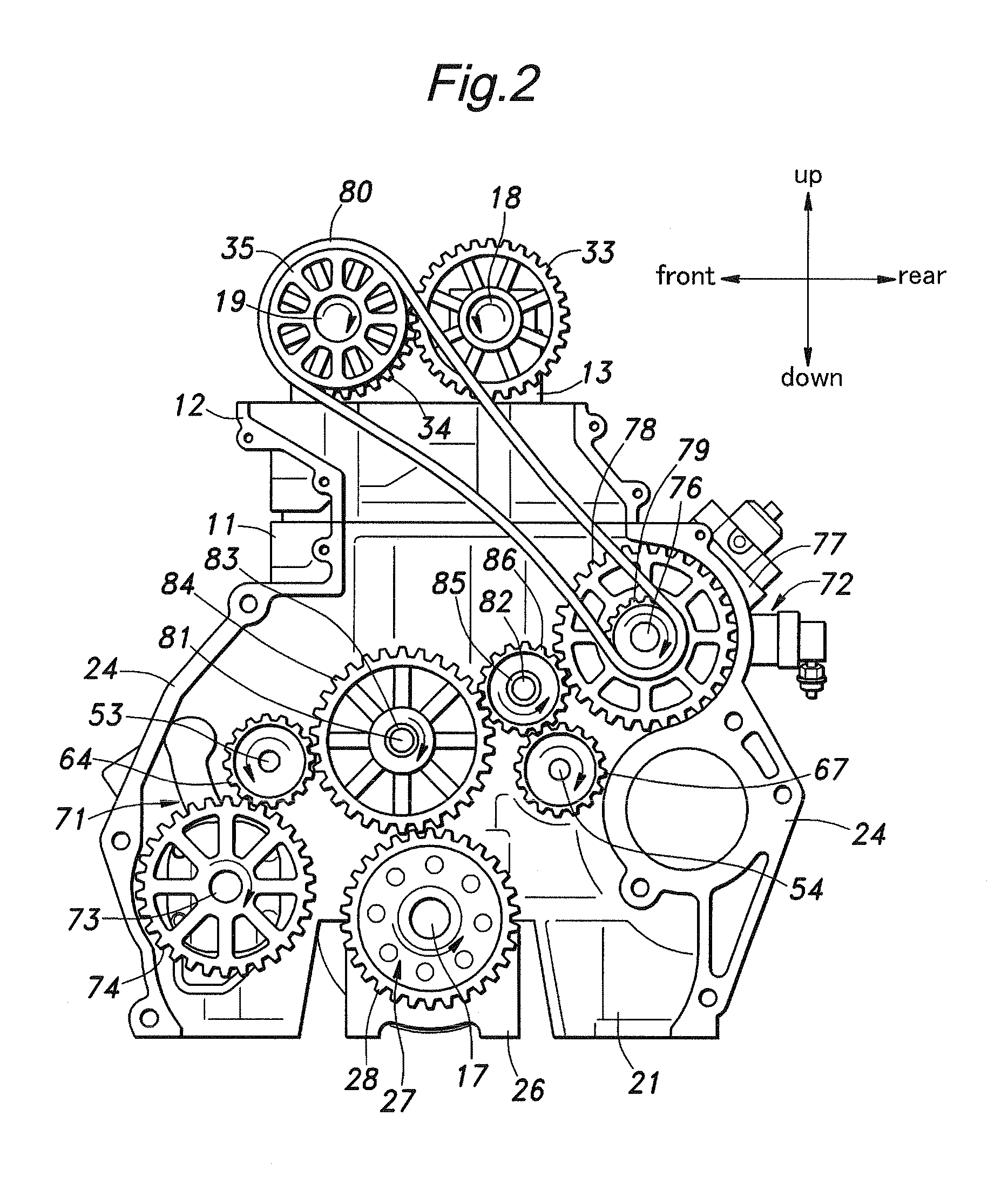

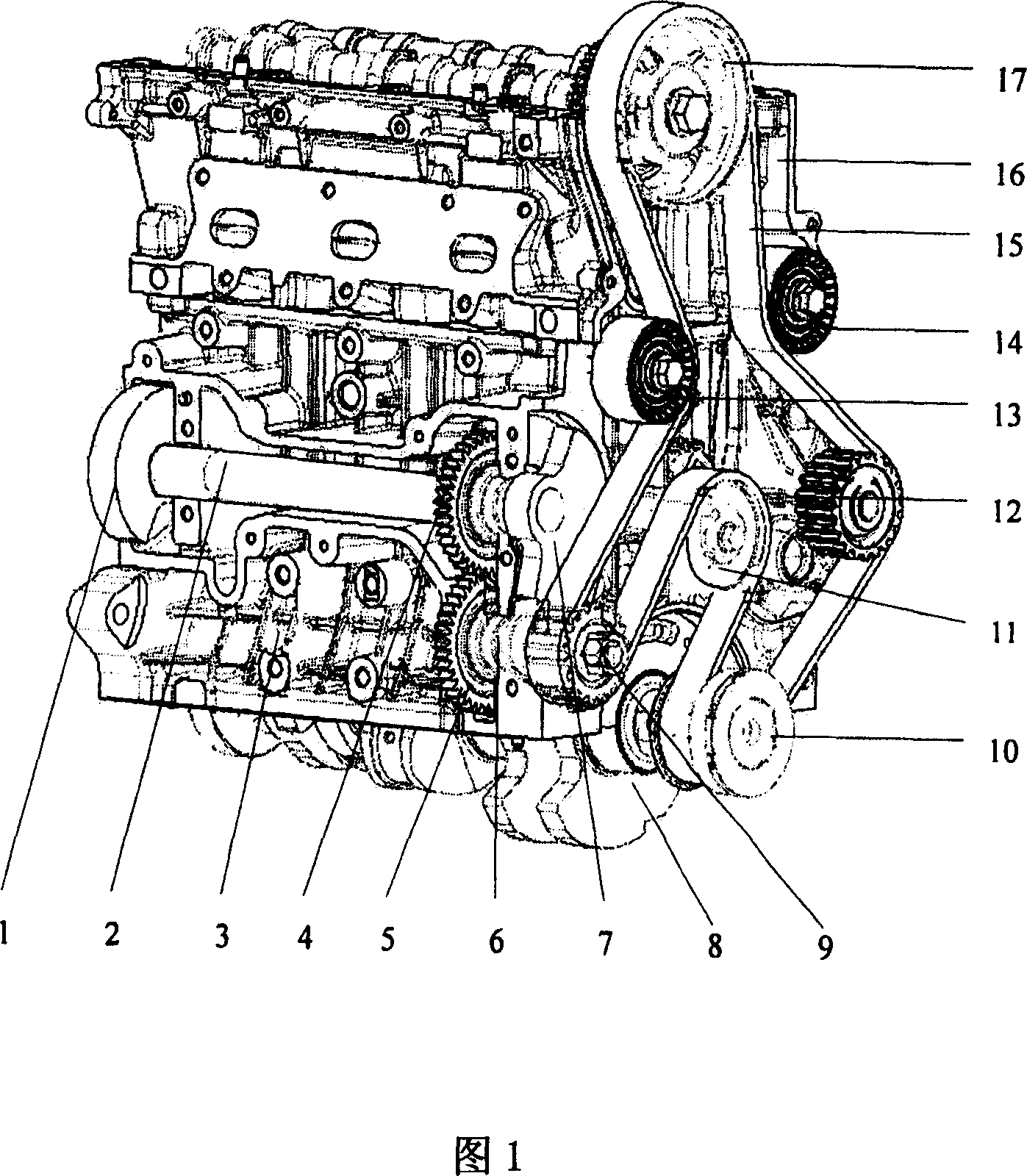

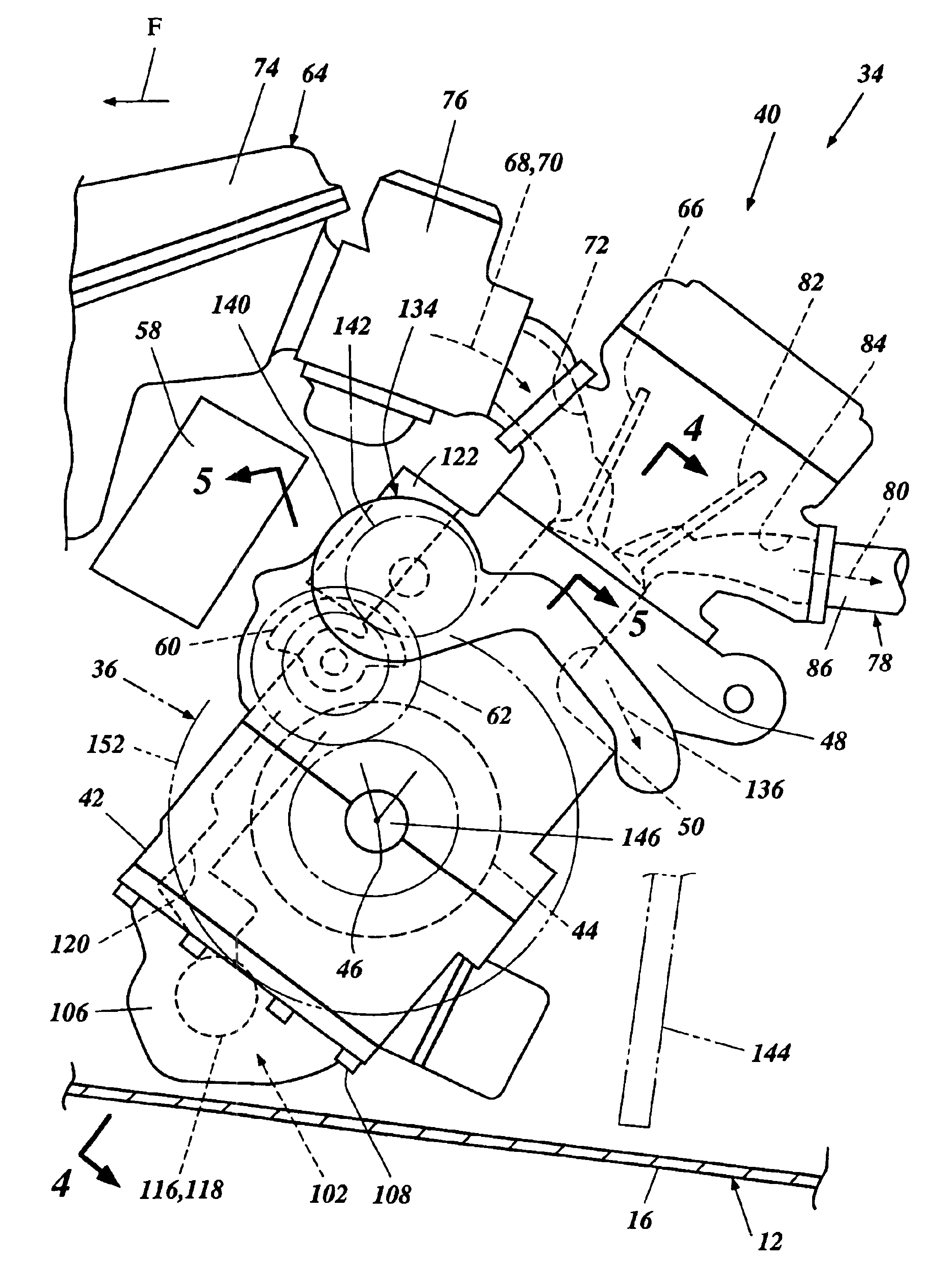

Internal combustion engine

InactiveUS20110209680A1Optimize layoutEfficient arrangementInertia force compensationMachines/enginesDrive shaftEngineering

In an internal combustion engine having a pair of balancer shafts (53, 54), an engine torque is transmitted from a crank gear (28) to an oil pump gear (74) on a drive shaft (73) of an oil pump (71) via a first idler gear (84) and the first balancer shaft gear (64). The engine torque is also transmitted to a fuel pump (72) from the crank gear to a fuel pump gear (78) via the first idler gear and a second idler gear (86), and to the second balancer shaft gear (67) via the first idler gear and second idler gear. Alternatively, the engine torque may be transmitted to the fuel pump from the crank gear to the fuel pump gear via the first idler gear, second balancer shaft gear and second idler gear. As the oil pump gear is actuated by the crank gear via the first idler gear, the oil pump gear is not subjected to the loading caused by the balancer shaft, and hence can be made of a compact and light-weight gear. Furthermore, this allows the various gears to be arranged in an efficient (in terms of the overall weight for the given mechanical strength requirements) and compact manner.

Owner:HONDA MOTOR CO LTD

Apparatus for regulating display device angle, and its connection support

InactiveCN1389658AFirmly connectedEasy to adjustTelevision system detailsDigital data processing detailsDisplay deviceEngineering

An apparatus for adjusting an angle of a display which easily controls the view angle of the display so as to comply with a user s wishes, and a connection bracket of the apparatus are provided. A series of guide brackets and connection brackets couple the display to a fixing bracket fixed to a wall or support. A flap-fixing bracket is attached to the fixing bracket, and a flap, comprising two crossed flap members coupling a balance shaft and an angle adjustable shaft allow a viewing angle to be adjusted through the spreading and the folding of the flap. The connection bracket includes a product bracket attached to a holding-down bracket. The product bracket attaches on one surface to the display, and at its ends to the holding doxvn bracket. The holding-down bracket is easily attached to and separated from the product bracket. Thus the angle of the display is easily adjusted, using limited force, so as to comply with a user's wishes.

Owner:LG ELECTRONICS INC

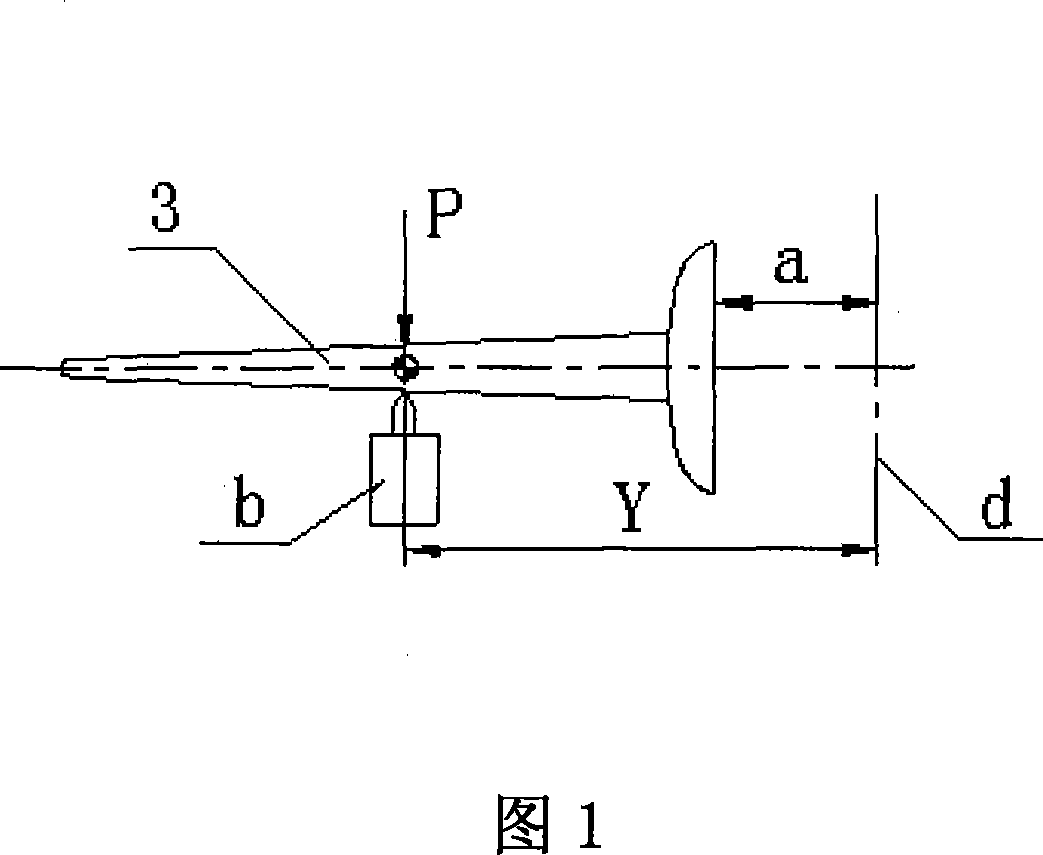

Method for measuring blade static-balance gravity center

InactiveCN101074896AIncrease manufacturing costSimple structureStatic/dynamic balance measurementMeasurement devicePropeller

A method for measuring torque of static balance gravity on blade sets balance shaft on hinge base and connects balance shaft to blade to separately measure out distance from blade gravity to center line of propeller and distance from blade gravity to center line of flange.

Owner:WUHAN MARINE MACHINERY PLANT

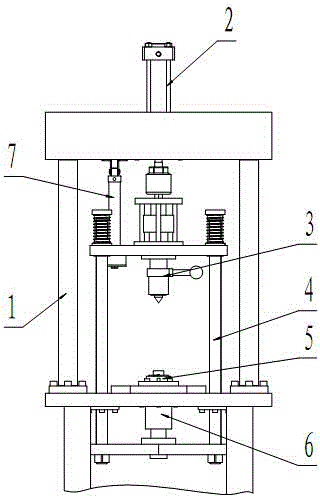

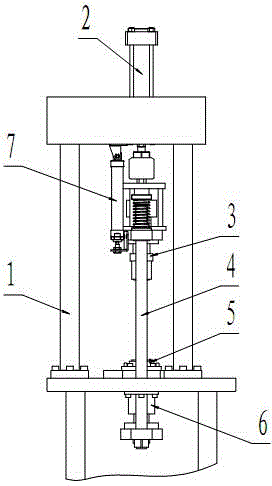

Press fitting device for timing gear of engine balance shaft

ActiveCN104308507AImprove versatilityVersatileMetal working apparatusProgrammable logic controllerControl system

The invention discloses a press fitting device for a timing gear of an engine balance shaft. The press fitting device comprises a main body framework, a press fitting oil cylinder, a press fitting execution mechanism, a following mechanism, a gear positioning mechanism, a balance shaft positioning mechanism and a PLC (Programmable Logic Controller) control system, wherein the main body framework consists of an upper cover plate, an upright post, a base plate and a bracket; the press fitting oil cylinder is fixed on the upper cover plate of the main body framework; a telescopic rod of the press fitting oil cylinder and the press fitting execution mechanism are assembled; the press fitting execution mechanism and the upper end of the following mechanism are fixedly assembled; the lower end of the following mechanism and the balance shaft positioning mechanism are assembled; the balance shaft positioning mechanism and the gear positioning mechanism are respectively matched with the base plate of the main body framework. The press fitting device disclosed by the invention has the characteristics of simple structure, high automatic degree and high generality; the requirement on timing angle when the balance shaft and the timing gear are assembled is met; besides, the working efficiency is improved, and the production cost is reduced.

Owner:GREAT WALL MOTOR CO LTD

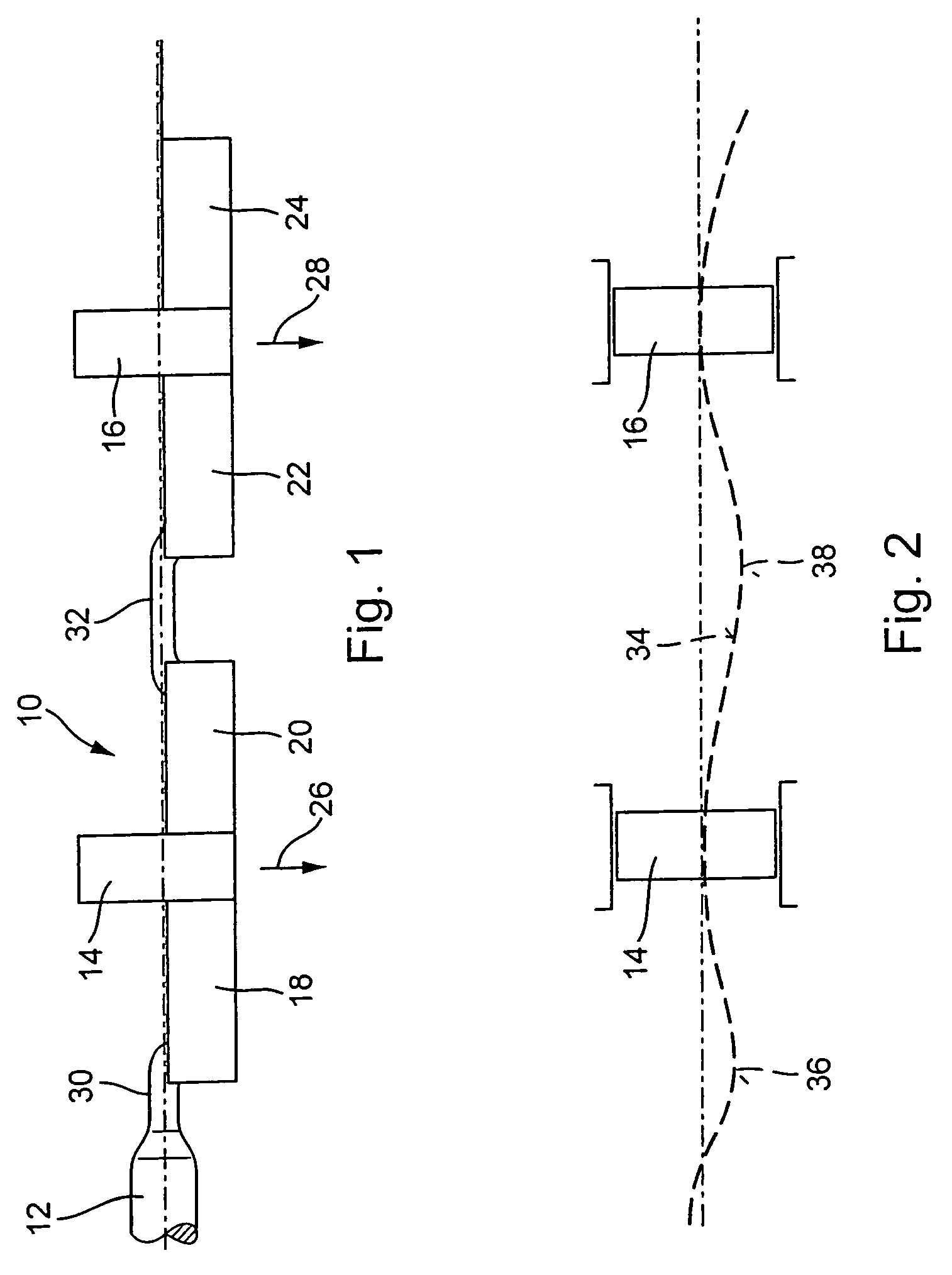

Balance shaft for a multicylinder in-line engine

ActiveUS7444976B2Less disturbed deflectionAvoid leaningEccentric-shaftsInertia force compensationCouplingEngineering

In a balance shaft for a multi-cylinder in-line engine with at least two imbalance weight sections and at least one bearing structure wherein the balance shaft has imbalance weight sections being arranged symmetrically relative to the bearing position and at least one of the imbalance weight sections is connected to a further shaft section at an end facing away from the bearing position, a flexible coupling element that enables a deflection of the end of the connected imbalance weight section in the direction of the resulting centrifugal forces when the balance shaft rotates is provided between the end of the at least one imbalance weight section facing away from the bearing position and the further shaft section.

Owner:DAIMLER AG

Double-needle-bar warp knitting machine

InactiveCN104452078AMeet weaving requirementsDensely wovenFlat warp knitting machinesEngineeringBilateral symmetry

The invention relates to a double-needle-bar warp knitting machine. The double-needle-bar warp knitting machine comprises a looping device, ground combing devices and a transmission device, wherein the looping device comprises front and rear needle bar parts and front and rear sinker bar parts; each ground combing device comprises an upper balance shaft, a yarn combing cradle and ground comb fixing bases in bilateral symmetry. The transmission device comprises front and rear needle bar transmission mechanisms, front and rear sinker bar transmission mechanisms, front and rear knocking-over transmission mechanisms and guide-bar cradle and upper balance shaft transmission mechanisms, wherein the front and rear needle bar transmission mechanisms supply power for the front and rear needle bar parts respectively, the front and rear sinker bar transmission mechanisms supply power for the front and rear sinker bar parts respectively, the front and rear knocking-over transmission mechanisms supply power for the front and rear balance shafts respectively, and the guide-bar cradle and upper balance shaft transmission mechanisms supply power for the yarn comb cradle respectively and control oscillation of the yarn comb cradle. The double-needle-bar warp knitting machine is capable of meeting the knitting requirements of short flock, medium flock and shag type warp knitting machines and can knit dense and jacquard pile fabric.

Owner:CHANGZHOU WUJIN WUYANG TEXTILE MACHINERY

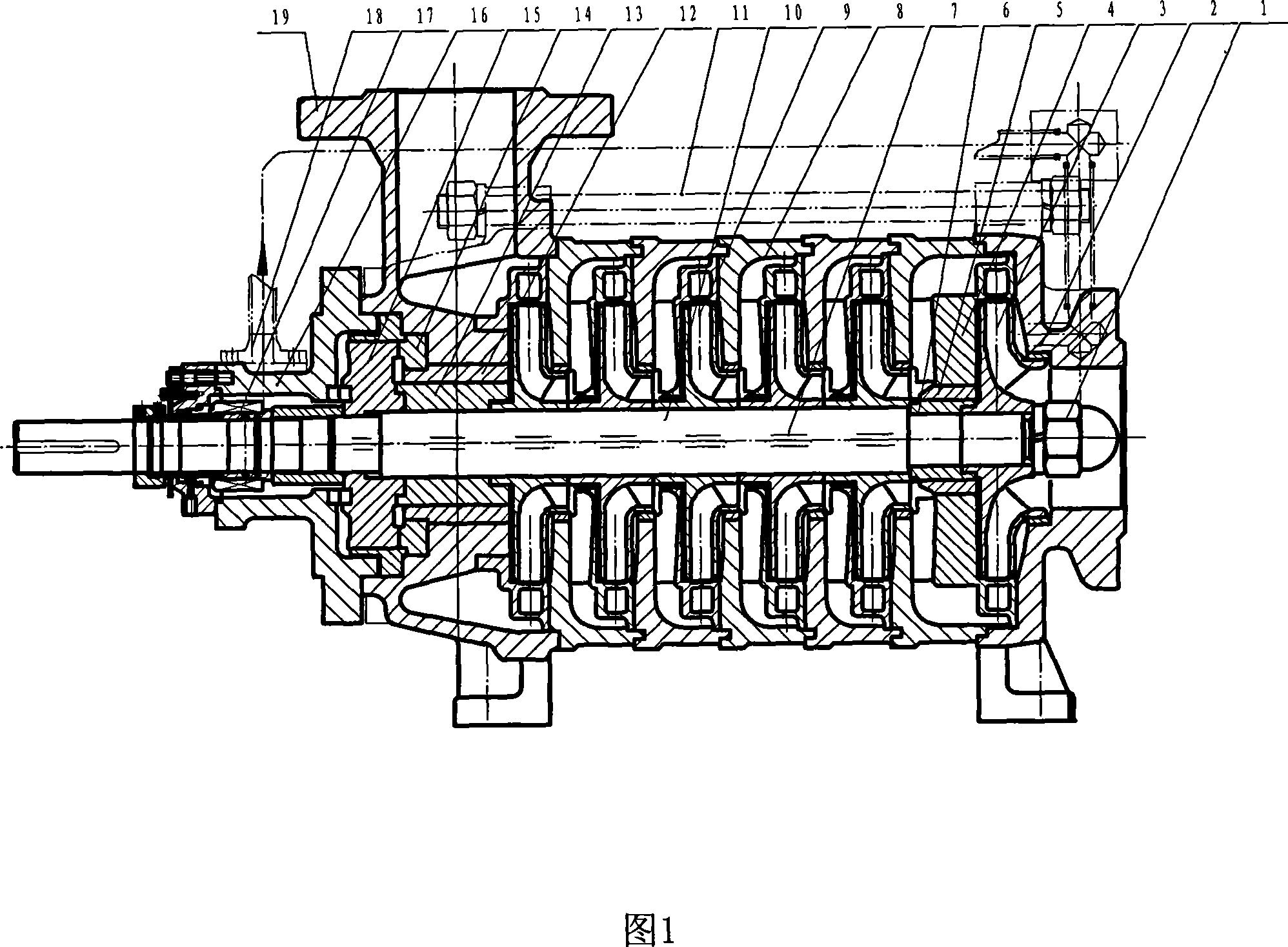

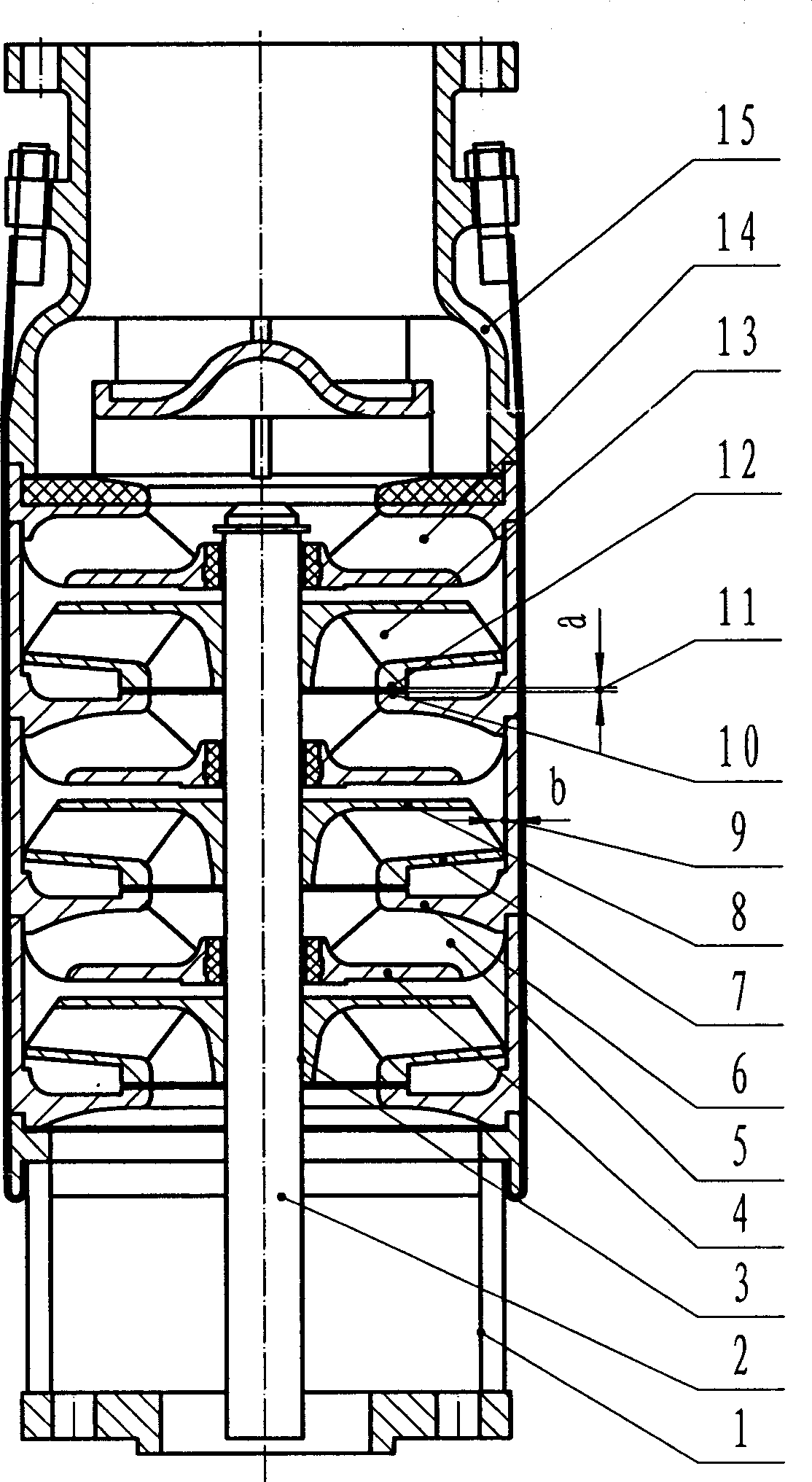

Efficient high-pressure horizontal multi-stage centrifugal pump

InactiveCN101070854AImprove efficiencyImprove pump cavitation performancePump componentsPump installationsCavitationHydraulic pump

An efficient high-pressure horizontal multi-stage centrifugal pump belongs to centrefugal pump technology field concluding indraft section, middle sect, guild blade, impeller, pump axle, water lubricate bearing, outlet sect, axial force balancing mechanism and seal etc. Its character is that indraft of the pump layouted radial is different from all preceding editions, so that it greatly improves the efficiency of the impeller and the hydraulic pump cavitation performance. The pump adopts water lubrecate bearing installed in wterpower components interor; the lubrecate bearing closed to the outlet be considered a balance hub cmbines with balacing tray to a auto balacing mechanism. The pump needed a seal is compact and have one axle body because of adopting water lubrecate bearing. Its advantage is: less friction, high efficiency, reliability, and vulnerability of small,ease of rapid entry. The present invention applies to all occasions conveyor cleaning liquid.

Owner:JIANGSU UNIV

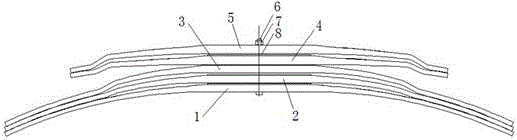

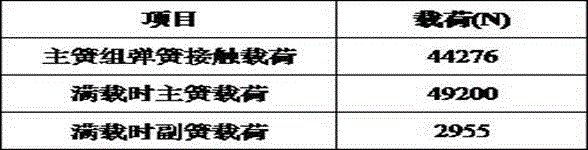

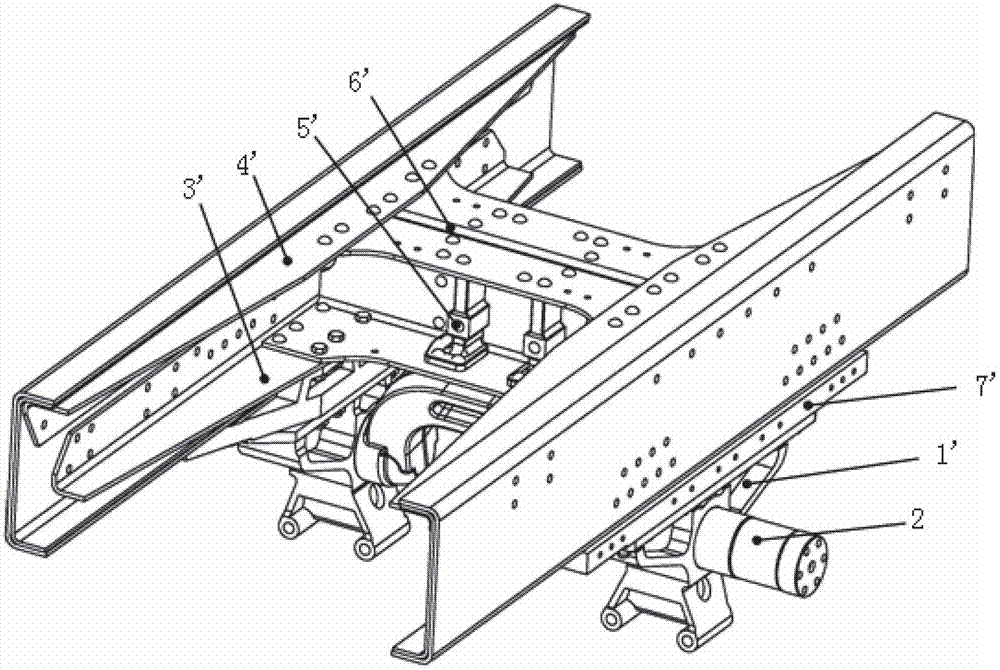

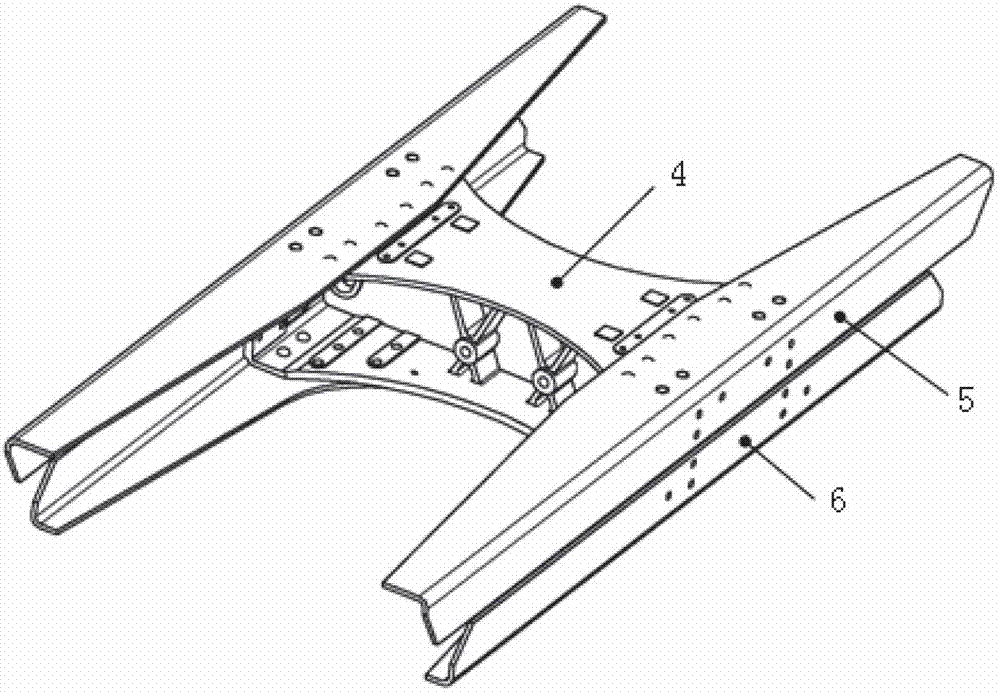

Hanging elastic element for heavy all-wheel drive off-road vehicle and design method of element

ActiveCN106321700ASolve smoothnessSolve the comfortLeaf springsSprings/dampers functional characteristicsVariable stiffnessVehicle frame

Owner:中国重汽集团济南特种车有限公司

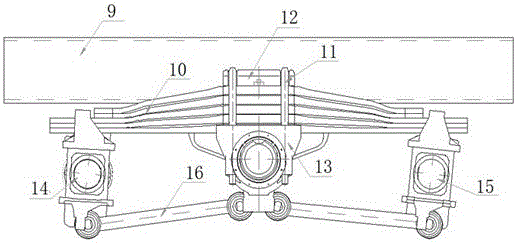

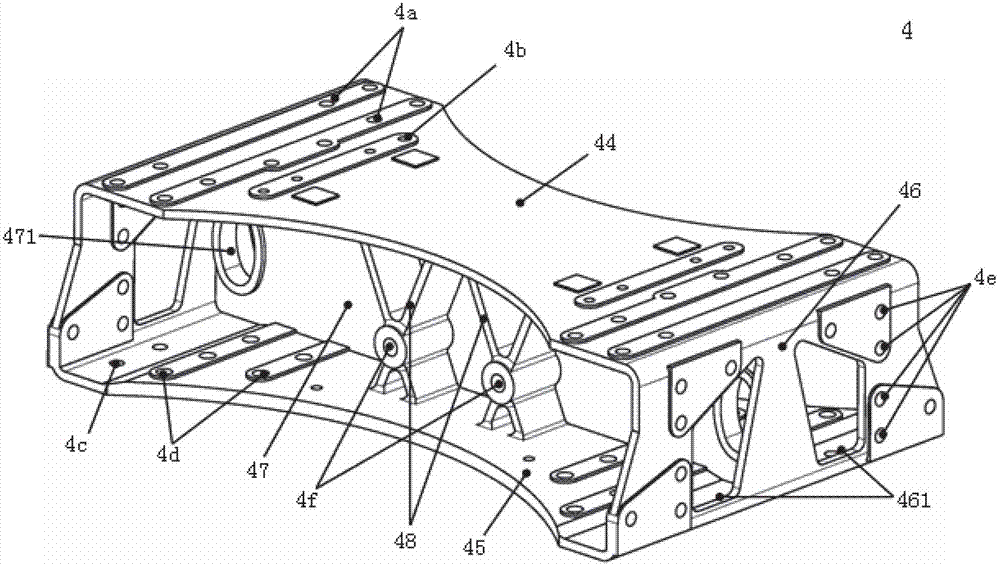

Rear balanced suspension frame system of heavy-duty car

InactiveCN102923193AGuaranteed stiffnessReduce bending deformationUnderstructuresInterconnection systemsCarrying capacitySection plane

Owner:SHAANXI HEAVY DUTY AUTOMOBILE

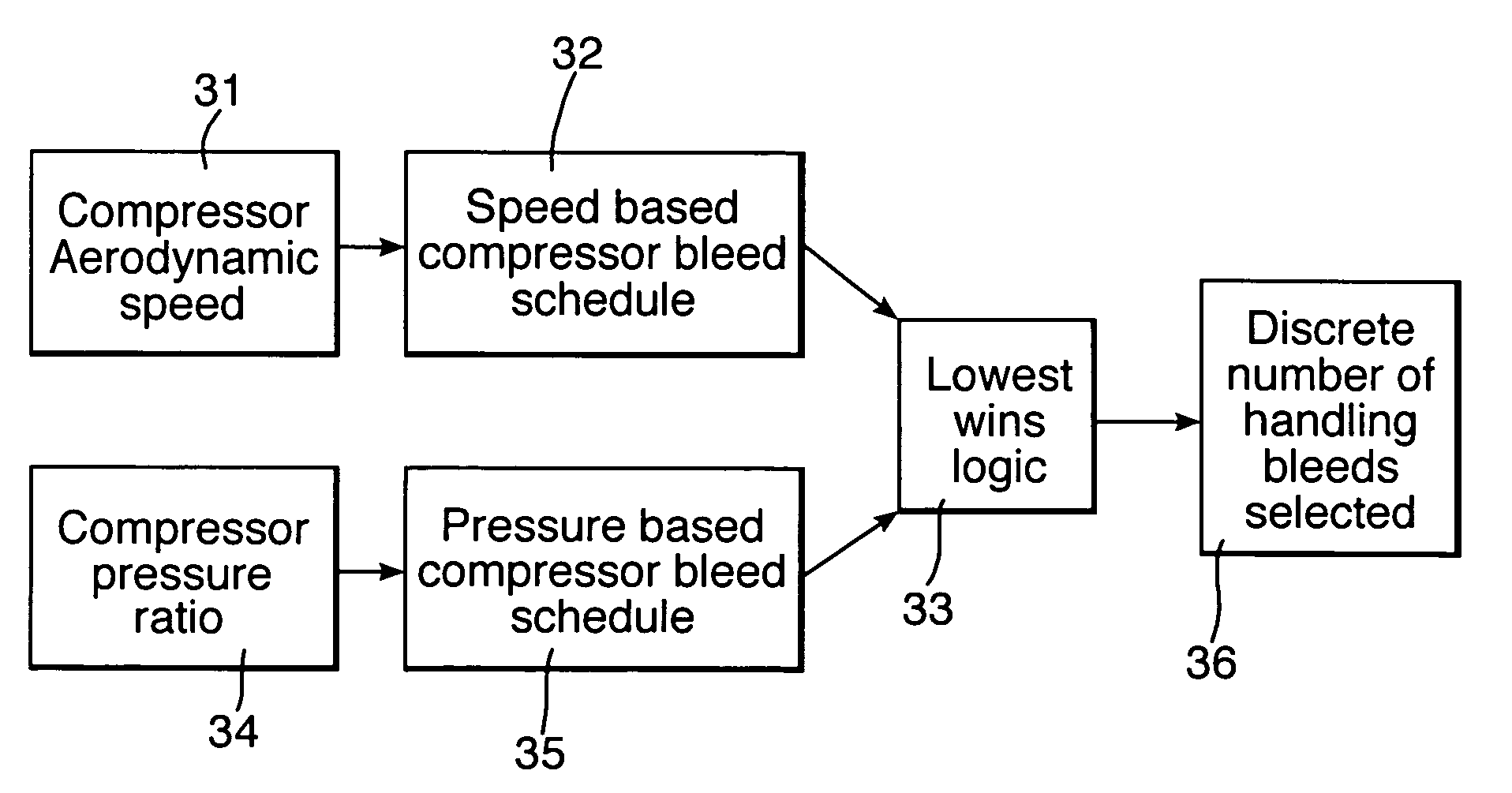

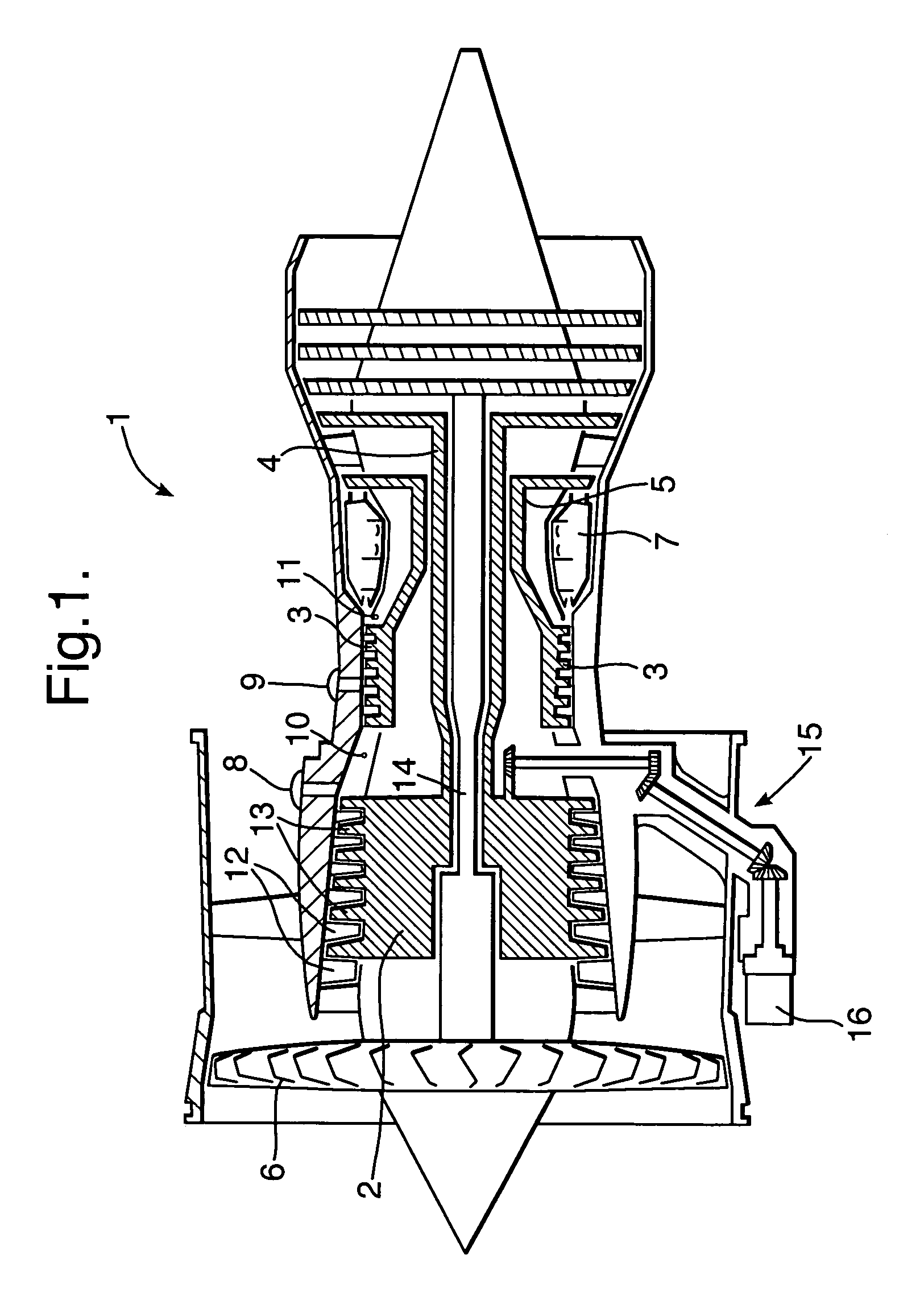

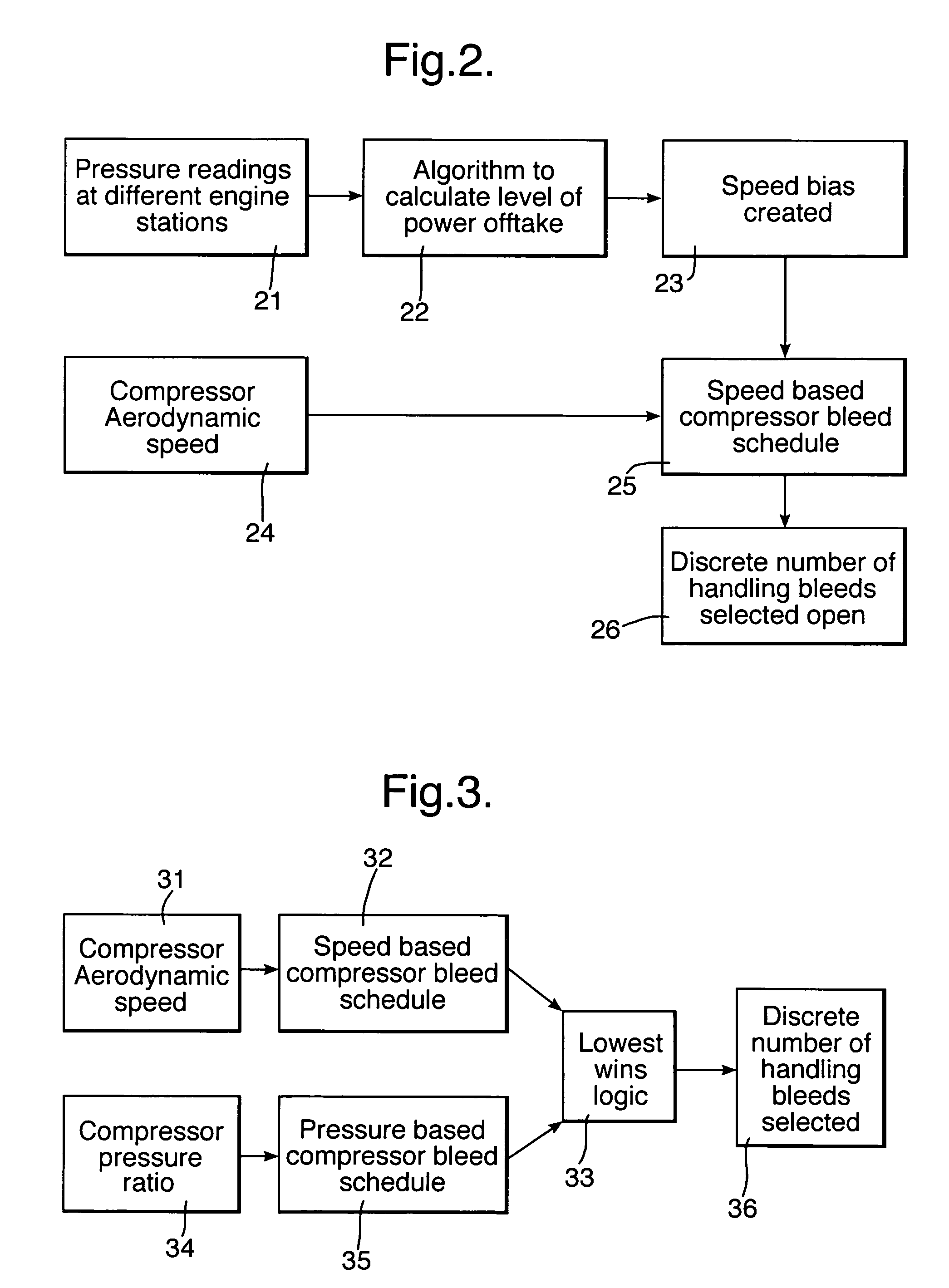

Engine arrangements and control

It is known that power is normally extracted within a gas turbine engine from a shaft in order to drive auxiliary devices such as electrical power generators. With high extraction rates from such shafts there is mismatching in rotational speeds between the shafts which must be adjusted through leakage taken from valves 8, 9. By measuring parameters and in particular pressure at a number of positions or parts within an engine arrangement 1 and comparing those parameters either through ratios or directly with reference values a controller can be configured in order to choose the correct sequence and scheduling of the valves 8, 9 opening to balance shaft speed. In such circumstances more efficient operation of the engine arrangement can be achieved over a wider range of engine speeds including idling.

Owner:ROLLS ROYCE PLC

Pressure Balanced Shaft Seal Assembly

InactiveUS20090194950A1Improve sealingImprove performanceEngine sealsRolling contact bearingsAxial pressureEngineering

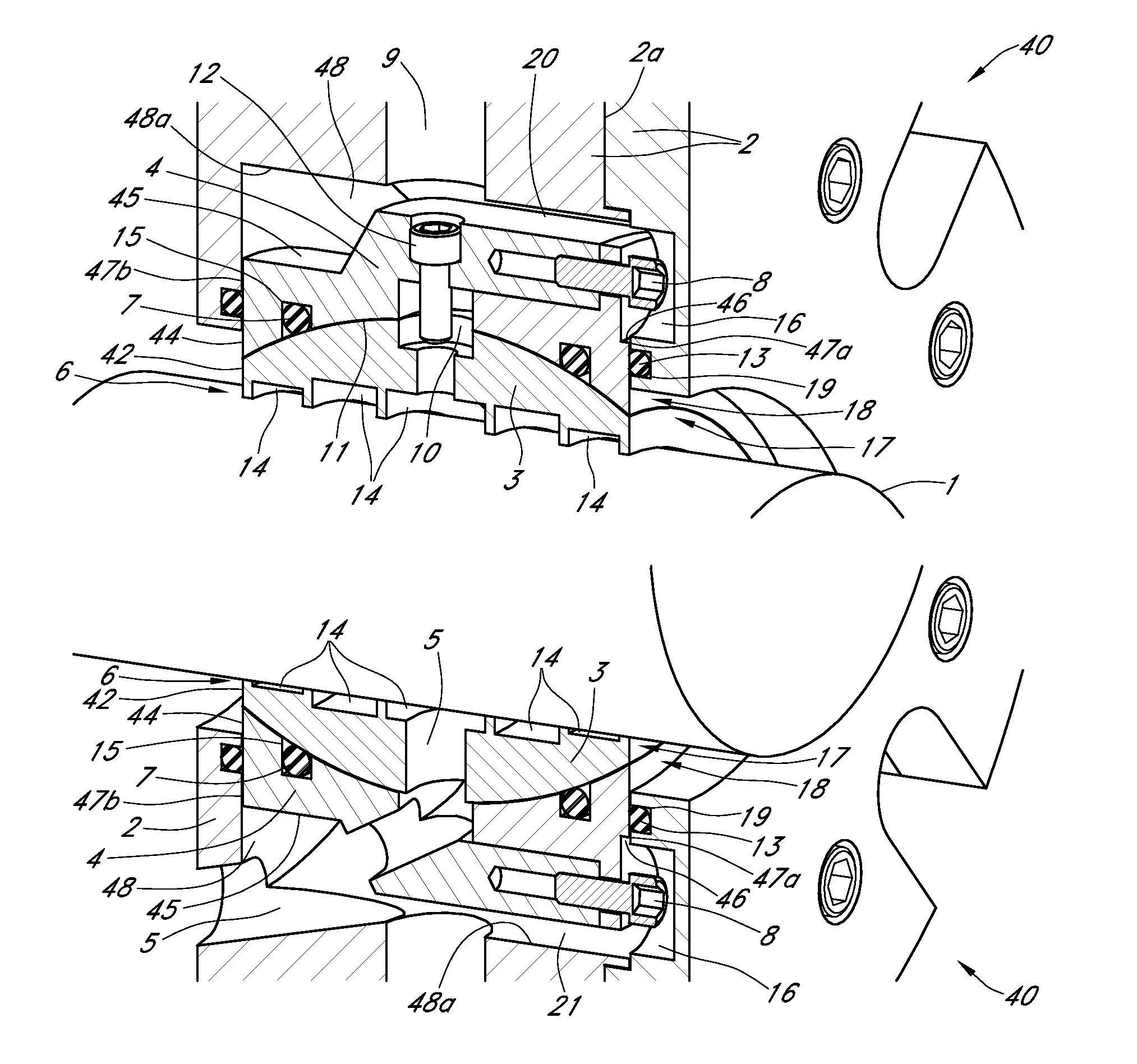

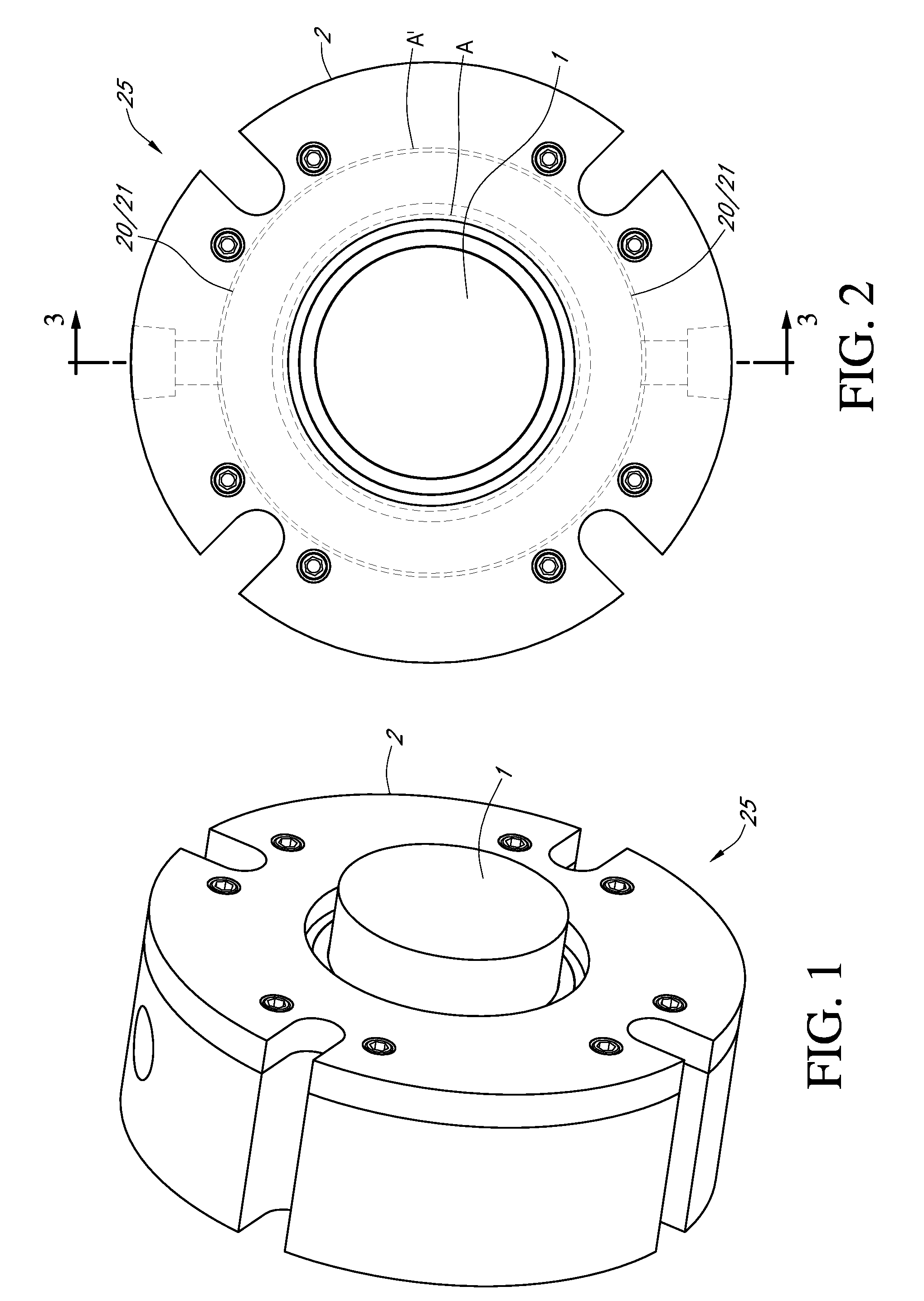

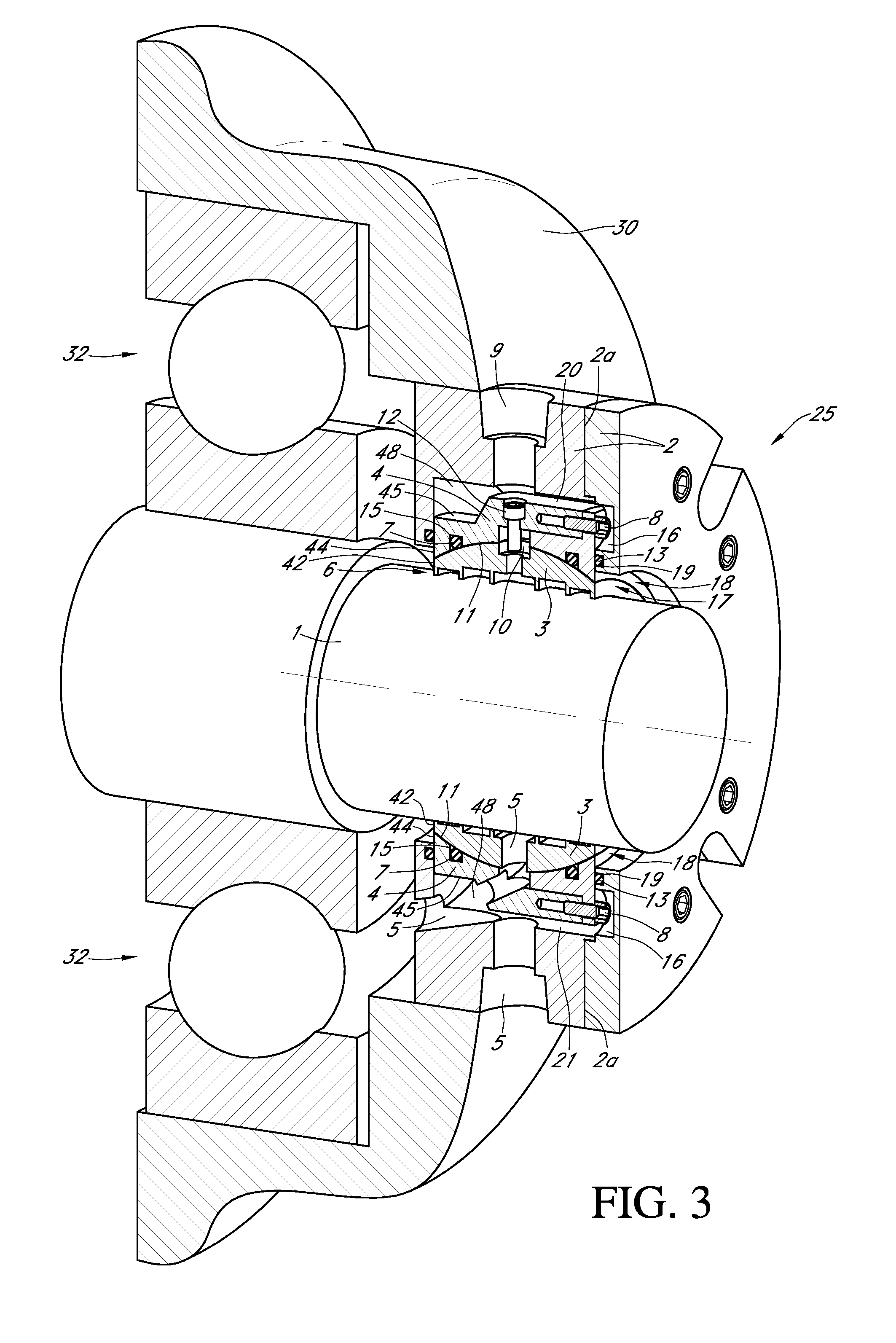

A pressure balanced shaft seal assembly that allows a seal to dynamically respond to angular or radial misalignment of a shaft is disclosed. The pressure balanced shaft seal assembly includes a fixed stator, a floating stator, and a labyrinth seal. In one embodiment, the floating stator and labyrinth seal are mounted within an annular groove formed in the fixed stator such that the floating stator and labyrinth seal may move a predetermined amount in the radial direction with respect to the fixed stator. A spherical interface between the labyrinth seal and floating stator may allow the labyrinth seal to pivot with respect to the floating stator during angular misalignment of a shaft around which the pressure balanced shaft seal assembly is mounted. A pressure balancing annular channel formed in the floating stator allows pressurized seal fluid to balance the axial pressure exerted on the floating stator by the process fluid.

Owner:INPRO INC

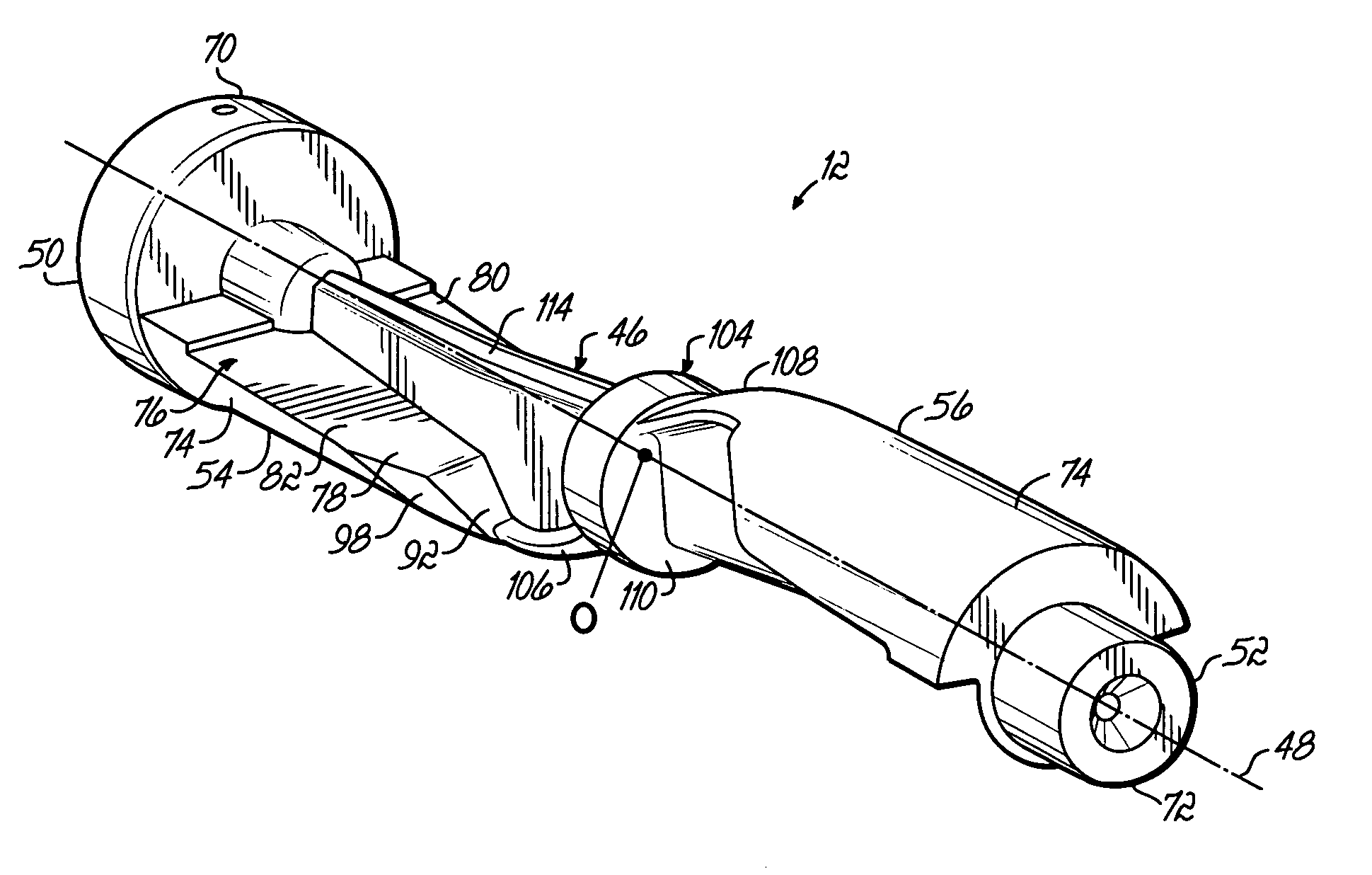

Internal combustion engine with balancer shaft and method of assembling the same

ActiveUS6868816B2Reduce and suppress secondary vibrationSimple working processInertia force compensationShaftsExternal combustion engineEngineering

An internal combustion engine includes a balancer housing, a balancer shaft having an eccentric weight portion and disposed within the balancer housing so as to be parallel with and rotatable in timed relation with a crankshaft, and a power transmitting mechanism that transmits rotation of the crankshaft to the balancer shaft, wherein the balancer shaft has an end portion protruding outward of the balancer housing, and wherein the end portion of the one balancer shaft is partially cut to have a flattened section that constitutes a device for positioning the balancer shaft in a predetermined rotational position. A method of assembling an internal combustion engine with a balancer shaft is also provided.

Owner:NISSAN MOTOR CO LTD +1

Engine crankshaft balance shaft mechanism

InactiveCN1924394ALower the altitudeCompact structureInertia force compensationGear wheelEngineering

Owner:CHERY AUTOMOBILE CO LTD

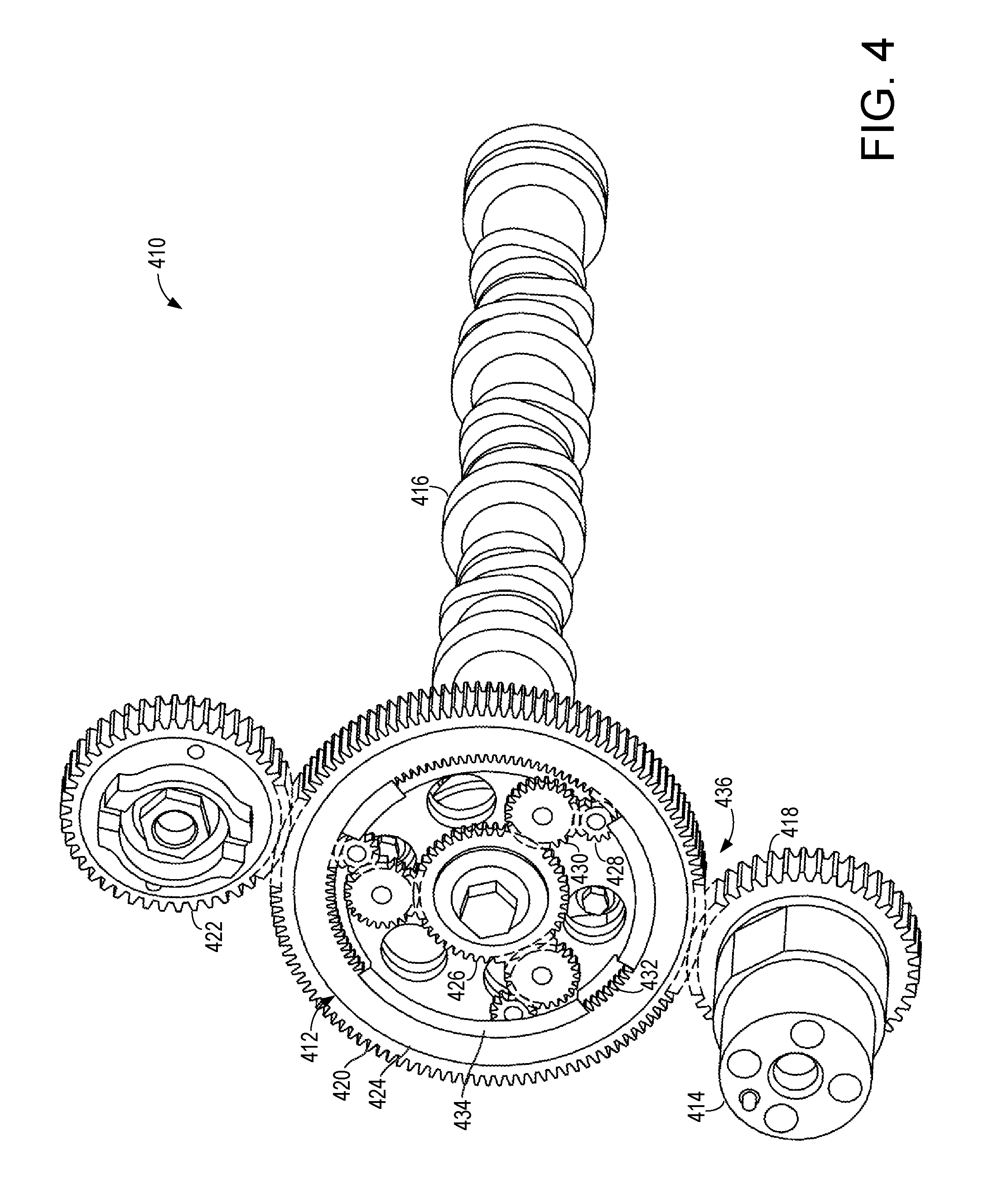

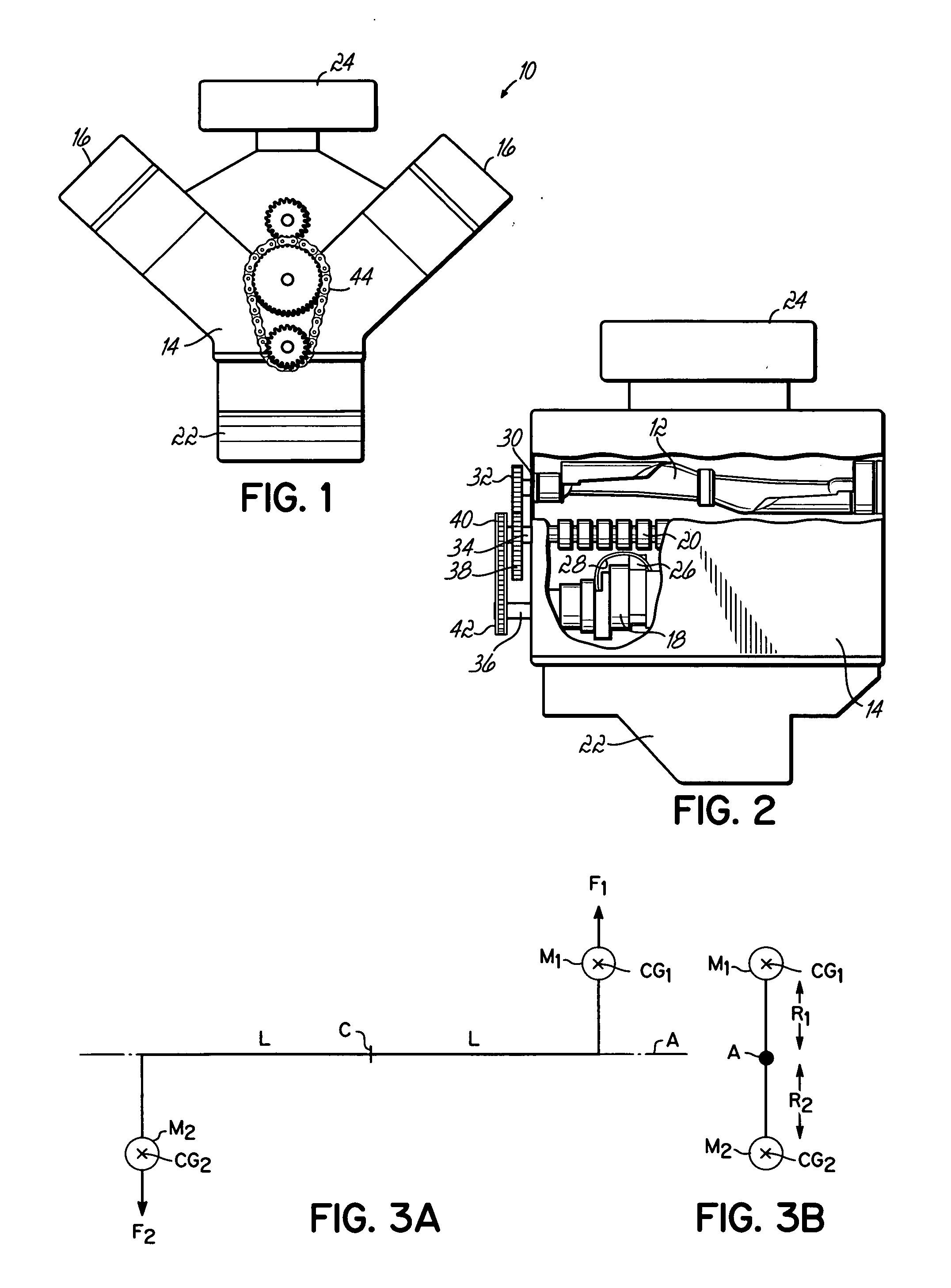

Engine balance masses and drives

ActiveUS8210148B2Reduce spacingMinimizes weight packaging spaceShaftsMachines/enginesEngineeringPinion

The present application relates to a drive and balance mass. In one example, an engine includes, a camshaft, a balance shaft disposed within an interior of the camshaft, and a first gear, intermediate the balance shaft and the camshaft and driving the balance shaft to rotate about a first axis substantially parallel to a crankshaft of the engine in a direction opposite of the crankshaft. In another example, a balance mass and drive for an engine includes, a planetary gear set including a sun gear, a ring gear and a plurality of pinions mounted on a carrier, an input coupled to an input gear of the planetary gear set, a balance mass coupled to an output gear of the planetary gear set, the output gear configured to drive the balance mass to rotate about a first axis substantially parallel to the crankshaft in a direction opposite of the crankshaft.

Owner:FORD GLOBAL TECH LLC

Component arrangement for snowmobile

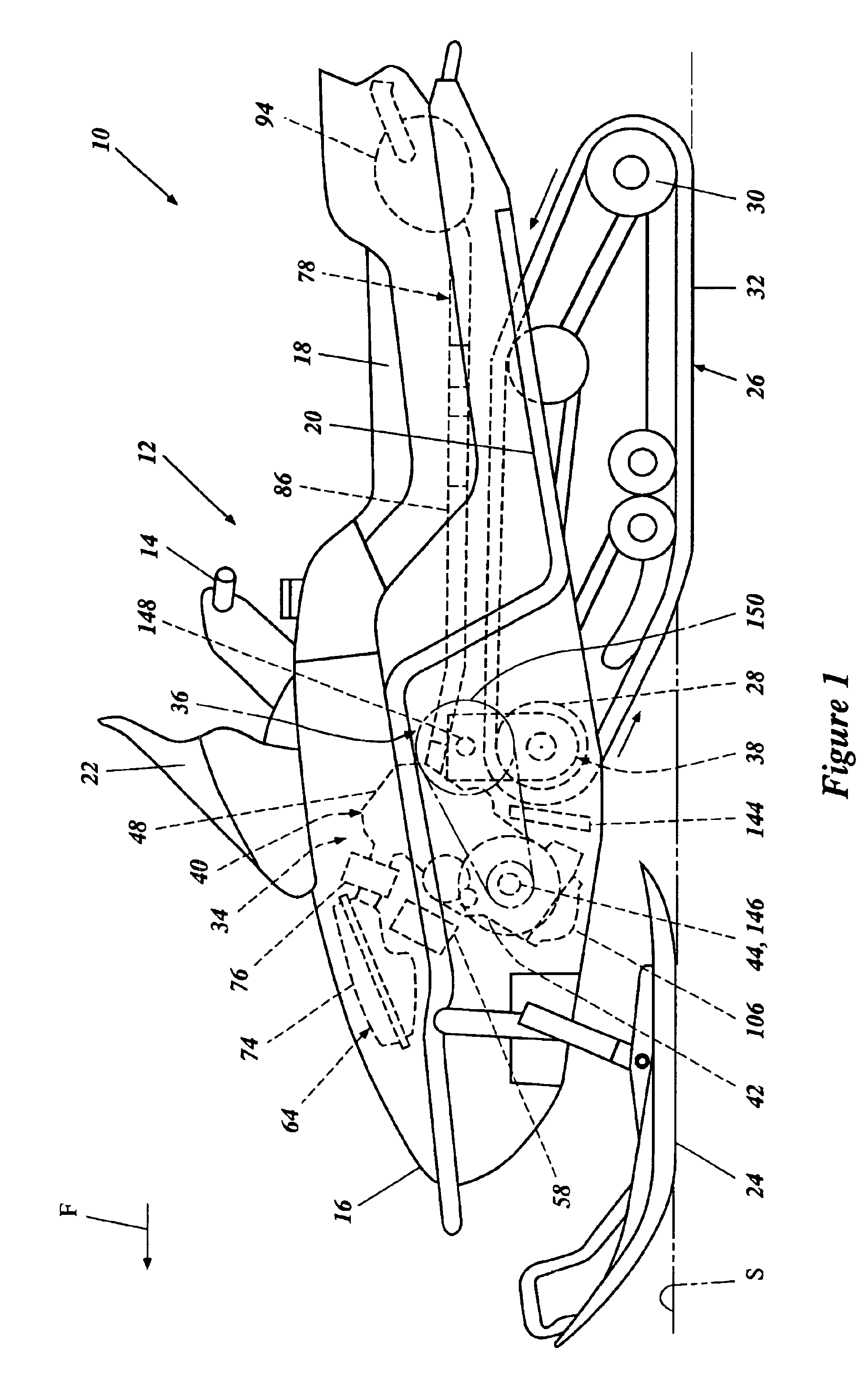

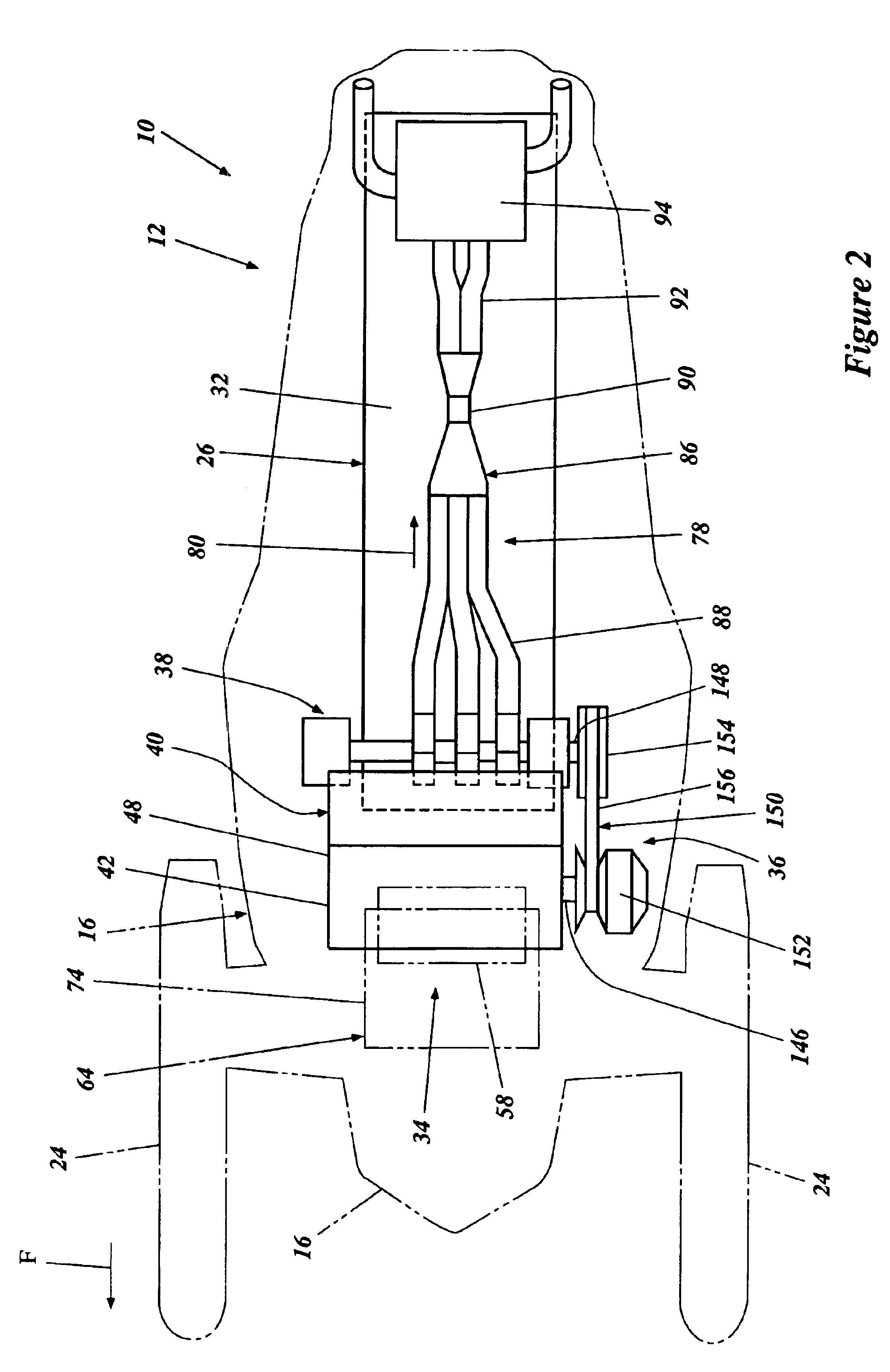

ActiveUS6880659B2Lower center of gravityImprove stabilityCasingsInertia force compensationReciprocating motionCrankcase

A snowmobile including a frame assembly and a drive assembly coupled to the frame assembly. The drive assembly including a drive belt adapted to contact a ground surface to propel the snowmobile over the ground surface. An engine is supported by the frame assembly and includes an engine body. The engine body includes a crankcase, a crankshaft rotatably journaled within the crankcase for rotation about a crankshaft axis, and a cylinder block assembly extending in an upward direction from the crankcase. The cylinder block assembly defines at least one cylinder bore adapted to support a piston for a reciprocal motion along a bore axis. A balancer shaft is rotatably coupled to the crankshaft and supported by the engine body for rotation about a balancer shaft axis. The cylinder assembly is canted such that the bore axis is inclined to rearwardly from a vertical axis and the balancer shaft axis is disposed above the crankshaft axis. At least a portion of the balancer shaft can be disposed directly above the crankshaft.

Owner:YAMAHA MOTOR CO LTD

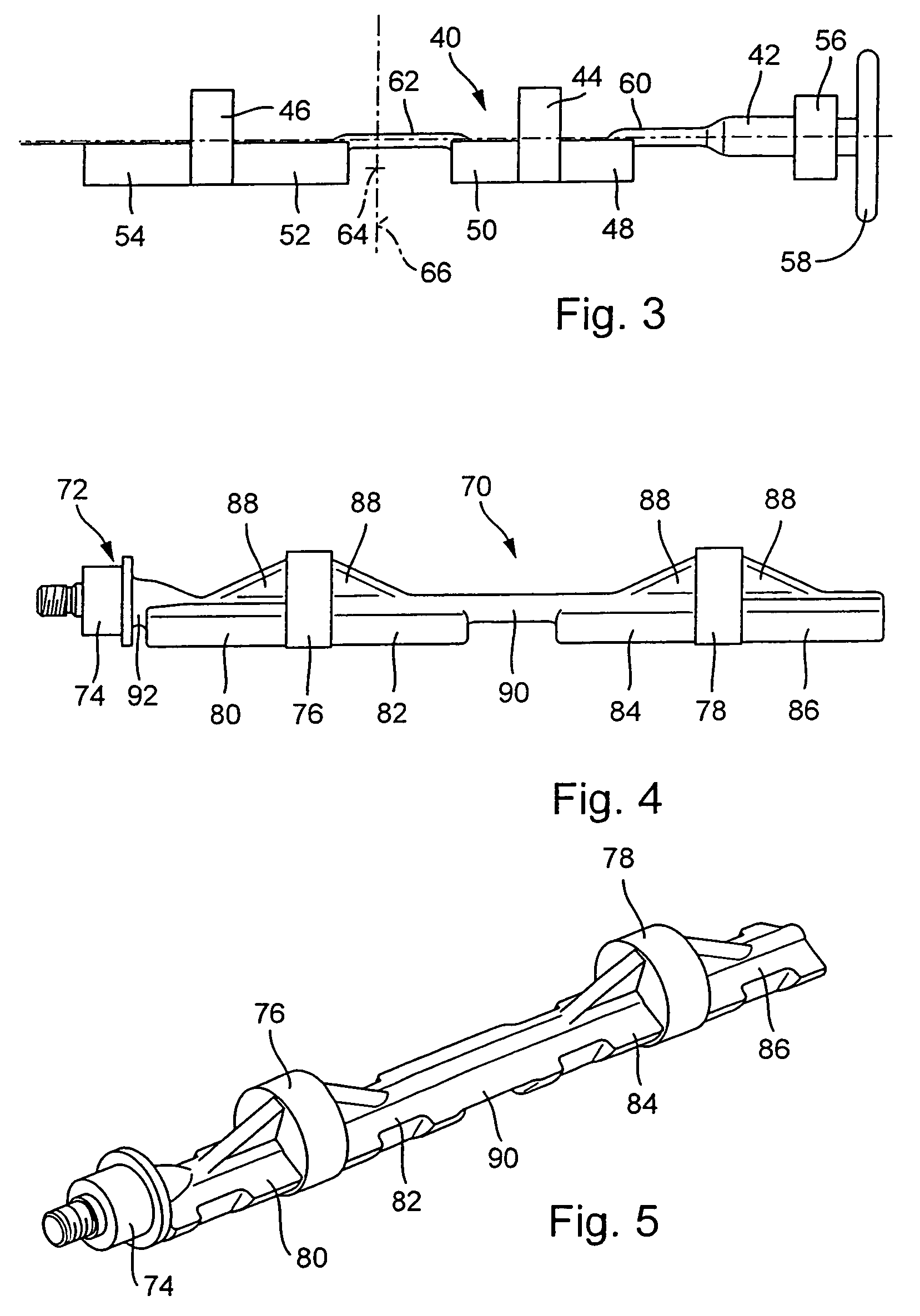

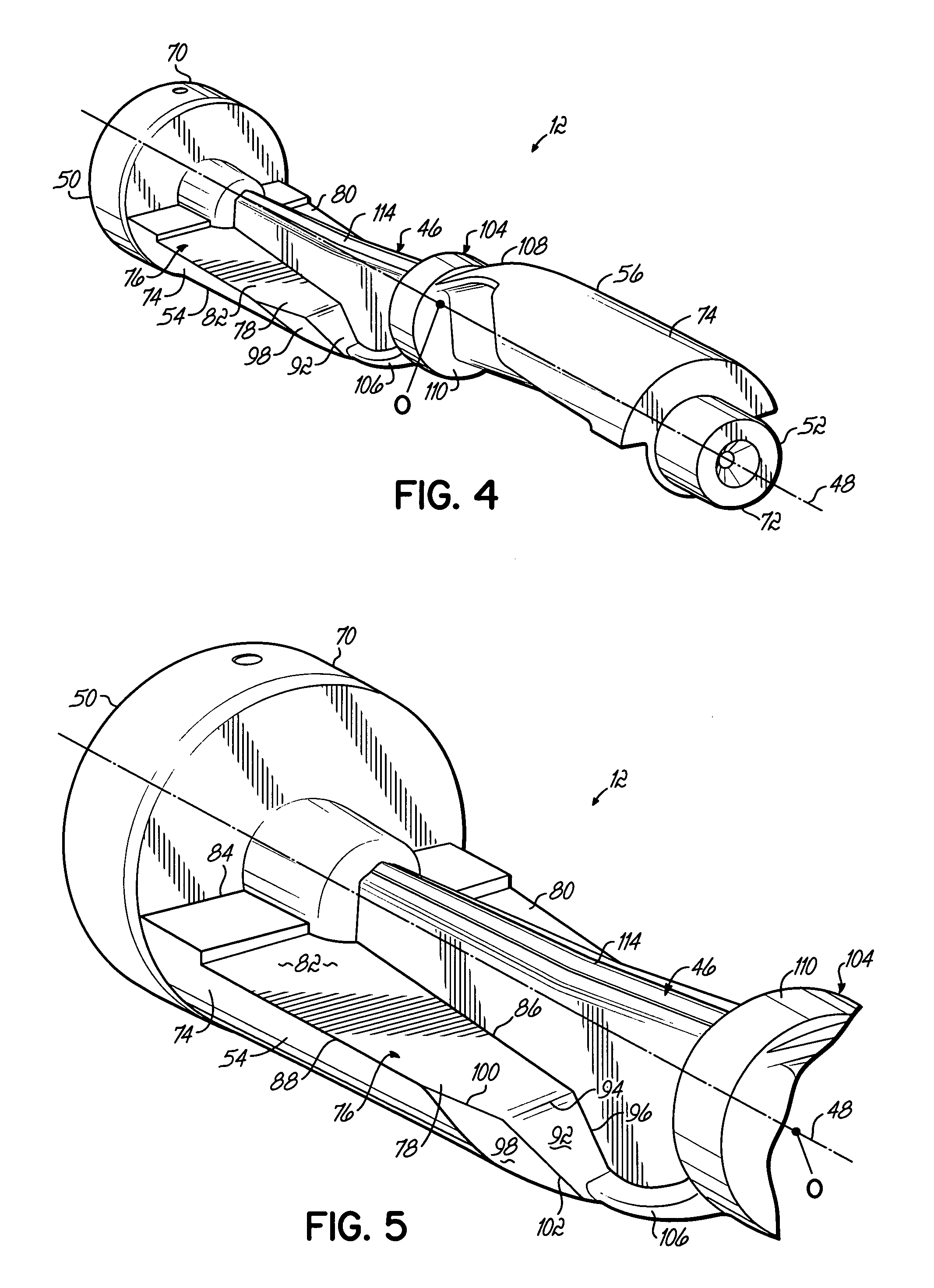

Balance shaft

InactiveUS20050284254A1High strengthReduce weightInertia force compensationShaftsBalance shaftEngineering

A balance shaft for an engine comprises an elongate member defining a longitudinal axis and having first and second ends. A first counterweight is adjacent the first end and a second counterweight is adjacent the second end and positioned on opposite sides of the longitudinal axis. Each of the counterweights includes a pair of weight portions that are mirror images of each other across the longitudinal axis. Each weight portion includes a first generally planar surface extending in the longitudinal direction, a second generally planar surface inclined with respect to the first surface, and a third generally planar surface inclined with respect to the first and second surfaces. The inclined relation between the three surfaces controls the location of the gravitational center of each counterweight so that when the balance shaft rotates about the longitudinal axis, a couple moment is provided that counteracts the unbalance moment generated by the engine.

Owner:HILLSDALE AUTOMOTIVE

Self regulating fluid bearing high pressure rotary nozzle with balanced thrust force

ActiveUS7635096B2Minimize abrasive wearEngine sealsMovable spraying apparatusAxial forceHigh pressure

A high pressure rotary nozzle having a rotating shaft operating within a fixed housing wherein the of axial force which acts upon the shaft due to the liquid pressure at the shaft inlet is balanced by allowing passage of a small amount of the pressurized liquid to be bled to an area or chamber between the outside of the opposite end of the shaft and the inside of the housing where the liquid pressure can act axially in an opposing direction upon the shaft to balance the axial inlet force. The balance of axial forces is self-regulating by controlling escape of the liquid through a tapered or frusto-conical region between the shaft and housing. This further provides a liquid bearing between the two surfaces and allows use of interchangeable rotating jet heads having jet orifices which can be oriented in virtually any desirable configuration including axially forward of the nozzle.

Owner:STONEAGE

Multi-stage centrifugal pump capable of self-balancing axial force by impeller

InactiveCN1815039ASolve the problem of axial force failureReduce manufacturing costPump componentsRadial flow pumpsThrust bearingAxial force

Said invention refers to multistage centrifugal pump with impeller self balancing axial force. Said invention adopts end surface sealed structure on impeller entrance, the impeller band being greater than impeller hub area, the fit between impeller band outside diameter with diversion shell being clearance fit, impeller entrance end surface sealing sub being thrust bearing sub etc method to realize completely balancing axial thrust effect depending on impeller itself, thoroughly solving multistage centrifugal pump axial force destruction problem, and reducing multistage centrifugal pump production costs.

Owner:JIANGSU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com