Automatic hot-pressing assembly device of balancing shaft and helical gear

An assembly device and balance shaft technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of helical gears without balance shafts, low assembly accuracy, high scrap rate, etc., and achieve good safety performance and reliable quality High performance and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present balance shaft helical gear hot pressing device will be further described below with reference to the accompanying drawings and specific embodiments.

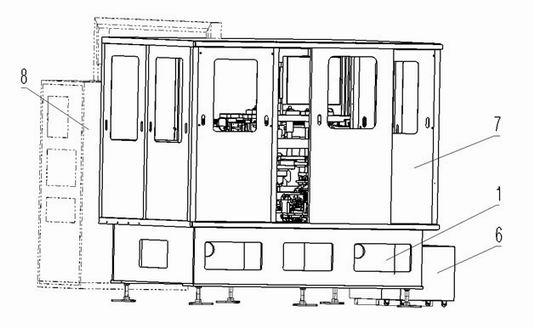

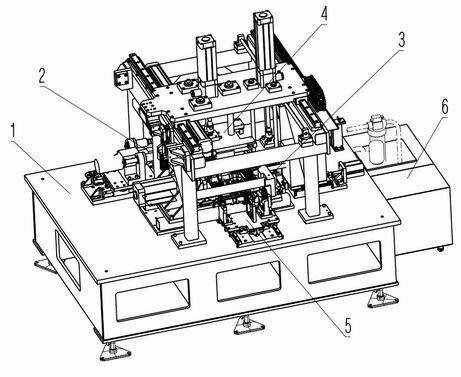

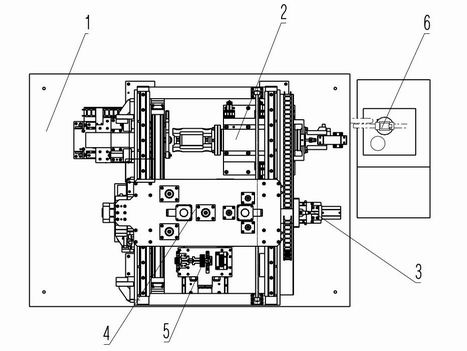

[0022] like Figure 1-9 As shown, the device consists of a base 1 , a dynamic balancing machine 2 , a gear heat press 3 , a manipulator 4 , a loading and unloading station 5 , a hydraulic station 6 , a casing 7 and a control part 8 .

[0023] The device of the invention completes the two processes of dynamic balance measurement, alignment and identification of the maximum dynamic unbalance position of the balance shaft of the automobile gearbox and hot-pressing assembly of the gears. In the dynamic balancing machine 2, the measurement of the dynamic balance amount of the balance shaft of the automobile gearbox and the alignment of the position of the maximum dynamic unbalance amount can be completed; and the position of the maximum dynamic unbalance amount can be identified by drilling; The assembly orientati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com