Patents

Literature

5134 results about "Spray coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Microstrip patch antenna for high temperature environments

ActiveUS7283096B2Improve performanceImprove reliabilitySimultaneous aerial operationsAntenna adaptation in movable bodiesMicrostrip patch antennaSpray coating

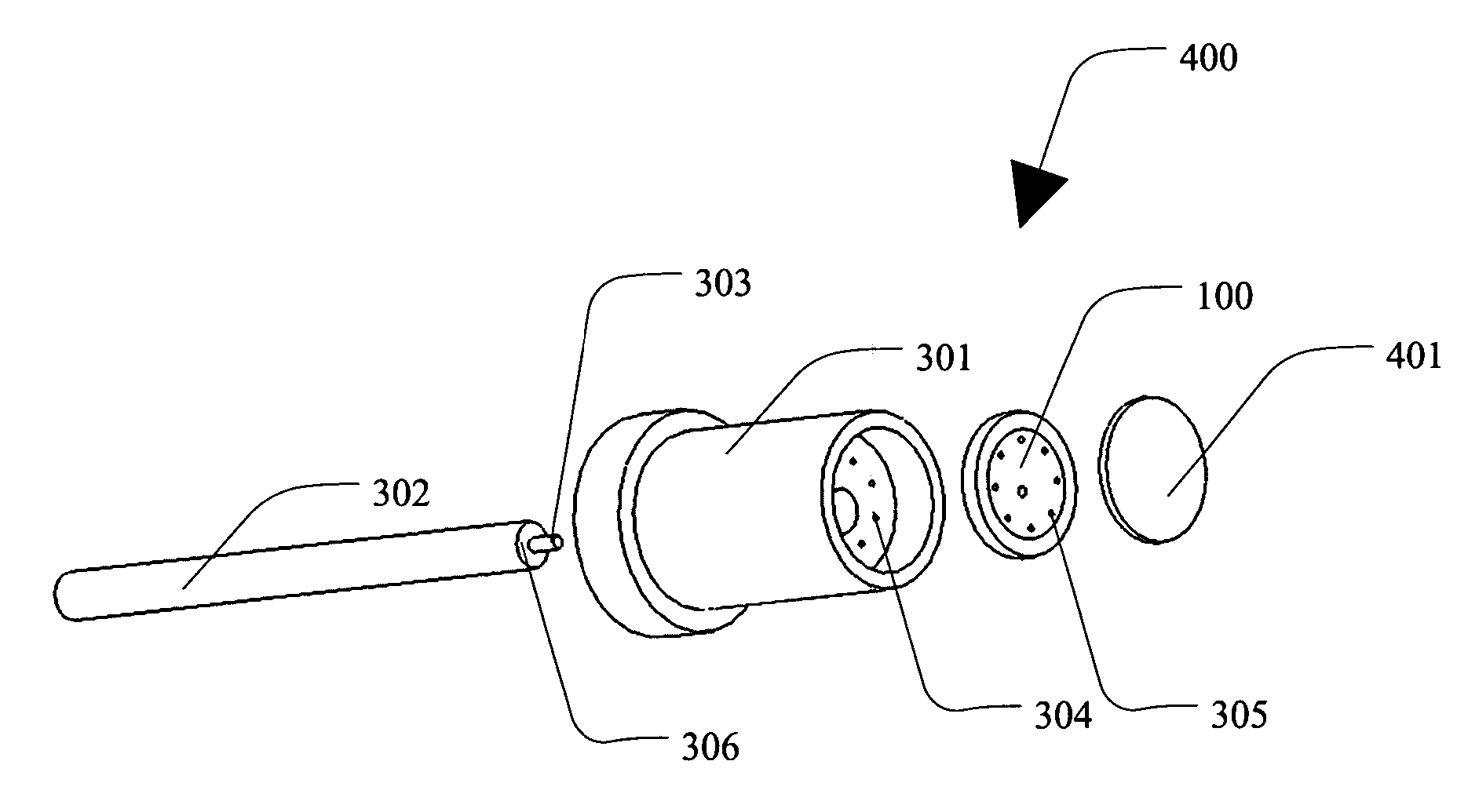

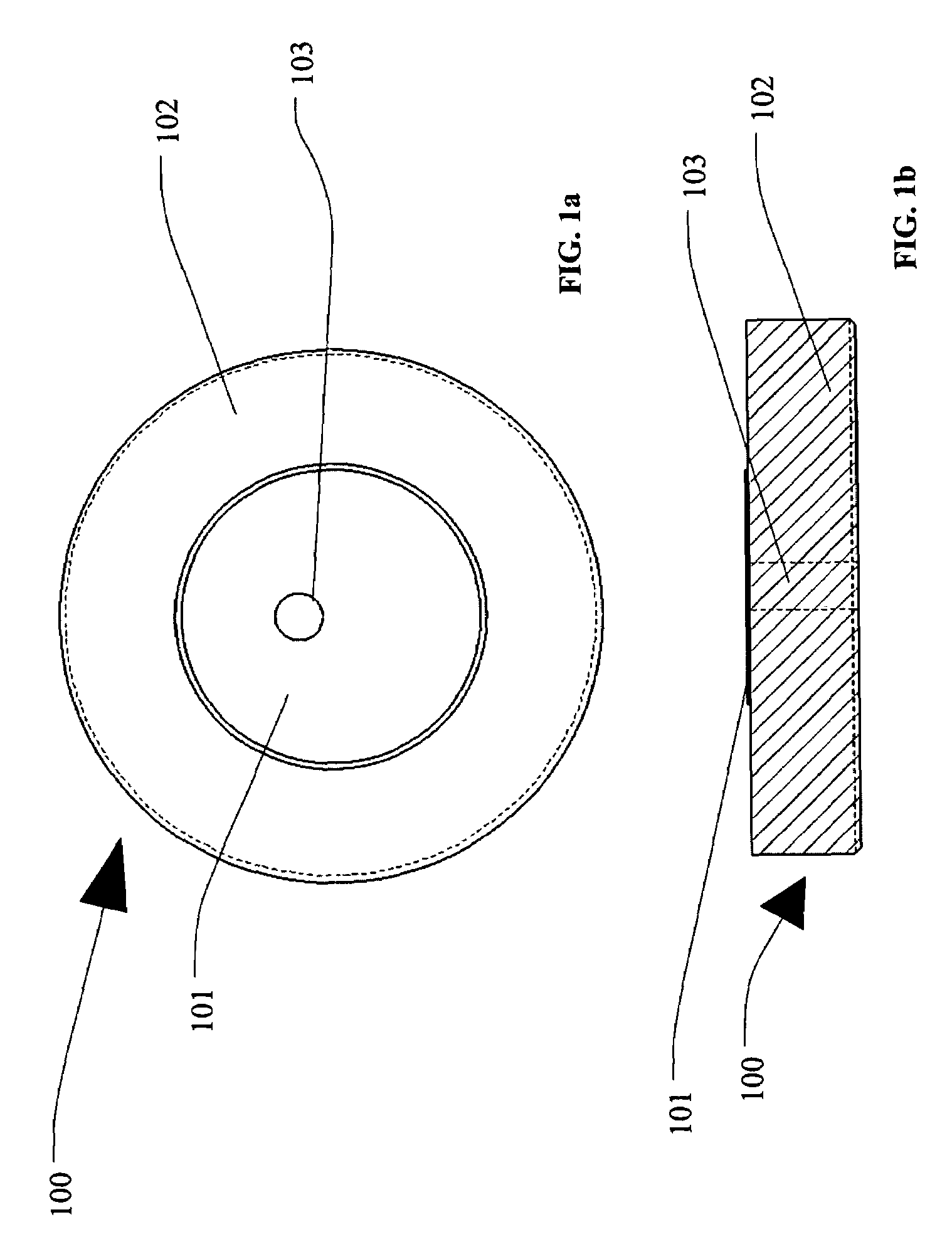

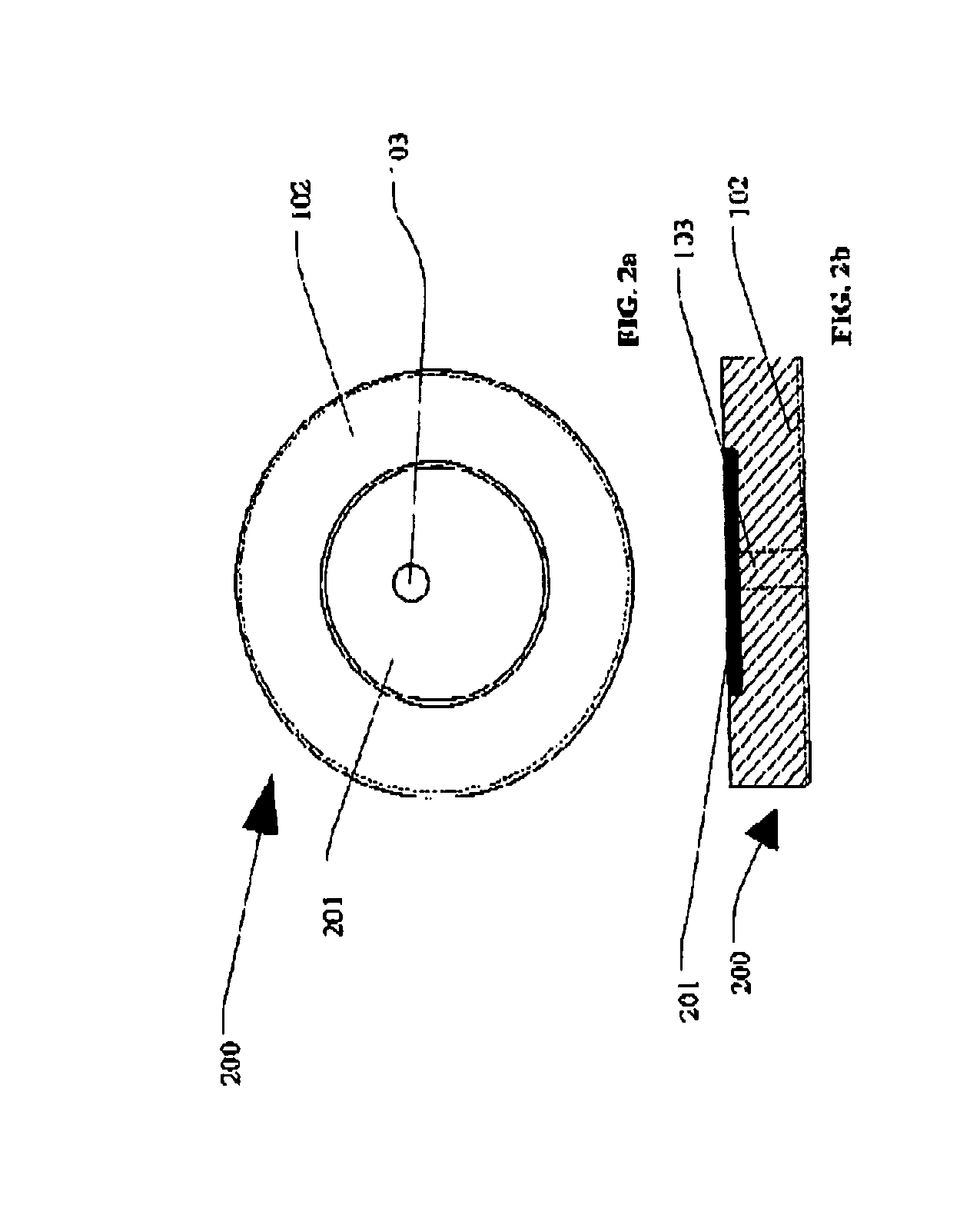

A patch antenna for operation within a high temperature environment. The patent antenna typically includes an antenna radiating element, a housing and a microwave transmission medium, such as a high temperature microwave cable. The antenna radiating element typically comprises a metallization (or solid metal) element in contact with a dielectric element. The antenna radiating element can include a dielectric window comprising a flame spray coating or a solid dielectric material placed in front of the radiating element. The antenna element is typically inserted into a housing that mechanically captures the antenna and provides a ground plane for the antenna. Orifices or passages can be added to the housing to improve high temperature performance and may direct cooling air for cooling the antenna. The high temperature microwave cable is typically inserted into the housing and attached to the antenna radiator to support the communication of electromagnetic signals between the radiator element and a receiver or transmitter device.

Owner:MEGGITT SA

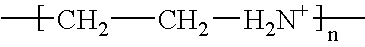

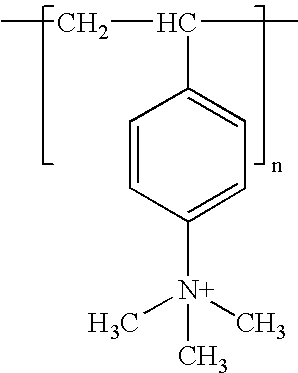

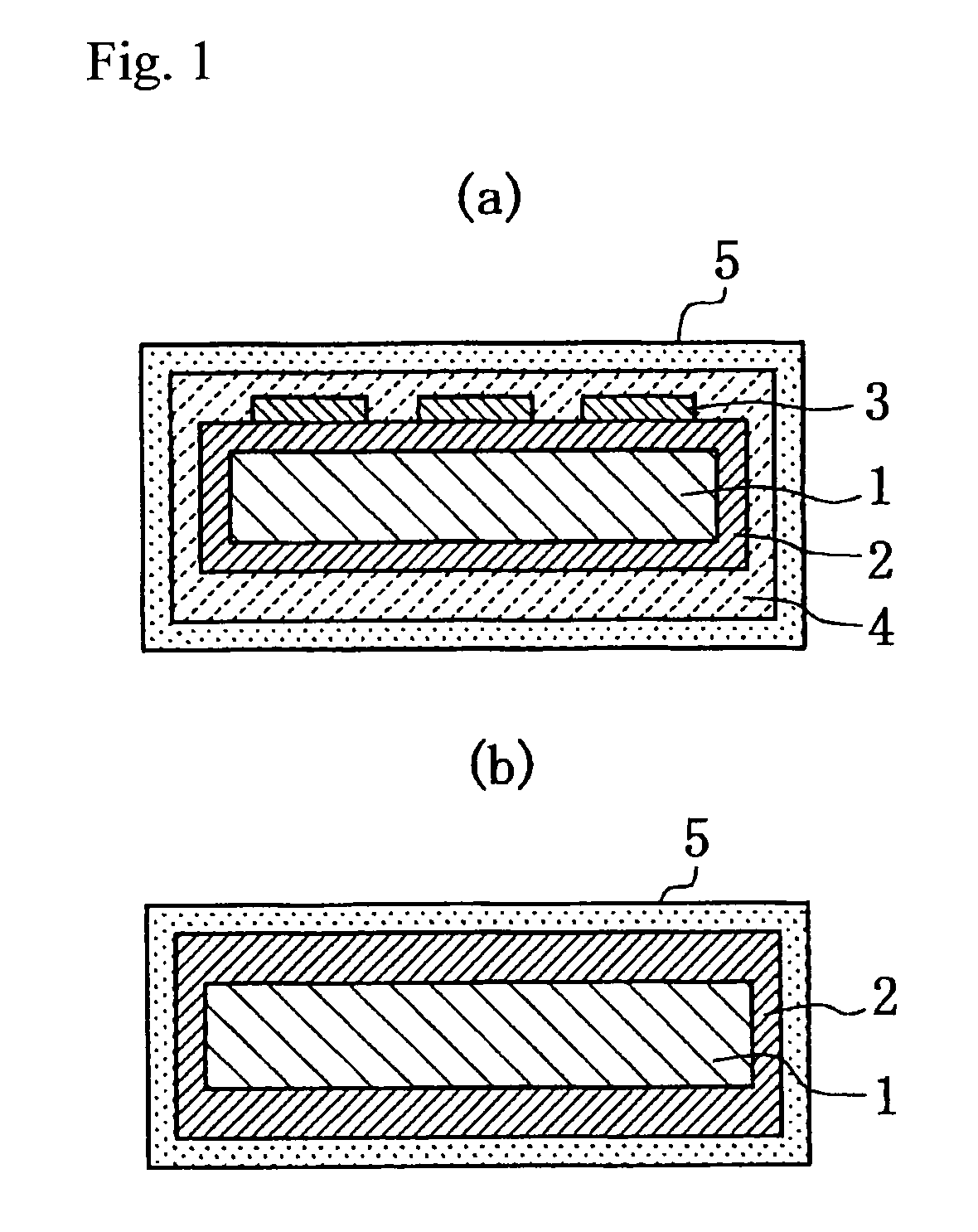

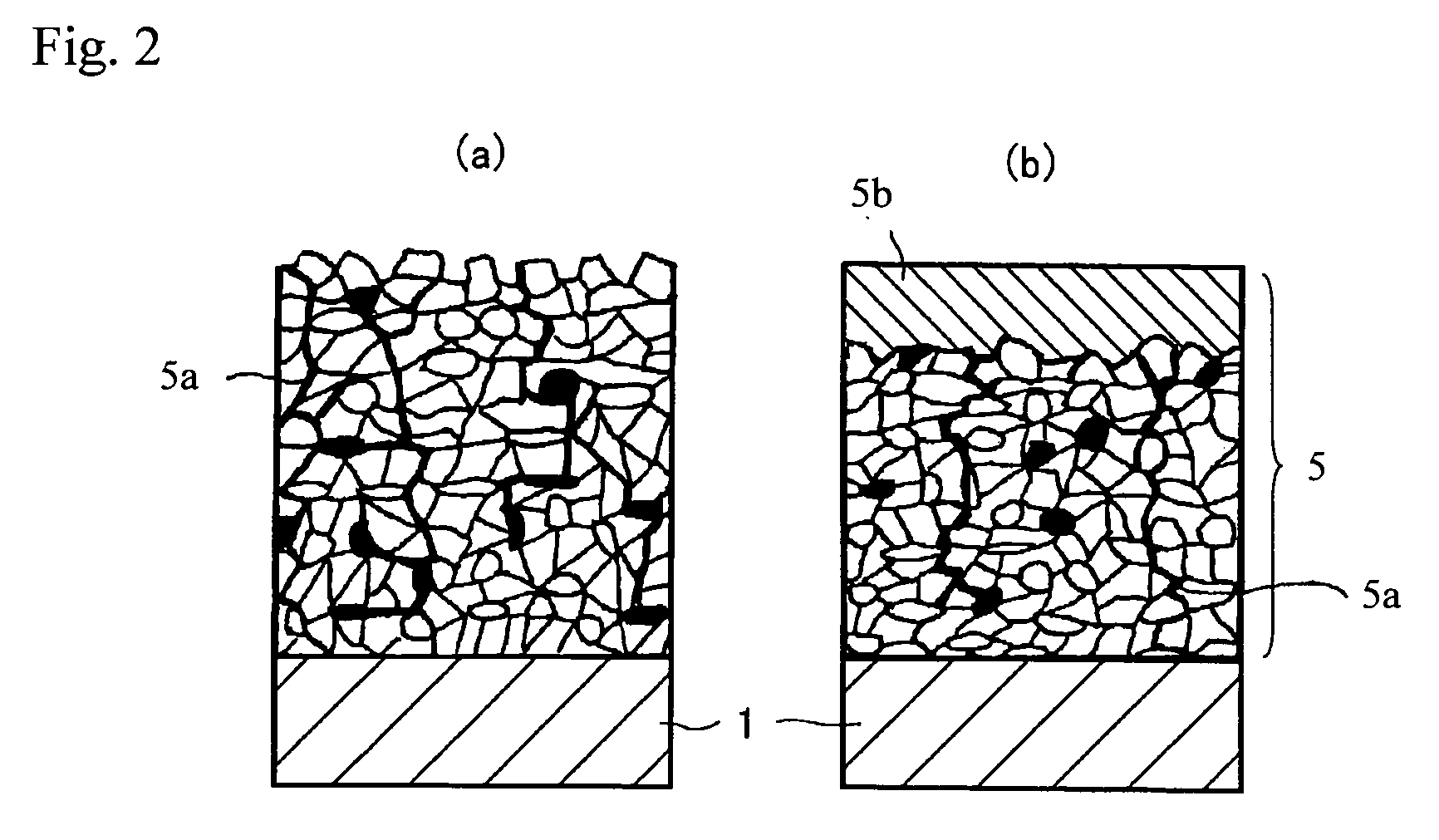

Biomedical devices having improved surface characteristics

InactiveUS7297725B2Reduce complexityHigh oxygen permeabilityOptical articlesCoatingsSpray coatingOxygen

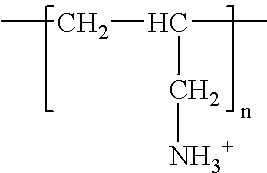

Biomedical devices, such as ophthalmic lenses, and methods of making such devices having a surface coating including at least one polyionic layer. A preferred method involves spray coating a polycationic material onto a core lens, rinsing and drying the lens, followed by spray coating a polyanionic material, rinsing and drying. The coating process may be applied a plurality of times to achieve a multi-layer coating on the lens surface. A particularly preferred embodiment is a contact lens comprising a highly oxygen permeable hydrophobic core coated with a 5 to 20 bilayers of hydrophilic polyionic materials.

Owner:NOVARTIS AG

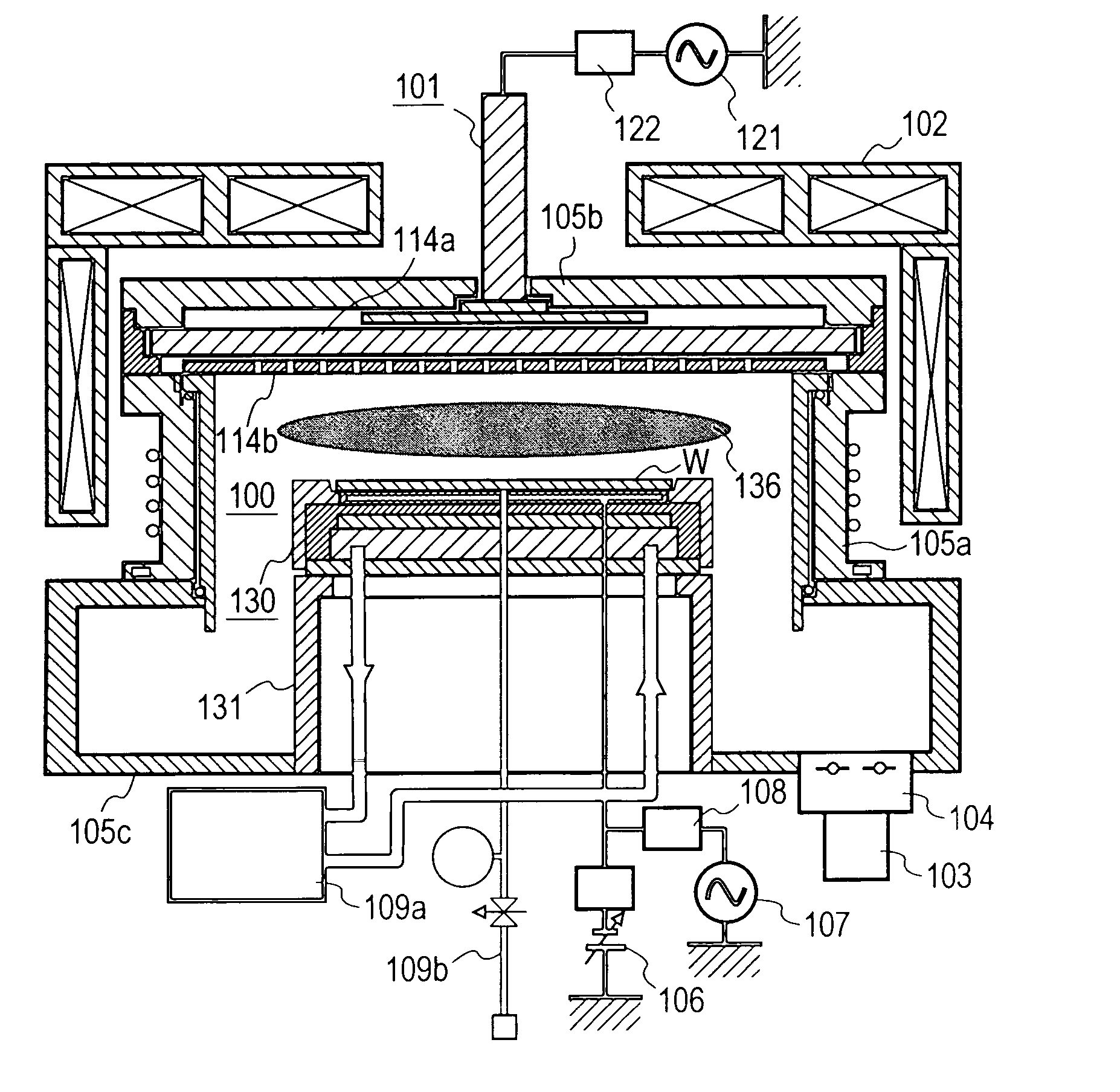

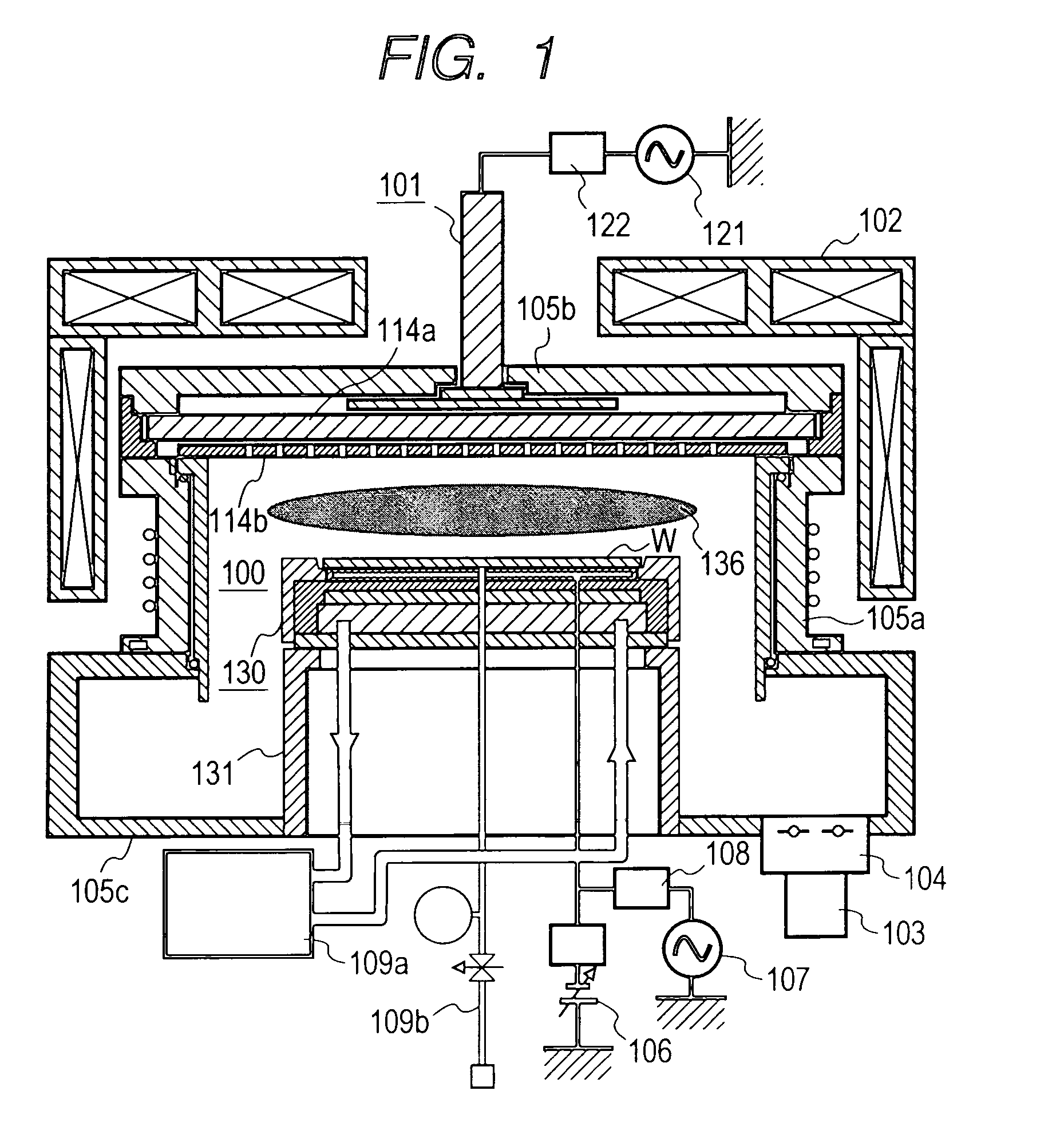

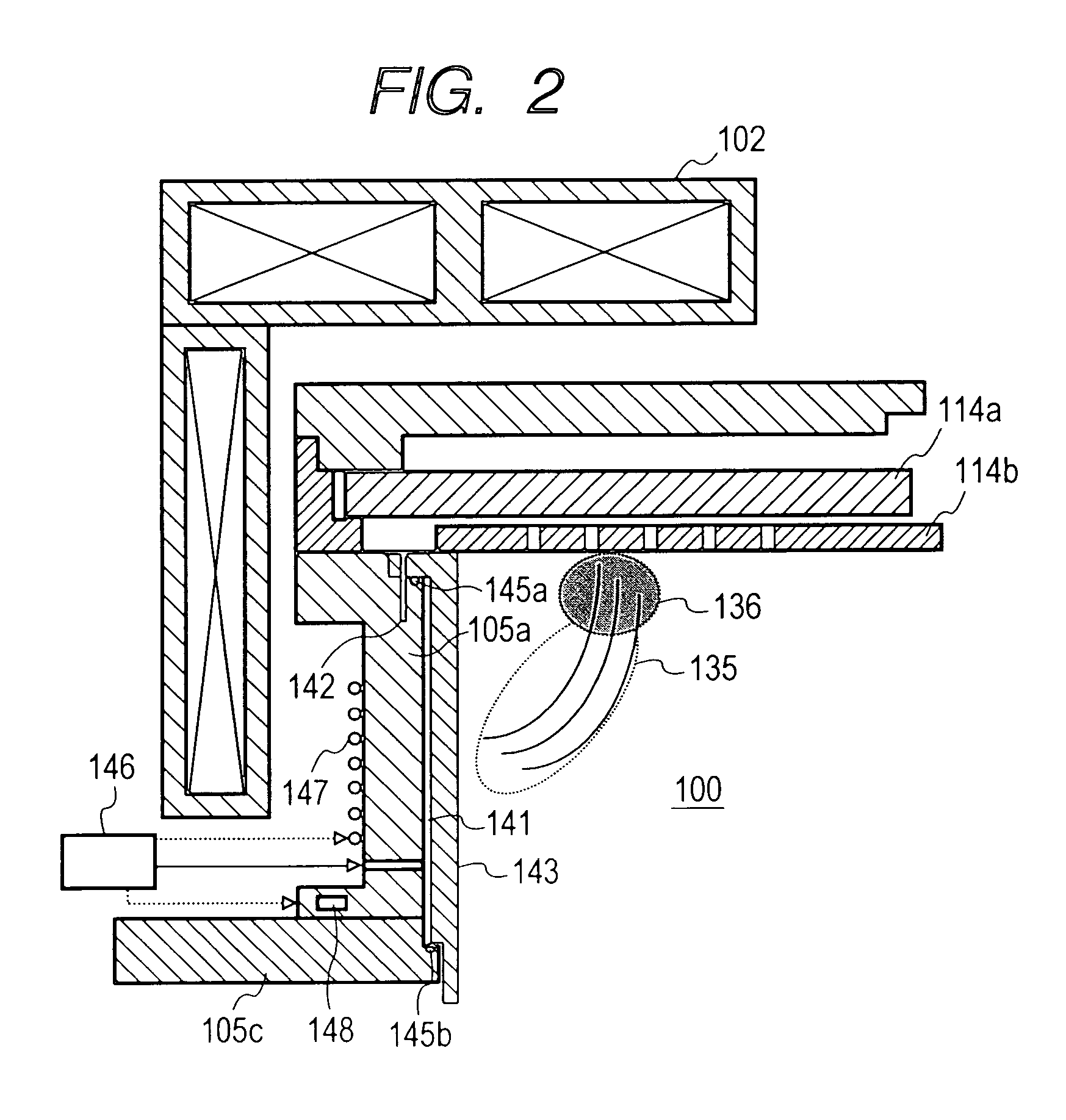

Plasma etching apparatus and method for forming inner wall of plasma processing chamber

InactiveUS20070215278A1Reduce corrosionDecreasing amountElectric discharge tubesSemiconductor/solid-state device manufacturingProduction rateHeat resistance

A plasma etching apparatus is provided which can prevent corrosion of an aluminum substrate constituting an etching processing chamber or an inside component thereof, thereby avoiding a reduction in productivity due to scattering of a sprayed coating. In the plasma etching apparatus, an anodic oxide film is disposed between a ceramic sprayed coating with excellent resistance to plasma, and the etching processing chamber and the inside component thereof made of aluminum alloy. The anodic oxide film has a thickness of 5 μm or less to have heat resistance.

Owner:HITACHI HIGH-TECH CORP

Electrostatic chuck member

InactiveUS20090080136A1Avoid damageAvoid layeringSemiconductor/solid-state device manufacturingElectrostatic holding devicesSurface roughnessSpray coating

An electrostatic chuck member comprises an electrode layer and an electric insulating layer, wherein a spray coating layer of an oxide of a Group 3A element in the Periodic Table is formed as an outermost layer of the member and a surface of the spray coating layer is rendered into a densified re-melting layer having an average surface roughness (Ra) Of 0.8-3.0 μm.

Owner:TOKYO ELECTRON LTD +1

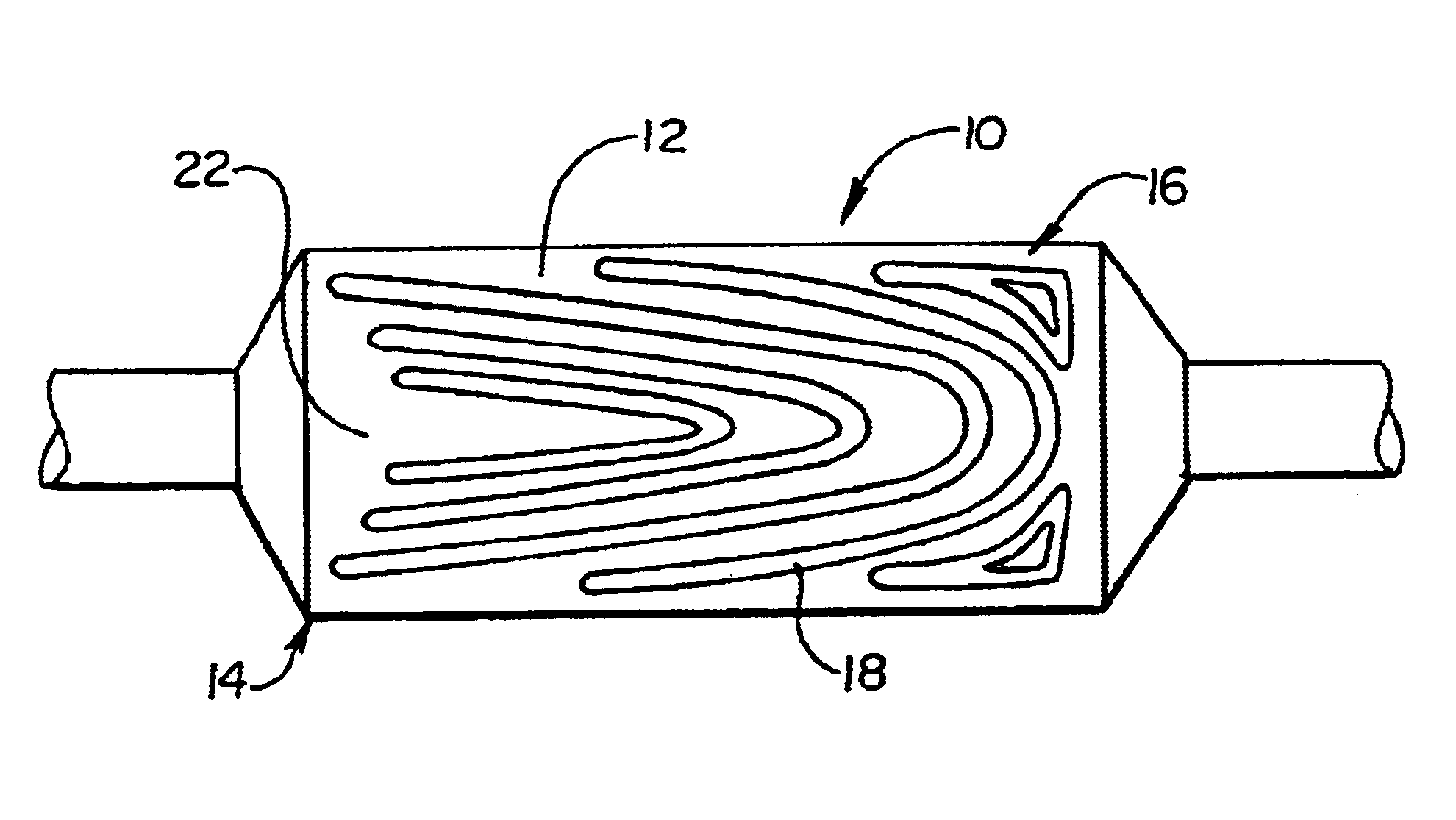

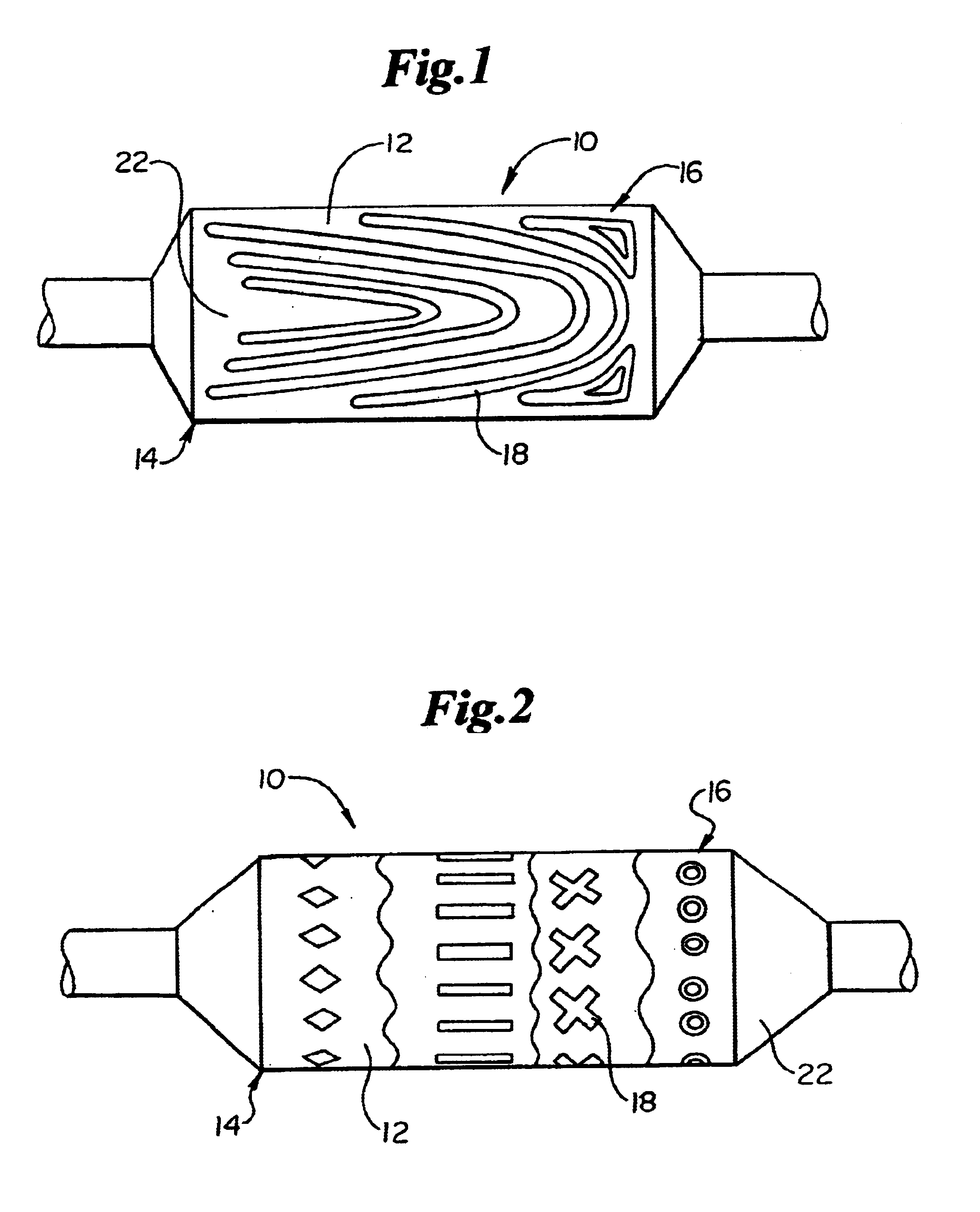

Elastomerically impregnated ePTFE to enhance stretch and recovery properties for vascular grafts and coverings

This invention relates to an elastomerically recoverable PTFE material that includes a longitudinally compressed fibrils of ePTFE material penetrated by elastomeric material within the pores defining the elastomeric matrix. The elastomeric matrix and the compressed fibrils cooperatively expand and recover without plastic deformation of the ePTFE material. This invention was used for various prosthesis, such as a vascular prosthesis like a patch, a graft and an implantable tubular stents. Furthermore, this invention discloses a method of producing the elastomerically recoverable PTFE material which include the steps of: providing the specified ePTFE, defined by the nodes and fibrils, to meet the desired end use; longitudinally compressing the fibrils of the ePTFE, the pore size sufficiently enough to permit penetration of the elastomeric material; applying the elastomeric material within the pores to provide a structurally integral elastomerically recoverable PTFE material defining an elastomeric matrix. The elastomeric material is applied to the ePTFE by dip, brush or spray coating techniques. The compression step and the application steps are interchangeable to produce the desired properties for the end use material. Finally, the elastomeric material is dried within the pores of the longitudinally compressed ePTFE to solidify the elastomeric matrix.

Owner:LIFESHIELD SCI

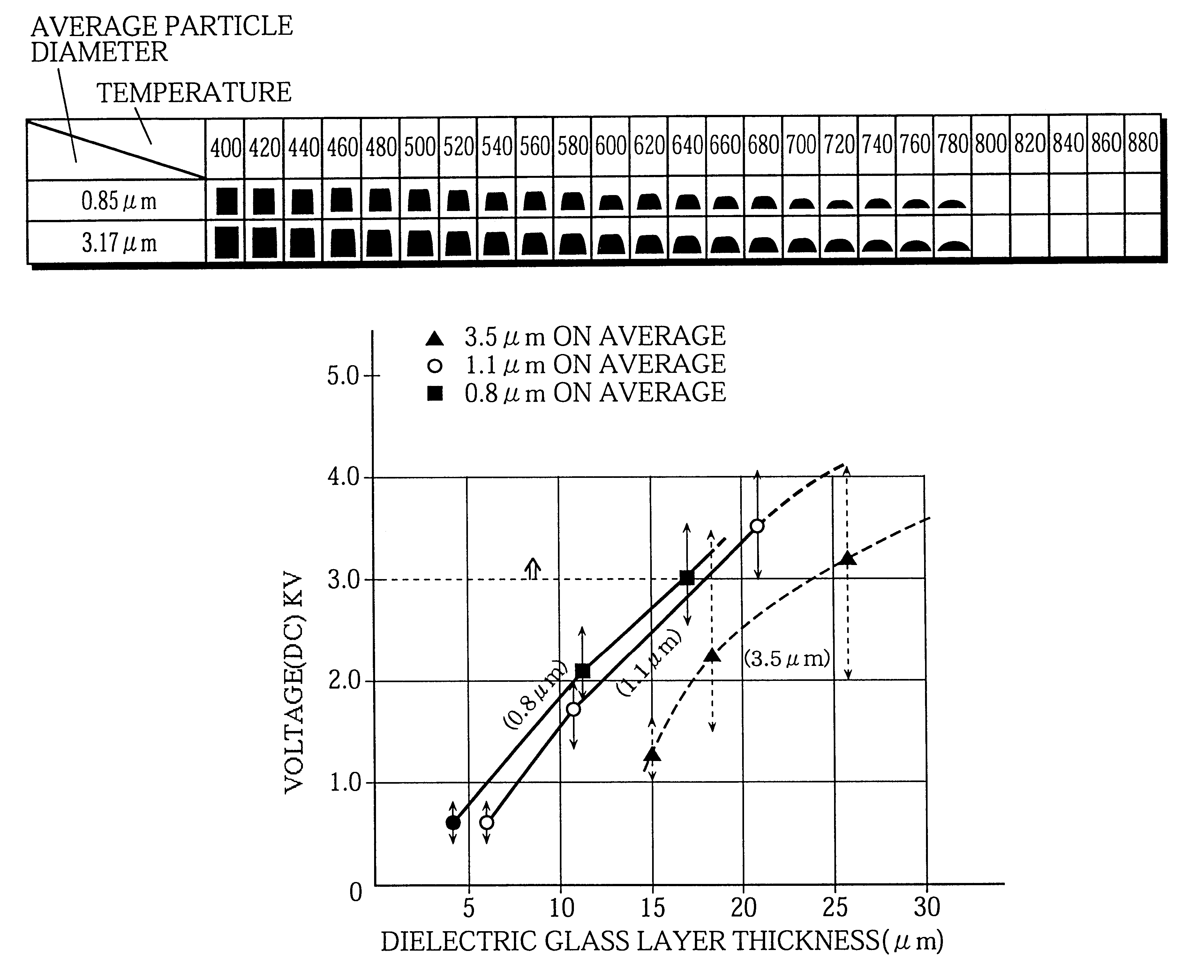

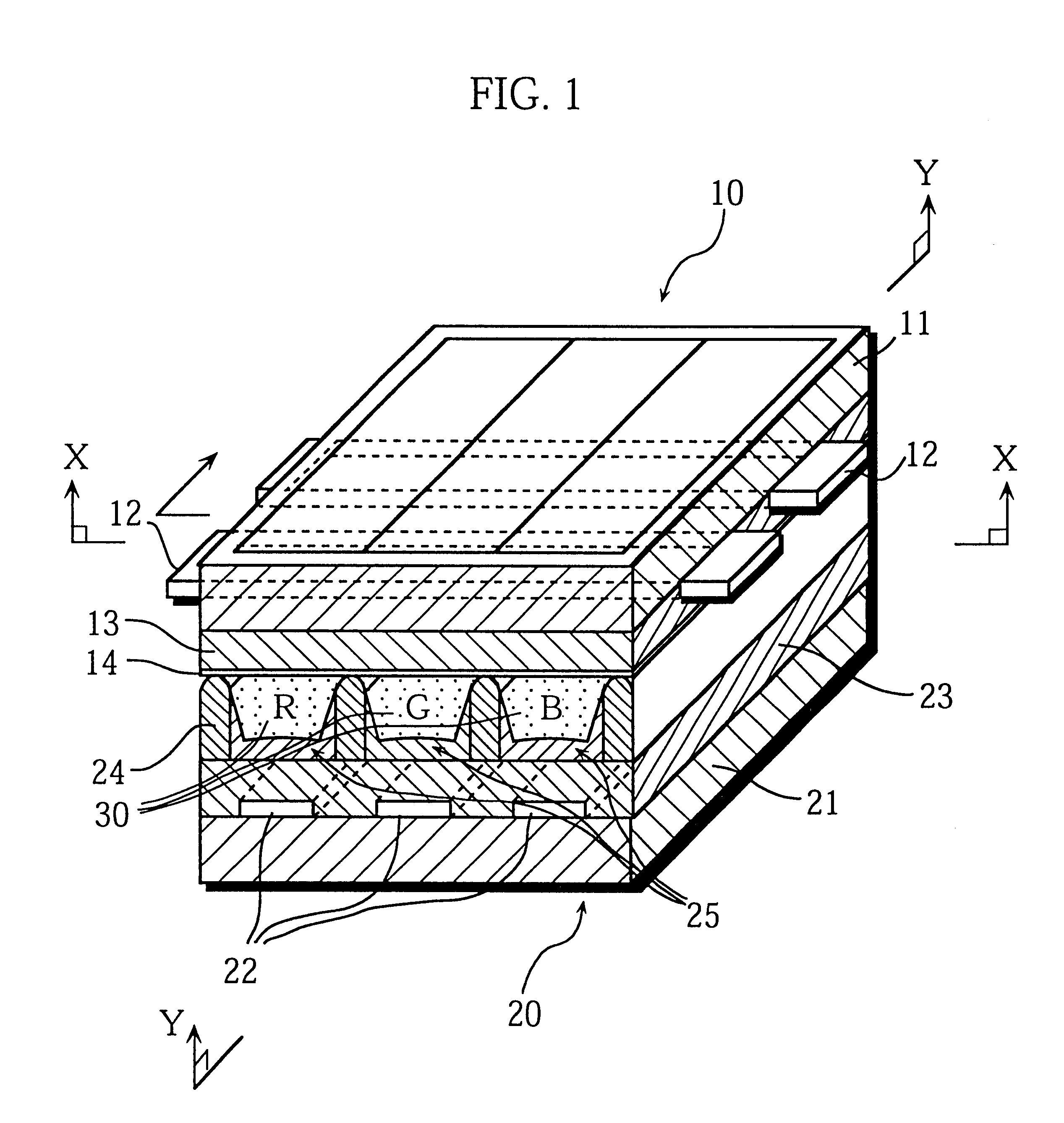

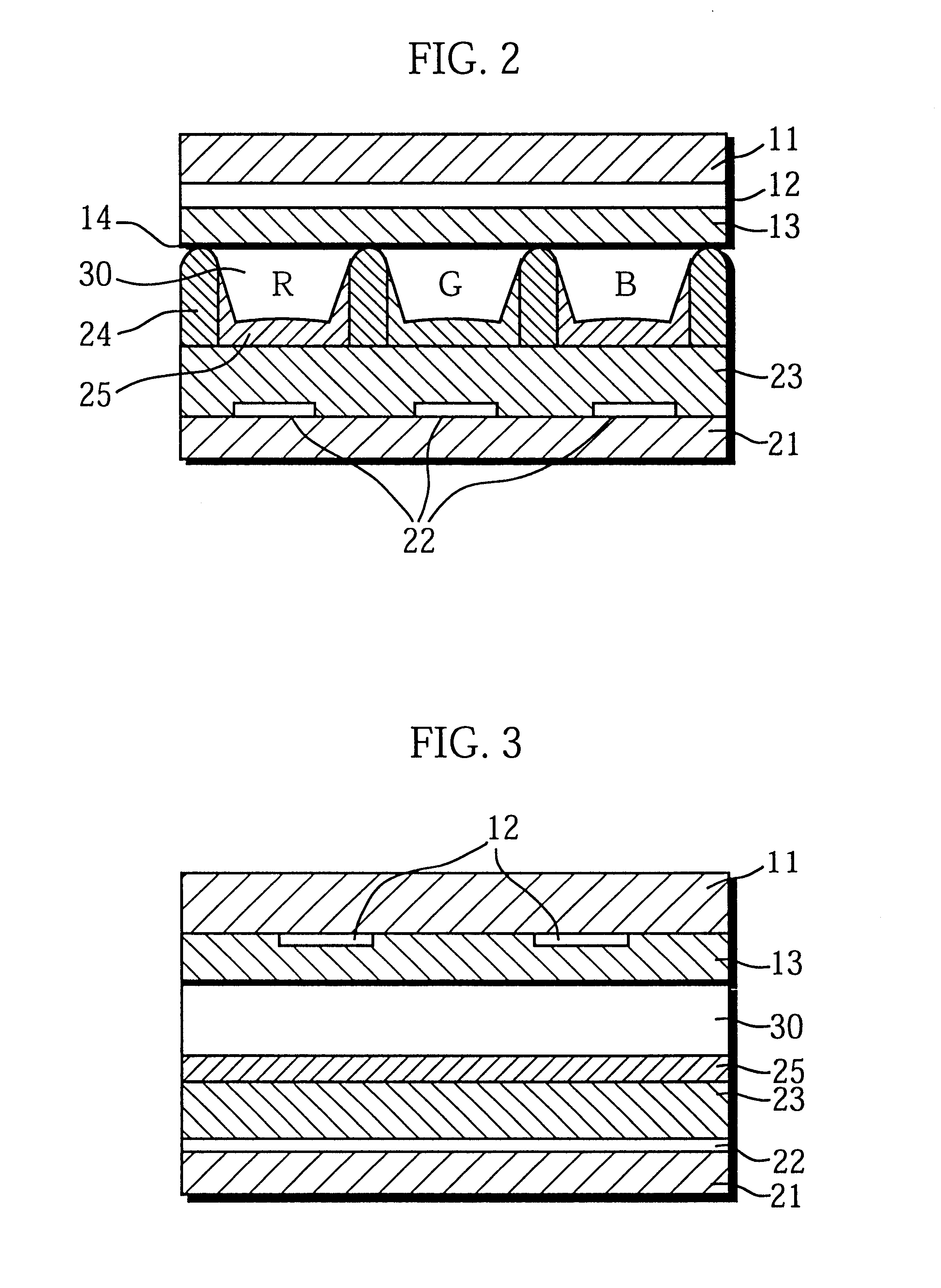

Manufacturing method of plasma display panel that includes adielectric glass layer having small particle sizes

InactiveUS6439943B1Alternating current plasma display panelsVessels or leading-in conductors manufactureScreen printingMetallurgy

The object of the present invention is to provide a high-intensity, reliable plasma display panel even when the cell structure is fine by resolving the problems such as a low visible light transmittance and low voltage endurance of a dielectric glass layer. The object is realized by forming the dielectric glass layer in the manner given below. A glass paste including a glass powder is applied on the front glass substrate or the back glass substrate, according to a screen printing method, a die coating method, a spray coating method, a spin coating method, or a blade coating method, on each of which electrodes have been formed, and the glass powder in the applied glass paste is fired. The average particle diameter of the glass powder is 0.1 to 1.5 mum and the maximum particle diameter is equal to or smaller than three times the average particle diameter.

Owner:PANASONIC CORP

Absorbent structure with improved water-absorbing material

Owner:PROCTER & GAMBLE CO

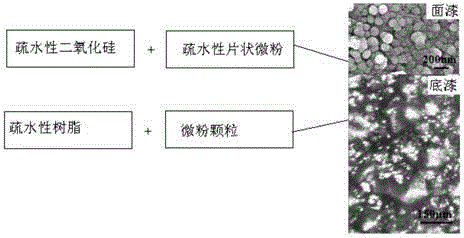

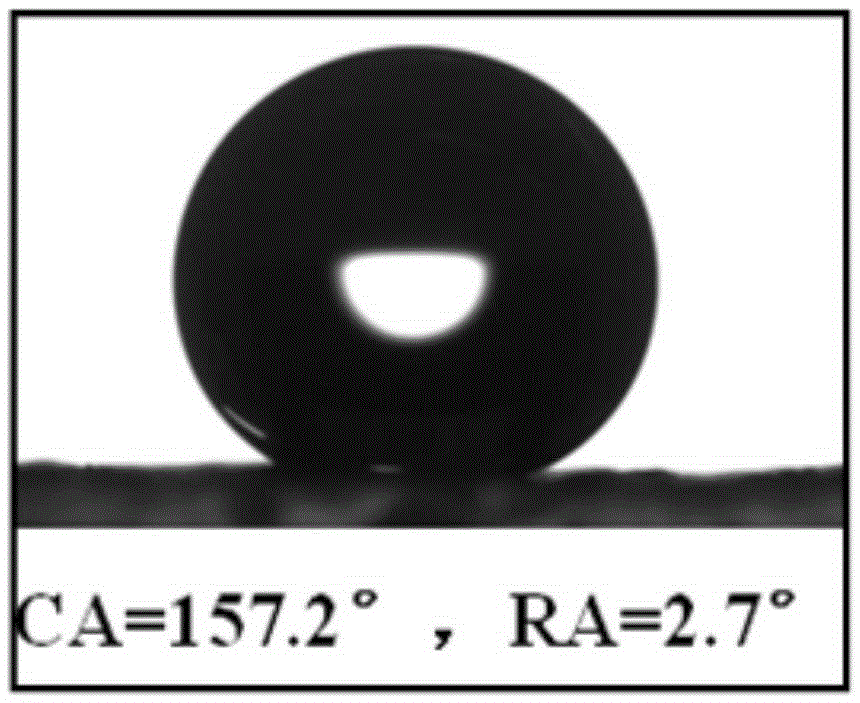

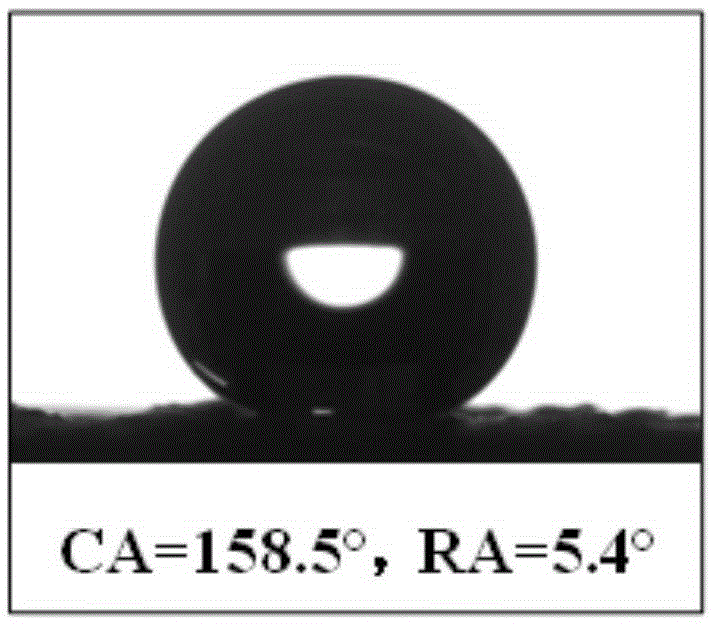

Highly-wear-resistant super-hydrophobic composite coating and preparation method thereof

The invention discloses a highly-wear-resistant super-hydrophobic composite coating and a preparation method thereof. The preparation method includes the steps that the surface of a base is coated with hydrophobic resin primer containing compound micropowder through a brush coating or spray coating method, the surface of the resin primer is sprayed with hydrophobic organic / inorganic hybrid nano-paint after semi-curing, and the highly-wear-resistant super-hydrophobic composite coating is obtained after complete curing. The highly-wear-resistant super-hydrophobic composite coating and the preparation method thereof have the advantages that equipment and the process are simple, operation is easy and cost is low, and have the industrial mass production prospect. The prepared super-hydrophobic composite coating can be applied to various hard / soft bases such as glass, copper, aluminum, stainless steel, exterior wall tiles, wood, paper and cloth and can bear damage of external force such as sanding.

Owner:SOUTHEAST UNIV

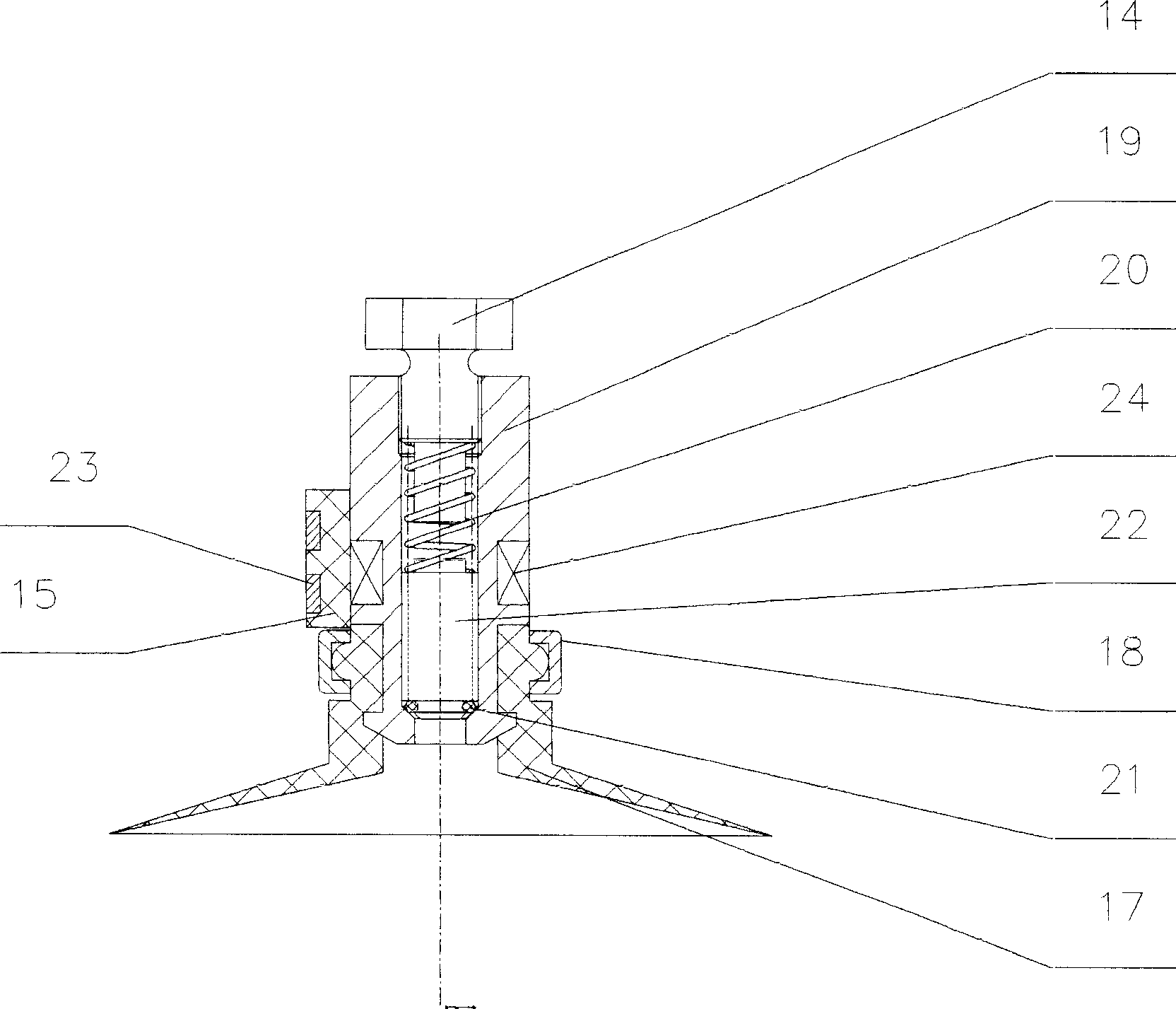

Multifunctional liquid rubber spray-coating material, preparation method, using method and special-purpose device

InactiveCN101235252AGood extensibilityImprove performanceSpraying apparatusConjugated diene hydrocarbon coatingsPolymer scienceSpray coating

Multifunctional liquid rubber spray coating comprises components of A, B, wherein A component comprises liquid rubber asphalt emulsion whose solid content is 50-75%, wherein 2-65% rubber elusion content, 30-97% asphalt elusion content, 0.0-5.0% carbon black, 0.0-6.0% ultra-fine powder, 0.025-2.50% anion dispersing agent and 0.025-3.00% anion surface activator, which is waterborne spray coating, and B component is water solution which comprises 3.0-18.0% concentration calcii chloridum (89.0-99.2%), sodium chloride (0.50-4.0%) and composite aluminum iron polymer (0.3-7.0%). The two components are sprayed on the same basal plane through adopting a double-component airless spraying device to form a gelatin film with 0.5-4mm after 3-5 seconds solidification, which has the characteristics of strong bonding, temperature resistance, weather resistance, and excellent chemical stability, heat insulation and puncture resistance. The A component can be individually sprayed, or can be combined with the double components.

Owner:大连美宸特环保节能产品有限公司

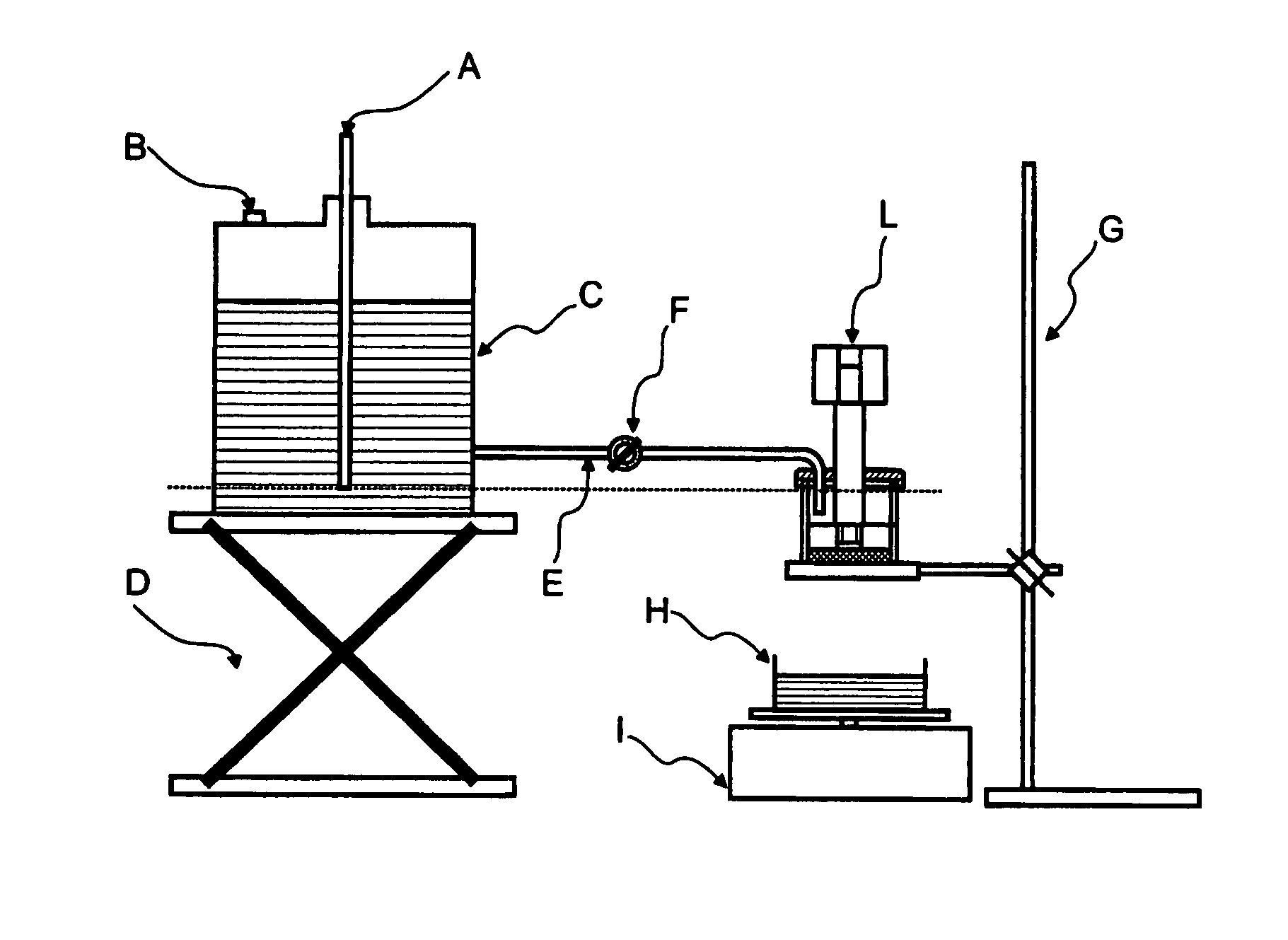

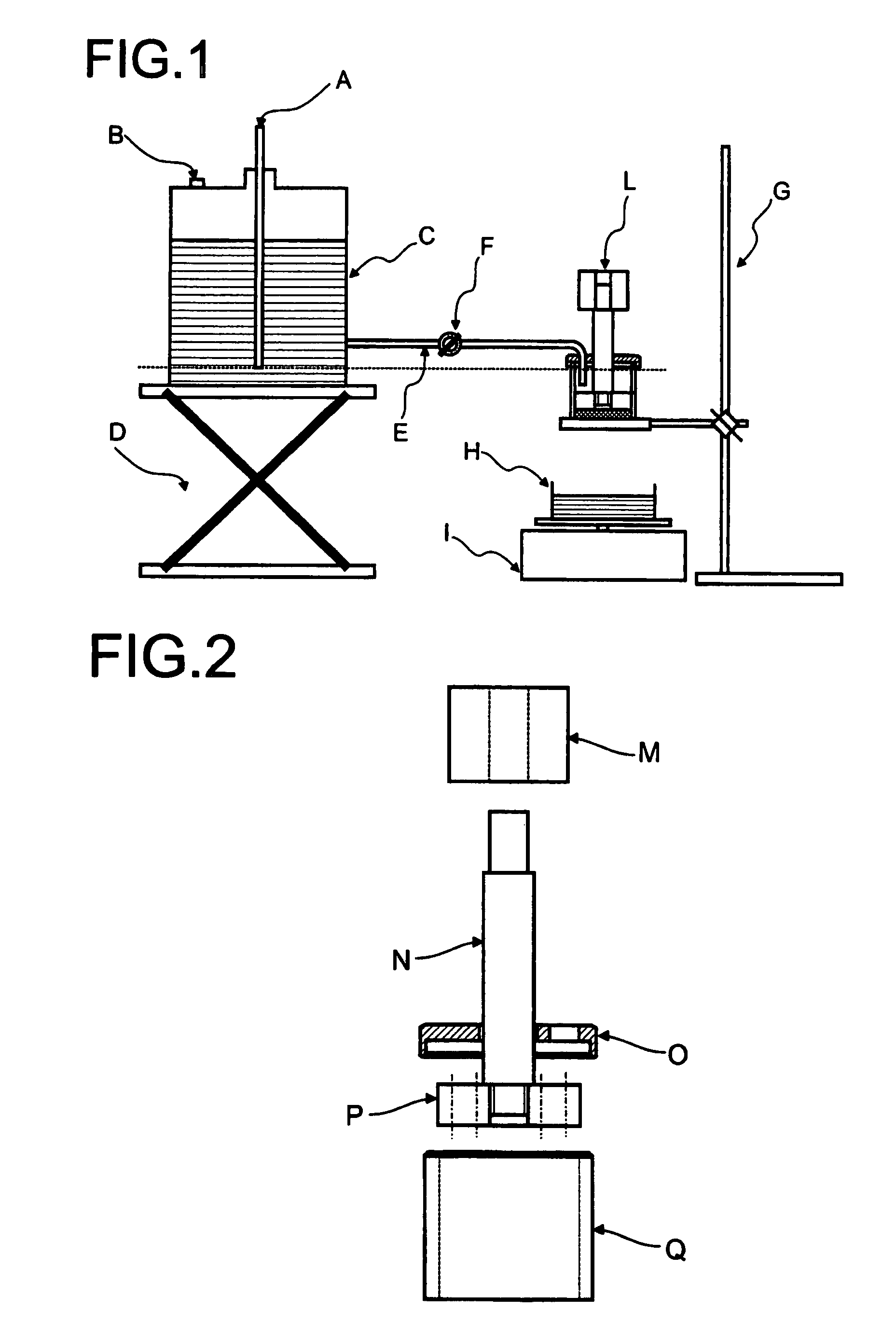

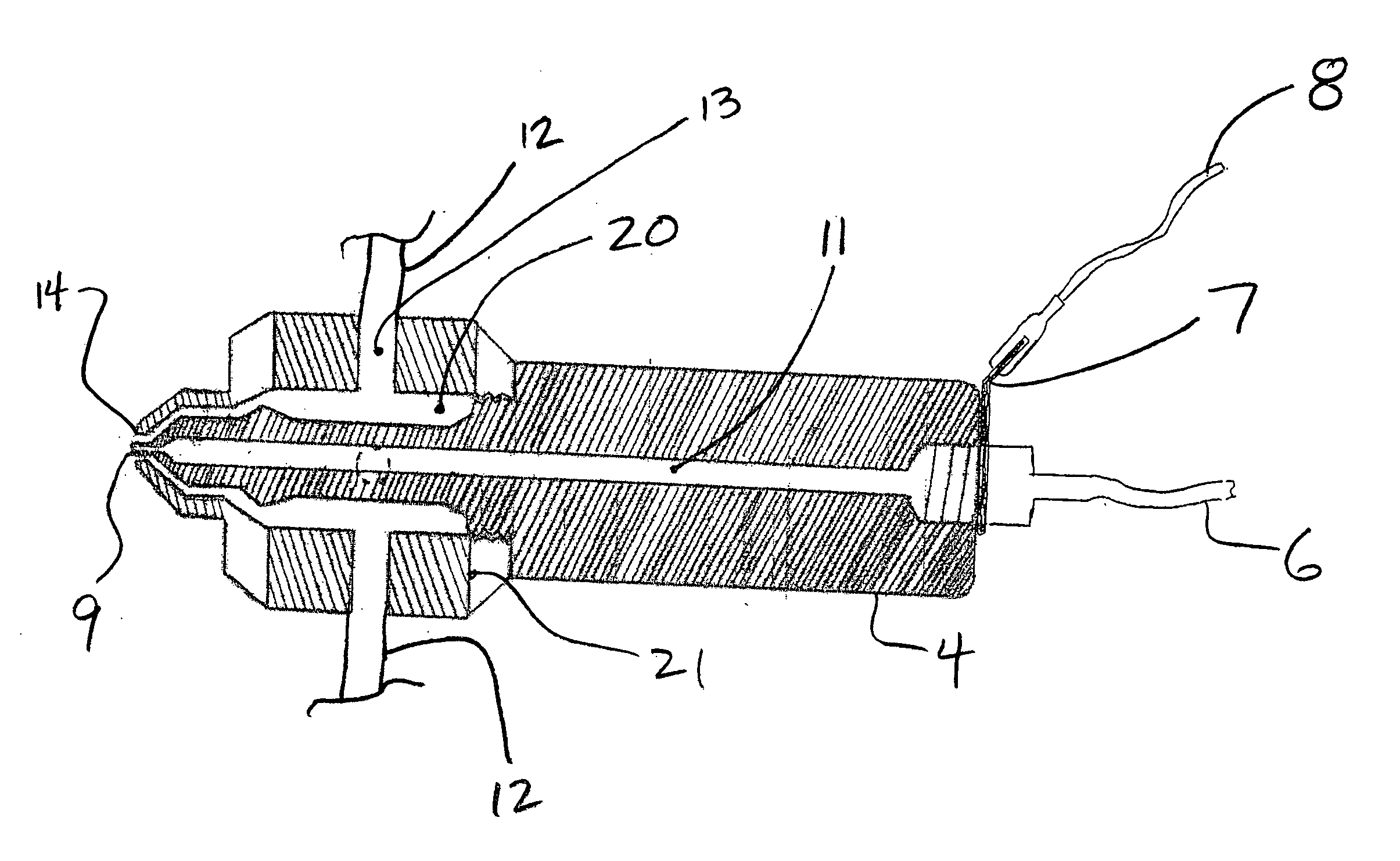

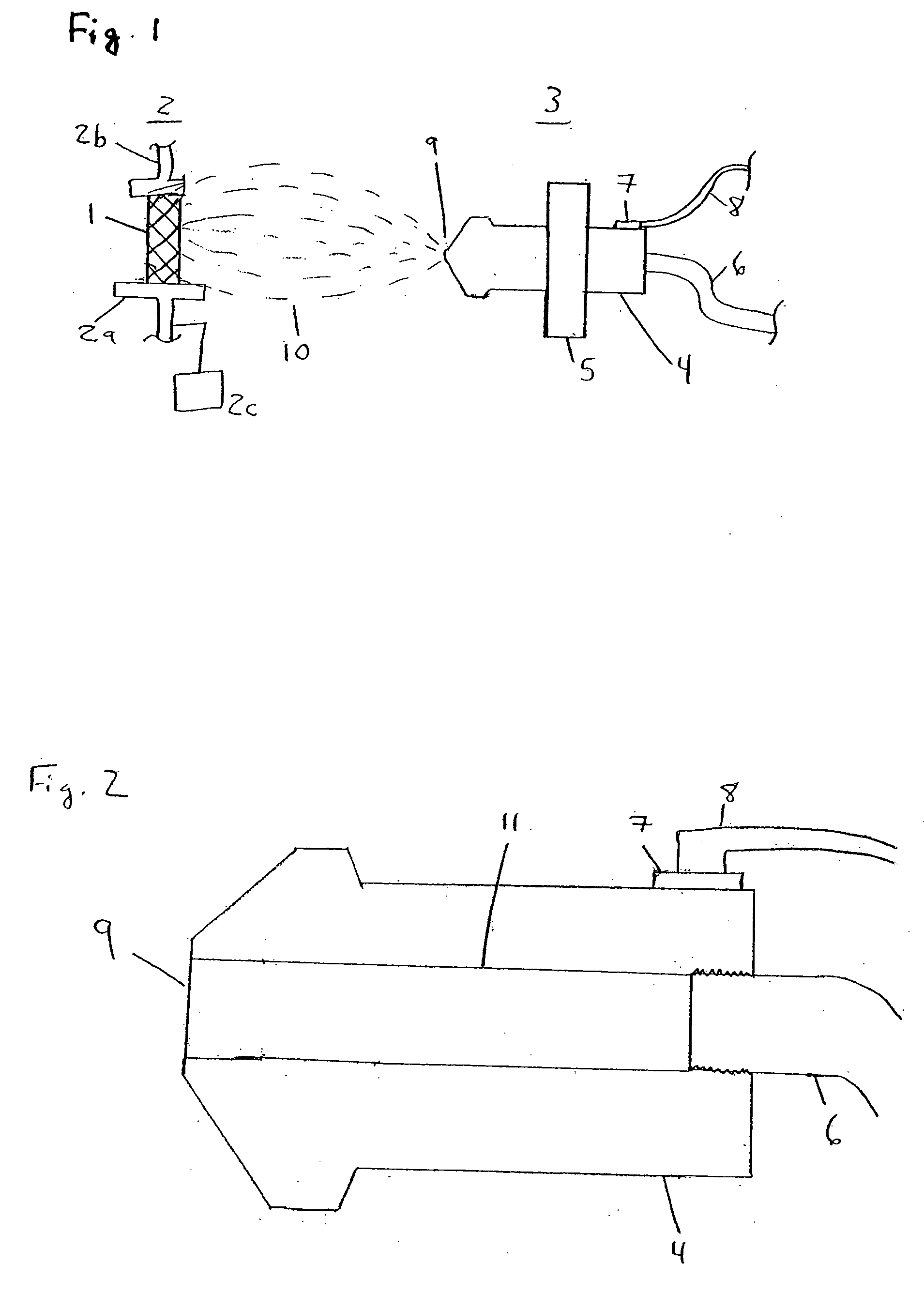

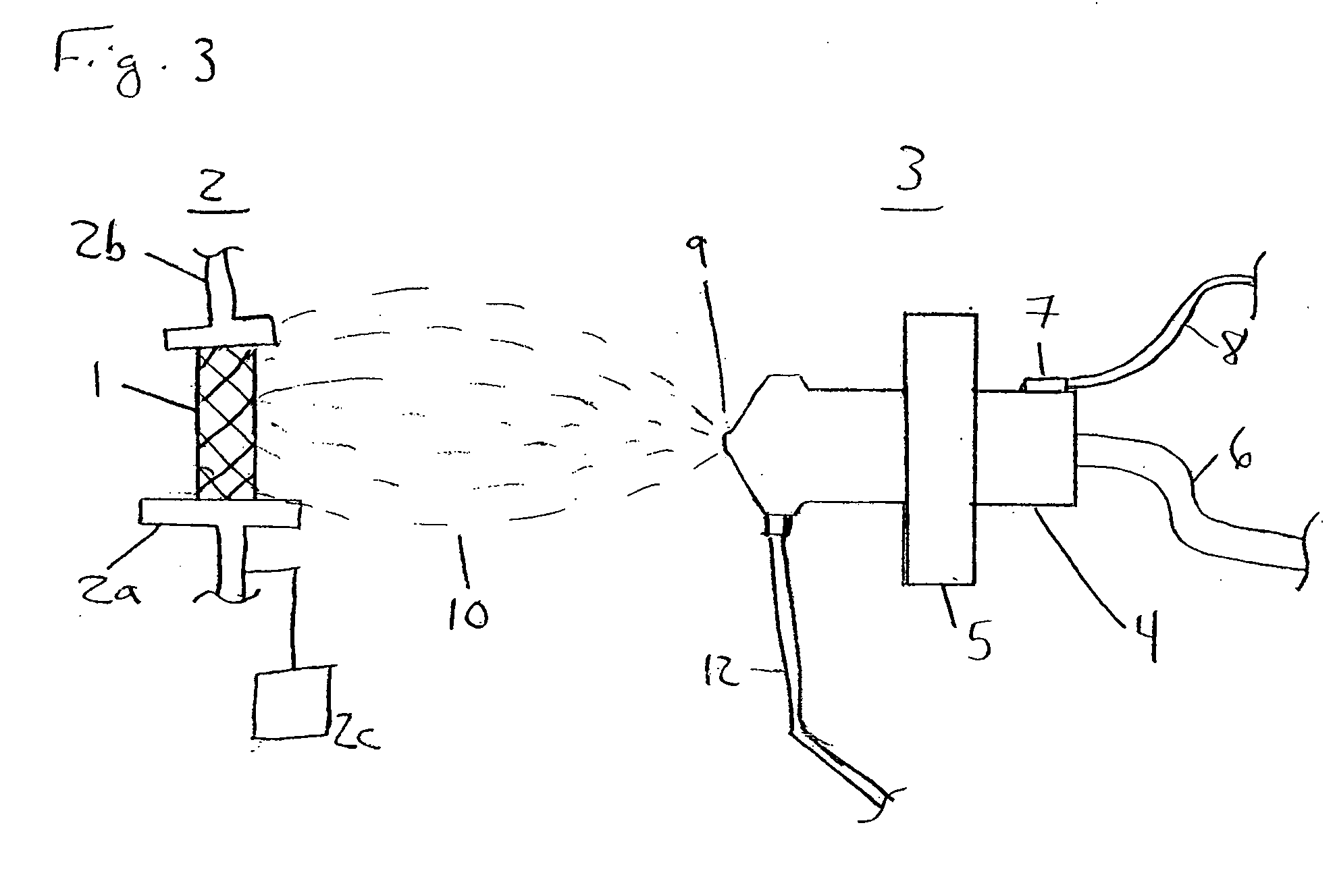

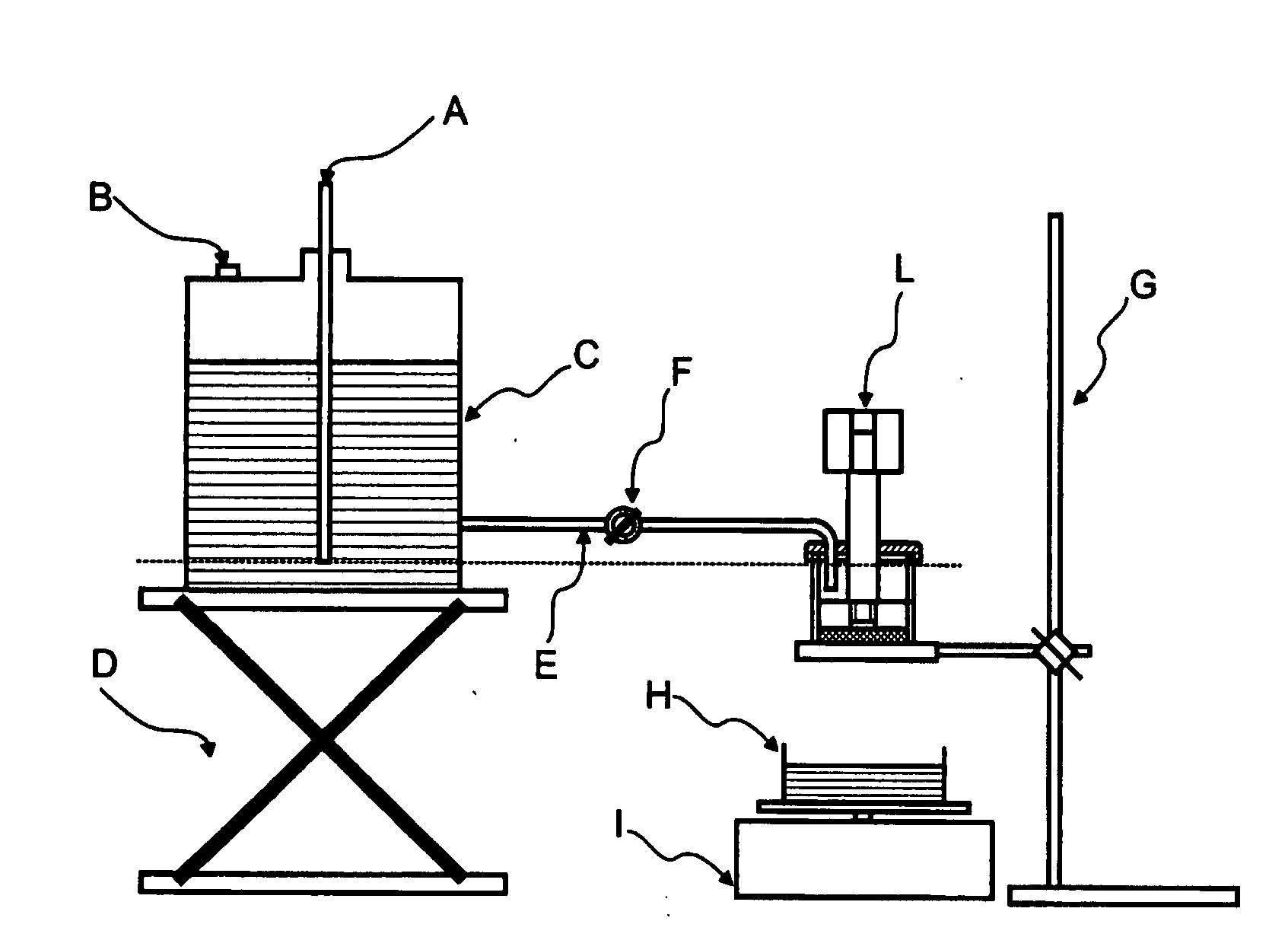

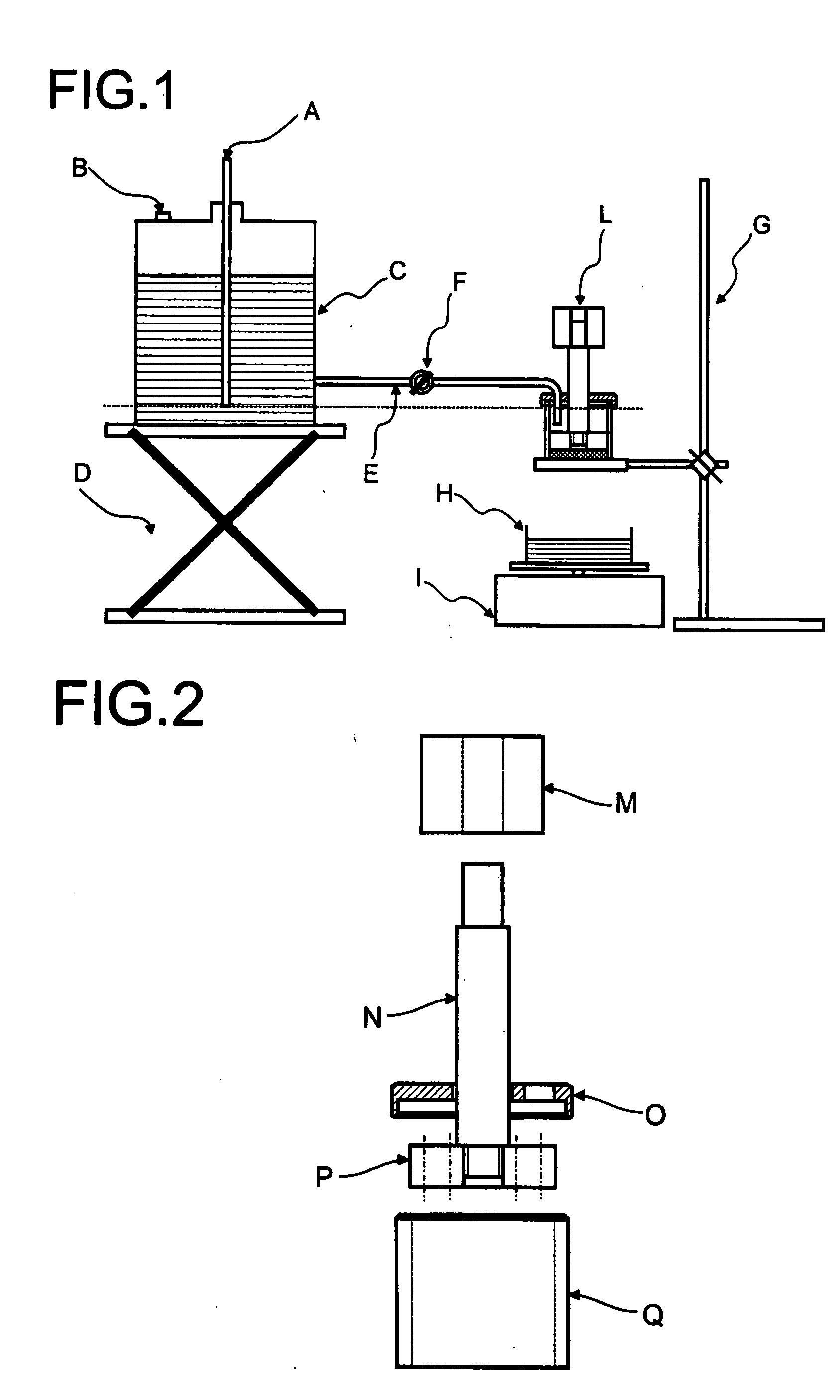

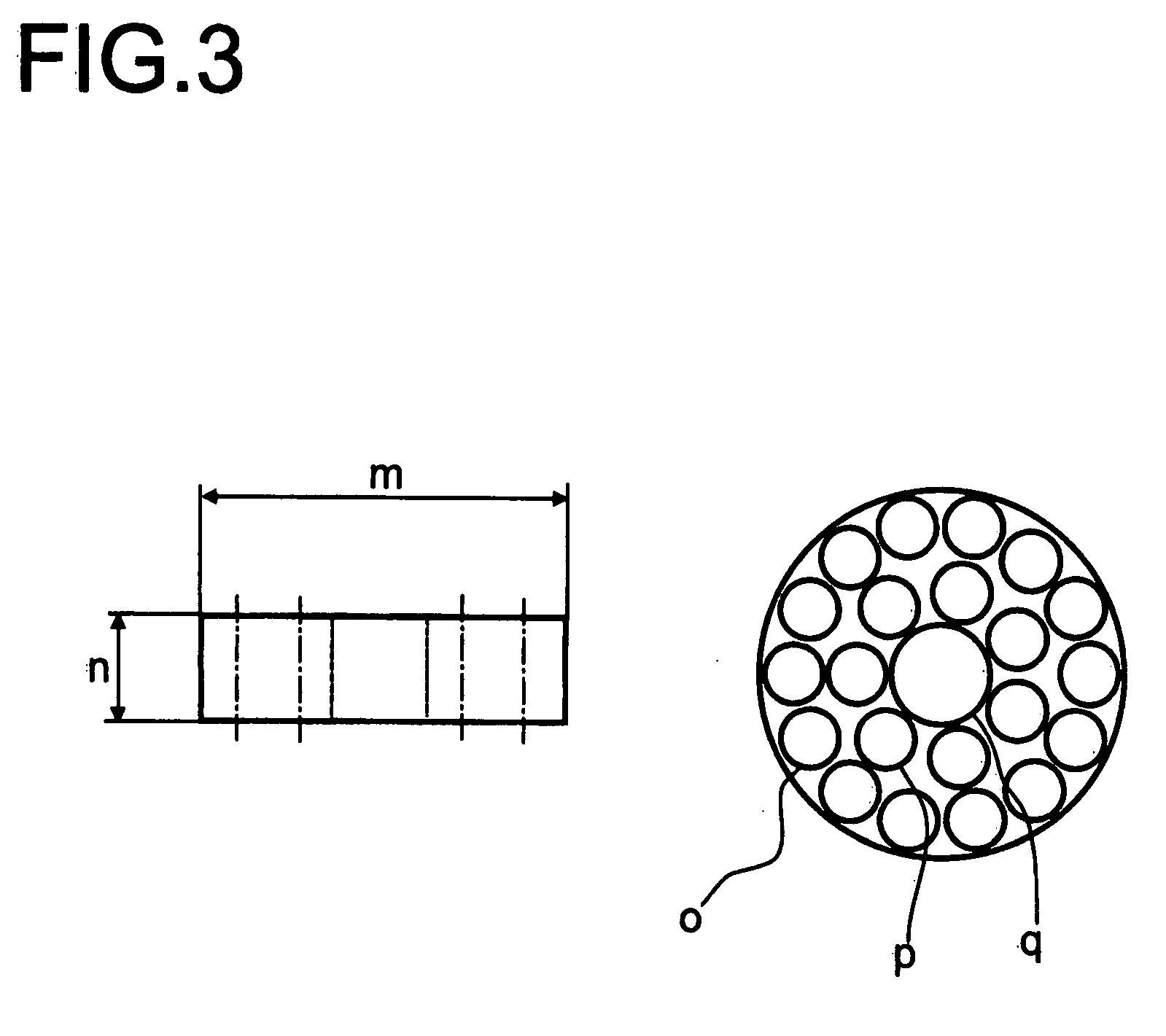

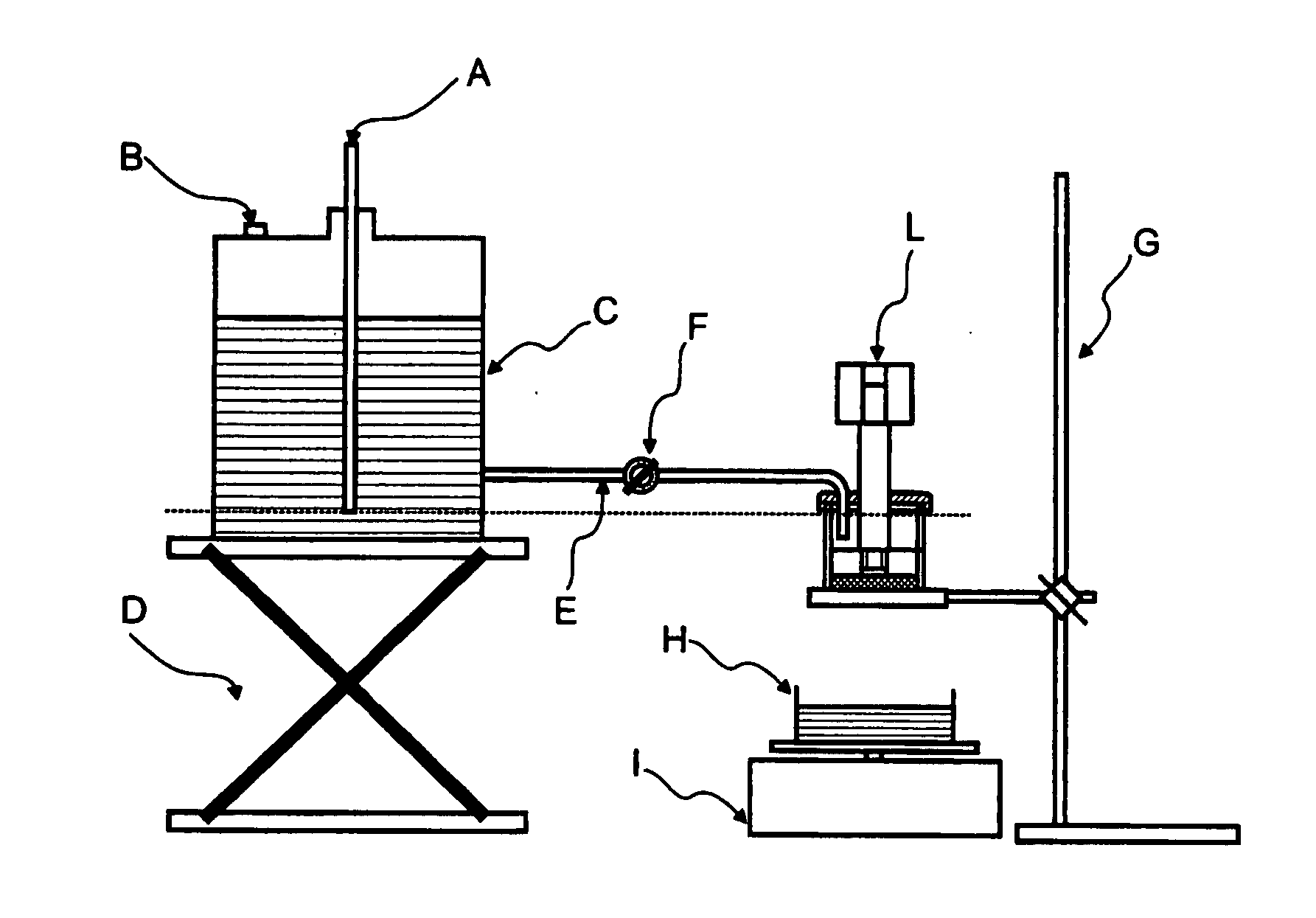

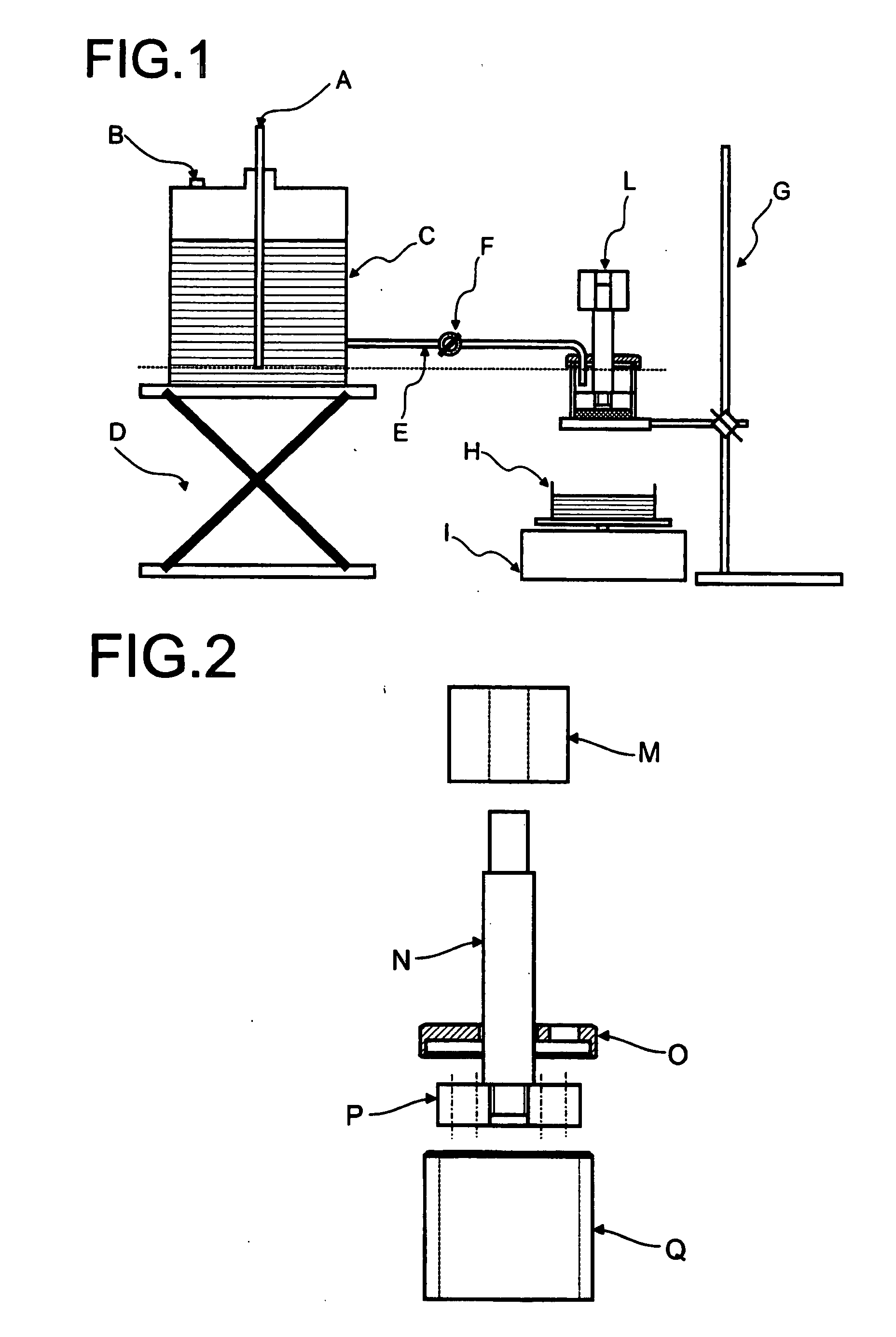

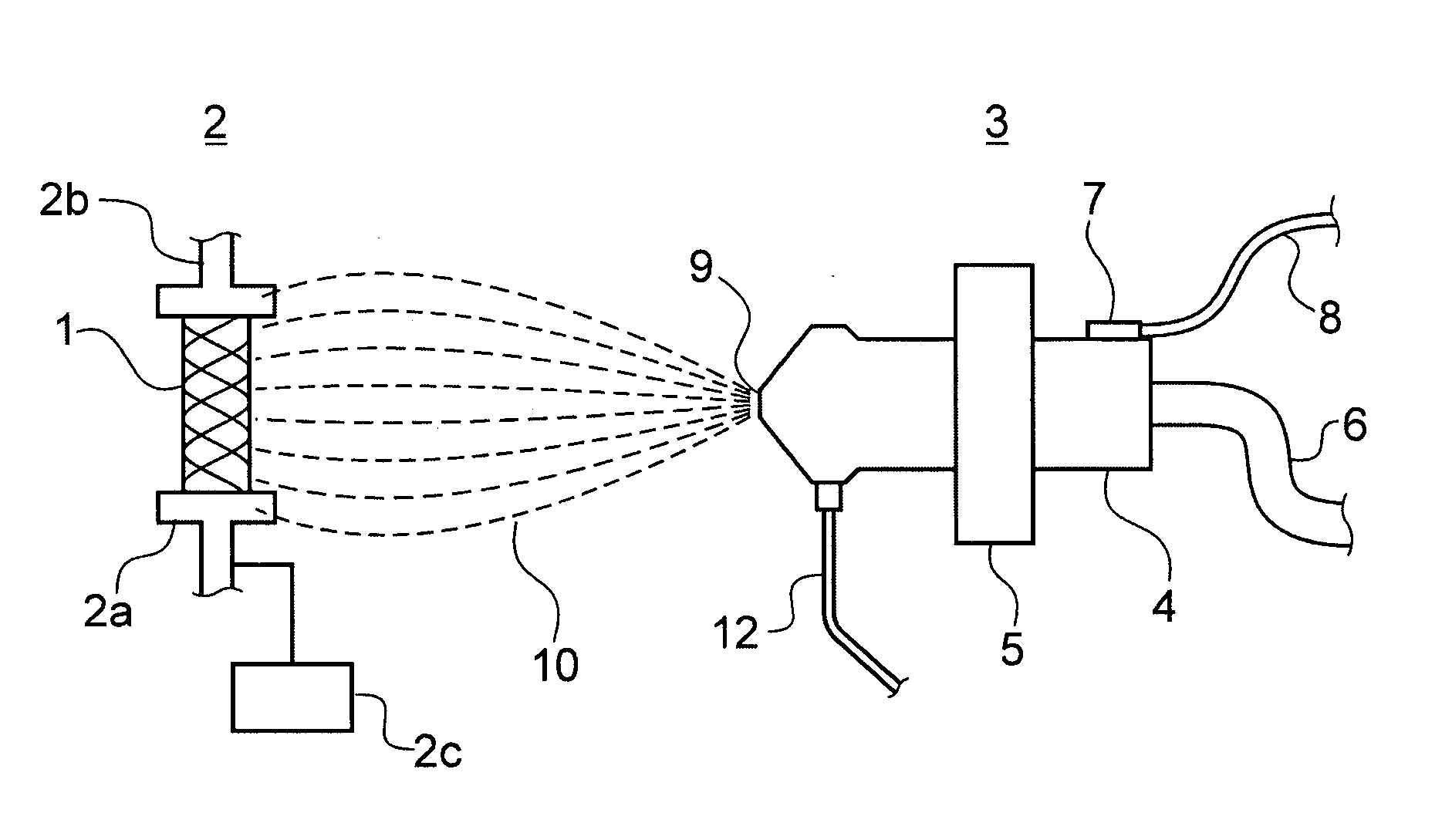

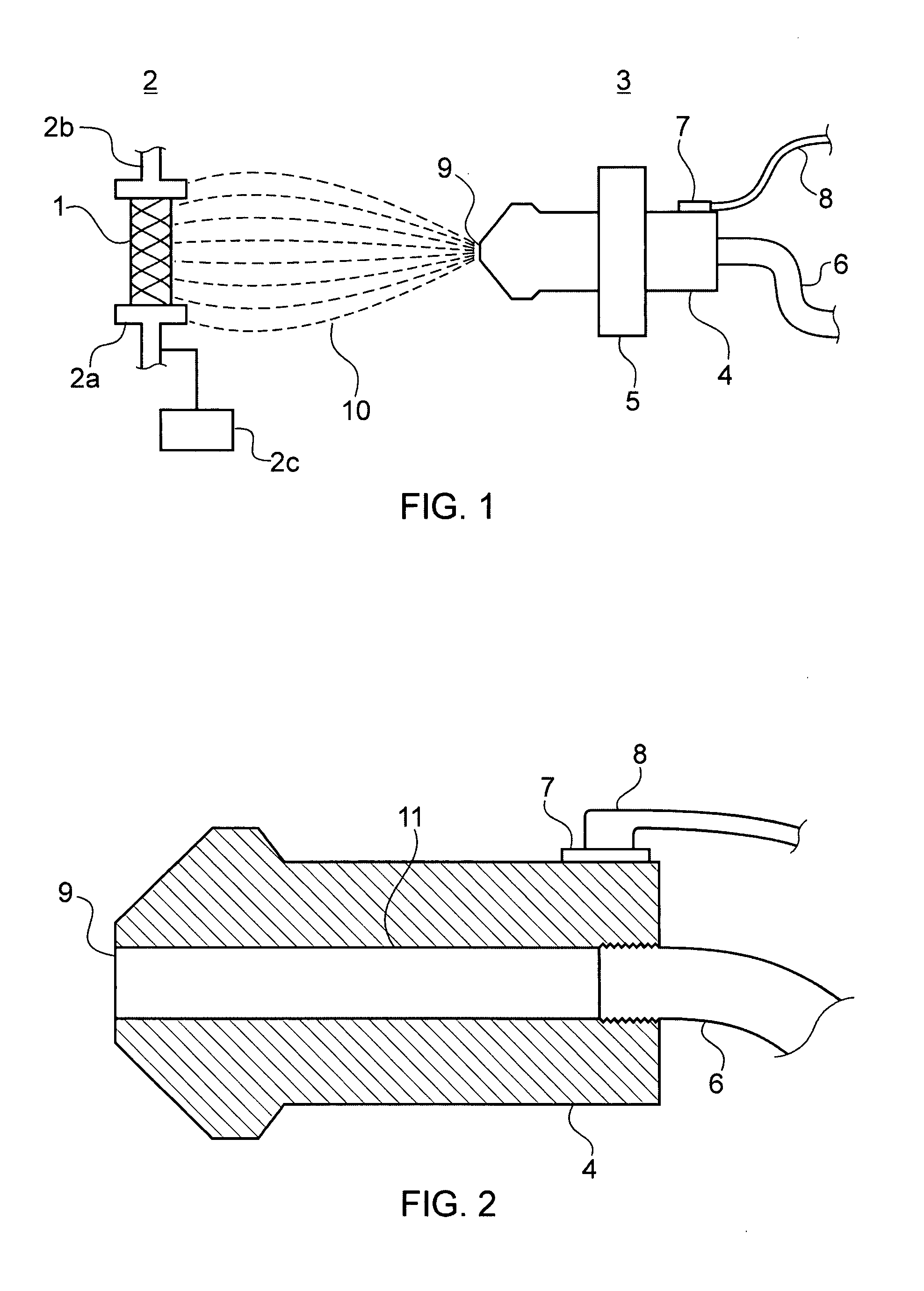

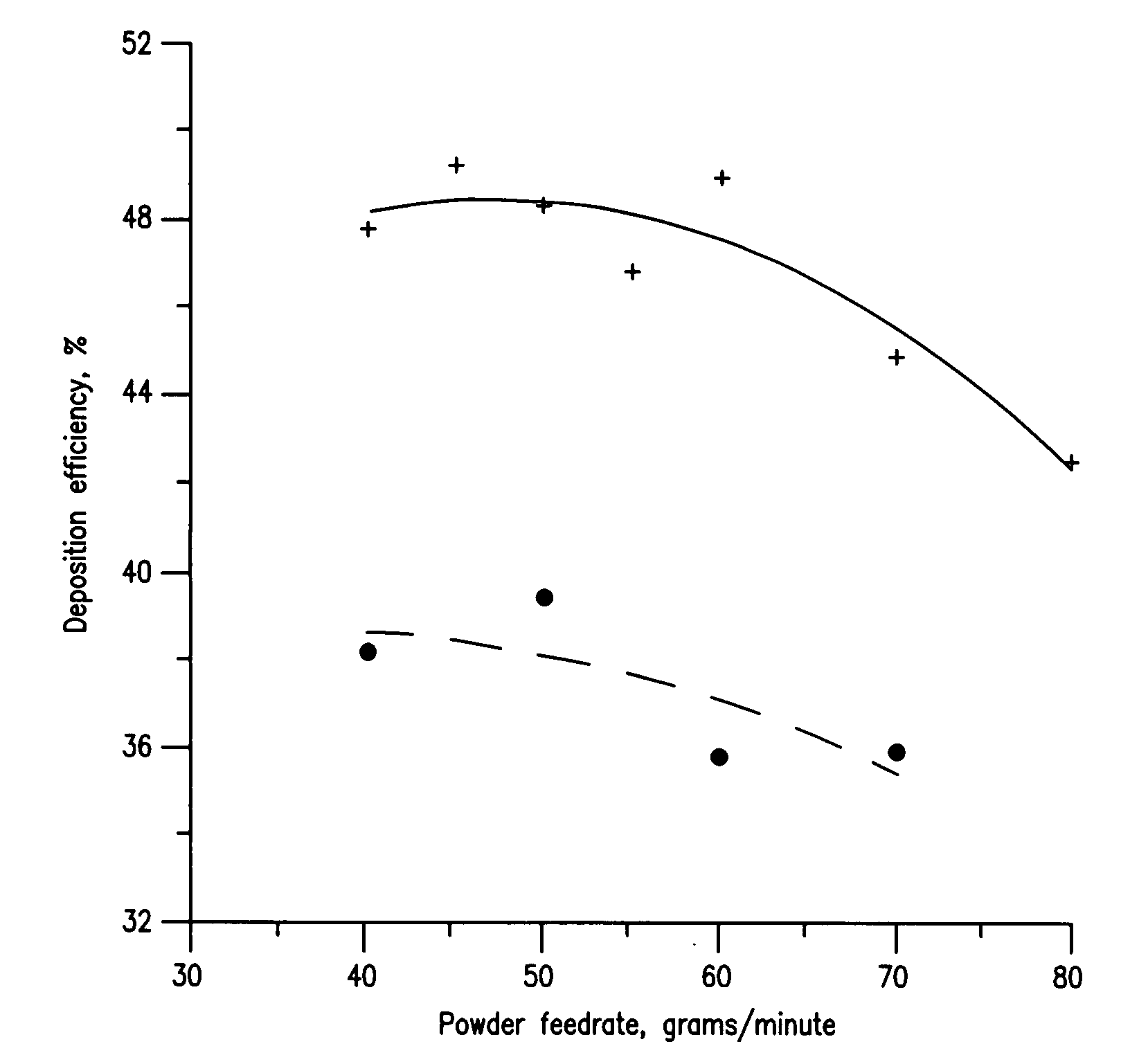

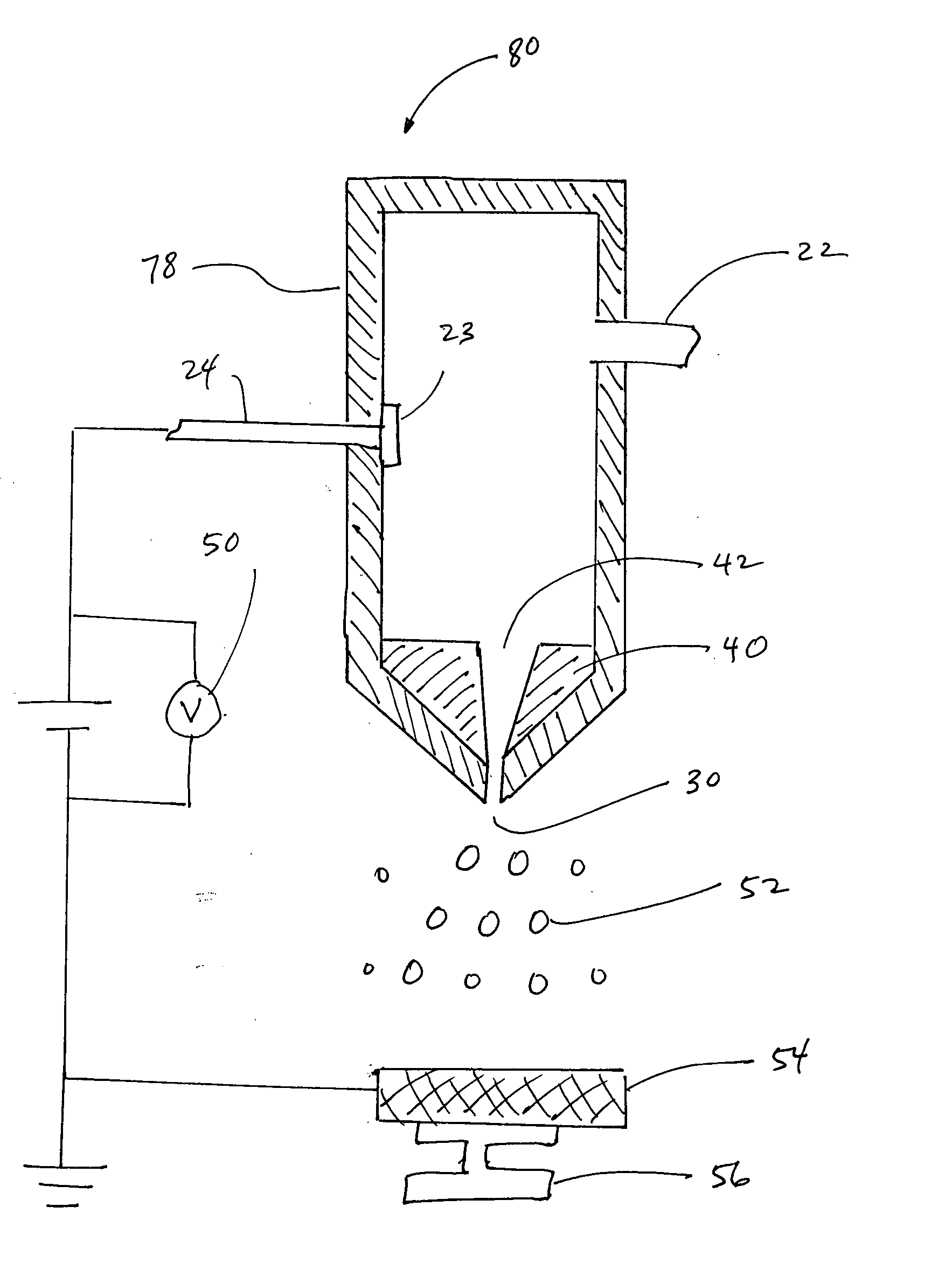

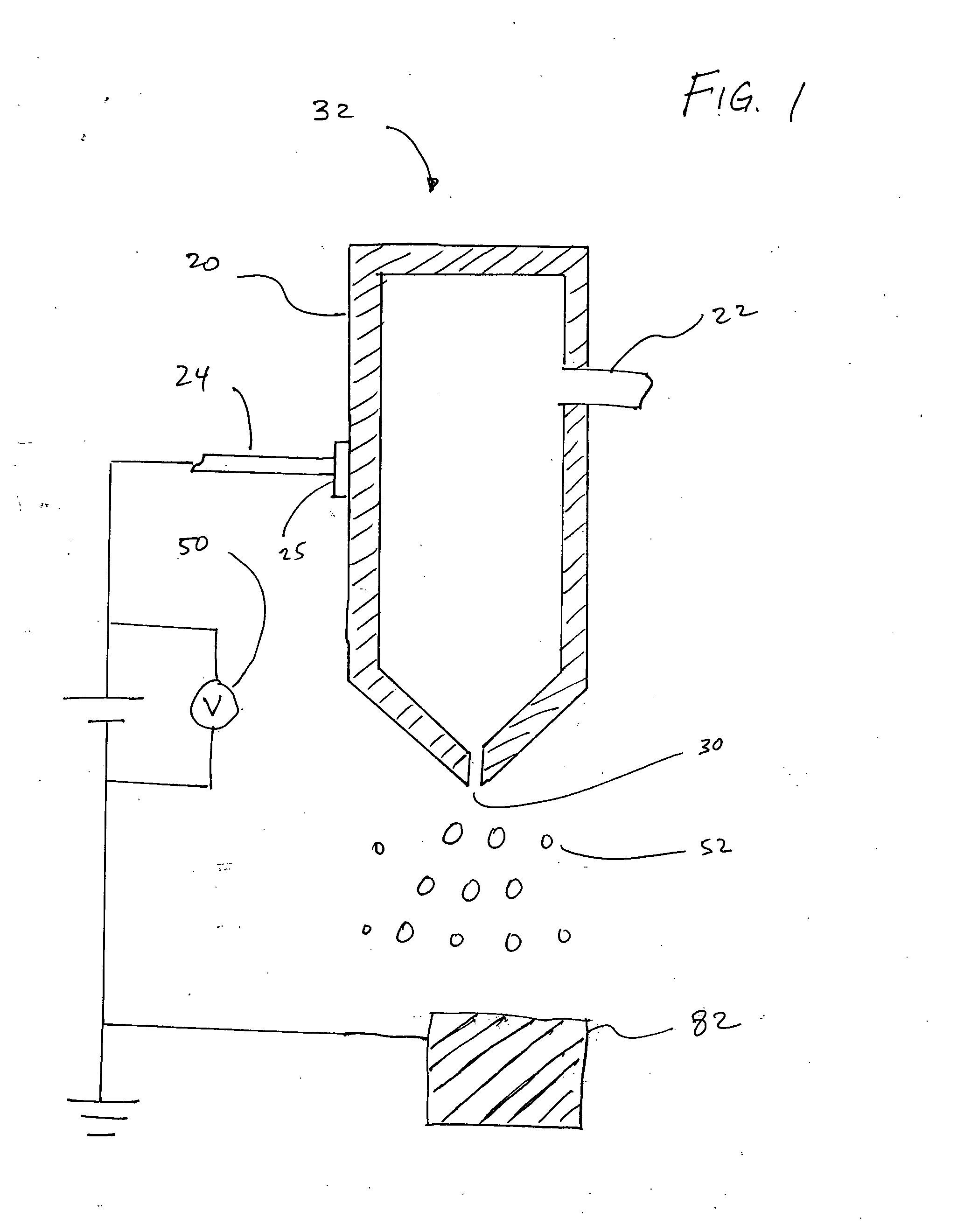

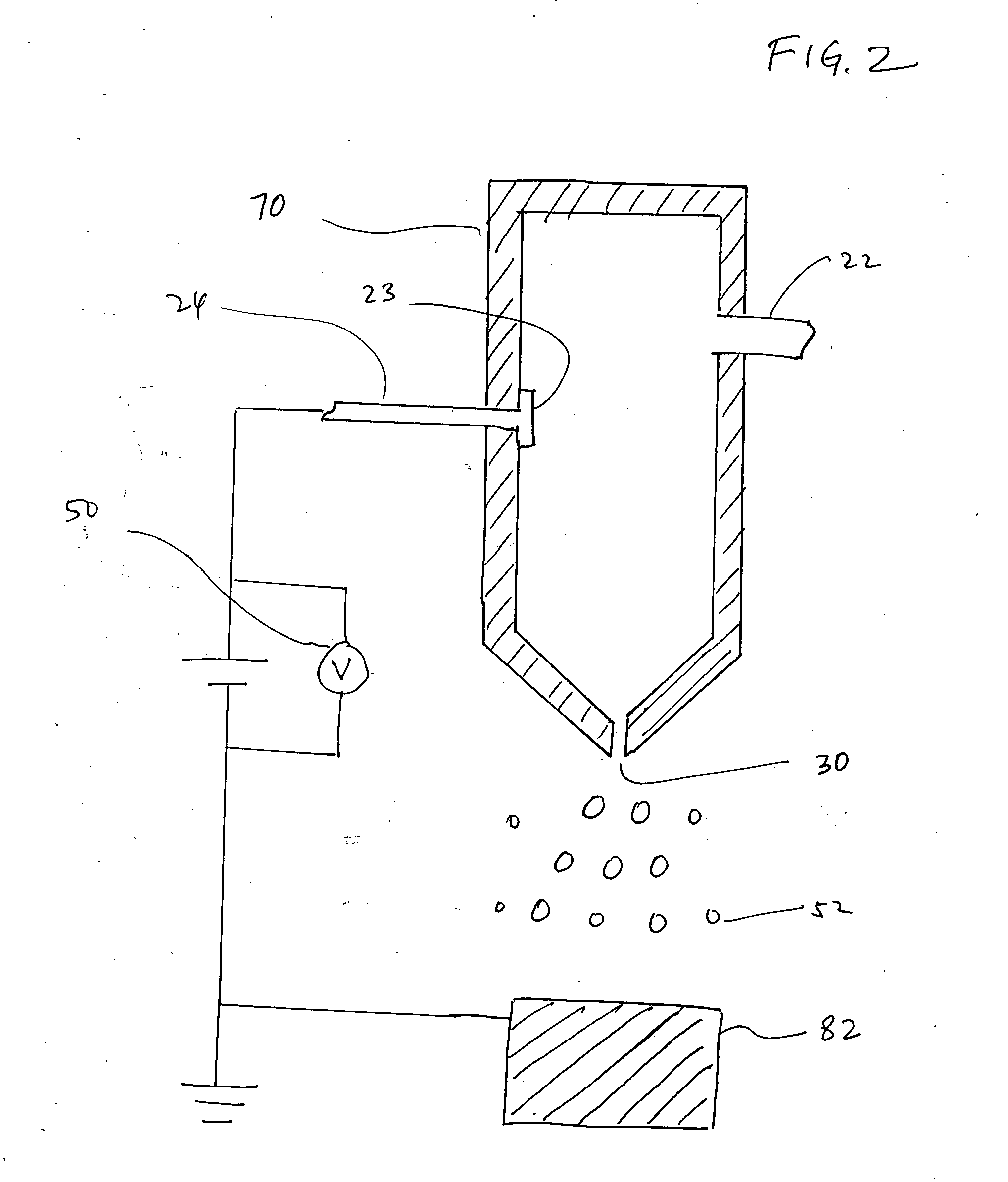

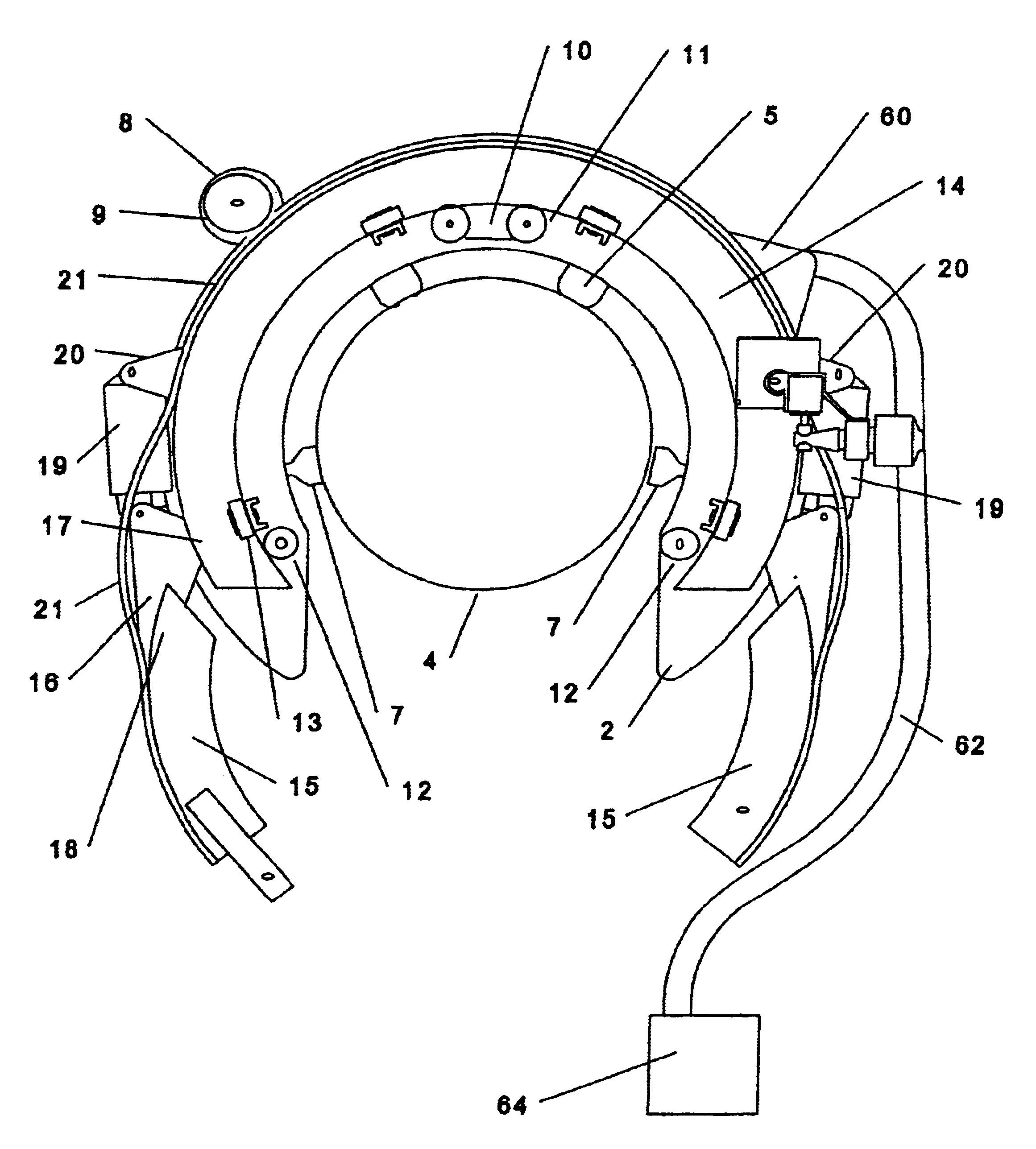

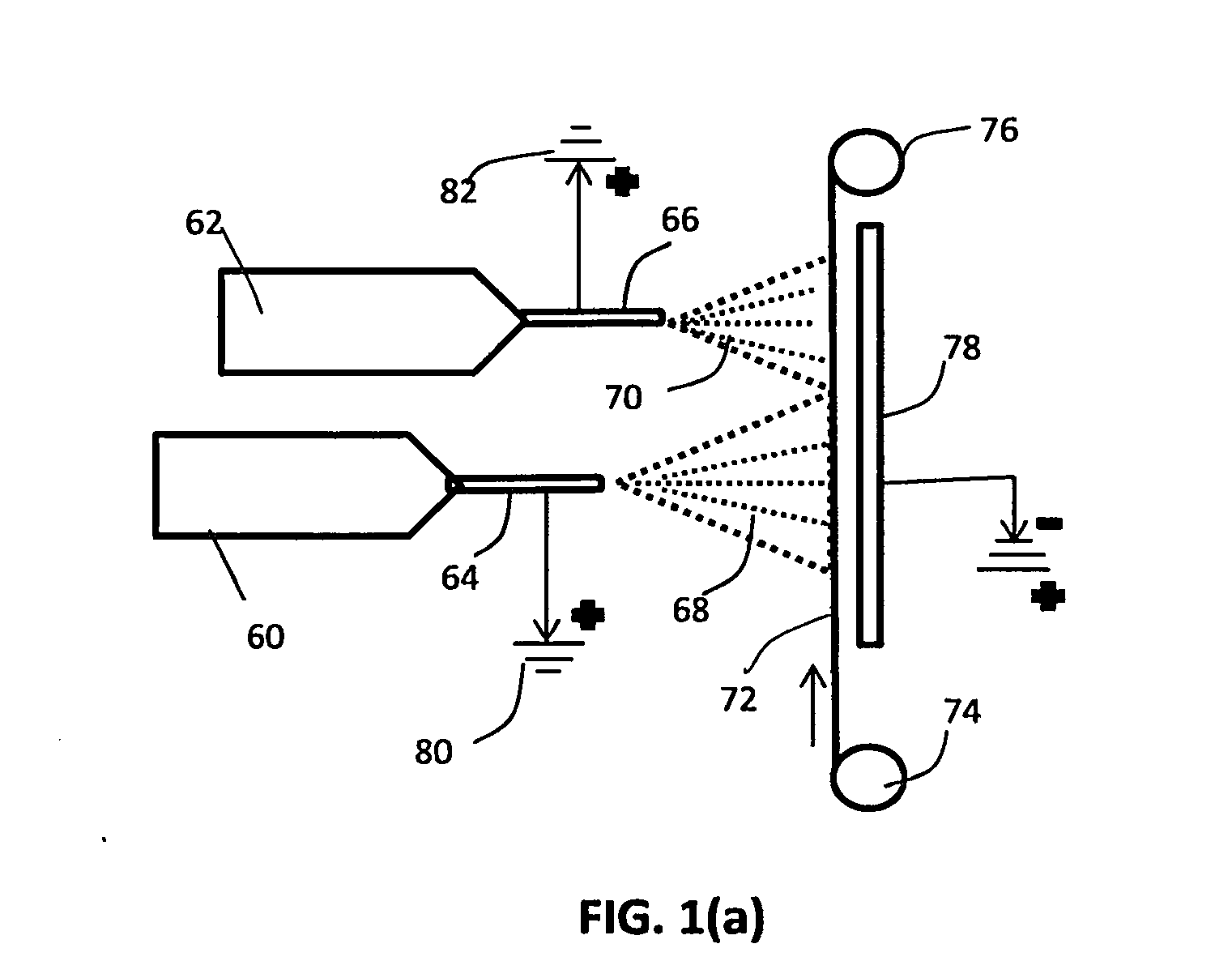

Apparatus and method for electrostatic spray coating of medical devices

ActiveUS20050175772A1Increased ionization increases the fraction of coating spray attractedIncrease electrode surface areaLiquid spraying plantsElectric shock equipmentsVoltage spikeSpray coating

An apparatus and method for electrostatic spray deposition of small targets, such as medical devices like stents. The apparatus includes a target holder which applies a first electrical potential to the target, and an electrostatic dispensing nozzle which applies a second potential sufficient to attract the coating fluid from the nozzle toward the target. Because the entire dispensing nozzle is conductive, the coating fluid may receive a greater charge than may be obtained with internal electrode-type nozzles. Electrostatic attraction of the coating fluid to the target is enhanced by the combination of higher charge density imparted to the coating fluid by the conductive nozzle, and application of a momentary voltage spike to the target to provide consistent conductivity between the target and its holder, thereby ensuring the target is presents the full first potential applied to the holder. The voltage spike may also be used independently of the conductive nozzle.

Owner:BOSTON SCI SCIMED INC

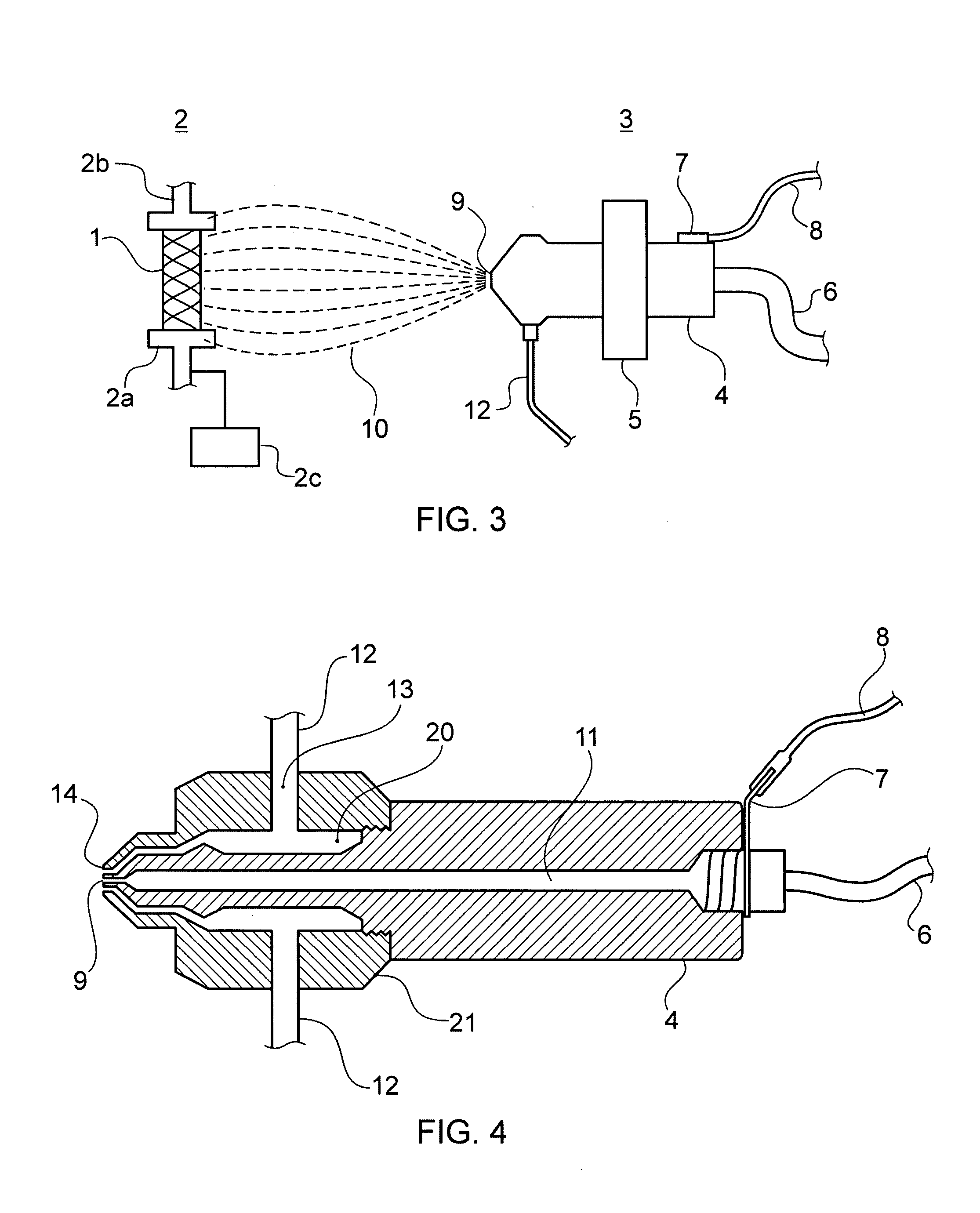

Absorbent structure with improved water-absorbing material

ActiveUS20080027402A1High core shell centrifuge retention capacityHigh saline flow conductivityPretreated surfacesAdhesive dressingsAntioxidantFluidized bed

The present invention relates to an absorbent structure suitable in, or being an adult or infant diaper or feminine hygiene article, comprising a water-absorbing material comprising water-absorbing particles that comprise a film coating, comprising an elastic film-forming polymer and an antioxidant. The invention also relates to an absorbent structure comprising a water absorbent material obtainable by a process of: a) spray-coating water-absorbing polymeric particles with an elastic film-forming polymer in a fluidized bed reactor at a temperature in the range from 0° C. to 150° C. and b) heat-treatment of the coated polymeric particles at a temperature above 50° C., wherein in step a) and / or b) an antioxidant is added.

Owner:THE PROCTER & GAMBLE COMPANY

Polymer supported electrodes

InactiveUS20110183203A1Prevent thermal runawayInhibit growthMaterial nanotechnologyNon-aqueous electrolyte accumulator electrodesSpray coatingPolymer supported

Methods and devices arising from the practice thereof for making and using battery electrodes formed onto ion permeable, electrically non-conductive substrates, preferably battery separators are disclosed herein. Electrodes are formed onto substrates using a variety of methods including, but not limited to, spray coating and electrophoretic deposition. Electrically conductive layers may be applied to the electrode coating layer side opposite or adjacent to the substrate to act as current collectors for the battery. Multilayer devices having alternating layers of conductive layers, electrode layers and substrates, wherein the conductive layers may be in electrical communication with other conductive layers to form a battery.

Owner:MOLECULAR NANOSYST

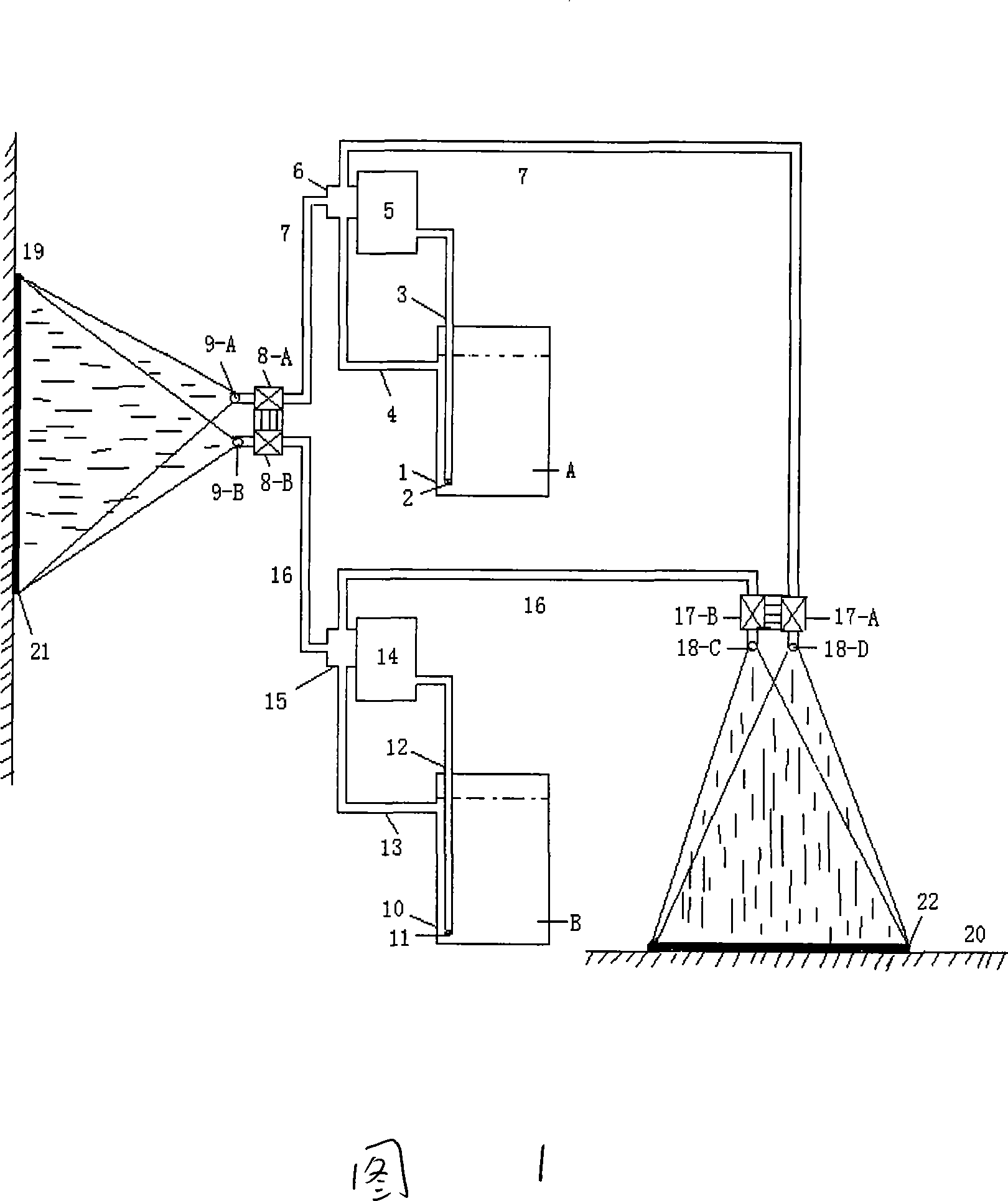

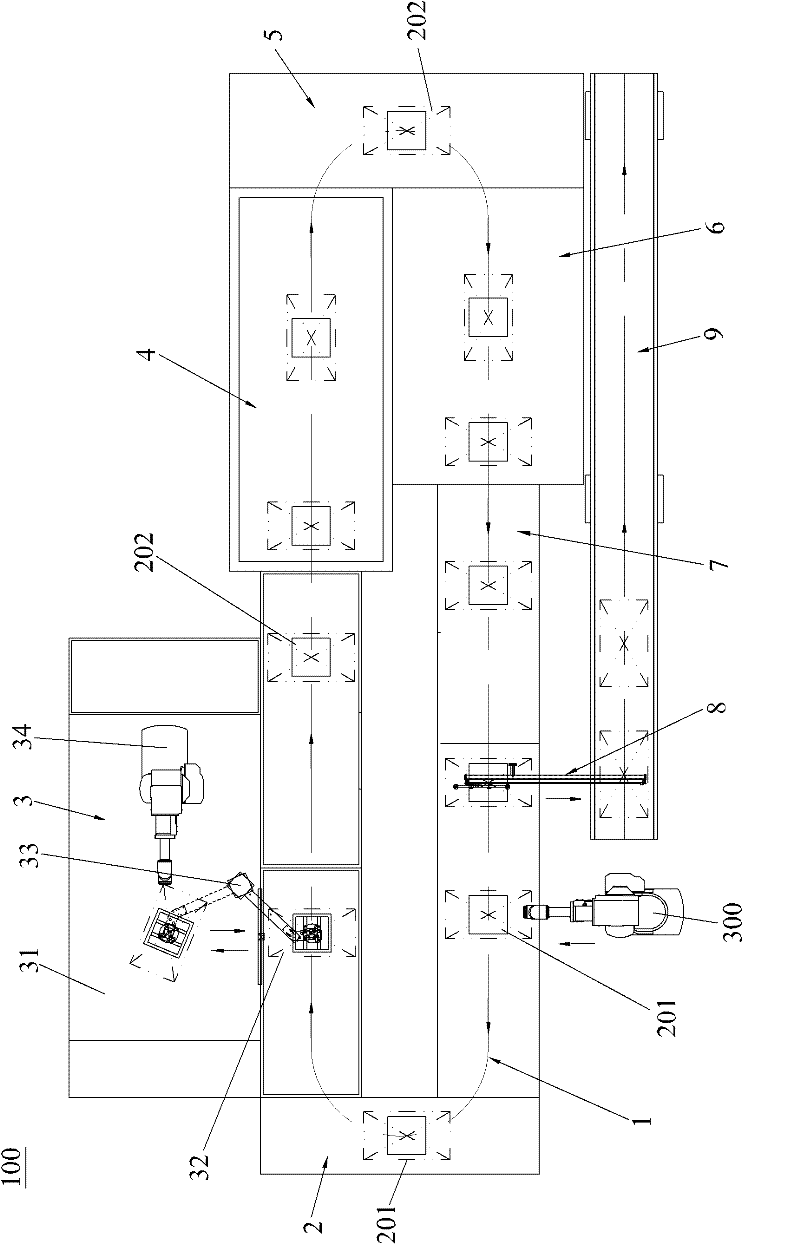

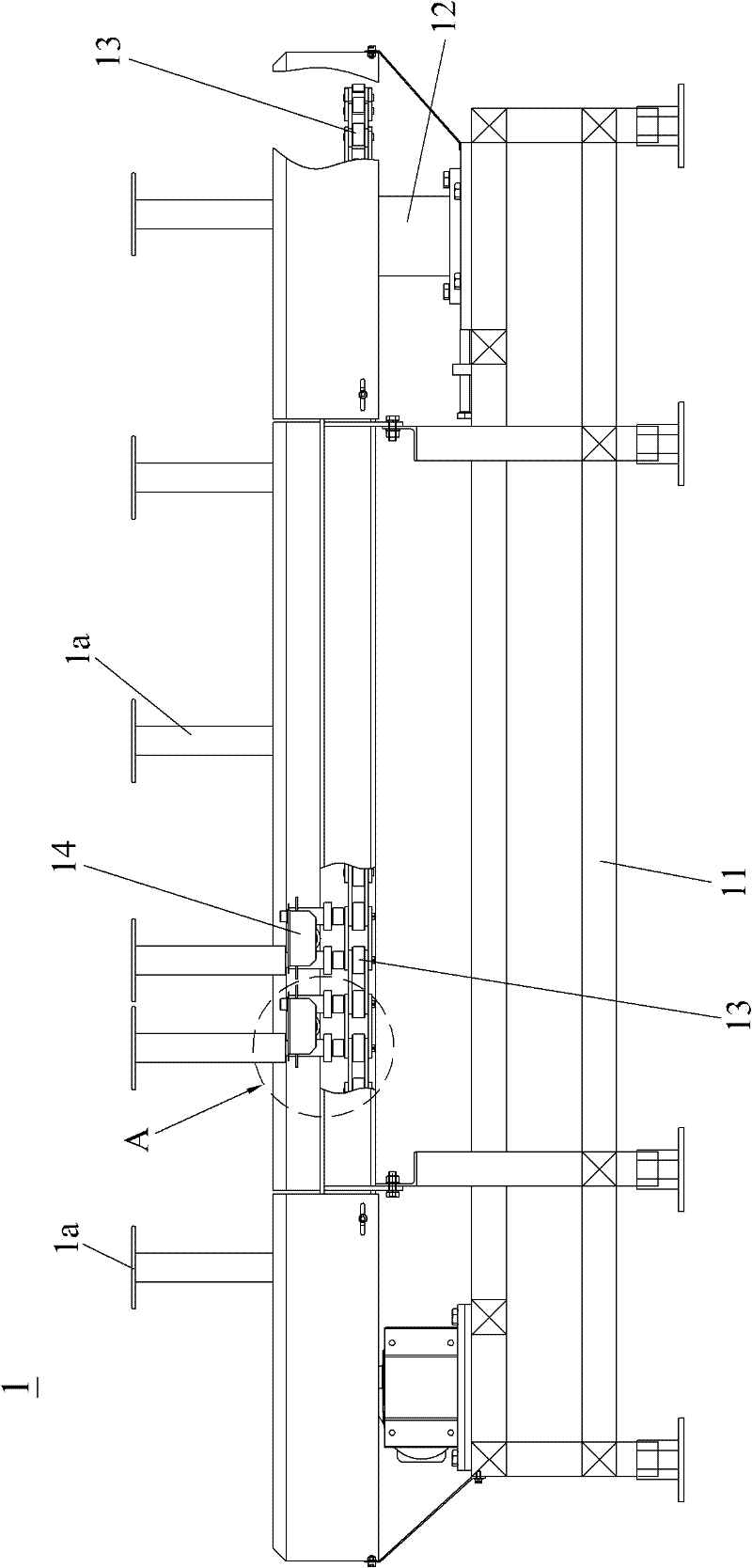

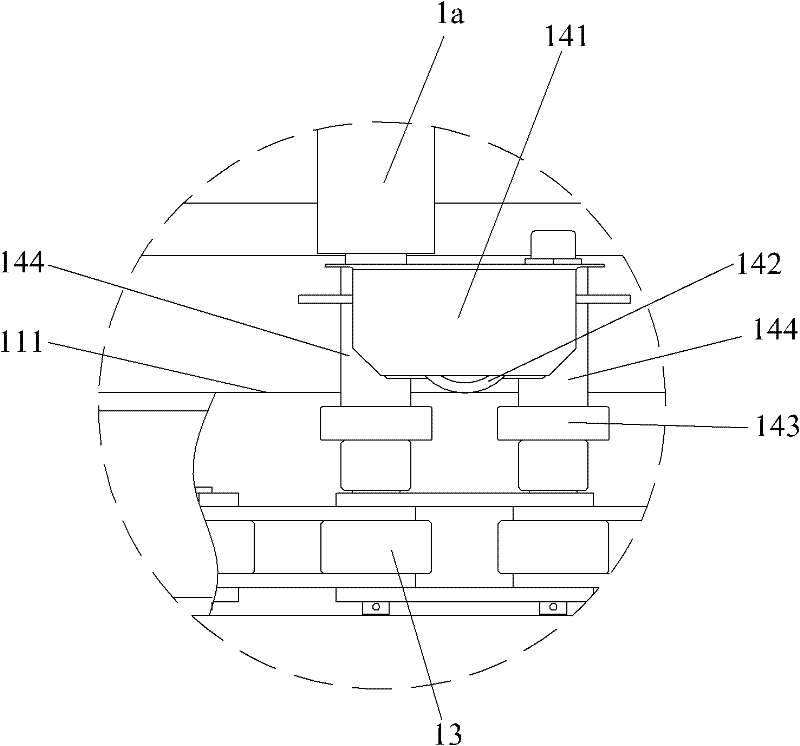

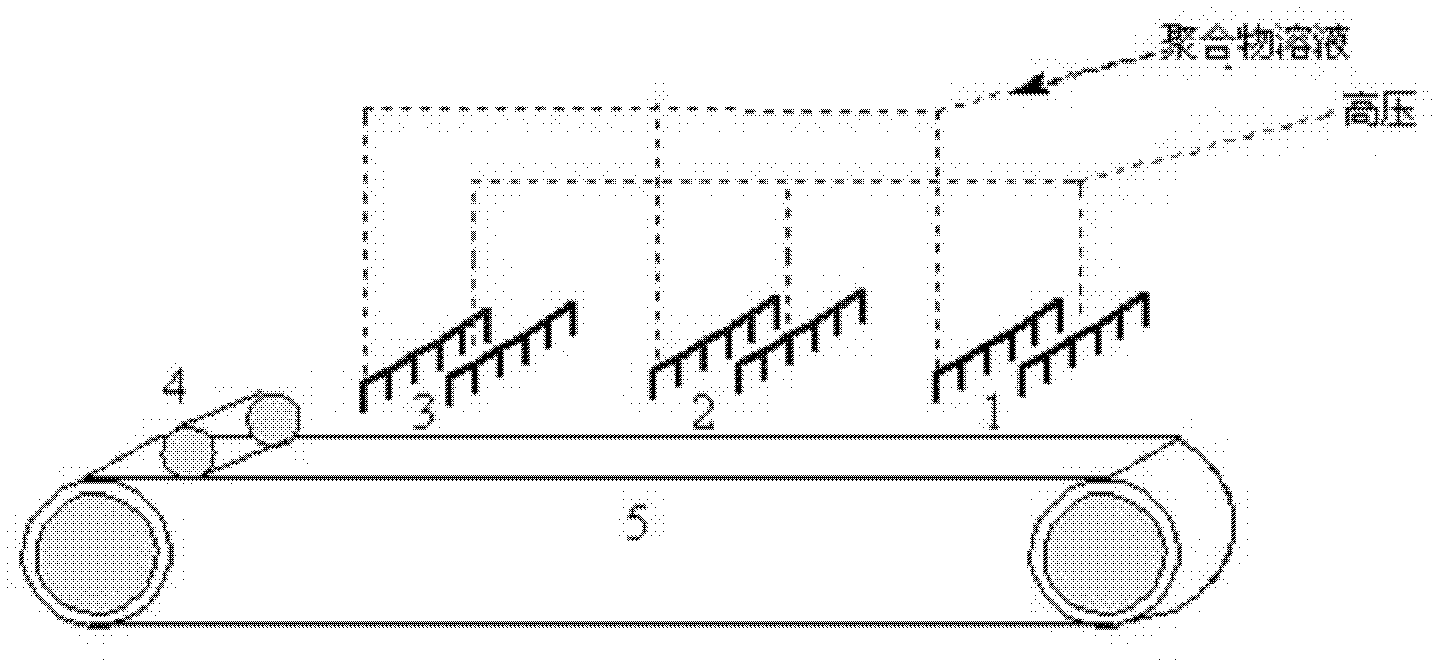

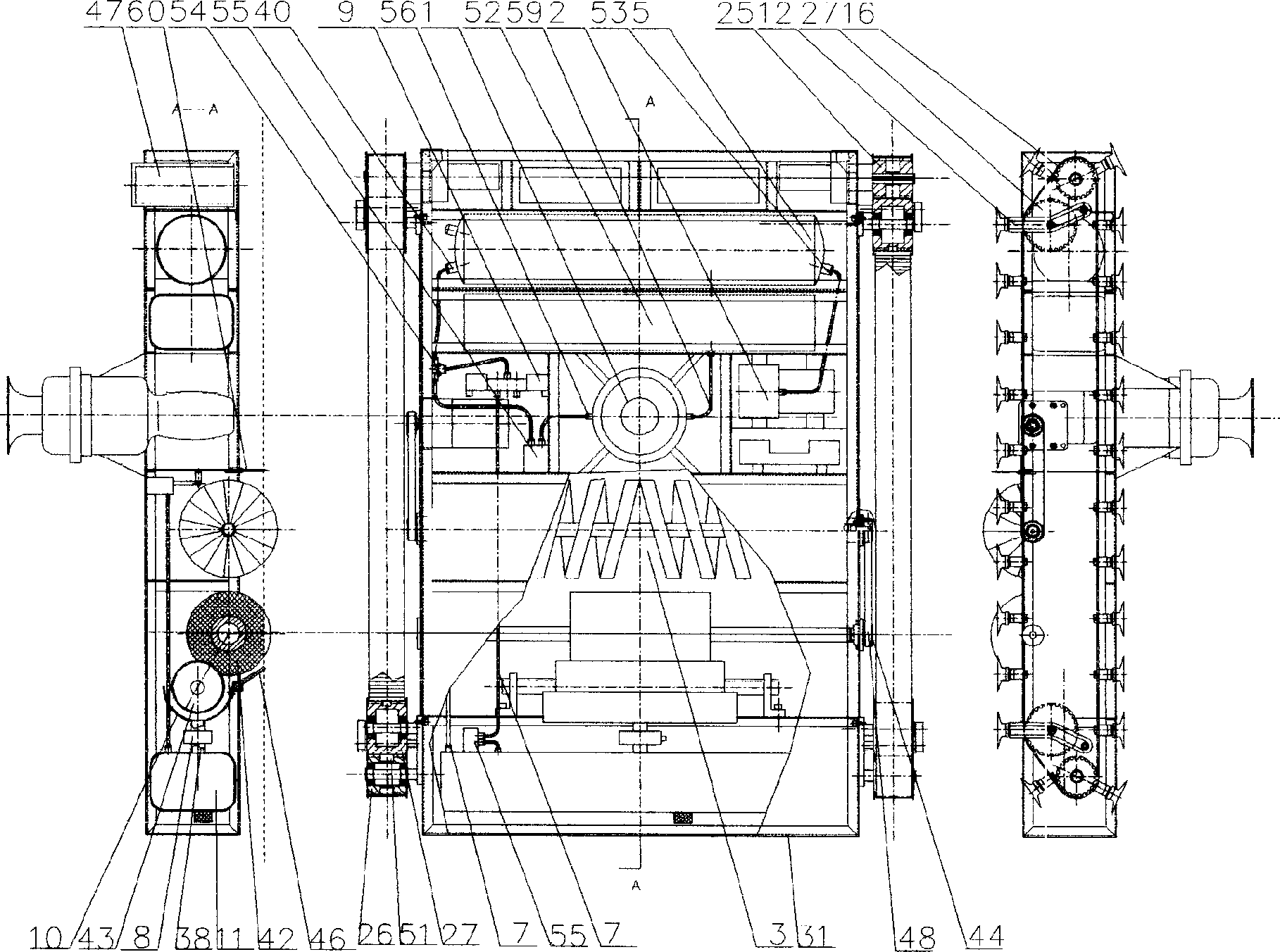

Automatic spraying equipment

InactiveCN102259071AAffect the spraying qualityReduce manual operationsSpraying apparatusPretreated surfacesElectricityControl system

The invention discloses fully-automatic spray coating equipment, which comprises a ground track type conveying chain, a cooling and dedusting device, a spray coating system, an infrared curing furnace, a cooling furnace, an ultraviolet curing furnace, an automatic discharging mechanical arm, an air supply and exhaust system and a control system. The ground track type conveying chain winds along awaist-like line and conducts closed circulating conveying of workpieces; the cooling and dedusting equipment cools and dedusts the workpieces; the spray coating system performs spray coating on the workpieces; the infrared curing furnace performs the infrared curing of the spray-coated workpieces; the cooling furnace is used for cooling the workpieces; the ultraviolet curing furnace is used for ultraviolet curing of the workpieces; the automatic discharging mechanical arm catches and unloads the workpieces; the air supply and exhaust system is arranged above the ground track type conveying chain and is used for supplying air to and exhausting all equipment; and the control system is electrically connected with all components and controls the operation of the components. The high automation degree of the fully-automatic spray coating equipment is high, the spraying effect of the fully-automatic spray coating equipment is desirable, and when the fully-automatic spray coating equipment is used, production space can be saved greatly.

Owner:东莞丰裕电机有限公司

Absorbent structure with improved water-absorbing material

Owner:PROCTER & GAMBLE CO

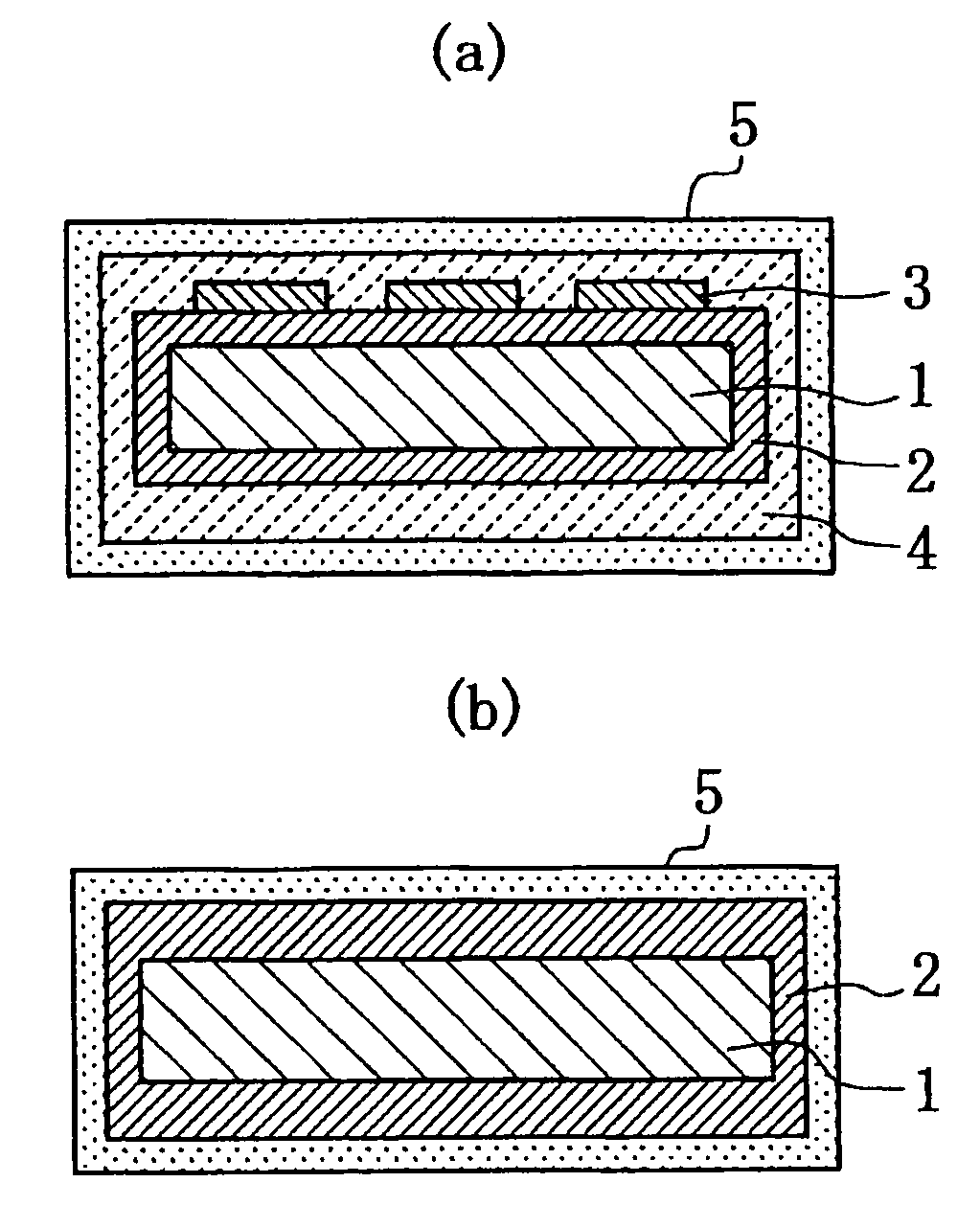

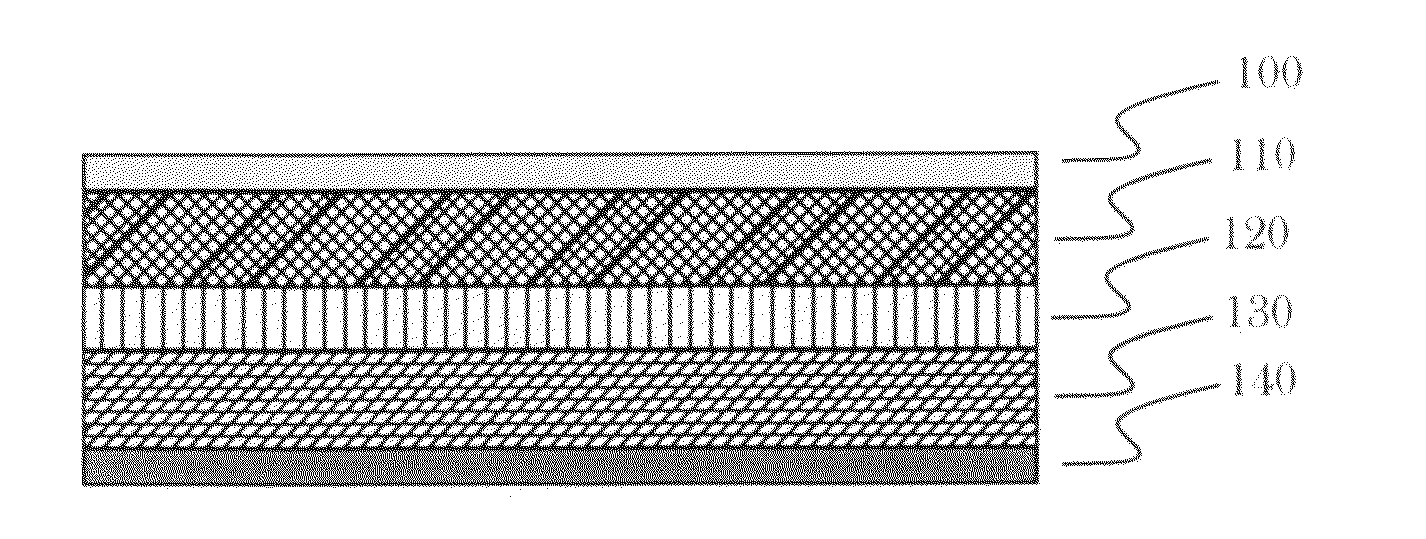

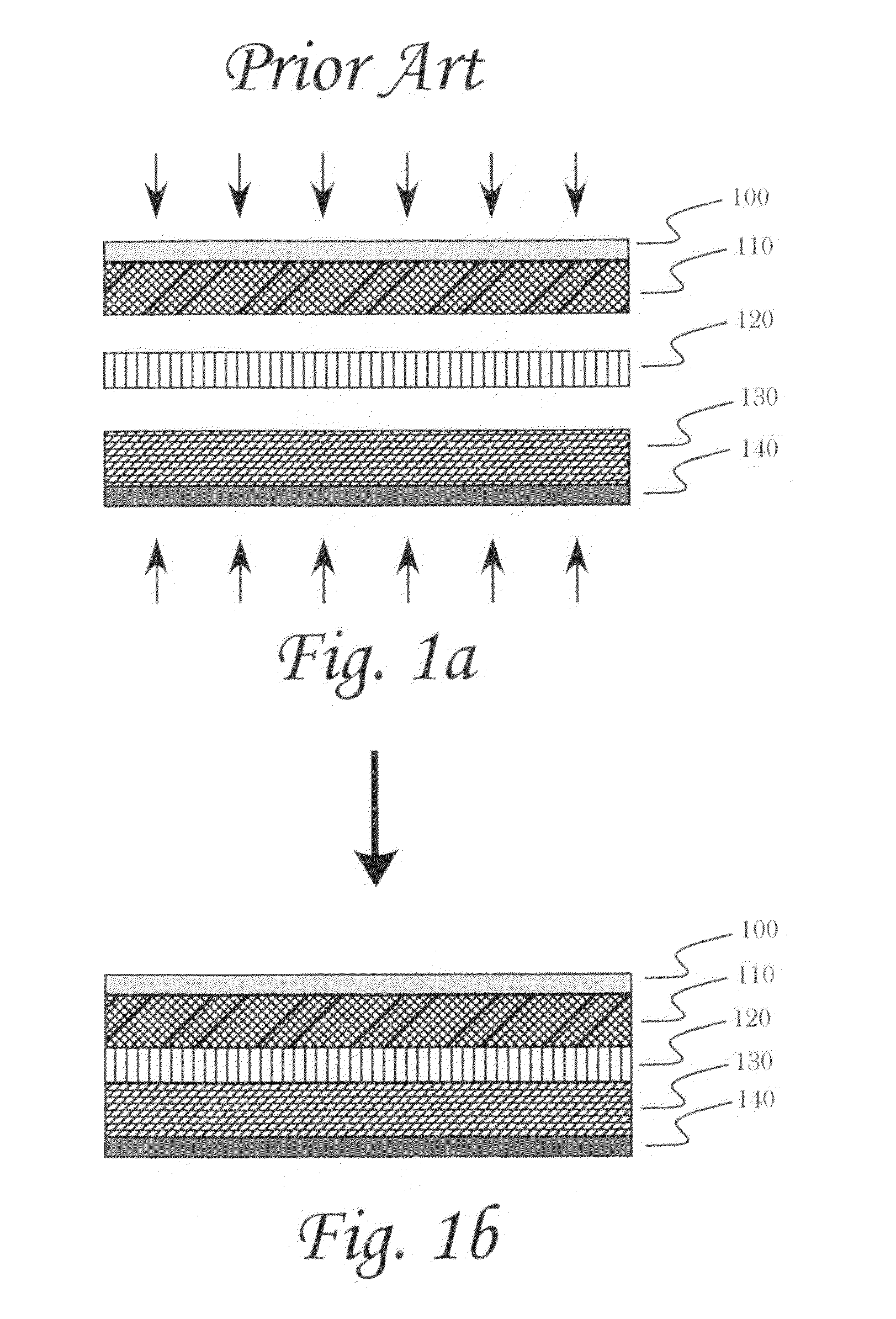

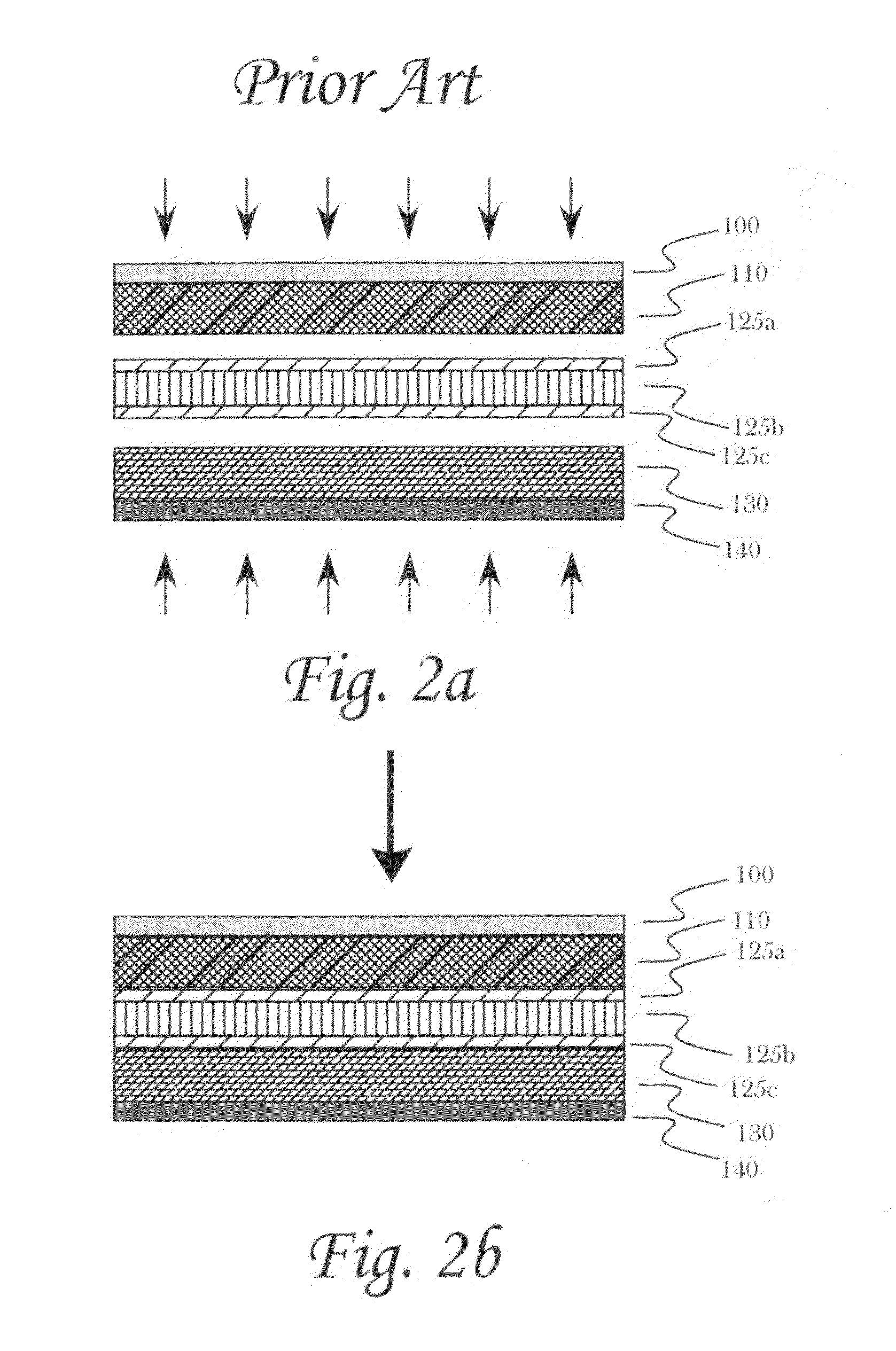

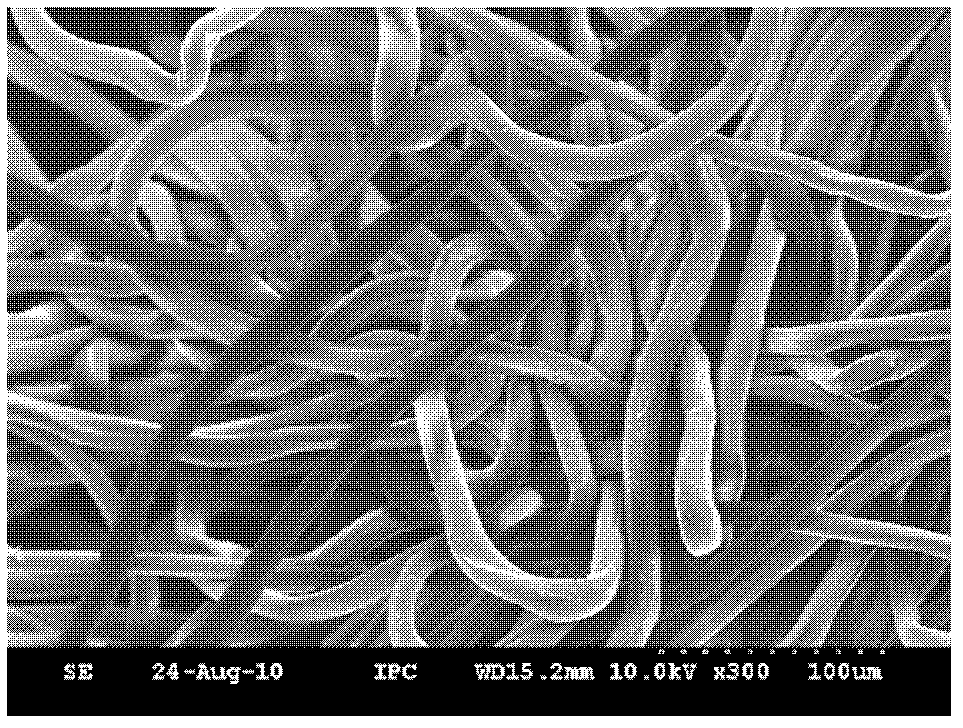

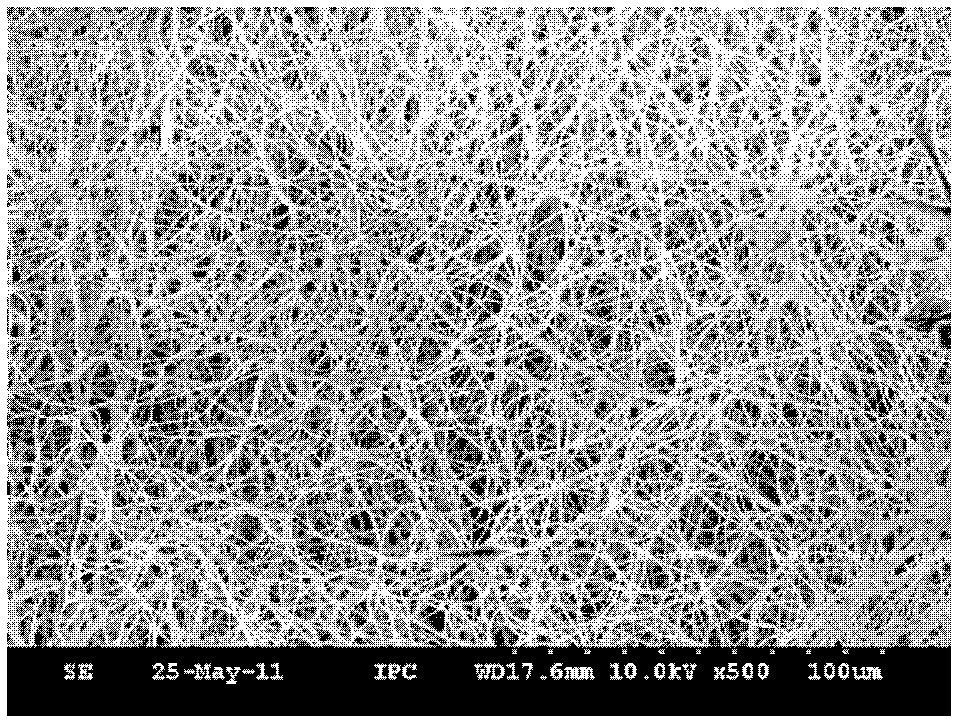

Nanometer fiber lithium ion battery diaphragm material with composite structure and preparation method of nanometer fiber lithium ion battery diaphragm material

ActiveCN102629679AHigh energyIncrease powerCell seperators/membranes/diaphragms/spacersLaminationSpray coatingLithium-ion battery

The invention relates to a three-layer nanometer fiber composite lithium ion battery diaphragm and a preparation technology of the three-layer nanometer fiber composite lithium ion battery diaphragm. The battery diaphragm comprises a middle layer, a first outer layer and a second outer layer, wherein the first outer layer and the second outer layer are respectively positioned at the two sides of the middle layer, the first outer layer and the second outer layer are static spinning spray coating layers, and the middle layer is combined with the first outer layer and the second outer layer through hot pressing. The porosity of the battery diaphragm is between 40 percent and 70 percent, and the middle layer is used as a support body and has high mechanical intensity. The first outer layer and the second outer layer are made of different materials from the middle layer and are used as functional layers to ensure that the materials have specific chemical and physical characteristics. A great amount of materials can be efficiently prepared by adopting the high-flow-rate static spinning technology and equipment. The material is used as the high-performance lithium ion battery diaphragm, can be applied to miniature and power lithium-ion batteries, and realizes the effects of reducing the battery internal resistance, prolonging the service life of the batteries, improving the charging and discharging performance and the like.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Animal litter containing activated carbon

Disclosed herein is the use of activated carbon in amounts as low as 0.03% by wt. to control odor combined with a color-masking agent in traditional litter compositions. Powdered activated carbon (PAC) having a mean particle diameter less than 500 μm is preferred. The color-masking agent and activated carbon can be incorporated into the litter composition by dry blending, agglomeration or spray coating.

Owner:THE CLOROX CO

Apparatus and method for electrostatic spray coating of medical devices

ActiveUS7241344B2Increased ionization increases the fraction of coating spray attractedIncrease electrode surface areaLiquid spraying plantsElectric shock equipmentsVoltage spikeSpray coating

An apparatus and method for electrostatic spray deposition of small targets, such as medical devices like stents. The apparatus includes a target holder which applies a first electrical potential to the target, and an electrostatic dispensing nozzle which applies a second potential sufficient to attract the coating fluid from the nozzle toward the target. Because the entire dispensing nozzle is conductive, the coating fluid may receive a greater charge than may be obtained with internal electrode-type nozzles. Electrostatic attraction of the coating fluid to the target is enhanced by the combination of higher charge density imparted to the coating fluid by the conductive nozzle, and application of a momentary voltage spike to the target to provide consistent conductivity between the target and its holder, thereby ensuring the target is presents the full first potential applied to the holder. The voltage spike may also be used independently of the conductive nozzle.

Owner:BOSTON SCI SCIMED INC

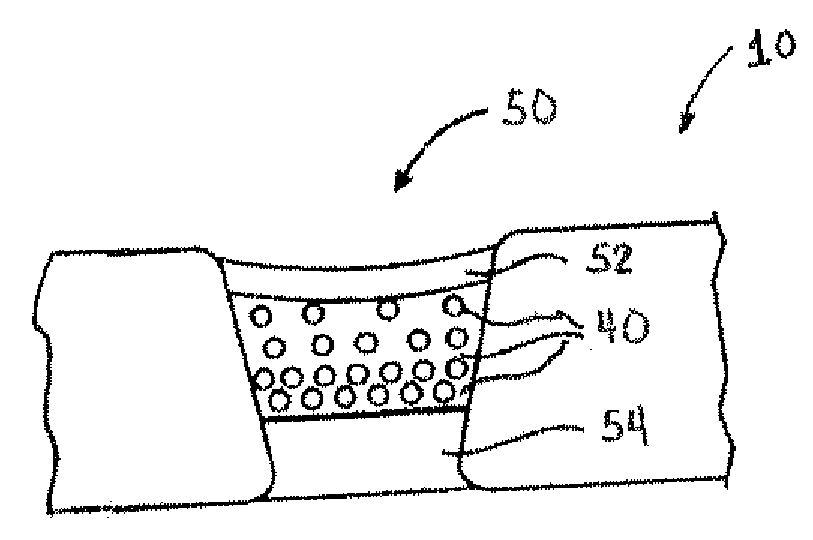

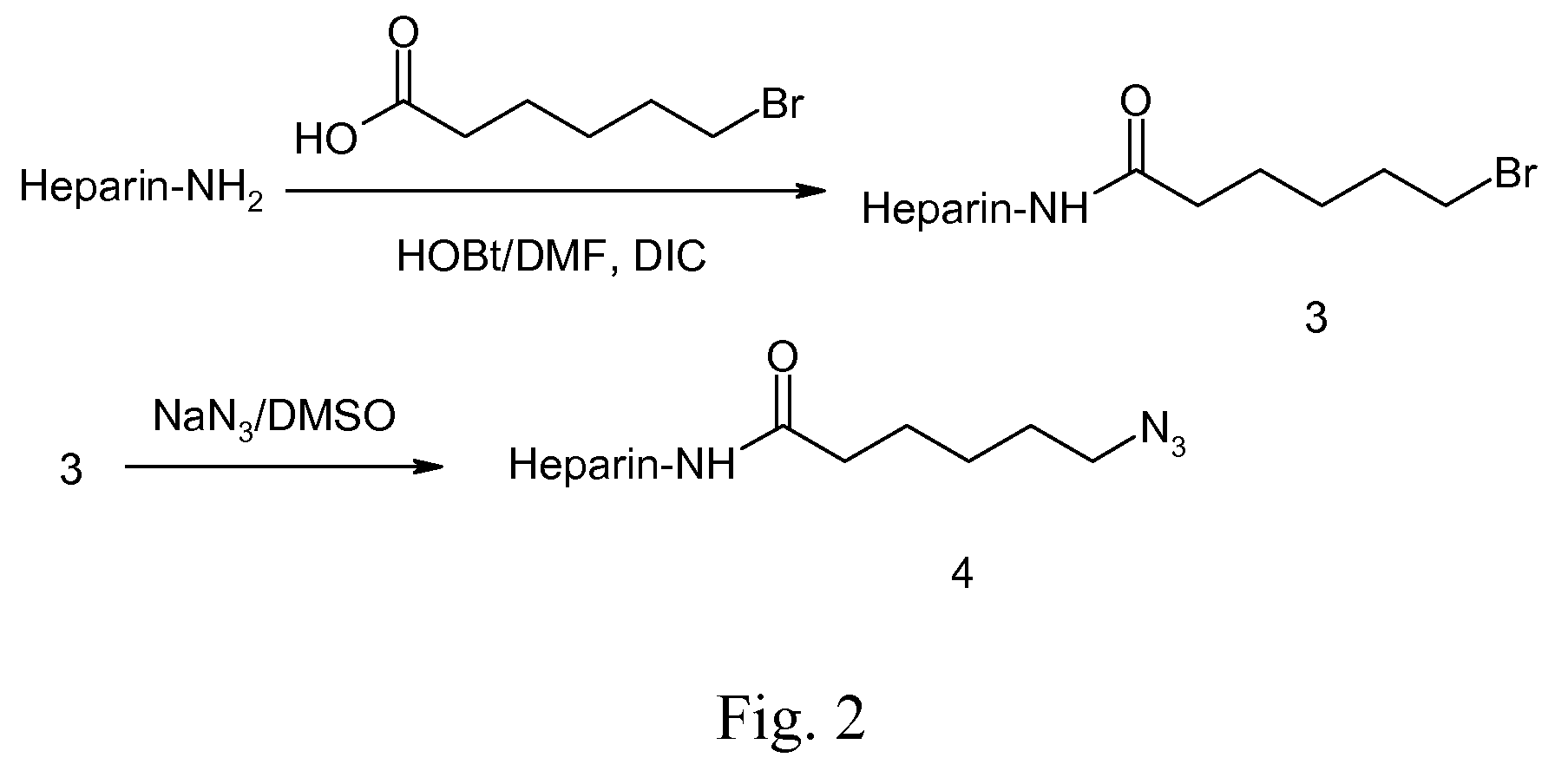

Coating Employing an Anti-Thrombotic Conjugate

InactiveUS20090018646A1Few stepsImprove versatilityStentsOrganic active ingredientsActive agentSide chain

A biodegradable antithrombotic conjugate having heparin and other anti-thrombotic moieties are introduced as side chains to the polymer backbone modified by click chemistry. Various bioabsorbable monomers and dimers such as valerolactone may be used in the monomer derivation, homo- and co-polymerization, and the conjugation with a biologically active molecule by click chemistry. A coating comprising a biocompatible and bioabsorbable polymer anti-thrombotic conjugate is applied to at least a portion of an implantable device to prevent or reduce the formation of thrombosis on the surface of the implantable device. A first or sub-layer of the coating is prepared by mixing a polymeric material and a biologically active agent with a solvent, thereby forming a homogeneous solution. A second or outer layer comprising the present anti-thrombotic conjugate may be applied over the inner drug-containing layers using, for example, a dip coating or spray coating process.

Owner:CORDIS CORP

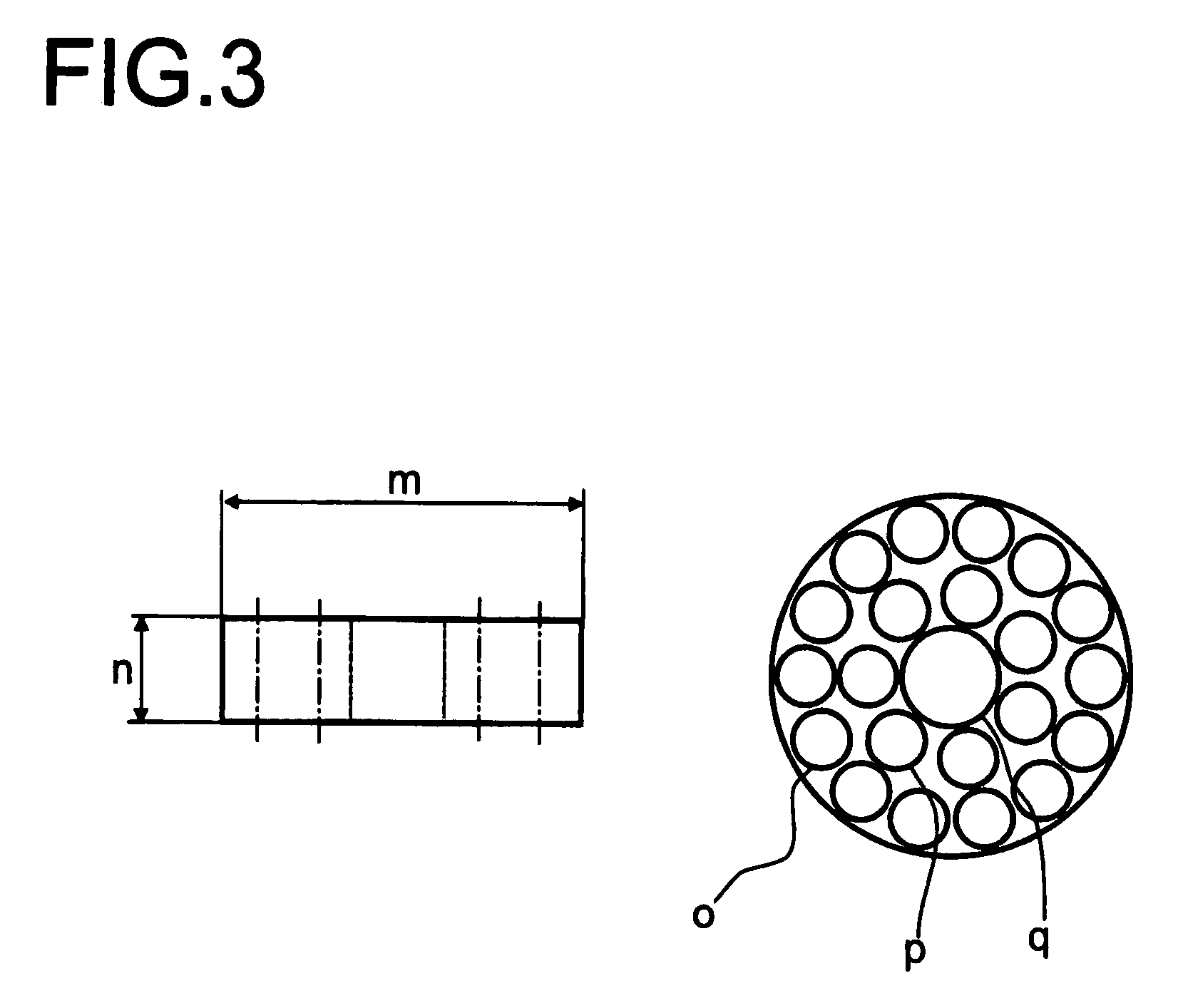

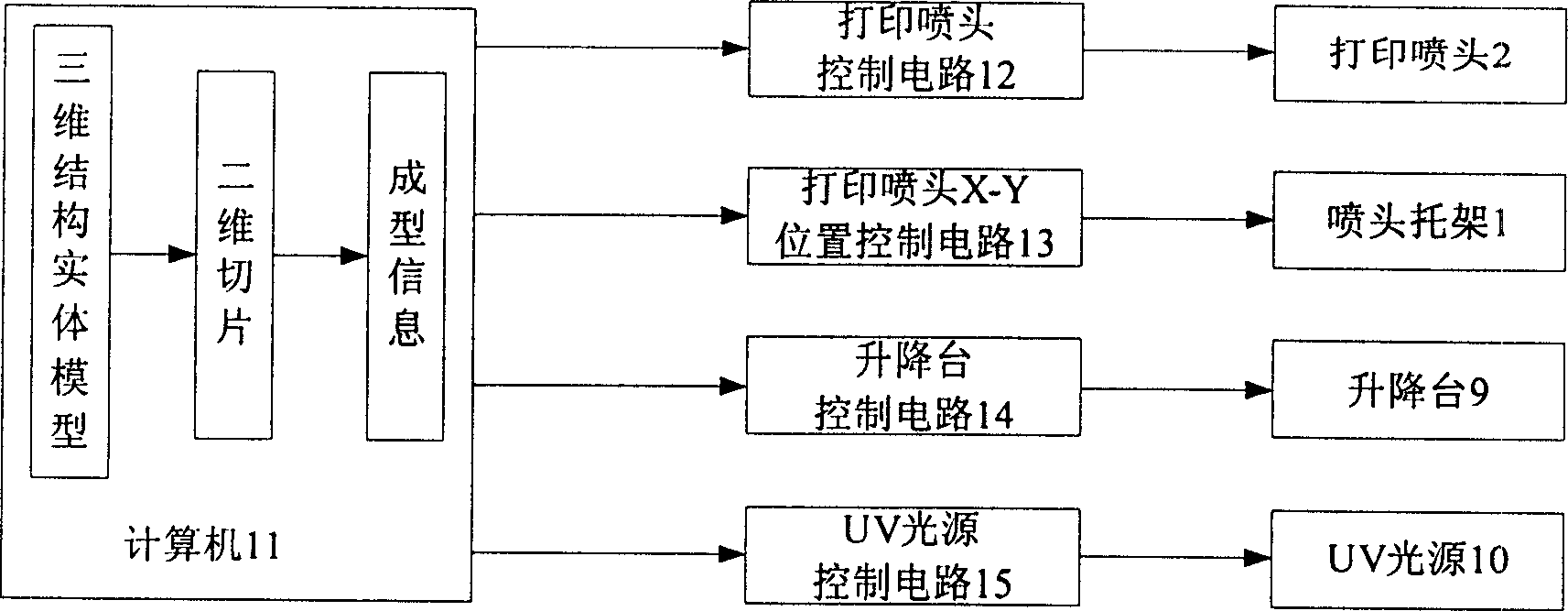

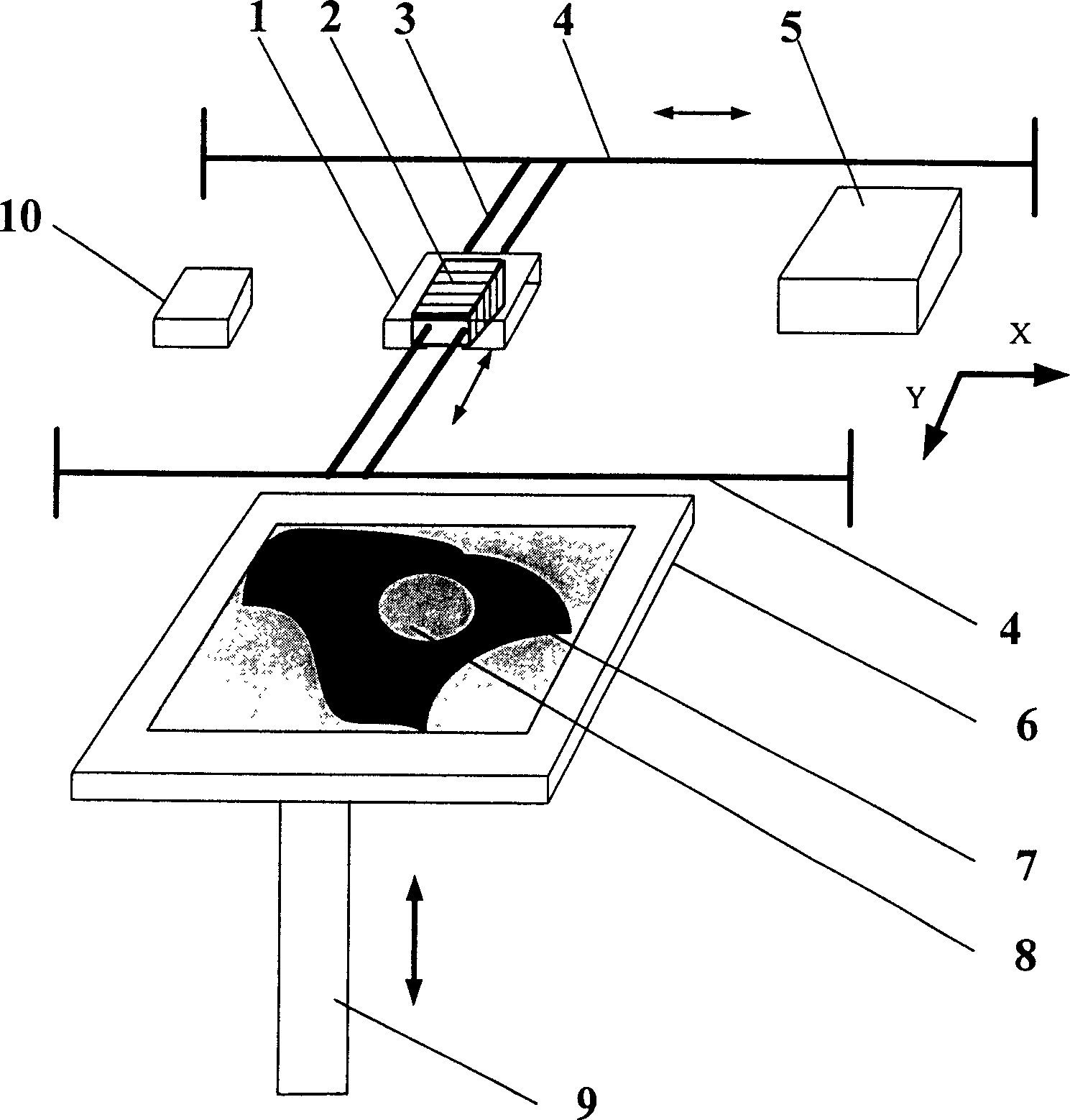

Method for manufacturing three-dimensional object by use of spray coating successively

The invention discloses a method for producing three-dimensional matter via plating layer-to-layer, which comprises following steps: building a computer solid model of three-dimensional matter to be sliced and layered; the computer controls the operation of printing injector and injecting UV liquid material according to the molding information of each layer to be solidified via ultraviolet light to form a layer with the same shape and strength of molding information; injecting support material in the non-injected area as support; adhering each layer to produce designed three-dimensional matter; removing filled support material of each layer to attain the three-dimensional matter of said computer solid model. The invention can quickly, reliably, and safely produce complex three-dimensional matter and composite color three-dimensional matter with lower cost. Wherein, the molding material in said invention is innocuous, therefore, the invention can be used in office.

Owner:NANJING NORMAL UNIVERSITY

Blade tip coatings

This invention relates to blades for a gas turbine engine, said blades having an inner end adapted for mounting on a hub and a blade tip located opposite the inner end, and wherein at least a portion of the blade tip is coated with a thermally sprayed coating of a high purity yttria or ytterbia stabilized zirconia powder, said thermally sprayed coating having a density greater than 88% of the theoretical density with a plurality of vertical macrocracks substantially homogeneously dispersed throughout the coating in which a cross-sectional area of the coating normal to the blade tip exposes a plurality of vertical macrocracks extending at least half the coating thickness in length up to the full thickness of the coating and having from about 5 to about 200 vertical macrocracks per linear inch measured in a line parallel to the surface of the blade tip and in a plane perpendicular to the surface of the blade tip, and said high purity yttria or ytterbia stabilized zirconia powder comprising from about 0 to about 0.15 weight percent impurity oxides, from about 0 to about 2 weight percent hafnium oxide (hafnia), from about 6 to about 25 weight percent yttrium oxide (yttria) or from about 10 to about 36 weight percent ytterbium oxide (ytterbia), and the balance zirconium oxide (zirconia).

Owner:PRAXAIR ST TECH INC

High-performance aqueous graphene paint and preparation method thereof

The invention discloses high-performance aqueous graphene paint and a preparation method thereof. The preparation method of the high-performance aqueous graphene paint comprises the following steps of: oxidizing natural graphite in an oxidant, adopting a two-step chemical reduction method to obtain organic molecule-modified graphene aqueous solution; and adding polyester, a neutralizing agent, a flatting agent, an antifoaming agent, a cross-linking agent and a catalyst by adopting a solution co-mixing method to obtain aqueous graphene paint. A conductive coating with high conductive performance and mechanical performance is obtained by carrying out spray-coating, ink-jet printing and printing on the obtained paint, the conductive coating can be applied to the field such as electromagnetic shielding, static electricity preventing, corrosion preventing, radiating, wear-resisting and electronic circuits, and therefore, the application value is extensive.

Owner:PEKING UNIV

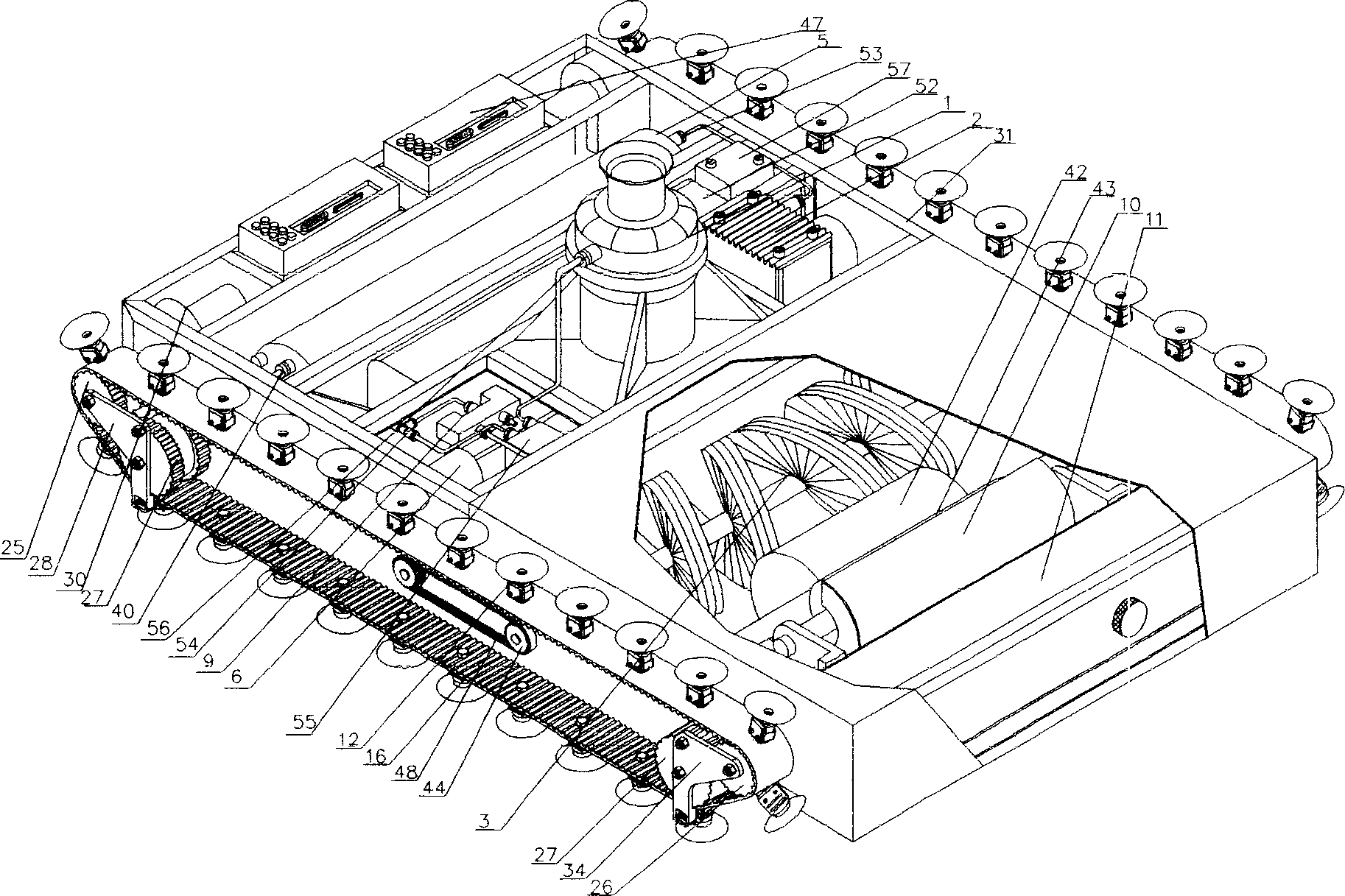

Crawler multi-sucker wall-climbing robot and its implement method

The present invention discloses a crawler multicup wall-lcimbing robot. The described robot incldues main body using vacuum cup and crawler multicup drive / conversion mechanism as main body, and cleaning mechanism using backpitch structure rolling-brush and water-recovering device as main component. Said robot is suitable for cleaning and spray-coating high-rice building, specially for cleaning high-rise building glass curtain wall.

Owner:吴志明

System and method for electrostatic-assisted spray coating of a medical device

A system and method for the electrostatic spray application of a coating material onto a medical device. The coating material is electrically charged and an atomizer is used to atomize the coating material, creating electrically charged droplets which coat the medical device. In alternate embodiments, a swirl atomizer, a pressure atomizer, an ultrasound atomizer, a rotary atomizer, and an effervescent atomizer are used to atomize the coating material.

Owner:BOSTON SCI SCIMED INC

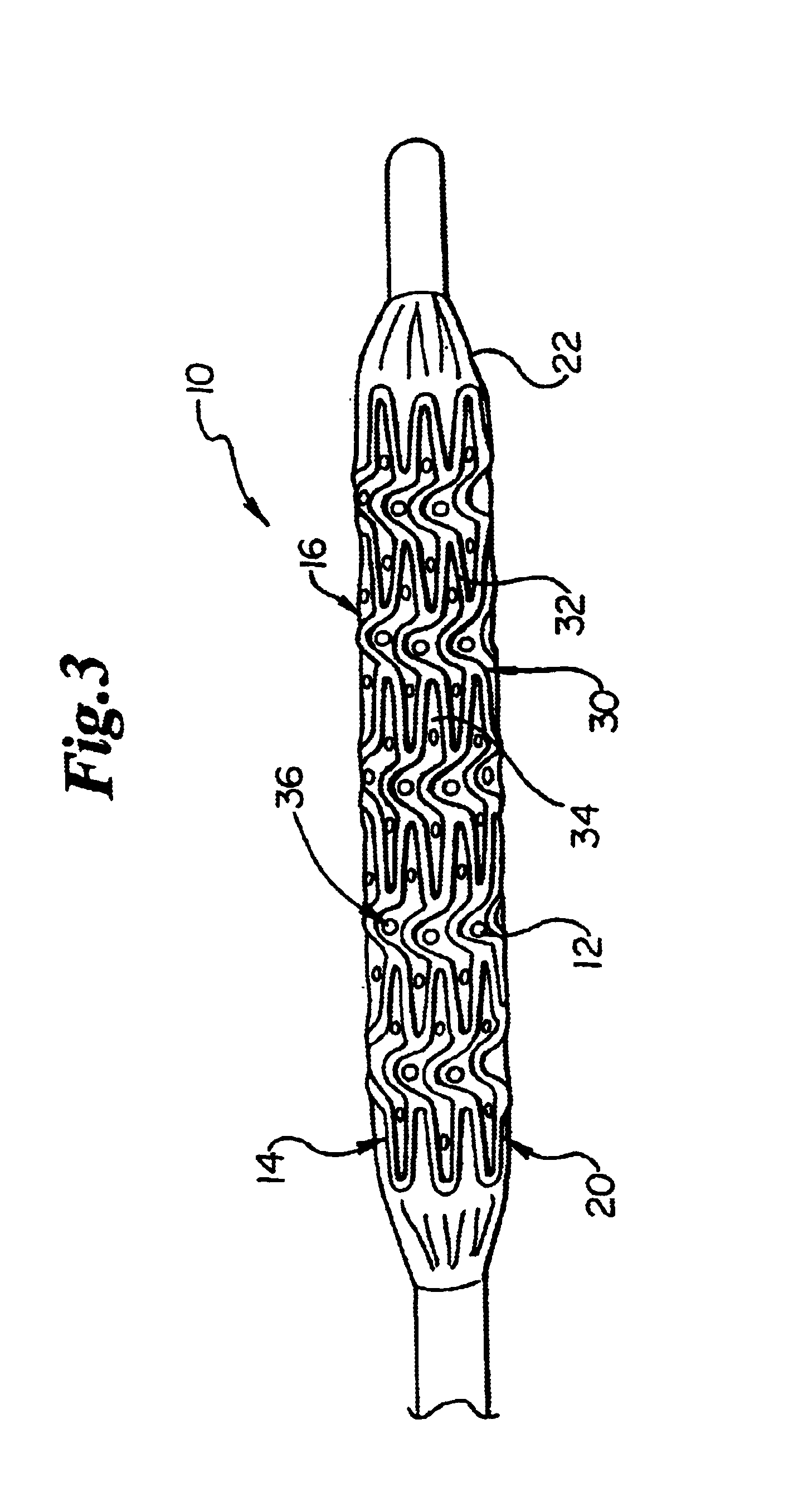

Fiber pattern printing

InactiveUS6841213B2Improved stent retaining characteristicHelp positioningSurgeryPretreated surfacesFiberSpray coating

A substantially tubular member comprises a body. The body is constructed from a first material and has an external surface. At least a portion of the external surface has a predetermined pattern of a second material deposited thereon. The predetermined pattern of the second material is deposited on the at least a portion of the external surface by one or more printing processes such as solution coating, spray coating, thermal printing, piezo jet printing, contact printing and any combination thereof.

Owner:BOSTON SCI SCIMED INC

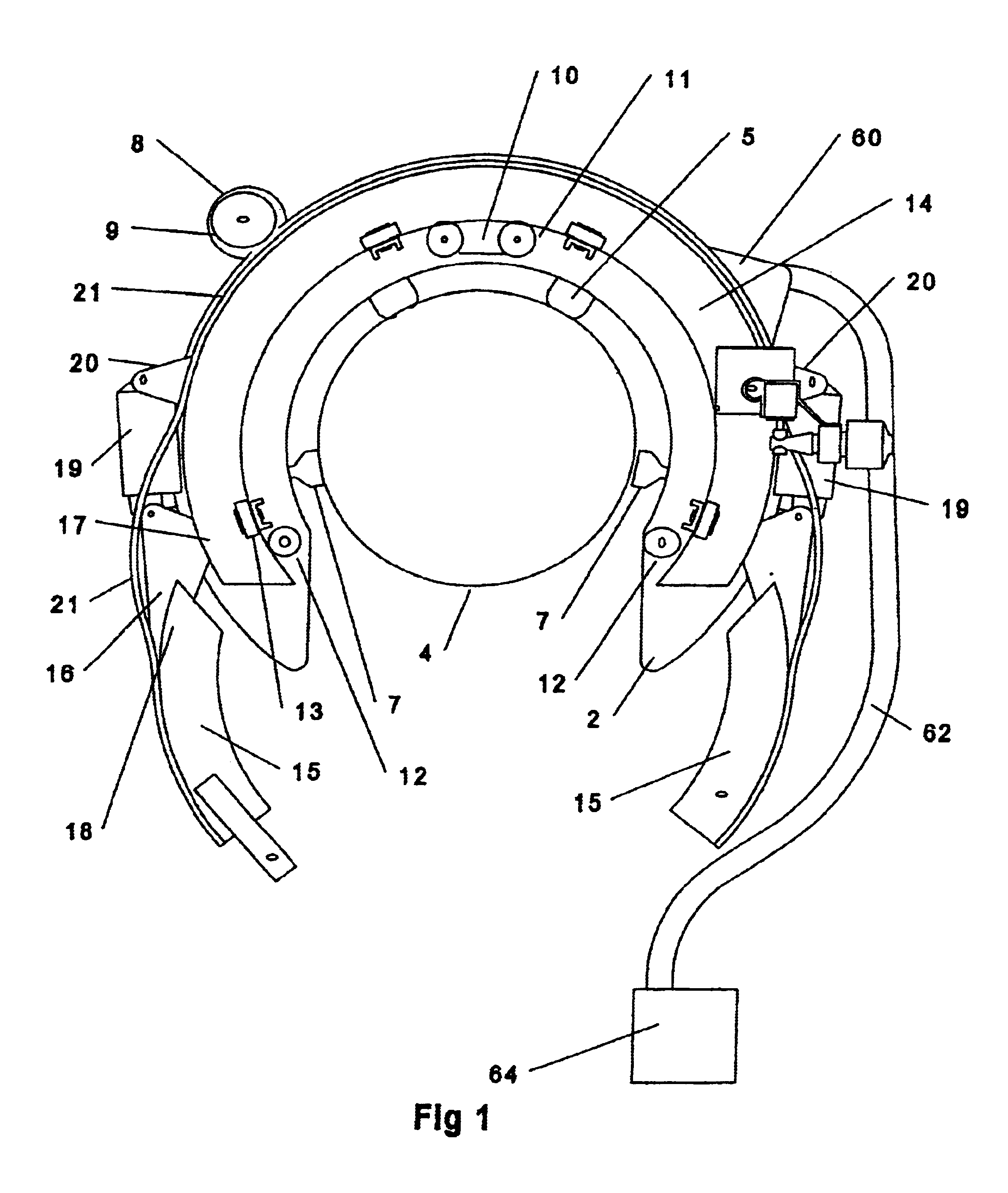

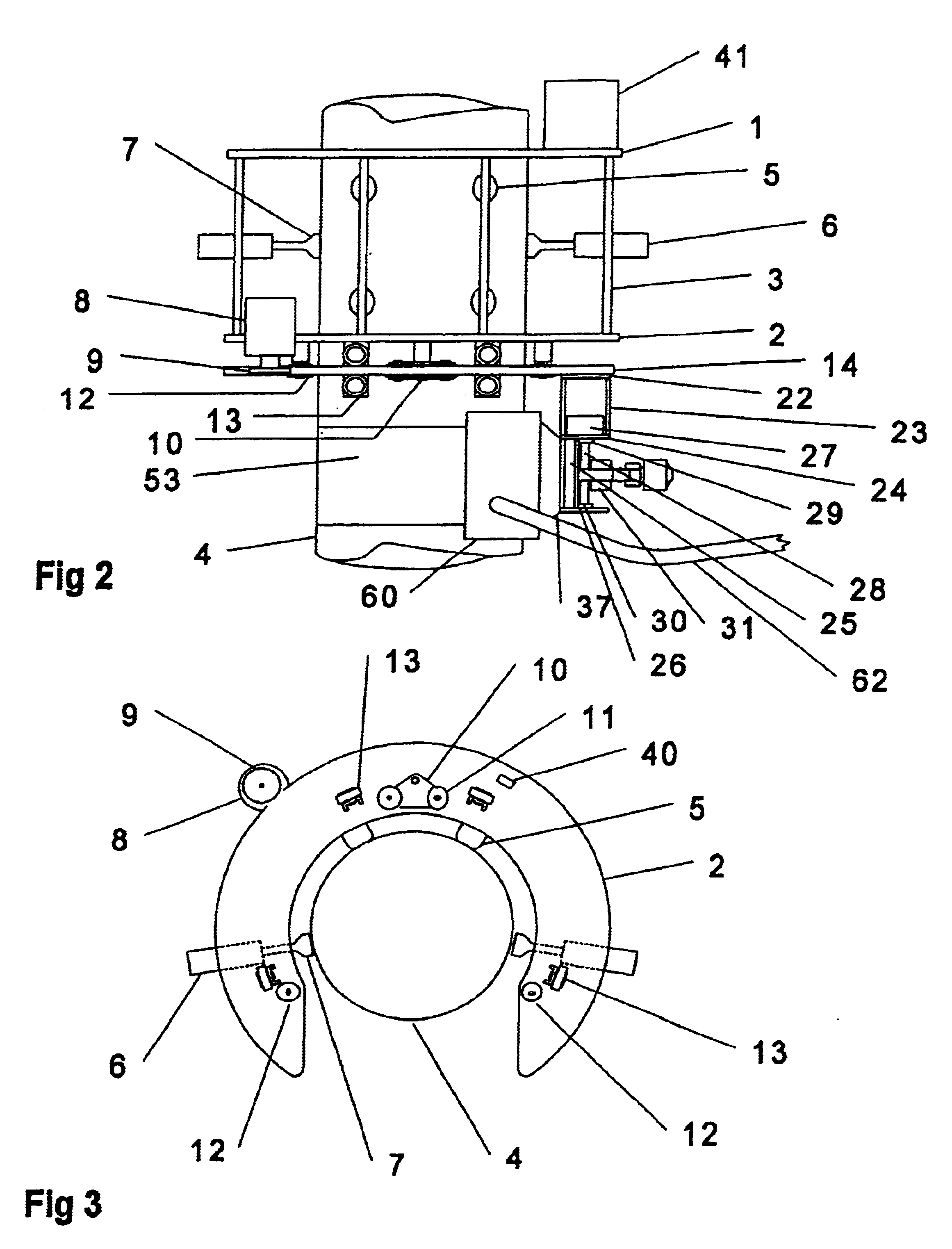

Apparatus and method for coating pipes

InactiveUS6881266B1Minimizes amount of wasteReduce riskMovable spraying apparatusVacuum evaporation coatingRange of motionSpray coating

Apparatus for spraying a coating onto the outside of a pipe includes a body for mounting on a pipe to be coated. A spray gun is mounted on the body such that it can move relative to the body to spray coating completely around the periphery of the pipe. The apparatus may include only a single spray gun which is able to travel in a 360 degree range of motion around the periphery of the pipe. The apparatus is particularty suited to coating girth welds of a pipeline.

Owner:PIPELINE INDUCTION HEAT

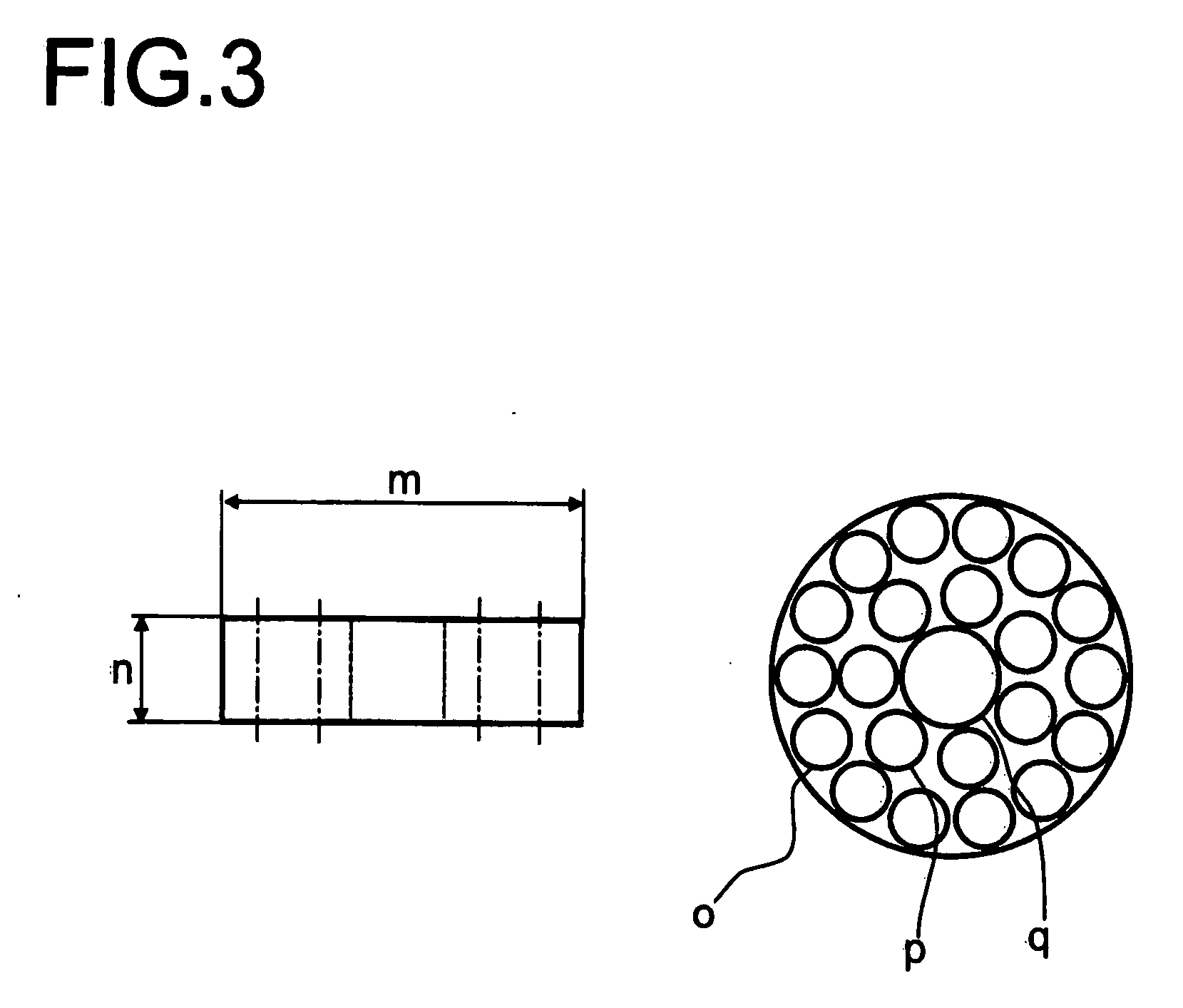

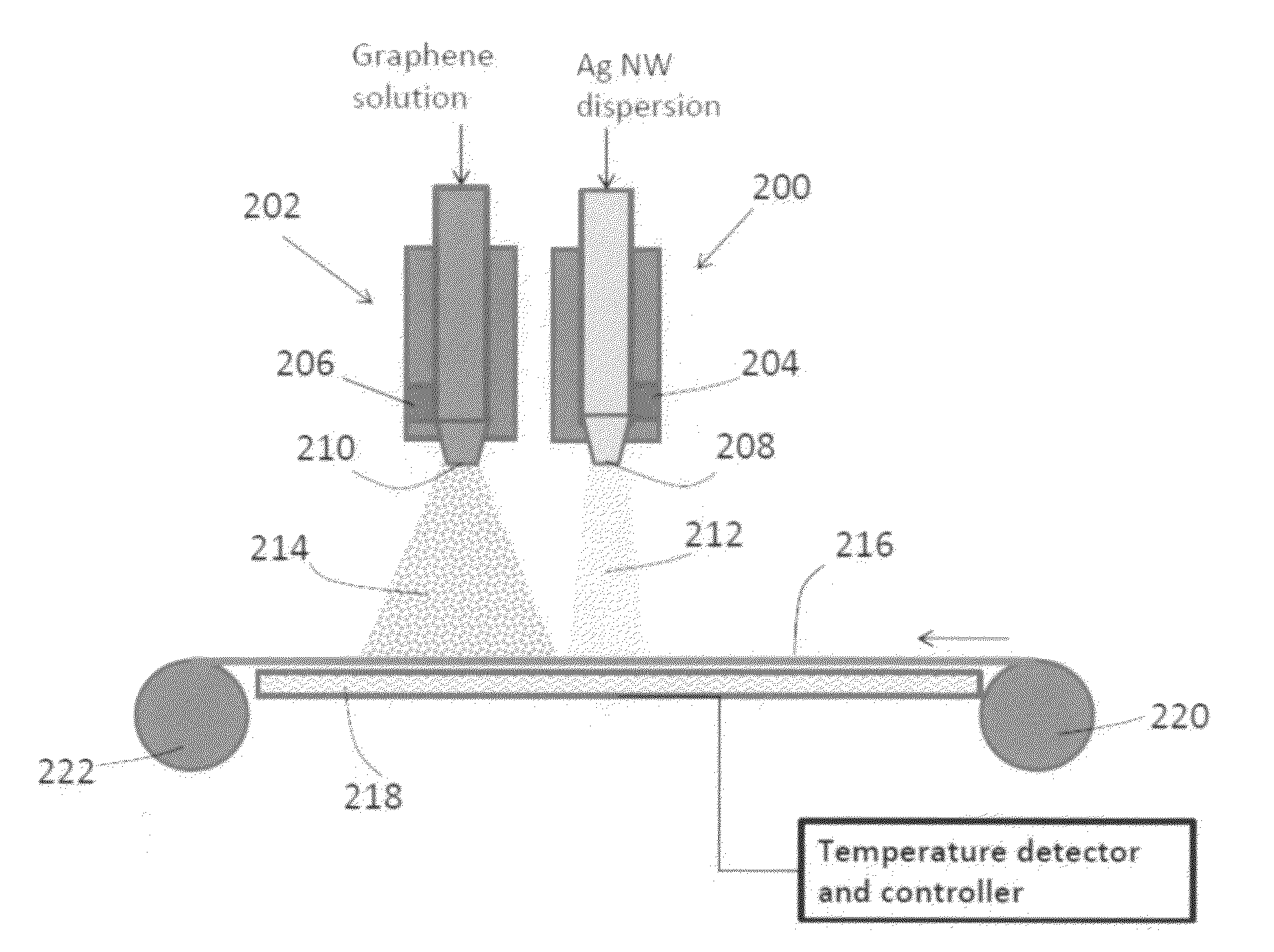

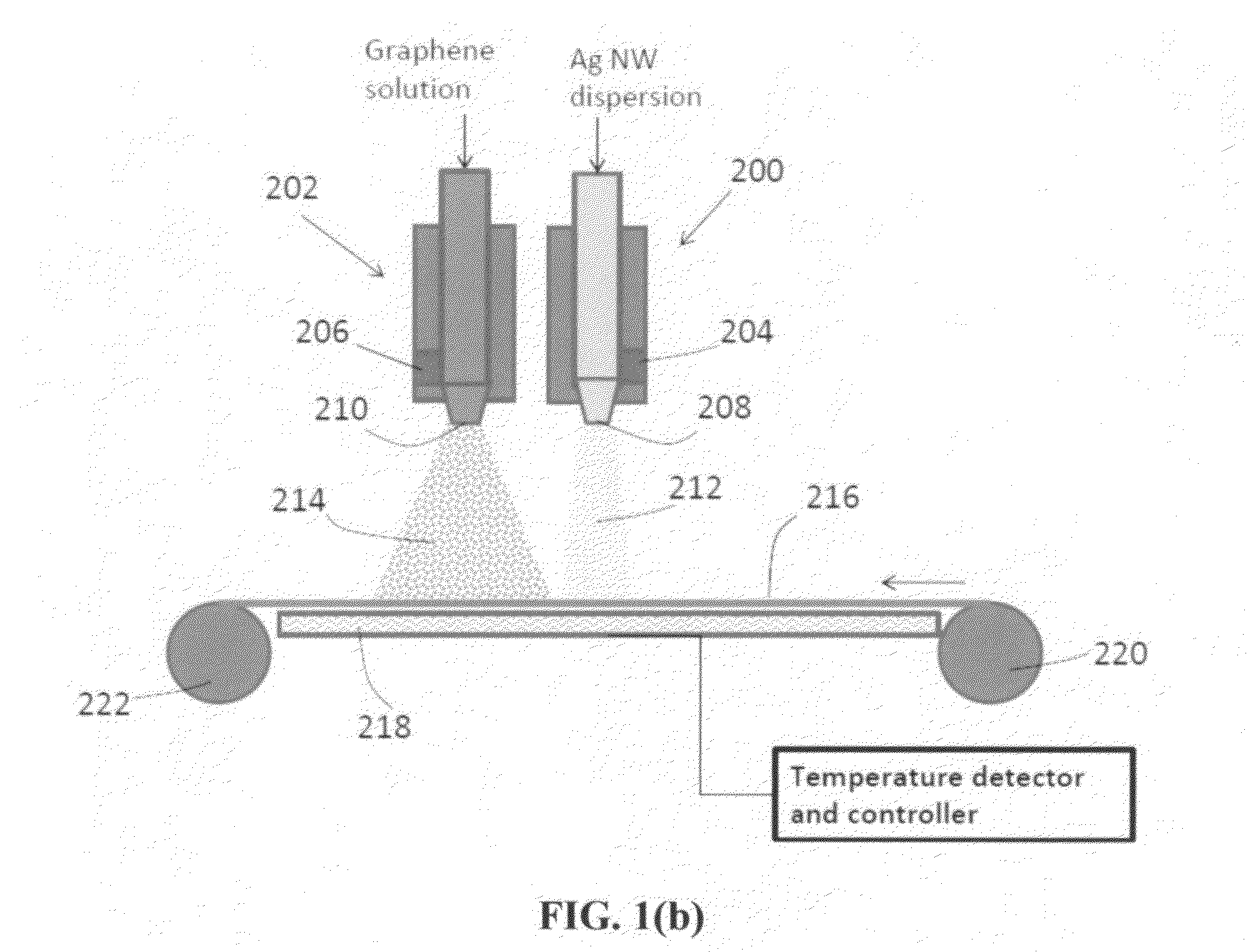

Ultrasonic spray coating of conducting and transparent films from combined graphene and conductive nano filaments

PendingUS20140272199A1Reduce sheet resistanceIncrease speedTransportation and packagingMetal-working apparatusFilm resistanceSpray coating

An ultrasonic spray coating method of producing a transparent and conductive film, comprising (a) operating an ultrasonic spray device to form aerosol droplets of a first dispersion comprising a first conducting nano filaments in a first liquid; (b) forming aerosol droplets of a second dispersion comprising a graphene material in a second liquid; (c) depositing the aerosol droplets of a first dispersion and the aerosol droplets of a second dispersion onto a supporting substrate; and (d) removing the first liquid and the second liquid from the droplets to form the film, which is composed of the first conducting nano filaments and the graphene material having a nano filament-to-graphene weight ratio of from 1 / 99 to 99 / 1, wherein the film exhibits an optical transparence no less than 80% and sheet resistance no higher than 300 ohm / square.

Owner:GLOBAL GRAPHENE GRP INC

Rare earth element oxyflouride powder spray material and sprayed article

InactiveUS20140057078A1Increase resistanceImprove corrosion resistanceFireproof paintsMolten spray coatingRare-earth elementHigh resistance

A spray material comprising rare earth element oxyfluoride particles having an aspect ratio of up to 2, an average particle size of 10-100 μm, and a bulk density of 0.8-2 g / cm3, and containing not more than 0.5 wt % of carbon and 3-15 wt % of oxygen is suitable for air plasma spraying. An article having a sprayed coating of rare earth element oxyfluoride has high resistance against plasma etching and a long lifetime.

Owner:SHIN ETSU CHEM IND CO LTD

Polyimide foam and method of producing the same

The invention discloses polyimide foam and a preparation method thereof. Aromatic dianhydride and / or aromatic acid ester, alcohol with low molecular, a catalyst and a surface active agent are mixed proportionally in a polar solvent and react so as to form foam precursor solution. The foam precursor solution and isocyanate react in a mould and freely foam into a foam intermediate. The intermediate is solidified by microwave radiation or / and oven heating to obtain solid polyimide foam. The preparation process has short path, simple technology, good stability for storage of the foam precursor solution, adaptation to processing technologies of pouring, spray coating, extrusion, and the like, no occurrence of defects of cracked foam, foam combination, subsidence and incomplete amination, low preparation cost as well as uniform hold diameter and stable performance of the solid polyimide form, and is convenient for popularization and application.

Owner:BEIJING RADIATION APPL RES CENT

Refractory spray coating with high steel fiber content and spraying method thereof

The invention discloses a refractory spray coating with high steel fiber content and a spraying method thereof, which belong to the technical field of refractory materials. The method comprises the following step of: 1, pneumatically conveying the refractory spray coating to a nozzle, adding water onto the nozzle, and spraying and bonding the coating on a wall; or 2, adding water or a liquid bonding agent into the refractory spray coating, stirring the mixture into mortar, conveying the mortar to the nozzle by a pumping method, spraying the mortar out of the nozzle by using high-pressure air,and bonding the mortar on the wall. The refractory spray coating comprises the following ingredients in part by weight: 30 to 80 parts of refractory aggregate, 30 to 50 parts of refractory powder, 5 to 20 parts of bonding agent, 0.5 to 15 parts of additive and 3 to 80 parts of steel fiber. The invention has the advantages that: by spraying the refractory spray coating on a blast furnace cooling wall, spraying on a blast furnace throat steel brick, spraying on various refractory linings with cold faces and hot faces and repairing, the service life of the refractory material for the inner wall of a blast furnace can be greatly prolonged, and the effects of protecting the environment, saving energy and reducing consumption are achieved.

Owner:北京联合荣大工程材料股份有限公司

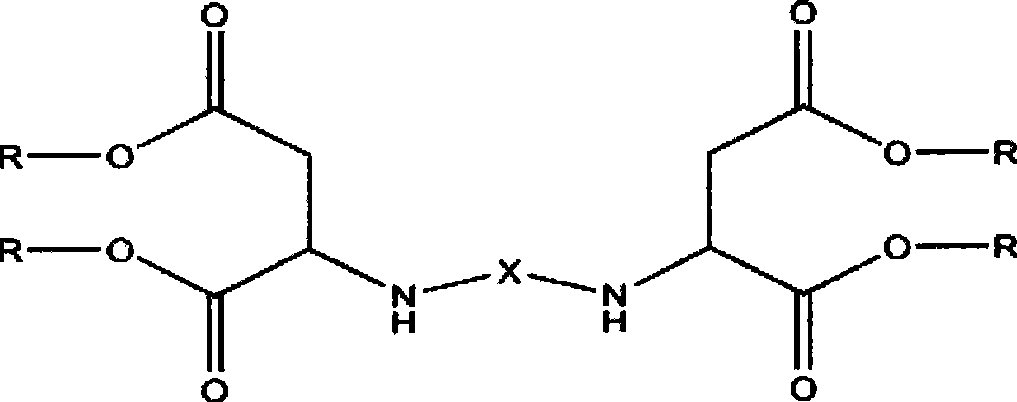

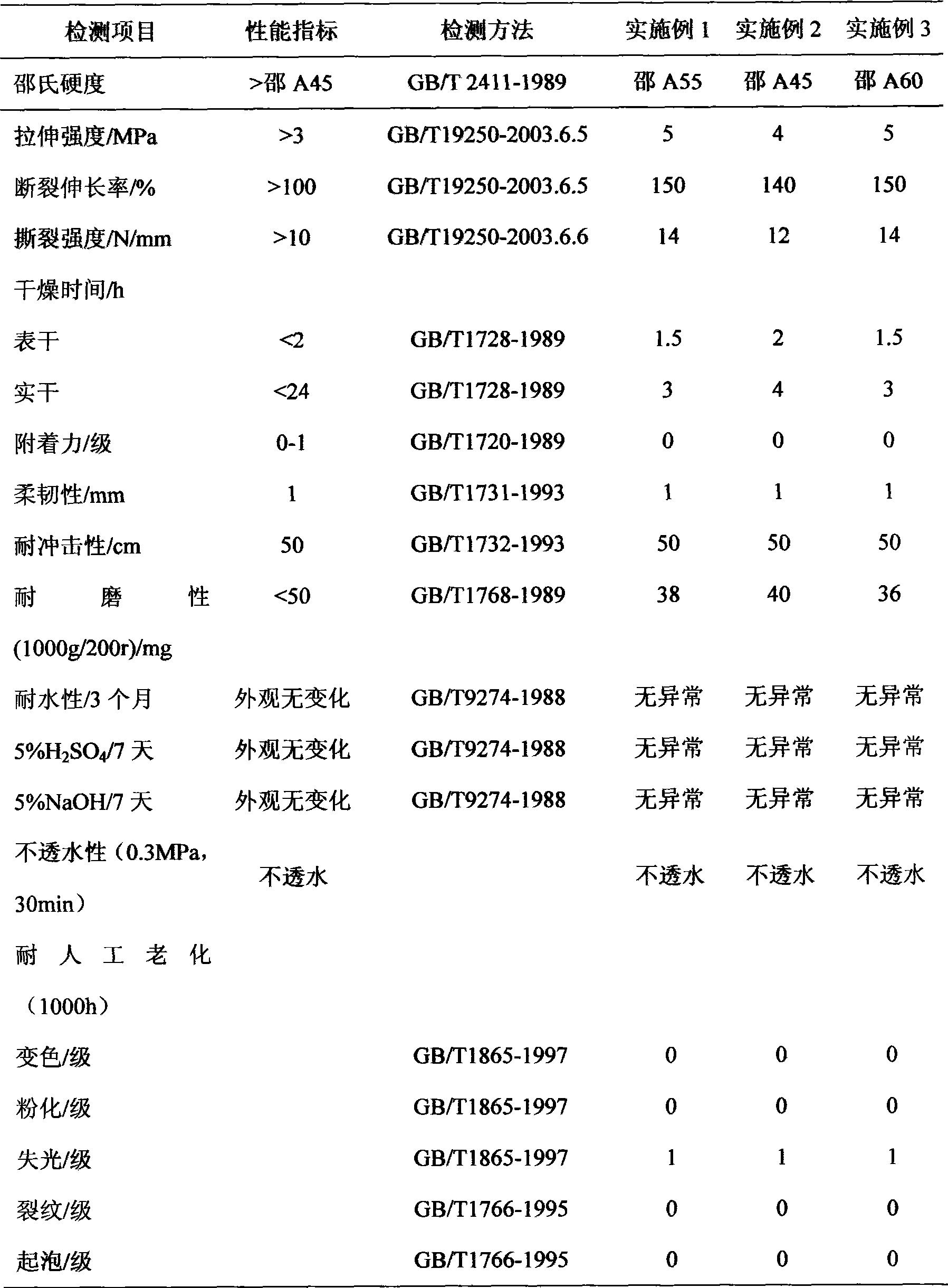

Preparation of polyaspartate polyurea waterproof coating material

InactiveCN101469246AStrong adhesionImprove toughnessAntifouling/underwater paintsPaints with biocidesAdhesion forceSpray coating

The invention discloses a method for preparing a polyaspartate polyurea waterproof coating, which is characterized in that the coating is based on polyaspartate polyurea and takes polyisocyanates as a curing agent. The coating material maintains the excellent performance of the prior polyurea coating, and also overcomes the disadvantages that the prior polyurea has overquick gelation time and needs special equipment for construction at the same time. The coating has the advantages of strong adhesion force, good toughness and wear resistance, good weather performance and so on, does not contain a solvent, is green and environment-friendly, and can reach the needed thickness through spray coating at one time.

Owner:SHANGHAI HUAYI FINE CHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com